Horizontal well hydraulic directional spraying gun

A horizontal well and hydraulic technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of high cost, low operation success rate, large impact, etc., and achieve low cost and high directional success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

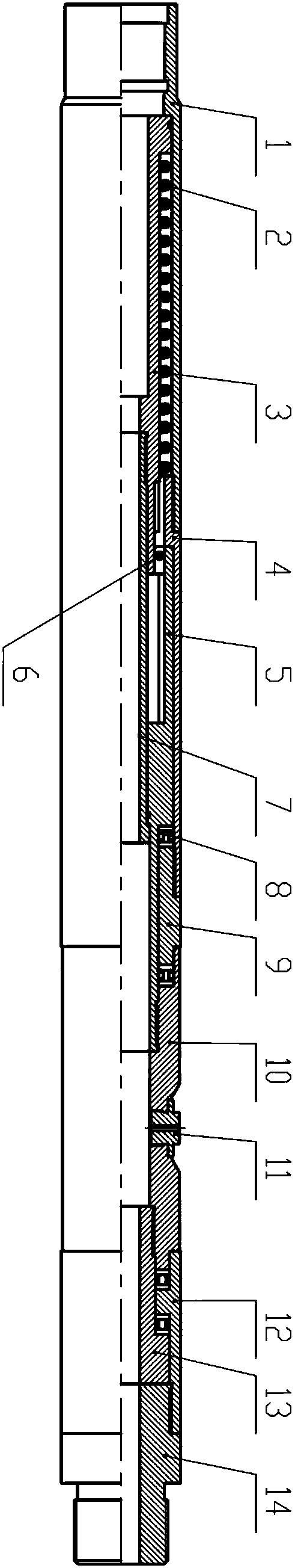

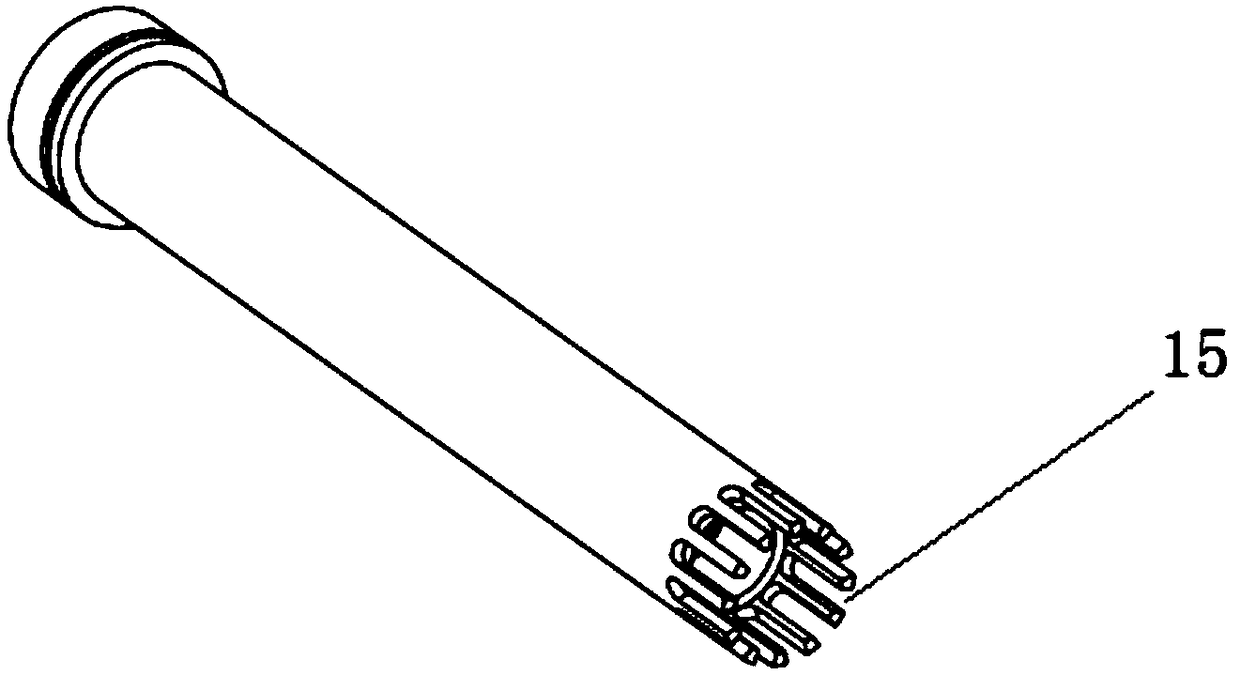

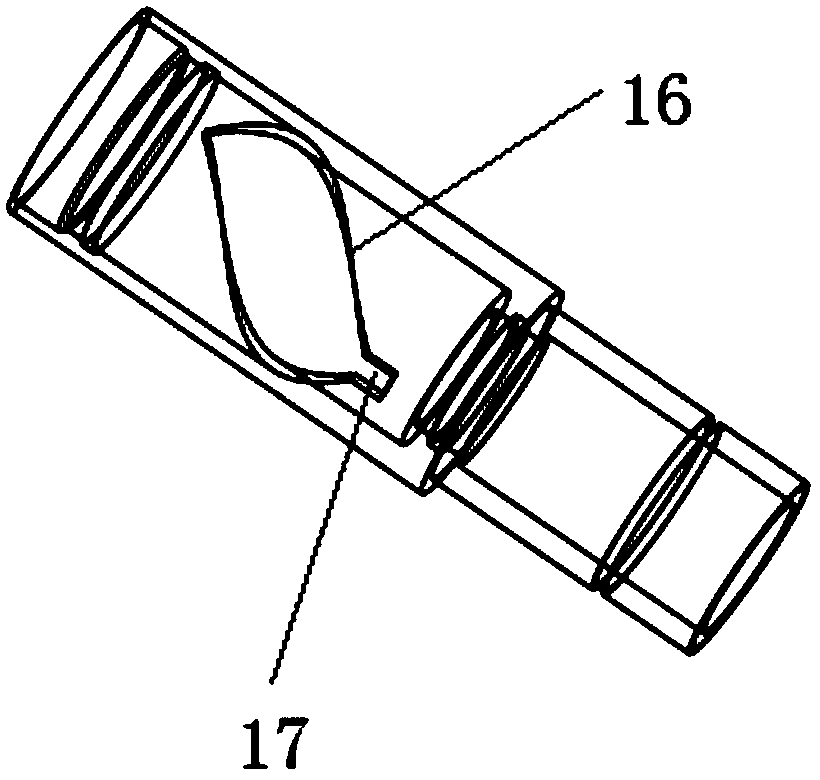

[0017] Such as Figure 1-3 As shown, a hydraulic directional spray gun for a horizontal well includes a directional split-tooth hydraulic cylinder 3, an envelope sleeve 5, a directional steel ball 6, a thrust bearing 8 and a nozzle 11, and the directional split-tooth hydraulic cylinder 3 is sleeved inside the upper joint 1, And form an annulus with the upper joint 1, a return spring 2 is arranged in the annulus, the right end of the upper joint 1 is connected with the upper shell 4, the inner part of the upper shell 4 is equipped with an envelope sleeve 5, and the center rod 7 passes through the envelope The sleeve 5 is internally connected to the internal thread at the right end of the directional split gear cylinder 3, and a closed space is formed between the upper shell 4, the directional split gear fluid cylinder 3 and the envelope sleeve 5, and the directional steel ball 6 is placed in the space, and the upper shell 4. The right end is threadedly connected with the connec...

Embodiment 2

[0021] A hydraulic directional spray gun for a horizontal well, comprising a directional split-tooth hydraulic cylinder 3, an envelope sleeve 5, a directional steel ball 6, a thrust bearing 8 and a nozzle 11, the directional split-tooth hydraulic cylinder 3 is sleeved inside the upper joint 1, and The joint 