Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6851 results about "Thrust bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thrust bearing is a particular type of rotary bearing. Like other bearings they permit rotation between parts, but they are designed to support a predominantly axial load. Thrust bearings come in several varieties.

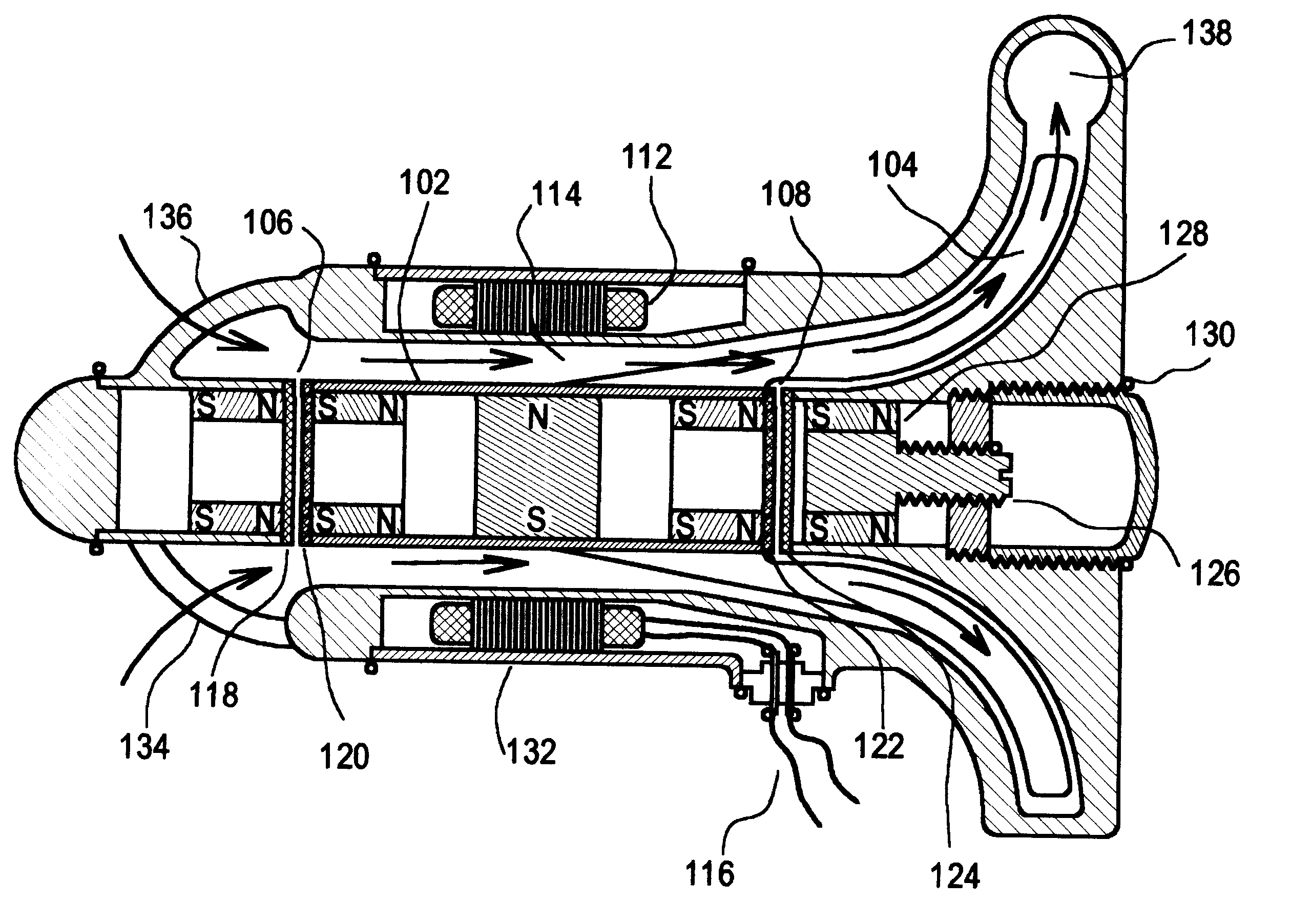

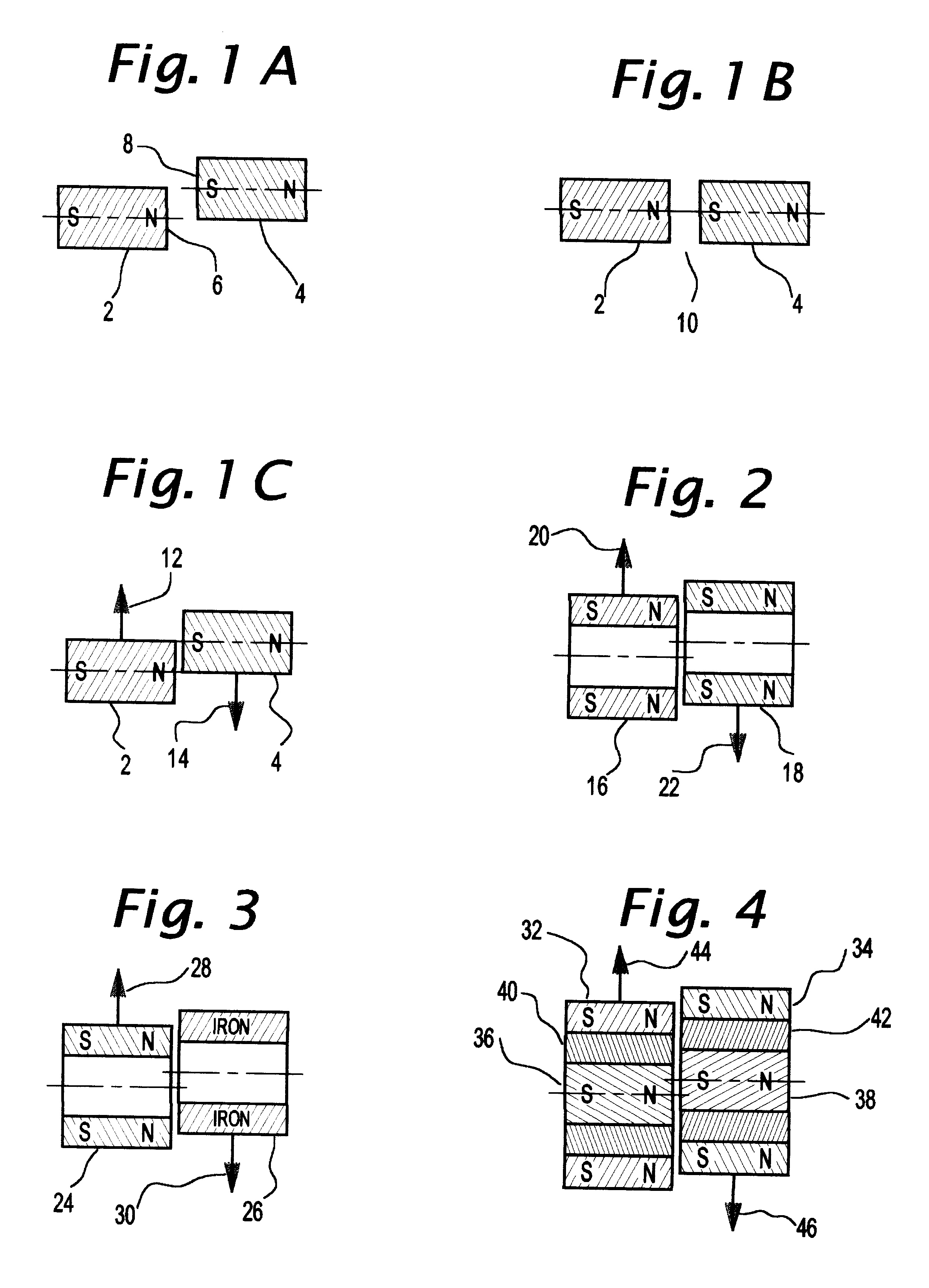

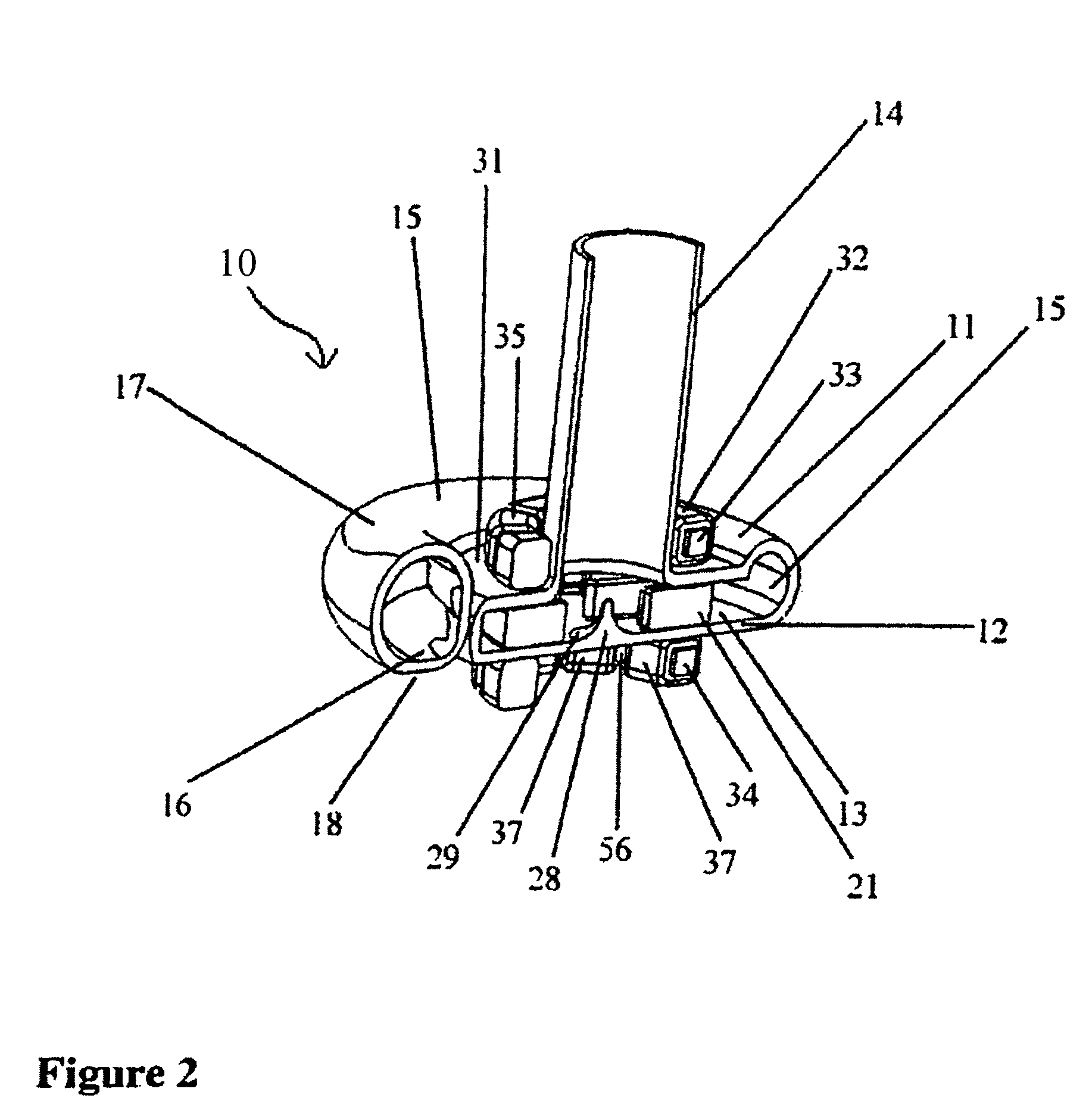

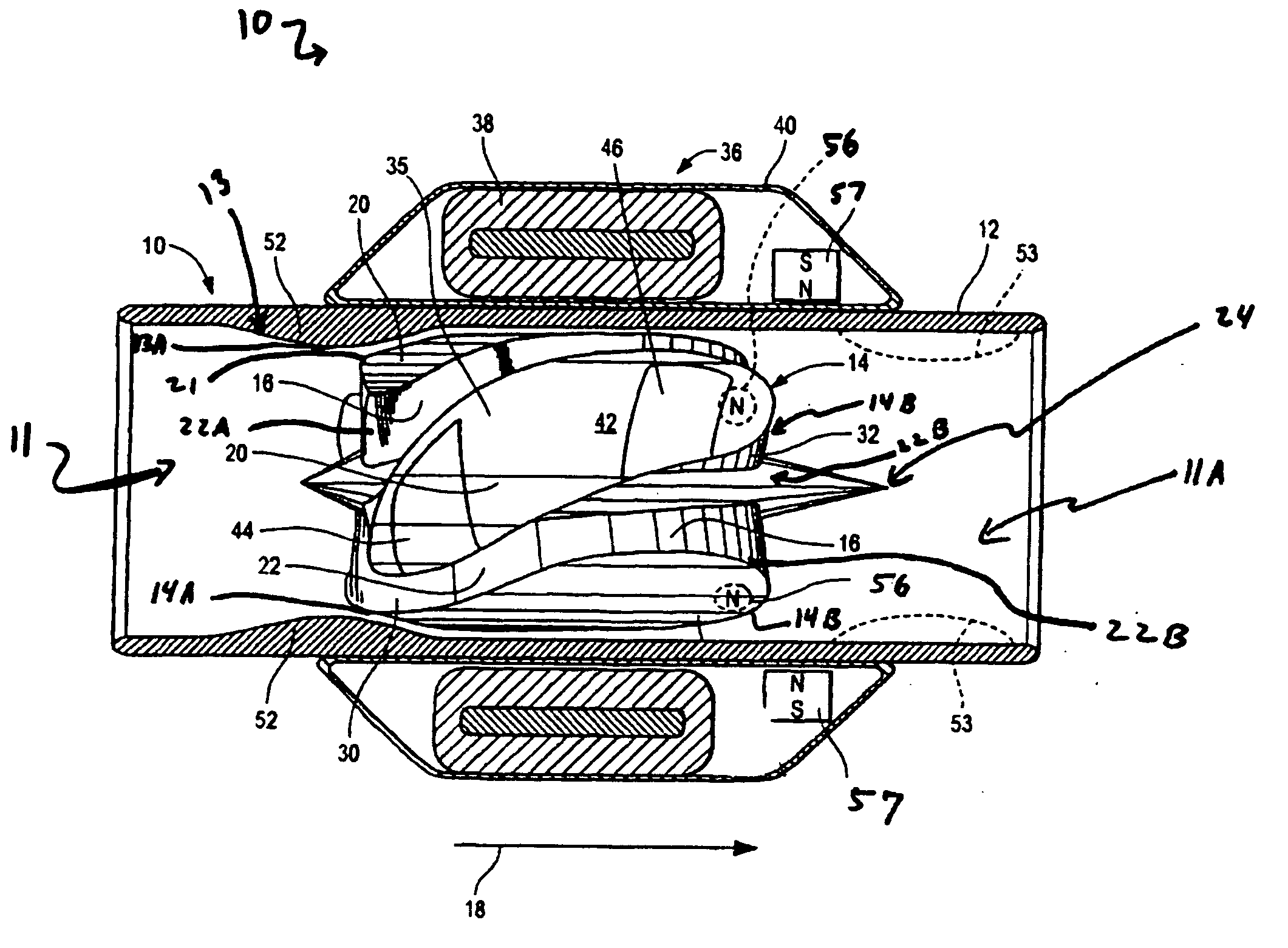

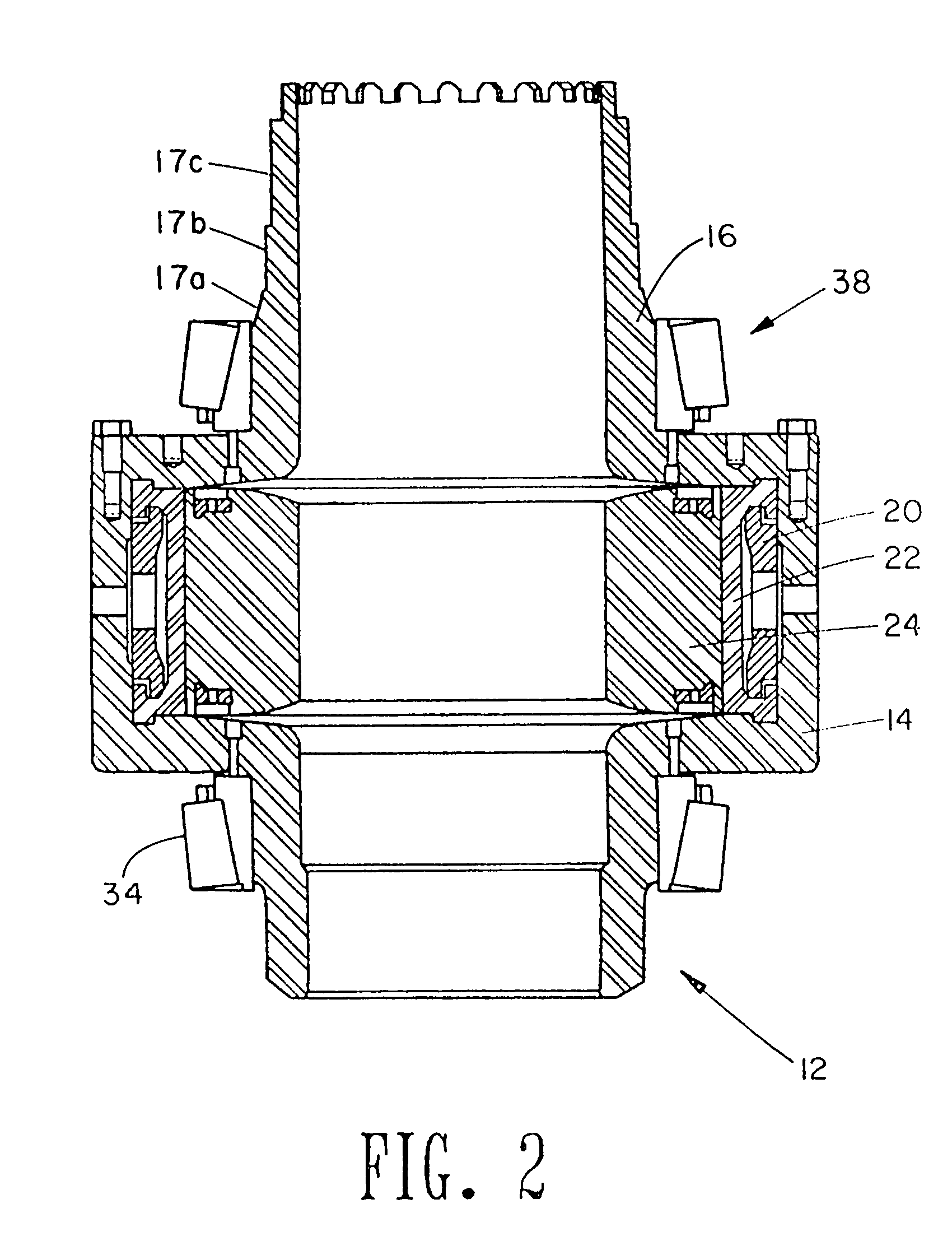

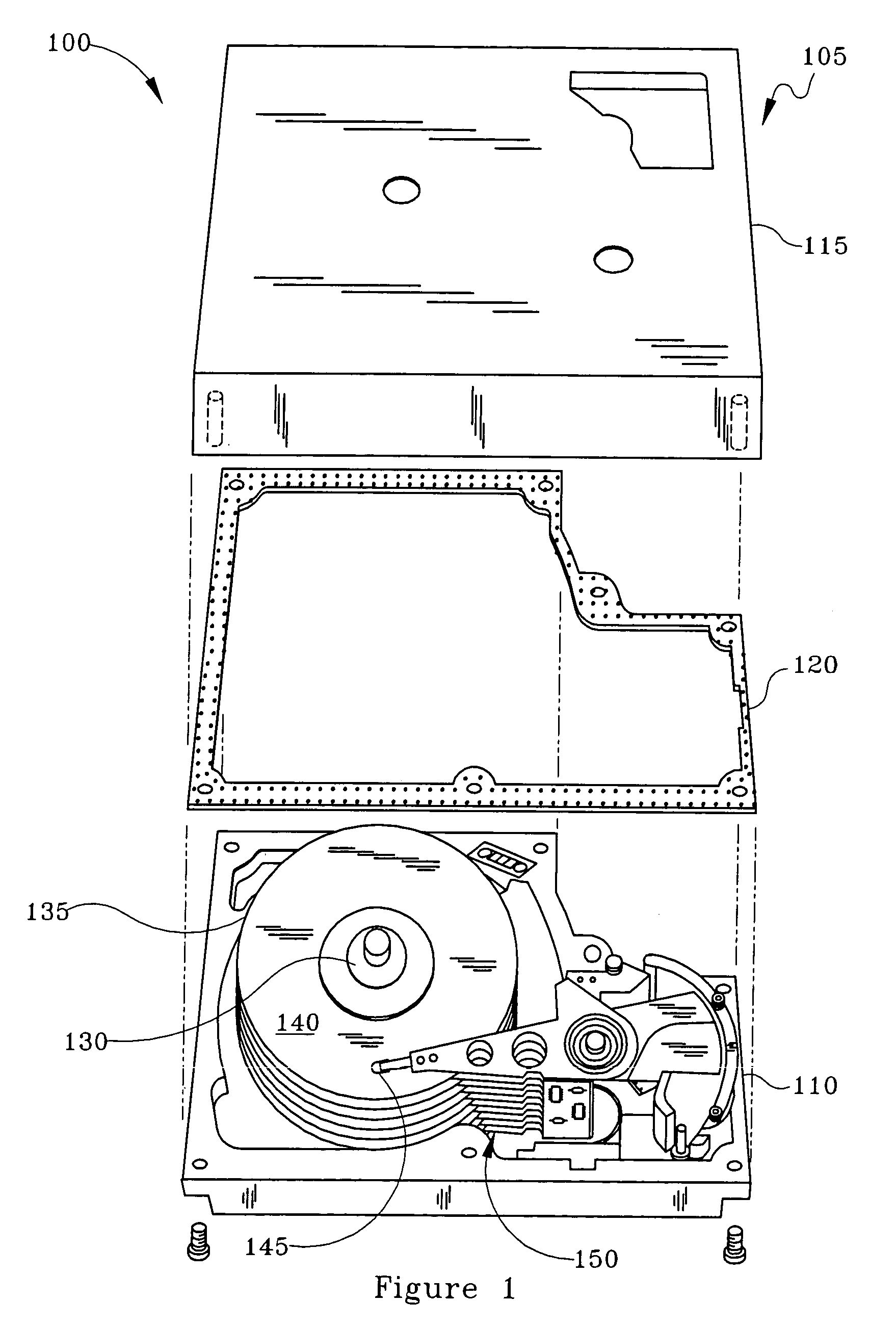

Axial force null position magnetic bearing and rotary blood pumps which use them

InactiveUS6227820B1Improve radial stiffnessSimple designPump componentsSurgeryAxial-flow pumpMagnetic tension force

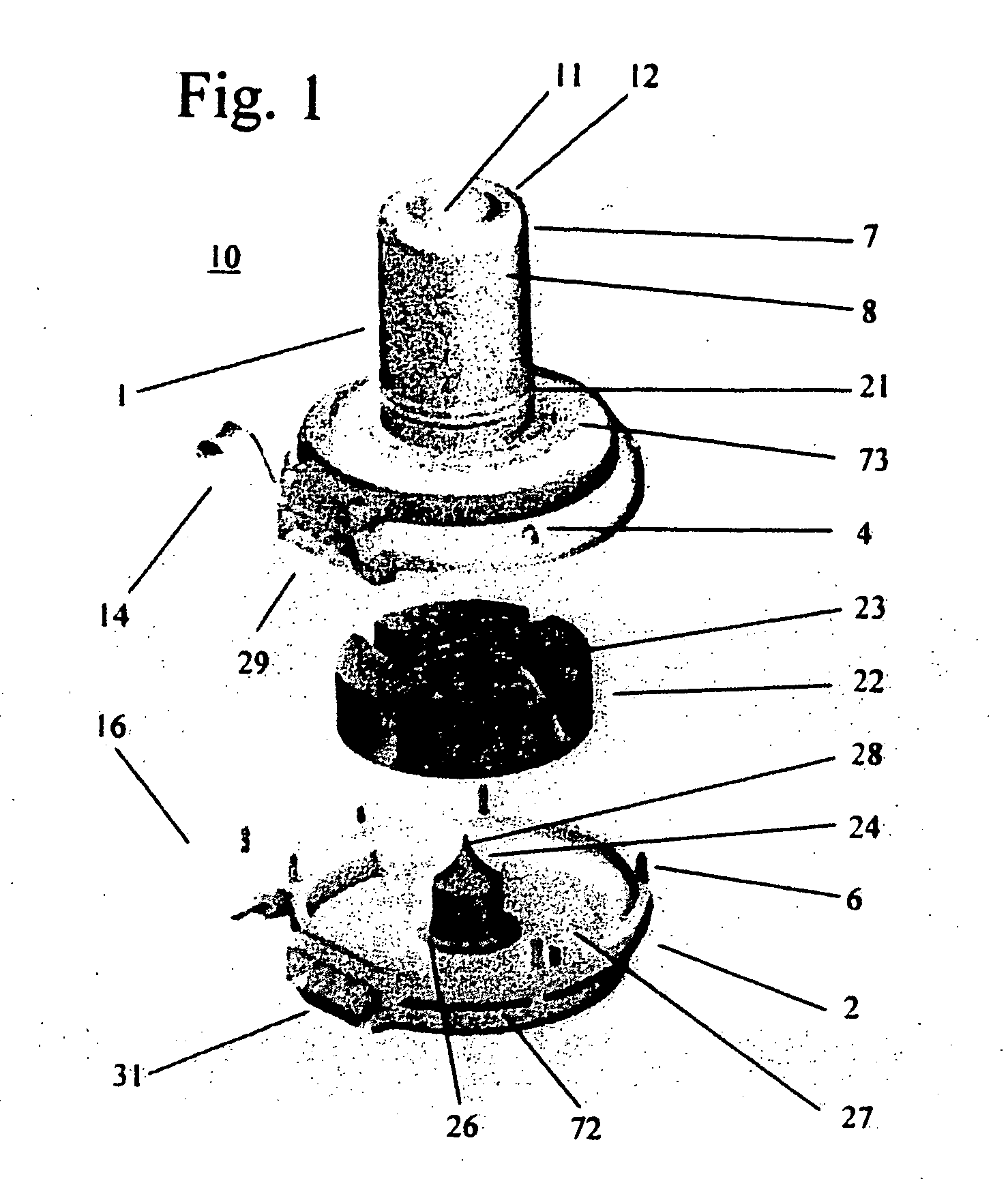

A generally cylindrical rotor very closely confined between two rigid thrust bearing surfaces is radially suspended by an array of attracting or repelling magnets or by a combination of permanent magnets and ring shaped members composed of ferromagnetic material. The geometry permits very small spacing between magnetic components to achieve high radial stiffness. High magnetic axial forces exerted between the rotor and stationary component on one end of the rotor are counter-balanced by equal and opposite forces at the other end of the rotor. Precise positioning of the rotor in the location where the opposing axial magnetic forces counterballance each other yields a net magnetic axial force on the rotor of near zero, hence the reference to this as the null position. Wear resistant mechanical thrust bearings confine the rotor axially to maintain this position during rotatioin. Precisely balance the magnetic axial forces in the proper geometry with relation to the mechanical thrust bearings. Blood pumps utilizing this type of bearing are disclosed, including both axial flow pump and centrifugal flow pump configurations with high flow washing of the junction of the rotating and stationary parts to prevent thrombus accumulation.

Owner:JARVIK ROBERT

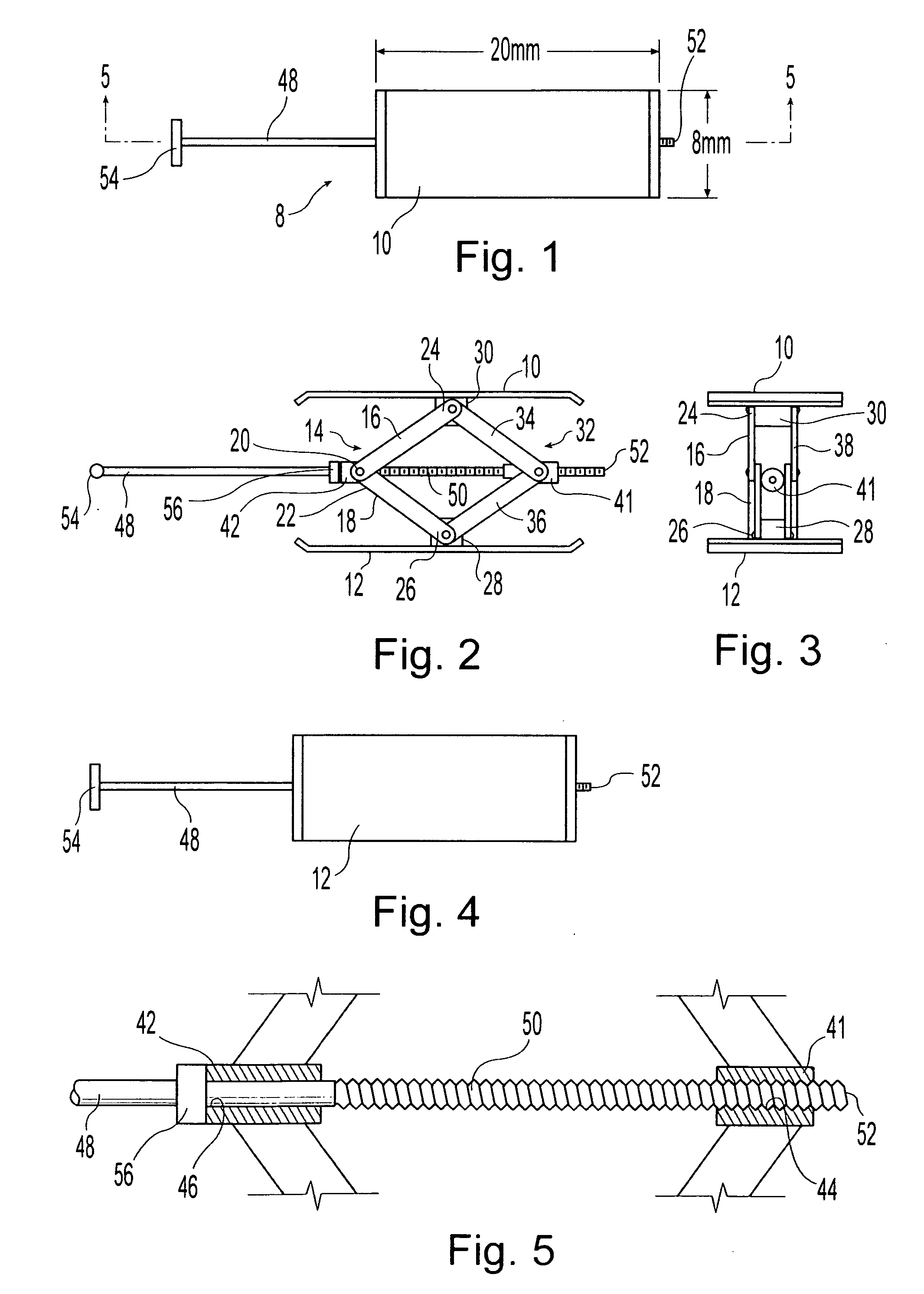

Method and relaxable distracters for in-situ formation of intervertebral disc prosthesis

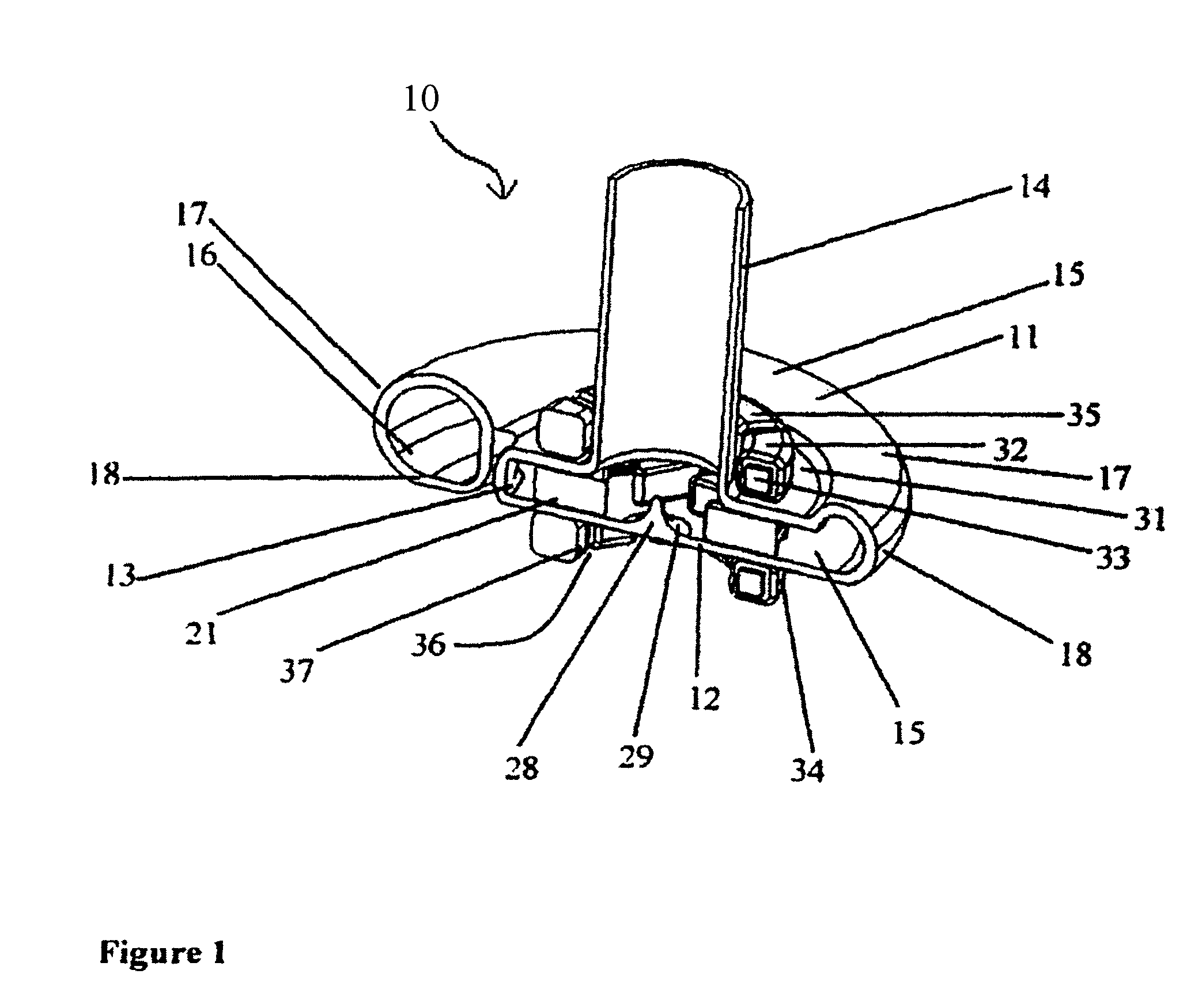

A method and a distracter for replacing a removed, intervertebral disc with a prosthesis. An inter-body distracter is inserted within the intervertebral space between adjacent vertebrae, the vertebrae are distracted and are supported by the distracter. A fluid, curable polymer is injected into the intervertebral space and around the distracter and then the polymer is cured to a semi-rigid, pliable, elastically deformable state. The distracter is then disabled from supporting compressive forces applied by the vertebrae and remains in place. The preferred distracter is a scissors jack having intermediate bearings joined by links to support feet. One of the bearings has a threaded lateral bore and the second bearing has a lateral bore. A rod extends through the bores and has a threaded portion extending from a first end of the rod and threadedly engaging the threaded bearing. The inside diameter of the second bore is greater than the outside diameter of the threaded portion of the rod so the rod is axially slidable through the second bore. A thrust bearing is fixed on the threaded rod and positioned laterally outwardly of the second bearing for forcing the second bearing laterally toward the first bearing upon rotation of the rod in one direction and for permitting the rod to be withdrawn from the bearing by rotating the rod in the opposite direction and disengaging it from the first bearing. Alternative distracters are also disclosed.

