Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15041 results about "Steel ball" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

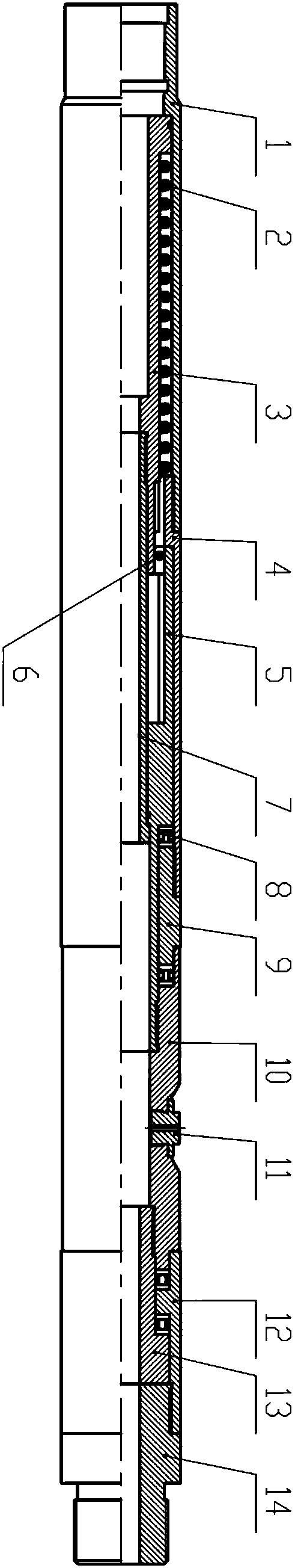

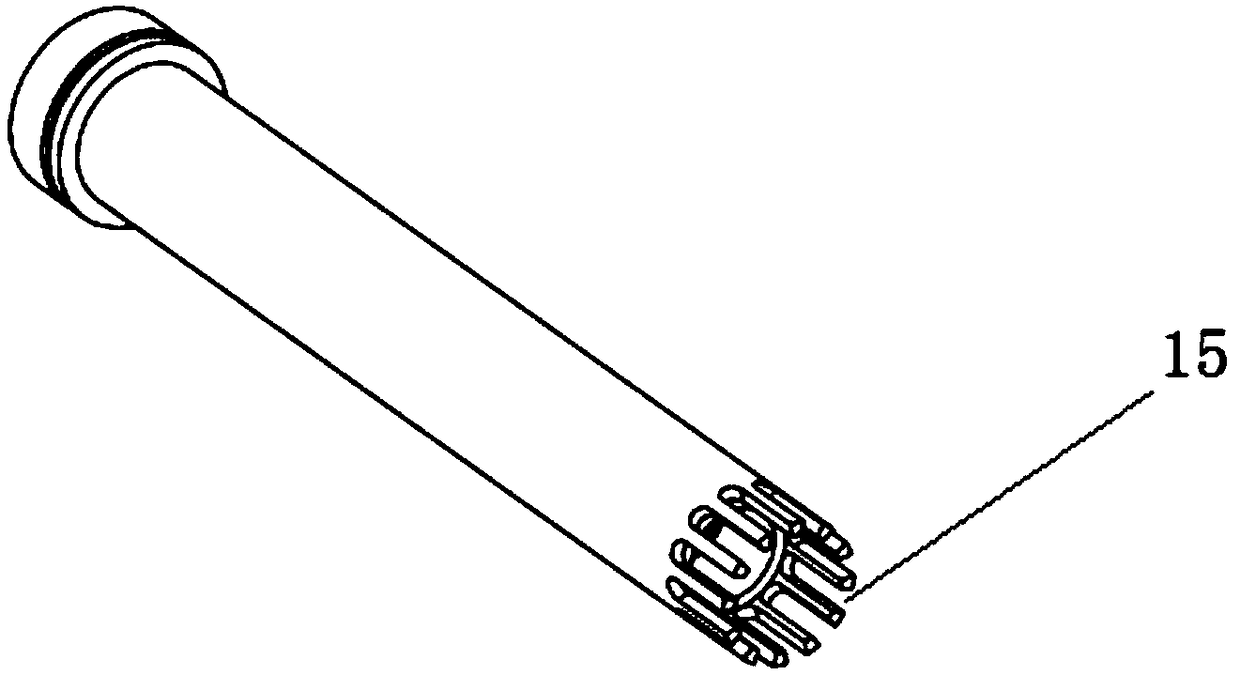

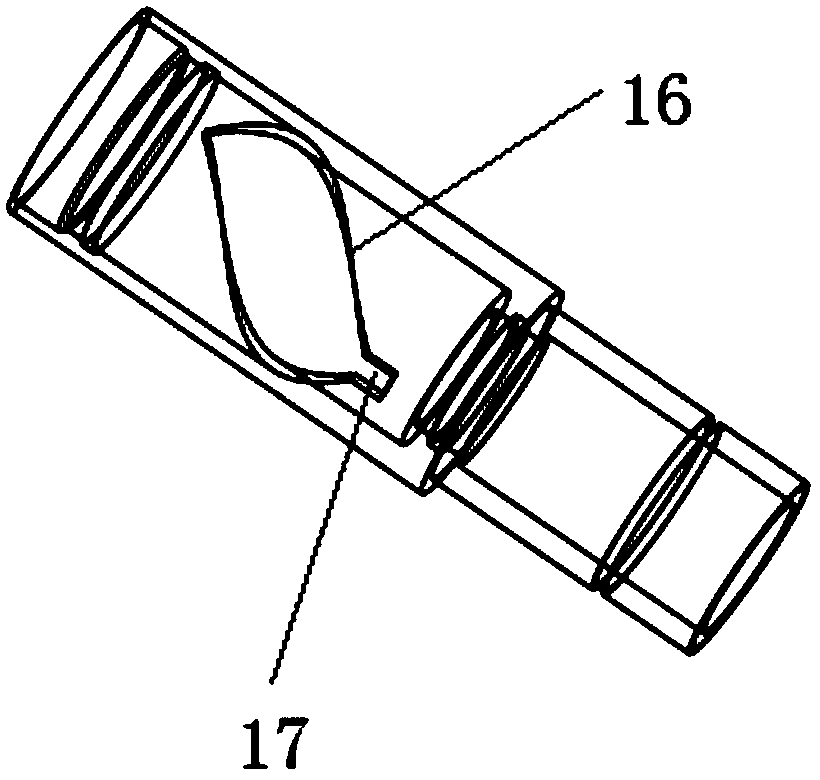

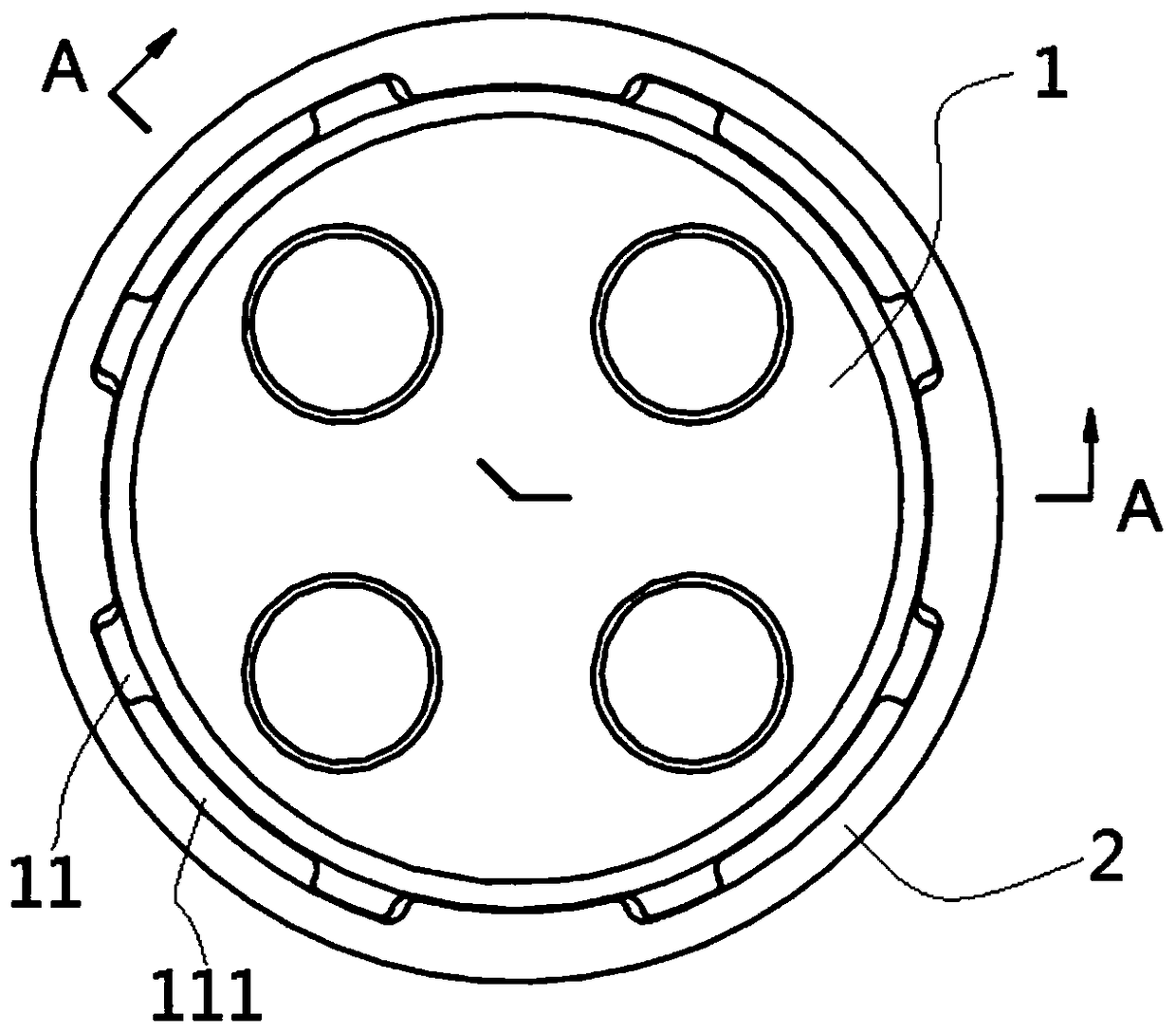

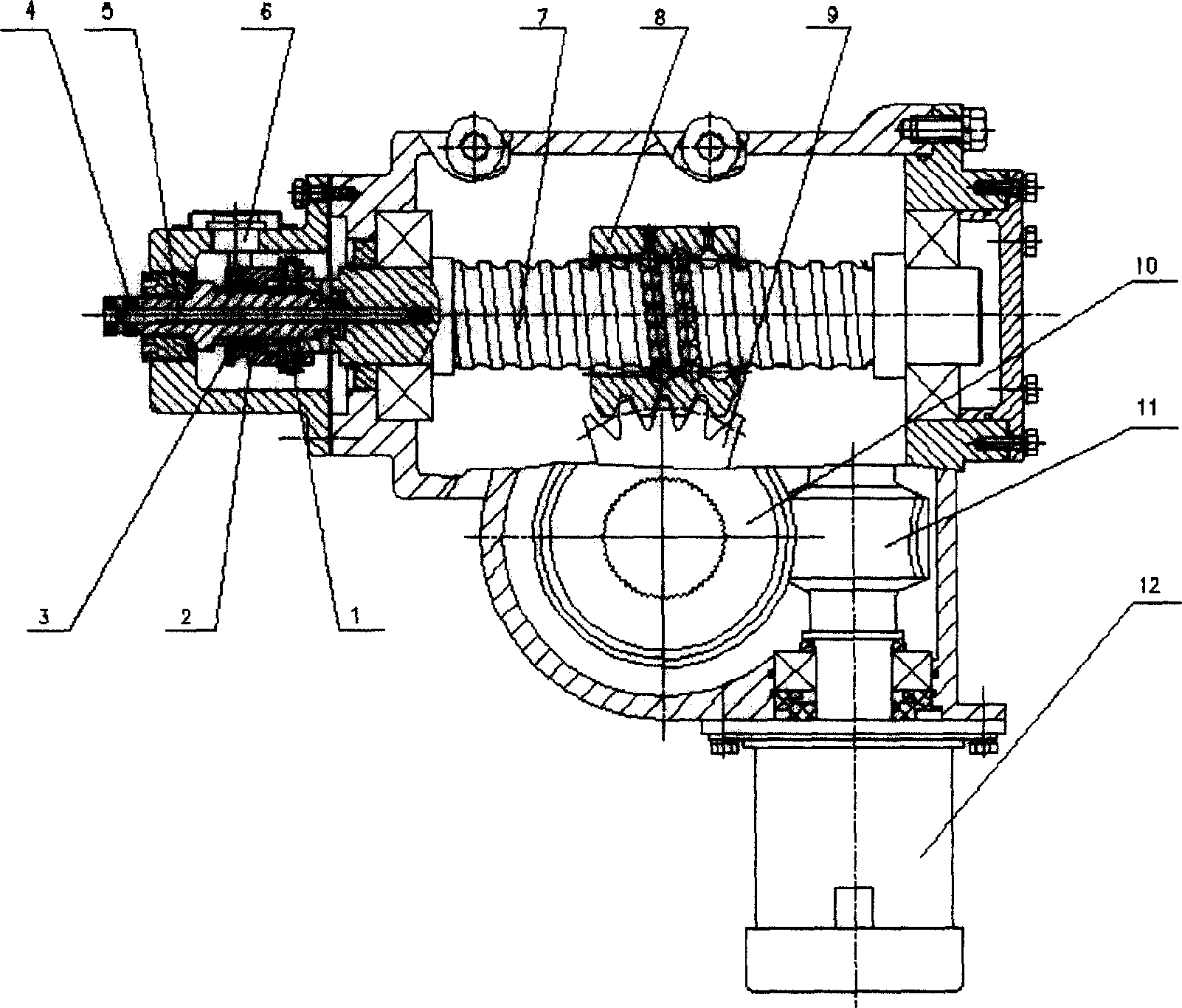

Horizontal well hydraulic directional spraying gun

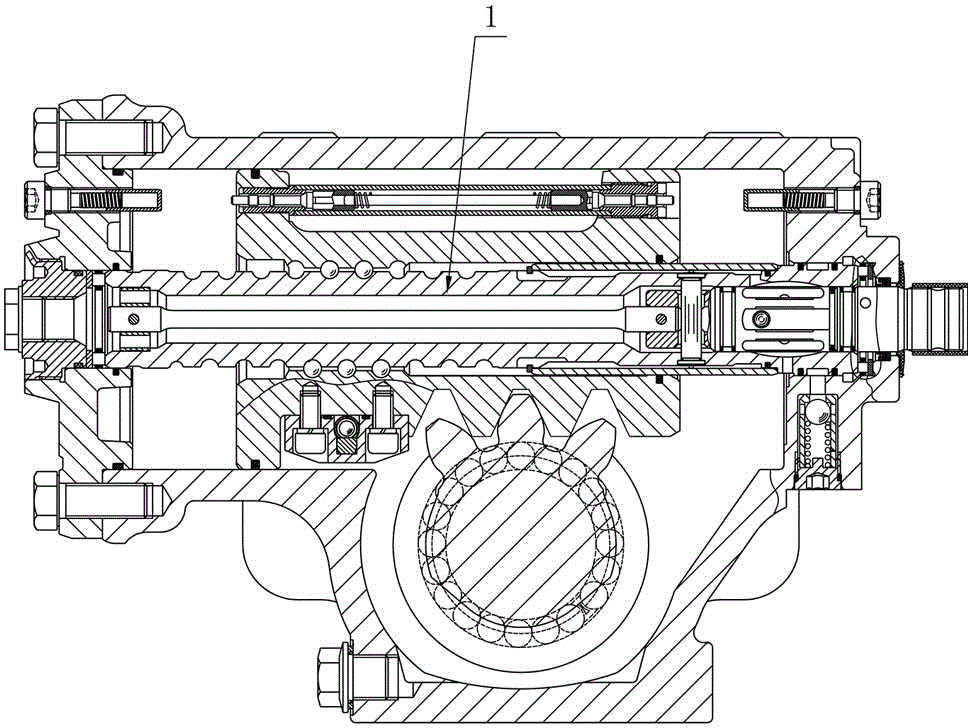

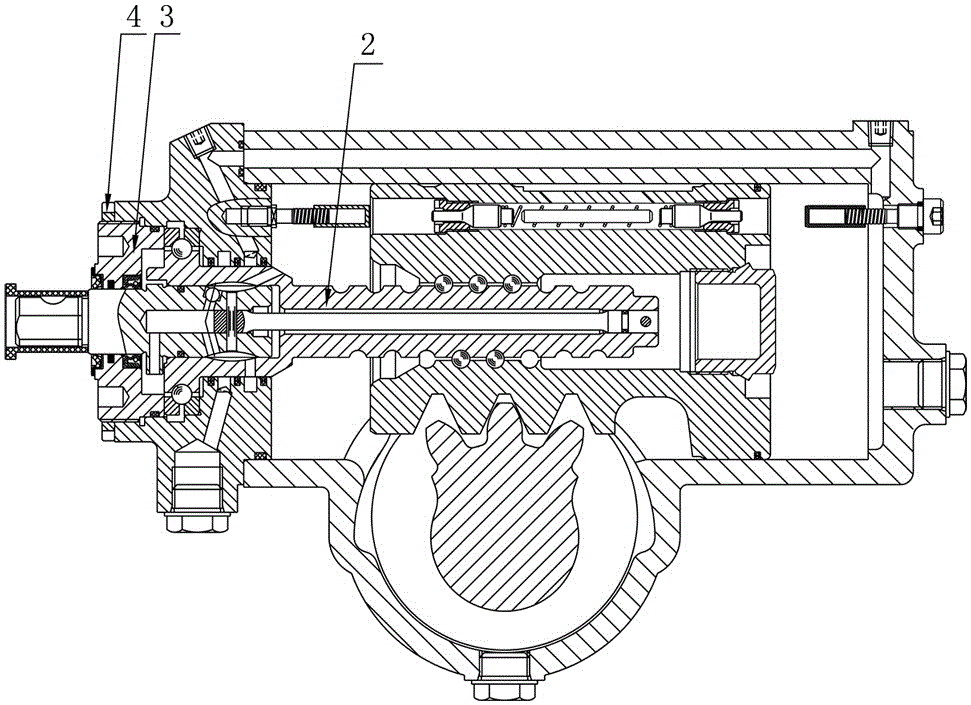

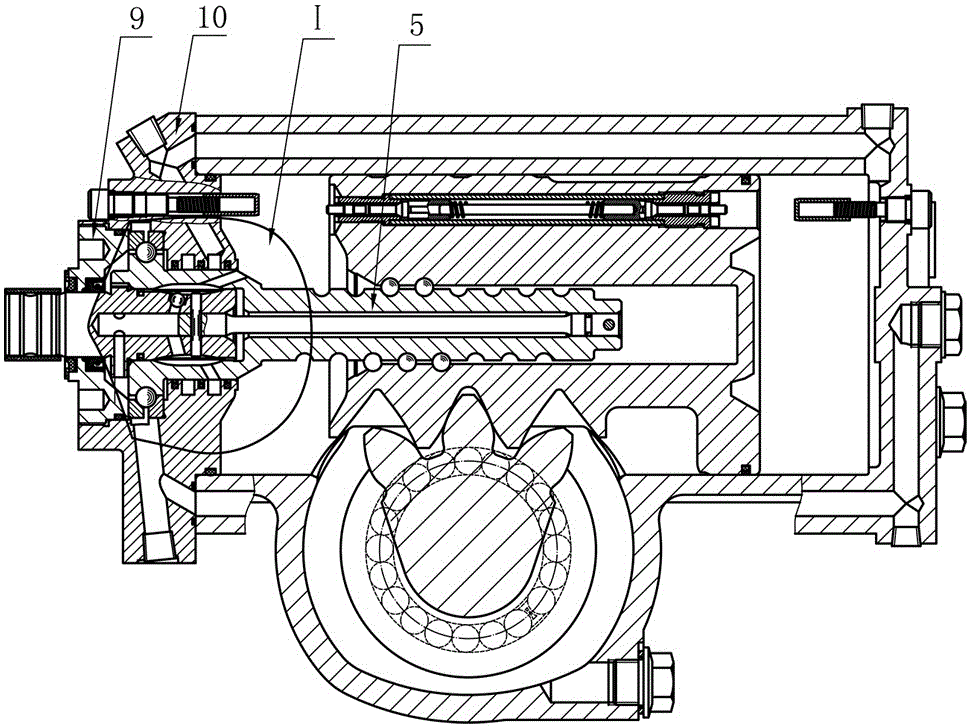

The invention relates to the technical field of oil and gas well production increase and fracturing operation, in particular to a horizontal well hydraulic directional spraying gun. The horizontal well hydraulic directional spraying gun comprises a directional split tooth cylinder, an enveloping line sleeve, a directional steel ball, thrust bearings and nozzles. The directional split tooth cylinder and an upper connector form an annular space, a reset spring is arranged in the annular space, the right end of the upper connector is connected with an upper housing, the enveloping line sleeve issleeved with the interior of the upper housing, a central rod penetrates through the interior of the enveloping line sleeve to be connected to an internal thread at the right end of the directional split tooth cylinder, and a closed space is defined by the upper housing, the directional split cylinder and the enveloping line sleeve; the directional steel ball is placed in the closed space, the right end of the upper housing is in threaded connection with a connecting sleeve, the thrust bearings are symmetrically disposed at both ends of the connecting sleeve, and the right end of the enveloping line sleeve is connected with a spraying gun casing. Forced orientation of the spraying gun casing can be achieved by a hydraulic driving mode, the orientation success rate is high, tools can be reused after maintenance and protection, and the cost is low.

Owner:JEREH ENERGY SERVICES

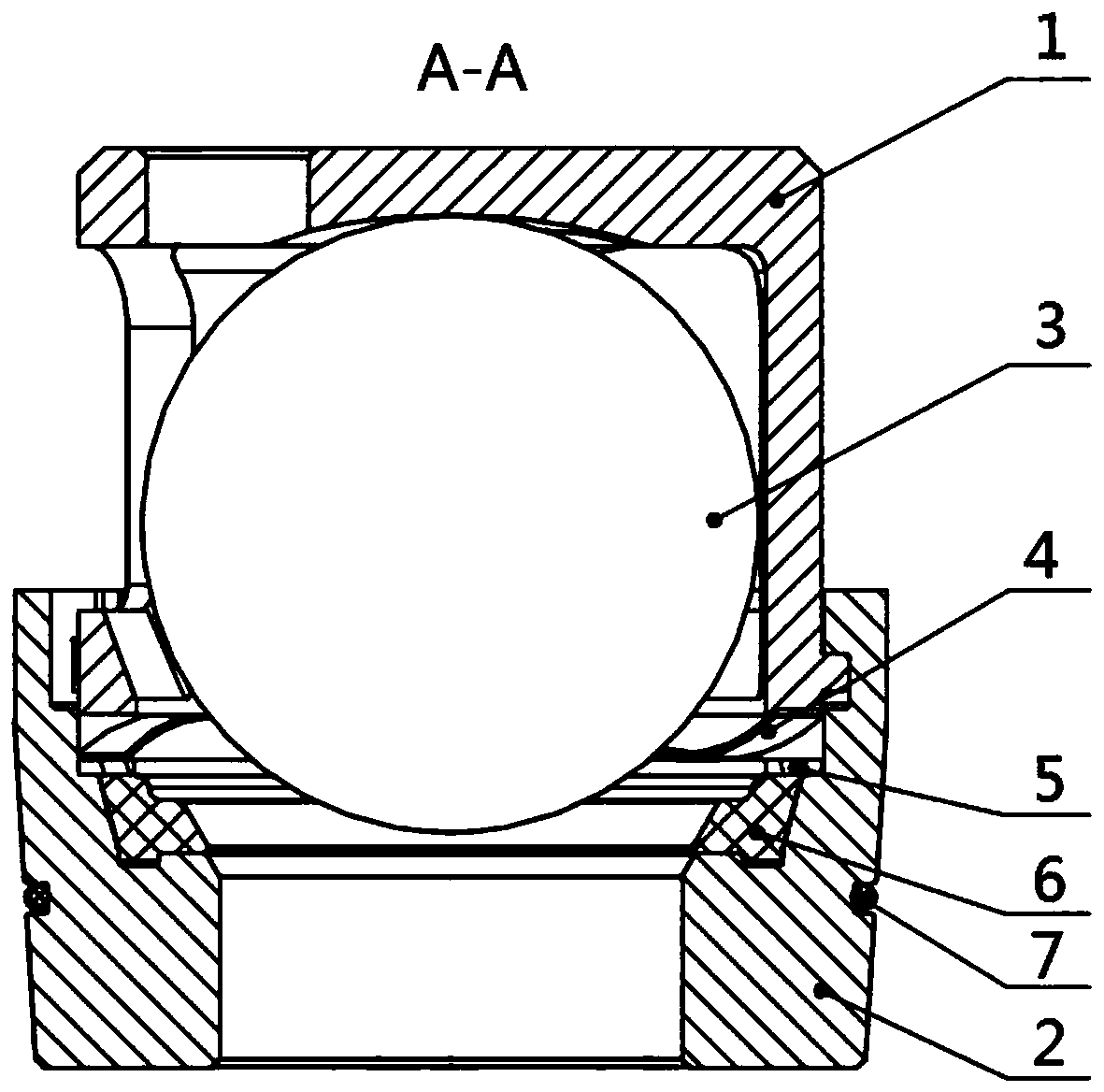

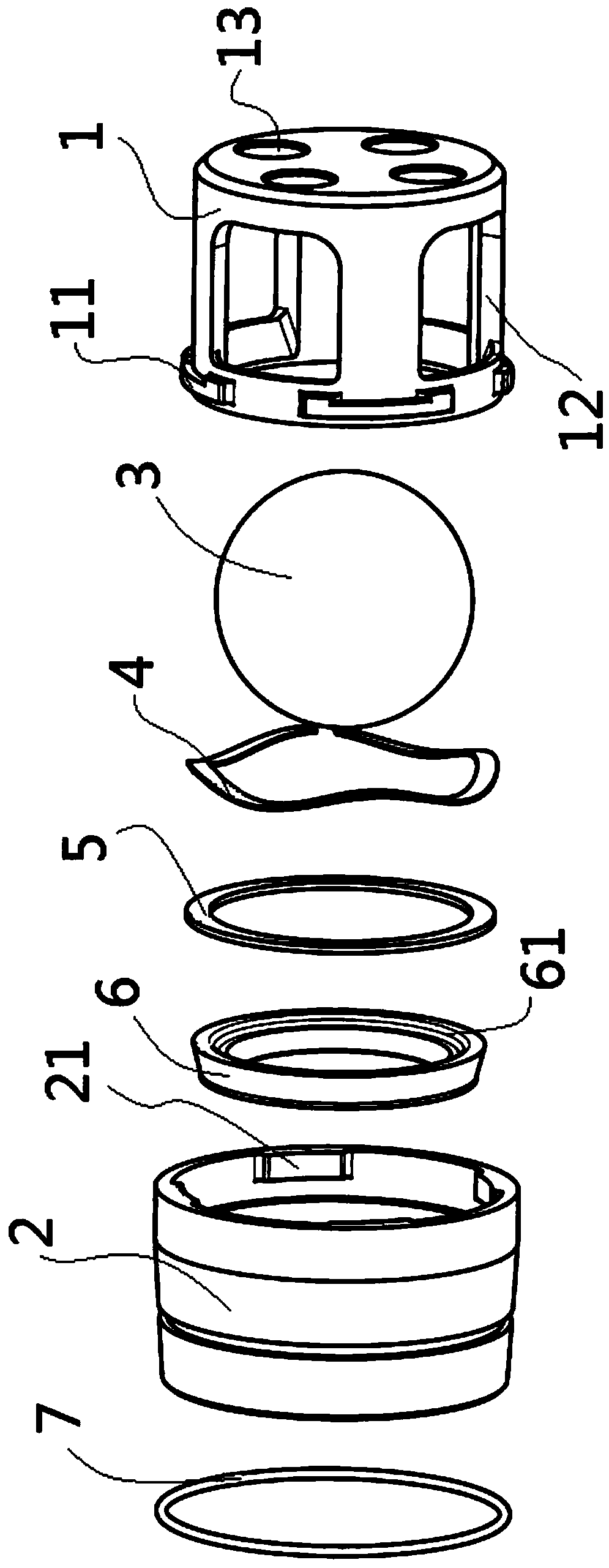

Ball-type valve assembly structure

PendingCN109058092AEasy to disassembleEasy to separatePositive displacement pump componentsLiquid fuel engine componentsSteel ballEngineering

The invention relates to a ball-type valve assembly structure, and belongs to the technical field of oil-gas exploitation equipment. The ball-type valve assembly structure comprises a valve seat, valve rubber arranged on the inner side of the valve seat, a steel ball positioned above the valve rubber, and a ball cage positioned outside the steel ball, a first clamping piece is arranged on the lower portion of the outer side of the ball cage, a second clamping piece matched with the first clamping piece is arranged on the upper portion of the inner side of the valve seat, and an elastic piece is arranged between the valve seat and the ball cage. The ball-type valve assembly structure has the advantages that the valve seat is connected with the ball cage through a clamping groove structure so that the situations that the clamping stagnation occurs and dismounting is difficult due to sand particle entering can be avoided, and the working efficiency of dismounting and checking a pump can be improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

