Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3097 results about "Burn out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

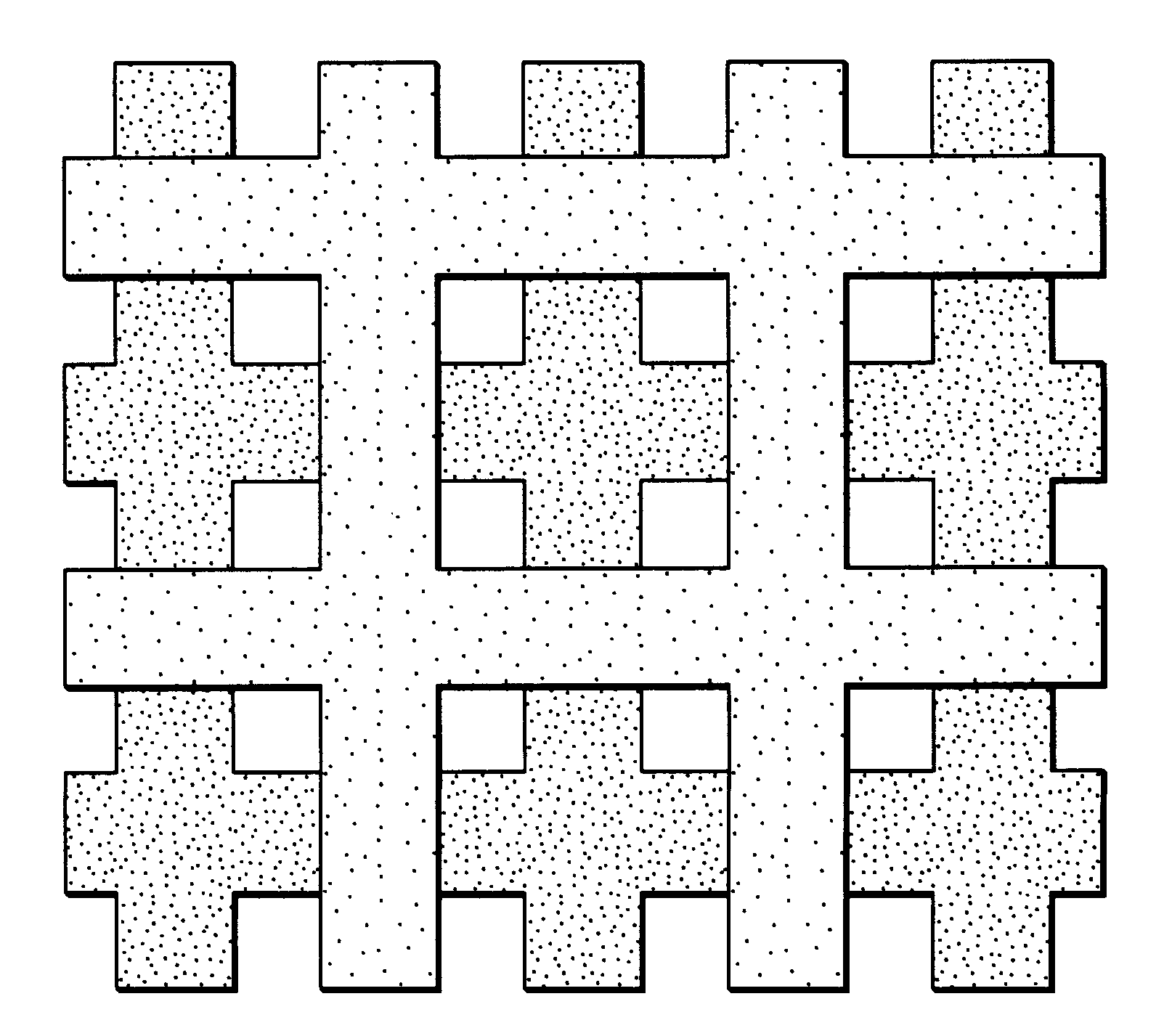

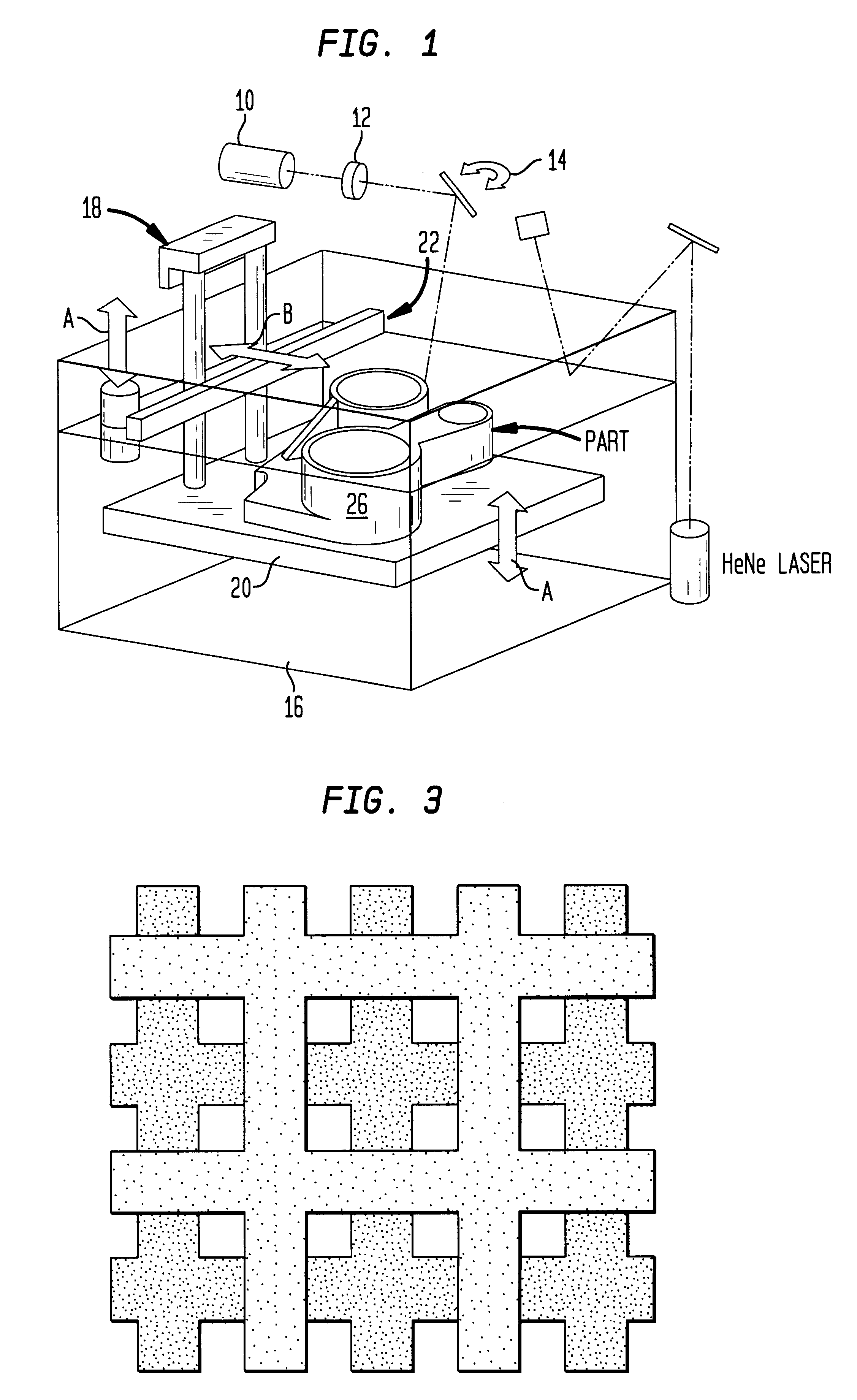

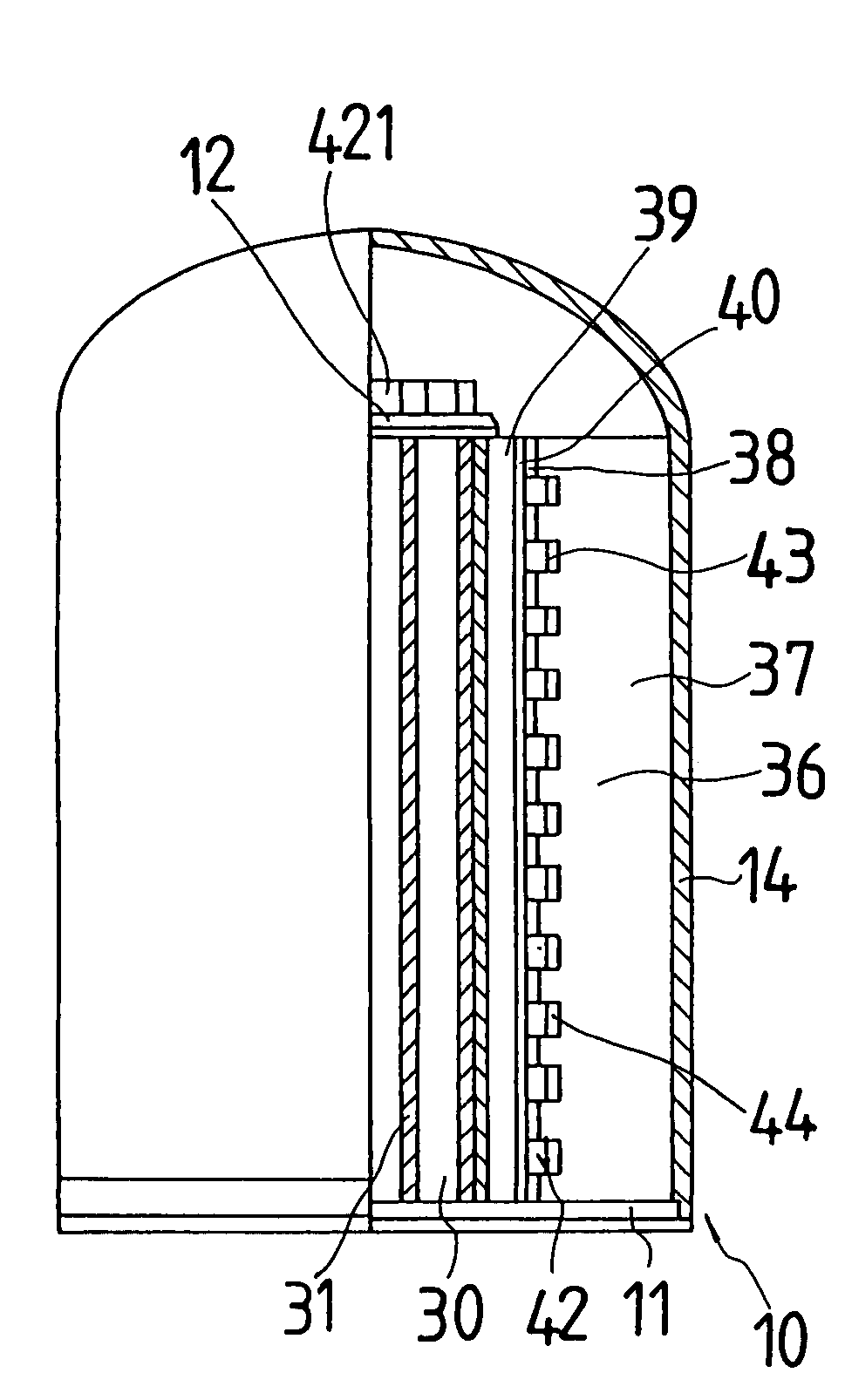

Controlled architecture ceramic composites by stereolithography

InactiveUS6283997B1Quality improvementFast preparationProgramme controlAdditive manufacturing apparatusCeramic compositeMetallurgy

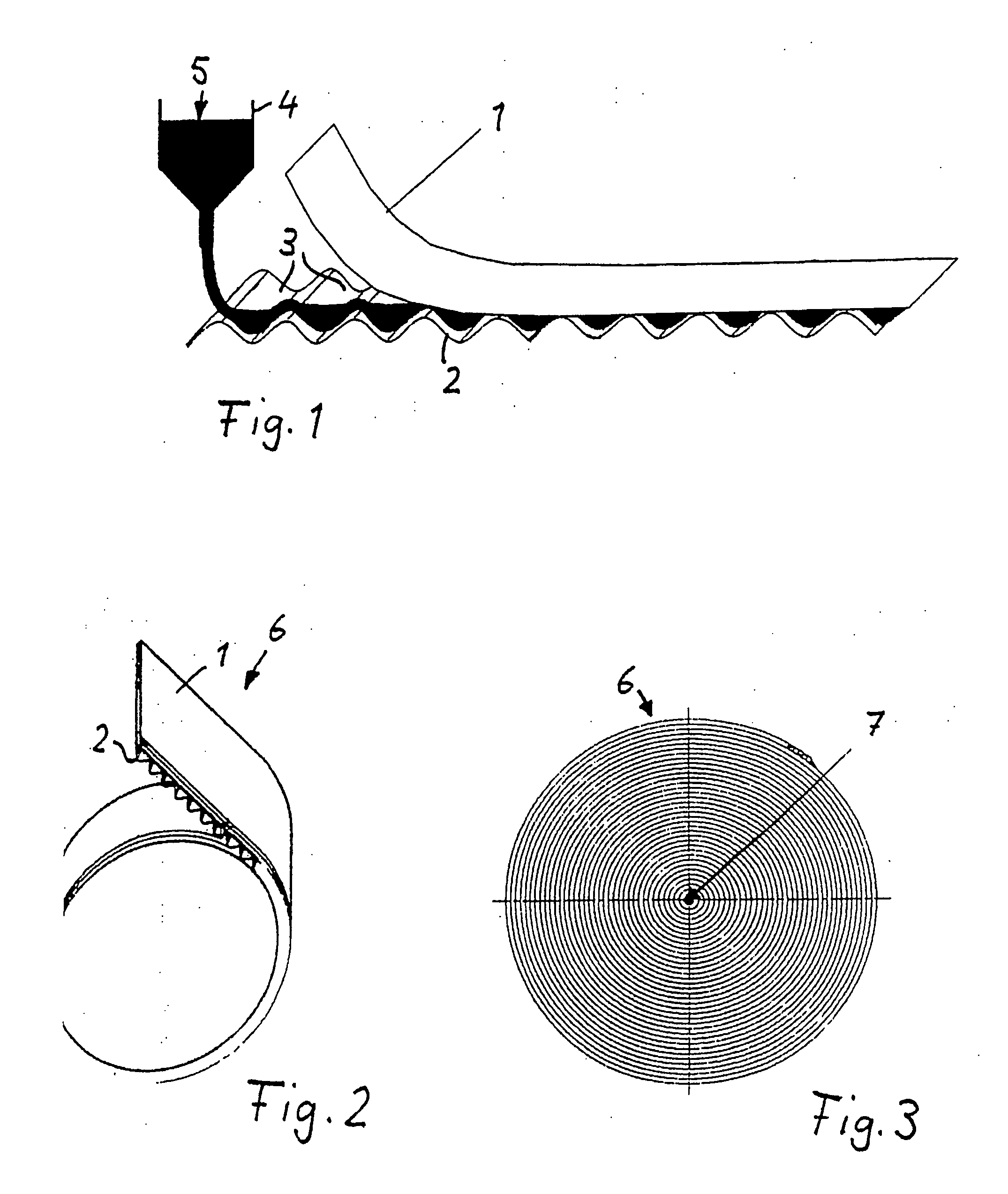

A process for producing a ceramic composite having a porous network. The process includes providing a photocurable ceramic dispersion. The dispersion consists of a photocurable polymer and a ceramic composition. The surface of the dispersion is scanned with a laser to cure the photocurable polymer to produce a photocured polymer / ceramic composition. The photocured composition useful as a polymer / ceramic composite, or the polymer phase can be removed by heating to a first temperature that is sufficient to burn out the photocured polymer. It is then heated to a second temperature that is higher than the first temperature and is sufficient to sinter the ceramic composition to produce a purely ceramic composition having a porous network.Preferably and more specifically, the process uses a stereolithographic technique for laser scanning. The process can form a high quality orthopedic implant that dimensionally matches the bone structure of a patient. The technique relies upon laser photocuring a dense colloidal dispersion into a desired complex three-dimensional shape. The shape is obtained from a CAT scan file of a bone and is rendered into a CAD file that is readable by the stereolithography instrument. Or the shape is obtained directly from a CAD file that is readable by the stereolithography instrument.

