Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133440 results about "Nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nozzle is a device designed to control the direction or characteristics of a fluid flow (especially to increase velocity) as it exits (or enters) an enclosed chamber or pipe. A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them. In a nozzle, the velocity of fluid increases at the expense of its pressure energy.

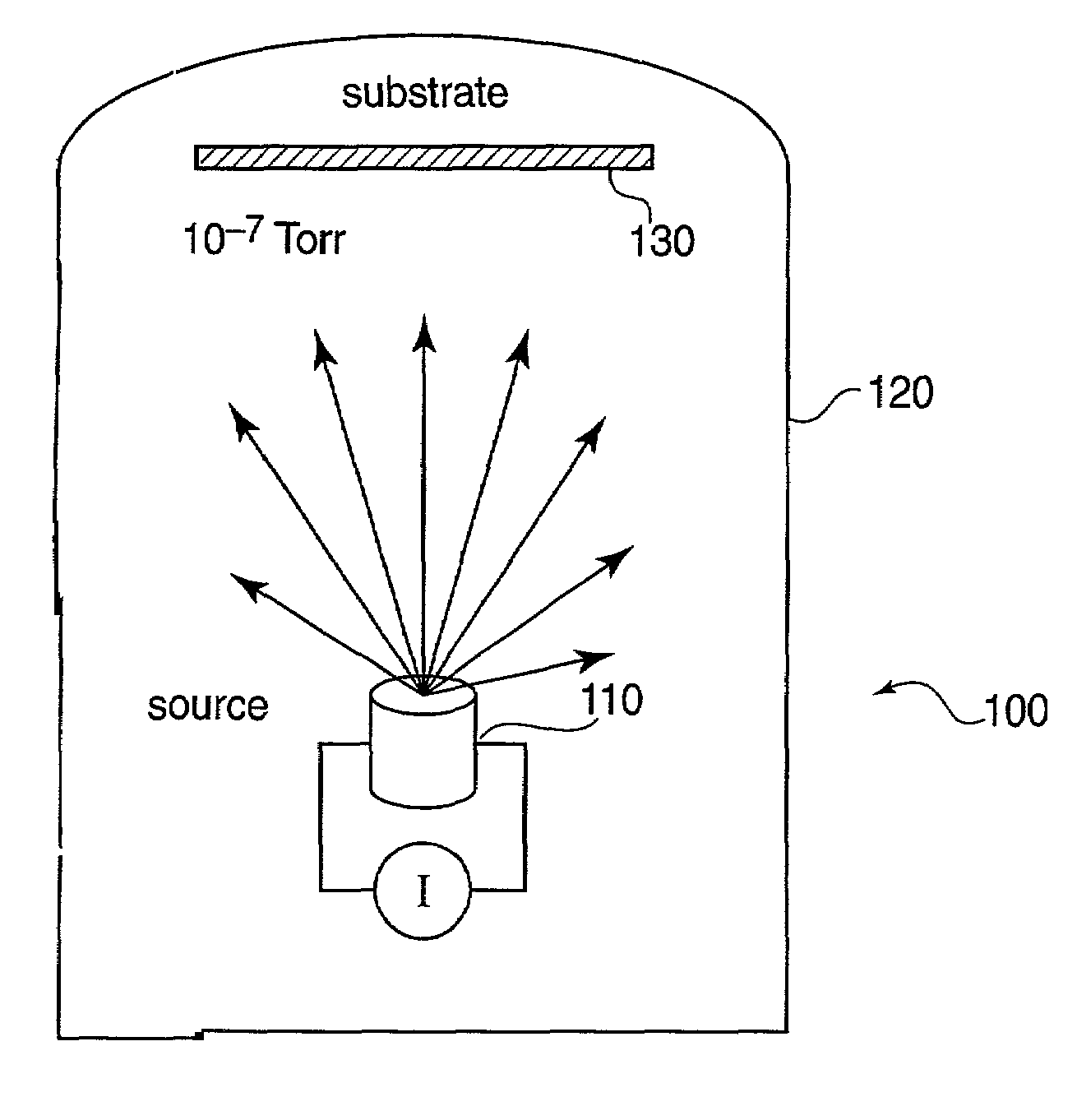

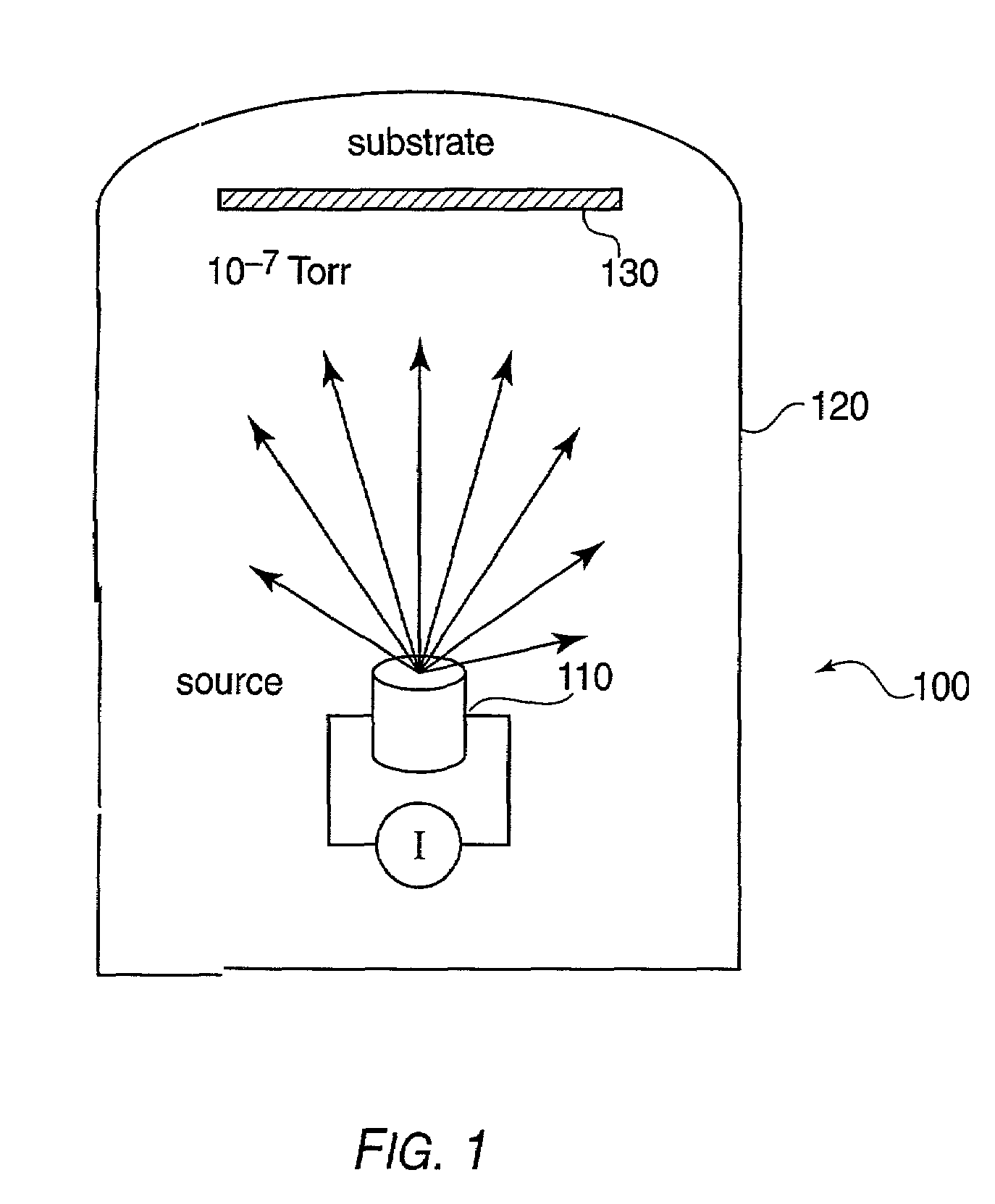

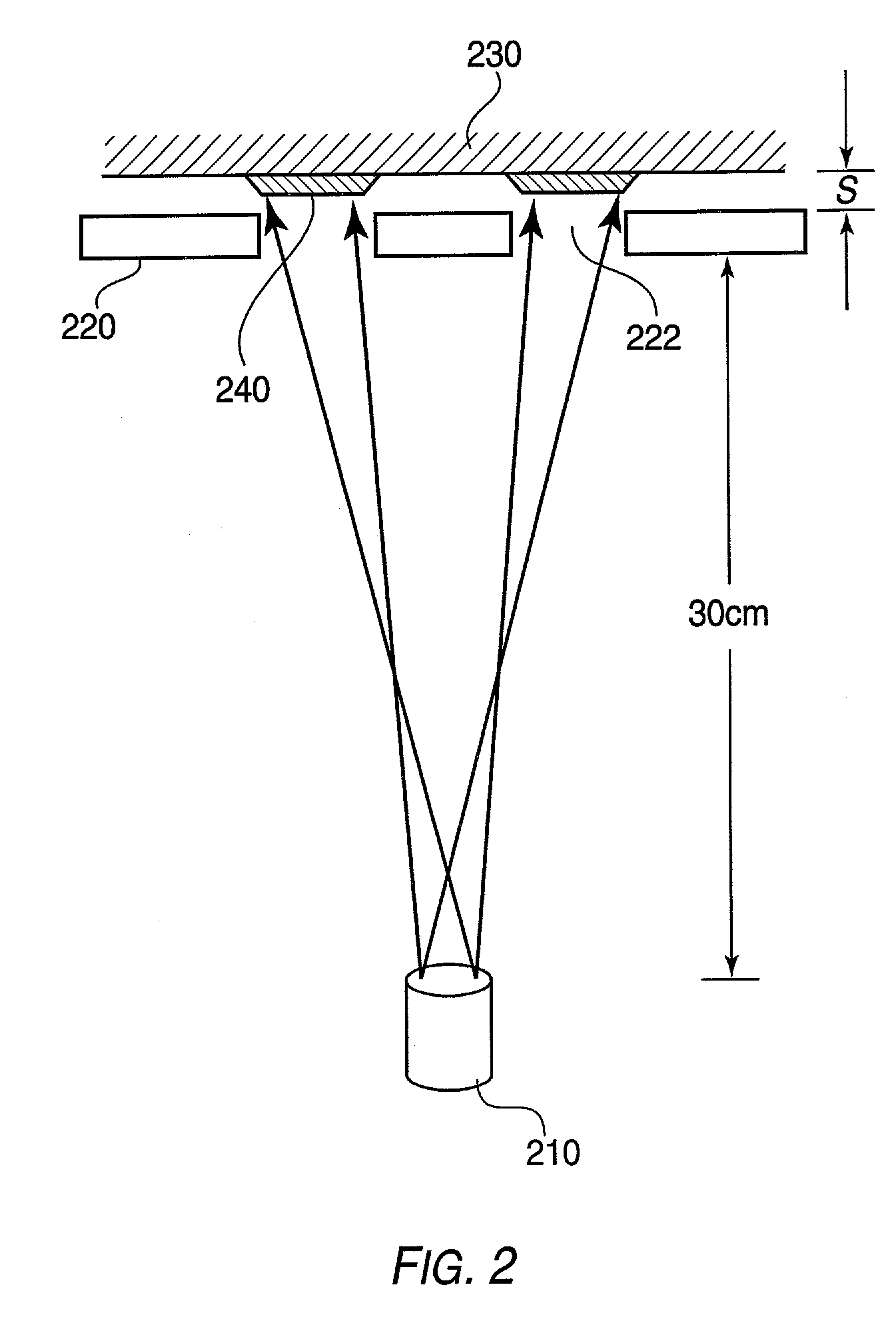

Process and apparatus for organic vapor jet deposition

ActiveUS7431968B1Good directionSharp pixelVacuum evaporation coatingSputtering coatingOrganic filmVacuum chamber

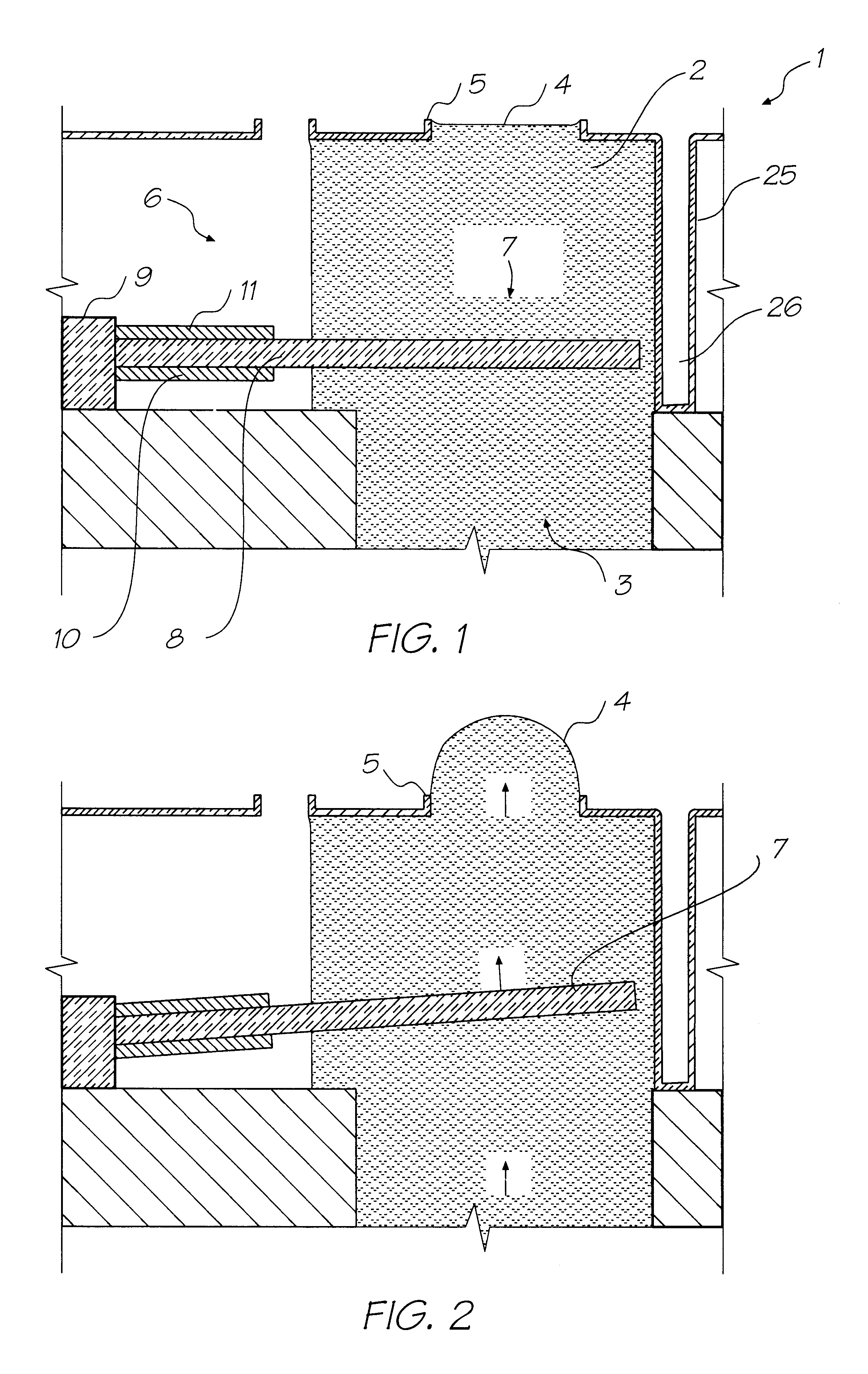

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

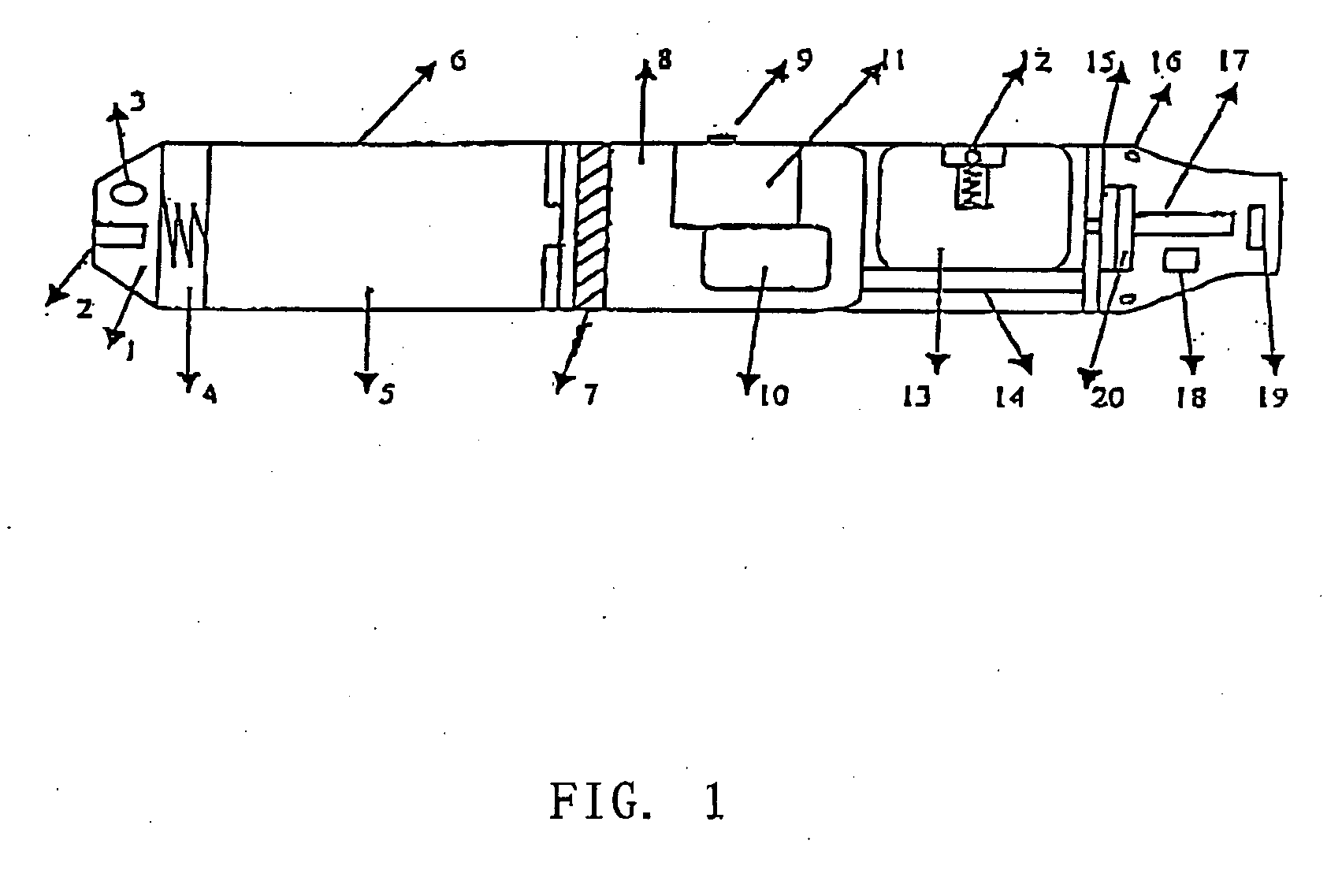

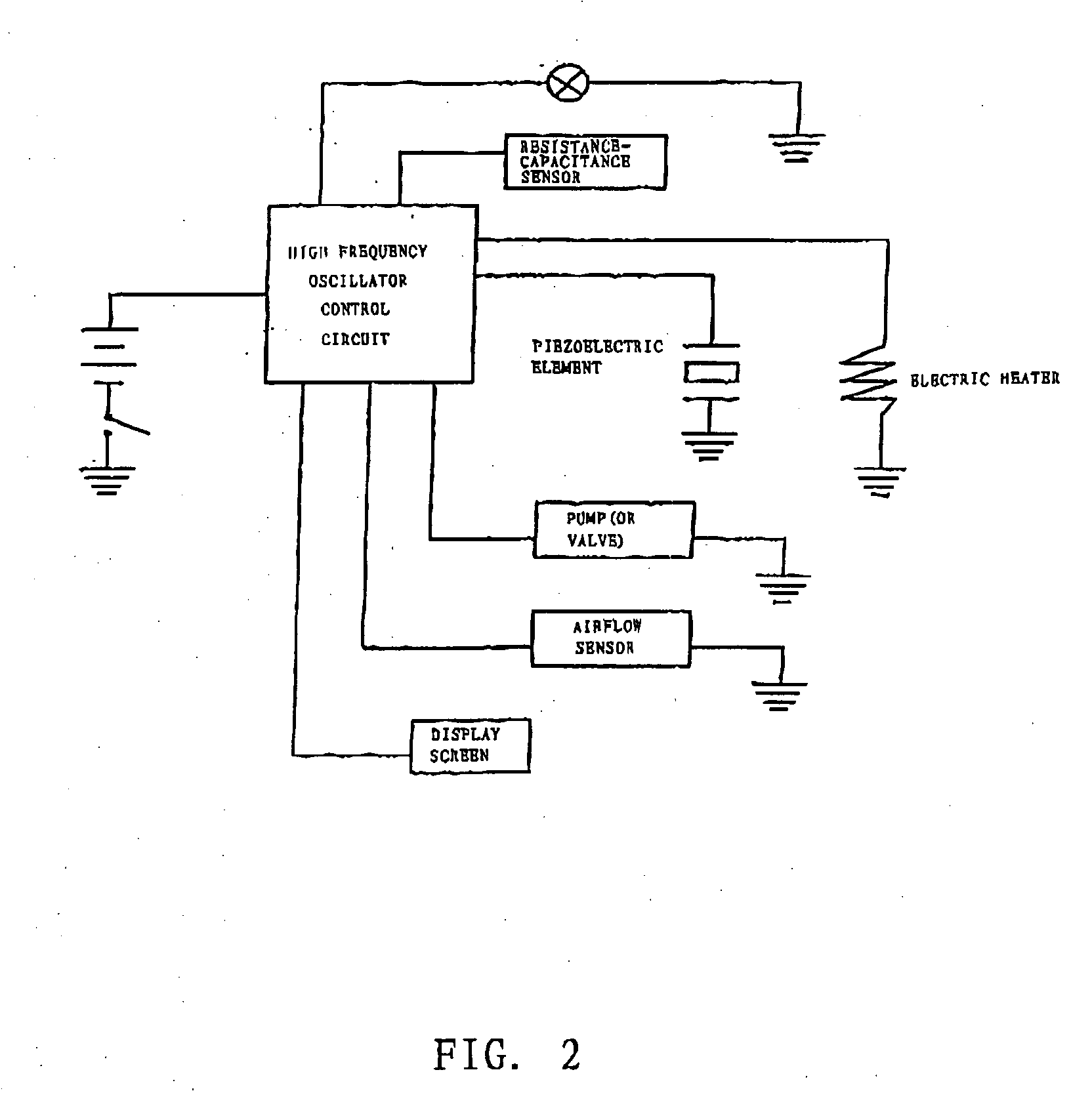

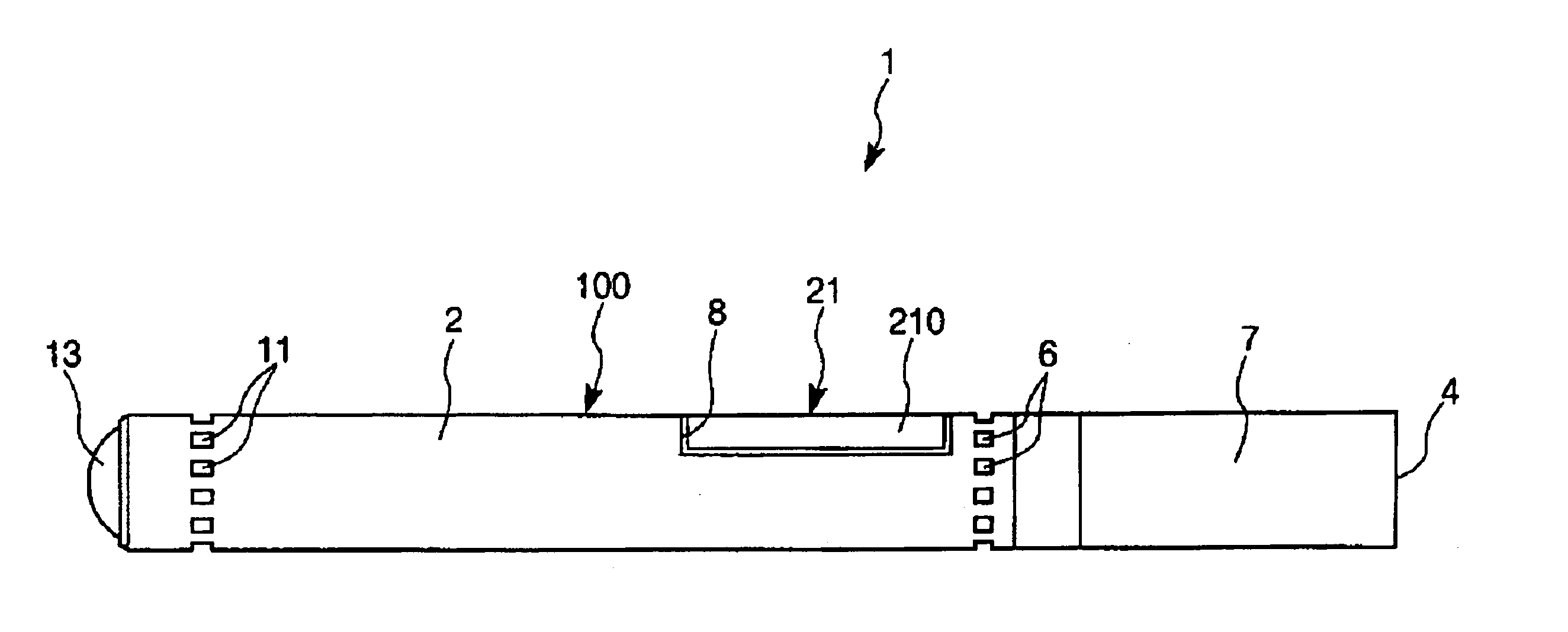

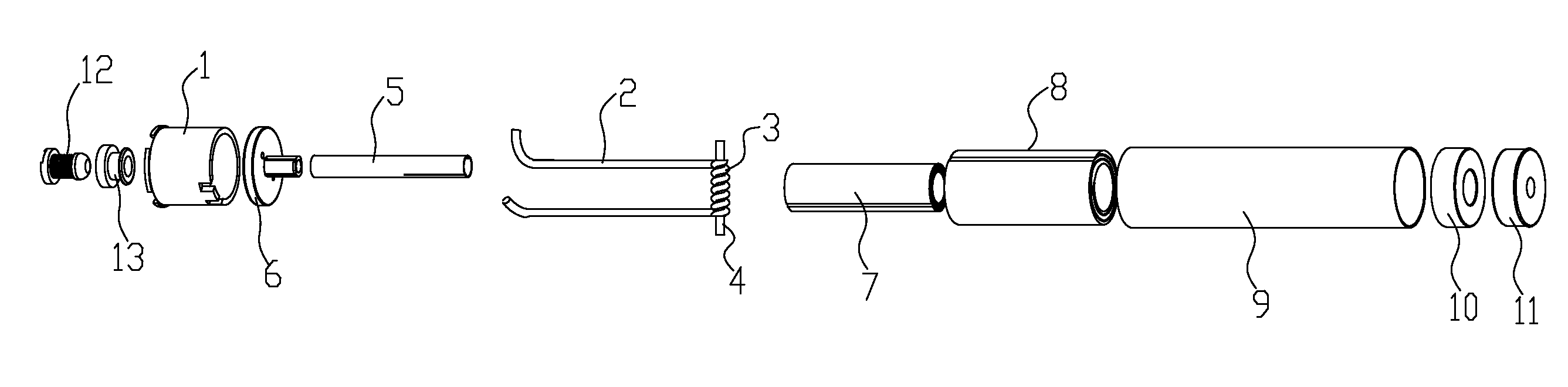

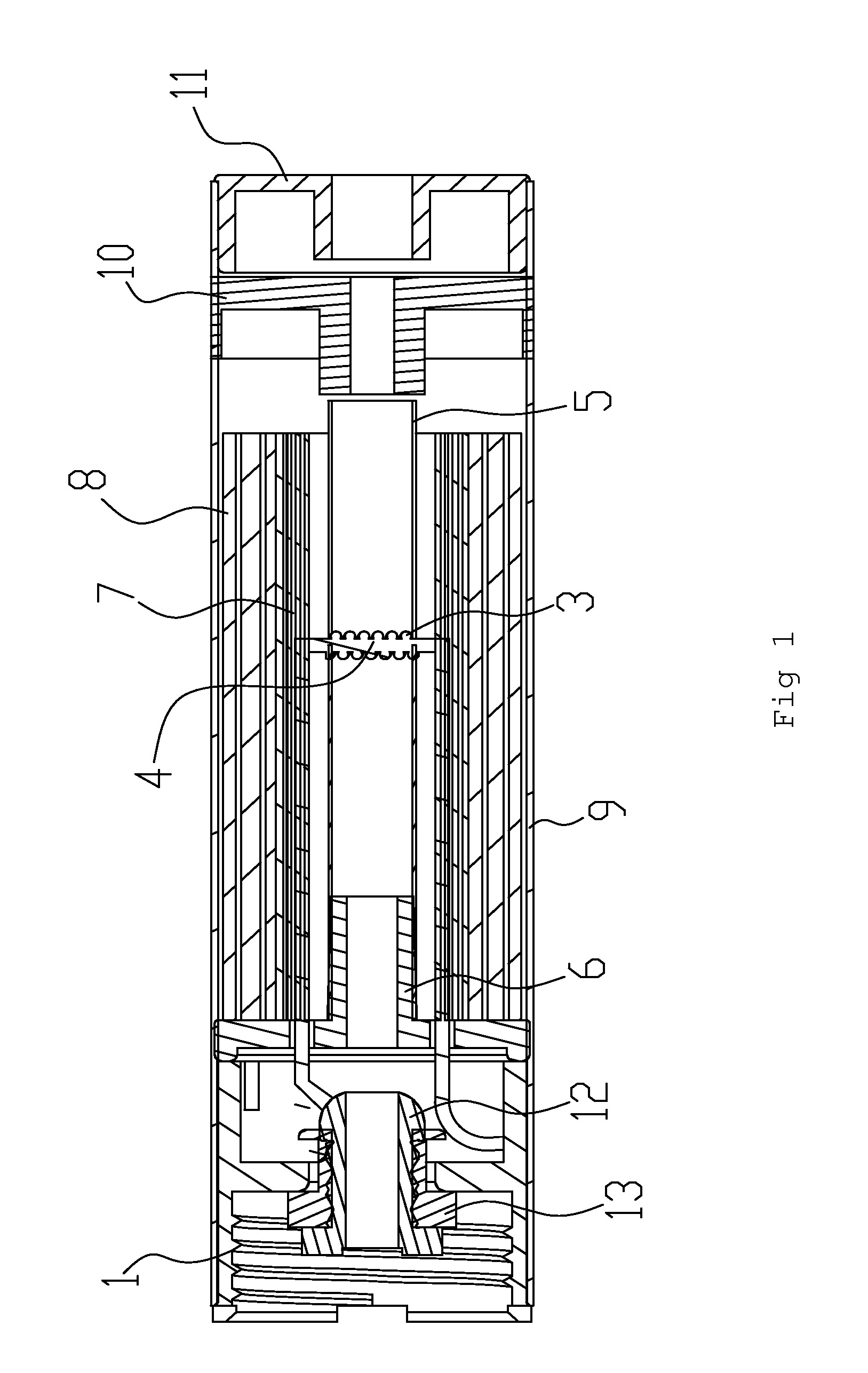

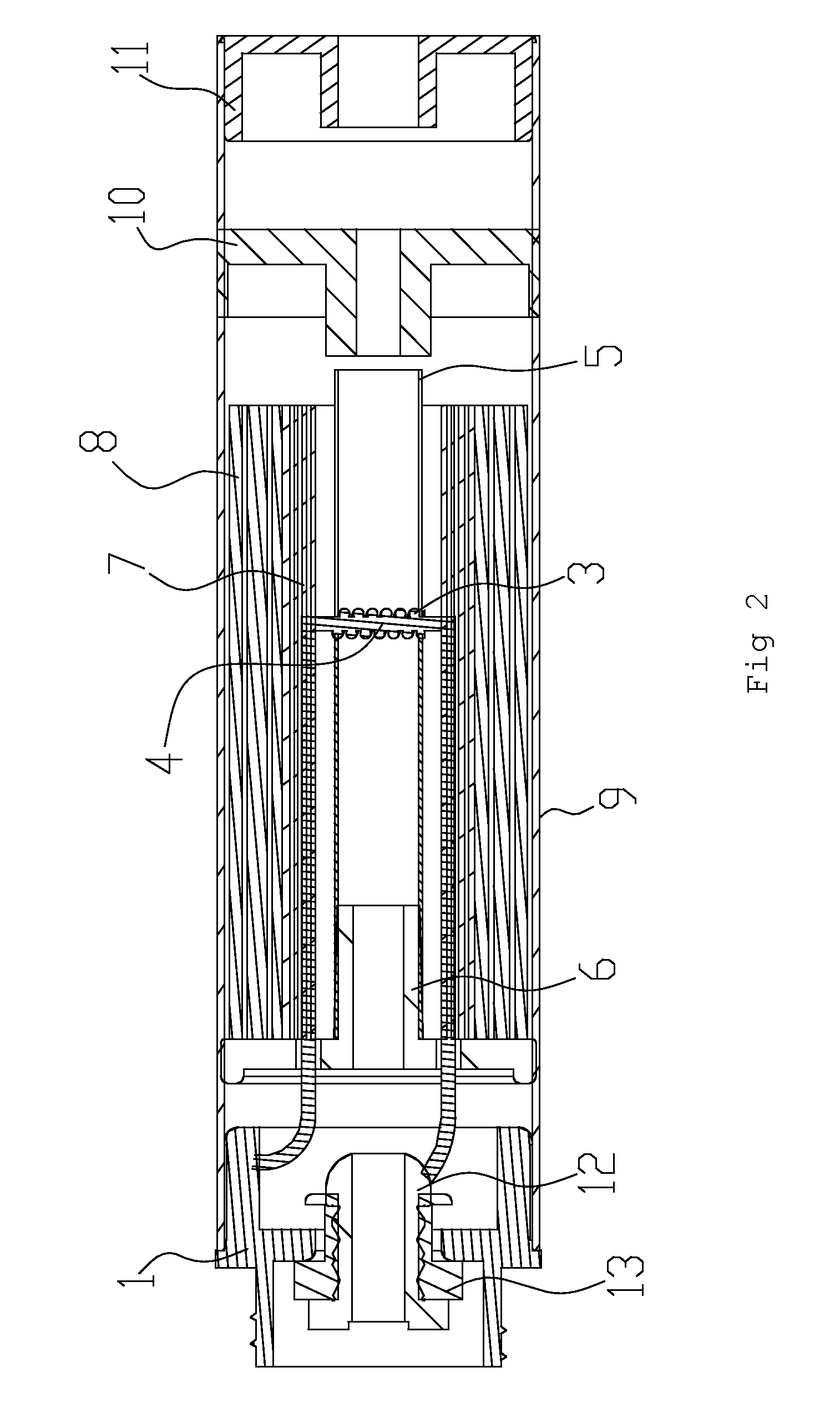

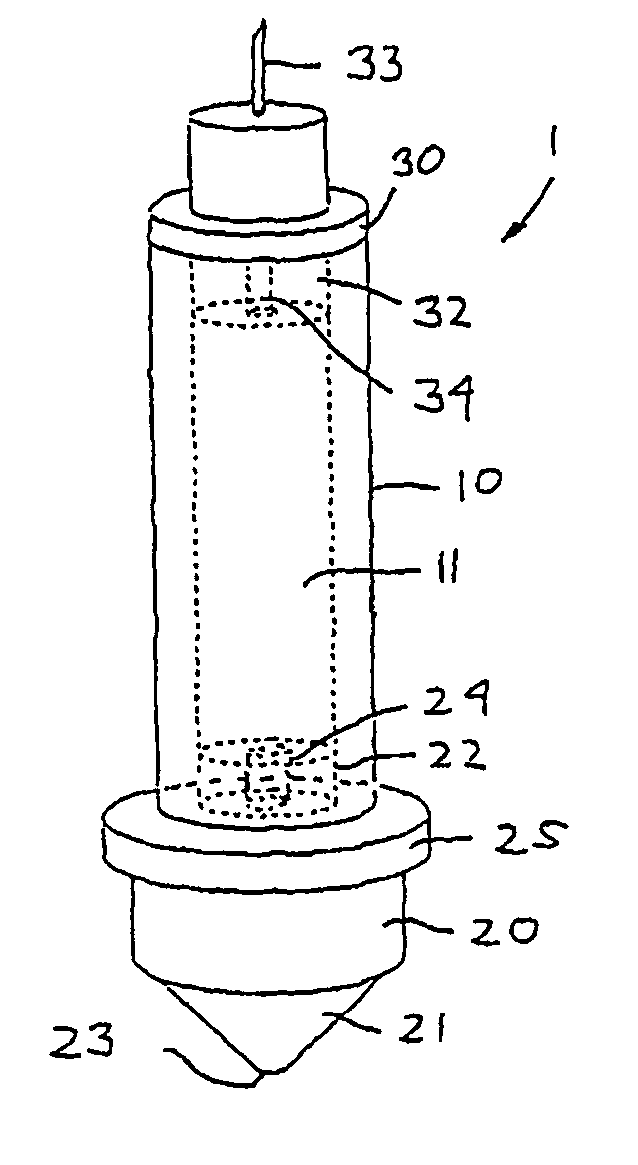

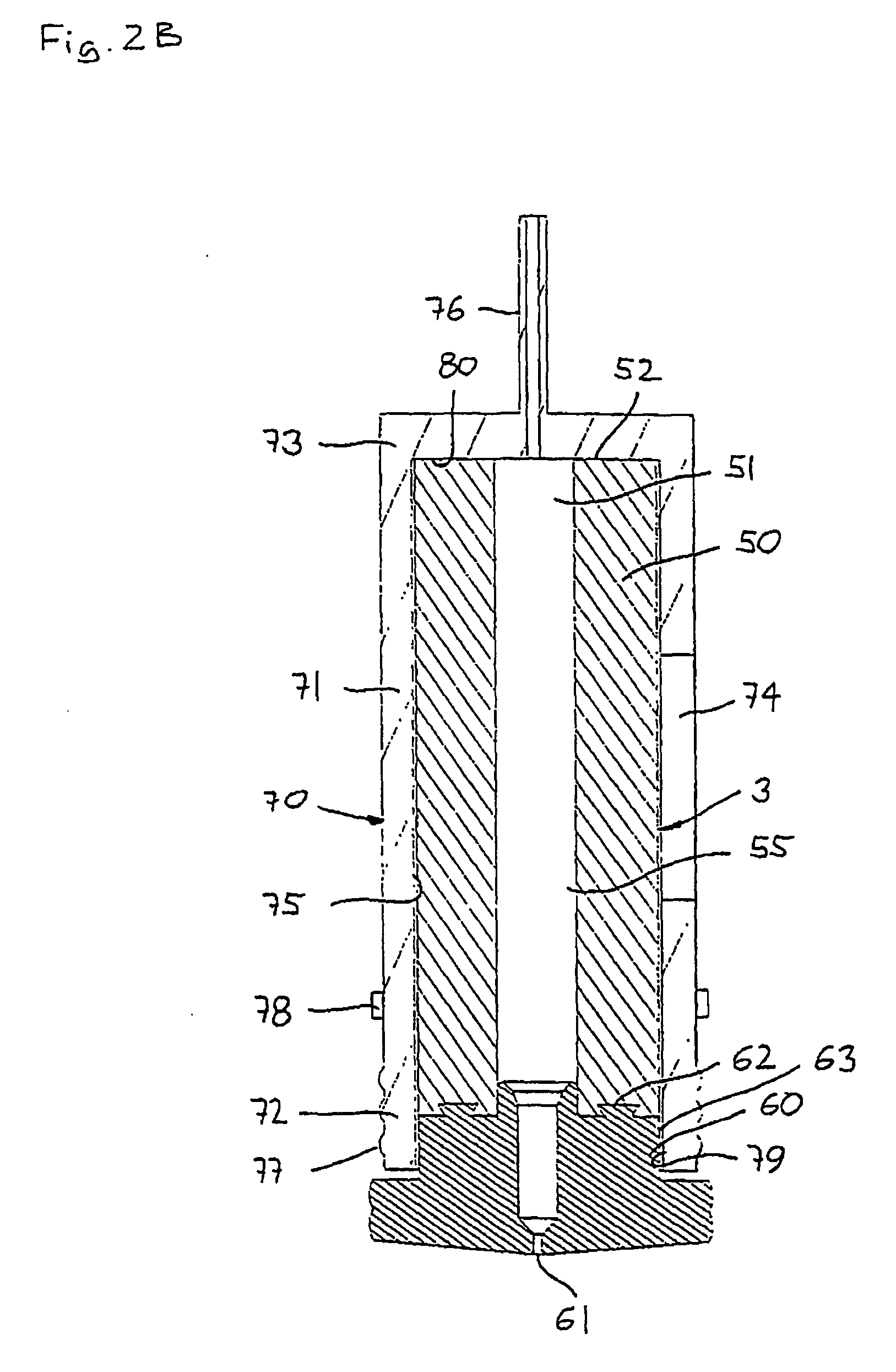

Flameless electronic atomizing cigarette

InactiveUS20060196518A1Reduce cancer riskTobacco preparationBatteries circuit arrangementsEngineeringElectric control

The invention relates to a non-smokable electronic spray cigarette which only comprises nicotine without harmful tar. The cigarette includes a smoke mouth integer comprised with a shell, a cell, a high frequency ionzer, nicotine solution storage and its container, control circuit, a display screen, a human contact sensor, a piezoelectric supersound atomizer, a high temperature vaporization nozzle and attachments, an electro-thermal vaporization nozzle installed in the air suction end of the shell goes through an electric control pump or a valve with a measuring chamber and a liquid storage container which contains nicotine solution and is connected to the electric control pump or a valve with a one-way flow valve, the control circuit plate has four export ends individually connected with the high frequency ionizer, electric heater, pump or valve and the display screen, a human resistence sensor and an air flow sensor are connected to the input end of the control circuit. The advantages of the present invention are smoking without tar, reducing the cancerogenic risk, the user still feel smoking and experiercing the excitement, the cigarette is no need to be lit and is no fire danger.