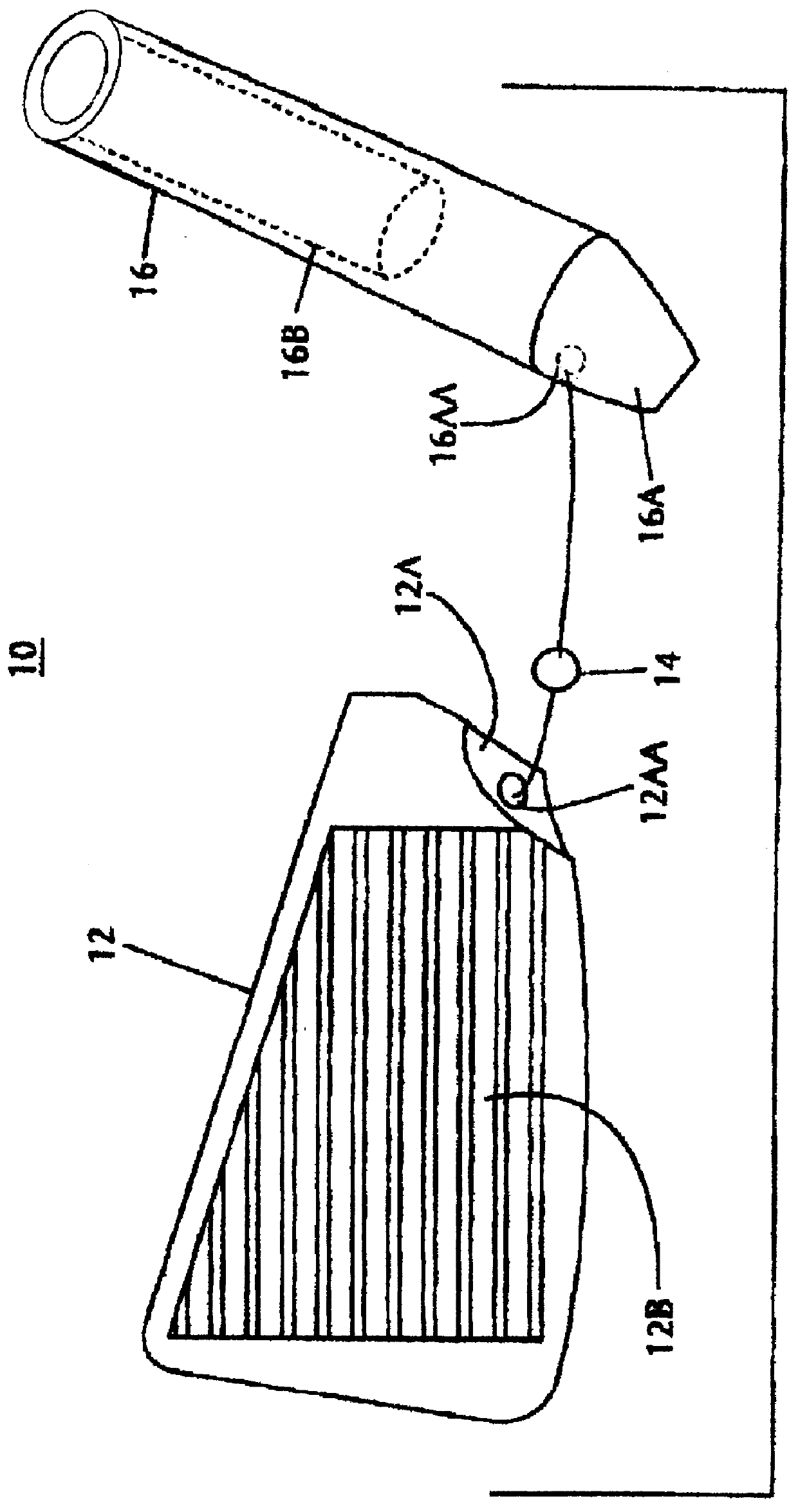

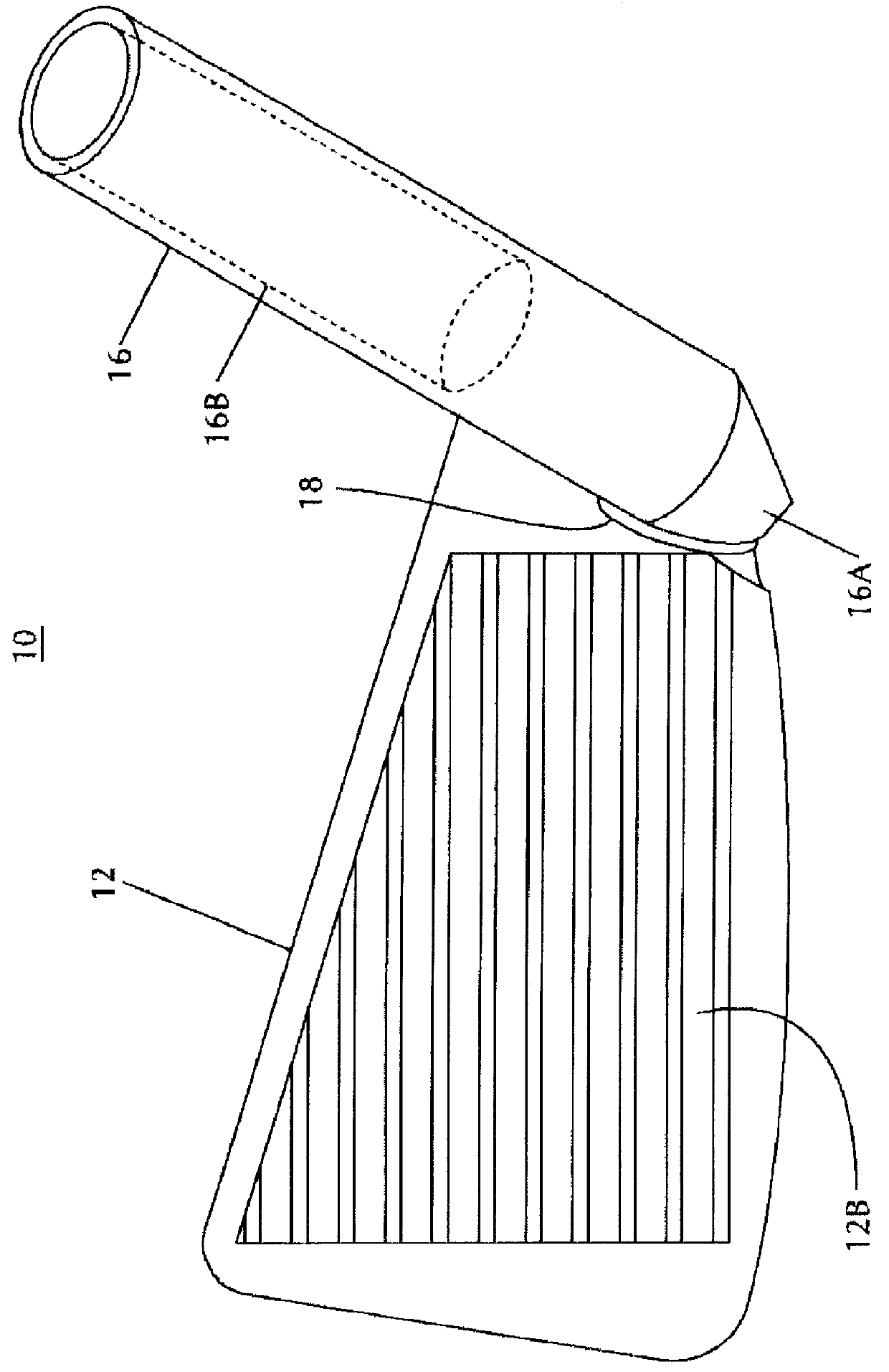

Custom-fabricated golf club device and method

InactiveUS6120384AWide rangeAccurate resolutionGolfing accessoriesGolf clubsManufacturing technologyCombined use

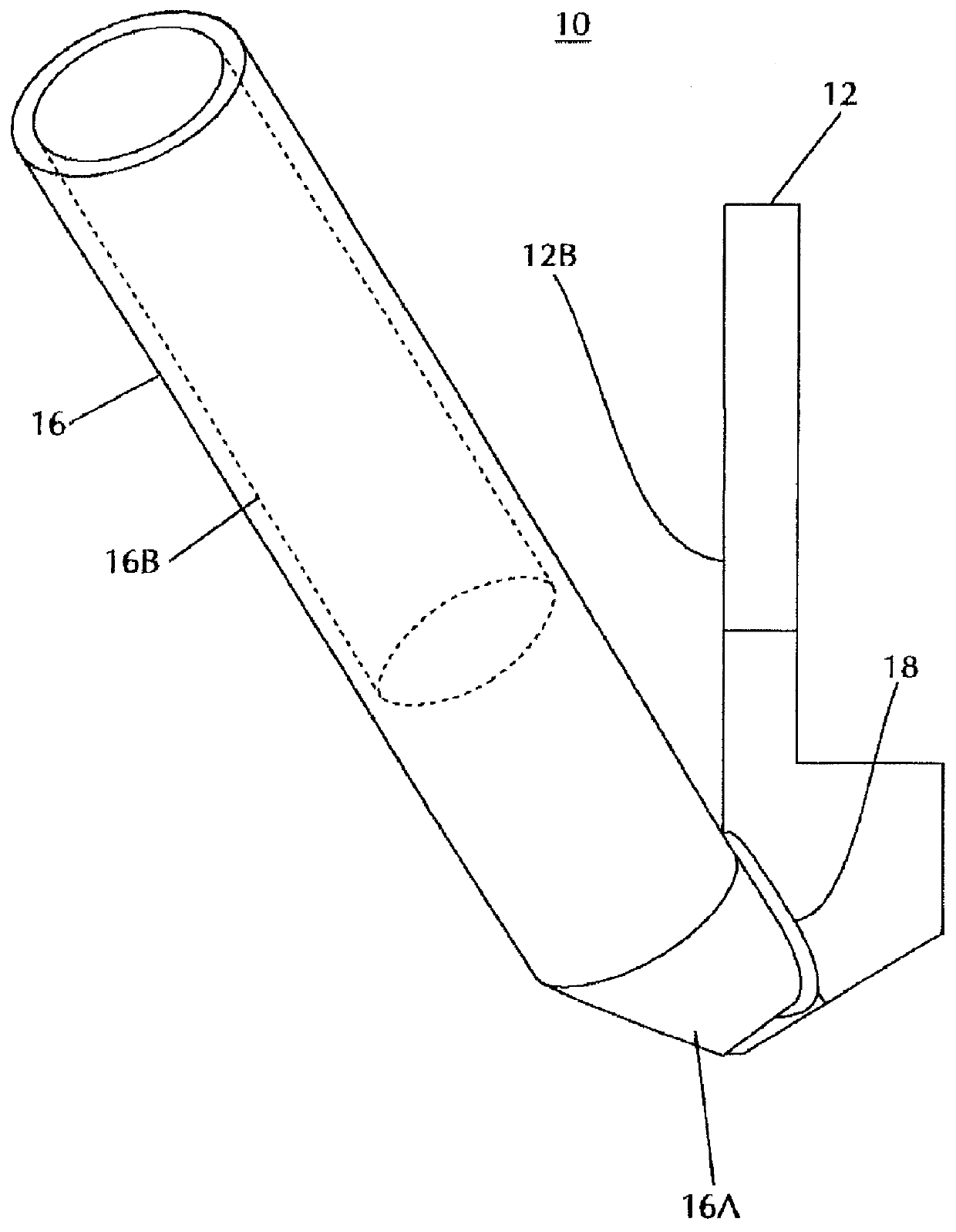

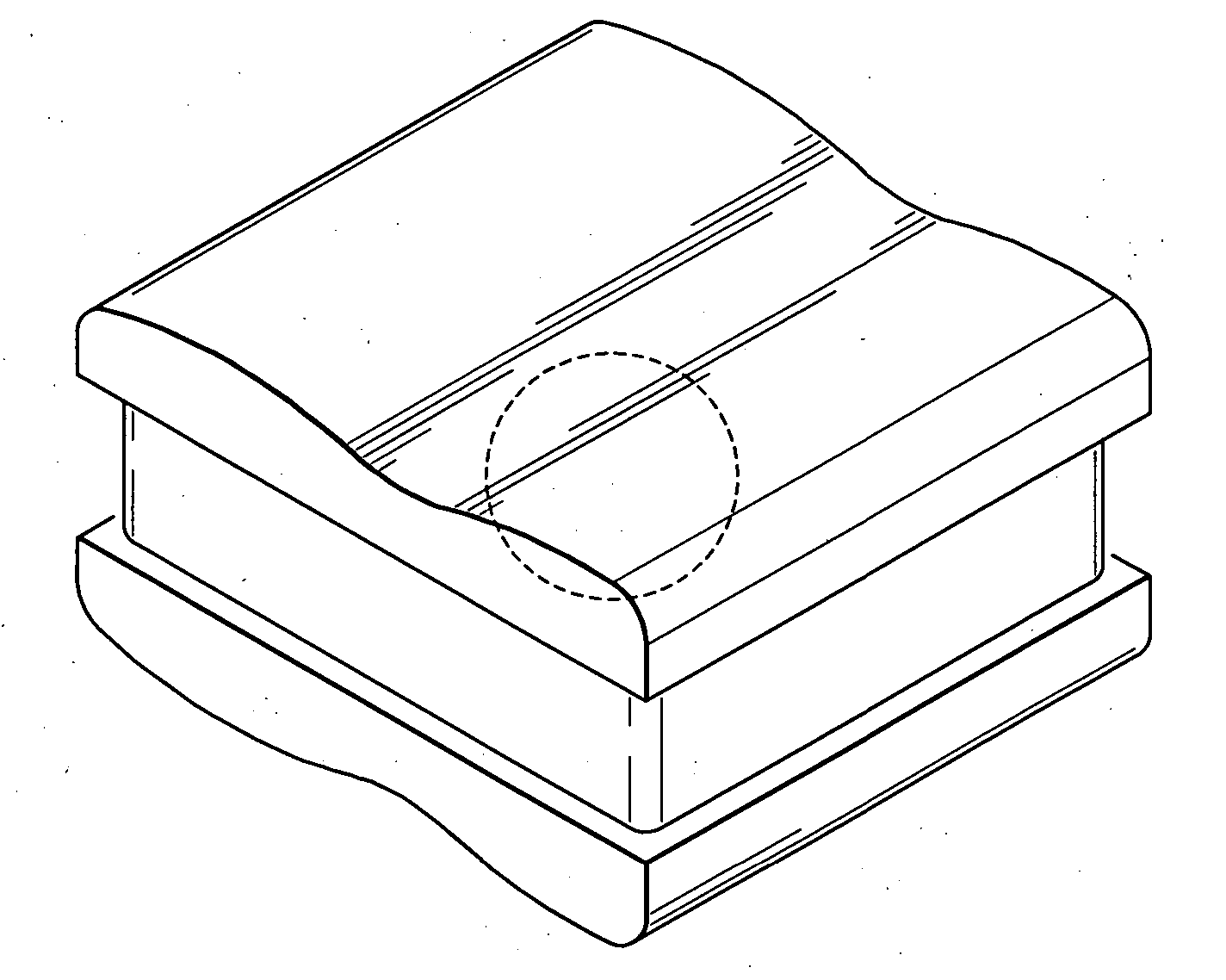

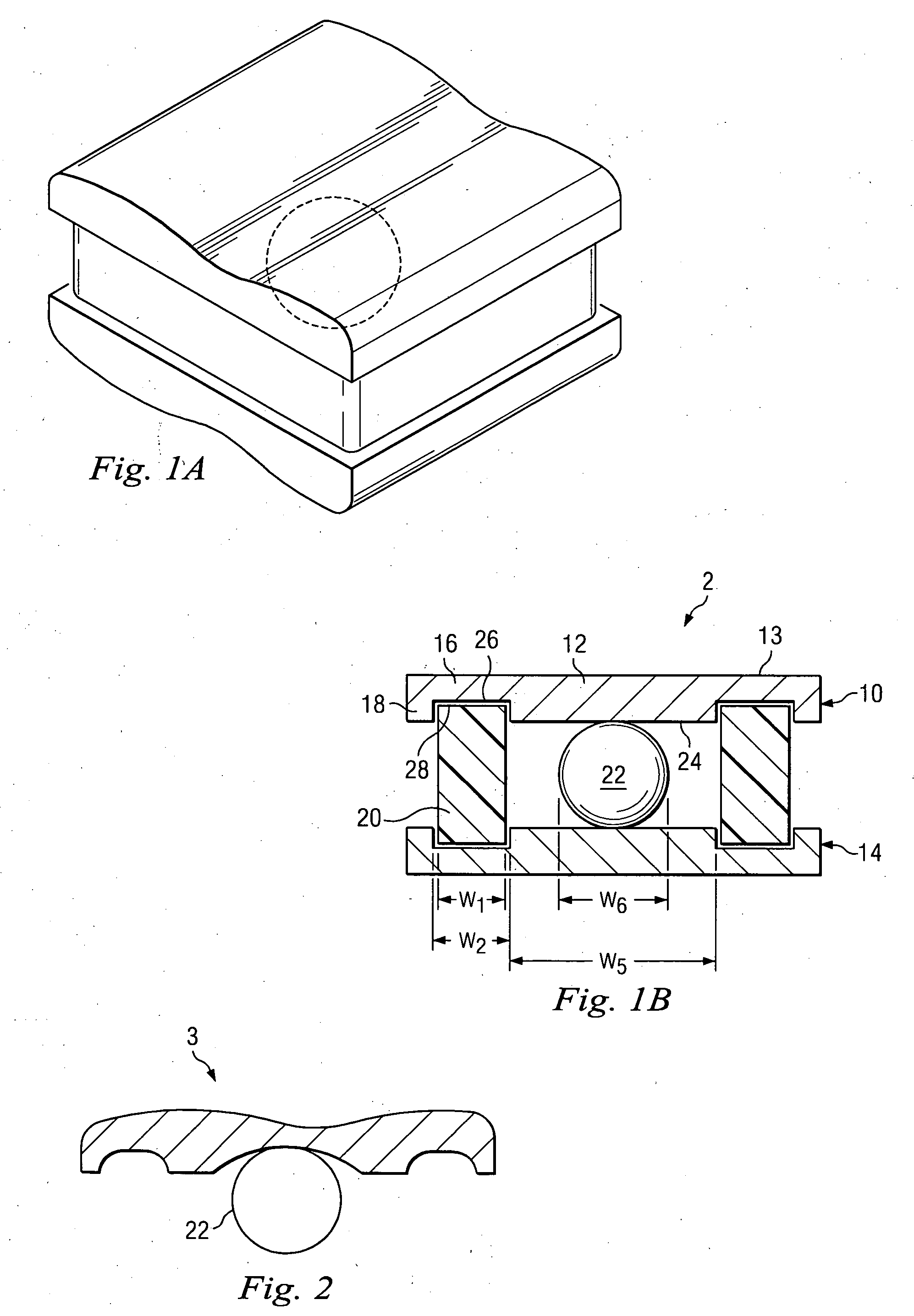

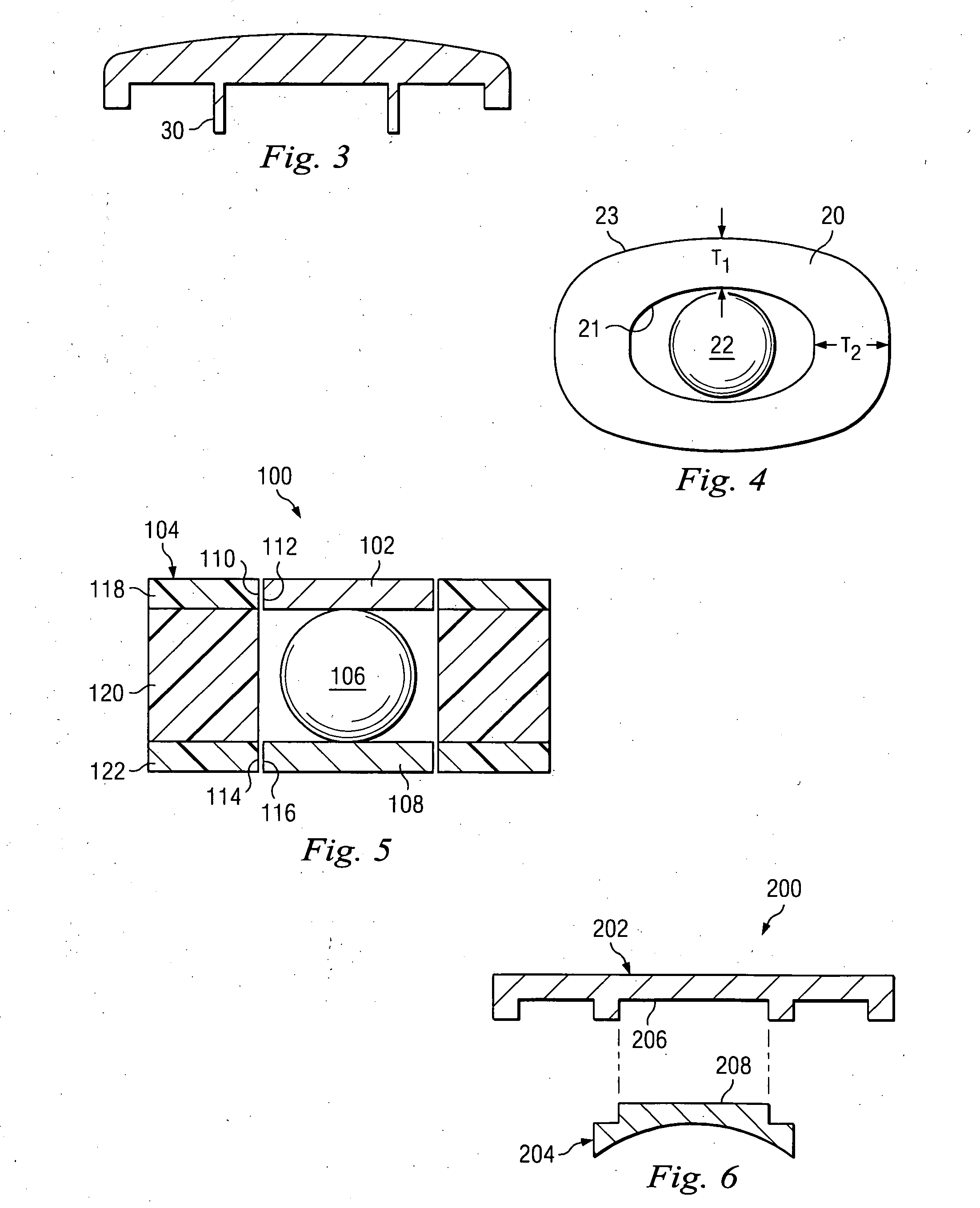

A custom-fabricated golf club device comprising a golf club head with a recessed portion located at the front heel portion of the head and machined therein, the recessed portion comprising a substantially semi-spherical aperture. A hosel assembly has a lower portion, having a substantially semi-spherical aperture that aligns with the aperture of the head recessed portion, the hosel assembly further having a recessed portion at an upper portion thereof. A steel ball is located securely within the aperture of head recessed portion and the aperture of the hosel assembly lower portion, functioning to provide positive location of the club head and hosel assembly. In the preferred mode, a permanent weldment functions to securely affix the lower portion of the hosel assembly to the club head at the heel portion of the club head. The device is utilized in conjunction with golf clubs of both the iron and wedge variety to provide a cost-effective and convenient way to custom-fabricate golf clubs to the unique physical characteristics of individual players. By taking advantage of machining, rather than forging or casting the components, a wide range of lie angles with precise resolution can be achieved. In addition, the manufacturing techniques of the present invention diligently conform to the USGA rule that clubs other than putters shall not be designed to be adjustable except for weight.

Owner:DRAKE STANLEY

Semi-constrained and mobile-bearing disc prosthesis

A disc replacement device is provided for replacing a spinal disc in an animal subject. The disc replacement device includes a shell, a fulcrum, and a damping sleeve. The shell further comprises a first portion adapted for articulating with the fulcrum such as a spherical stainless steel ball, and a second portion adapted for coupling with the damping sleeve.

Owner:WARSAW ORTHOPEDIC INC

Seat excitation apparatus used for MEMS dynamic characteristics test

InactiveCN101476970AReduce shear forceAvoid pulling forceSemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityElectronic systems

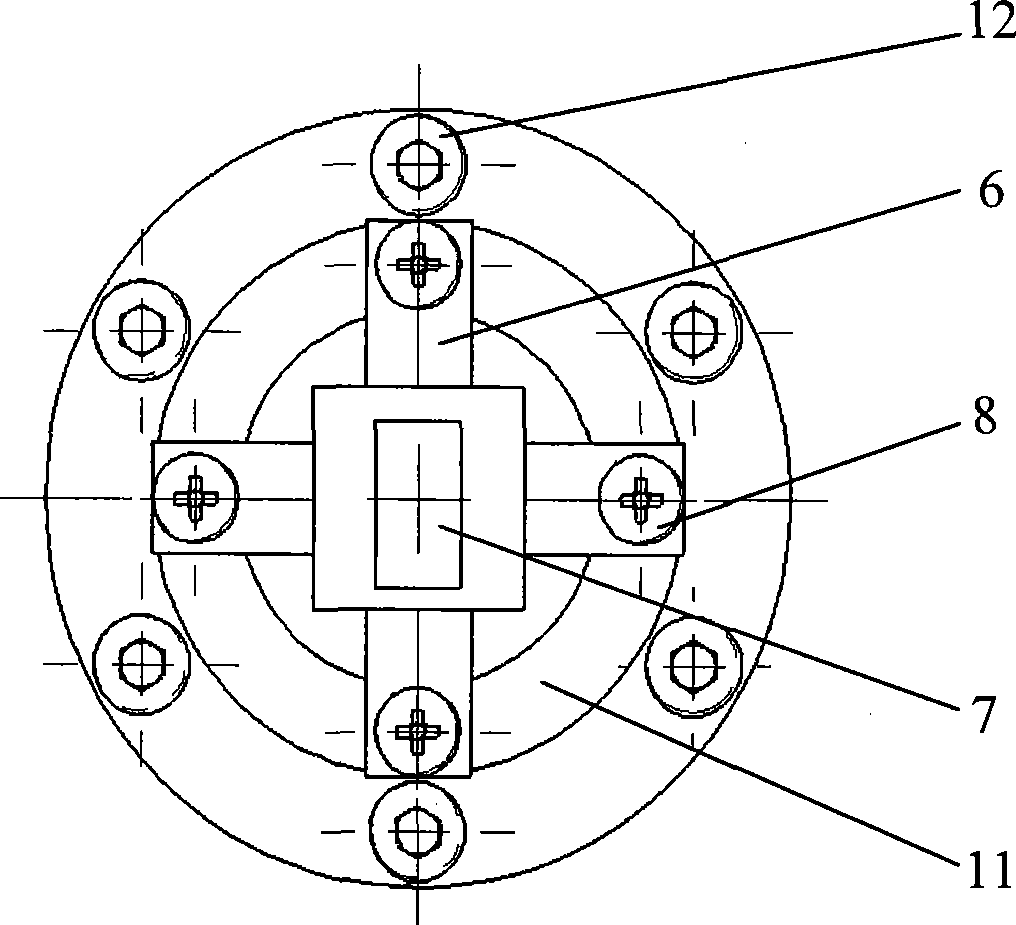

The invention discloses an exciting device for testing dynamic property of an MEMS microstructure or micro-device and belongs to a minitype mechanical electronic system. A structure of the device comprises that: a microstructure to be tested is arranged on a crossed spring strip of the top part; the crossed spring strip is arranged on the top part of a sleeve by a bolt; piezoelectric ceramics, an upper connecting block, a steel ball, a lower connecting block and a pressure sensor are arranged inside the sleeve; the bottom of the piezoelectric ceramics is fixed on the upper connecting block; the top part is contacted with the crossed spring strip to change the thickness of an adjustable washer; the piezoelectric ceramics is pressed by the crossed spring strip; the pressure sensor is arranged on a base plate; and the base plate and the sleeve are connected by a bolt. The exciting device has the advantages that in normal environment the device can carry out excitation on the MEMS microstructure, can remove shearing force produced in the using process of the piezoelectric ceramics and effectively prolong the service life of the piezoelectric ceramics through exertion of certain pretightening force on the piezoelectric ceramics at the same time; and the device can measure the output force of the piezoelectric ceramics by the pressure sensor, thereby conveniently seeking a frequency response function of the microstructure and obtaining dynamic property parameters of the microstructure.

Owner:DALIAN UNIV OF TECH

Double-inlet double-outlet steel ball coal mill straight blowing type milling system optimized control method

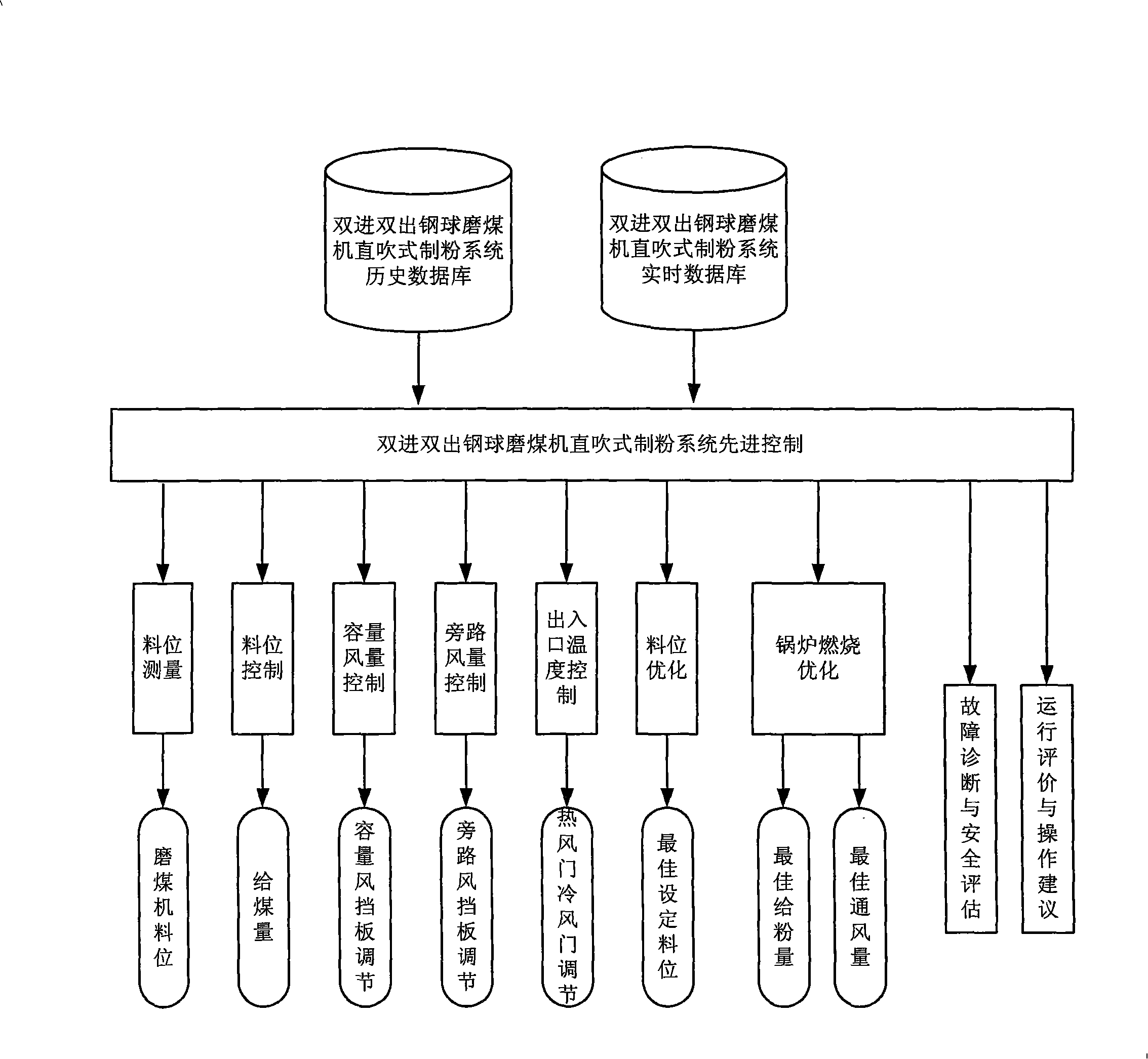

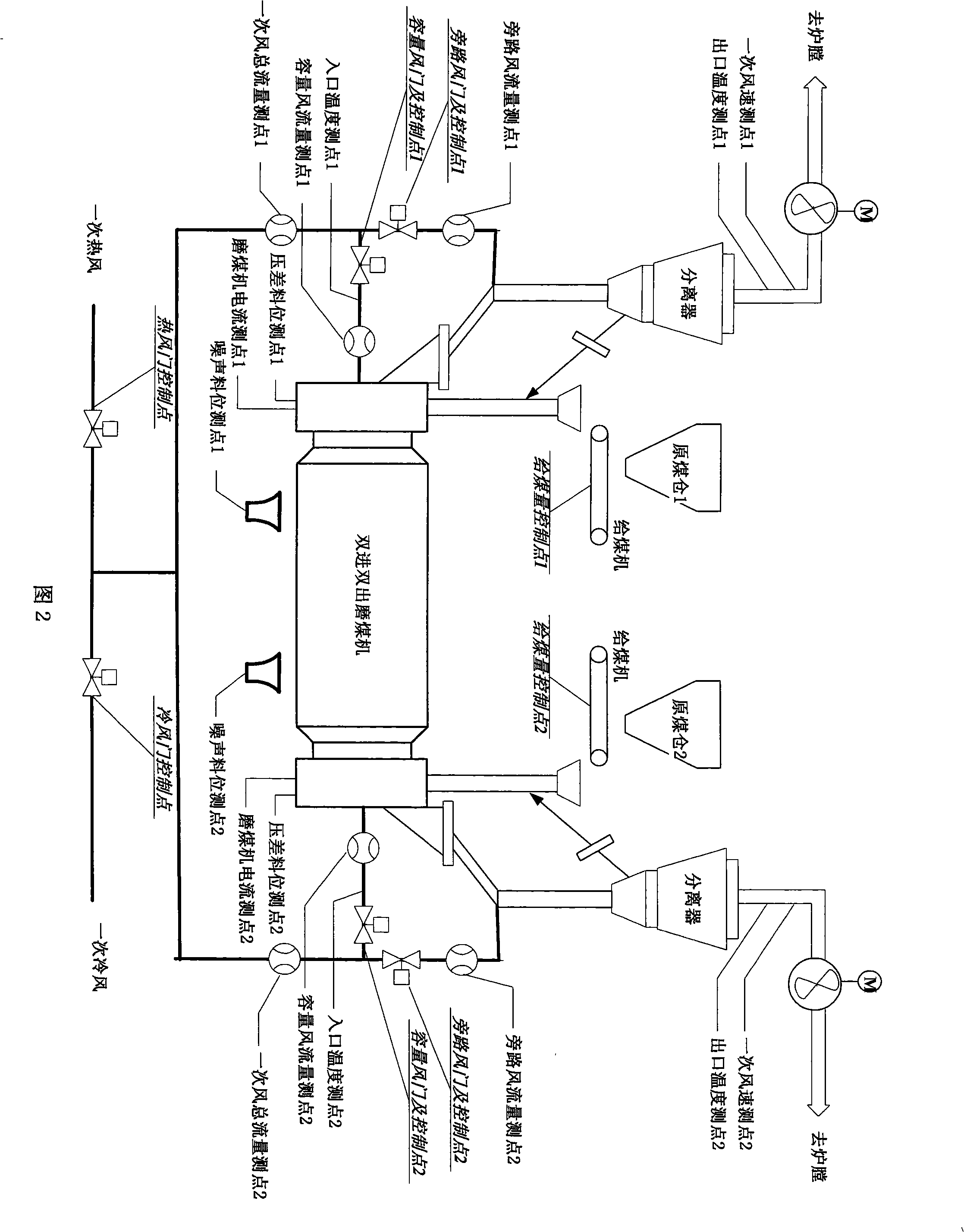

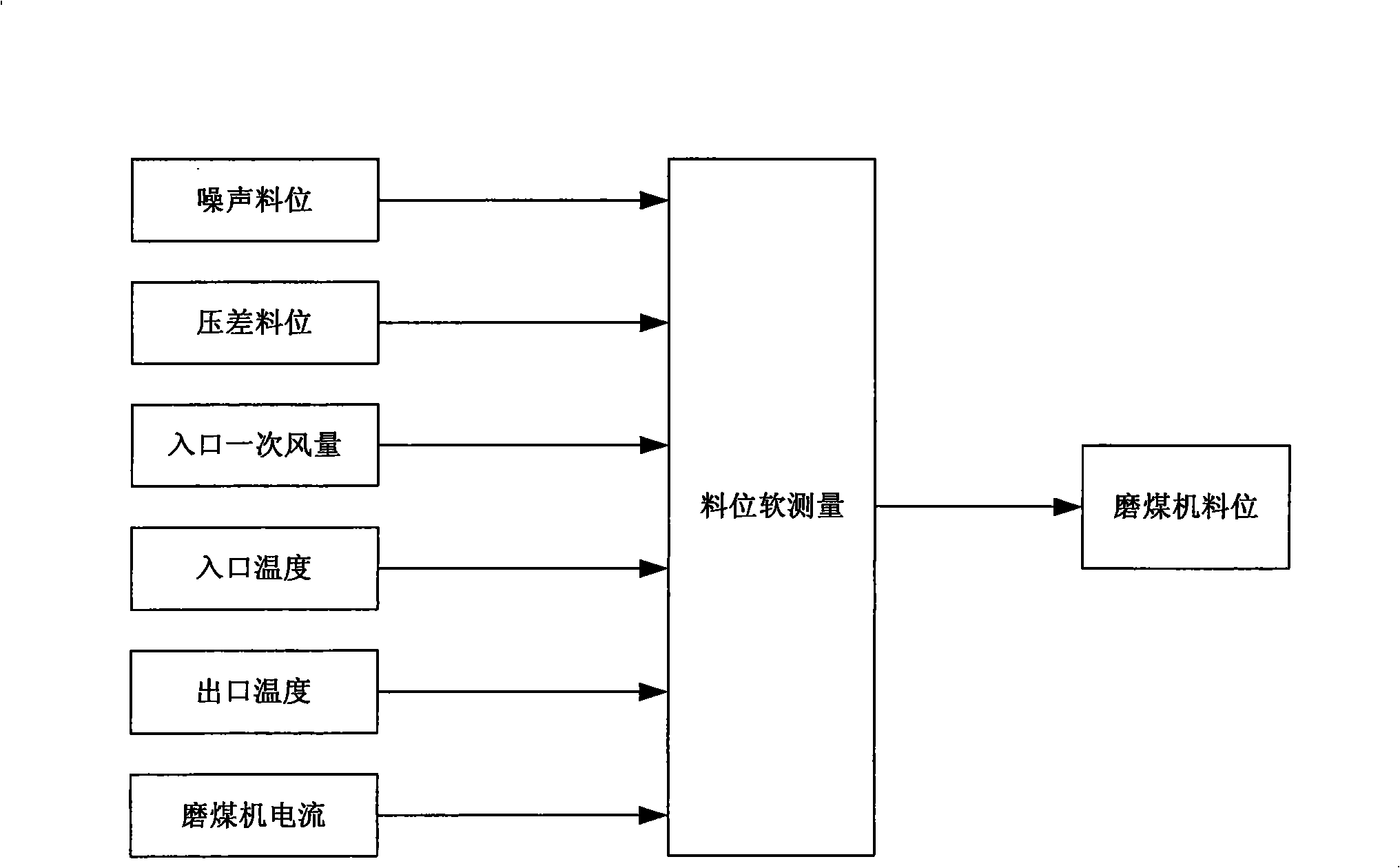

ActiveCN101334666AImprove combustion efficiencyGuaranteed uniformityGrain treatmentsProgramme total factory controlTemperature controlCombustion

