Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

499 results about "Split pin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A split pin, also known in the United States as a cotter pin or cotter key, is a metal fastener with two tines that are bent during installation, similar to a staple or rivet. Typically made of thick wire with a half-circular cross section, split pins come in multiple sizes and types.

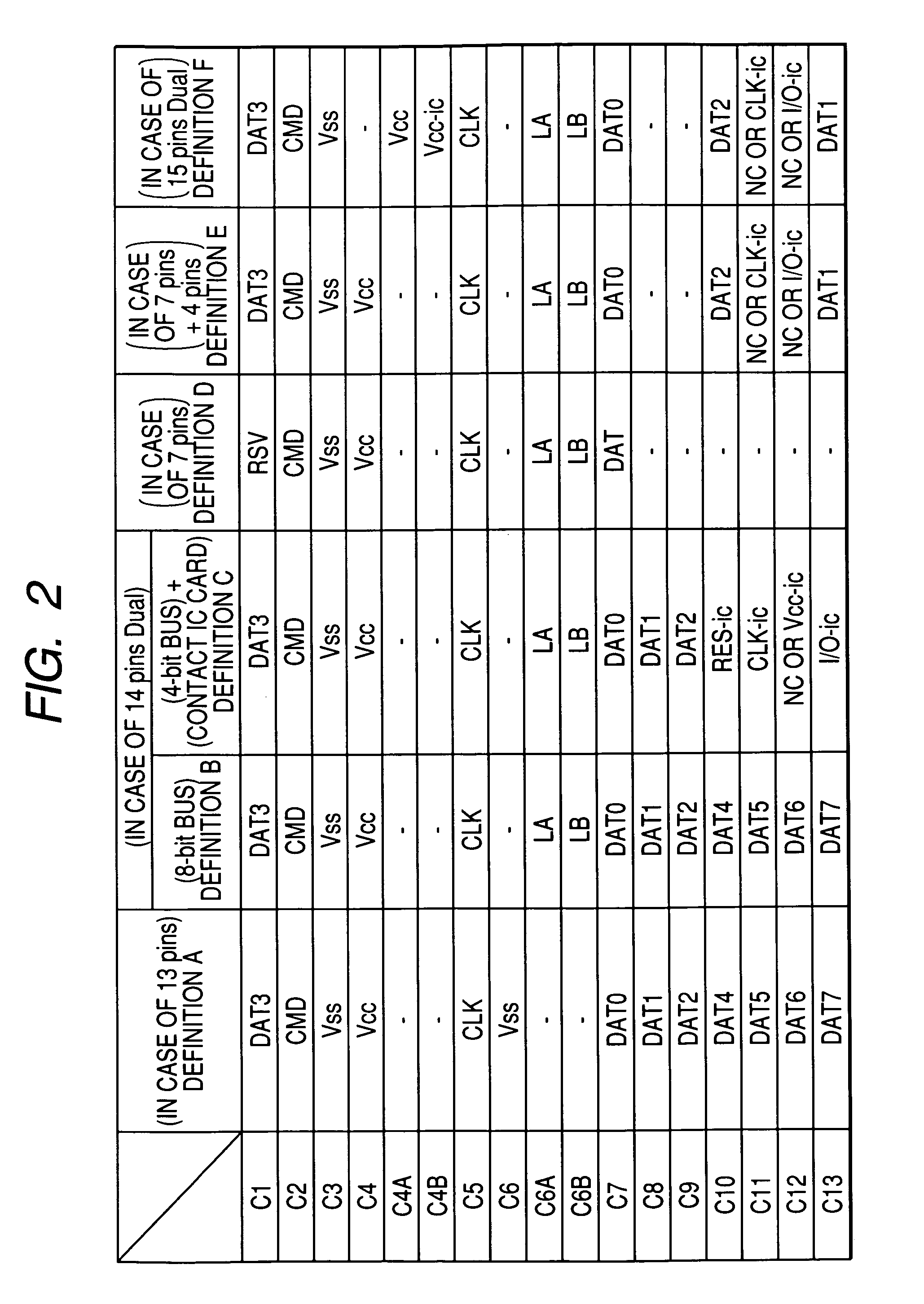

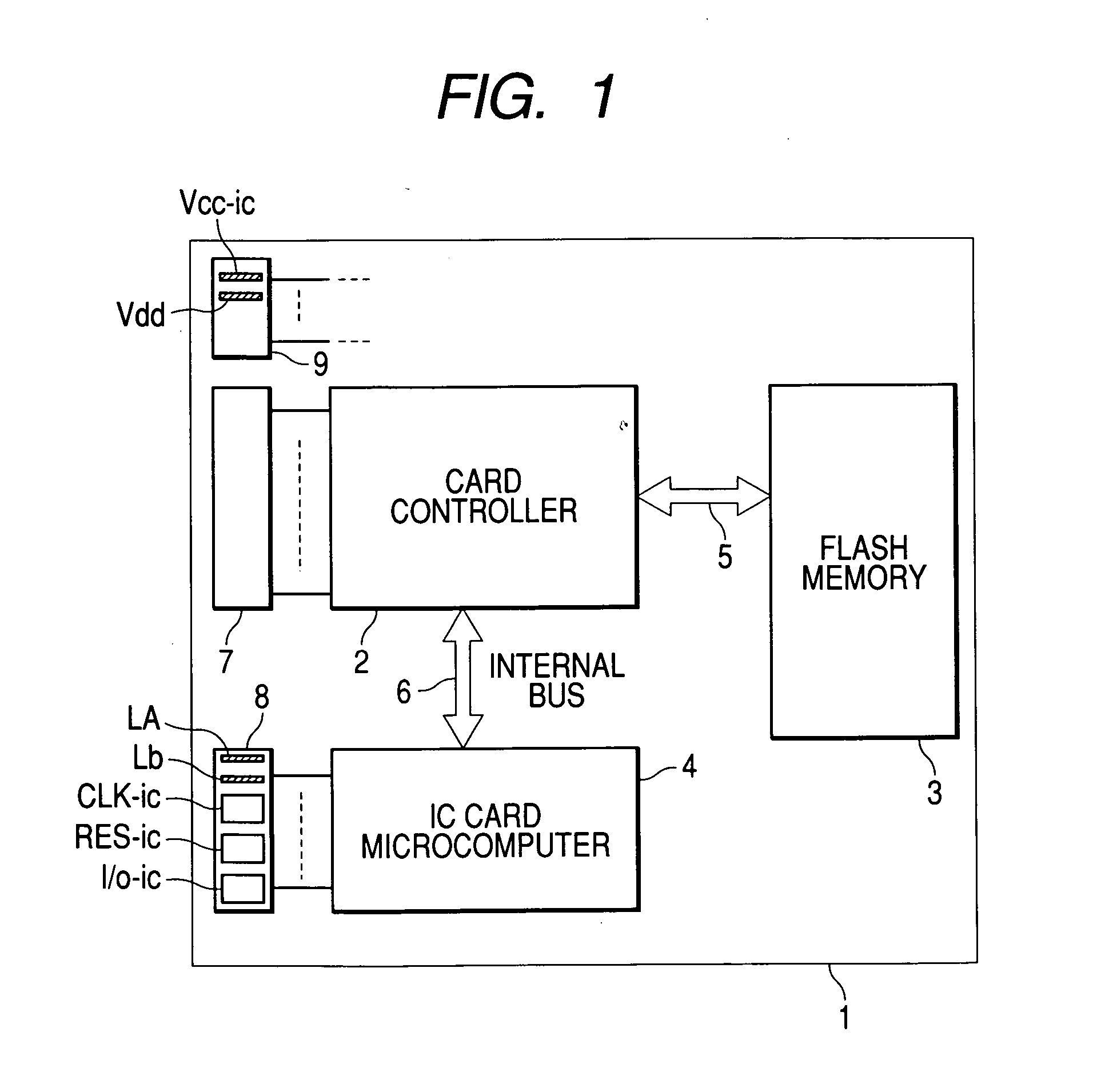

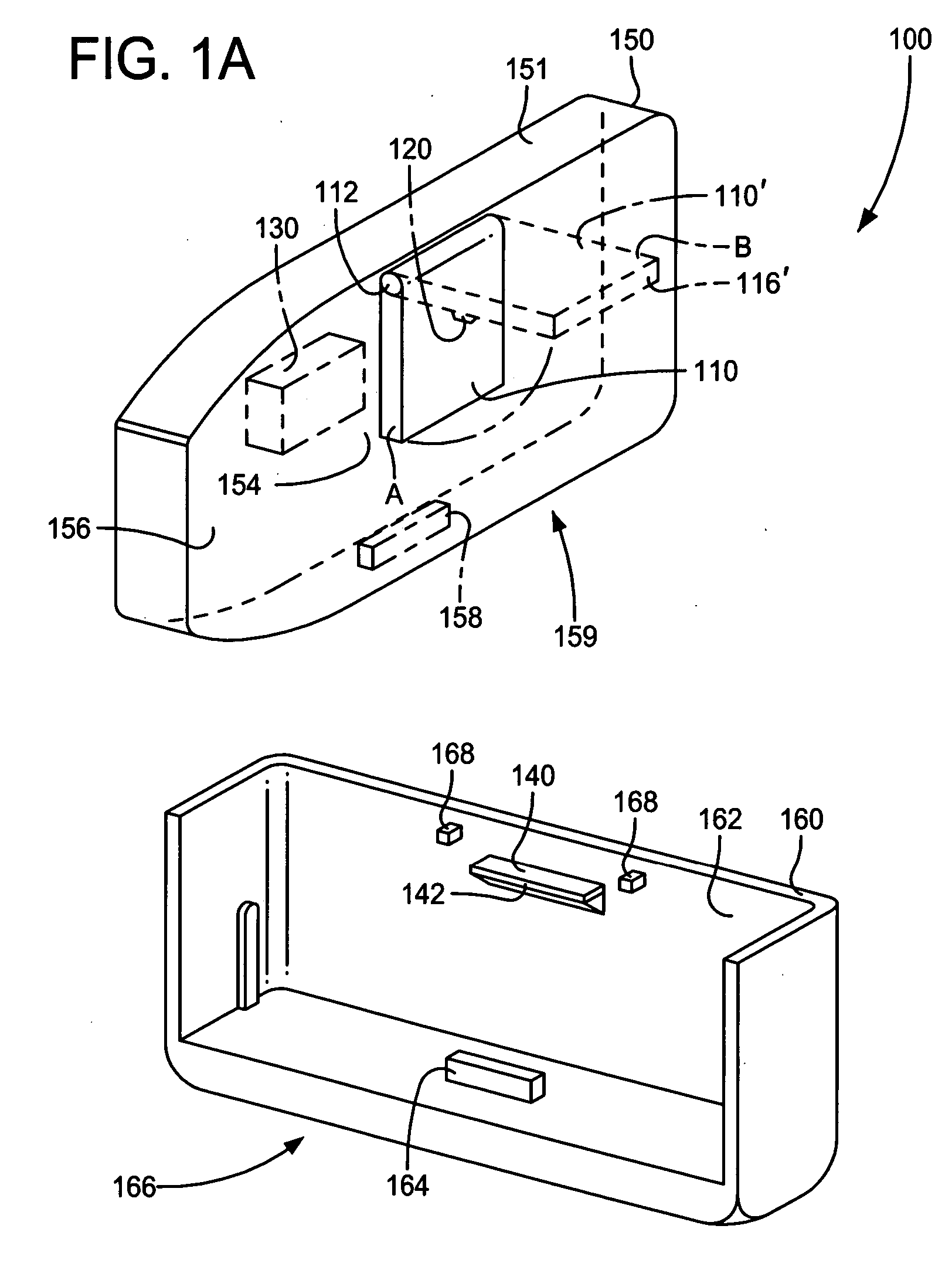

Memory card and semiconductor device

An antenna connection function for a noncontact interface is provided by suppressing a modification in a pin arrangement and a pin shape of a memory card that does not correspond to the noncontact interface. Two antenna connecting pins having the memory card are divided into two areas in which a size of one potential supply pin is the largest and used as a split pin arranged at intervals. Because a size of the two antenna connecting pins is at maximum as large as the size of the potential supply pin, the two antenna connecting pins are provided and the memory card that corresponds to the noncontact interface is obtained by devoting a pin area having the size of the one potential supply pin to the memory card that does not correspond to the noncontact interface.

Owner:RENESAS ELECTRONICS CORP

Hole enlargement apparatus

InactiveUS6305885B1Simple and inexpensive to manufactureEasy to disassembleThread cutting toolsWood turning toolsCombined useEngineering

A hole enlargement apparatus which uses a simple spring biased disc to center a larger hole cutter in the existing hole and a disc retention means to ensure that the disc does not fall unretrievably into the enlarged hole. The apparatus is used in conjunction with a conventional large hole cutter of the type having a toothed cylindrical cup, a hub axially secured in a bottom portion of the cup, and a pilot bit axially and removably secured through the hub and cup. The hole enlargement apparatus comprises: a guide member having a disc portion dimensioned to matingly fit within the existing hole, a rim portion connected to a rear portion of the disc portion adapted to seat on the workpiece, and a disc center guide opening dimensioned to slidingly accept a shaft the diameter of the pilot bit; a drill bit replacement shaft having a hub end portion and an opposite disc end portion; a cotter pin carried by the disc end portion of the drill replacement shaft to prevent the guide member from sliding off the disc end portion of the shaft; and, a spring to bias and maintain the disc portion in the existing hole.

