Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23071results about "Lifting devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

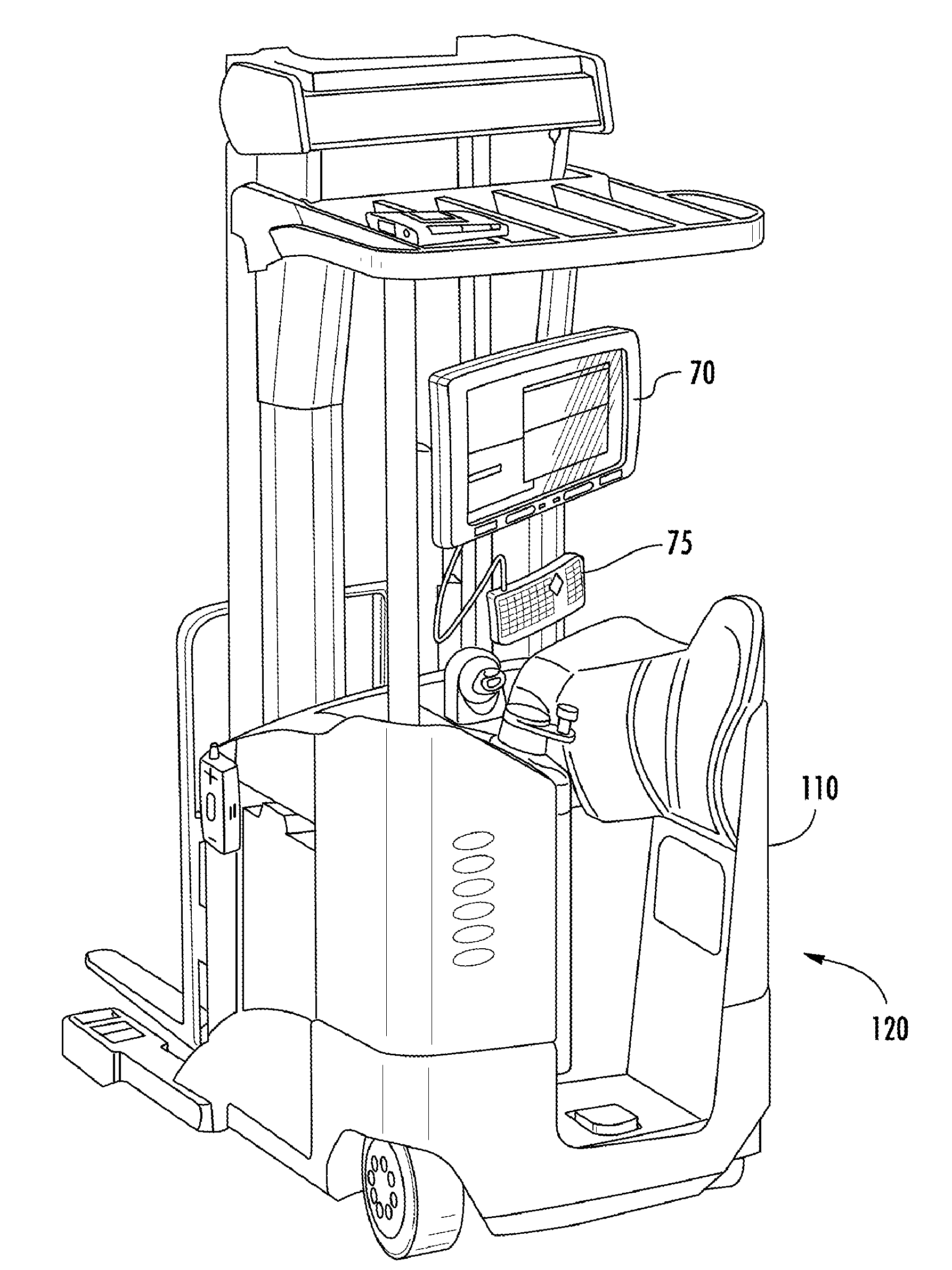

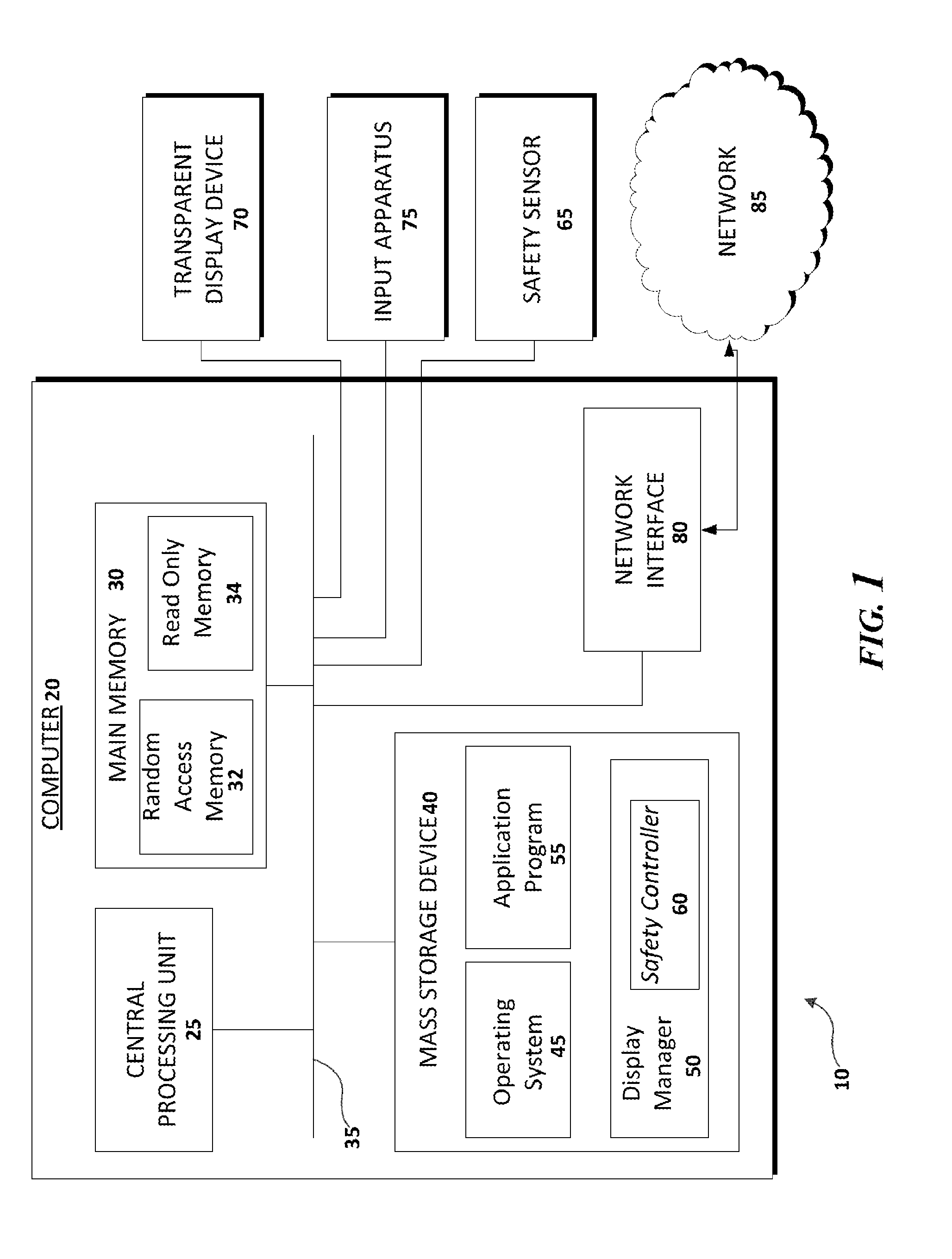

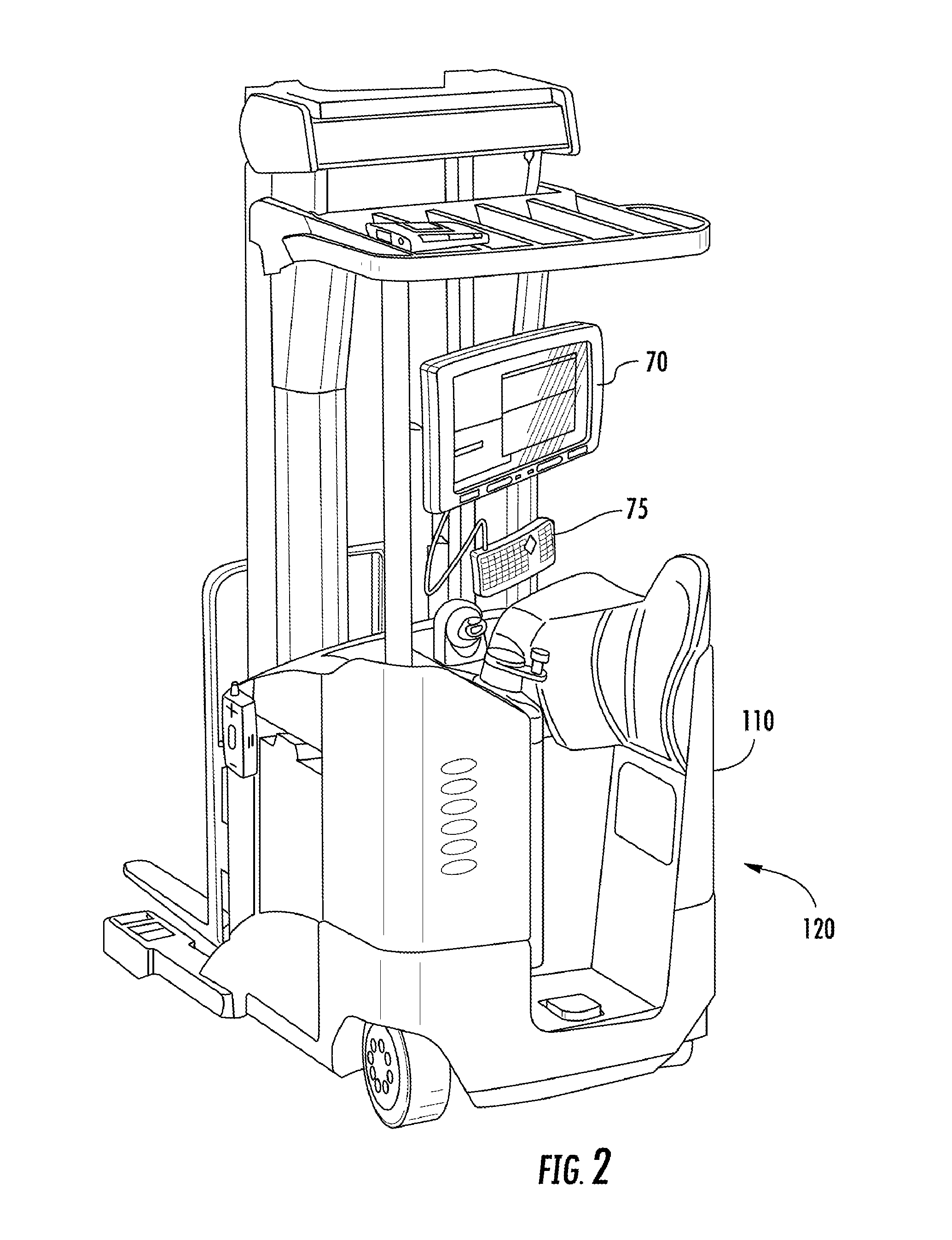

Vehicle computer system with transparent display

ActiveUS20140114530A1Good operating visionImprove visibilityRoad vehicles traffic controlDigital data processing detailsComputerized systemEngineering

The invention relates to a vehicle computer system. The vehicle computer system gathers data from a safety sensor to determine whether the proper safety conditions are present for the vehicle operator to interact with the vehicle computer system. A safety controller receives safety condition data gathered from the safety sensor and instructs the display manager to disable the display of information to the vehicle operator during unsafe operating conditions. The vehicle computer system advantageously employs a transparent display screen to provide greater field of vision of the vehicle operator than could be provided by a traditional display screen.

Owner:HAND HELD PRODS

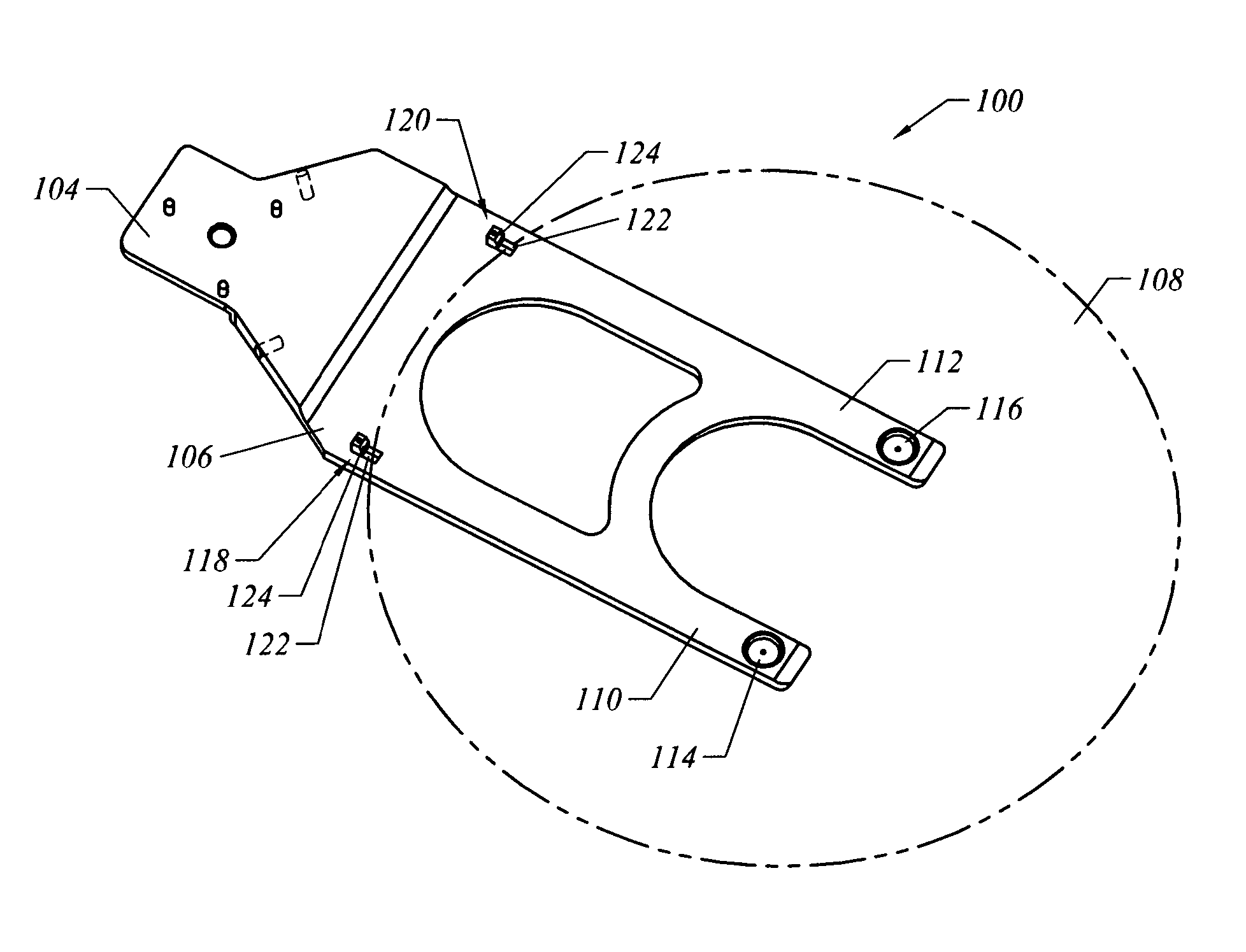

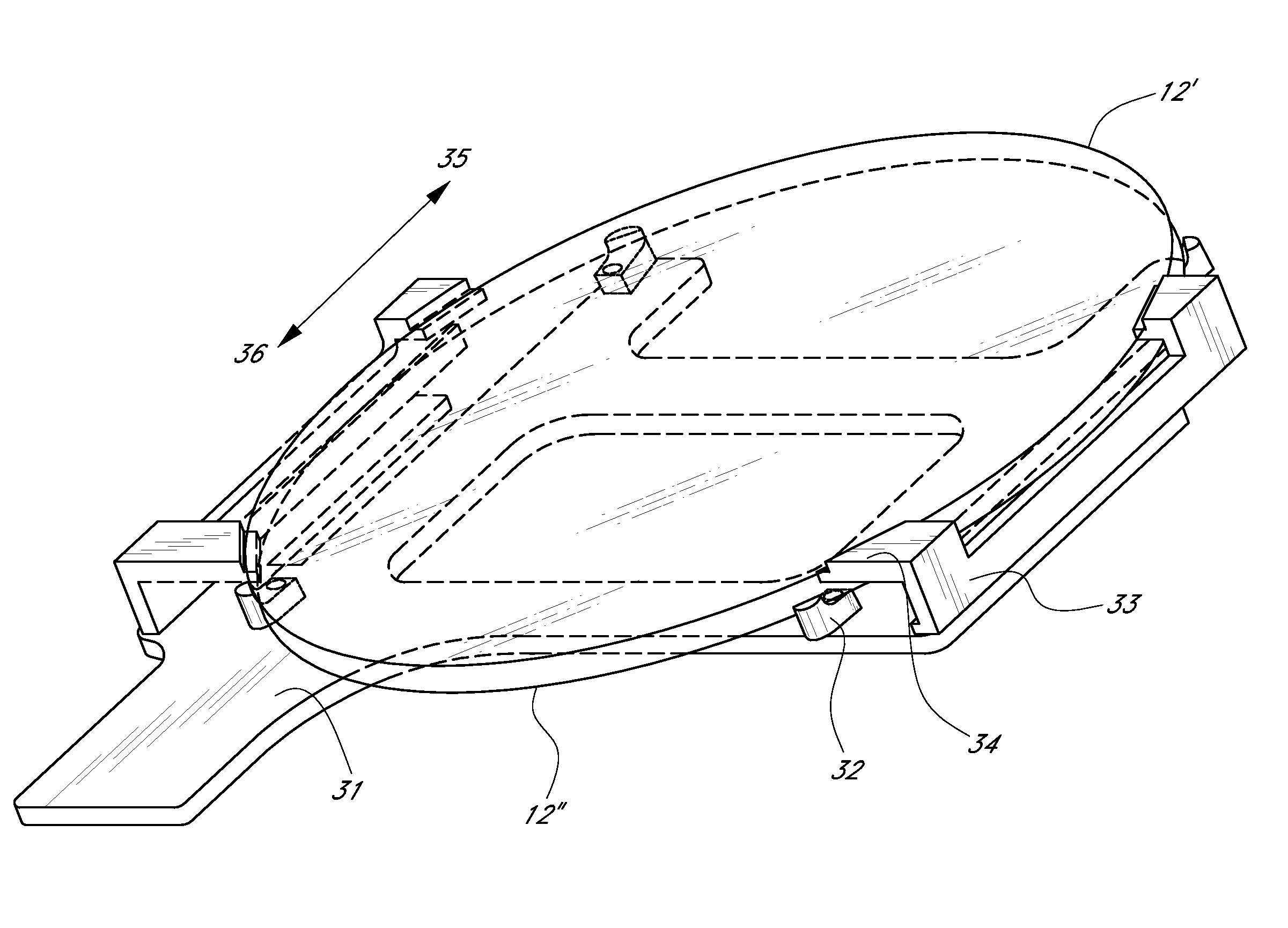

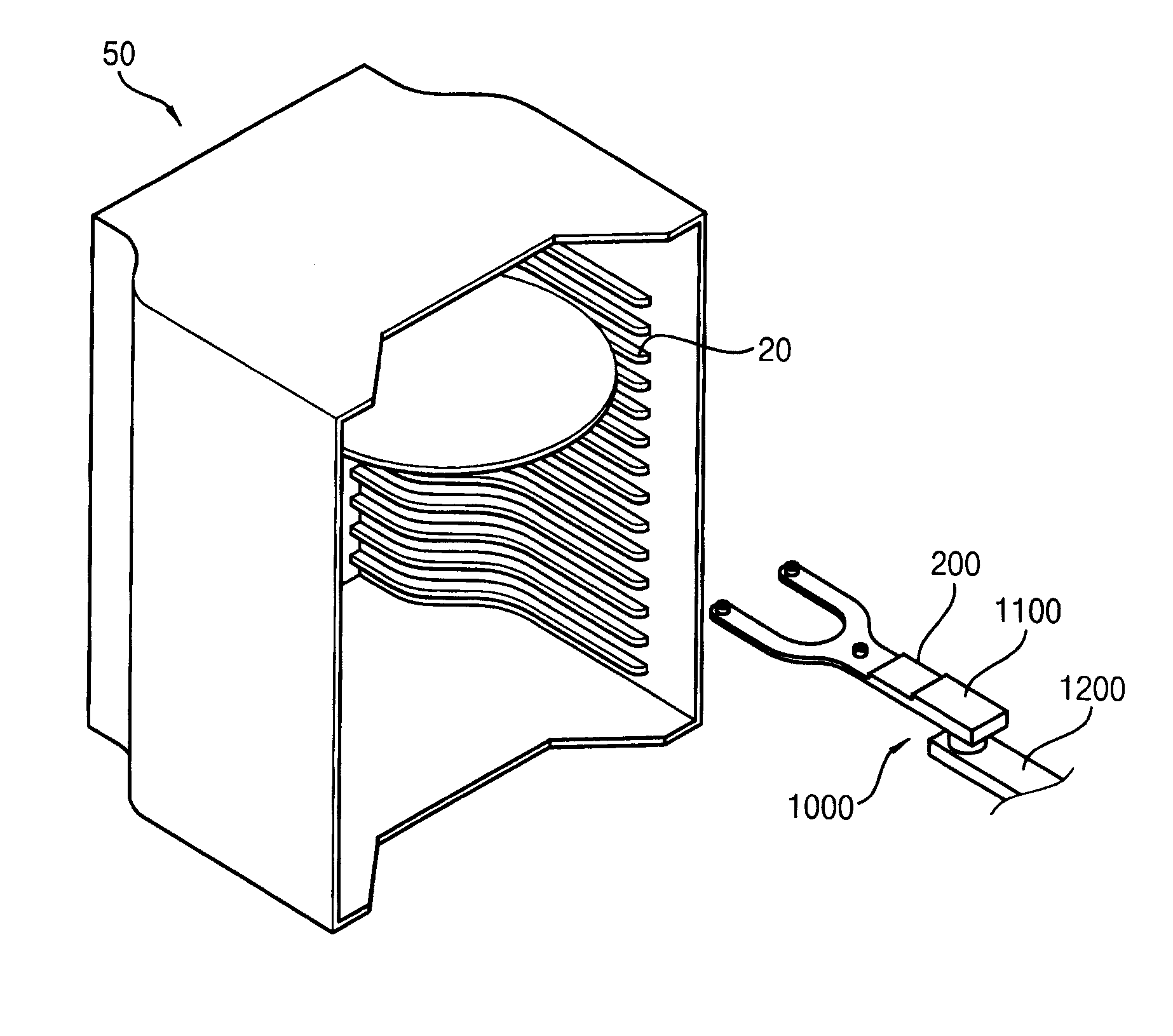

Ultra low contact area end effector

ActiveUS7055875B2Eliminates and greatly minimizes particulate transferImprove sealingGripping headsSemiconductor/solid-state device manufacturingEngineeringActuator

The present invention comprises a vacuum end effector having workpiece supports that work in conjunction with distorted workpiece surfaces. In one embodiment, each workpiece support has the ability to gimbal and conform the workpiece surface in contact with an outer edge of the support. Each workpiece support preferably provides a knife-like contact edge to minimize the contact area between the support and the workpiece while still providing an effective vacuum area to hold the wafer securely on the support. In another embodiment, each workpiece support is replaceable without having to remove the end effector from the robot assembly