Owner:UNITED STATES SURGICAL CORP +2

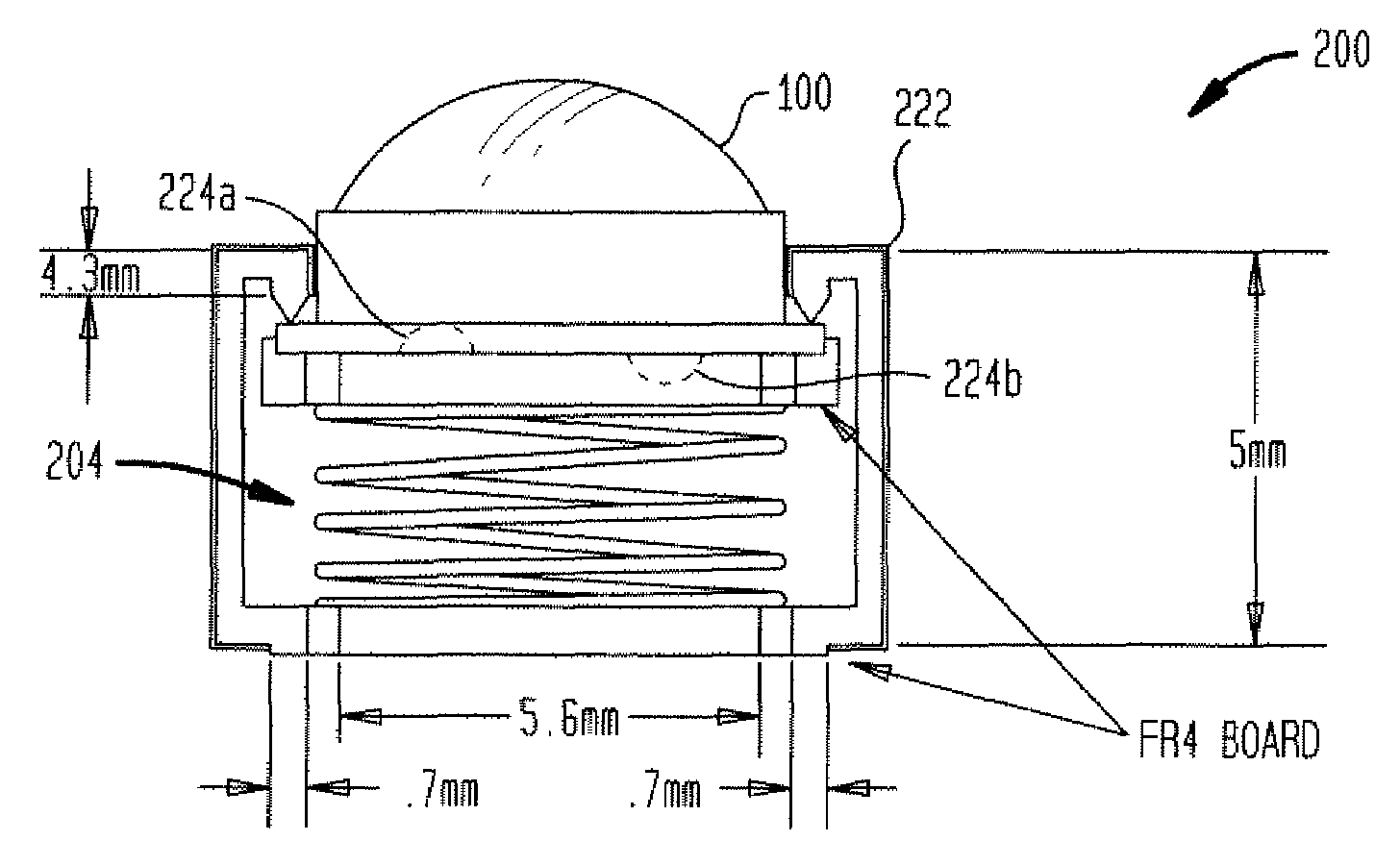

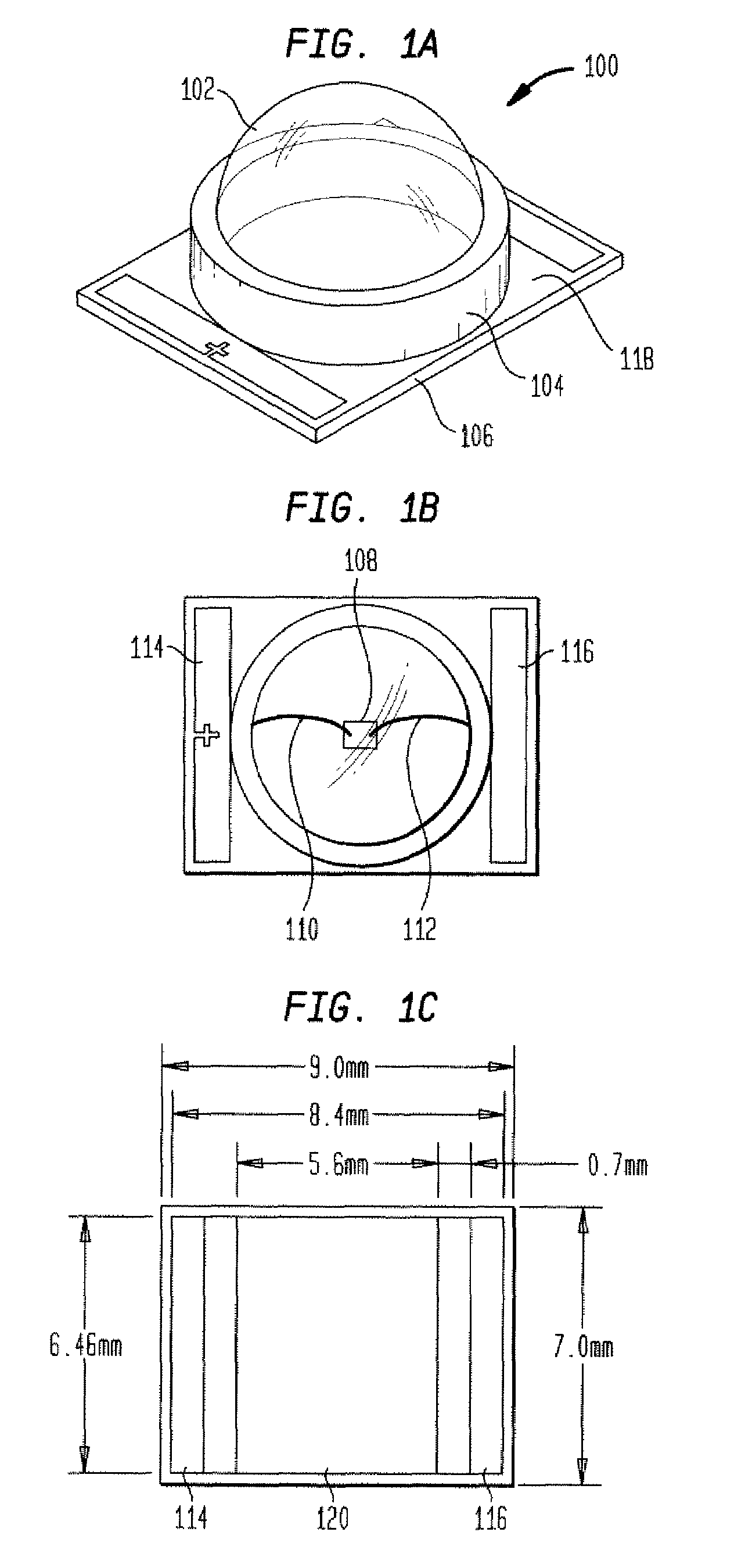

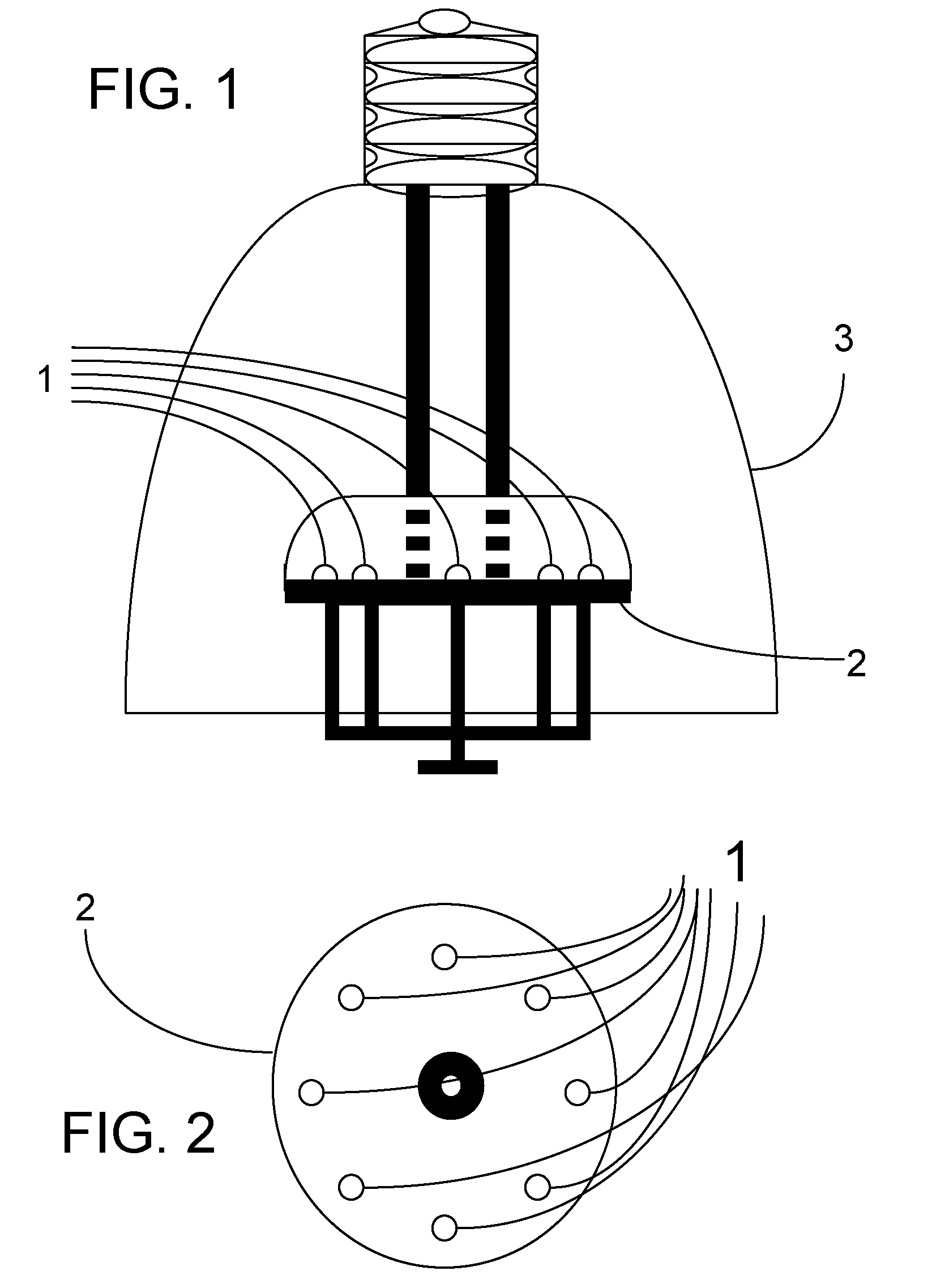

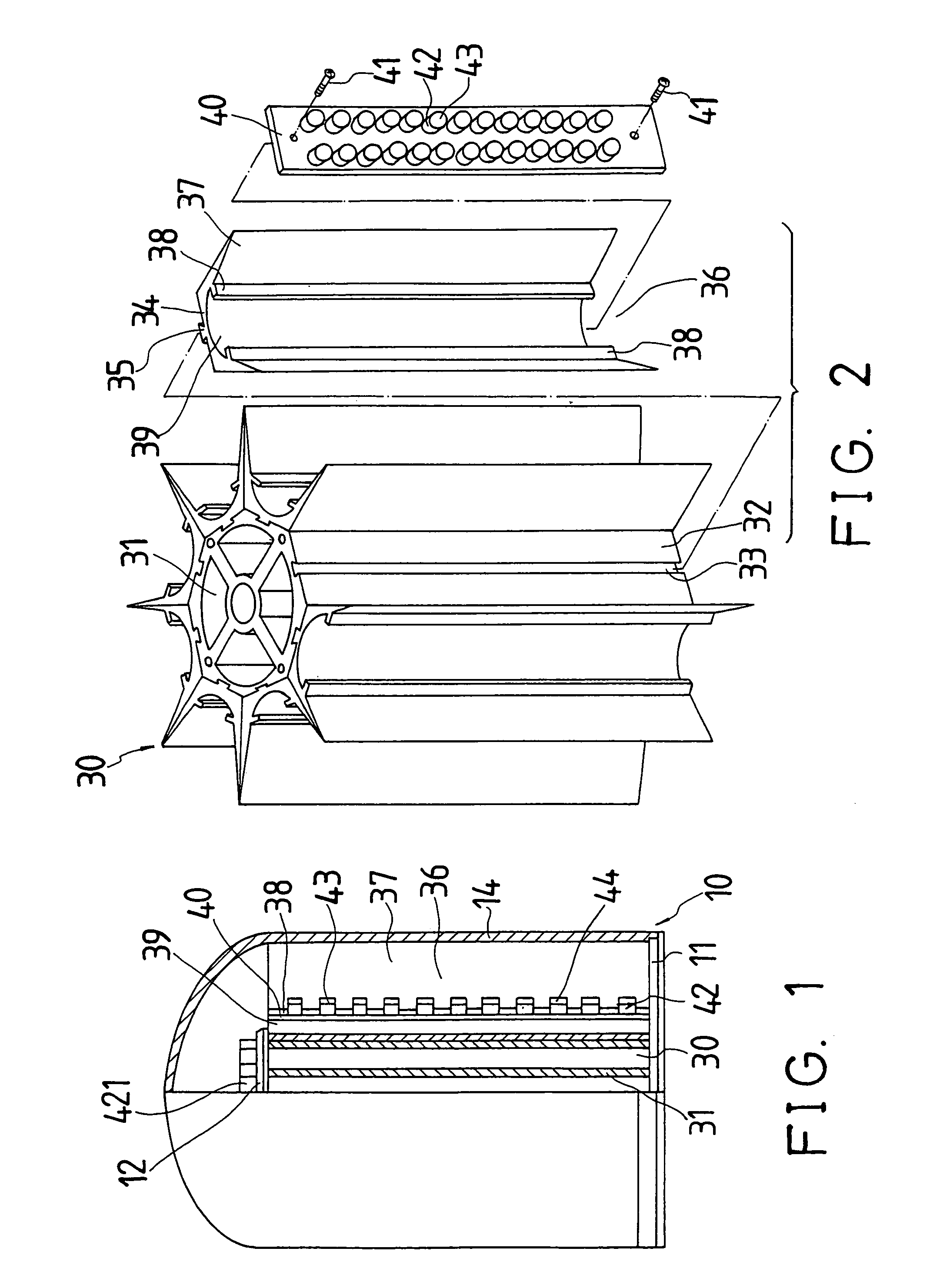

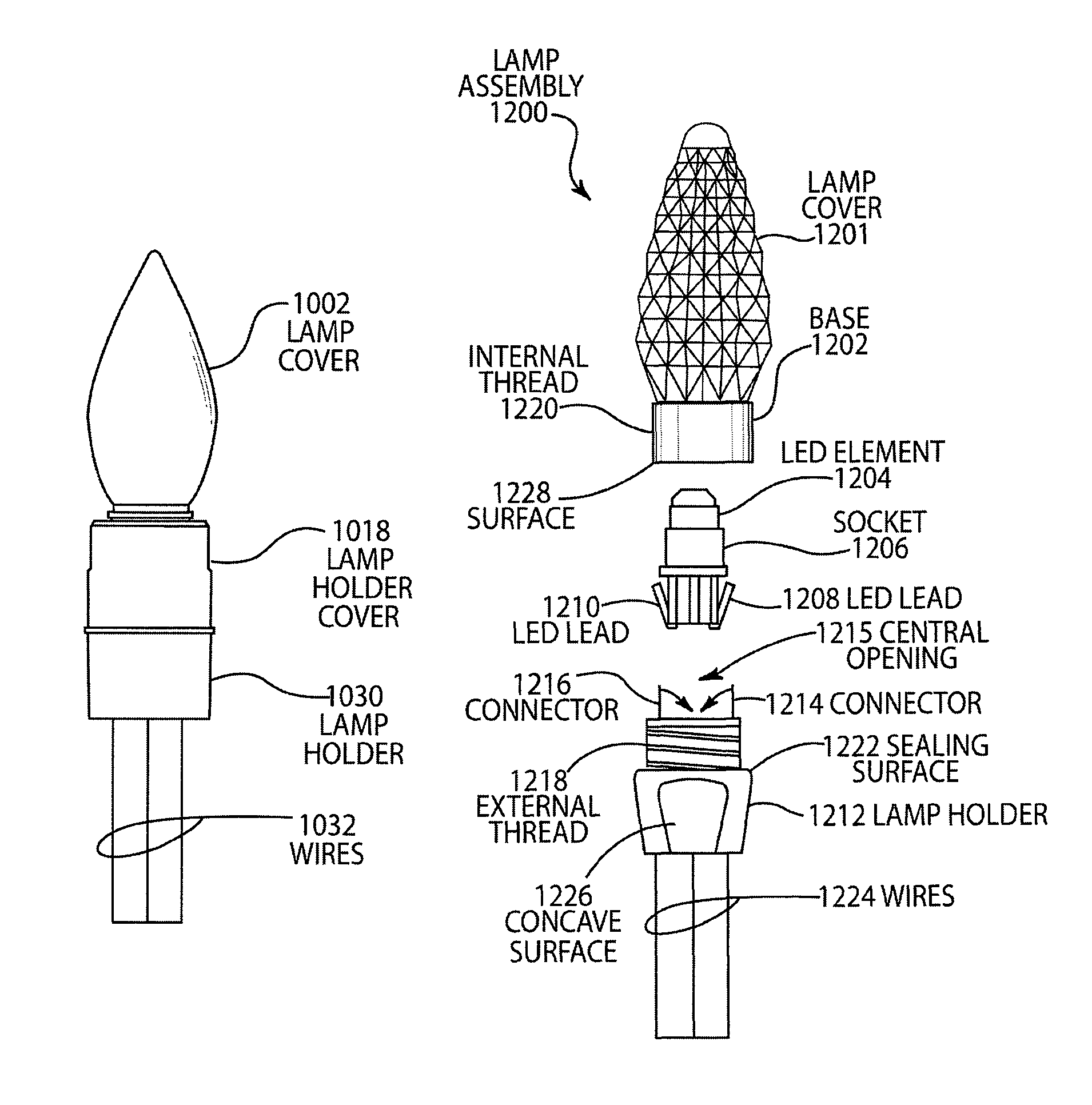

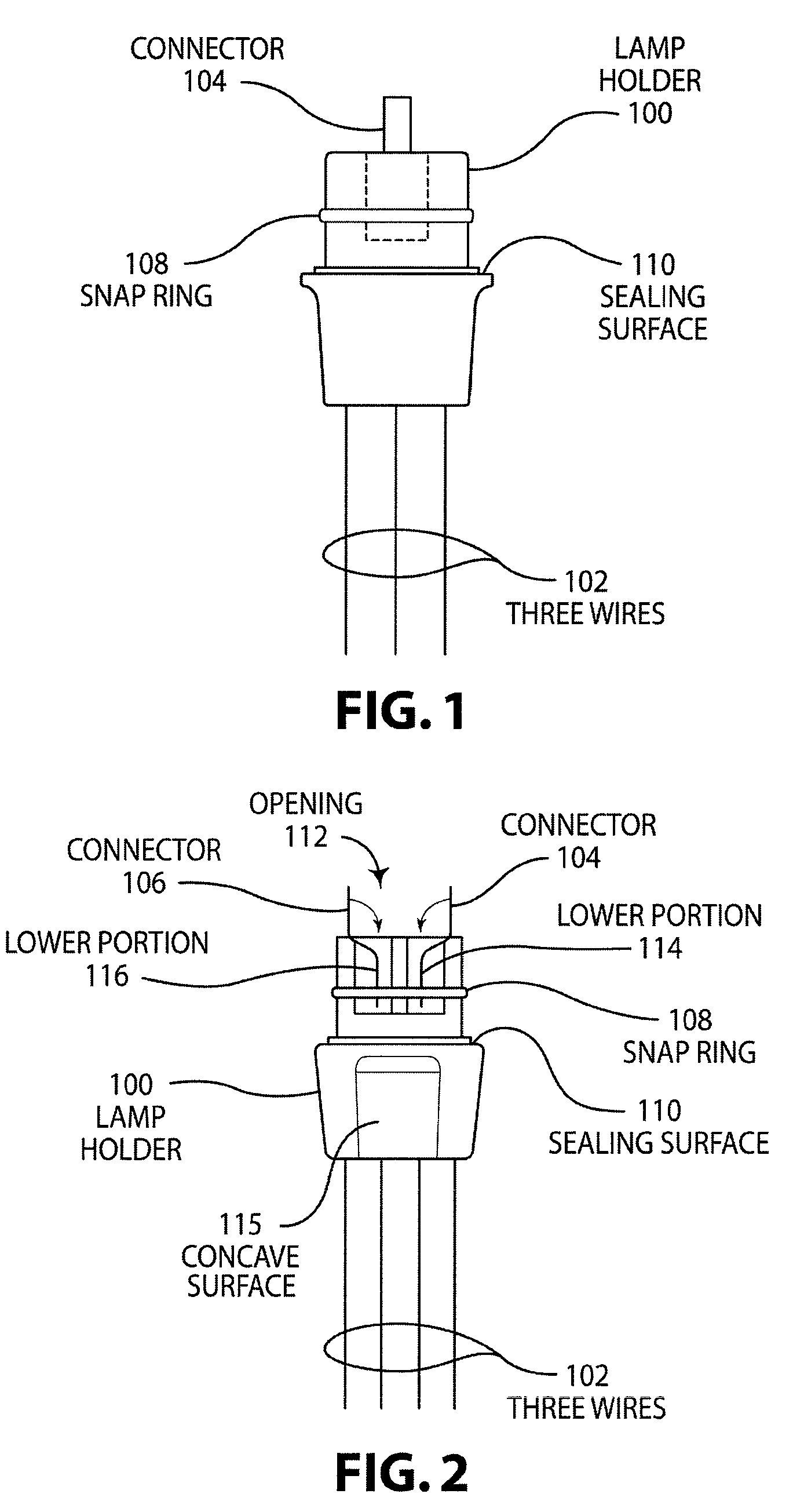

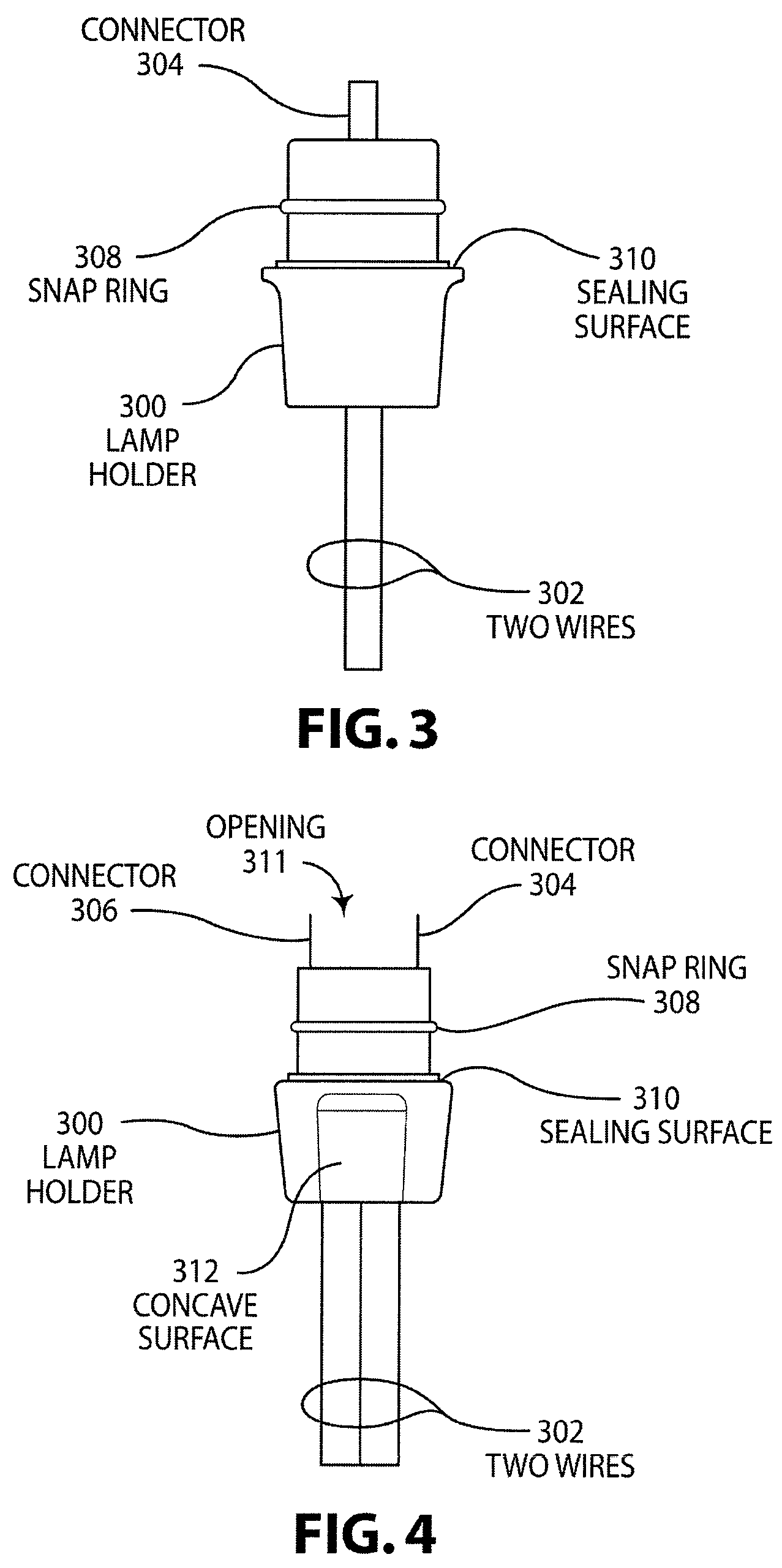

LED socket and replaceable LED assemblies

ActiveUS7549786B2Easy to remove and replacePoint-like light sourceLighting support devicesEngineeringSingle lead

Socket arrangements for releasably mounting LEDs and light fixtures or assemblies employing such sockets are described. The socket arrangements facilitate the replacement of LEDs to replace an original LED with a brighter replacement, to change the color of the LED, to replace a single LED with a multiple chip LED, to replace a damaged or burned out LED with a new one, or the like. In further assemblies with plural LEDs, the use of ready release sockets facilitates selective replacement of an LED or LEDs and greatly enhances the flexibility of such units.

