Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15385results about "3D object support structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

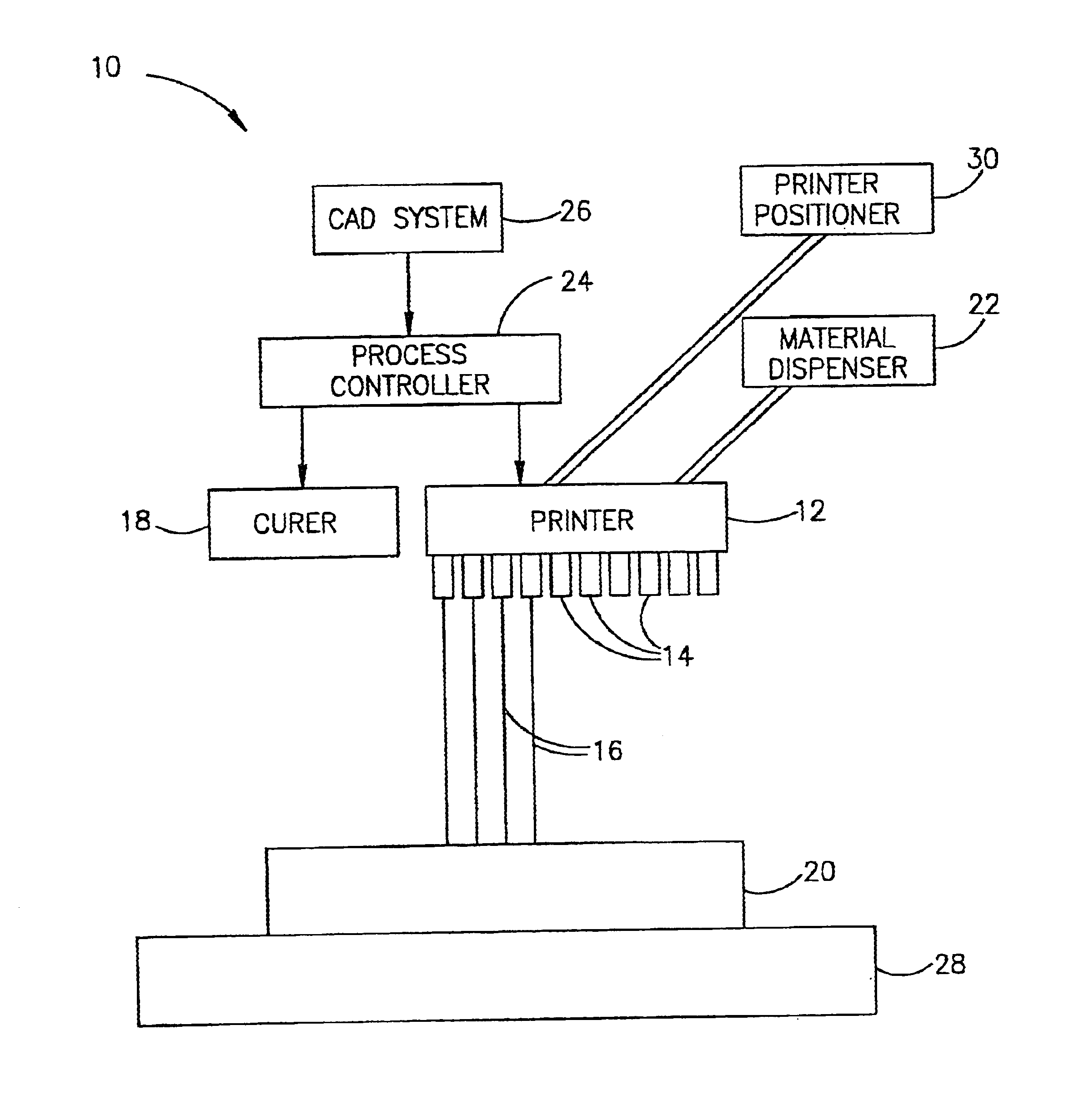

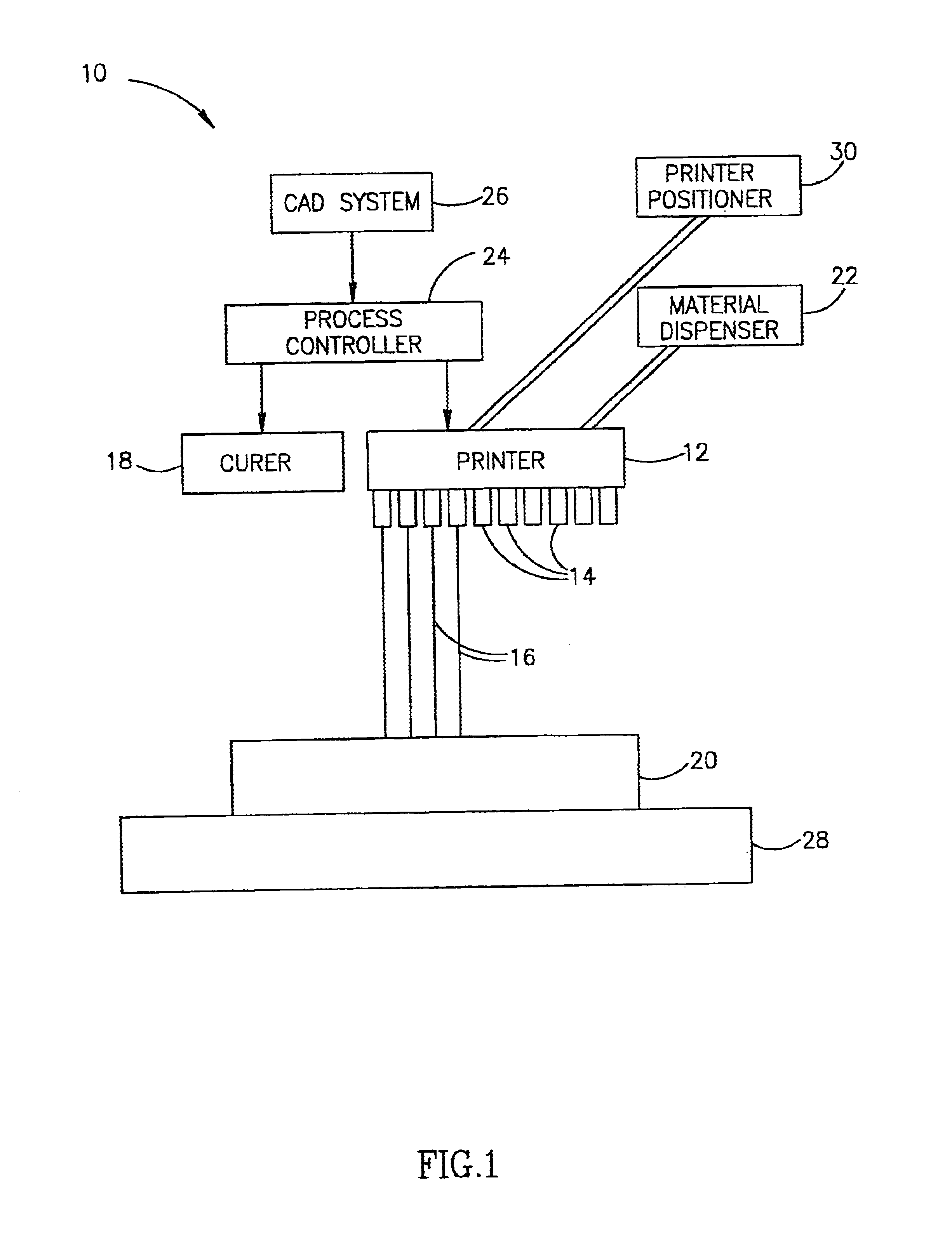

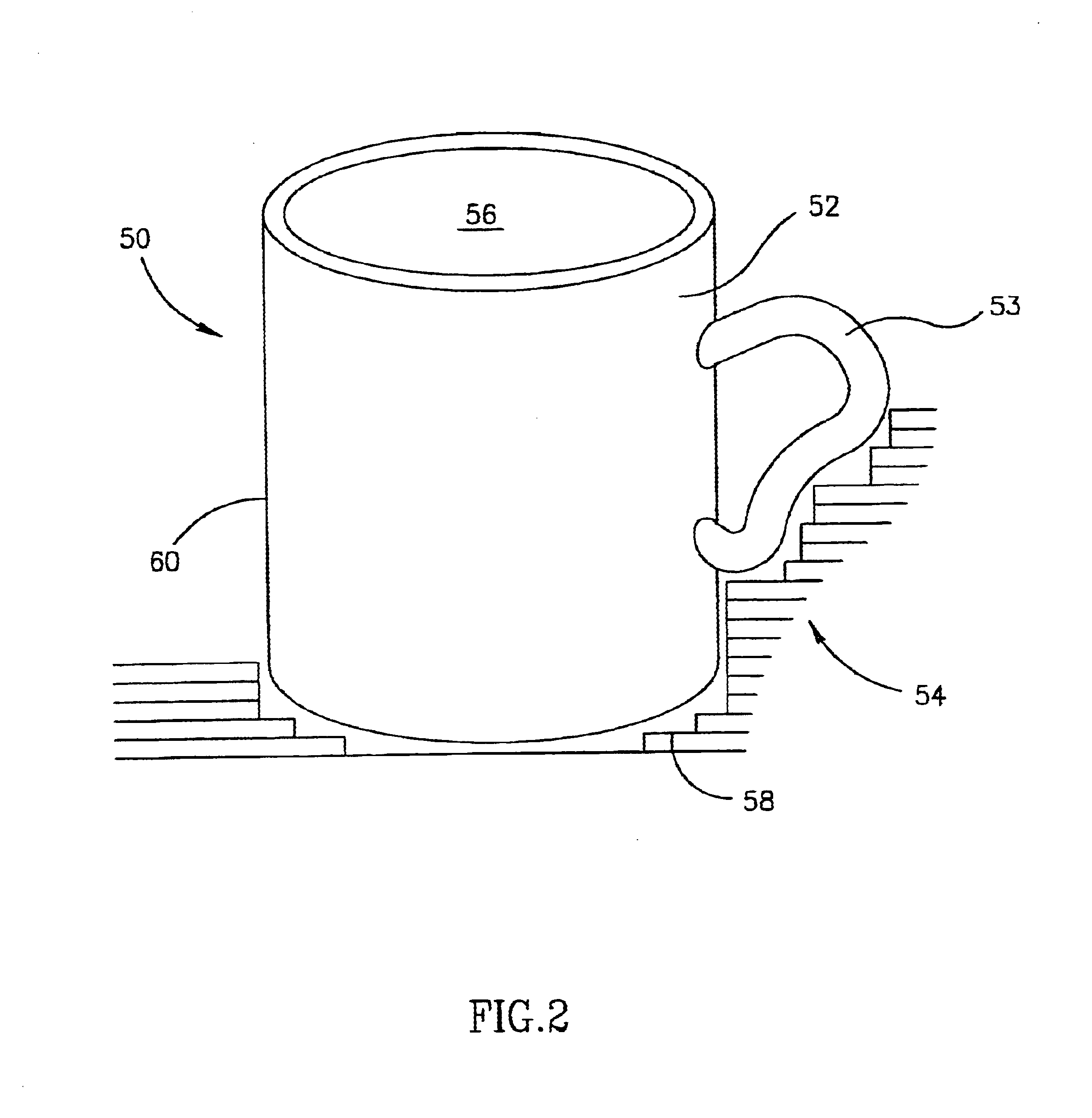

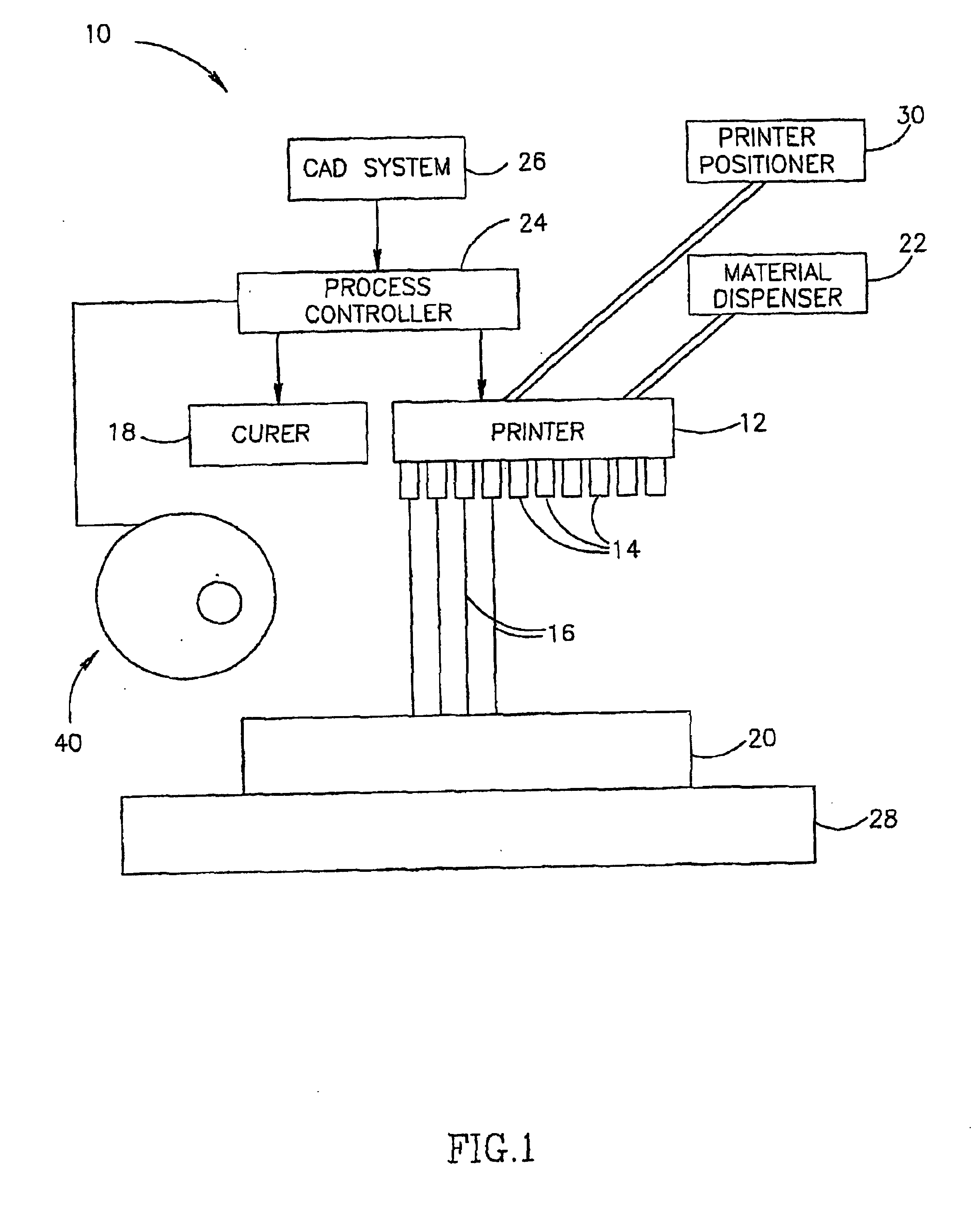

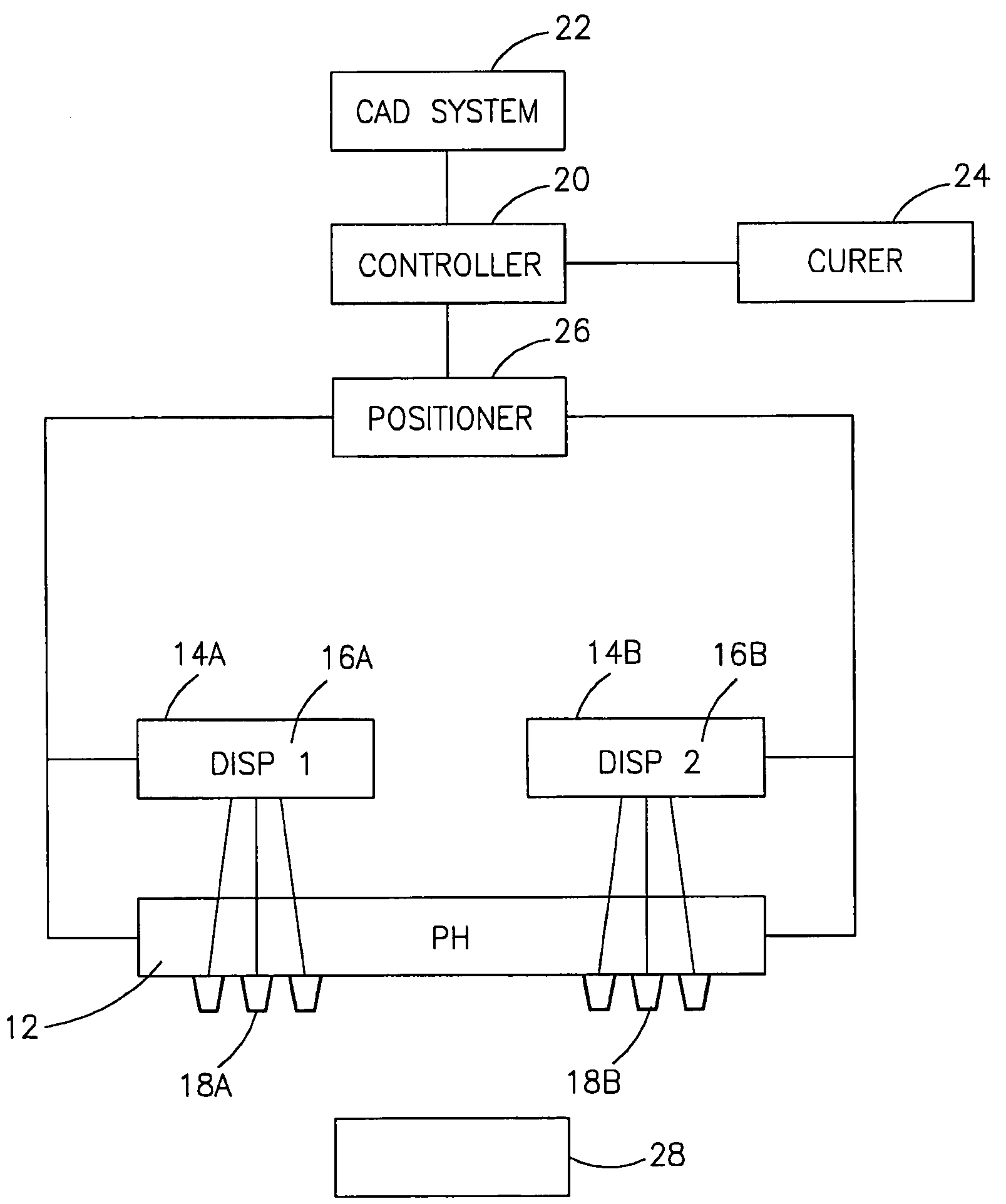

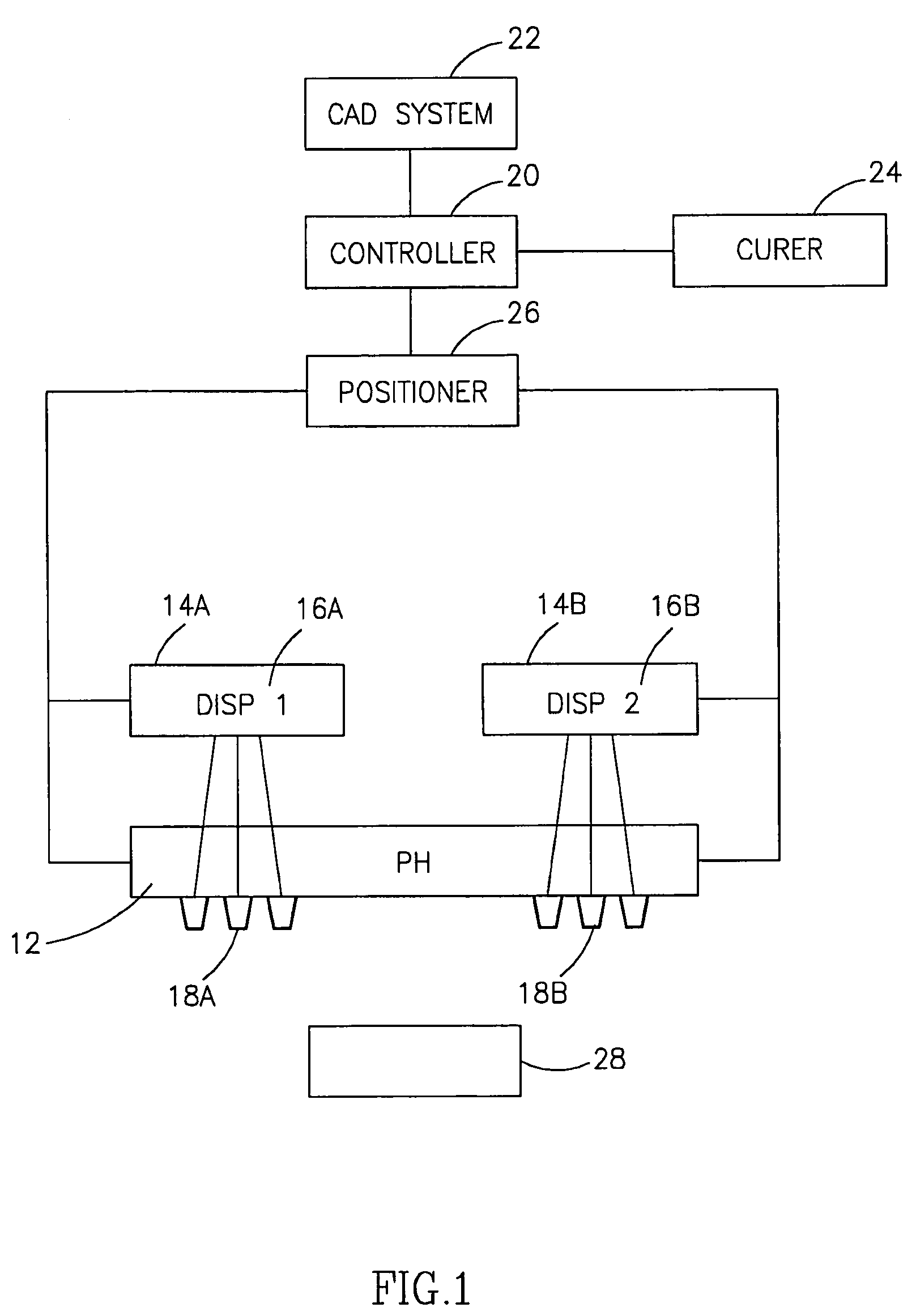

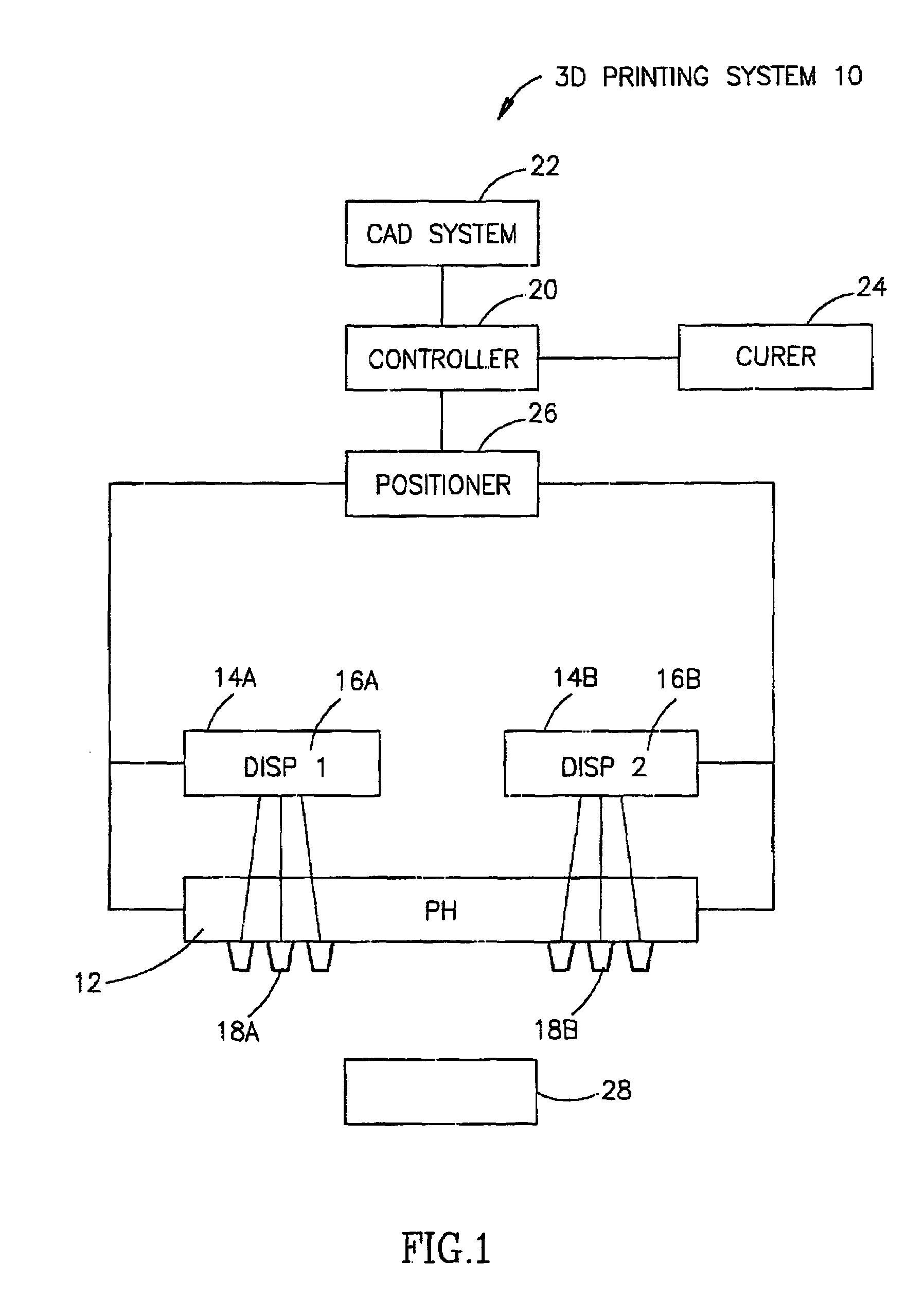

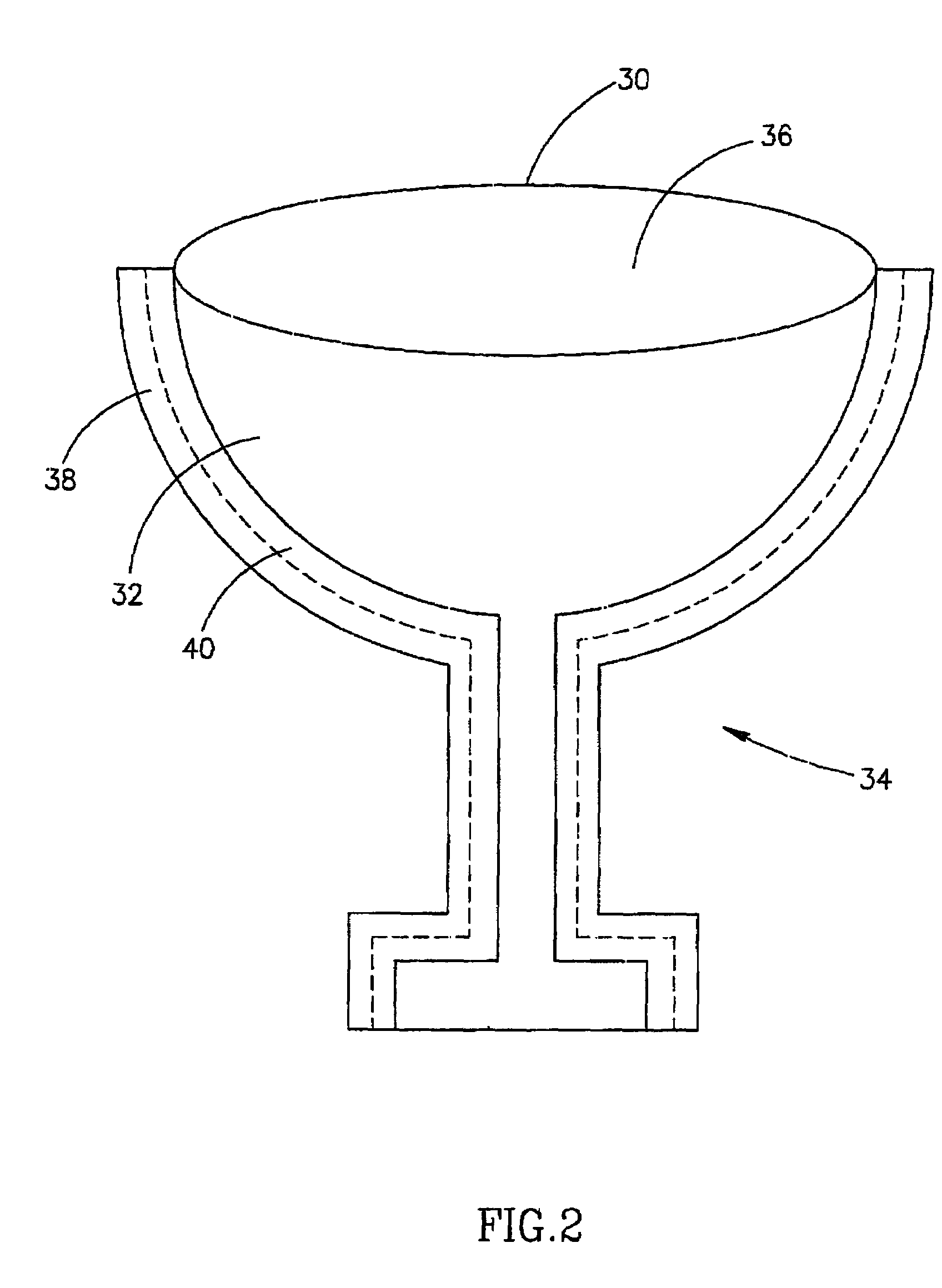

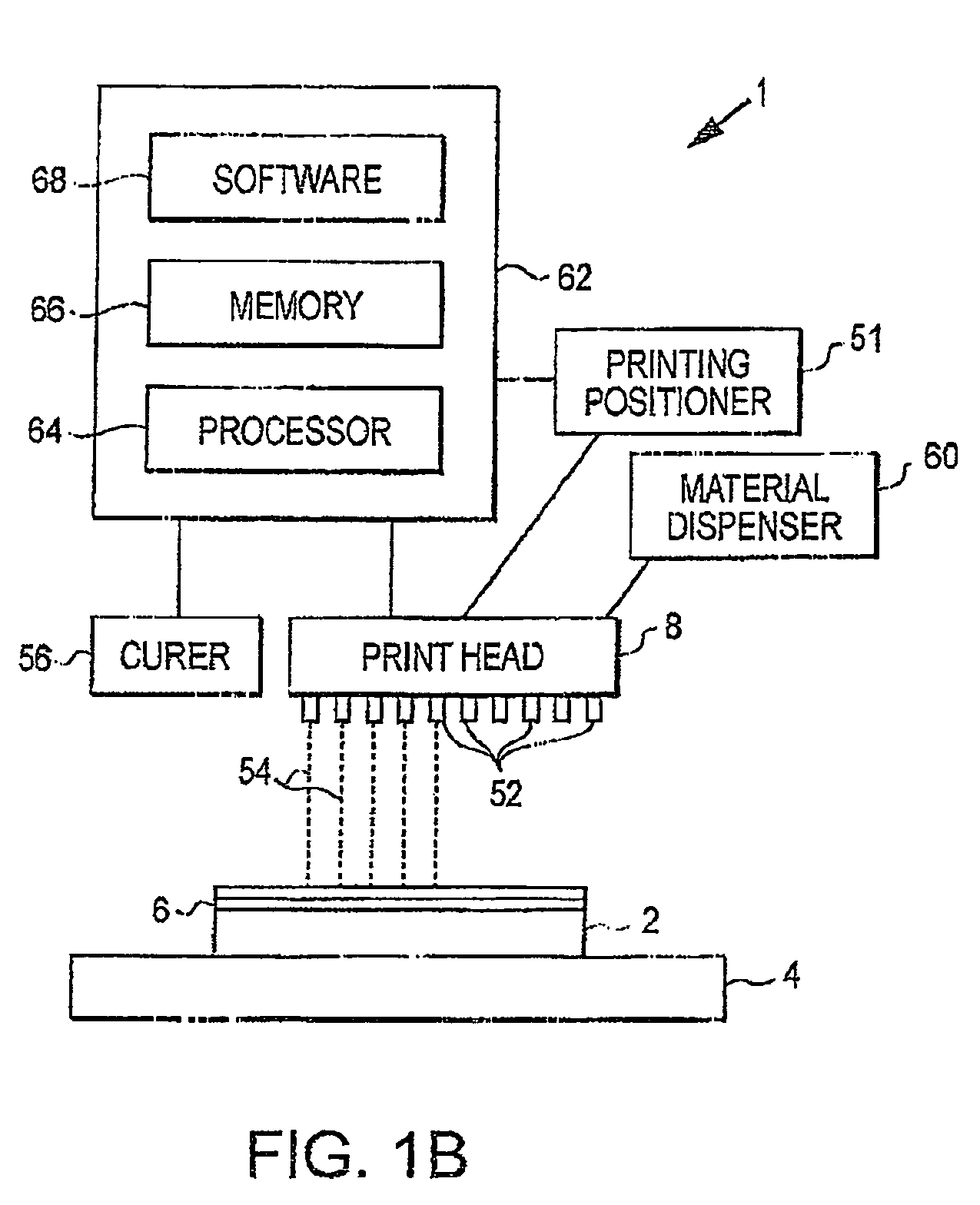

System and method for three dimensional model printing

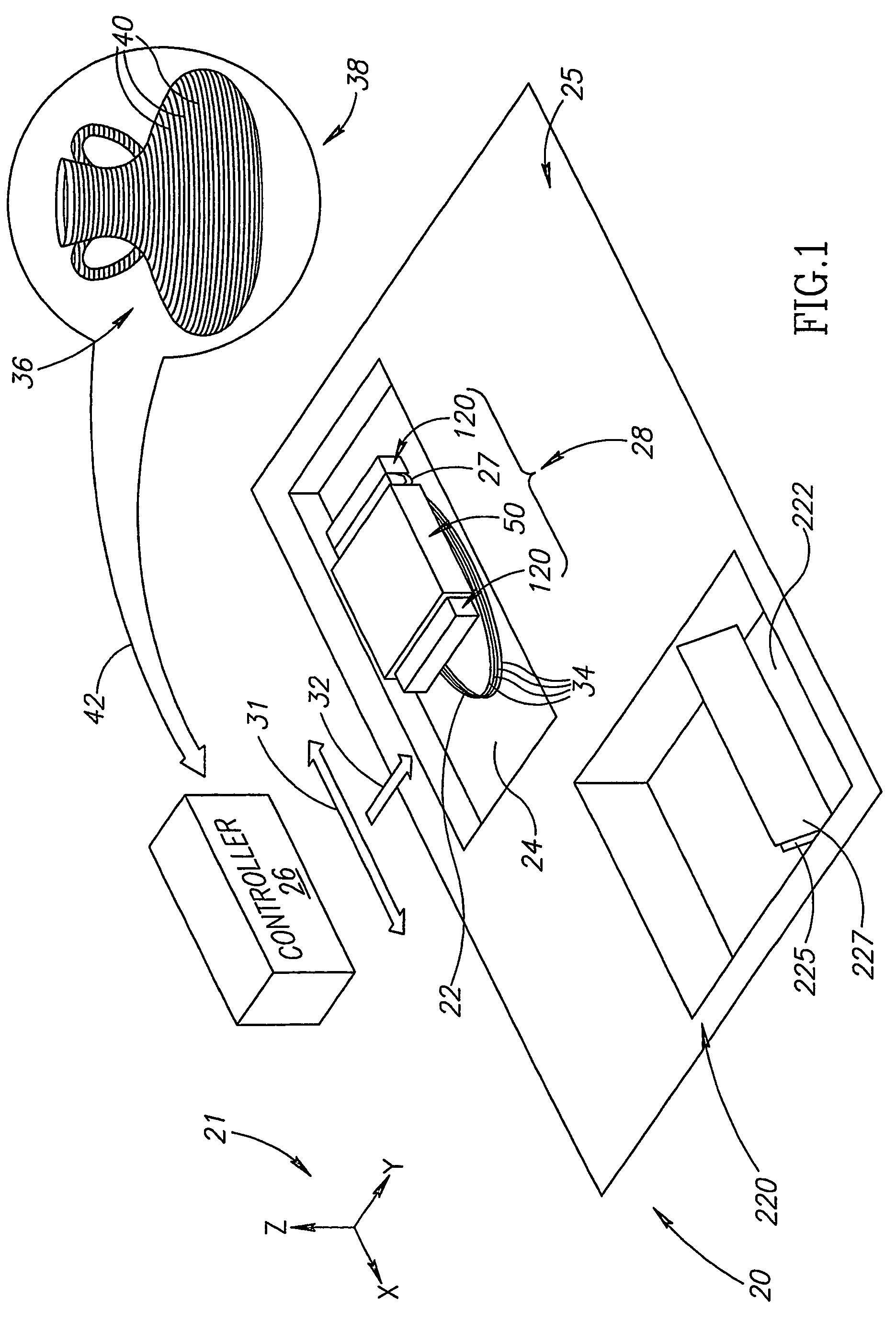

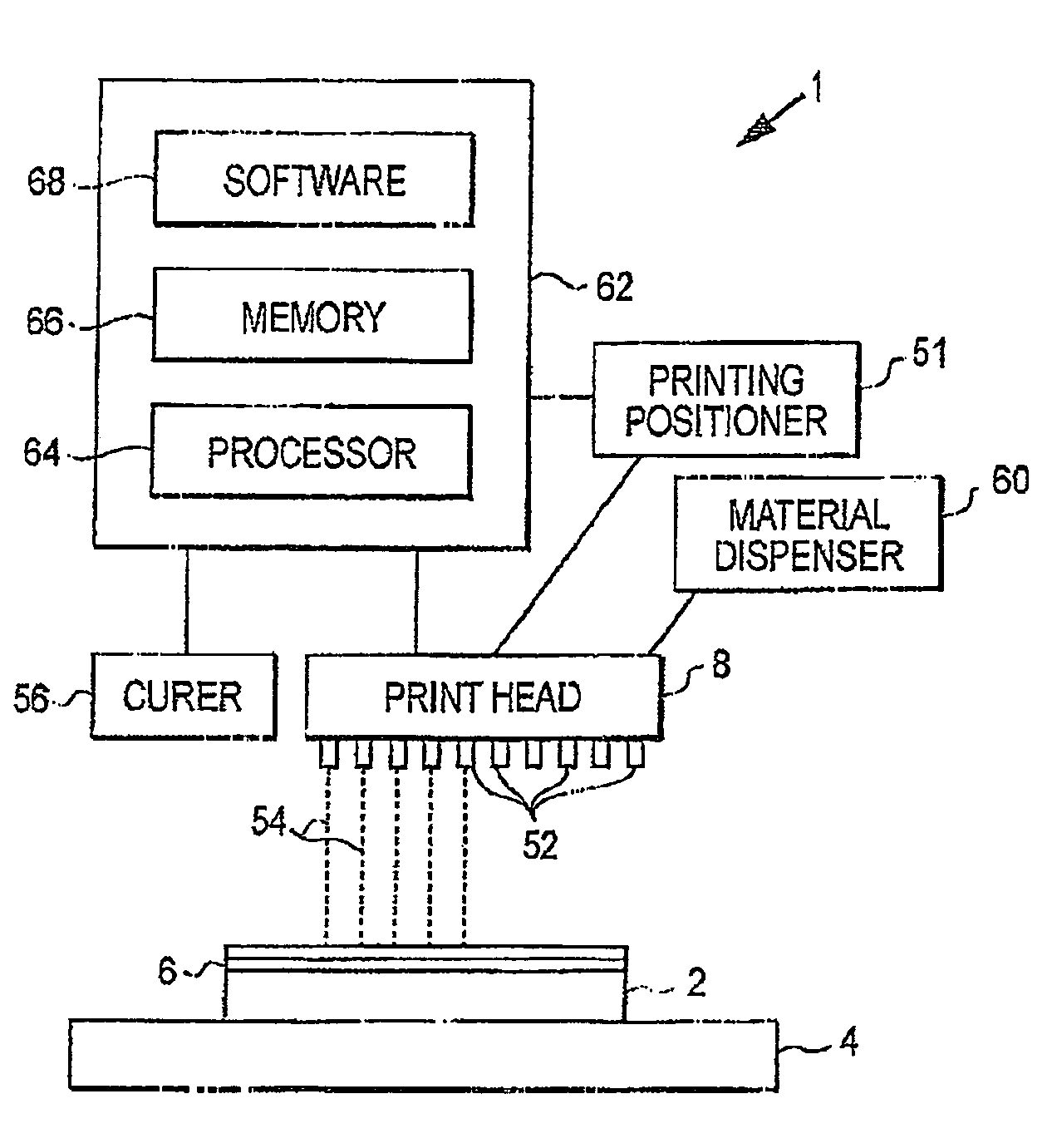

InactiveUS6658314B1Limited hardnessAdditive manufacturing apparatusPhotomechanical treatmentThree dimensional shapeEngineering

A method and a system for three-dimensional printing of a three-dimensional model is provided. The method includes dispensing a first interface material from a printing head, dispensing at least a second interface material from the printing head and combining the first and second interface material in pre-determined proportions to produce layers for forming the three-dimensional model. In one embodiment, the layers forming the construction layers of the model are formed from interface material having a harder modulus of elasticity from the layers forming the release layers, thereby allowing for the forming complex three-dimensional shapes.

