Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5085results about "Hoisting equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

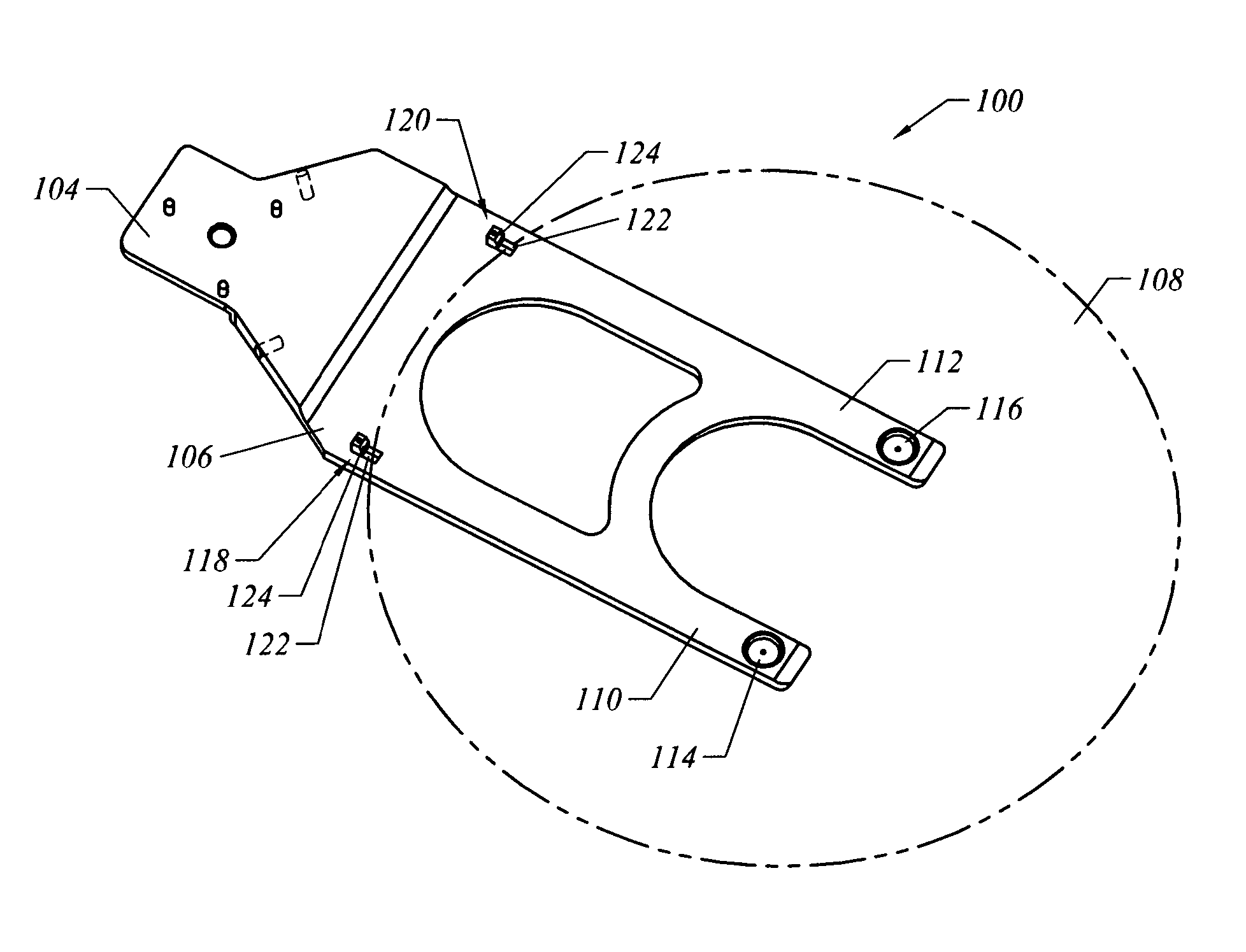

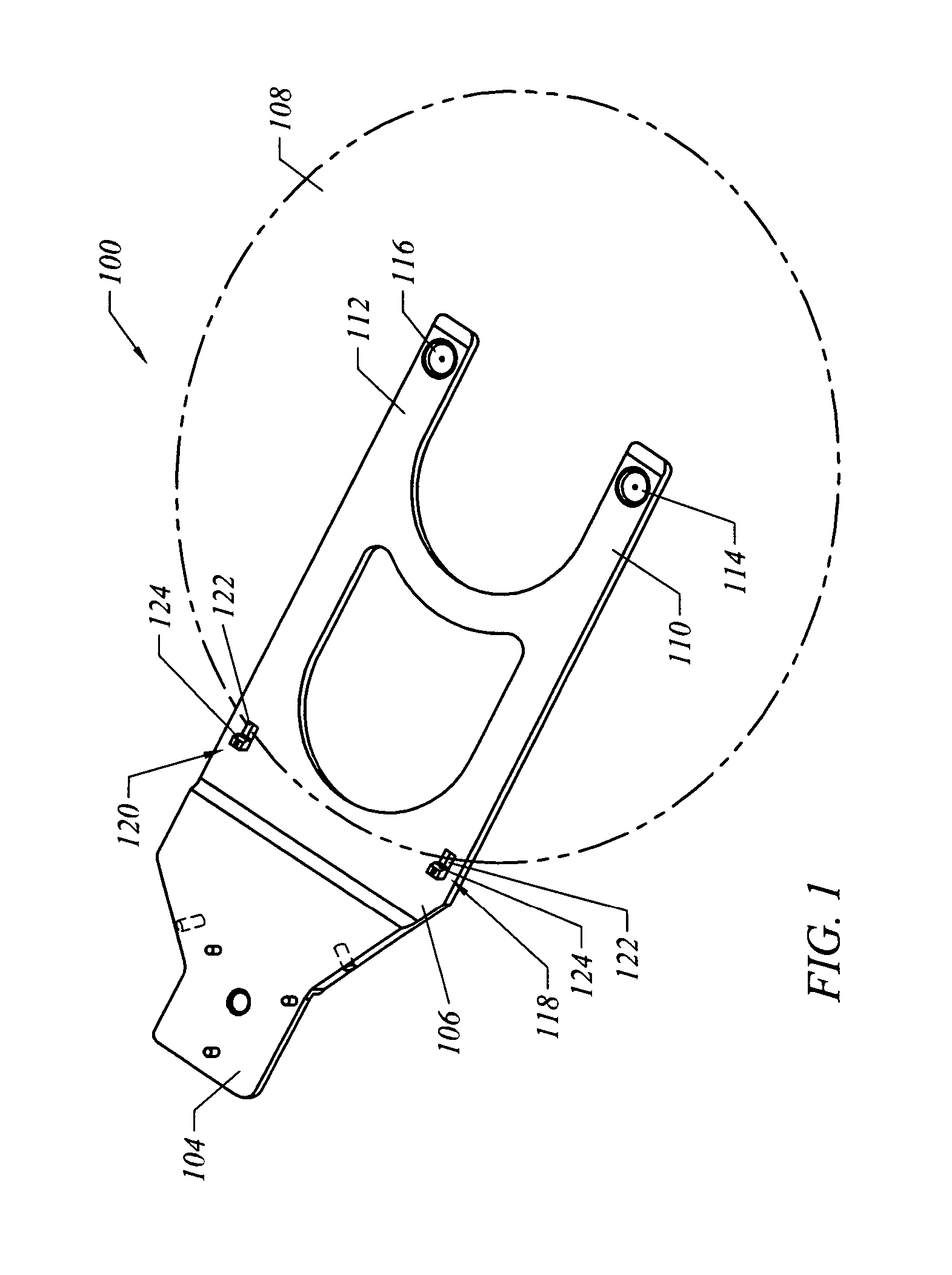

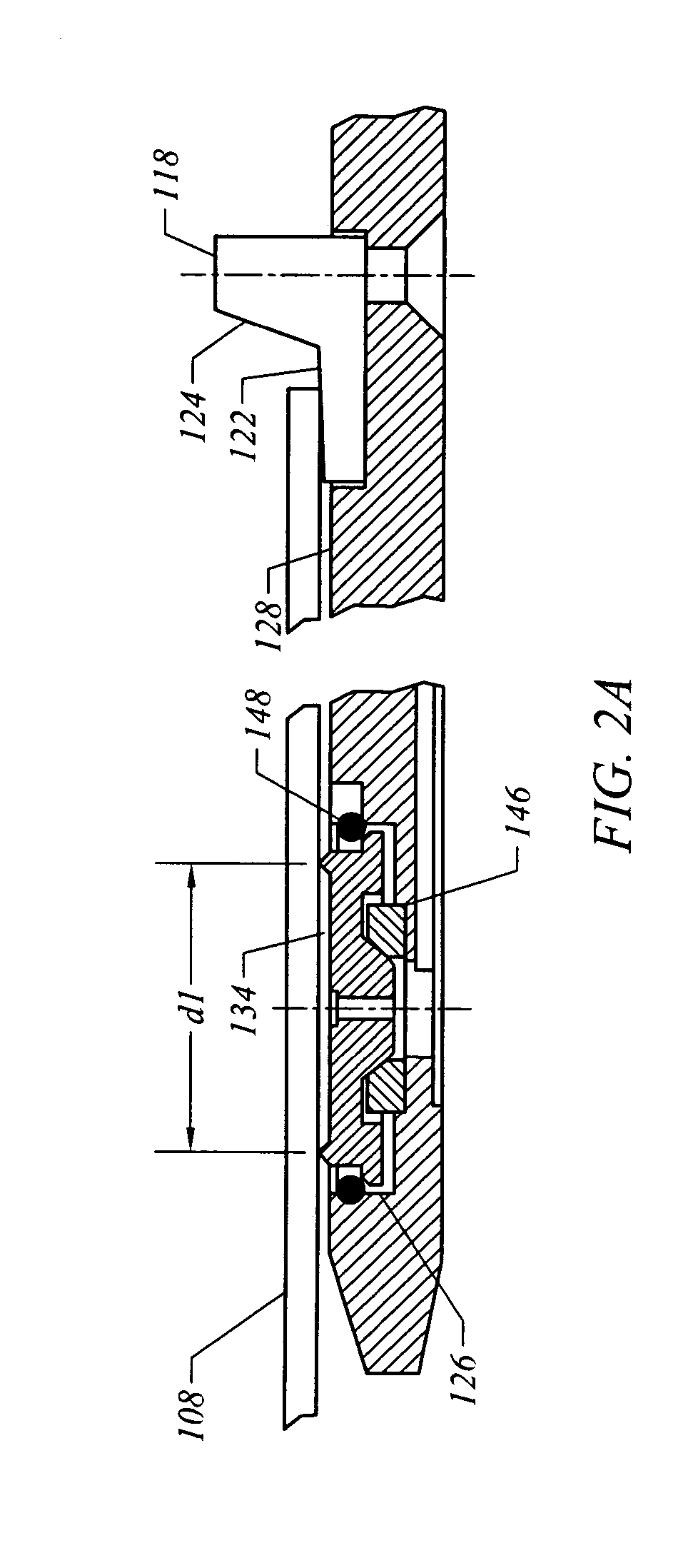

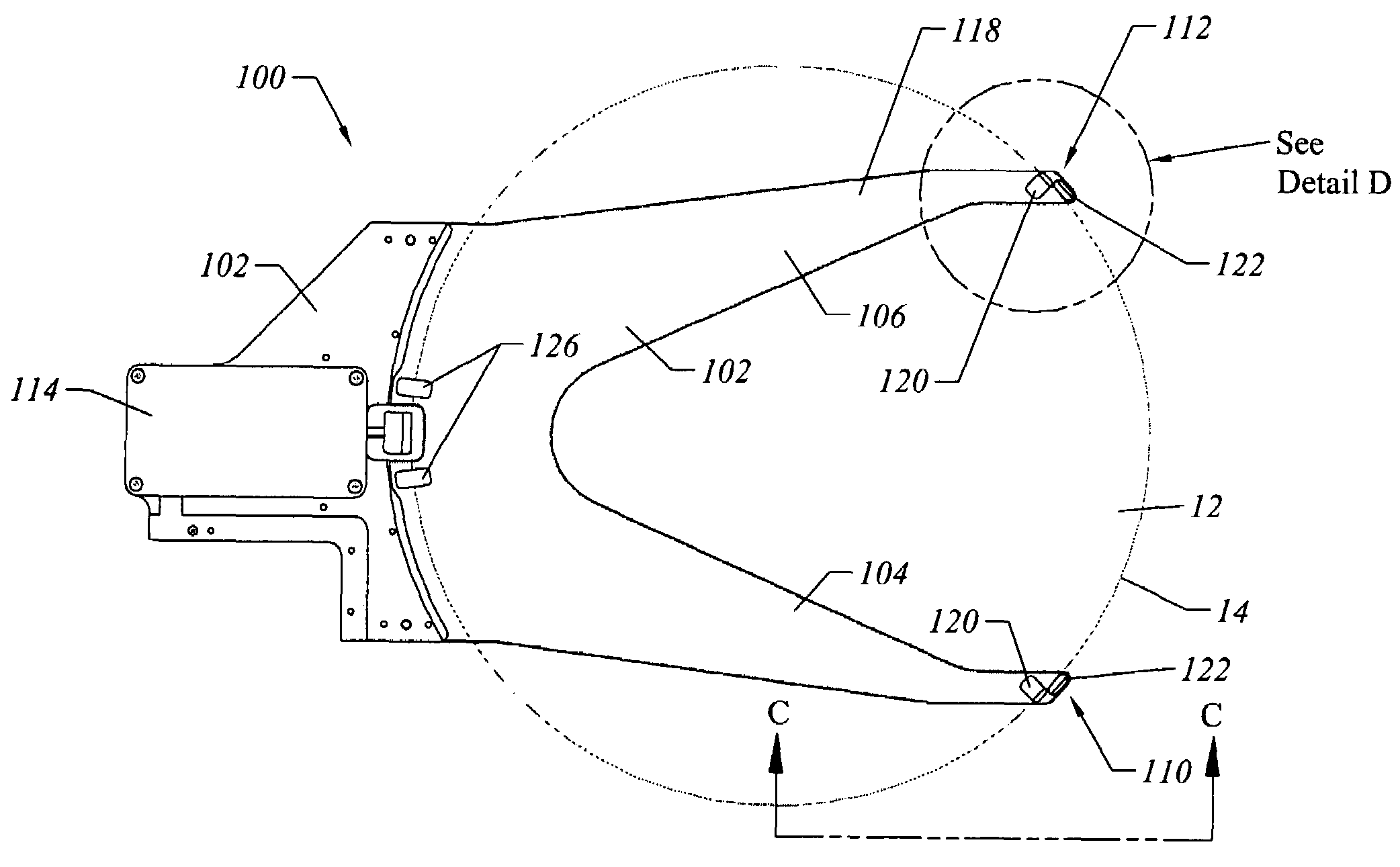

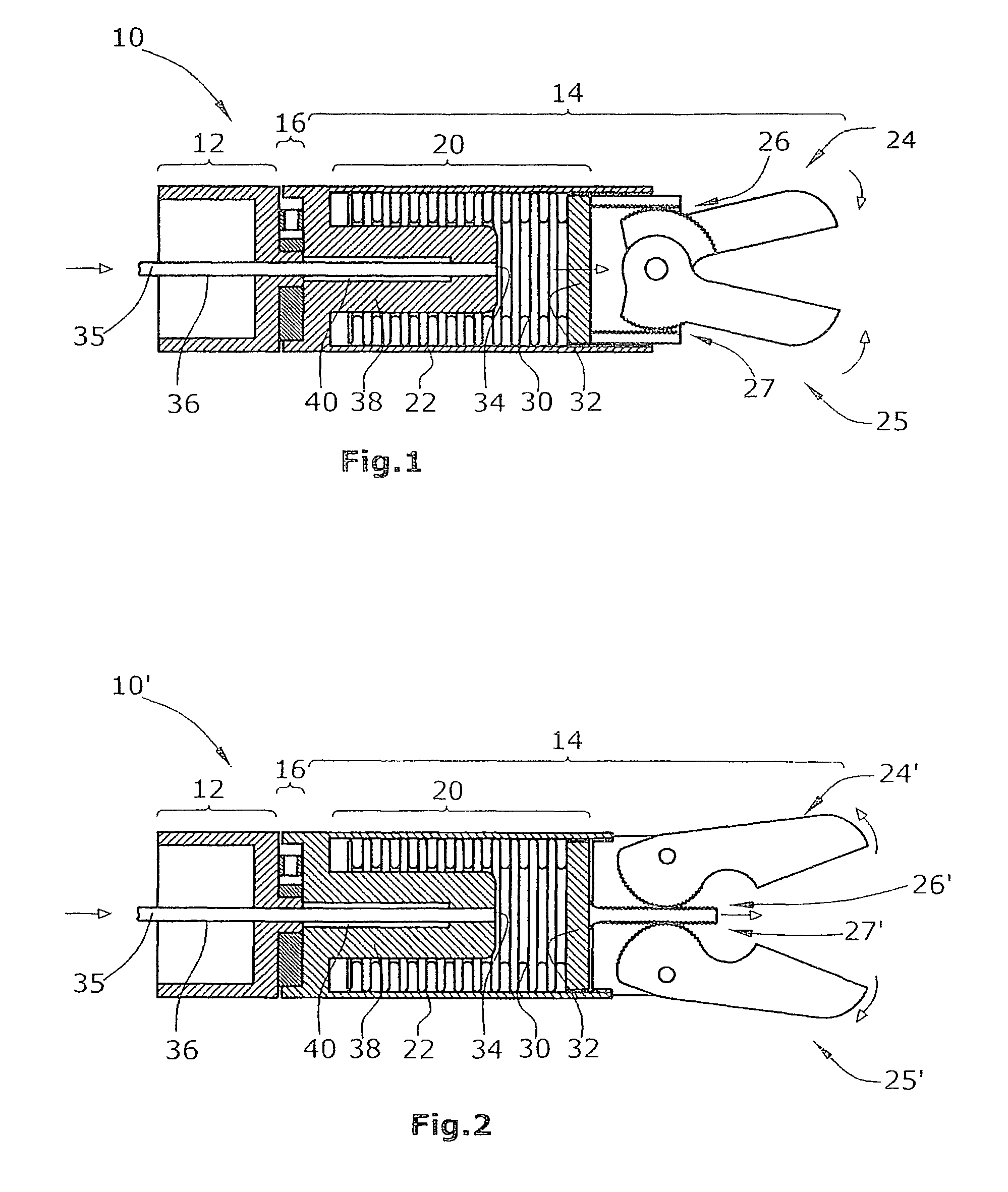

Ultra low contact area end effector

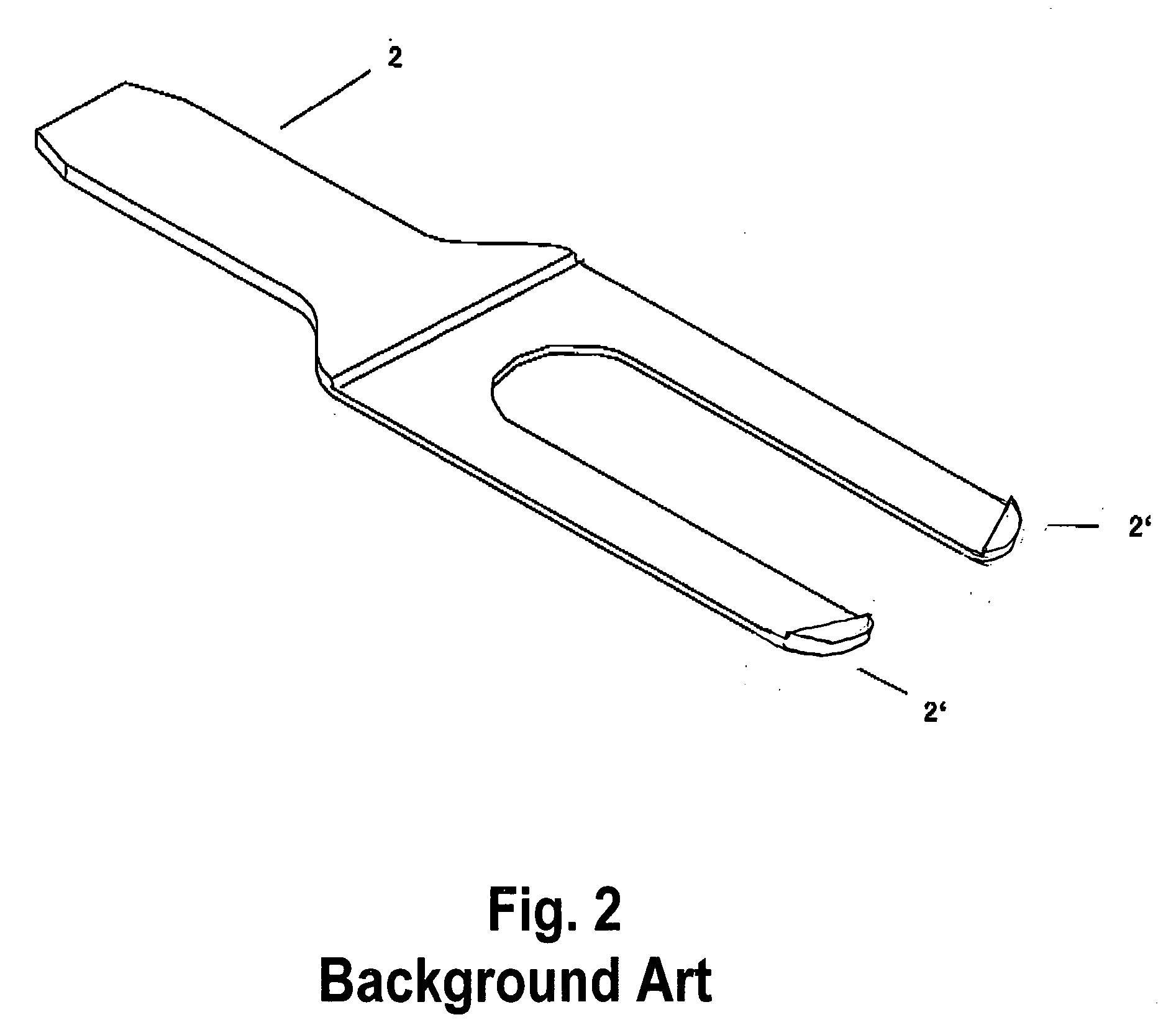

ActiveUS7055875B2Eliminates and greatly minimizes particulate transferImprove sealingGripping headsSemiconductor/solid-state device manufacturingEngineeringActuator

The present invention comprises a vacuum end effector having workpiece supports that work in conjunction with distorted workpiece surfaces. In one embodiment, each workpiece support has the ability to gimbal and conform the workpiece surface in contact with an outer edge of the support. Each workpiece support preferably provides a knife-like contact edge to minimize the contact area between the support and the workpiece while still providing an effective vacuum area to hold the wafer securely on the support. In another embodiment, each workpiece support is replaceable without having to remove the end effector from the robot assembly

Owner:BOOKS AUTOMATION US LLC

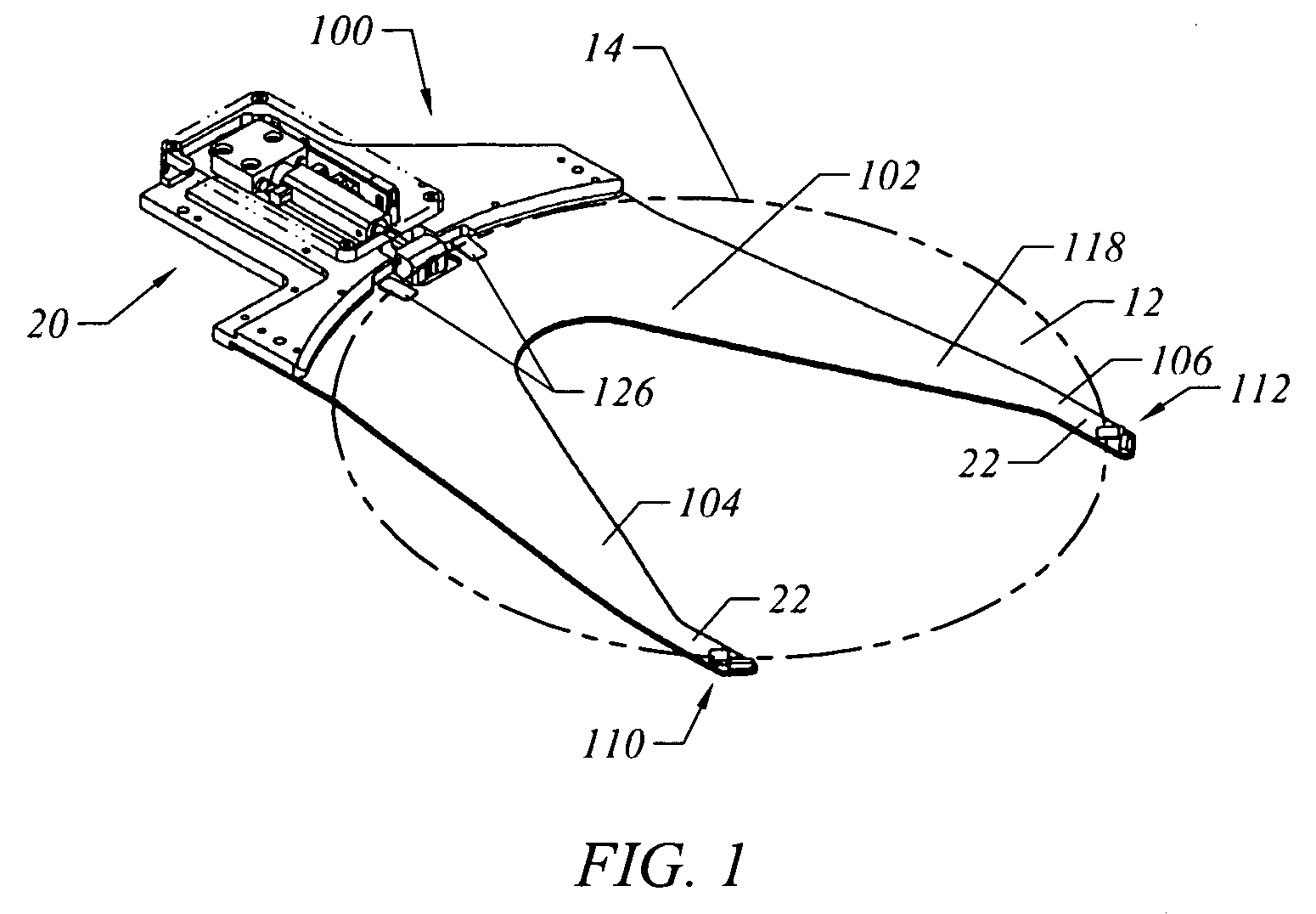

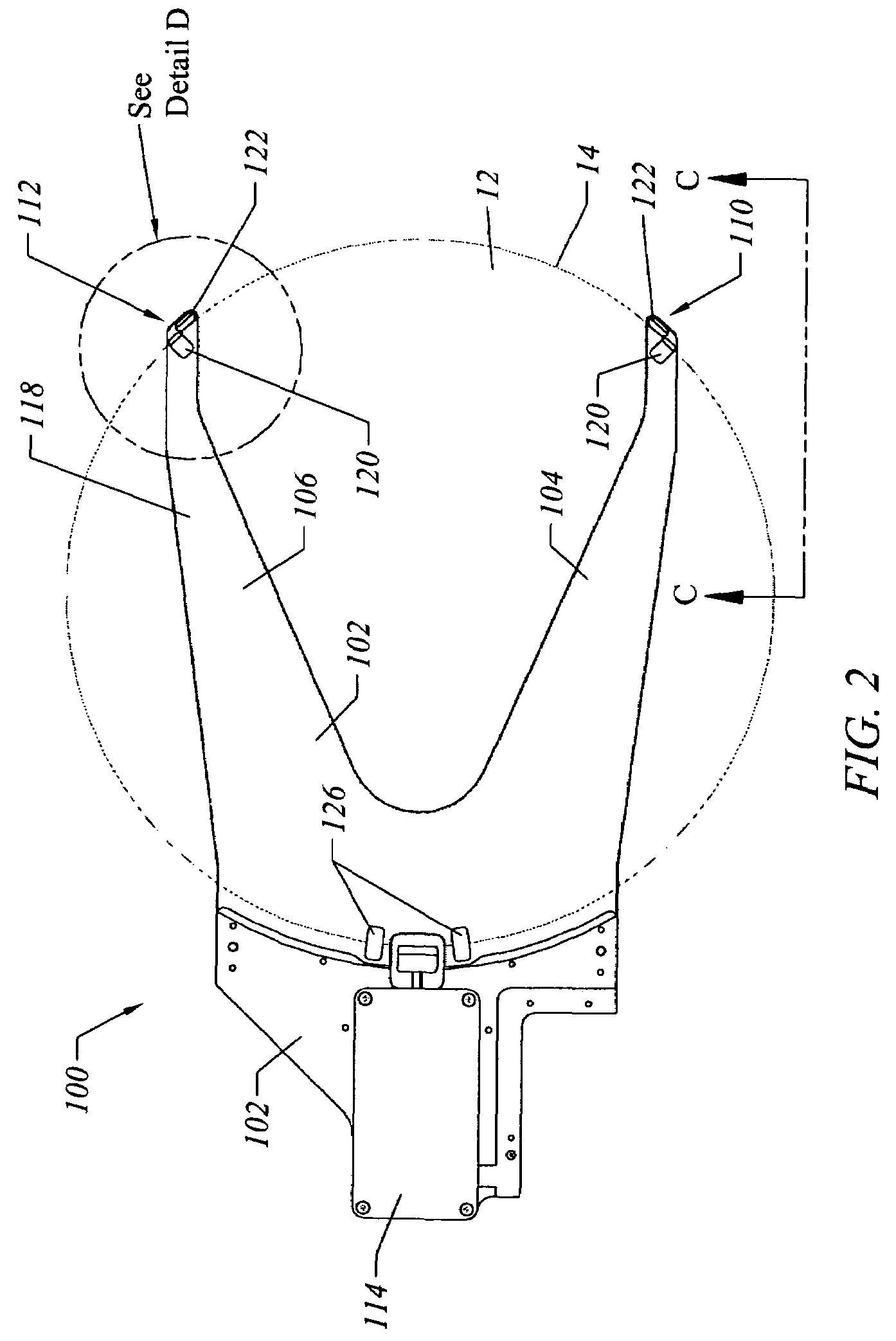

Active edge grip rest pad

ActiveUS7290813B2Precise and repeatable placementLow profileSemiconductor/solid-state device manufacturingLifting devicesActive edgeEngineering

The present invention comprises a distal rest pad for supporting a portion of a wafer seated on an end effector. In one embodiment, the rest pad includes a bottom support pad and an edge stop. Each element is mounted separately to the distal end of a support plate. The bottom support pad includes an inclined surface that transitions to a substantially horizontal surface at its distal end. The edge stop has a substantially vertical wafer contact surface that the peripheral edge of a wafer eventually contacts as the wafer is urged towards the distal rest pad. In another embodiment, the bottom support pad comprises an inclined surface. In yet another embodiment, the distal rest pad comprises a single structure. This distal rest pad includes a backstop portion and a bottom support separated by a particle collection groove. The bottom support may include an inclined lead-in surface that transitions into a flat contact surface or only comprise an inclined lead-in surface.

