Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2462results about "Pliers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

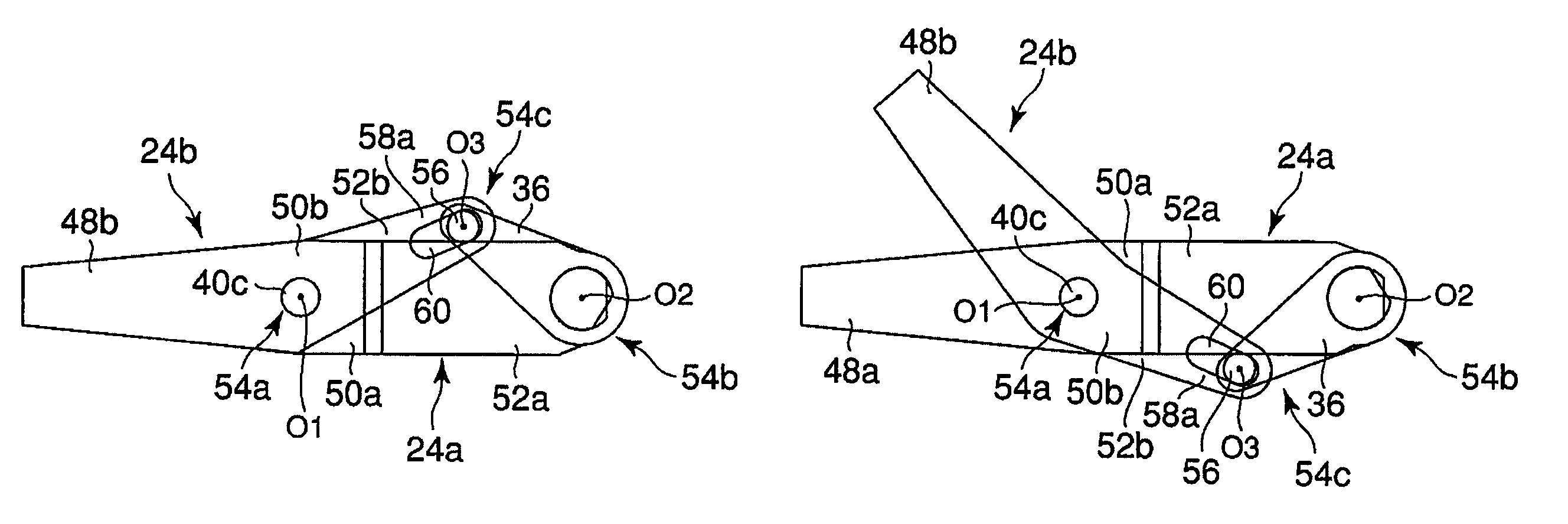

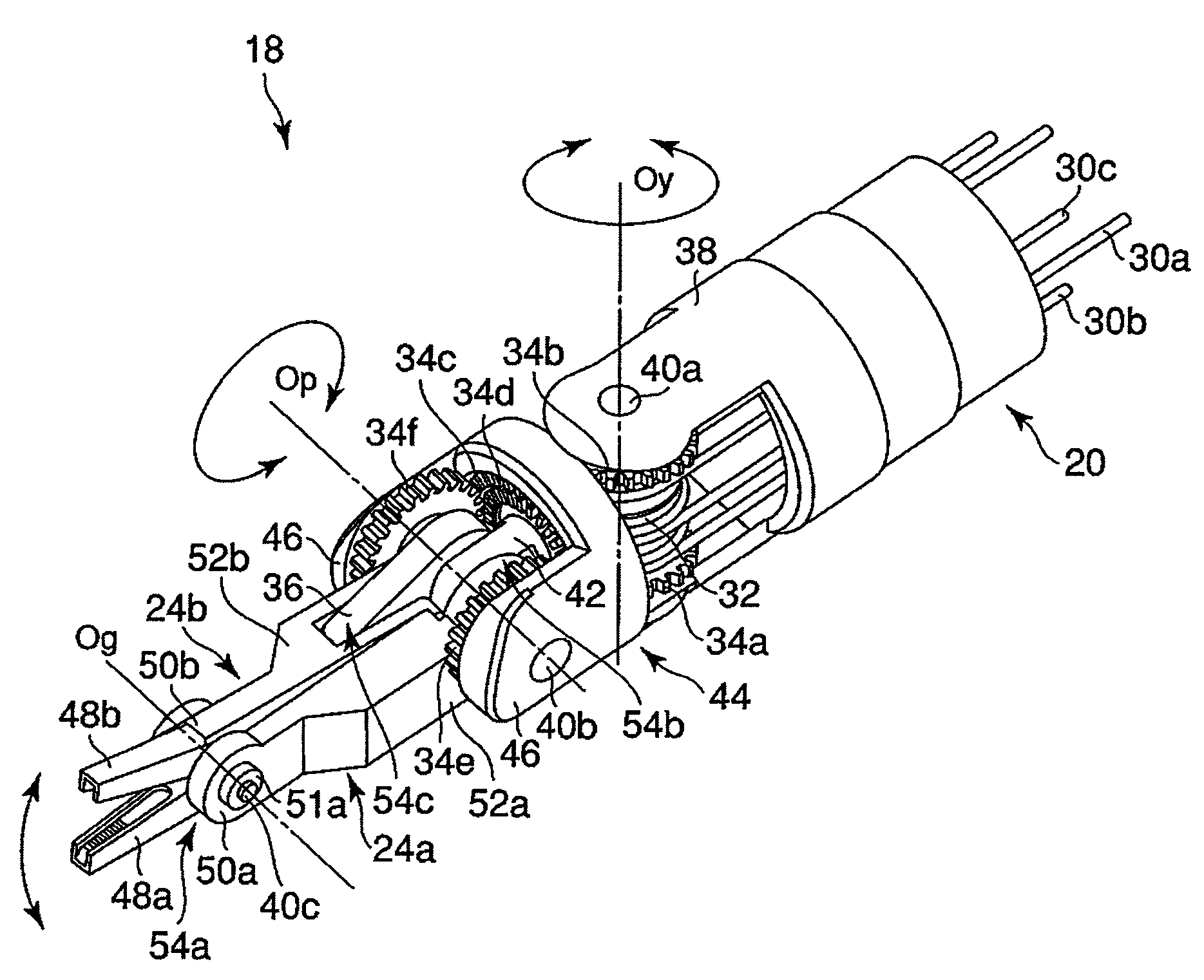

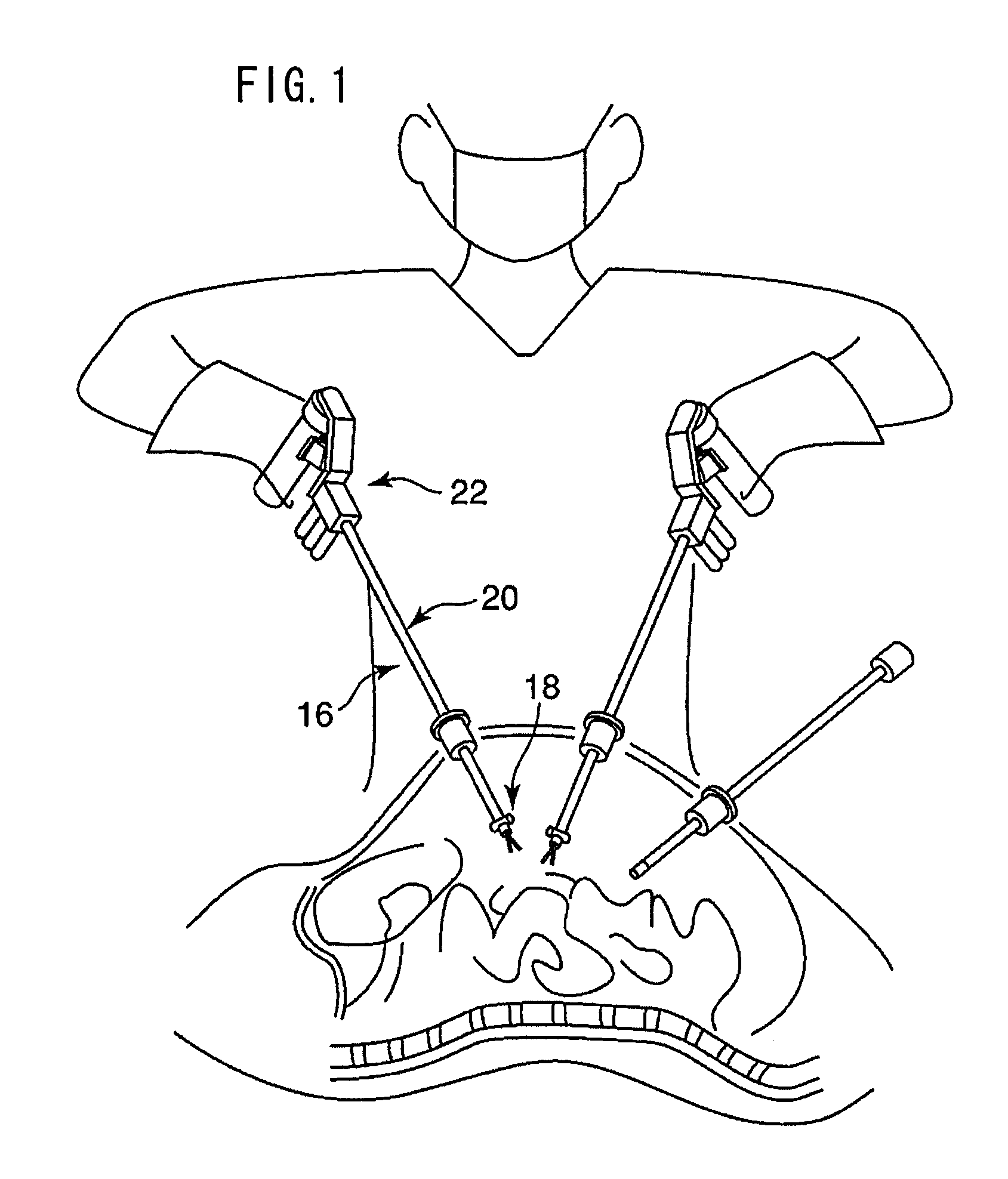

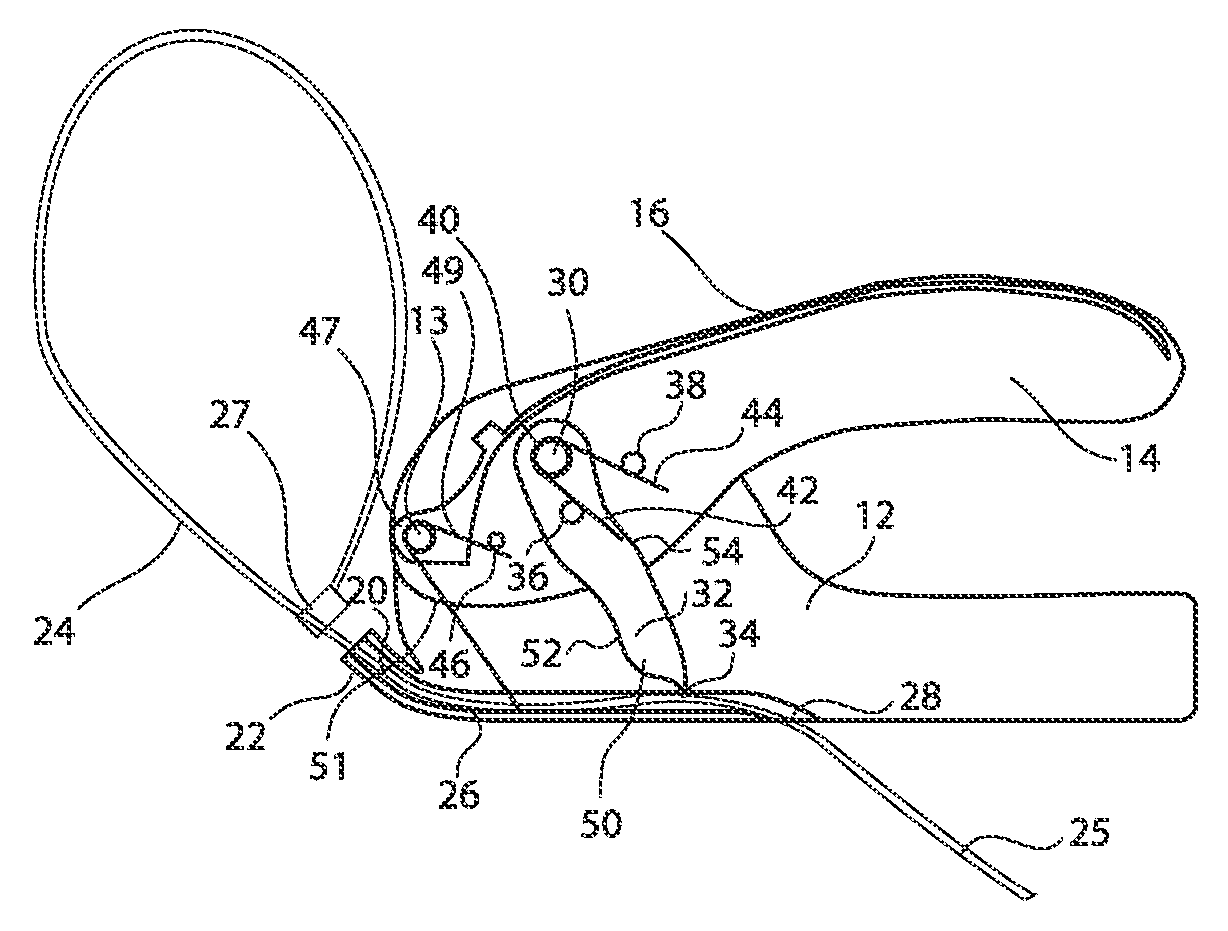

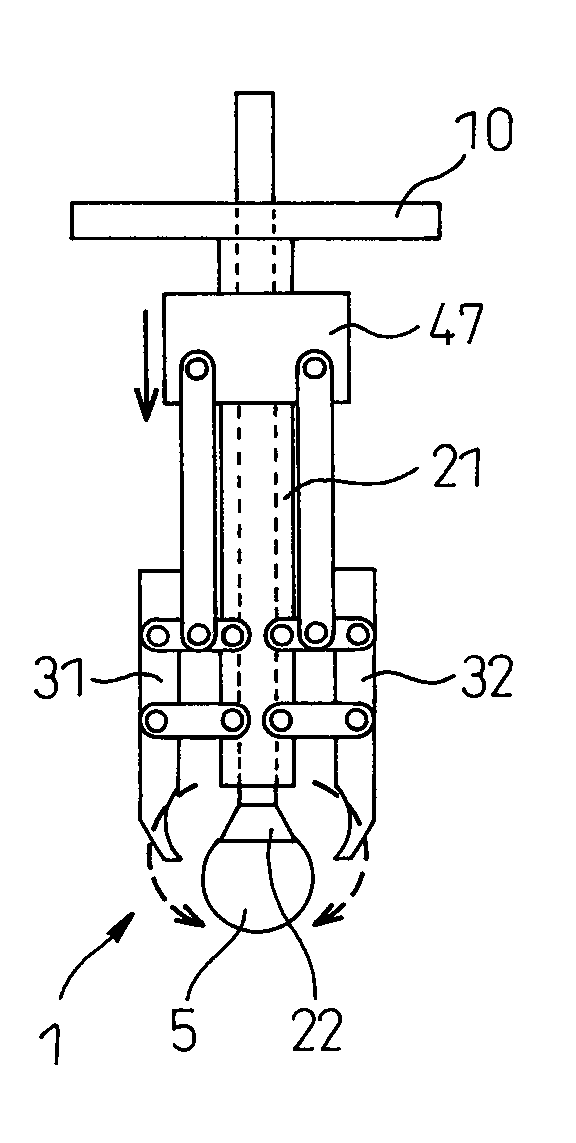

Manipulator

A manipulator has a working unit in which when at least a first end effector finger and a second end effector finger are maximally closed on each other, at least the distance between a third joint axis and a first joint axis is greater than the distance between the first joint axis and a distal end of the second end effector finger, or the distance between the third joint axis and the first joint axis is greater than the distance between third joint axis and a second joint axis, or the angle formed between a direction from the third joint axis to the first joint axis and a direction from the third joint axis to the second joint axis is not π.

Owner:KARL STORZ GMBH & CO KG

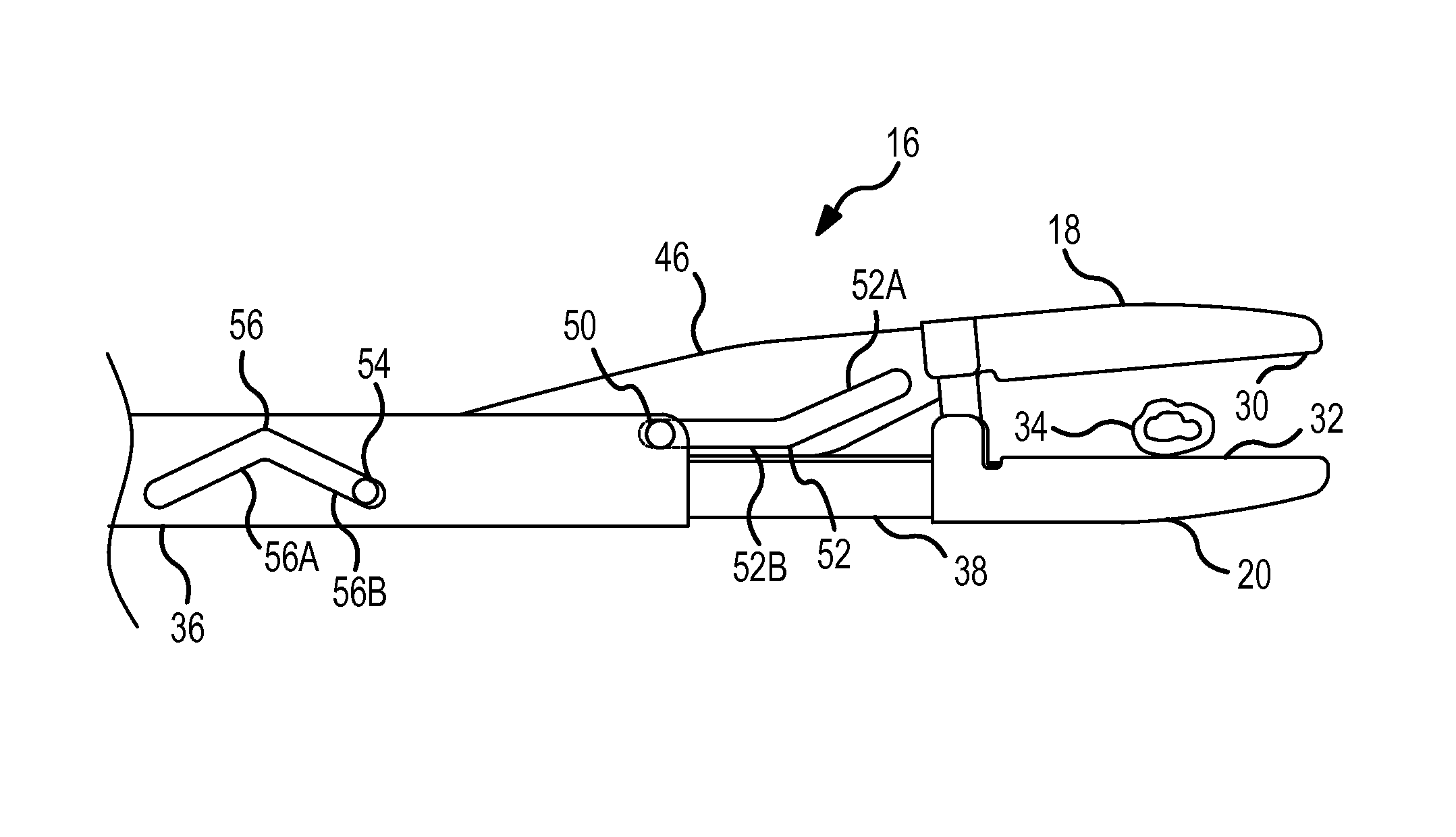

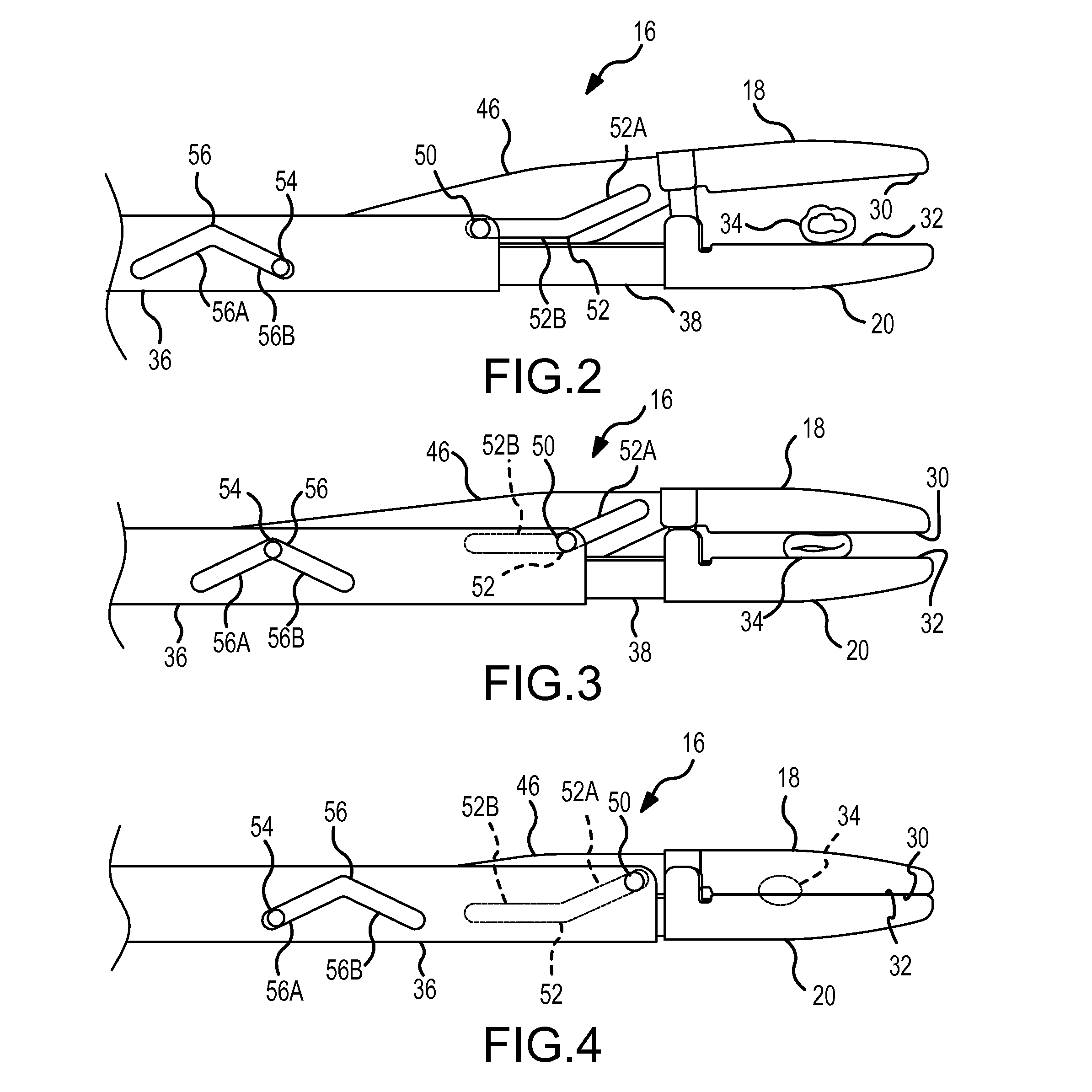

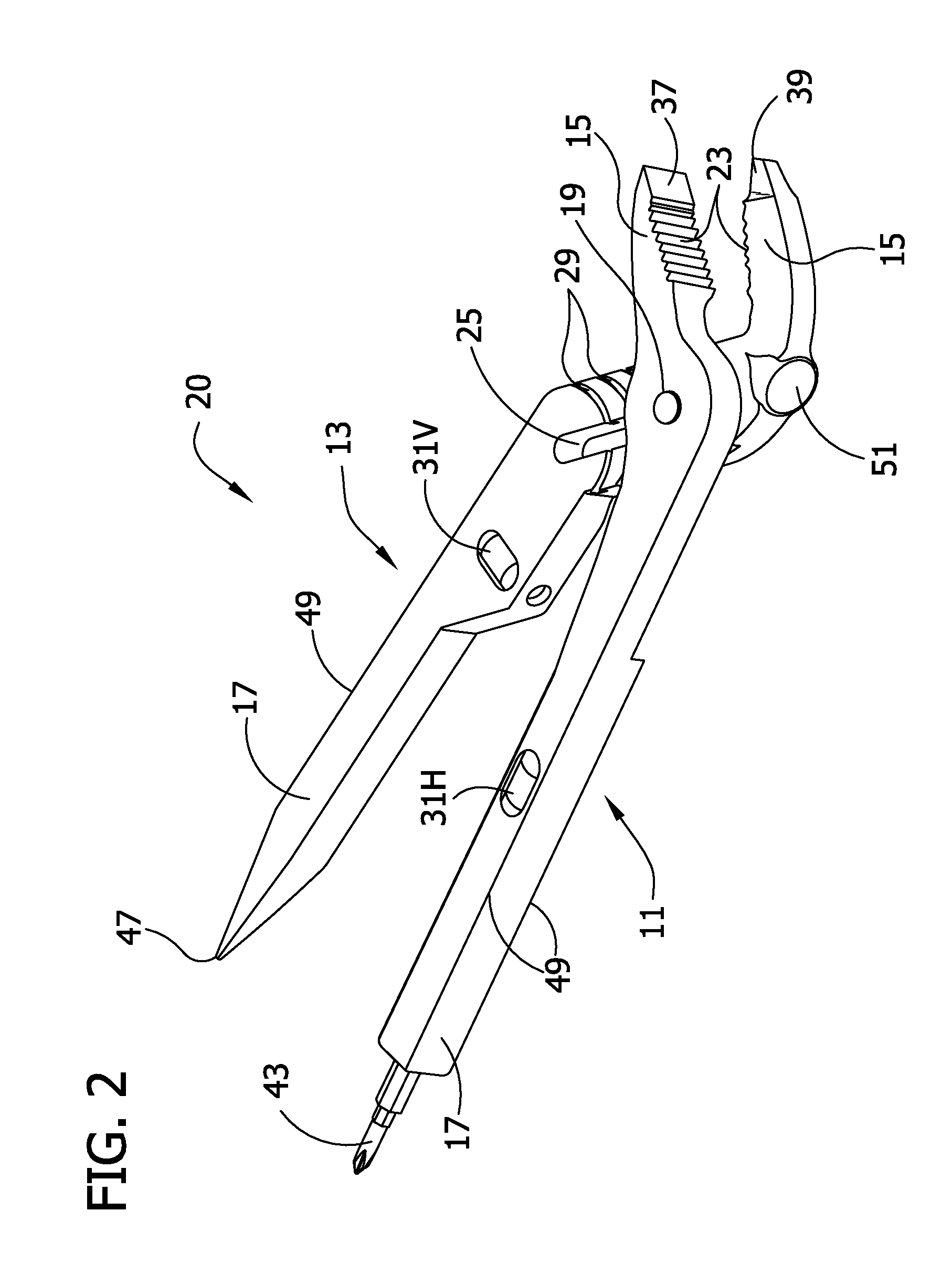

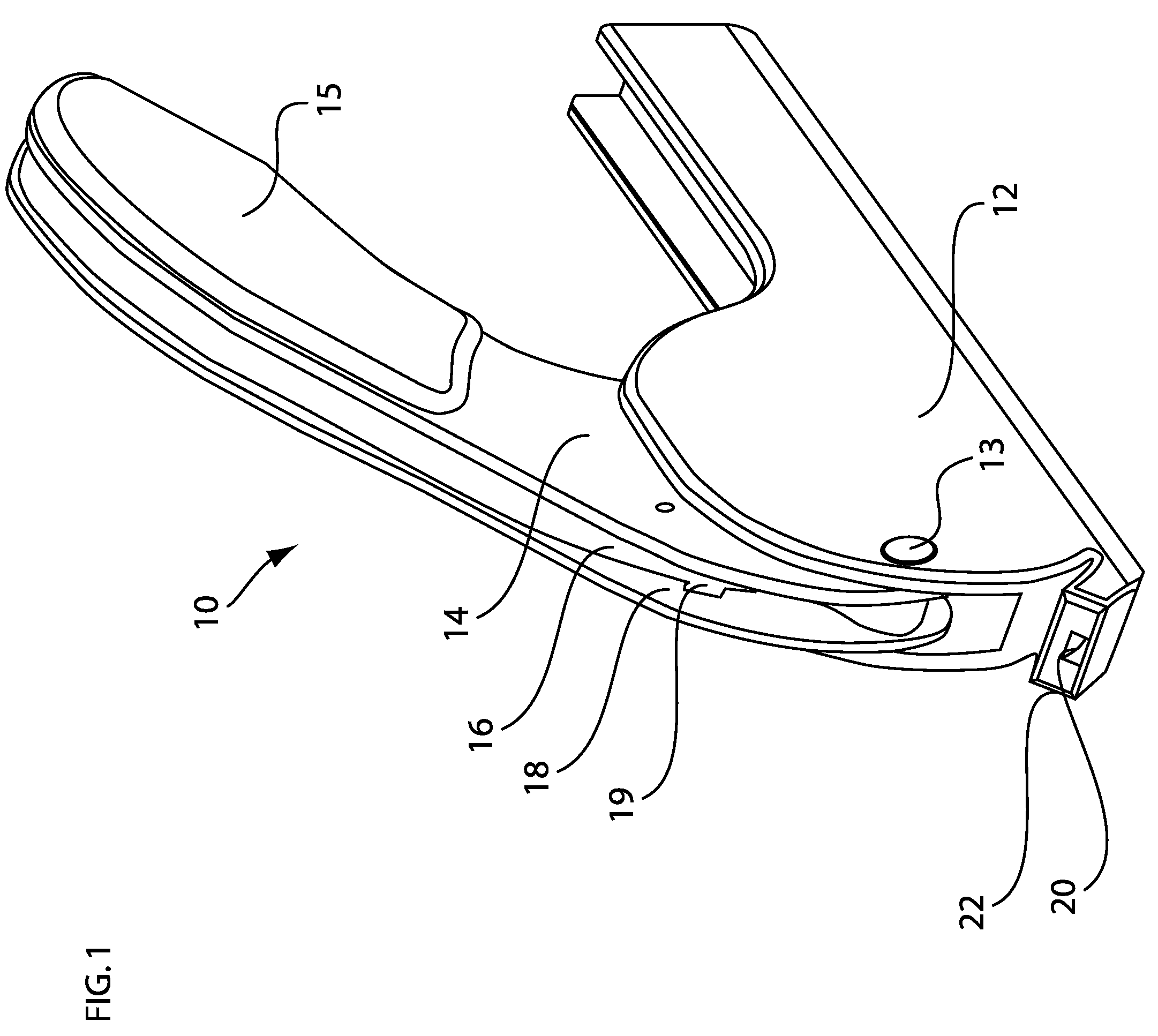

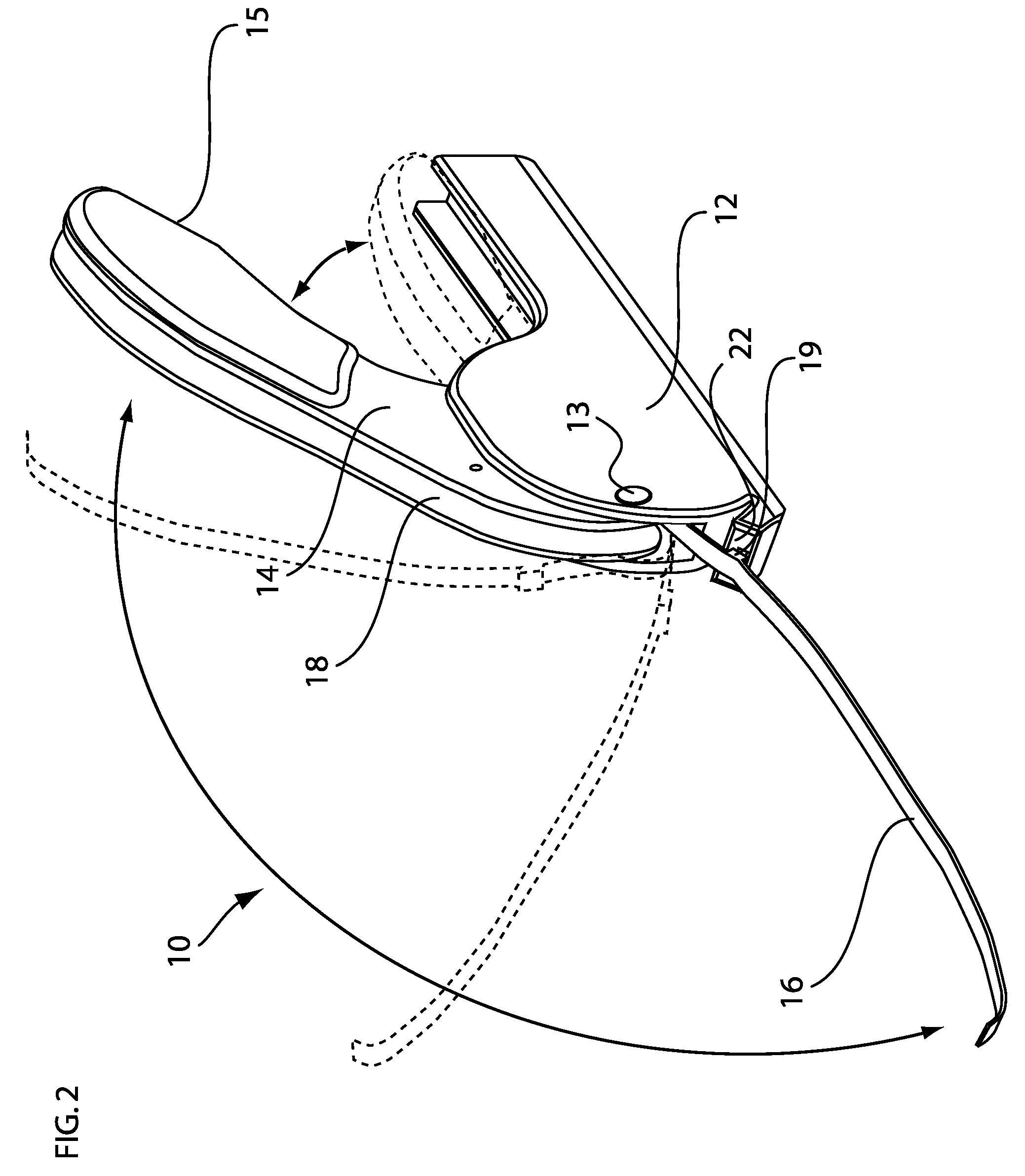

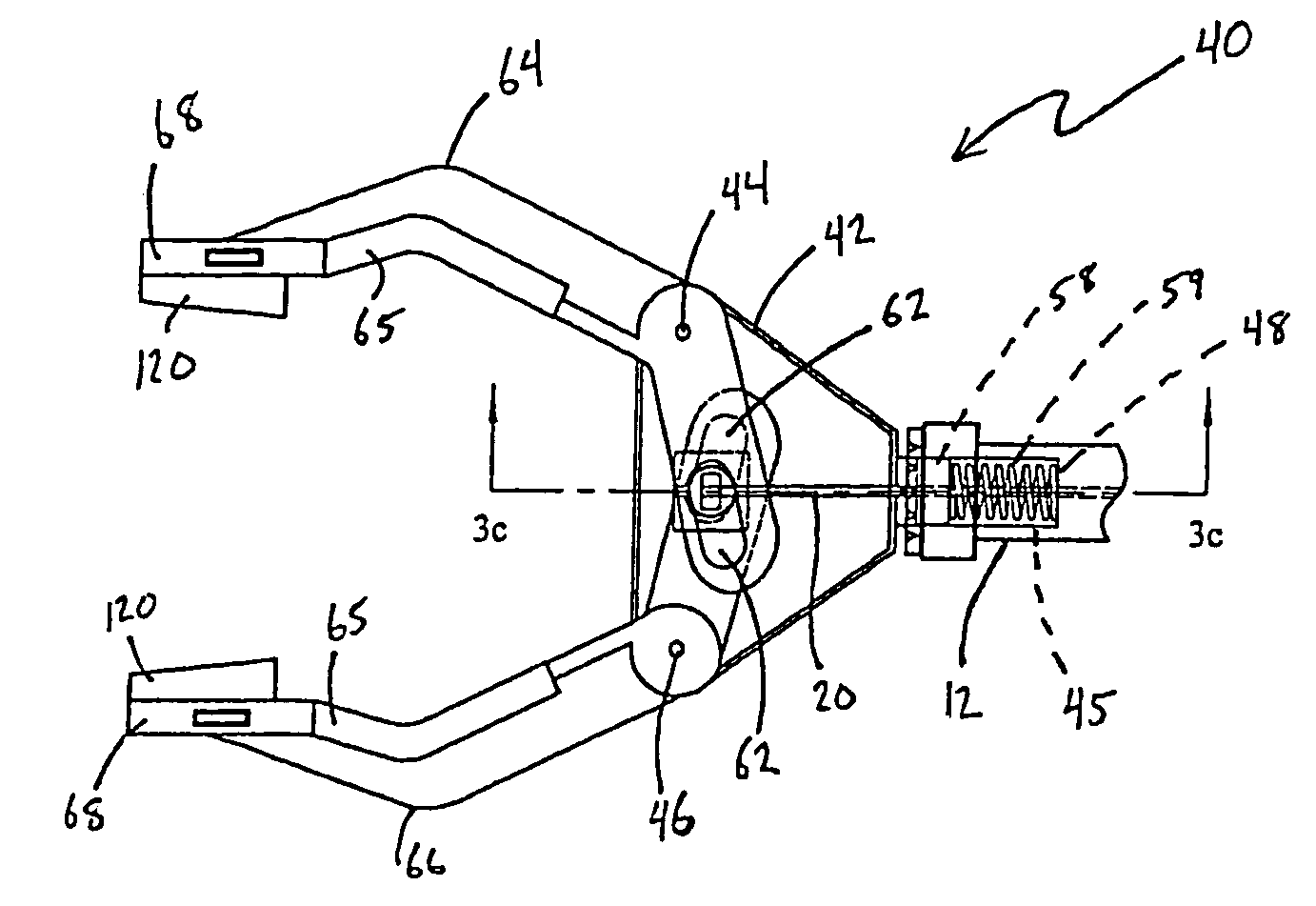

Jaw movement mechanism and method for a surgical tool

ActiveUS8663270B2Reduce the amount requiredEnhances mechanical force transferring capability and efficiencyPliersSurgical instrument detailsEngineeringJaw movement

A jaw movement mechanism for surgical tools has improved mechanical efficiency and other advantages. The jaw movement mechanism controls the orientation and position of a movable jaw relative to a fixed jaw through a range of movement of the movable jaw. The jaws maintain a parallel orientation throughout a portion of the range of movement of the movable jaw. The jaws maintain an angular relationship throughout a portion of the range of movement of the movable jaw.

