Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Curling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curling is a sheet metal forming process used to form the edges into a hollow ring. Curling can be performed to eliminate sharp edges and increase the moment of inertia near the curled end. Other parts are curled to perform their primary function, such as door hinges.

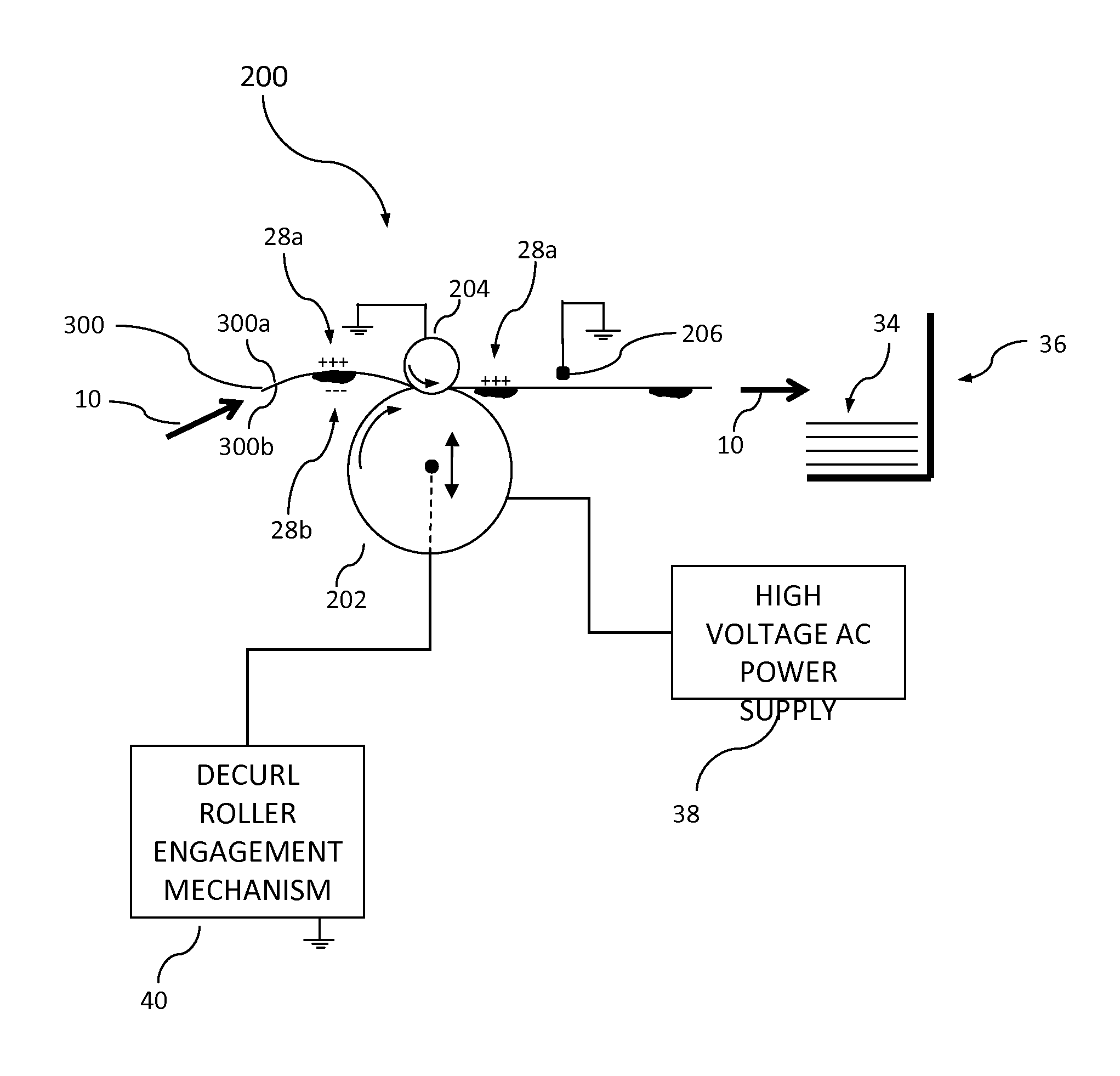

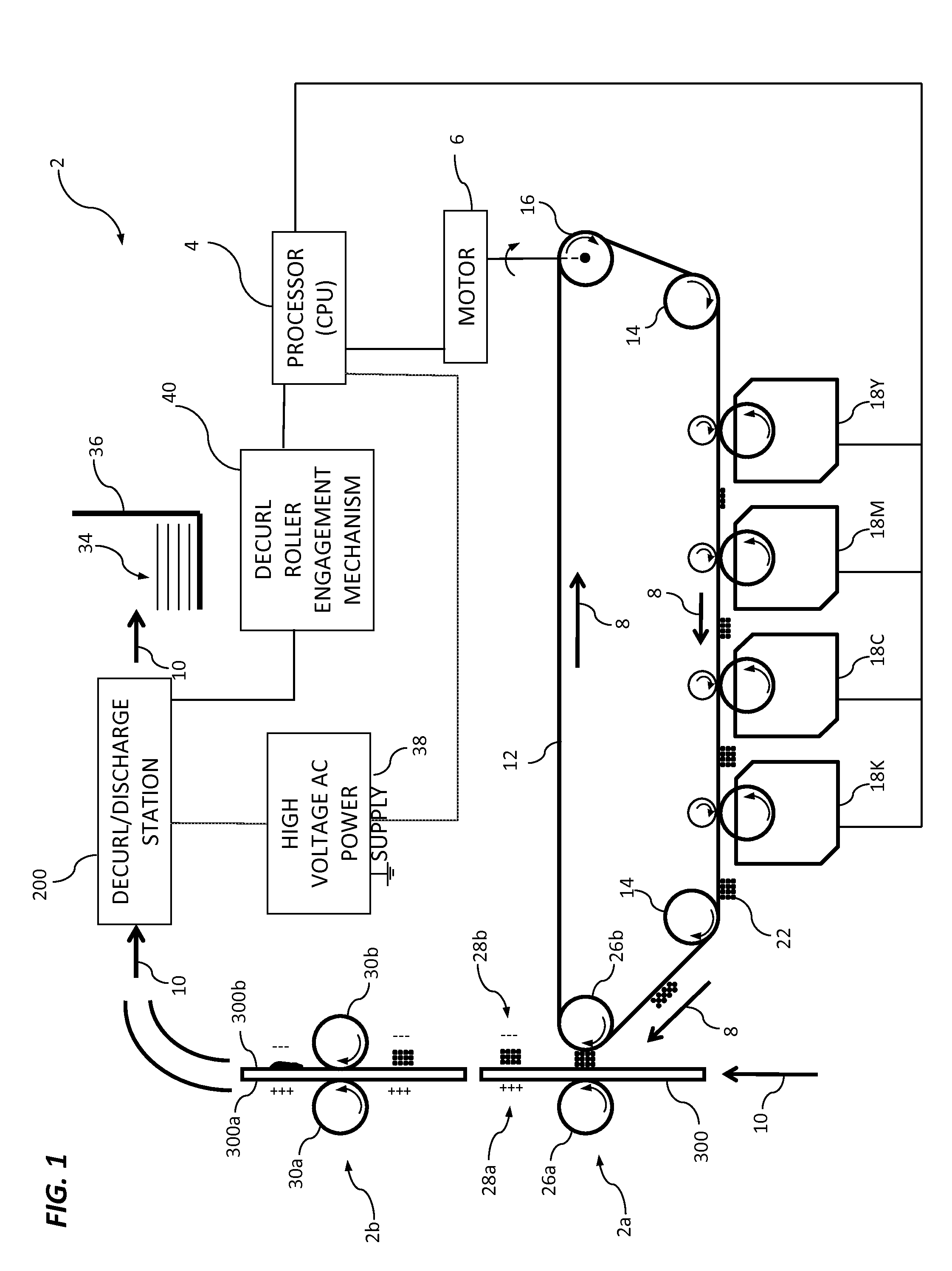

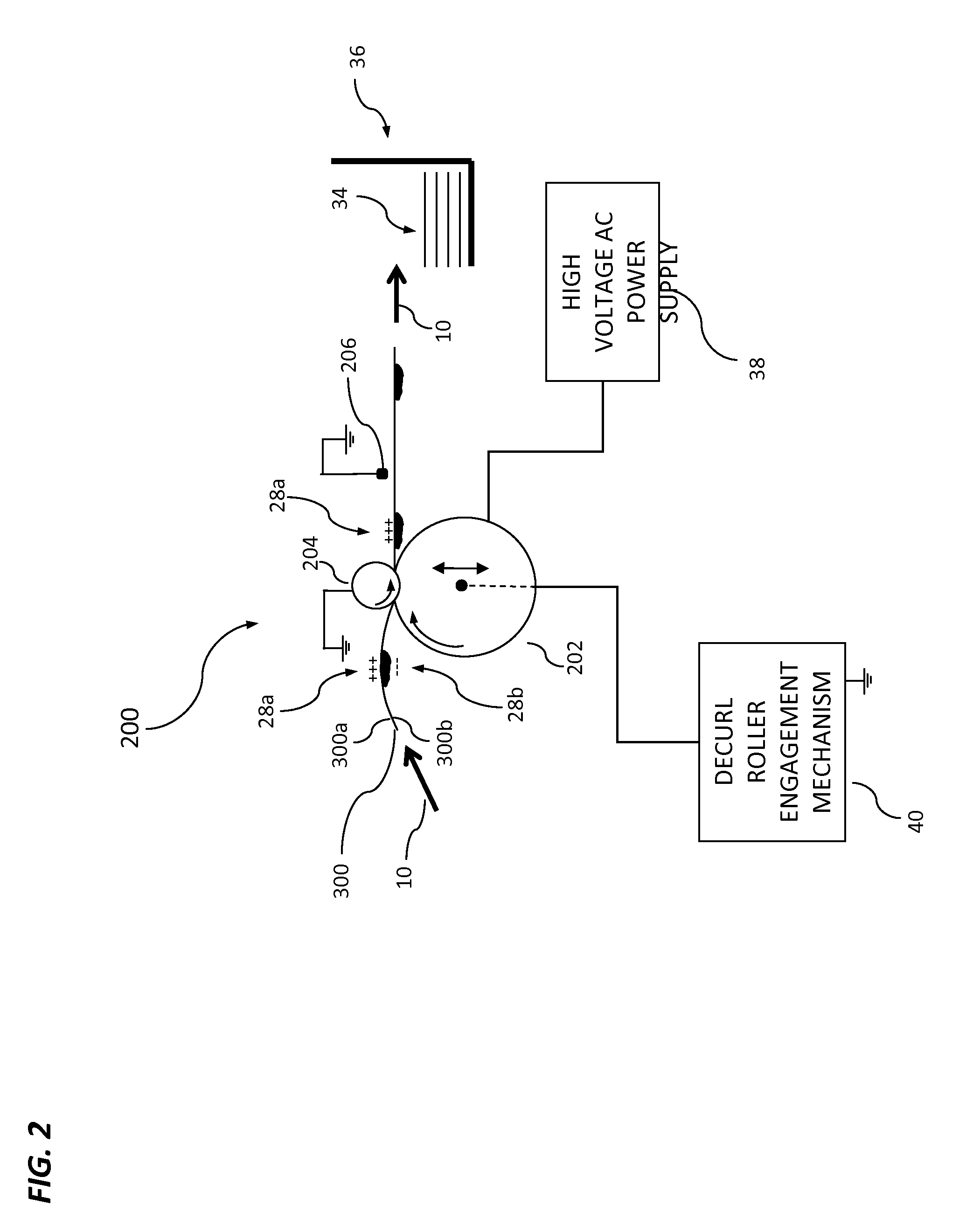

Concurrently removing sheet charge and curl

InactiveUS20120099911A1Less frizzReduce size and costElectrographic process apparatusEngineeringVoltage

Decurling a charged sheet and removing charge from the charged sheet prior to stacking, includes forming a nip between a roller and a compliant surface and applying pressure between the roller and compliant surface so that the nip has a decurling shape and when the nip engages the sheet it will perform a decurling function; and moving the charged sheet through the nip while the compliant surface has an AC voltage applied thereto so that a first side of the charged sheet is in contact with the compliant surface and has its charge substantially dissipated, whereby charge substantially remains on a second side of the charged sheet in contact with the roller and curling of the charged sheet is reduced. The method further includes using at least one non-contact charge removal device to remove charge from the second side of the charged sheet; and stacking the discharged sheet.

Owner:EASTMAN KODAK CO

Nickel-based self-fluxing hard-facing flux-cored wire for plasma surfacing

InactiveCN106271208AGood self-fluxingReduce manufacturing costPlasma welding apparatusWelding/cutting media/materialsIron powderHardness

The invention belongs to the field of welding materials, and particularly relates to a nickel-based self-fluxing hard-facing flux-cored wire for plasma surfacing. The flux-cored wire comprises all elemental components including, by weight, 0.3% to 1.0% of carbon, 14% to 19% of chromium, 3.5% to 5.0% of silicon, 3.0% to 4.5% of boron, 0% to 6% of iron and the balance nickel. The wire is prepared through the following method: a certain amount of chromium powder, boron powder, nickel powder and silicon and iron powder are weighed and sufficiently stirred to be evenly mixed, a Ni80Cr20 stainless steel strip bent into a U shape is filled with the mixed powder, curling and opening sealing are carried out, the strip is drawn down to the diameter of 2.0 stage by stage through a wire drawing machine, and the flux-cored wire is obtained. The nickel-based self-fluxing hard-facing flux-cored wire has the beneficial effects of being low in production cost, good in self-fluxing, high in surfacing efficiency, high in cladding rate and the like, and is suitable for plasma surfacing; a surfacing layer is large in combination strength and high in hardness and has the extremely high hard-faced wear resistance, abrasive particle wear resistance and erosive wear resistance properties.