Owner:BOOKS AUTOMATION US LLC

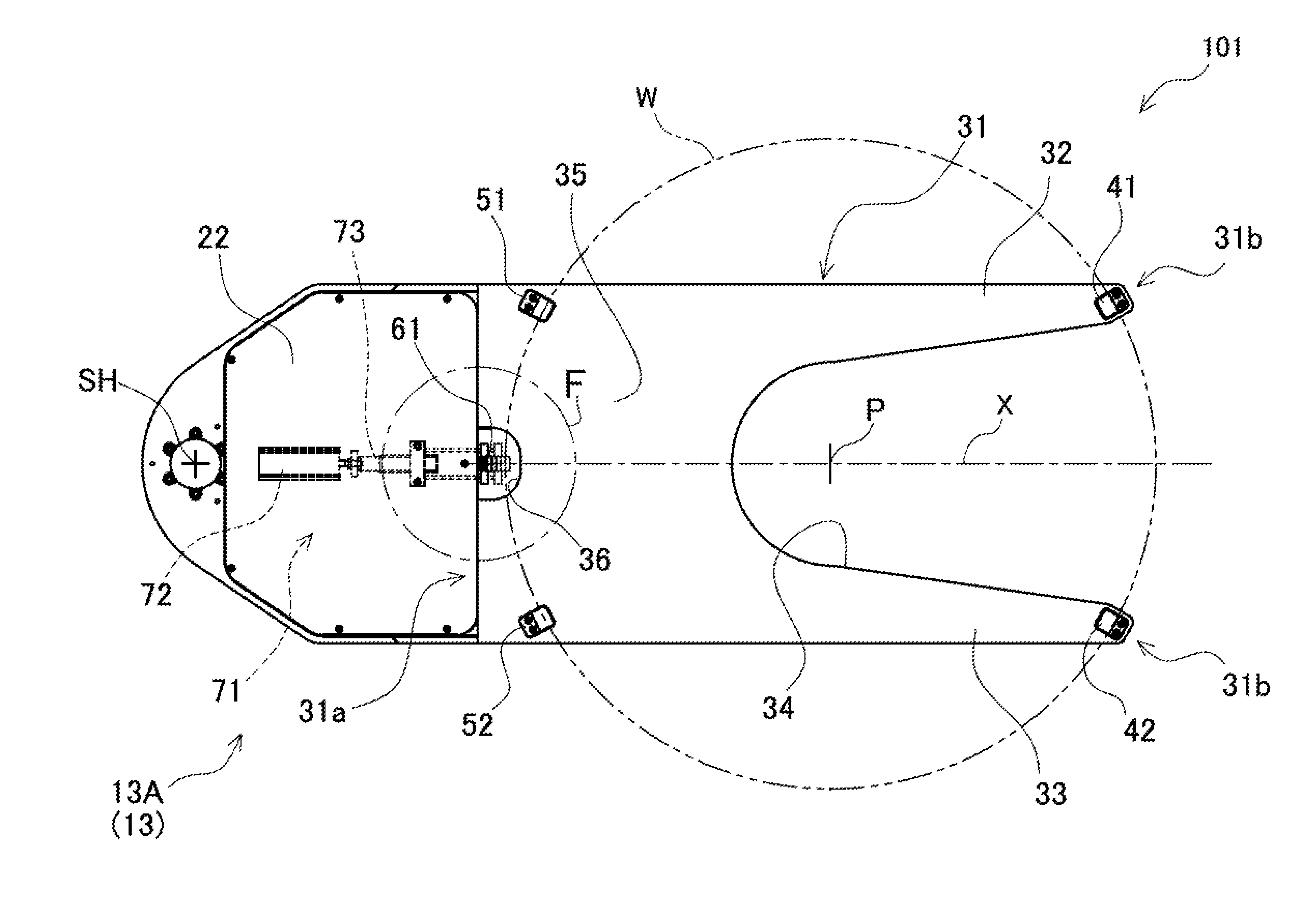

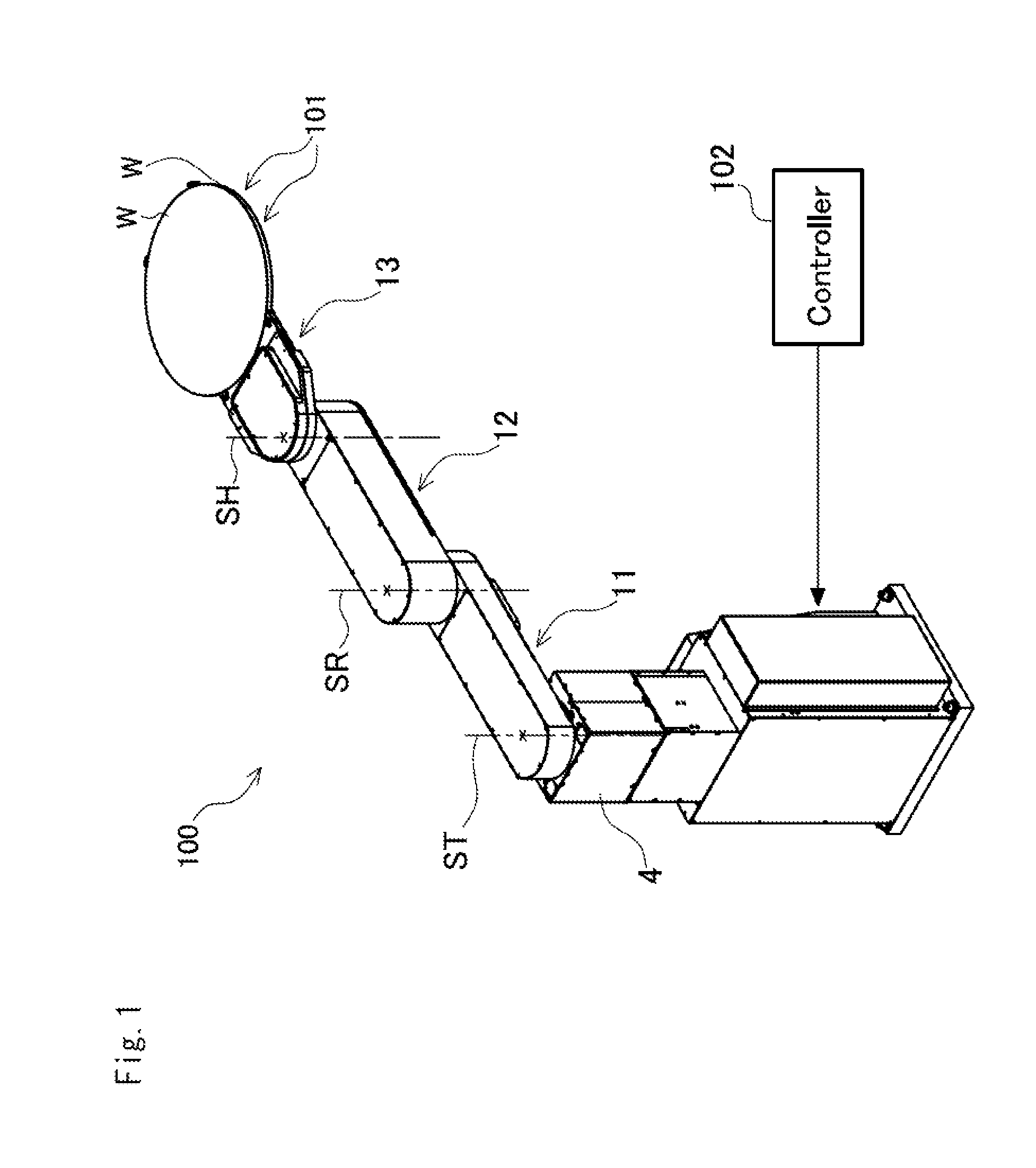

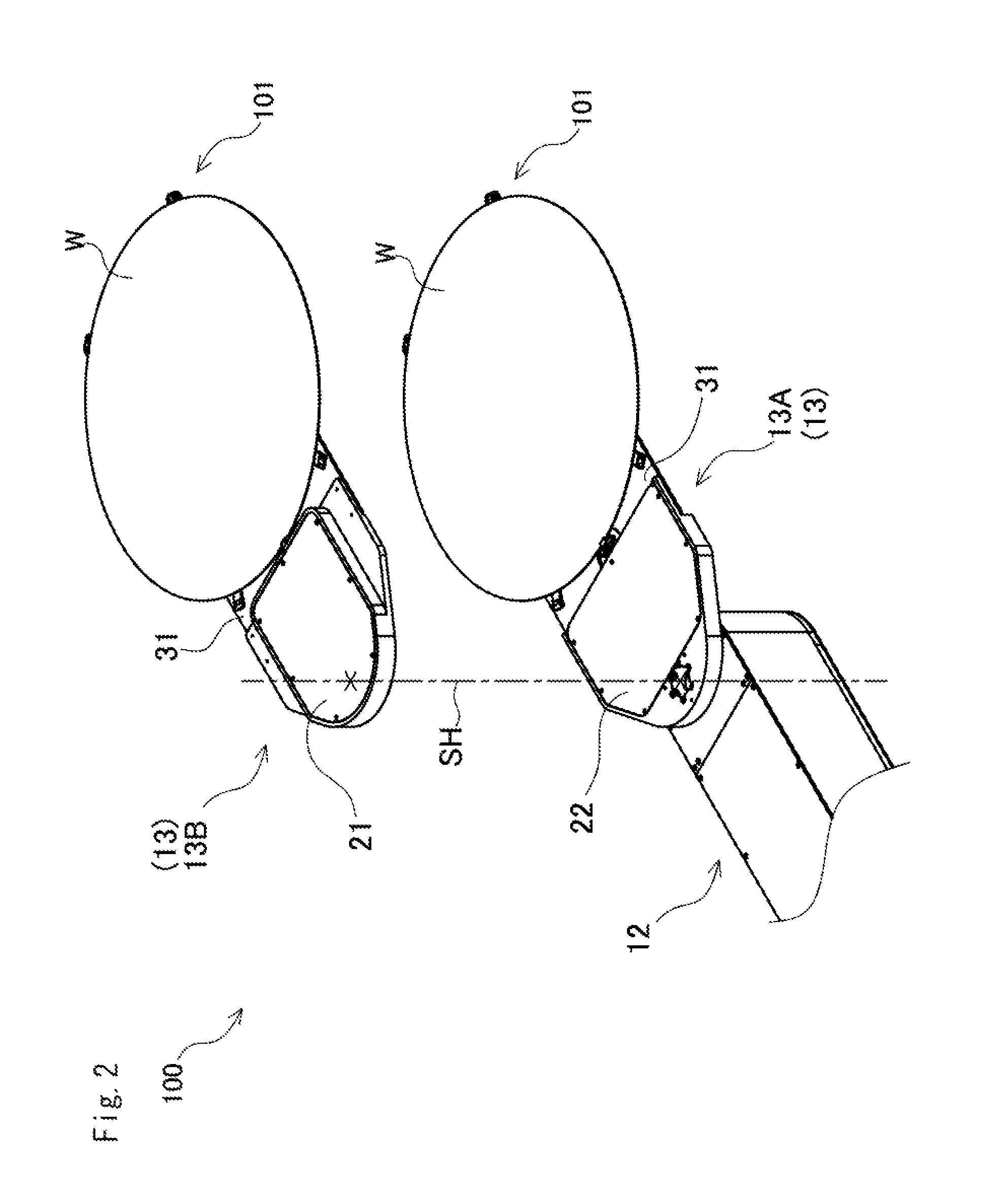

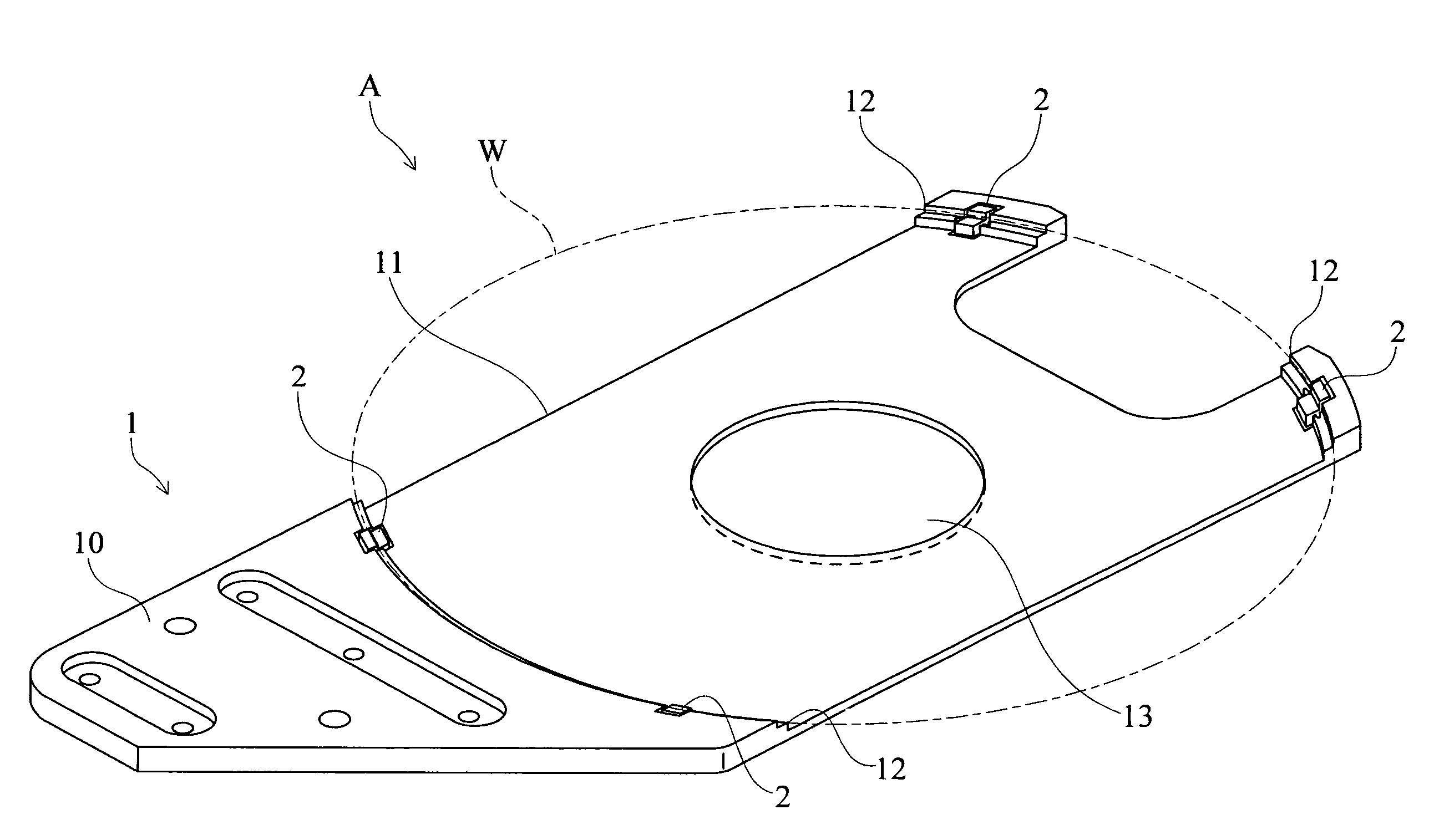

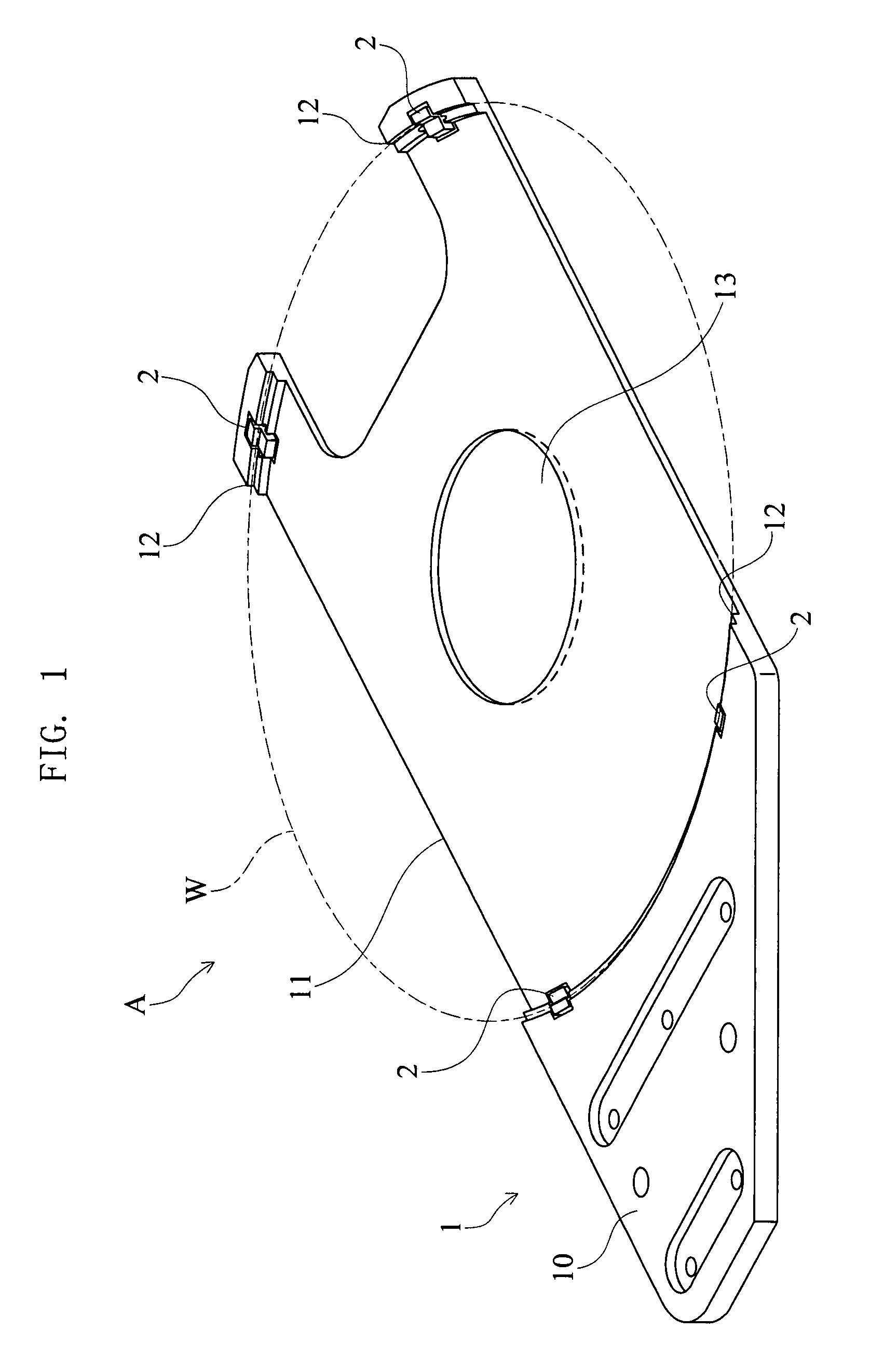

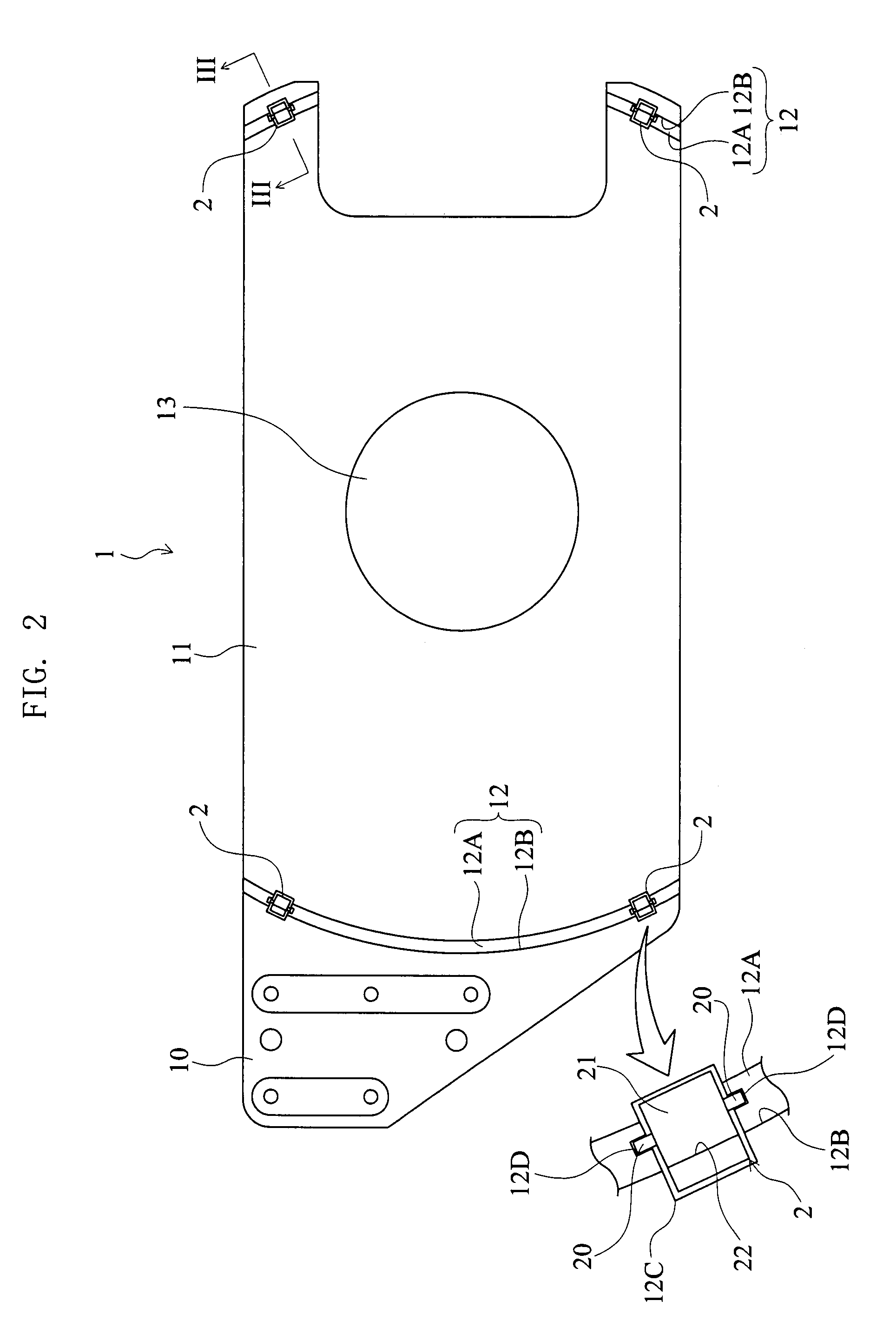

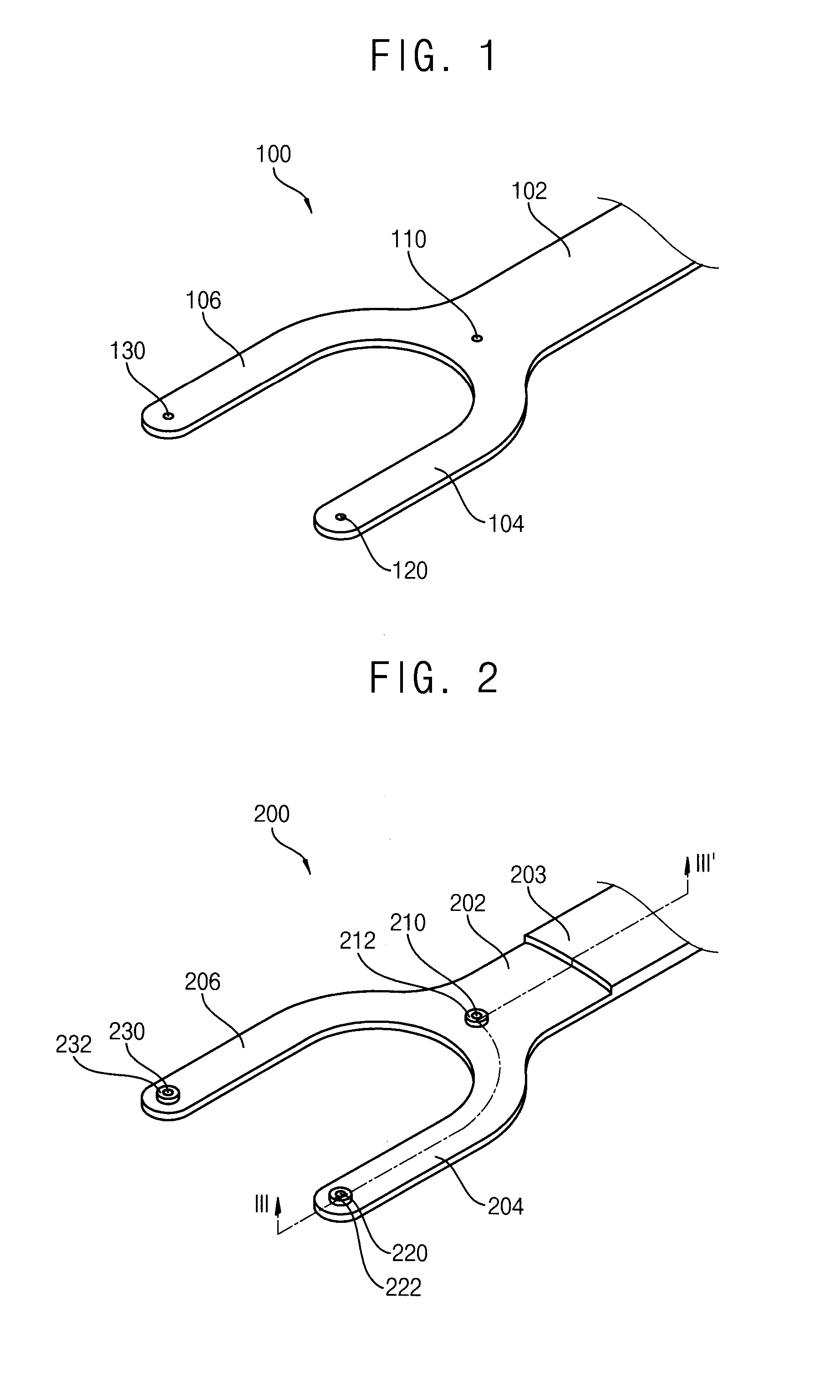

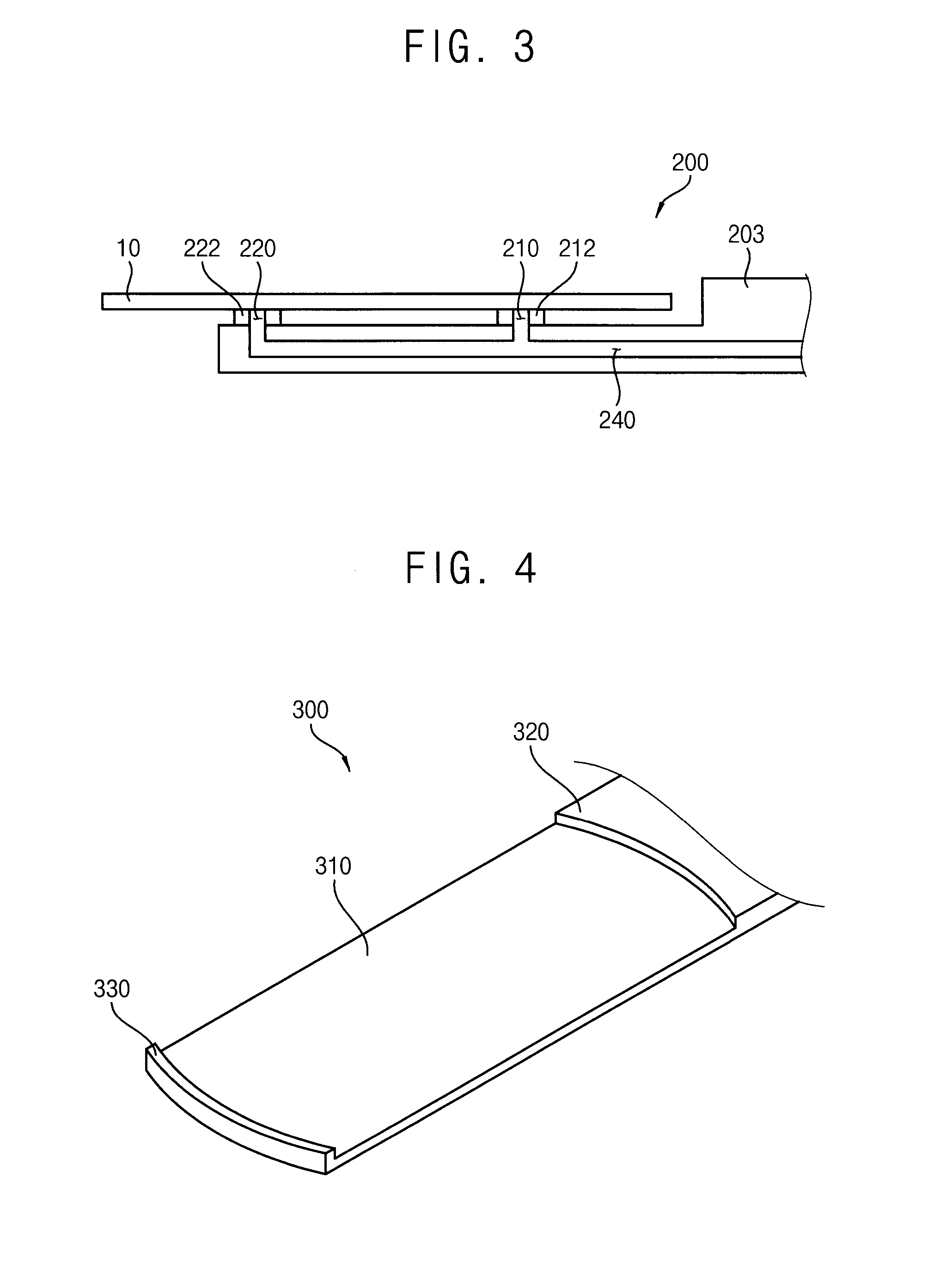

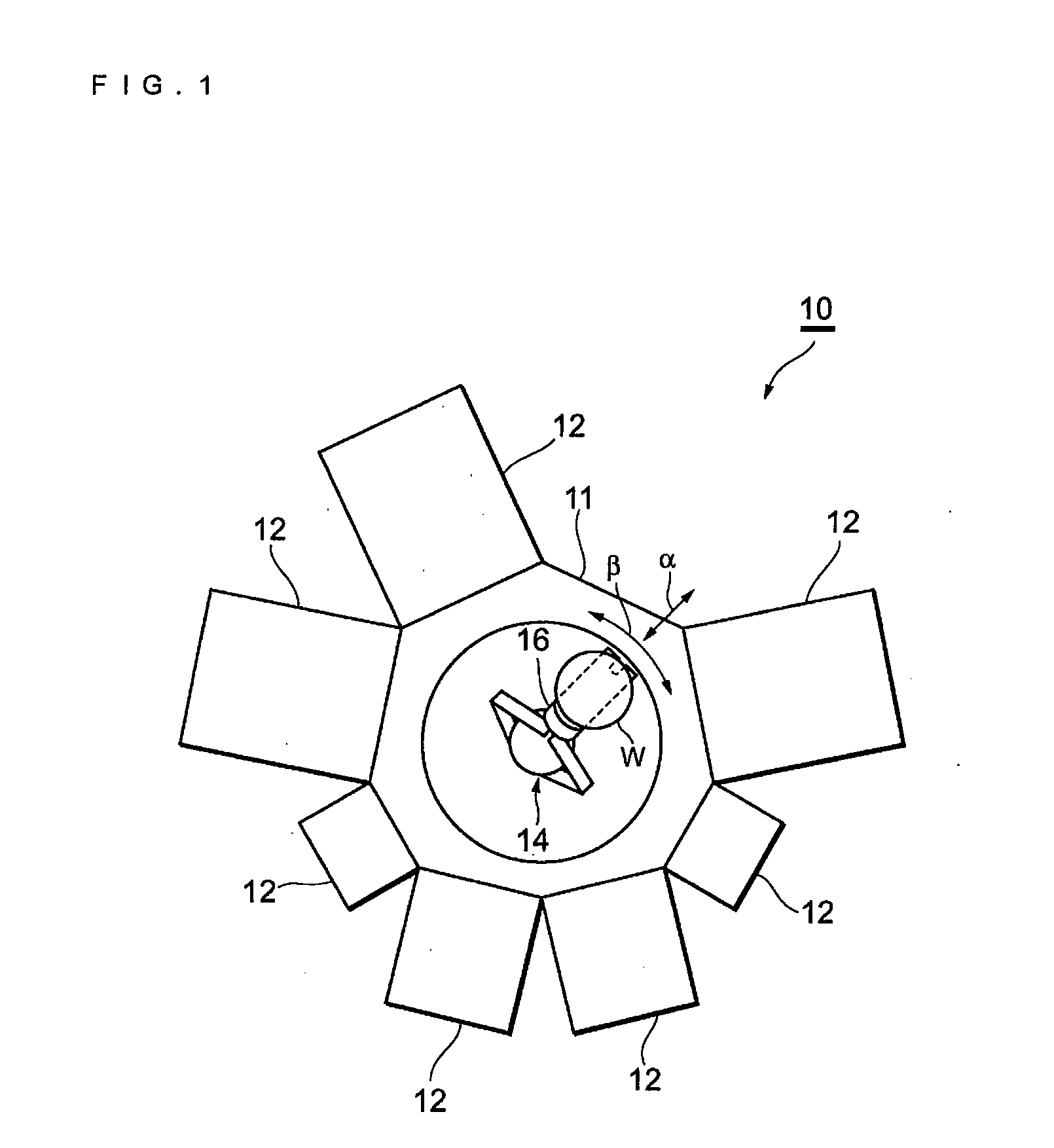

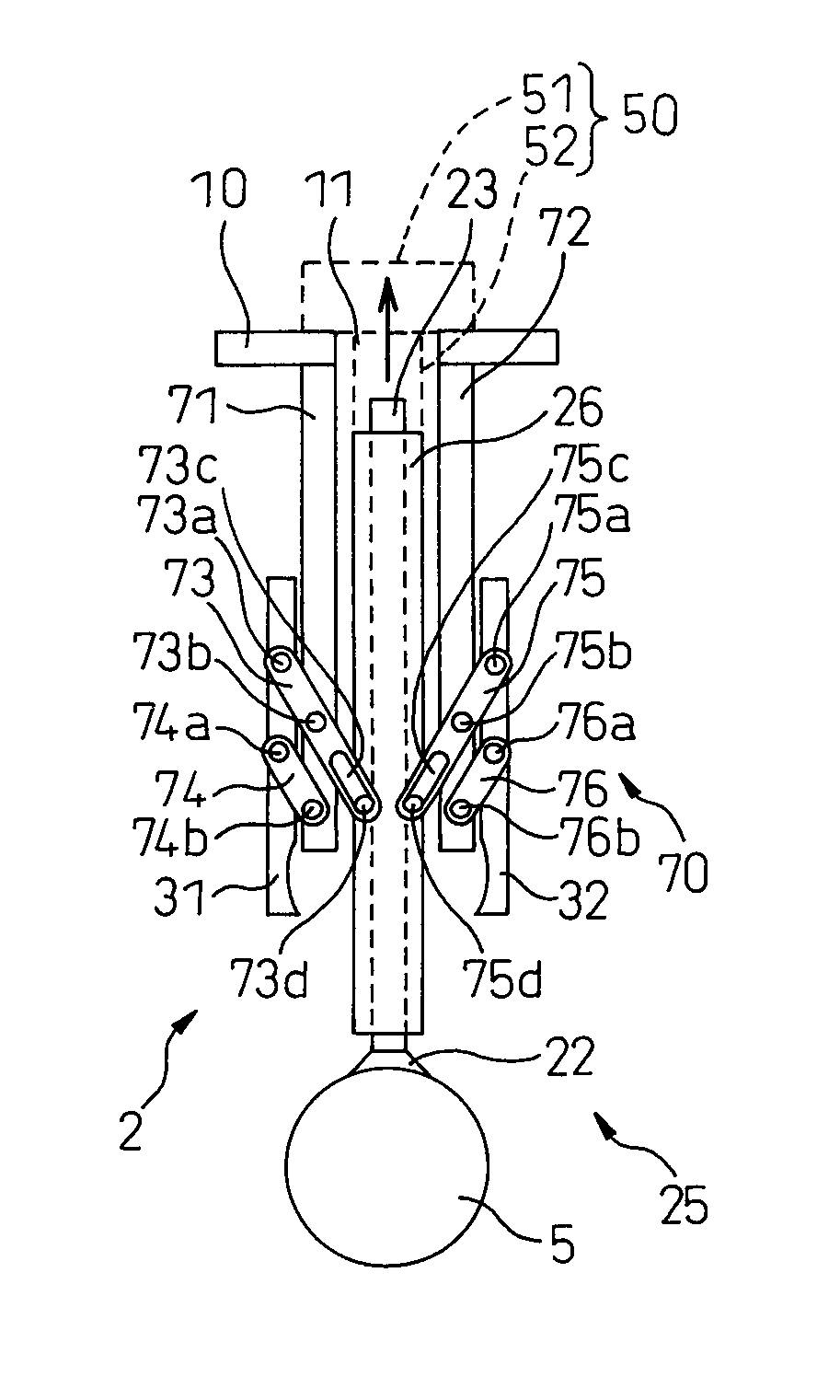

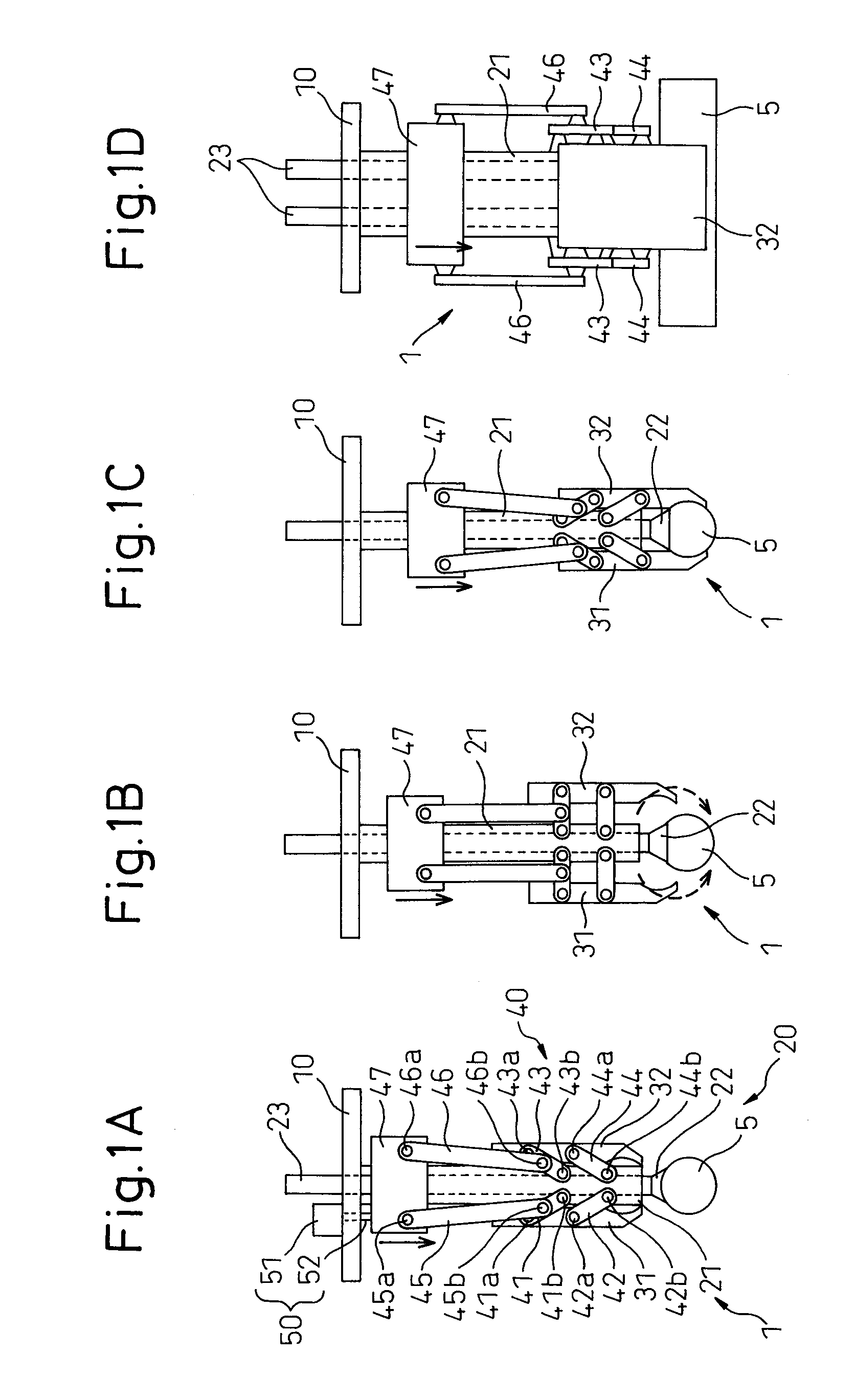

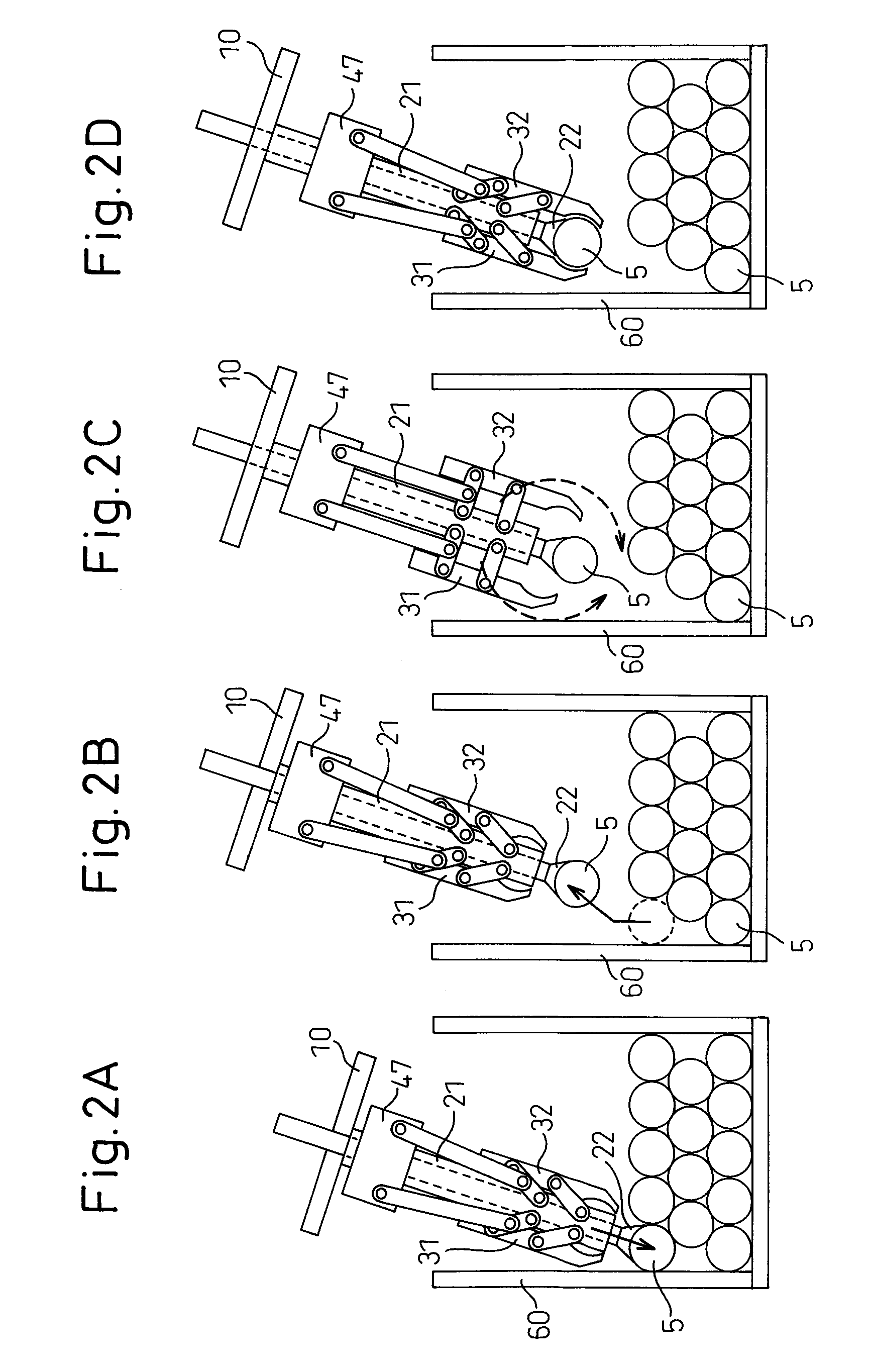

Clamping device and workpiece conveying robot

InactiveUS8764085B2High positionalImprove retentionGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SINFONIA TECHNOLOGY CO LTD