Owner:SYBERSPINE

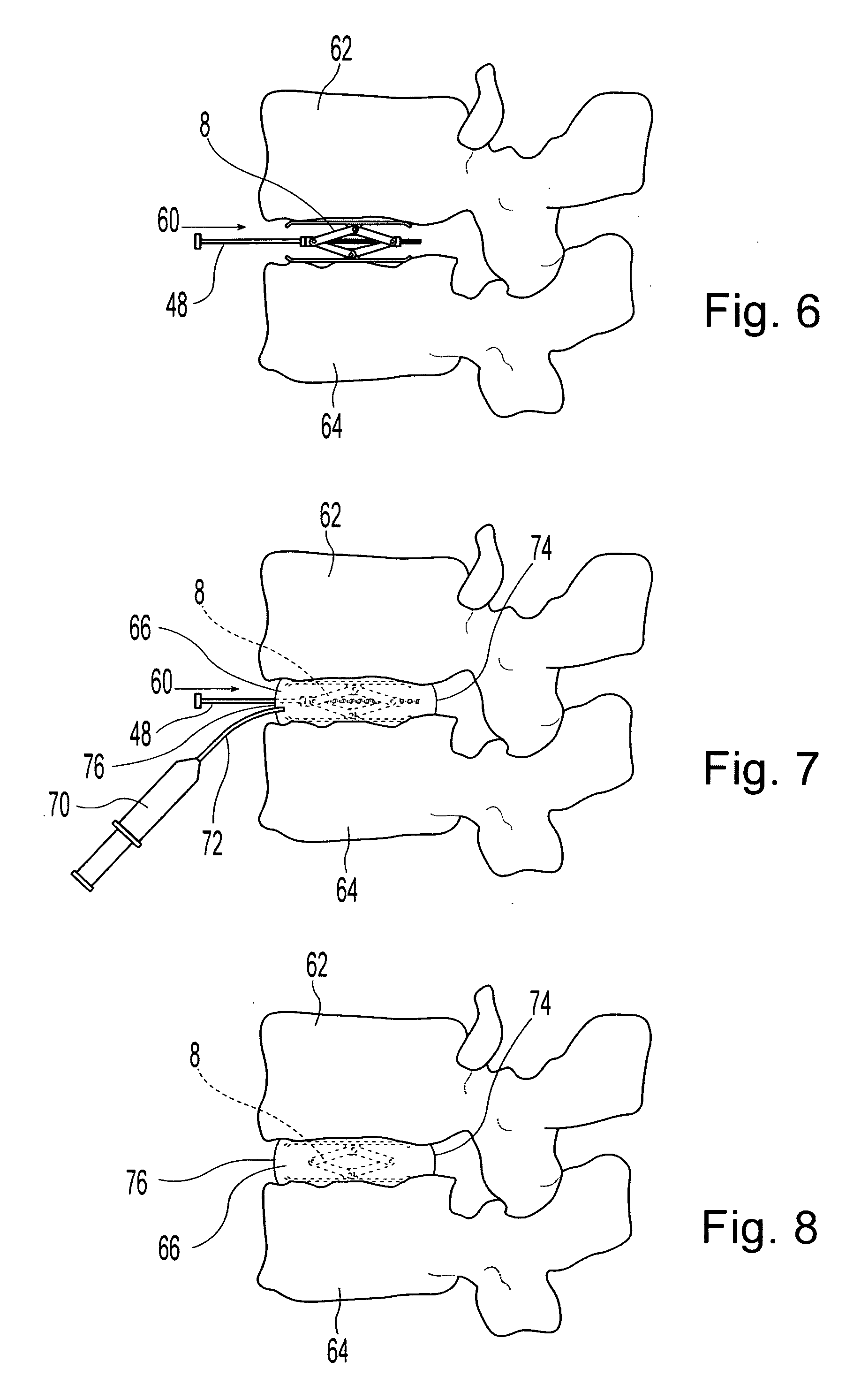

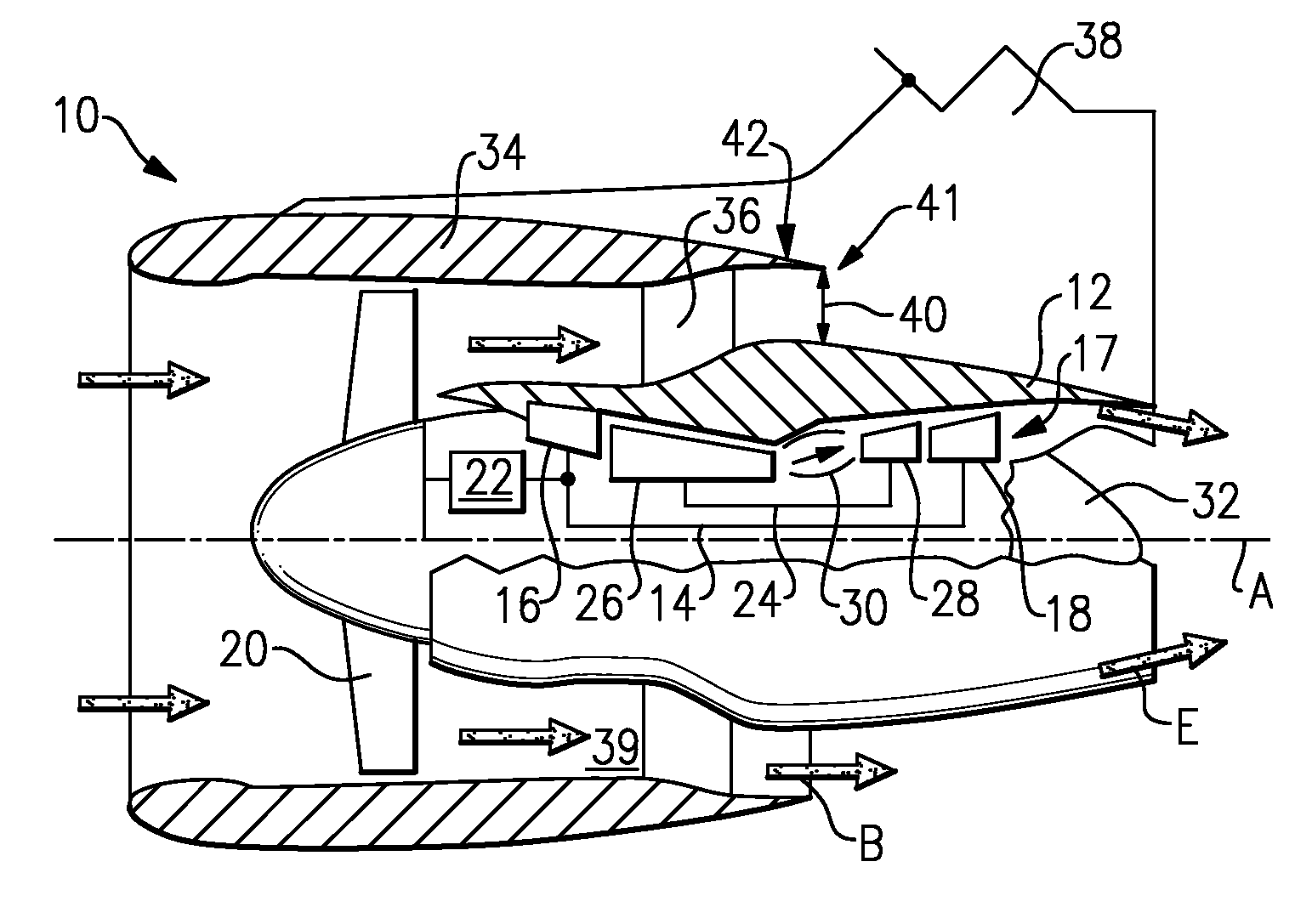

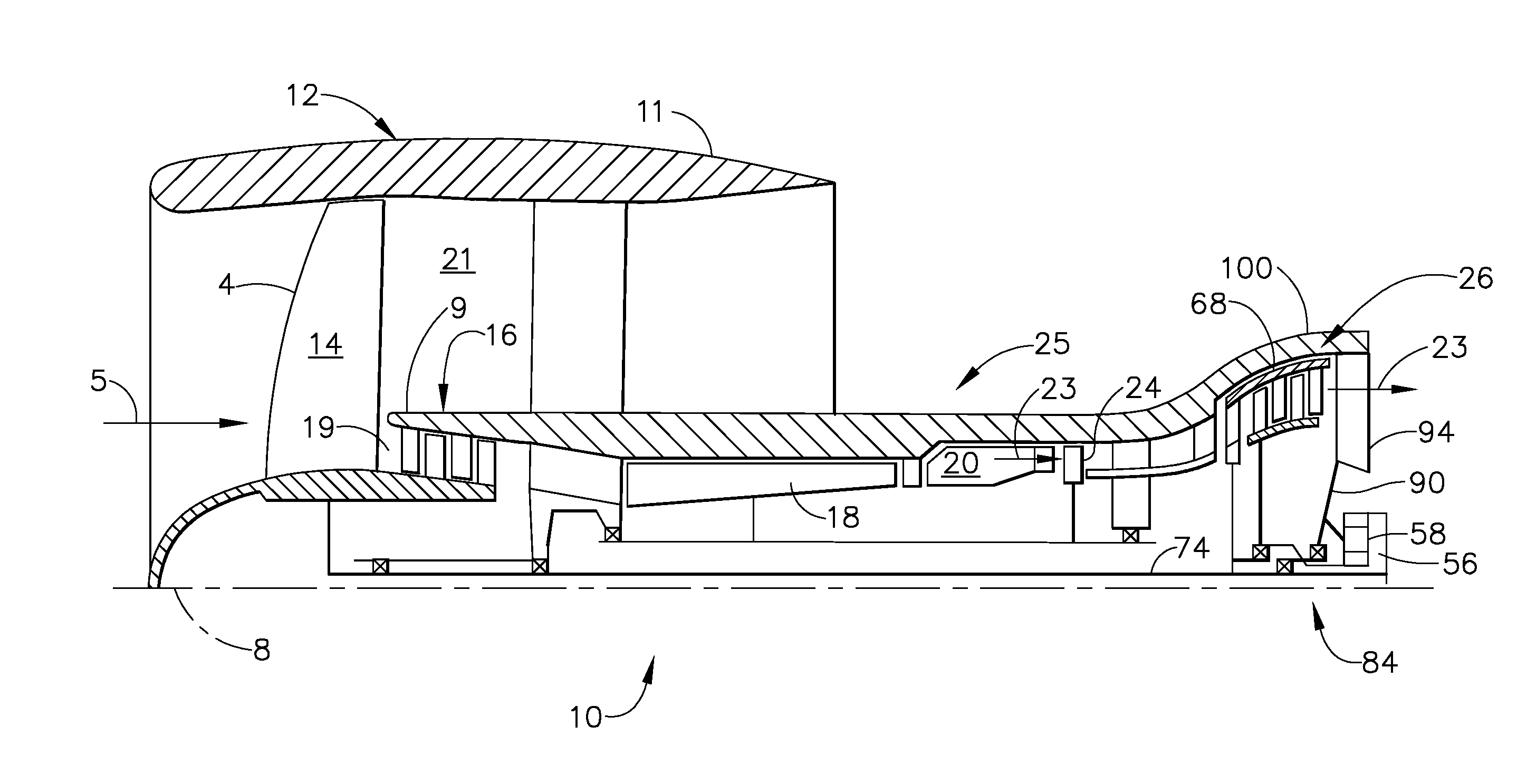

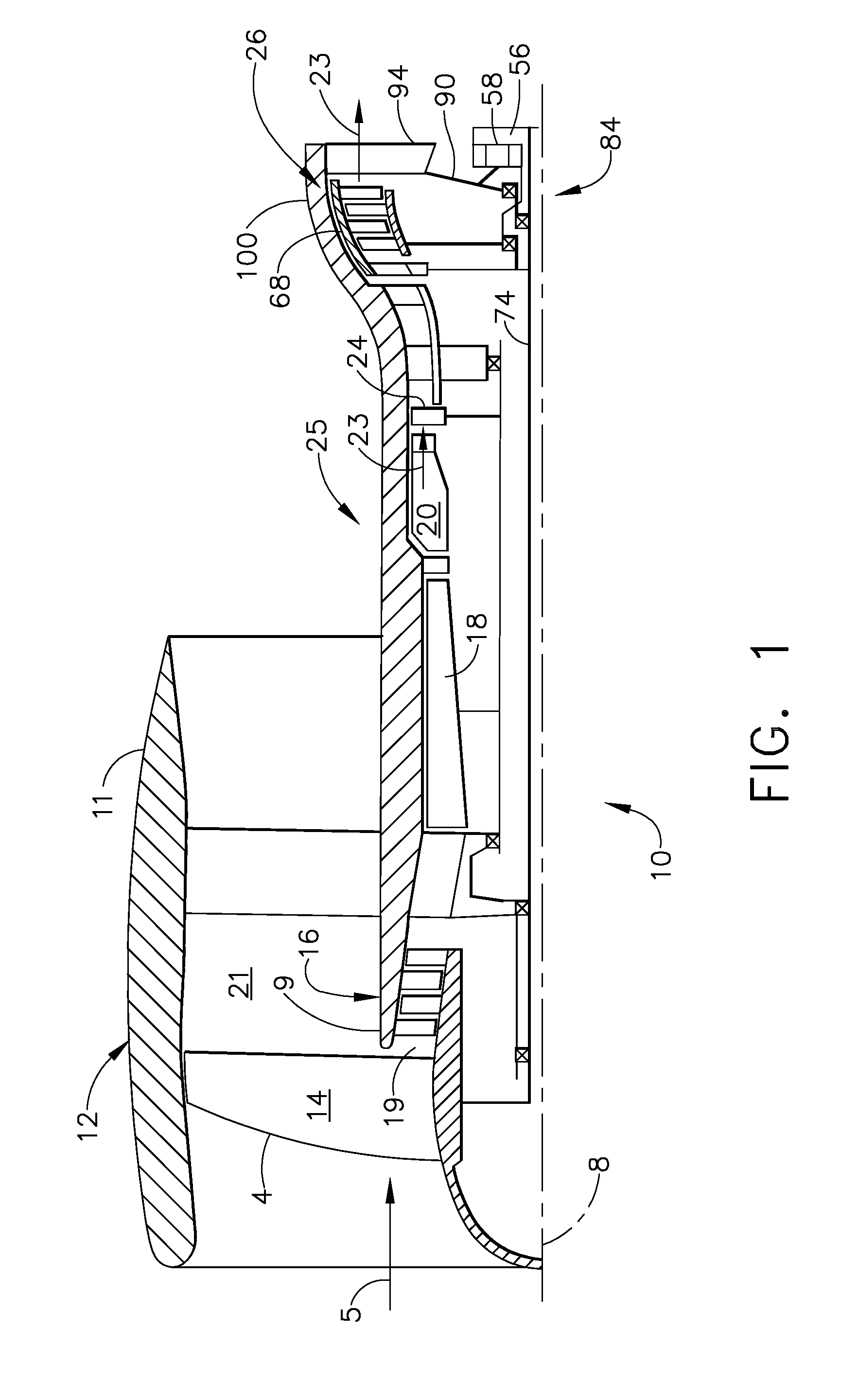

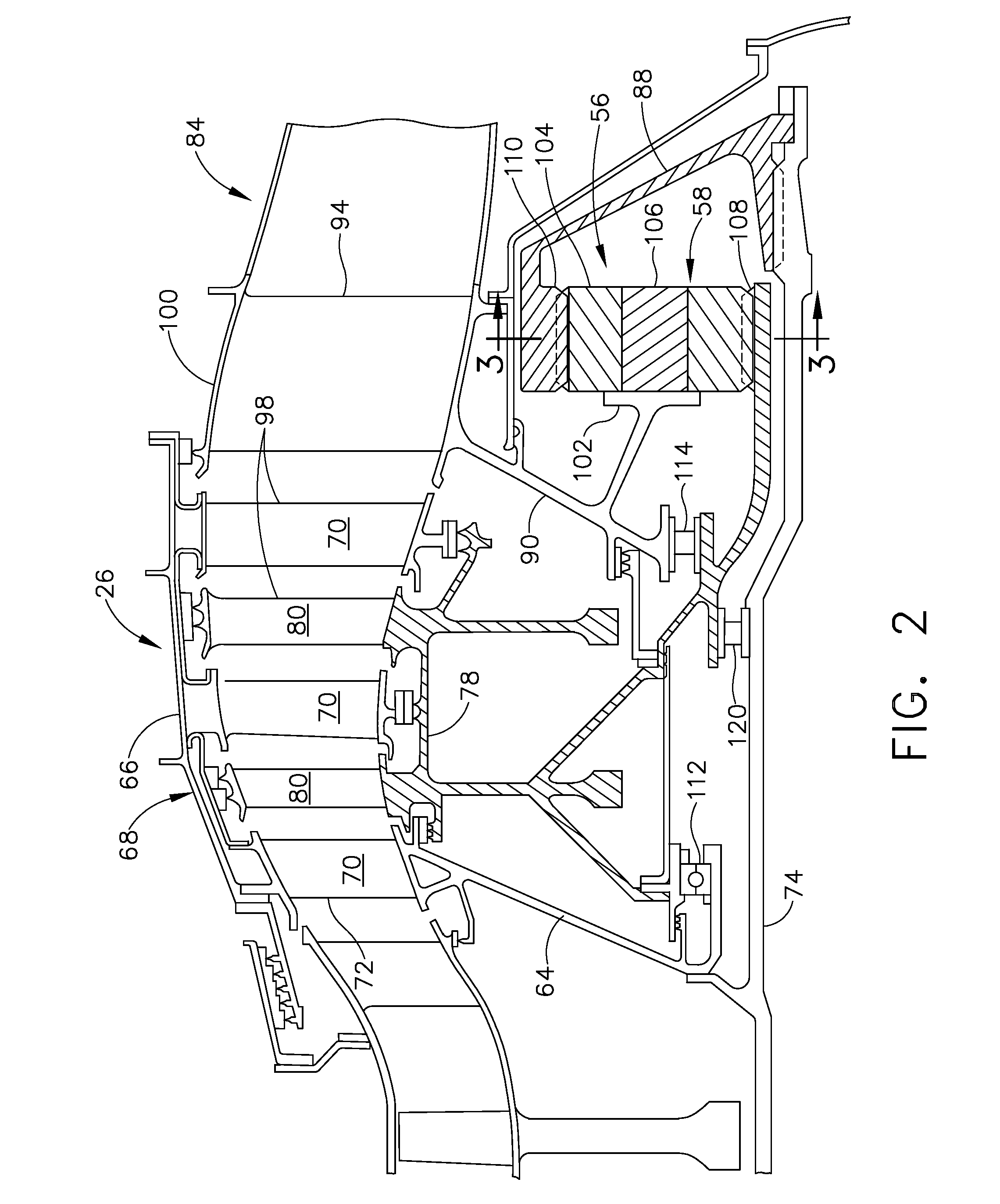

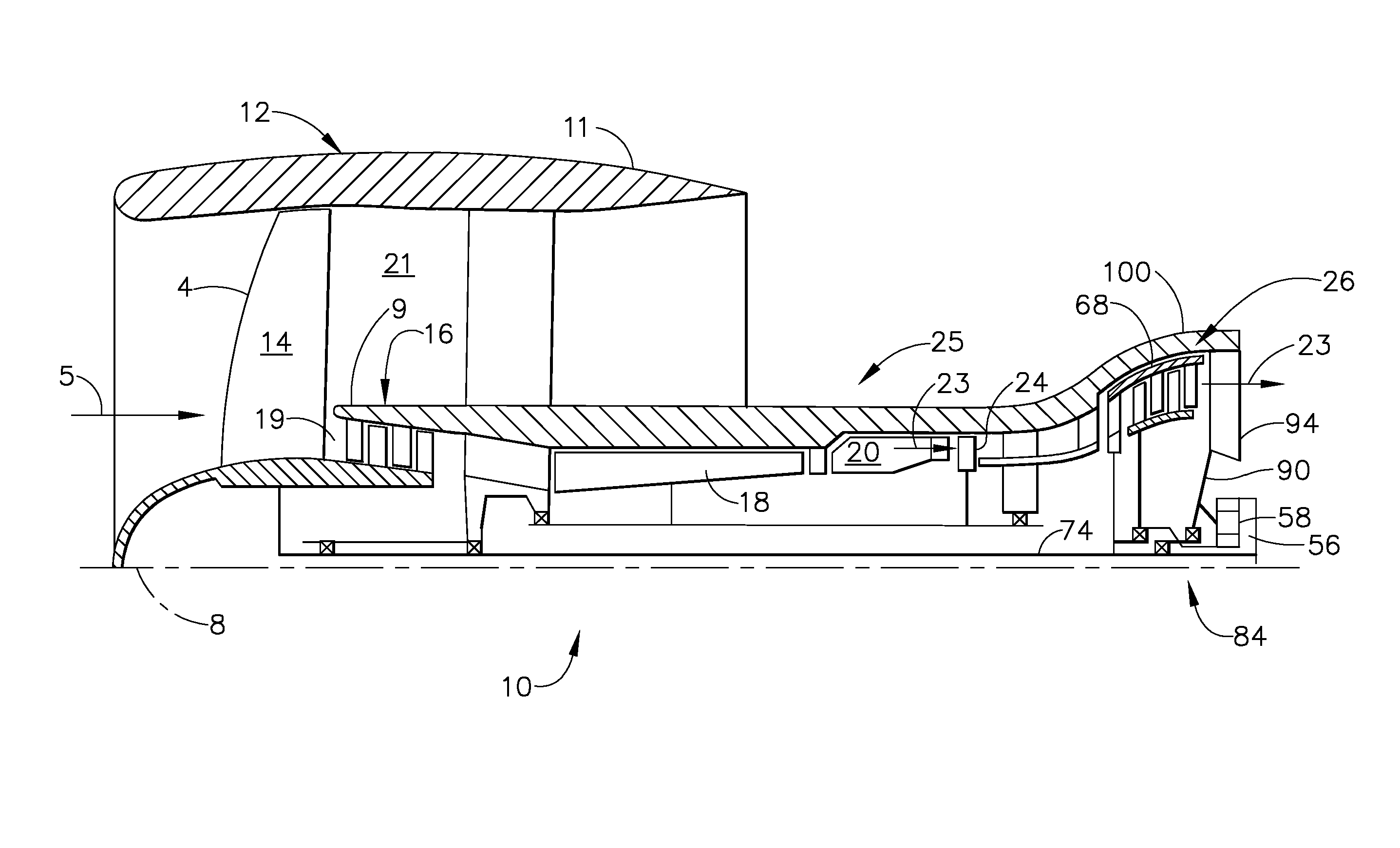

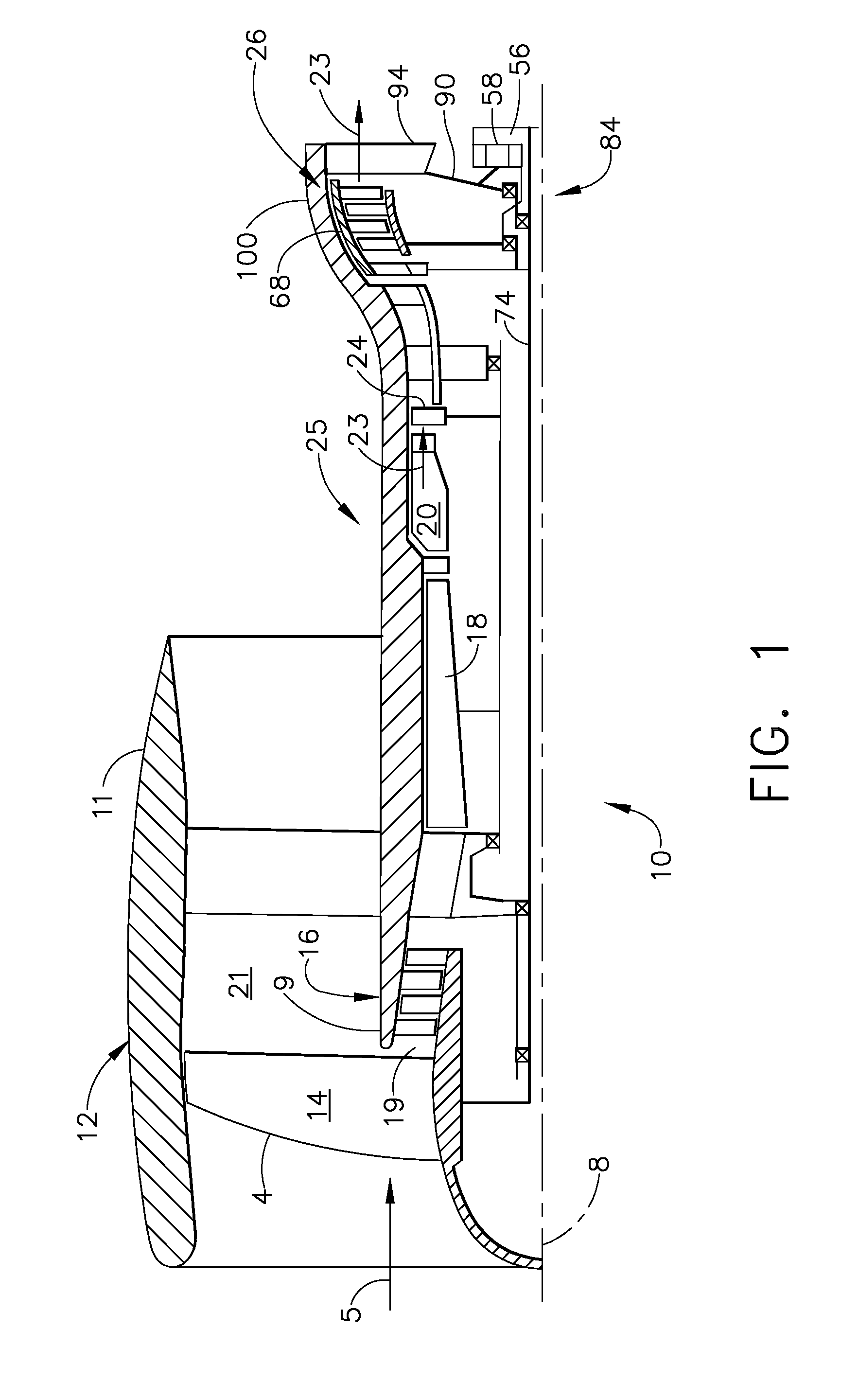

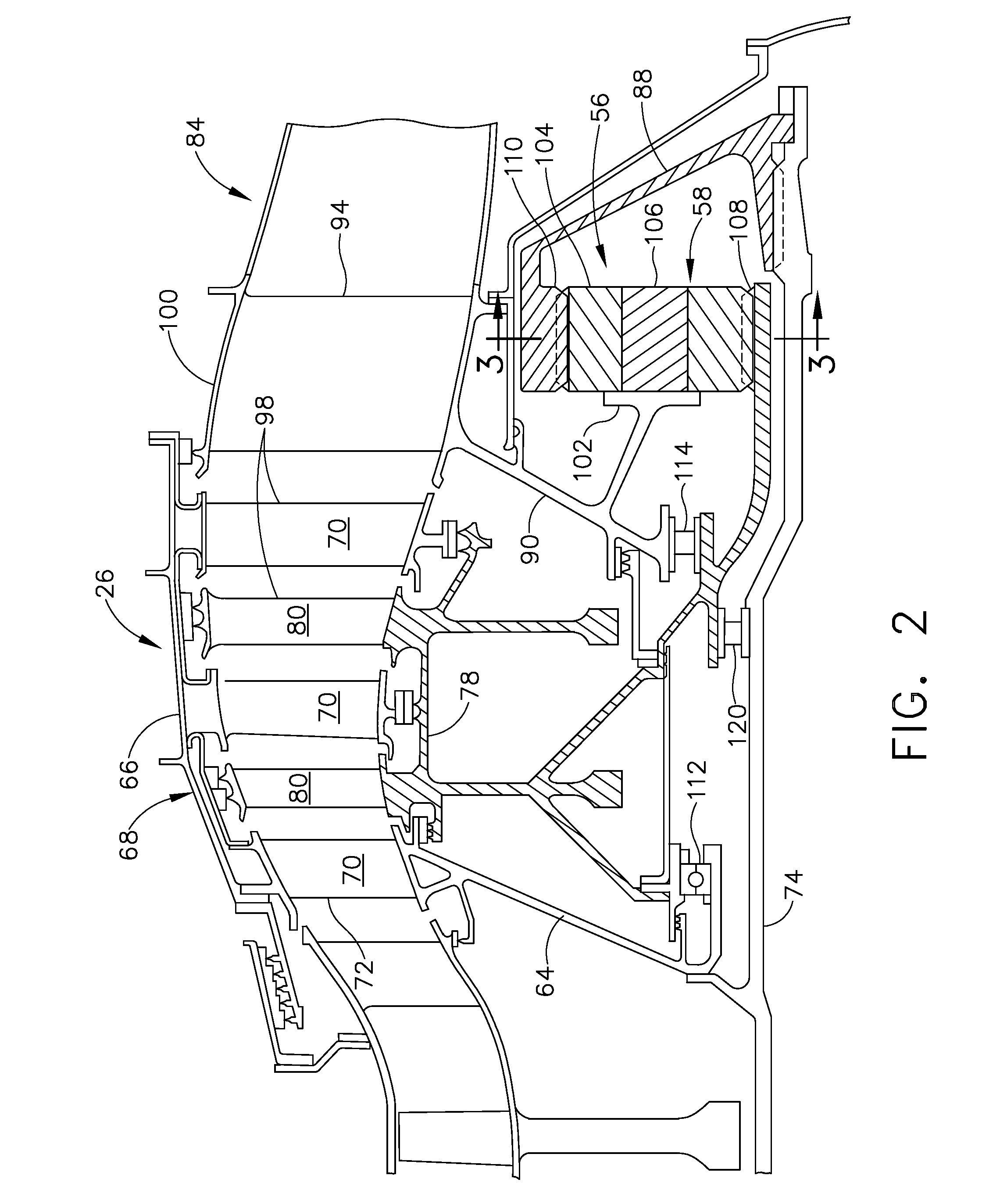

Managing spool bearing load using variable area flow nozzle

A turbine engine provides a spool supporting a turbine. The spool is arranged in a core nacelle and includes a thrust bearing. A fan is arranged upstream from the core nacelle and is coupled to the spool. A fan nacelle surrounds the fan and core nacelle and provides a bypass flow path that includes a fan nozzle exit area. A flow control device is adapted to effectively change the fan nozzle exit area. A controller is programmed to monitor the thrust bearing and command the flow control device in response to an undesired load on the thrust bearing. Effectively changing the fan nozzle exit area with the flow control device actively manages the bearing thrust load to desired levels.

Owner:RTX CORP

Liquid pump with axial thrust washer

A liquid pump, in particular a water pump, comprises a pump housing, which has a thrust bearing seat, a bearing bolt and a bearing mounted on the bearing bolt. In this case, a thrust washer is arranged between the thrust bearing seat of the pump housing and the bearing. Furthermore, a flexible washer is arranged between the thrust bearing seat and the thrust washer.

Owner:ROBERT BOSCH GMBH

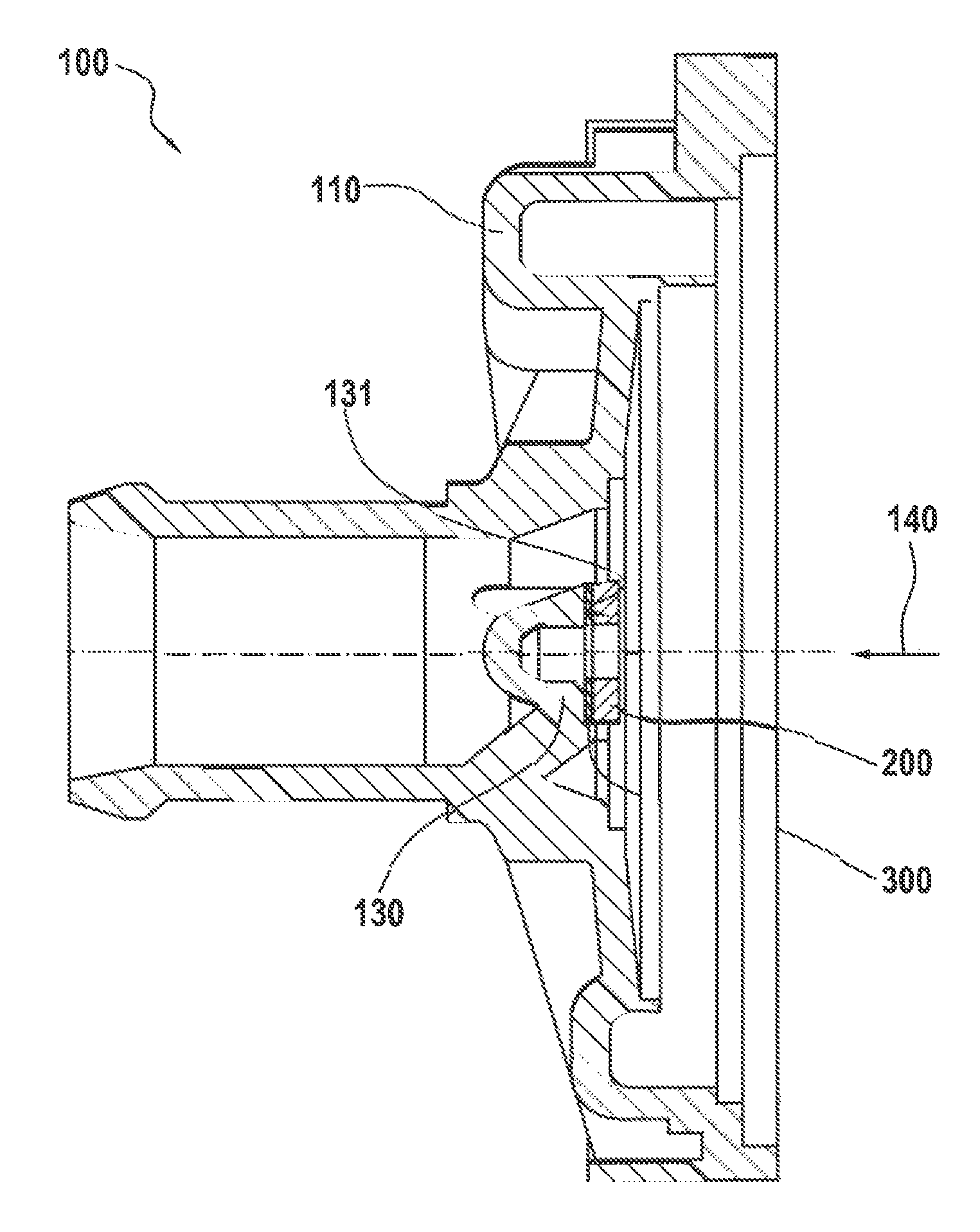

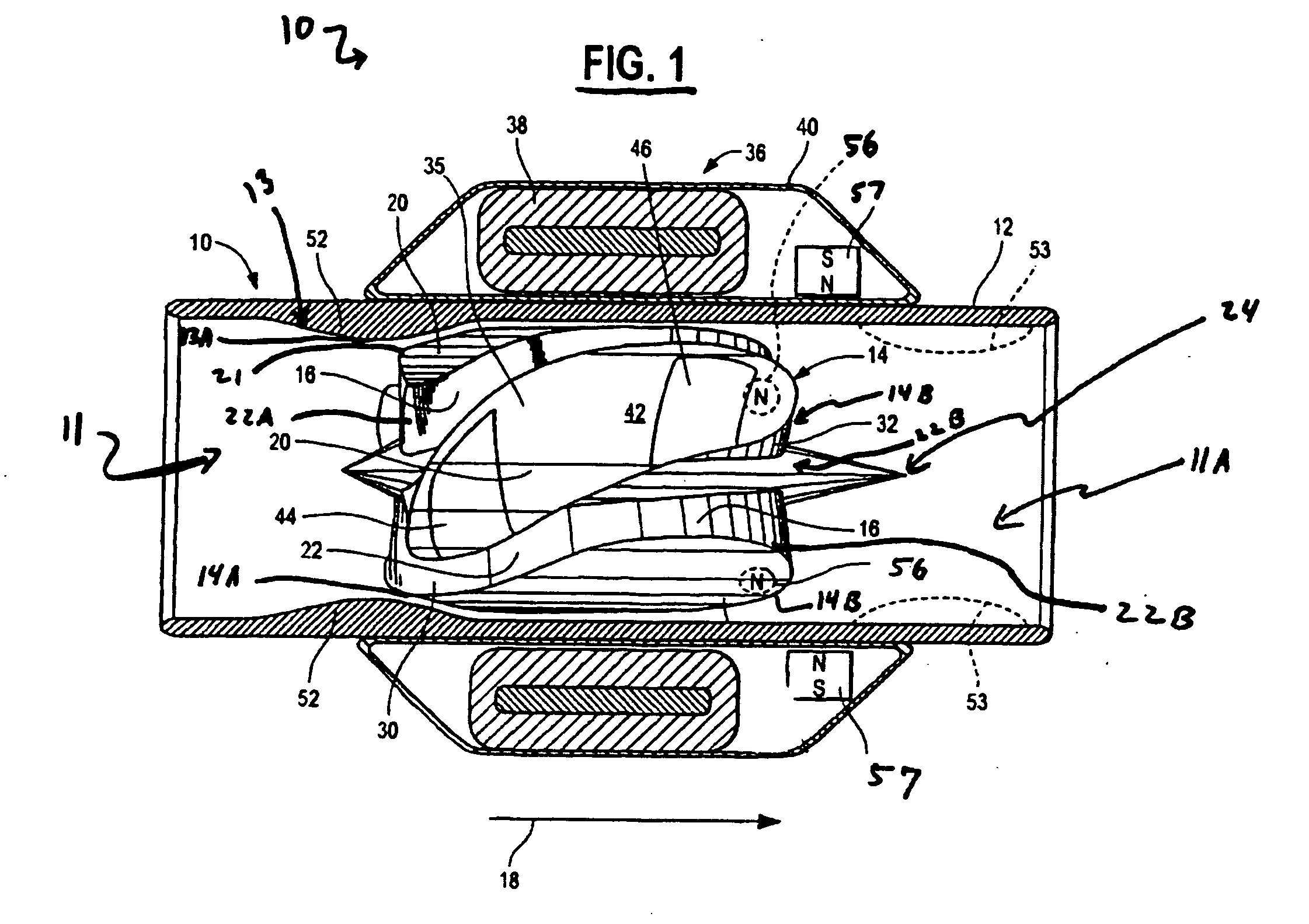

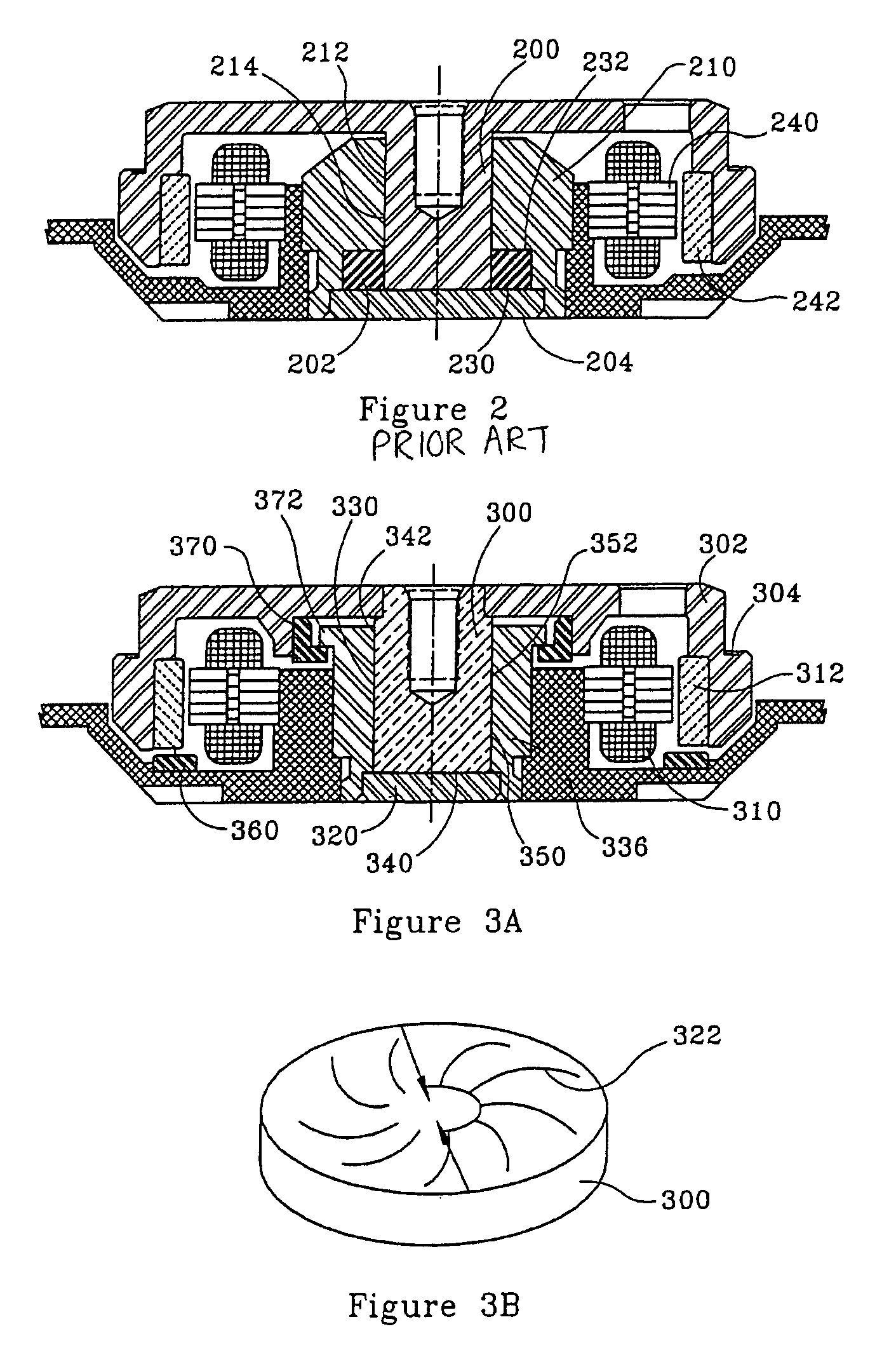

Stabilizing drive for contactless rotary blood pump impeller

ActiveUS20080021394A1Good for healthSpeed up the flowSpecific fluid pumpsPump componentsImpellerCoupling

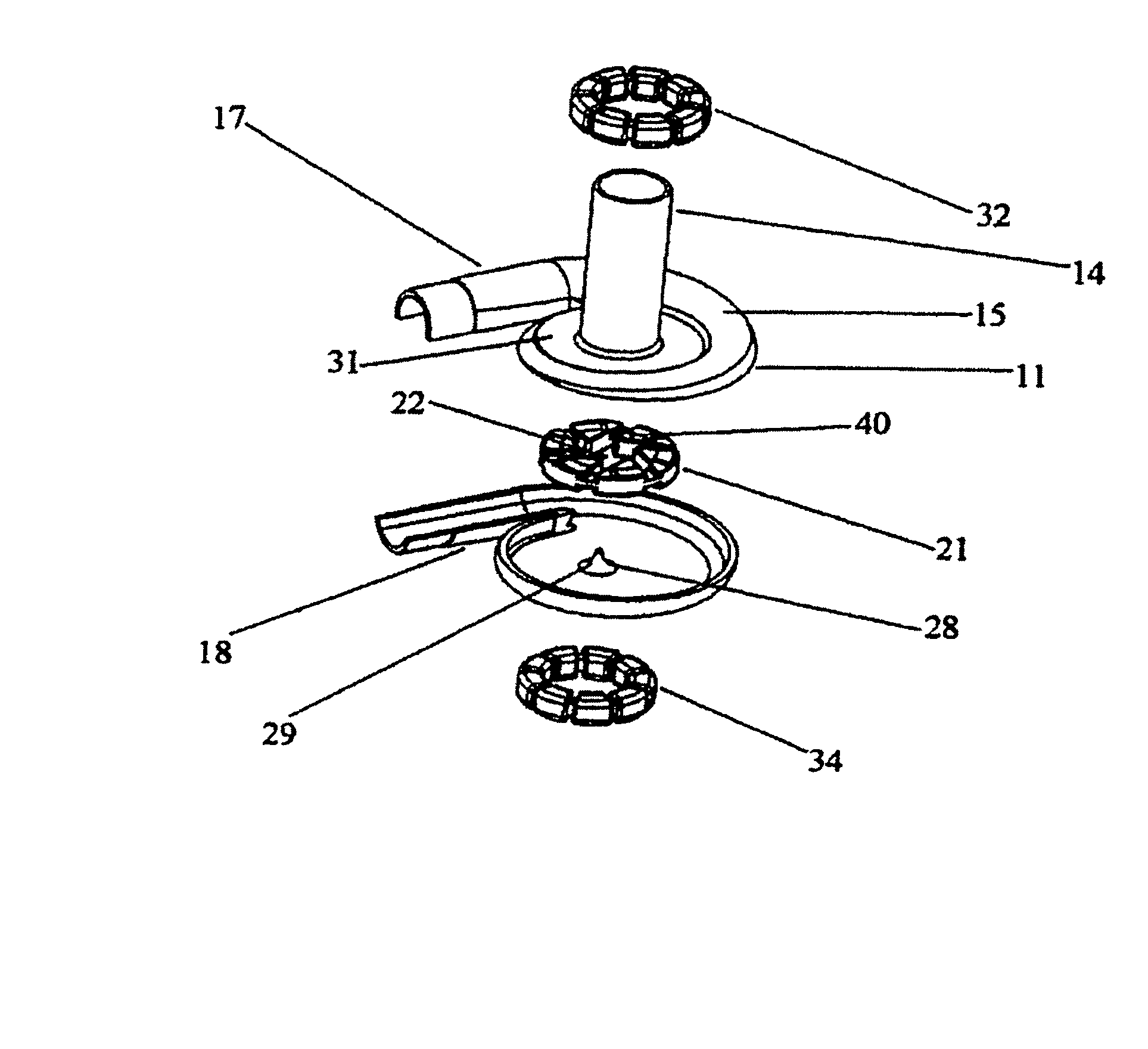

A rotary blood pump includes a casing defining a pumping chamber. The pumping chamber has a blood inlet and a tangential blood outlet. One or more motor stators are provided outside of the pumping chamber. A rotatable impeller is within the pumping chamber and is adapted to cause blood entering the pumping chamber to move to the blood outlet. The impeller has one or more magnetic regions. The impeller is radially constrained in rotation by magnetic coupling to one or more motor stators and is axially constrained in rotation by one or more hydrodynamic thrust bearing surfaces on the impeller.