Owner:WUHAN UNIV OF TECH

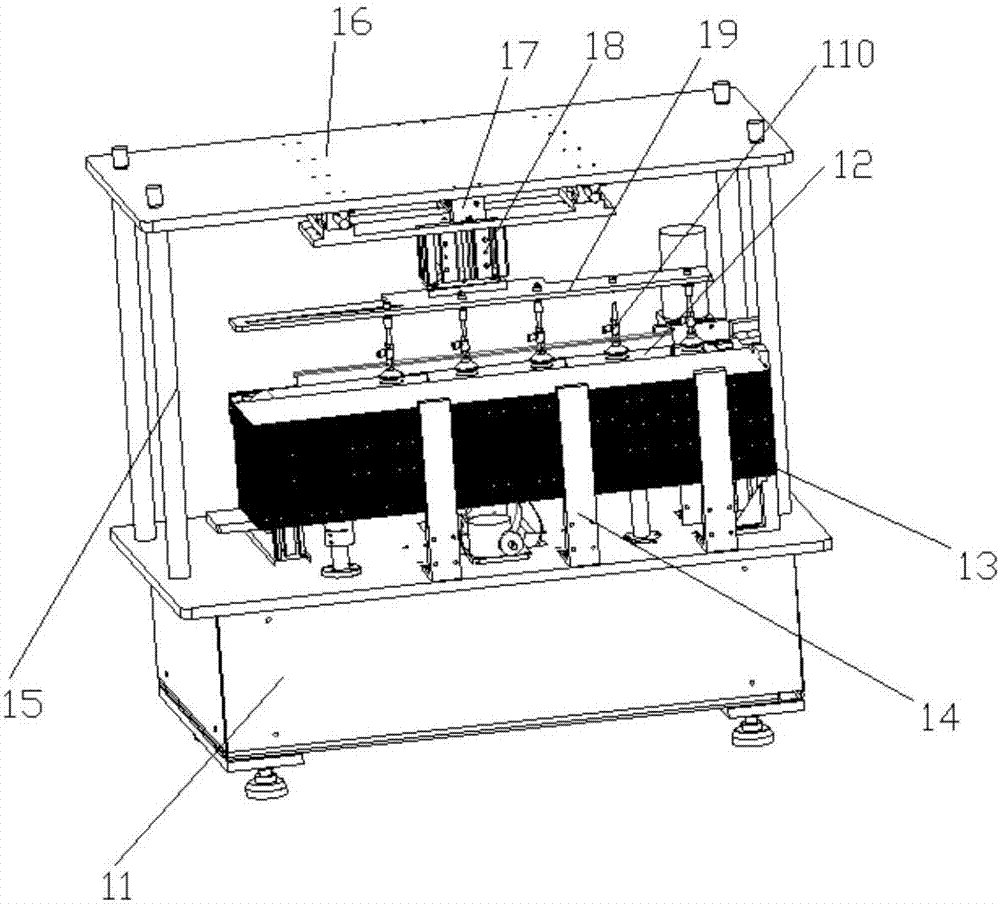

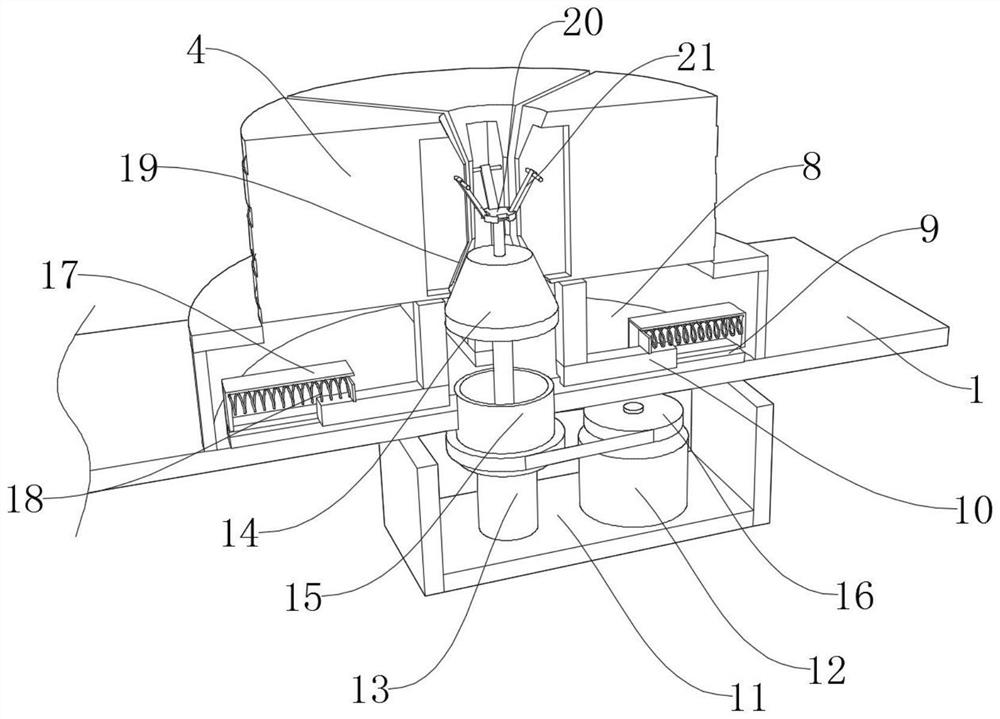

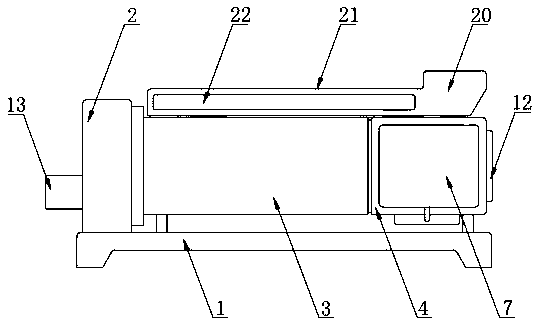

Electric cooker shell machining production line

PendingCN107350347AReduce widthSave installation spaceMetal-working feeding devicesPositioning devicesCookerManufacturing line

The invention discloses an electric cooker shell machining production line. The electric cooker shell machining production line comprises a metal plate feeding mechanism, a notch punching mechanism, a handle hole stamping mechanism, a furnace opening hole stamping mechanism, a pre-curling mechanism, a manual notch buckling station and an automatic rounding and curling mechanism, wherein the metal plate feeding mechanism conducts adsorption and feeding through vacuum suction cups; the notch punching mechanism sequentially and continuously punches notches in metal plates; the handle hole stamping mechanism continuously stamps two groups of handle hole groups on each metal plate; the furnace opening hole stamping mechanism stamps a furnace opening hole site in the middle of each metal plate; and the pre-curling mechanism pre-curls the edges on the two sides of each metal plate. The metal plates are longitudinally conveyed. When punching the metal plates longitudinally conveyed, the notch punching mechanism punches the two notches of the two adjacent metal plates at the same time each time. The automatic rounding and curling mechanism comprises a metal plate rounding device and an automatic curling device, wherein the metal plate rounding device rounds the metal plates manually buckled into annular, and the automatic curling device curls the upper edges and the lower edges of the round metal plates. According to the electric cooker shell machining production line, the mode of longitudinally conveying the metal plates is adopted, the width of a conveyor platform can be reduced, and the installation space of the equipment is reduced; and the mode of continuously machining the metal plates is adopted, so that the machining efficiency is high, and forming is rapid.

Owner:DONGGUAN ZHENGTAI HEXIN AUTOMATION EQUIP CO LTD

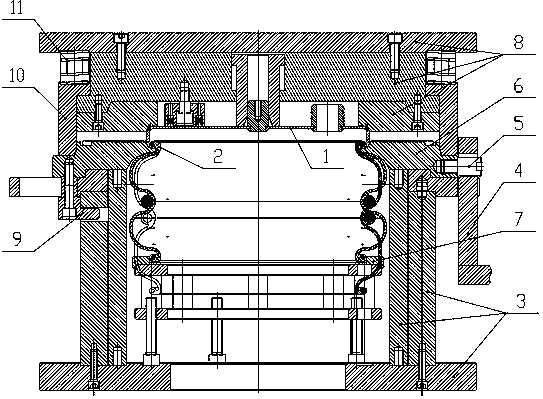

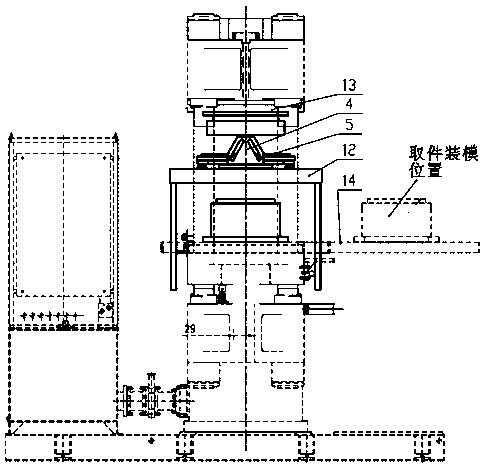

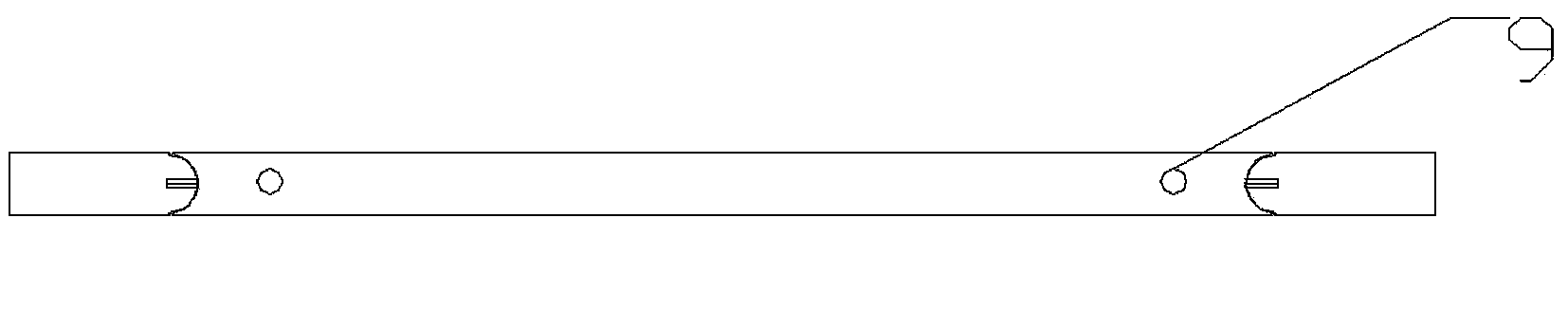

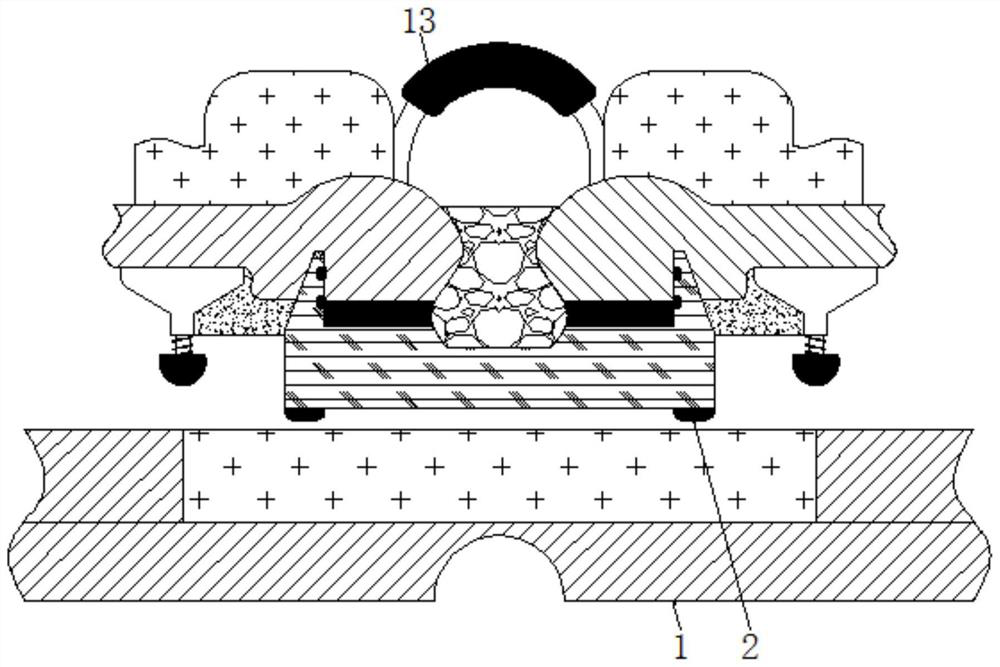

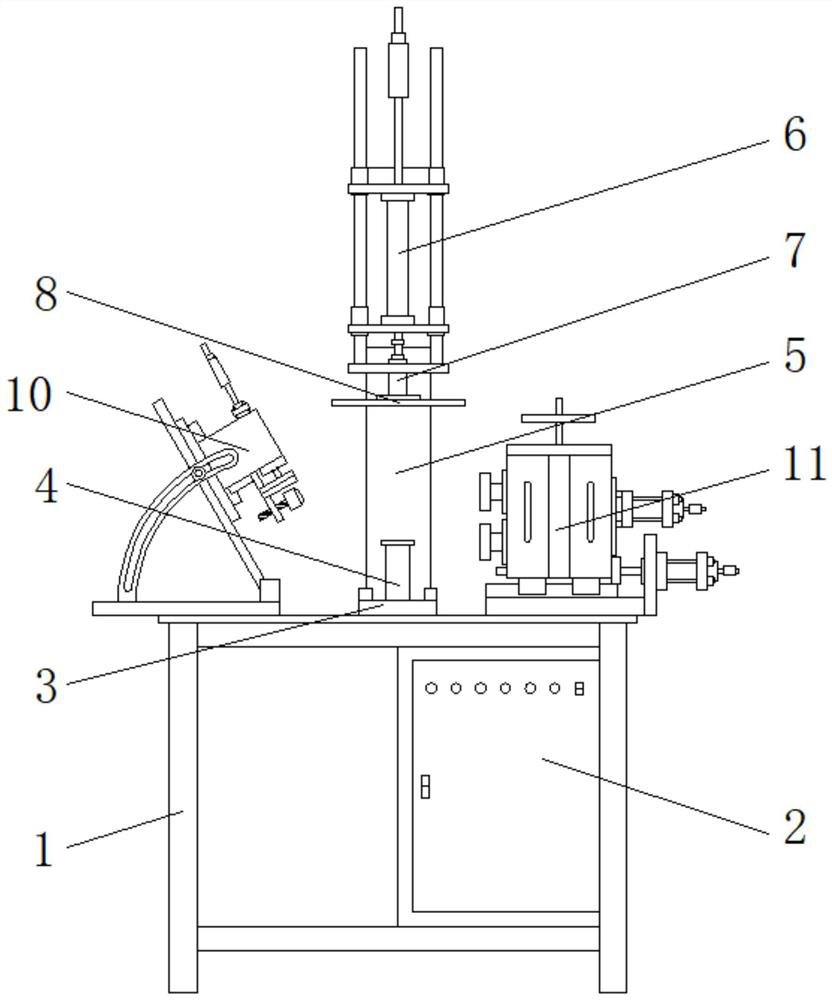

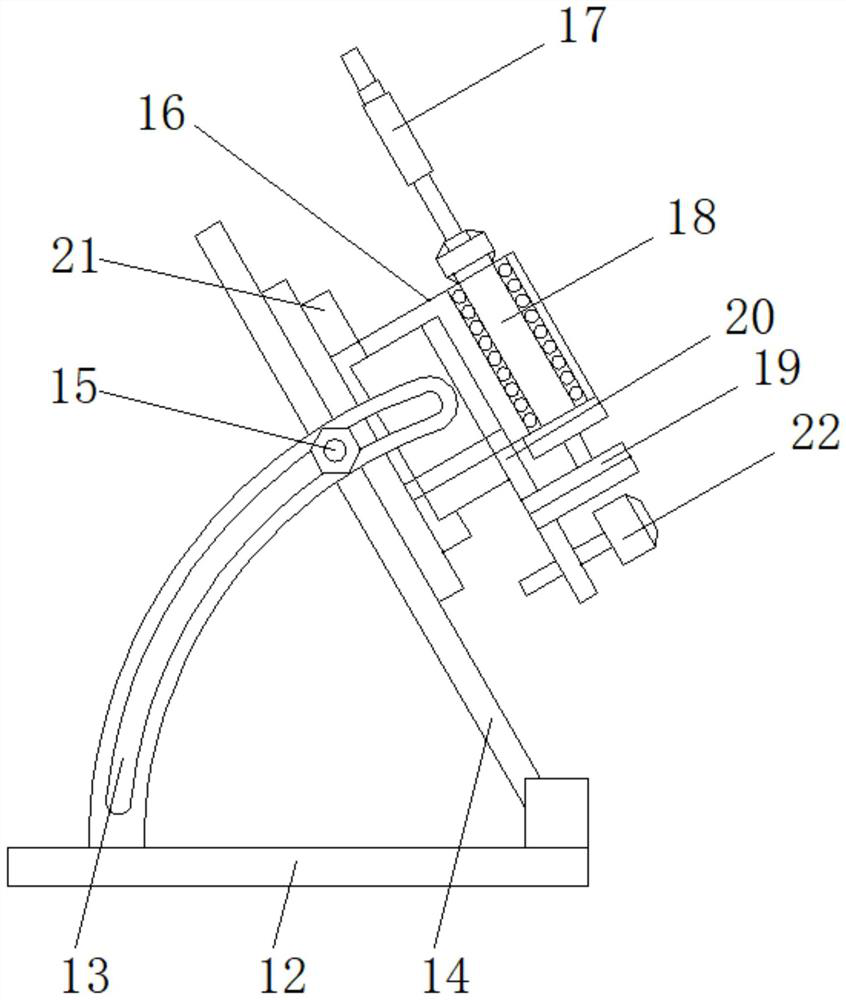

Universal curling tool and universal curling method for air spring

The invention relates to the field of air spring manufacturing. A universal curling tool for an air spring comprises an oil press, a lower die assembly, a triangular wedge block, a split pin, a bivalve setting ear die, an air spring positioning assembly and an upper die assembly. The upper die assembly and the lower die assembly are respectively arranged on an upper die fixed plate and a lower die fixed plate of the oil press; the triangular wedge block is arranged on an oil press bottom plate; and the bivalve setting ear die is connected onto the triangular wedge block by the split pin. A universal curling method for the air spring comprise the following steps of die setting, ear die assembly, integral die assembly curling, die sinking and pickup. According to the universal curling tool and the universal curling method for the air spring disclosed by the invention, by the integrated design of various mechanisms, the equipment input cost is reduced, the operation is convenient, the danger is reduced, the potential safety hazard is eliminated, the efficiency is improved, the labor strength of an operator is reduced, and enough space is also provided for realizing automatic product pickup and placement during the curling process of the air spring.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Suspension device for detecting hot rolled steel coils

The invention discloses a suspension device for detecting hot rolled steel coils. The suspension device comprises a suspension rod, an inclined plate is fixedly connected to the bottom end of a vertical rod of a first L-shaped rod, a plurality of second pressure sensors are annularly and fixedly embedded into an inner ring of a first circular ring, the second pressure sensors are electrically connected with an external controller through a circuit, a cross rod is rotationally sleeved with two second circular rings, the second circular rings are fixedly sleeved with a cover body, a dovetail groove is annularly formed in the side wall of a cavity, two dovetail blocks are rotationally arranged in the dovetail groove in an attached mode, the model of a first three-phase asynchronous motor is Y2-80M2-4S150, the wall thickness of a first barrel is 3-5 cm, the steel coils with different models and inner diameters can be suspended, the phenomenon that the side edges are stressed for a long time, and consequently edge curling is caused is effectively prevented, subsequent detection is facilitated while the quality of finished products is improved, the corresponding first barrel can stay under the finished products, repeated debugging is not needed, suspension of the steel coils is facilitated, the working efficiency is improved, and the use requirement is met.