Owner:FONTEM HLDG 1

External mixer assembly

An external mixer assembly is provided which externally mixes and delivers a first and a second component of a biological adhesive to tissues or organs for sealing wounds, stopping bleeding and the like. The first and second components are mixed immediately after exiting from separate outlet ports disposed in fluid communication with component reservoirs. In on embodiment, the external mixer assembly includes a housing having a housing head for enclosing therein a first reservoir containing the first component, and a second reservoir containing the second component. The housing further includes a discharge nozzle defining a longitudinal axis for enclosing therein a conduit assembly having a first and a second conduit in communication with the first and second reservoir, respectively. A deflector assembly is connected to the discharge nozzle. The deflector assembly includes a deflector plate to provide a space for initial mixing of the first and second components. The deflector plate is oriented in generally parallel juxtaposed relation distal to the distal face of the discharge nozzle. The first and second components are preferably fibrinogen and thrombin which intermix to form a fibrin sealant.

Owner:TYCO HEALTHCARE GRP LP

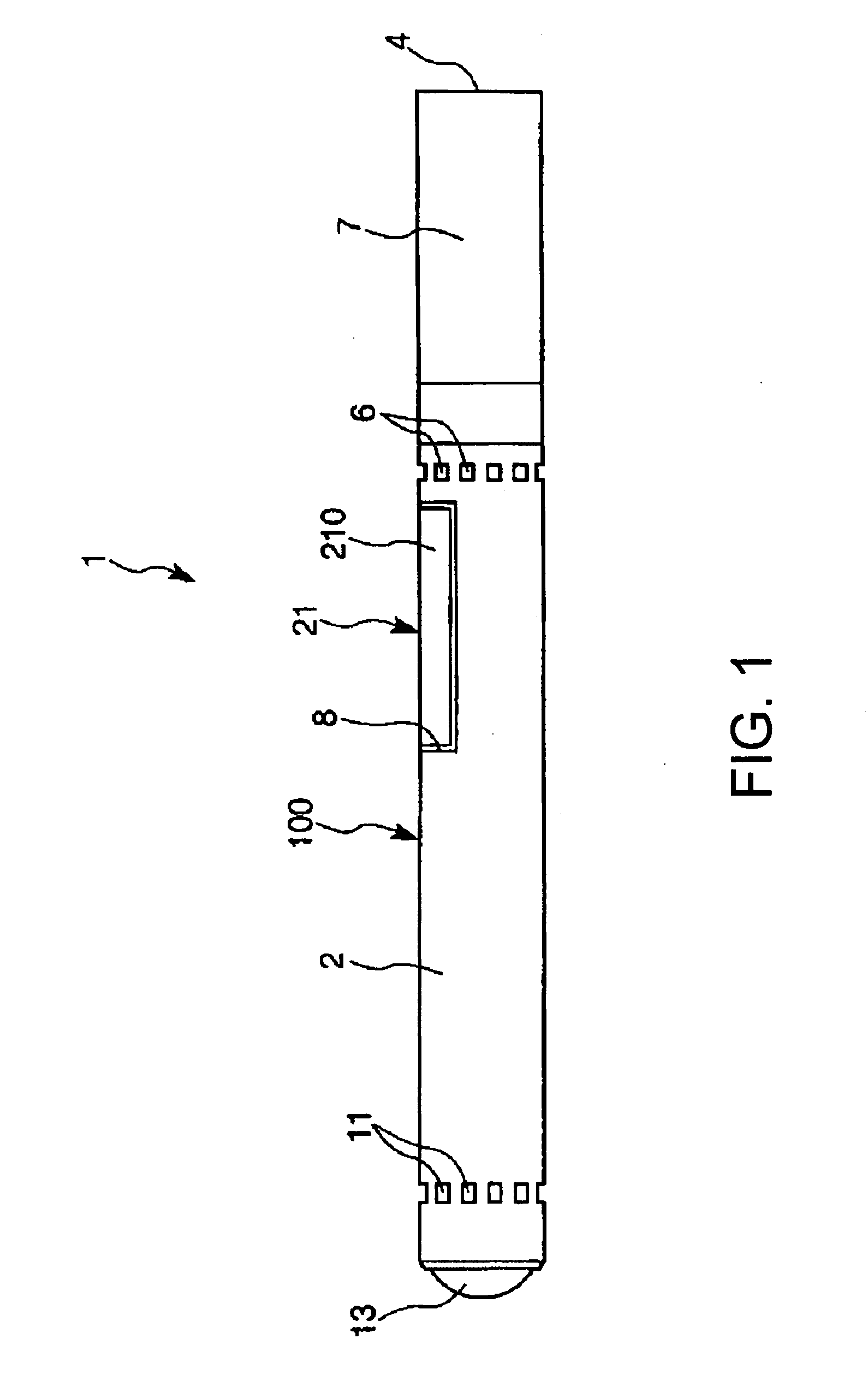

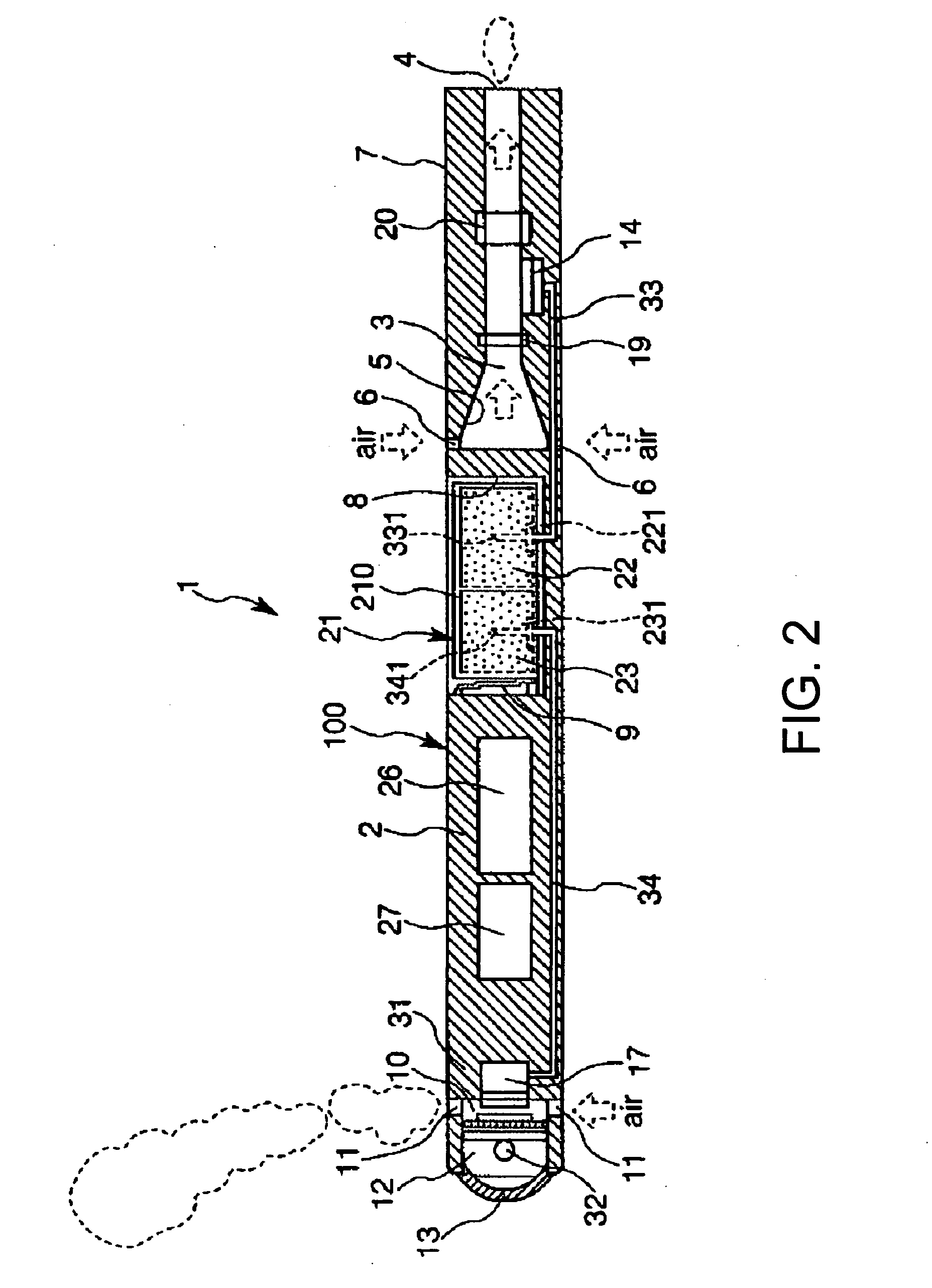

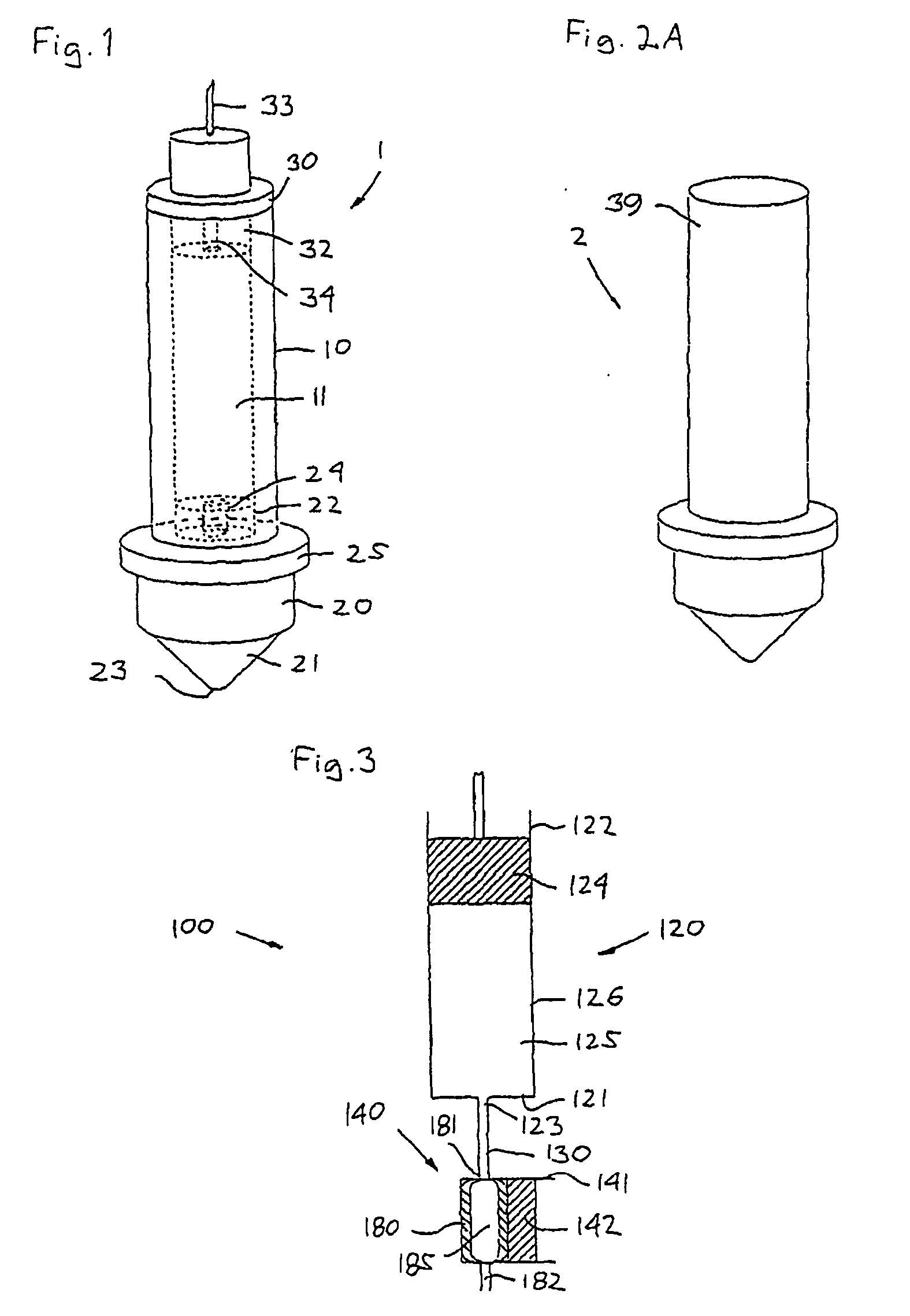

Electronic cigarette

InactiveUS20050016550A1Efficient disseminationGood adhesionTobacco preparationCigar manufactureInhalationEngineering

An electronic cigarette is provided. The electronic cigarette includes a casing having an inhalation hole and a substantially cylindrical configuration, ejection means (first ejection means) provided in the casing and at least one ejection head. Pressure in a cavity filled with a liquid flavor generating medium is changed by driving an actuator to eject the flavor generating medium as droplets from a nozzle in communication with the cavity. Control means provided in the casing controls the driving of the ejection means.

Owner:SEIKO EPSON CORP

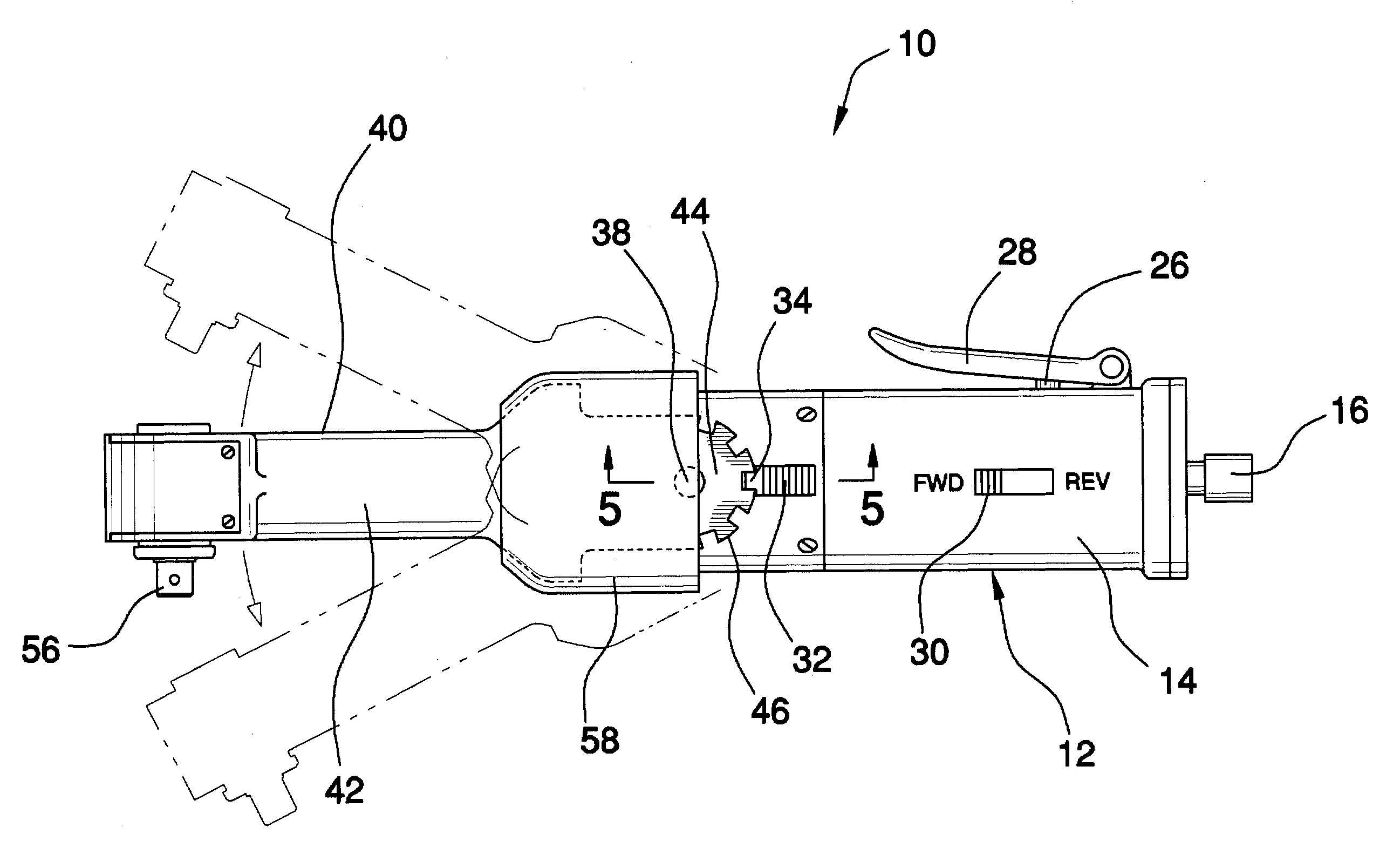

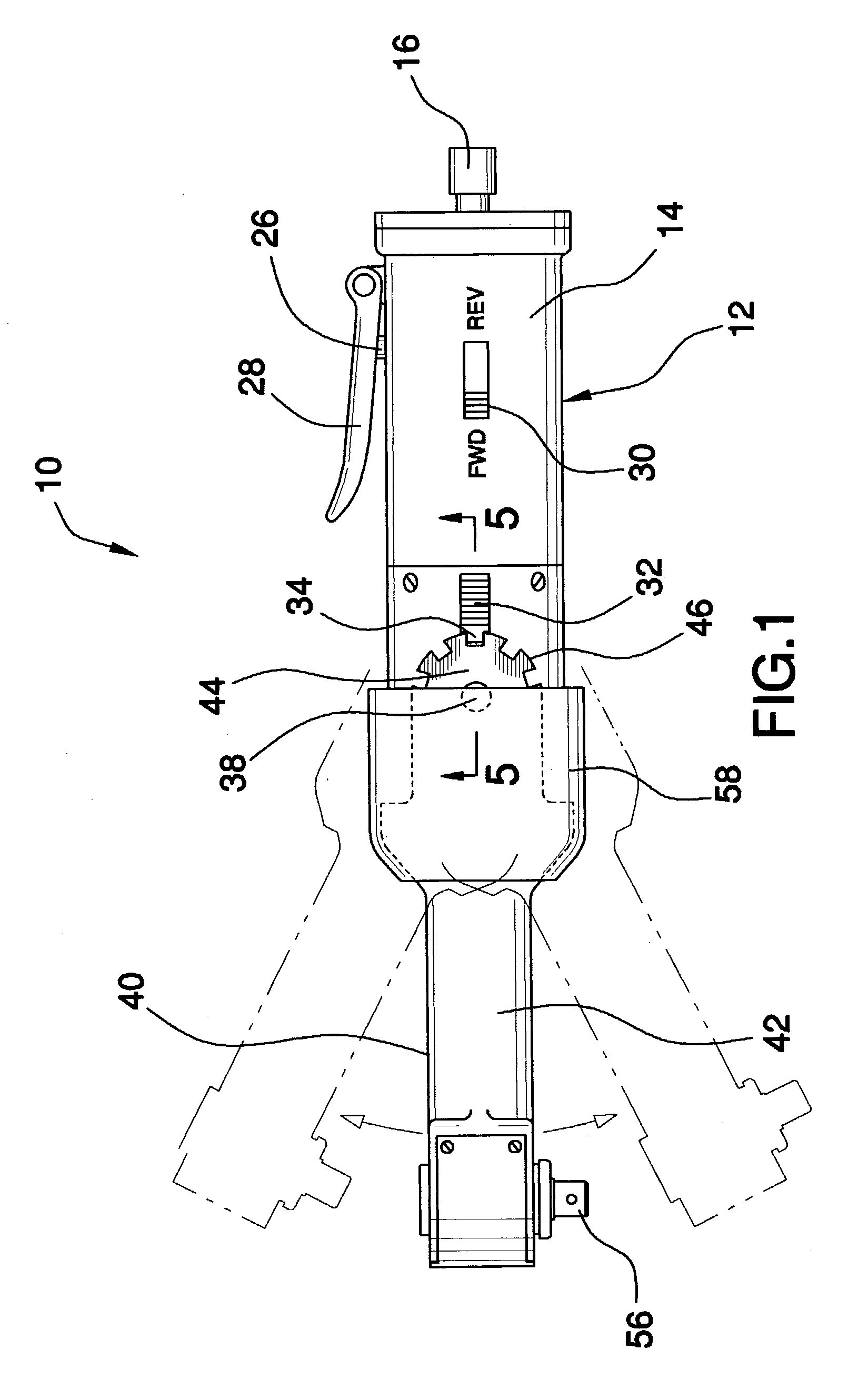

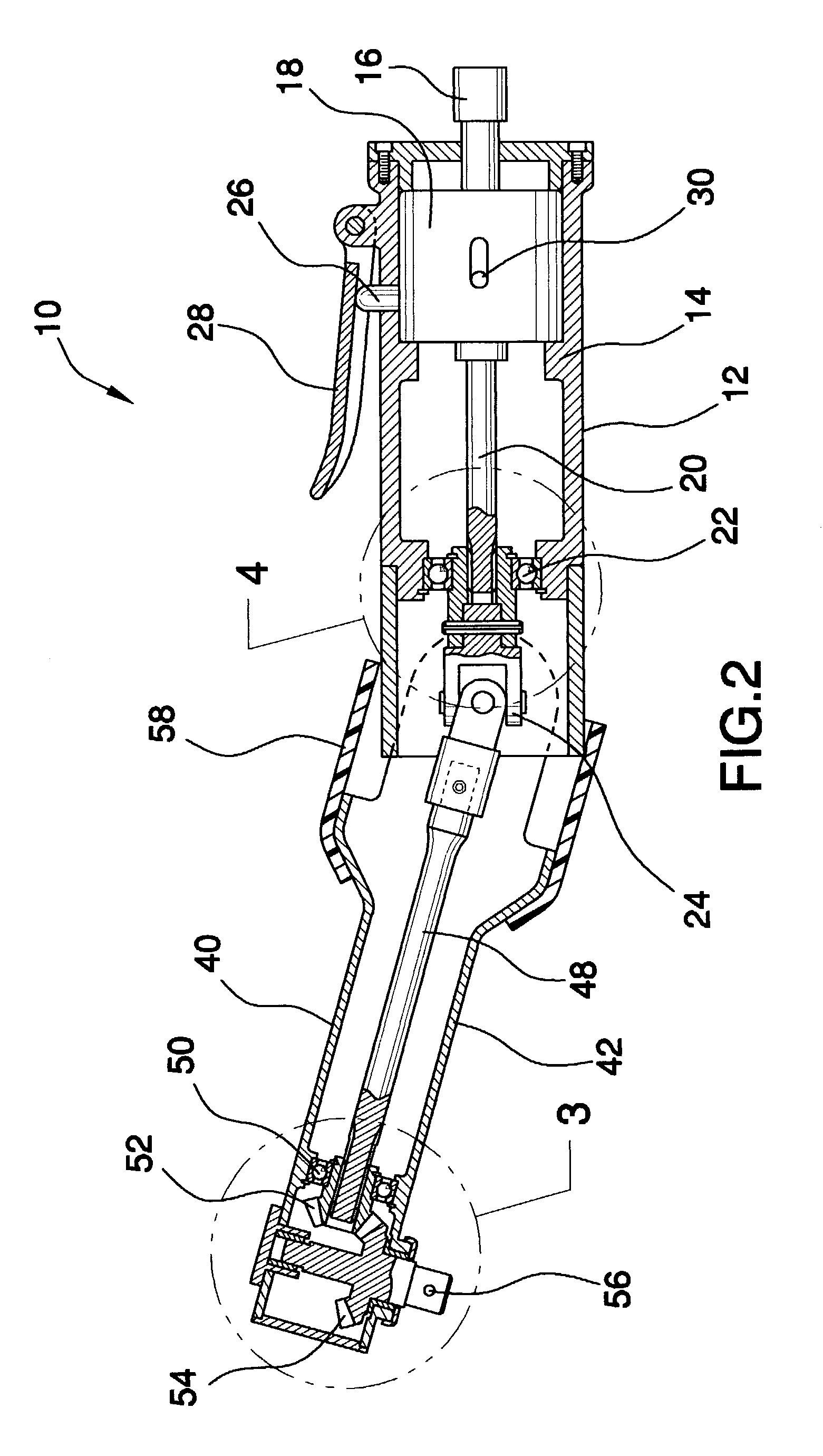

Air powered wrench device with pivotable head and method of using

InactiveUS6928902B1Easy and efficient to manufactureLower sales priceSpannersWrenchesBall bearingUniversal joint

An air powered wrench device with a pivotable head and associated method of using. The device comprises a handle pivotally attached to an arm. The handle comprises a housing, an air intake nozzle, an air driven motor, a drive shaft, a ball bearing collar, a universal joint, an on / off button, a trigger switch, a directional throw switch, a lock pin, a spring, and a pivot post. The arm is pivotally attached to the handle via the pivot post. The arm includes: an outer casing, an extension rod, a ball bearing sleeve, a first pawl gear, a second pawl gear, and a bit connector. The method of using the device comprises the steps of adjoining, affixing, aligning, allowing, enshrouding, getting, moving, obtaining, putting, rotating, shifting, squeezing, and tightening.

Owner:EYSSALLENNE LUIS P

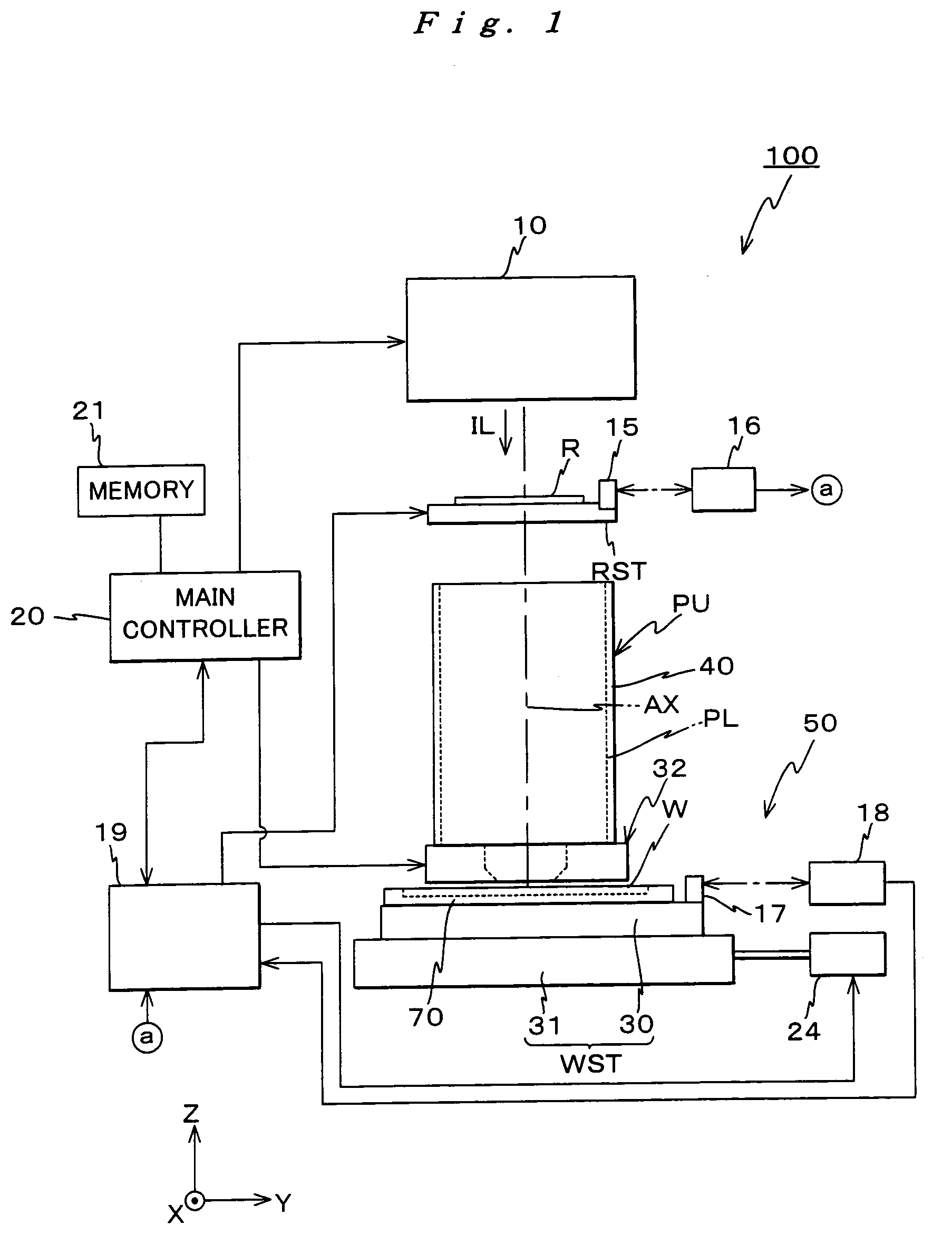

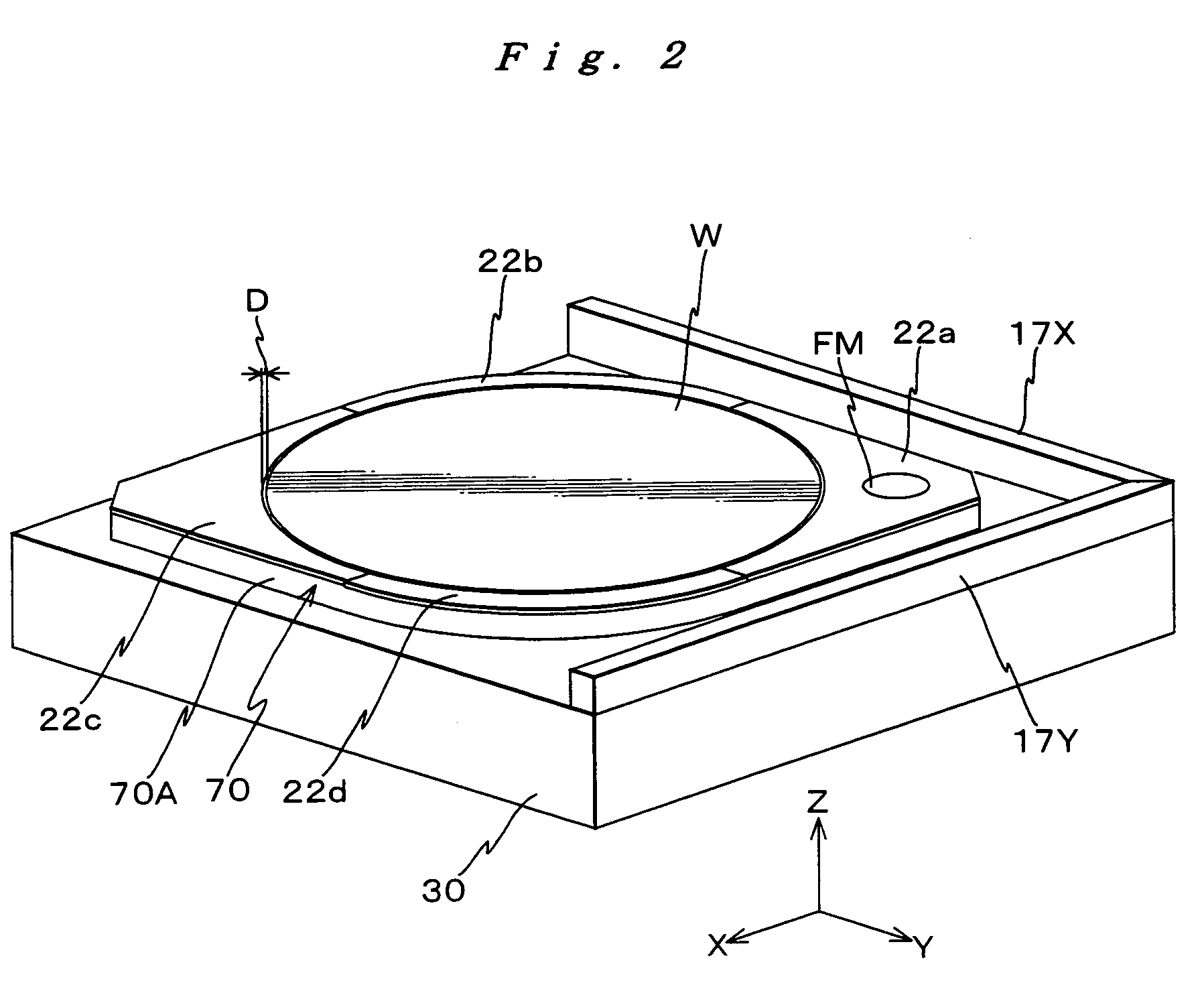

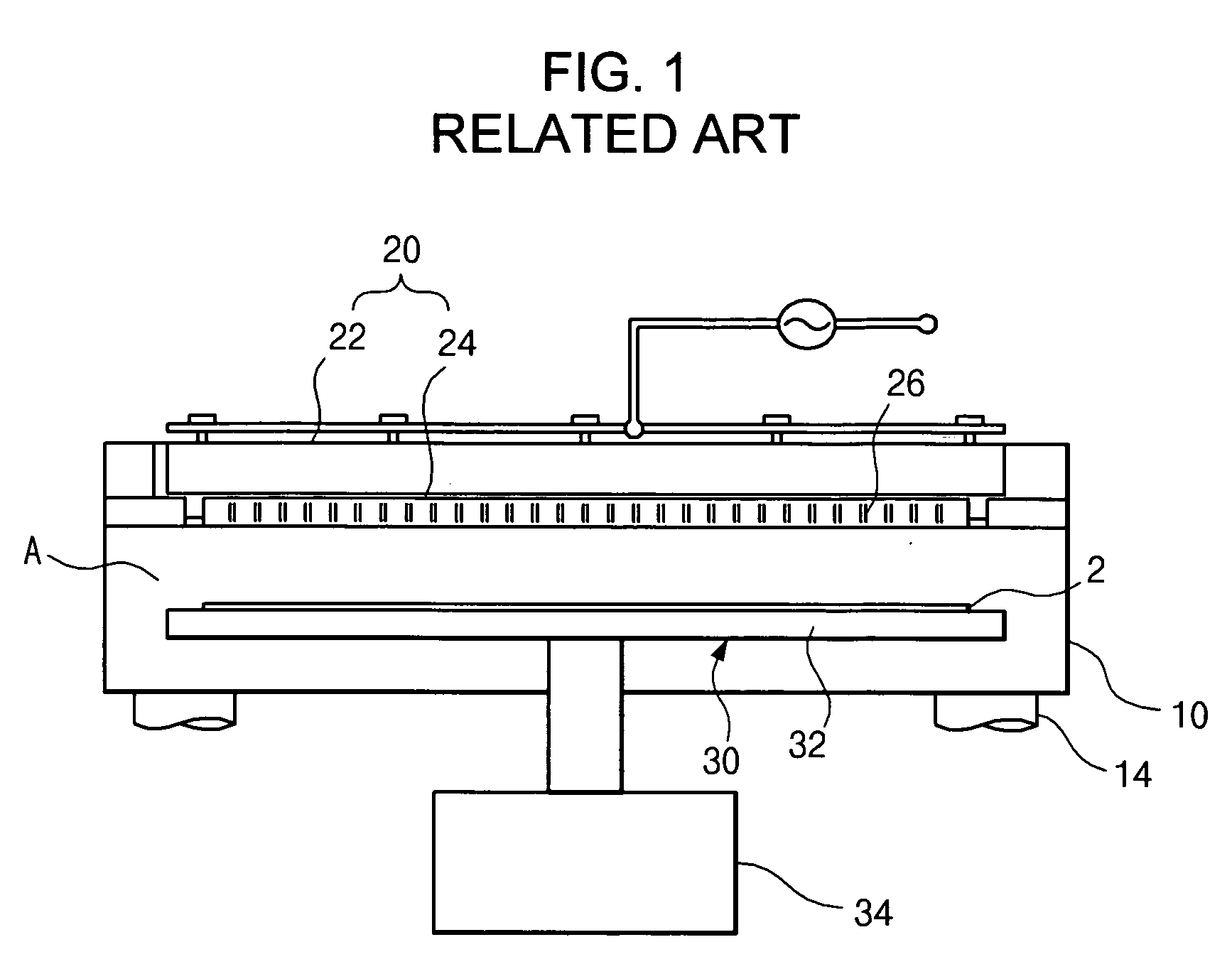

Exposure apparatus and device manufacturing method

InactiveUS20050259234A1Pressure of waterRaise transfer toSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringElectrical and Electronics engineering

Liquid is supplied by a supply mechanism to a space between a lens and a wafer via a supply nozzle on one side of the lens, and the liquid is recovered by a recovery mechanism via a recovery pipe on the other side of the lens. When the supply and the recovery of the liquid are performed in parallel, a predetermined amount of liquid (exchanged at all times) is held between the lens and the substrate on the stage. Accordingly, when exposure (pattern transfer on the substrate) is performed in this state, an immersion method is applied and a pattern is transferred with good precision onto the substrate. In addition, in the case the liquid leaks out from under the lower edge of a peripheral wall, the liquid that could not be recovered is recovered by an auxiliary recovery mechanism via a slit. And, by such operations, the substrate is freed from the residual liquid on the substrate.