Owner:CONMED CORP

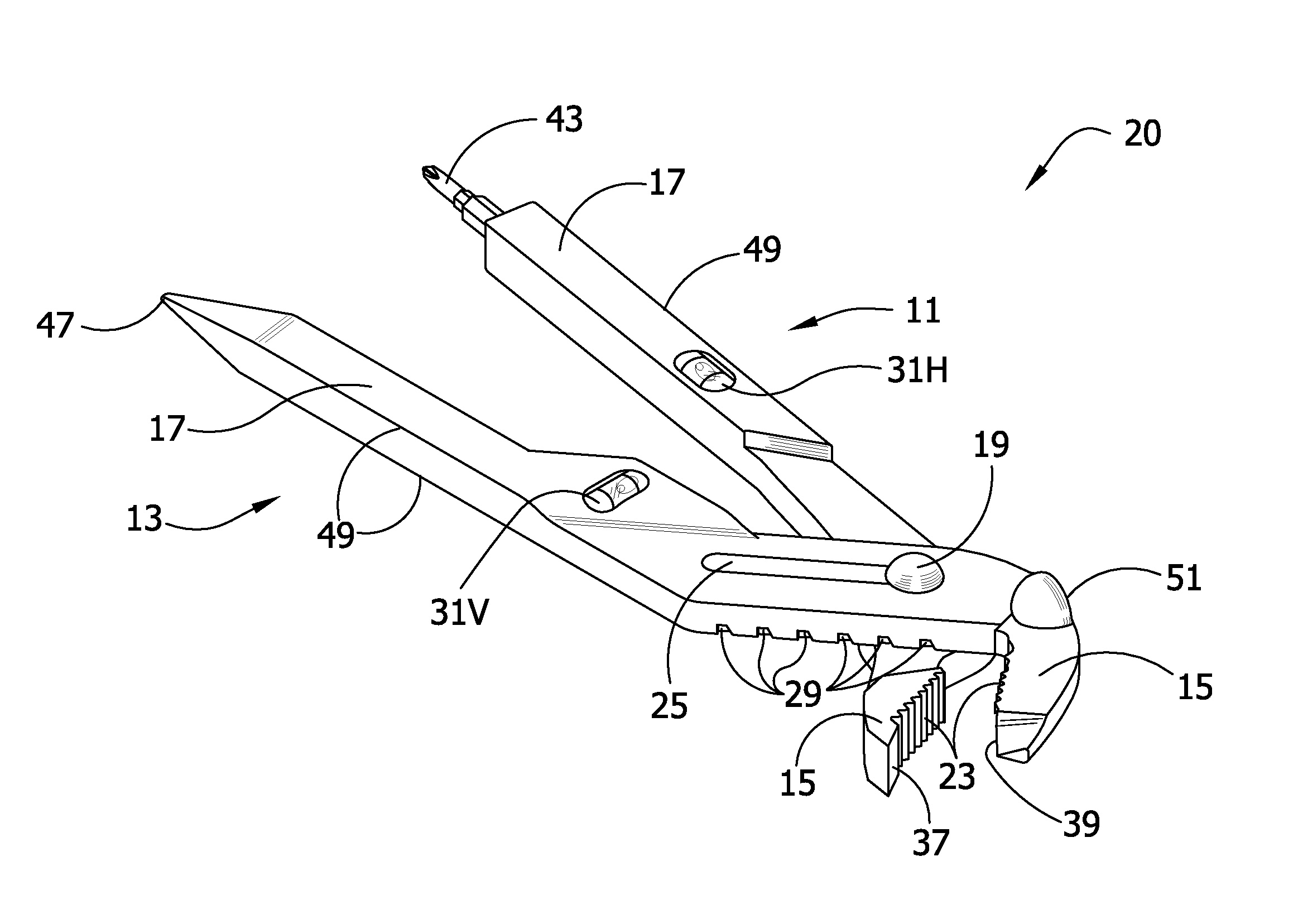

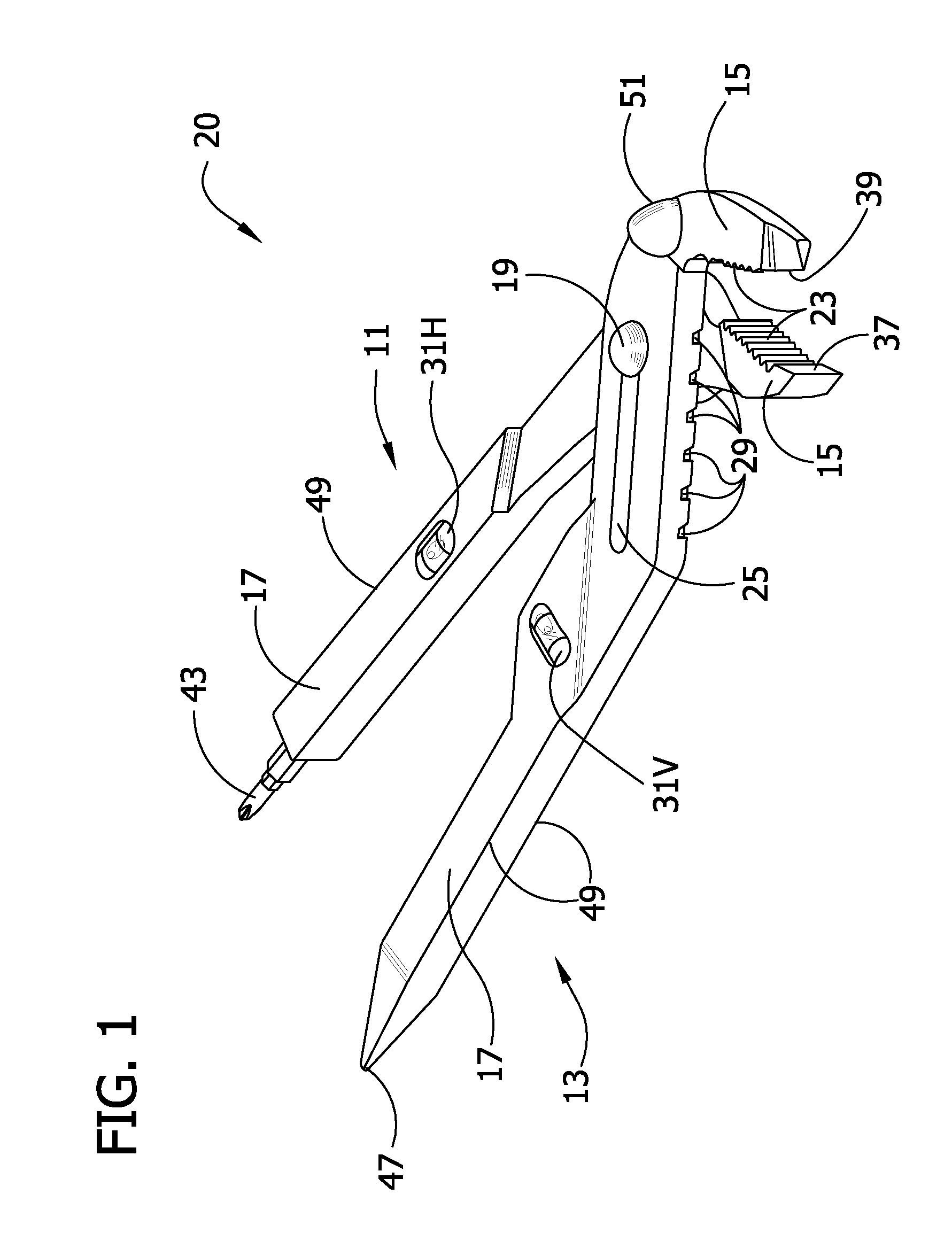

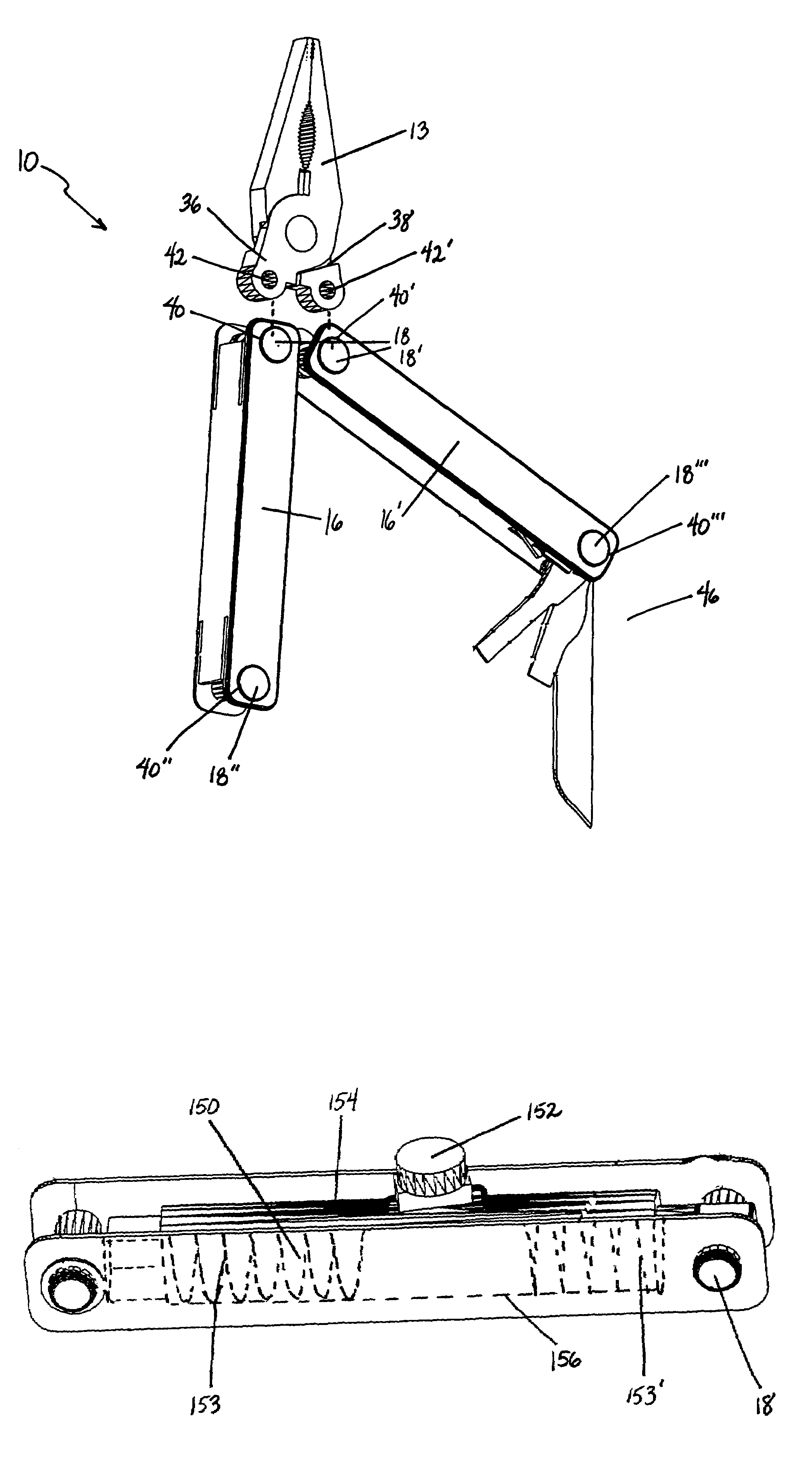

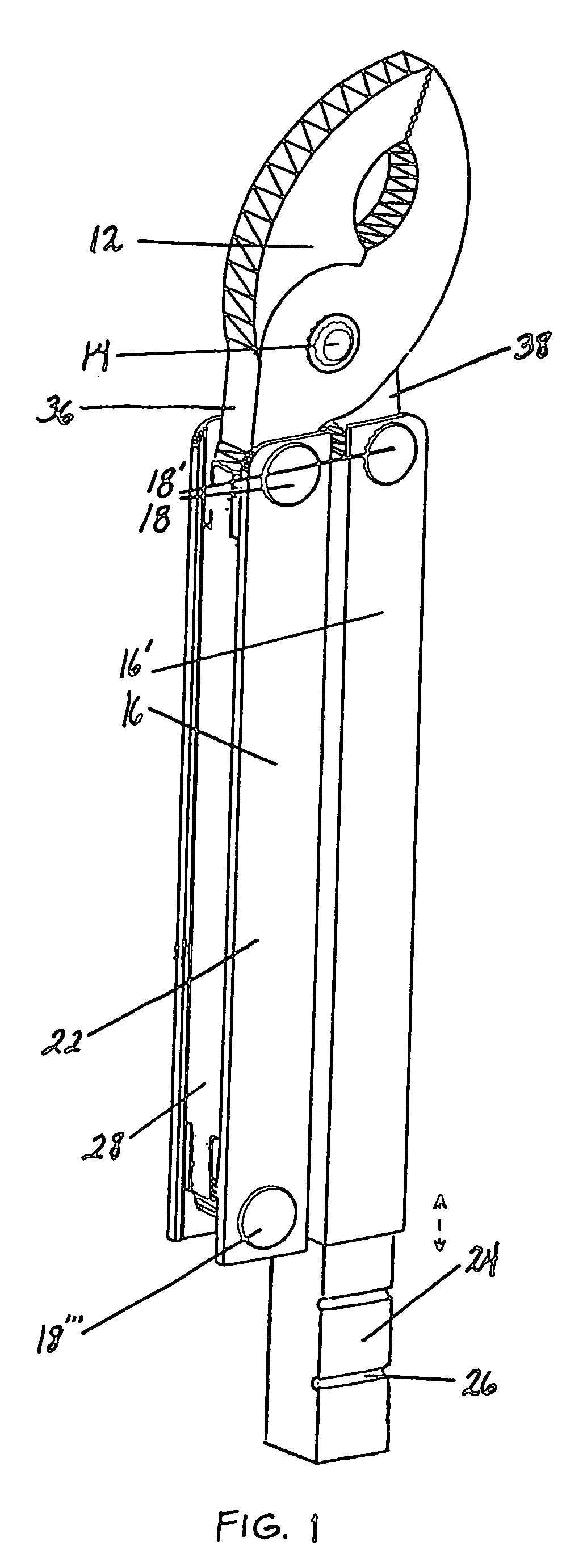

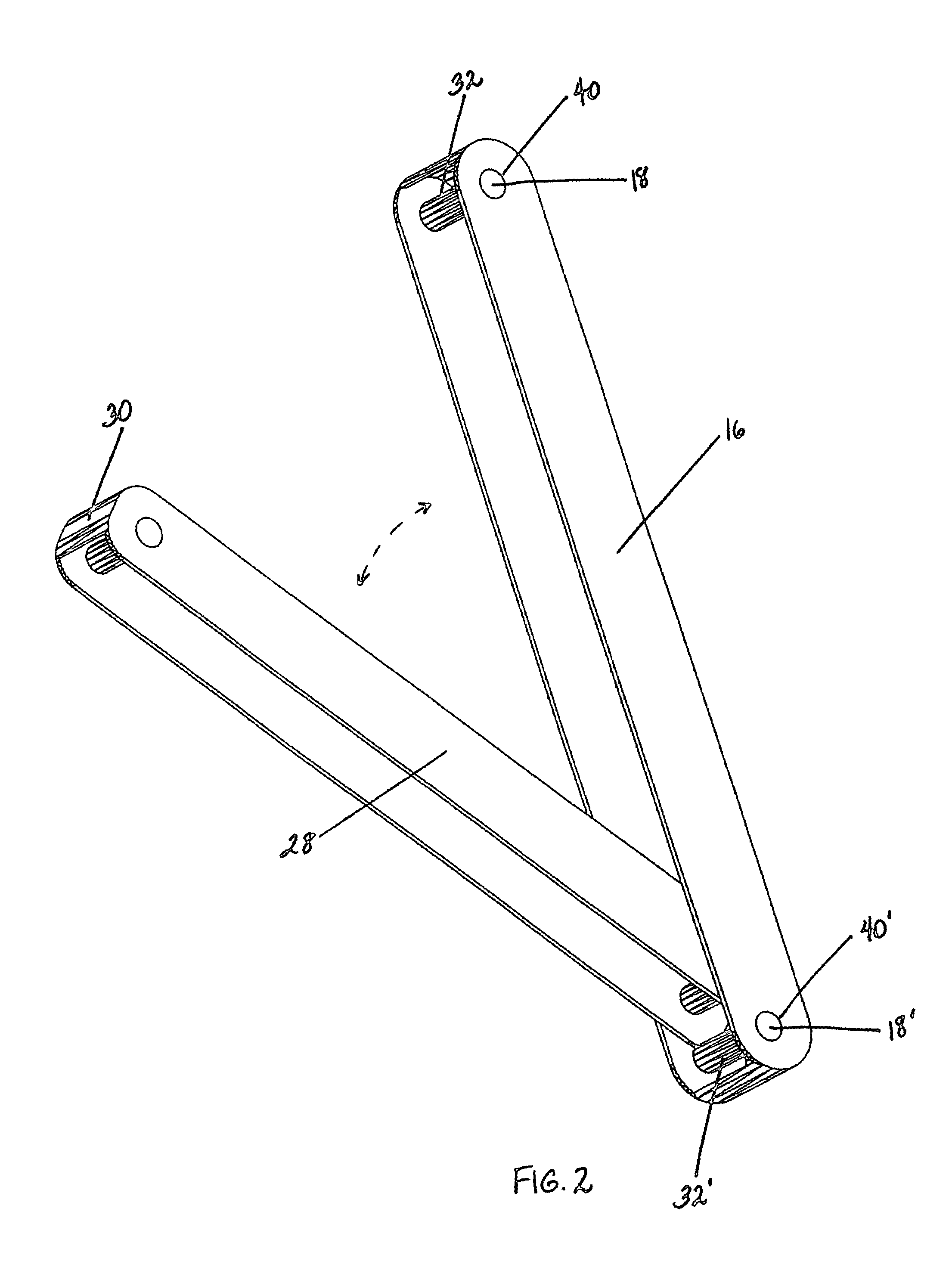

Multipurpose gripping tool

A multipurpose tool for gripping an object and determining an orientation of a surface comprises a first arm with a jaw at one end and a grip at an opposite end and a second arm pivotally connected to the first arm about a pivot point. The second arm also has a jaw at one end and a grip at the opposite end. The grips are moveable between an open position for opening the jaws and a closed position for closing the jaws. At least one level vial is mounted on at least one of said arms such that the arm may be placed into engagement with the surface for determining the orientation of the surface.

Owner:SKINNER LYLE J

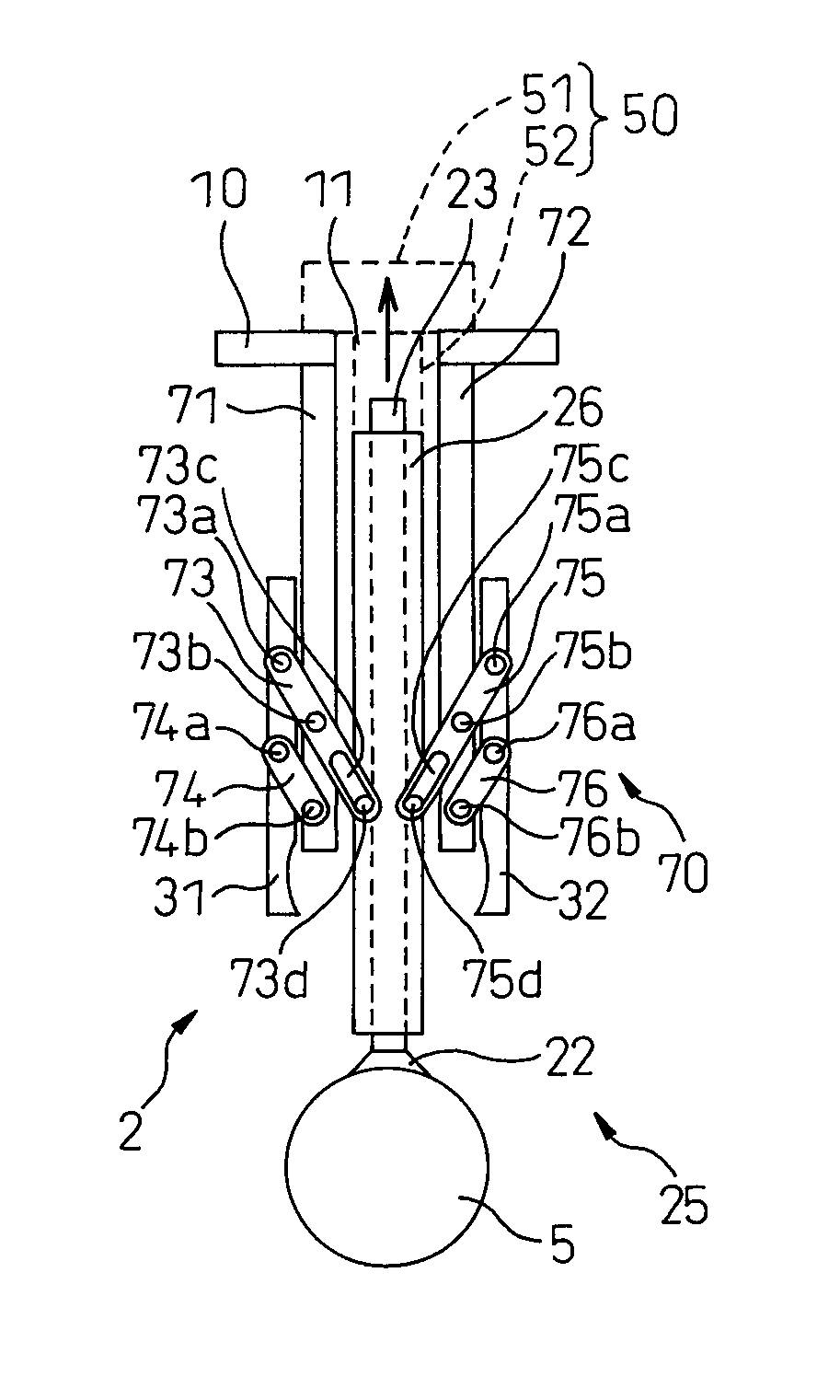

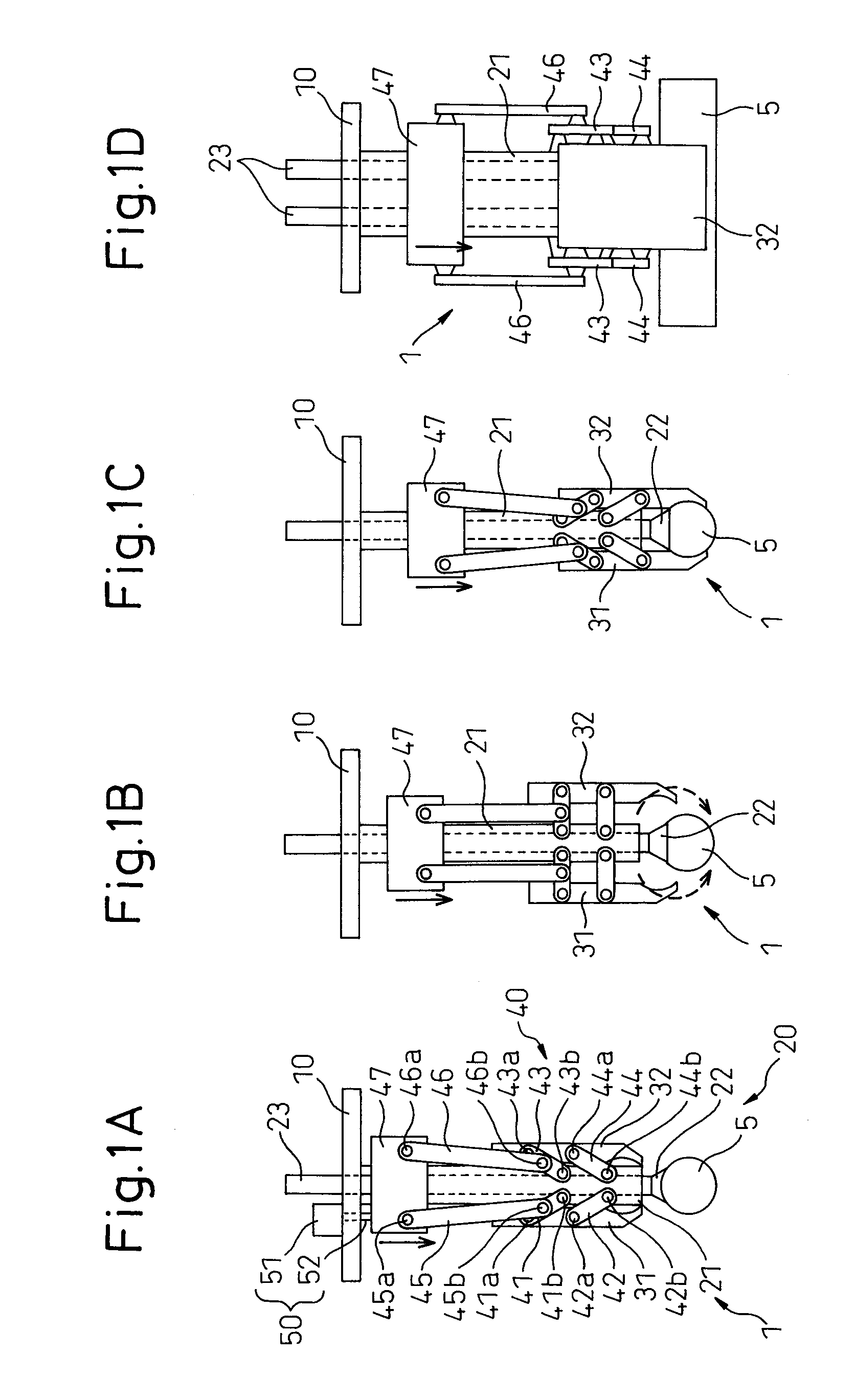

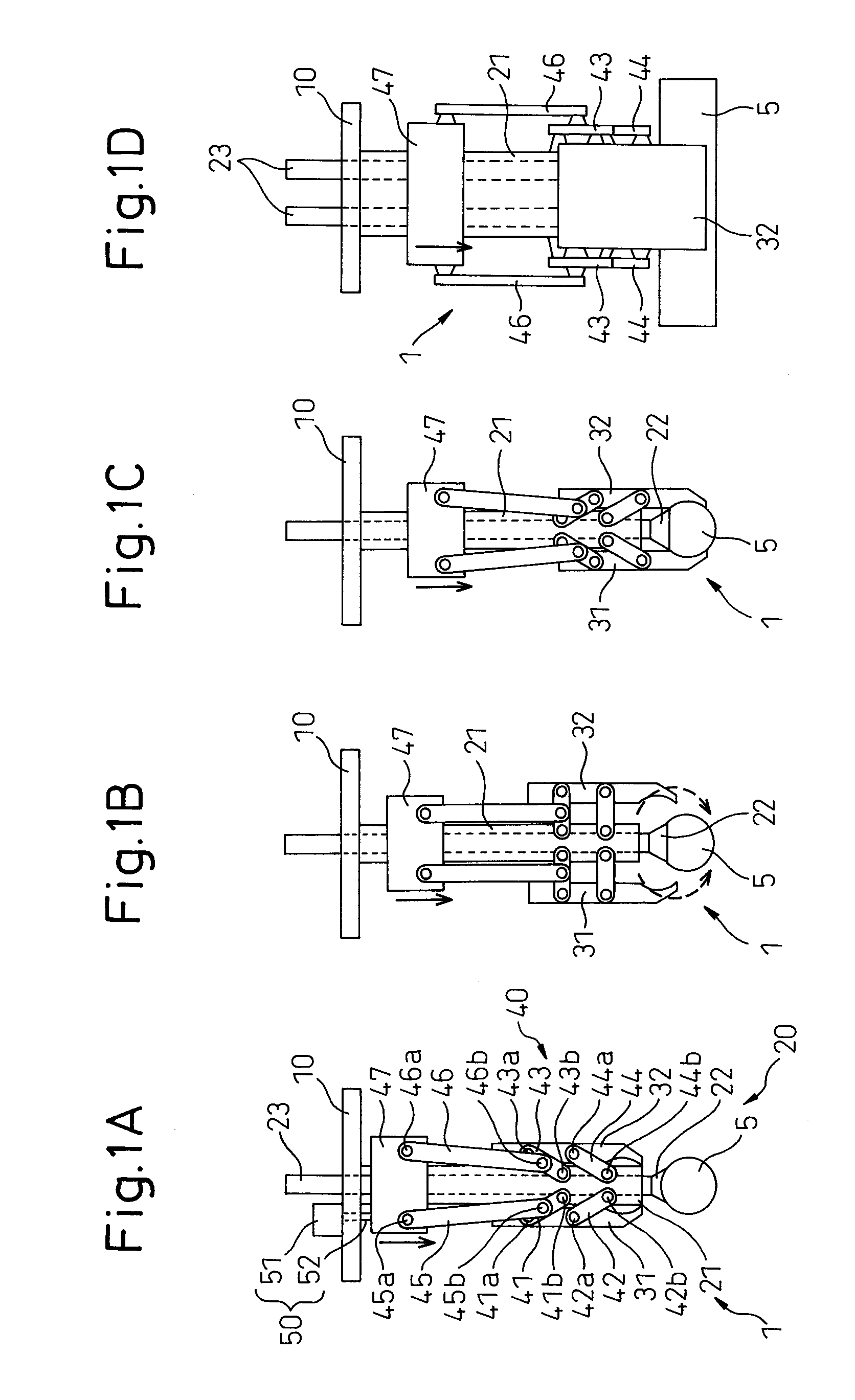

Manipulator

A manipulator has a working unit in which when at least a first end effector finger and a second end effector finger are maximally closed on each other, at least the distance between a third joint axis and a first joint axis is greater than the distance between the first joint axis and a distal end of the second end effector finger, or the distance between the third joint axis and the first joint axis is greater than the distance between third joint axis and a second joint axis, or the angle formed between a direction from the third joint axis to the first joint axis and a direction from the third joint axis to the second joint axis is not π.