Owner:XINJIANG BAYI IRON & STEEL

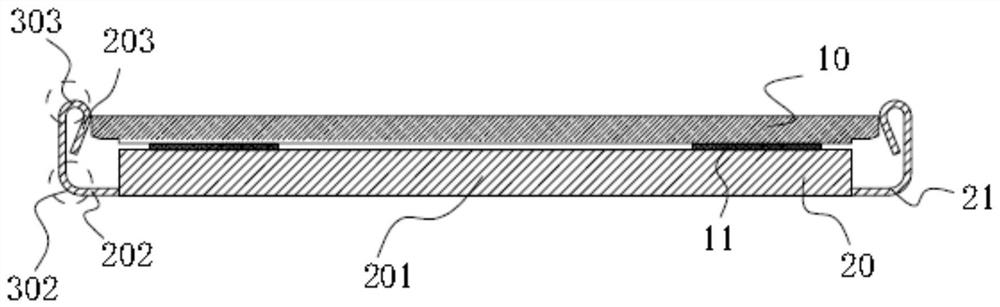

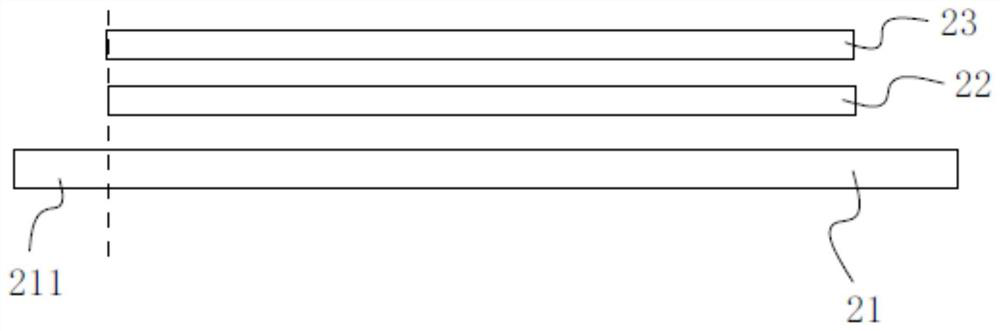

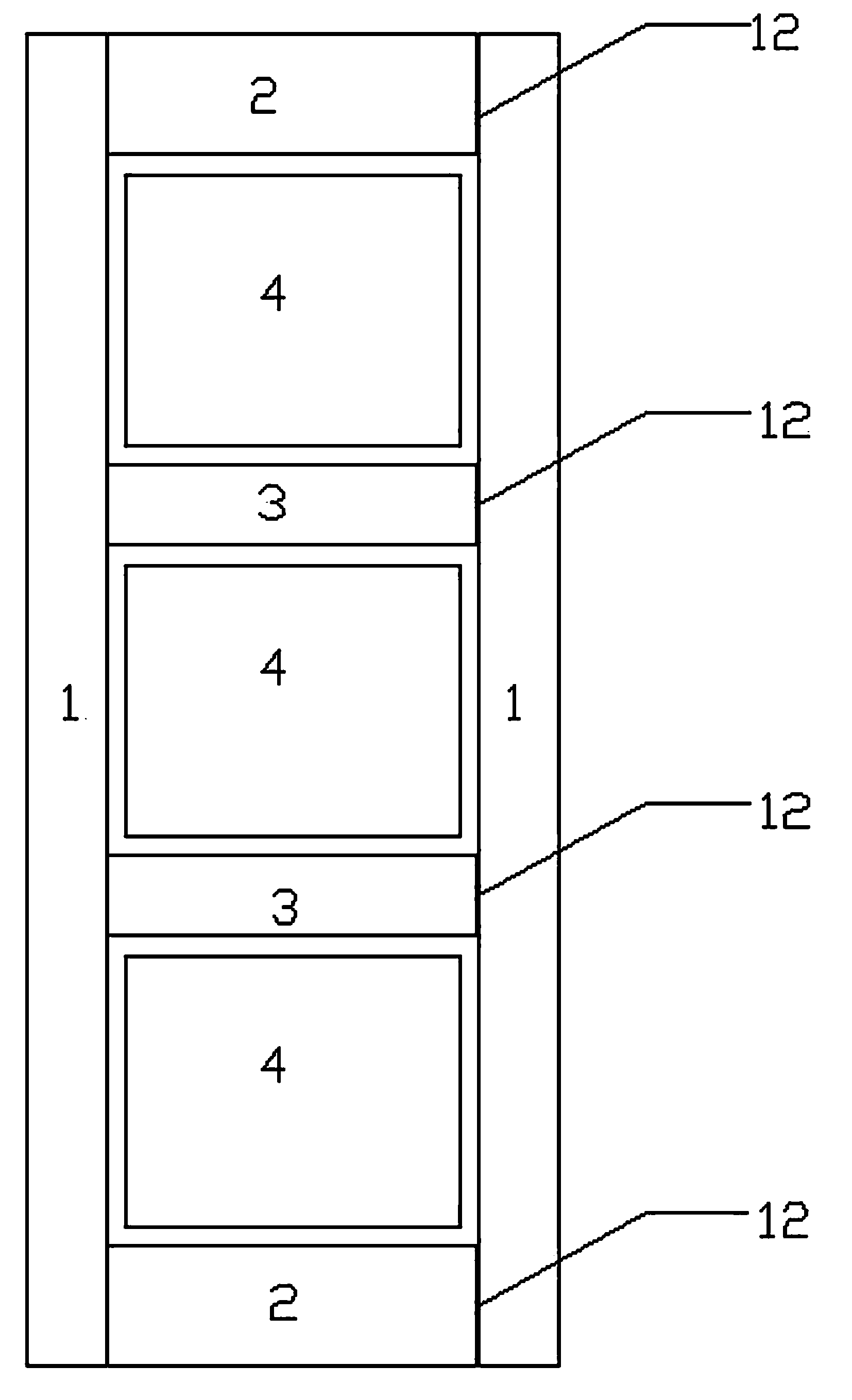

Edge-curled steel-plastic back plate for displayer and manufacturing method thereof

The invention provides an edge-curled steel-plastic back plate for a displayer and a manufacturing method thereof. The manufacturing method comprises the following steps that firstly, a steel-plasticplate is cut to form the shape of an unfolded edge-curled steel-plastic back plate, wherein the steel-plastic back plate comprises a thick body structure and thin body structures located on the periphery of the thick body structure; pre-edge-curling treatment and pre-bending treatment are conducted on the thin body structures of the steel-plastic plate to form to-be-curled and to-be-bent structures; each thin body structure of the steel-plastic plate is bent by 90 degrees to form a bent structure; and the end of each bent structure is subjected to edge curling or edge rolling treatment from bottom to top to form a curled body structure. According to the edge-curled steel-plastic back plate for the displayer and the manufacturing method thereof, the problems of edge curling and bending of the steel-plastic plate are solved, the stability of edge curling and bending of the steel-plastic plate is ensured, mass production of edge curling and bending of the steel-plastic plates is realized,the defect that a traditional steel-plastic plate cannot be bent is overcome, and the utilization space of a film-coated plate is widened; and the procedures are reduced, and the purposes of reducingmanpower and material resources and reducing the cost are achieved.

Owner:DONGGUAN HAOSHUN PRECISION TECH CO LTD

Manufacturing process of deformation-proof solid wood dismounting and mounting door

The invention discloses a manufacturing process of a deformation-proof solid wood dismounting and mounting door. The manufacturing process is characterized by comprising a manufacturing process, a dismounting and mounting process, a natural seam processing process and a respective paint spraying processing process of deformation-proof door edges and door planks. The manufacturing process effectively solves a series of problems of deformation, curling, cracking, expanding, contracting, core plate and four-frame lacquer painting cracks and the like of a wood door manufactured by a traditional process.

Owner:HARBIN SHENGSHI HUALIN TECH

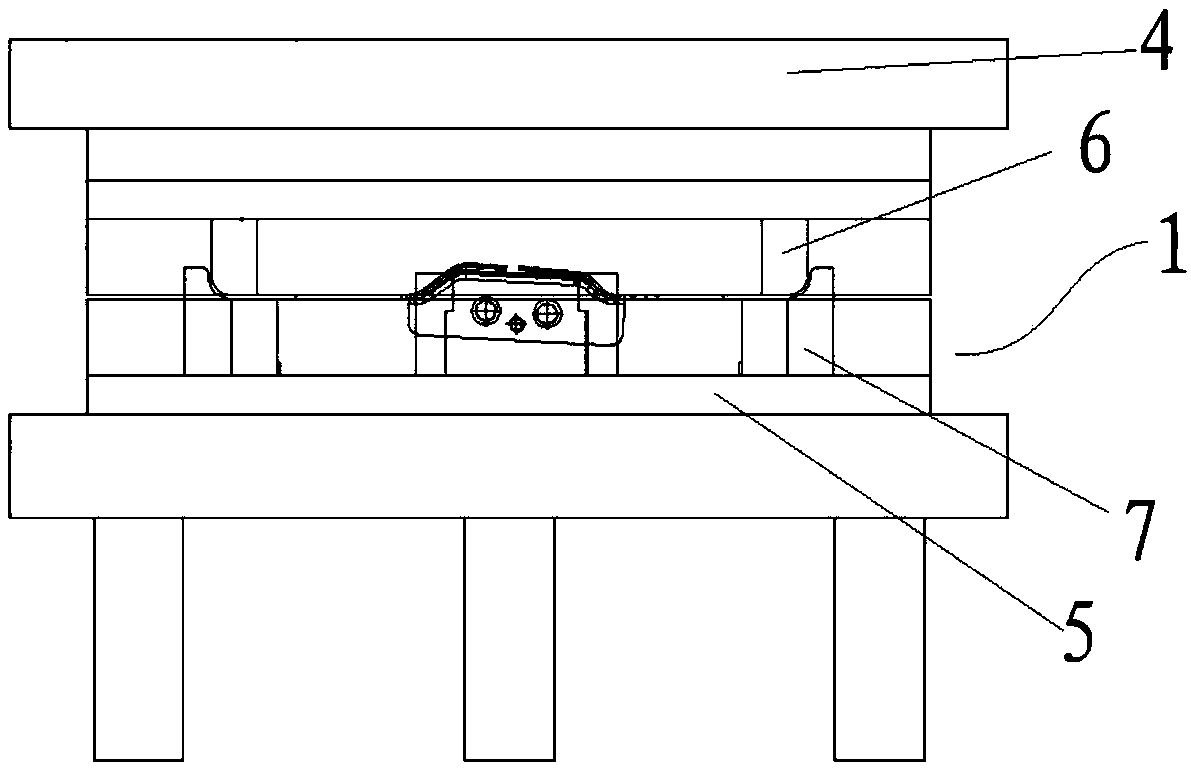

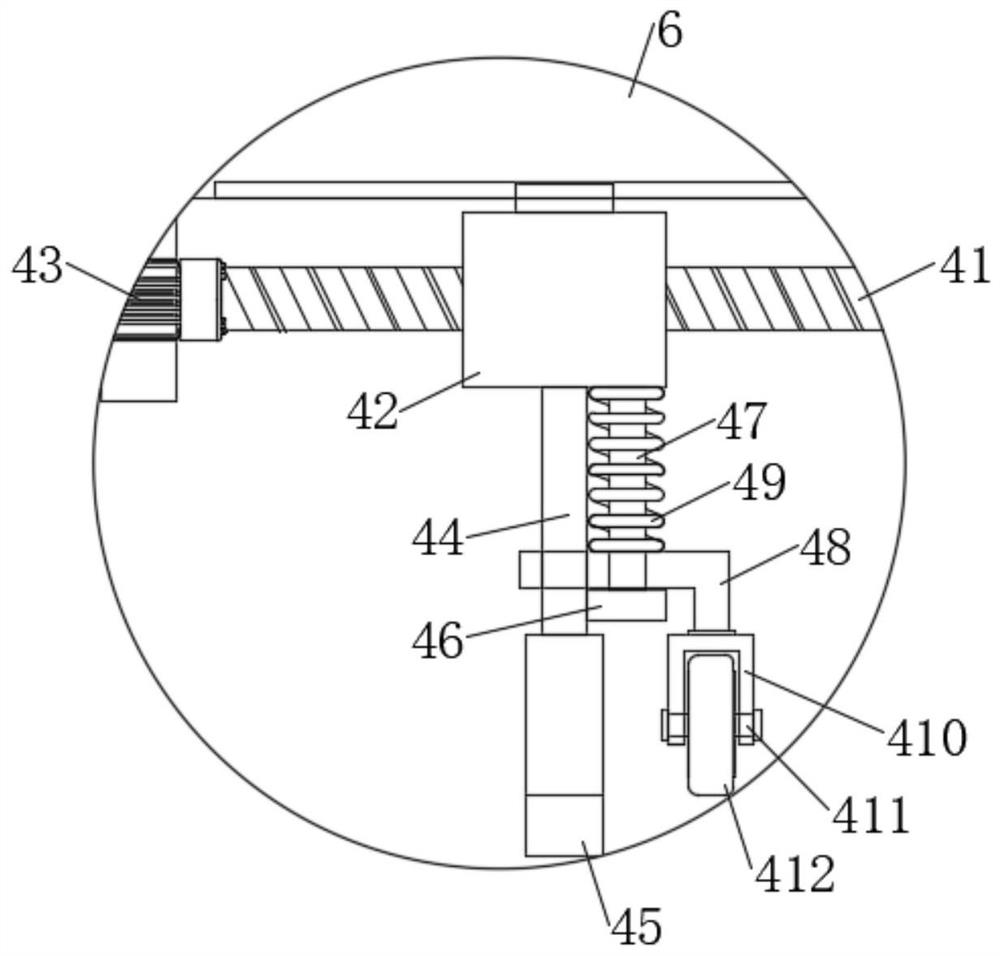

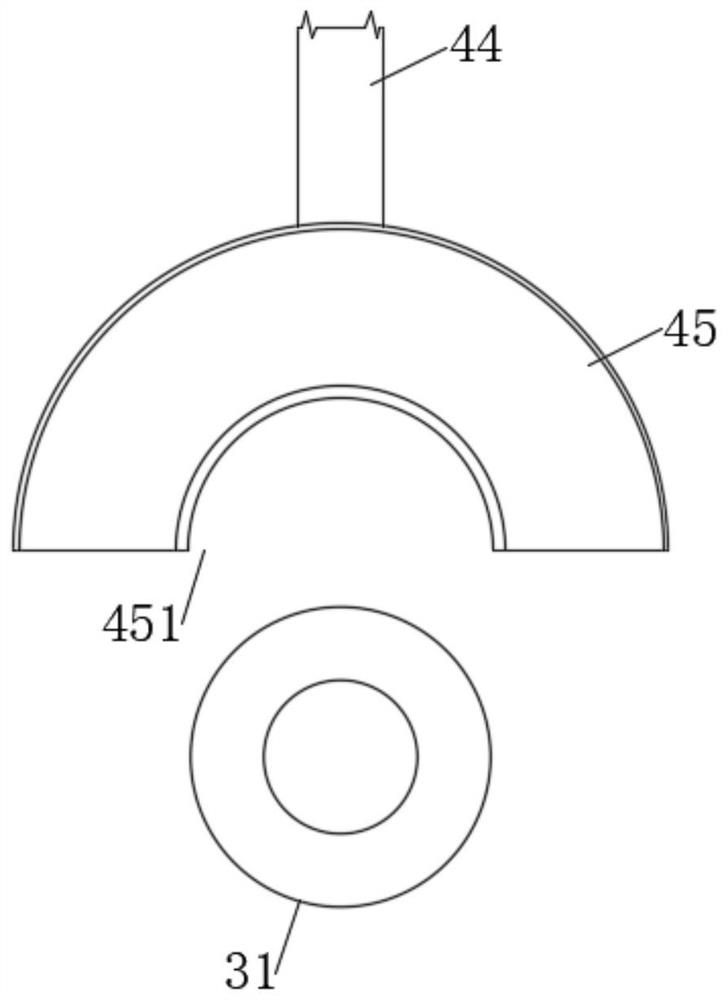

Edge curling method of stamping part and mold of edge curling method

InactiveCN108580666AGuaranteed accuracyRealize the shapeShaping toolsVehicle componentsEngineeringCurling