Owner:STRATASYS LTD

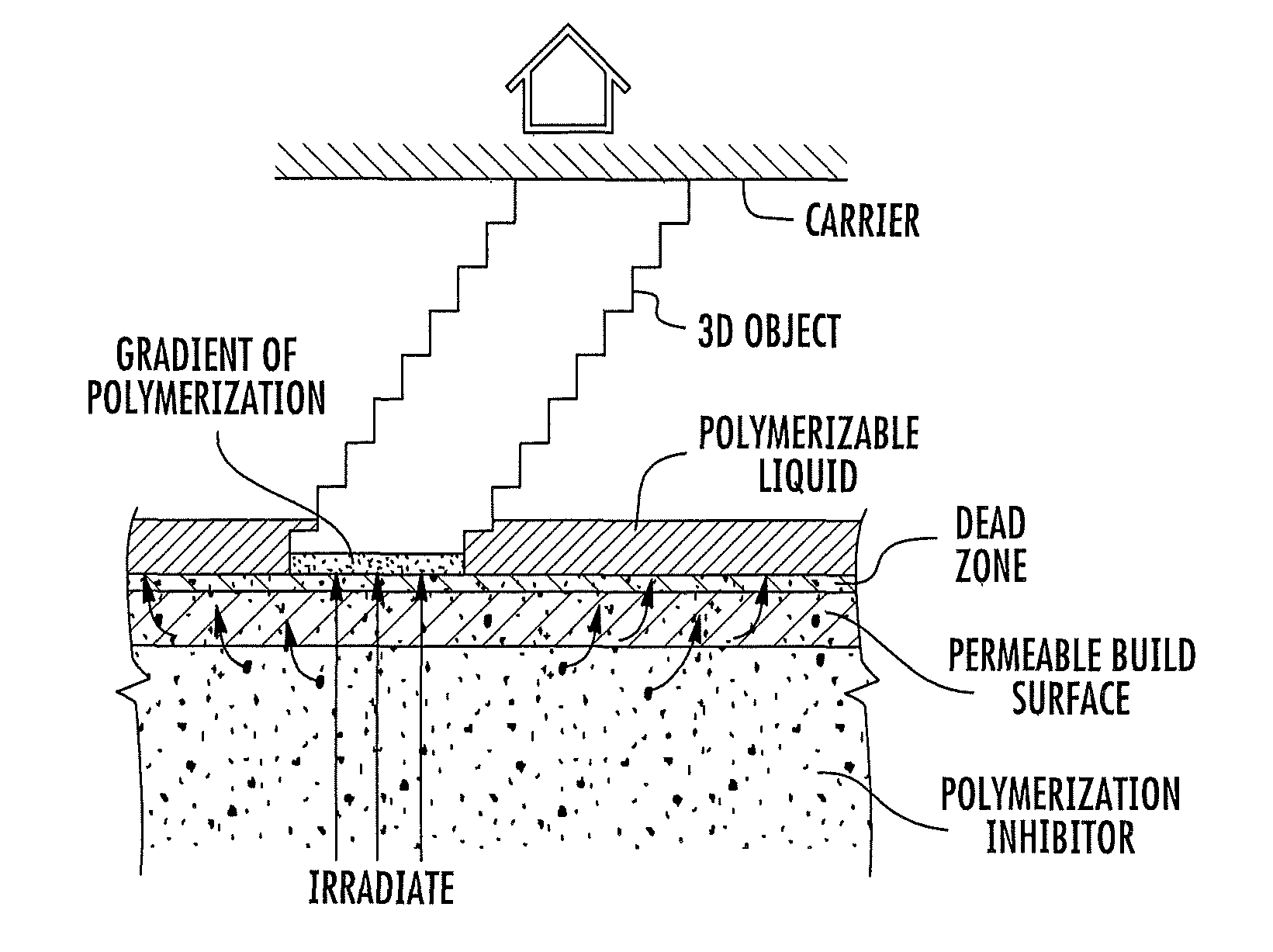

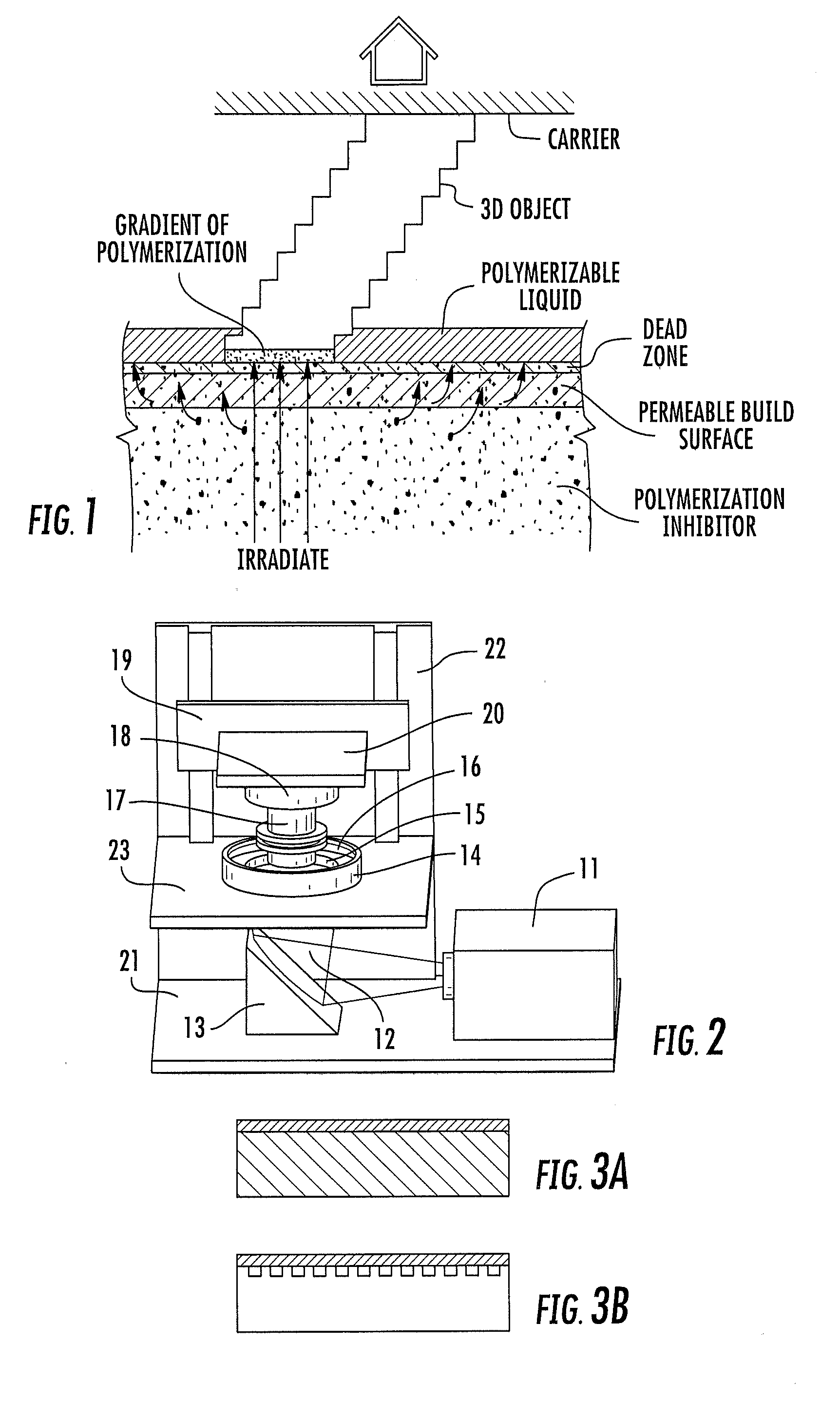

Continuous liquid interphase printing

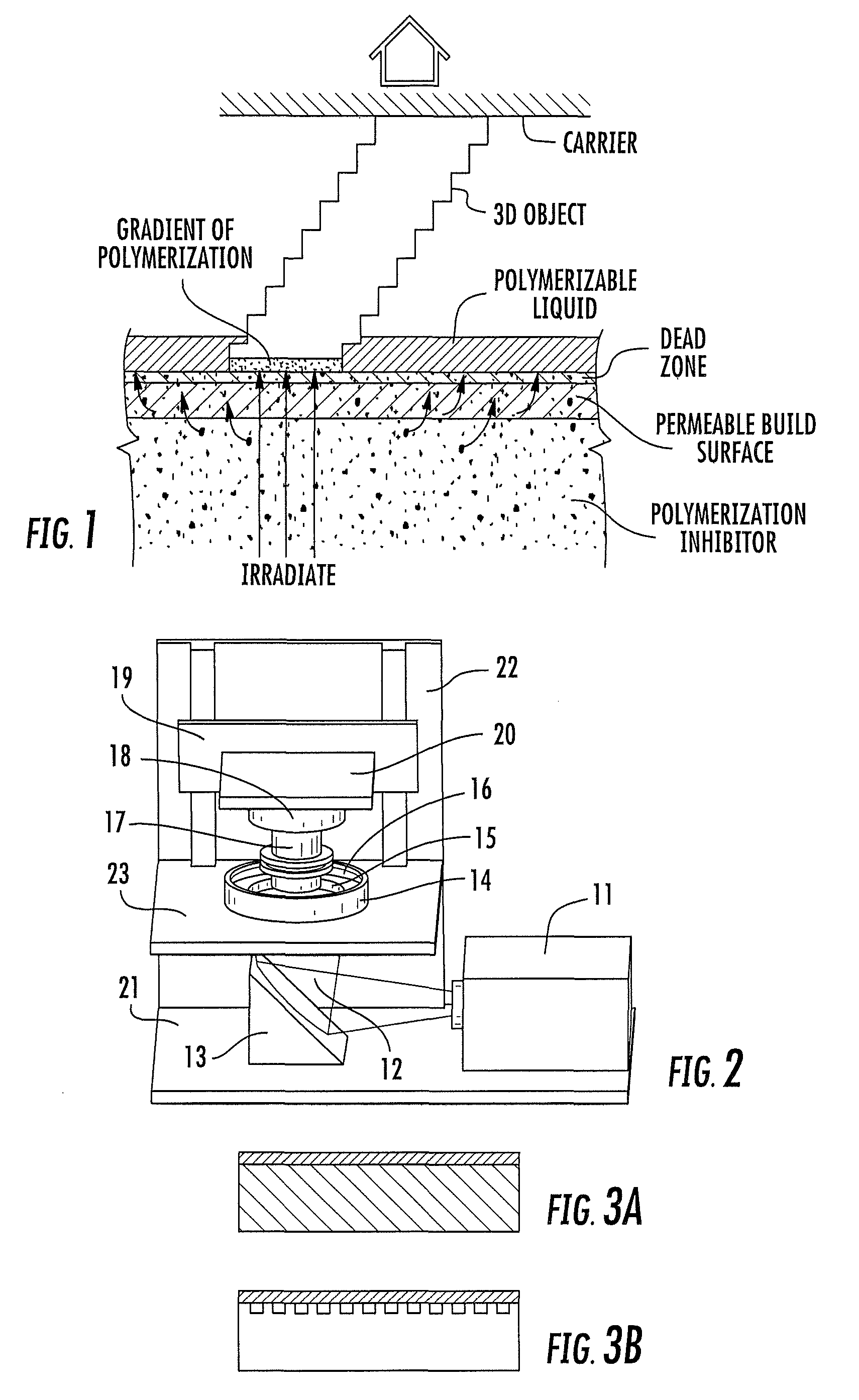

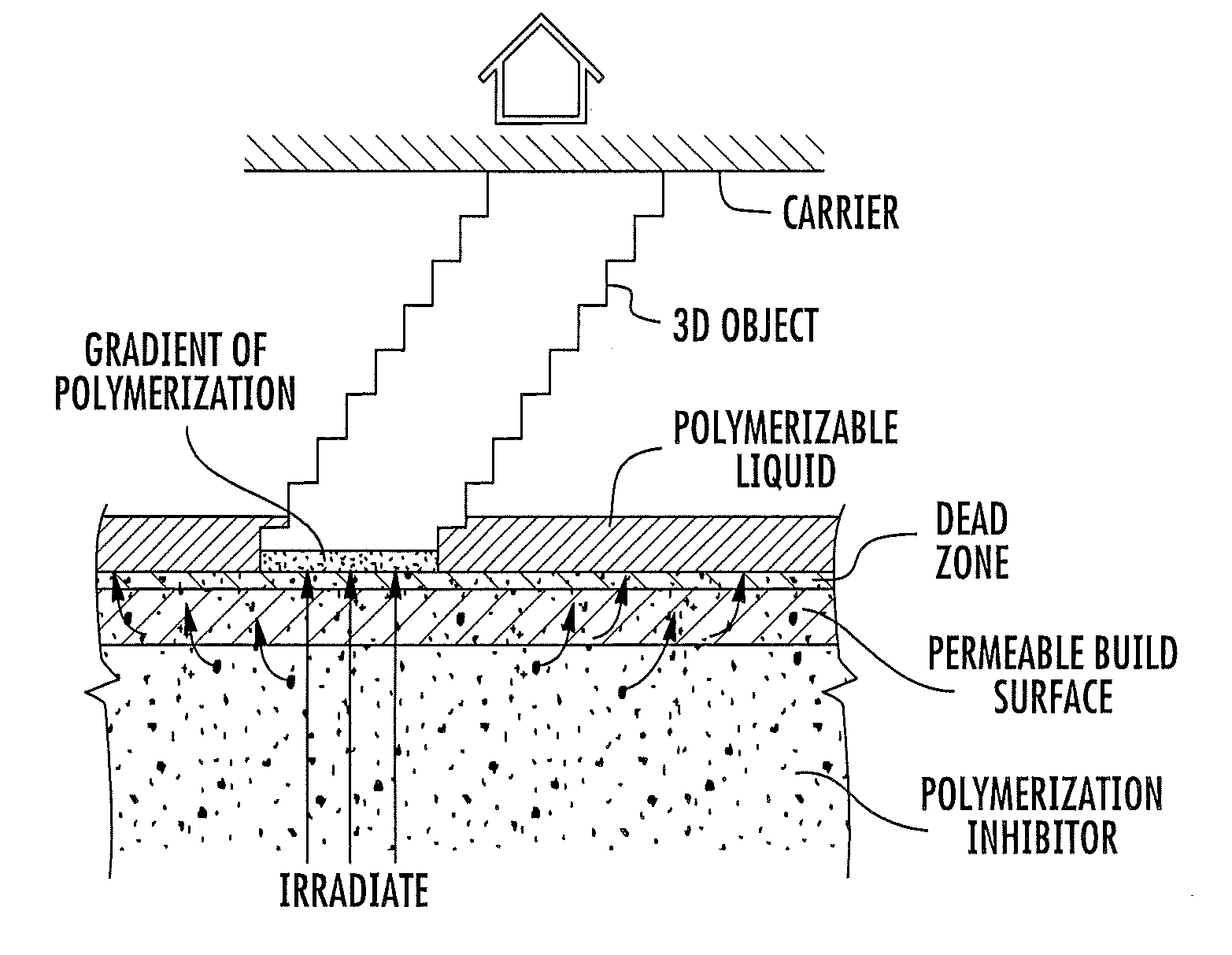

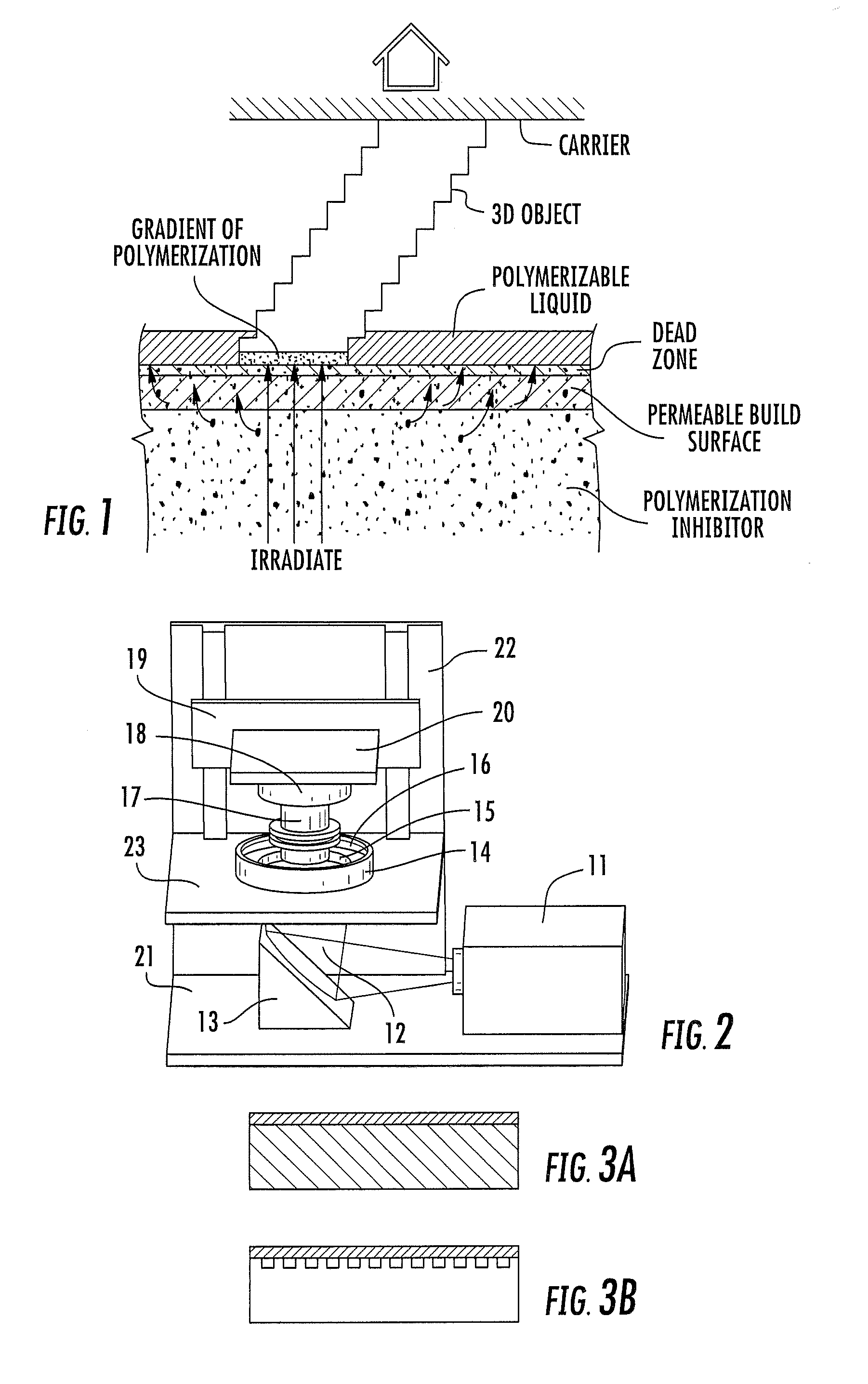

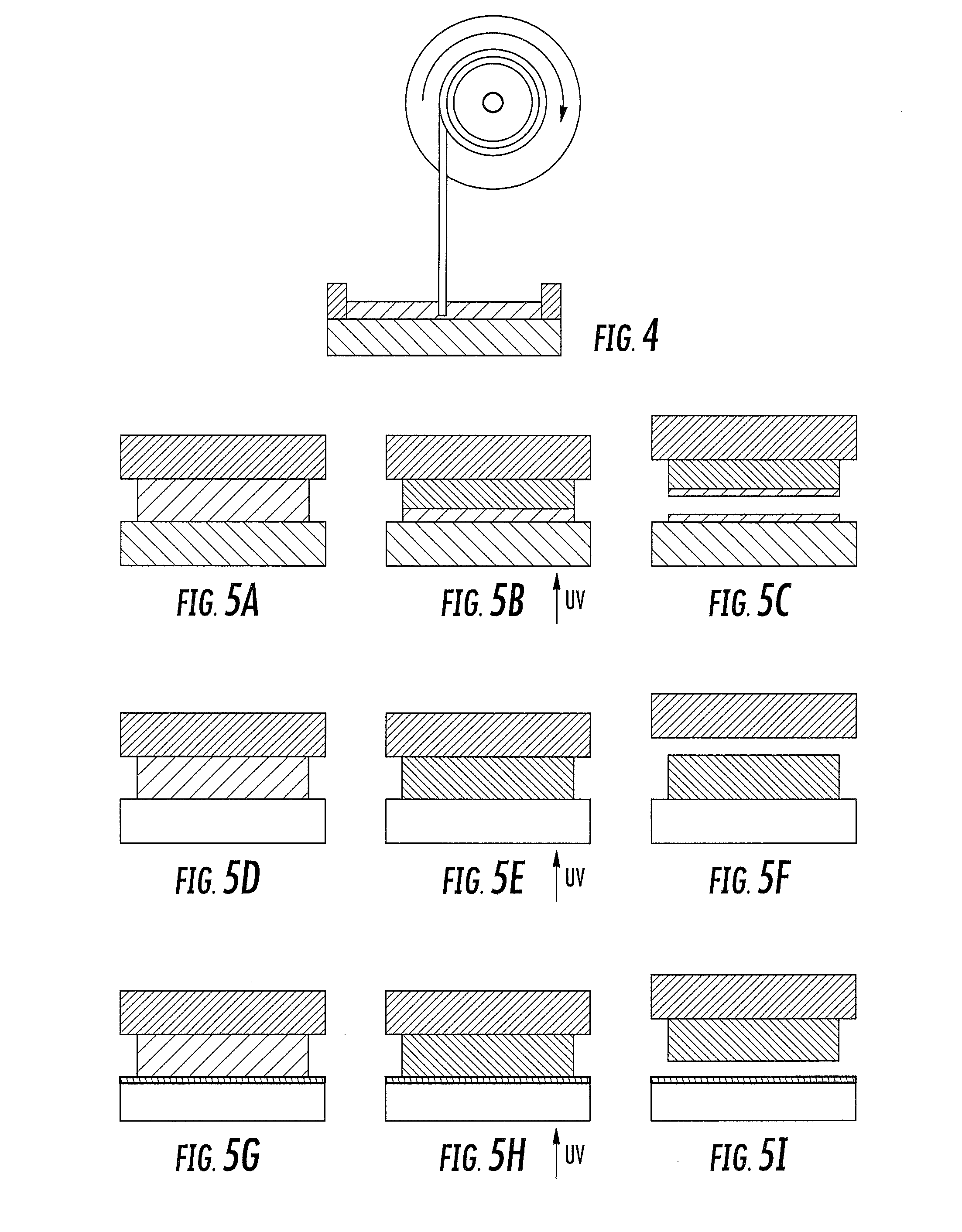

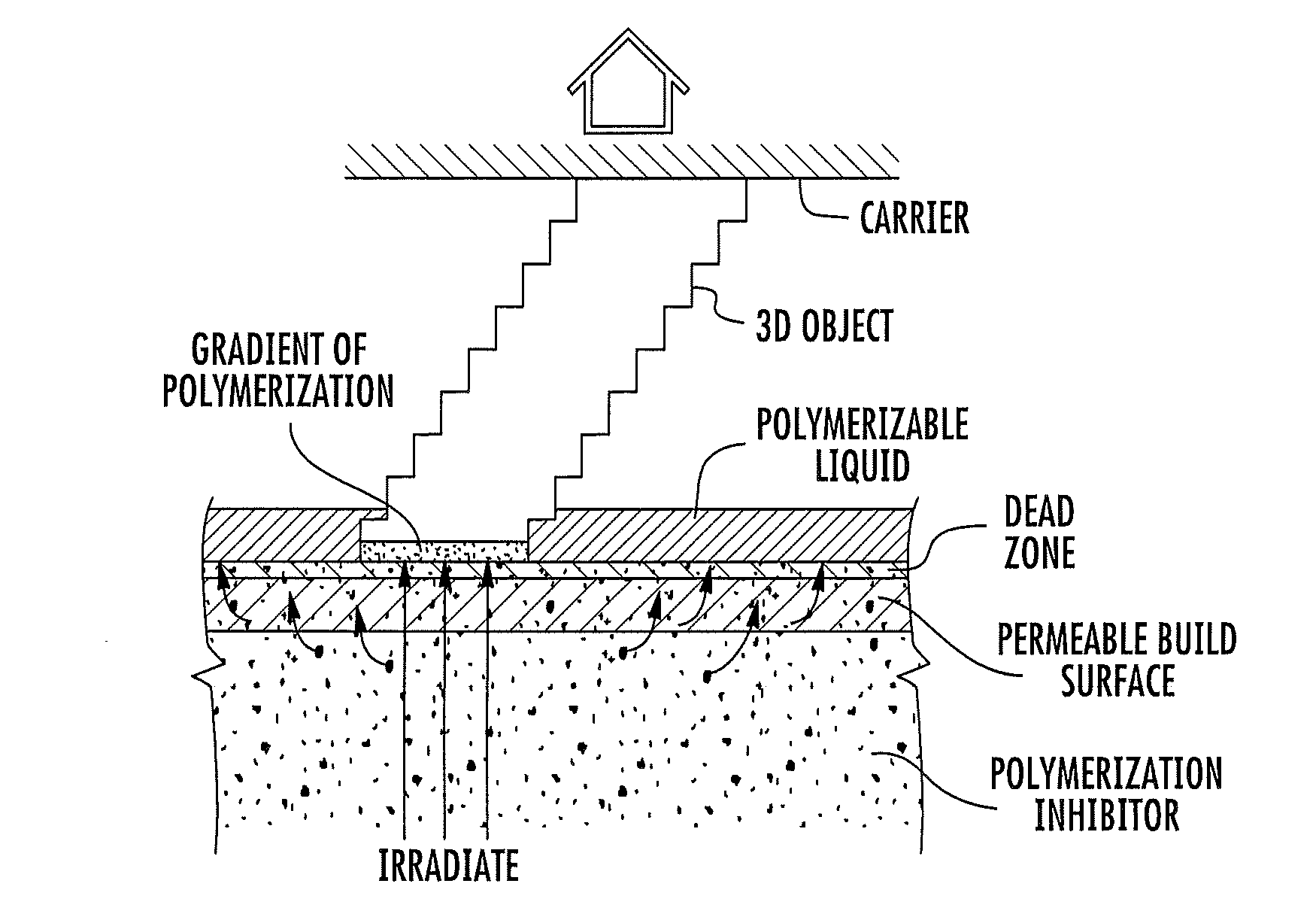

A method of forming a three-dimensional object, comprises providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid while concurrently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form. Apparatus for carrying out the method is also described.

Owner:CARBON INC

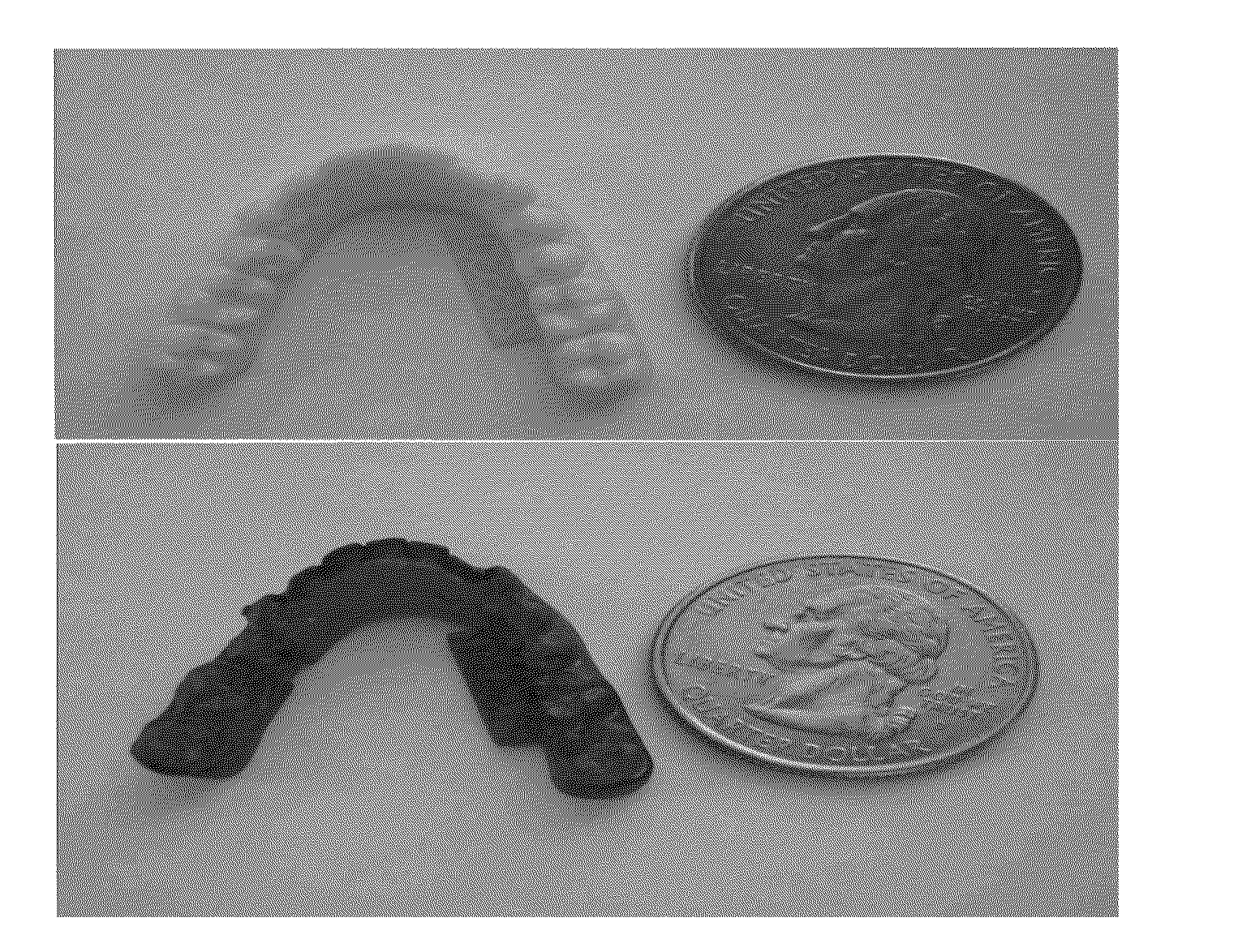

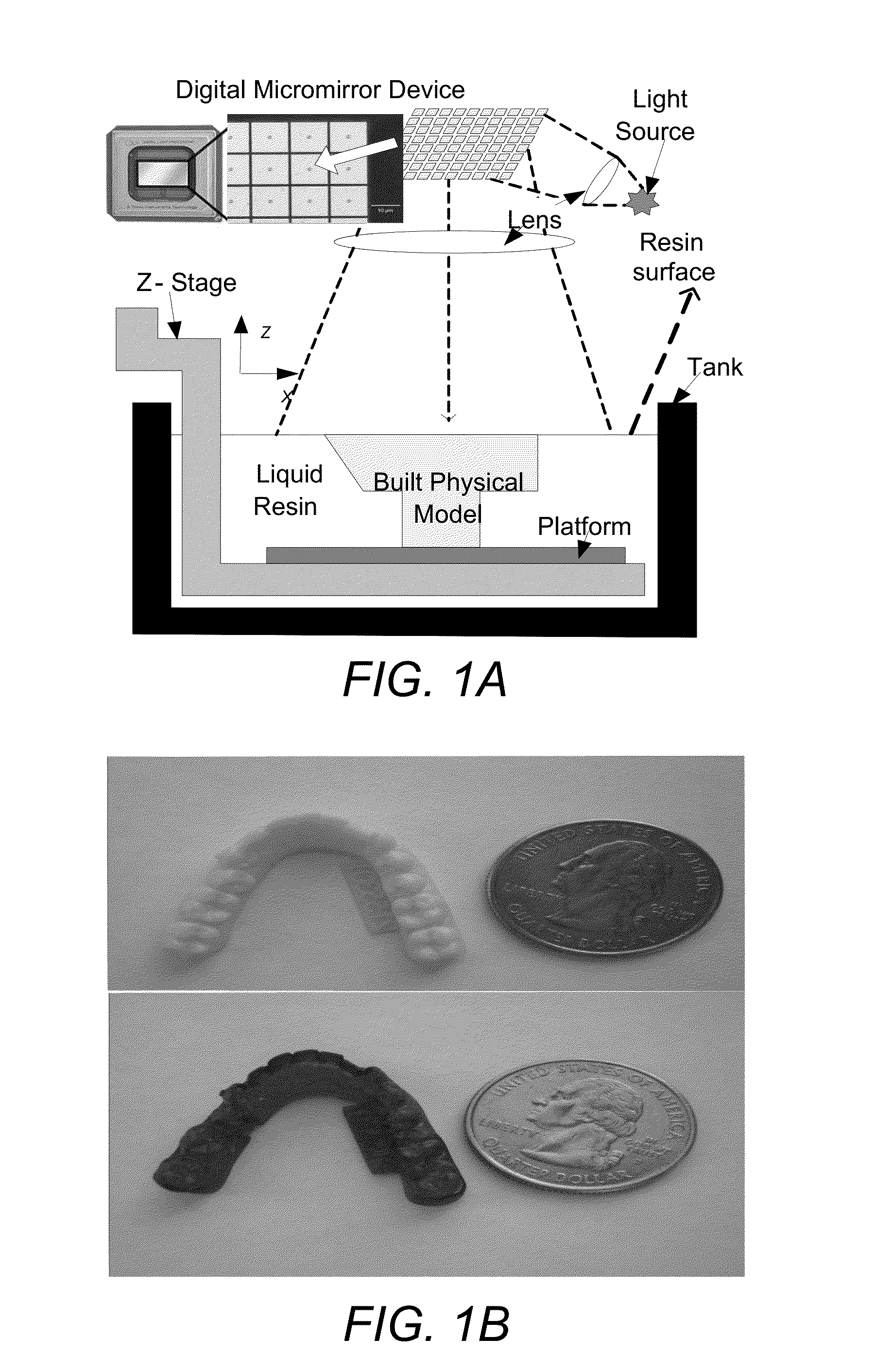

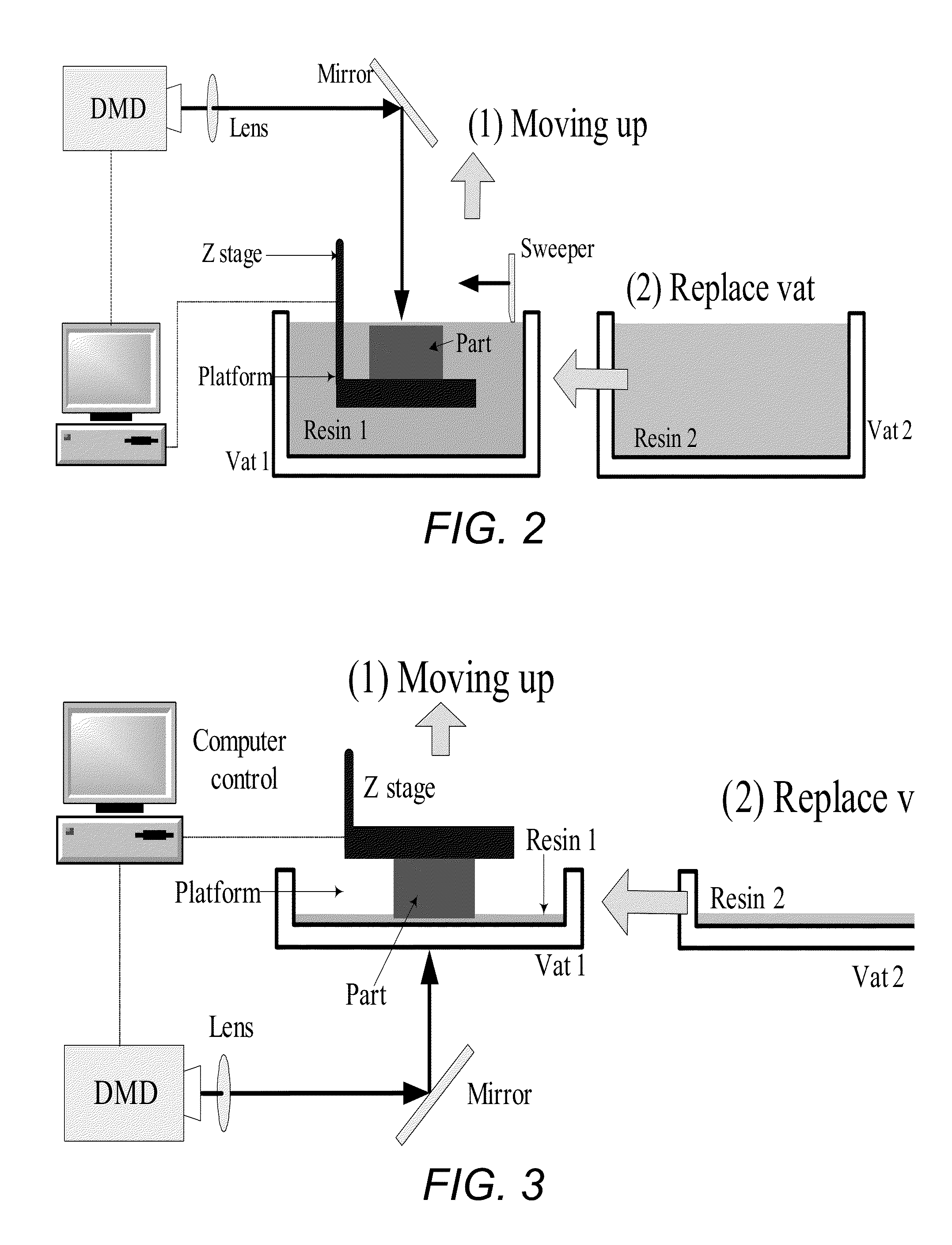

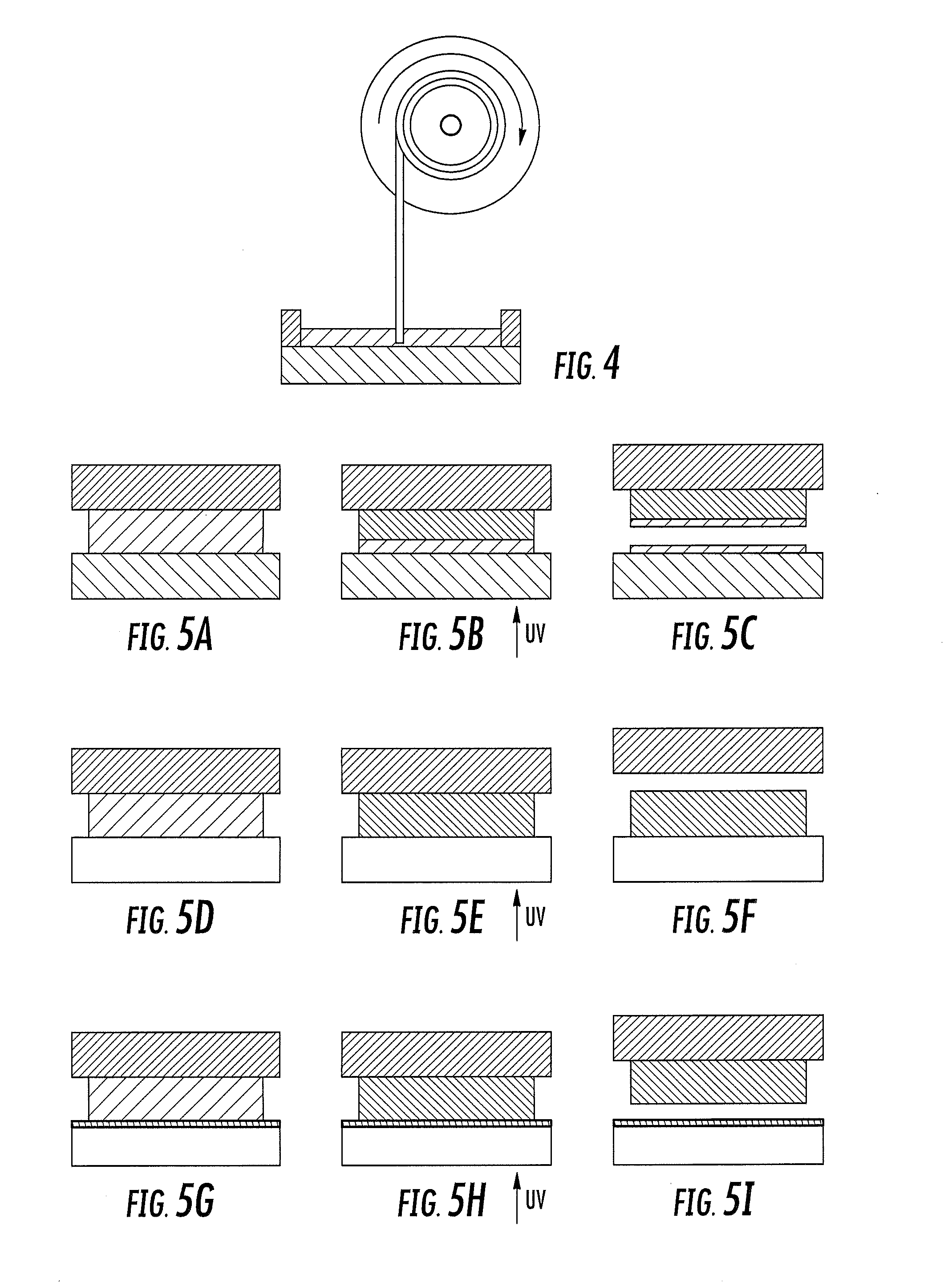

Digital mask-image-projection-based additive manufacturing that applies shearing force to detach each added layer

ActiveUS20130295212A1Additive manufacturing apparatusAuxillary shaping apparatusComputer graphics (images)Projection system

A three-dimensional object may be produced in cascaded layers from a liquid resin that solidifies upon exposure to light. A translation stage may be positioned relative to a vat that is suitable for solidifying the highest un-solidified layer of the three-dimensional object directly beneath any existing, solidified layers of the three-dimensional object. A mask image projection system may project a two-dimensional image of the highest un-solidified layer through a transparent bottom of the vat and into the liquid resin. This may cause at least a portion of the liquid resin to solidify in the shape of the two-dimensional image and to adhere to the bottom of a surface beneath the solidified layer. A shearing force may be applied between the bottom surface of the solidified layer and the surface beneath that is great enough to detach the solidified layer from the surface beneath.