Owner:KARL STORZ GMBH & CO KG

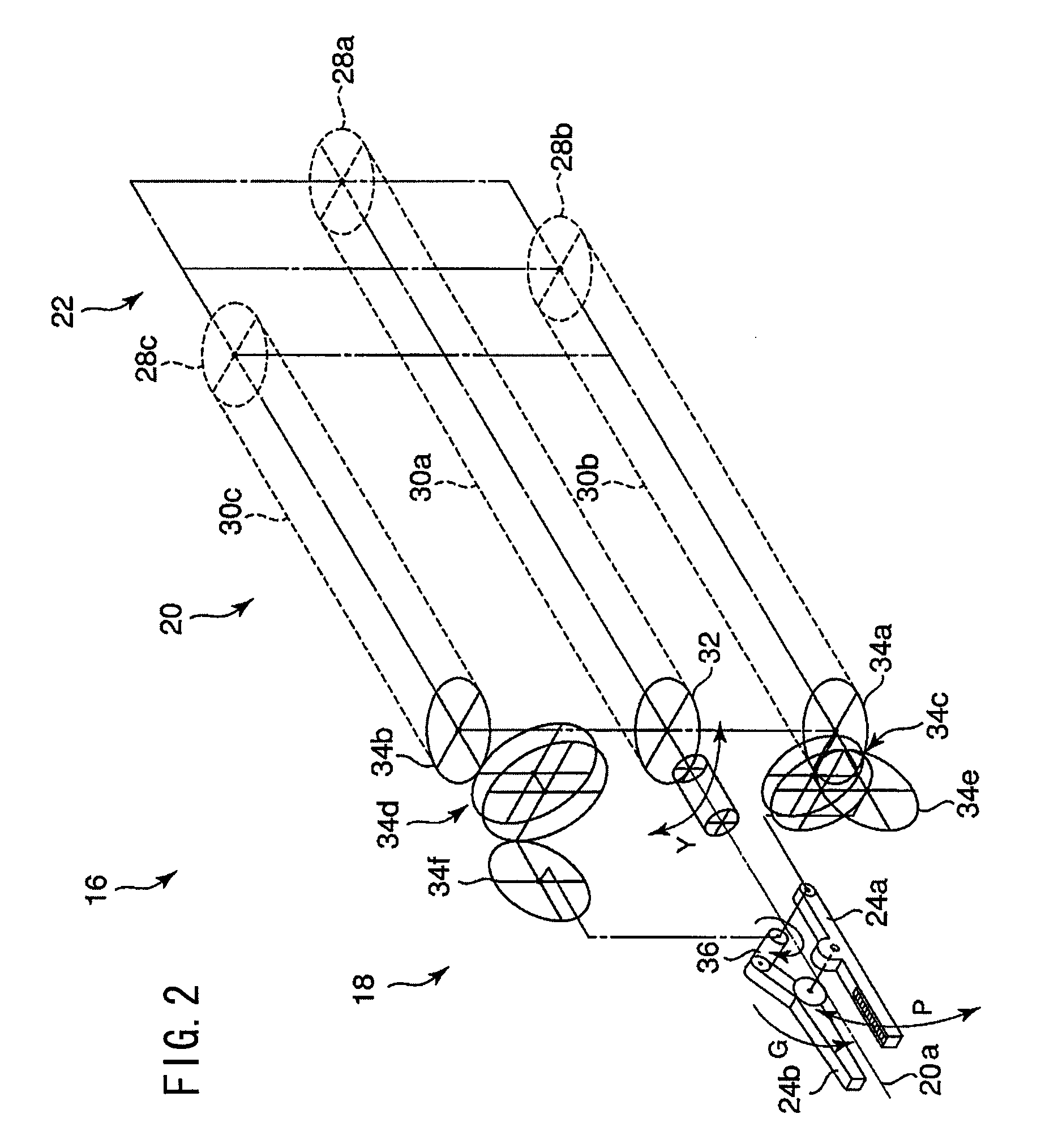

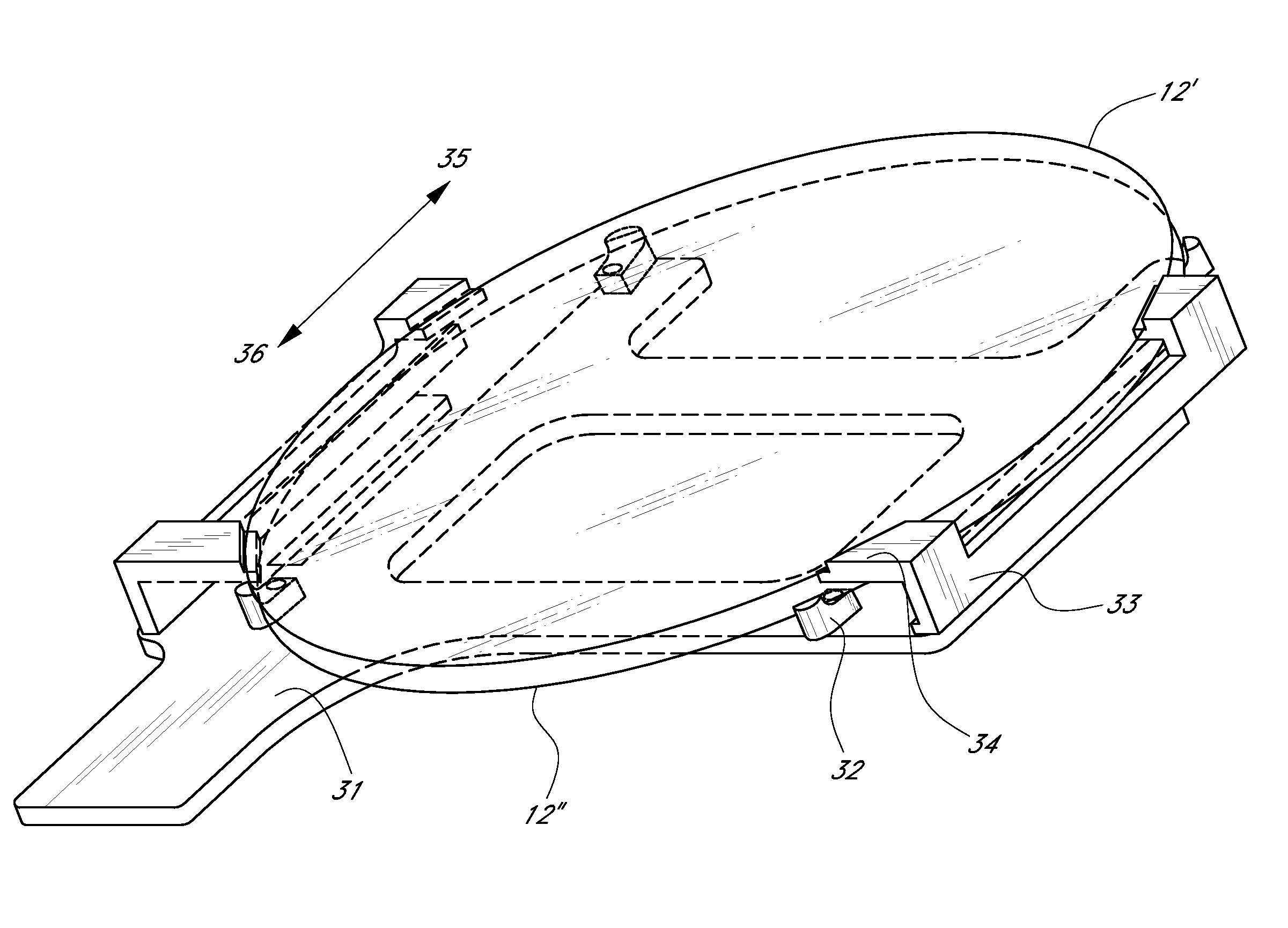

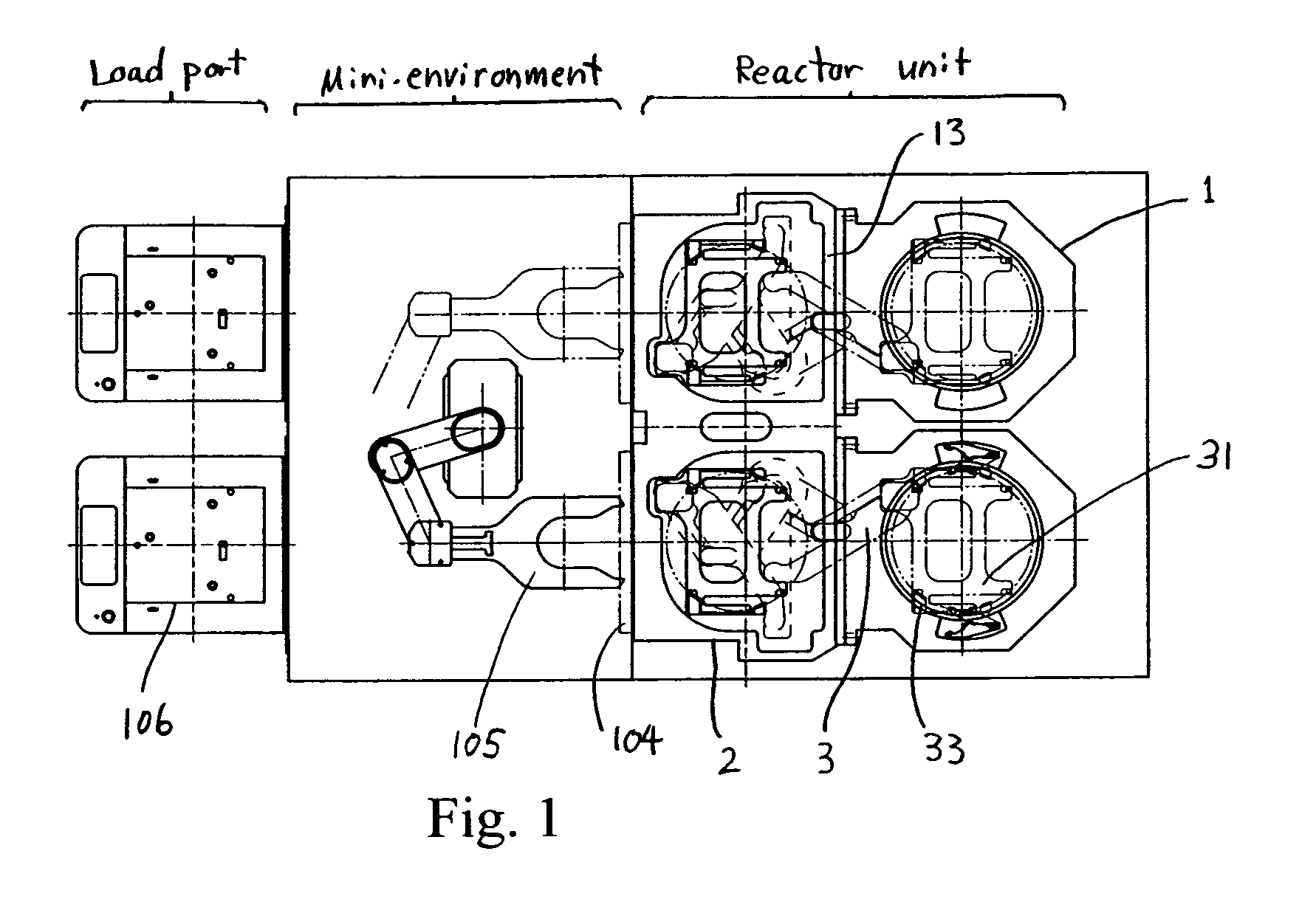

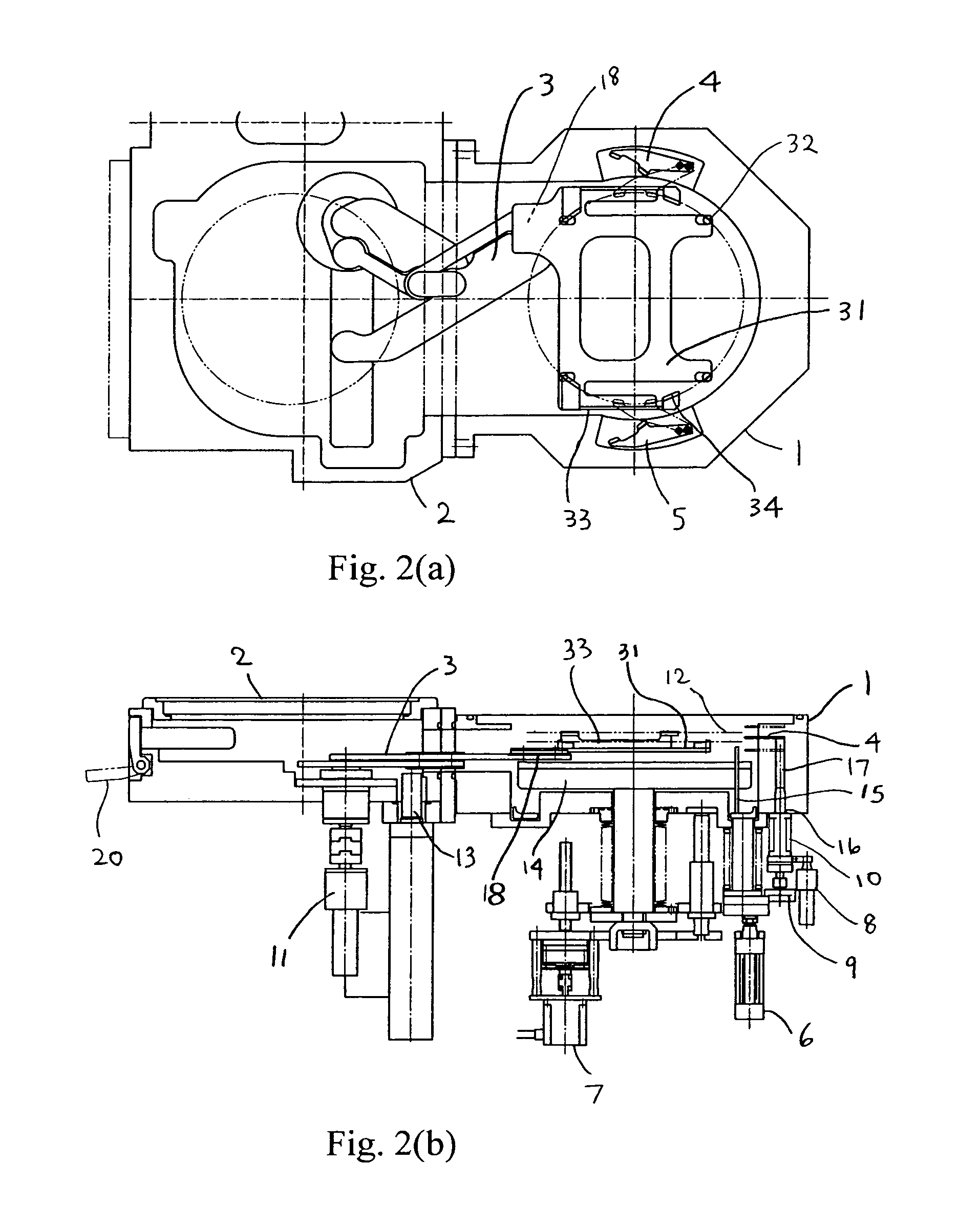

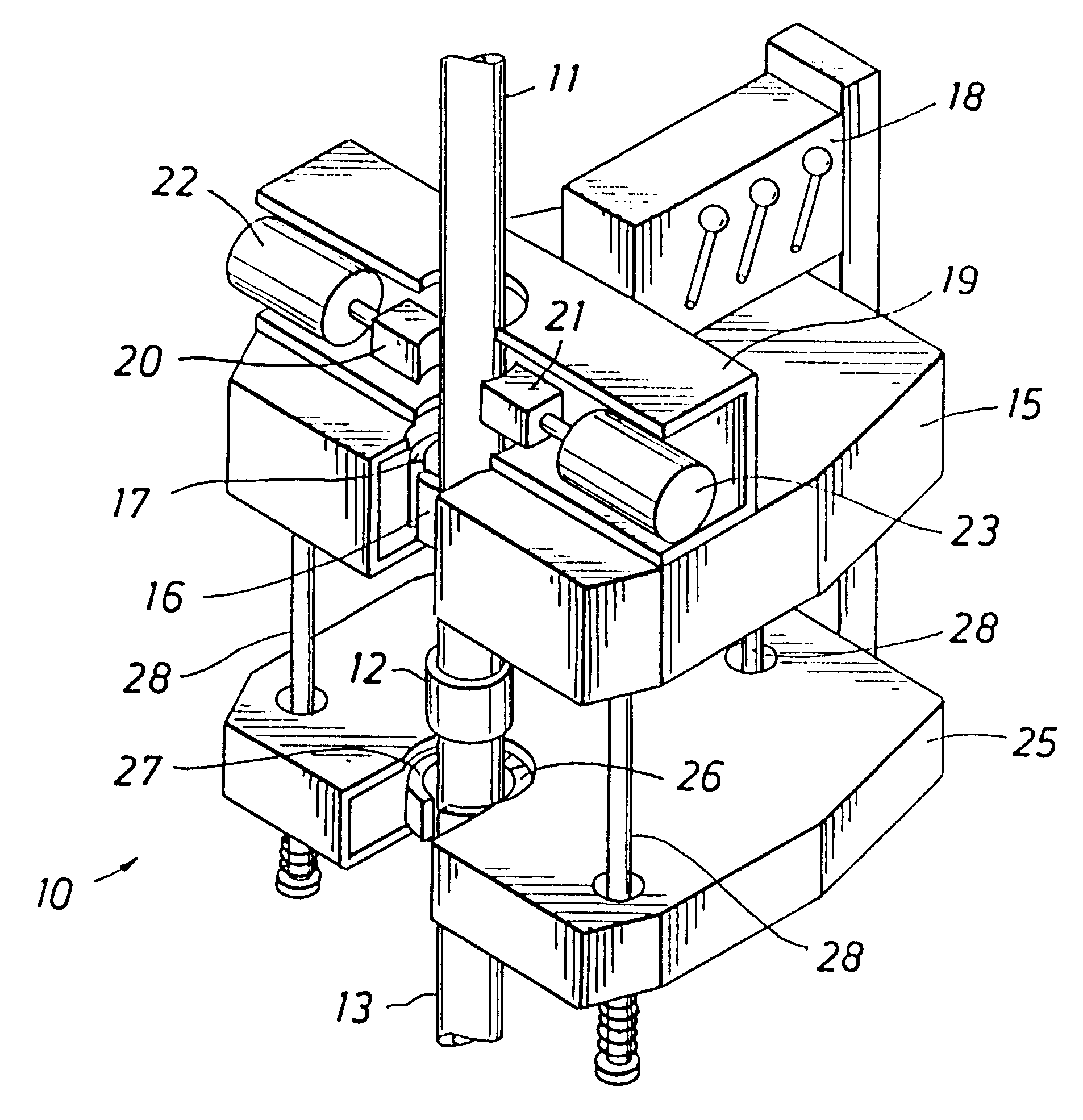

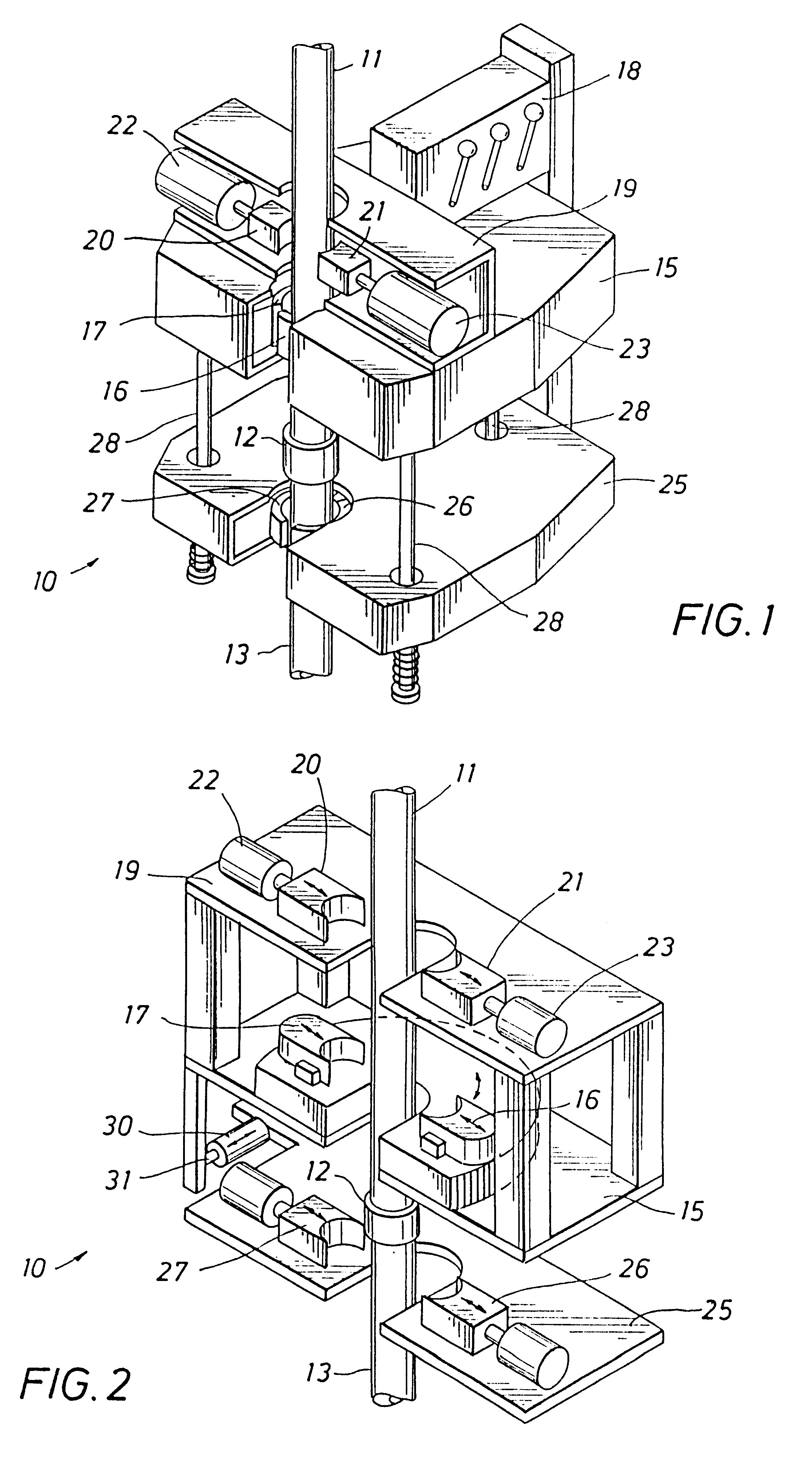

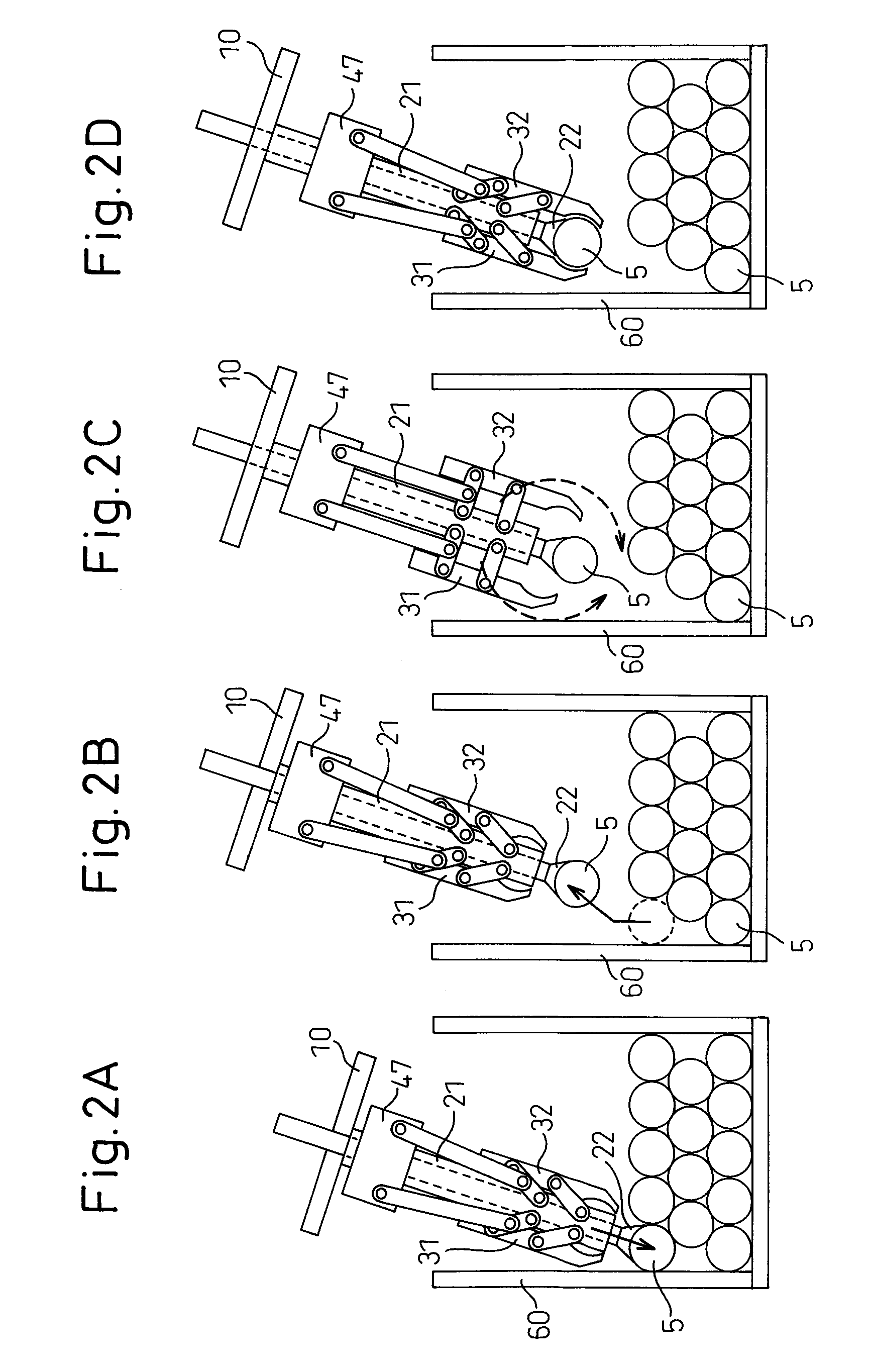

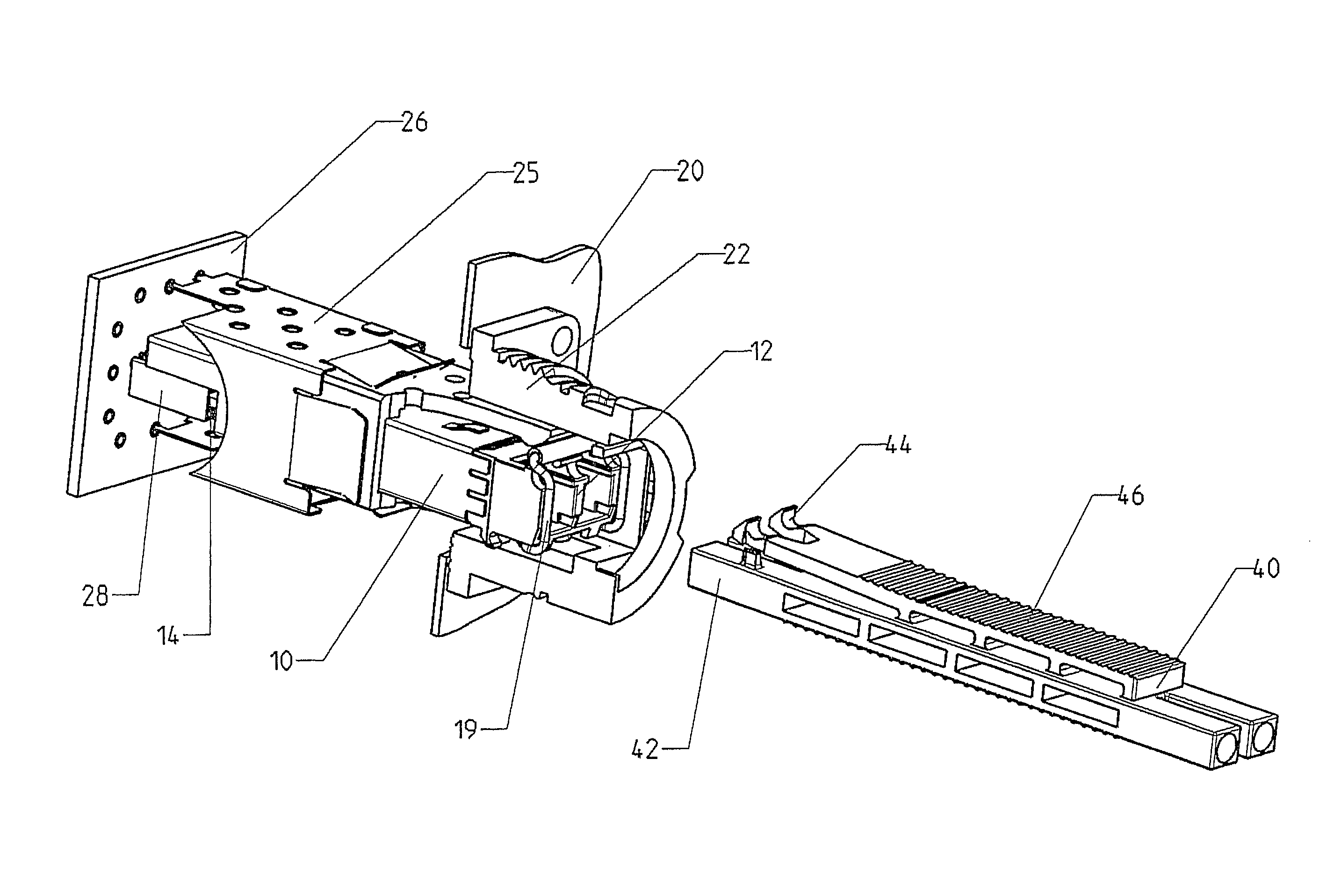

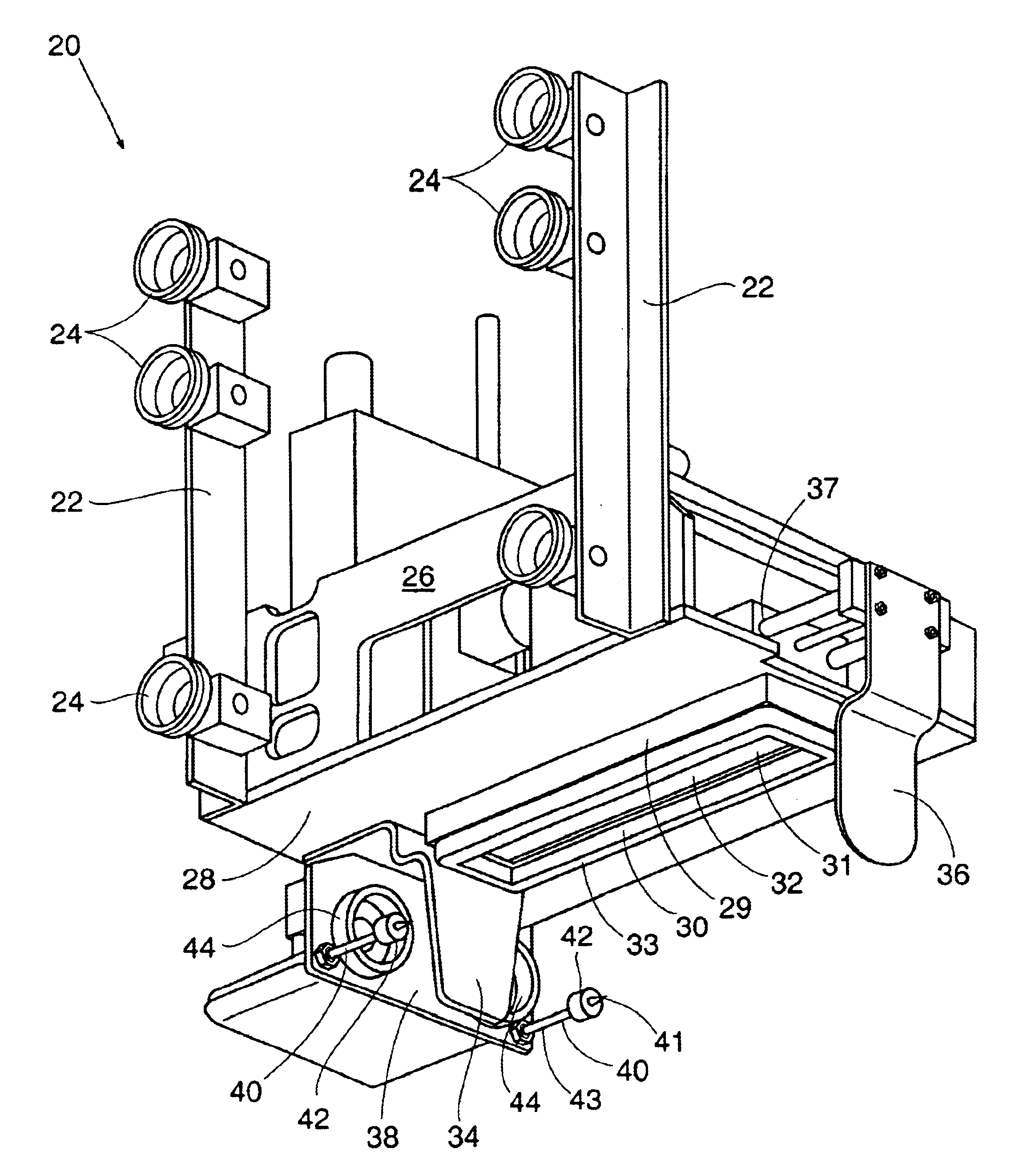

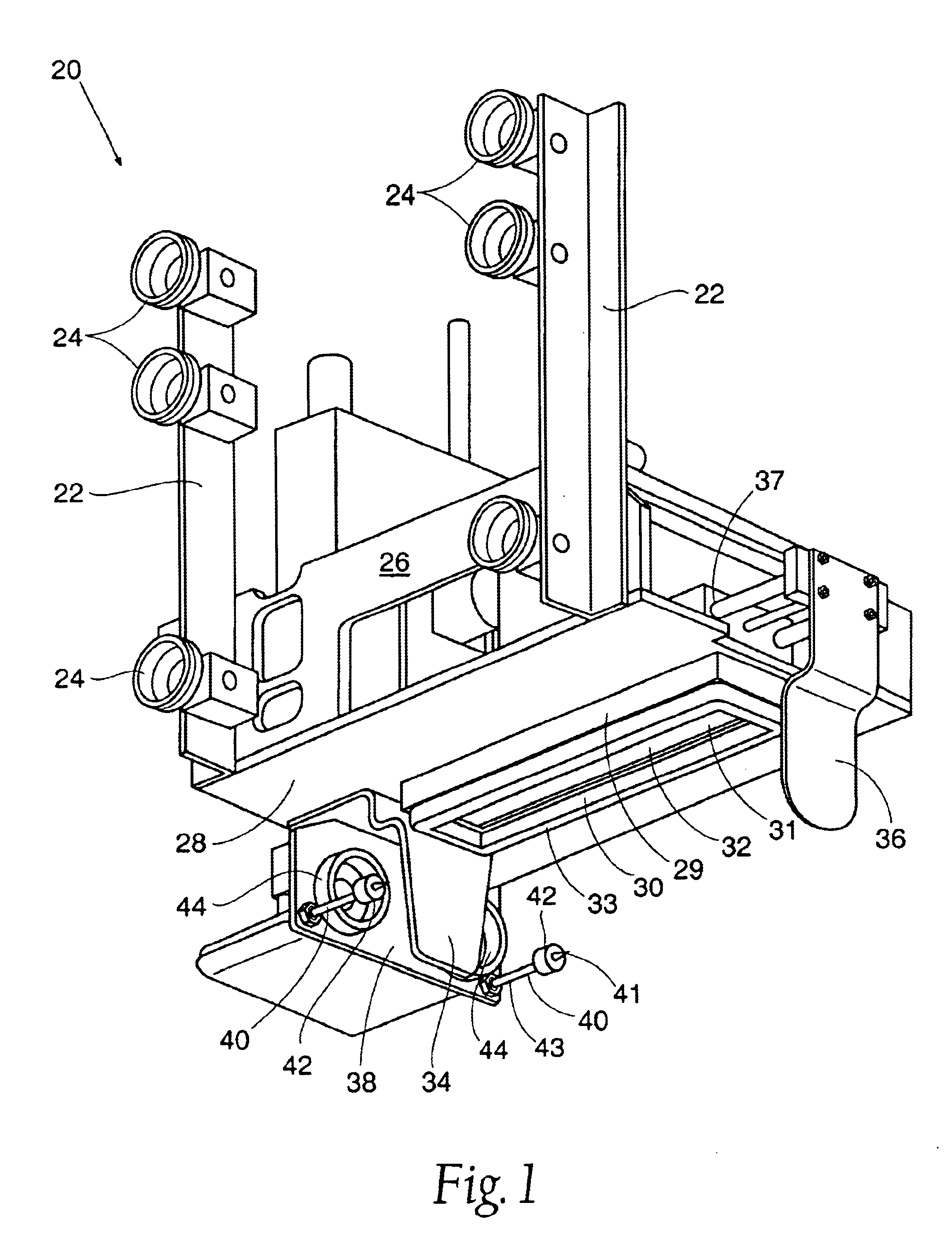

Substrate-processing apparatus with buffer mechanism and substrate-transferring apparatus

ActiveUS7690881B2Low costSmall footprintPliersSemiconductor/solid-state device manufacturingEngineeringActuator

A substrate transfer apparatus for loading and unloading substrates in a reaction chamber, includes: an arm having a distal end which is laterally movable in a straight line direction; and end-effectors for loading and unloading substrates in a reaction chamber, which include a lower end-effector and an upper end-effector. One of the lower end-effector or the upper end-effector is movably coupled to the arm at a distal end of the arm, and the other end-effector is fixed to the movably coupled end-effector. The fixed end-effector is fixed to the movably coupled end-effector.

Owner:ASM JAPAN

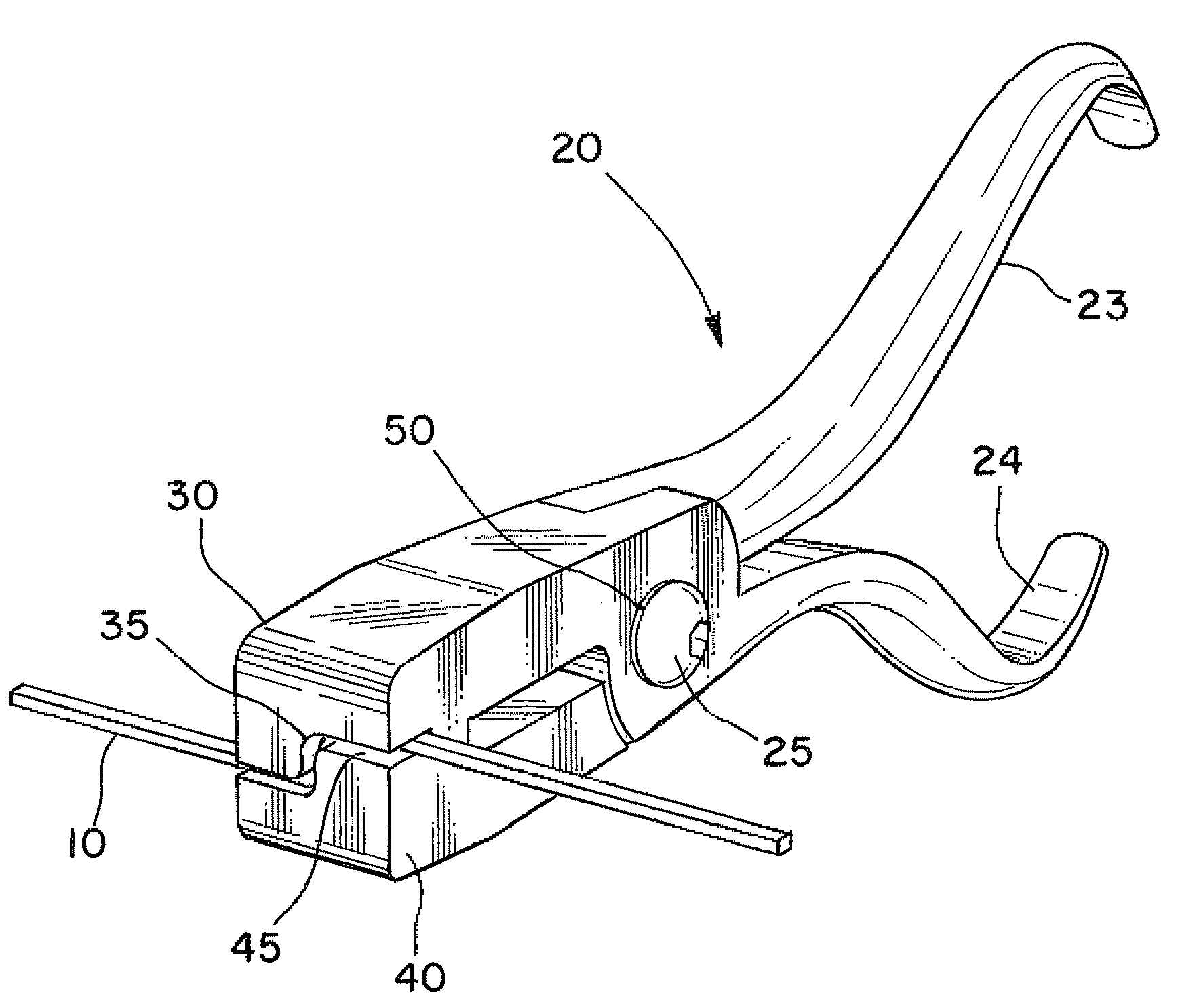

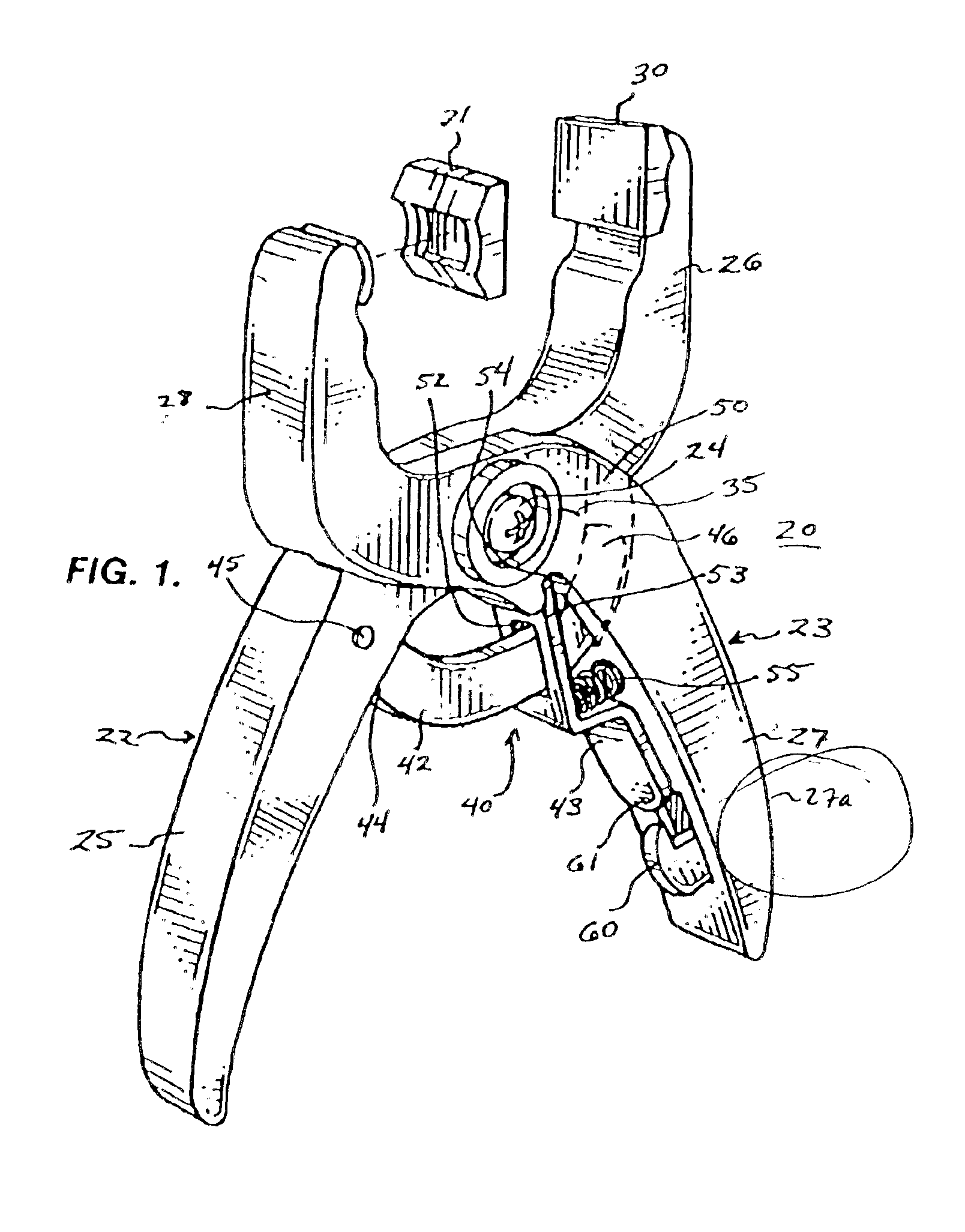

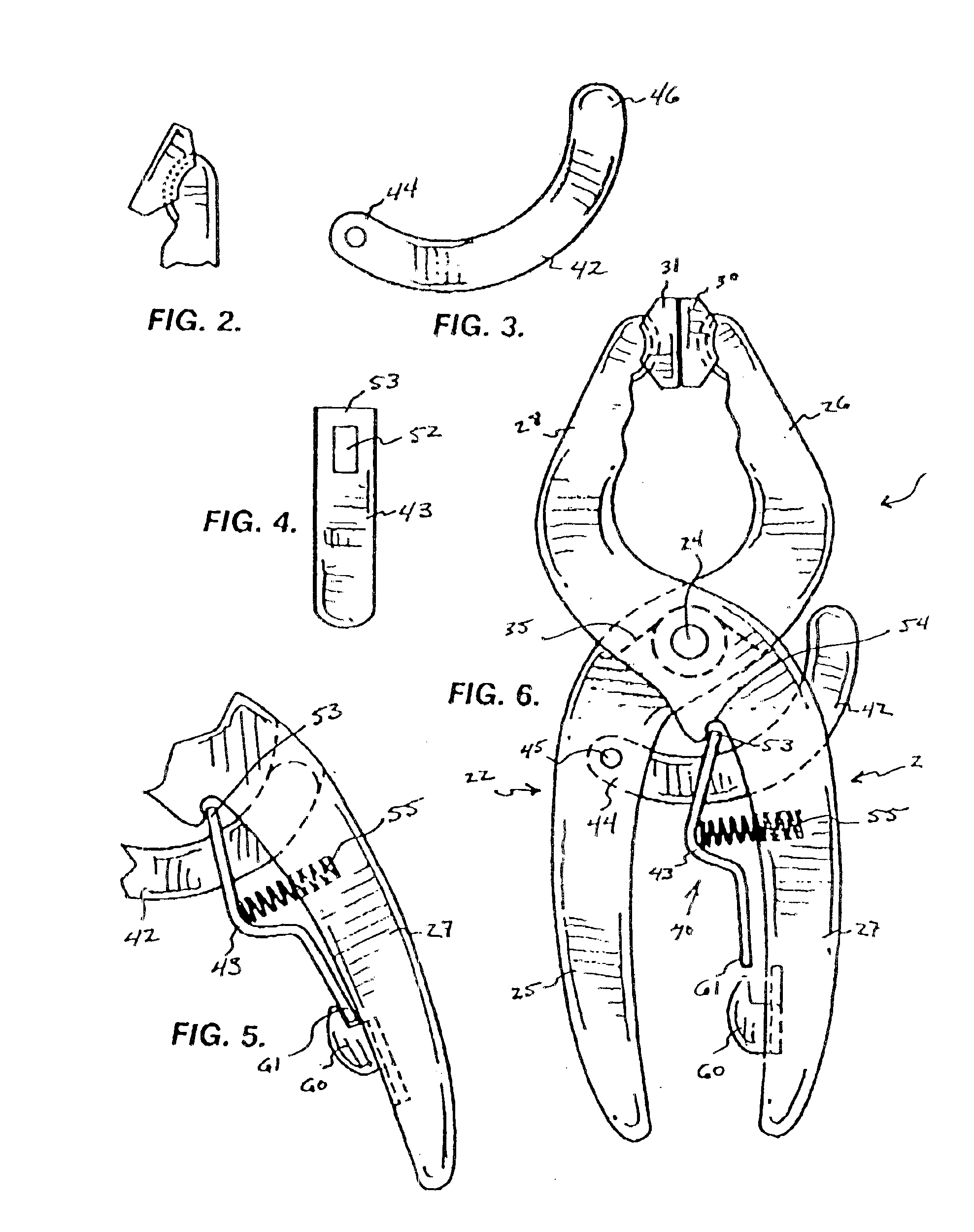

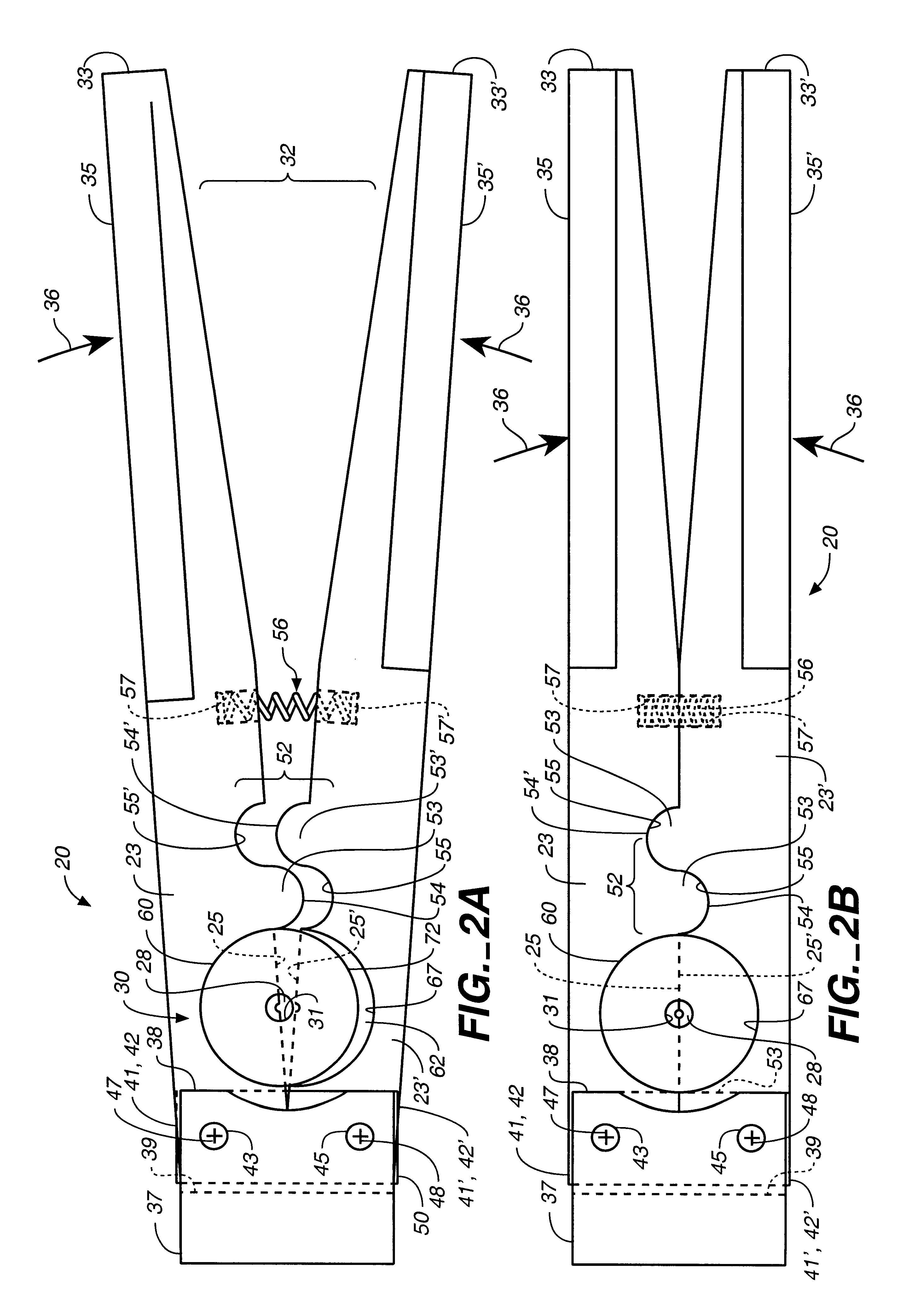

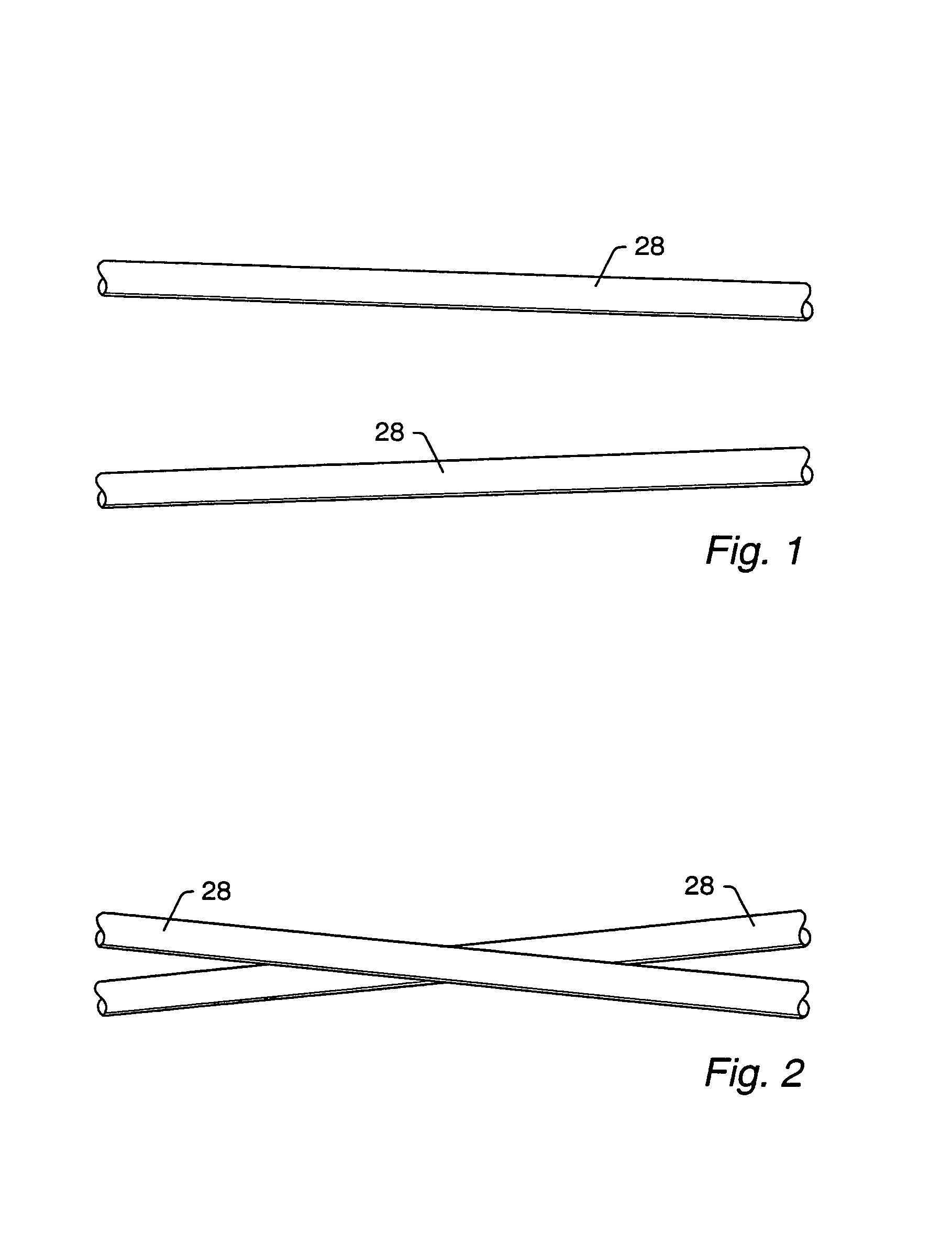

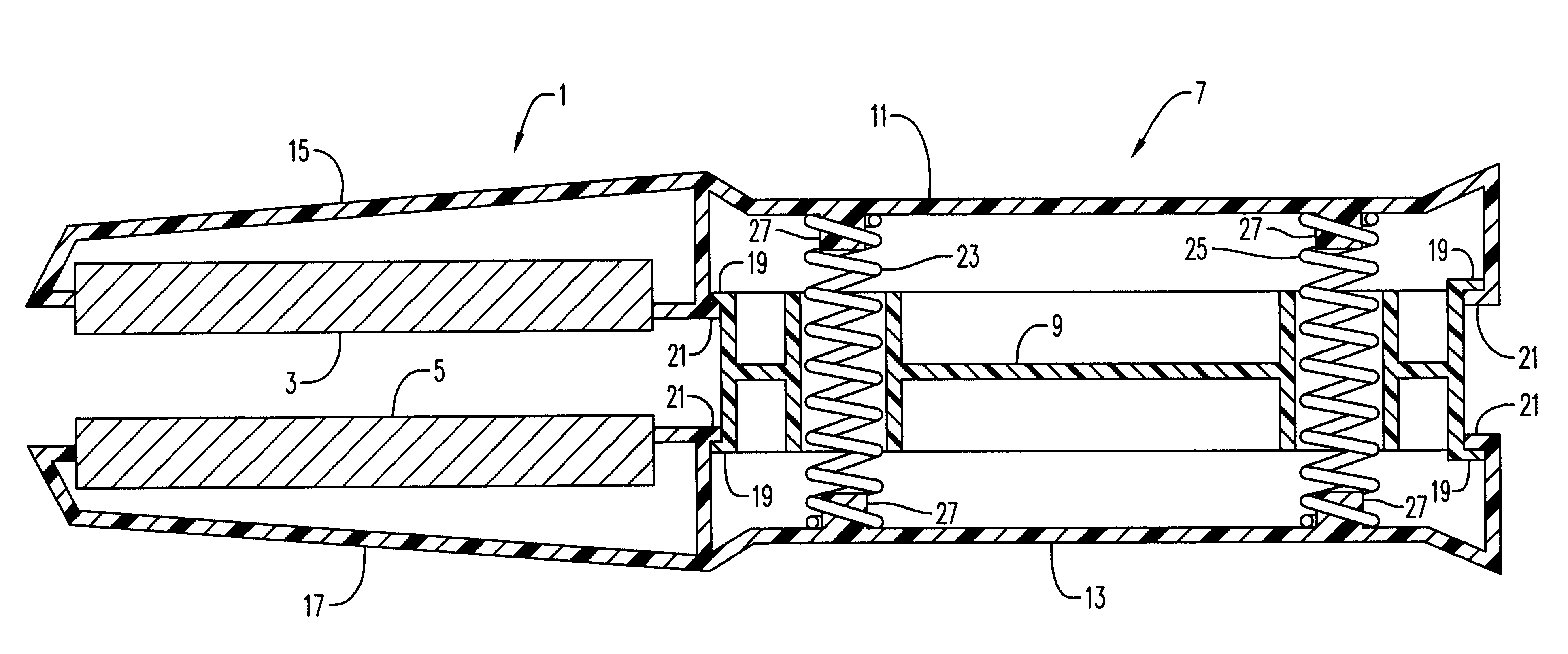

Pliers for forming orthodontic wires

A pliers for forming orthodontic wires has opposing beaks with complementary wire-forming surfaces that include interfering portions. A hinge mechanism enables the beaks to open and close by rotating about an axis, and also allows a range of axial motion between the beaks sufficient to prevent interference between the wire-forming surfaces as the beaks are closed. By preventing such interference, novel over-bending capabilities can be achieved to form useful bending of low spring rate wire. A spring, such as a Belleville washer, exerts a biasing force parallel to the hinge axis to maintain alignment of the beaks, but allows the required range of axial motion between the beaks to prevent interference.