Owner:HEARTWARE INC

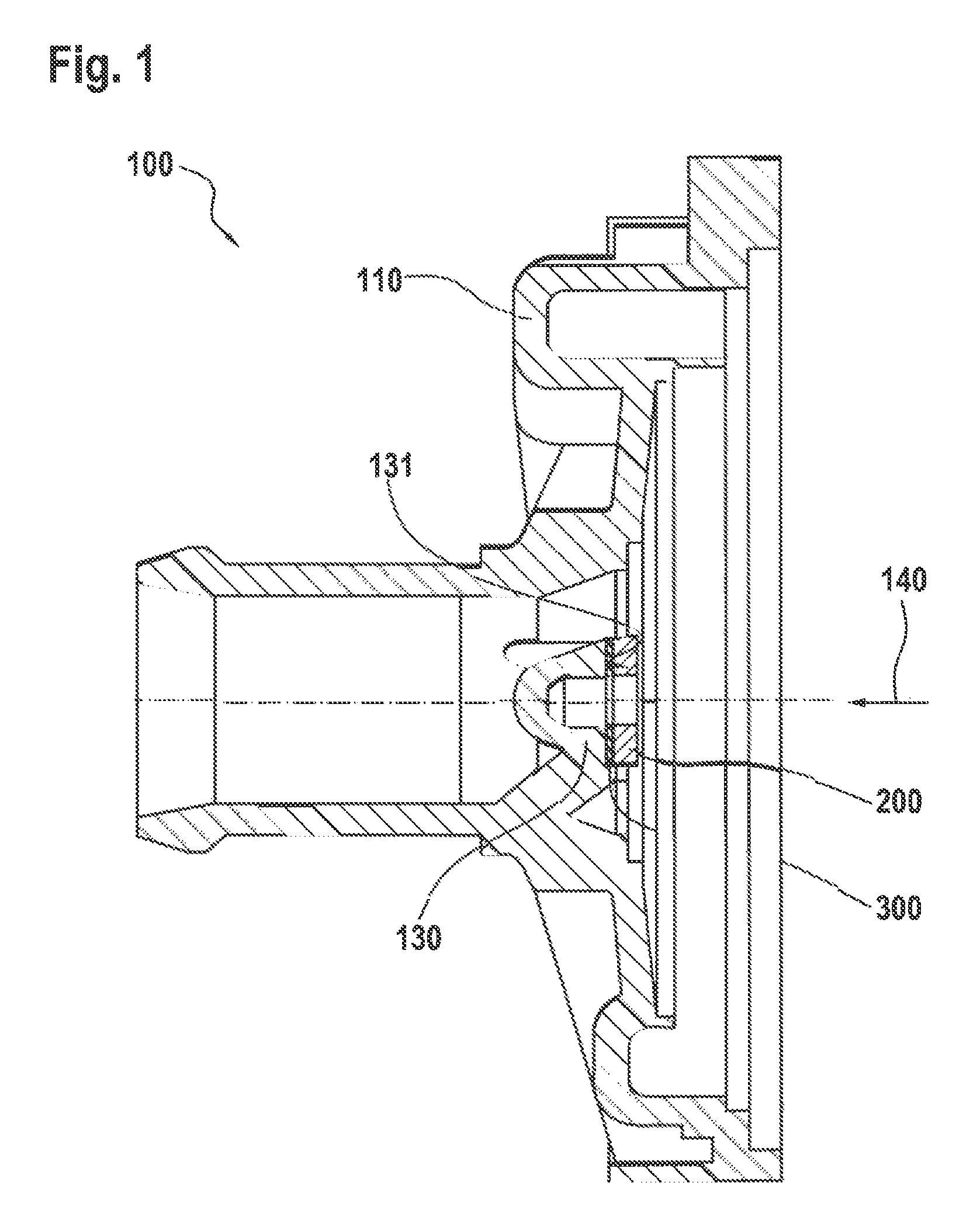

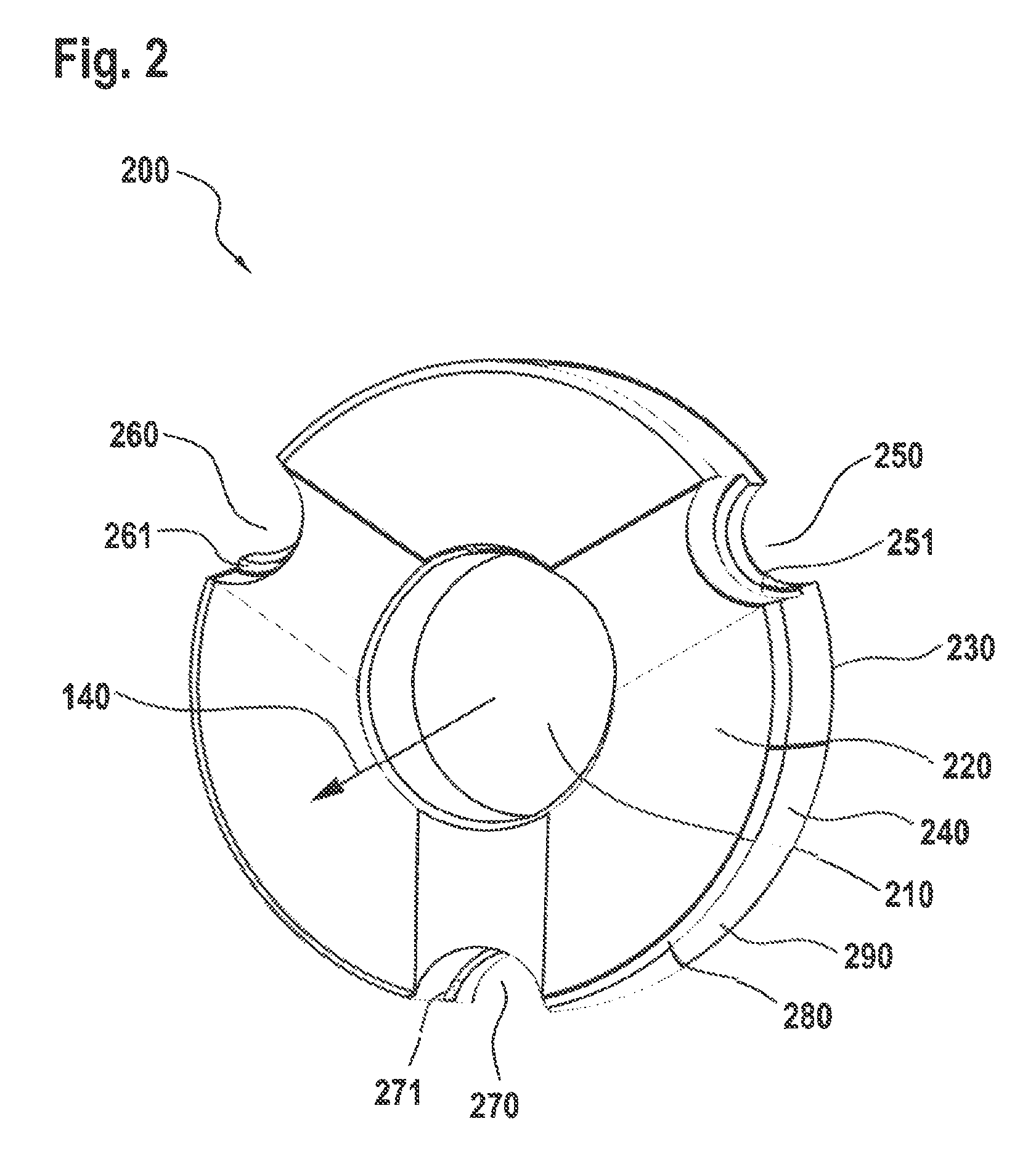

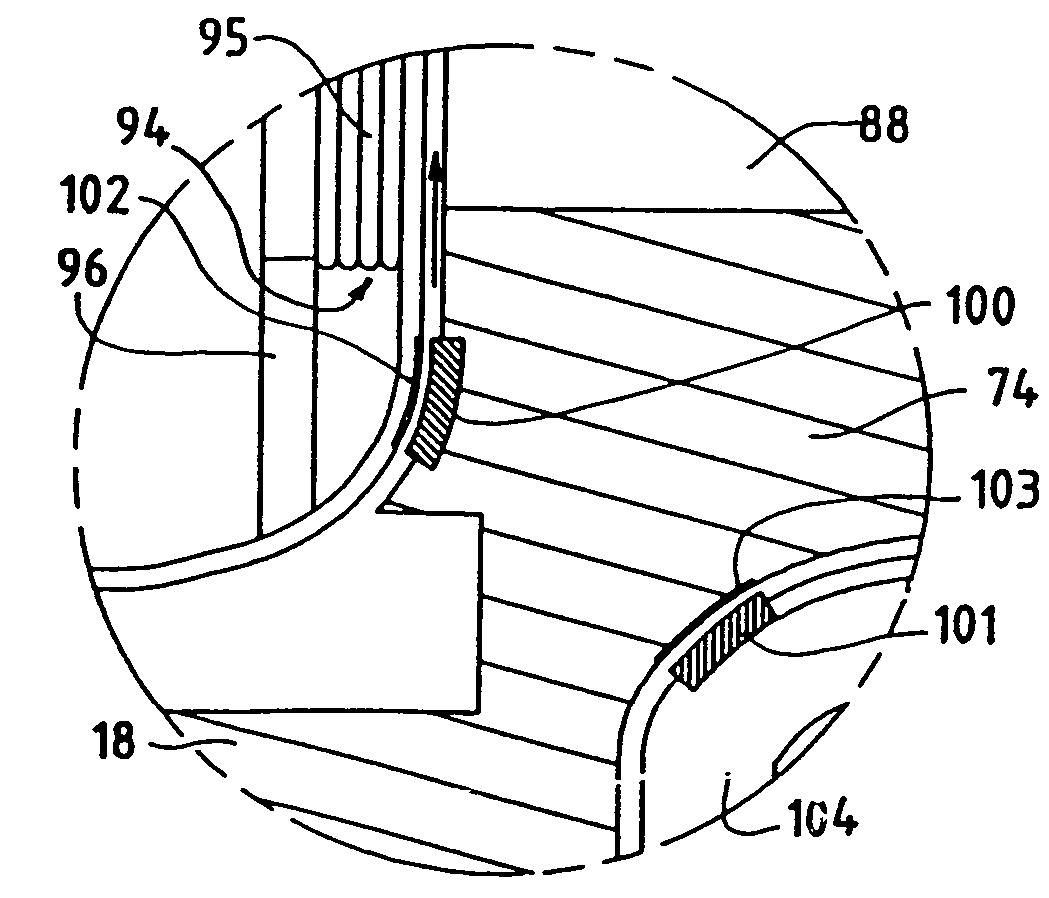

Centrifugal rotary blood pump with impeller having a hydrodynamic thrust bearing surface

ActiveUS8152493B2Facilitate the fit of the blood pumpSpeed up the flowPump componentsControl devicesImpellerMagnetic tension force

A rotary blood pump may include one or more motor stators overlying exterior surfaces of a wall defining a pumping chamber. A rotatable impeller within the pumping chamber may have a hydrodynamic thrust bearing surface adapted to constrain a position of the impeller along an axis of rotation relative to the wall when the impeller is rotating about the axis of rotation. The impeller position may then be constrained without requiring a constant polarity magnetic force to be applied in the axial direction from a fixed position of the housing.

Owner:HEARTWARE INC

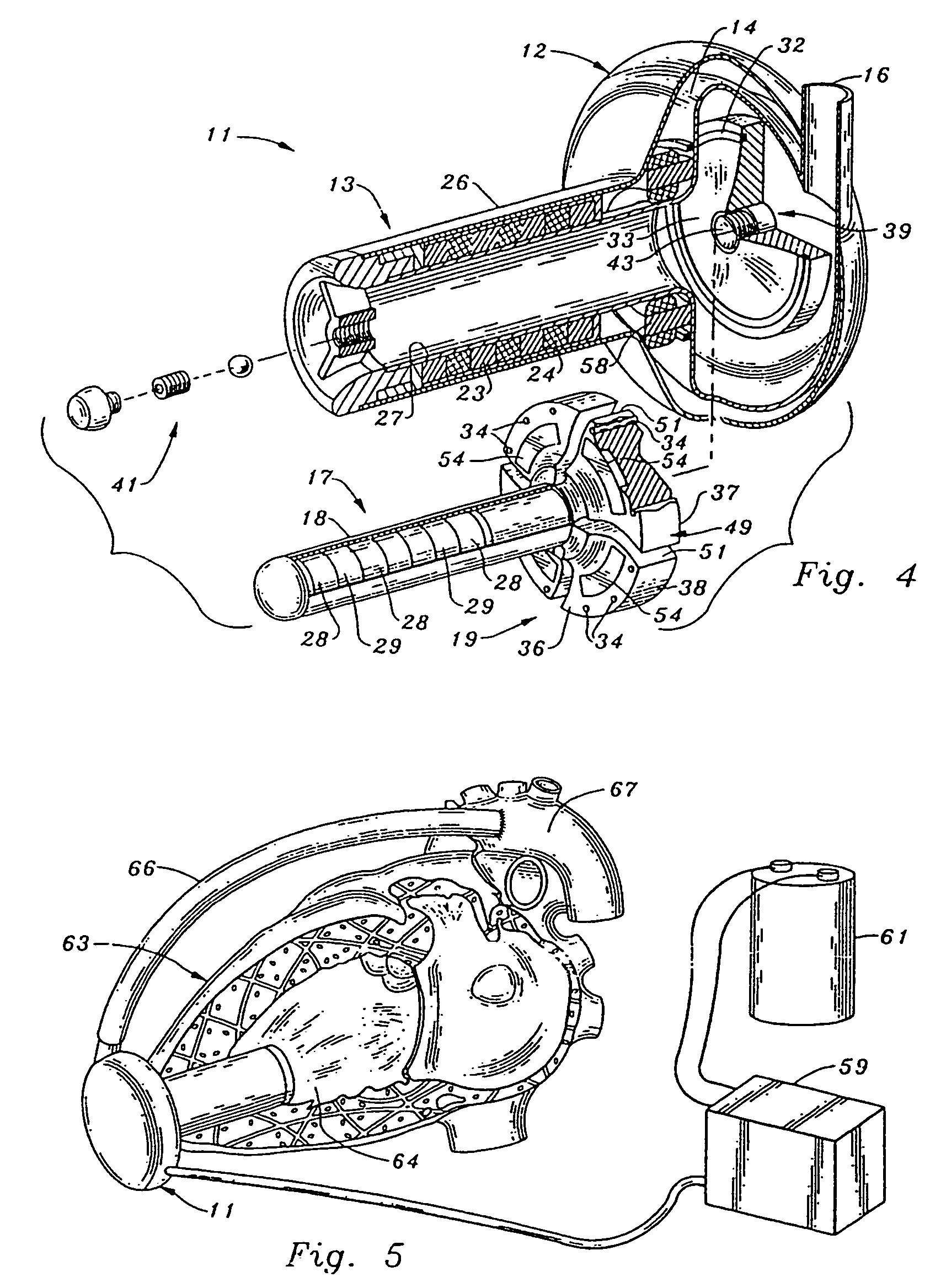

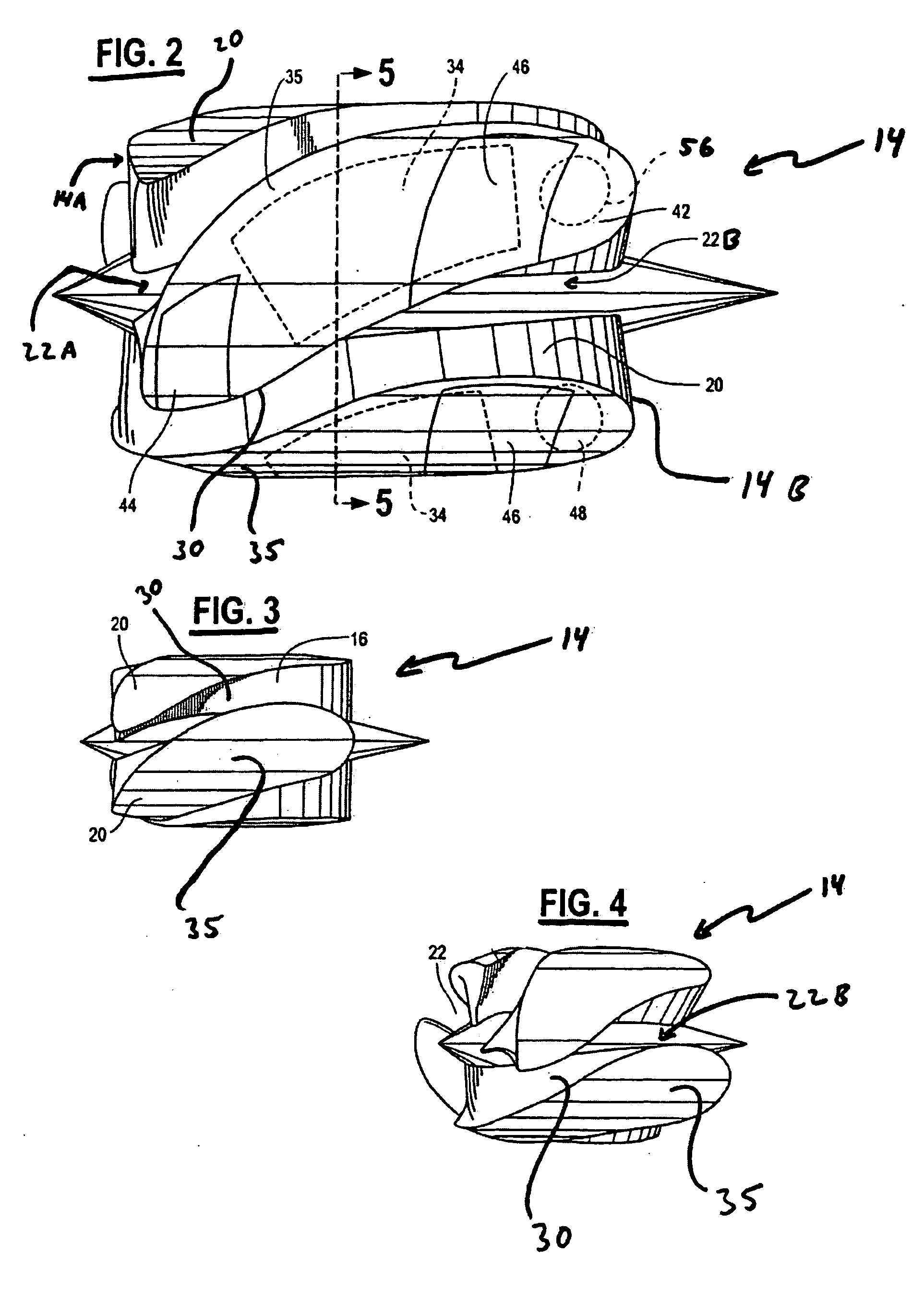

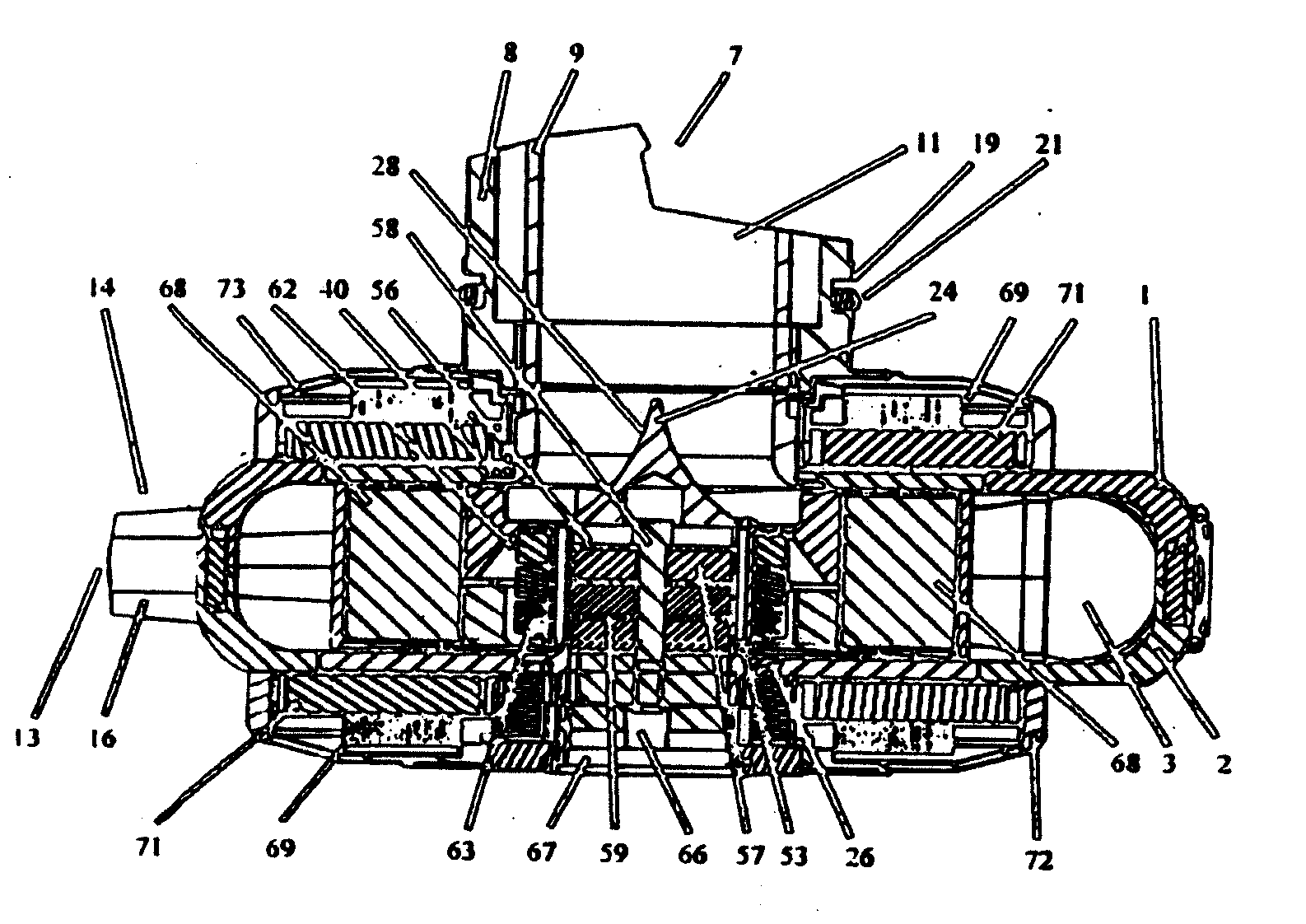

Sealless rotary blood pump

InactiveUS7575423B2Minimize the possibilityShortening its residence timePump componentsMedical devicesImpellerThrust bearing

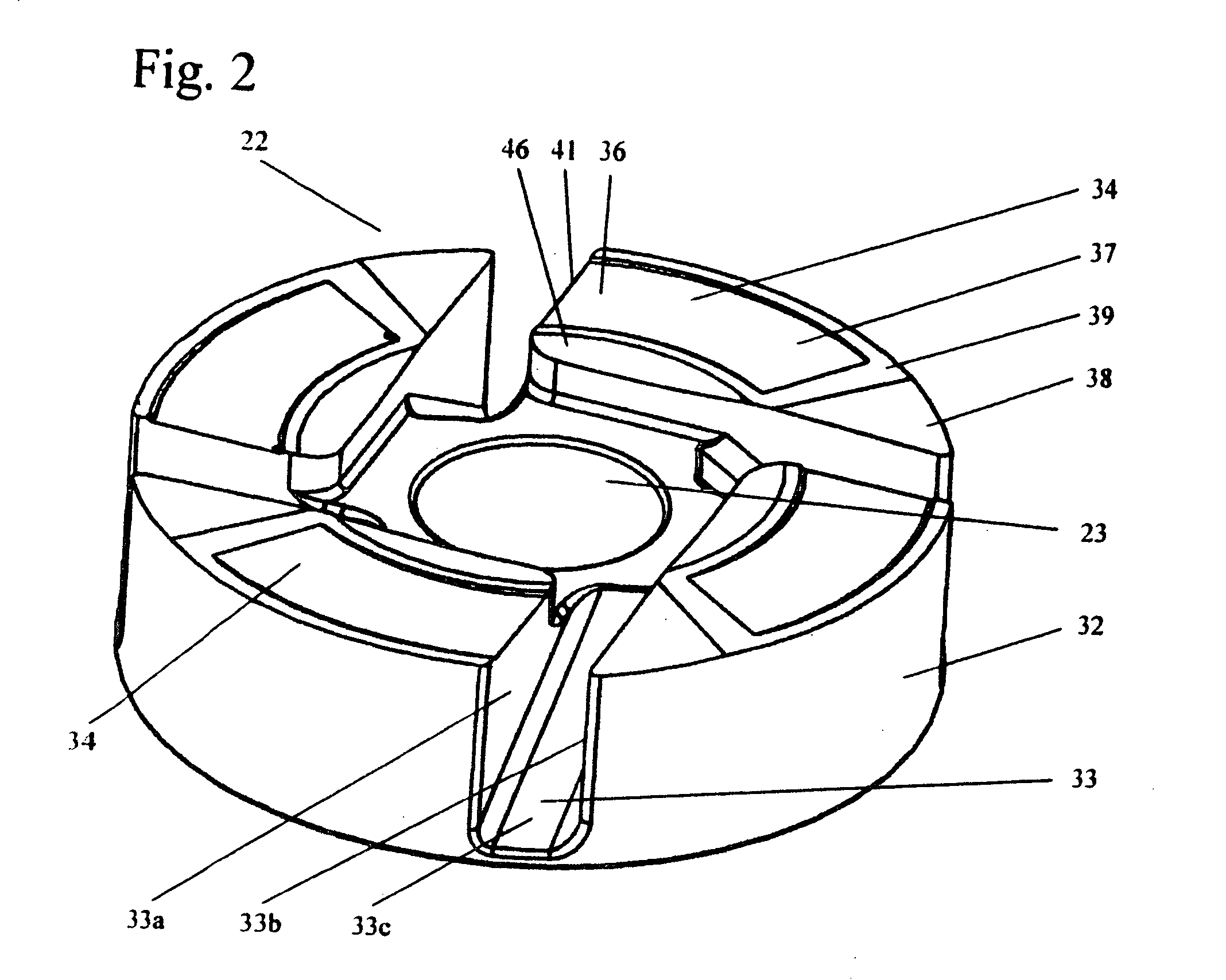

A rotary blood pump is provided which includes a pump housing and a rotor mounted for rotation with the housing. The rotor has an impeller. A rotor motor is provided including a plurality of permanent magnets carried by the impeller. A first motor stator is positioned on one side of the impeller and a second motor stator is positioned on an opposite side of the impeller. The motor stators each include a plurality of electrically conductive coils and pole pieces located within the housing. A plurality of wedge-shaped hydrodynamic thrust bearings are located outside of the axis of the rotor. During rotation of the impeller, the hydrodynamic bearings are separated from the housing by a fluid film and are not in direct mechanical contact with the housing.

Owner:THORATEC CORPORTION

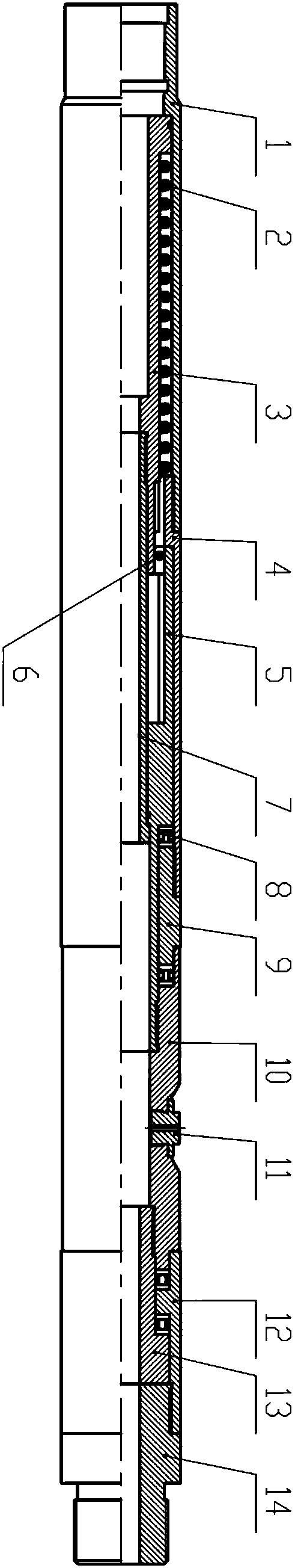

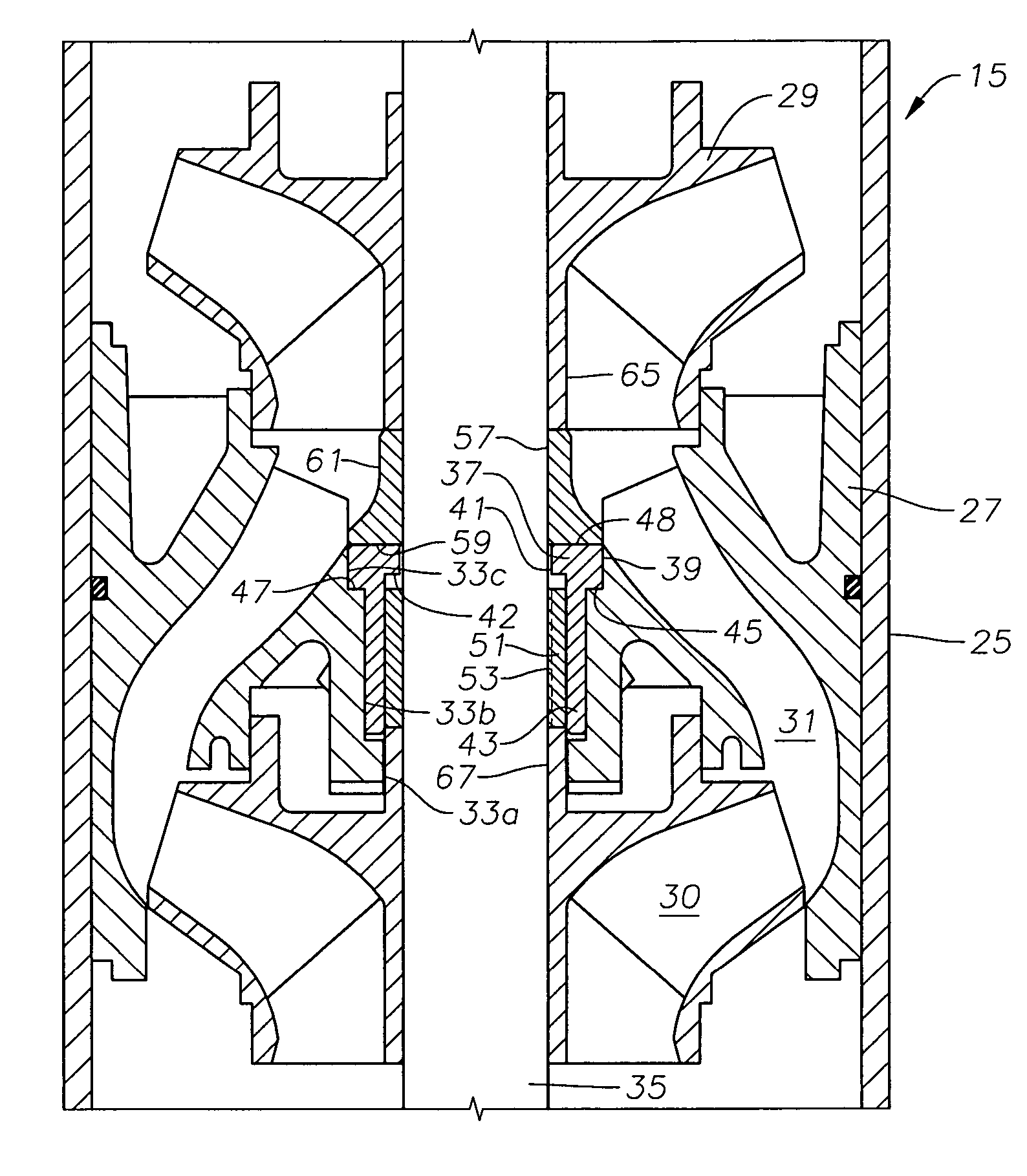

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

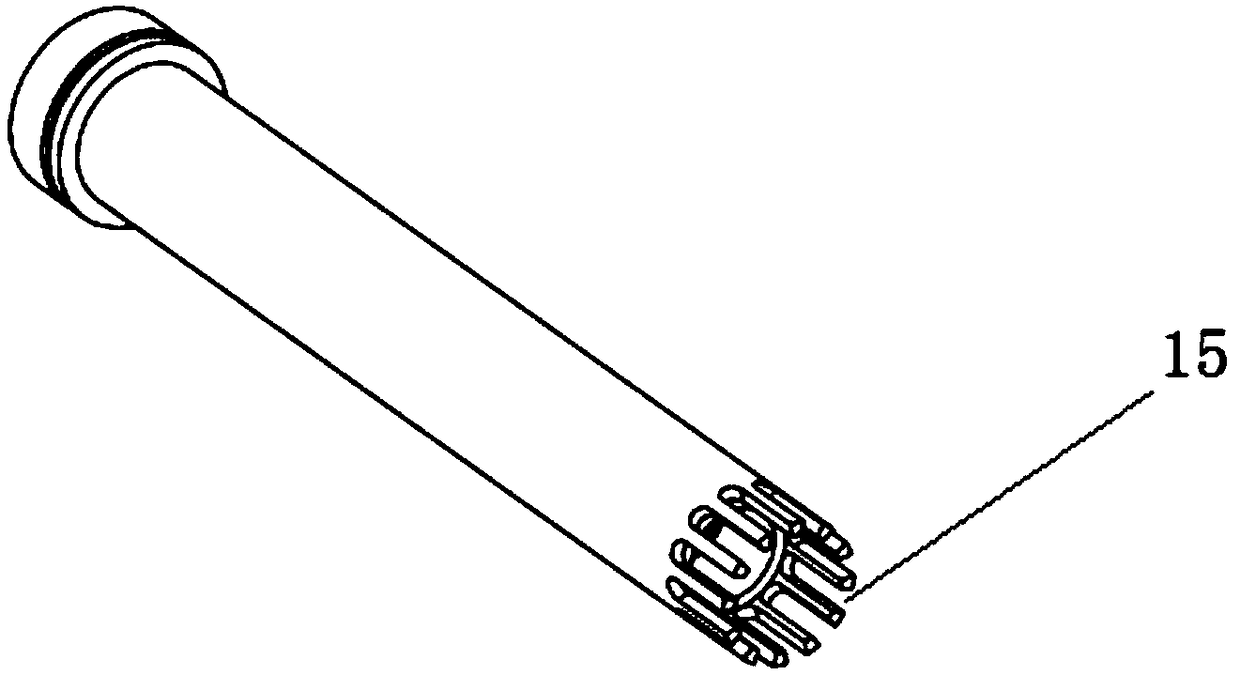

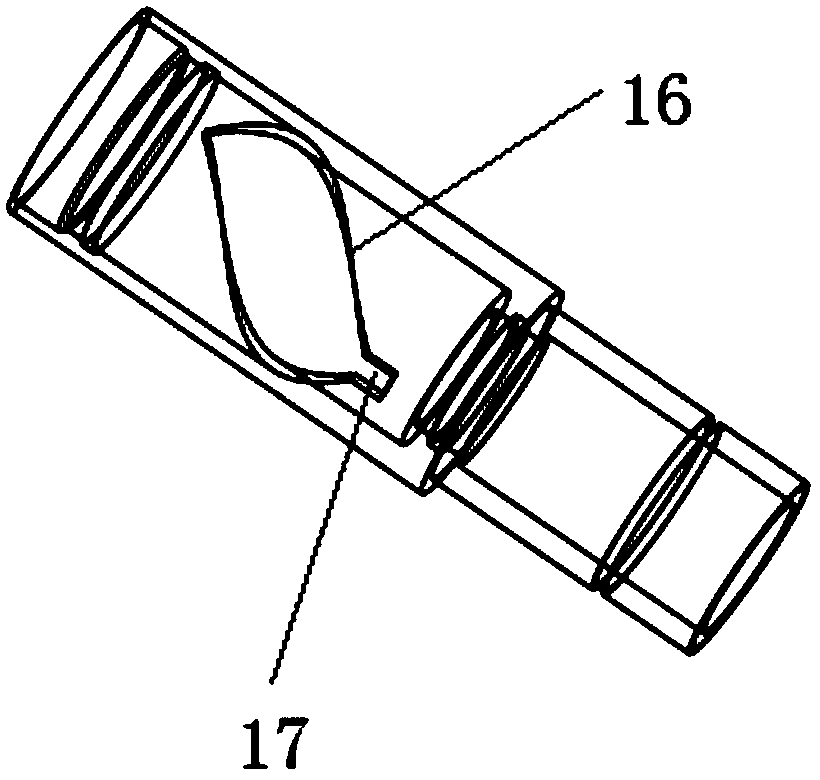

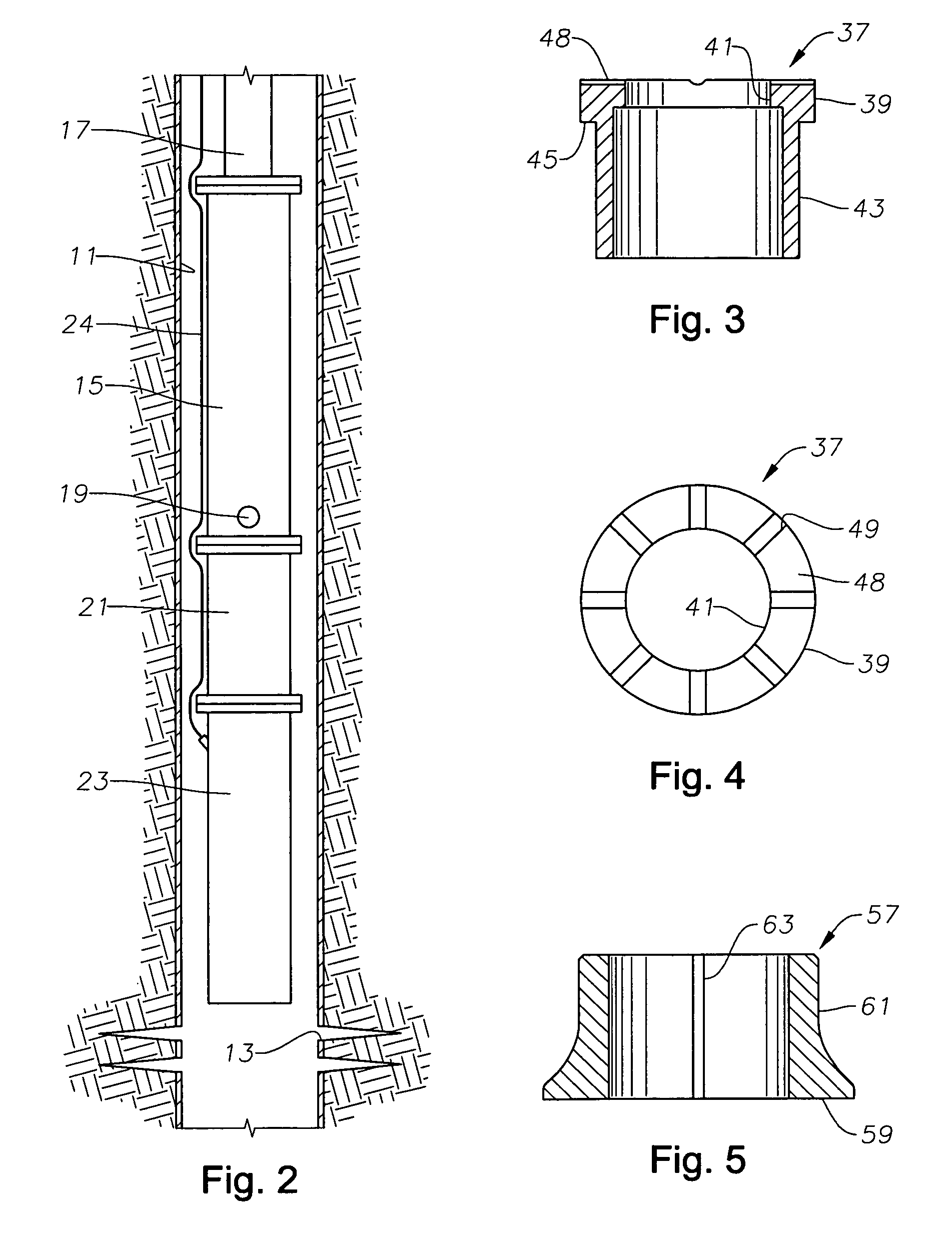

Horizontal well hydraulic directional spraying gun

The invention relates to the technical field of oil and gas well production increase and fracturing operation, in particular to a horizontal well hydraulic directional spraying gun. The horizontal well hydraulic directional spraying gun comprises a directional split tooth cylinder, an enveloping line sleeve, a directional steel ball, thrust bearings and nozzles. The directional split tooth cylinder and an upper connector form an annular space, a reset spring is arranged in the annular space, the right end of the upper connector is connected with an upper housing, the enveloping line sleeve issleeved with the interior of the upper housing, a central rod penetrates through the interior of the enveloping line sleeve to be connected to an internal thread at the right end of the directional split tooth cylinder, and a closed space is defined by the upper housing, the directional split cylinder and the enveloping line sleeve; the directional steel ball is placed in the closed space, the right end of the upper housing is in threaded connection with a connecting sleeve, the thrust bearings are symmetrically disposed at both ends of the connecting sleeve, and the right end of the enveloping line sleeve is connected with a spraying gun casing. Forced orientation of the spraying gun casing can be achieved by a hydraulic driving mode, the orientation success rate is high, tools can be reused after maintenance and protection, and the cost is low.