The invention discloses an optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method. The method obtains the material position of the coal grinding machine after carrying out soft-measurement processing by collecting the noise material position of the coal grinding machine, the material position of pressure difference, the current of the coal grinding machine, one-time air quantity, one-time opening of the hot wind door and the cold wind door of an inlet, inlet temperature and outlet temperature; the control comprises material position control, air quantity capacity control, bypass air quantity control and the temperature control of the inlet and the outlet; the material position is optimized and the best material position of the coal grinding machine is searched online so as to ensure the combustion safety of the boiler and coal powder supply quantity when the load of the boiler is adjusted. The boiler combustion is optimized: according to the boiler technology, the load and the running working conditions, the powder supply quantity and the ventilation quantity of each coal grinding machine are optimized and the combustion efficiency of the boiler is improved. Malfunction diagnosis, running evaluation and analysis are carried out to the system and reasonable suggestions are provided so as to ensure the system to run continuously, stably, safely and economically; the optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method is widely applied to the dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation system or industrial similar systems in other industries.

Owner:西安蓝海机械仪表成套有限责任公司

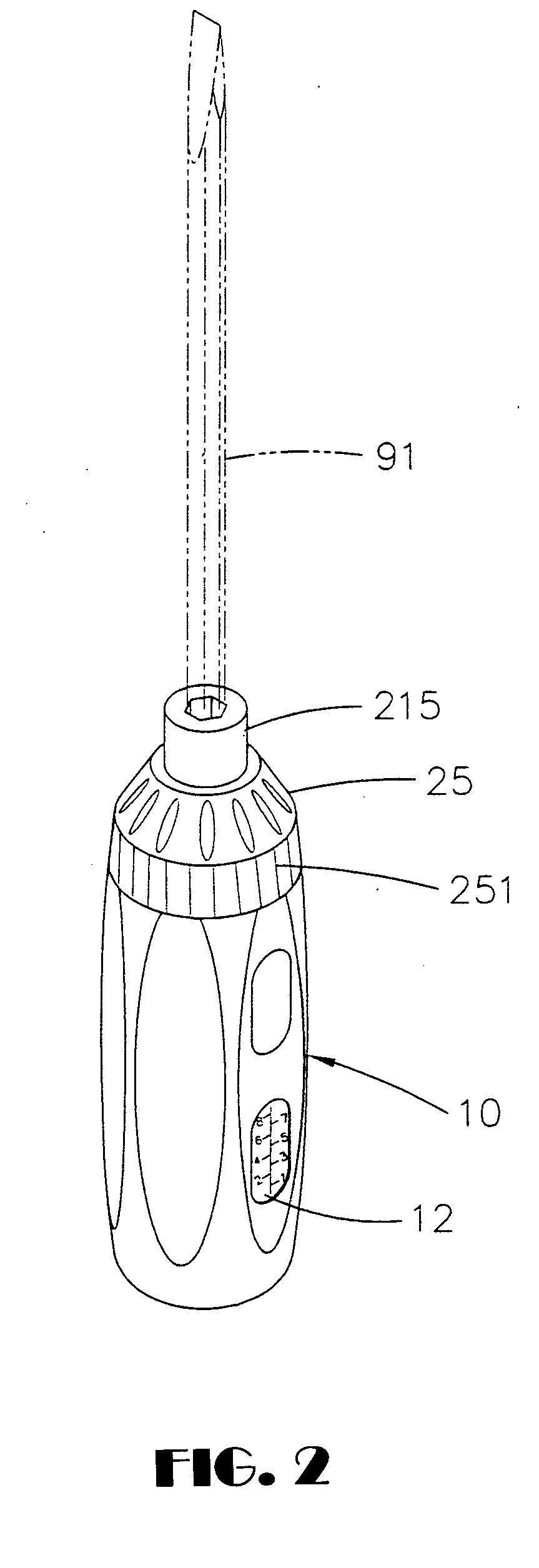

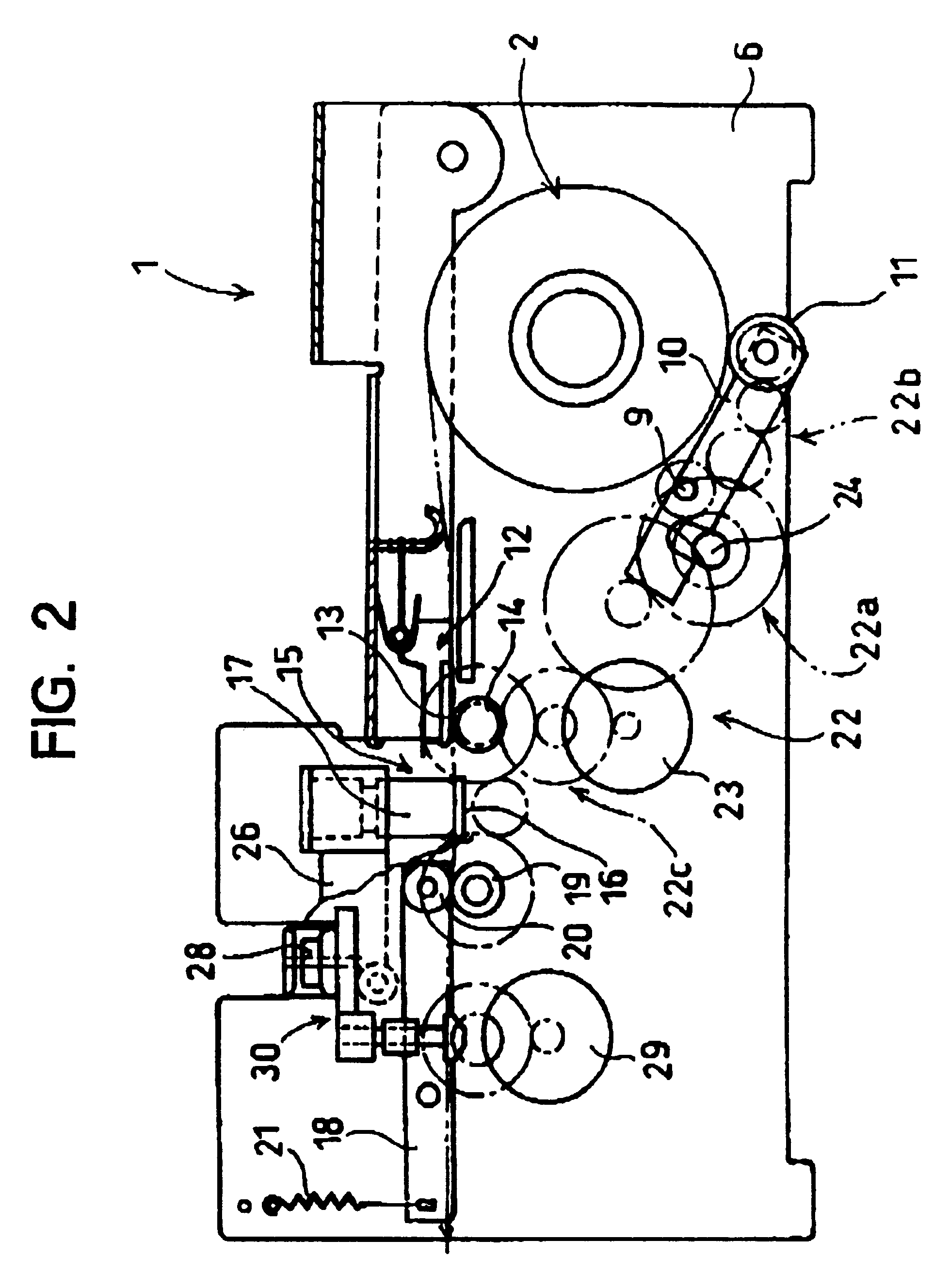

Screwdriver with torque setting mechanism

A screwdriver comprises a torque setting mechanism including a torque adjustment ring, an actuation rod threadedly secured to the upper torque adjustment ring and a lower torque adjustment nut, a spring biased sleeve with the actuation rod passed, and a clutch ring snugly put on two opposing intermediate flats of the actuation rod and having an upper surface engaged the torque adjustment ring and a lower surface formed with recesses engaged with steel balls on an upper surface of a support ring in the sleeve. Turning a rotatable handle will turn the sleeve. The clutch ring will disengage with the steel balls if the torque exceeds a set value. Thus, the torque exerted on the handle will not transmit to a shank secured to the actuation rod so as to prevent a screw from being over-driven by the shank.

Owner:WANG CHUN FU

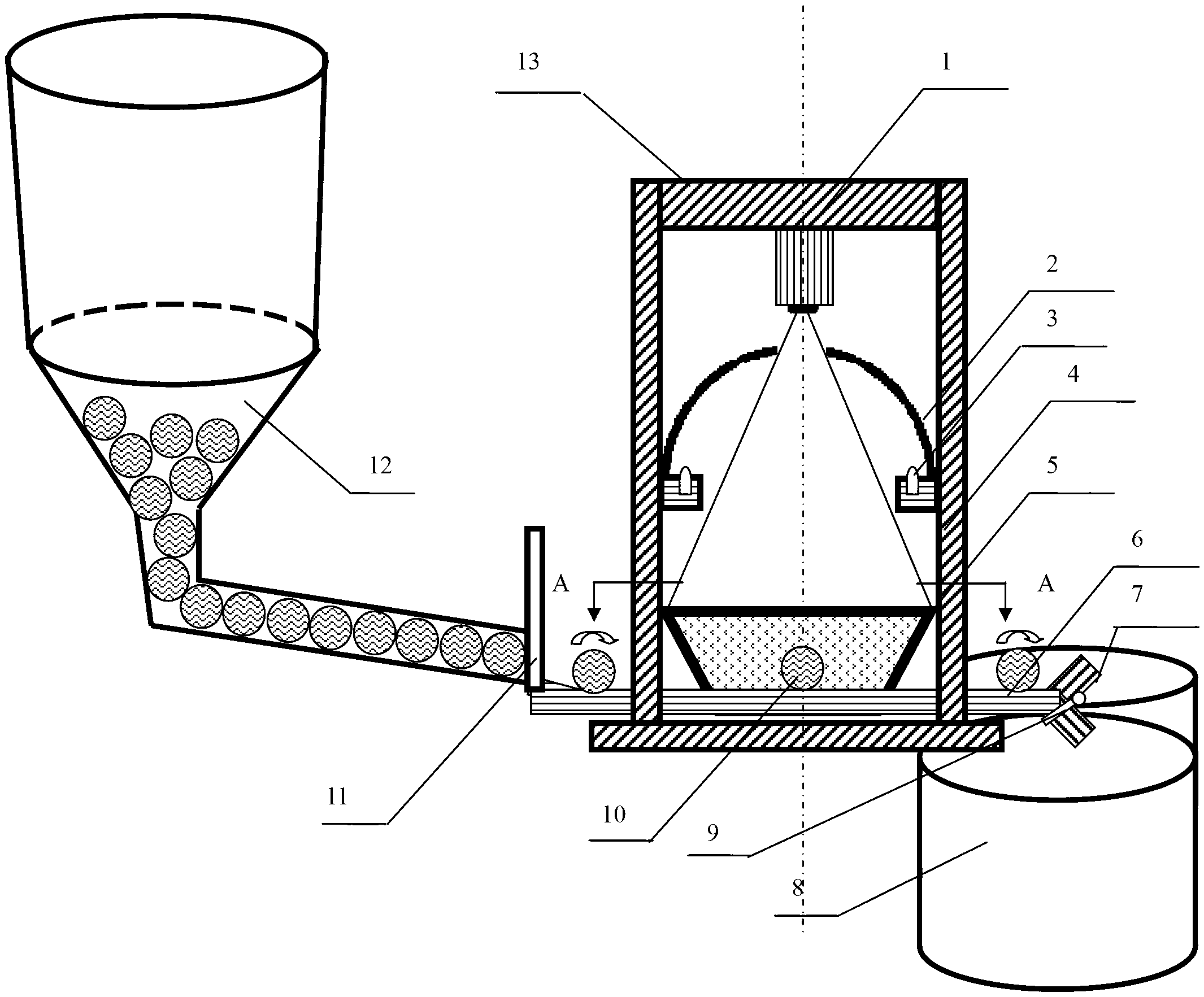

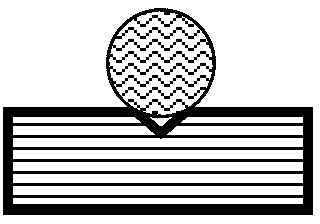

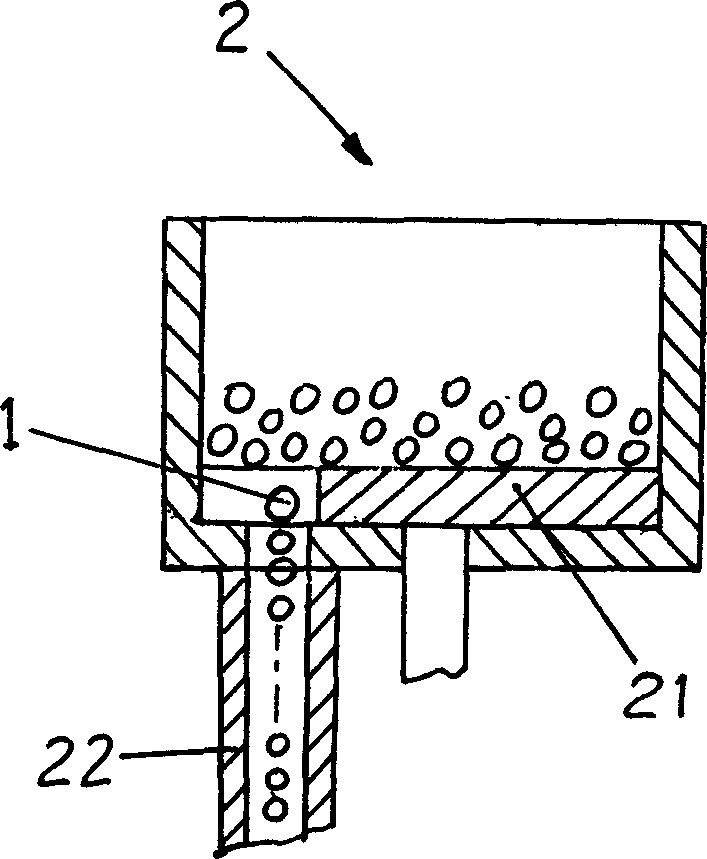

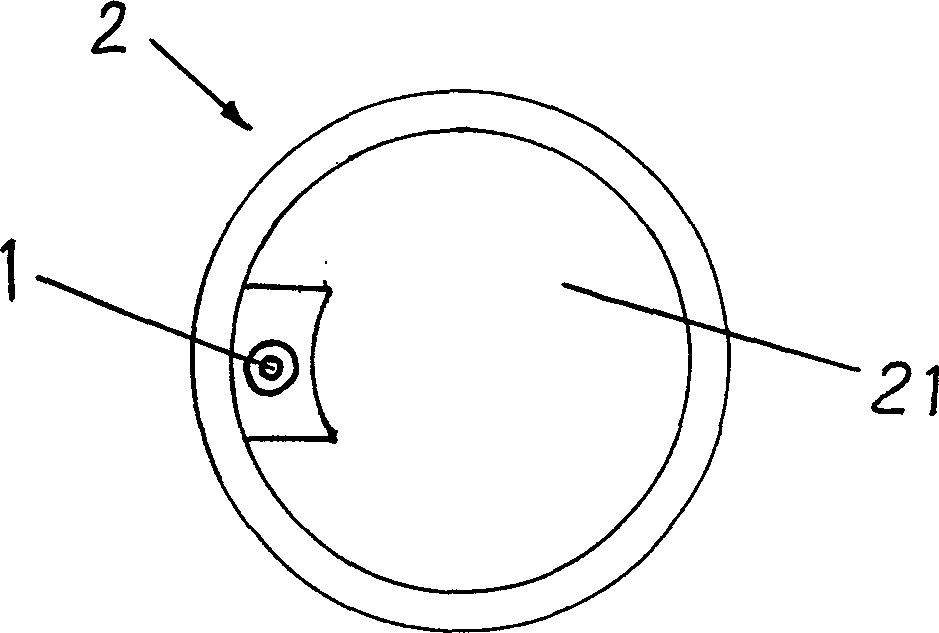

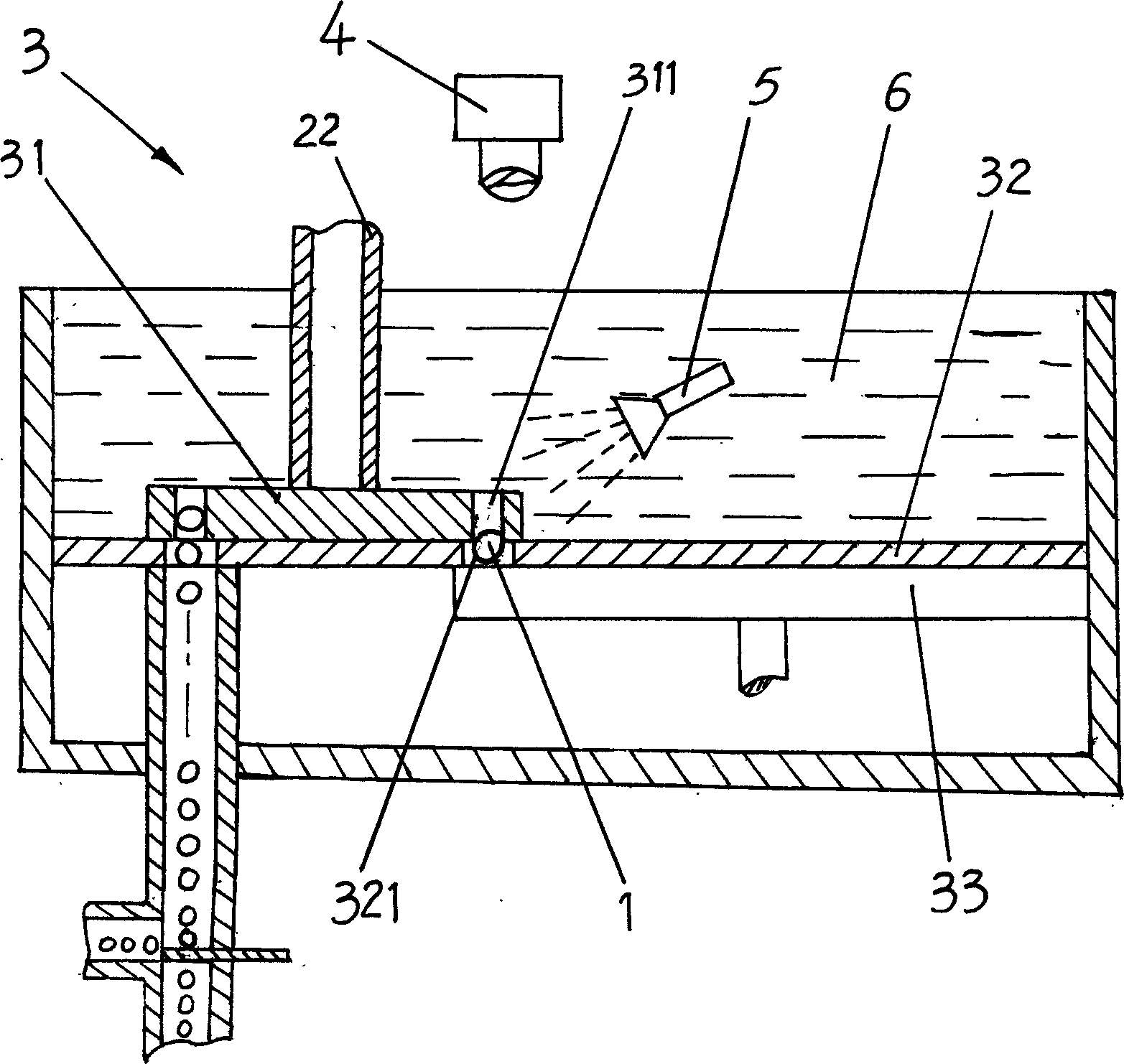

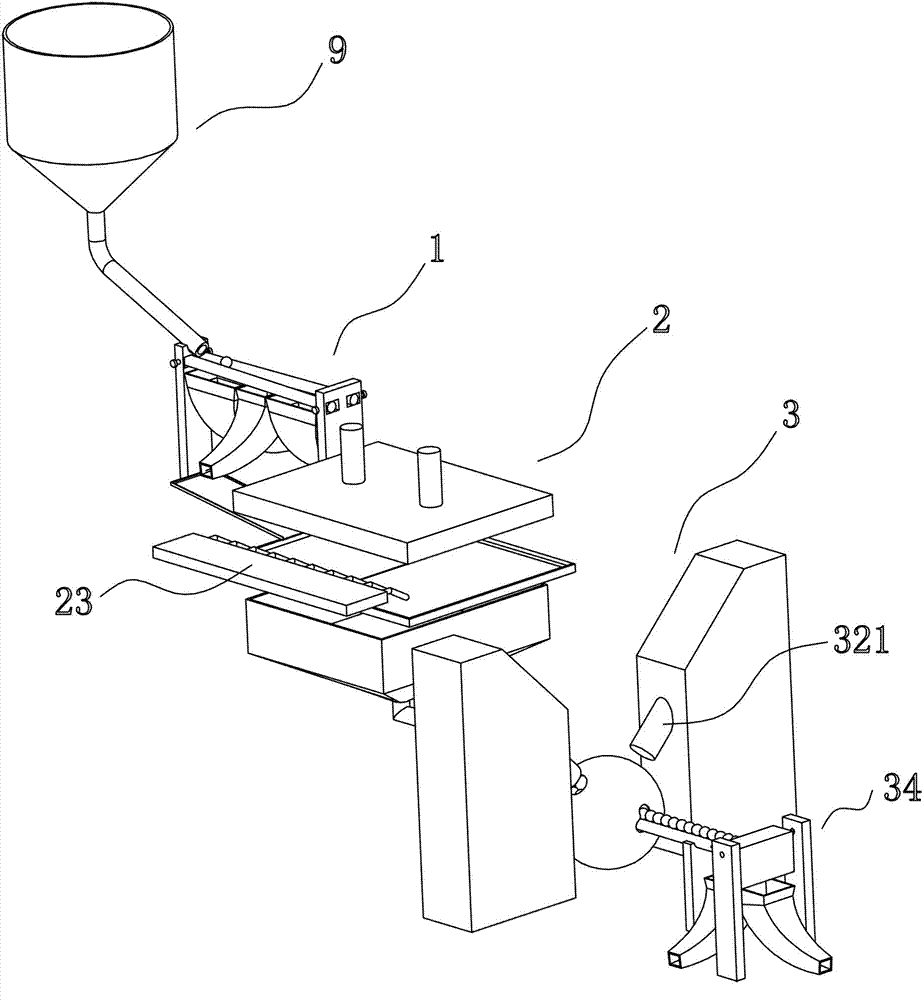

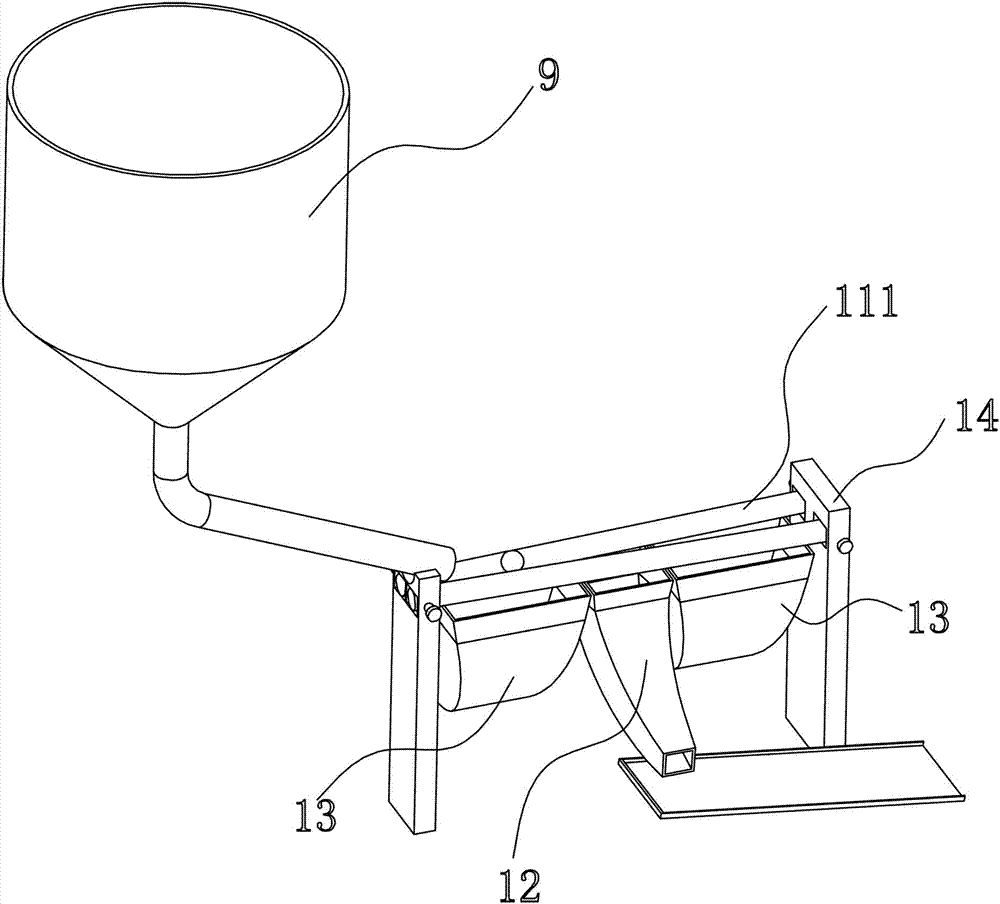

Monocular multi-perspective machine vision-based online automatic sorting device for steel ball surface defect

ActiveCN103286081ASimplify complexityImprove detection efficiencyMaterial analysis by optical meansSortingMachine visionImaging processing

The invention relates to a monocular multi-perspective machine vision-based online automatic sorting device for steel balls. The online automatic sorting device comprises an assembly line, a monocular multi-perspective machine vision device and a microprocessor, wherein the assembly line is used for automatically detecting and sorting the steel balls, the monocular multi-perspective machine vision device is used for shooting images of the detected steel balls, the microprocessor is used for performing image processing, detection, identification and classification on the images of the detected steel balls and coordinately controlling each actuating mechanism on the assembly line to coordinately move, and the assembly line comprises a feeding actuating mechanism, a transmission mechanism and a sorting actuating mechanism. The invention provides the monocular multi-perspective machine vision-based online automatic sorting device for the steel balls based, which has the advantages of simple mechanism, low manufacturing cost, high sorting efficiency and convenience in operation and maintenance.