Owner:LINDQUIST JOHN T II +1

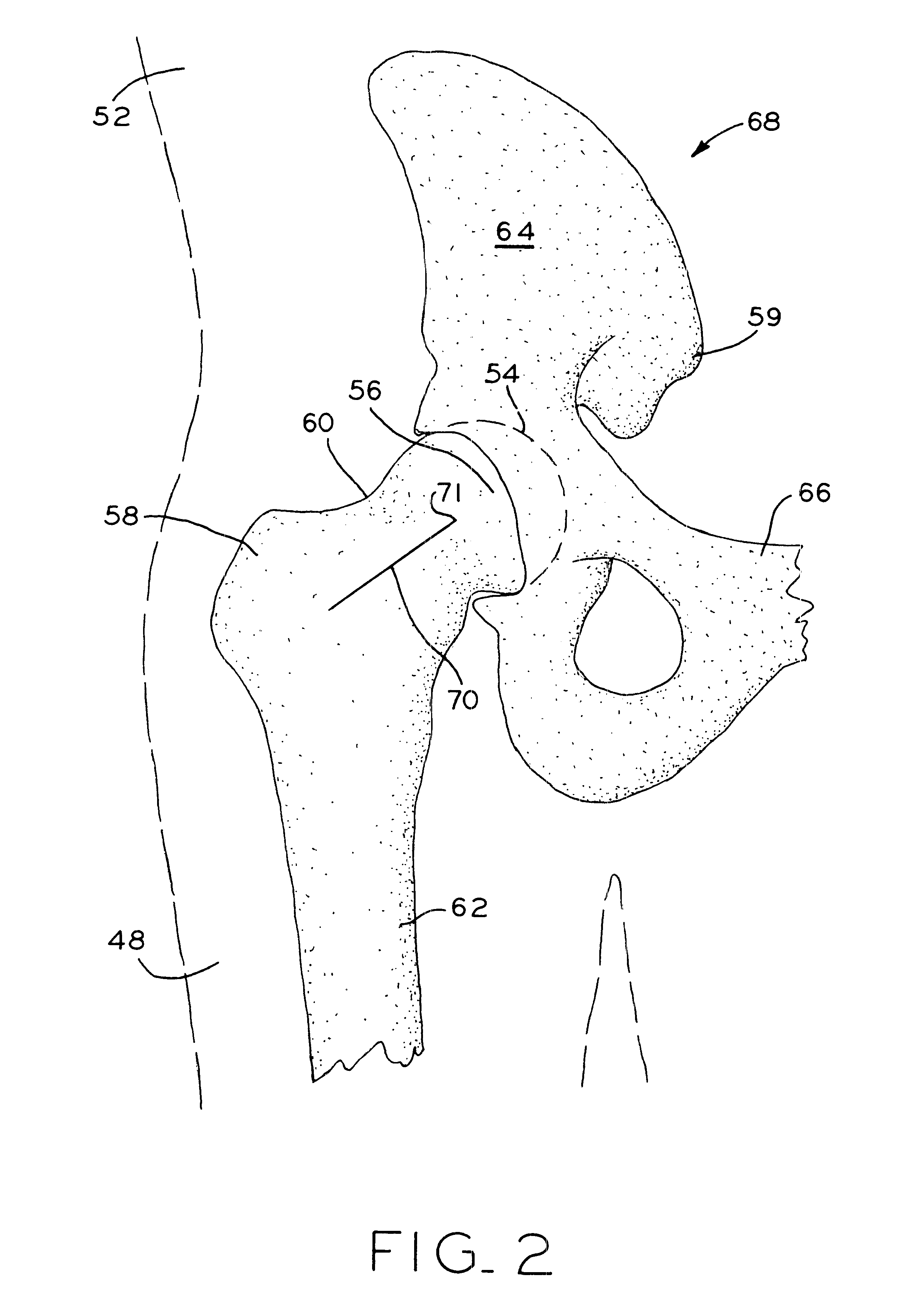

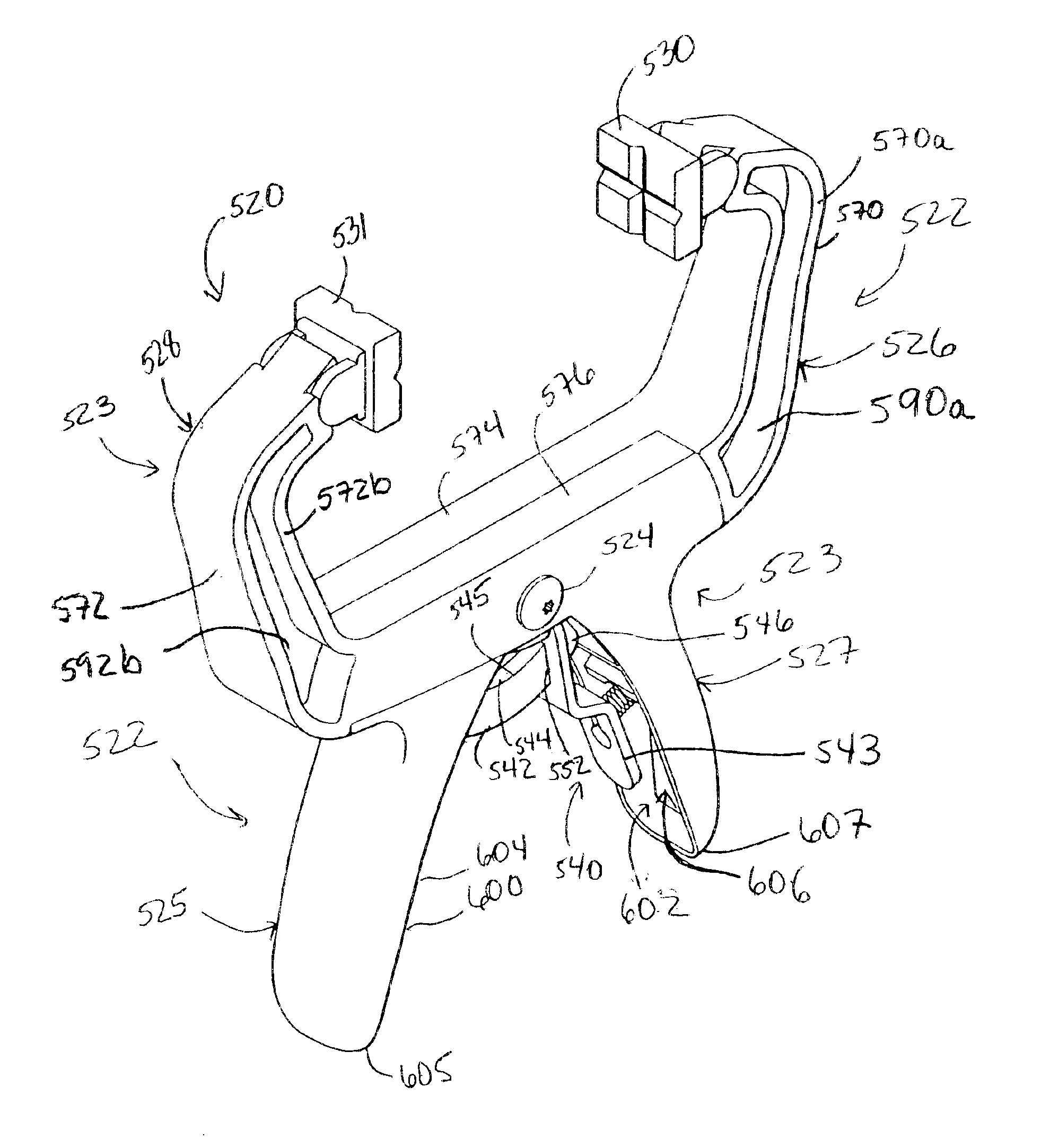

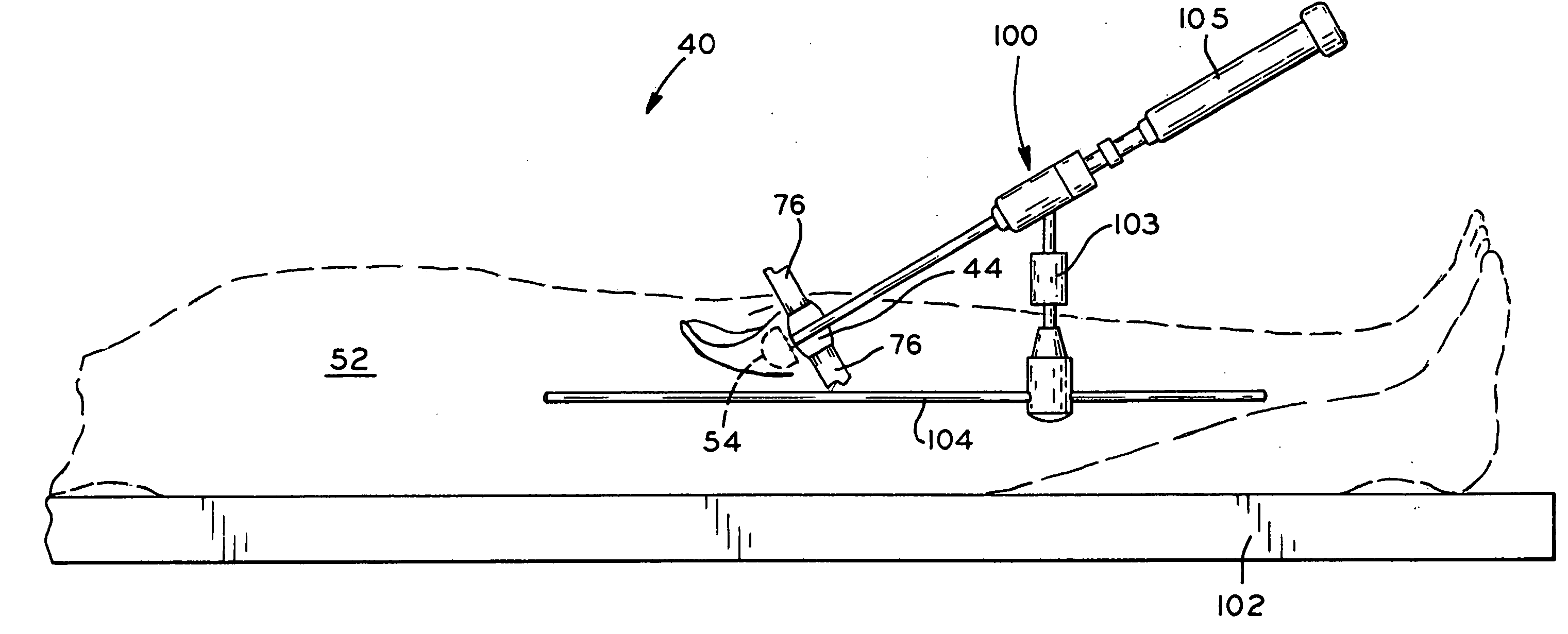

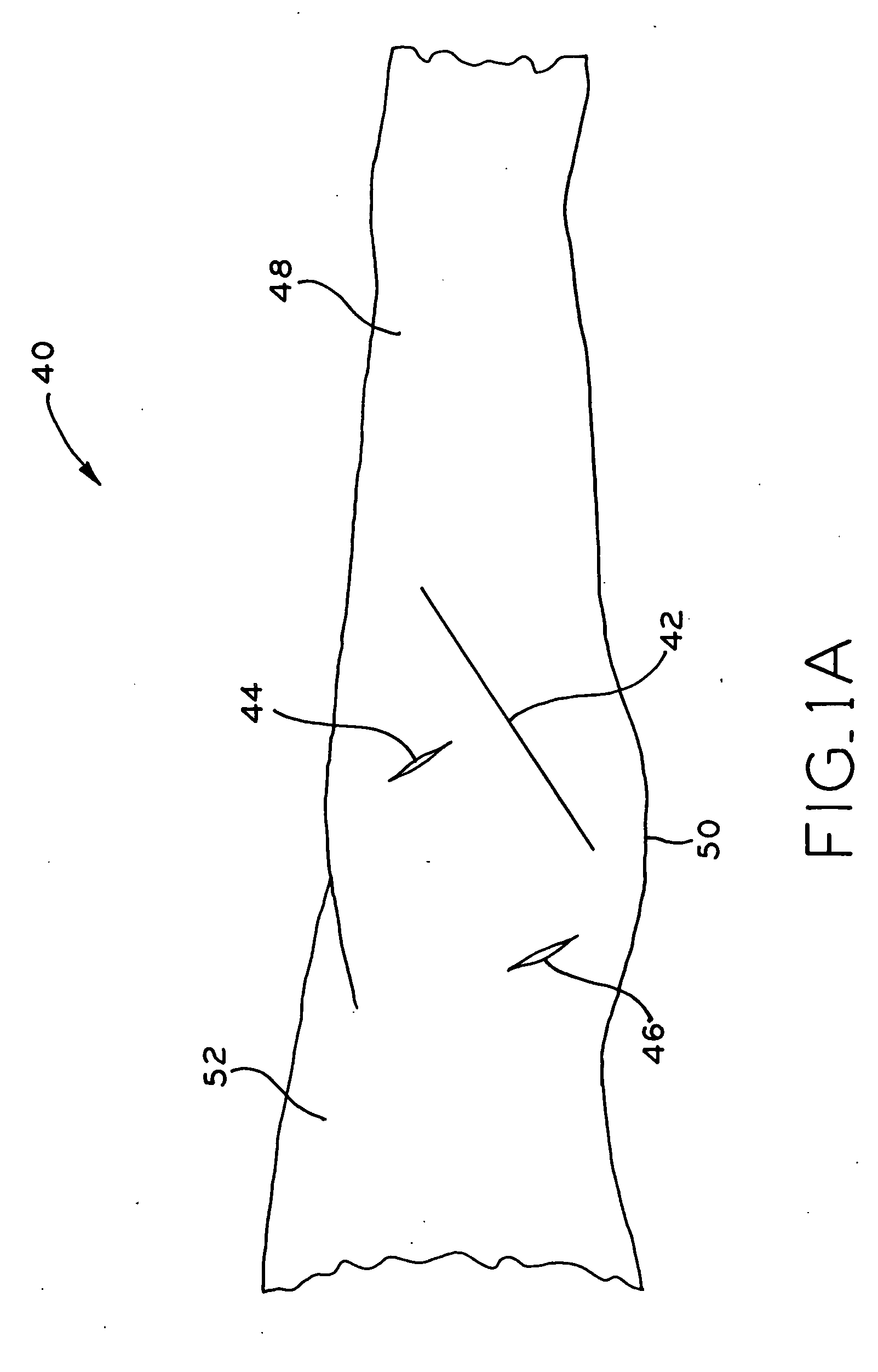

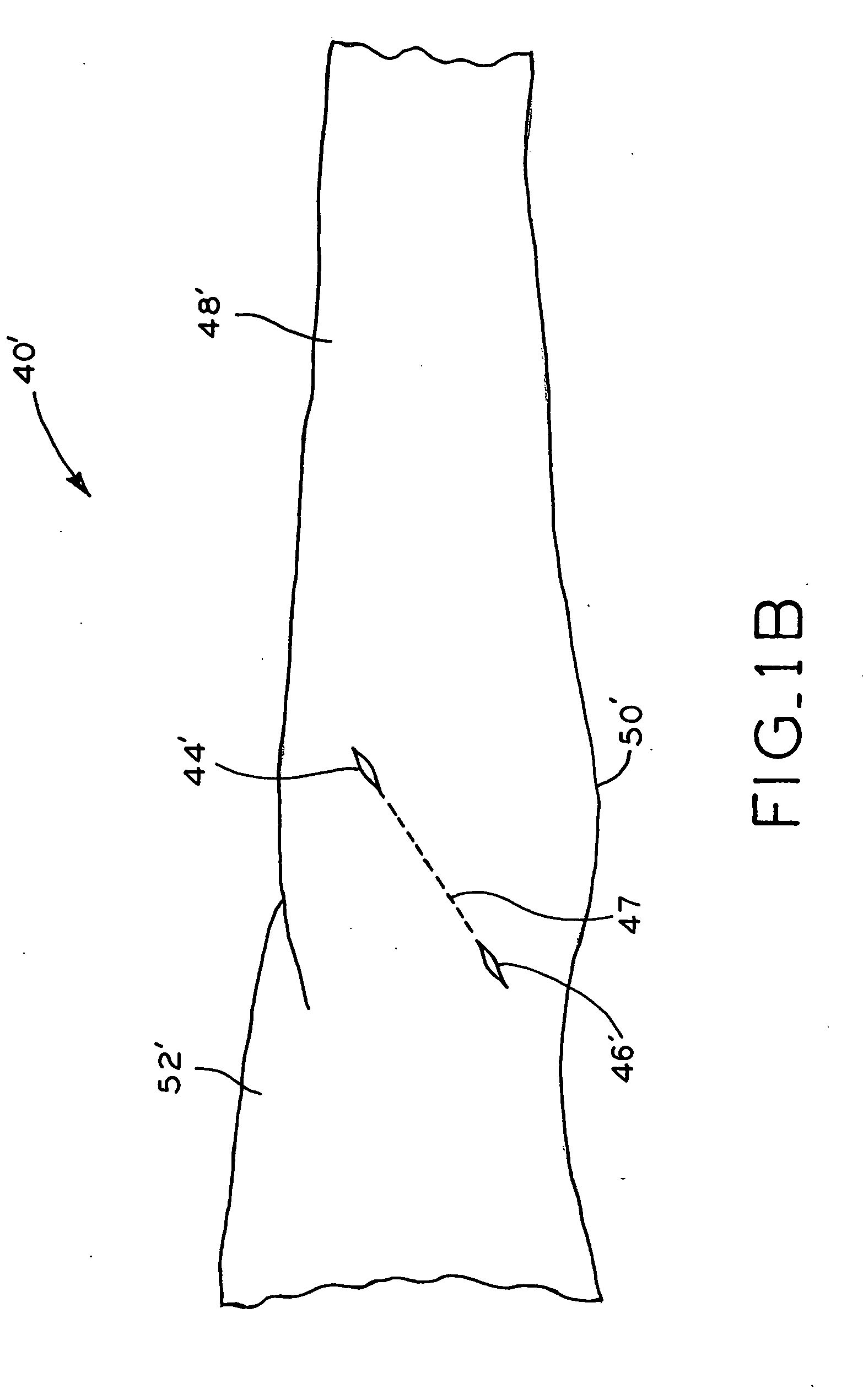

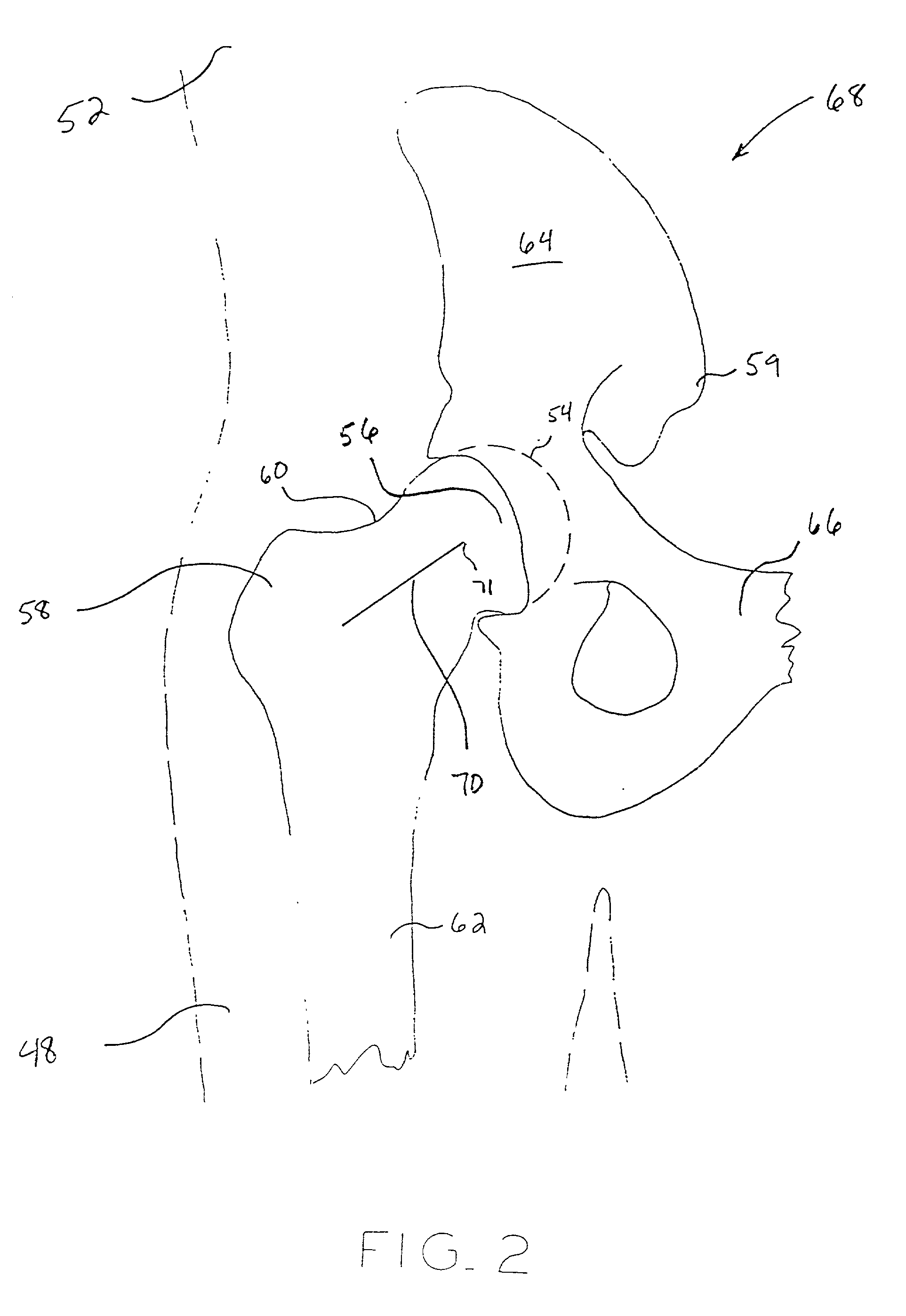

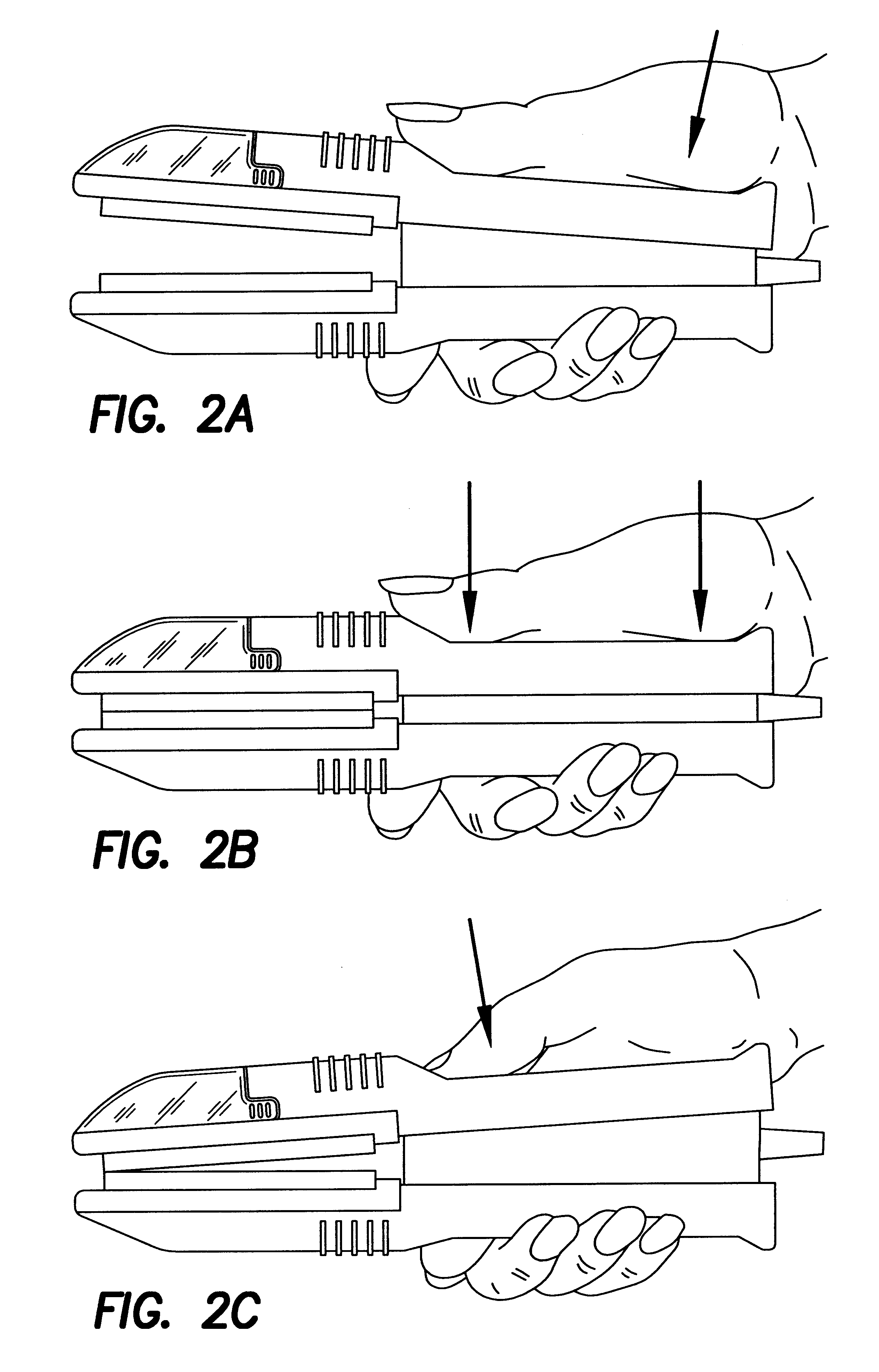

Method and apparatus for performing a minimally invasive total hip arthroplasty

A method and apparatus for performing a minimally invasive total hip arthroplasty. An approximately 3.75-5 centimeter (1.5-2 inch) anterior incision is made in line with the femoral neck. The femoral neck is severed from the femoral shaft and removed through the anterior incision. The acetabulum is prepared for receiving an acetabular cup through the anterior incision, and the acetabular cup is placed into the acetabulum through the anterior incision. A posterior incision of approximately 2.5-3.75 centimeters (1-1.5 inches) is generally aligned with the axis of the femoral shaft and provides access to the femoral shaft. Preparation of the femoral shaft including the reaming and rasping thereof is performed through the posterior incision, and the femoral stem is inserted through the posterior incision for implantation in the femur. A variety of novel instruments including an osteotomy guide; an awl for locating a posterior incision aligned with the axis of the femoral shaft; a tubular posterior retractor; a selectively lockable rasp handle with an engagement guide; and a selectively lockable provisional neck are utilized to perform the total hip arthroplasty of the current invention.

Owner:ZIMMER INC

Clamp device

A clamp device is disclosed having a first member having a handle portion and a jaw portion. A second member has a handle portion and a jaw portion. The handle portion and jaw portion of the second member define a notch extending from an inner surface of the handle portion of the second member at least partially into the jaw portion of the second member, the second member being formed as a single piece. A pivot is pivotally coupling the first member and the second member intermediate their respective handle portion and jaw portion for opposed pivotal motion. An arcuate clamp bar has a first end coupled to the first member and a second end, an arc of the arcuate clamp bar being concentric with the pivot. A brake lever has an end pivotally coupled to the second member at the notch. The end contacts the jaw portion of the second member. The brake lever has an aperture with the arcuate clamp bar extending therethrough. The brake lever is movable laterally between a frictionally engaged position, frictionally engaging the arcuate clamp bar and a disengaged position.

Owner:BLACK & DECKER INC

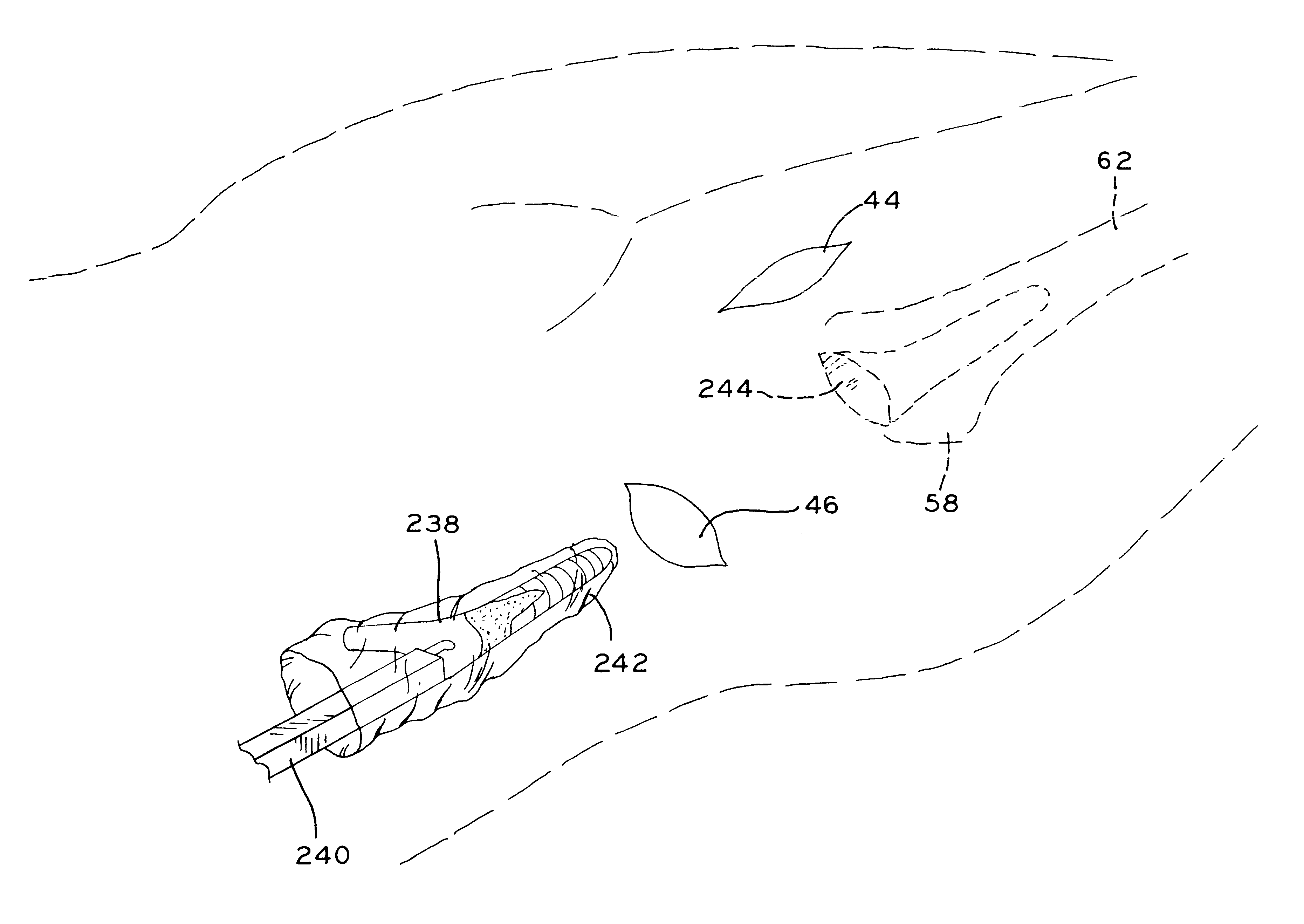

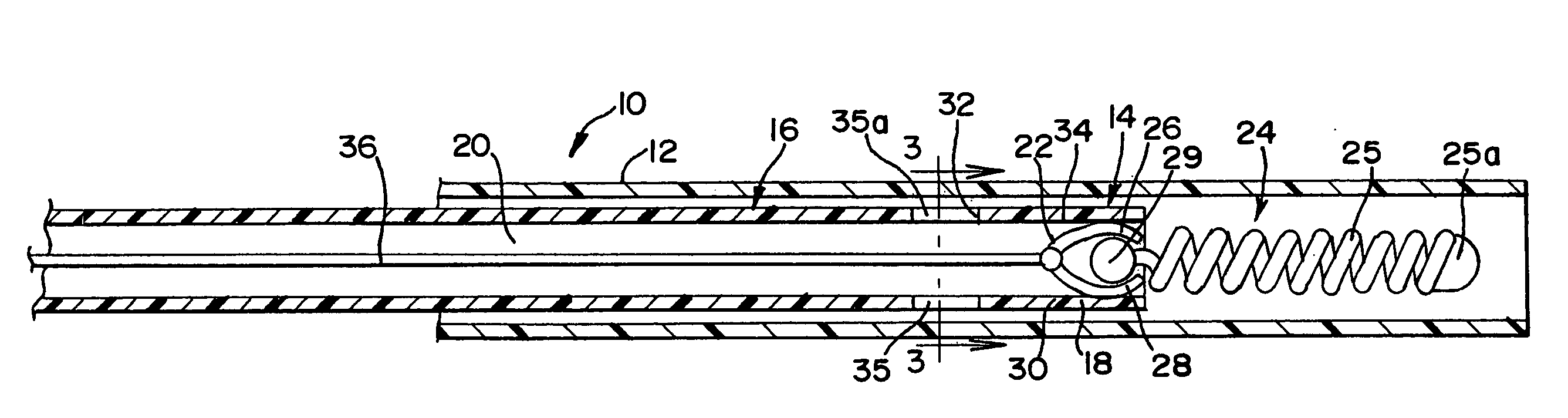

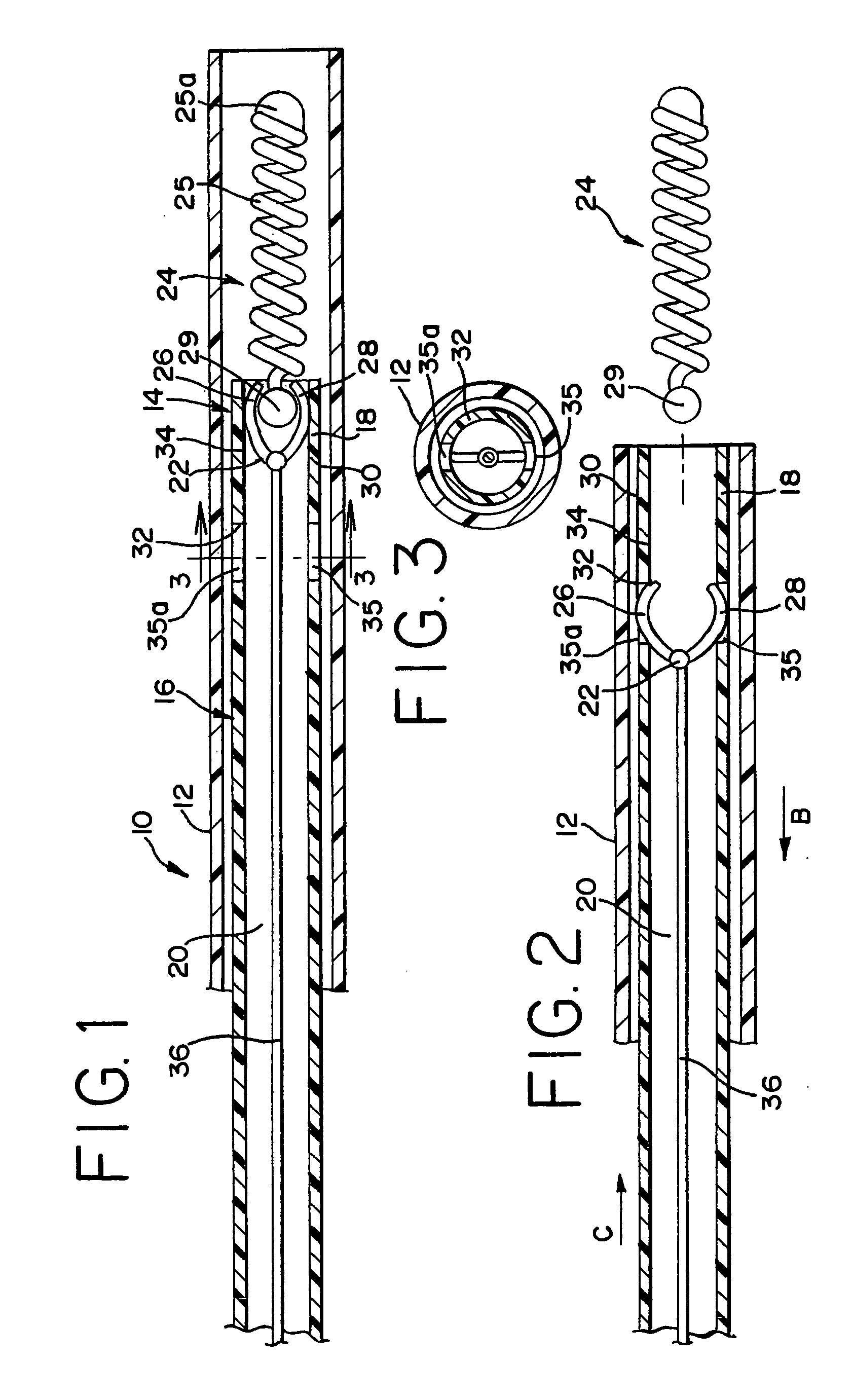

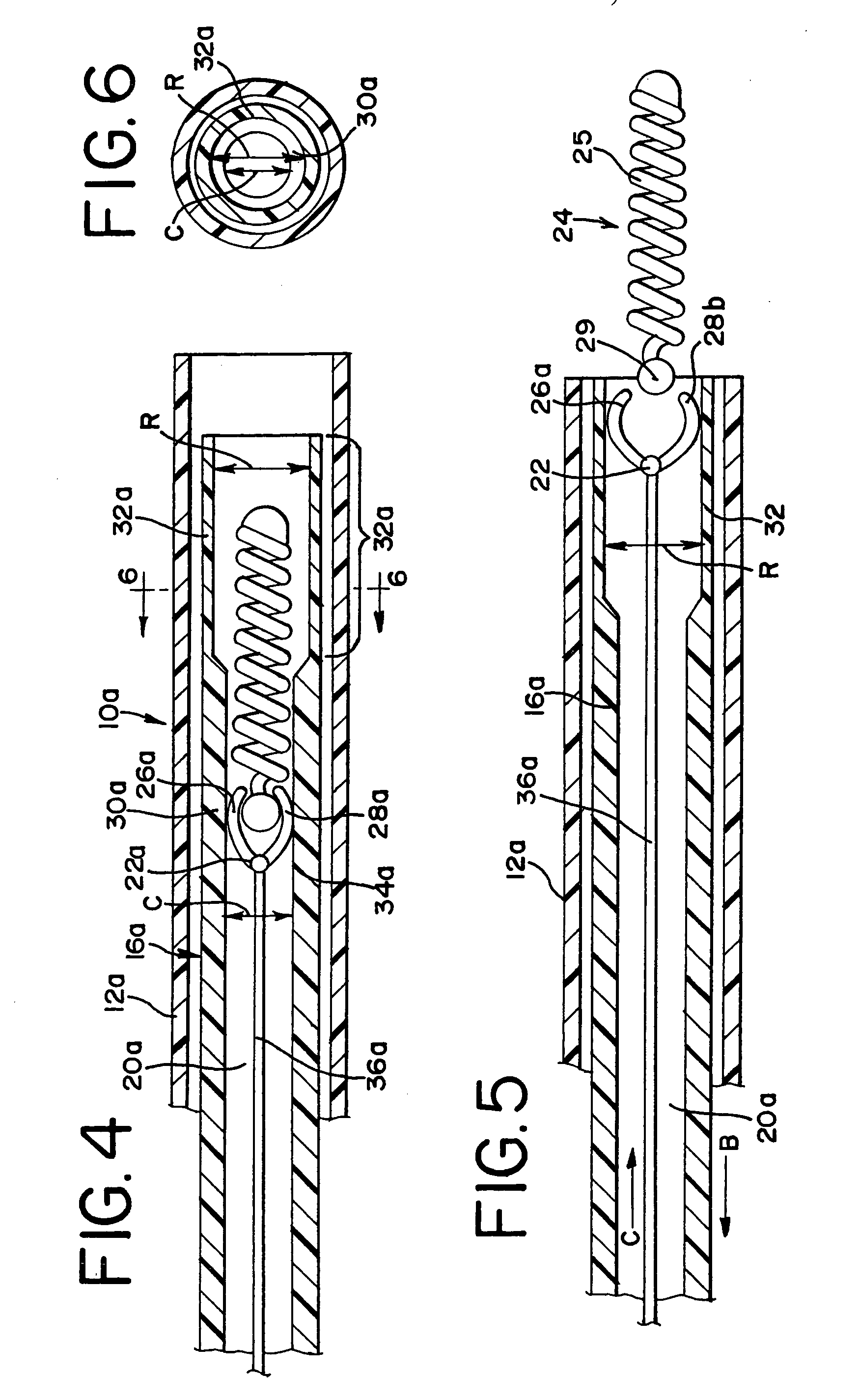

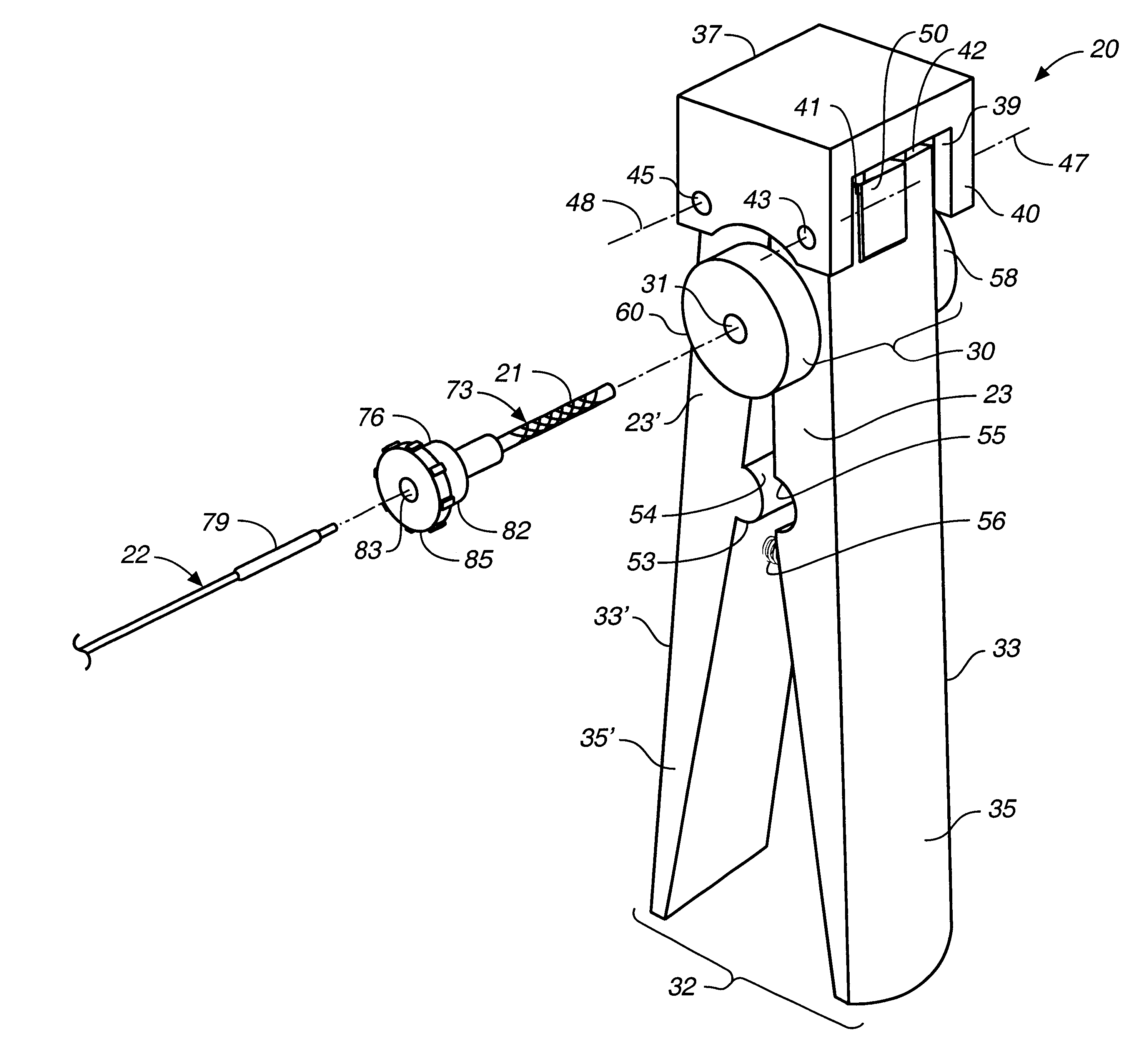

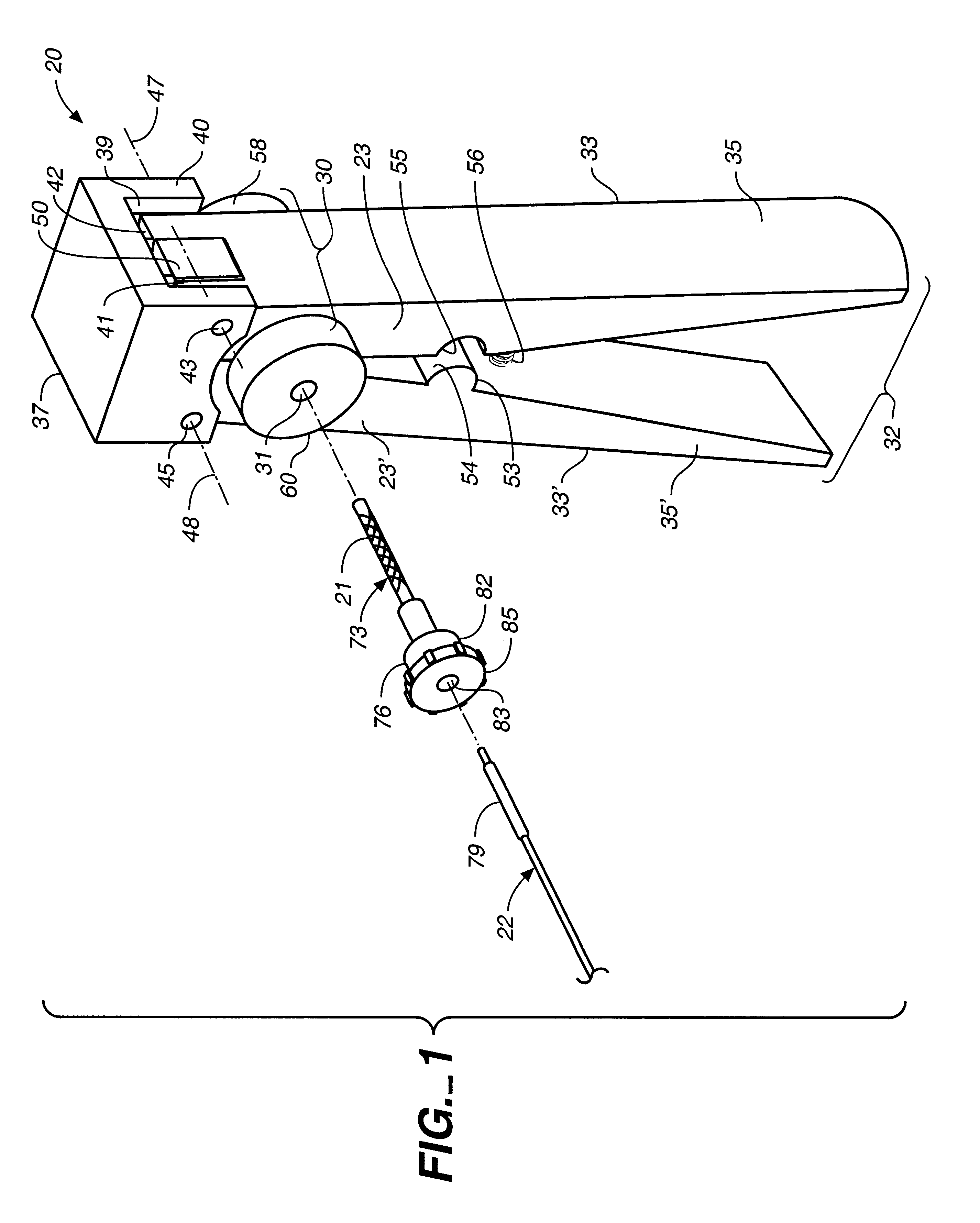

Embolic device delivery system

InactiveUS20070179520A1Accurately and rapidly deployingEar treatmentPliersEngineeringBiomedical engineering

