Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

703results about "Closure decorative/protective covers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

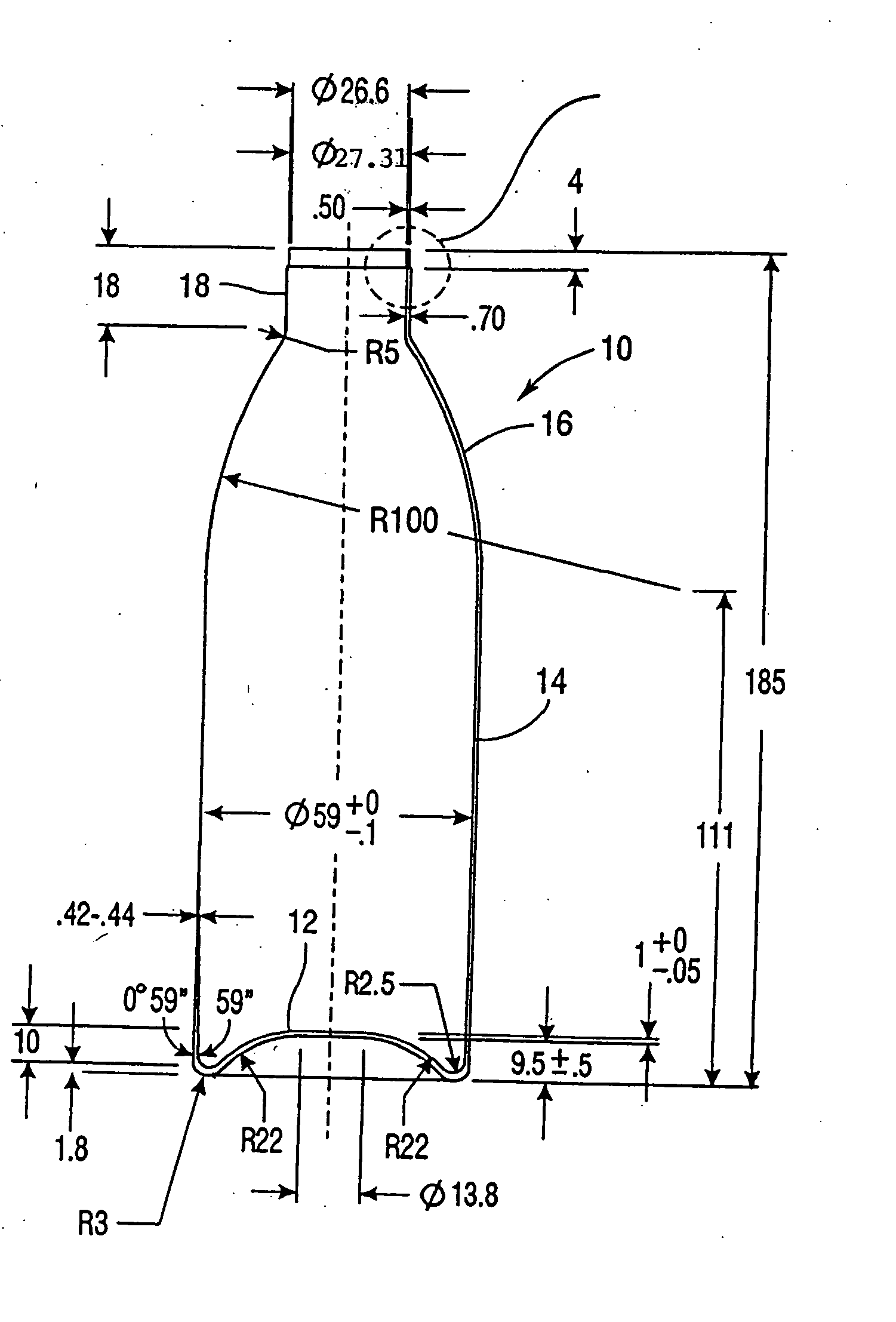

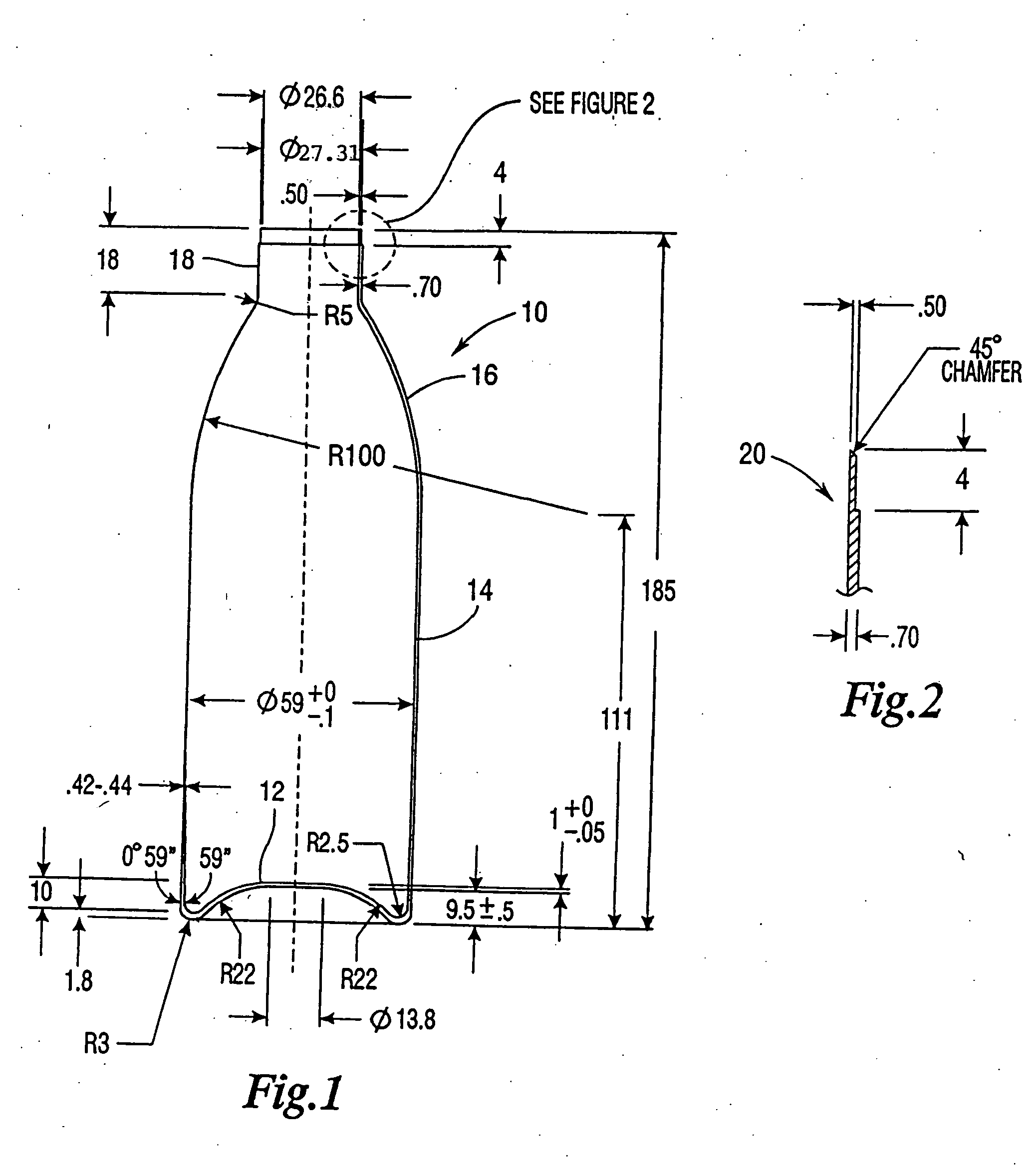

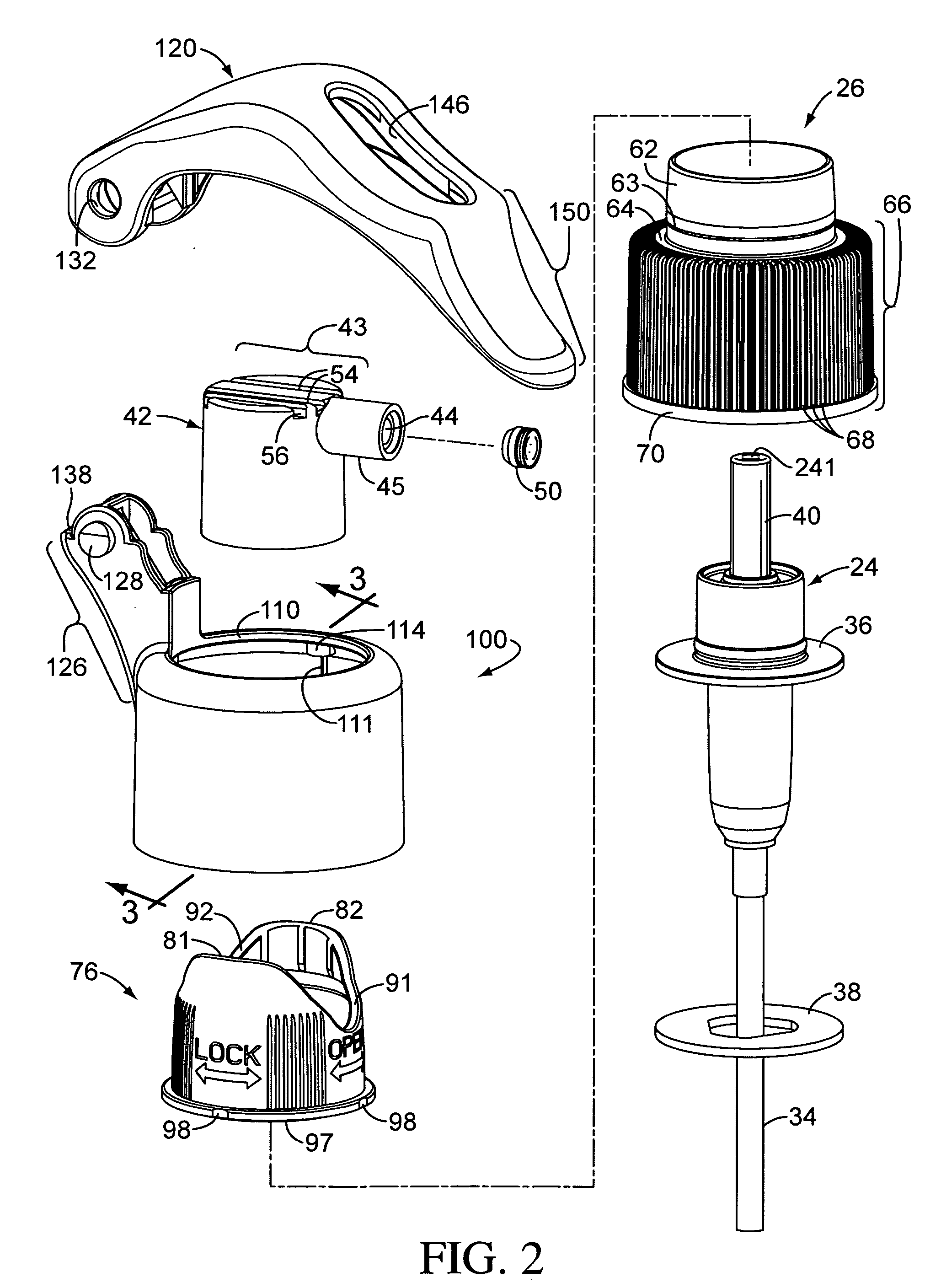

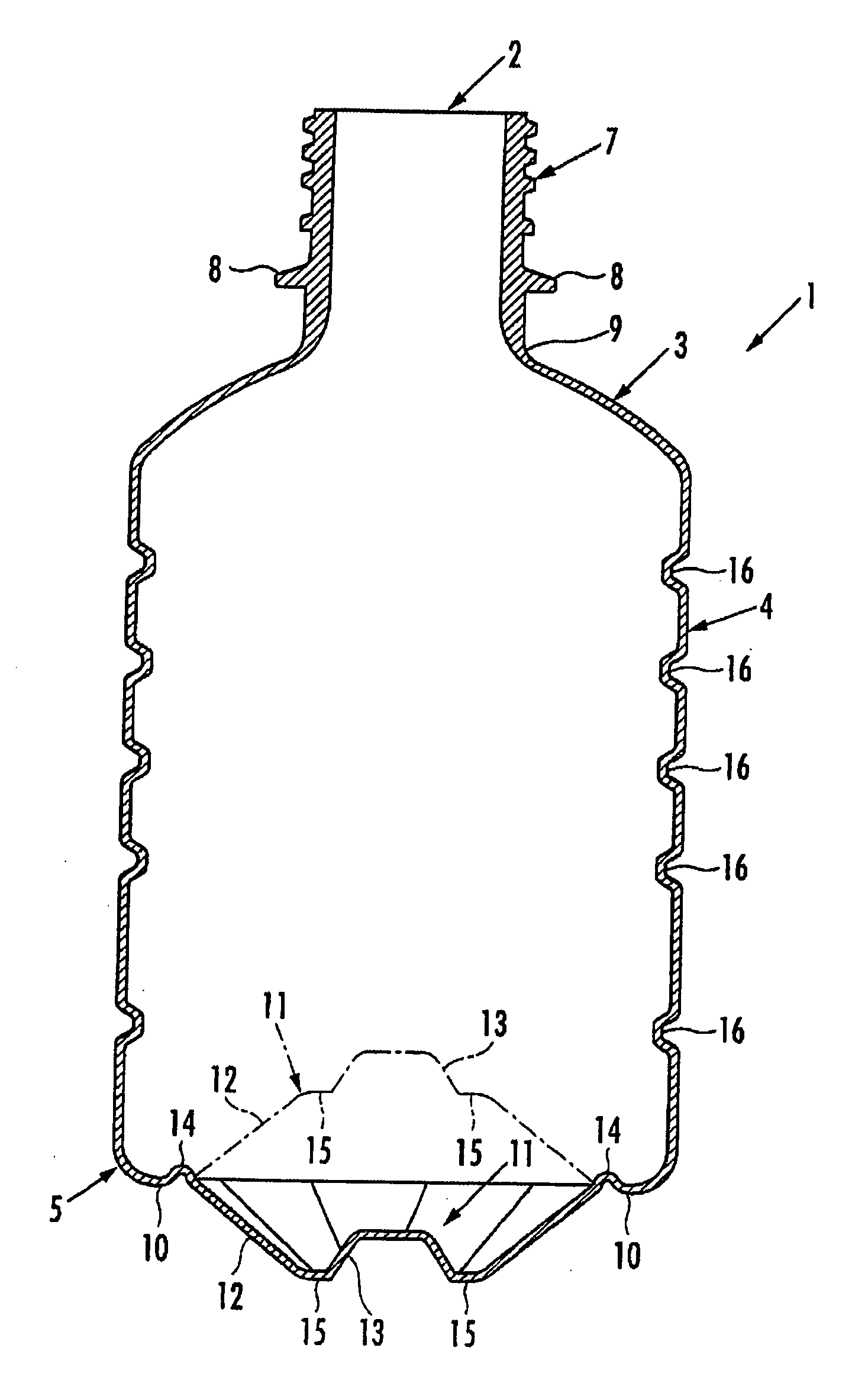

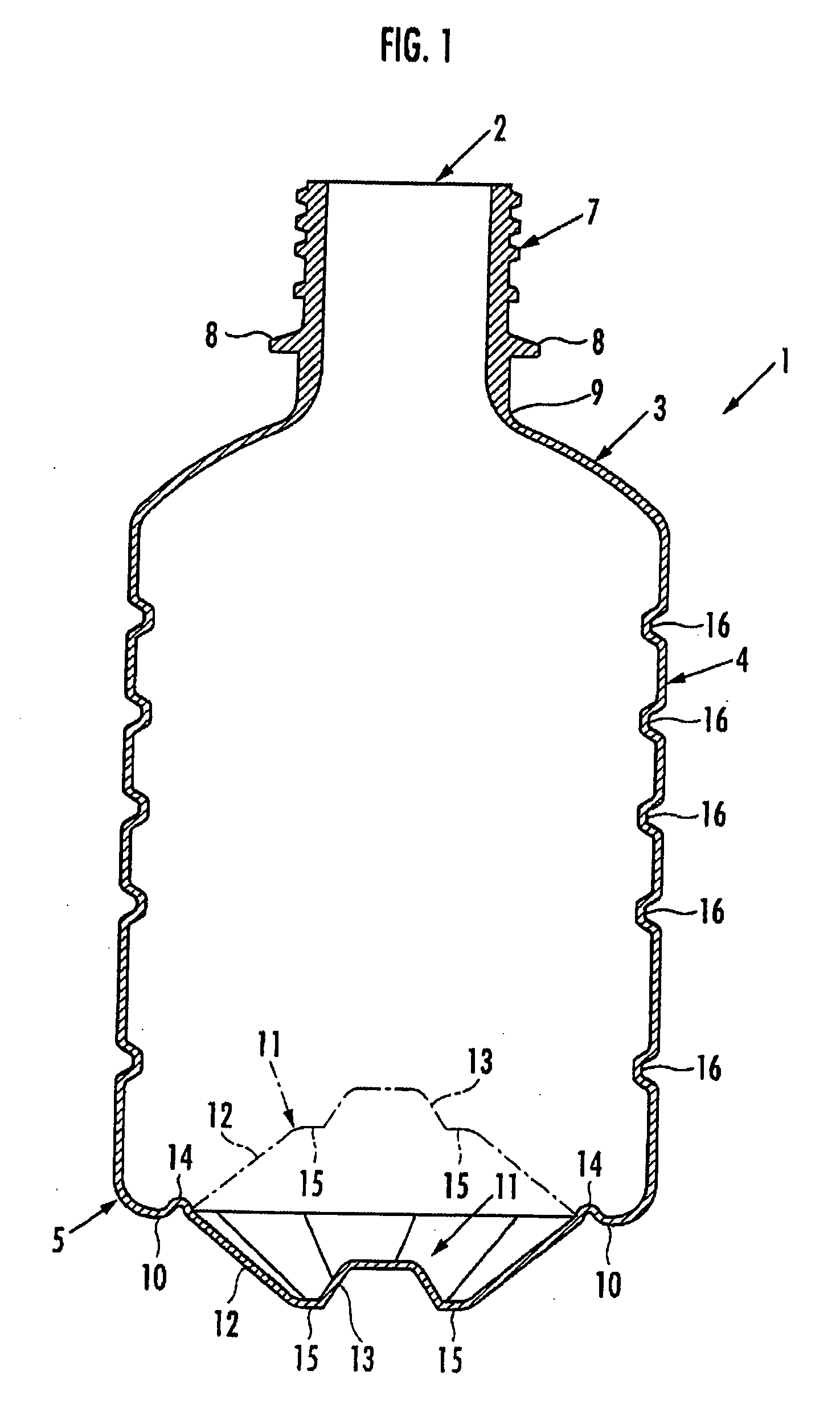

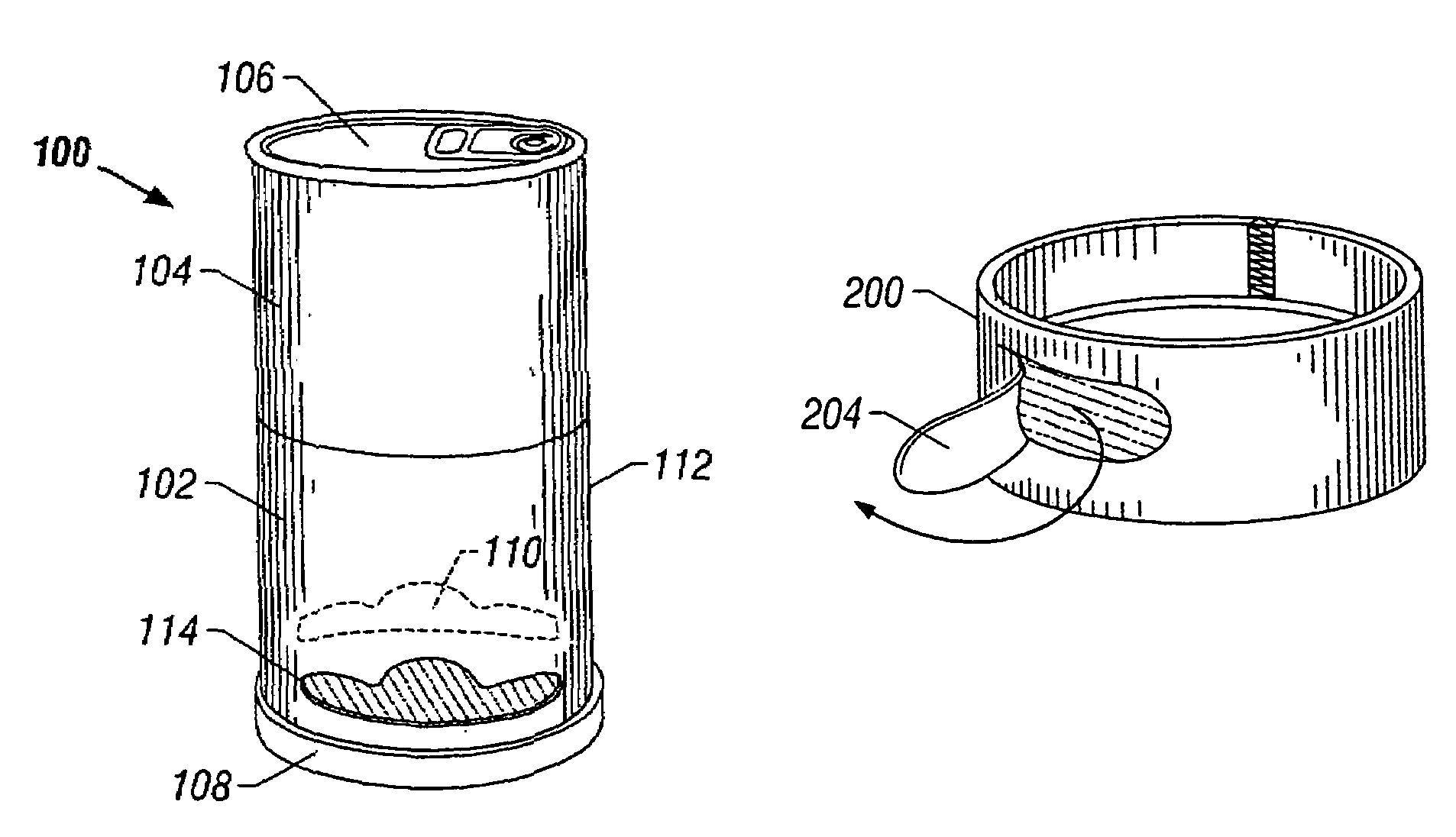

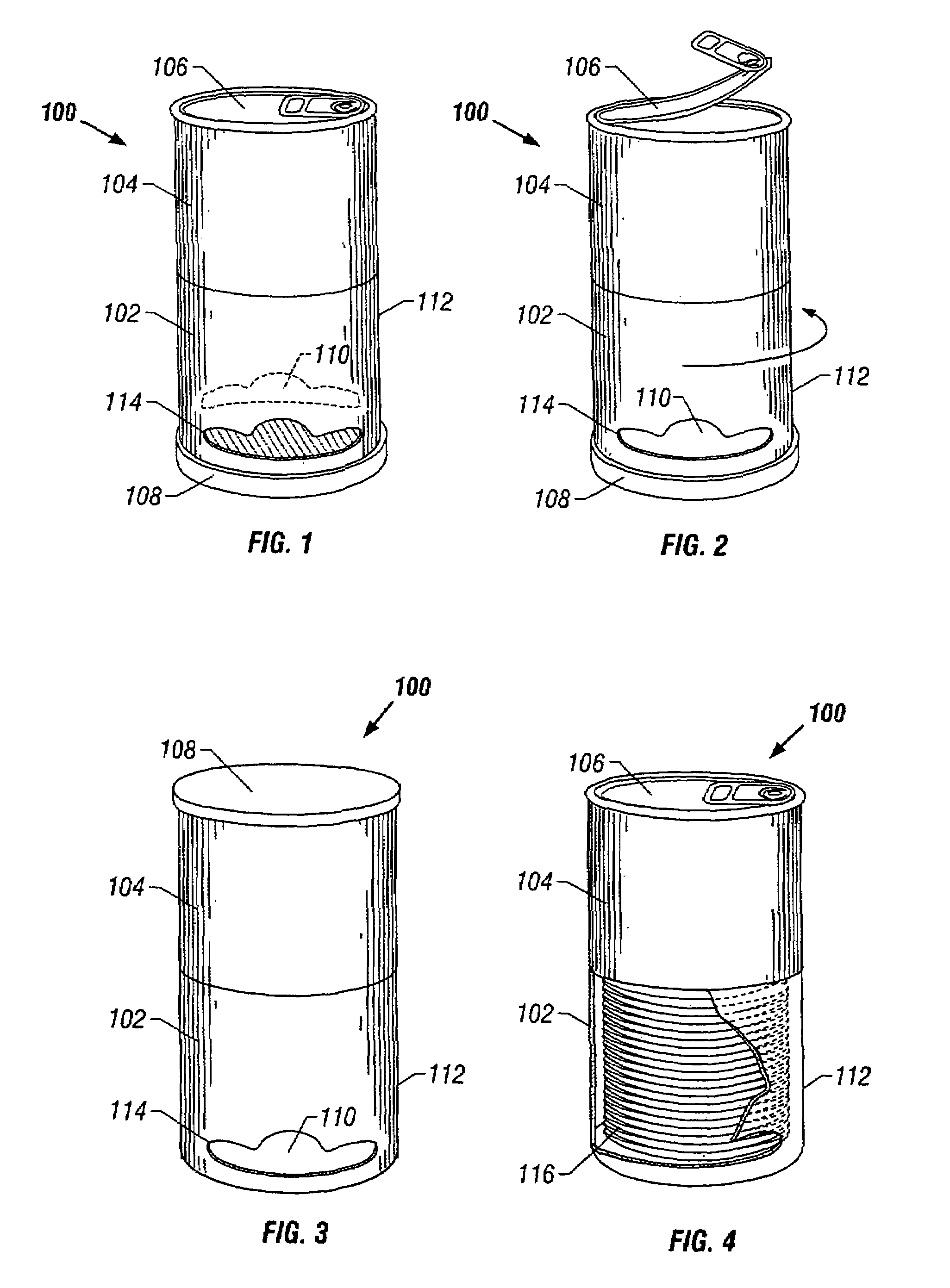

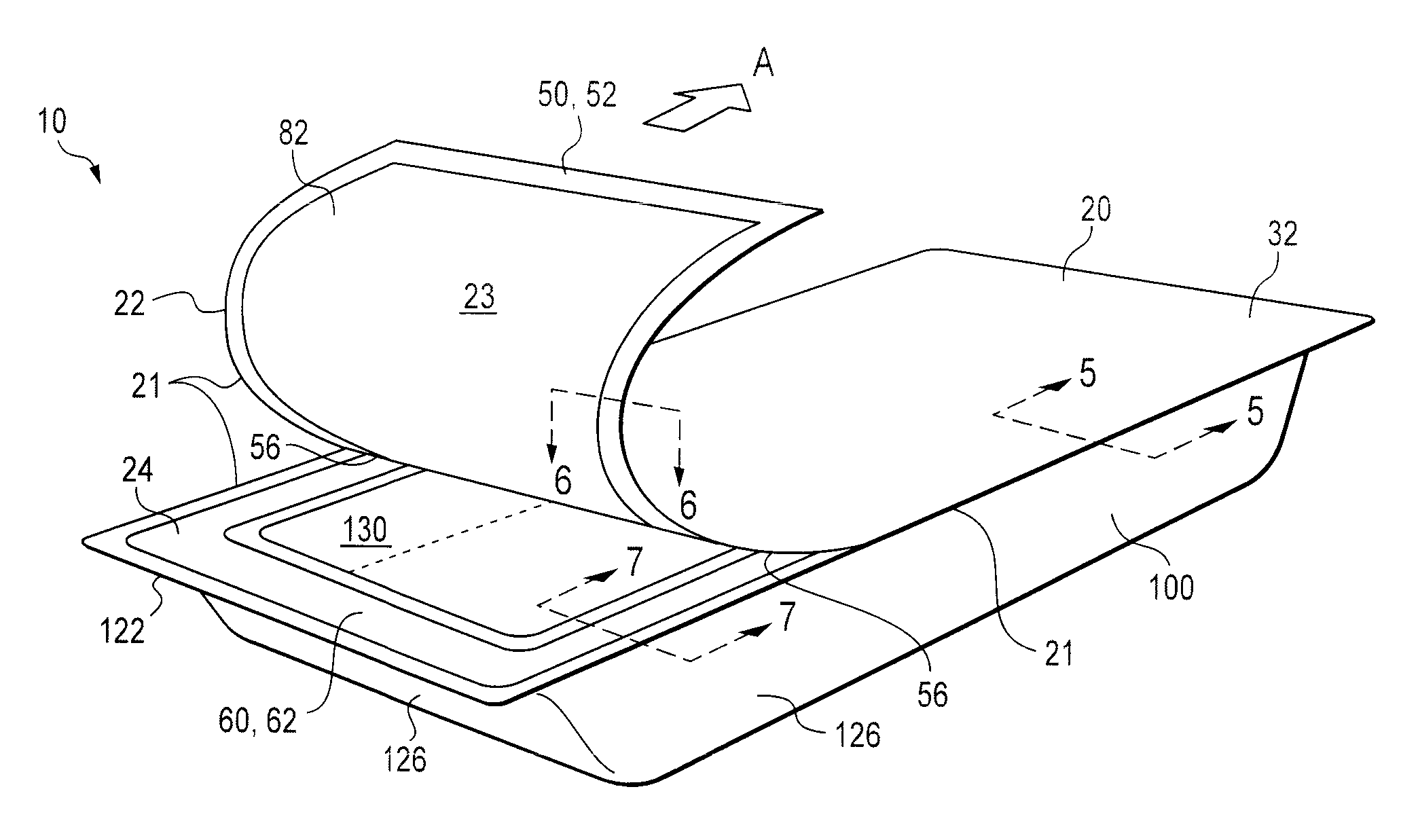

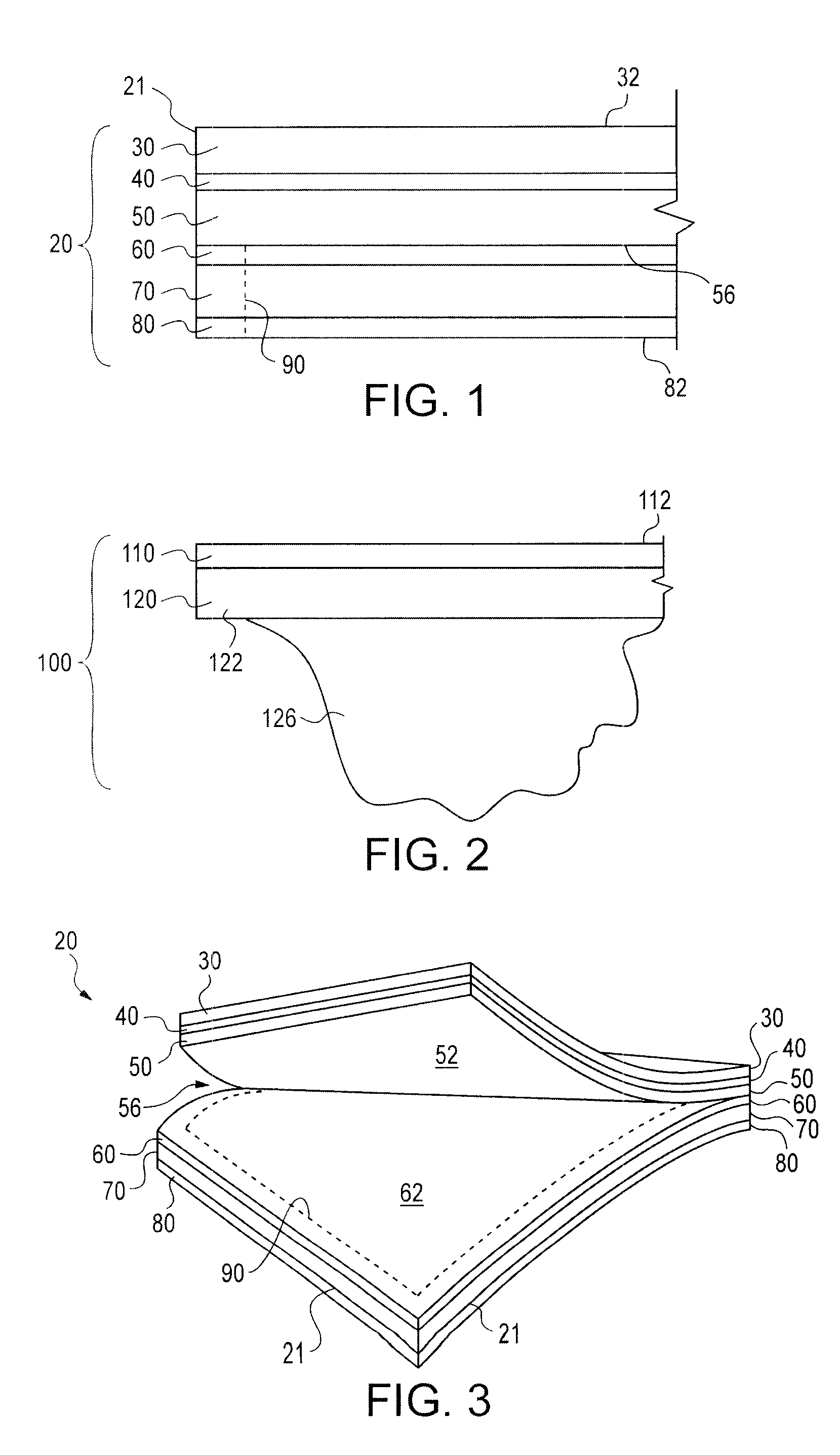

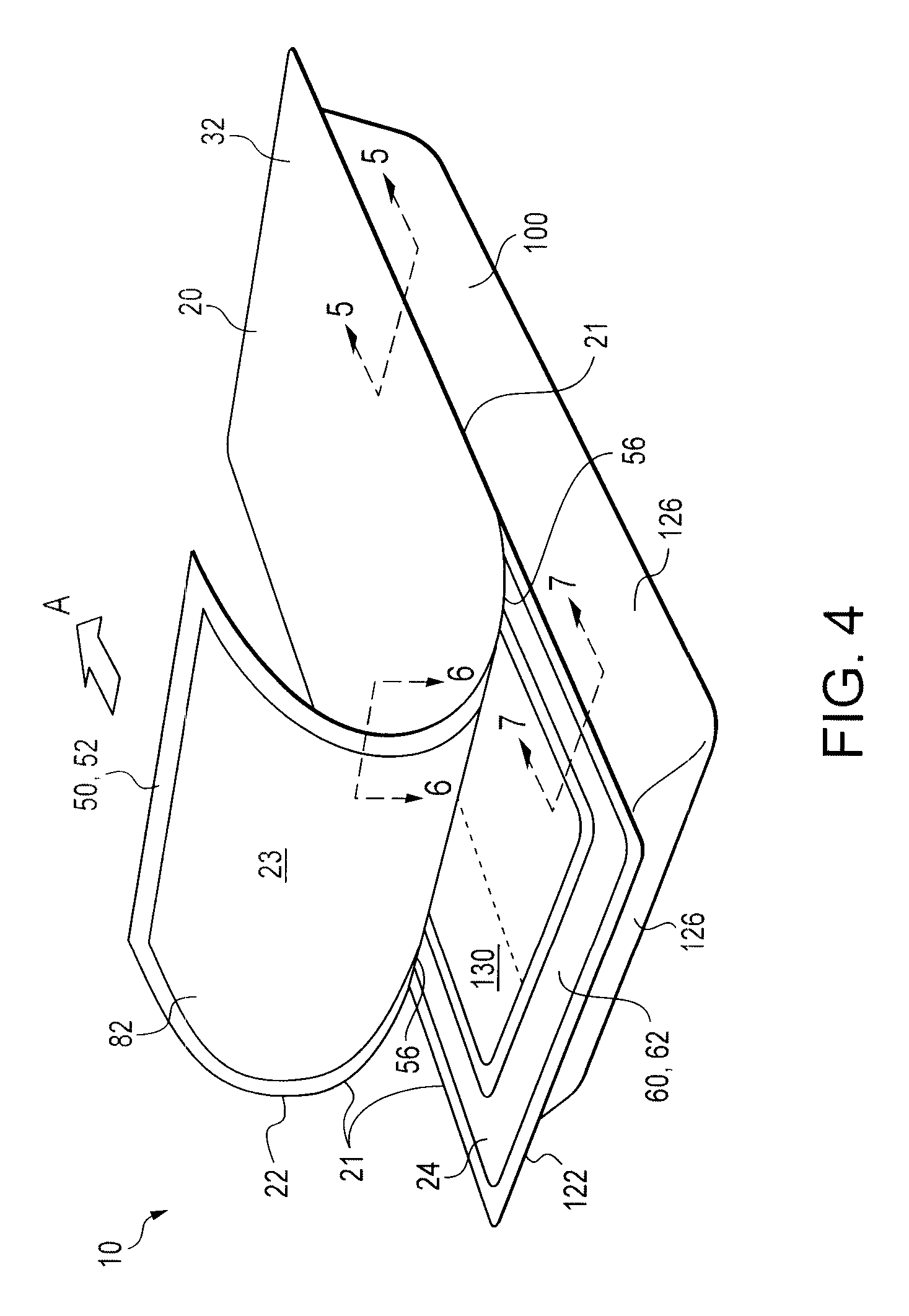

Repositionable base structure for a container

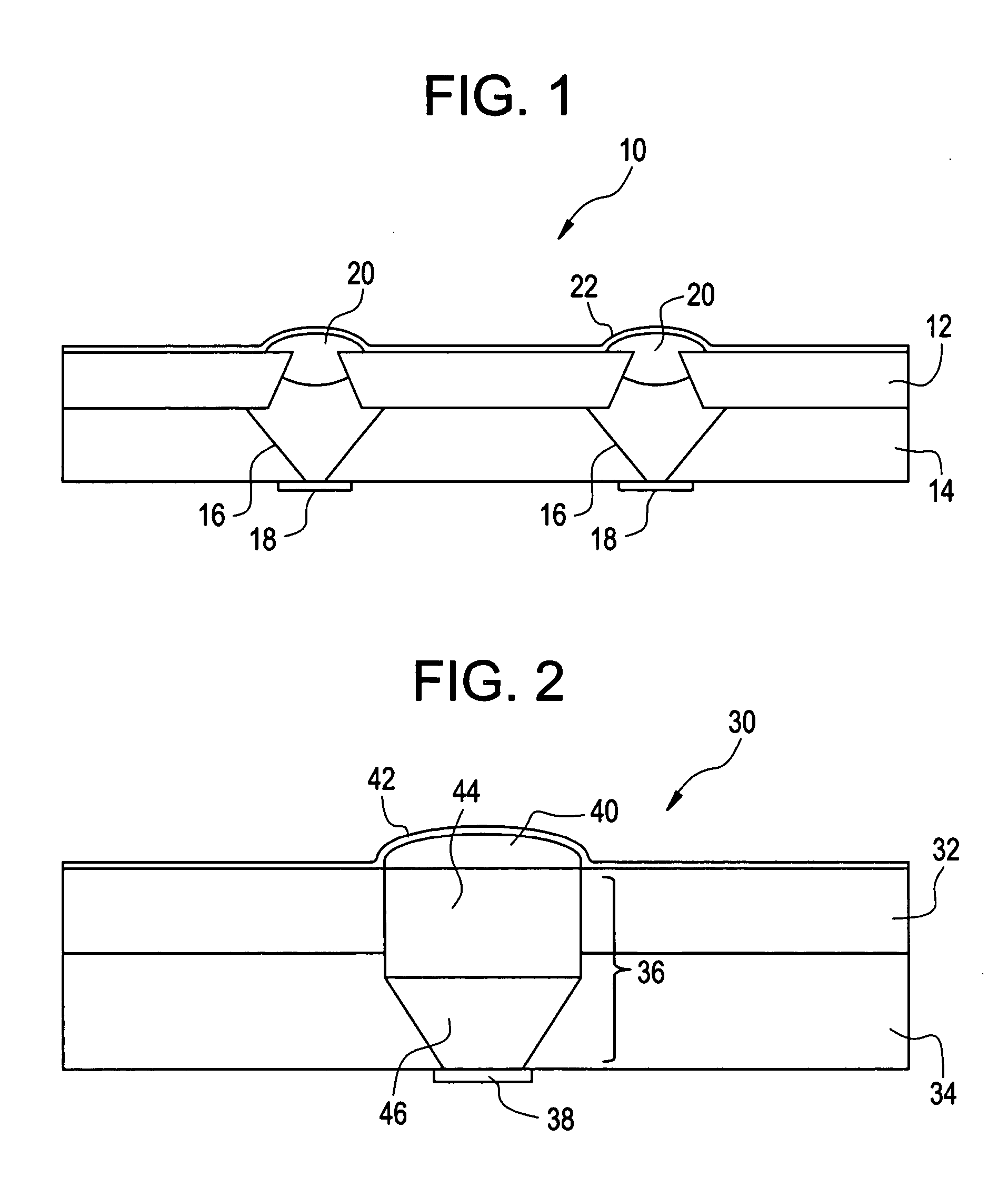

A base of a container including a bearing surface, a hinge, a first wall, and a second wall. The first wall sloping in a first direction from the bearing surface to the hinge, and the second wall sloping in a second direction away from the hinge. The second wall is adapted to be repositioned about the hinge with substantially no movement of the first wall.