Owner:ZHEJIANG UNIV OF TECH

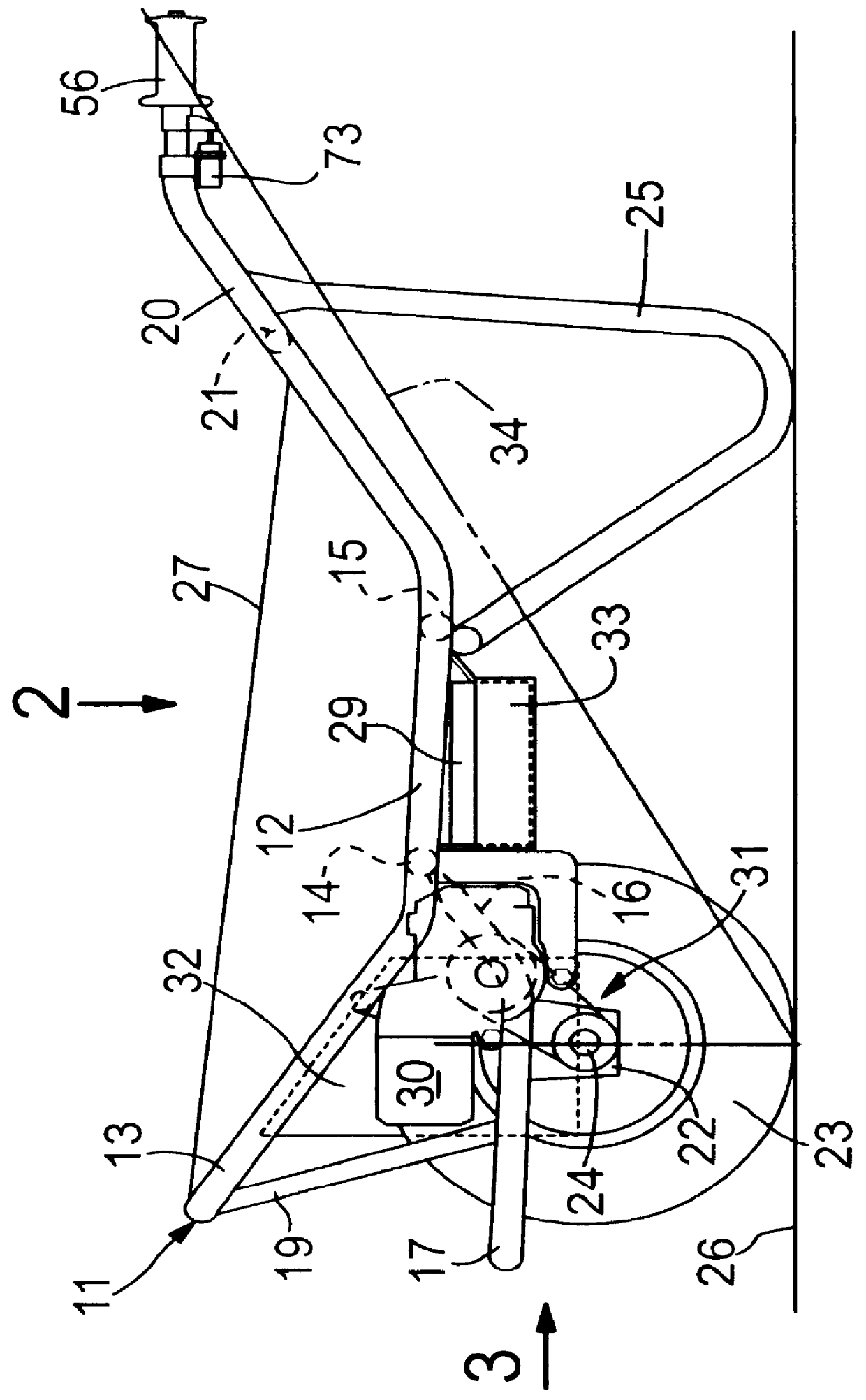

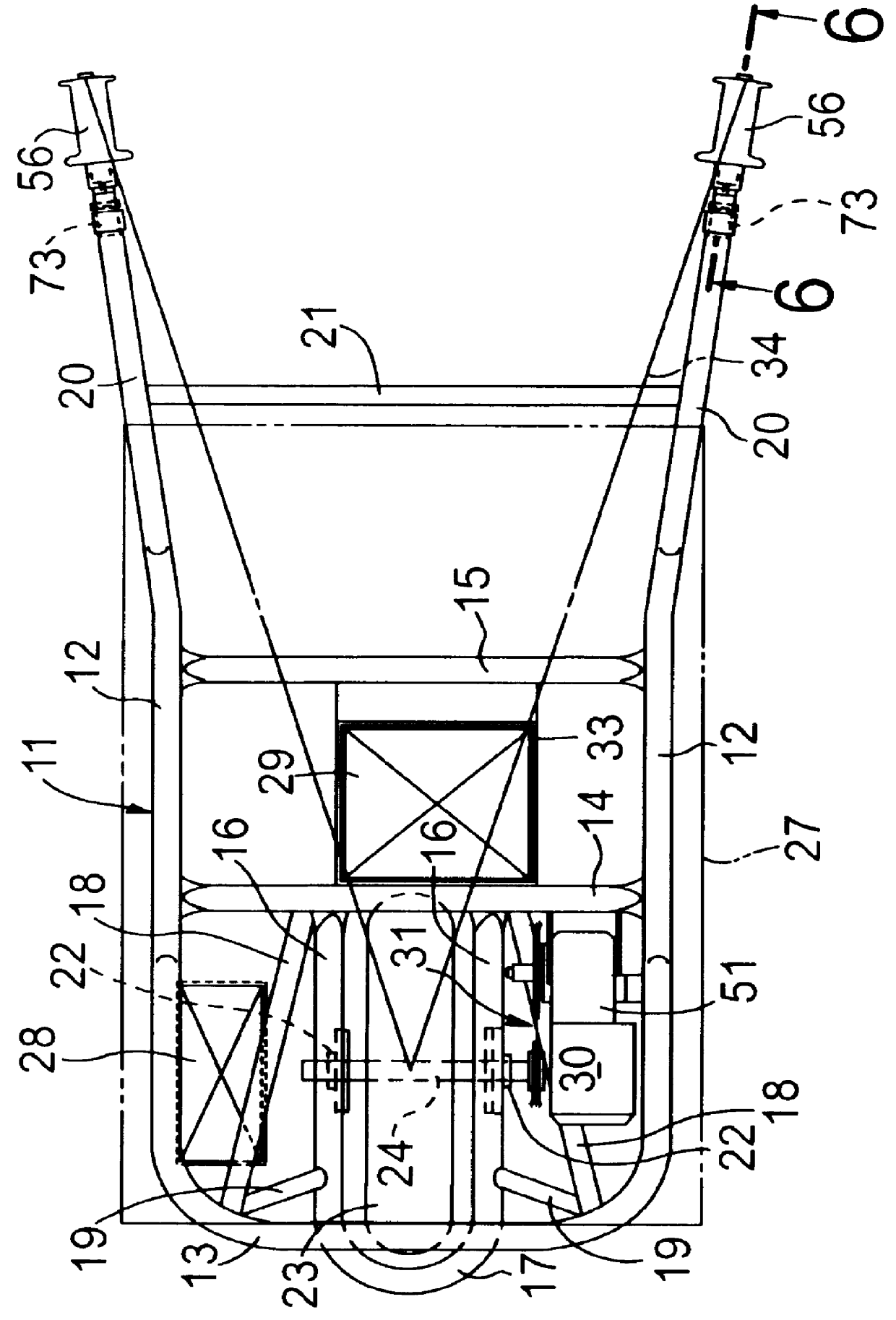

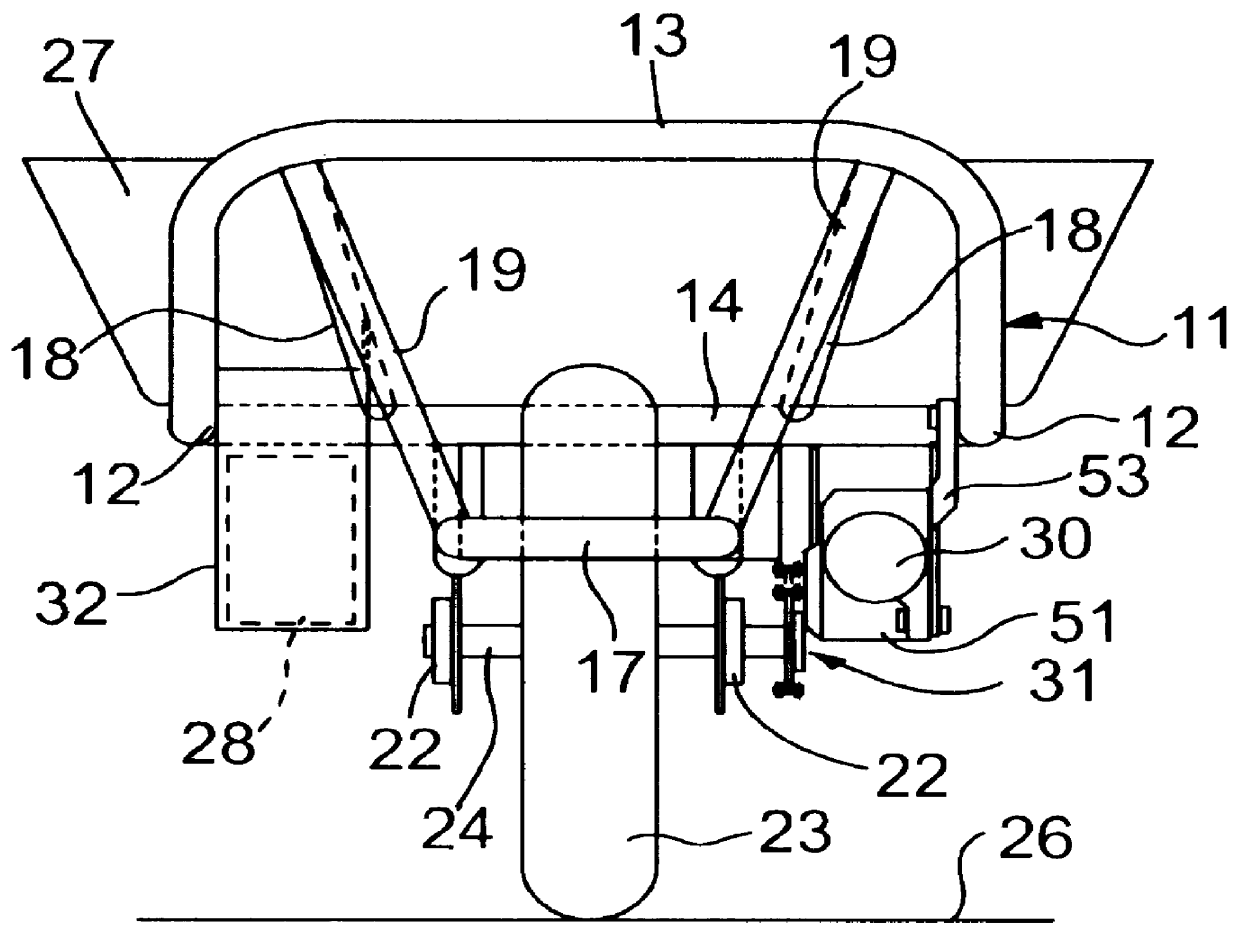

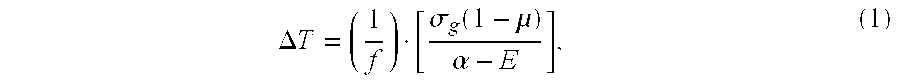

Power-assisted wheelbarrow

A power-assisted wheelbarrow applies an assisting function using an electric motor. Handle shafts connecting to the rear end portions of two handles are covered with grips which are allowed to move axially relative to the handle shafts. More than one steel balls are fitted between the handle shafts and the grips. At the sides of the grips or the handles, pushing force detecting sensors are disposed for detecting the axial movements of the grips relative to the handle shafts in accordance with the pushing forces applied to the grips. The operation of the electric motor is controlled on the basis of the detected values of the two pushing force detecting sensors. As a result, the assisting force by the electric motor can be effectively applied to the wheel of a manual-push type single-wheeled carrier so that manual labor can be reduced while minimizing the consumption of a battery.

Owner:HONDA MOTOR CO LTD

Translucent or opaque colored glass-ceramic article providing a cooking surface and its use

InactiveUS20050252503A1Minimizing contentEasy resistanceCooking-vessel materialsStoves/ranges foundationsChemical reactionAdditive ingredient

The translucent or opaque colored glass-ceramic article provides a cooking surface and has an adjustable light transmission in a visible range under 15%, as measured for a 4 mm sample thickness; a flaw-free upper surface with an impact resistance of greater than 18 cm breaking height, as tested with a 200 g steel ball in a falling ball test; a temperature difference resistance of greater than 500° C.; a high crystallinity with keatite mixed crystals as principal crystal phase in an interior of the glass-ceramic article and with a residual glass phase fraction of less than 8% by weight; a glassy upper surface layer of from 0.5 to 2.5 μm thick, which is substantially free of high quartz mixed crystals and which inhibits chemical reactions, and a content of enriched ingredients in the residual glass phase in the interior of the glass-ceramic and in the glassy surface layer of ΣNa2O+K2O+CaO+SrO+BaO+F+refining agents of from 0.2 to 1.6% by weight.

Owner:SCHOTT AG

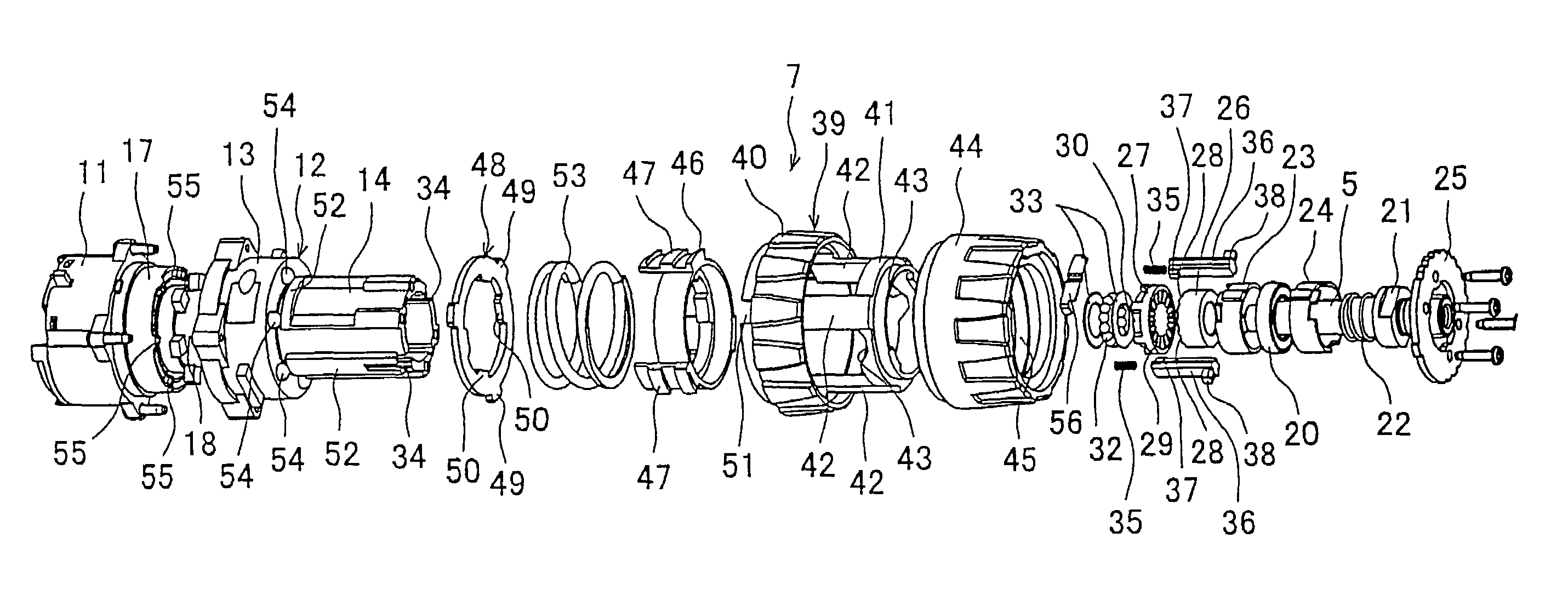

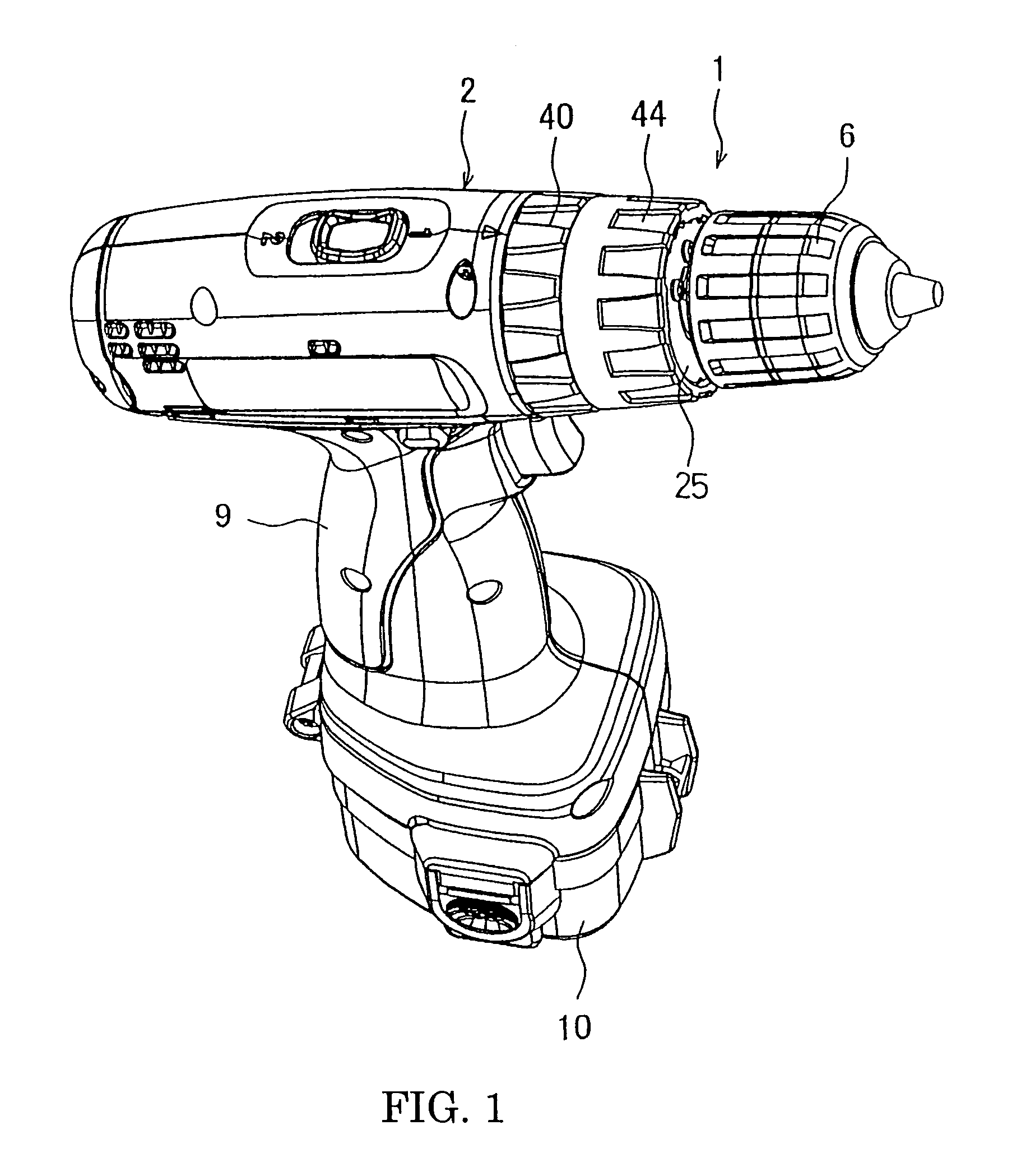

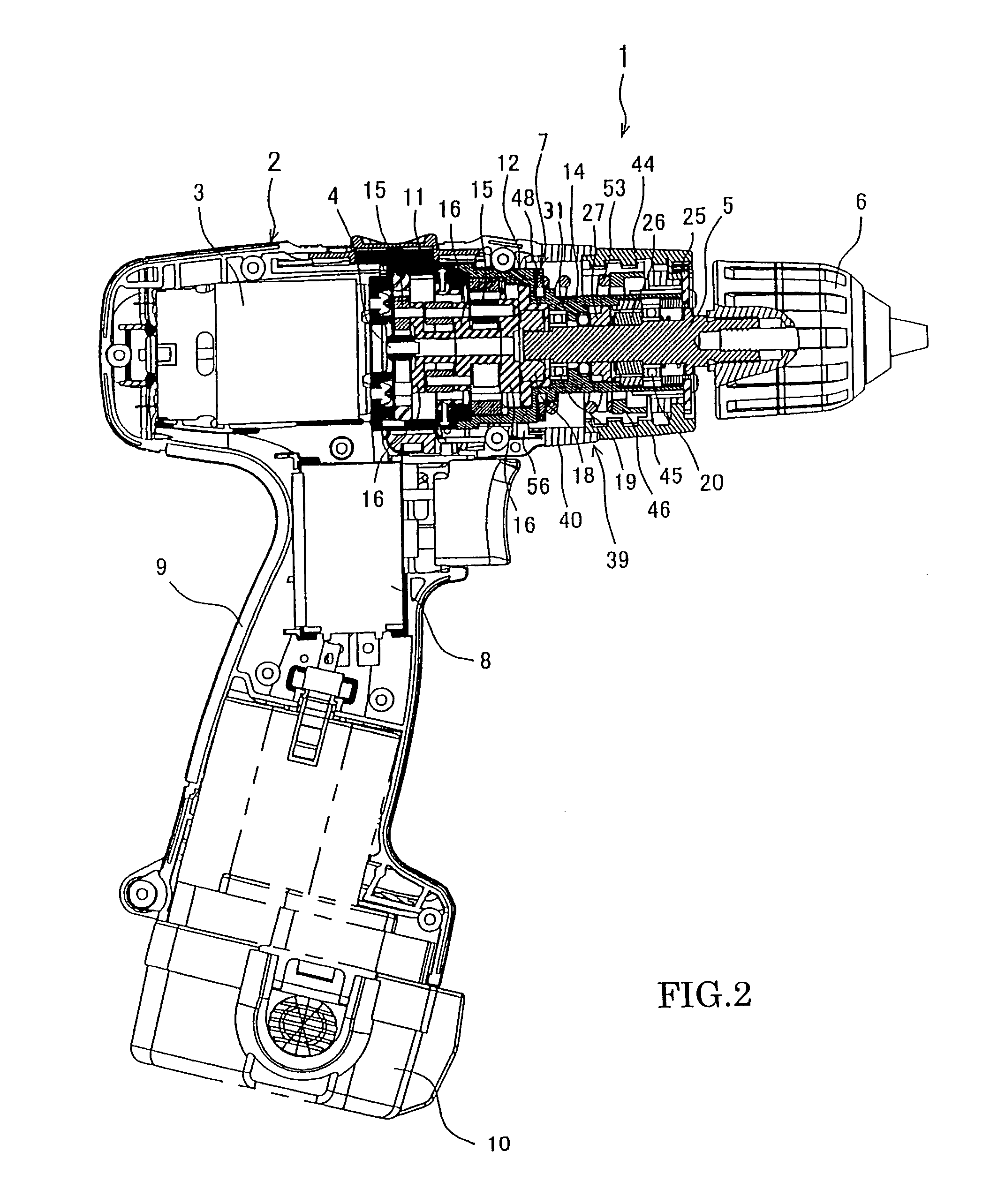

Driver drill

ActiveUS7201235B2Prevent erroneous clutch operationImprove reliabilityDrilling rodsConstructionsGear wheelCoil spring

A driver drill that can effectively prevent erroneous clutch operation in a drill mode is provided. A flat washer positioned between steel balls for locking an internal gear and a coil spring is rotatable by rotative operation of a mode-change ring. Also, protruding streaks are provided on a small-diameter unit of a second gear case around which a flat washer is externally mounted. The protruding streaks interfere with internal projections on an inner circumference of the flat washer at its predetermined rotating position to regulate a forward movement of the flat washer. When a drill mode is selected with the mode-change ring, the flat washer is locked by the protruding streaks.

Owner:MAKITA CORP

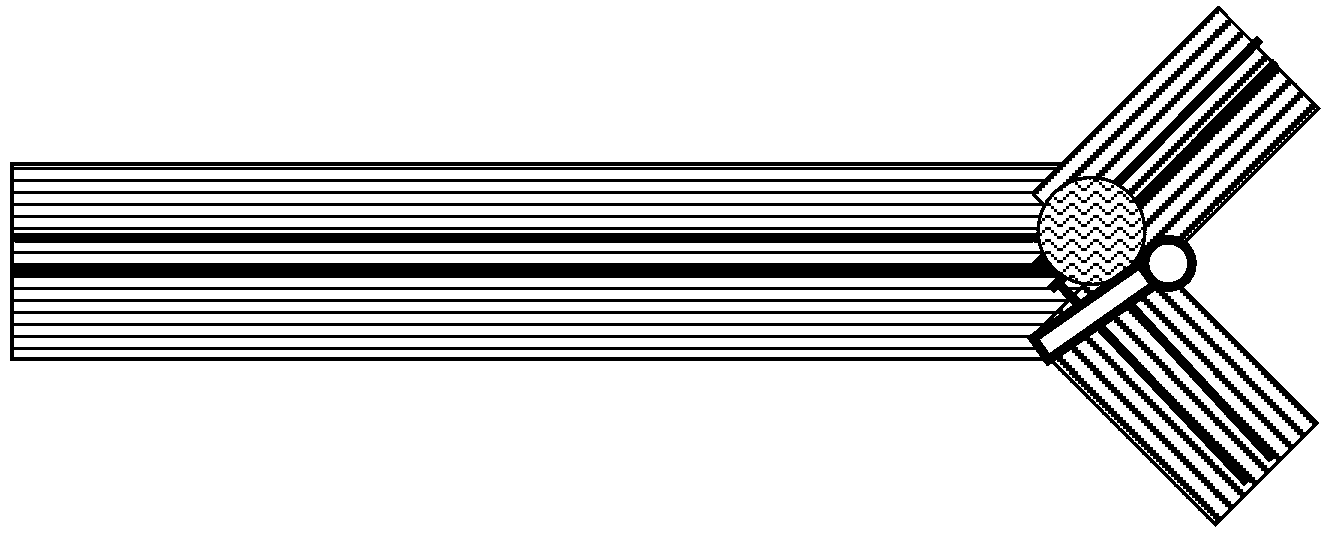

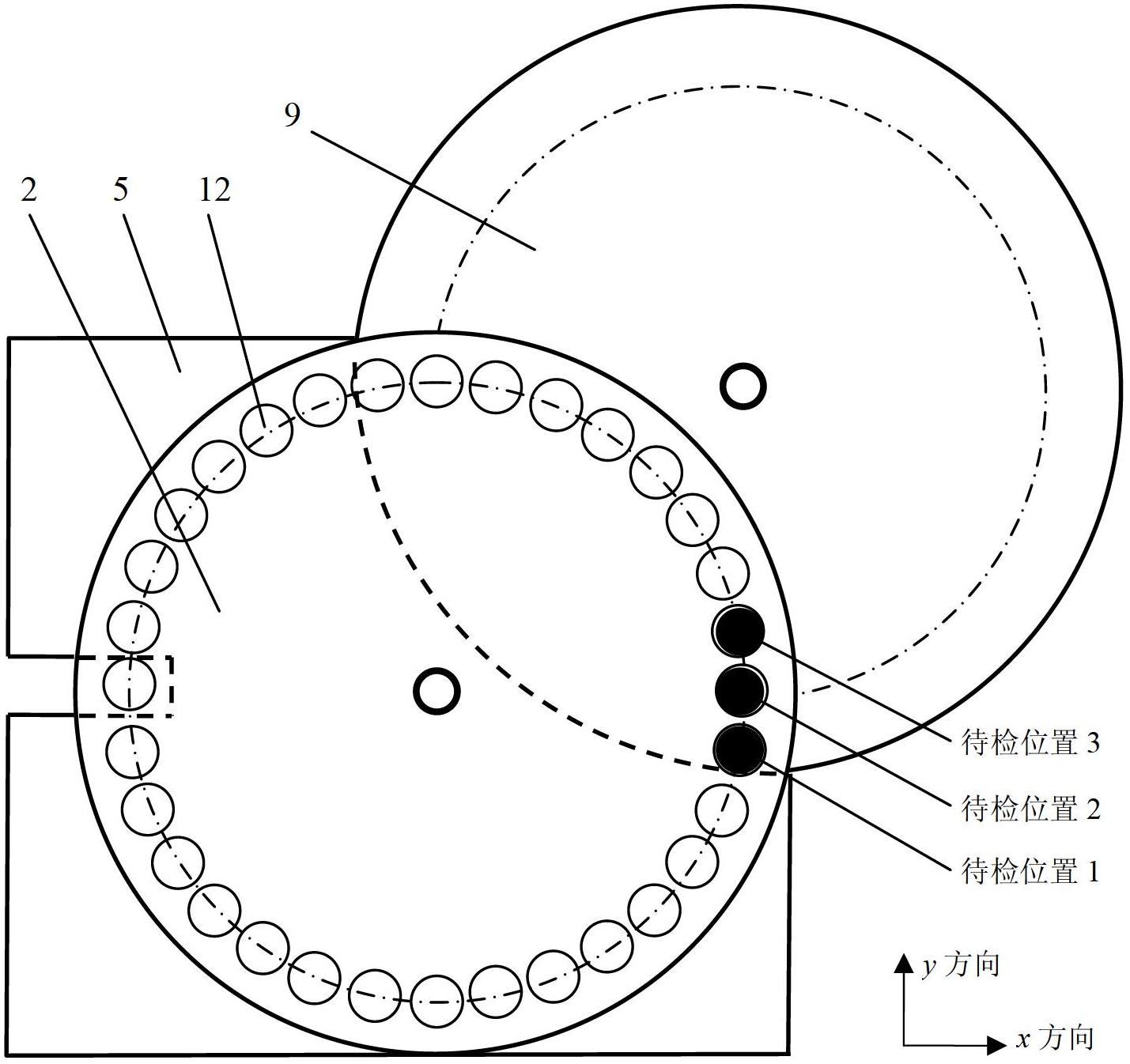

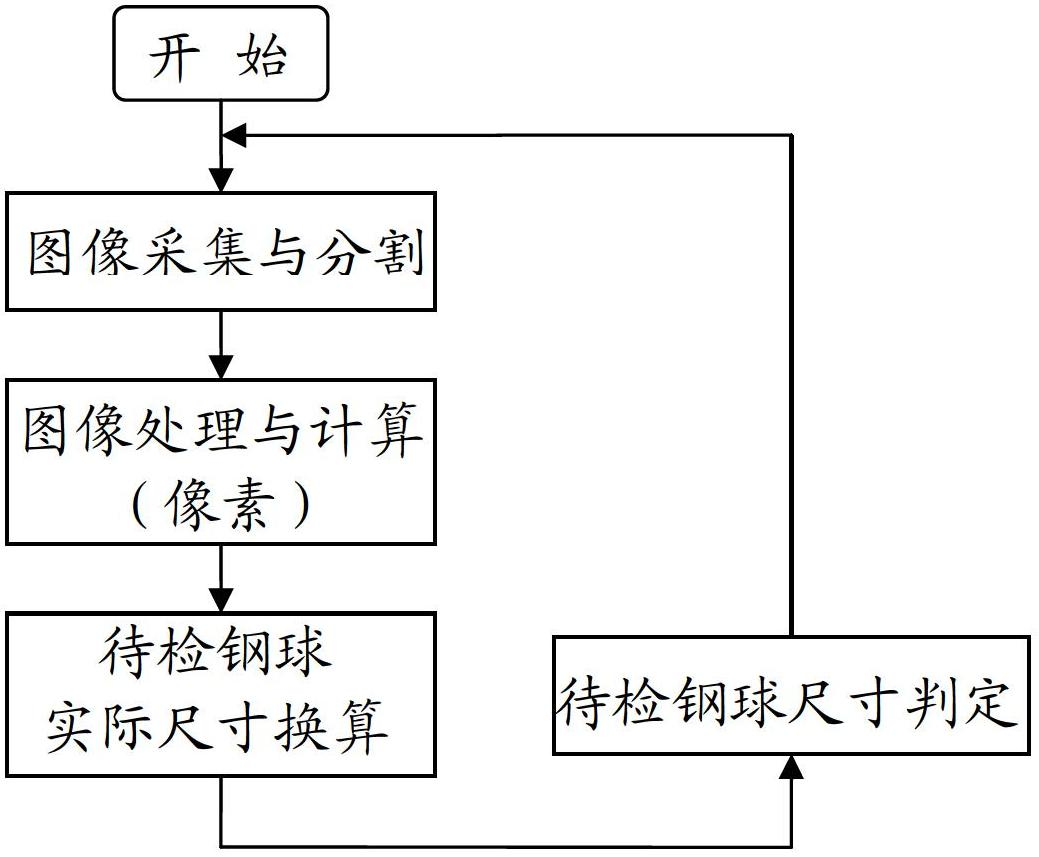

Steel ball sorting device and method based on machine vision

InactiveCN102658266AOvercome the shortcomings of complex overall structureGuaranteed uptimeOptically investigating flaws/contaminationUsing optical meansMachine visionQuality control

The invention provides a steel ball sorting device and a method based on machine vision. Surface characteristics of steel balls are obtained on line; the sorting of the steel balls is realized according to a quality control target; the surface of each steel ball to be detected is sufficiently expanded by coordinated rotation movement of a feeding disc and an expanding disc, and the expanding disc does not need to swing, so that the operation of a detection device is more stable and more reliable, and the structure is simple; and therefore, the existence of swing movements in a detection process is avoided and a detection result is more accurate. Meanwhile, a method for measuring the outer diameters of the steel balls in introduced in and the steel balls which cannot meet size requirements are removed according to a measuring result, so that the sorting device can more perfectly meet actual requirements.