Owner:BOOKS AUTOMATION US LLC

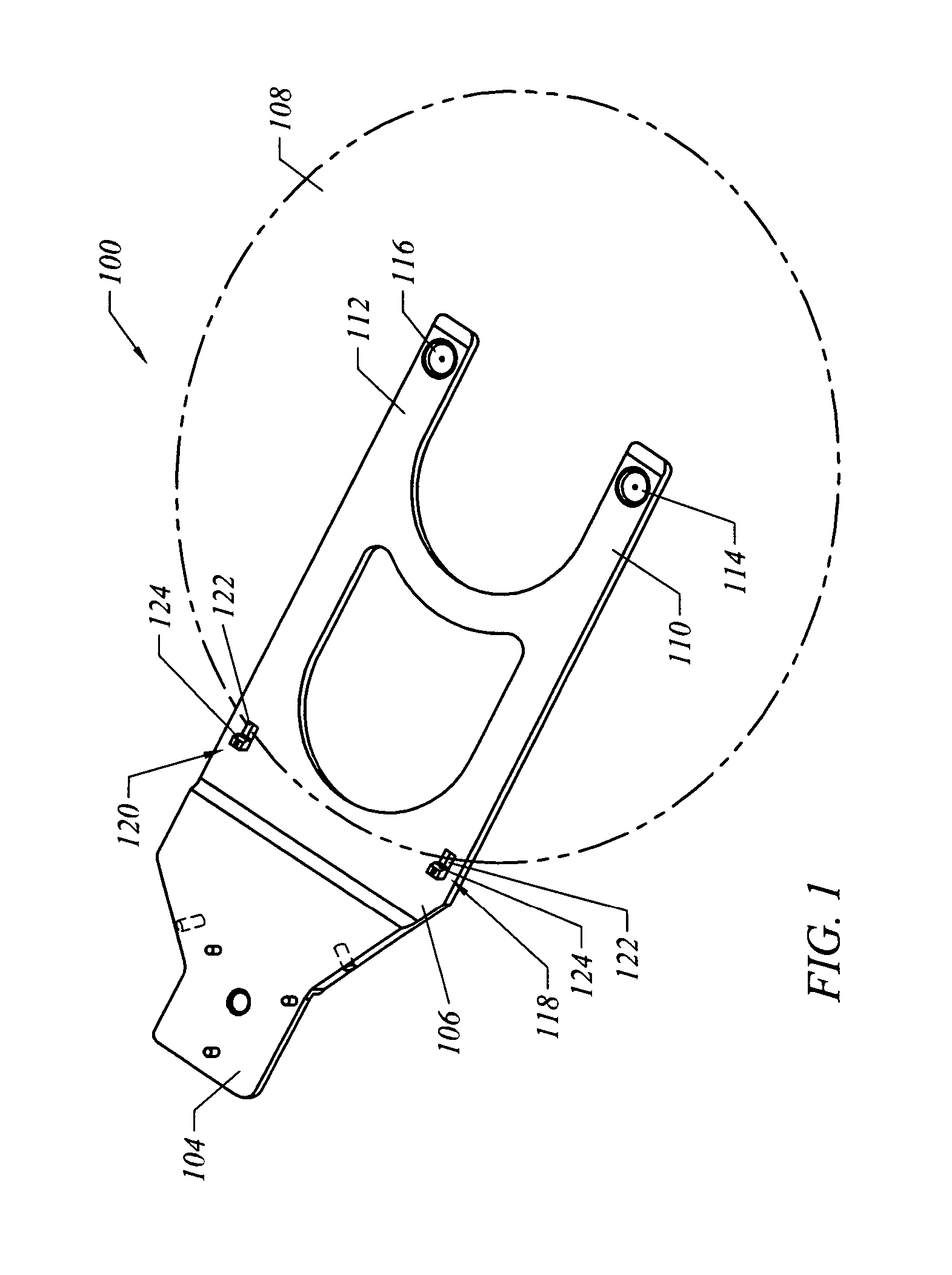

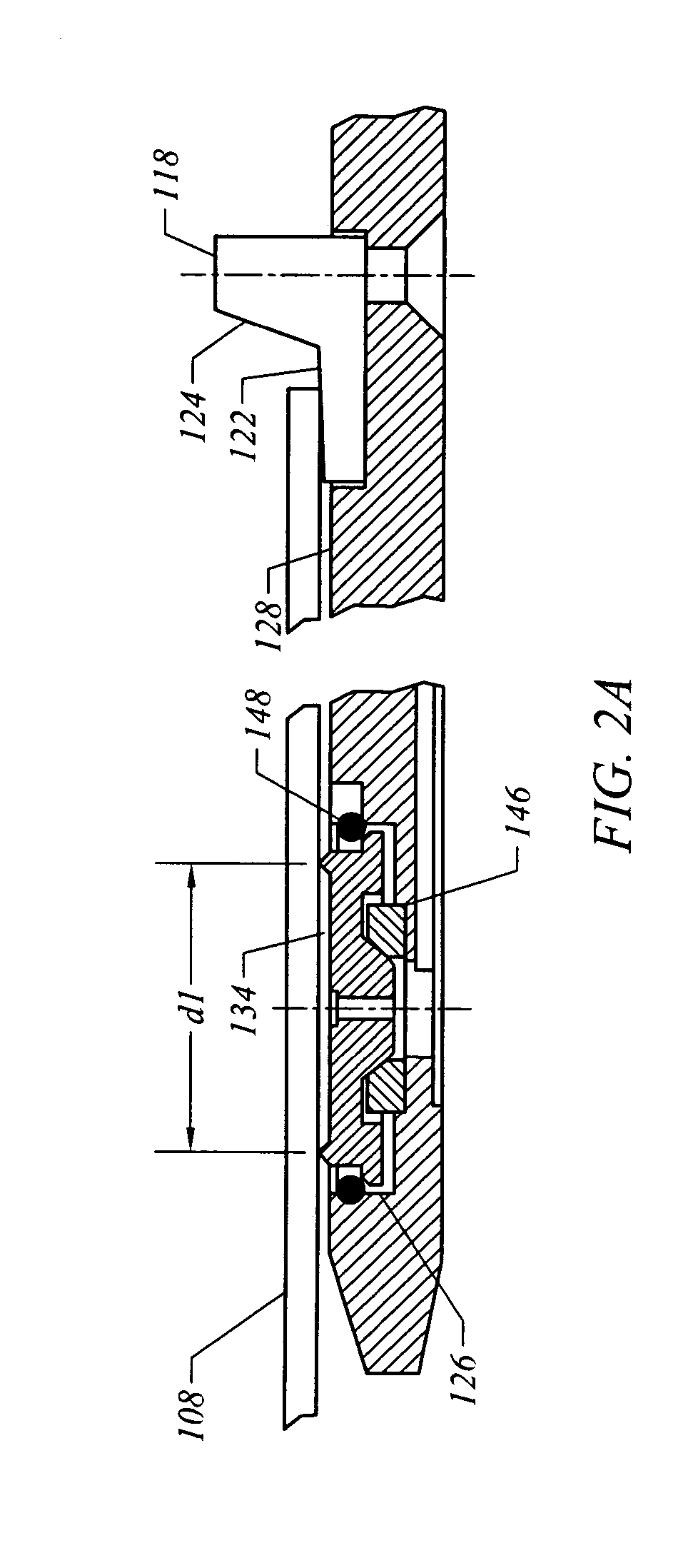

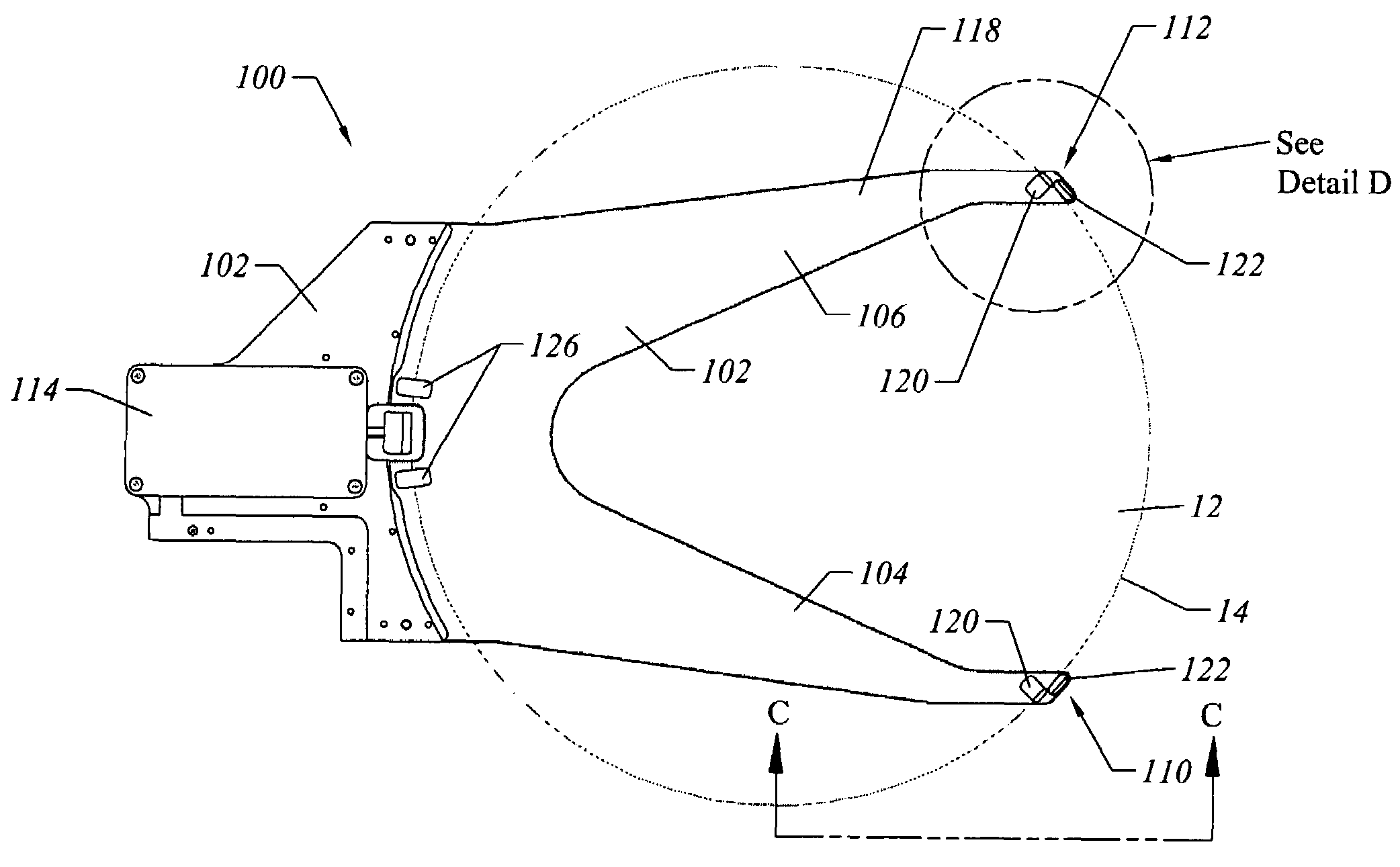

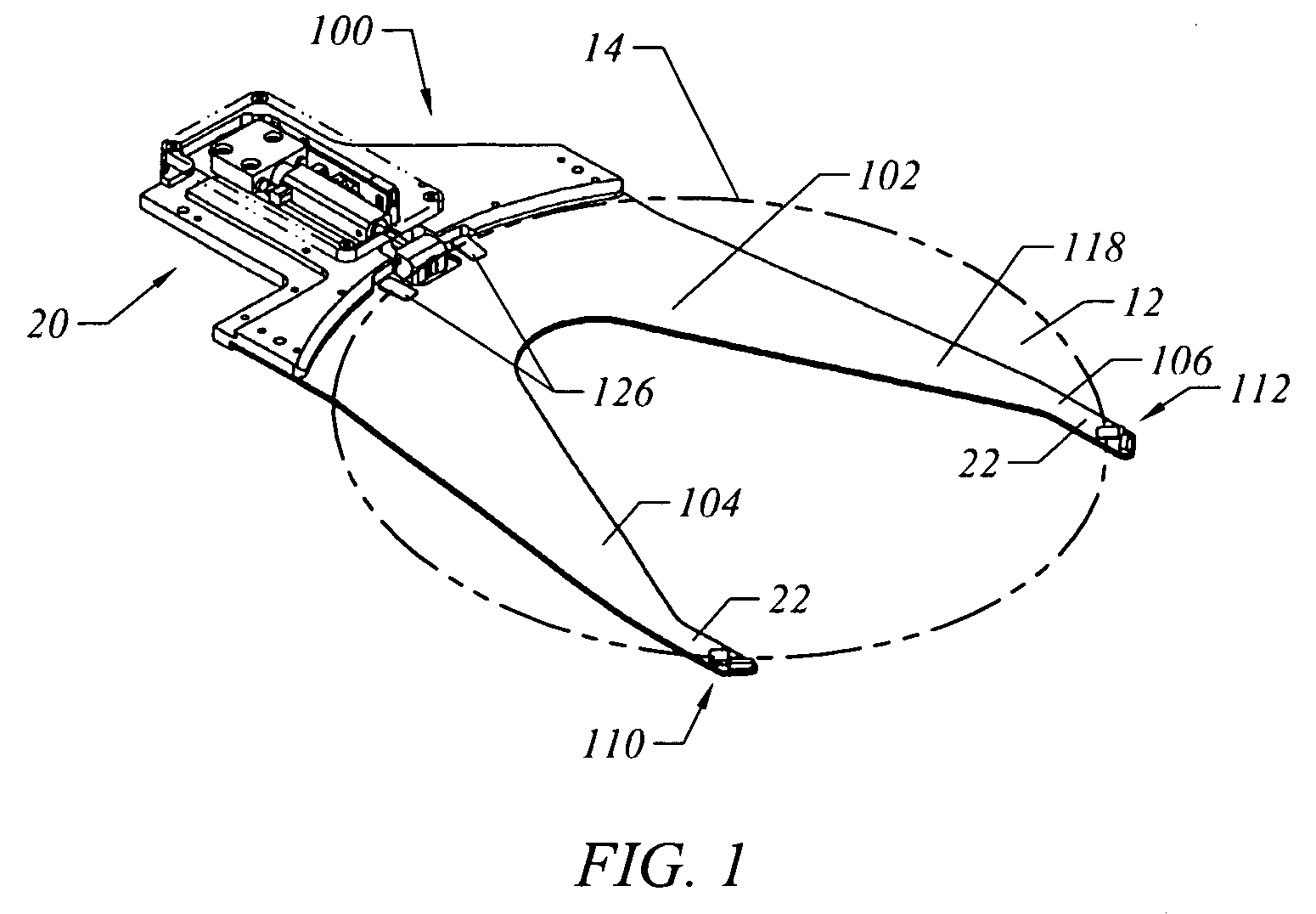

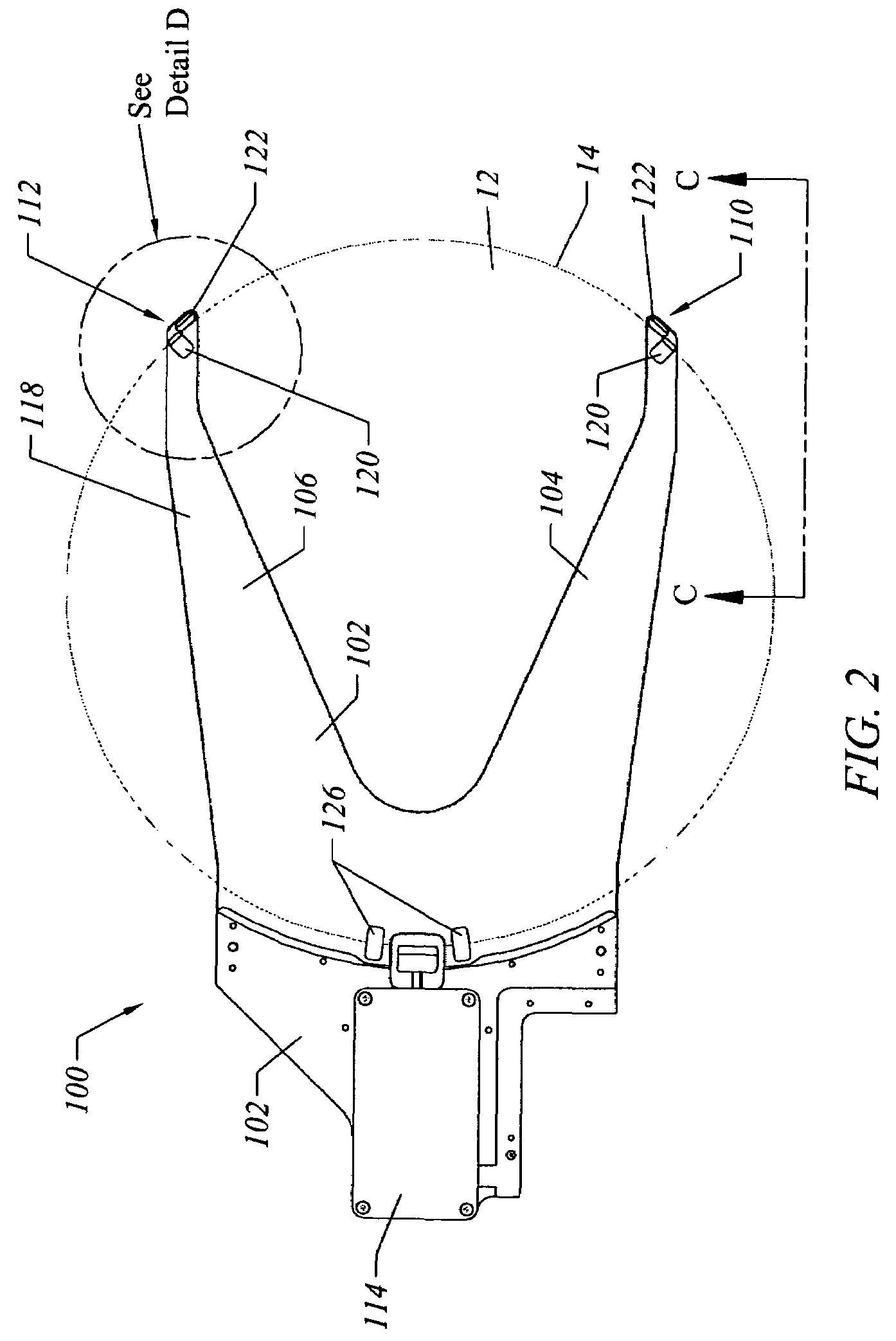

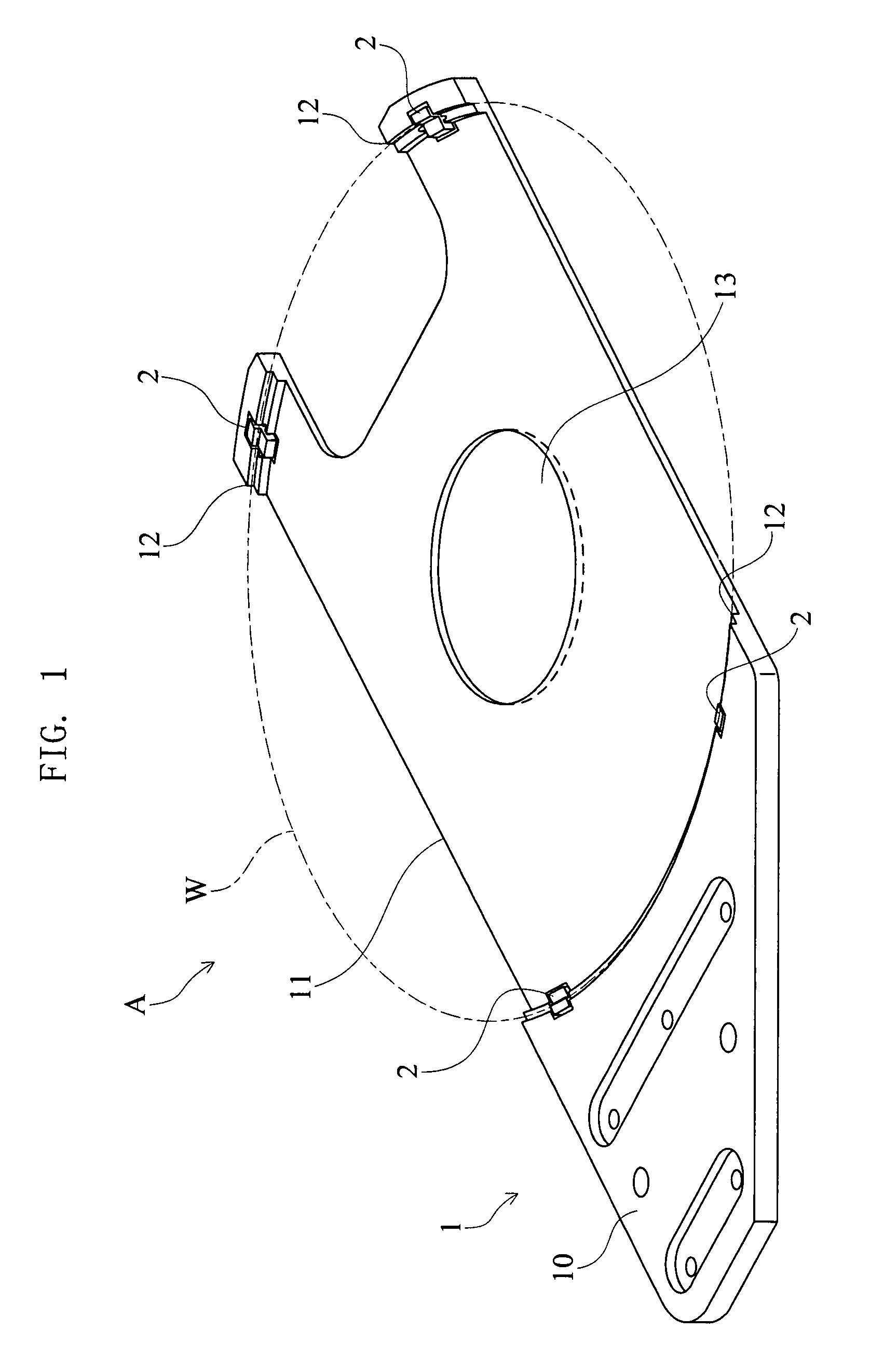

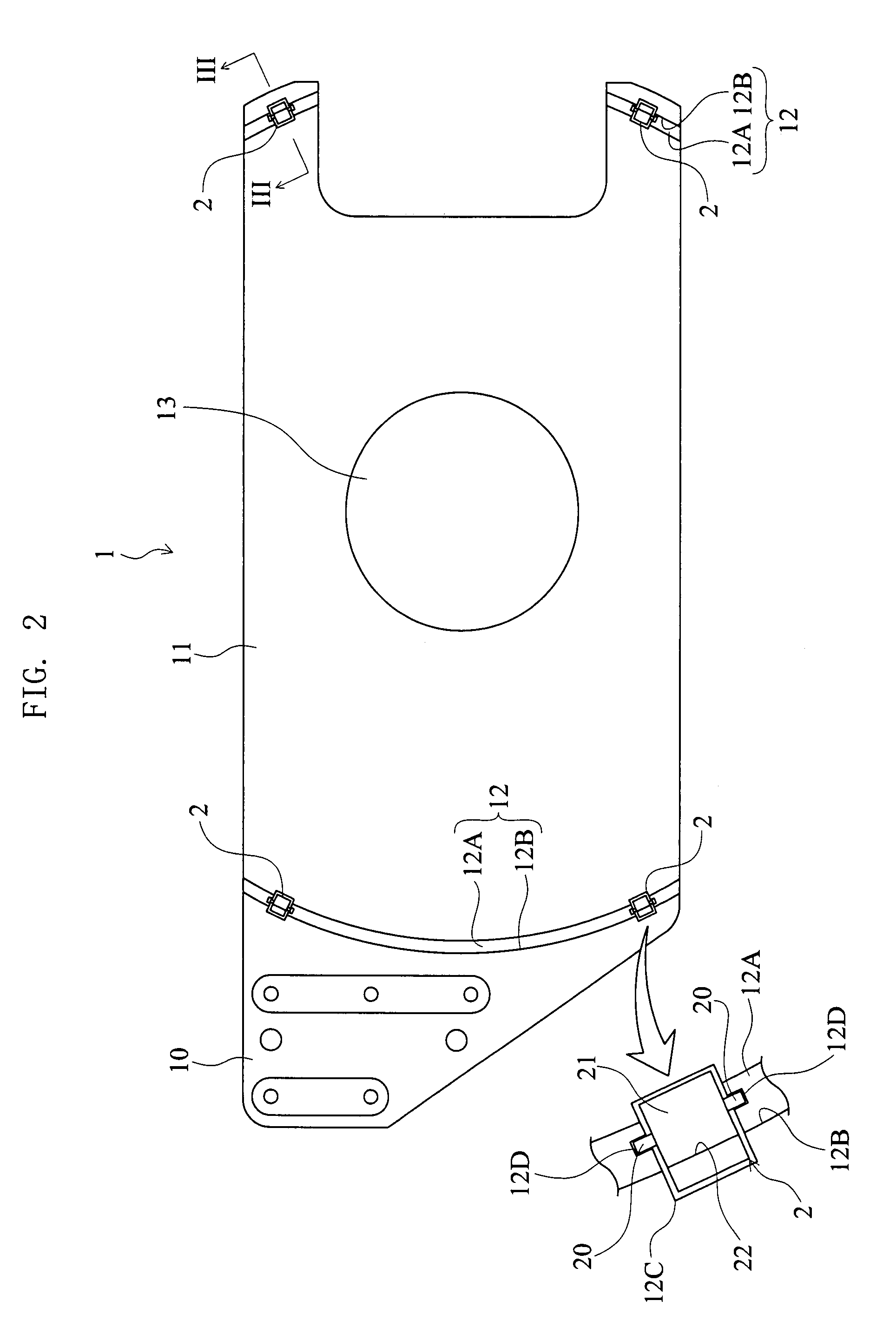

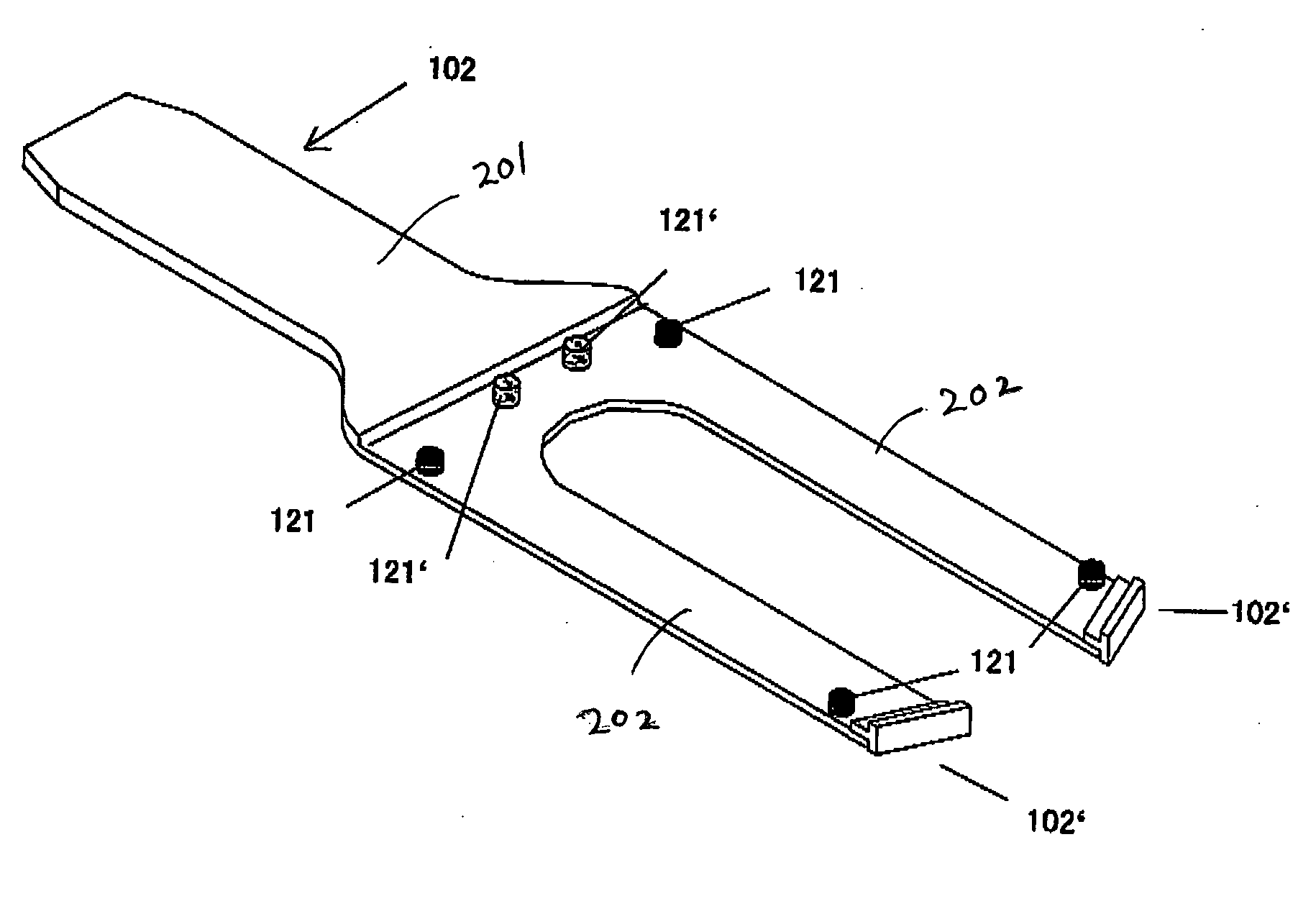

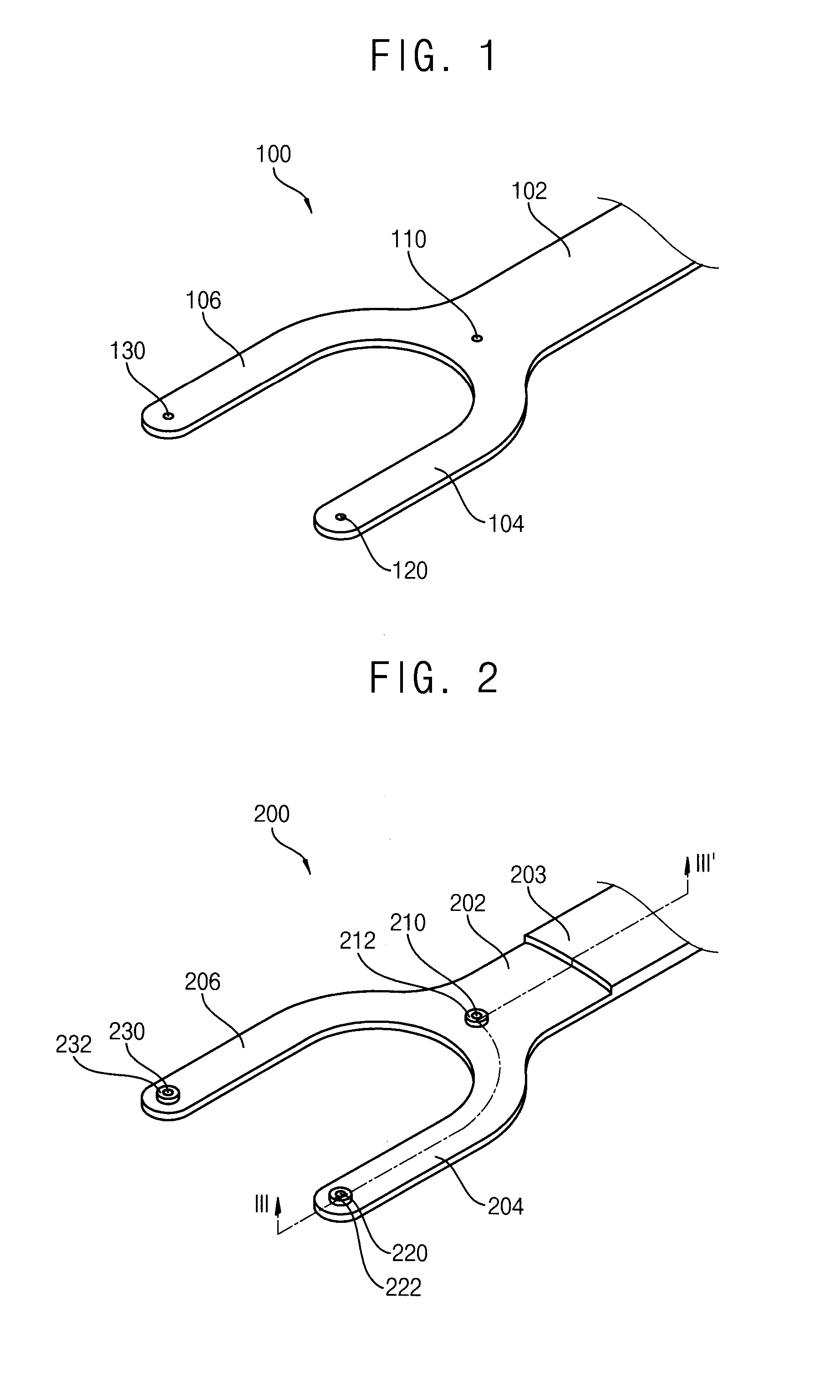

Active edge grip rest pad

ActiveUS7290813B2Precise and repeatable placementLow profileSemiconductor/solid-state device manufacturingLifting devicesActive edgeEngineering

The present invention comprises a distal rest pad for supporting a portion of a wafer seated on an end effector. In one embodiment, the rest pad includes a bottom support pad and an edge stop. Each element is mounted separately to the distal end of a support plate. The bottom support pad includes an inclined surface that transitions to a substantially horizontal surface at its distal end. The edge stop has a substantially vertical wafer contact surface that the peripheral edge of a wafer eventually contacts as the wafer is urged towards the distal rest pad. In another embodiment, the bottom support pad comprises an inclined surface. In yet another embodiment, the distal rest pad comprises a single structure. This distal rest pad includes a backstop portion and a bottom support separated by a particle collection groove. The bottom support may include an inclined lead-in surface that transitions into a flat contact surface or only comprise an inclined lead-in surface.

Owner:BOOKS AUTOMATION US LLC

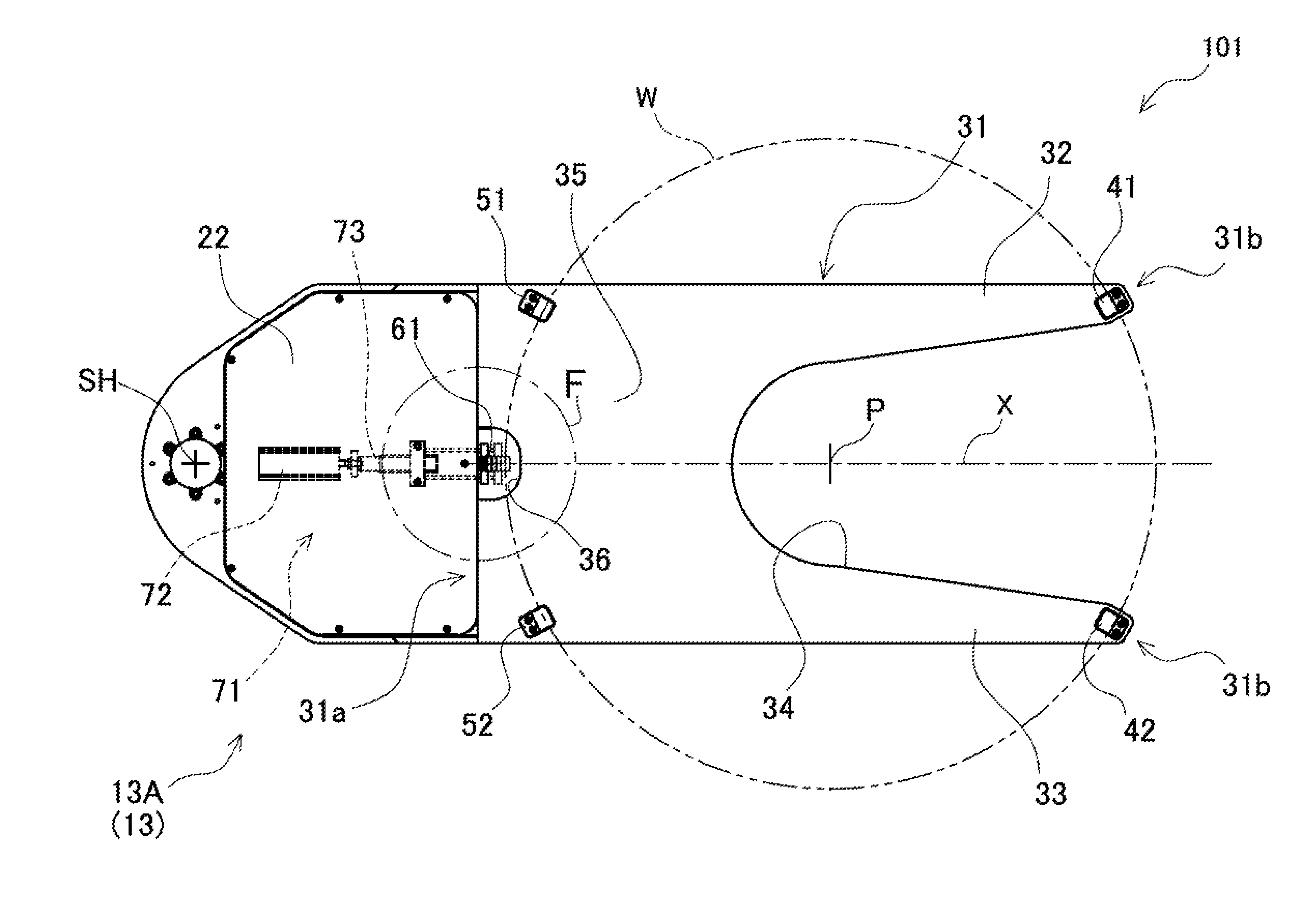

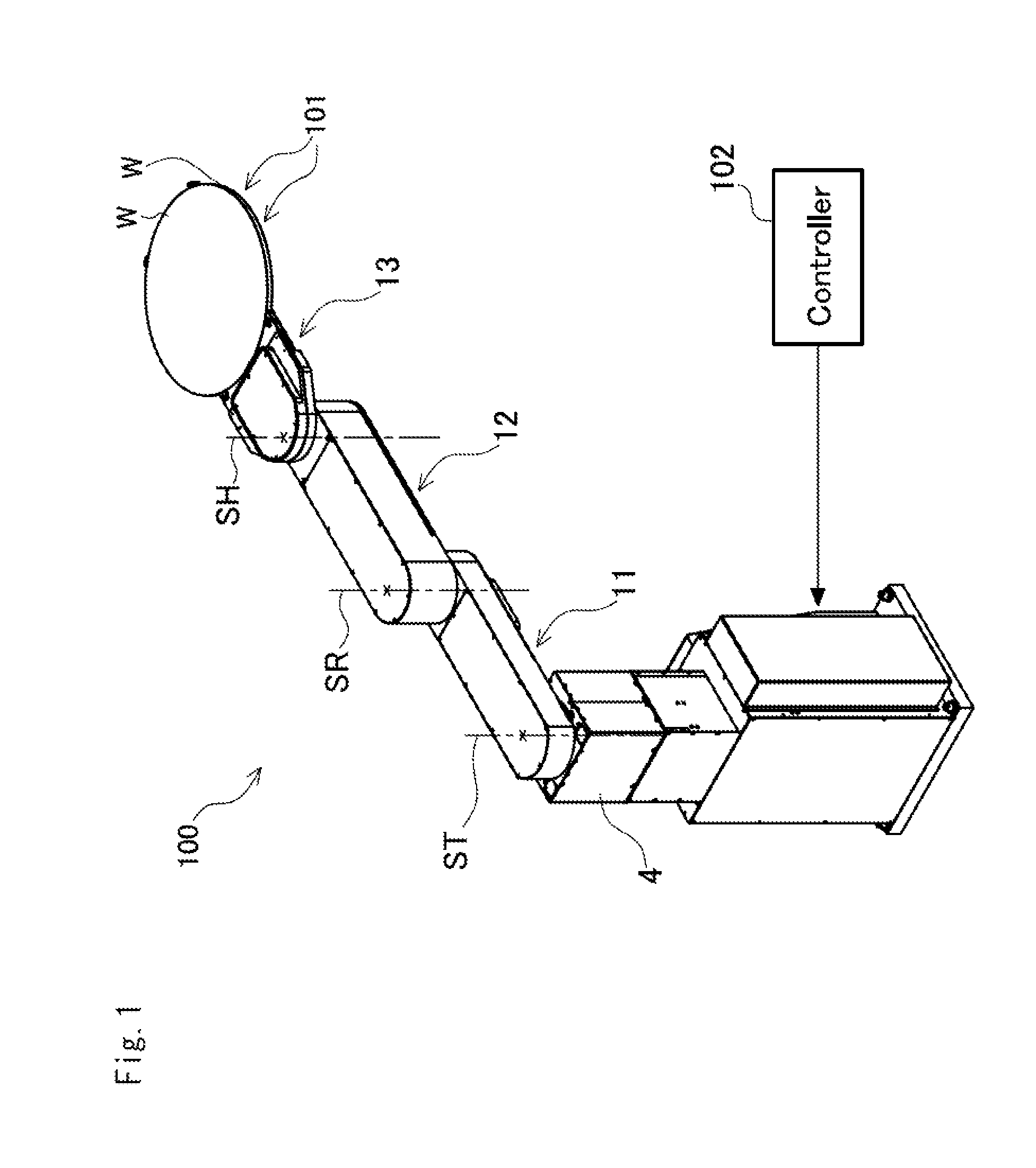

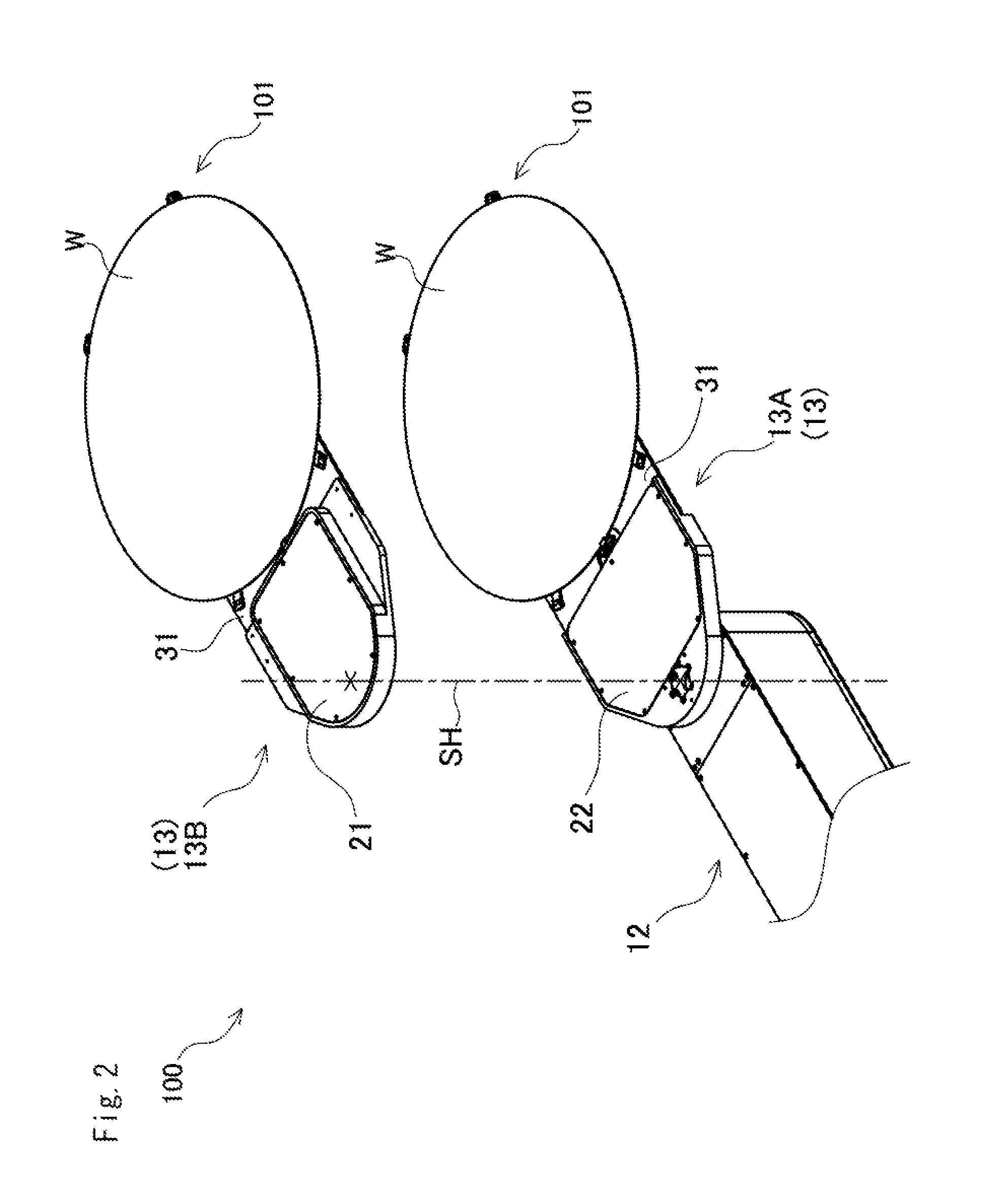

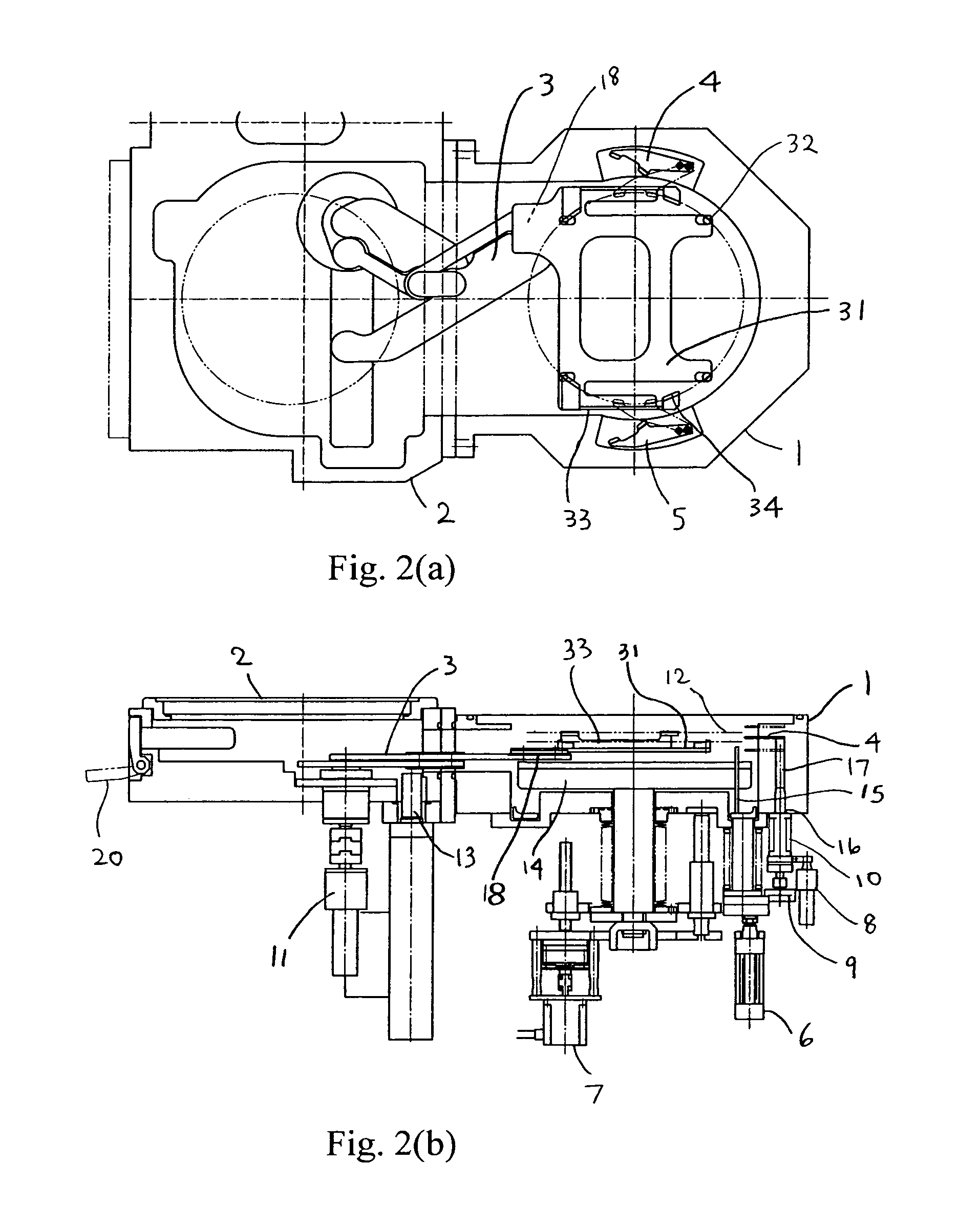

Clamping device and workpiece conveying robot

InactiveUS8764085B2High positionalImprove retentionGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SINFONIA TECHNOLOGY CO LTD

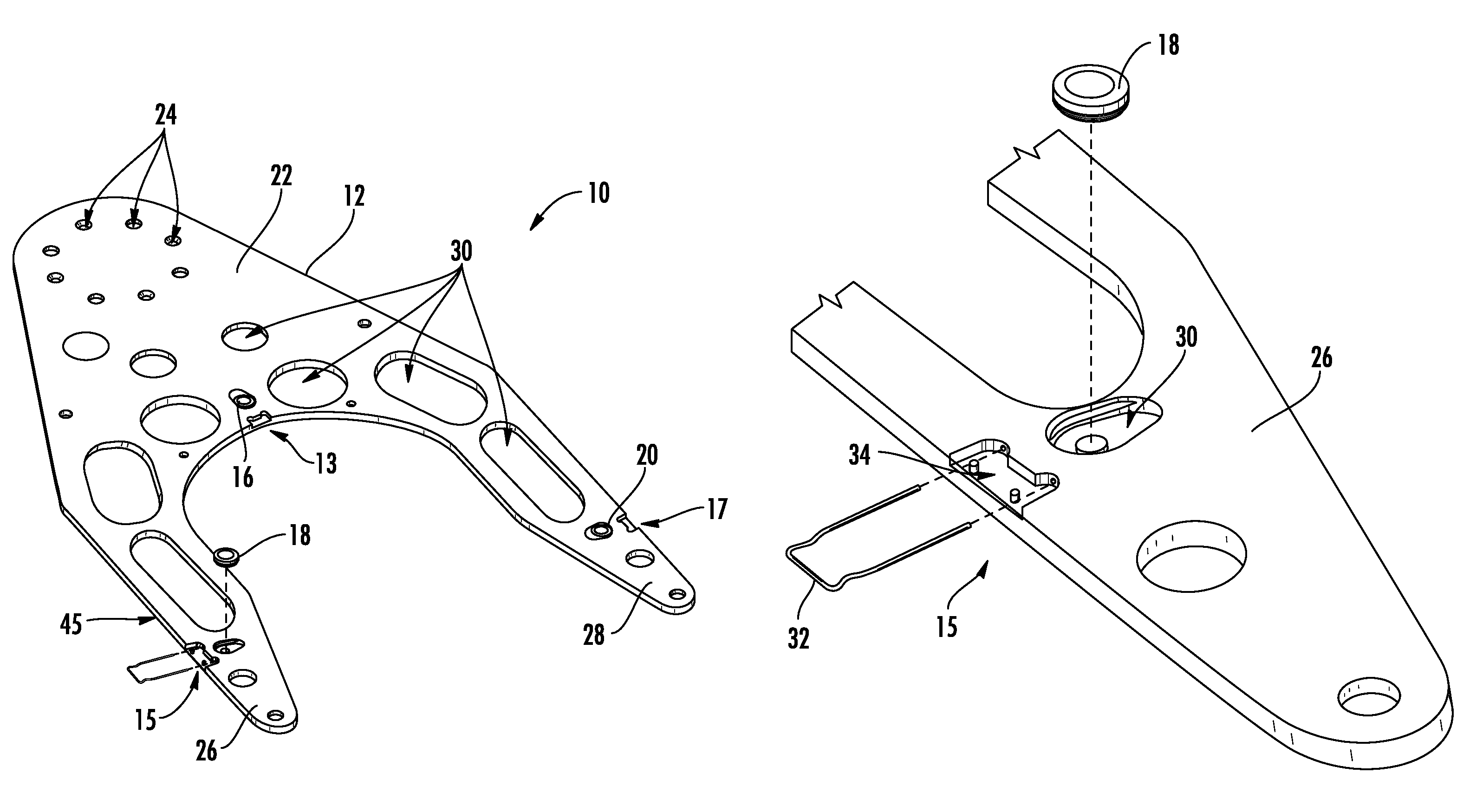

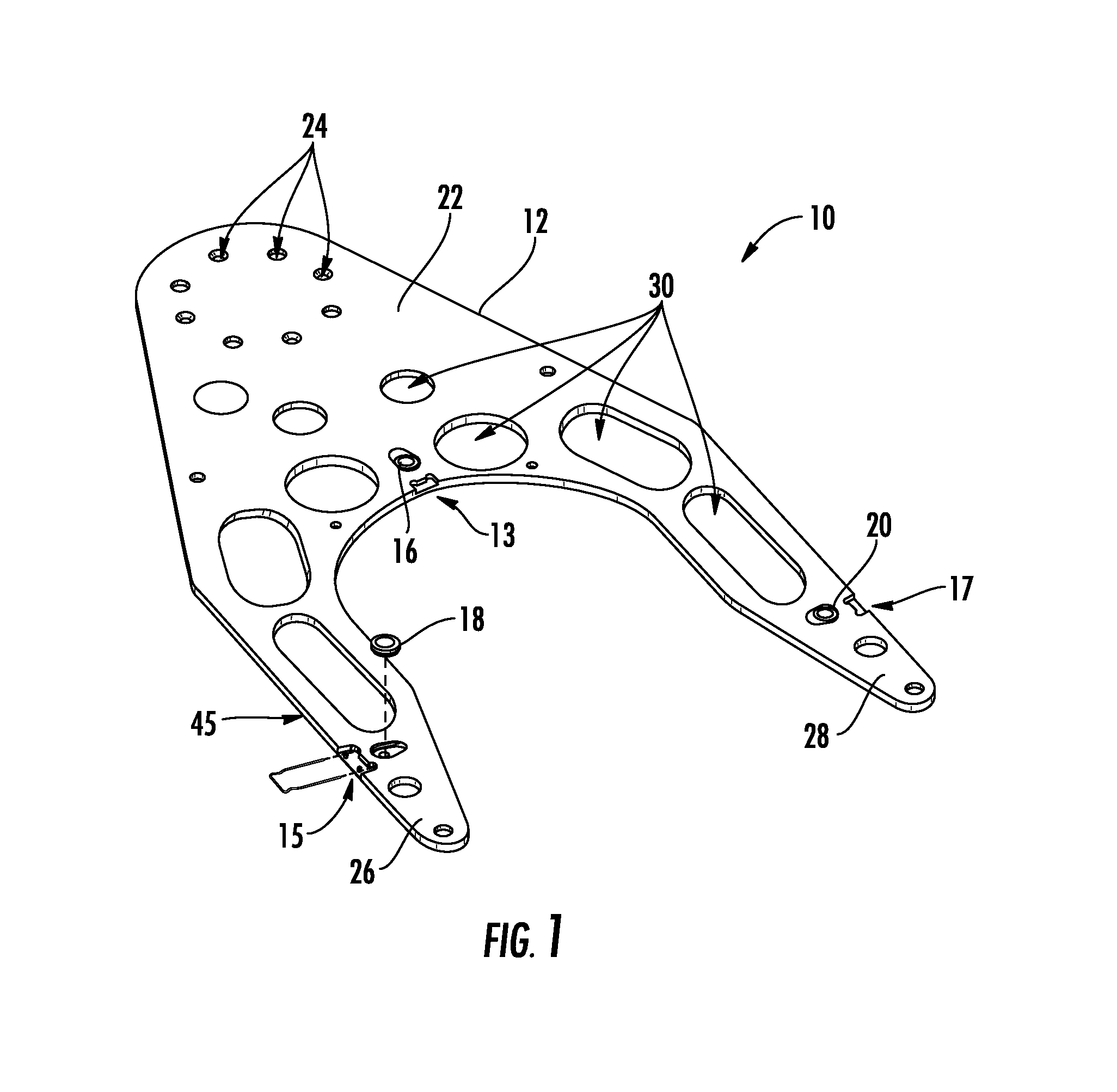

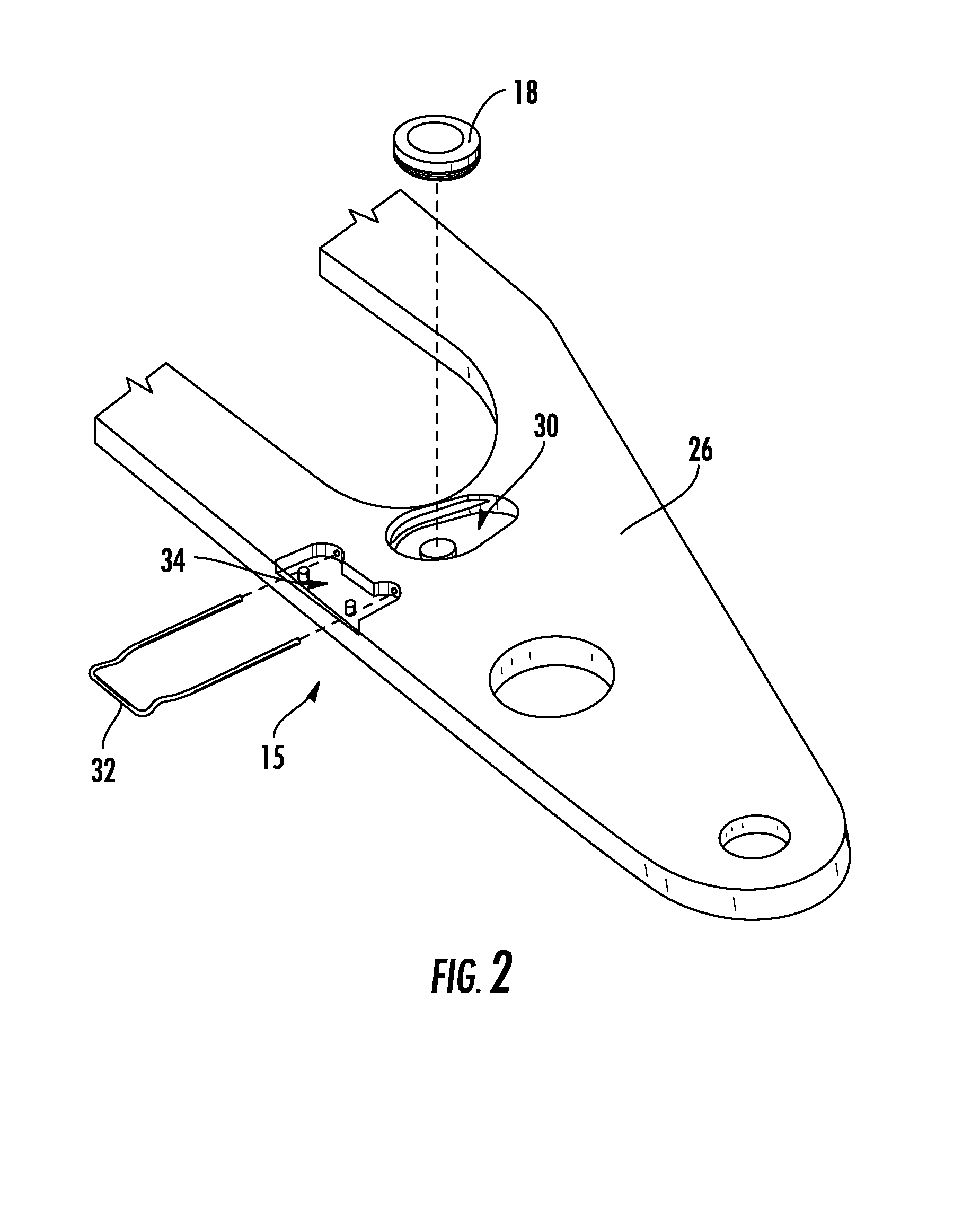

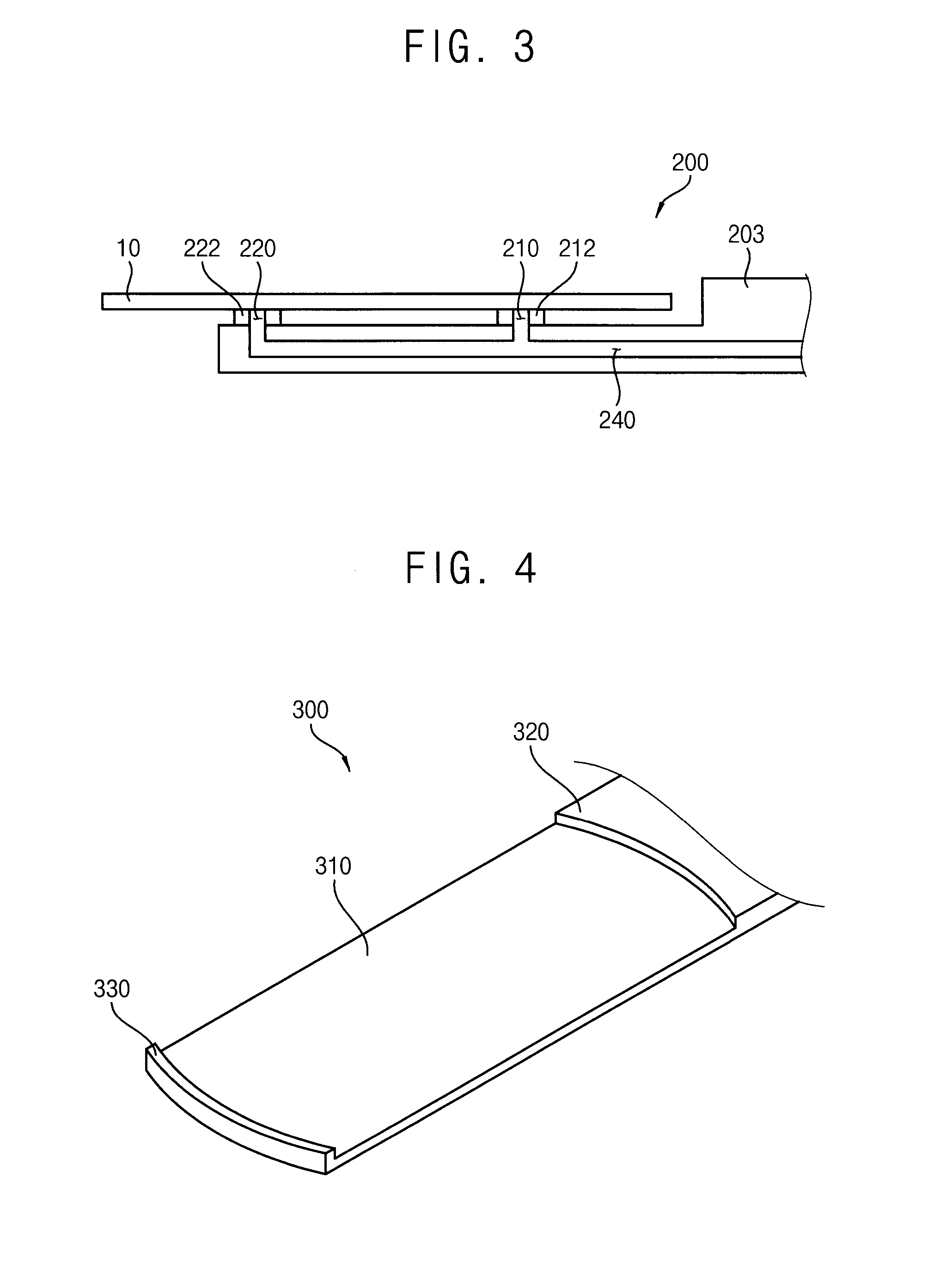

Spring retained end effector contact pad

ActiveUS8864202B1Reduce dispersionSecure attachmentGripping headsSemiconductor/solid-state device manufacturingContact padActuator

An end effector is disclosed for use in substrate processing. The end effector includes a effector body portion, a contact pad pocket formed in the end effector body, a spring retaining pocket formed in the end effector body adjacent the contact pad pocket and extending to an edge of the end effector body, and a pair of through-holes extending from the spring retaining pocket to the contact pad pocket. The end effector can include a contact pad seated within the contact pad pocket, the contact pad having at least one retaining channel formed therein, and a retaining spring having a pair of retaining arms extending from the retaining spring pocket through the through-holes and into the contact pad pocket. The retaining arms may extend at least partially into the at least one retaining channel of the contact pad and may thereby restrict movement of the contact pad.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Work holding mechanism

ActiveUS7748760B2Improve shipping speedVacuum operationGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DAIHEN CORP

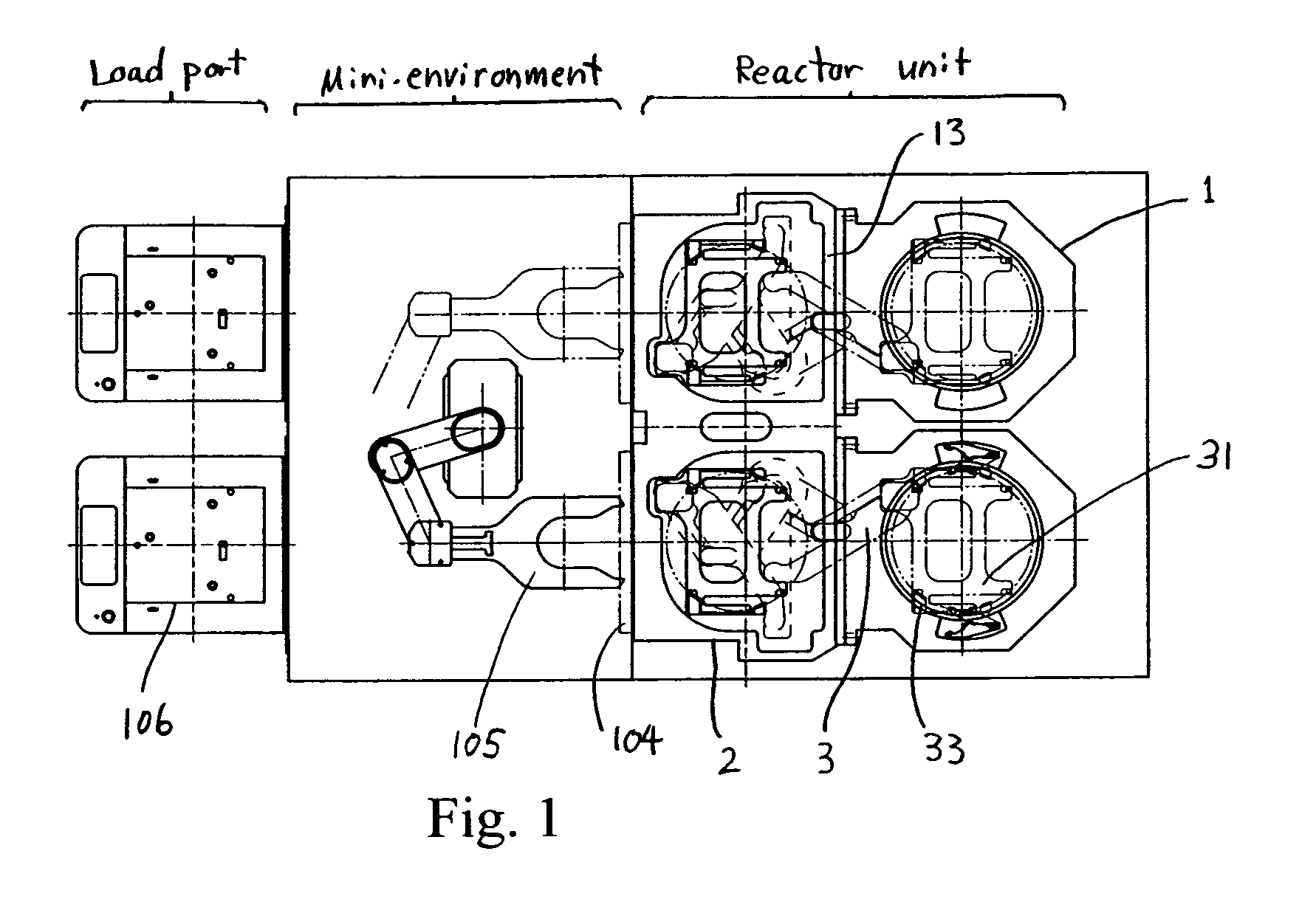

Substrate-processing apparatus with buffer mechanism and substrate-transferring apparatus

ActiveUS7690881B2Low costSmall footprintPliersSemiconductor/solid-state device manufacturingEngineeringActuator

A substrate transfer apparatus for loading and unloading substrates in a reaction chamber, includes: an arm having a distal end which is laterally movable in a straight line direction; and end-effectors for loading and unloading substrates in a reaction chamber, which include a lower end-effector and an upper end-effector. One of the lower end-effector or the upper end-effector is movably coupled to the arm at a distal end of the arm, and the other end-effector is fixed to the movably coupled end-effector. The fixed end-effector is fixed to the movably coupled end-effector.