Owner:IDEAL IND LIGHTING LLC

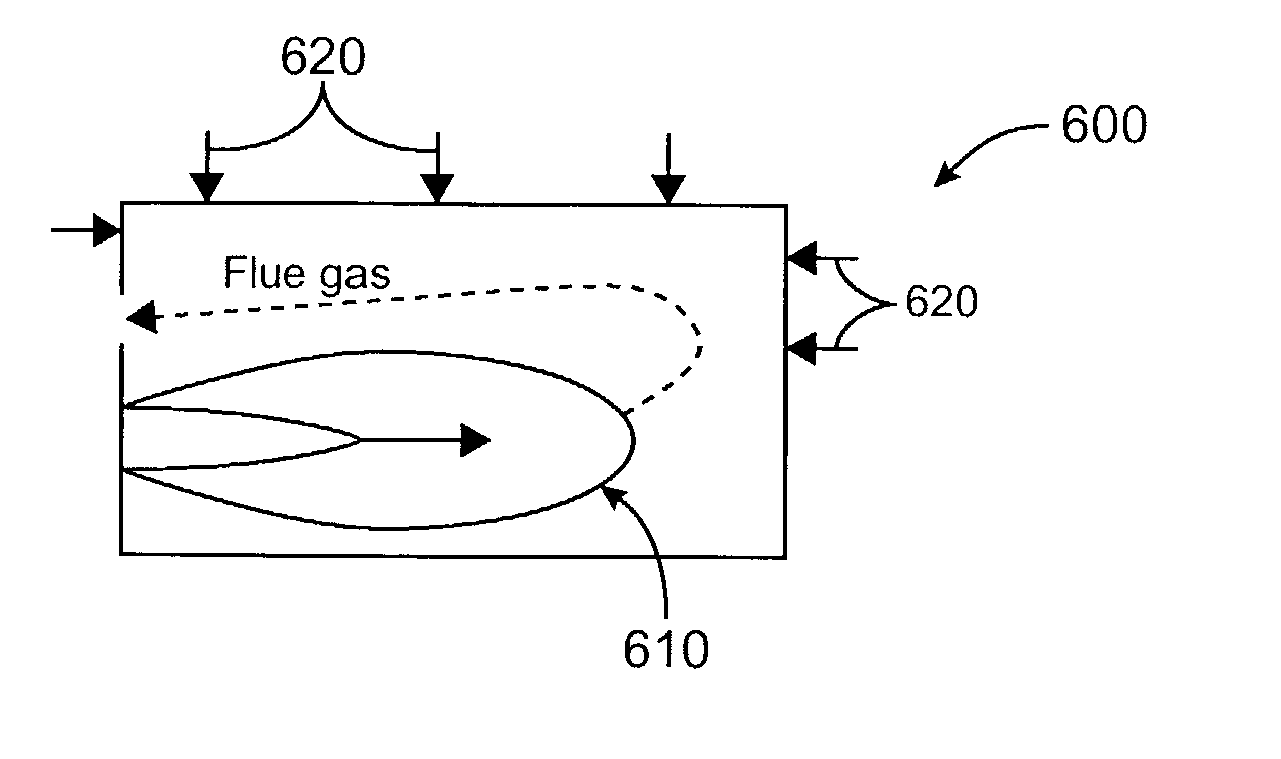

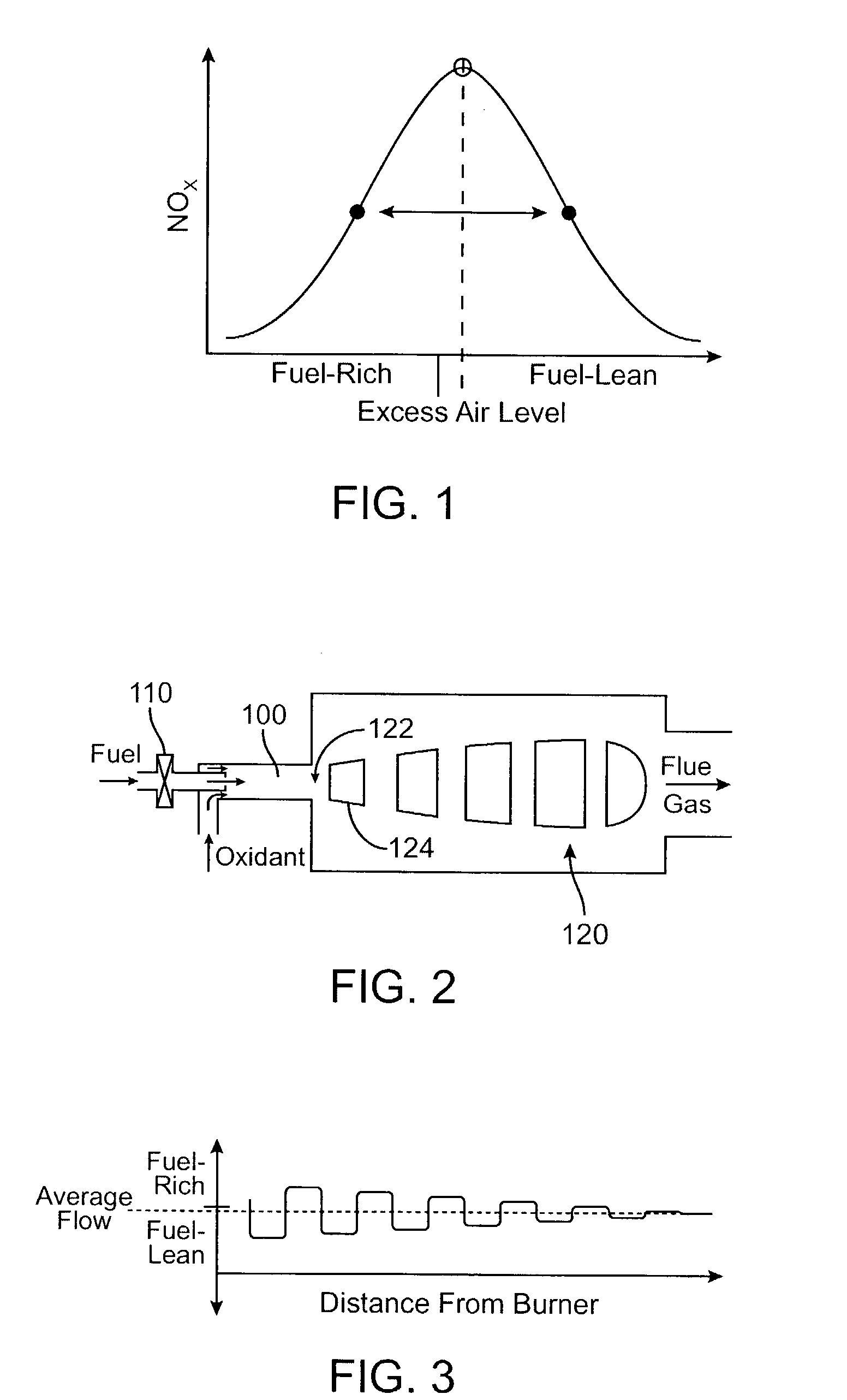

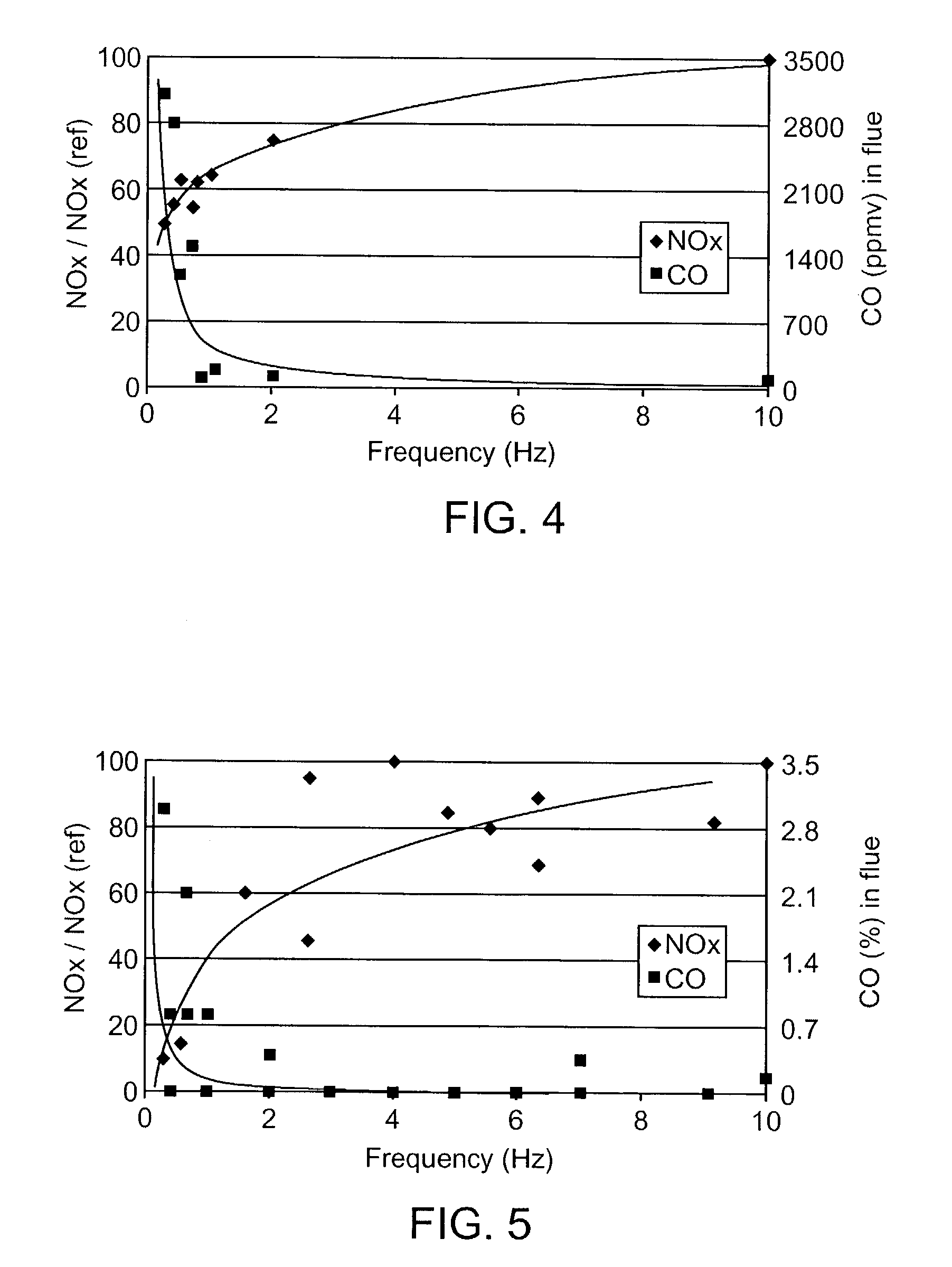

Process and apparatus of combustion for reduction of nitrogen oxide emissions

InactiveUS20030134241A1Special fuel supply arrangementsIndirect carbon-dioxide mitigationNitrogen oxidesControl system

A combustion control system allows the dramatic reduction of NOx emission levels from industrial combustion processes without having recourse to expensive flue gas clean up methods. The system combines the technique of oscillating combustion with an adapted system for post combustion burn out of the excess of CO resulting from the low-NOx combustion zone. A process for fuel combustion includes generating an oscillating combustion zone by oscillating at least one of the fuel flow and the oxidant flow to achieve a reduced nitrogen oxide emission, selecting oscillating parameters and furnace operating parameters to maximize nitrogen oxide reduction efficiency to the detriment of carbon monoxide production, and combusting carbon monoxide downstream of the oscillating combustion zone by injecting a post combustion oxidant.

