Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

192 results about "Joint axis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The axis is the second cervical vertebra; it has what is called the odontoid process about which the atlas rotates. The joint between the atlas and axis is a pivot type of joint. It allows the head turn from side to side. It is also called the atloaxoid joint.

Pavement joint

InactiveUS7806624B2Reduce wastePotential tripping hazards to pedestrians are reducedPaving detailsBuilding insulationsRoad surfaceEngineering

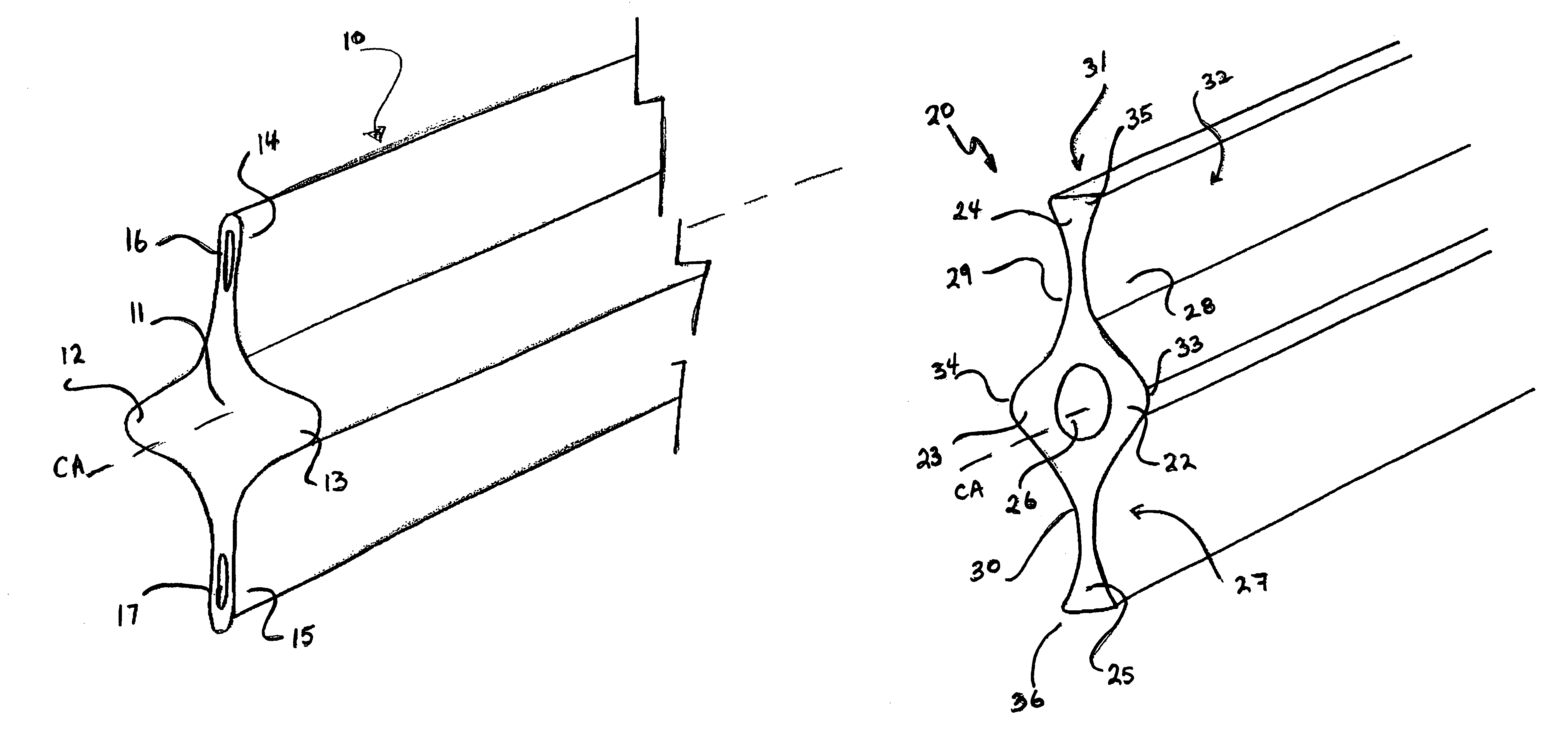

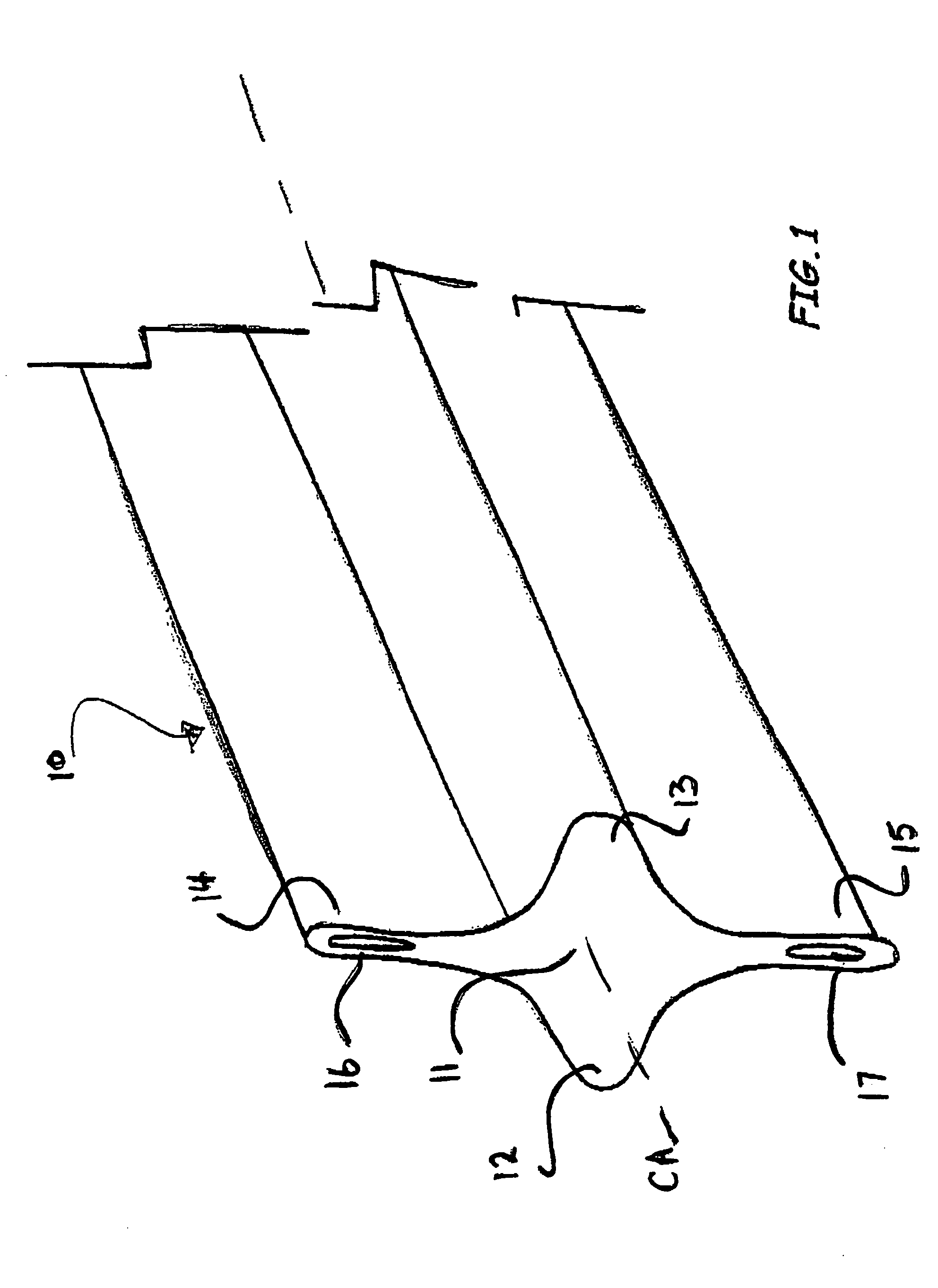

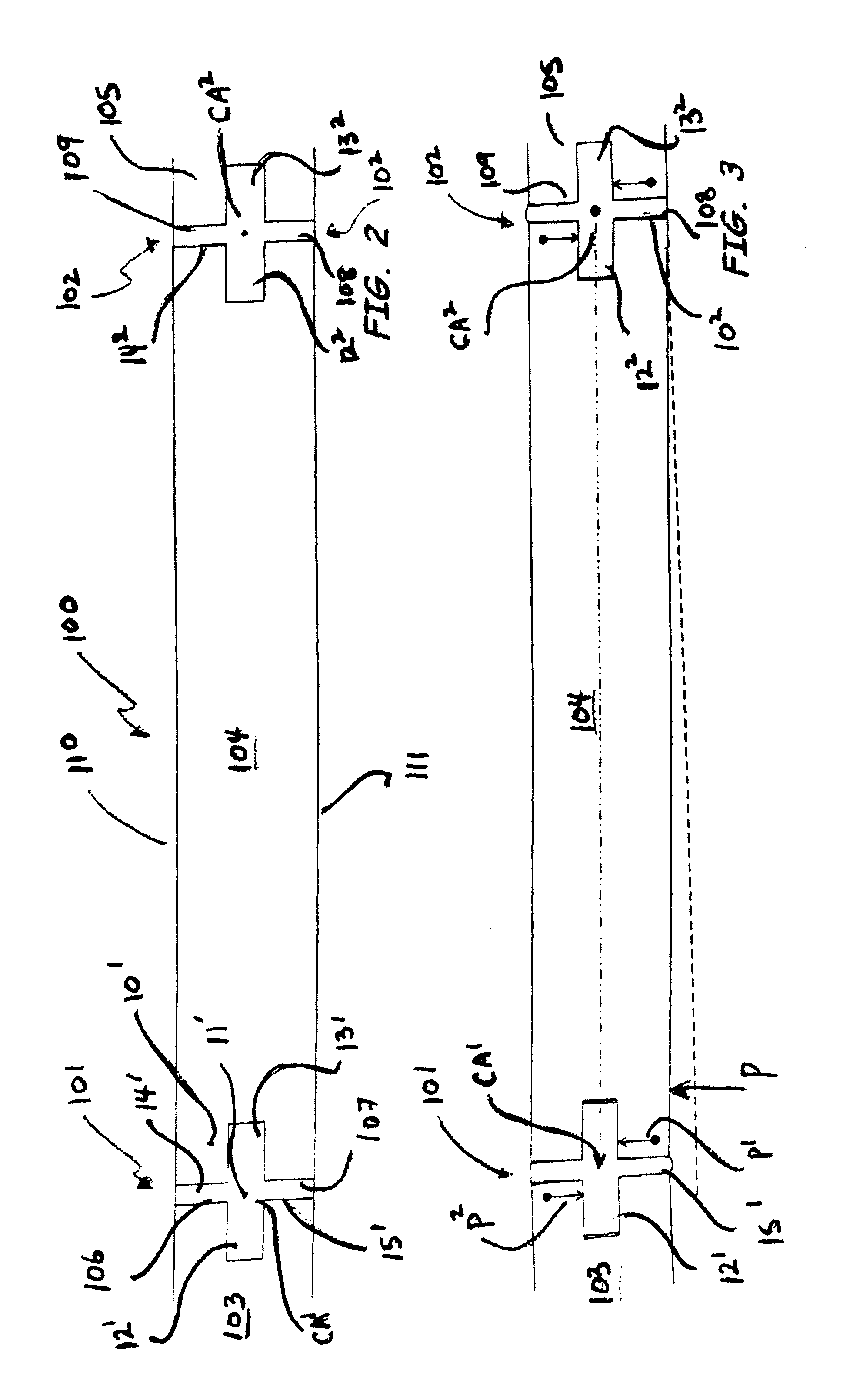

A pavement joint 101, 102 disposed between two contiguous pavement slabs 103, 104 and 105 incorporating a shear key (12, 13, 22 and 23) and at least one hinge (37, 38, 39 and 40). The shear key and the at least one hinge are operative when at least one of the slabs is subjected to out-of-plane action P with the shear key transferring shear between the slabs, and the at least one hinge accommodating angular displacement of the slabs relative to the joint axis in at least one direction. In one form, a joint member 10, 20, 40, 50 and 60 is disposed between the slabs to provide the shear key and hinge. A joint member and pavement slab for use in the joint is also described.

Owner:TRIPSTOP TECH

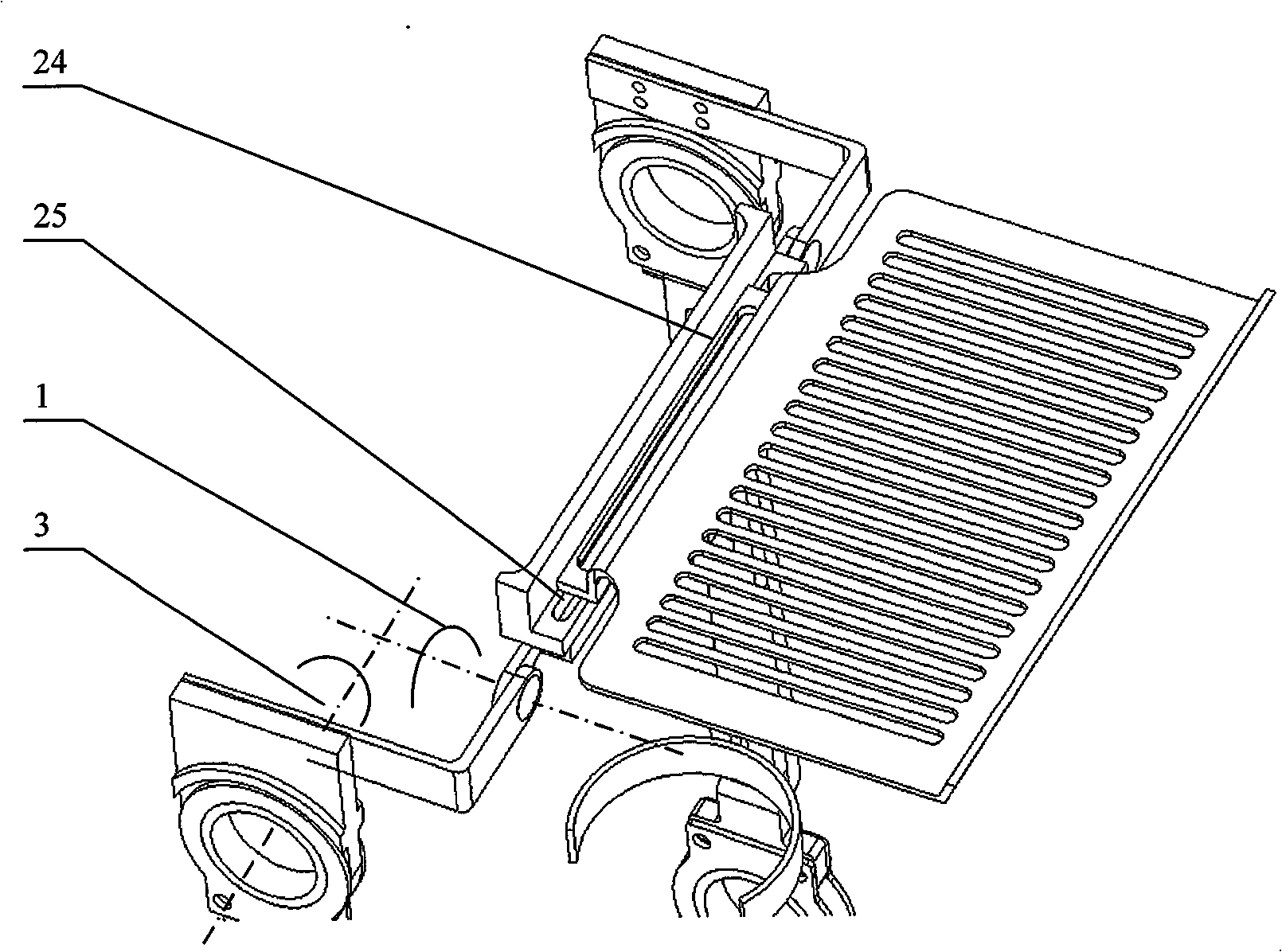

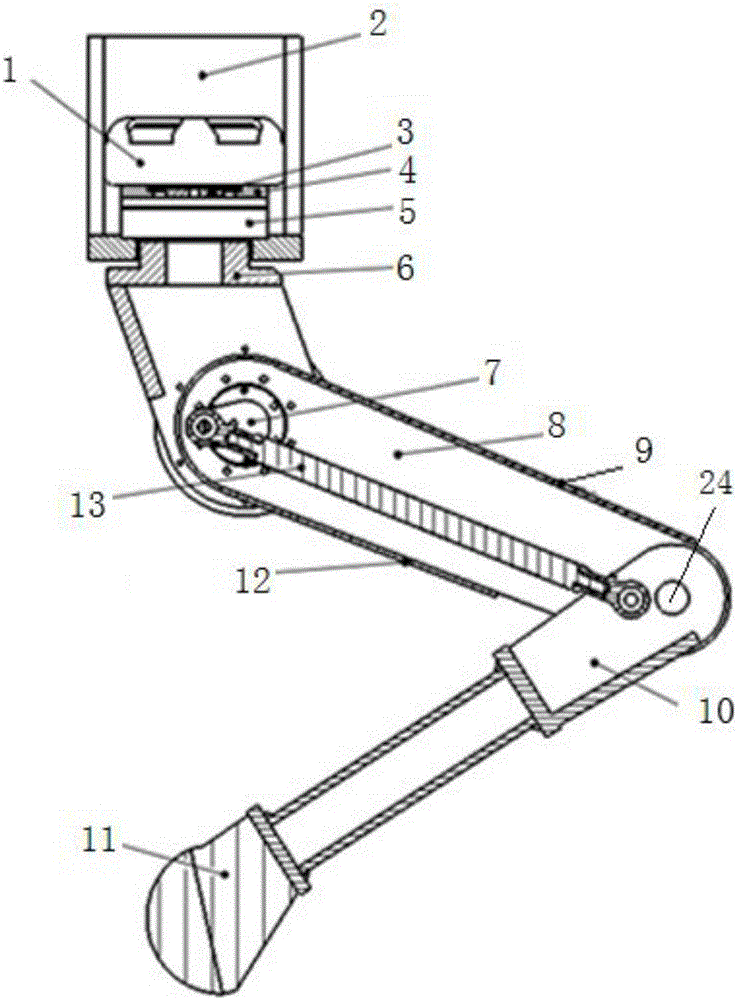

Wearable lower limb exoskeleton device

InactiveCN101589983AImprove consistencySmall coaxialityWalking aidsInvalid friendly devicesHuman bodyKnee Joint

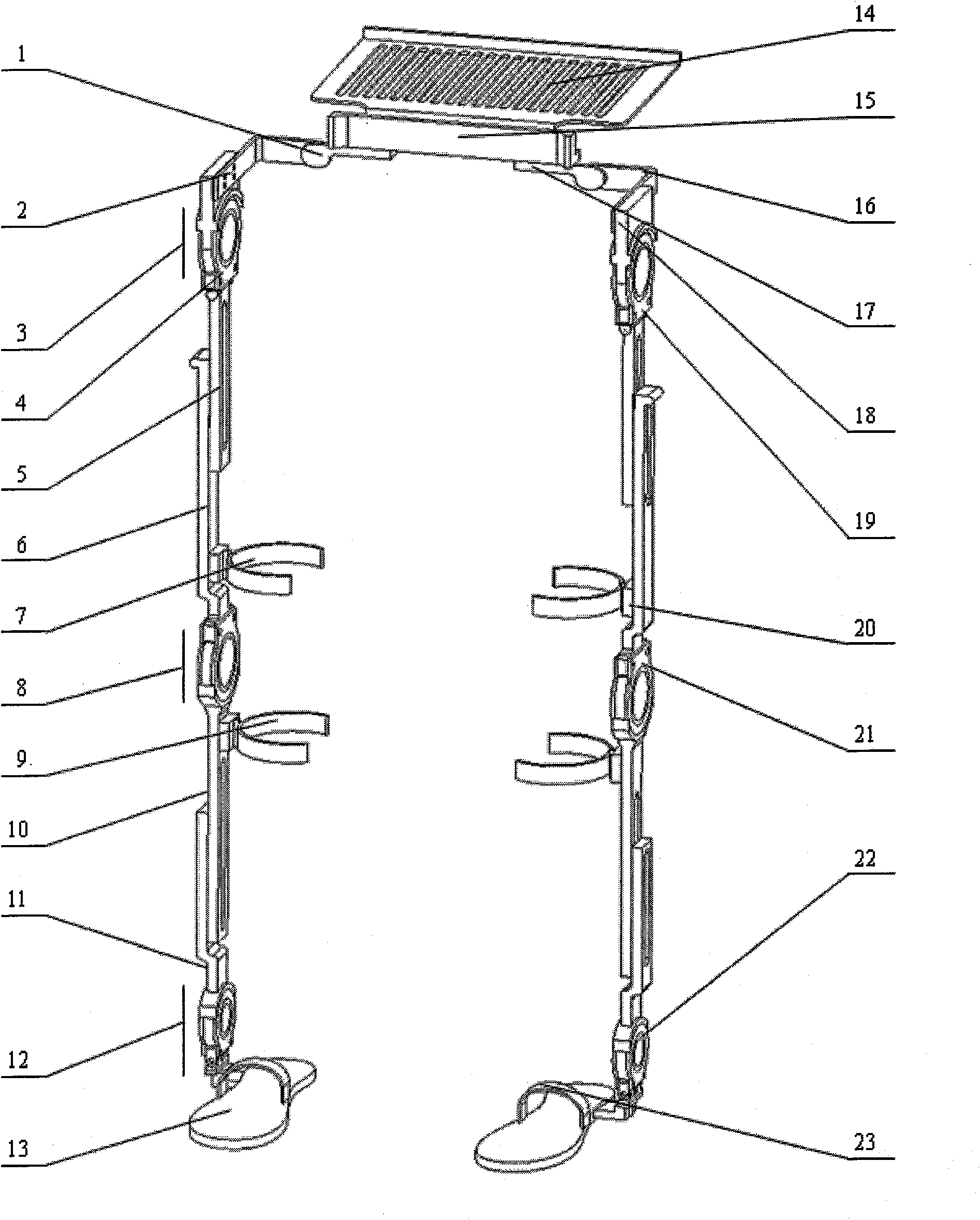

The invention discloses a wearable lower limb exoskeleton device, which comprises a waist supporting frame, a waist object carrier, an adjustable hip mechanism, a connecting rod adjustable knee joint mechanism, a connecting rod adjustable ankle joint mechanism, pressure detection shoes, a leg connecting rod, a constraint part and various connecting pieces. Both lower limbs have twelve rotational freedoms, the single lower limb has six degrees of freedom respectively, a hip has two degrees of freedom which finish bending and stretching as well as adduction and abduction movements of a hip joint, two joint axes always intersects at the center of the hip joint of a human body through the adjustment of the hip mechanism, and a knee joint has one degree of freedom which is coaxial with the knee joint of the human body and corresponds to the bending and stretching movement of the knee joint of the human body; and an ankle joint has three degrees of freedom. The device has good consistency of the movement of the hip joint and the movement of the human body during the walking of people; human-machine knee joints have small coaxality and position deviation; and the ankle joint has a compact structure. The device can be used for strengthening the abilities of walking with load and walking for a long time of wearers and detecting walking information of the wearers, and can also be used for helping people with slight obstacle of lower limb movement to normally walk and gradually rehabilitate.