Owner:NIKON CORP

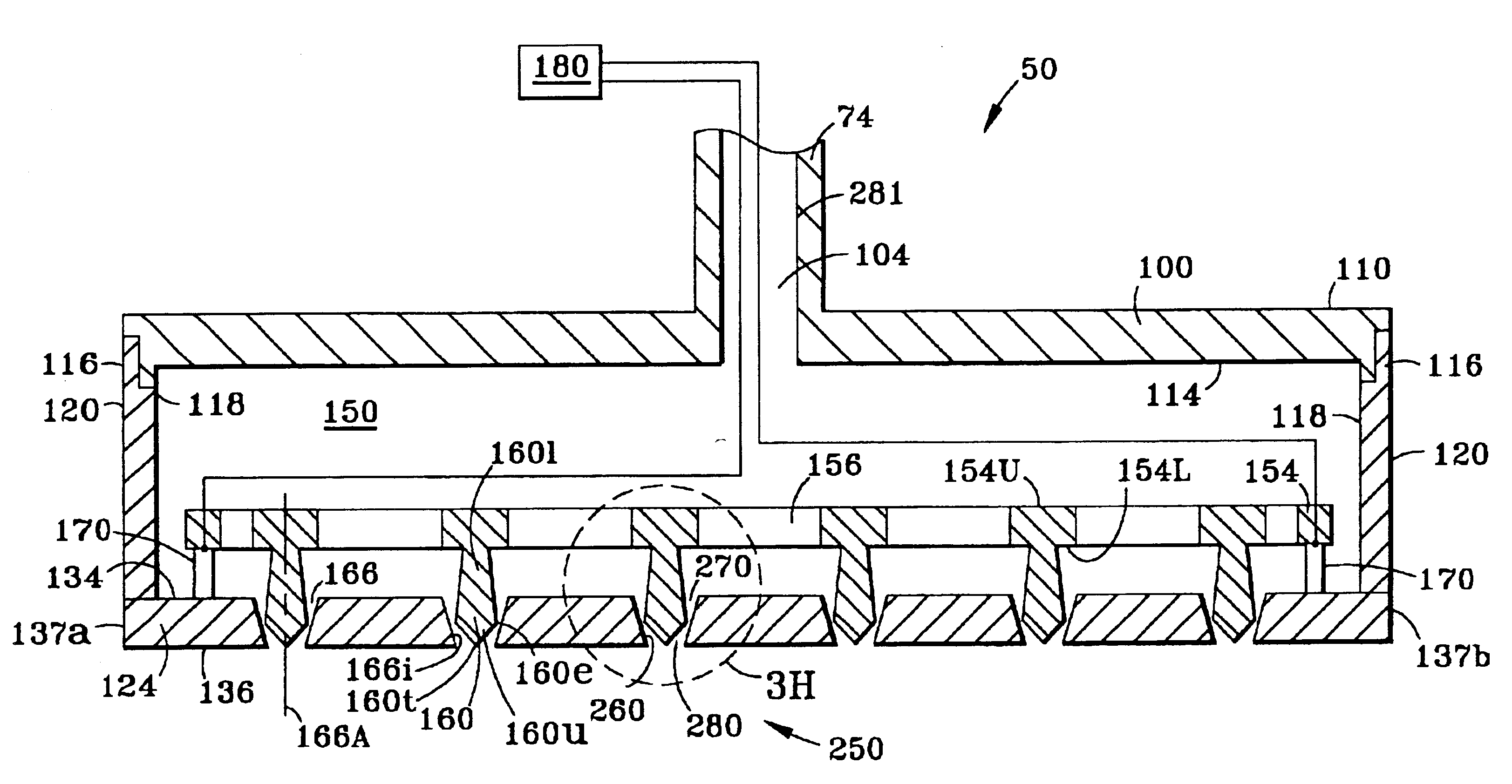

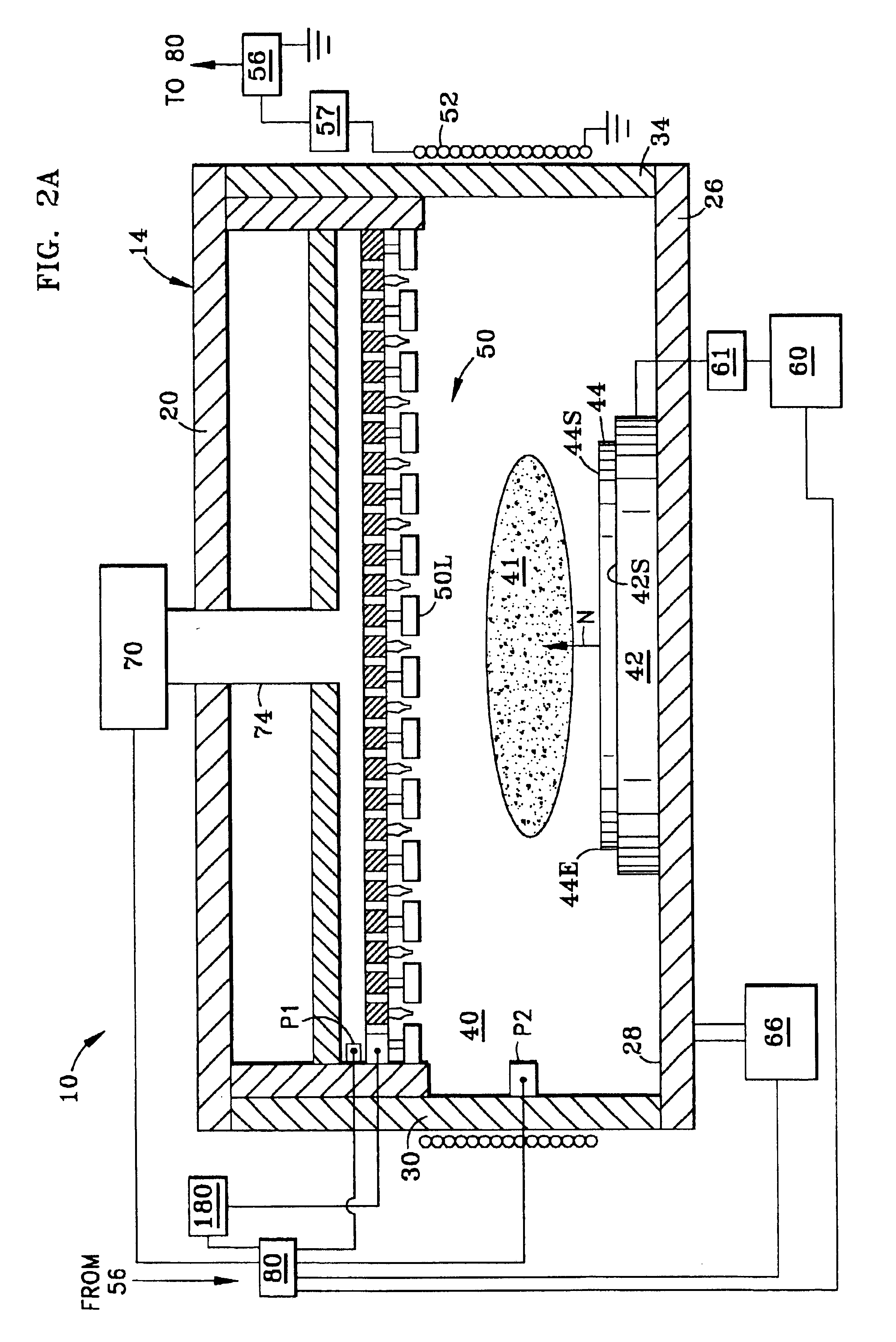

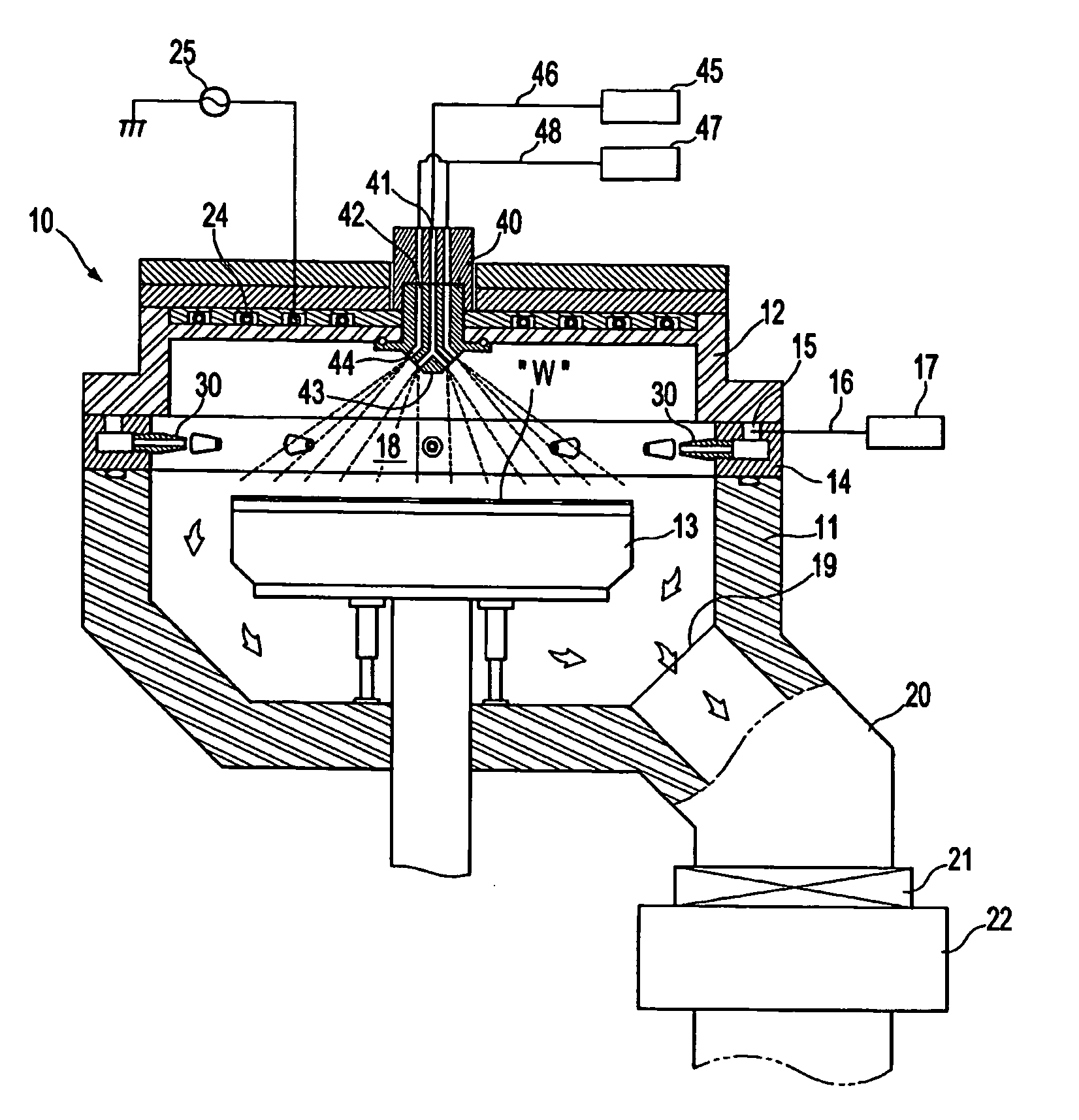

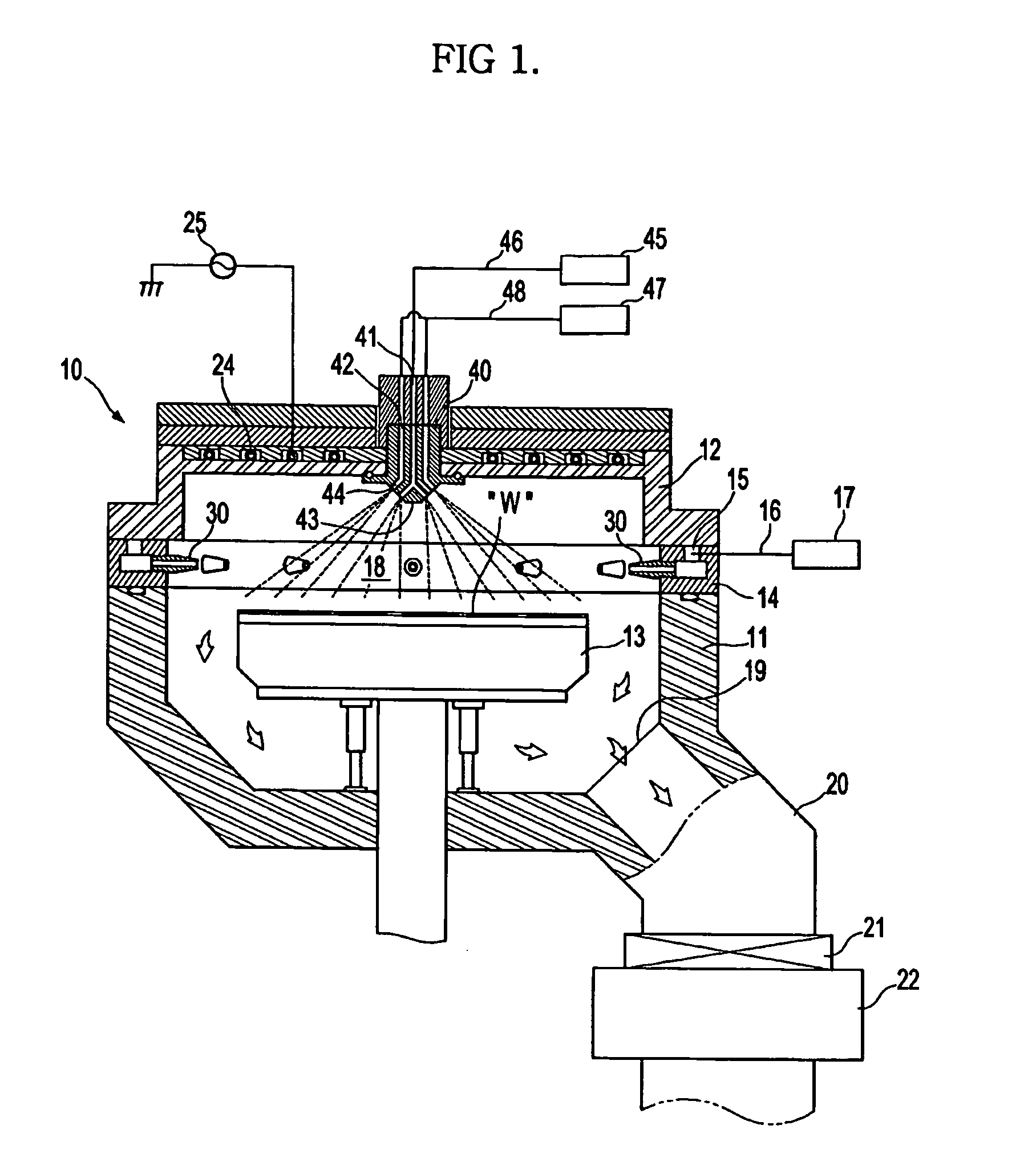

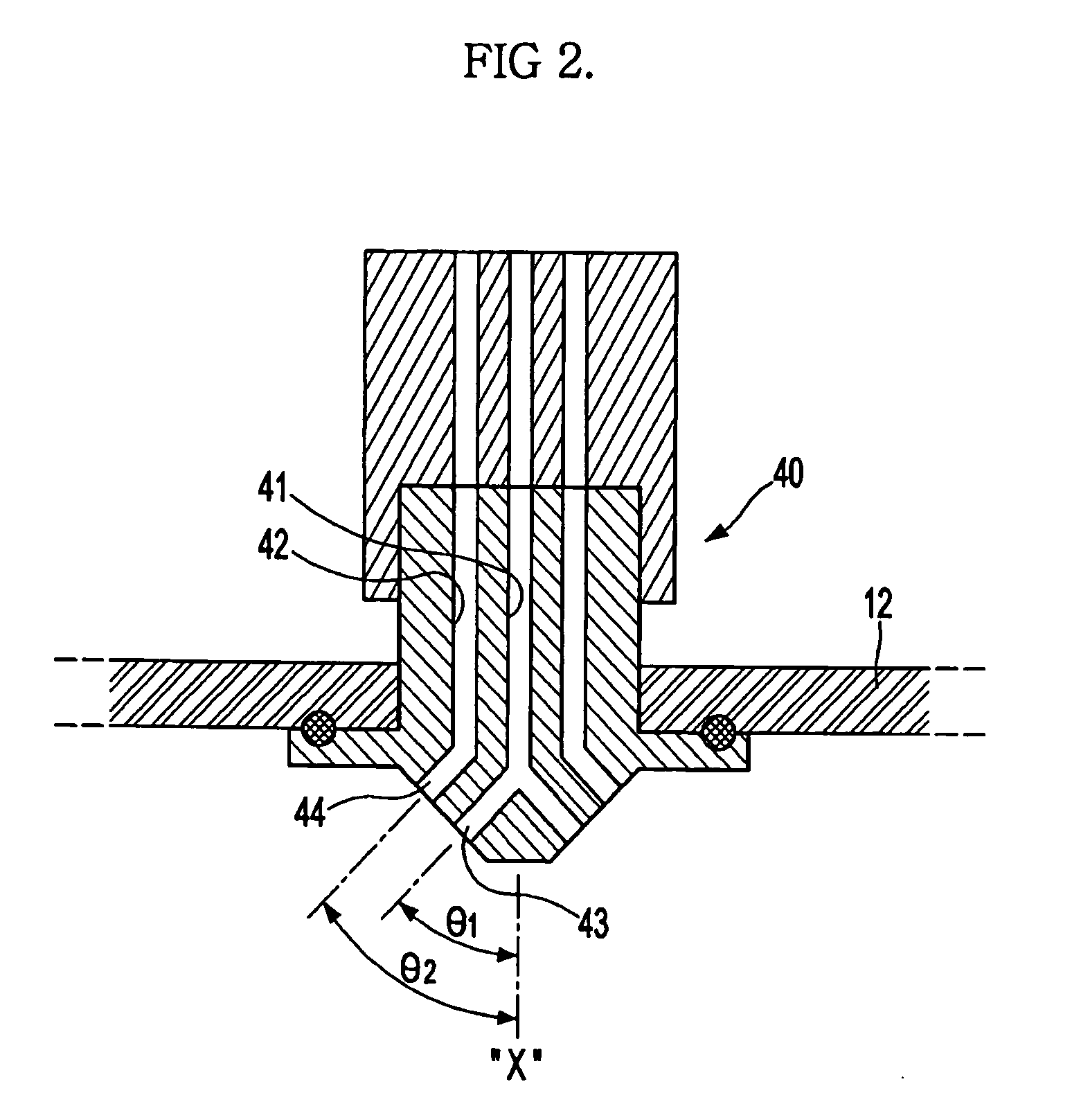

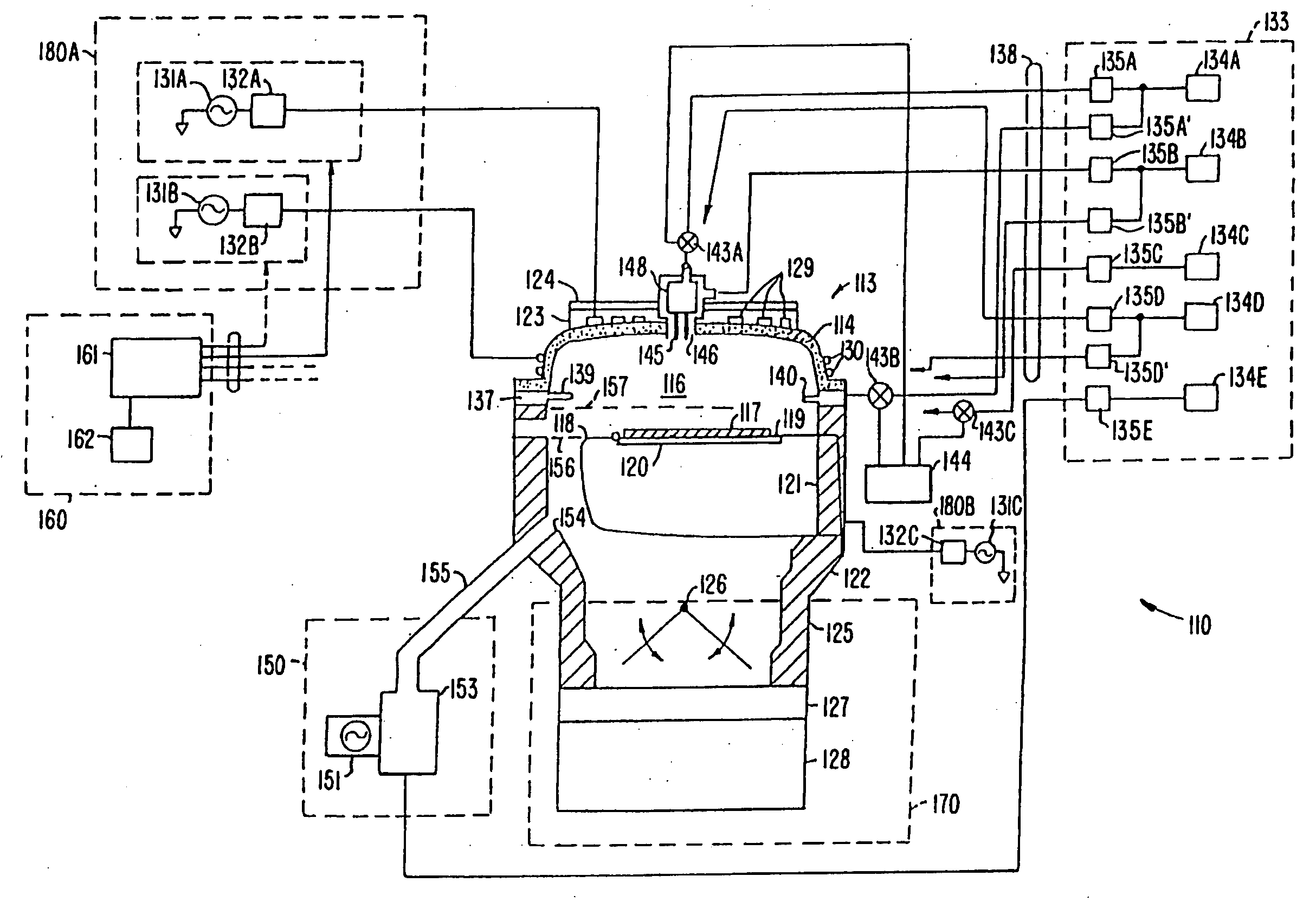

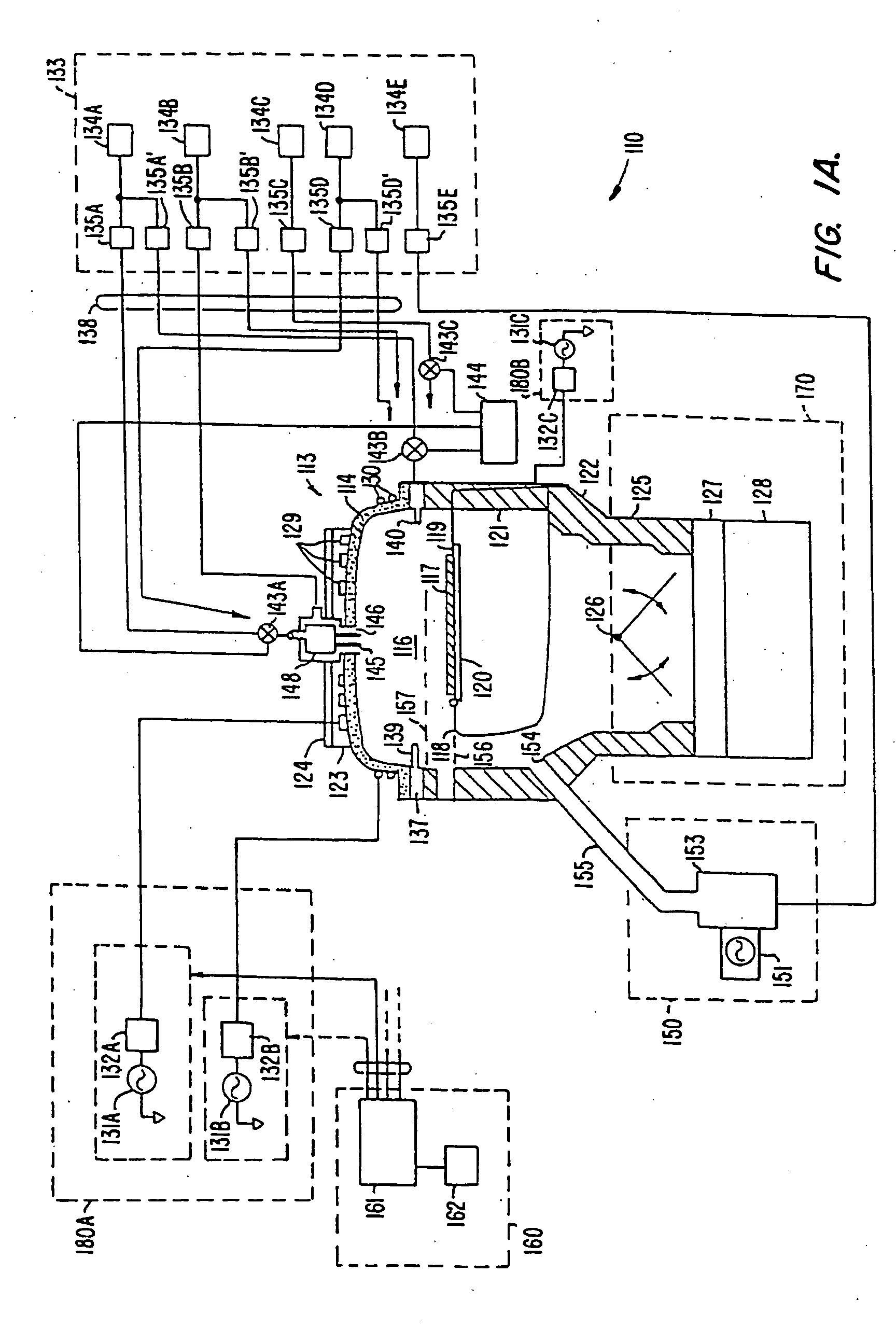

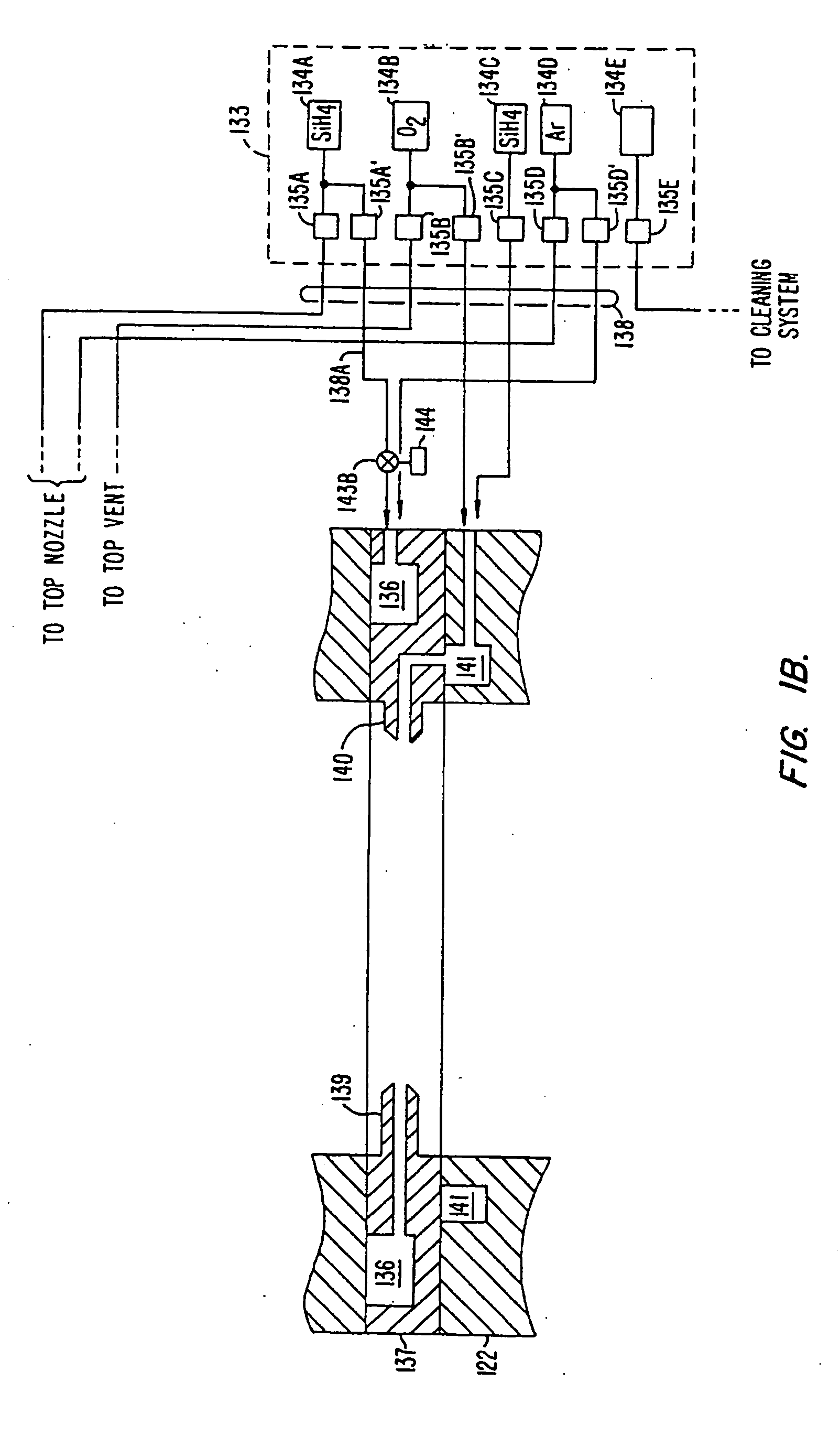

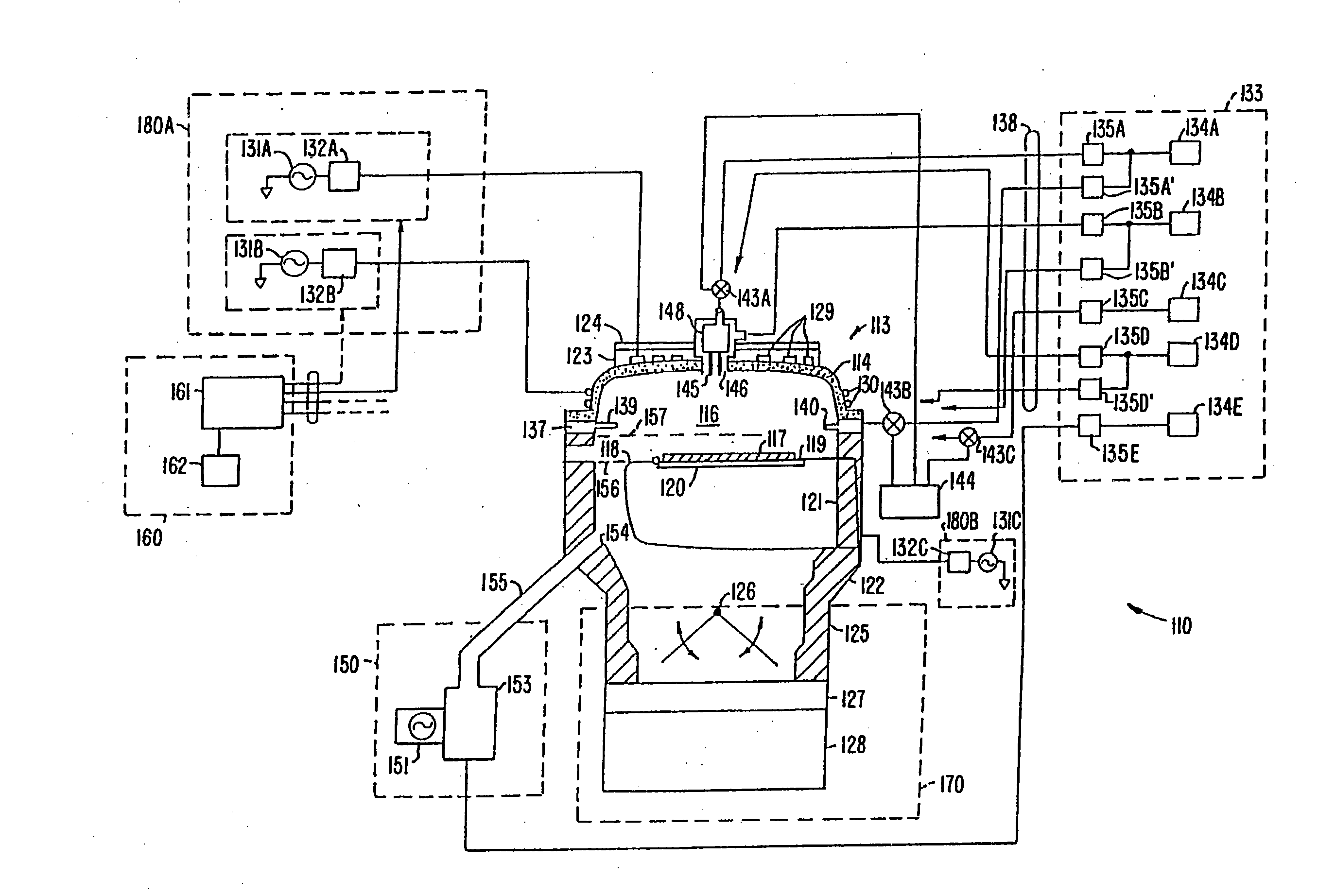

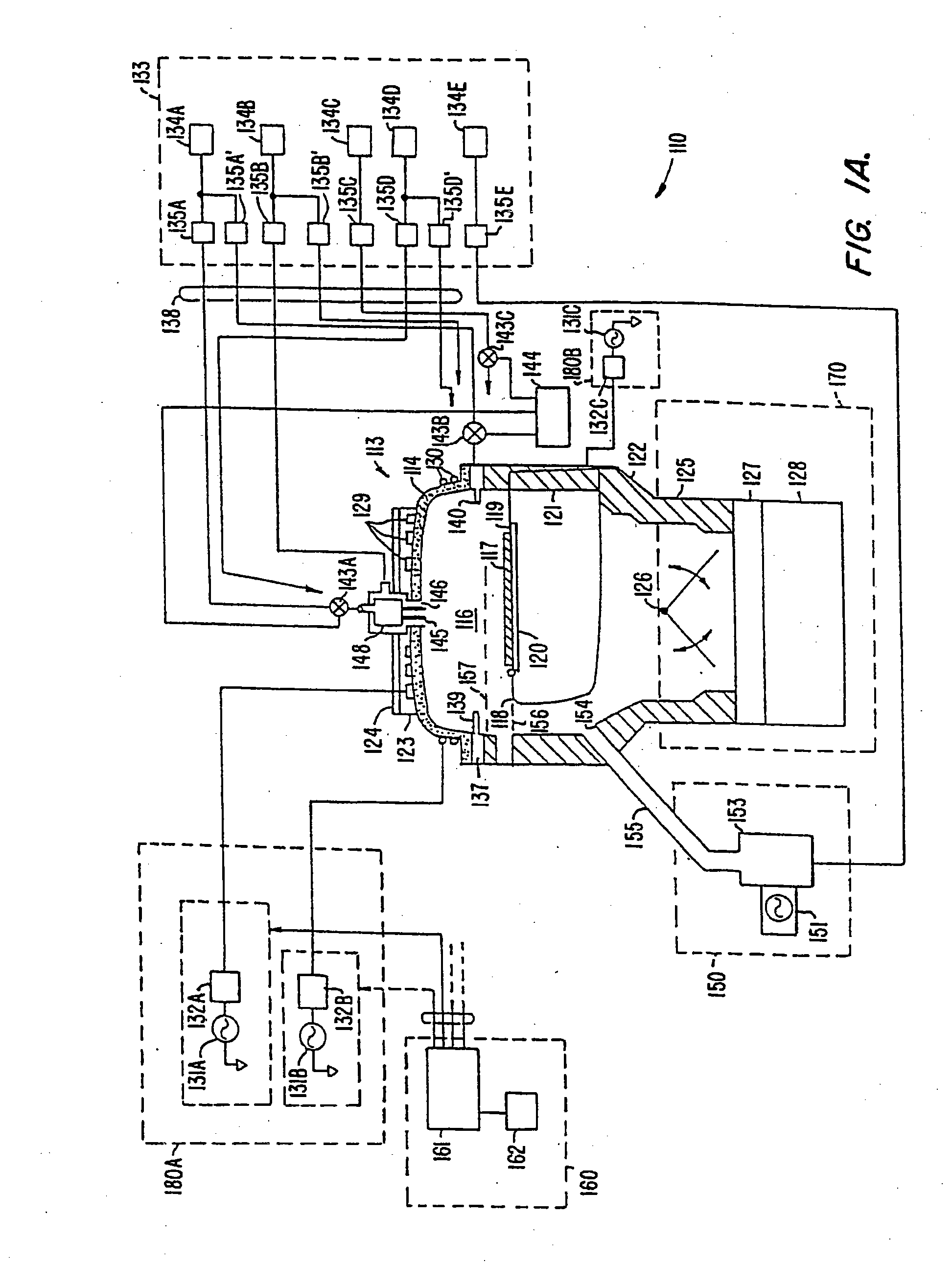

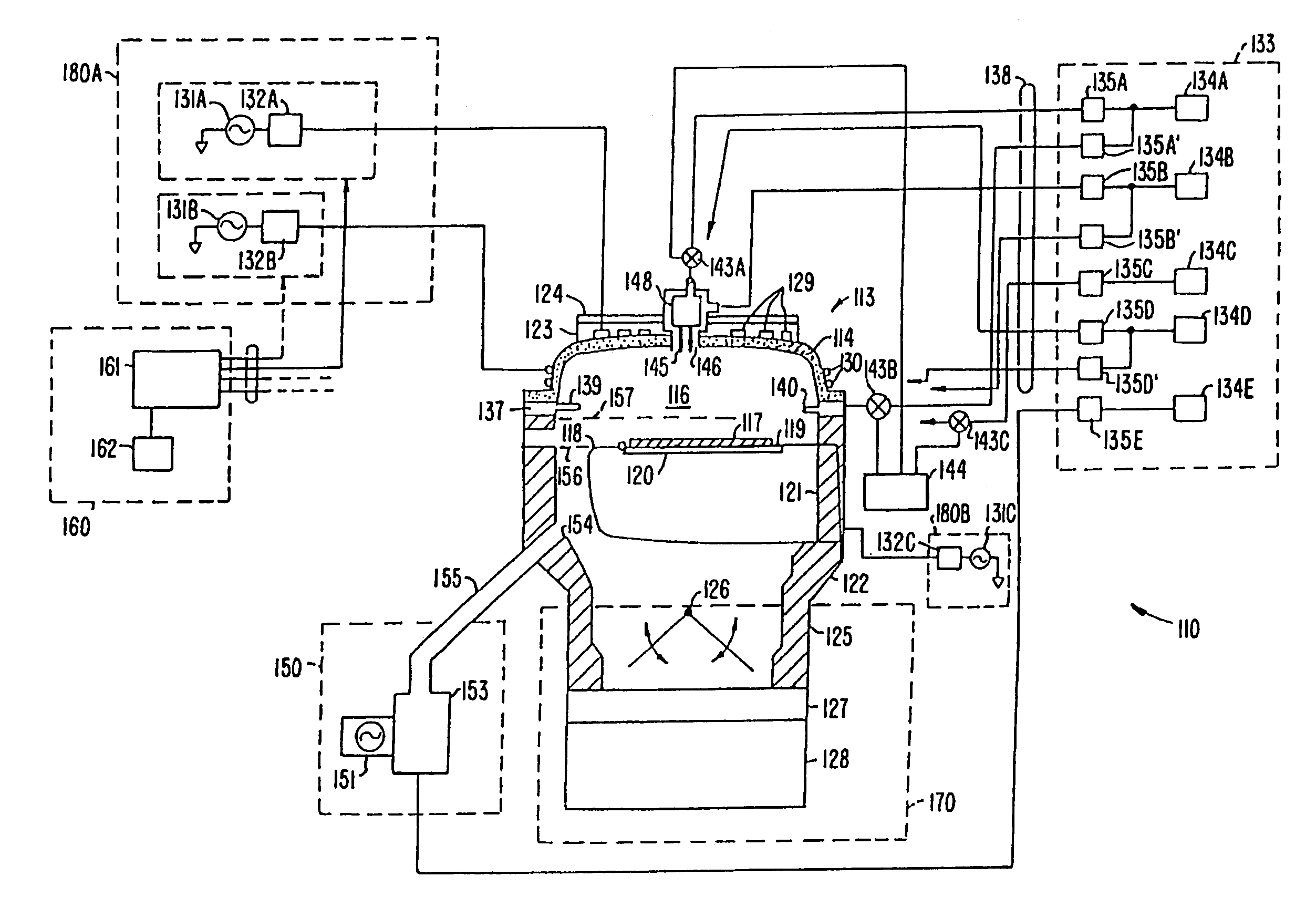

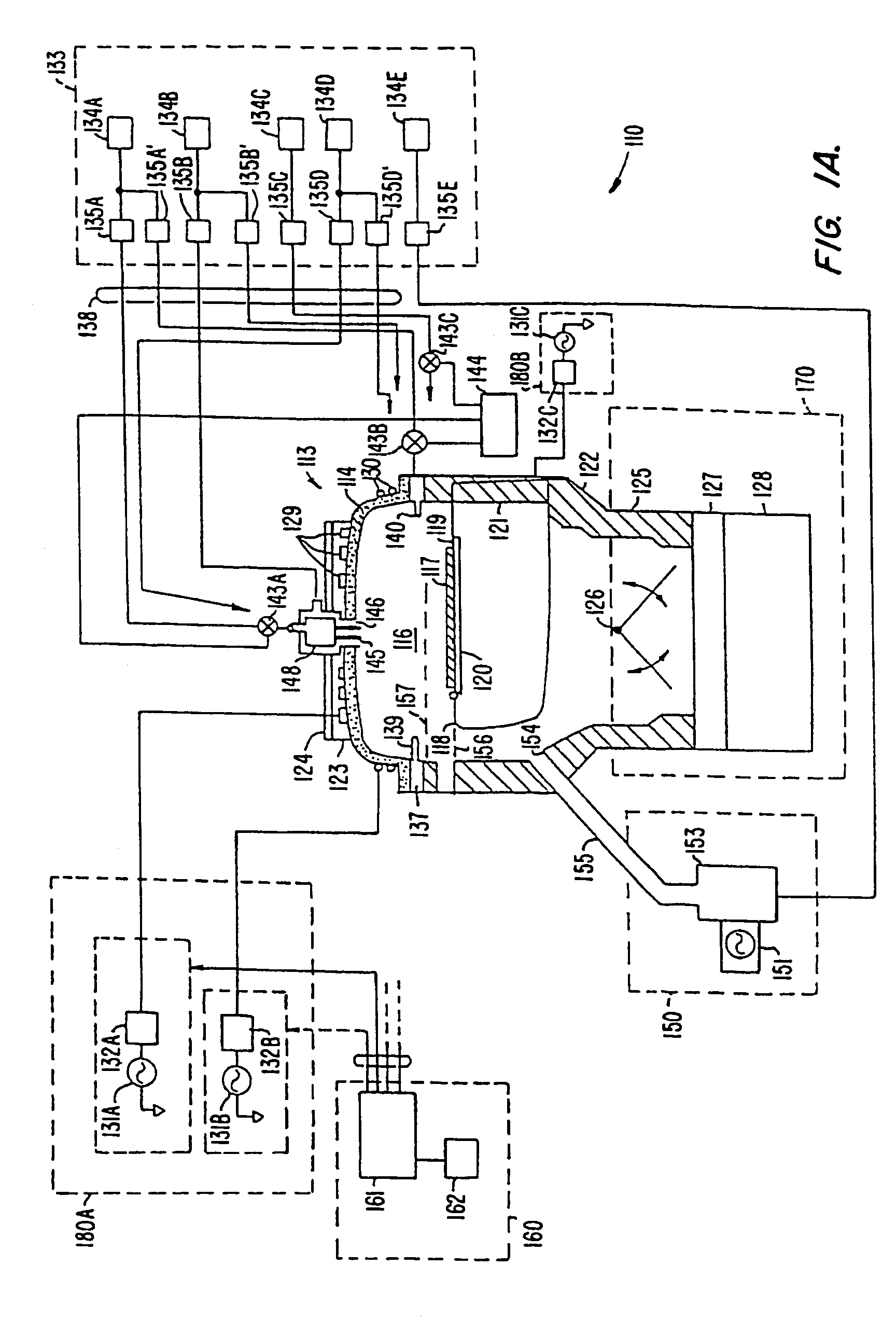

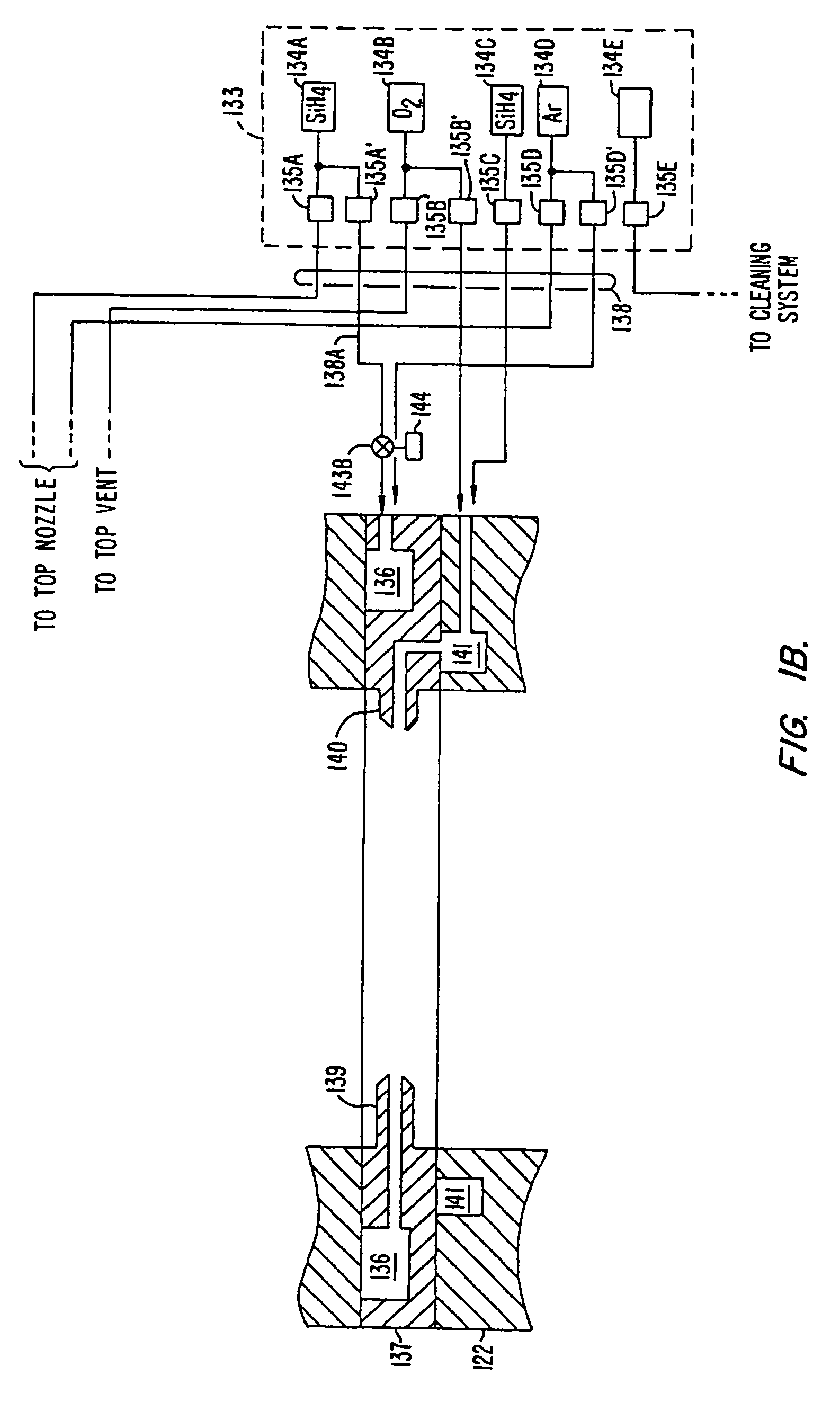

Method of and apparatus for tunable gas injection in a plasma processing system

InactiveUS6872259B2Control expansionElectric discharge tubesSemiconductor/solid-state device manufacturingElectronic communicationProduct gas