The invention discloses an edge curling method of a stamping part and a mold. The method comprises the steps of firstly, blanking, wherein the stamping part is obtained, and a plate of the needed sizeand shape is produced later; secondly, body forming, wherein the non-edge-curling portion of the procedure part obtained in the first step is formed; thirdly, edge curling and prebending, wherein forming of an upper R angle of the edge curling area of the procedure part obtained in the second step is achieved; fourthly, edge curling and turnover, wherein forming of a lower R angle of the edge curling area of the procedure part obtained in the third step is achieved; and fifthly, edge curling and press fitting, wherein final forming of the procedure part obtained in the fourth step is achieved. Compared with the prior art, through three procedures of edge curling forming, modeling of an edge curling product is achieved, based on the edge curling process, a designed edge curling mold is simple in structure, easy to machine and low in manufacturing cost, and the edge curling precision is guaranteed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

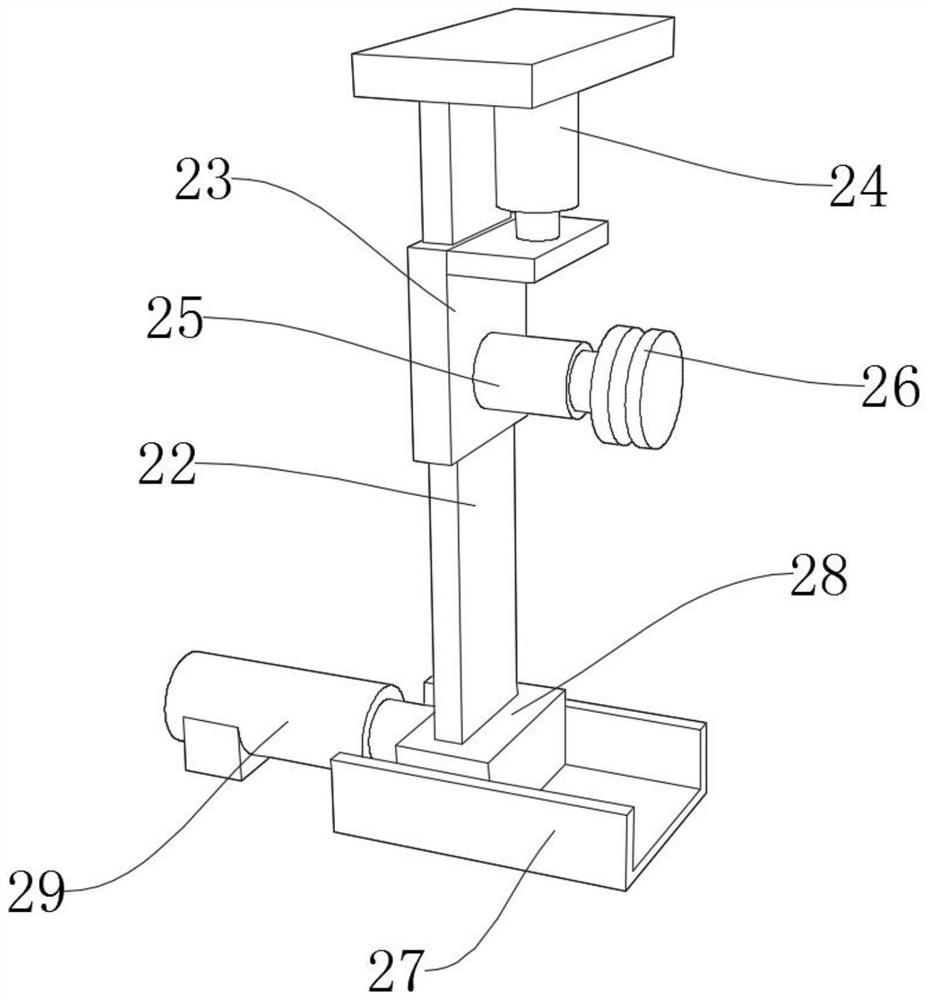

Drawing winding device for environmental art design

The invention discloses a drawing winding device for environmental art design. The drawing winding device comprises a base and a supporting frame, wherein the supporting frame is fixedly installed atthe top of the base and is of a U-shaped structure, a winding mechanism is fixedly installed on the supporting frame, a protection mechanism is arranged above the winding mechanism and is fixedly installed at the bottom of a lifting support, the top of the lifting support is fixedly installed with the output end of a hydraulic cylinder through a hydraulic rod, the hydraulic cylinder is fixedly installed at the top of the supporting frame, and guide frames are fixedly installed on the supporting frame on the two opposite sides of the lifting support. The drawing winding device has the beneficial effects that drawing winding is initially fixed, drawing curling is avoided through a feeding assembly, the winding stability is improved, an anti-deviation limiting assembly prevents uneven drawingwinding, can be suitable for anti-deviation winding of drawings of different widths and is convenient to adjust, an anti-loosening limiting assembly conducts winding and pressing on the drawings, thedrawings are wound compactly, the free ends of the wound drawings are prevented from loosening, the compactness and uniformity of drawing winding are improved, and winding is better.

Owner:RIZHAO POLYTECHNIC

Method for covering outer surface of large cylinder and covering machine thereof

InactiveCN102336282AImprove adaptabilityLess prone to jammed failuresPaper article packagingWrapping material feeding apparatusPack materialMechanical engineering

The invention relates to a method for covering packing materials on the outer surface of a large cylinder, in particular to a method for packing steel coil outer package through adopting measures of straightening packing materials by a floating guide plate, adopting a coiling curtain for smoothly coiling the packing materials onto a scroll, adopting a ball hinge support scroll for adapting to theprocessing precision and the like. The problem of equipment fault caused by packing material curling is effectively solved, and the problems of concentric interference, full width full expansion and the like when the method is adopted for packing are solved.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