Owner:BEIJING UNIV OF TECH

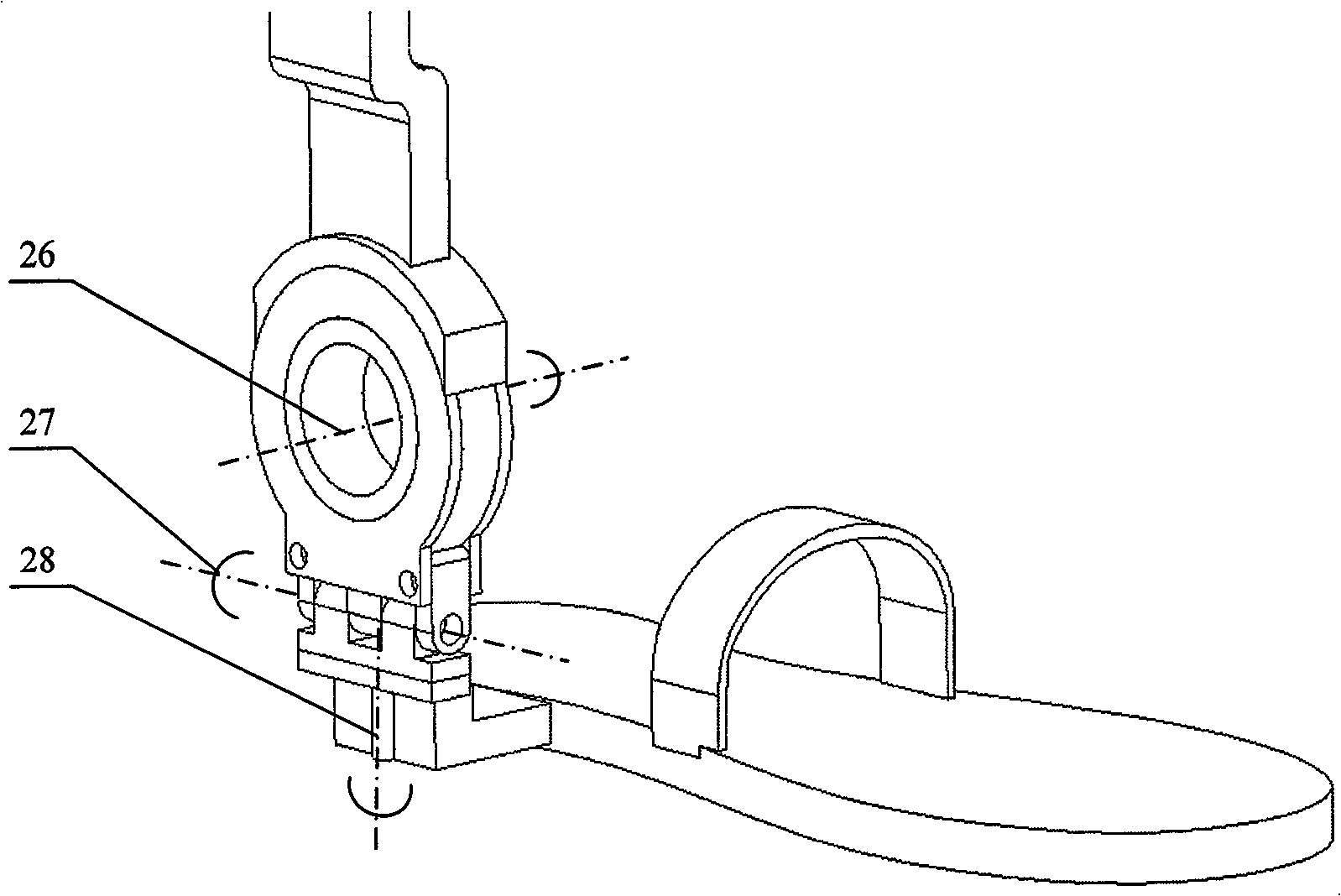

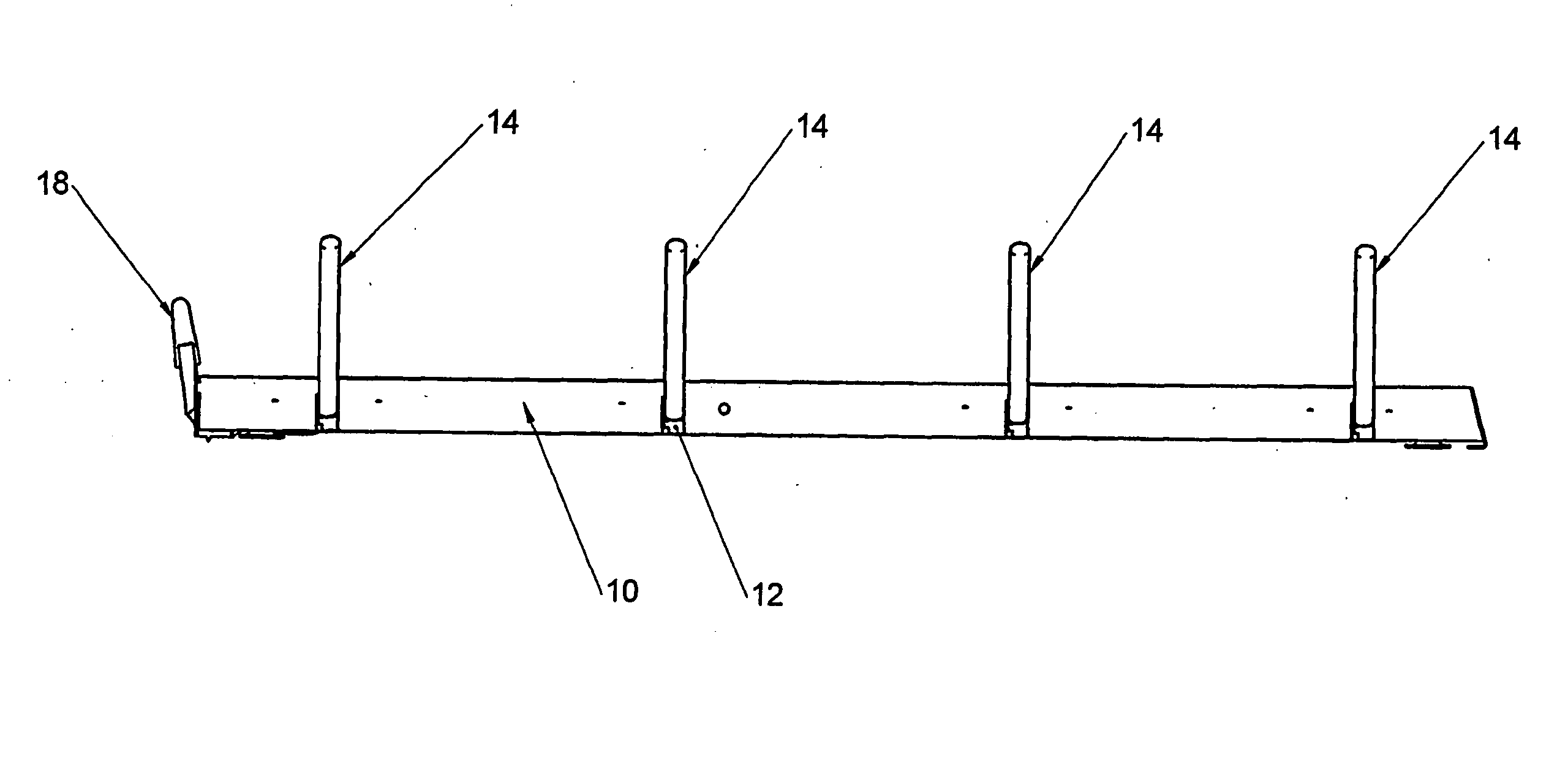

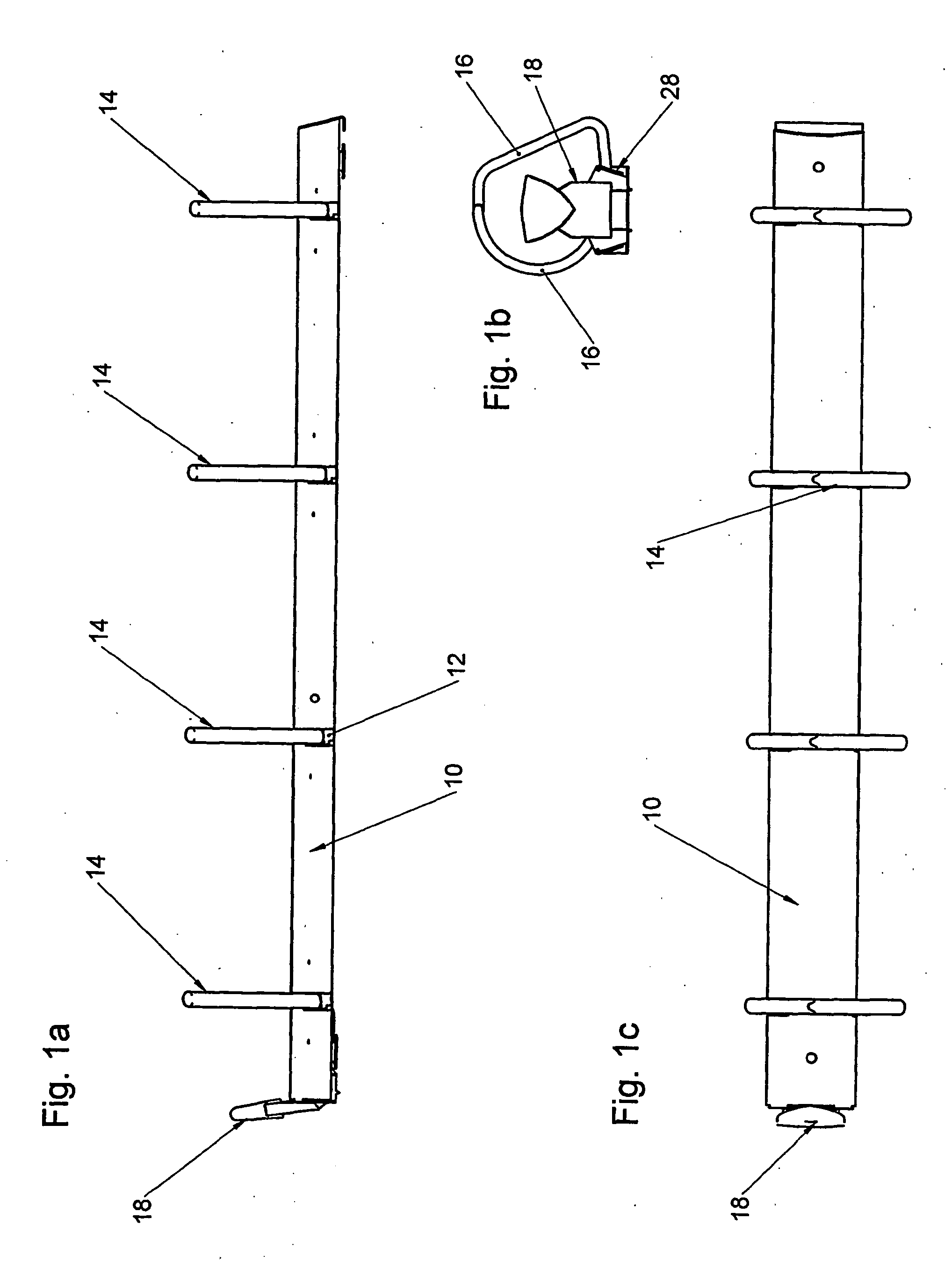

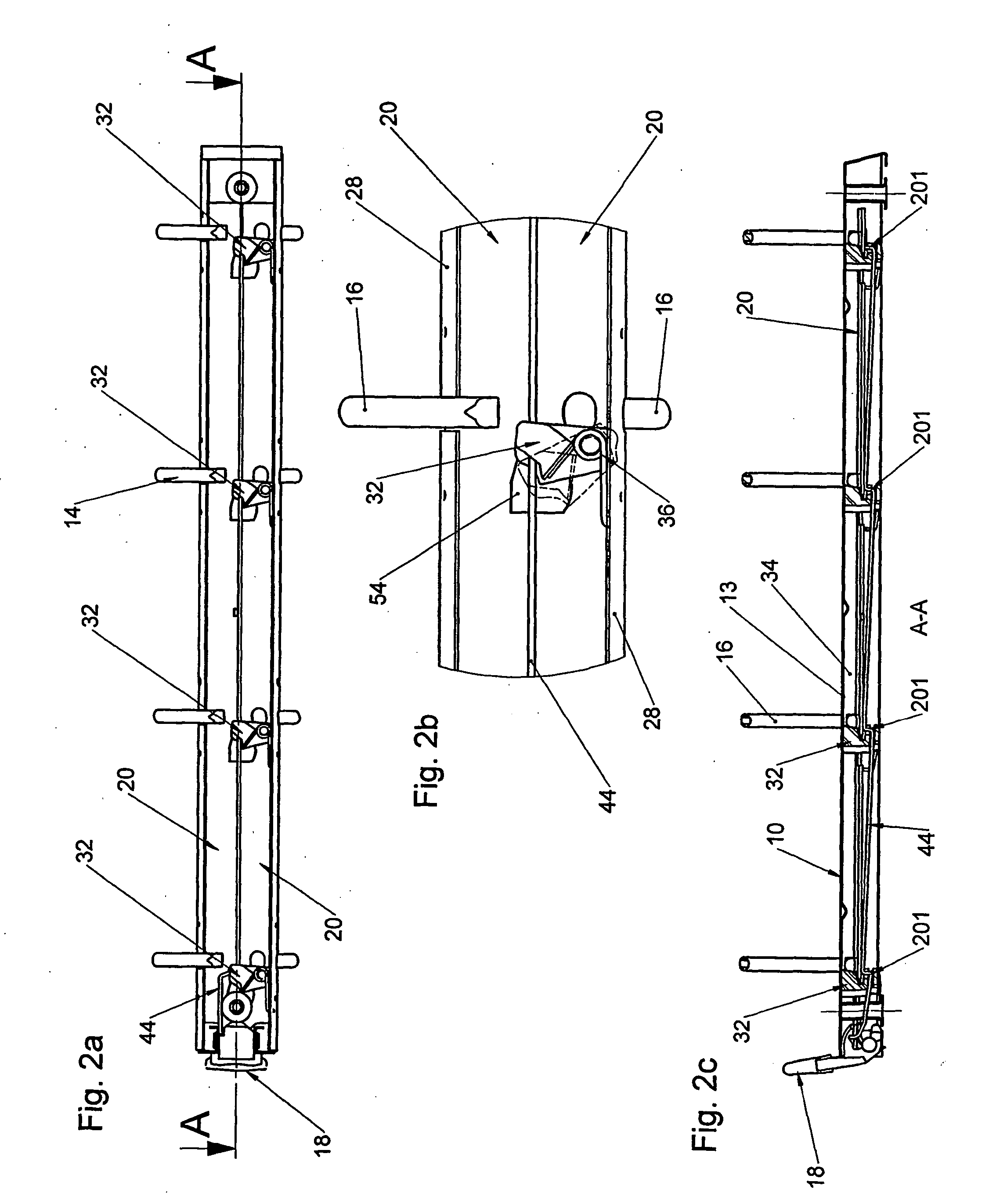

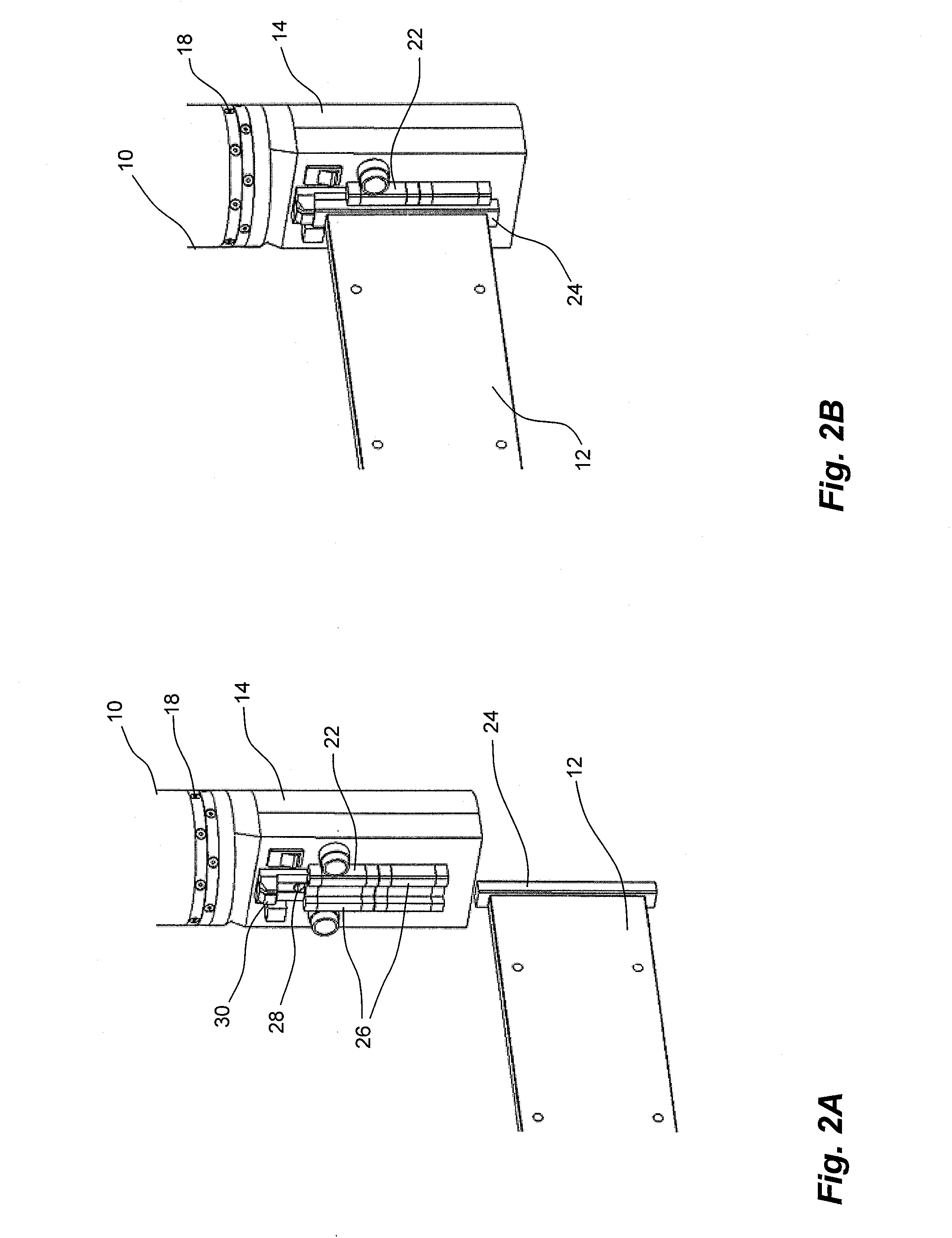

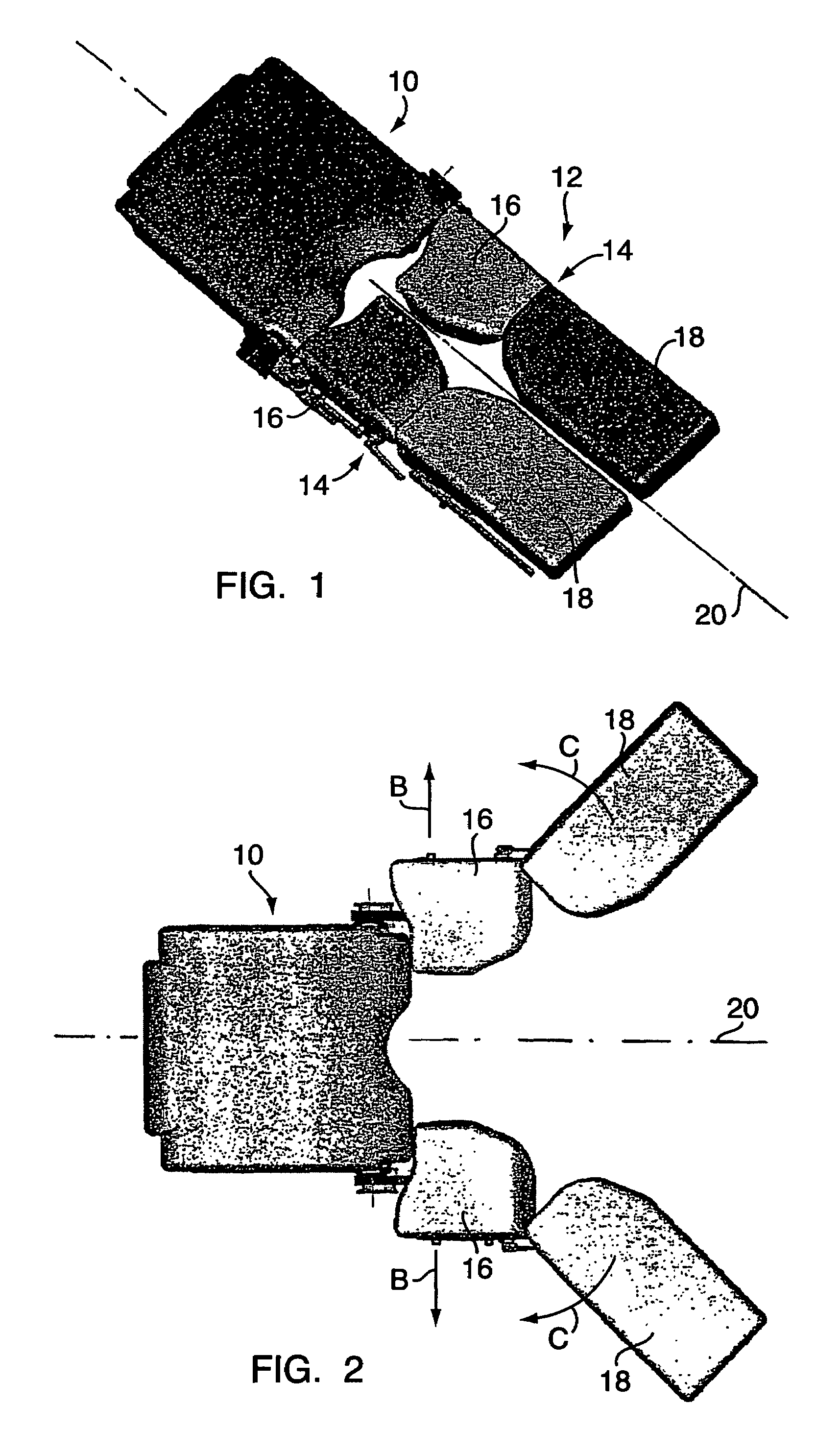

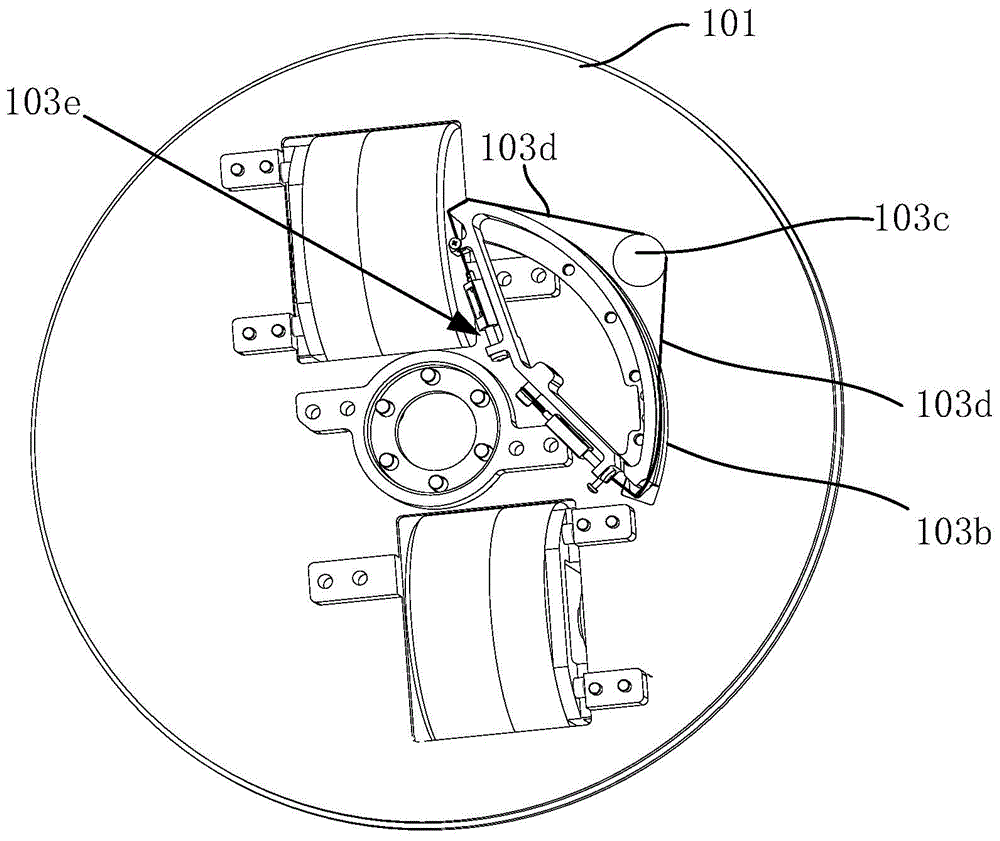

Ring binder mechanism

InactiveUS20060056906A1Improve retentionFiling appliancesSheet bindingEngineeringDocument preparation

The invention relates to a ring binder mechanism for housing perforated documents. The ring binder mechanism comprises a housing (10) with spring elastically flexible housing flanks (28). Two carrier rails (20) are arranged within the housing (10), which may be pivoted towards each other by the spring action of the housing flanks (28) in the manner of an elbow joint in the region of the longitudinal edges thereof which face each other. At least two half rings (16), which pair-wise form a ring (14), are rigidly connected to the support rails (20) at defined longitudinal separations from each other. At least two locking elements (32), operated by means of an actuating element (18) and a tie rod (44), are further provided, which engage in a free space (34), formed between the carrier rails (20) and a housing wall (13), in the locked position, with locking of the pivoting movement of the carrier rails (20) and which release the pivoting path about the joint axis (22) in the opened state, whereby the locking elements (32) are pre-tensioned in the closing direction by the action of a closing spring (36). According to the invention, only one single tie rod (44) is provided, the tie rod comprising several dogs (201), each of which is provided for cooperating with one of the locking elements (32).

Owner:ESSELTE LEITZ GMBH & CO KG

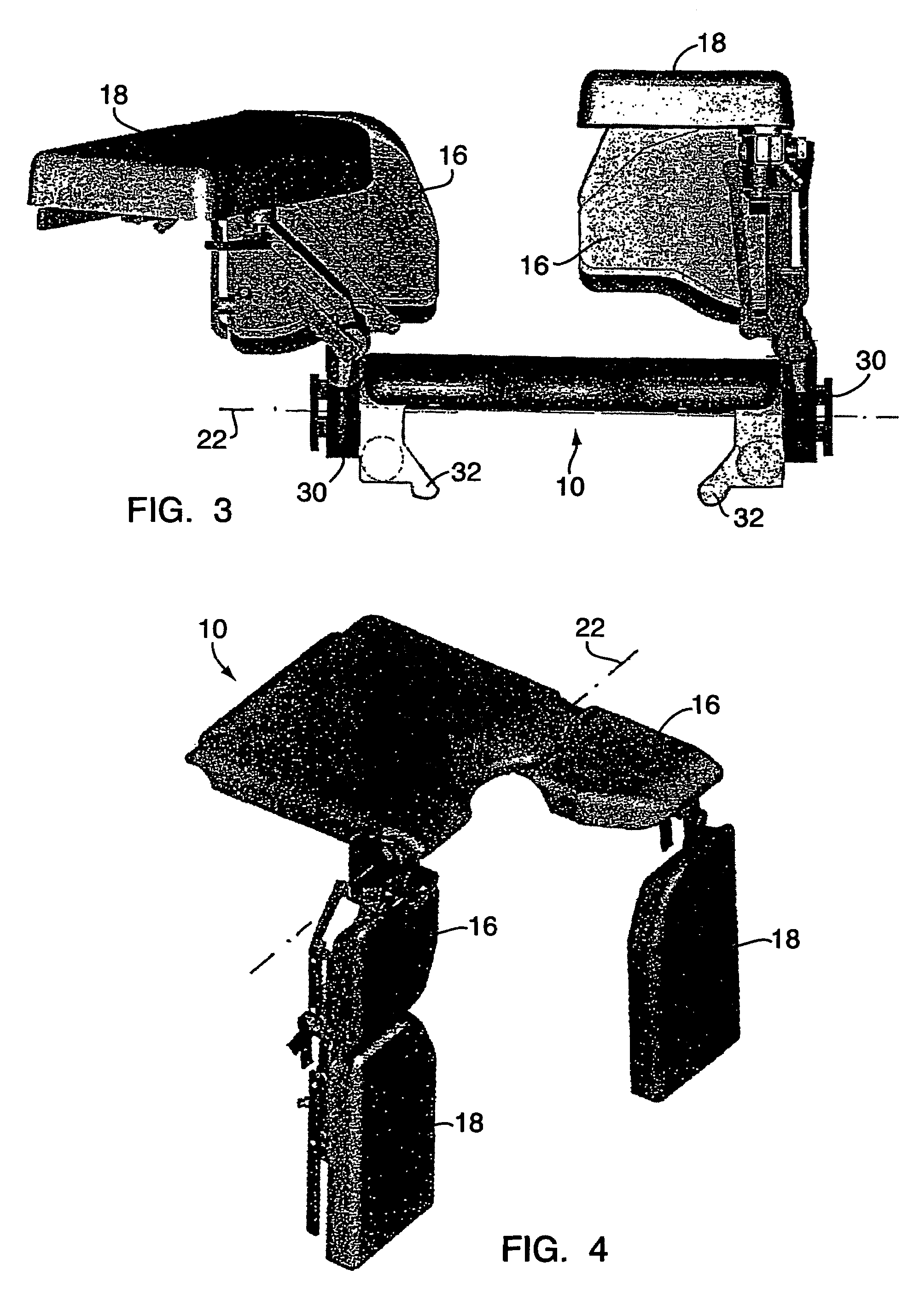

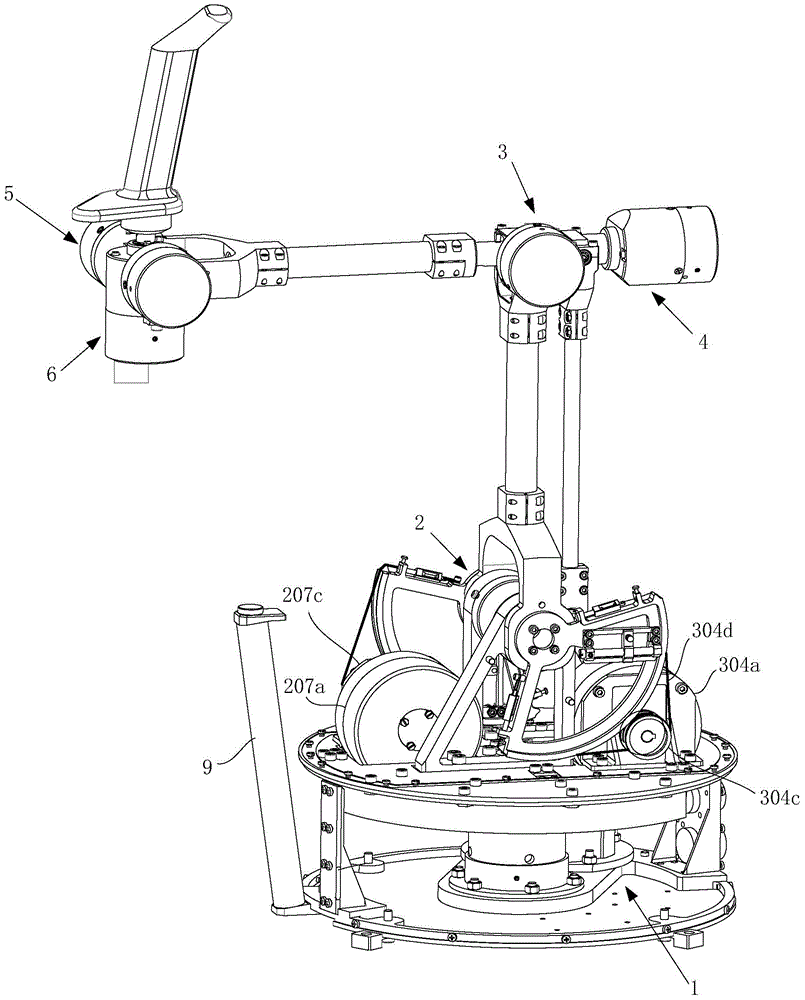

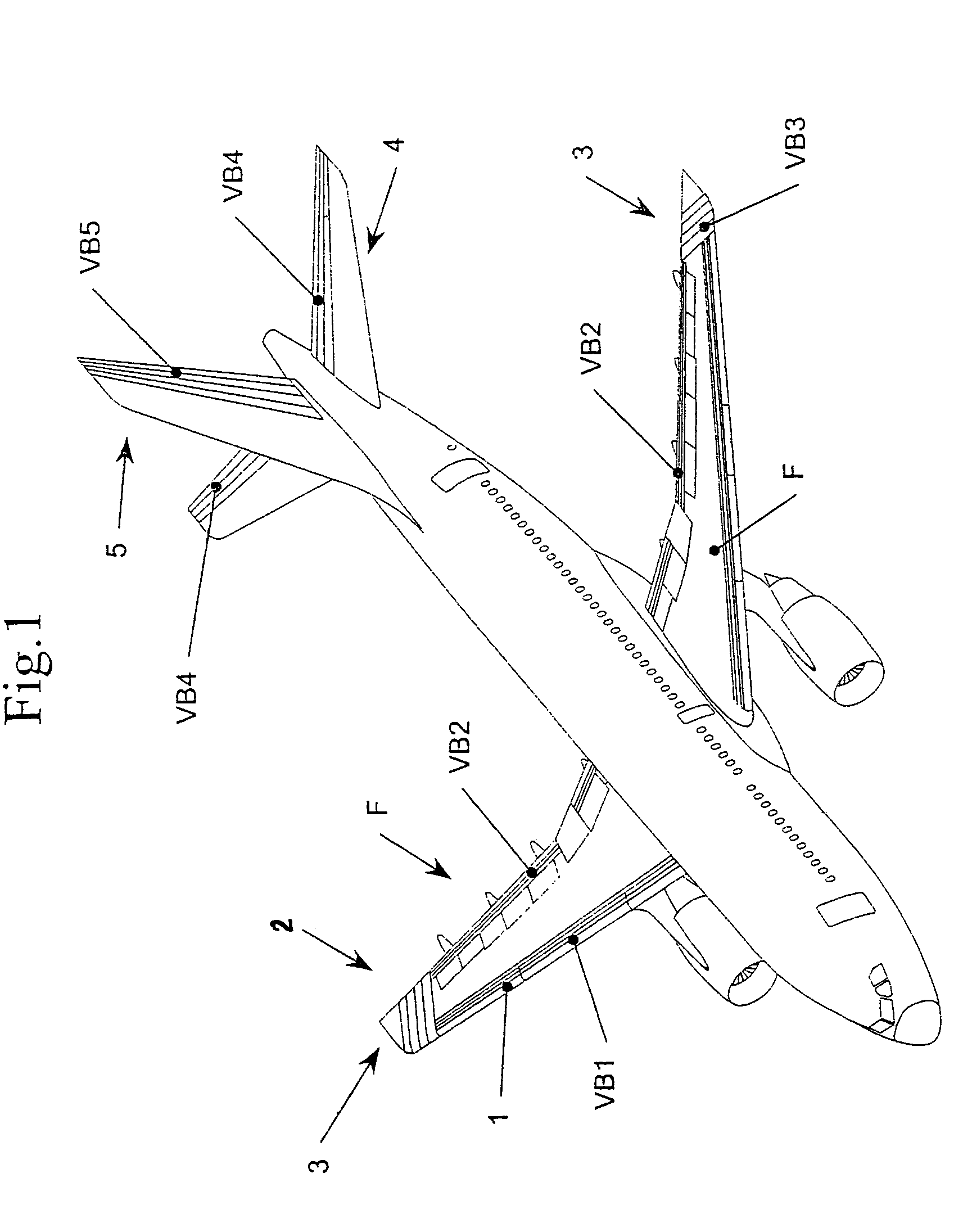

Portable robotic arm