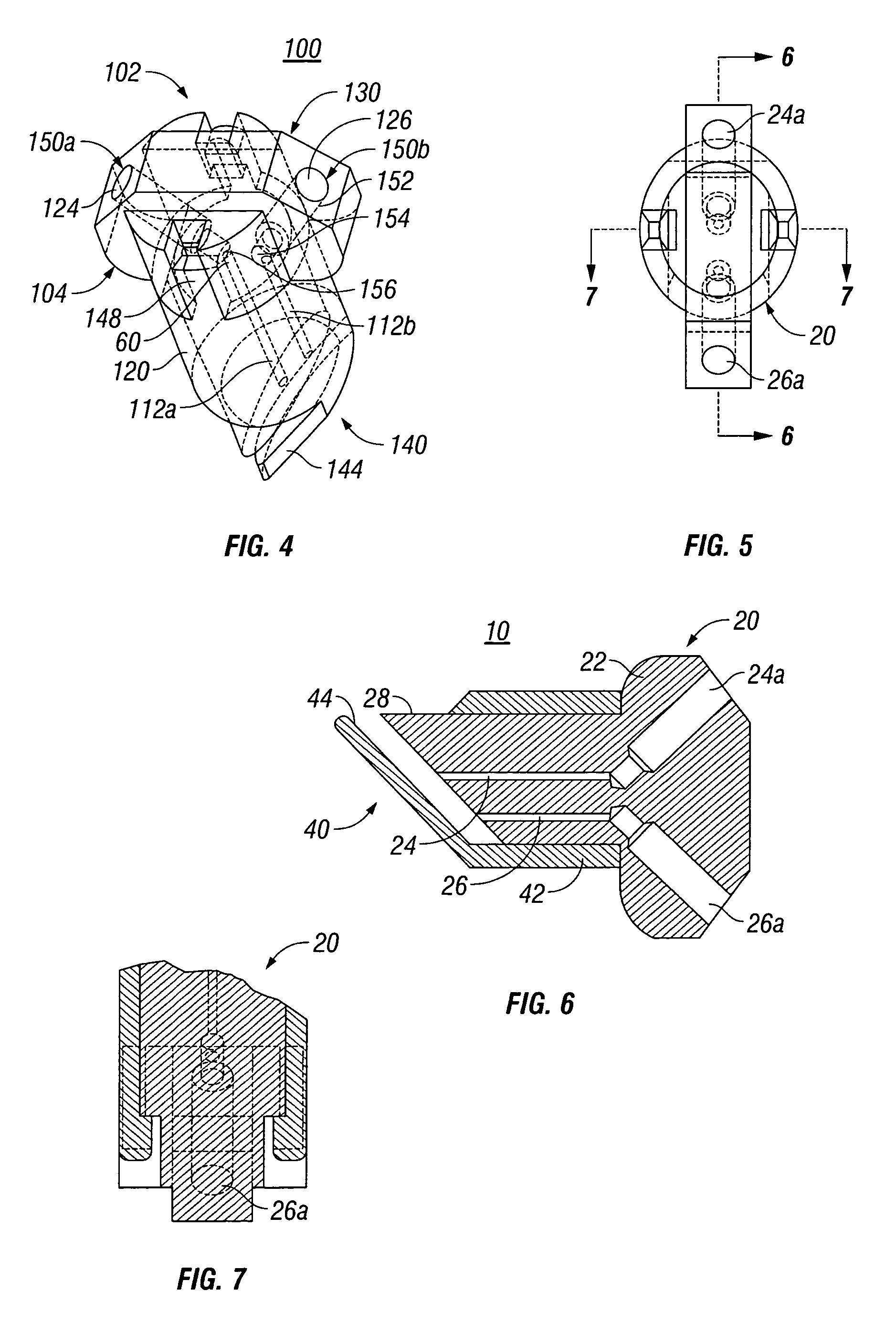

A method of and apparatus for providing tunable gas injection in a plasma processing system (10, 10′). The apparatus includes a gas injection manifold (50) having a pressurizable plenum (150) and an array of adjustable nozzle units (250), or an array of non-adjustable nozzles (502, 602), through which gas from the plenum can flow into the interior region (40) of a plasma reactor chamber (14) capable of containing a plasma (41). The adjustable nozzle units include a nozzle plug (160) arranged within a nozzle bore (166). A variety of different nozzle units are disclosed. The nozzle plugs are axially translatable to adjust the flow of gas therethrough. In one embodiment, the nozzle plugs are attached to a plug plate (154), which is displacable relative to an injection plate (124) via displacement actuators (170) connecting the two plates. The displacement actuators are controlled by a displacement actuator control unit (180), which is in electronic communication with a plasma processing system control unit (80). The gas flow into the chamber interior region is preferably controlled by monitoring the pressure in the plenum and in the chamber and adjusting the nozzle units accordingly. Where the nozzle units are not adjustable, a portion of the nozzles are sized to a first flow condition, and another portion of the nozzles are sized to a second flow condition.

Owner:TOKYO ELECTRON LTD

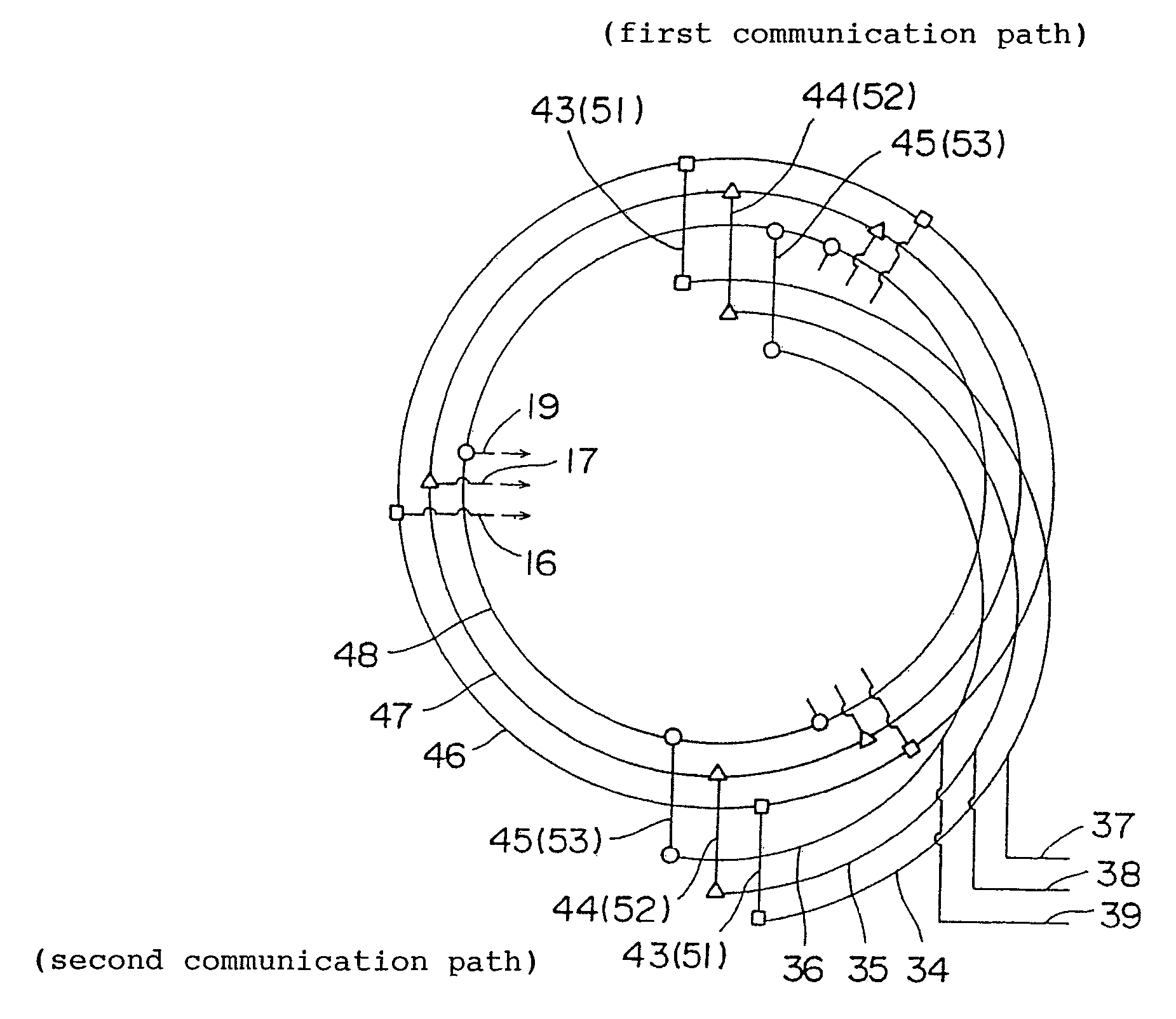

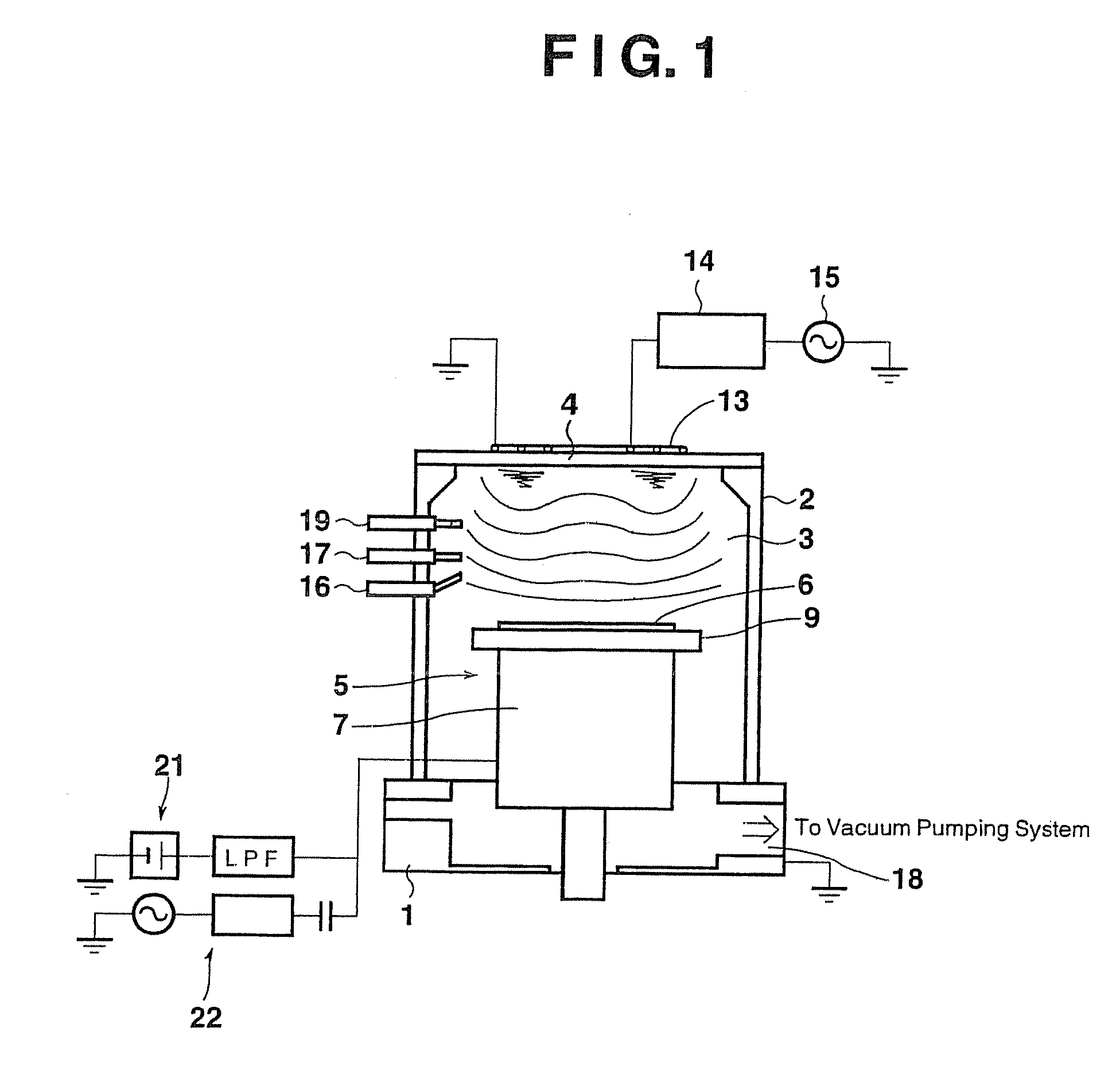

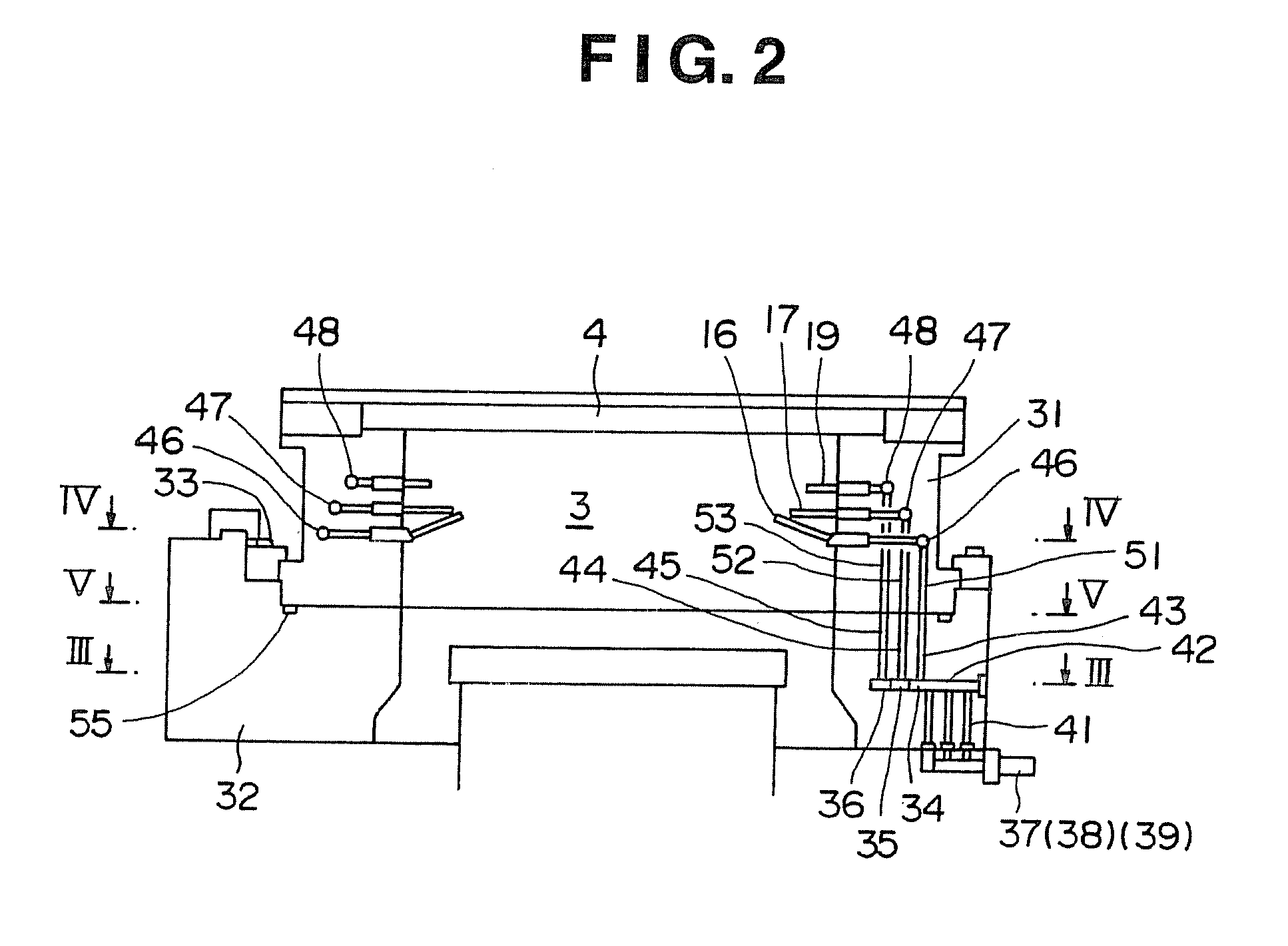

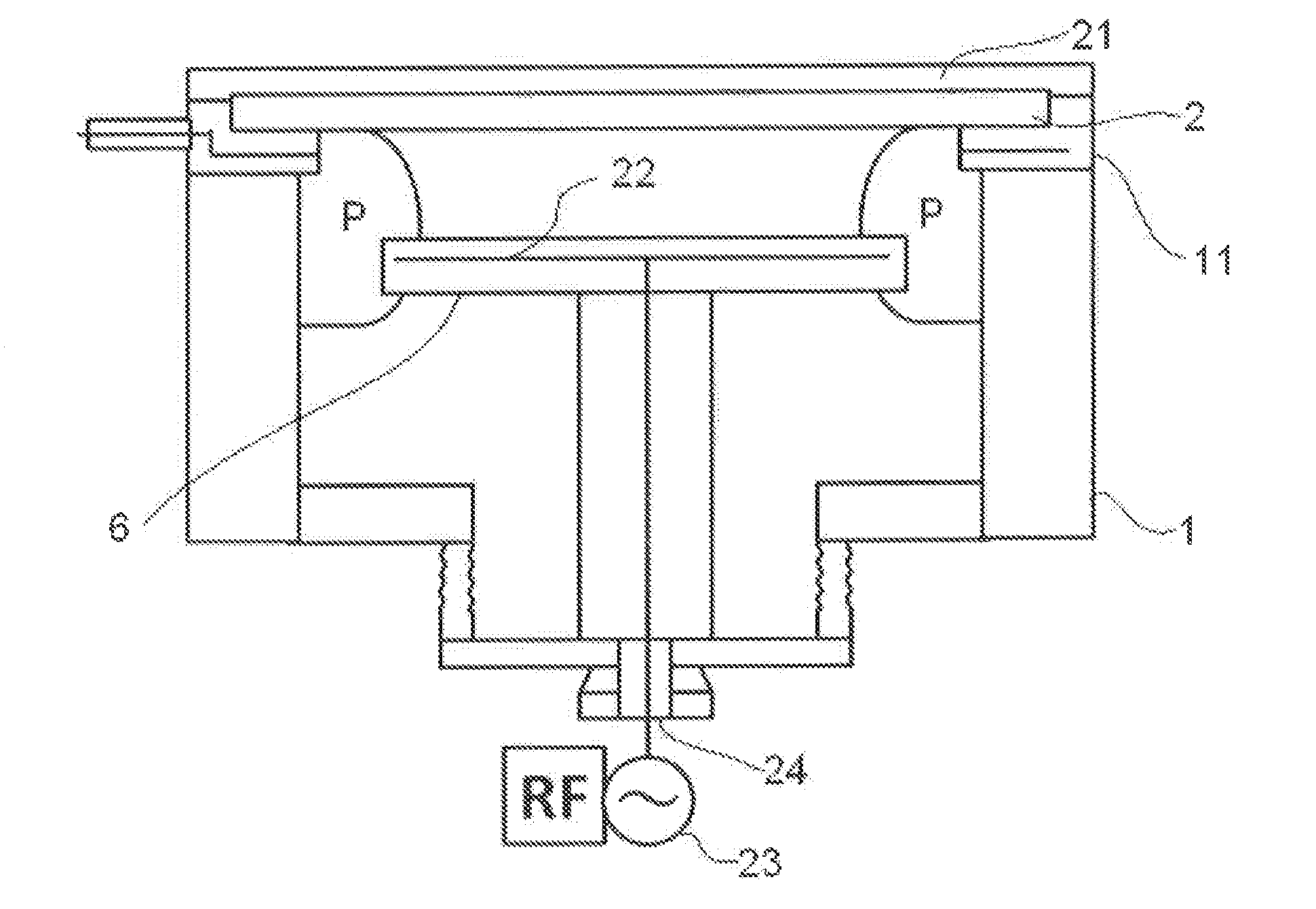

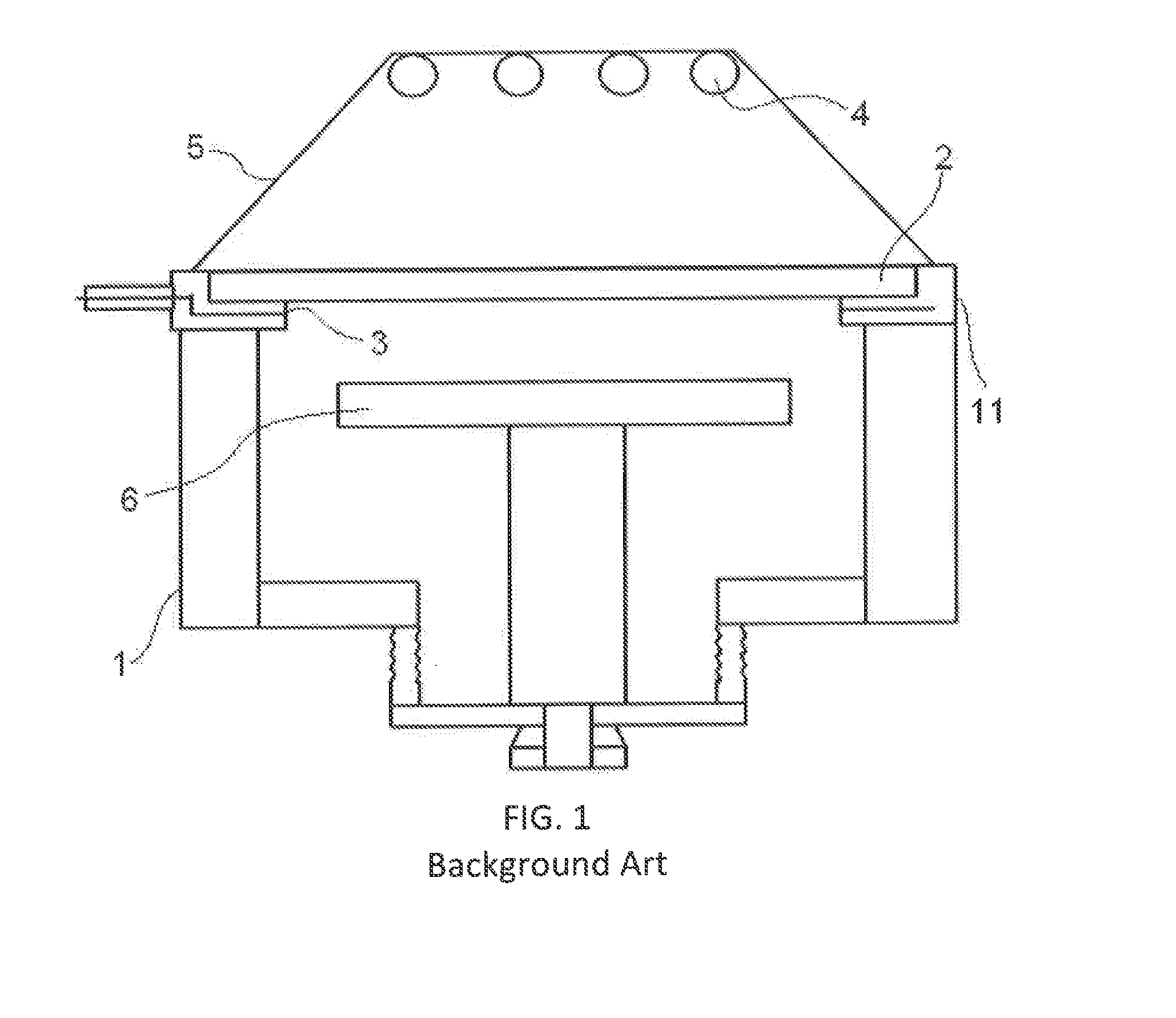

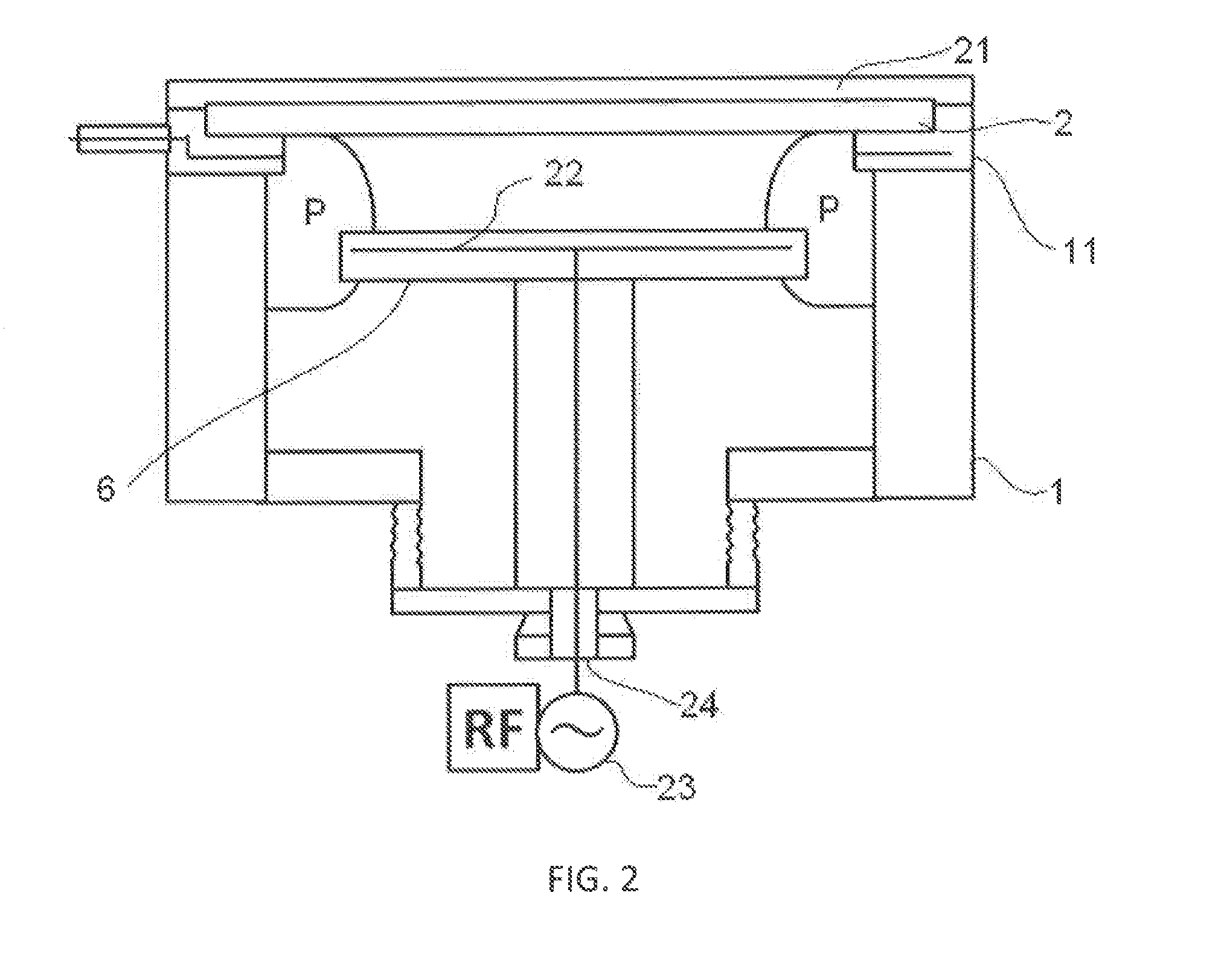

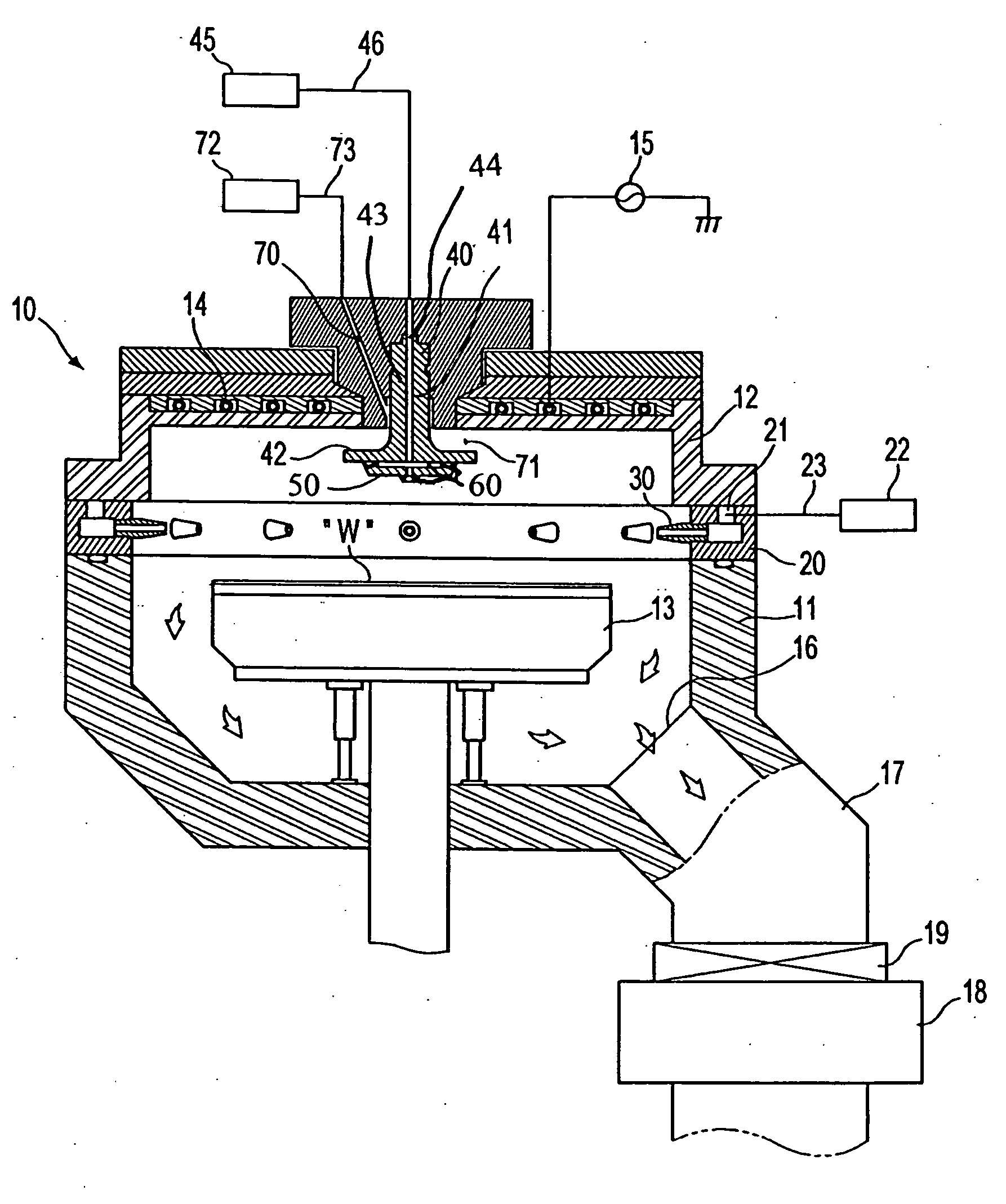

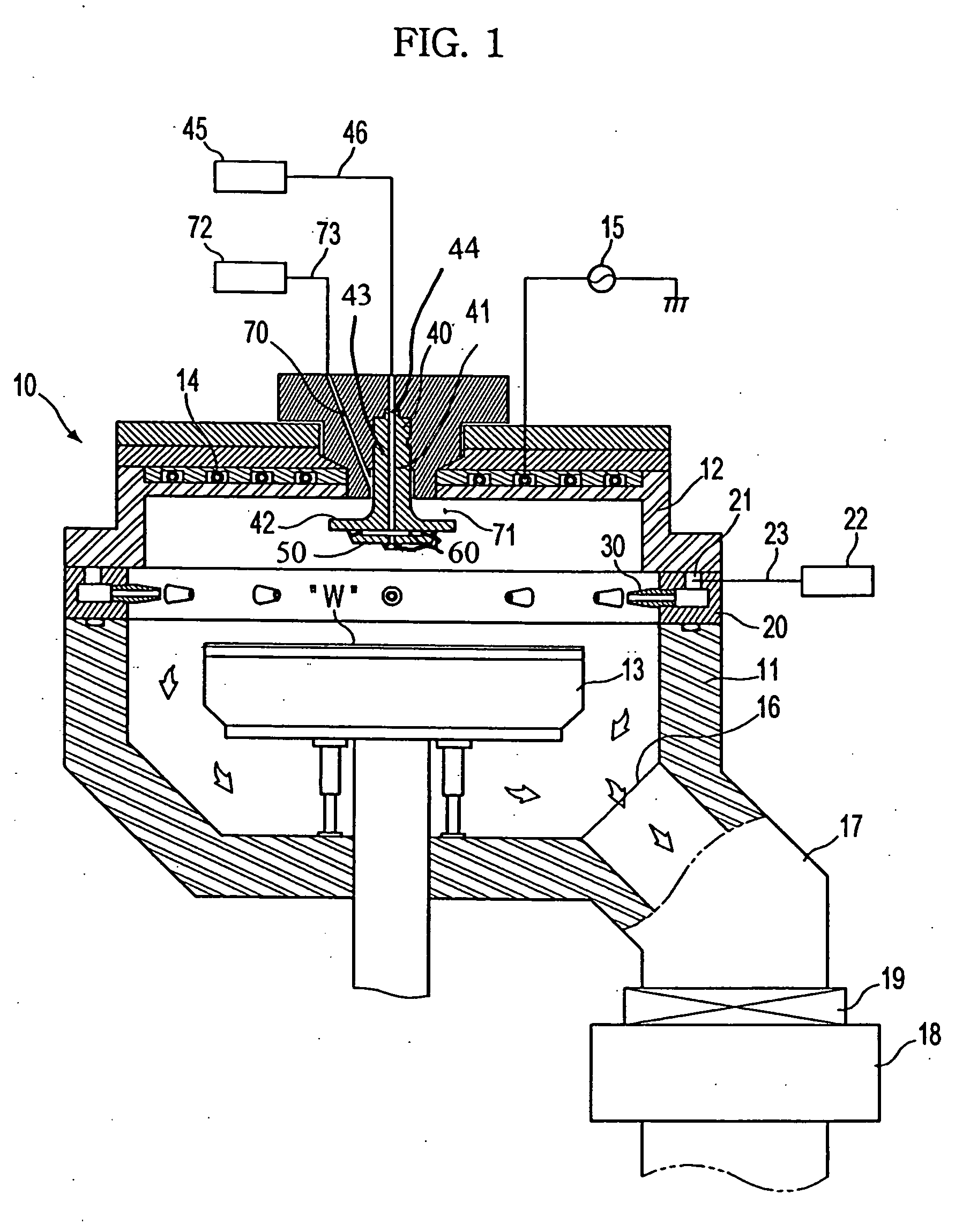

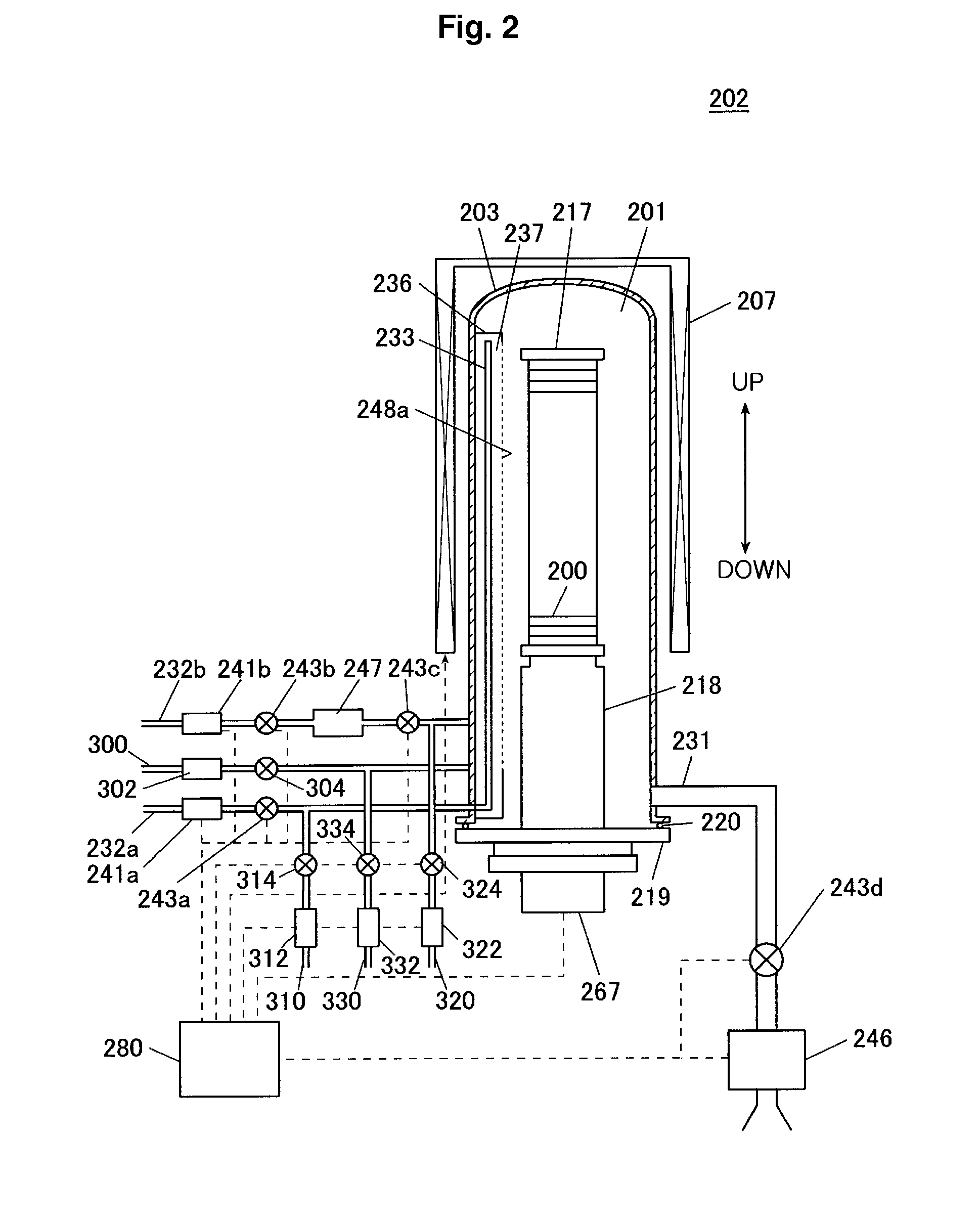

Plasma treatment apparatus

InactiveUS7806078B2Simply the configuration of the containerContainer can be simplifiedElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

A plasma CVD apparatus has a container, and channels composed of introduction grooves and circumferential grooves for different types of gases are formed within the container. The gases introduced through source gas piping, auxiliary gas piping, and cleaning gas piping are equally supplied to a plurality of supply nozzles, a plurality of auxiliary gas supply nozzles, and a plurality of cleaning gas nozzles. The configuration of the container can be simplified without complicating pipings for the gases.

Owner:MITSUBISHI HEAVY IND LTD

Apparatus to manufacture semiconductor

InactiveUS20060096540A1Expand the scope of diffusionUniformlySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringGas supply

An apparatus to manufacture a semiconductor, in which distribution of process gases supplied to a reaction region in a reaction chamber is uniform, includes a gas supply nozzle to supply process gases to a semiconductor substrate in the reaction chamber, wherein the gas supply nozzle includes a first supply channel formed in a longitudinal direction, and first outlet channels formed at an outlet of the first supply channel such that the first outlet channels are inclined with respect to the direction of the first supply channel at a designated angle to diffuse the process gas supplied through the first supply channel.