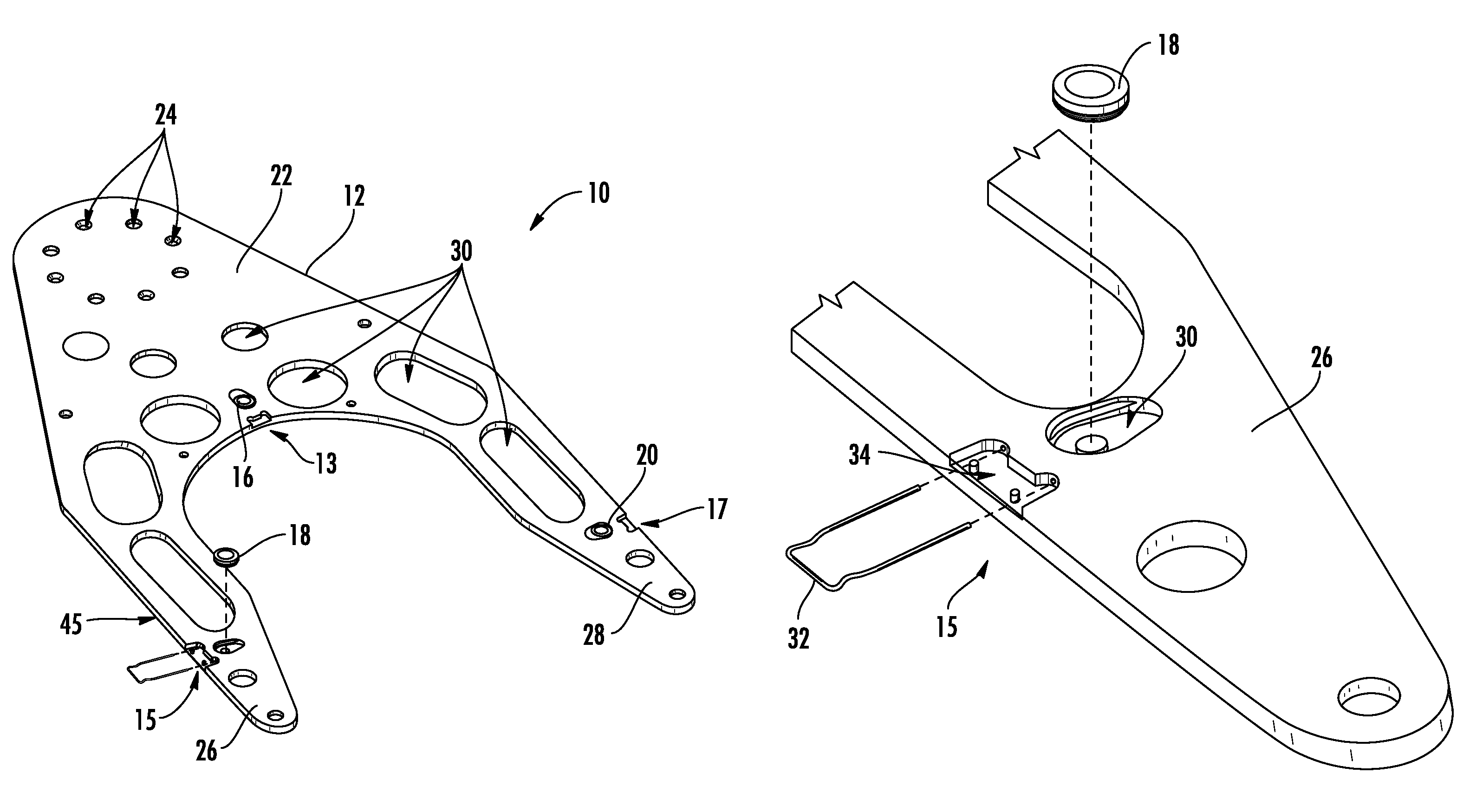

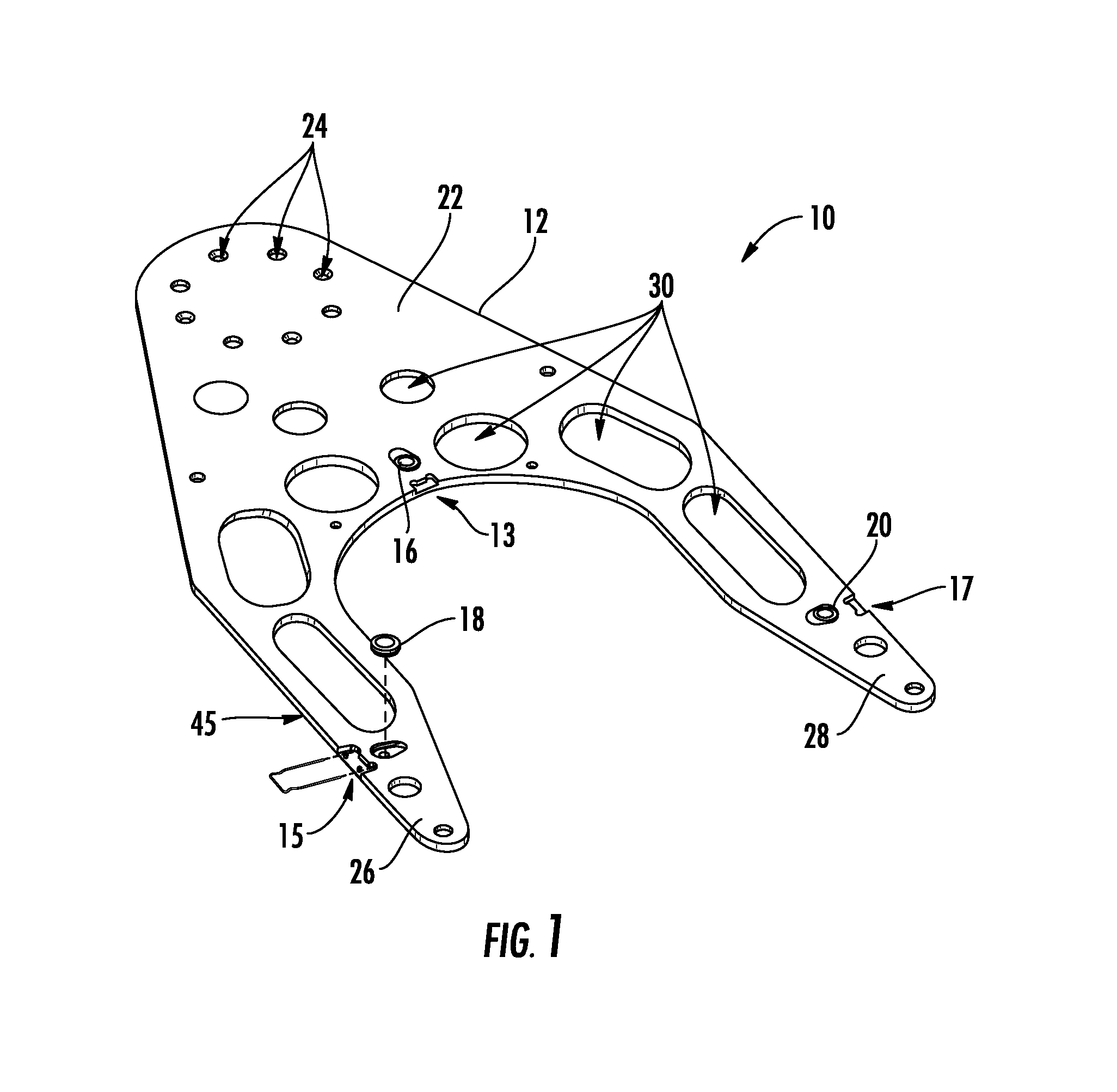

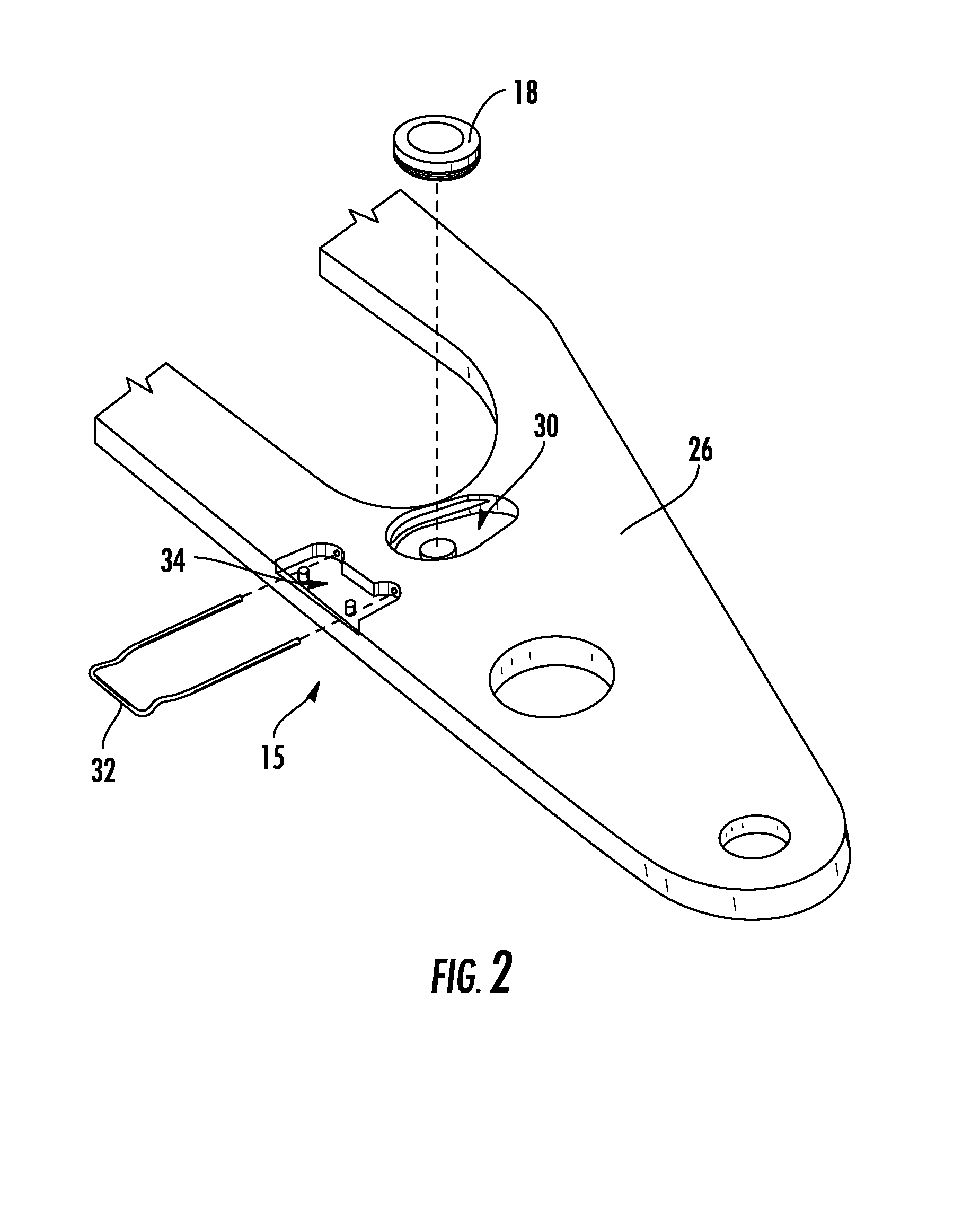

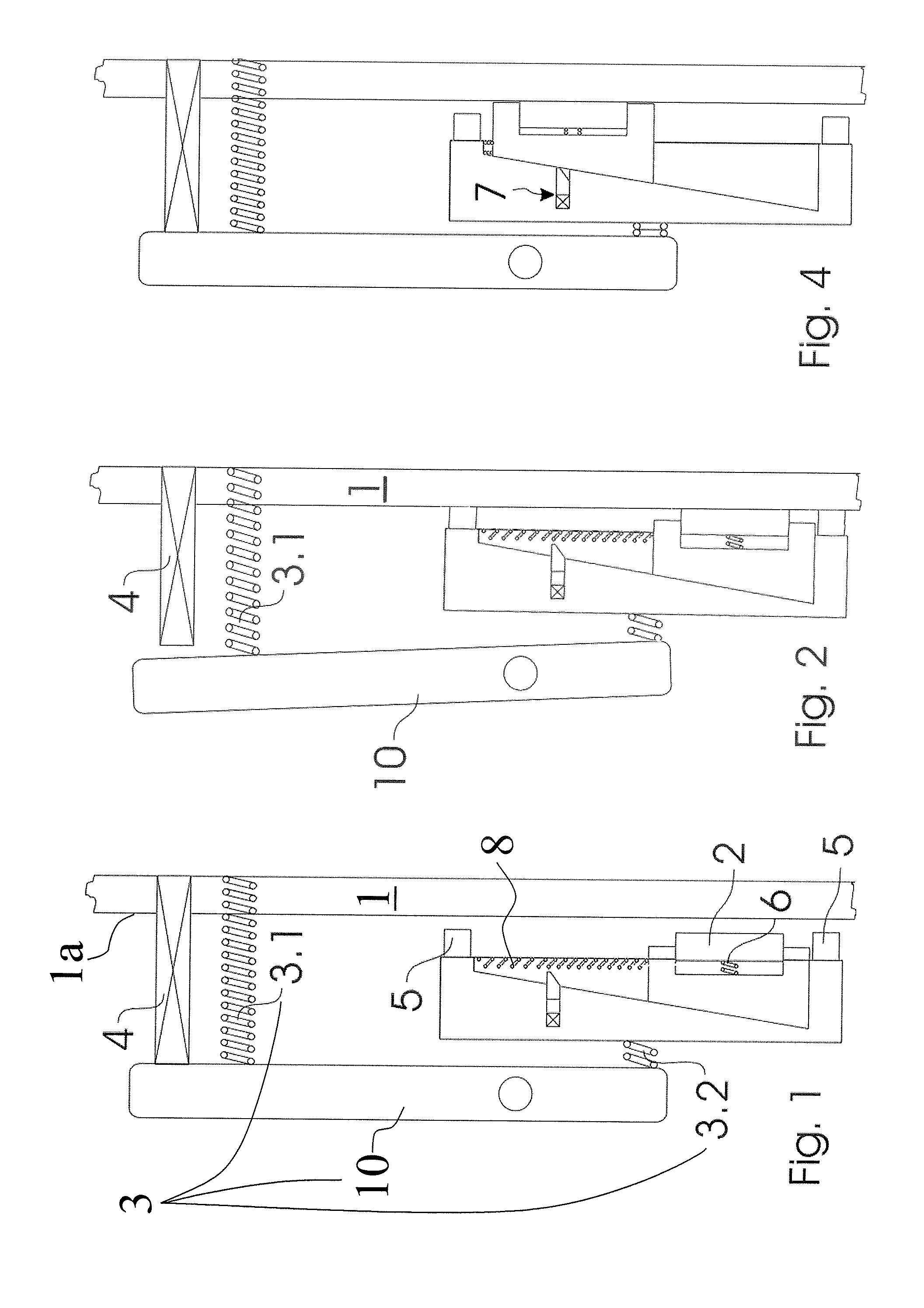

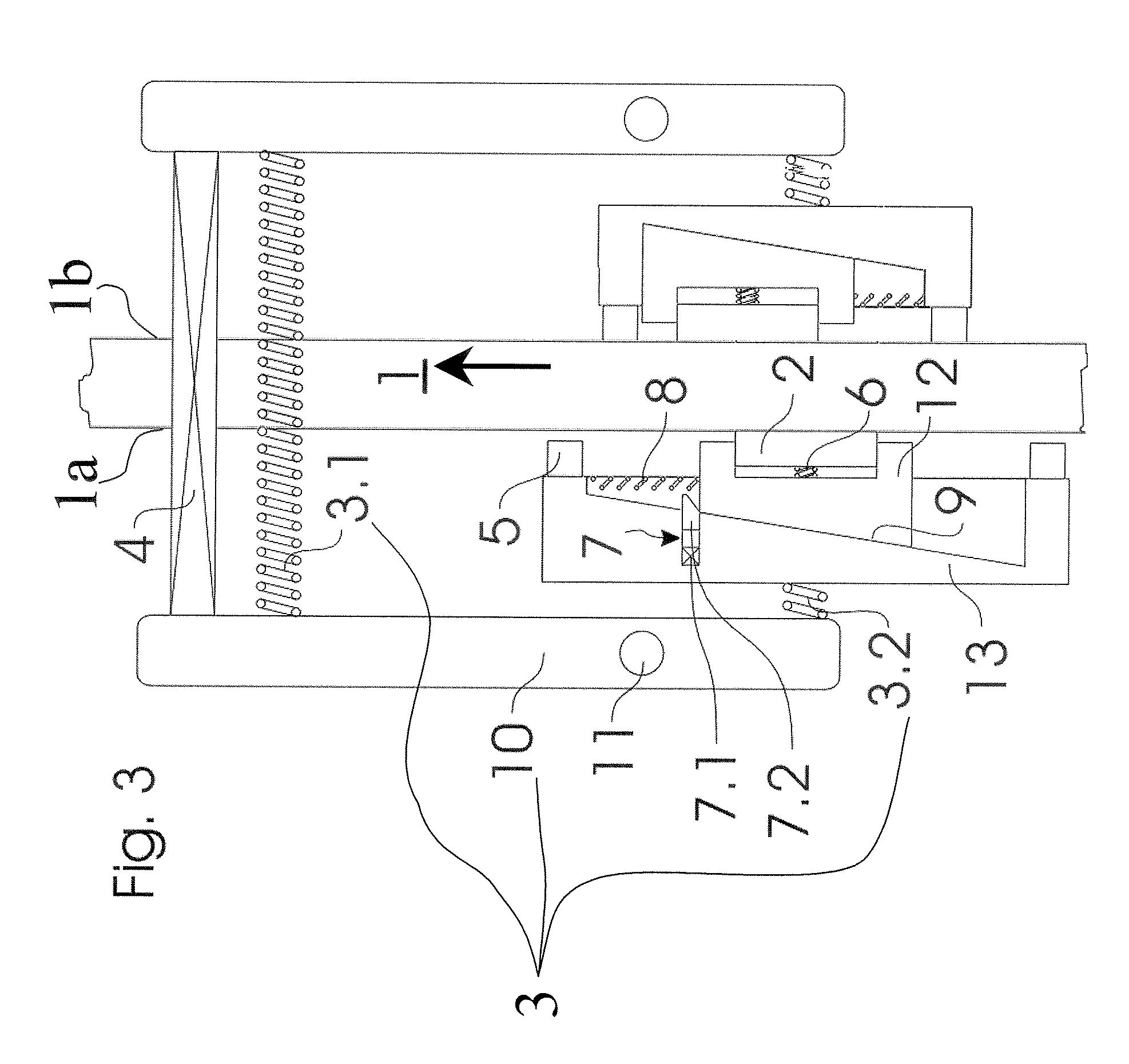

Spring retained end effector contact pad

ActiveUS8864202B1Reduce dispersionSecure attachmentGripping headsSemiconductor/solid-state device manufacturingContact padActuator

An end effector is disclosed for use in substrate processing. The end effector includes a effector body portion, a contact pad pocket formed in the end effector body, a spring retaining pocket formed in the end effector body adjacent the contact pad pocket and extending to an edge of the end effector body, and a pair of through-holes extending from the spring retaining pocket to the contact pad pocket. The end effector can include a contact pad seated within the contact pad pocket, the contact pad having at least one retaining channel formed therein, and a retaining spring having a pair of retaining arms extending from the retaining spring pocket through the through-holes and into the contact pad pocket. The retaining arms may extend at least partially into the at least one retaining channel of the contact pad and may thereby restrict movement of the contact pad.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Work holding mechanism

ActiveUS7748760B2Improve shipping speedVacuum operationGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DAIHEN CORP

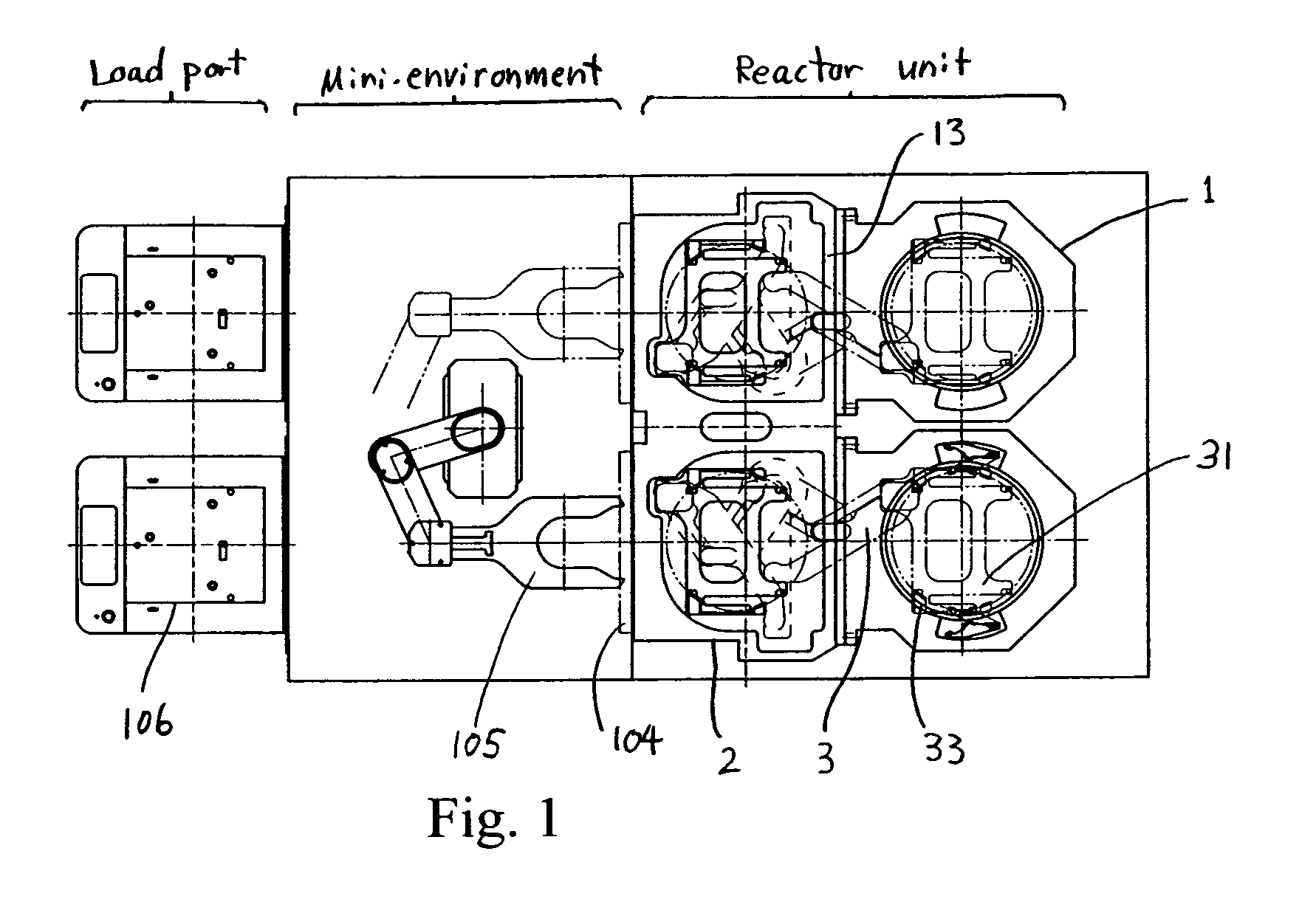

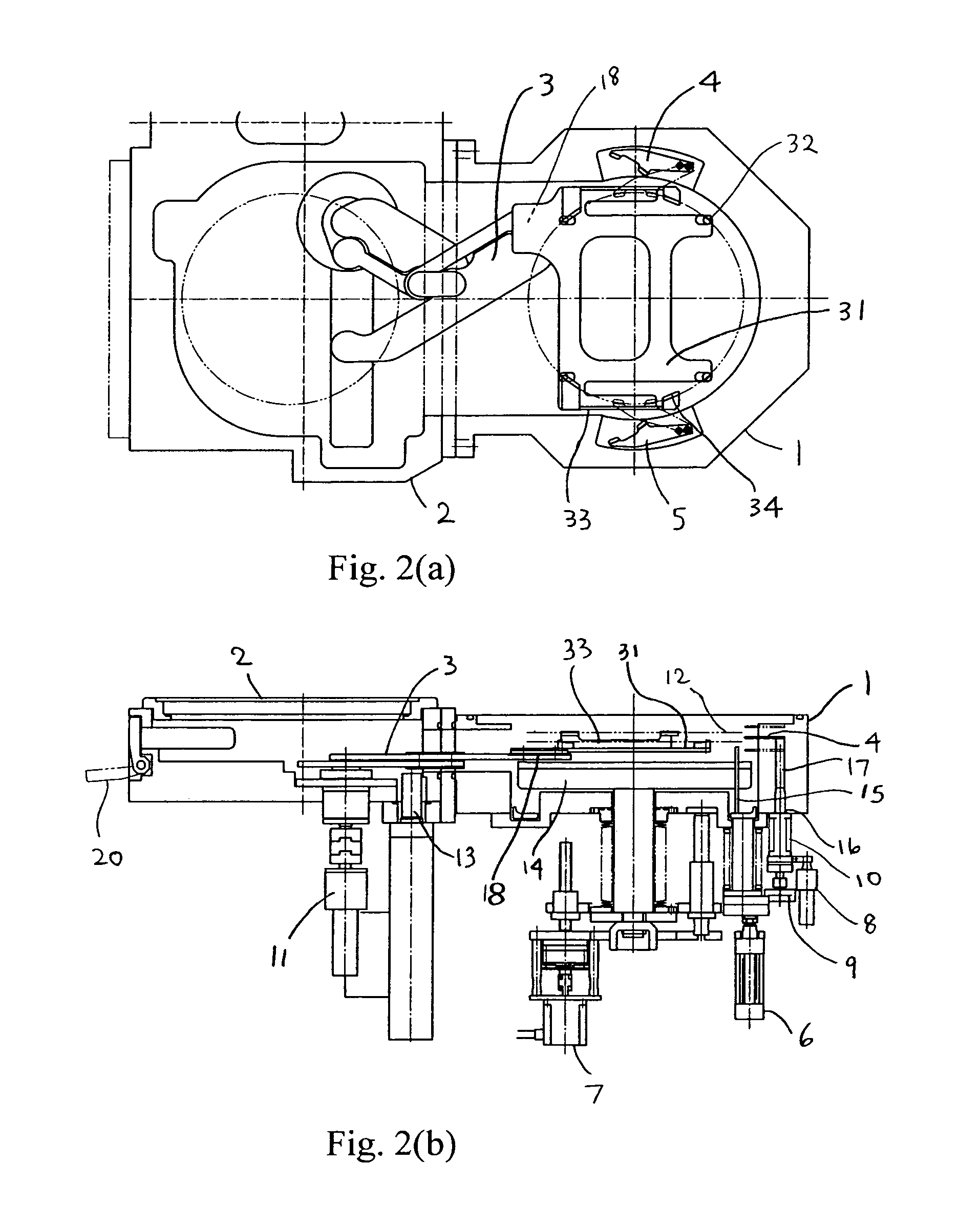

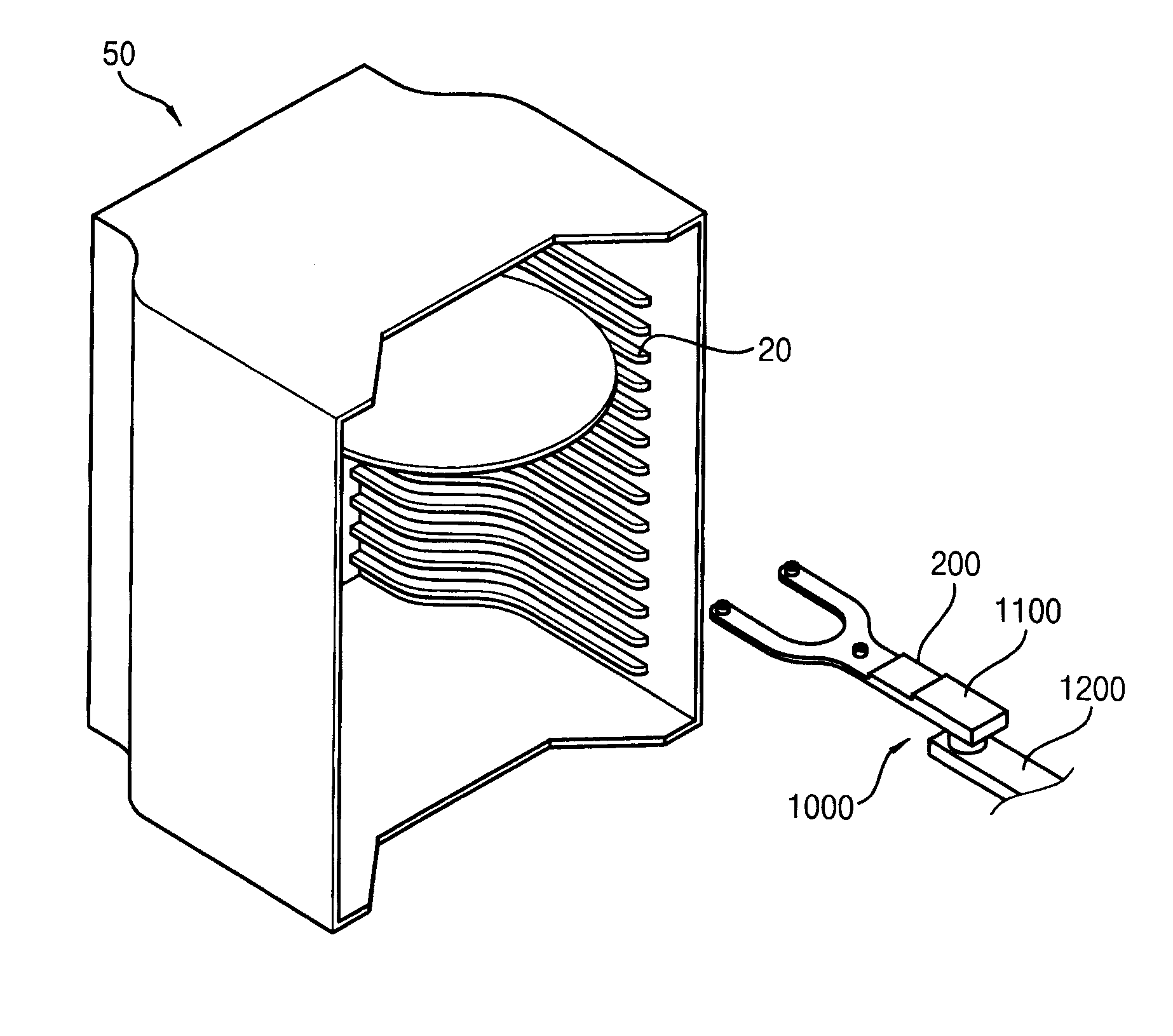

Substrate-processing apparatus with buffer mechanism and substrate-transferring apparatus

ActiveUS7690881B2Low costSmall footprintPliersSemiconductor/solid-state device manufacturingEngineeringActuator

A substrate transfer apparatus for loading and unloading substrates in a reaction chamber, includes: an arm having a distal end which is laterally movable in a straight line direction; and end-effectors for loading and unloading substrates in a reaction chamber, which include a lower end-effector and an upper end-effector. One of the lower end-effector or the upper end-effector is movably coupled to the arm at a distal end of the arm, and the other end-effector is fixed to the movably coupled end-effector. The fixed end-effector is fixed to the movably coupled end-effector.

Owner:ASM JAPAN

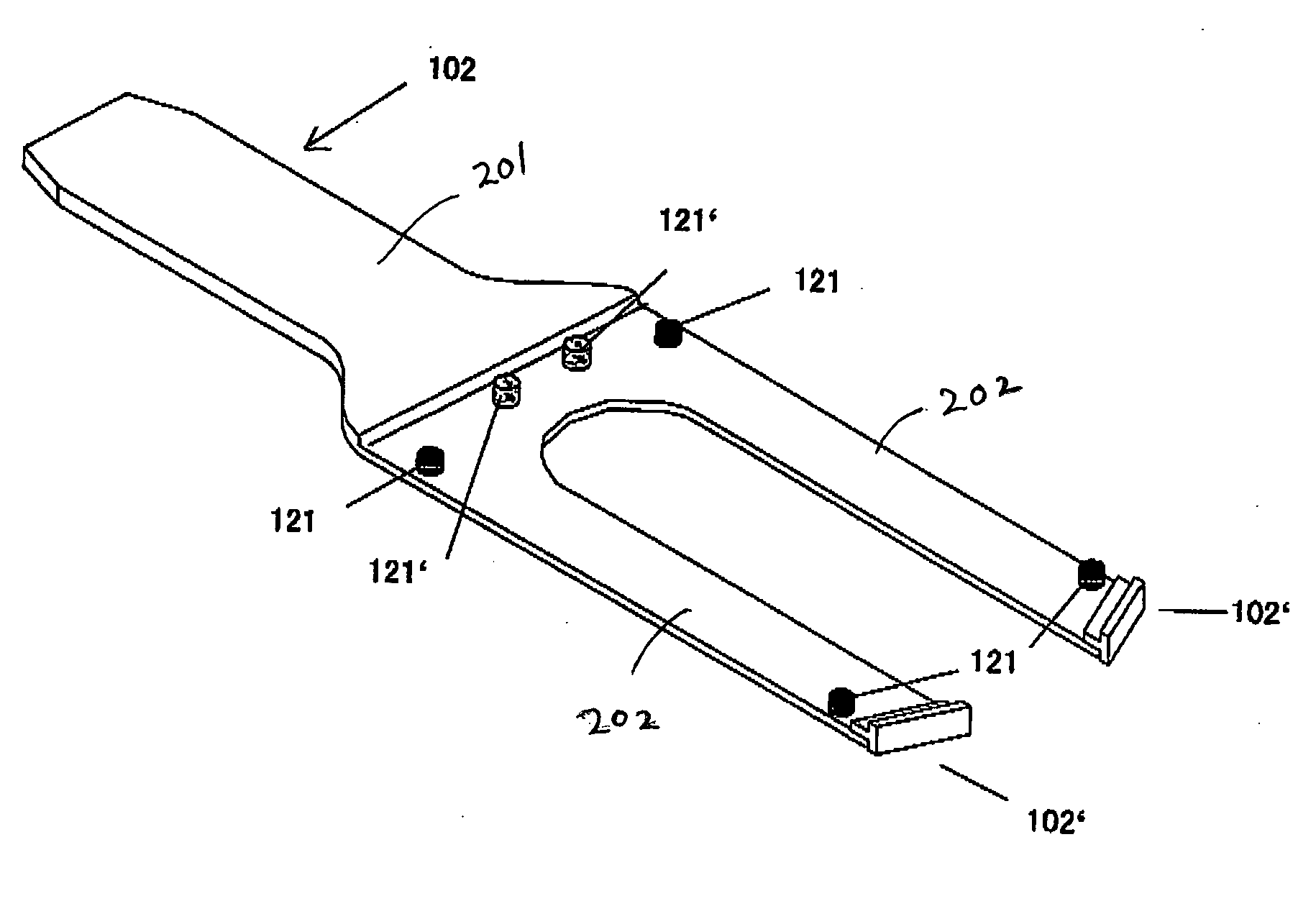

Wafer transfer mechanism

InactiveUS20060113806A1Easy to useEasy transferSemiconductor/solid-state device manufacturingCharge manipulationEngineeringTransfer mechanism

A transfer mechanism for transferring a workpiece includes an arm member including a tip projection provided at a tip end thereof for contacting a periphery of the workpiece and restricting movement of the workpiece. The arm member further includes multiple supporting projections protruding from a top surface thereof for contacting and supporting a back side of the workpiece.

Owner:ASM JAPAN

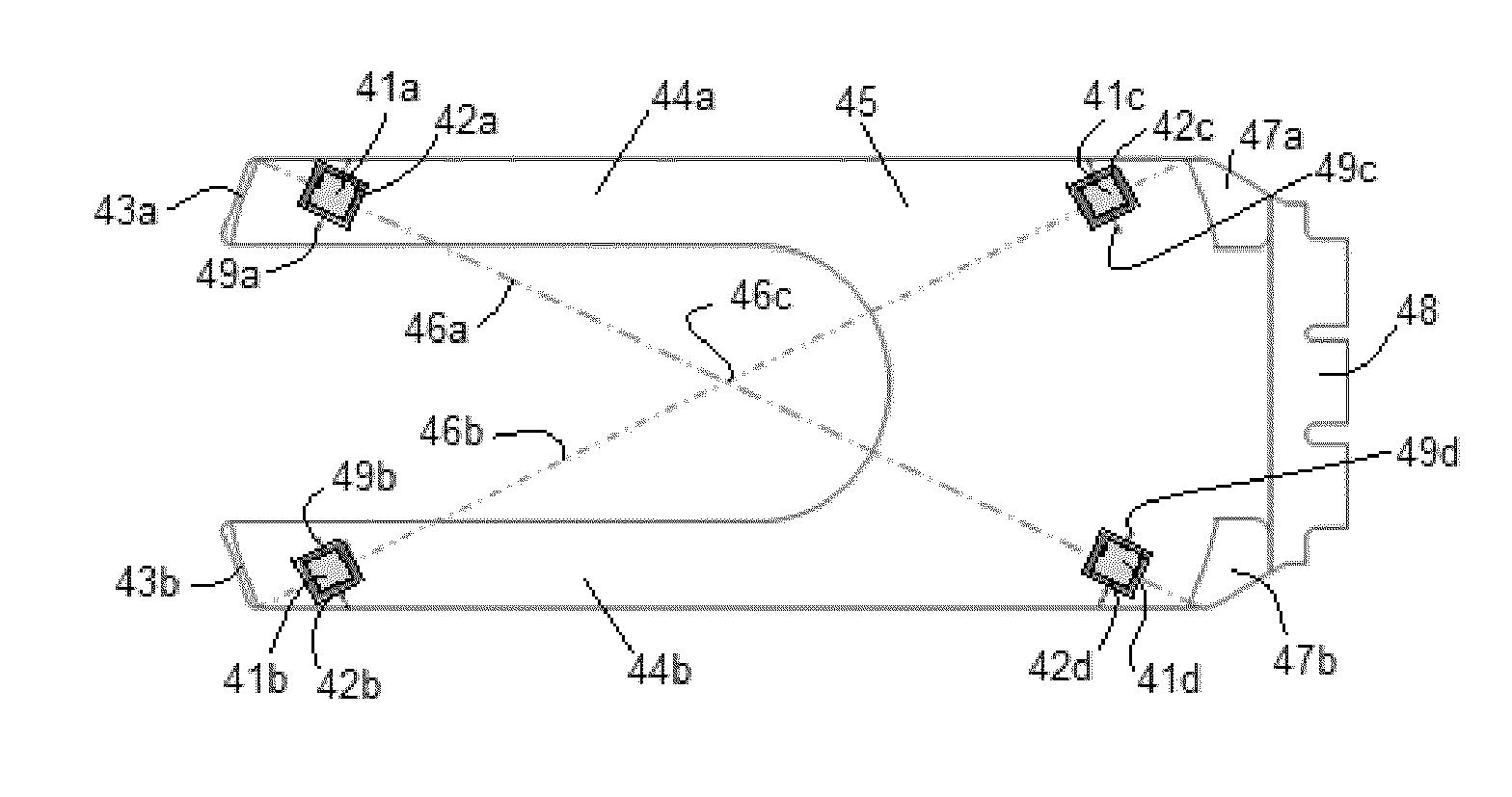

Wafer transfer blade and wafer transfer apparatus having the same

InactiveUS20140227072A1Damage is prevented and mitigatedDamage can be prevented and mitigatedGripping headsSemiconductor/solid-state device manufacturingVacuum pressureEngineering

A wafer transfer blade including a body including metal oxide and configured to support a wafer, and an adsorbing part on the body, the adsorbing part having at least one therein and configured to apply vacuum pressure to attach the wafer on the body may be provided. The body may include metal oxide to prevent static electricity.

Owner:SAMSUNG ELECTRONICS CO LTD

Anti-Slip End Effector For Transporting Workpiece Using Van Der Waals Force

ActiveUS20150287626A1Prevent slippingImprove shipping speedSemiconductor/solid-state device manufacturingLifting devicesRobotic armEngineering

An anti-slip end effector for transporting a workpiece, configured to be attached to a robotic arm, includes: a workpiece-supporting area for placing a workpiece thereon for transportation; and at least one anti-slip protrusion disposed in the workpiece-supporting area for supporting a backside of the workpiece, said anti-slip protrusion having a top face capable of contacting and adhering to the backside of the workpiece by van der Waals force and capable of pivoting on a pivot axis, said pivot axis being disposed away from a center of the top face as viewed from above.

Owner:ASM IP HLDG BV

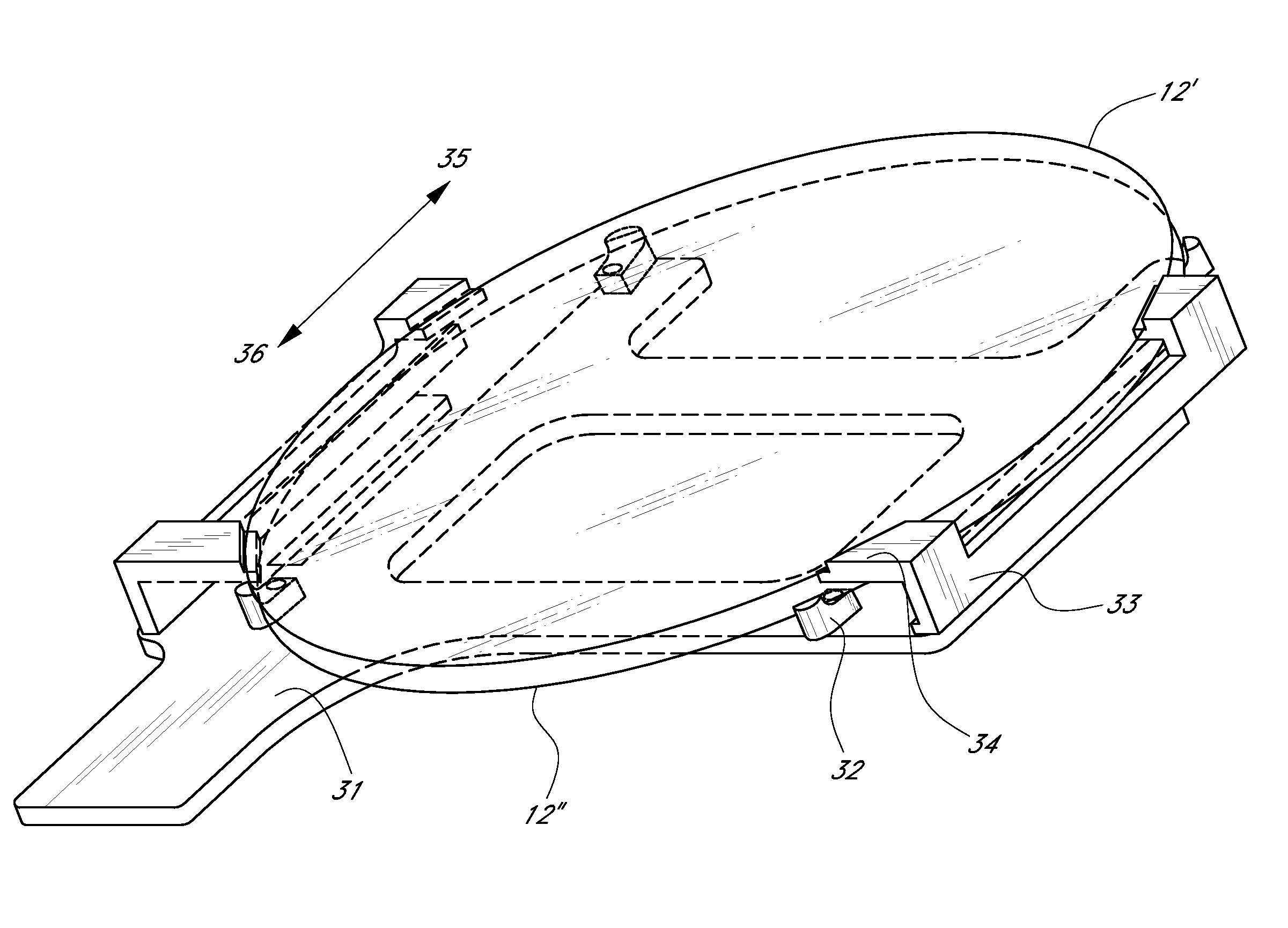

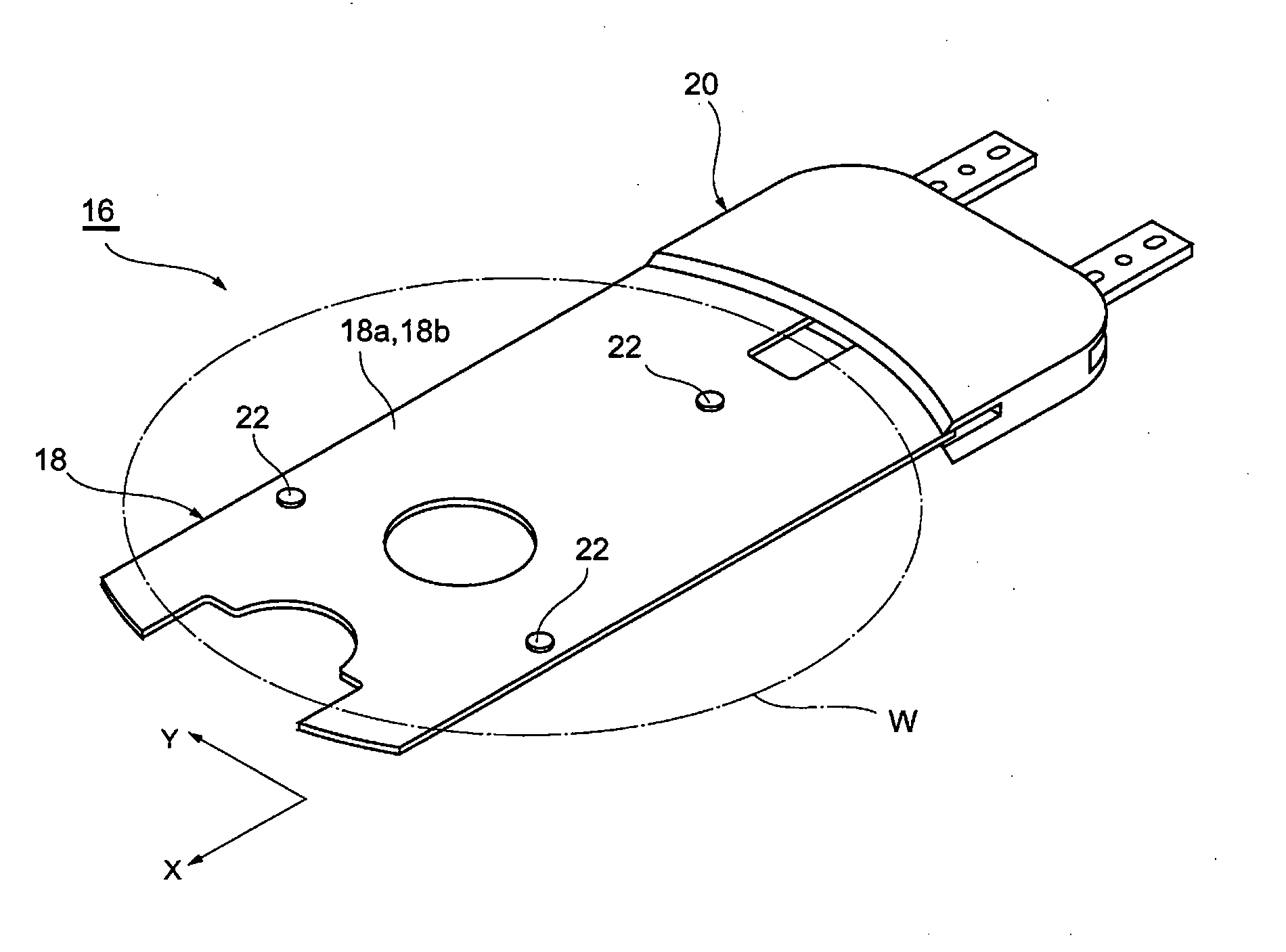

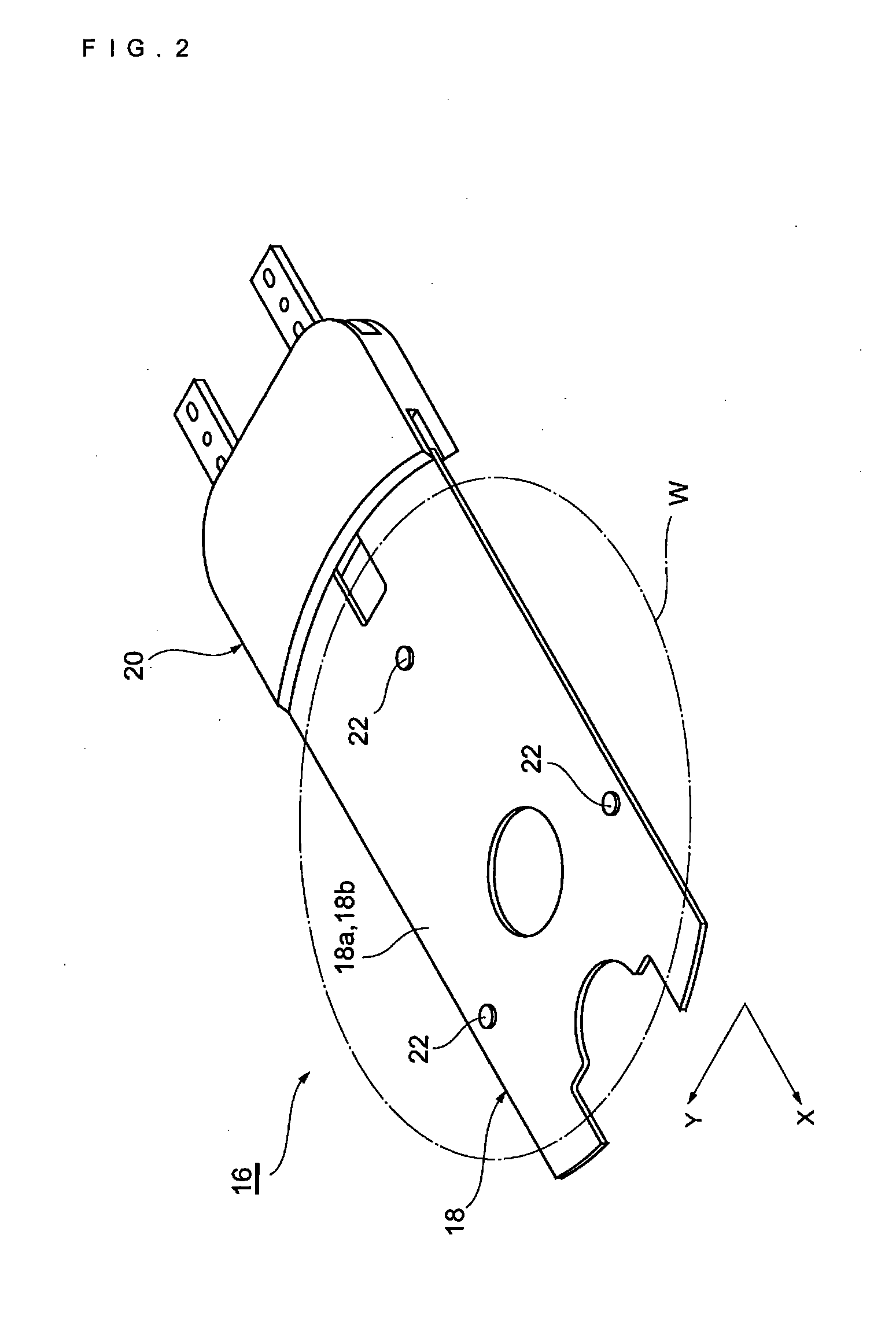

Wafer transfer blade

InactiveUS20090250955A1Reduce defectsSimple structureSemiconductor/solid-state device manufacturingLifting devicesEngineeringSurface roughening

Projections 22 of the blade 16 provided on a blade surface in a wafer-loading region 18b of a body 18 support a wafer W loaded on the blade surface 18a. Since the projections 22 have microgrooves formed by surface roughening the wafer W is retained on the projections 22 with a suppressed displacement. The blade 16 has a simple structure that retains the wafer W without vacuum suction and has no receiving hole to retain the wafer W in the body 18 of the blade 16. This can effectively prevent formation of defects on the wafer W.