Owner:ASM JAPAN

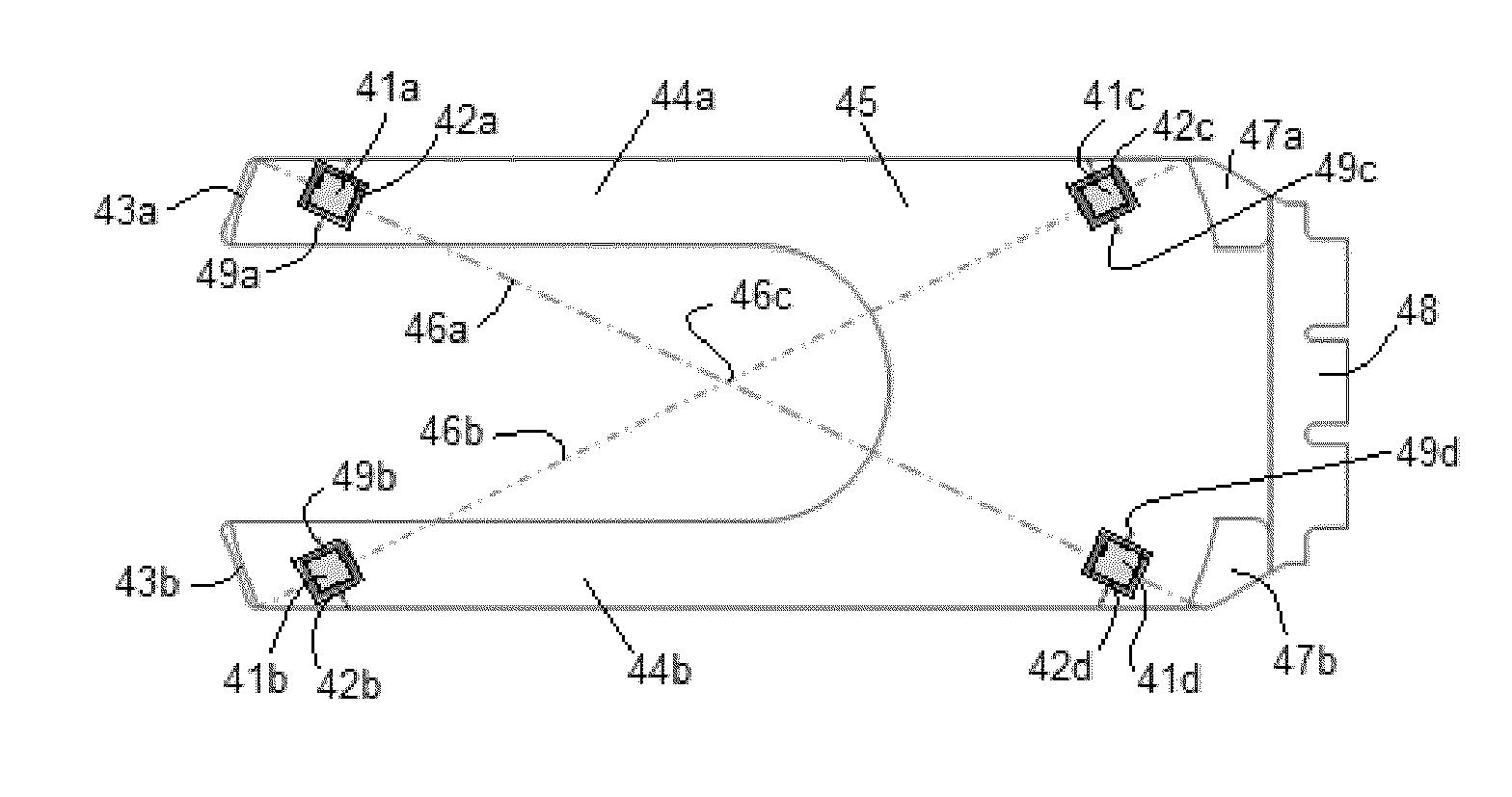

Wafer transfer mechanism

InactiveUS20060113806A1Easy to useEasy transferSemiconductor/solid-state device manufacturingCharge manipulationEngineeringTransfer mechanism

A transfer mechanism for transferring a workpiece includes an arm member including a tip projection provided at a tip end thereof for contacting a periphery of the workpiece and restricting movement of the workpiece. The arm member further includes multiple supporting projections protruding from a top surface thereof for contacting and supporting a back side of the workpiece.

Owner:ASM JAPAN

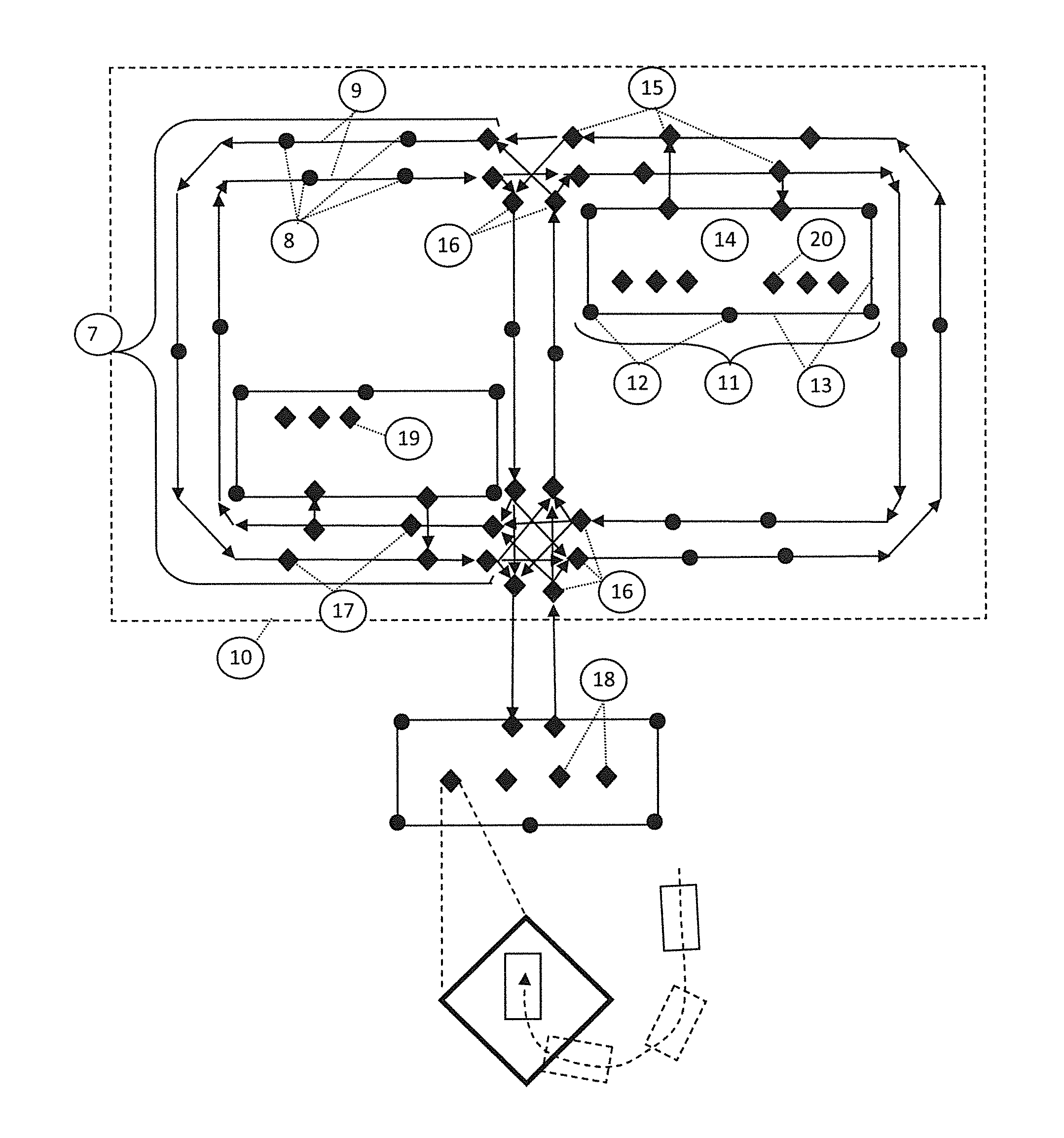

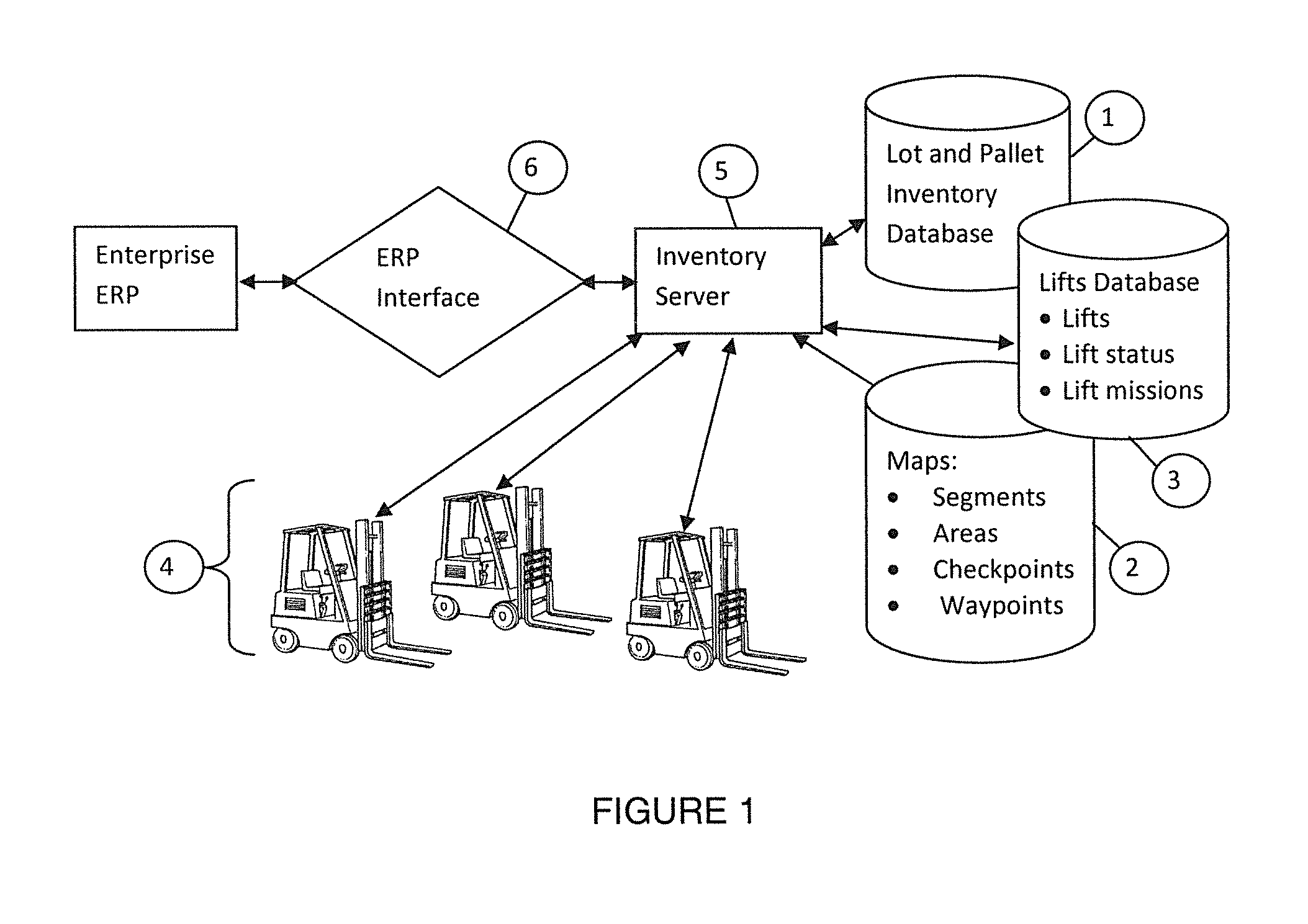

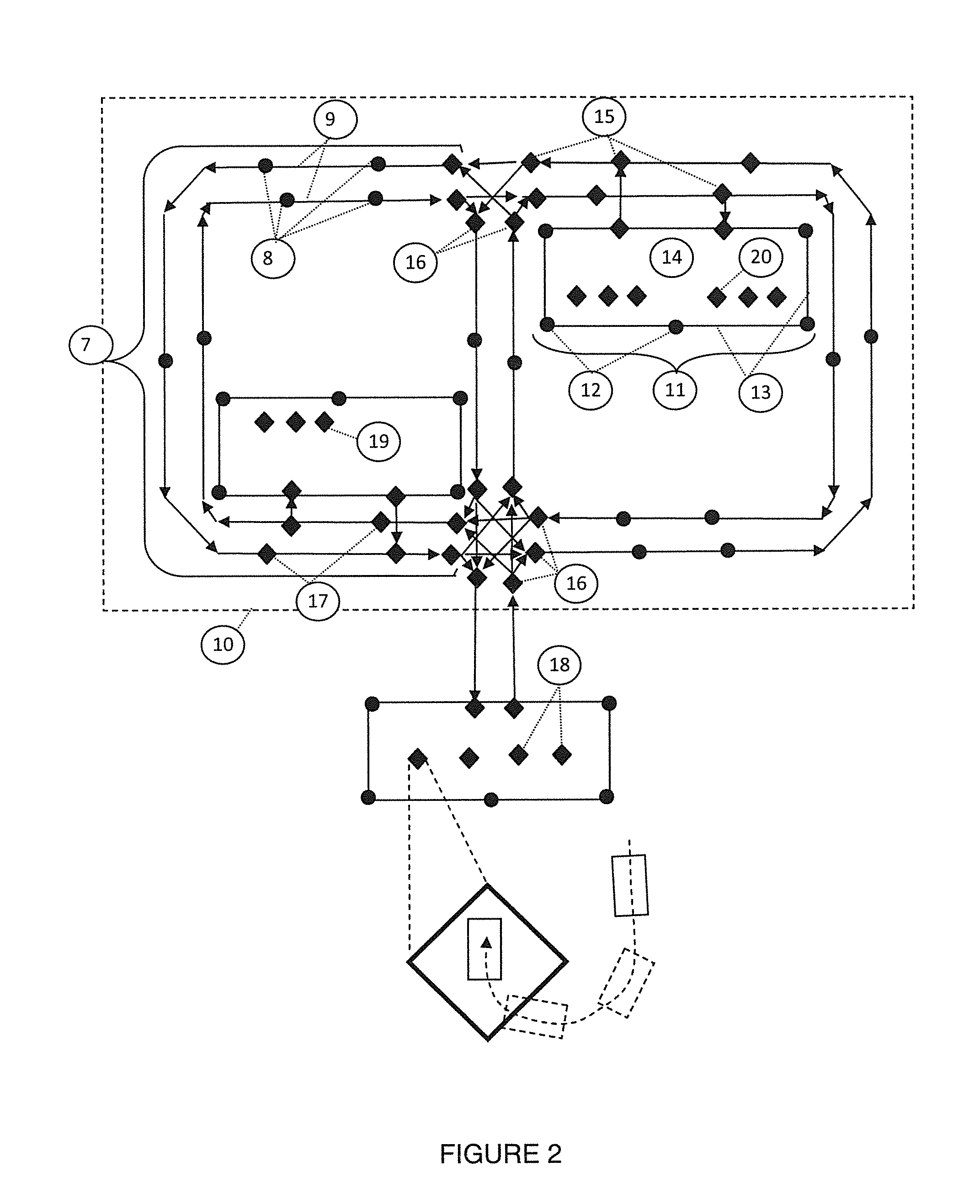

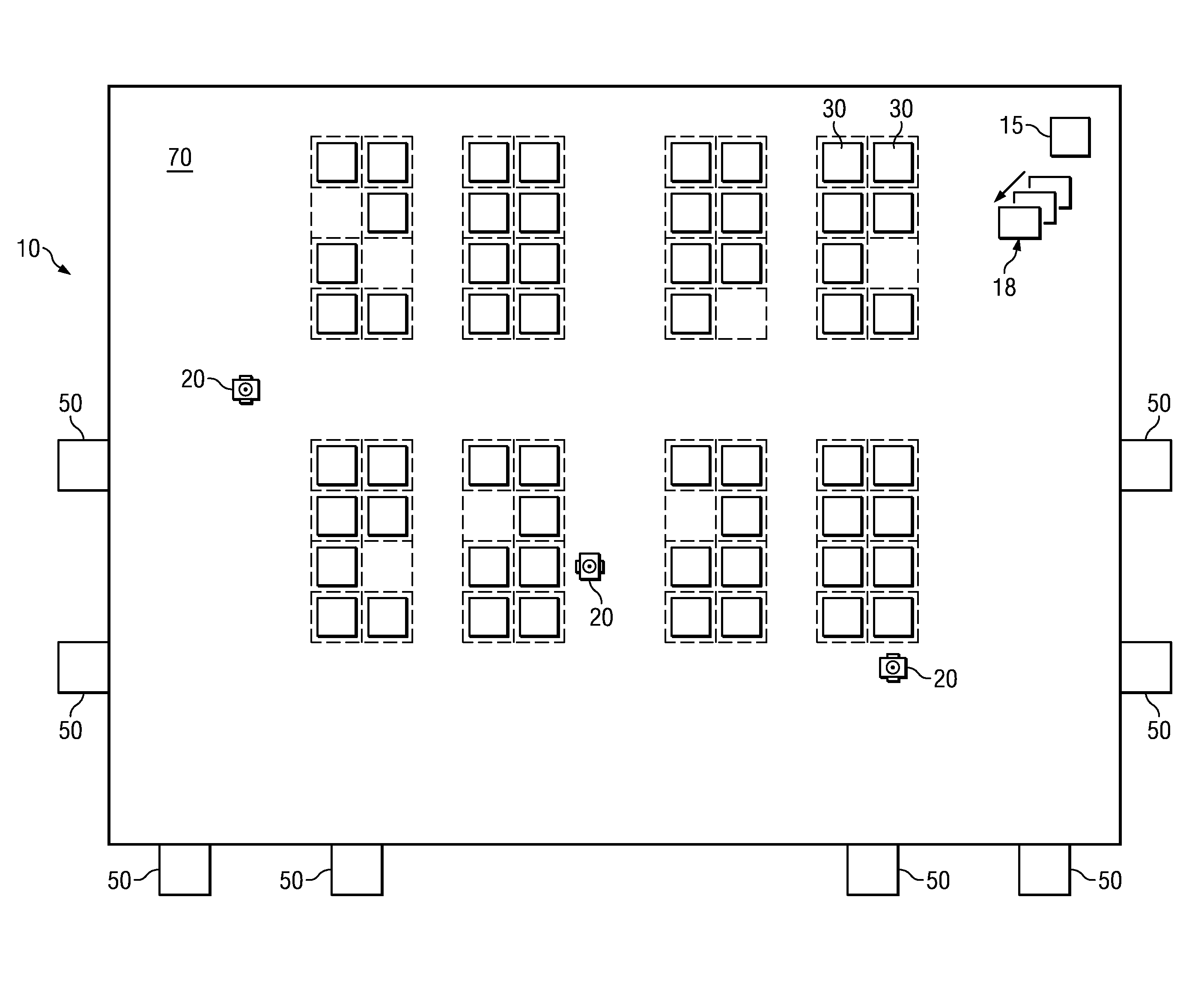

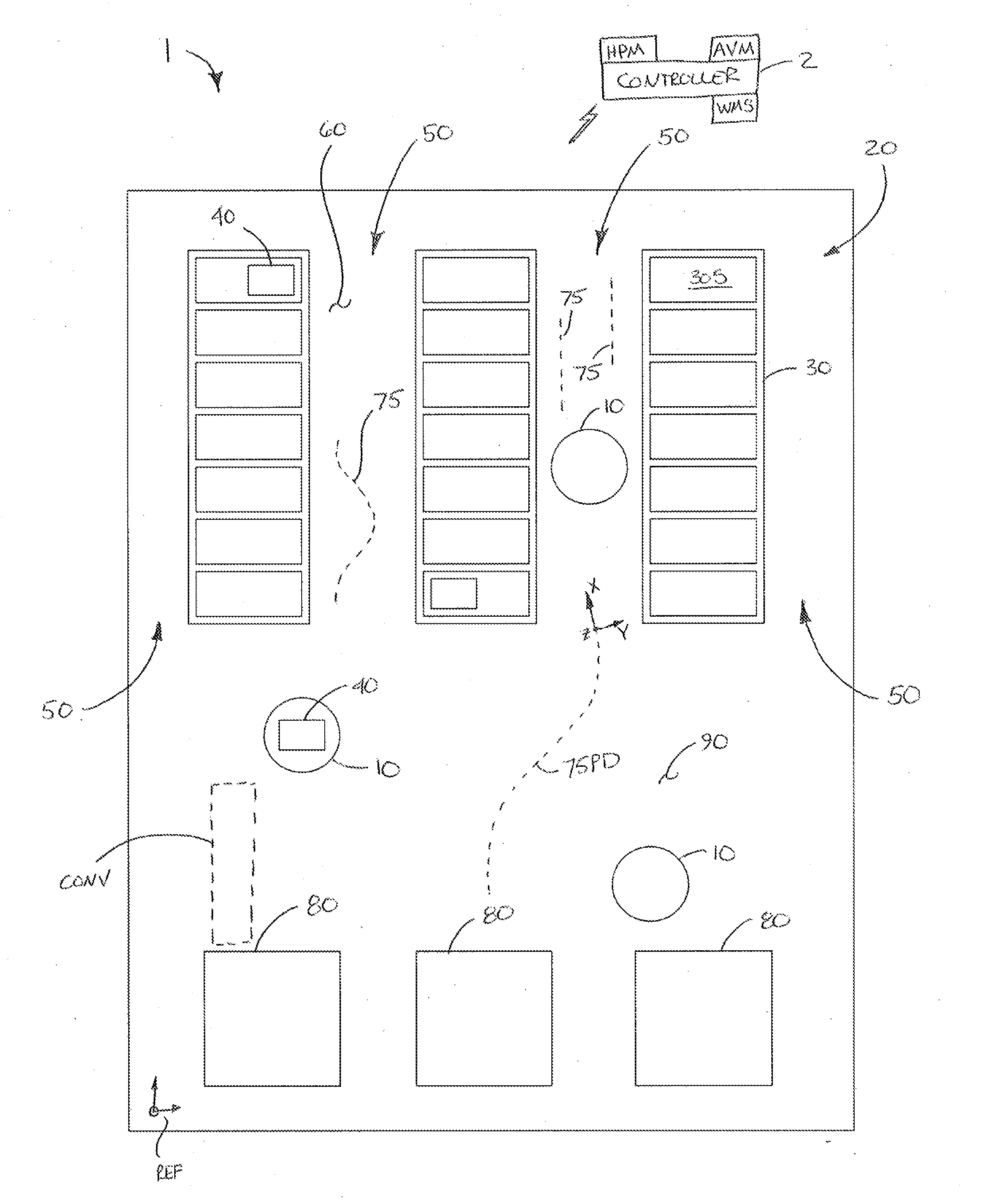

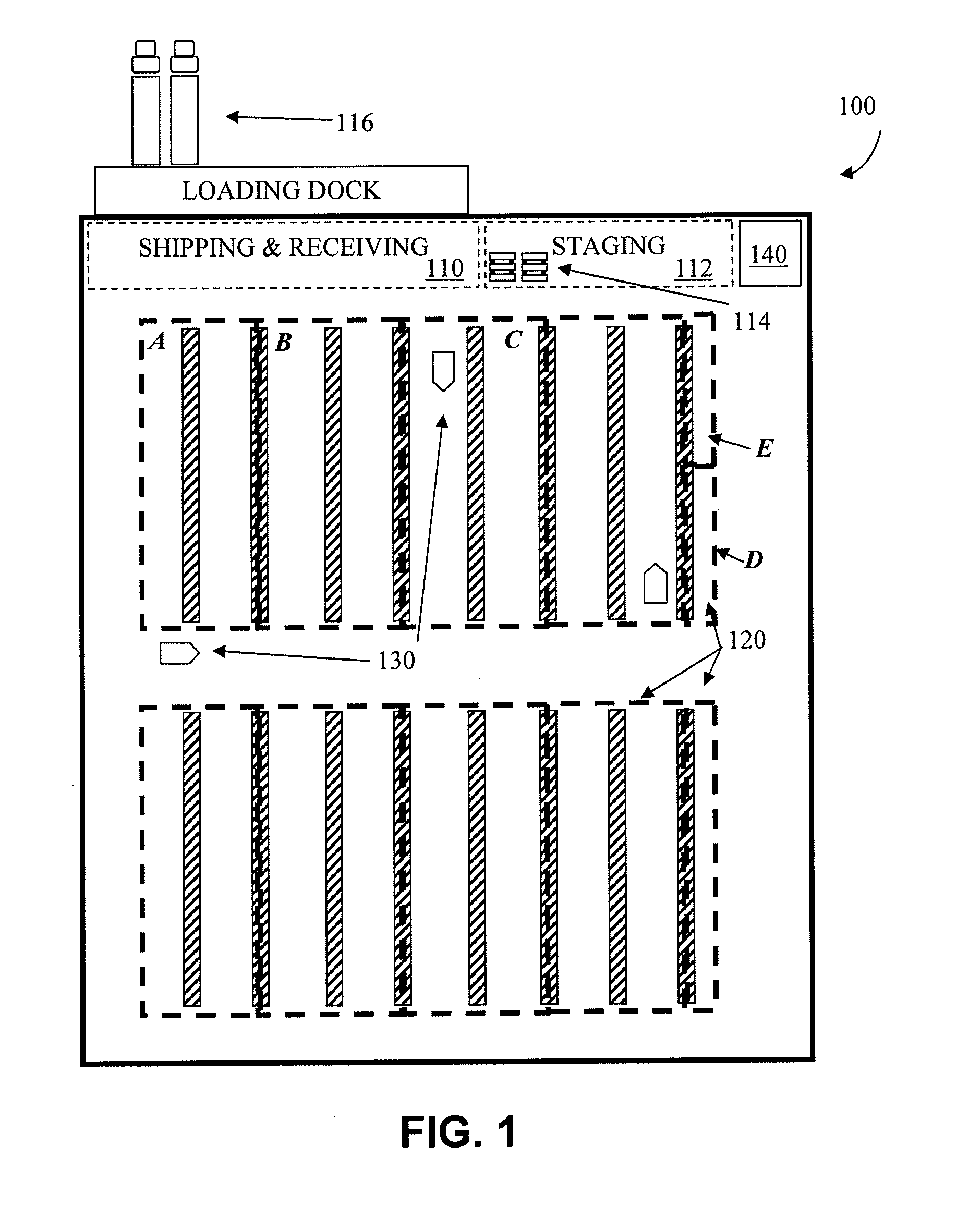

Automated warehousing using robotic forklifts

ActiveUS20140277691A1Low costReduce rateDigital data processing detailsLifting devicesOn boardInventory management

A system for automated inventory management and material handling removes the requirement to operate fully automatically or all-manual using conventional vertical storage and retrieval (S&R) machines. Inventory requests to place palletized material into storage at a specified lot location or retrieve palletized material from a specified lot are resolved into missions for autonomous fork trucks, equivalent mobile platforms, or manual fork truck drivers (and their equipment) that are autonomously or manually executed to effect the request. Automated trucks plan their own movements to execute the mission over the warehouse aisles or roadways sharing this space with manually driven trucks. Automated units drive to planned speed limits, manage their loads (stability control), stop, go, and merge at intersections according human driving rules, use on-board sensors to identify static and dynamic obstacles, and human traffic, and either avoid them or stop until potential collision risk is removed.

Owner:CYBERNET SYST

Wafer transfer blade and wafer transfer apparatus having the same

InactiveUS20140227072A1Damage is prevented and mitigatedDamage can be prevented and mitigatedGripping headsSemiconductor/solid-state device manufacturingVacuum pressureEngineering

A wafer transfer blade including a body including metal oxide and configured to support a wafer, and an adsorbing part on the body, the adsorbing part having at least one therein and configured to apply vacuum pressure to attach the wafer on the body may be provided. The body may include metal oxide to prevent static electricity.

Owner:SAMSUNG ELECTRONICS CO LTD

Anti-Slip End Effector For Transporting Workpiece Using Van Der Waals Force

ActiveUS20150287626A1Prevent slippingImprove shipping speedSemiconductor/solid-state device manufacturingLifting devicesRobotic armEngineering

An anti-slip end effector for transporting a workpiece, configured to be attached to a robotic arm, includes: a workpiece-supporting area for placing a workpiece thereon for transportation; and at least one anti-slip protrusion disposed in the workpiece-supporting area for supporting a backside of the workpiece, said anti-slip protrusion having a top face capable of contacting and adhering to the backside of the workpiece by van der Waals force and capable of pivoting on a pivot axis, said pivot axis being disposed away from a center of the top face as viewed from above.