Owner:ZHEJIANG UNIV +1

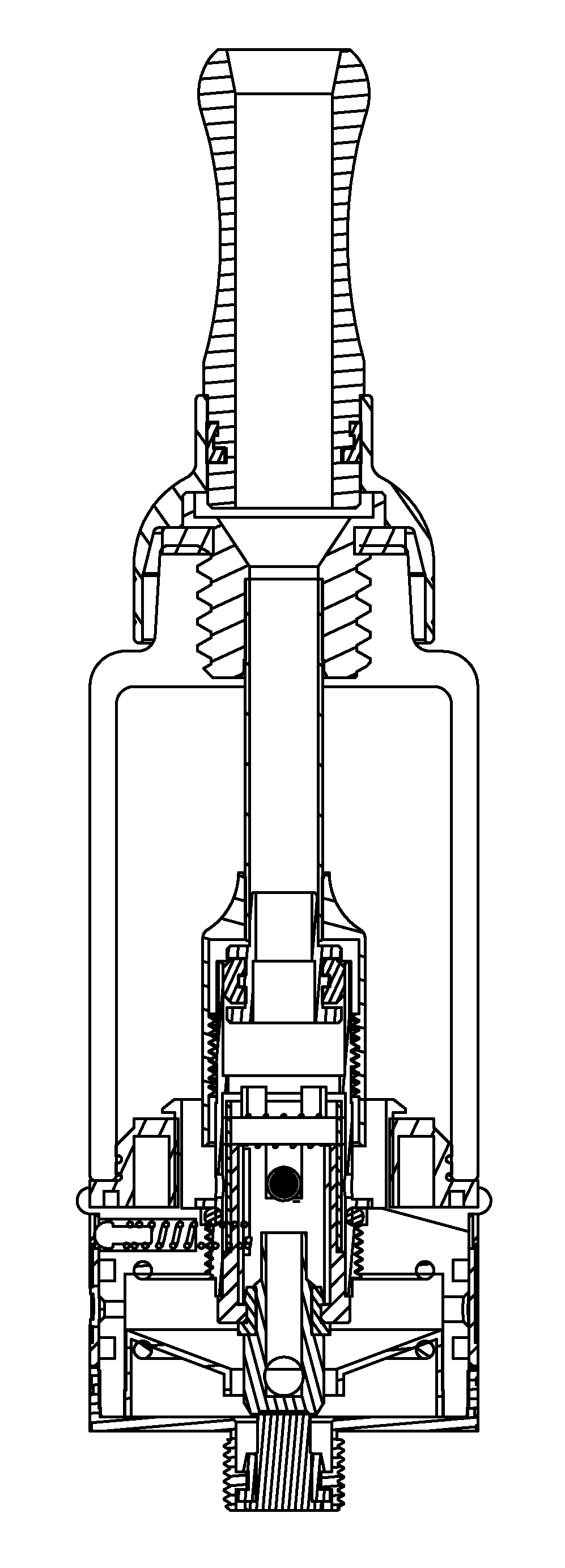

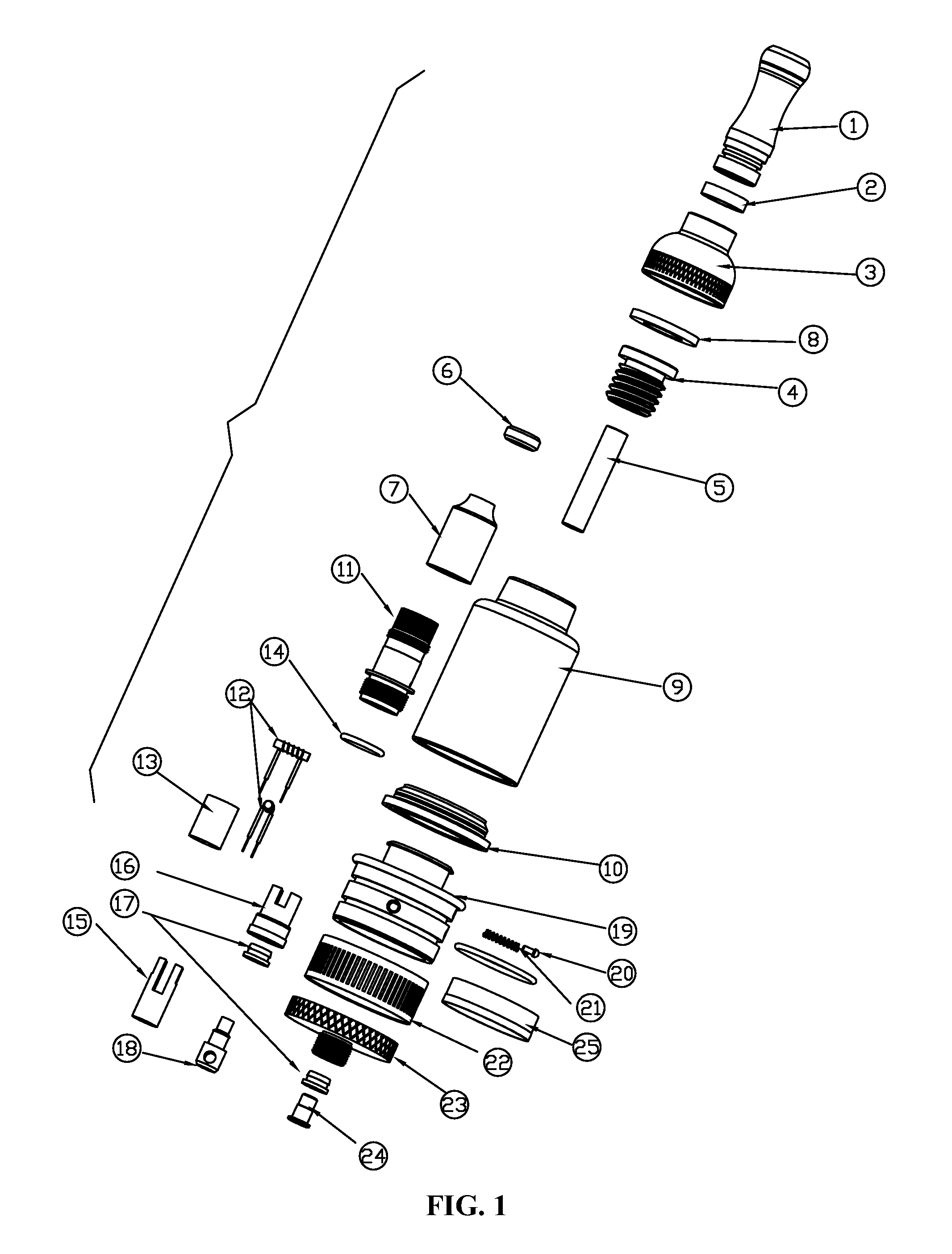

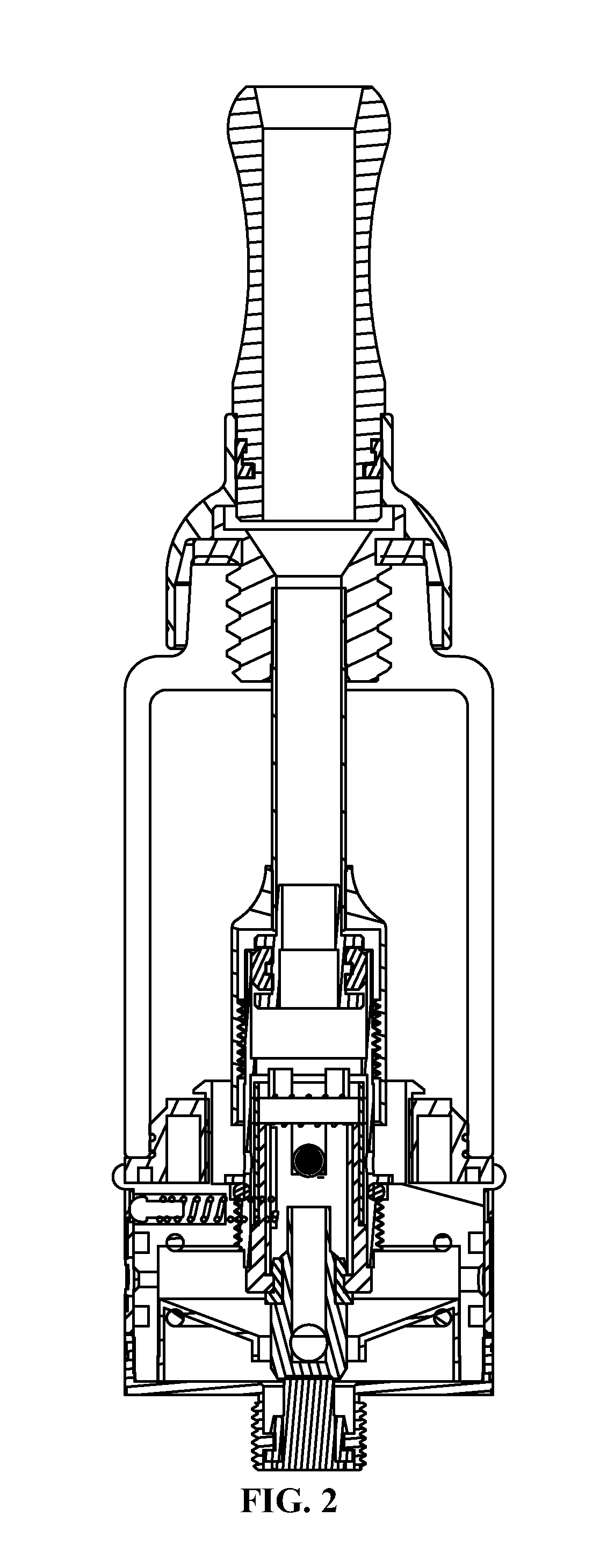

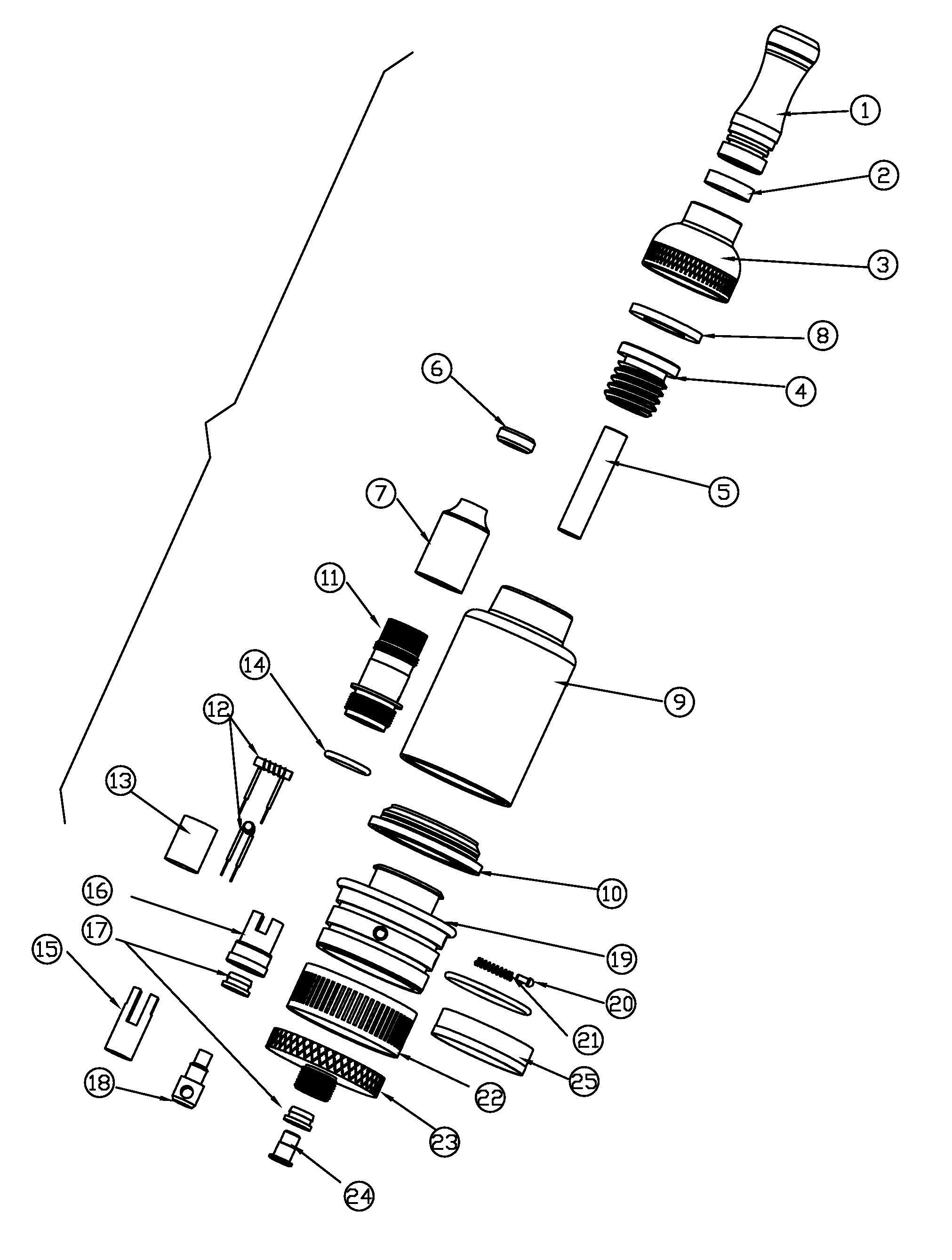

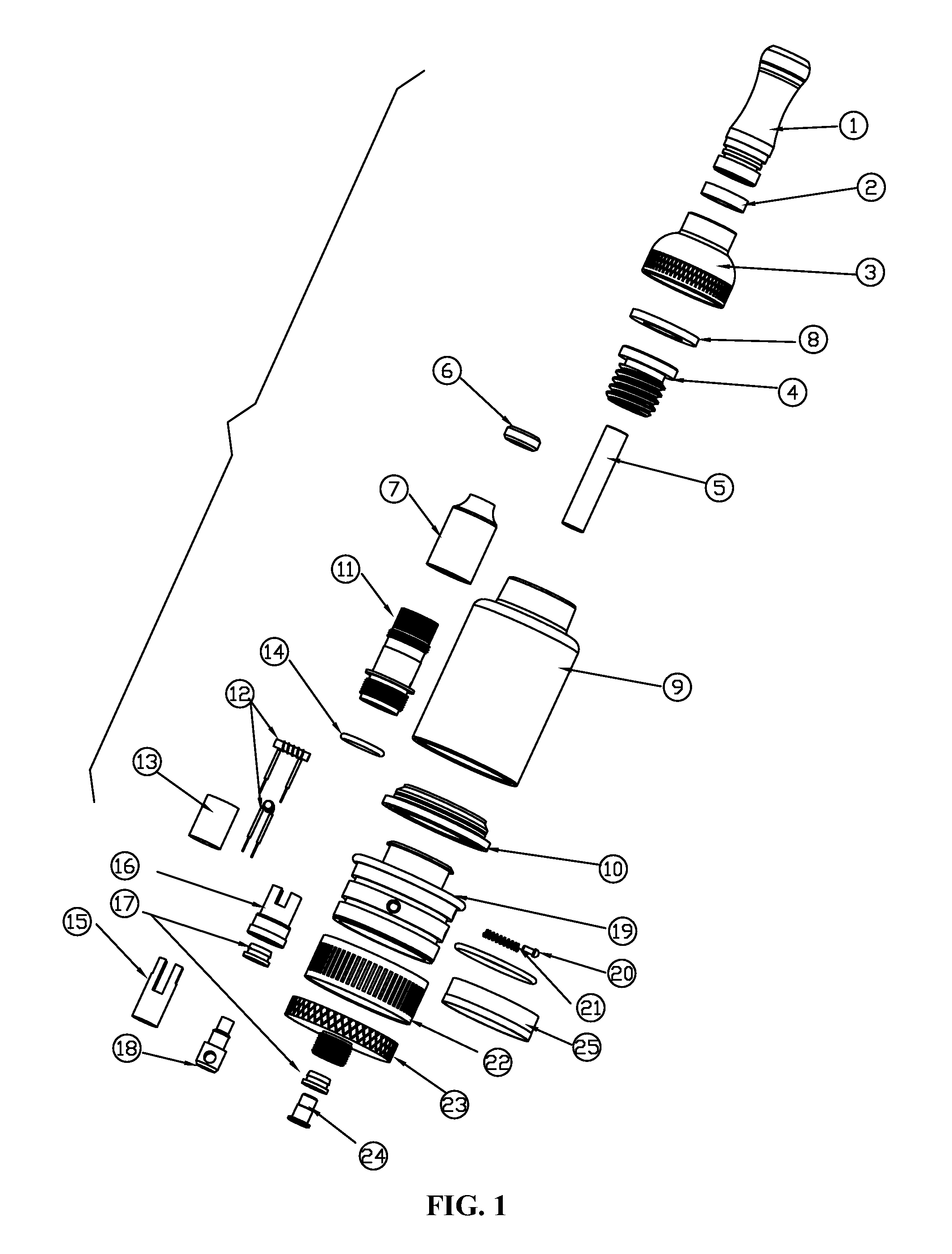

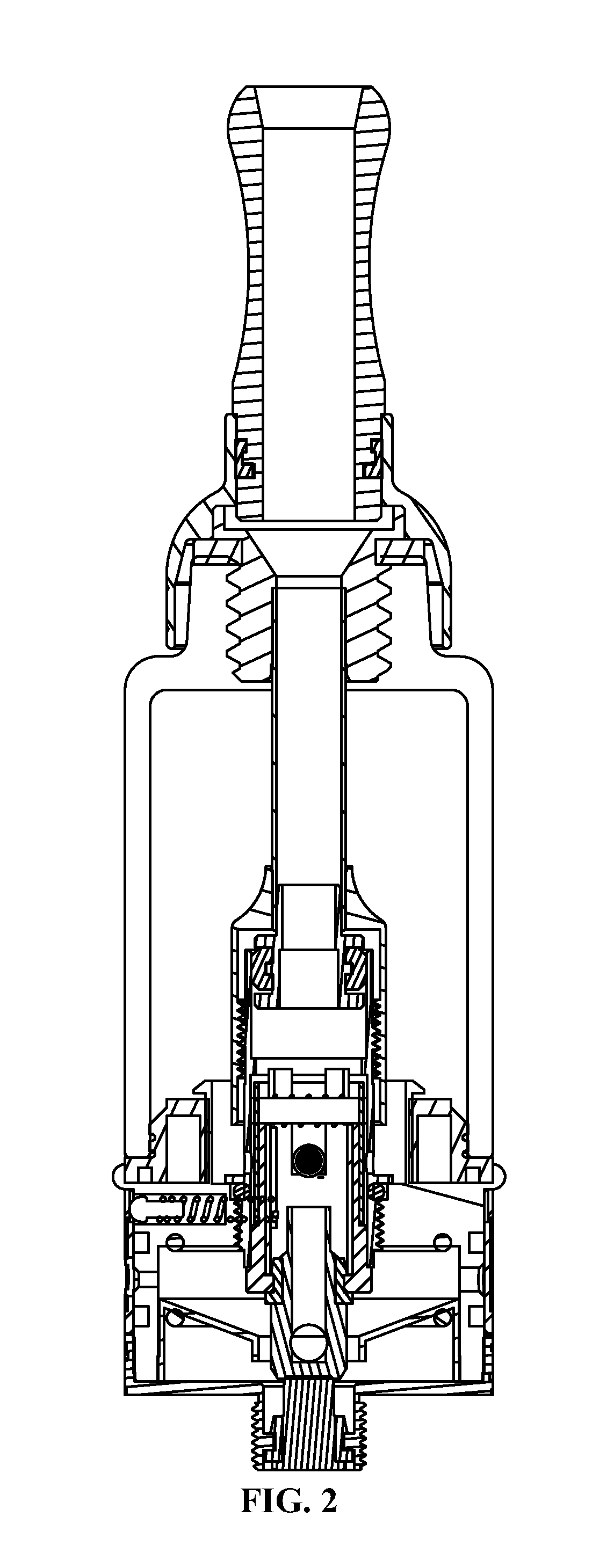

Electronic cigarette

ActiveUS20150136157A1Easy to useNot to polluteMedical devicesTobacco pipesEngineeringElectronic cigarette

An electronic cigarette, including a cigarette holder assembly, an atomization assembly, a glass container for accommodating smoke oil, and a gas flow regulator. The cigarette holder assembly includes a mouthpiece, a first sealing ring, a seat for supporting the mouthpiece, a fixed screw, and a pole. The atomization assembly includes a pair of heating wires, a glass casing, a second sealing ring, a third sealing ring, oil-guiding cotton, a limit cover, an insulating ring, and a fixed ring. The glass container includes a first sealing gasket and a second sealing gasket which are respectively disposed at both ends of the glass container. The gas flow regulator includes a control ring, a steel ball, a spring, and a rotary button. The first sealing ring of the cigarette holder assembly is sleeved on the mouthpiece, and the mouthpiece is fixed on the seat via the fixed screw.

Owner:LIU TUANFANG

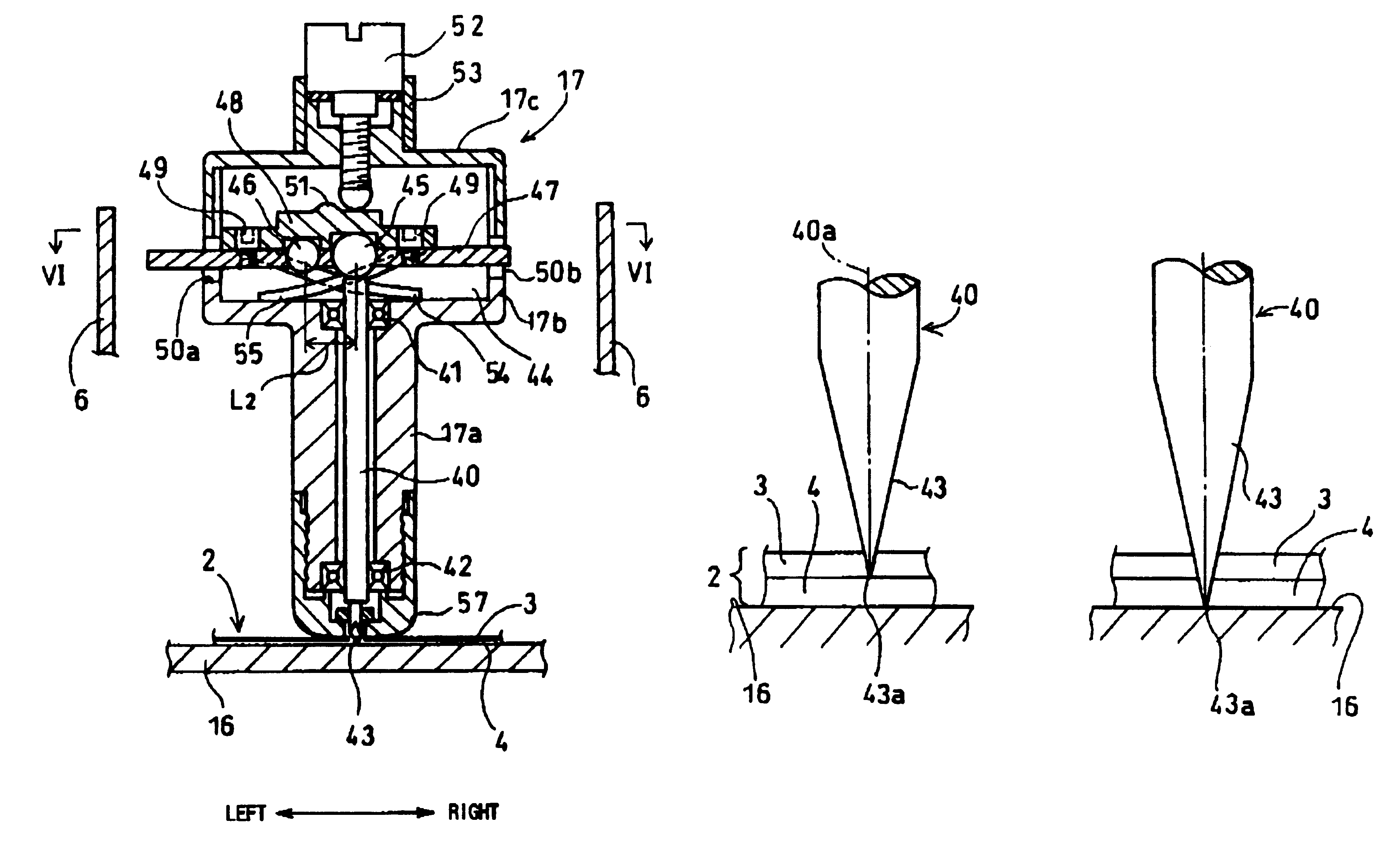

Device for adjusting distance of cutting blade from workpiece sheet

A cutter shaft 40 provided with a cutter 43 as its lower tip is freely vertically movably disposed in a guide cylinder portion 17a of a cutter holder 17. A horizontal support body 47 is supported in a hollow case portion 17b. A large diameter first steel ball 45 and a small diameter second steel ball 46 are supported in the horizontal support body 47 separated by a suitable distance. The horizontal support body 47 supports the steel balls 45, 46 exposed from a lower end of the horizontal support body 47 but in a manner that prevents the steel balls 45, 46 from falling out of the horizontal support body 47. A cover body 48 is fixed on the upper surface of the horizontal support body 47 to prevent the first and second steel balls 45, 46 from moving in a vertical direction. The side edges of the horizontal support body 47 protrude from guide grooves 50a, 50b formed inside surfaces of the hollow case portion 17b. An adjustment screw screwingly engaged in a lid portion 17c presses downward on the cover body 48. On the other hand, resilient plate springs 54, 55 extending downward from the cover body 48 urge the cover body 48 upward.

Owner:BROTHER KOGYO KK

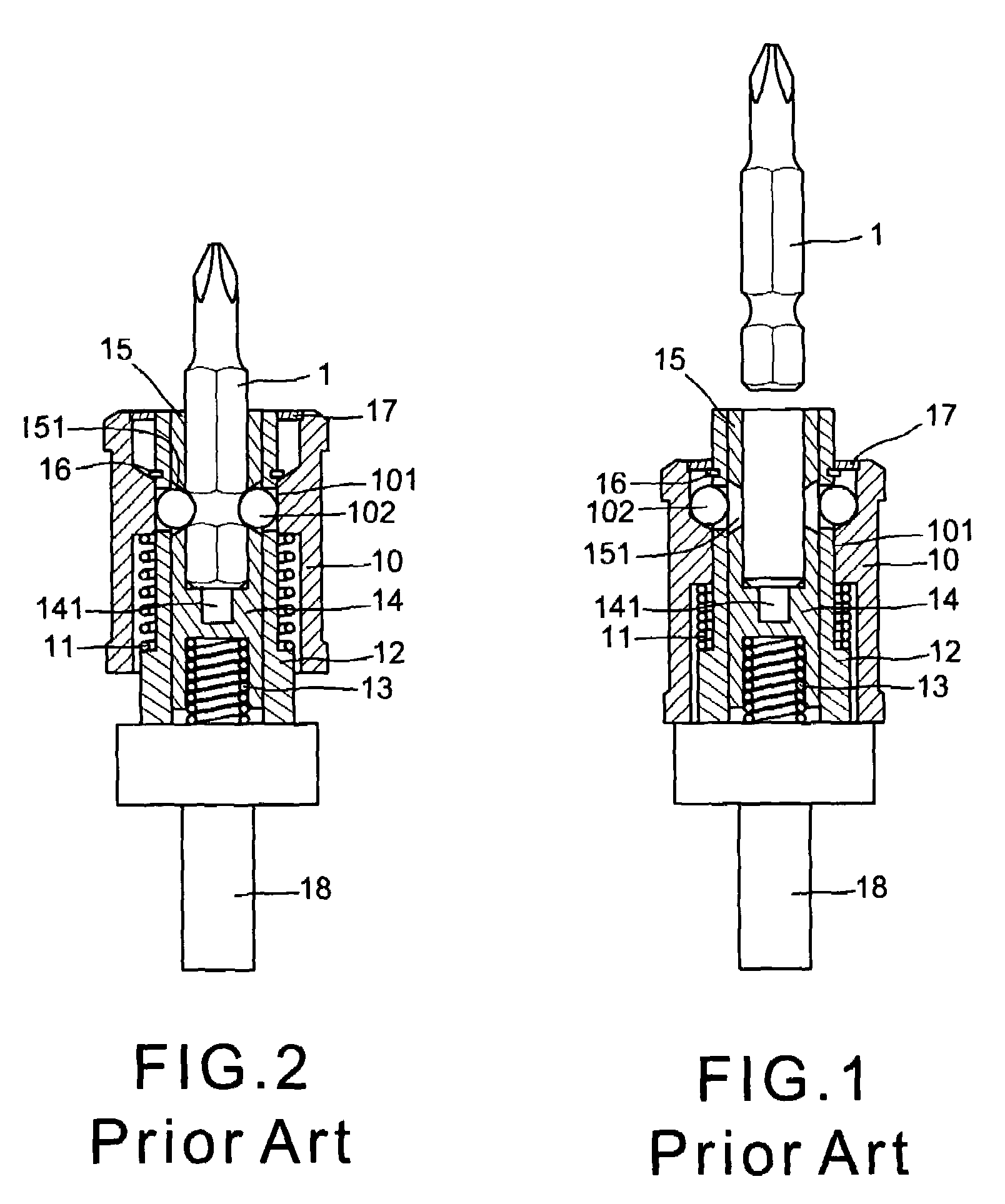

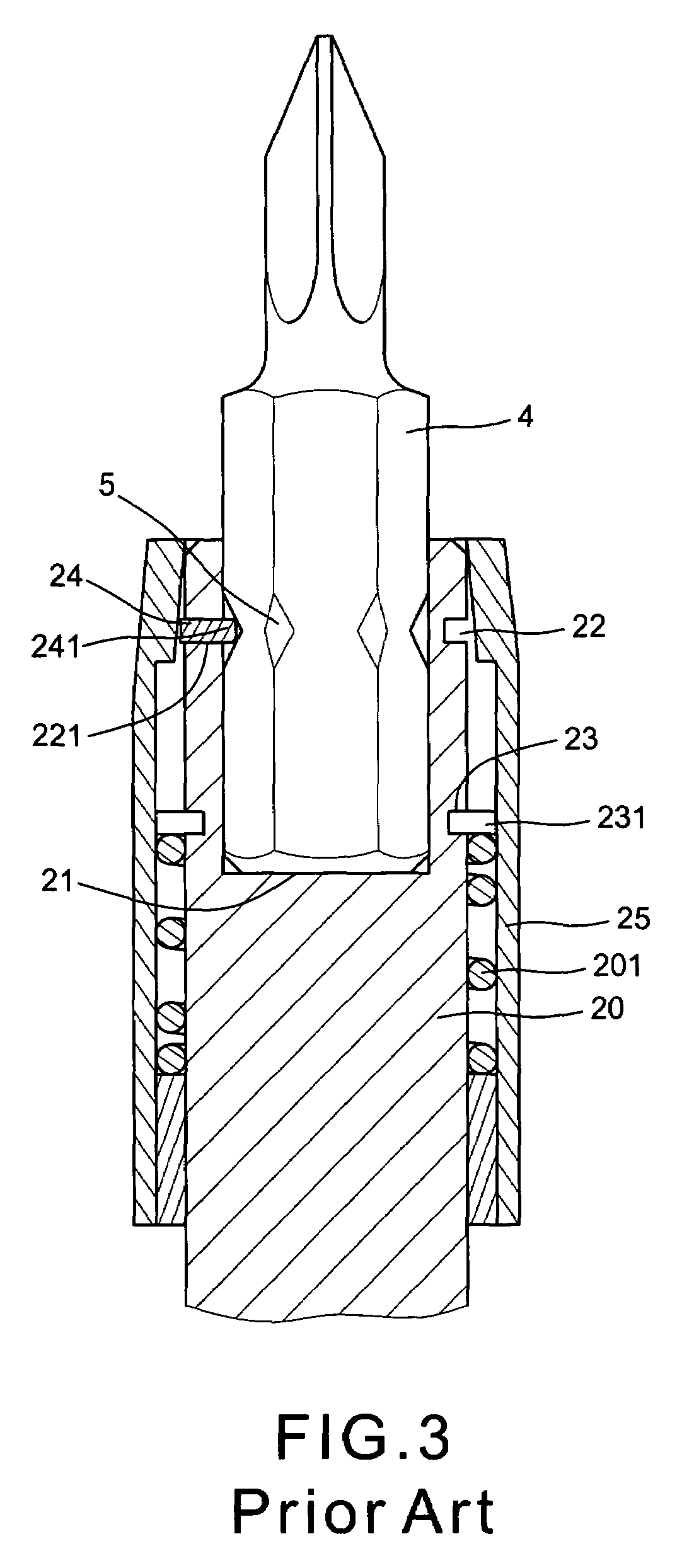

Adapter coupling device

InactiveUS7448302B2Avoid breakingEasy to disassembleSleeve/socket jointsSpannersEngineeringSteel ball

An adapter coupling device includes an adapter wrapped byan outer sleeve and biased by a large spring. The adapter has a polygonal recess in the upper portion, a circular recess under the polygonal recess for receiving a positioning block which is biased by a small spring, two pairs of the first and second radial through hole in upper and lower peripheries for engaging with two pairs of steel balls. The outer sleeve has an introrse upper portion which has an asymptotic inner wall, an annular groove in a middle inner wall and an annular flange on lower end, a screwdriver inserted into the polygonal recess of the adapter has a hexagon shank, a rhombic notch in each of the corners of the shank, when inserting the screwdriver into the adapter, the asymptotic wall of the sleeve is functioned to press the steel balls in the first radial through holes engaging within the rhombic notches of the shank so that the screwdriver is checked.