ActiveUS20110257786A1Easy to assembleReduce riskProgramme controlProgramme-controlled manipulatorWheelchairRobotic arm

A portable robotic arm comprises a base, a plurality of motorized joints, a plurality of body members and a manipulator. Each motorized joint is operative to rotate in its respective rotation plane and on its respective joint axis, which is normal to the respective rotating plane. Each body member is sequentially connected to one other body member through one of the motorized joints. A last body member is connected to the base through a last motorized joint. A manipulator is connected to a first body member through a first motorized joint. At least two consecutive rotation planes are placed at an angle from each other that is greater than 0 degrees and smaller than 90 degrees. Optionally, the manipulator comprises three fingers and a tool port centered between the three fingers. A tool connected in the manipulator's tool port may be gripped with the three fingers. The robotic arm and a wheelchair support for the robotic arm may also be provided as a kit.

Owner:KINOVA INC

Exoskeleton

ActiveUS20120330198A1Easy to adjustReduce frictionProgramme-controlled manipulatorChiropractic devicesEngineeringActuator

An exoskeleton for humans including a joint element that interacts directly or indirectly with a human's joint via an end-effector mount, wherein the end-effector mount is arranged to perform an arbitrary planar parallel movement in a plane, allowing superimposed translational and rotational movements of the end-effector mount relative to a body of the joint element. The exoskeleton allows for excellent adjustment of the joint axes, i.e. the exoskeleton's and the human's joint, for effecting simultaneous translational and rotational movements. Particularly, the exoskeleton is self-aligning to the movements of a human's joint independent from differences in the attachment of the exoskeleton to the body and anatomical differences of the patients.