A vascular occlusion device deployment system is provided for deploying an embolic device at a preselected site within the vasculature of a patient. The deployment system includes a tubular element having a catch movably located within the tubular element. The catch has a normal open configuration and a closed configuration. When in the closed configuration, the catch grasps a headpiece of an embolic device. The tubular element has a constraining section and a releasing section. When the catch is within the constraining section of the tubular element, the constraining section acts upon the catch to keep the catch in a closed configuration. When the catch is moved to the releasing section, the catch returns to its normally open configuration and releases its grasp of the embolic device headpiece.

Owner:CODMAN & SHURTLEFF INC

Mechanical torque amplifier

A power tong system is used to make up and break out threaded pipe connections. Rotary power tongs are connected to an integral backup tong through an extendable hydraulic cylinder and rod. A brake is secured to the rotary tong to selectively hold the pipe stationary relative to the rotary tong. When rotation of the pipe by the rotary tong ceases, the brake is applied, and the cylinder and rod are actuated to angularly displace the power tongs and the backup tong to apply a torque force to the pipe connection disposed between the power tongs and the backup. A resulting torque force is obtained that is greater than the maximum torque that can be exerted by the rotary tong acting alone. The system may also be deployed to apply and hold precise torque forces on the pipe connections. When used to obtain a makeup torque below the maximum rated rotary tong output, the rotary tong is regulated to limit its torque output. When the limited torque is reached, the brake is applied and the cylinder and rod are actuated to apply a smooth, closely controlled increase in torque to the connection. The final torque level may be held constant for a desired length of time. In both the high and low torque applications, the brake prevents the rotary tong from being turned backwardly by the increased torque force applied by actuation of the rod and cylinder assembly. Operation of the system may be manually or automatically controlled.

Owner:TESCO HLDG I

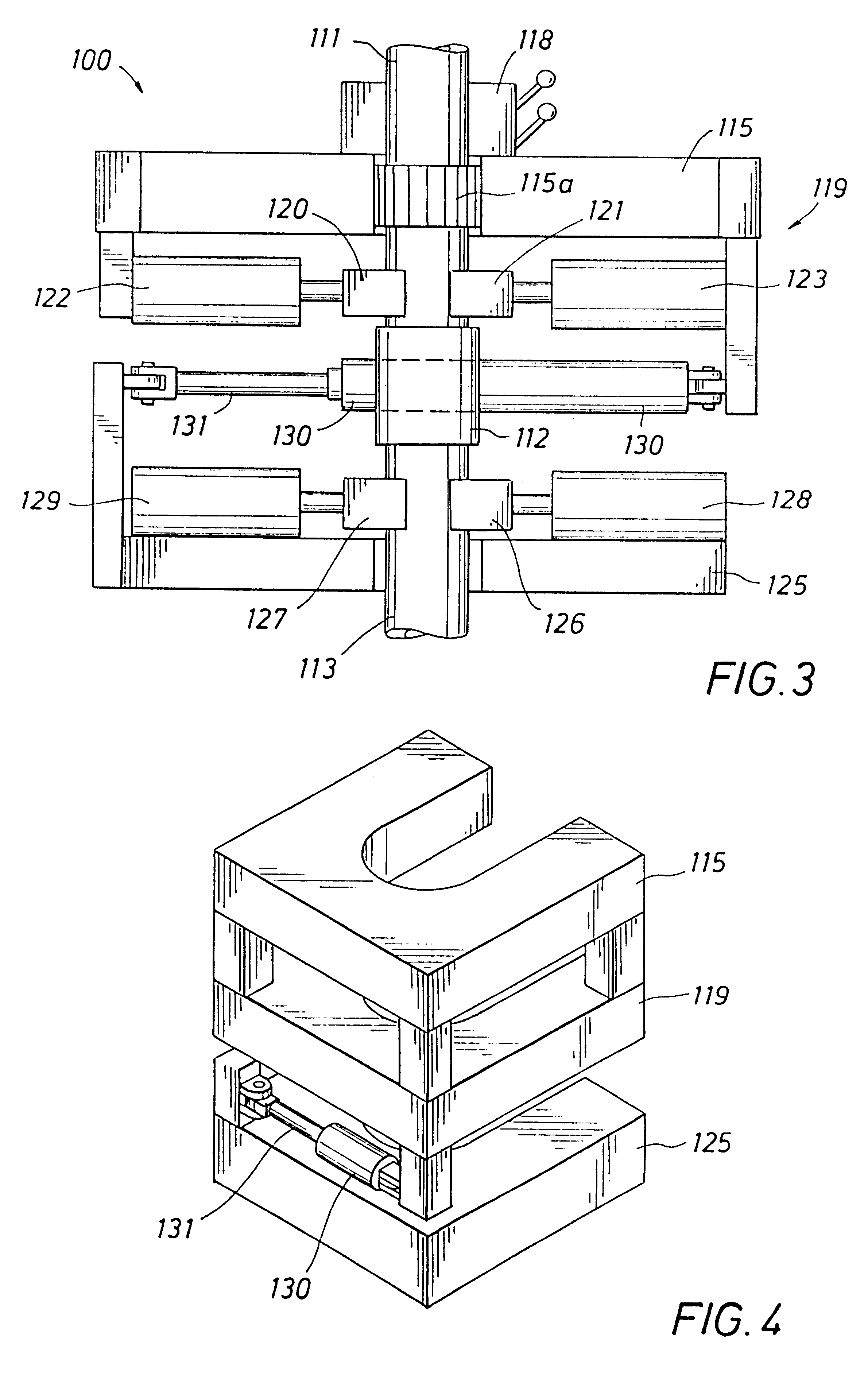

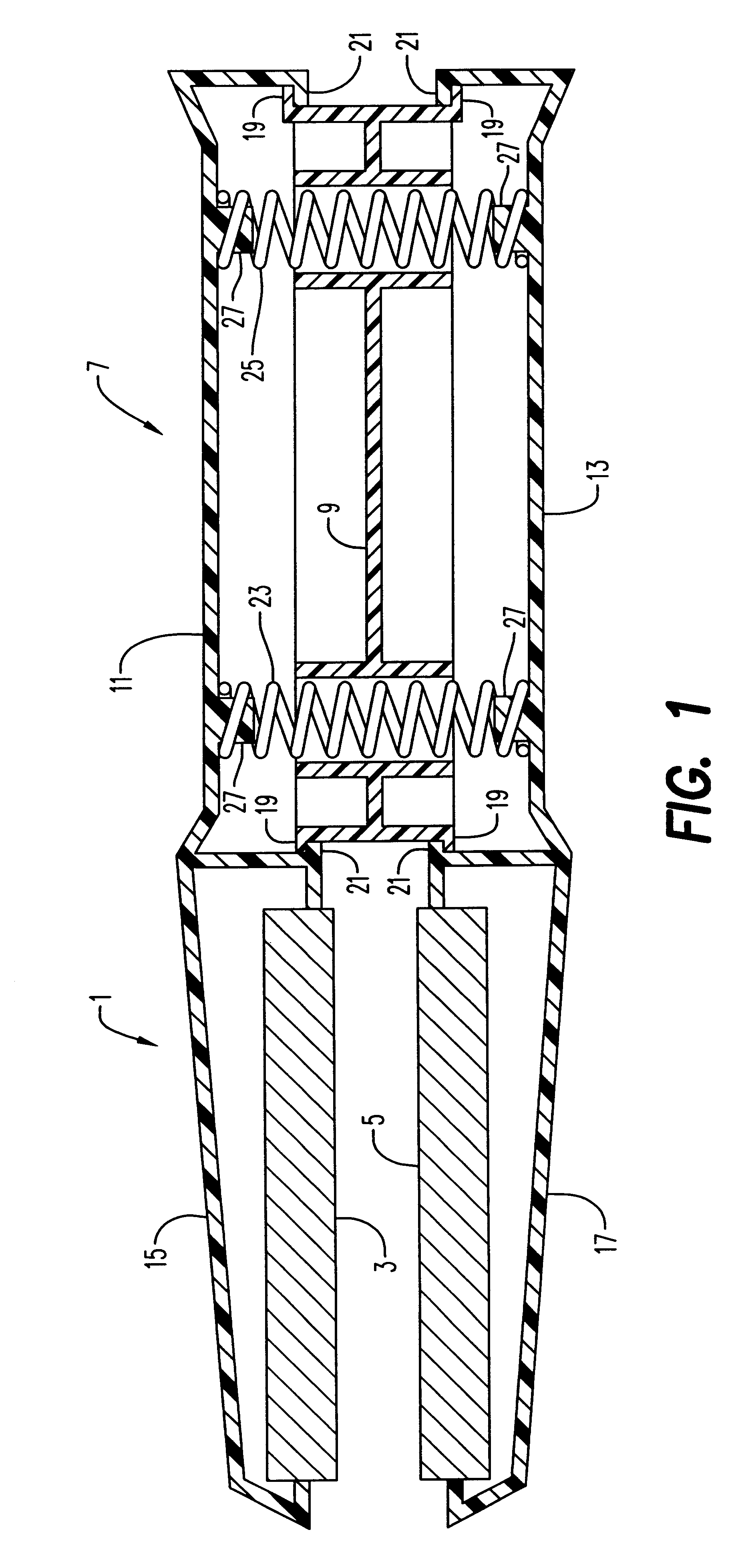

Stent crimper apparatus with radiation shied

A stent crimping apparatus for crimping a deformable radioactive stent onto a deployment device which includes a first jaw member defining a shielded first compression surface, and an opposed, second jaw member defining a shielded second compression surface oriented opposite the first compression surface. The first and second compression surfaces are adapted to collectively form an elongated guide bore formed for axial receipt of the deformable stent and the deployment device therein. To protect against exposure to the radioactive stent, a shield assembly is provided defining an opening into a bore therein which is formed and dimensioned for longitudinal receipt of the deformable stent in an uncrimped condition. A shield assembly defines an opening into the bore, and cooperates with the first and second jaw members to substantially prevent radioactive particles emitted by the radioactive stent from passing out of the crimping apparatus. An operating mechanism is operatively coupled to the first and second jaw members for selective movement between a loading condition and a crimping condition. In the loading condition, the uncrimped stent and the deployment device may be inserted through the opening and into the bore. In the crimping condition, the deformable stent is radially compressed onto the deployment device between the first and second compression surfaces.

Owner:ISOSTENT

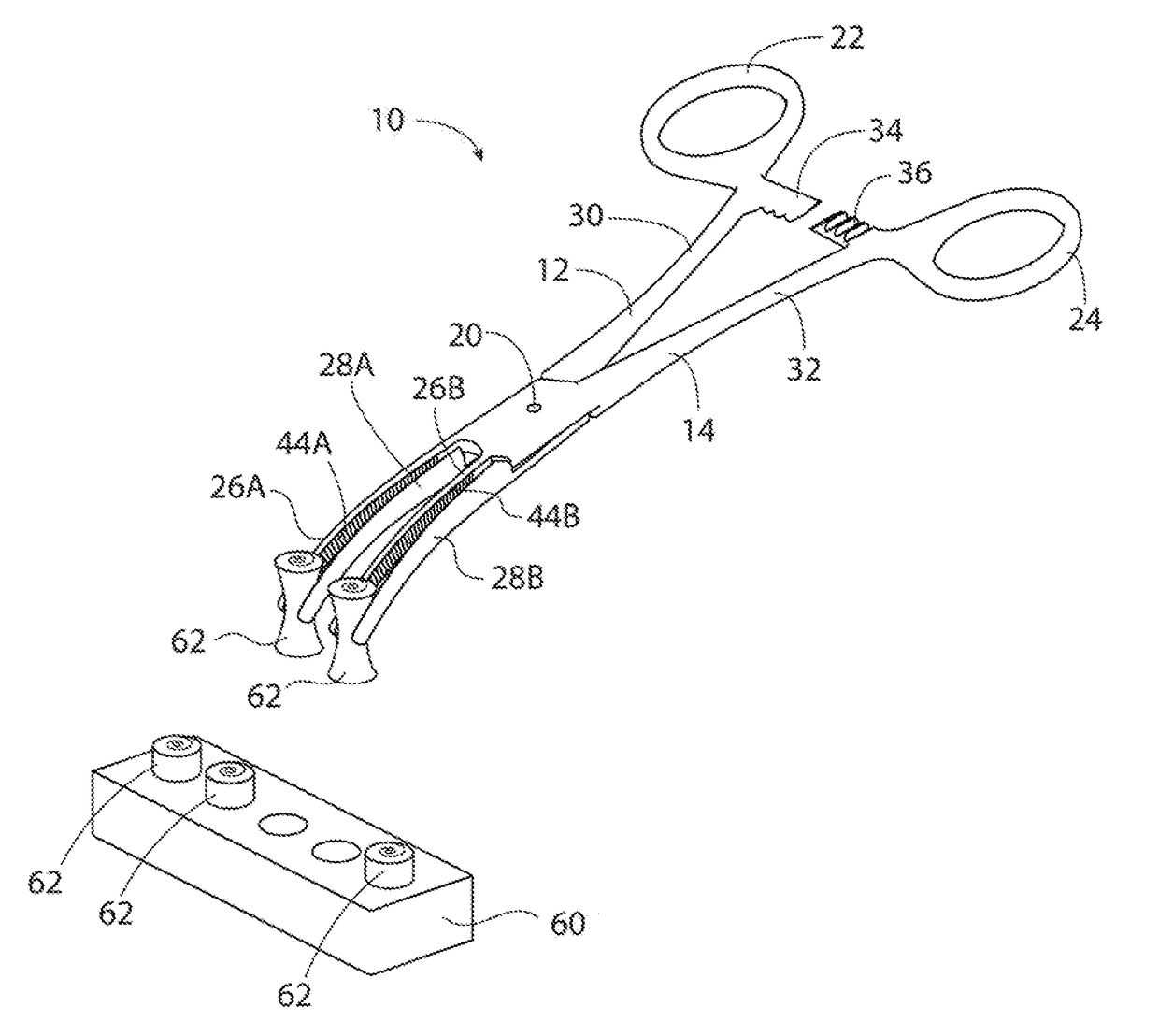

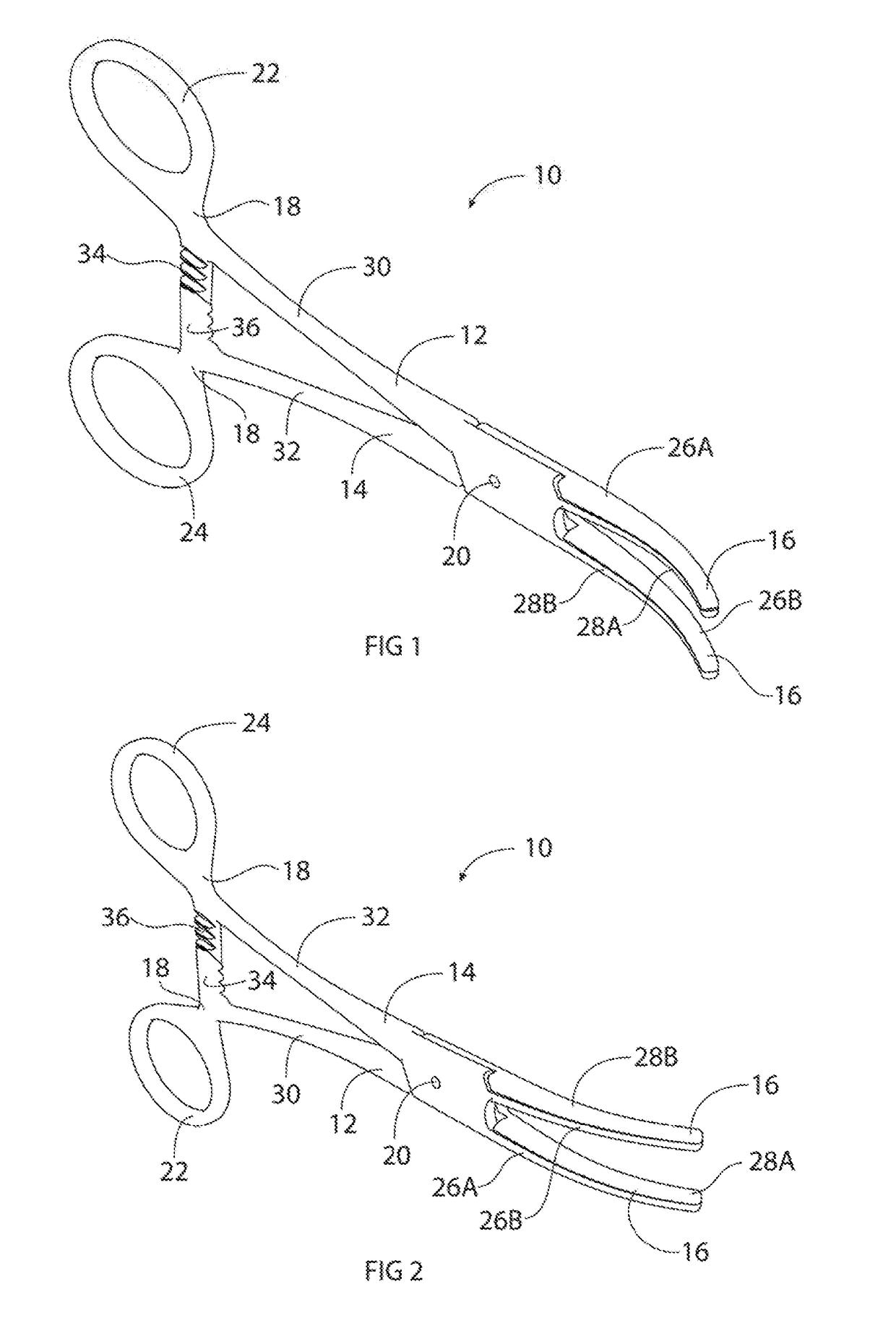

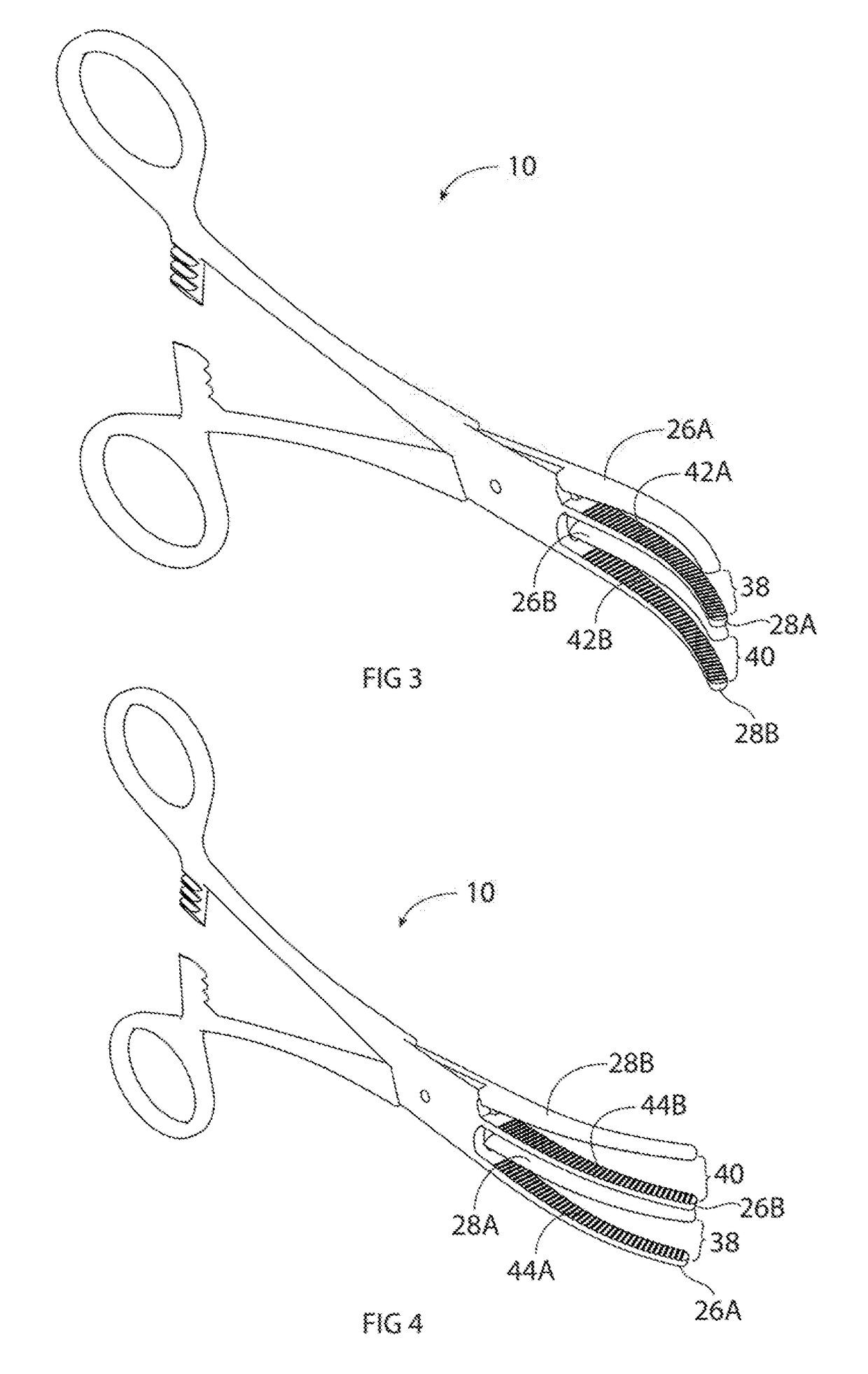

Double Forceps

Handheld forceps having plural pincers for grasping and holding multiple objects, such as Peanut or Cotton Kittner sponges, at the same time are disclosed. The handheld forceps include opposing arms having proximal and distal ends. A hinge connects the opposing arms together between the proximal and distal ends. The opposing arms articulate relative to each other about the hinge. A handle portion at the proximal ends of the opposing arms has an open and closed position for articulating the distal ends open and closed. Distal ends are configured with plural pincers whereby jaws are formed between the plural pincers for grasping and holding multiple objects at the same time.

Owner:THRASHER III RICHARD DEVERE

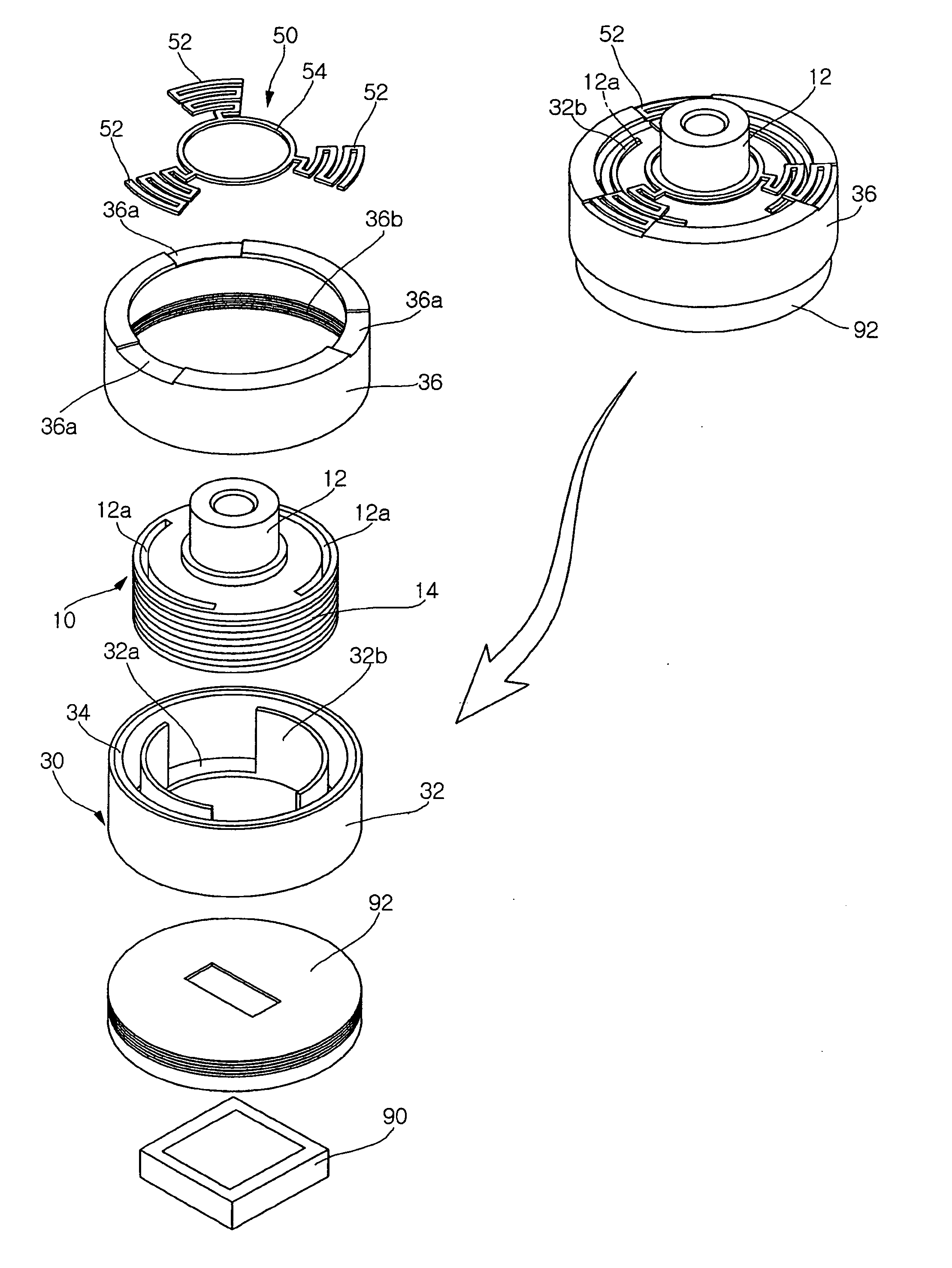

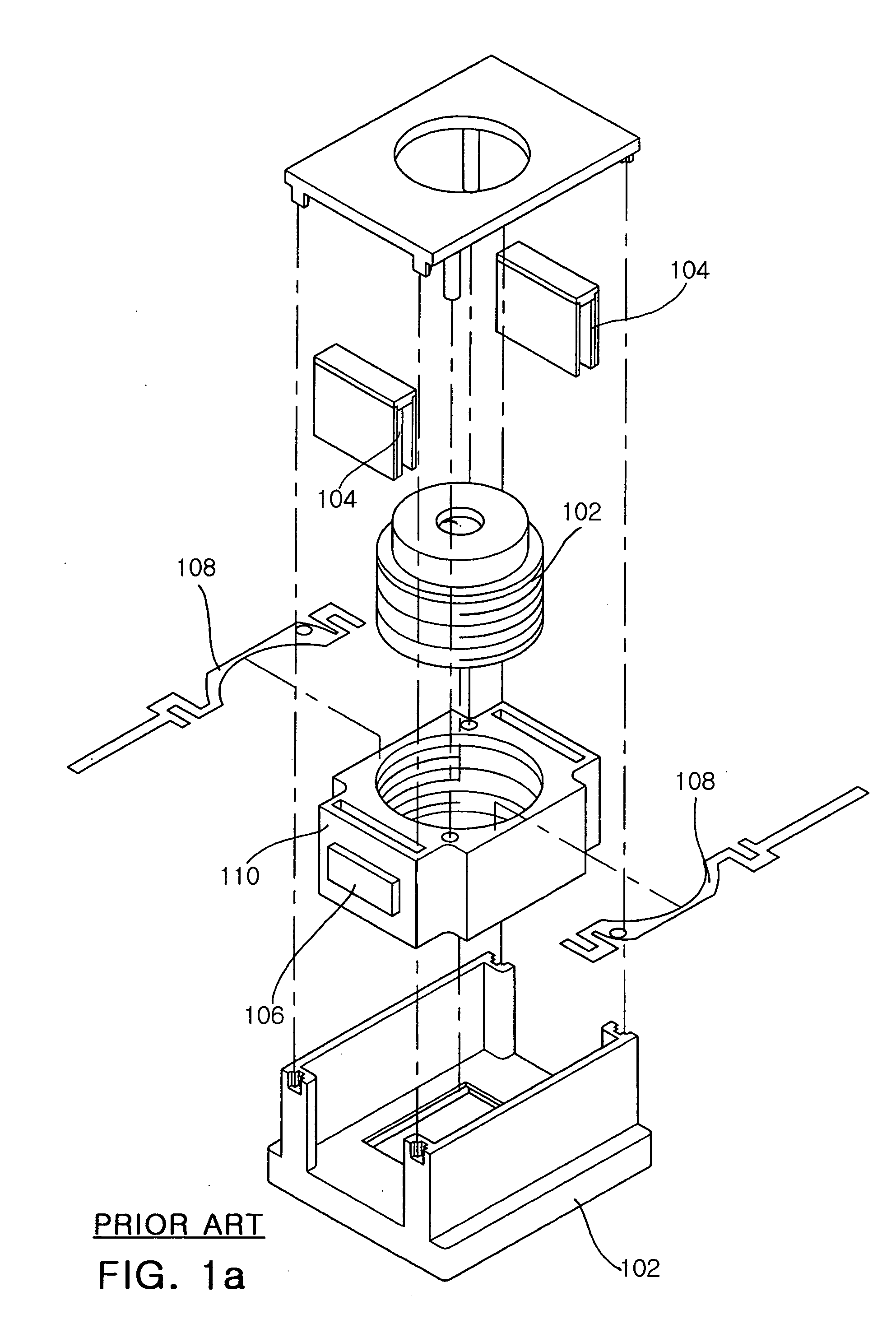

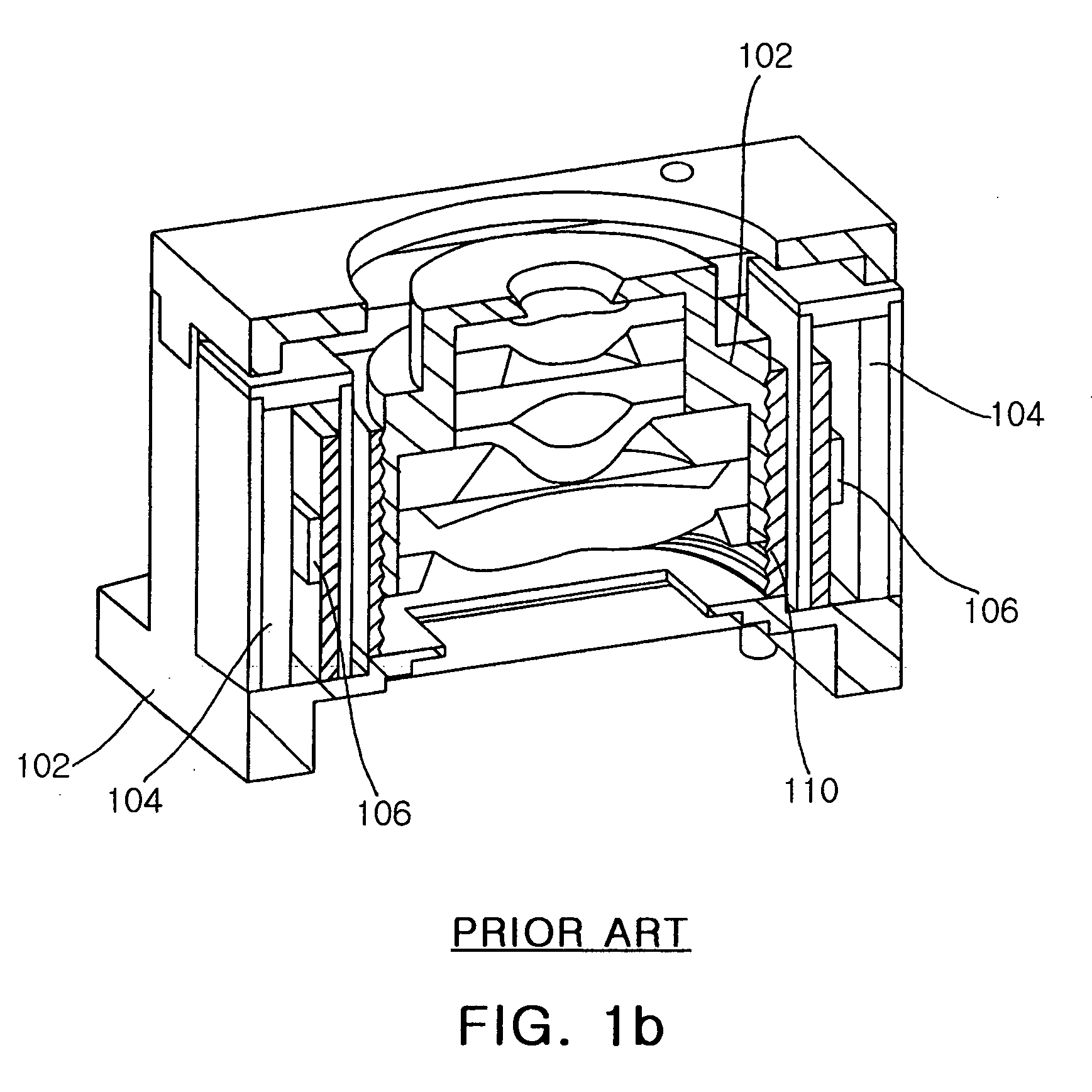

Focal length adjustment apparatus with improved vibration and impact-resistance properties

InactiveUS20060153556A1Improve damping effectHigh magnetic flux densityProjector focusing arrangementPliersUltrasound attenuationMagnetic flux

Disclosed herein is a focal length adjustment apparatus in which a magnetic fluid that serves as attenuation means is injected between a magnet and a coil to achieve an improvement in a magnetic flux density and damping effect. The apparatus comprises a moving unit including a lens barrel that contains at least one lens therein, and a coil arranged on an outer circumference of the lens barrel, a fixed unit including a yoke formed with an opening for receiving the lens barrel, a case into which the yoke is inserted and mounted, and a magnet affixed to the yoke to be arranged adjacent to the coil, a supporting member used to elastically support the moving unit relative to the case, and attenuation means interposed between the coil and the magnet to attenuate vibration of the moving unit.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