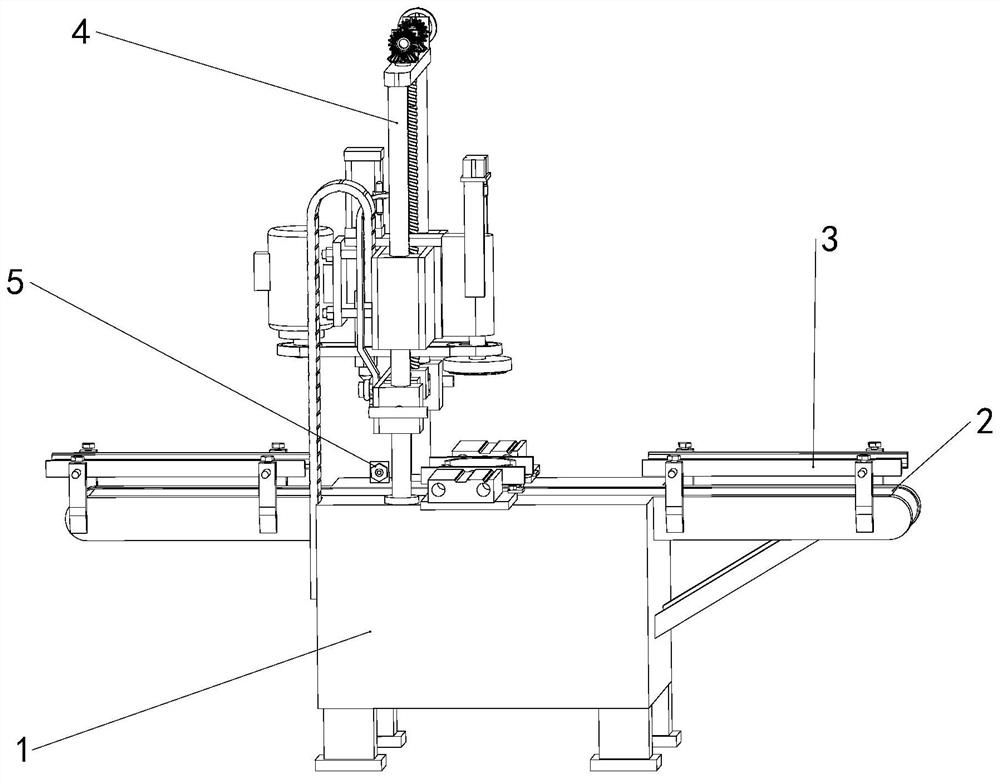

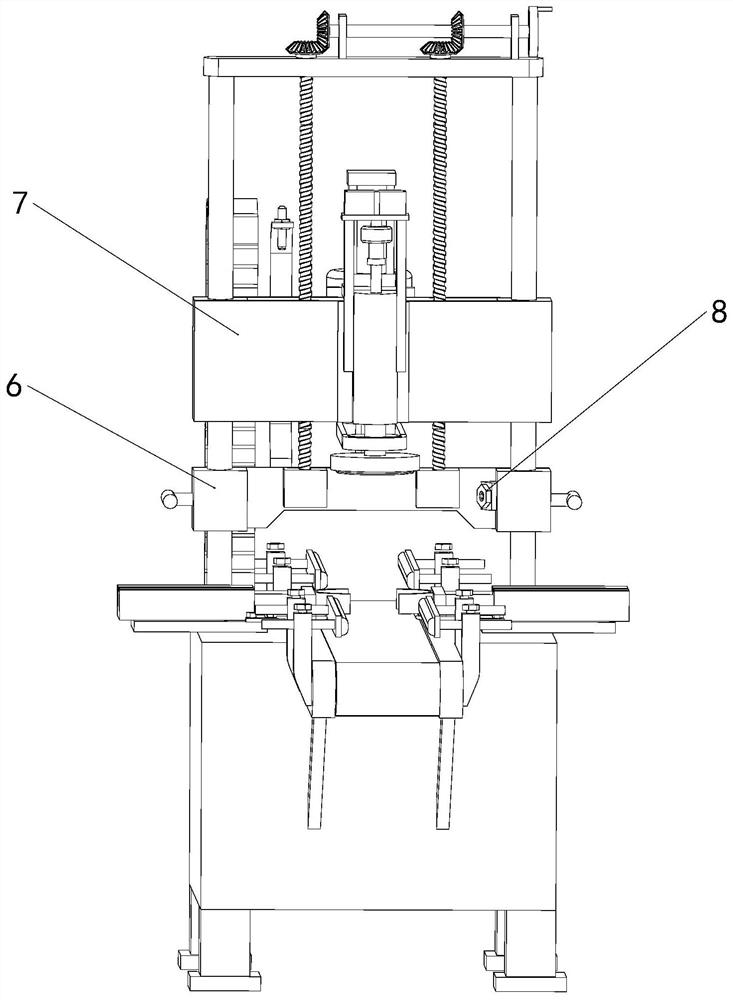

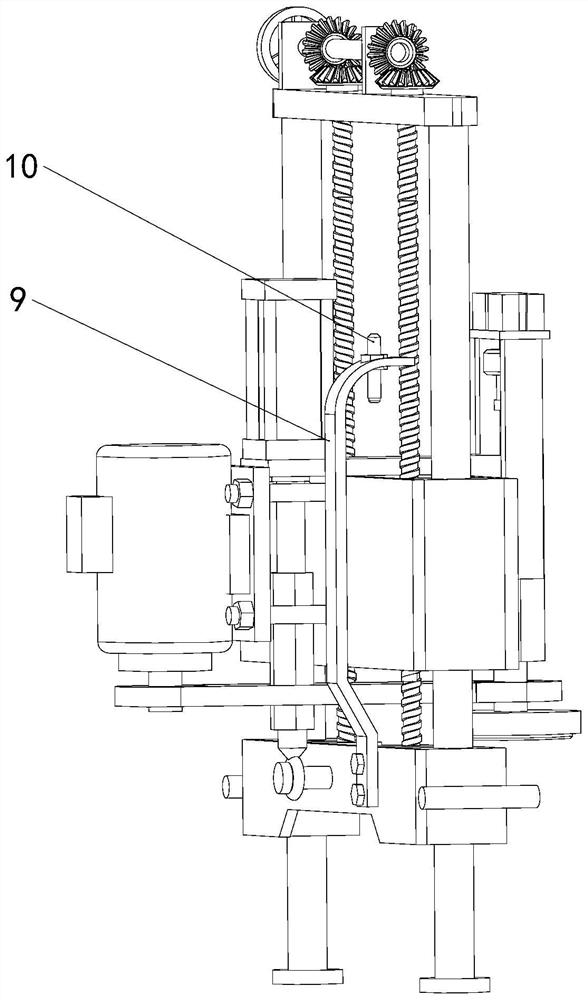

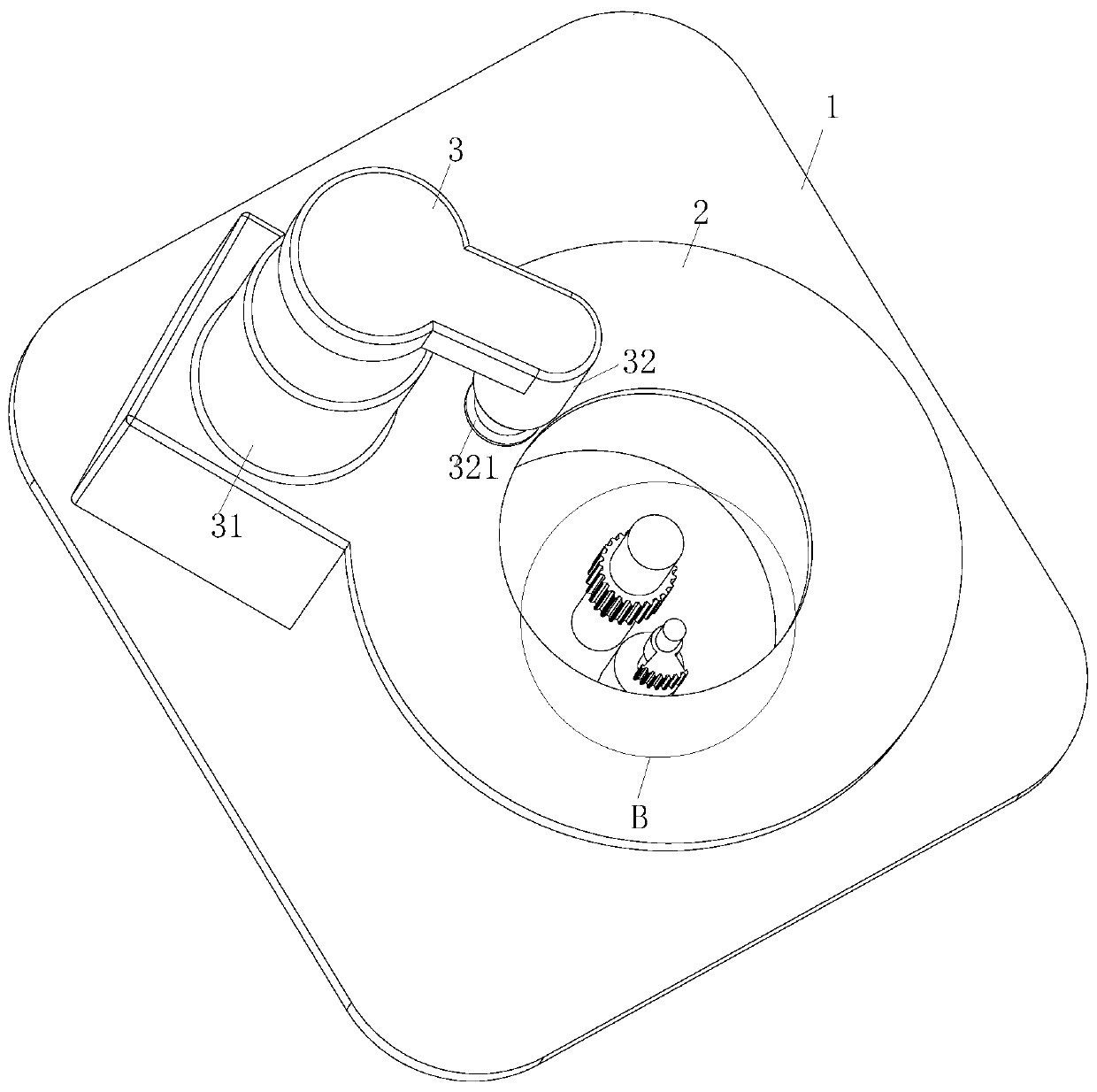

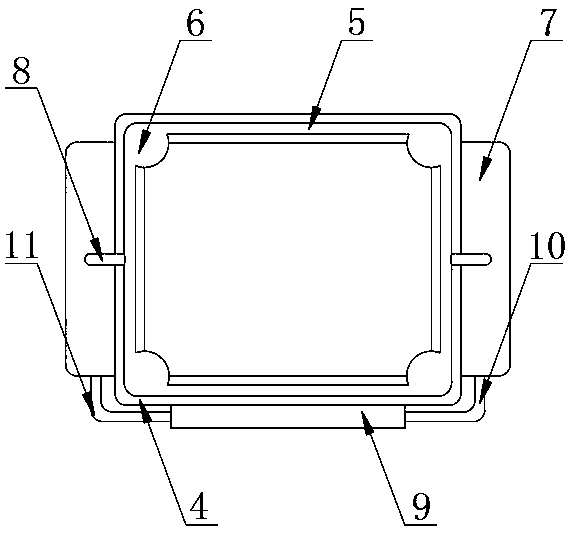

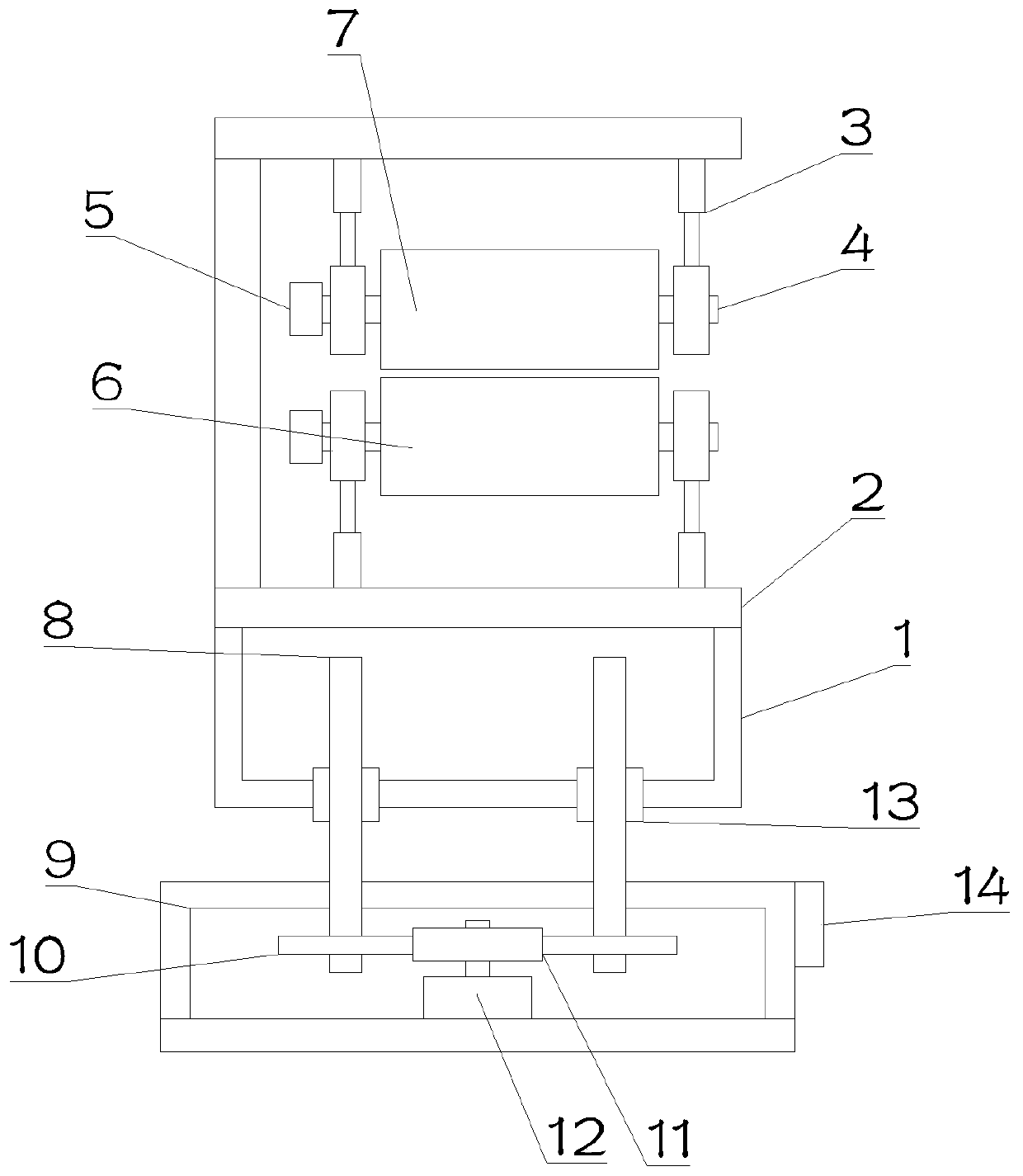

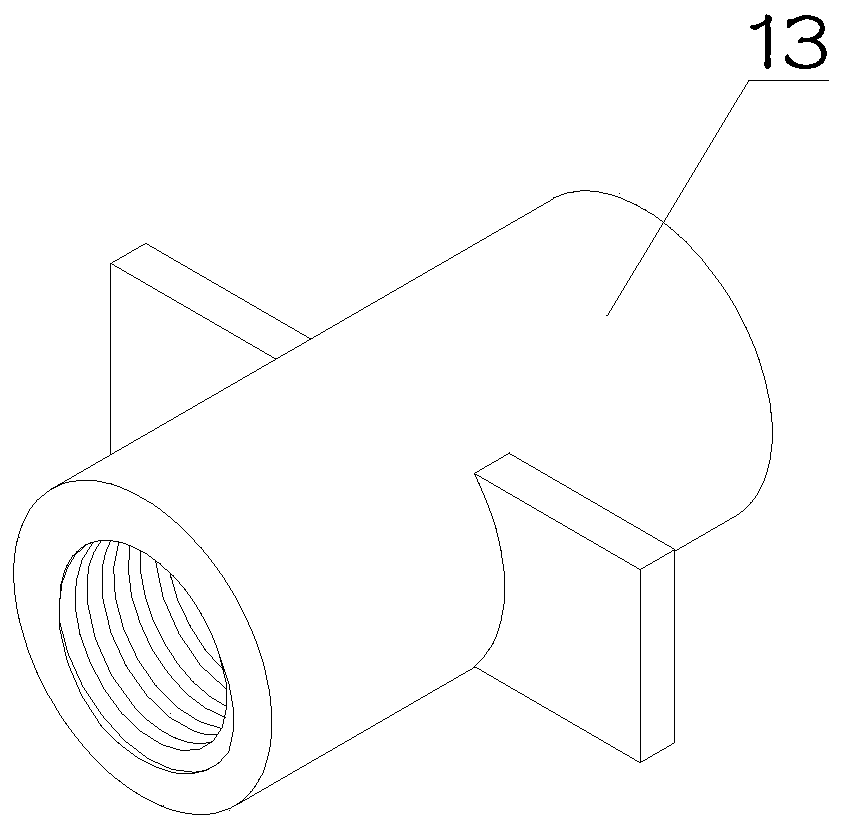

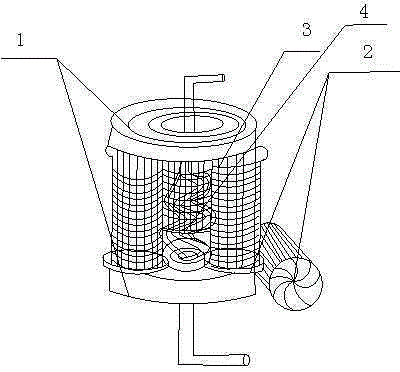

Edge curling and bottom sealing device of combined firework outer cylinder

The invention discloses an edge curling and bottom sealing device of a combined firework outer cylinder. The device comprises a turntable intermittently rotated; multiple positioning mechanisms are distributed at the periphery of the turntable; the positioning mechanisms comprise cylinder body positioning cavities of the firework outer cylinder, and pass through an unloading station, an edge curling station and a paperboard punching station fixedly arranged on a frame in the process of rotating along with the turntable; the edge curling station comprises rotary pressure applying molds arranged corresponding to ports of the cylinder body positioning cavities; and the paperboard punching station comprises paperboard cutting mechanisms and paperboard punching mechanisms arranged corresponding to the ports of the cylinder body positioning cavities. As a multi-station and multi-angle working platform formed by combining the positioning cylinders with the turntable is built, the device realizes organic fusion of two procedures of edge curling and paperboard punching, prevents reduction of the mechanism redundancy and the efficiency caused by multiple times of positioned conveying of cylinders, and realizes efficient and reliable edge curling and bottom sealing on the basis of guaranteeing the quality.

Owner:浏阳市顺发烟花制造有限公司

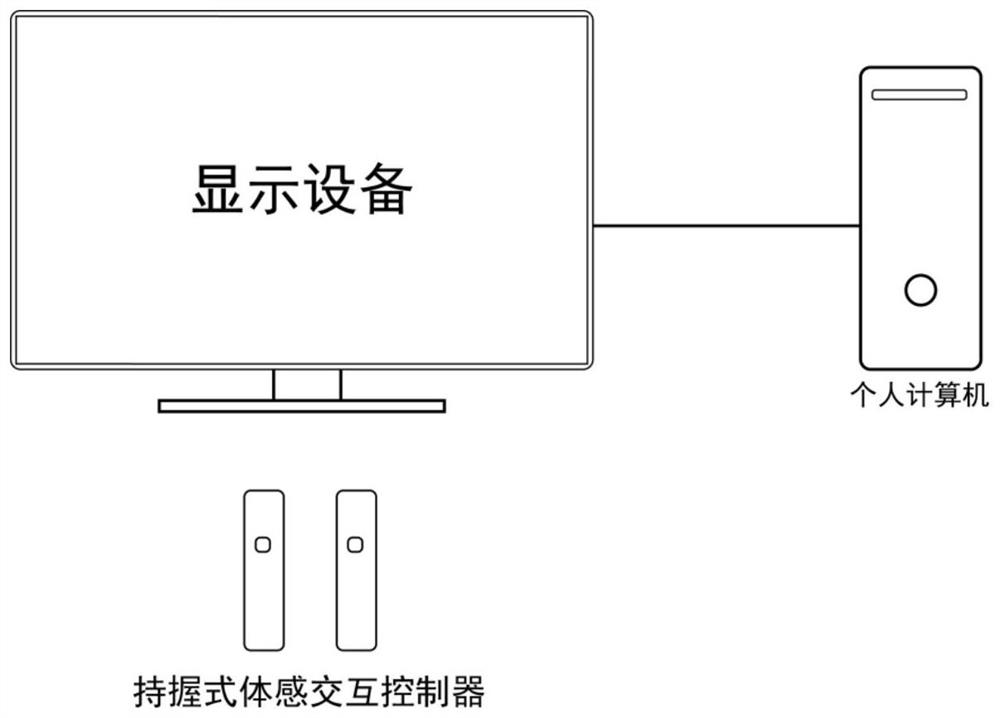

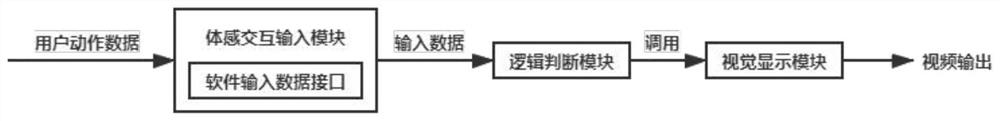

Modern curling motion simulation system and method based on virtual reality somatosensory interaction

PendingCN113867523ALower the thresholdSolve the requestInput/output for user-computer interactionDesign optimisation/simulationVirtualizationCurling

The invention discloses a modern curling motion simulation system and method based on virtual reality somatosensory interaction, and belongs to the technical field of computer simulation. According to the method, computer graphics is utilized to digitally virtualize modern curling movements and allow users to perform virtual modern curling movements through somatosensory interaction techniques. Due to the fact that any public who are interested in curling sports can experience in a relatively free area, the threshold of the curling sports is greatly reduced. The problems that in the modern curling sports experience in reality, the site environment requirement is high, real curling and ice brushes are inconvenient to use, and the resource consumption is large are solved. And popularization of the ice and snow sports is facilitated. The somatosensory interaction technology is combined, and the problem that the experience effect is poor due to the fact that the skill level of experiencers is insufficient is solved. The user can concentrate on experiencing complete modern curling sports through simple interaction, and does not need to worry about own skills or competition rules and other problems, so that the interactivity and interestingness of experience are improved.