Owner:SABANCI UNIVERSITY

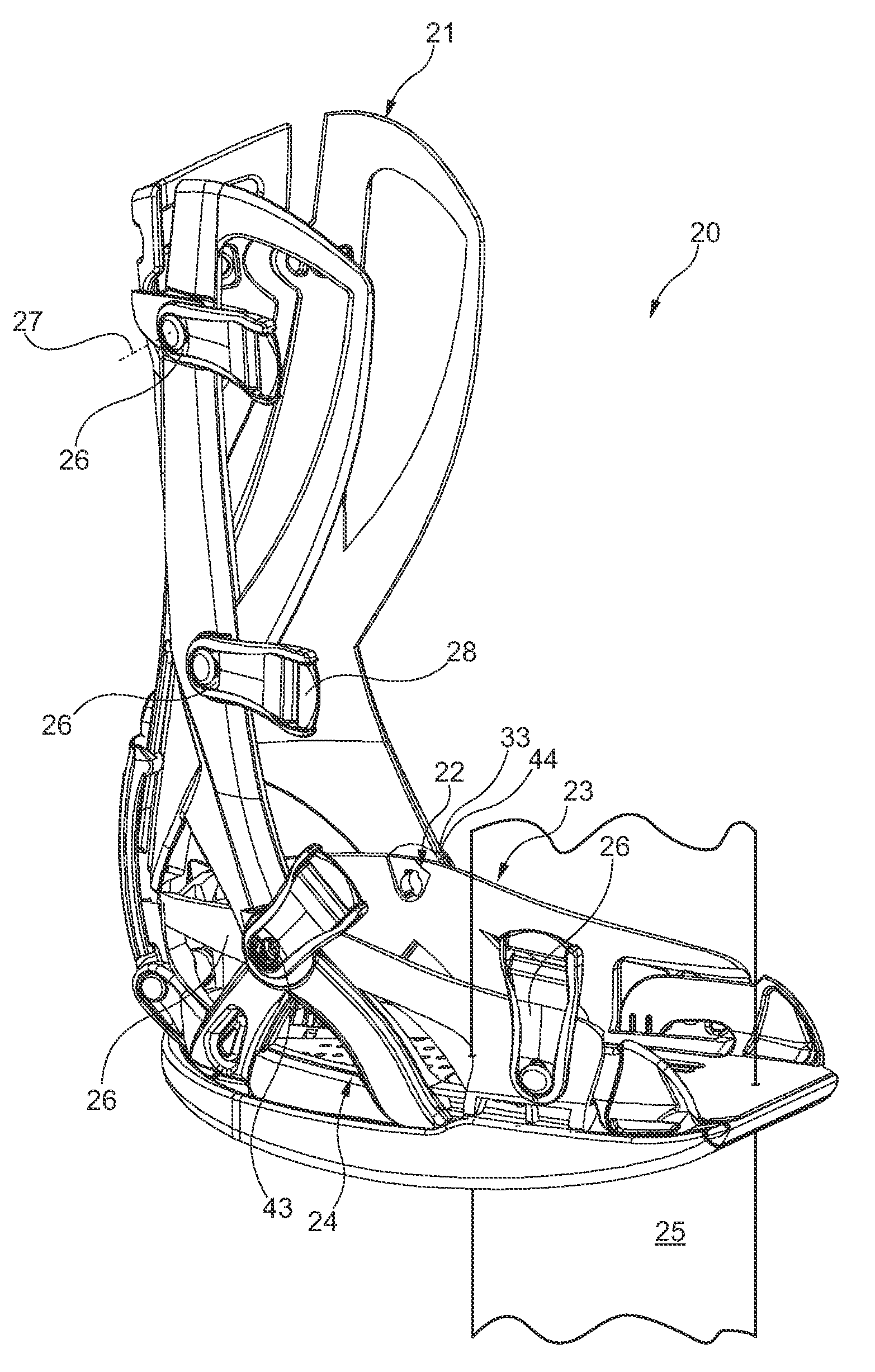

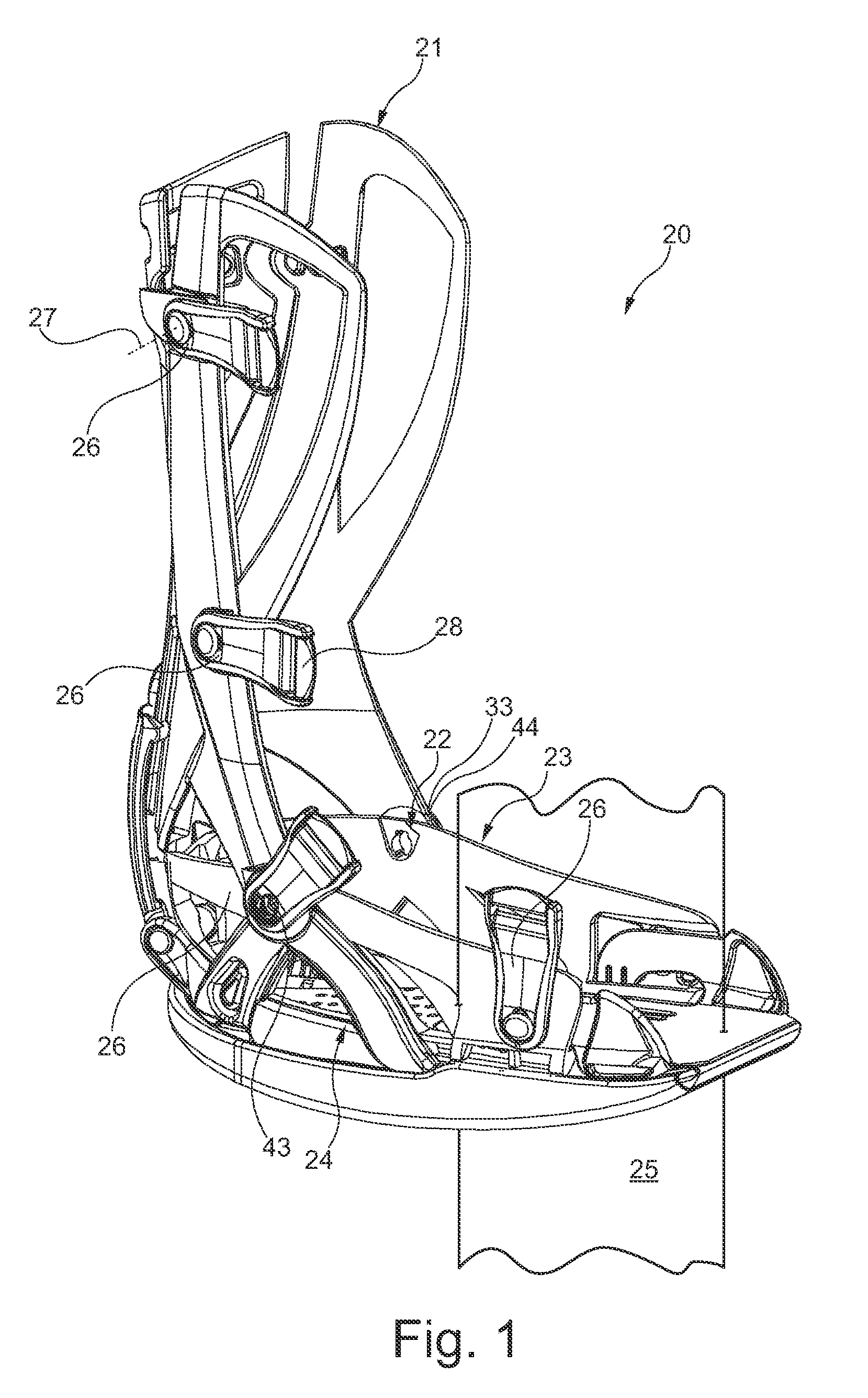

Support shell arrangement for arrangement at a lower leg

A support shell arrangement (20) is provided for arranging on a lower leg, having a foot part (23) and a calf part (21). The calf part includes two calf struts (29, 30) disposed at the side of an entry opening (32) of the calf part, extending in the longitudinal axis of the calf part, and a heel strut connected to the calf struts in a strut connection and extending toward a heel part of the foot part. A support bow arrangement (24) has two bow struts (34, 35) extending in a U-shape about a sole area, the free strut ends thereof being pivotally connected in pairs in a common pivot joint (43, 44) on a joint axis corresponding to the ankle joint and connected to a calf strut, and connected to each other in a V-shape by a common support basis (36). The support basis is pivotally connected to the heel strut of the calf part at the heel side end thereof.

Owner:OPED

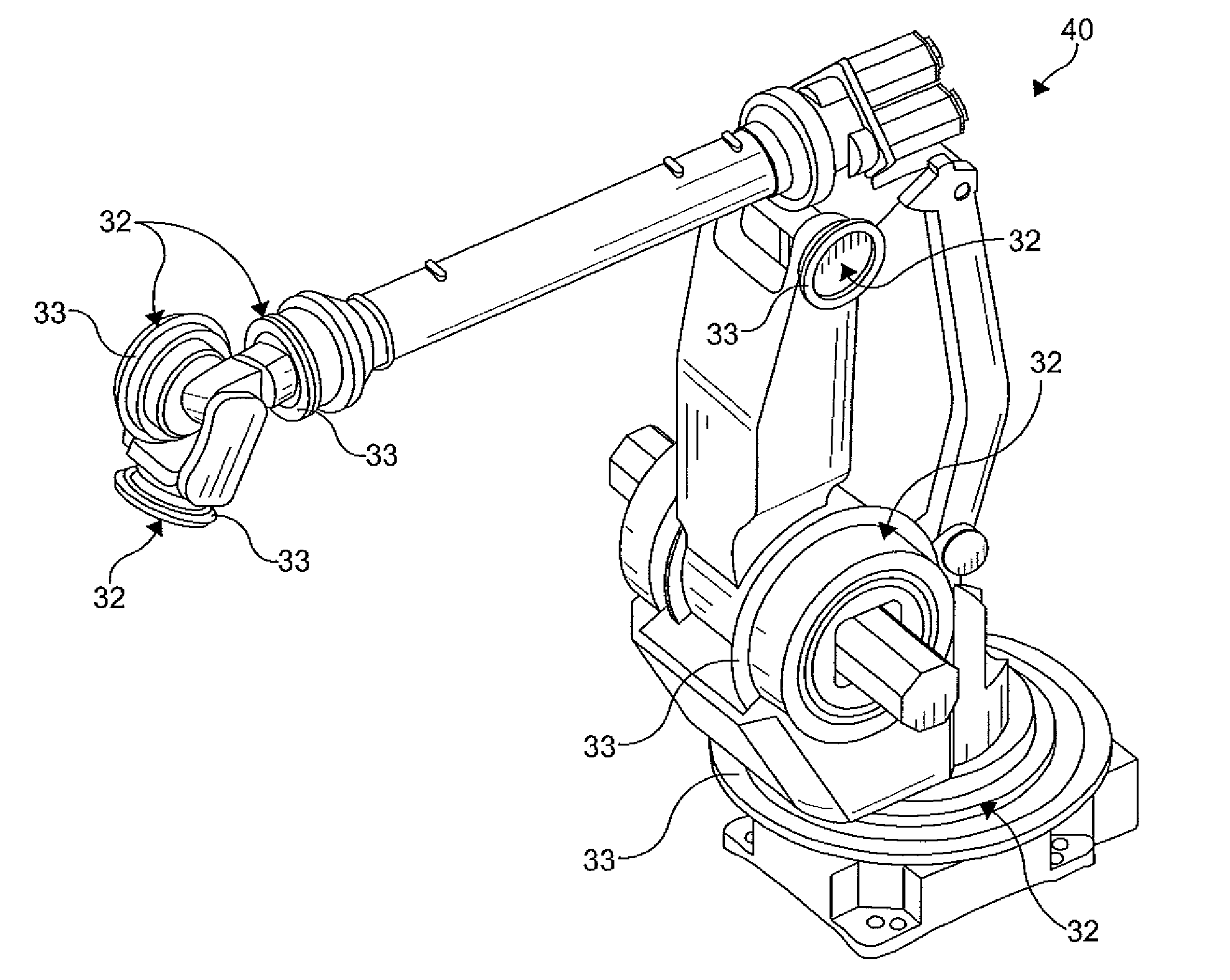

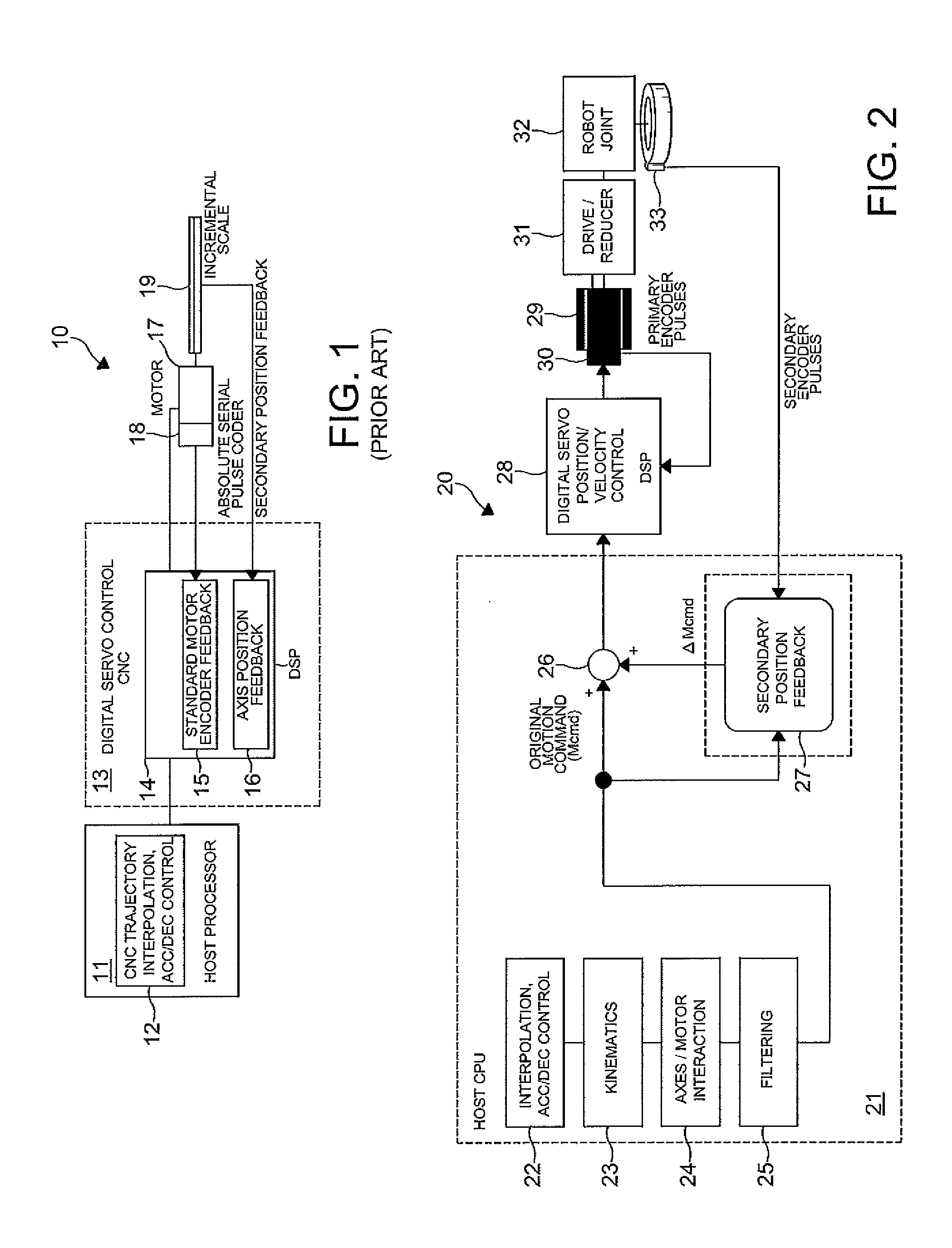

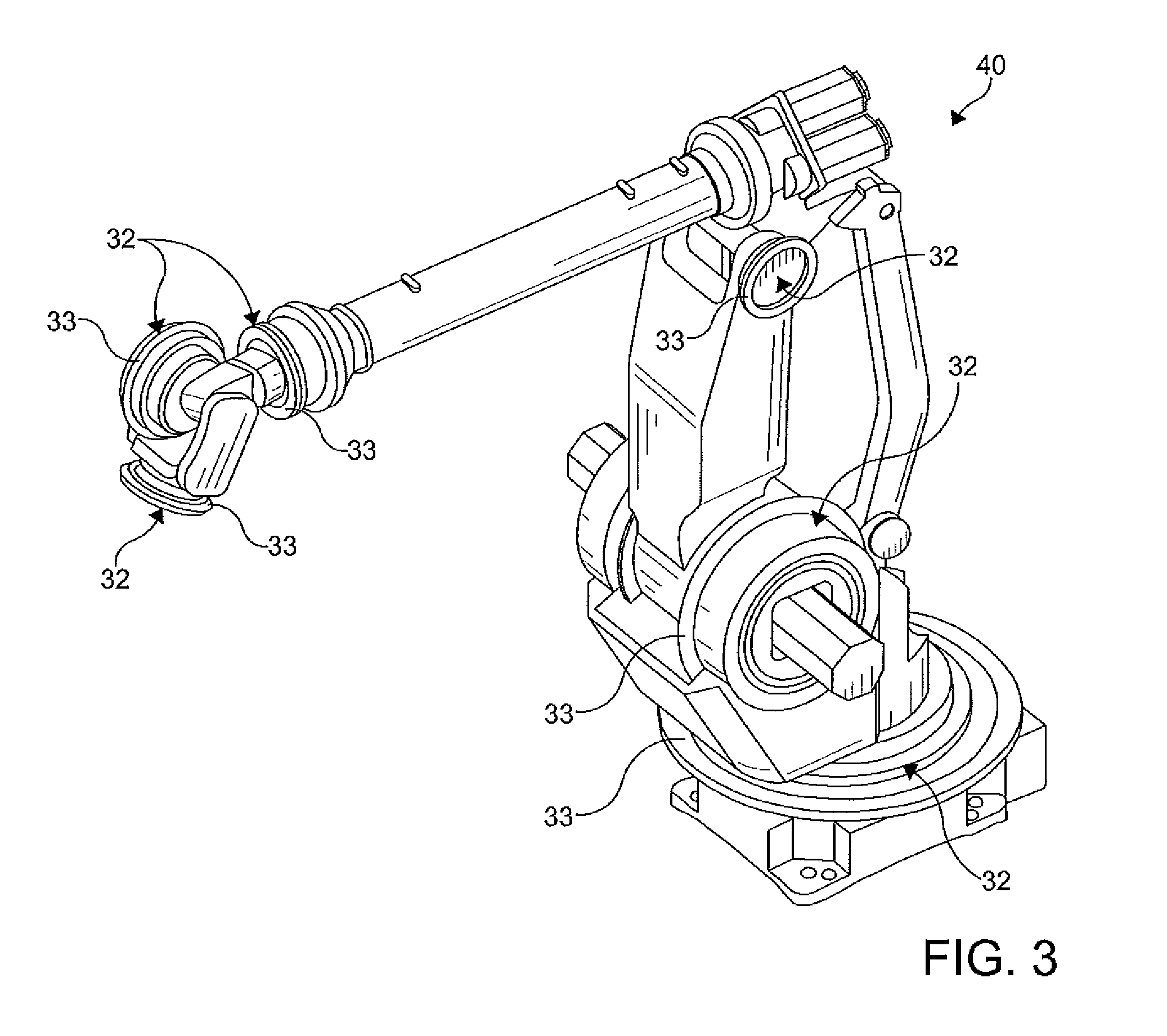

Secondary position feedback control of a robot

ActiveUS20100191374A1Remove complexityMaintain abilityComputer controlSimulator controlDual loop controlGear train

A method of and apparatus for achieving dynamic robot accuracy includes a control system utilizing a dual position loop control. An outer position loop uses secondary encoders on the output side of the gear train of a robot joint axis, while the inner position loop uses the primary encoder attached to the motor. Both single and dual loop control can be used on the same robot and tooling axes.

Owner:FANUC ROBOTICS NORTH AMERICA

Prosthetic foot

InactiveUS20040225376A1Improves footDecrease residual limb to socket shear forceArtificial legsFoot dorsiflexionProsthetic feet

A prosthesis is disclosed for improving the gait and comfort qualities of the amputee that participates in walking, running and jumping activities. A foot and an ankle of the prosthesis are monolithically formed as a resilient member including a strut which forms an ankle joint. A hole extends through the resilient member with the periphery of the hole forming an anterior side surface of the strut. The resilient member anterior to the hole includes a gap to permit motion about the ankle joint axis while providing a stop in dorsiflexion. The hole is elongated upwardly such that the strut is upstanding and anterior convexly curved.