Owner:SAMSUNG ELECTRONICS CO LTD

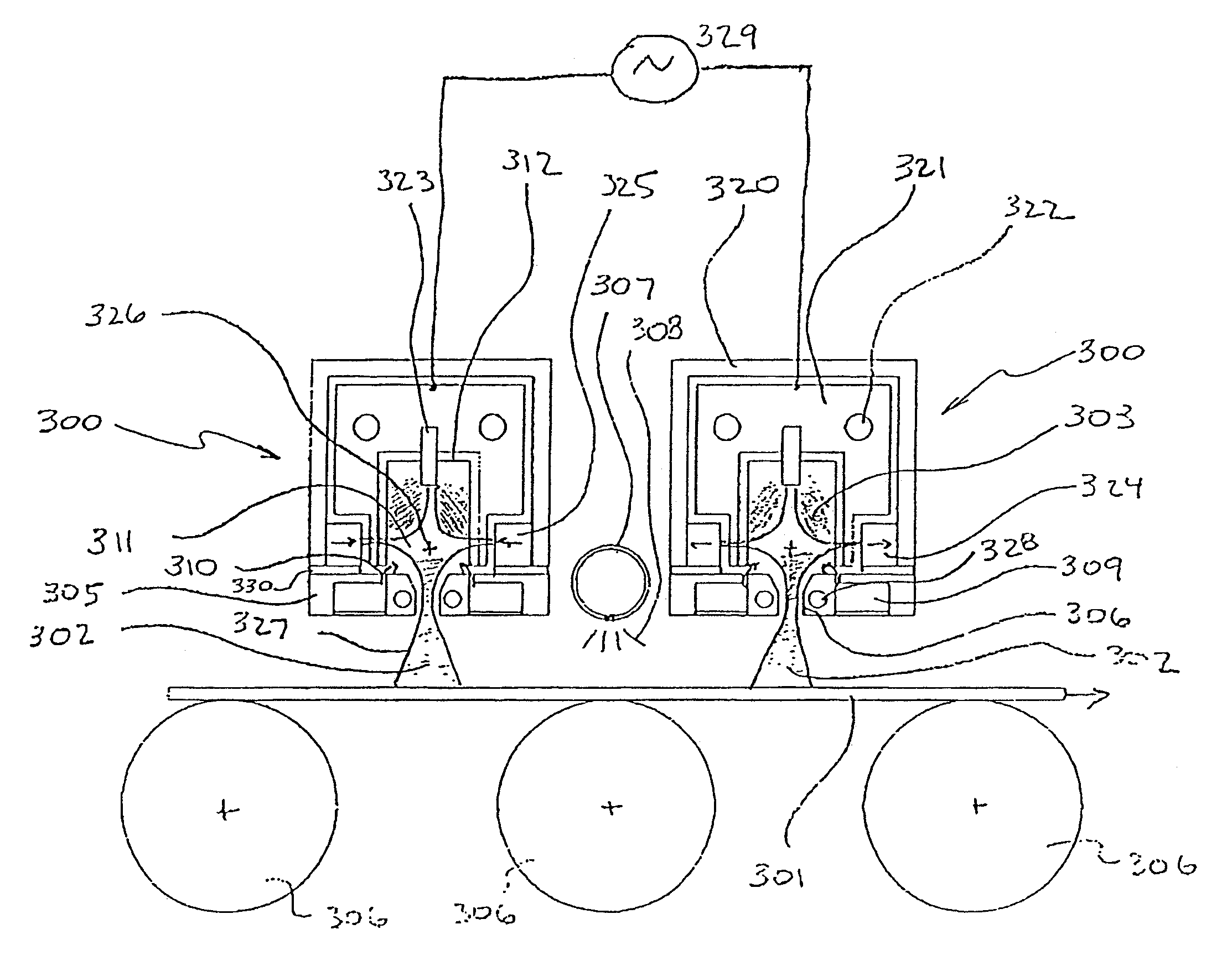

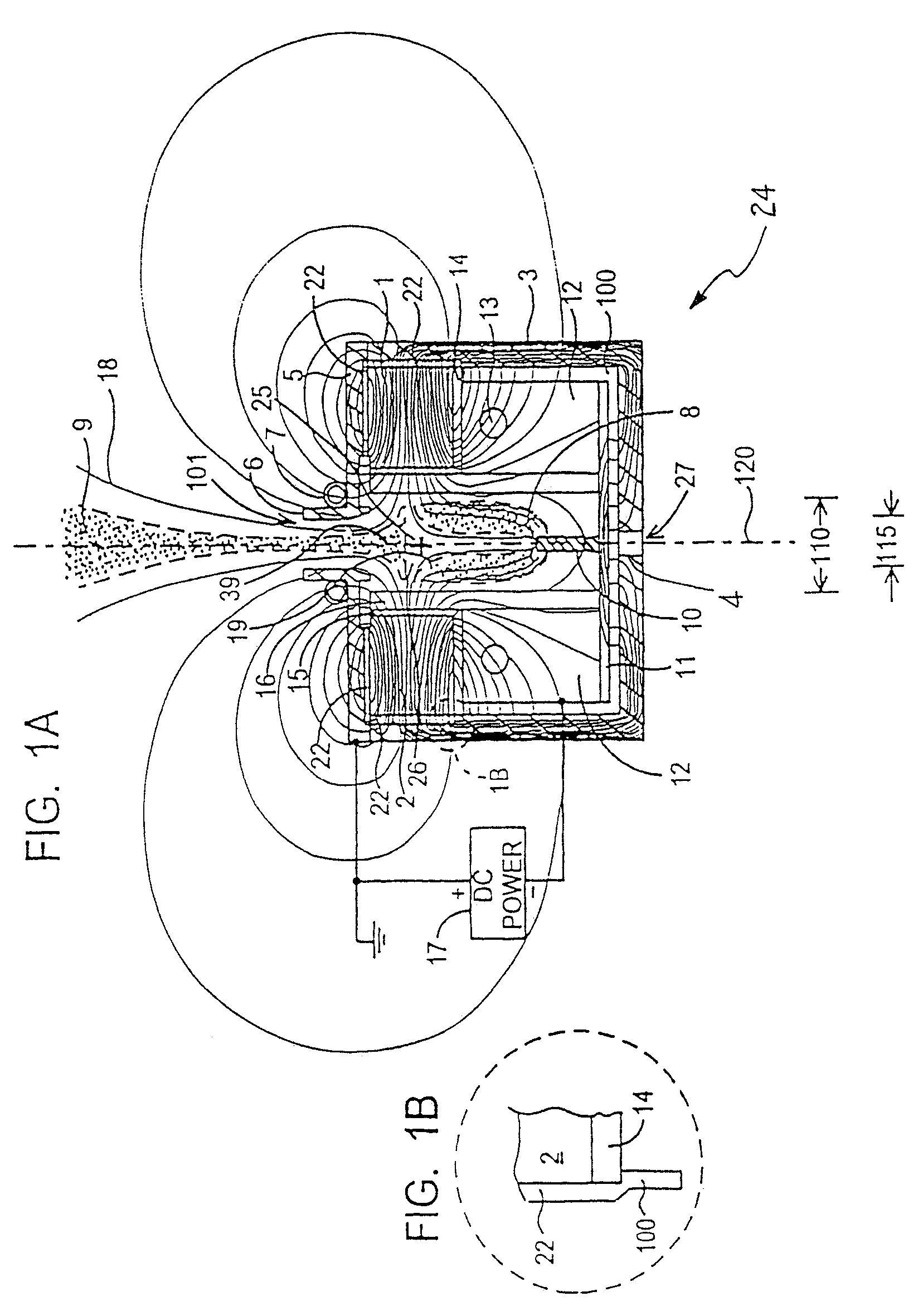

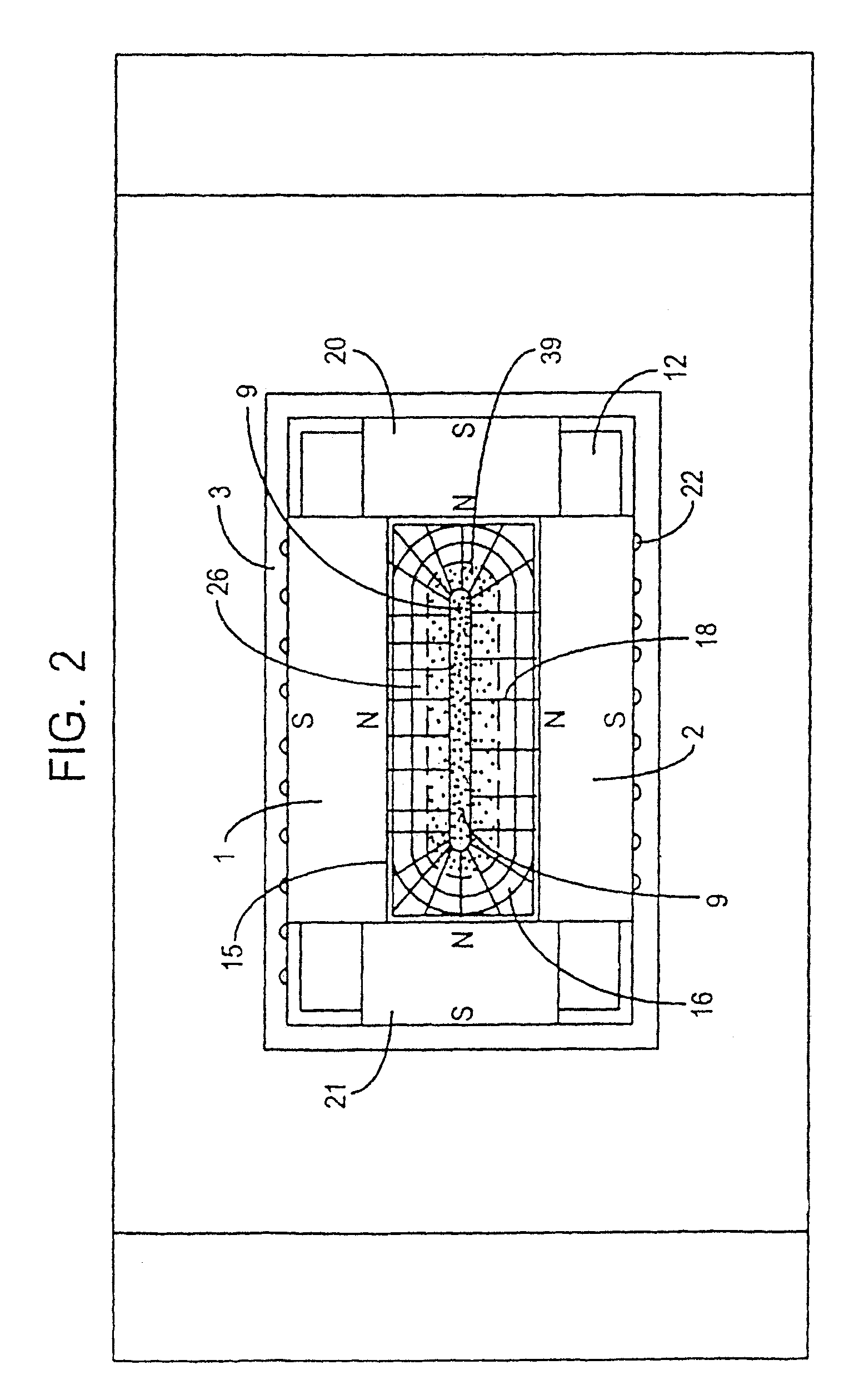

Dual plasma beam sources and method

A pair of plasma beam sources are connected across an AC power supply to alternatively produce an ion beam for depositing material on a substrate transported past the ion beams. Each plasma beam source includes a discharge cavity having a first width and a nozzle extending outwardly therefrom to emit the ion beam. The aperture or outlet of the nozzle has a second width, which second width is less than the first width. An ionizable gas is introduced to the discharge cavity. At least one electrode connected to the AC power supply, alternatively serving as an anode or a cathode, is capable of supporting at least one magnetron discharge region within the discharge cavity when serving as a cathode electrode. A plurality of magnets generally facing one another, are disposed adjacent each discharge cavity to create a magnetic field null region within the discharge cavity.

Owner:GENERAL PLASMA

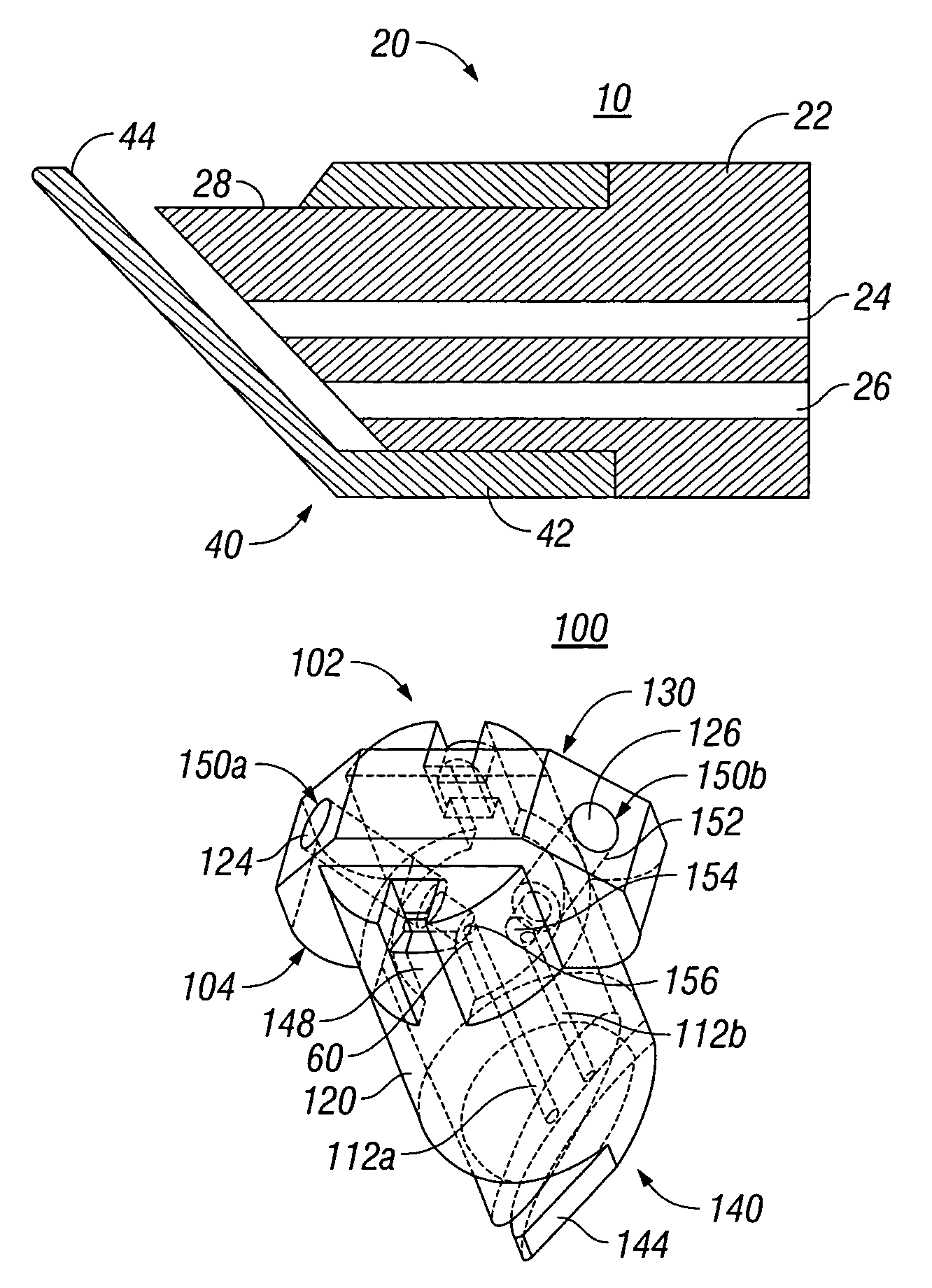

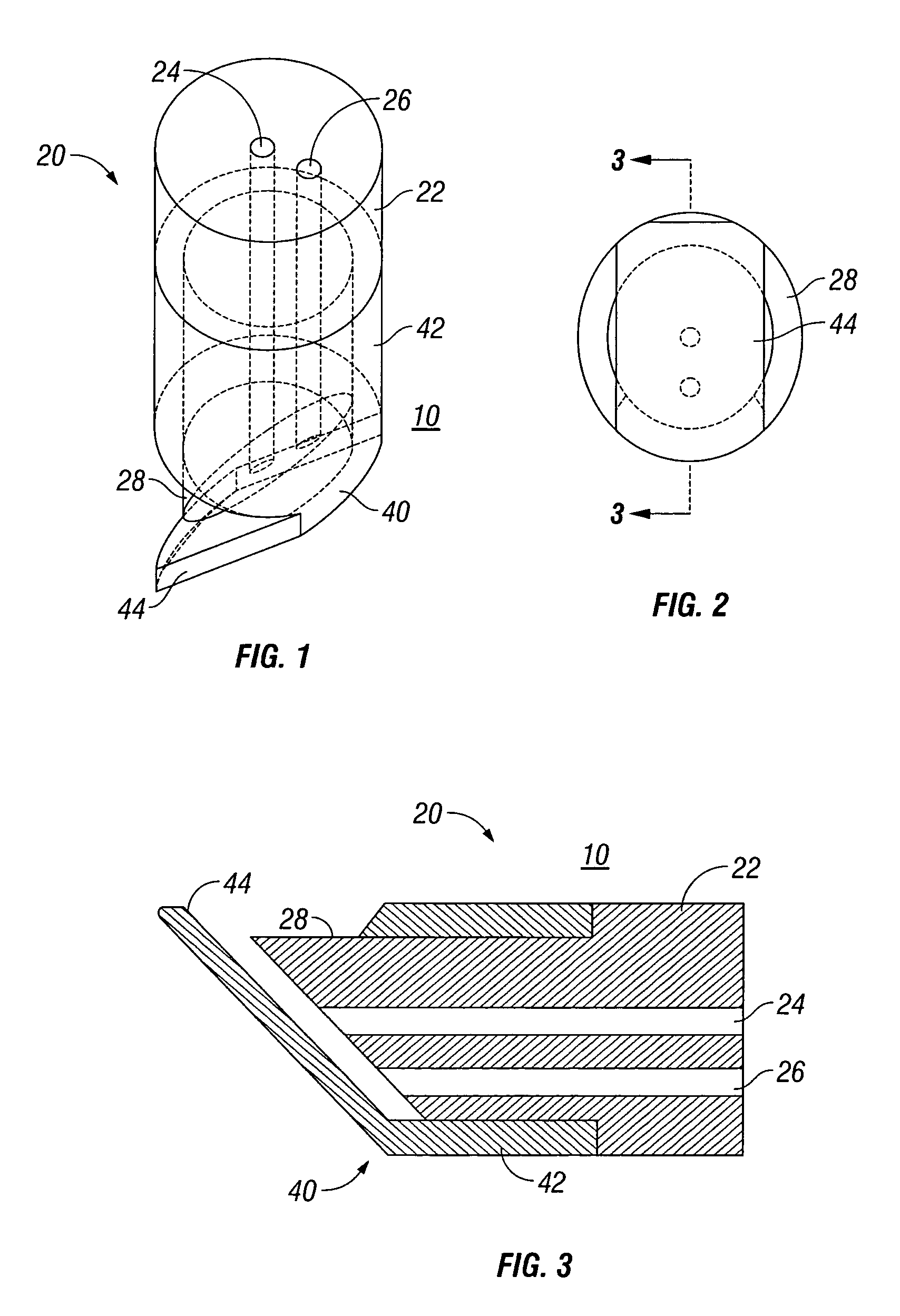

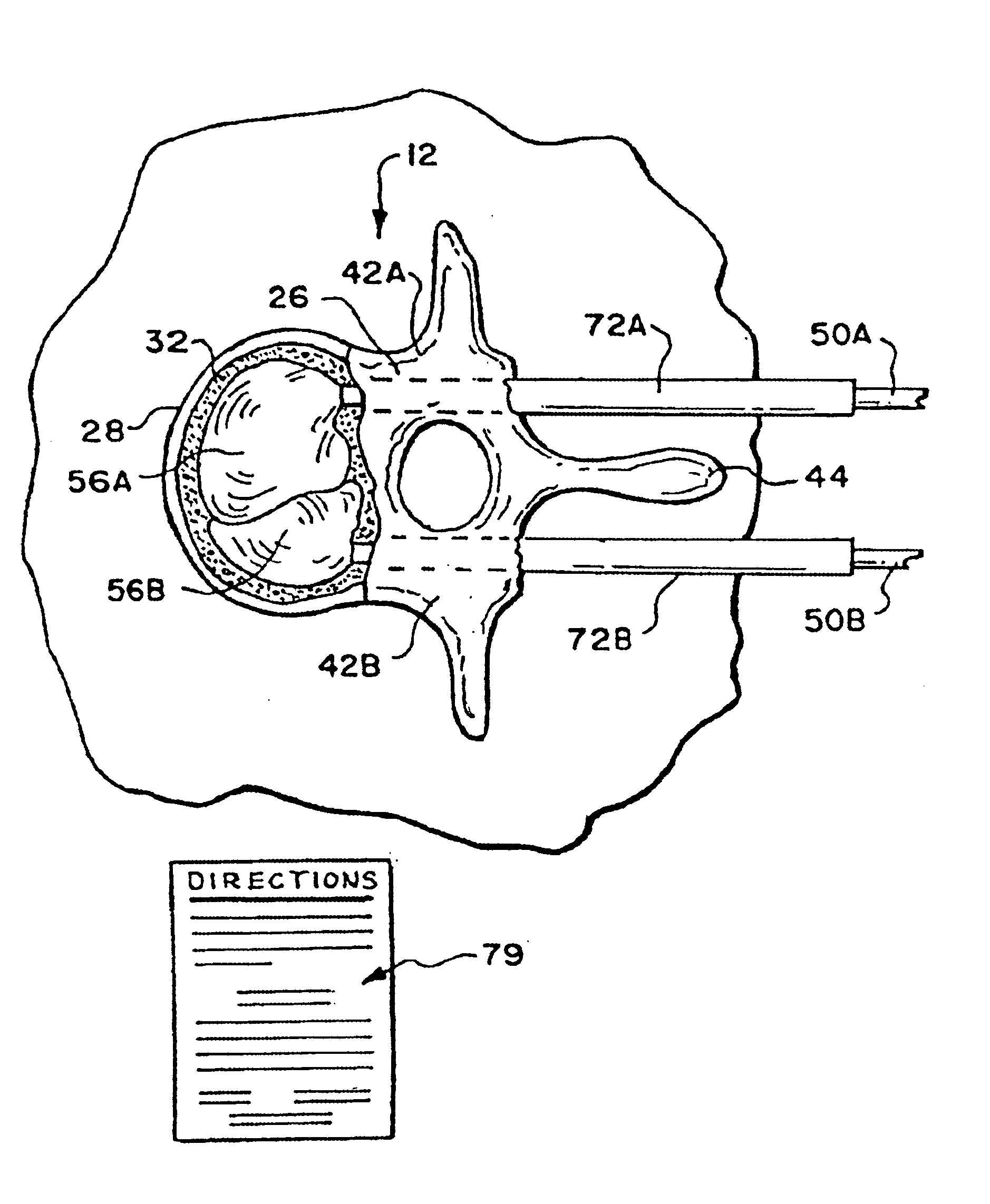

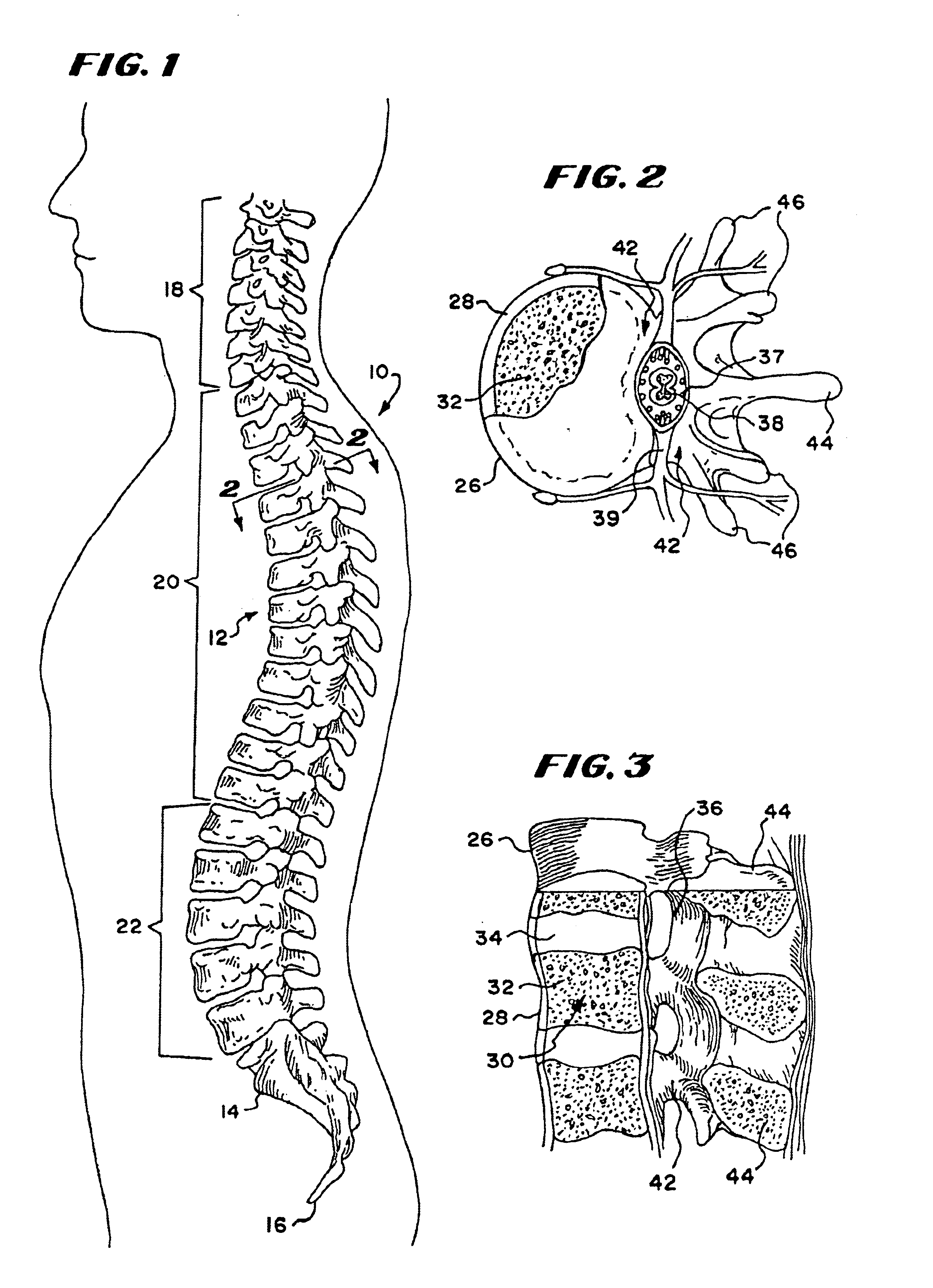

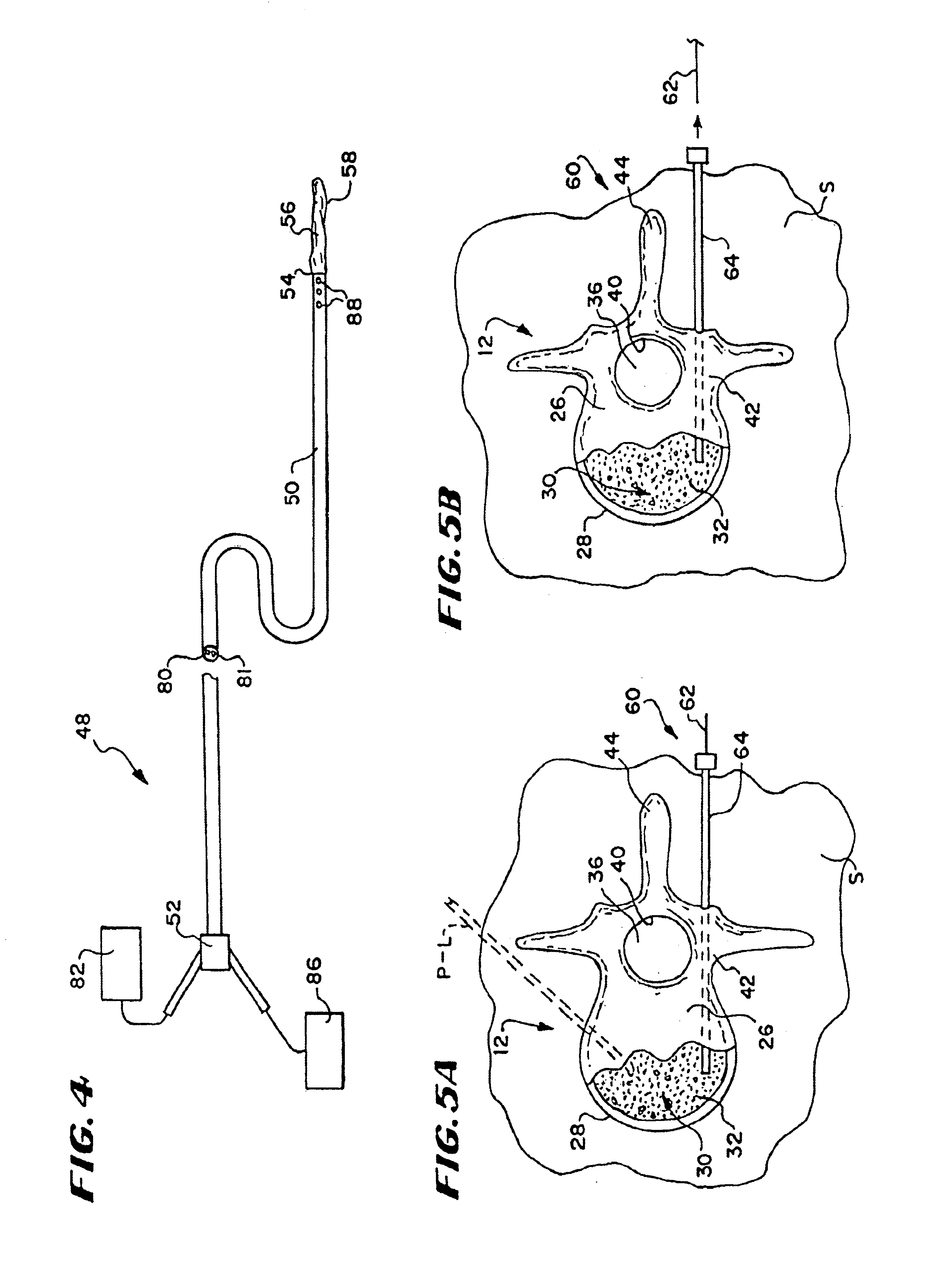

Systems and methods for treating fractured or diseased bone using expandable bodies

Systems and methods treat fractured or diseased bone by deploying more than a single therapeutic tool into the bone. In one arrangement, the systems and methods deploy an expandable body in association with a bone cement nozzle into the bone, such that both occupy the bone interior at the same time. In another arrangement, the systems and methods deploy multiple expandable bodies, which occupy the bone interior volume simultaneously. Expansion of the bodies form cavity or cavities in cancellous bone in the interior bone volume.

Owner:ORTHOPHOENIX

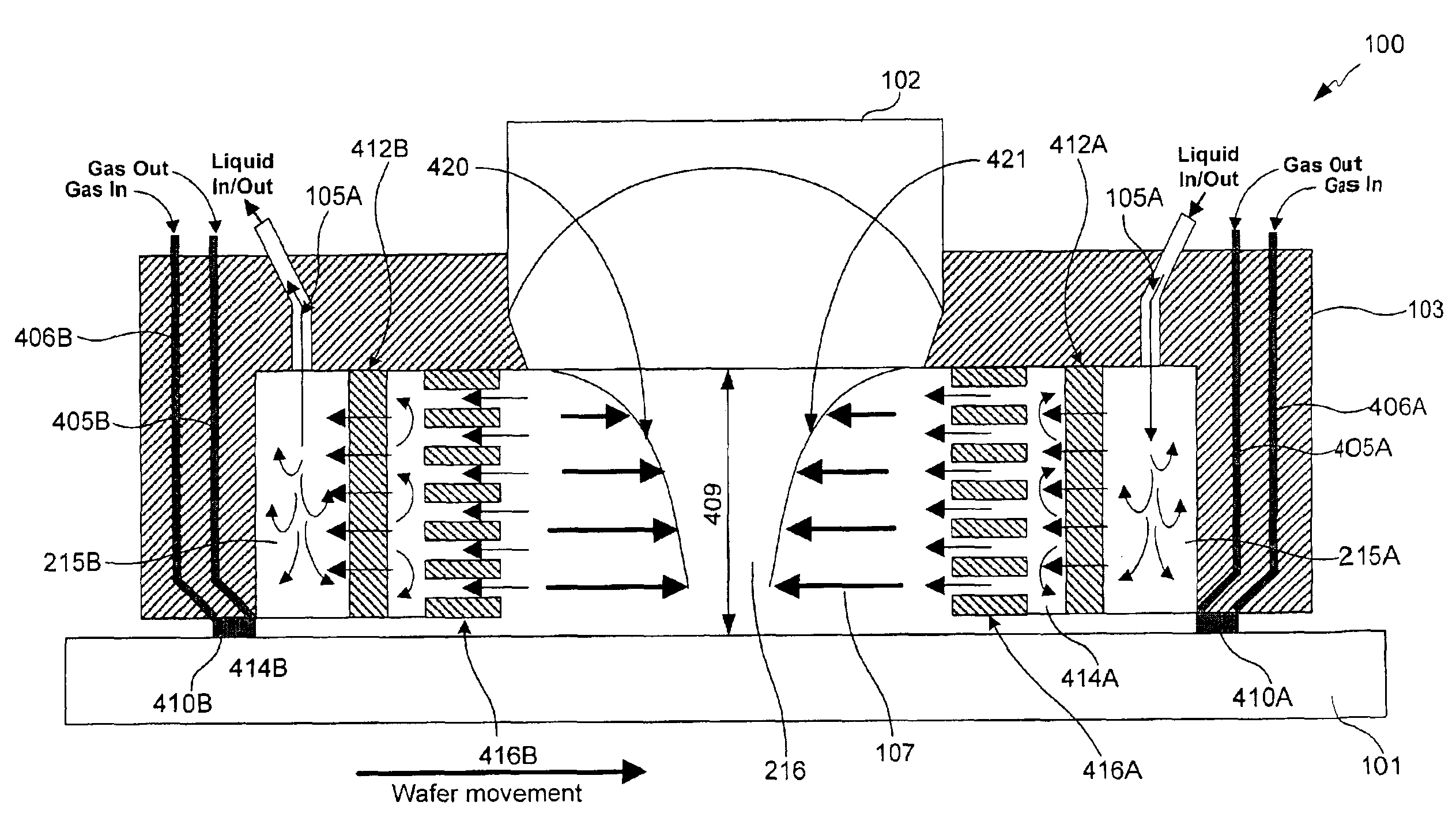

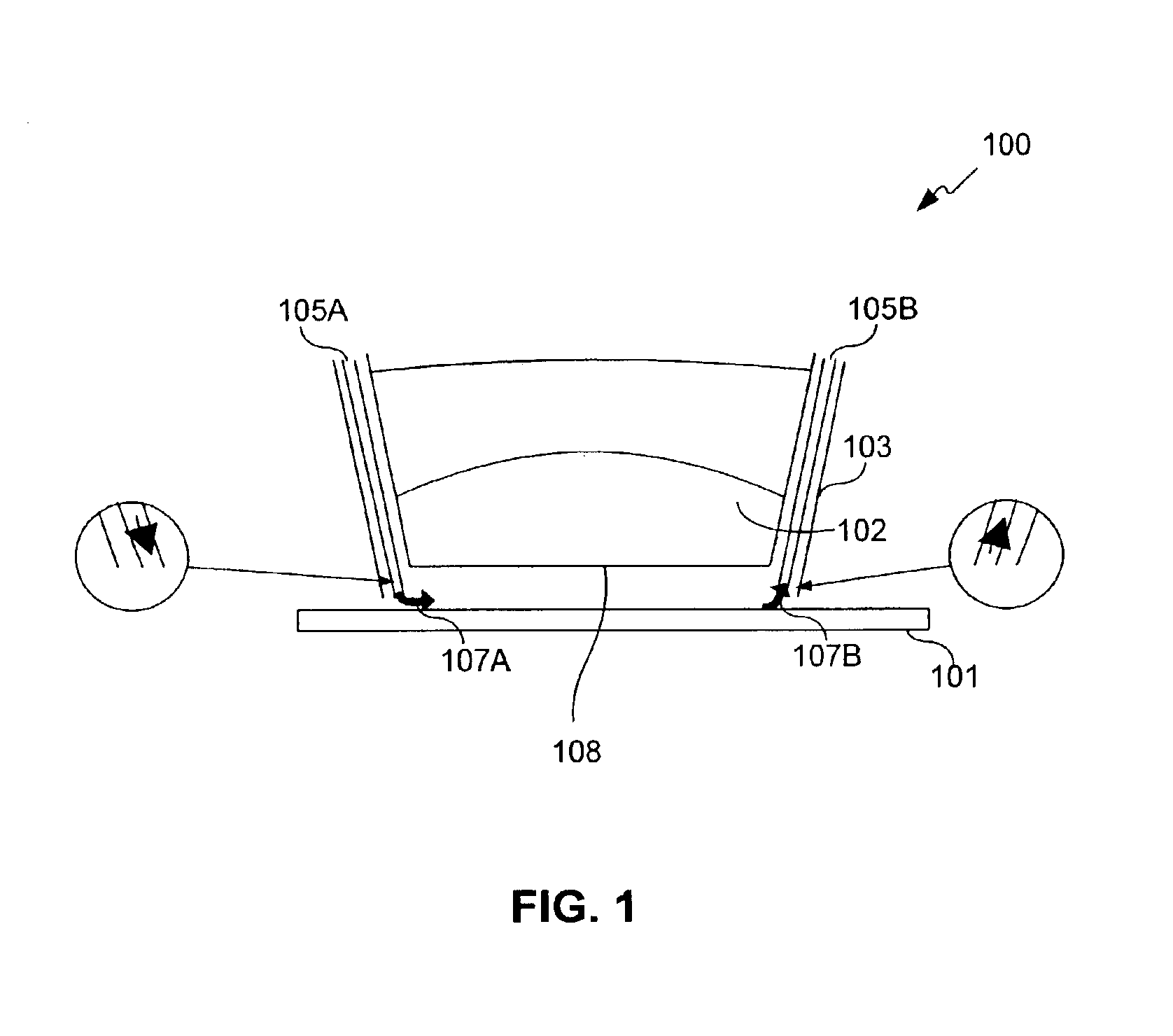

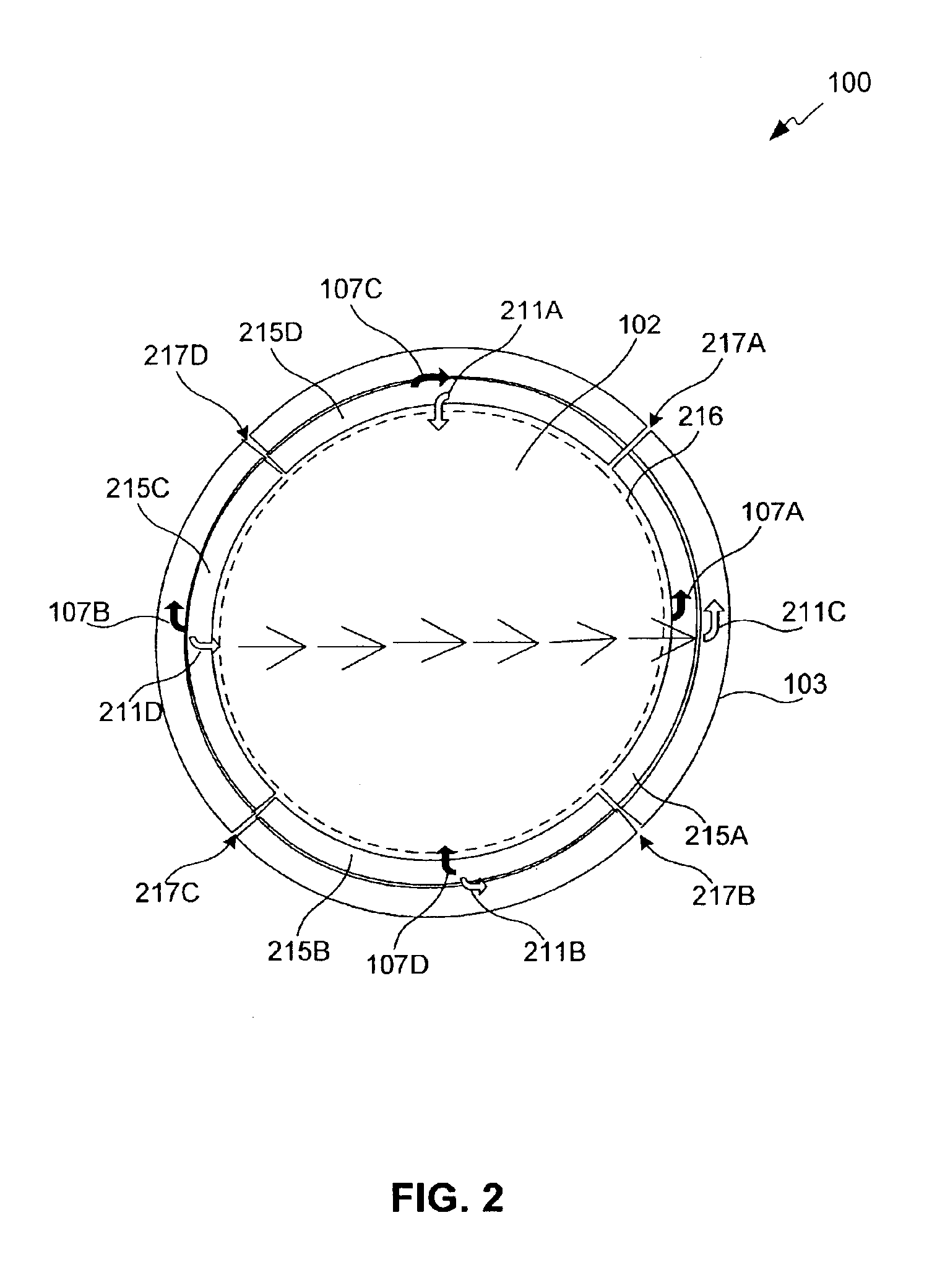

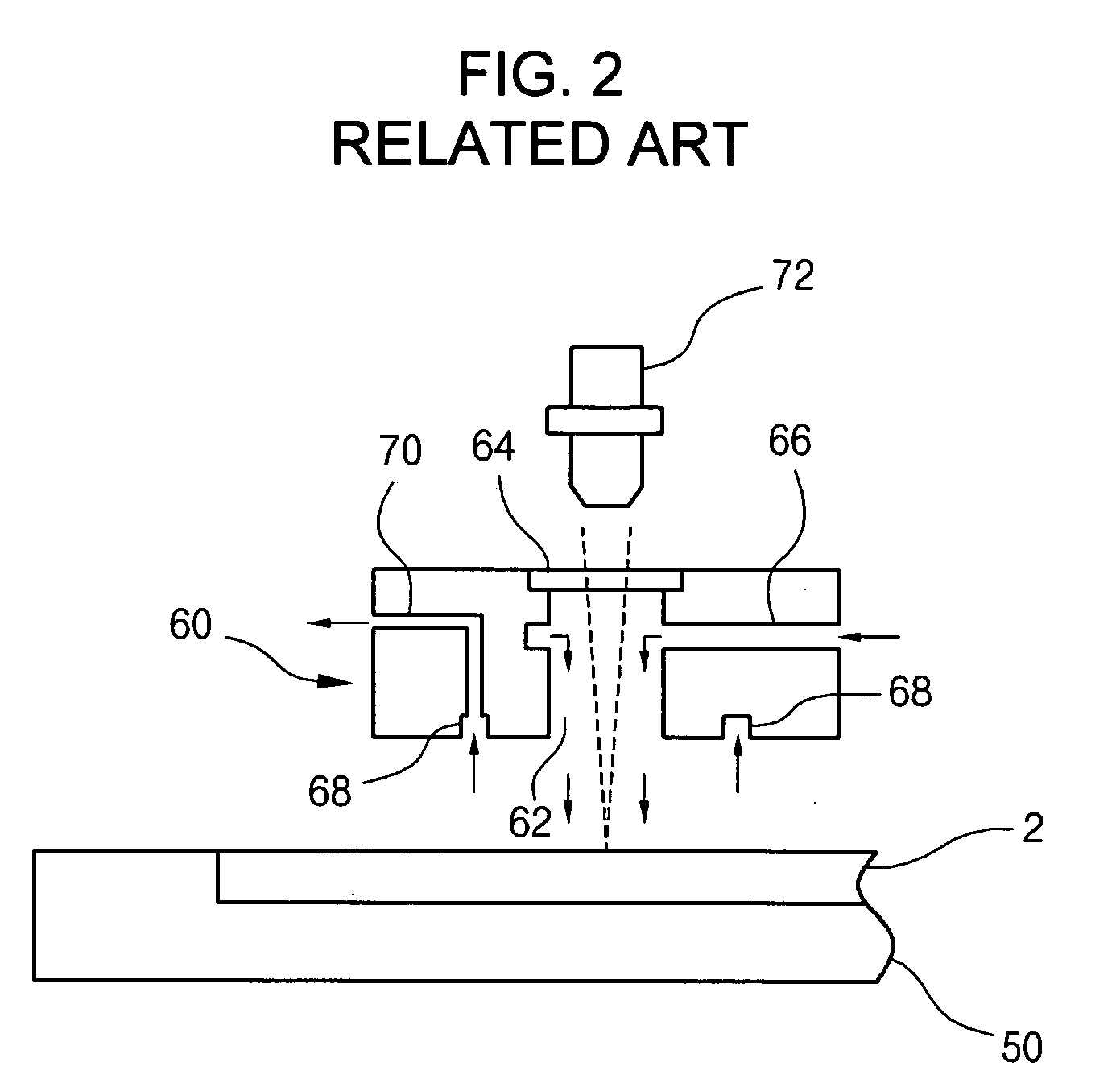

Immersion photolithography system and method using microchannel nozzles

InactiveUS6867844B2Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusElectromagnetic radiationPhotolithography

A liquid immersion photolithography system includes an exposure system that exposes a substrate with electromagnetic radiation and includes a projection optical system that focuses the electromagnetic radiation on the substrate. A liquid supply system provides liquid flow between the projection optical system and the substrate. An optional plurality of micronozzles are arranged around the periphery of one side of the projection optical system so as to provide a substantially uniform velocity distribution of the liquid flow in an area where the substrate is being exposed.