Owner:CO2 PAC

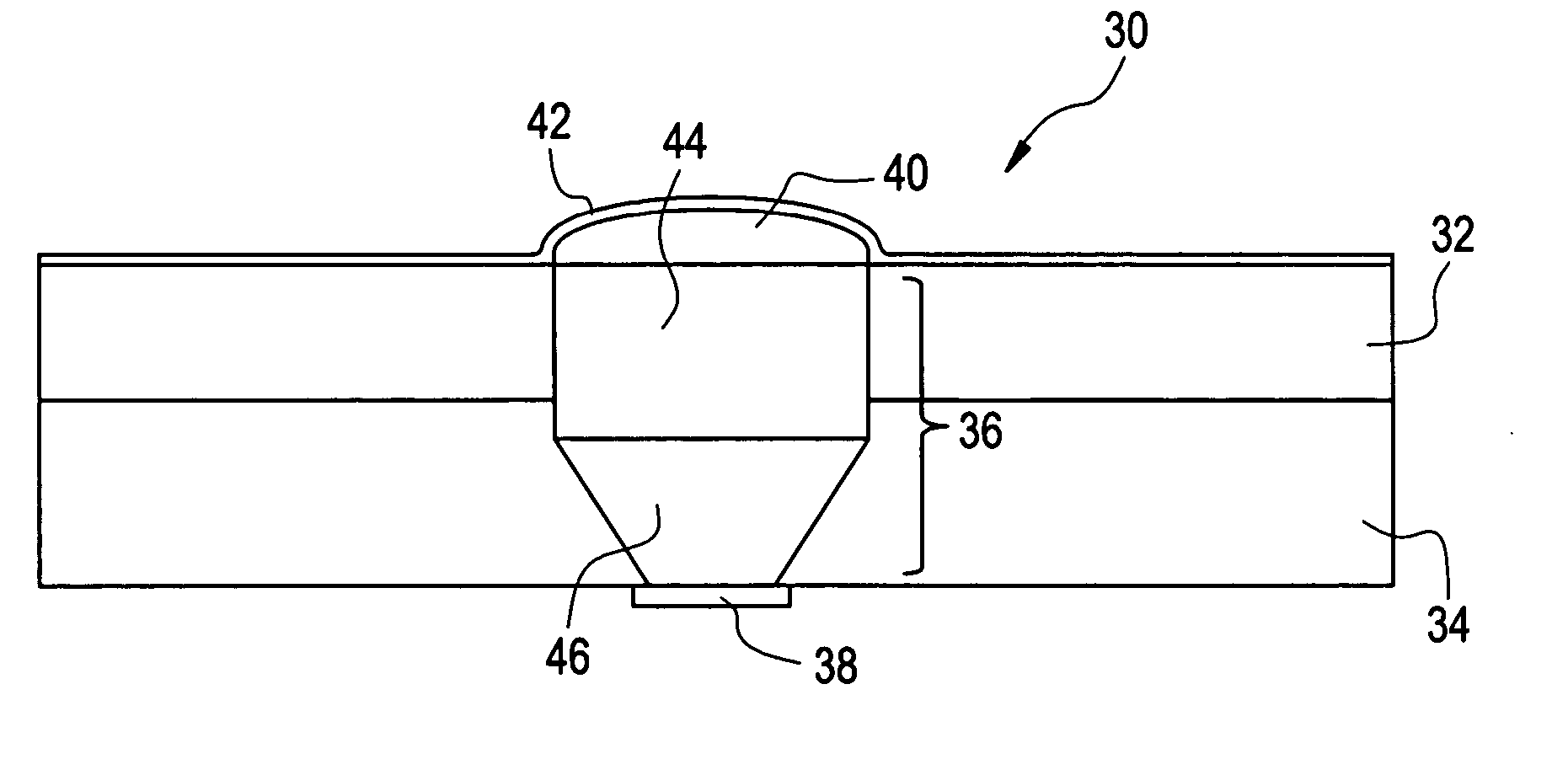

Low temperature methods for hermetically sealing reservoir devices

Methods are provided for hermetically sealing an opening in a reservoir of a containment device. The method comprises applying a polymeric material to an opening in a reservoir of a containment device, the reservoir comprising reservoir contents (such as a drug or a sensor) to be hermetically isolated within the reservoir, the applied polymeric material closing off the opening and forming a temporary seal; and adhering a hermetic sealing material onto the polymeric material to hermetically seal the opening. The reservoir can be a micro-reservoir. The containment device can comprises an array of two or more of reservoirs, and the method comprises hermetically sealing each of the two or more reservoirs.

Owner:MICROCHIPS BIOTECH INC

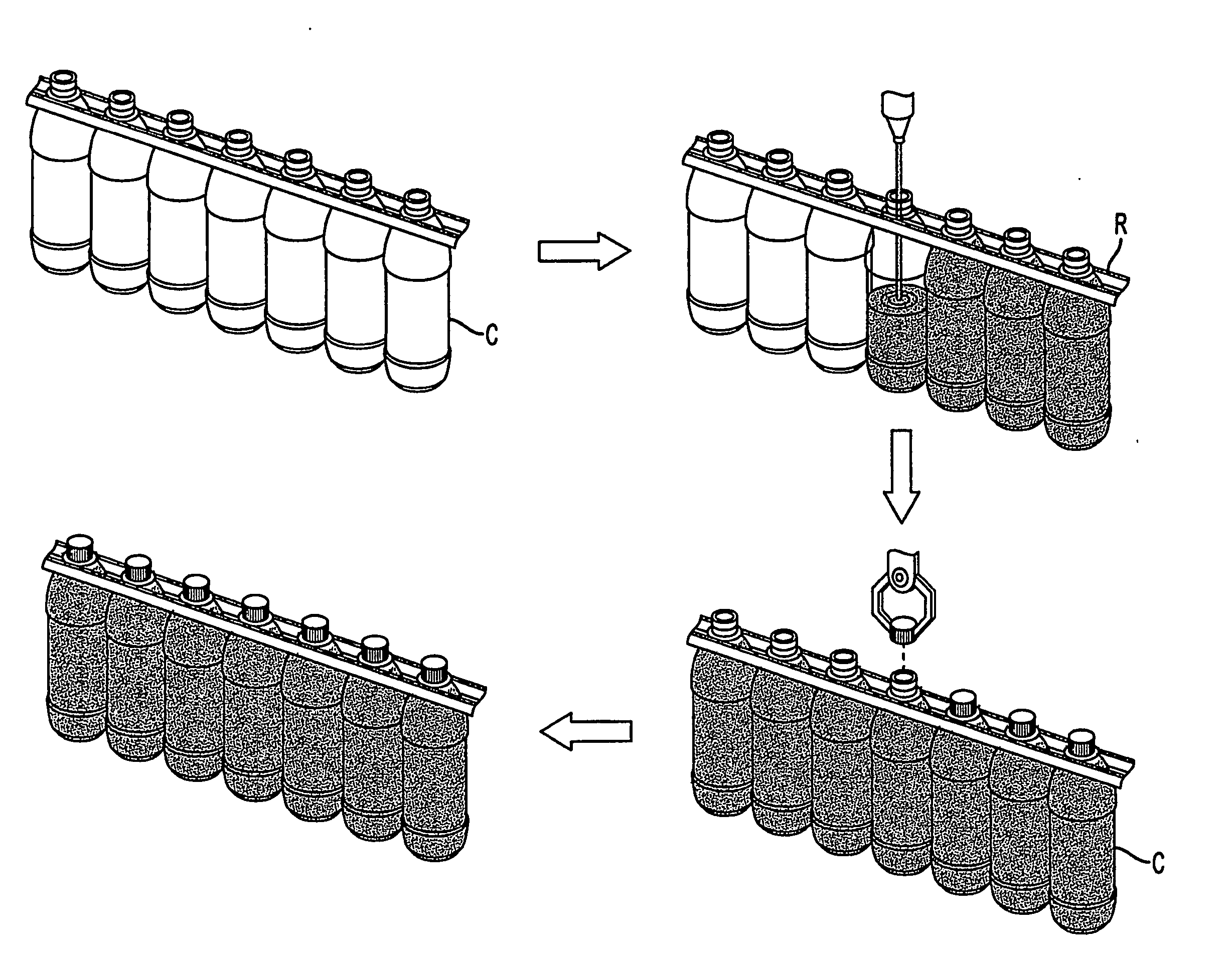

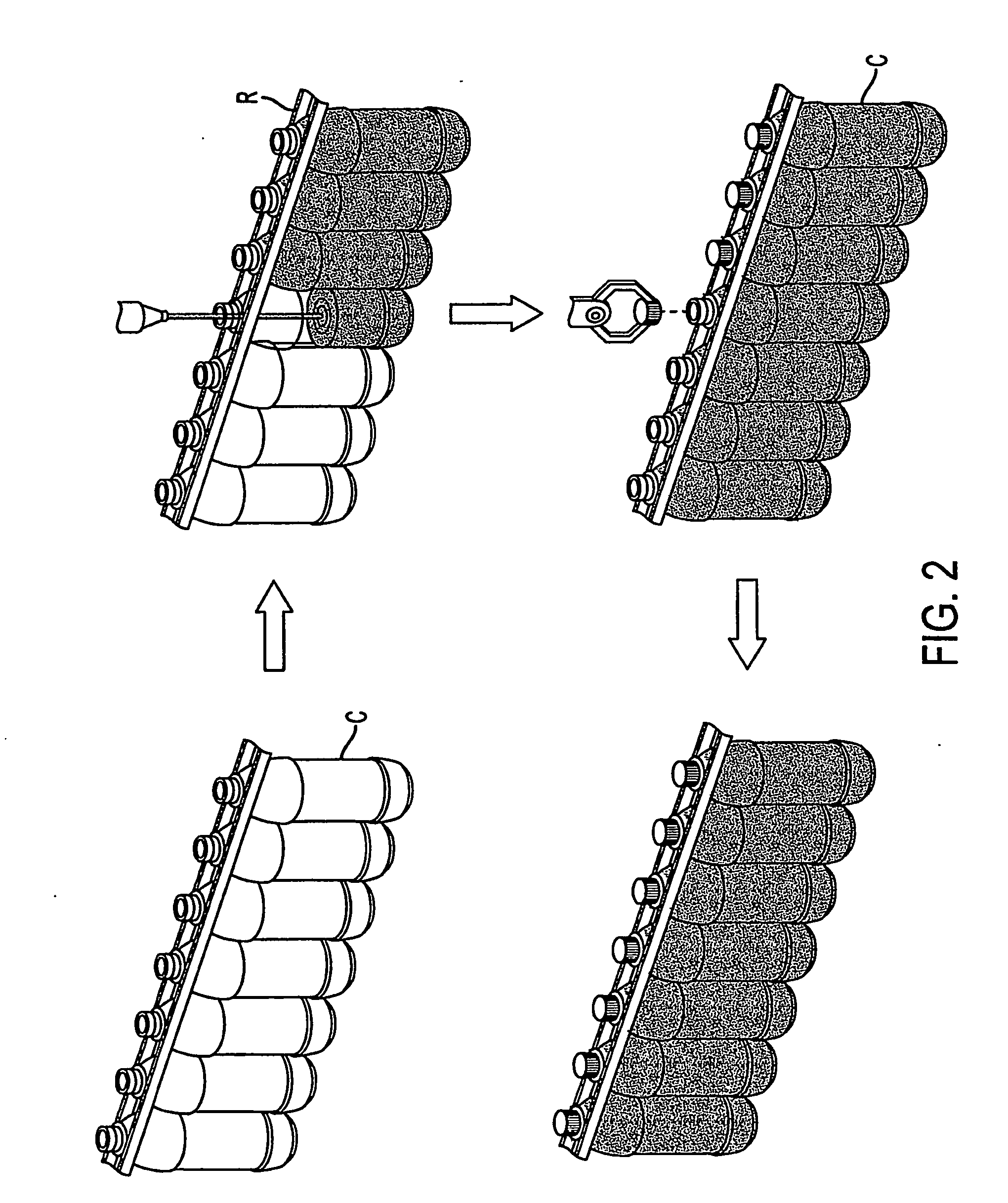

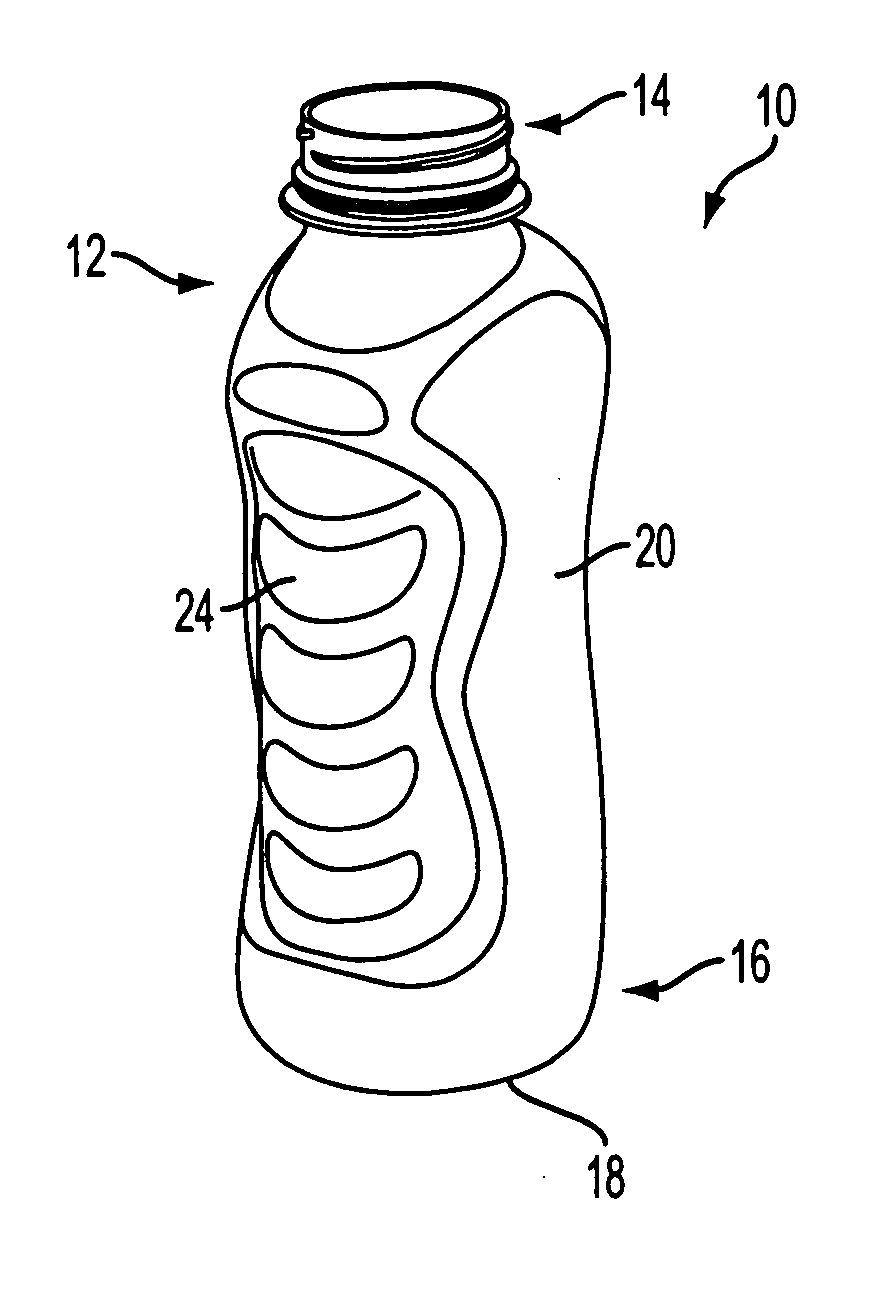

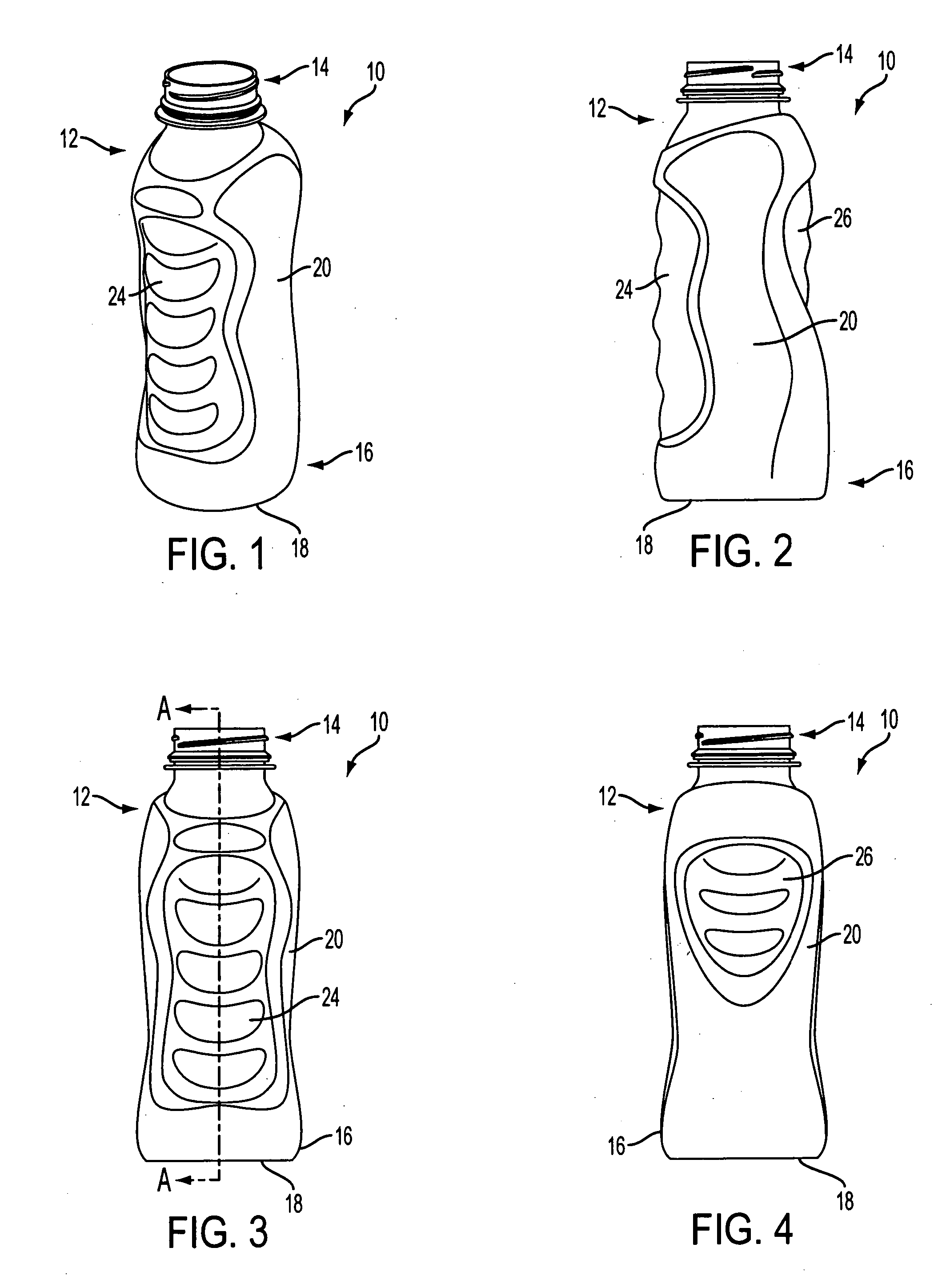

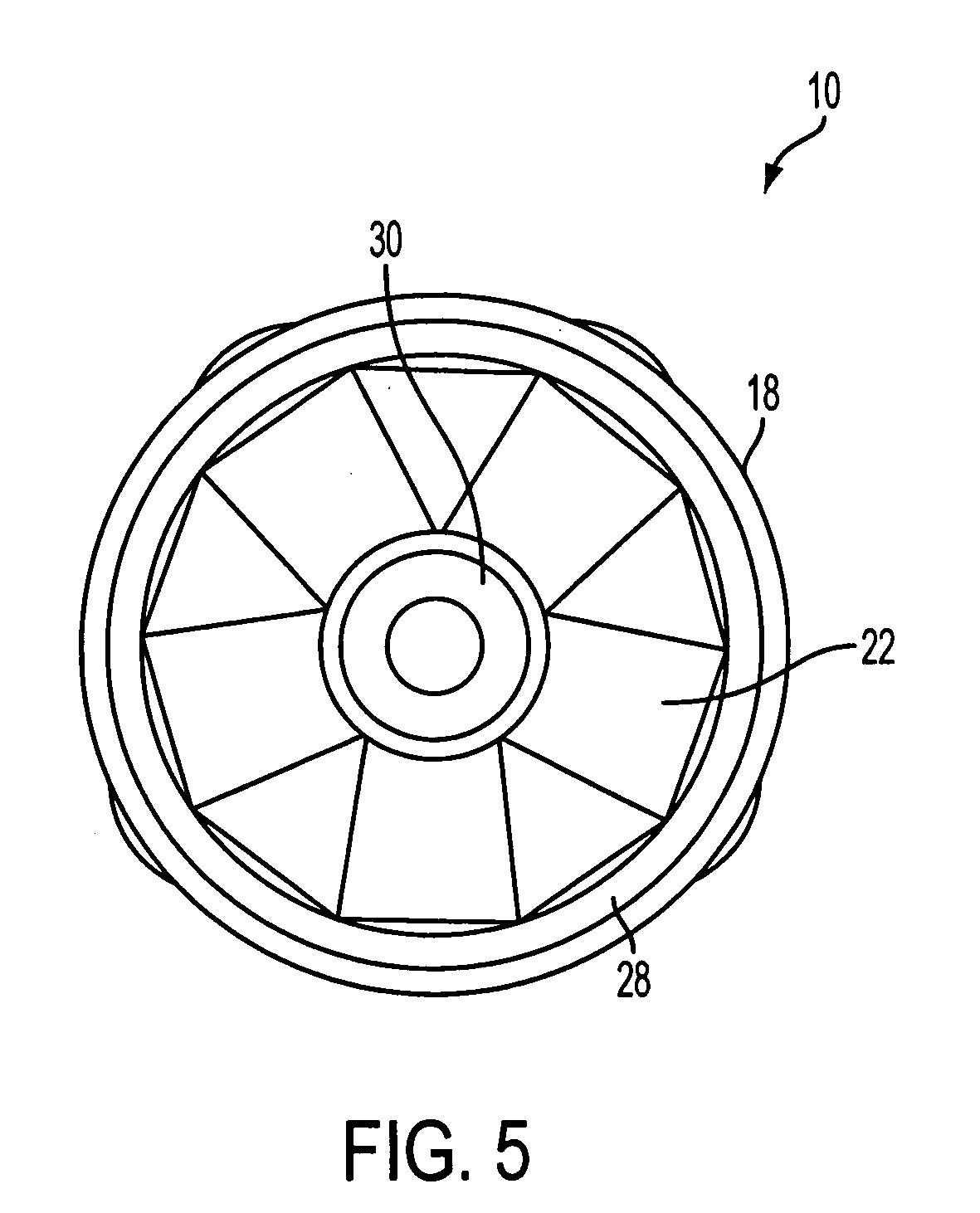

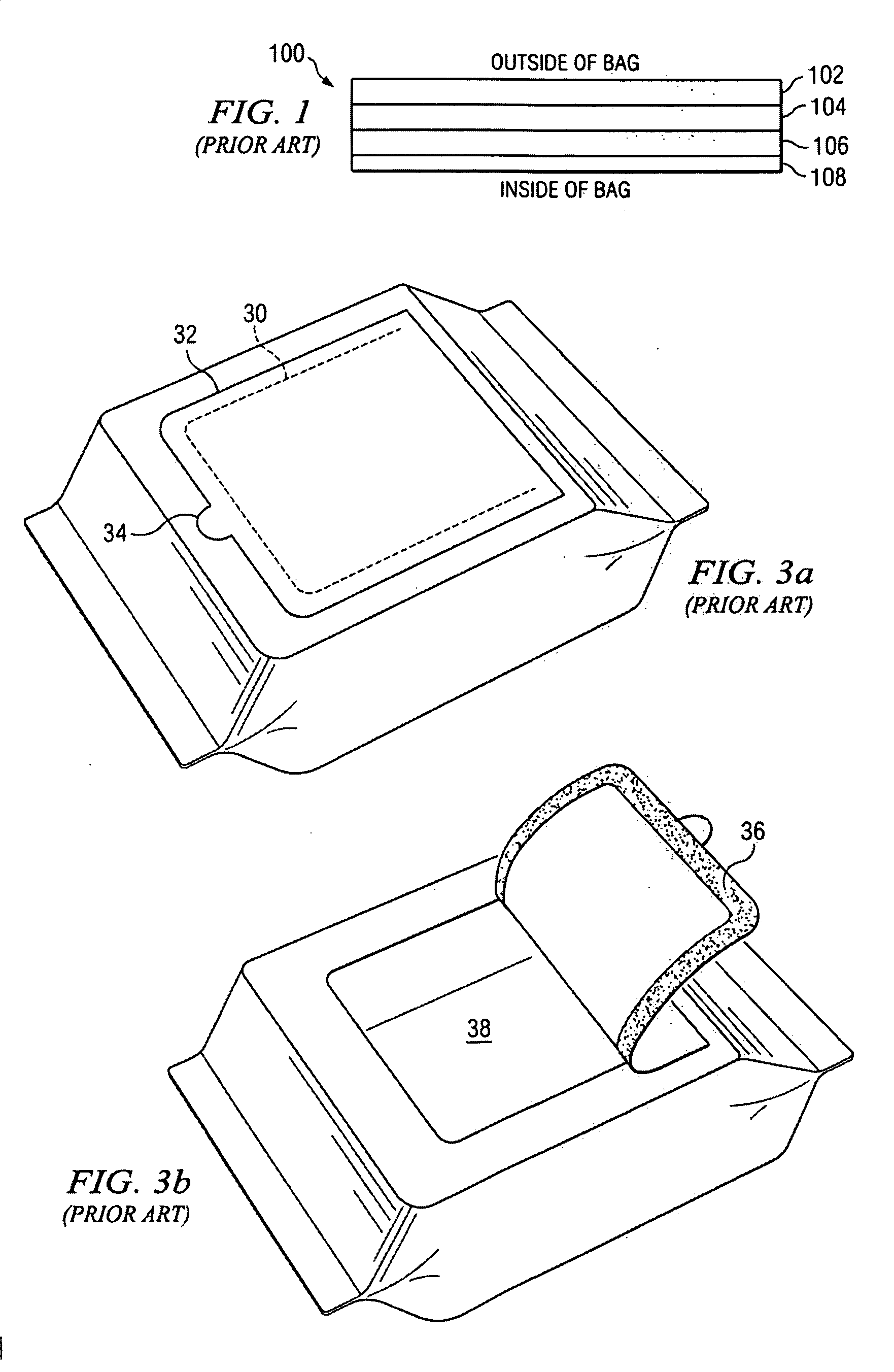

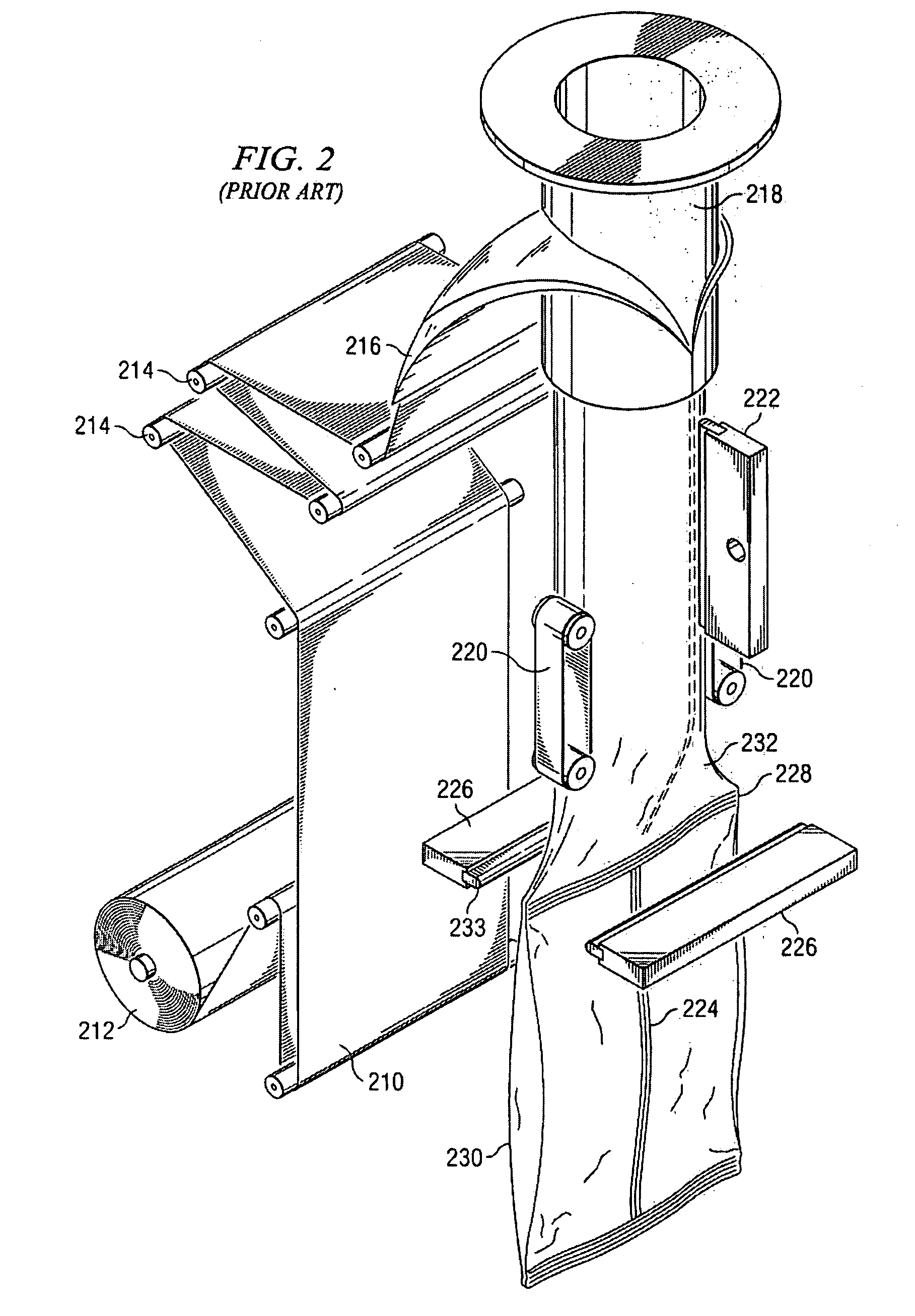

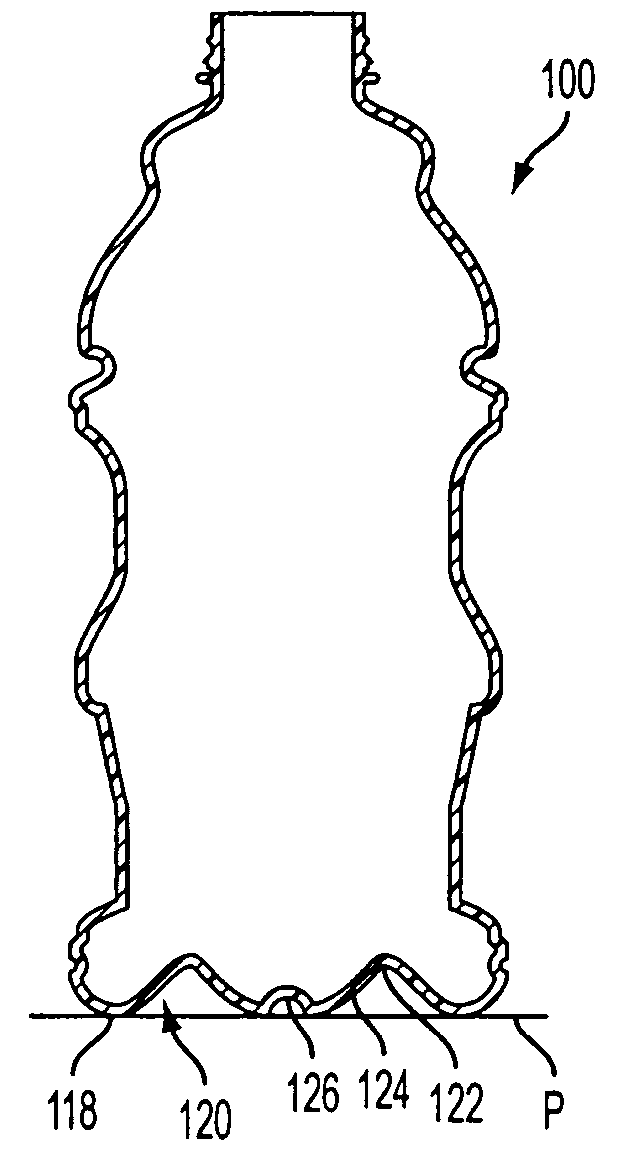

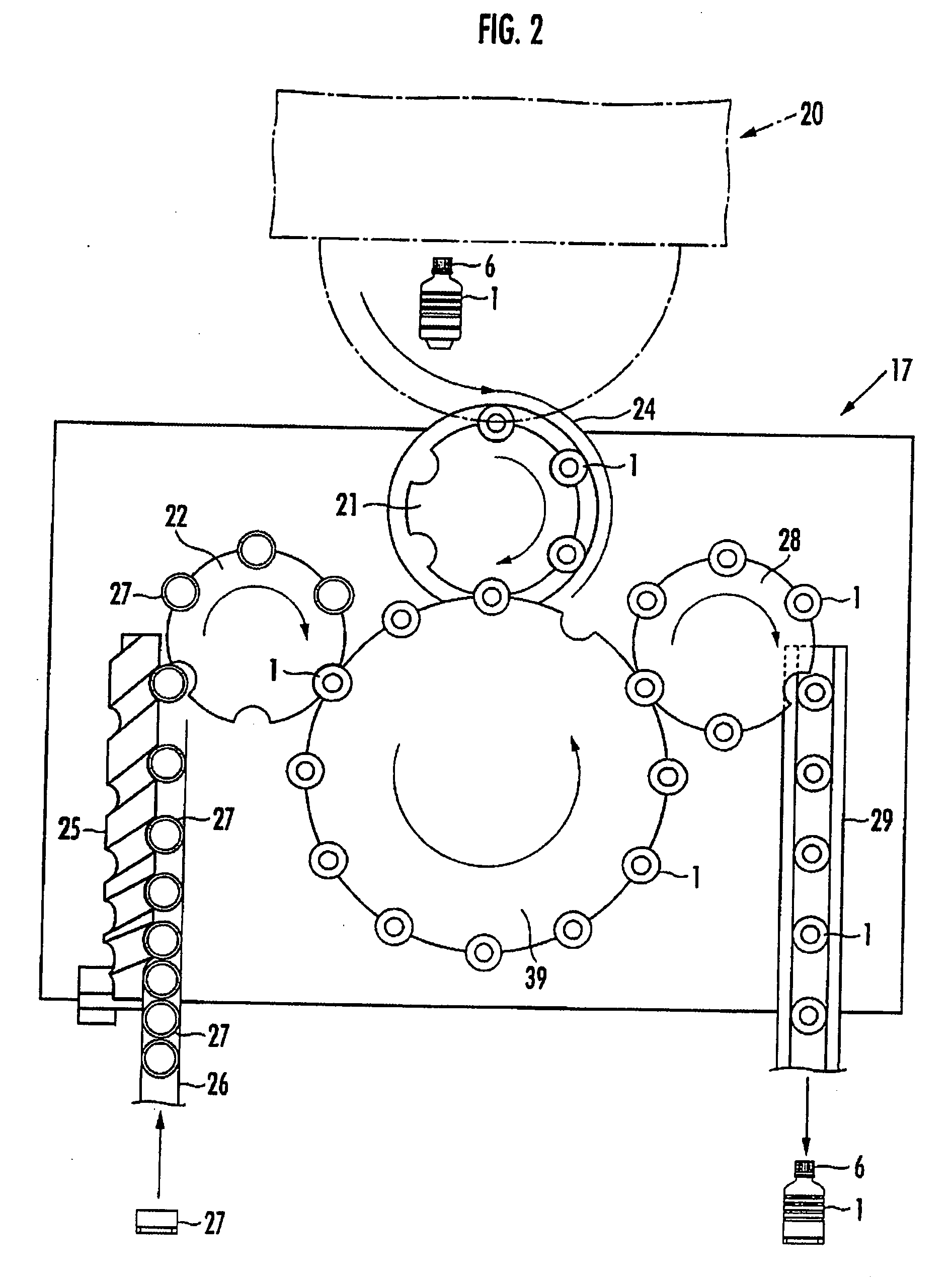

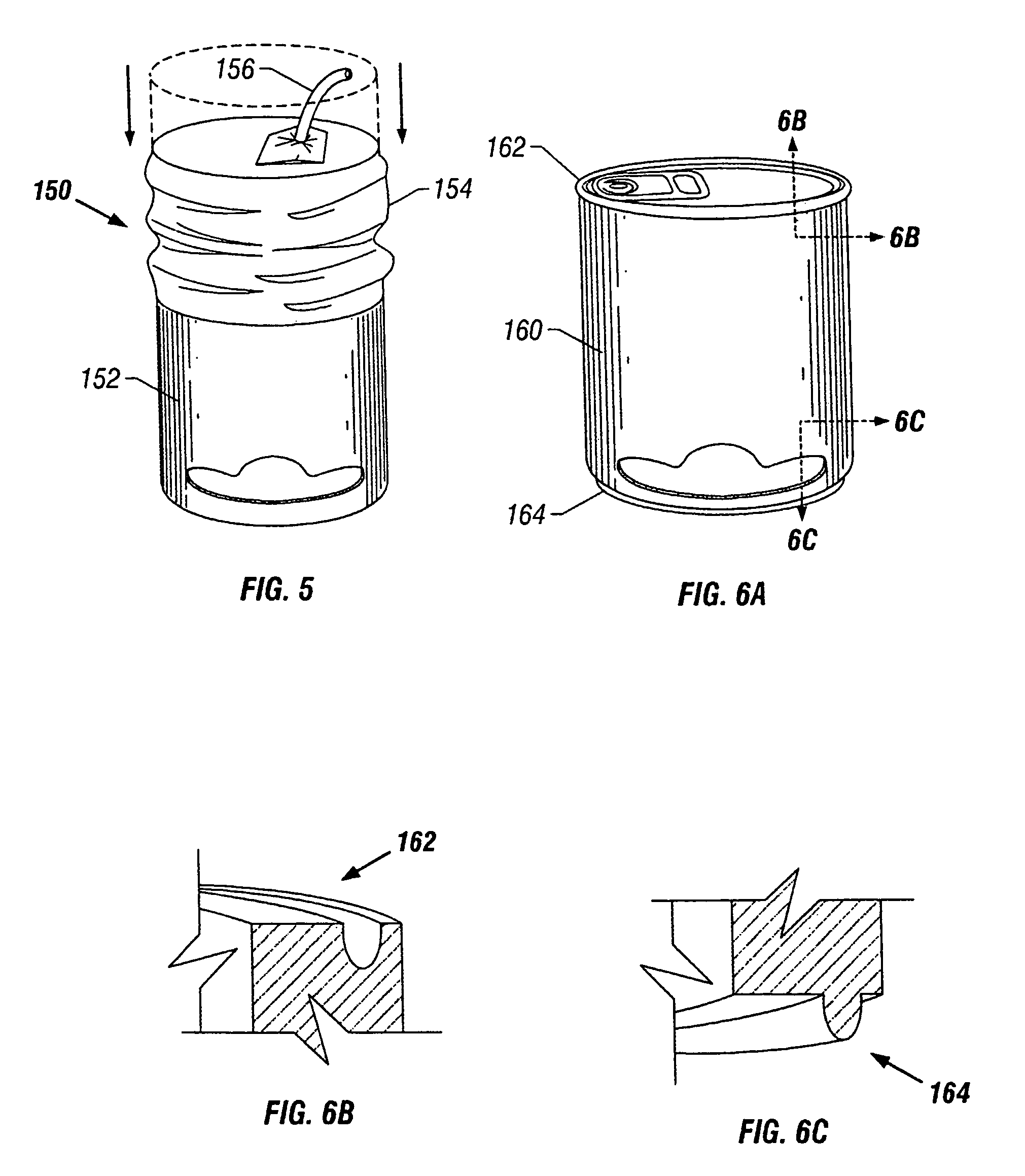

Container handling system

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

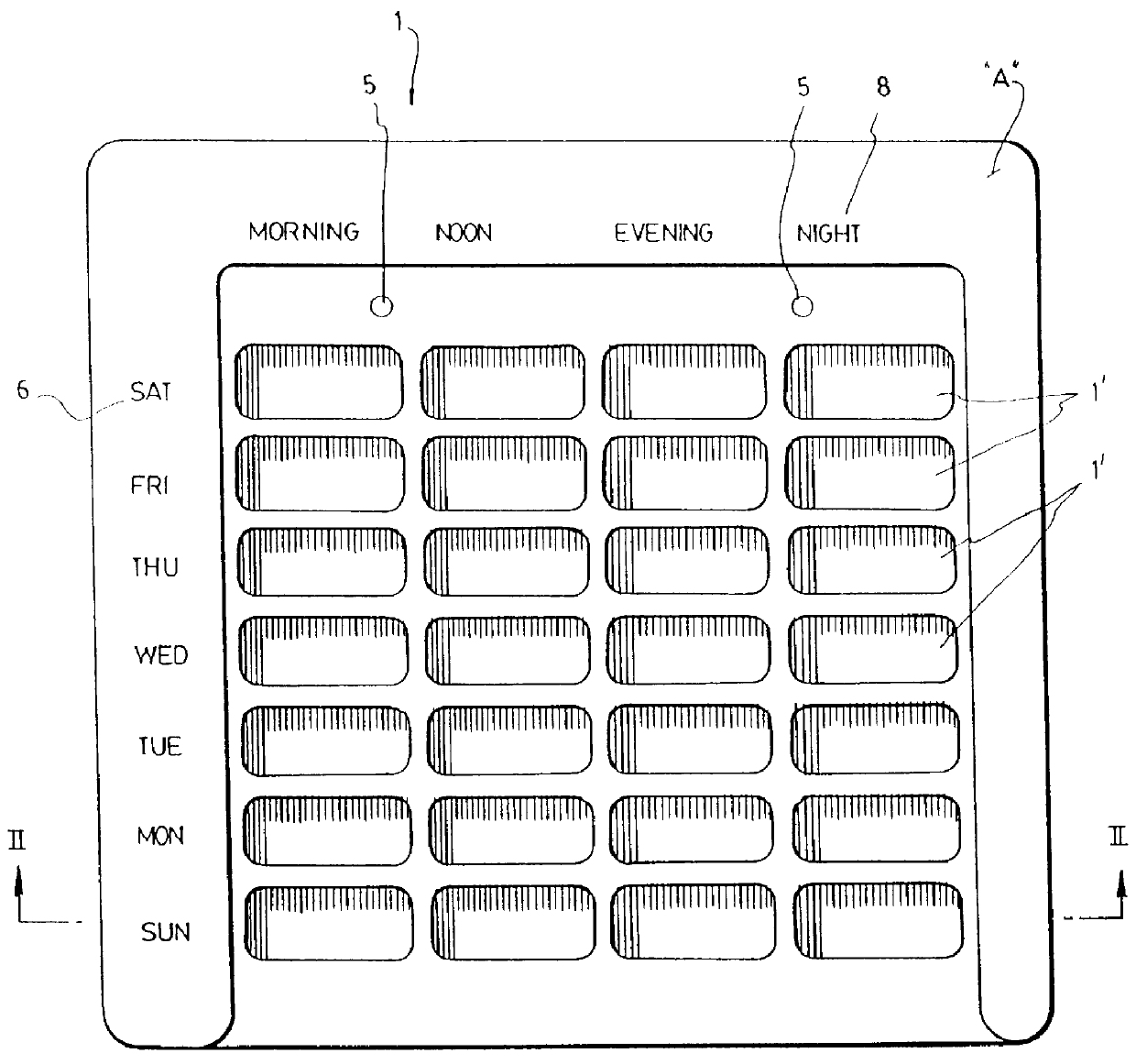

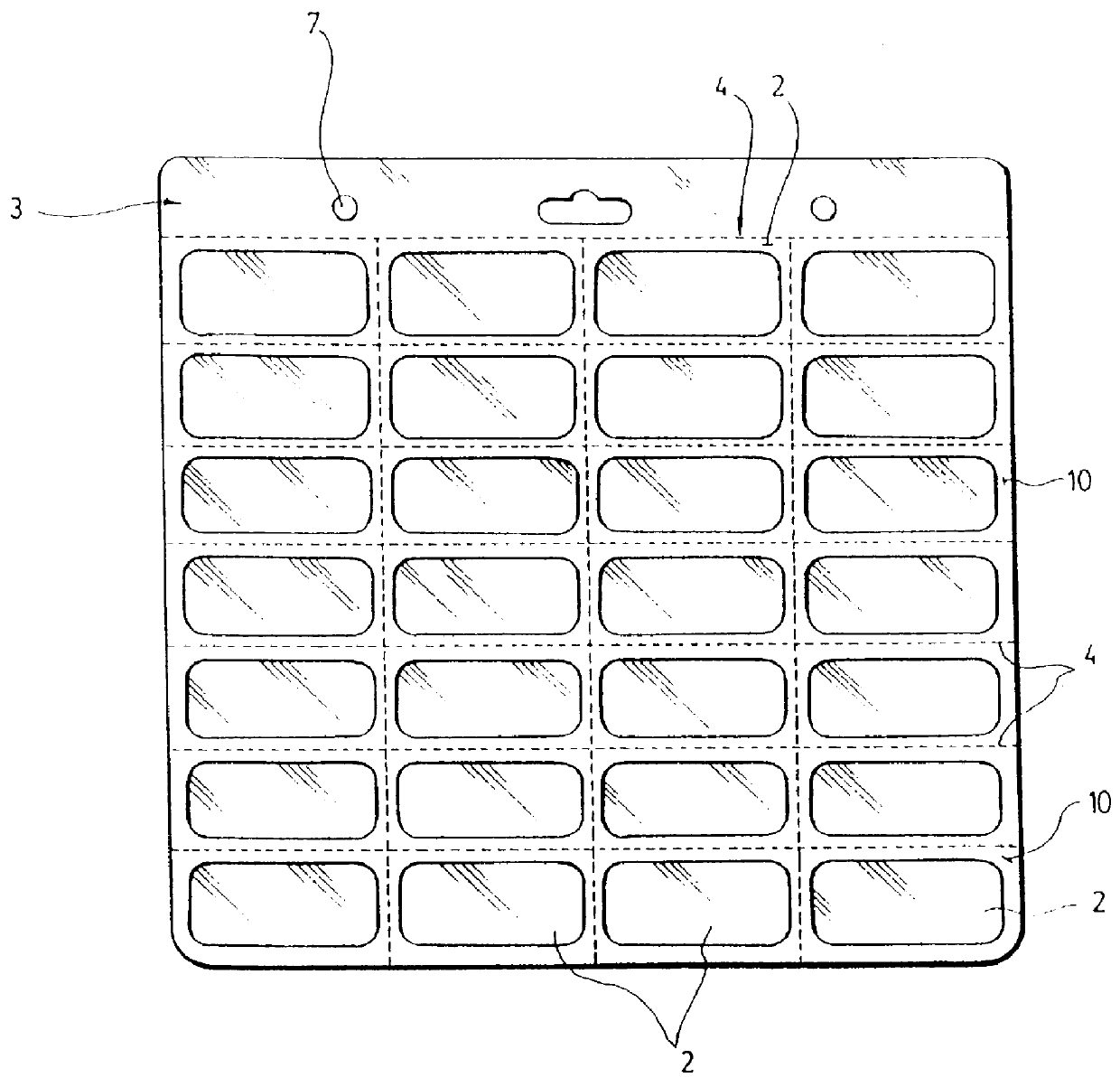

Kit and process for the manufacture of a set of individual pill containers

A kit to sort out pills, tablets or capsules, which comprises a recessed support, a container-defining sheet designed to fit into the support, and a sealing sheet made of self-adhesive paper as having substantially the same dimension as the container-defining sheet, so as to close the same. Positioning elements are provided on the sealing sheet and on the support and / or the container-defining sheet in order to facilitate proper fixation of the sealing sheet on top of the container-defining sheet. A pill-sorting device made of two sliding panels with hollow bottomed recesses can be used to insert the pills into the containers of the container-defining sheet.