Owner:BIOQUEST PROSTHETICS

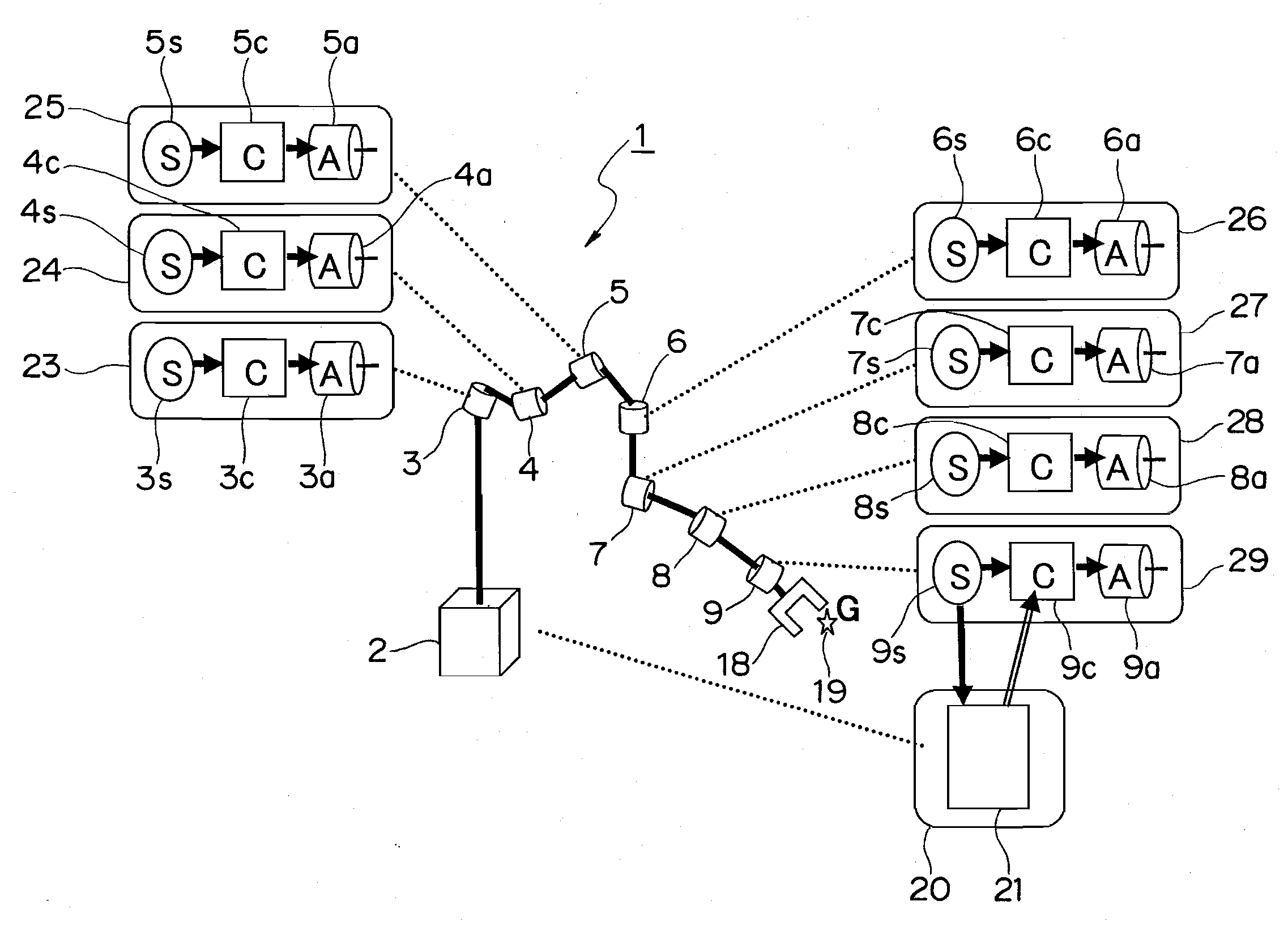

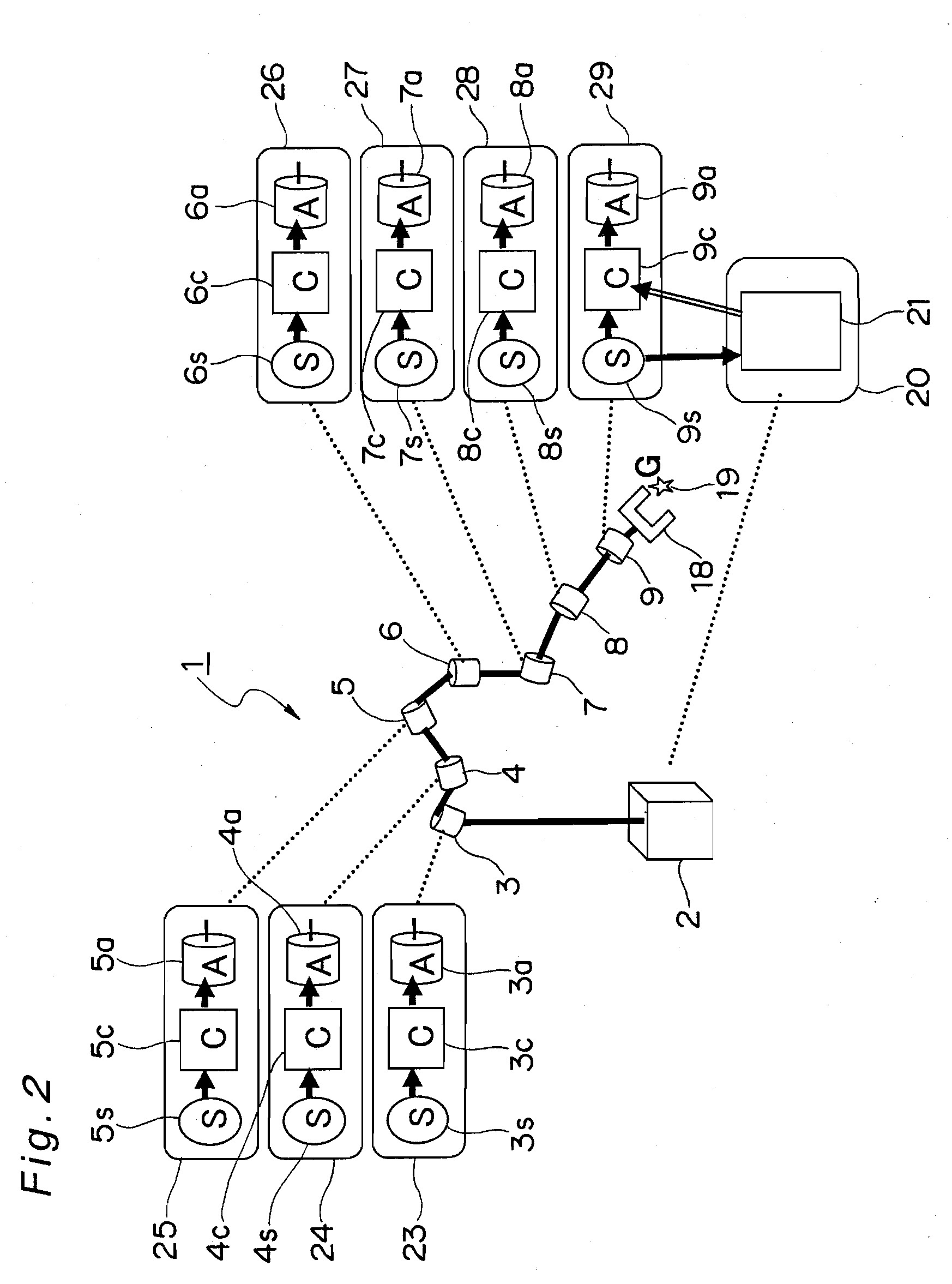

Control method and control system for manipulator

InactiveUS20100168919A1Reliably carry-outIncrease freedomSampled-variable control systemsProgramme-controlled manipulatorControl systemManipulator

In a control method of a multi-jointed manipulator, the manipulator is controlled through a process to transmit a difference between an end position of the manipulator and a target position to the joint axes, and a process to adjust joint displacements and joint velocities of the joint axes independently of one another of the joint axes based on the difference, these processes being repeated until the end position coincides with the target position. By such a manipulator control method, there can be realized position control which is robust against ambient environments and which is easy to achieve even with redundancy or nonlinear drive elements involved.

Owner:PANASONIC CORP

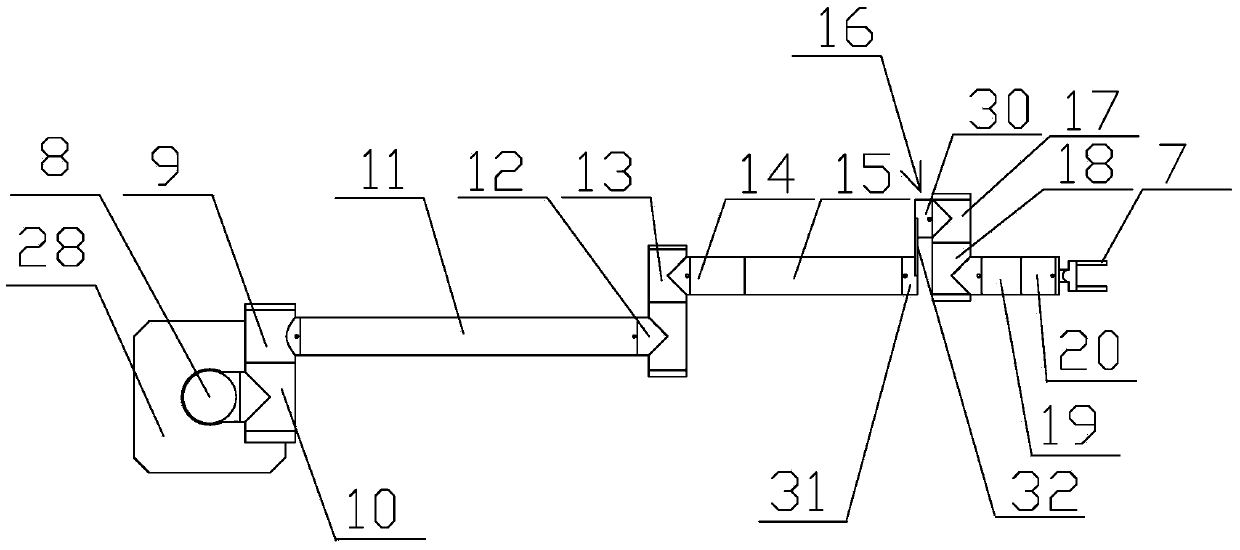

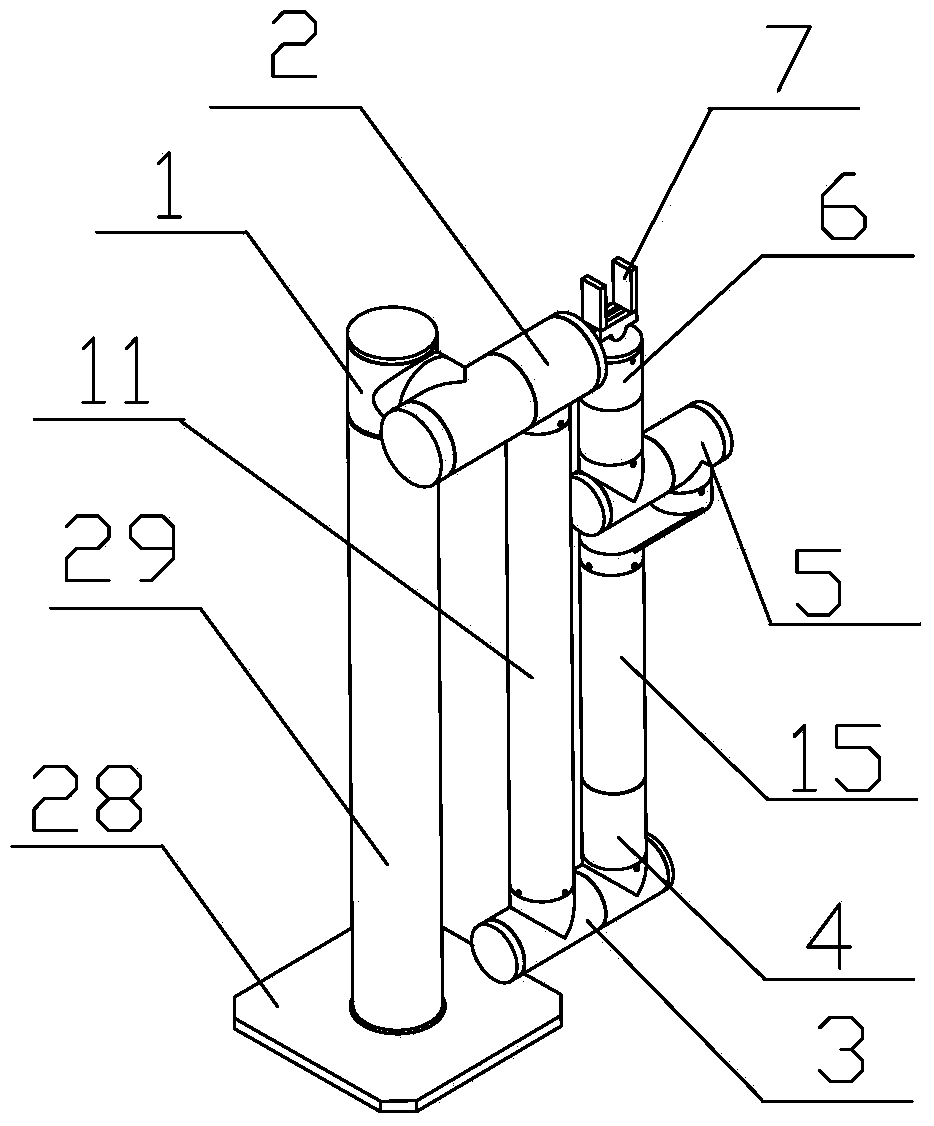

Foldable six degrees of freedom light type operating arm with joint axis orthogonal relation

InactiveCN103753528ASimple structureLight in massProgramme-controlled manipulatorArmsSingle degree of freedomDegrees of freedom

A foldable six degrees of freedom light type operating arm with a joint axis orthogonal relation is characterized in that a first rotating joint, a second rotating joint, a large arm connecting rod, a third rotating joint, a forth rotating joint, a fifth rotating joint and a sixth rotating joint are arranged on a foundation base in sequence, an output end of the sixth rotating joint is connected with a tail-end single degrees of freedom paw, wherein an axis of the first rotating joint is arranged coaxially with the foundation base and is perpendicular to an axis of the second rotating joint, the axis of the second rotating joint is parallel to an axis of the third rotating joint, the axis of the third rotating joint is perpendicular to an axis of the forth rotating joint, the axis of the forth rotating joint is perpendicular to an axis of the fifth rotating joint, the axis of the fifth rotating joint is perpendicular to an axis of the sixth rotating joint, and the axis of the forth rotating joint, the axis of the fifth rotating joint and the axis of the sixth rotating joint are intersected at one point in space. By means of the foldable six degrees of freedom light type operating arm with the joint axis orthogonal relation, the integrated structure of an operating arm is simpler and more convenient, and quality is more portable and convenient, so that the optimal operating flexible performance of the tail end of the operating arm can be assured.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Prosthetic foot

Owner:BIOQUEST PROSTHETICS

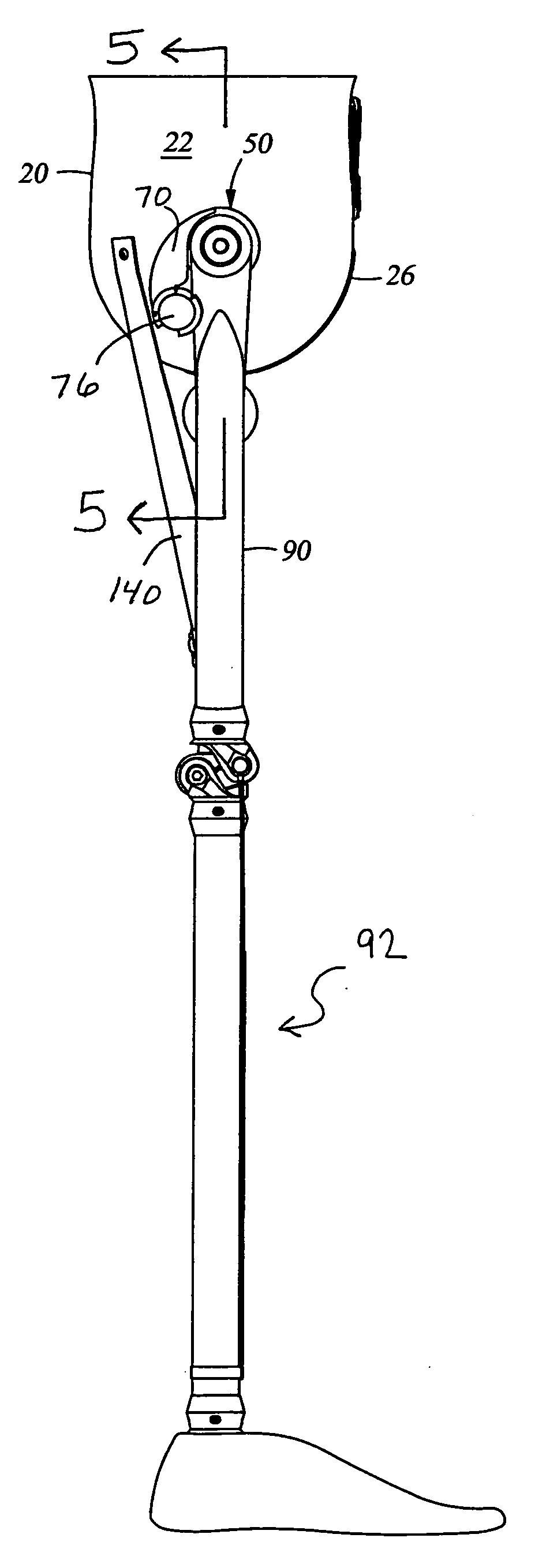

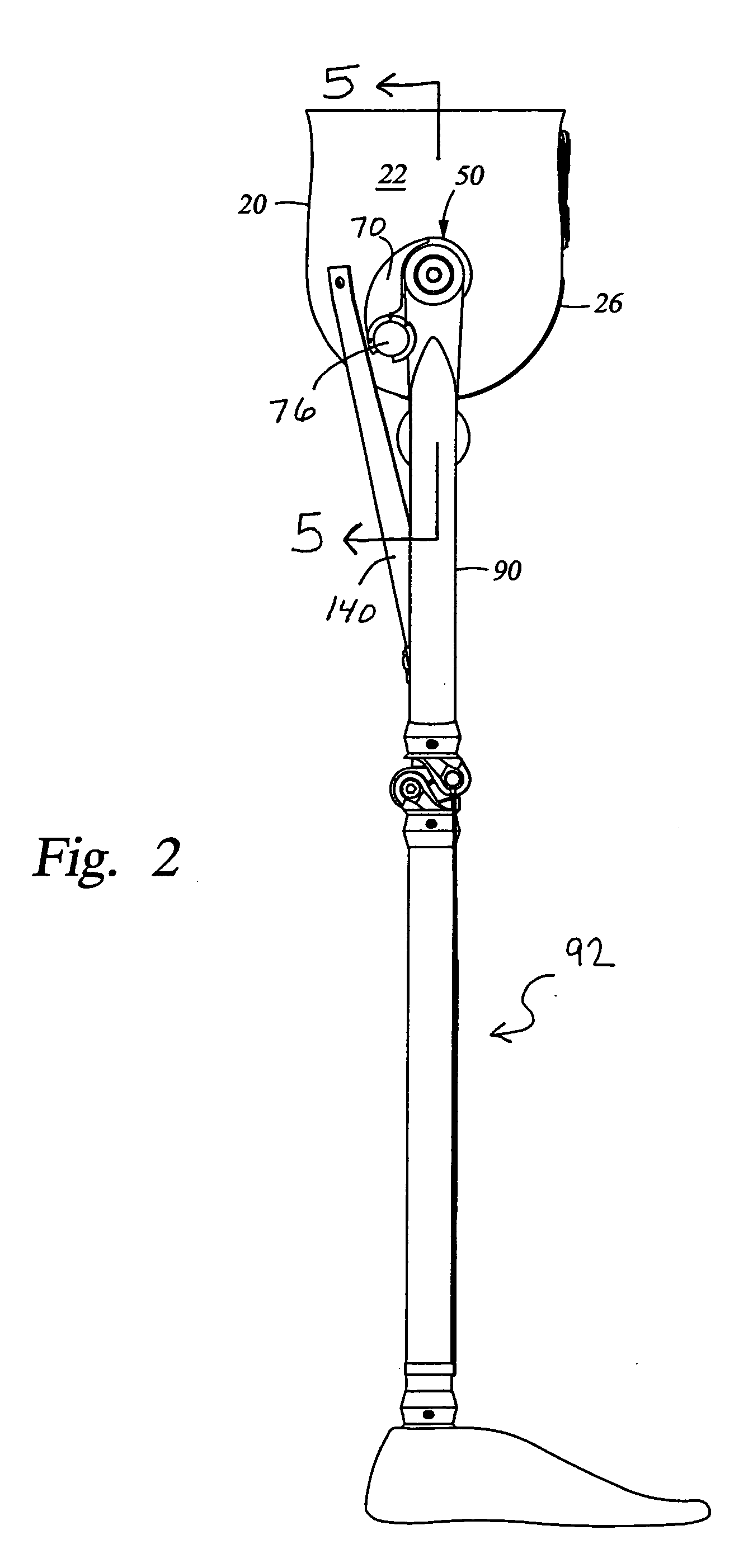

Prosthetic hip joint with side pivot

A prosthetic hip for supporting on a patient a prosthetic leg comprises a socket, a mount on the outer surface of the socket and defining a joint axis, the joint axis substantially coinciding with the natural axis of rotation of the patient's natural leg when rotated in a sagittal plane, and a first member adjustably affixed to the socket's outer surface. The first member includes an extension stop member and the upper end of the leg is pivotably mounted on the mount such that and pivoting of the leg in at least one direction is limited by the stop member. The prosthetic hip may also include a roller on a load arm extending medially from the upper leg end so as to engage the outer surface of the socket transmit a load from the socket directly to the prosthetic leg.