Owner:ASML HLDG NV

Tobacco Solution Atomizing Device For Electronic Cigarette

A tobacco solution atomizing device for electronic cigarette is disclosed the device comprises an atomizer installed in a fixing sleeve; a suction nozzle component and electrode connectors coupled on respective ends of the fixing sleeve, wherein the electrode connectors comprises a positive electrode connector and a negative electrode connector; the atomizer comprising a glass fiber tube, a glass fiber yarn, a heating coil, a cotton cloth layer and a synthetic fiber layer, wherein the glass fiber yarn is insert into the heating coil which is then located inside the glass fiber tube; the ends of the glass fiber silk and two wires which are used to electronically connect the heating coil to the positive and negative electrode connectors extends outward through the glass fiber tube; the cotton cloth layer enwraps the outside wall of the glass fiber tube and reveal ends of the glass fiber yarn are pressed tightly between the cotton cloth layer and the glass fiber tube; a synthetic fiber layer is filled within the annular shape space between the cotton cloth layer and the fixing sleeve for holding the tobacco solution.

Owner:LI YONGHAI +1

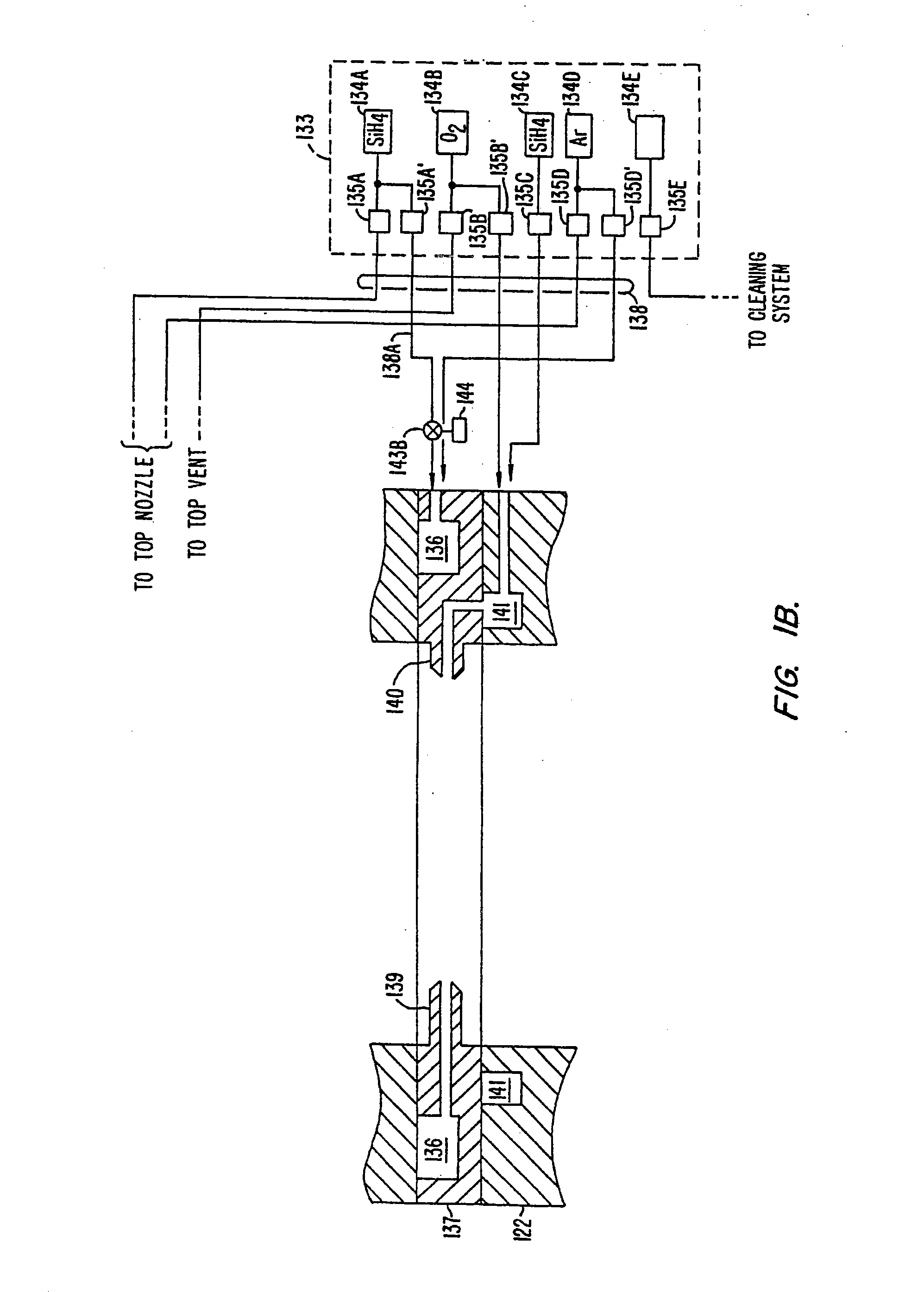

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS20050250340A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

Method and apparatus for filling liquid crystal display (LCD) panels

InactiveUS6055035AElectroluminescent light sourcesVessels or leading-in conductors manufactureLiquid-crystal displayEngineering

A system, apparatus, and method for filling a display panel having first and second plates, with liquid crystal material, includes a nozzle for depositing a layer of liquid crystal material over a surface of a first plate of the panel, a scanning arm, coupled to the nozzle, for uniformly forming the layer of liquid crystal material over the surface of the first plate of the panel, and an attachment mechanism for placing the second plate over the first plate having the liquid crystal material thereover, thereby to form the display panel.

Owner:AU OPTRONICS CORP

Hdp-cvd seasoning process for high power hdp-cvd gapfil to improve particle performance

InactiveUS20060219169A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

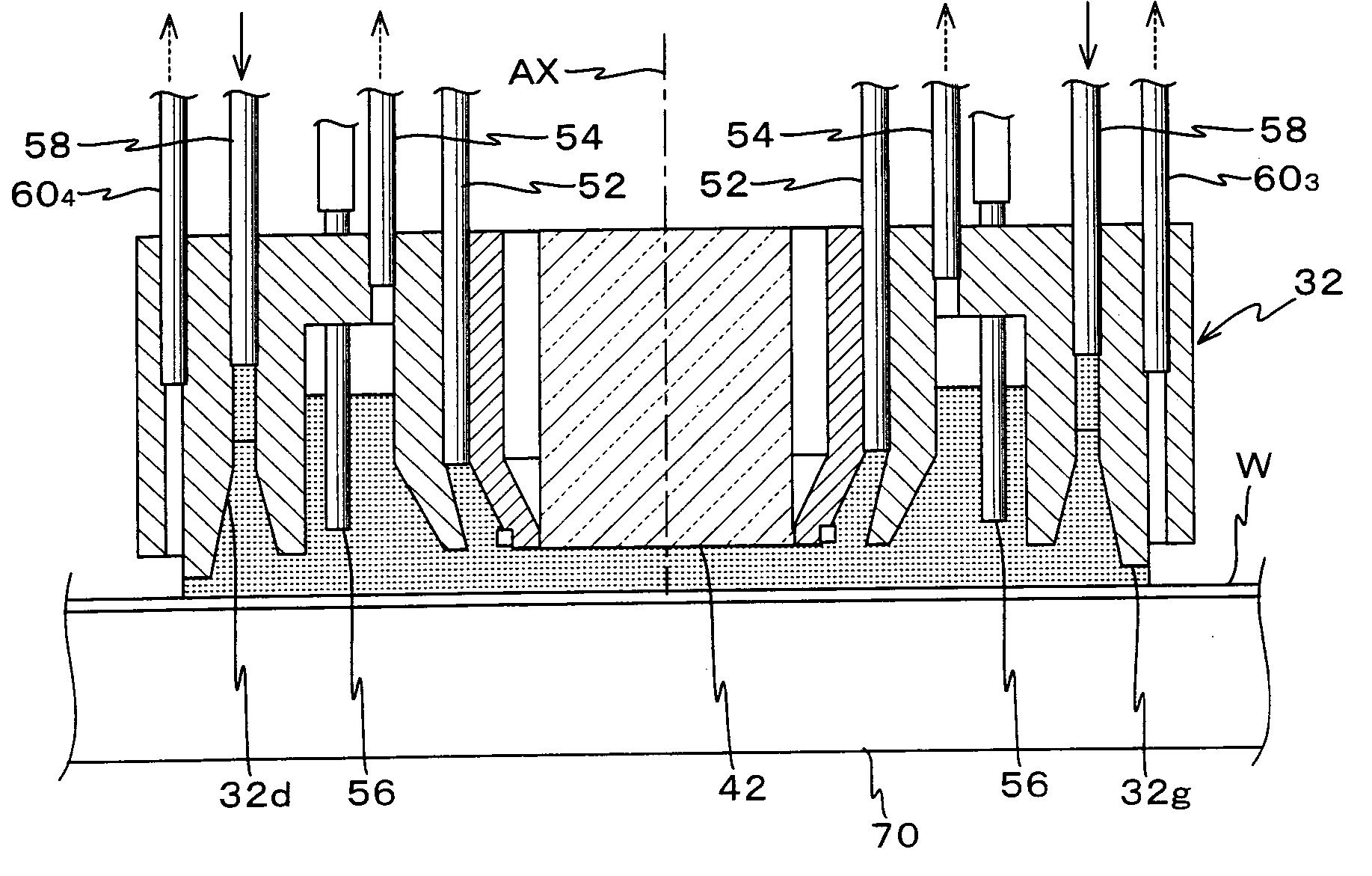

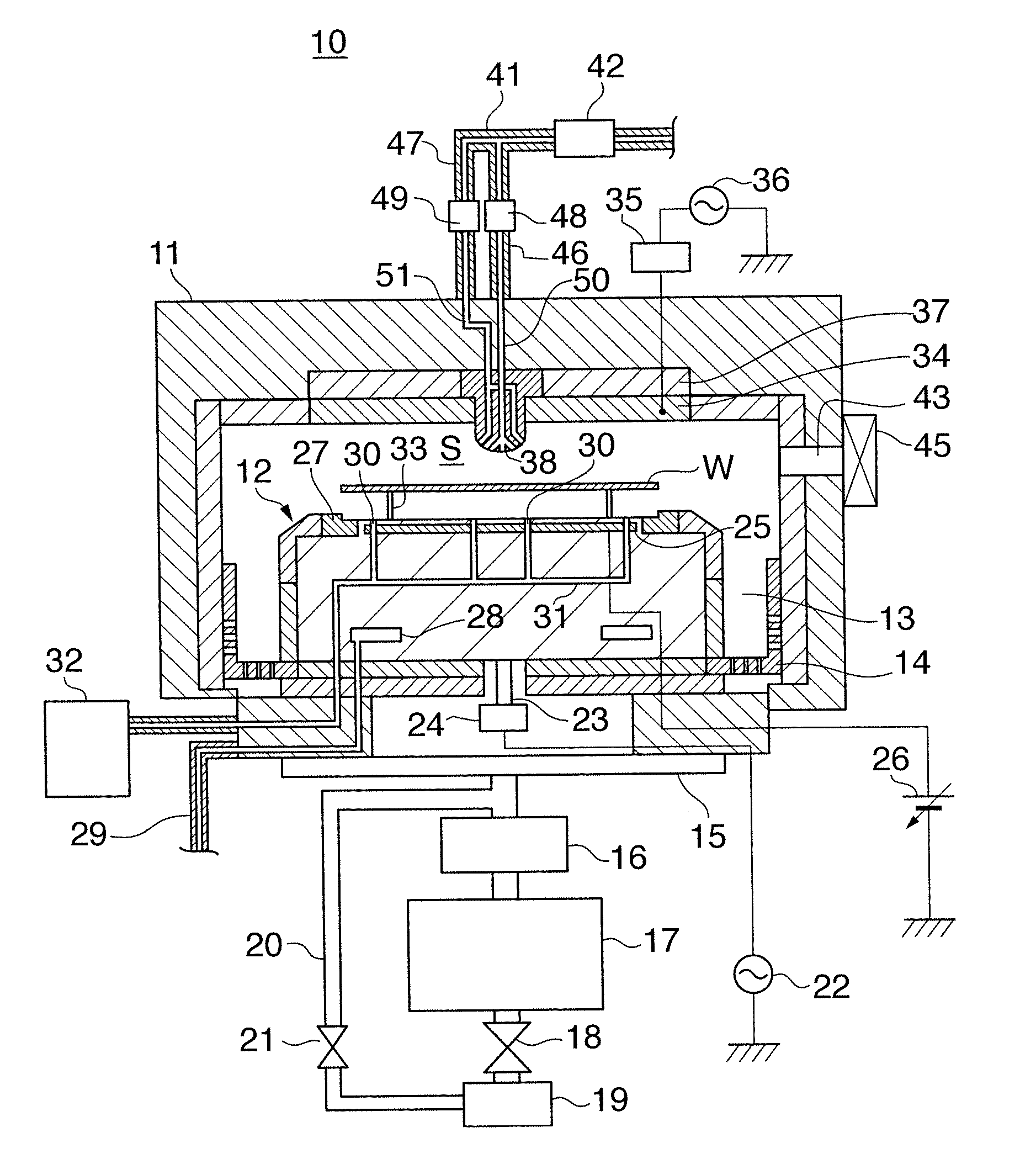

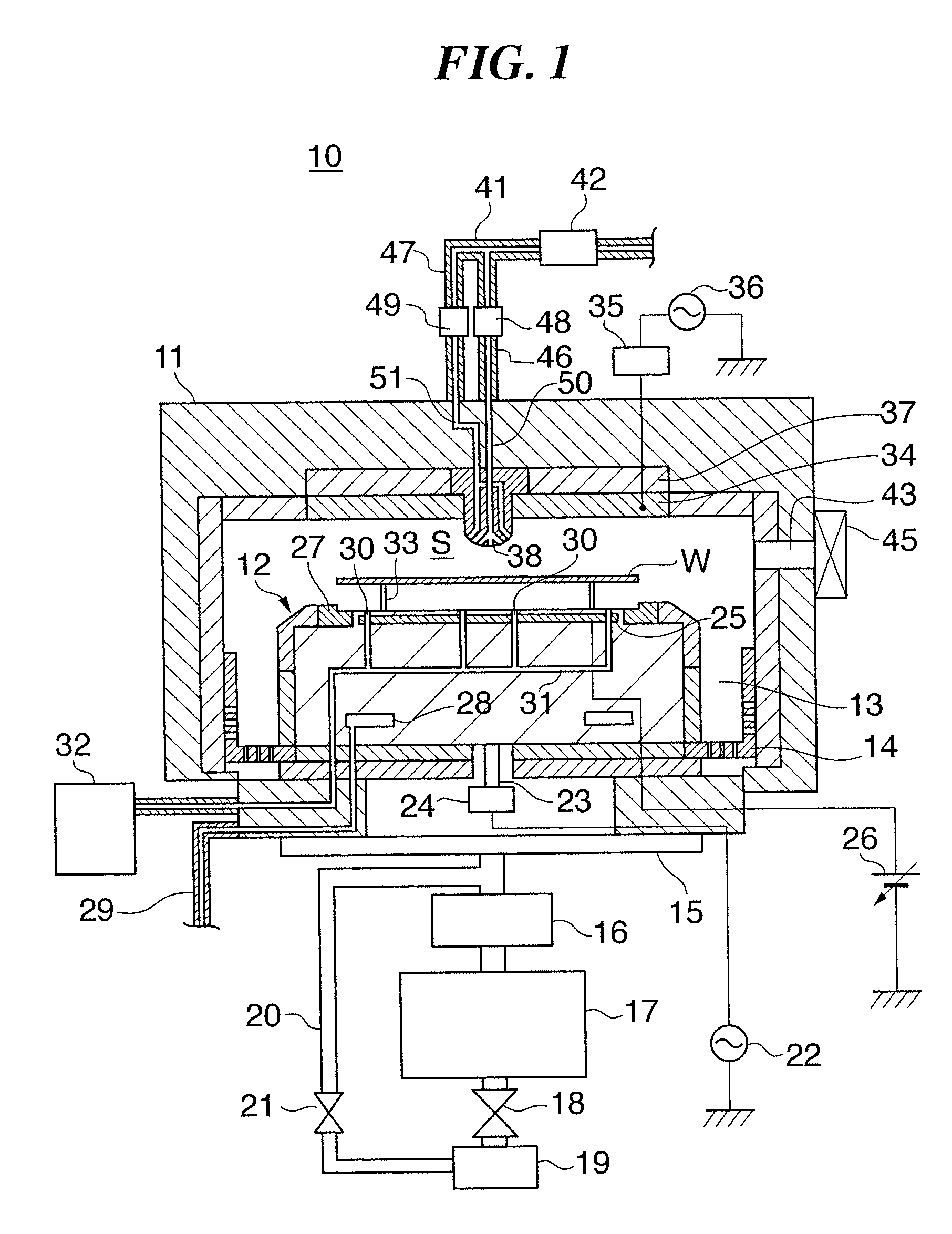

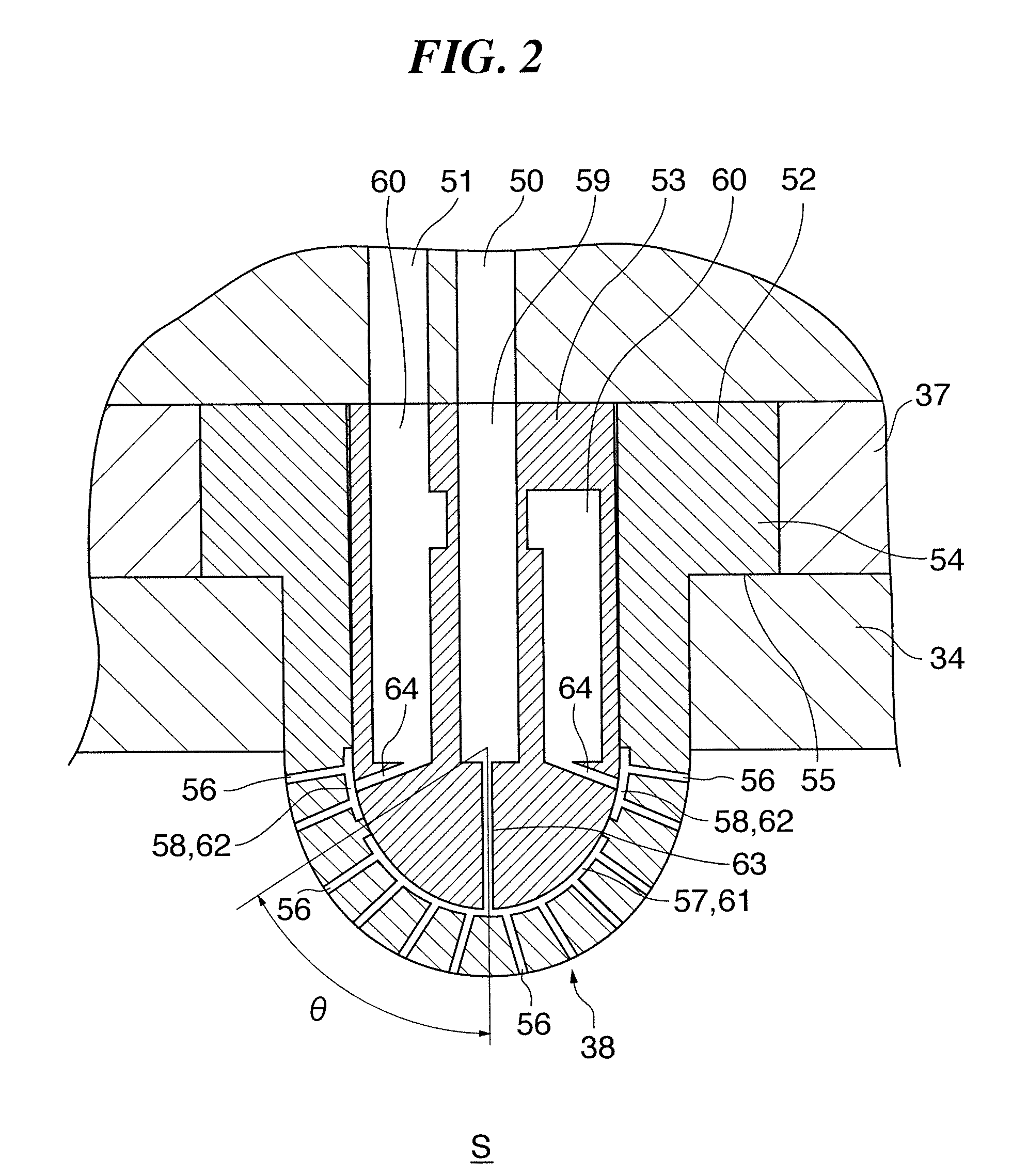

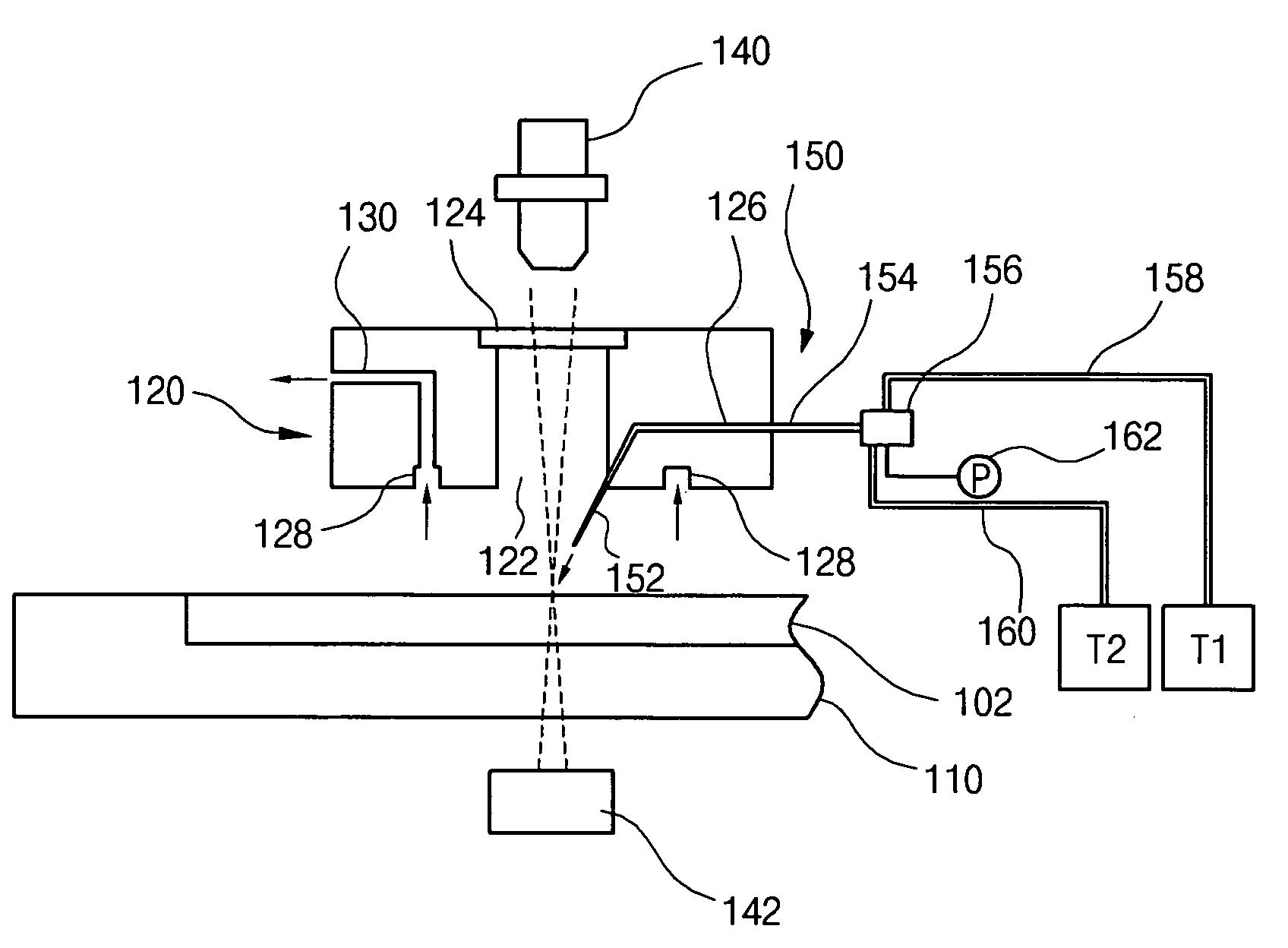

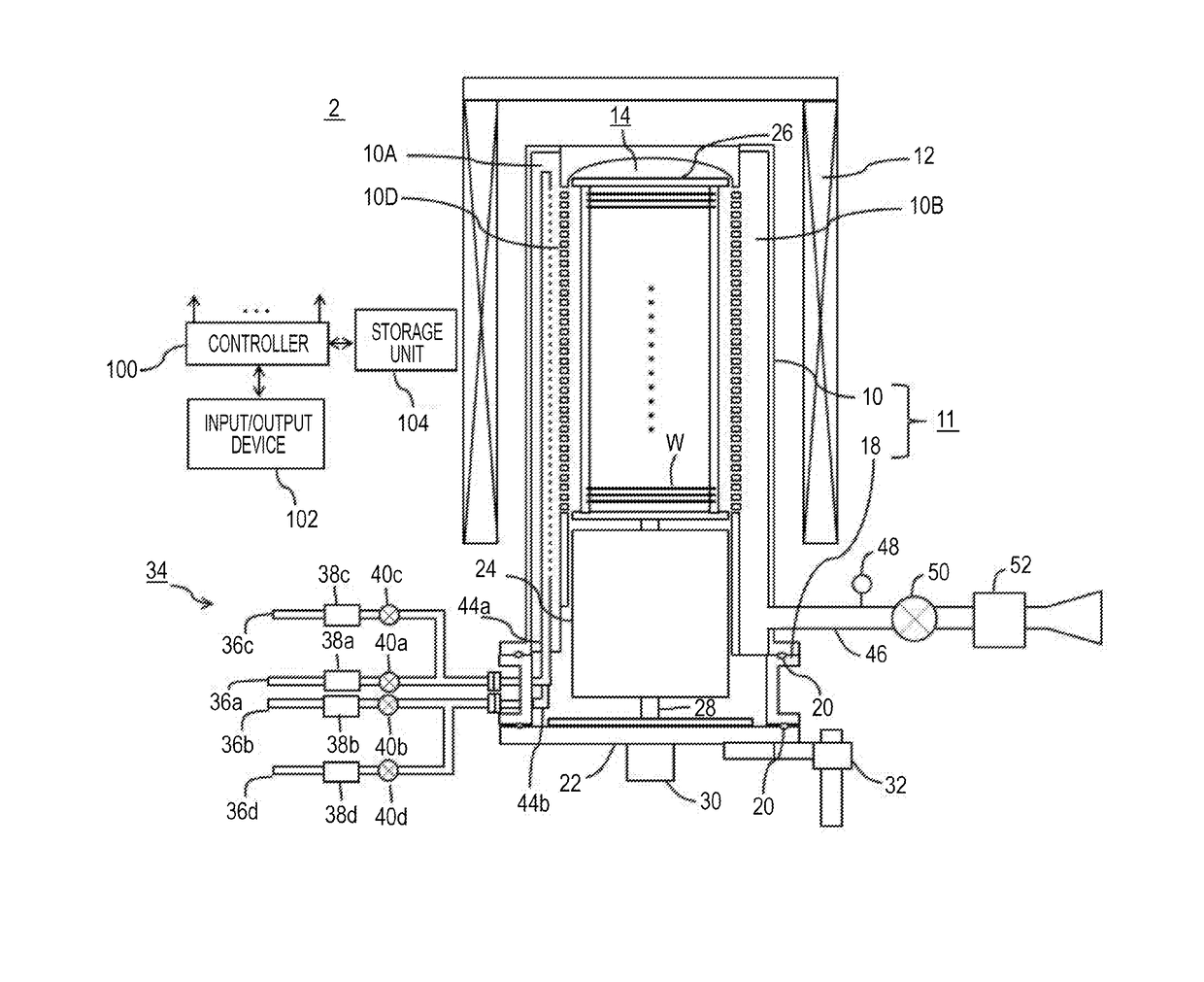

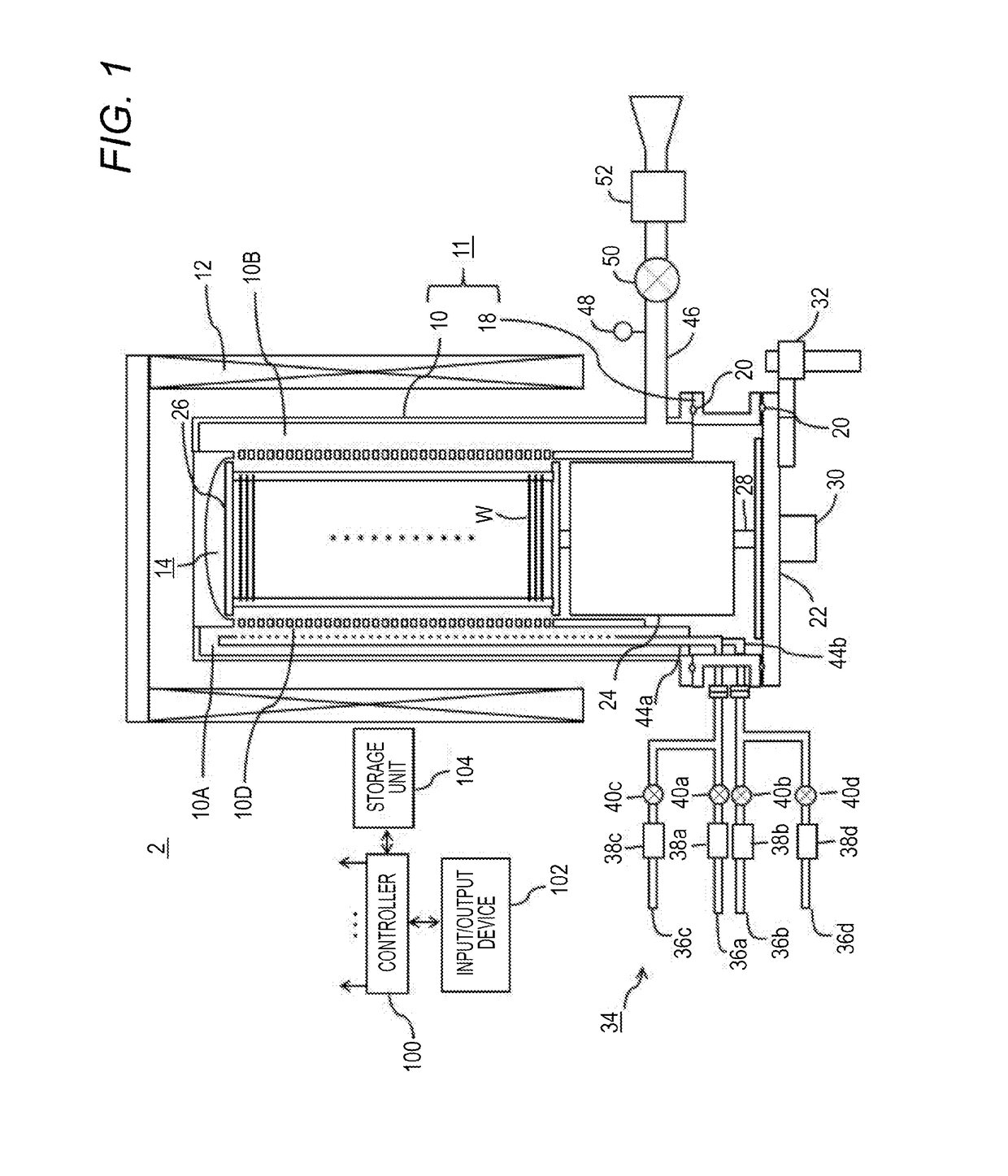

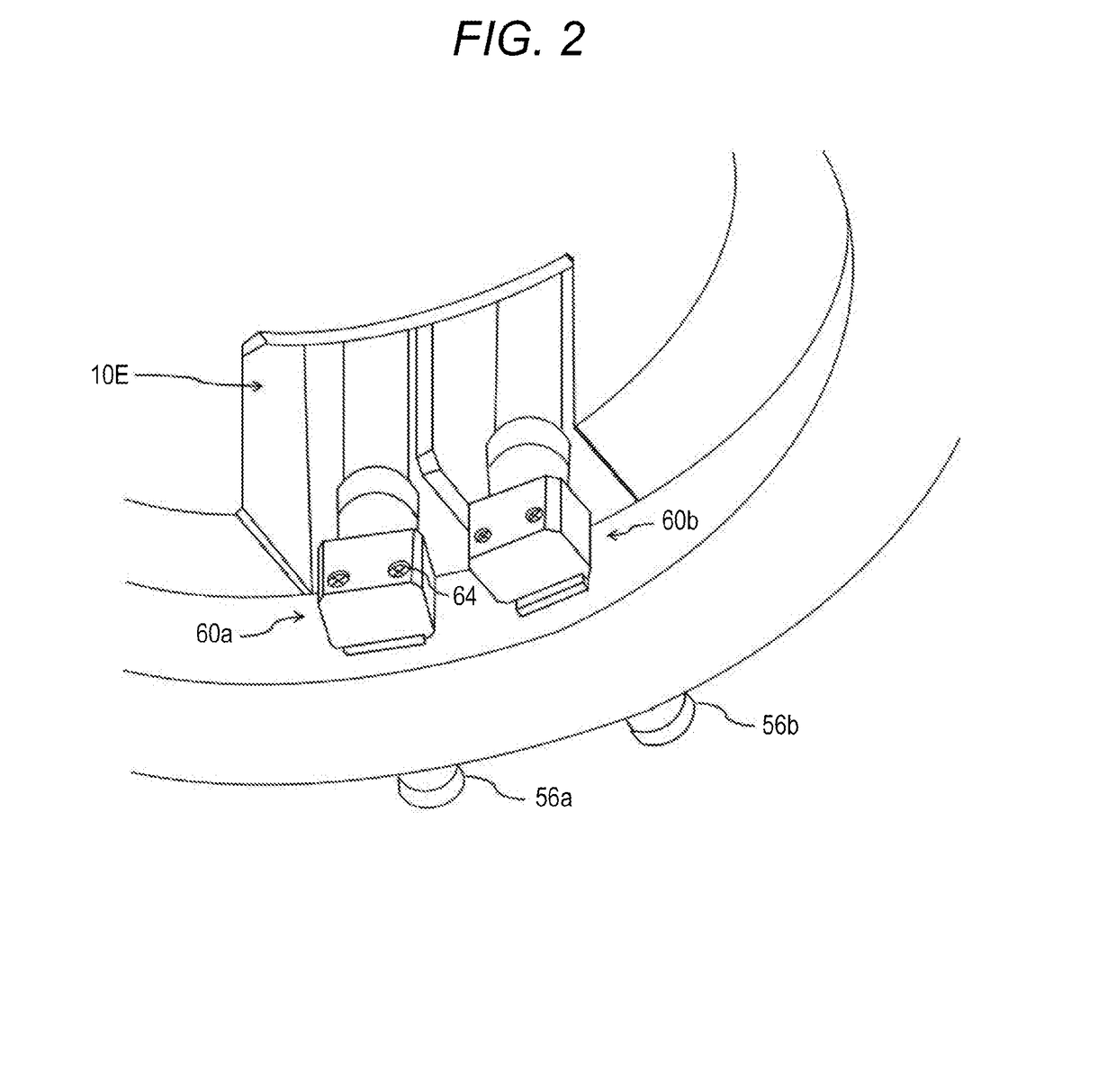

Substrate processing apparatus and substrate processing method

InactiveUS20070187363A1Easy maintenanceElectric discharge tubesVacuum gauge using ionisation effectsEngineeringPlasma processing

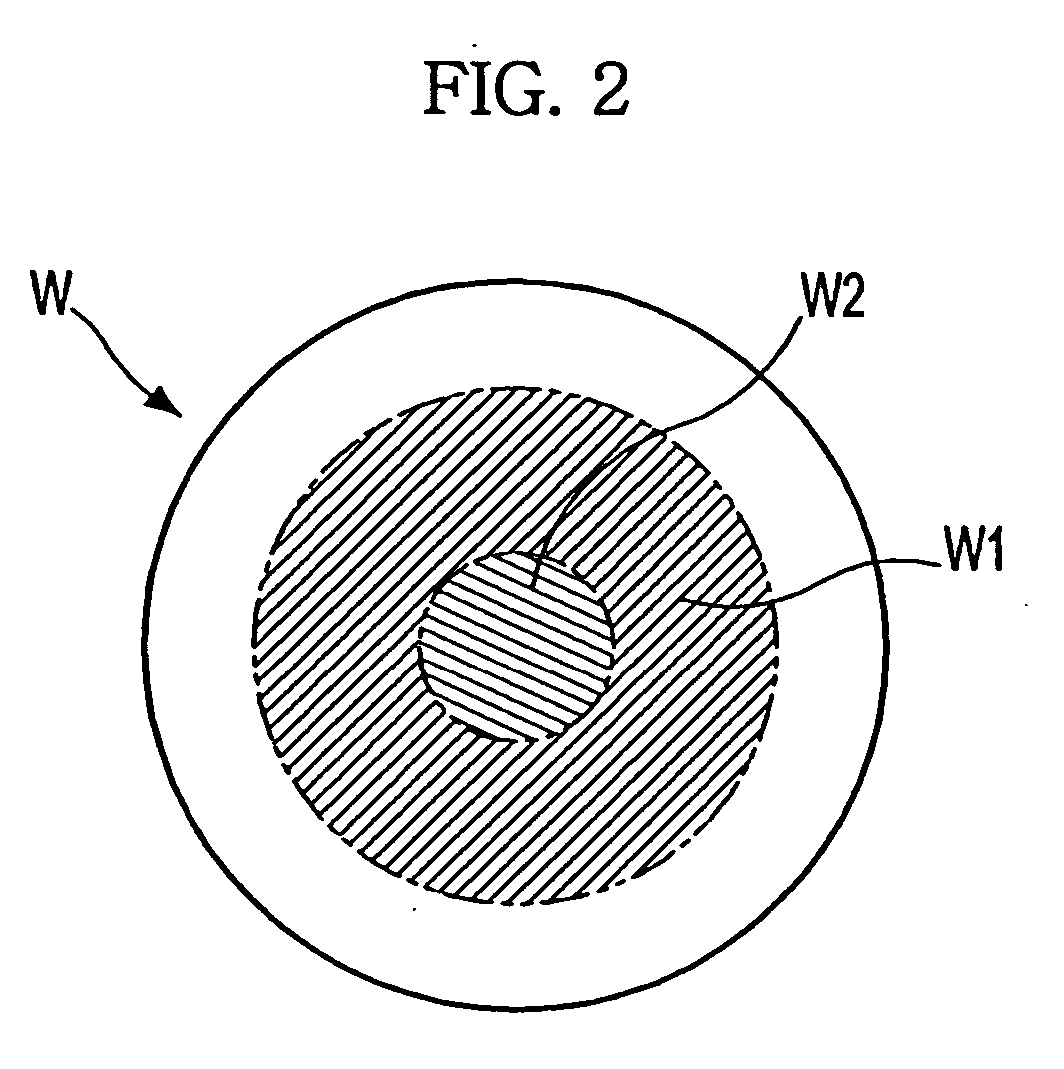

A substrate processing apparatus that enables a state of plasma over a substrate to be maintained in a desired state easily. A plasma processing apparatus 10 that has therein a camber 11, a stage 12, and a processing gas introducing nozzle 38 carries out etching on a wafer W. The chamber 11 houses the wafer W. The stage 12 is disposed in the chamber 11 and the wafer W is mounted thereon. The processing gas introducing nozzle 38 is a projecting body that projects out into the chamber 11, and has therein a plurality of processing gas introducing holes 56 that open out in different directions to one another.