Owner:ASM IP HLDG BV

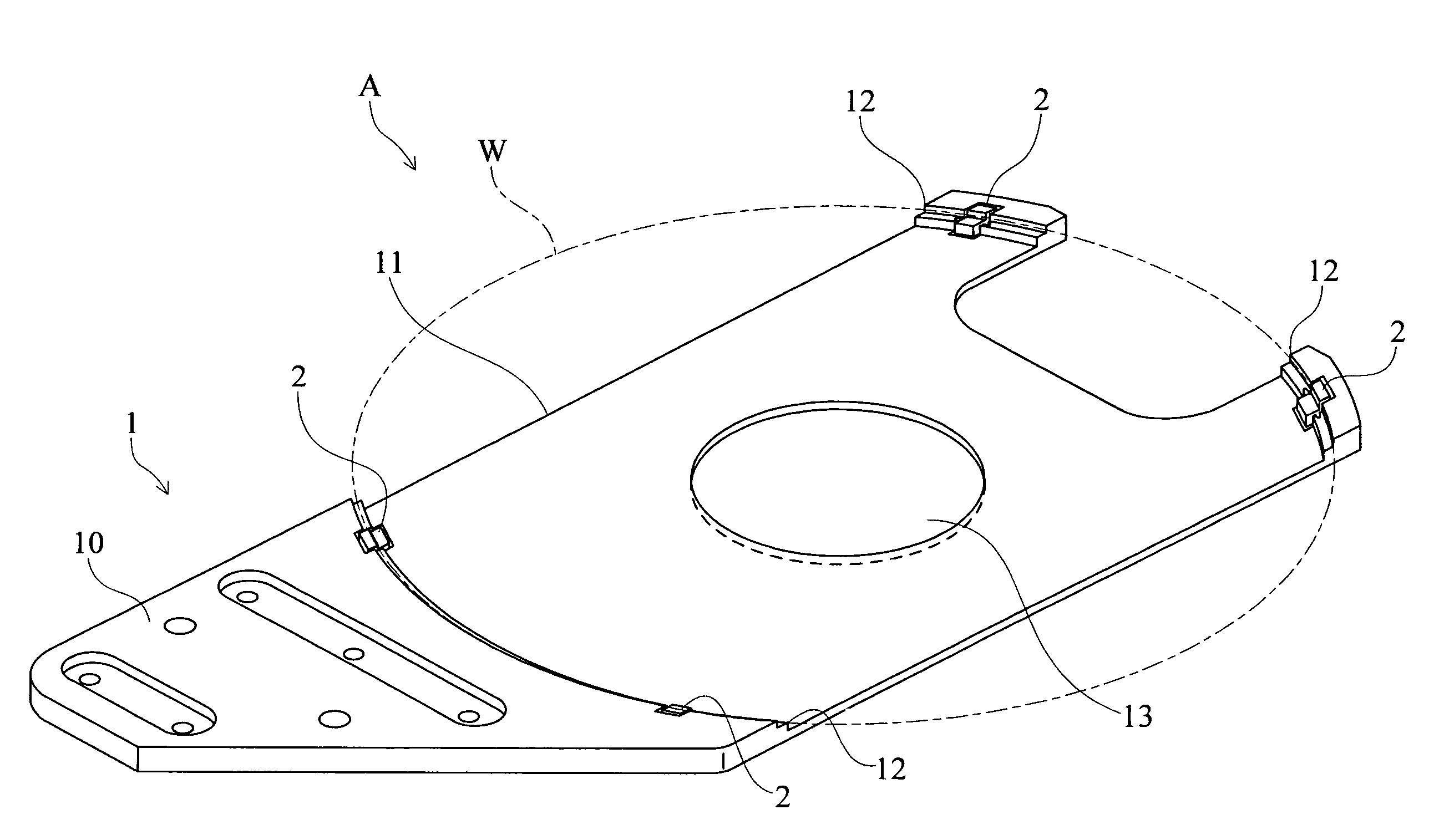

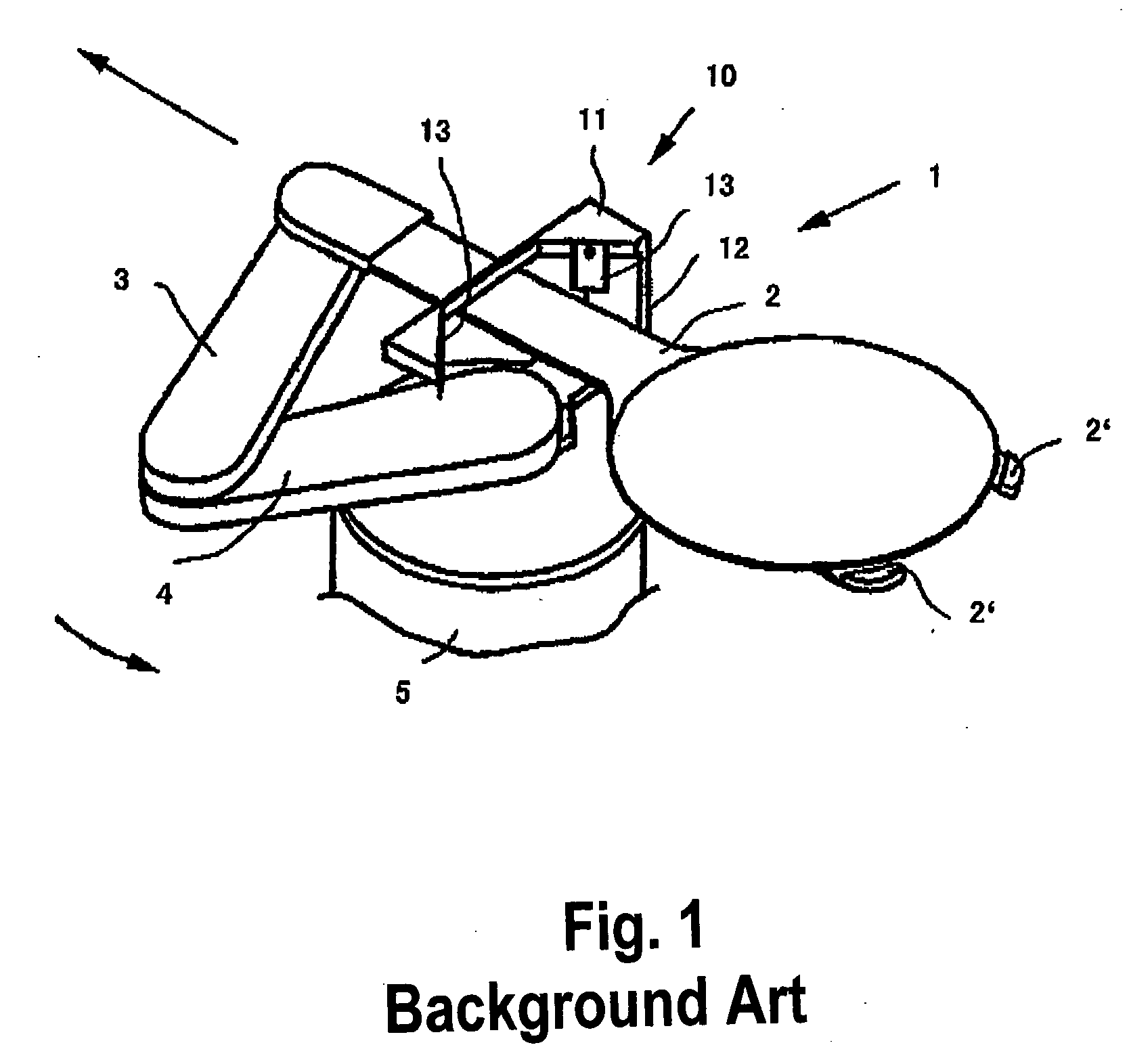

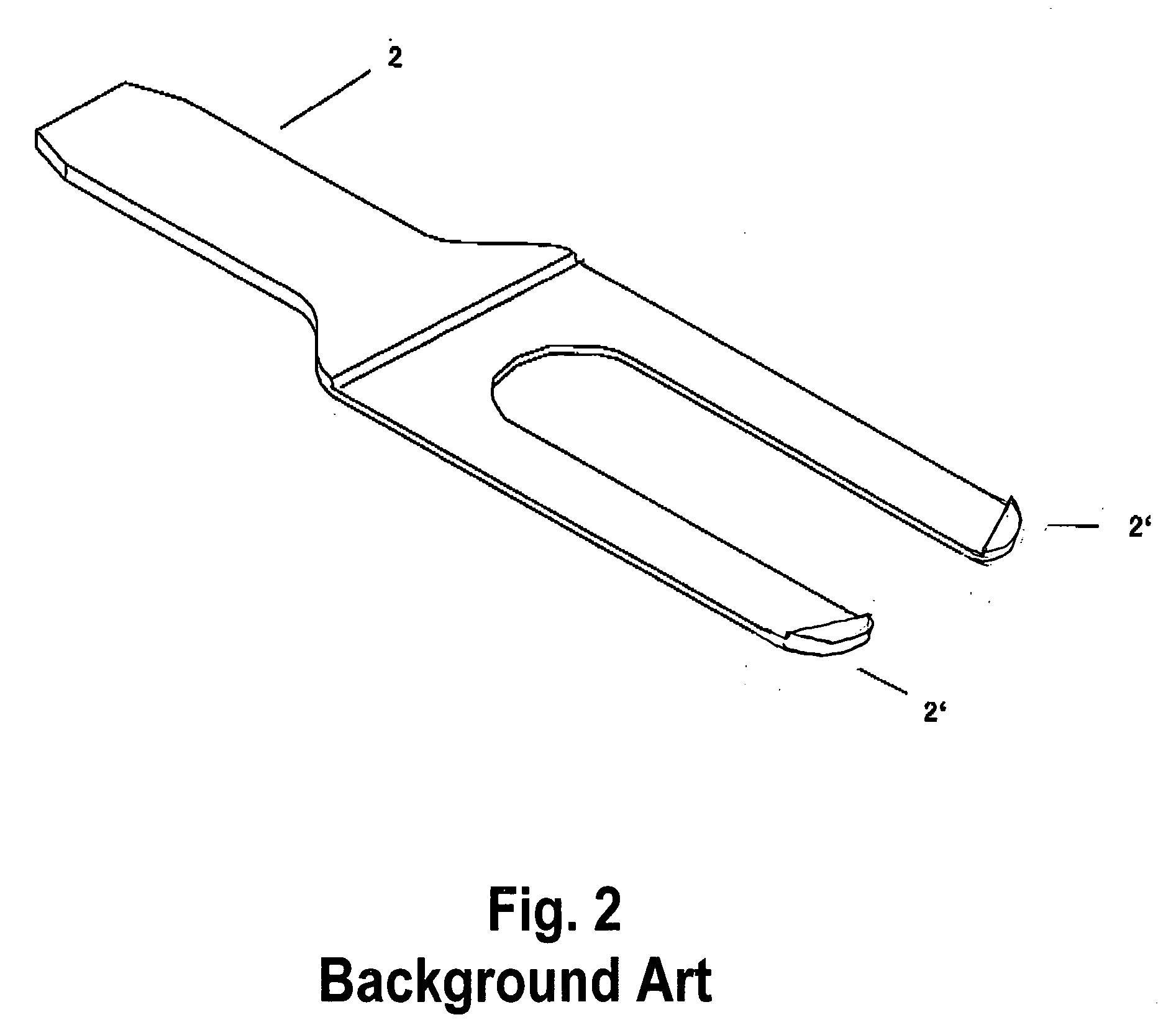

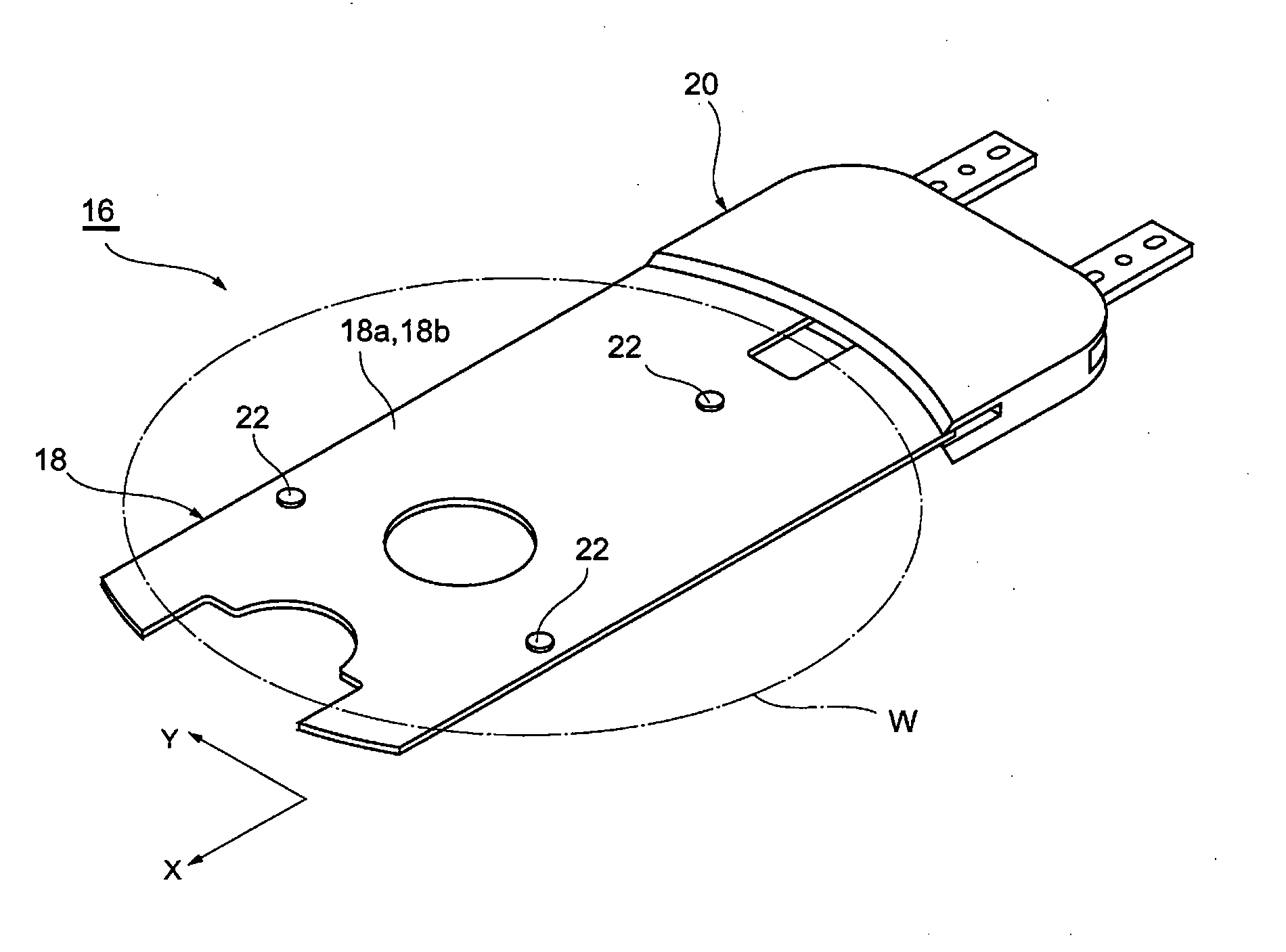

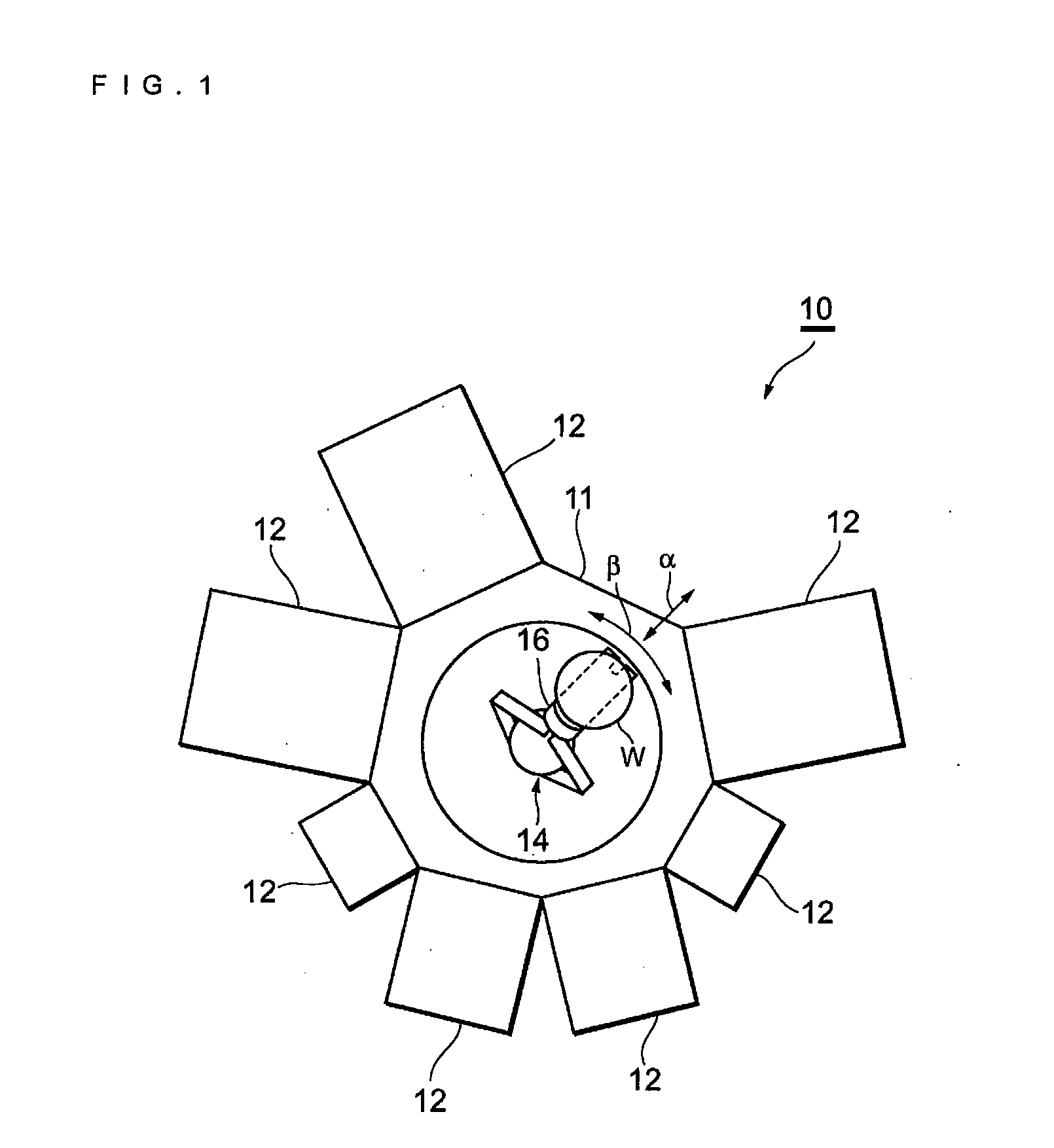

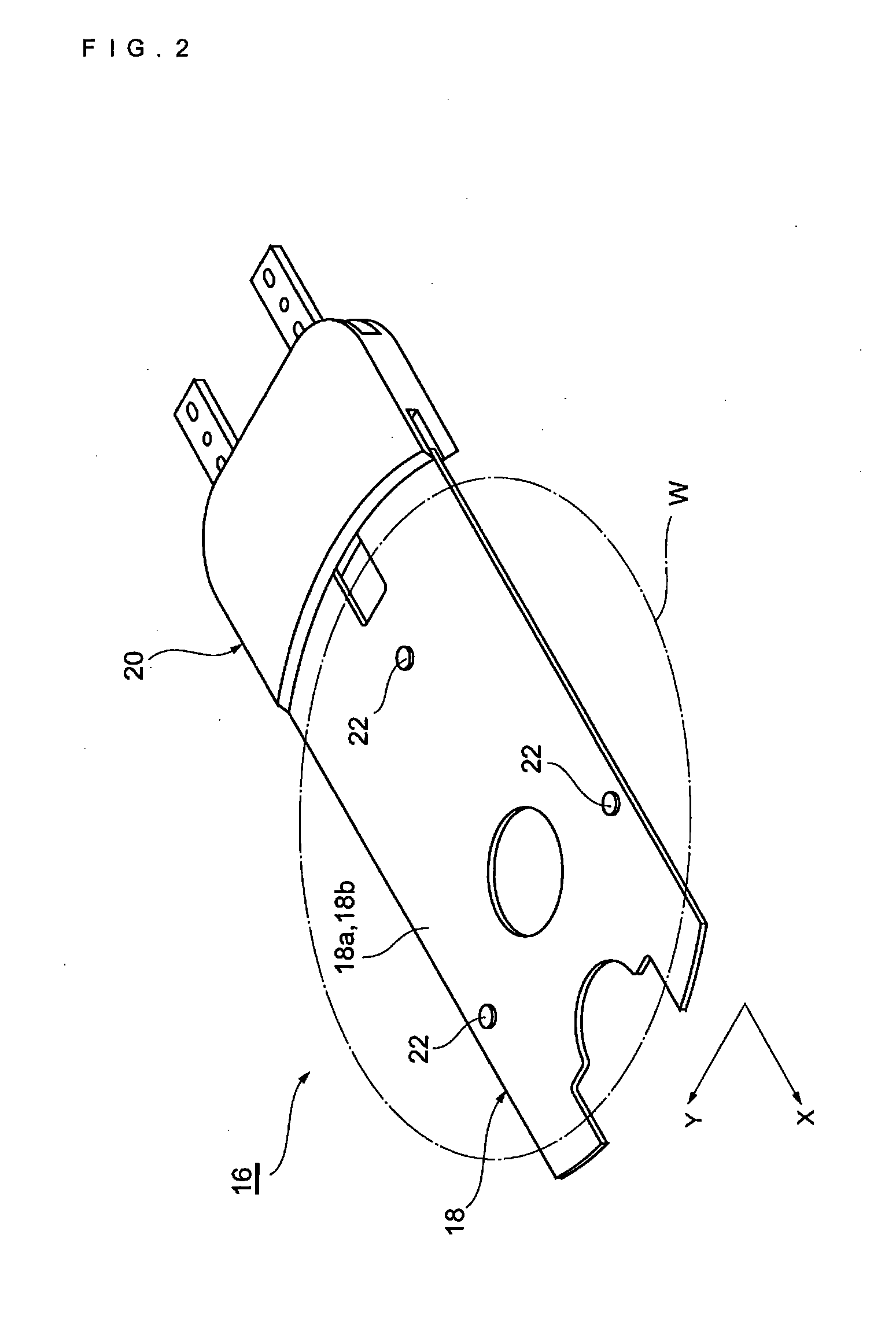

Wafer transfer blade

InactiveUS20090250955A1Reduce defectsSimple structureSemiconductor/solid-state device manufacturingLifting devicesEngineeringSurface roughening

Projections 22 of the blade 16 provided on a blade surface in a wafer-loading region 18b of a body 18 support a wafer W loaded on the blade surface 18a. Since the projections 22 have microgrooves formed by surface roughening the wafer W is retained on the projections 22 with a suppressed displacement. The blade 16 has a simple structure that retains the wafer W without vacuum suction and has no receiving hole to retain the wafer W in the body 18 of the blade 16. This can effectively prevent formation of defects on the wafer W.

Owner:APPLIED MATERIALS INC

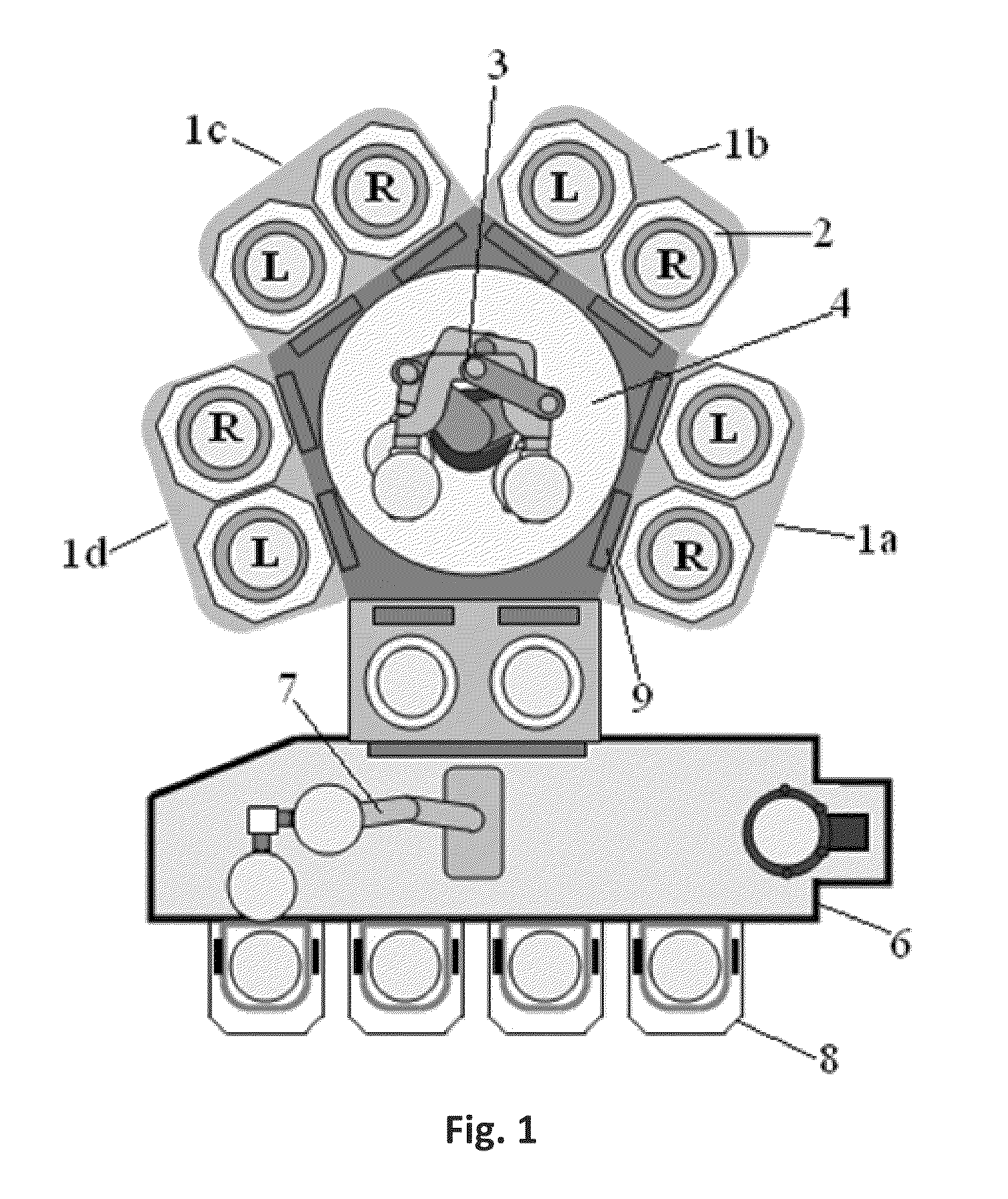

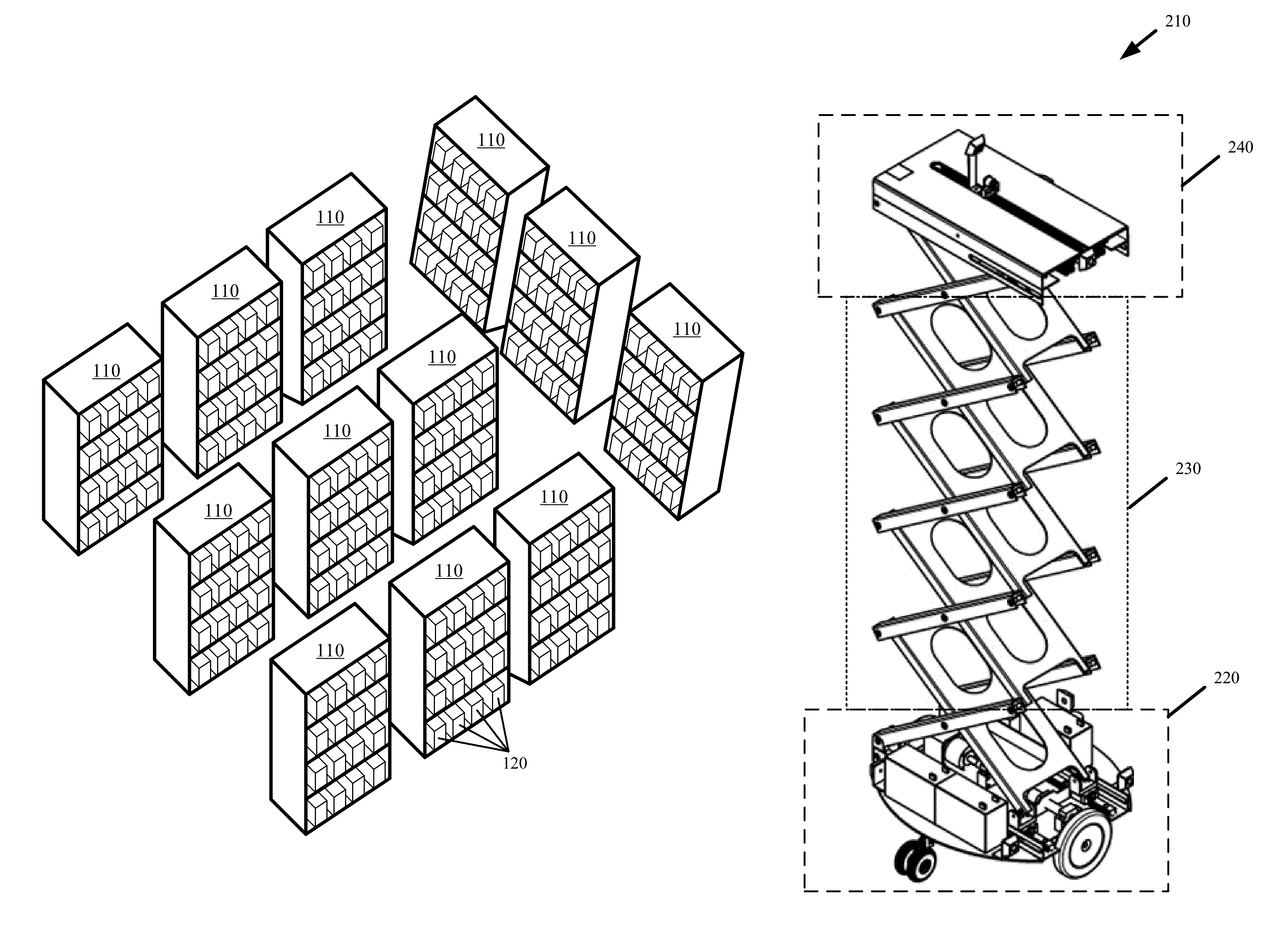

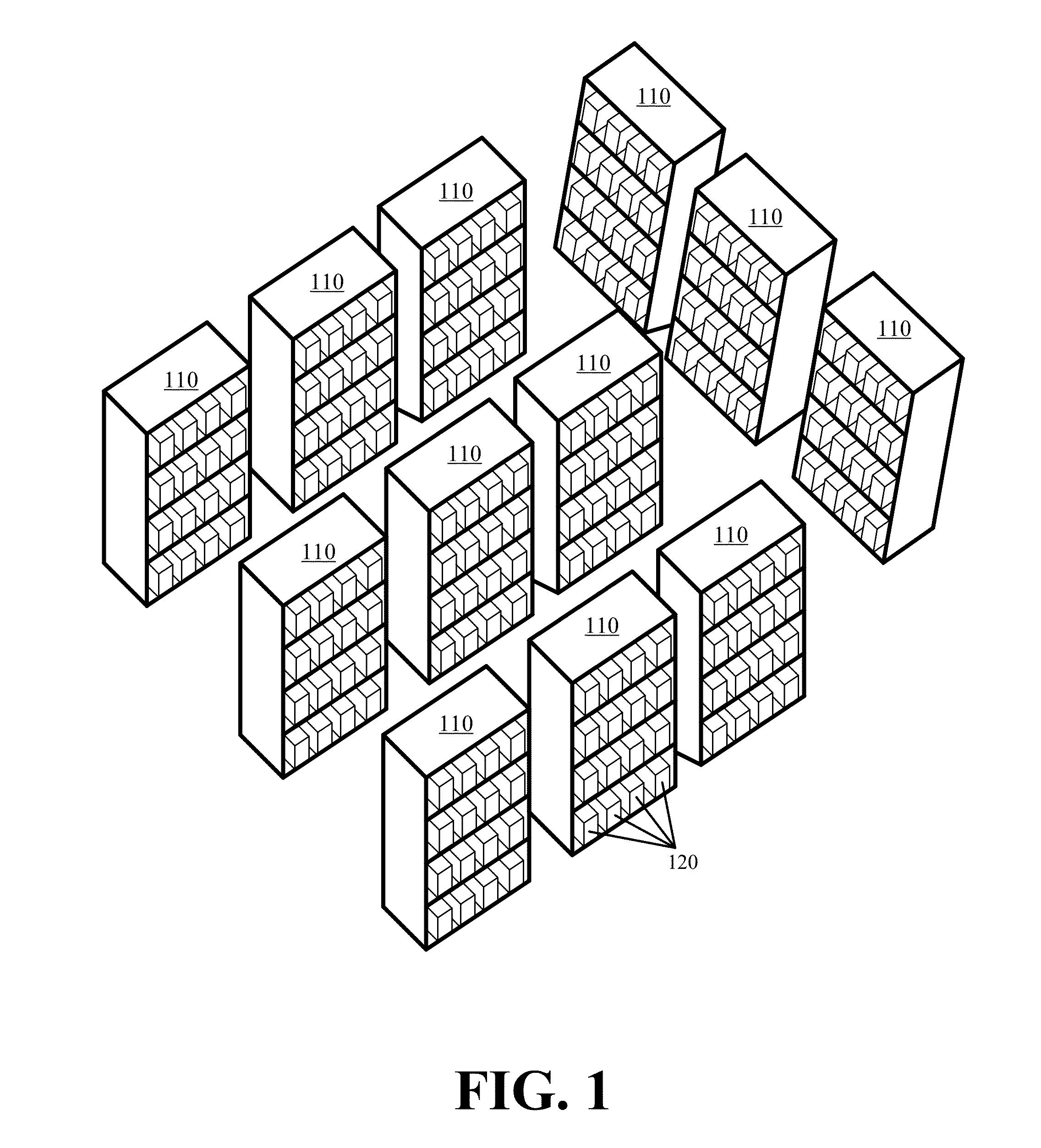

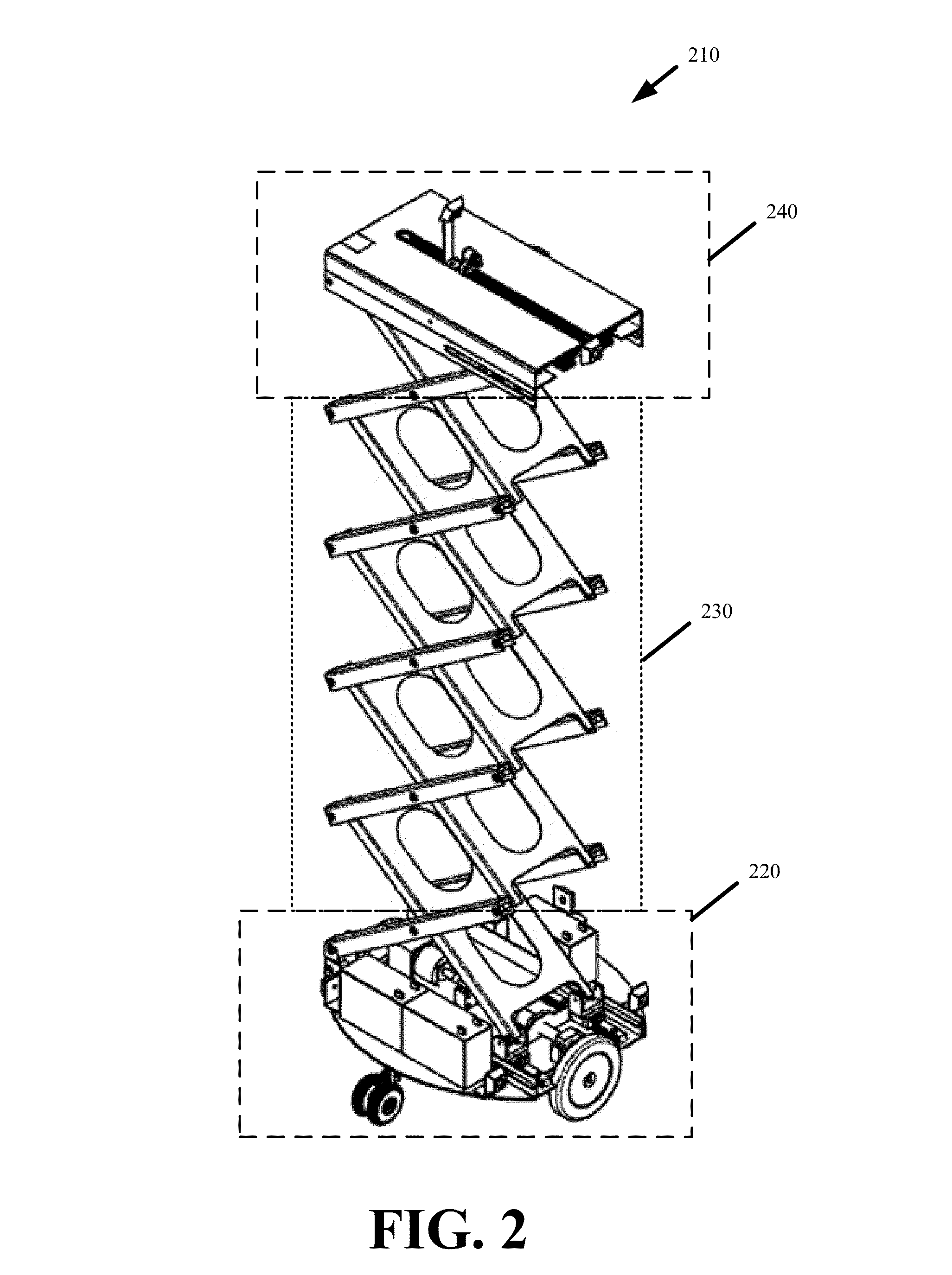

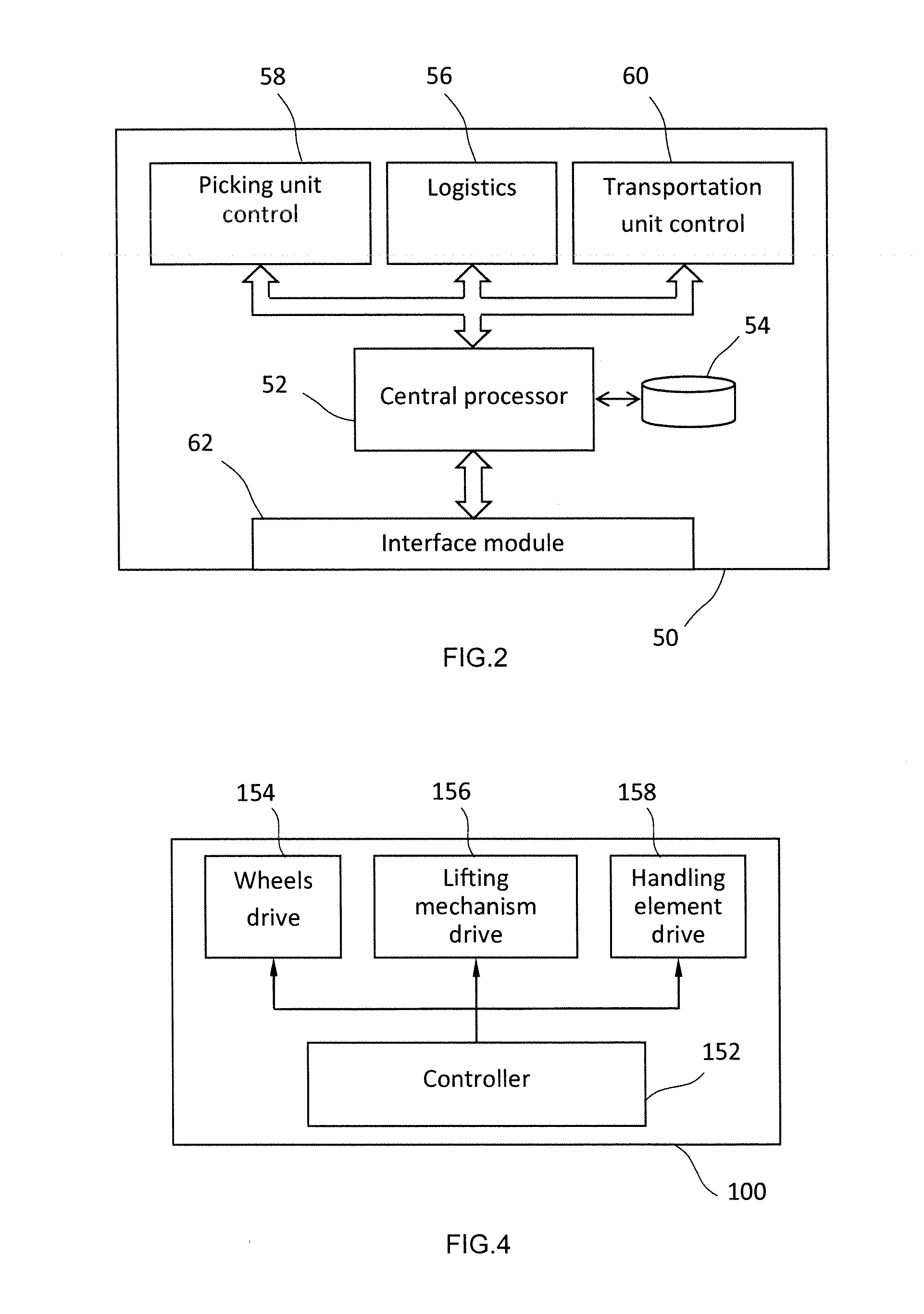

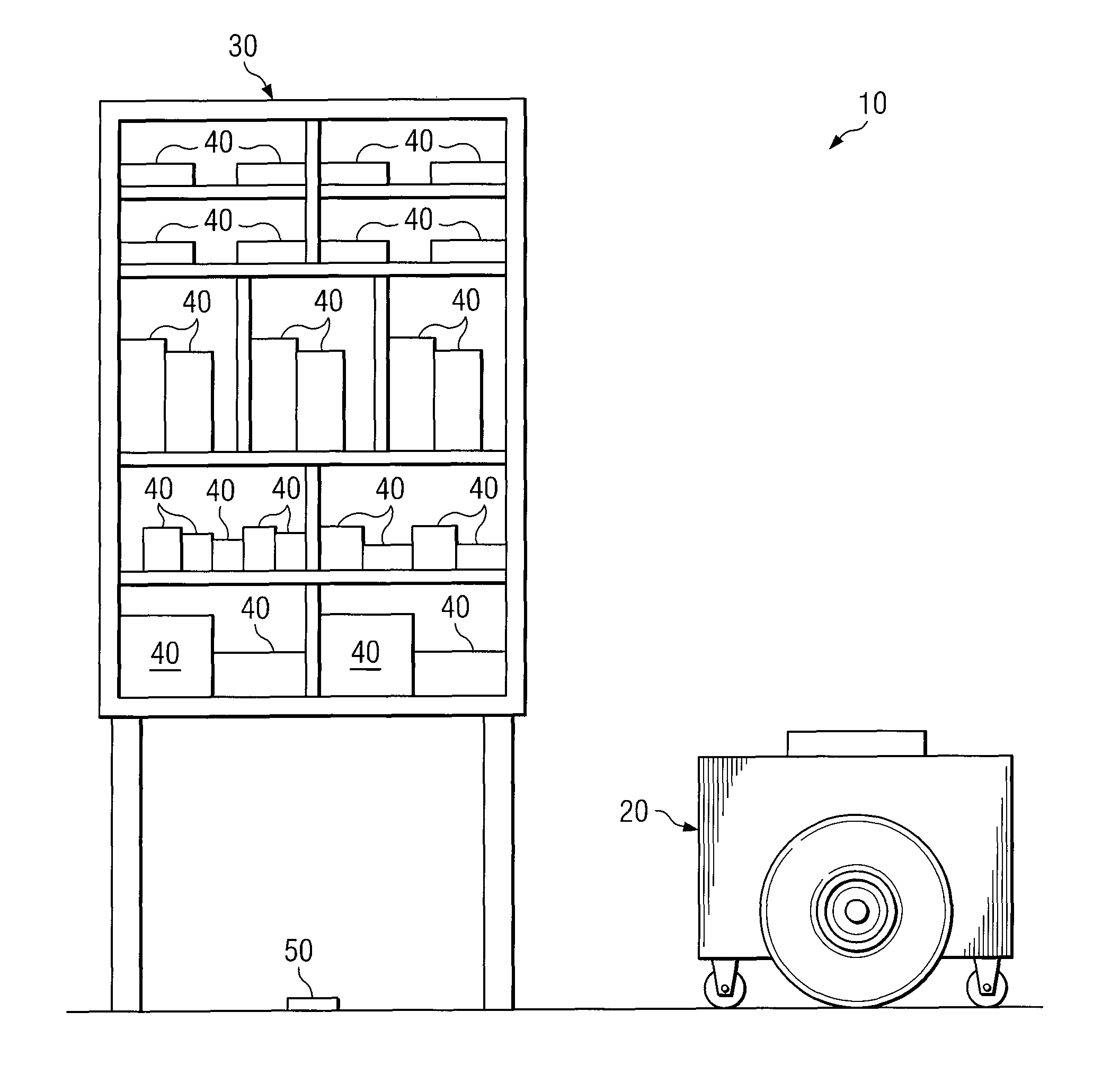

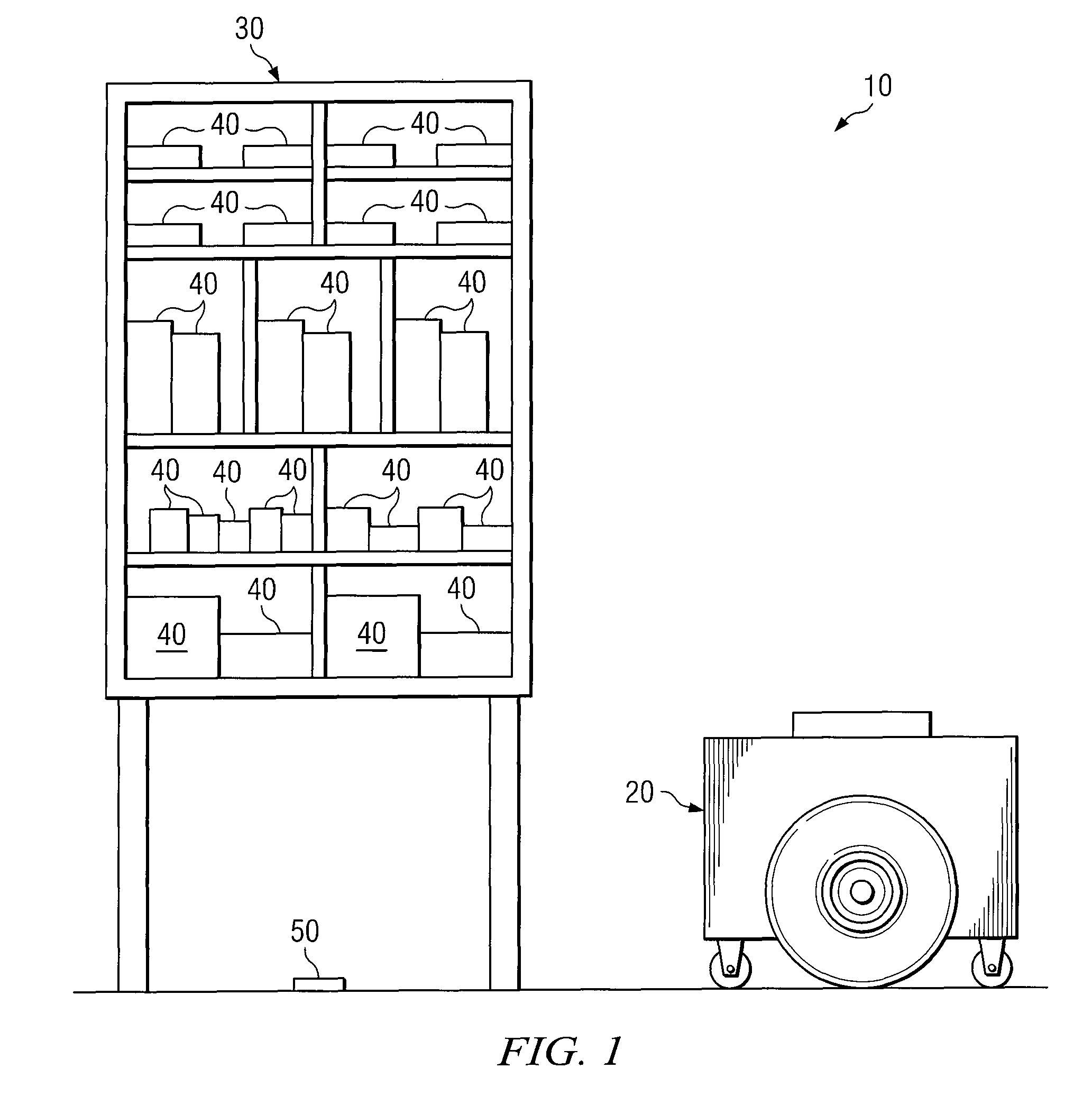

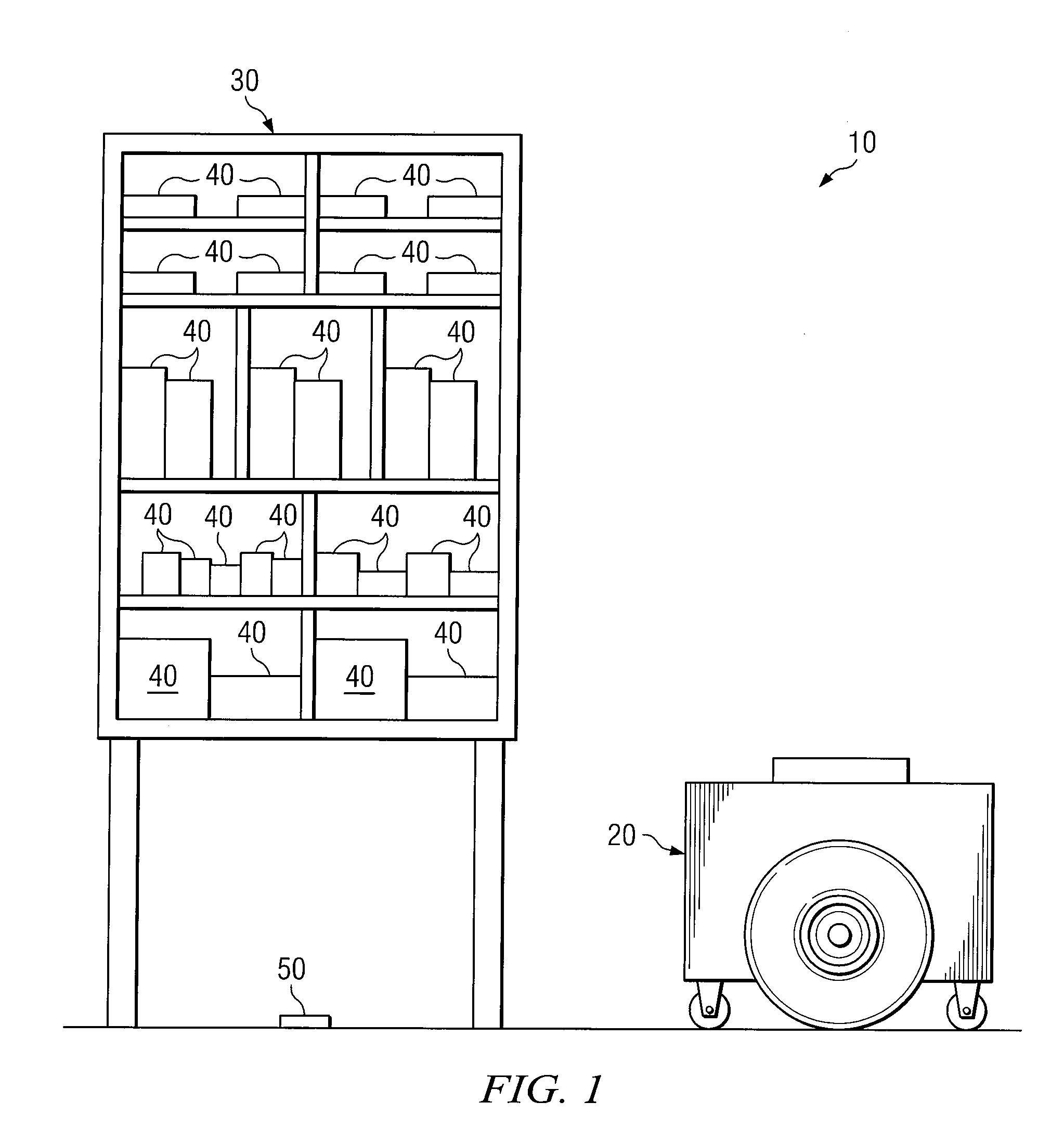

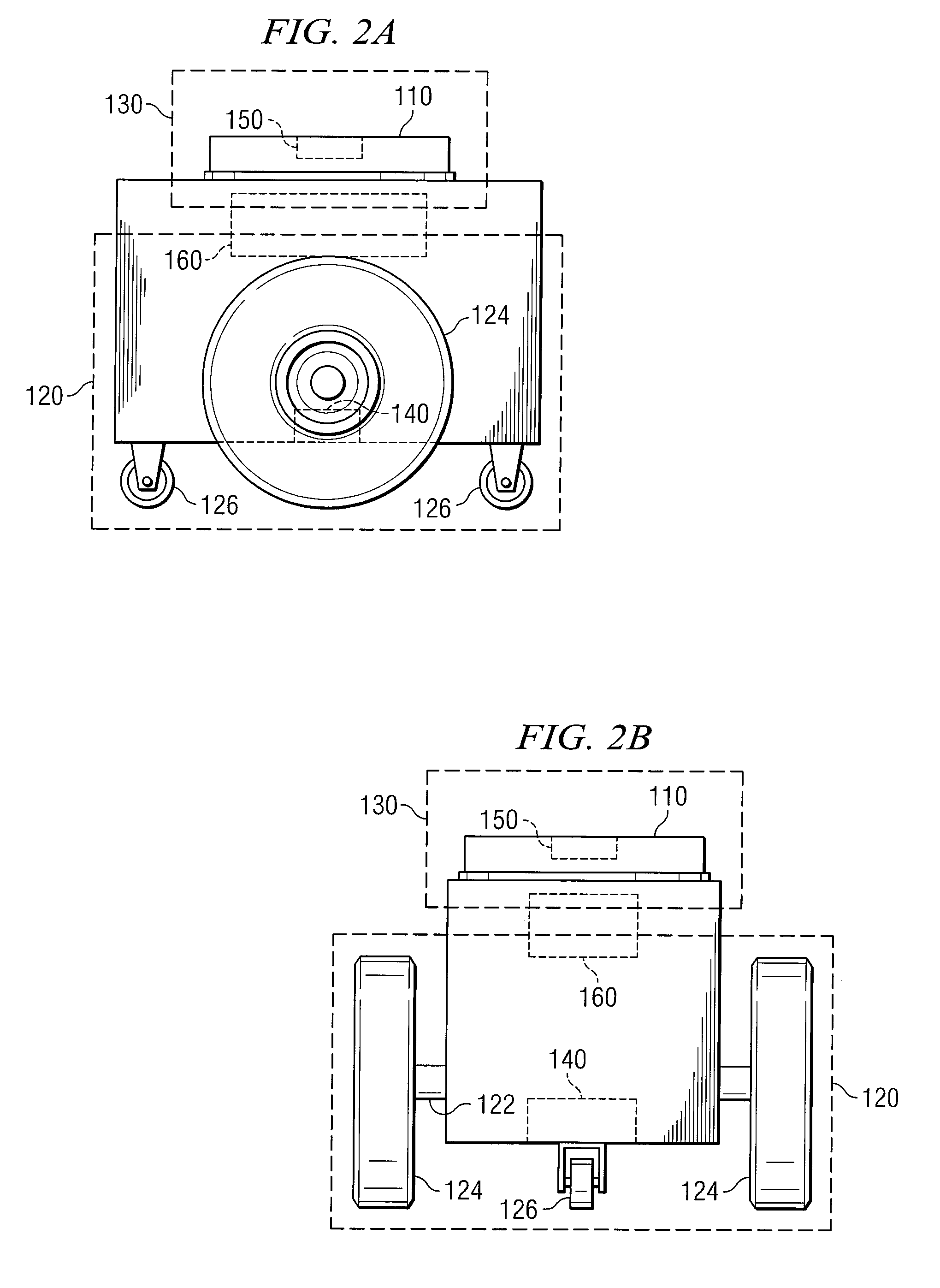

Autonomous order fulfillment and inventory control robots

ActiveUS9120622B1Programme-controlled manipulatorDigital data processing detailsOrder fulfillmentInventory management

Some embodiments provide a system for fully autonomous order fulfillment and inventory management within a distribution site or warehouse. The system operates by autonomous robots directly pulling customer order items from distribution site shelves or pulling individual bins from distribution site shelves and dispensing appropriate quantities of items from the bins until all items of a customer order are retrieved without human involvement. The system further involves the robots autonomously monitoring item quantities within the distribution site, identifying and autonomously responding to shortages, and organizing the items within the distribution site for most efficient order fulfillment.