Owner:WILSON MICHAEL T

Zero calibration method of six-axis industrial robot

The invention discloses a zero calibration method of a six-axis industrial robot. The zero calibration method comprises the following steps that reference positions are selected and set as initial zeros; a first joint axis is rotated on the basis of the reference positions; a second joint axis is adjusted to allow the inner side of the second joint axis to be kept in a horizontal position; a group of positions, where a difference value of a rotation angle of the second joint axis is maximum, in various groups of positions where a difference value of a rotation angle of the first joint axis is 180 degrees is determined; the first joint axis is rotated to a position perpendicular to the group of positions, which is the zero position of the first joint axis; on this basis, the second joint axis to a sixth joint axis are calibrated horizontally or perpendicularly by a precise level gauge; the rotation angles of the joint axes are written down; and the zero positions of the joint axes, namely the zero positions of the six-axis industrial robot are acquired finally. According to the method, the scale-free six-axis industrial robot can acquire the zero positions easily and quickly under the condition that the zeros are lost, and the motion precision of the industrial robot is improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

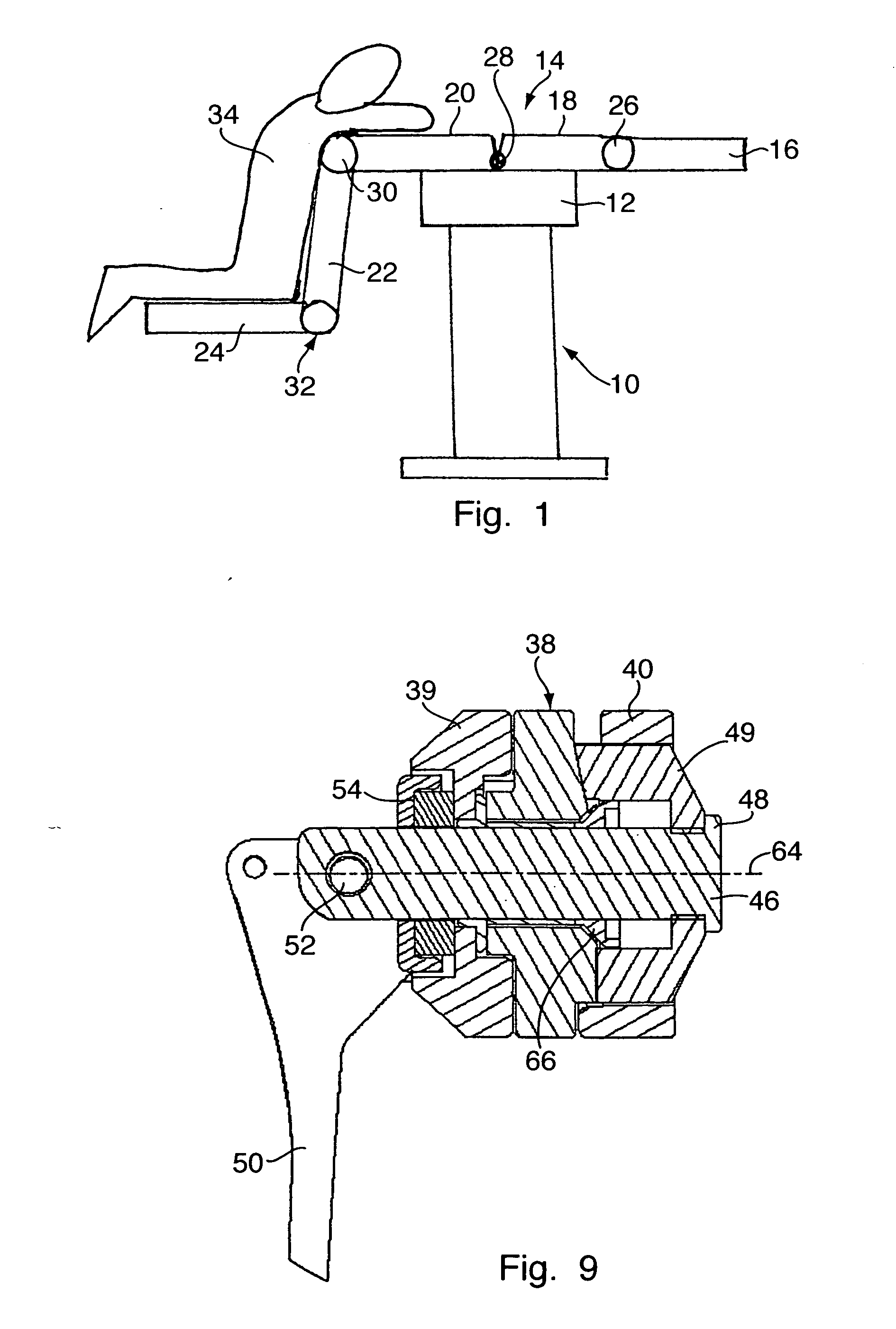

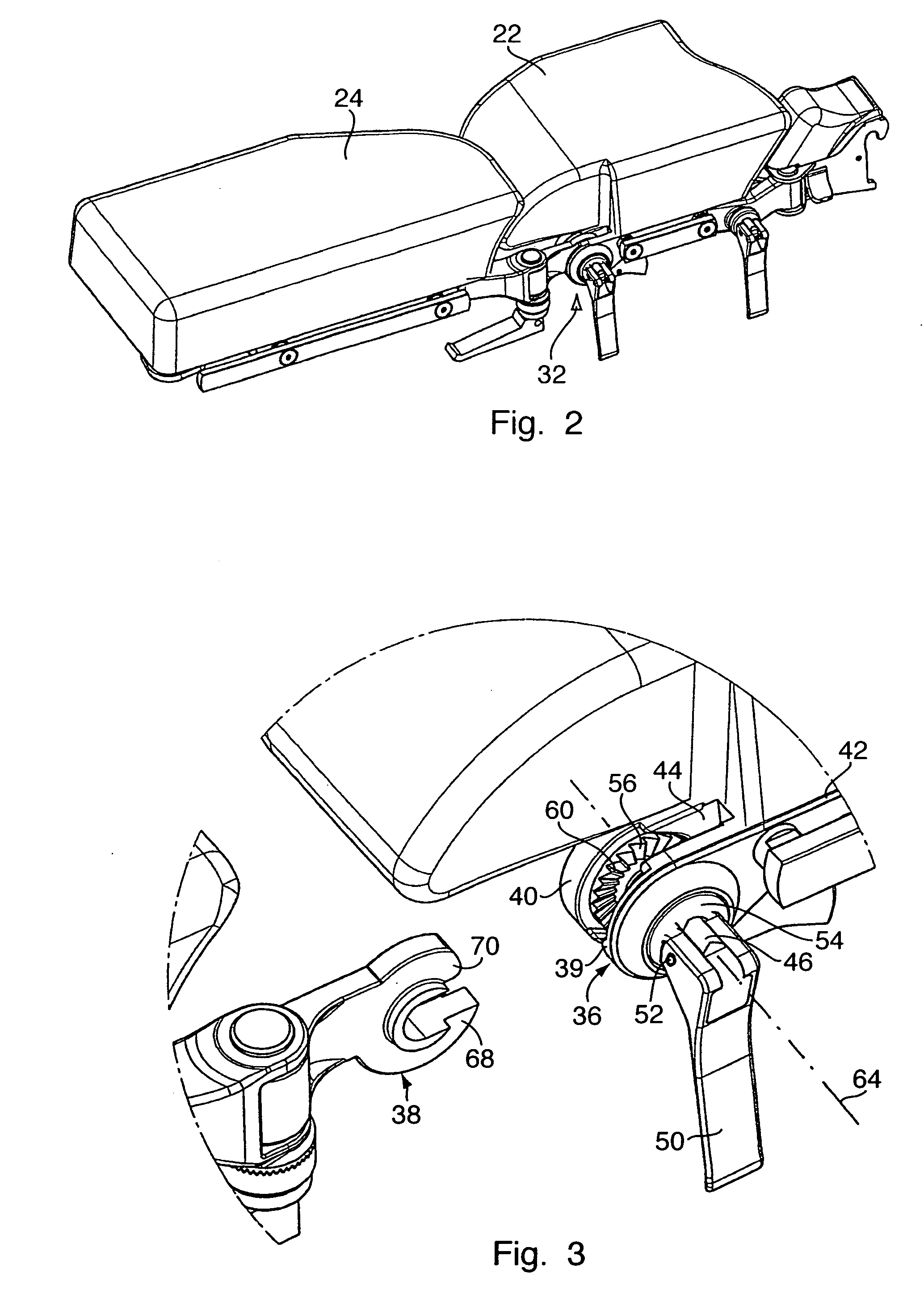

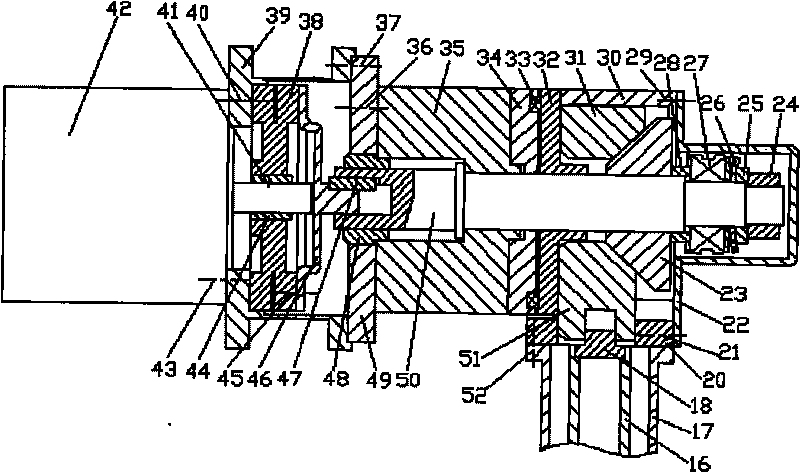

Joint arrangement for the connection of two segments of a patient bed

ActiveUS20070116512A1Improve carrying capacityReliable functionYielding couplingOperating tablesSacroiliac jointMechanical engineering

What is described is a joint arrangement for the articulated connection of two segments of a patient bed, with two joint parts (36, 38), each of which is connected rigidly to one of the segments and which are pivotable relative to one another about a common joint axis (64) by means of a shaft journal (46), the joint parts (36, 38) carrying, in each case on at least one of their faces confronting one another axially, blocking faces (60) intended for bearing against one another, and the joint parts (36, 38) being capable of being tensioned axially relative to one another by means of a tensioning mechanism (46, 54, 50), and the blocking faces (60) lying in each case at least approximately in a plane containing the joint axis (64).

Owner:MAQUET GMBH

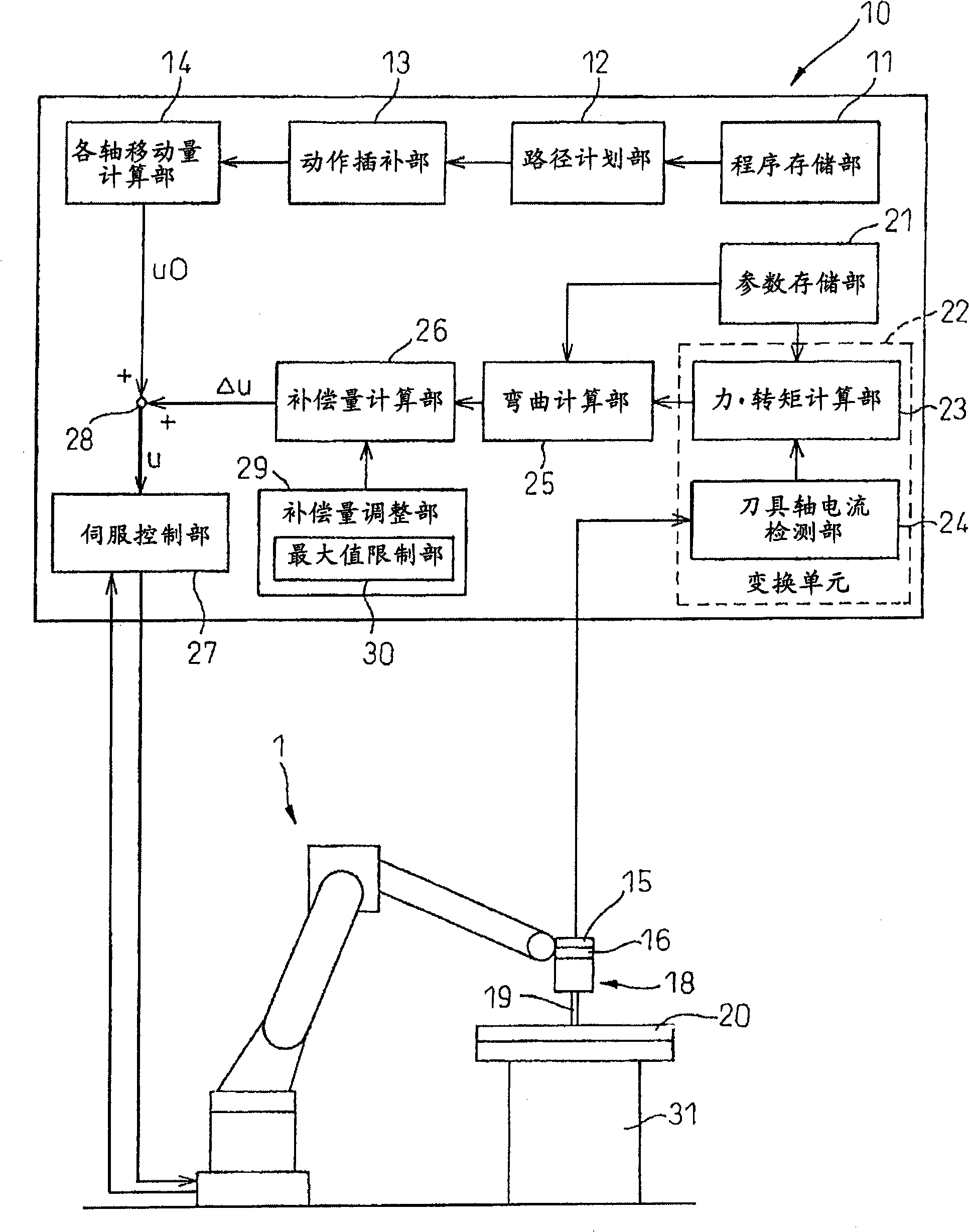

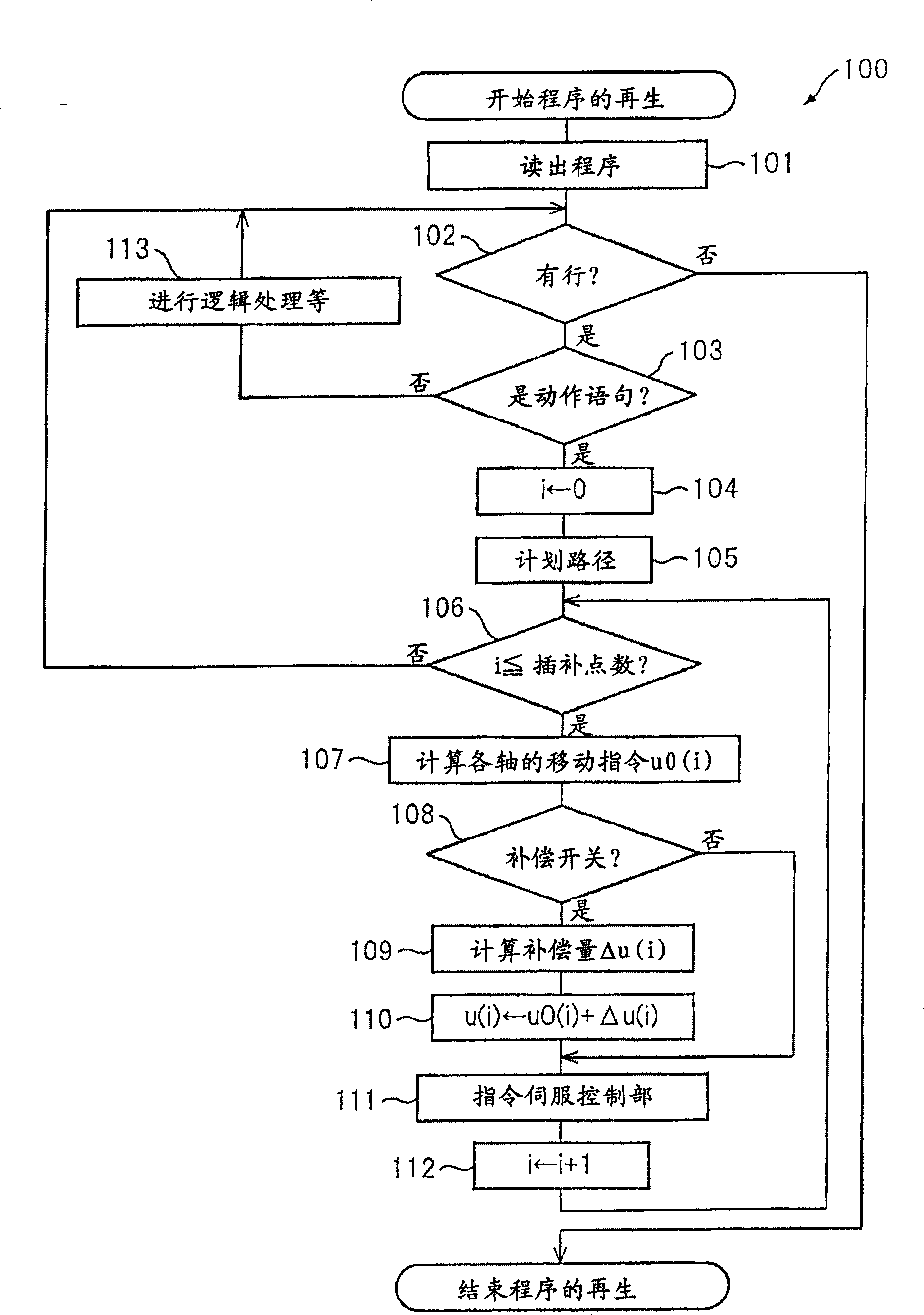

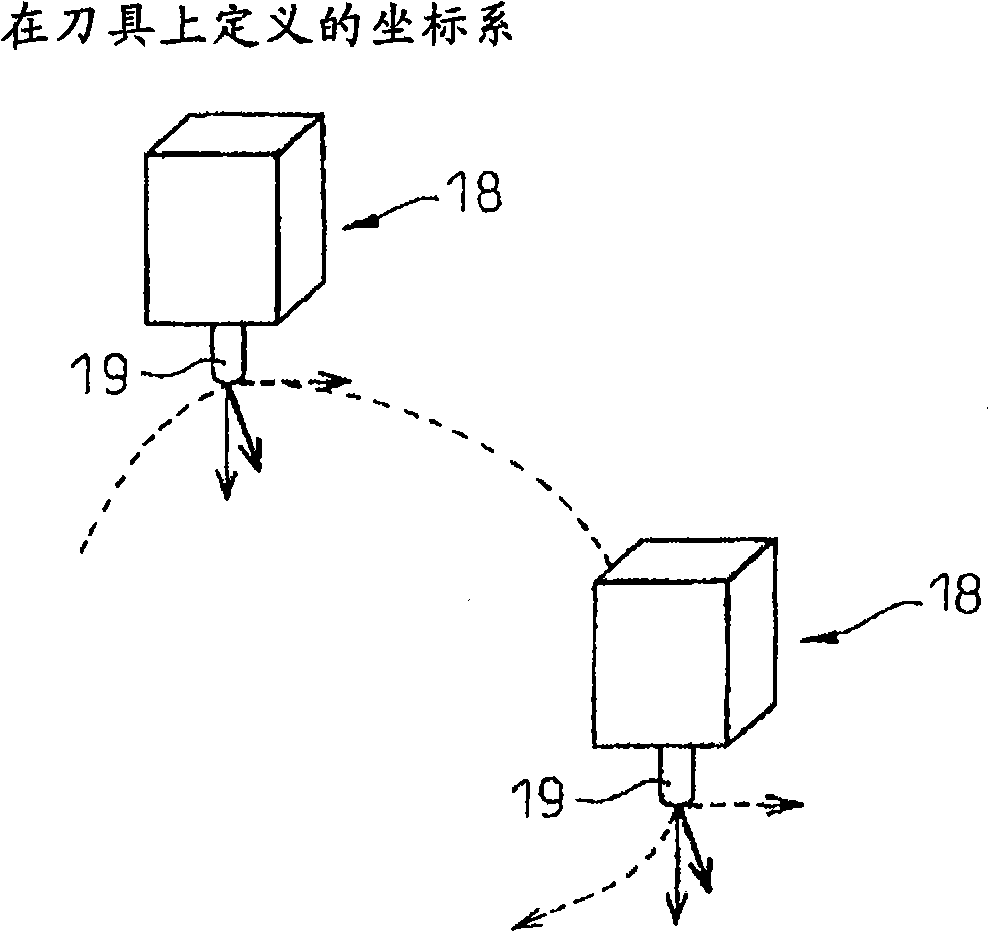

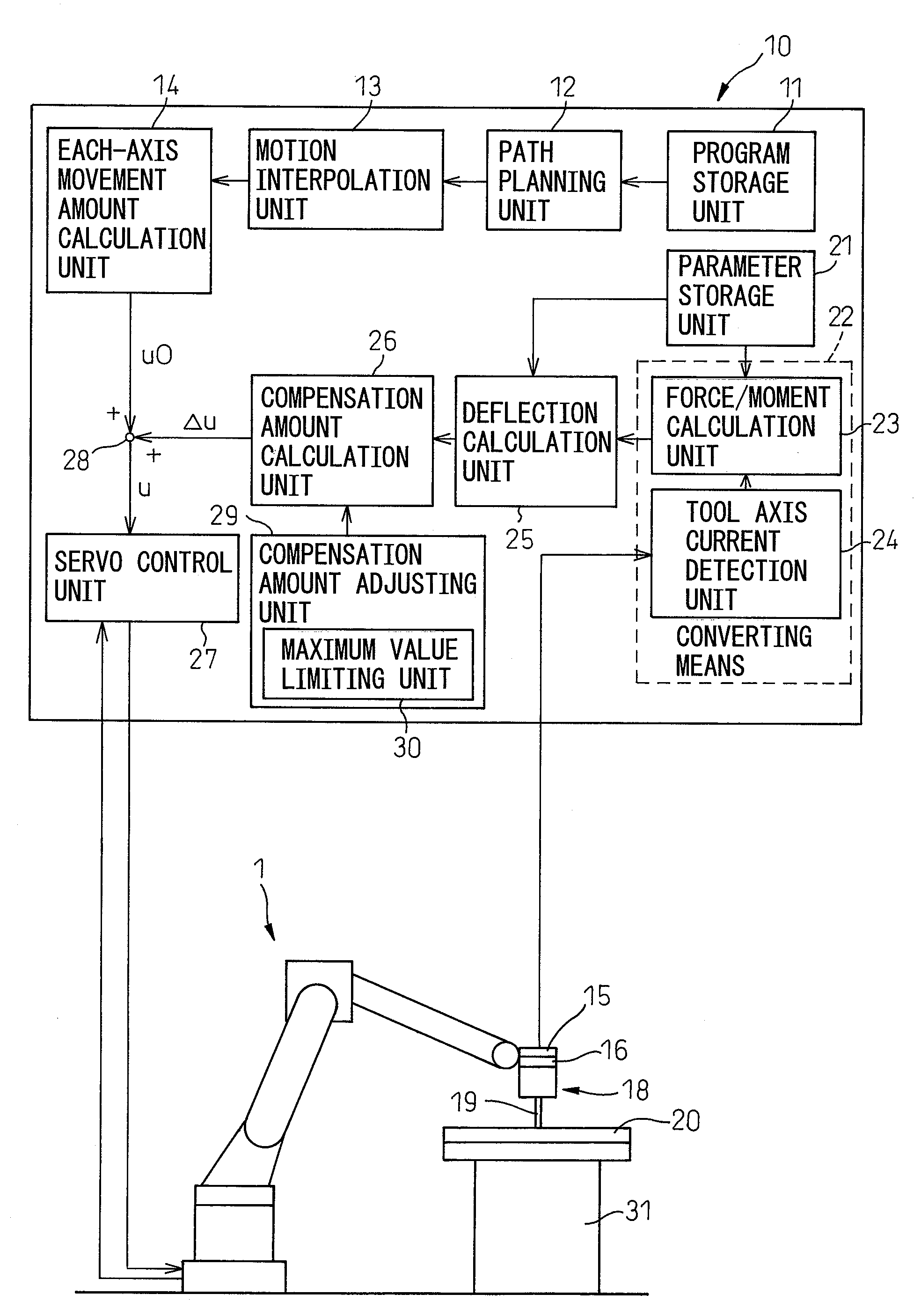

Machining robot control apparatus

InactiveCN101314224AAdd purposeWith a clear purposeProgramme-controlled manipulatorAutomatic control devicesRobot controlControl theory

A control apparatus (10) for a machining robot (1) adapted to machine a workpiece (20) by coming into contact with an effector (19) of a tool (18) attached to the machining robot with the workpiece comprises: detecting means (15) for detecting a force or moment acting between the effector of the tool and the workpiece; converting means (22) for converting the force or moment detected by the detecting means into a force or moment acting on the joint axis of the machining robot; deflection calculating means (25) for calculating a deflection occurring at the joint axis of the machining robot on the basis of the force or moment acting on the joint axis of the machining robot and obtained from the converting means; ; and correcting means (28) for correcting at least one of a position command or a speed command for the joint axis of the machining robot in such a manner as to compensate for the deflection calculated by the deflection calculating means. Accordingly, the position of the robot is accurately corrected without being affected by the deflection of the joint axis.