Owner:BEIJING UNIV OF TECH

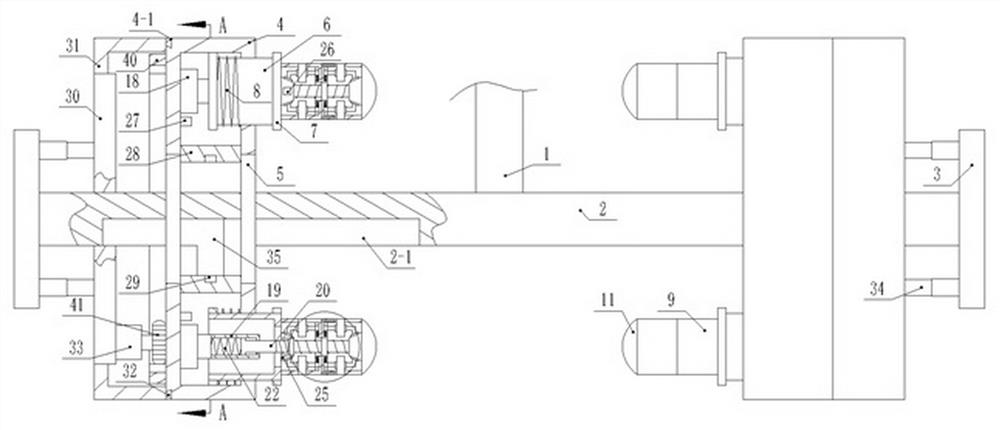

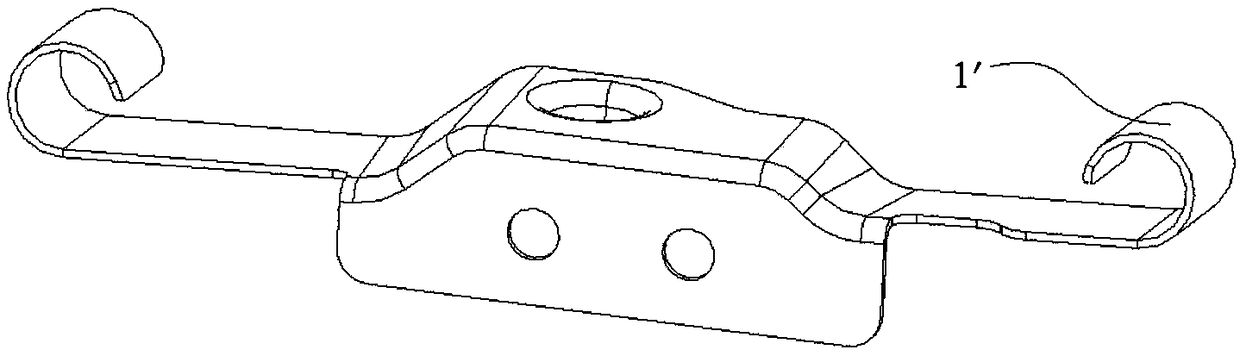

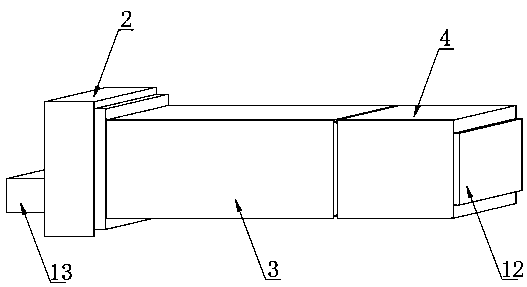

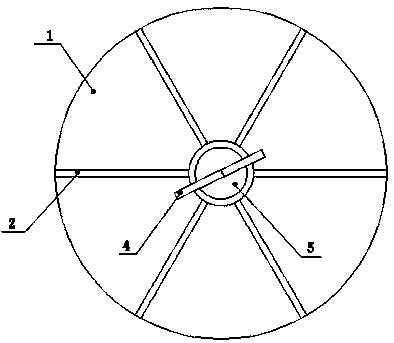

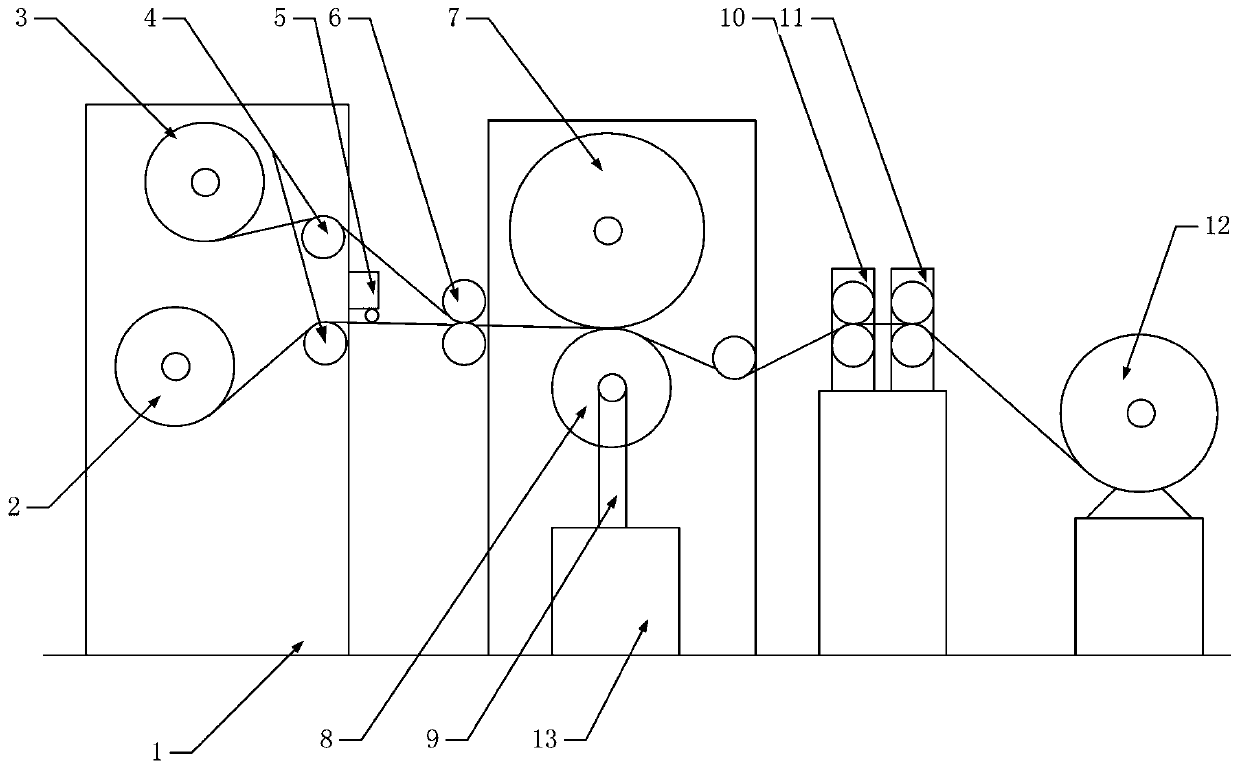

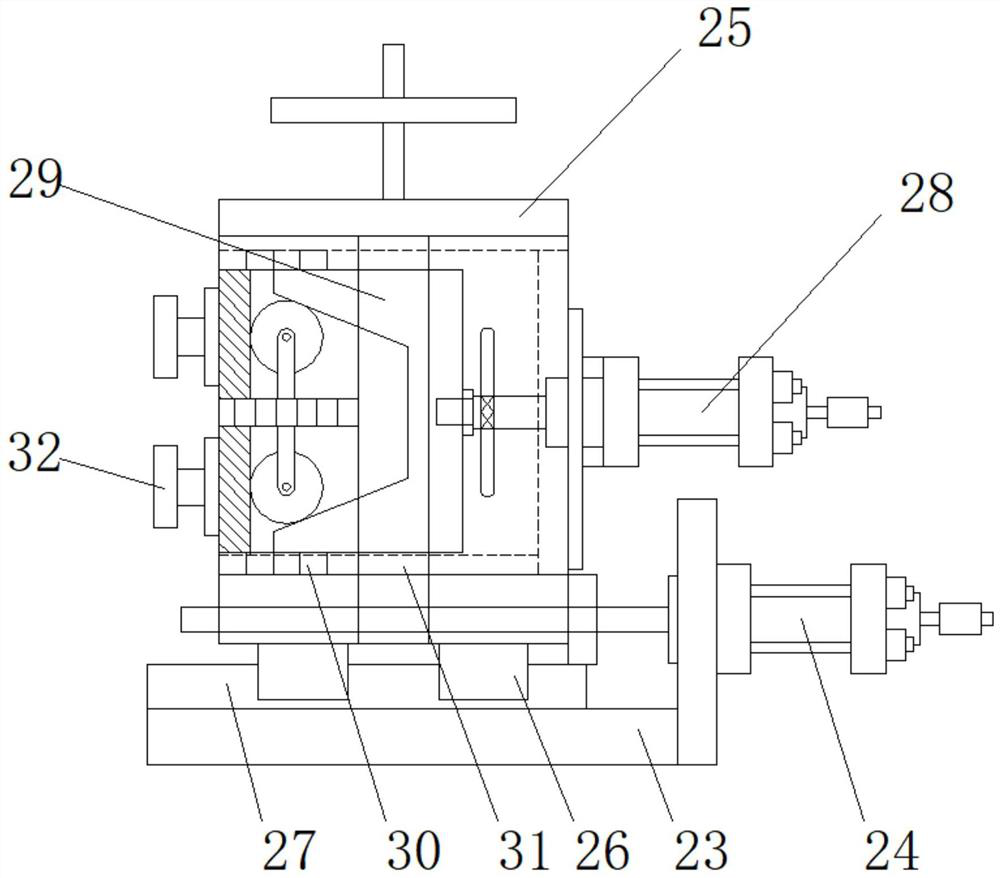

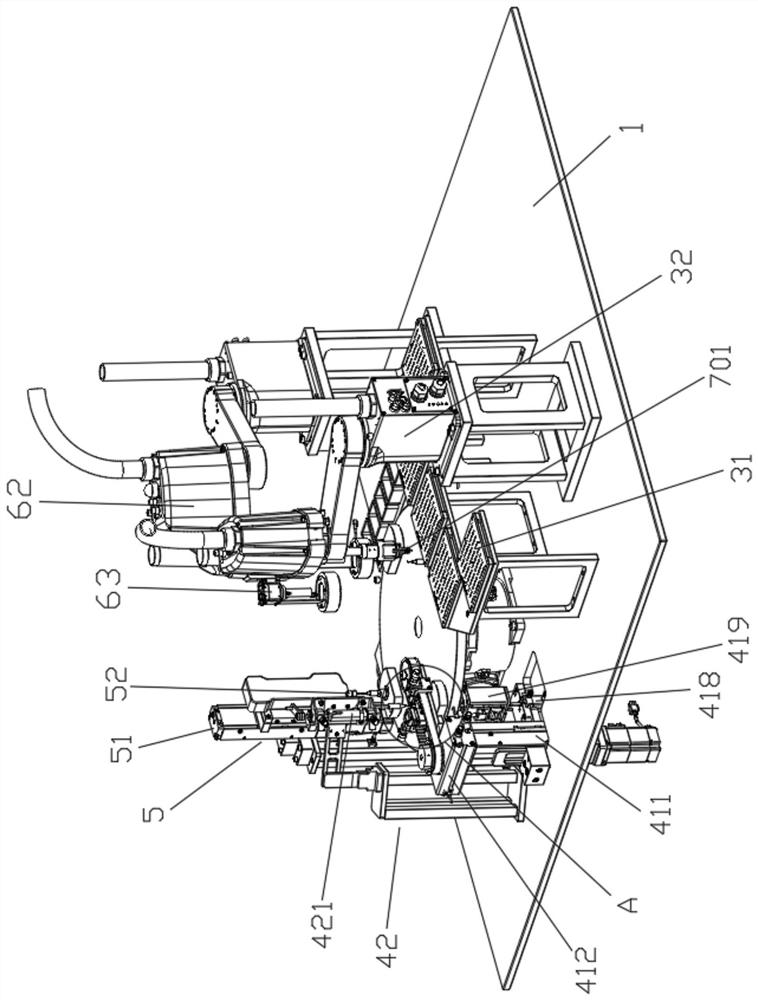

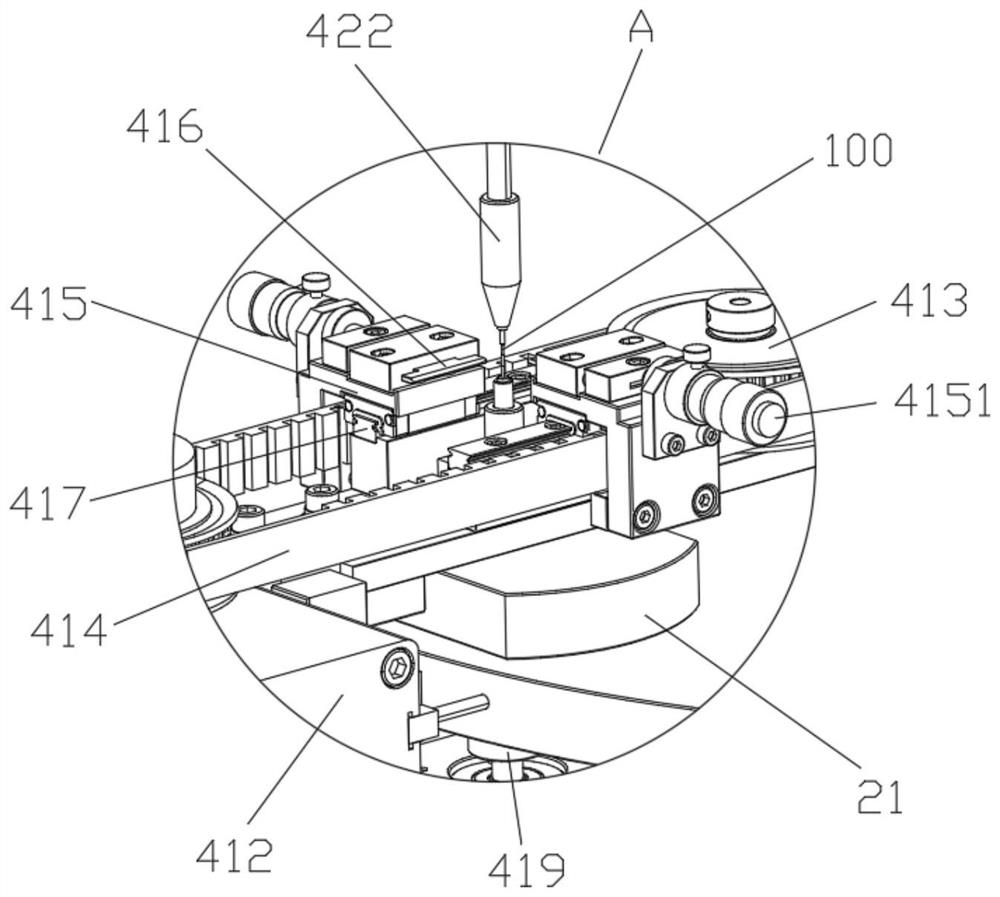

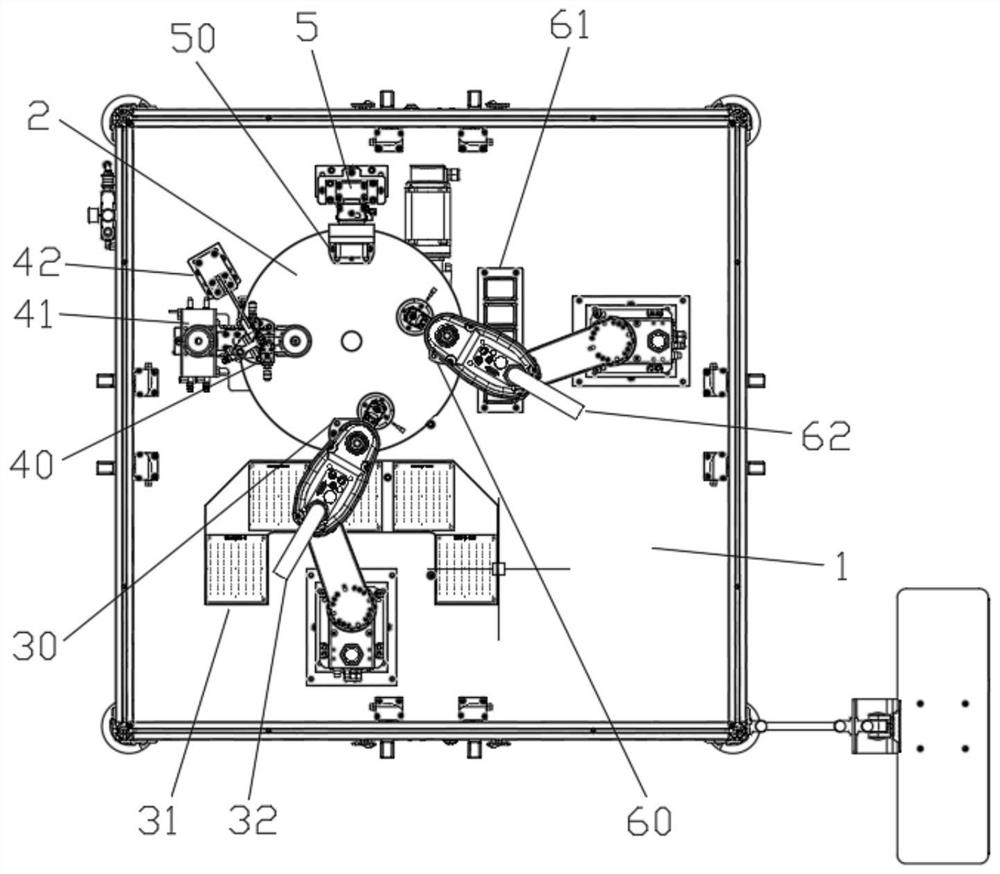

Cotter spring pin curling production method and equipment thereof

The invention relates to the field of hardware production and manufacturing, in particular to a cotter spring pin curling production method and equipment thereof. The cotter spring pin curling production equipment comprises a driving device, a feeding device, a positioning and forming device and curling devices; wherein the driving device comprises a driving shaft; the driving shaft is horizontally arranged and circumferentially rotates; the output end of the driving shaft is connected with the positioning and forming device and drives the positioning and forming device to rotate around the driving shaft; the curling devices are distributed in the circumferential direction of the positioning and forming device; the positioning and forming device drives the curling devices to rotate througha gear assembly; the positioning and forming device and the curling devices are opposite in rotating directions; the feeding device is used for placing raw materials into the positioning and formingdevice; and raw materials are fed to a forming rotary disk, and extruded by the forming rotary disk and the curling devices to form a cotter spring pin. The cotter spring pin curling production methodand the equipment thereof have the technical effects that the raw materials do not need to wait from feeding to curling, the working continuity is high, and the processing efficiency is improved.

Owner:何东海

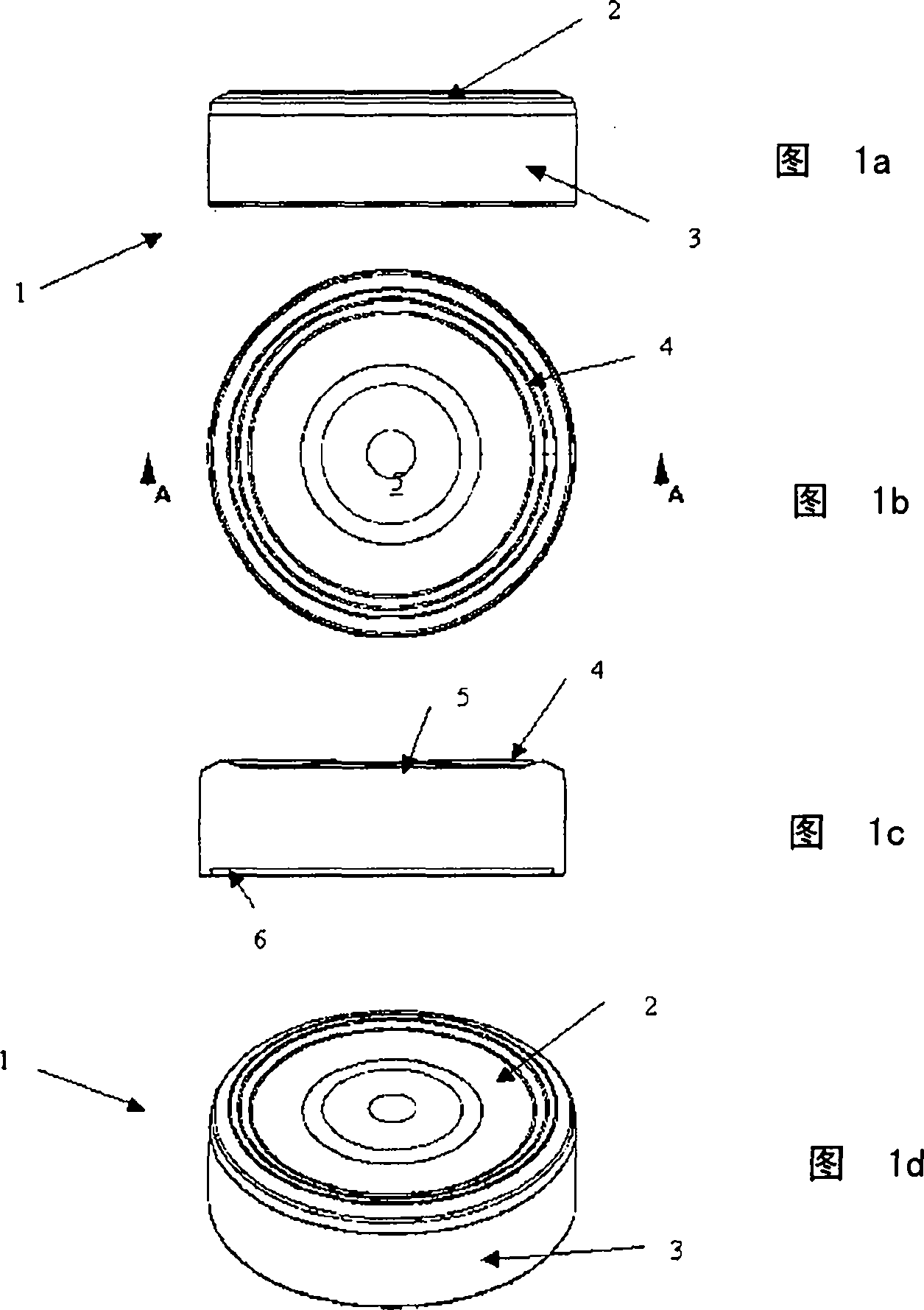

Cutting method and apparatus

A method and apparatus for manufacturing a two-part article from a cup (1) formed from a single sheet metal blank. The method includes forming a 'V'-shaped groove (15) by pressing and rolling an anvil (25) on one side of the cup sidewall (3), against one or more cutting rings (21) on the opposite side of the sidewall. Generally, this stage is followed by a second stage, which cuts the cup (1) into a separate ring (11) and shallower cup (10). This second stage enables profiled edges (17, 18) such as slight bends or flares to be formed which are beneficial when flanging or curling of the edges is subsequently required.