Owner:9155 0020 QUEBEC

Method and device for pressurizing containers

Owner:INOFLATE

Pressure reinforced plastic container and related method of processing a plastic container

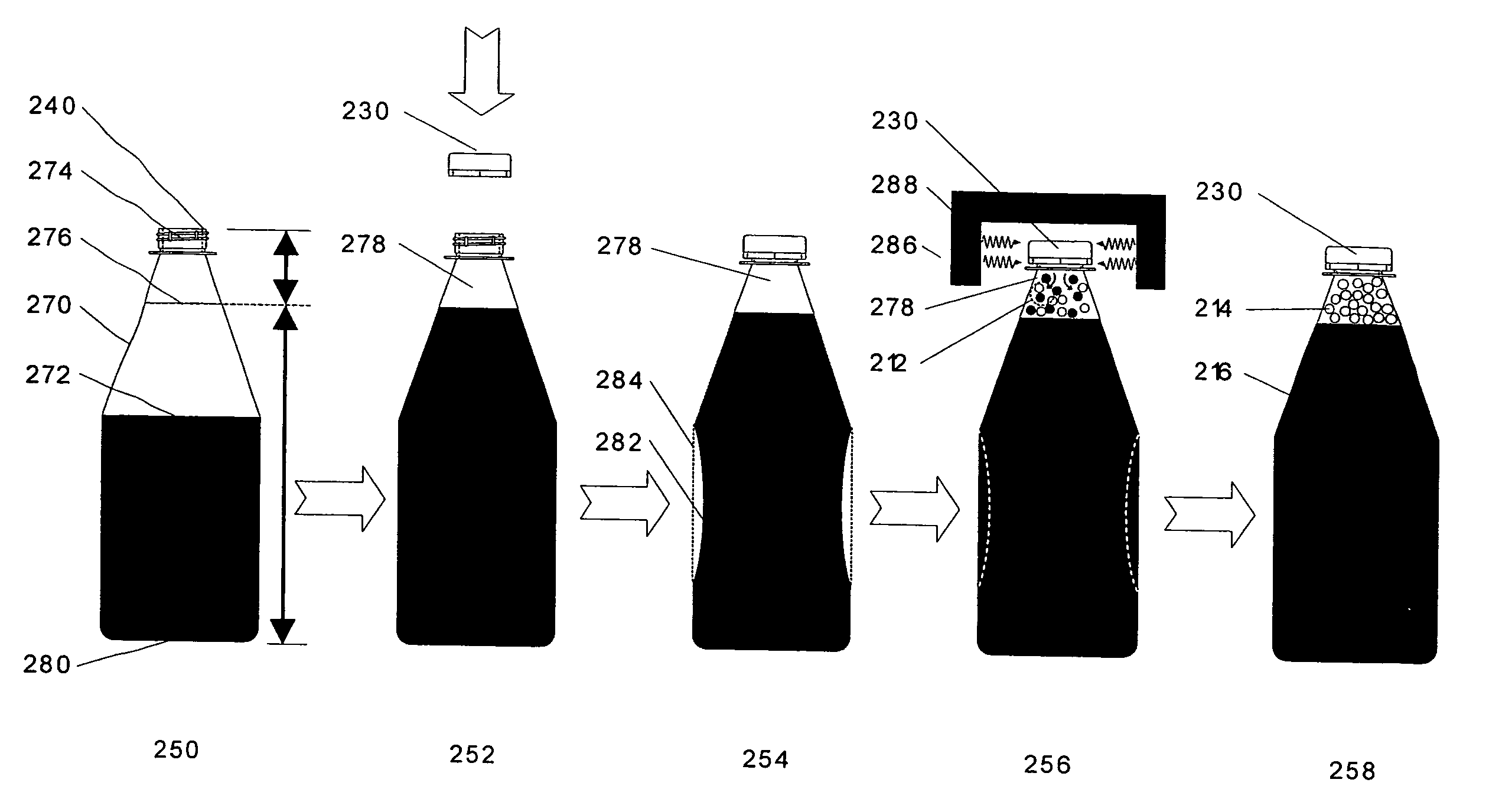

InactiveUS20060255005A1Reduce internal volumeReduce needCapsThreaded caps applicationPositive pressureEngineering

A plastic container comprises an upper portion including a finish adapted to receive a closure, a lower portion including a base, and a sidewall extending between the upper portion and the lower portion. The upper portion, the lower portion, and the sidewall define an interior volume for storing liquid contents. The plastic container further comprises a pressure panel located on the container and moveable between an initial position and an activated position. The pressure panel is located in the initial position prior to filling the container, and is moved to the activated position after filling and sealing the container. Moving the pressure panel from the initial position to the activated position reduces the internal volume of the container and creates a positive pressure inside the container. The positive pressure reinforces the sidewall. A method of processing a container is also disclosed.

Owner:CO2 PAC

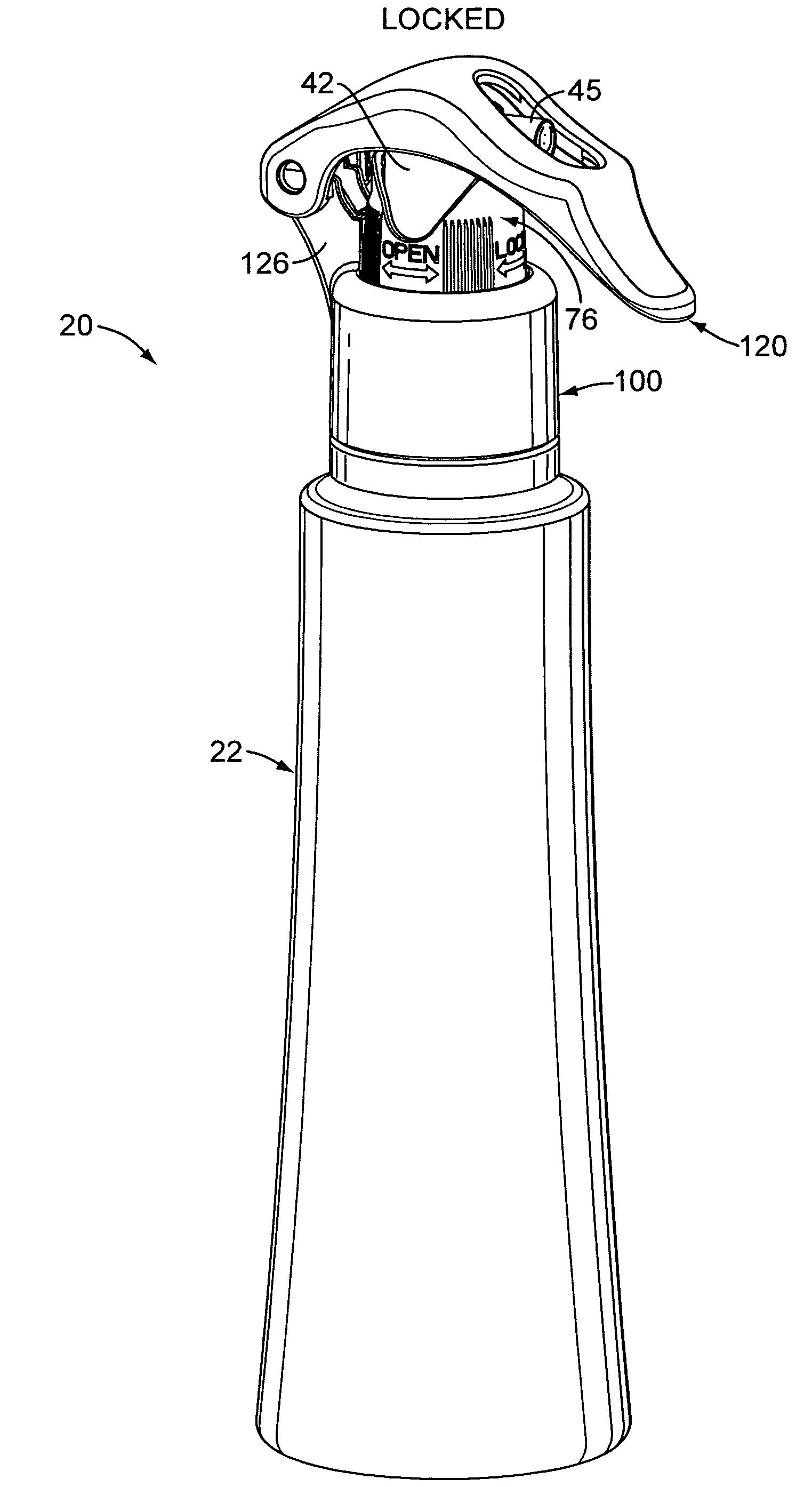

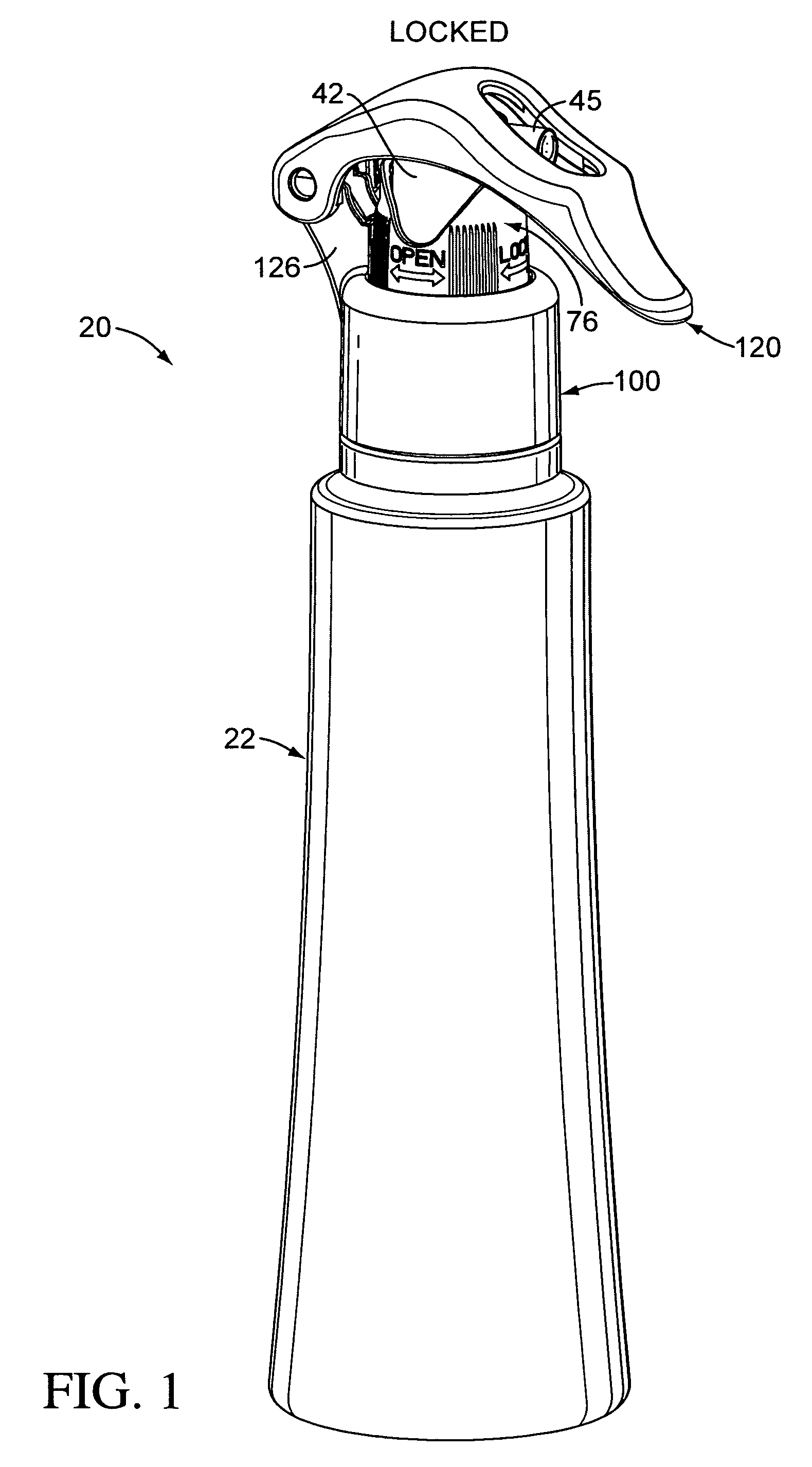

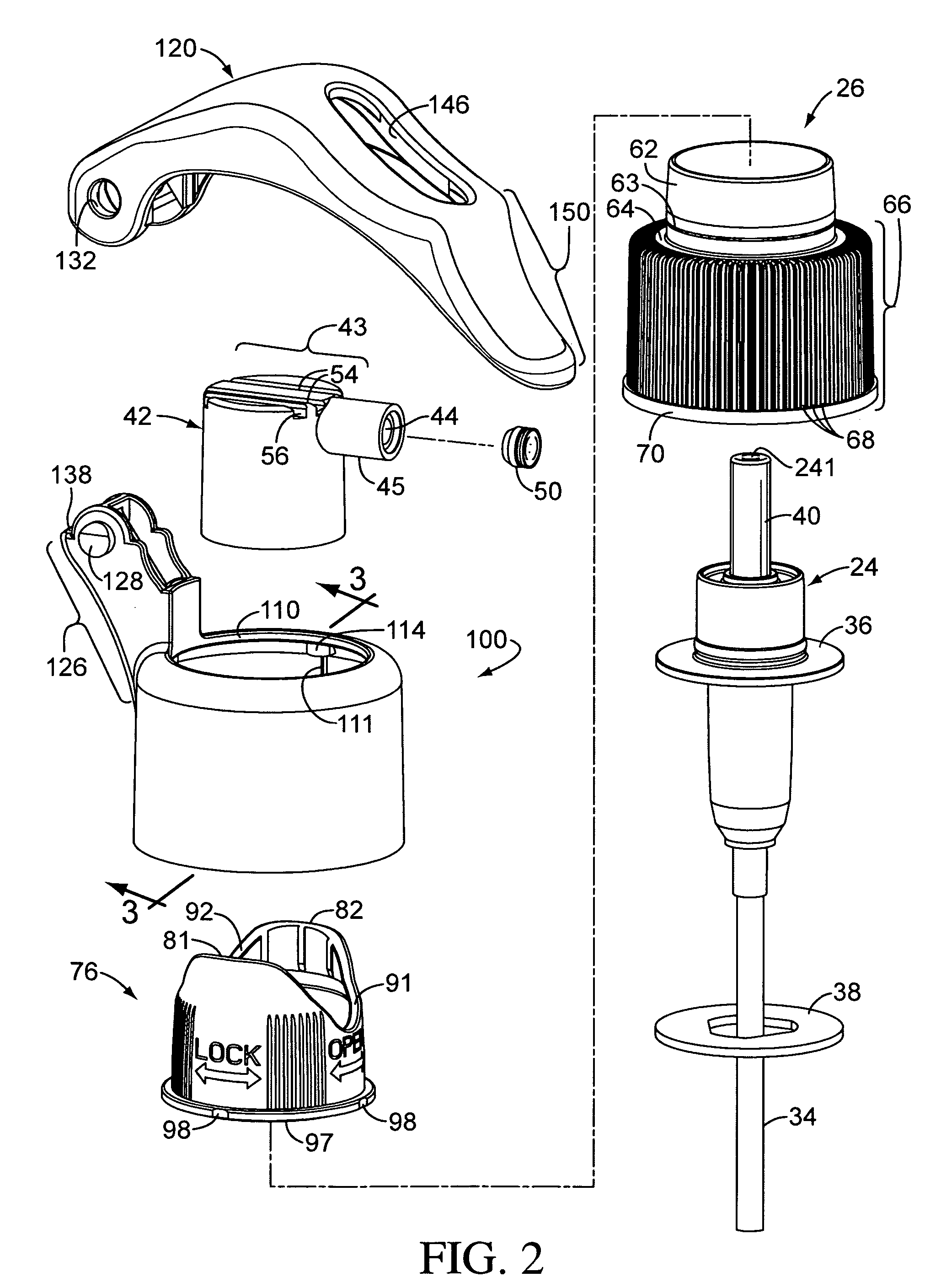

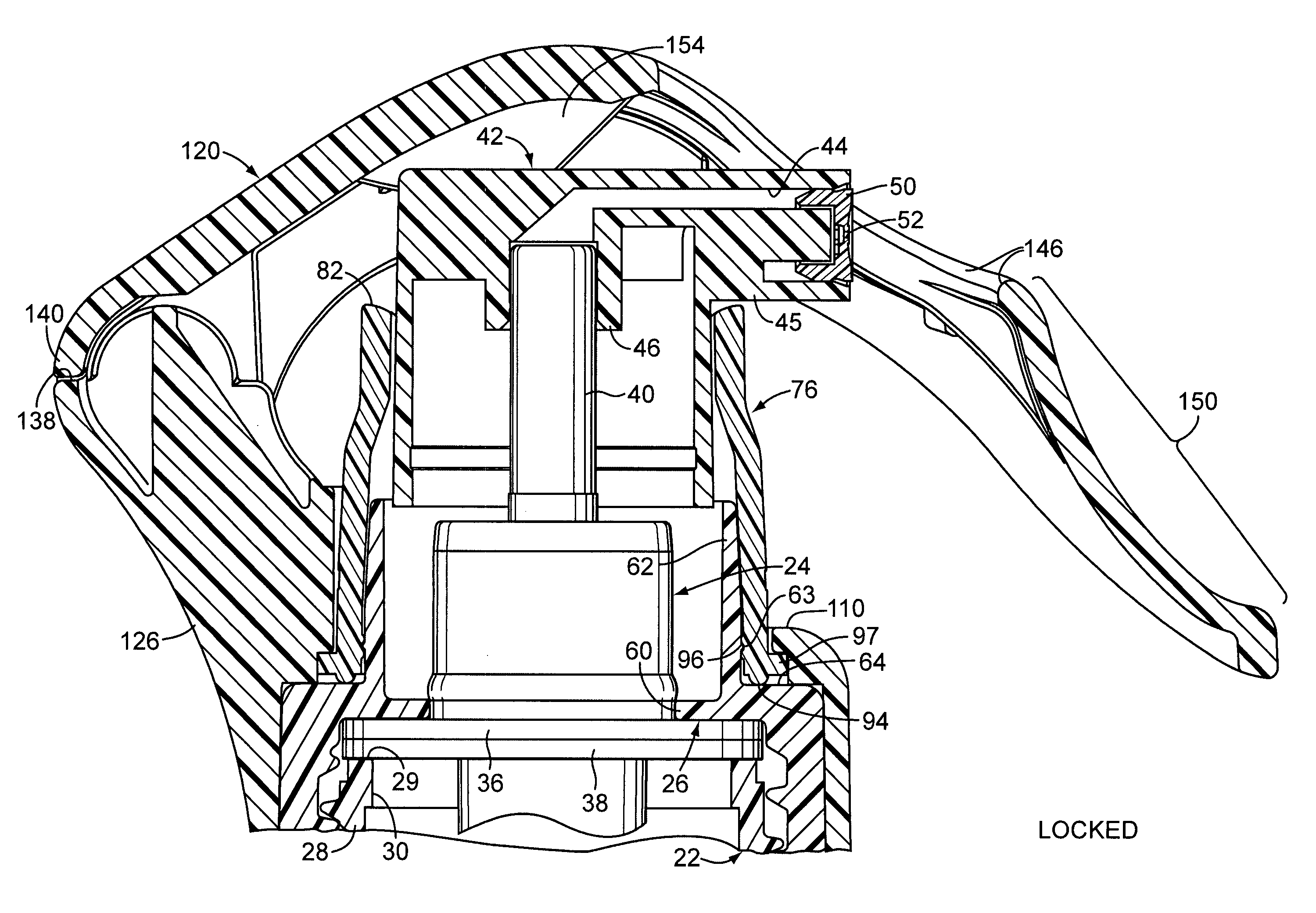

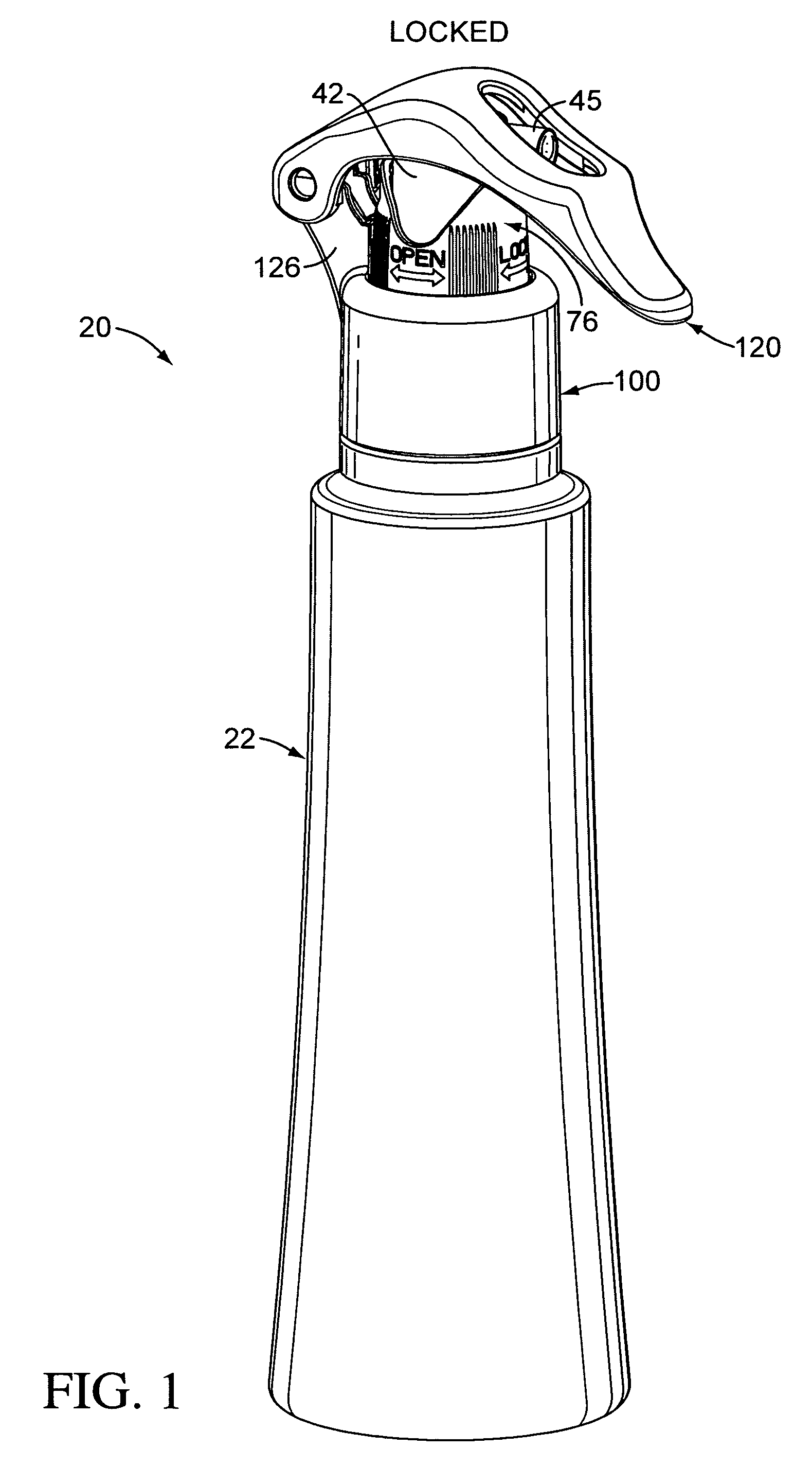

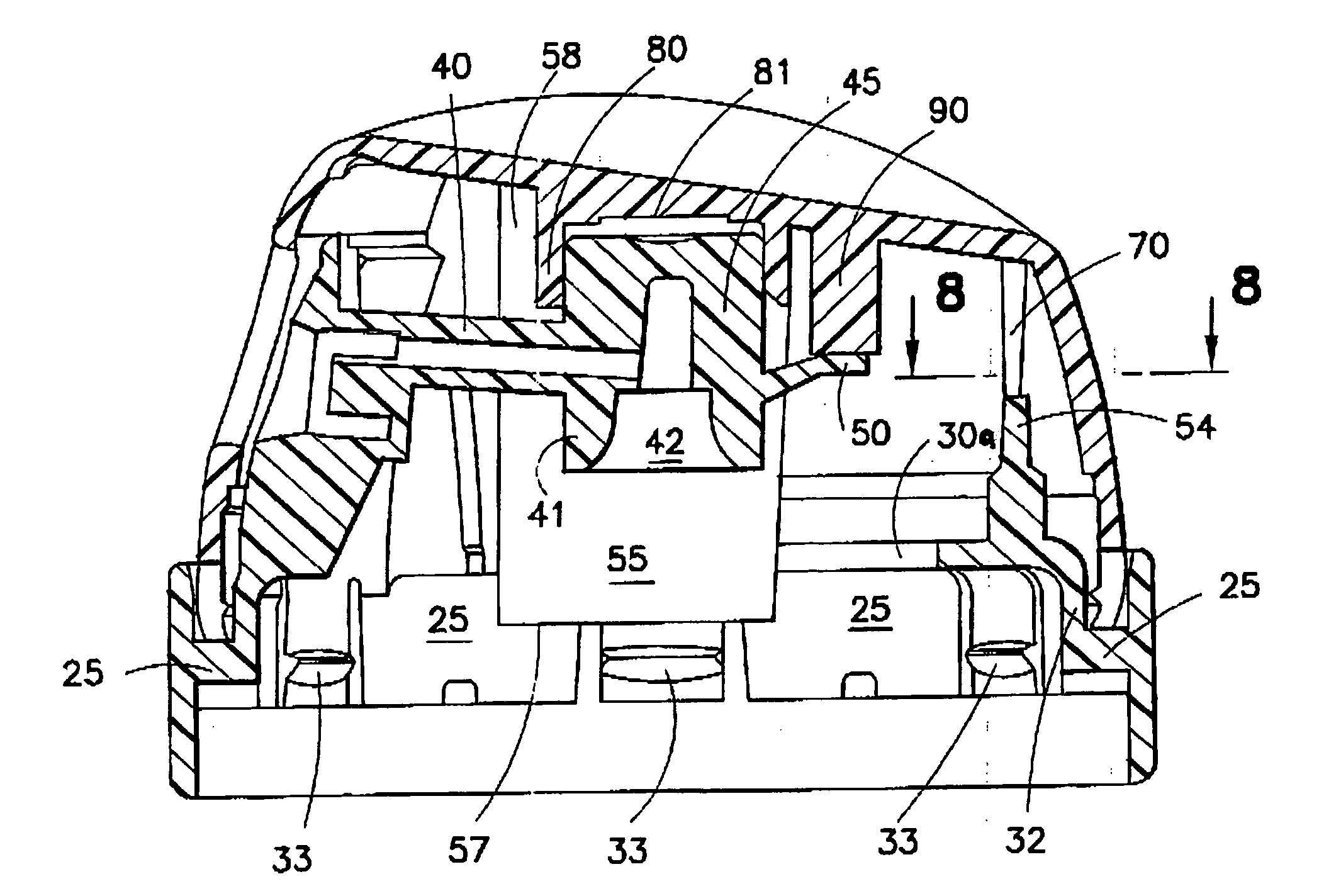

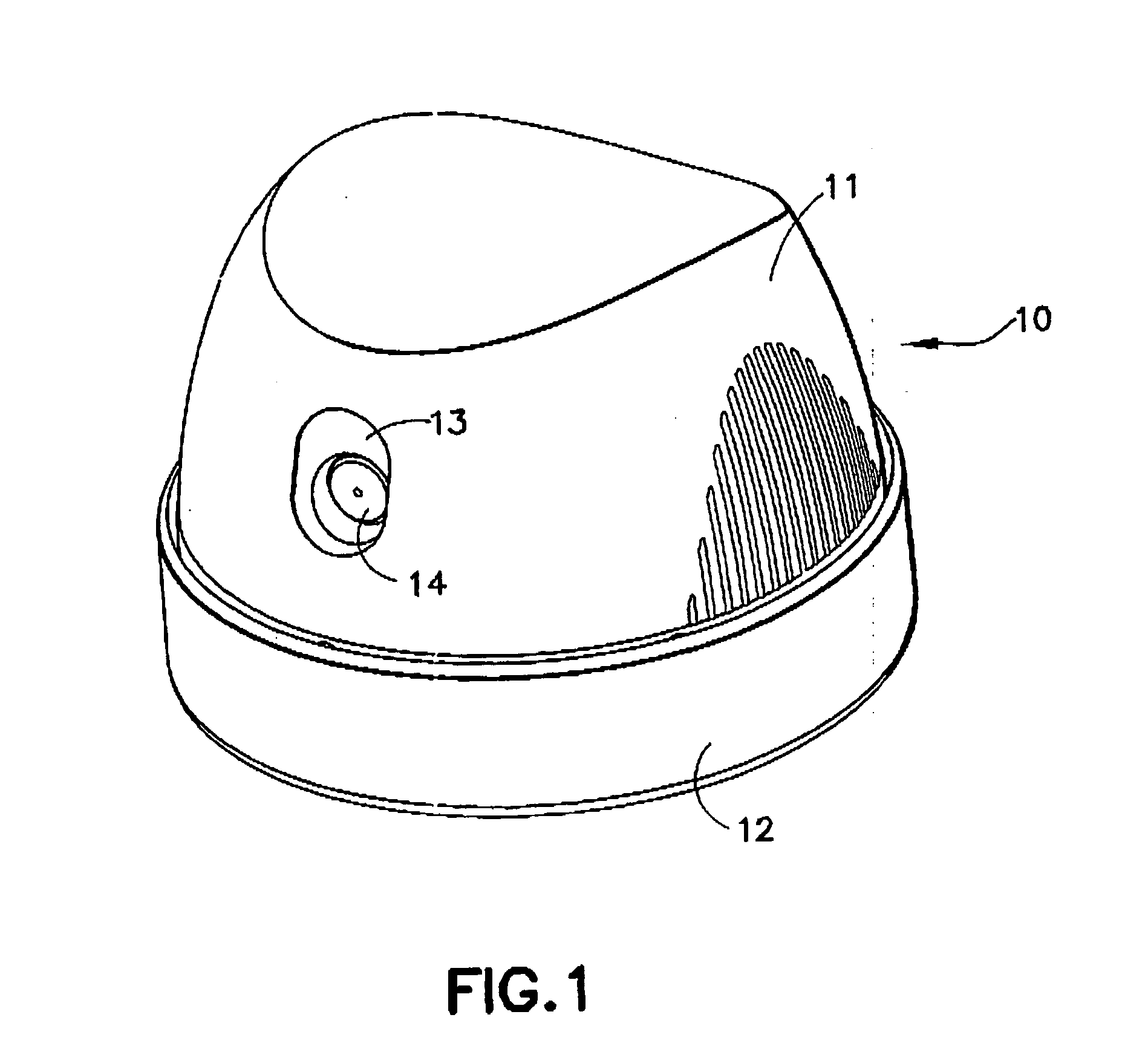

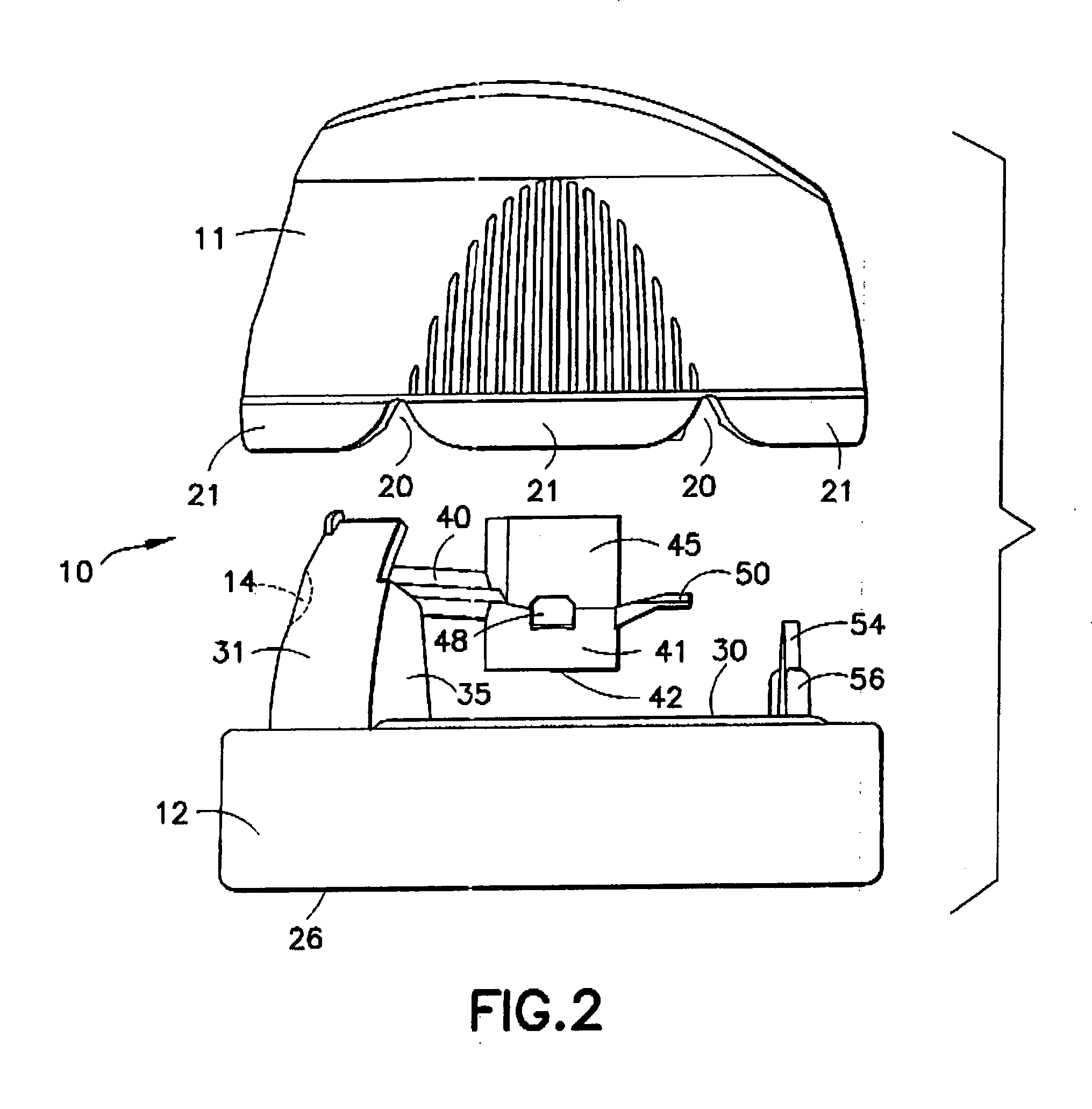

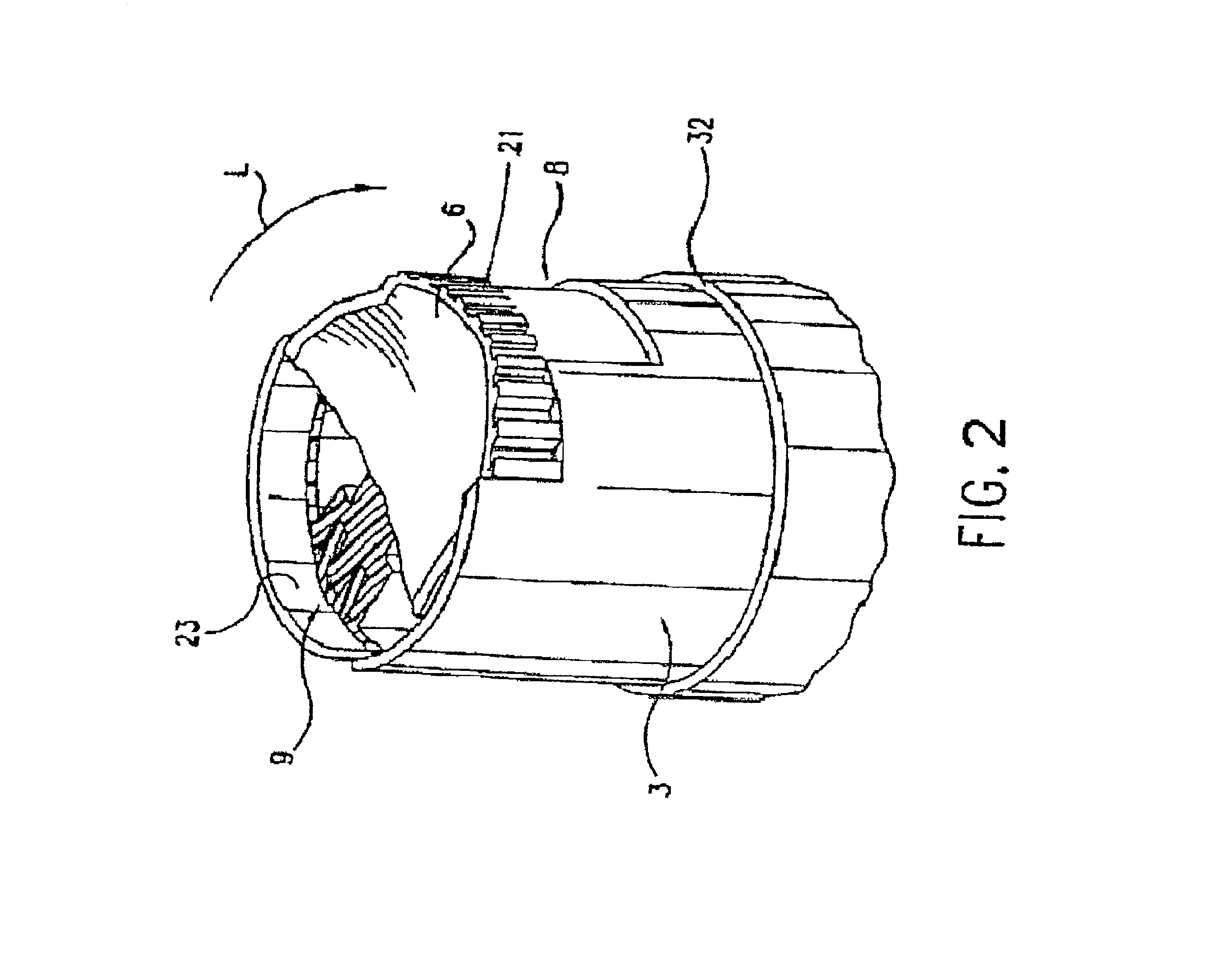

Dispenser with lock

ActiveUS7249692B2Prevent downward movementPrevent removalDecorative coversClosure decorative/protective coversSpray nozzleEngineering

A dispensing assembly is provided for a container of fluent material. A hand-operable dispenser cartridge is adapted to be mounted to the container. An actuator, which may include a nozzle or spout, is mounted on the cartridge. A locking sleeve is mounted around the cartridge and has an upper abutment edge and a recess. The locking sleeve can be rotated between a first rotated position preventing actuation of the dispensing assembly and a second rotated position permitting actuation of the dispensing assembly.