Owner:LINTHICUM LEO

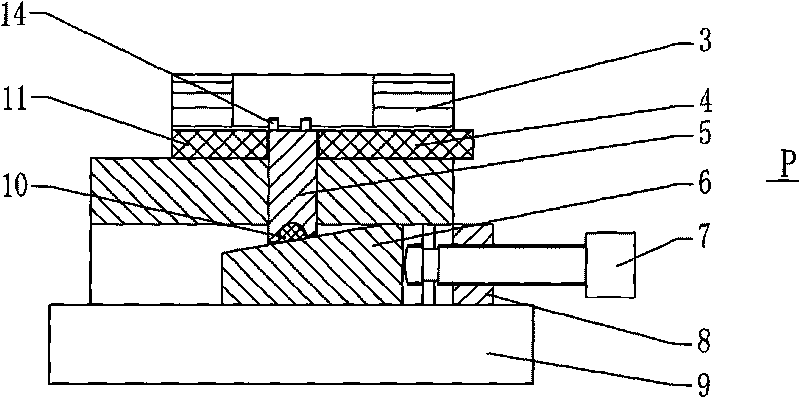

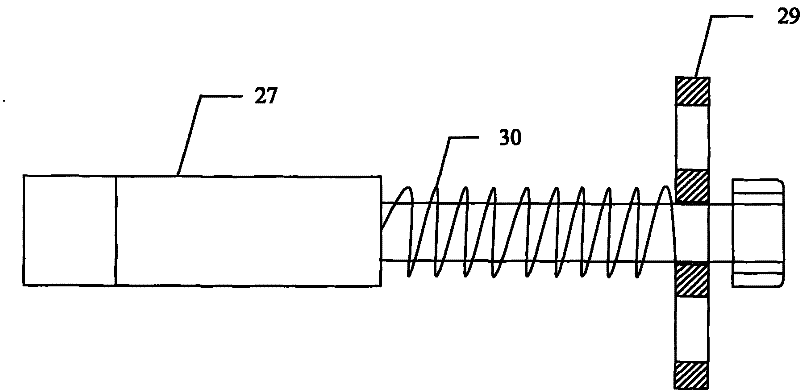

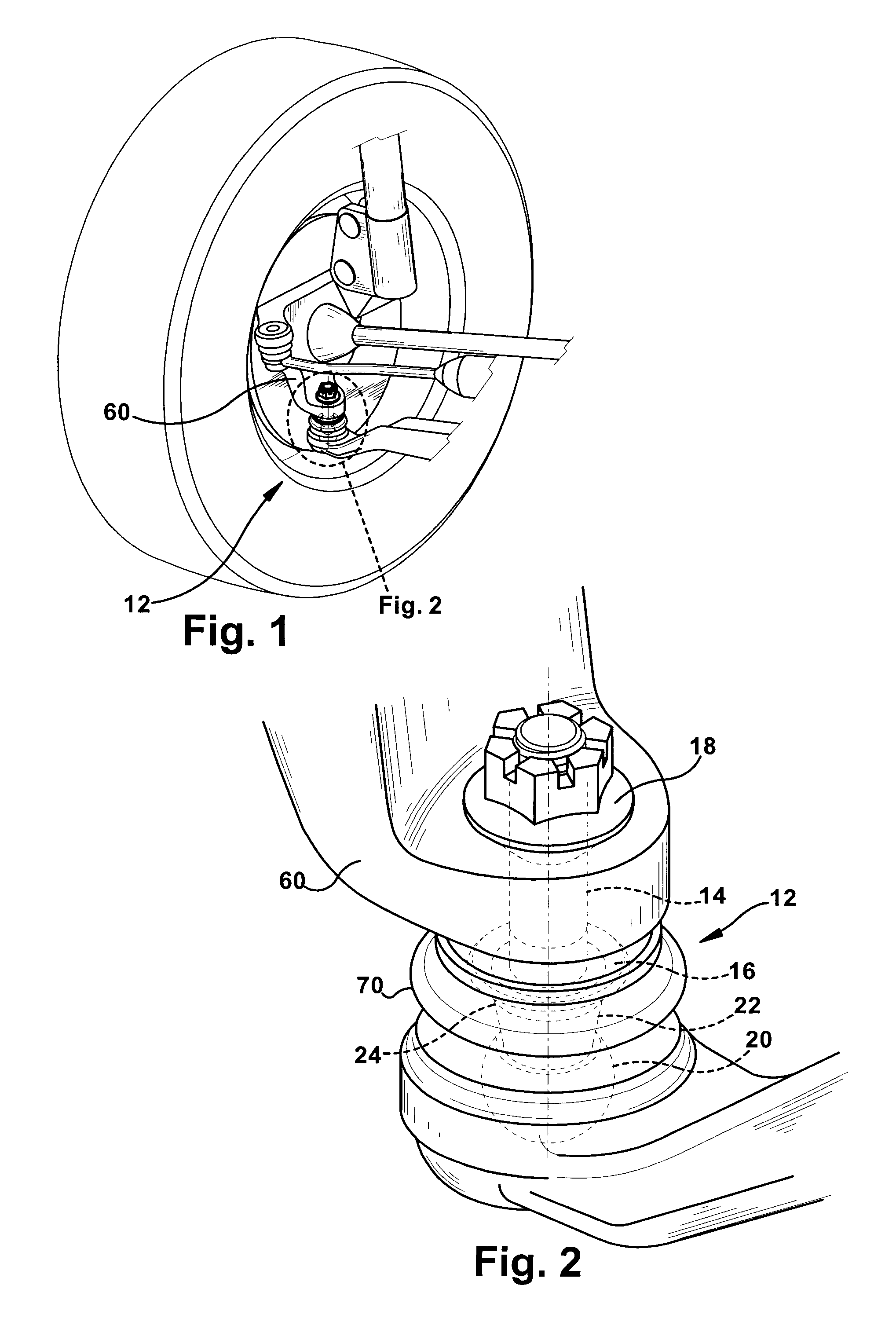

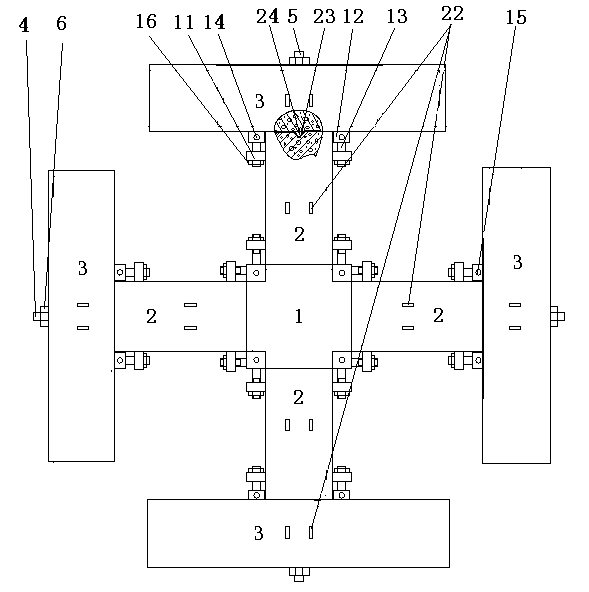

Improved novel clamp for rotary milling of compressor blades

ActiveCN101700626AEasy to operateFit tightlyMilling equipment detailsPositioning apparatusSplit pinEngineering

The invention provides an improved novel clamp for rotary milling of compressor blades. The clamp has the advantages of stable and reliable clamping, uniform reference and stable rotary milling processing. The clamp comprises a blade root support base, a blade root side surface positioning block and a blade root side surface pressing block are mounted on two sides of the blade root support base respectively, and the blade root support base is mounted at a rotary disc. The clamp is characterized in that a wheel groove is mounted at the upper part of the blade root support base, a padding block is mounted at the bottom of the wheel groove, a rectangular through slot is transversely formed at the bottom of the blade root support base, a slide block is mounted in the rectangular through slot, the slide block is connected with a guide rod through a split pin, and the guide rod vertically penetrates the blade root support base.