Owner:TOKYO ELECTRON LTD

UV Irradiation Apparatus with Cleaning Mechanism and Method for Cleaning UV Irradiation Apparatus

InactiveUS20140116335A1Efficient implementationEfficient cleaning methodLiquid surface applicatorsElectric discharge tubesUltravioletEngineering

A UV irradiation apparatus for processing a semiconductor substrate includes: a UV lamp unit; a reaction chamber disposed under the UV lamp unit; a gas ring with nozzles serving as a first electrode between the UV lamp unit and the reaction chamber; a transmission window supported by the gas ring; an RF shield which covers a surface of the transmission window facing the UV lamp unit; a second electrode disposed in the reaction chamber for generating a plasma between the first and second electrodes; and an RF power source for supplying RF power to one of the first or second electrode.

Owner:ASM IP HLDG BV

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS7109114B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

High density plasma chemical vapor deposition apparatus

InactiveUS20060196420A1Unified performanceEasy to handleElectric discharge tubesVacuum evaporation coatingHigh densityEngineering

A high density plasma chemical vapor deposition apparatus includes an upper gas supply nozzle which includes a nozzle body, a gas supply passage formed vertically in the nozzle body, a nozzle cover attached to a lower surface of the horizontal portion of the nozzle body, and a plurality of gas inlets formed through the nozzle cover to uniformly supply the processing gas towards a semiconductor wafer within the processing chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Apparatus for treating thin film and method of treating thin film

An apparatus for treating a thin film on a substrate includes a stage on which the substrate is disposed. A gas shield faces the substrate. An energy source irradiates a part of the substrate with light emitted therefrom through a retention space of the gas shield. A dispense unit includes a pin nozzle that injects a reaction gas towards the part of the substrate.

Owner:LG ELECTRONICS INC +1

Impulse chamber for jet delivery device

InactiveUS20070049873A1Lower the volumeSimple and cost-efficient to manufactureAmpoule syringesJet injection syringesCost effectivenessEngineering

The invention relates to an impulse chamber which can be used for expelling an amount of a fluid compound at a high pressure. The impulse chamber comprises a variable-volume impulse chamber adapted for containing a volume of a flowable drug, an outlet nozzle in fluid communication with the impulse chamber and being adapted to be arranged against the skin of a subject, and a fluid inlet in fluid communication with the impulse chamber. The impulse chamber is defined substantially by a deformable chamber portion, such that deformation thereof reduces the volume of the cavity. In an exemplary embodiment the compressible chamber portion is in the form of an elastomeric tube, this providing a simple, yet reliable and cost-effective impulse chamber unit.

Owner:NOVO NORDISK AS

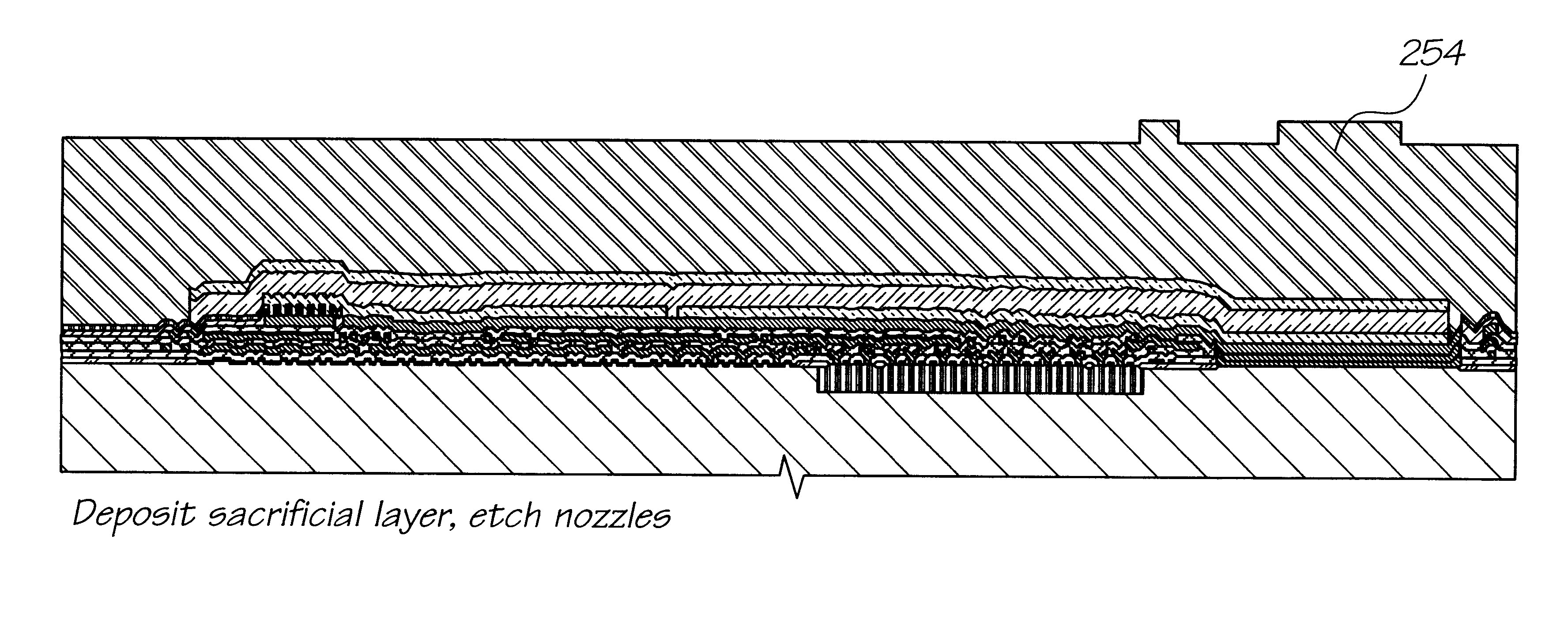

Inkjet printhead having a self aligned nozzle

An inkjet printing arrangement having a series of nozzles for the ejection of ink wherein the nozzle rims are formed as a result of the deposition of a rim material layer and a subsequent planar etching of the material layer so as to form the nozzle rim. The planar etching can comprise chemical-mechanical planarization of the rim material layer and any associated sacrificial layers.

Owner:ZAMTEC +1

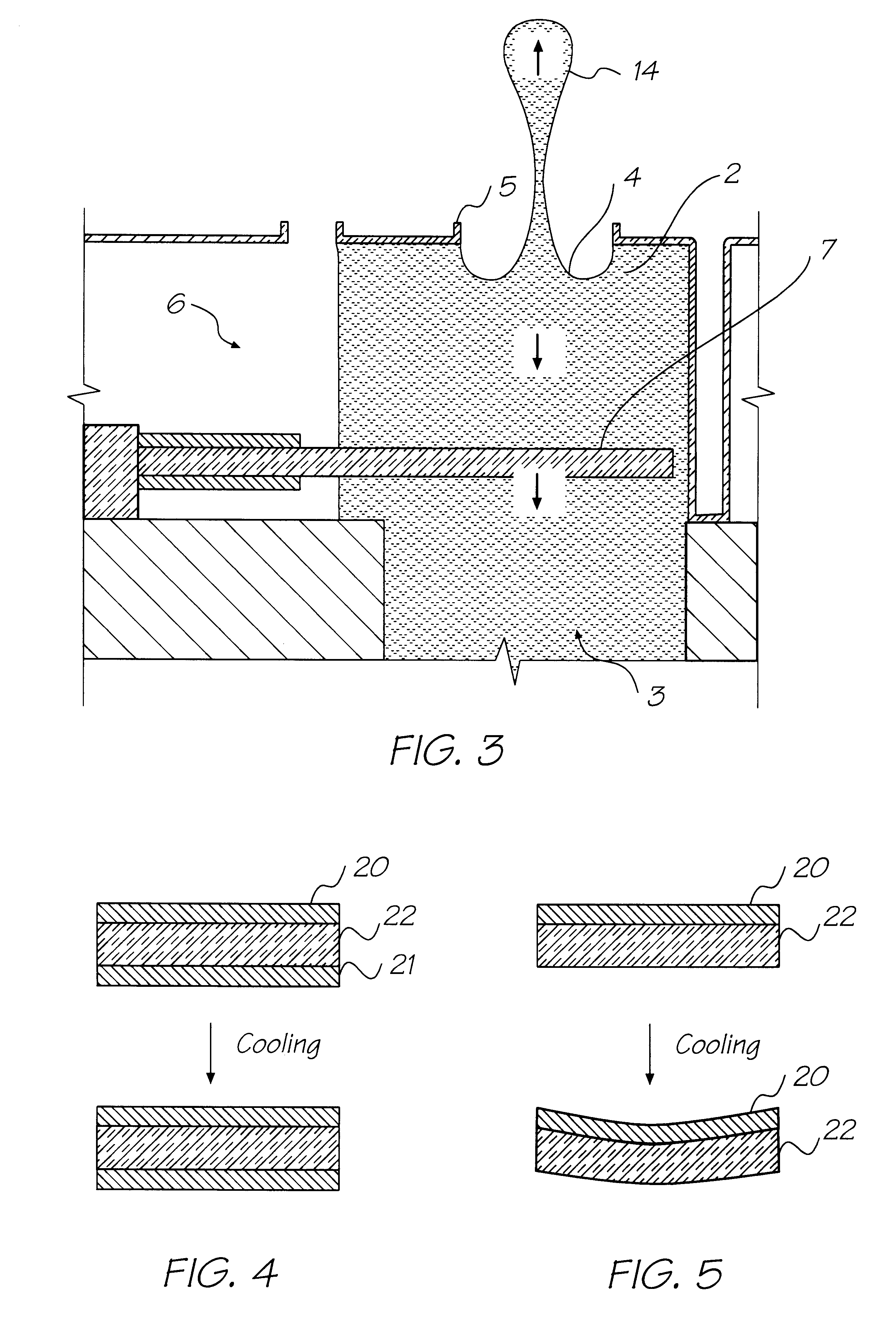

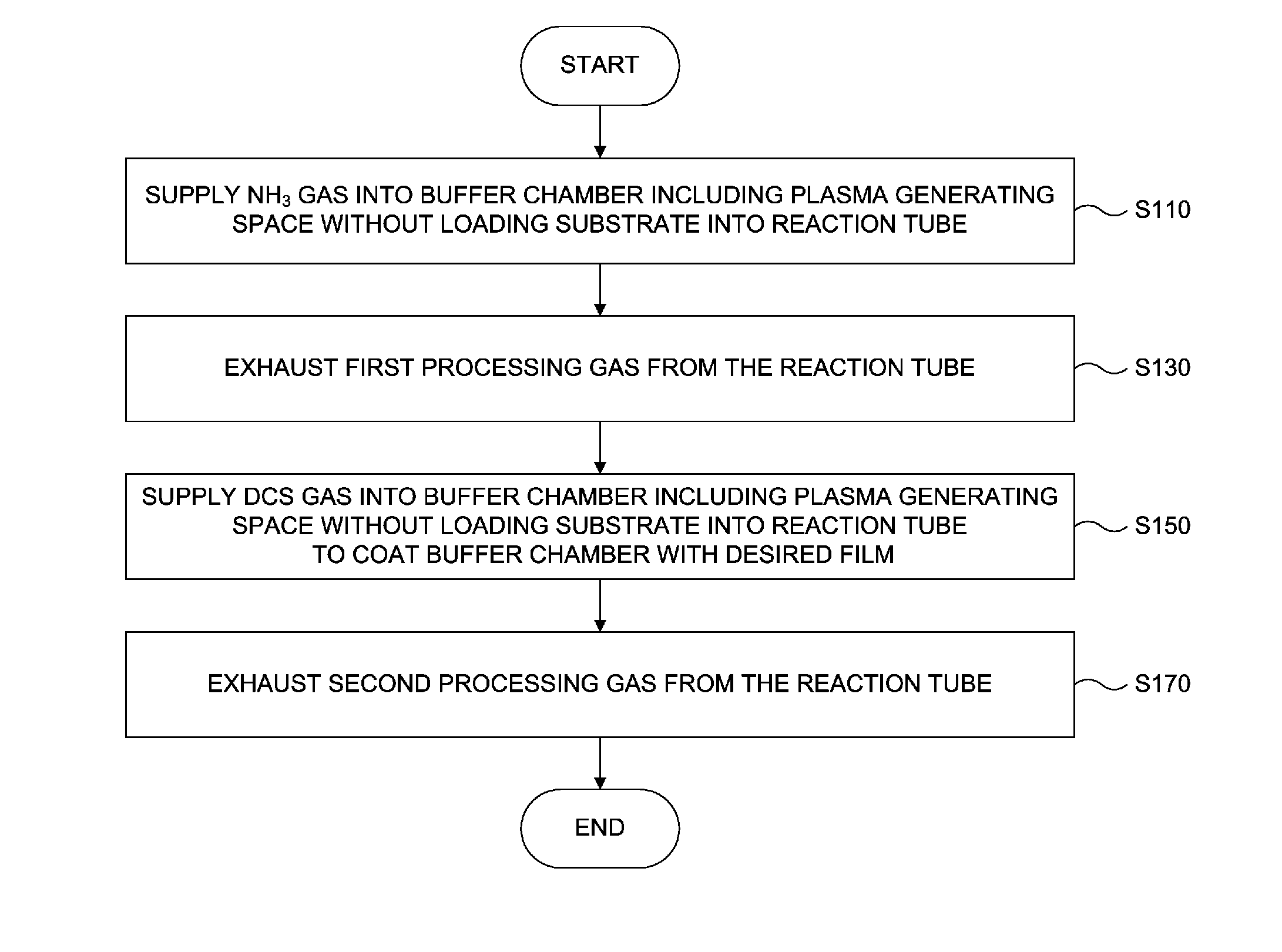

Coating method for coating reaction tube prior to film forming process

InactiveUS20120122319A1Prevent and restrainElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringContamination

Contamination of a substrate can be prevented or suppressed. A substrate processing apparatus includes a reaction tube having an inner space divided by a barrier wall into a film forming space and a plasma generating space. When a desired film is formed on a substrate placed inside the reaction tube, first and second processing gases are supplied to the reaction tube through nozzles. On the other hand, when a part of the reaction tube constituting the plasma generating space is coated with a film, second and third processing gases are supplied to the plasma generating space through the nozzle.

Owner:SHIMIZU HIRONOBU

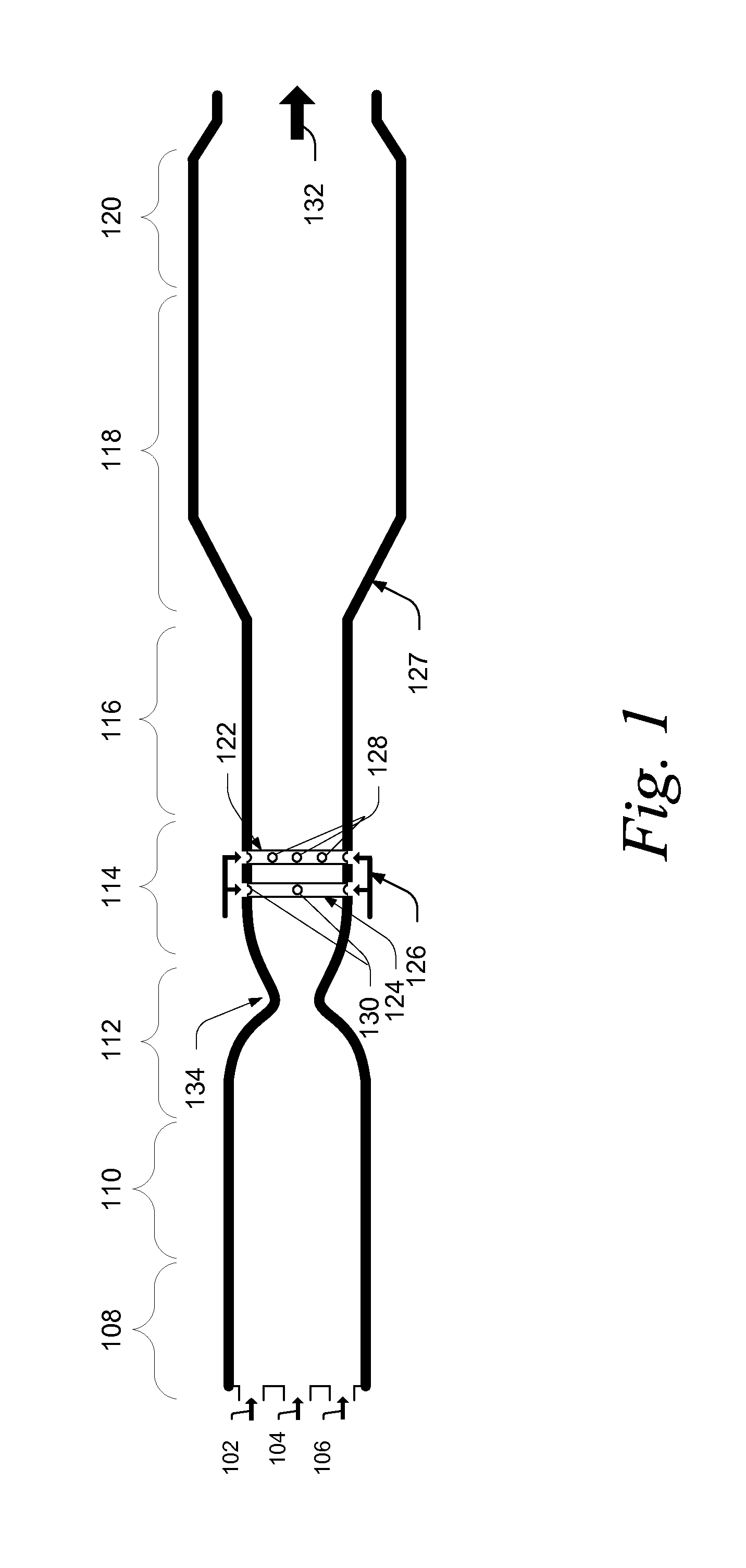

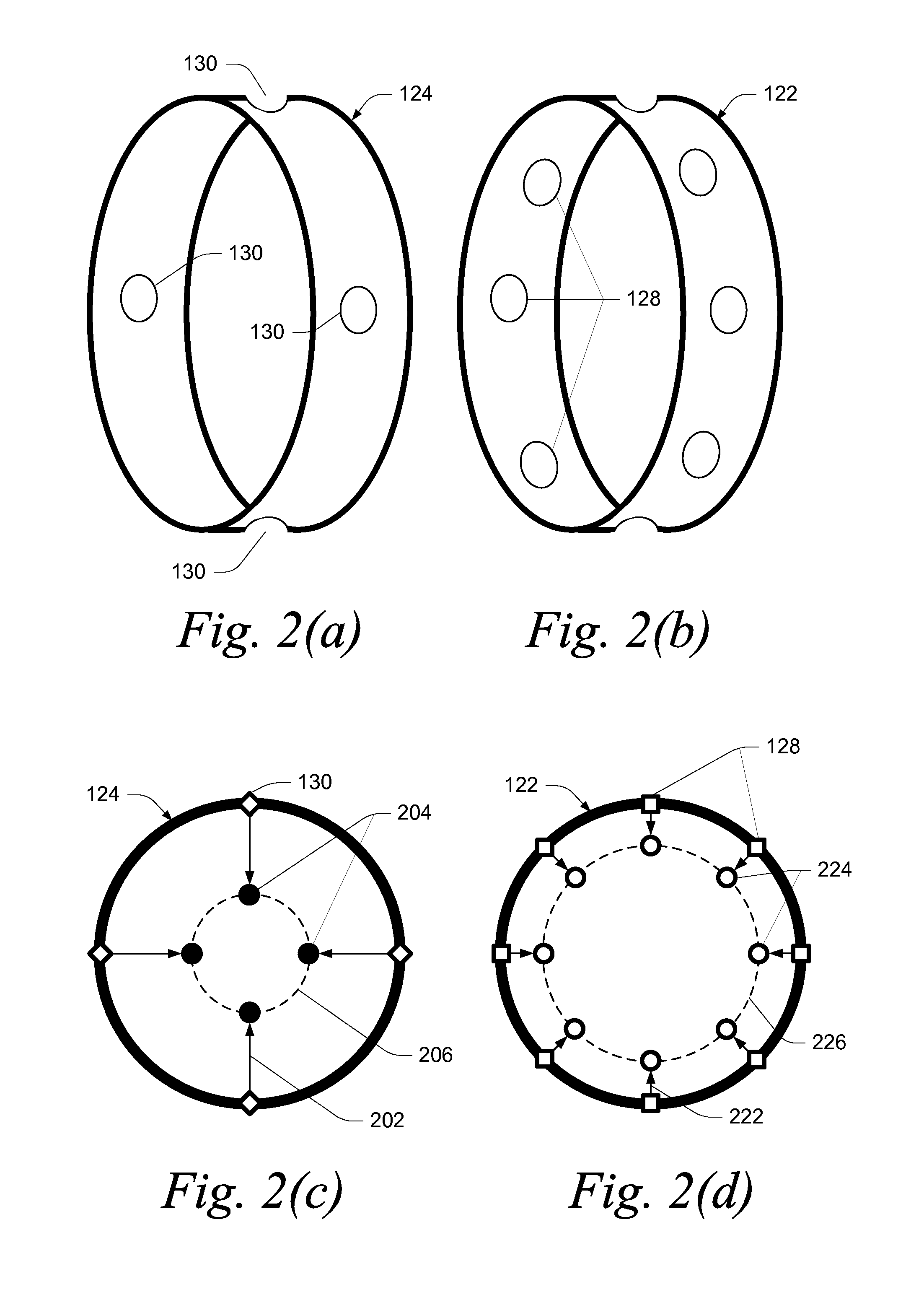

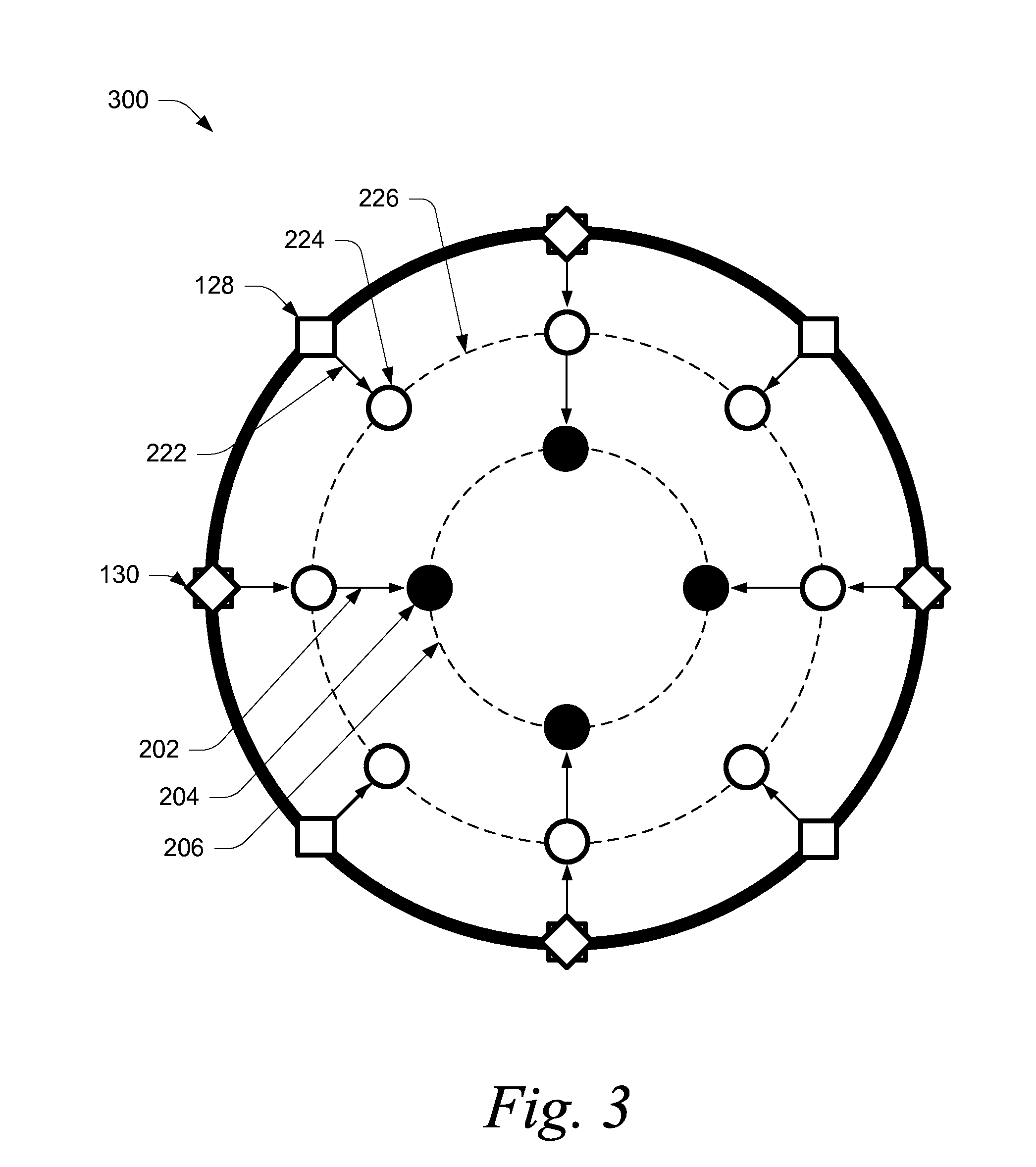

Pyrolytic reactor

A pyrolytic reactor comprising a fuel injection zone, a combustion zone adjacent to the fuel injections zone, an expansion zone adjacent to the combustion zone, a feedstock injection zone comprising a plurality of injection nozzles and disposed adjacent to the expansion zone, a mixing zone configured to mix a carrier stream and feed material and disposed adjacent to the feedstock injection zone, and a reaction zone adjacent to the mixing zone. The plurality of injection nozzles are radially distributed in a first assembly defining a first plane transverse to the feedstock injection zone and in a second assembly transverse to the feedstock injection zone.