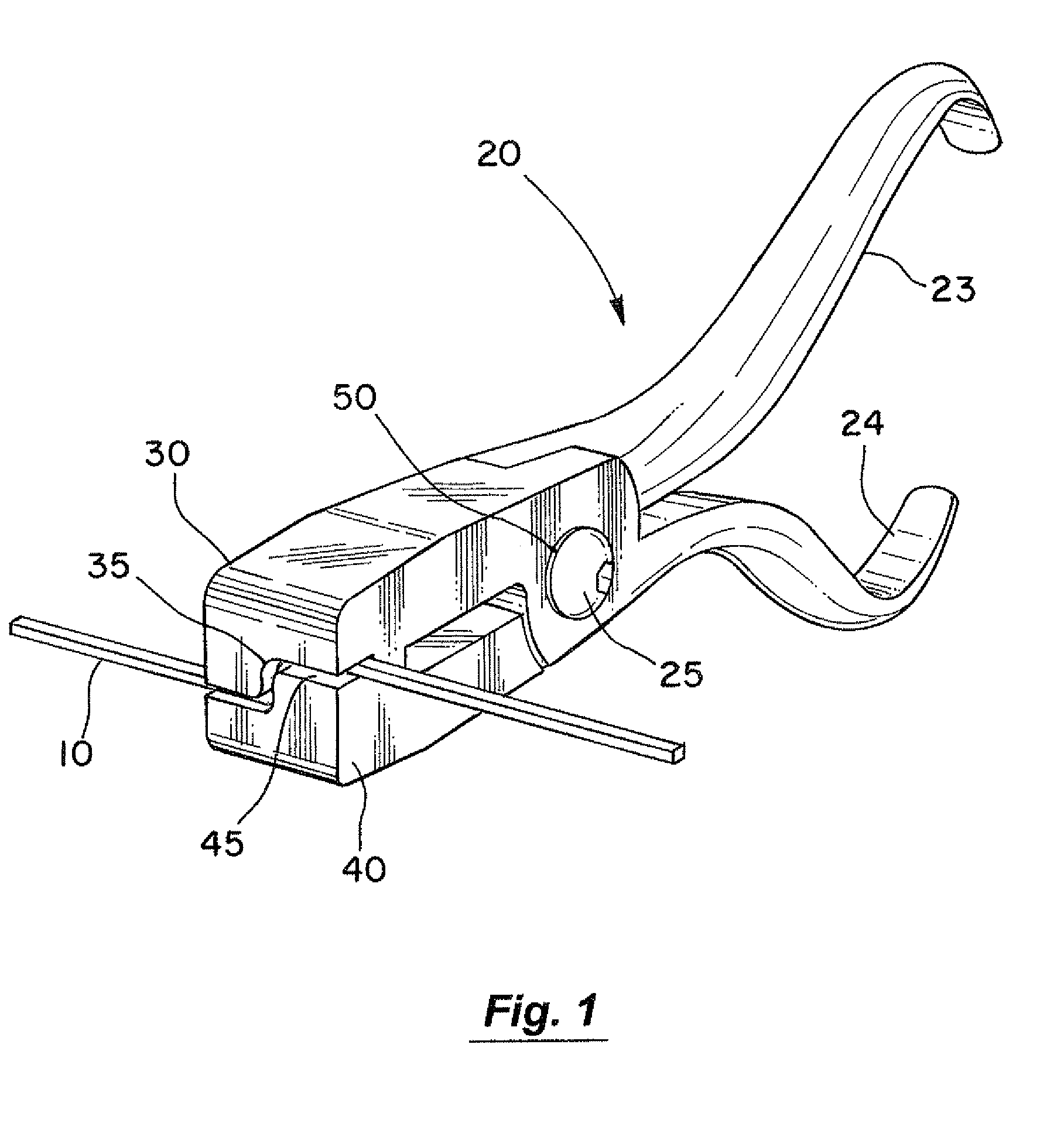

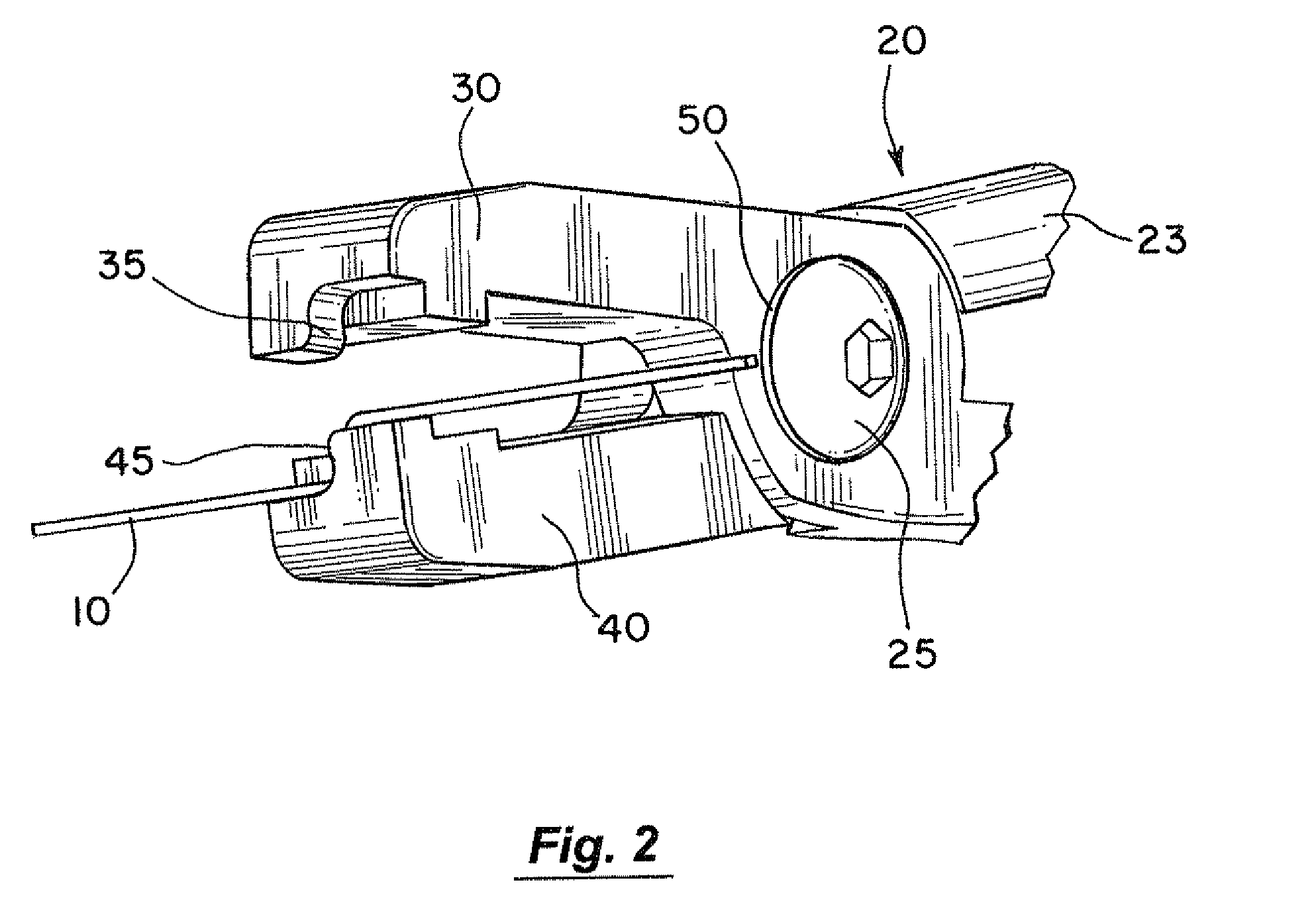

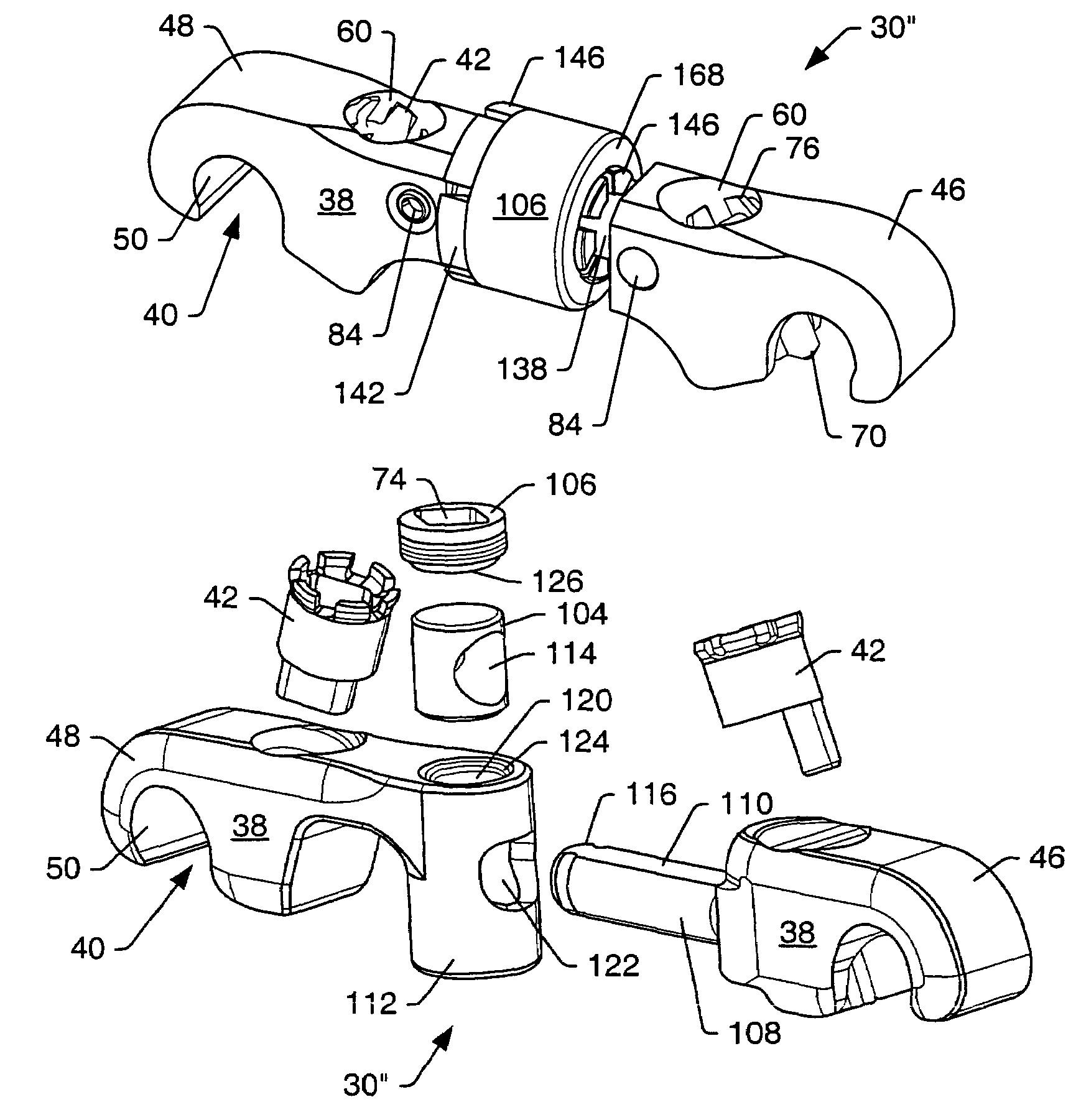

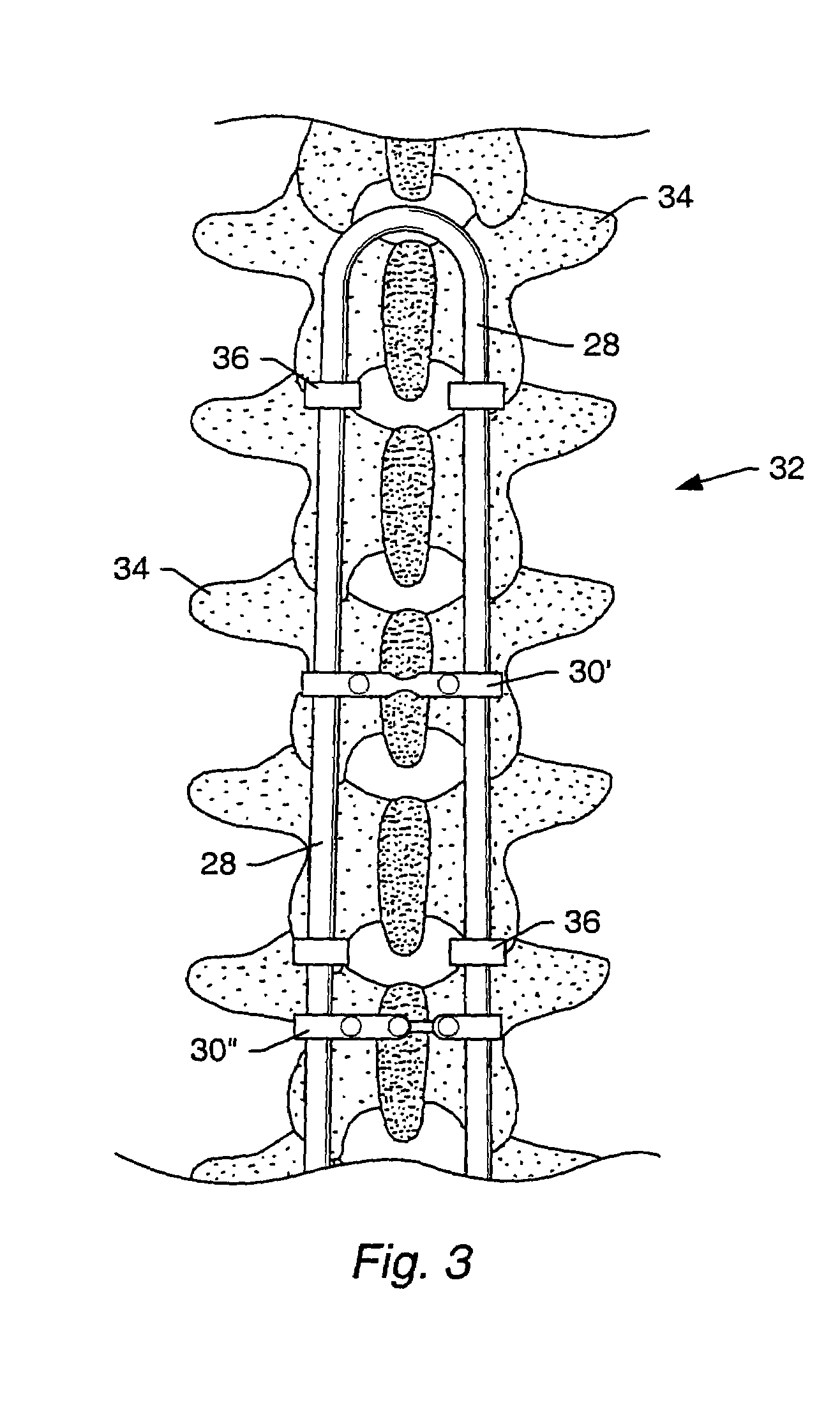

Transverse connector with cam activated engagers

A transverse connector may be attached to rods of an orthopedic stabilization system by cam locks. Rotation of a cam system may extend a rod engager into a rod opening. The rod engager may be a portion of the cam system. The extension of the rod engager into the rod opening may push a rod against a body of the transverse connector to form a frictional engagement between the transverse connector, the rod, and the rod engager. The cam system allows the formation of an un-threaded, unitary transverse connector that has a low profile. The transverse connector may be easily and securely attached to a rod.

Owner:ZIMMER SPINE INC +1

Workpiece gripping device

Owner:FANUC LTD

Thoracic closure device and methods

A thoracic closure device. The device has a handle member, a base member, and a feed path, and is designed to accept and, with a ratcheting mechanism, tension a toothed closure tie. A guide member is also provided, and assists in the placement of a closure tie prior to tensioning. Methods of closing a median sternotomy using toothed closure ties are also disclosed.

Owner:DEVICE EVOLUTIONS

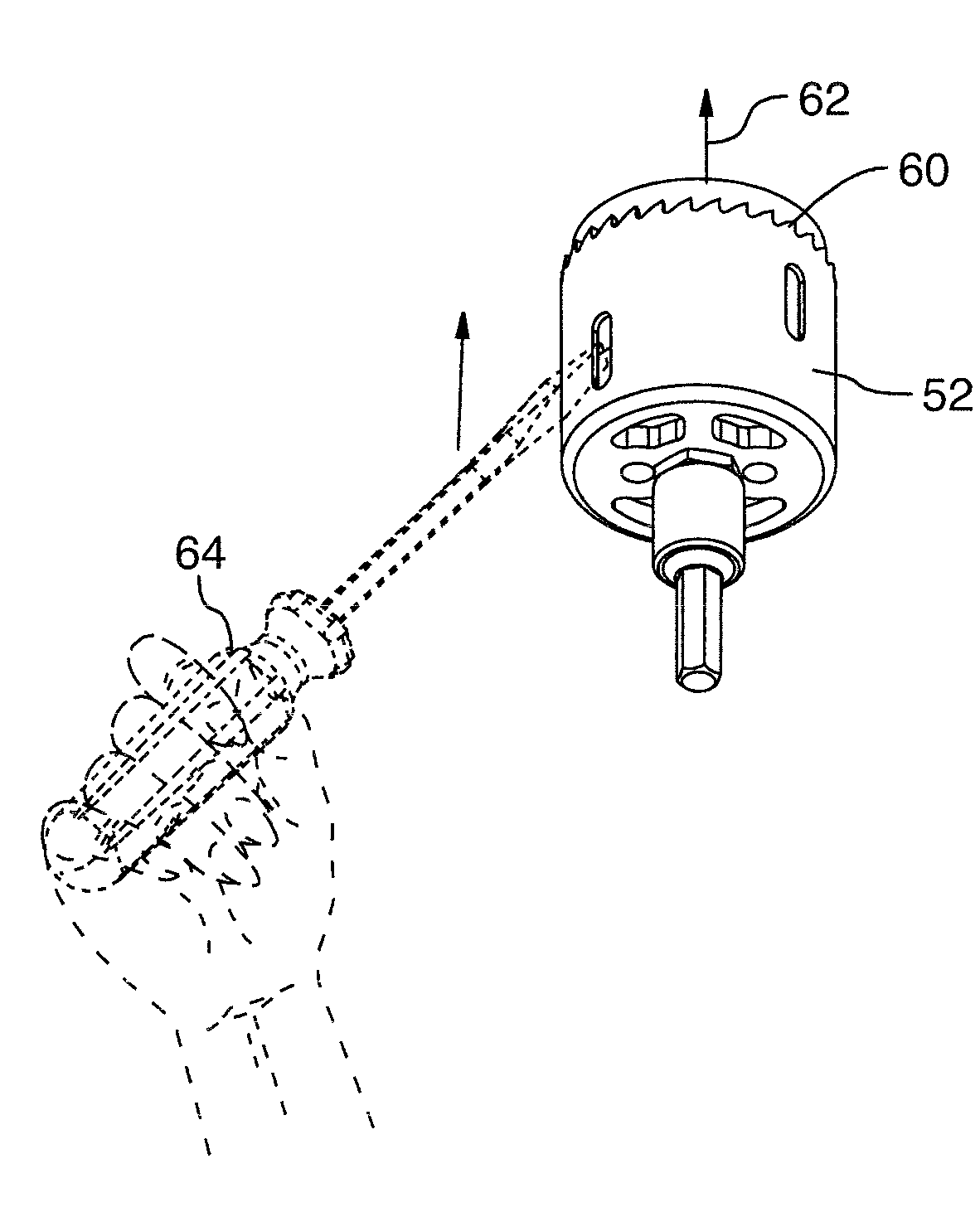

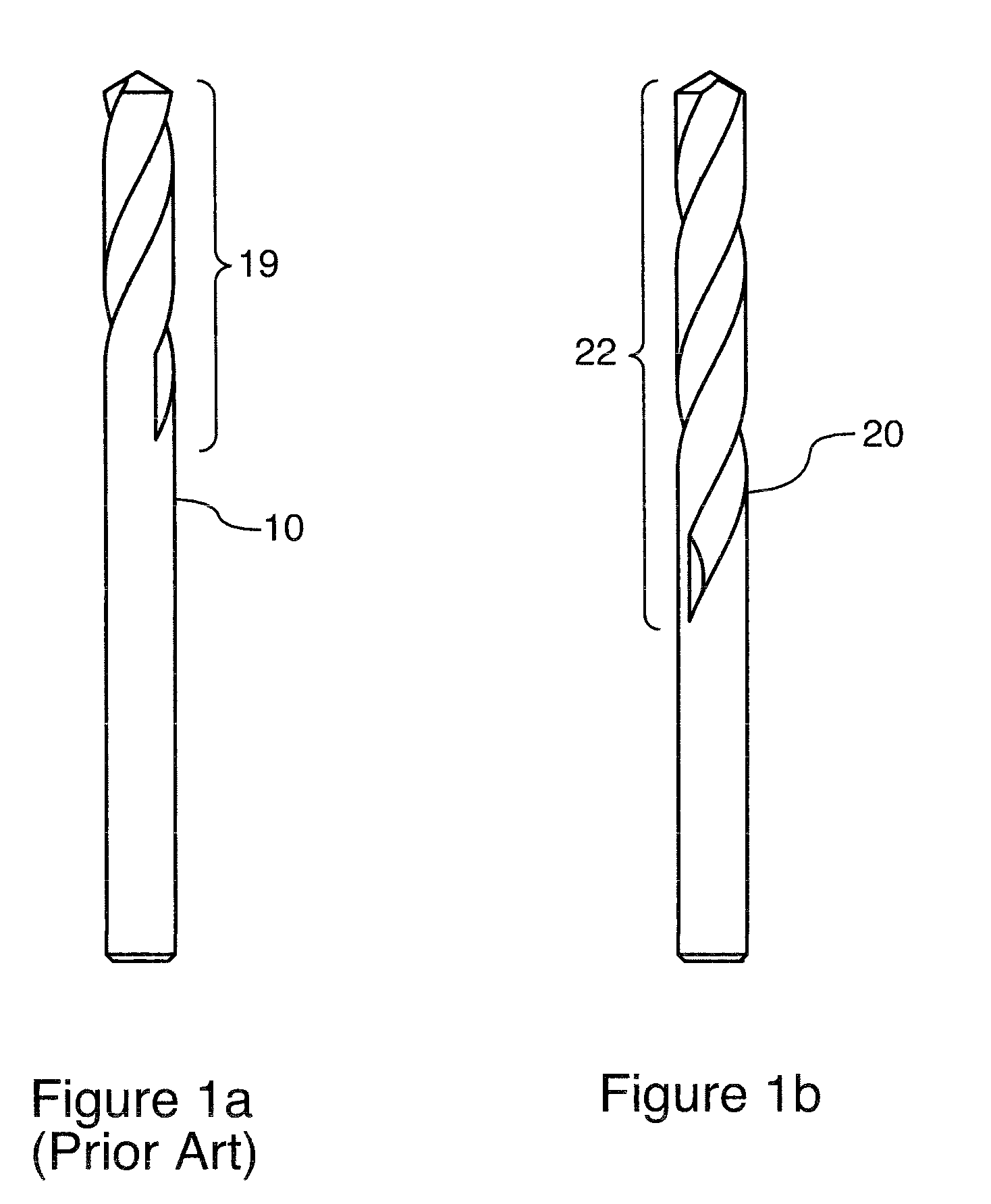

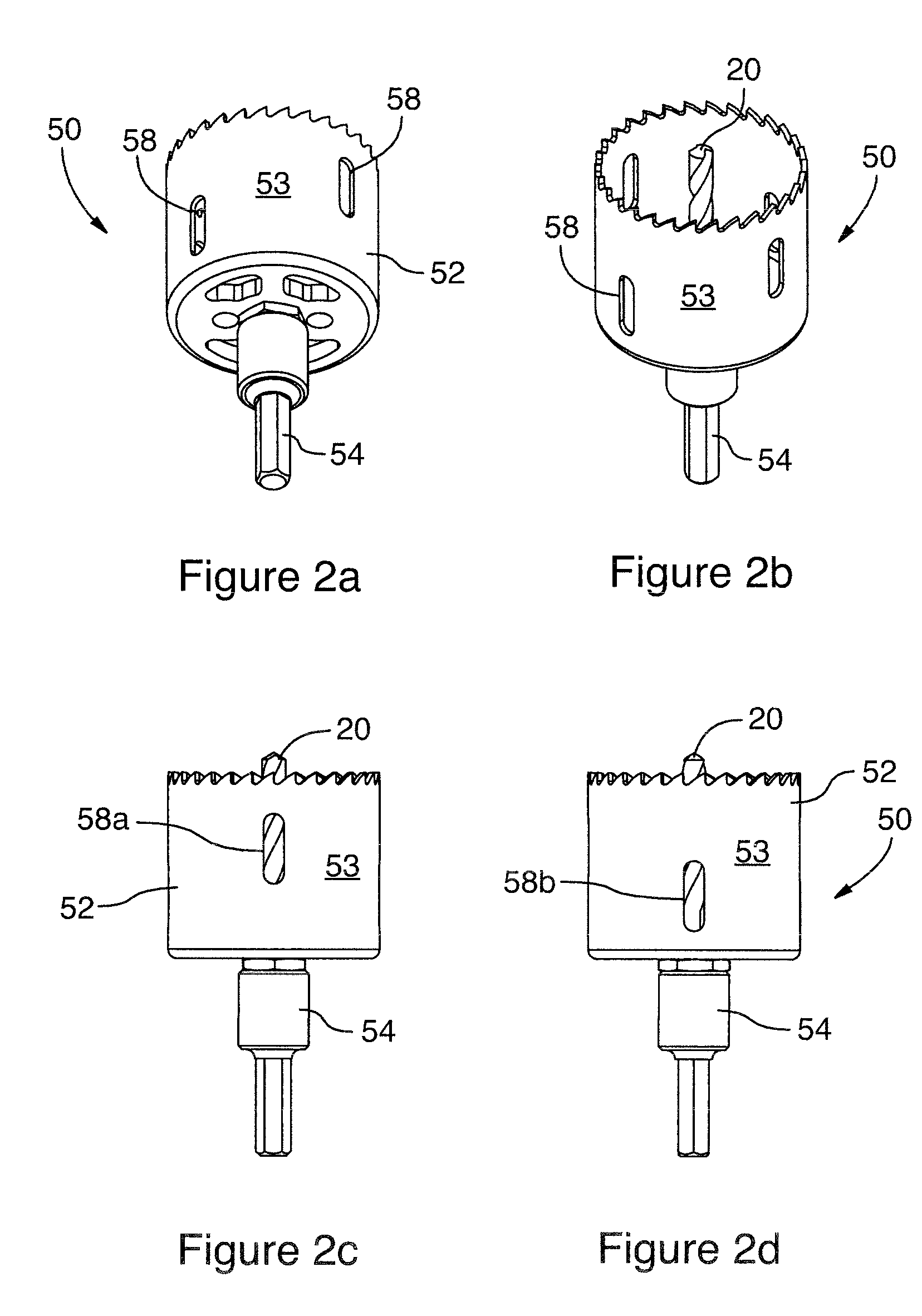

Hole saw system with improved slug removability

InactiveUS20090035082A1Reduce weightEasy to disassembleTransportation and packagingPliersHole sawEngineering

There is provided a hole saw system comprising a hole saw including a bottom portion and a body portion; a mandrel, including apparatus for receiving the hole saw; wherein the hole saw includes a plurality of slot pairs, the slot pairs being offset from each other on the body portion allowing a tool to be inserted into one of the slot pairs for removal of a slug.

Owner:TEAM FAIR HLDG

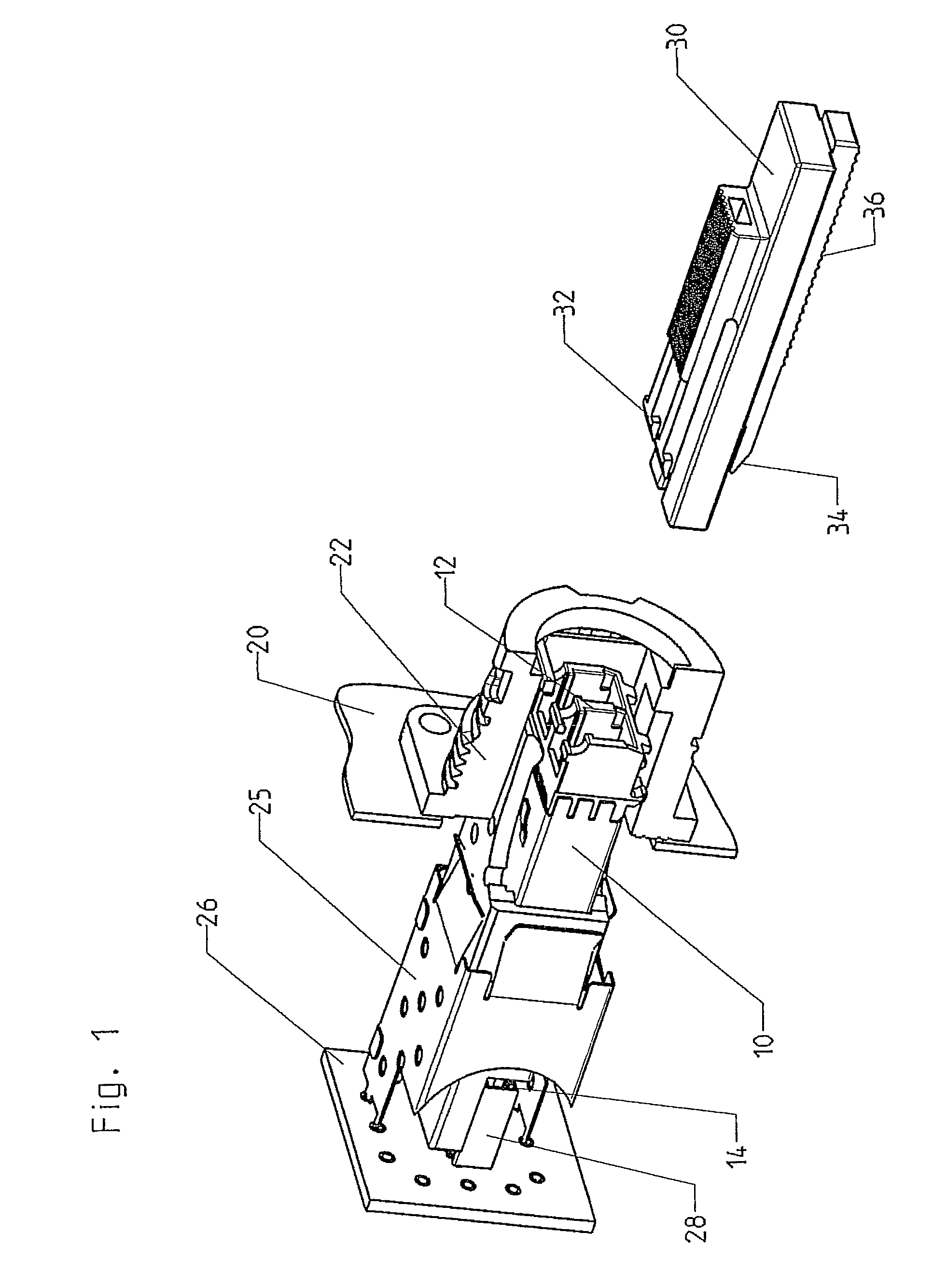

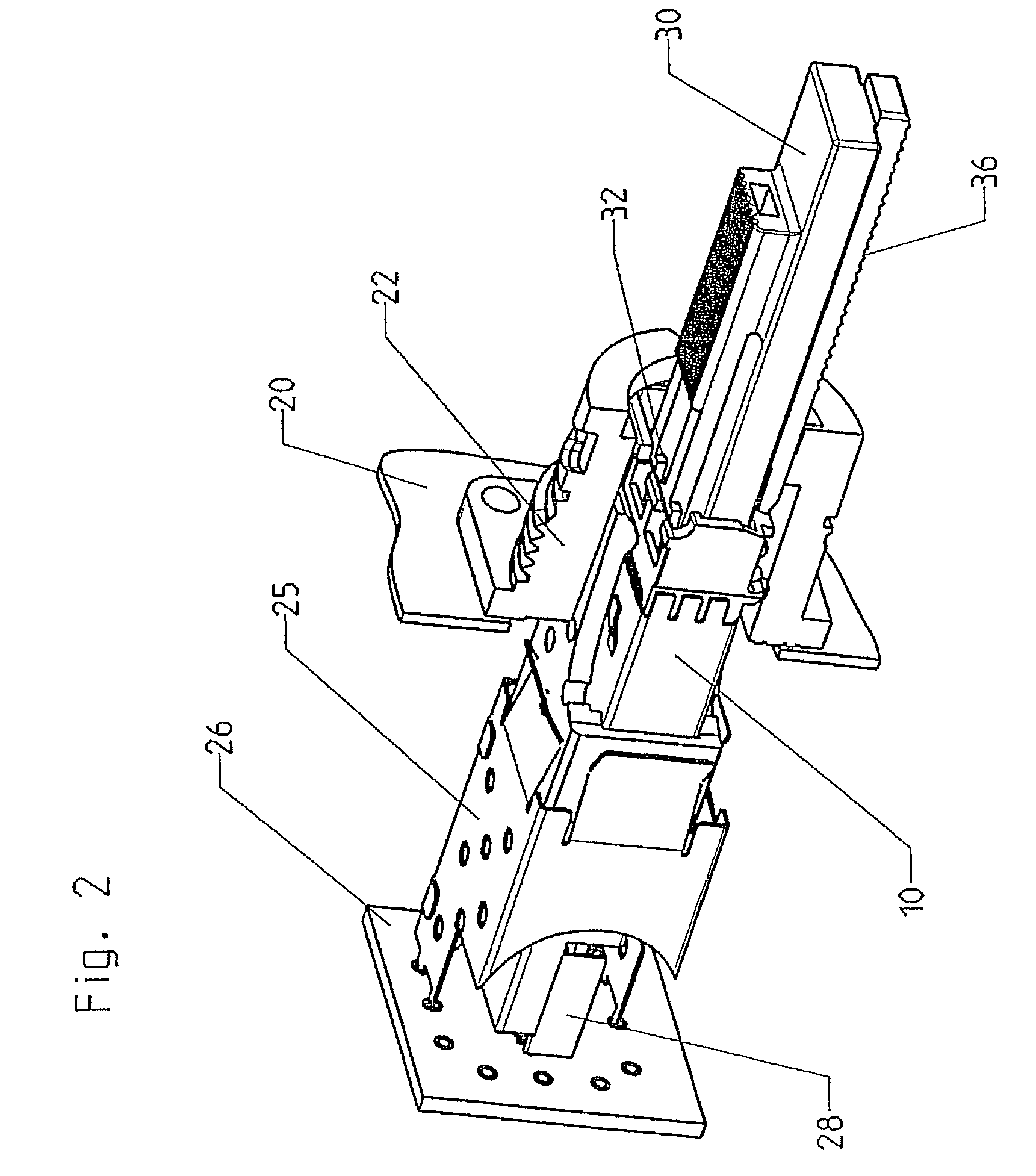

Device for releasing a transceiver fixed in a housing via a connection from the housing

ActiveUS8956058B2For quick replacementFacilitated releaseBottle/container closurePower operated devicesTransceiver

The invention concerns a device for releasing a transceiver, fixed in a housing via a connection, from the housing, wherein the device is releasably connectable and insertable into a plug contour of the transceiver via first means and wherein the device has second means for releasing the connection between the transceiver and the housing.

Owner:MC TECH GMBH (DE)

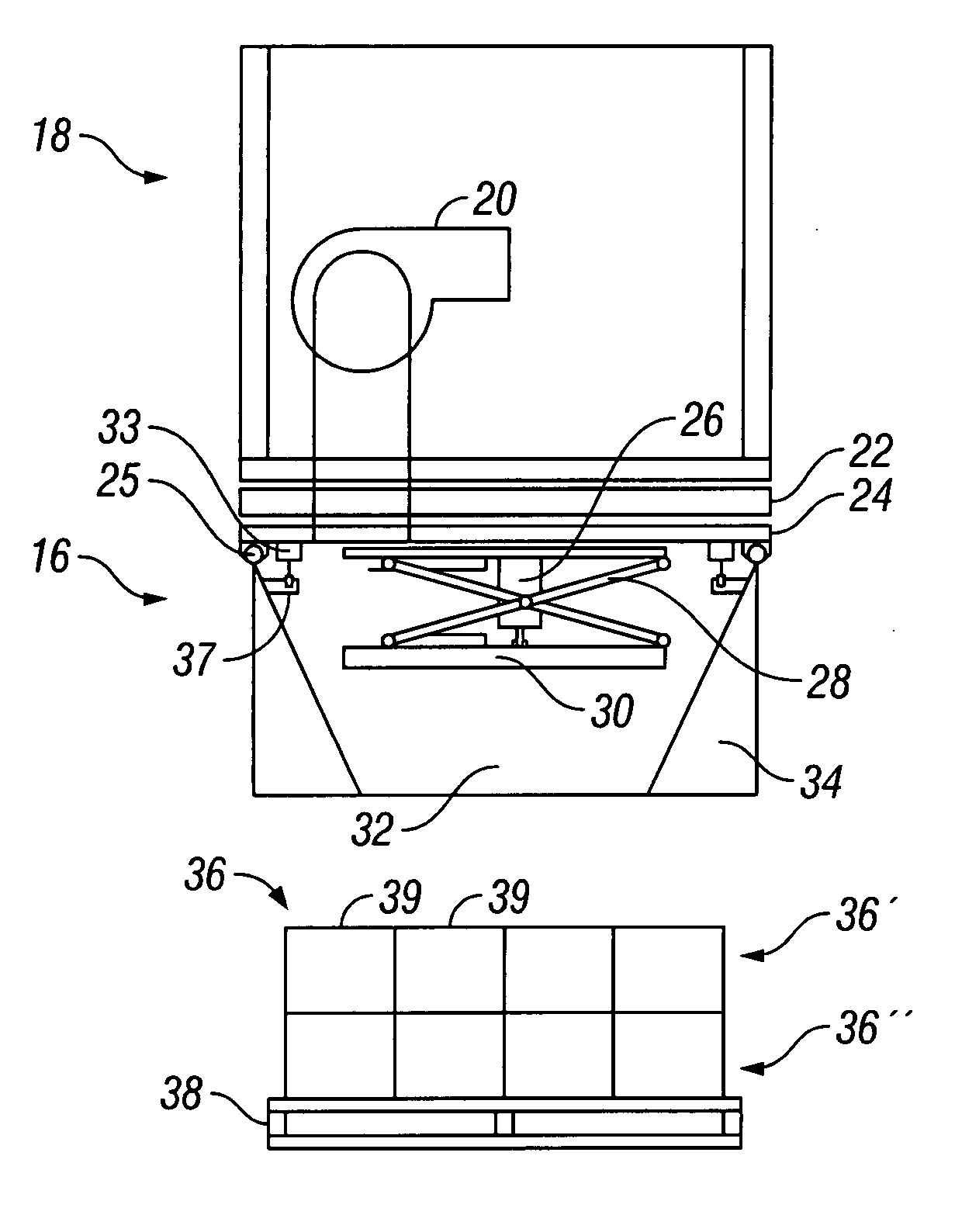

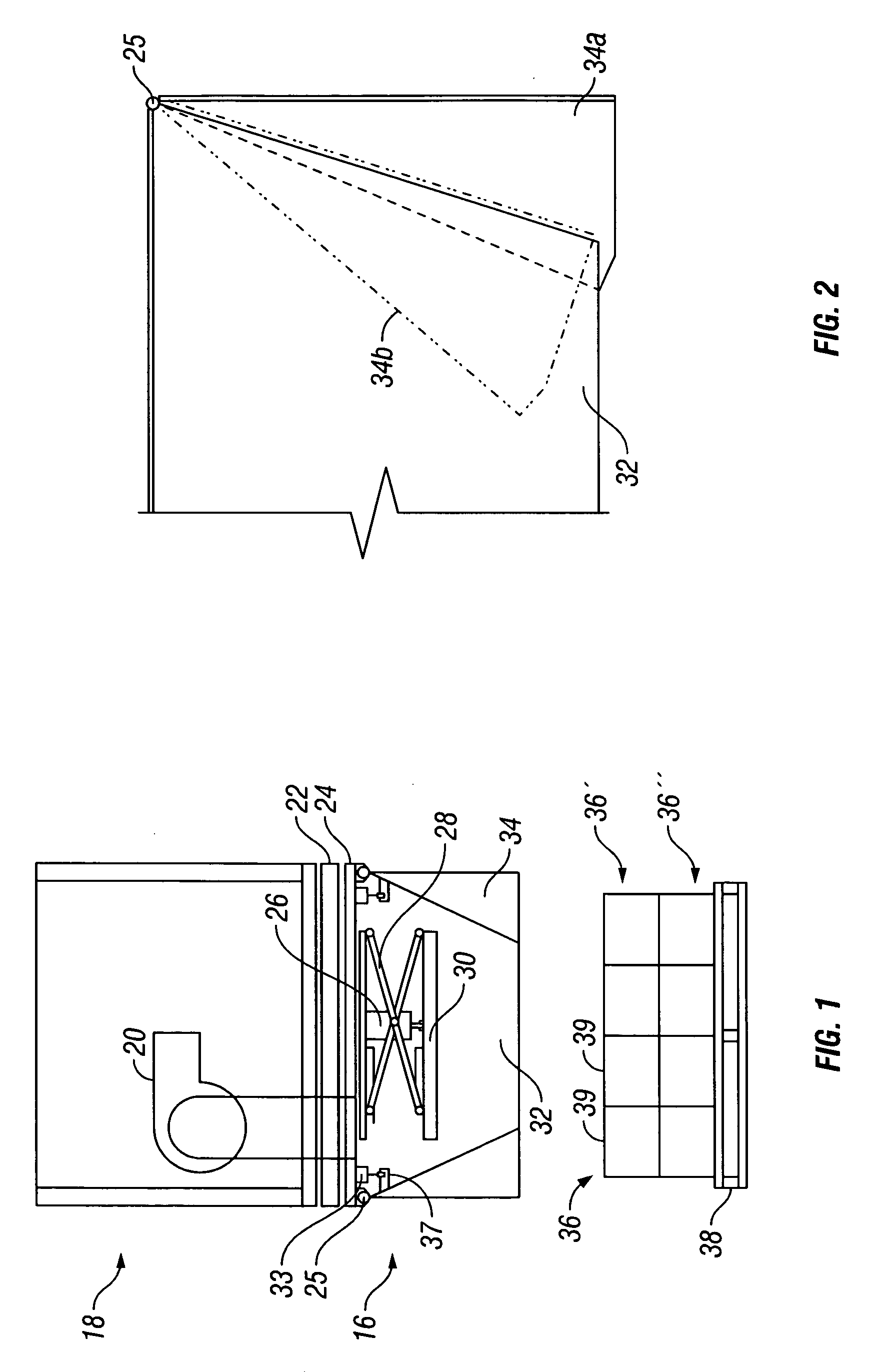

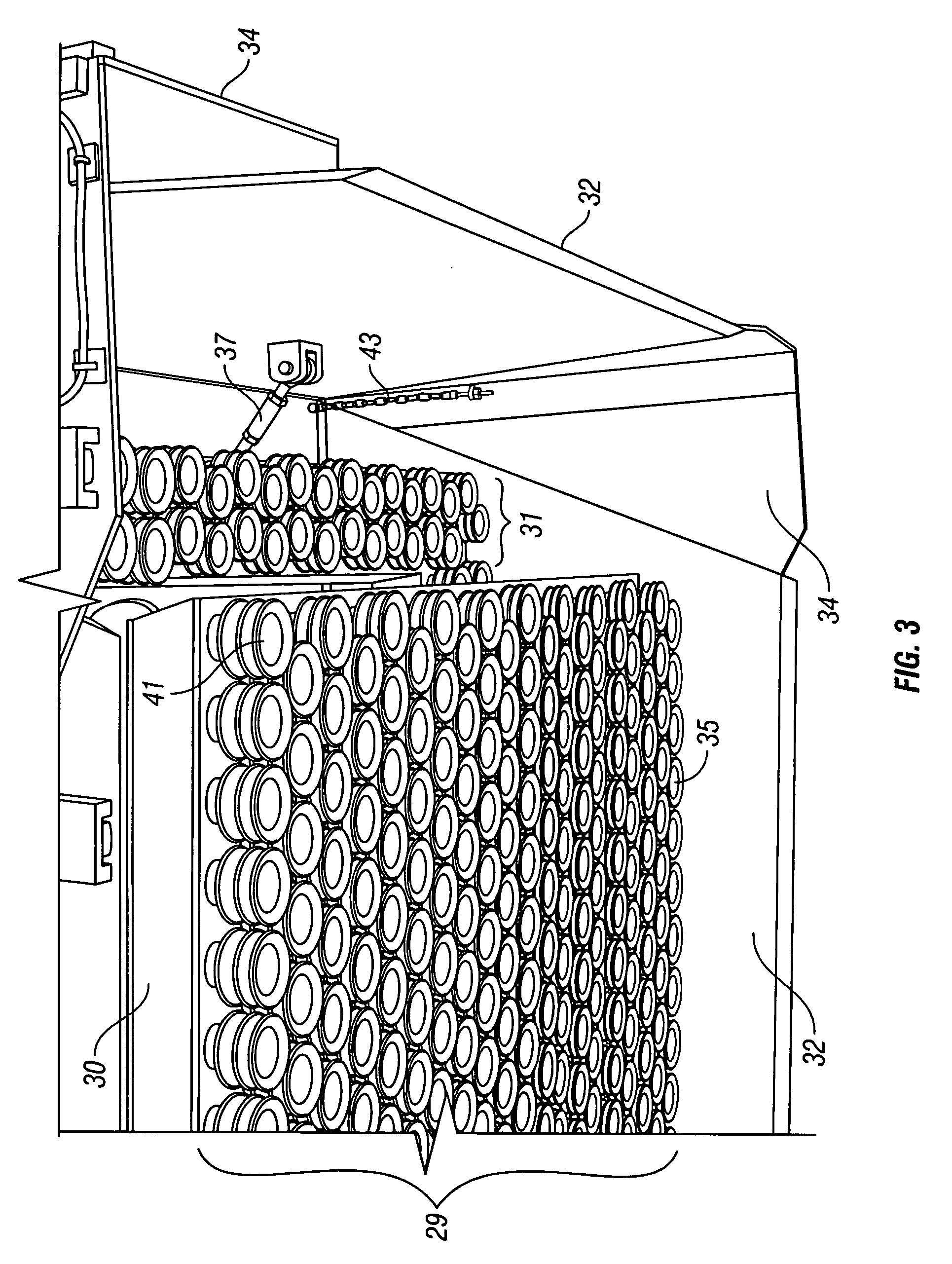

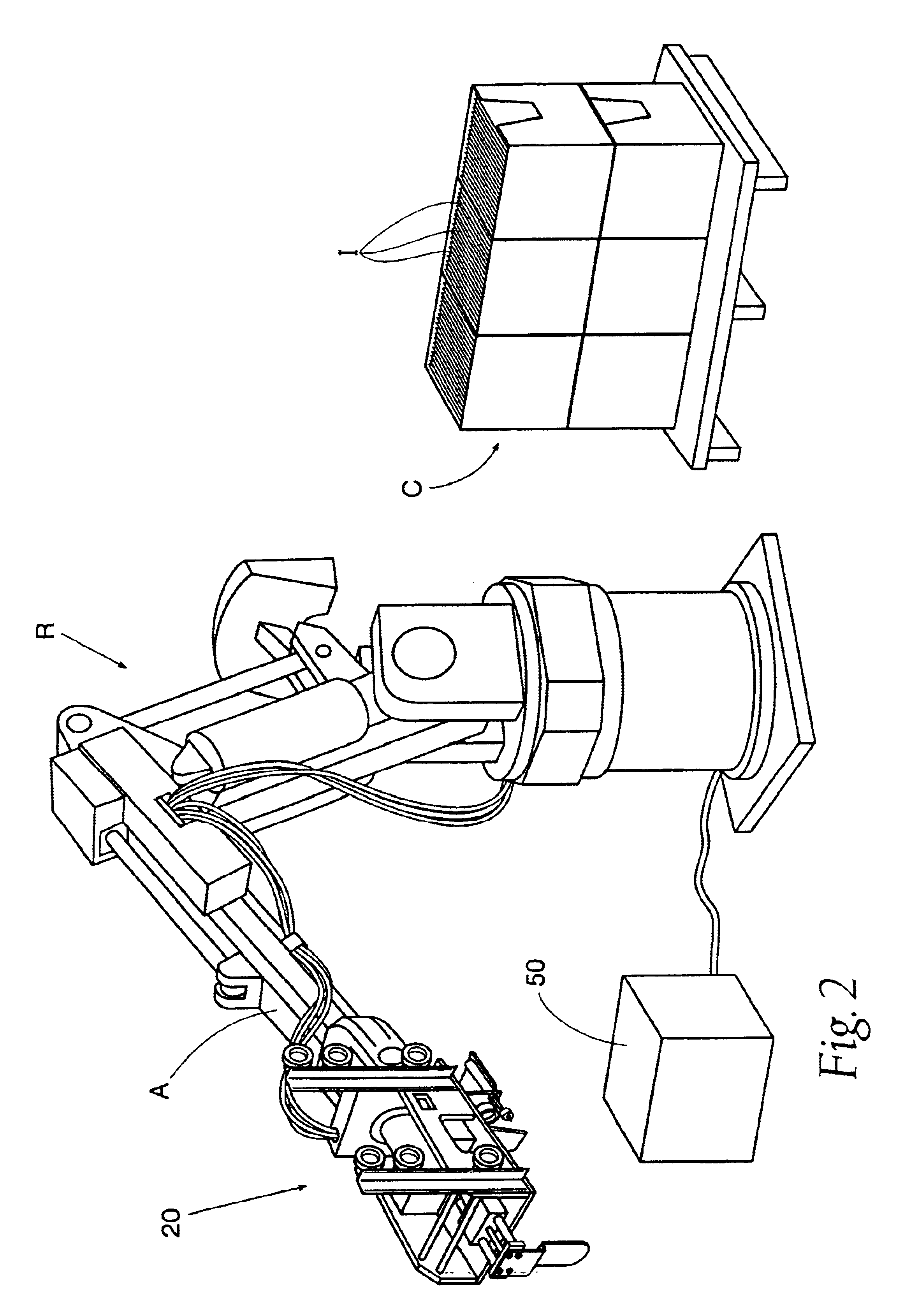

Layer picking end effector system, apparatus and method

A system, method and apparatus for handling and moving a layer of articles, such as cased products. The system and apparatus comprise a hood enclosure having four side panels, and four interconnected corner member. The side walls and corner members interoperate to form an adjustable enclosure to pick the layer of articles. A vacuum generate is utilized to evacuate air from the hood enclosure to assist in lifting the layer of articles. The hood enclosure may utilize an array of vacuum cups to assist in the lifting of articles into the hood enclosure. The method is directed towards utilizing the hood layer end effector to move and hand articles.