Owner:SEAQUIST PERFECT DISPENSING FOREIGN INC

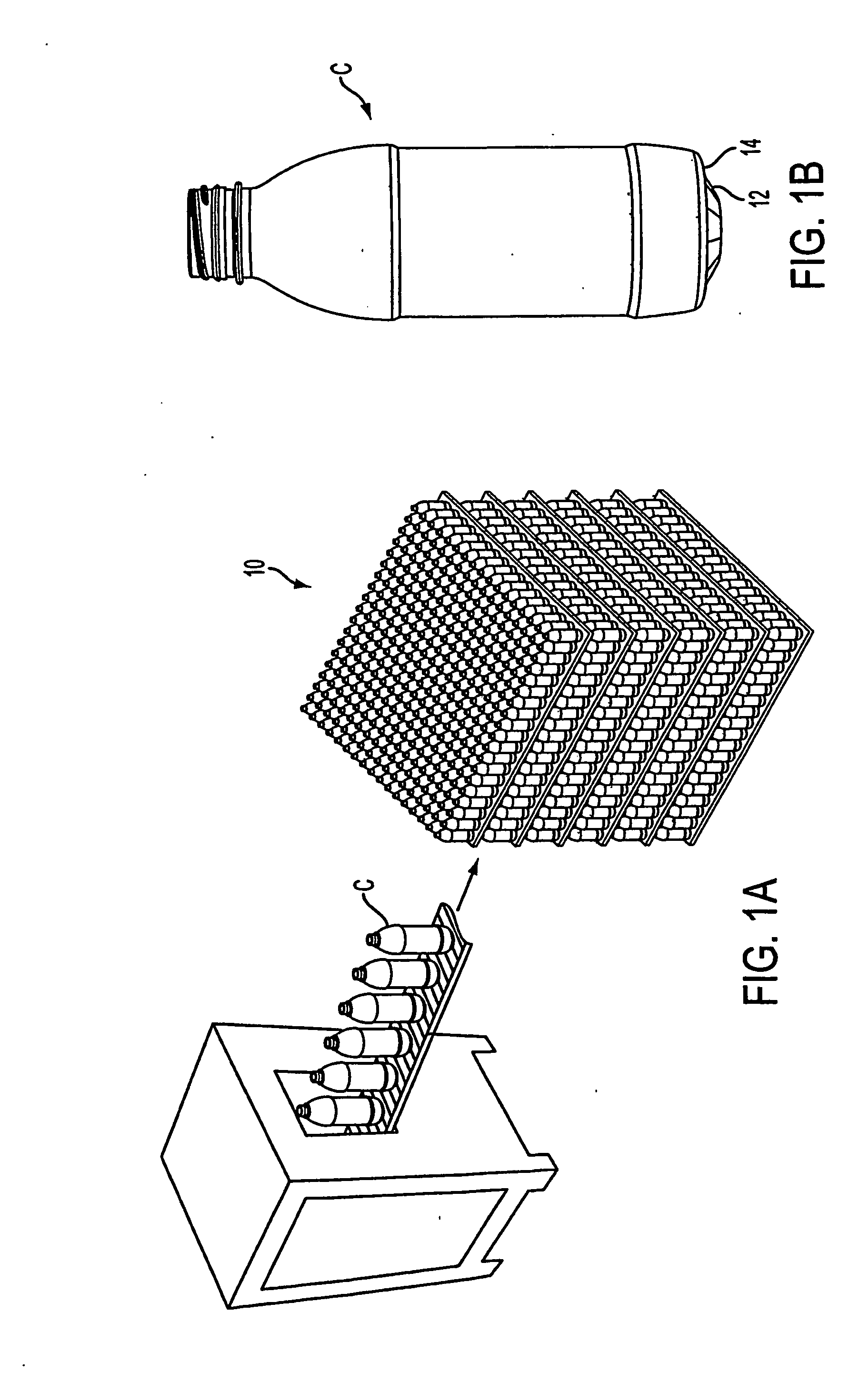

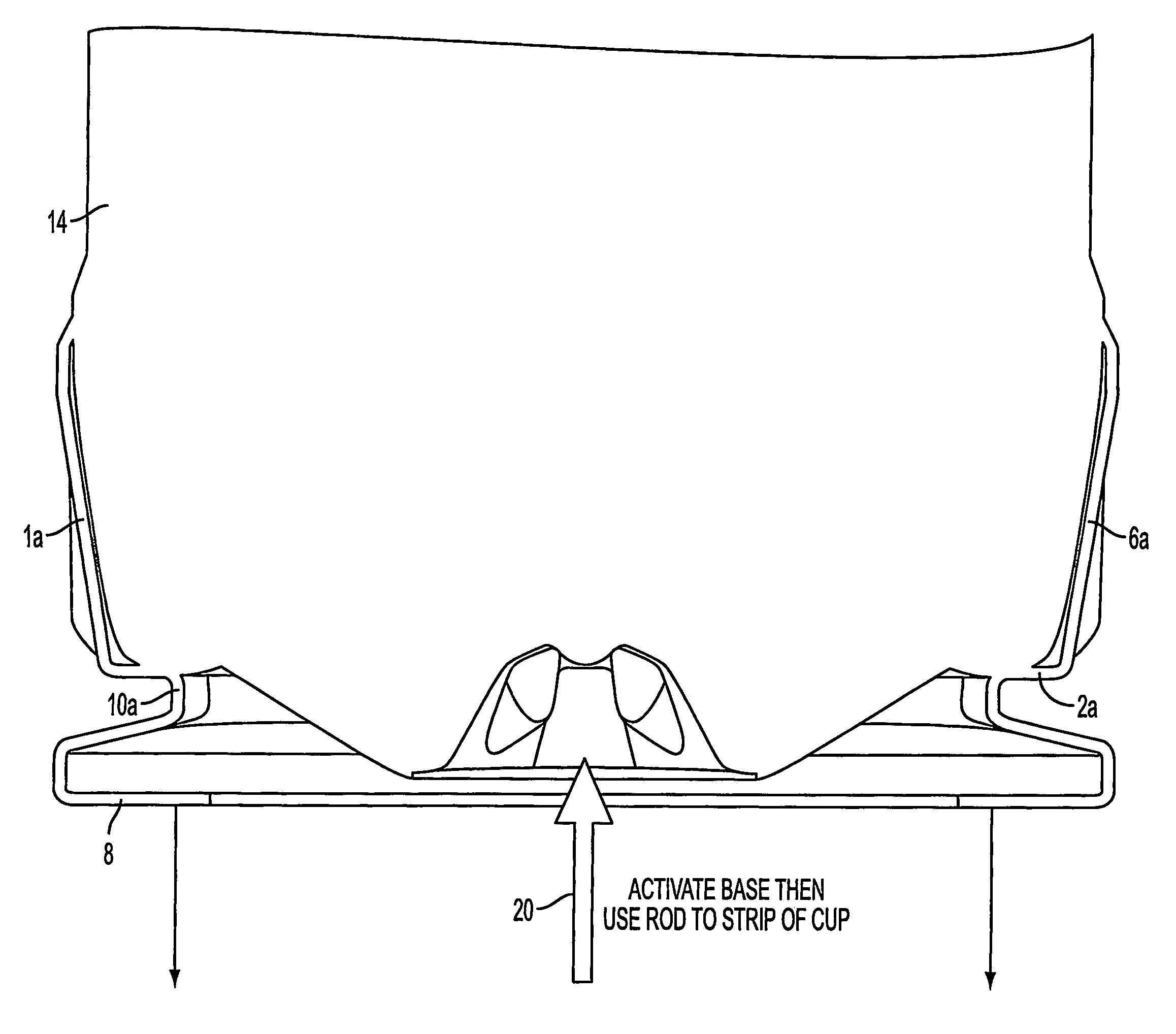

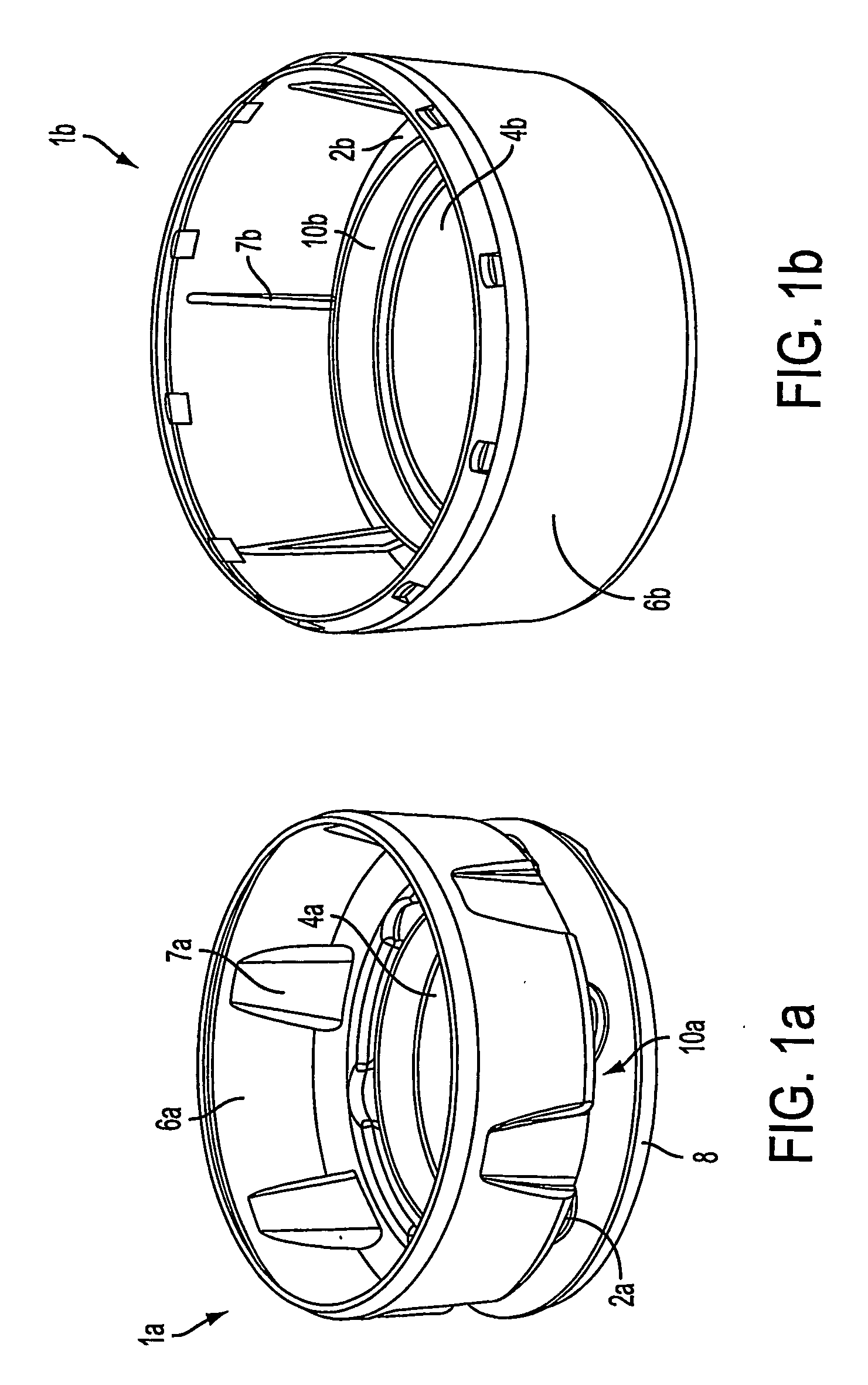

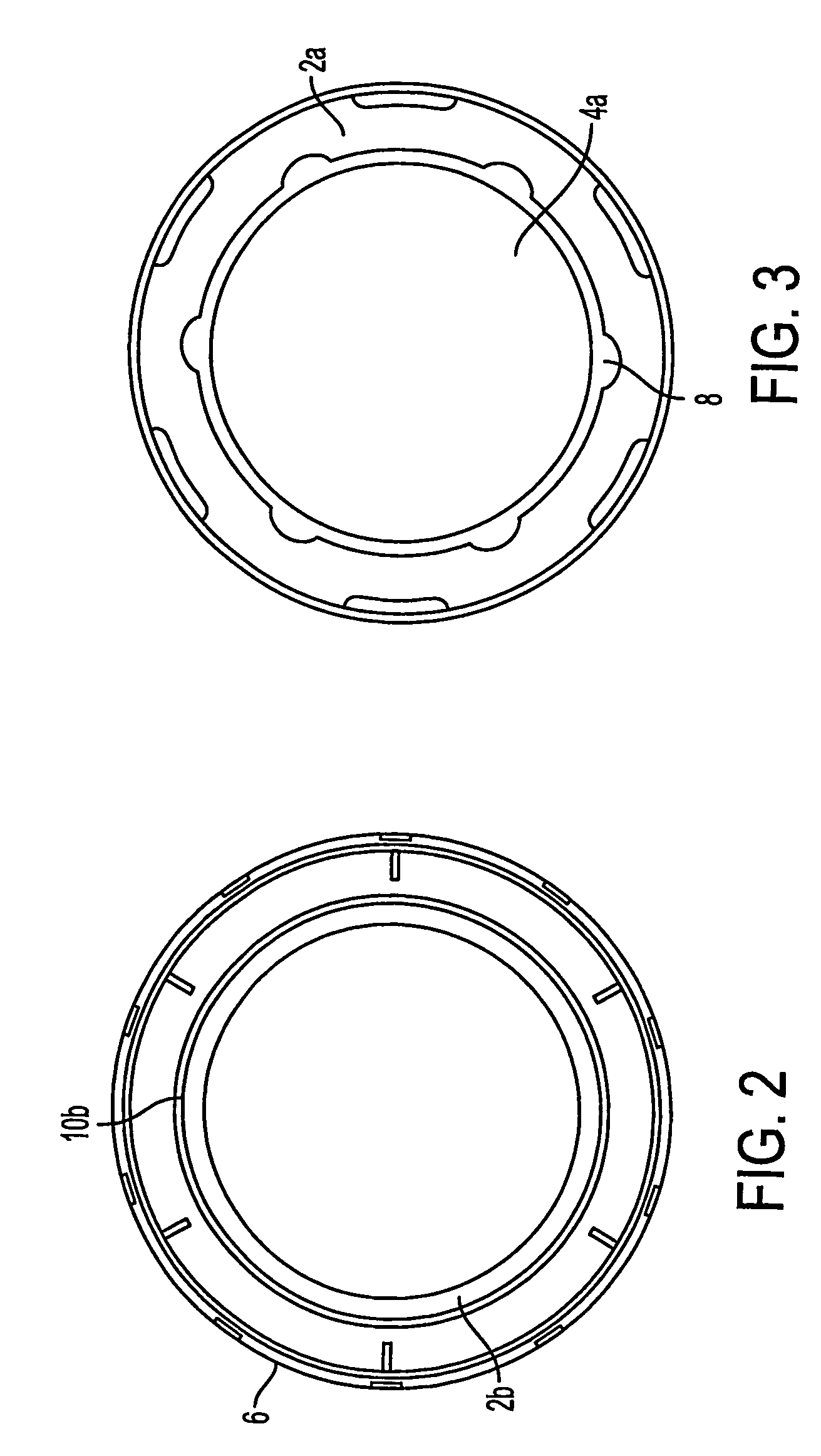

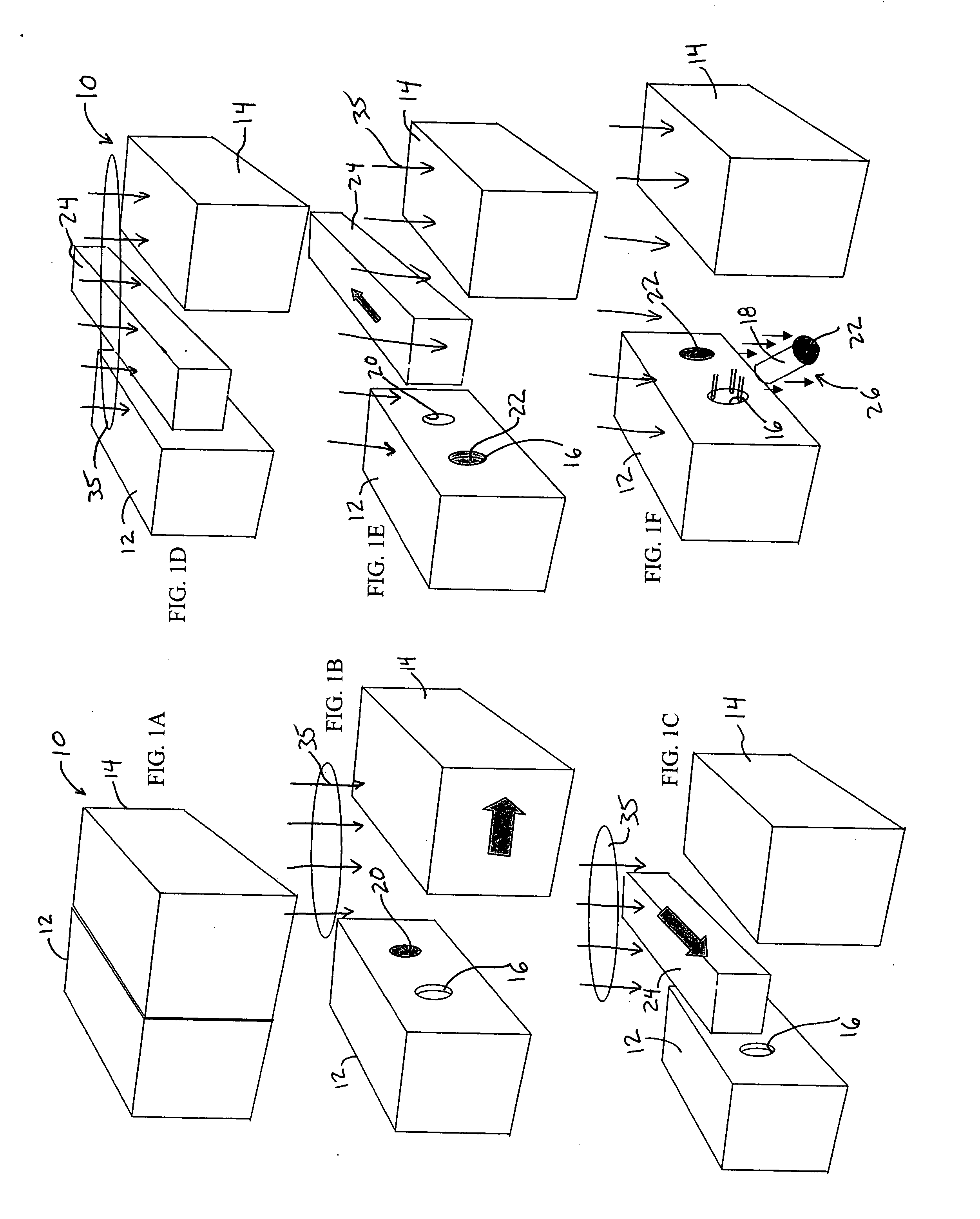

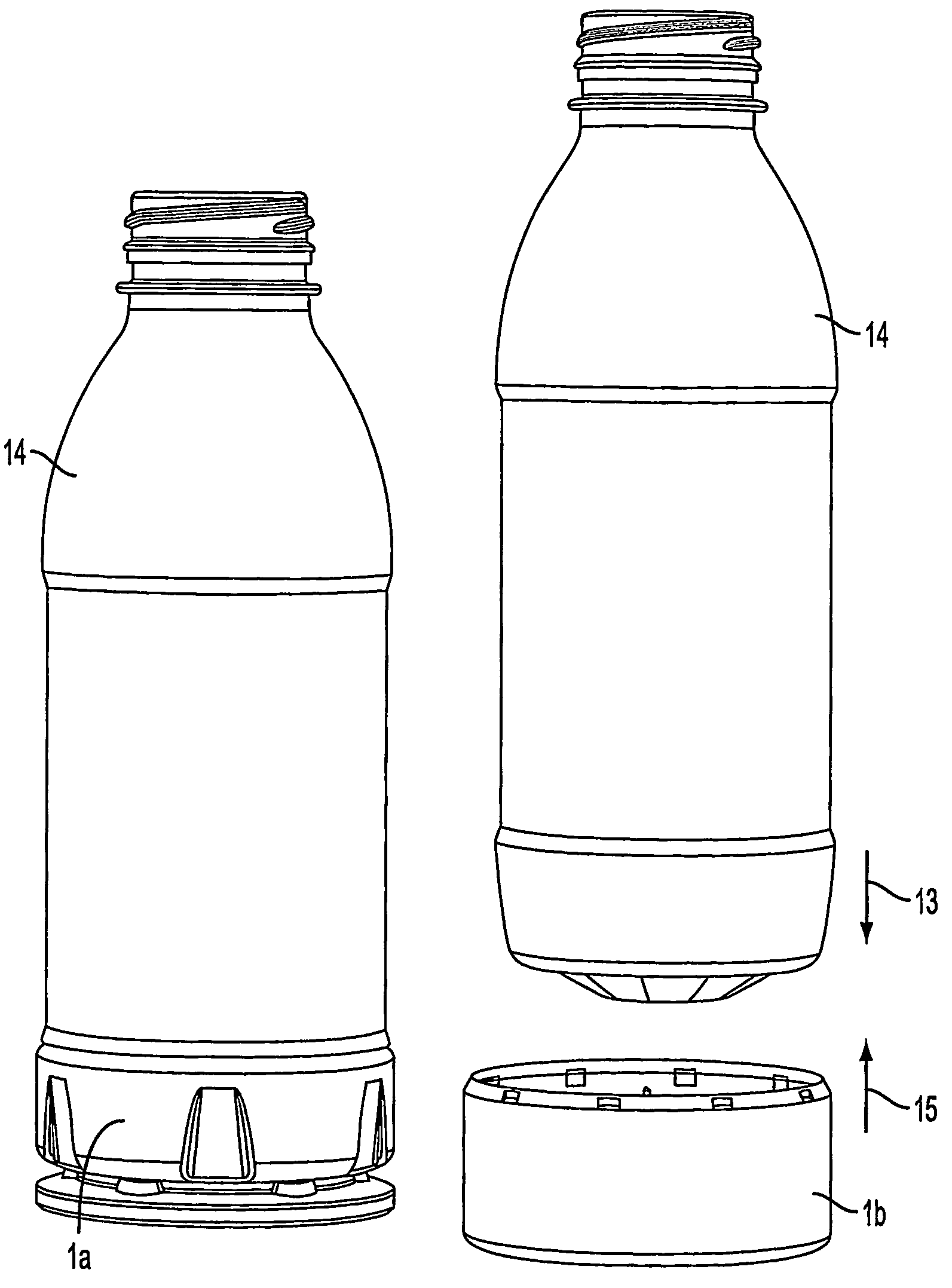

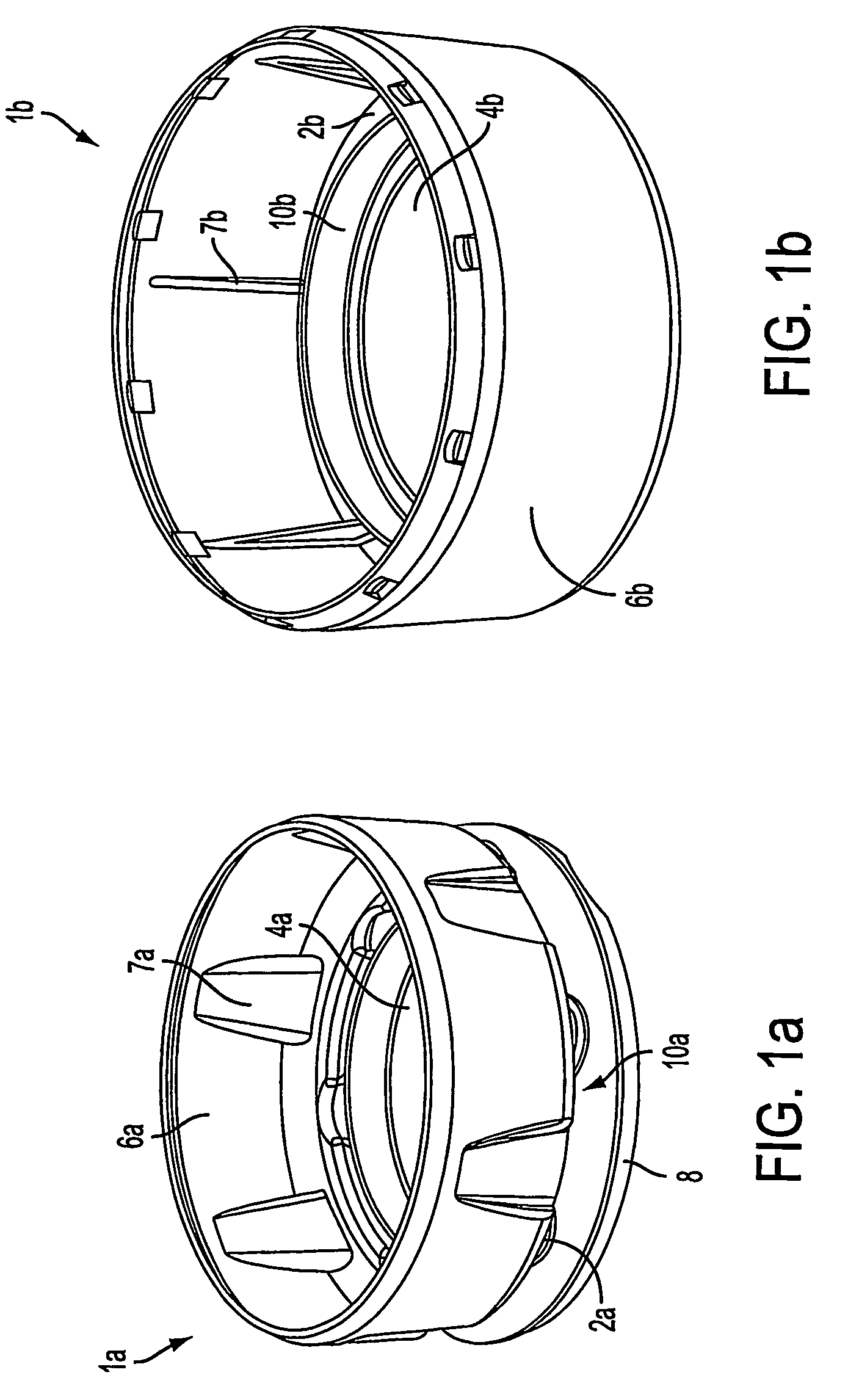

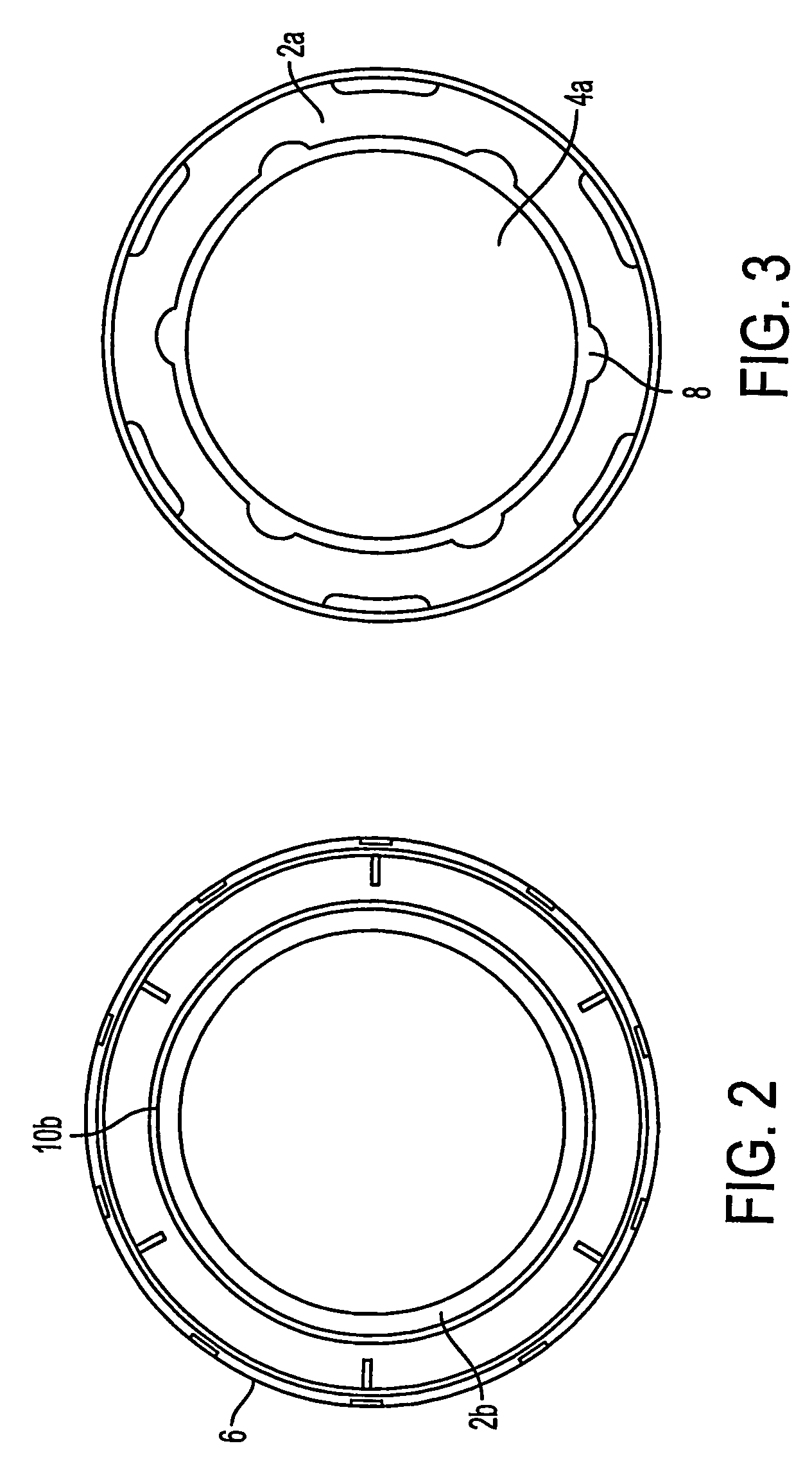

Process and device for conveying odd-shaped containers

A process for efficiently conveying containers along a table-top conveying system includes the steps of temporarily securing a transfer stabilizing support (1a, 1b) to a bottom end of a formed container (14) so that the container can freely move along a production line using the table-top conveying system where the transfer stabilizing support has a bottom surface (2a, 2b) with an opening (4a, 4b), a sidewall (6a, 6b) extending substantially perpendicular to the bottom surface, and a ridge area (10b) surrounding the opening and inside the sidewall of the support; and after the container has gone through operations of the production line, the transfer stabilizing support is removed so that aesthetic qualities of the formed container shape are revealed.

Owner:CO2 PAC

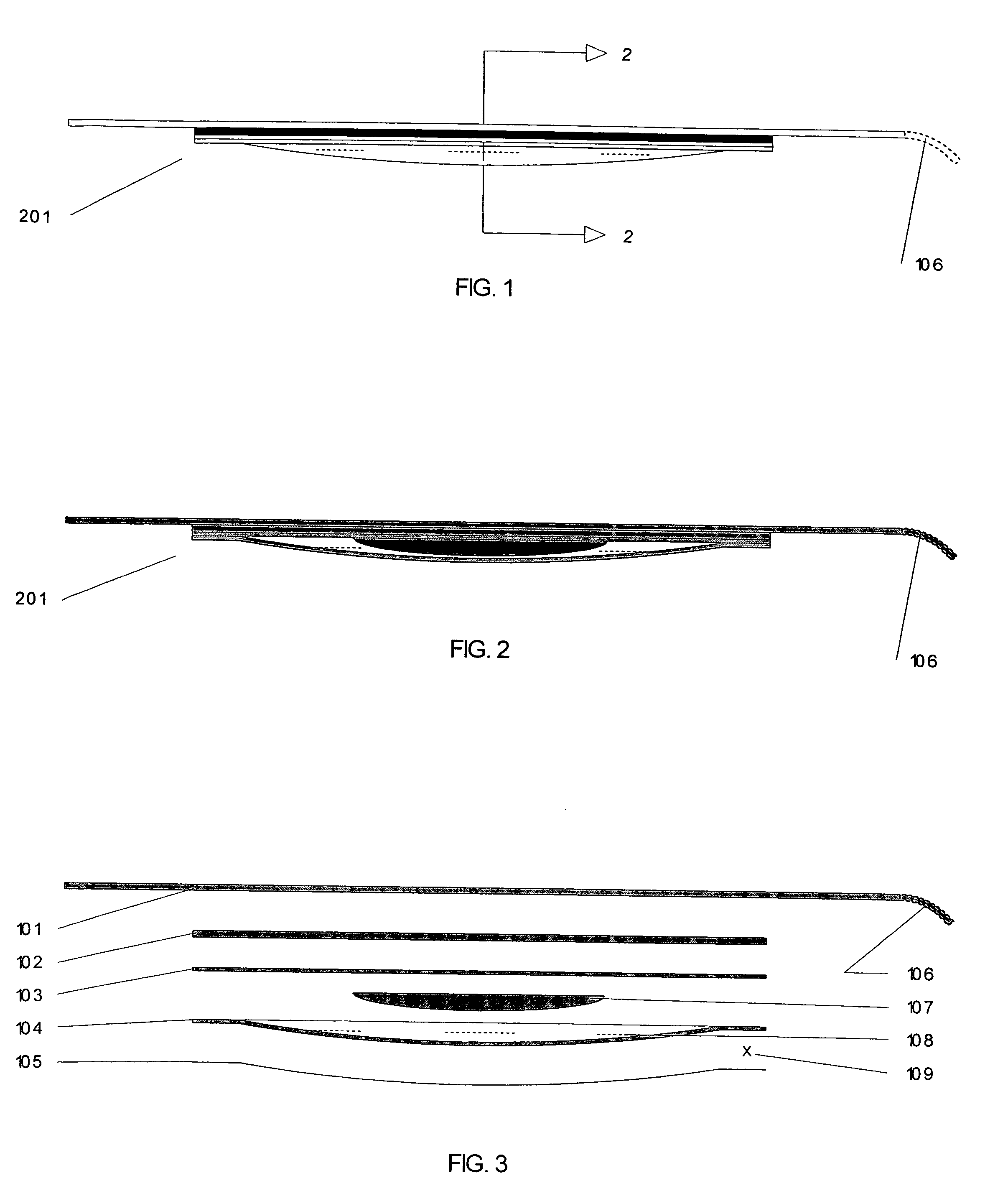

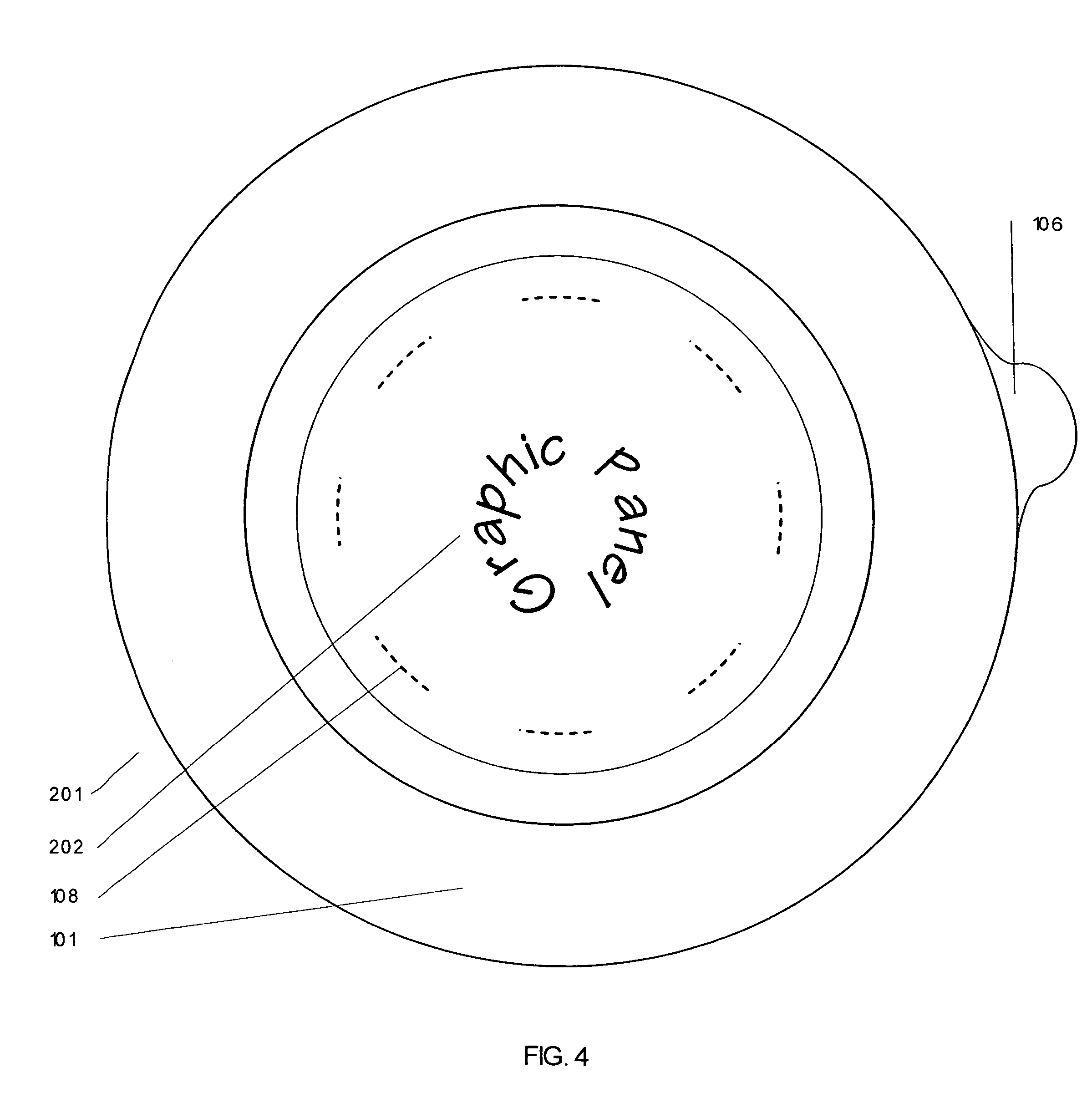

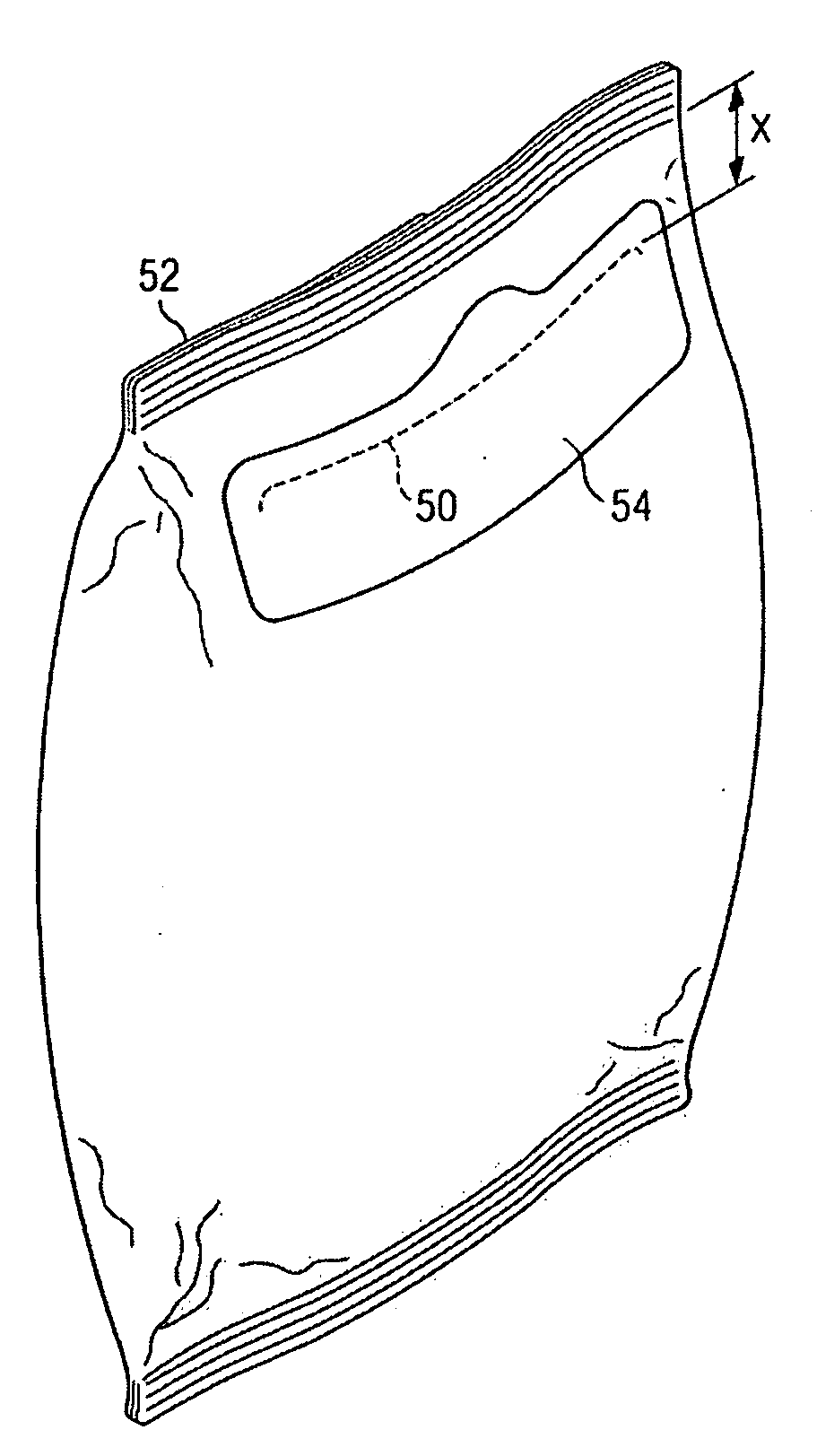

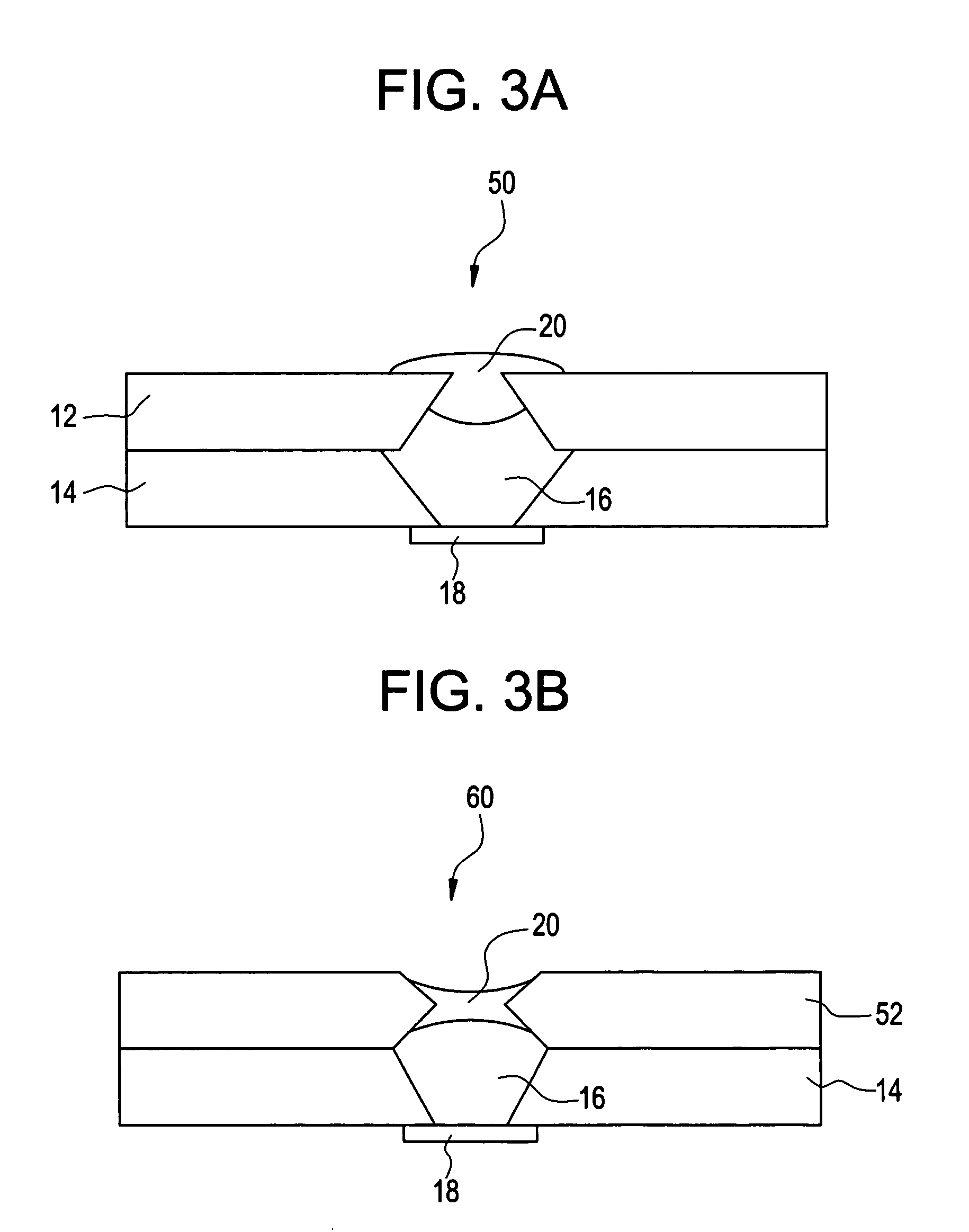

Two Side Cut Reseal With Pressure Sensitive Adhesive and the Method for Making Same

InactiveUS20100111453A1Prevent premature deterioration of qualityAvoid damageCapsDecorative coversSheet filmHermetic packaging

Two side cut reseal with pressure sensitive adhesive. A flexible package having a reseal integrated within the opposite layers of its film is constructed using existing vertical form fill and seal packaging machines. The invention involves a single sheet of flexible packaging film web having at least three layers. In a preferred embodiment, the reseal is comprised of two offsetting score lines on interior and exterior sides of the film and spaced apart by 0.5 to 1 inch. The scoring creates lines of weakness, which define an opening in the package. Upon opening, a pressure sensitive adhesive layer, which is pattern applied in between the offsetting score lines, is exposed from an interior side of the film. The adhesive releasably adheres the inner and outer layers of the film back together once separated by a consumer.