Owner:HUANG DANIEL

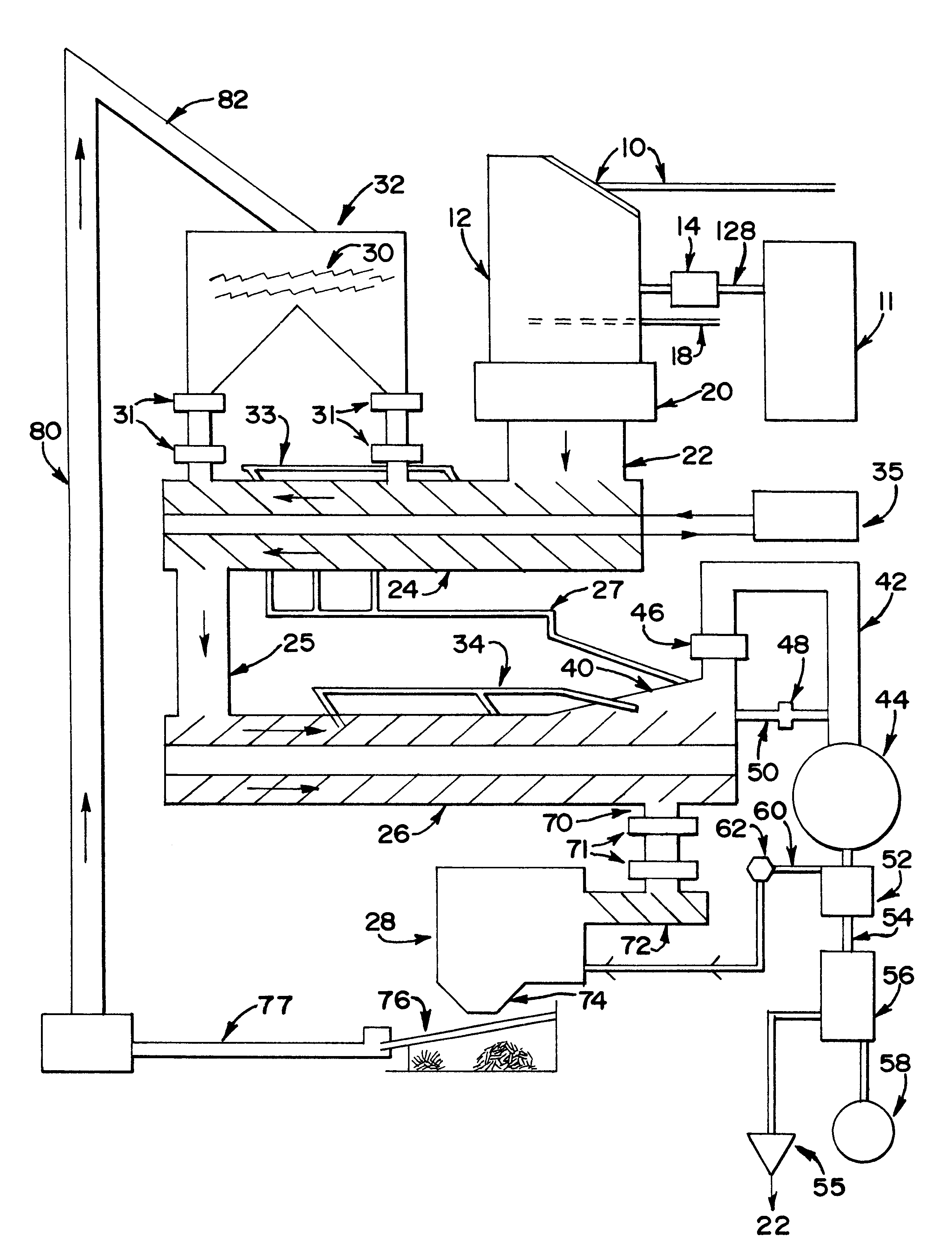

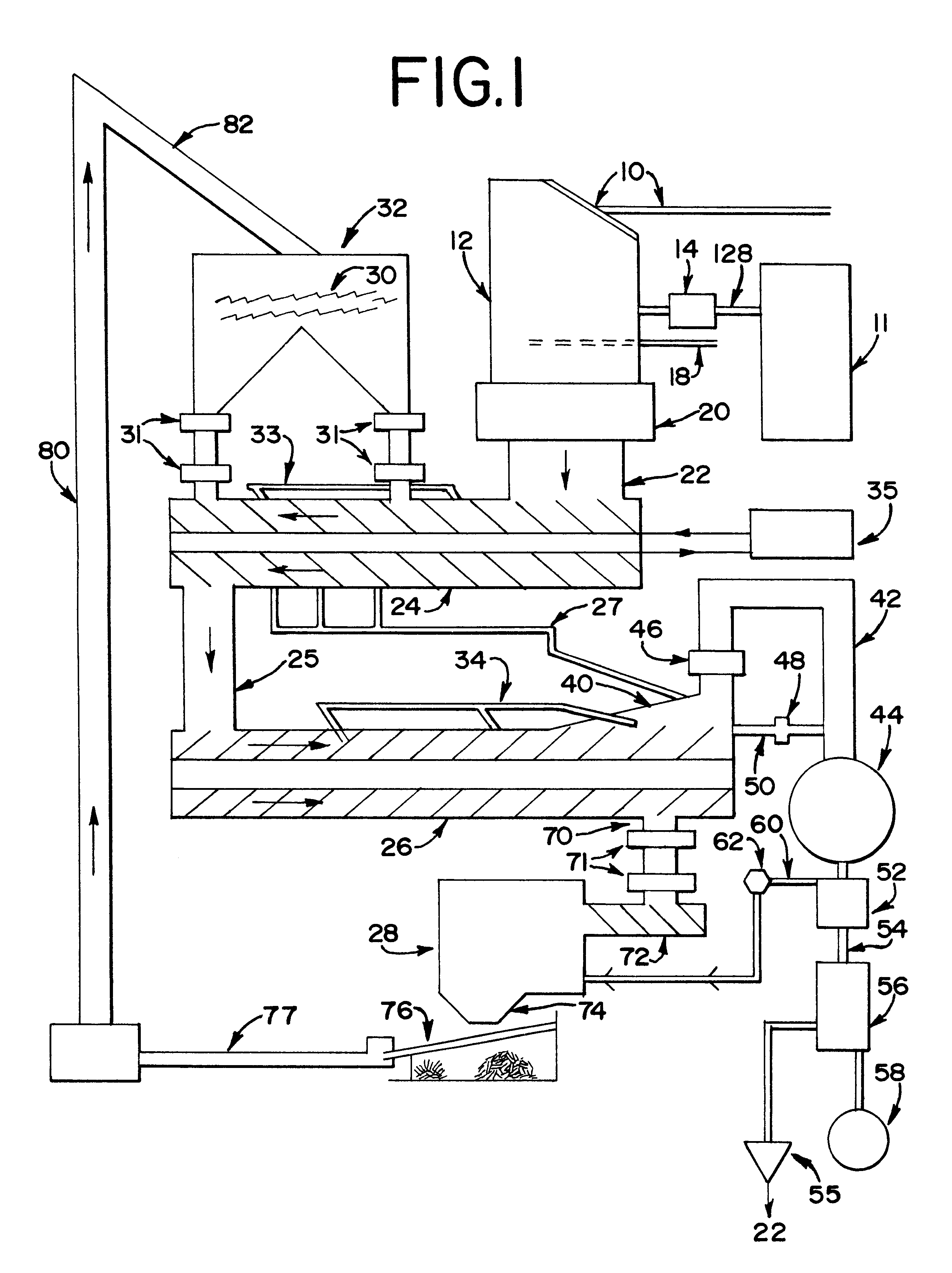

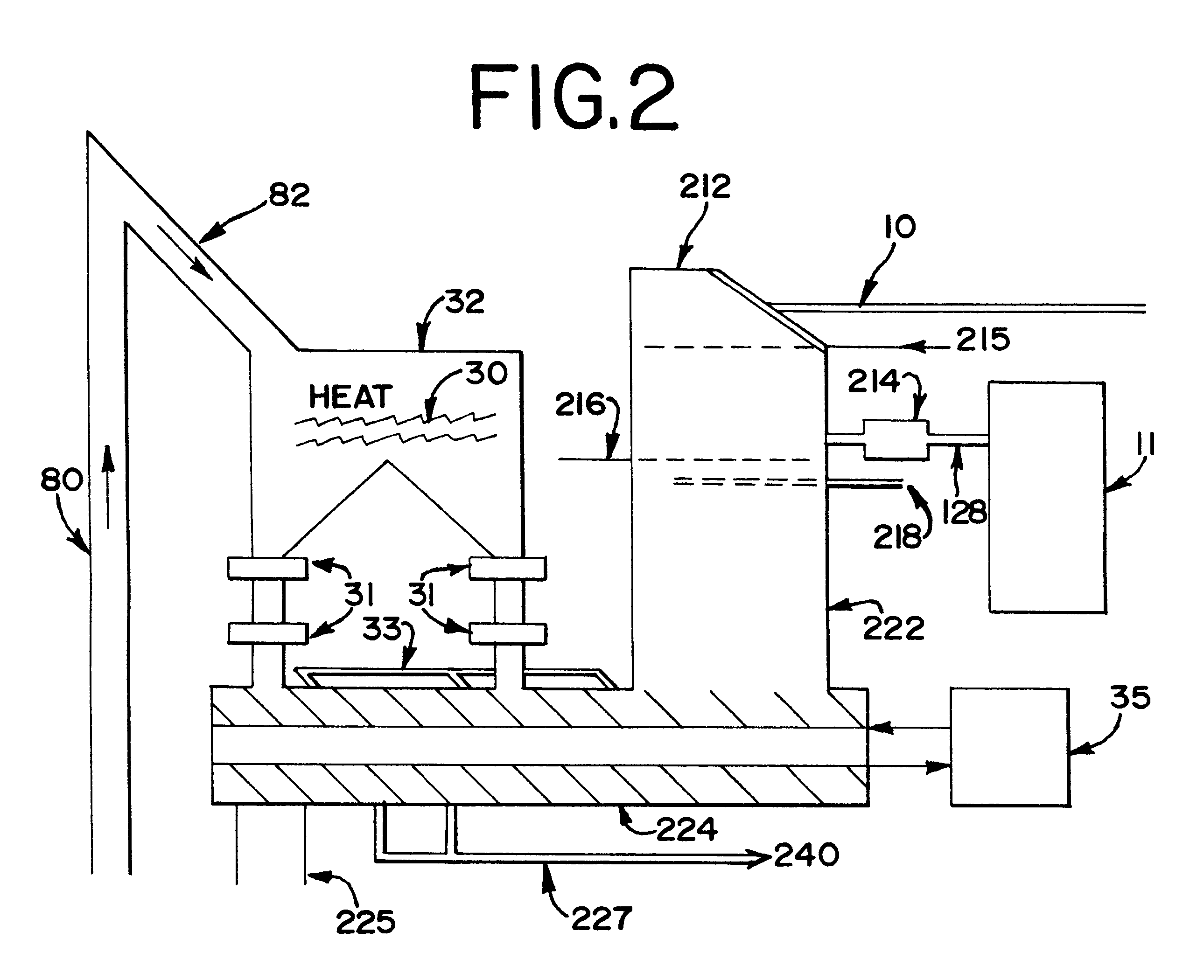

Processing method and system to convert garbage to oil

InactiveUS6387221B1Improve rendering capabilitiesIncrease speedCombustible gas coke oven heatingDirect heating destructive distillationPetroleum productHydrocotyle bowlesioides

Garbage and waste of all types that includes or comprises organic matter, particularly including medical waste, plastics, paper, food waste, animal by-products, and the like, can be economically recycled into petroleum products, including oil. Machinery performs a method that mimics natural processes but accomplishes the task in minutes, at rates of about 15 tons per day in a typical processing machine, rather than taking hundreds of thousands of years in nature. The process and apparatus of the invention may chop the waste into small pieces, under negative pressure if appropriate, and then pass the waste into first and then second augers for compression and heating. Destructive distillation occurs, in which large molecular weight hydrocarbons and petrochemicals are heated by hot oil passing through the hollow shaft and by circulating hot, dense, hard material, such as steel balls or fragments or hard rock pieces and such, under pressure with steam, to produce low molecular weight hydrocarbons. The volatile hydrocarbons are released through a pressure relief valve, into a column of catalyst material, and then to a heat exchanger, which cools the gases to condensation temperatures of water and oil. Gases remaining, such as methane, are passed to a furnace or other use, and the water and oil are separated. The hot items used to put heat into the compressed material in the first stage auger are retrieved after processing is completed and then reheated and cycled back into the first stage auger.

Owner:WASTE PROCESSORS INC TOM BECVAR TRACEY MUSGROVE & HIMSELF

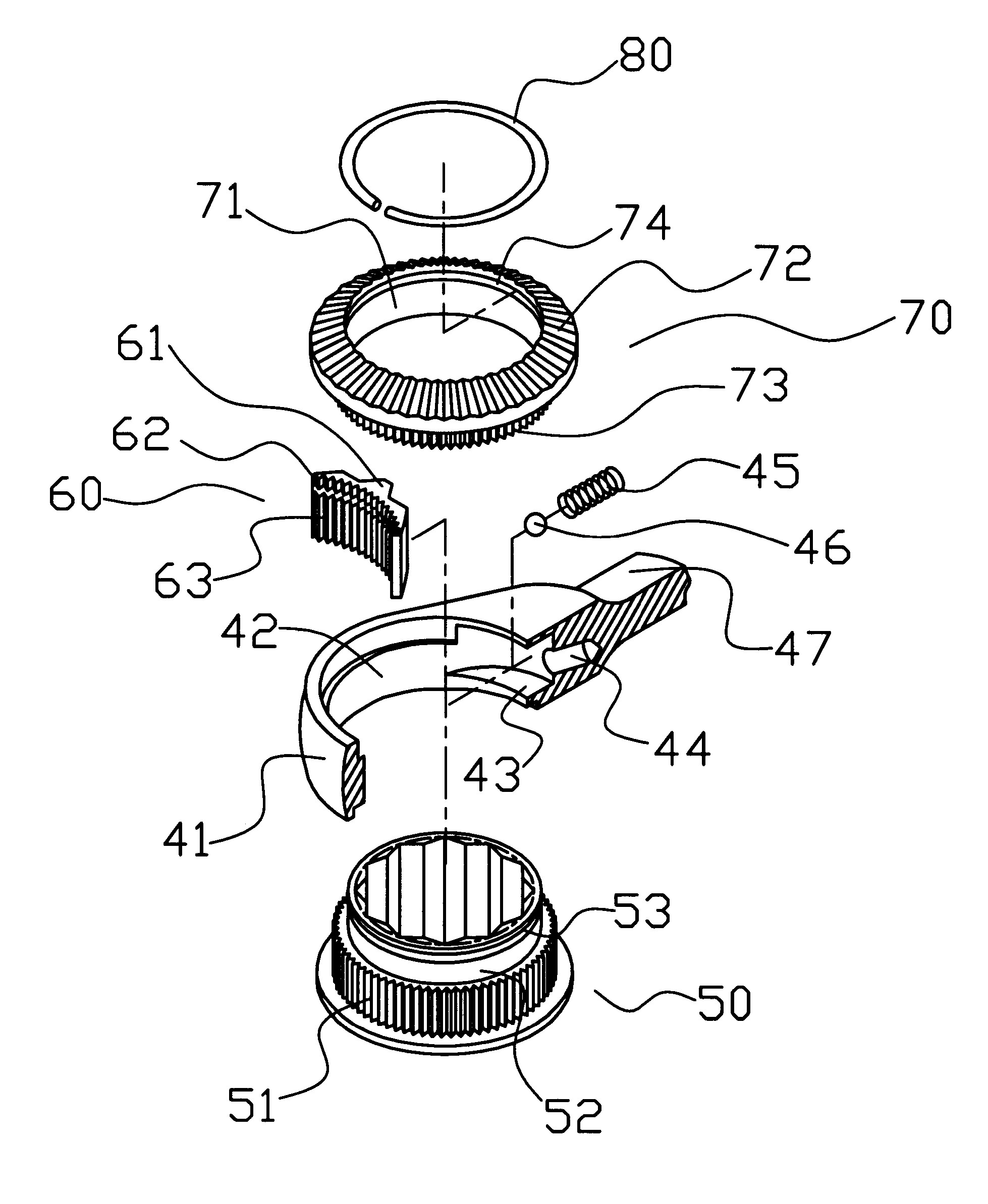

Structure of a ratchet wrench

The present invention relates to the structure of a ratchet wrench, and in particular, to a ratchet wrench which can provides high torque engagement in application, wherein a ratchet wheel is inserted into a circular opening on the wrench head of a common ratchet wrench, and a cavity is provided to the circular opening adjacent to one side of the rod body of the wrench for mounting a restrictive teeth structure, the end terminal of the cavity is provided with a ball hole to contain a spring and a steel ball, and the restrictive teeth structure is urged by the steel ball, thereby the high torque movement of the ratchet wheel is controlled.

Owner:CHEN YU TANG

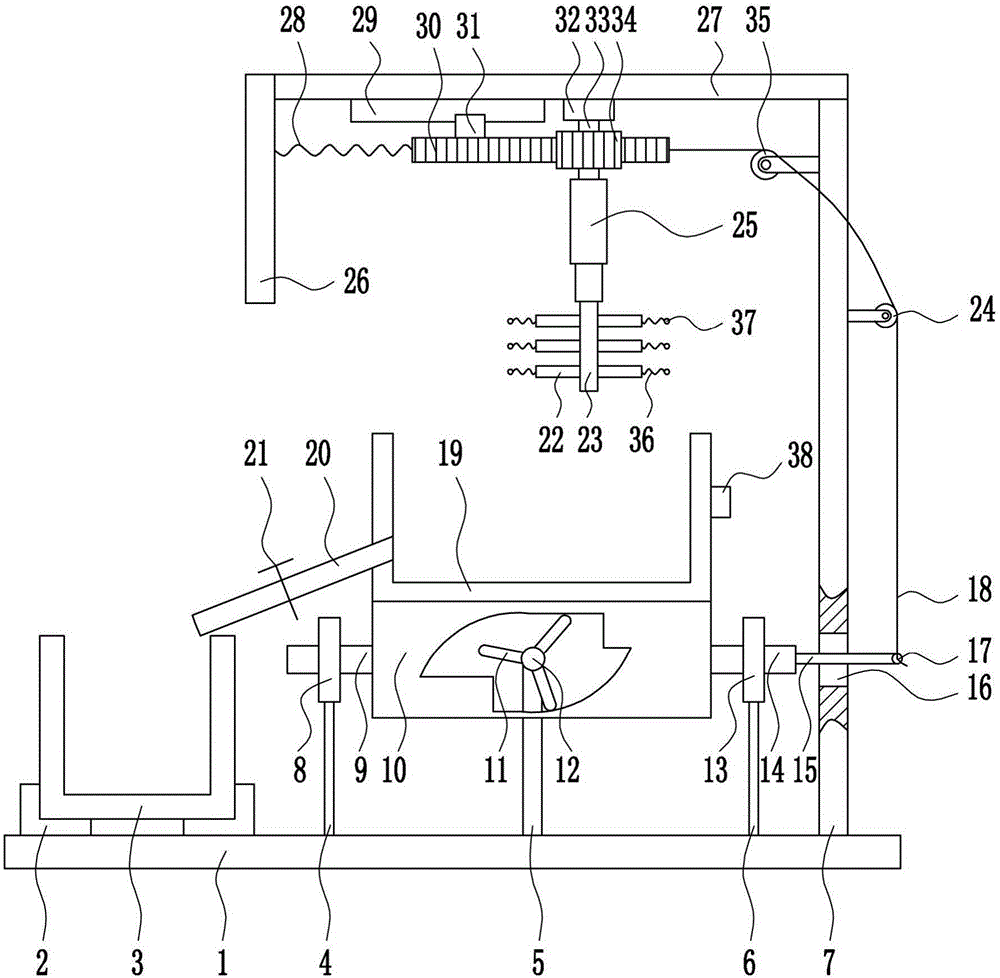

Rapid adhesive stirring device applied to shoe industry

ActiveCN106110989AImprove plasticityGood welding performanceShaking/oscillating/vibrating mixersRotary stirring mixersShoe industryAdhesive

The invention relates to an adhesive stirring device and particularly relates to a rapid adhesive stirring device applied to shoe industry. The invention is to provide a rapid adhesive stirring device to the shoe industry. The rapid adhesive stirring device is novel in structure, simple and convenient to operate and high in operating efficiency. In order to solve the technical problem, the invention provides such a rapid adhesive stirring device applied to the shoe industry. The rapid adhesive stirring device comprises a bottom plate, fixed blocks, a collection framework, a first support rod, a second support rod, a third support rod, a right frame, a first guide sleeve, a first guide rod, a movable framework, a rotating rod, a motor, a second guide sleeve, a second guide rod, a movable rod, a wire tying ring, a drawing wire, a stirring framework and a pipeline; the fixed blocks are symmetrically arranged on the left side of the top of the bottom plate. Through the rapid adhesive stirring device, the effects of being novel in structure, simple and convenient to operate and high in operating efficiency can be achieved; the adhesive can be rapidly and uniformly stirred; the rapid adhesive stirring device can be conveniently applied to production of the shoe industry; through a second spring and a steel ball, the adhesive can be stirred more thoroughly.

Owner:大化瑶族自治县计量检定测试所

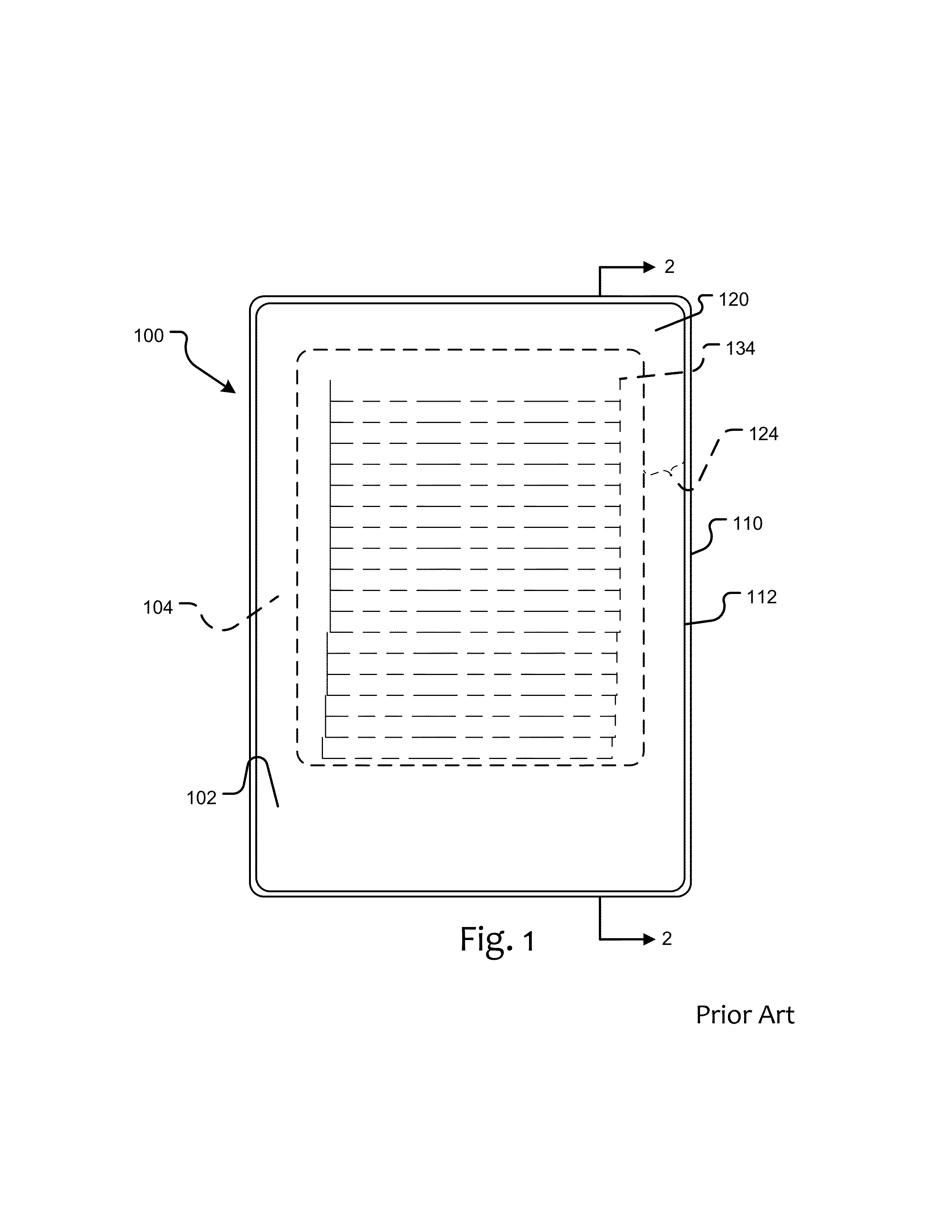

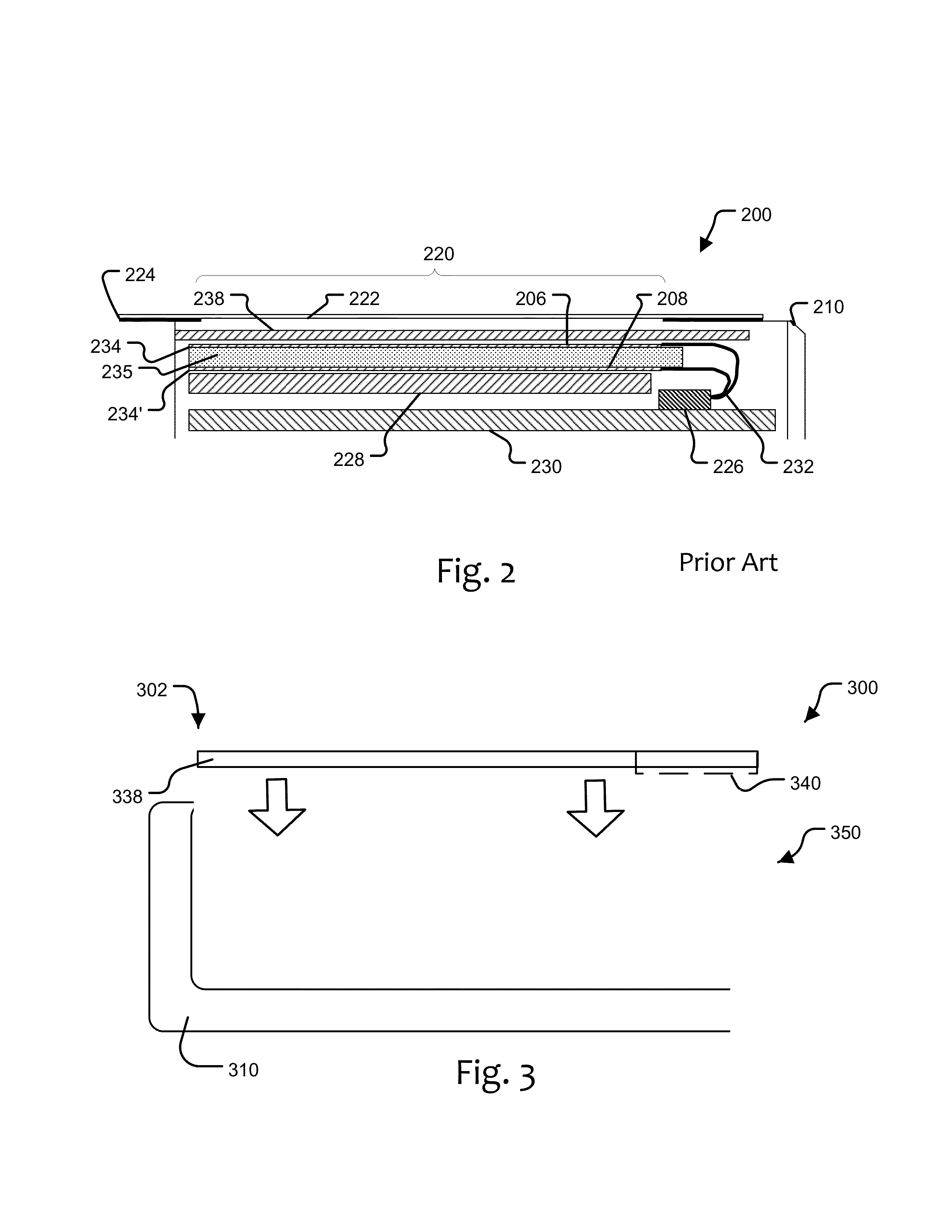

Structures and manufacturing methods for glass covered electronic devices

The disclosure is directed to electronic device displays which are constructed to withstand damage from an impact resistance test wherein a steel ball of 2 g having a diameter of 8 mm is dropped from a designated height greater than 1 ft, more preferably greater than 2 ft, even more preferably greater than 3 ft, still even more preferably greater than 4 ft, yet even more preferably greater than 5 ft and even more preferably greater than 6 ft. The displays are configured using, for example, ultrathin glass adhered to a base glass, wherein the adhesive layer is optimized for thinness and stiffness.