Owner:JEREH ENERGY SERVICES

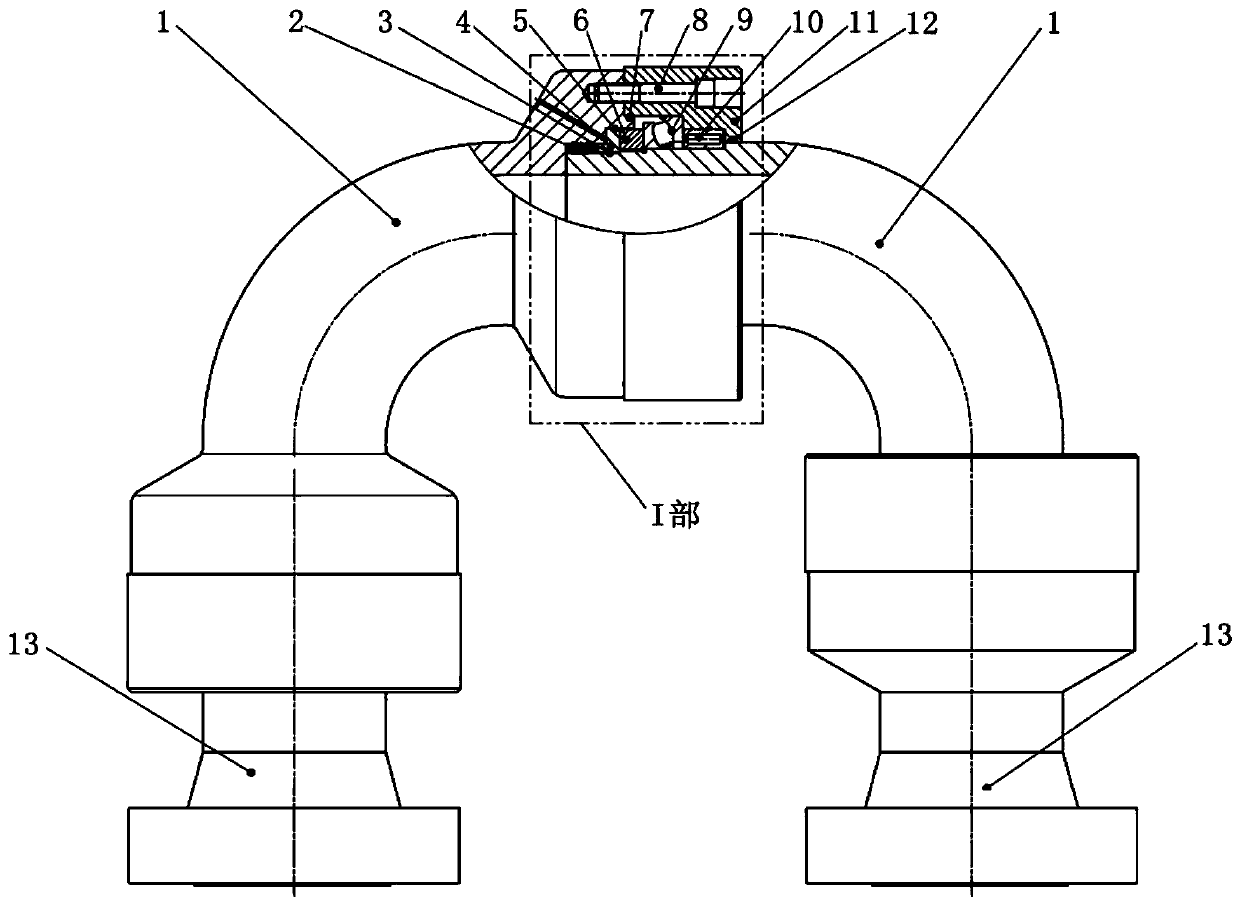

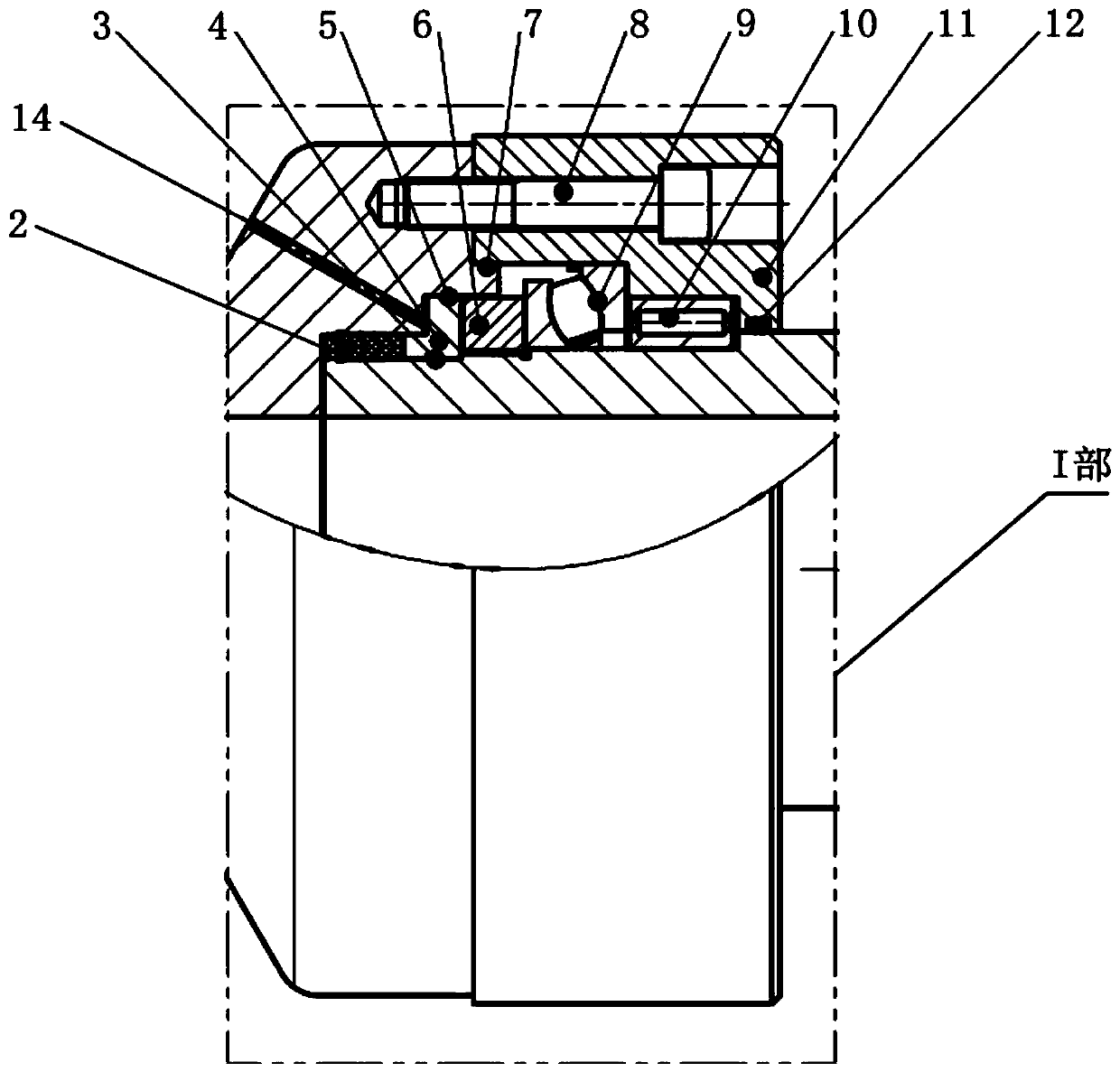

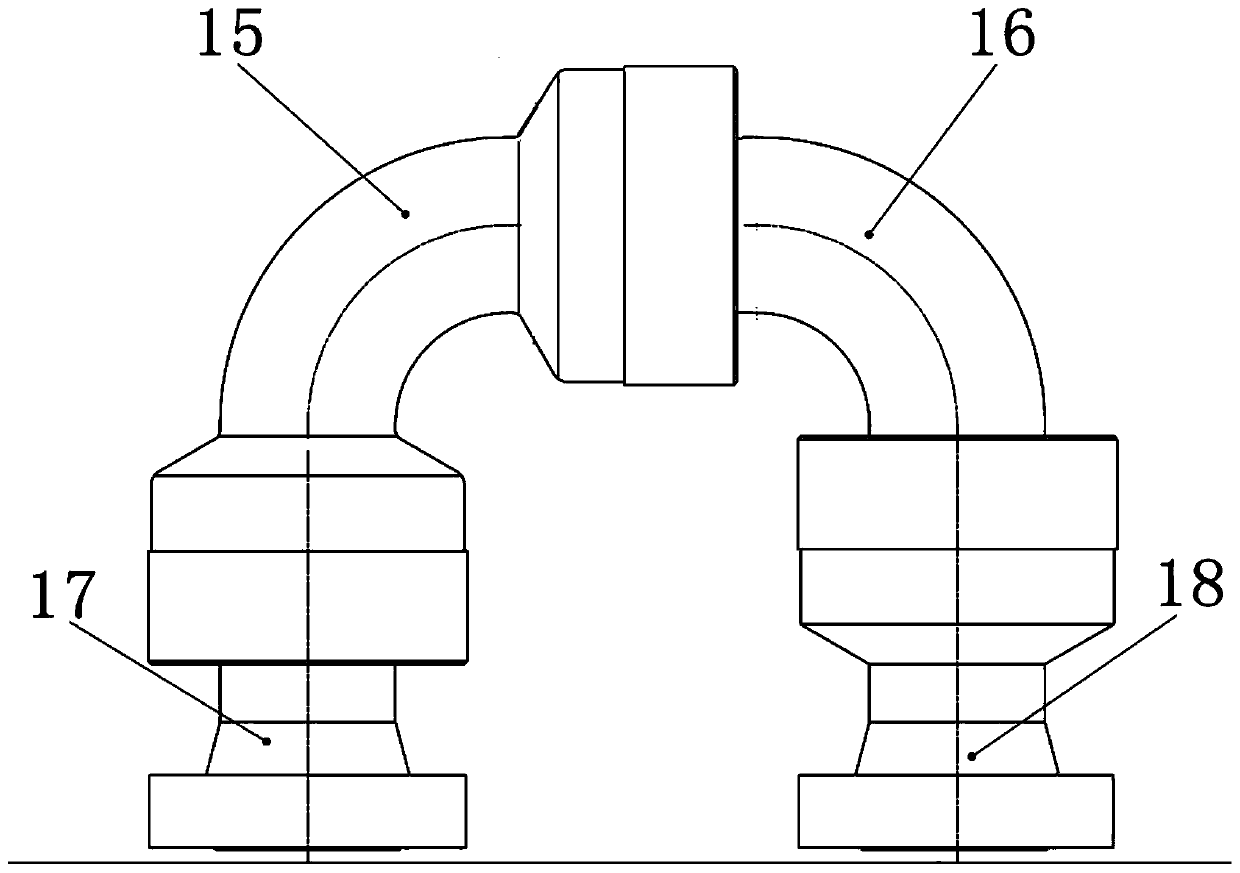

Combination bearing type large-specification movable elbow mechanism

PendingCN111594059ASimple structureReduce volumeDrilling rodsSealing/packingThrust bearingStructural engineering

The invention discloses a combination bearing type large-specification movable elbow mechanism. The combination bearing type large-specification movable elbow mechanism comprises elbows, connection heads, a pressing cover, a packing seal component and a rotating component, wherein positions between the elbows and the connection heads as wall as between the elbows are fixedly connected through thepressing cover and are sealed through the packing seal component, cavities are formed at the positions between pressing cover and the connection heads as wall as between the pressing cover and the elbows and are internally provided with the rotating component, the rotating component is used for relative rotating of the connection heads or the elbows and comprises a centripetal bearing and a thrustbearing, and the elbows and the connection heads as wall as the elbows are flexibly connected. The combination bearing type large-specification movable elbow mechanism has the beneficial effects thatthe combination bearing type large-specification movable elbow mechanism is flexible in connection, smooth in rotating, simple in structure, not limited by the pipe diameter, also not limited by theelbow structure molding method, small in volume and diversified in molding method.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

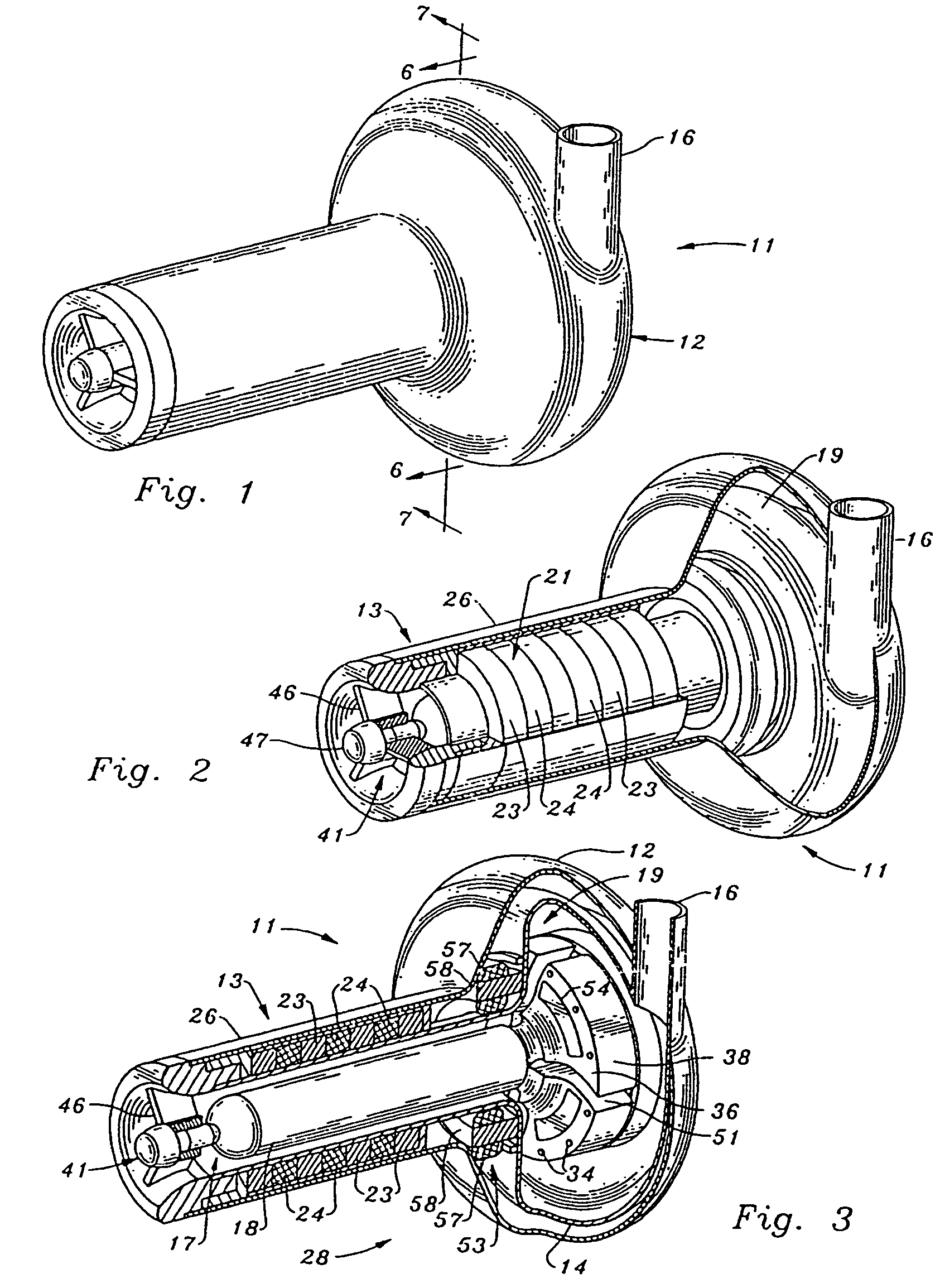

Axial flow pump with mult-grooved rotor

InactiveUS20070100196A1Improve the immunityEasy to washPump componentsControl devicesAxial-flow pumpImpeller

An axial-flow blood pump for pumping blood includes a substantially cylindrical outer enclosure. A tubular housing concentric with and located within the outer enclosure has at one end an inlet and at an opposite end an outlet. A motor stator is concentric with and located between the outer enclosure and the tubular housing. An impeller is concentric with and located within the tubular housing. The impeller is suspended in operation by a combination of passive magnetic forces between magnets within the impeller or magnetized regions of the impeller and the motor stator and hydrodynamic thrust forces generated as blood flows between the tubular housing and a plurality of hydrodynamic thrust bearing surfaces located on the impeller. A volute may be in fluid-tight connection with the outlet of the tubular housing for receiving blood in the axial direction and directing blood in a direction normal to the axial direction. The volute has a flow-improving member extending axially from the volute and into and coaxially with the tubular housing.

Owner:HEARTWARE INC

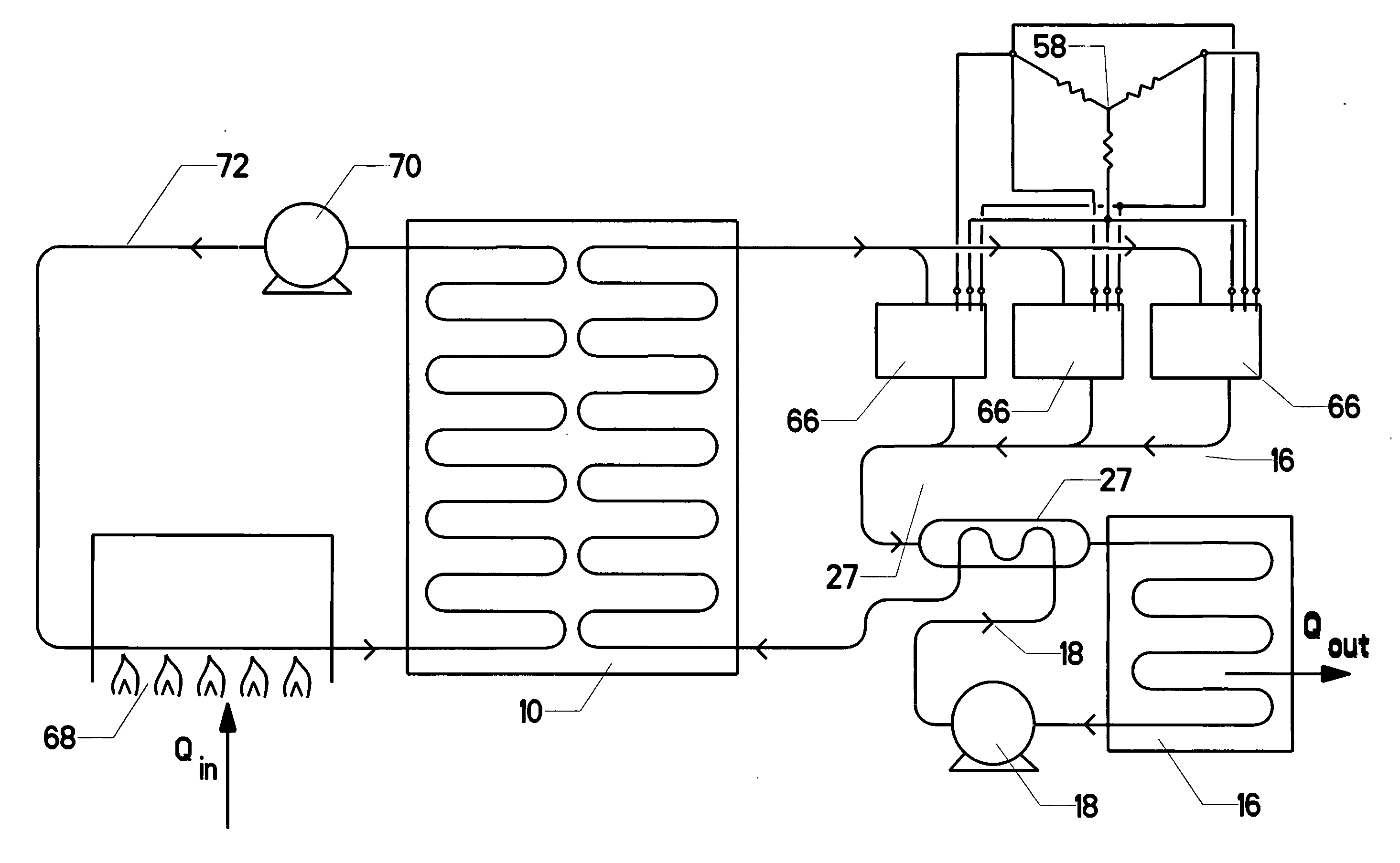

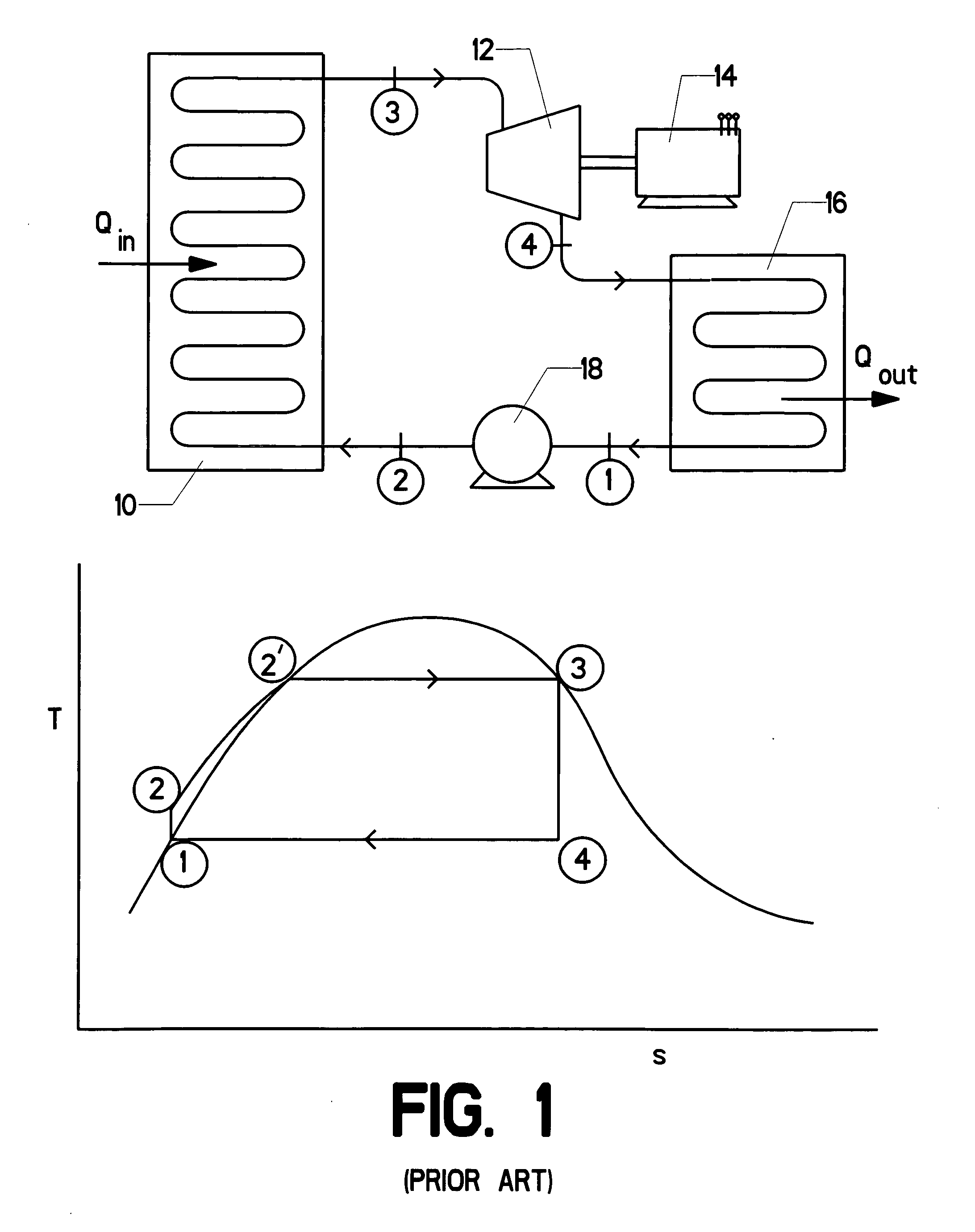

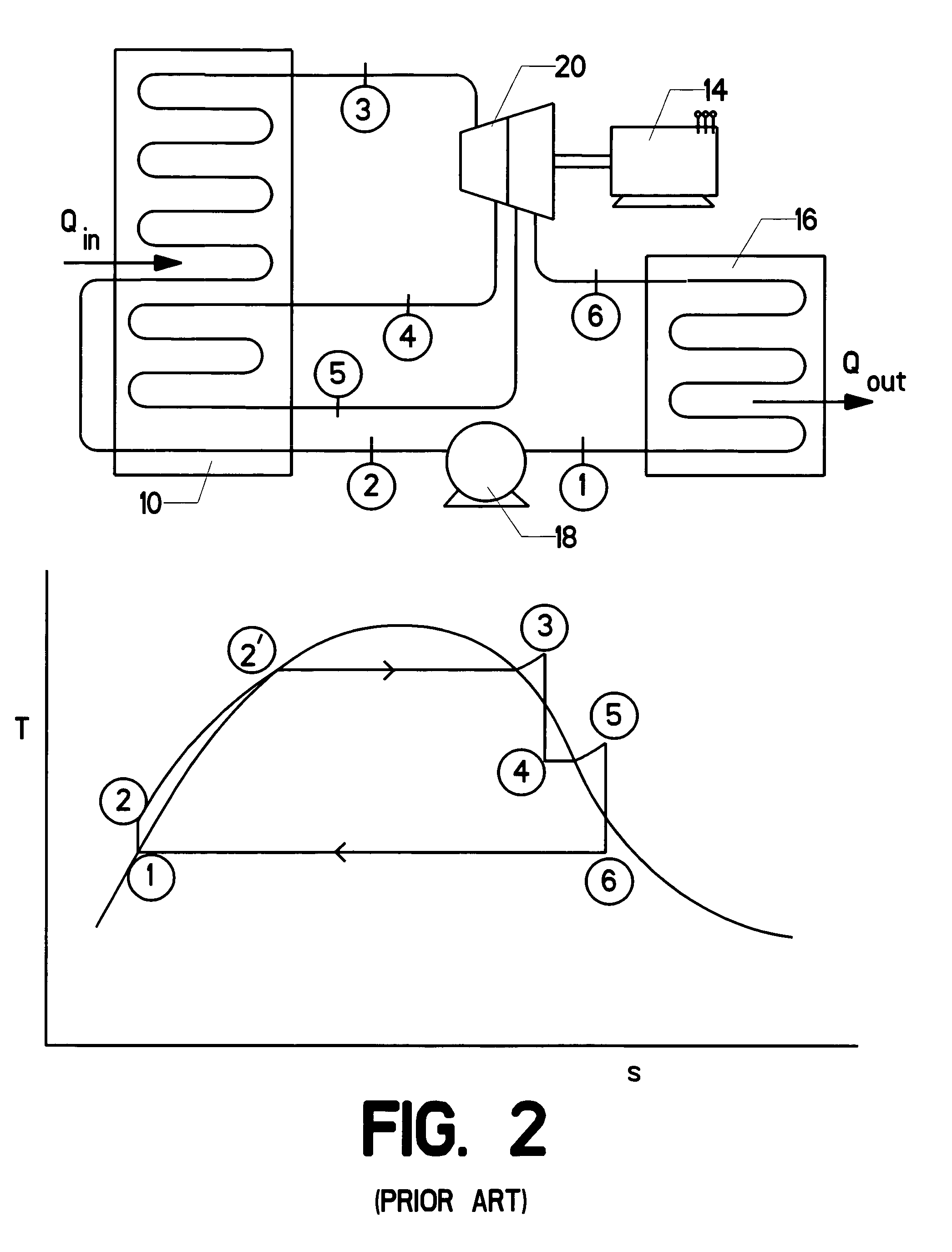

Rankine cycle heat recovery methods and devices

InactiveUS20090277400A1Minimize frictional lossIncrease speedLiquid coolingCoolant flow controlRecovery methodMagnetic bearing

An integrated expansion turbine / electrical generator assembly (collectively referred to as a “turbo-generator”) suitable for use in waste heat recovery and similar applications. The turbo-generator uses a common shaft mounting a one or more stage expansion turbine and a homopolar electrical generator. Magnetic levitating axial and thrust bearings are used to hold the common shaft in its proper position with a fixed housing. The magnetic bearings minimize frictional losses, allowing the common shaft to spin at a very high rotational velocity. Sensor rings continually monitor the common shaft's position. This information is used by control electronics to regulate the magnetic bearings in order to hold the rotating shaft's position. Electrical energy is extracted from the rotating shaft in the form of a direct current. Preferably integrated power-switching electronics are used to generate single or three-phase AC power, which can be phase-matched to an existing power grid or other application.

Owner:DANFOSS AS

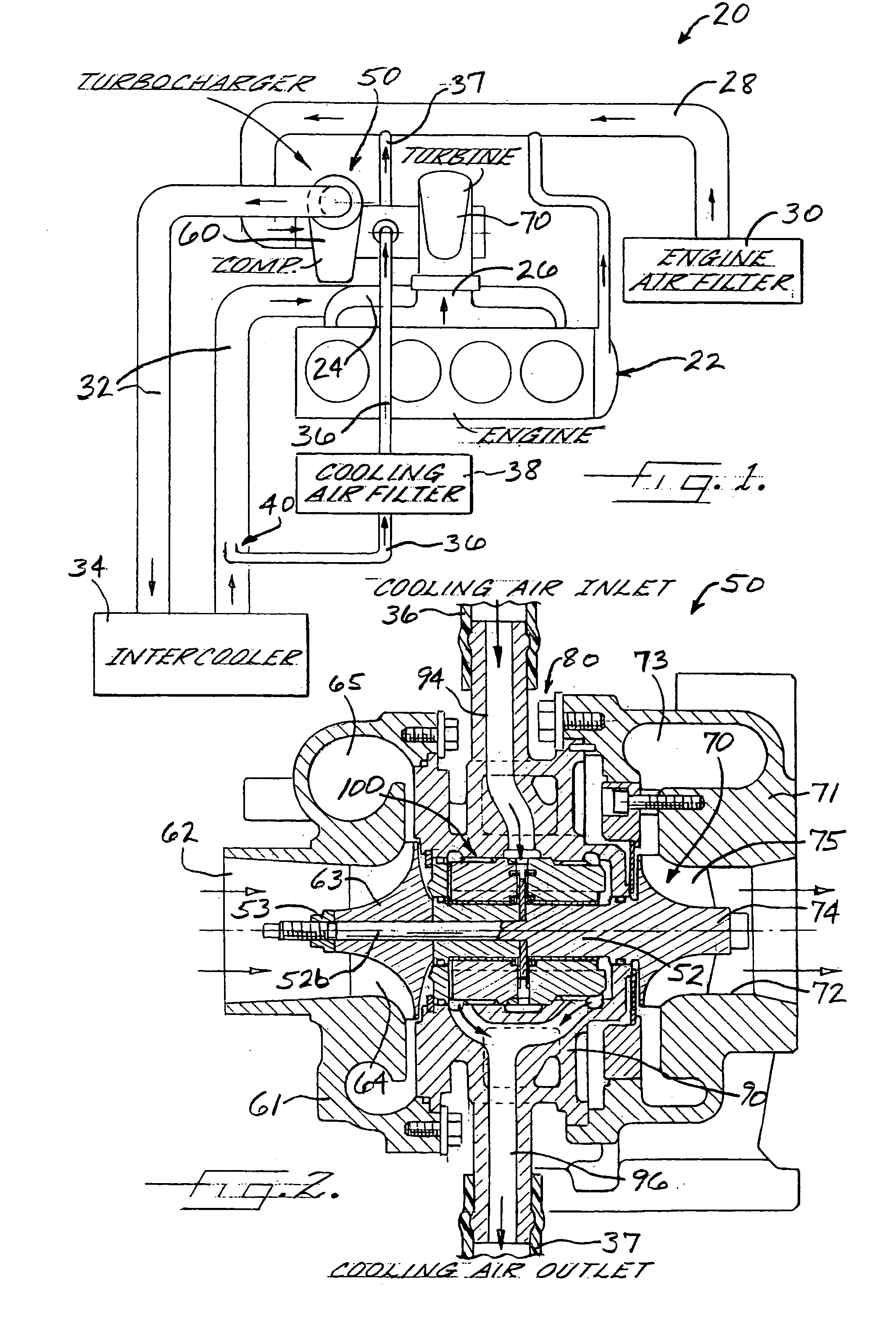

Rotating blowout preventer with independent cooling circuits and thrust bearing

A rotary blowout preventer has a first and a second fluid circuit. Each of the fluid circuits are defined into and out of a stationary body and between the stationary body, a rotating body, and two seals. The first fluid circuit is physically independent from the second fluid circuit although they share a seal interface. A fluid is introduced into the first fluid circuit at a pressure responsive to the well bore pressure. A fluid is introduced into the second fluid circuit at a pressure responsive to and lower than the pressure of the fluid in the first circuit. Adjustable orifices are connected to the outlet of the first and second fluid circuits to control such pressures within the circuits. Such pressures affect the wear rates of the seals. The system can therefore control the wear rate of one seal relative to another seal. A thrust bearing is added to share the load placed upon the upper bearings. The thrust bearing is connected between the top end of a packer sleeve and the stationary body.

Owner:WEATHERFORD CANADA PARTNERSHIP

Stabilizing drive for contactless rotary blood pump impeller

A rotary blood pump includes a casing defining a pumping chamber. The pumping chamber has a blood inlet and a tangential blood outlet. One or more motor stators are provided outside of the pumping chamber. A rotatable impeller is within the pumping chamber and is adapted to cause blood entering the pumping chamber to move to the blood outlet. The impeller has one or more magnetic regions. The impeller is radially constrained in rotation by magnetic coupling to one or more motor stators and is axially constrained in rotation by one or more hydrodynamic thrust bearing surfaces on the impeller.