Owner:FANUC LTD

Electric quadruped robot with variable mechanism configuration

The invention discloses an electric quadruped robot with variable mechanism configuration. The electric quadruped robot with the variable mechanism configuration comprises a trunk and four legs connected to the trunk; each leg comprises three transmission chains which are respectively a first transmission chain, a second transmission chain and a third transmission chain, the first transmission chain is connected with the trunk, the second transmission chain is connected with the first transmission chain, and the third transmission chain is connected with the second transmission chain. The first transmission chain drives a hip joint axis to rotate, the second transmission chain drives a thigh rod piece to rotate, and the third transmission chain drives a shank rod piece to move. The mechanism configuration of the electric quadruped robot can be transformed according to specific terrains, the electric quadruped robot has multiple motion modes of quadruped crawling, quadruped walking and partial crawling-partial walking, when the mechanism configuration of crawling is used, the electric quadruped robot is high in stability, and can better pass through rugged and complex terrains; when the mechanism configuration of walking is adopted, the electric quadruped robot is quick in action speed and high in efficiency and energy utilization rate; the electric quadruped robot with the variable mechanism configuration is driven by the motor, therefore, noises can be greatly reduced, and a mechanical main body is lighter and more flexible.

Owner:SHANDONG UNIV

Machining robot control apparatus

InactiveUS20080297092A1Easy to trackAccurate correctionProgramme-controlled manipulatorComputer controlEngineeringRobot control

A control apparatus (10) for a machining robot (1) adapted to machine a workpiece (20) by coming into contact with an effector (19) of a tool (18) attached to the machining robot with the workpiece comprises: detecting means (15) for detecting a force or moment acting between the effector of the tool and the workpiece; converting means (22) for converting the force or moment detected by the detecting means into a force or moment acting on the joint axis of the machining robot; deflection calculating means (25) for calculating a deflection occurring at the joint axis of the machining robot on the basis of the force or moment acting on the joint axis of the machining robot and obtained from the converting means; and correcting means (28) for correcting at least one of a position command or a speed command for the joint axis of the machining robot in such a manner as to compensate for the deflection calculated by the deflection calculating means. Accordingly, the position of the robot is accurately corrected without being affected by the deflection of the joint axis.

Owner:FANUC LTD

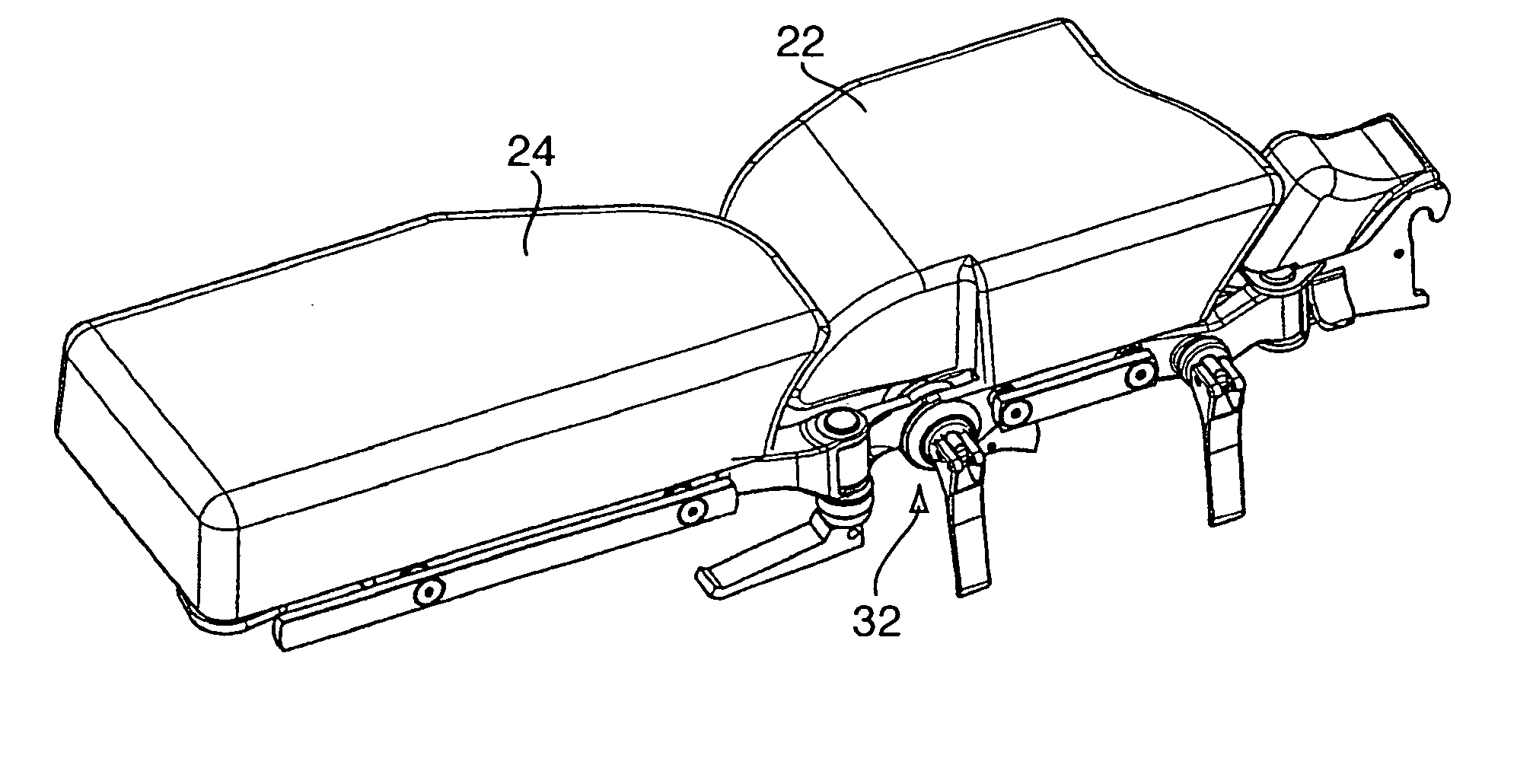

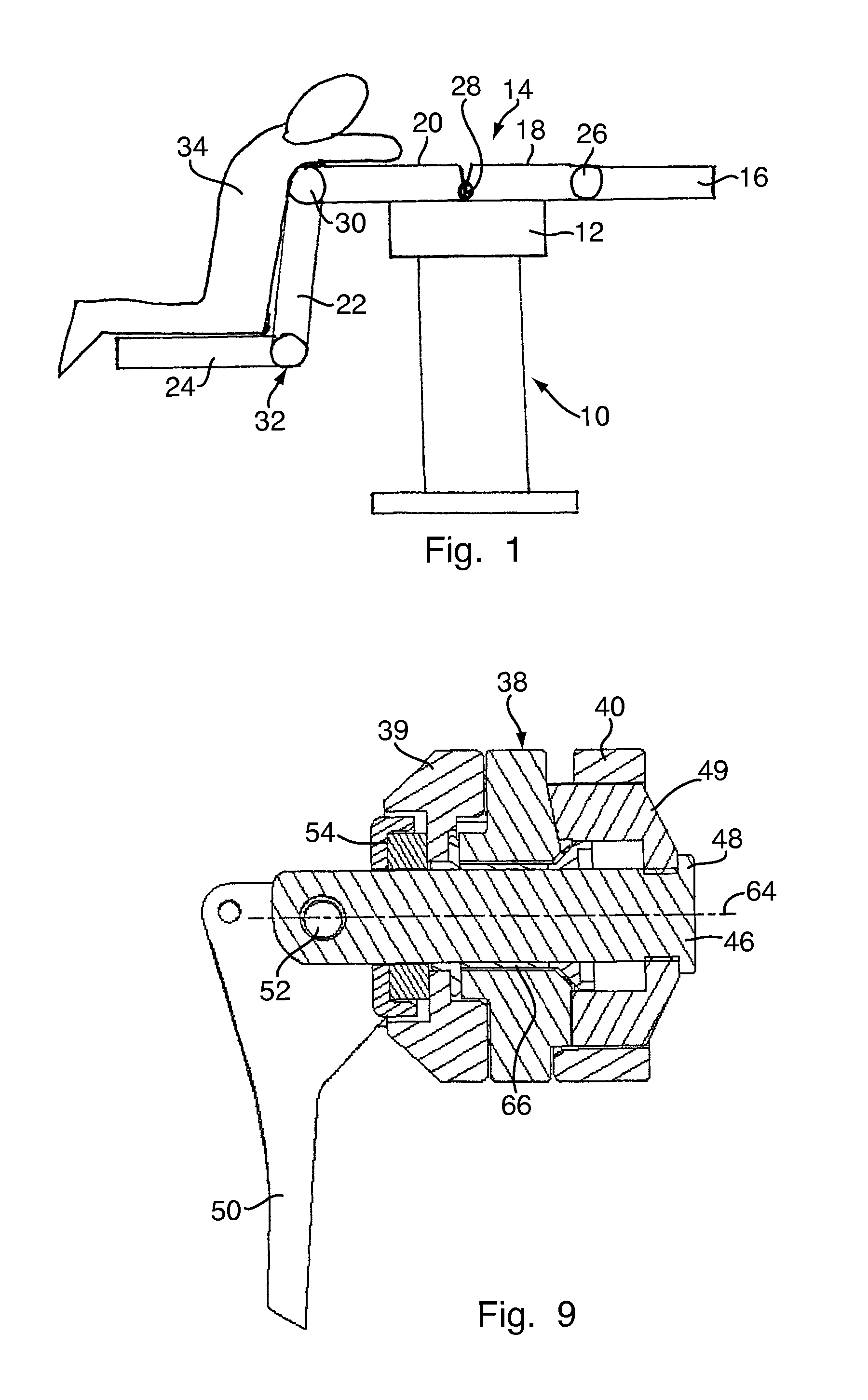

Leg support arrangement for operating tables

ActiveUS7454806B2Prevent slidingEasy and quick connectionOperating tablesSofasEngineeringTarsal Joint

The invention relates to a leg support arrangement for operating tables comprising two leg supports, connected to a base element of an operating table such that, the above are adjustable between a base position, lying adjacent to each other parallel to the longitudinal mid-axis of the operating table and a spread position with a separation from the longitudinal mid-axis, whereby each leg support is connected to the base element by means of a parallelogram joint, the joint axes (36, 52, 44, 54) of which are arranged perpendicular to the plane of the base element.

Owner:MAQUET GMBH

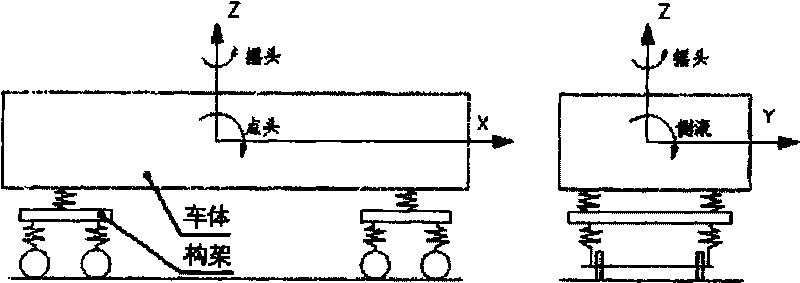

Anti-side rolling torsion rod axis for railway vehicle and manufacturing method thereof

ActiveCN101708726AAvoid manufacturing defectsBogie-underframe connectionsAxial displacementInterference fit

The invention relates to an anti-side rolling torsion rod axis for a railway vehicle and a manufacturing method thereof. The anti-side rolling torsion rod axis for the railway vehicle mainly comprises a torsion rod axis, torsion arms, a supporting seat, a lower joint axis of a vertical connecting rod, the vertical connecting rod, an upper joint axis of the vertical connecting rod and the like, wherein the torsion rod axis is connected with the left torsion arm and the right torsion arm in a conical surface matching way. Compared with the current typical torsion rod types (cylindrical surface interference fit and splined connection), the invention has the advantages that the torsion rod axis and the torsion arms can be assembled through the action of high pressure oil without heating or cooling; the purposes of disassembly and assembly for many times can be realized, and the combined surface of the torsion rod axis and the torsion arms can not be damaged; the magnitude of interference can be accurately adjusted by controlling the displacement in the axial direction; and the type of connecting with a steering frame is more flexible, and the influence caused by the steering frame structure is little.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

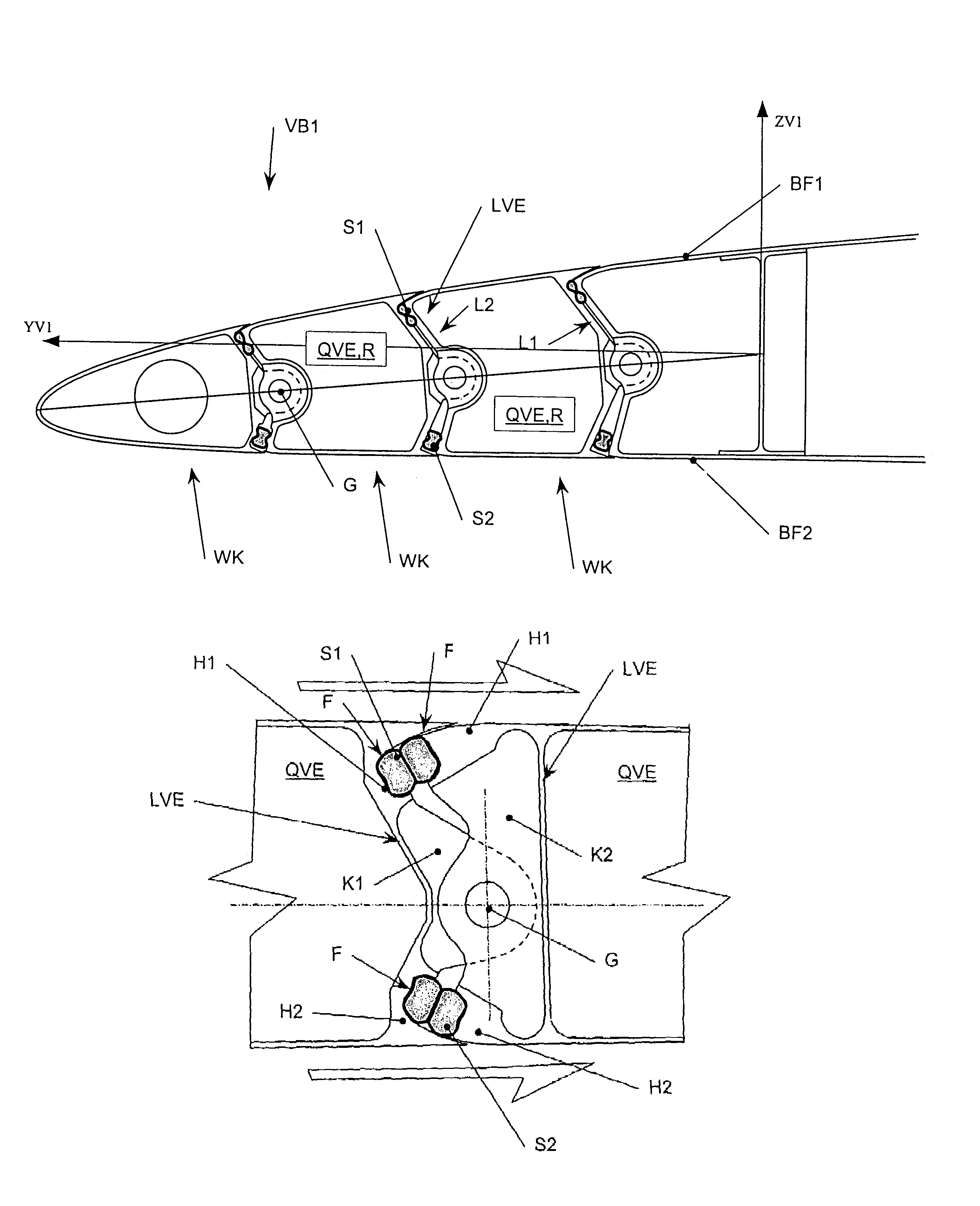

Adjustment mechanism for a variable-shape wing

InactiveUS20050103945A1Increase redundancyIncrease in equipment-related expenditureAircraft stabilisationWing adjustmentsSkin surfaceEngineering

Adjustment mechanism for adjustment area of variable-shape flow surface with two opposite skin surfaces includes plurality of whirl chambers swivelably arranged next to one another so that the whirl chambers are swivelable relative to one another, and the whirl chambers include lateral stiffening elements and longitudinal stiffening elements. Joints are structured and arranged to jointedly couple lateral stiffening elements and longitudinal stiffening elements of the whirl chambers, and a first drive tube section and a second drive tube section are arranged between adjacent longitudinal stiffening elements. A pump is coupled to first and second drive tube sections and control device is functionally connected to pump to swivel adjacent whirl chambers around joint axes via complementary volume changes in first and second drive tube sections. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:EADS DEUT GMBH

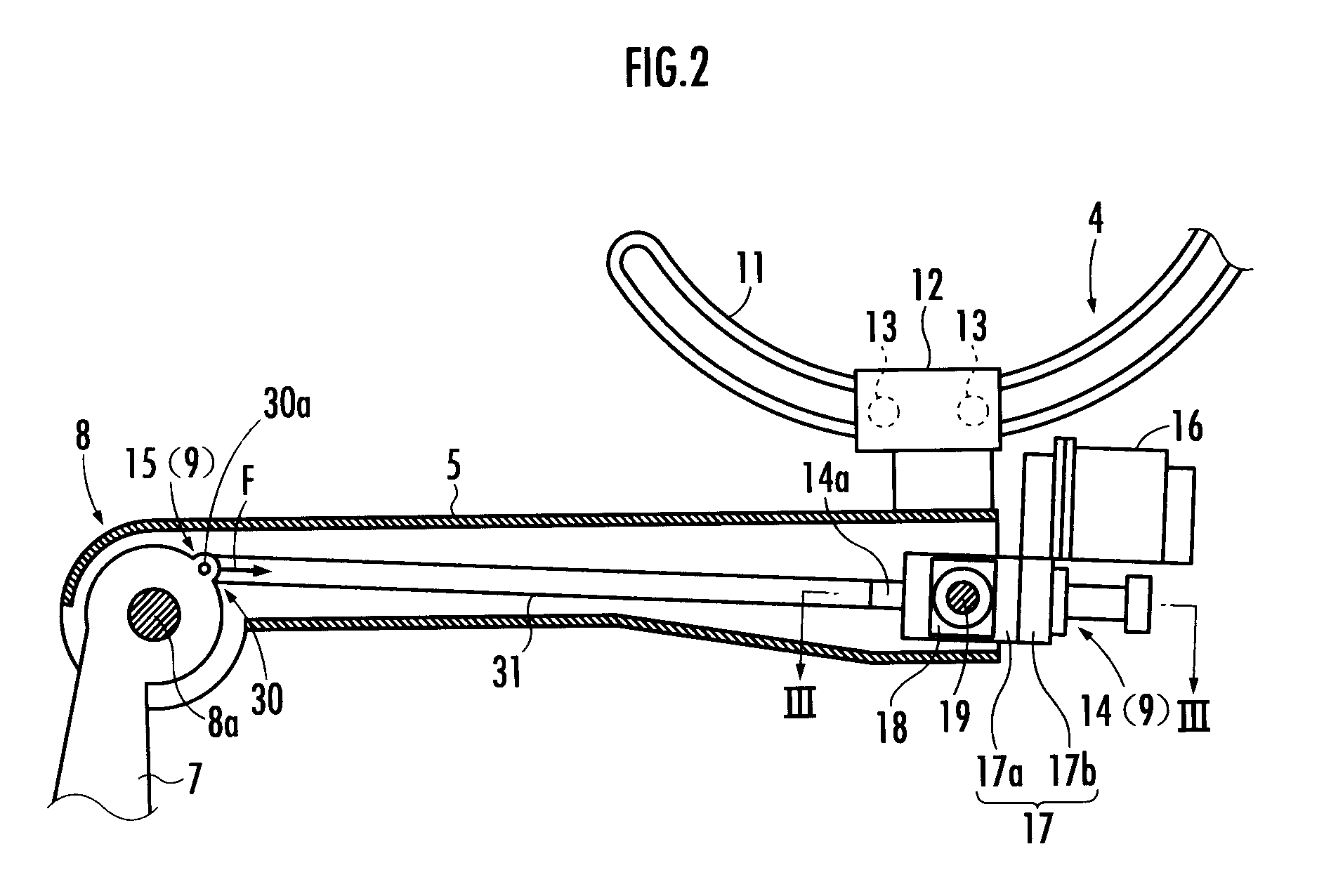

Walking assistance device

ActiveUS20100113988A1Small diameterIncreased durabilityChiropractic devicesWalking aidsLinear motionEngineering

A walking assistance device has a drive mechanism, which is provided with a linear-motion actuator including an electric motor installed in the upper link member, nut members which are rotationally driven by the electric motor, and a linear-motion output shaft which linearly moves in the direction of the axial centers of the nut members, and a crank arm which is secured to the lower link member coaxially with a joint axis of a third joint and swingably attached to one end of the linear-motion output shaft. The drive mechanism is constructed such that a translational force output from the linear-motion output shaft of the linear-motion actuator is converted into a rotational driving force of the third joint through the crank arm.