Owner:INVIA ROBOTICS INC

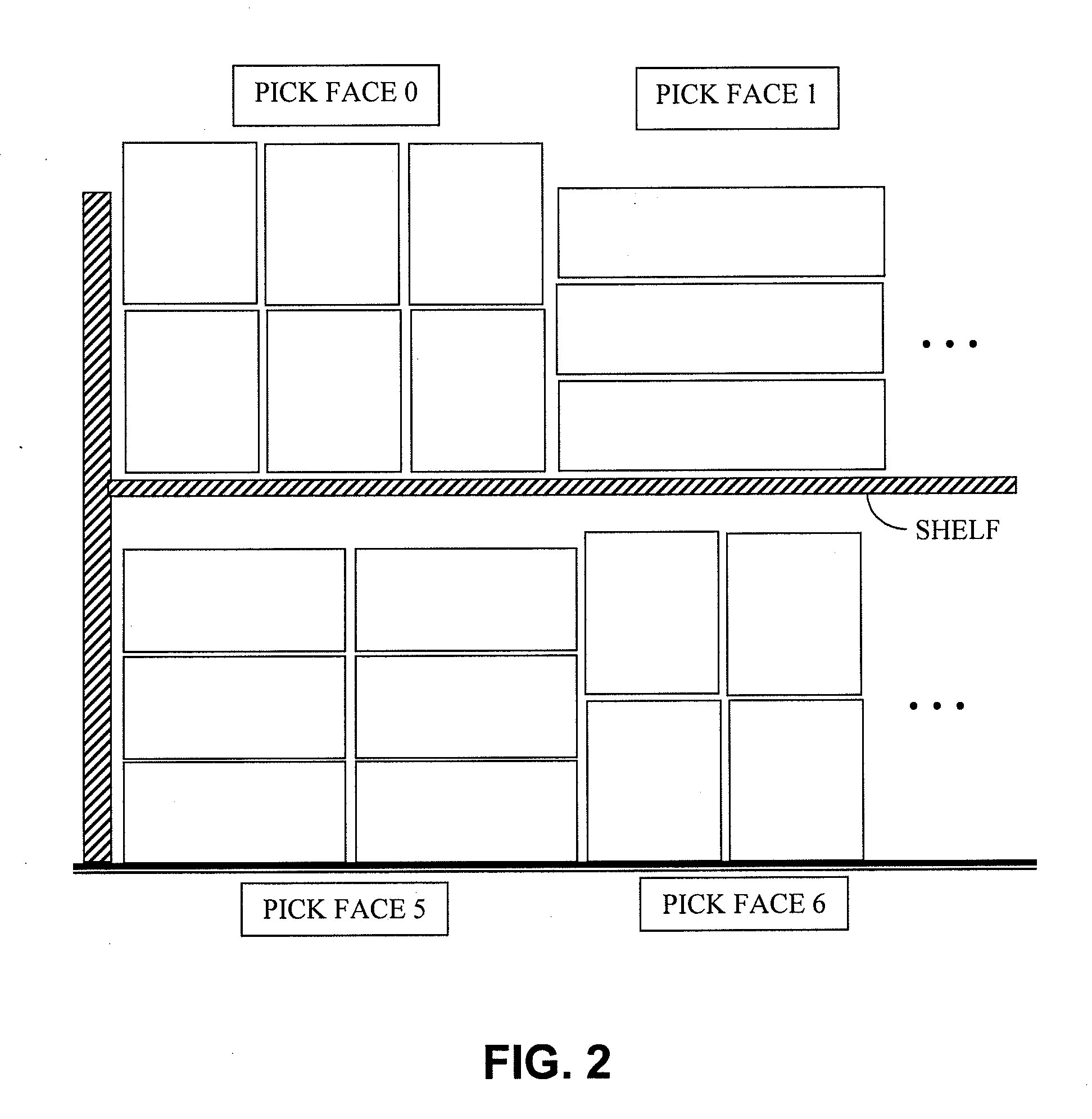

Automatic order picking system and method in retail facility

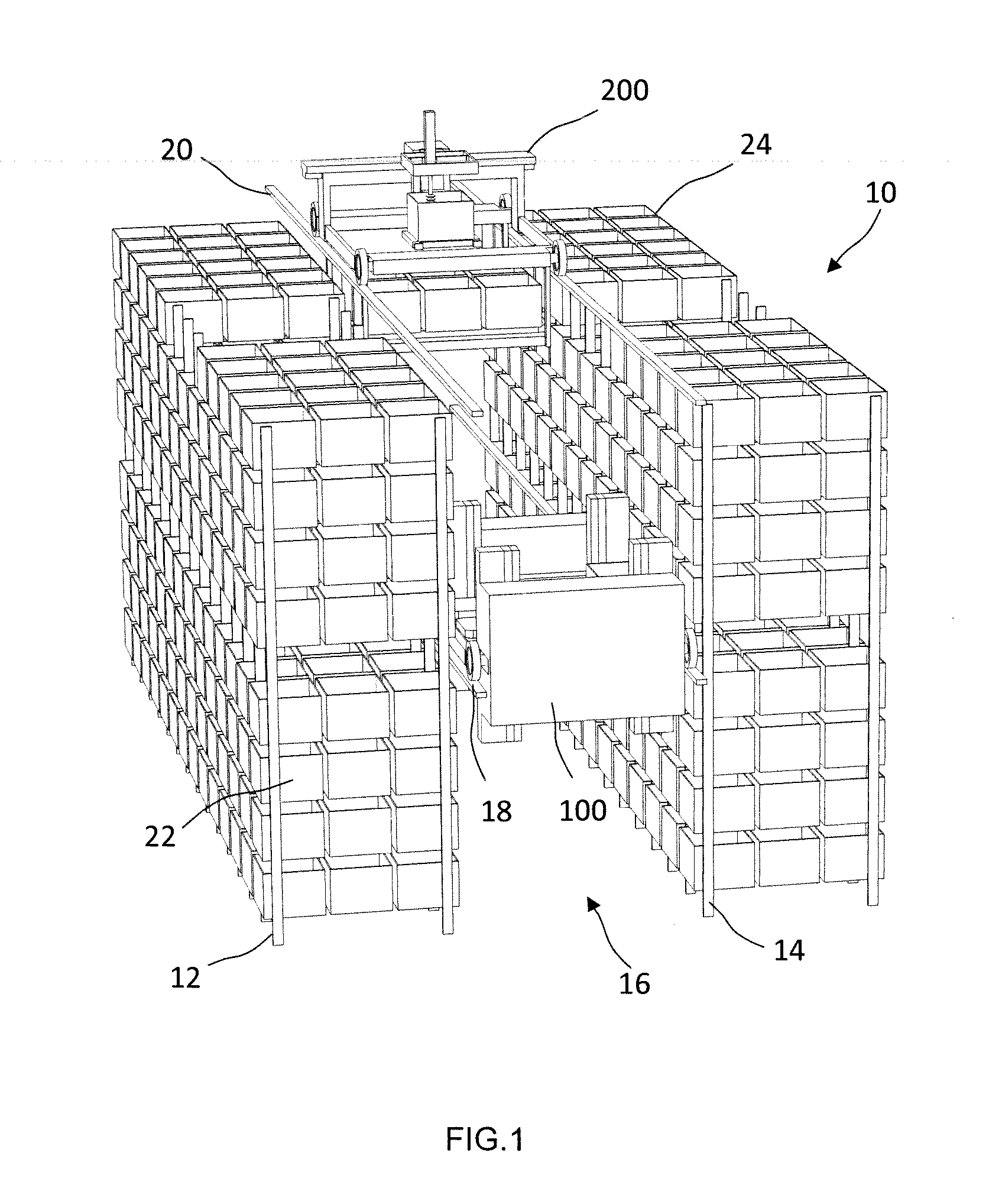

InactiveUS20150098775A1Reduce order picking timeShorter picking timeConveyorsLifting devicesTransport engineering

An order picking system includes a storage system for storing containers arranged in multiple rows at various horizontal levels with respect to ground, the containers including source containers with goods stored in the storage system and reception containers to be filled with the ordered goods. At least one mobile picking unit may be moved in a horizontal direction along an upper level of the storage system, the picking unit is configured for taking ordered goods from the source containers arranged at the upper level and placing the ordered goods into the reception containers for delivery to the customers. At least one transportation unit may be moved along a lower level of the storage system arranged lower than the upper level. The transportation unit is configured for taking the containers from levels of the storage system lower than the upper level, and delivering the containers to the upper level.

Owner:ATOOL TRADING LTD

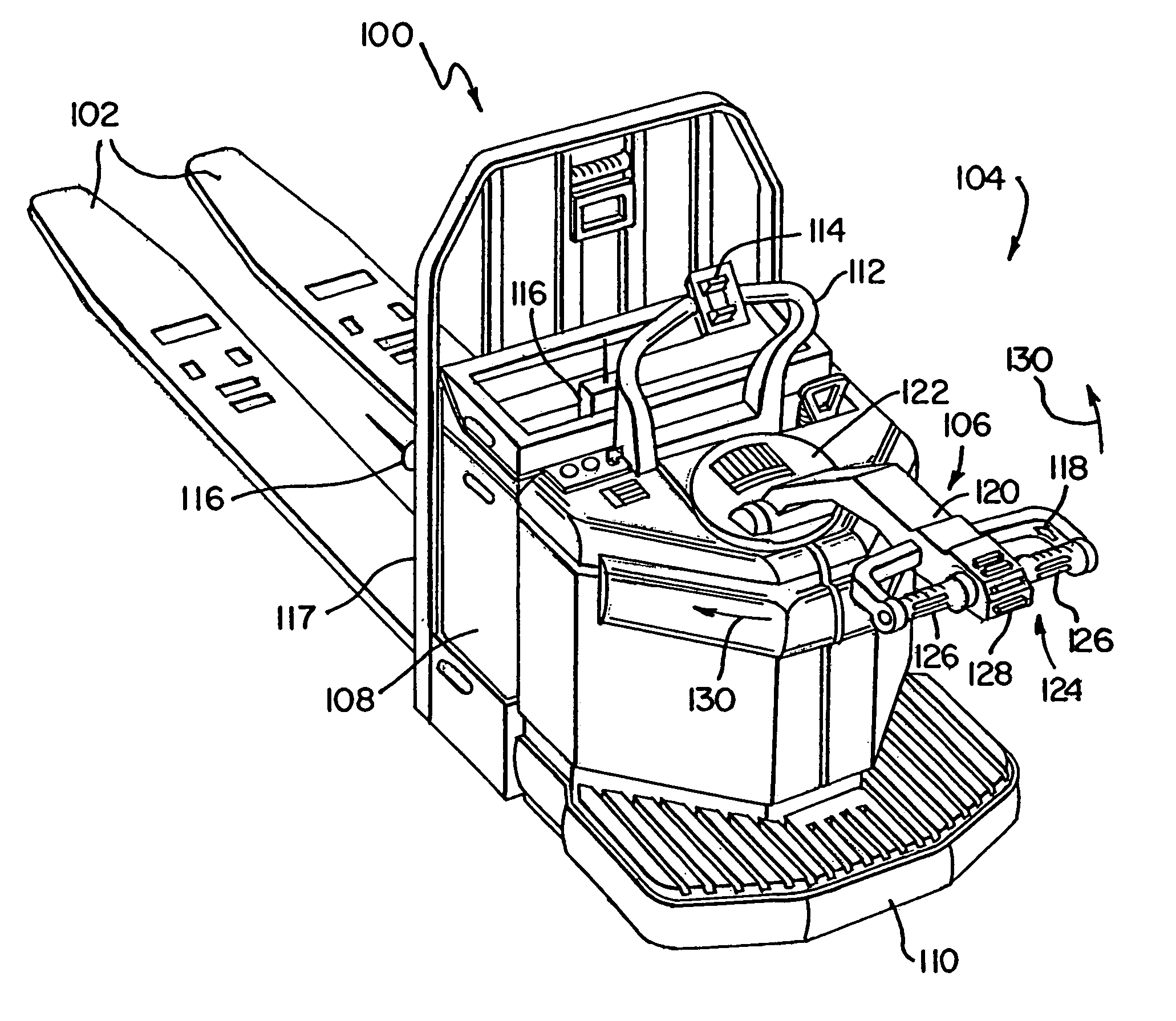

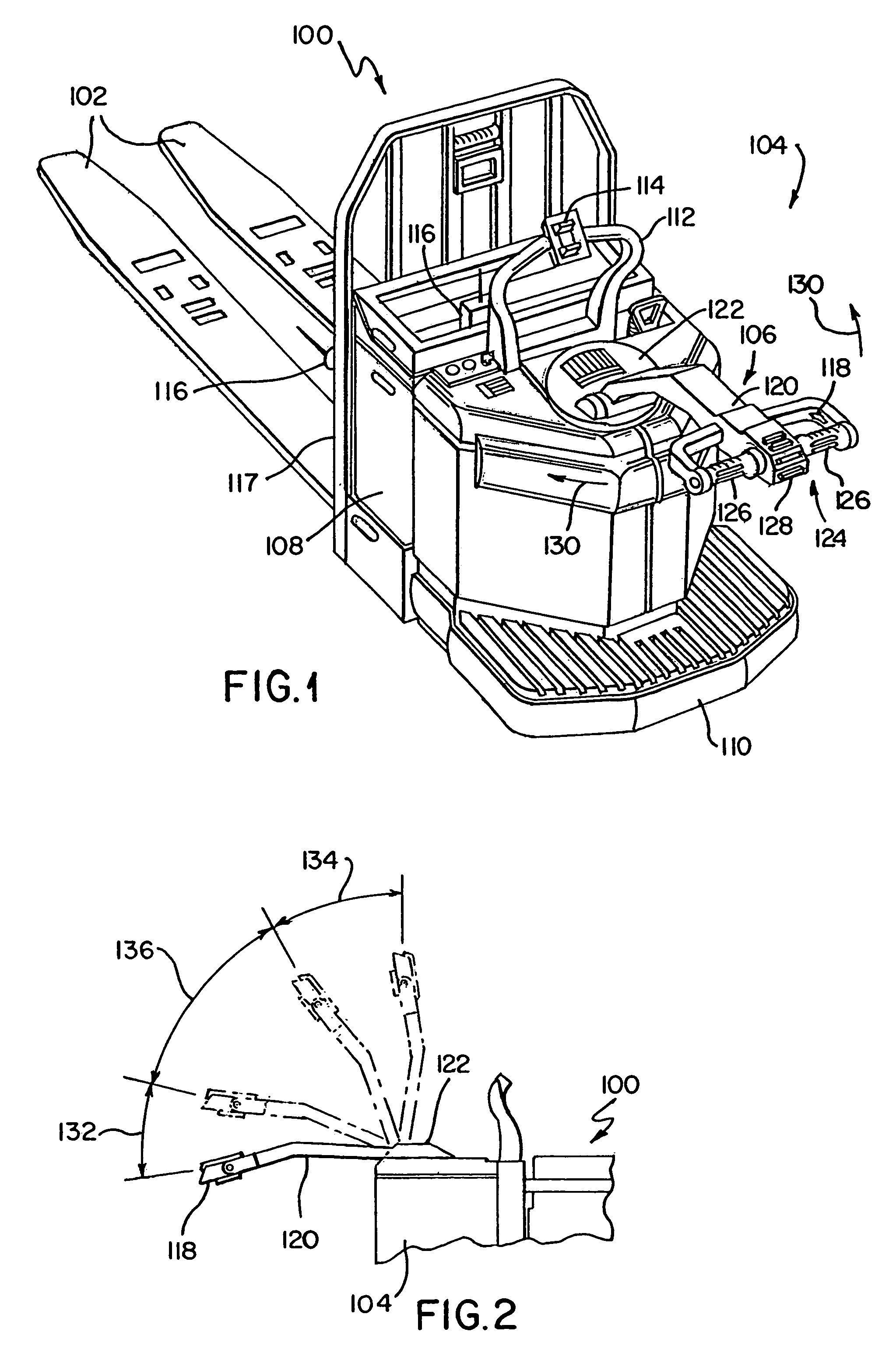

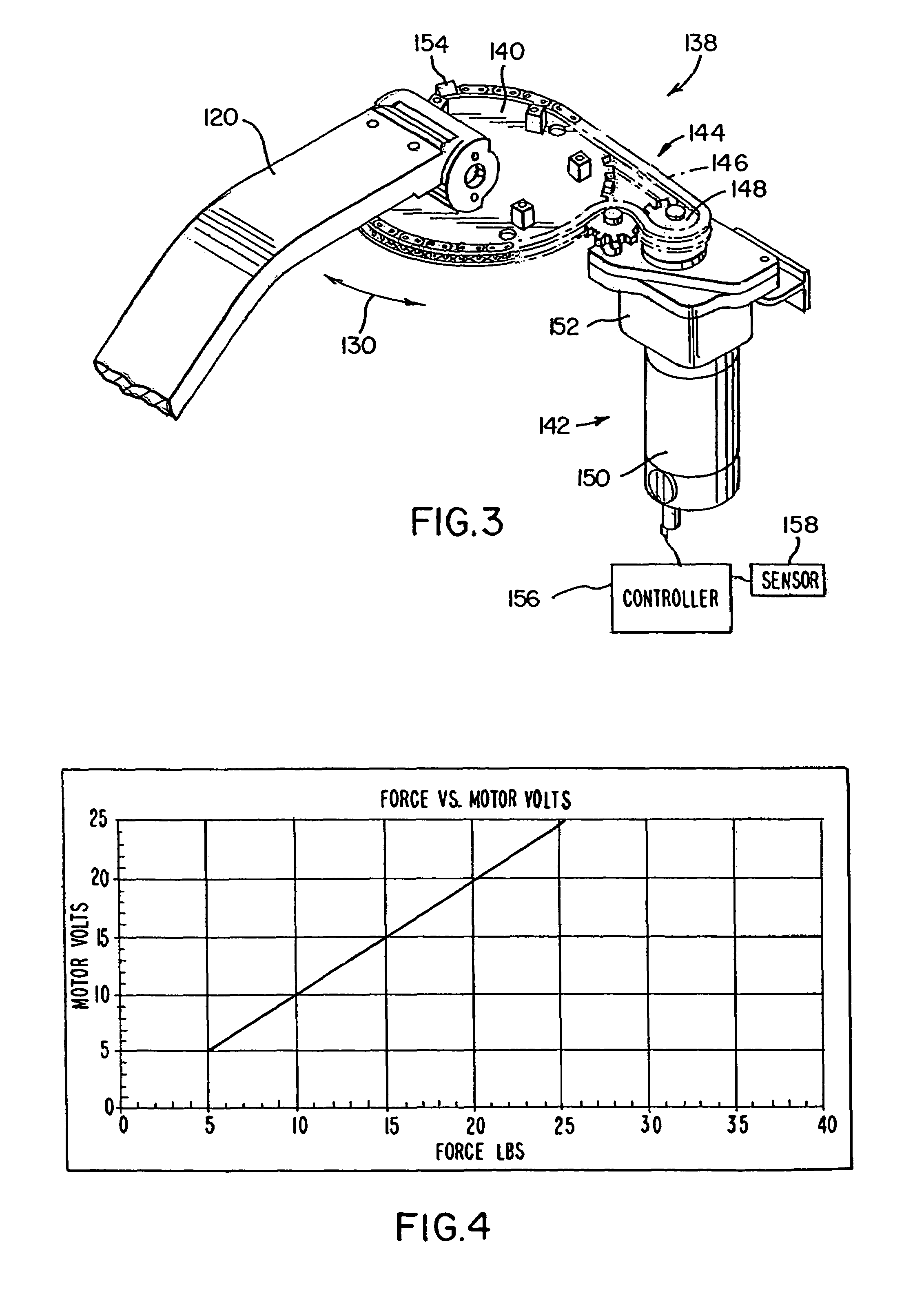

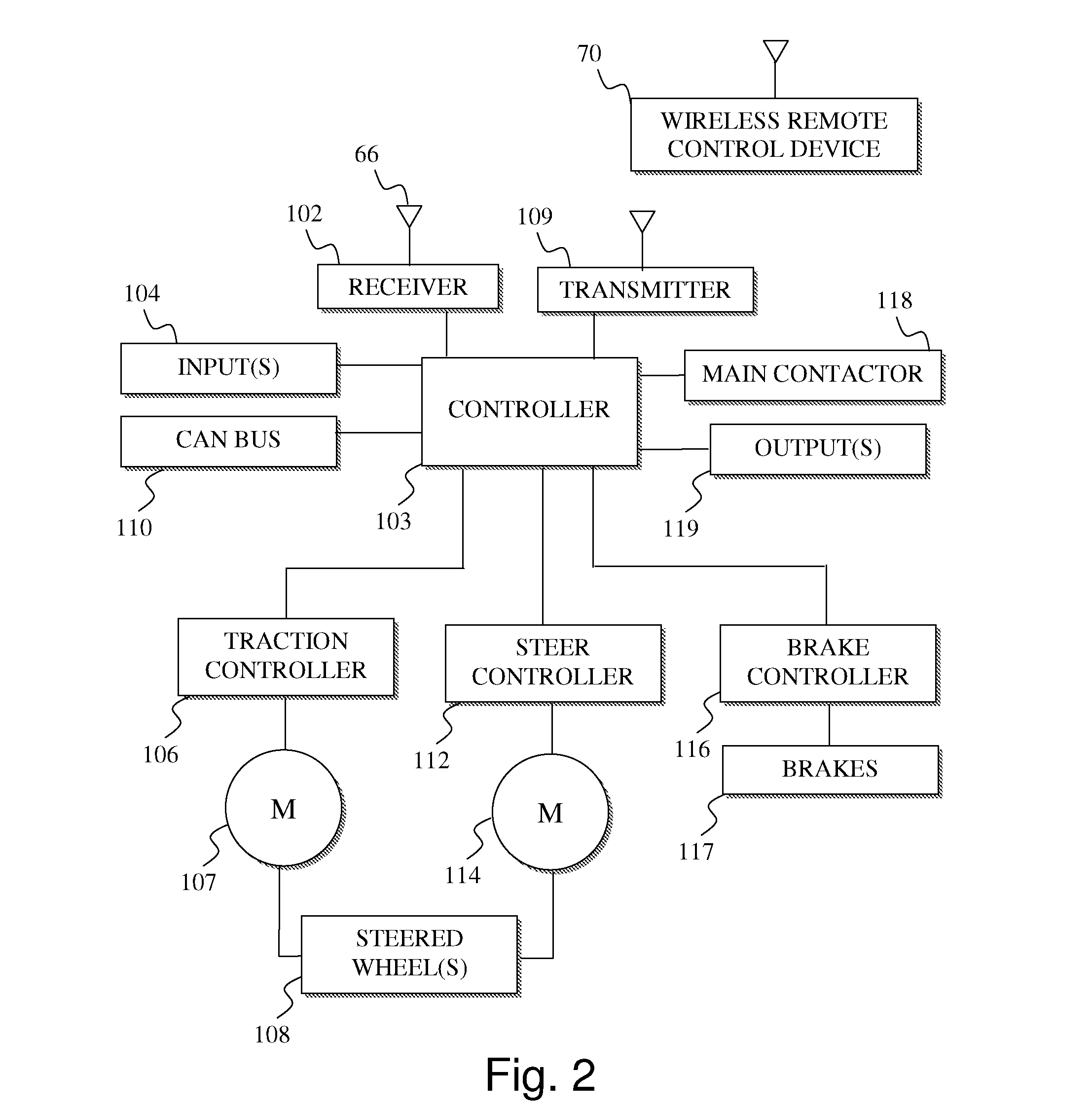

Electrical steering assist for material handling vehicles

Electrical steering assist systems reduce the operator applied steering effort necessary to operate material handling vehicles. A steer drive unit including a motor is coupled to a steerable wheel for providing steering assist. The amount of steering assist provided by the steer drive unit is determined by a controller that receives input from one or more input sensing devices. The input sensing device(s) may include force sensors that detect an operator applied turning force. The input sensing device(s) may also detect the movement of one steering component relative to another. Further, the input sensing device(s) may include operator activated controls such as a joystick, potentiometer, switches and voice initiated commands. Input sensing device(s) may additionally be provided to detect operational parameters such as the load on the material handling vehicle, vehicle speed, or environmental conditions such as travel path obstruction detection, homing and proximity sensing.

Owner:CROWN EQUIP CORP

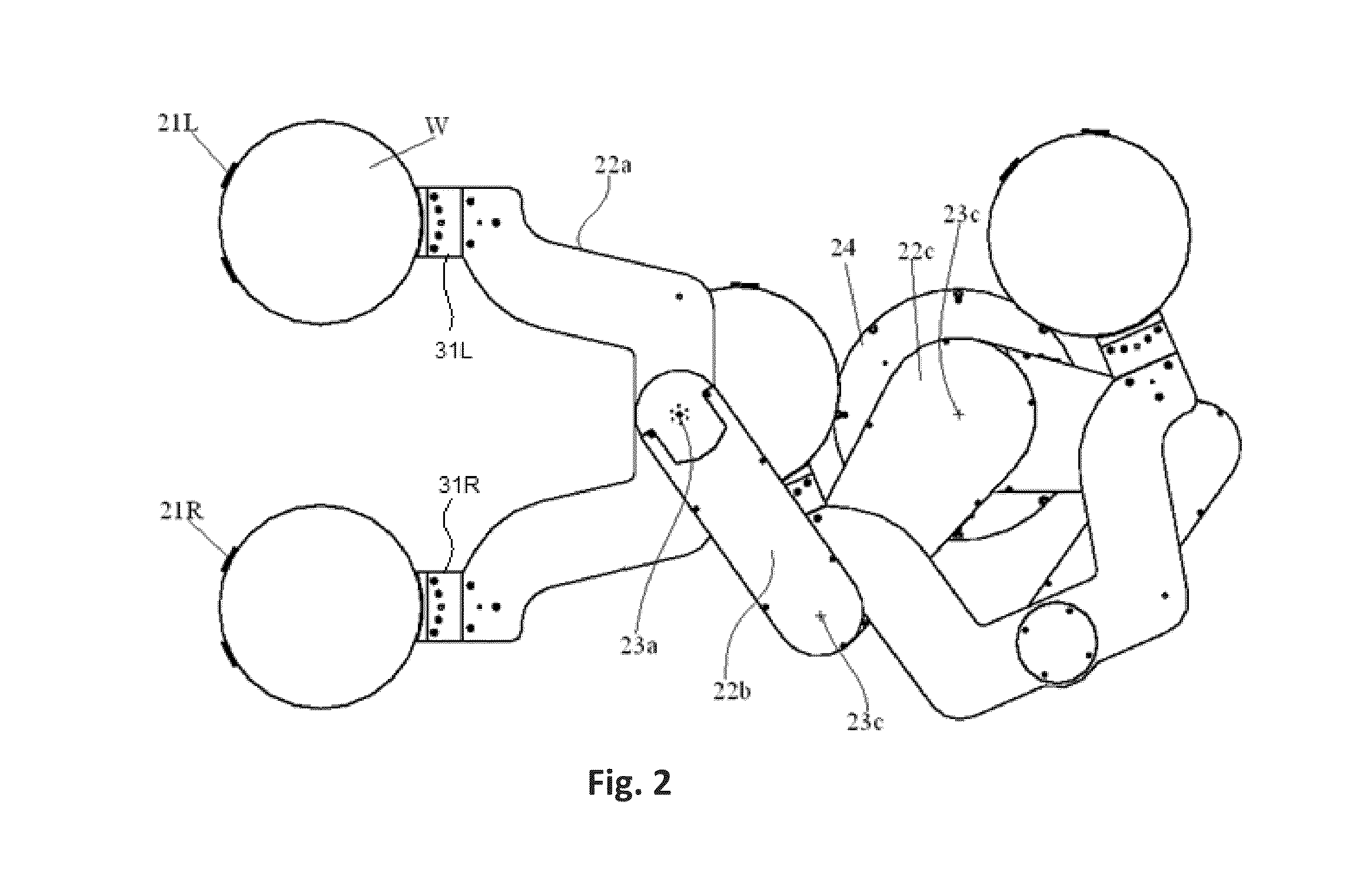

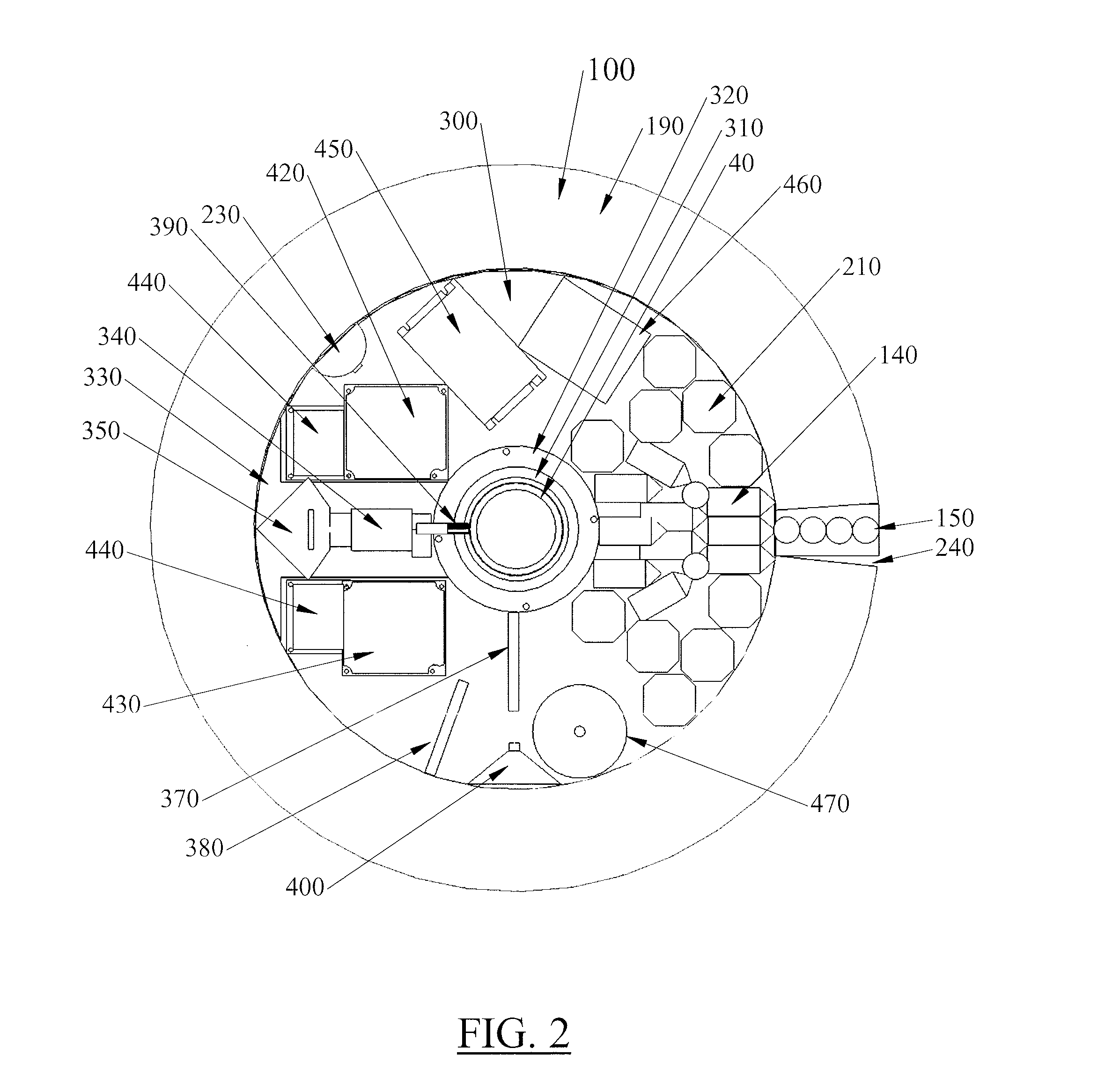

Modular hybrid snake arm

ActiveUS20080302200A1Reduced arm manufacturing costImprove work performanceMechanical apparatusJointsModularitySimulation

An intelligent modular hybrid robot arm system is usable with mobile robots, and is applicable to stationary industrial arms. The intelligent modular hybrid robot arm system provides a large work envelope and a controlled and directed rotational movement for a flexible snake robot arm. The intelligent modular hybrid robot arm system has the ability to change end effector tools and sensors. The platform computers have the ability to interact with other subsystems for coordinated as well as independent tasks. The flexibly snake robot arm can be covered with a flexible sensor network, or “skin”. The intelligent modular hybrid robot arm system can manage its energy use, stores the arm in a compact shape and uses a central support tube offering unobstructed arm access to all sectors of its working envelope.