Owner:MARIN OVIDIU +3

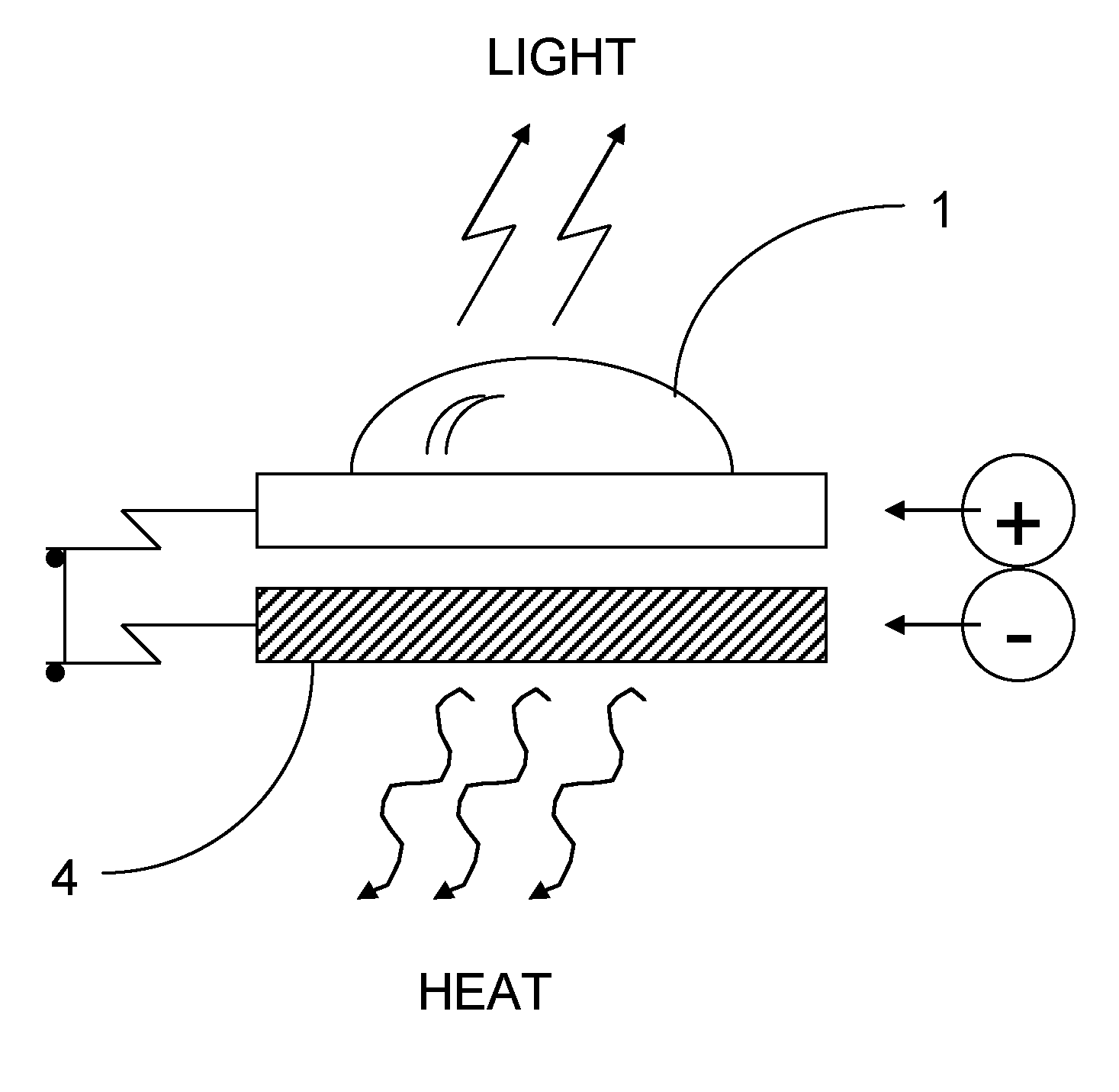

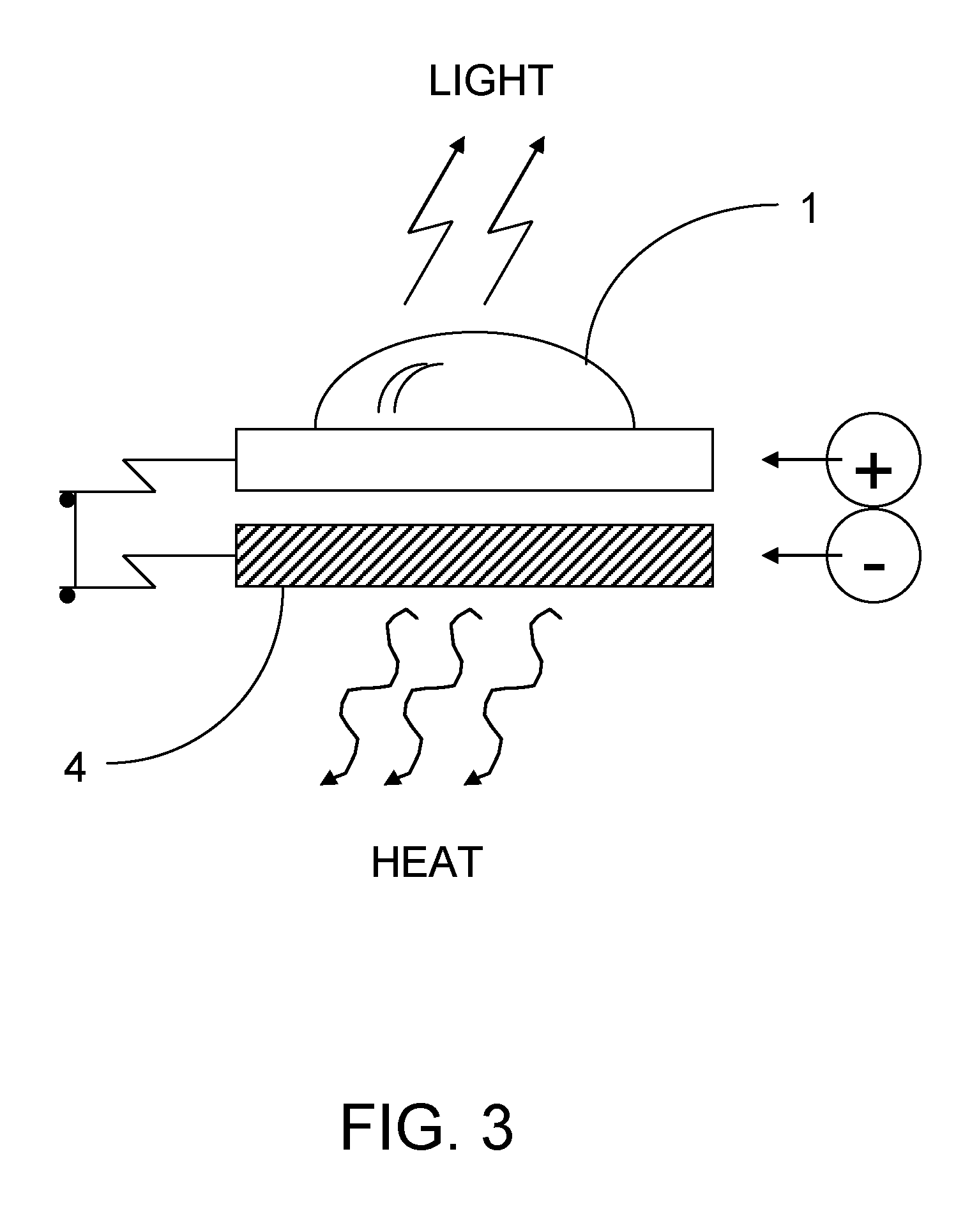

Dynamic heat sink for light emitting diodes

InactiveUS20070102033A1Less power dissipationPoint-like light sourceThermoelectric device with peltier/seeback effectThermoelectric coolingEngineering

Dynamic heat sink that uses a thermoelectric cooler, such as a Peltier Junction, to move the heat at a LED junction to the other side of the cooling chip. This would allow the LED to run with more current in a much smaller area than a passive metal heat sink without burning out the junctions. The Present Invention would therefore permit a compact light device comprising a plurality of LED's to be constructed. Such a light device would be competitive with standard fluorescent bulbs by outputting light of equivalent brightness with less power dissipation.