Owner:APPLIED MATERIALS INC

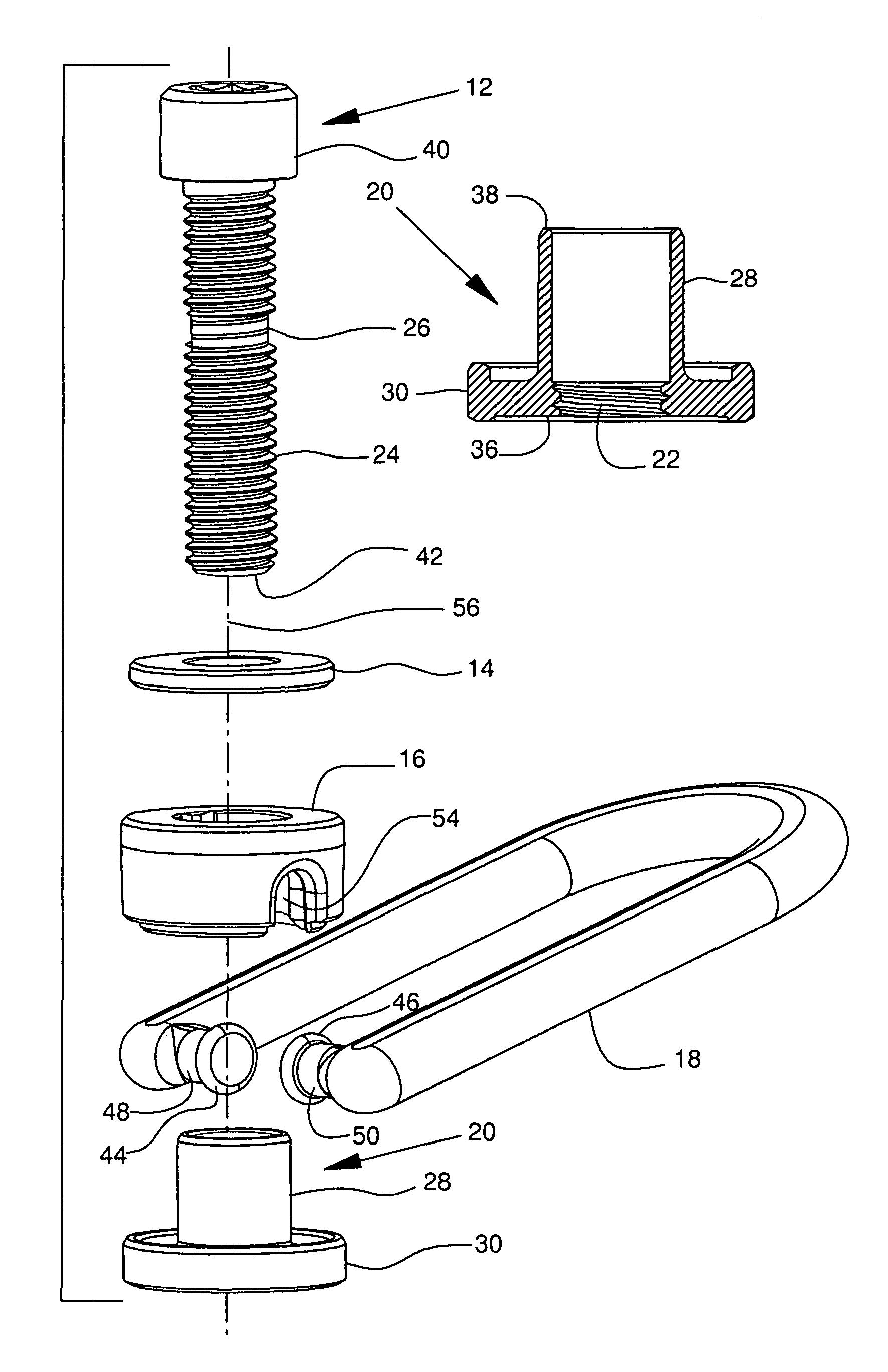

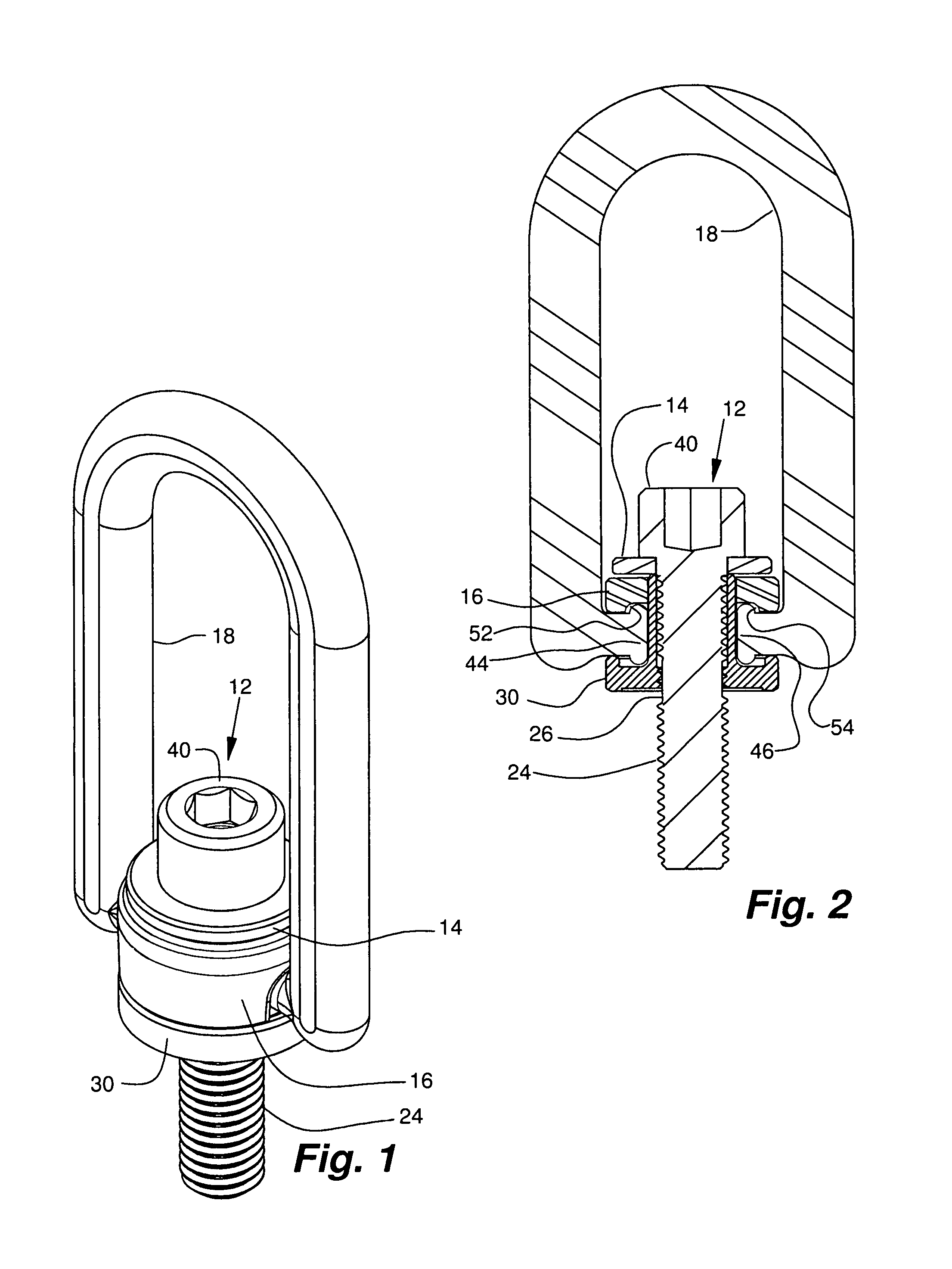

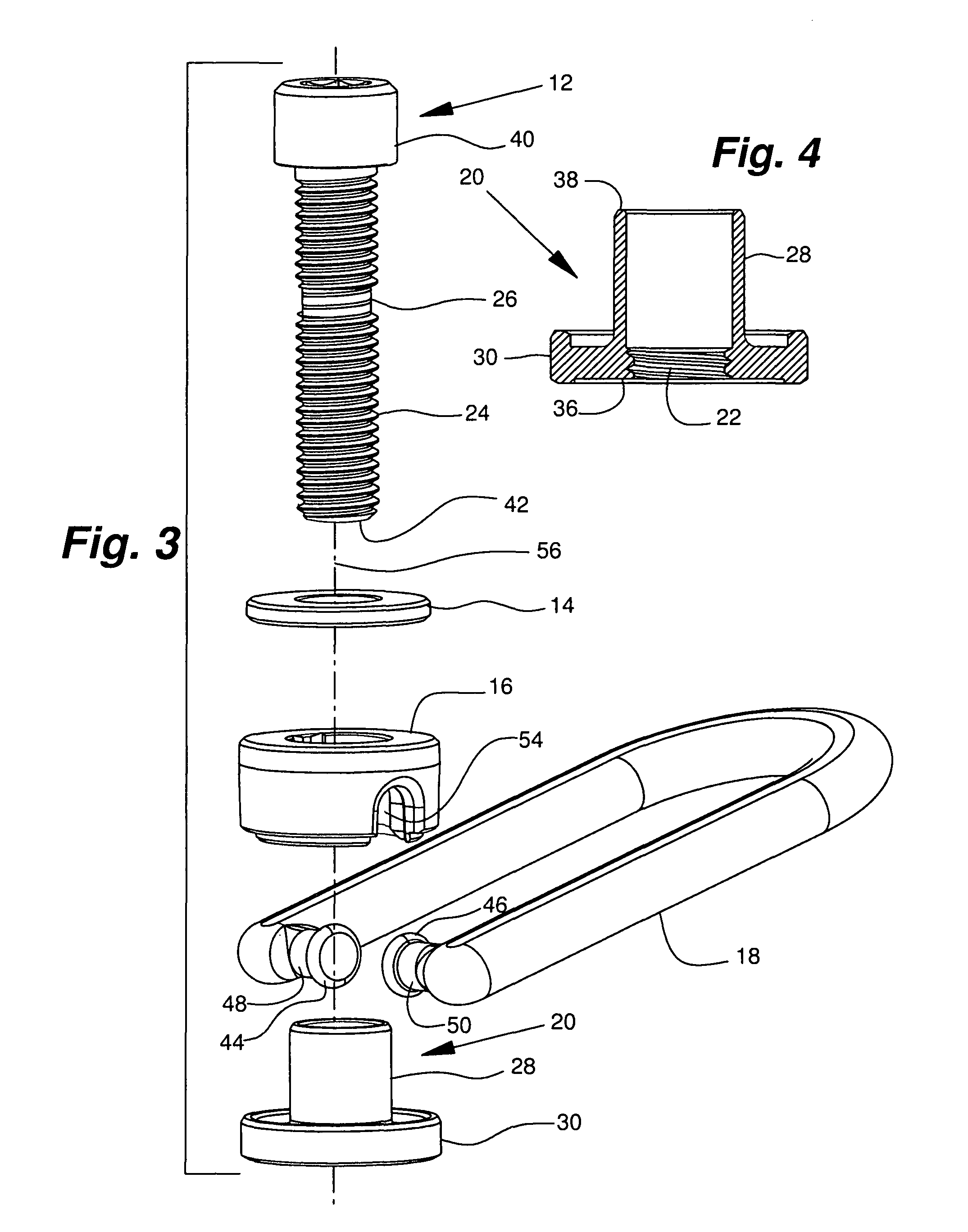

Threaded hoist ring screw retainer

An omni-positional hoist ring assembly including a bushing element that includes a sleeve with an axial length, a proximal end and a distal end. A load bearing flange is radially disposed about the proximal end of the sleeve. The sleeve has an internal thread extending at least part way of the axial length of the sleeve. A mounting screw element has a major axis, a head, and a shank disposed generally co-axially around the major axis. The shank includes a threaded shank portion and a bearing portion. The bearing portion is a generally cylindrical axially extending portion of the shank that has a diameter approximately equal to the minor diameter of the thread in the threaded shank portion. A thrust washer element is provided between the head and the distal end of the sleeve. A body element receives the in-turned opposed ends of the legs of a lifting loop element in sockets. The lifting loop is free to pivot. The body element is free to rotate about the sleeve, so the lifting loop will self align with a load that is applied to it from any direction within a hemisphere centered on the major axis of the mounting screw element. The elements of the hoist rig assembly are assembled by aligning them and inserting the mounting screw element into the sleeve and threadably advancing it until the bearing is aligned with the internal thread so further rotation of the mounting screw element does not threadably advance the mounting screw element relative to the sleeve.

Owner:MJT HLDG

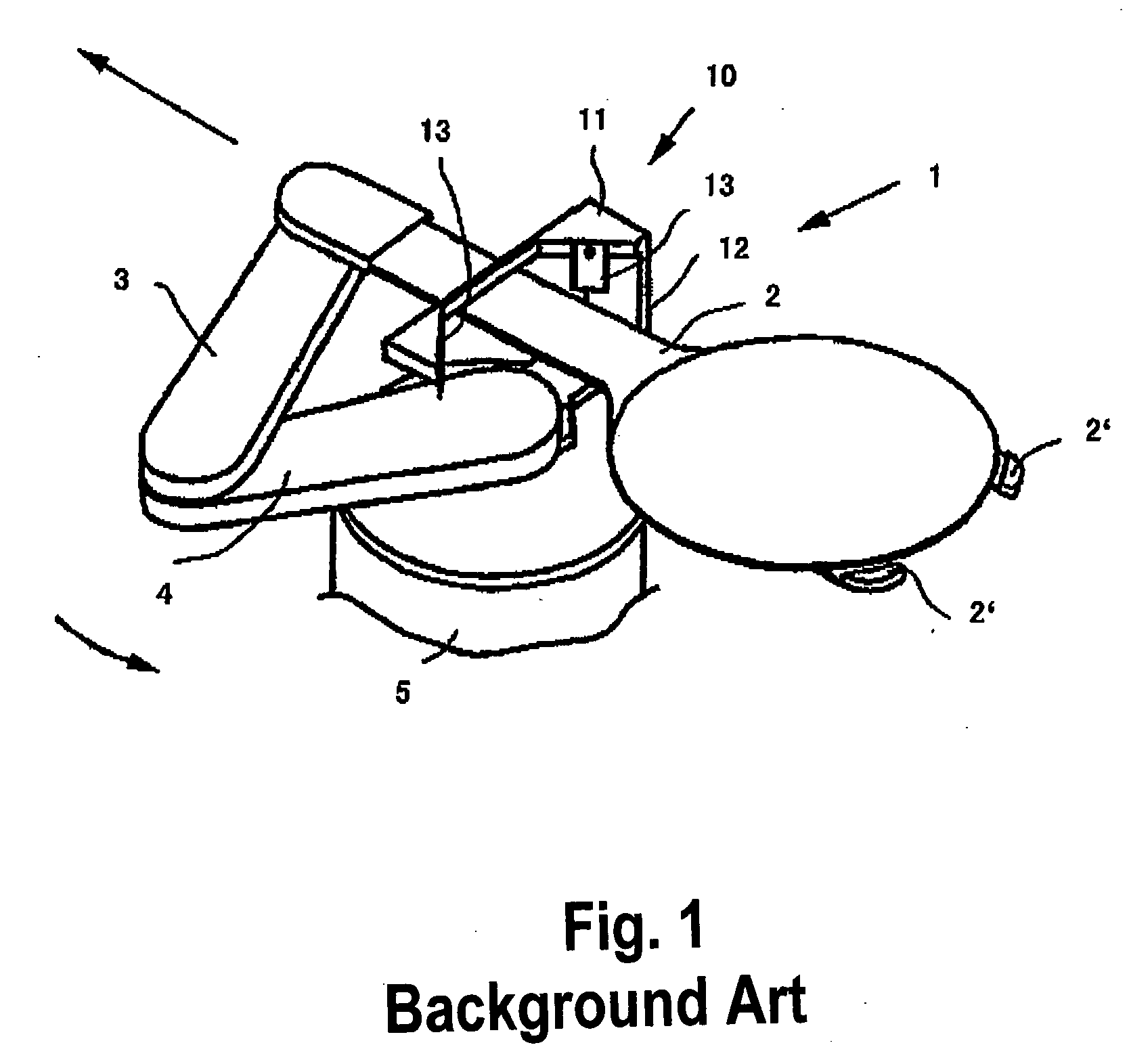

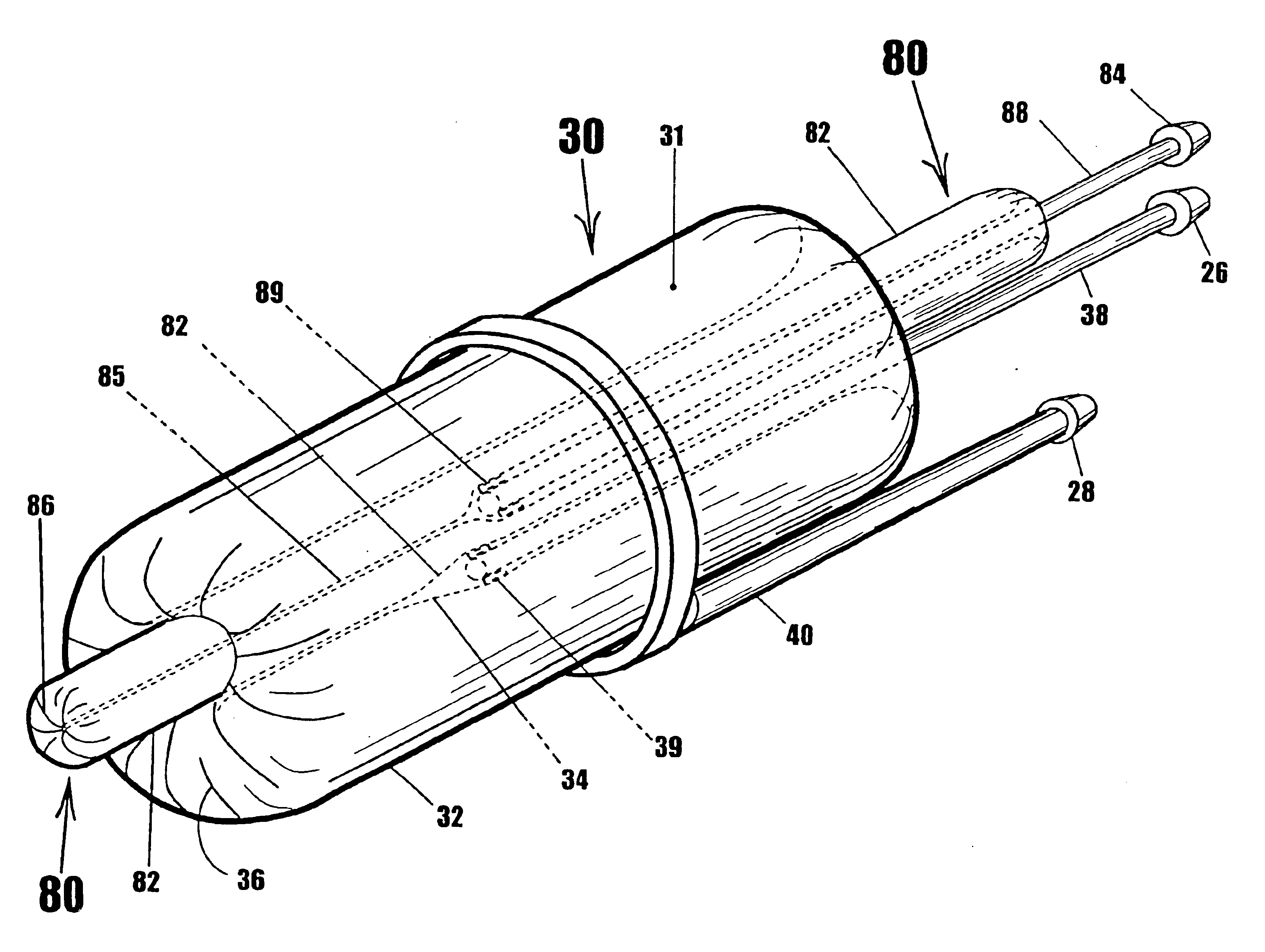

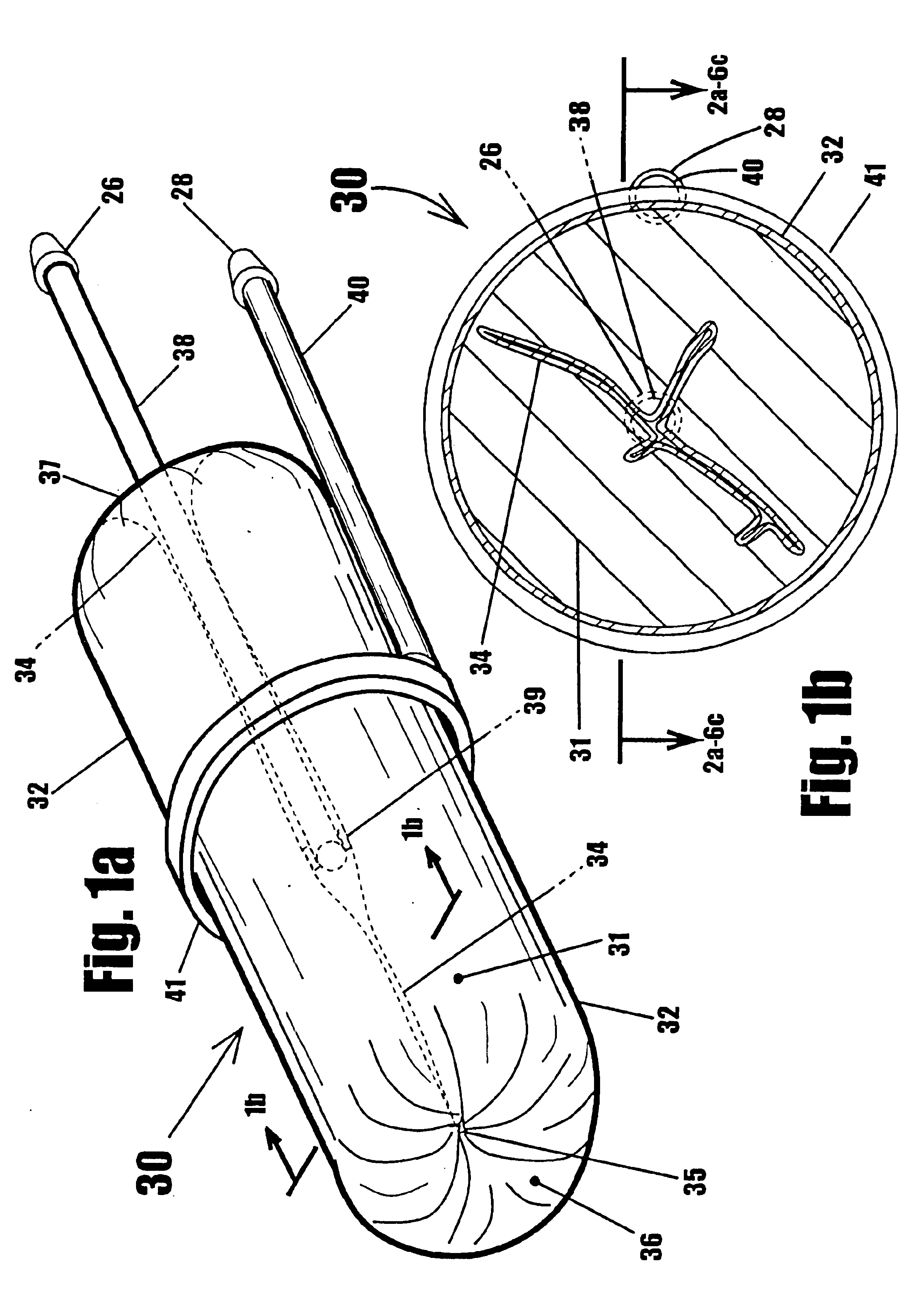

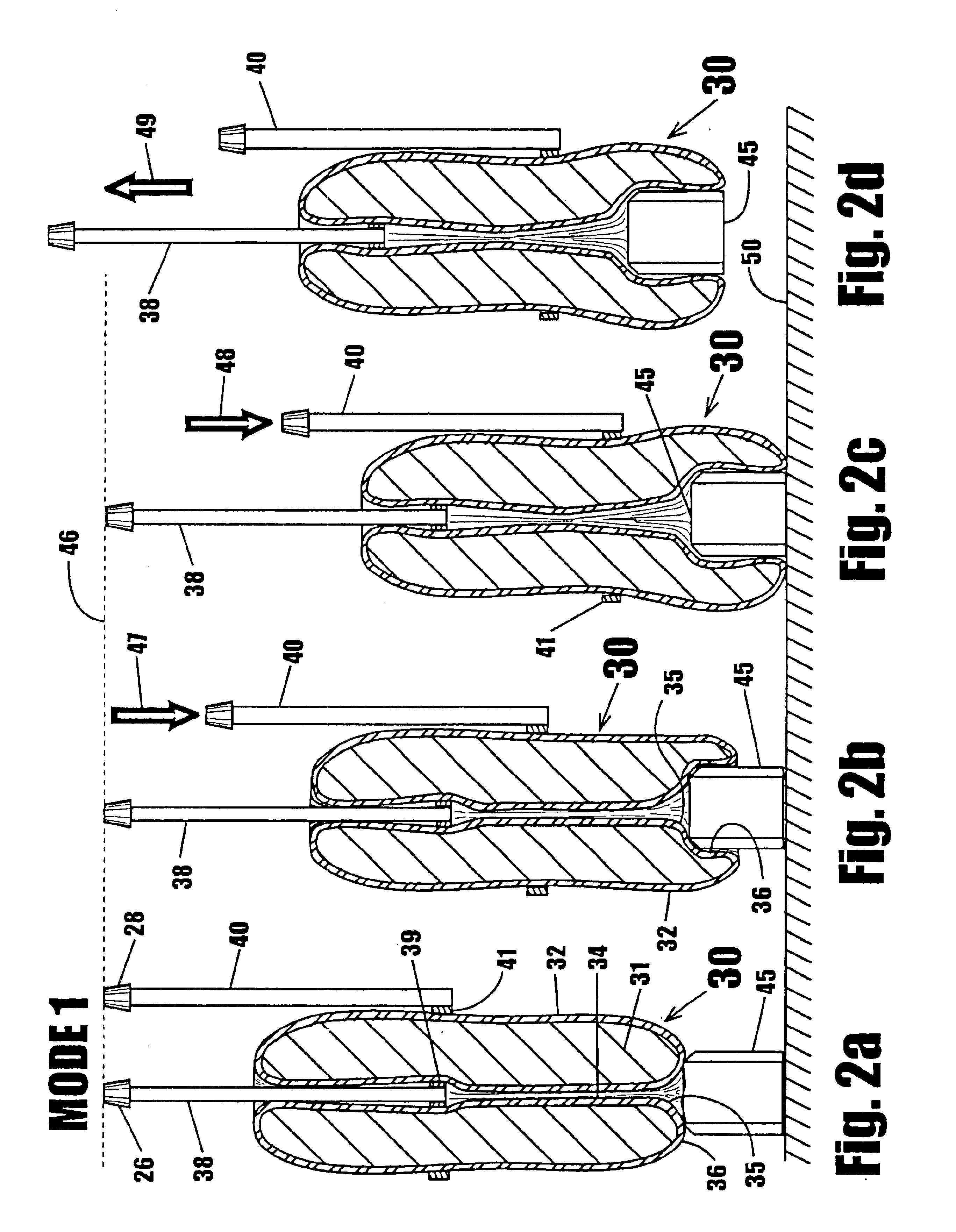

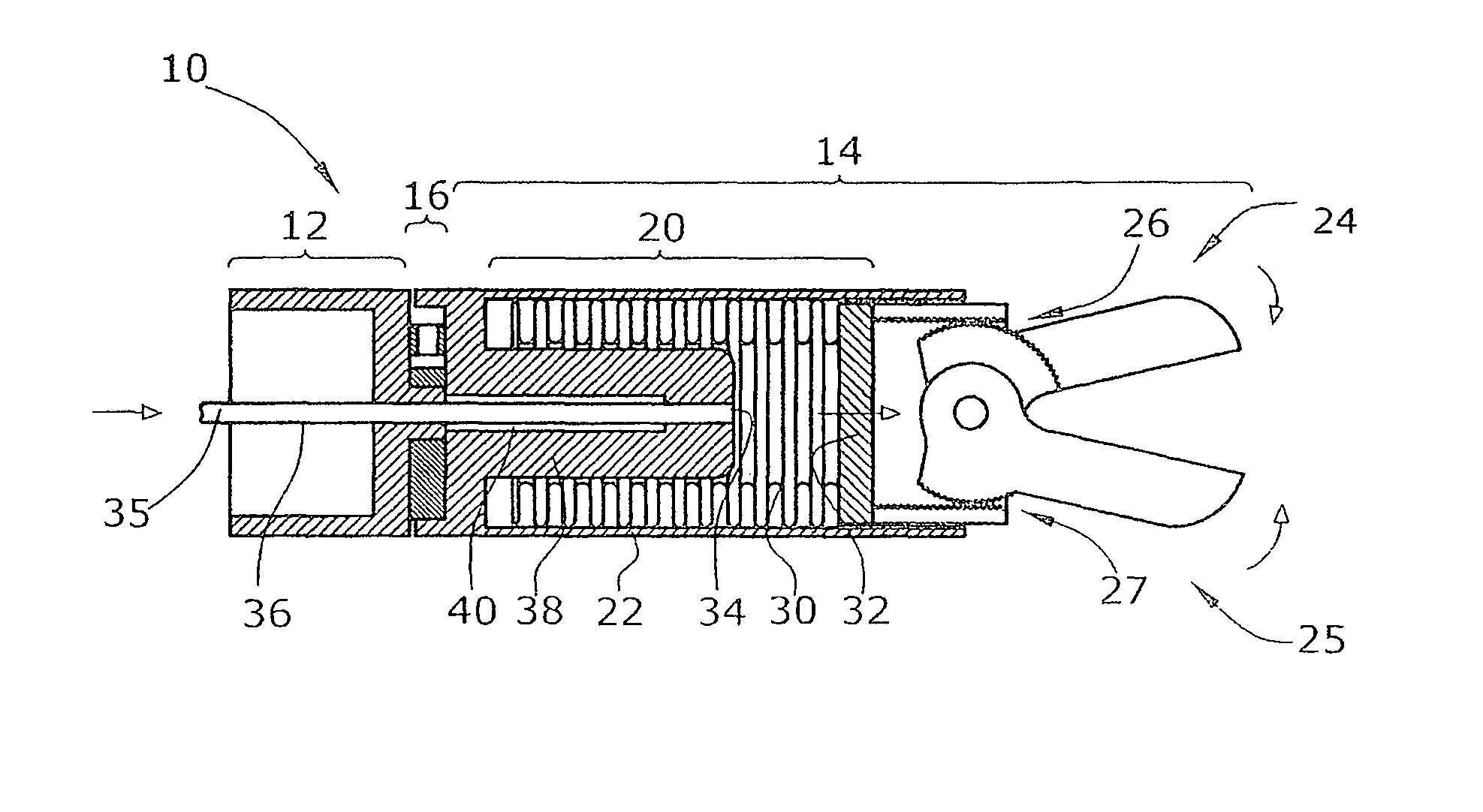

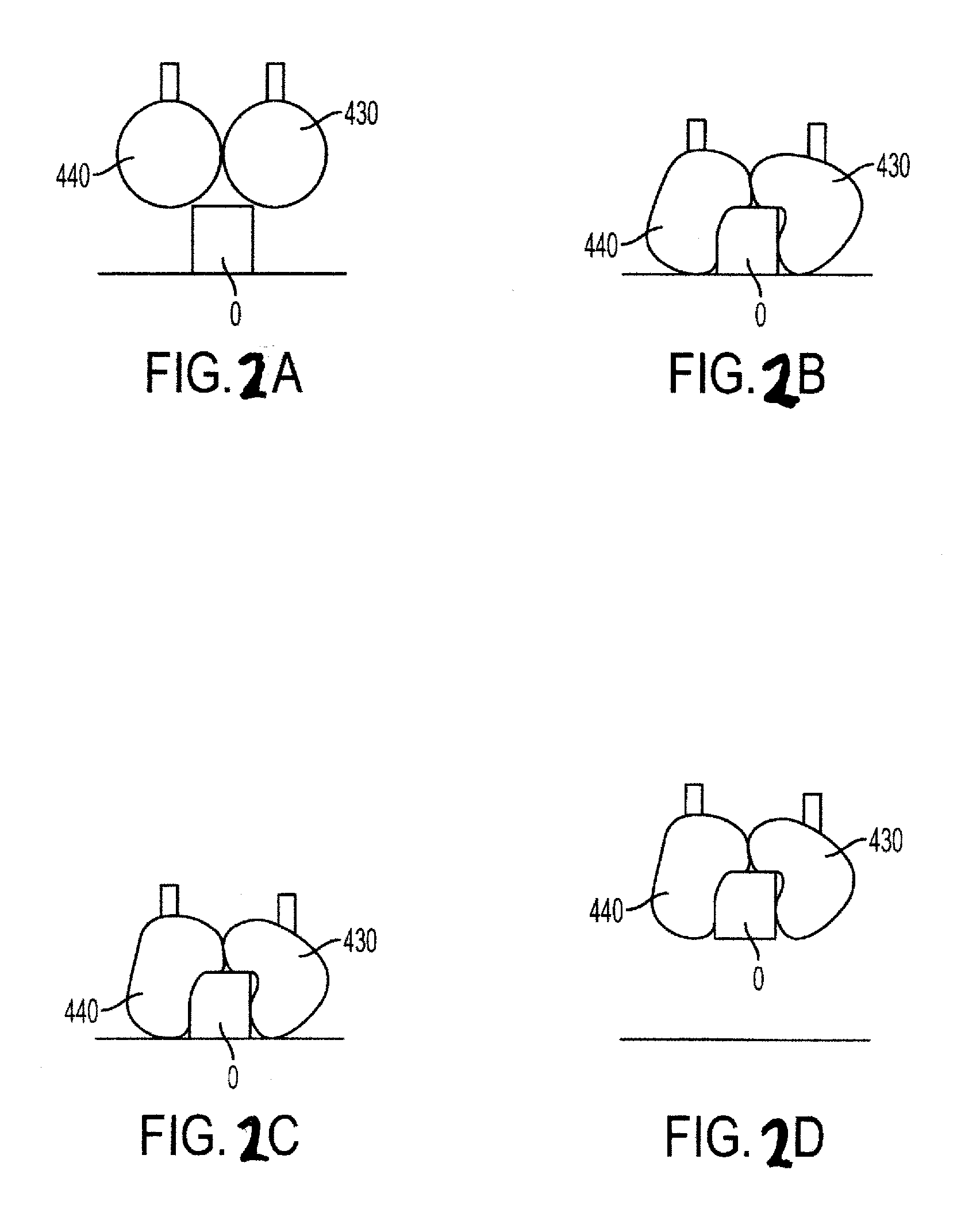

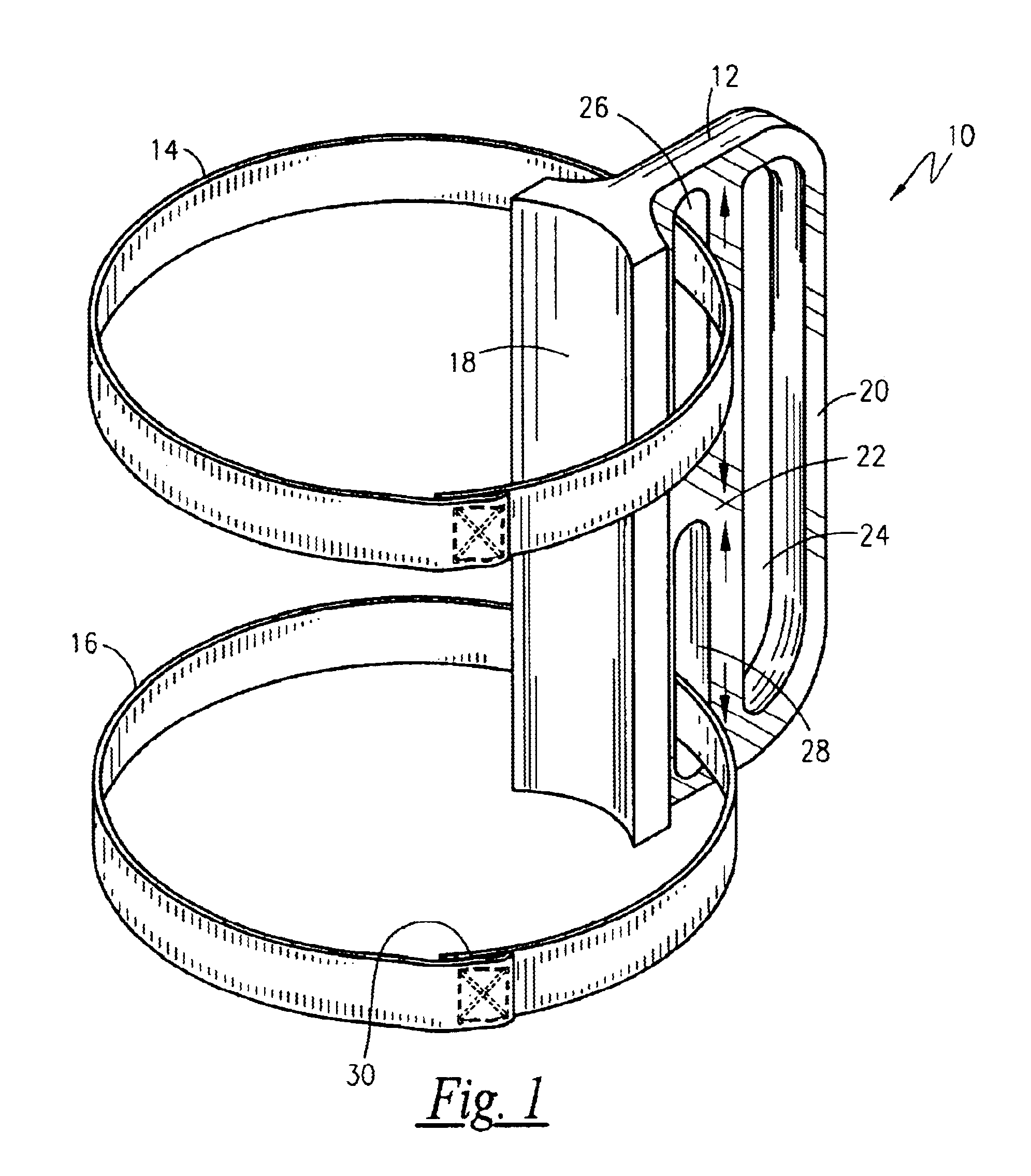

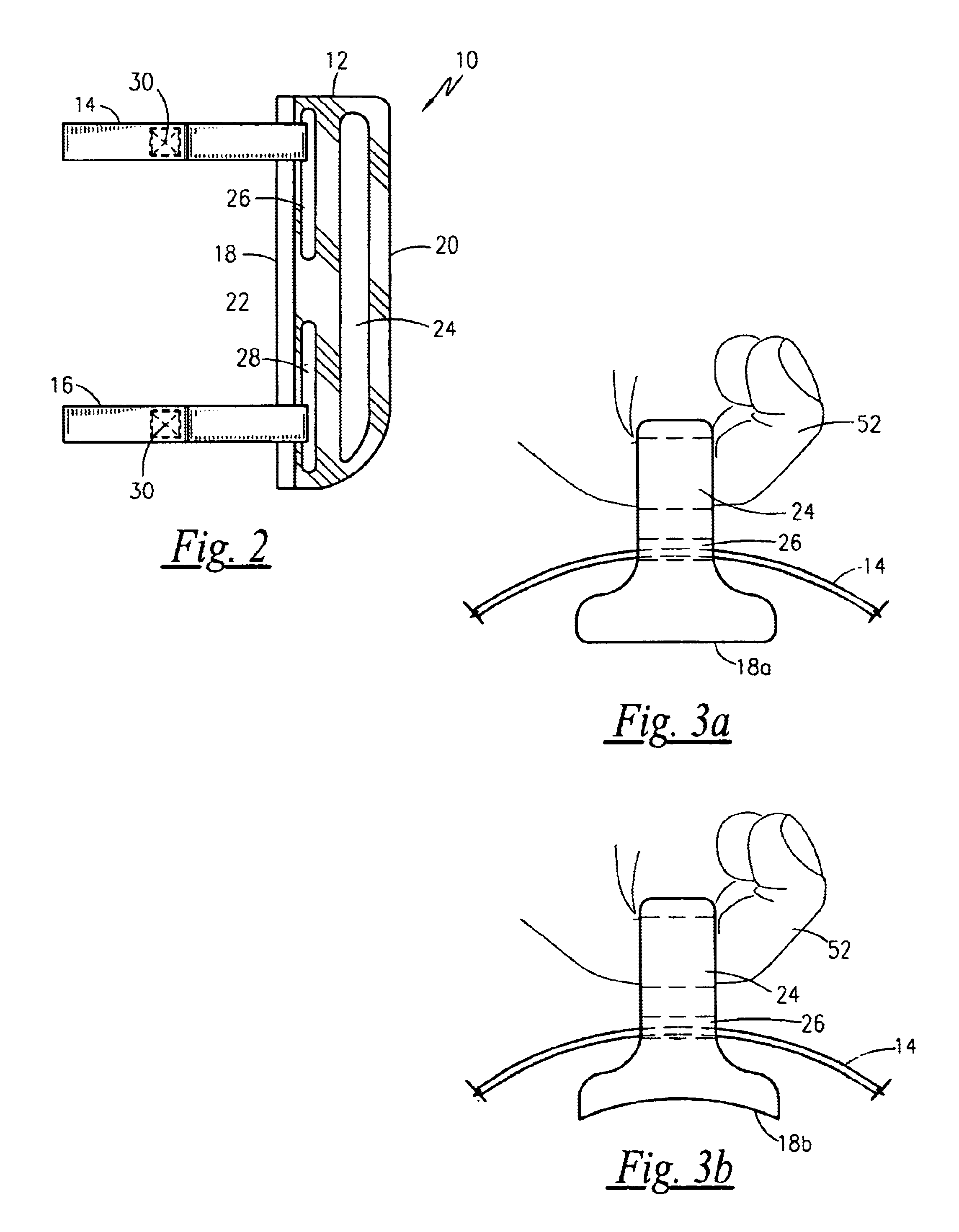

Torus-shaped mechanical gripper

A device for gripping, holding, and releasing objects of varying sizes and shapes, which comprises an elongated torus (30) enclosing a fluid material (31), an external control rod (40), and an internal control rod (38). Torus (30) may be made of a flexible membrane and able to seal in fluid material (31). Fluid material (31) can be a gas, liquid, solid particles, semisolid particles, or mixtures of these. Central channel (34) of torus (30) is collapsed due to pressure of fluid material (31) within torus (30). Both control rods are securely attached to torus (30), with rod (38) attached to the interior portion of the torus along collapsed central channel (34), and rod (40) attached to the exterior portion of the torus on outer surface (32). Gripping action is achieved by differential linear motion of control rods (38) and (40) along the longitudinal (elongated) axis of torus (30). This causes front portion (36) of the torus to slide radially inward or outward to grip objects. Further movement of the control rods can cause the object to be pulled completely inside the collapsed channel for secure gripping by completely surrounding the object. The soft flexible nature of torus (30) allows grasping even the most delicate objects without damaging them. Even over-ripe strawberries can be rapidly grasped without bruising.