Owner:UNIV OF SOUTHERN CALIFORNIA

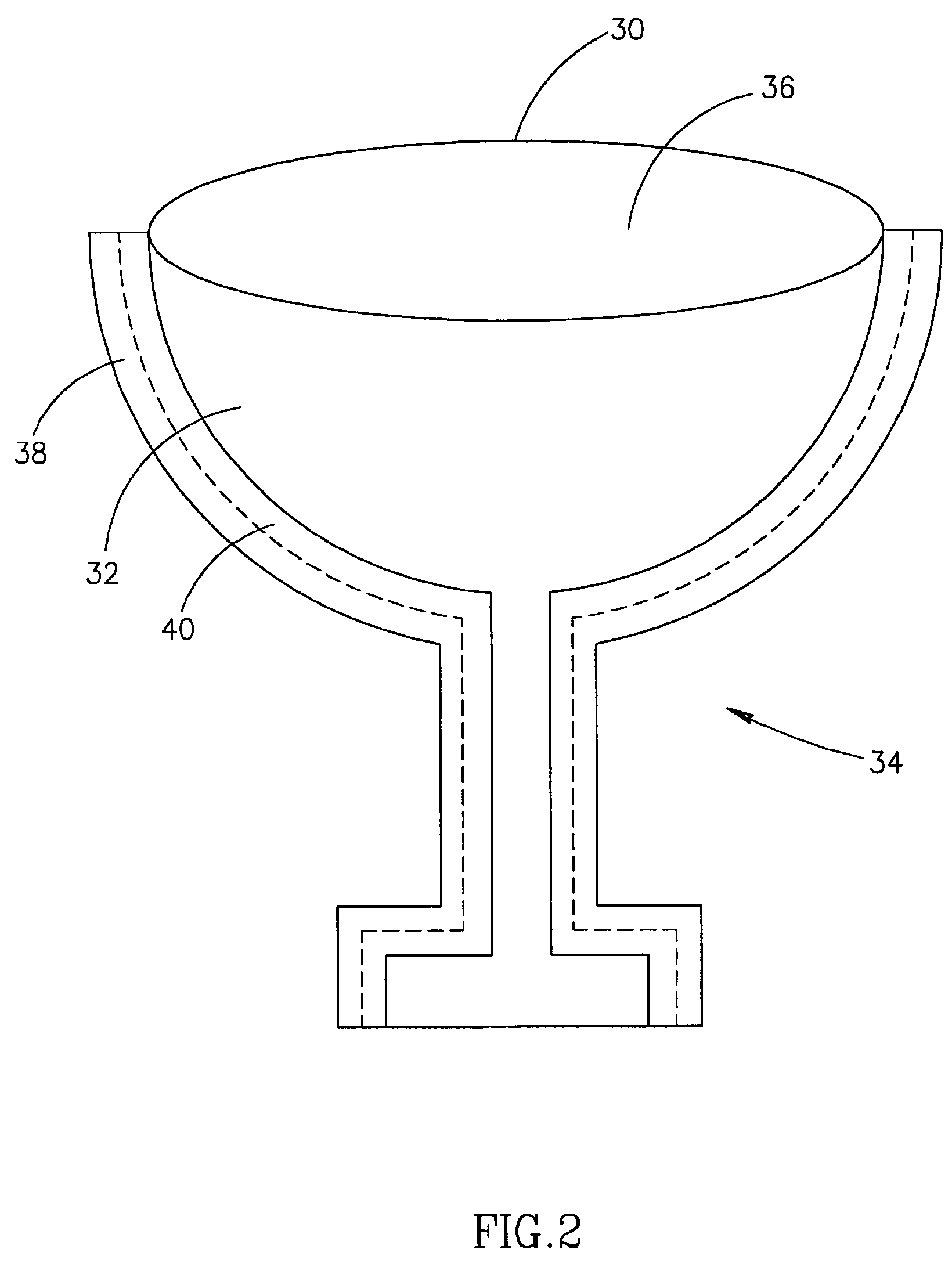

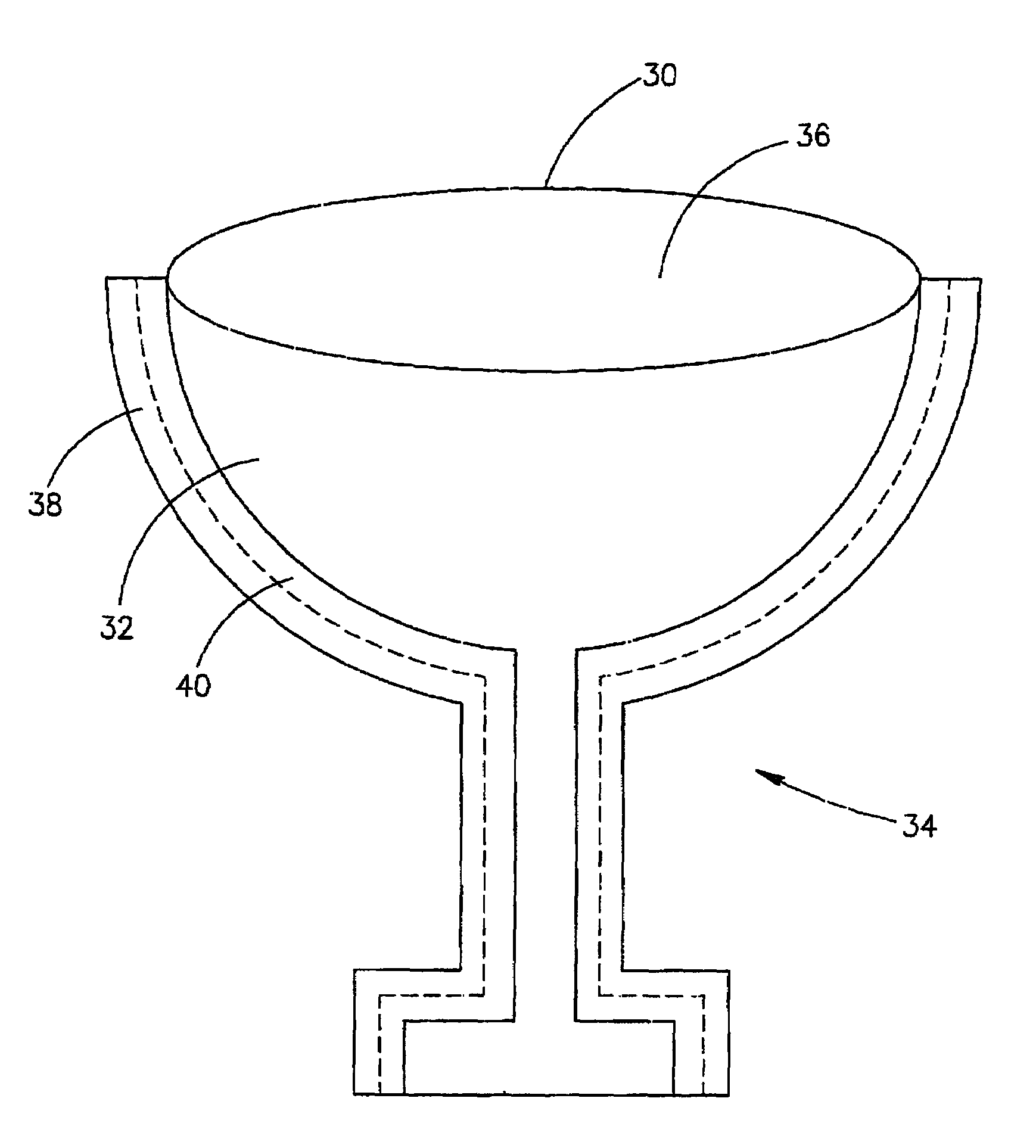

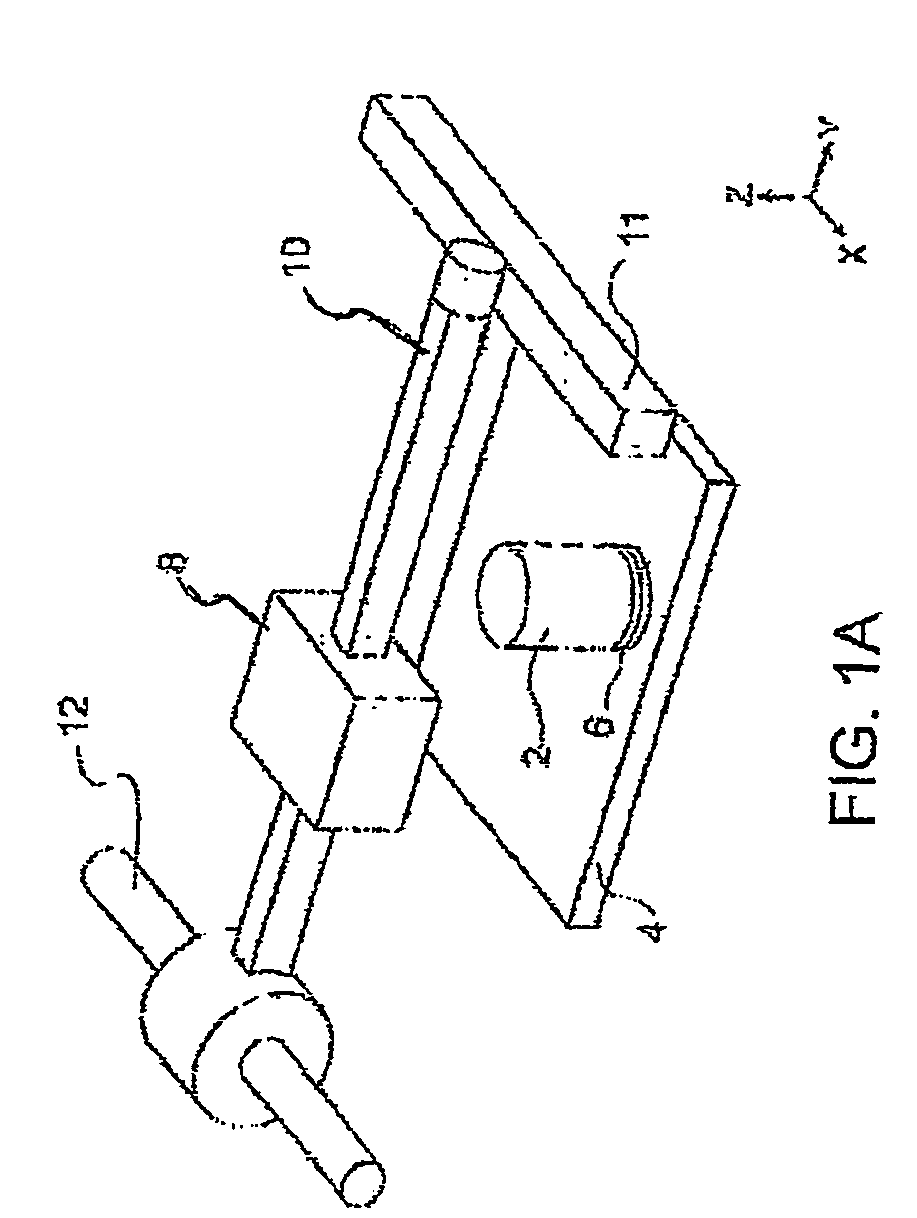

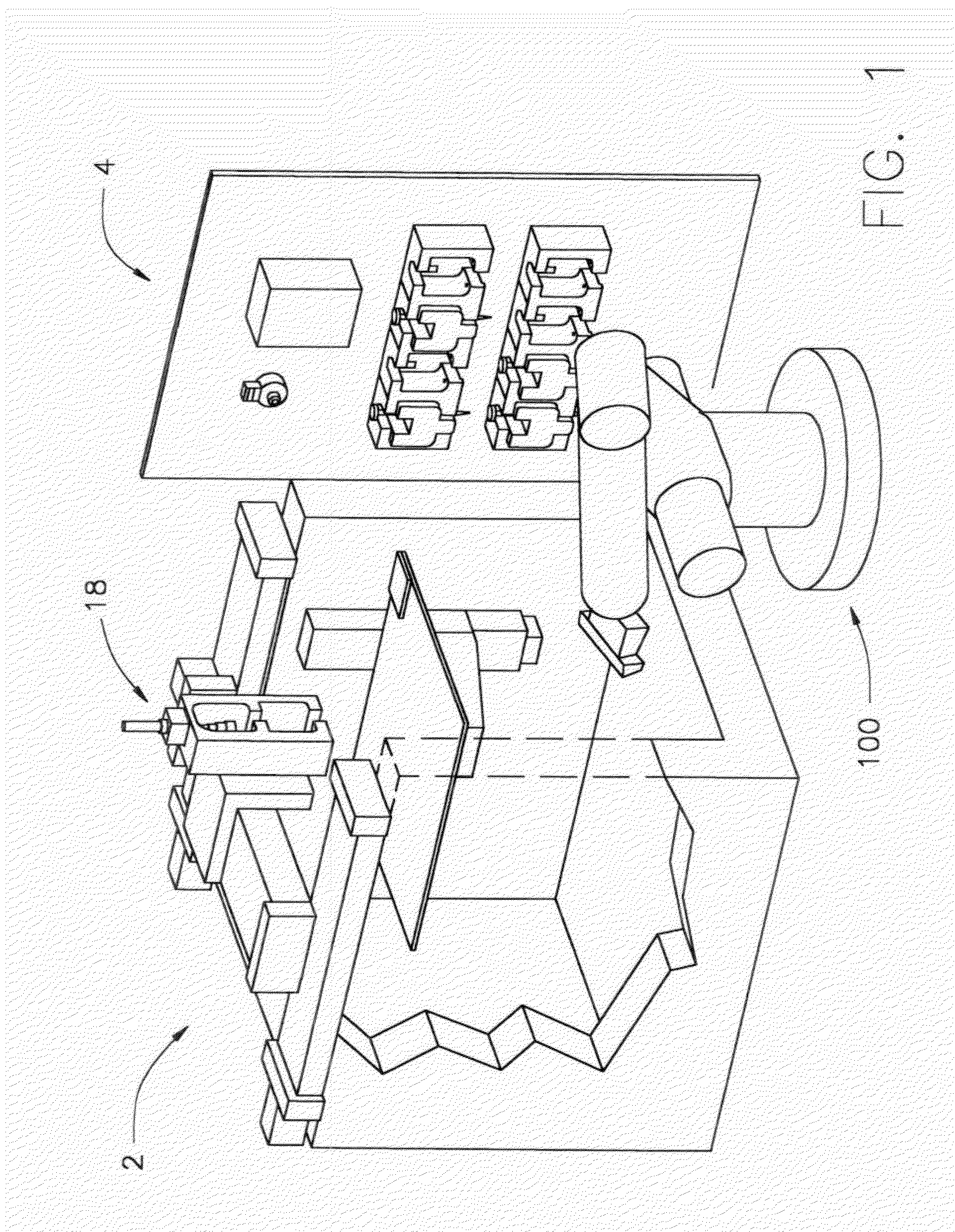

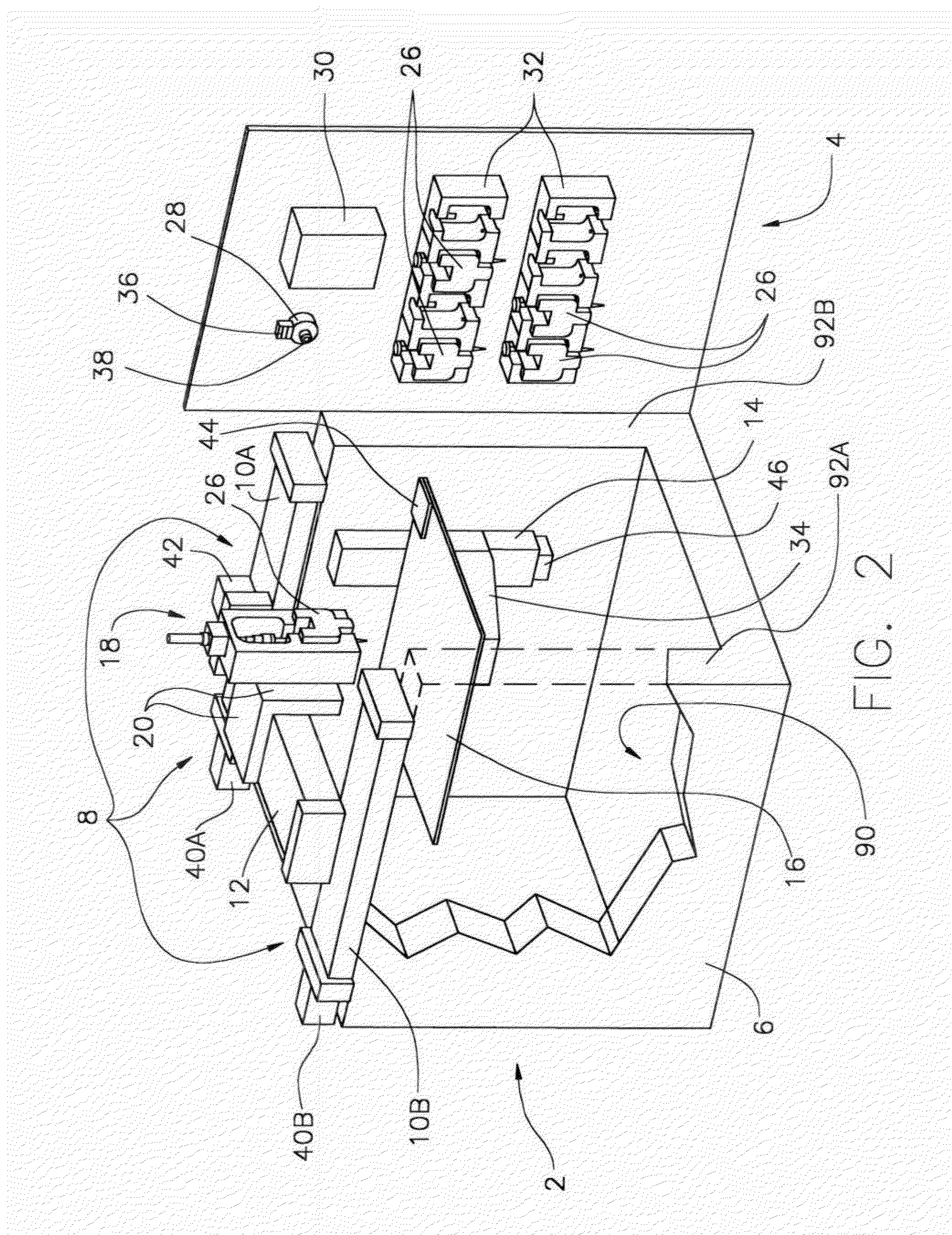

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

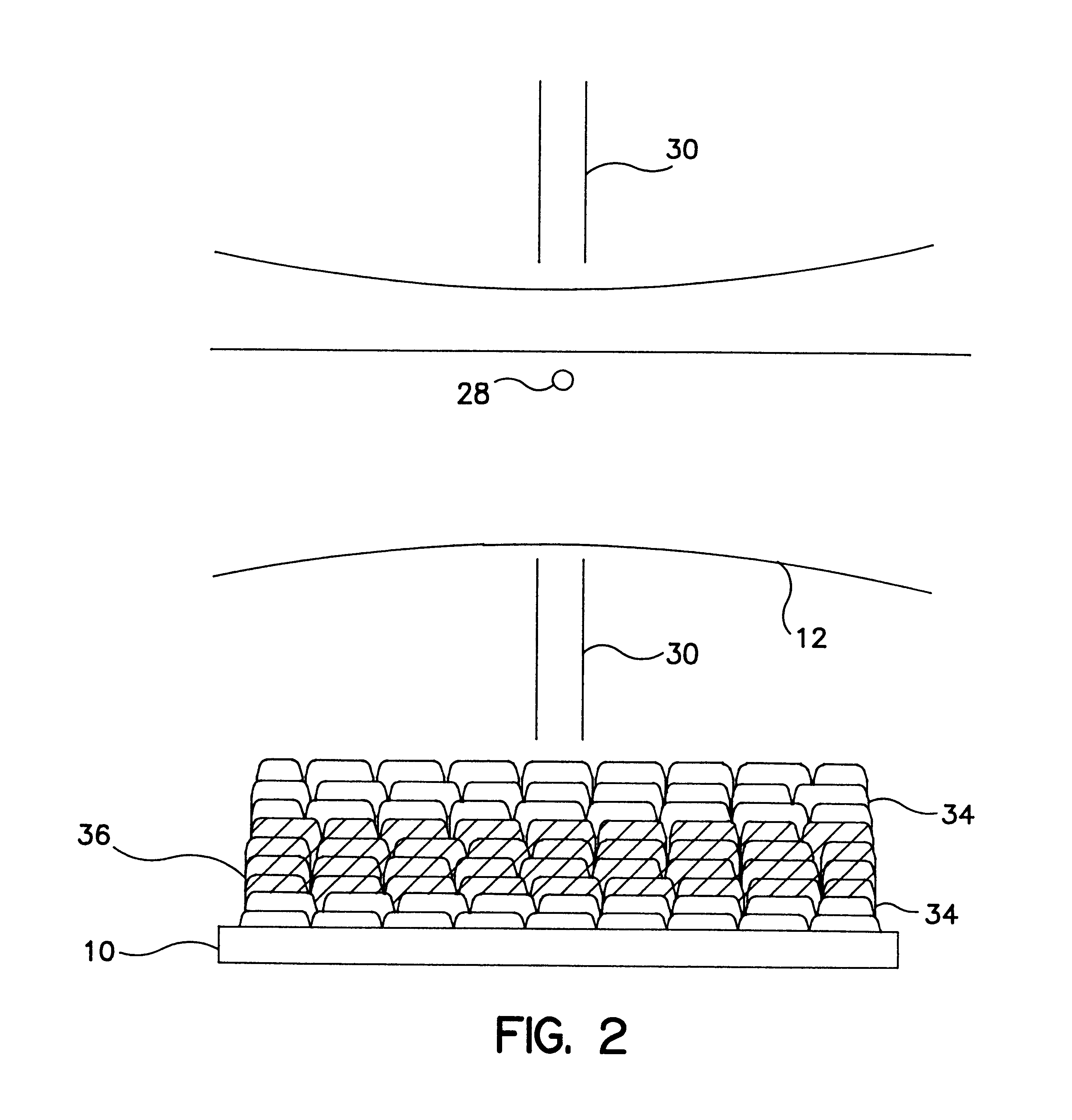

InactiveUS6193923B1Easy to disassembleMinimal damageAdditive manufacturing apparatusCeramic shaping apparatusEngineeringSelective deposition

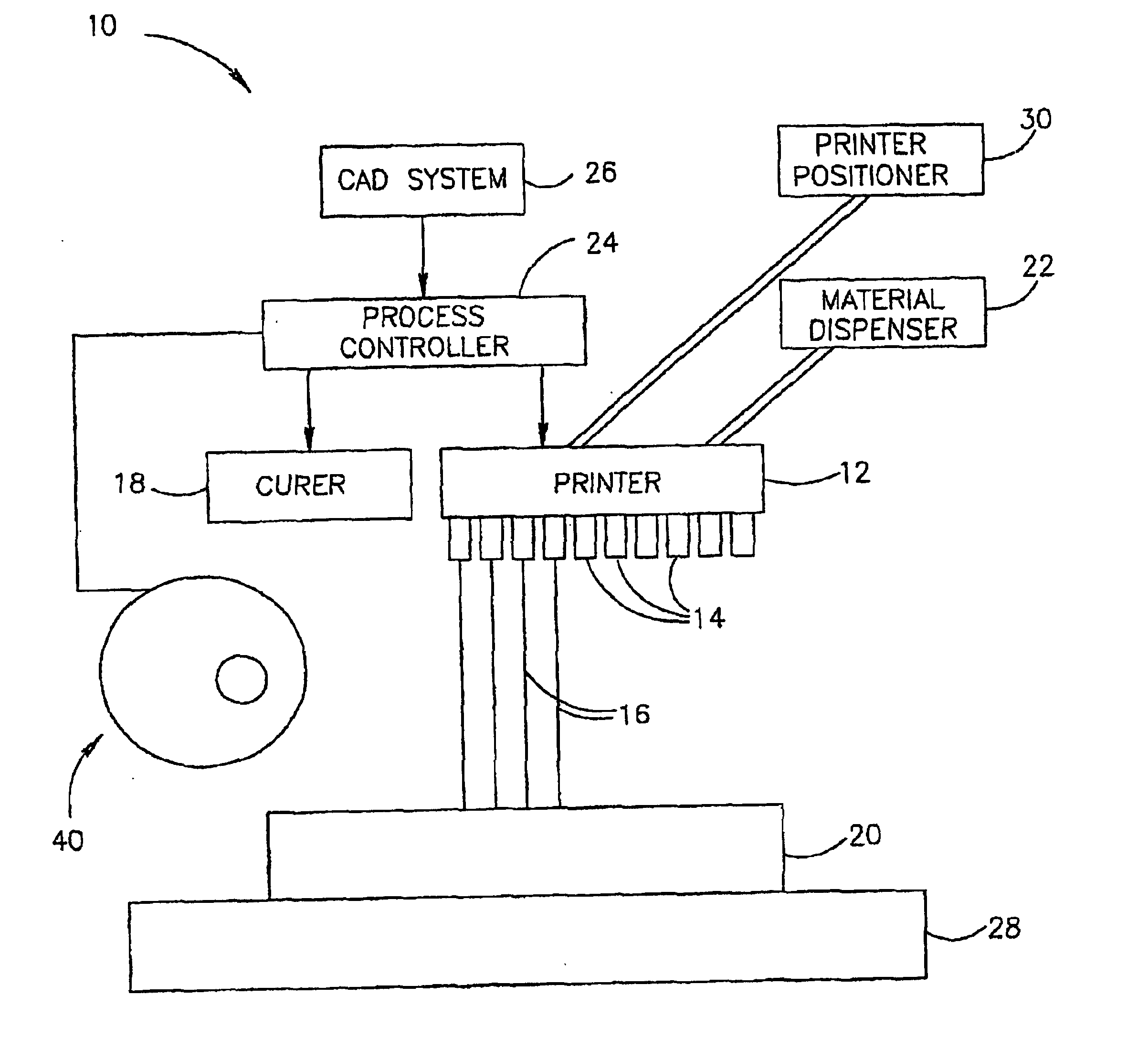

A variety of support structures and build styles for use in Rapid Prototyping and Manufacturing systems are described wherein particular emphasis is given to Thermal Stereolithography, Fused Deposition Modeling, and Selective Deposition Modeling systems, and wherein a 3D modeling system is presented which uses multijet dispensing and a single material for both object and support formation.

Owner:3D SYST INC

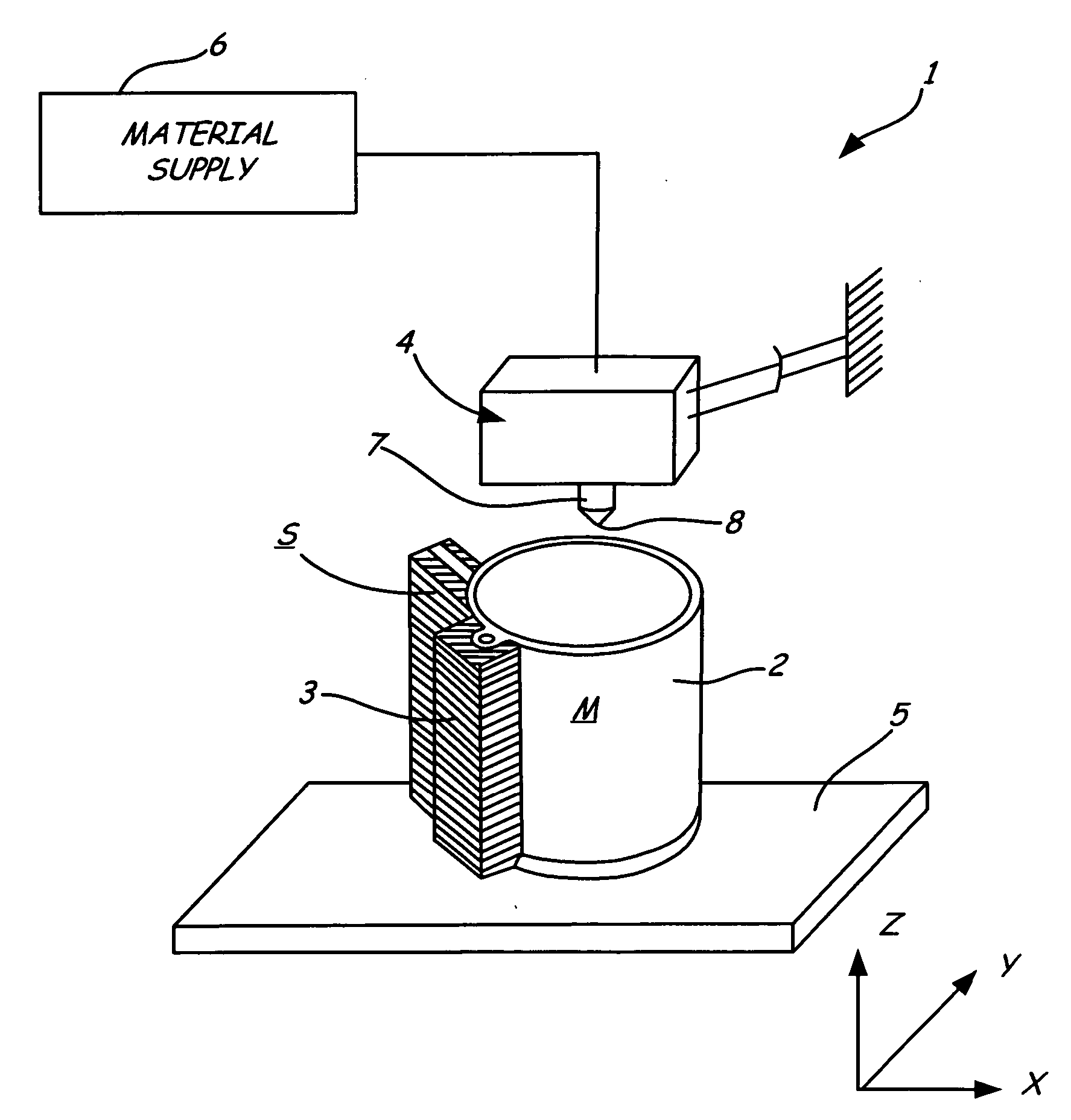

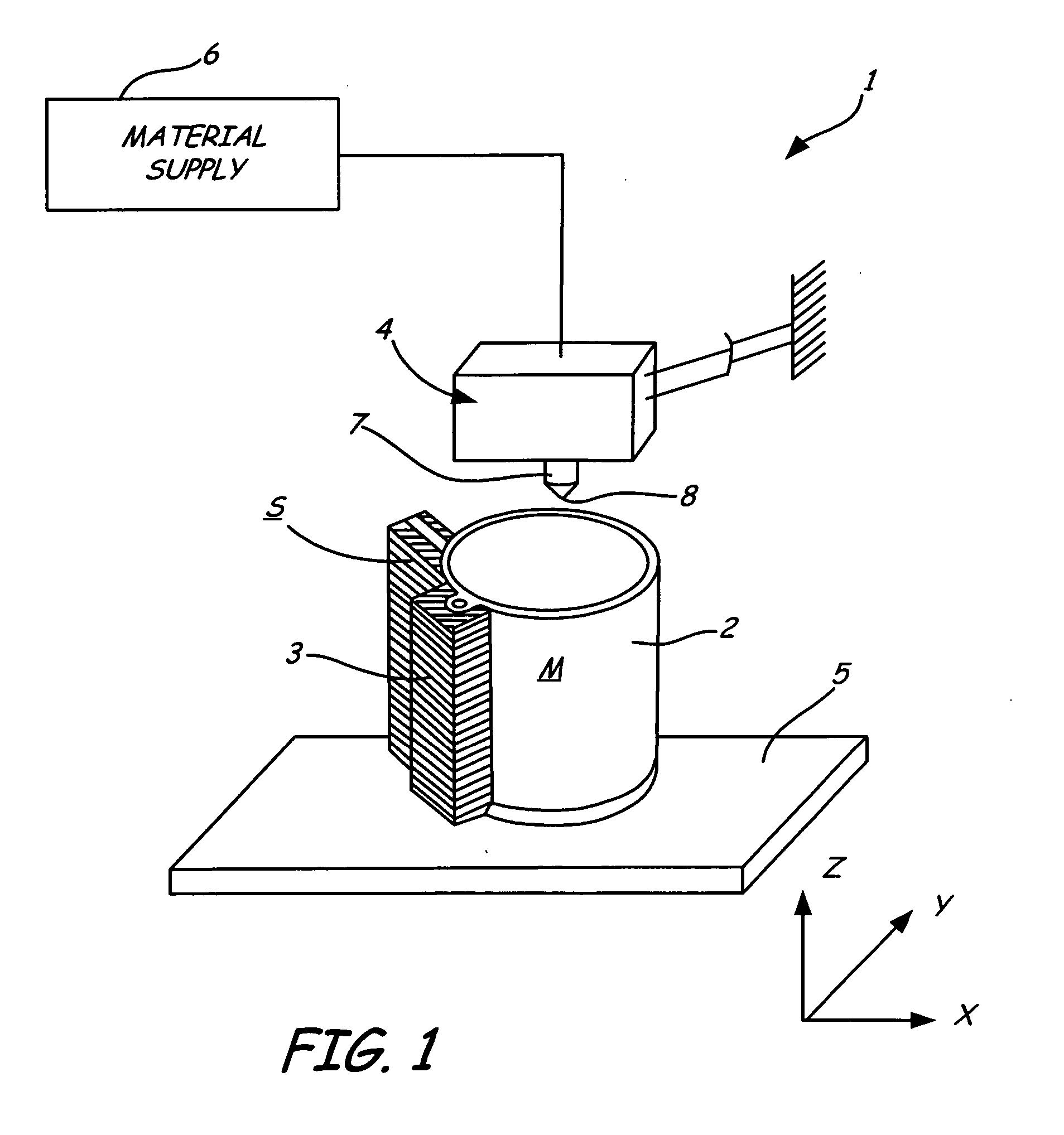

Solid freeform fabrication using a plurality of modeling materials

InactiveUS20100191360A1Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeMaterial supply