Owner:SAGE AUTOMATION

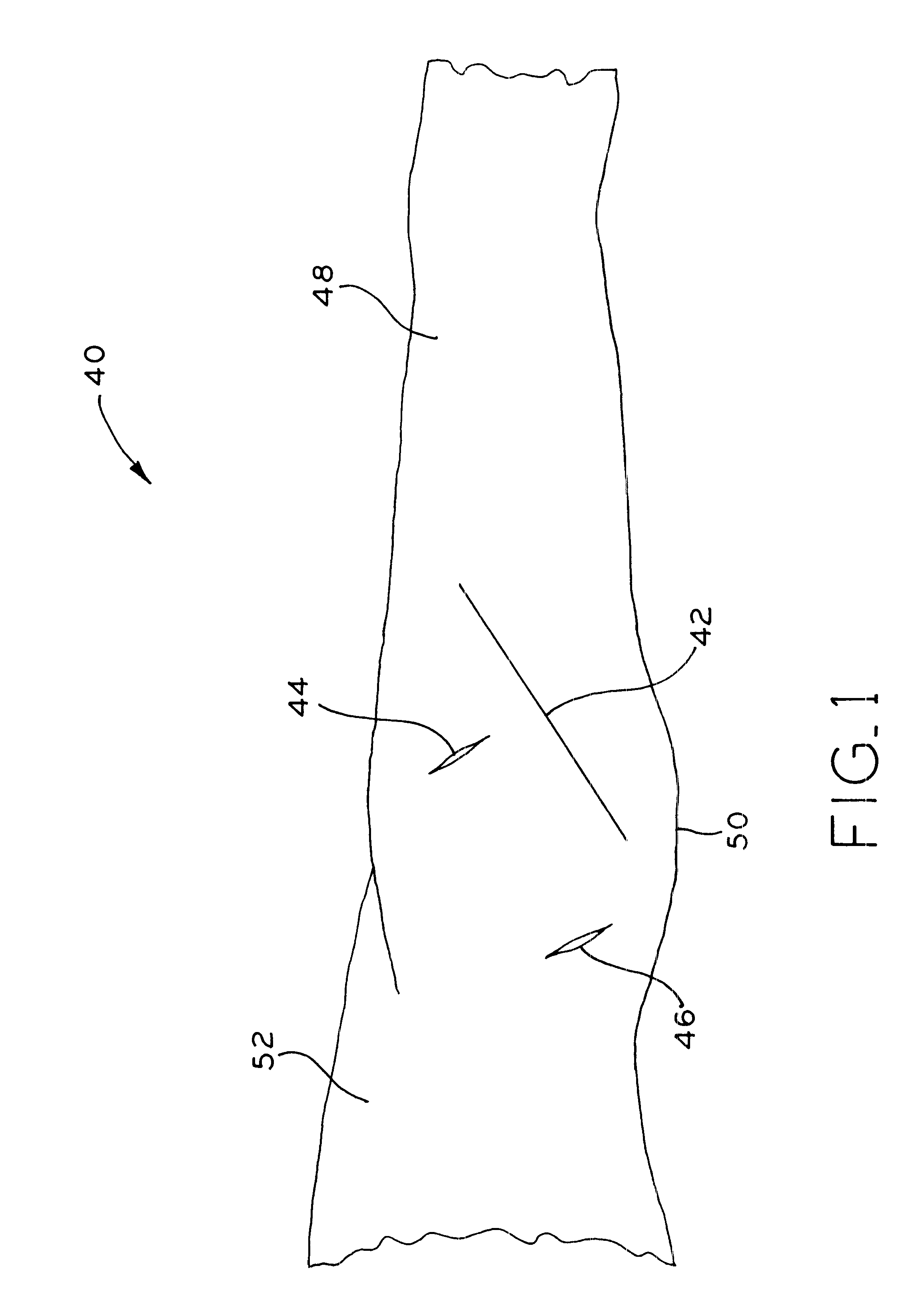

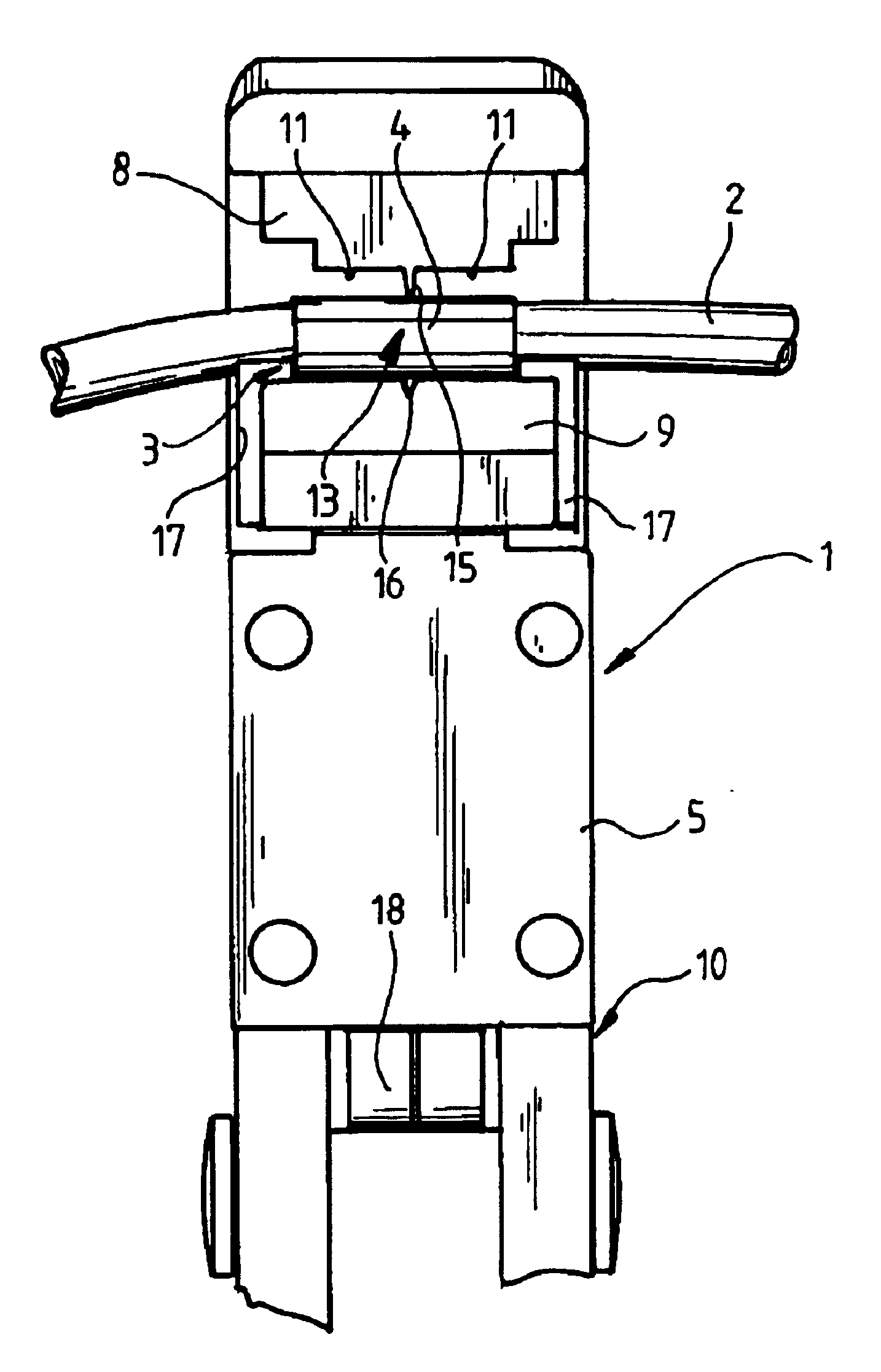

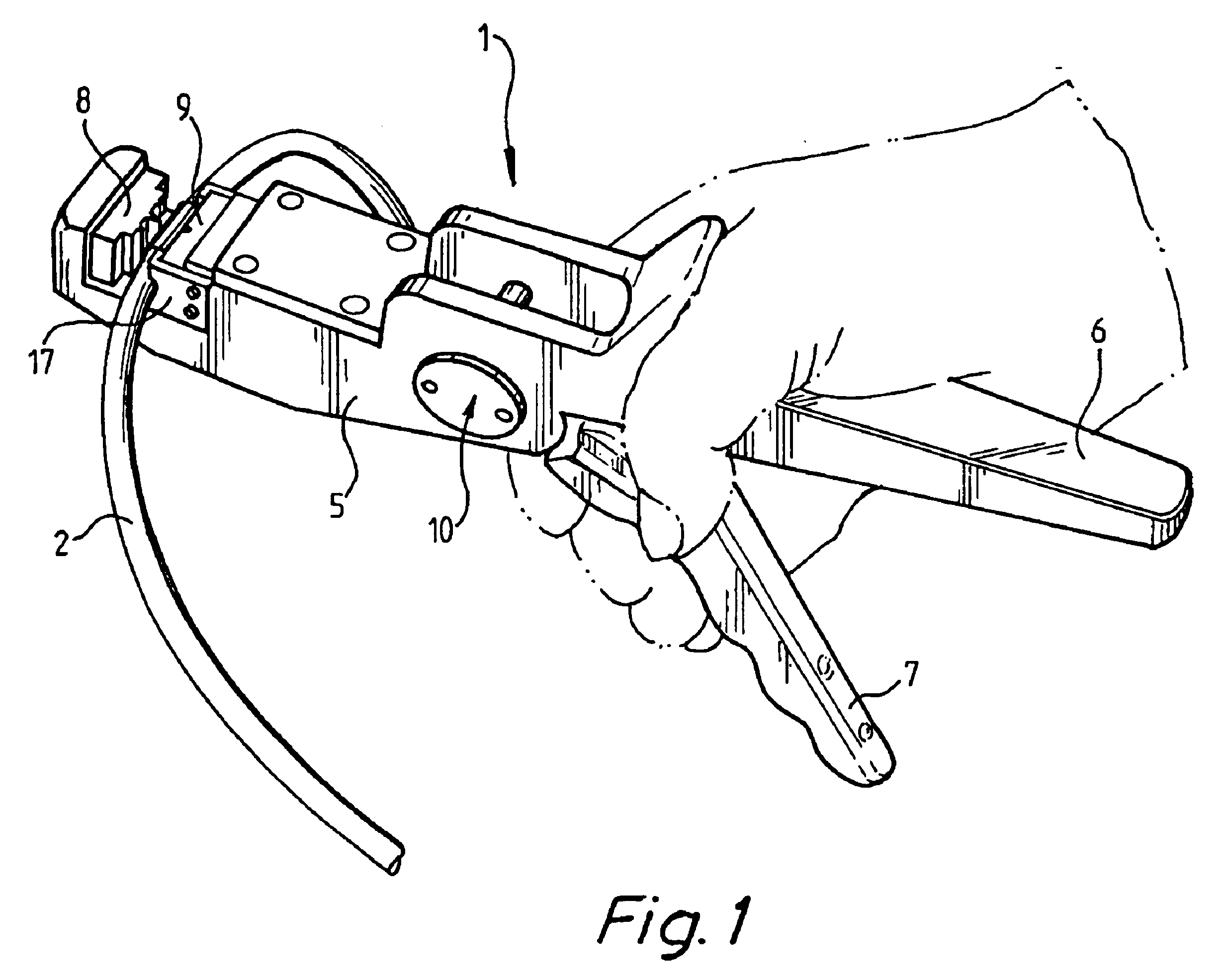

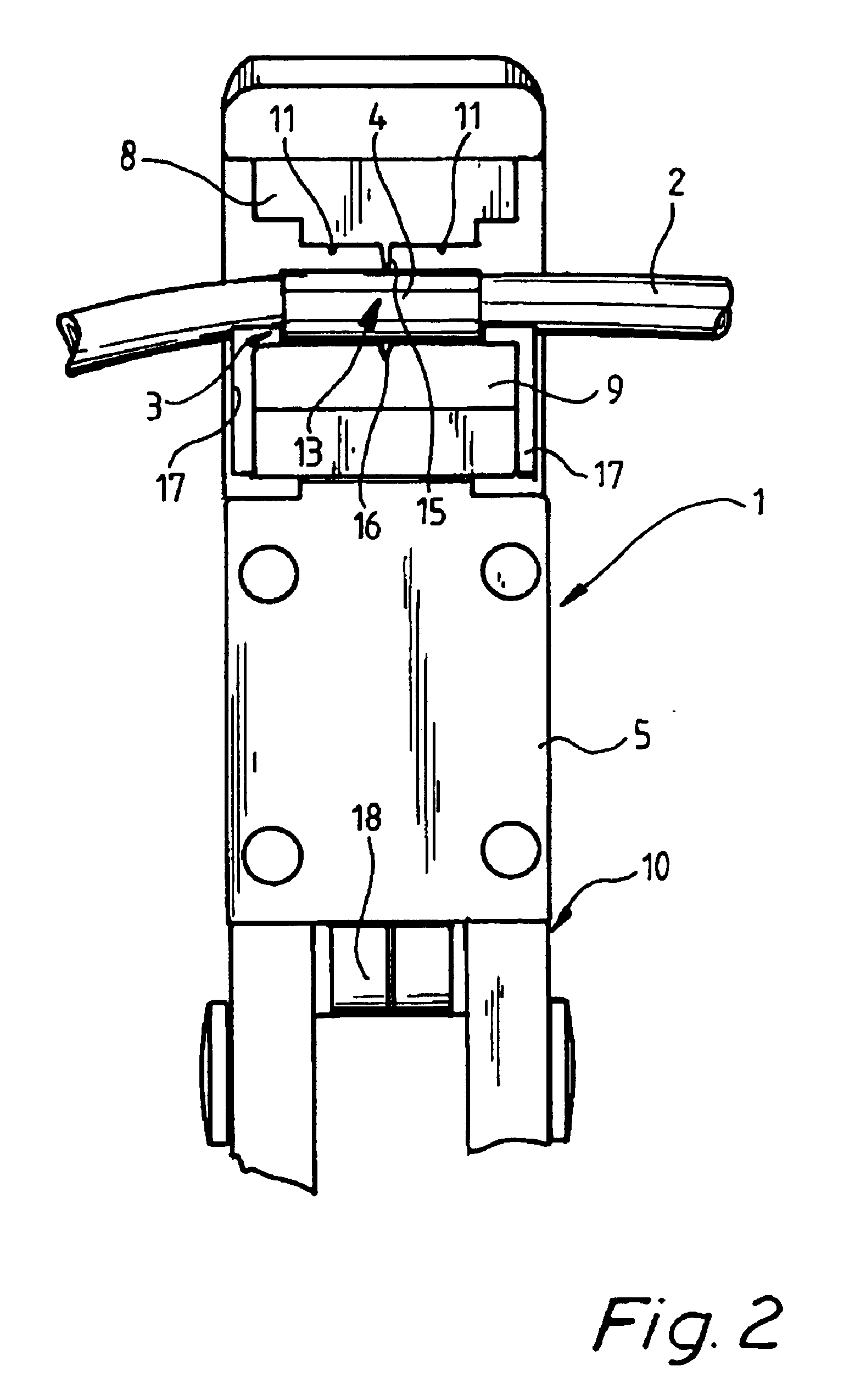

Sealing appliance

InactiveUS6779575B1Simple and efficient mannerVaccination/ovulation diagnosticsGlass pressing apparatusEngineering

An appliance for sealing elastic hoses with a sleeve, which is plastically deformable and slipped onto the hose, has two jaws which are movable towards and away from each other. One jaw has two straight bars which project towards the other jaw and extend transversely of the sleeve to make two transverse indentations in the sleeve and the hose when the jaws are moving towards each other. The same jaw has a cutting edge which projects towards the other jaw and is directed transversely of the sleeve, the cutting edge making a substantially transverse cutting indication in the sleeve and the hose when the jaws are moving towards each other.

Owner:MERCK CHEM & LIFE SCI AB

Method and apparatus for performing a minimally invasive total hip arthroplasty

InactiveUS20050177172A1Less scarringHastens patient recoveryCannulasOperating tablesAcetabular componentProsthesis

A method and apparatus for performing a minimally invasive total hip arthroplasty including an acetabular cup inserter is provided. The cup inserter is utilized for securing a prosthetic acetabular component thereto for implantation into a hip joint. The acetabular cup inserter includes a frame having an offset frame leg to allow for placement of an acetabular cup in the correct anteversion and abduction without interference from soft tissue.

Owner:ZIMMER TECH INC

Gripping and vacuum end effector for transferring articles

InactiveUS6860531B2Reduce operating costsImprove performanceGripping headsArticle unpackingVacuum pressureEngineering

An end effector for a robot is used to unpack flattened stackable items from a container using a fixed sized vacuum plenum and simple adjustable gripping elements. The gripping elements comprise a pair of adjustable, smooth blades. In addition, the end effector includes mechanisms for retaining and transporting the container.

Owner:ABB INC

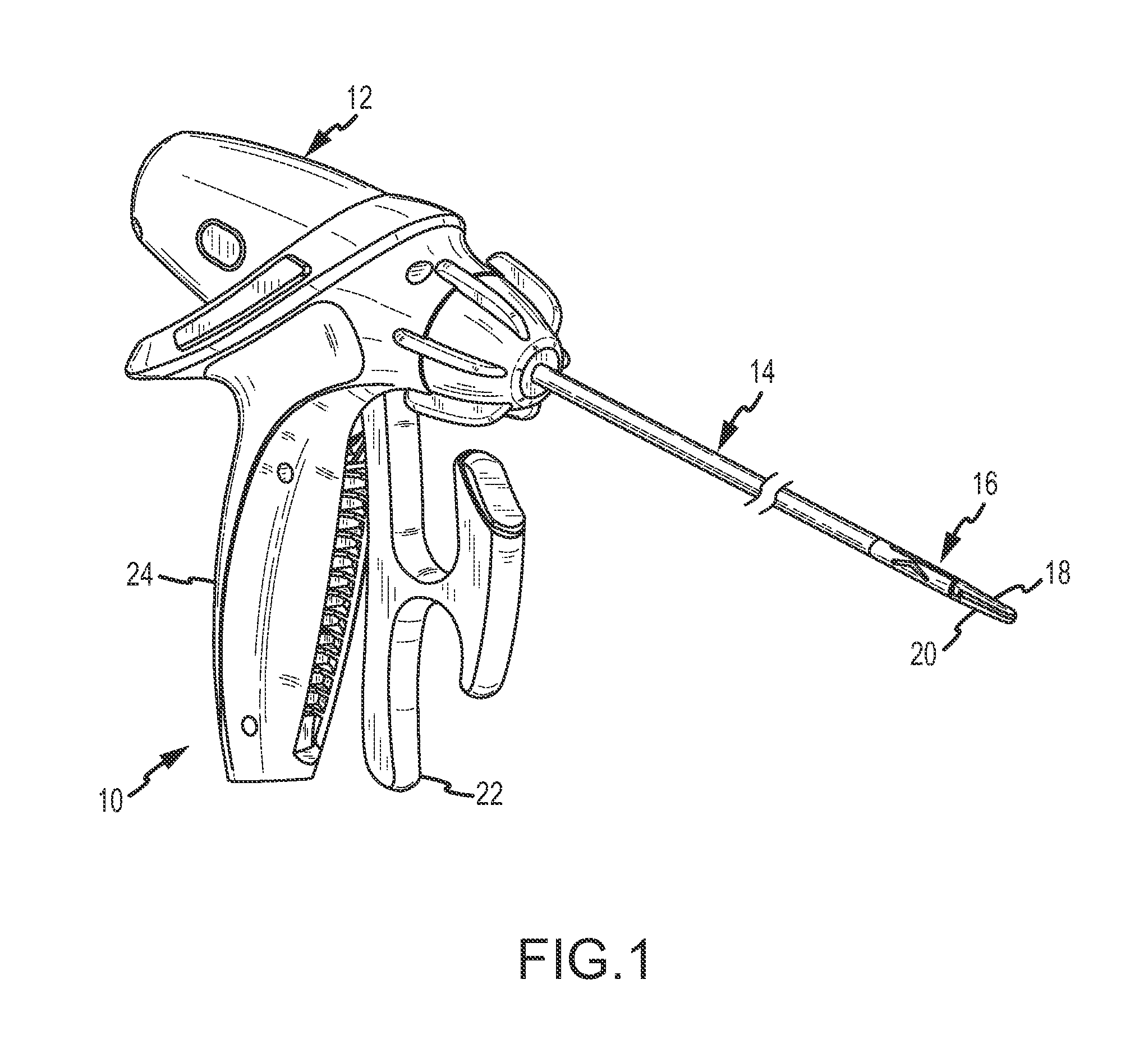

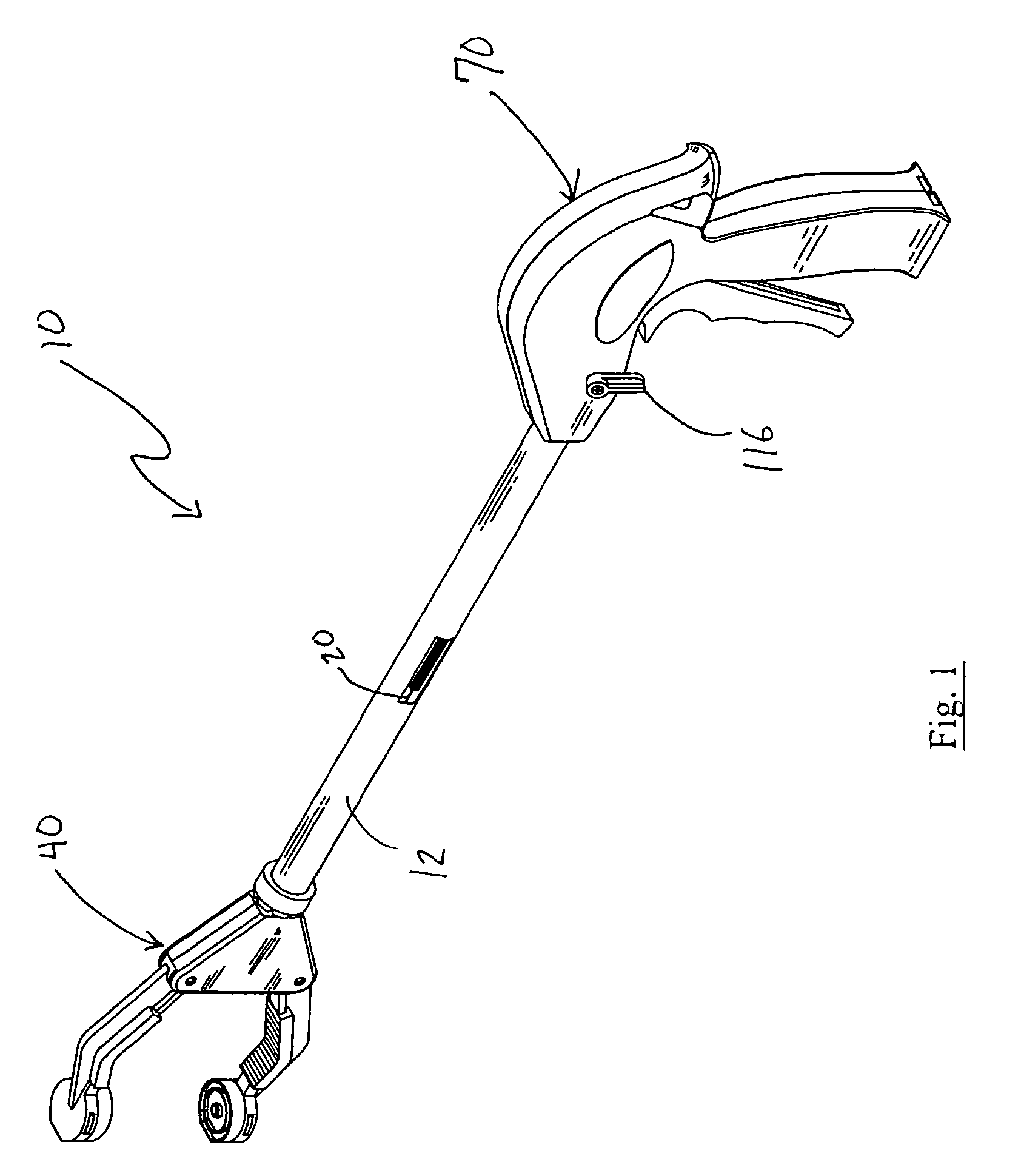

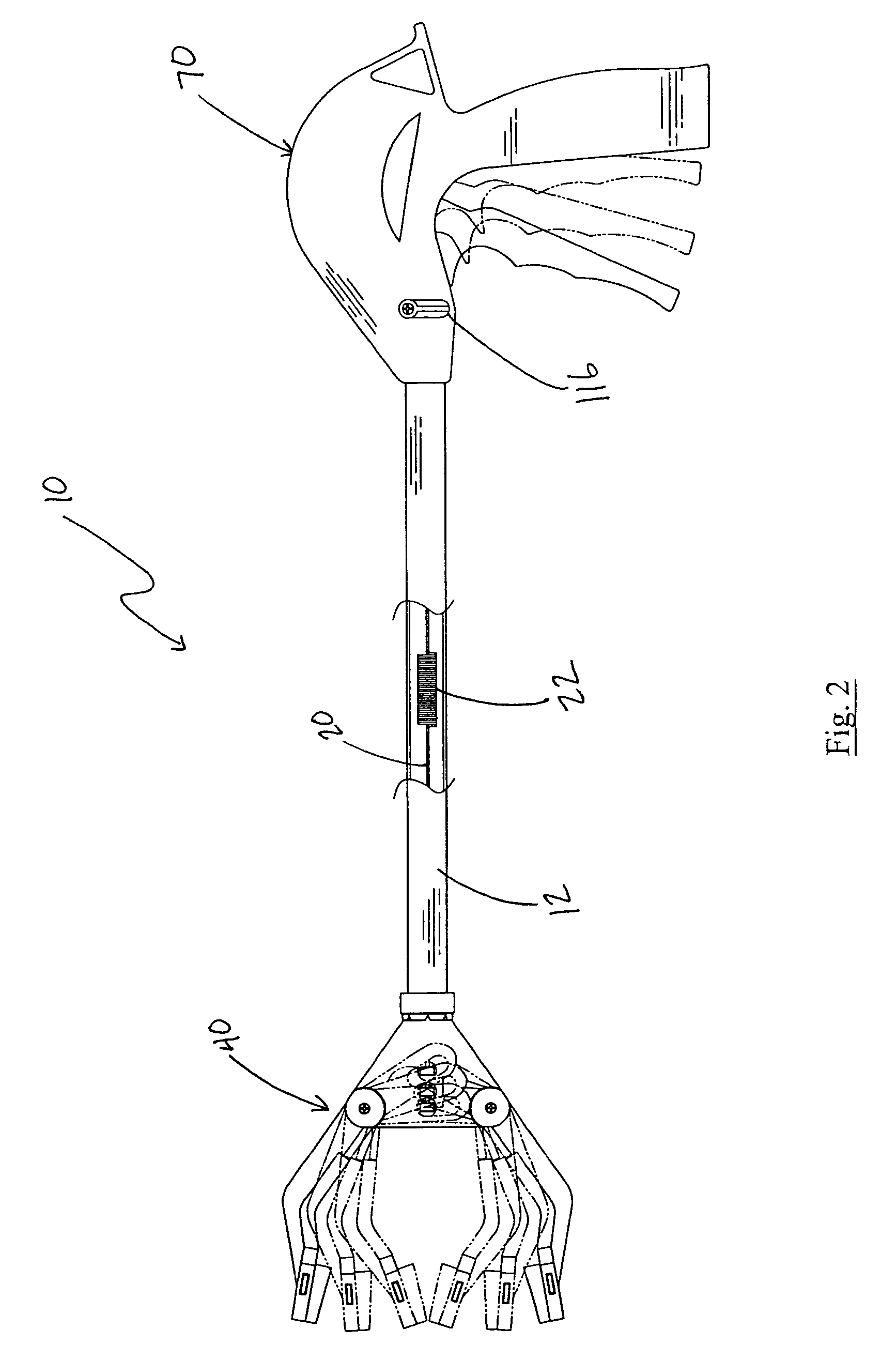

Hand-held device for picking up objects

A hand-held device for gripping objects positioned beyond arm's length, comprising a pair of jaws movable relative to each other between an unclamped position and a fully clamped position; a handle spaced apart from the jaws by a central portion, the handle including a trigger connected to the jaws by a pull member, whereby actuation of the trigger is operative to move the jaws between the unclamped and fully clamped positions thereof, and a locking mechanism selectively operable to lock the jaws in at least one intermediate position defined between the unclamped and fully clamped positions; and wherein the pull member is sufficiently resilient so as to permit the jaws to be temporarily urged away from each other towards the unclamped position when the pair of jaws are locked in the at least one intermediate position.