Owner:FRITO LAY NORTH AMERICA INC

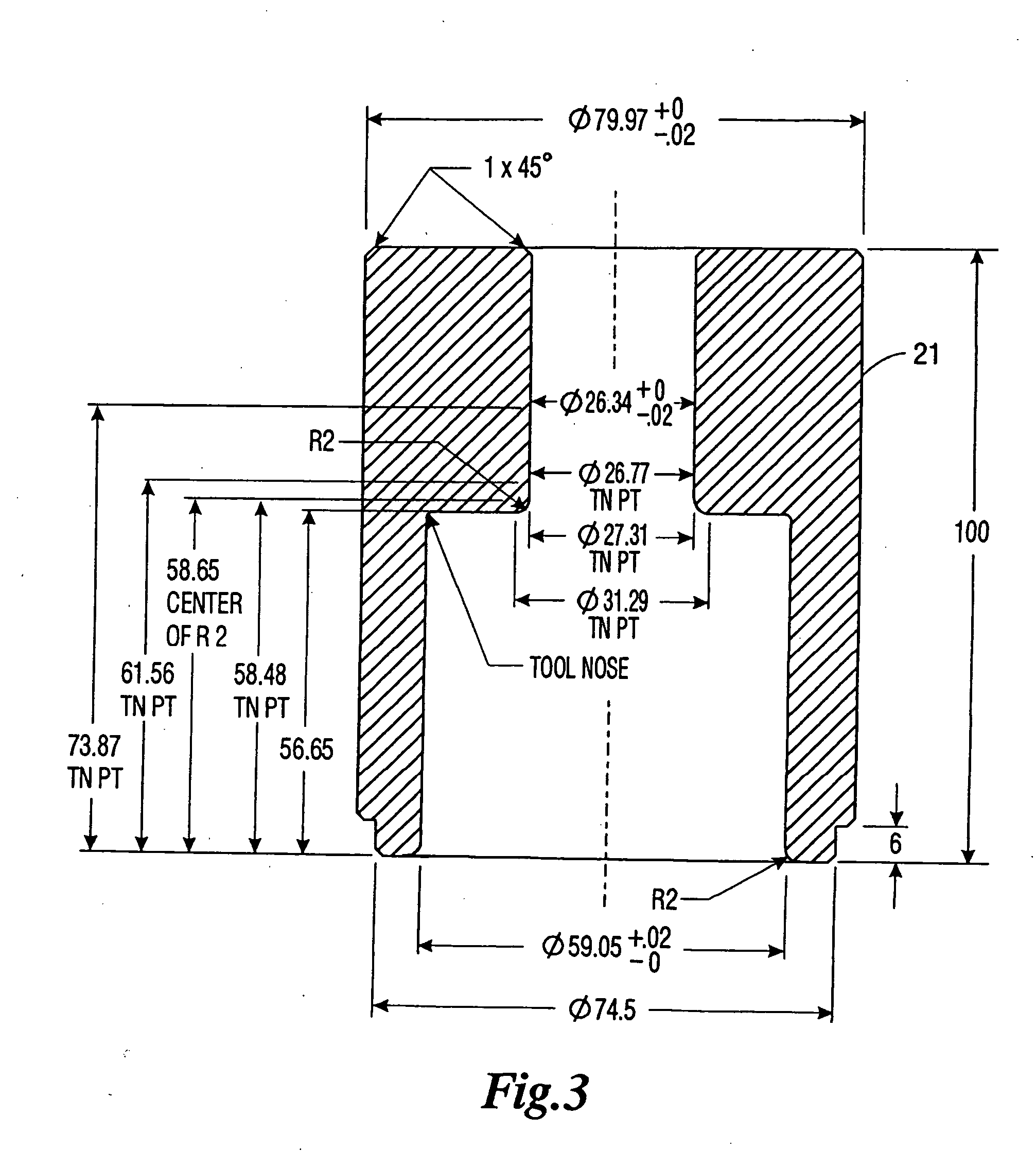

Method of manufacturing an aluminum receptacle with threaded outsert

A method of affixing a sleeve to the neck of an aluminum container of the type having a tapered neck and wherein said sleeve has a complementary taper. The method comprises positioning said sleeve onto said neck wherein a portion of the neck extends beyond said sleeve and wherein said positioning causes said complementary taper of the sleeve and said taper of the neck to form a friction fit, said friction fit preventing rotation of said sleeve relative to said neck, wherein said friction fit is formed without expansion or deformation of said neck, and curling the portion of the neck extending beyond the sleeve so that the curl covers at least a portion of the upper end of said sleeve. Because of the rules governing abstracts, this abstract should not be used to construe the claims.

Owner:EXAL

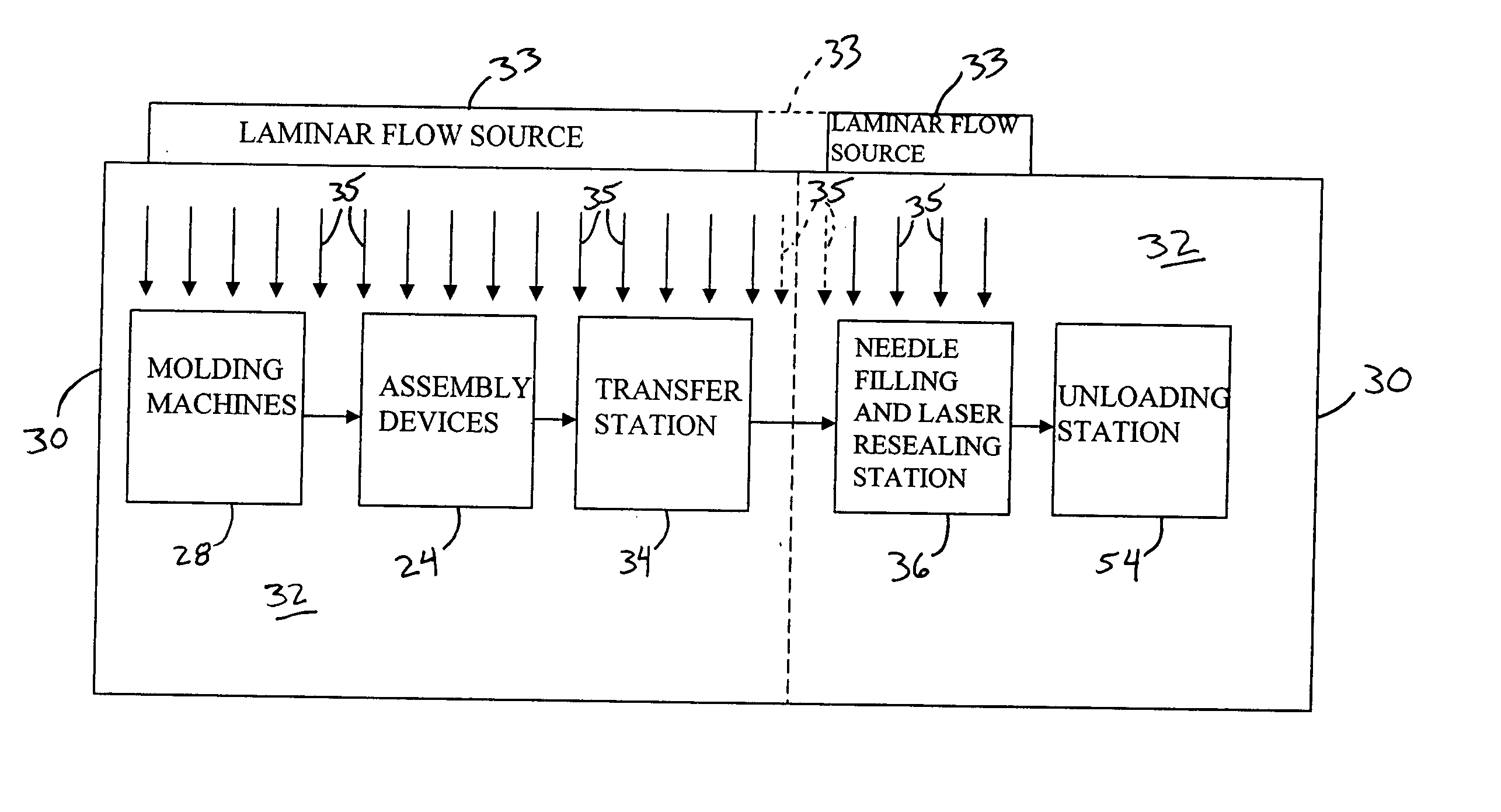

Method for molding and assembling containers with stoppers and filling same

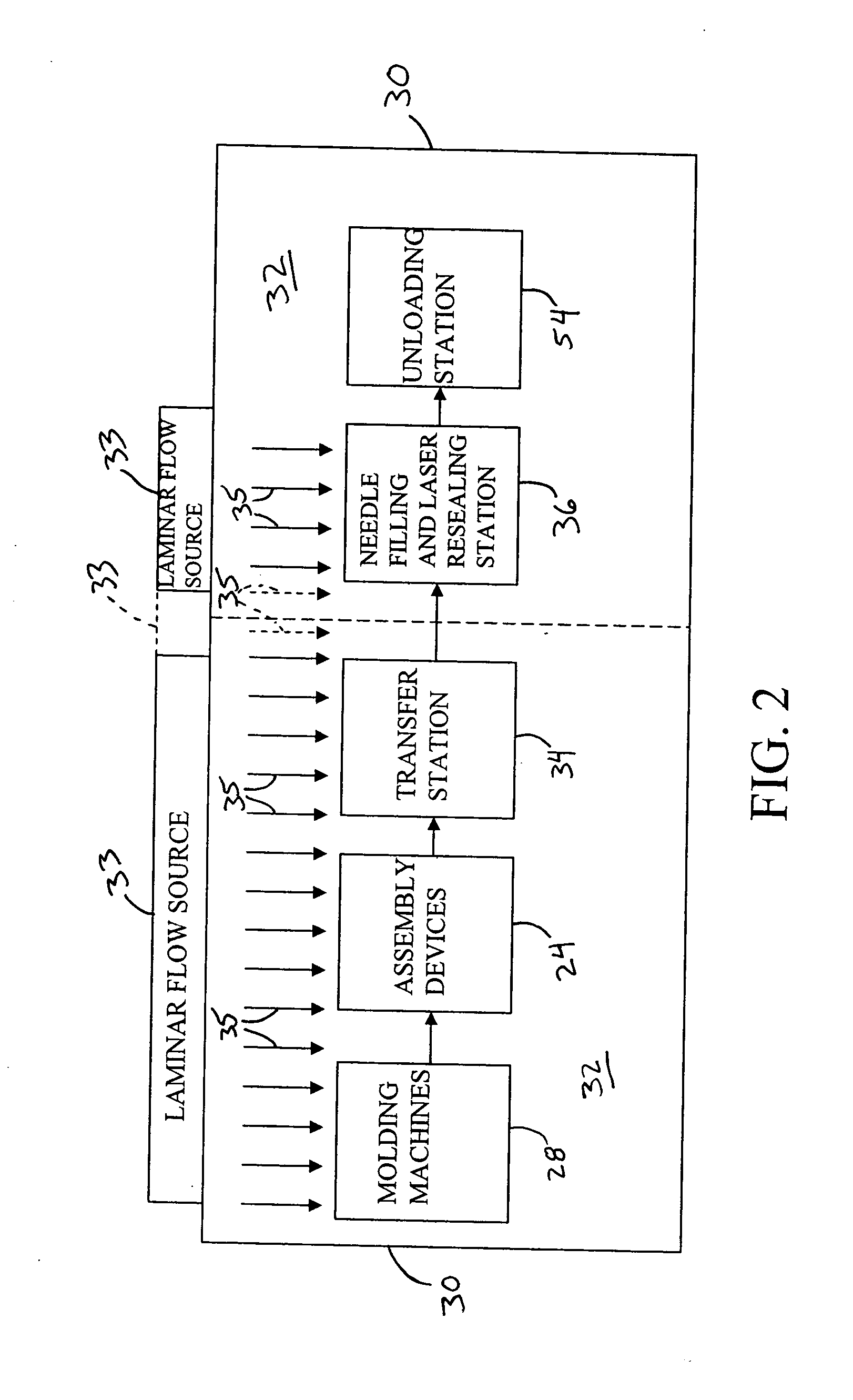

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

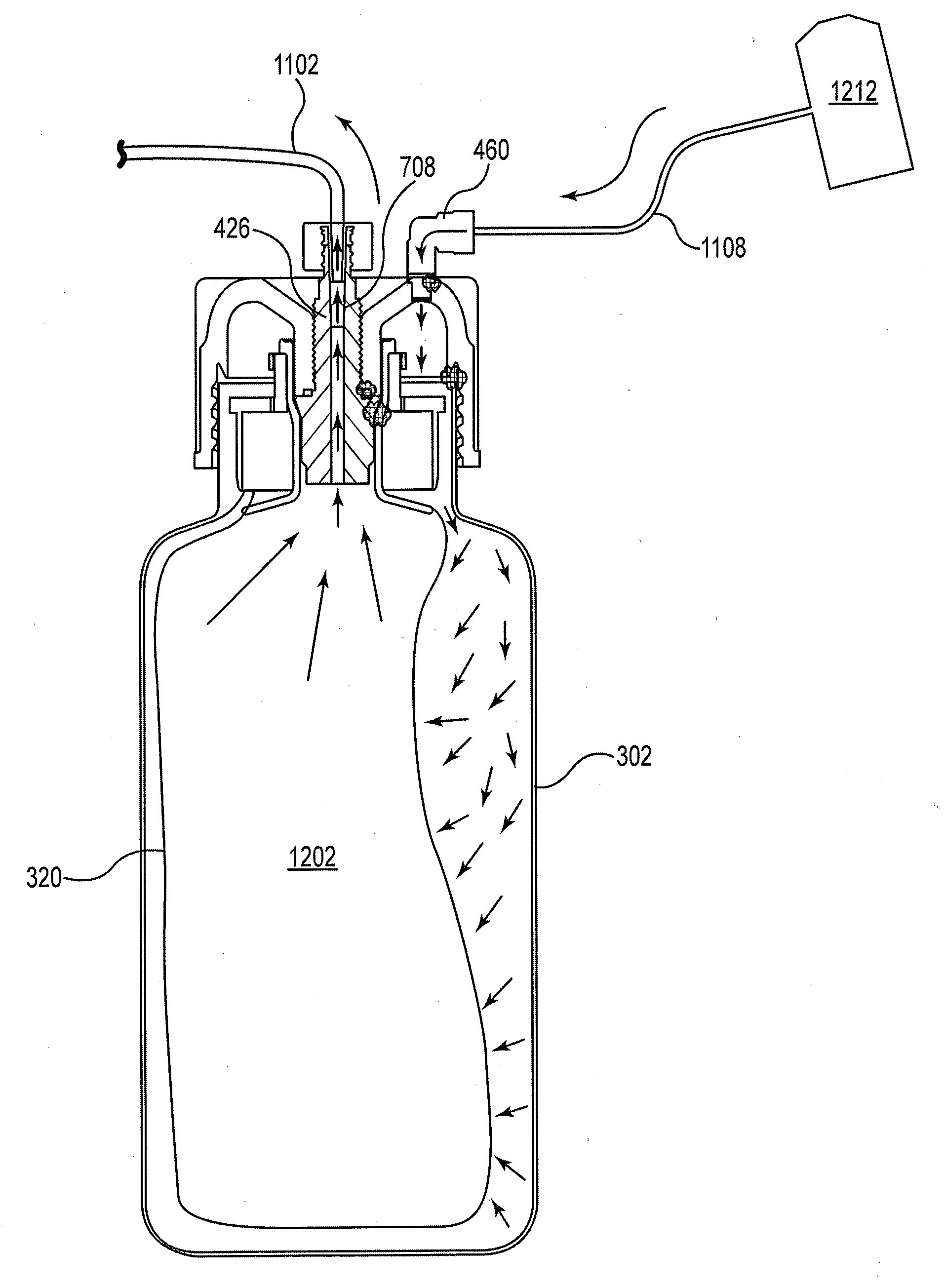

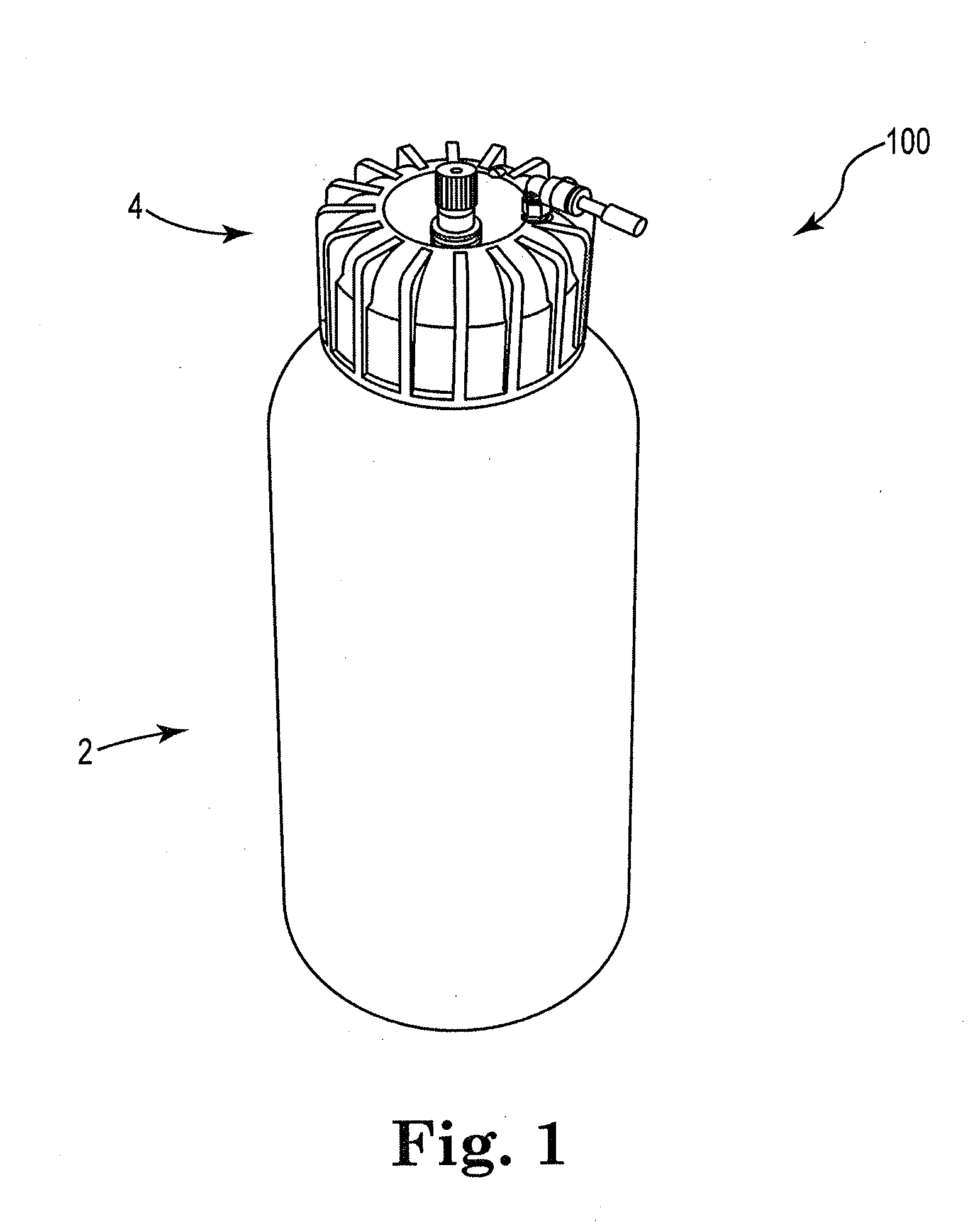

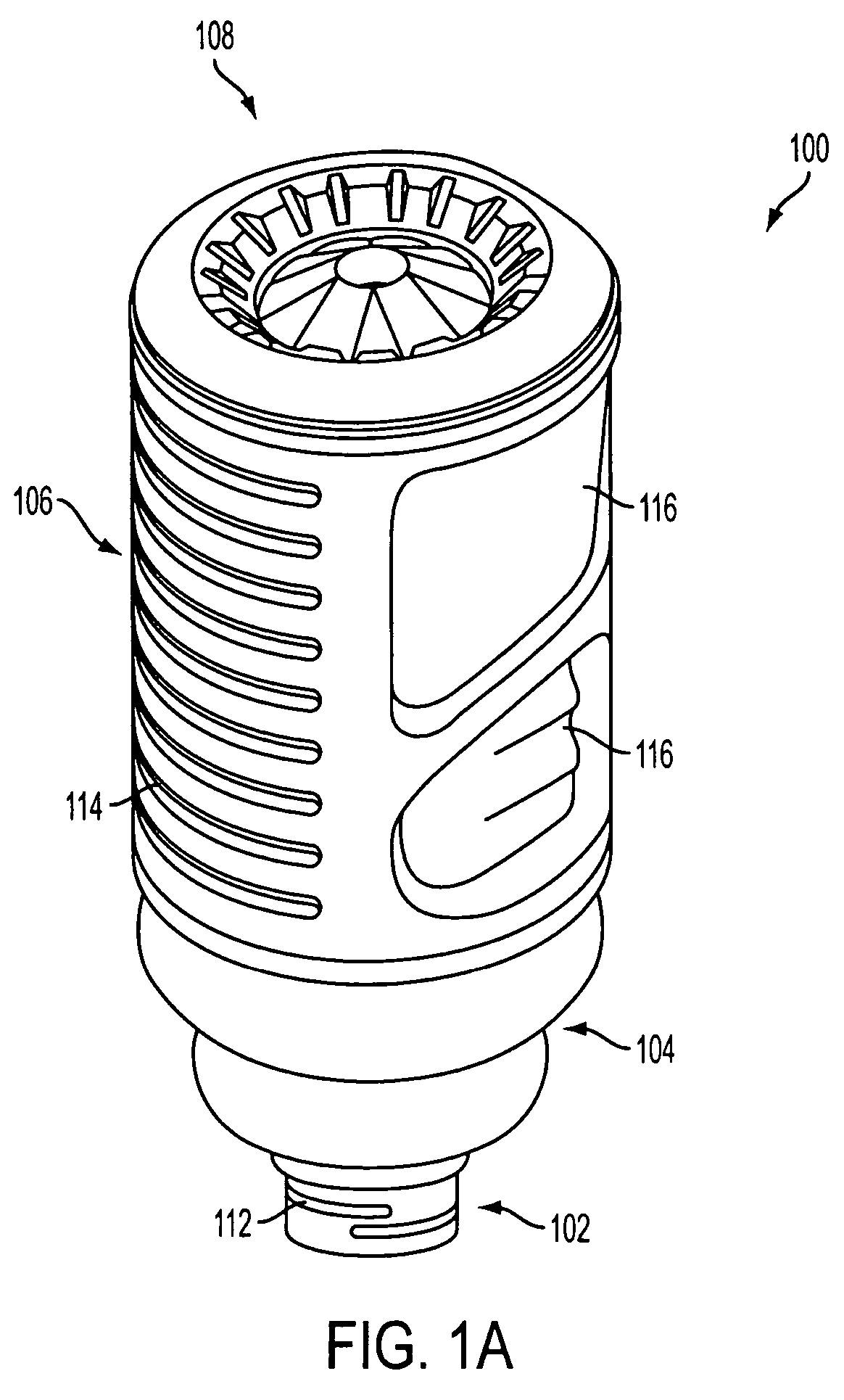

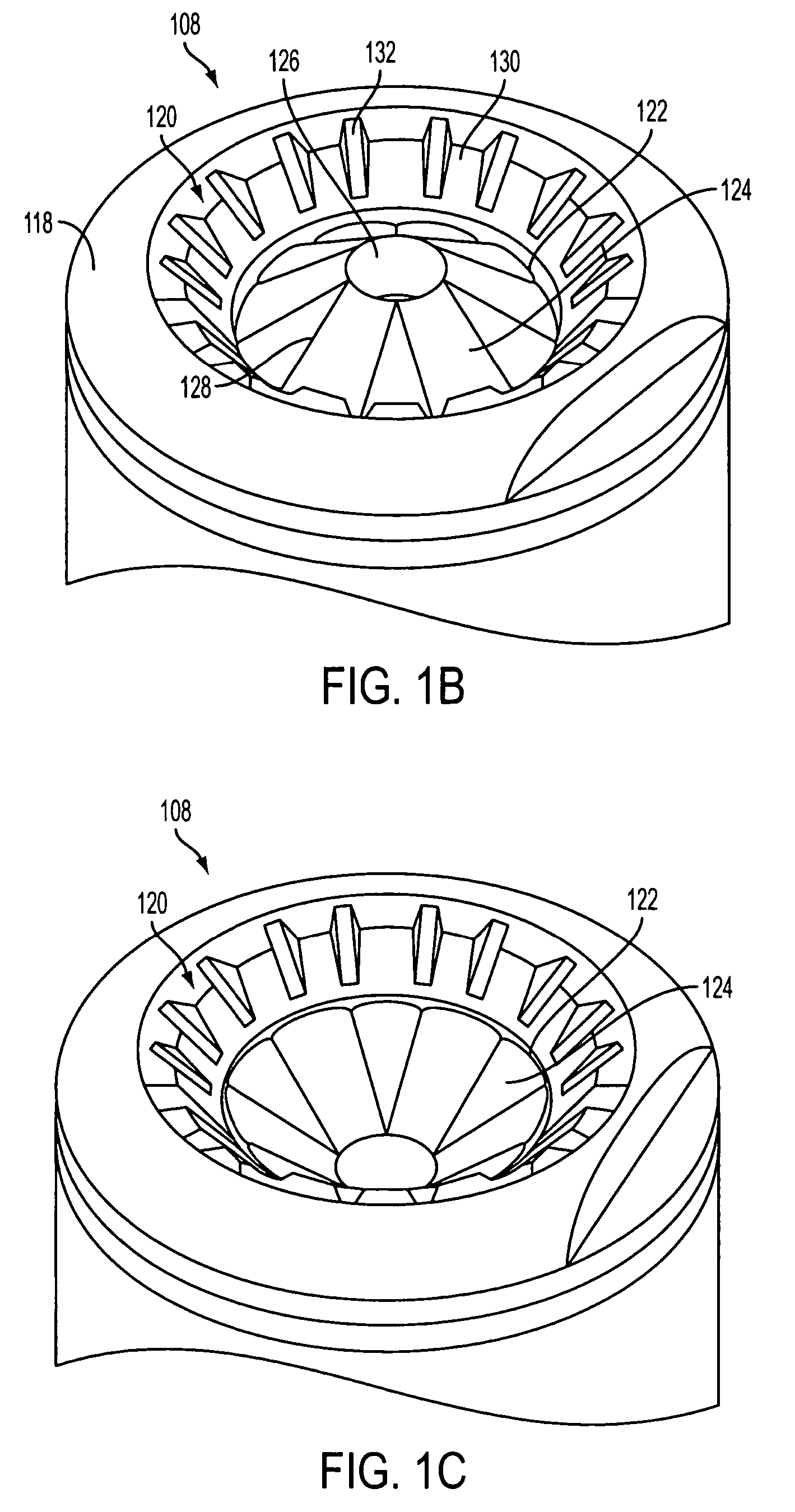

Closure/Connector for Liner-Based Dispense Containers

The present disclosure relates to novel and advantageous closure / connector assemblies for use with a dispense assembly. The closure / connector includes a closure body as well as a cap seat adaptor for operable connection to the closure body. The cap seat adapter has a proximal end and a distal end and is configured for fluid communication with a source of material to be dispensed. The closure / connector also has a cap for connection to the distal end of the cap seat adaptor. A pressurizing gas inlet fitting adapted for connection to a pressure source is also included as a part of the closure / connector. The closure / connector assembly, in conjunction with the dispense assembly, is configured for the secure transport and dispense of the material to be dispensed.

Owner:ADVANCED TECH MATERIALS INC

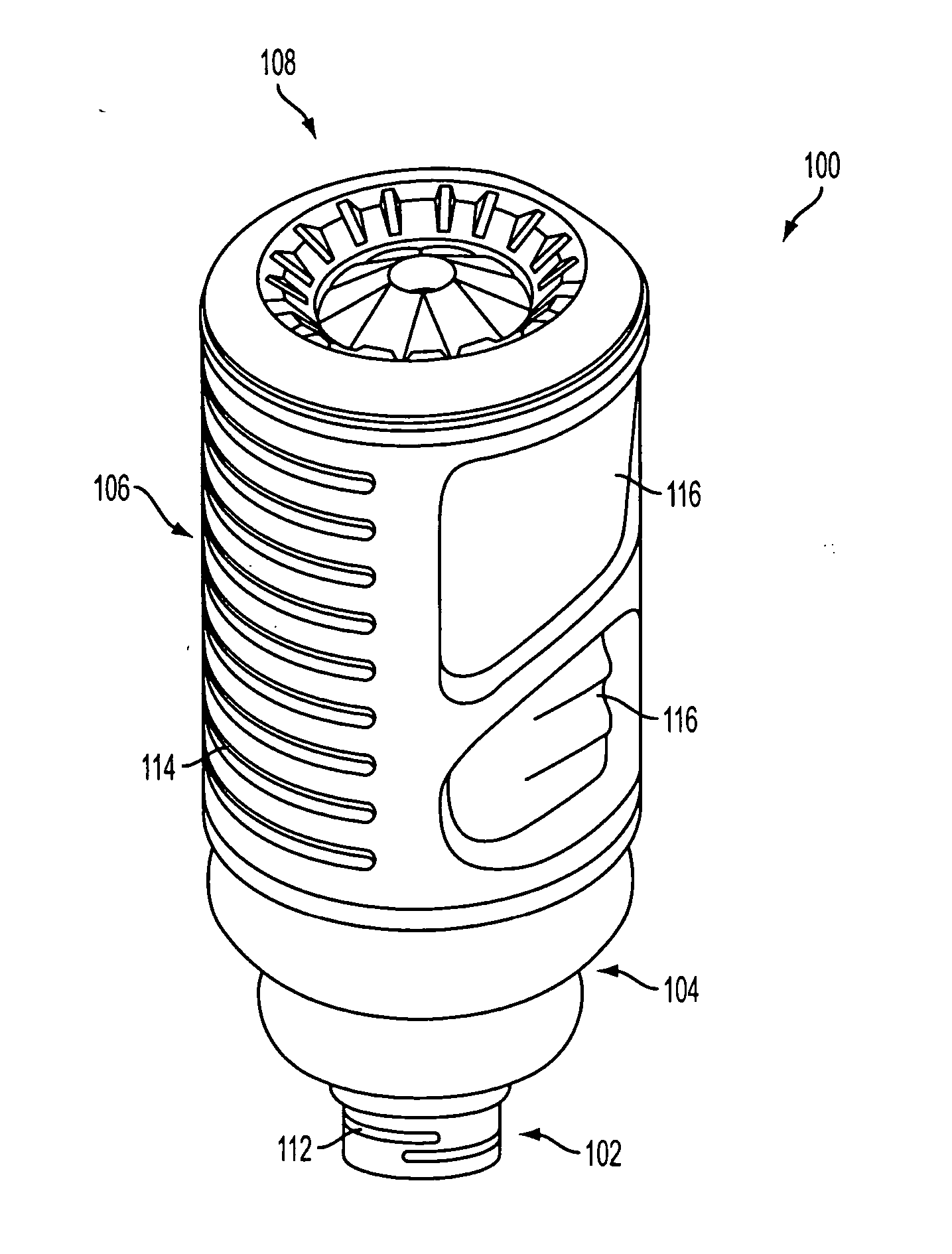

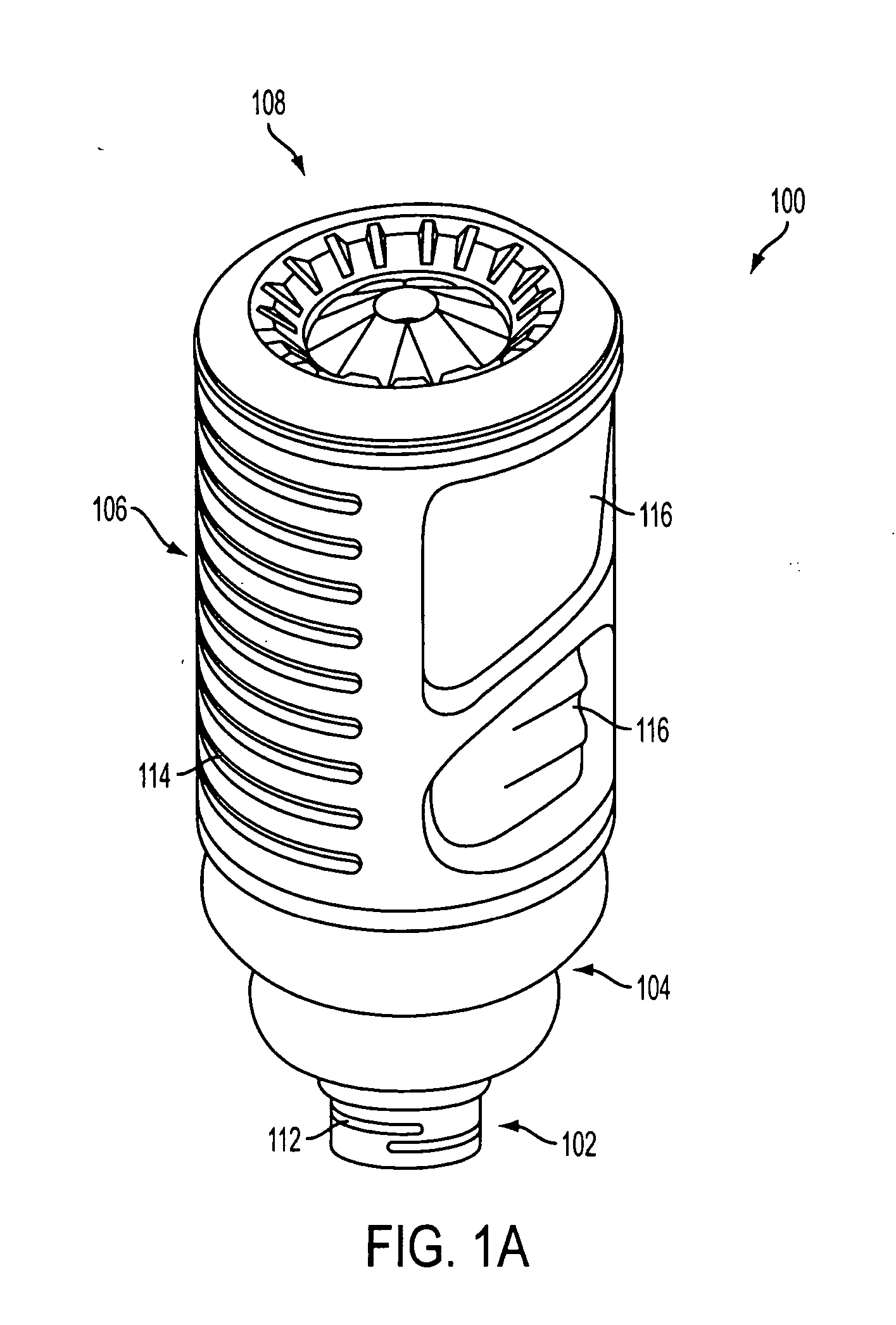

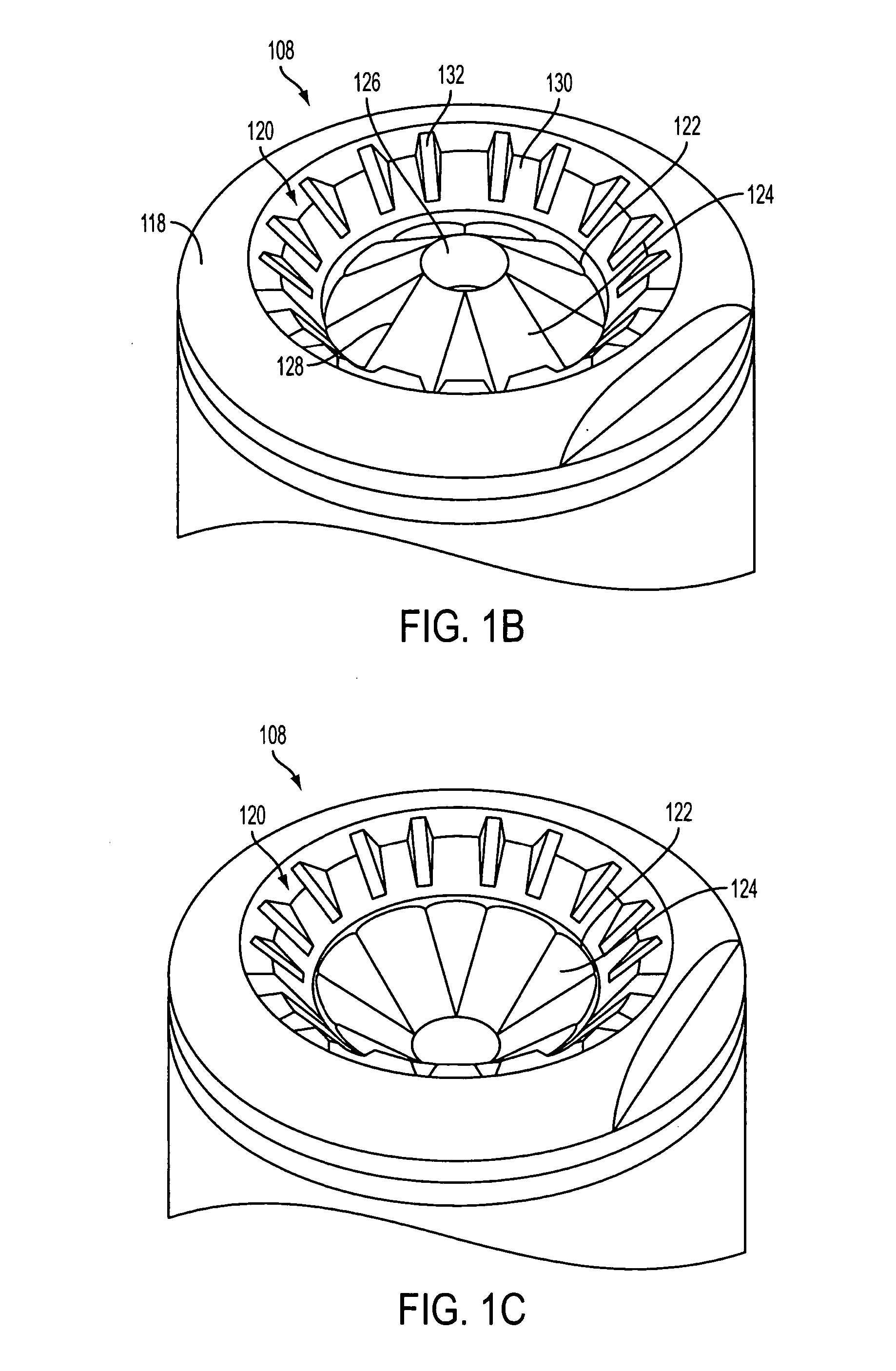

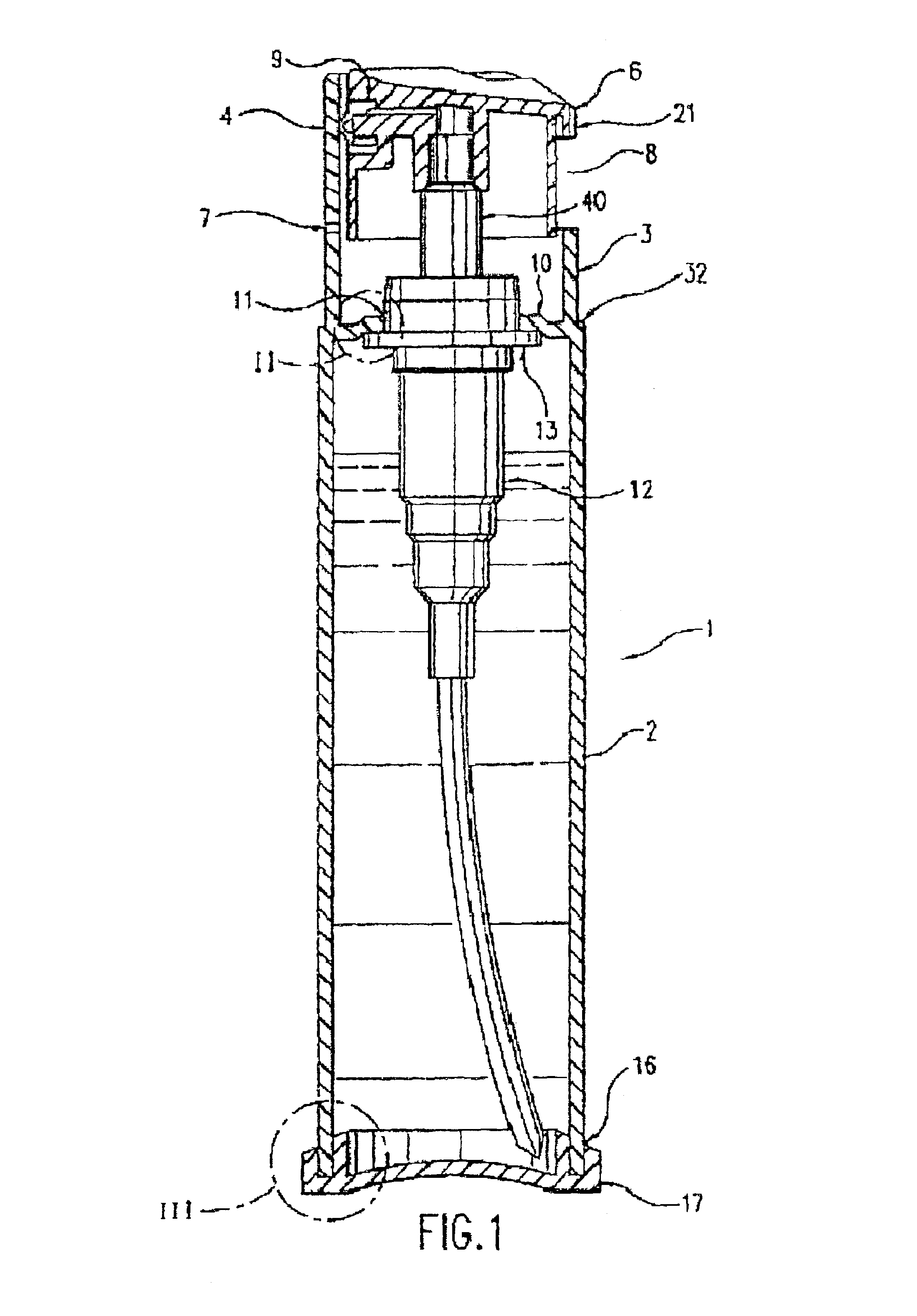

Dispenser with lock

ActiveUS20060113327A1Improve the immunityPrevent downward movementDecorative coversClosure decorative/protective coversSpray nozzleEngineering

A dispensing assembly is provided for a container of fluent material. A hand-operable dispenser cartridge is adapted to be mounted to the container. An actuator, which may include a nozzle or spout, is mounted on the cartridge. A locking sleeve is mounted around the cartridge and has an upper abutment edge and a recess. The locking sleeve can be rotated between a first rotated position preventing actuation of the dispensing assembly and a second rotated position permitting actuation of the dispensing assembly.