Owner:SYNAPTICS INC

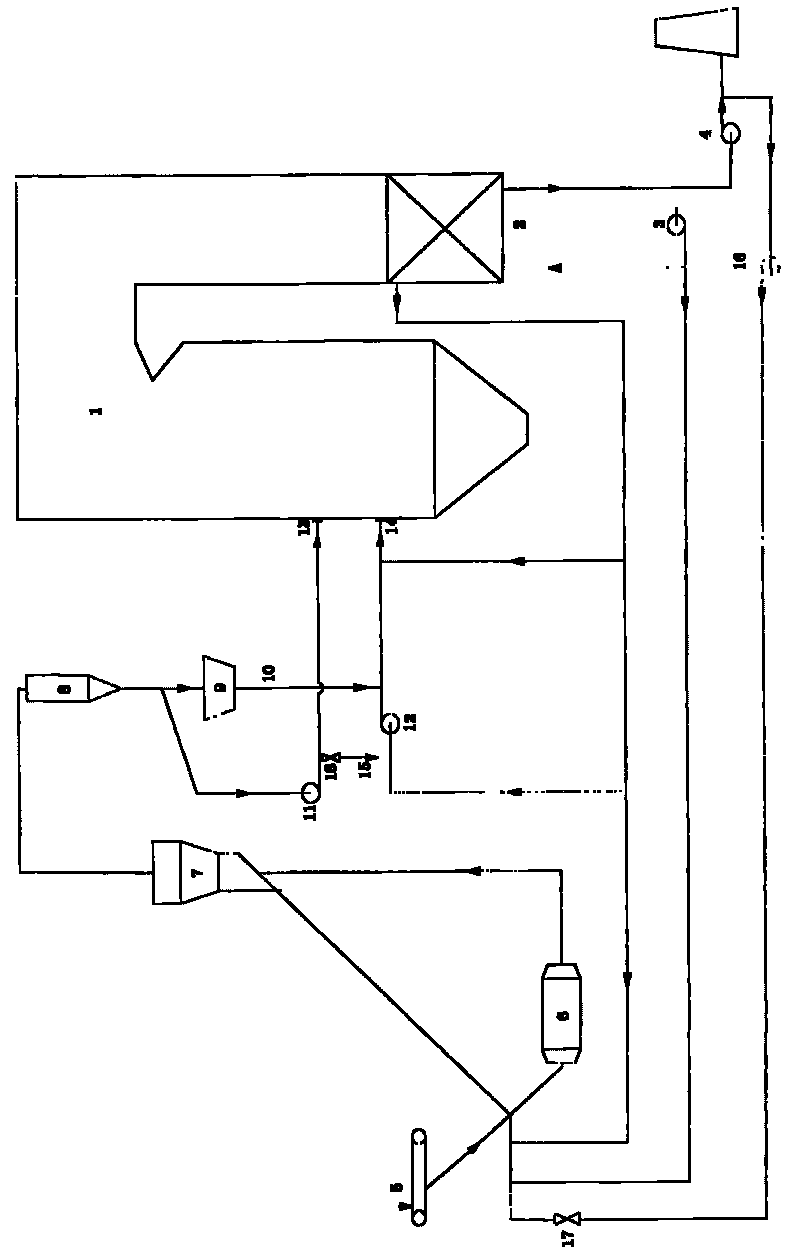

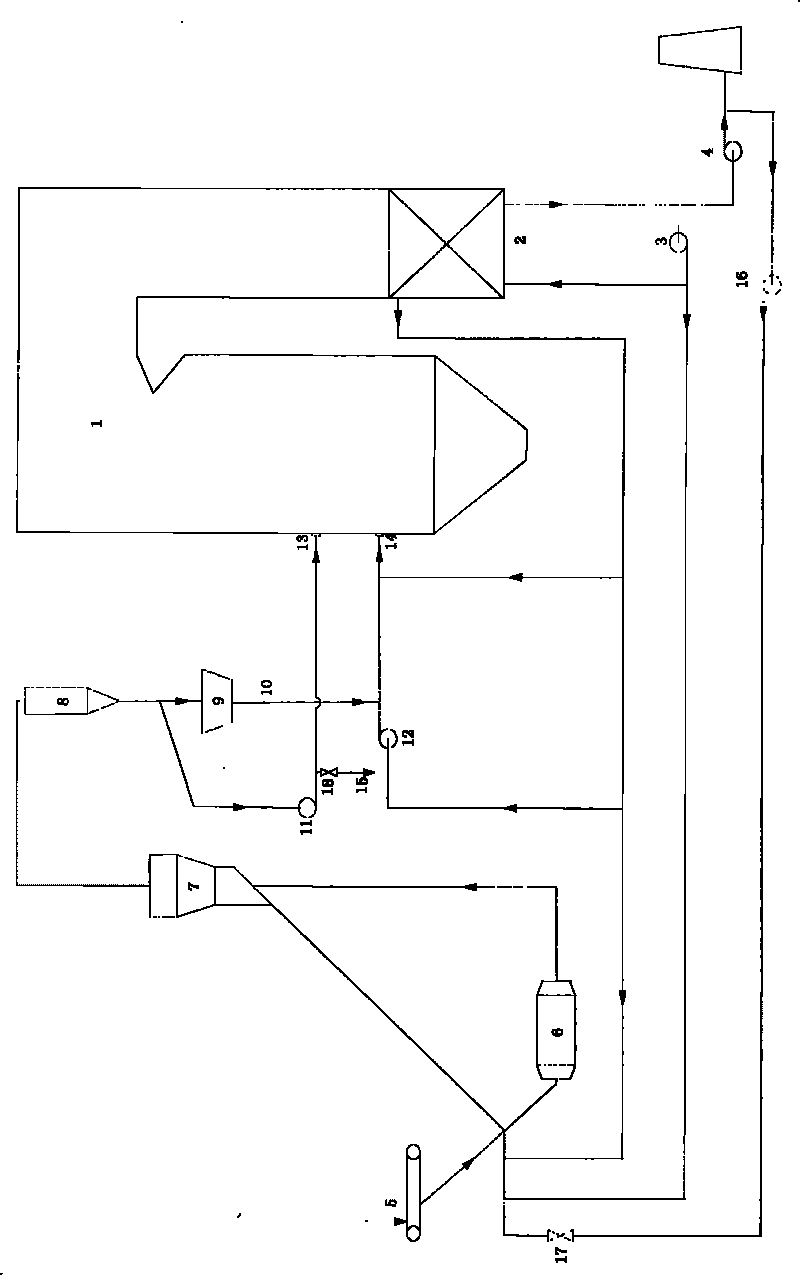

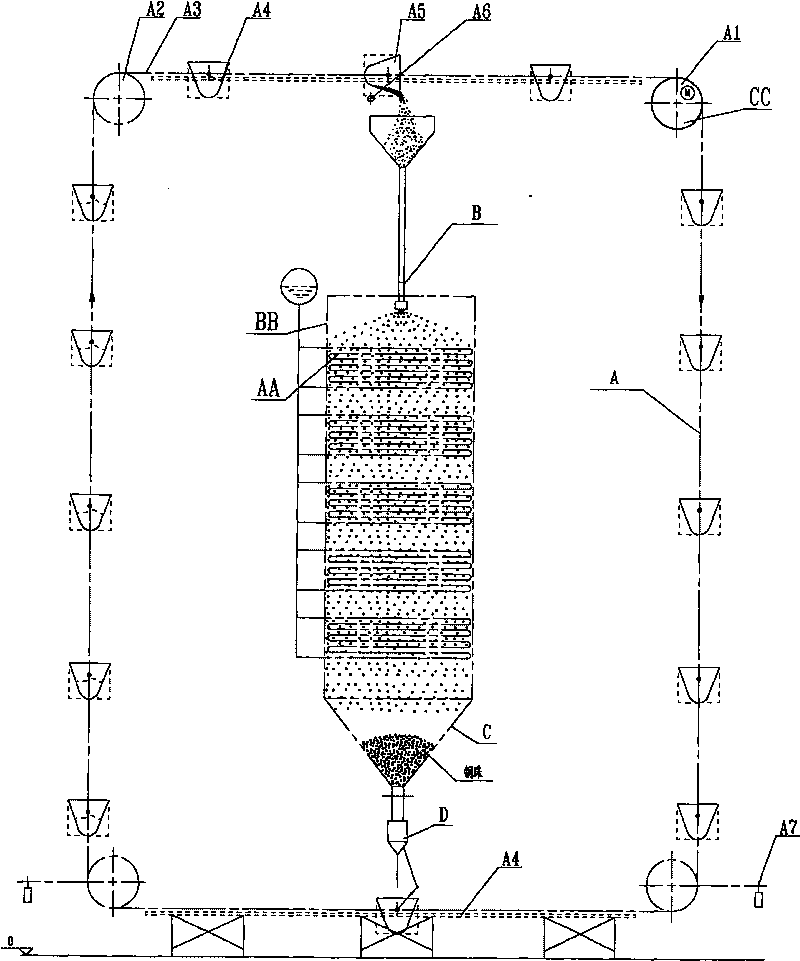

Low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system

ActiveCN101761933ALow oxygenReduce the temperatureGrain treatmentsLump/pulverulent fuel feeder/distributionAir preheaterPowder mixture

The invention relates to a low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system. A middle bin storage type steel ball coal mill hot air power feeding and meagre coal power preparation system is adopted as a prototype, and part of low-temperature furnace smoke is sucked from an outlet of a suction fan by a furnace smoke fan as an inert medium and part of drying mediums to be mixed with hot air taken from an outlet of an air preheater to enter a coal mill for drying and delivering coal powder; the oxygen content of the powder preparation system is reduced, and the explosion preventing requirement on grinding bituminous coal can be met. In addition, part of exhaust gas at an outlet of a power exhauster is led to an inlet of a heat primary fan by an exhaust gas transfer pipeline to be mixed with hot air to enter a primary bellows for delivering the coal powder; the temperature of a primary air and powder mixture and the oxygen concentration of the system are effectively reduced, and the combustion and explosion preventing requirement of bituminous coal delivery is met. Isolating doors are both installed on a furnace smoke system and an exhaust gas transfer system; by the switch control of the isolating doors, the switching of a typical hot air power feeding meagre coal system and a low-temperature furnace smoke exhaust gas and hot air drying composite powder feeding bituminous coal system is realized, and the invention is not only suitable for the meagre coal, but also suitable for the bituminous coal.

Owner:XIAN THERMAL POWER RES INST CO LTD

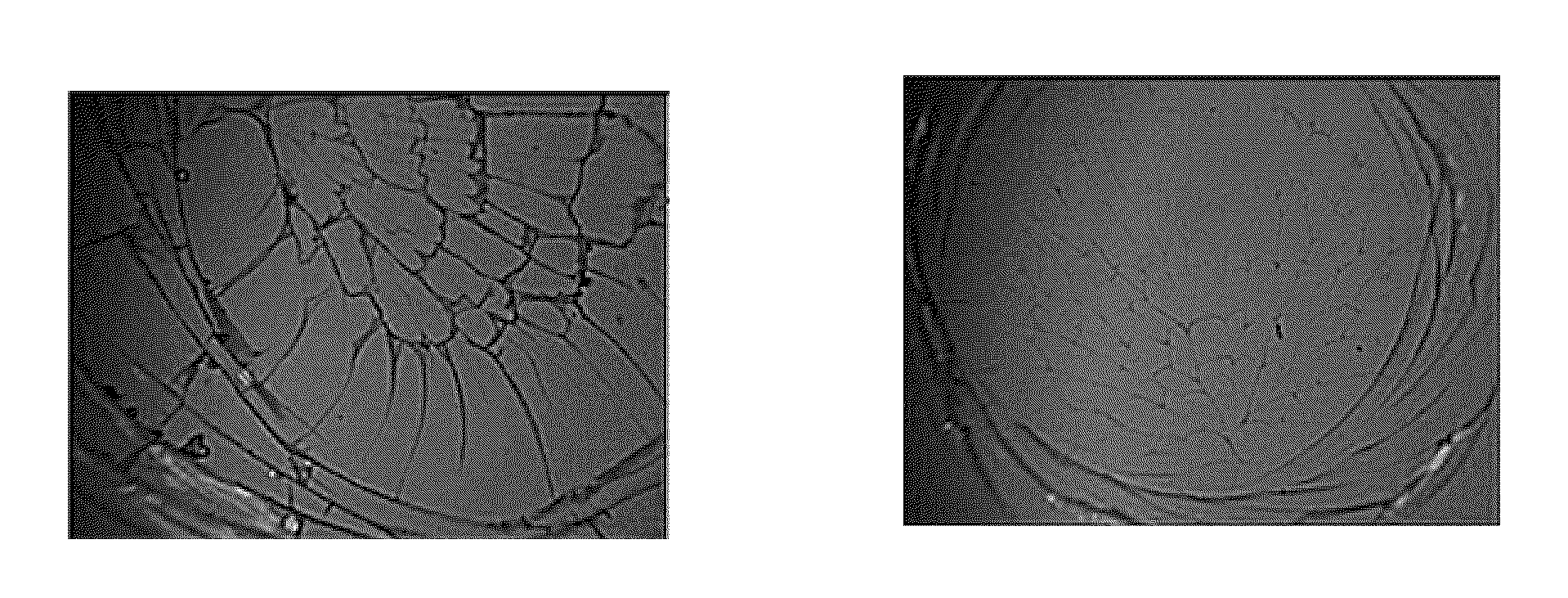

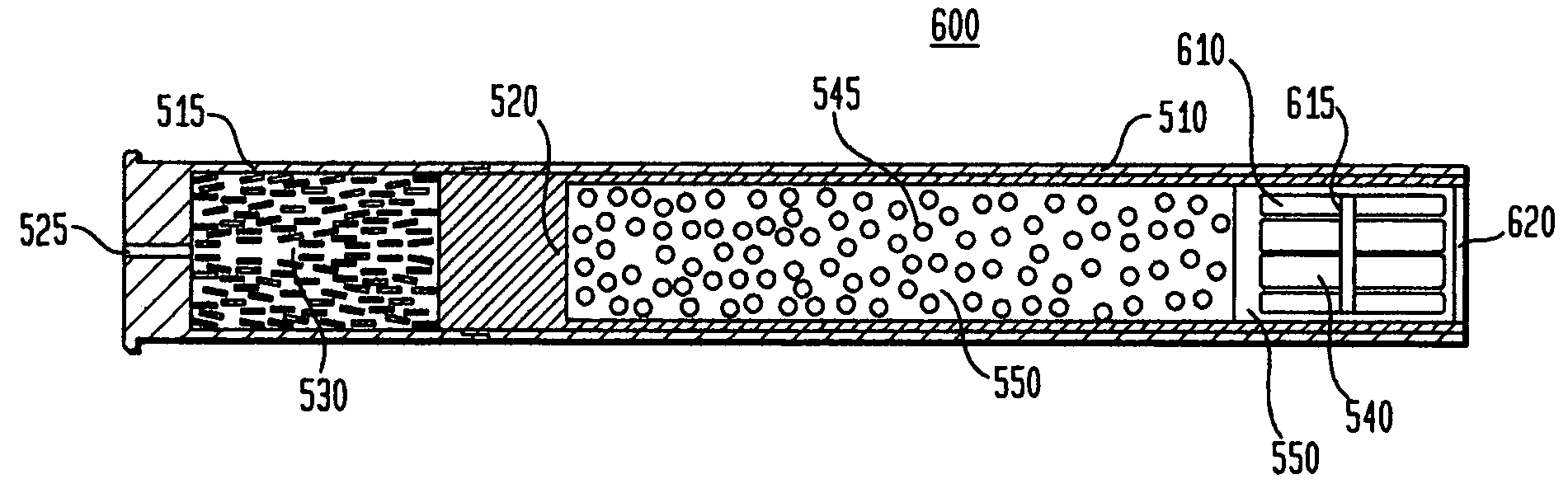

Method for detecting fault of steel-ball surface

InactiveCN1529152AImprove efficiencyAccurate detectionOptically investigating flaws/contaminationKeroseneDisplay device

Feed mechanism feeds balls to be tested to poroid detection cavity positioned on circumference of feeding rotary table and holes corresponding to clapboard positioned under feeding rotary table in detection mechanism. Balls to be tested on feeding rotary table and its holes are immersed in kerosene. The deploying rotary table under the clapboard supports balls to be tested to rotate in order to expanse entire spherical surface. CCD camera above the balls collects information of extended surface of balls to be tested. The said collected information is input into and processed by computer. Display in terminal displays magnified image of extended surface of rolled ball. Computer recognition system through magnified image on the display determines surface quality of the ball. Thus, qualified balls are sent to finished product bin, and unqualified balls are sent to reject bin in automatic or manual control. The method is in high accuracy and high efficiency.

Owner:李季秀

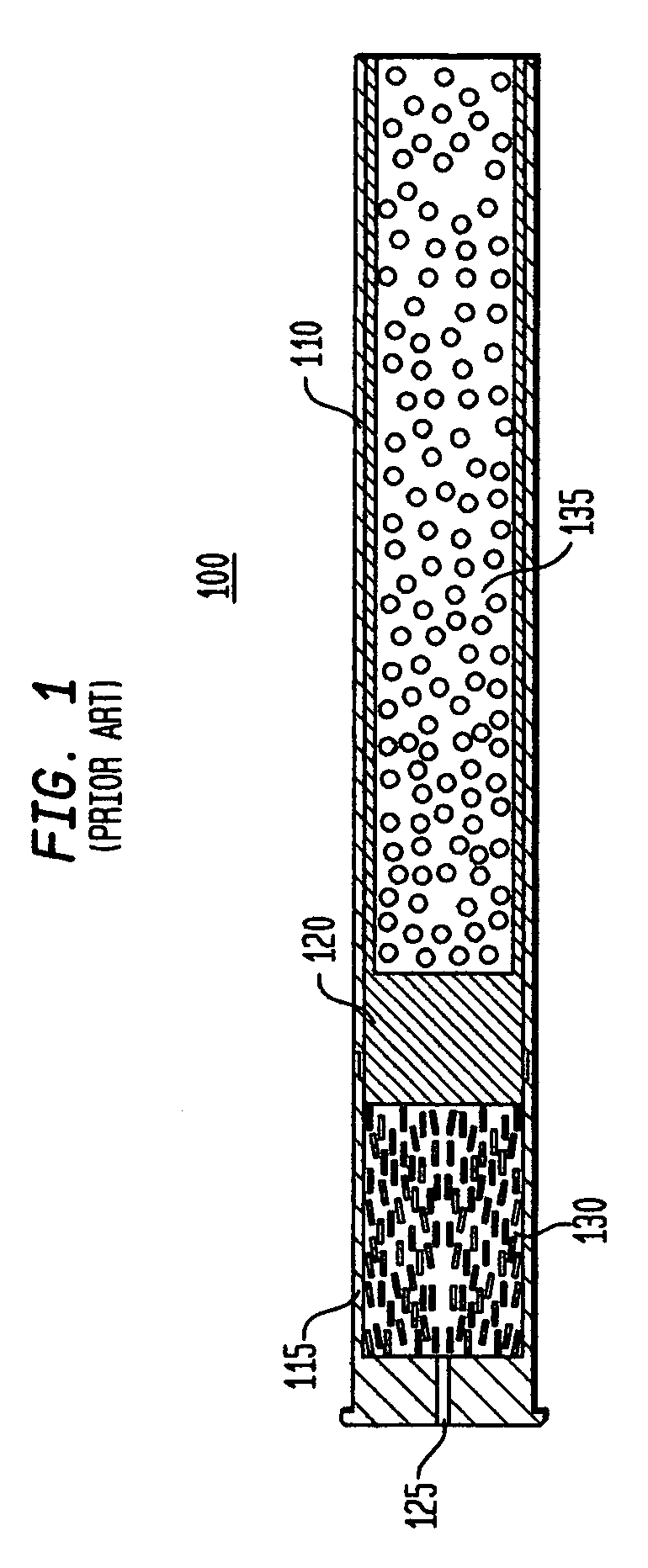

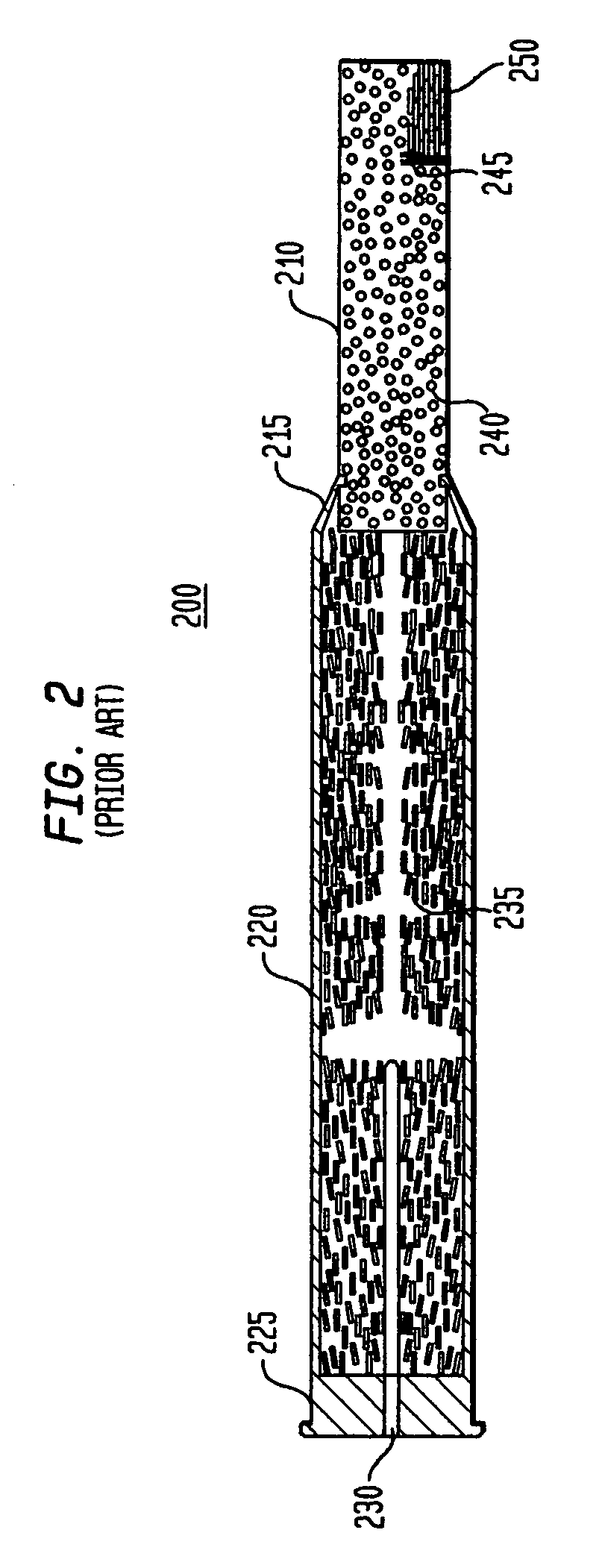

System and method for a flameless tracer / marker for ammunition housing multiple projectiles utilizing chemlucent chemicals

InactiveUS6931993B1Evaluate effectivenessAmmunition projectilesShotgun ammunitionSteel ballEngineering

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

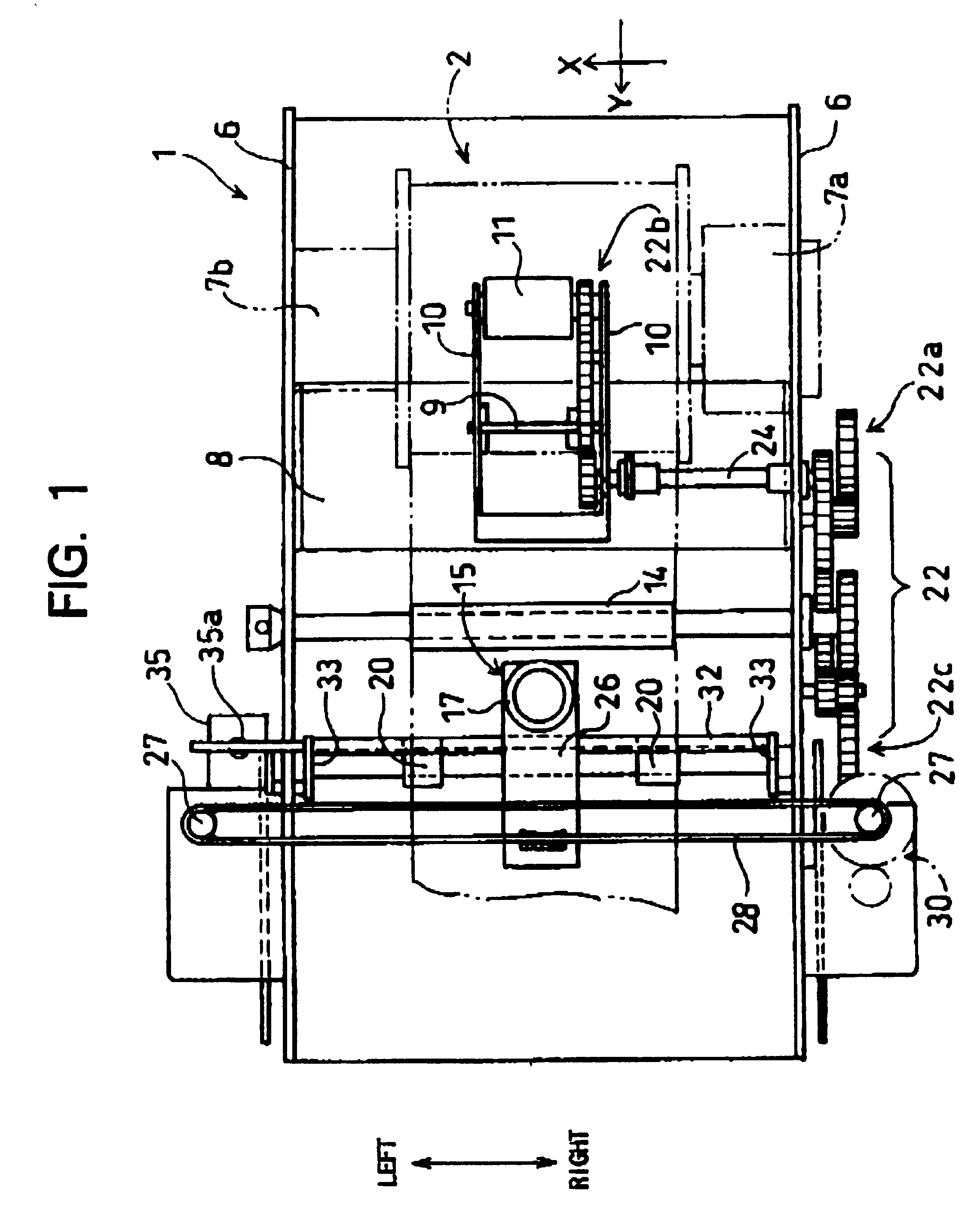

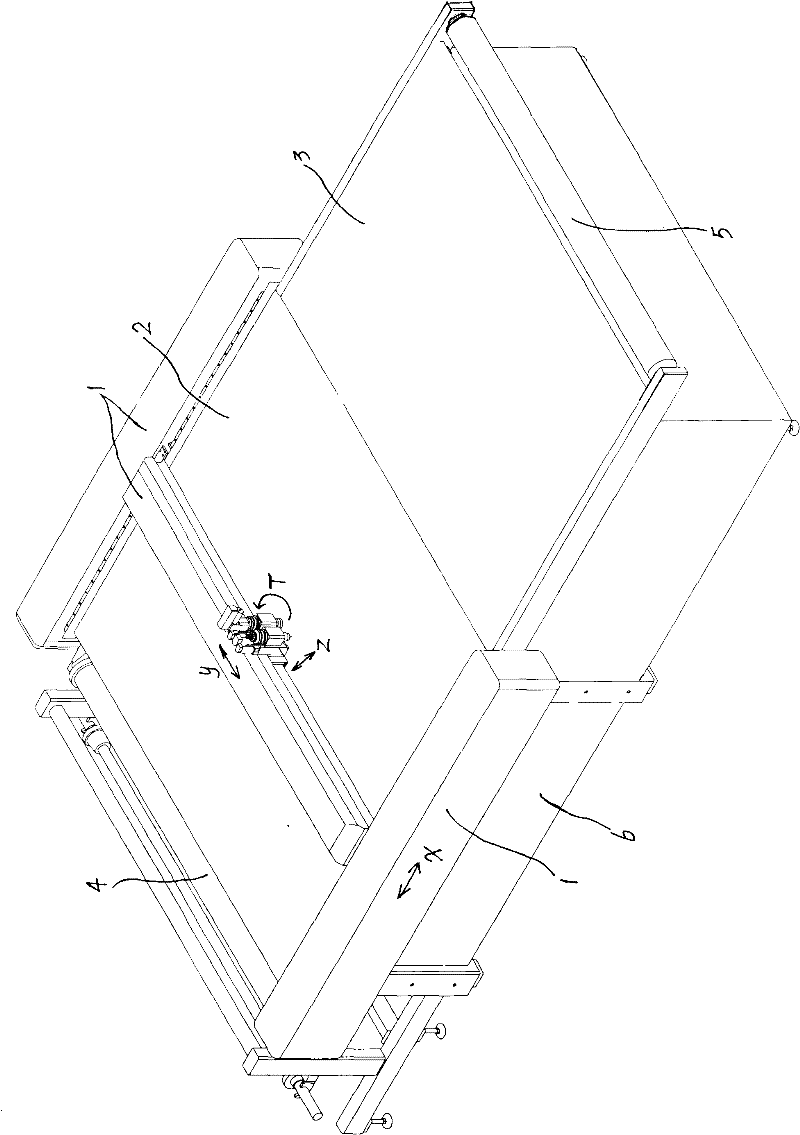

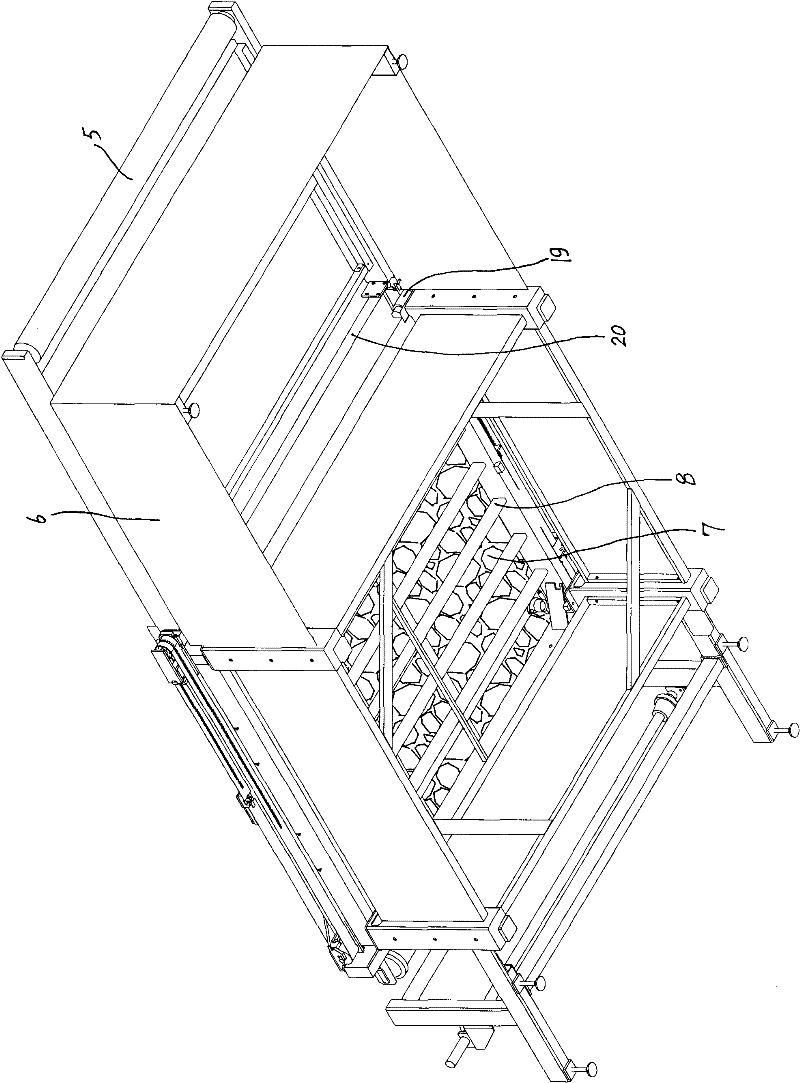

High-speed precision cutting machine

The invention relates to a high-speed precision cutting machine which is mainly suitable for cutting flexible materials, including paper, fabric, leather, composite materials and the like. The high-speed precision cutting machine is characterized in that the high-speed precision cutting machine is further provided with a high-frequency vibration device mounted in a machine head, a linear sliding block mounted on a cross beam and a one-way floating device mounted on a framework; and two motors are respectively arranged on the machine head, a material pressing mechanism comprises a knife seat, a pressing pad, a spring and a seal ring, a transmission mechanism is a steel strip structure with an open hole and flanged edges, a balancing block, an eccentric crankshaft, a knife bar and a bearingare arranged in a mounting seat of the high-frequency vibration device, the linear sliding block comprises a steel ball rolling path and a steel ball retainer, and a guide column, a pressure plate, aY-direction connecting plate and an X-direction connecting plate are arranged on the one-way floating device. The structural design is more compact and reasonable, the volume is small, the mounting is more convenient and the cost is lower; and simultaneously, the high-speed precision cutting machine is convenient and reliable to use and wide in range of applications, and can precisely cut all flexible materials at high speed.