Owner:WUXI TURBINE BLADE

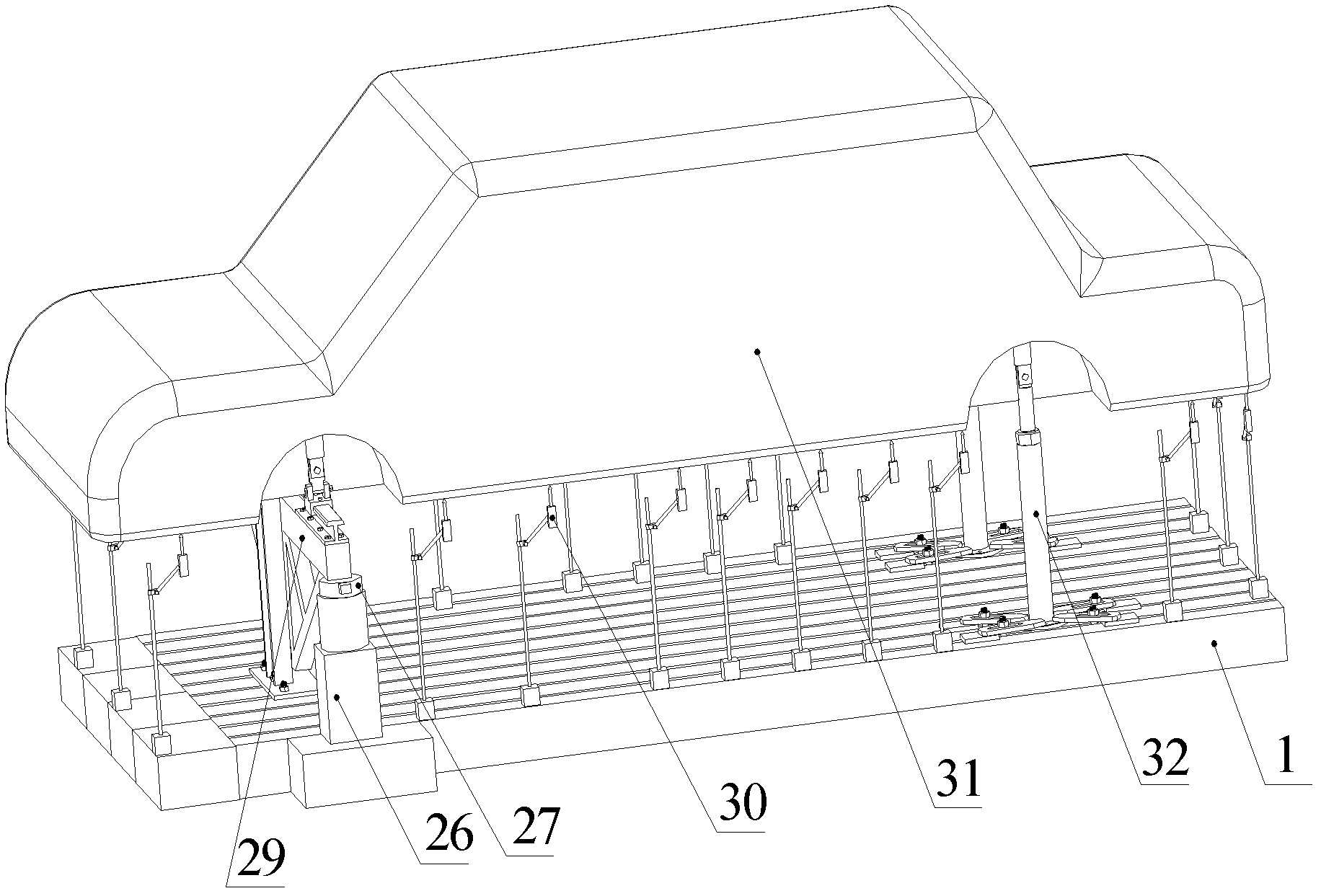

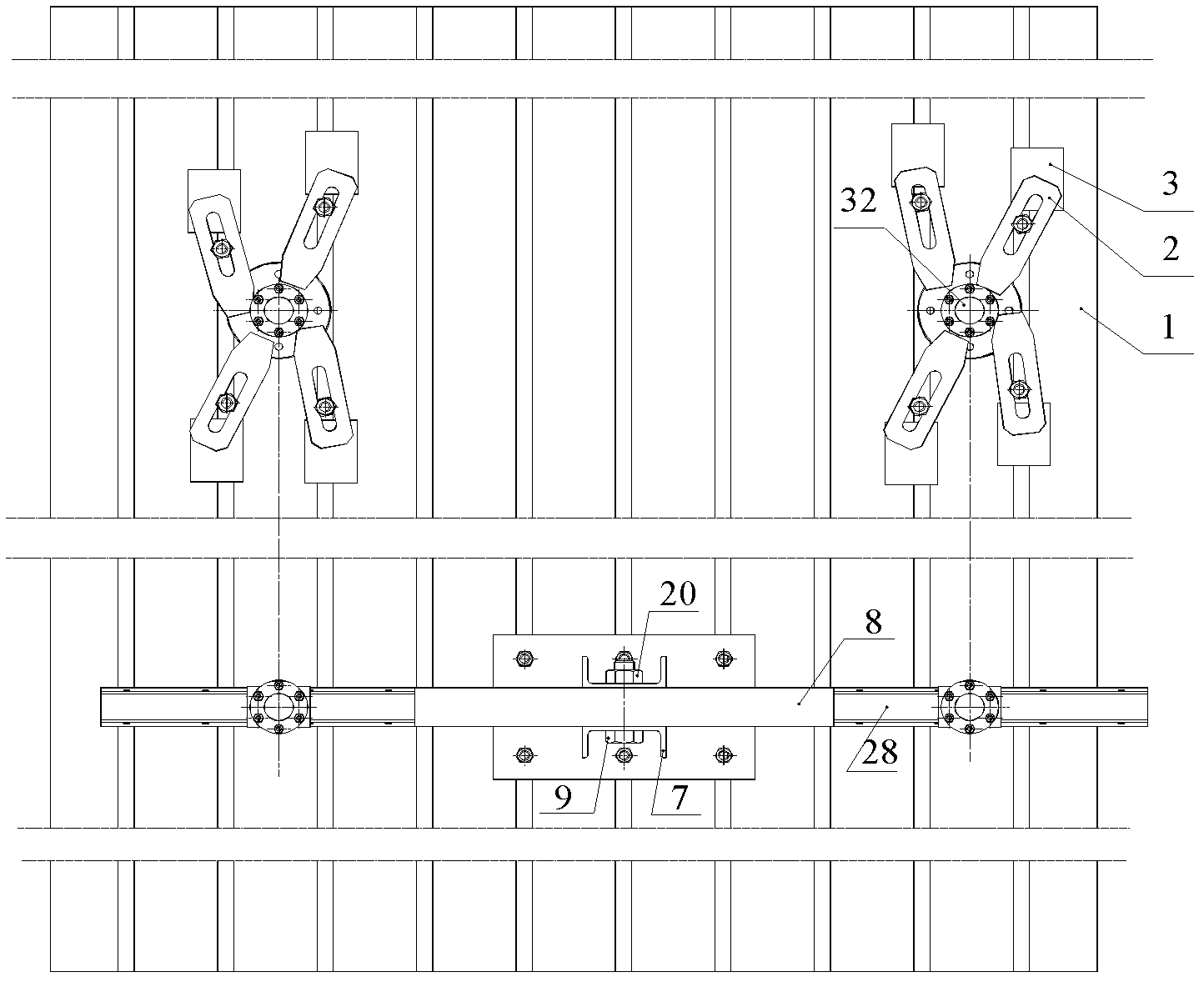

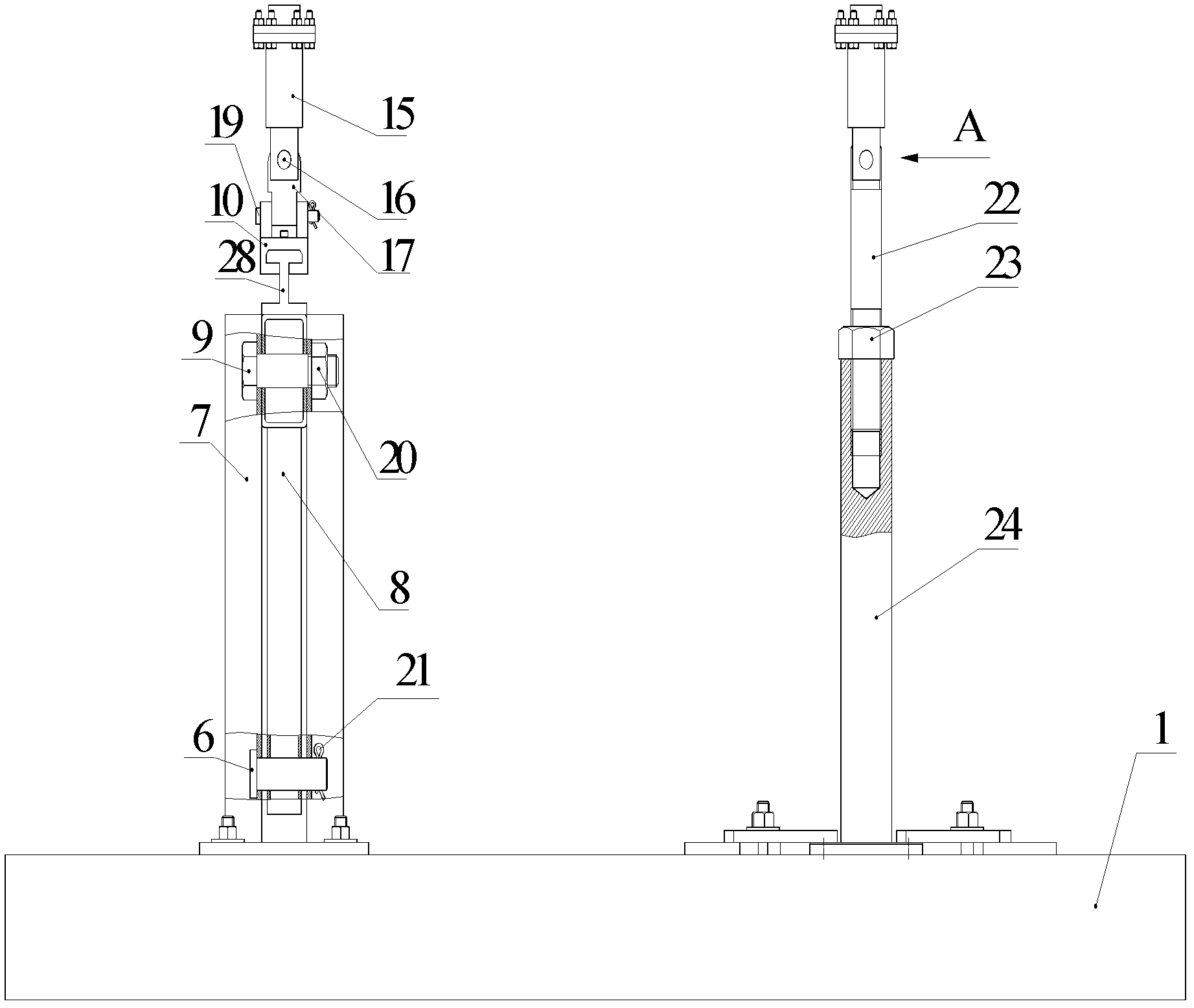

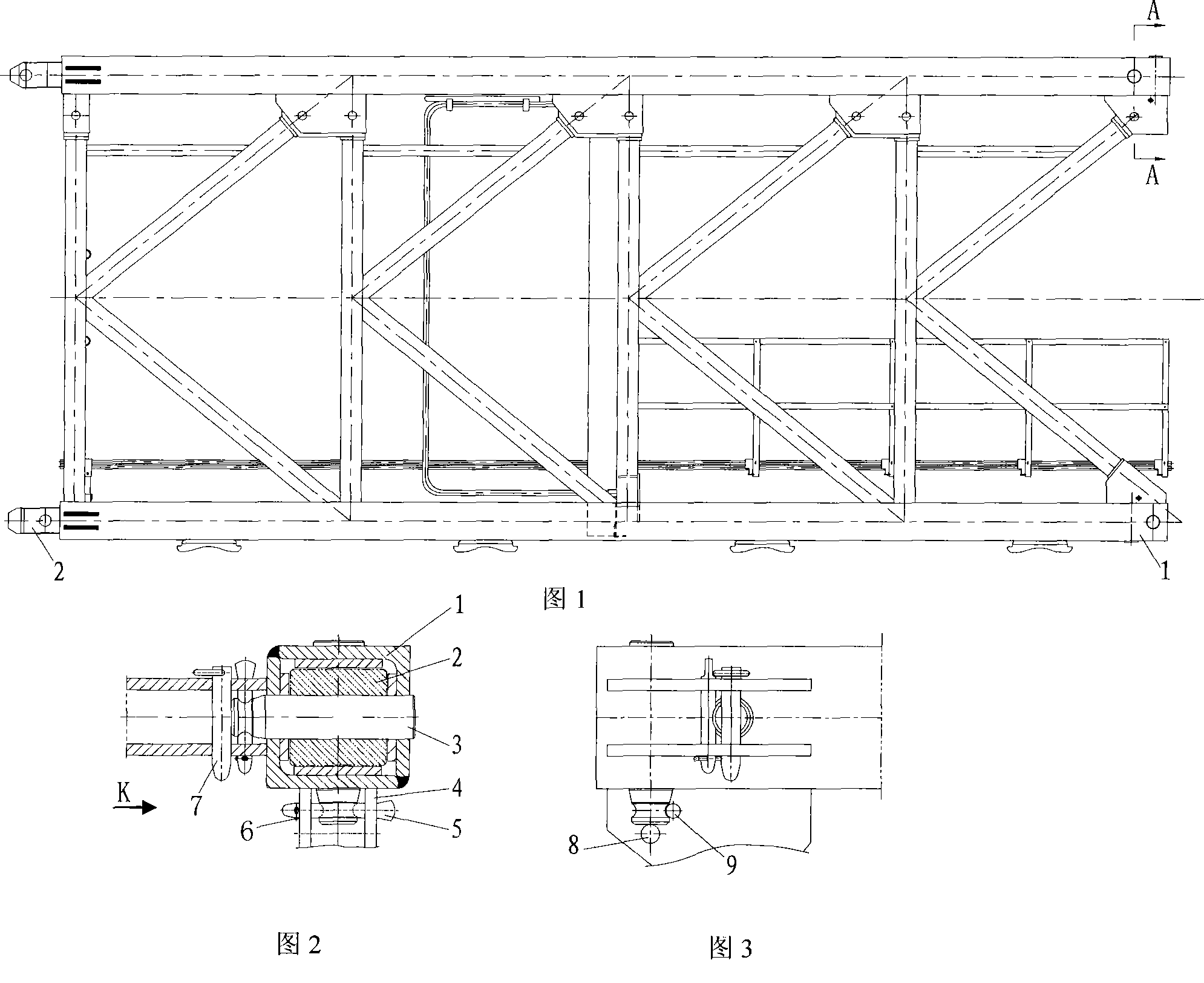

White car body static stiffness restriction device and static stiffness detection method

InactiveCN102435508AImprove structural performanceImprove test efficiencyMaterial strength using steady torsional forcesSplit pinStructural engineering

The invention discloses a white car body static stiffness restriction device of a passenger car and a static stiffness detection method. The device is characterized in that: one side of a front bearing support is provided with a pressure transducer and a hydraulic jack, a plurality of displacement sensors are arranged at the periphery of the white car body bottom surface; the front bearing support comprises a front rack, a T-shaped rack, and a I-shaped guide rail, wherein, the end portion of the front rack is connected with the very center of a crossbeam of the T-shaped rack through bolts and nuts, the crossbeam of the T-shaped rack is arranged at the left and right side of the white car body, and the lower side of the crossbeam is provided with the hydraulic jack; the bottom of the T-shaped rack is connected with the bottom of the front rack through a pin roll and a split pin; the upper surface of the crossbeam of the T-shaped rack is symmetrically provided with I-shaped guide rails; a torque value of the applied load is divided by a twisting angle to calculate a twisting stiffness, and the actual value of the load is divided by a car body deformation displacement to obtain a bending stiffness. According to the invention, the efficiency of various vehicle tests is increased, and the device cost is obviously reduced on the premise that the test accuracy is guaranteed.

Owner:JIANGSU UNIV OF SCI & TECH

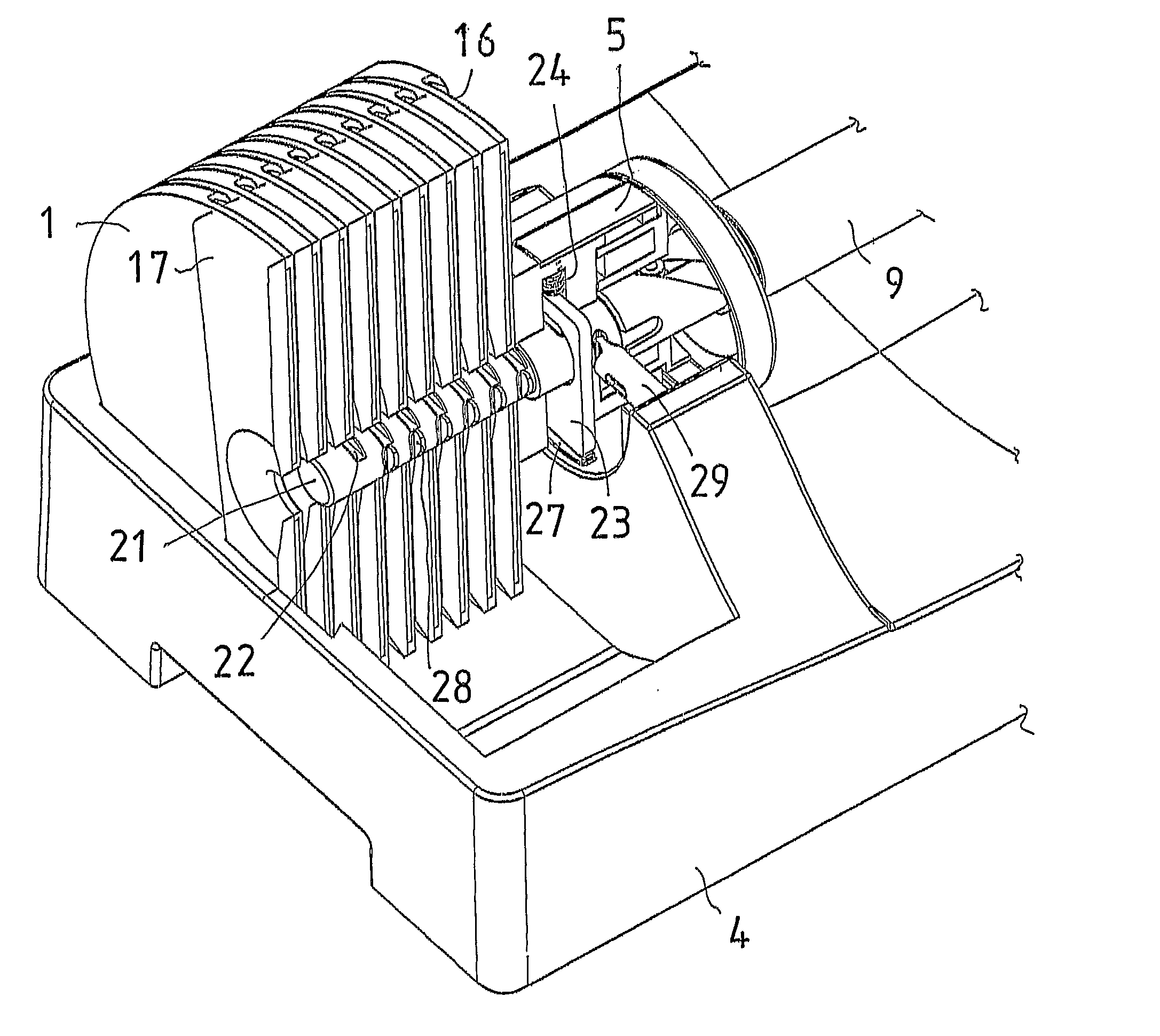

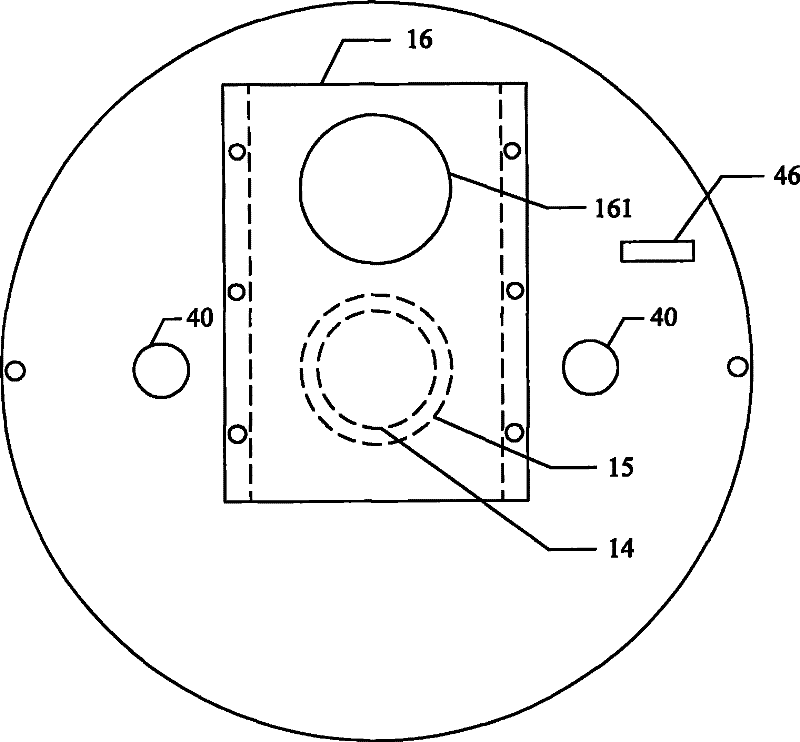

Dumbbell

A dumbbell with a selectable number of weight disks includes a handle with projectable pins in opposing directions, with end surfaces, a base assembly for accommodating two sets of weight disks standing upright, the weight disks having central openings. The projection lengths of the pins are stepwise selectable by an indexing device in order thereby to permit selection of the number of weight disks supported on the handle. Neighboring weight disks and the handle have mutually engaging connecting arrangements which axially interconnect the weight disks and the handle but which permit radial separation. In order to prevent the set projection lengths of the pins from being unintentionally altered, when a dumbbell lifted up out of the base assembly is used, the handle has a locking arrangement which locks the pins in the set projection positions.

Owner:PERSONALITY GYM AB

Support type universal drilling machine

InactiveCN1693653AAdjust the drilling angle arbitrarilyReduce labor intensityConstructionsDerricks/mastsLeft halfSplit pin

This invention discloses a bracket type all directions drilling machine; it includes bracket, drilling machine and connecting device. The connecting device is consisted by connecting parts, rotation parts and clamp parts. The connecting parts include connecting backplane and rotation pin jointed on its central hole. The rotation parts includes rotating dead plate, rotating pin bush and all kinds of bolts, one end of rotating pin bush is jointed to rotating dead plate. Clamp parts include left half loop sleeve, right half loop sleeve, hinge pin, short hinge sleeve long hinge sleeve, cotter pin and stiffener. Hinge sleeve is jointed on each of the two half loop sleeves and connected to hinge pin, left half loop sleeve is jointed to rotating pin sleeve. Connecting backplane is fixed at certain height of the bracket, rotating pi is inserted in rotating pin sleeve, and rotating dead plate is fixed through bolt. Any directions of drill hole can be realized and labor intensity is reduced, and drilling speed is high.