Owner:RAGNER GARY DEAN +1

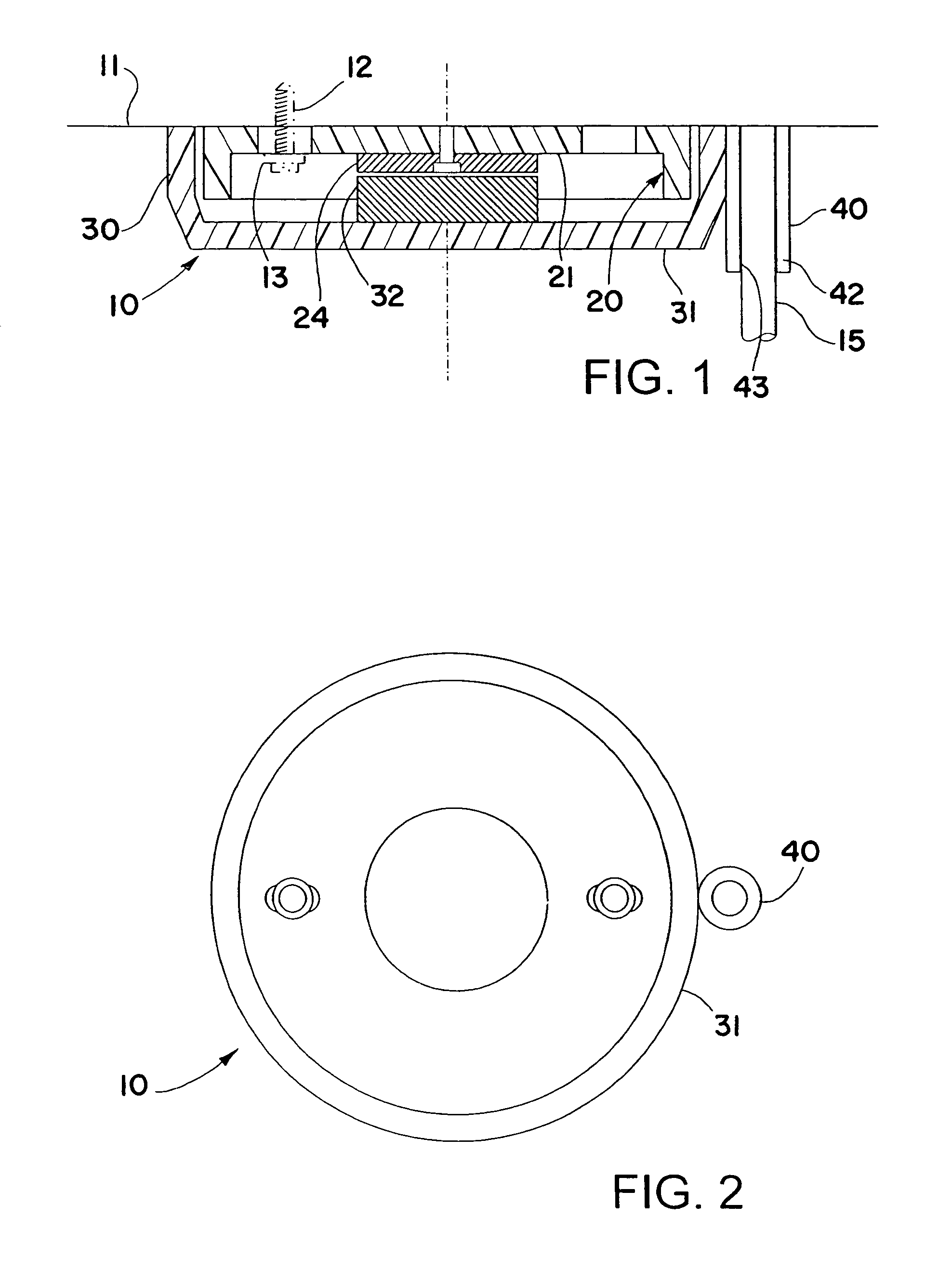

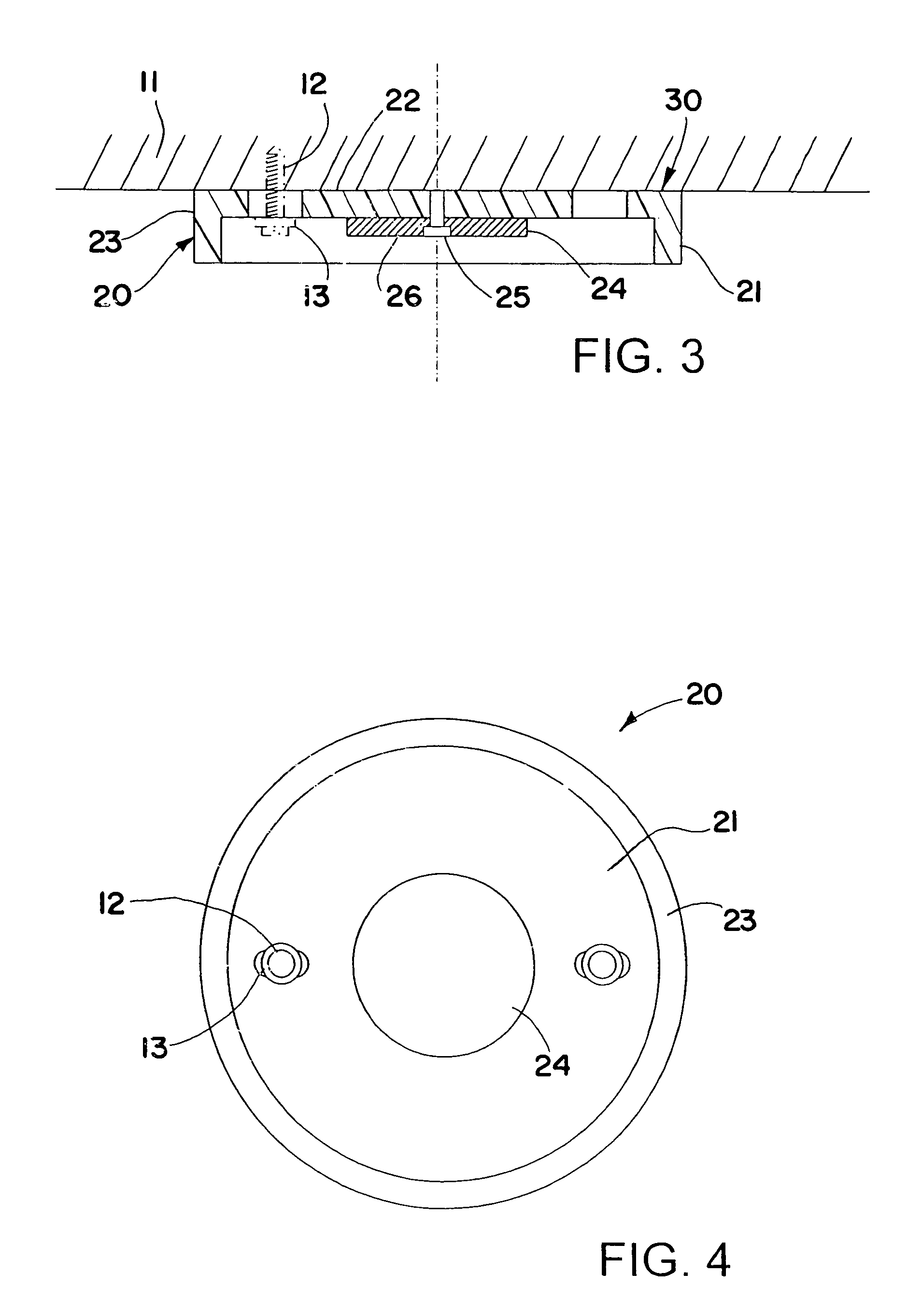

Remotely attachable and separable coupling

InactiveUS7287738B2Easy to disengageSecure supportSubstation/switching arrangement detailsPicture framesSmoke detectorsCoupling

An article for mounting from or against the ceiling is removably coupled to a base fixedly secured to the ceiling, by a person standing on the floor, supporting the article on an elongated rod, and thrusting the article against the base to couple the article and the secured base. The article is removed by inserting the rod into the article, exerting a force on the rod to uncouple the article from the base, and supporting the article on the rod as the article is lowered. The article is thus positioned on or hung from the ceiling, without being manually contacted by the person. The article may be used to mount other devices, such as a sign, smoke detector, etc. or may include such device as a part of the mount.

Owner:ACCESSMOUNT LLC

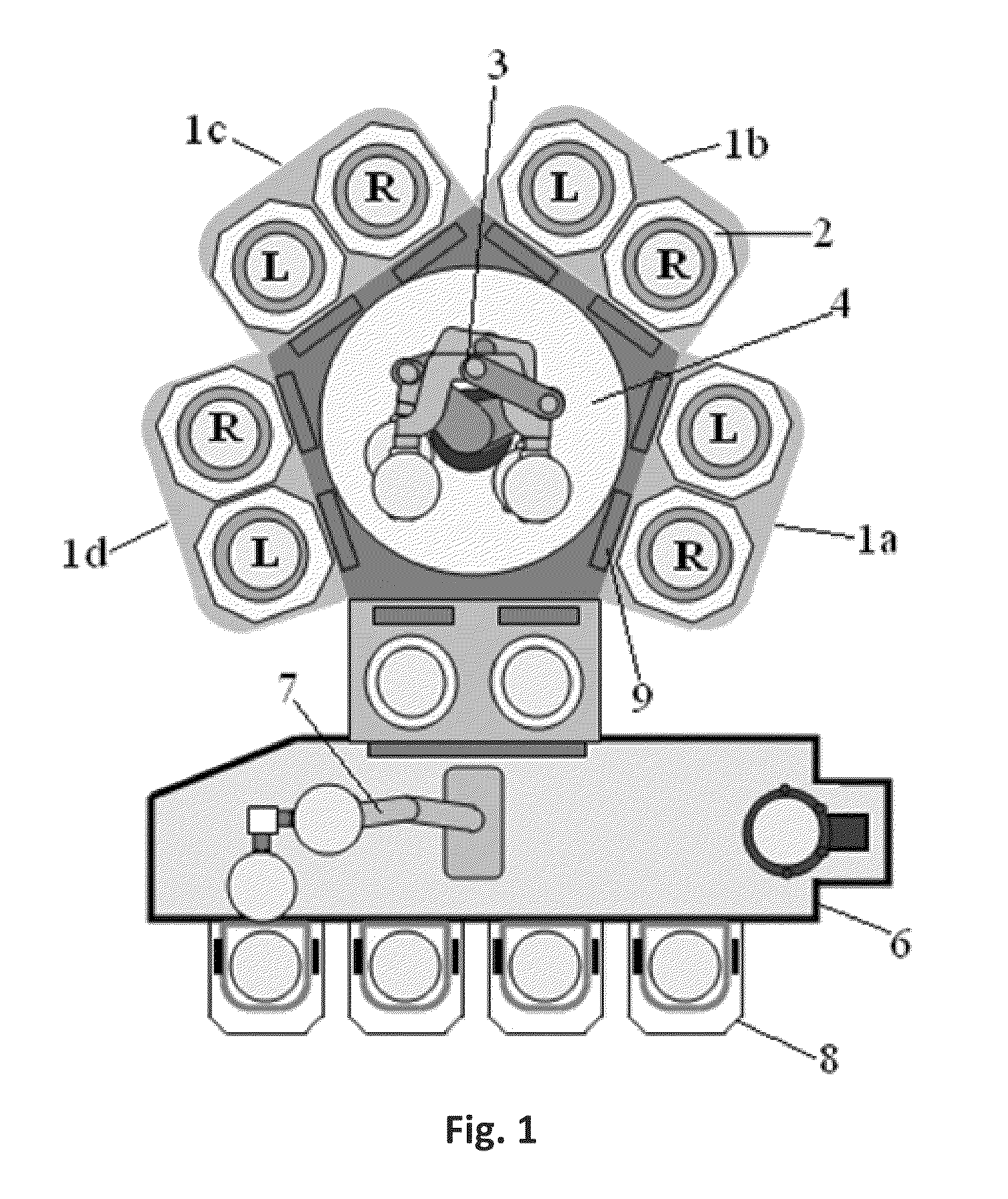

Surgical robotic system

ActiveUS7988215B2Simple and compact designReduce rateWaterborne vesselsDiagnosticsHydraulic cylinderRobotic arm

A surgical robotic system includes a robotic arm, an end effector movably connected thereto and provided with a movable end effector element driven by an actuator, and a force sensor arranged between the robotic arm and the end effector. The actuator is formed by a hydraulic cylinder. The robotic arm is provided with a hydraulic line connected to said hydraulic cylinder of the end effector.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

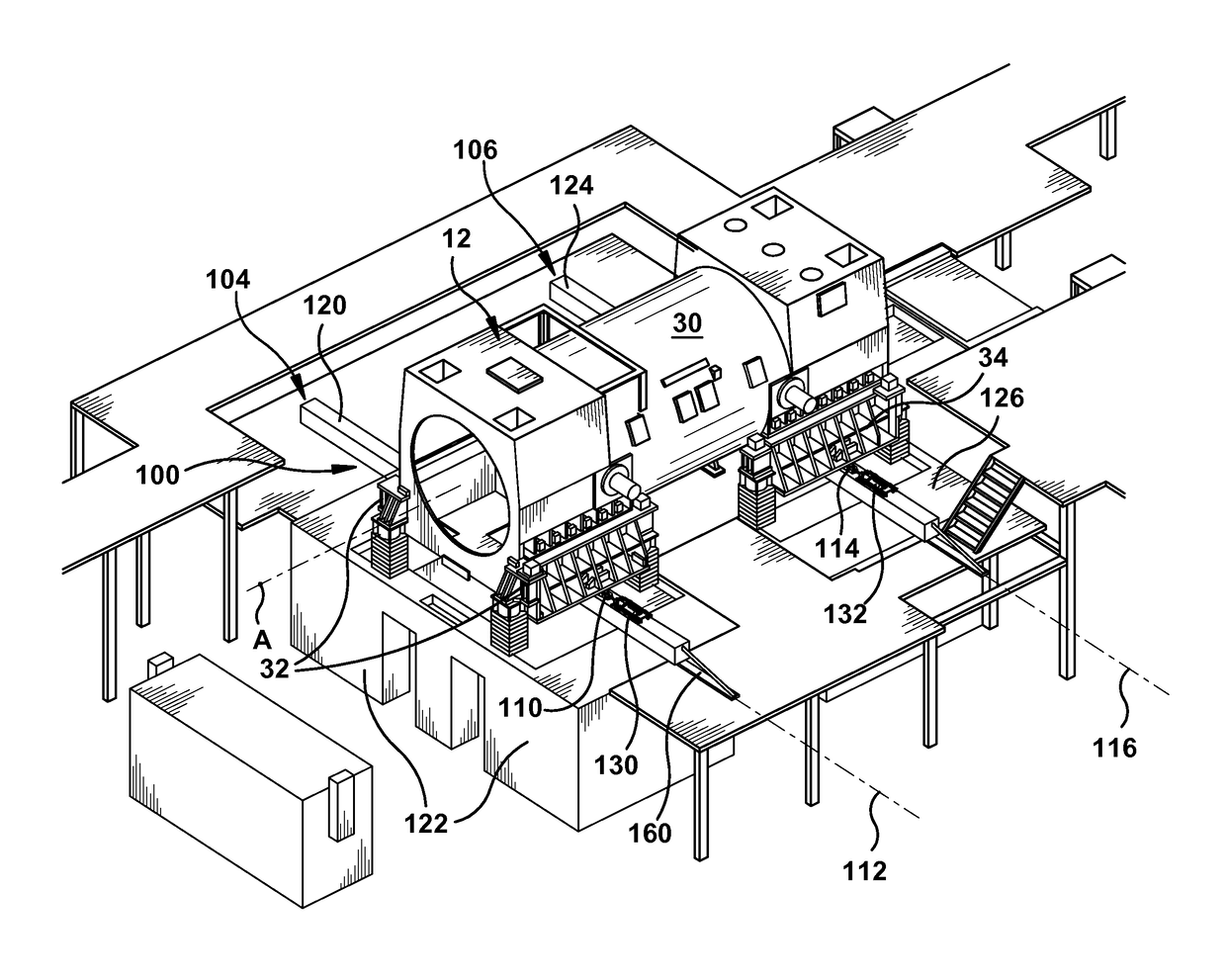

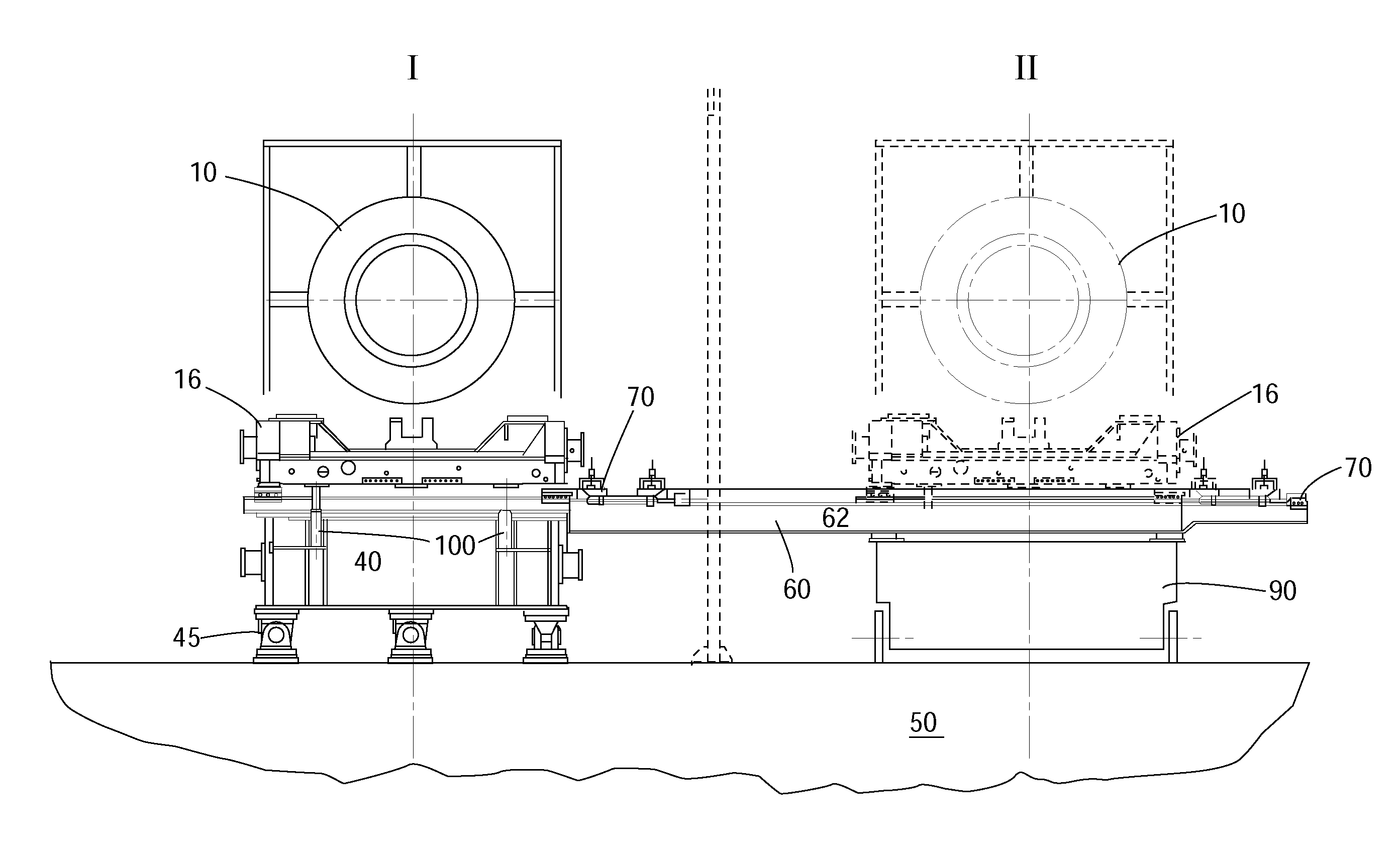

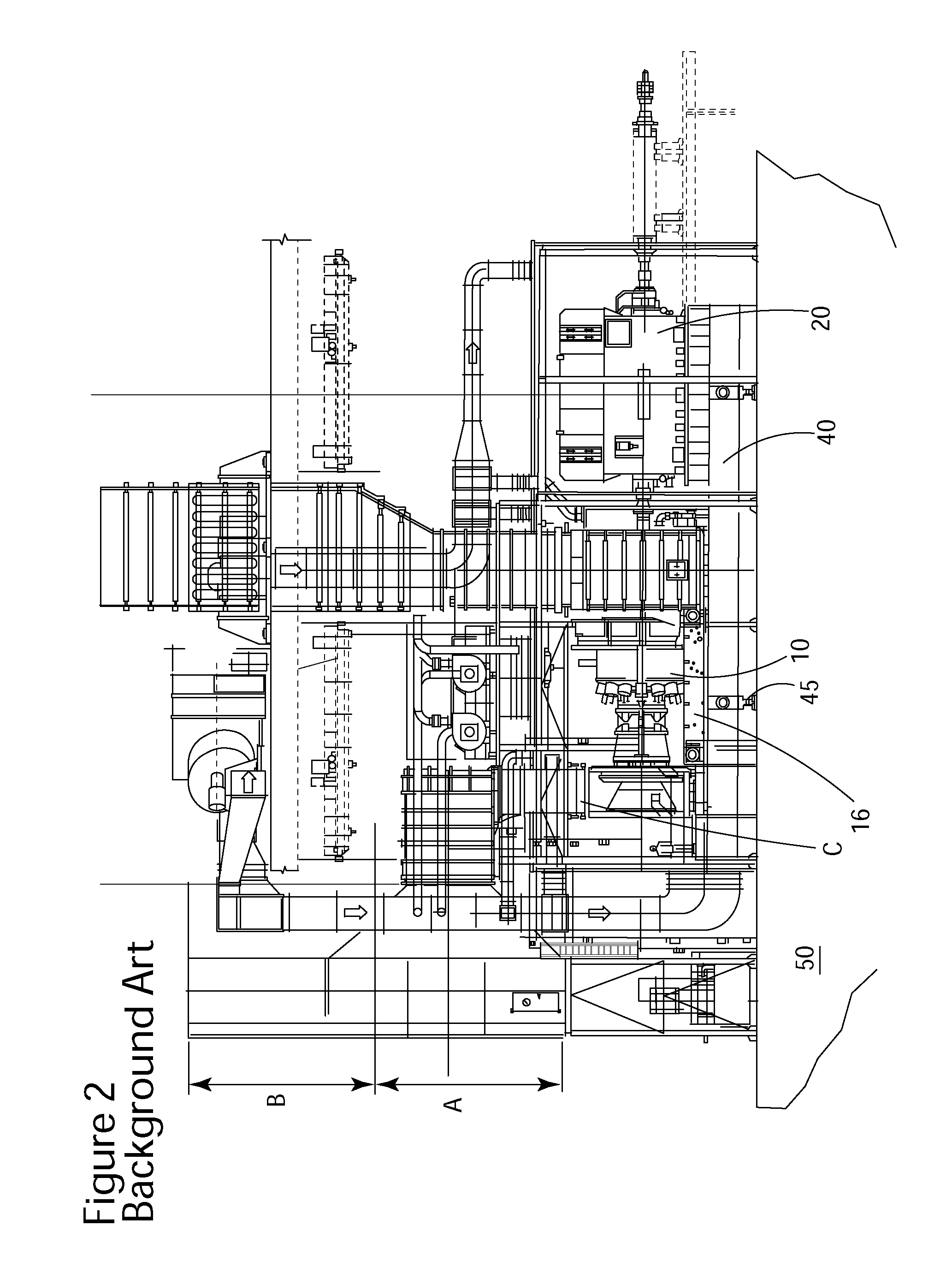

Method for laterally moving industrial machine

A method for laterally moving an industrial machine is provided. The method may include: supporting the industrial machine on a pair of rail elements configured to be positioned laterally below and support the industrial machine, the rail elements allowing the industrial machine to be moved laterally from a first operative position to a second, maintenance position. A pair of linear actuators configured to laterally move the industrial machine from the first, operative position to the second, maintenance position.

Owner:GE INFRASTRUCTURE TECH INT LLC

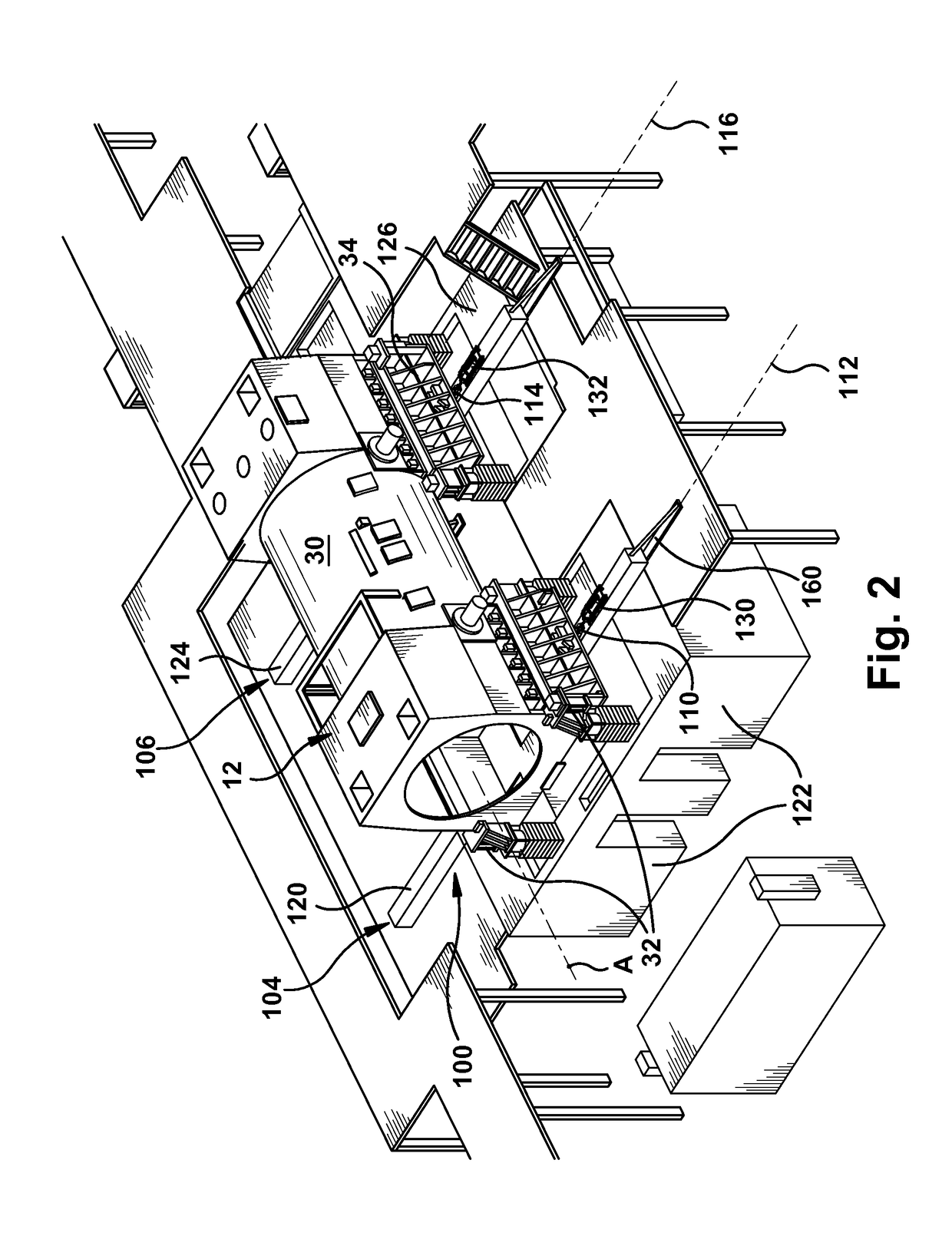

Method for moving and aligning heavy device

ActiveUS9032620B2Assembly machinesSemiconductor/solid-state device manufacturingEngineeringLift system

Method for laterally replacing a heavy component of a plant assembly, the method including disconnecting the heavy component from other components of the plant assembly and from a base plate to which the heavy component is fixed; lifting the heavy component above the base plate with a lifting system provided within the base plate; connecting at least a pair of rails to the base plate, under the lifted heavy component, such that the at least a pair of rails extends at substantially a right angle relative to a longitudinal axis of the heavy component; lowering the heavy component on crawling mechanisms disposed on the at least a pair of rails; and laterally replacing the heavy component from the base plate and the other components of the plant assembly by actuating the crawling mechanisms.