Owner:HANGZHOU ECHO SCI TECH

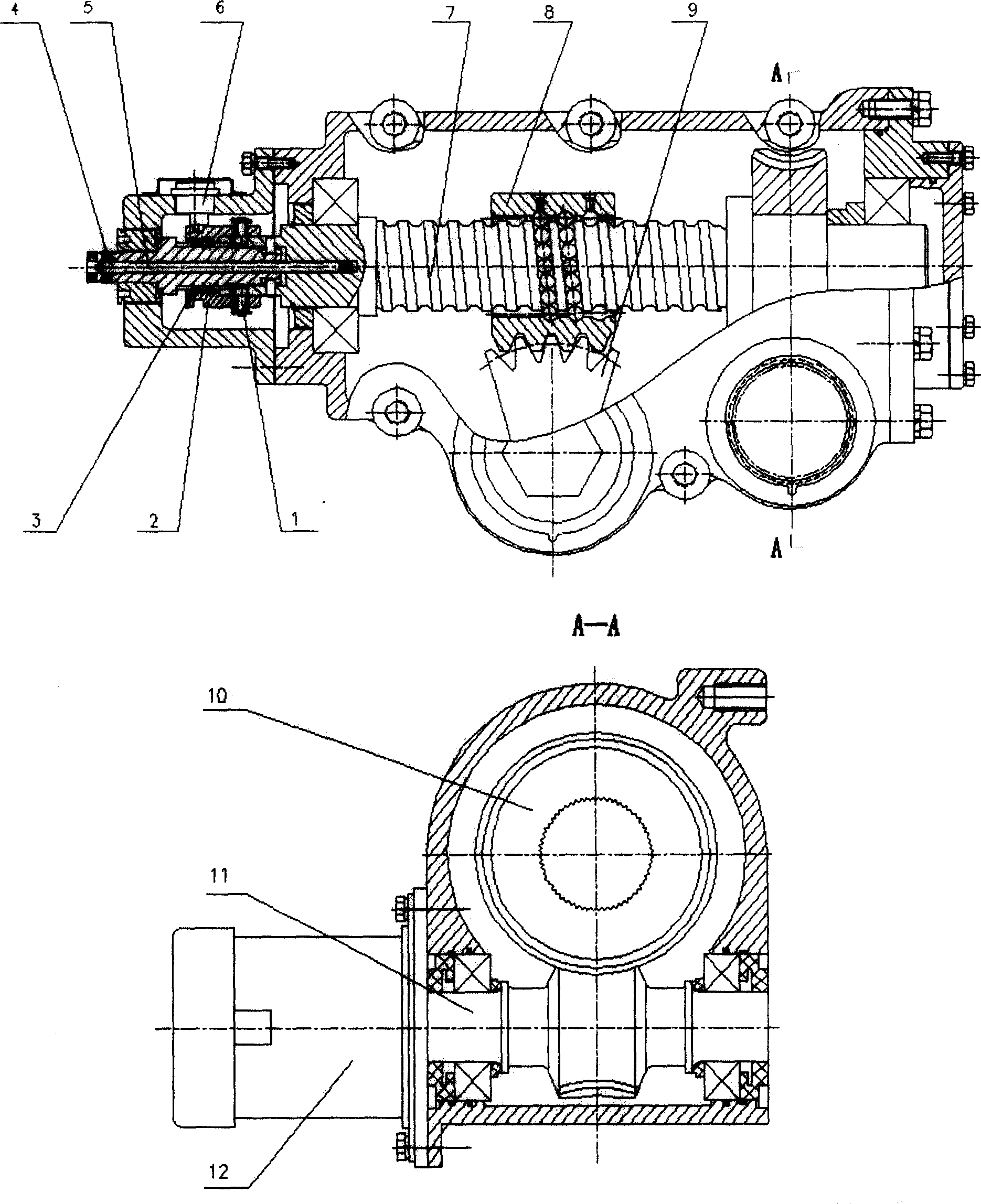

Thrust bearing for screw of ball-nut type steering gear

InactiveCN106481655AExtended service lifeSave assembly spaceBall bearingsMechanical steering gearsBall bearingPunching

The invention provides a thrust bearing for the screw of a ball-nut type steering gear. The thrust bearing comprises a screw. A thrust ball type thrust bearing is arranged on screw. The thrust ball type thrust bearing comprises a steel ball and a ring. The ring is composed of a left semi-ring and a right semi-ring. The cross section of the thrust ball type thrust bearing raceway is a four point contact type. The left semi-ring and the right semi-ring are both provided with a corresponding arc outer raceway. Two arc inner raceways are arranged on the screw. The radius of two inner raceways is the same as that of two outer raceways. The centers of four arc raceways are in a same circumference, but four arc raceways are non-concentric. The steel ball is arranged between the screw and the ring. Four contact points are formed between the steel ball and two outer raceways and two inner raceways, and thus a four point contact type thrust ball bearing is formed. In assembly, a punching-riveting anti-loosening structure is adopted between an adjusting nut and a valve body. For the bearing, a screw is used to replace a shaft washer, a holder is not needed any more, and the installation becomes convenient. The inner raceway and outer raceway are both composed of two arcs, a four point contact ball bearing is formed and is capable of bearing a large axial / radial force, the wear is reduced, and the service life is prolonged.

Owner:DONGFENG MOTOR PARTS & COMPONENTS GROUP

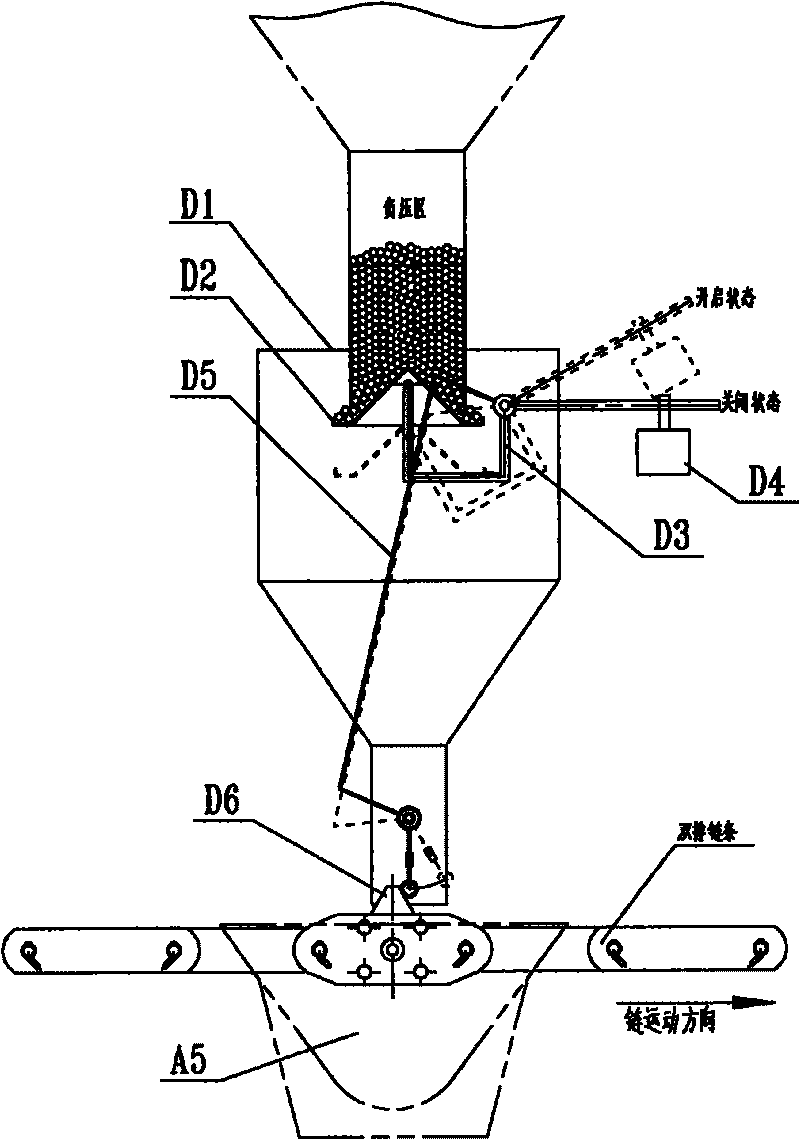

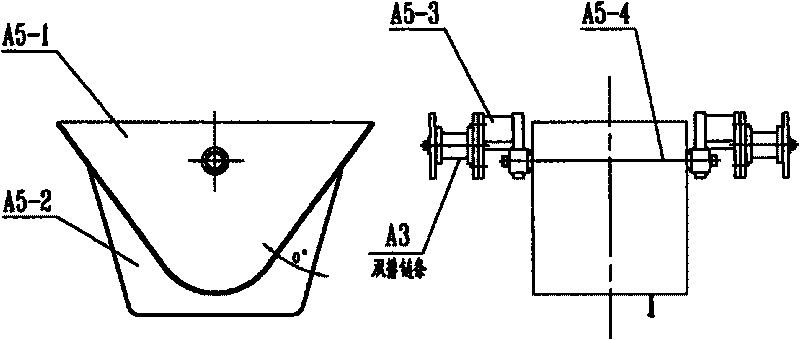

Residual heat boiler of steel ball dedusting type ore heat furnace

ActiveCN101701775AEfficient removalGuaranteed uptimeIncreasing energy efficiencySolid removalBottom ashDrive wheel

The invention relates to a residual heat boiler of a steel ball dedusting type ore heat furnace. The residual heat boiler at least comprises a boiler heated surface, a seal boiler flue gas passage, a furnace top and a furnace bottom ash hopper, wherein the boiler heated surface comprises coil pipe groups; and the seal boiler flue gas passage is formed at the periphery of the boiler heated surface. The residual heat boiler is characterized in that the furnace top is provided with a steel ball spreading device, a steel ball separating and collecting device is arranged under the furnace bottom ash hopper; a circulating type steel ball mechanical transporting device is arranged between the steel ball spreading device and the steel ball separating and collecting device; the circulating type steel ball mechanical transporting device comprises at least one drive wheel, at least three driven wheels, a double-row chain, a horizontal guide rail, a steel ball transporting hopper and a mechanical discharge blocking wheel; the at least one drive wheel and the at least three driven wheels are fixed on a boiler frame, and the steel ball transporting hopper is hung on the double-row chain surrounded between the drive wheels and the driven wheels; and the furnace top is provided with the mechanical discharge blocking wheel capable of turning over the steel ball transporting hopper. The invention has simple mechanism, recycled steel ball, mechanical automation running, low investment and running cost and favorable dedusting effect, and the like, can effectively remove and collect accumulated ash and sticking dust on the residual heat boiler heated surface of the ore heat furnace and greatly develops the energy-conservation and emission-reduction technology of the ore heat furnace smelting industry.

Owner:HANGZHOU HANGGUO INDUSTRIAL BOILER CO LTD

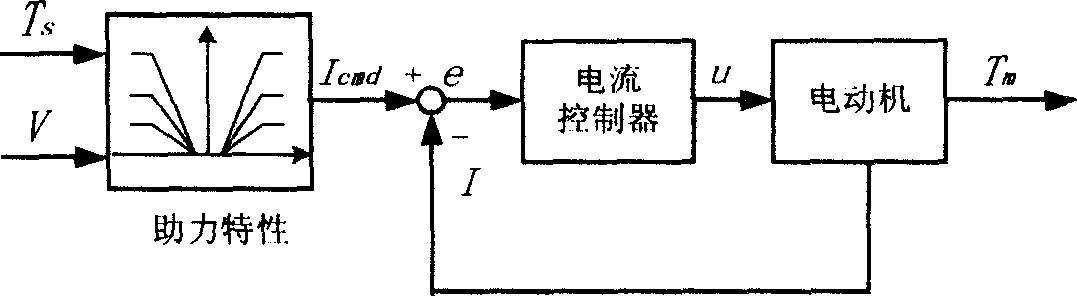

Circular ball type electric booster steering device

ActiveCN1647984AReduce disturbanceReduce pollutionMechanical steering gearsElectrical steeringElectric power steeringElectronic controller

The circular ball type electric booster steering device has, except screw, nut, gear sector, steel ball and other mechanical parts, torque sensor, boosting motor, decelerating mechanism, electronic controller unit, etc. The electronic controller unit determines the target current of the motor based on the steering disc torque and the vehicle speed to complete the feedback tracking control of the motor current. The decelerating mechanism has input connected to the motor and output connected to the screw or gear sector shaft in the circular ball steering unit. The present invention has saving in energy, provides proper power force fitting different running conditions, and has less parts, light weight, compact structure and high automation.

Owner:BEIJING AUTONICS TECH

Electronic cigarette

An electronic cigarette, including a cigarette holder assembly, an atomization assembly, a glass container for accommodating smoke oil, and a gas flow regulator. The cigarette holder assembly includes a mouthpiece, a first sealing ring, a seat for supporting the mouthpiece, a fixed screw, and a pole. The atomization assembly includes a pair of heating wires, a glass casing, a second sealing ring, a third sealing ring, oil-guiding cotton, a limit cover, an insulating ring, and a fixed ring. The glass container includes a first sealing gasket and a second sealing gasket which are respectively disposed at both ends of the glass container. The gas flow regulator includes a control ring, a steel ball, a spring, and a rotary button. The first sealing ring of the cigarette holder assembly is sleeved on the mouthpiece, and the mouthpiece is fixed on the seat via the fixed screw.

Owner:LIU TUANFANG

Steel ball separation system and method

The invention discloses a steel ball separation system and method. The steel ball separation system comprises a material tray, a rolling rod sorting device, an electromagnetic sorting device and a photoelectric sorting device. The steel ball separation method is used for separating steel balls by virtue of the rolling rod sorting device, the electromagnetic sorting device and the photoelectric sorting device respectively, so that not only can the steel balls with different specifications, sizes and materials be separated, but also the steel balls with defects on surfaces can be selected. Therefore, the steel ball separation system can be used for outputting qualified steel balls, can achieve very high detection accuracy and high detection efficiency by virtue of automated assembly line work, and effectively solves the problems of low detection accuracy and long working time for detection of the steel balls in industry.

Owner:中山市乾润精密钢球制造有限公司

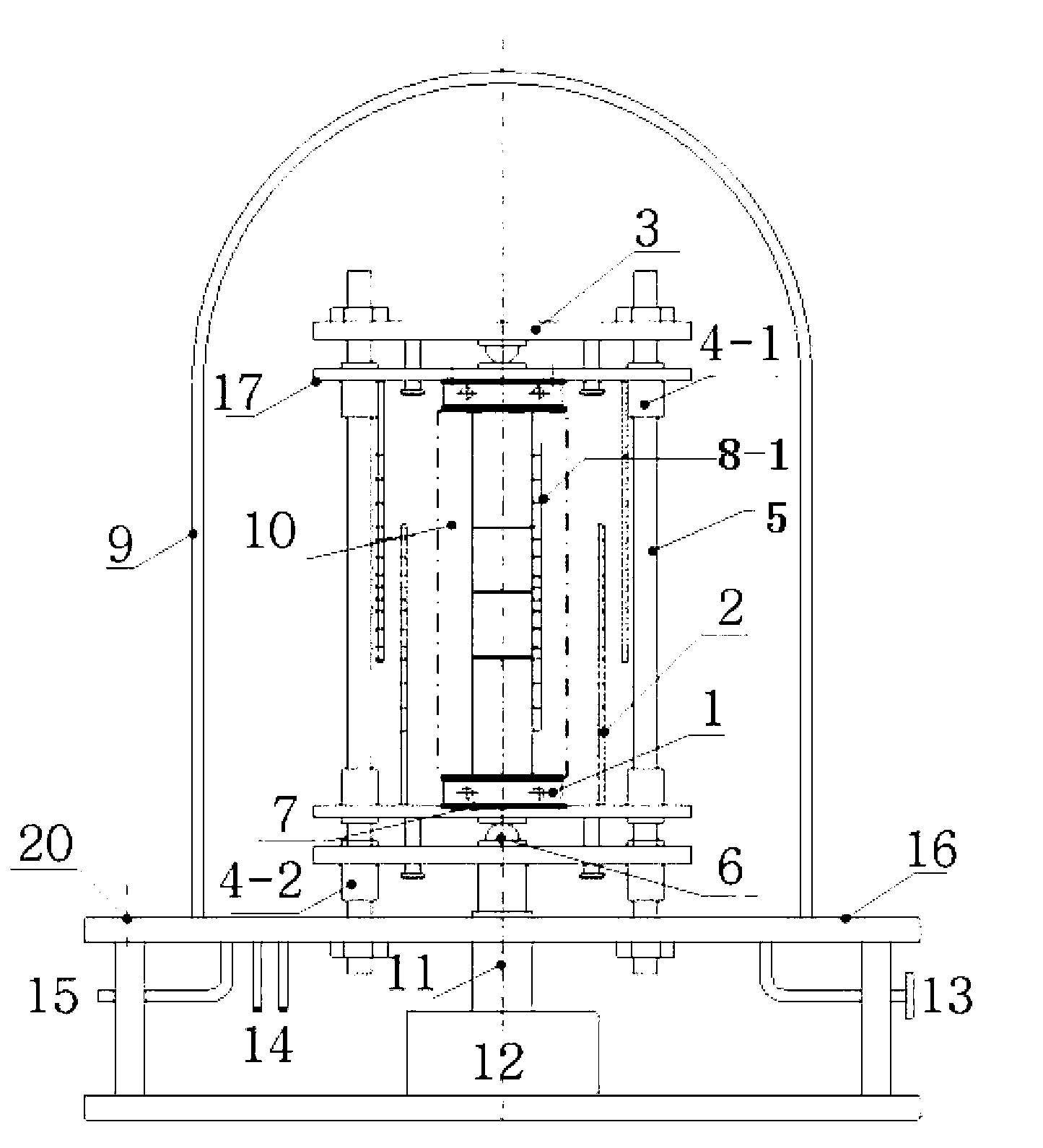

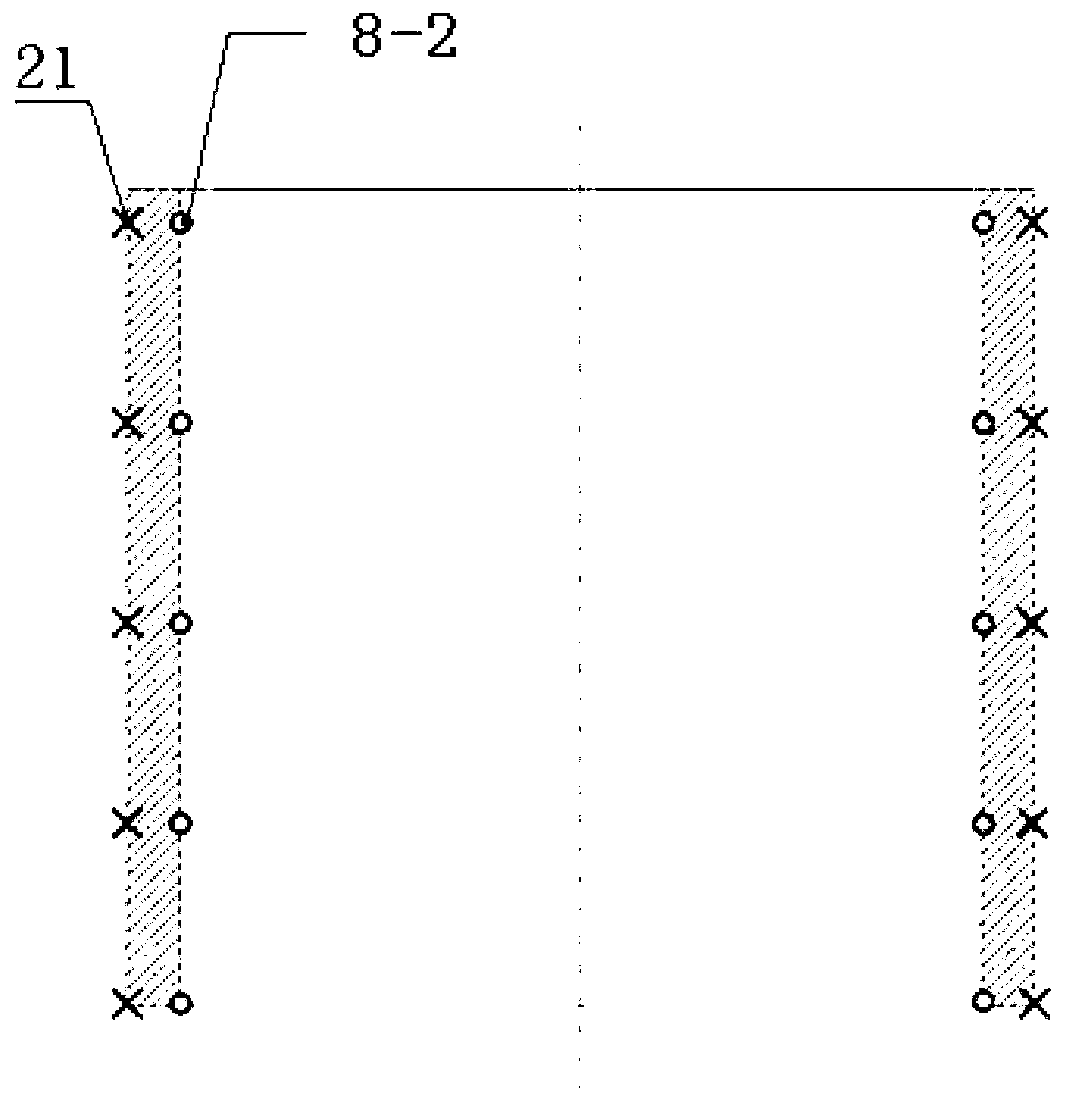

Heat conduction coefficient and contact thermal resistance testing device

ActiveCN102798645AEliminate Uncertainty ErrorsImprove test accuracyMaterial heat developmentData acquisitionSteel ball

The invention discloses a heat conduction coefficient and contact thermal resistance testing device. The testing device comprises a control system, a support 3, a first ball sleeve 4-1, a second ball sleeve 4-2, a sliding screw rod 5, an oriented steel ball and a pressure sensor 6, an auxiliary heater 7, a first temperature sensor 8-1, a second temperature sensor 8-2, a vacuum cap 9, a test piece test zone 10, a stress loading device, a vacuum drainage air port 13, water inlet and outlet ports 14, a data acquisition system, a sealing chassis 16, a mounting plate 17, a horizontal adjusting rod 20 and a heater strip 21, wherein a thermal flowmeter 22, the oriented steel ball and the pressure sensor 6, the support 3, the mounting plate 17 and heating refrigeration sleeves 1 are symmetrical in an up-down manner. According to the invention, the auxiliary heater which can reduce the axial heat loss is arranged along the y-direction, and a temperature gradient of a controllable temperature radiation shield simulation test region is arranged at the periphery of the test zone so as to reduce heat loss of a cross section direction.

Owner:NANJING UNIV OF SCI & TECH

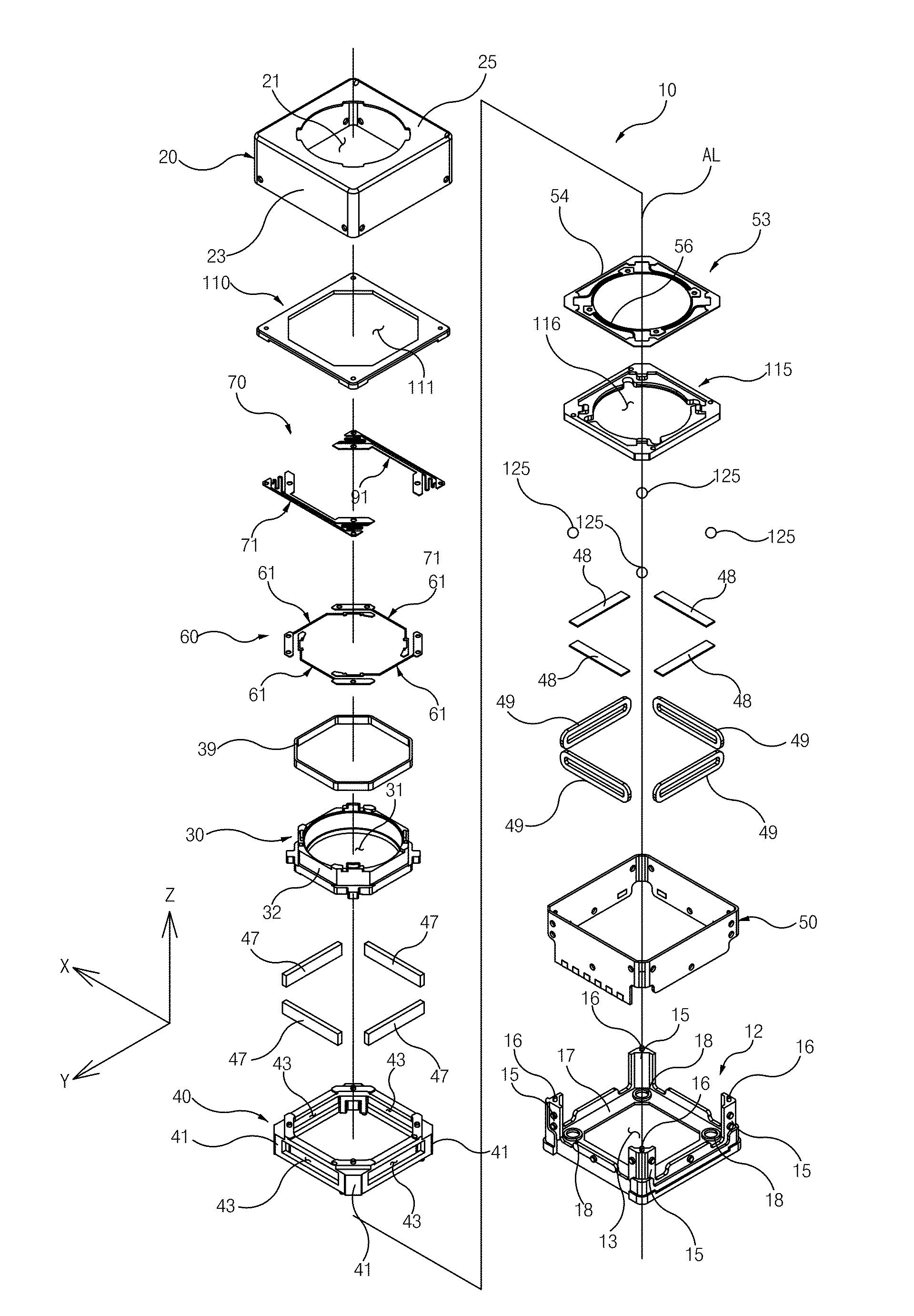

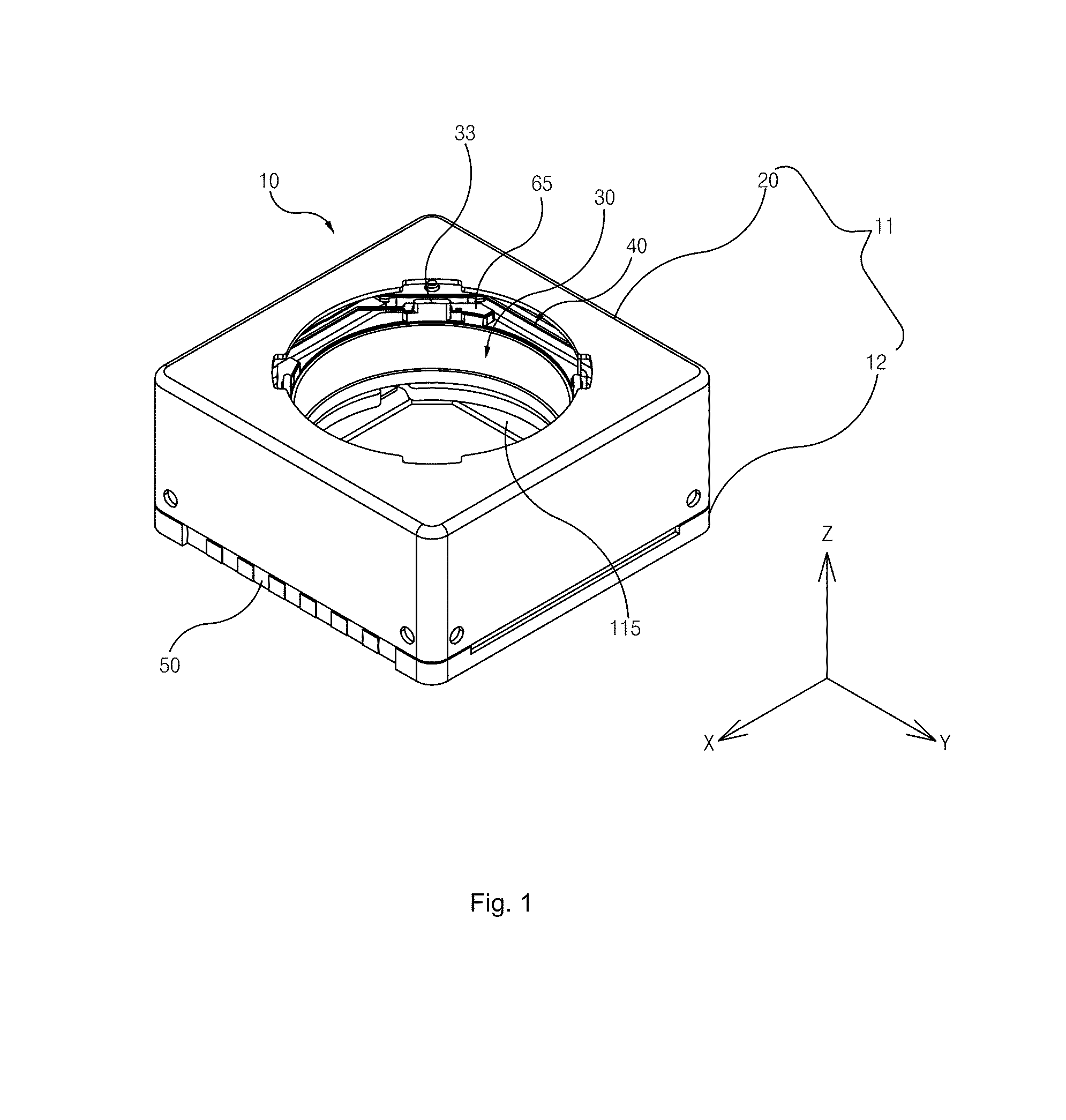

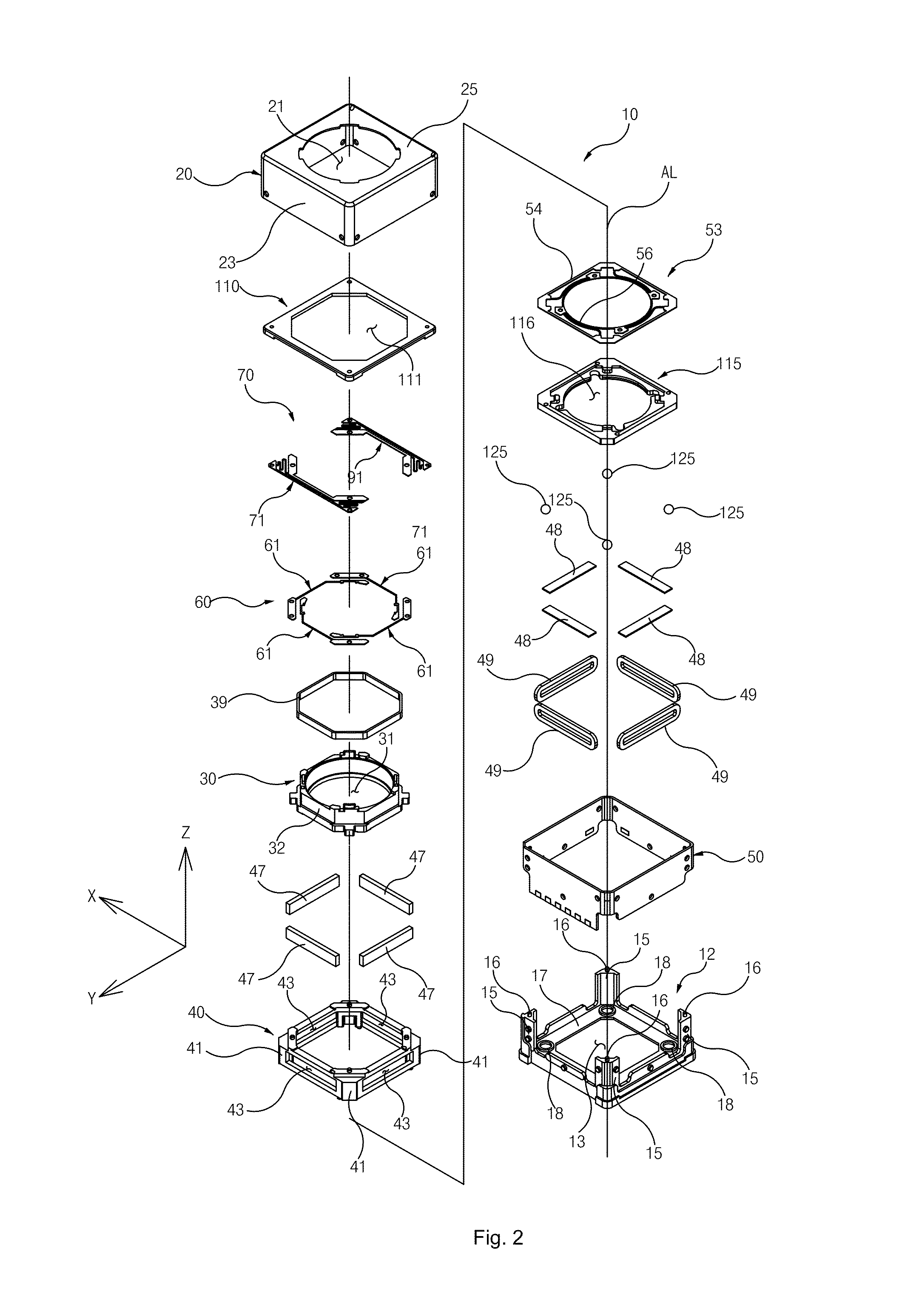

Lens Driving Device

A lens driving device is disclosed. The lens driving device includes a housing including a base, and a cover body forming a receiving space together with the base; a lens barrel assembled inside the housing and moveable along an optical axis of the lens barrel; an anti-shake carrier assembled inside the housing for suspending the lens barrel along the optical axis; an anti-shake spring having one end thereof fixed to the housing, and another end fixed on the anti-shake carrier; a plurality of bearing steel balls provided between the base and the anti-shake carrier for reducing friction force when the anti-shake carrier moves perpendicular to the optical axis; wherein the anti-shake carrier depends on elastic force of the anti-shake spring when it moves perpendicular to the optical axis, and the anti-shake carrier will return to an initial position.

Owner:AAC OPTICS (CHANGZHOU) CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com