Owner:BEIJING JIAOTONG UNIV

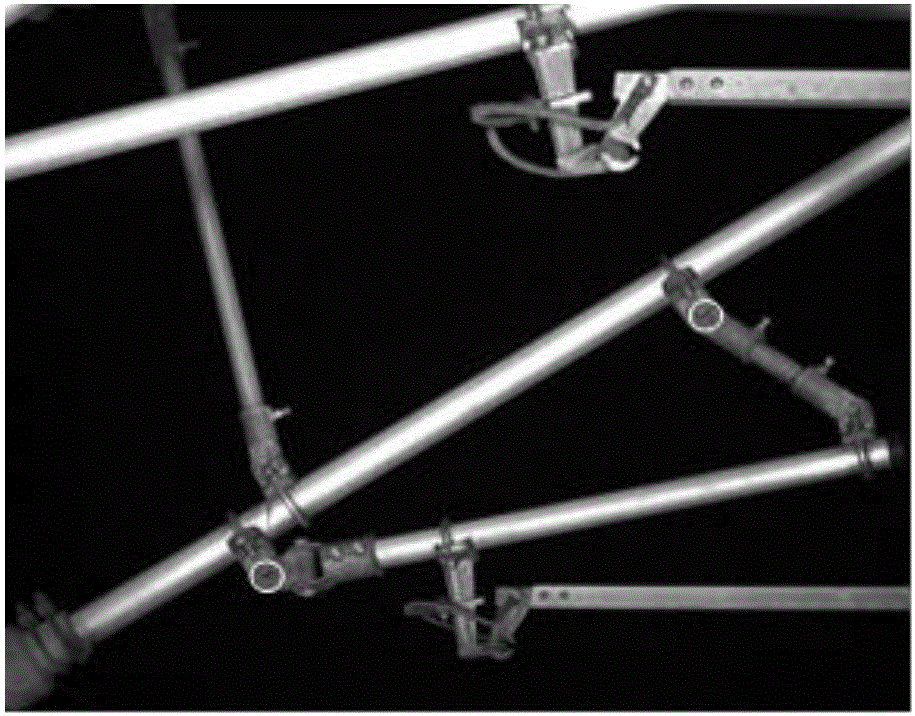

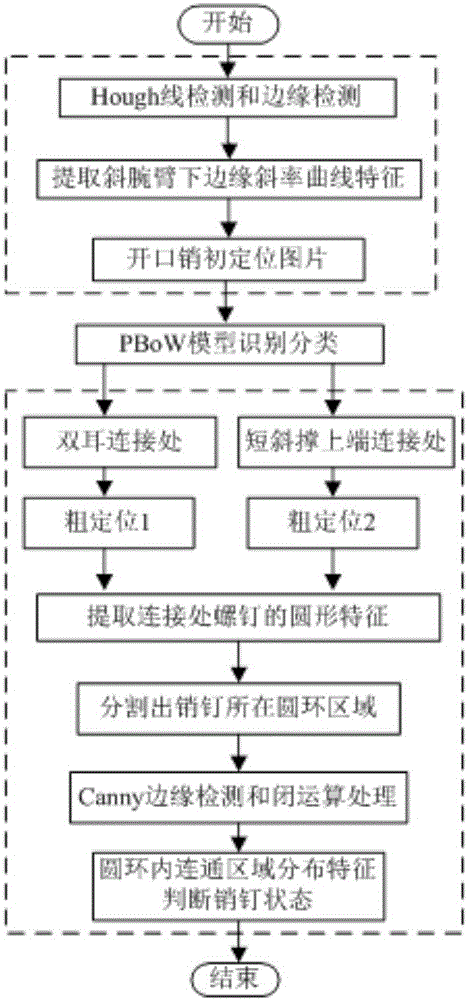

Adverse state detection method of transverse pins of rotation double lugs of high-speed rail overhead contact line equipment

InactiveCN106326894AAvoid defectsObjective detection and analysis resultsCharacter and pattern recognitionHough transformEngineering

The invention discloses an adverse state detection method of transverse pins of rotation double lugs of high-speed rail overhead contact line equipment. The method includes following steps: in a positioning stage, firstly, according to line characteristics of a connecting position at which a cotter pin is located and inclined cantilevers in an image, detecting lower edges of the inclined cantilevers by employing Hough transform and extracting slope characteristics thereof to realize primary positioning of the cotter pin, and then classifying primary positioning pictures by employing a PBoW model; and in a detection stage, performing coarse positioning by employing target geometric distribution characteristics, performing image enhancement by employing a Retinex method according to characteristics of small size, darkness, and weakness of the cotter pin, extracting a circular characteristic of a screw at the connecting position by employing a Hough accumulation matrix, realizing accurate extraction of a circular ring area in which the cotter pin is located, and finally giving detection criteria of deletion of the cotter pin and insufficient field angle according to a in-circular-ring non-communication area distribution rule. According to the method, positioning accuracy of the connecting position of double lugs and the connecting position of upper ends of short diagonal braces and fault detection of falling of the cotter pins and insufficient field angle are realized.

Owner:SOUTHWEST JIAOTONG UNIV

Memory card and semiconductor device

An antenna connection function for a noncontact interface is provided by suppressing a modification in a pin arrangement and a pin shape of a memory card that does not correspond to the noncontact interface. Two antenna connecting pins having the memory card are divided into two areas in which a size of one potential supply pin is the largest and used as a split pin arranged at intervals. Because a size of the two antenna connecting pins is at maximum as large as the size of the potential supply pin, the two antenna connecting pins are provided and the memory card that corresponds to the noncontact interface is obtained by devoting a pin area having the size of the one potential supply pin to the memory card that does not correspond to the noncontact interface. Accordingly, the pin area of the memory card that corresponds to the noncontact interface can be formed without departing from the pin area of the memory card that does not correspond to the noncontact interface.

Owner:RENESAS ELECTRONICS CORP

Automatic water discharge device

ActiveCN102128046ATo achieve the purpose of automatic dischargeDrainageGas removalWater dischargeEngineering

The invention provides an automatic water discharge device which comprises a shell, an end cover, a long guide rod, a water inlet device, a water discharge device and a ventilation device, wherein the end cover is arranged on the top of the shell; the water inlet device is positioned on the end cover and is communicated with the shell; one end of the long guide rod is arranged in a guide sleeve in a sliding way, and the other end of the long guide rod is provided with a plugging block; the guide sleeve is fixedly arranged at the bottom in the shell; the rod diameter of the long guide rod is sequentially and fixedly provided with a high-position cotter pin and is sheathed with a floating block in a sliding way; the water discharge device is arranged at the outer side close to the bottom ofthe shell, and is communicated with the shell; when the long guide rod rises, a water discharge switch device arranged on the long guide rod also rises along with the long guide rod, so that the water discharge device can be started; and when the water inlet device is plugged by the plugging block, a ventilation switch device arranged on the long guide rod is used for starting the ventilation device arranged on the end cover, so that the water can be automatically discharged. The automatic water discharge device realizes the aim of automatically discharging seepage.

Owner:HUAINAN MINING IND GRP

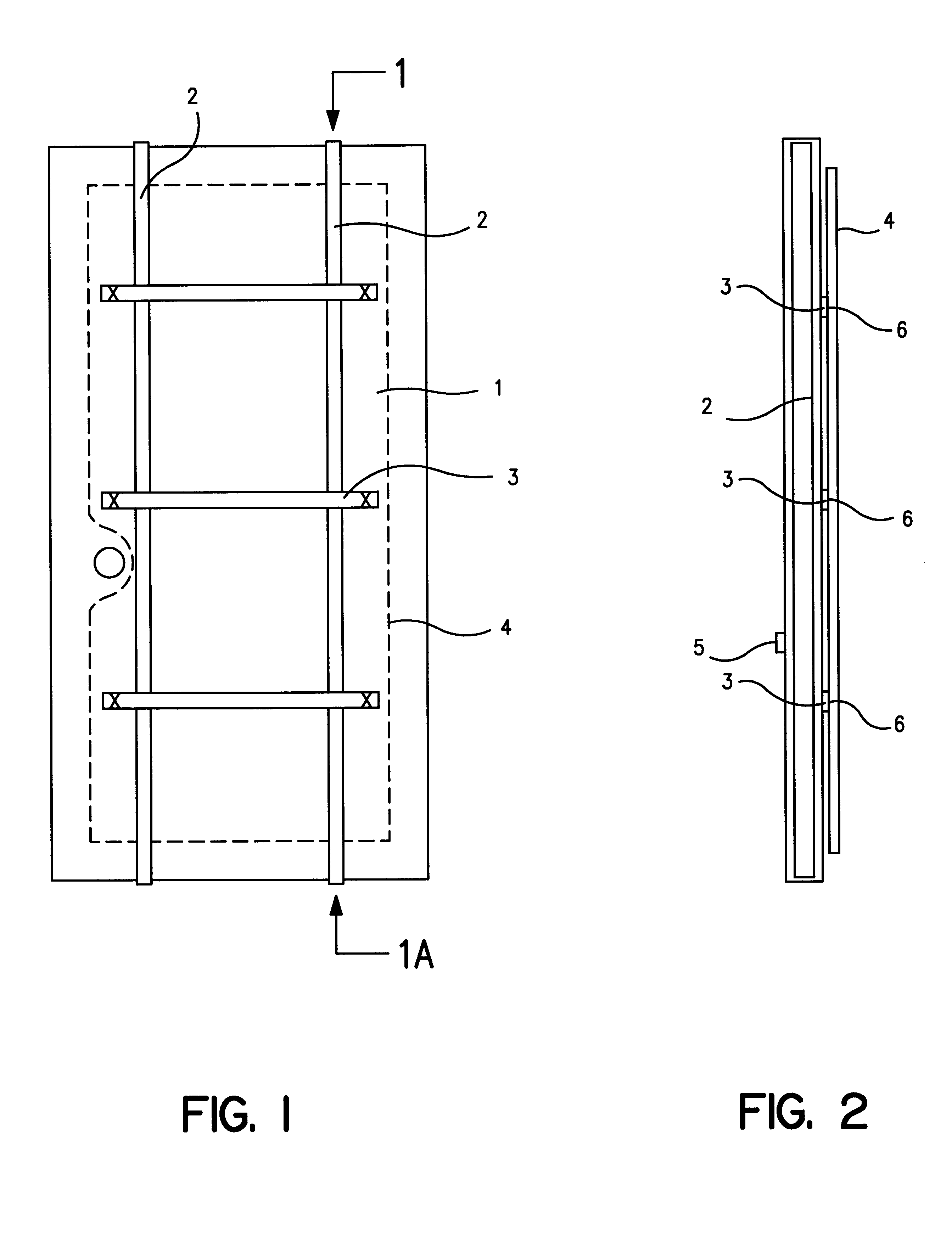

Method and apparatus for decorating doors

InactiveUS6367204B1Conveniently integrityConveniently removedDoor/window protective devicesDecorative surface effectsSplit pinDisplay device

Apparatus for displaying images on doors especially sectional overhead garage doors comprises a lattice of interconnected horizontal and vertical members removably attached to each horizontal door panel. The horizontal members are looped around the top and bottom of the panel and detachably joined at the back of the panel to form a complete loop. The horizontal members are held by removable attachment to the vertical members on the outer side of the panel using split pin connectors as a means of attachment. The pin connectors may also be used as an attachment point for lighting displays.