Owner:HEARTWARE INC

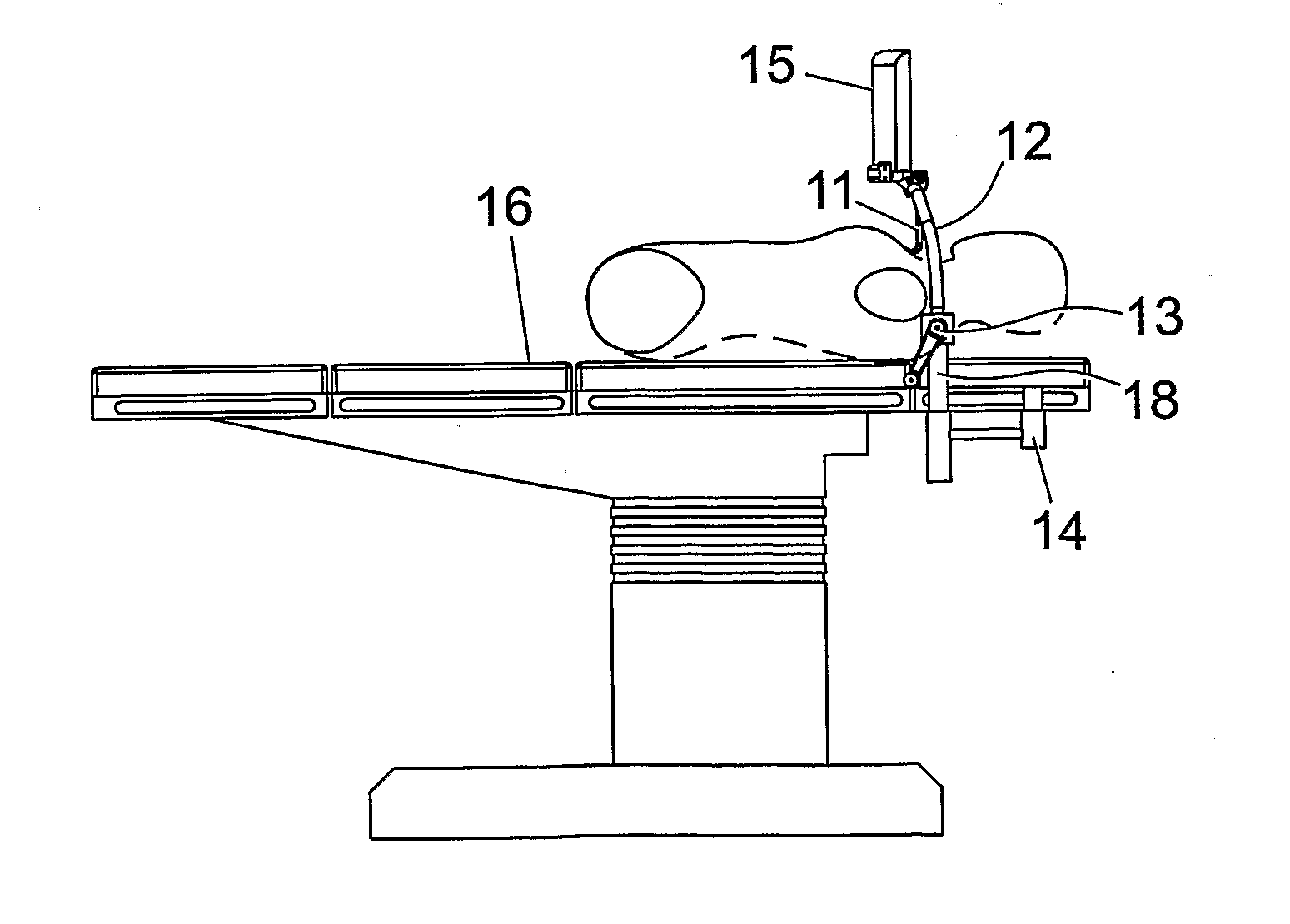

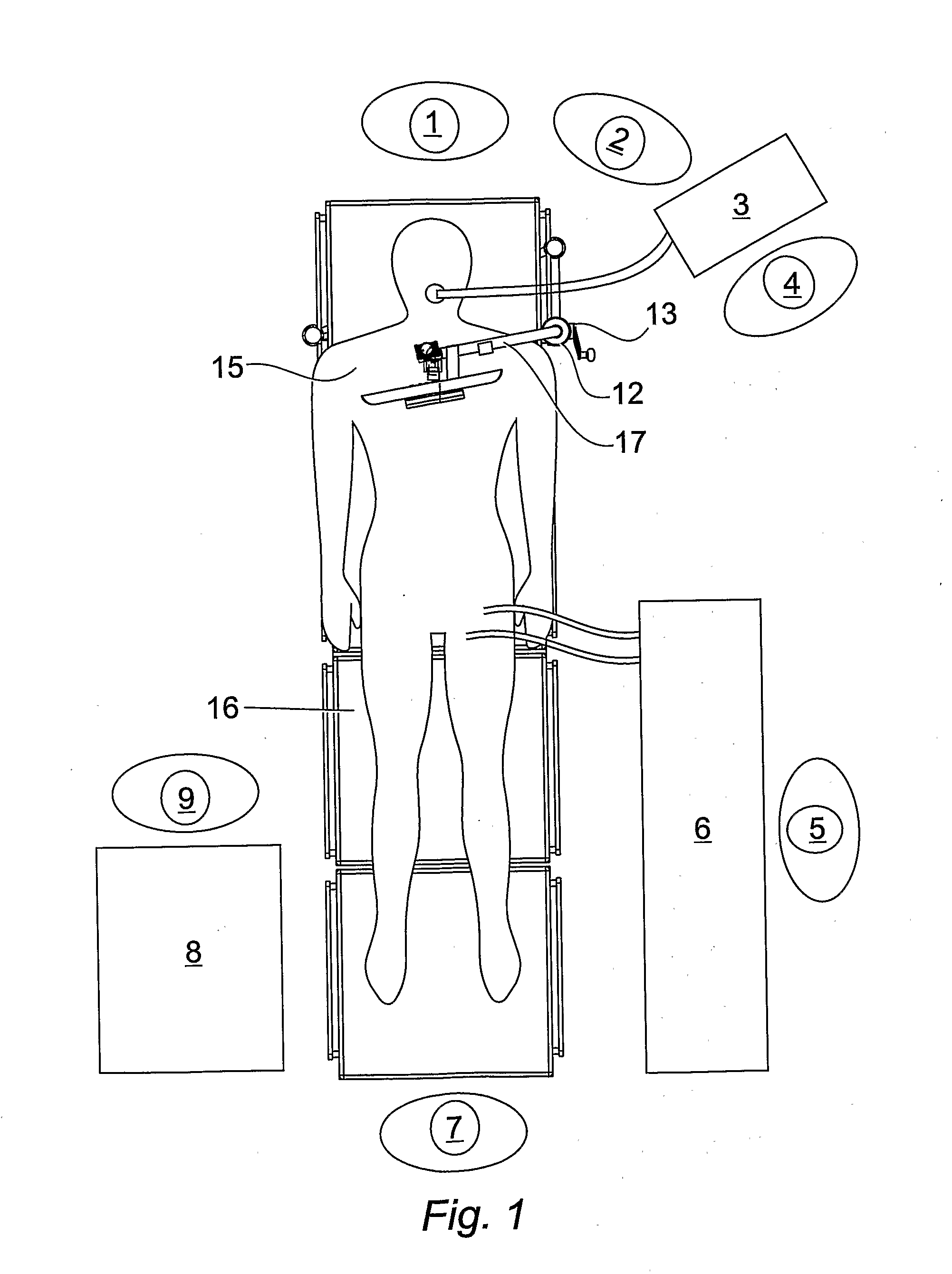

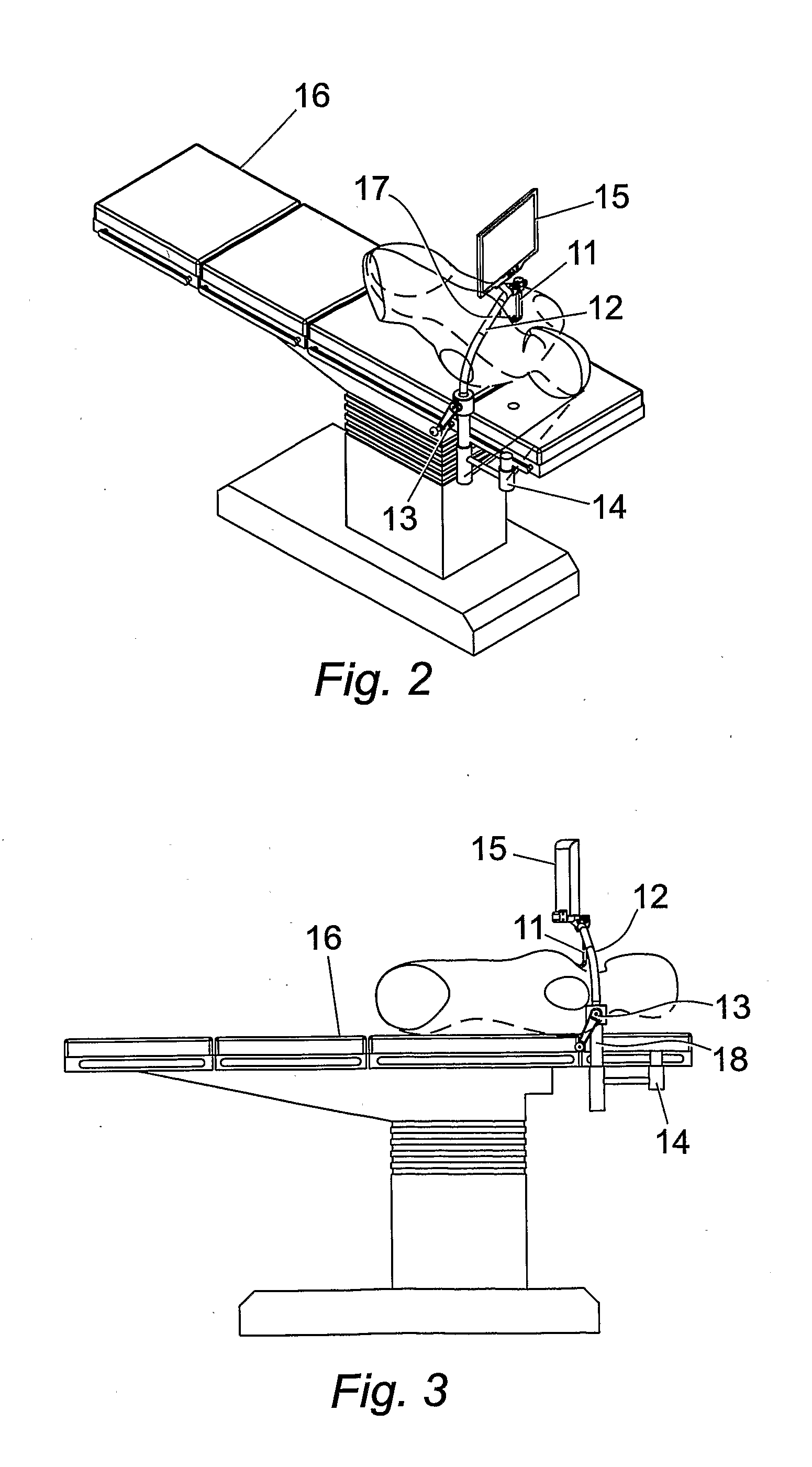

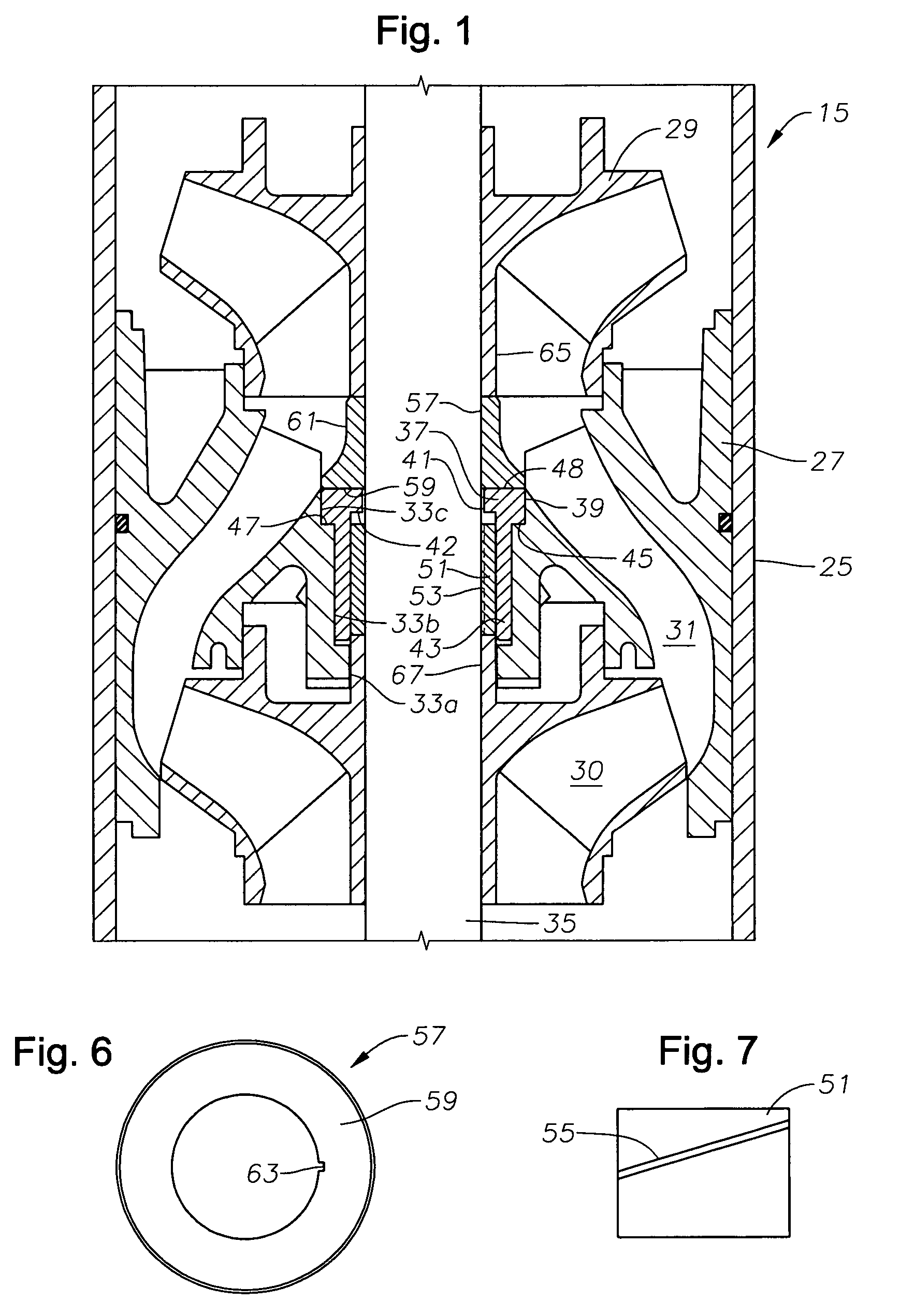

Retractor

ActiveUS20100312069A1Prevent slippingIncreased riskDiagnosticsOperating tablesThrust bearingOperating theatres

Apparatus for use in an operating theatre equipped with a surgical table, comprises a lifting frame (12) attachable to the surgical table and adapted for lifting a body part of a subject undergoing a surgical procedure upon the surgical table, and comprising an upright support post (18) incorporating a jack (54), and a lifting arm (17) pivotally mounted upon the post, whereby the arm can be turned about the upright support post on thrust bearing (57) to either overhang the surgical table, or be pivoted away to permit access to the surgical table. The arm is adapted to support a retractor that comprises a blade portion incorporating a plurality of independent lighting devices positioned in light ports (71, 72, 73) and configured to provide discrete illumination selectively to zones within the surgical field according to (a) a predetermined sequence programme, or (b) a sequence determined by a user of the retractor.

Owner:CARDIOPRECISION

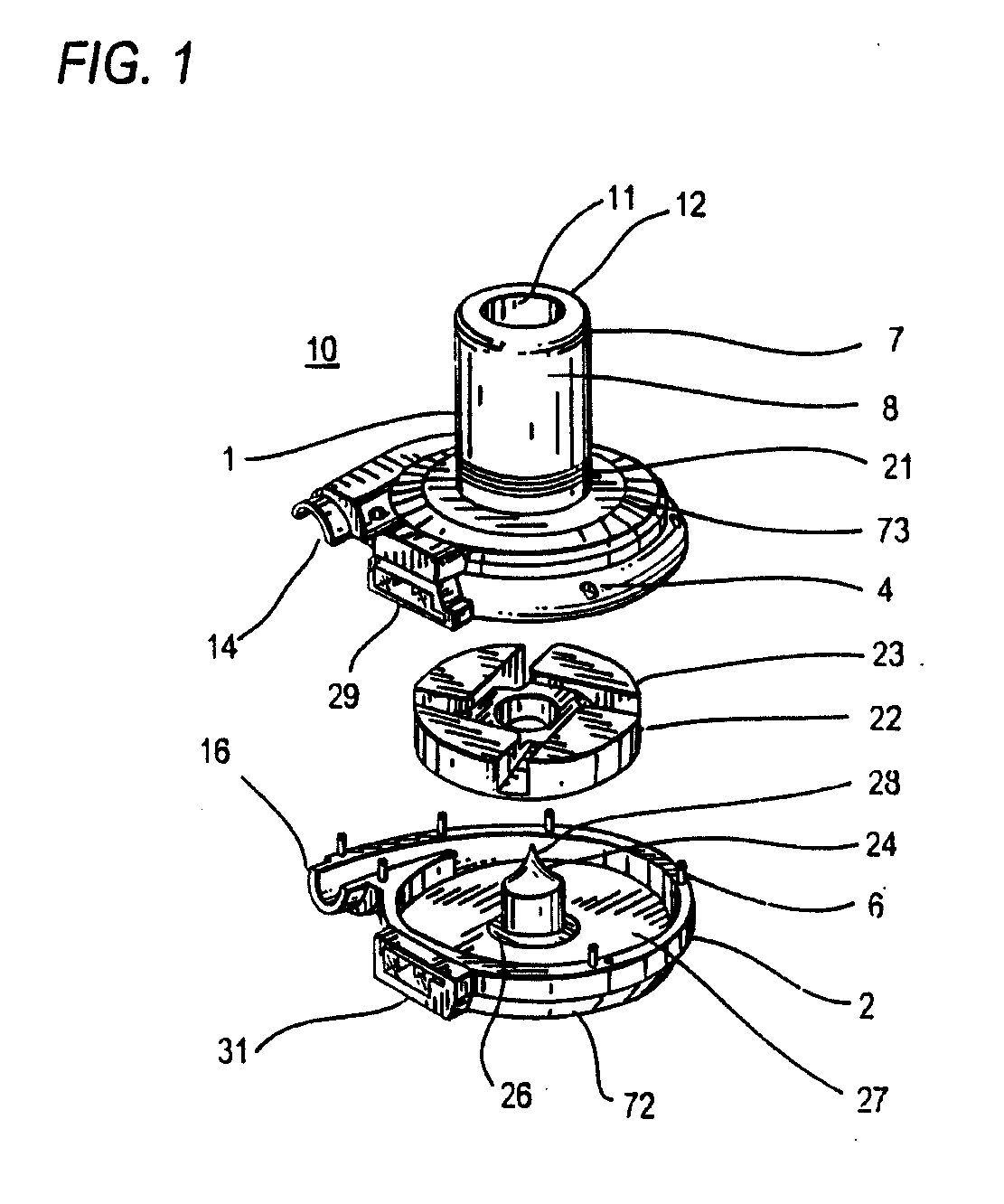

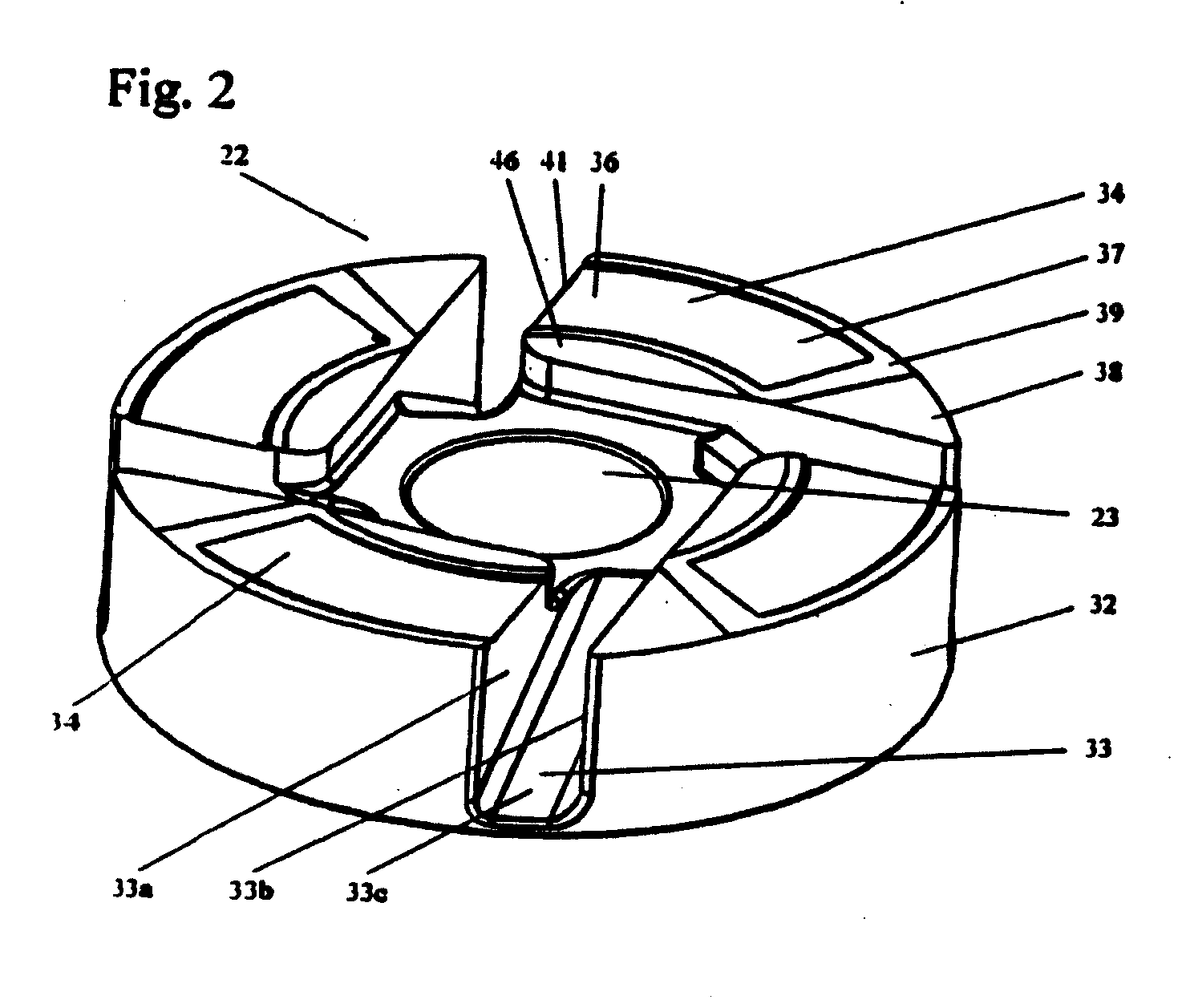

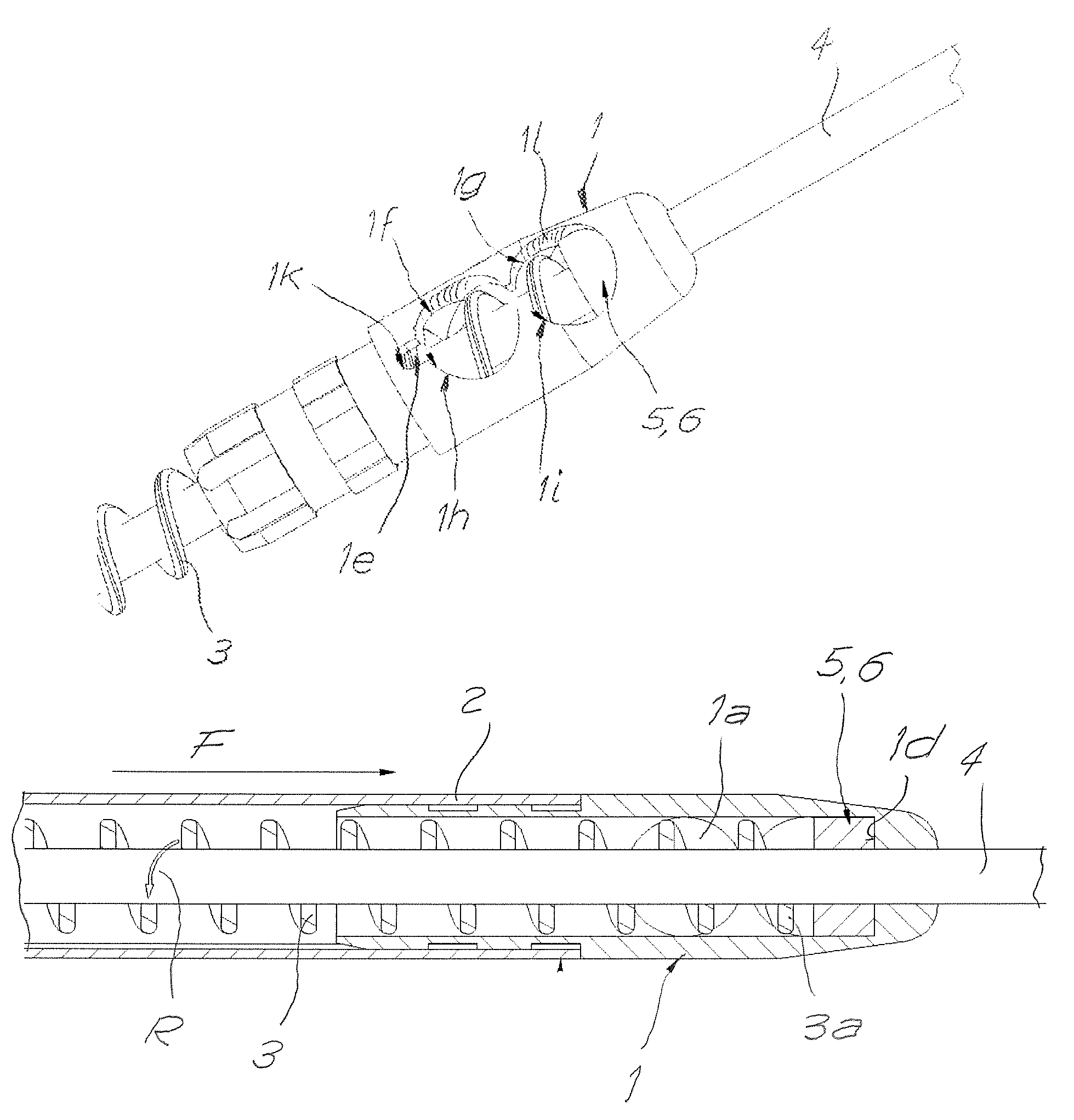

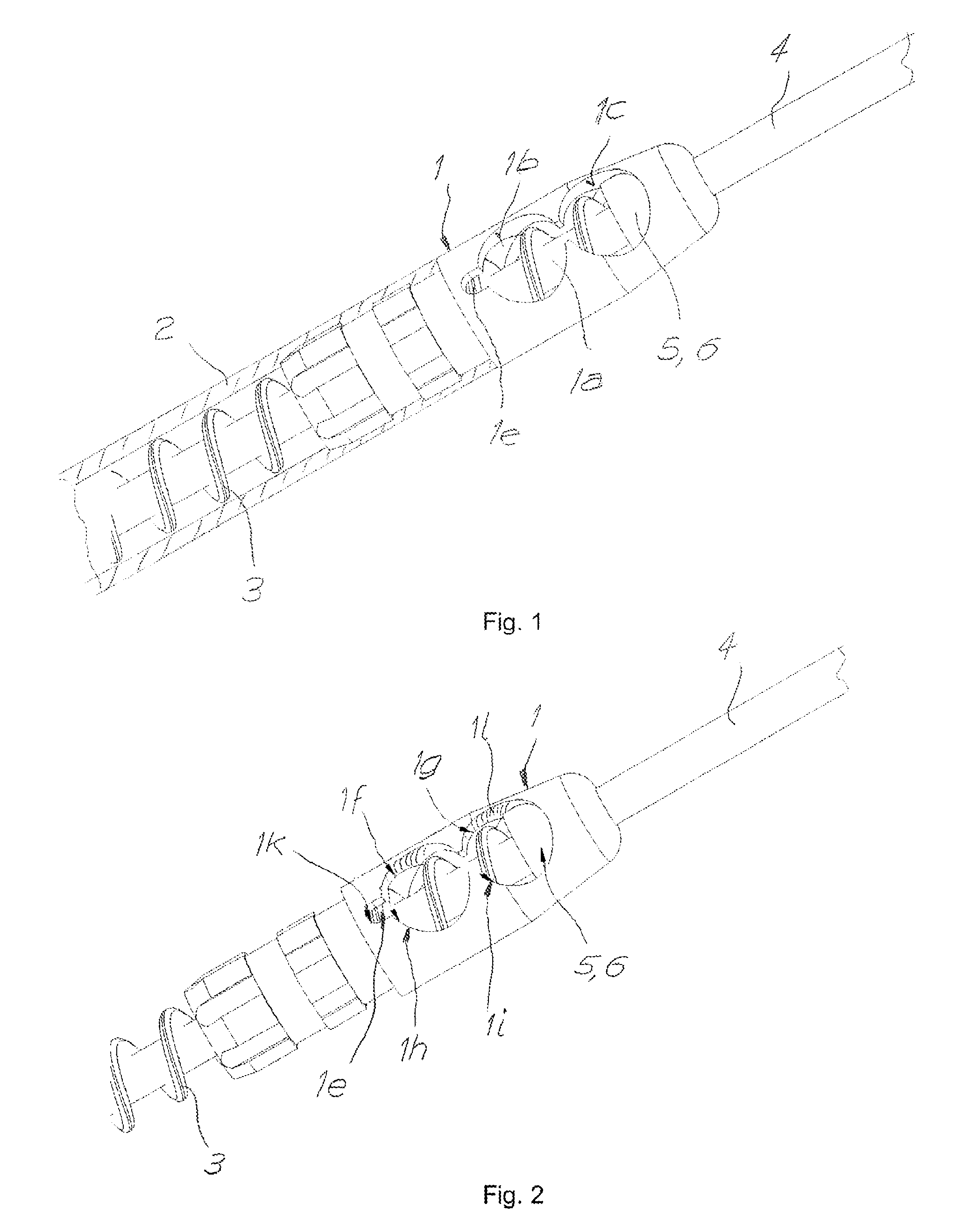

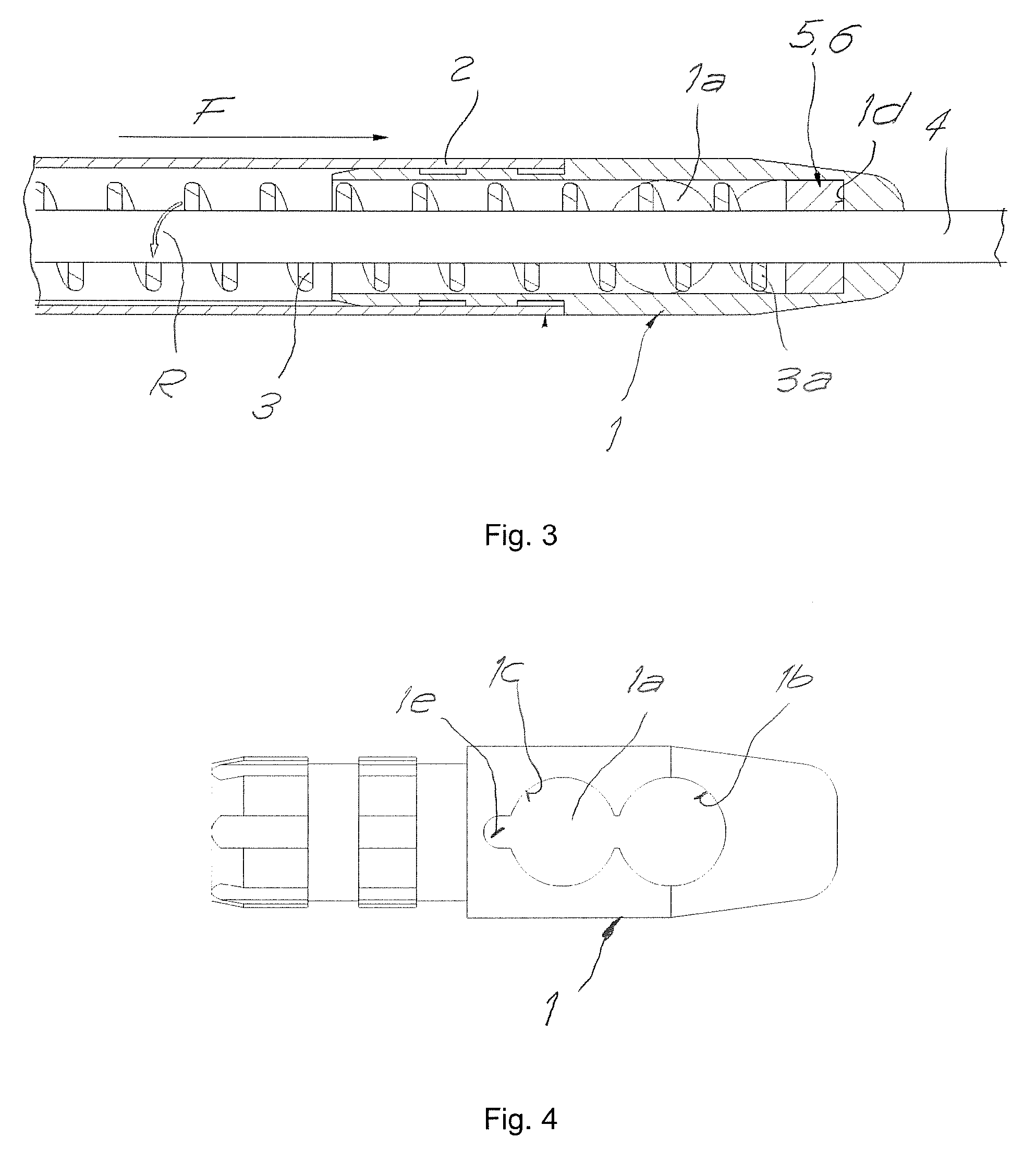

Catheter for aspirating, fragmenting and removing extractable material from blood vessels

The invention relates to a catheter for aspirating, fragmenting and removing extractable material from hollow bodies, in particular thrombi and emboli from blood vessels, with a working head, which is arranged at the distal end of the catheter, is axially displaceable along a guide wire, independently thereof, and comprises at least one lateral opening. The catheter comprises a flexible feed screw which has a distal end and a proximal end and which can be rotated at a speed of rotation by means of a rotary drive of a drive unit remote from the working head. A flexible tube which surrounds the feed screw and is connected to the working head removes the material or the detached thrombi and emboli fragments. The feed screw is designed as a shearing cutting tool which cooperates with the opening in the working head in order to size-reduce and remove the materials or aspirated and / or detached thrombi and emboli which penetrate between the peripheral edges of the feed screw and edges of the openings. A thrust bearing is arranged between the distal end of the feed screw and the working head so as to axially support the feed screw, and is designed as a disc which can be rotated by the feed screw during operation.