Owner:UOP LLC

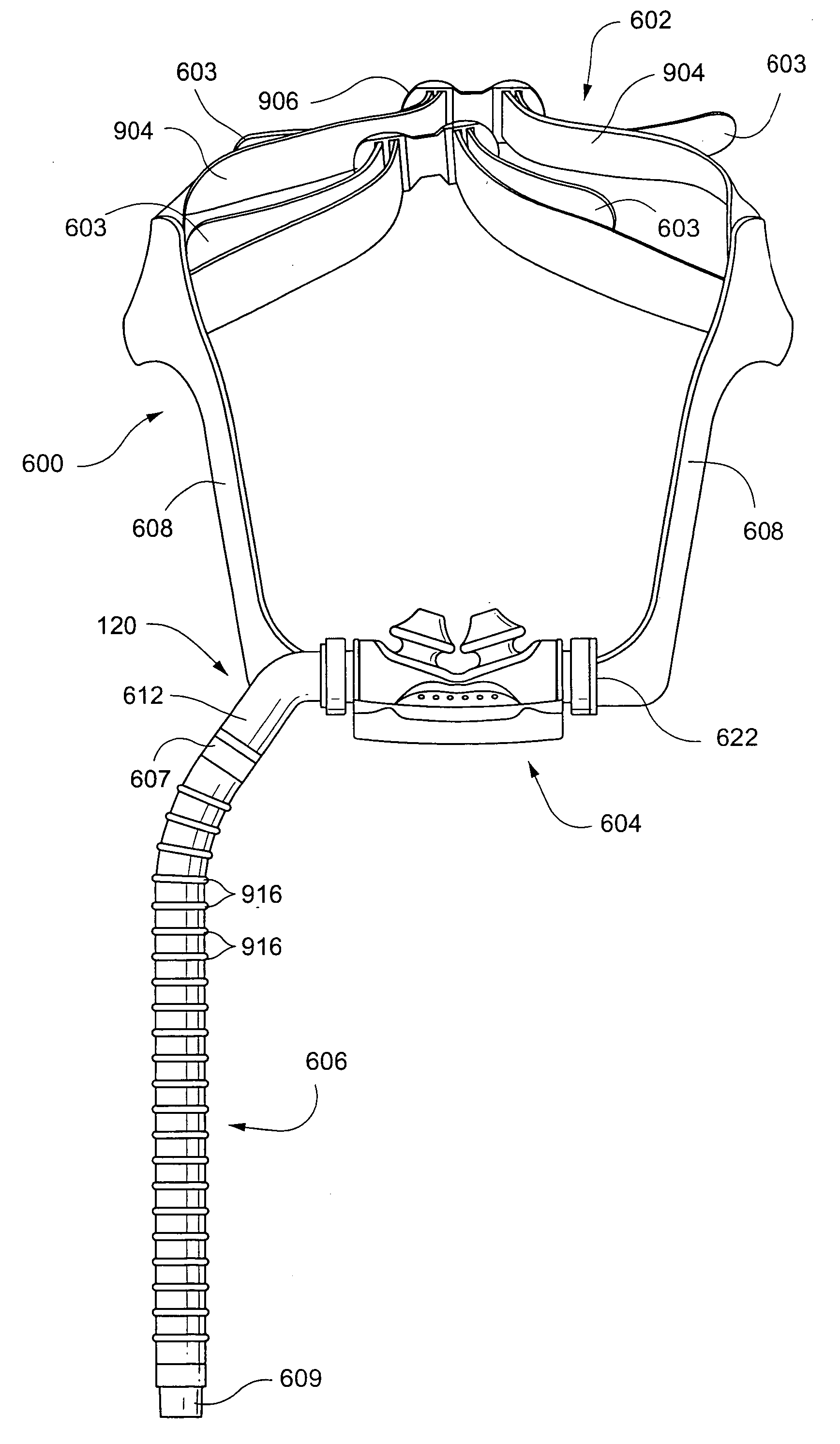

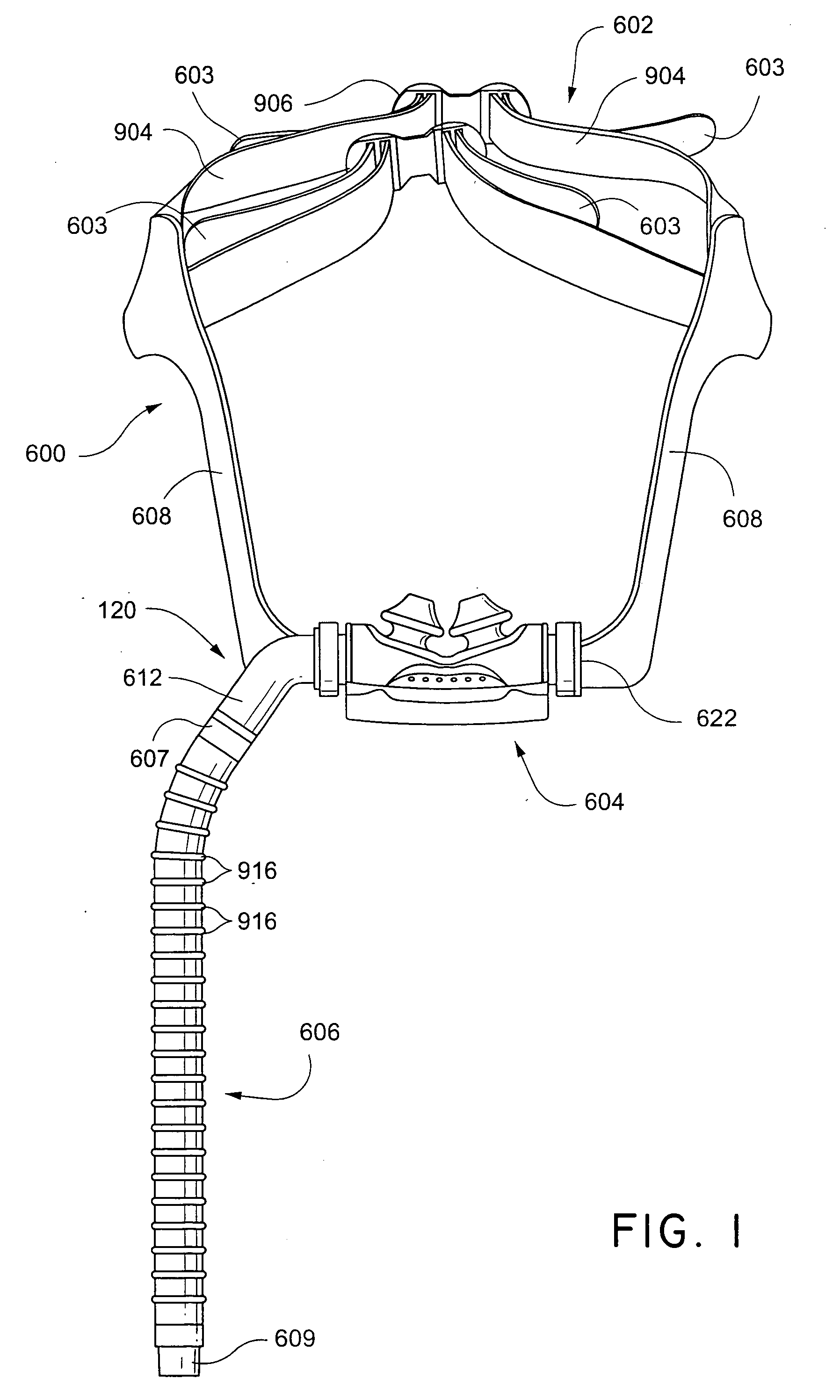

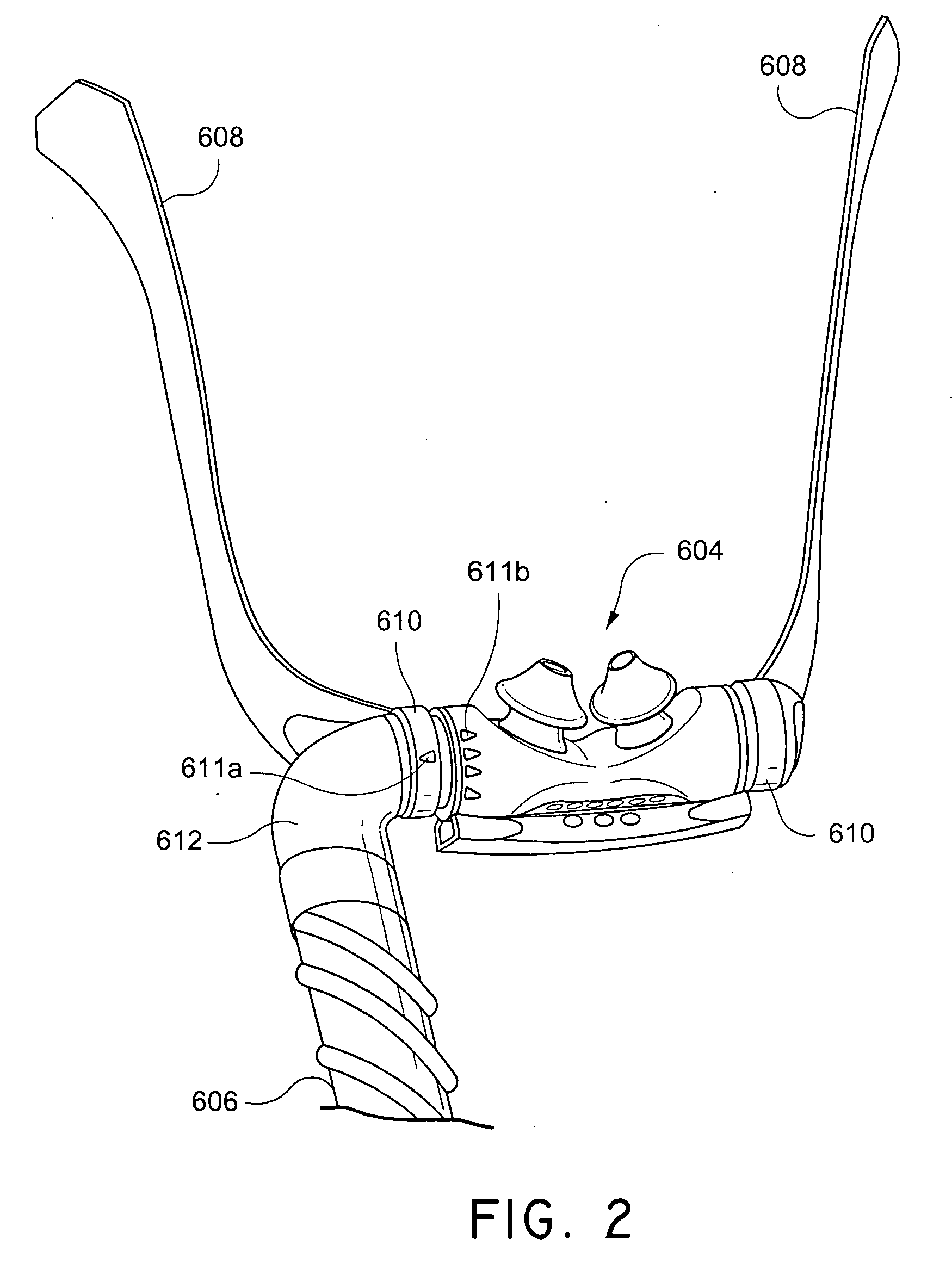

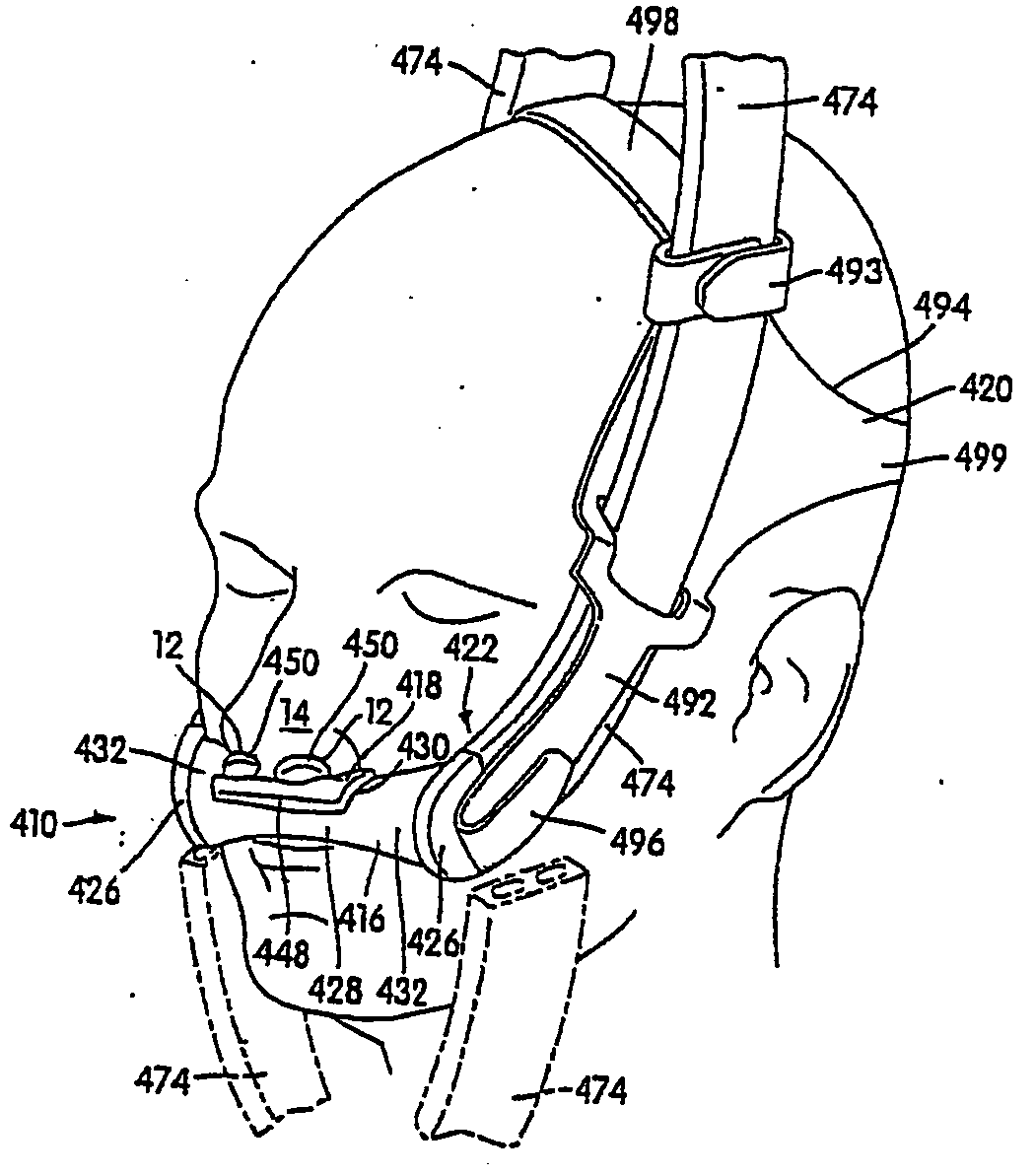

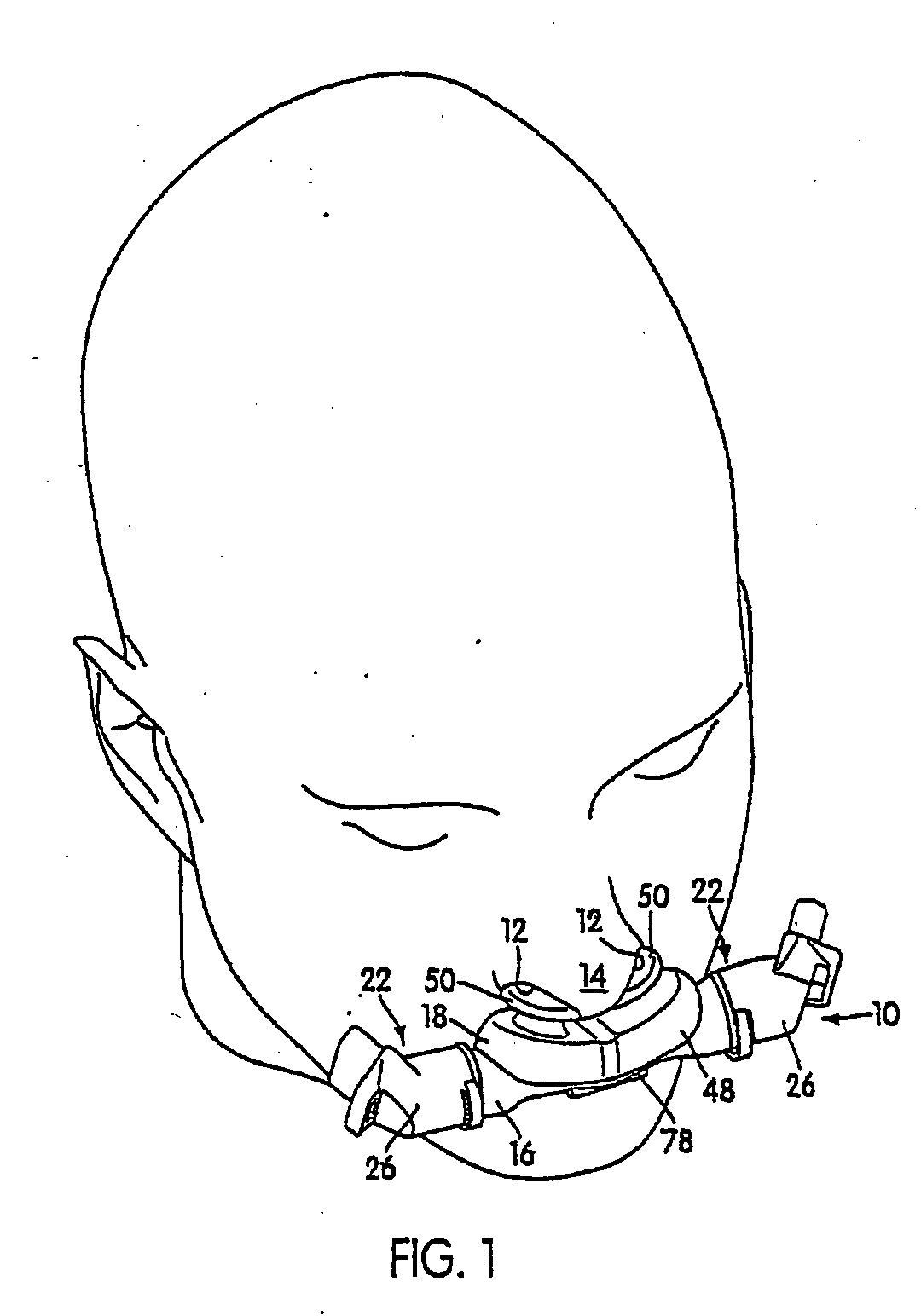

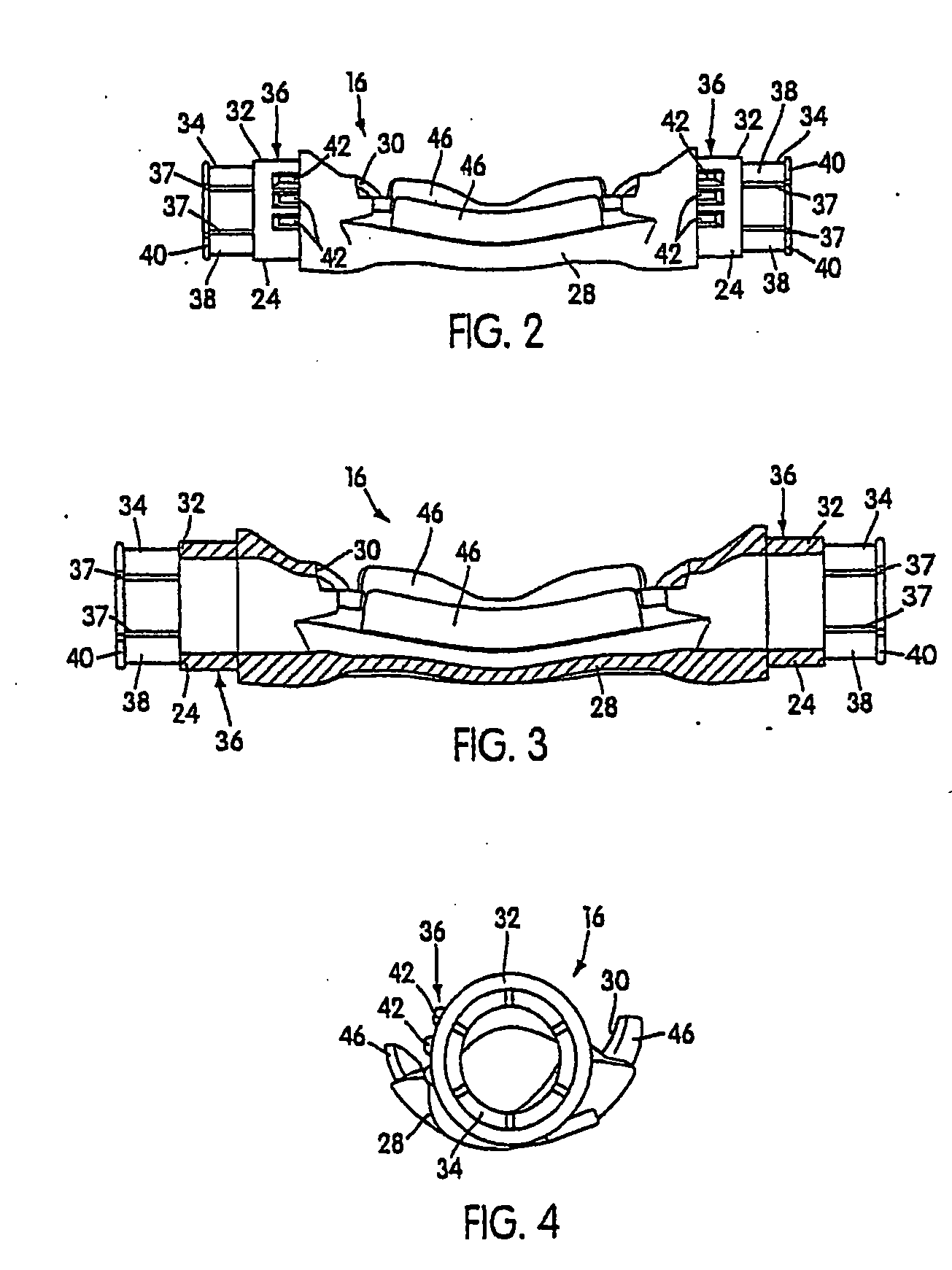

Nasal assembly

ActiveUS20050241644A1More comfortableEasy to useBreathing masksRespiratory masksNasal cavityEngineering

A nasal assembly for delivering breathable gas to a patient includes a frame having an integrally formed first connector portion. A nozzle assembly includes a gusset or base portion and a pair of nozzles. At least one inlet conduit is structured to deliver breathable gas into the frame and nozzle assembly for breathing by the patient. A pair of second connector portions are removably and rotatably connected to respective first connector portions of the frame and are in communication with respective inlet conduits, e.g., directly or via angle connectors. A headgear assembly is removably connected to the pair of second connector portions and / or the angle connectors so as to maintain the frame and the nozzle assembly in a desired adjusted position on the patient's face.

Owner:RESMED LTD

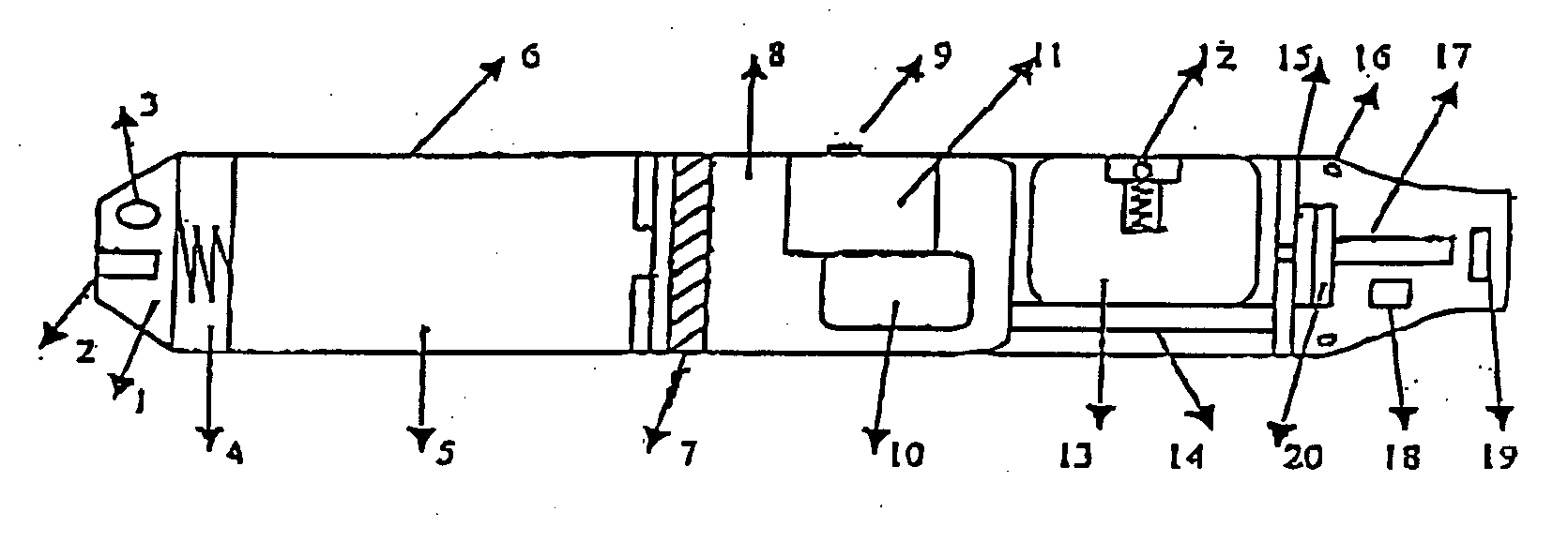

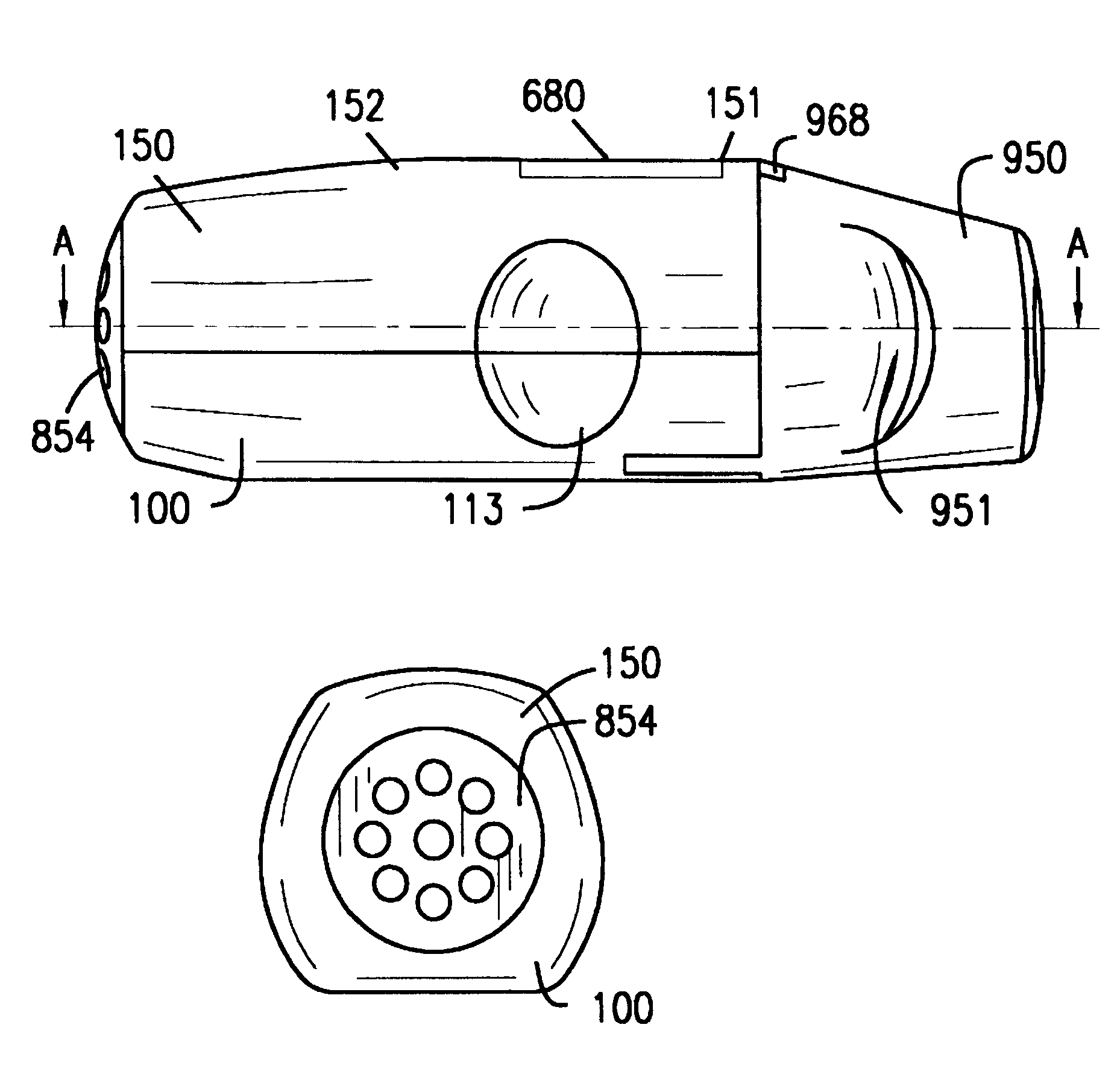

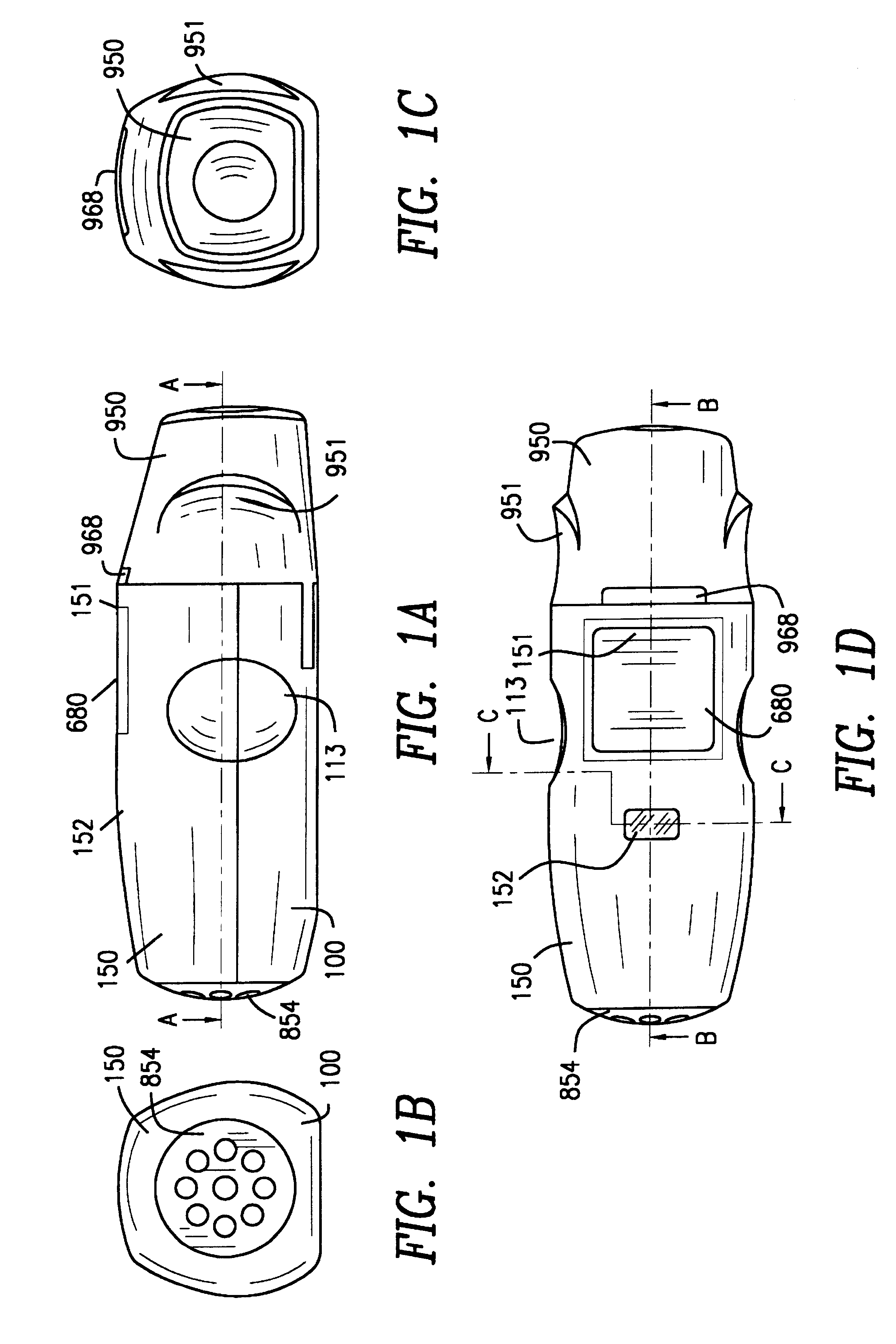

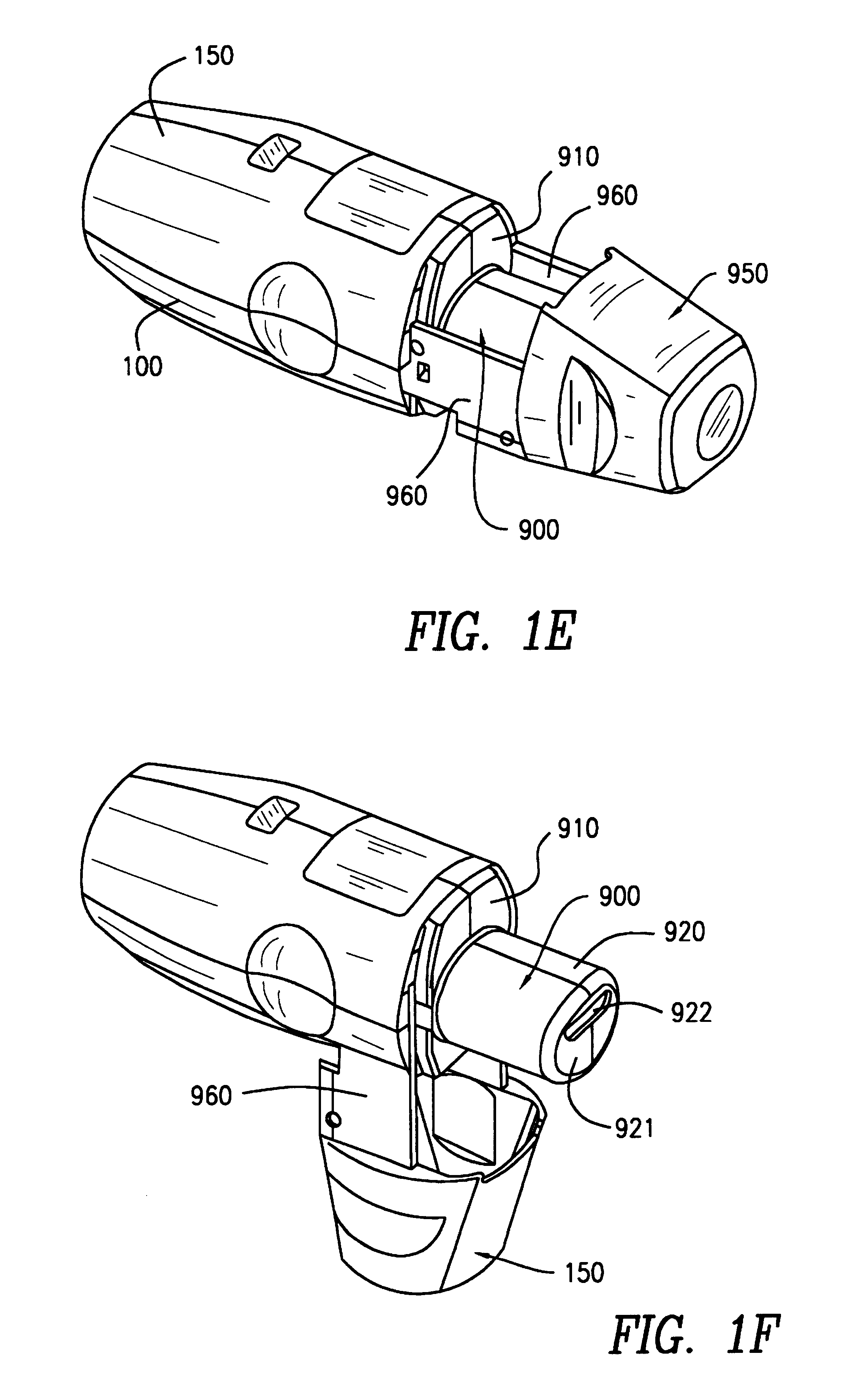

Inhaler for multiple dosed administration of a pharmacological dry powder

InactiveUS6182655B1Avoid possibilityReducing powder flow rateRespiratorsLiquid surface applicatorsMouth pieceEngineering

An inhaler for multiple dosed administration of a pharmacological dry powder consists externally of a housing (100,150) and of a protective cap (950) which can be removed from a special mouthpiece (900) fitted on the housing. Arranged on the inside there are a slide rail (200), a dosing slide (300), a shutter (400), a carriage (500), a funnel arrangement (600), a counter device (700), a valve shield (800) and a valve guide (850). Removal of the protective cap (950) initiates the dosing, with a dose received in the dosing cavity (302) being transported to the mouth-piece (900) by means of the dosing slide (300). Only upon application of a defined minimum intensity of inhalation is the shutter (400) moved by the suctioned valve shield (800), as a result of which the dose is released for inhalation. Completed with an electronic module and a controllable nozzle, all inhalation-relevant data can be recorded and the flow conditions regulated.

Owner:JAGOTEC AG

Nasal assembly

ActiveUS20060137690A1Sealing stability forceLarge range of motionBreathing filtersRespiratory masksNasal cavityEngineering

A nasal assembly for delivering breathable gas to a patient includes a frame having an integrally formed first connector portion. A nozzle assembly includes a gusset or base portion and a pair of nozzles. At least one inlet conduit is structured to deliver breathable gas into the frame and nozzle assembly for breathing by the patient. A pair of second connector portions are removably and rotatably connected to respective first connector portions of the frame and are in communication with respective inlet conduits, e.g., directly or via angle connectors. A headgear assembly is removably connected to the pair of second connector portions and / or the angle connectors so as to maintain the frame and the nozzle assembly in a desired adjusted position on the patient's face.

Owner:RESMED LTD

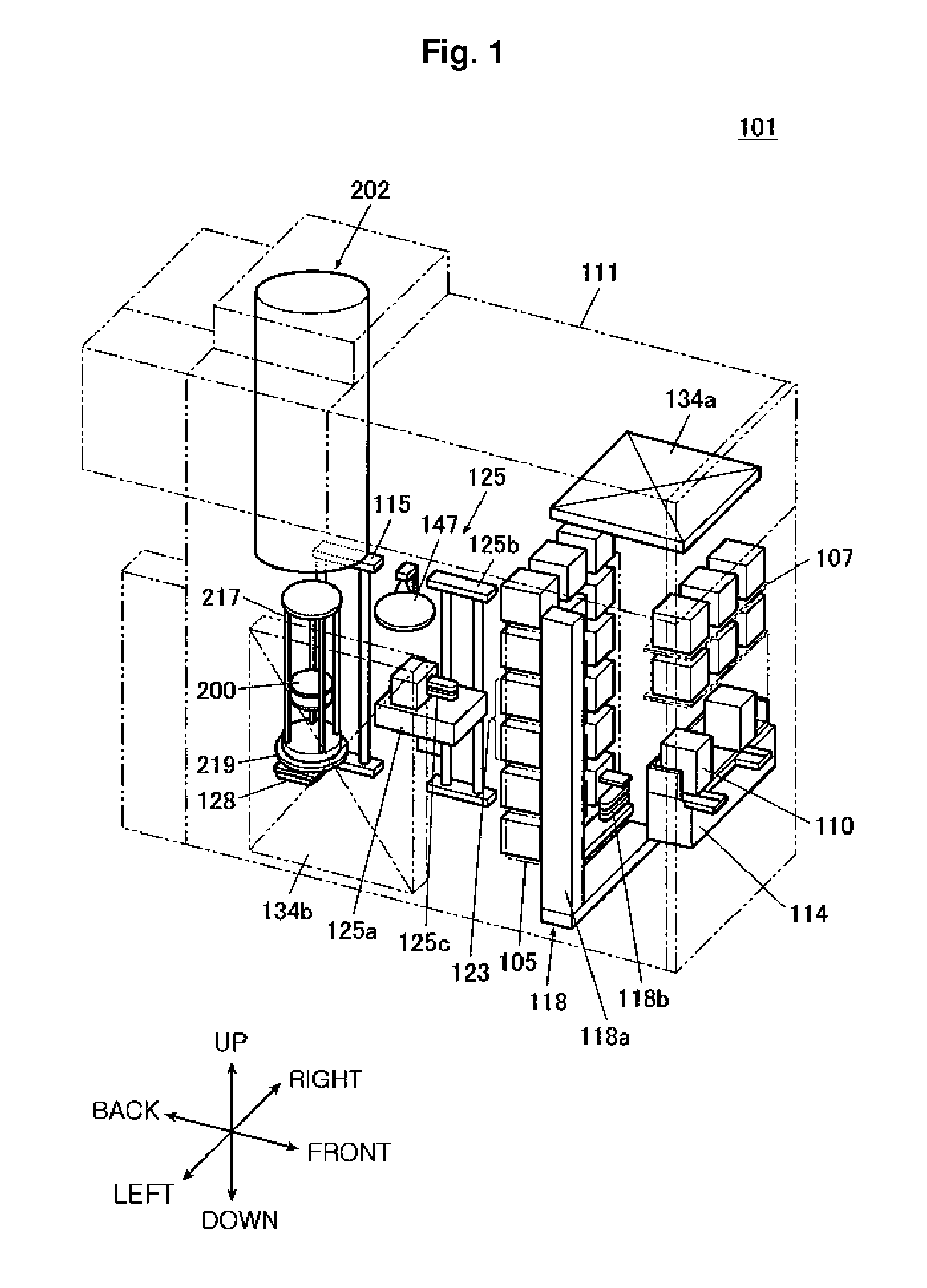

Substrate processing apparatus, nozzle base, and manufacturing method for semiconductor device

ActiveUS20180087152A1Low costImprove maintainabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialEngineering

Provided is a processing container formed of a reaction tube and a manifold that supports the reaction tube from below, and adapted to process a substrate inside, a nozzle adapted to supply a processing gas to the substrate, and a connecting portion adapted to erect the nozzle inside the processing container. The connecting portion includes (1) a fixing portion formed of a cylindrical portion inserted into an introduction portion provided at the manifold, and a flange plate formed at an end portion of the cylindrical portion, and (2) a detachable portion formed of an elbow engaged with the flange plate, and an installation portion in which the nozzle is installed.

Owner:KOKUSA ELECTRIC CO LTD

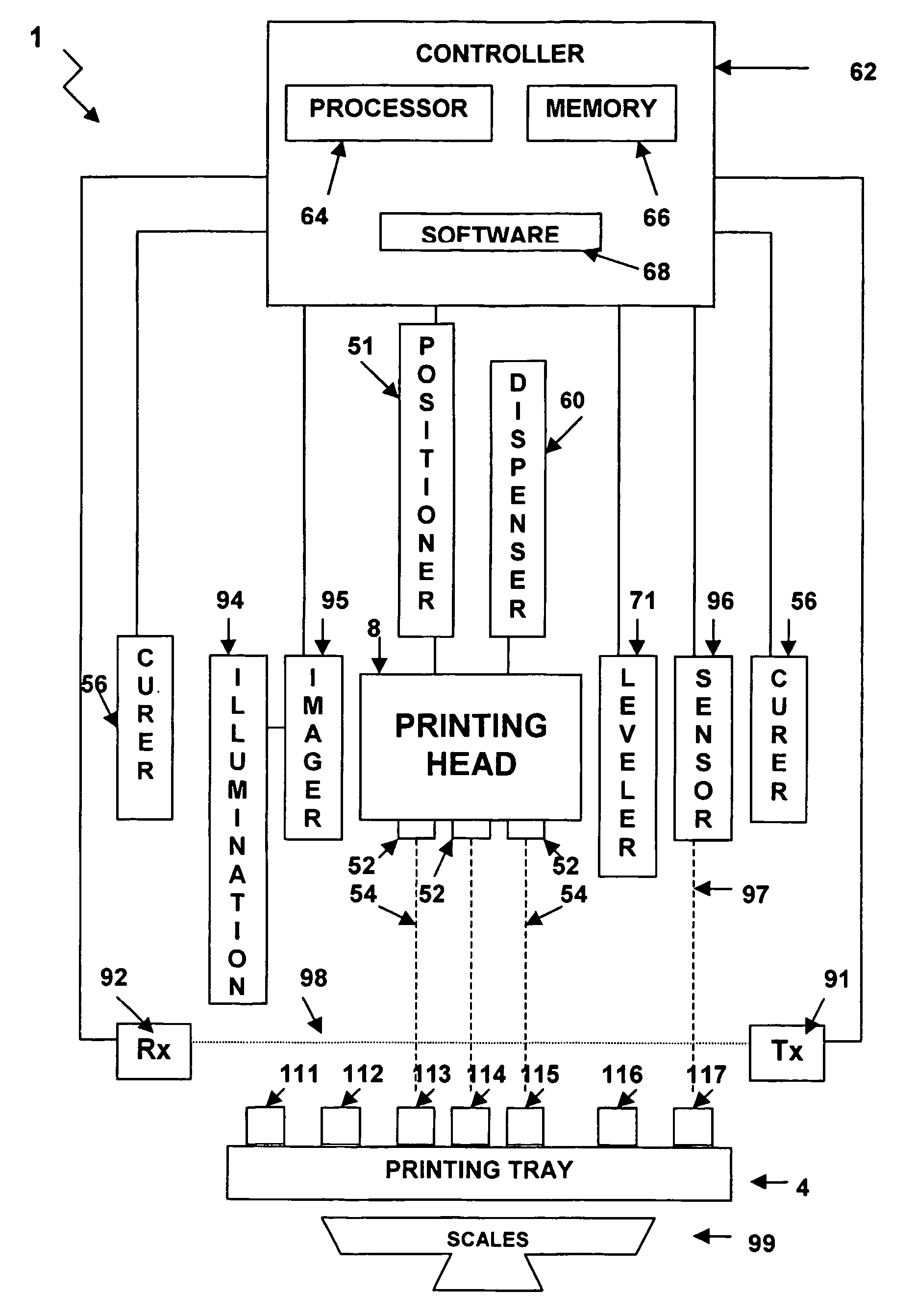

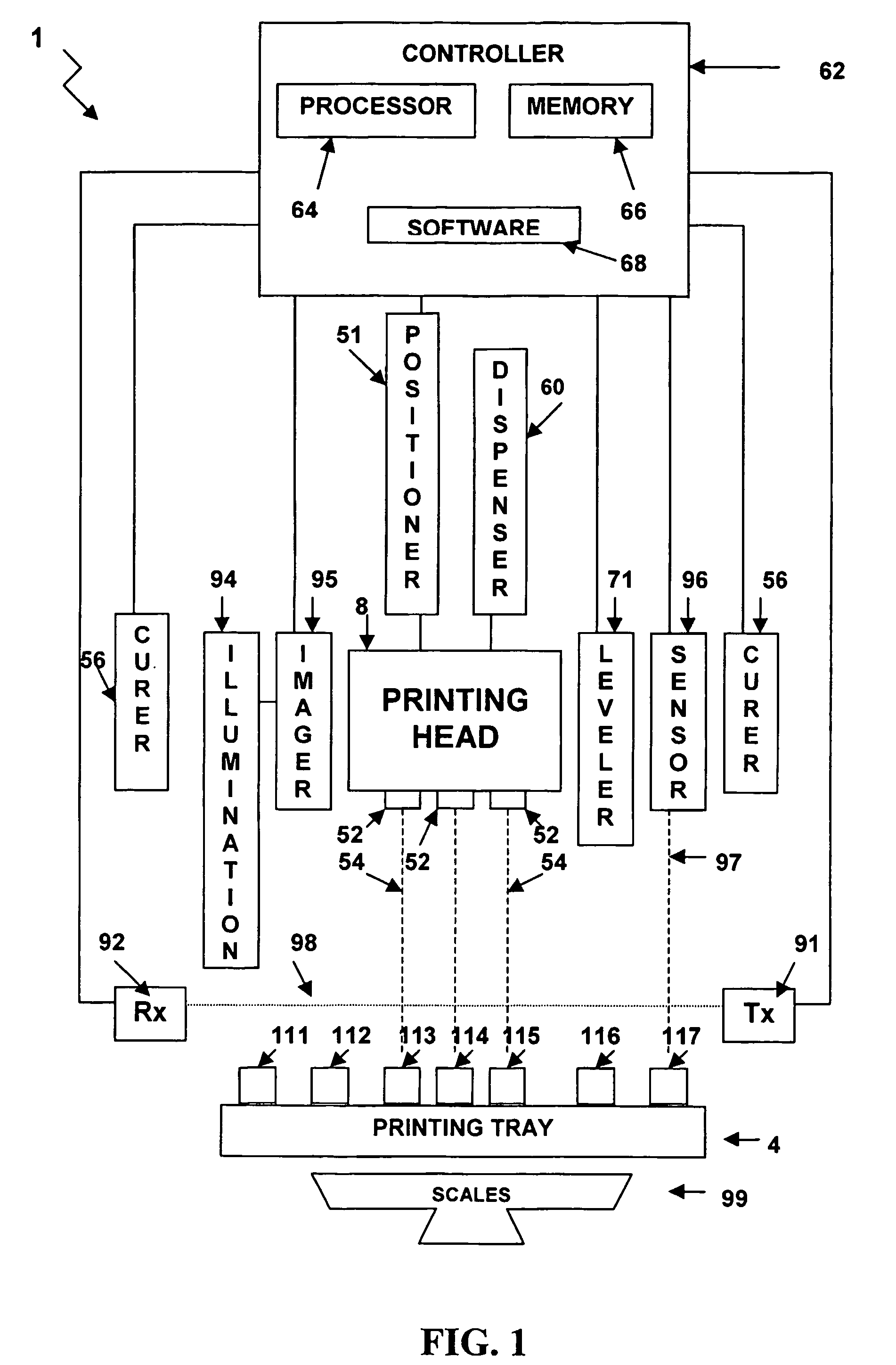

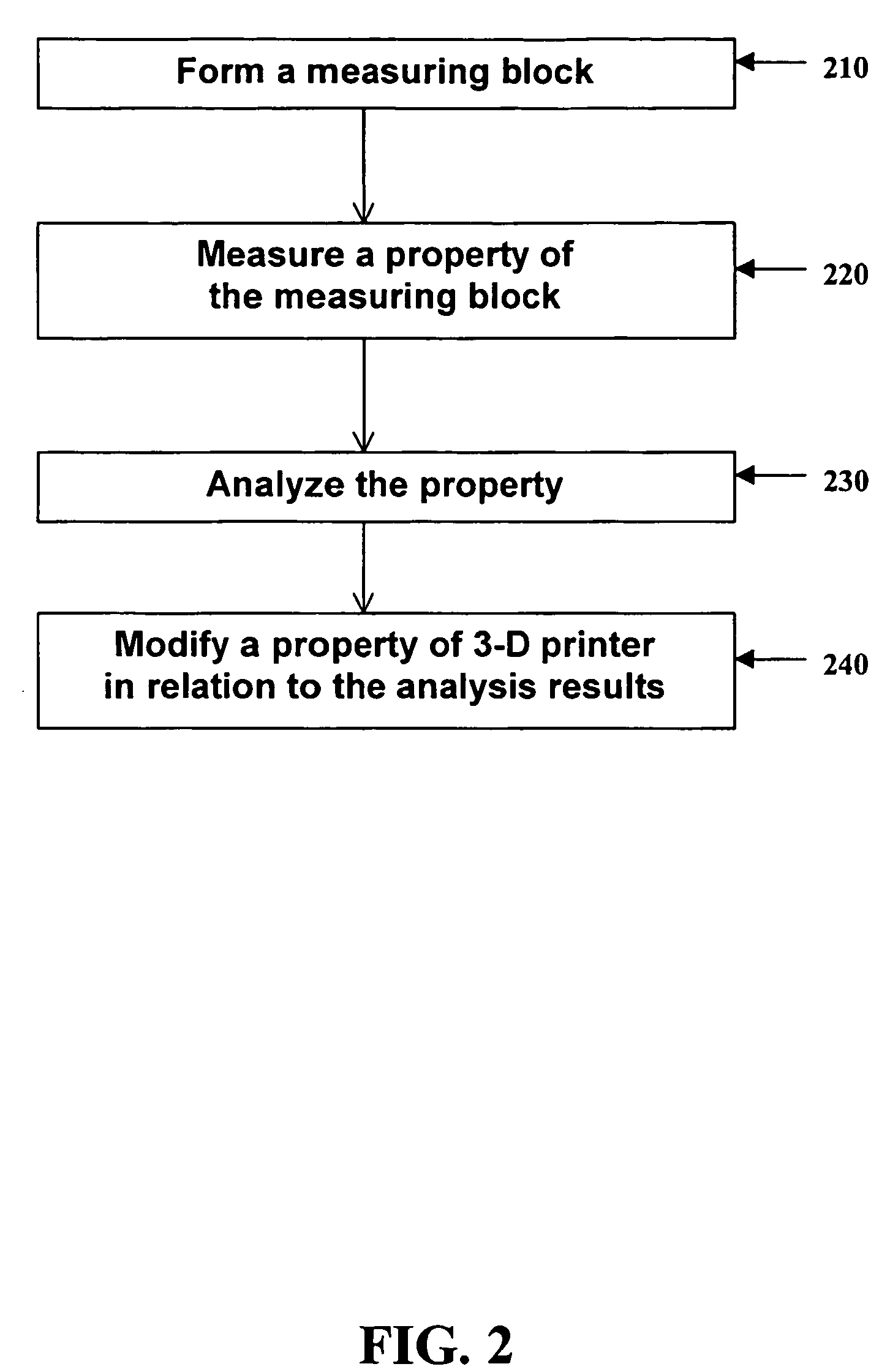

Device, system and method for calibration in three-dimensional model printing

InactiveUS20060111807A1Additive manufacturing apparatus3D object support structuresEngineeringThree dimensional model

Owner:OBJET GEOMETRIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com