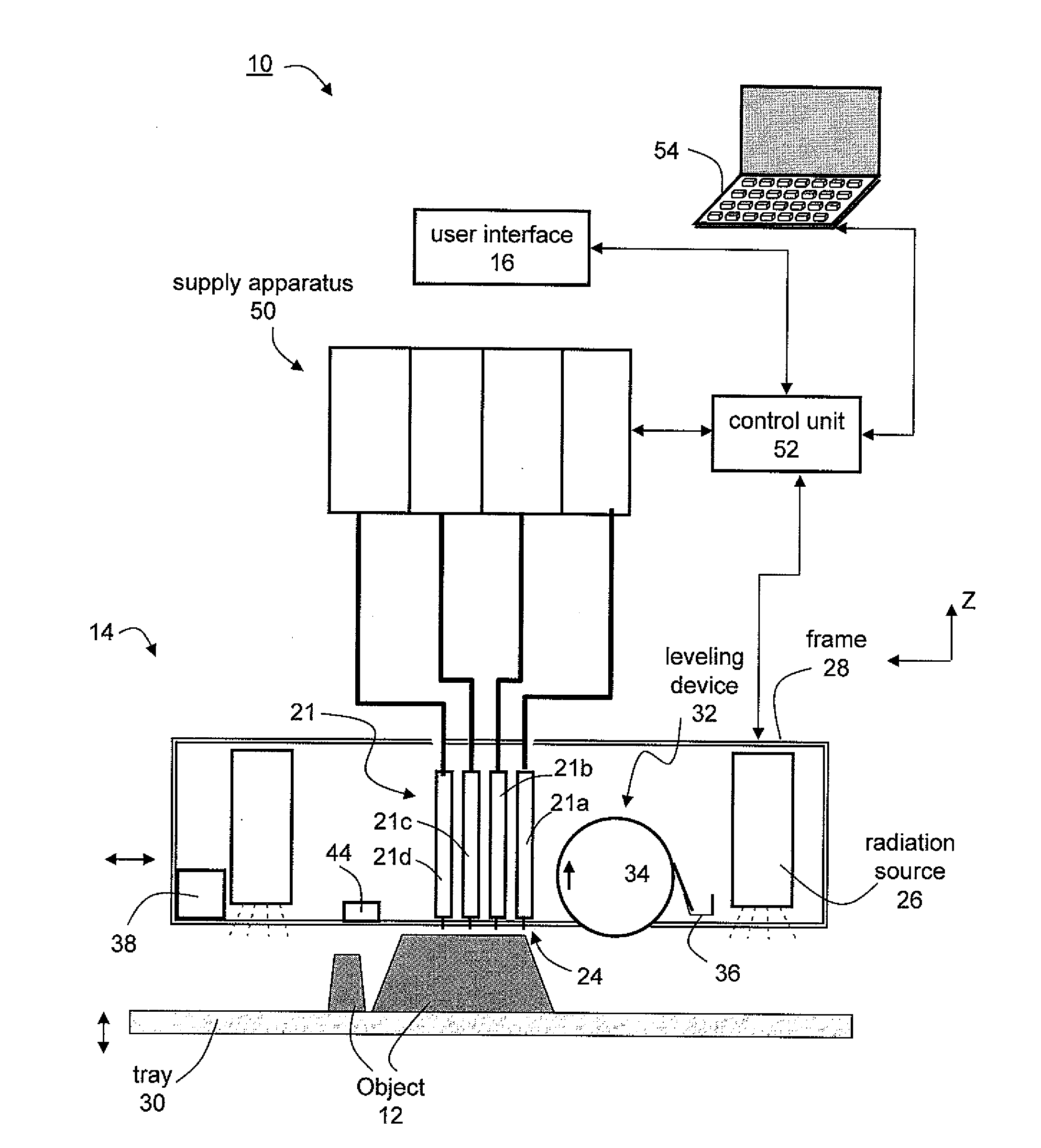

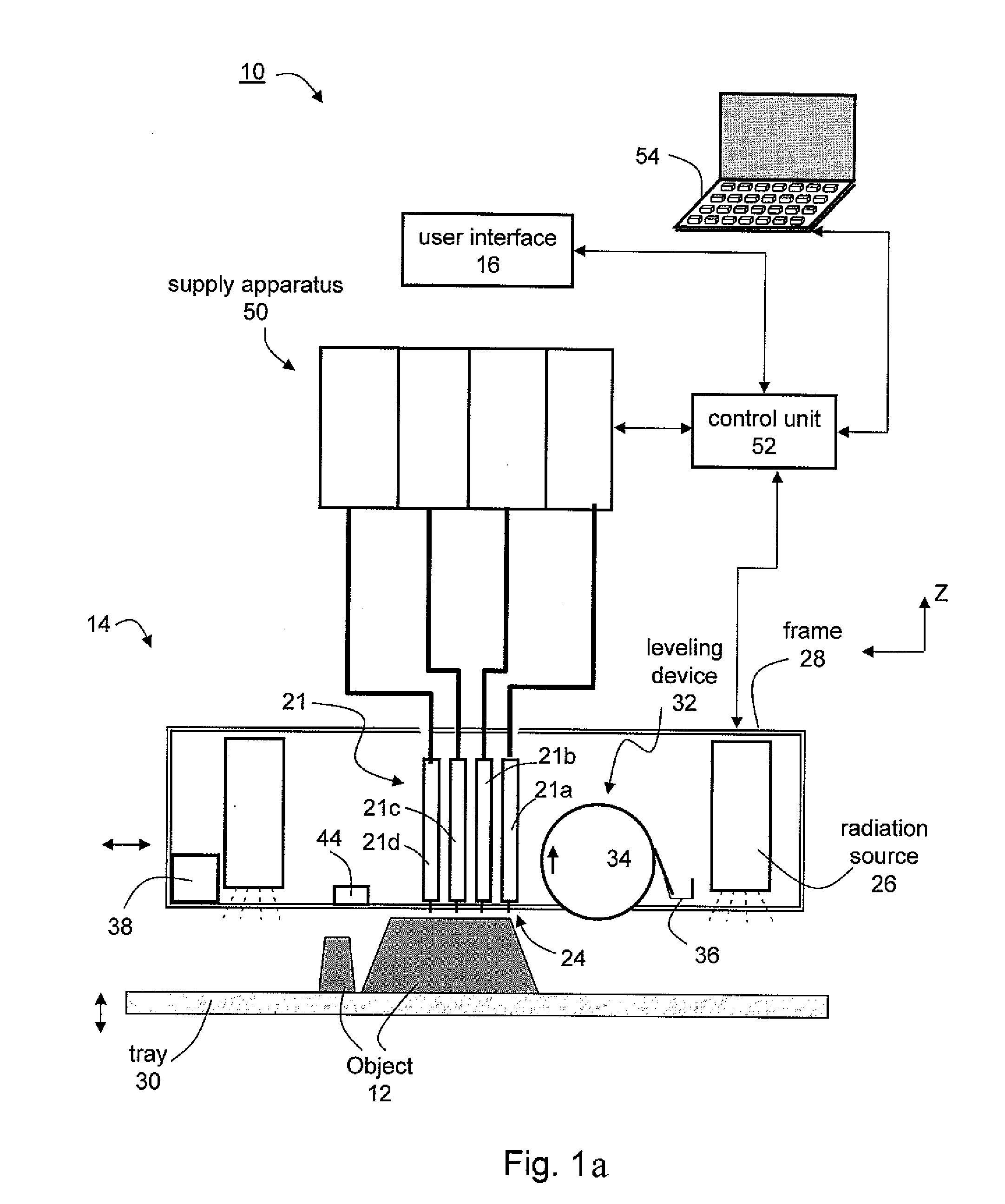

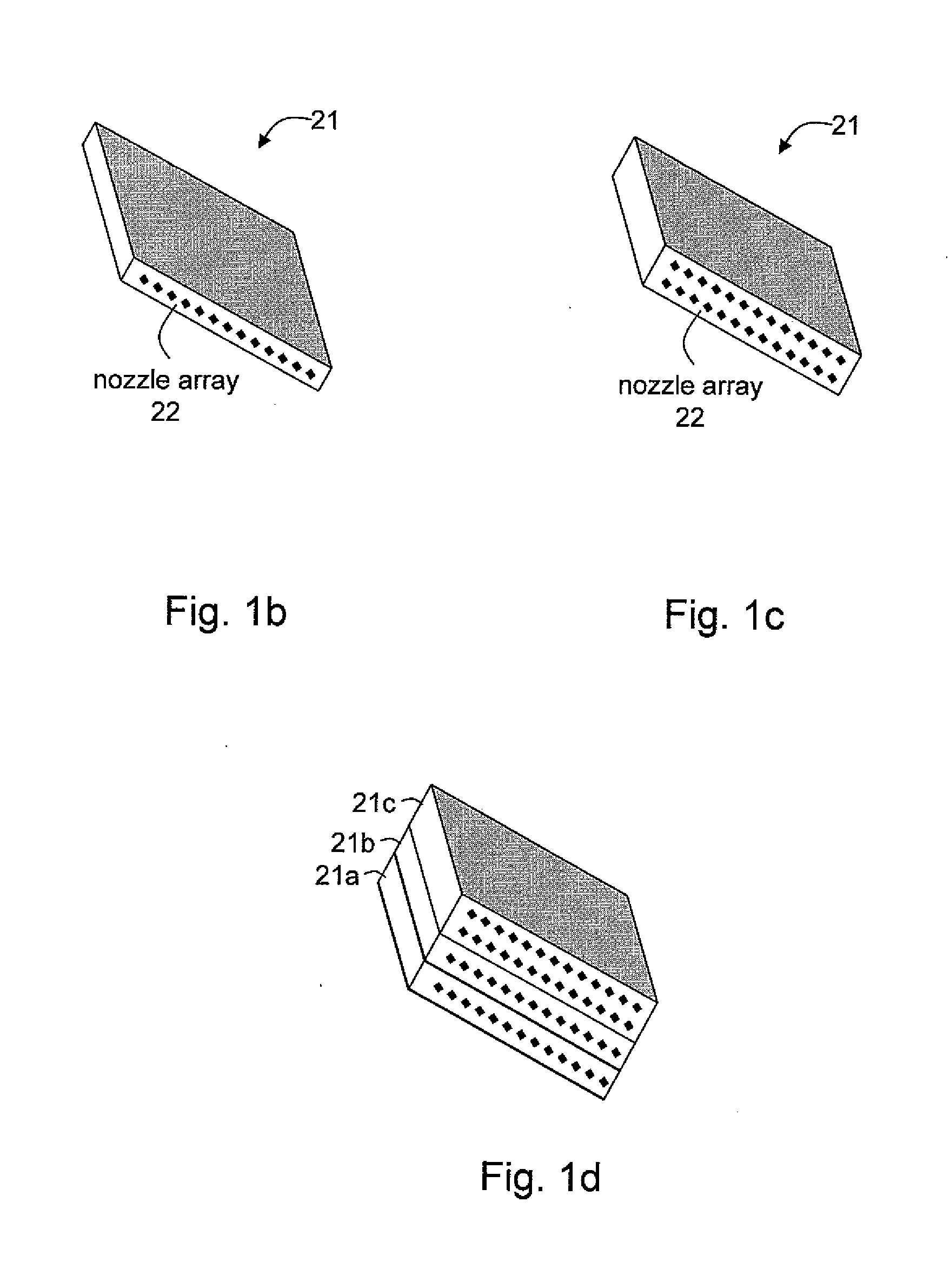

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:OBJET GEOMETRIES

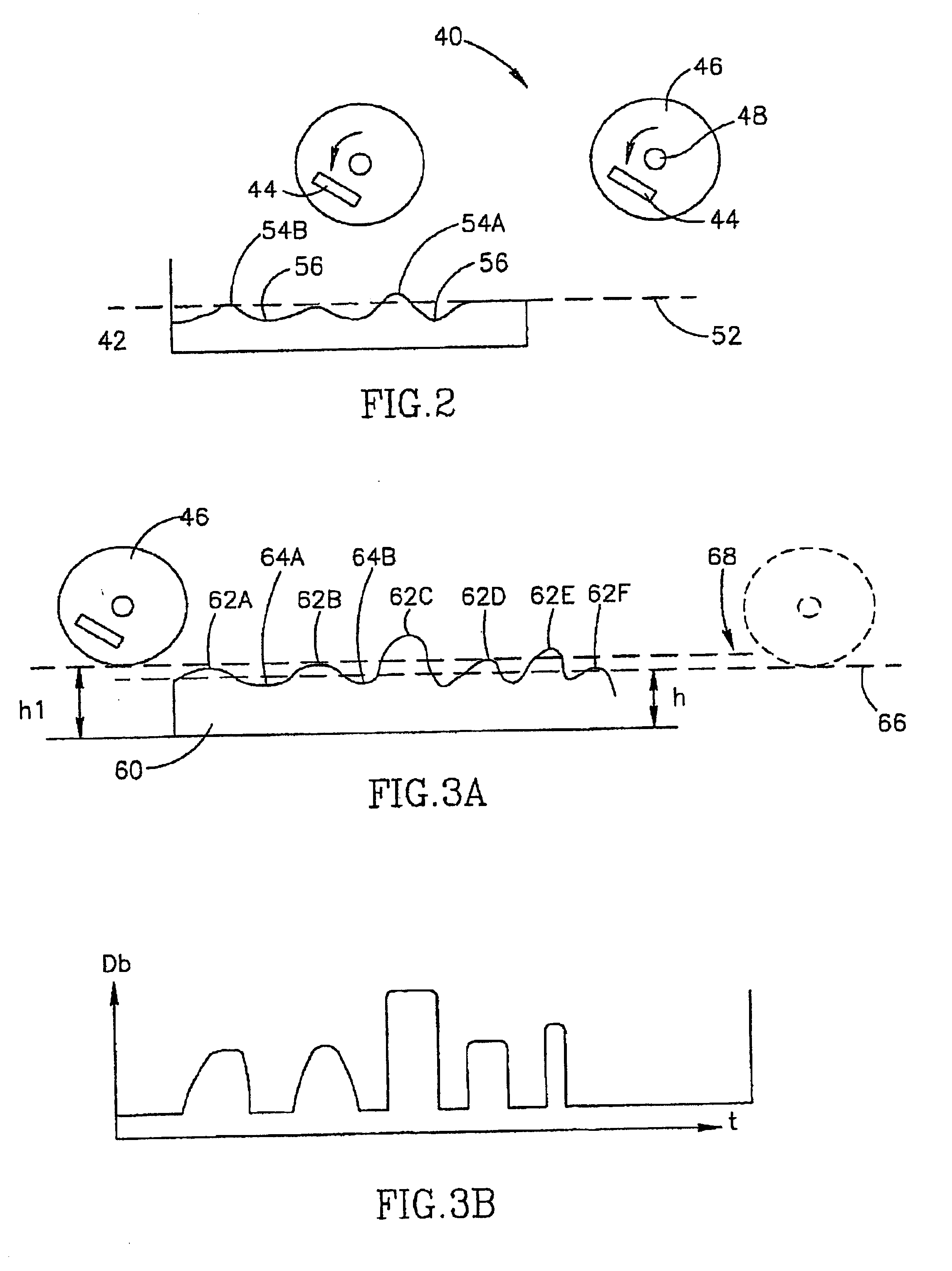

System and method for three dimensional model printing

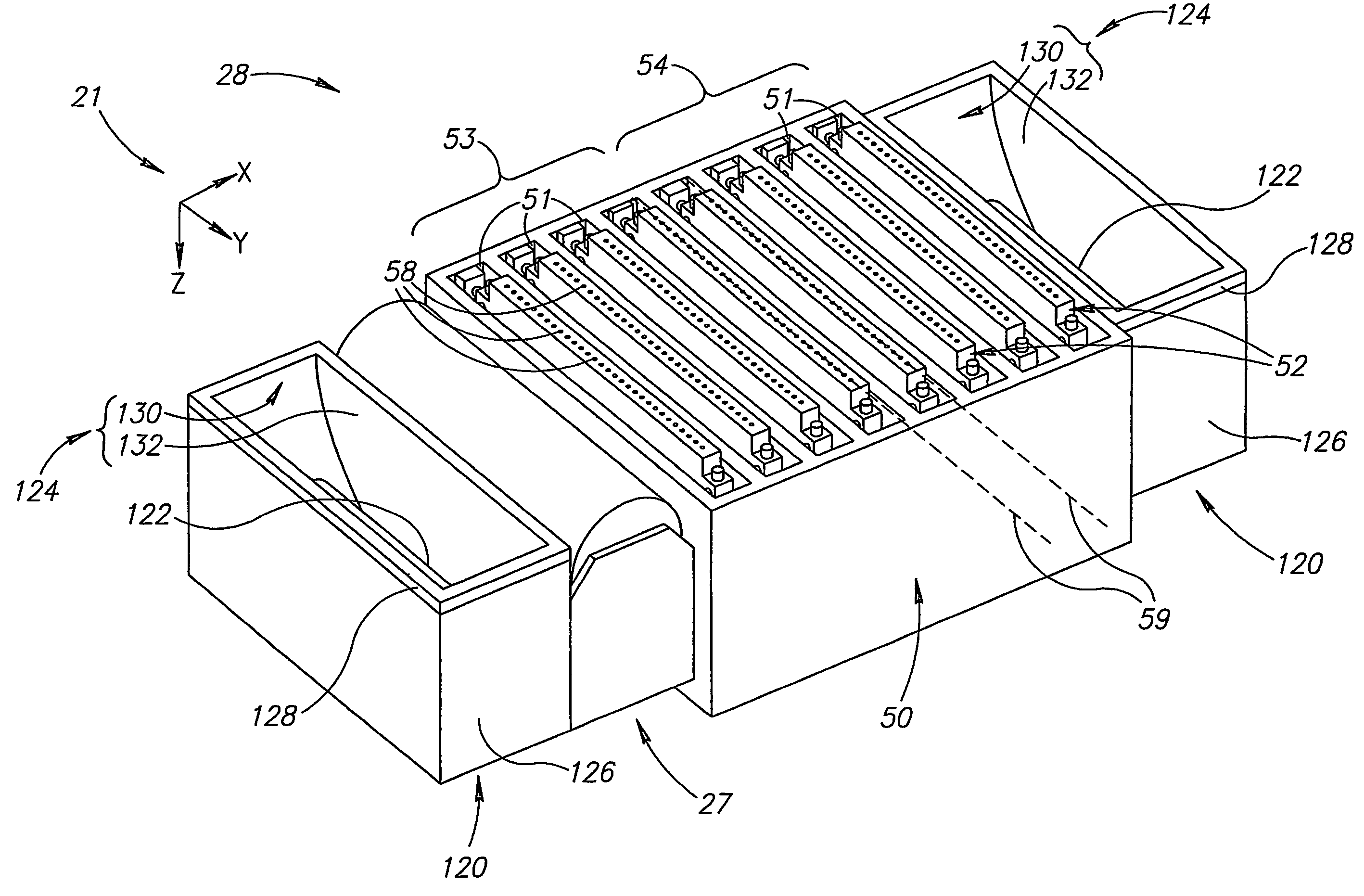

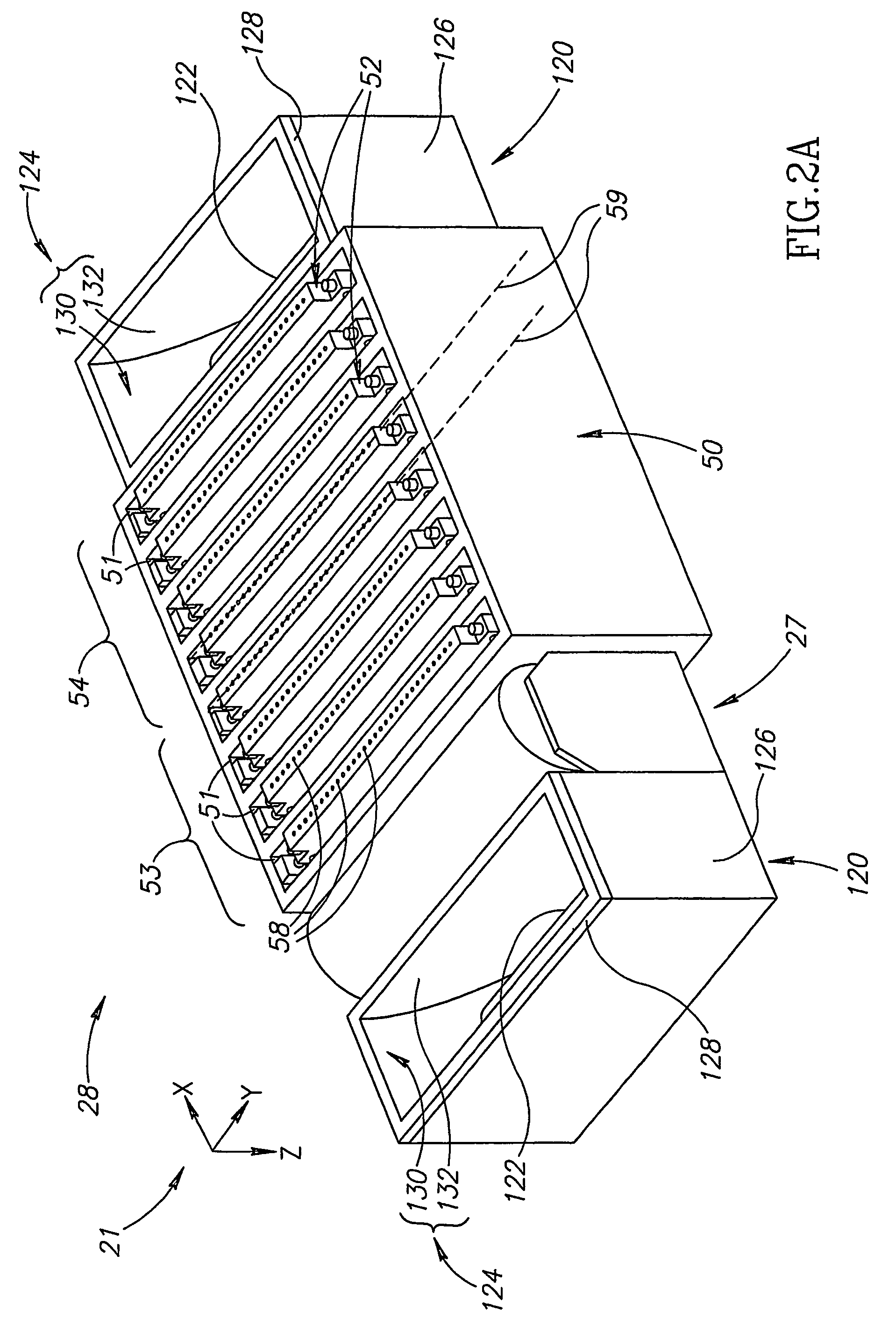

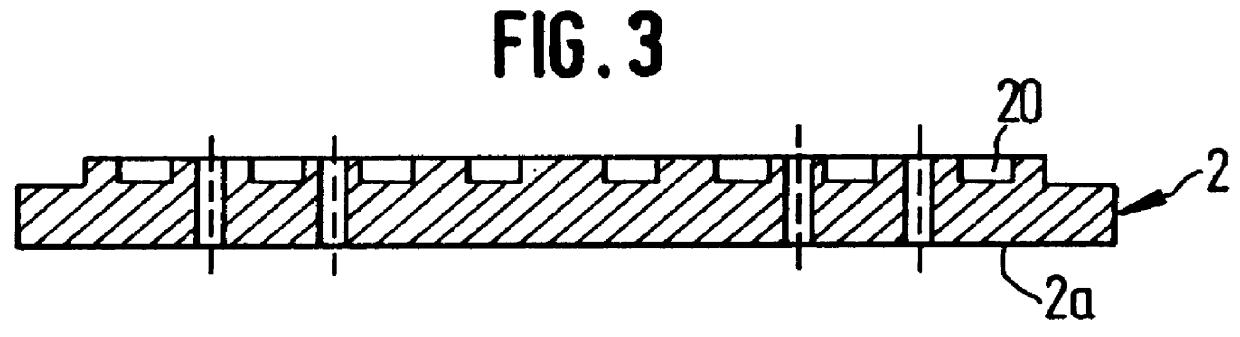

InactiveUS6850334B1Digitally marking record carriersAdditive manufacturing apparatusInterface layer3 dimensional printing

A system and a method for printing of three-dimensional models and apparatus for controlling the height and thickness of the layers of interface material forming the 3-D models being printed, is provided. The method includes the steps of dispensing a pre-determined quantity of interface material from at least one printing head to form at least one interface layer; leveling the dispensed interface material to a pre-determined height; curing the leveled interface material; and repeating the steps of dispensing, leveling and curing thereby producing a plurality of interface layers to a configured pattern layer for forming the three-dimensional model.

Owner:STRATASYS LTD

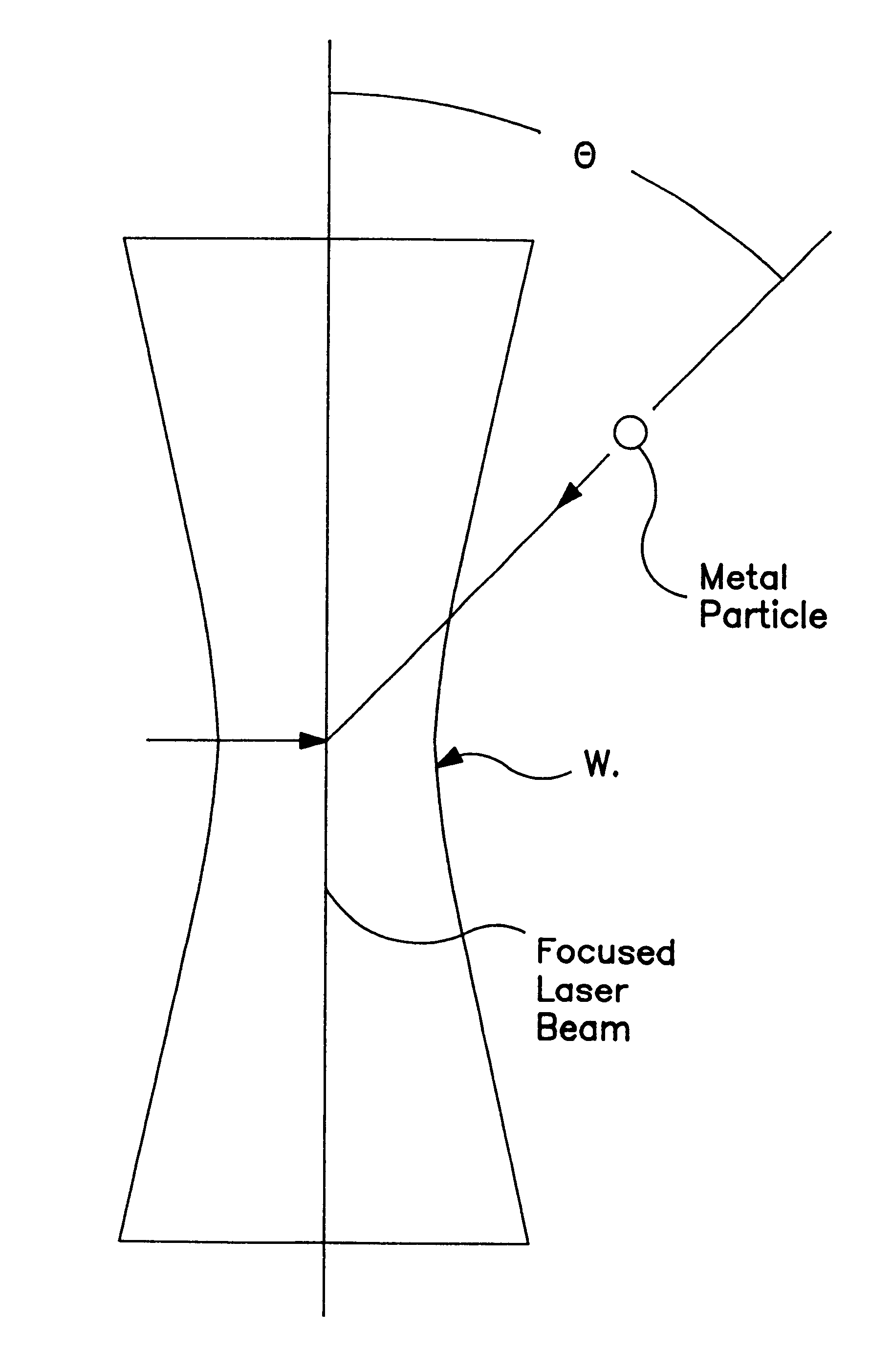

Precision spray processes for direct write electronic components

InactiveUS6251488B1Keep for a long timeIncrease probabilityMolten spray coatingVacuum evaporation coatingElectrical resistance and conductanceElectronic component

This invention combines the precision spray process with in-flight laser treatment in order to produce direct write electronic components. In addition to these components, the process can lay down lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging. This process is revolutionary in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

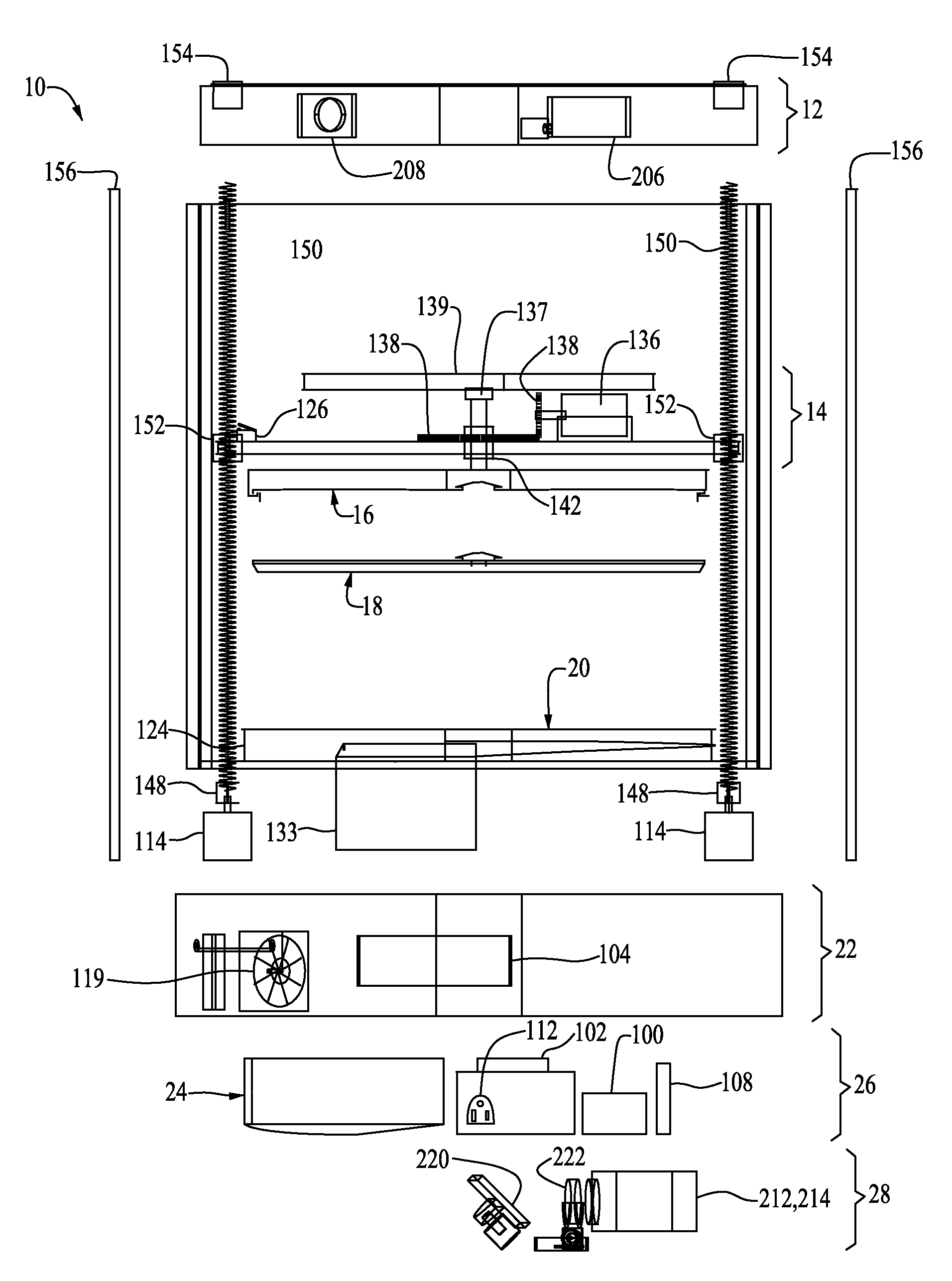

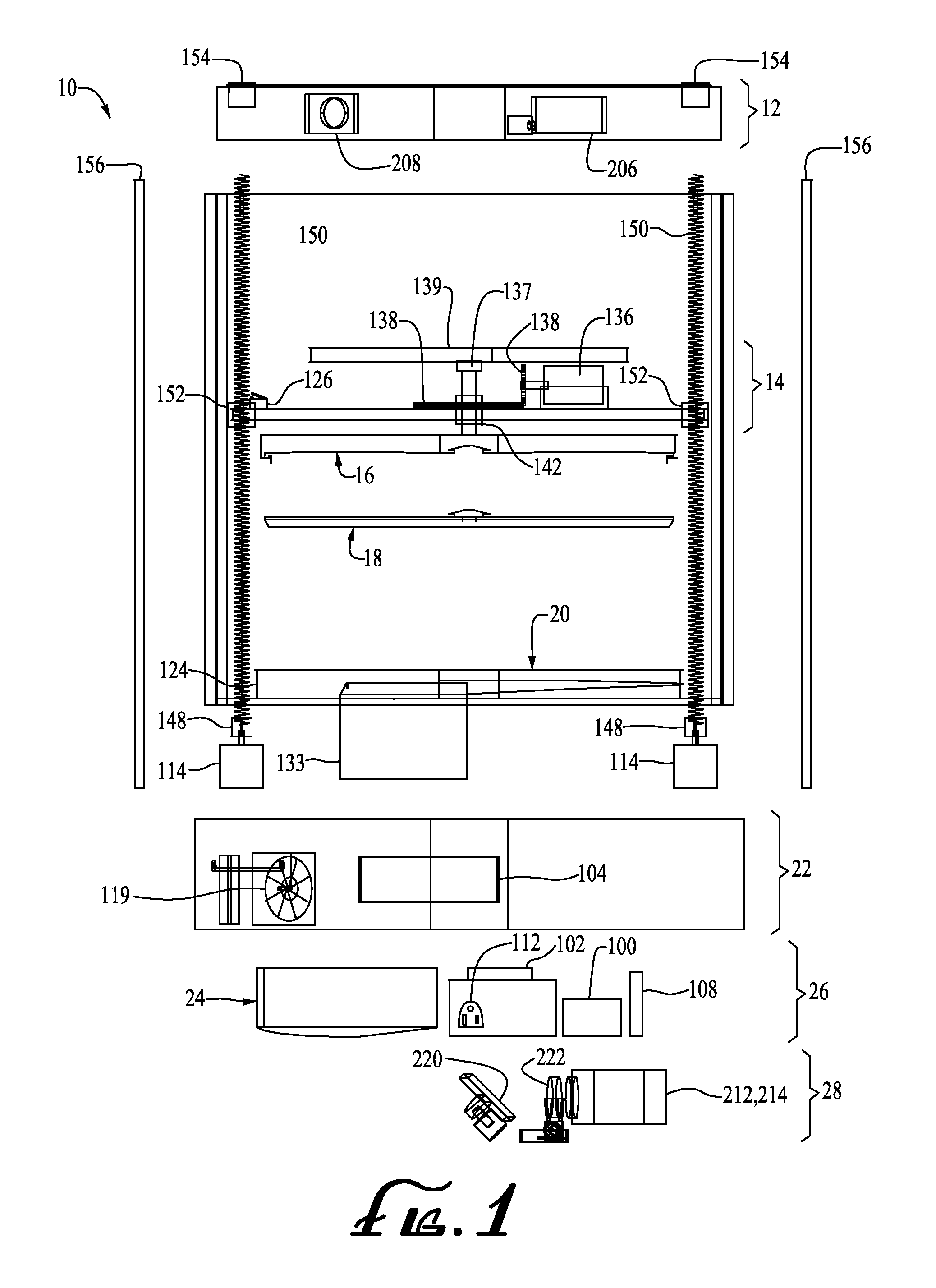

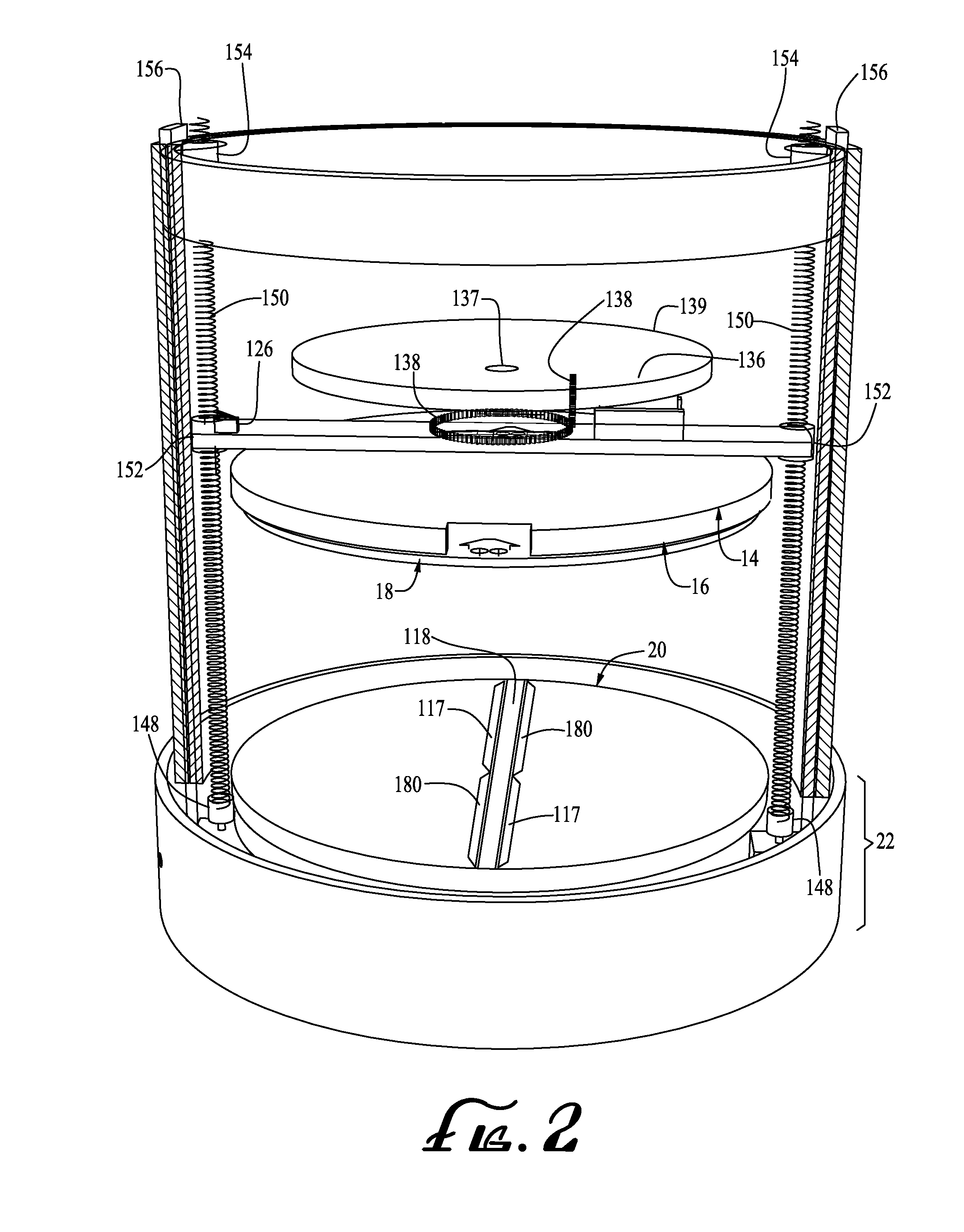

3D printing using spiral buildup

ActiveUS20140265034A1High and accurate level of detailShort timeManufacturing platforms/substratesManufacturing driving meansSingle CenterPhotopolymer

Methods, devices and systems for efficient 3D printing that address conventional inefficiencies while utilizing a single compact device are set forth. Some embodiments utilize a circular-shaped build area revolving symmetrically around a single center point utilizing a continuous helical printing process. In one embodiment a liquid photopolymer for solidification is deposited on a build platform to form the physical object The Build platform is continuously rotated and simultaneously raised in a gradual programmed manner. Focused from below the platform produces a single continuous “layer” of material deposited and bonded in a helical fashion.

Owner:ORANGE MAKER

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

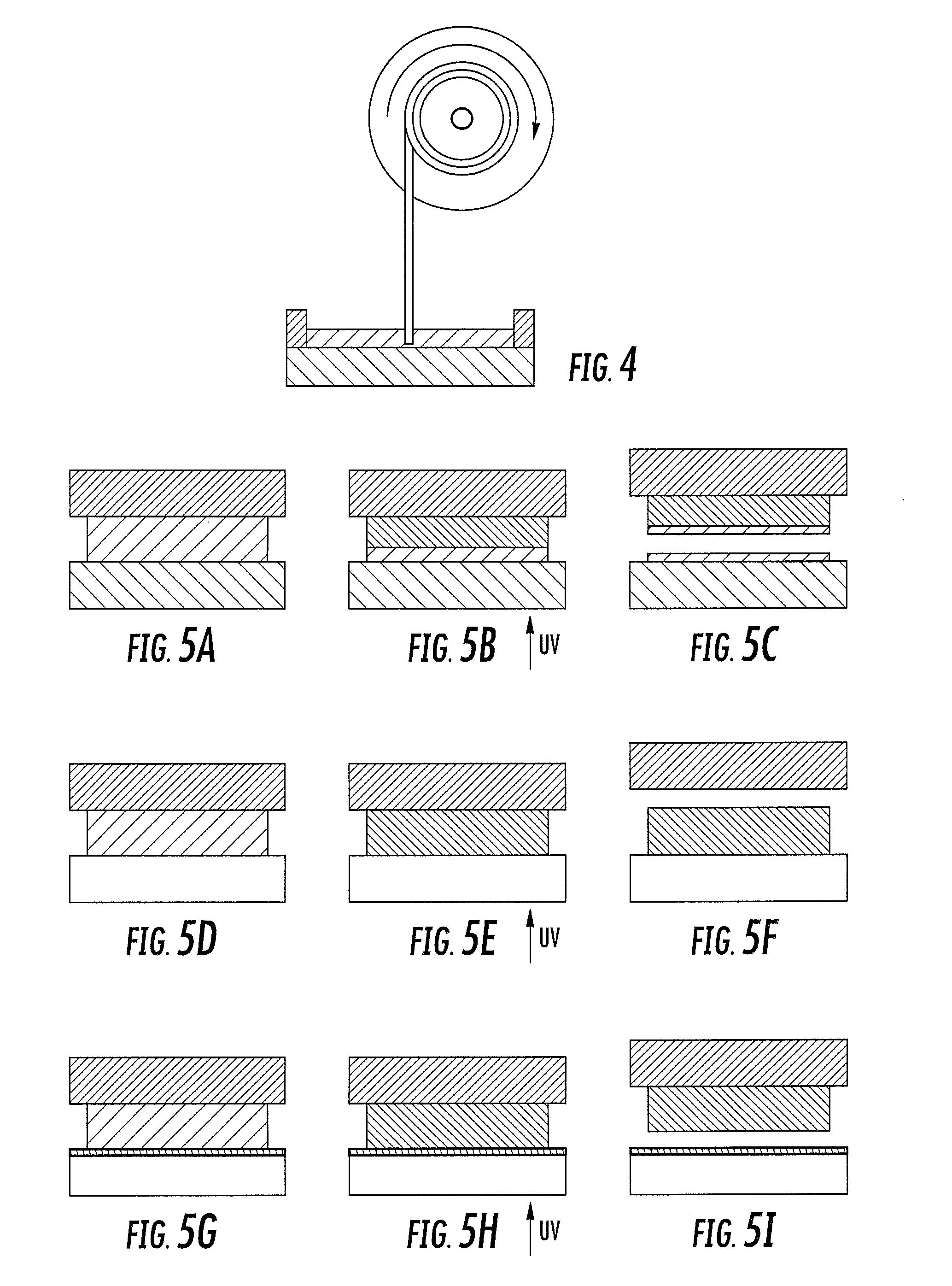

Method and apparatus for three-dimensional fabrication with feed through carrier

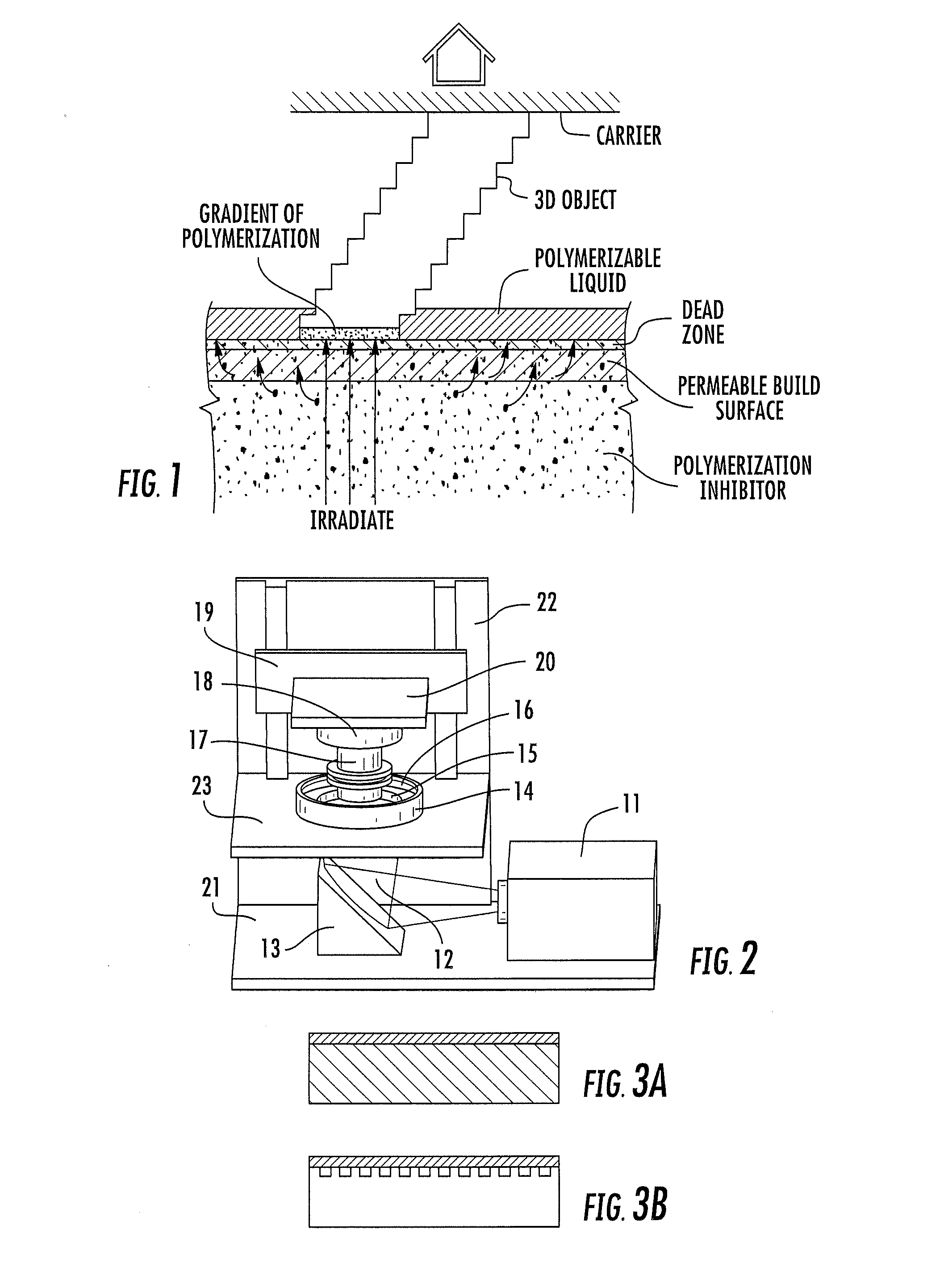

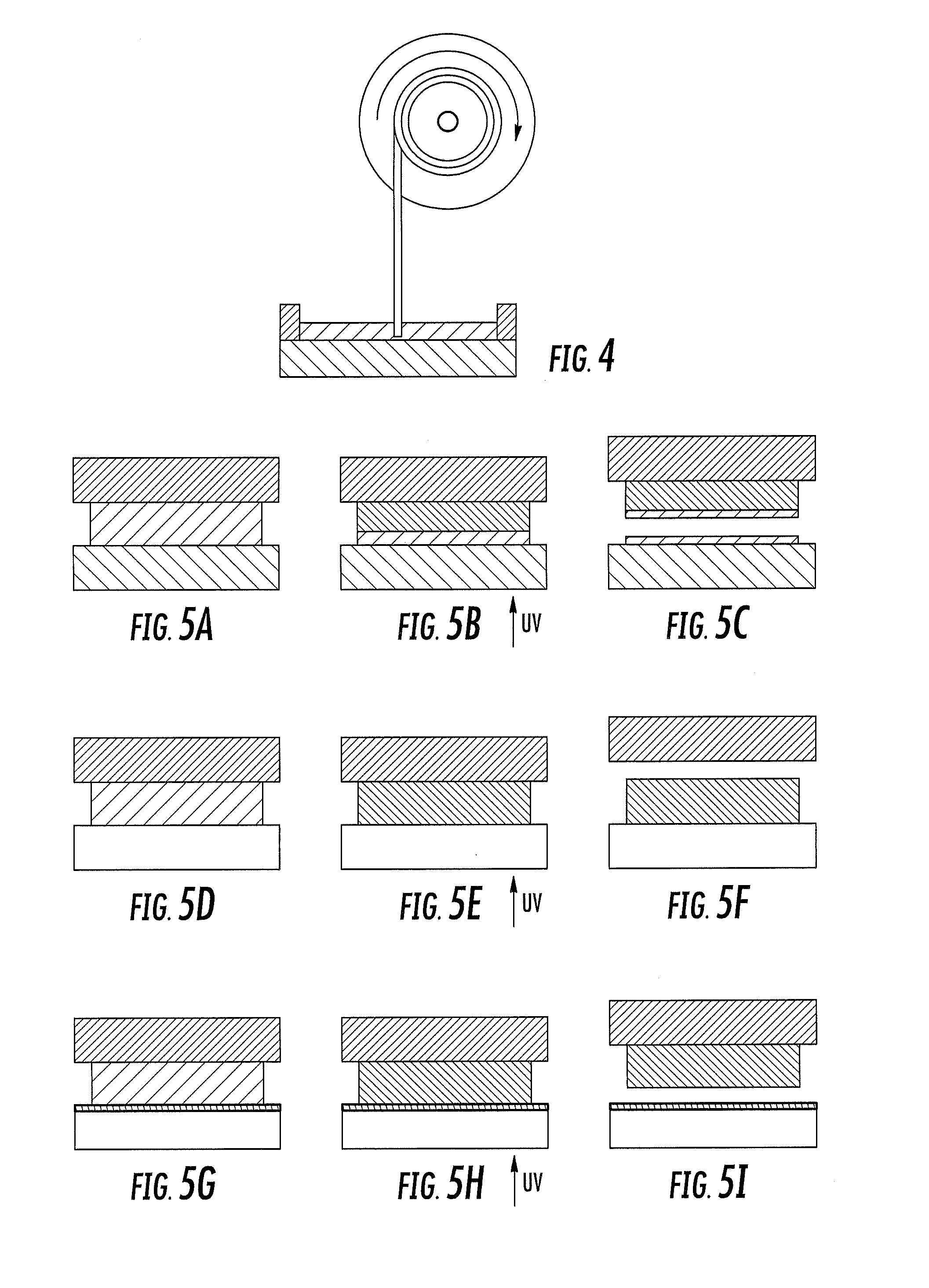

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquid contacting the build surface; (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface; (e) wherein the carrier has at least one channel formed therein, and the filling step is carried out by passing or forcing the polymerizable liquid into the build region through the at least one channel. Apparatus for carrying out the method is also described

Owner:CARBON INC

Method and apparatus for three-dimensional fabrication

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquidcontacting the build surface, (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, wherein the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface while concurrently filling the subsequent build region with polymerizable liquid as in step (b). Apparatus for carrying out the method is also described.