Owner:STRAUB MEDICAL AG

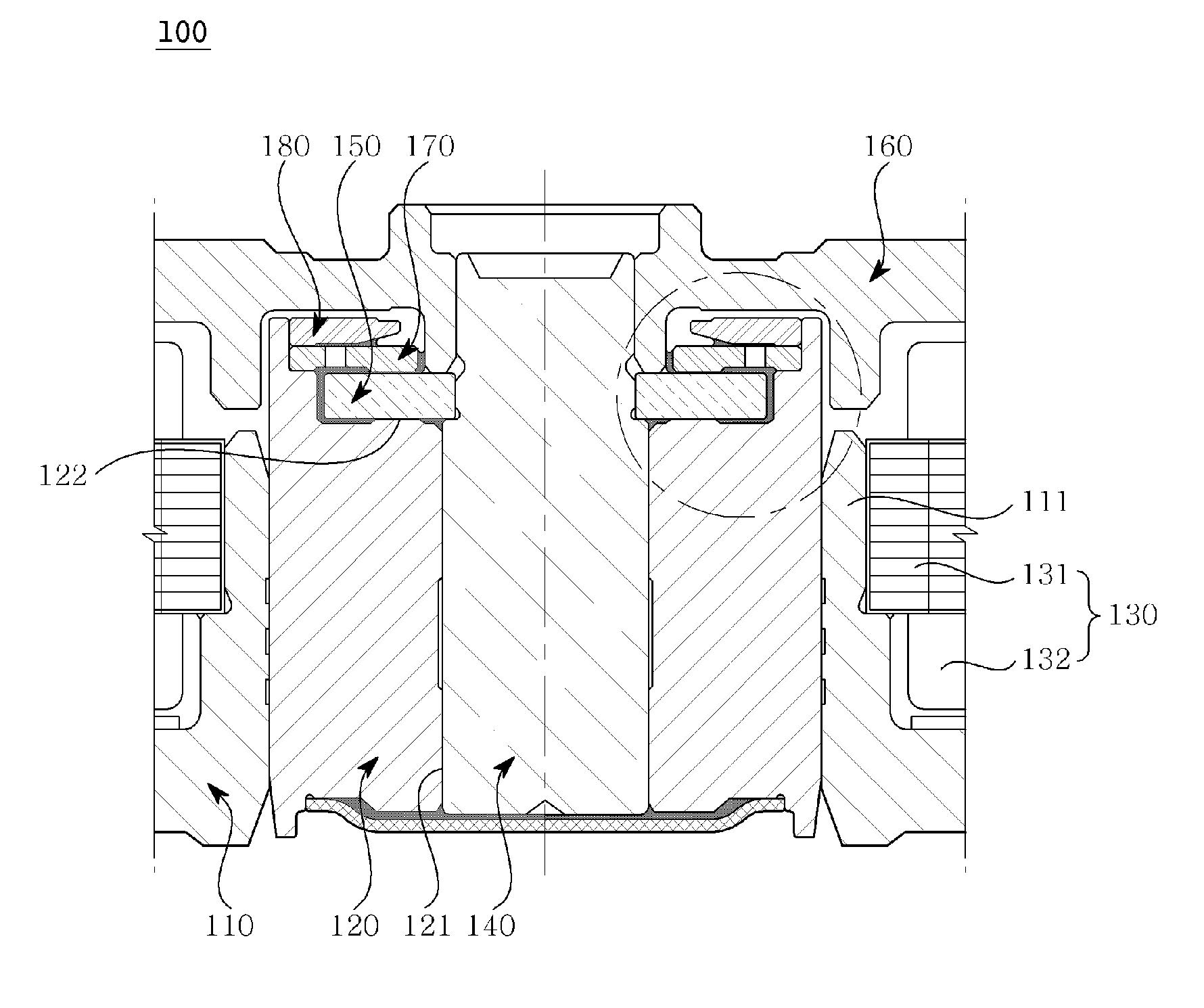

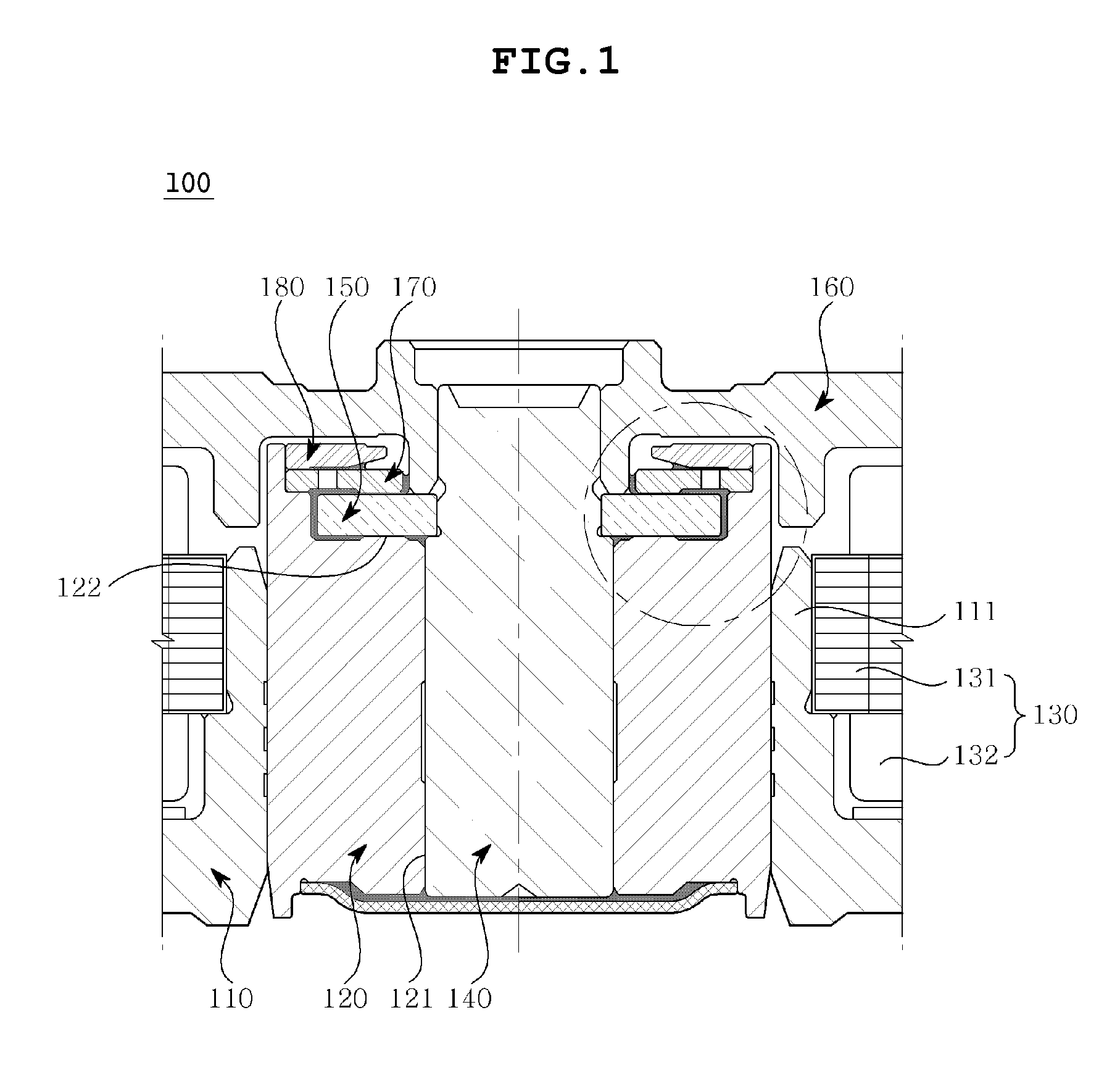

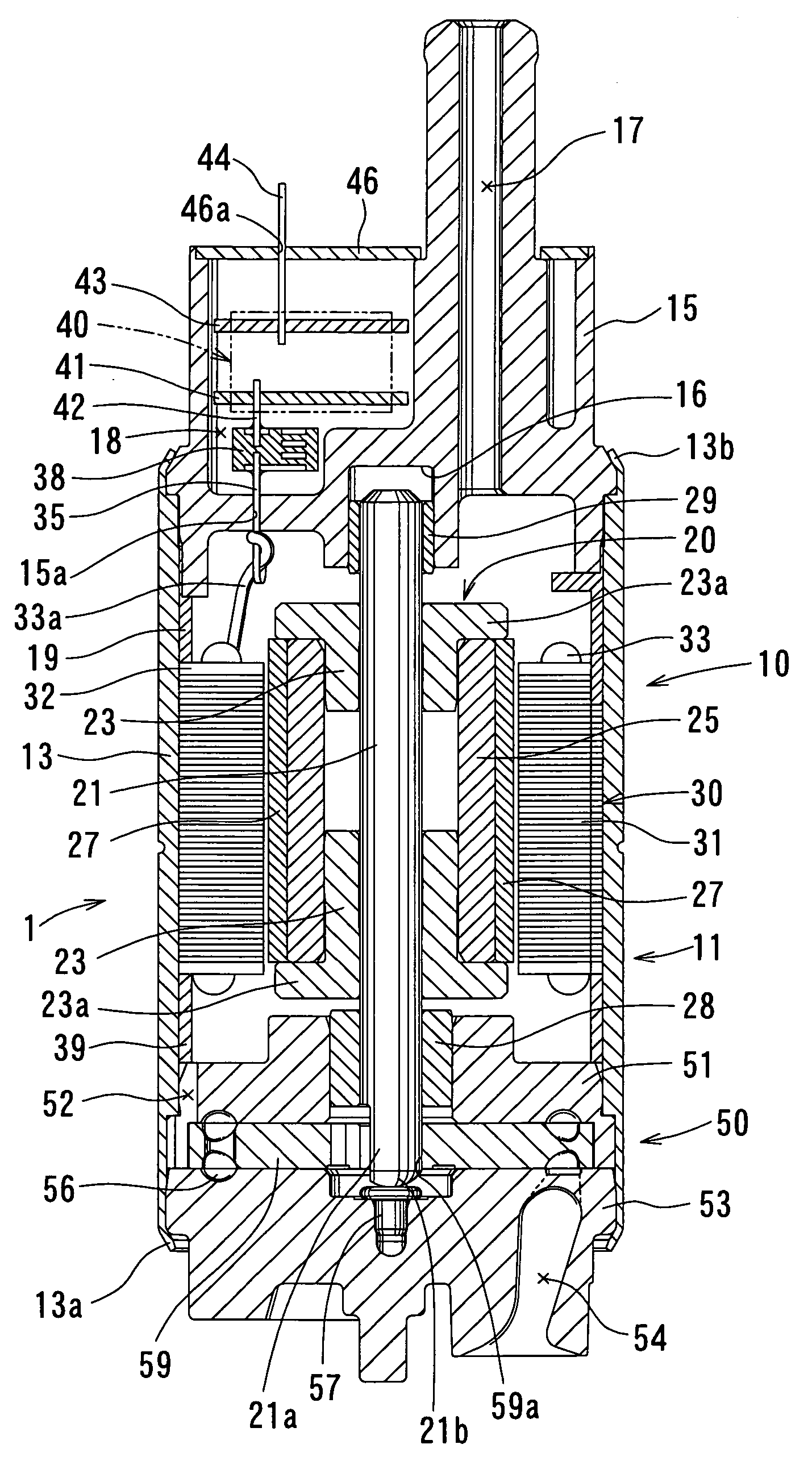

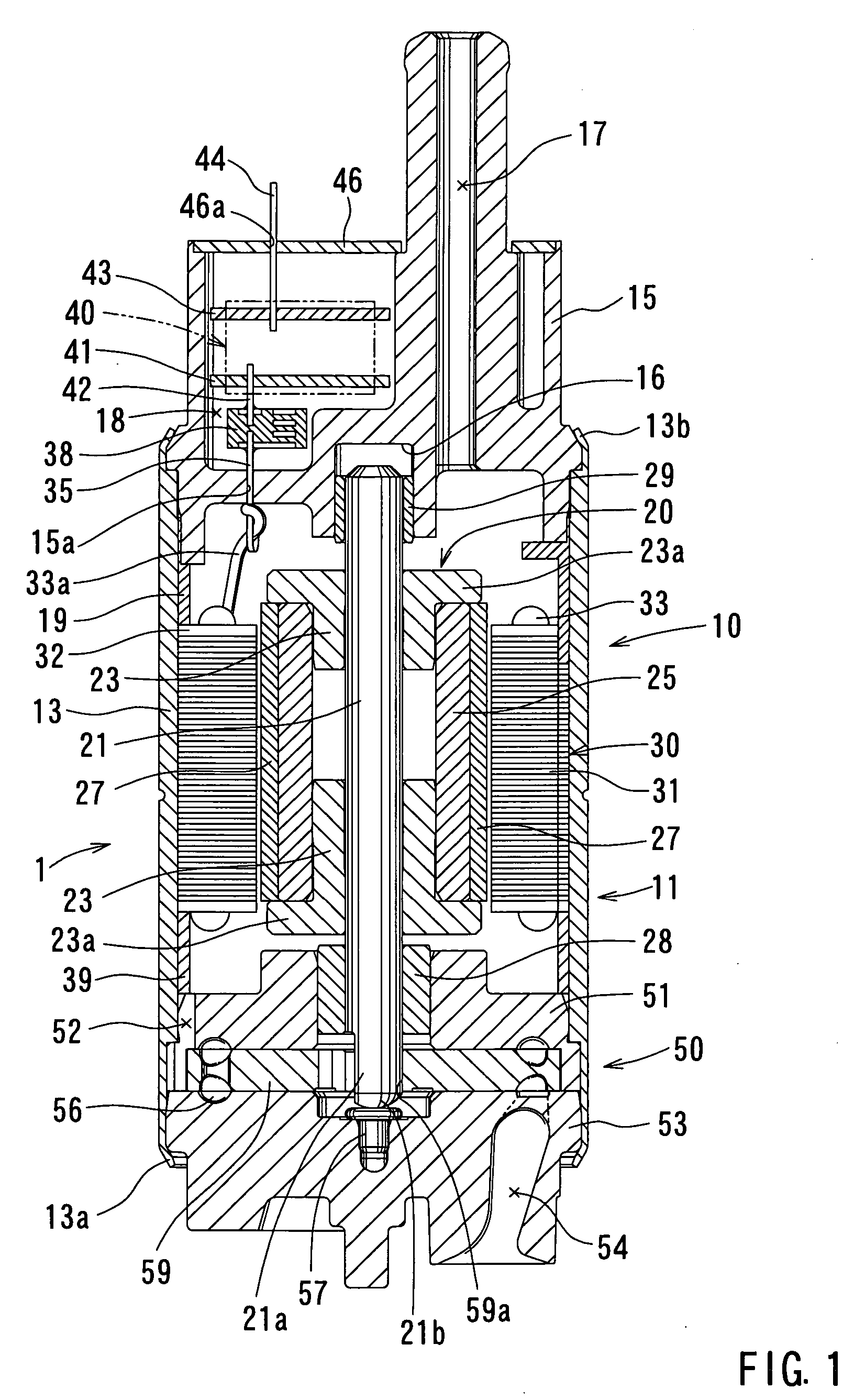

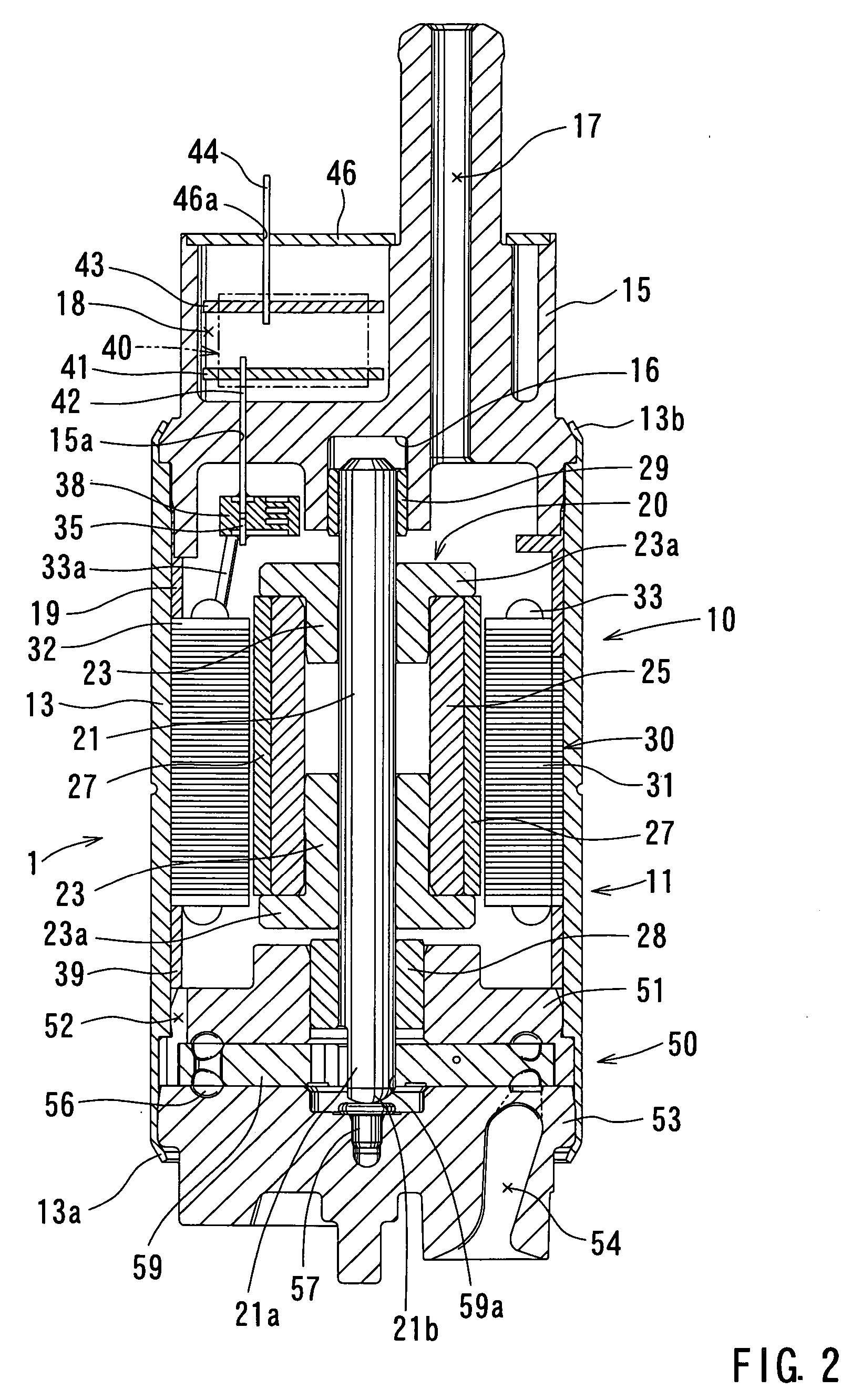

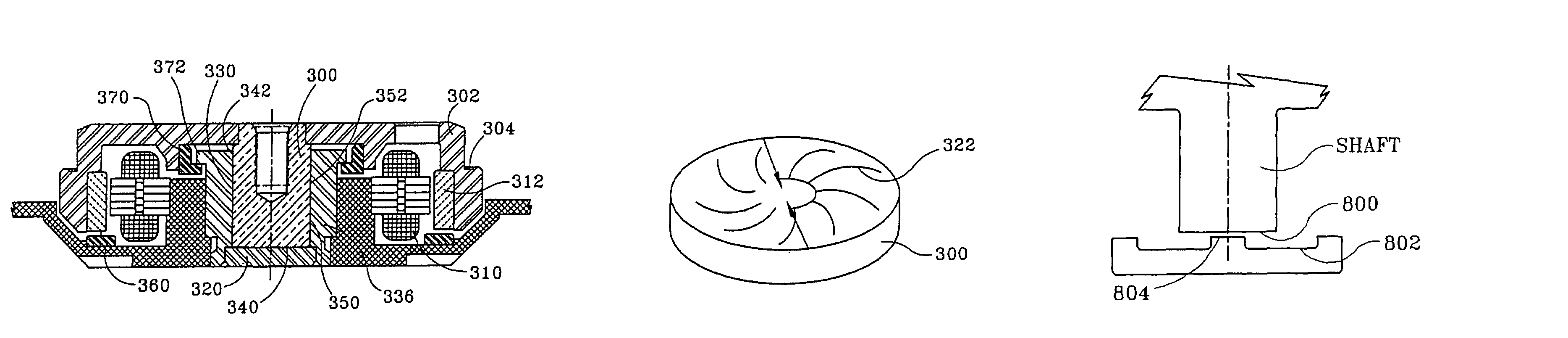

Spindle motor

InactiveUS20100207470A1Easily and intuitively control interfaceMore fluidShaftsRecord information storageElectric machineThrust bearing

Disclosed herein is a spindle motor including a journal bearing and a thrust bearing, thus preventing the lack of fluid occurring as a result of the evaporation or scattering of fluid, and making it easy to control the injected amount of fluid. The spindle motor includes a rotating shaft having a thrust plate inserted perpendicularly into the upper portion thereof. A sleeve accommodates and rotatably supports the rotating shaft. A plate is provided such that the sleeve is secured to the plate. An inner cap is secured to the sleeve in such a way as to face the upper surface of the thrust plate, and a first fluid sealing part is defined between the thrust plate and the inner cap. An outer cap is secured to the upper portion of the inner cap, and a second fluid sealing part is defined between the inner and outer caps.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

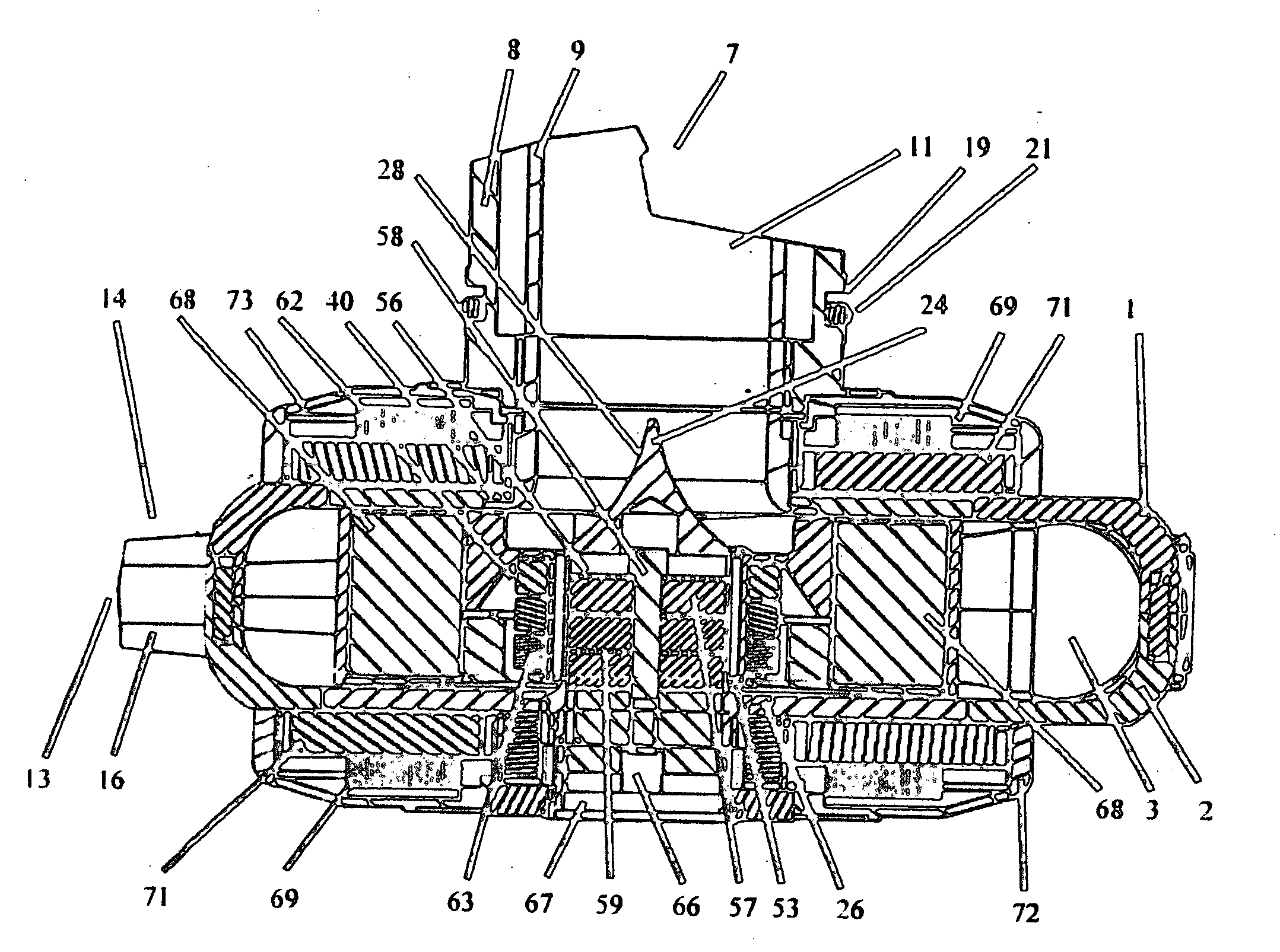

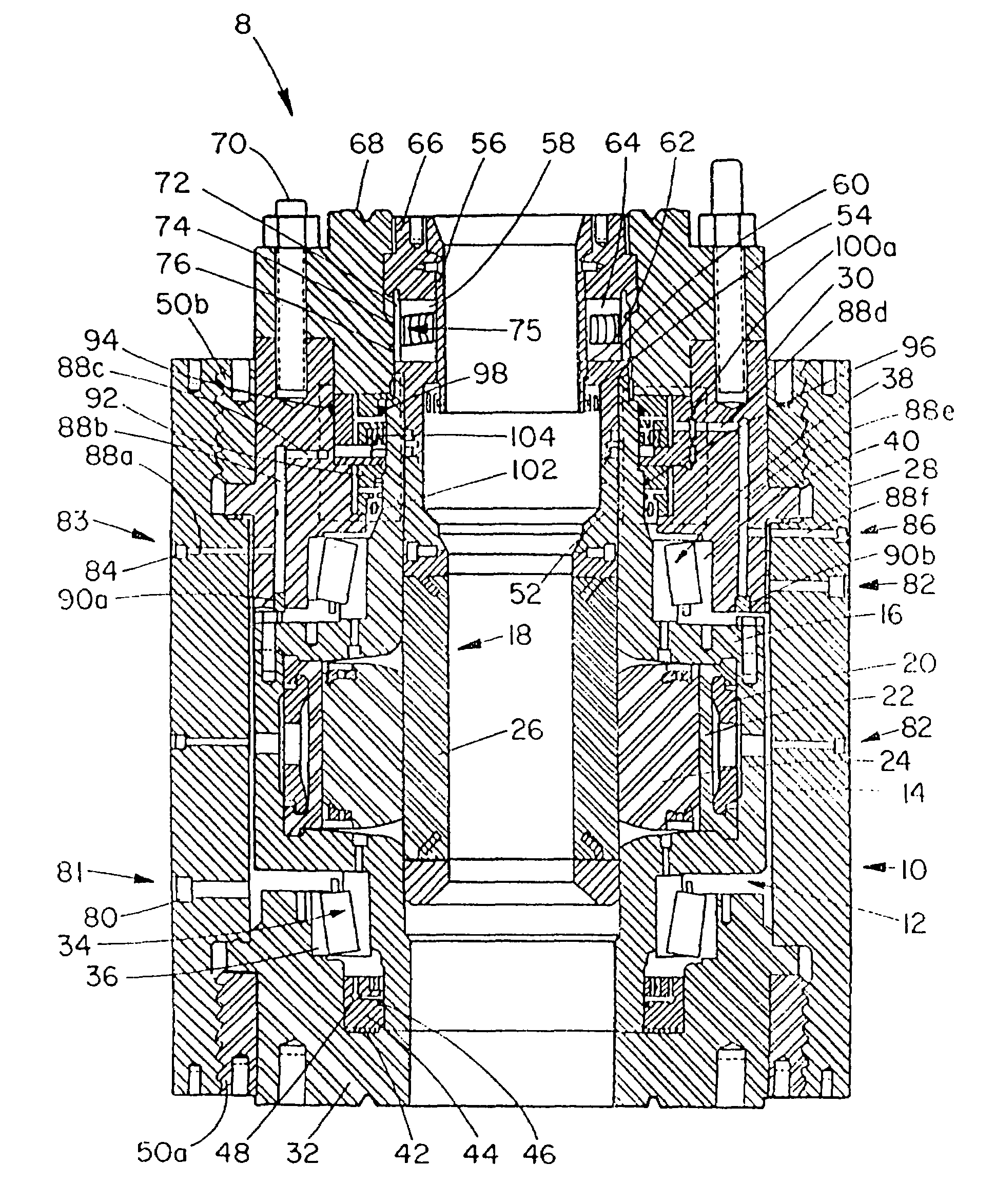

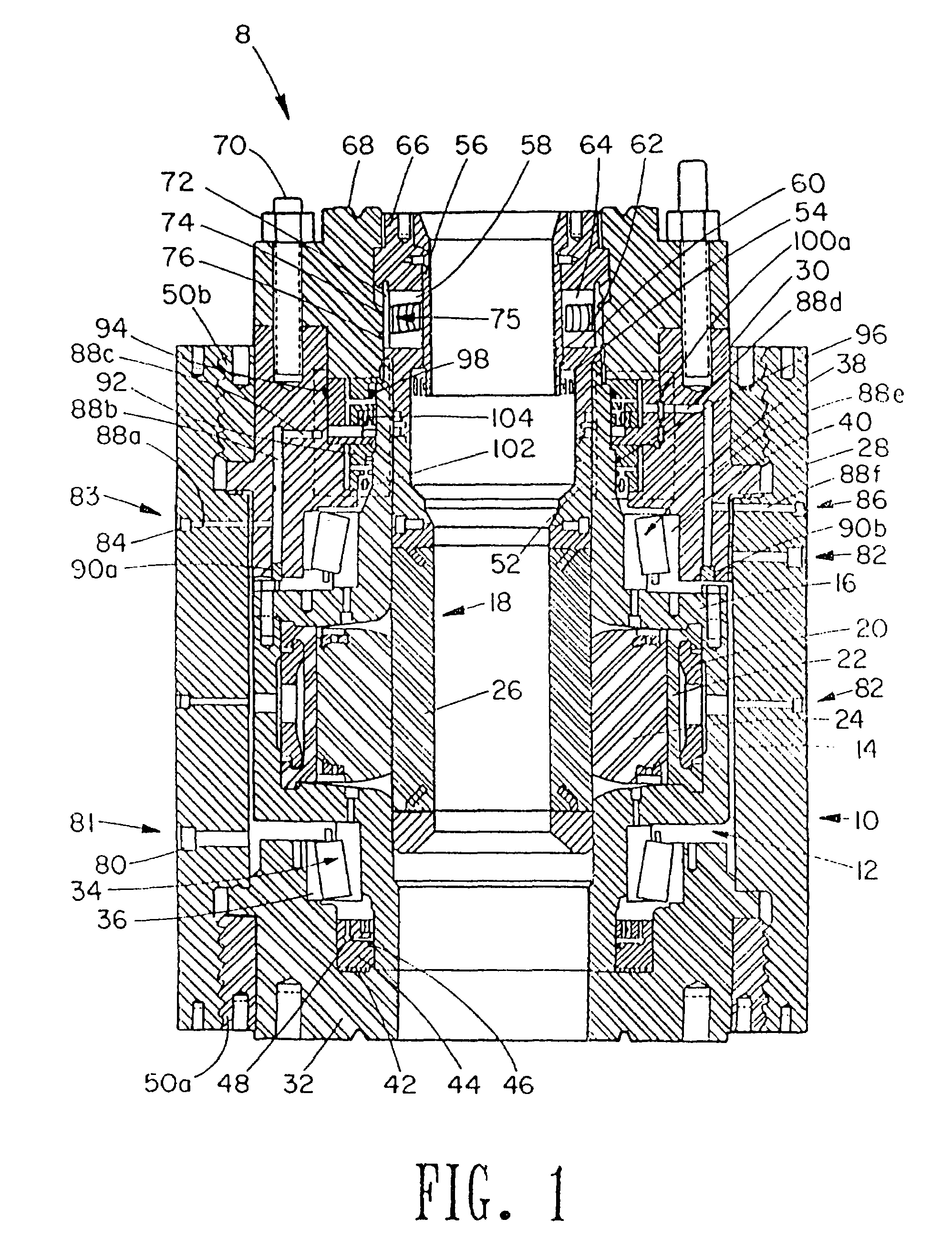

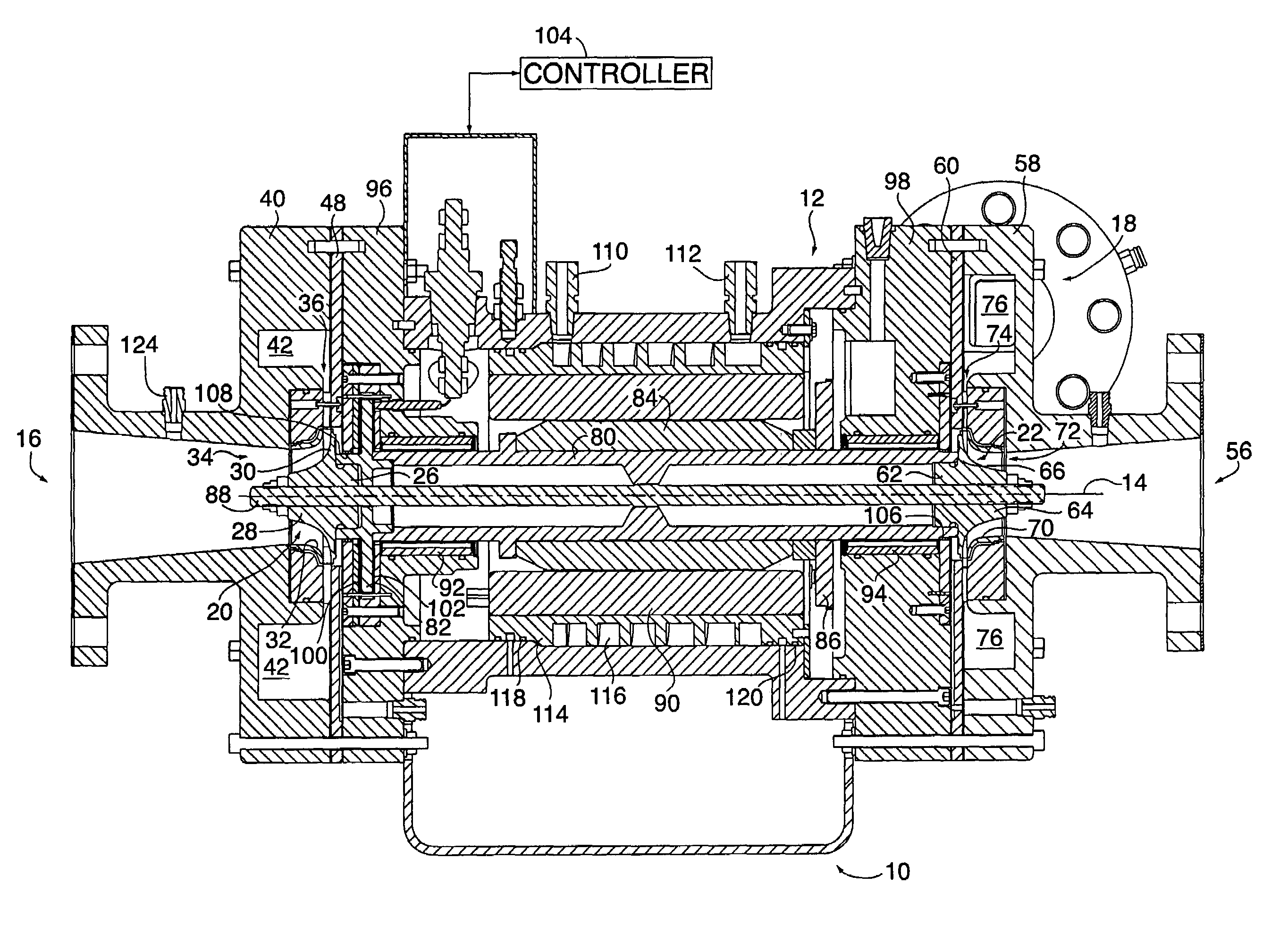

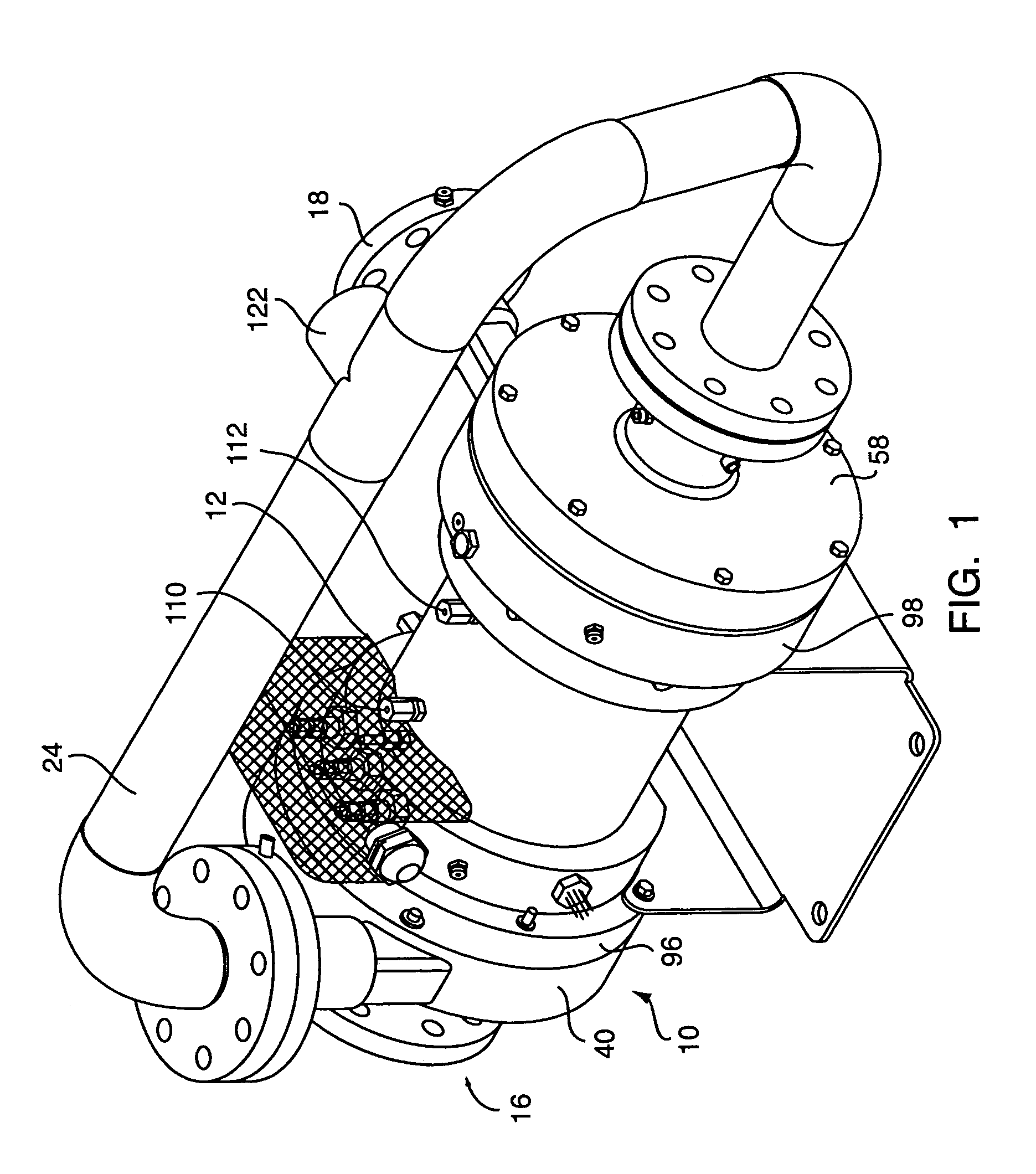

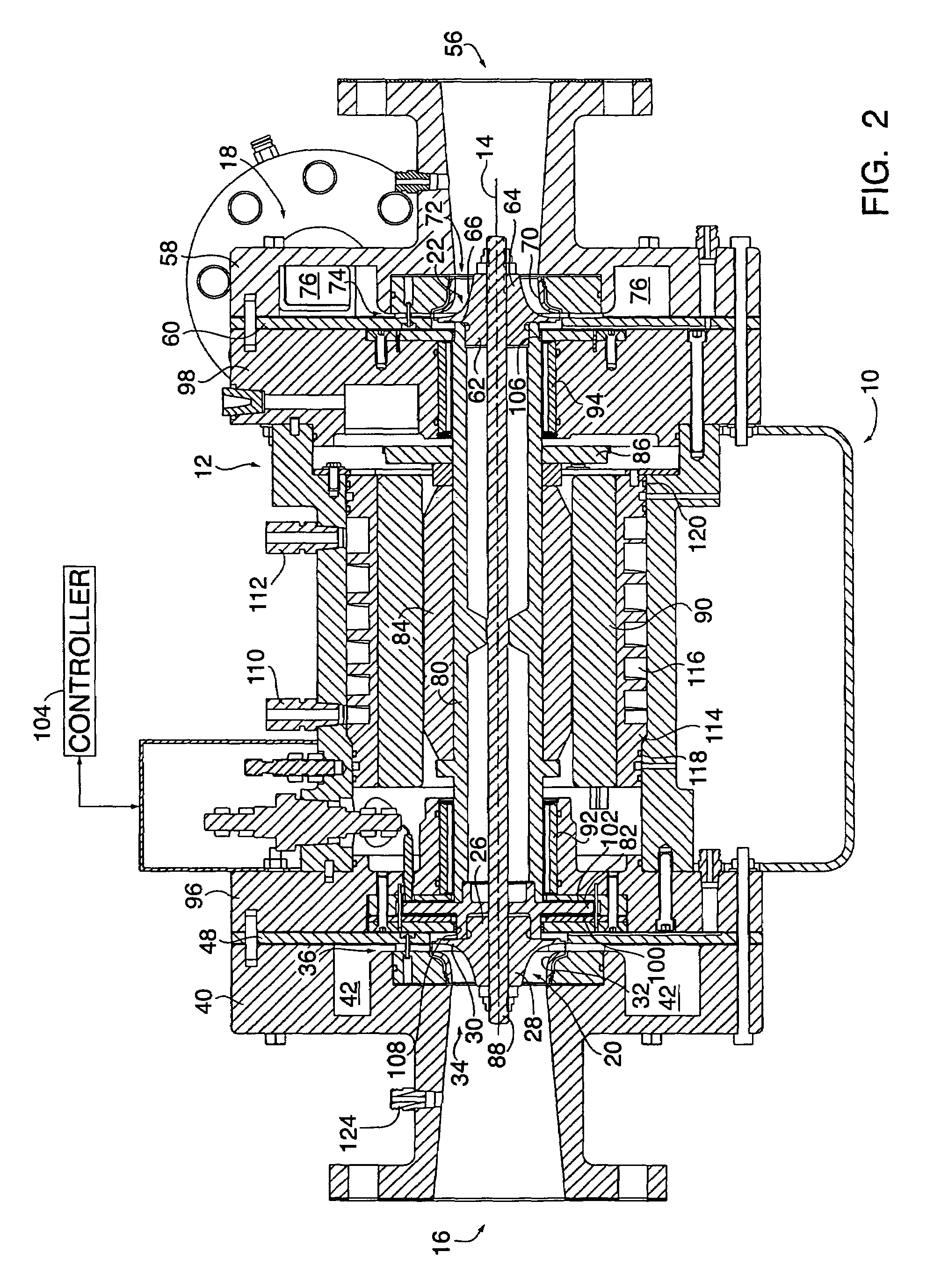

Motor driven two-stage centrifugal air-conditioning compressor

ActiveUS6997686B2Improve cooling effectEnhanced compressor energy efficiencyPositive displacement pump componentsPump controlImpellerMotor drive

A two-stage compressor for generating necessary pressure differential for air-conditioning applications with air-cooled, water-cooled and evaporative-cooled condensing systems using low-pressure refrigerant, such as R134a, is provided. A rotating assembly is mounted for rotation in a compressor housing and includes a shaft, a thrust bearing disk associated with the shaft to maintain an axial position of the rotating assembly, a motor rotor mounted on the shaft, and first and second impellers mounted for rotation with the shaft. First and second journal bearings are mounted in the compressor housing to support the shaft and maintain radial positioning of the rotating assembly. Volute housings including a spiral-shaped volute are associated with each of the impellers to collect and further discharge gas compressed by the impellers. Diffusers having air-foil shaped vanes are locate in the volute channels adjacent the discharge outlets of the impellers to aide in the discharge of gas from the impellers.