Owner:EICHLER DONALD LEWIS

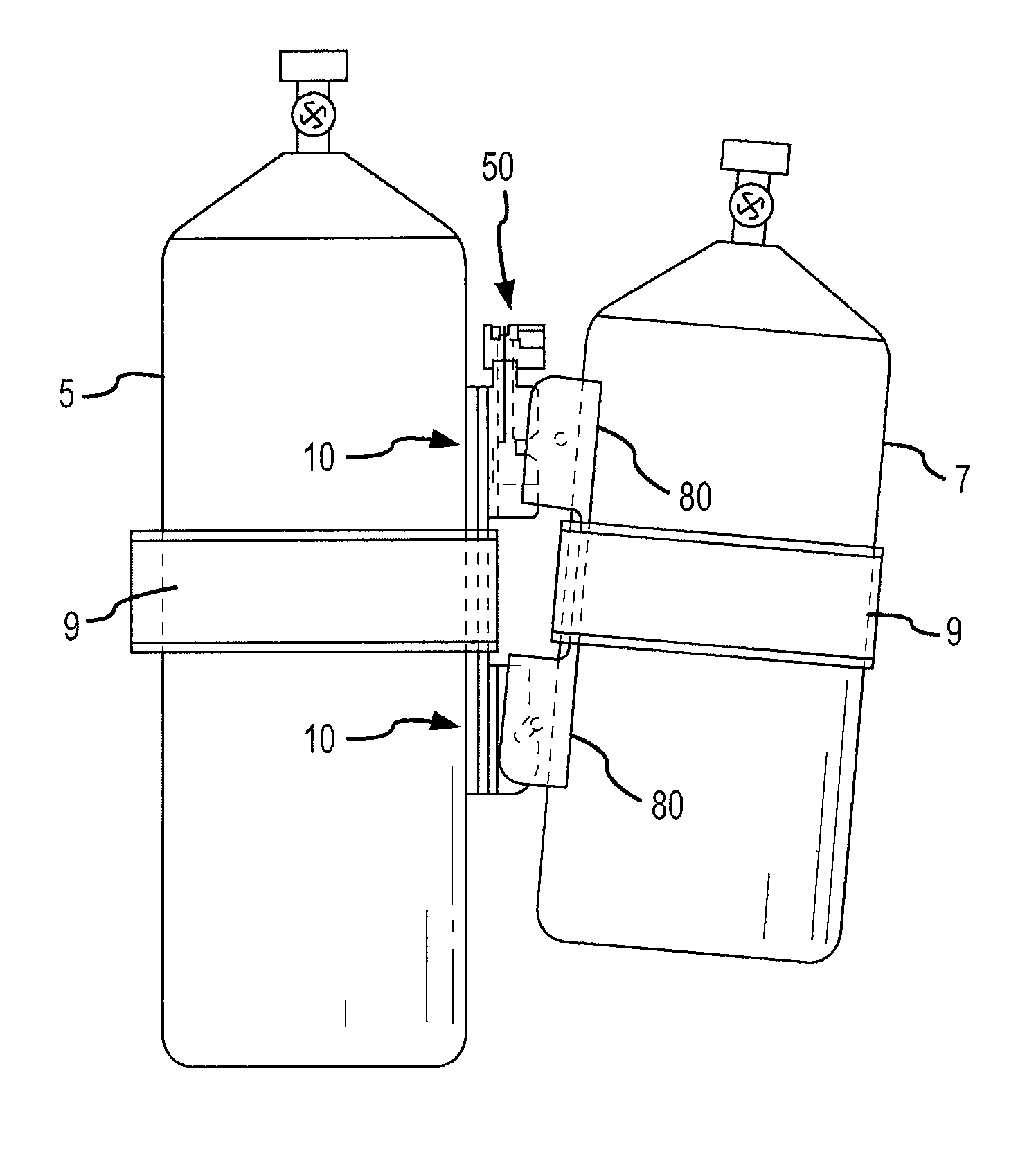

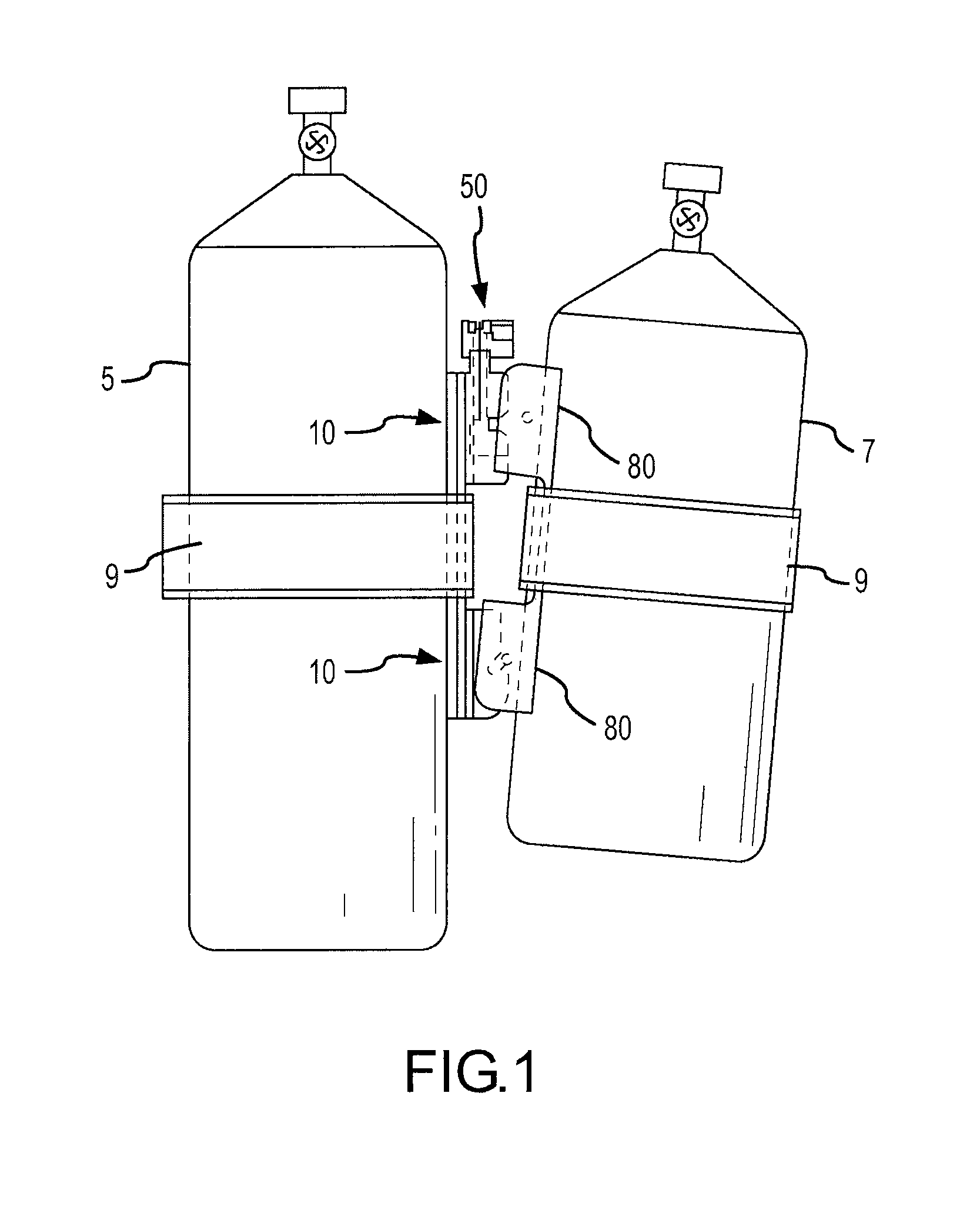

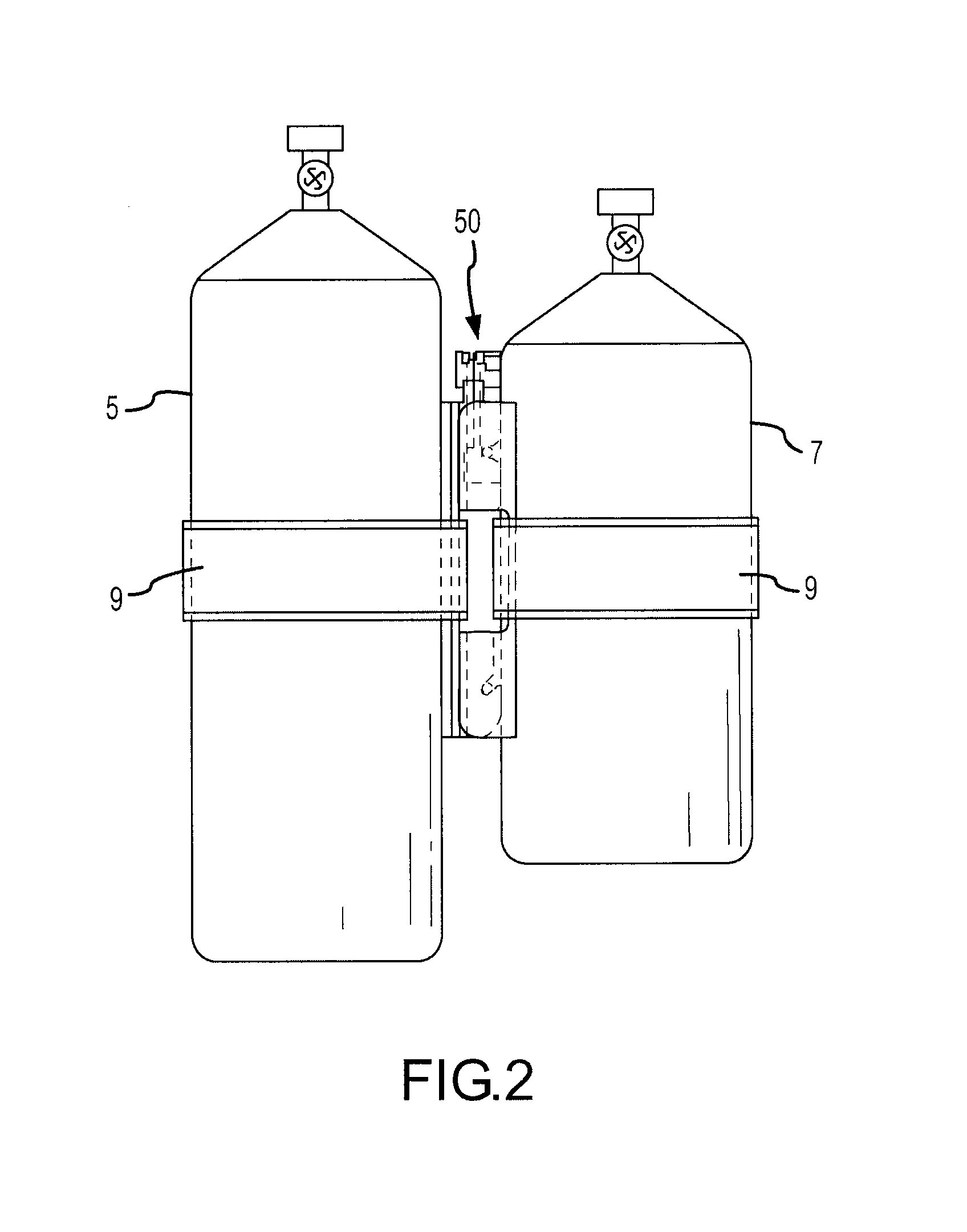

Release bracket system and method

An improved pony bottle bracket that is light weight, compact, simple to use, and facilitates a quick and easy set-up is disclosed. A push button latch enables a diver to quickly disconnect the pony bottle from the main bottle. The pony tank bracket and base unit bracket are mounted by use of a belt and adjustable band straps. The locking mechanism is self-contained, thereby eliminating or minimizing the use of separate components (e.g., no clevis, hitch, cotter or quick release pins) which may be lost. The bracket also eliminates or reduces the use of any items which may entangle the diver or entangle other objects in the diver's surroundings (e.g., no string, cord, chain or lanyards). The bracket is bidirectional (e.g., reversible) such that the top bracket mount may be rotated between about 0 and 180 degrees.

Owner:NORTH SOUTH MACHINE SHOP

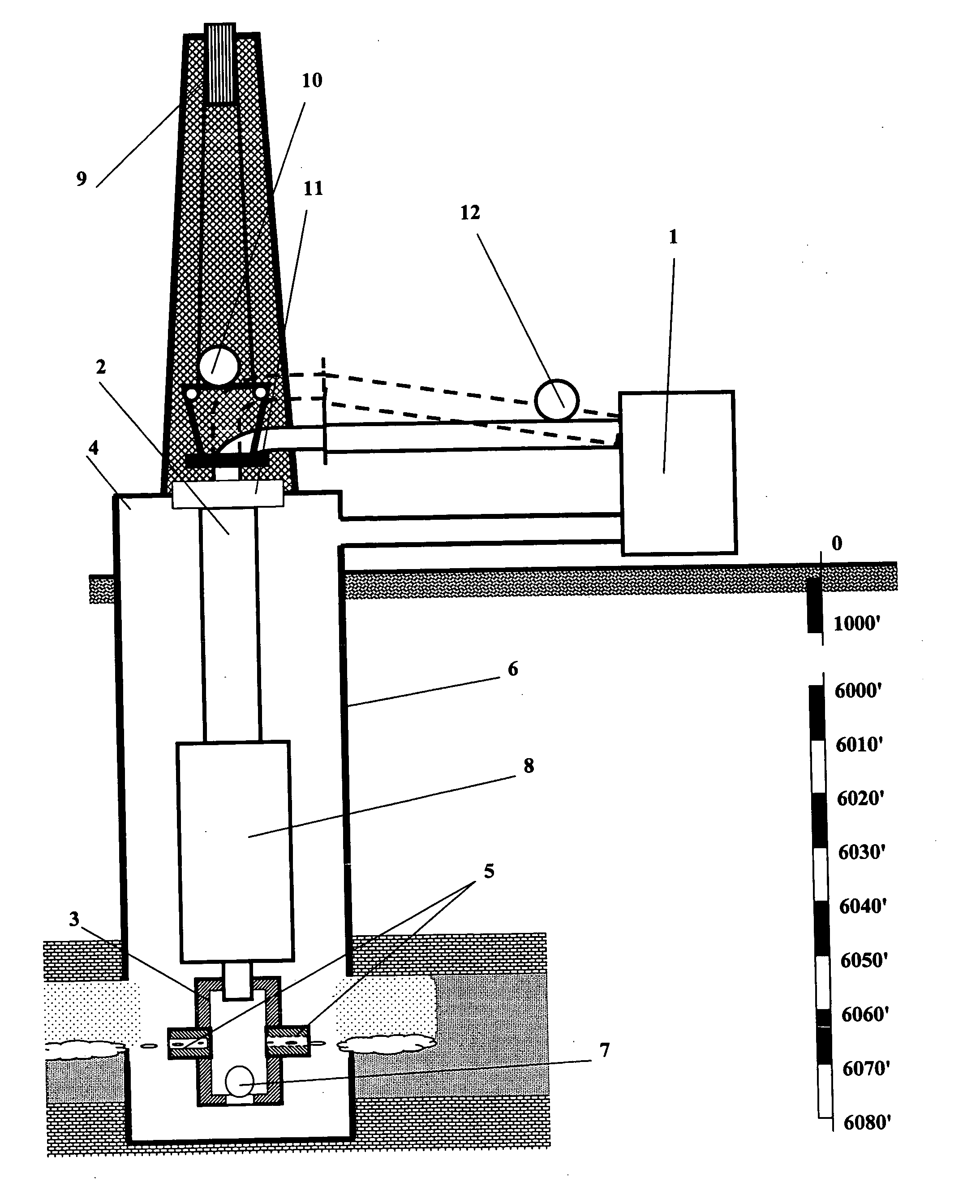

Device for cutting slot-shaped seats in wells by hydro-sandblasting method

This device relates to the fields of mining, specifically oil and gas industry, hydro-geological, geological engineering and water supply industries and is intended for cutting slot-shaped seats in well side zones of producing formation by hydro-abrasive blast. The determined task is solved by introducing essential changes into the known device for construction of cutting slot-shaped seats from the well wall inside the rock consisting of the hydro-abrasive jet generator connected with the perforator through the pump-and-compressor tubing string; the perforator is put into the casing pipe and has two diametrical nozzles which are directed at the well wall; there is a ball valve at the perforator end, as well as devices for adjustable partial unloading of PCS, PCS weight measuring device, abrasive jet pressure measuring device and the sealer for sealing of wellhead. The changes are as follows:—The perforator is directly connected with PCS;—A pin mounted under the perforator with possible axial movements is introduced;—A cylindrical retainer washer is put on the upper part of the perforator above nozzles; the washer is fixed so as to permit axial movement;—PCS indexing mechanism, step rings and a tripping muff are mounted bottom up and in alignment on the lower tube of PCS which is in series connected with the perforator;—At the same time the pin is connected with the cylindrical washer situated on the upper part of the perforator by control-rods with possible axial movement;—The indexing mechanism is put on PCS with the possibility of fixed coupling of its body with the casing pipe wall and split engagement of its body by step rings. Step rings are to be rigidly fixed on the lower PCS tube, and the tripping muff-on the PPS with its skirt down. At least a couple of rotary fluke-claws, with one end of each hingedly connected with the body of indexing mechanism, and the other end clasped to the casing pipe wall by spacer springs mounted between the indexing mechanism body and the fluke-flaw end, can be a variant of engagement of the indexing mechanism body with the casing pipe wall. At least a couple of spring-mounted pins installed on the interior surface of the indexing device body can be a variant of split engagement of the indexing mechanism by step rings. At that the pin heads are of round shape at the contacting end set against PCS. A muff with conical inside surface and the exterior of streamlined form can be a variant of tripping muff for forced tripping of the indexing mechanism from the casing pipe wall. The optimum distance between the step rings equals to one drain port diameter D±5%, and the number of rings has to amount to prescribed length of the slot-shaped seat divided by the drain port diameter D. At the same time adjacent drainage canals will unite and form a single slot-shaped seat. The recommended force for coupling of the split pin heads with PCS lies within the limits of 10-20% of PCS weight. The recommended force for coupling of the indexing device body with the casing pipe wall is in the range from 30% of PCS weight up to breaking strength point of the casing pipe.