Owner:CARBON INC

Rapid prototyping apparatus

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

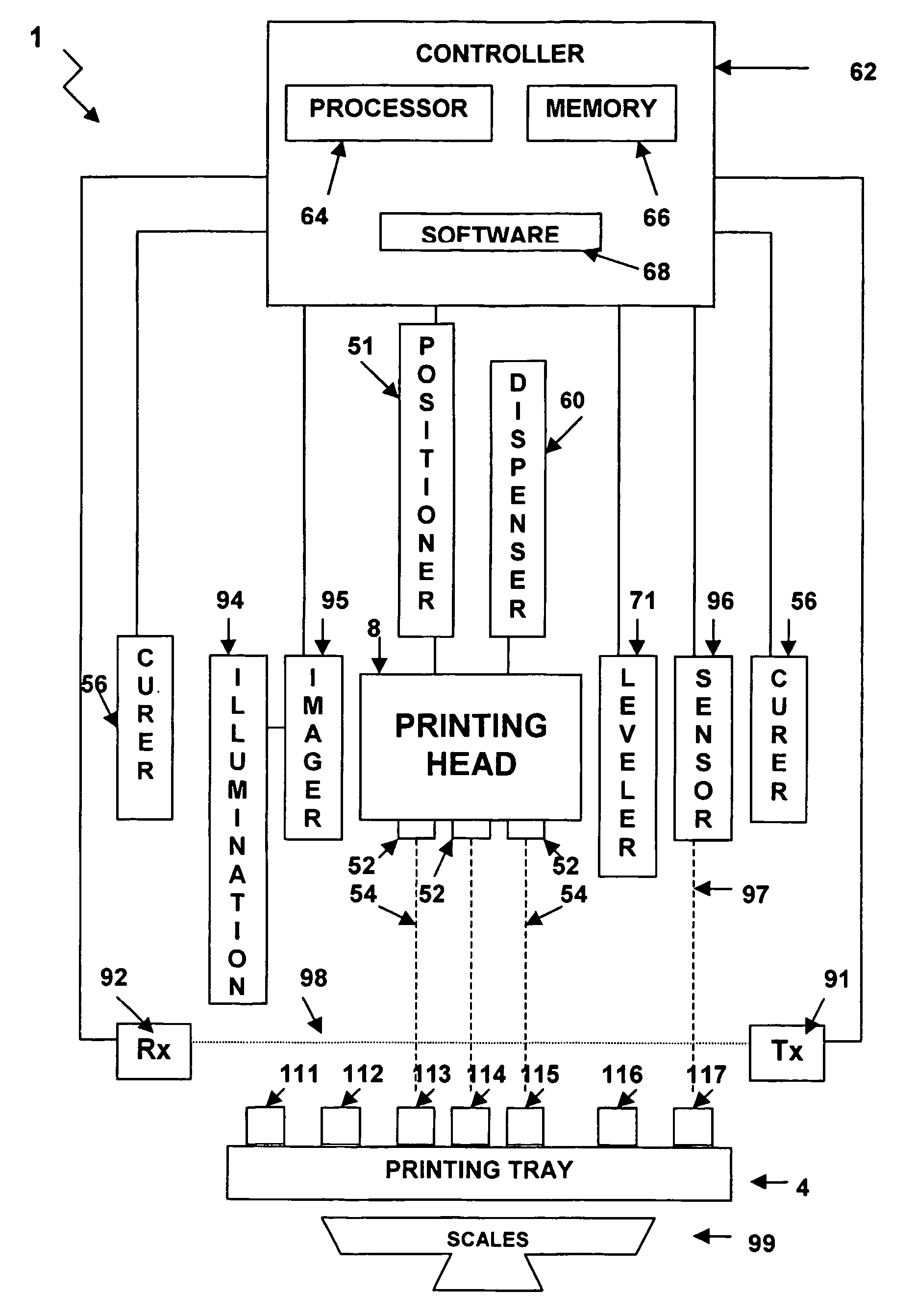

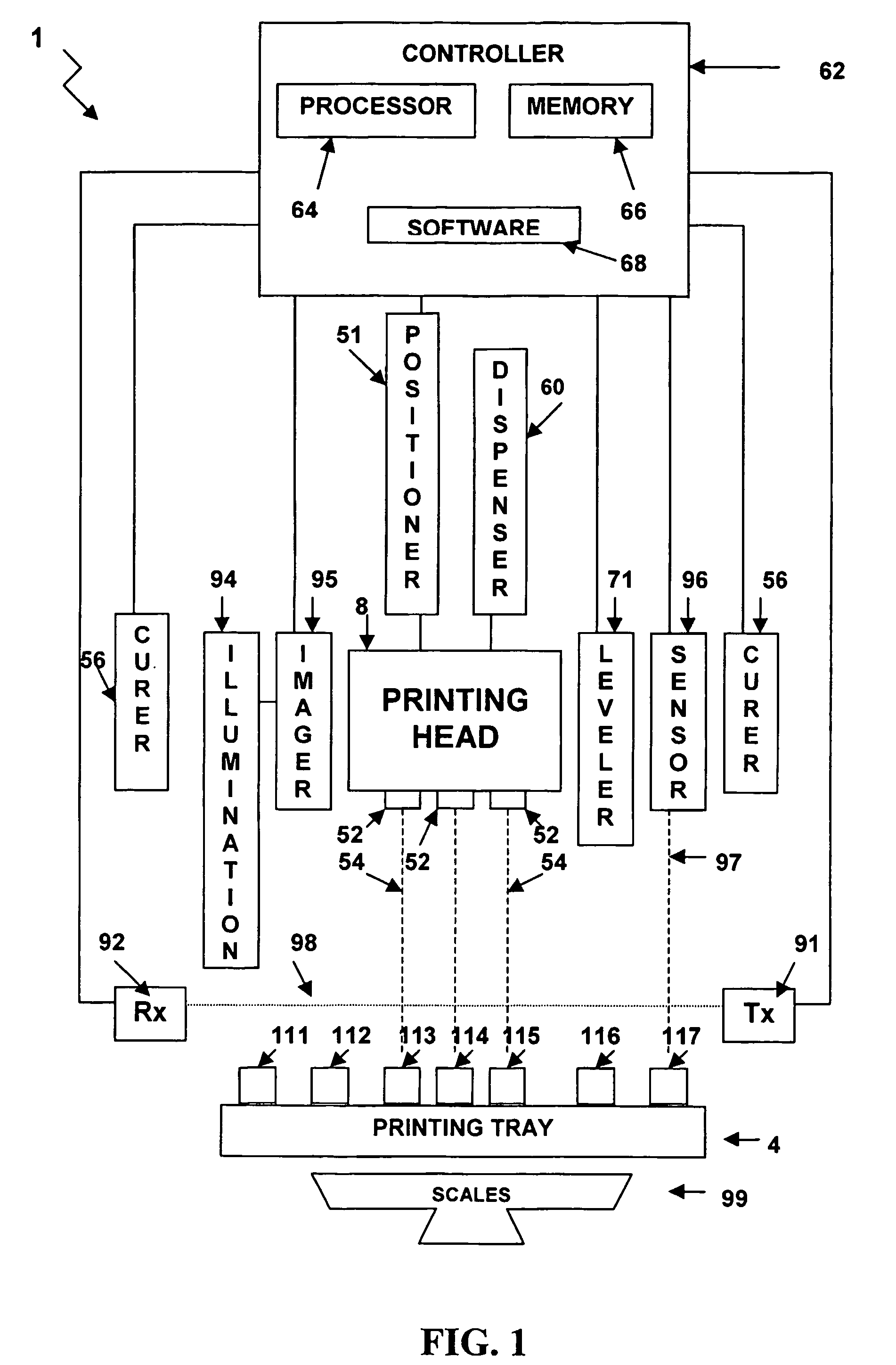

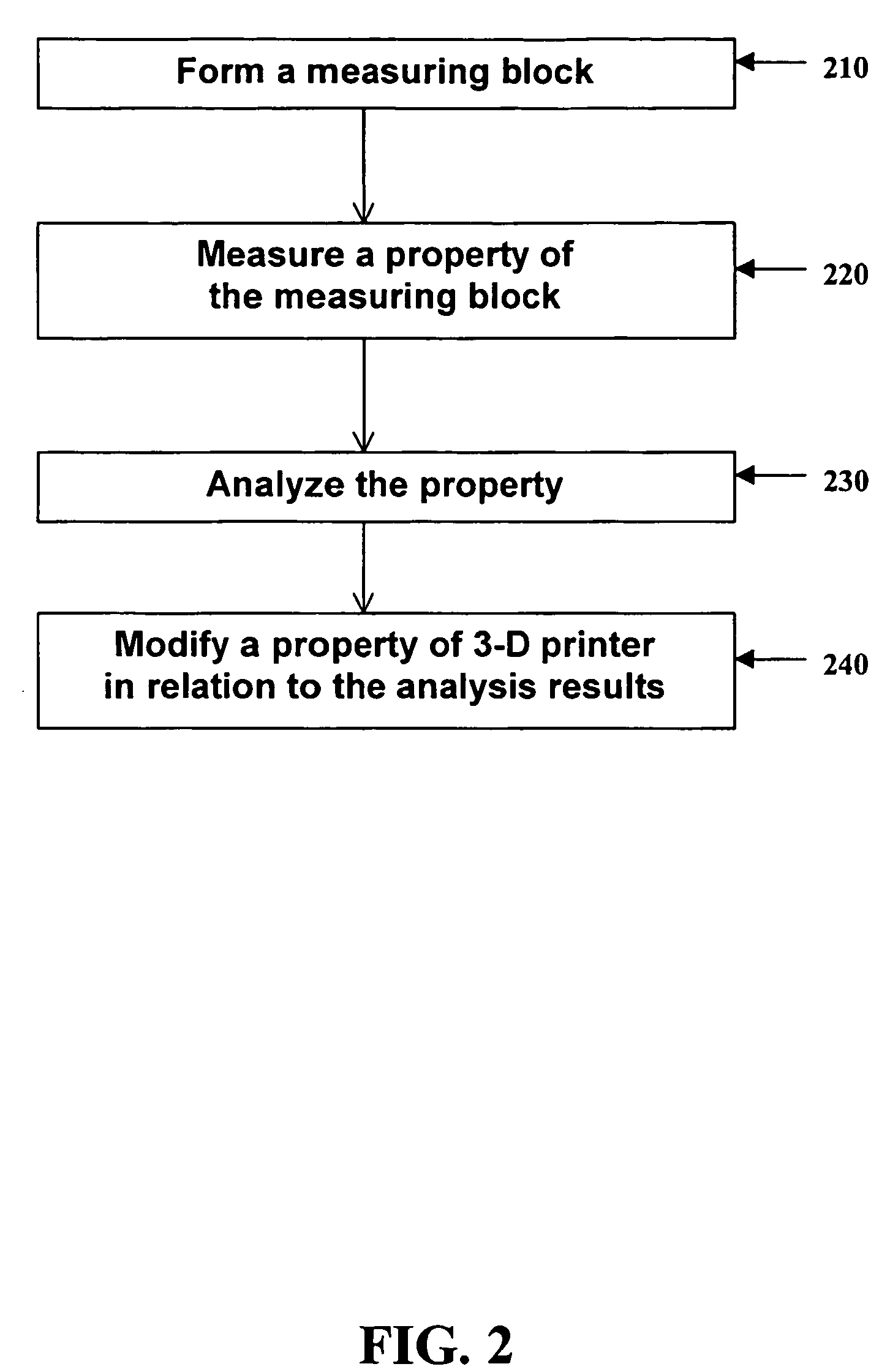

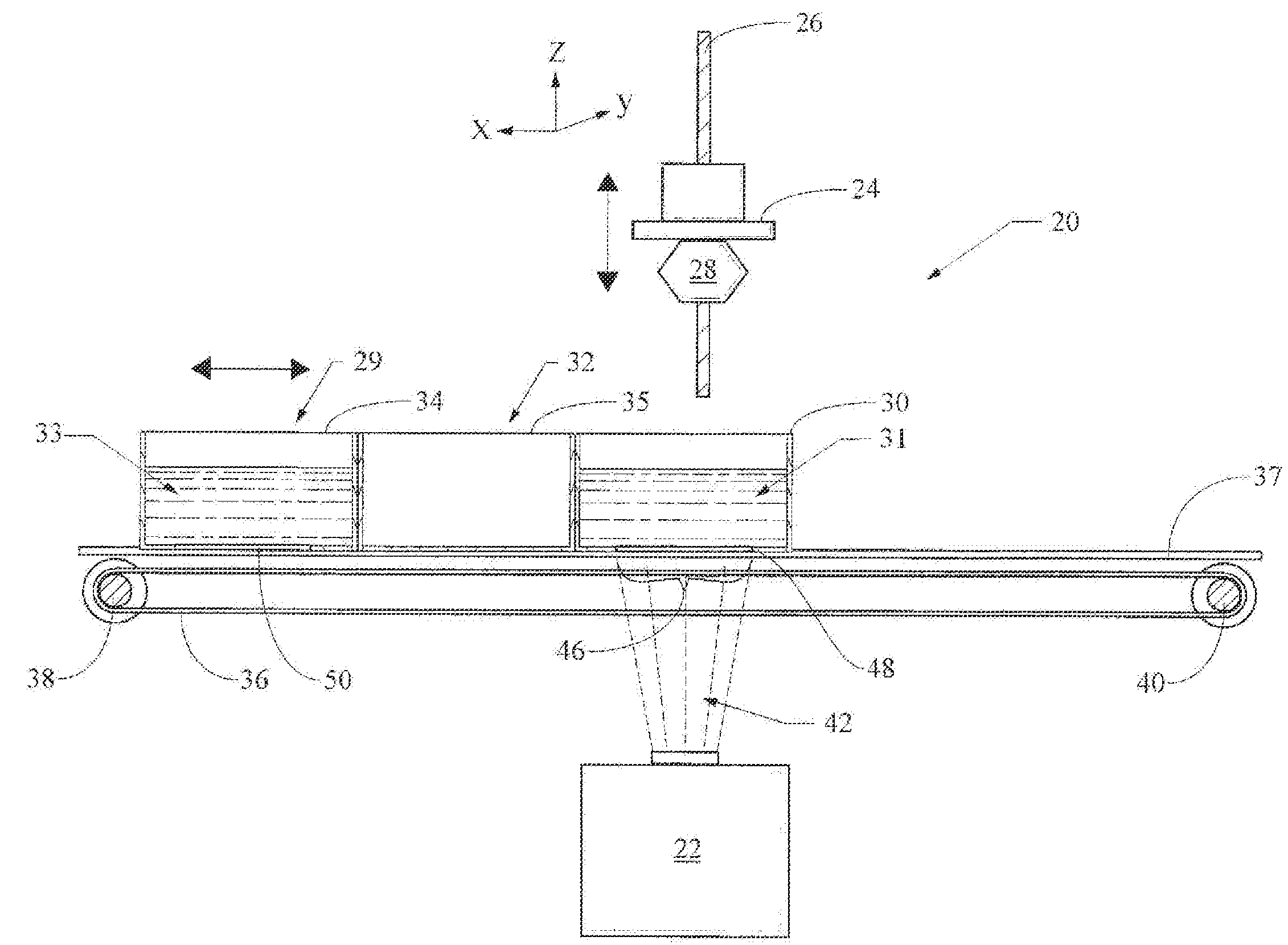

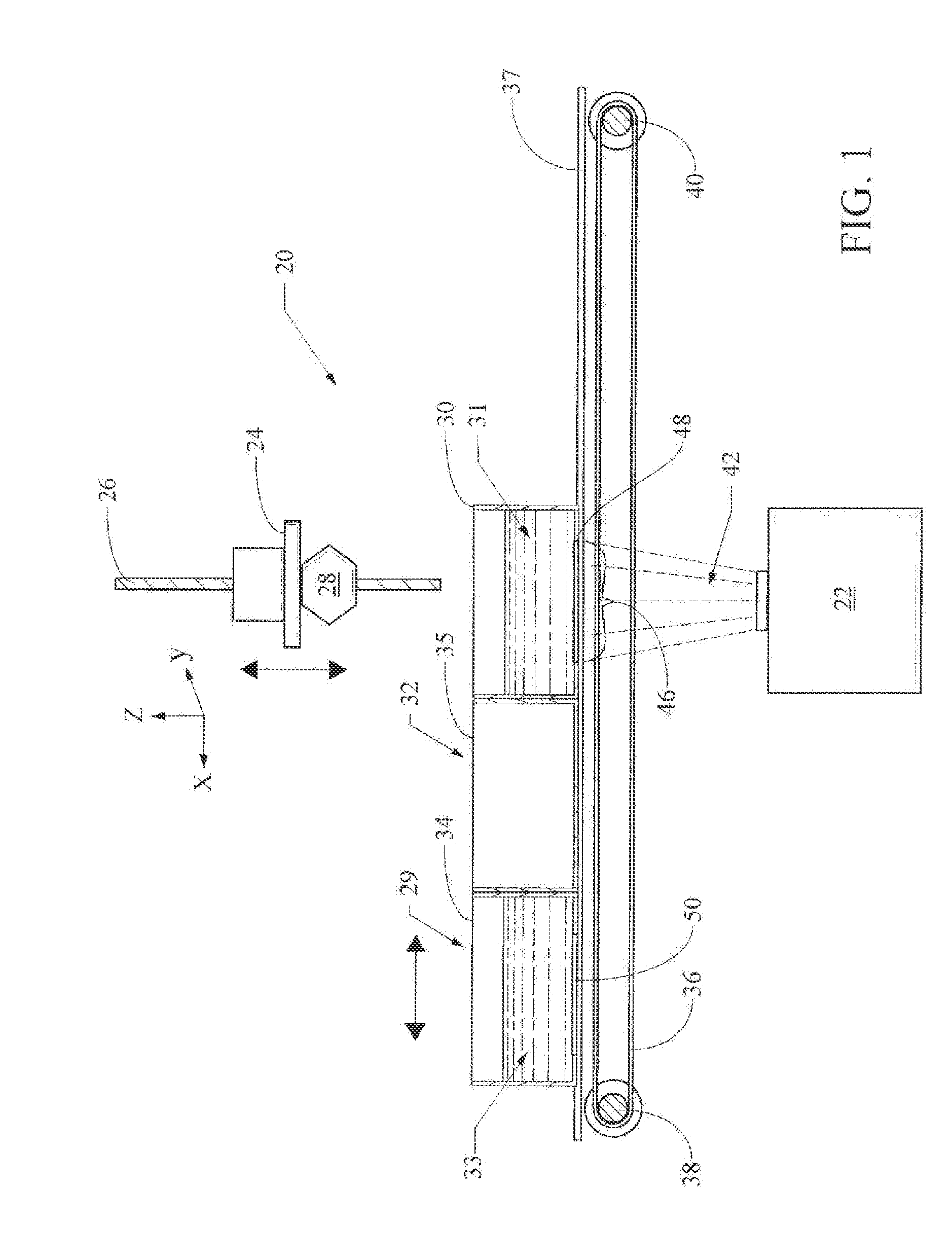

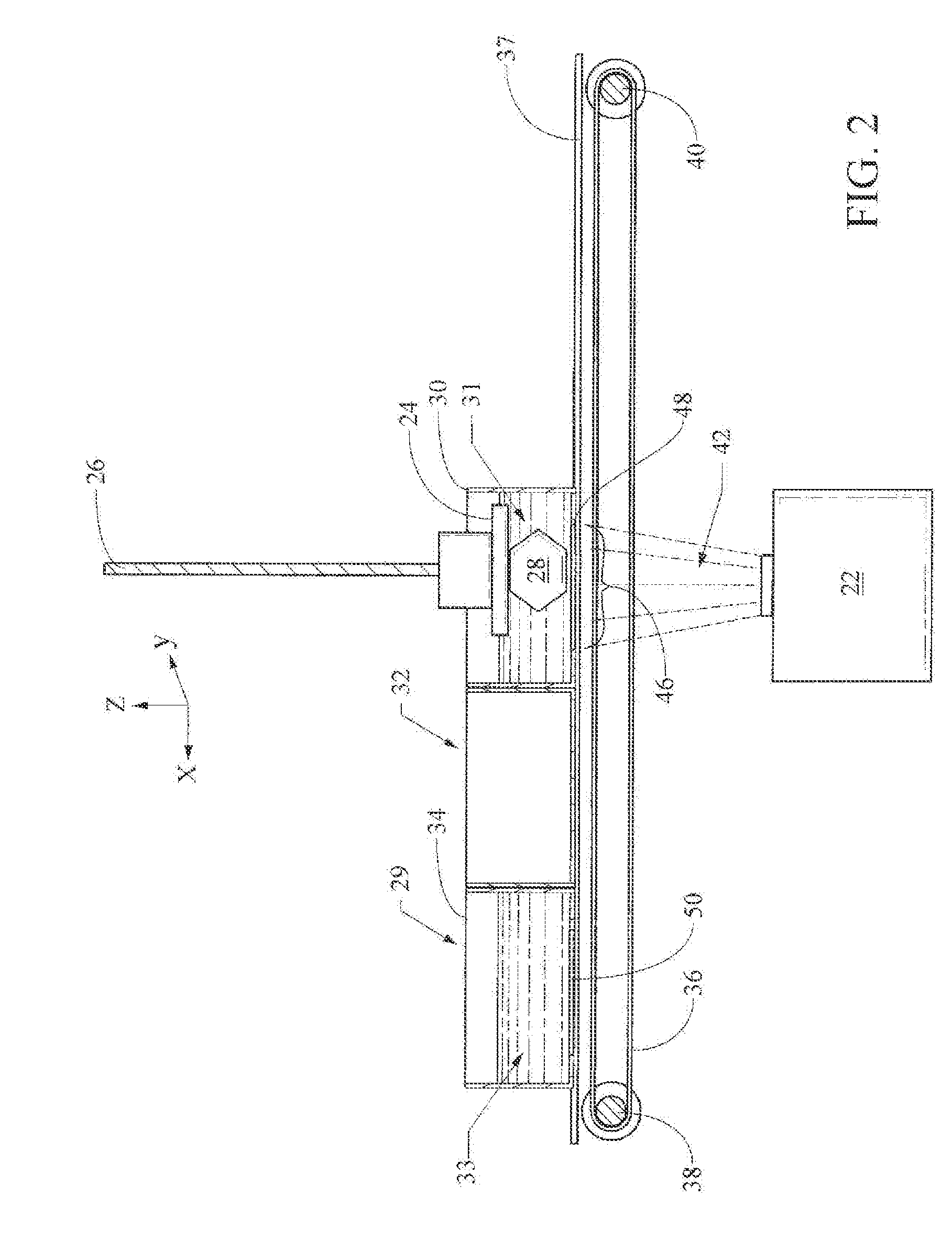

System and method for accurate printing of three dimensional models utilizing adjustment parameters

InactiveUS7209797B2Quality improvementAdditive manufacturing apparatusMeasurement apparatus componentsDimensional modeling3D modeling

A system and method for building three dimensional objects may adjust data used to build the objects to, for example, improve quality or correct for defects. A printer may, for example, accept data representing the object and modify the data according to an adjustment parameter; the printer may build the object according to the parameter. The parameter may be, for example, fixed in the printer, user entered, and / or calculated by the printer. In one embodiment, a support pedestal may be built of deposited material before the object is built.

Owner:STRATASYS LTD

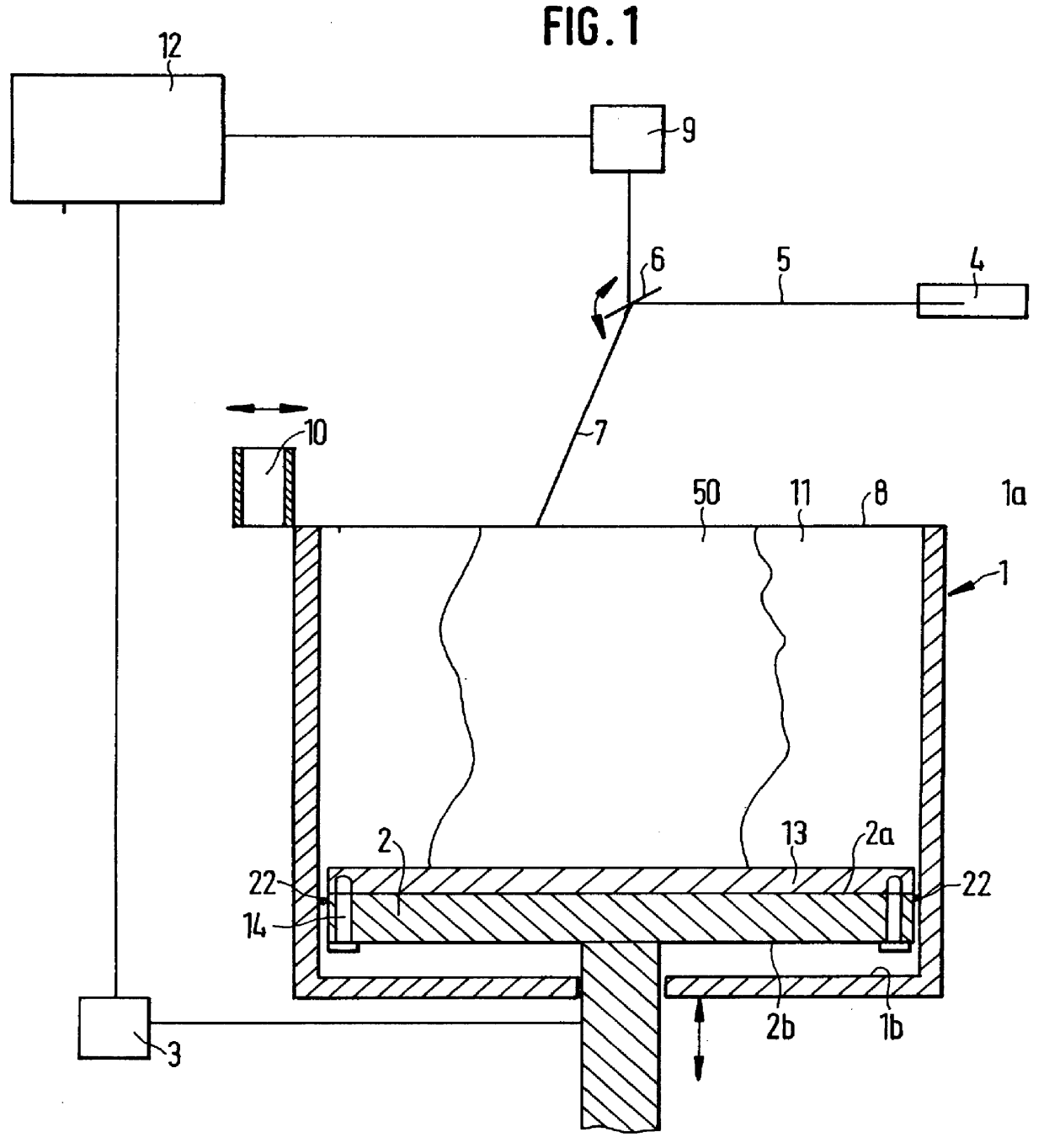

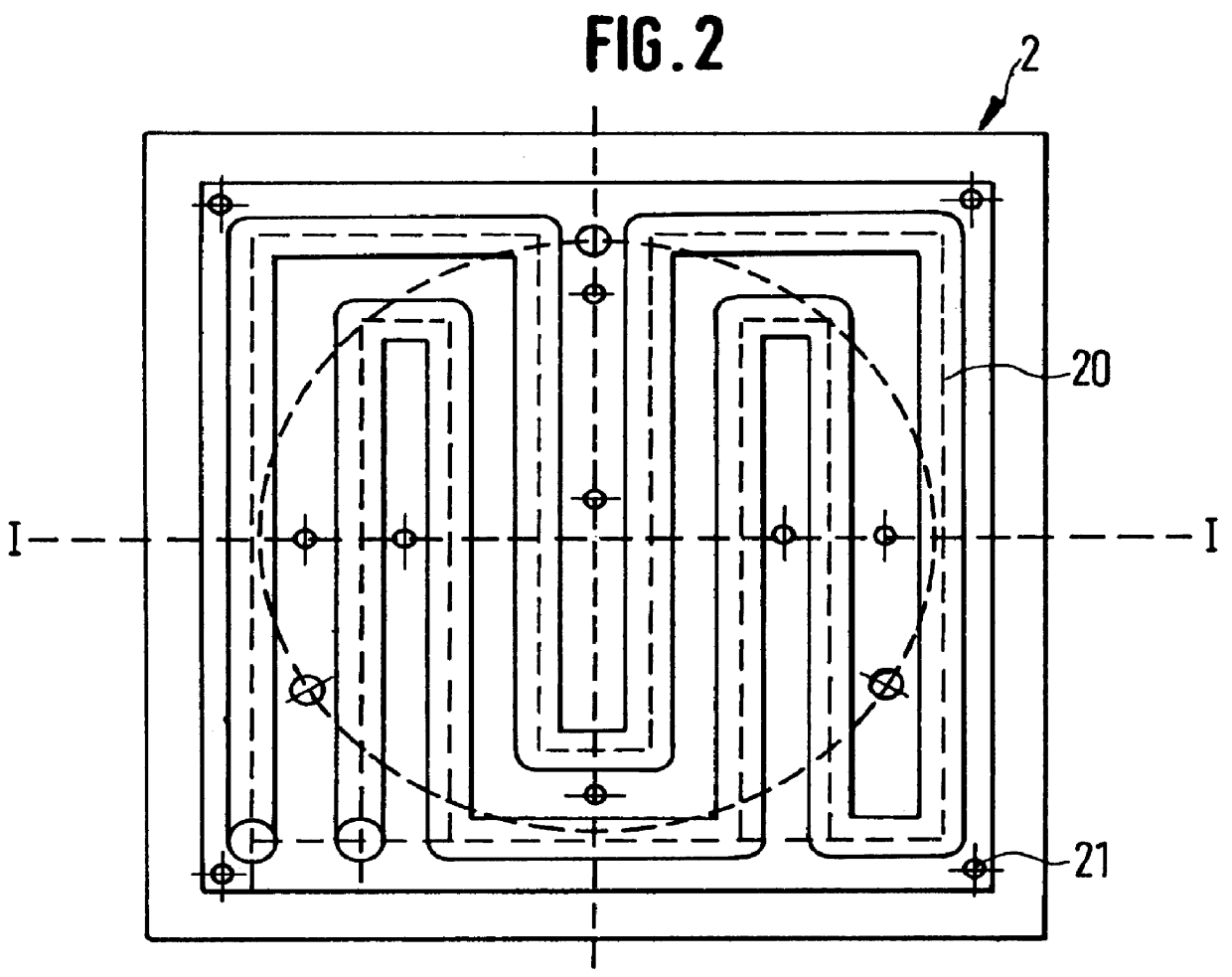

Method for producing a three-dimensional object

InactiveUS6042774AShorten production timeAdditive manufacturing apparatus3D object support structuresIrradiationMaterials science

A method of producing an object by successive solidification of layers of a powder material is disclosed. The method provides a preformed base plate having a metal plate with a solidified layer of a powder material formed thereon. Then, successive layers of said powder material are applied and solidified on the solidified layer of the base plate to form the object. In further detail, the method for produces a three-dimensional by providing a support and a preformed base plate having an upper surface for supporting the object. The base plate is removably attached to the support. Means are provided for adjusting the elevation of said upper surface. A layer of the powder material is applied to the upper surface of the base plate. The powder material is solidified at points corresponding to a cross-section of the object by irradiation with electromagnetic or particle radiation. Then, the applying and solidifying steps are repeated for completing the object.

Owner:EOS ELECTRO OPTICAL SYST

Device, system and method for calibration in three-dimensional model printing

InactiveUS20060111807A1Additive manufacturing apparatus3D object support structuresEngineeringThree dimensional model

Owner:OBJET GEOMETRIES

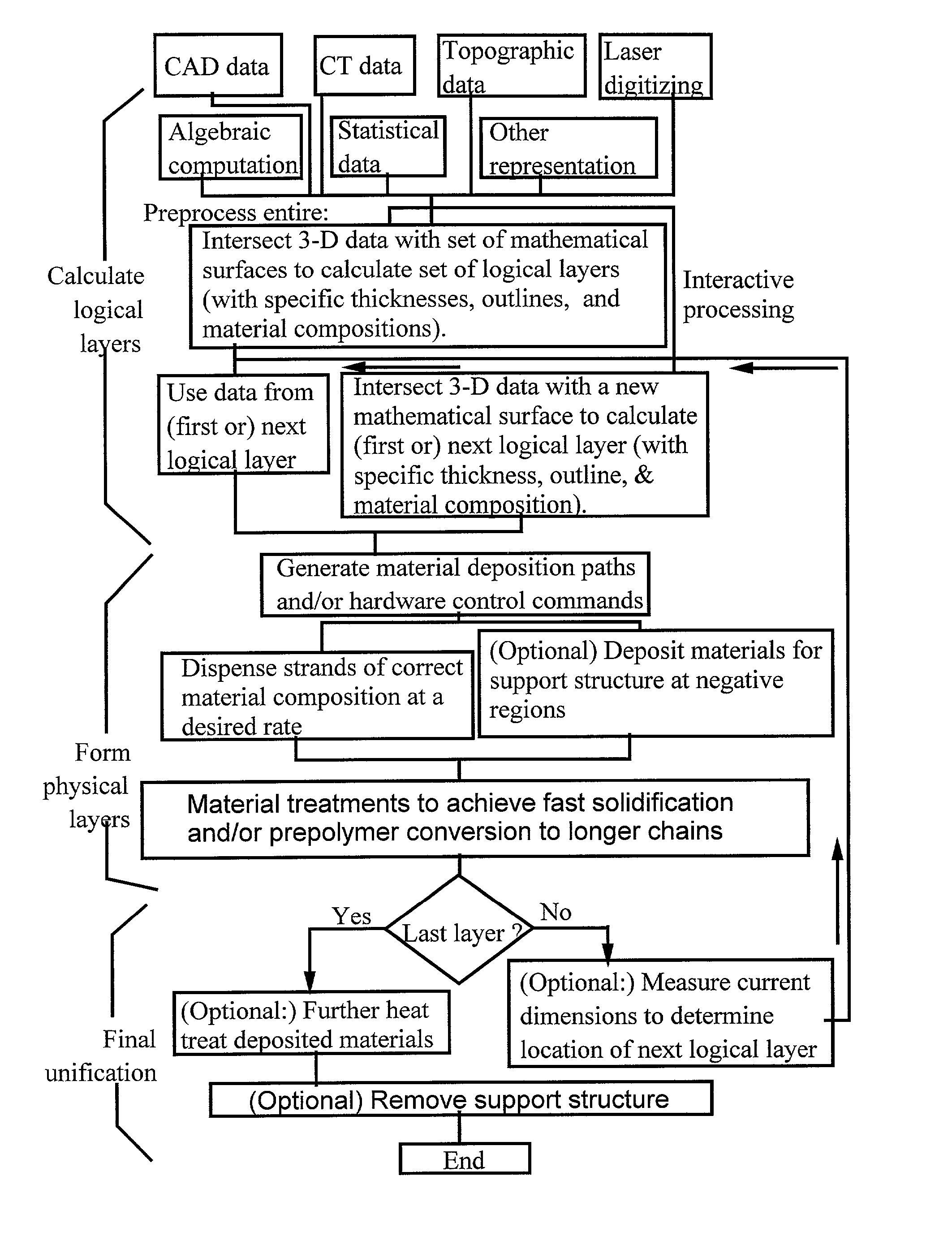

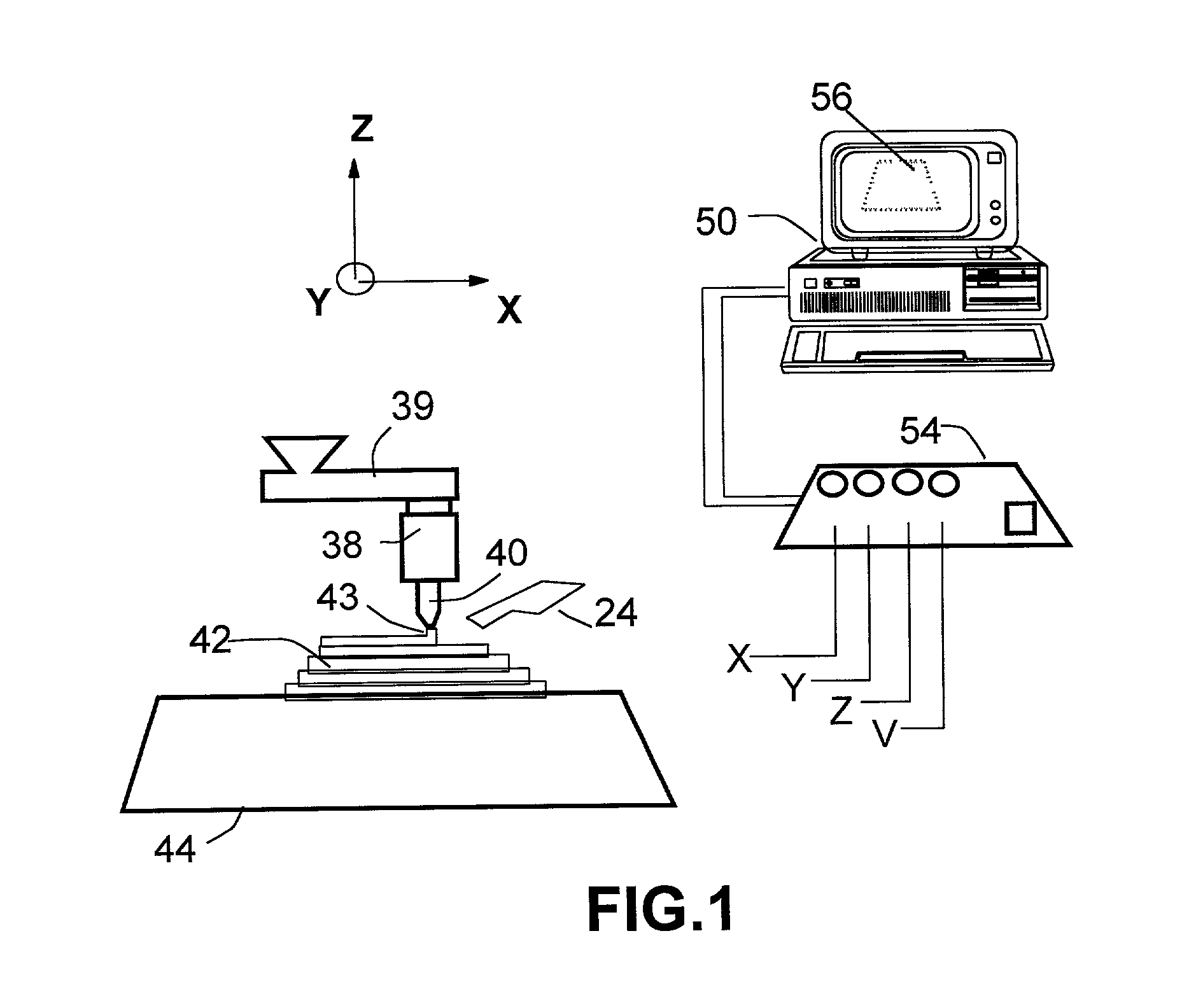

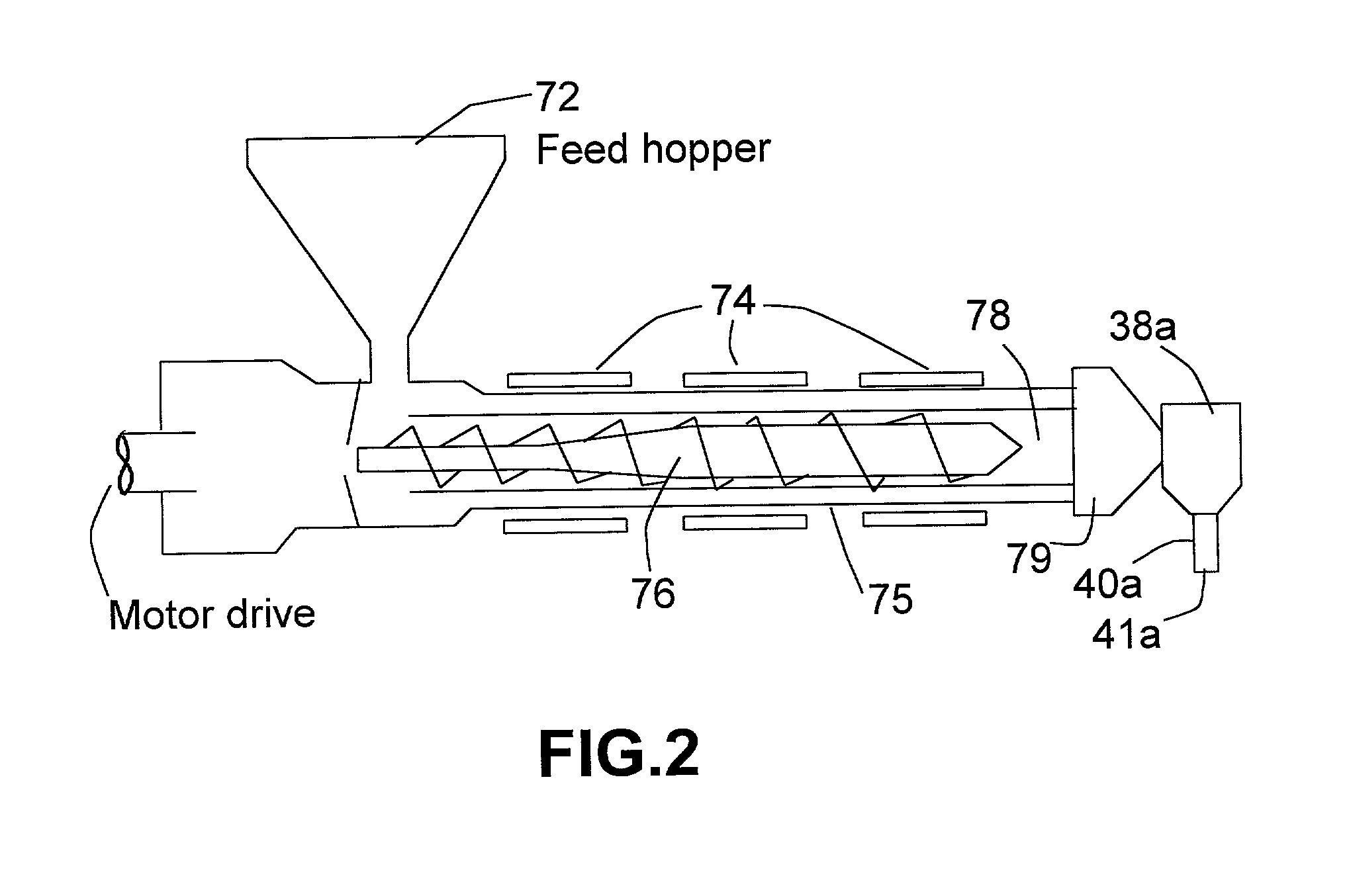

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

Continuous liquid interphase printing

A method of forming a three-dimensional object, comprises providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid while concurrently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form. Apparatus for carrying out the method is also described.