1 forms an annular space, and a return spring 2 is arranged in the annular space. The right end of the upper joint 1 is connected with the upper shell 4. The upper shell 4 is equipped with an envelope sleeve 5, and the central rod 7 passes through the envelope sleeve 5. Connected to the internal thread on the right end of the directional split gear cylinder 3, a closed space is formed between the upper casing 4, the directional split gear fluid cylinder 3 and the envelope sleeve 5, and the directional steel ball 6 is placed in this space, and the right end of the upper casing 4 is connected to the The connecting sleeve 9 is threaded, the two ends of the connecting sleeve 9 a...

Embodiment 3

[0025] A hydraulic directional spray gun for a horizontal well, comprising a directional split-tooth hydraulic cylinder 3, an envelope sleeve 5, a directional steel ball 6, a thrust bearing 8 and a nozzle 11, the directional split-tooth hydraulic cylinder 3 is sleeved inside the upper joint 1, and The joint 1 forms an annular space, and a return spring 2 is arranged in the annular space. The right end of the upper joint 1 is connected with the upper shell 4. The upper shell 4 is equipped with an envelope sleeve 5, and the central rod 7 passes through the envelope sleeve 5. Connected to the internal thread on the right end of the directional split gear cylinder 3, a closed space is formed between the upper casing 4, the directional split gear fluid cylinder 3 and the envelope sleeve 5, and the directional steel ball 6 is placed in this space, and the right end of the upper casing 4 is connected to the The connecting sleeve 9 is threaded, the two ends of the connecting sleeve 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com