Owner:HONDA MOTOR CO LTD

Multi-joint flexible mechanical arm

The present invention is polyarticular flexible mechanical arm, and belongs to the field of flexible robot technology. The polyarticular flexible mechanical arm includes M serially connected joint modules comprising one torsion joint and one bending joint each mounted on the pedestal. The torsion joint driving the bending joint and the next joint module to rotate around the said joint axis includes one input reversing gear set, one clutch set, one output reversing gear set, one speed reducer, one driving arm, and one spur gear-planet gear train. The bending joint driving the next joint module to rotate around the axis of the said joint speed reducer includes one input reversing gear set, one clutch set, one output reversing gear set, one speed reducer, one driving arm, and one bevel gear-planet gear train. The present invention has standard modules, great flexibility, light weight, several freedoms and high expandability.

Owner:HUAZHONG UNIV OF SCI & TECH

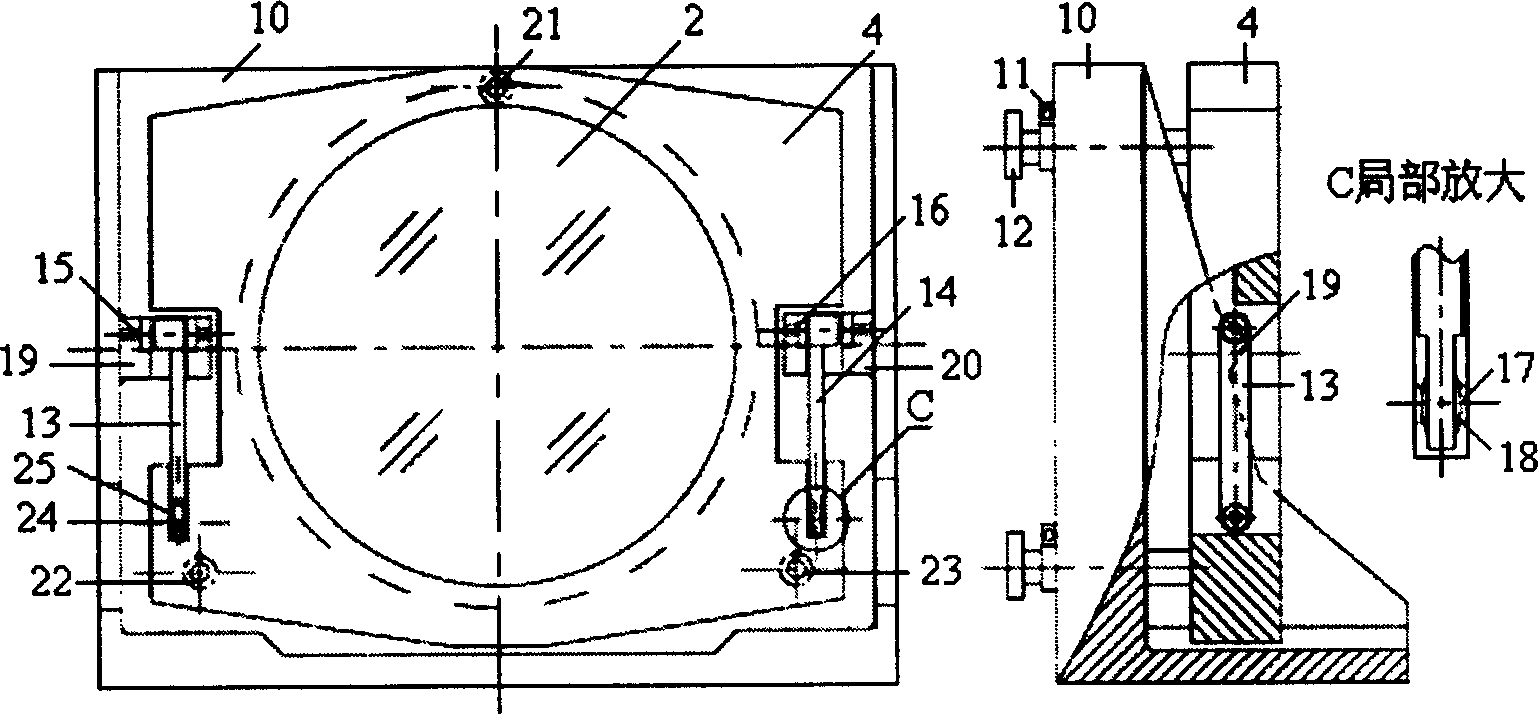

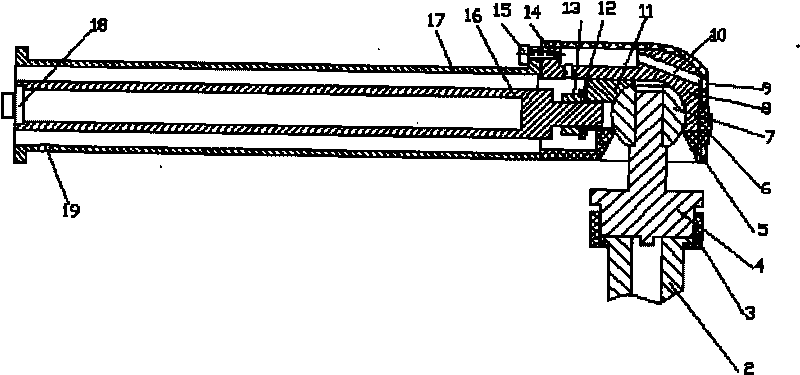

Multidimensional adjustable optical image moving device

InactiveCN1737492ACompact structureLarge adjustment rangeUsing optical meansOptical elementsElectricitySteel ball

This invention relates to one optical displacement device to realize multi-dimension adjusting controlled by machine, which comprises base socket, lens socket, referent lens inside, hanging arm, acting joint axis and the three same displacement device, wherein, each displacement device is composed of screw area, locking structure and piezoelectricity ceramics; the ceramics is fixed on the case with one end contact to the v shape groove of the lens socket and steel ball; the case can slide inside the groove; the screw bar is located with locking structure on the base socket.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Force sense manipulator with mechanical arm

The invention discloses a force sense manipulator with a mechanical arm. The force sense manipulator comprises six rotation joints and has six freedom degrees. The rotation joints are arranged in way similar to the serial connecting rods of an industrial mechanical arm, the first joint is located at the bottommost part, and the sixth joint is located at the tail-most end. The second joint and the third joint adopt a parallel connecting rod mechanism arrangement manner, a third joint motor is placed on a rotary disc, an angle sensor is placed on a joint axis, and position precision and structure rigidity are guaranteed and structure rotation inertia is reduced. In the three lower joints, a rope transmission mechanism with a tensioning device is used, large force feedback capability is provided when gaps are avoided. The three upper joints are driven by direct transmission. The joint shaft of each of the fifth joint, the second joint, the third joint, the fourth joint and the fifth joint adopts a U-shaped shifting force connecting manner, and structural strength and precision are guaranteed.

Owner:BEIHANG UNIV

Adjustment mechanism for a variable-shape wing

InactiveUS7108231B2Increase in equipment-related expenditureIncrease redundancyAircraft stabilisationWithout power ampliicationSkin surfaceElectrical and Electronics engineering

Adjustment mechanism for adjustment area of variable-shape flow surface with two opposite skin surfaces includes plurality of whirl chambers swivelably arranged next to one another so that the whirl chambers are swivelable relative to one another, and the whirl chambers include lateral stiffening elements and longitudinal stiffening elements. Joints are structured and arranged to jointedly couple lateral stiffening elements and longitudinal stiffening elements of the whirl chambers, and a first drive tube section and a second drive tube section are arranged between adjacent longitudinal stiffening elements. A pump is coupled to first and second drive tube sections and control device is functionally connected to pump to swivel adjacent whirl chambers around joint axes via complementary volume changes in first and second drive tube sections. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:EADS DEUT GMBH

Universal Joint

InactiveUS20080108446A1Precise positioningReduce stip slick effectYielding couplingUniversal jointEngineering

A universal joint includes a first joint fork having a joint axis and a second joint fork having a joint axis, the joint axes being borne by plain bearings and the joint forks each being formed by a base part and two fork elements. Each fork element has a closable bore, and the joint axes intersect between the bores, whereby a bearing prestress unit allows the joint fork to function without play about the joint axis thereof so that the universal joint can be positioned precisely.

Owner:FAUDE DIETER

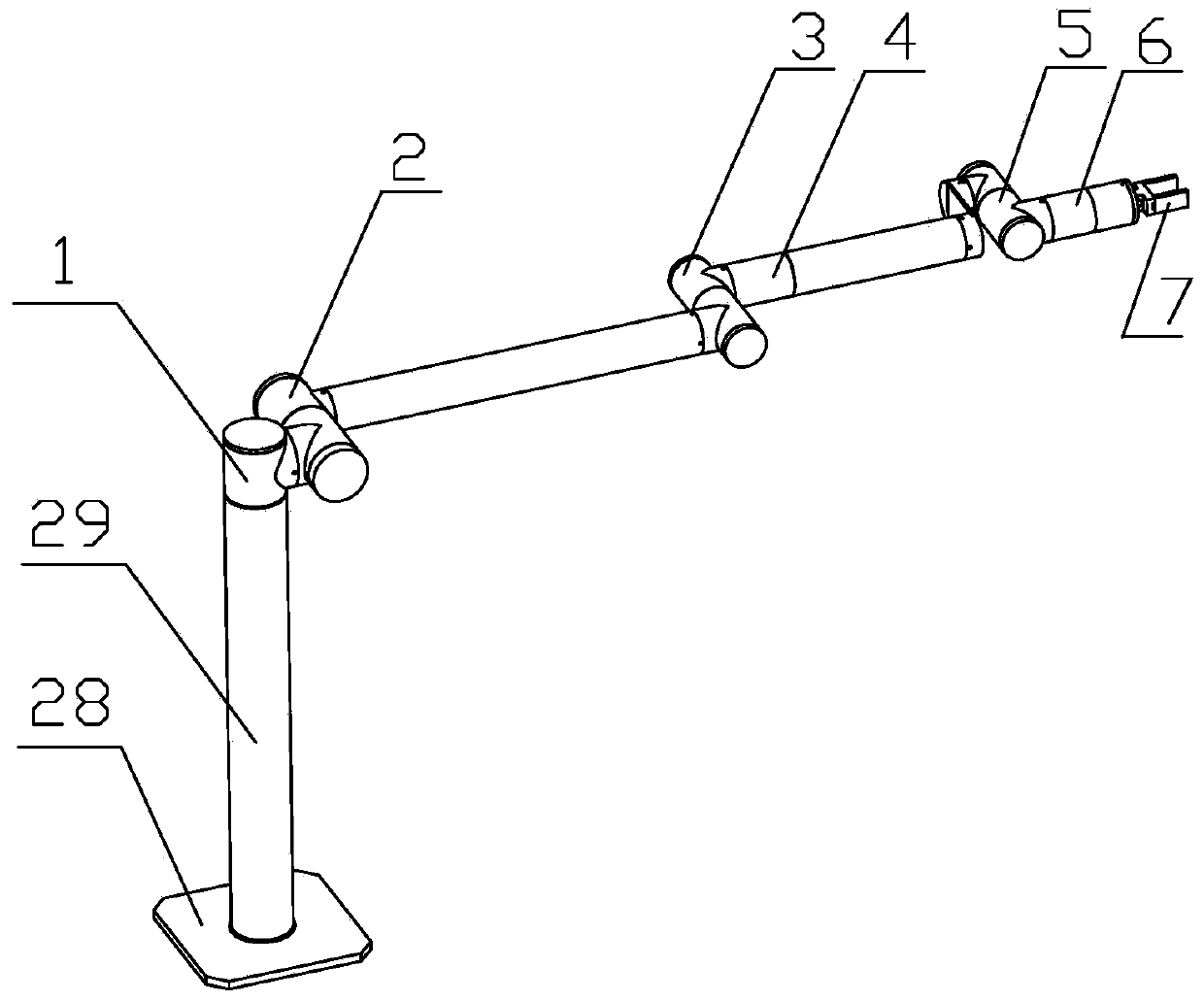

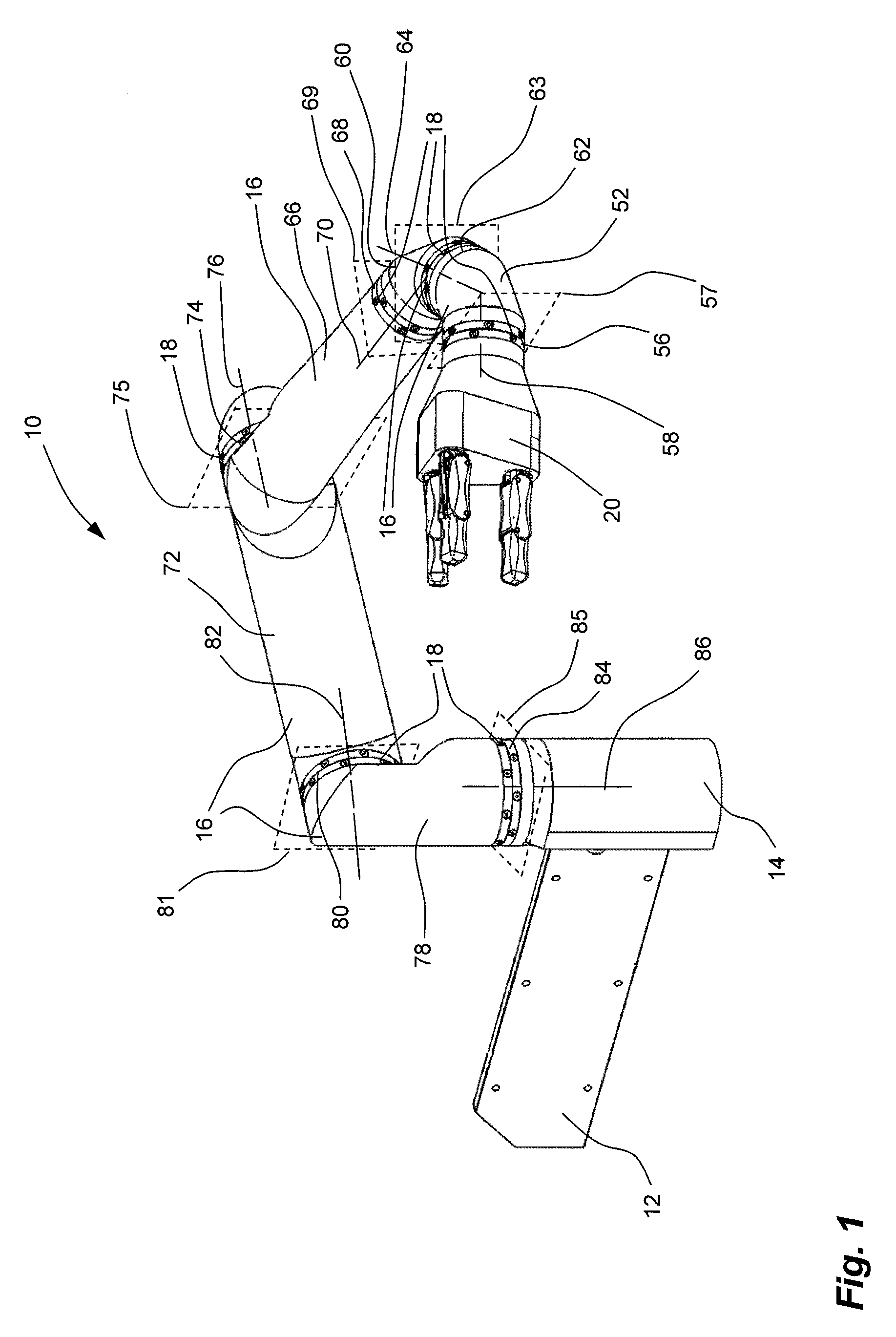

Robotic arm with a plurality of motorized joints

ActiveUS9126332B2Easy to assembleReduce riskProgramme controlProgramme-controlled manipulatorWheelchairRobotic arm

A portable robotic arm comprises a base, a plurality of motorized joints, a plurality of body members and a manipulator. Each motorized joint is operative to rotate in its respective rotation plane and on its respective joint axis, which is normal to the respective rotating plane. Each body member is sequentially connected to one other body member through one of the motorized joints. A last body member is connected to the base through a last motorized joint. A manipulator is connected to a first body member through a first motorized joint. At least two consecutive rotation planes are placed at an angle from each other that is greater than 0 degrees and smaller than 90 degrees. Optionally, the manipulator comprises three fingers and a tool port centered between the three fingers. A tool connected in the manipulator's tool port may be gripped with the three fingers. The robotic arm and a wheelchair support for the robotic arm may also be provided as a kit.

Owner:KINOVA INC

Surgical operation-assisting electrical locking bracket

InactiveCN101703423AMeet needsLarge working space at the end pointDiagnosticsSurgical robotsSurgical operationEngineering

Owner:昆山市工业技术研究院有限责任公司

Joint arrangement for the connection of two segments of a patient bed

ActiveUS7896569B2Improve carrying capacityReliable functionYielding couplingOperating tablesEngineeringSacroiliac joint

What is described is a joint arrangement for the articulated connection of two segments of a patient bed, with two joint parts (36, 38), each of which is connected rigidly to one of the segments and which are pivotable relative to one another about a common joint axis (64) by means of a shaft journal (46), the joint parts (36, 38) carrying, in each case on at least one of their faces confronting one another axially, blocking faces (60) intended for bearing against one another, and the joint parts (36, 38) being capable of being tensioned axially relative to one another by means of a tensioning mechanism (46, 54, 50), and the blocking faces (60) lying in each case at least approximately in a plane containing the joint axis (64).

Owner:MAQUET GMBH

Robot original point demarcating method and device, storage medium and computer equipment

ActiveCN107443375ALow costImprove efficiencyProgramme-controlled manipulatorJoint coordinatesEngineering

The invention relates to a robot original point demarcating method and device, a storage medium and computer equipment. The method comprises the following steps that initial joint coordinates corresponding to each joint axis initial state of a robot are obtained, according to the initial joint coordinates, preset reference points at the terminal of the robot in various different attitude trends and current initial joint coordinates corresponding to the joint axis initial states when the preset reference points are coincide are obtained, according to the current joint coordinates, position coordinates corresponding to each attitude are obtained, distance deviation of the every two position coordinates are calculated, when any distance deviation is higher than a preset value, the initial joint coordinates are updated by using a search algorithm, according to the updated initial joint coordinates, the current joint coordinates are updated, the step that according to the current joint coordinates, position coordinates corresponding to each attitude are obtained is entered, and until each distance deviation is less than the preset value, the corresponding target initial joint coordinates are obtained to be used as an original point of the robot. By means of the robot original point demarcating method, the cost can be reduced, and the efficiency can be improved.

Owner:SHENZHEN TONGCHUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com