Owner:CARBON INC

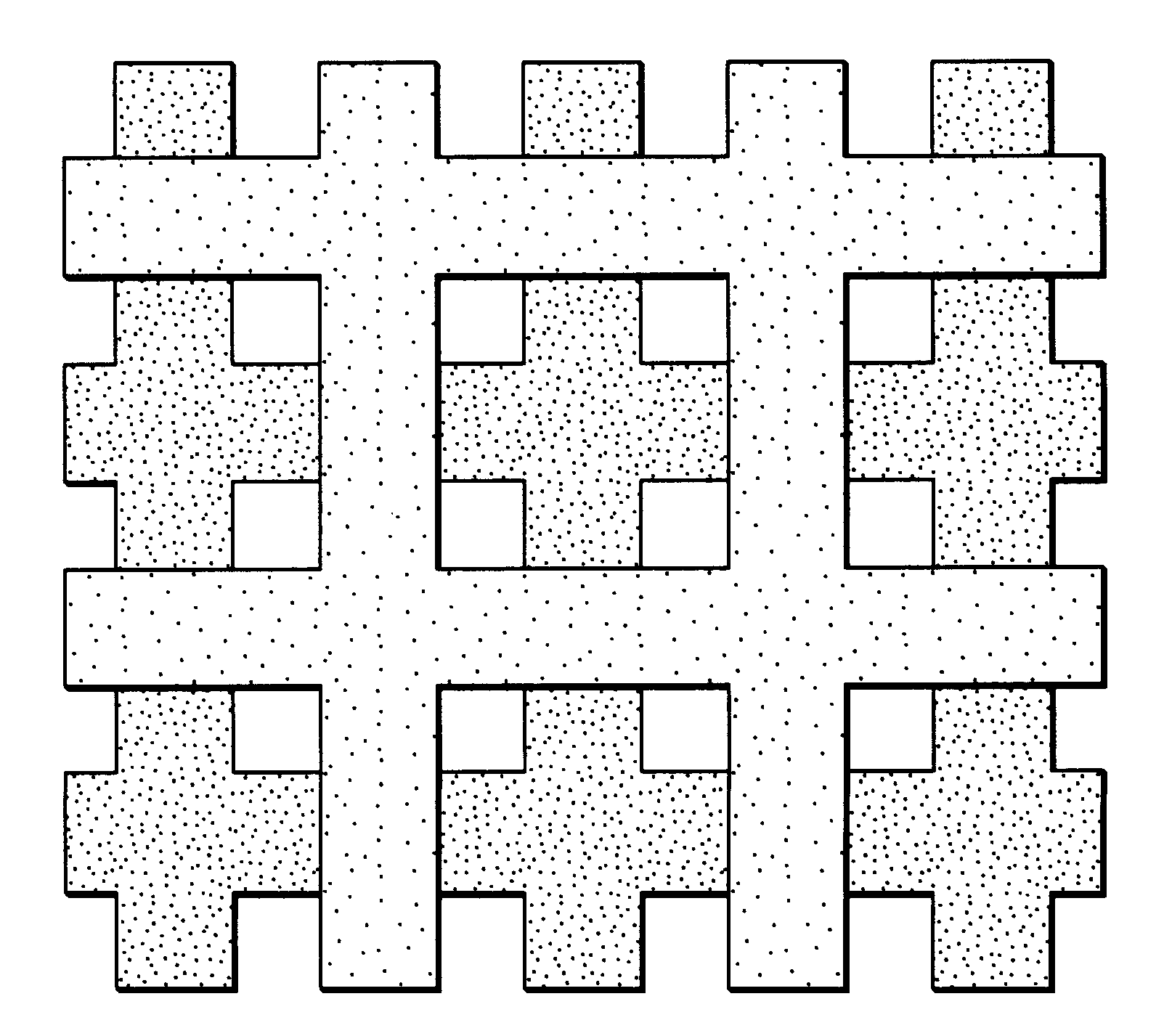

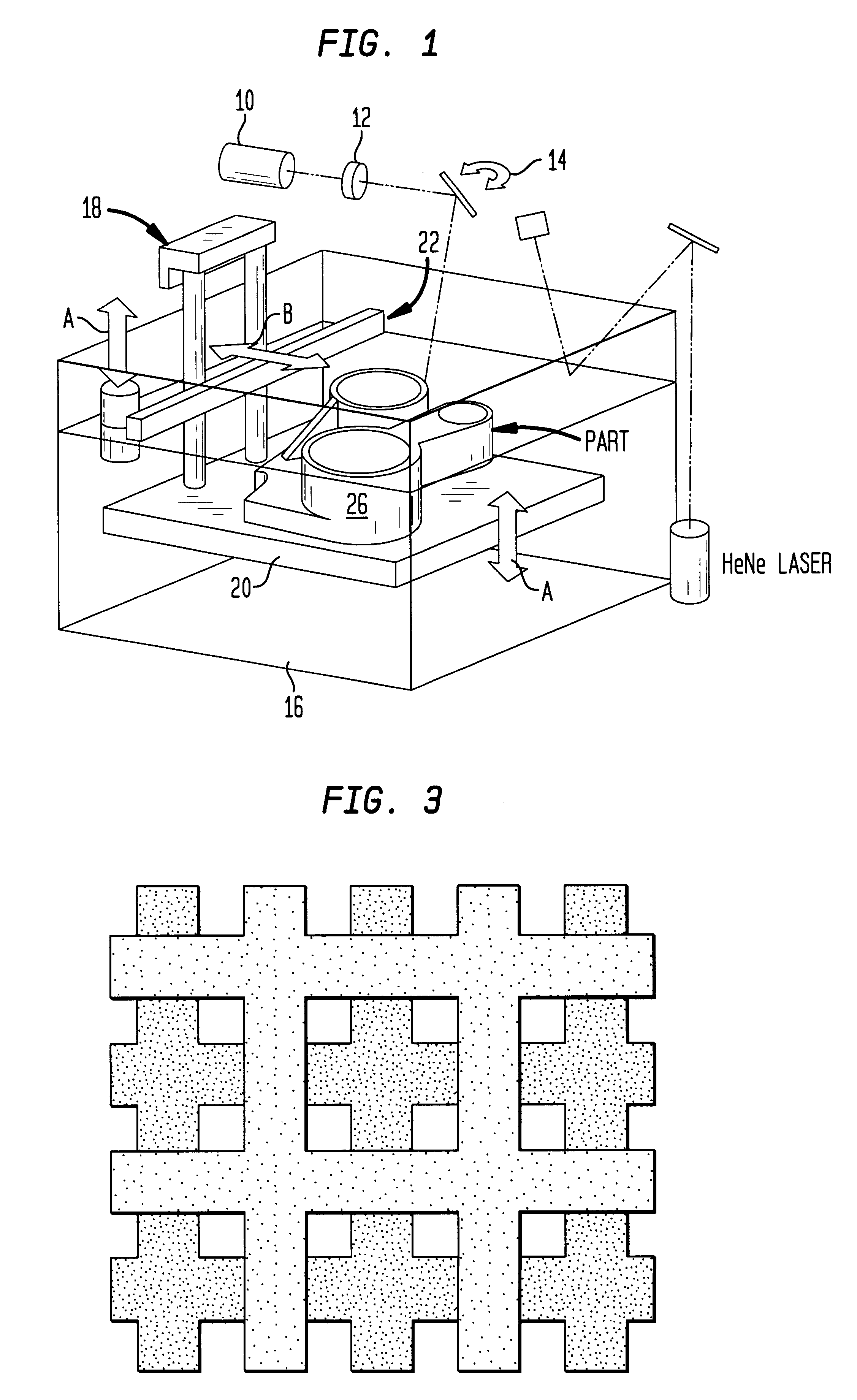

Controlled architecture ceramic composites by stereolithography

InactiveUS6283997B1Quality improvementFast preparationProgramme controlAdditive manufacturing apparatusCeramic compositeMetallurgy

A process for producing a ceramic composite having a porous network. The process includes providing a photocurable ceramic dispersion. The dispersion consists of a photocurable polymer and a ceramic composition. The surface of the dispersion is scanned with a laser to cure the photocurable polymer to produce a photocured polymer / ceramic composition. The photocured composition useful as a polymer / ceramic composite, or the polymer phase can be removed by heating to a first temperature that is sufficient to burn out the photocured polymer. It is then heated to a second temperature that is higher than the first temperature and is sufficient to sinter the ceramic composition to produce a purely ceramic composition having a porous network.Preferably and more specifically, the process uses a stereolithographic technique for laser scanning. The process can form a high quality orthopedic implant that dimensionally matches the bone structure of a patient. The technique relies upon laser photocuring a dense colloidal dispersion into a desired complex three-dimensional shape. The shape is obtained from a CAT scan file of a bone and is rendered into a CAD file that is readable by the stereolithography instrument. Or the shape is obtained directly from a CAD file that is readable by the stereolithography instrument.

Owner:UNITED STATES SURGICAL CORP +2

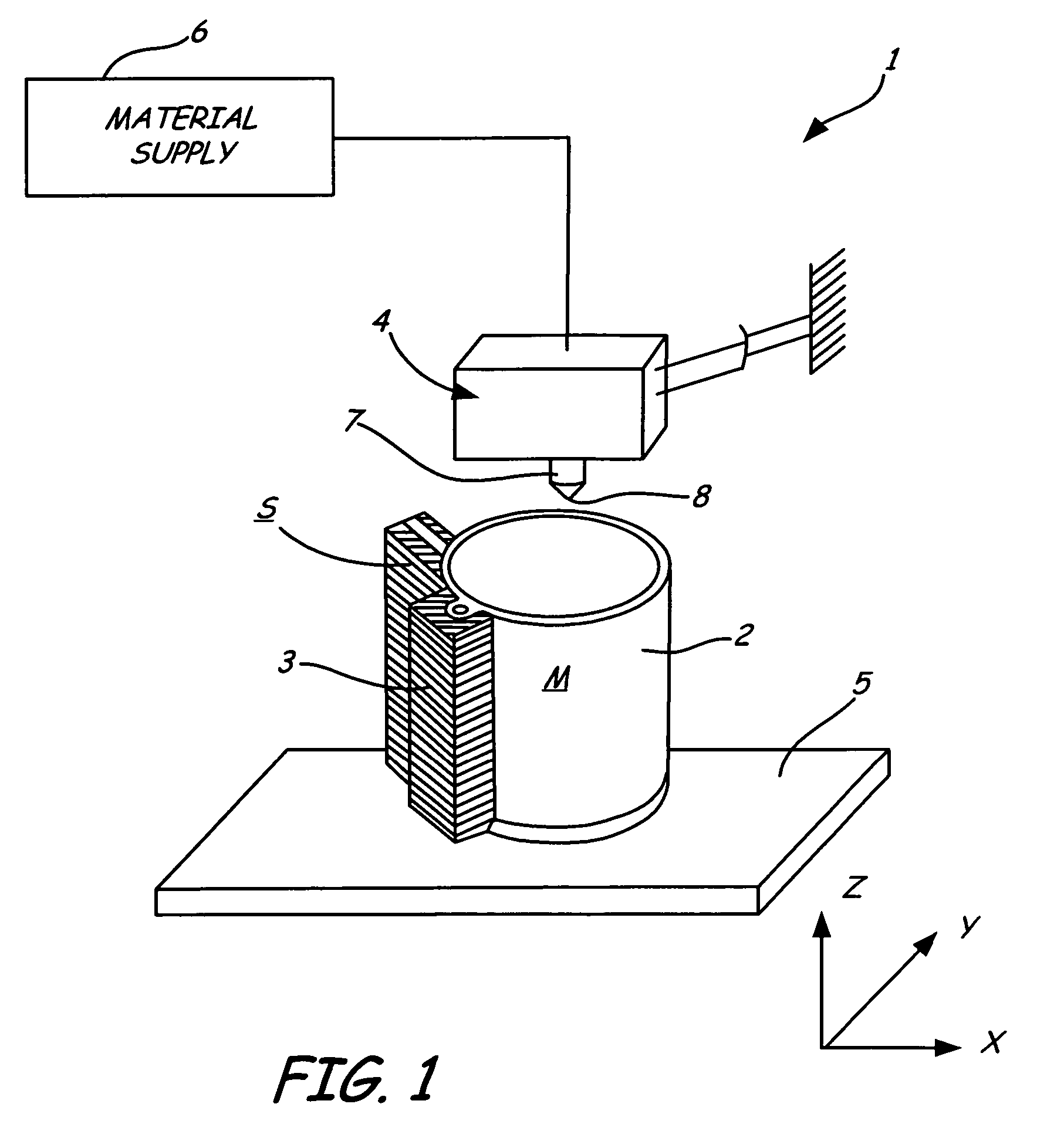

Method and apparatus for making three-dimensional objects from multiple solidifiable materials

Owner:GLOBAL FILTRATION SYST

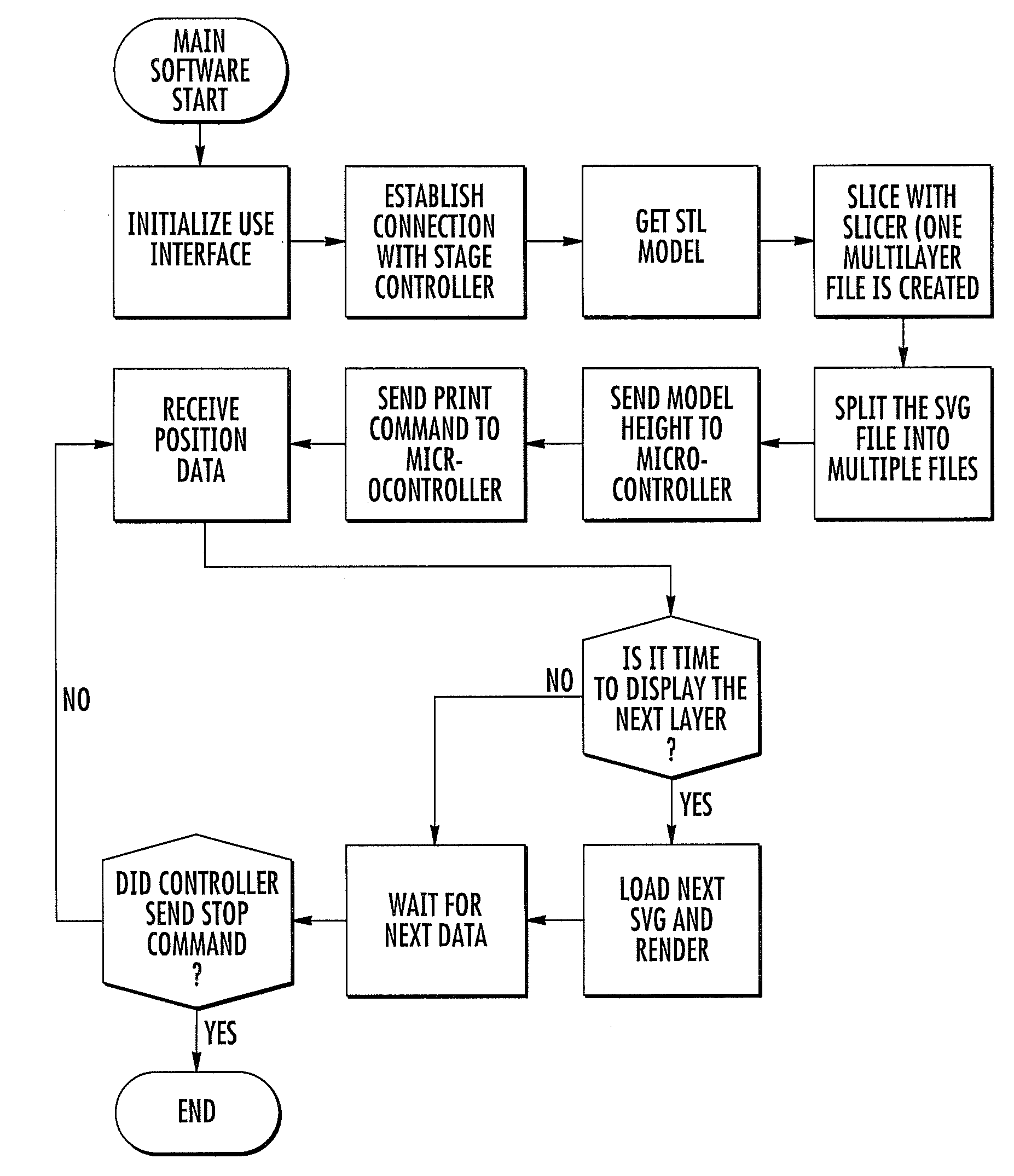

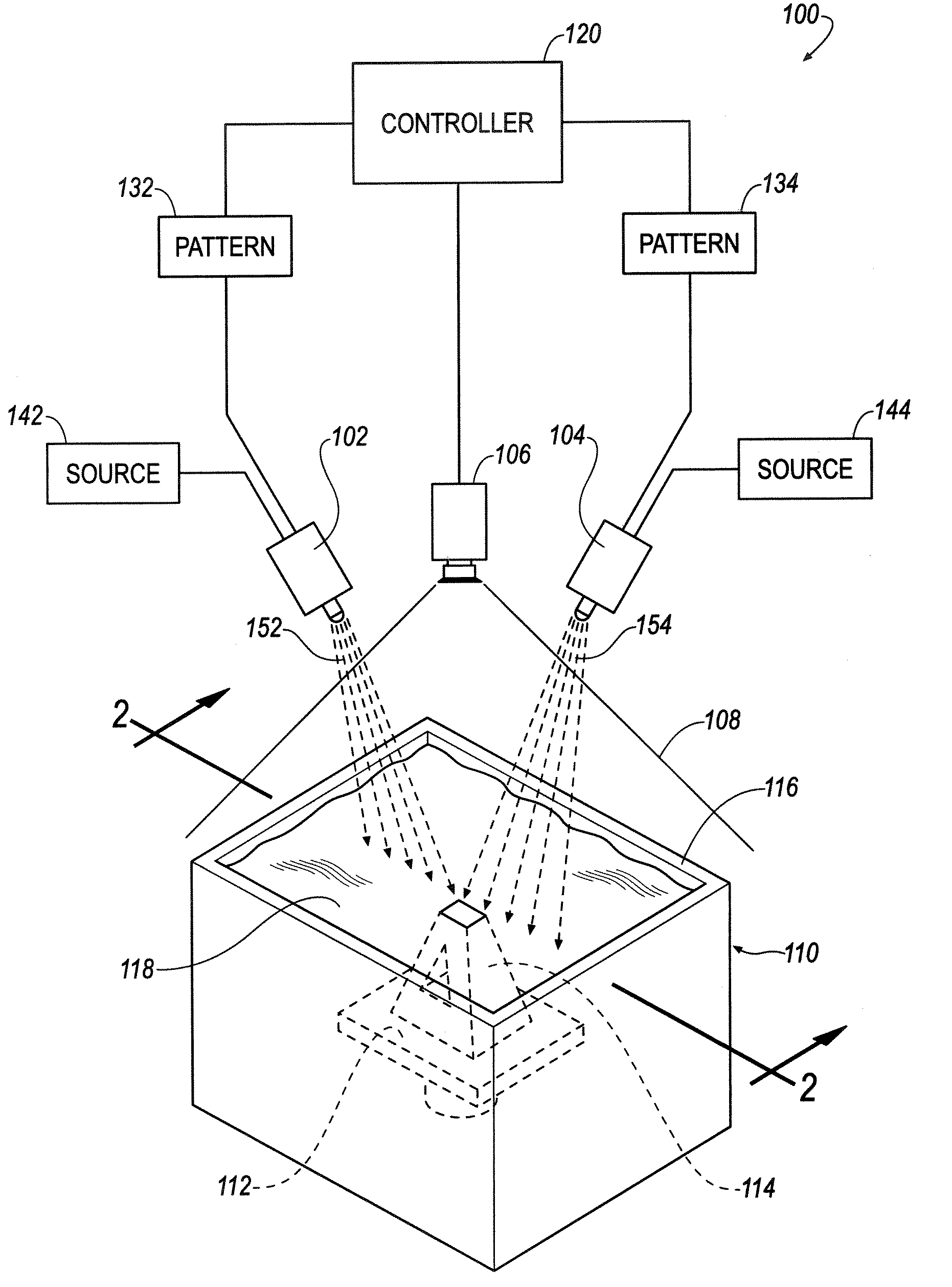

System and Method for Manufacturing

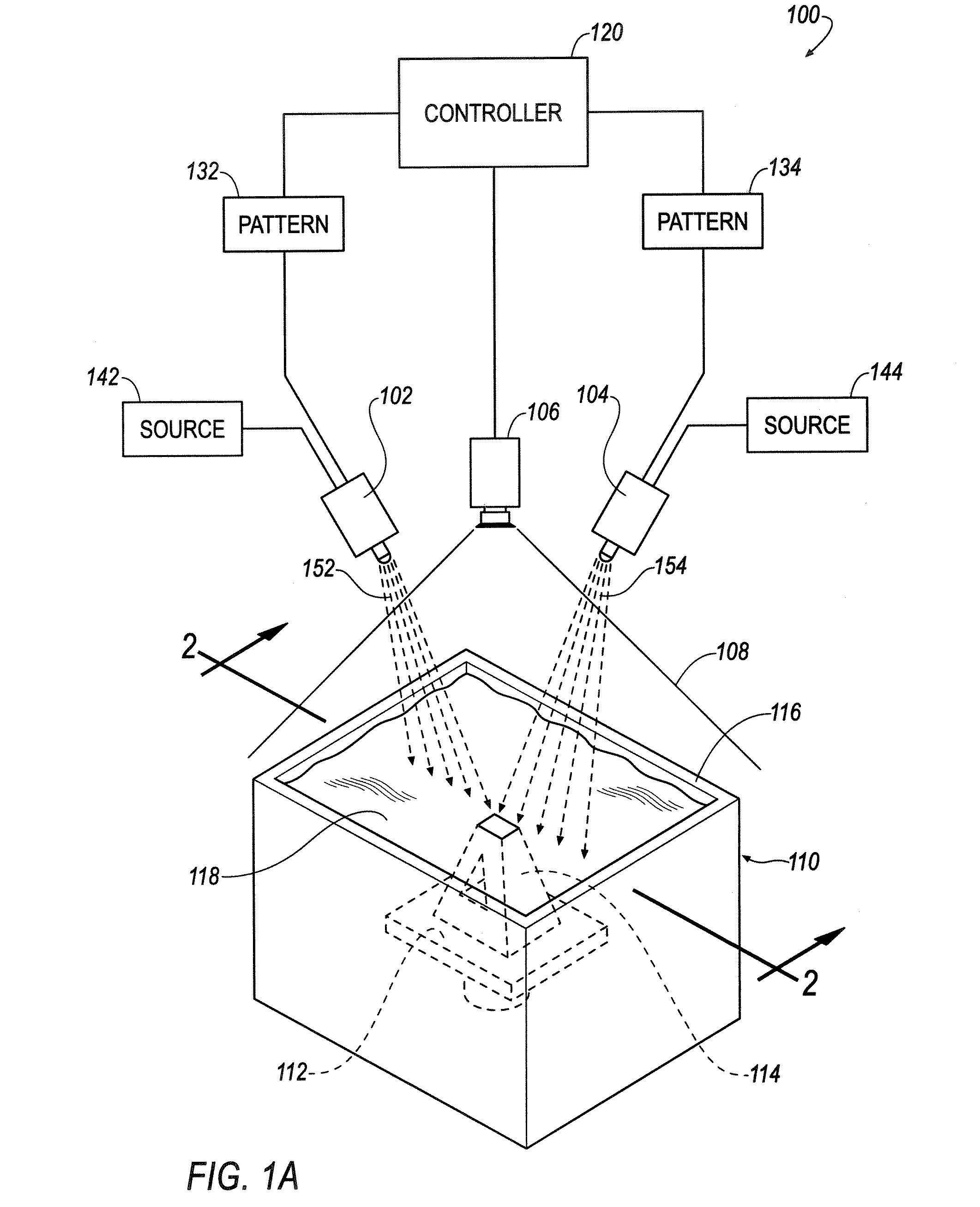

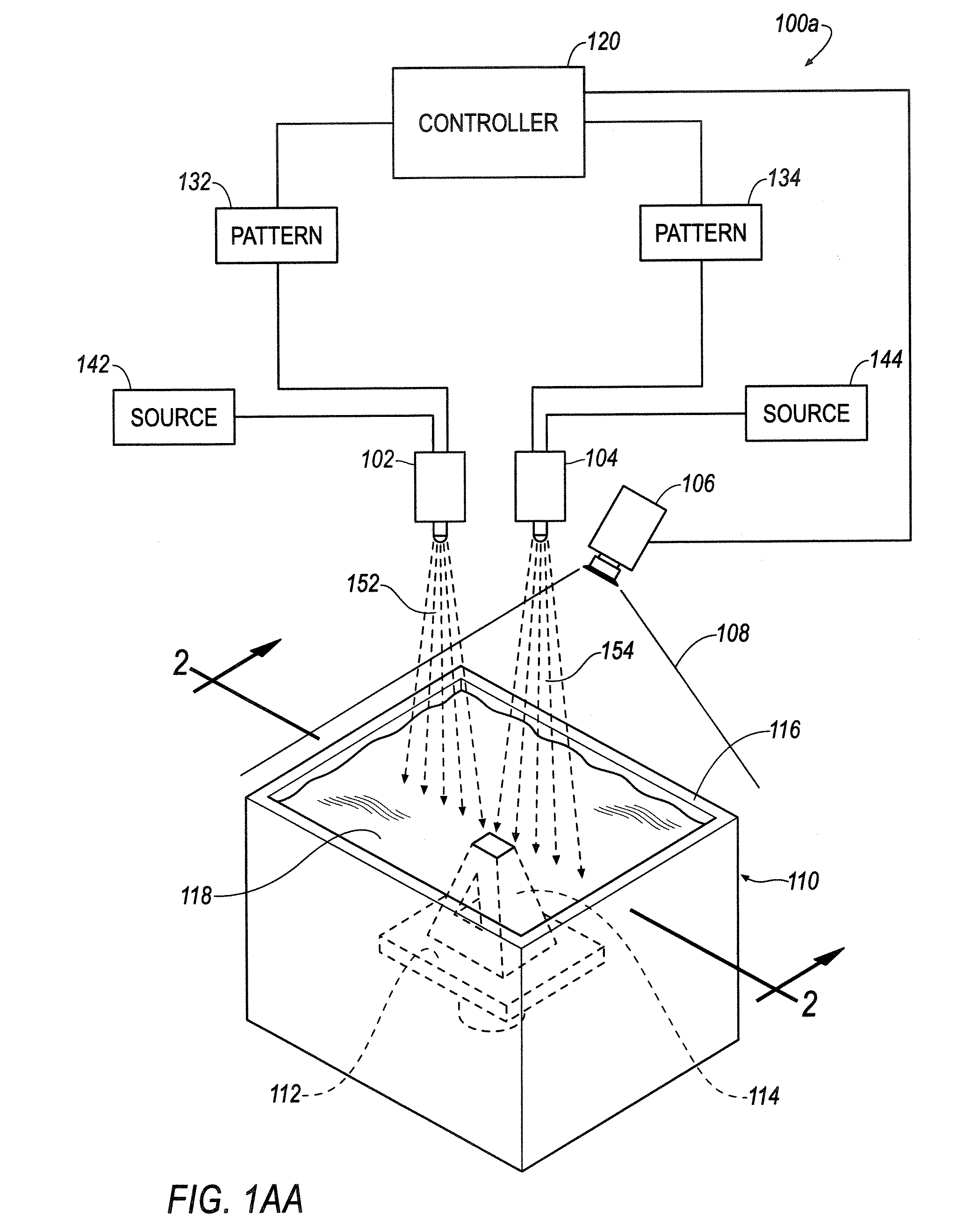

ActiveUS20100125356A1Image enhancementAdditive manufacturing apparatusComputer graphics (images)Reactive material

A method includes receiving a predetermined object pattern representing a portion of a three-dimensional object, modifying the predetermined object pattern to correct for geometric distortion of a pattern generator, and generating the modified pattern using the pattern generator. The generated pattern interacts with a reactive material to form the portion of the three-dimensional object defined by the predetermined object pattern.