Owner:CROWN PACKAGING TECH

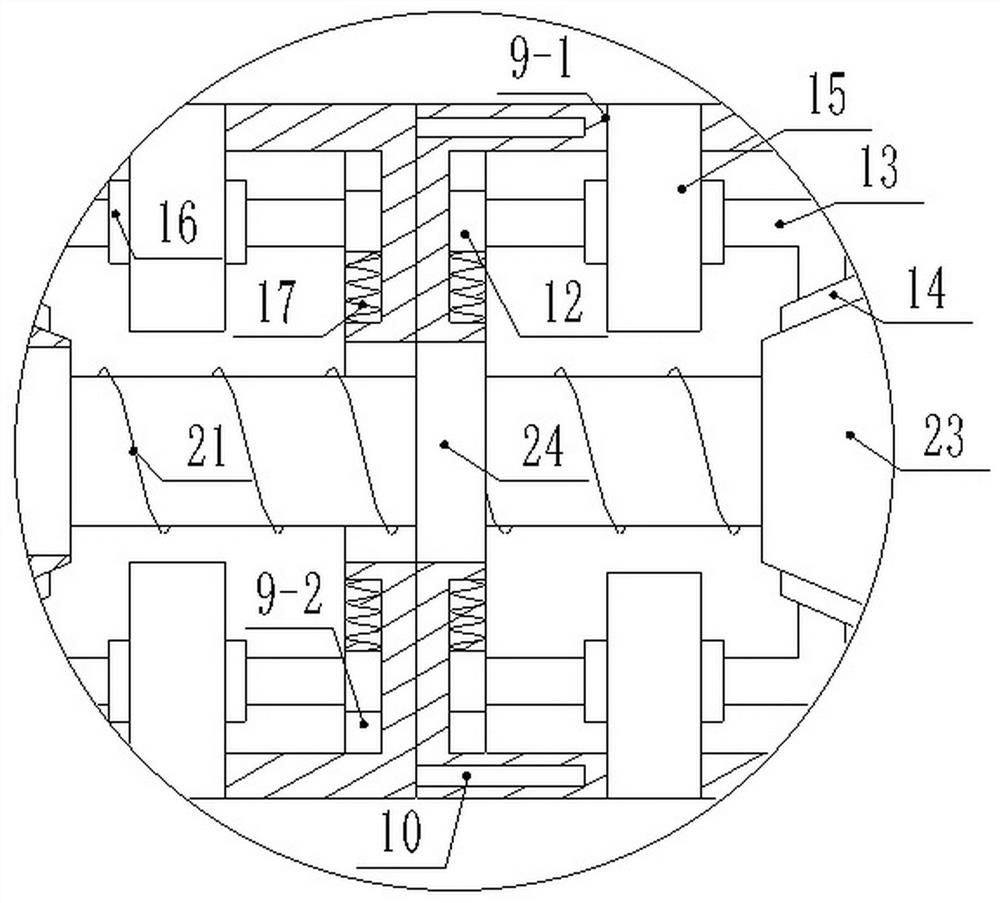

Paper tube curling device

The invention discloses a paper tube curling device. A curling mechanism comprises an upper curling mechanism and a lower expansion mechanism; the lower expansion mechanism comprises a pressing plate,outward expansion plates, a spring ring, screws and nuts; the pressing plate is positioned at the bottom; the pressing plate is circular; four moving grooves are formed in the edge of the pressing plate at equal intervals; the outward expansion plates are positioned on the upper part of the pressing plate; the outward expansion plates comprise upper plates, lower plates and vertical plates; the upper plates and the lower plates are fixedly connected by the vertical plates, so that a groove is formed between the upper plates and the lower plates; the screws are arranged vertically; the tops ofthe screws are fixedly connected to the lower plates; the bottoms of the screws penetrate through the moving grooves; the nuts are positioned under the lower part of the pressing plate and are in threaded connection with the screws; the nuts fix the pressing plate to the lower parts of the lower plates; the four screws and the four nuts are arranged in correspondence with the moving grooves; thefour outward expansion plates are adjacent to each other to form a circular ring; the spring ring is positioned in the groove formed by the upper plates and the lower plates; and a through hole is formed in the middle of the four outward expansion plates. The paper tube curling device realizes efficient curling through the upper curling mechanism and the lower expansion mechanism.

Owner:嘉善创日纸管有限公司

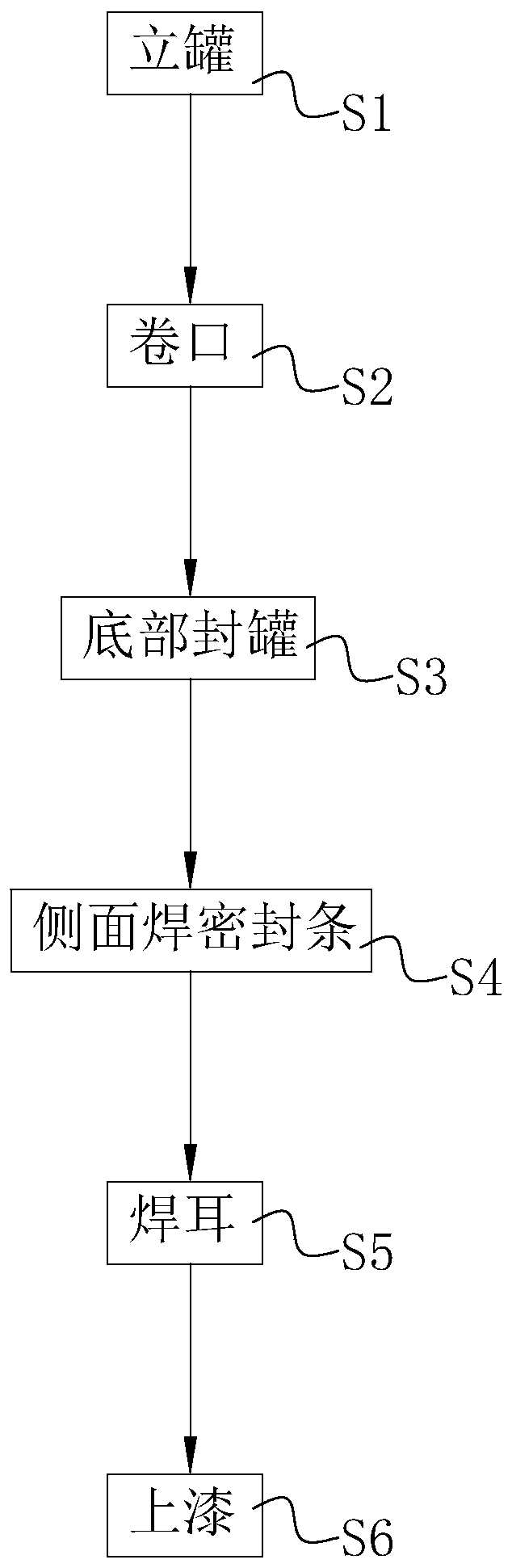

Production process of flower basket barrel

InactiveCN111571124AImprove sealingQuality improvementLiquid surface applicatorsCoatingsCurlingWeld seam

The invention relates to a production process of a flower basket barrel. The production process includes the following steps of: (S1), standing up of a pot: carrying out standing up of the pot after seam-welding of raw materials, processing and afterwards carrying out taper expansion and flanging procedures to obtain a round barrel-shaped pot body; (S2), opening curling: conveying the pot body toan opening curling machine for curling the edge, and processing the pot body by using a flower basket bucket rib-expansion edge turning machine after opening curling is completed; (S3), pot bottom sealing: vertically turning the processed pot body and afterwards carrying out pot bottom sealing operation so that the bottom of the pot is sealed; (S4), side surface sealing strip welding: after seam welding of the side surface, welding a sealing strip on the outer sidewall of the pot body at a weld seam; (S5), lug welding: after rotating the pot body 180 degrees, welding a bucket lug at one side,close to an upper cover, of the outer sidewall of the pot body; and (S6), painting: after lug welding is completed, conveying the pot body to a painting chamber for painting, and packaging the pot body and putting into storage after the paint is naturally dried in air. According to the production process, the weld seam of the outer sidewall of the flower basket bucket is additionally provided witha sealing strip so that the leakproofness of the flower basket bucket is improved to a quite high extent.

Owner:JIUJIANG YONGXIN CAN EQUIP

Silencer production curling machine and using method thereof

PendingCN114769391AEasy to curlImprove stabilityEdge grinding machinesShaping toolsCurlingRotating disc

The invention belongs to the field of silencer production, particularly relates to a curling machine for silencer production, and aims to solve the problems that an existing device is difficult to place a silencer in the middle and influences the curling effect of the silencer, the curling machine for silencer production comprises a cabinet body, a through mounting opening is formed in the top of the cabinet body, and a mounting cylinder is movably connected in the mounting opening; a rotating disc is fixedly connected to the outer wall of the top of the mounting cylinder, and a plurality of sliding grooves are formed in the upper surface of the rotating disc. The invention further provides a using method of the curling machine for silencer production, and the using method comprises the following steps that S1, a silencer needing to be curled is arranged on the circumferential outer walls of a plurality of fan-shaped supporting blocks in a sleeving mode. The silencer can be kept in the center position of the rotating disc, the edge curling block can conduct edge curling conveniently, meanwhile, friction generated when the edge curling block conducts edge curling on the silencer can be reduced, the edge curling quality is improved, the silencer subjected to edge curling can be ground, and the quality of the silencer is improved.

Owner:长沙昊博机械设备有限公司

Multi-station can making equipment

InactiveCN111283113AImprove efficiencyAvoid the dangers that occur when manual contact with machineryHollow articlesCircular discCurling

The invention belongs to the technical field of can making machines, and particularly relates to multi-station can making equipment. The multi-station can making equipment comprises a workbench, wherein a sleeve and an edge curling unit are arranged on the workbench, and the edge curling unit comprises an air cylinder and a first motor; and clamping rods are in arc shapes and are hinged into a clamping groove between a first disc and a second disc. According to the multi-station can making equipment, in an initial state, the distance between one ends of the adjacent clamping rods is larger than the diameter of the clamping groove, and the push rods fixedly connected to the other ends of the adjacent clamping rods are mutually close but do not make mutual contact; through cooperation of theedge curling unit and a clamping mechanism, edge curling of a can opening of a can body is achieved; and the can body is placed on the first disc and the second disc to be transferred, and a curled edge is curled out of an upper can opening of the can body, so compared with the mode that the can body is manually placed below a rotary plate, the can body can be transferred below the rotary plate through the first disc and the second disc, and accordingly efficiency is higher, and meanwhile the situation that danger occurs when a mechanical hand is manually touched due to the fact the can bodyis manually placed below the rotary plate can be avoided.

Owner:关杨

Retard-bonded prestressed reinforcement beam top curling-up tensioning assembly and construction process thereof

PendingCN110005130AImprove layout qualityVibrate compactGirdersJoistsPrestressed concrete beamPre stress

The invention discloses a retard-bonded prestressed reinforcement beam top curling-up tensioning assembly and a construction process thereof. During construction, retard-bonded prestressed reinforcements are arranged in prestressed concrete beams in bundles in the longitudinal direction or evenly, start to be dispersed at retard-bonded prestressed reinforcement curling-up tensioning ends evenly and are sequentially curled up according to a parabola to form a plurality of rows of tensioning ends; then beam top tensioning is conducted, the tensioning assembly used in the tensioning process comprises beam longitudinal common reinforcements and pressure bearing plates vertically sleeving the retard-bonded prestressed reinforcement curling-up tensioning ends, and additional reinforcements are arranged between the beam longitudinal common reinforcements and the pressure bearing plates; spiral reinforcements sleeving the retard-bonded prestressed reinforcements are arranged on the inner sidesof the pressure bearing plates; and cavity molds are arranged on the positions, perpendicular to the pressure bearing plates, on the outer sides of the pressure bearing plates. The prestressed reinforcements are tensioned at the beam tops, large grooves do not need to be reserved in the beams, and the weakening influence on the beam sections is small; and additionally, when the beam tops are tensioned, the operation space is large, and construction is flexible and convenient.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP +1

High-efficiency production line of masterbatch and preparation method of production line

PendingCN111055399AConvenient to observe the feeding statusObserve the feeding statusMasterbatchProduction line

The invention discloses a high-efficiency production line of masterbatch and a preparation method of the production line, and relates to the technical field of masterbatch production lines. The production line comprises a base, a fixing seat is fixedly connected to the left side of the top of the base, and a shell is fixedly connected to the right side of the fixing seat; and the right side of theshell communicates with a cooling shell, and a concentric-square-shaped pipe is fixedly connected to the interior of the edge of the cooling shell, protrusions are arranged on one side of the concentric-square-shaped pipe, and one side of each protrusion penetrates the cooling shell and extends to the exterior of the cooling shell. According to the high-efficiency production line of the masterbatch and the preparation method of the production line, the right side of the shell communicates with the cooling shell, the concentric-square-shaped pipe in the edge of the cooling shell is used to form a water circuit, the protrusions are arranged to increase a contact area, water tanks, a connecting pipe, a water suction pump, a water inlet pipe and a water outlet pipe are arranged to circularlypump cold water to cool masterbatch materials, so that masterbatch extrudates can be shaped quickly to avoid curling, and operation of a subsequent pelletizer is facilitated.

Owner:DONGGUAN JINFULIANG PLASTIC & RUBBER TECH CO LTD

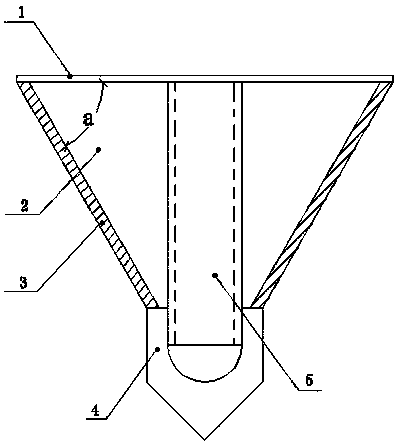

Application of cone bit of hydraulic drilling rig to treatment of bottom opening edge curling of steel pipe pile

InactiveCN109837902AGuaranteed uptimeWorkmanship is feasibleDrill bitsBulkheads/pilesDrill bitDrill hole

The invention discloses application of a cone bit of a hydraulic drilling rig to treatment of bottom opening edge curling of a steel pipe pile. The cone bit of the hydraulic drilling rig comprises a top plate, a center post, a plurality of rib plates and a drill cutter blade, wherein the center post is fixed to the bottom center of the top plate; the rib plates are fixed between the side wall of the center post and the top plate; and the drill cutter blade is fixed at the bottom of the center post. When drilling sticking occurs in the drill hole forming process, the occurrence of the edge curling of the steel pipe pile is determined; a drill pipe is lifted out of the steel pipe pile; the cone drill is installed; the low-speed rotating drilling is performed; and the drilling depth exceeds abottom opening of the steel pipe pile for 50cm, so that the treatment on the edge curling section is totally completed. When being used for solving the problem of bottom opening edge curling of the steel pipe pile, the cone bit of the hydraulic drilling rig has the advantages that safety and reliability are realized; the operation is simple; and economic performance and reasonableness are realized, and the like. The popularization conditions are realized.