Owner:CYCOGS

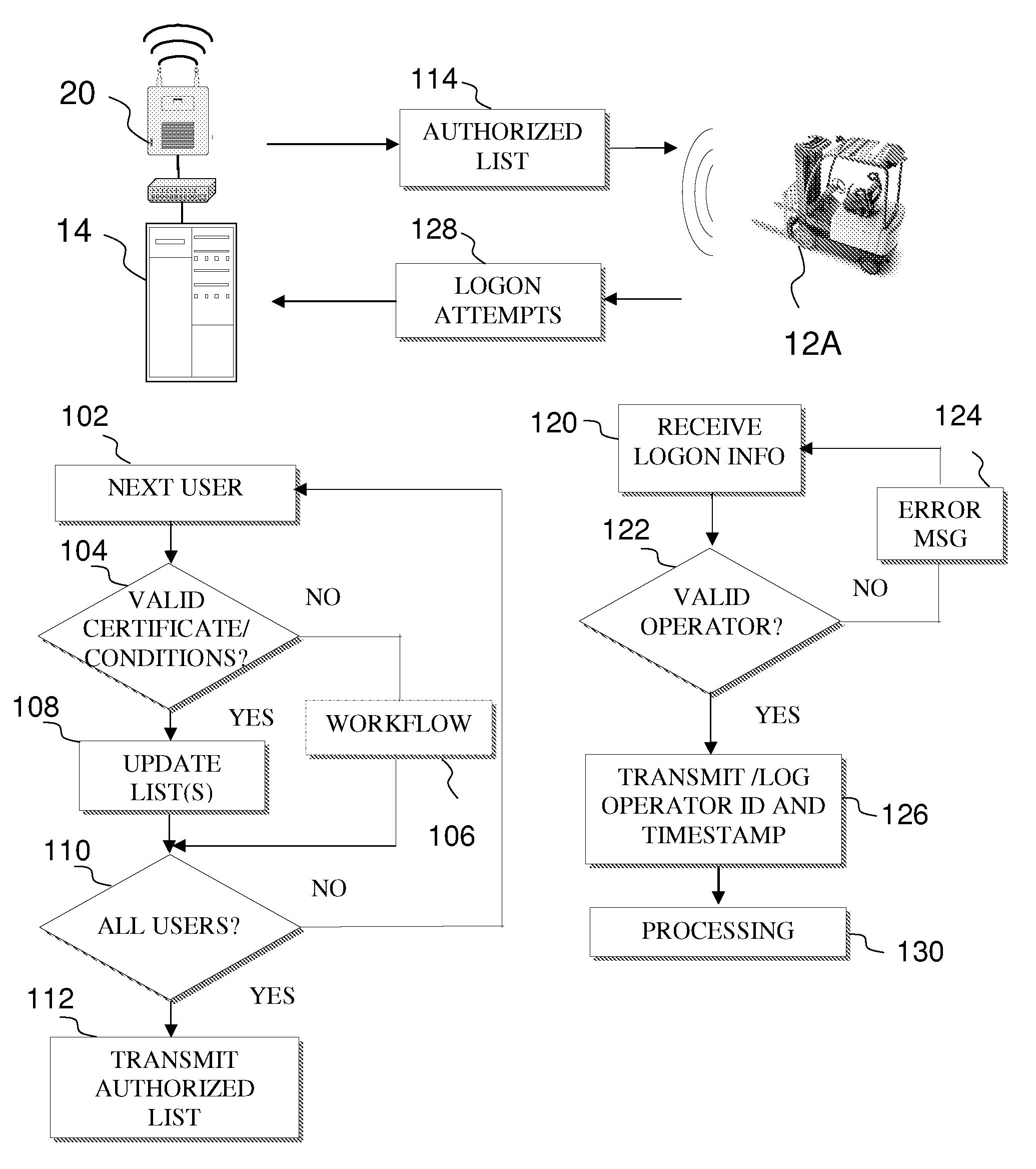

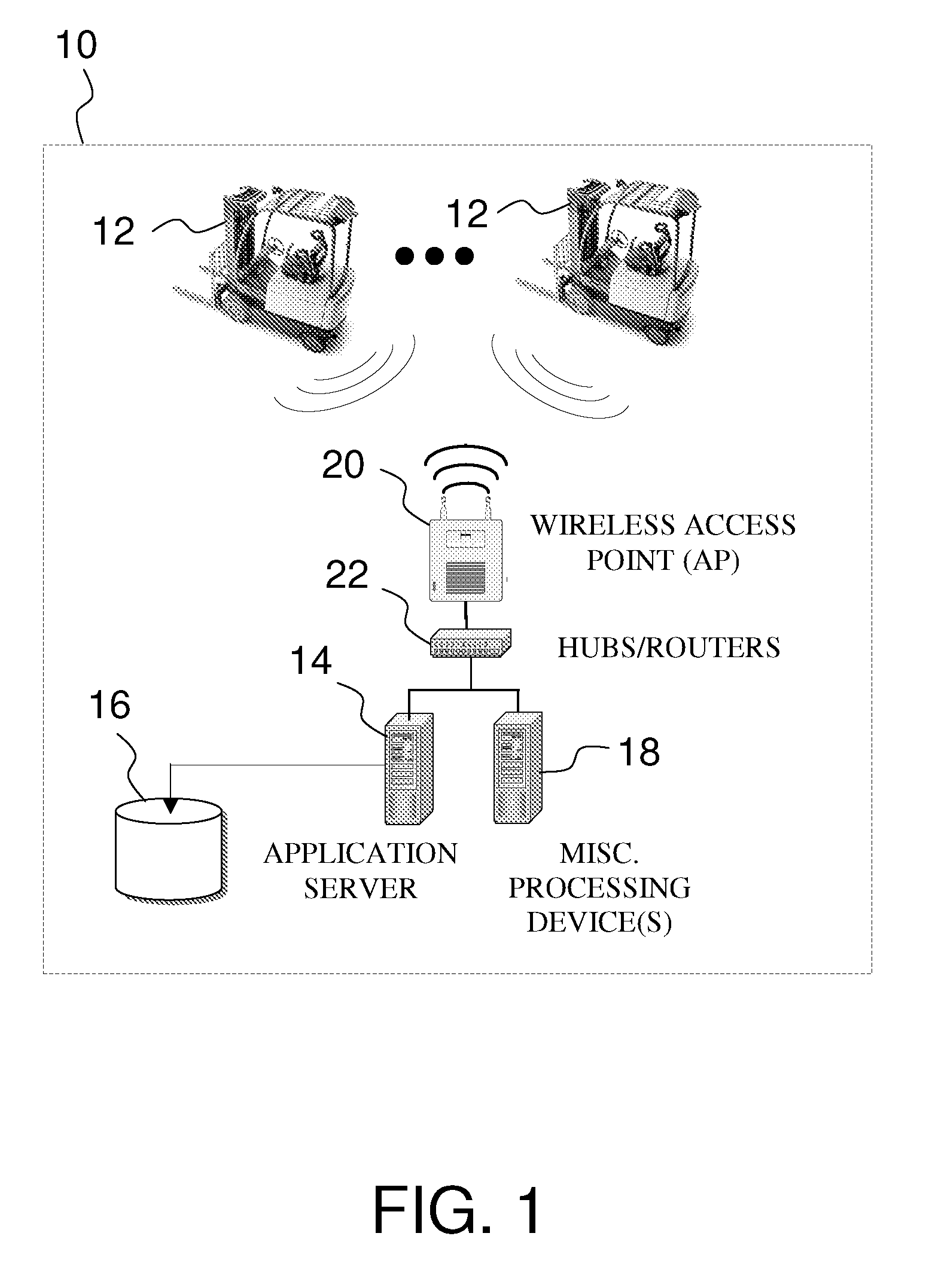

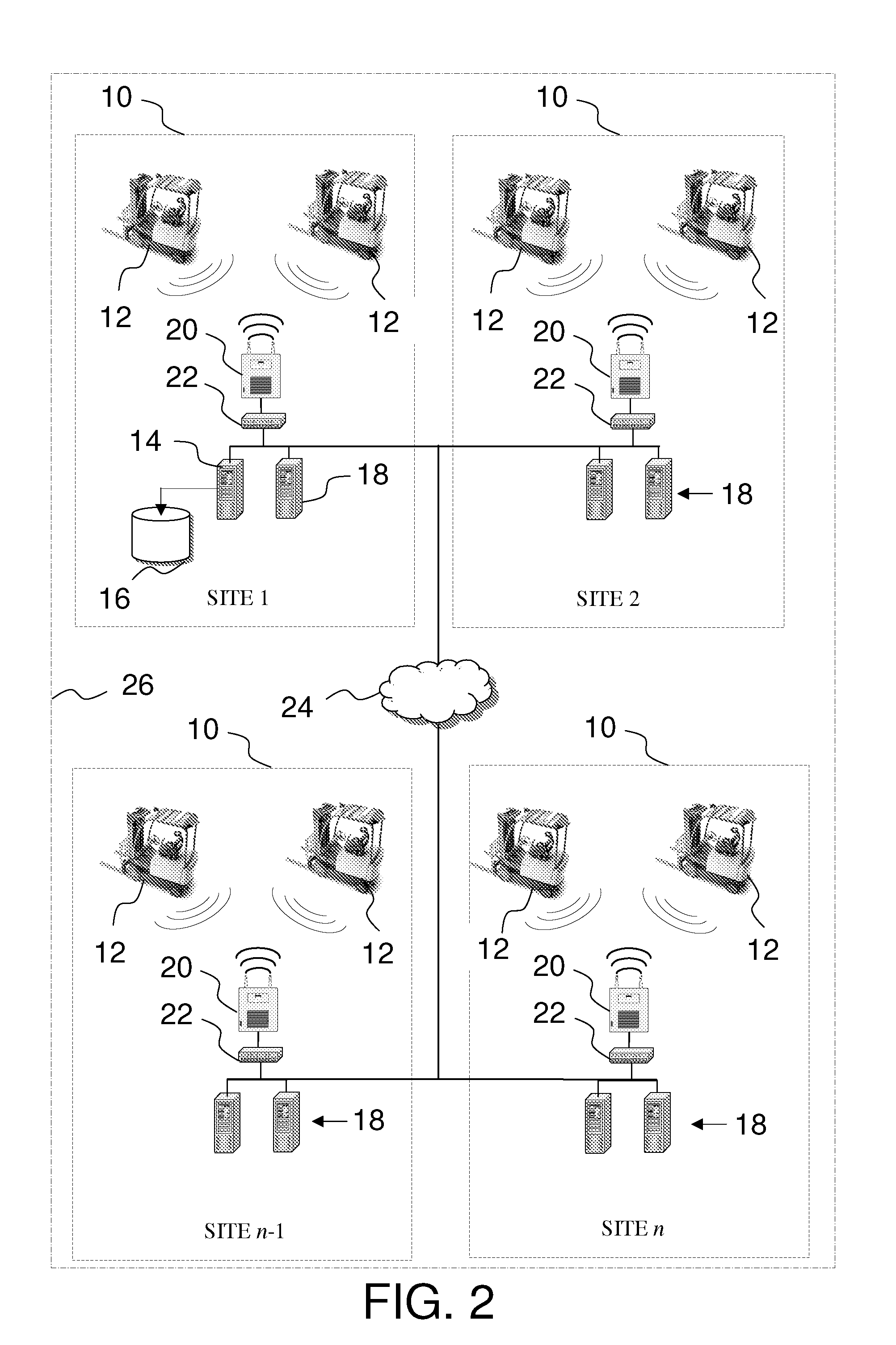

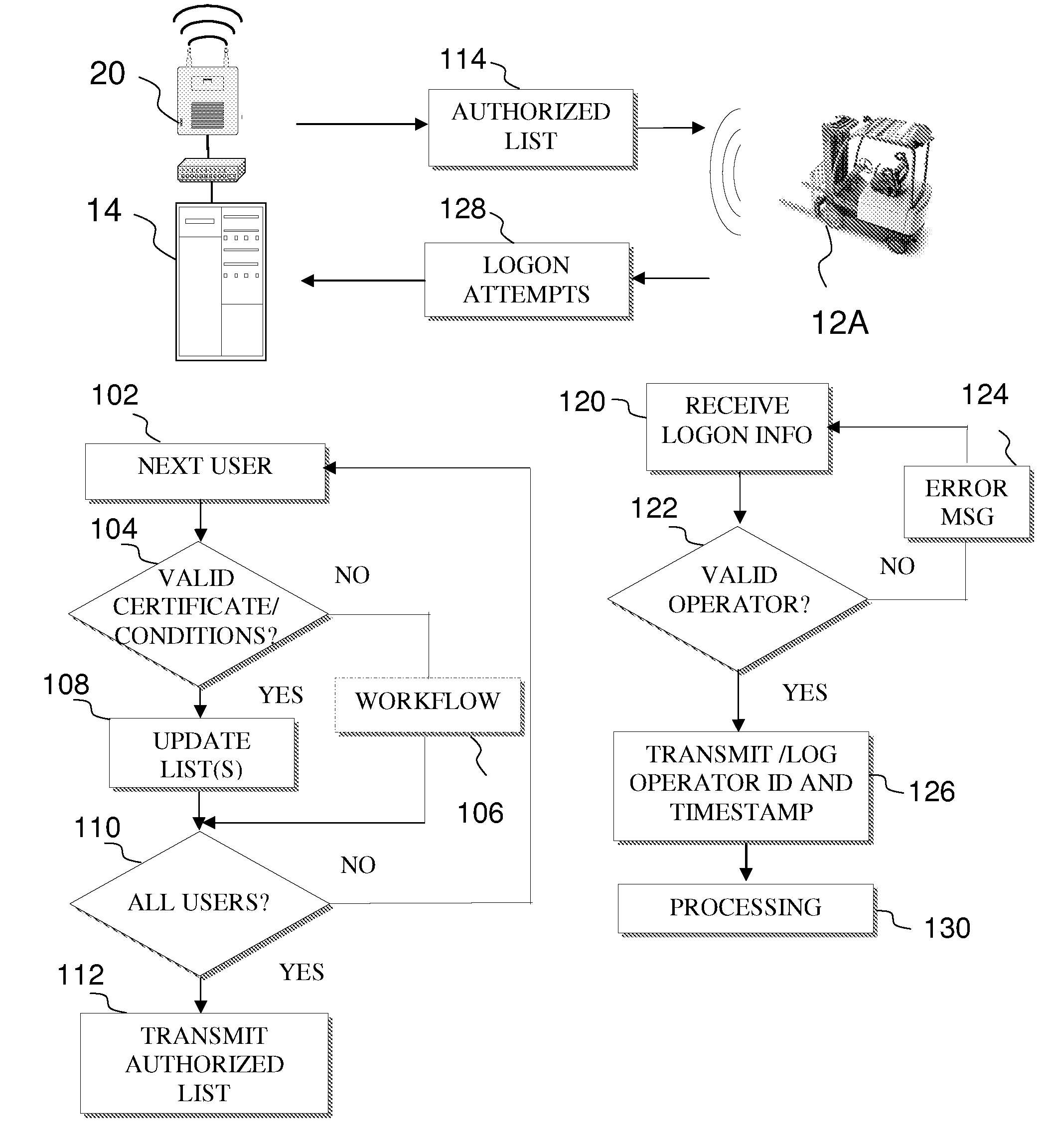

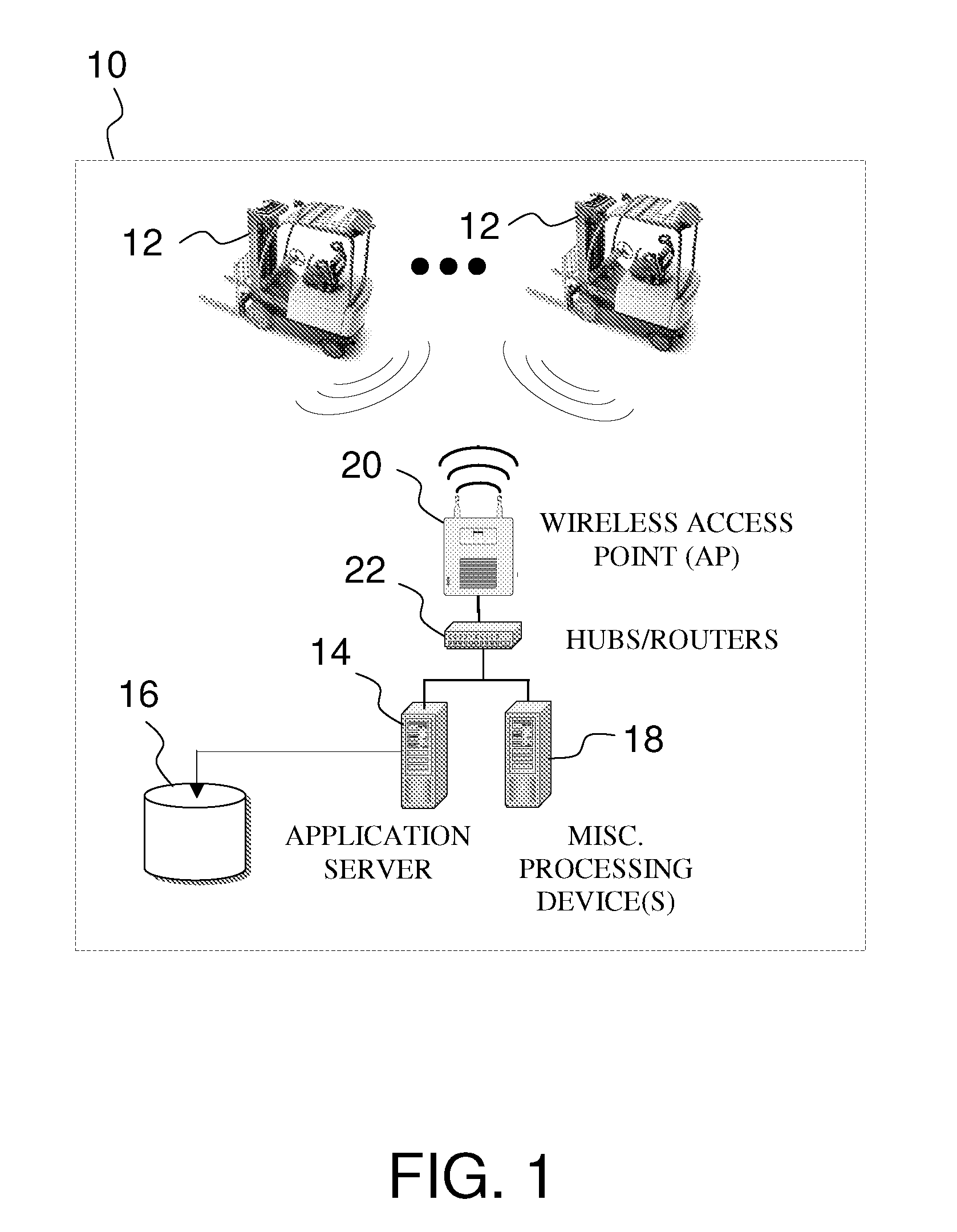

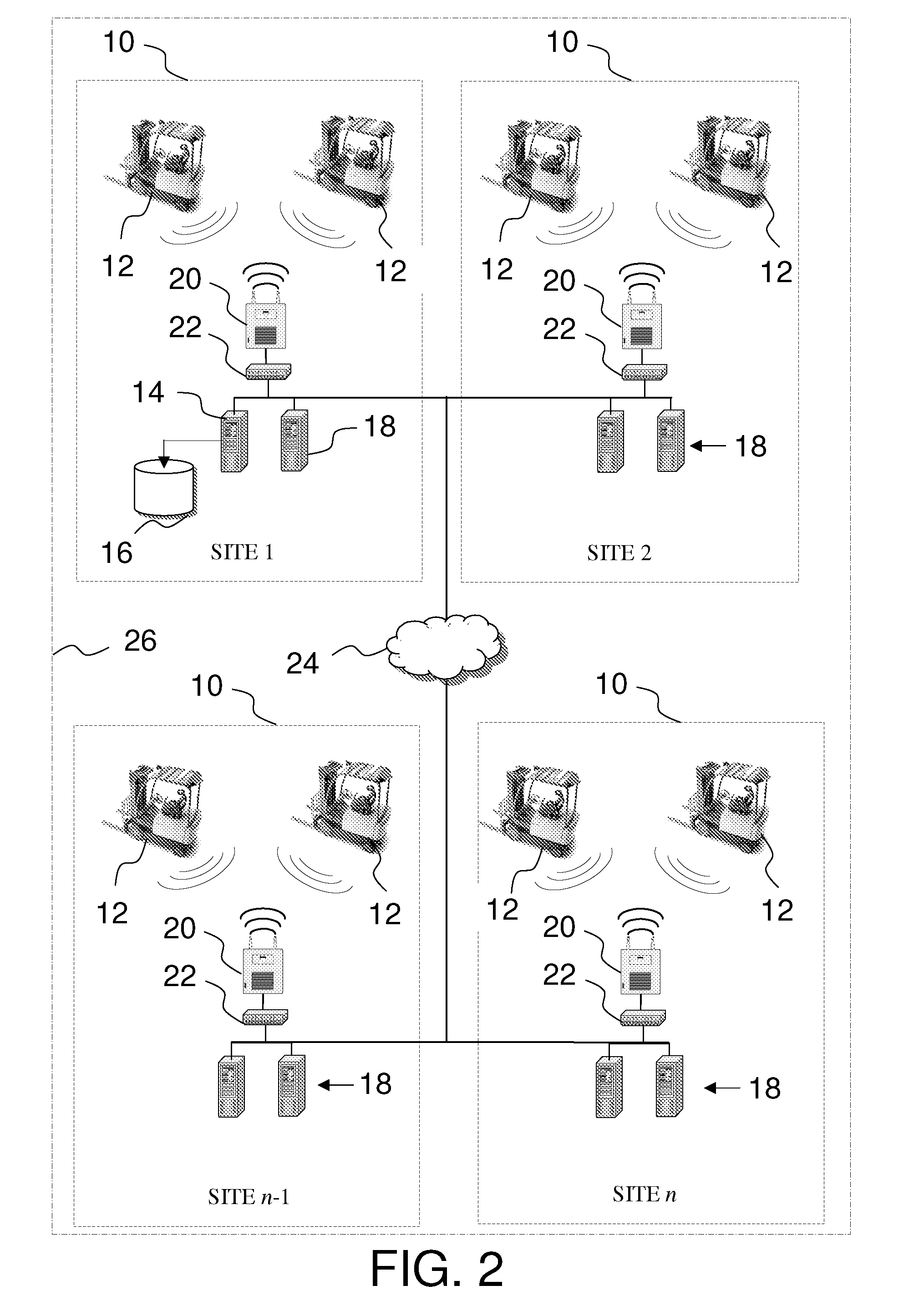

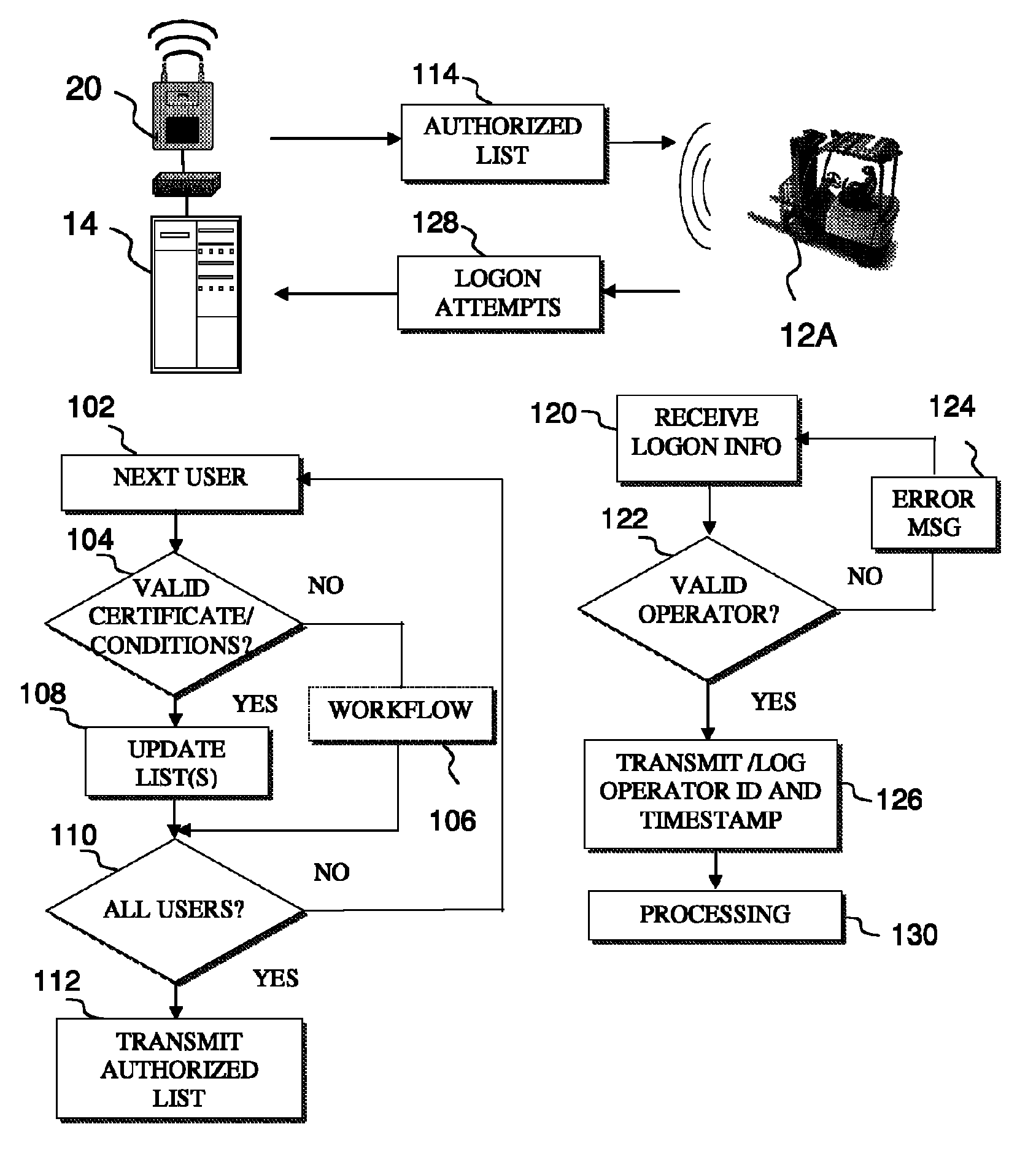

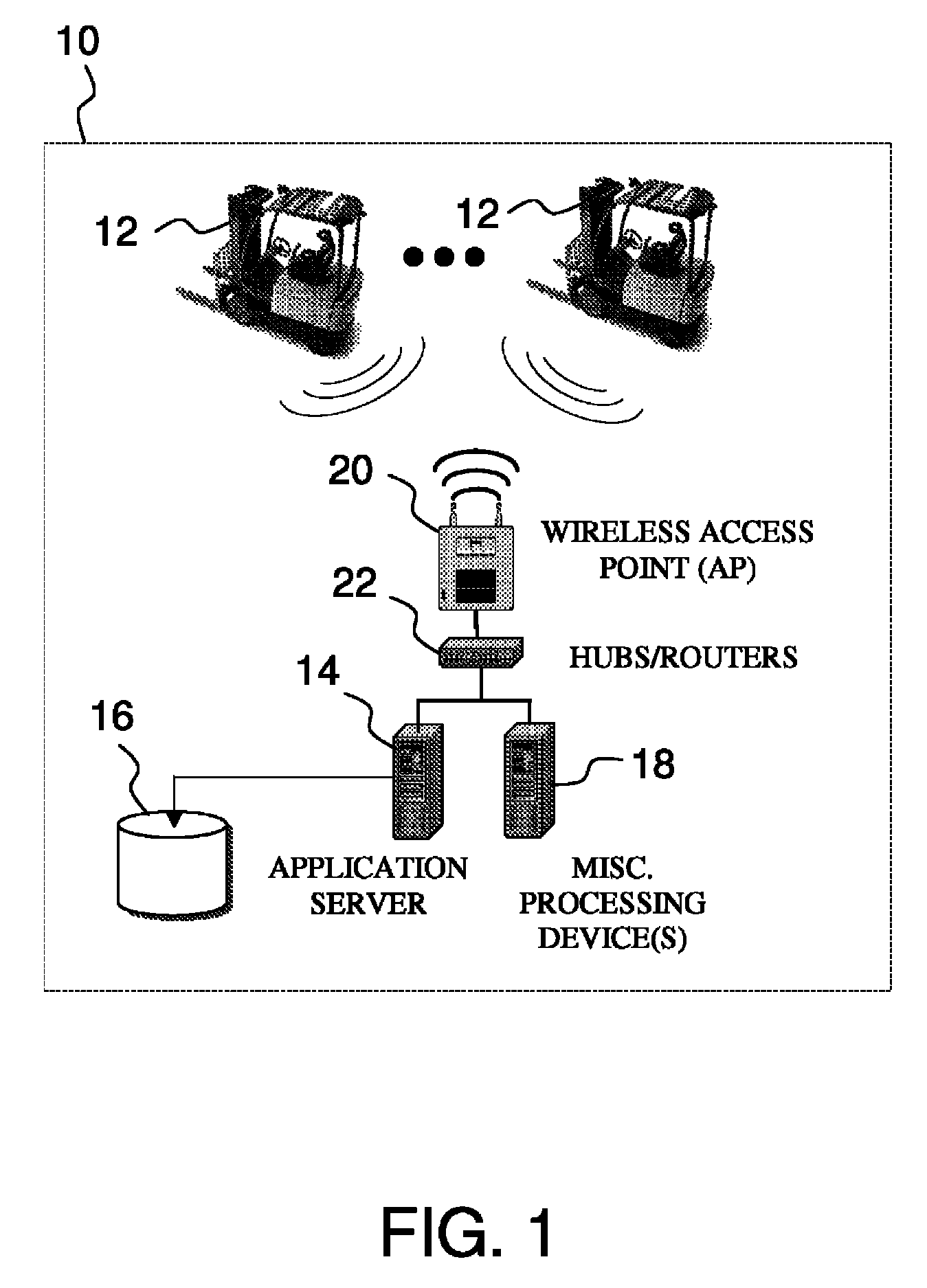

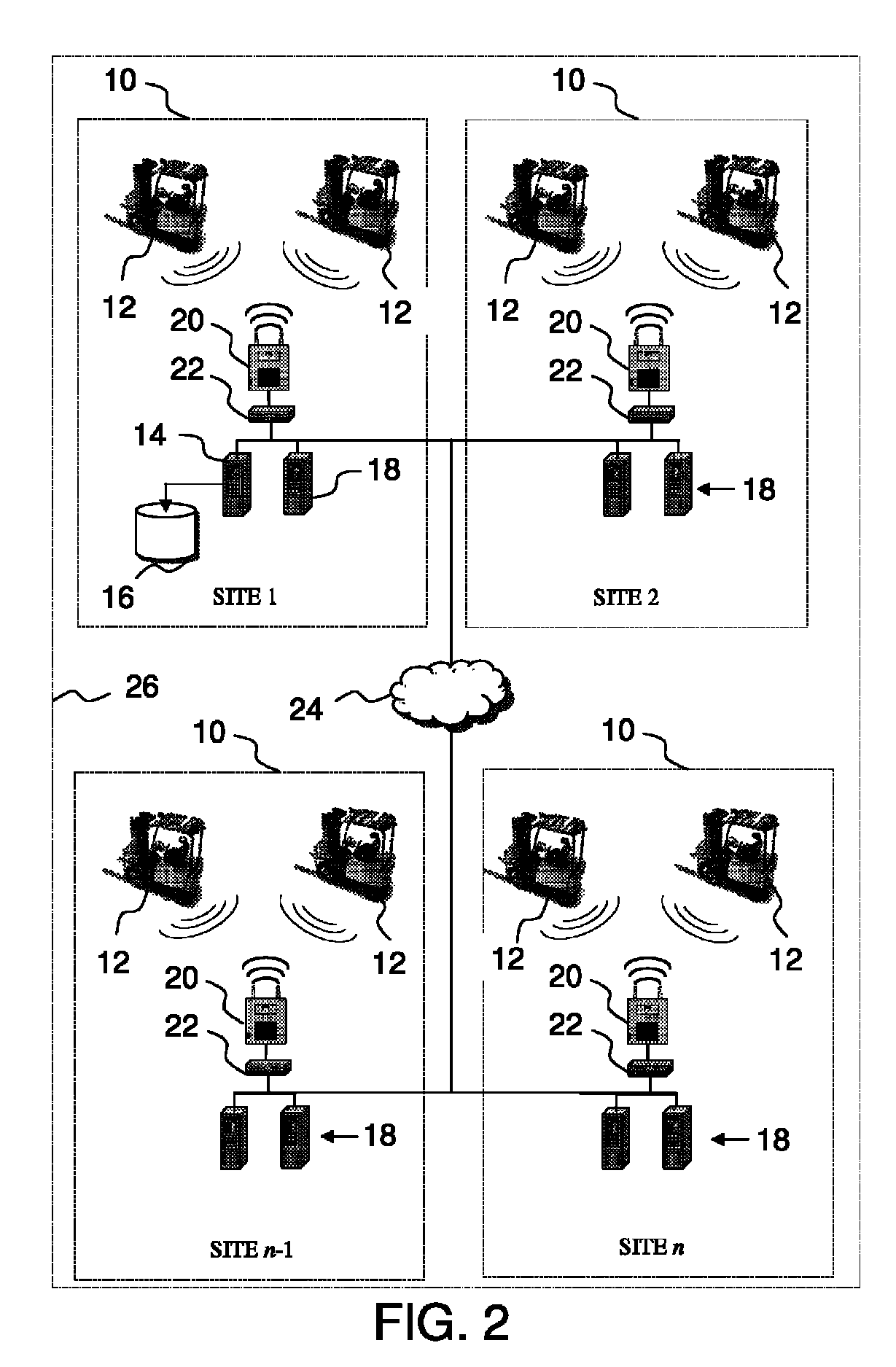

Fleet management system

ActiveUS20080154712A1Ticket-issuing apparatusRegistering/indicating working of vehiclesFleet managementSoftware system

Systems of hardware and software are provided for enabling mobile assets to communicate across a wireless network environment. Systems, computer-implemented methods and computer program products are also provided for leveraging wireless communication and / or processing capabilities of mobile assets against a robust software solution to implement enterprise wide asset management functions, to integrate mobile asset data into existing enterprise workflows and / or to enable trusted third party integration into the enterprise for enhanced asset and / or workflow management.

Owner:CROWN EQUIP CORP

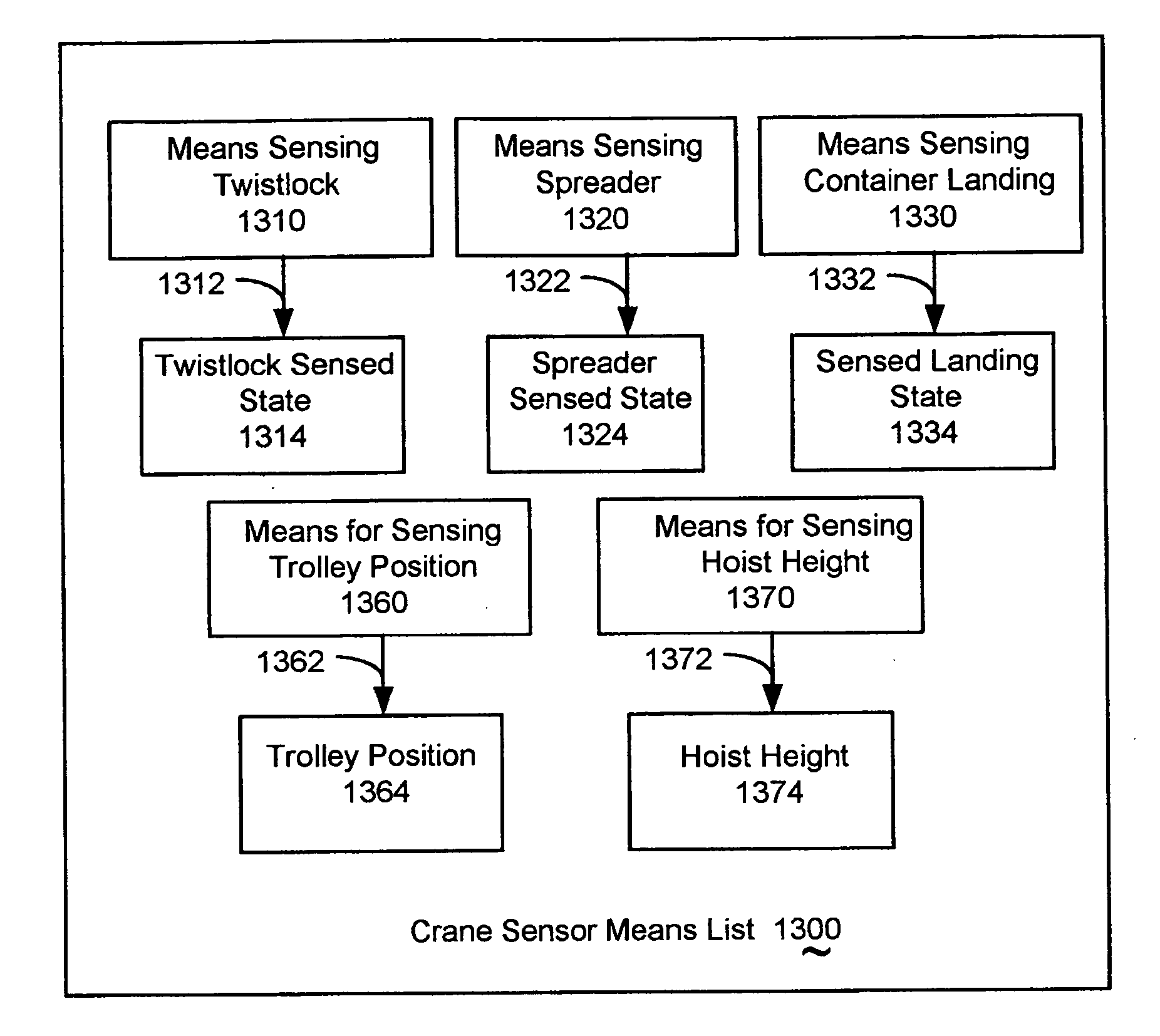

Method and apparatus for making status reporting devices for container handlers

ActiveUS20050256608A1Improve reliabilityDigital data processing detailsRoad vehicles traffic controlEngineeringComputer access

A mechanism and method for making status reporting devices for container handlers, including: providing a micro-controller module, and installing a program system into memory accessed by a computer directing the micro-controller module. The micro-controller module communicatively couples with means for wirelessly communicating and for sensing a state of the container handler. Means for wirelessly communicating may include means for wirelessly determining container handler location. The micro-controller module may be communicatively coupled to a separate means for determining location. An apparatus making the devices may include a second program system directing the invention's method through a second computer, which may control an assembly device in creating the micro-controller, coupled with the means for sensing and for wirelessly communicating.