Owner:GLOBAL FILTRATION SYST

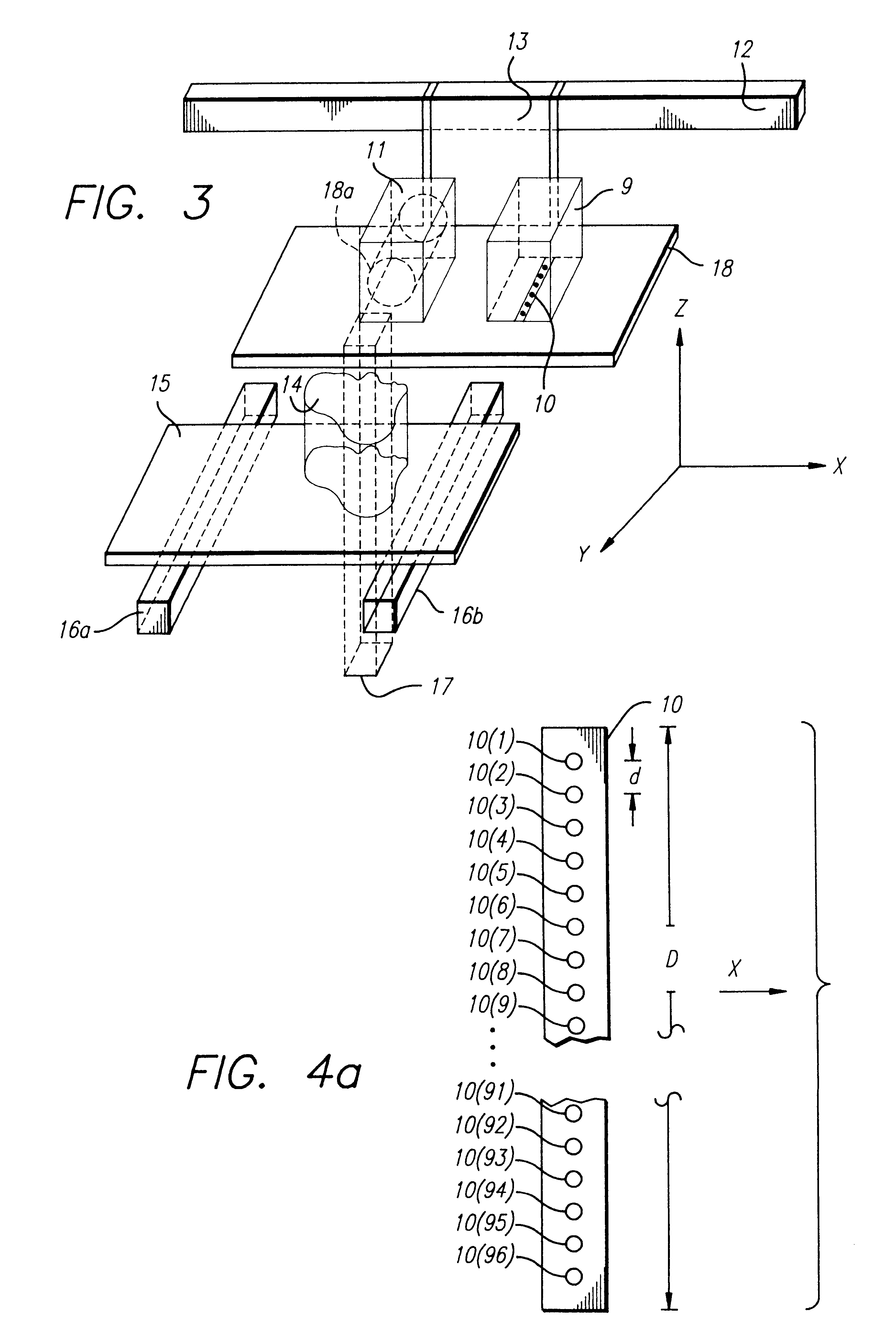

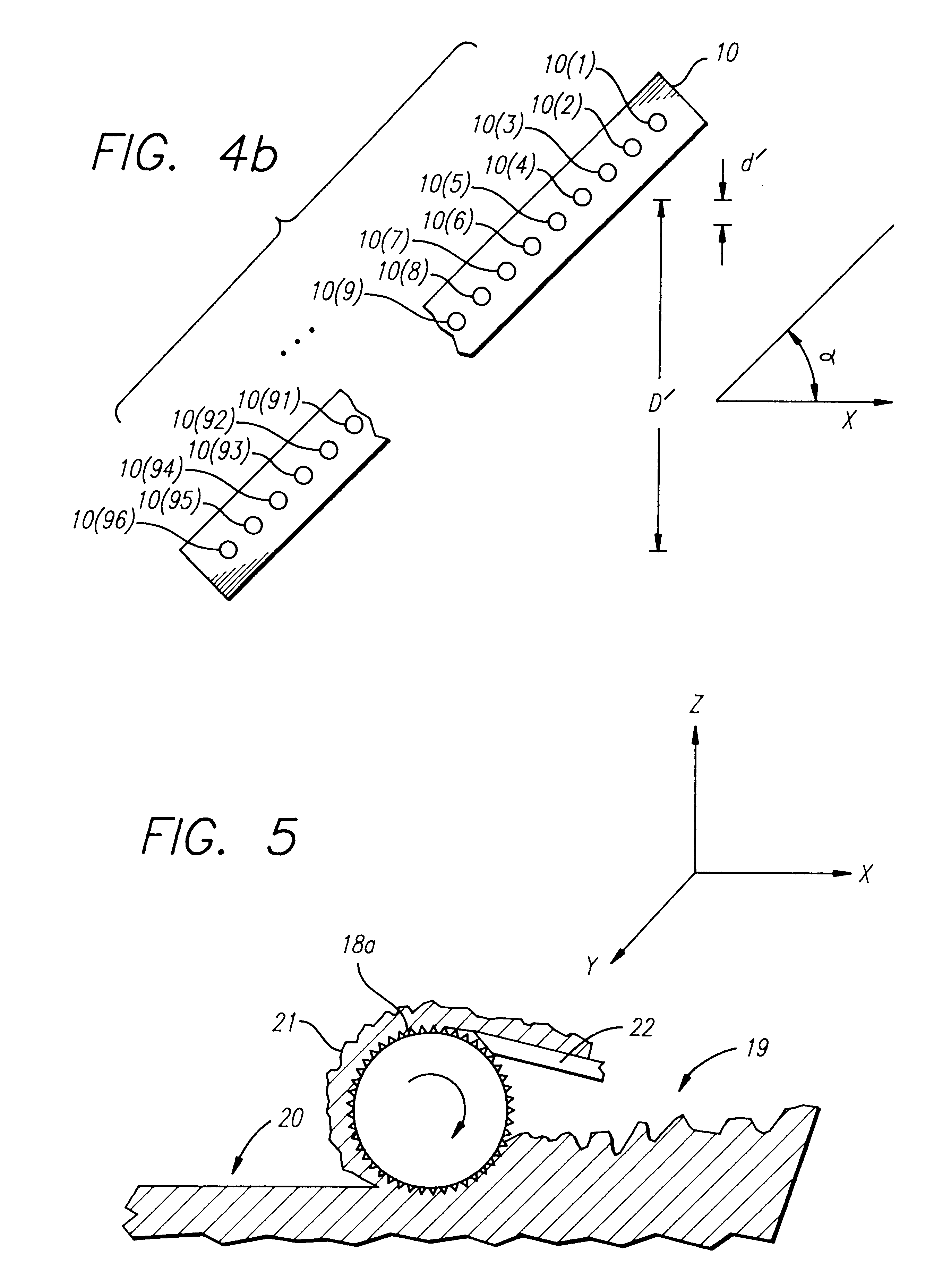

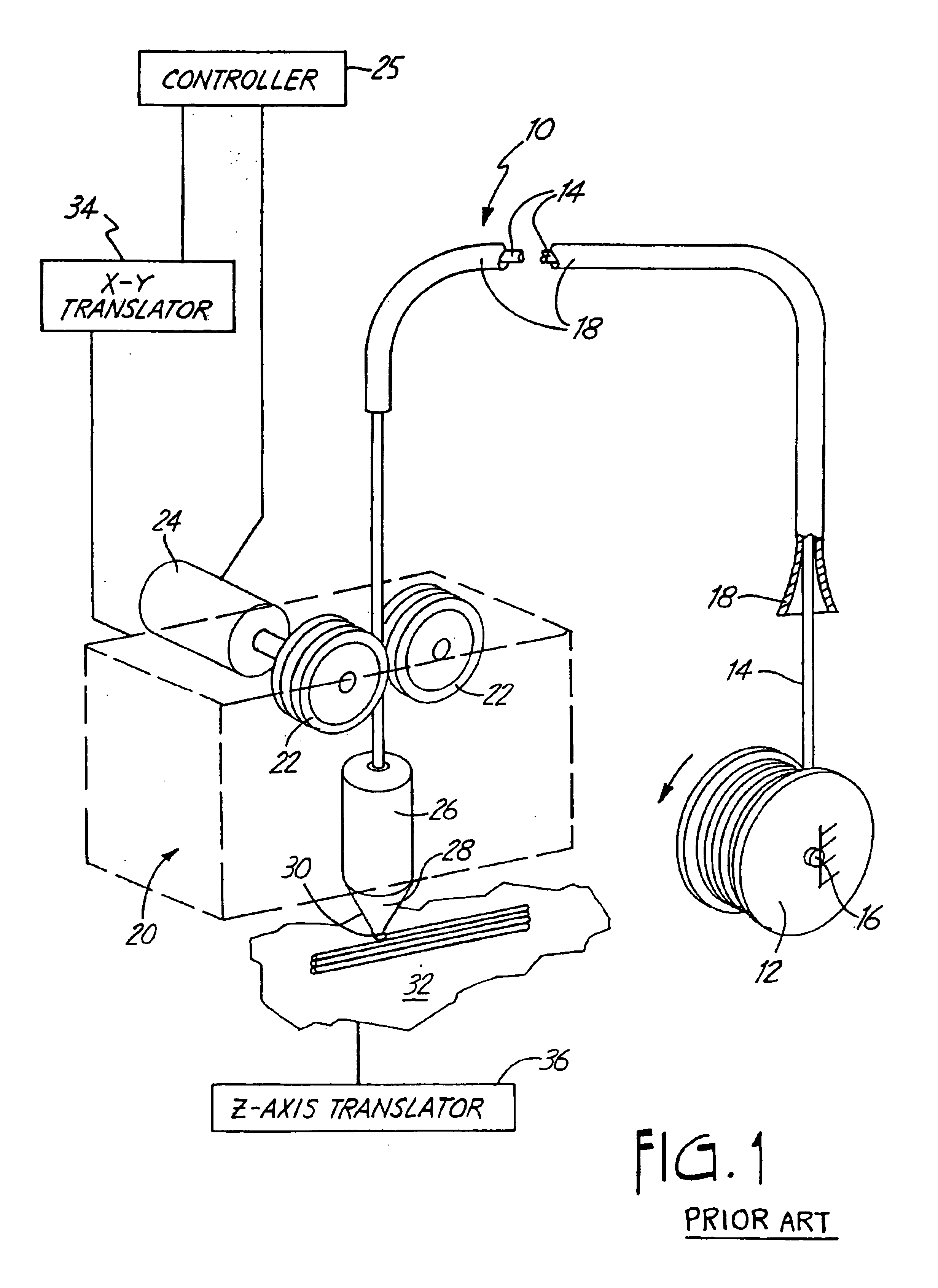

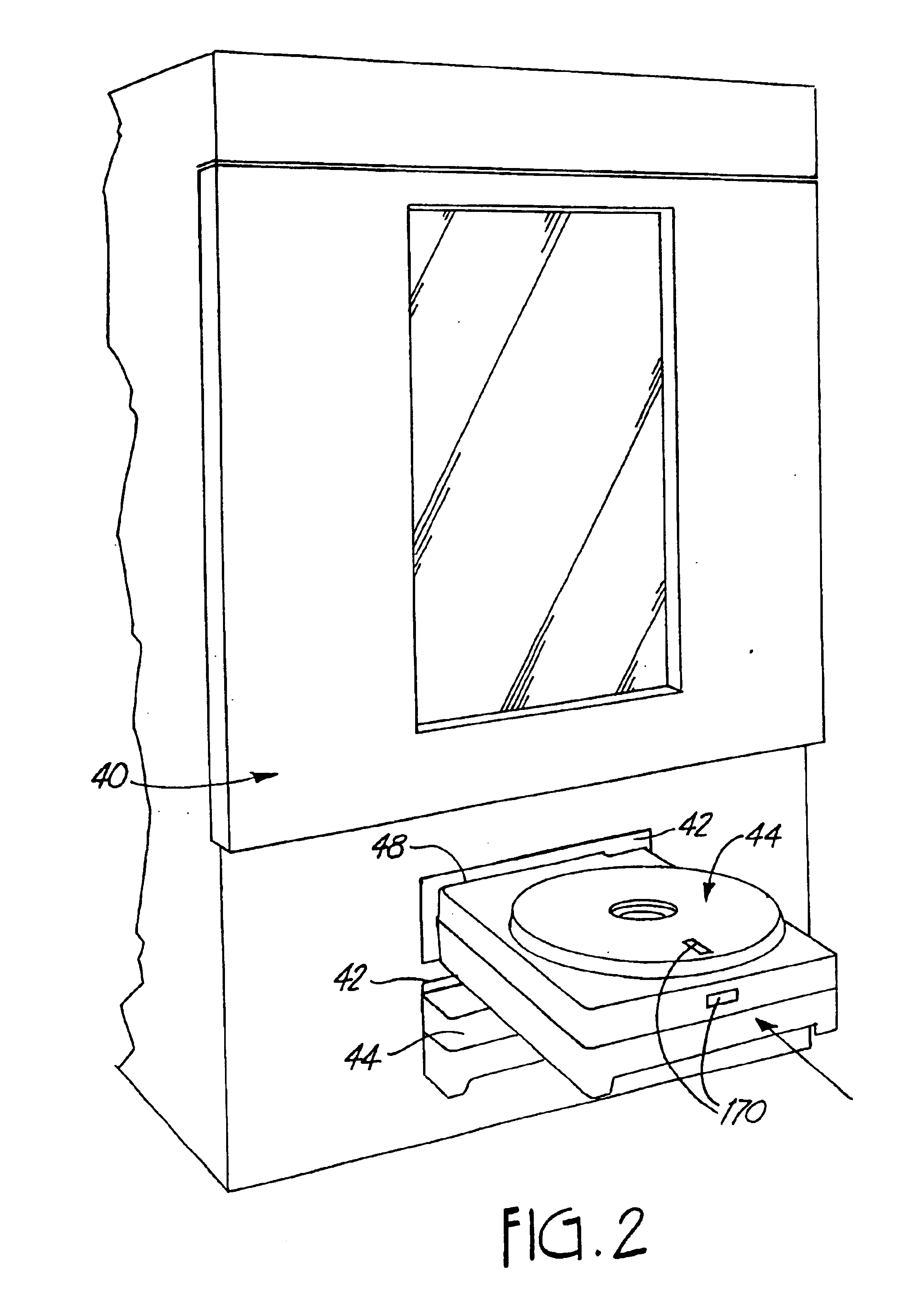

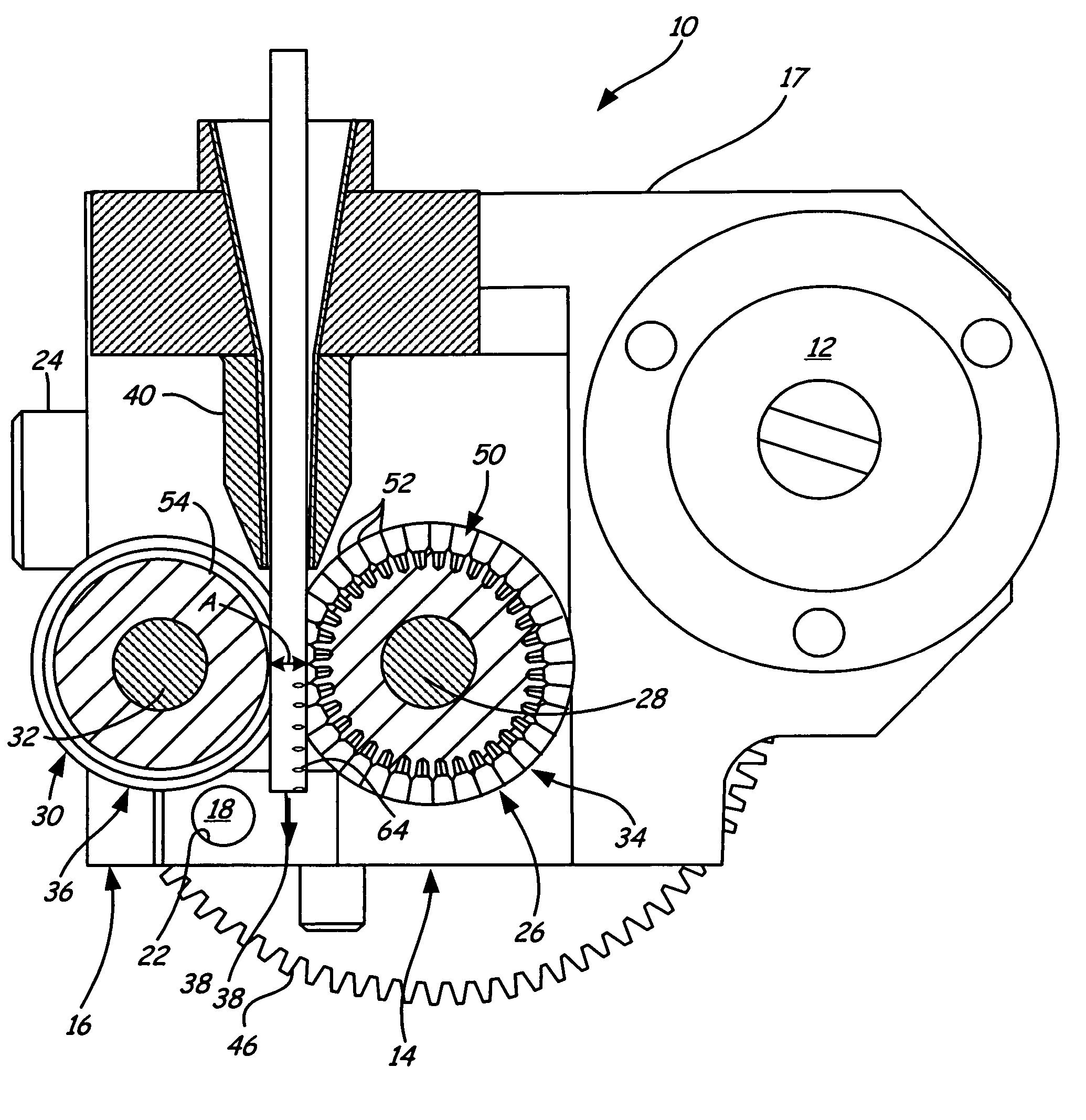

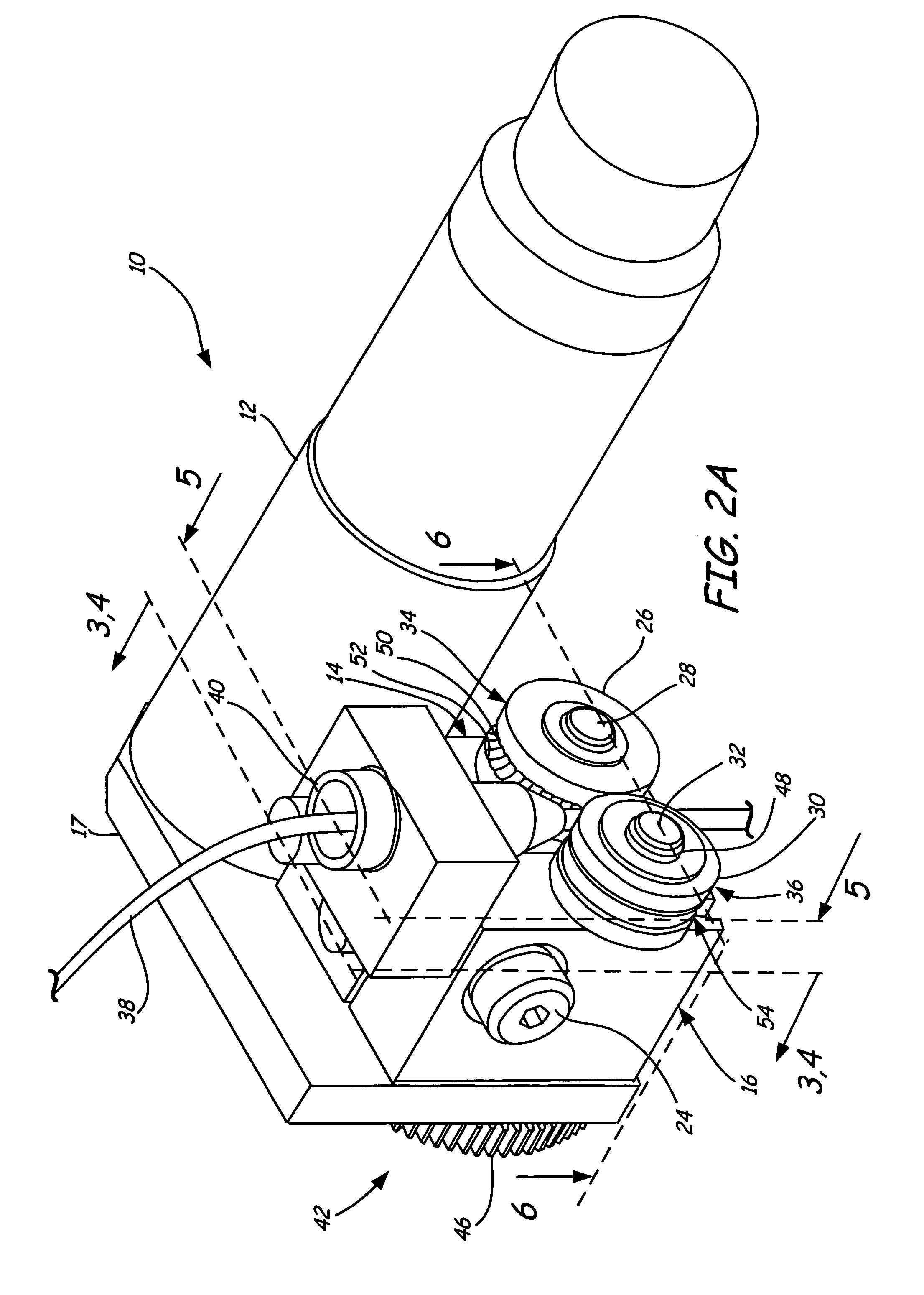

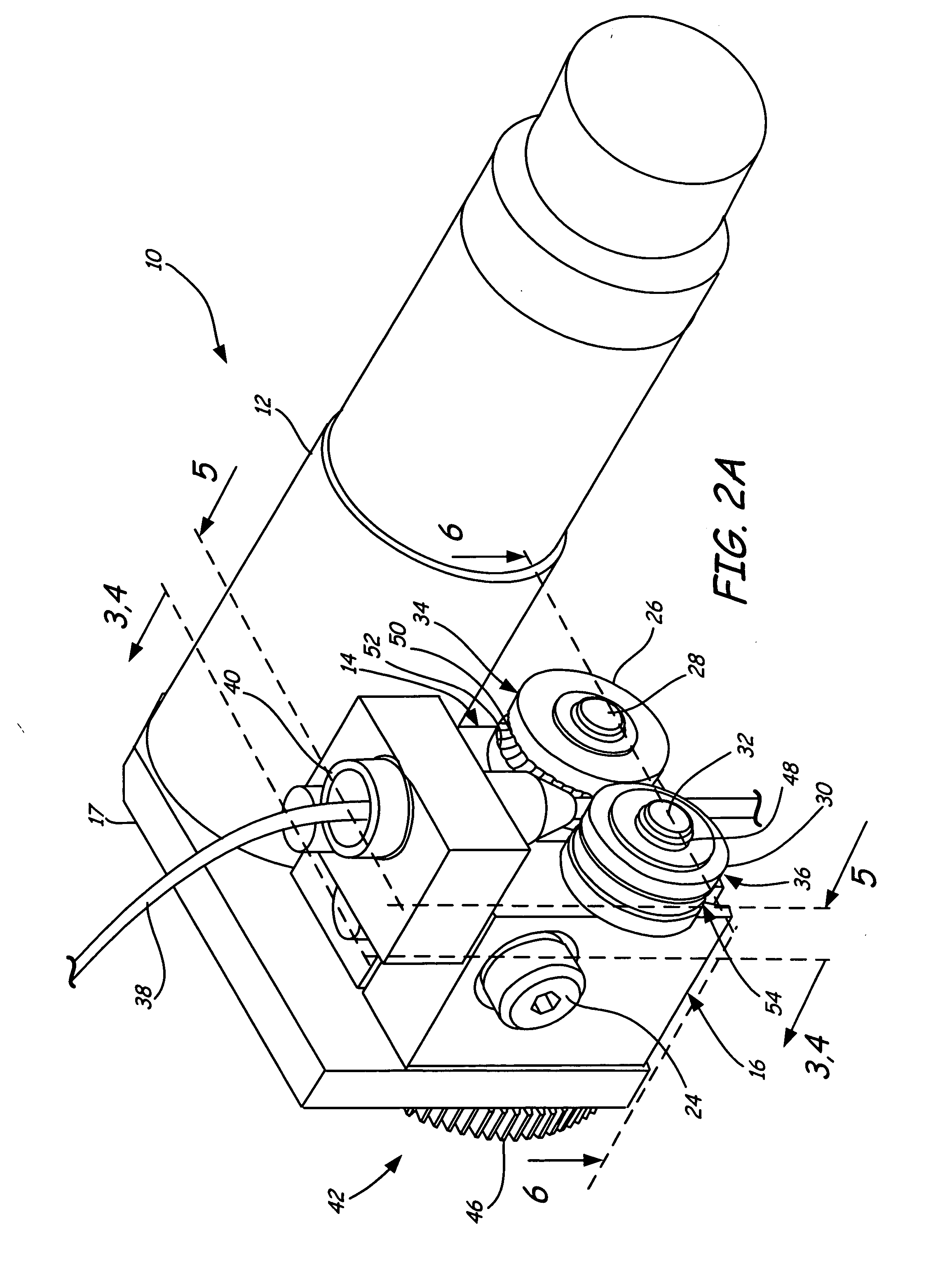

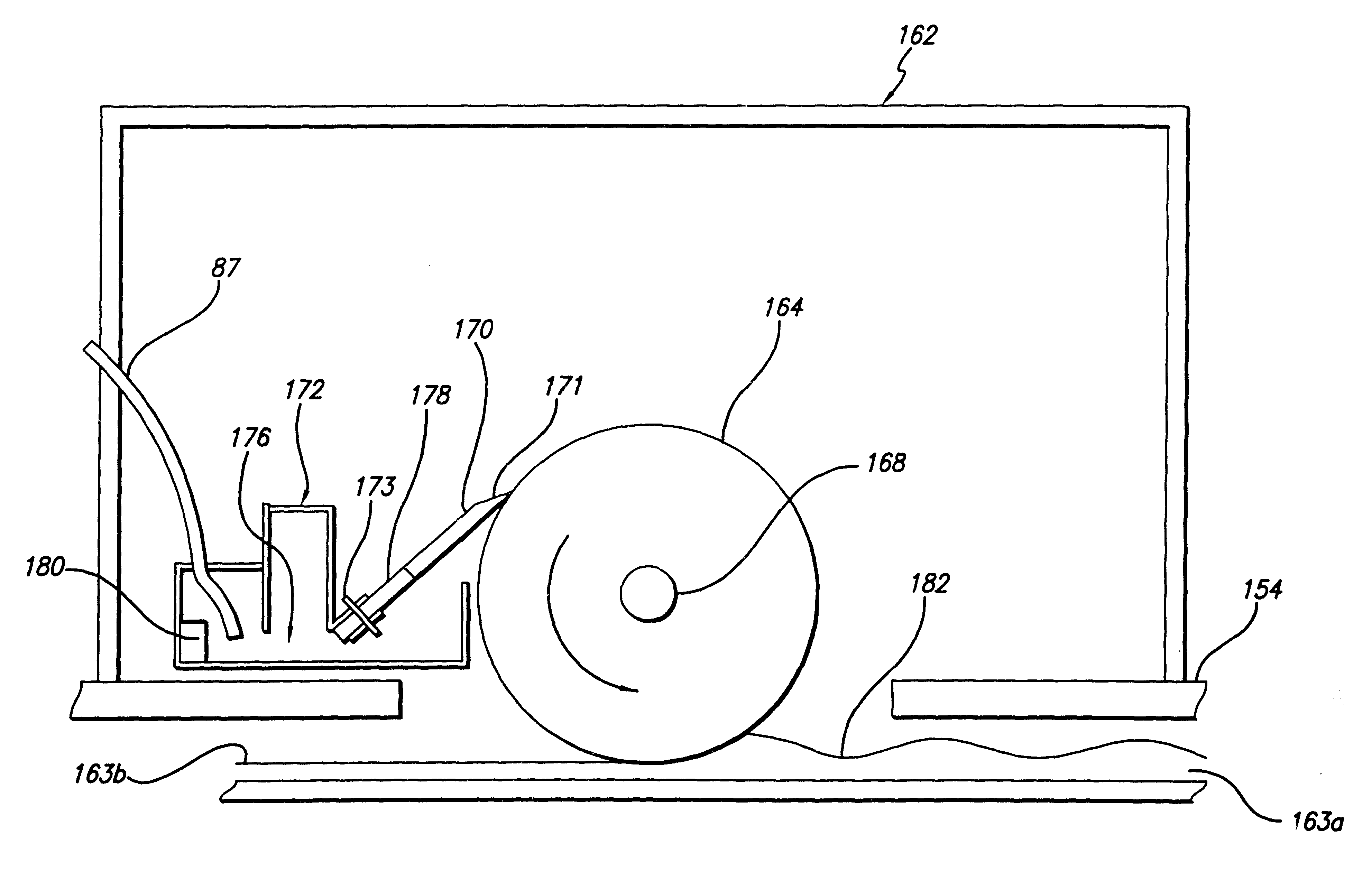

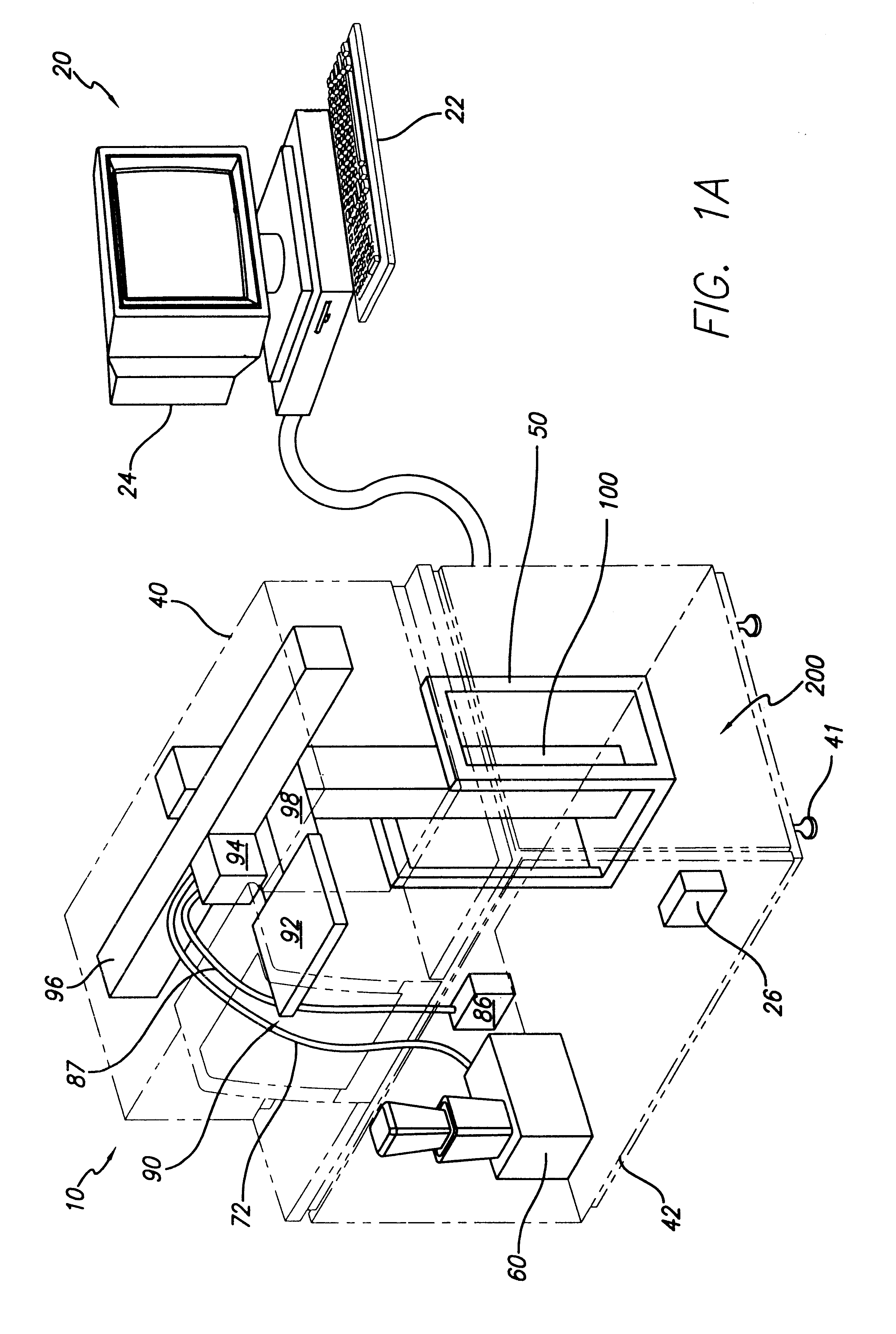

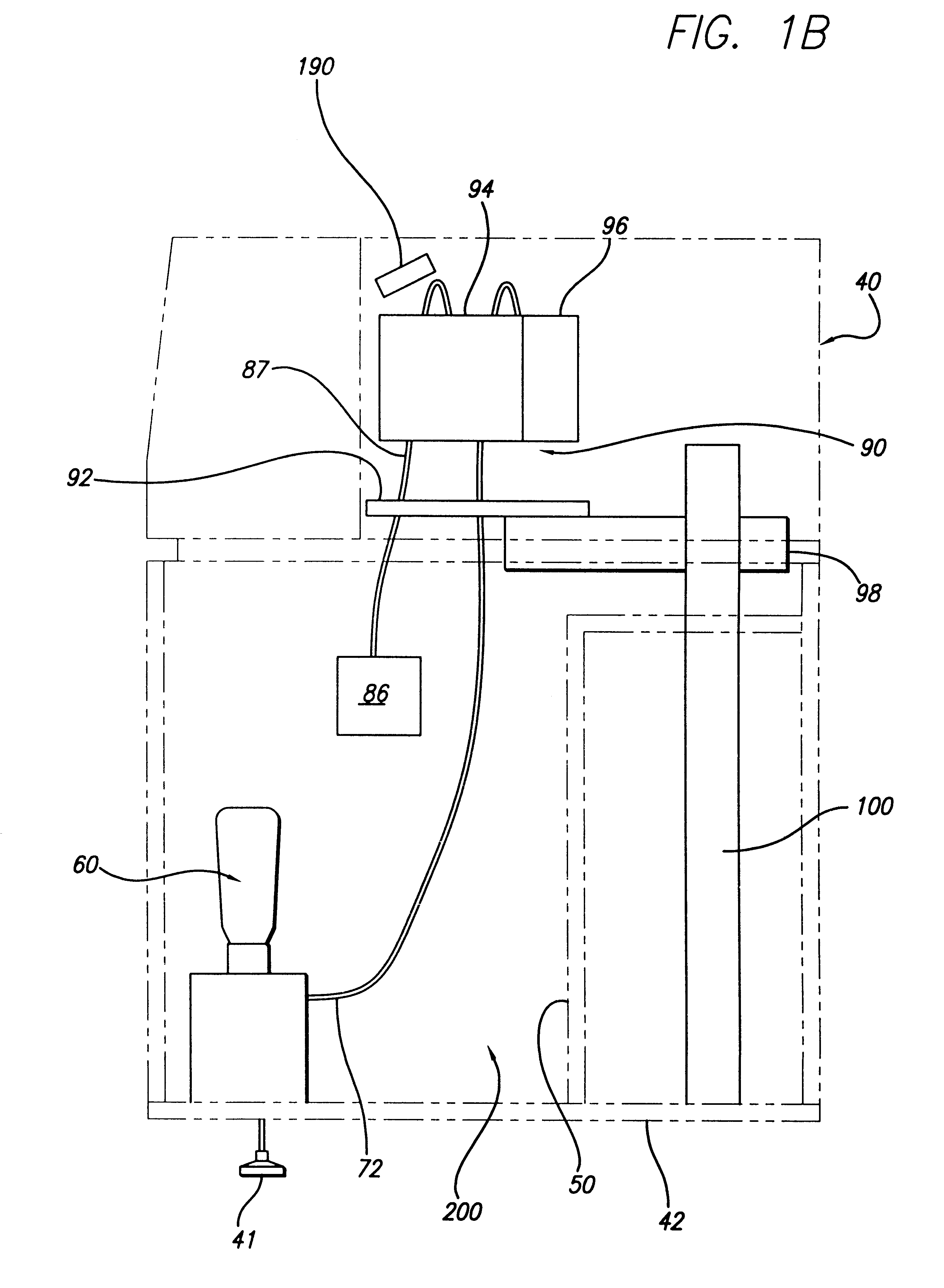

Filament loading system in an extrusion apparatus

InactiveUS6923634B2Protect environmentEasy loadingConfectionerySweetmeatsDrive wheelDimensional modeling

An apparatus which extrudes flowable material from a liquifier includes a system for loading filament supplied in a cassette. The cassette is loaded into a loading bay of the apparatus. A strand of filament from the cassette is engaged and advanced along a path to the liquifier using a drive wheel or roller pair. A conduit having an entrance in the loading bay guides the filament as it is advanced. The filament loading system of the present invention provides a convenient manner of loading and unloading filament in a three-dimensional modeling machine, and can be implemented in a manner that protects the filament from environmental moisture.

Owner:STRATSYS INC

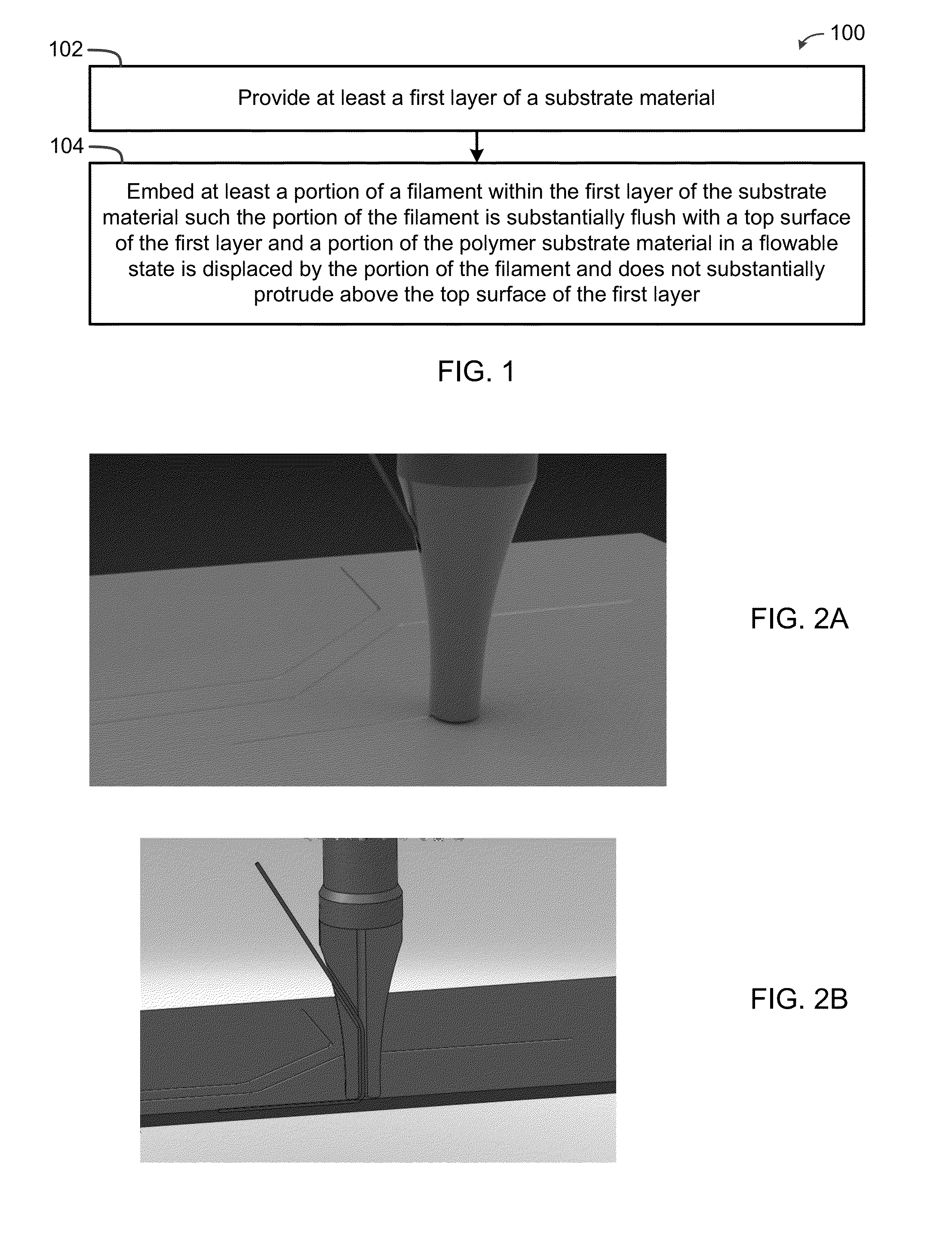

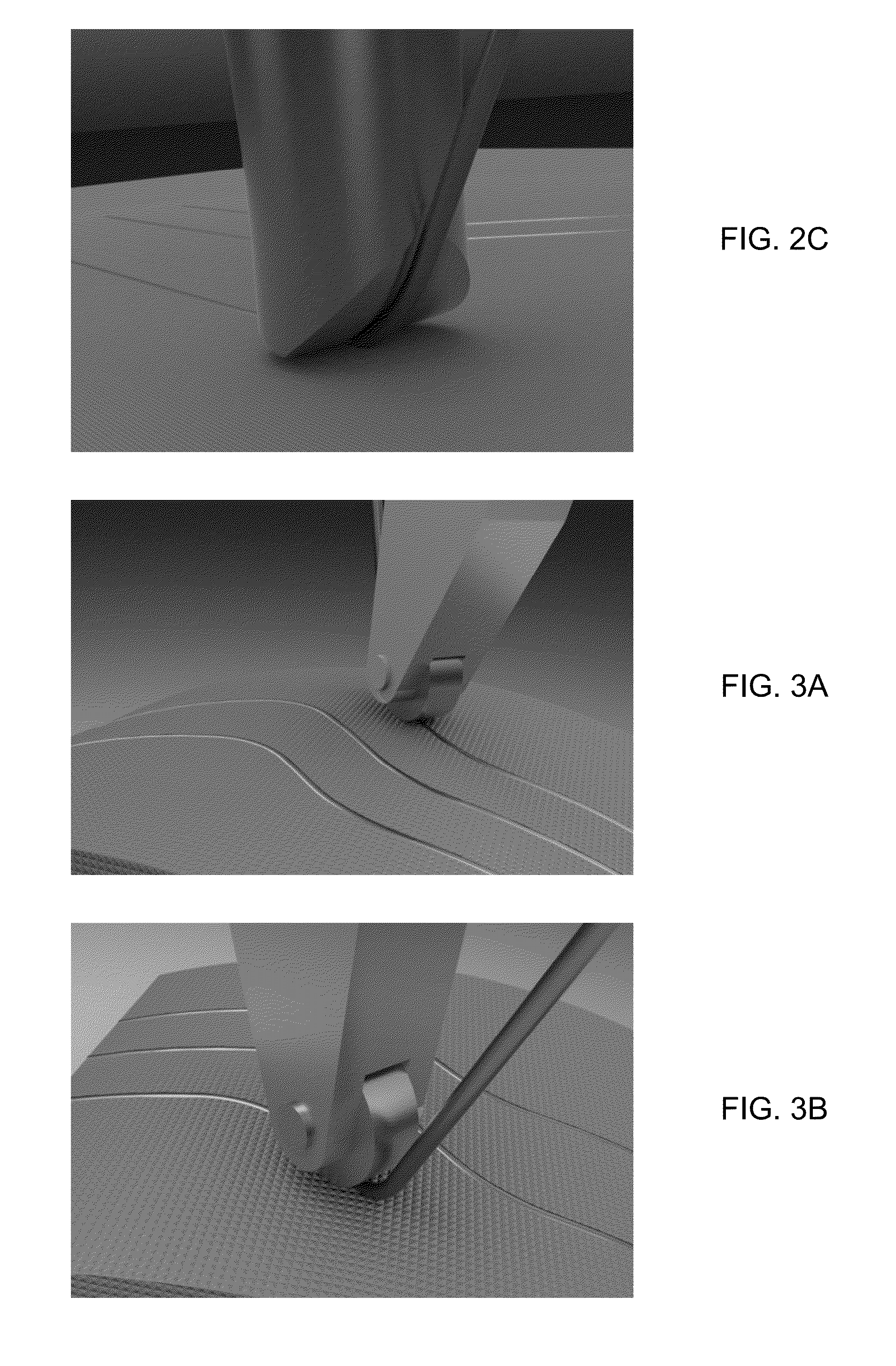

Methods and Systems For Embedding Filaments in 3D Structures, Structural Components, and Structural Electronic, Electromagnetic and Electromechanical Components/Devices

ActiveUS20140268604A1High mechanical strengthElectric discharge heatingCeramic shaping apparatusElectricityEngineering

The present invention provides systems and methods for embedding a filament or filament mesh in a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device by providing at least a first layer of a substrate material, and embedding at least a portion of a filament or filament mesh within the first layer of the substrate material such the portion of the filament or filament mesh is substantially flush with a top surface of the first layer and a substrate material in a flowable state is displaced by the portion of the filament and does not substantially protrude above the top surface of the first layer, allowing the continuation of an additive manufacturing process above the embedded filament or filament mesh. A method is provided for creating interlayer mechanical or electrical attachments or connections using filaments within a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