Owner:SEAQUIST PERFECT DISPENSING FOREIGN INC

Method for handling a hot-filled container having a moveable portion to reduce a portion of a vacuum created therein

Systems and methods for vacuum compensation in hot-filled and cooled containers. Each container reduces, via one or more vacuum panels, a first portion of a vacuum created in the container. Each container also has a repositionable portion to reduce a second portion of the vacuum. During hot-filling, no portion of the repositionable portion extends below a standing or bearing surface of the container.

Owner:CO2 PAC

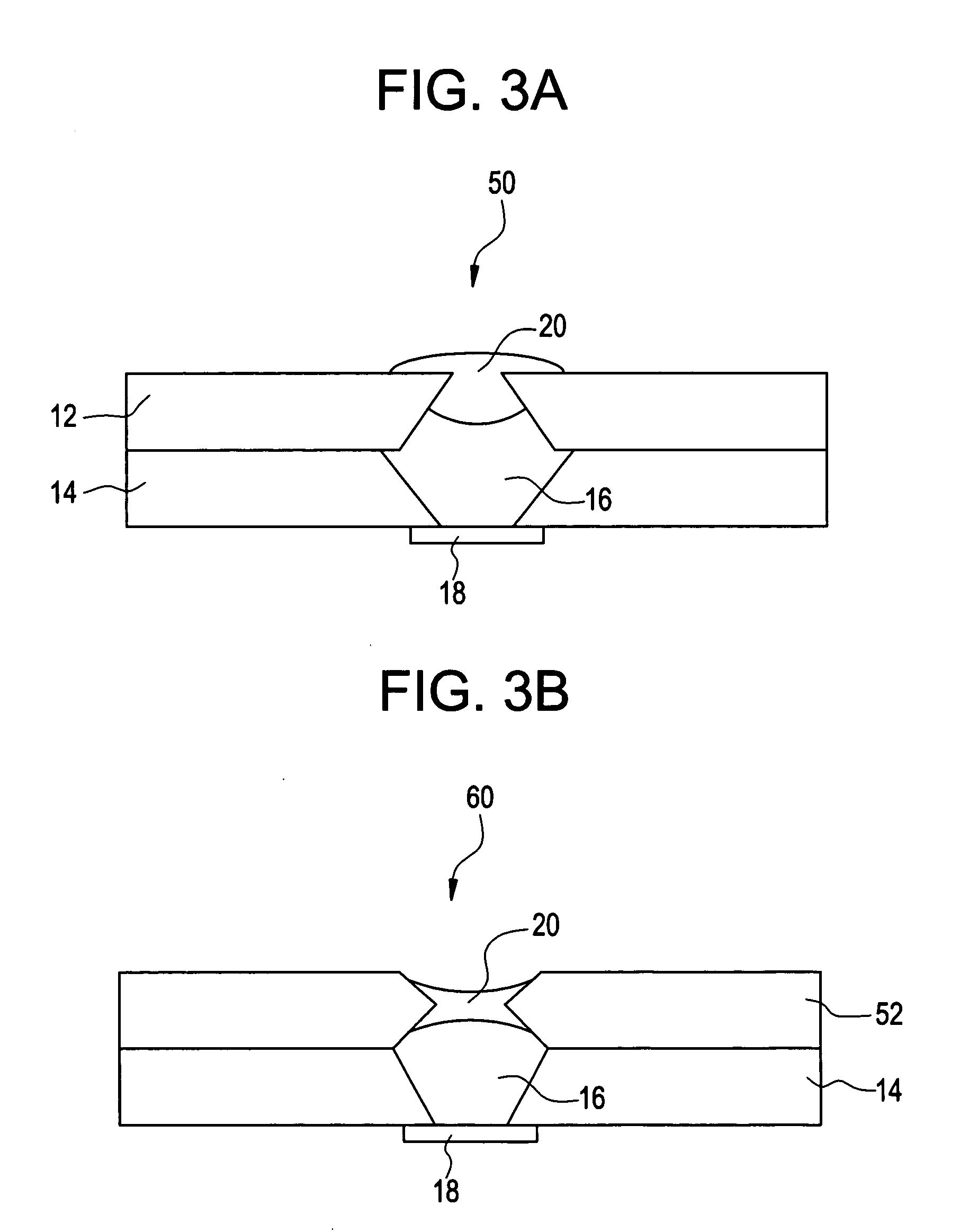

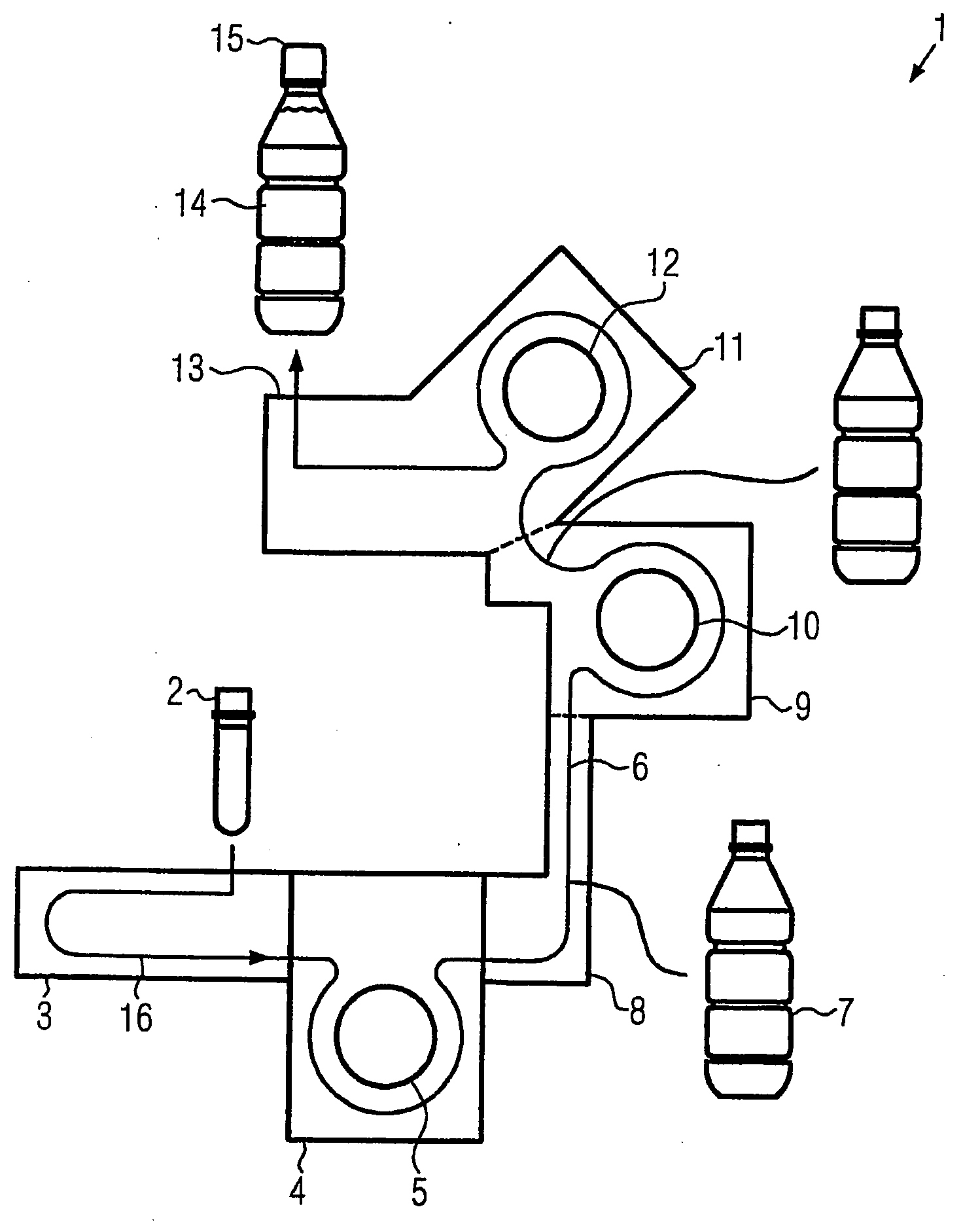

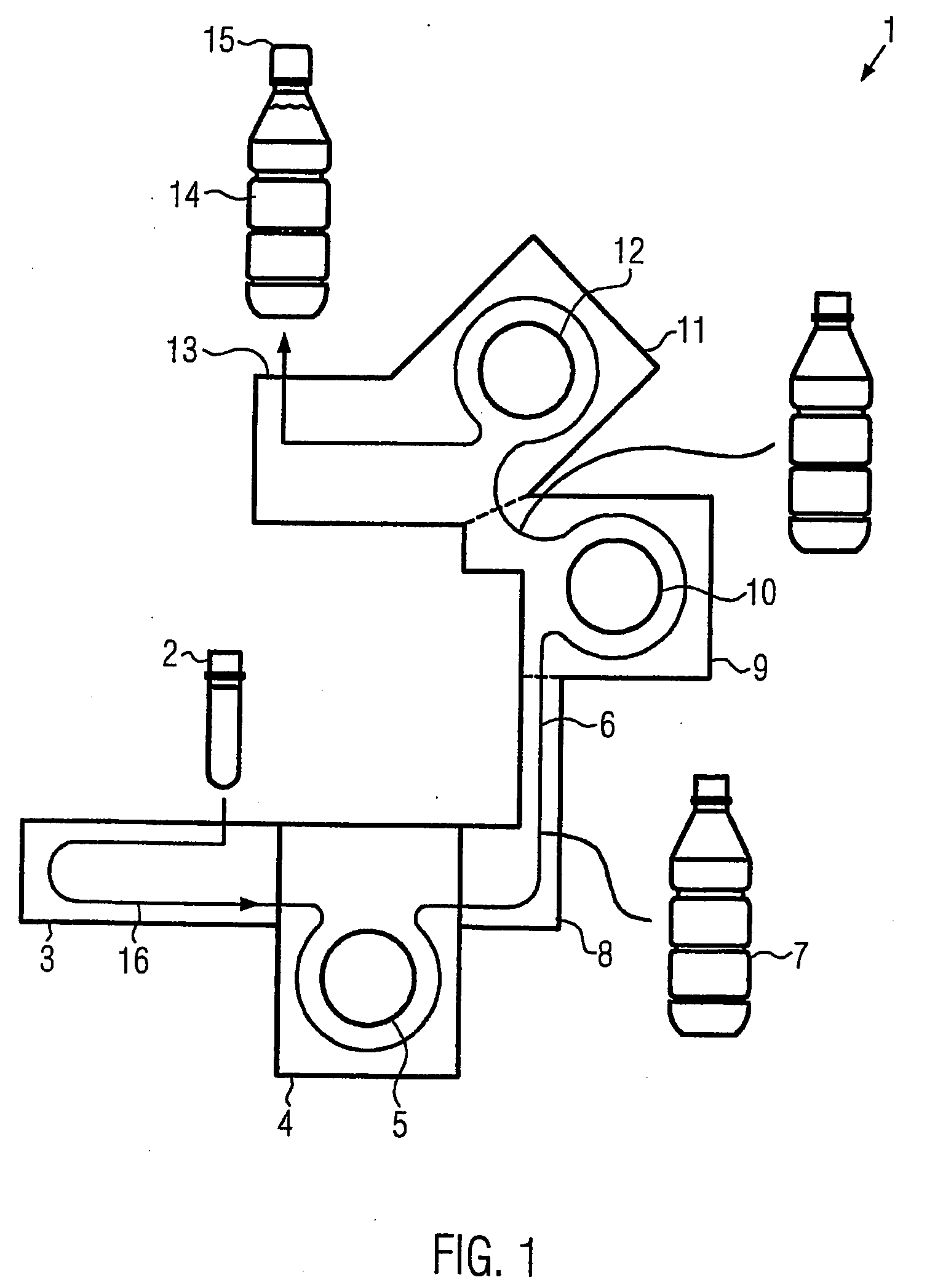

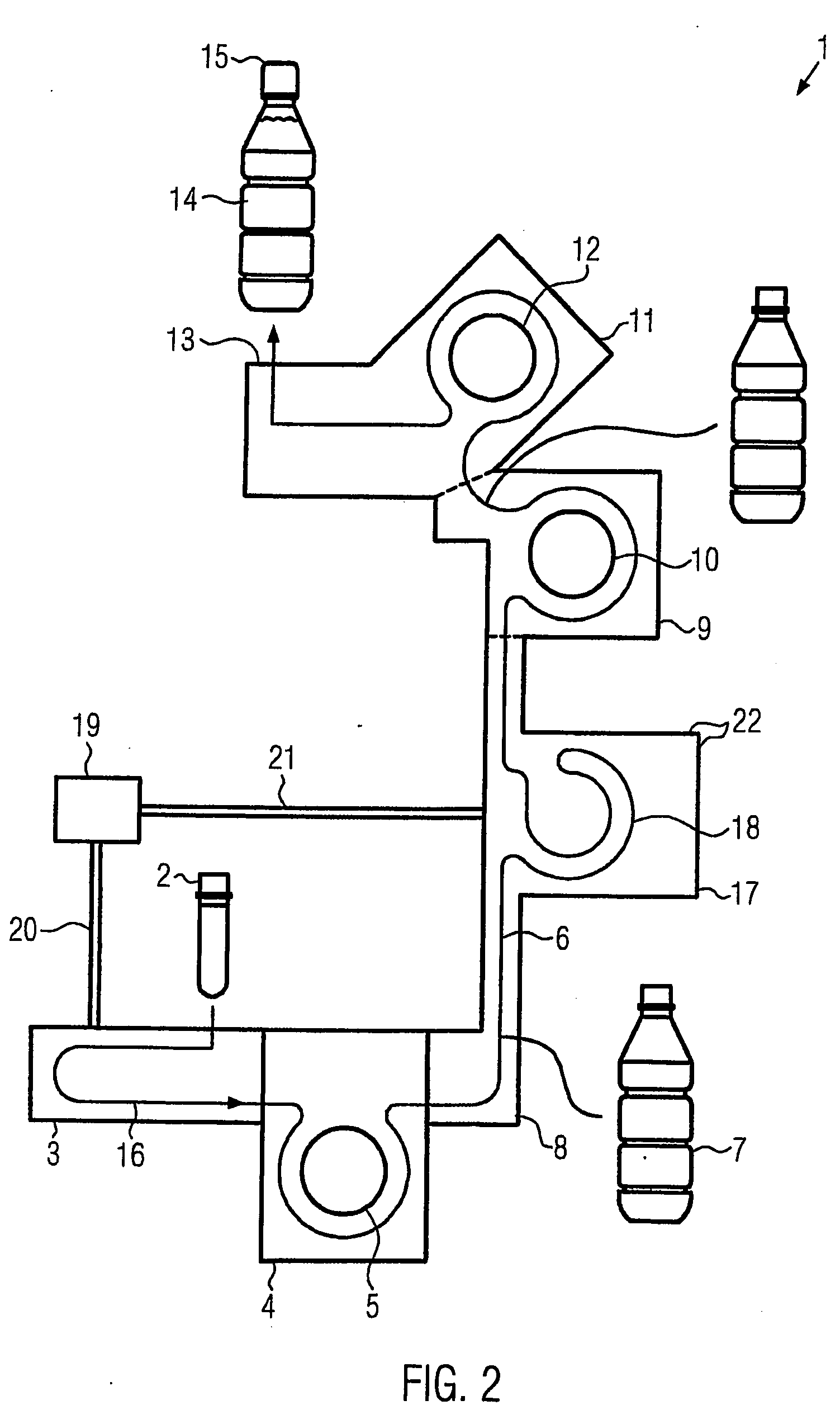

Method and Device for Producing Content Filling Bottle

The present invention provides a method and device for producing a content filling bottle including a bottom part that is inverted between a concave shape and a convex shape to prevent a body part from being subjected to reduced pressure deformation, the method and device being capable of efficiently producing a sanitary and high-quality content filling bottle. Contents are filled into an empty bottle 1 with an inversion part 11 projecting outwardly from the body part. A cap 6 is fitted onto an opening of the bottle 1 to seal the bottle 1. An auxiliary tool 27 is then installed on the bottom part 5 of the bottle 1. Then, the bottom part of the bottle 1 with the auxiliary tool 27 installed thereon is supported via the auxiliary tool 27. The downwardly projecting inversion part 11 is pressed up so as to be inverted and recessed inwardly into the bottle 1. Subsequently, with the opening of the bottle 1 gripped, the auxiliary tool 27 is separated from the bottle 1.

Owner:CO2 PAC

Locking aerosol dispenser

ActiveUS20080164285A1Avoid confusionPrevent rattlingDecorative coversClosure decorative/protective coversValve actuatorShort stem

An aerosol valve actuator with a top portion rotatable on a bottom portion. The entire top portion in one rotatable position is depressible vertically to actuate the valve. A click post and clicking rib provide a single click in each direction of rotation. Flanges on top and bottom portions interact to stop rotation as soon as each click occurs. Plastic springs interact with spring biasing members only when the top portion is in actuating position, and assure return of the actuator top portion to full upward position for rotation after actuation of even a short-stemmed valve. Downwardly extending flexible connecting flanges connect the actuator top and bottom portions. The top portion has a lower periphery with a plurality of upwardly extending indentations to overlie lateral ribs in the lower portion in actuation position. The top and bottom portions have interfitting cylinders to stabilize the top portion and maintain verticality.

Owner:PRECISION VALVE CORP

Aerosol dispensing device

InactiveUS6932244B2Easy sliding movementDecorative coversClosure decorative/protective coversSpray nozzleEngineering

An aerosol dispensing device includes a rotating actuator, an upstanding wall partially surrounding the actuator, and a sliding nozzle closure. The actuator may include a spray nozzle and a downwardly extending projection, in fluid communication with the spray nozzle, to sealingly engage an upwardly projecting stem of an aerosol valve. The upstanding wall may include an upper opening, a lower opening below the upper opening, and a spray opening. The sliding nozzle closure may include an upper projection, fitting into the upper opening and the spray nozzle, to seal the spray nozzle when the actuator is in a non-dispensing position, and, a lower member, fitting into the lower opening, to facilitate the sliding movement of the nozzle closure.

Owner:DISPENSING PATENTS INT

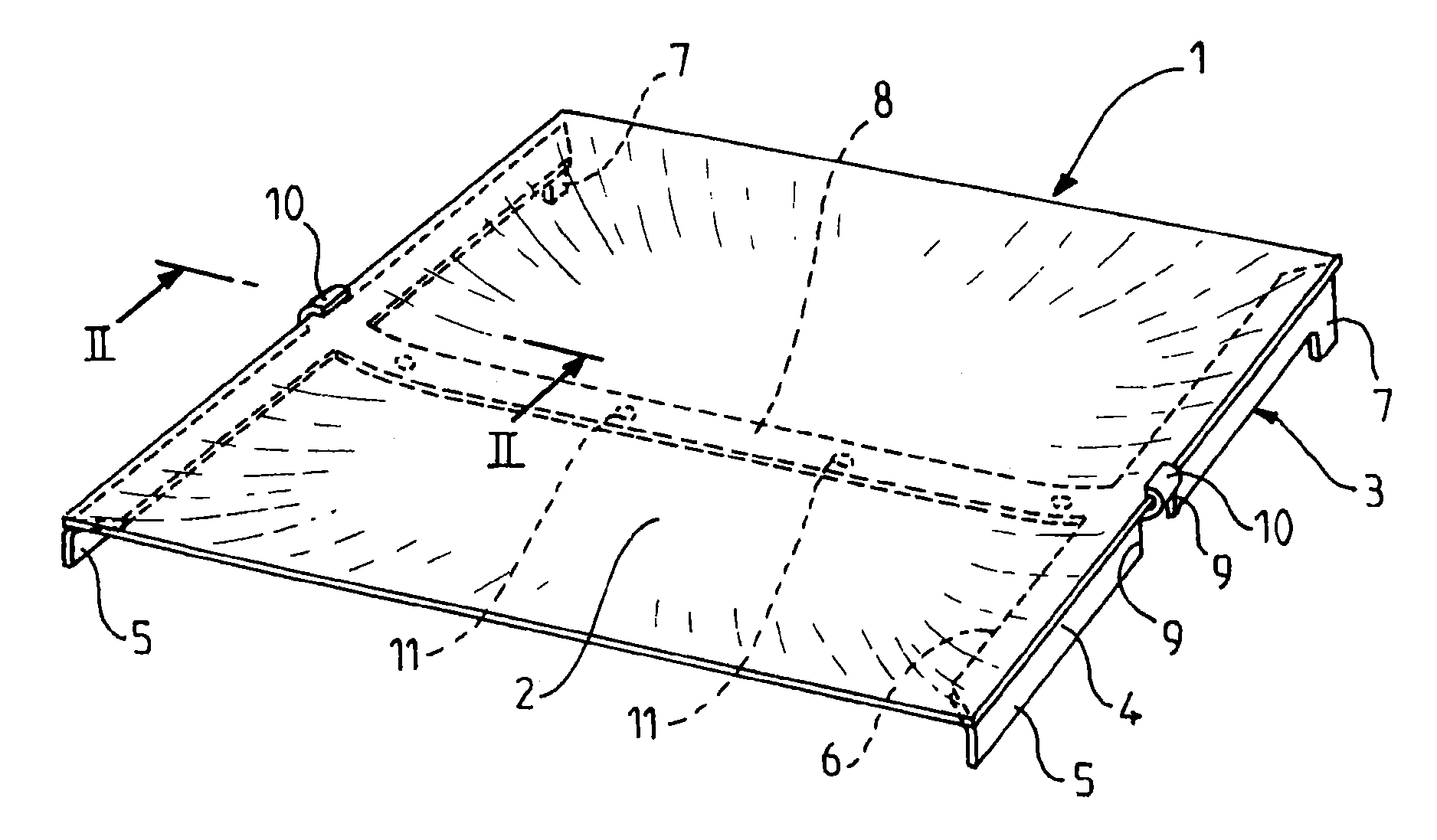

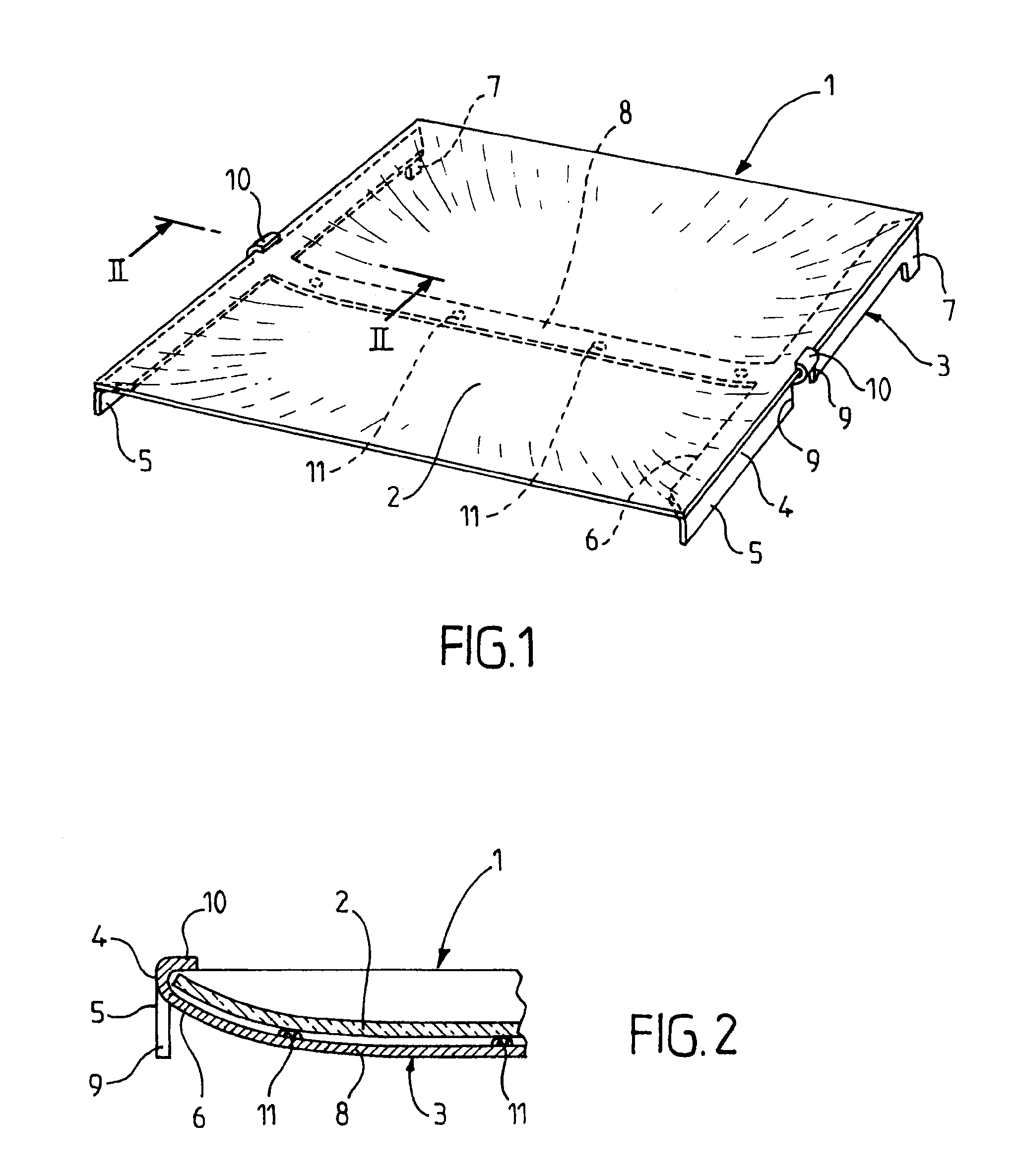

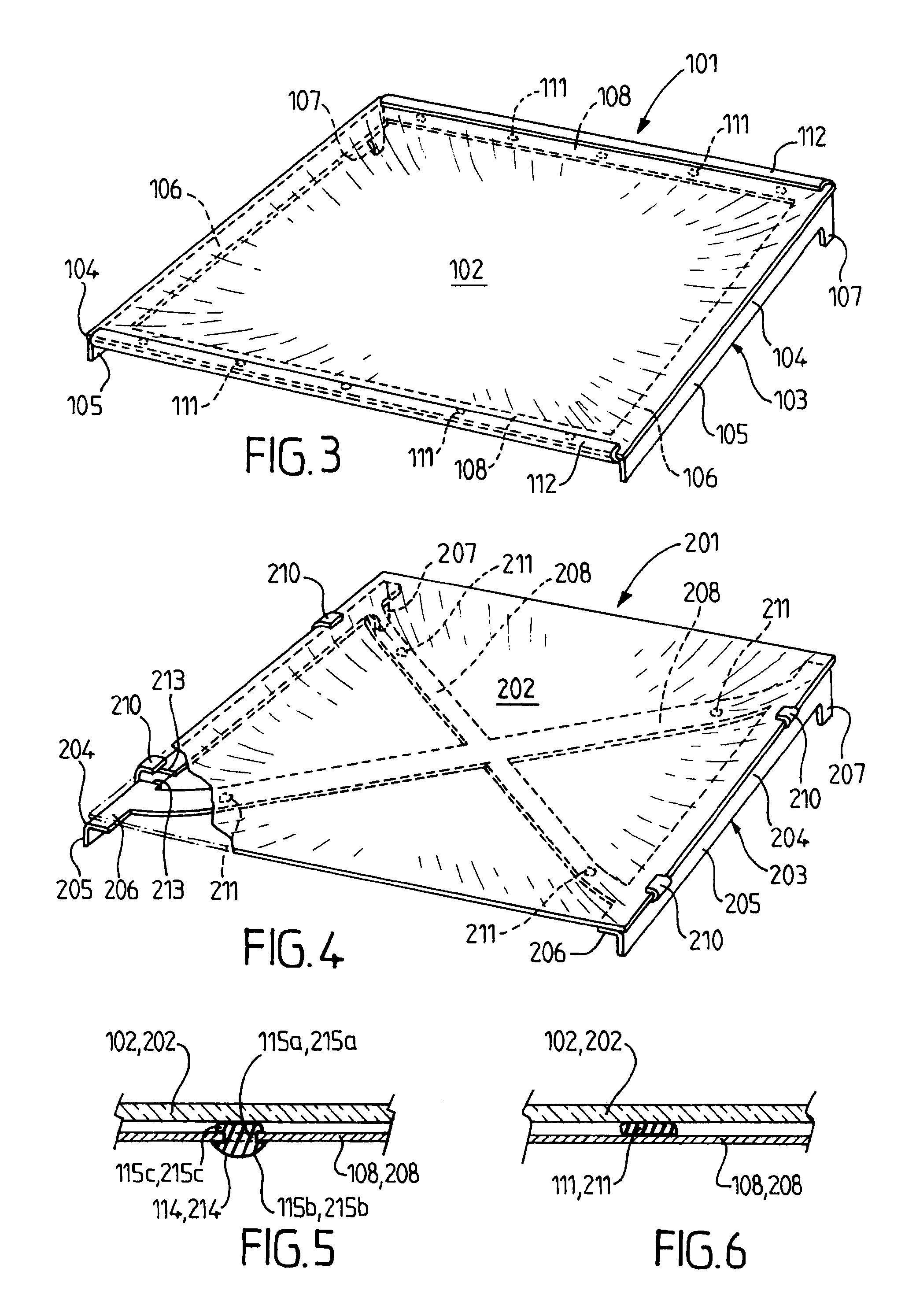

Shelf for refrigeration units

A shelf for a cabinet, for a refrigerator or the like, includes a glass plate for holding items which is supported along its side edges by track or rail type brackets suitable for fastening or mounting in said cabinet and aligned with a support structure formed or held by said cabinet. The brackets are joined by at least one crosspiece and with said crosspiece(s) form a cradle to hold said plate that is suitable for supporting the mechanical strength of the shelf.

Owner:SAINT-GOBAIN GLASS FRANCE

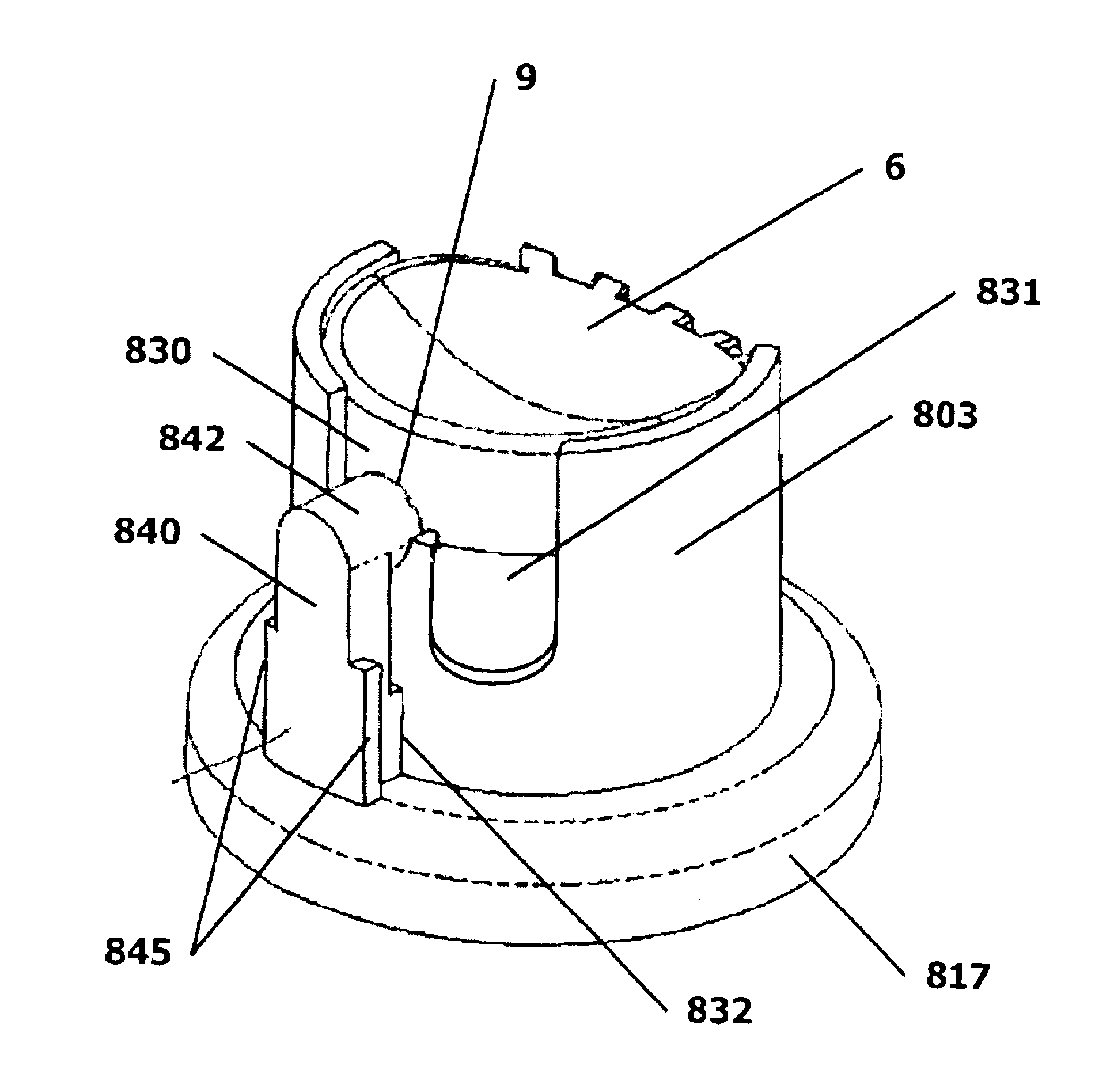

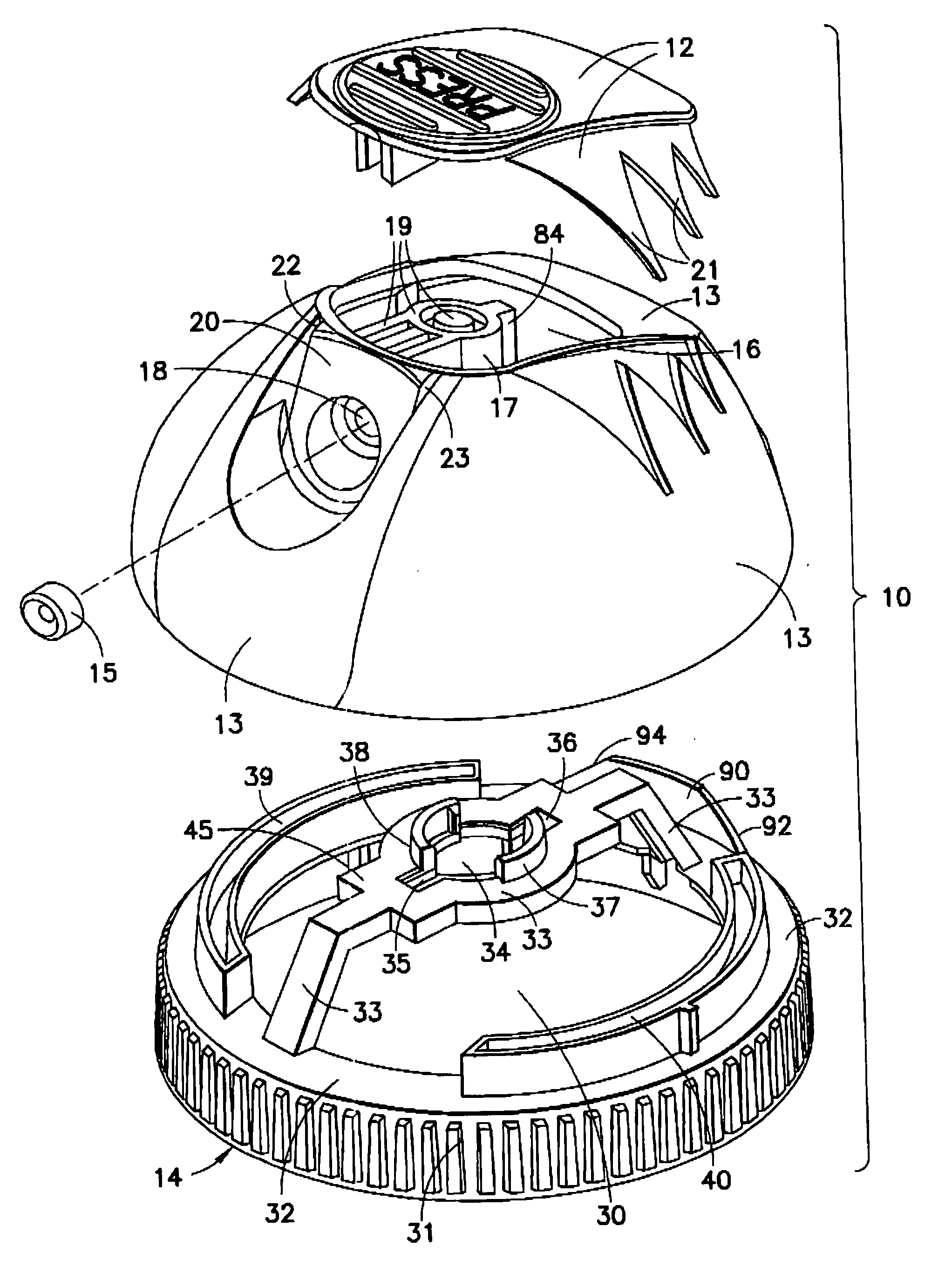

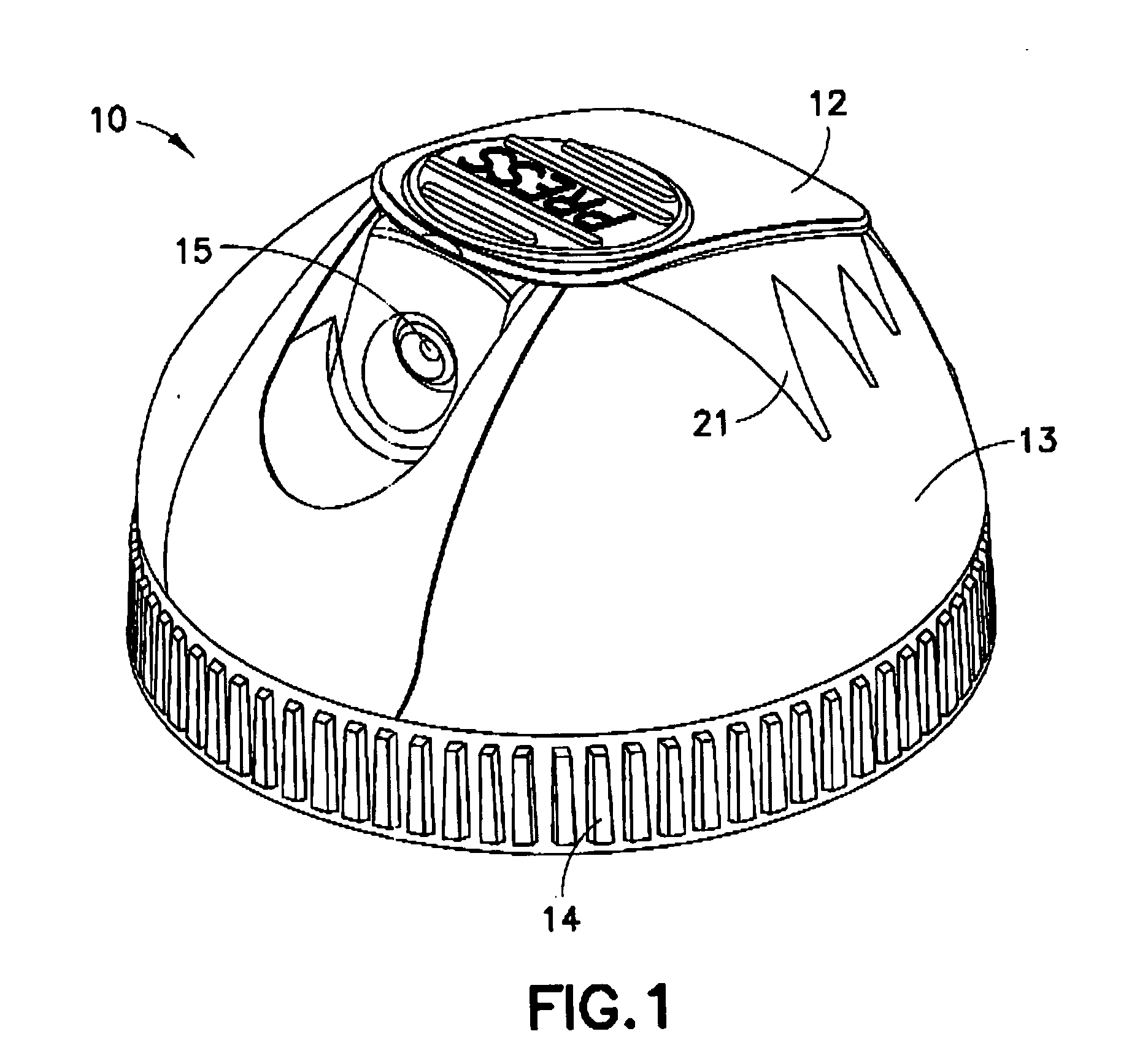

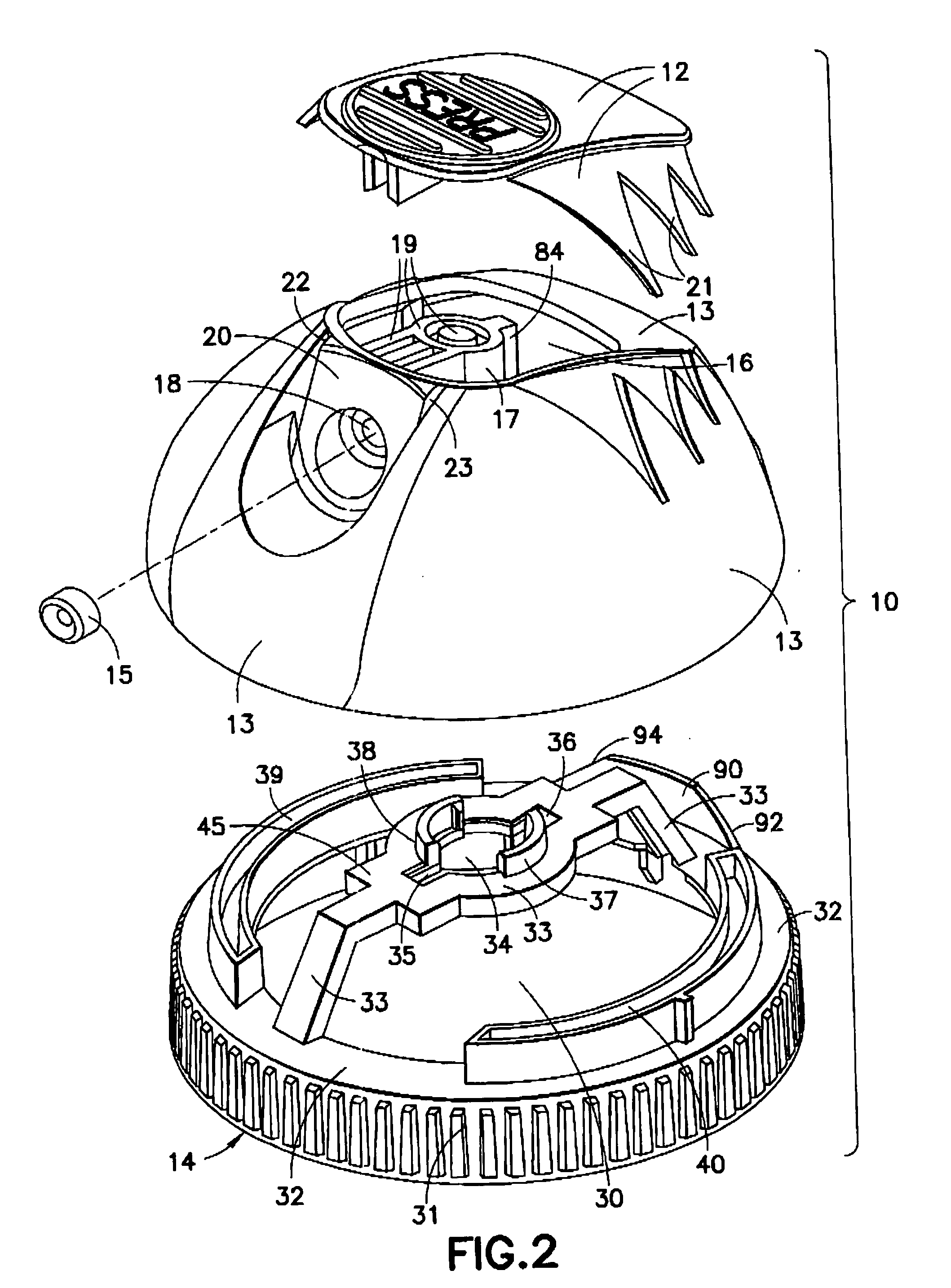

Locking aerosol dispenser

ActiveUS20070235474A1Robust constructionEasy to assembleDecorative coversClosure decorative/protective coversEngineeringVALVE PORT

A locking aerosol dispenser with a dome, a top thermoplastic elastomeric button member molded over a dome opening, and a base lock member. The rotatable base lock rotates from locked to unlocked position with respect to the essentially non-rotatable dome. A product channel member in the dome is held by the elastomeric button, and not otherwise attached to the dome. The base lock has an upstanding bridge with unlocking slots within which extend fingers on the product channel member when the dispenser is unlocked and actuated. The base lock is not attached to the aerosol valve mounting cup. The dome is attached to the base lock member and the aerosol valve mounting cup, the dome capturing the base lock member between the dome and aerosol container.