Owner:CCCC FIRST HARBOR ENG +1

Automatic floor laying device capable of avoiding edge curling and unevenness

InactiveCN113027096AImprove compactnessGuaranteed flatnessBuilding constructionsCurlingAgricultural engineering

The invention relates to the technical field of decorative materials, and discloses an automatic floor laying device capable of avoiding edge curling and unevenness. The automatic laying device comprises wood boards, wherein the wood boards are used for being laid; through the cooperative use of a rotating disc, a limiting sleeve, the wood board, a sliding piece, a pressing plate and a special-shaped wheel, the wood boards are automatically pressed when being laid, so that the compactness of the wood boards during laying is increased, meanwhile, the wood boards are pressed, so that the flatness of the wood boards during laying is guaranteed, and the attractiveness of the wood boards is prevented from being influenced; through the cooperative use of a moving plate, a small gear and a push rod, when the wood boards are pressed, the push rod is used for driving a rubber hammer to automatically knock the joints of the wood boards, so that the wood boards are directly connected more tightly, and the phenomenon that the wood boards are warped or curled during laying is avoided; and a heat conduction plate and an arc-shaped groove are arranged in each wood board, so that a hot water pipe is limited when each wood board is laid, and the heat conduction plate is used for transferring heat, so that the loss of the heat is reduced.

Owner:宿州市尖端木业有限公司

Production process of laser welding double-deck screen

The invention discloses a production process of a laser welding double-deck screen. The production process comprises the following steps that step 1, stainless iron or stainless steel is selected as a raw material; step 2, the raw material is subjected to laser welding; step 3, a hydraulic machine is used for pressing to enable a product in step 2 to shrink inwards, and an inner-layer component and an outer-layer component are obtained; step 4, the inner-layer component is placed in a clamp with glue spraying, the product is clamped through inward pulling of an air cylinder, and edge curling is conducted on an opening; step 5, the bottom inward-shrinking part of the outer-layer component is pressed through a parallel-bar hydraulic machine; step 6, reinforcing ribs are pulled out of the outer-layer component; and step 7, a screen and the inner-layer component obtained in step 4 are placed in the outer-layer component obtained in step 6 and combined through a press machine, and the double-deck screen is obtained. According to the production process, the screen produced by the novel process has the advantages of being not prone to rust, bright in surface, high in strength and easy to overlay, and the production process is low in cost, free of waste materials, environment-friendly and worthy of popularization.

Owner:浙江展辉仪器科技有限公司

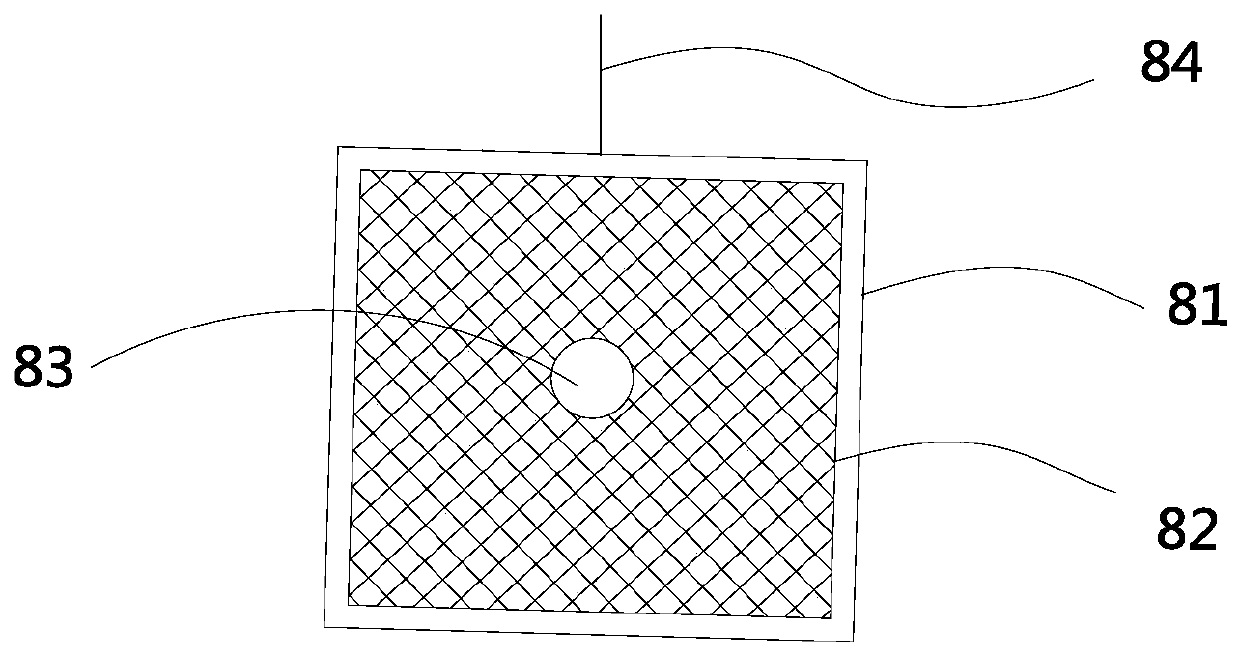

Curling device for processing packaging material

InactiveCN110861355AMeet the needs of different curlsImprove work efficiencyBag making operationsPaper-makingCurlingElectric machinery

The invention discloses a curling device for processing a packaging material and relates to the technical field of packaging material processing equipment. The curling device comprises a support for supporting installation, wherein a height adjusting component is arranged on the support; a frame is fixedly mounted on the height adjusting component; a first curling component and a second curling component are arranged on the frame and have the same mechanism; each of the first curling component and the second curling component comprises a curling wheel, a motor A and a telescopic cylinder; theupper end of the telescopic cylinder is fixedly mounted on a support piece; the two ends of the curling wheel are rotatably mounted at the output ends of the two telescopic cylinders; the output end of the motor A is connected onto the curling wheel; and the first curling component is arranged below the second curling component. The curling device can simultaneously curl a plurality of curling wheels, is high in working efficiency and convenient to adjust the height, and meets the curling demands of different heights.

Owner:ANHUI THE PARKSON SOURCE PACKAGING MATERIALS

Transformer for welding machine

InactiveCN105225803AEasy connection and disassemblyEasy to operateTransformers/inductances coolingTransformers/inductances magnetic coresCurlingTransformer

The invention discloses a transformer for a welding machine. The transformer comprises yokes, multiple core columns, coils and a water circulating pipeline. The yokes are formed by rolling strip-shaped cold-rolling silicon steel sheets. The multiple core columns are located between the two yokes. The two yokes and the core columns are fixed through bolts. The water circulating pipeline penetrates from the center of one yoke, is spirally wound, extends downwards to penetrate through a cavity enclosed by the multiple core columns, and penetrates out of the middle of the other yoke. By means of the principle, the transformer is convenient to disassemble, even if iron cores are disassembled many times, the quality is not prone to being reduced, edge curling or piling of the yokes is avoided, heat dissipation is ensured, and the situation that because temperature rises too fast, the transformer ages fast is avoided.

Owner:SICHUAN MORROW WELDING DEV

a composite machine

ActiveCN108995349BGuaranteed flatnessNo tensile deformationLamination ancillary operationsLaminationCurlingProcess engineering

The invention provides a novel compound machine. According to the novel compound machine, the upper surfaces of raw materials are provided with static electricity by utilizing a static electricity generator; then the primary raw material and the secondary raw material jointly enter a pre-compounding device; and under the action of static electricity adsorption, the two raw materials are flatly compounded together and then enter into a compounding device formed by a compound steel roller and a compression steel roller to be compounded. According to the novel compound machine, the flatness of compounding is effectively ensured, the phenomena such as tensile deformation, edge crack, rough selvedge and curling are not caused, the compounding of multiple raw materials can be realized and the application range is wide.

Owner:江苏金峰轻工装备有限公司盐城市质量技术监督综合检验检测中心

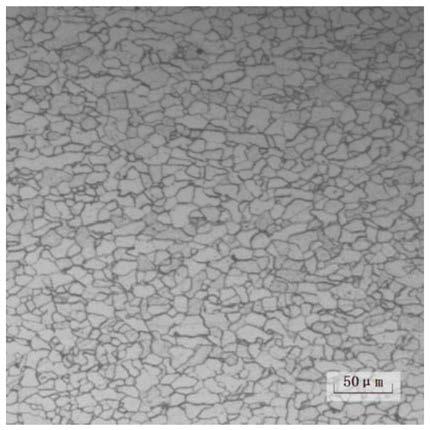

Substrate for compressor shell and production method of substrate

The invention discloses a substrate for a compressor shell and a production method of the substrate. The chemical composition and weight percentage of the substrate comprises the following: 0.03-0.06%of C, 0.15- 0.3% of Mn, no greater than 0.005% of N, no greater than 0.02% of P, no greater than 0.010% of S, no greater than 0.03% of Si, 0.02-0.06% of Als, 0.0015-0.0025% of B, no greater than 0.01% of S and the balance iron and the inevitable impurities, wherein B-N*11 / 14=0, and the substrate is prepared by steelmaking, hot rolling, leveling and pickling processes. According to the substrate,through reasonable composition design, steelmaking process route, roughing double-pass descaling, hot rolling low-temperature finishing rolling and low-temperature curling, after suitable pickling process and leveling process treatment, the substrate for the compressor shell and with high welding performance and punching performance is obtained, the yield strength of the substrate is 220-300 MPa,the tensile strength is greater than or equal to 300 MPa, and the elongation A80 is greater than or equal to 45%; and by means of the method, the substrate for the compressor shell and with high welding performance, molding performance and formed surface quality can be obtained, and high market potential is achieved.

Owner:新余钢铁股份有限公司

Edge curling and pressing device for an inner container

InactiveCN111760951AHemming realizationAdjustable sizeMetal-working feeding devicesHeat exchange apparatusCurlingStructural engineering

The invention discloses an edge curling and pressing device for an inner container, and relates to the technical field of inner container processing. The device comprises a work bench, wherein an edgecurling device located on the left side of a fixed base and an edge pressing device located on the right side of the fixed base are fixedly mounted on the top of the workbench; the edge curling device comprises an adjusting device and an edge curling main body located on the top of the adjusting device; an edge curling stroke adjusting unit is arranged on the left side of the edge curling main body, and edge curling wheel is arranged on the right side of the edge curling main body. By arrangement of the edge curling device, the edge curling wheel is pushed by an edge curing oil cylinder to approach the edge of the inner container gradually by adjusting the edge curling stroke, so that the edge of the inner container is curled gradually under extrusion of the edge curling wheel, and edge curling of the inner container is achieved. According to the edge curling and pressing device, the edge curling angle of the edge curling wheel can be adjusted under cooperative use of a reel frame anda reel handle, so that the size of the edge curling port diameter is adjusted.

Owner:GUANGDONG HUAQIANG ELECTRICAL APPLIANCE GROUP

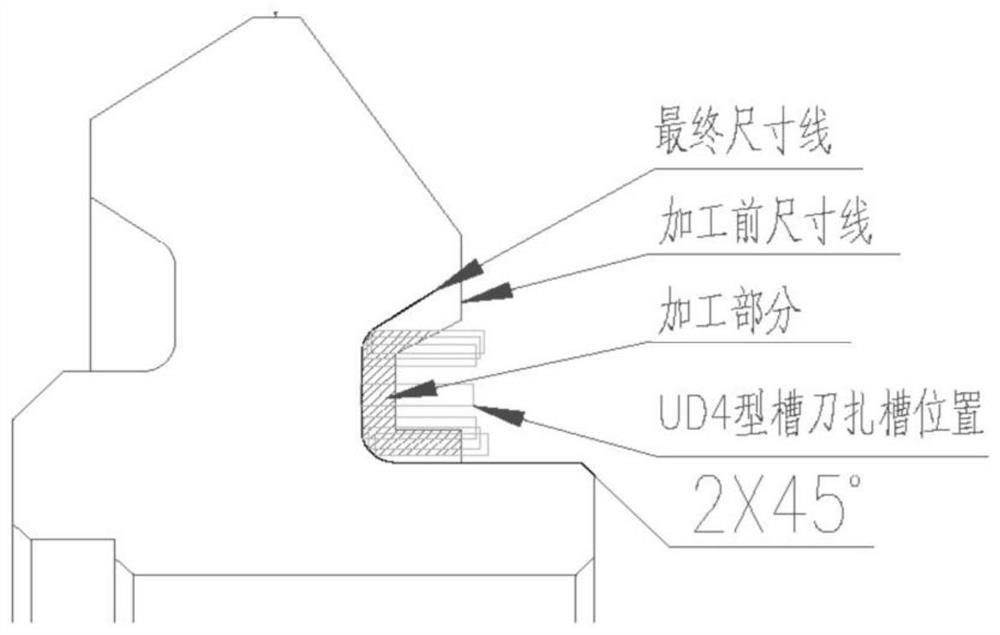

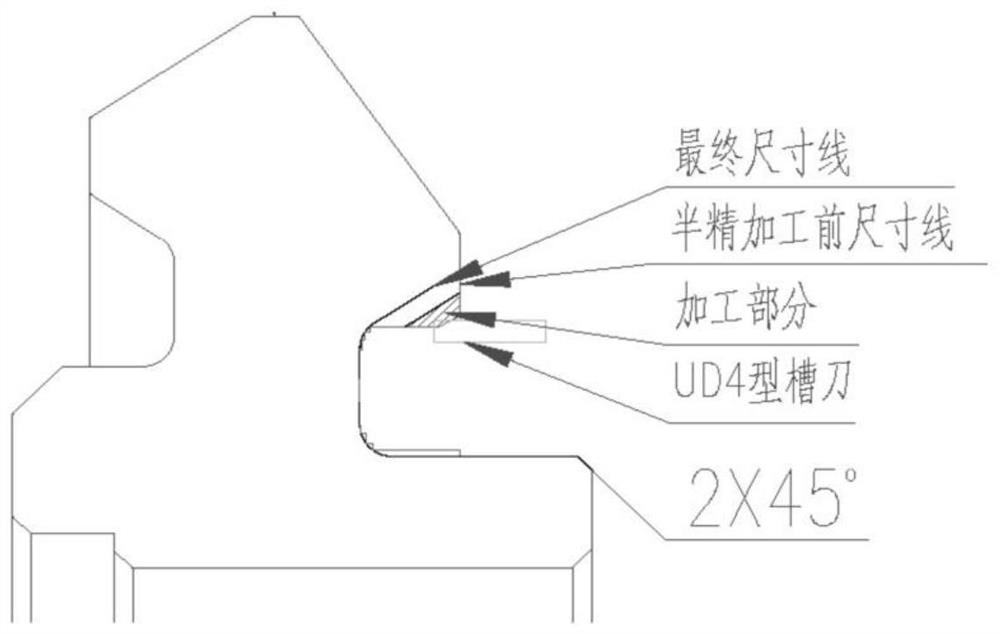

Machining method for finish turning of inner circular groove of spiral bevel gear

The invention provides a machining method for finish turning of an inner circular groove of a spiral bevel gear. Compared with an original traditional machining method of directly and circularly feeding according to the shape of the inner circular groove, by changing a machining path, firstly, a plurality of grooving points are selected from a linear arc and an angle connecting arc of the inner circular groove to form a plurality of steps when grooving is conducted through a grooving cutter; machining of the inner circular groove is simplified into three-step machining according to the shape of the inner circular groove, specifically, grooving is conducted firstly and then semi-finish machining is conducted on the shape of the arc groove, finish machining is conducted on the shape of the arc groove; and an effective grooving path is designed to cut off transverse curling of scrap iron, the scrap iron breaking situation can be improved, and the scrap winding situation is reduced. The method is simple and easy to implement, the quality of the machined surface can be guaranteed, and then the machining and clamping process exchange efficiency is improved.

Owner:BEIJING NORTH VEHICLE GROUP CORP

Multi-station rotary type full-automatic edge curling machine for microprobes

ActiveCN113909407ARealize automatic loading and unloadingImprove efficiencySortingMetal working apparatusRotary stageCurling

The invention discloses a multi-station rotary type full-automatic edge curling machine for microprobes. A plurality of clamping tools are arranged on a rotating table to form a feeding station, an edge curling station and a discharging station; a feeding mechanism, a cutting mechanism, a positioning mechanism and a discharging mechanism are arranged on a machine table in a matched mode; the feeding mechanism feeds probes to the feeding station; the positioning mechanism abuts against the upper ends of the probes to position the probes in the vertical direction; the cutting mechanism comprises a cutting part and a rotating part; the rotating part drives the probes to rotate; the cutting part comprises a driving assembly and forming cutters, and the driving assembly drives the forming cutters to horizontally move to cut the rotating probes to form curled edges; and the discharging mechanism moves the edge-curled probes away from the clamping tools. By arranging the feeding mechanism, the edge curling mechanism and the discharging mechanism, automatic feeding, edge curling and automatic discharging of the probe can be achieved, efficiency is high, and precision is high; and the edge curling mechanism cuts the self-rotating probe through the pair of forming cutters which horizontally move in a reciprocating mode, so that the edge curling efficiency is high, the edge curling precision is high, and the product quality is excellent.

Owner:SUZHOU UIGREEN MICRO & NANO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com