Owner:DAVIDSON DRILLING

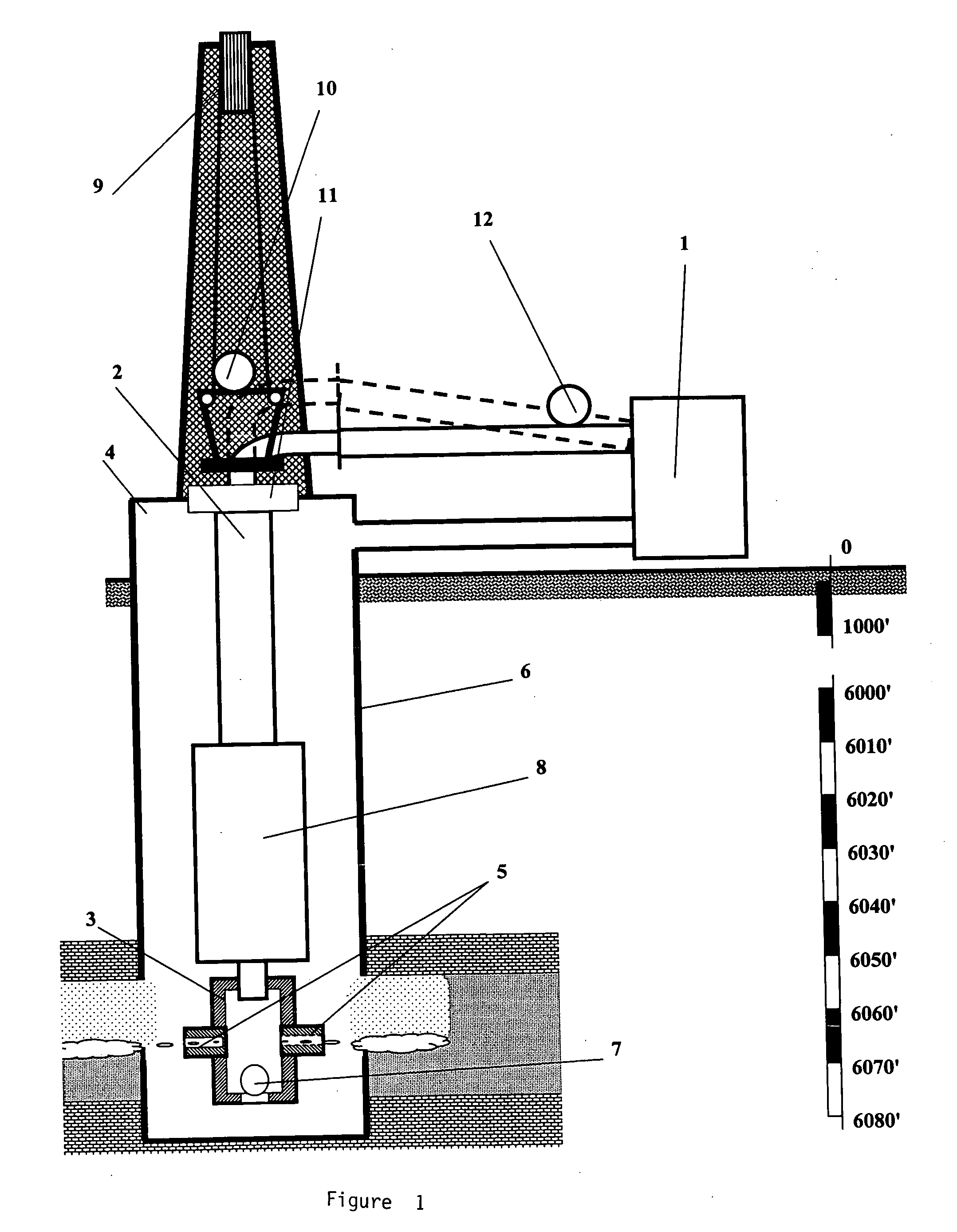

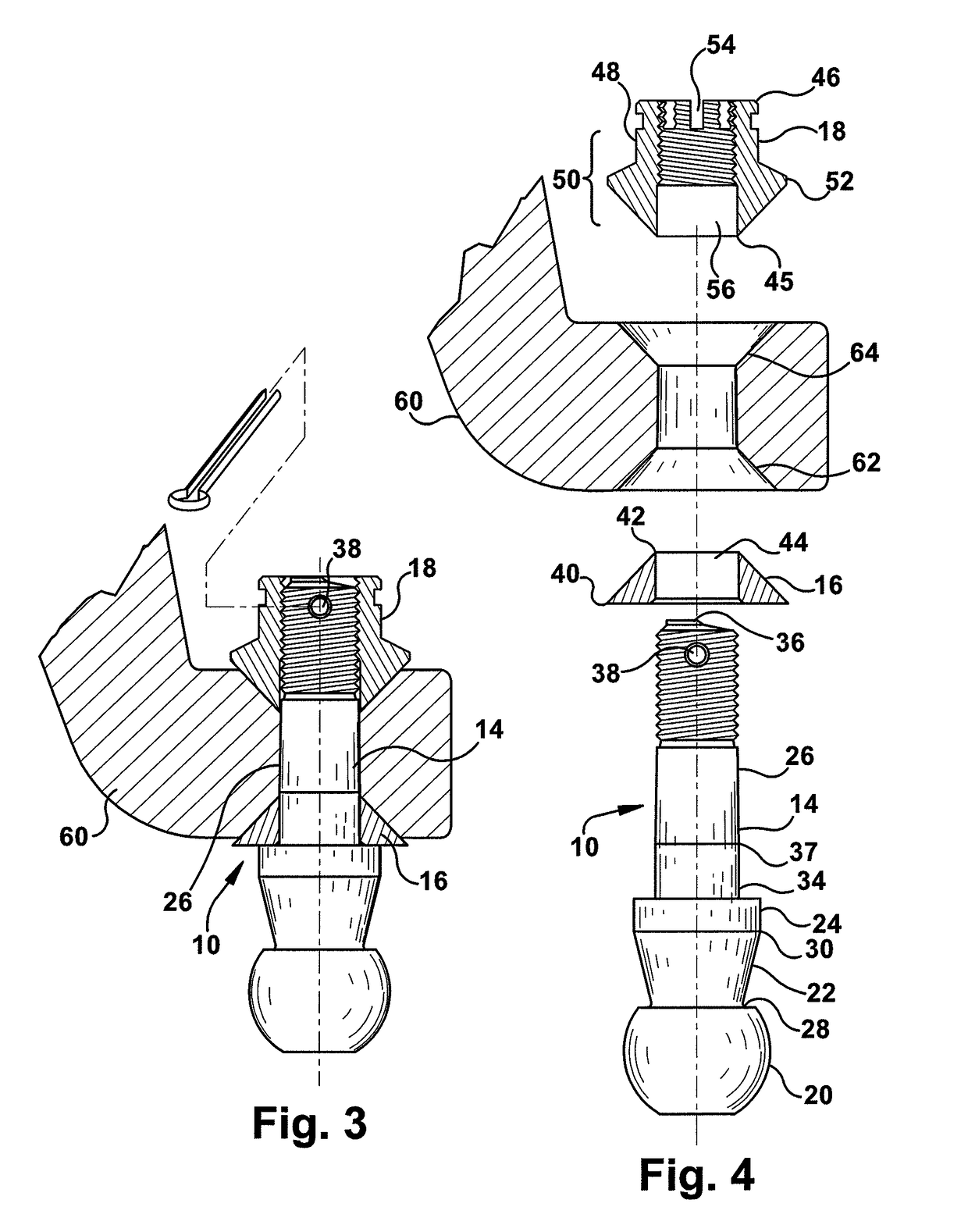

Ball stud system for use within a ball joint

ActiveUS20090103974A1Prevent rotationNot fail or loosen easilyYielding couplingSteering linkagesSplit pinBall joint

A ball stud system that provides a ball stud that will not loosen easily under the application of repetitive side loading on the ball portion of the stud. The ball stud is secured to the vehicle steering knuckle arm using the combination of a tapered nut and tapered washer. The tapered nut includes slots and the pin of the ball stud an aperture. A cotter pin may be placed through the slots and aperture in order to further prevent rotation of the nut.

Owner:HONDA MOTOR CO LTD

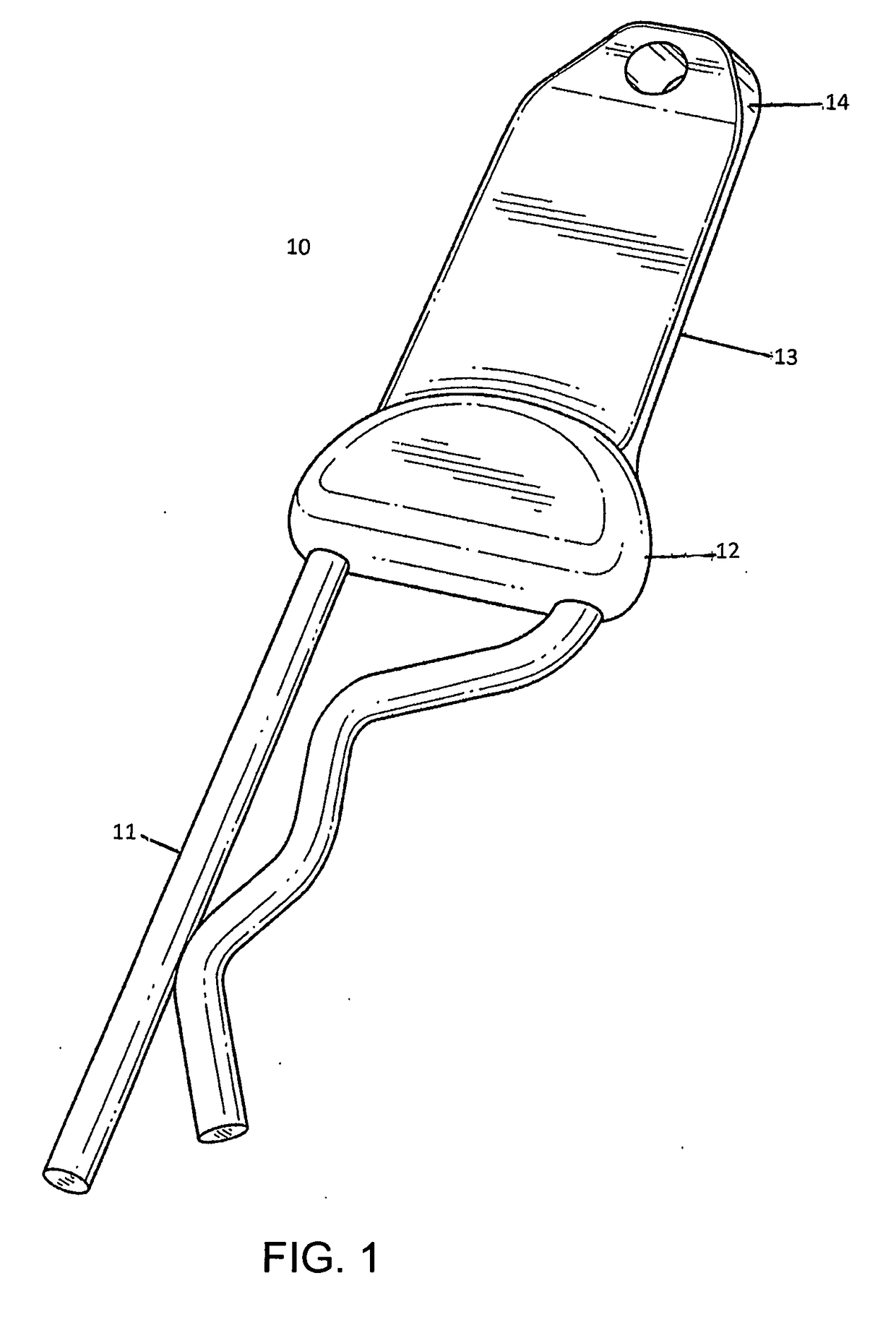

Simplified rear squeegee linkage for surface cleaning equipment

A rear squeegee linkage for surface cleaning equipment, which uses a pair of compliant bushings for improved shock absorption. The actuator is mounted with a pair of clevis pins and cotter pins, and may be replaced if needed without screwing or unscrewing any bolts or screws, or resetting any springs.

Owner:TENNANT COMPANY

Locking quick connect fitting

InactiveUS20150132044A1High breaking strengthReadily attached to and made modularVessel superstructuresRopes and cables for vehicles/pulleySplit pinModularity

A locking quick connect fitting allows for the easy attachment and detachment of stays and rigging on sailboats and other related applications. The invention eliminates the need to handle clevis pins and cotter pins when setting up or tearing down the rigging of a sailboat, and especially for the standing rigging of a trailer able sailboat. A more secure lockable device is provided that is less susceptible of being dislodged by the rubbing action of passing lines and sheets. Further, it can be tightened by wrench for even more security. In addition, the fitting helps keep the connection secure even if in the unlocked state and resists the snagging of passing lines. The presented invention is also designed to be modular and readily connectable to the rigging or fittings on existing sailboats.

Owner:TYLASKA TIMOTHY T +1

Carcass cutting methods and apparatus

Methods of automated meat processing including an end to end processing method in which carcasses are cut into major portions at a first robotic processing station and into minor portions at robotic processing sub-stations. In one processing method carcass portions are acquired by a robotic arm, imaged and then cuts performed without transfer. In another a first series of processing steps are performed by rotating carcass portions through a plurality of processing stations and a second series of processing steps are performed as carcass portions are advanced along a linear conveyor. In another processing method a plurality of clamps are employed to stabilize a saddle section during a flap cut. In another processing method split pins are used to position a saddle section for a vertebrae cut. In another method a spinal cord is removed by applying a pressurized fluid stream against one end of the spinal cord and applying suction at the other end of the spinal cord.

Owner:ROBOTIC TECH

Stacker crane body node-pin shaft connection mode and connection pin shaft

InactiveCN101428738ADoes not affect the import processSave high-strength metal materialsCranesSplit pinTower crane

The invention discloses a tower crane tower body section pin shaft connecting method and a connecting pin shaft, and belongs to the technical field of tower cranes. The the tower body section pin shaft connecting method comprises the following steps: arranging a tower body section tenon after an inner hole at the end part of a main branch; arranging a bumper pin in a bumper pin hole of an ear board; arranging the connecting pin shaft which has a lockpin groove end in a connecting hole of the main branch of the tower body section; causing the end part of the lockpin part of the connecting pin shaft to contact with the bumper pin; arranging the lockpin in a lockpin hole of the ear board to lock the connecting pin shaft, using a cotter lockpin to fix the lockpin; exiting from the bumper pin, and completing the connection of a pin shaft. The connecting pin shaft comprises a pin shaft main body, an introducing part and a lockpin part, wherein, the introducing part is positioned between the pin shaft main body and the lockpin part; the lockpin groove used for fixing the lockpin is formed on the lockpin part along a circumference direction. The lockpin groove is formed on the connecting pin shaft of the invention and is free from the direction restrain during the lockpin process; and the introducing part is positioned between the connecting pin shaft main body and the lockpin groove, thereby causing the lockpin groove not to influence the introducing process of the connecting pin shaft. The invention has the advantages of convenient installation and detachment.