Owner:PRECISION VALVE CORP

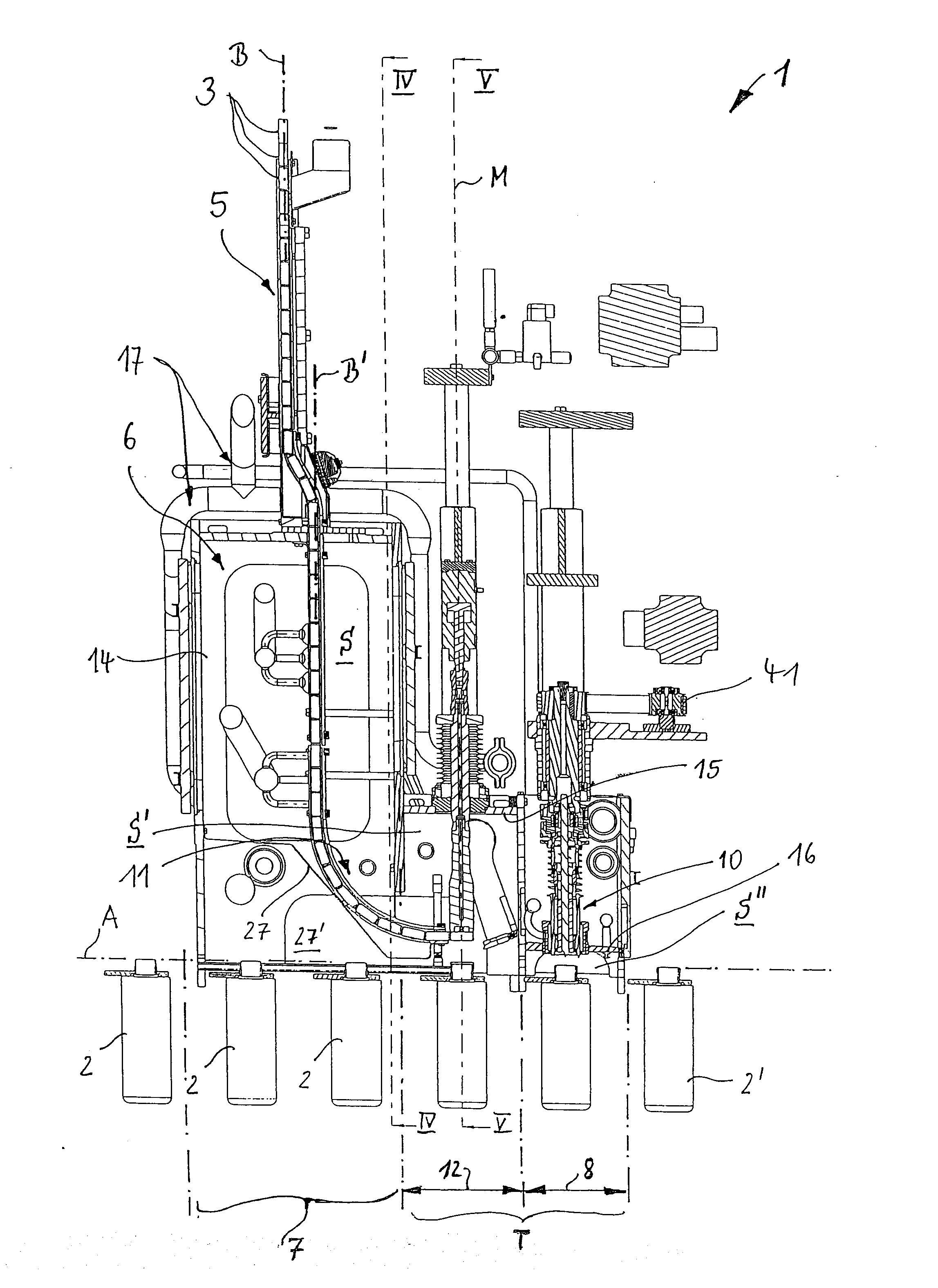

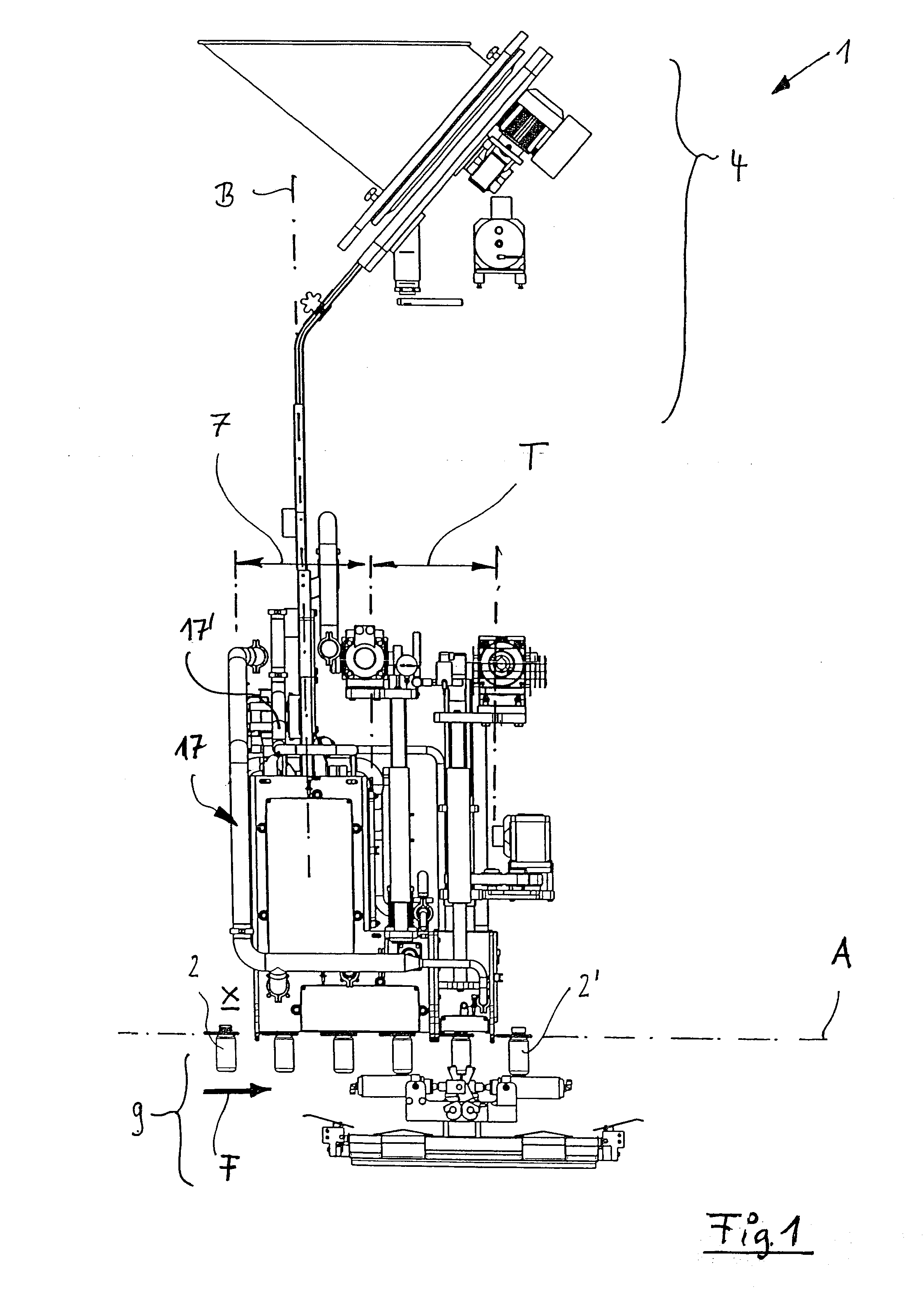

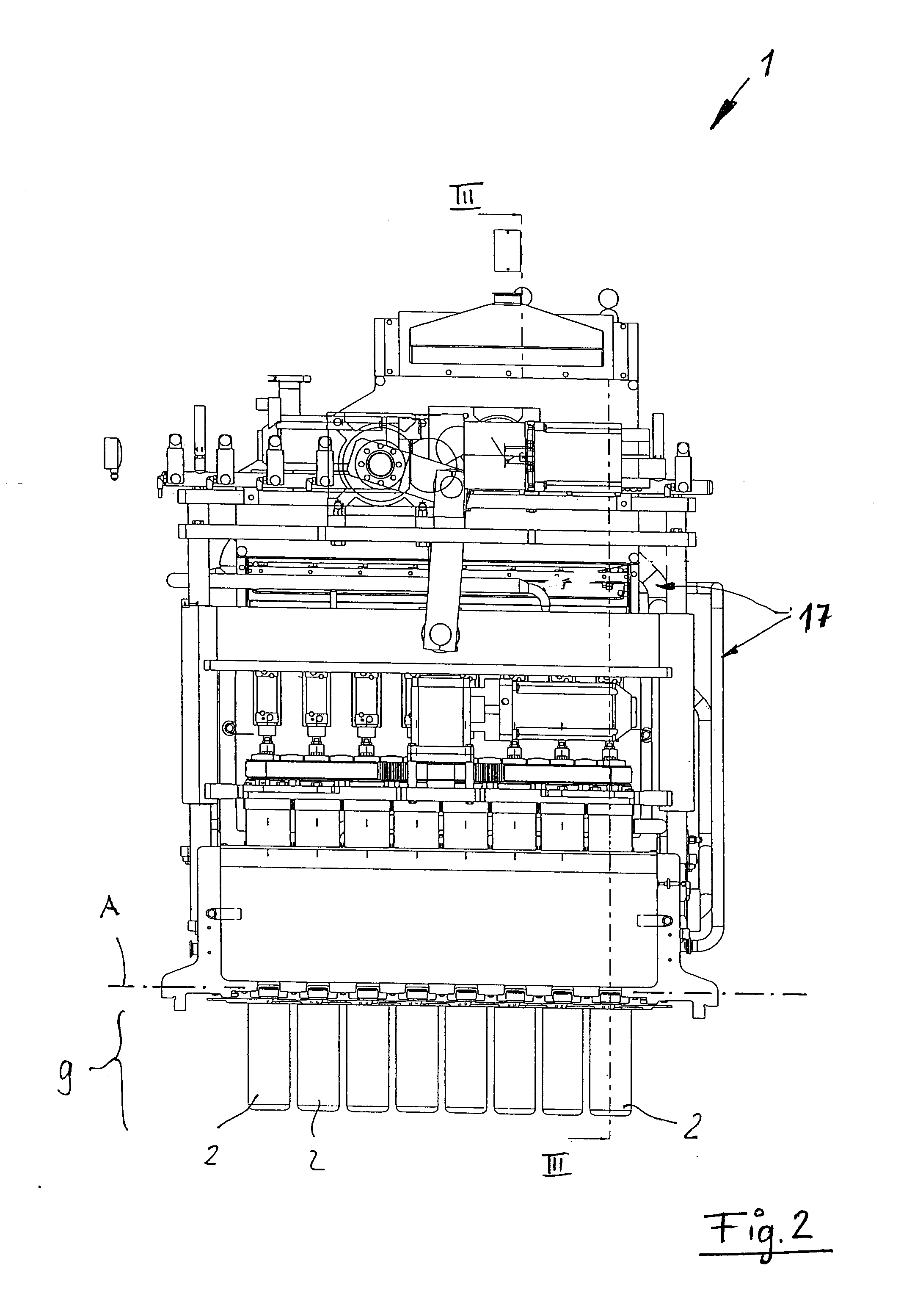

Method and Machine for Closing Bottles with Sterile Caps

ActiveUS20070006550A1Improve throughputImprove protectionCapsThreaded caps applicationSterile environmentLinear machine

For closing bottles with sterile caps, the caps are placed in a non-sterile environment in a vertical arrangement and are supplied vertically to a first sterile area. The interior of the caps is arranged to be accessible horizontally. The caps are sterilized in the first sterile area and transferred to a second sterile area where the caps are placed onto bottles. Subsequently, the bottle is closed with the cap. The machine for sterile closing of bottles with caps has a sterilization device with an individualization device for picking up caps and a vertical transport path feeding the caps to the sterilization chamber. A placing device receives the caps from the sterilization device and places the caps onto bottles. A closing device closes the bottles with the cap placed thereon. The sterilization device, the placing device, and the closing device operate as synchronized modules of a linear machine.

Owner:KHS CORPOPLAST GMBH & CO KG

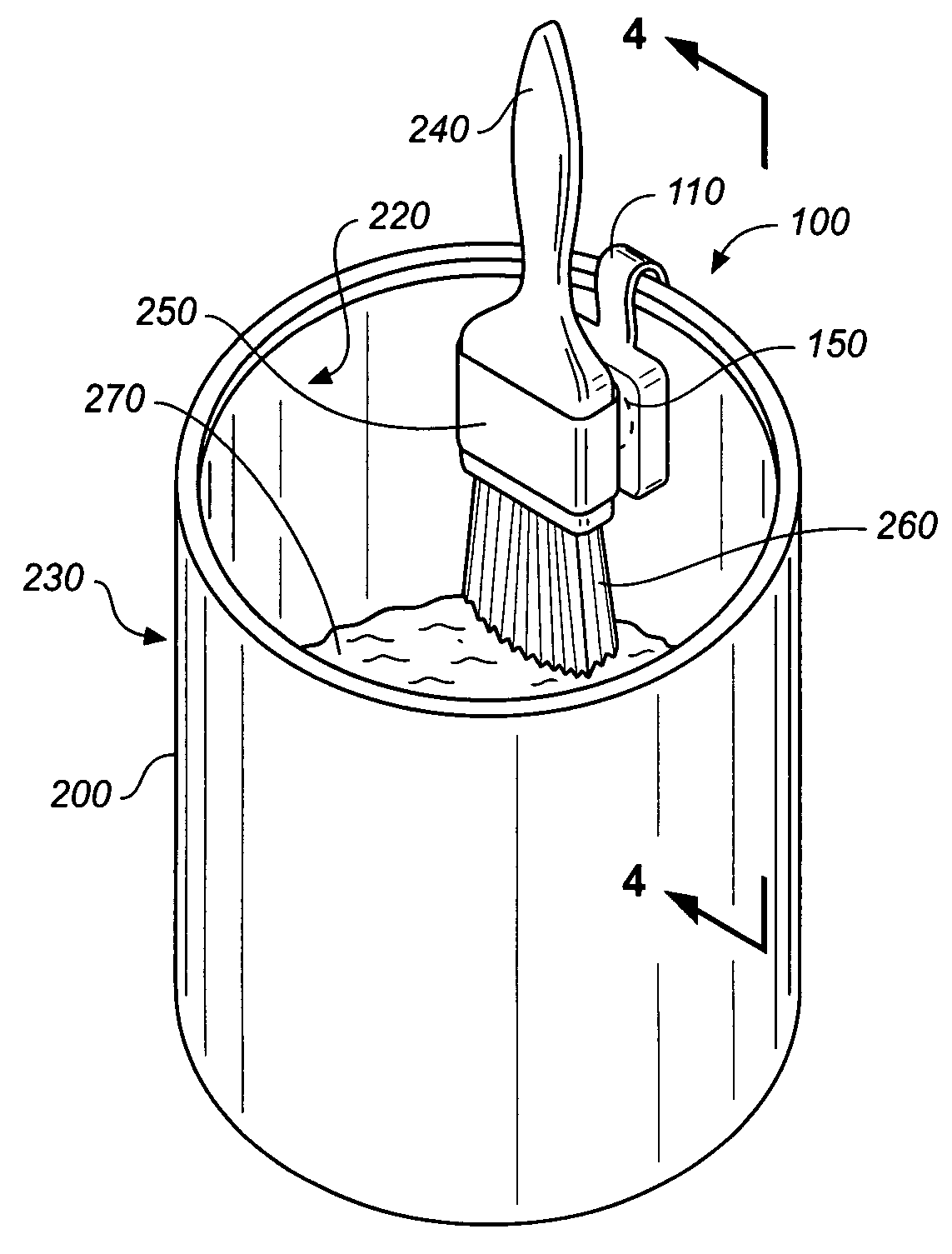

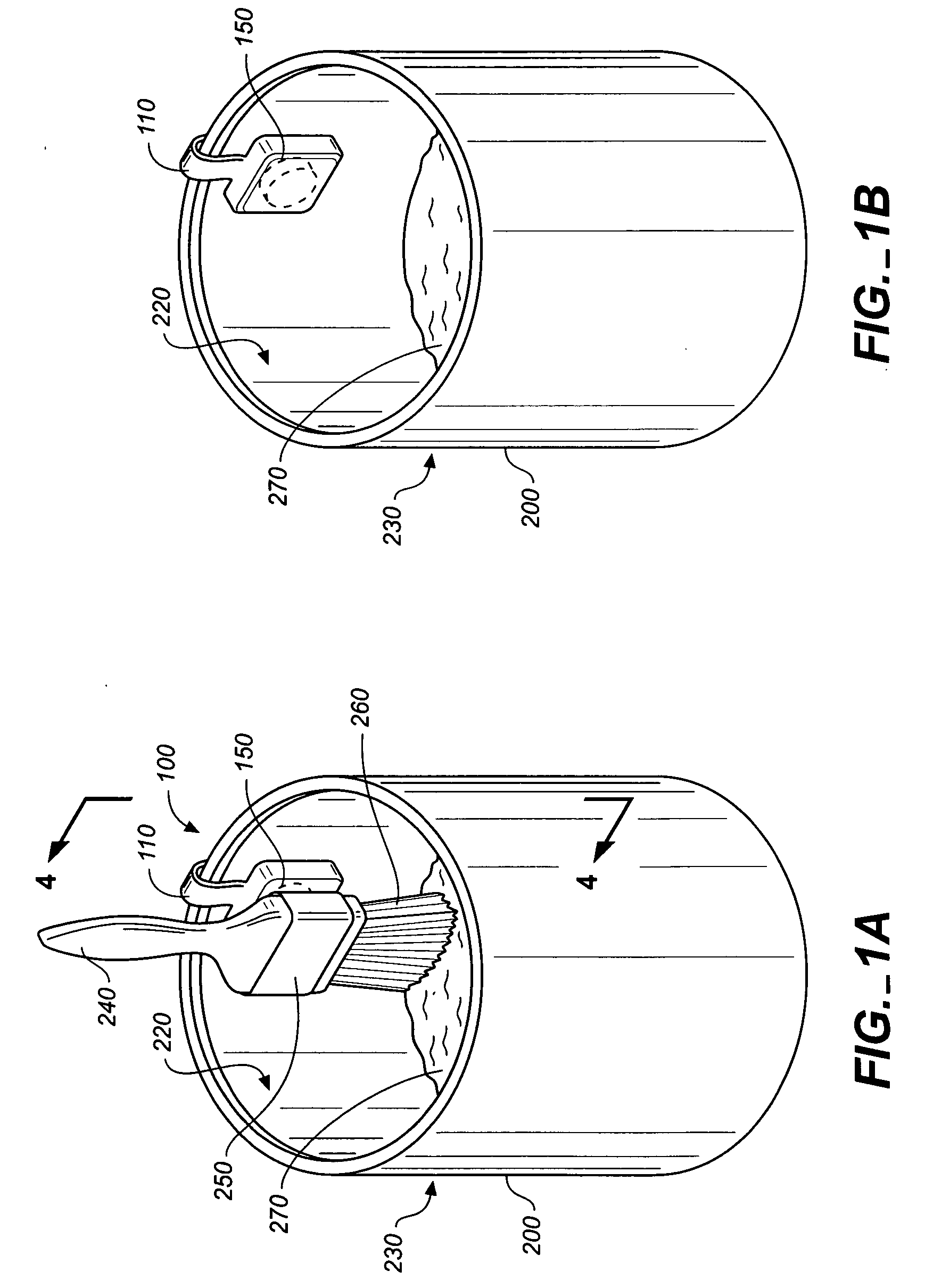

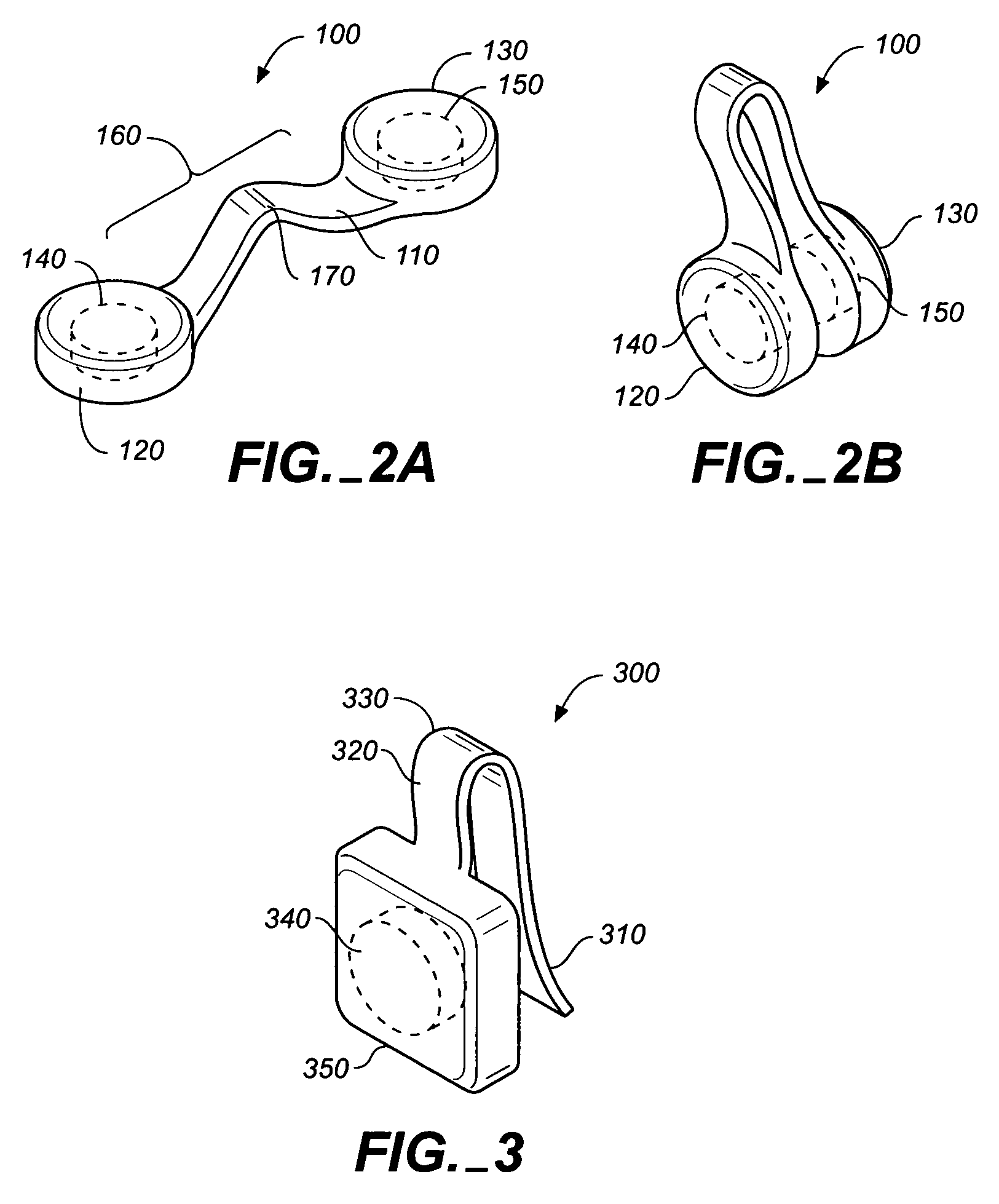

Magnetic paint brush holder

InactiveUS20050156085A1Great contributionEasy to useCandle holdersDecorative coversEngineeringMagnet

A paint brush holder including a strap having a first end, a second end, and a medial portion, and at least one permanent magnet disposed at one of the first or second ends. The magnet or magnets may be encased in an expansion integral with the strap or simply affixed to one or both of the ends of the strap. The strap may be entirely flexible or partly flexible, but includes either a fold or arcuate portion that may be draped over the upper rim of a paint container such that the magnet or magnets are disposed at a selected height above the surface of a volume of paint within the container.

Owner:RADOVAN TOMISLAV

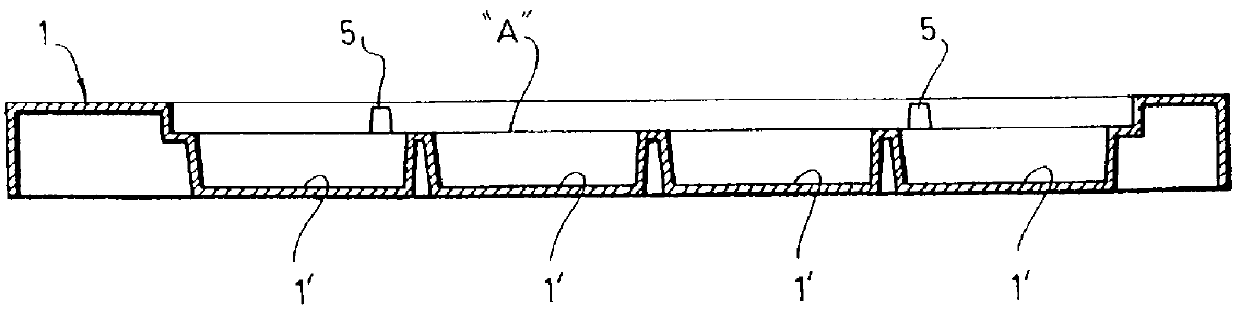

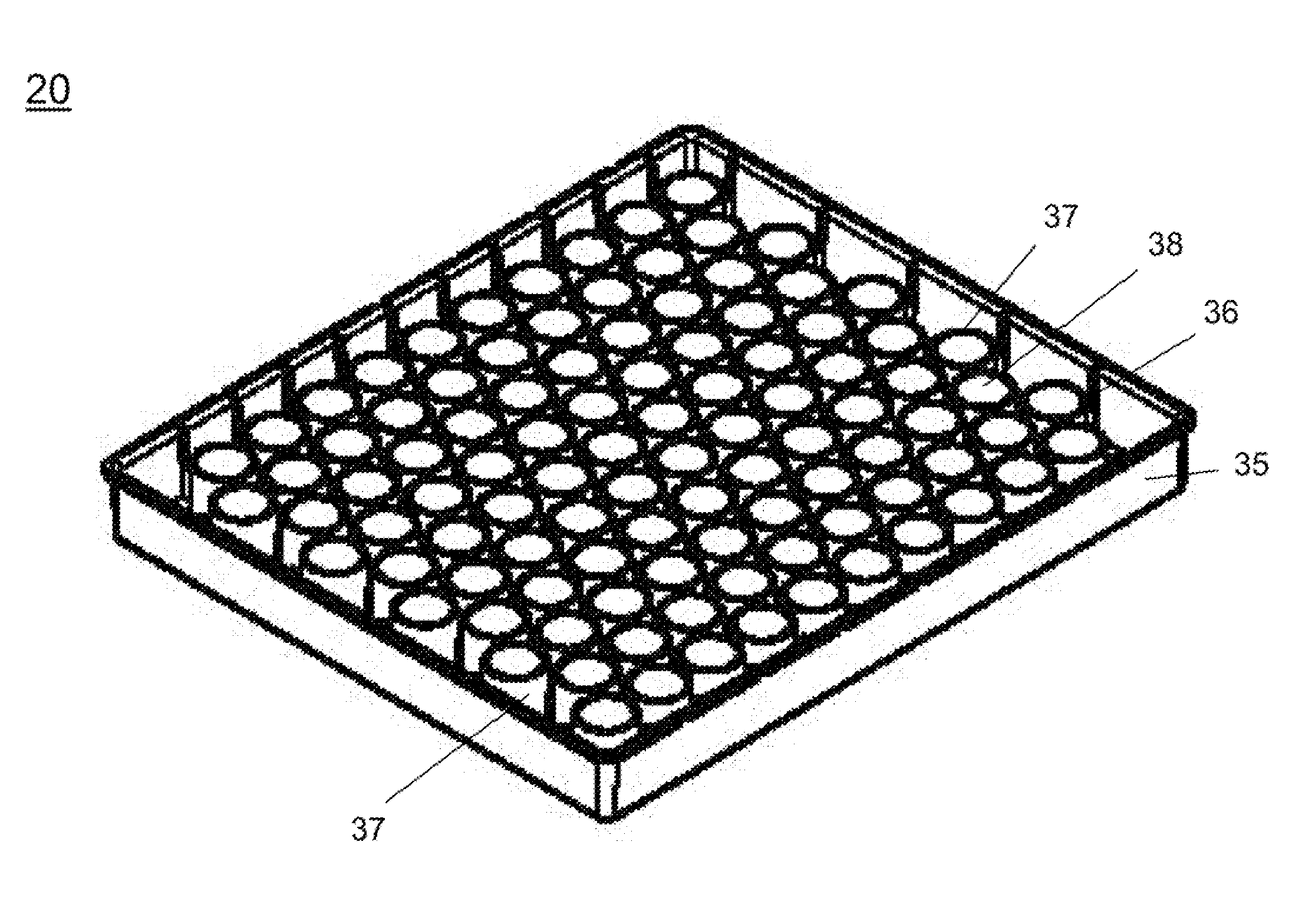

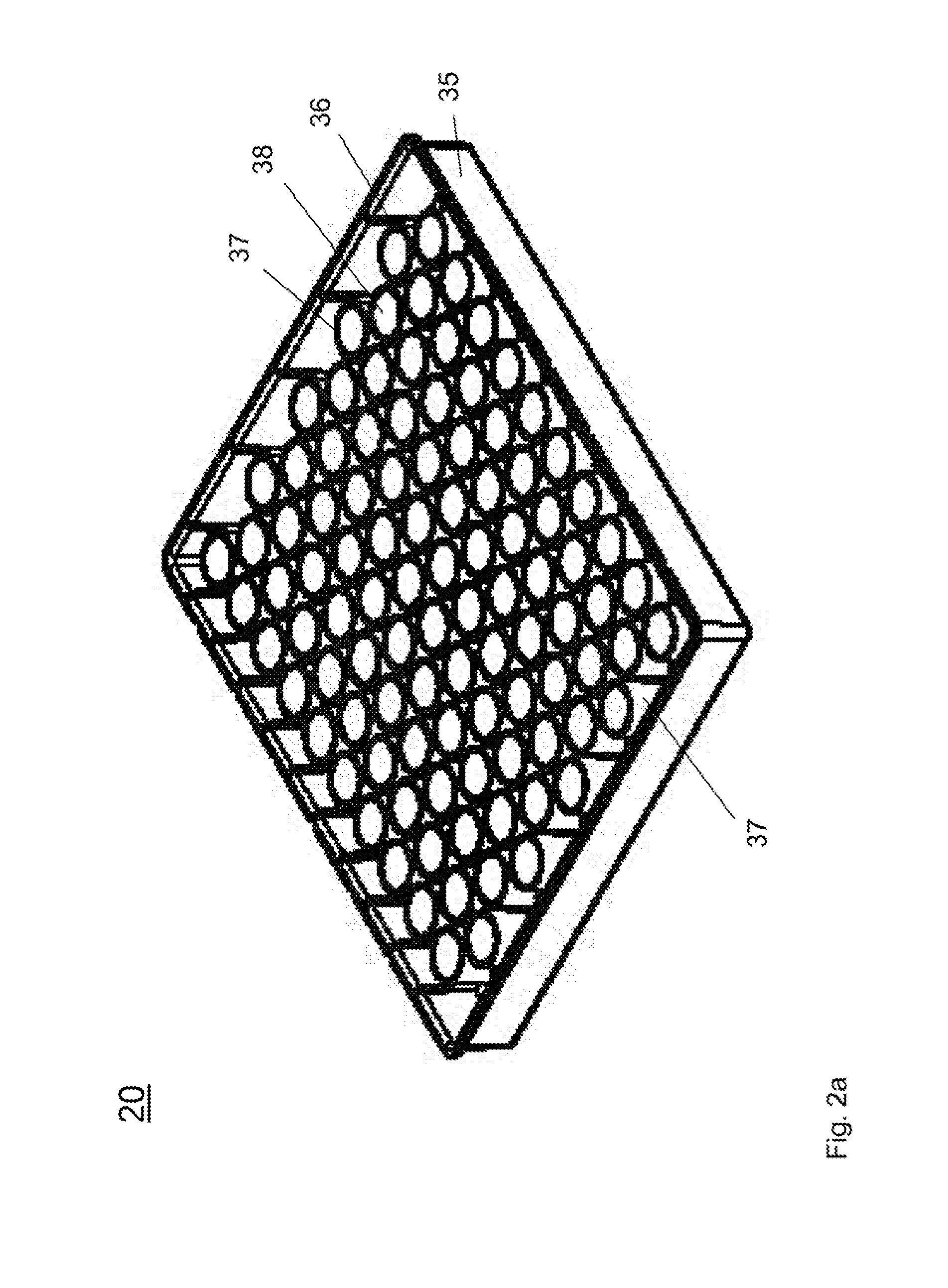

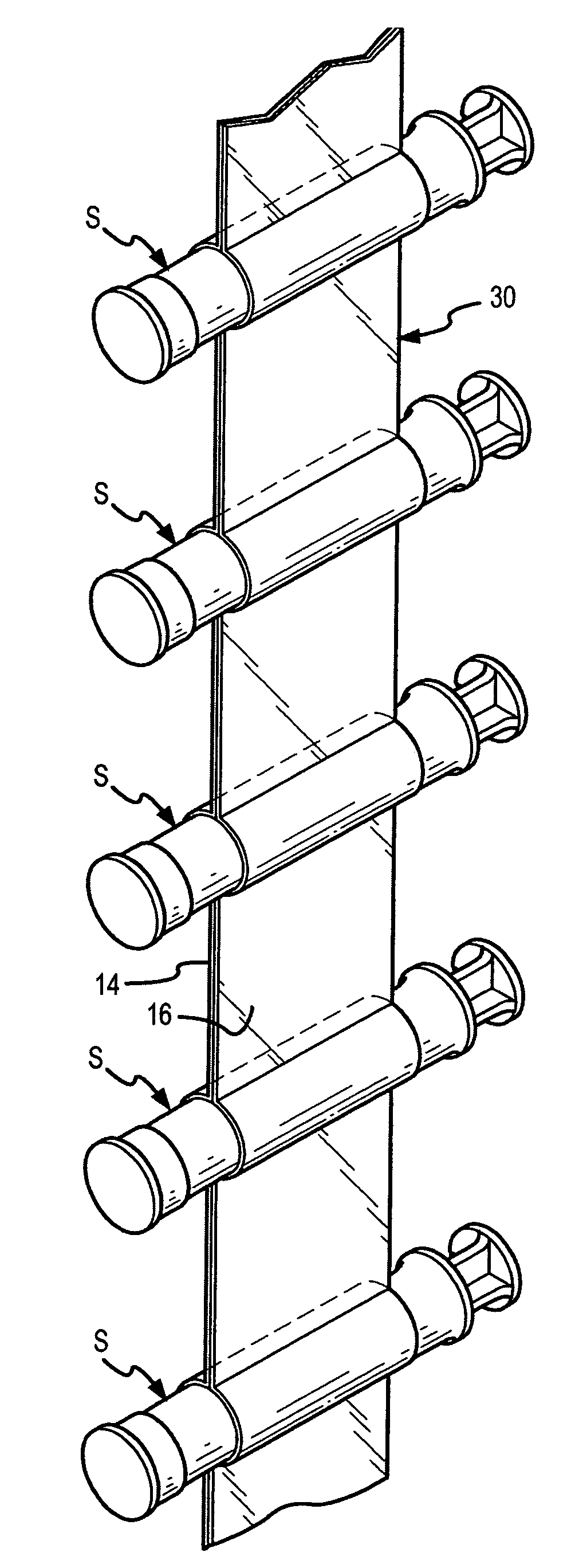

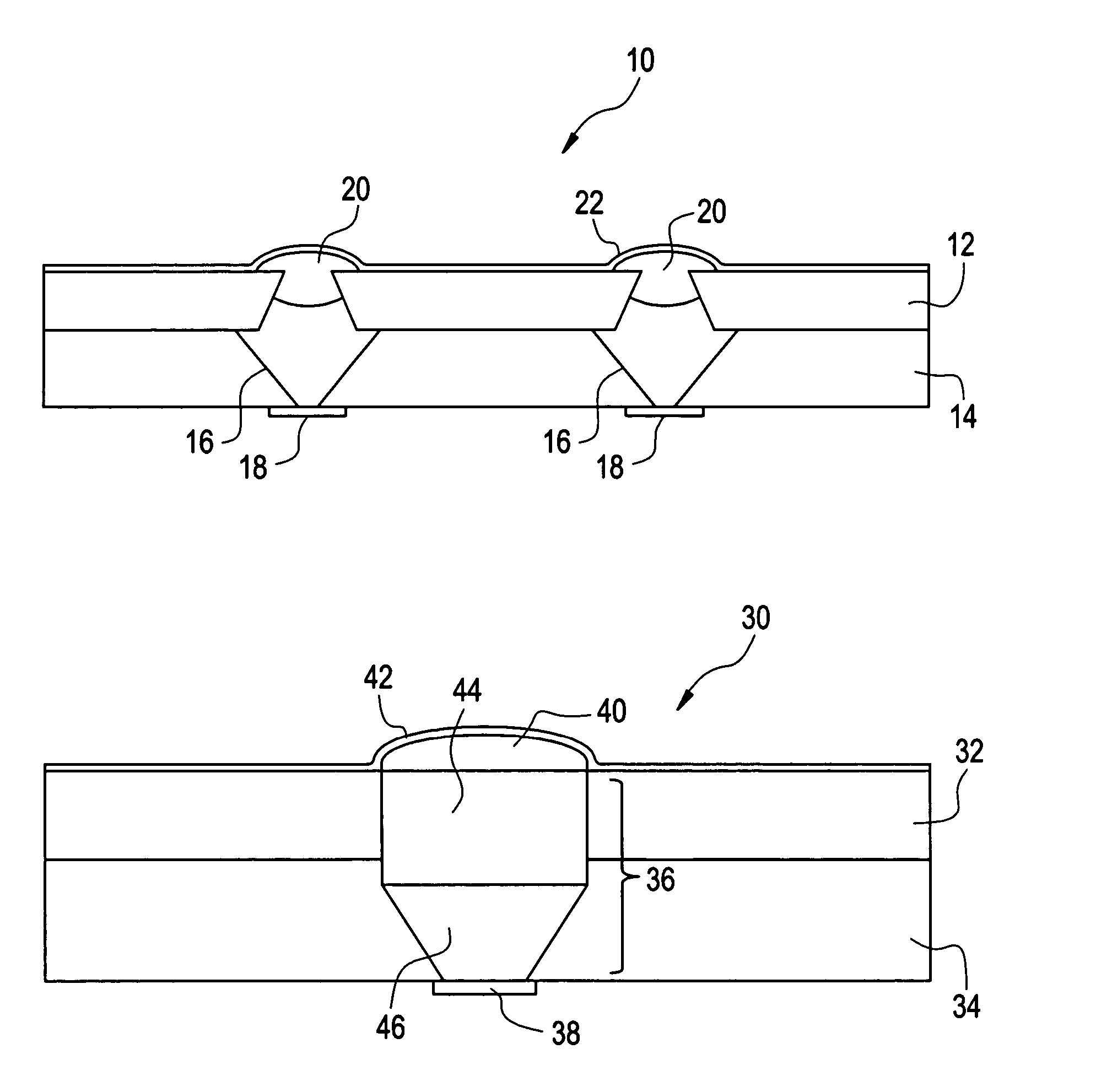

Supporting structure for concurrently supporting a plurality of containers for substances for medical, pharmaceutical or cosmetic applications

ActiveUS20150122693A1Add supportSterile packagingCapsDecorative coversMechanical engineeringMedical treatment

A supporting structure for concurrently supporting a plurality of containers having a predetermined length for medical, pharmaceutical or cosmetic applications is provided. The support structure includes a carrier having a plurality of supports for the containers on the carrier, optionally, at least in a first orientation (e.g. upright) or in a second orientation (upside-down or also upright). The carrier is matched to the lengths of the containers such that the upper ends of the containers are arranged in a first position at the same distance to the carrier as the lower ends of the containers in the second position and that the upper ends and / or lower ends of the containers are accessible for a further processing of the containers while they are supported on the carrier.