Owner:HKI SYST & SERVICE

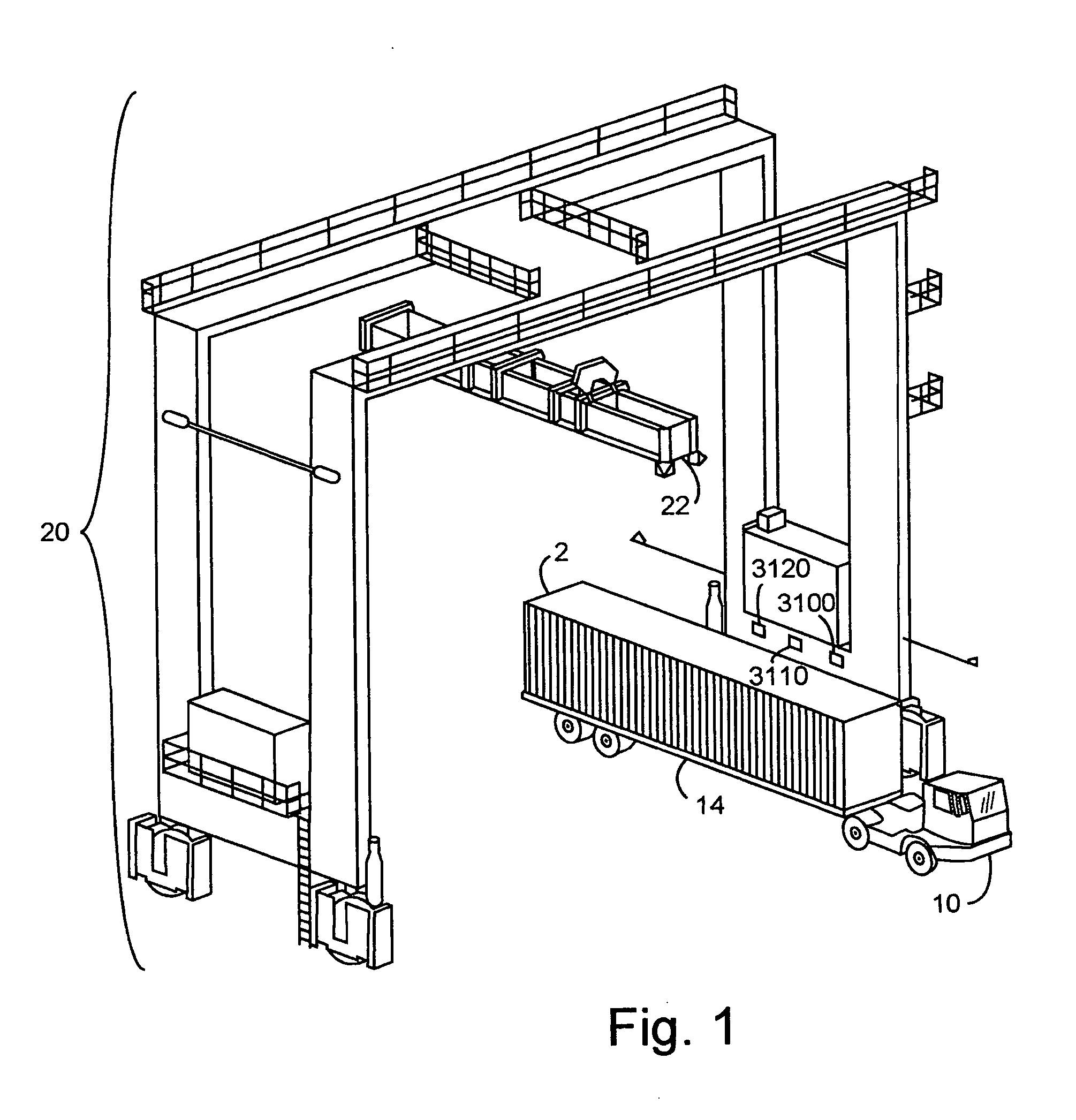

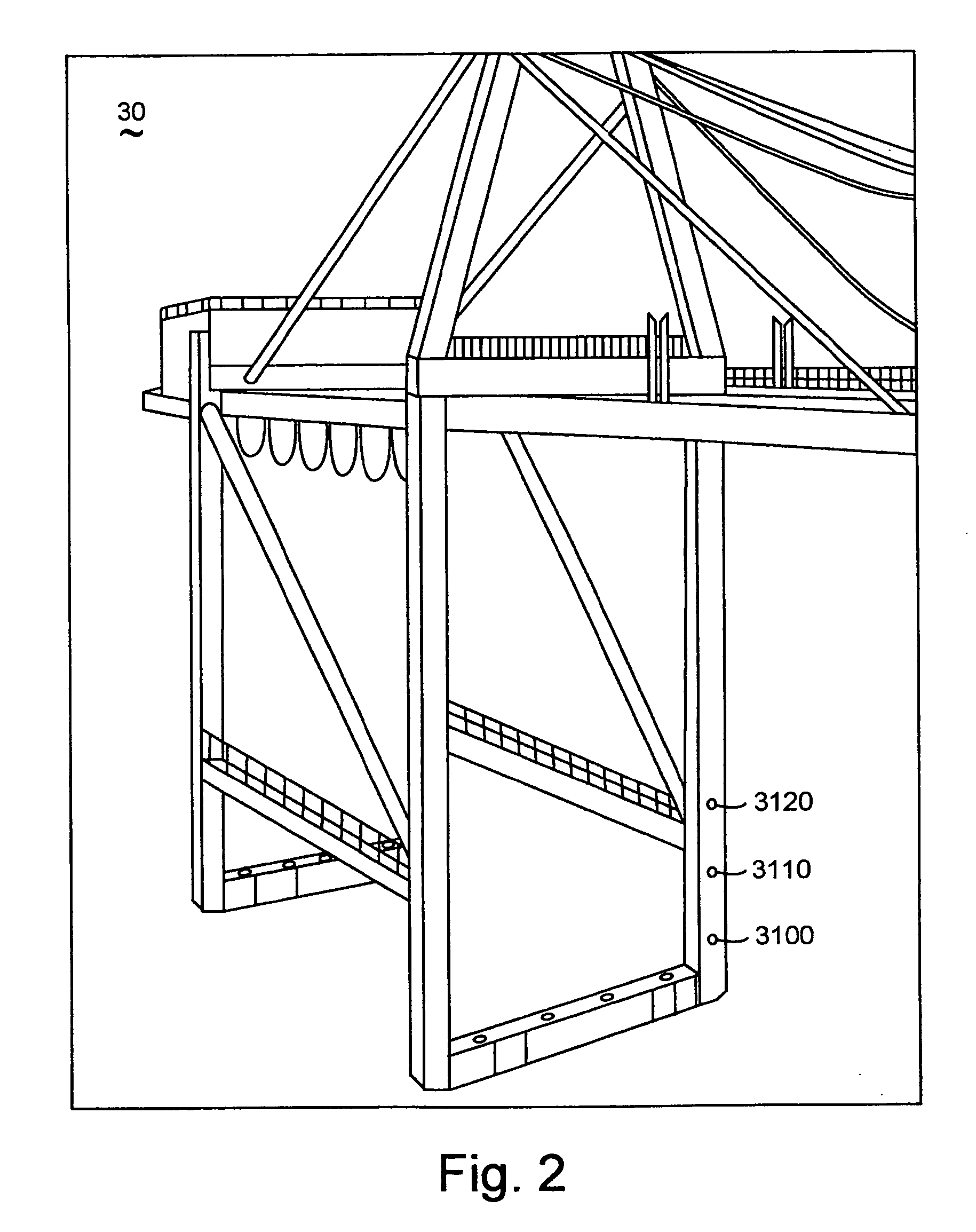

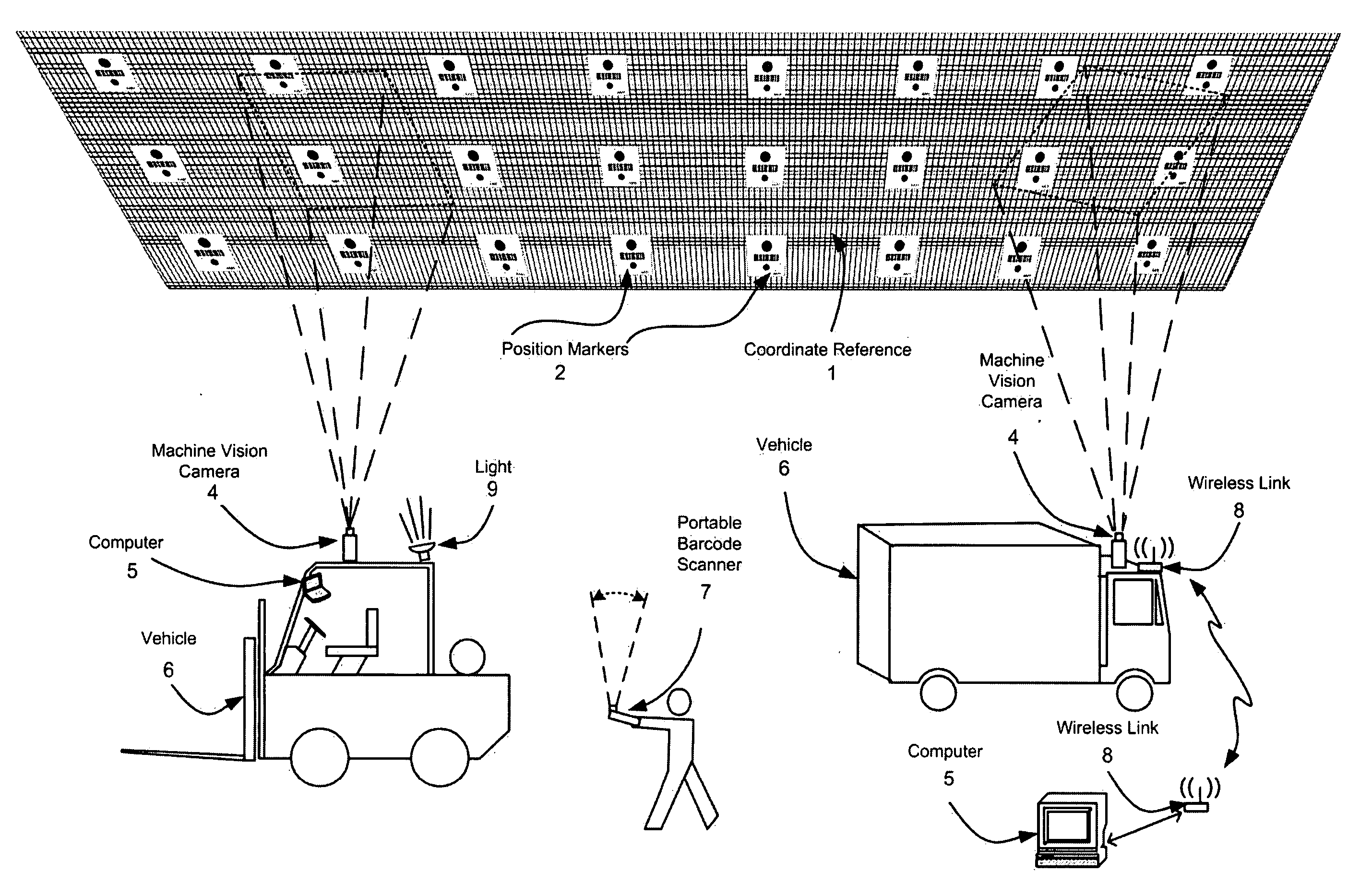

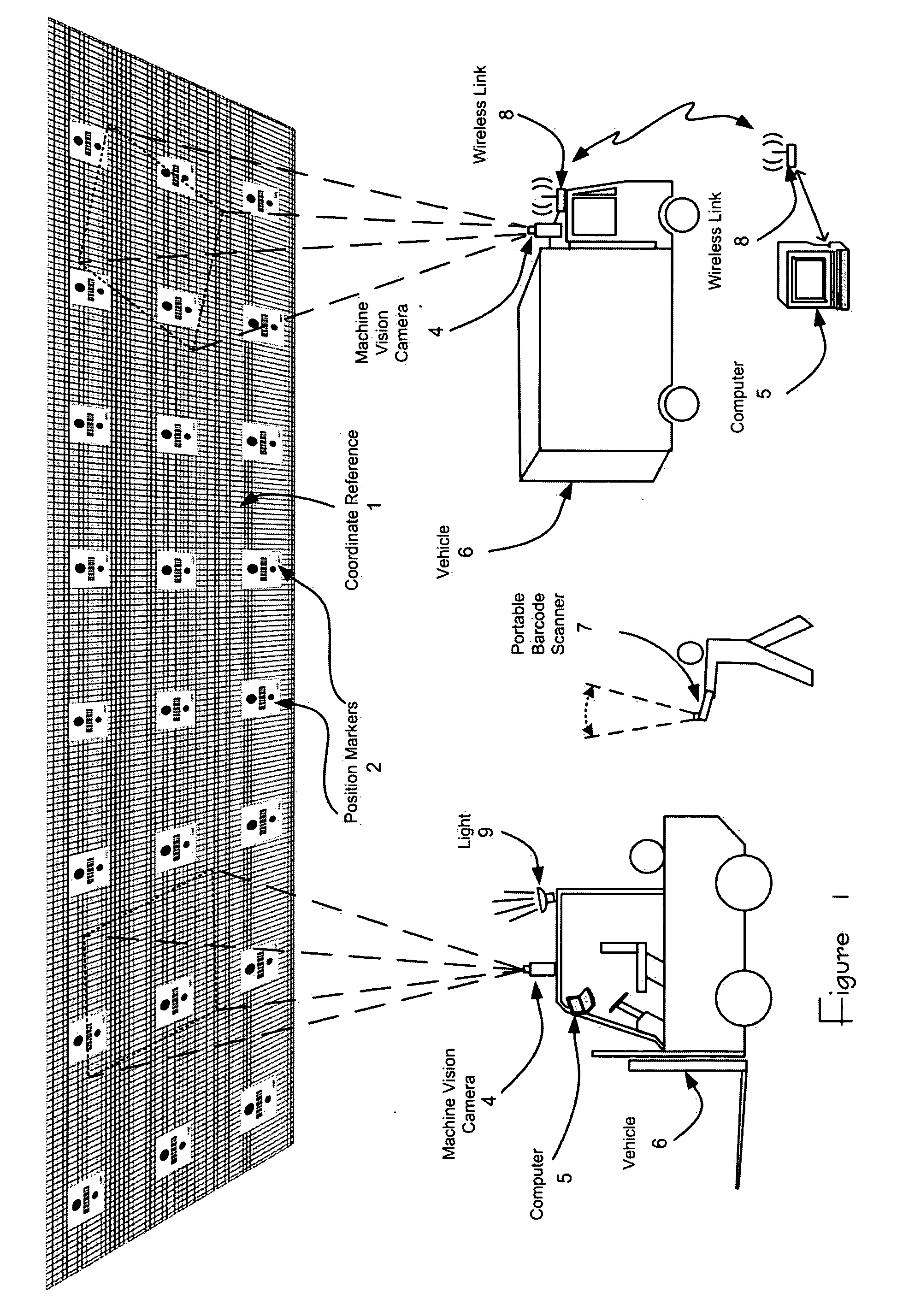

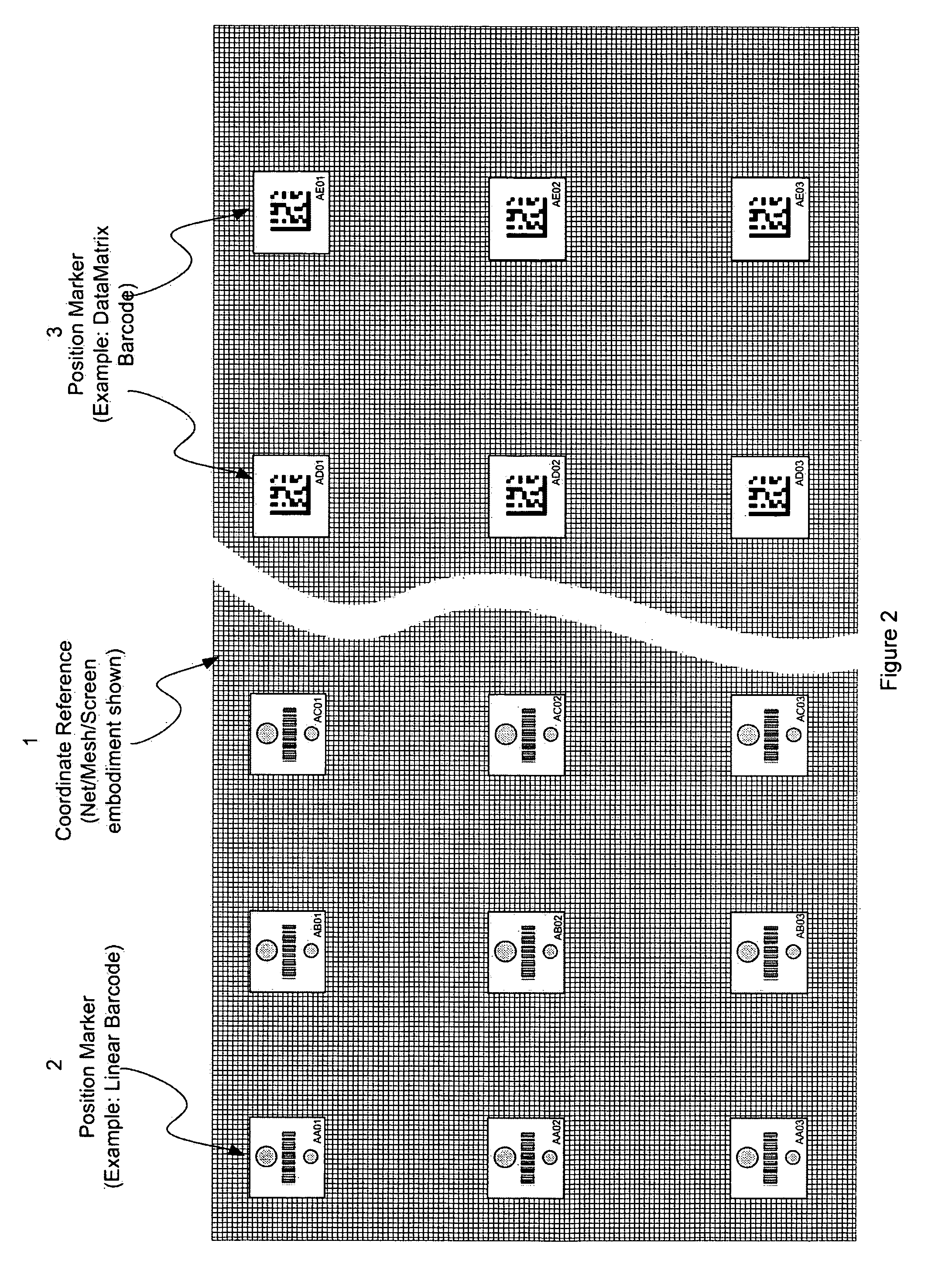

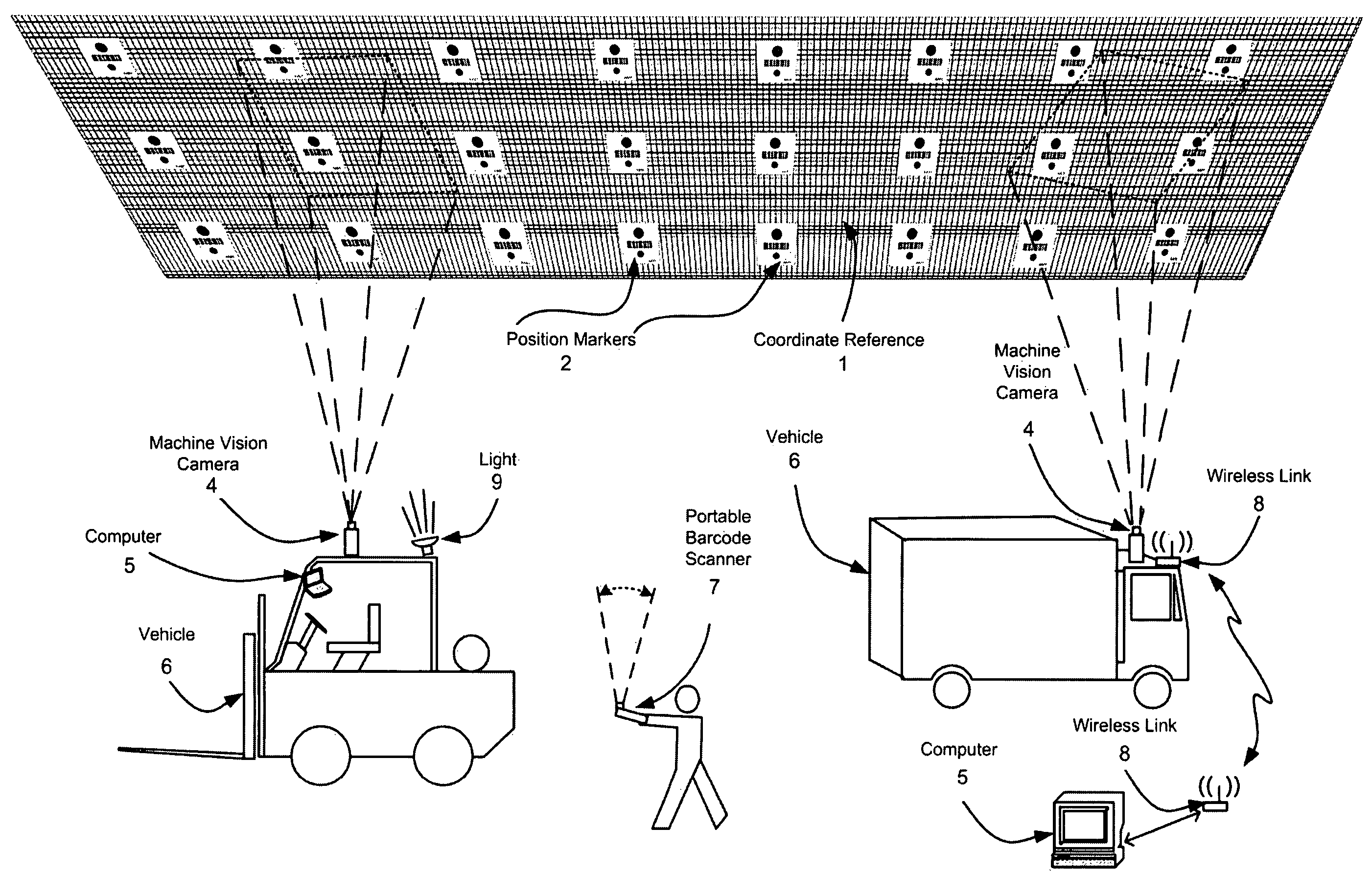

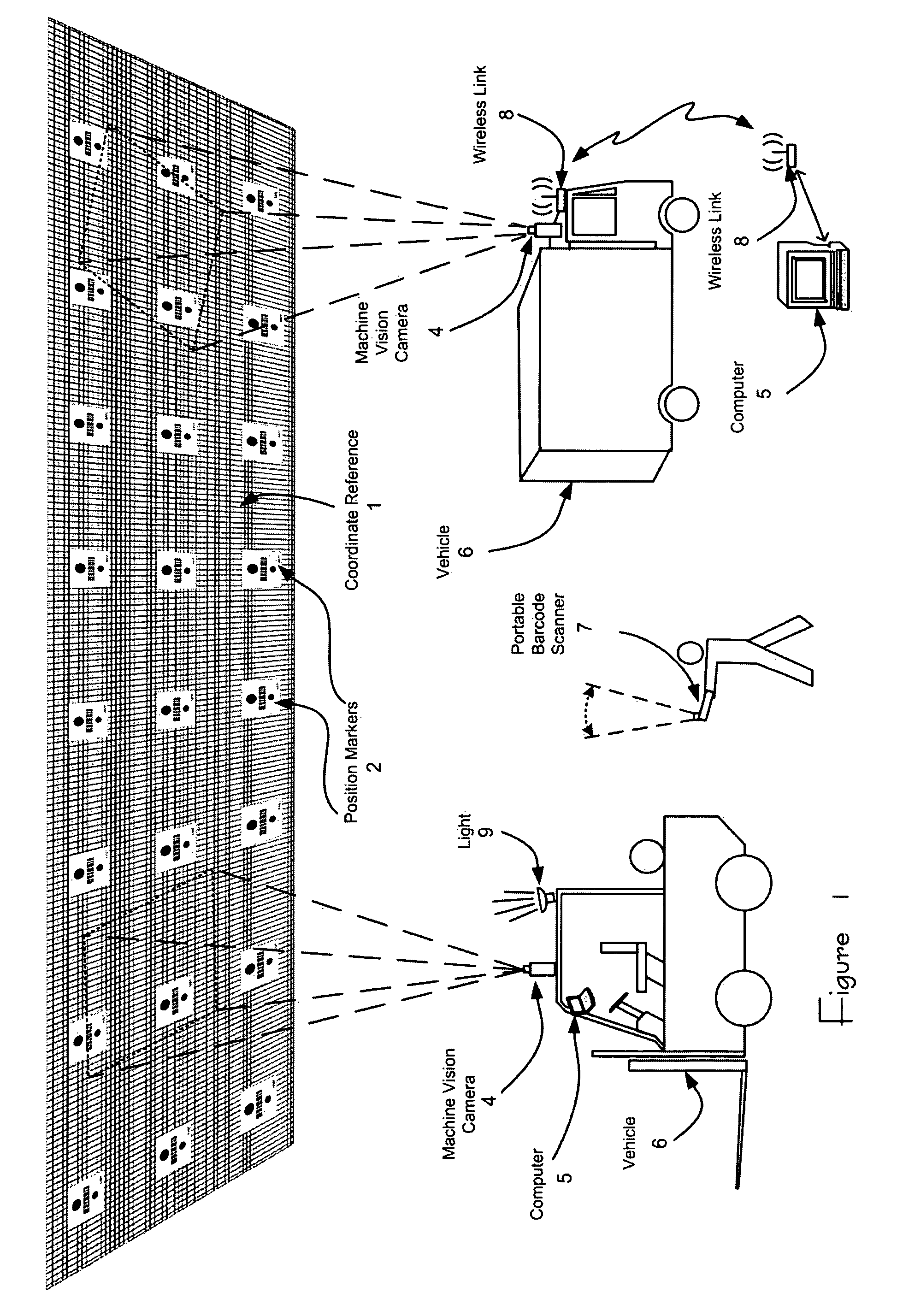

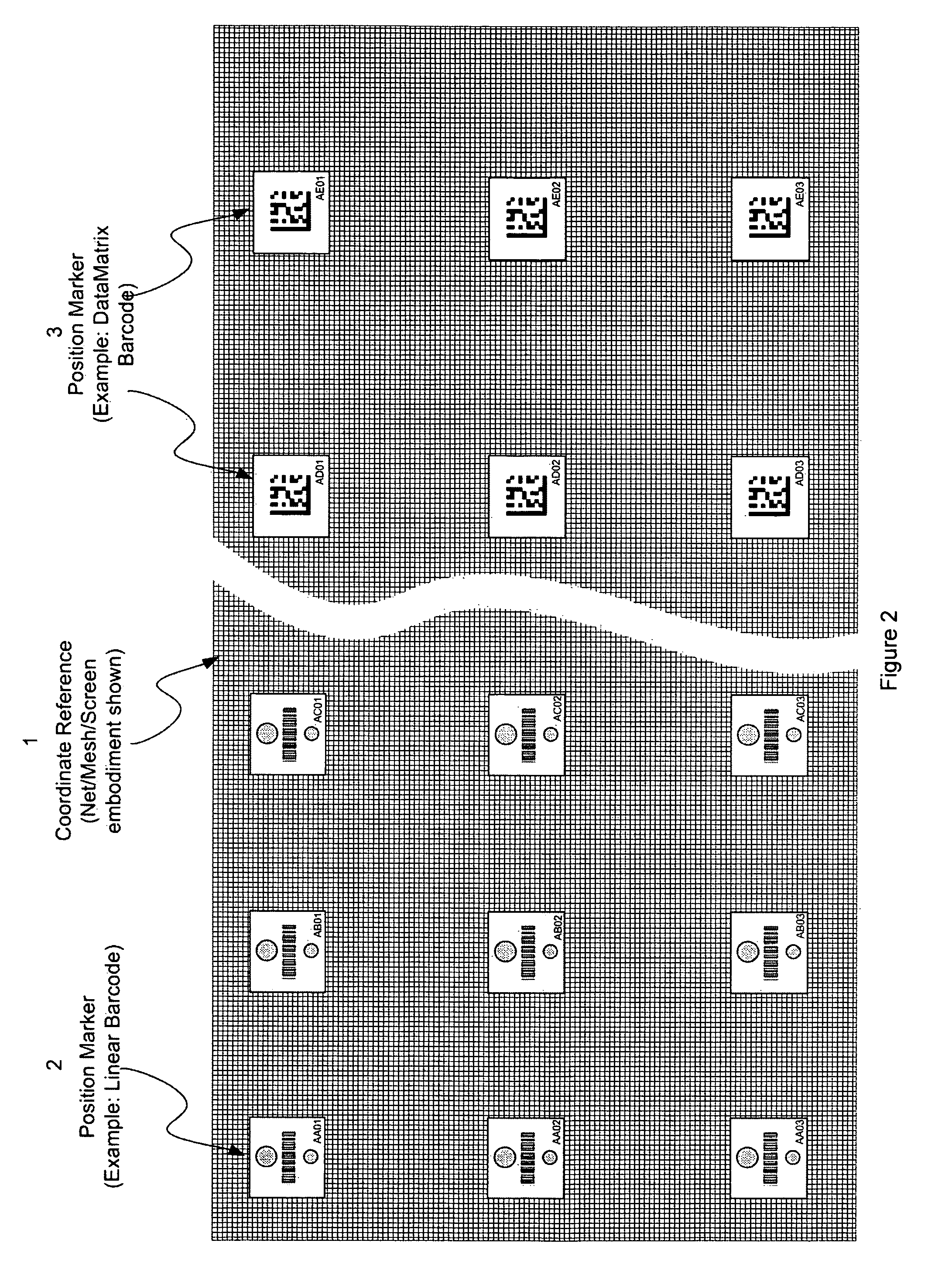

Method and apparatus for determining position and rotational orientation of an object

ActiveUS20060184013A1Accurately determineAccurately determinedPosition fixationLifting devicesBarcodeLinearity

Owner:SHENZHEN INVENTION DISCOVERY CO LTD

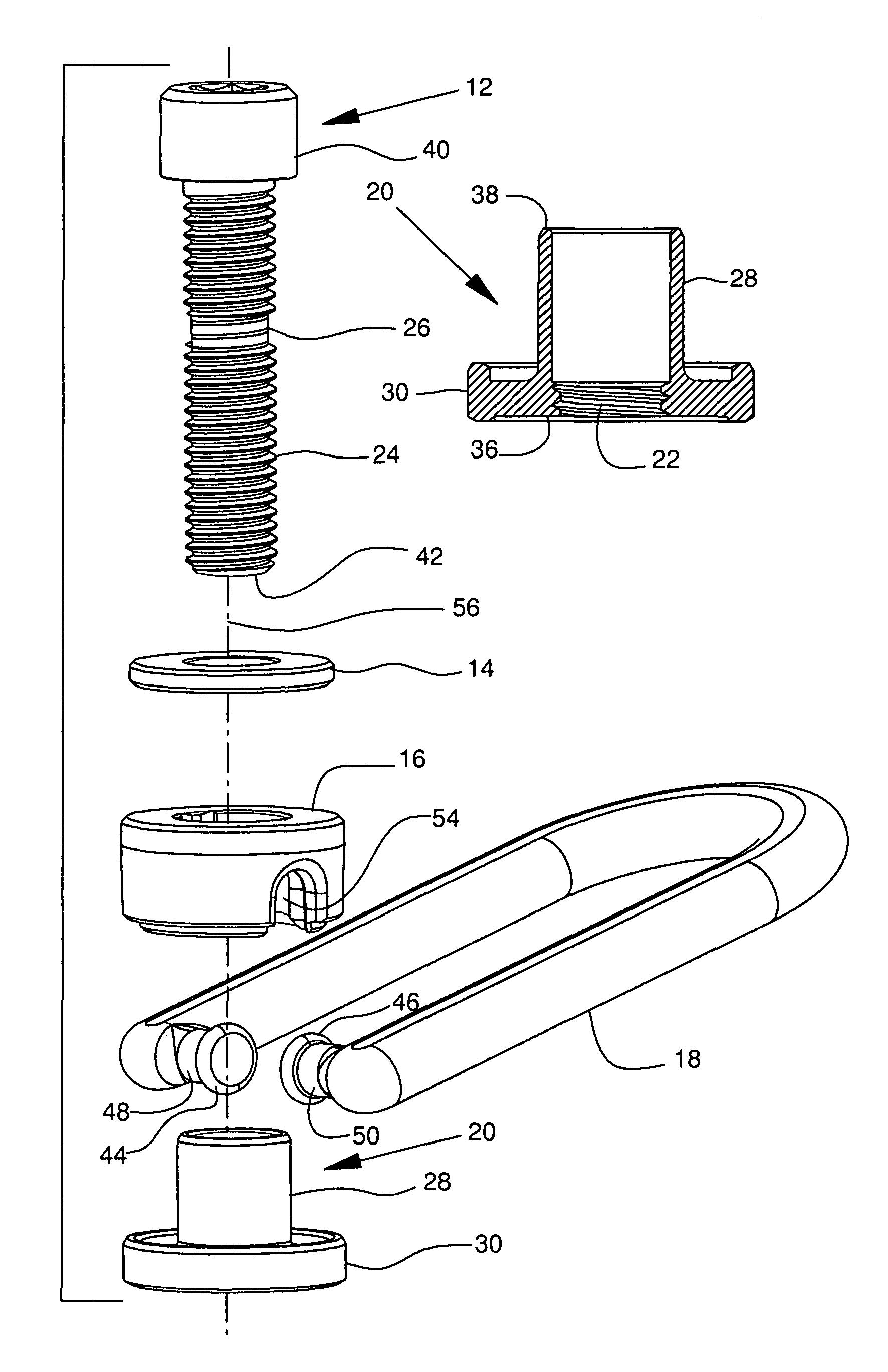

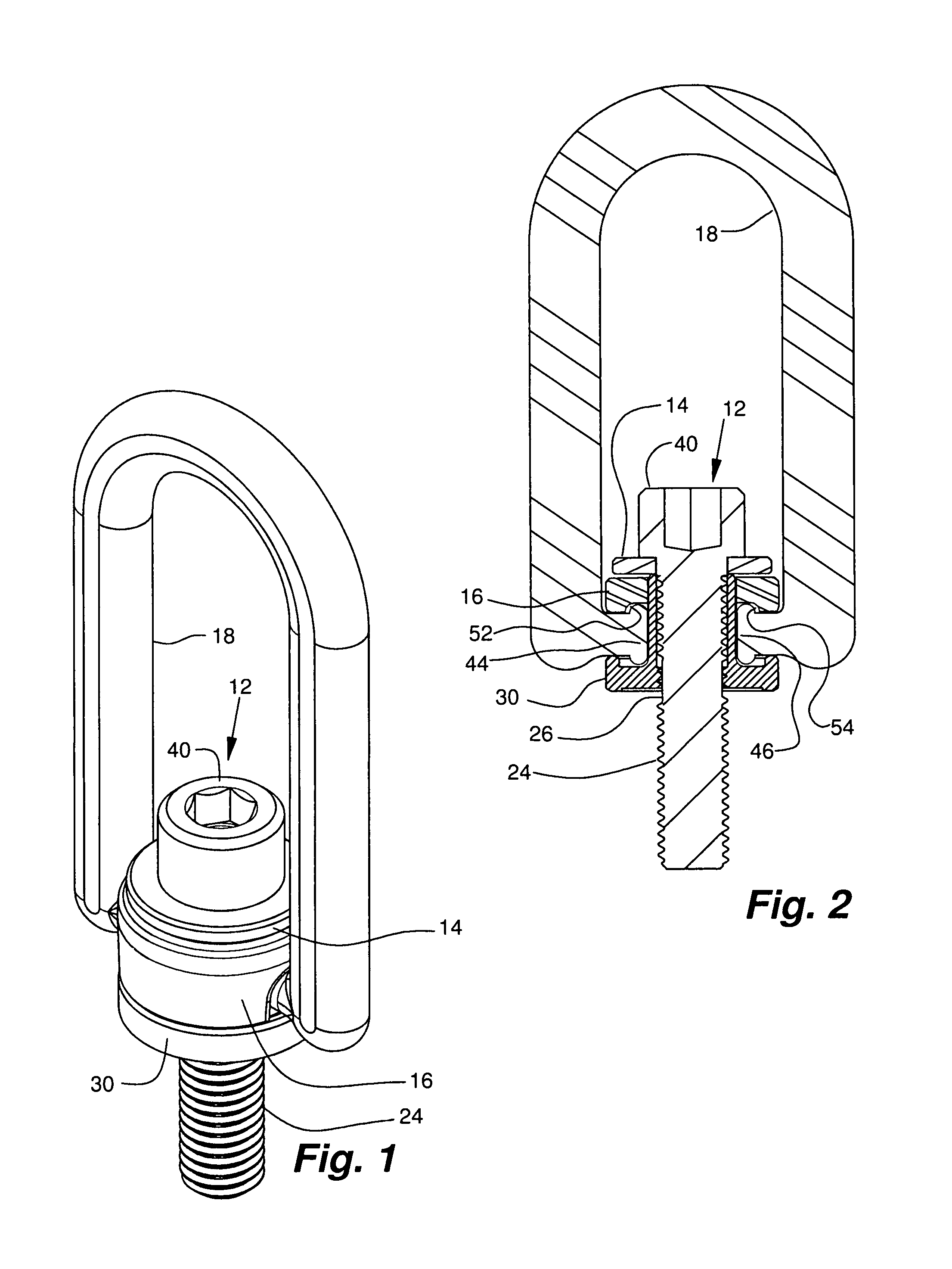

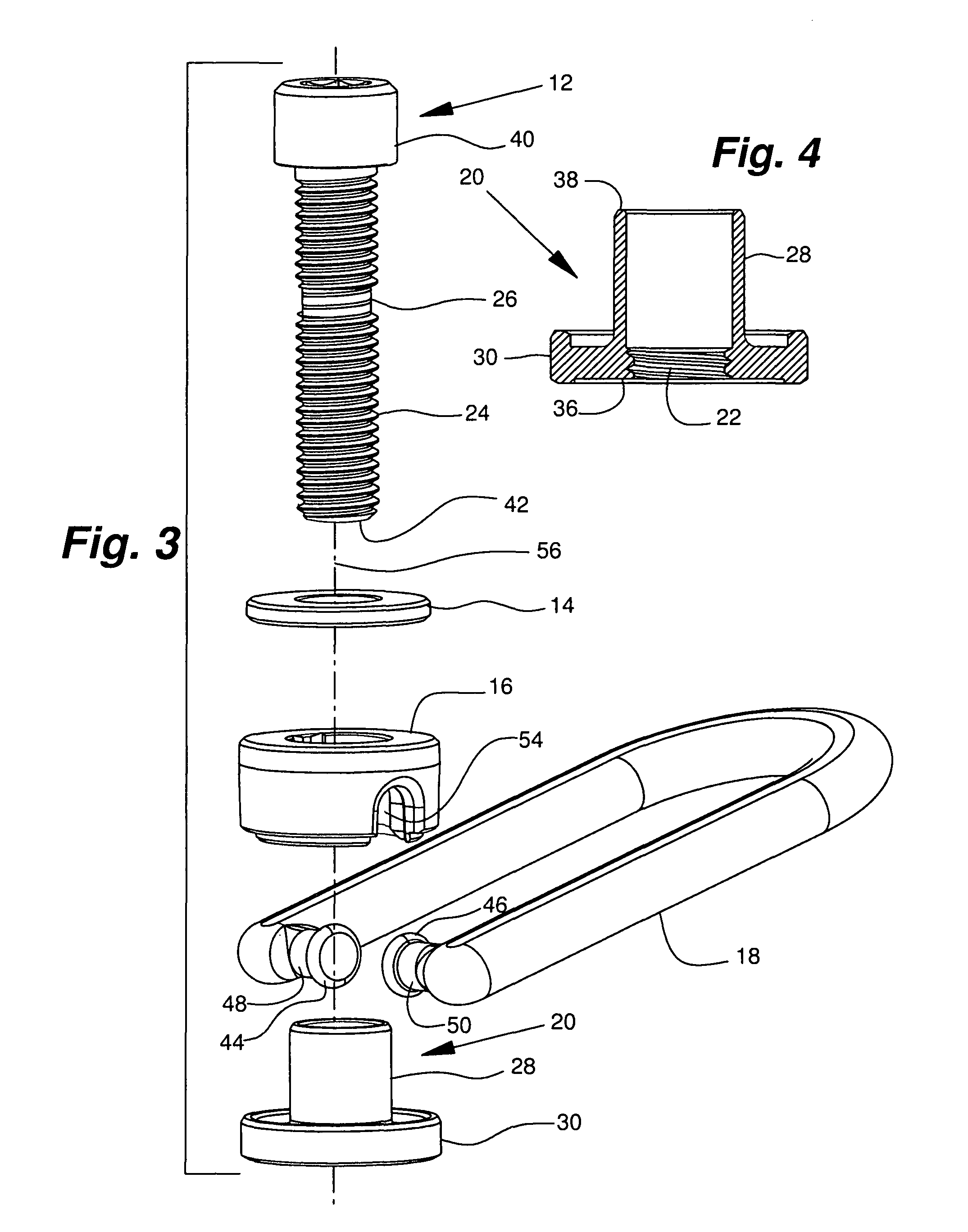

Threaded hoist ring screw retainer

An omni-positional hoist ring assembly including a bushing element that includes a sleeve with an axial length, a proximal end and a distal end. A load bearing flange is radially disposed about the proximal end of the sleeve. The sleeve has an internal thread extending at least part way of the axial length of the sleeve. A mounting screw element has a major axis, a head, and a shank disposed generally co-axially around the major axis. The shank includes a threaded shank portion and a bearing portion. The bearing portion is a generally cylindrical axially extending portion of the shank that has a diameter approximately equal to the minor diameter of the thread in the threaded shank portion. A thrust washer element is provided between the head and the distal end of the sleeve. A body element receives the in-turned opposed ends of the legs of a lifting loop element in sockets. The lifting loop is free to pivot. The body element is free to rotate about the sleeve, so the lifting loop will self align with a load that is applied to it from any direction within a hemisphere centered on the major axis of the mounting screw element. The elements of the hoist rig assembly are assembled by aligning them and inserting the mounting screw element into the sleeve and threadably advancing it until the bearing is aligned with the internal thread so further rotation of the mounting screw element does not threadably advance the mounting screw element relative to the sleeve.

Owner:MJT HLDG

Fleet management system

ActiveUS20080154691A1Registering/indicating working of vehiclesElectric testing/monitoringFleet managementSoftware system

Systems of hardware and software are provided for enabling mobile assets to communicate across a wireless network environment. Systems, computer-implemented methods and computer program products are also provided for leveraging wireless communication and / or processing capabilities of mobile assets against a robust software solution to implement enterprise wide asset management functions, to integrate mobile asset data into existing enterprise workflows and / or to enable trusted third party integration into the enterprise for enhanced asset and / or workflow management.

Owner:CROWN EQUIP CORP

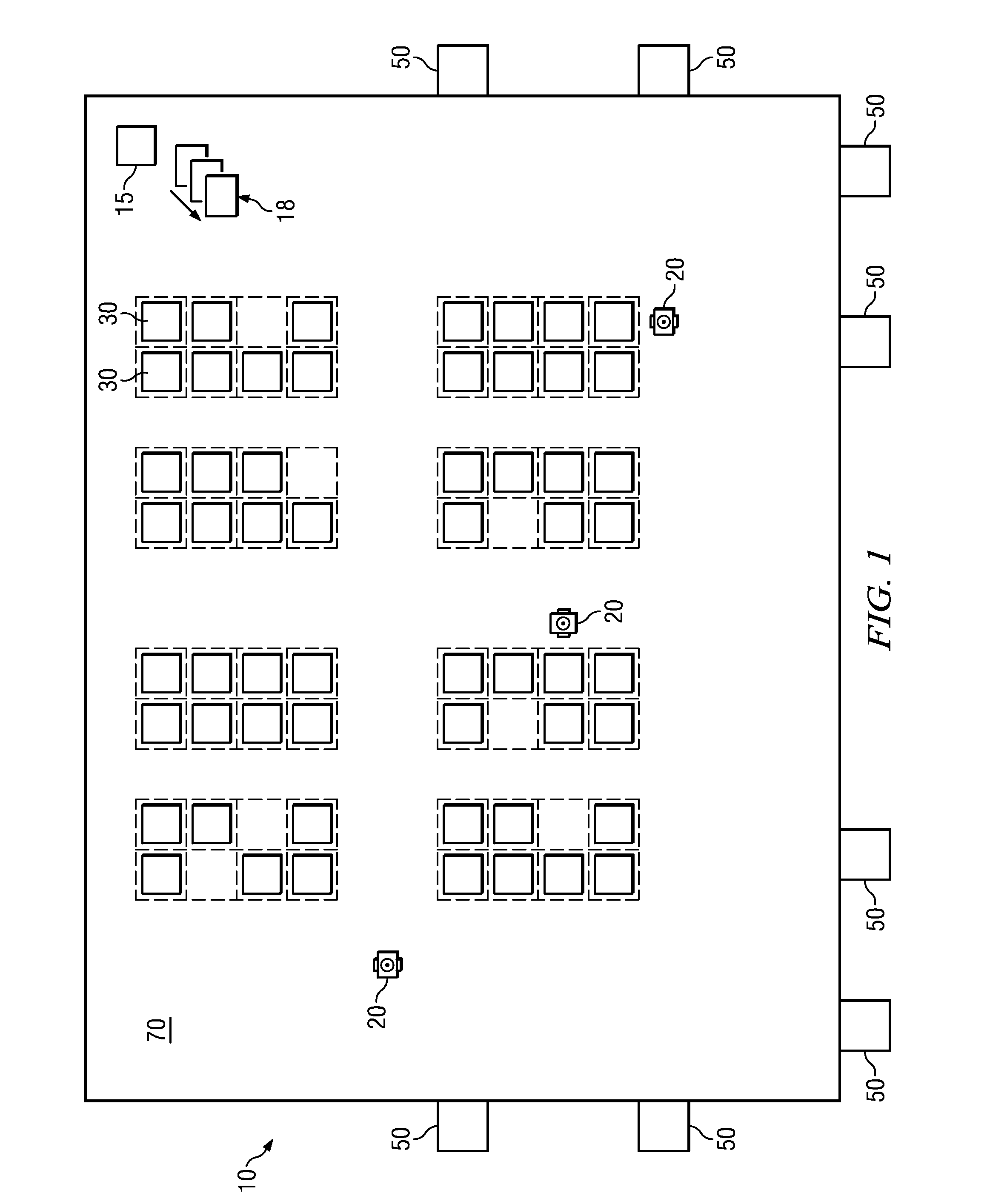

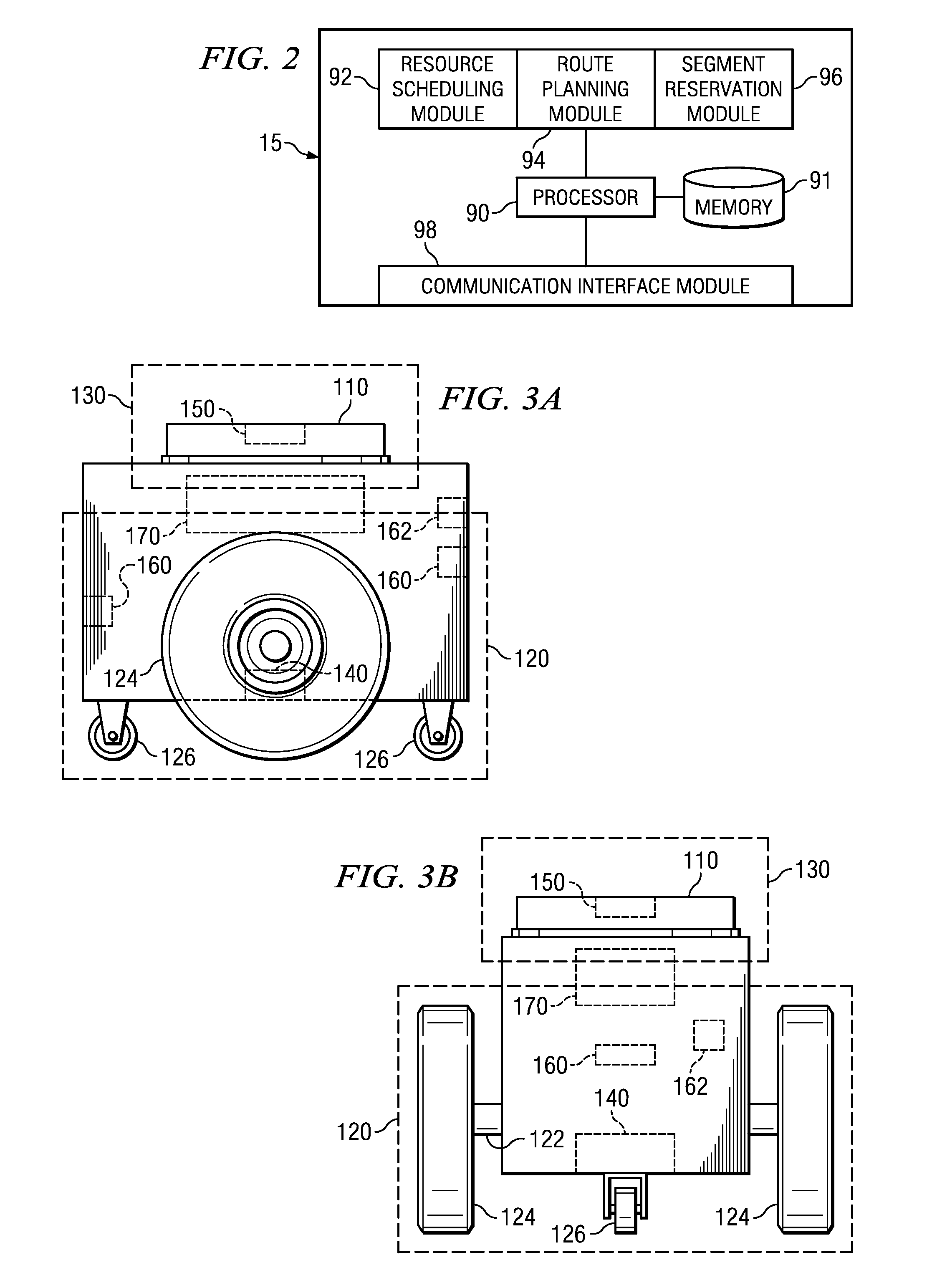

System and Method for Maneuvering a Mobile Drive Unit

InactiveUS20130302132A1Disadvantages and reduced eliminatedInventory reduced eliminatedLifting devicesLogisticsEngineeringMechanical engineering

Owner:AMAZON TECH INC

Method and apparatus for determining position and rotational orientation of an object

ActiveUS7845560B2Accurately determinedHigh precisionPosition fixationLifting devicesBarcodeLinearity

Owner:SHENZHEN INVENTION DISCOVERY CO LTD

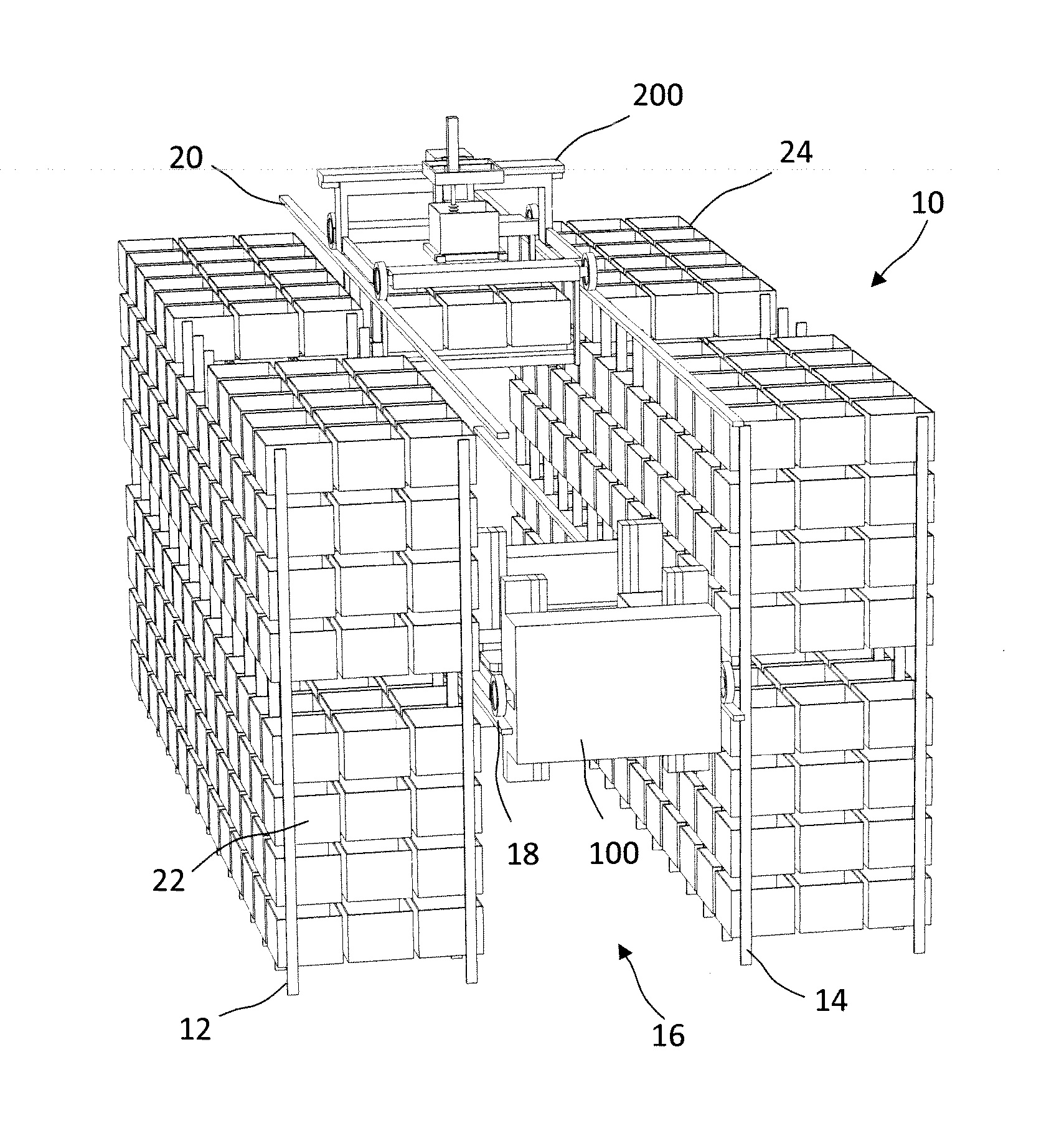

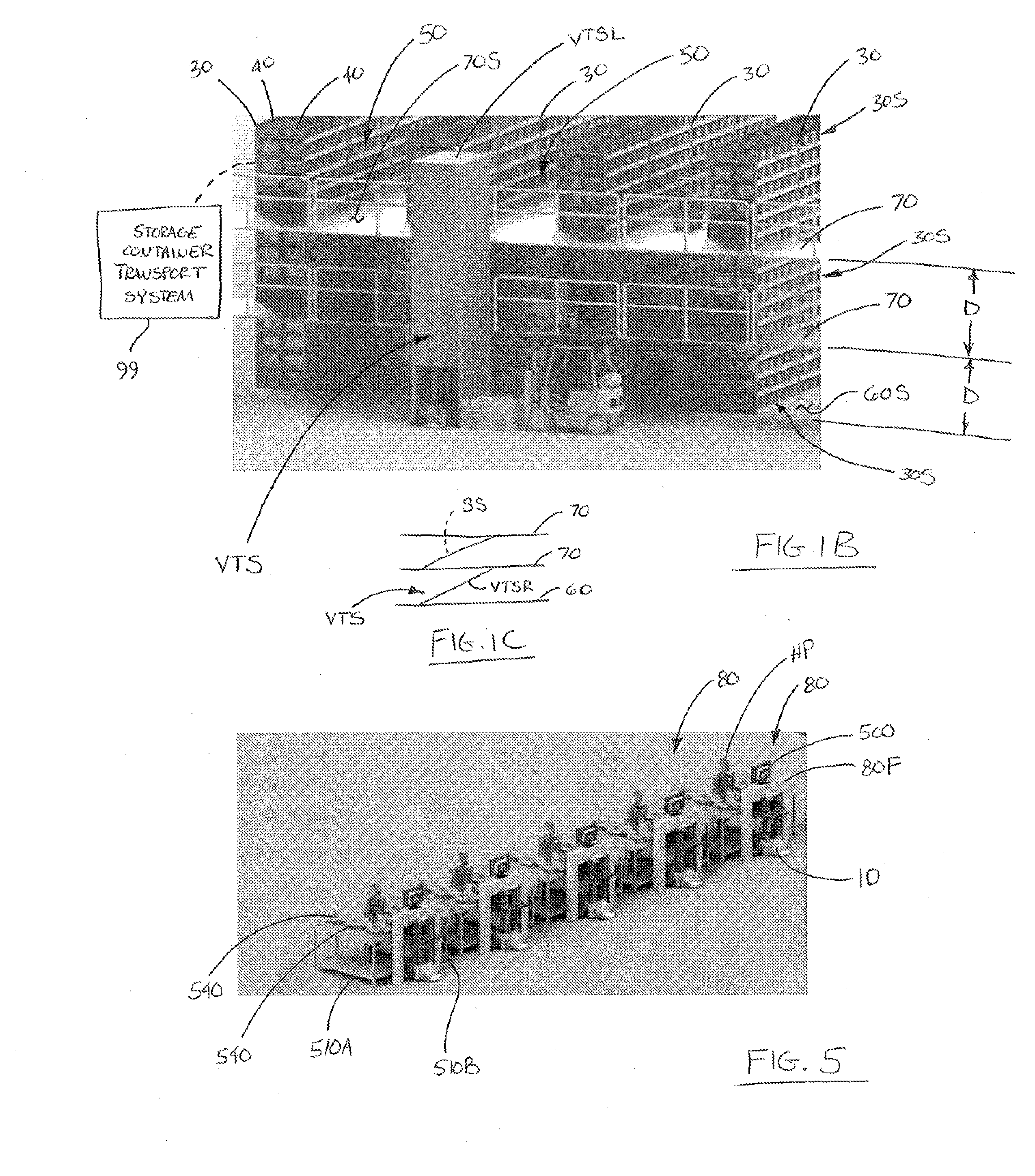

Method and system for automated transport of items

ActiveUS20160176638A1Programme controlAutonomous decision making processAutomated guided vehicleIndustrial engineering

An automated distribution center includes an array with storage locations arranged along aisle(s) having a floor, and a mezzanine platform above the floor, the floor and mezzanine being configured for human picker access to the storage locations, an automated guided vehicle (AGV) configured for traverse of the floor and mezzanine to the storage locations, and for transporting a storage container to and from the storage locations, the floor and mezzanine each having an undeterministic traverse surface for the AGV, the AGV is configured so that the surface provides holonomic selectable paths for the AGV substantially everywhere on the surface, each path being selectable by the AGV, and an order filling station, where one or more goods are picked from container(s) to fill order(s), wherein the AGV is configured to pick the container from a storage location and transport the container on the surface between the storage array and the station.