Owner:R & D DYNAMICS

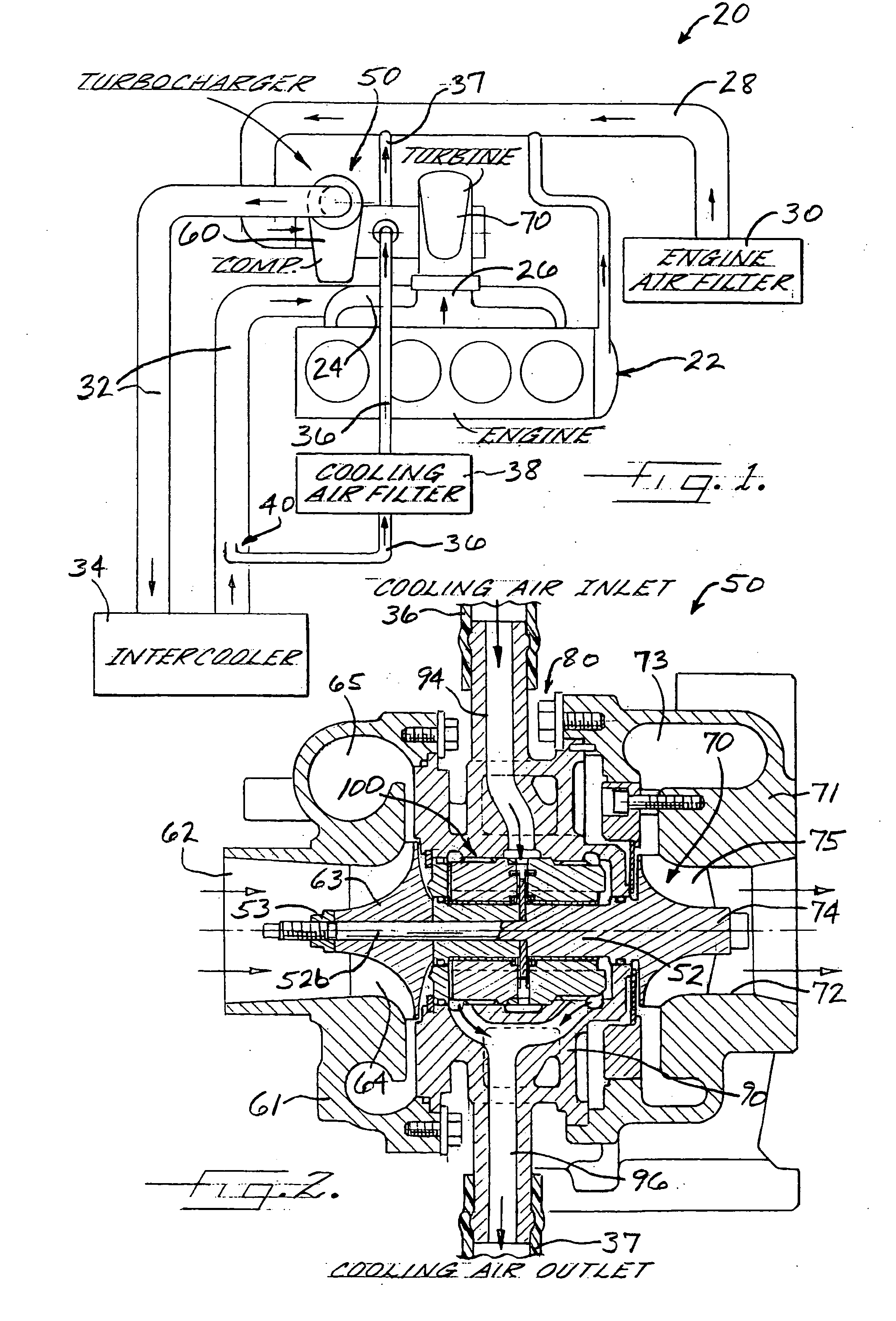

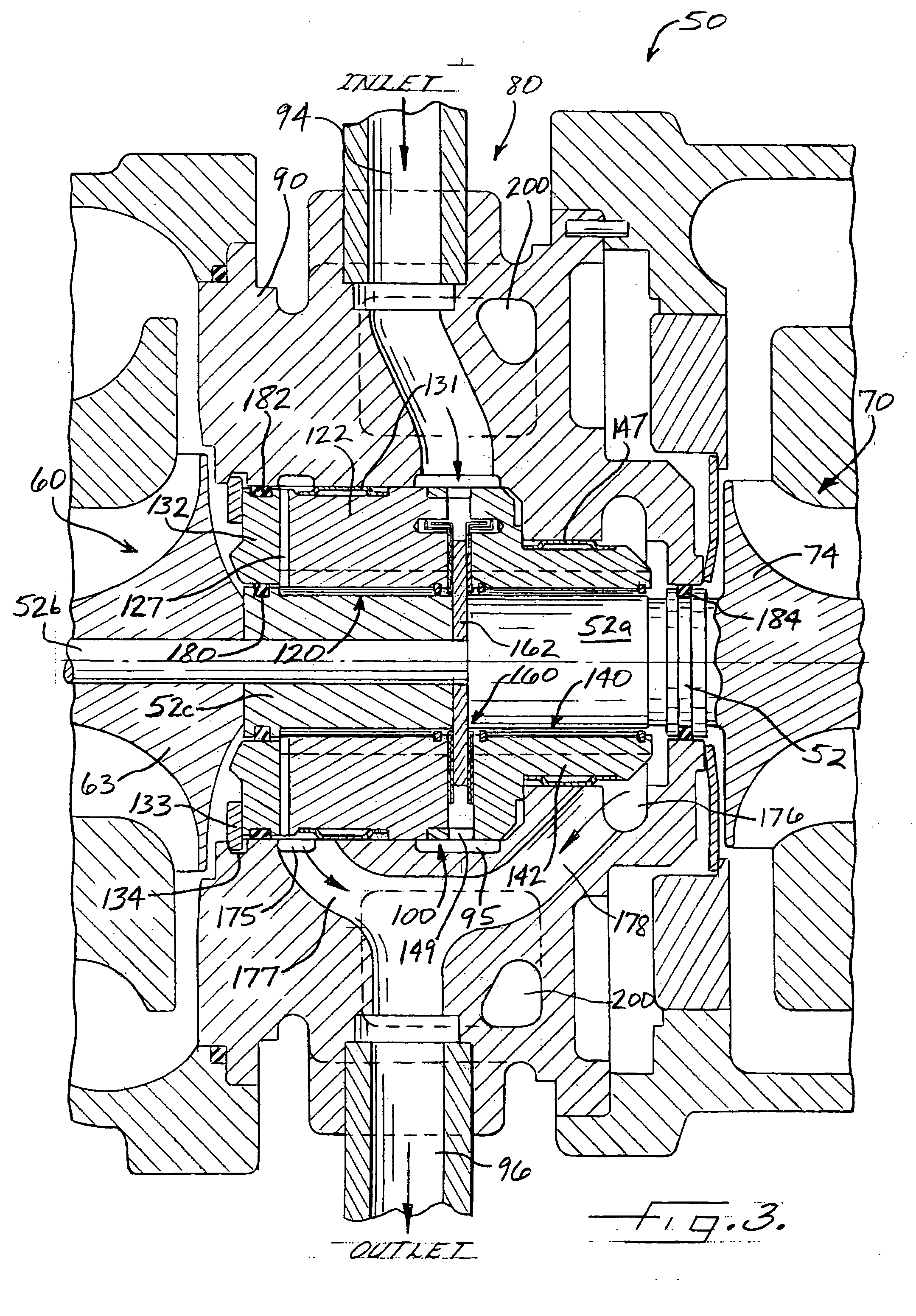

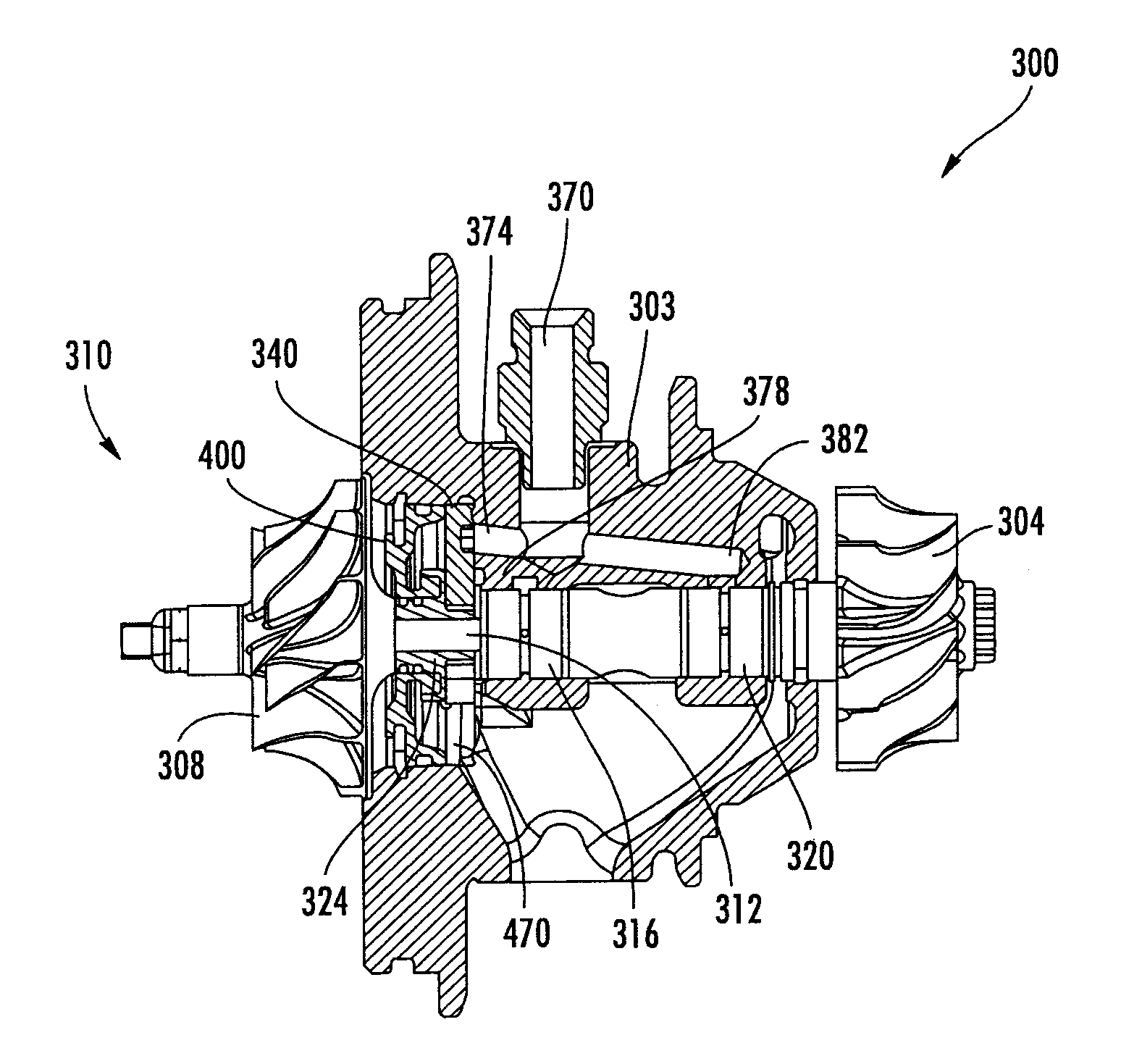

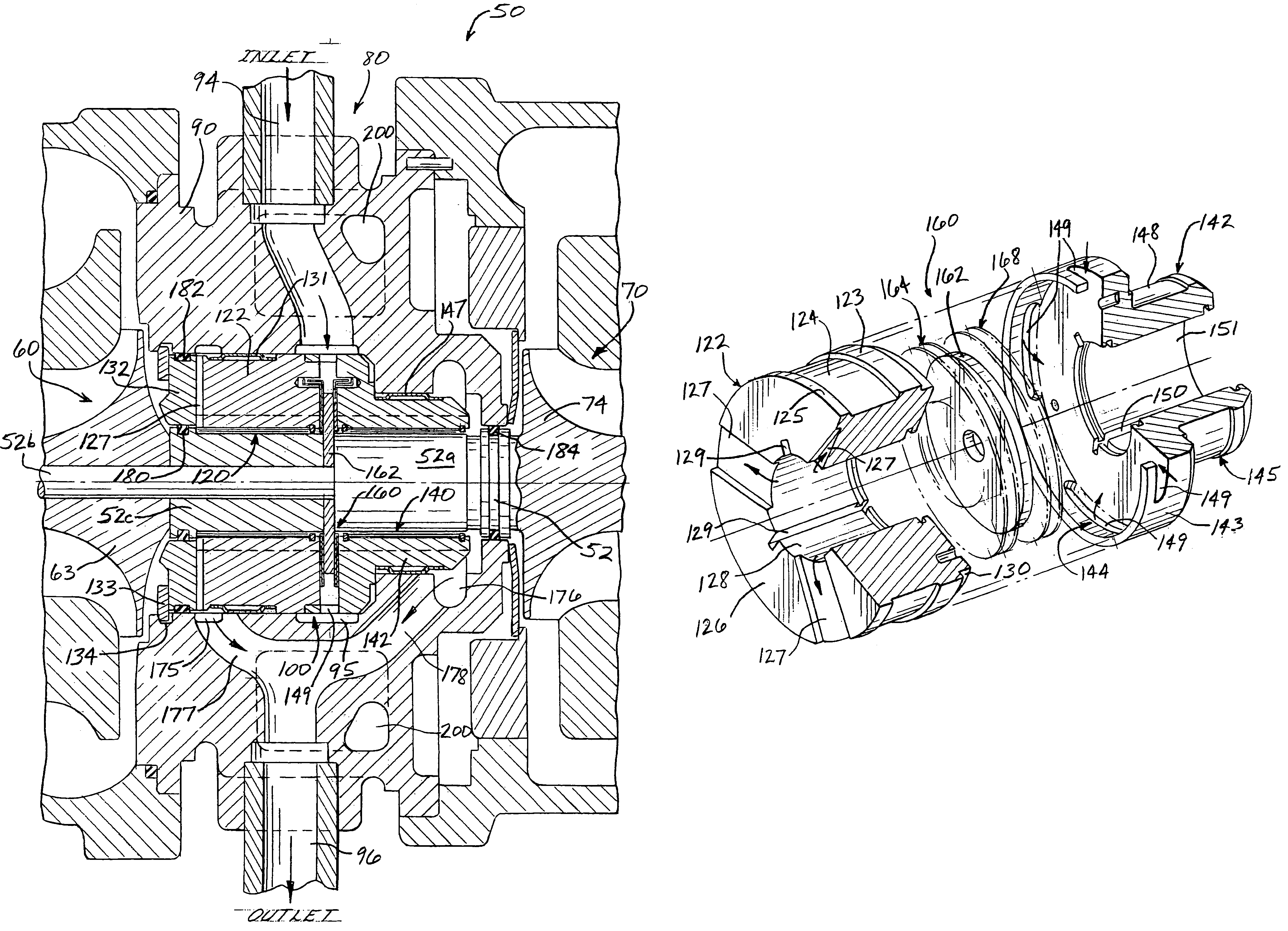

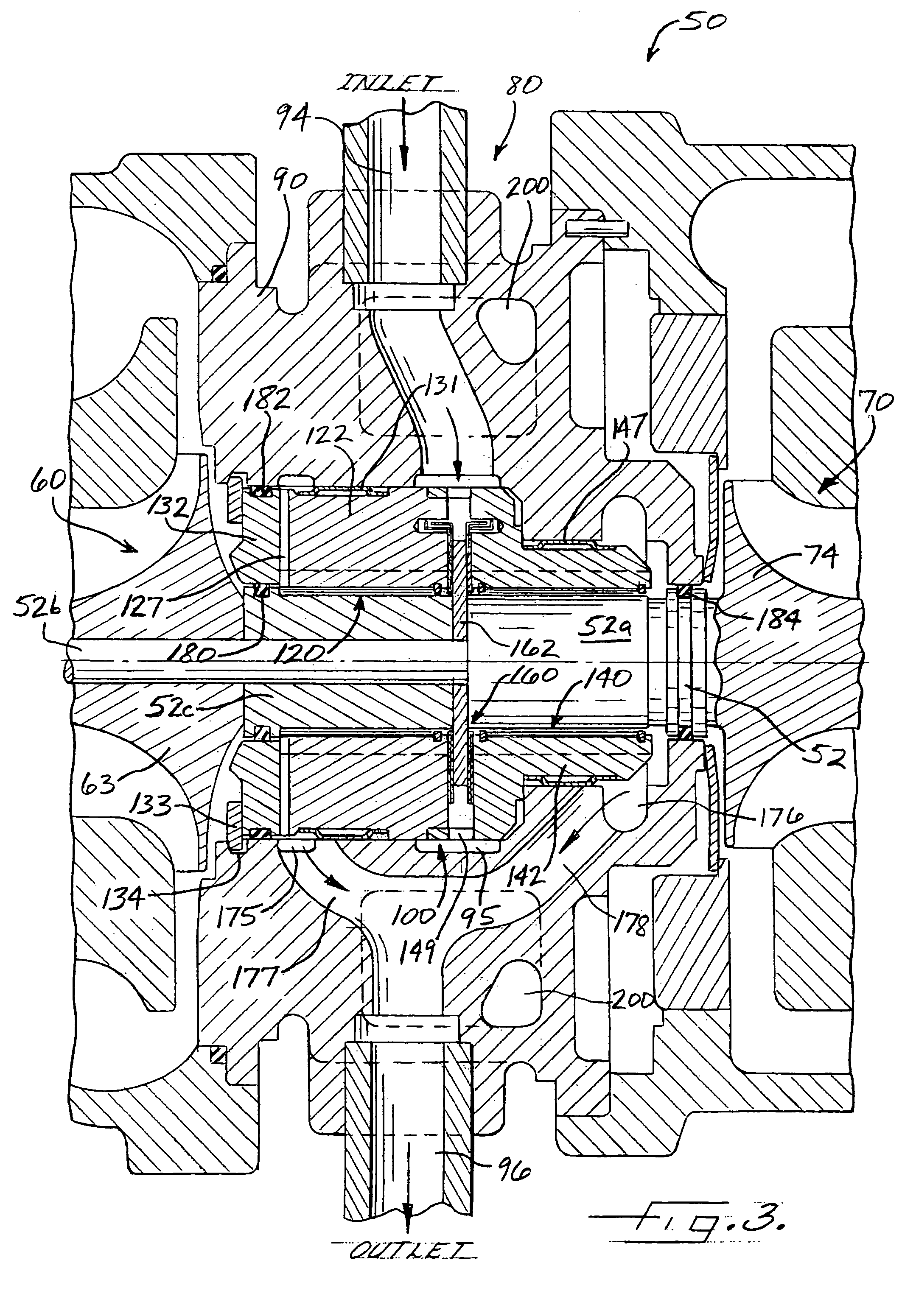

Turbocharger with hydrodynamic foil bearings

A turbocharger includes a foil bearing assembly mounted in a center housing between a compressor and a turbine of the turbocharger. The bearing assembly forms a unit installable into the center housing from one end thereof, and the center housing is a one-piece construction. The bearing assembly includes a foil thrust bearing assembly disposed between two foil journal bearings. The journals foils are mounted in annular bearing carriers fixedly mounted in the center housing. A radially inner portion of a thrust disk of the thrust bearing assembly is captured between a shaft and a shaft sleeve of the turbocharger. The center housing defines cooling air passages for supplying cooling air to the foil bearings, and optionally includes a water jacket for circulating engine coolant through the center housing.

Owner:GARRETT TRANSPORATION I INC

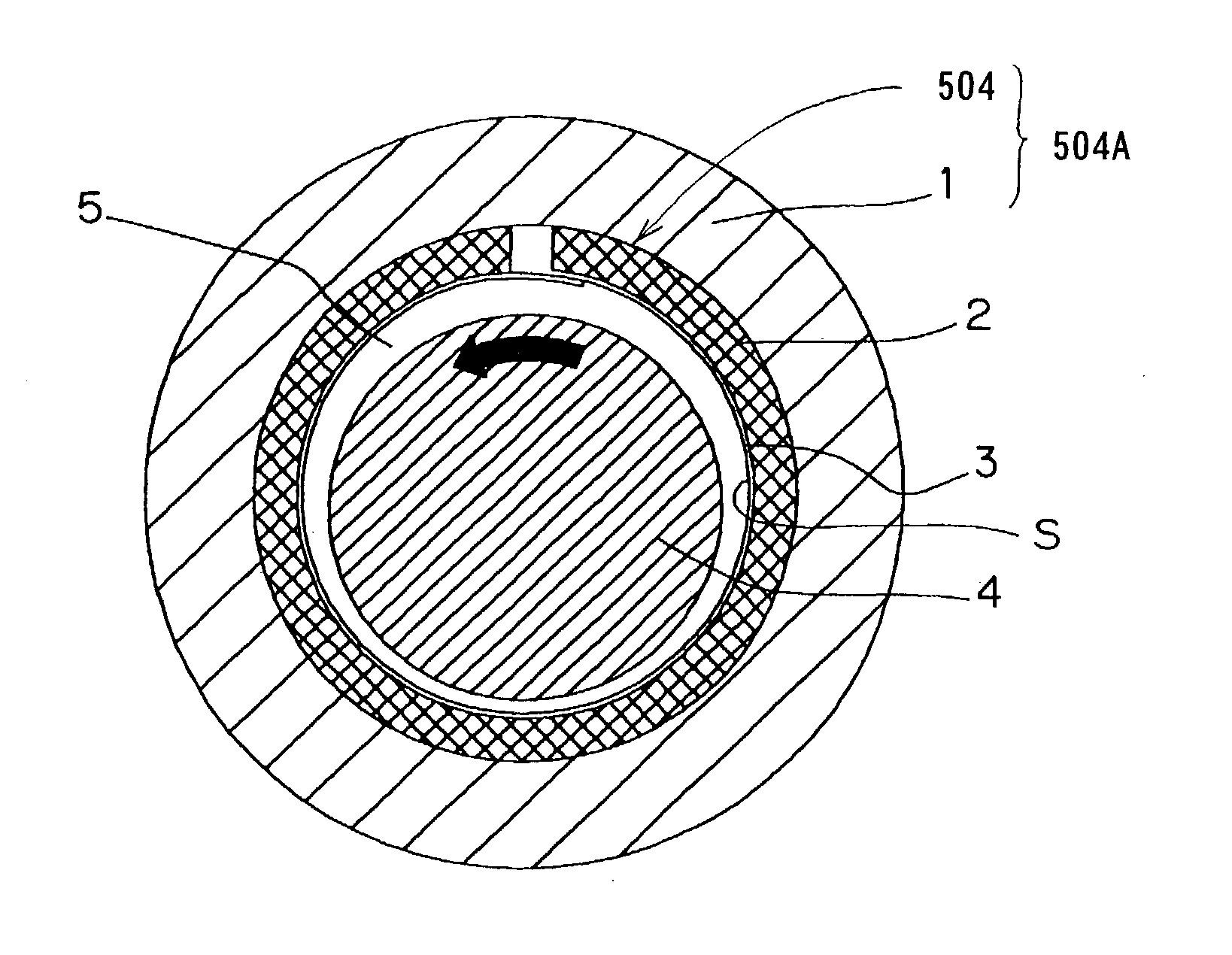

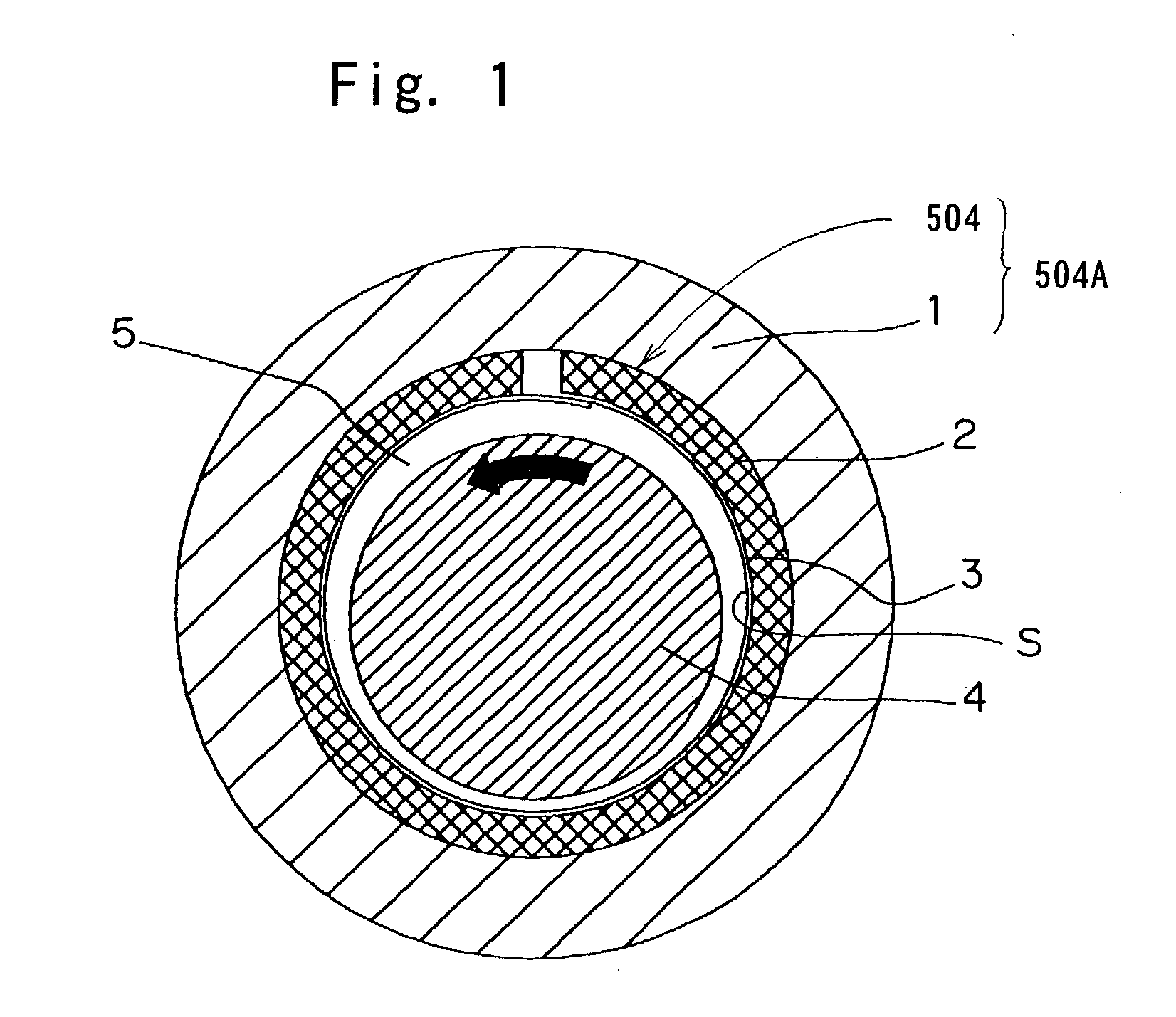

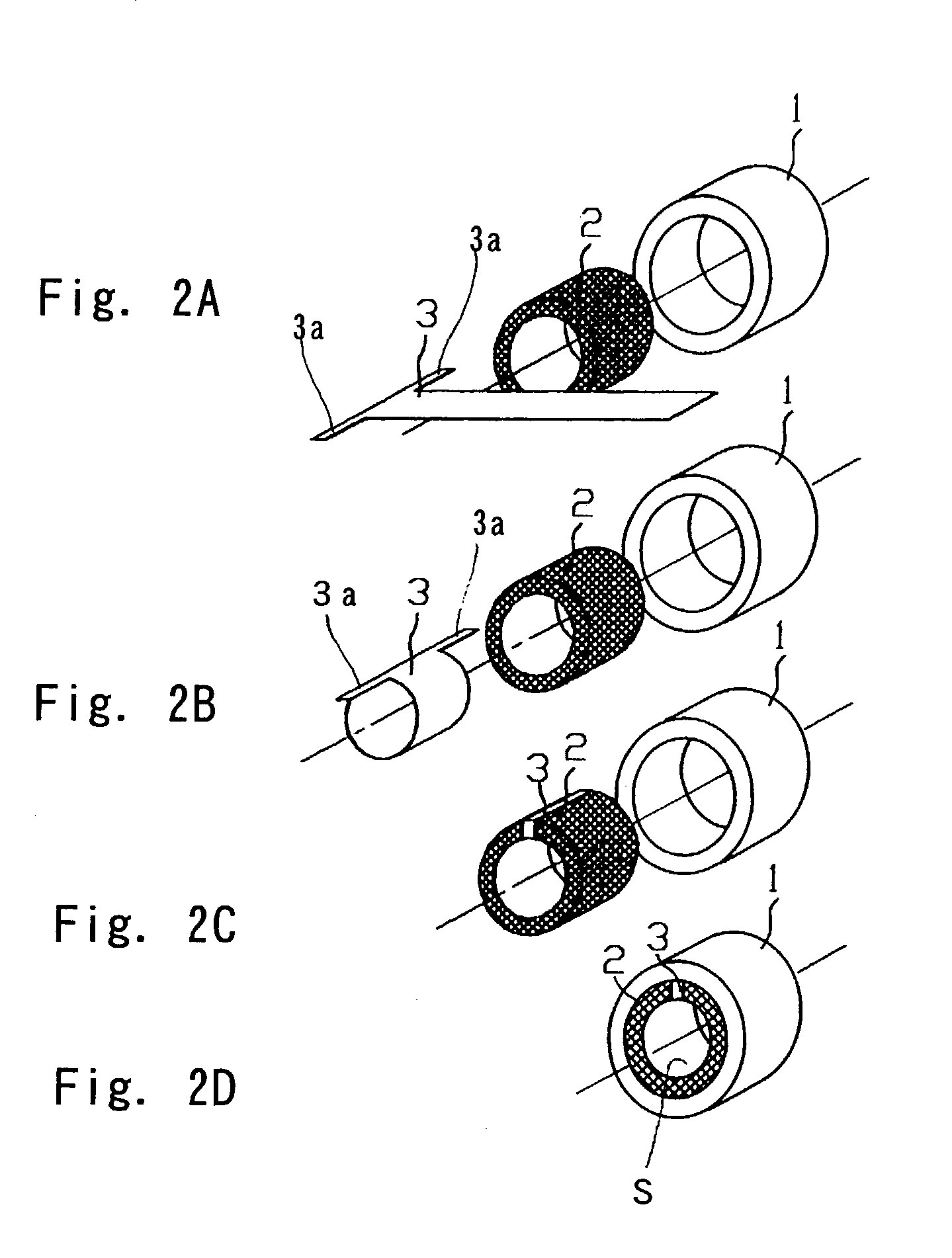

Foil bearing and spindle device using the same

InactiveUS20030169951A1Liquid spraying apparatusSliding contact bearingsThrust bearingBearing surface

A foil bearing is provided, which is simple in structure, has a large load capacity and a large damping capability and can therefore allow a rotary shaft having a large unbalance as compared with the conventional bearing to be driven stably at a high speed. A spindle device utilizing such foil bearing is also provided, which is designed to increase the permissible amount of unbalance and also to have a light-weight feature. Each of the foil bearings 504 and 505 includes an elastic member 2 prepared from a wire net formed by braiding wires, and a thin bearing foil 3 supported by the elastic member 2 and defining an elastic bearing surface S. The respective foil bearing 504 and 505 is used at least as a radial bearing 504 in the spindle device including a rotary shaft 4 having a head mount 501a, on which an atomizer head is mounted, and the radial and thrust bearings 504 and 505 for rotatably supporting the rotary shaft 4.

Owner:NTN CORP

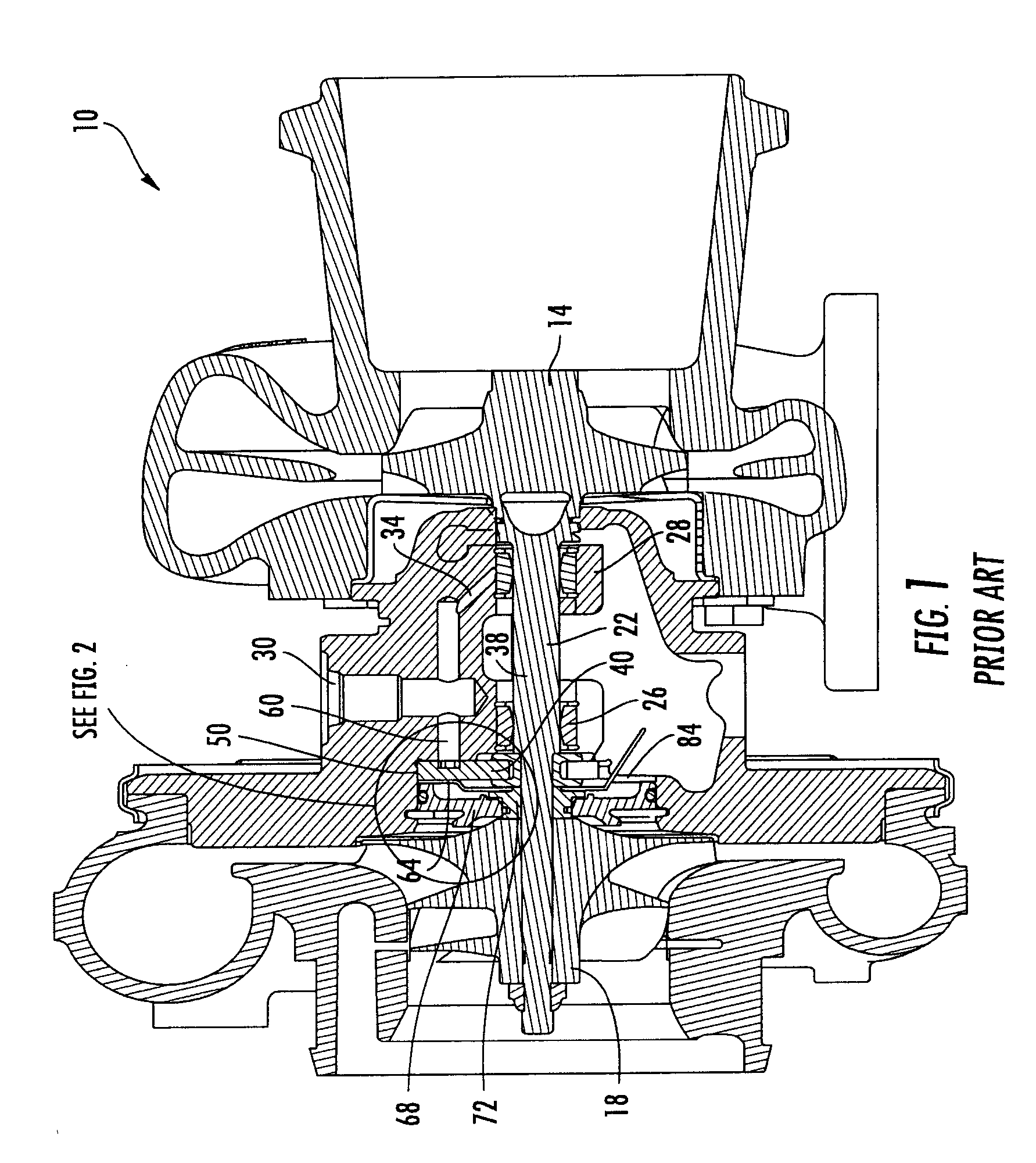

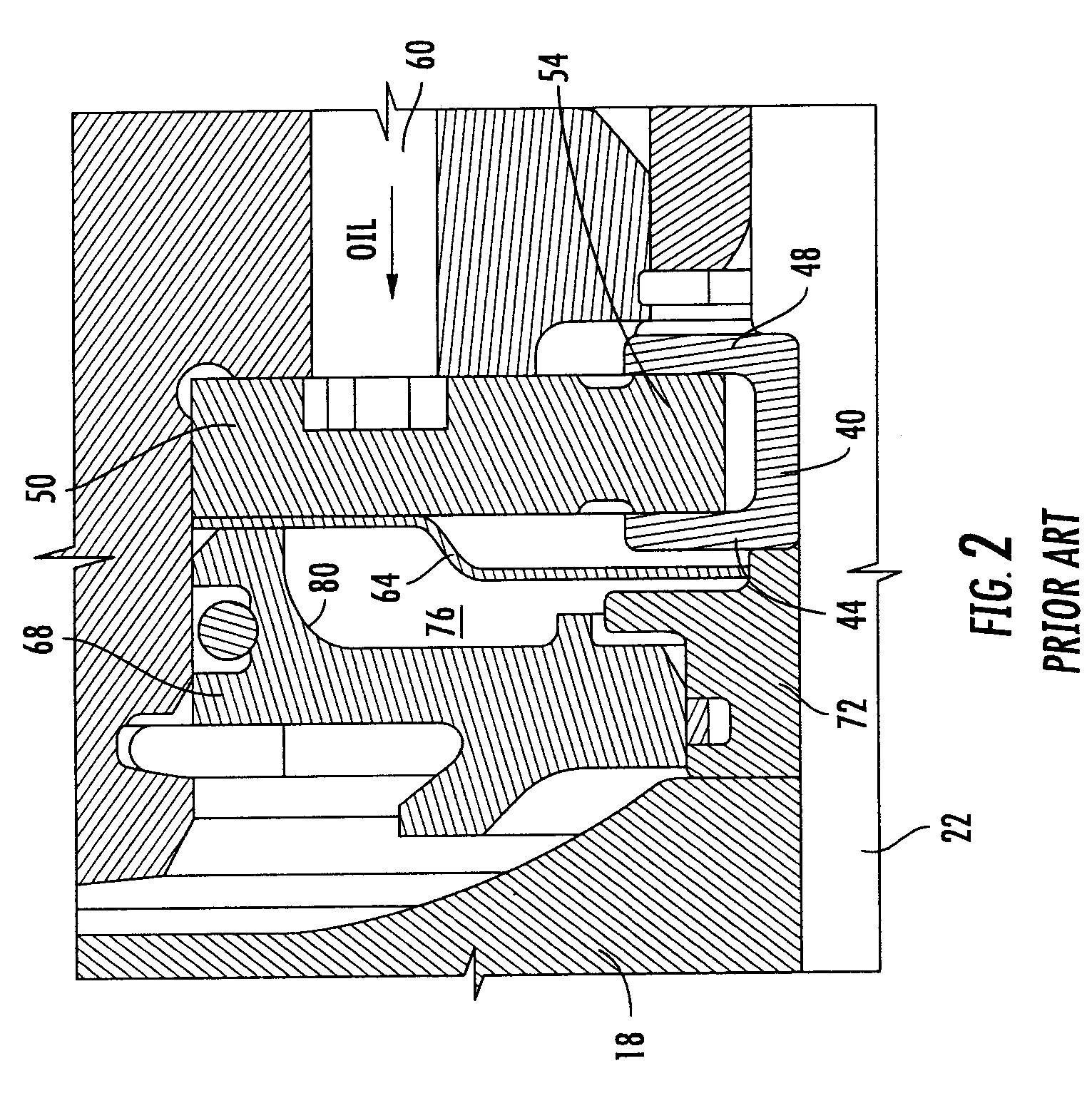

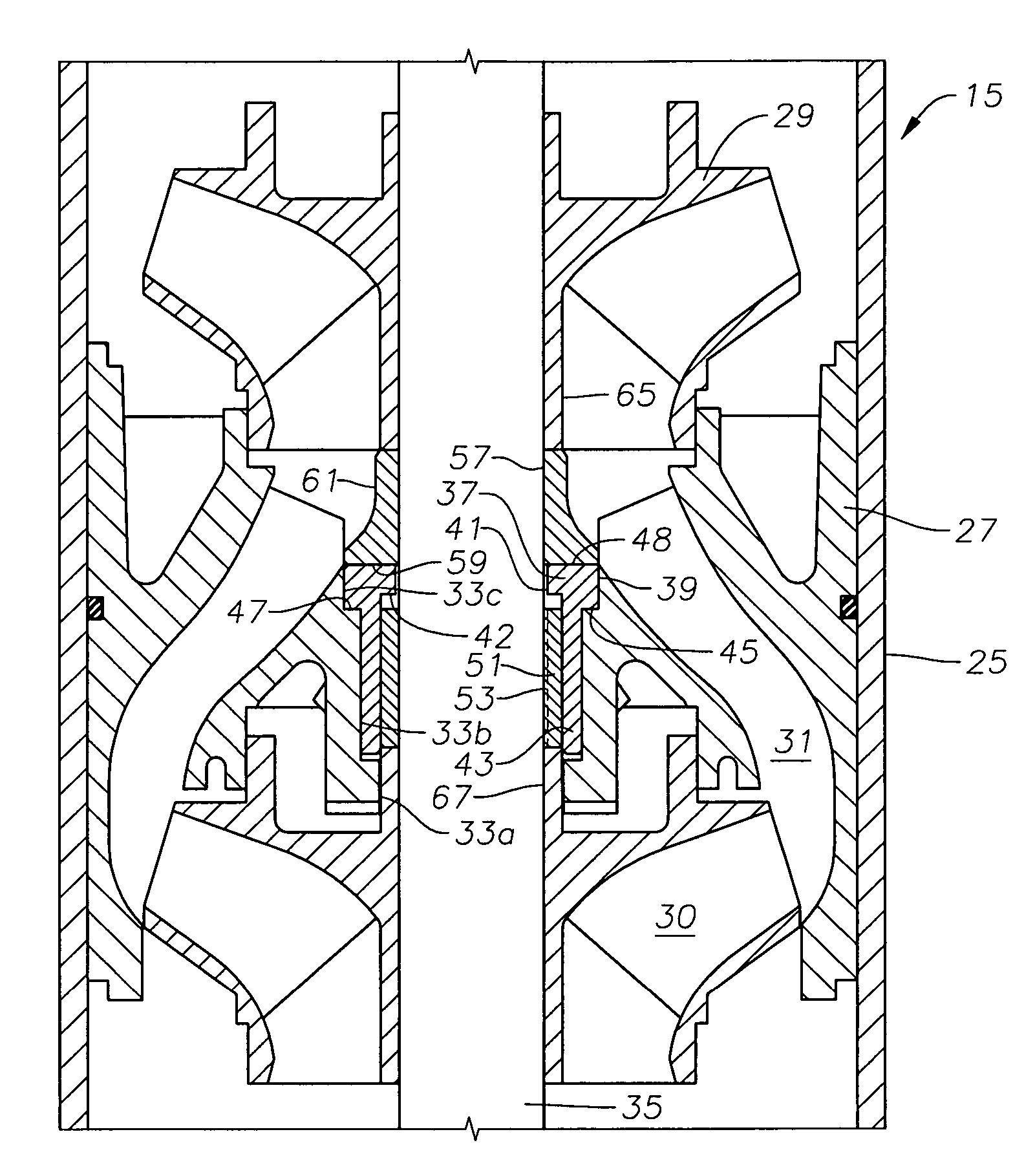

Sealing system between bearing and compressor housing

ActiveUS20100139270A1Efficient and cost-effectiveExtend your lifeCrankshaftsPump componentsTurbochargerThrust bearing

A turbocharger oil discharge assembly (301, 501, 701, 901) can have a thrust collar (324, 524, 724, 924) with a first radially outwardly extending wall and a second radially outwardly extending wall to define a first annular channel. The first radially outwardly extending wall can have an annular flange that at least in part defines a second annular channel. The assembly can also have a thrust bearing (340, 540, 740, 940) having a radially inner end received in the first annular channel, and an insert (400, 600, 800, 1000). An oil collection chamber (440, 640, 840, 1040) can be defined at least in part by a drainage channel of the insert (400, 600, 800, 1000), the annular flange of the thrust collar (324, 524, 724, 924) and the thrust bearing (340, 540, 740, 940). Pressurized oil discharged from an oil release interface can be directed towards a radially outer region of the oil collection chamber (440, 640, 840, 1040) and can be collected in the oil collection chamber (440, 640, 840, 1040) for subsequent exhaust.

Owner:BORGWARNER INC

Turbocharger with hydrodynamic foil bearings

A turbocharger includes a foil bearing assembly mounted in a center housing between a compressor and a turbine of the turbocharger. The bearing assembly forms a unit installable into the center housing from one end thereof, and the center housing is a one-piece construction. The bearing assembly includes a foil thrust bearing assembly disposed between two foil journal bearings. The journals foils are mounted in annular bearing carriers fixedly mounted in the center housing. A radially inner portion of a thrust disk of the thrust bearing assembly is captured between a shaft and a shaft sleeve of the turbocharger. The center housing defines cooling air passages for supplying cooling air to the foil bearings, and optionally includes a water jacket for circulating engine coolant through the center housing.

Owner:GARRETT TRANSPORATION I INC

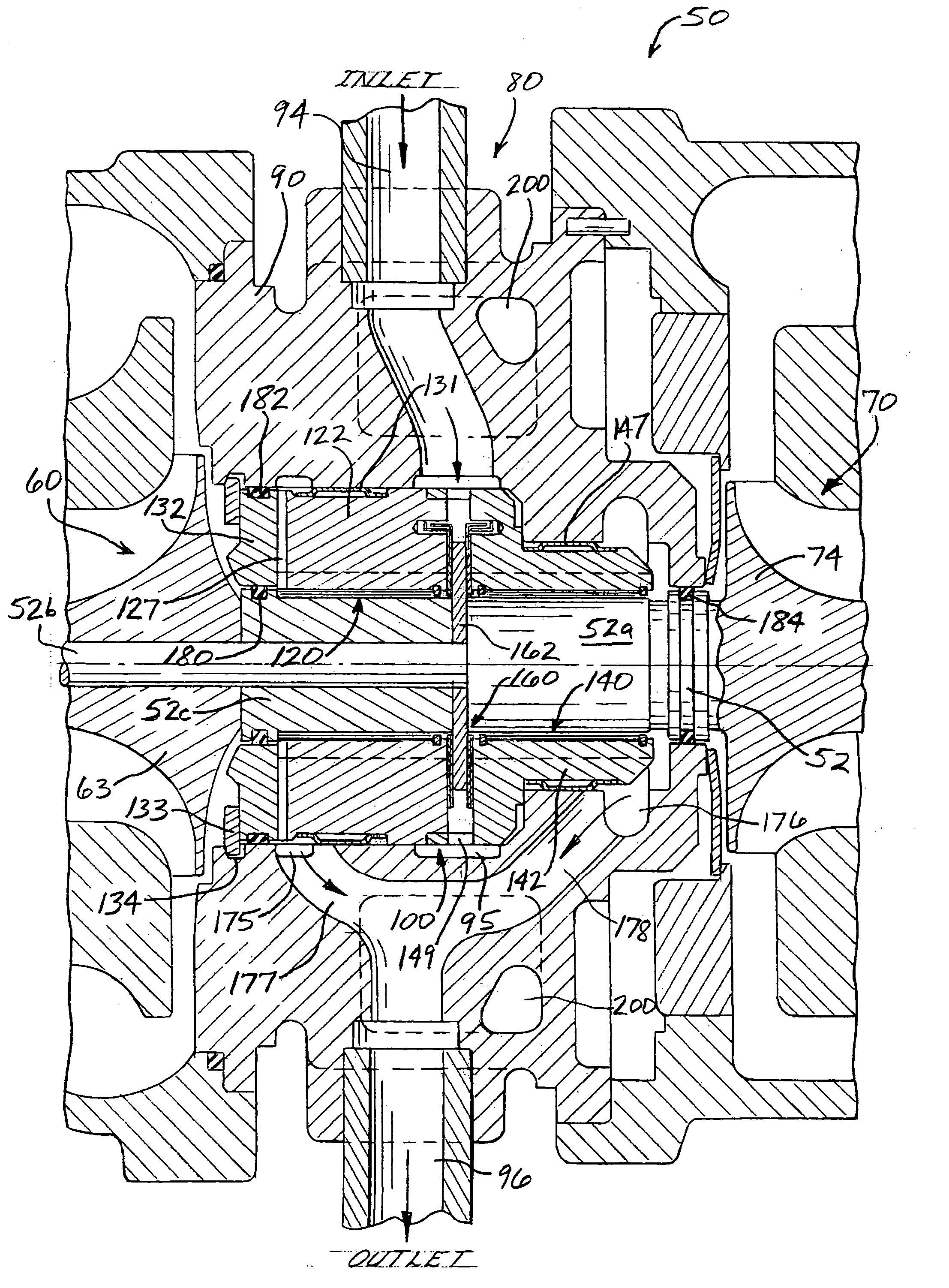

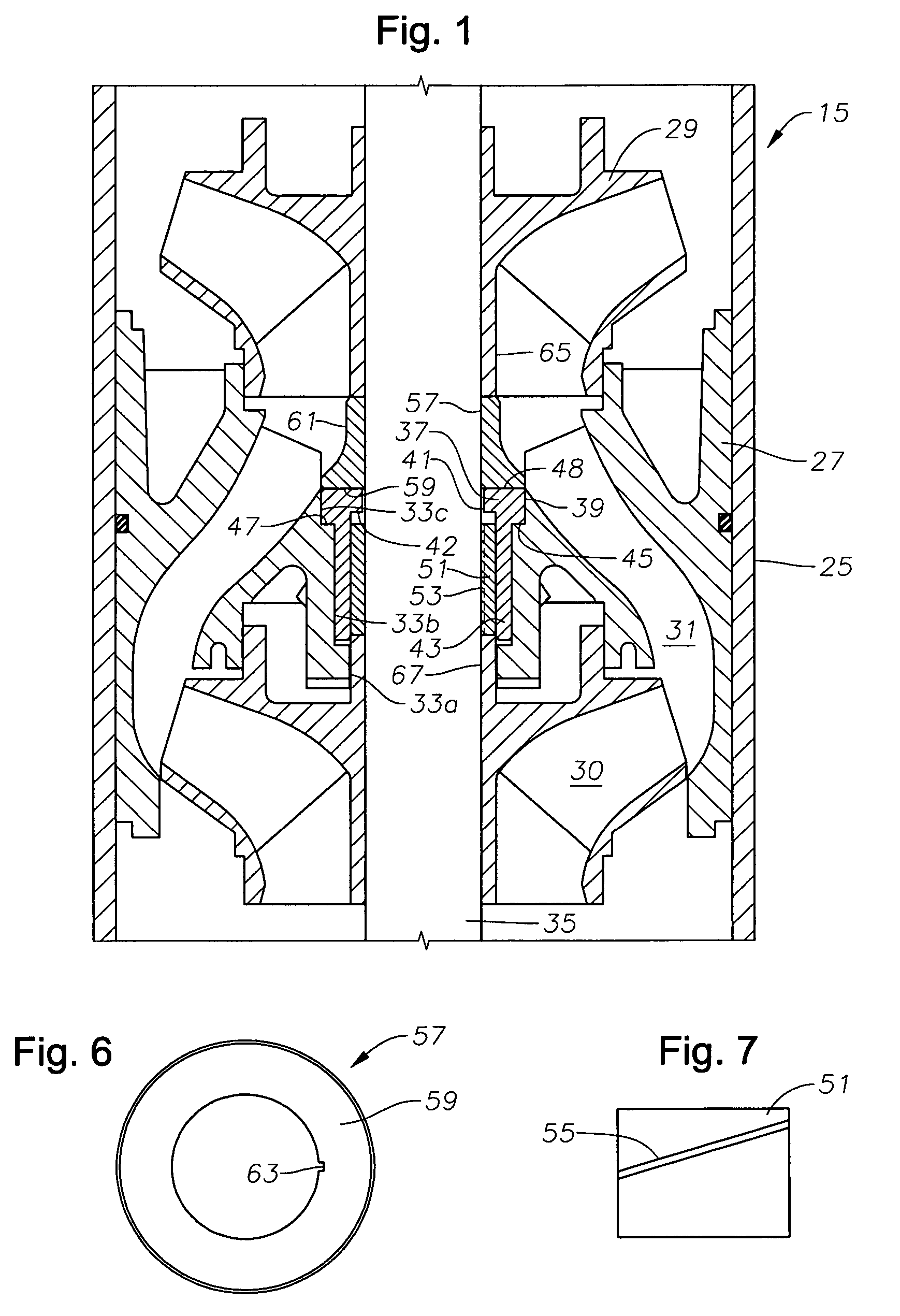

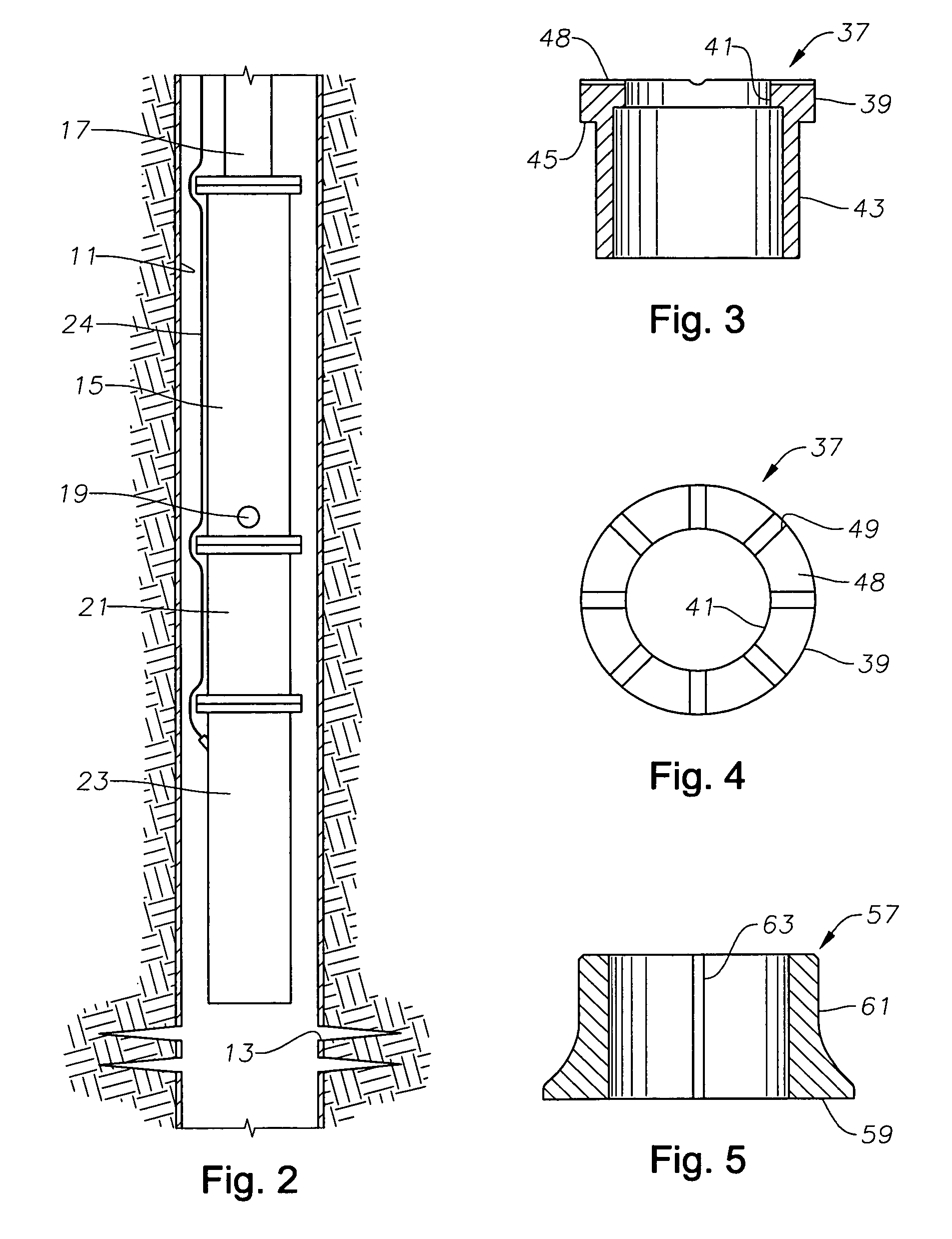

Abrasion resistant pump thrust bearing

ActiveUS20060204359A1Increase surface areaPump componentsBlade accessoriesThrust bearingSupport surface

A centrifugal pump has a stationary diffuser with a bore. A thrust bearing has a tubular portion that inserts into the bore. The thrust bearing has an external shoulder that contacts a support surface in the bore of the diffuser for transmitting downward thrust from an upstream impeller to the diffuser. The thrust bearing has an internal shoulder for transmitting upward thrust from a downstream impeller to the diffuser.