Owner:SCHOTT PHARMA AG & CO KGAA

Process and device for conveying odd-shaped containers

ActiveUS7574846B2Aesthetic qualities of the formed container shape are revealedImprove stabilityCapsDecorative coversProduction lineEngineering

A process for efficiently conveying containers along a table-top conveying system includes the steps of temporarily securing a transfer stabilizing support (1a, 1b) to a bottom end of a formed container (14) so that the container can freely move along a production line using the table-top conveying system where the transfer stabilizing support has a bottom surface (2a, 2b) with an opening (4a, 4b), a sidewall (6a, 6b) extending substantially perpendicular to the bottom surface, and a ridge area (10b) surrounding the opening and inside the sidewall of the support; and after the container has gone through operations of the production line, the transfer stabilizing support is removed so that aesthetic qualities of the formed container shape are revealed.

Owner:CO2 PAC

Method and device for the sterile filling with fluids

A device for the sterile filling of liquids in bottles, having a sterilizer which is used to sterilize the bottles with H2O2, a filling element which is used to fill the bottles, a closing element which is used to apply a closing element as a closing lid, and structure to adjust the temperature of the bottle whereby condensation of the H2O2 on the surface of the bottle is prevented. Also, a method for sterile filling of liquids in bottles comprising the steps of the bottles are sterilized with H2O2, then filled and closed. During sterilization, the bottles have such a temperature that condensation of the H2O2 is prevented on the surface of the bottles.

Owner:KRONES AG

Food container and methods of forming and using thereof

A method of forming a multiple food product container for dispensing one food product from at or near one region of the container, and dispensing another food product at or near the other region of the container, is provided. In the method the two containers are coupled together (i.e., permanently or separably coupled). A preferred embodiment comprises an upper food compartment, a lower food compartment, wherein a top of the lower food compartment is coupled to a bottom of the upper food compartment, a resealable opening disposed at a top of the first food compartment, a resealable second opening disposed proximate a bottom of the second food compartment, a first food disposed in the upper food compartment, and a second food disposed in the lower food compartment.

Owner:DUNAWAY LENDY

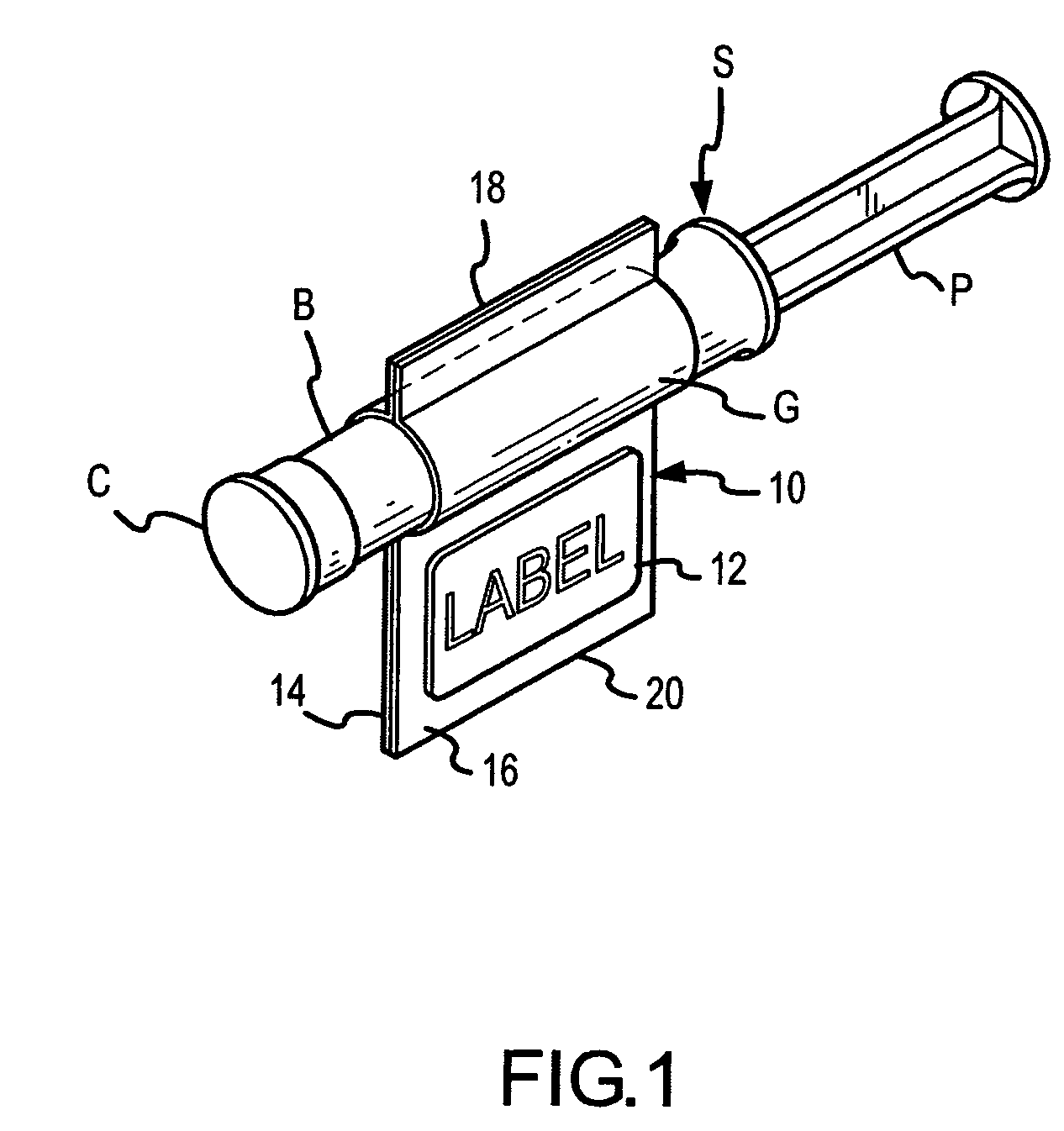

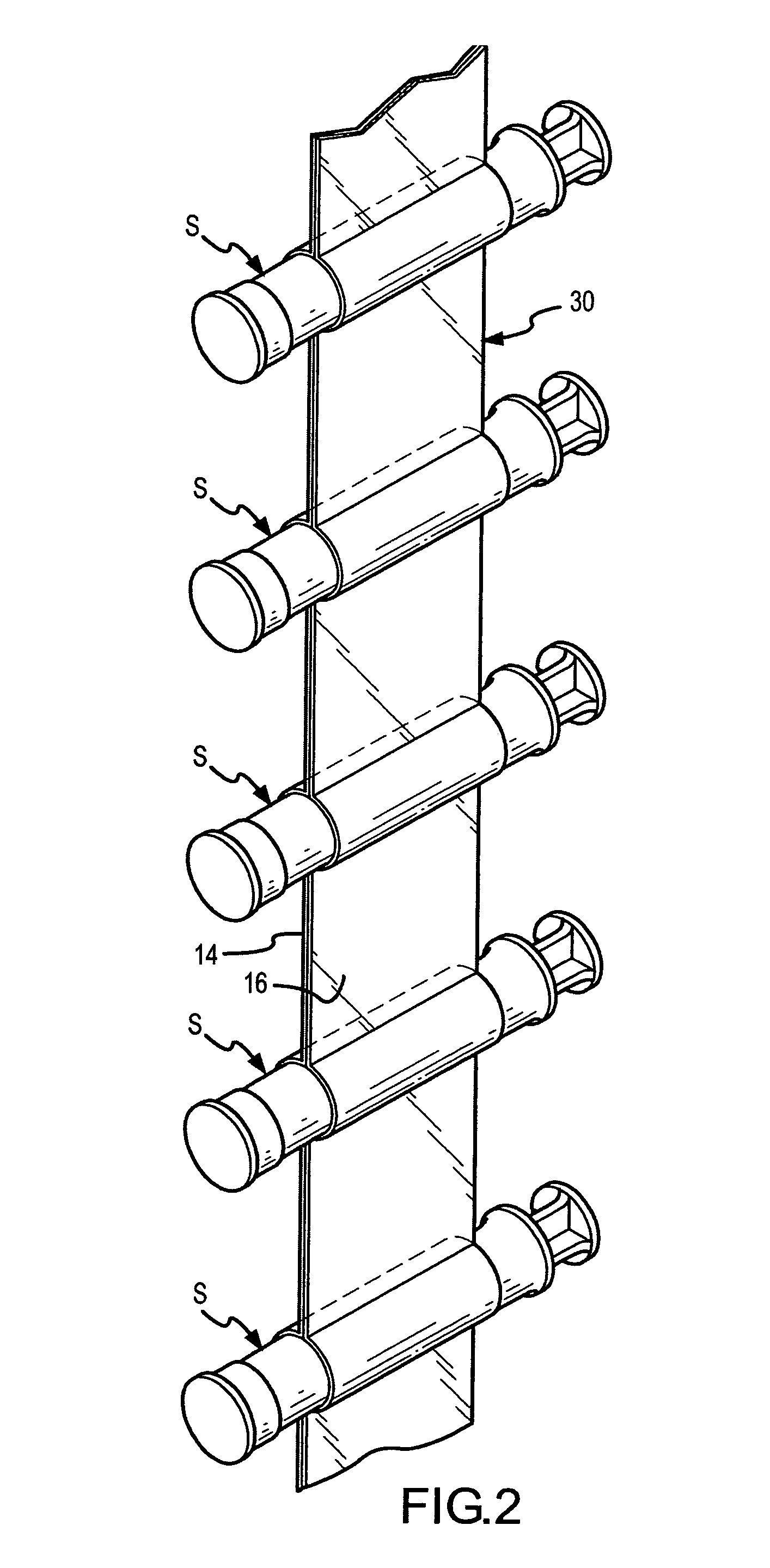

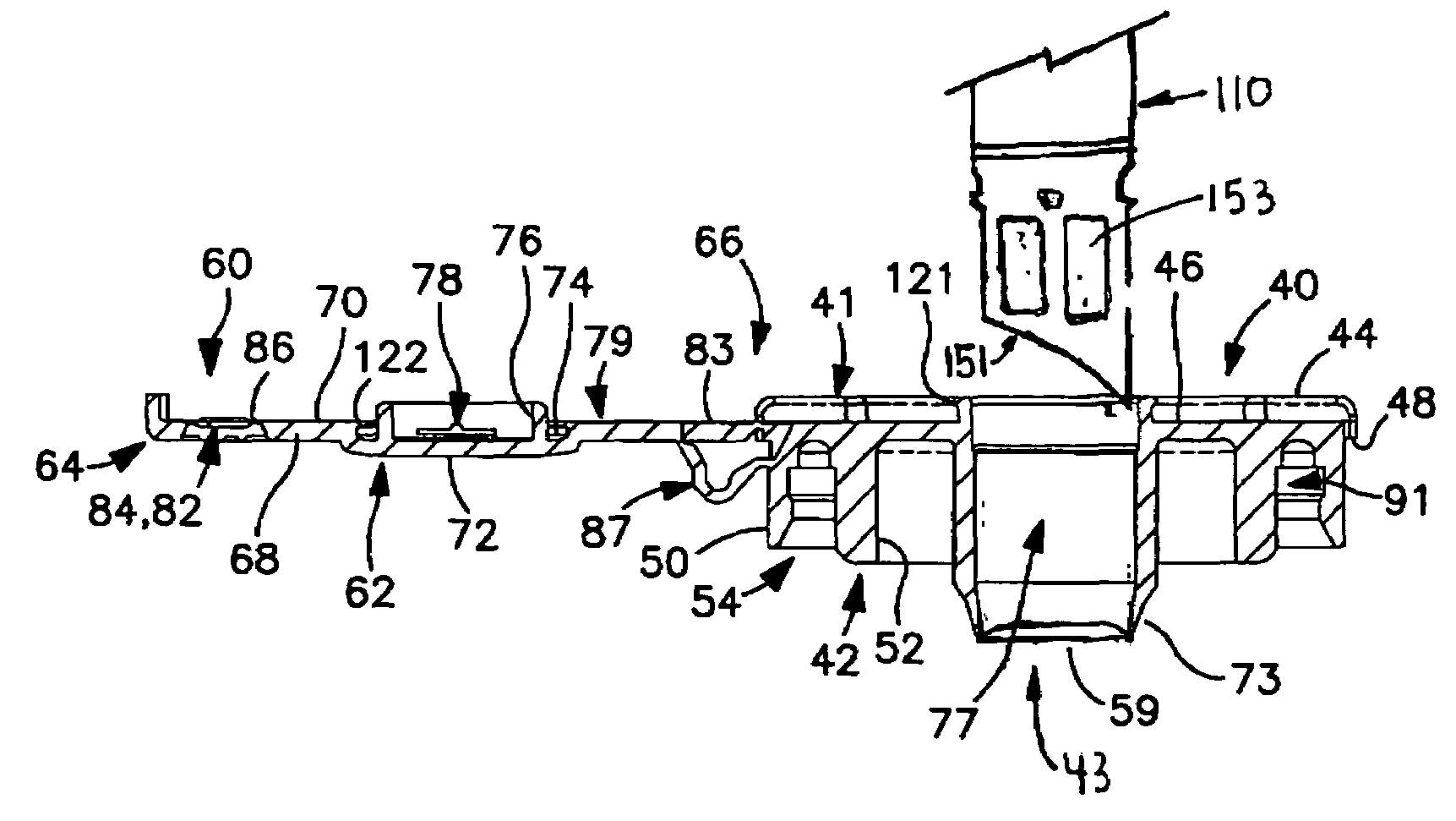

Method, system, and apparatus for handling, labeling, filling, and capping syringes with improved cap

InactiveUS7392638B2Easy to handleEasy to carryCapsDecorative coversManual handlingBiomedical engineering

Owner:BAXTER ENGLEWOOD

Low temperature methods for hermetically sealing reservoir devices

Methods are provided for hermetically sealing an opening in a reservoir of a containment device. The method comprises applying a polymeric material to an opening in a reservoir of a containment device, the reservoir comprising reservoir contents (such as a drug or a sensor) to be hermetically isolated within the reservoir, the applied polymeric material closing off the opening and forming a temporary seal; and adhering a hermetic sealing material onto the polymeric material to hermetically seal the opening. The reservoir can be a micro-reservoir. The containment device can comprises an array of two or more of reservoirs, and the method comprises hermetically sealing each of the two or more reservoirs.

Owner:MICROCHIPS BIOTECH INC

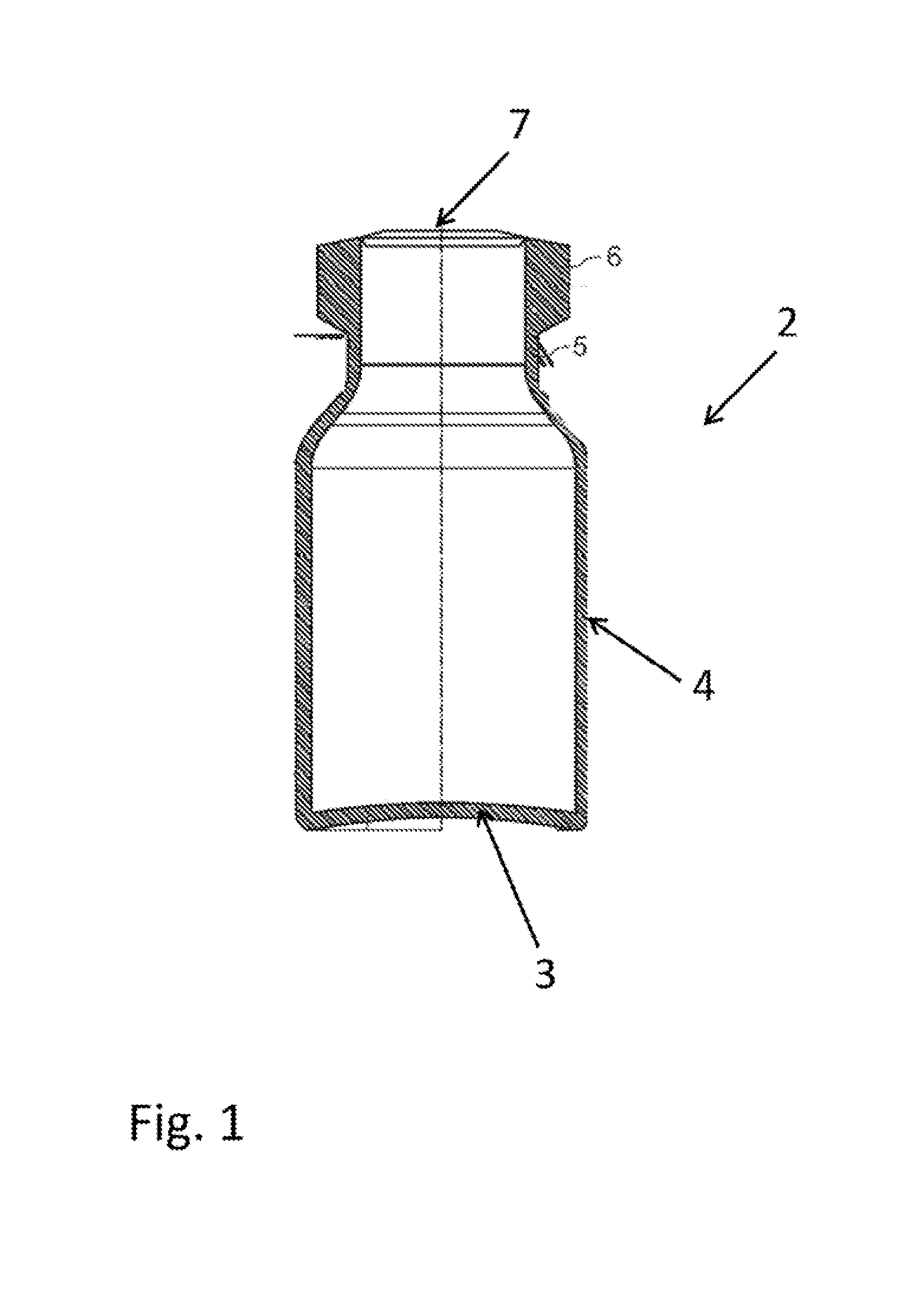

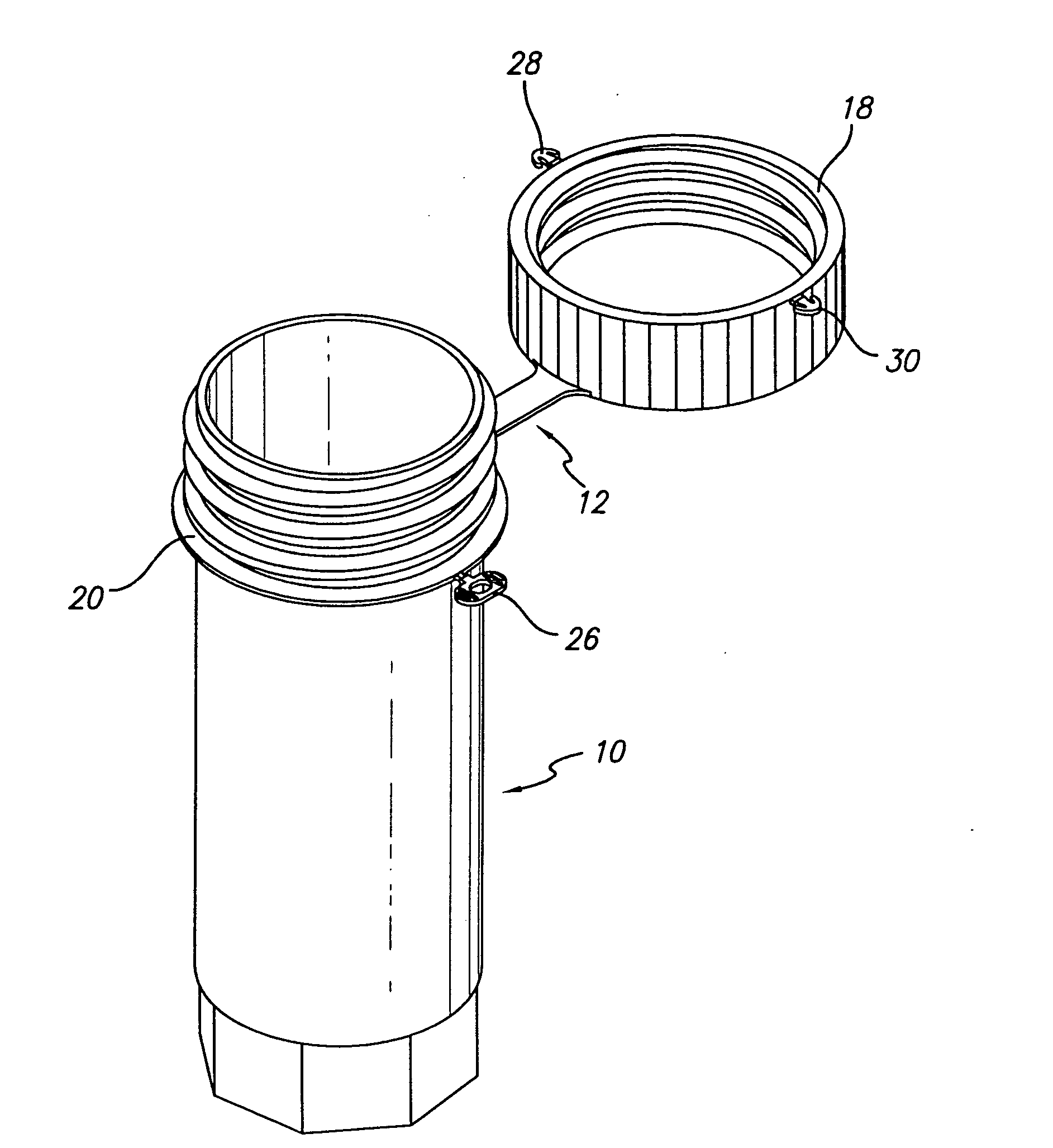

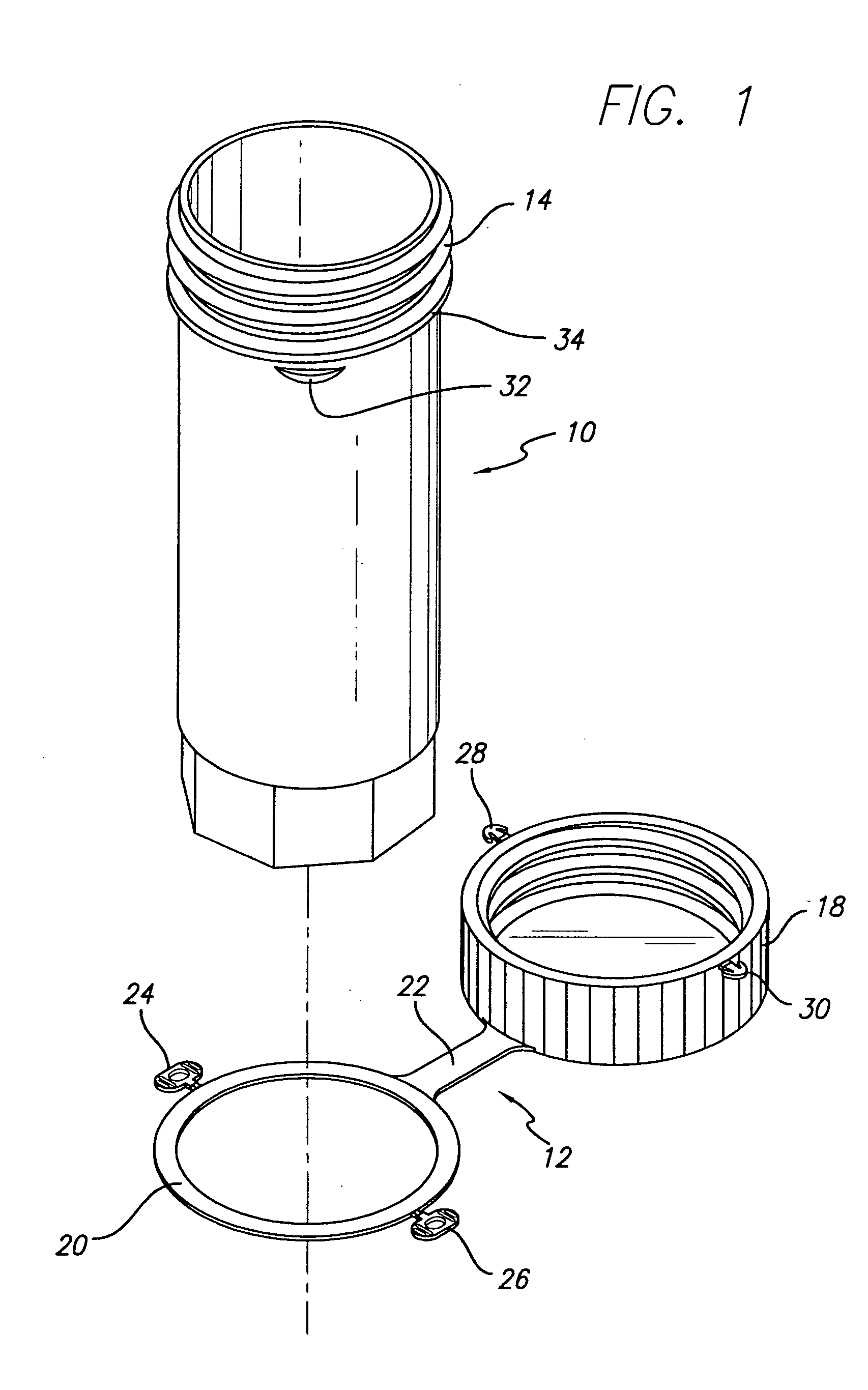

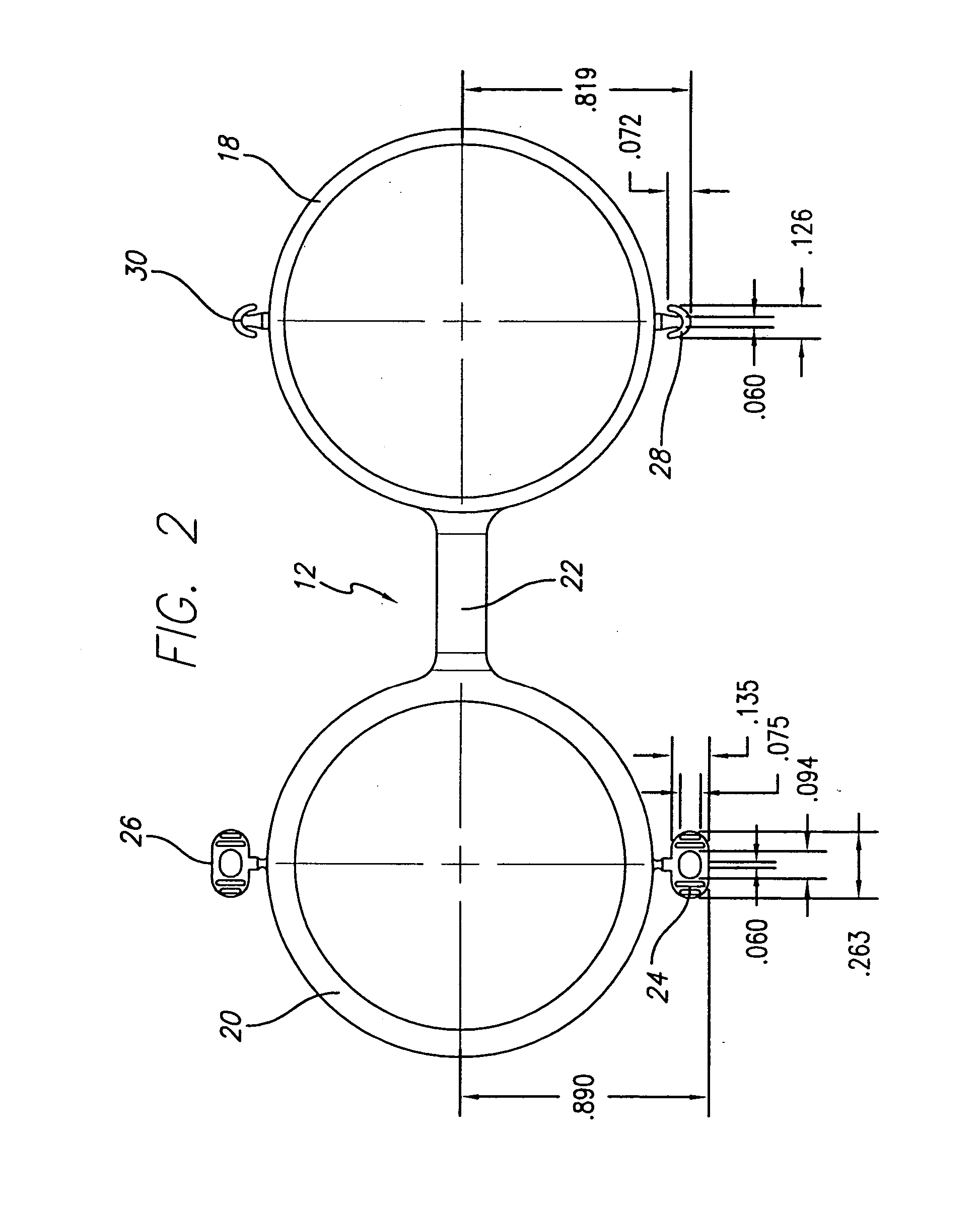

Tamper evident vial cap and integrity assurance method

ActiveUS20050023238A1Limit upward movementPrevent downward movementCapsDecorative coversEngineeringScrew thread

A tamper evident cap assembly, more particularly a combination of vial and cap assembly, assures the integrity of a specimen and of the specimen collection process. The screw cap is locked to the screw threads of a vial, when the vial is empty, with one of two latches that are integral to the cap assembly and can lock the cap to the vial. The lock is broken in the presence of the specimen donor or in the presence of a witness who can testify as to chain of custody, a specimen is placed in the vial, following which the cap is locked to the vial with the other of the two latches, which is broken when received by a testing laboratory. A loop formed to encircle the vial is connected by a tether to the cap and slipped onto the vial. At least one restraining rib on the vial is spaced below the screw thread top and is sized to permit the loop to be forced upwardly thereover to be restrained from downward movement. In addition, a limiting flange on the vial is spaced below the screw thread and above the loop restraining rib sufficient to accommodate the loop, and is sized to limit upward movement of the loop. In a specific embodiment, latch staples extend from the cap which can be inserted into, and irreversibly lock with, respective hasps extending from the loop.

Owner:PII EVERGREEN

Resealable Laminate for Heat Sealed Packaging

A resealable and disposable package assembly is described. The assembly includes a container and a multilayer cover laminate that are bonded to one another to initially seal the contents of the package. The package can then be easily opened by at least partially separating the cover laminate along a predesignated interface. The package can be reliably and effectively sealed by recontacting the previously separated cover portions to one another.

Owner:AVERY DENNISON CORP

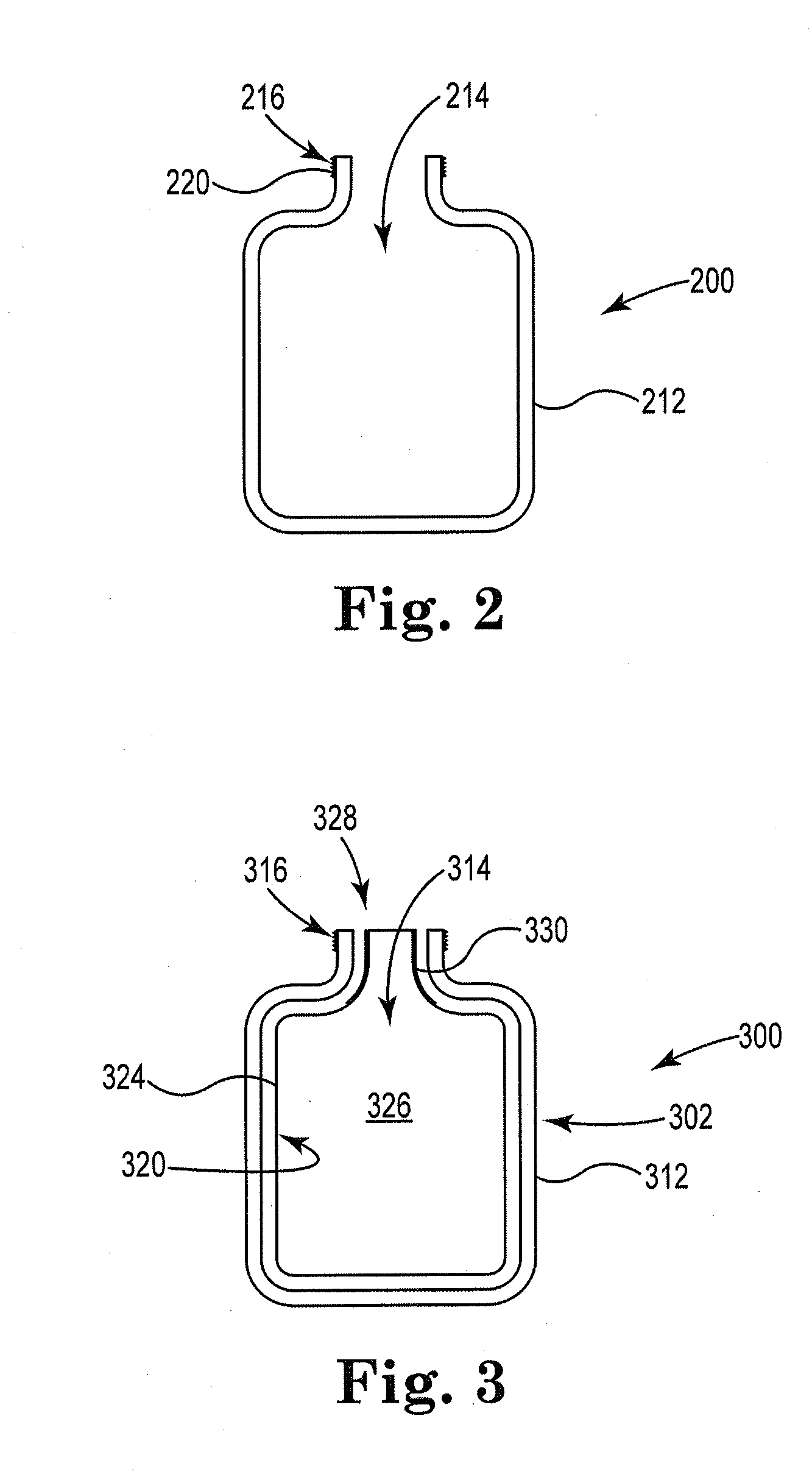

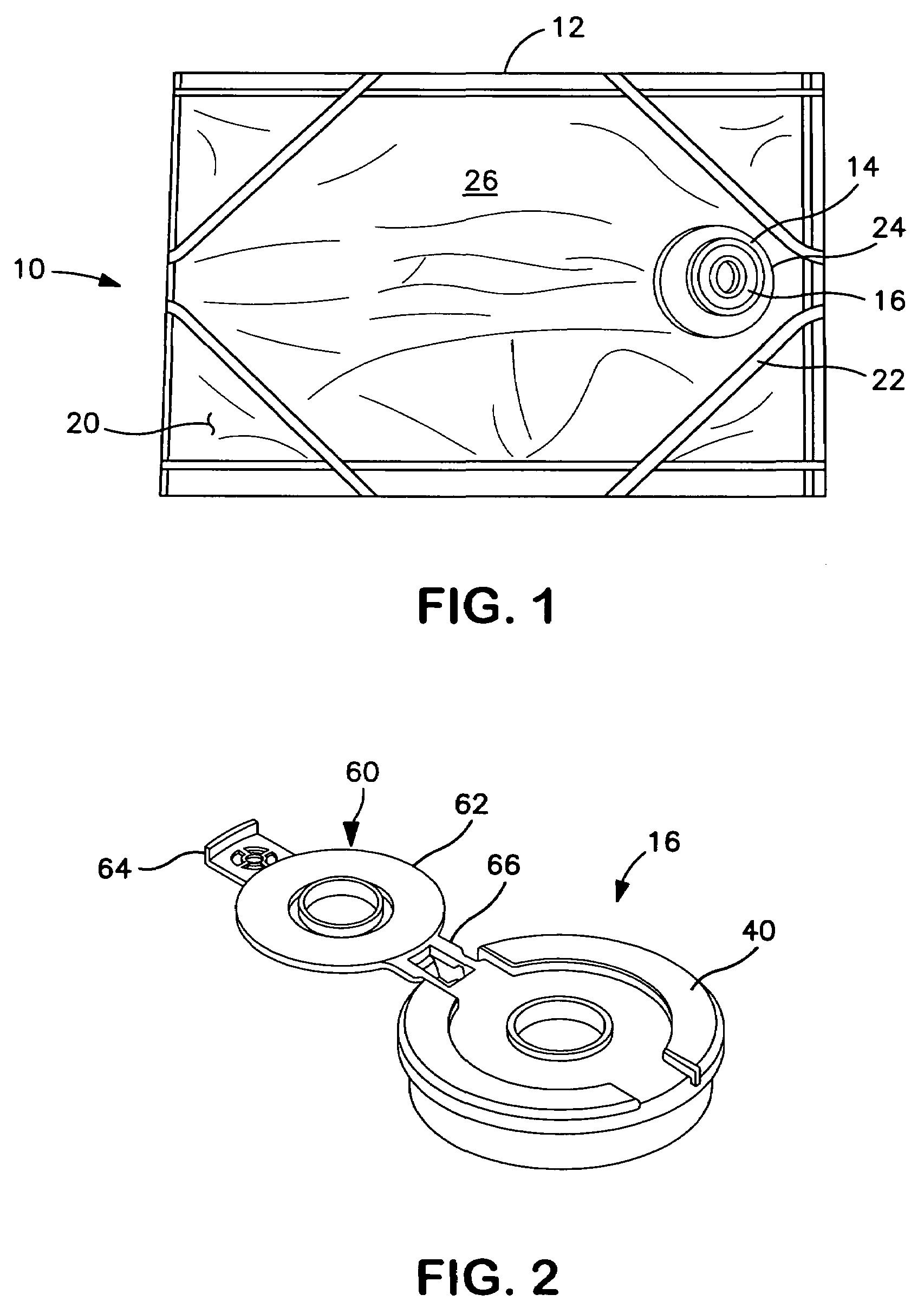

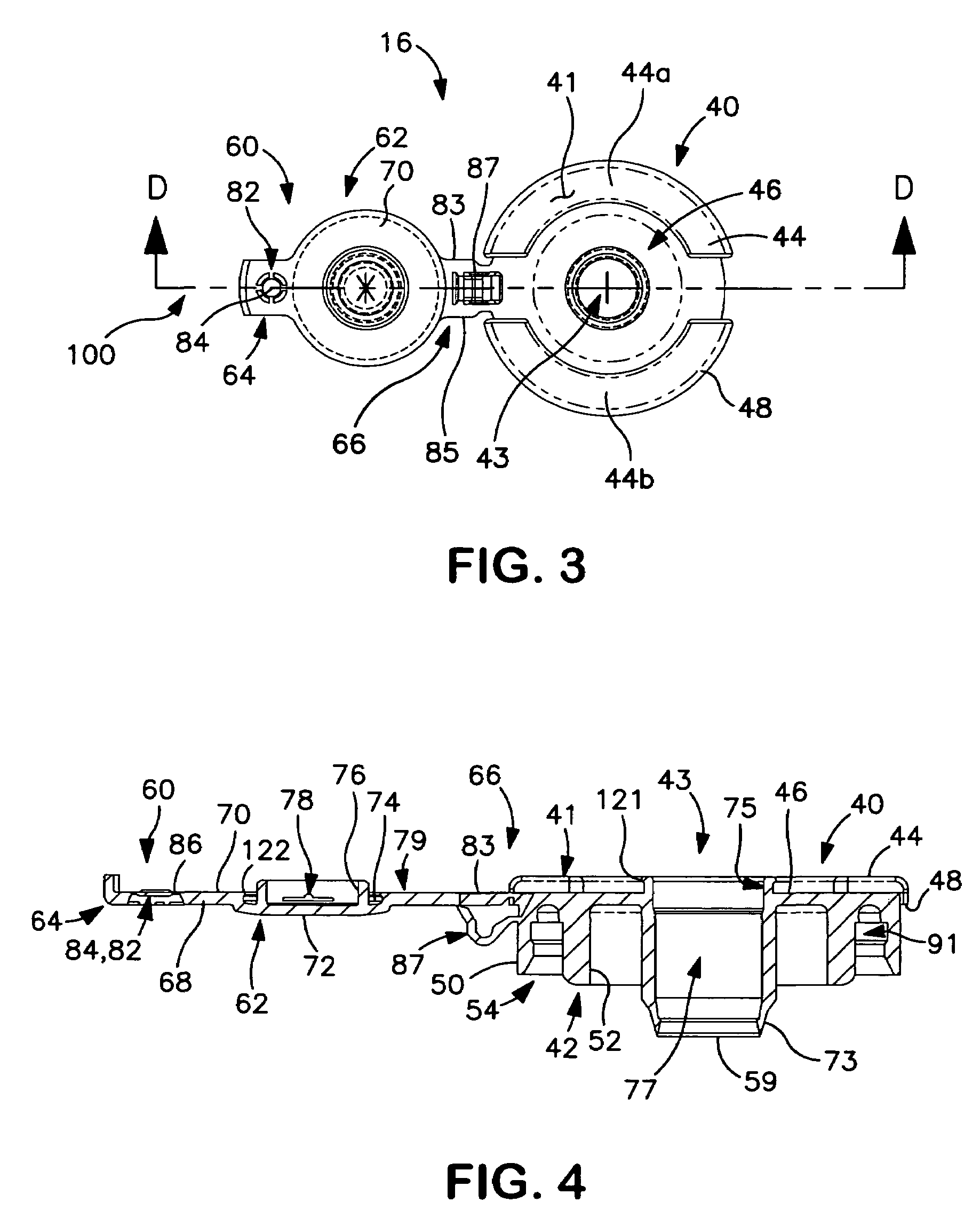

Cap assembly and container used therewith

A container assembly having a container, a fitment and a cap assembly. The container has at least one panel and at least one seal sealing the at least one panel to define a cavity. The fitment is coupled with the container, comprising a body having a first end and a second end. The second end extends away from the container, wherein the fitment provides fluid communication with the cavity. The cap assembly is releasably attachable to the second end of the fitment. The cap assembly comprises a base and a cover. The base includes an upper surface, a lower surface and an opening extending therethrough. The opening including an upper annular rim extending from the upper surface of the base and a lower annular rim extending from the lower surface of the base. The cover is attachable to the base to cover the opening. The cover includes an annular ring that extends along at least a portion of the upper annular rim of the opening. The annular ring forms a hermetic seal with the upper annular rim of the opening. A frangible cover is integrally molded with the cap extending across the lower annular rim.

Owner:SCHOLLE IPN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com