Owner:SHENYANG JIANZHU UNIVERSITY

Ball stud system for use within a ball joint

ActiveUS9643645B2Prevent rotationNot fail or loosen easilyYielding couplingSteering linkagesSplit pinEngineering

A ball stud system that provides a ball stud that will not loosen easily under the application of repetitive side loading on the ball portion of the stud. The ball stud is secured to the vehicle steering knuckle arm using the combination of a tapered nut and tapered washer. The tapered nut includes slots and the pin of the ball stud an aperture. A cotter pin may be placed through the slots and aperture in order to further prevent rotation of the nut.

Owner:HONDA MOTOR CO LTD

Integrated lifting apparatus

An integrated lifting apparatus for attaching a sling or other lifting means to a load having an upright and substantially hollow post. A bore is provided near the upper extent of such hollow post, said bore extending horizontally through said hollow post. A threaded bolt having an enlarged head on one end, preferably constructed of high strength and / or shear resistant material, is disposed through said bore. A lock nut having an outer diameter greater than the diameter of said bore is threaded onto the end of said bolt. If desired, a cotter pin can also be used to secure such lock nut on said bolt.

Owner:SEGURA VICTOR JOSEPH

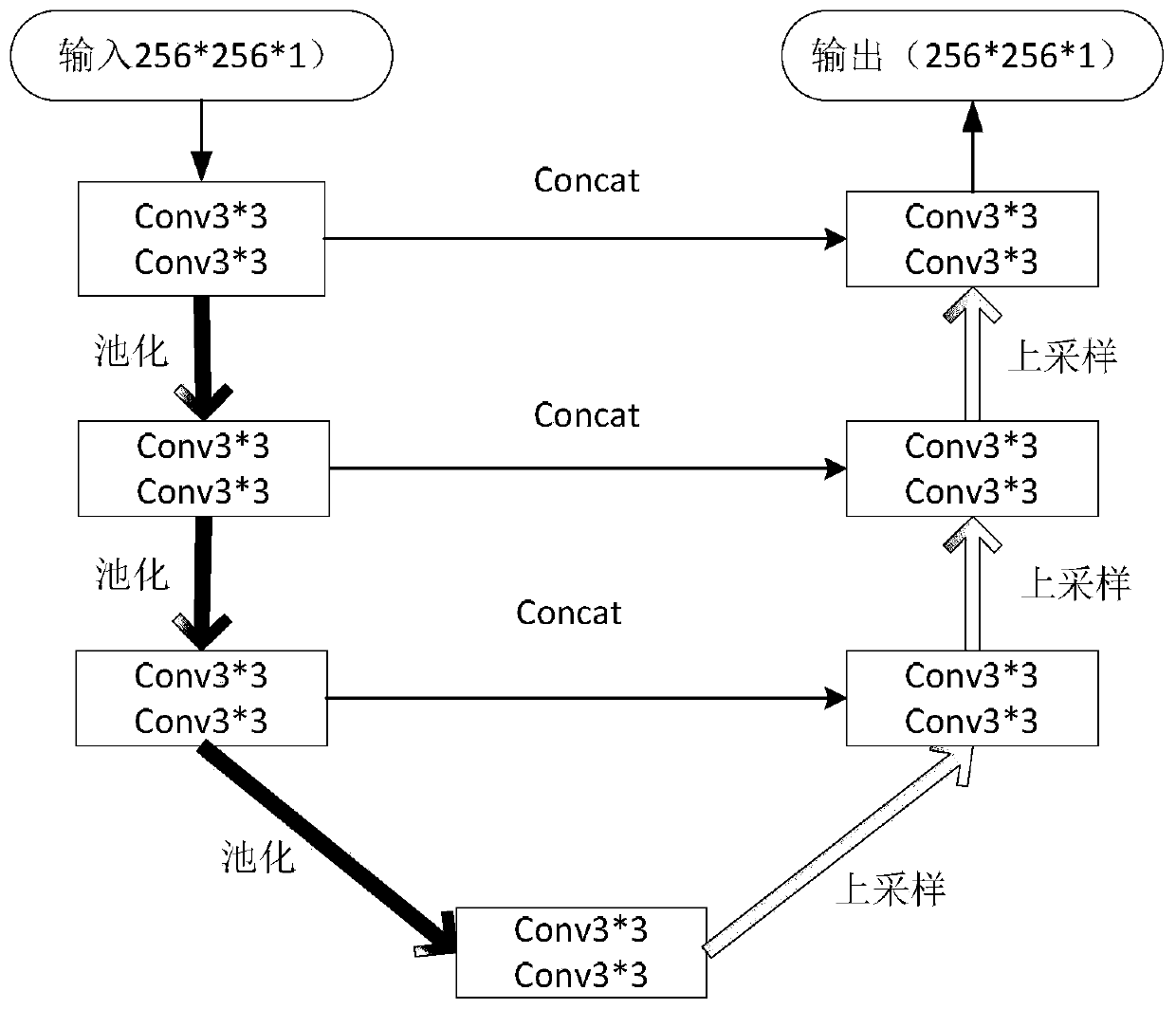

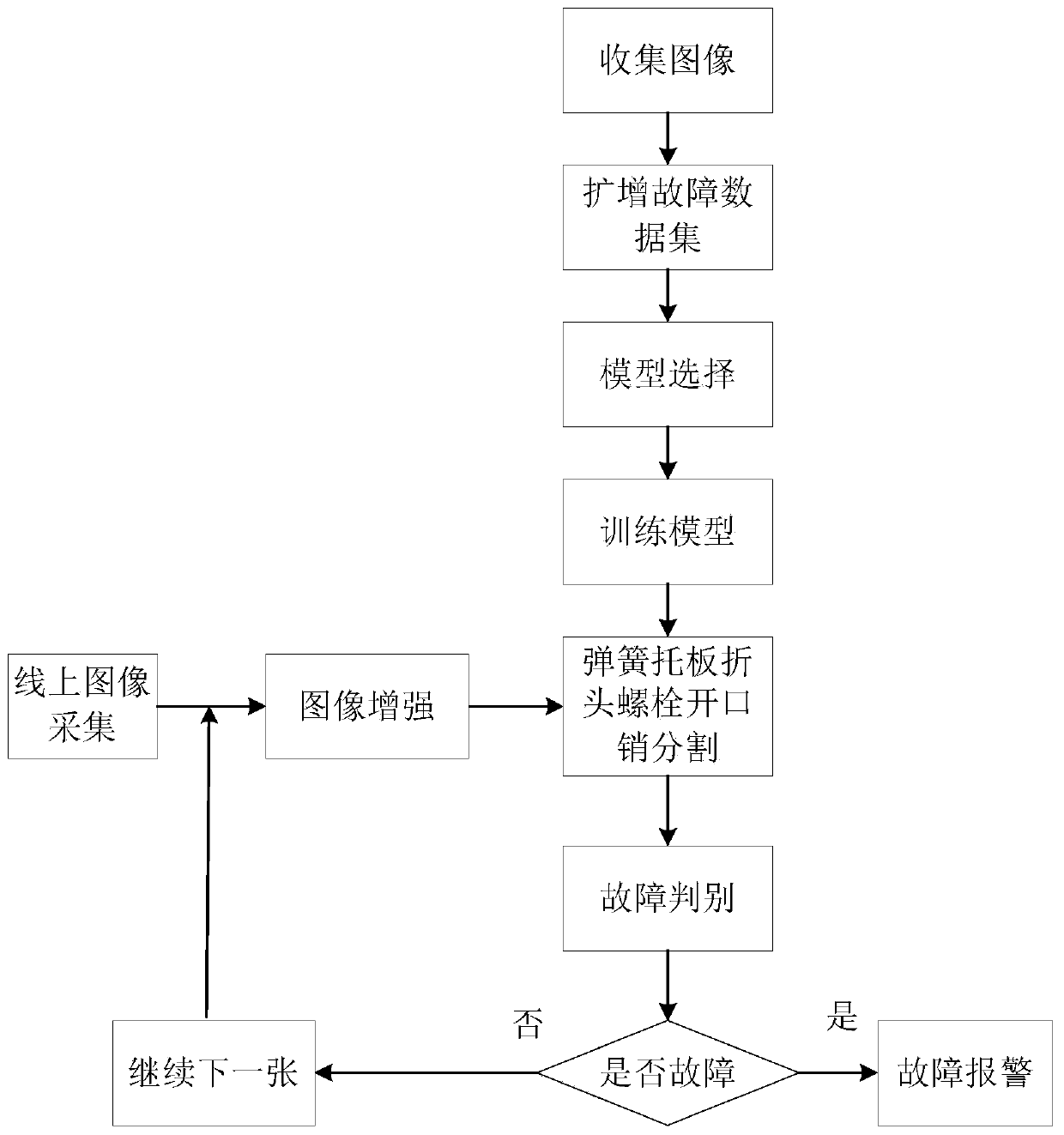

Fault identification method for cotter pin on spring supporting plate of railway wagon

The invention discloses a fault identification method for a cotter pin on a spring supporting plate of a railway wagon, solves the problem that missing detection is easily caused when cotter pin lossfault detection is carried out by adopting a manual image observation mode, and belongs to the field of railway wagon fault identification. The method comprises the steps: collecting images on the twosides of a rail wagon, and constructing a sample set; inputting the images in the sample set into a U-Net segmentation network for training, and obtaining a segmentation model, wherein the U-Net segmentation network is used for reducing two convolution and down-sampling of a first layer and two convolution and up-sampling of a last layer on the basis of an existing U-Net network, and changing thenumber of feature maps of each layer into half of the original number; inputting a to-be-detected railway wagon image into the segmentation model, and obtaining a segmentation region of the cotter pin; carrying out fault analysis on the segmentation area, judging whether the cotter pin is lost or not, if yes, judging that the cotter pin is lost, and giving an alarm for the lost cotter pin.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

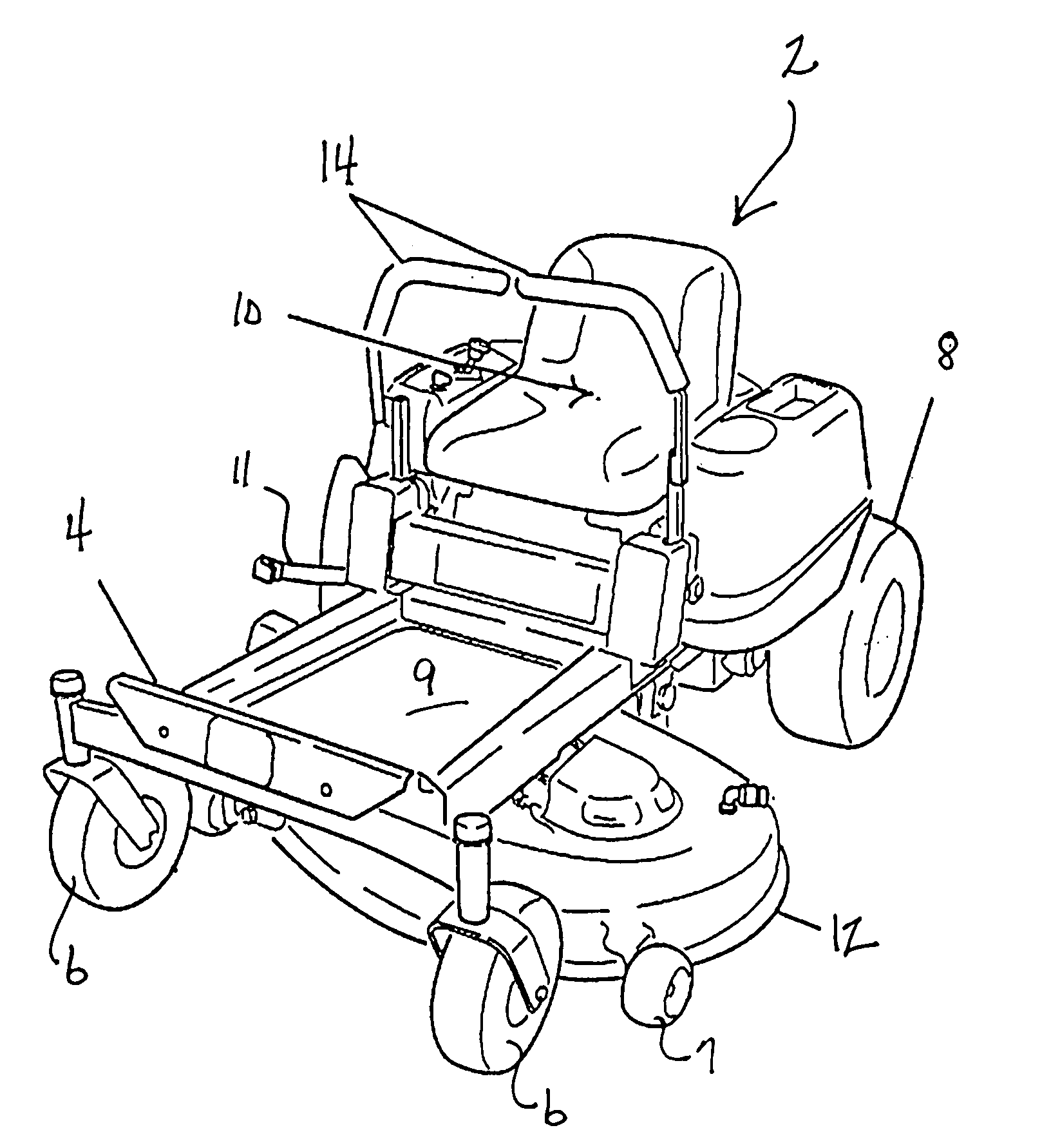

Easily removable mower cutting deck

A rotary cutting deck is suspended from the frame of a lawn mower to hang beneath the frame of the mower between the front and rear ground engaging wheels of the mower. A single front pull arm is pinned by a pivot pin to the front of the cutting deck. This pivot pin can be easily released and pulled by removing a single hairclip pin or cotter pin. The rear of the cutting deck is hung by two downwardly facing suspension hooks onto the cross rod of a pivotal hanger. After the front pull arm is disconnected from the front of the cutting deck, the operator lifts up the rear of the cutting deck to unhook the suspension hooks, pulls the cutting deck slightly rearwardly, and then lowers the cutting deck to the ground to allow the cutting deck to be slid out from underneath the mower after also removing any deck drive belt or similar cutting blade drive system. This can be easily and quickly done.

Owner:TORO CO THE

Connector assembly for mounting lighting fixture

InactiveUS20170051905A1Easy to installReduce associated installationLighting support devicesElectric circuit arrangementsSplit pinPhysics

Provided is a lighting assembly comprising a pin end connector and a knuckle end connector. The pin end connector includes a protrusion having at least one wall and a rotational fastener configured to be received through and retained by the wall. The knuckle end connector includes a discontinuous seat having a first opening configured to receive the protrusion and a second opening configured to receive the rotational fastener. The pin end connector is configured to be received by the knuckle end connector and pivotally rotate to attach the first connector assembly with the second connector assembly. Also provided is a method for joining the pin end connector with the knuckle end connector.