Owner:NUOVO PIGNONE TECH SRL

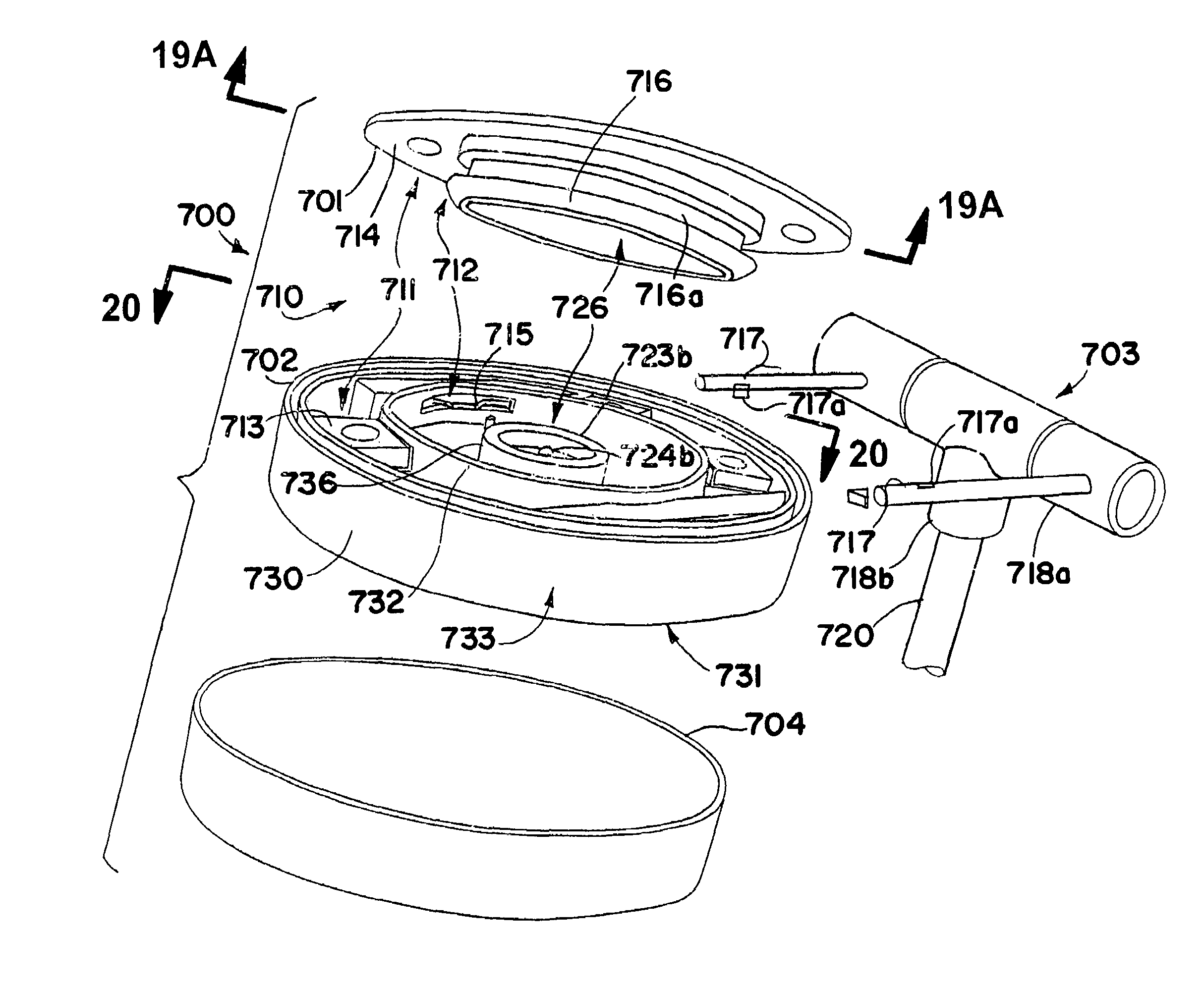

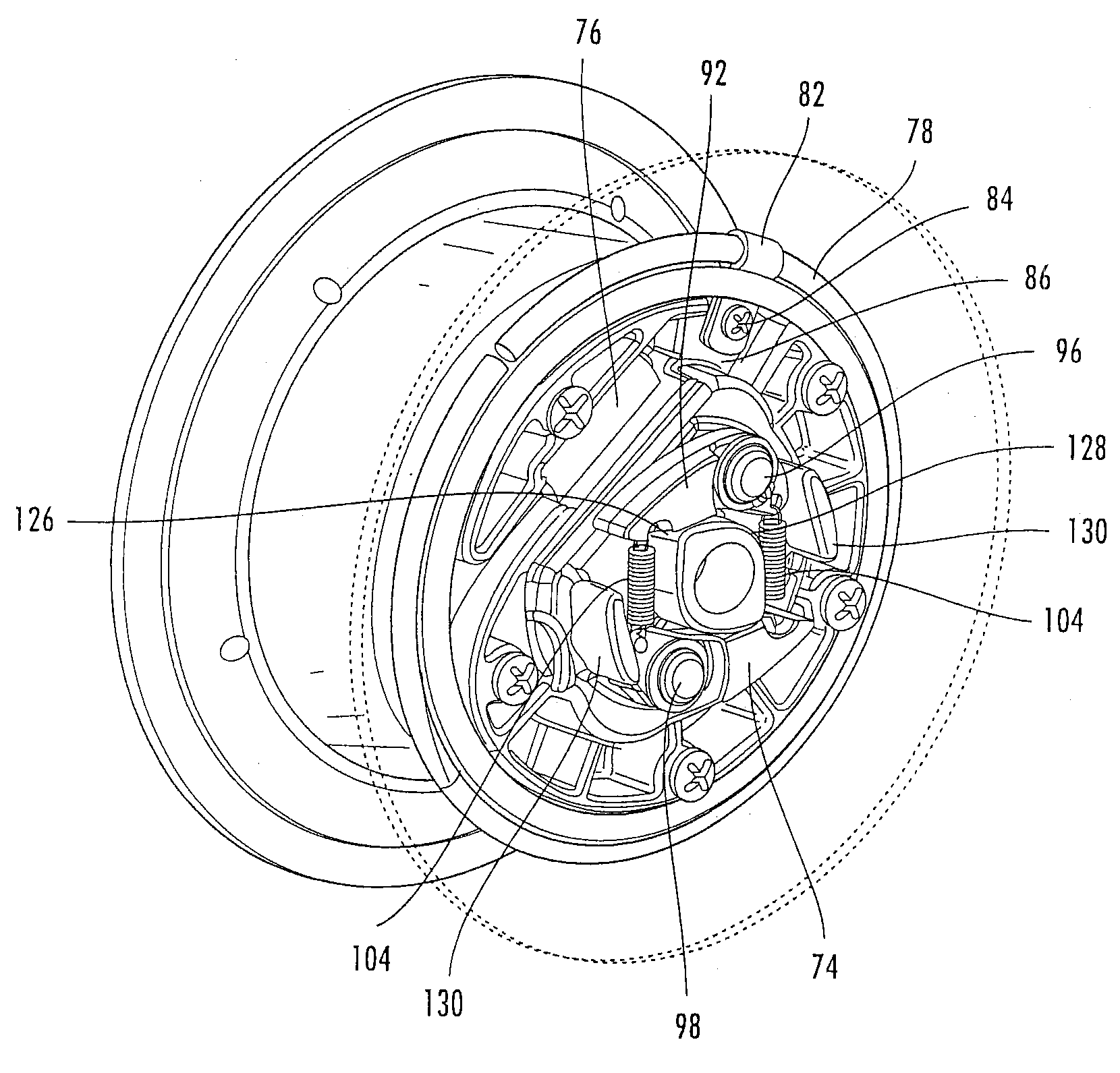

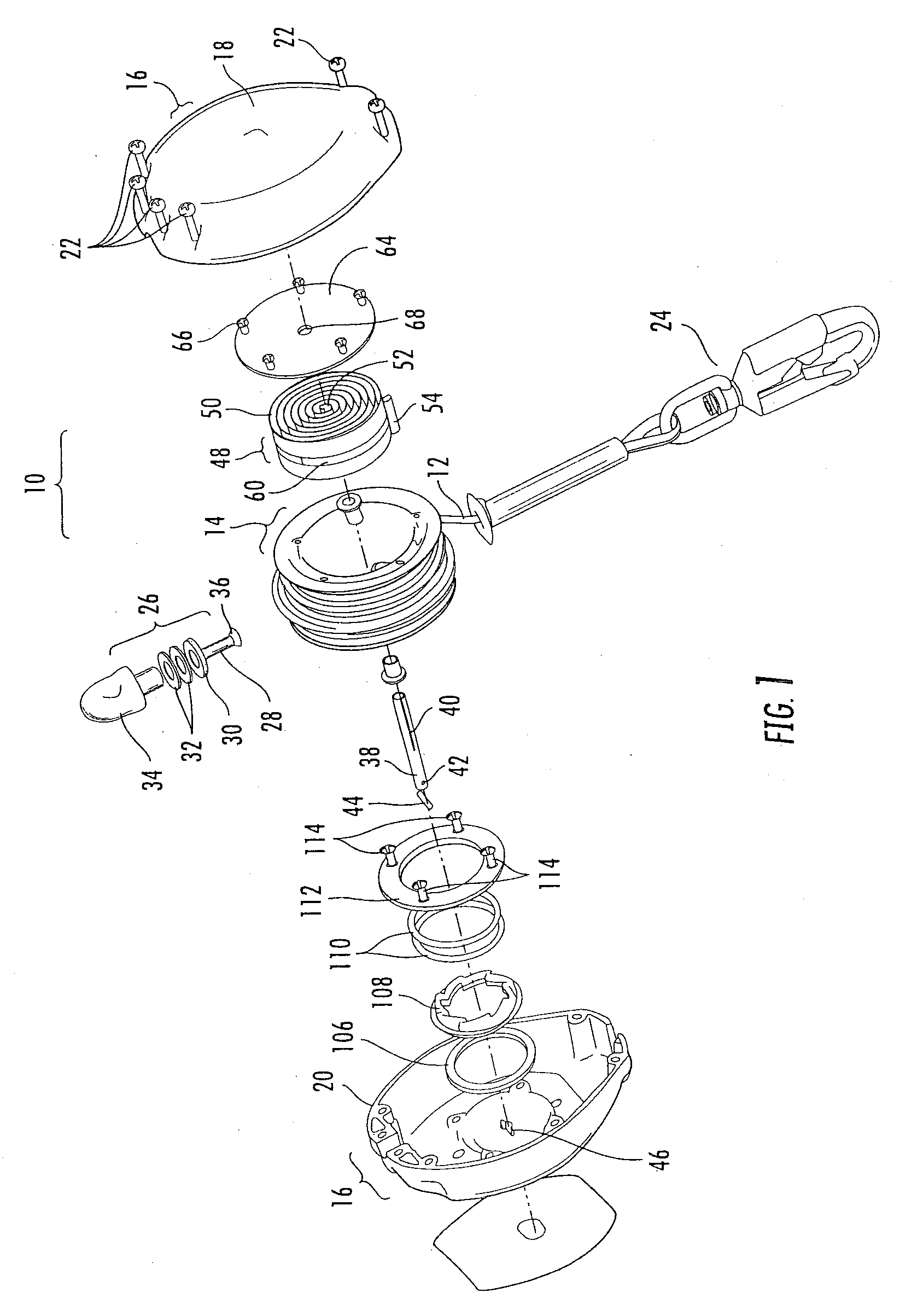

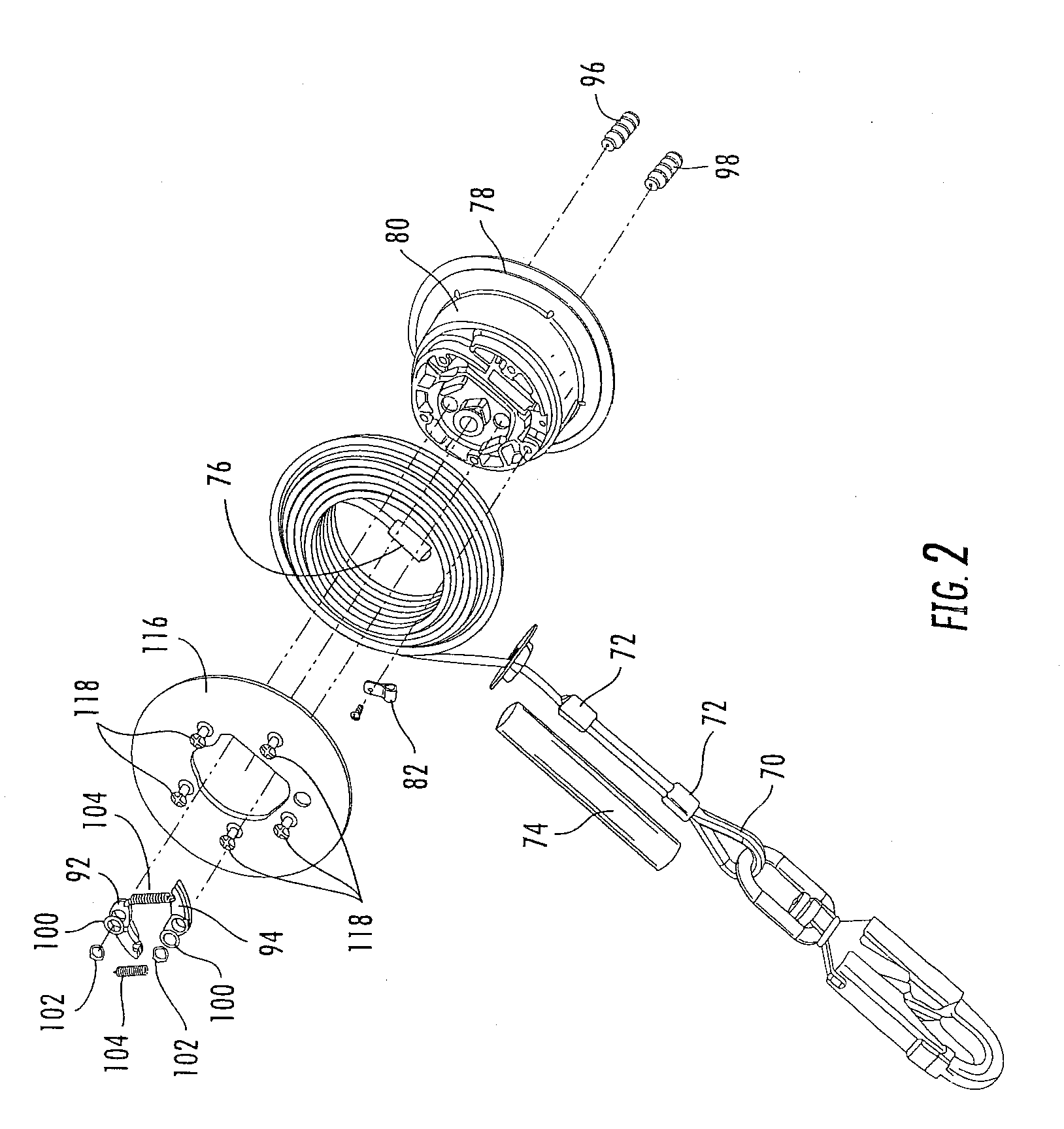

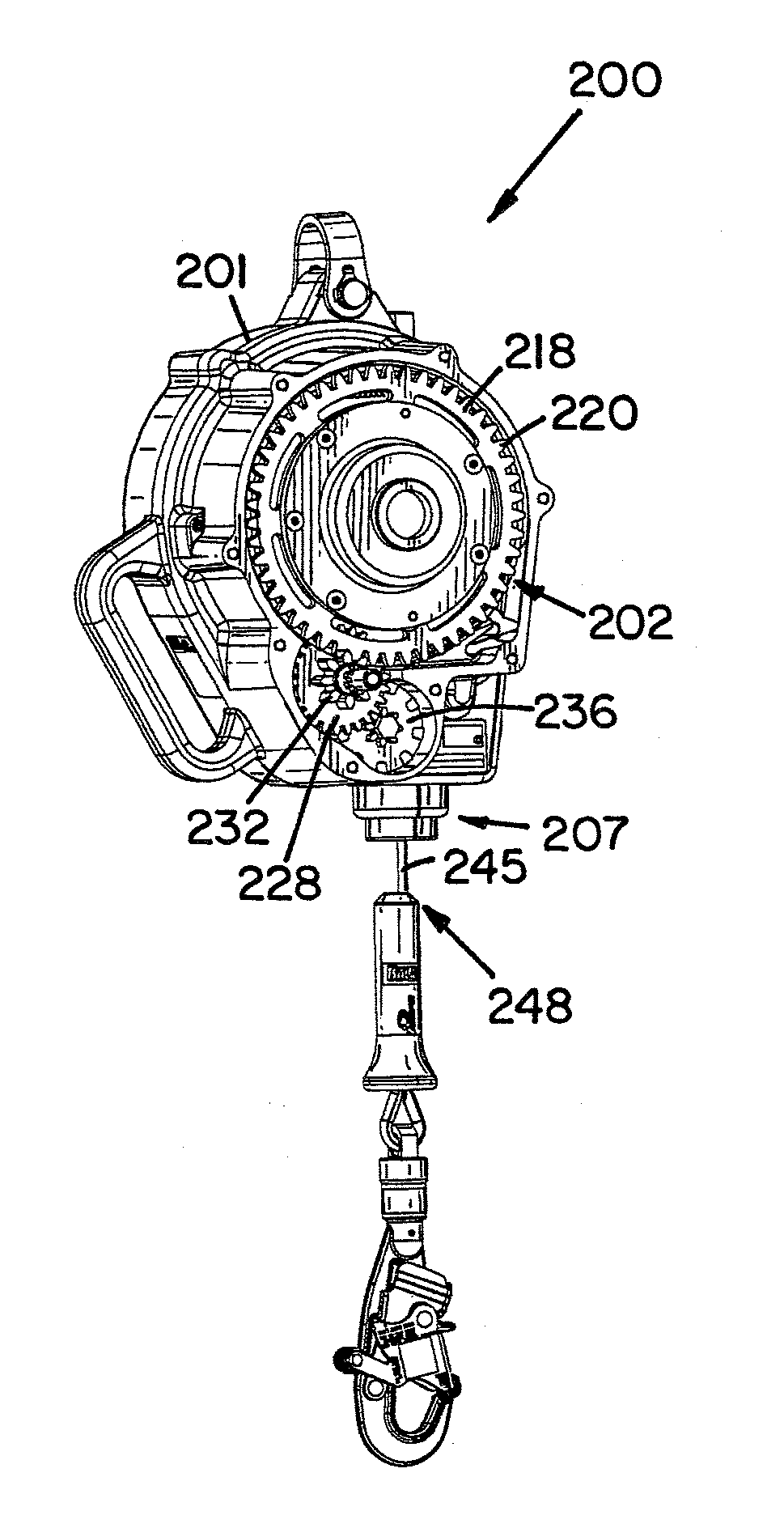

Retractable lifeline safety device

InactiveUS20090178887A1Overcome deficiency and shortcomingReduce manufacturing costSafety beltsBuilding rescueSprocketEngineering

A retractable lifeline safety device usable as heights above the ground. The safety device is attached to the structure on which the worker is performing the task, and a lifeline such as a cable is withdrawn from the housing thereof, the end of which is attached to a belt or harness worn by the worker. The cable may be easily drawn out of the housing in response to the worker moving about normally in the appropriate work space, and the cable is automatically drawn back into the housing of the safety device as the worker draws closer thereto. However, should the worker fall, a brake mechanism within the safety device is automatically engaged by a sprocket and pawl system, stopping the worker's descent.

Owner:SIGMA IND

Method and Device for Manipulating an Object

InactiveUS20100054903A1Gripping headsSemiconductor/solid-state device manufacturingEngineeringActuator

A method for manipulating an object with a remote vehicle having an end effector attached to a manipulator arm. The end effector comprises a jamming material in a housing. The method comprises pressing the end effector housing to the object, activating the jamming material to grasp the object, and moving the manipulator arm to manipulate the object.

Owner:IROBOT CORP

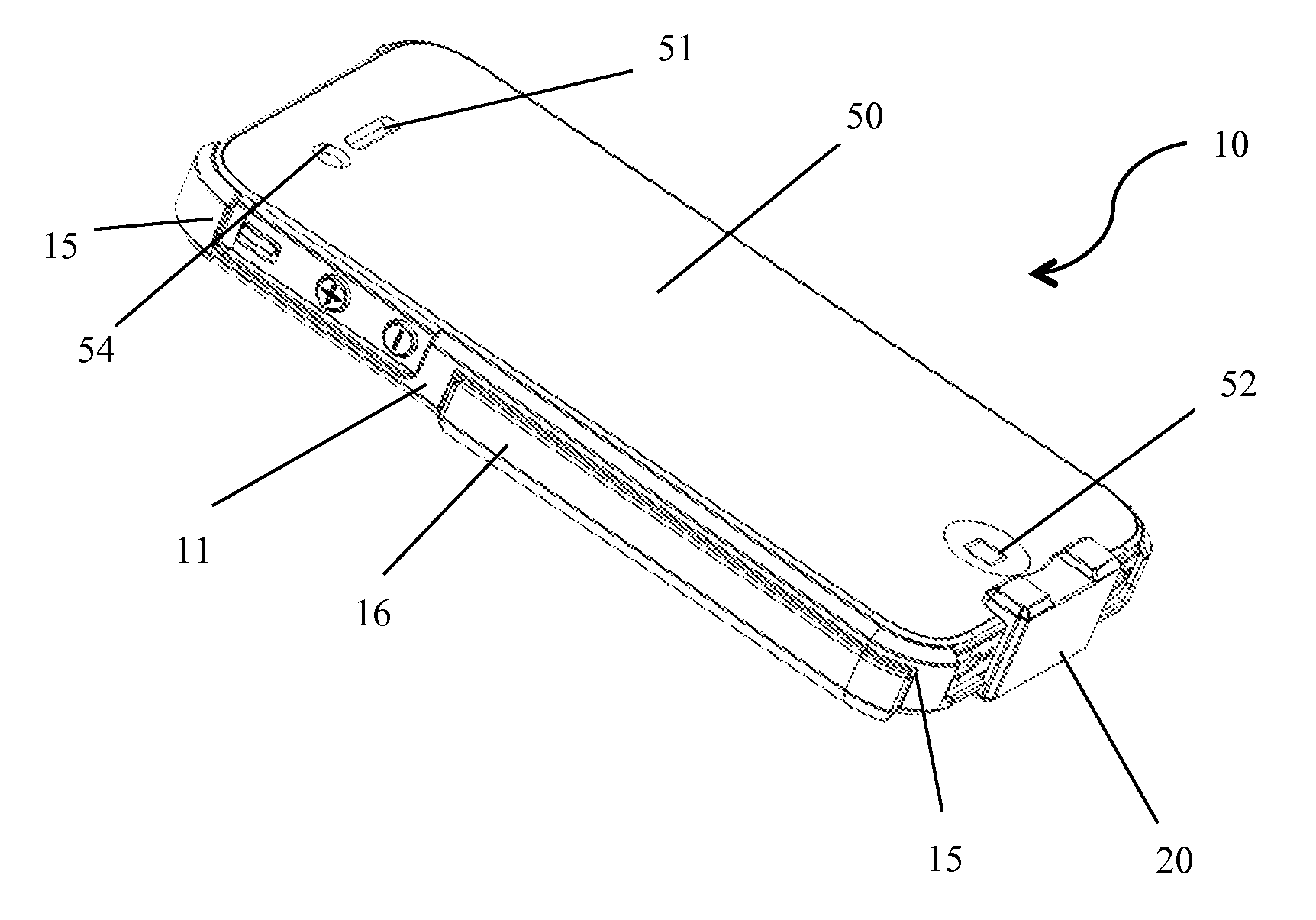

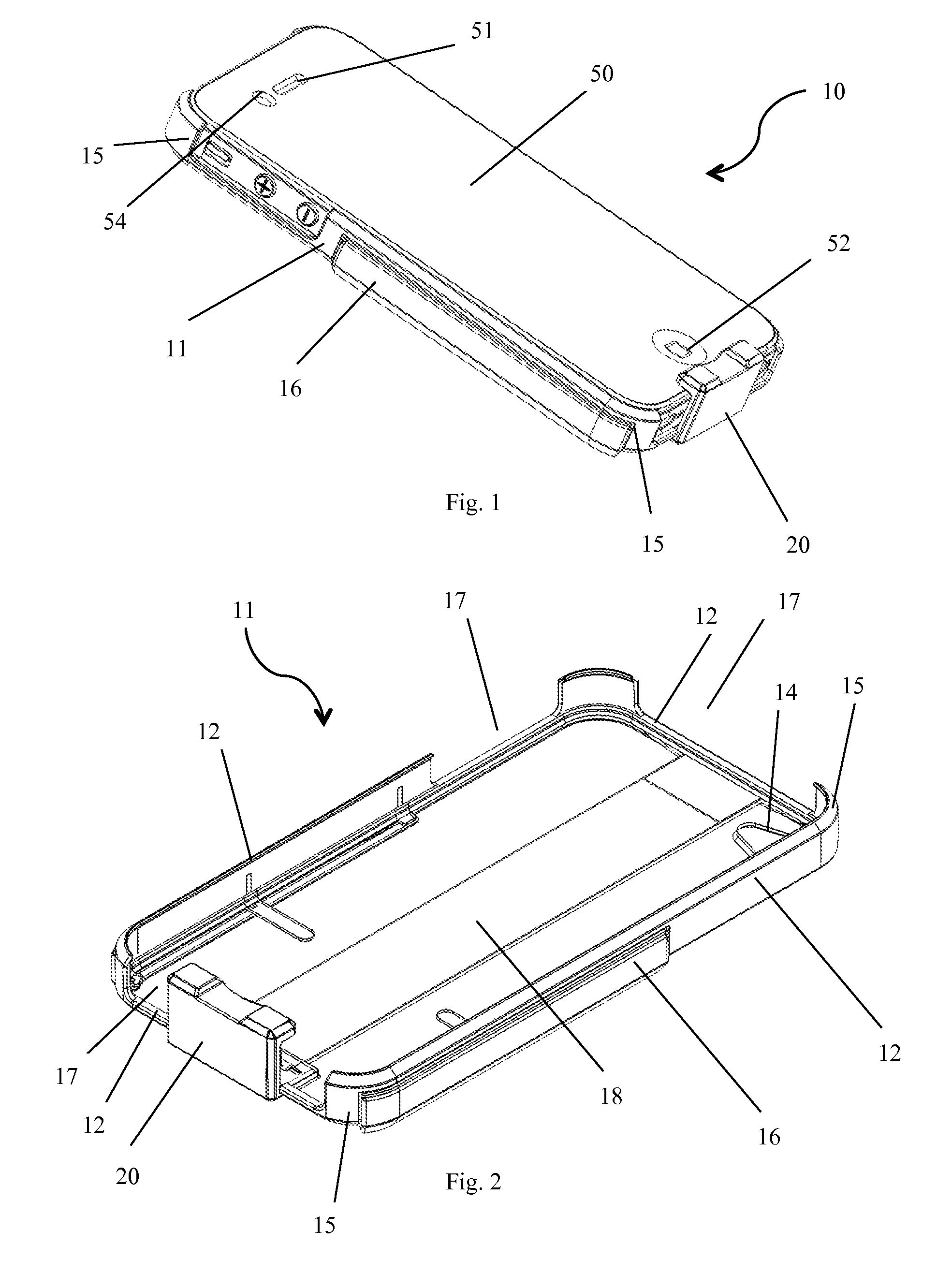

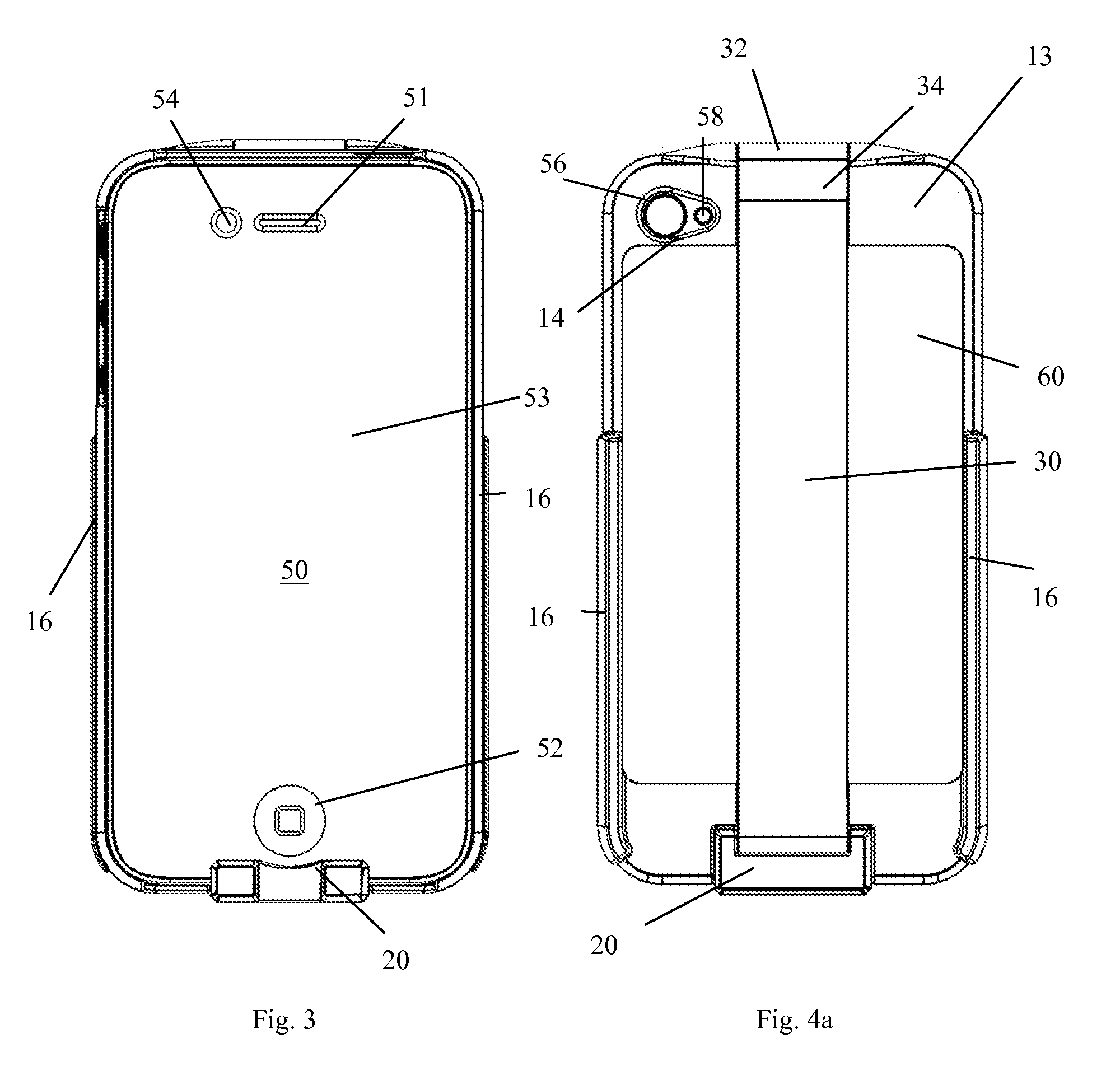

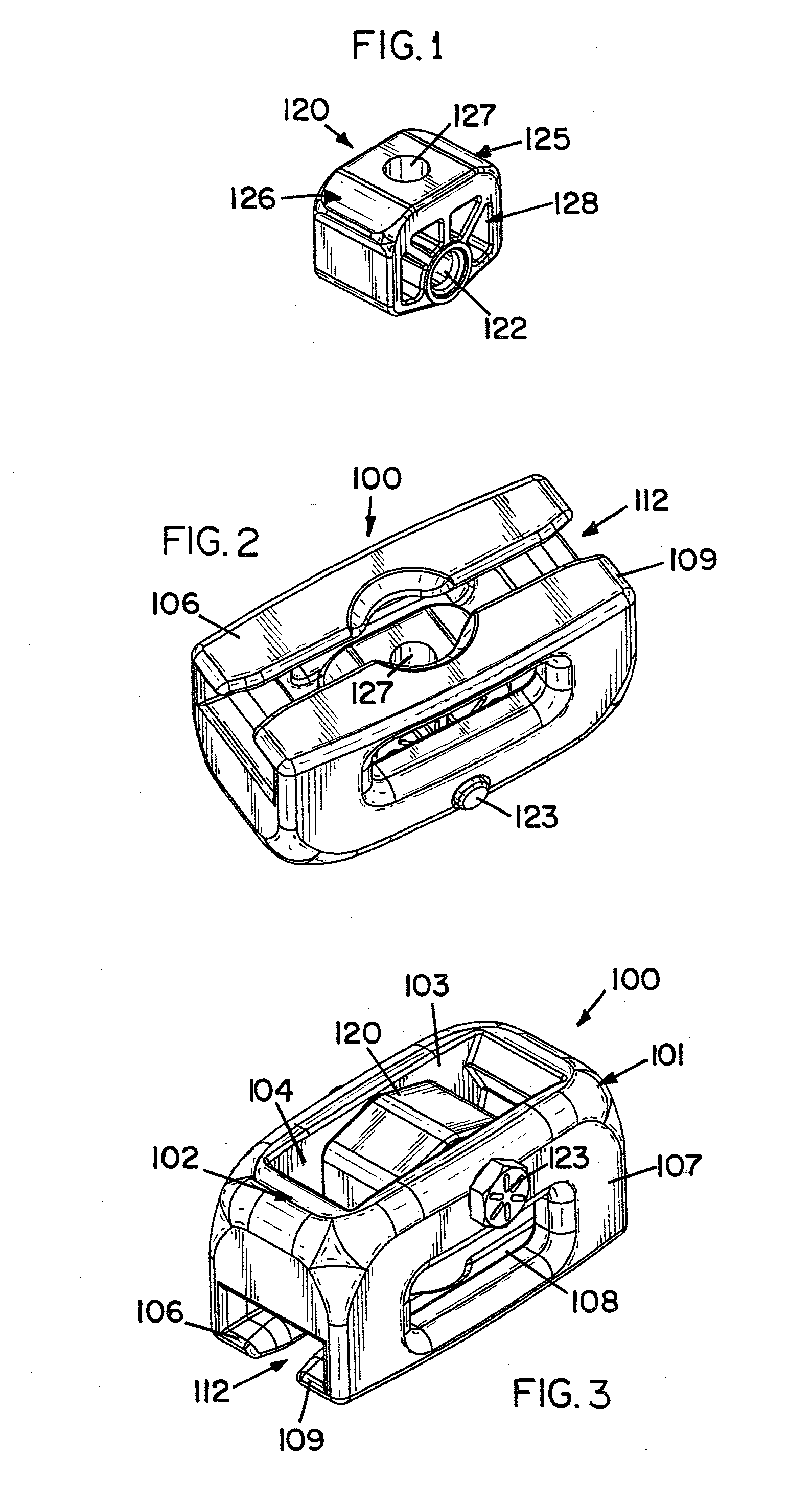

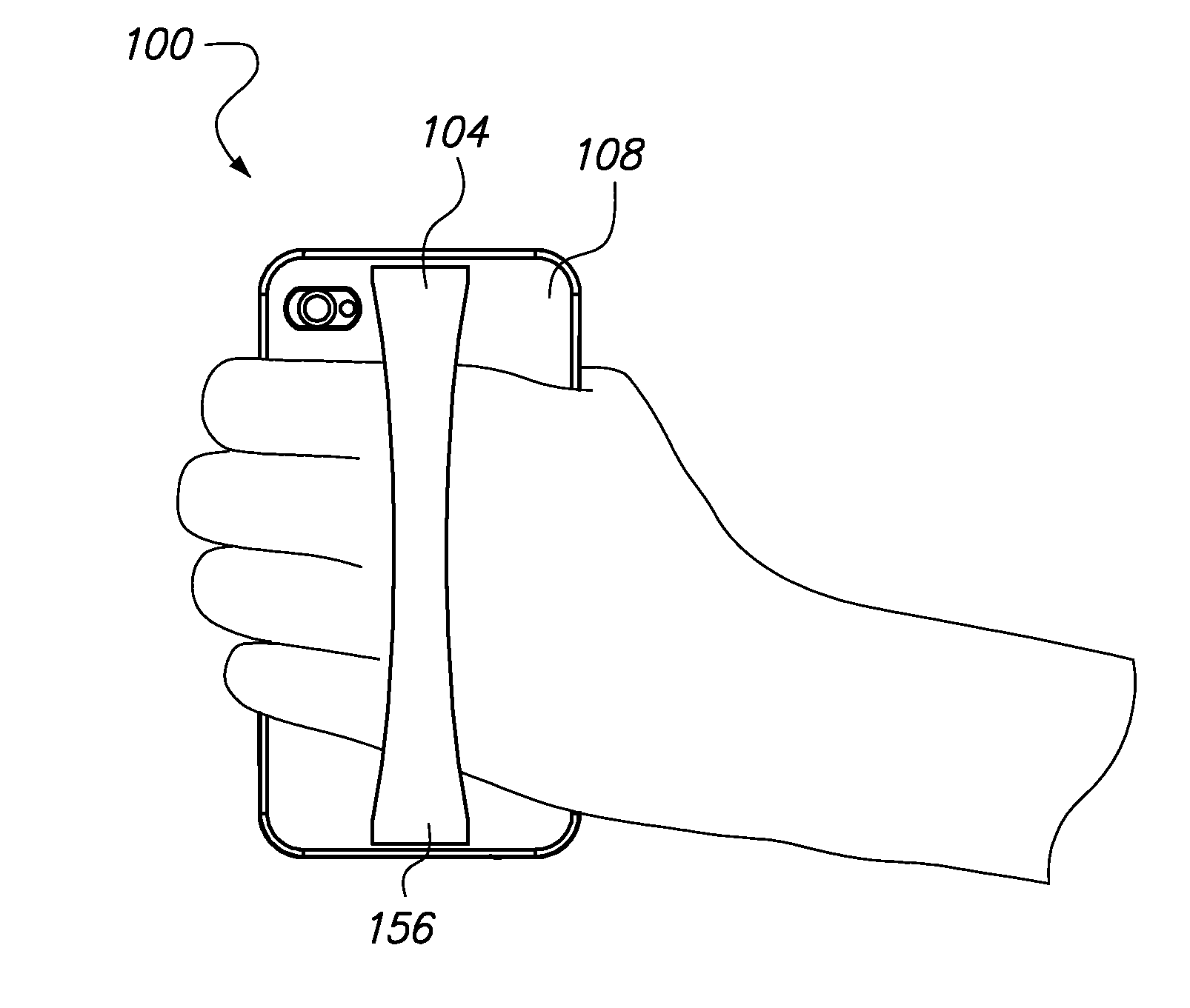

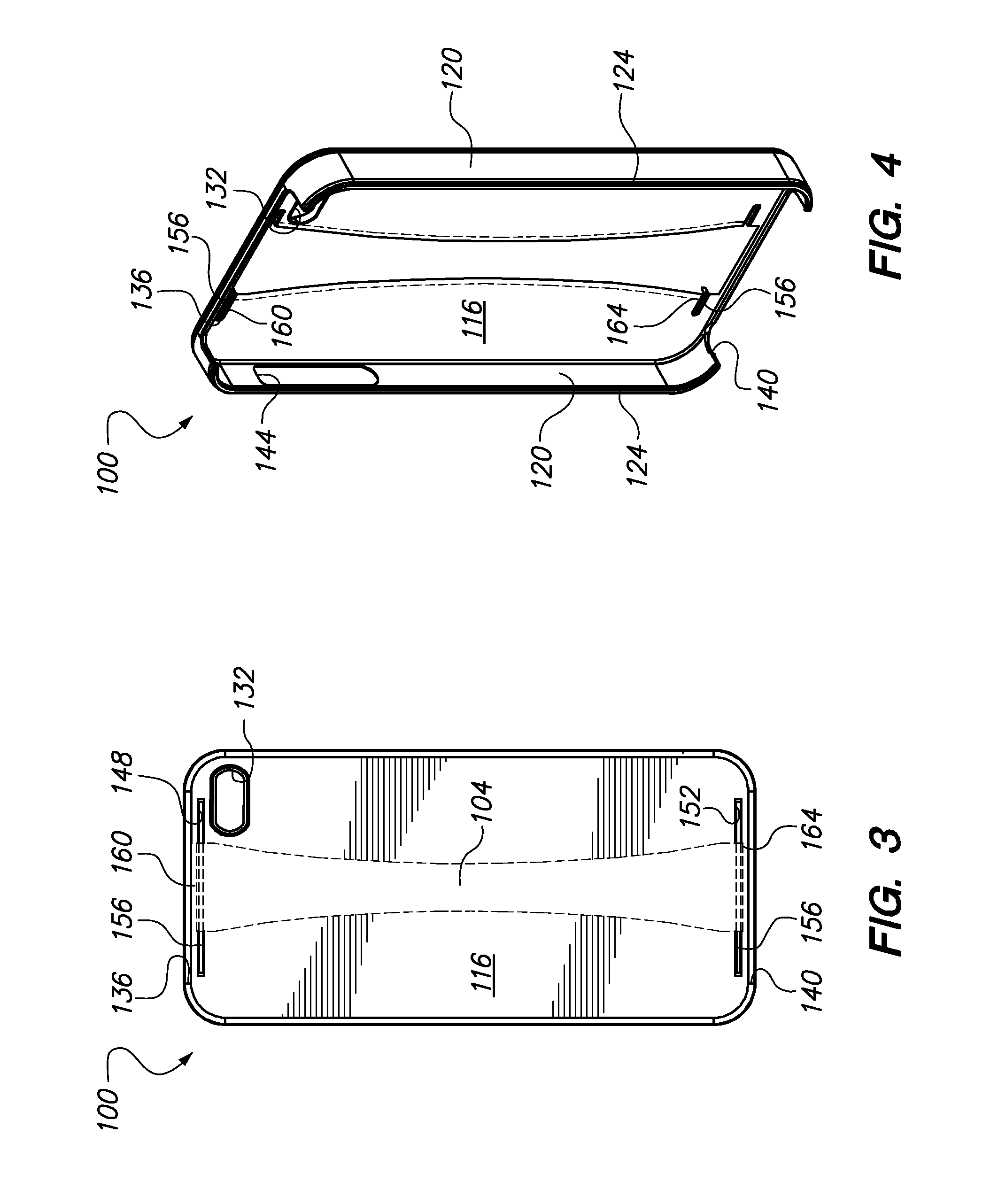

Multifunctional strap system for handheld portable electronic devices

ActiveUS20130009413A1Solve the lack of tensionTravelling carriersHoldersEmbedded systemElectronic equipment

A multifunctional strap system for portable electronic devices having a case and a strap on the back of the case. The case securely holds a protective electronic device while allowing access to all necessary features of the device. The strap securely couples a user's hand or other personal effects to the device. The strap may also be attached to a clip that removably attaches the strap to the bottom of the device. The detachable clip of the strap allows the strap system to loop around and be secured onto an object. The case may have an insert that can be used as a kickstand or a protective cover of a card held into place by the strap.

Owner:FABX INNOVATIONS

Fall protection safety device with a braking mechanism

ActiveUS20110147125A1Assisted movementSolve the lack of tensionDynamo-electric brakes/clutchesSafety beltsFall protectionElectromagnetic field

A fall protection safety device including a braking mechanism comprises a first component, a second component configured and arranged to move relative to the first component, and at least one magnet operatively connected to one of the components and another of the components being at least partially made of a non-ferromagnetic and electrically conductive material. The at least one magnet and the non-ferromagnetic and electrically conductive material creating an electromagnetic field force when the second component moves at a rate greater than a predetermined rate relative to the first component.

Owner:D B IND

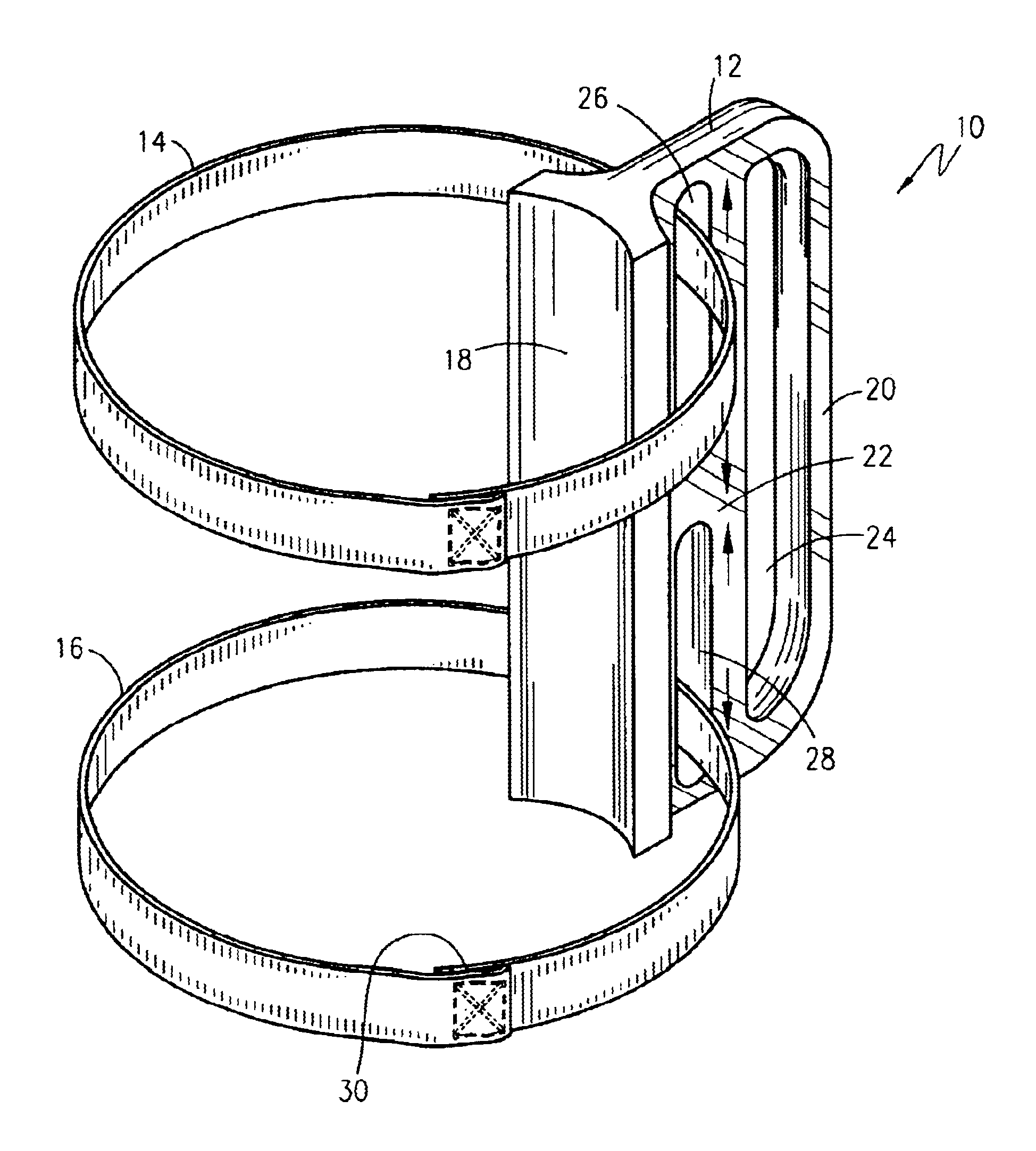

Adjustable pouring handle

An adjustable pouring handle is a linearly elongated body having a pair of adjustable container straps that are detachably affixed to the body. The body includes a grasping aperture, a first aperture and a second aperture. The grasping aperture allows a user to firmly and comfortably grasp the handle body so as to permit the pouring or movement of the affixed beverage container. The first and second apertures each receive an adjustable container strap. The adjustable container straps are placed about the outer circumference of the beverage container and detained by a securing mechanism. The securing mechanism may be one of a variety of securing devices, including hook and loop material, snap fasteners, button snaps, buttons or buckles.