Owner:NEXTSHIFT ROBOTICS INC

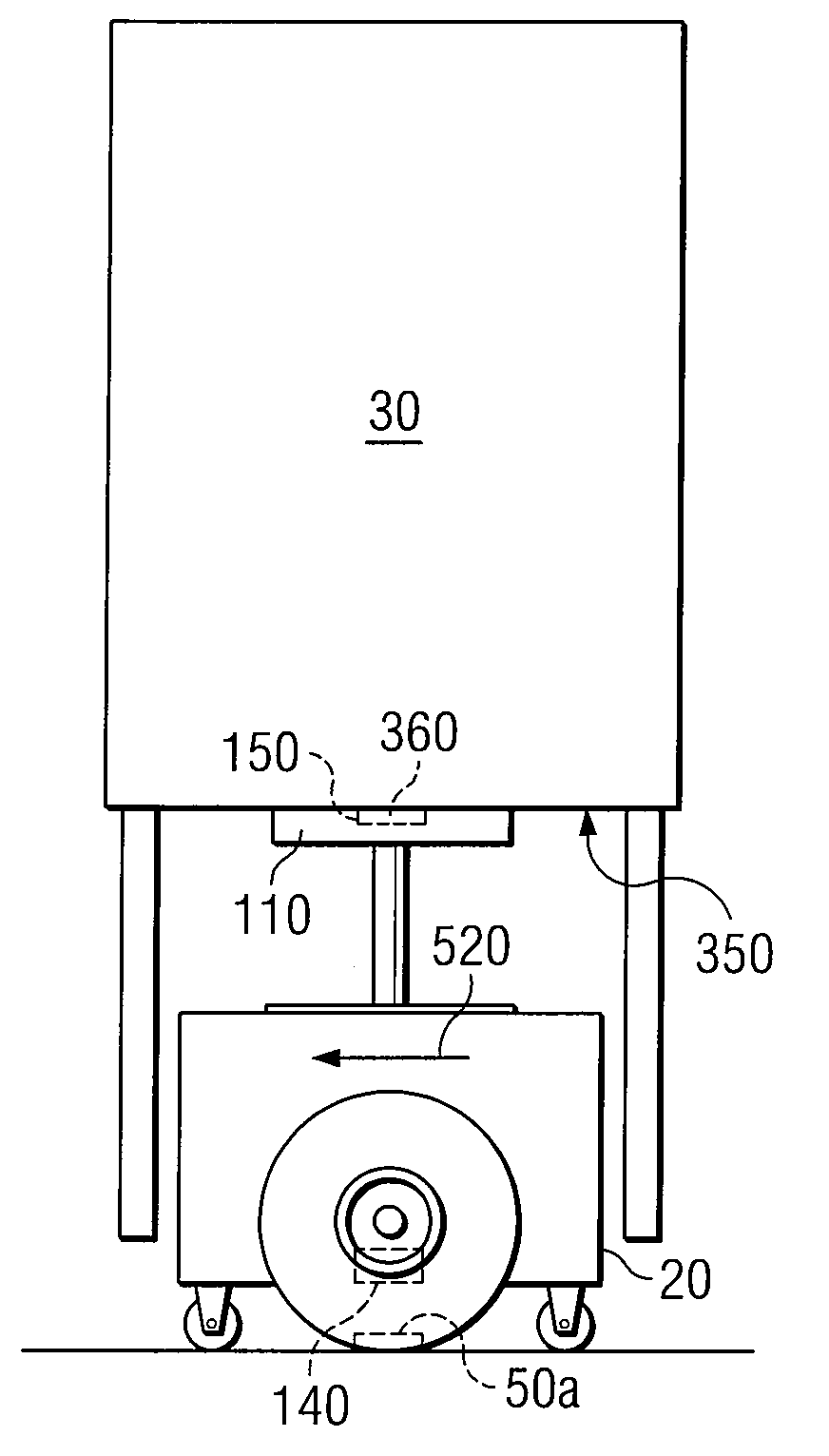

Method and system for transporting inventory items

ActiveUS7826919B2Disadvantages and reduced eliminatedInventory reduced eliminatedDigital data processing detailsLifting devicesEngineeringMechanical engineering

A system for transporting inventory items includes an inventory holder capable of storing inventory items and a mobile drive unit. The mobile drive unit is capable of moving to a first point with the inventory holder at least one of coupled to and supported by the mobile drive unit. The mobile drive unit is additionally capable of determining a location of the inventory holder and calculating a difference between the location of the inventory holder and the first point. The mobile drive unit is then capable of determining whether the difference is greater than a predetermined tolerance. In response to determining that the difference is greater than the predetermined tolerance, the mobile drive unit is also capable of moving to a second point based on the location of the inventory holder, docking with the inventory holder, and moving the mobile drive unit and the inventory holder to the first point.

Owner:AMAZON TECH INC

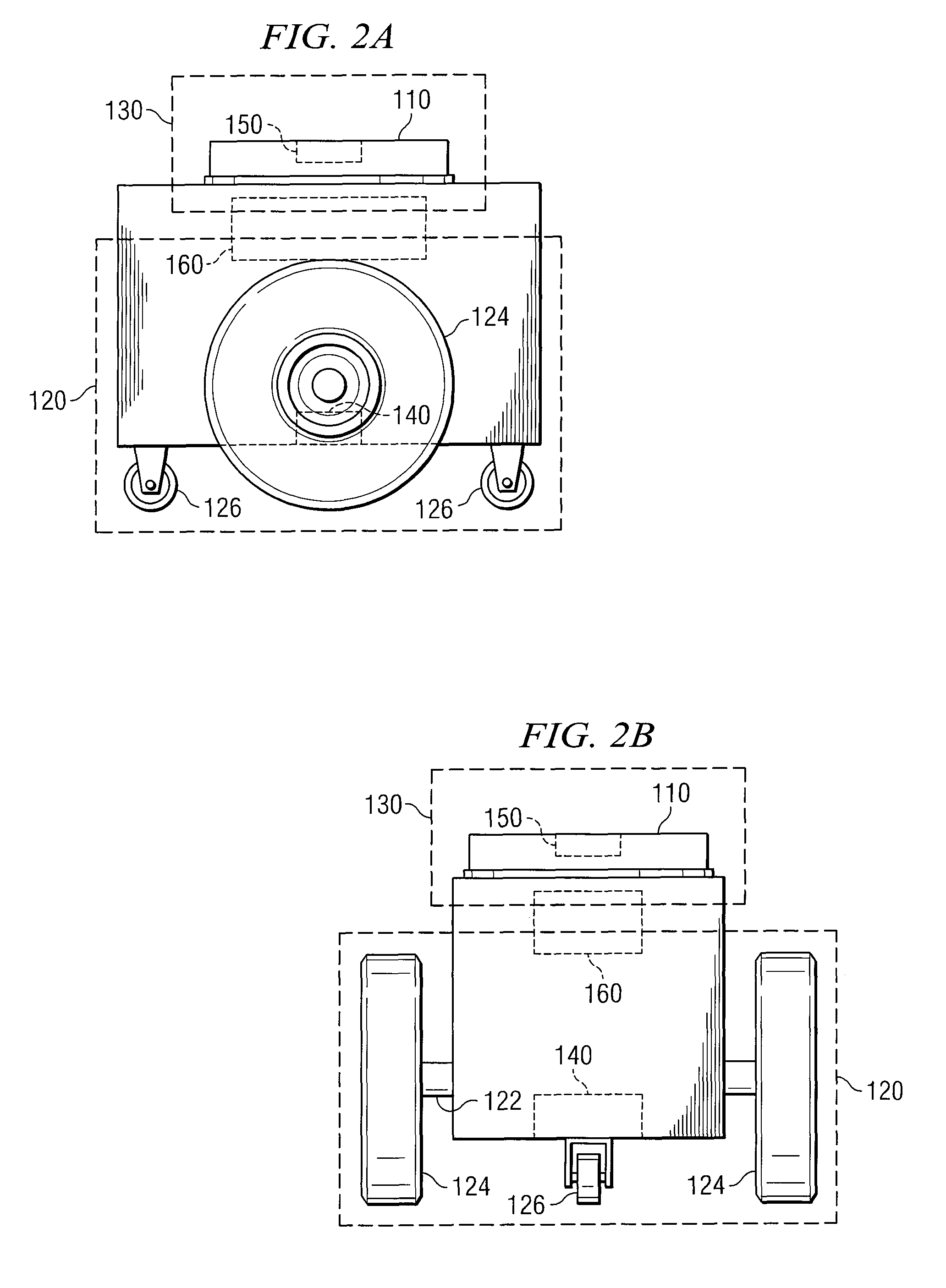

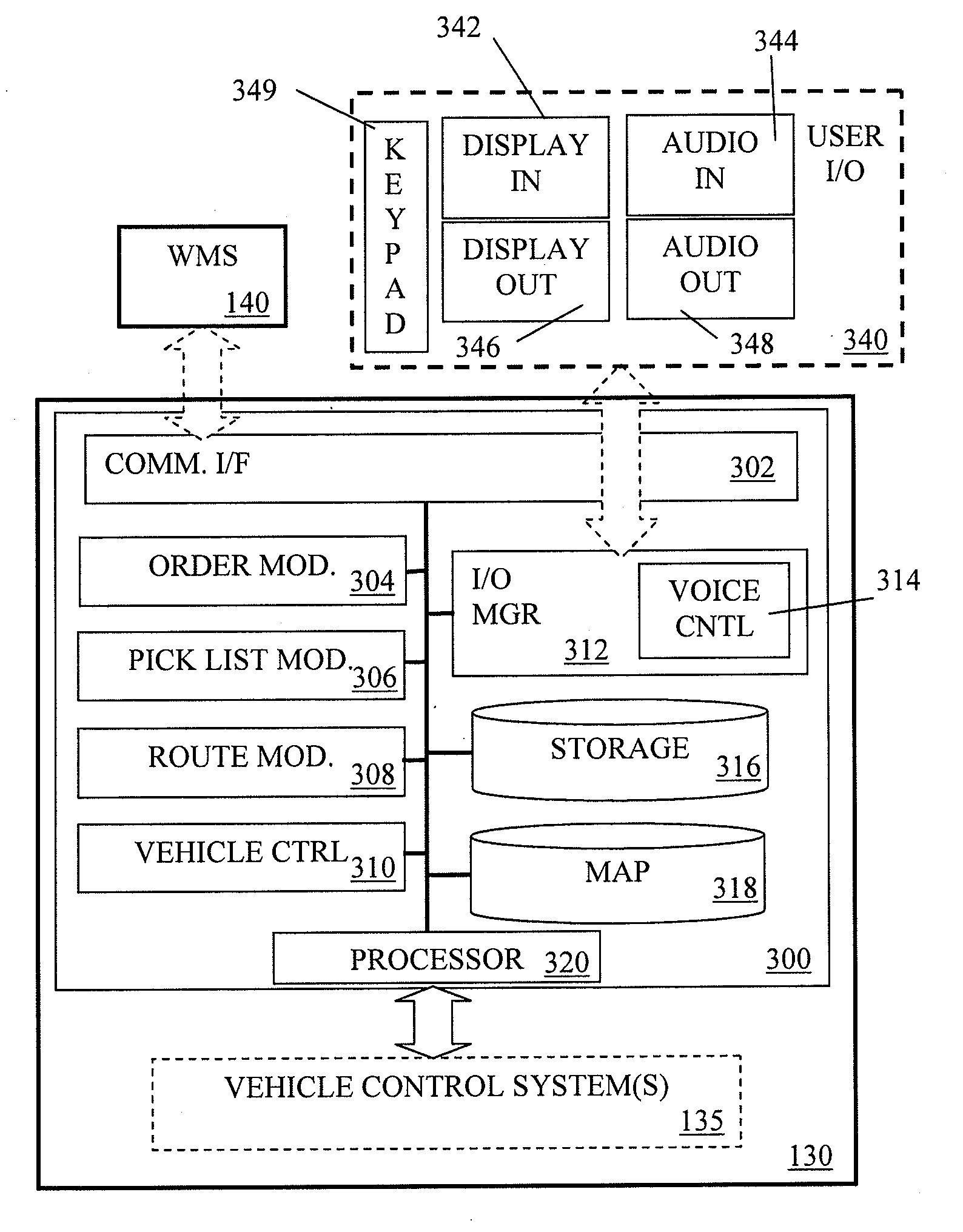

Robot-enabled case picking

ActiveUS20120330458A1Minimize travel distanceMinimize order distanceProgramme controlDigital data processing detailsUser inputOutput device

A robot-enabled method of picking cases in a warehouse is provided. A robotic vehicle includes a processor configured to access a memory, a user input device, an output device, and a load platform, and has access to an electronically stored representation of a warehouse. The representation includes a map that defines aisles for storing items arranged as pick faces within the warehouse. A pick list is generated from an order; the pick list provides identifications of items to be picked to fulfill the order. Determined from the pick list is a plurality of stops at pick faces associated with the items. A route within the map is generated that includes the plurality of stops. The robotic vehicle iteratively guides itself along the route and automatically stops at each of the plurality of stops to enable loading of the items from the pick list onto the load platform.

Owner:SEEGRID CORPORATION

Method and system for transporting inventory items

ActiveUS20070288123A1Disadvantages and reduced eliminatedInventory reduced eliminatedDigital data processing detailsLifting devicesEngineeringMechanical engineering

A system for transporting inventory items includes an inventory holder capable of storing inventory items and a mobile drive unit. The mobile drive unit is capable of moving to a first point with the inventory holder at least one of coupled to and supported by the mobile drive unit. The mobile drive unit is additionally capable of determining a location of the inventory holder and calculating a difference between the location of the inventory holder and the first point. The mobile drive unit is then capable of determining whether the difference is greater than a predetermined tolerance. In response to determining that the difference is greater than the predetermined tolerance, the mobile drive unit is also capable of moving to a second point based on the location of the inventory holder, docking with the inventory holder, and moving the mobile drive unit and the inventory holder to the first point.

Owner:AMAZON TECH INC

Fleet management system

ActiveUS8060400B2Ticket-issuing apparatusRegistering/indicating working of vehiclesFleet managementSoftware system

Owner:CROWN EQUIP CORP

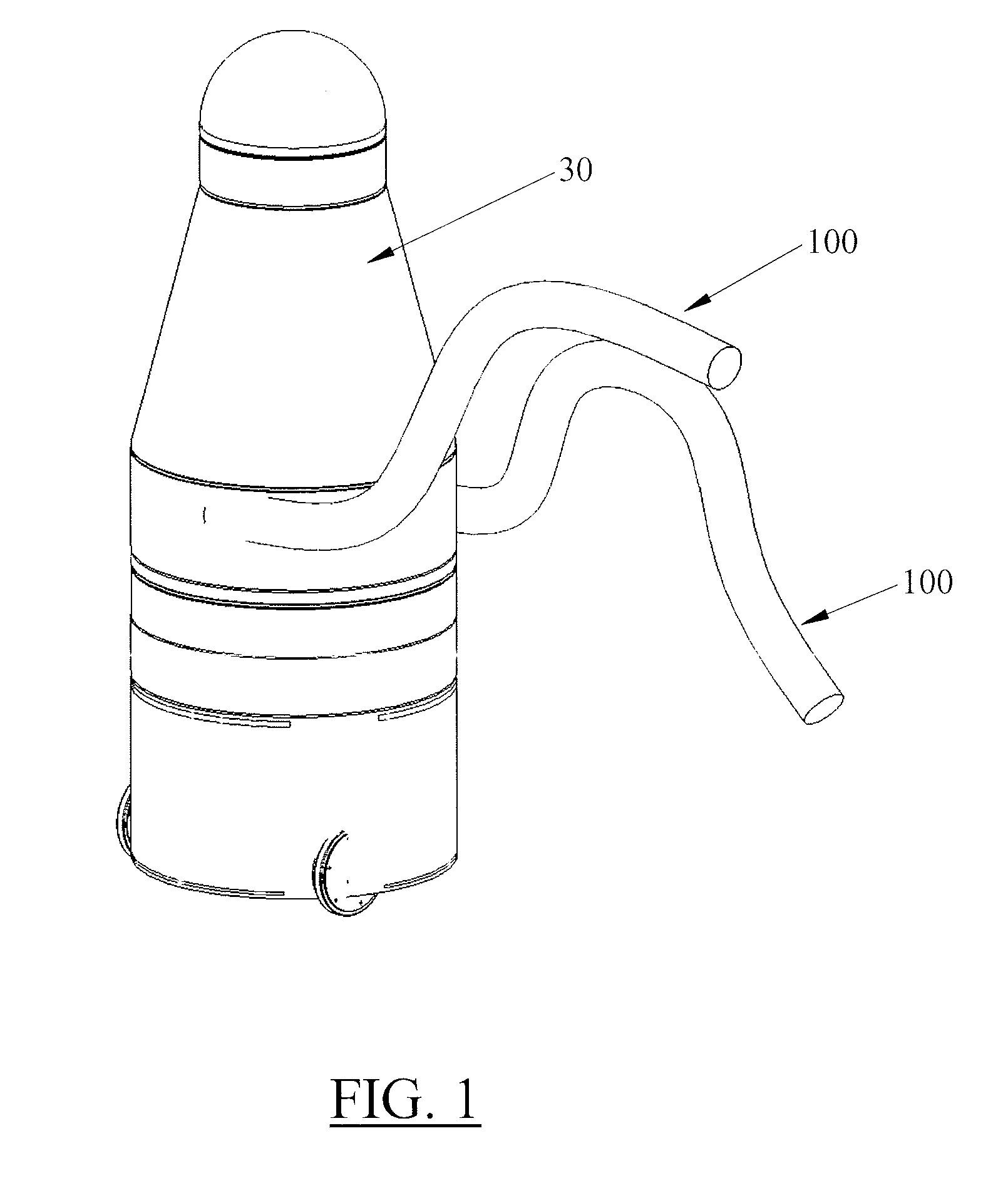

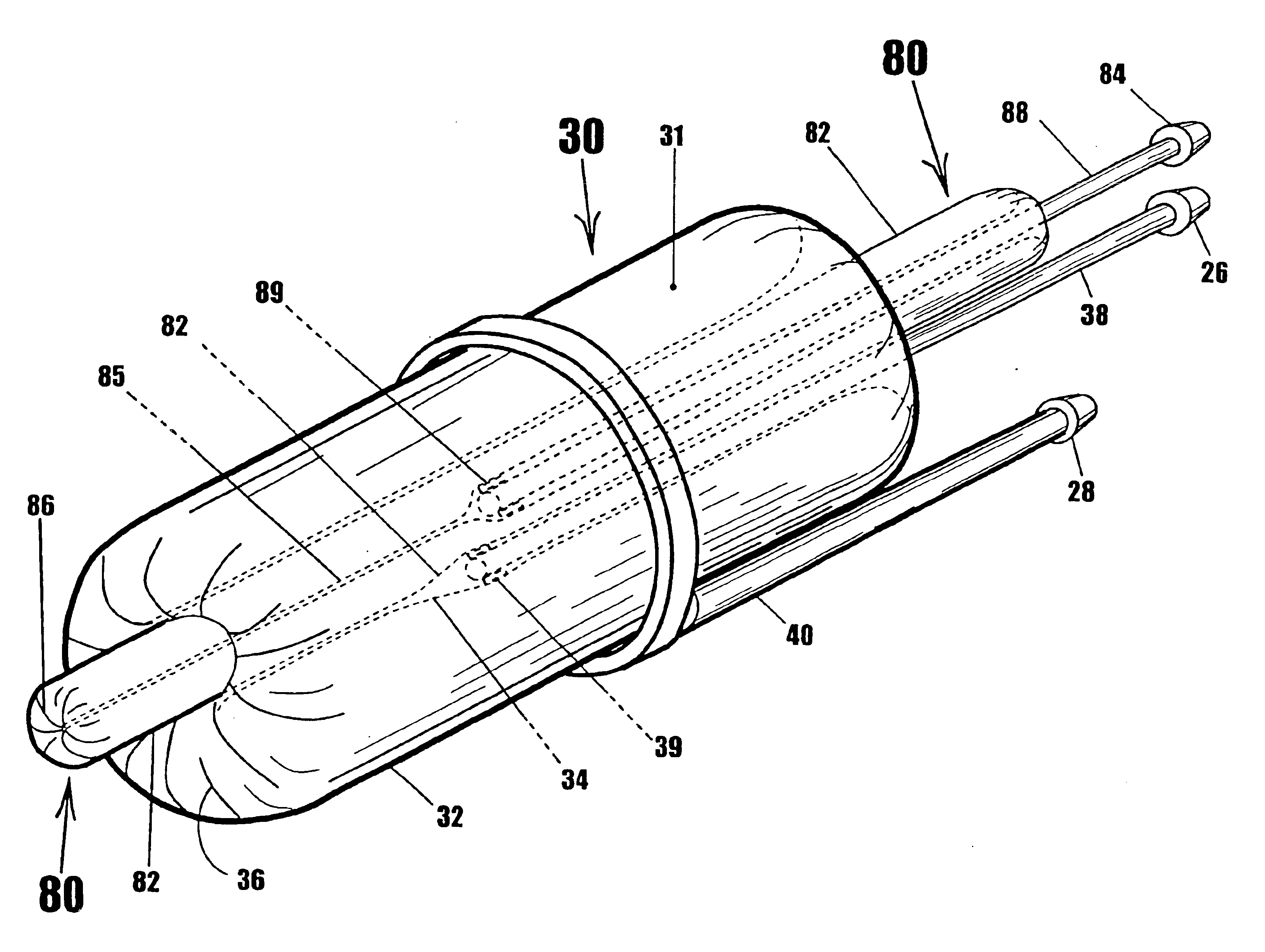

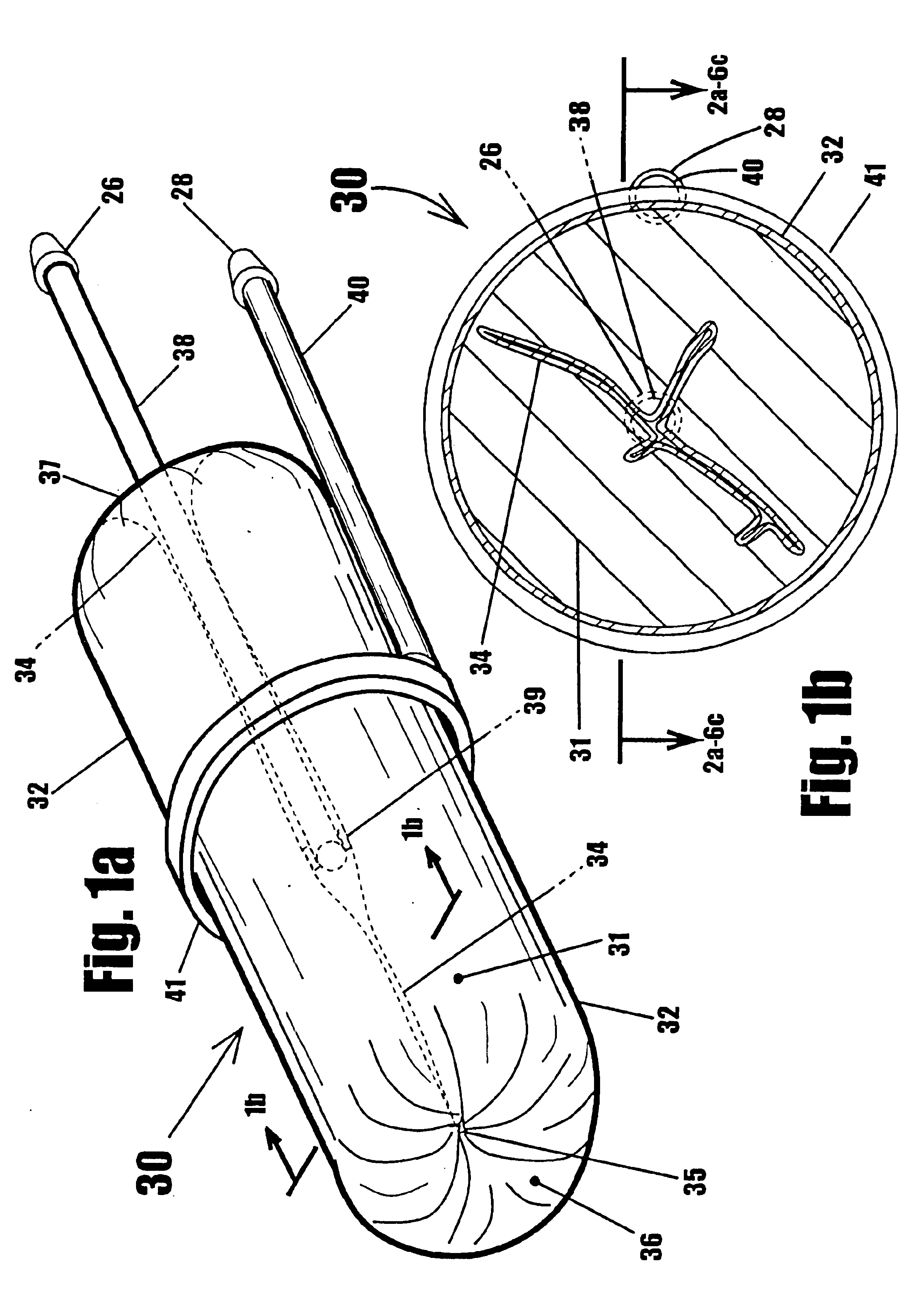

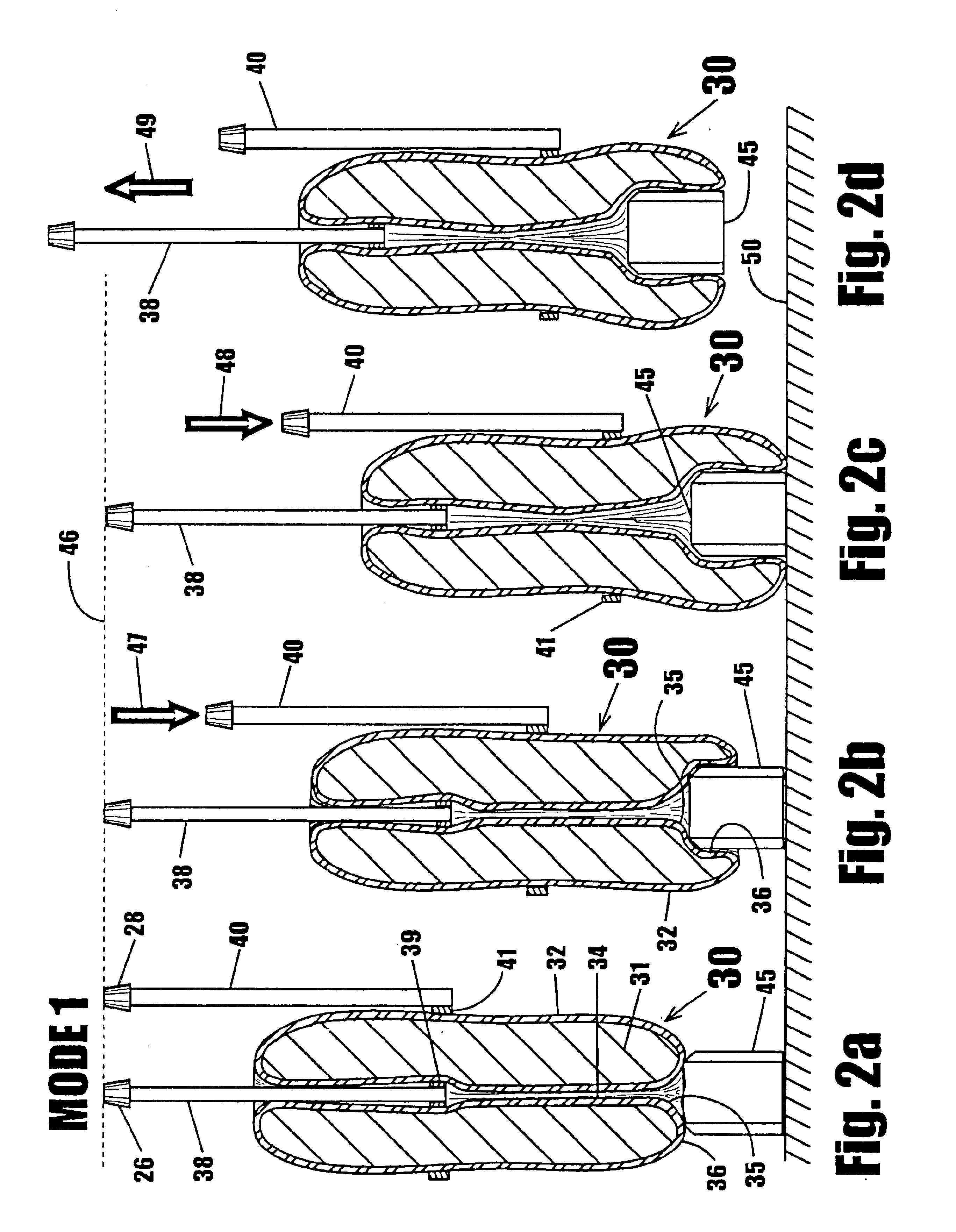

Torus-shaped mechanical gripper

A device for gripping, holding, and releasing objects of varying sizes and shapes, which comprises an elongated torus (30) enclosing a fluid material (31), an external control rod (40), and an internal control rod (38). Torus (30) may be made of a flexible membrane and able to seal in fluid material (31). Fluid material (31) can be a gas, liquid, solid particles, semisolid particles, or mixtures of these. Central channel (34) of torus (30) is collapsed due to pressure of fluid material (31) within torus (30). Both control rods are securely attached to torus (30), with rod (38) attached to the interior portion of the torus along collapsed central channel (34), and rod (40) attached to the exterior portion of the torus on outer surface (32). Gripping action is achieved by differential linear motion of control rods (38) and (40) along the longitudinal (elongated) axis of torus (30). This causes front portion (36) of the torus to slide radially inward or outward to grip objects. Further movement of the control rods can cause the object to be pulled completely inside the collapsed channel for secure gripping by completely surrounding the object. The soft flexible nature of torus (30) allows grasping even the most delicate objects without damaging them. Even over-ripe strawberries can be rapidly grasped without bruising.

Owner:RAGNER GARY DEAN +1

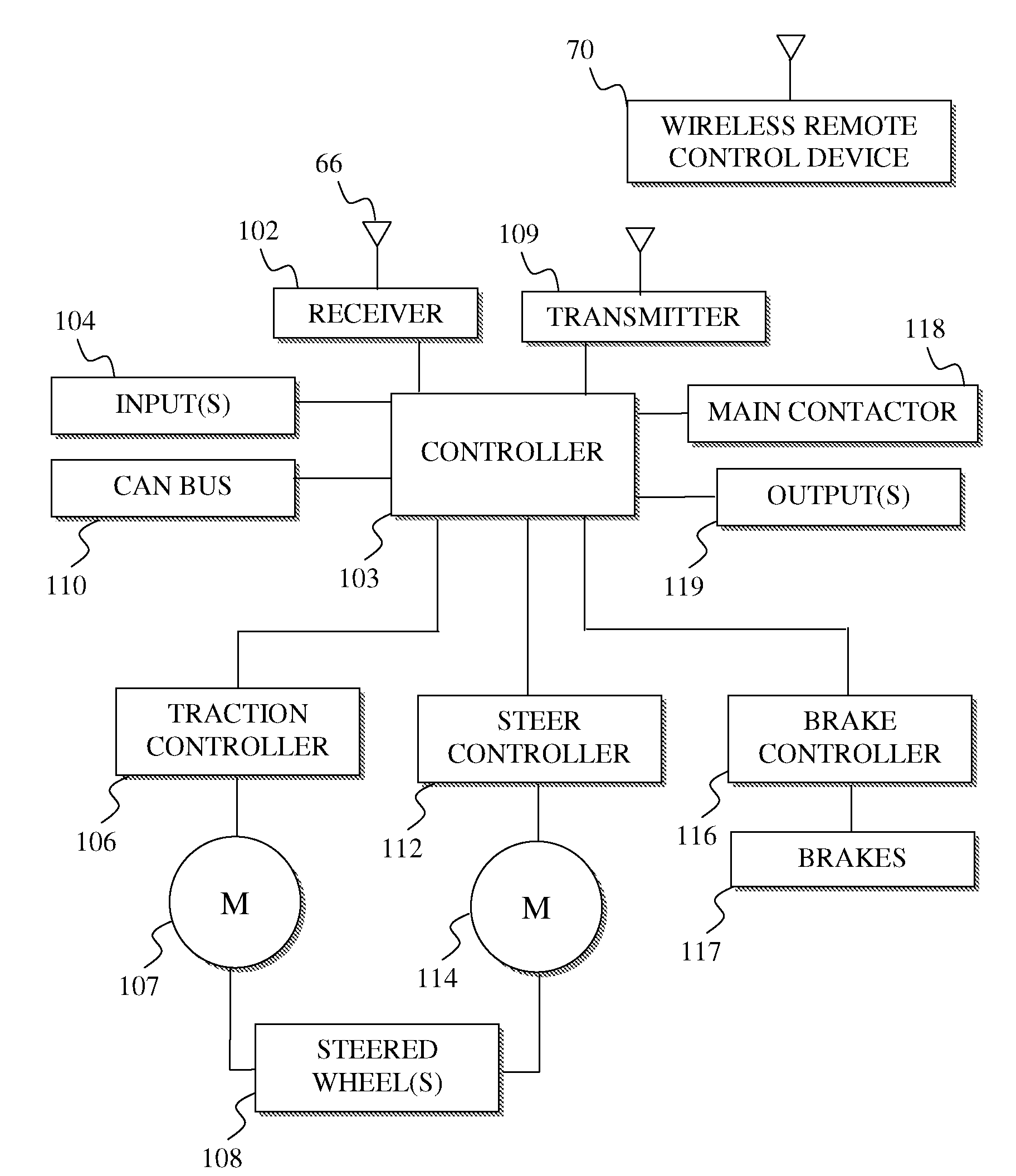

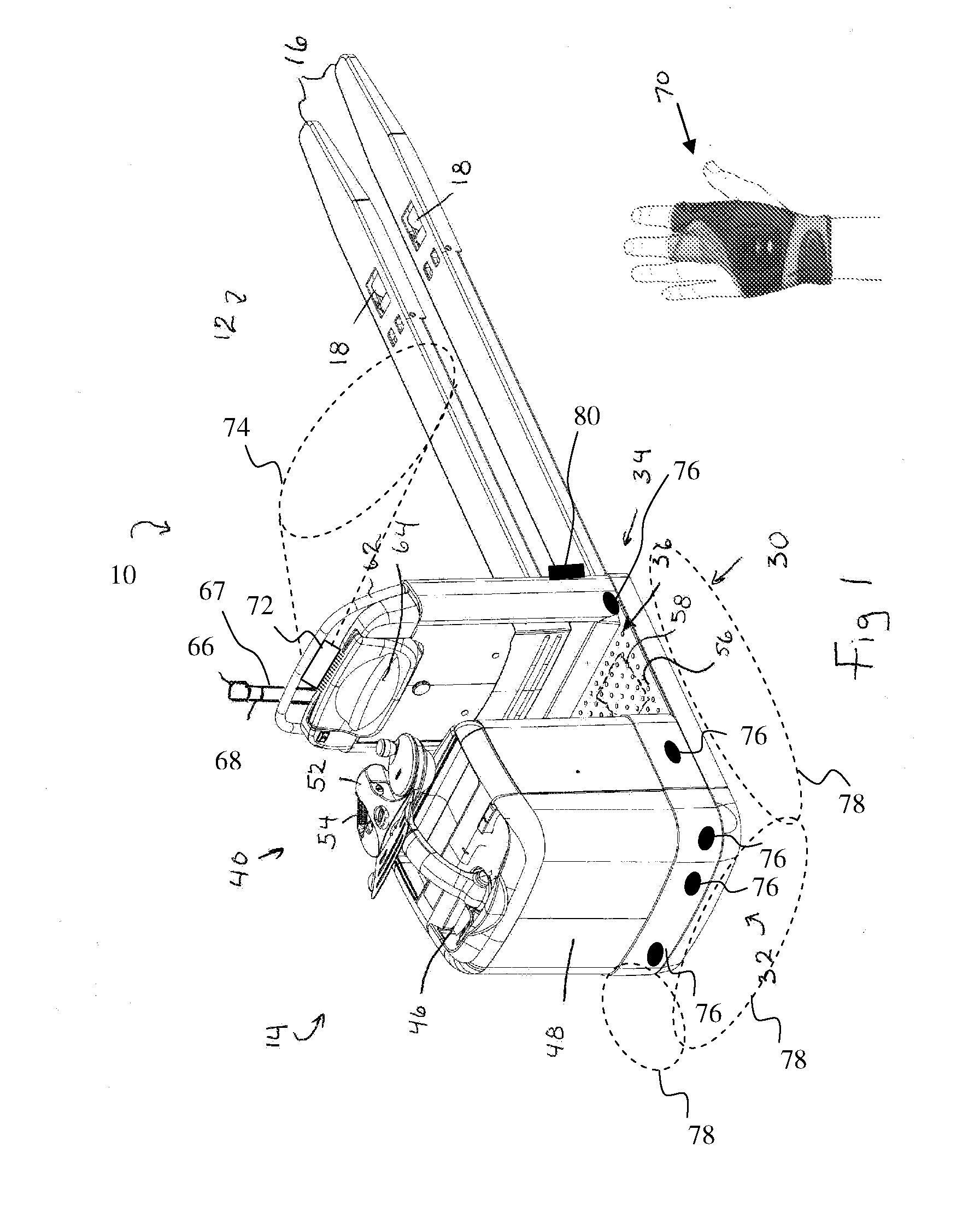

Systems and methods of remotely controlling a materials handling vehicle

ActiveUS20080129445A1Electric signal transmission systemsMultiple keys/algorithms usageControl systemEngineering

A supplemental control system for a materials handling vehicle comprises a wearable control device, and a corresponding receiver on the materials handling vehicle. The wearable control device is donned by an operator interacting with the materials handling vehicle, and comprises a wireless transmitter and a travel control communicably coupled to the wireless transmitter. Actuation of the travel control causes the wireless transmitter to transmit a first type signal designating a request to advance the vehicle in a first direction. The receiver is supported by the vehicle for receiving transmissions from the wireless transmitter. A traction control of the vehicle is responsive to a receipt of the first type signal by the receiver to cause the vehicle to advance.

Owner:CROWN EQUIP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com