Owner:GE LIGHTING SOLUTIONS LLC

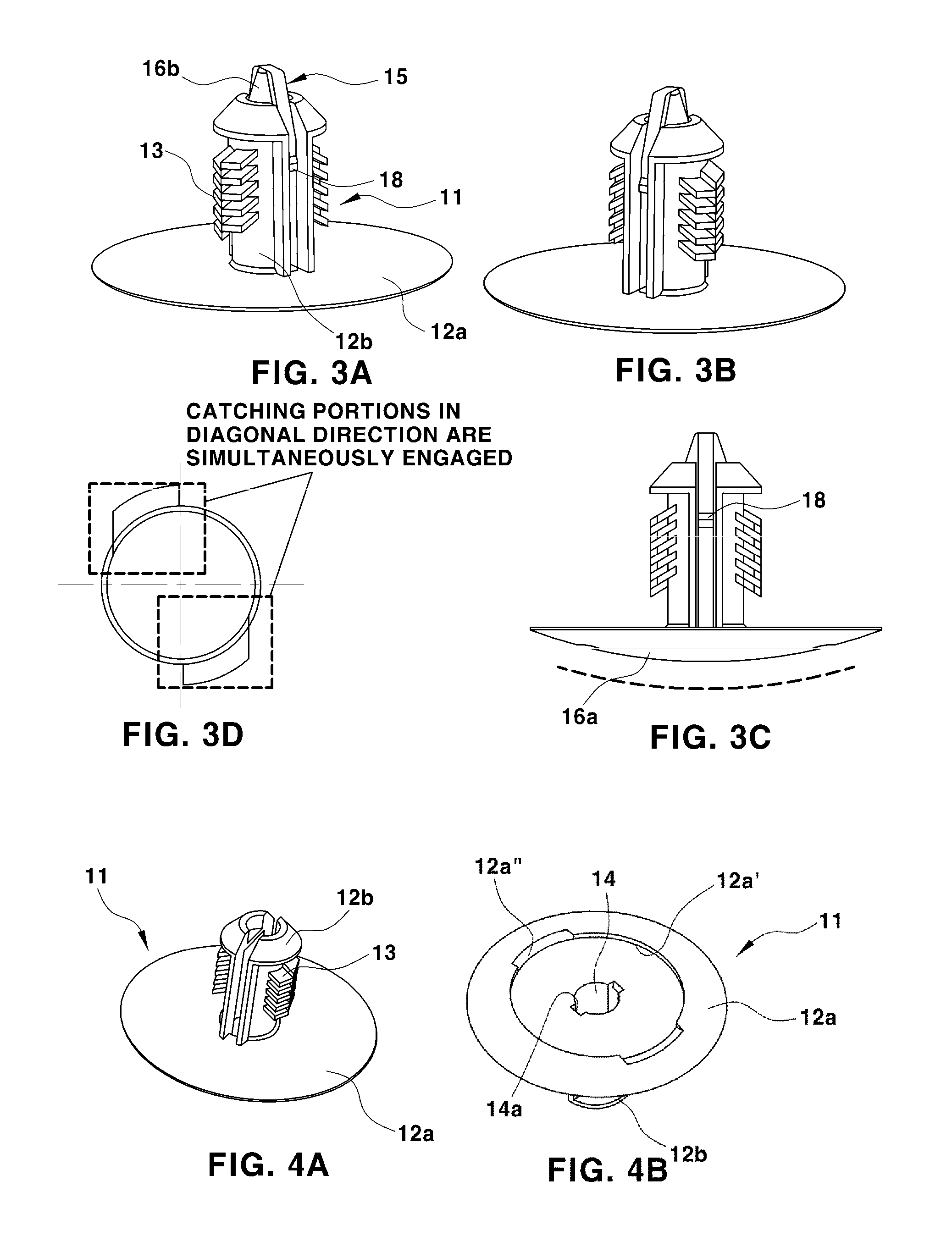

Fastener for vehicle

A fastener for a vehicle may include an outer piece and an inner piece. The outer piece may include two split pin portions that are spaced apart and are elastically deflectable and retractile, and a plurality of catching portions that is arranged on an outer surface of each of the split pin portions in a longitudinal direction of the outer piece to perform an engagement action in fastening holes of a component and a panel. The inner piece may include a pin portion that is to be longitudinally inserted into a space formed by the spaced two split pin portions. The pin portion of the inner piece may deflect the two split pin portions outward in a state in which the pin portion is inserted into the space formed by the spaced two split pin portions of the outer piece so that the catching portions are engaged in the fastening holes, thus fastening the component and the panel.

Owner:HYUNDAI MOTOR CO LTD

Laser centering measure system and centering measure method thereof

ActiveCN104251695AEasy to measureEfficient measurementActive open surveying meansNuclear monitoringSplit pinDiagonal

The invention discloses a laser centering measure system and a centering measure method thereof. The system comprises a lower centering tool, an upper centering tool and a laser tracker; the lower centering tool is installed on two fuel guiding pins diagonally distributed on a lower reactor internals through two lower pin positioning holes on the lower centering tool, and is used to perform centering measure through a lower measure hole on the lower centering tool; the upper centering tool is installed at two split pin holes on an upper reactor core plate on an upper reactor internals through two upper pin positioning holes on the upper centering tool, and is used to perform centering measure through an upper measure hole on the upper centering tool; the laser tracker is installed inside a reactor cavity formed by the upper reactor internals and the lower reactor internals, and the laser tracker, the upper reactor internals and the lower reactor internals are at a same horizontal state; 3D measure is performed on the upper measure hole and the lower measure hole by utilizing a three-dimension figure measure software in the laser tracker, so that the measure data of all preset measure positions of the upper reactor internals and the lower reactor internals is obtained; and a reference coordinate system of the reactor internals is established for analyzing and analyzing the measure data, so that a centering measure result on the reactor internals is obtained.

Owner:上海第一机床厂有限公司

Pin assist devices, hitch pins, and hitch pin assemblies

Owner:TRUCK SHIELDS LLC

Wheel hub

InactiveUS20100320830A1Decreases mass weightDecreases static weightHubsSpoked wheelsMoment of inertiaEngineering

A hub for a wheel having a low mass and low moment of inertia includes a tubular body with a bore having, and three radially-extending arms that terminate with a tab. The hub is adapted for mounting on the radial flange of a wheel rim. The arms are space 120 degrees apart and extend from the body tapering from a relatively thick and wide portion to a relatively narrow and thin portion. A bore in the tab receives a fastener for securing the tab to the flange. Mounting hardware including spacers, bearings, O-rings, and an oil seal are secured within the body bore for mounting the hub onto the spindle of a vehicle steering mechanism. A hub nut and cotter pin secures the hub to the spindle. A center cap covers the open end of the body. The hub may optionally include three flanges for mounting a brake rotor.

Owner:WELD RACING

Cotter Pin Assist Device

Owner:TRUCK SHIELDS LLC

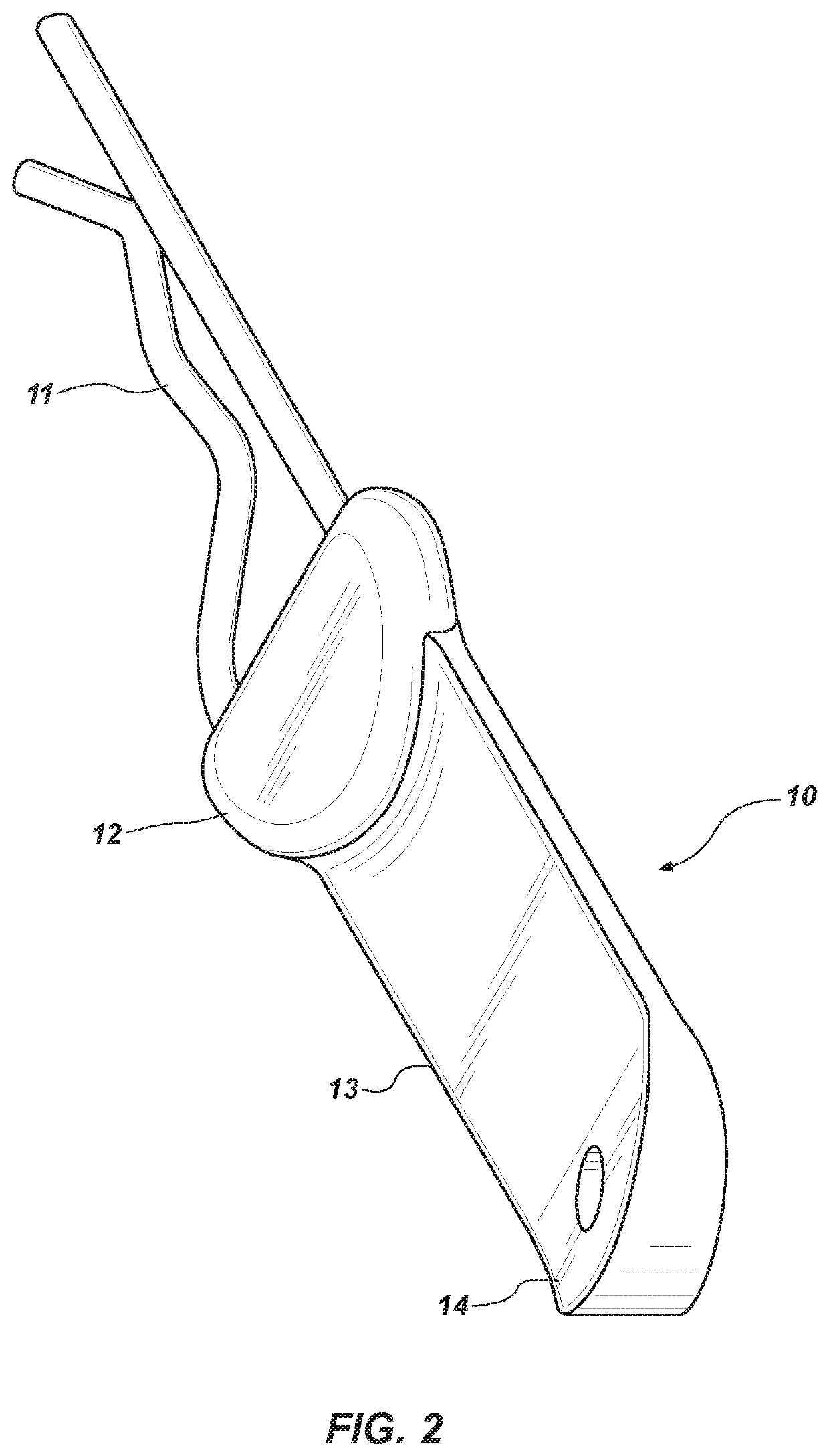

Latch apparatus for portable electronic devices

InactiveUS20080021634A1Easy to installSufficient withstandInstruments for road network navigationRoad vehicles traffic controlSplit pinDisplay device

The latch apparatus for portable display devices has a pin portion and an actuator. The latch apparatus has an opening into which the pin portion is inserted to secure the display device in a device mount. The actuator applies force to release the pin to remove the display device from the device mount. Both the actuator and the pin portion have ramps that are designed to make contact with each other and slide as force is exerted to the actuator. Due to the ramps, the pin portion moves to withdraw from the opening of the display device as force is applied to the actuator. Biasing means maintains the position of the pin such that the pin portion securely holds the display device in the device mount unless the actuator is pressed for releasing the pin portion.

Owner:ALPINE ELECTRONICS INC

Dual-connection type tower crane foundation

ActiveCN103015453AImprove deformation resistanceImprove bearing capacityFoundation engineeringSplit pinArchitectural engineering

The invention relates to the technical field of tower crane equipment, in particular to a dual-connection type tower crane foundation. The dual-connection type tower crane foundation is characterized in that a fastening device is arranged between a main concrete foundation unit and transitional concrete foundation units as well as between the transitional concrete foundation units and end concrete foundation units and comprises locking lug plates, connecting lug plates, connecting bolts, connecting pin shafts, cotter pins and positioning nuts; two sides of two ends of the transitional concrete foundation units are respectively connected with the locking lug plates, the connecting lug plates are connected around the main concrete foundation unit, the inner ends of the end concrete foundation units corresponding to the locking lug plates on two sides of the transitional concrete foundation units are respectively connected with the connecting lug plates, one ends of the connecting bolts penetrate through connecting through holes on the connecting lug plates and connecting blocks through the connecting pin shafts and are fixedly connected with the cotter pins, and the other ends of the connecting bolts penetrate through gaps in the middle of the locking lug plates to fixedly contact with the locking lug plates via the positioning nuts. The dual-connection type tower crane foundation has the advantages of novel structure, high safety, convenience in mounting, demounting and transporting and the like.

Owner:相起兵

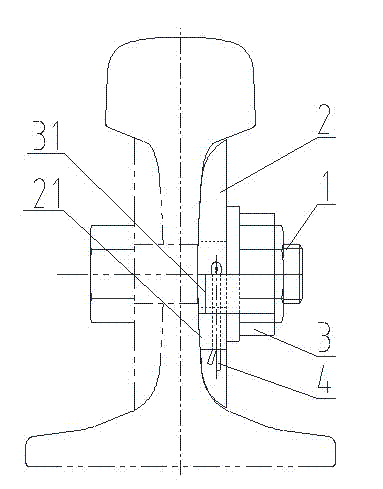

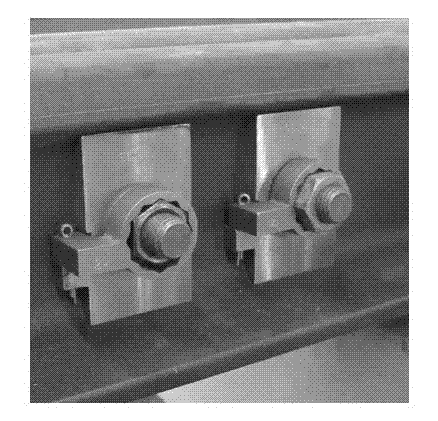

Nut anti-loosening mechanism special for railway turnout

The invention relates to a nut anti-loosening mechanism special for a railway turnout. A steel rail gasket is fixedly installed at a steel rail web through a bolt and a nut, and an anti-rotating gasket which is installed on the bolt and the nut in a sleeved mode is connected with the steel rail gasket through a split pin, so that the nut is prevented from rotating in the loosening direction to achieve a self-locking function. The nut anti-loosening mechanism has the advantages that the mechanical type bolt and nut anti-loosening mechanism is simple in structure and convenient to operate, the problem that bolts and nuts are prone to loosening, which troubles a turnout work maintenance department for a long time is effectively solved, in the maintenance or after disassembling adjusting, the bolts and nuts can be continuously used, and turnout cost is greatly reduced; contributions are made to durability, safety and few maintenance of the railway turnout; the mechanism is obvious in anti-loosening effect, the maintenance load of the turnout work maintenance department can be reduced substantially, and the mechanism is adaptive to needs of railway rapid development.

Owner:CHINA RAILWAY BAOQIAO (NANJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com