Owner:POSEY ALBERT E +1

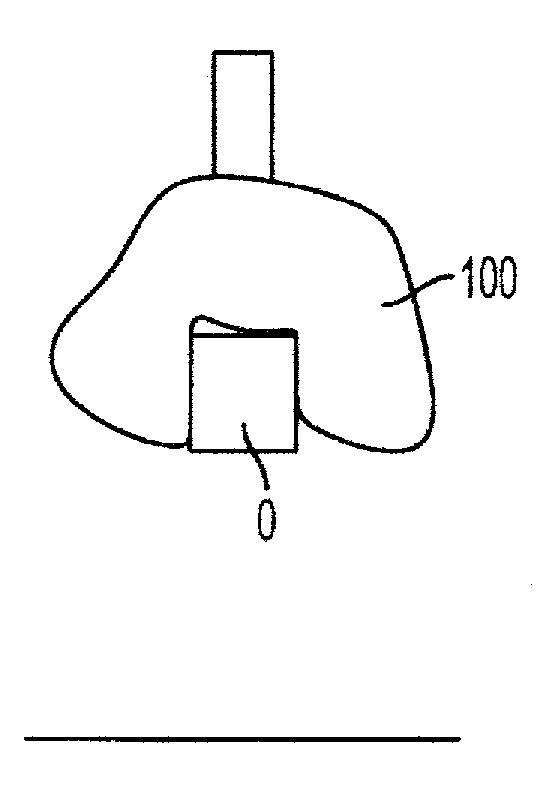

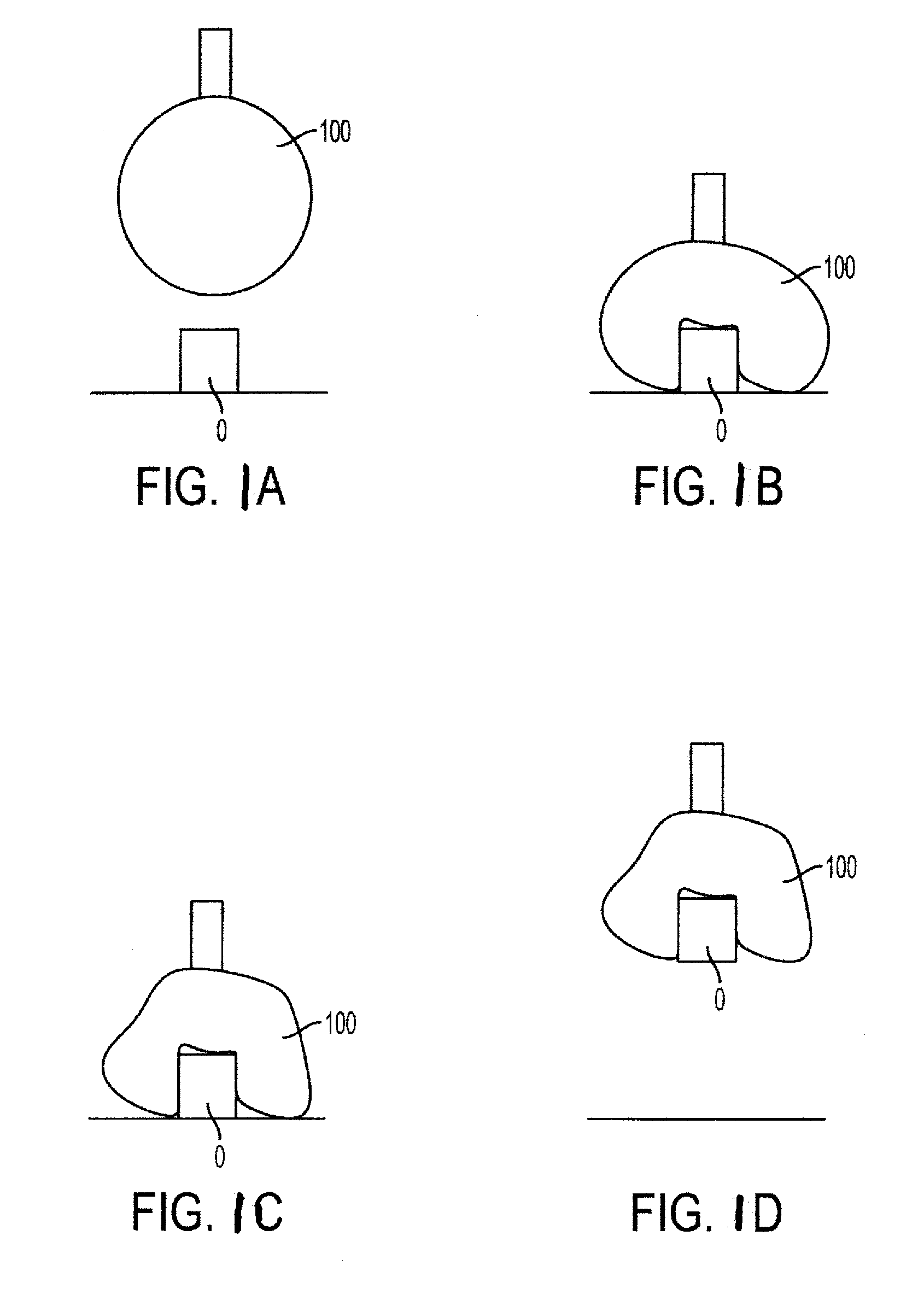

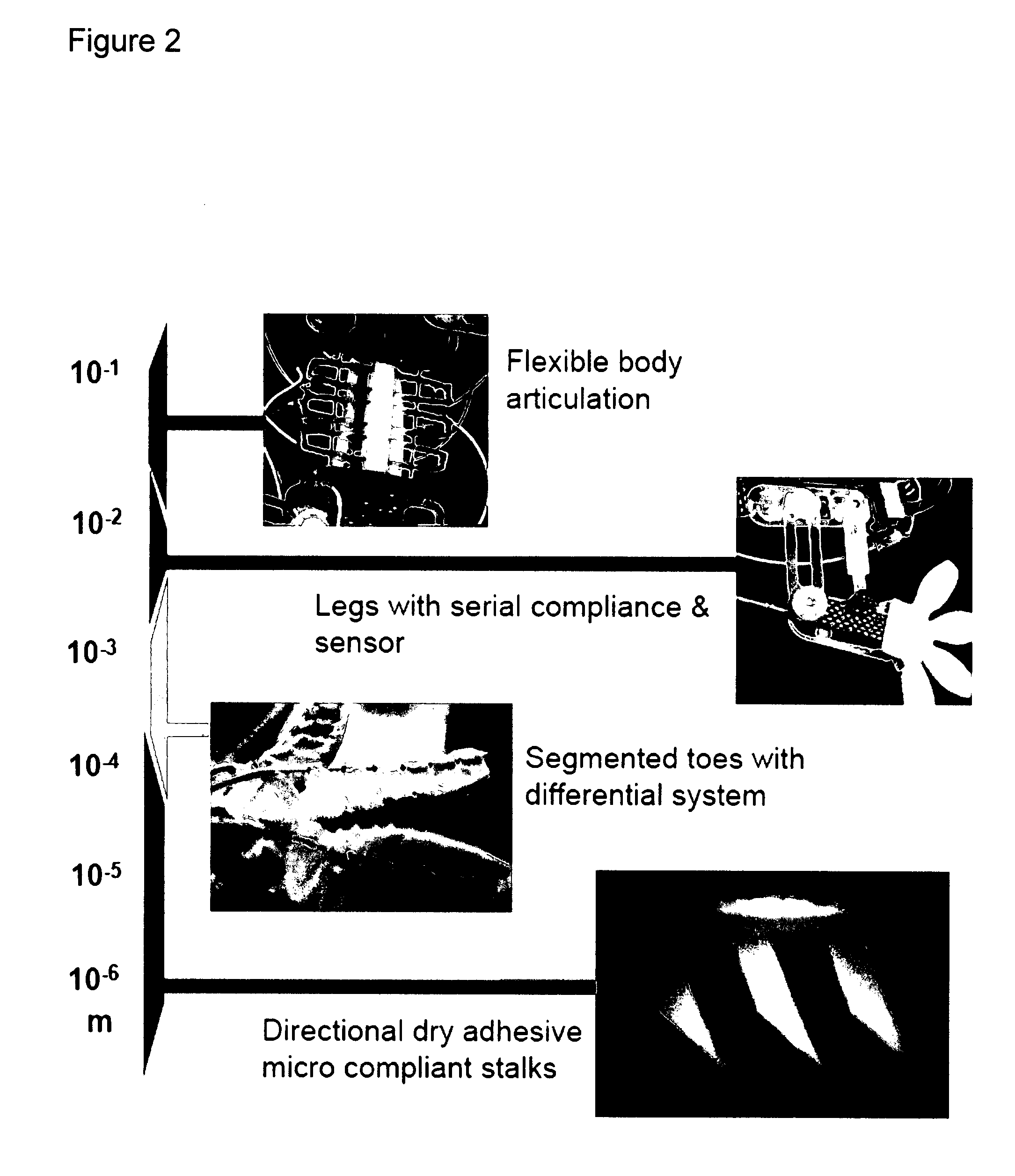

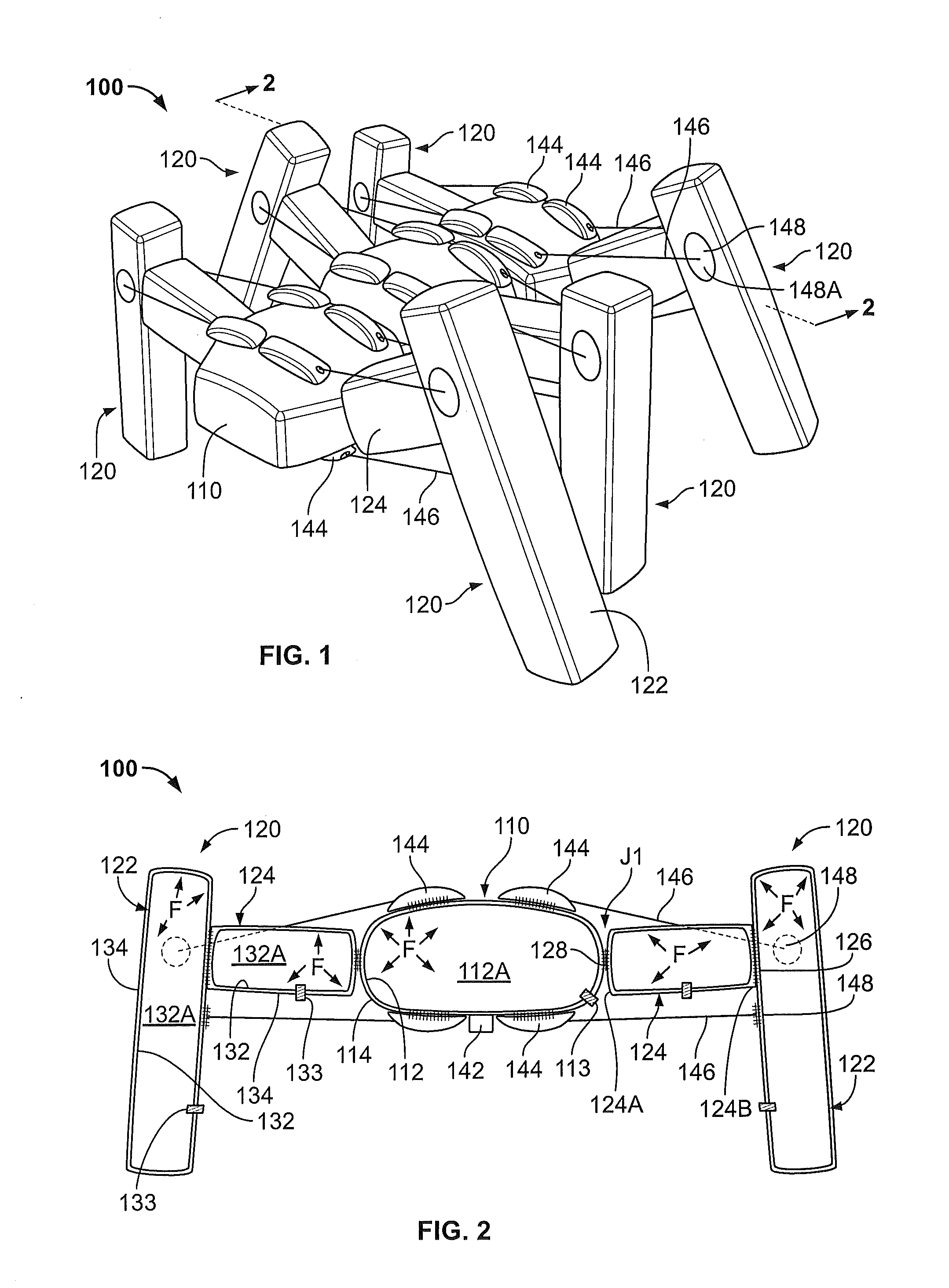

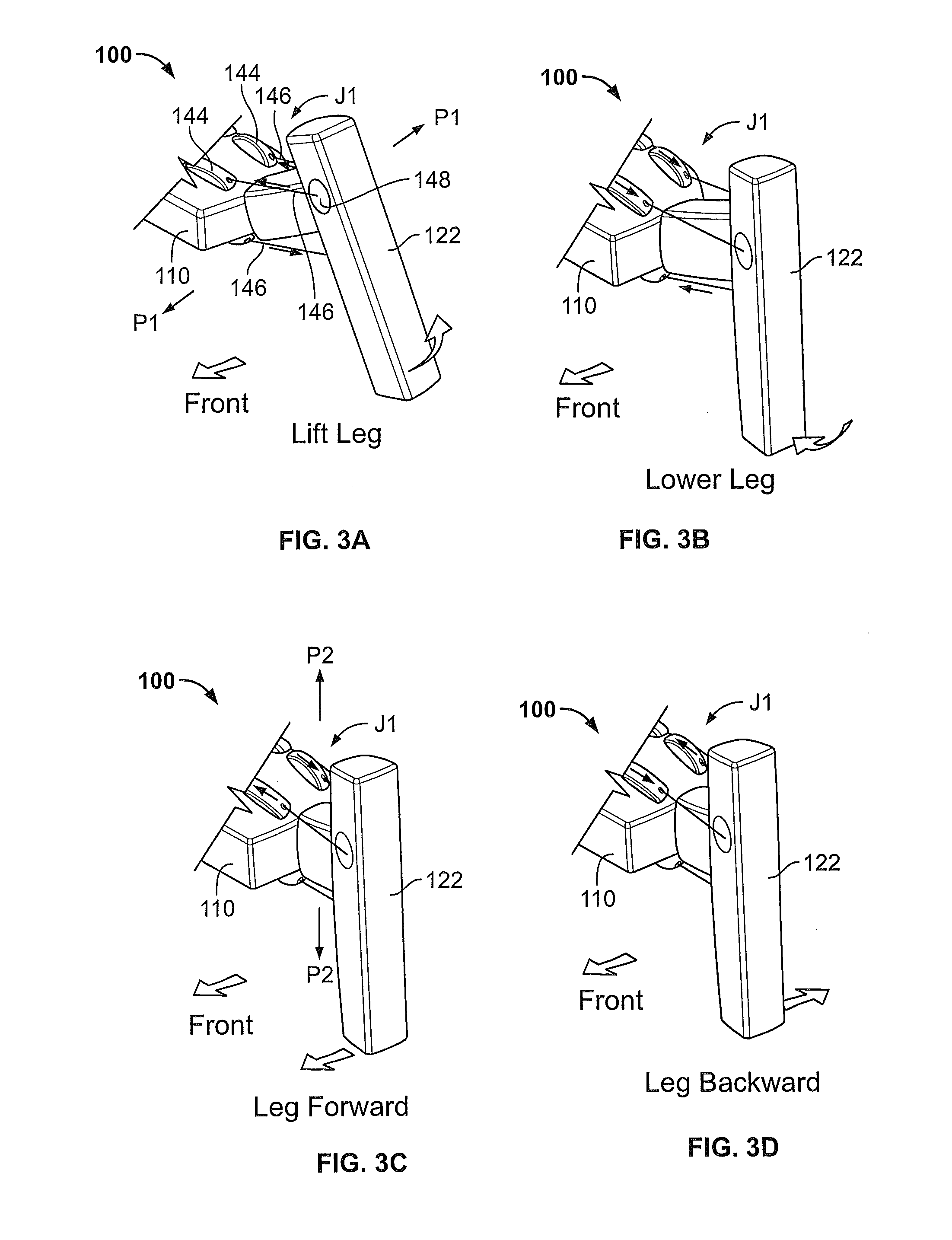

Climbing with dry adhesives

ActiveUS20070289786A1Facilitate disengagementSolve the lack of adhesionLifting devicesVehiclesStress distributionMicrometer

A bio-inspired device is provided designed to scale smooth vertical surfaces using anisotropic frictional materials. The device draws its inspiration from geckos and other climbing lizards and employs similar compliance and force control strategies to climb (or hang onto) smooth vertical surfaces including glass, tile and plastic panels. Foremost among the design features embodied in the device are multiple levels of compliance, at length scales ranging from centimeters to micrometers, to allow the device to conform to surfaces and maintain large real areas of contact so that adhesive forces can support it. Structures within the feet ensure even stress distributions over each toe and facilitate engagement and disengagement of the adhesive materials. A force control strategy works in conjunction with the anisotropic adhesive materials to obtain sufficient levels of friction and adhesion for climbing with low attachment and detachment forces.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

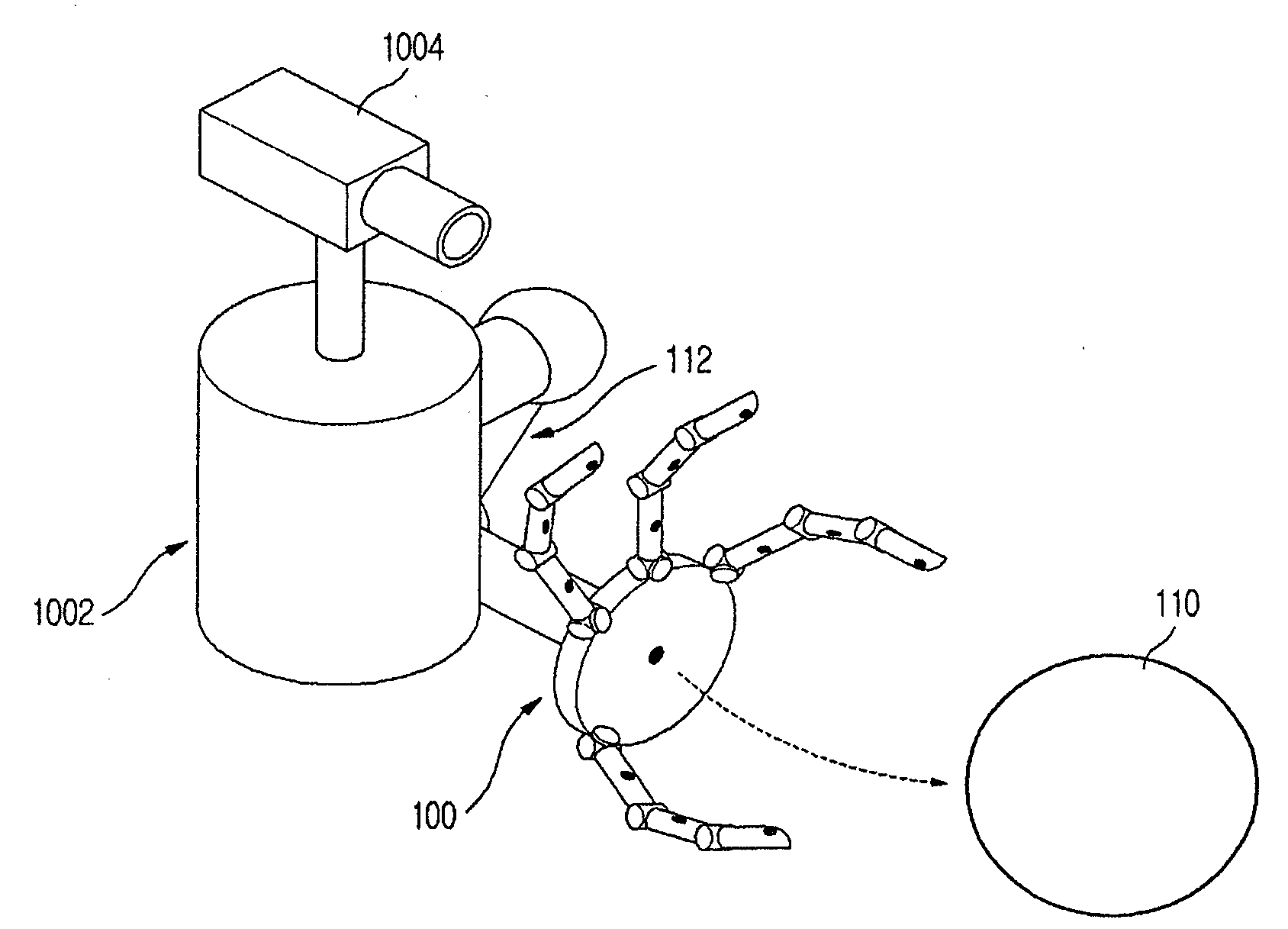

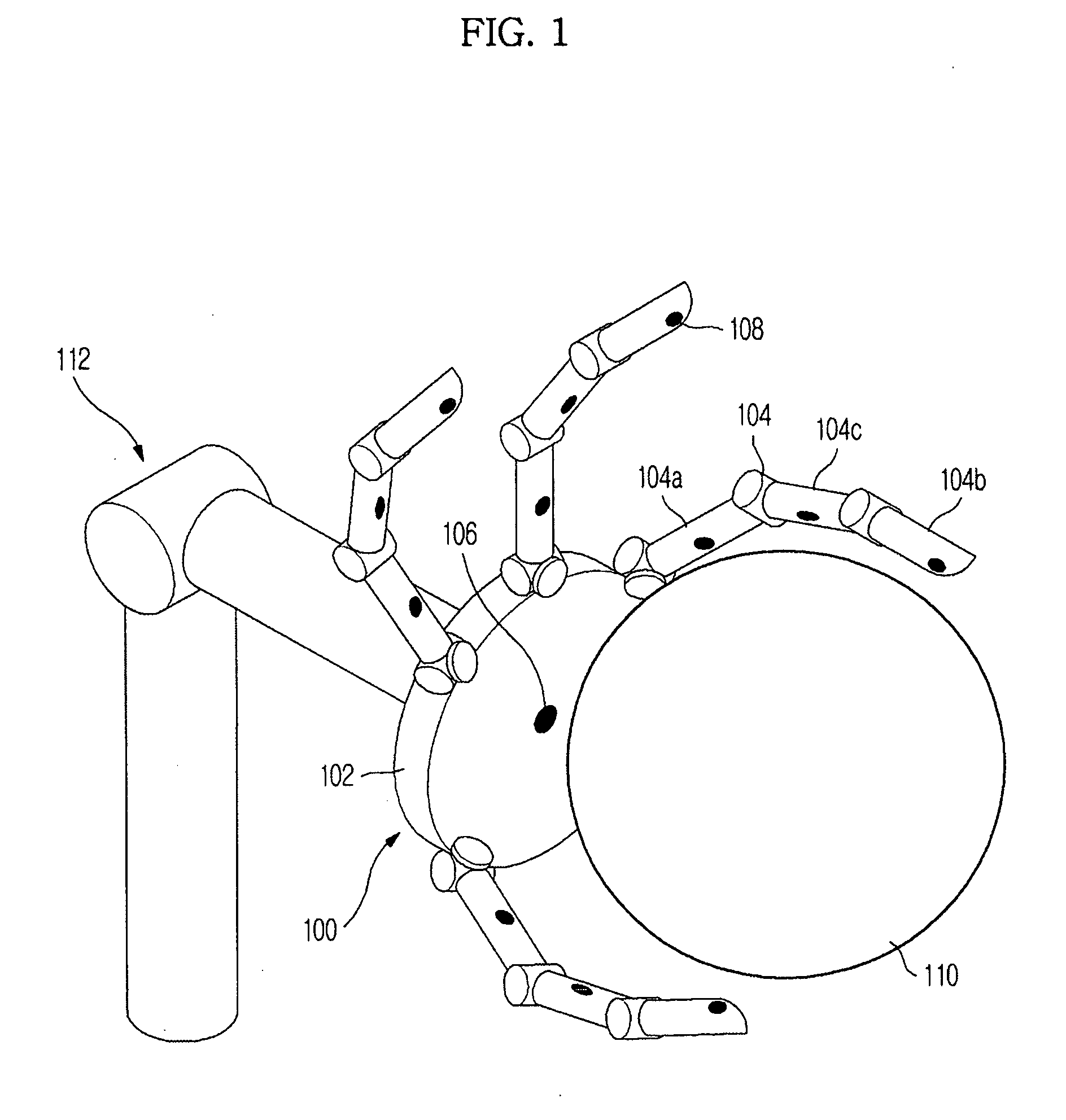

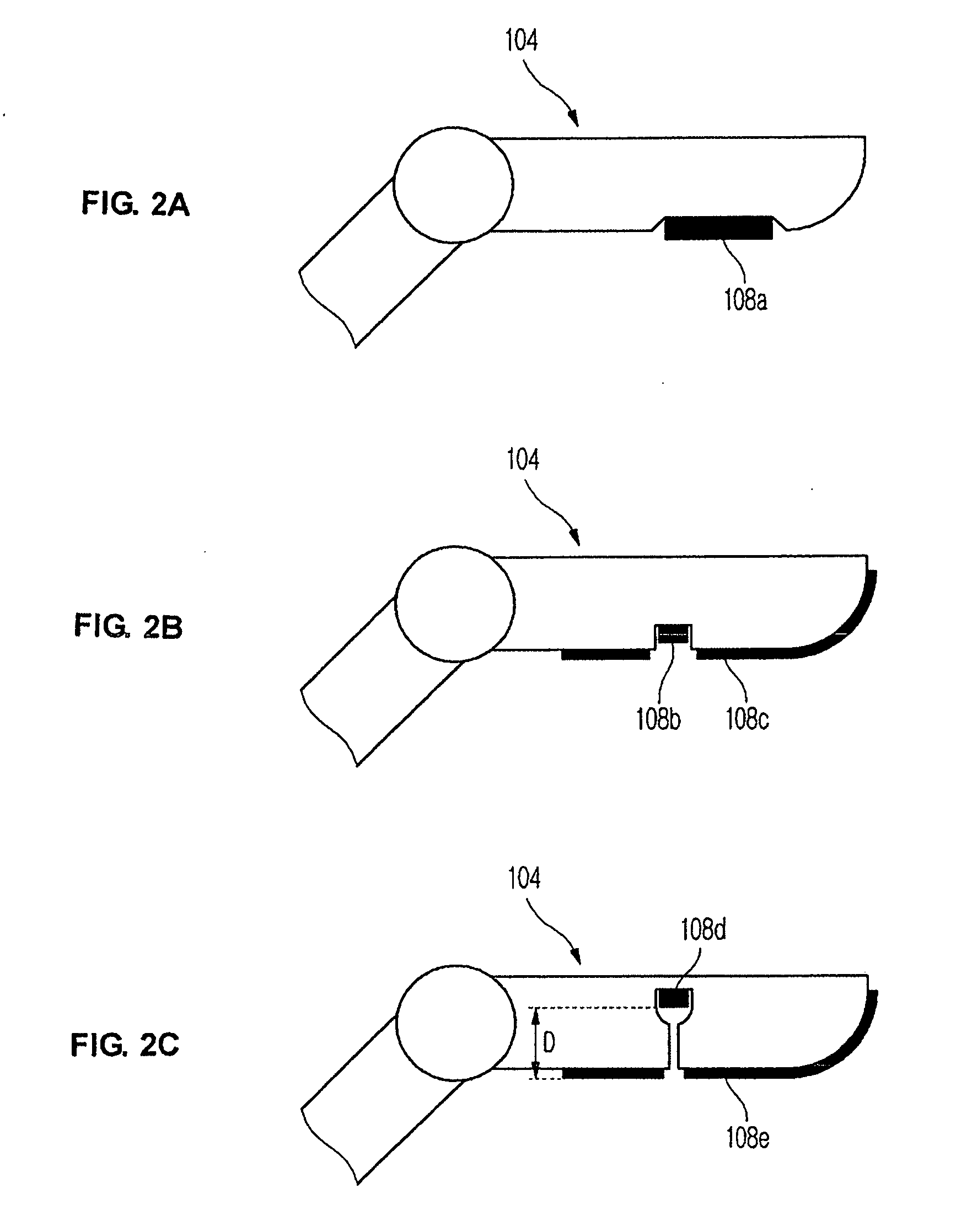

Robot, robot hand, and method of controlling robot hand

ActiveUS20090285664A1Safe gripAvoid interferenceProgramme-controlled manipulatorComputer controlRobot handDistance sensors

Disclosed are a robot, a robot hand, and a method of controlling the robot hand, in which the robot hand rapidly and correctly approaches an object to be gripped and safely grips the object regardless of the shape and material of the object. The method of controlling a robot hand, which has a palm, and a plurality of fingers, each having a plurality of segments, connected to the palm, includes causing the palm to approach an object using at least one first distance sensor installed on the palm; causing the plurality of fingers to approach the object using at least one second distance sensor installed on the plurality of fingers; and causing the palm and the plurality of fingers to come into contact the object to grip the object.

Owner:SAMSUNG ELECTRONICS CO LTD

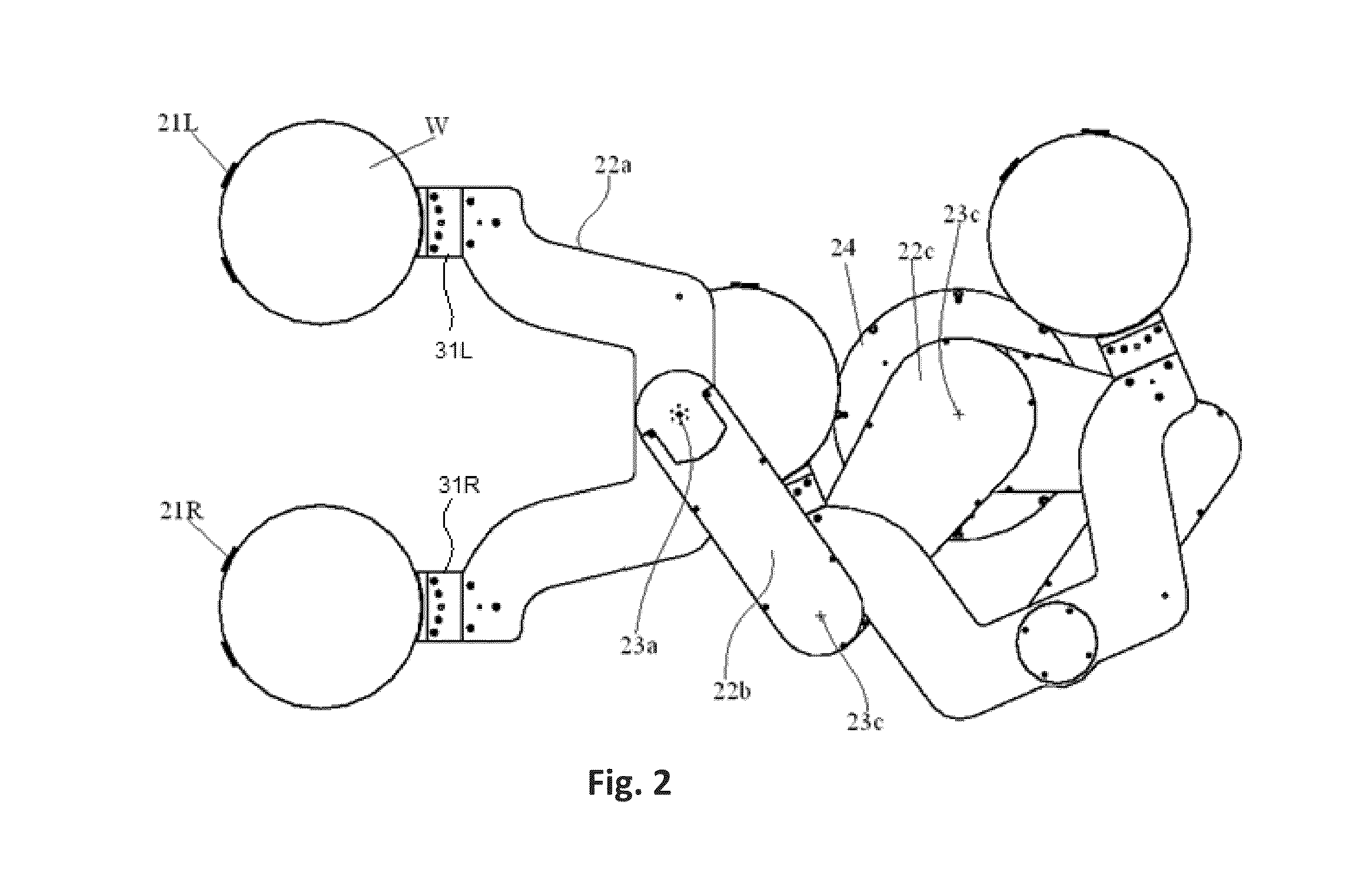

Inflatable Robots, Robotic Components and Assemblies and Methods Including Same

InactiveUS20130152724A1Programme-controlled manipulatorMechanical apparatusDegrees of freedomEngineering

A robotic joint assembly includes a first structural member, a second structural member, and a rolling flexure joint joining the first structural member to the second structural member to provide at least one degree of freedom between the first and second structural members. The rolling flexure joint includes first and second flexible hinge members each having one end secured to the first structural member and an opposing end secured to the second structural member. The first and second flexible hinge members cross one another between the first and second structural members.

Owner:IROBOT CORP

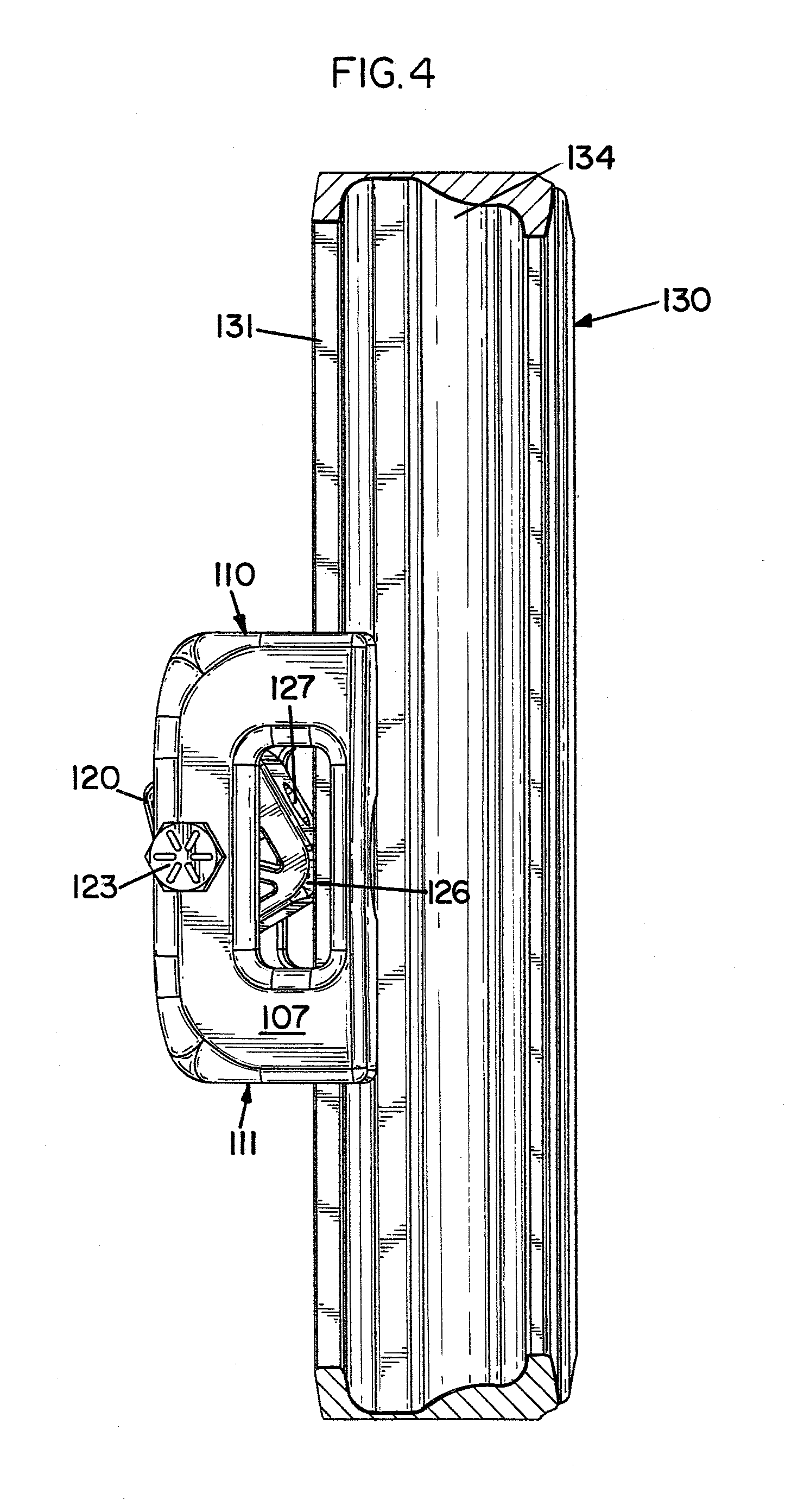

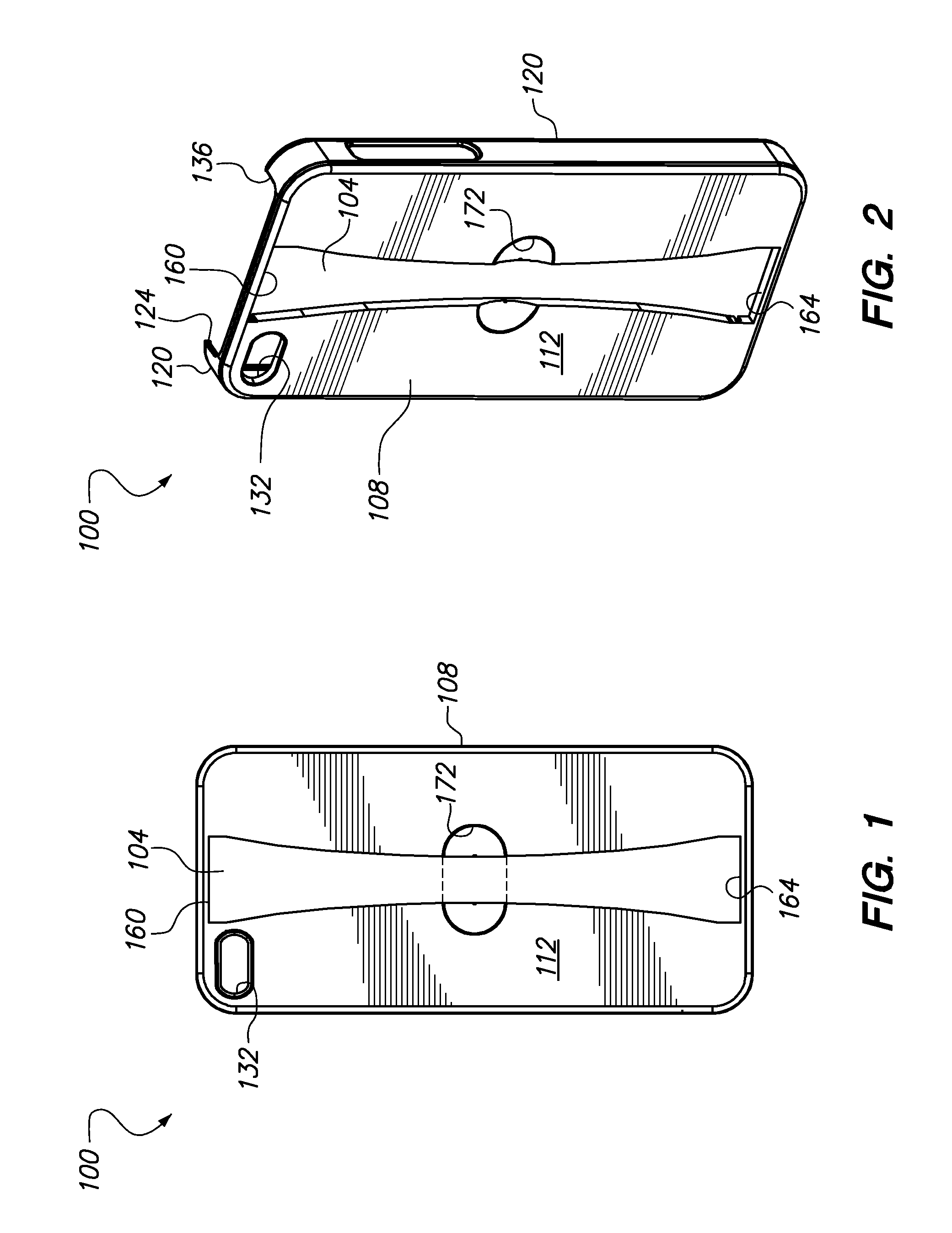

Device case with strap

InactiveUS20140152034A1Solving the Insufficiency of ElasticityTravelling carriersHoldersRest positionEngineering

A case for a portable electronic device includes a base plate, a device securing mechanism operable to hold the electronic device adjacent to the base plate, and a stretchable strap connected to the base plate. The strap is biased toward a rest position, wherein the strap lies substantially flush with the base plate. The strap is configured to be stretchable between the rest position and a stretched position away from the back of the base plate to allow a user's hand or other item to be placed between the strap and the case.