Owner:BAKER HUGHES INC

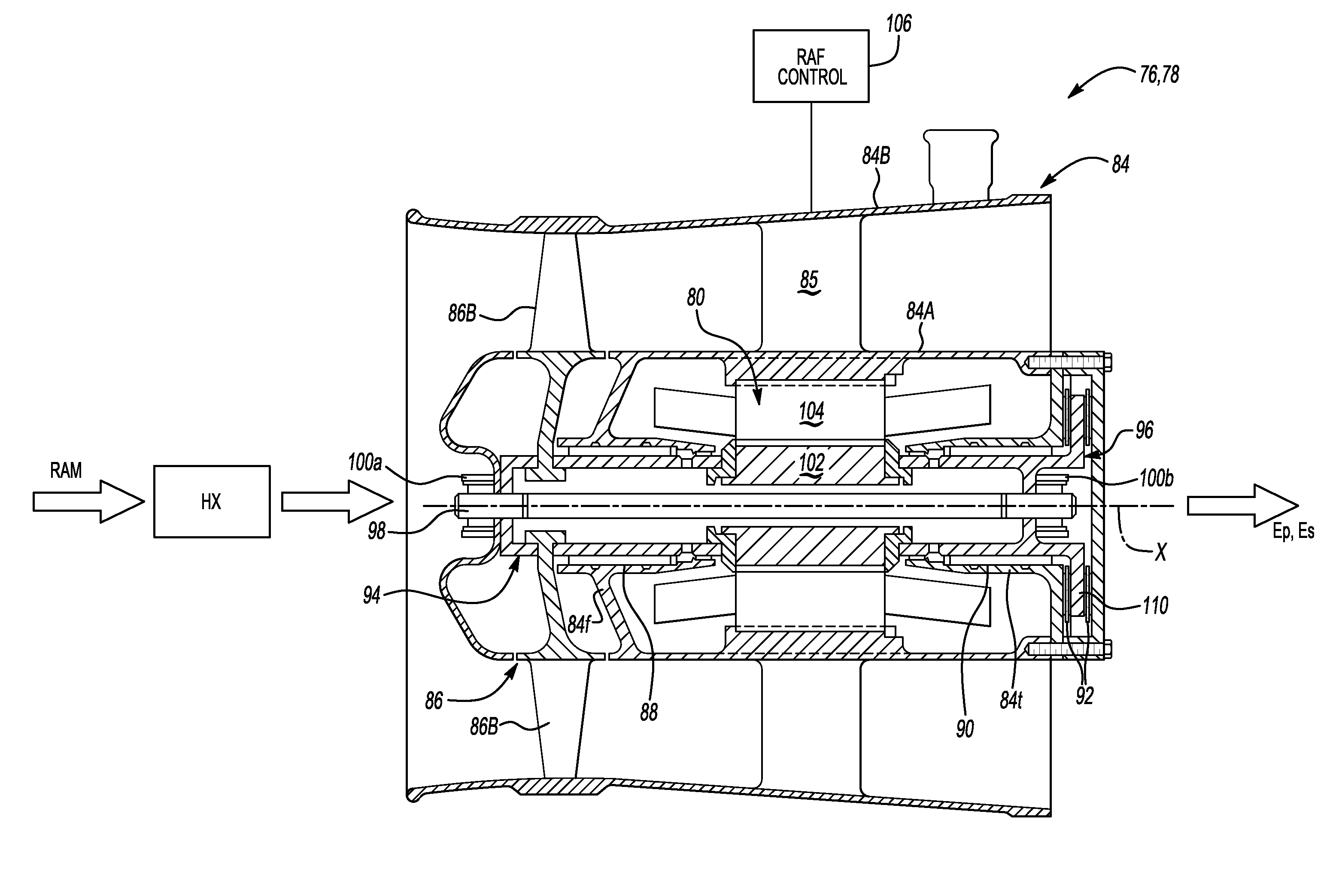

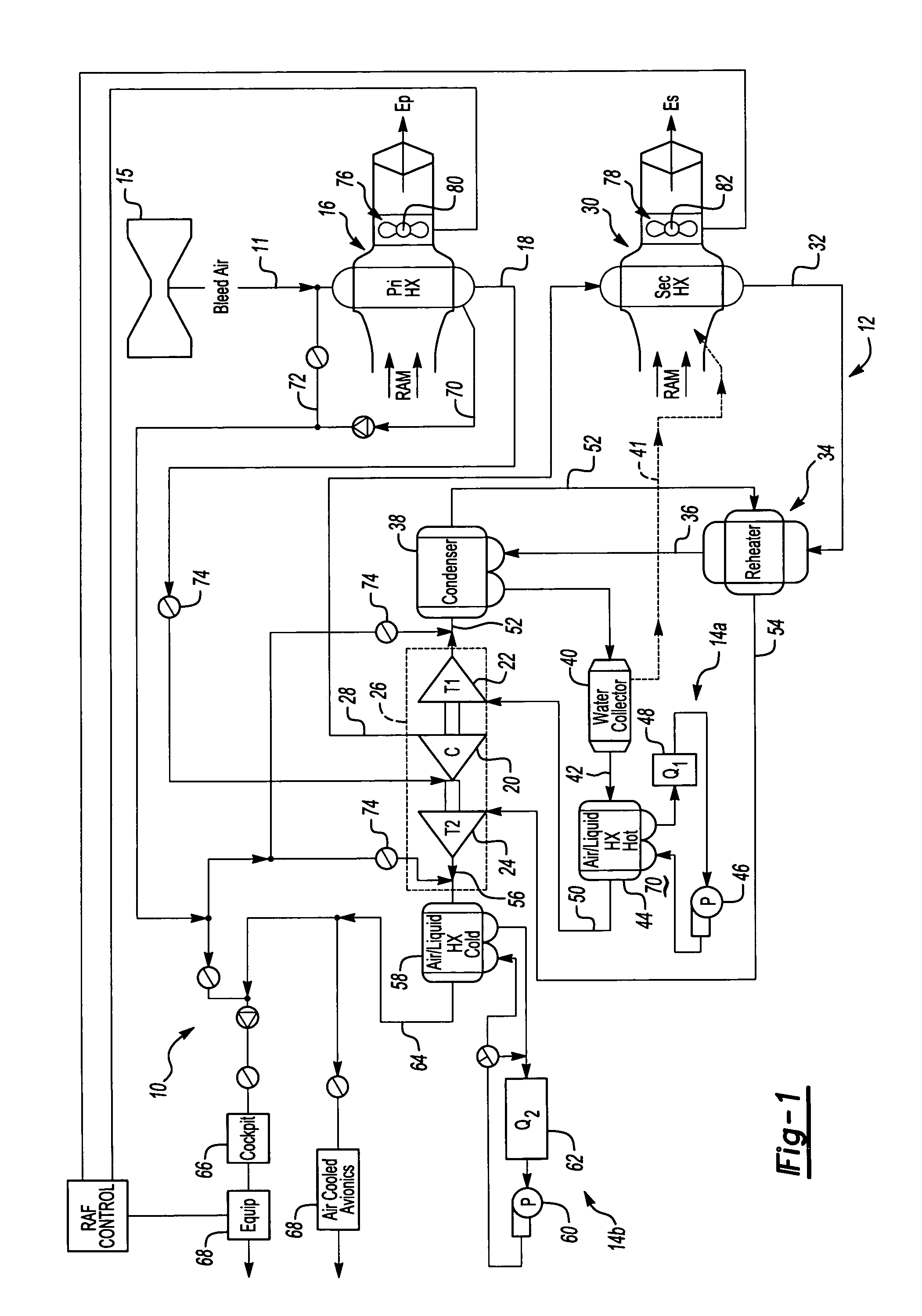

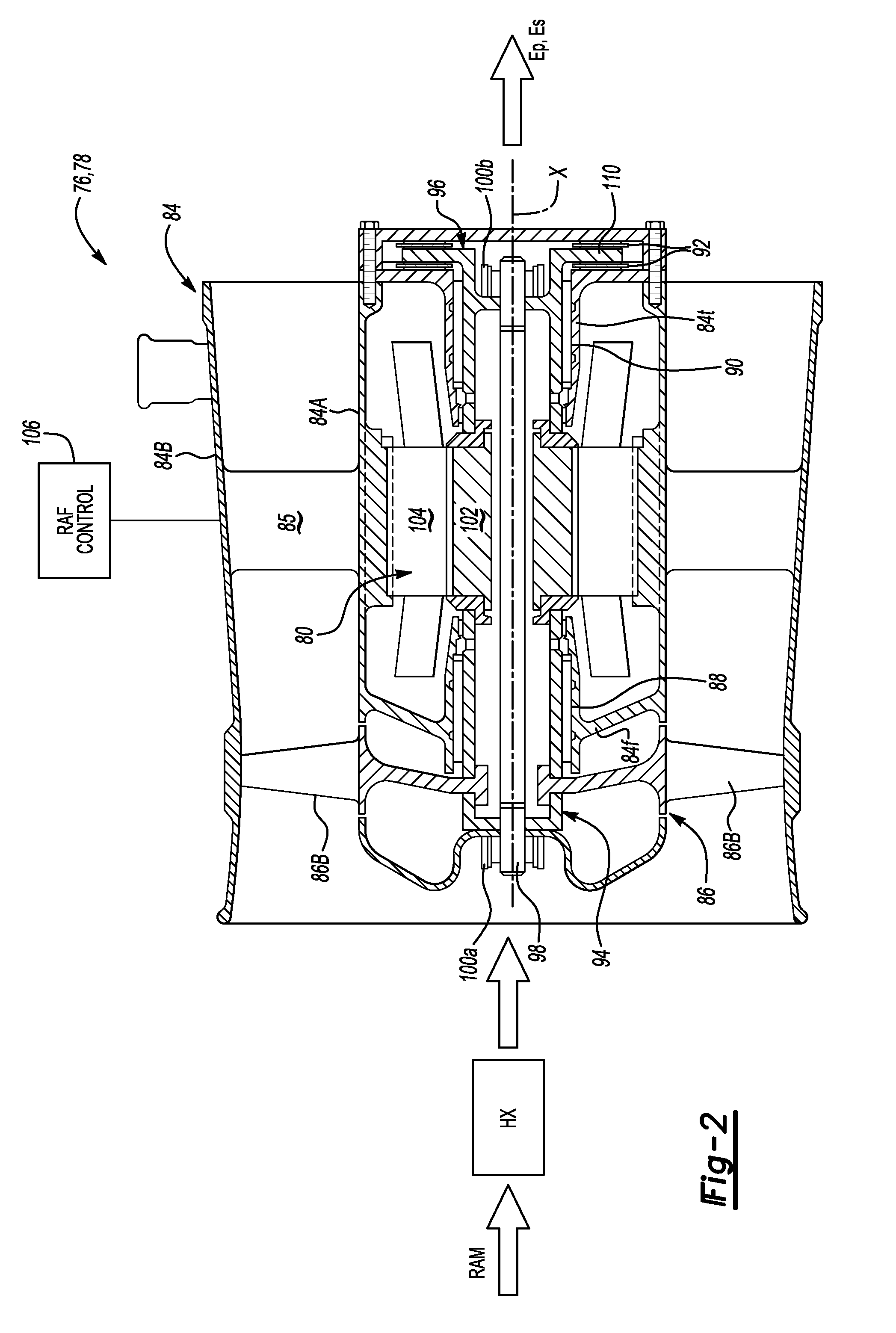

RAM fan system for an aircraft environmental control system

InactiveUS7757502B2Reduce noiseEasy to operateDomestic cooling apparatusSteam/vapor condensersAir cycle machineControl system

An environmental control system includes a RAM air fan system downstream of a respective heat exchanger in the relatively high temperature RAM exhaust. The RAM air fan includes a RAM air fan electric motor such that the RAM air fan is driven at a speed independent of an air cycle machine. A fan rotor is completely supported by hydrodynamic foil journal and thrust bearings. As the RAM air fan is driven by the RAM air fan electric motor the RAM air fan is installed in the environmental control system as a self-contained system.

Owner:HAMILTON SUNDSTRAND CORP

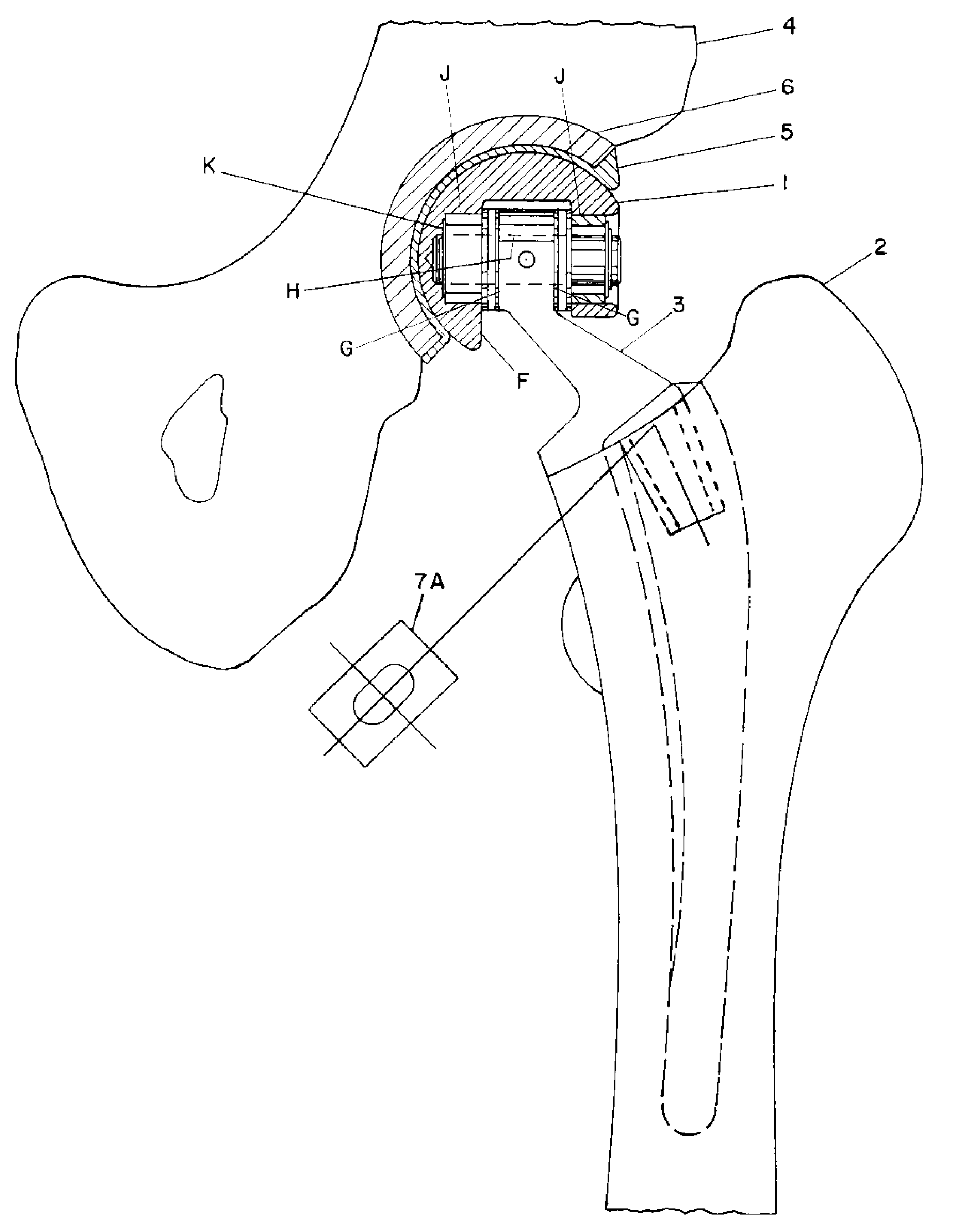

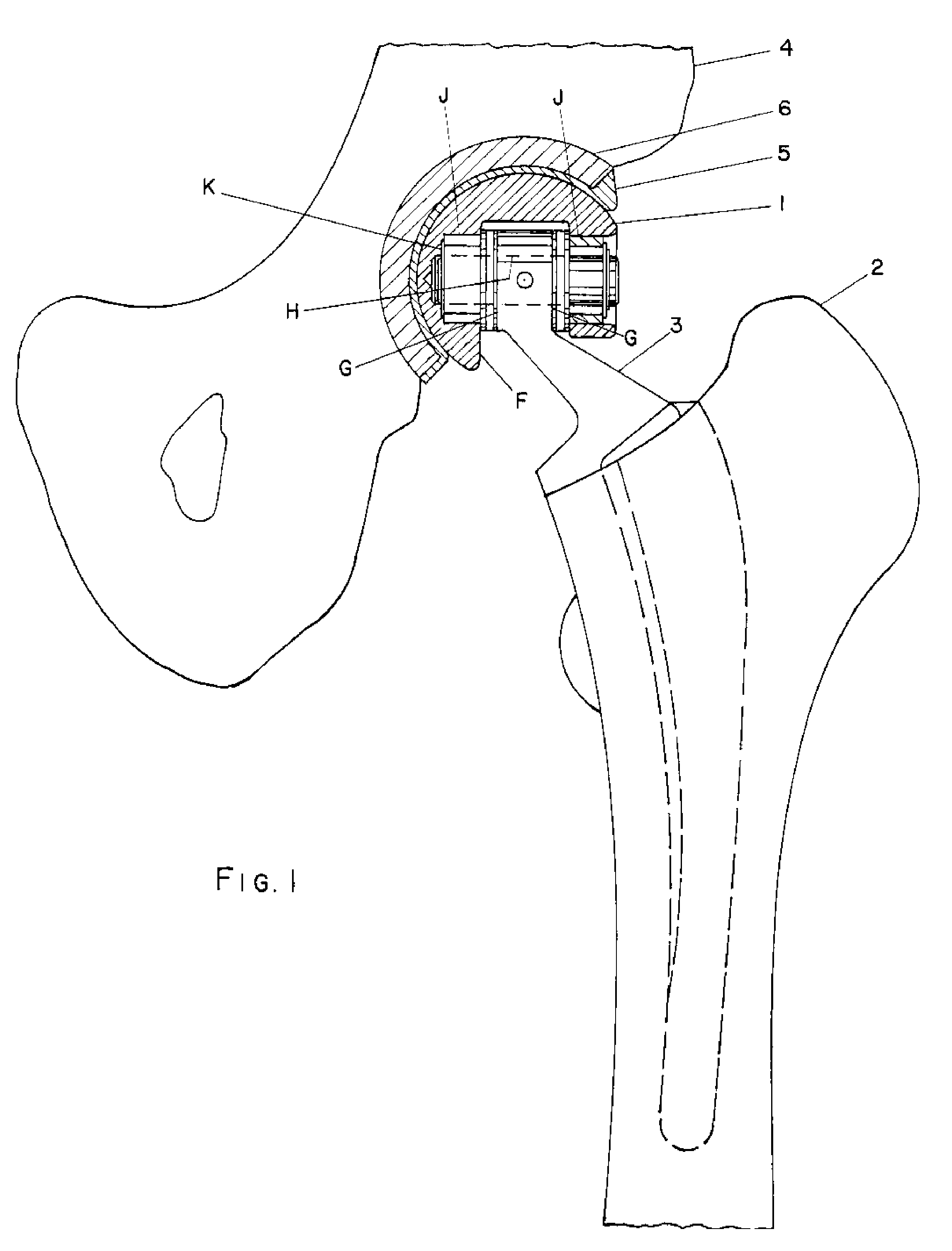

Hip prosthesis and the use thereof

InactiveUS7179298B2Reduce relative motionReduce wearJoint implantsFemoral headsNeedle roller bearingCoxal joint

Hip prosthesis. The femur side hip prosthesis includes both a ball and socket bearing and another (secondary) bearing system which facilitates motion of the type which is primarily in the forward and backward swinging of the leg. In certain embodiments of the invention, the secondary bearing system includes needle bearings and thrust bearings. That secondary bearing system lessens the motion of the ball and socket joint required during common activities such as walking. Certain embodiments of the invention include a modular connection between the stem for placement within the femur and the assembly that includes the secondary bearing.

Owner:GREENLEE WILFRED E

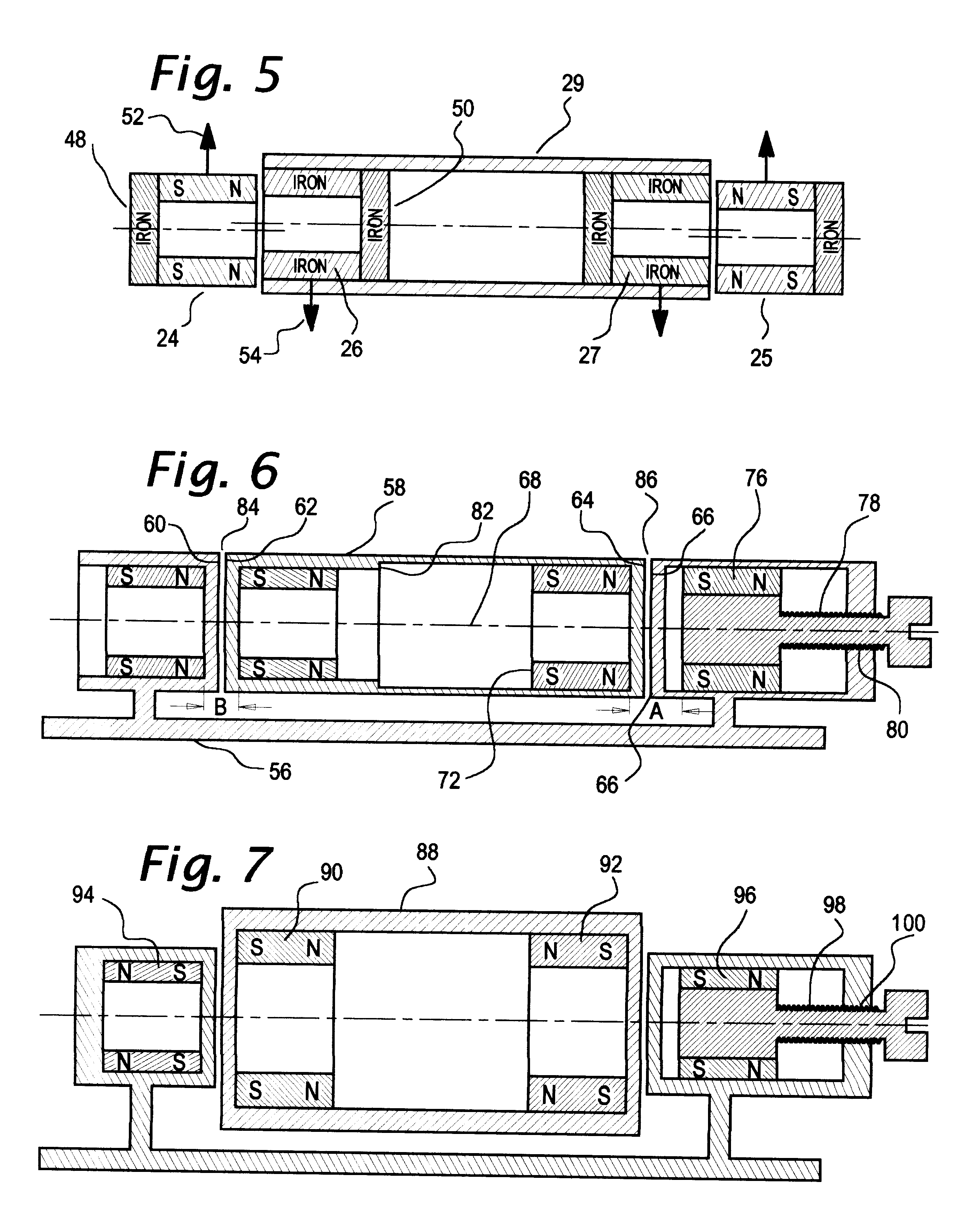

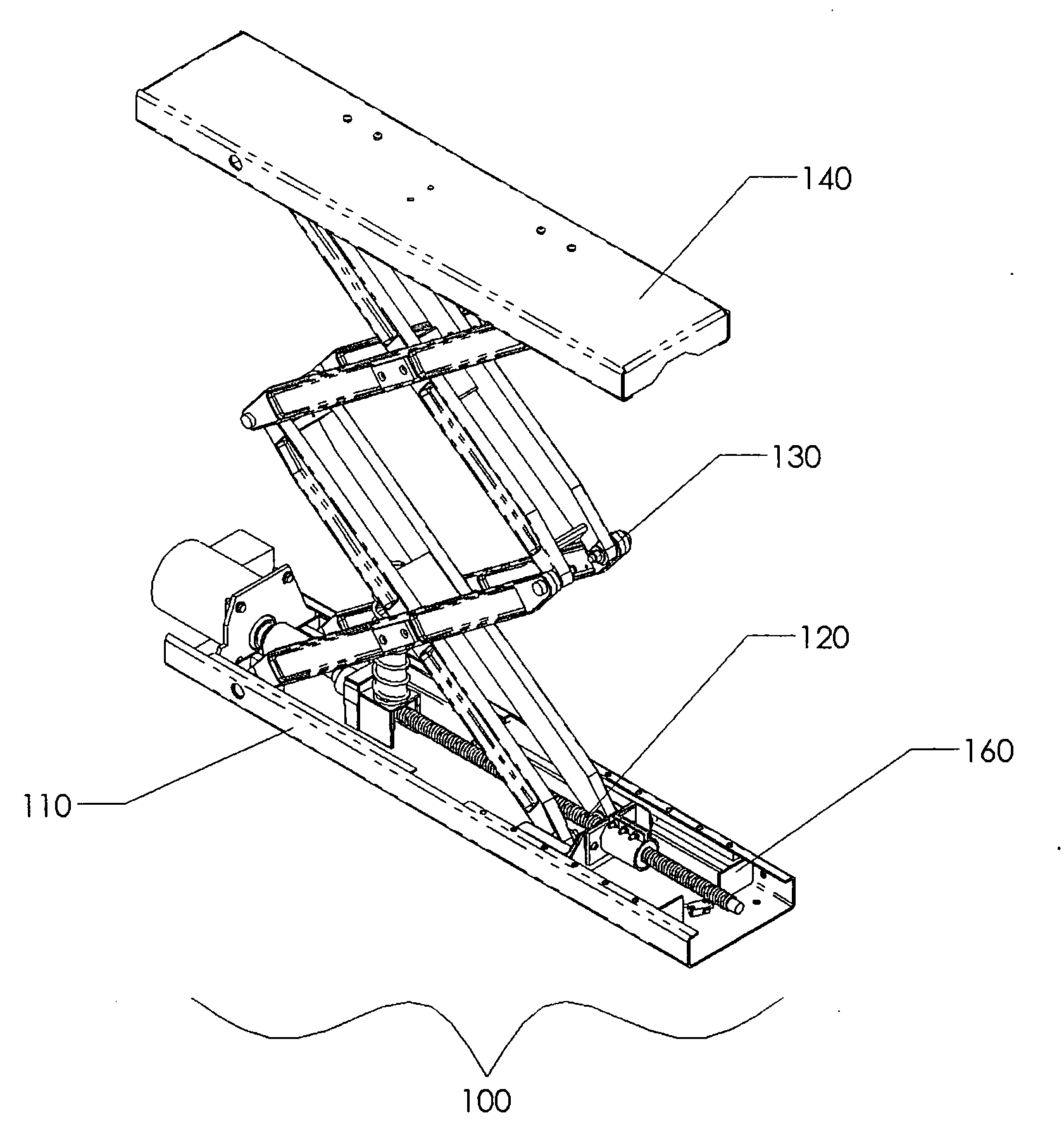

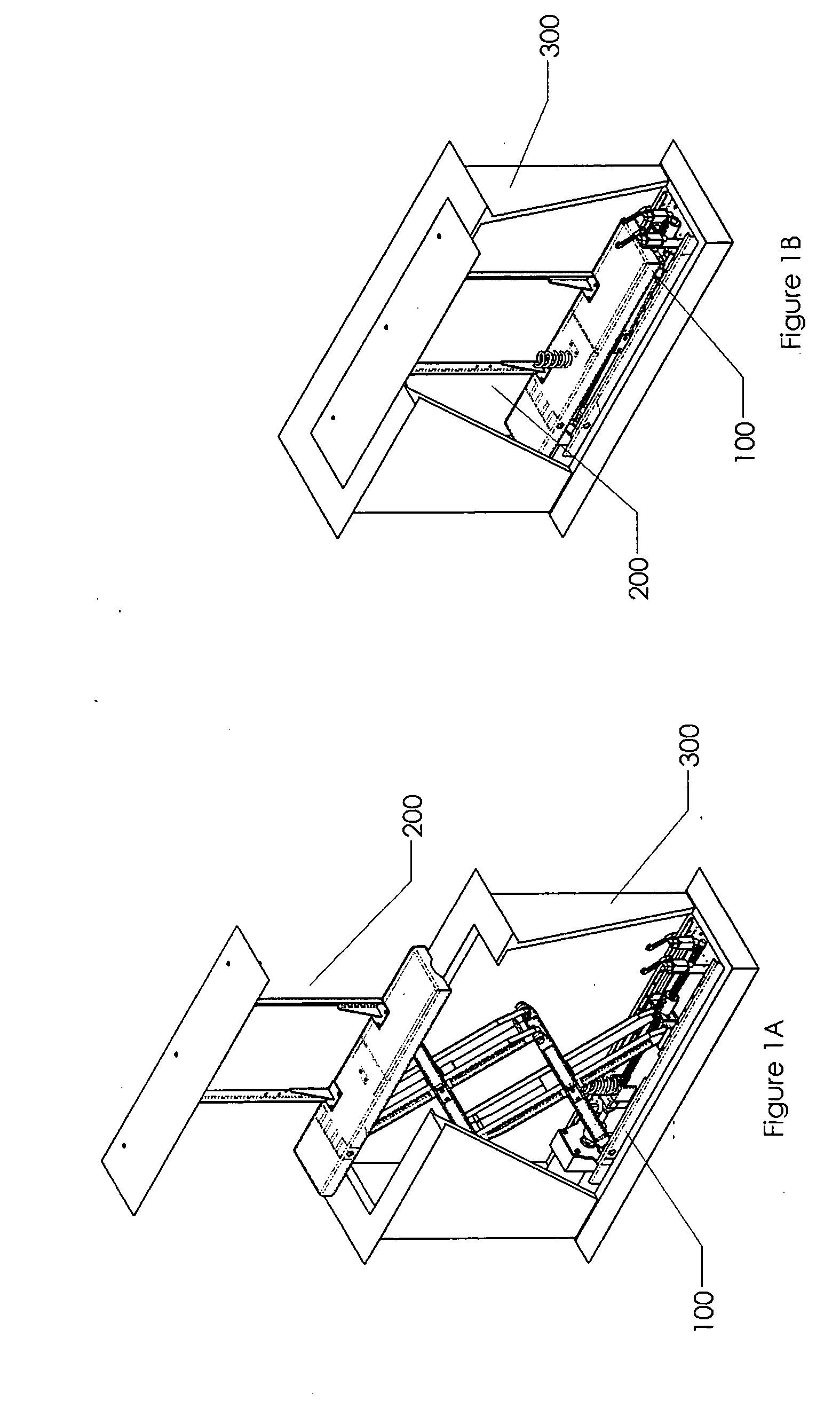

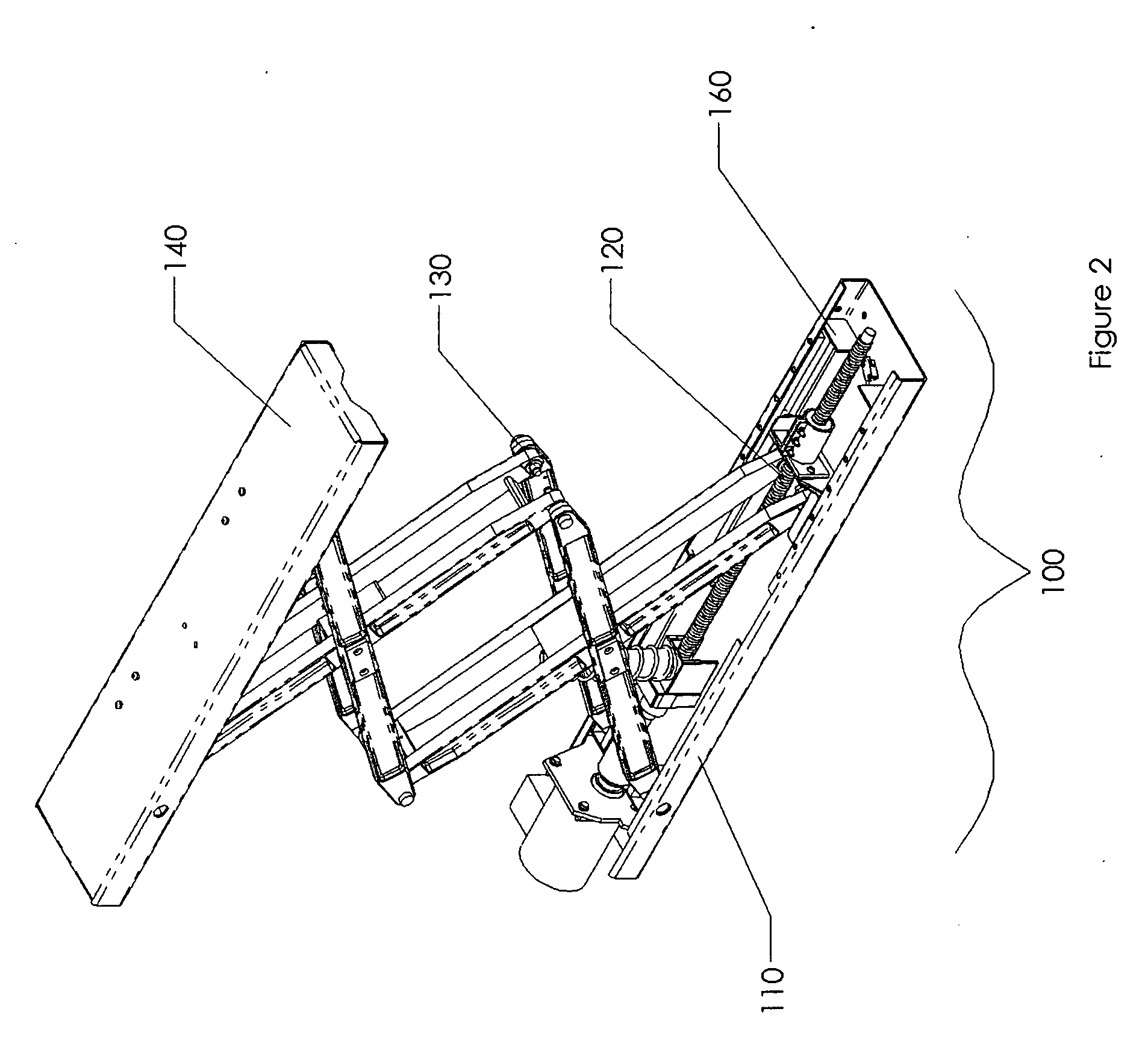

Screw scissor lift

A scissor lift includes an energy storage device that stores energy as the payload is lowered, and provides further lift to the payload as the payload is raised. This allows the scissors to achieve a support angle of up to 180° between the two arms (down to 0° between the screw drive and the lowest arm of the scissors), making the inventive scissor lifts considerably more compact than prior art lifts. The energy storage device is preferably a helical wire spring, but can alternatively be any suitable spring, piston, or even an elastomeric mass. Side to side movement of the scissors arms can be restricted using a thrust bearing with hardened washers at the inter-arm pivot, and / or a guided connector that transmits motive force to the scissors.

Owner:HANLON ENG

Abrasion resistant pump thrust bearing

A centrifugal pump has a stationary diffuser with a bore. A thrust bearing has a tubular portion that inserts into the bore. The thrust bearing has an external shoulder that contacts a support surface in the bore of the diffuser for transmitting downward thrust from an upstream impeller to the diffuser. The thrust bearing has an internal shoulder for transmitting upward thrust from a downstream impeller to the diffuser.

Owner:BAKER HUGHES INC

Electrically driven motors and pumps having such motors

InactiveUS20050074343A1Minimize parts countNumber of partCircumferential flow pumpsTransverse flow pumpsThrust bearingEngineering

A motor, possibly for a pump, has a housing, a first member disposed within the housing and mounted on an inner wall of the housing, and a second member rotatably disposed within the housing and having a rotary shaft. A thrust bearing is mounted within the housing in order to support a first end of the rotary shaft in an axial direction of the rotary shaft. A core and coils wound around the core are provided on one of the first and second members. A set of magnets is provided on the other of the first and second members. The core and the set of magnets are positioned such that a magnetic force is produced in an area where a magnetic flux is generated between the core and the set of magnets. The magnetic force causes the second member to move toward the thrust bearing.

Owner:AISAN IND CO LTD

Low profile fluid dynamic bearing

InactiveUS6982510B1Simple and scalable in designReduce the amount of powerShaftsRecord information storageAxial displacementThrust bearing

The design comprises a shaft and sleeve supported for relative rotation by a journal type fluid dynamic bearing utilizing grooves on one of the shaft or sleeve surfaces. A grooved pattern of a design similar to that usually found on a thrust plate is defined on an axial end surface of the shaft or the counterplate facing the axial end of the shaft, so that thrust is created to maintain separation of the end of the shaft and the facing thrust plate during relative rotation.In one embodiment, to establish and maintain the gap between the shaft end and the facing counterplate, the journal bearing has an asymmetry to pump toward the shaft end having the bearing. In a further refinement, to maintain the shaft and gap within an optimum spacing, a magnet is mounted to provide an axially directed magnetic force on the shaft which works against the axial force created by shaft end thrust bearing.To prevent separation of the shaft and sleeve or hub, the hub which is integrated with a rotating shaft, further incorporates a shoulder which extends axially beneath a cooperating shoulder on the sleeve surrounding the shaft to prevent any more than a limited axially displacement of the hub and shaft relative to the sleeve.

Owner:SEAGATE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com