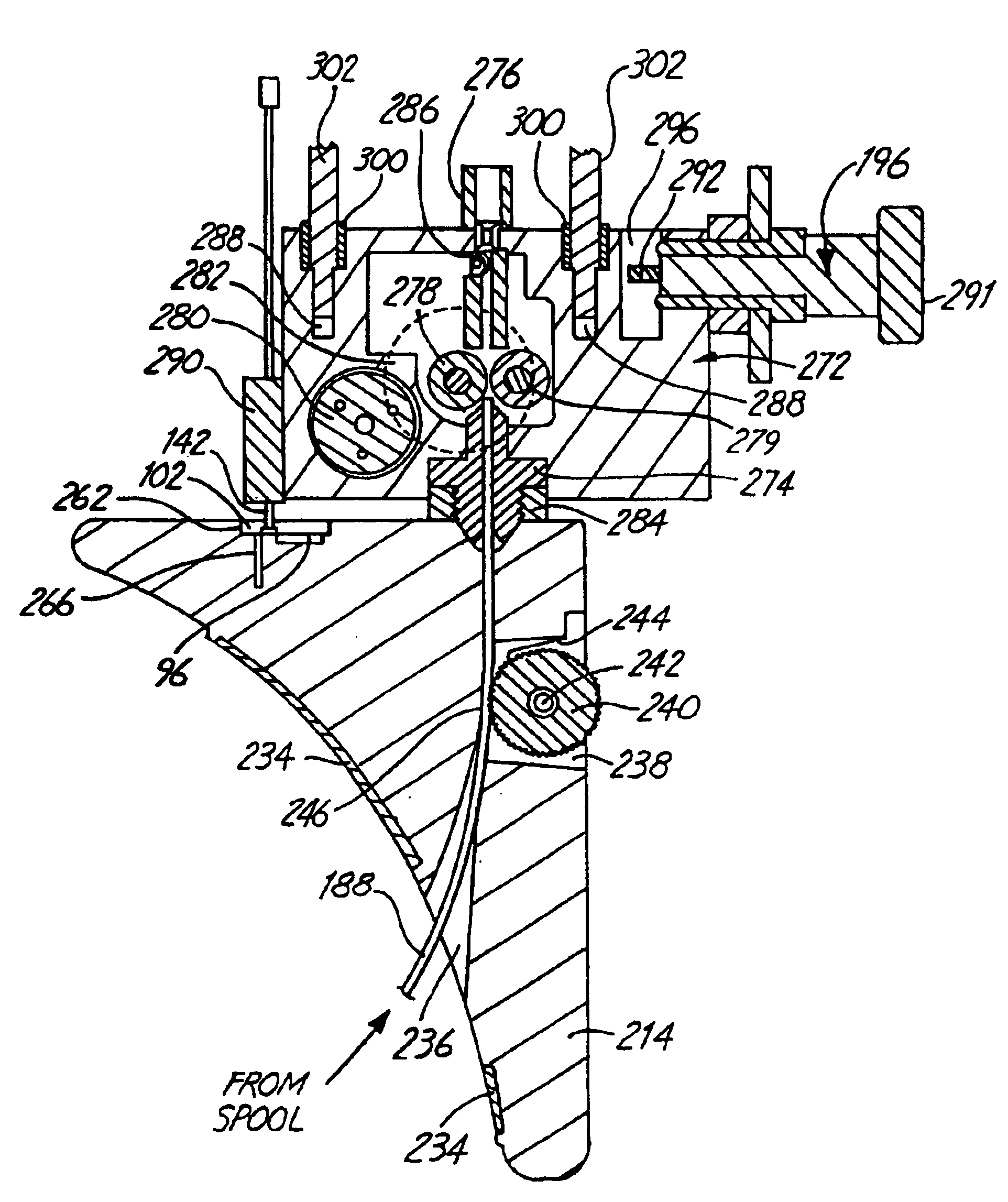

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

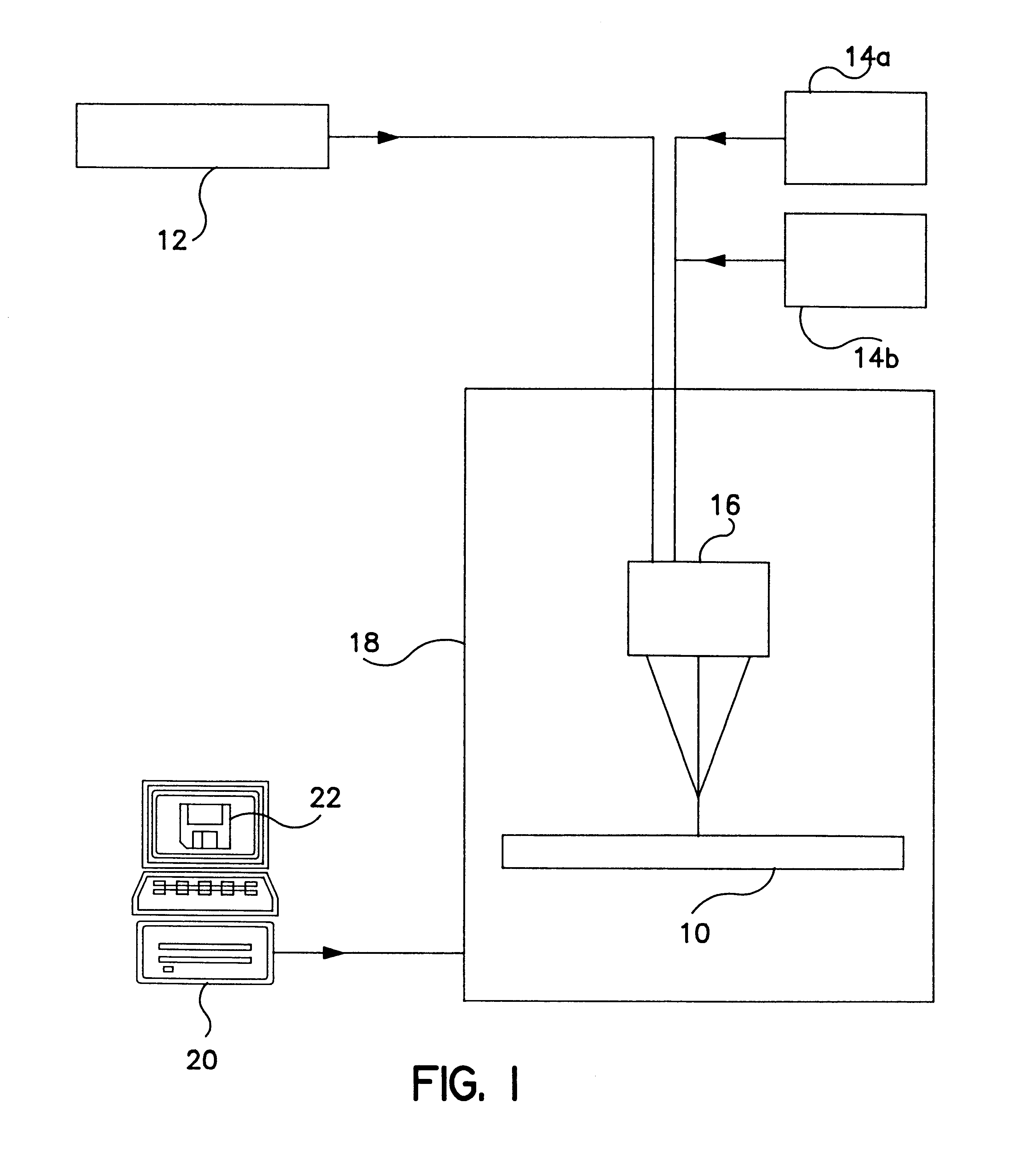

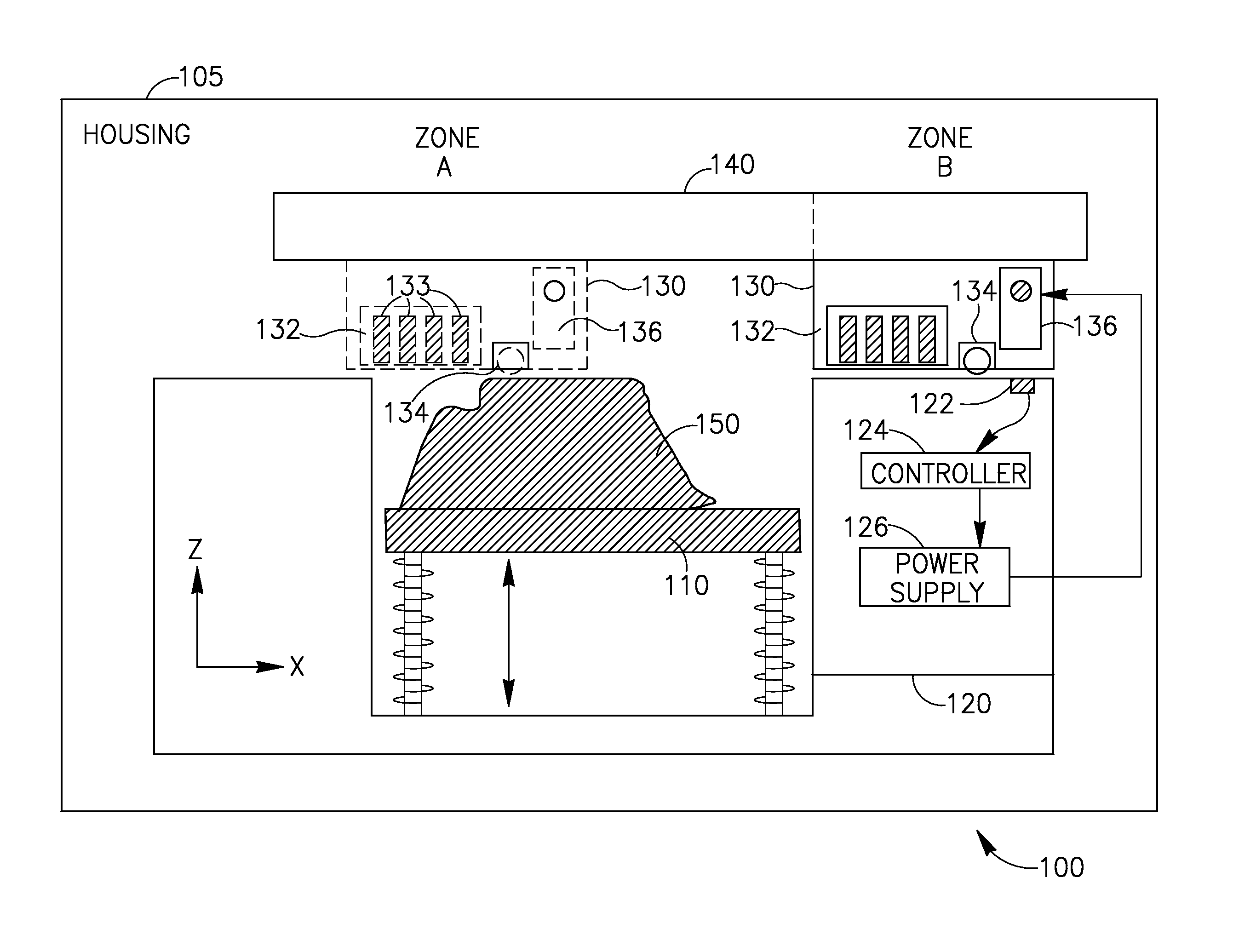

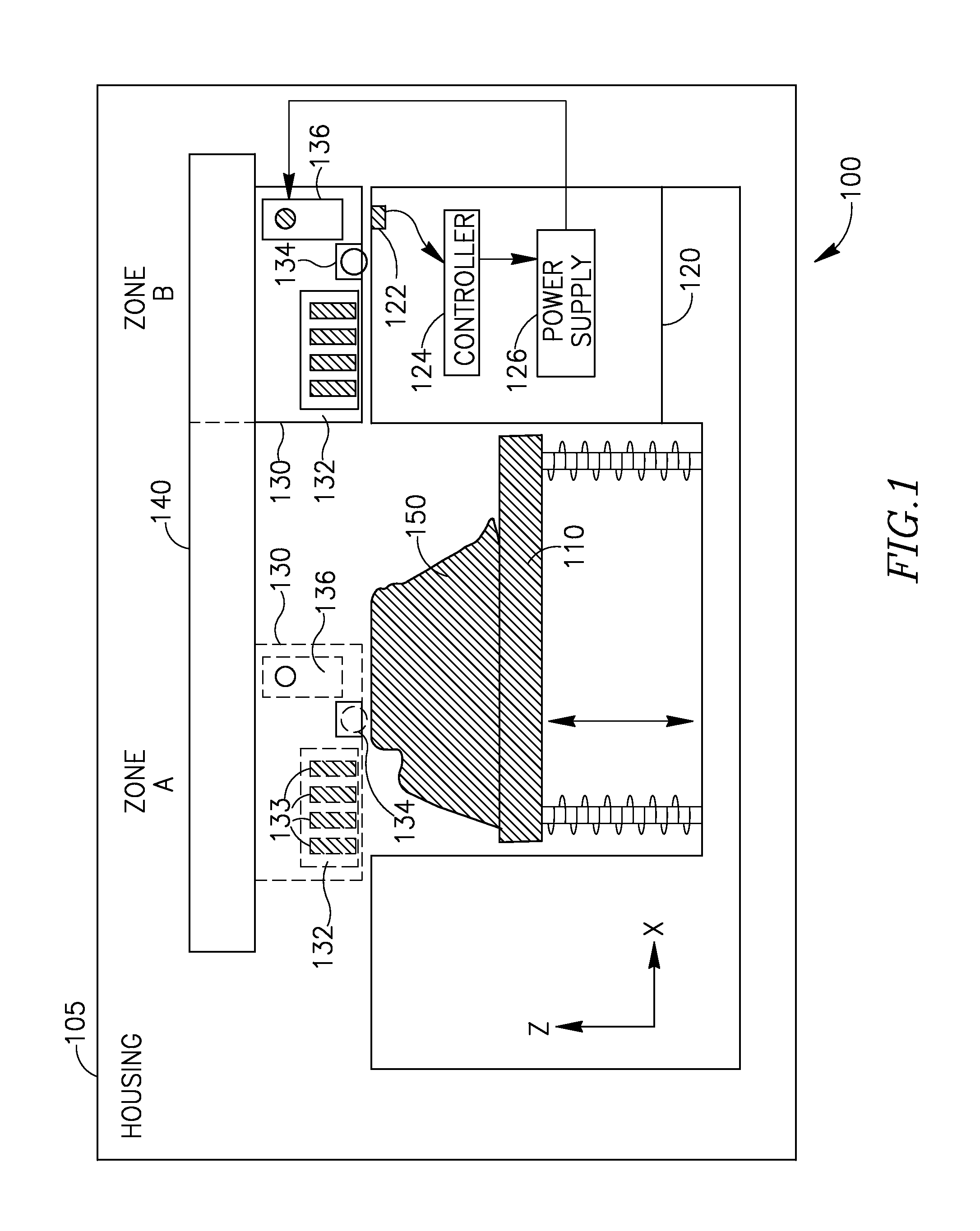

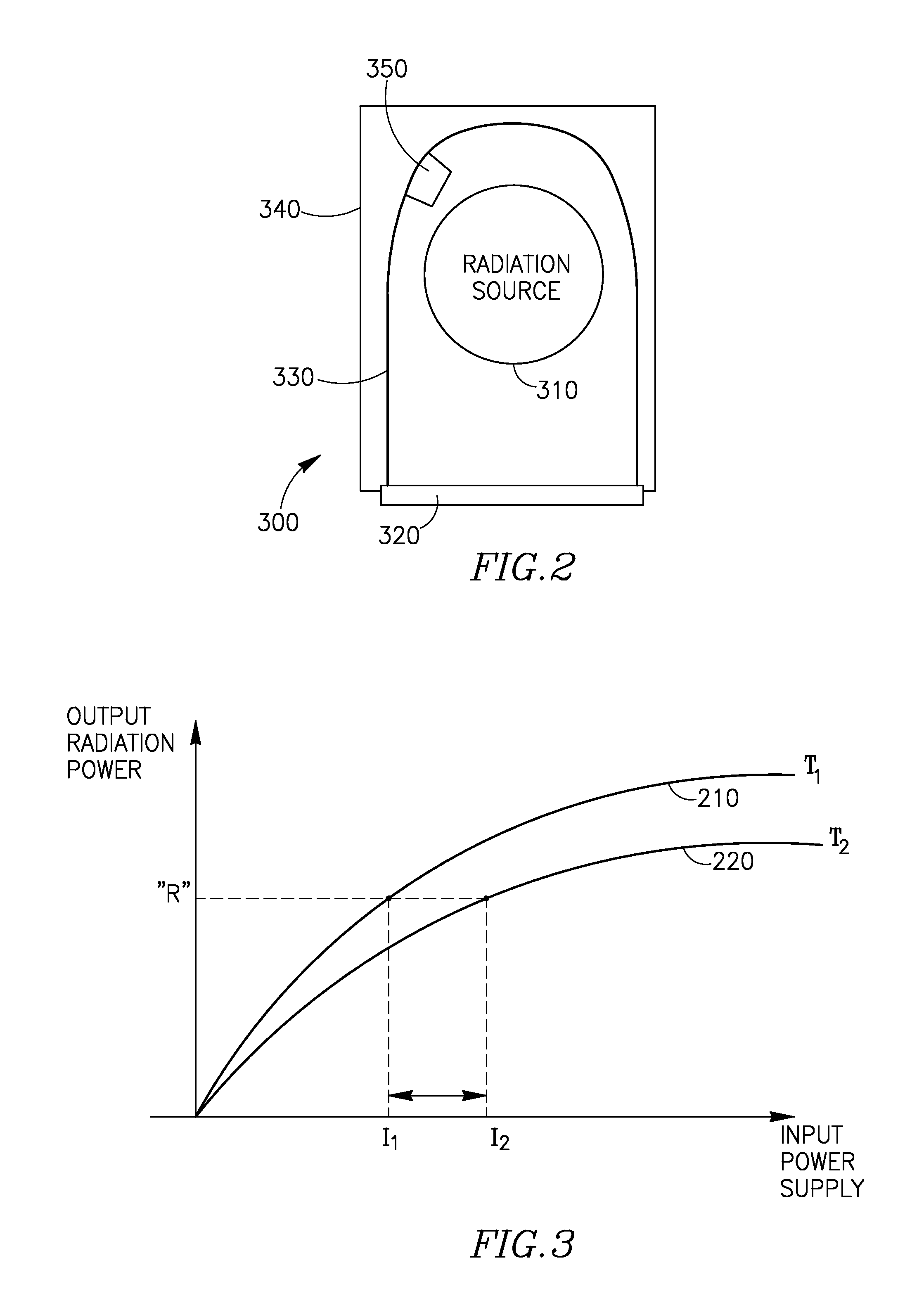

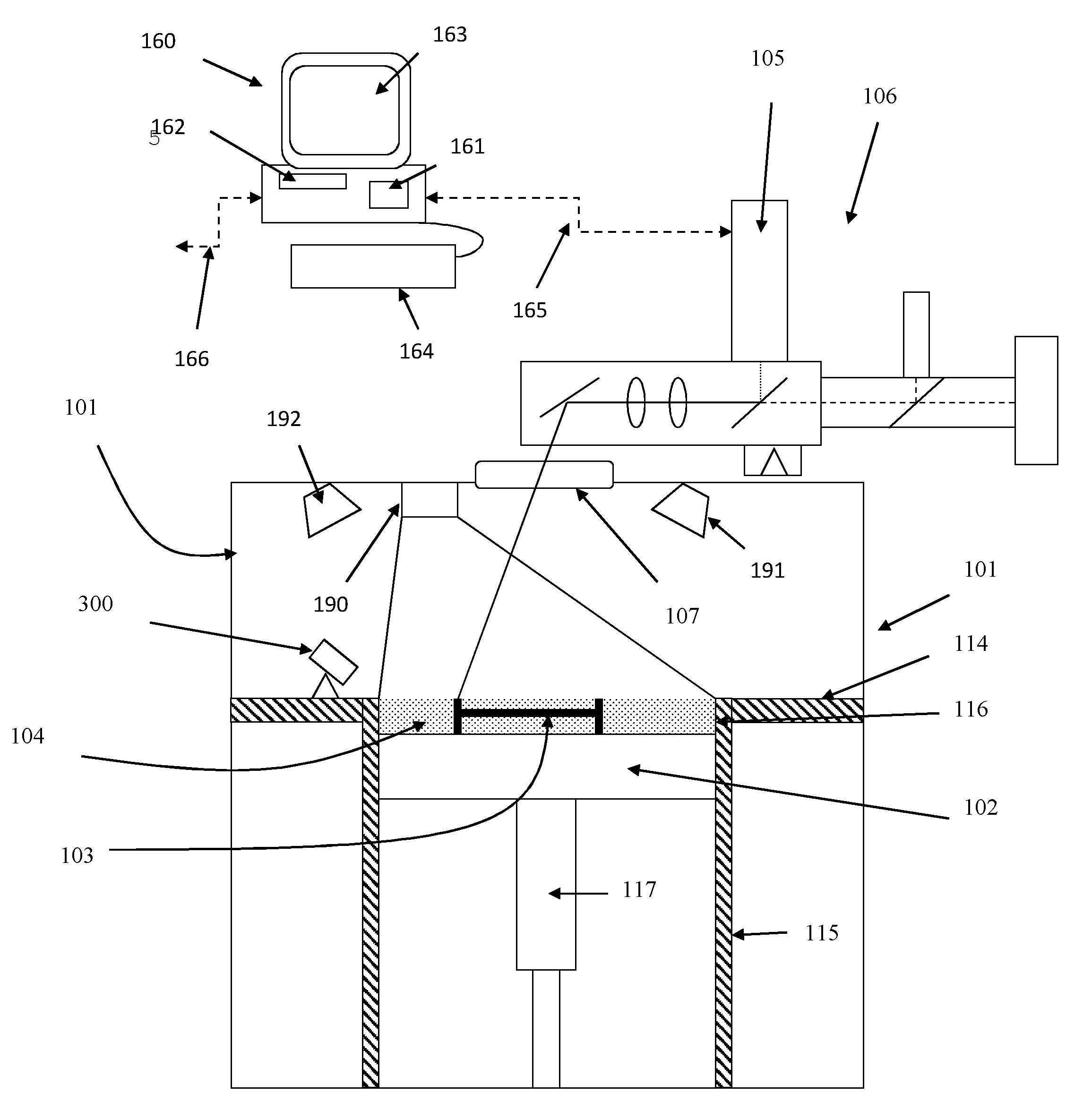

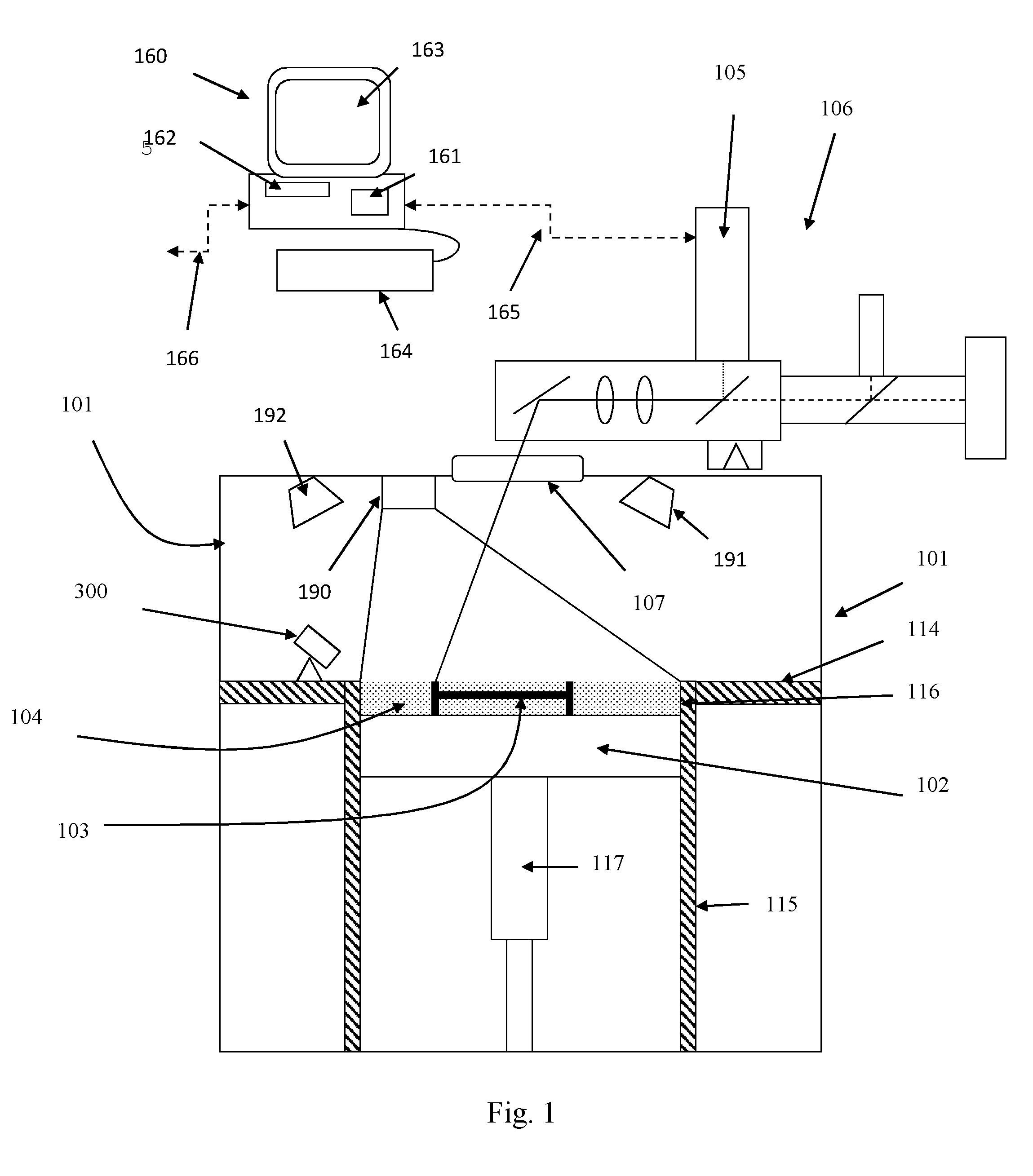

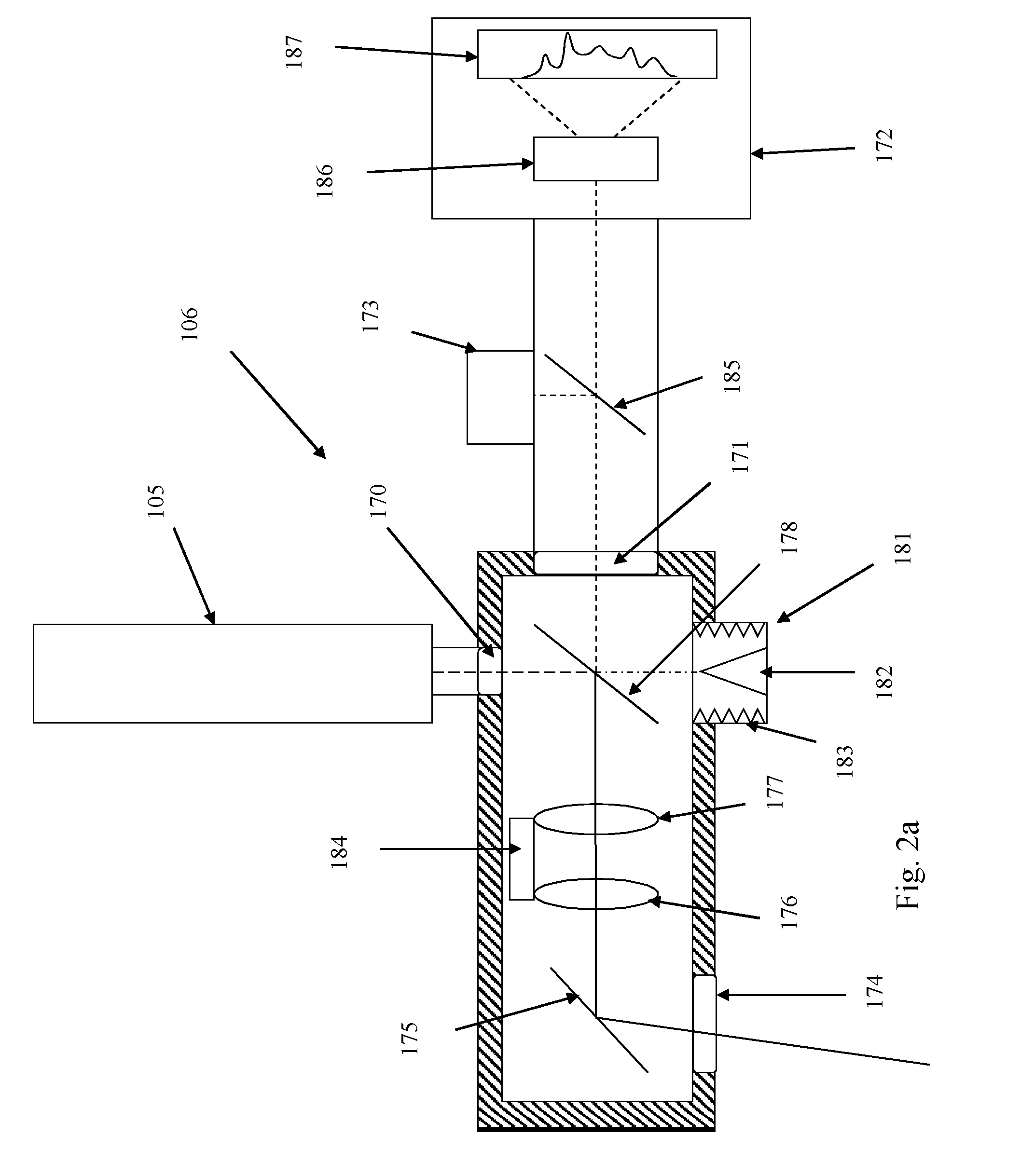

Method and apparatus for monitoring electro-magnetic radiation power in solid freeform fabrication systems

Owner:STRATASYS LTD

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

Additive manufacturing apparatus and method

ActiveUS20160236279A1Sufficient reflectivityAdditive manufacturing apparatusSpectrum investigationManufactured apparatusFeedback control

This invention concerns a laser solidification apparatus for building objects by layerwise solidification of powder material. The apparatus including a build chamber containing a build platform, a device for depositing layers of powder material on to the build platform, an optical unit for directing a laser beam to selectively solidify areas of each powder layer and a spectrometer for detecting characteristic radiation emitted by plasma formed during solidification of the powder by the laser beam. The invention also relates to a spectrometer for detecting characteristic radiation generated by interaction of the metal with the or a further laser beam. The spectra recorded using the spectrometer may be used for feedback control during the solidification process.

Owner:RENISHAW PLC

Selective deposition modeling system and method

InactiveUS6305769B1Additive manufacturing apparatus3D object support structuresEngineeringSelective deposition

A system and associated method for forming three-dimensional objects under computer control and from a material which may be rendered flowable and then dispensed on a layer-by-layer basis. The layers of the material solidify or otherwise physically transform upon being dispensed thereby forming successive cross-sections. The dispensing process is repeated whereby successive layers adhere to each other thereby forming the object.

Owner:3D SYST INC

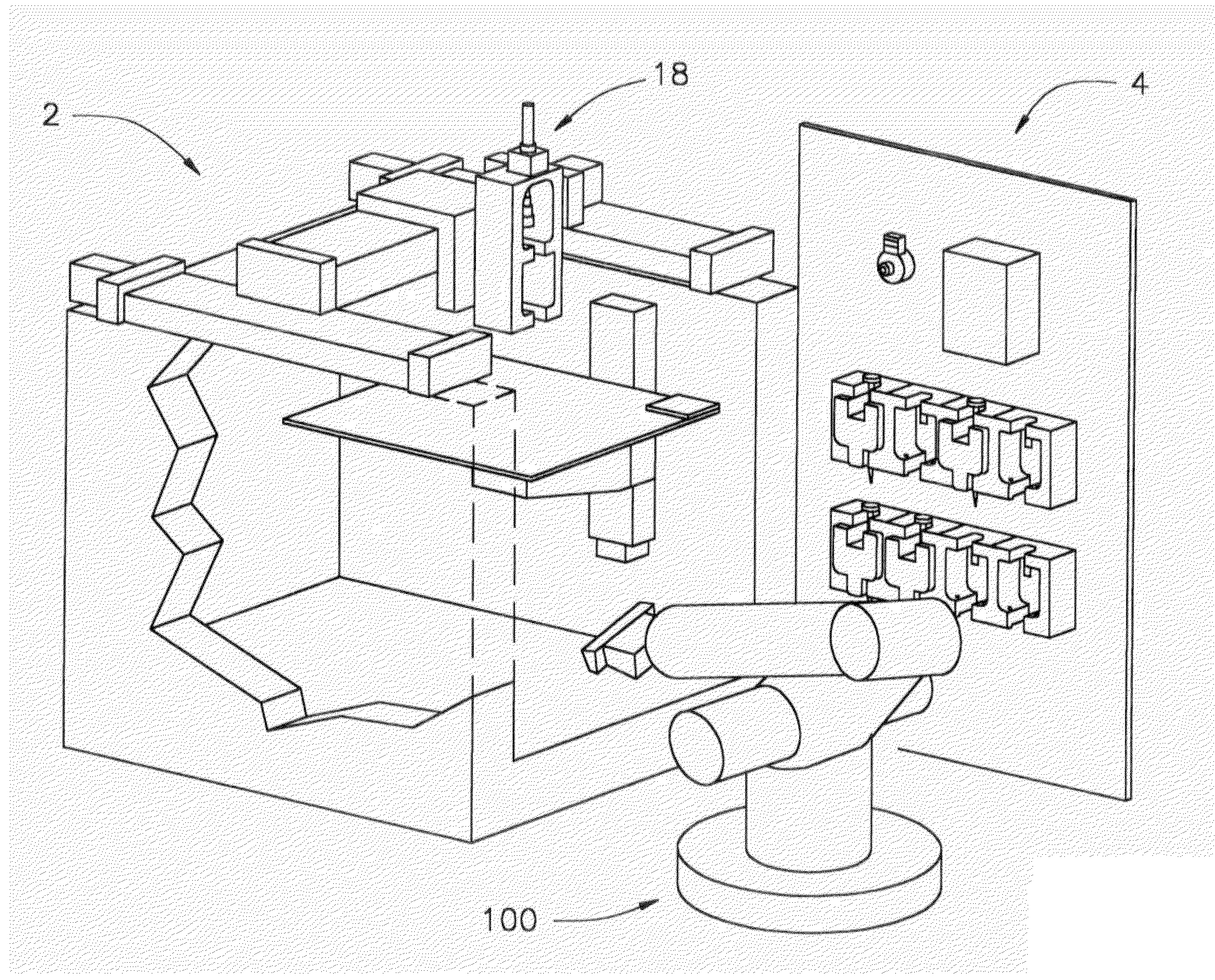

Modular fabrication systems and methods

ActiveUS20130089642A1Improve throughputHigh-throughput applicationsReady-for-oven doughsAuxillary shaping apparatusEngineeringSystem controller

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating edible foodstuffs.

Owner:CORNELL UNIVERSITY

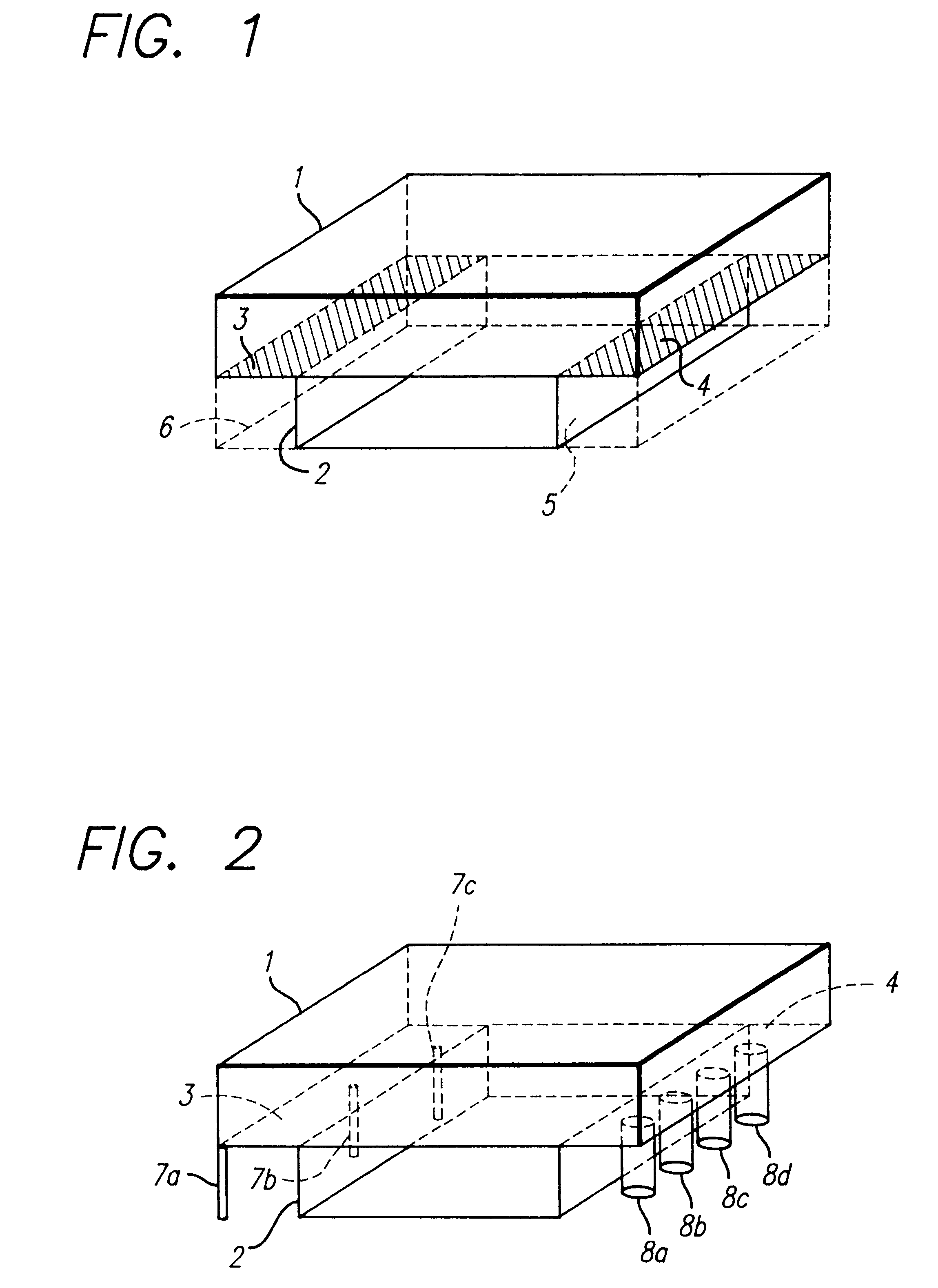

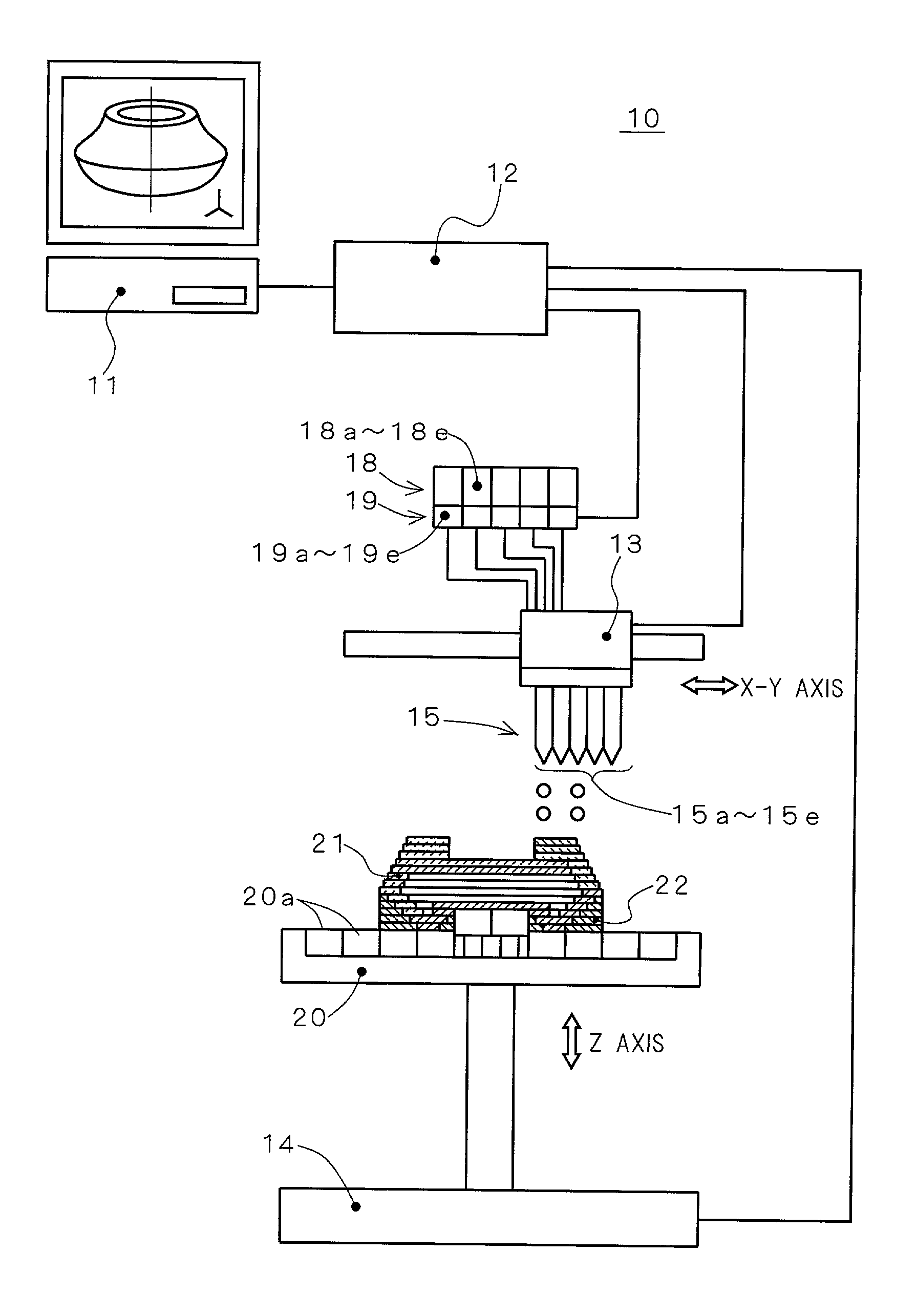

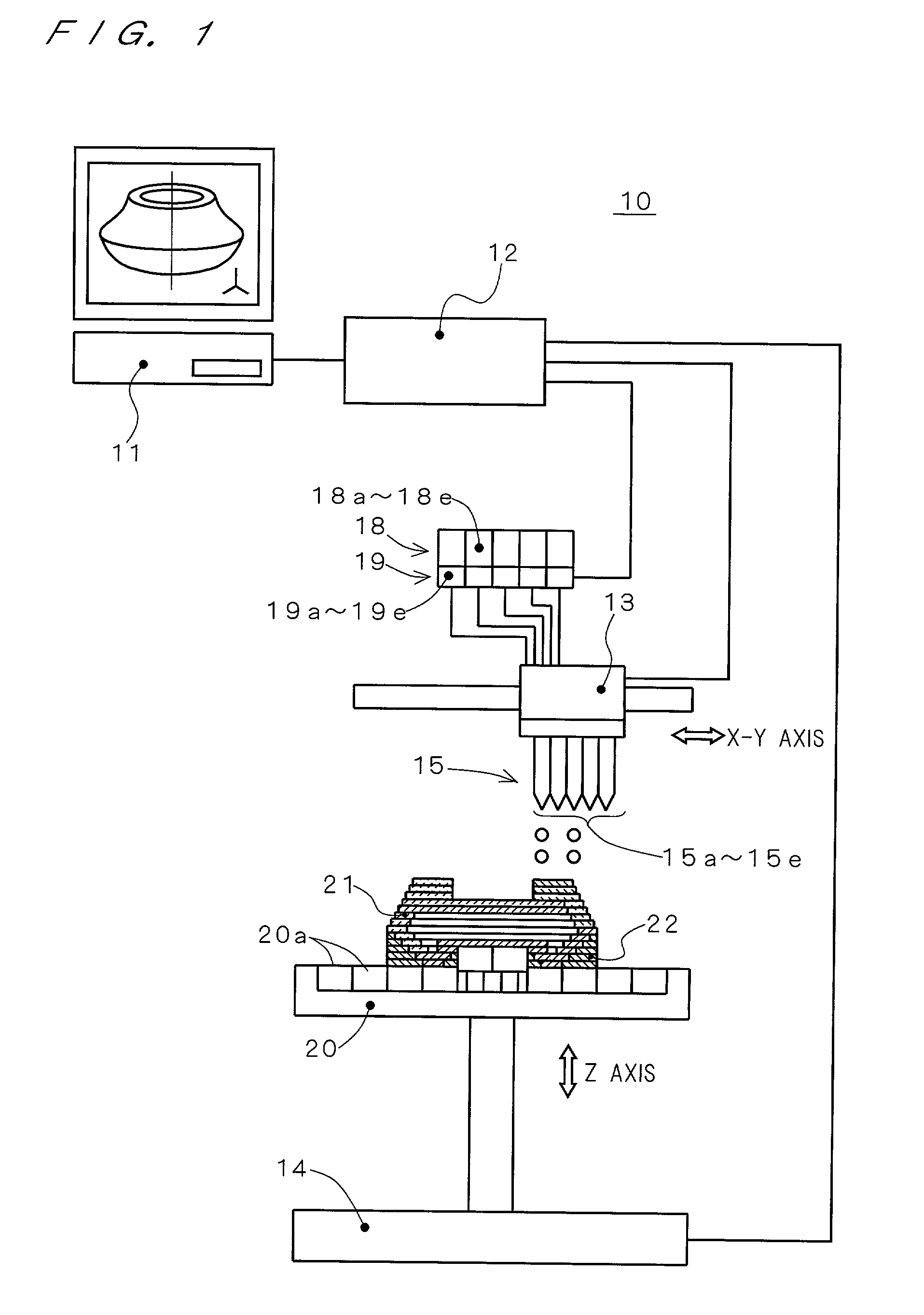

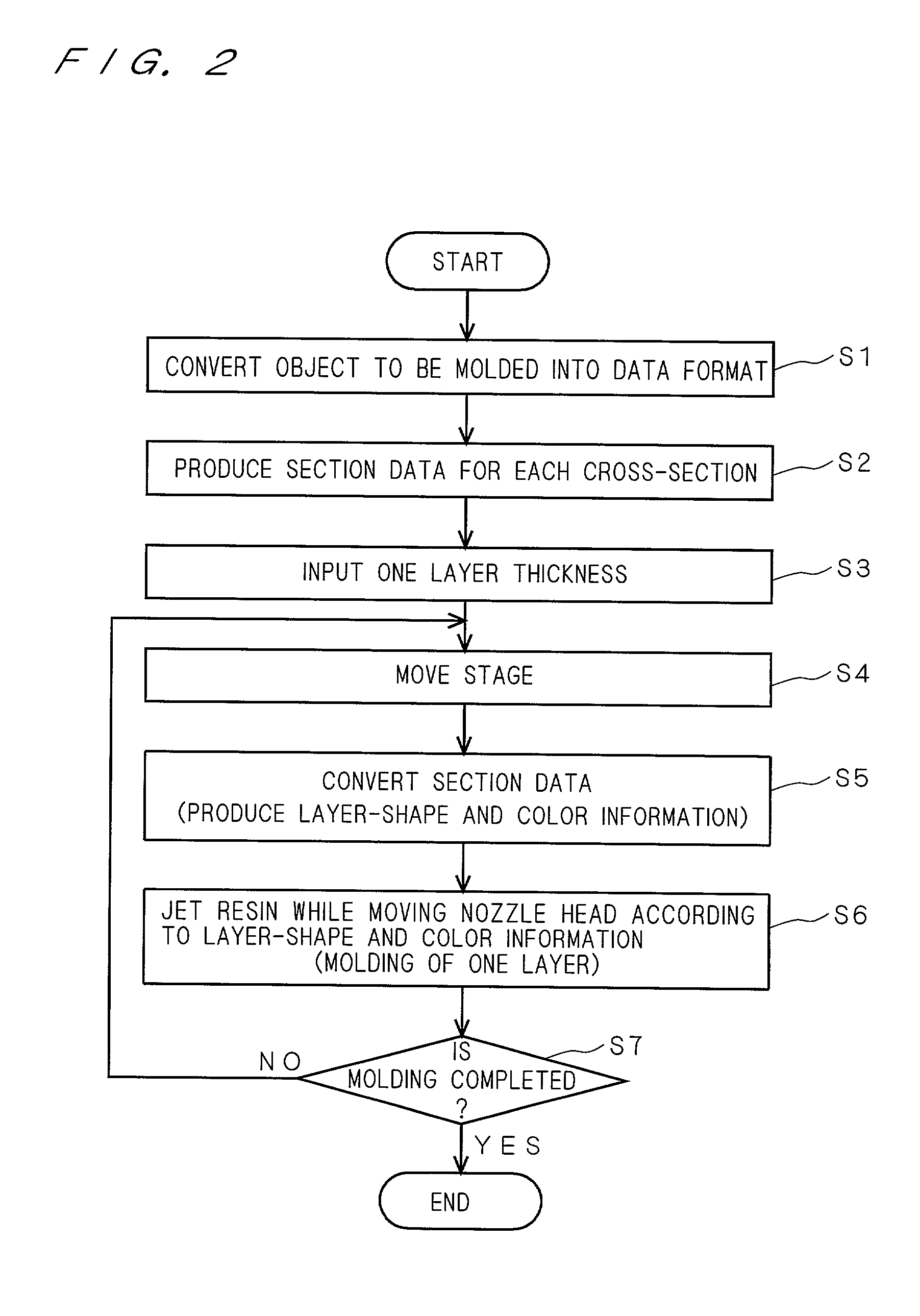

Three-dimensional object molding apparatus and method

InactiveUS20020167101A1Facilitate short-time low-cost moldingShort-time low-cost coloringConfectioneryPattern printingShell moldingColor intensity

In a 3D object molding apparatus (10), a tank (18d) holds an uncolored or white resin as a first material for use in interior molding, and tanks (18a to 18c) hold colored resins as second materials for use in surface molding. These resin materials are jetted from injection nozzles (15a to 15d) in the direction of a stage (20). A drive control unit (12) serving as control means moves a nozzle head (15) in the XY plane and controls jets of resin materials from the injection nozzles (15a to 15d). In the interior molding of a 3D molded product (21), at least the first material is jetted, while in the surface molding, at least the second materials are jetted. The injection nozzles (15a to 15c) are coloring nozzles to jet colored resins in molding color portions of the 3D molded product, and the injection nozzle (15d) is a molding nozzle to jet an uncolored molding resin in molding the other portions. The apparatus 10 provided with the coloring nozzles to jet predetermined coloring agents such as colored resins can jet coloring agents from the coloring nozzles in molding the 3D molded product, thereby achieving coloring of the 3D molded product in the molding process. Further, the use of a white resin allows representation of blight colors that are not available only with three colors (Y, M, C), thereby permitting reproduction of the color intensity and gradations in the coloring of the 3D molded product (21) in the molding process.

Owner:MINOLTA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com