Owner:TUSSY KEVIN ALAN

Workpiece gripping device

Owner:FANUC LTD

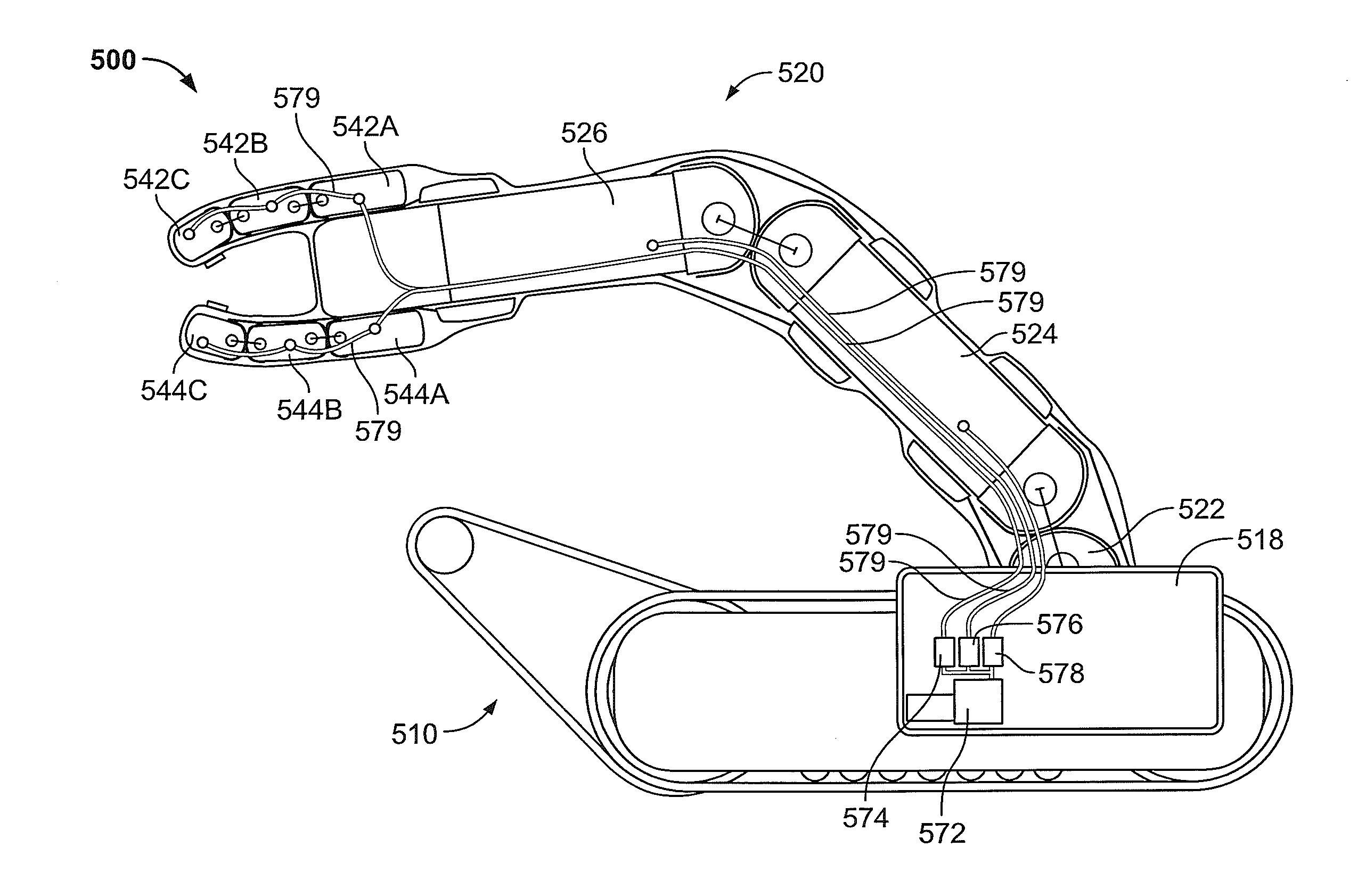

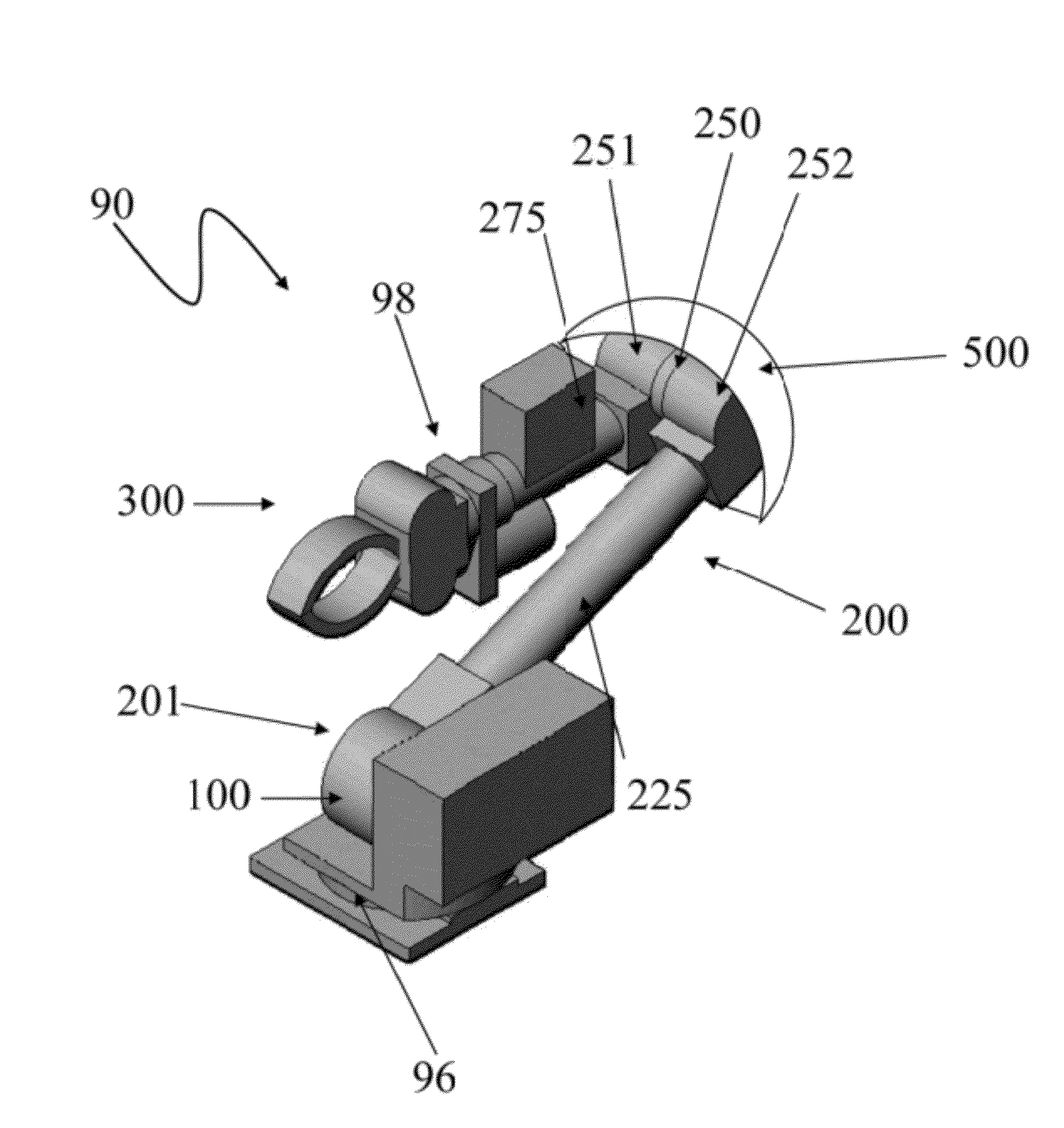

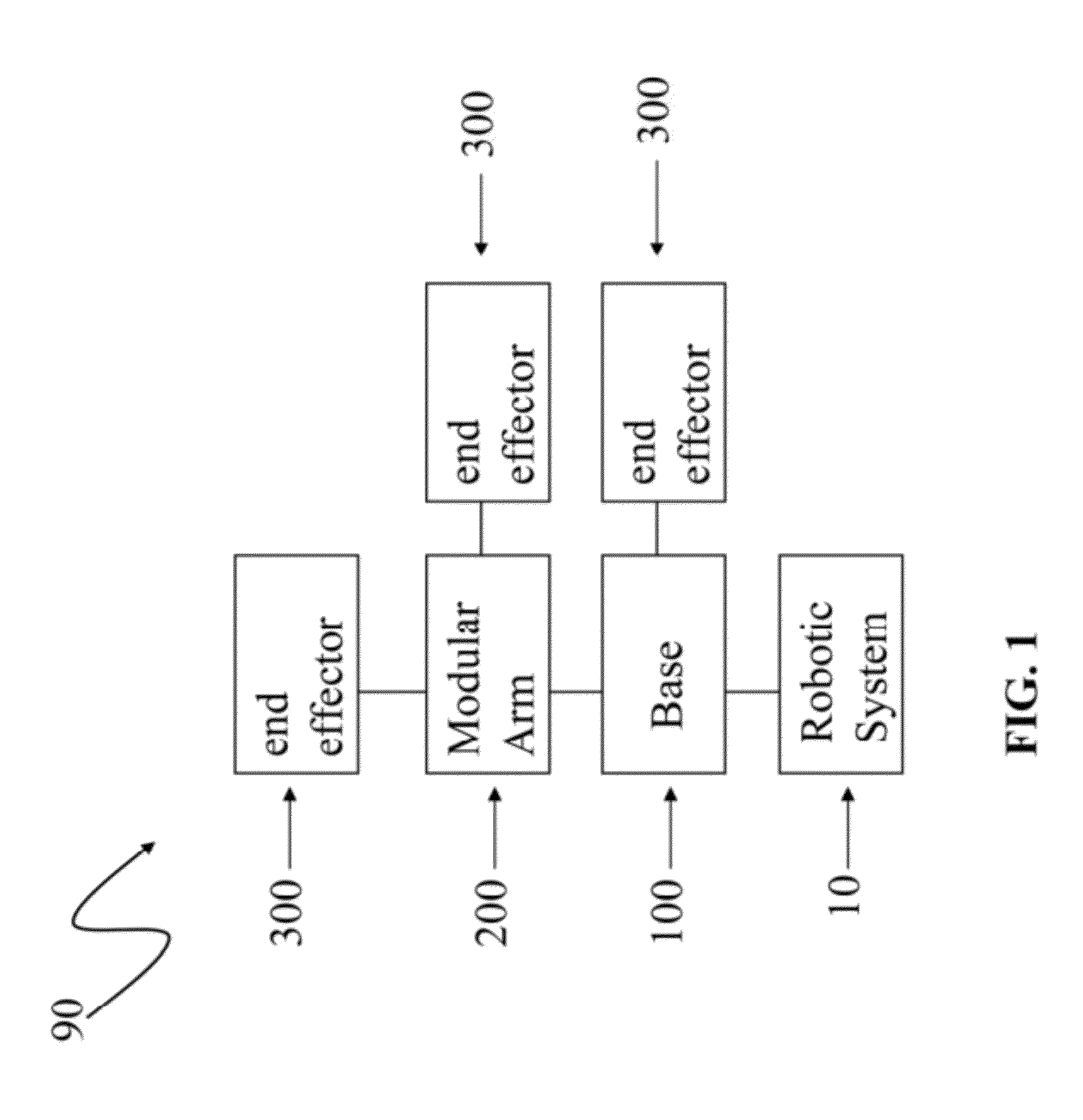

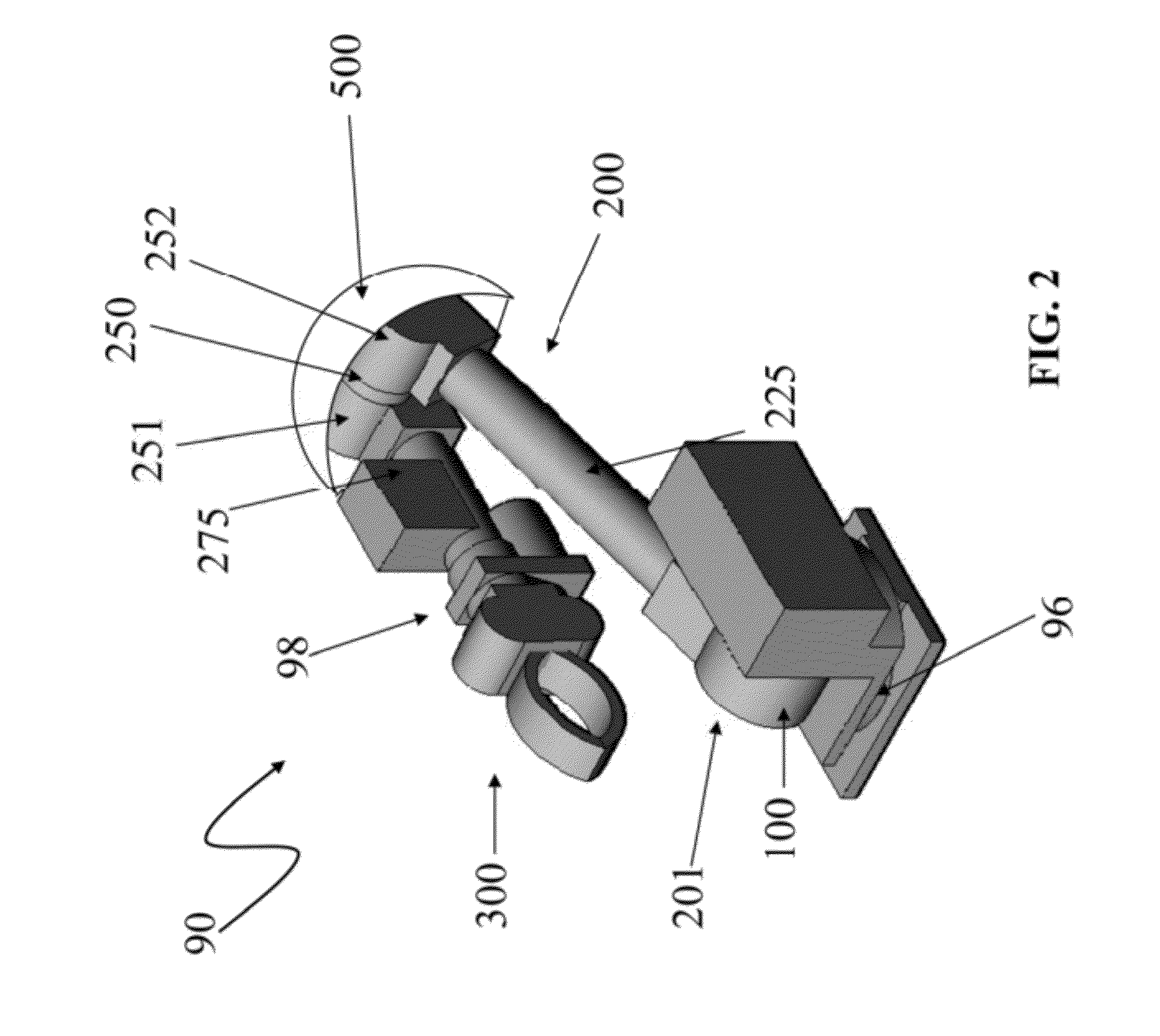

Robotic arm system

InactiveUS20120215358A1Programme-controlled manipulatorMechanical apparatusRobotic systemsRobotic arm

A robotic arm for use with a robotic system and methods for making and using the same are described. The arm can have multiple joints and can have one or more articulating end effectors. The arm and end effectors can have safety releases to prevent over-rotation. The arm can have individual cooling.

Owner:ROBOTEX

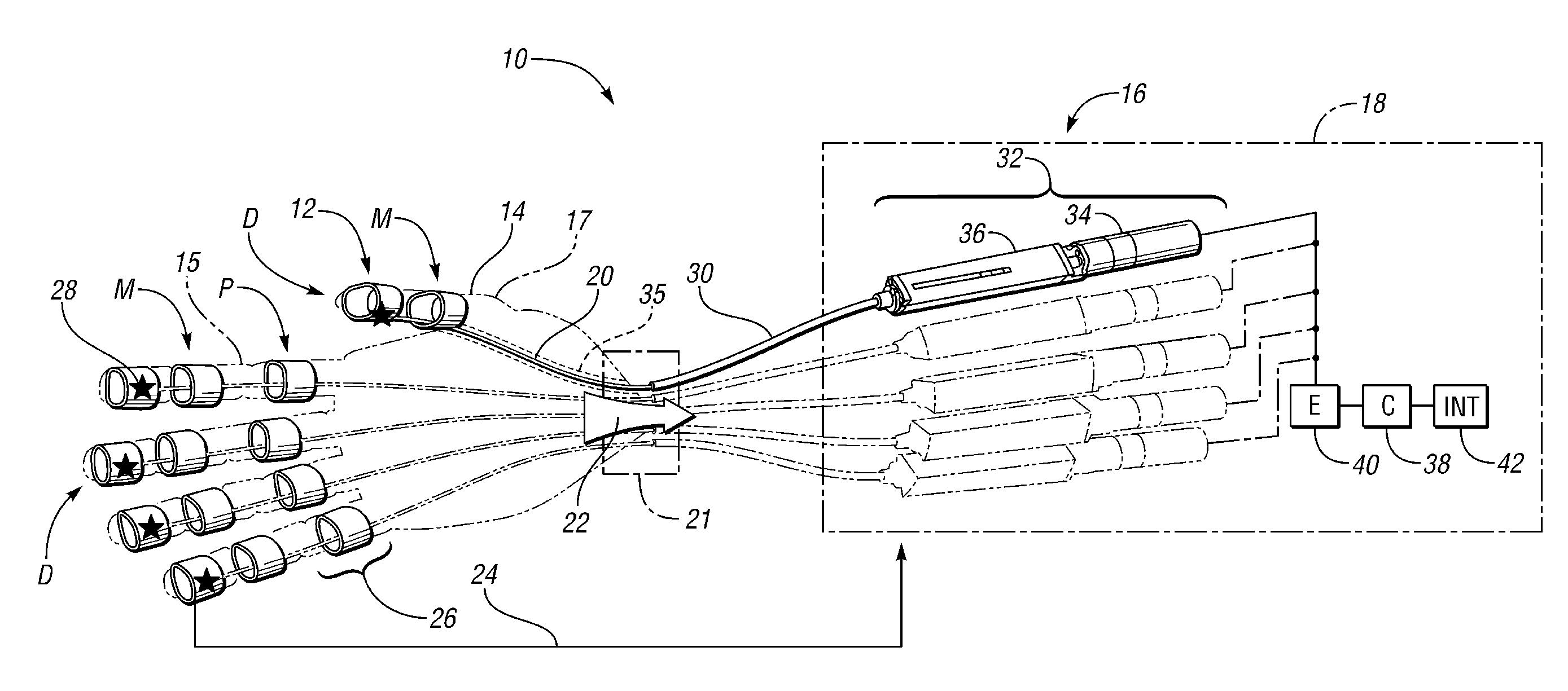

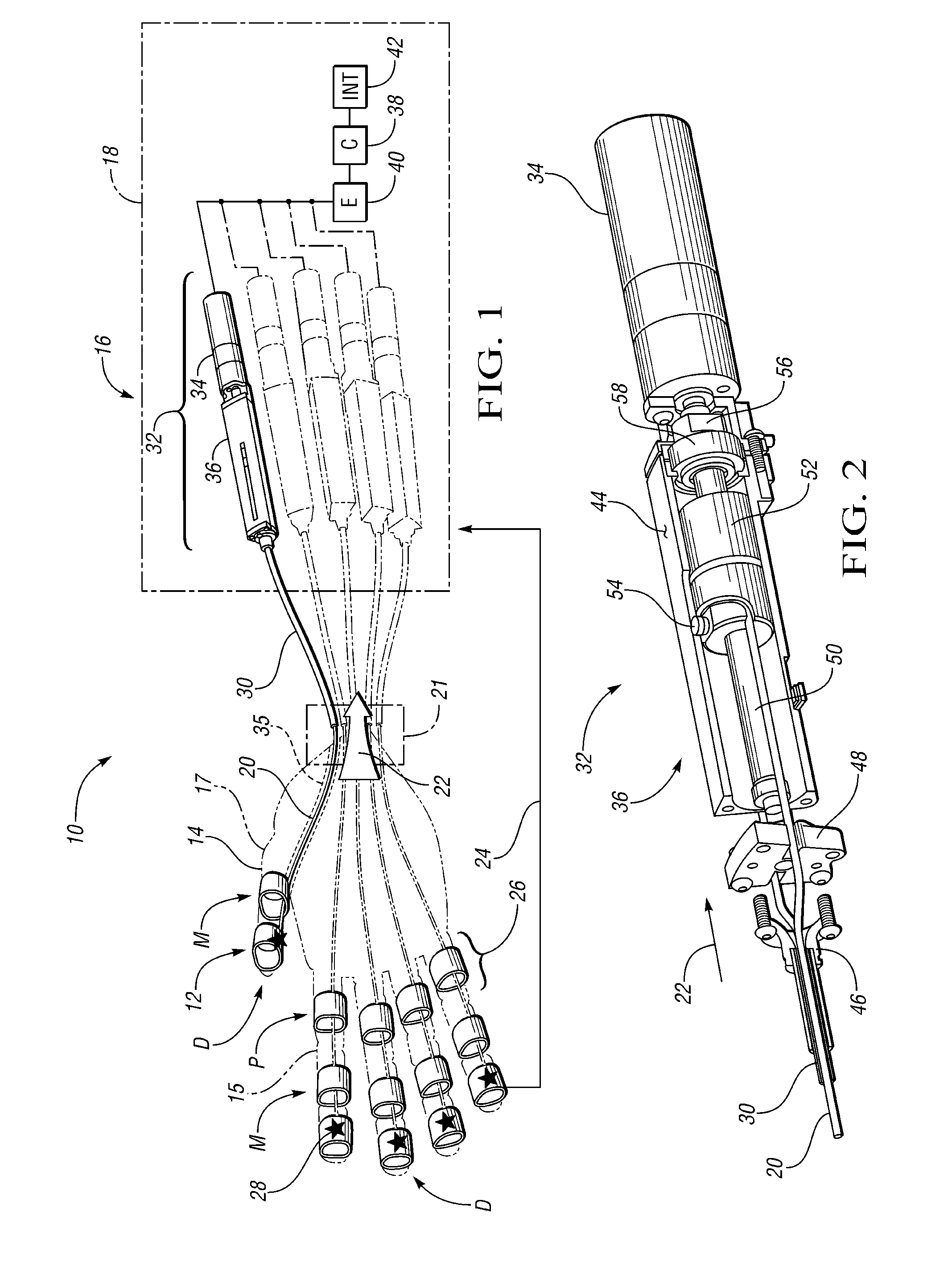

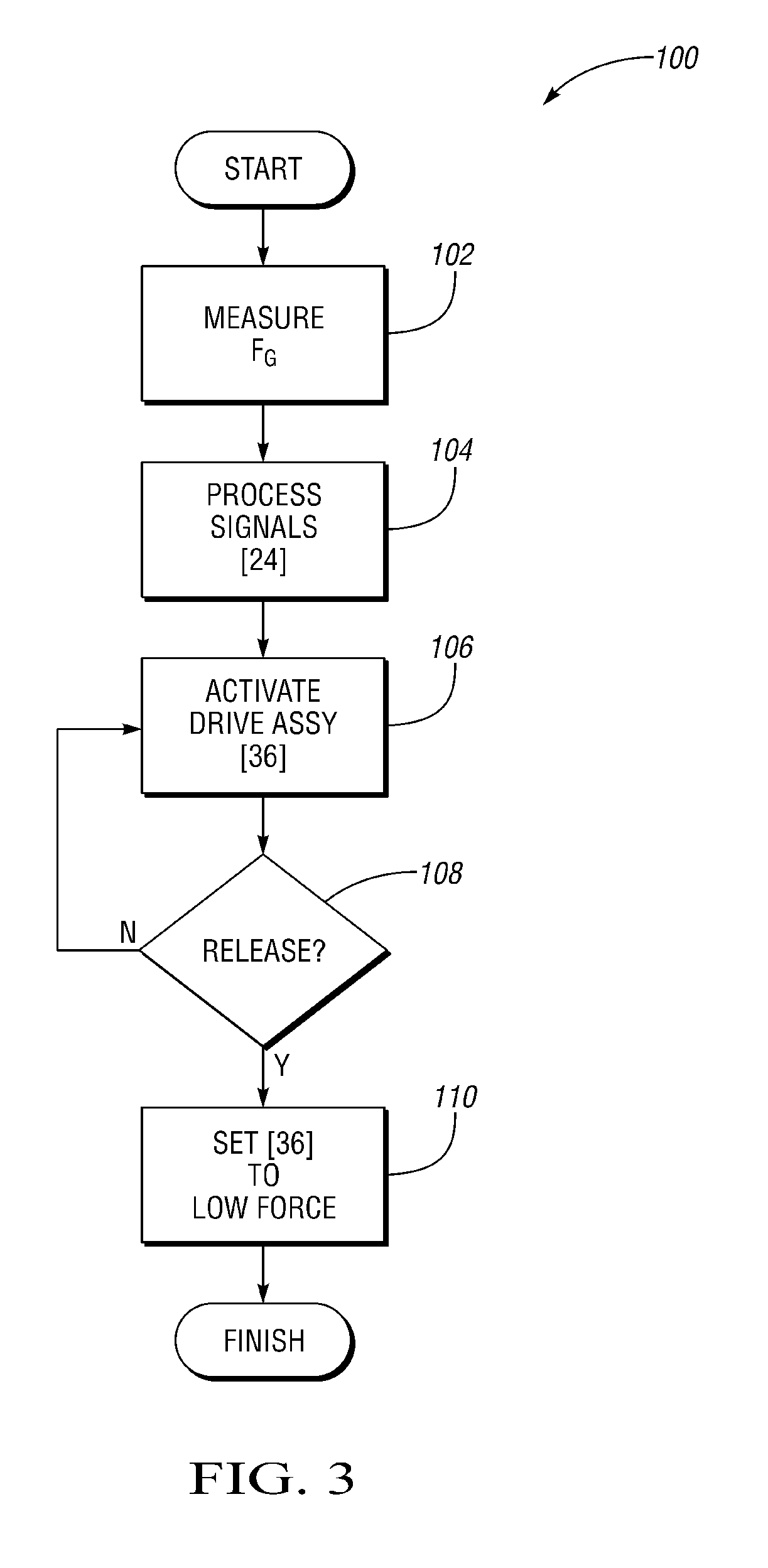

Human grasp assist device and method of use

ActiveUS20110071664A1Improve abilitiesConvenient amountProgramme-controlled manipulatorDigital data processing detailsMicrocontrollerEngineering

A grasp assist device includes a glove portion having phalange rings, contact sensors for measuring a grasping force applied by an operator wearing the glove portion, and a tendon drive system (TDS). The device has flexible tendons connected to the phalange rings for moving the rings in response to feedback signals from the sensors. The TDS is connected to each of the tendons, and applies an augmenting tensile force thereto via a microcontroller adapted for determining the augmenting tensile force as a function of the grasping force. A method of augmenting a grasping force of an operator includes measuring the grasping force using the sensors, encoding the grasping force as the feedback signals, and calculating the augmenting tensile force as a function of the feedback signals using the microcontroller. The method includes energizing at least one actuator of a tendon drive system (TDS) to thereby apply the augmenting tensile force.

Owner:NASA +1

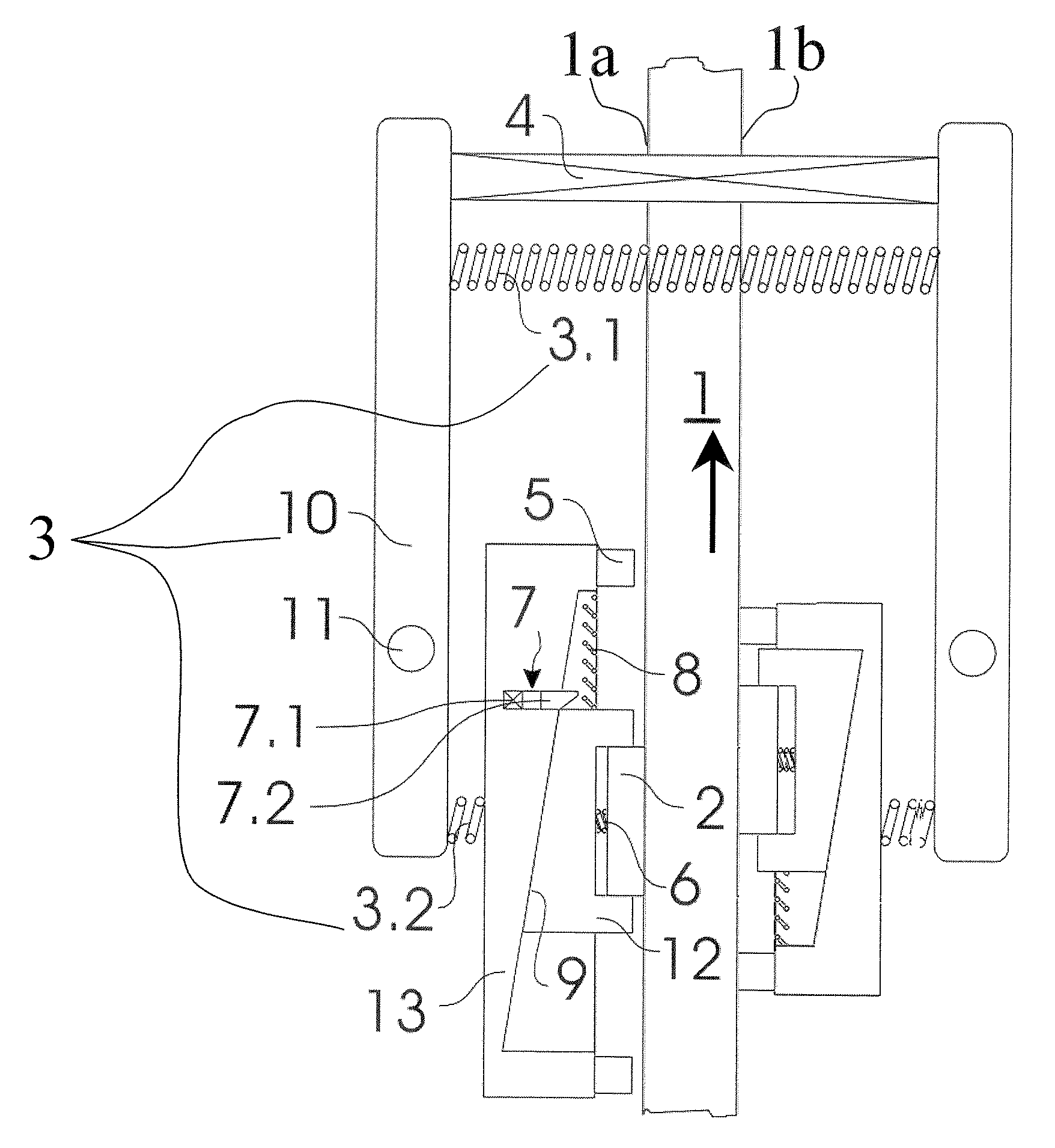

Brake equipment for holding and braking an elevator car in an elevator installation and a method of holding and braking an elevator installation

Brake equipment for holding and braking an elevator car in an elevator installation, which is arranged to be movable along a brake track in two directions of travel, includes a mount with a brake lining which automatically adjusts under friction couple with the brake track on movement of the elevator car relative to the rail and in that case tightens a first tightening means, which can be released by an actuator. The first tightening means tightens the mount together with the brake lining against the brake track by a biasing force. The brake equipment produces, with unmoved brake equipment and an unreleased state of the actuator, a holding force acting in both directions of travel. The holding force is determined substantially by the biasing force acting on the mount.

Owner:INVENTIO AG

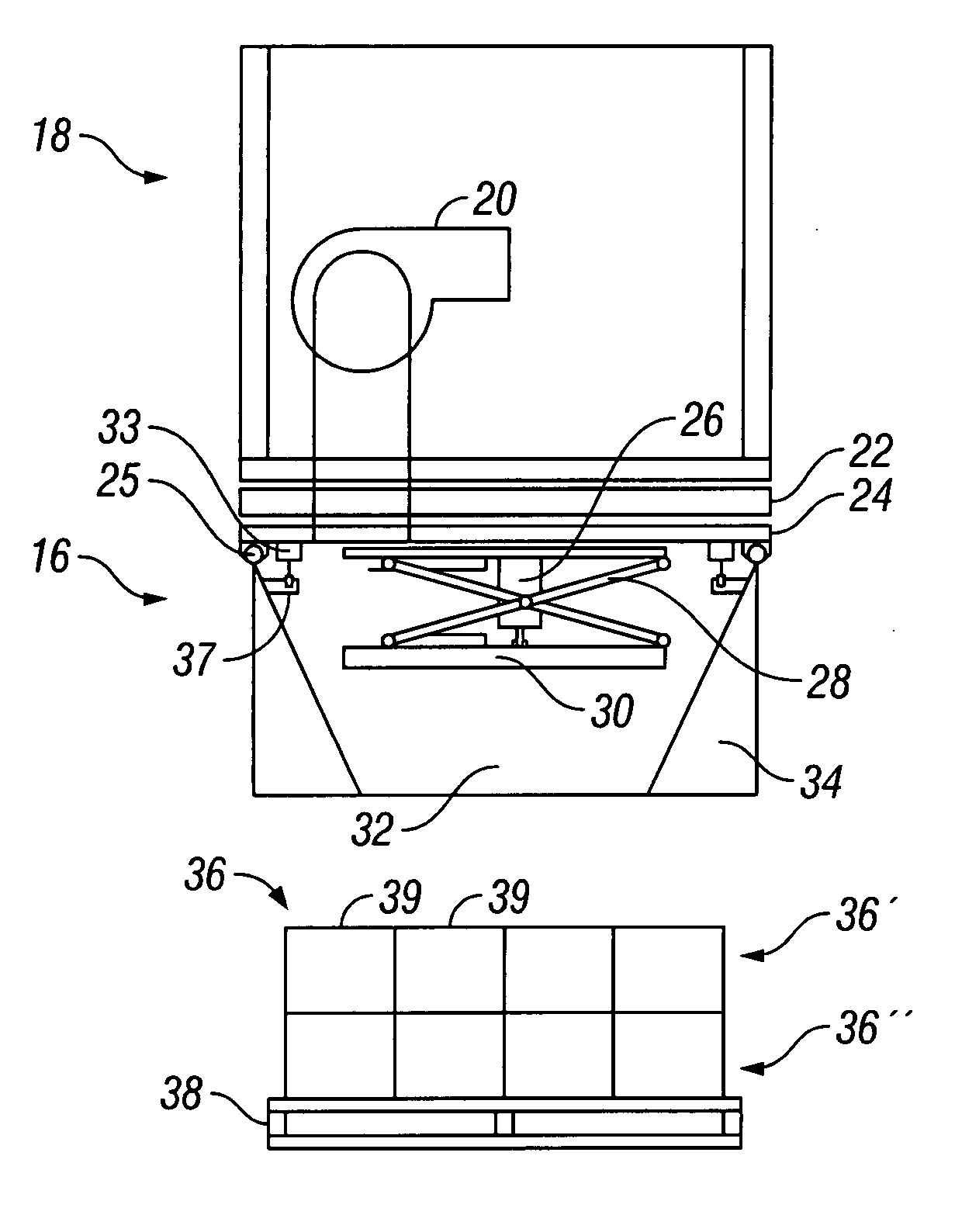

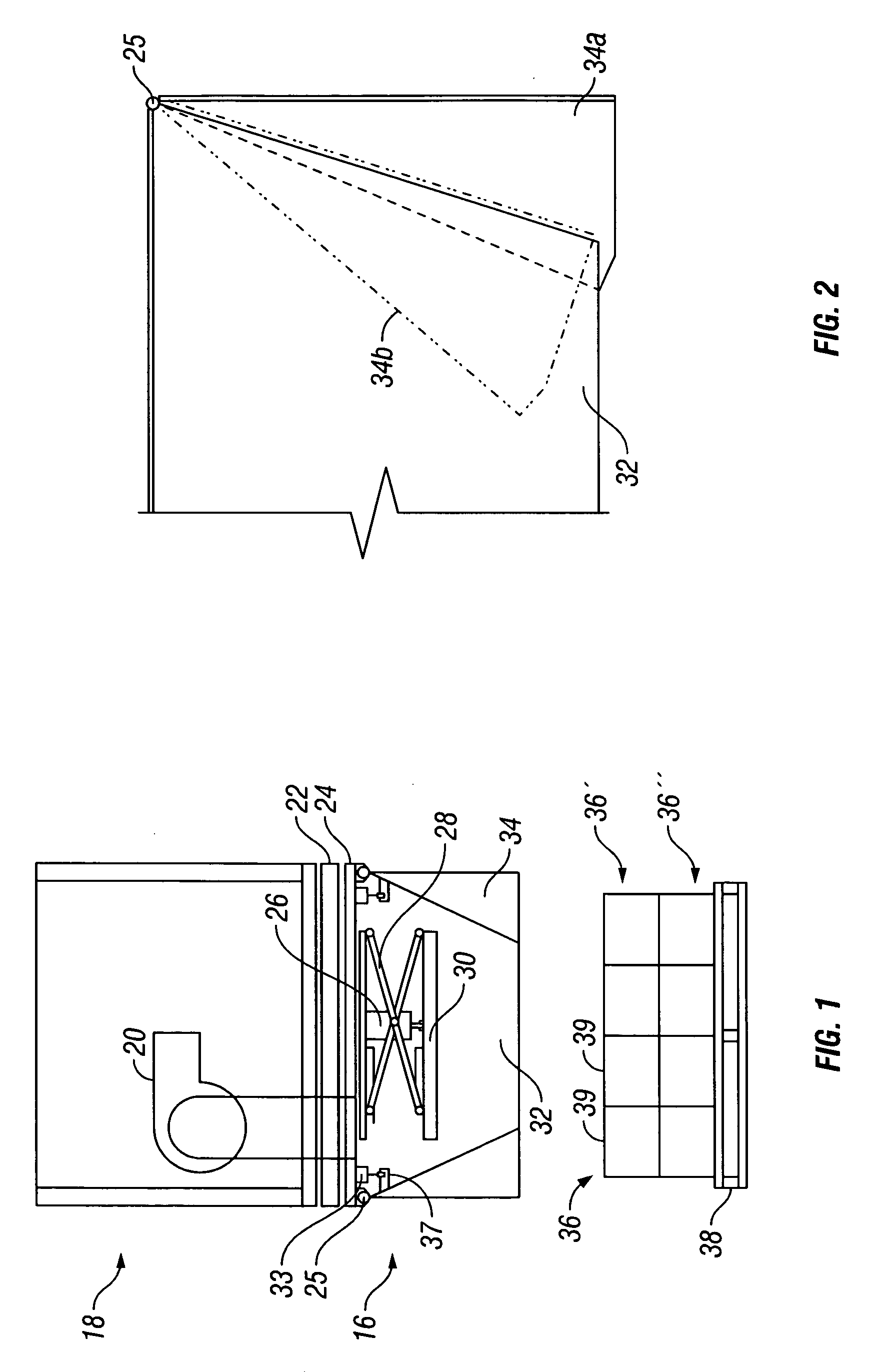

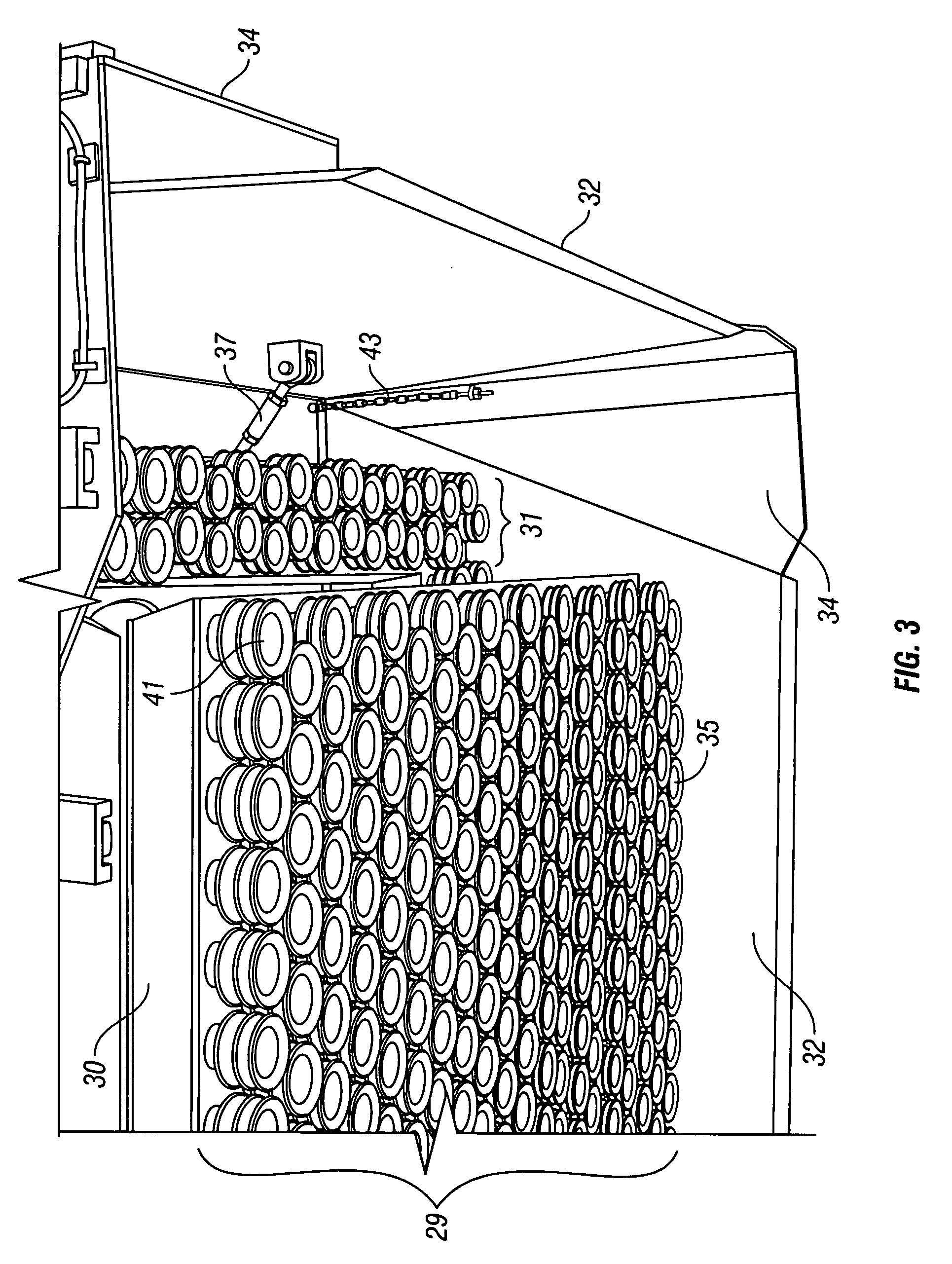

Layer picking end effector system, apparatus and method

A system, method and apparatus for handling and moving a layer of articles, such as cased products. The system and apparatus comprise a hood enclosure having four side panels, and four interconnected corner member. The side walls and corner members interoperate to form an adjustable enclosure to pick the layer of articles. A vacuum generate is utilized to evacuate air from the hood enclosure to assist in lifting the layer of articles. The hood enclosure may utilize an array of vacuum cups to assist in the lifting of articles into the hood enclosure. The method is directed towards utilizing the hood layer end effector to move and hand articles.

Owner:SAGE AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com