Owner:IDM WORLDWIDE

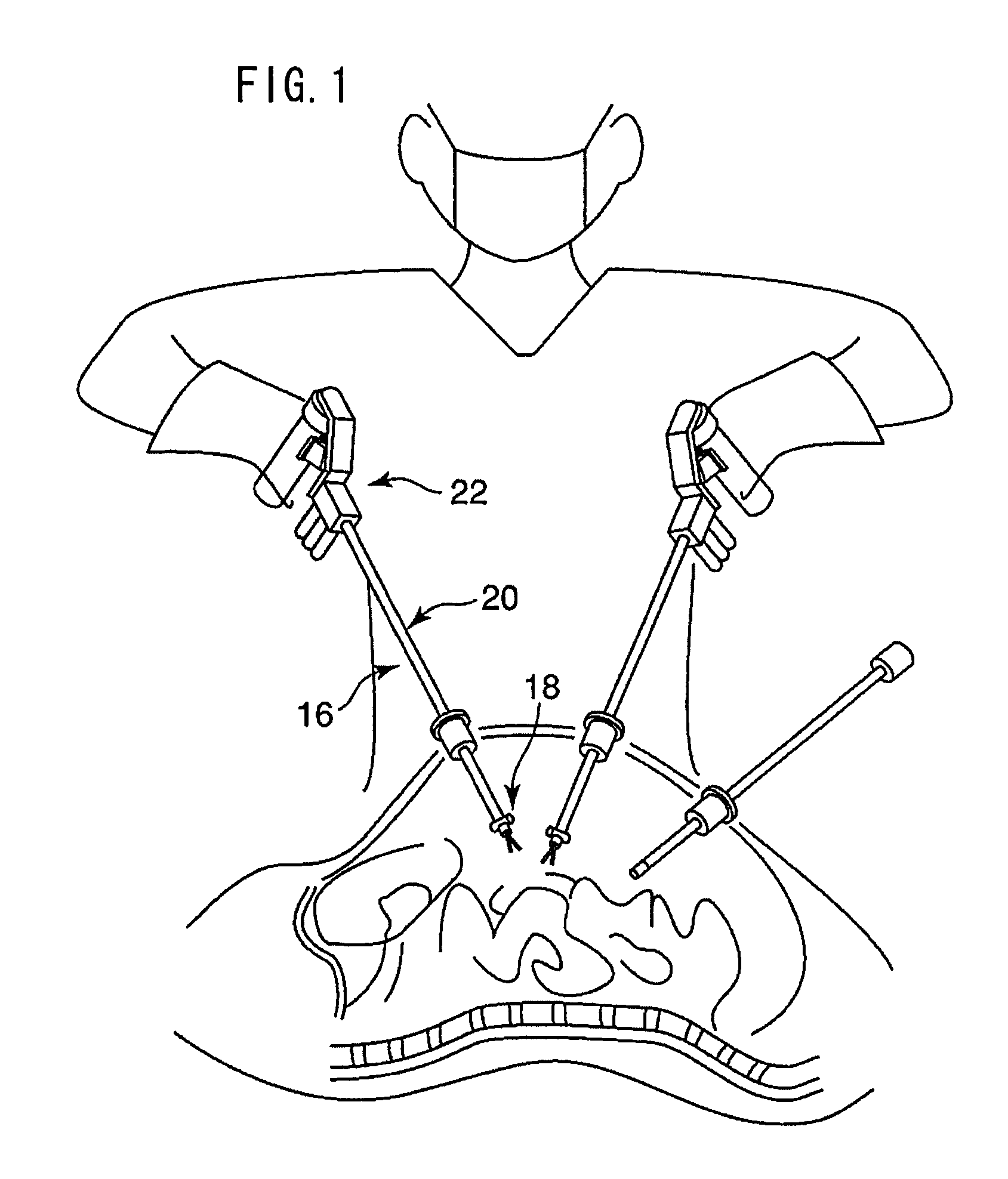

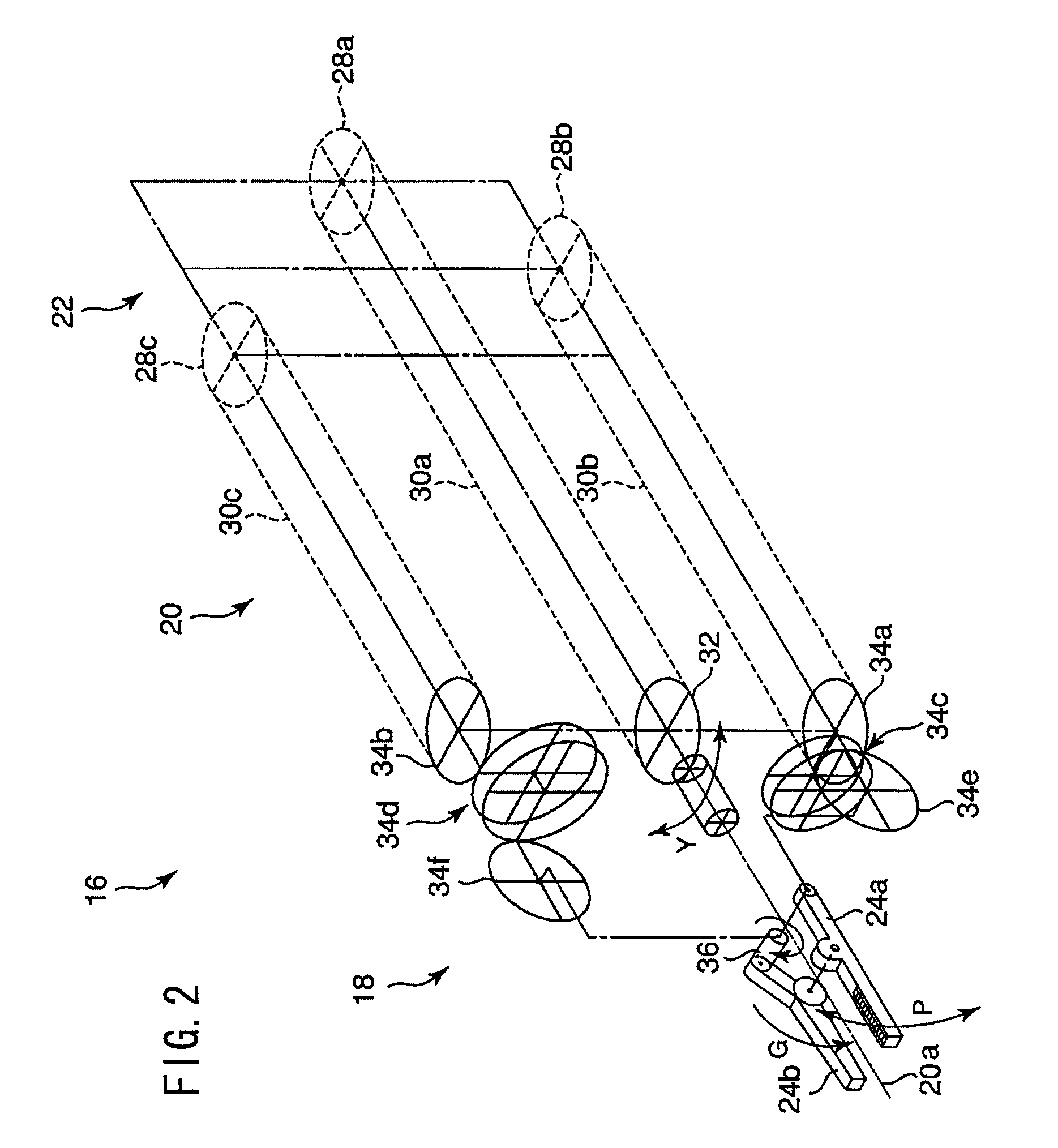

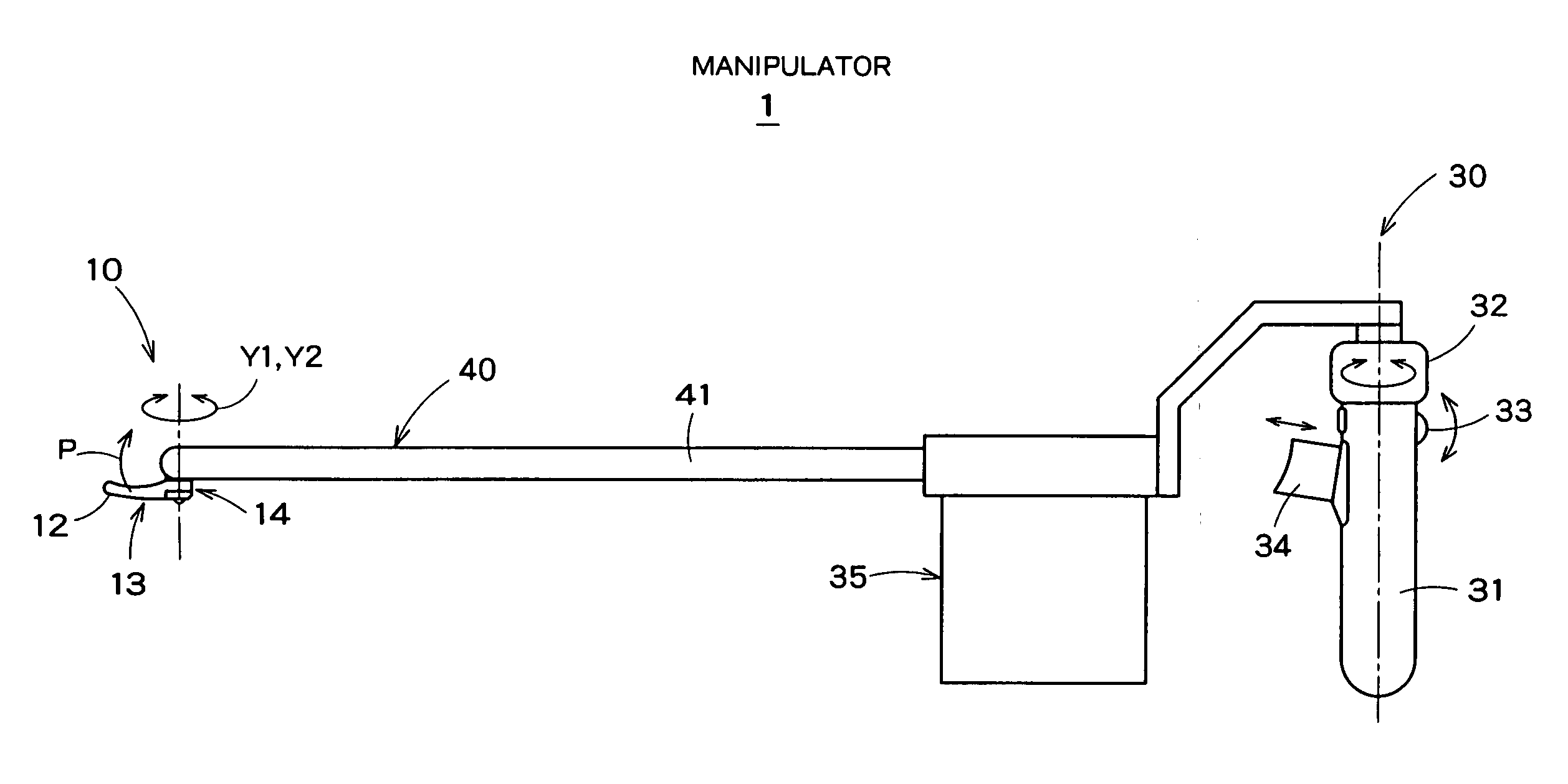

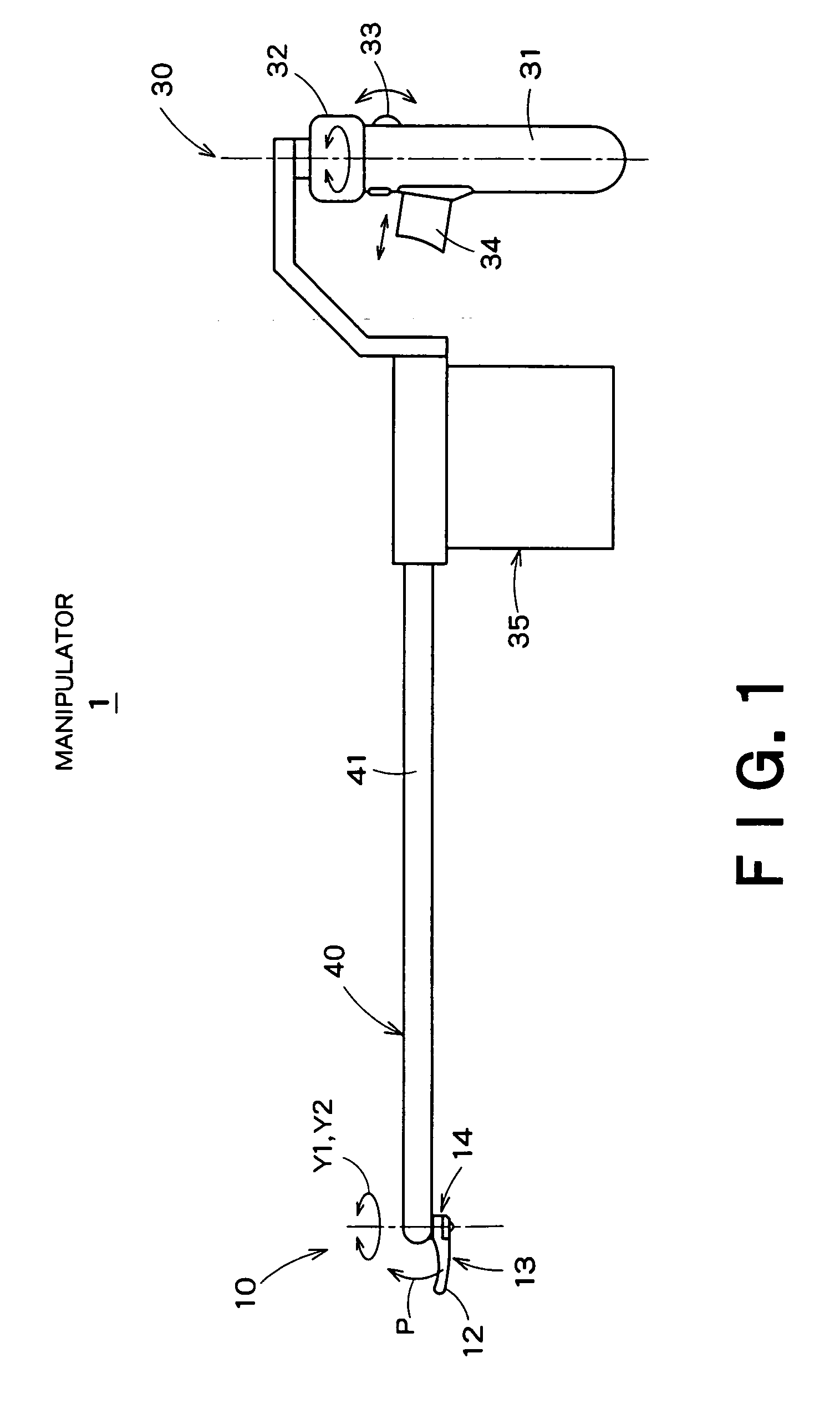

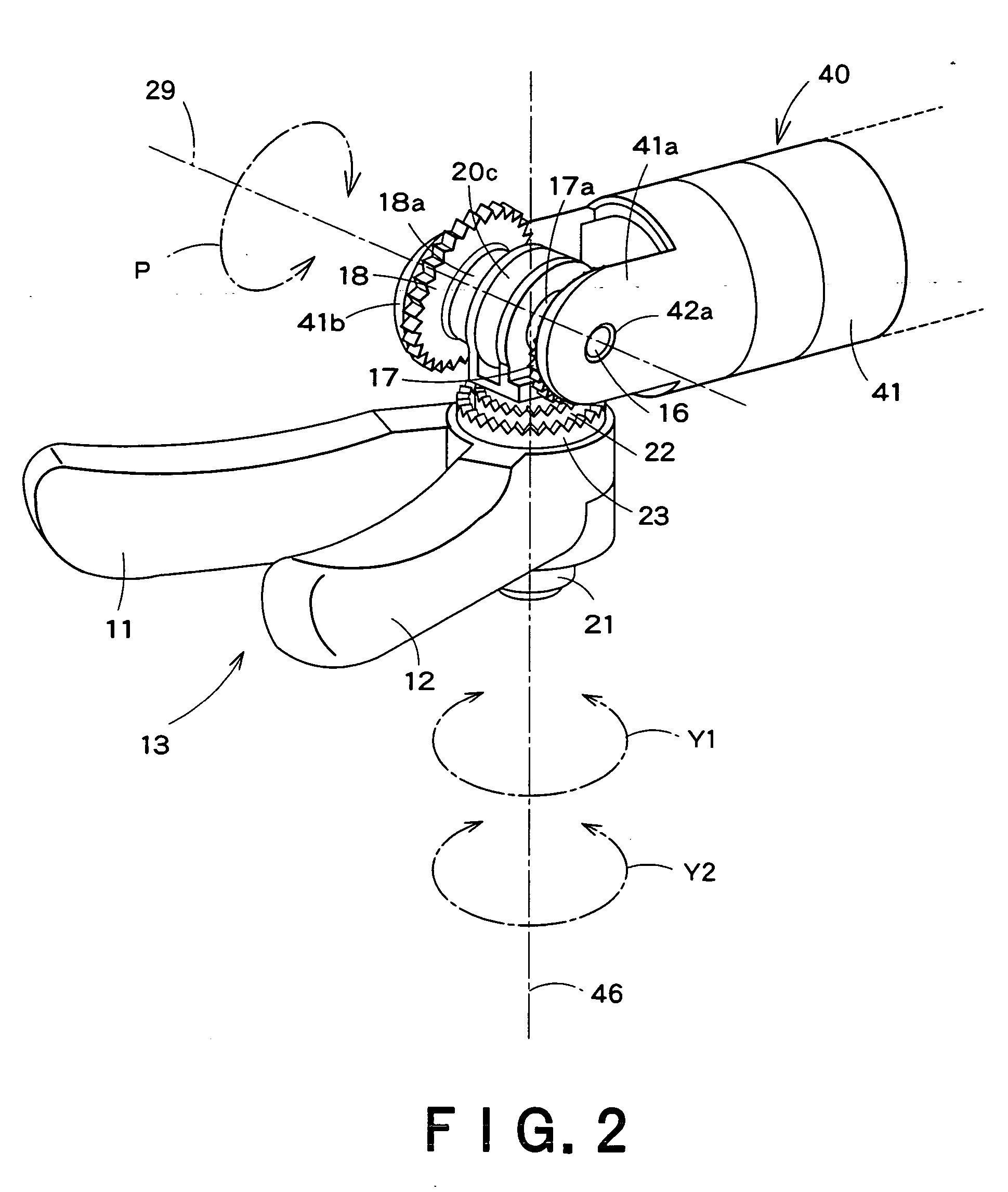

Manipulator

ActiveUS20060219065A1Increase freedomSimple structureMechanical apparatusPliersEngineeringManipulator

A manipulator has a treating portion, a driving portion which are connected by a connecting portion, a first pulley on which a first wire which passes through inside of the connecting portion and is driven by the driving portion is hung for rotation, and a main shaft portion which rotatably supports the treating portion around a main shaft along a direction different from a first rotor axis that the first pulley rotates, one end portion of which is fixed to the first pulley.

Owner:TERUMO KK

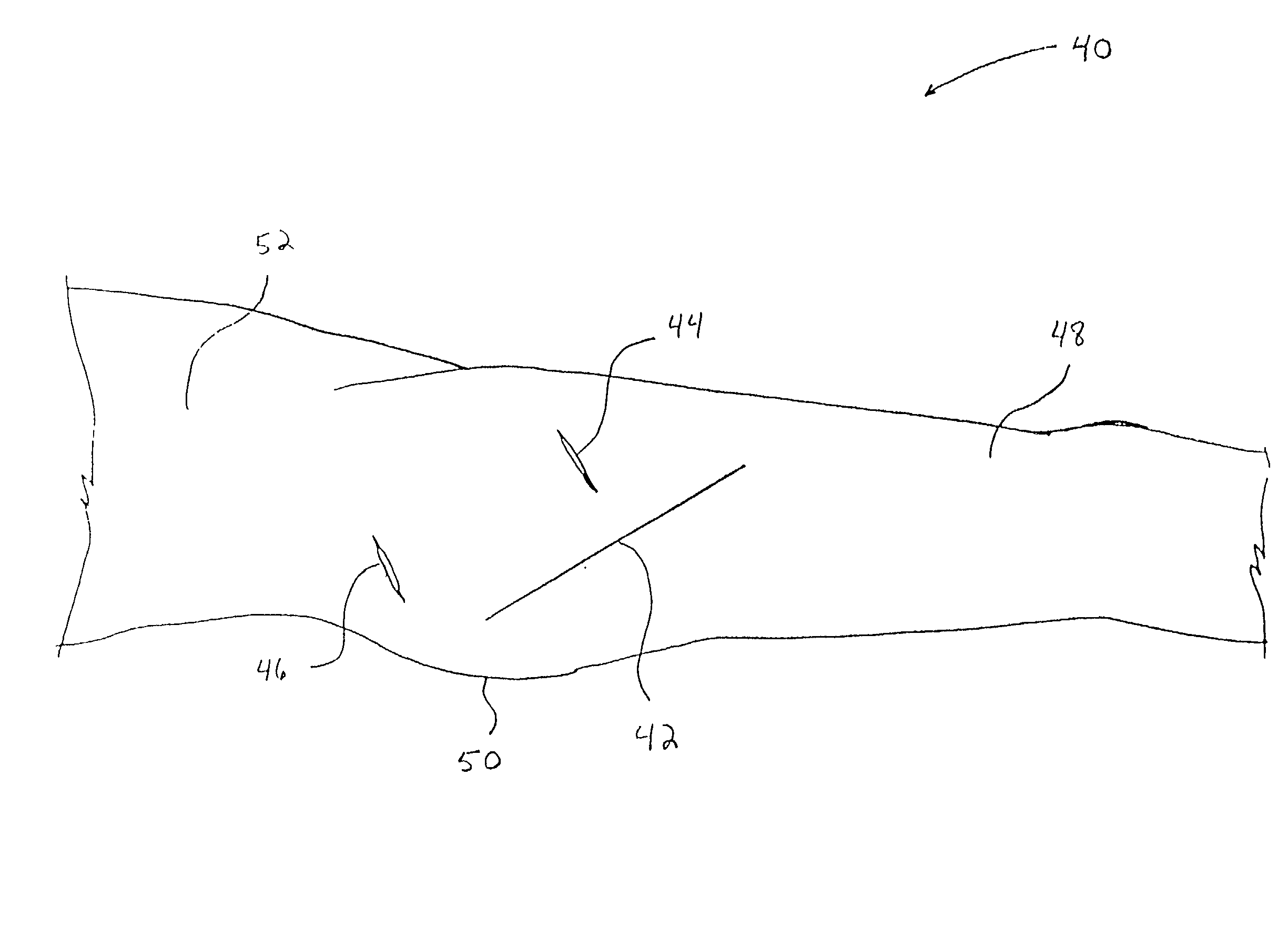

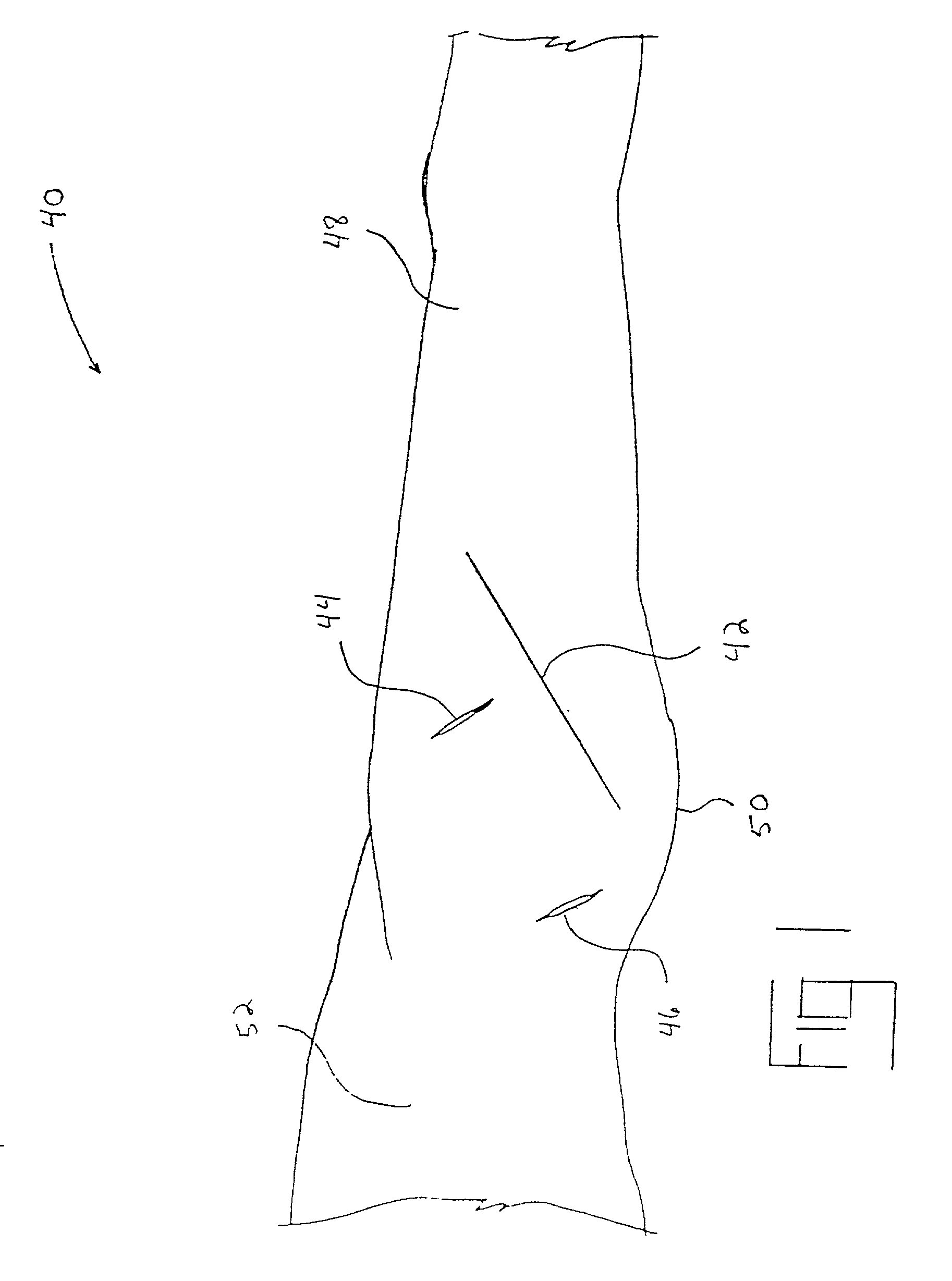

Method and apparatus for performing a minimally invasive total hip arthroplasty

A method and apparatus for performing a minimally invasive total hip arthroplasty. An approximately 3.75-5 centimeter (1.5-2 inch) anterior incision is made in line with the femoral neck. The femoral neck is severed from the femoral shaft and removed through the anterior incision. The acetabulum is prepared for receiving an acetabular cup through the anterior incision and the acetabular cup is placed into the acetabulum through the anterior incision. A posterior incision of approximately 2-3 centimeters (0.8-1.2 inches) is generally aligned with the axis of the femoral shaft and provides access to the femoral shaft. Preparation of the femoral shaft including the reaming and rasping thereof is performed through the posterior incision, and the femoral stem is inserted through the posterior incision for implantation in the femur. A variety of novel instruments including an osteotomy guide an awl for locating a posterior incision aligned with the axis of the femoral shaft, a tubular posterior retracter, a selectively lockable rasp handle with an engagement guide; and a selectively lockabele provisional neck are utilized to perform the total hip arthroplasty of the current invention.

Owner:ZIMMER INC

Hair styling tongs with biased handles

Hairdressing tongs have a pair of arms extending from handles. Each arm has a heating pad affixed thereto. The handles have opposed openings. A central element is positioned between the handles and fitted within the openings such that the central element is slidable toward the handles. The central element has guide openings. Springs are positioned in the guide openings for biasing apart the handles. The springs enable hand pressure to move the handles and arms together from a completely open position to a completely closed position and, in absence of the hand pressure, to maintain the handles and arms in relatively parallel configuration, biased against stops of the central element.

Owner:CONAIR CORP

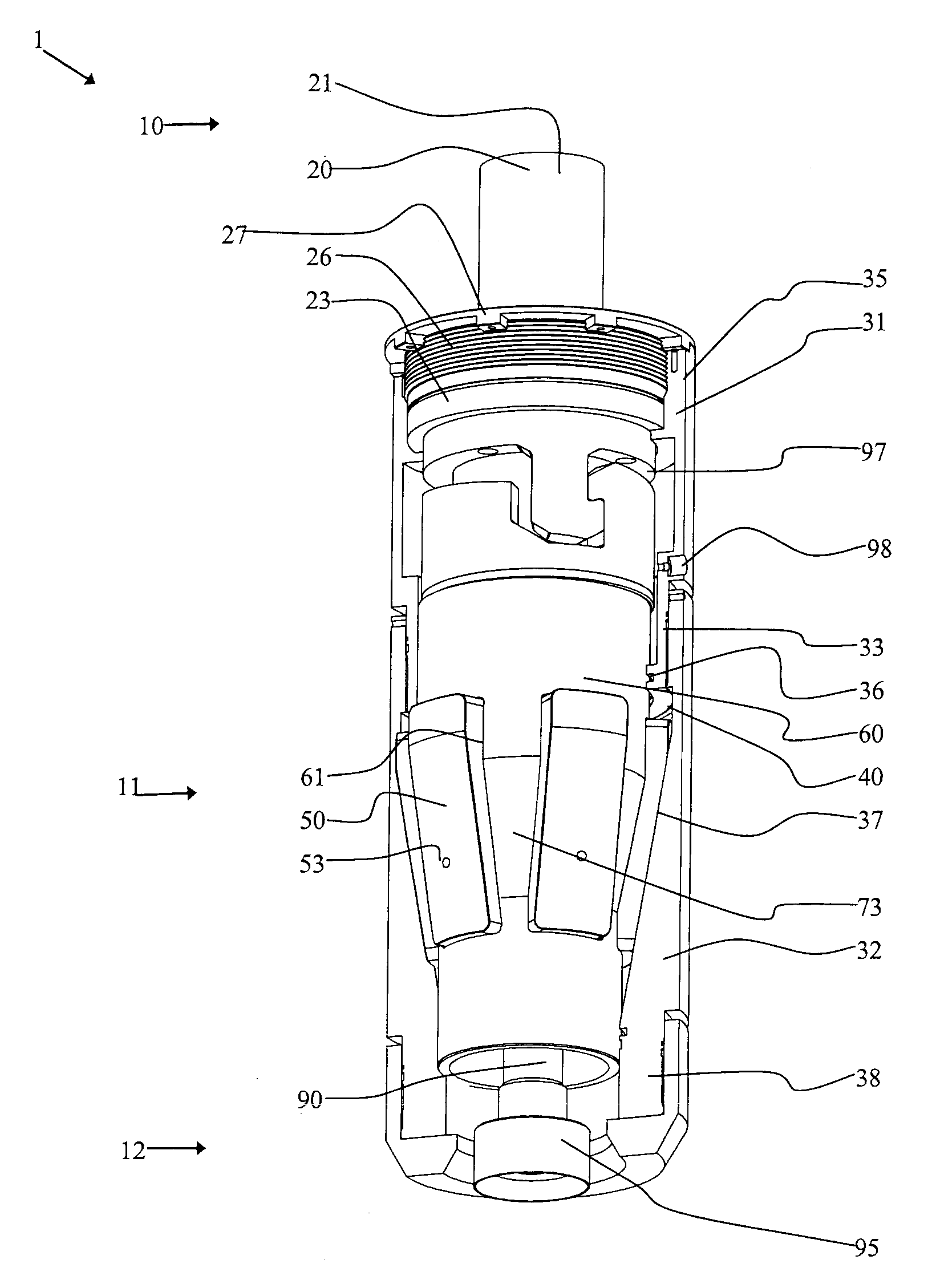

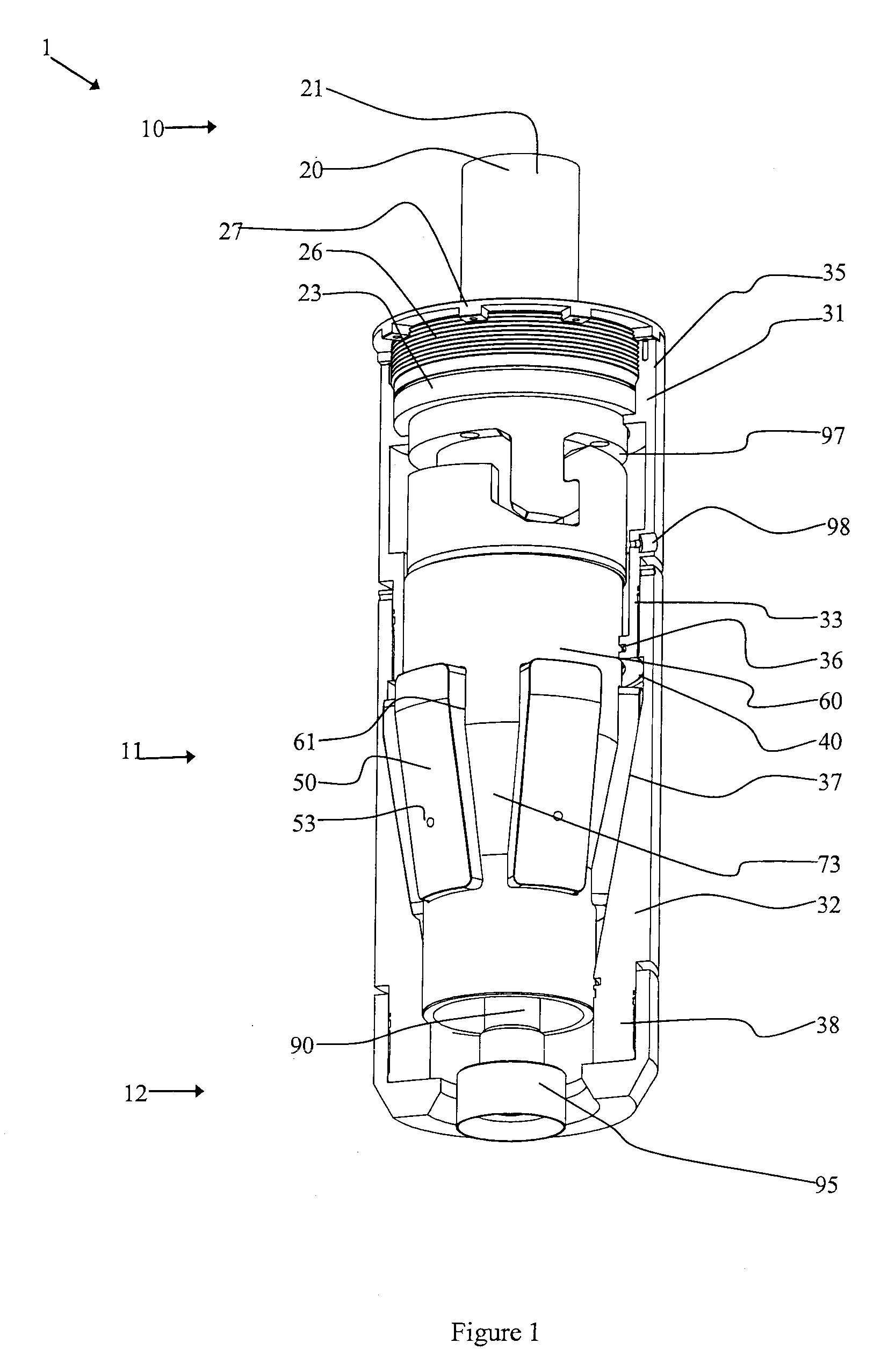

Gripping Tool

A gripping tool includes a body assembly and gripping assembly with a grip surface adapted to move from a retracted position to an engaged position to radially engage a work piece in response to relative axial displacement. A linkage is provided to act between the body assembly and the gripping assembly which, upon relative rotation in at least one direction, of the body relative to the grip surface results in relative axial displacement of the grip surface to activate the gripping elements. This tool was developed for use on drilling and service rigs having top drives, and supports rapid engagement and release, hoisting, pushing, and rotating.

Owner:NOETIC TECH INC

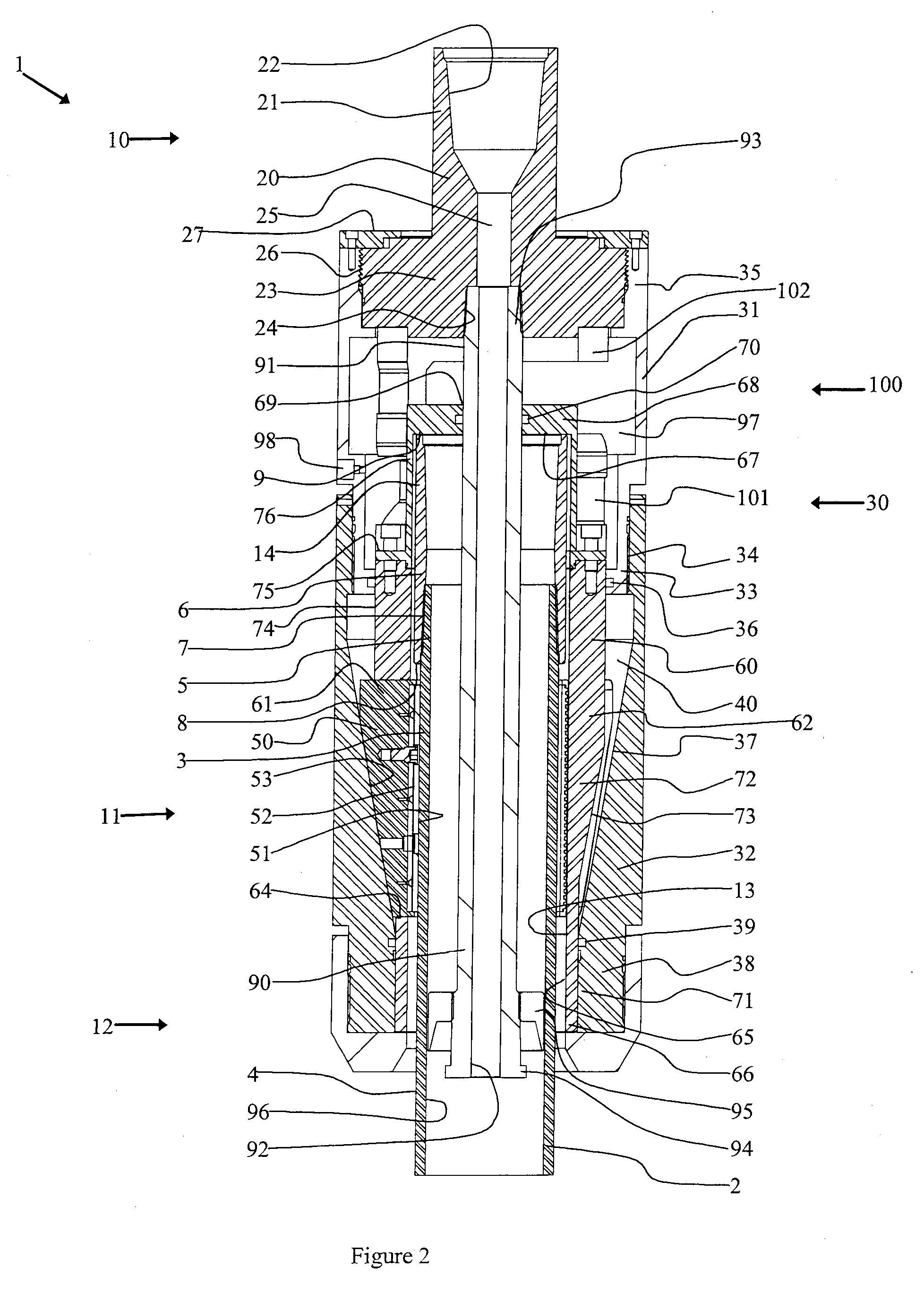

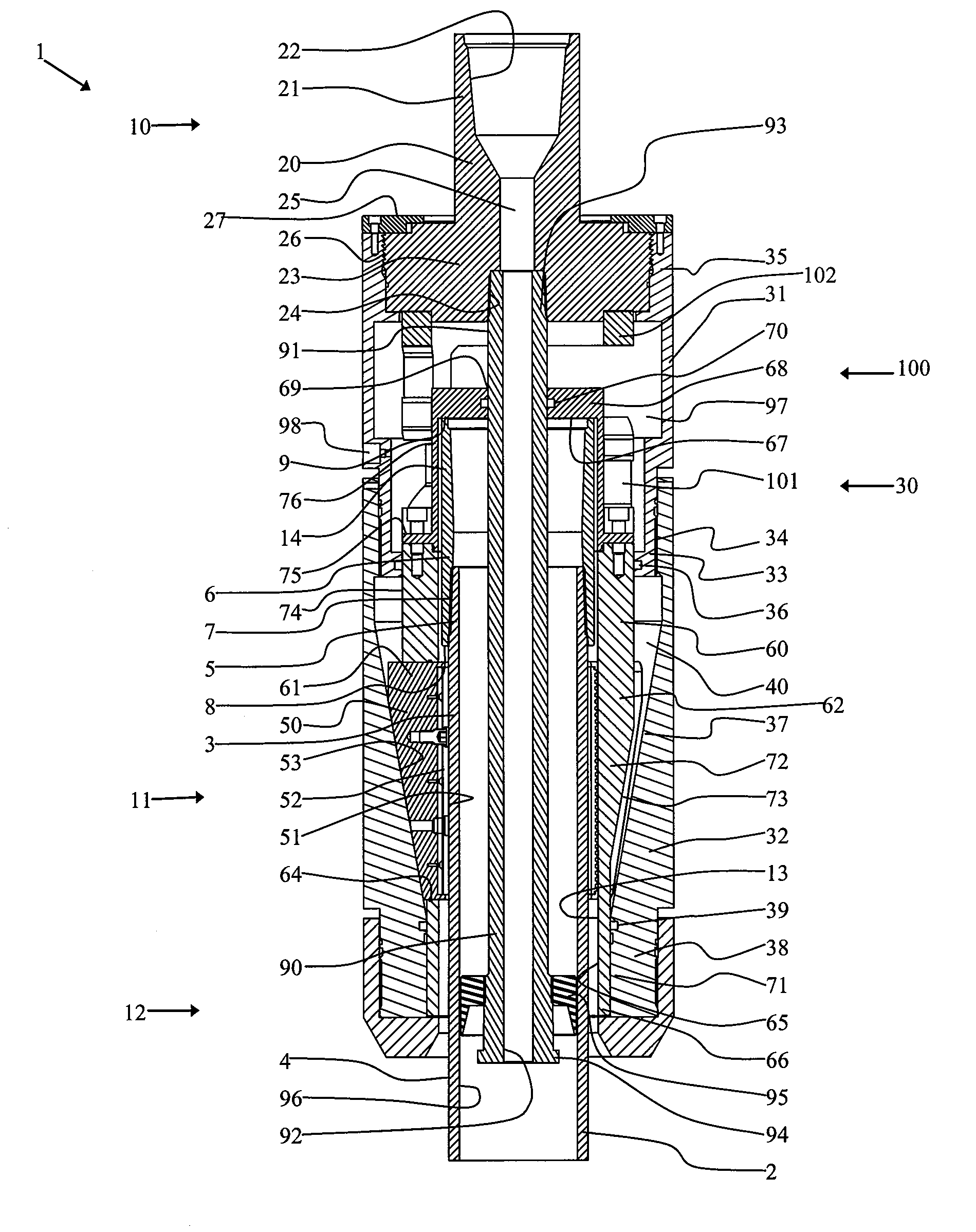

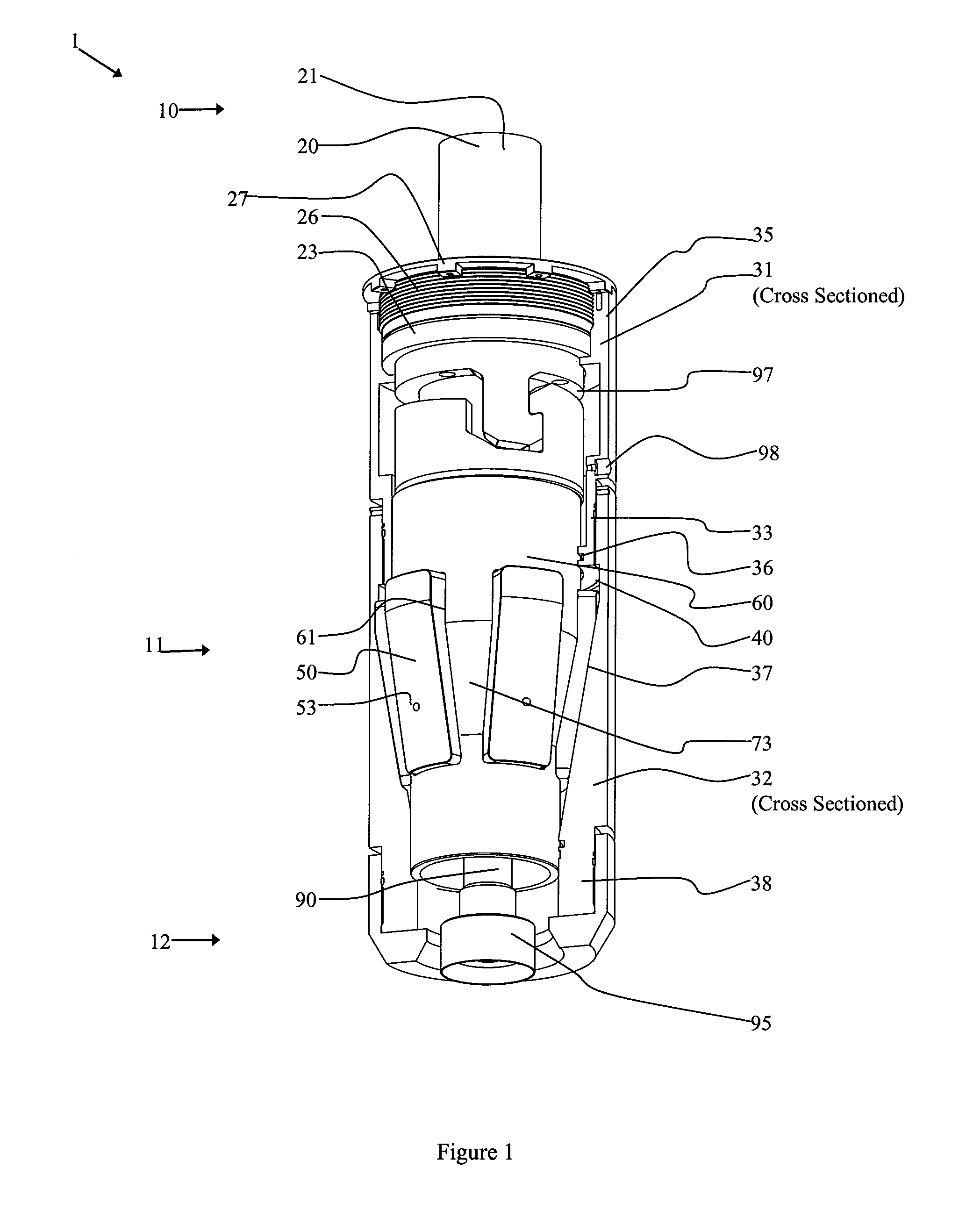

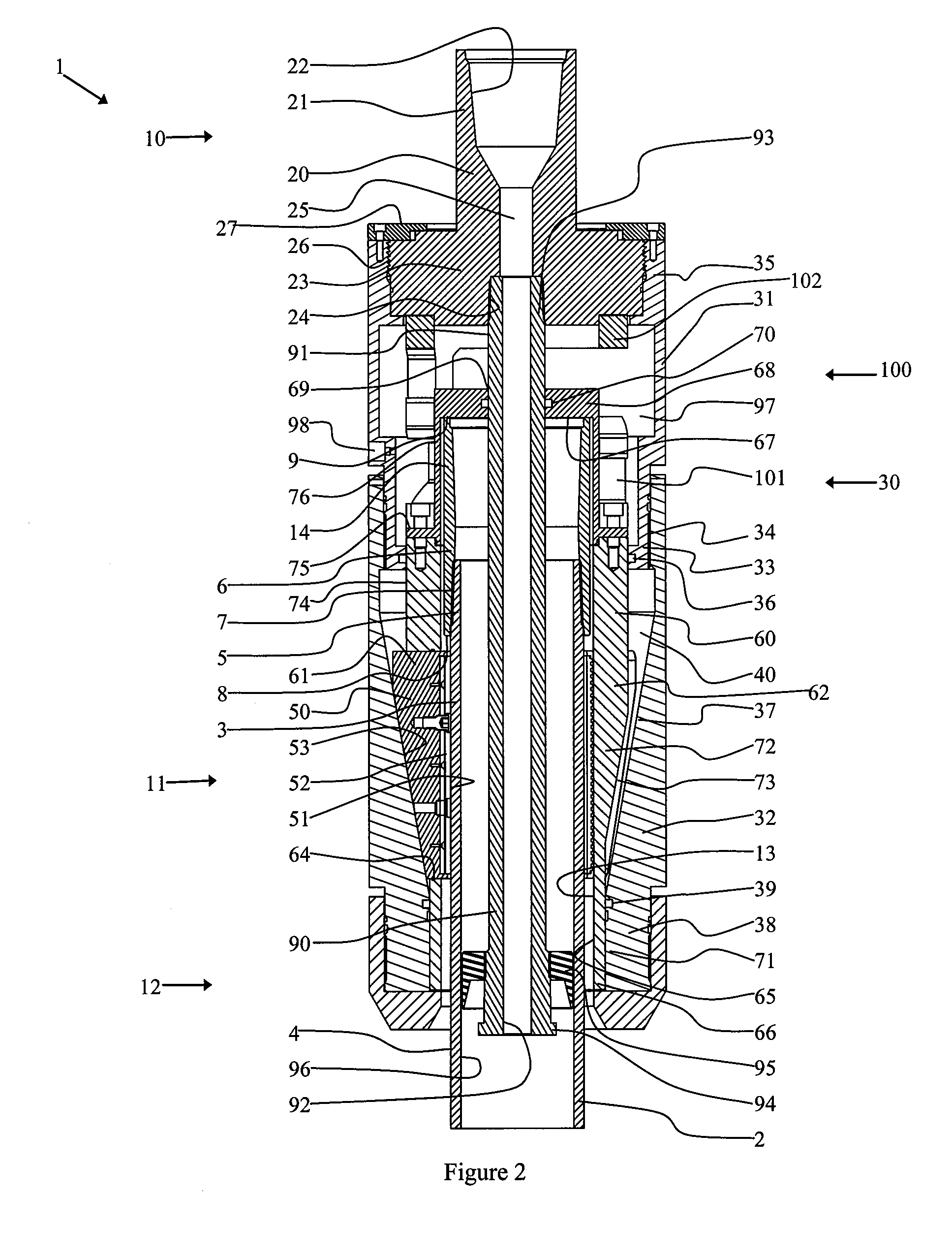

Gripping tool

A gripping tool includes a body assembly and gripping assembly with a grip surface adapted to move from a retracted position to an engaged position to radially engage a work piece in response to relative axial displacement. A linkage is provided to act between the body assembly and the gripping assembly which, upon relative rotation in at least one direction, of the body relative to the grip surface results in relative axial displacement of the grip surface to activate the gripping elements. This tool was developed for use on drilling and service rigs having top drives, and supports rapid engagement and release, hoisting, pushing, and rotating.

Owner:NOETIC TECH INC

Universal, interchangeable tool attachment system

A universal, interchangeable attachment system, comprising various tool operator heads, removable / interchangeable handles, removable / replaceable tools and tool bits, hex drive, and clamp for securing tools. An electronic subsystem provides an alternating current detector, an indicator, such as an LED or light bulb, and continuity circuit indicator. A reversible double helical drive enables a user to drive a screw or bolt.

Owner:KAIZEN SYST

Workpiece gripping device

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com