Owner:UNIVERSAL MEDIA SYST

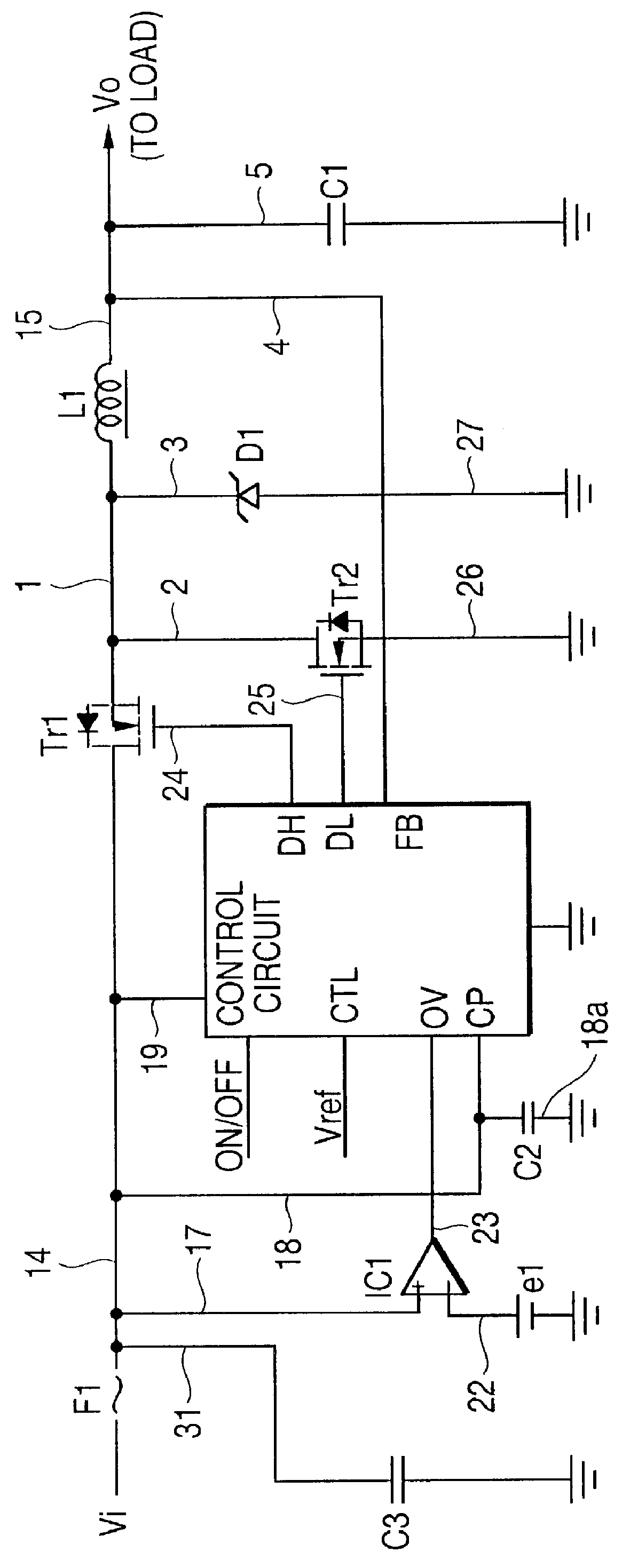

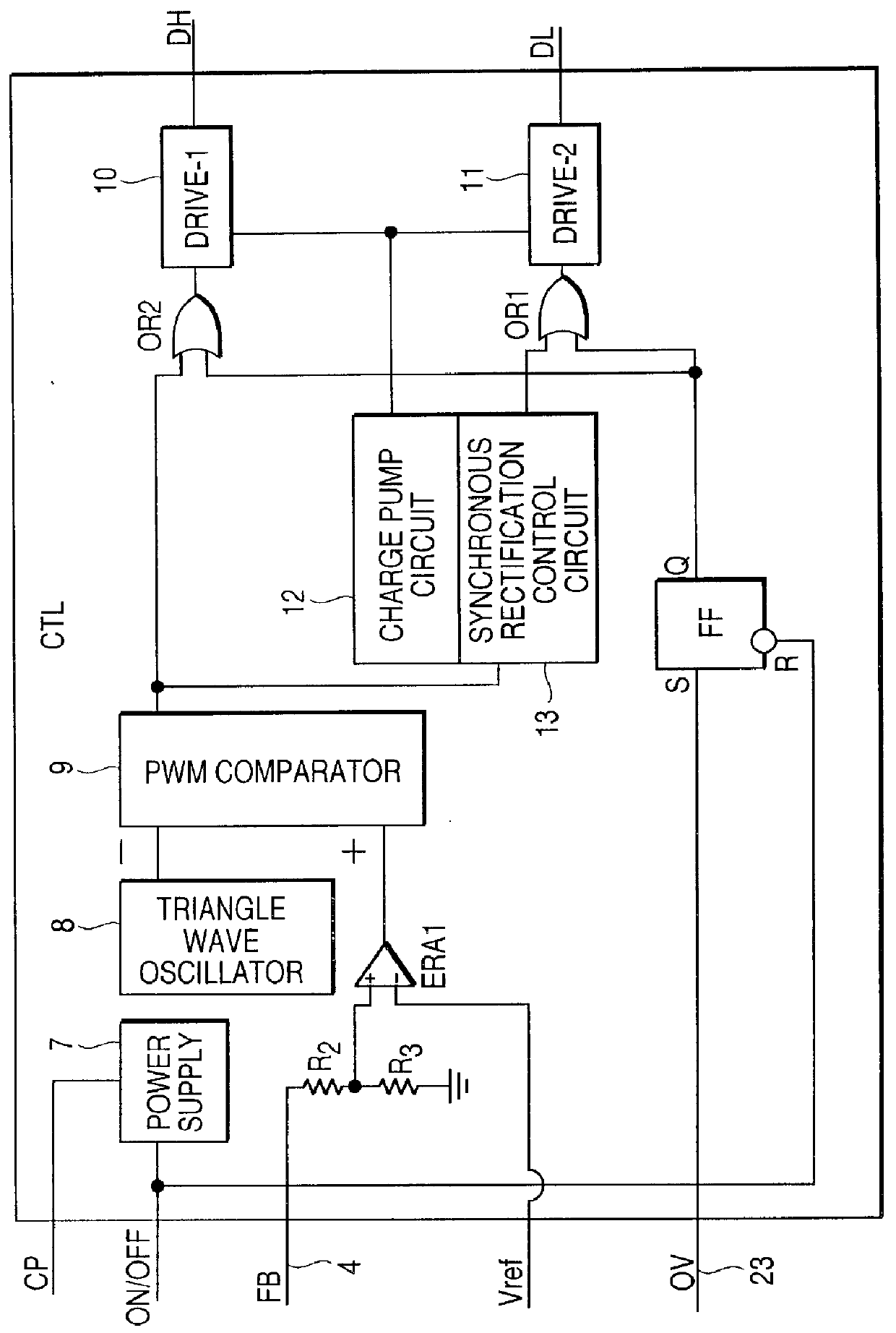

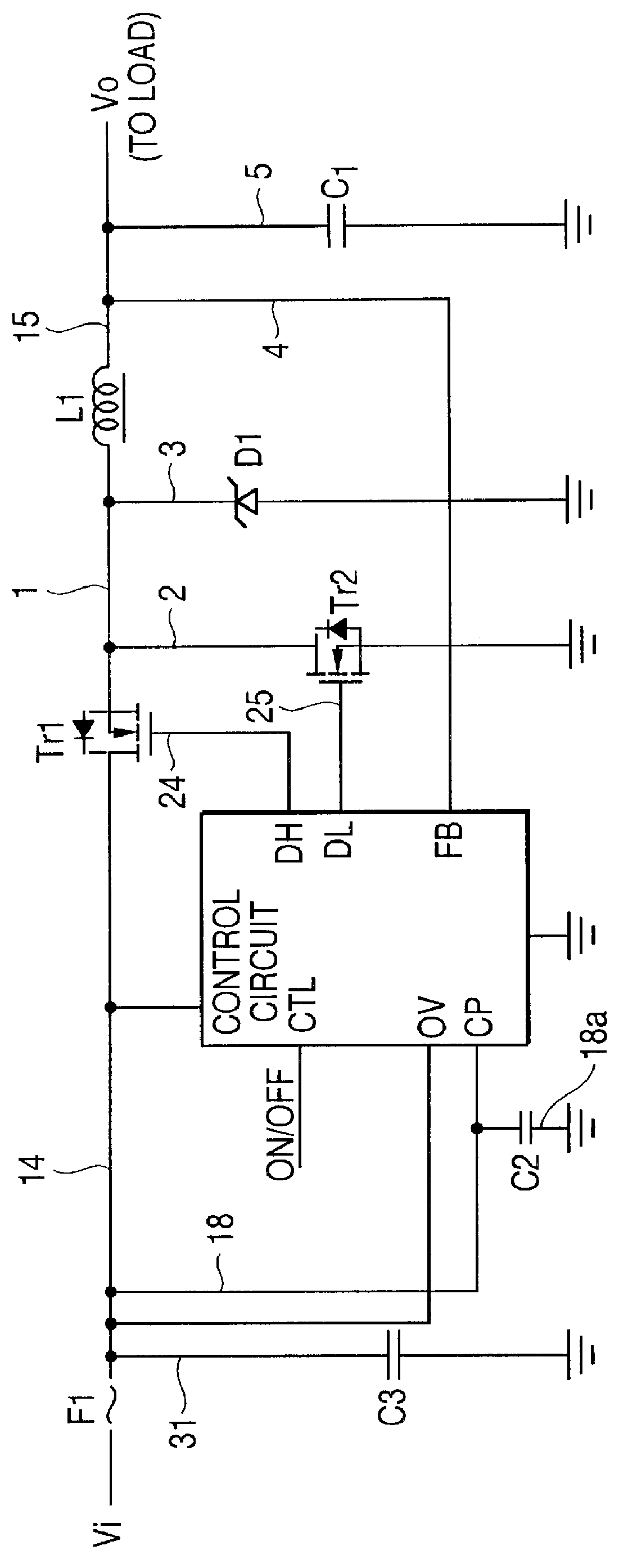

DC-to-DC converter capable of preventing overvoltage

InactiveUS6028755AAvoid Overvoltage ProblemsAvoid fireEfficient power electronics conversionApparatus without intermediate ac conversionOvervoltageEngineering

To avoid burning out a capacitor in a synchronous rectification type DC-to-DC converter due to overvoltages, the synchronous rectification type DC-to-DC converter includes a storage unit storing therein power derived from a power supply, switching elements connecting and disconnecting respective signal paths from power and ground, and a control unit controlling the connecting / disconnecting operations of the switching elements to maintain a voltage output from the storage unit at a predetermined value. The DC / DC converter also includes an overvoltage detecting unit monitoring a voltage derived from the power supply to thereby output an alarm signal when the voltage derived from the power supply exceeds a preselected voltage value, a shortcircuiting unit influencing the connecting conditions of the switching elements when the alarm signal from the overvoltage detecting unit is input therein, whereby the voltage derived from the power supply is shortcircuited, and an interrupting unit interrupting one of the signal paths by the power shortcircuited by the shortcircuiting unit.

Owner:FUJITSU LTD

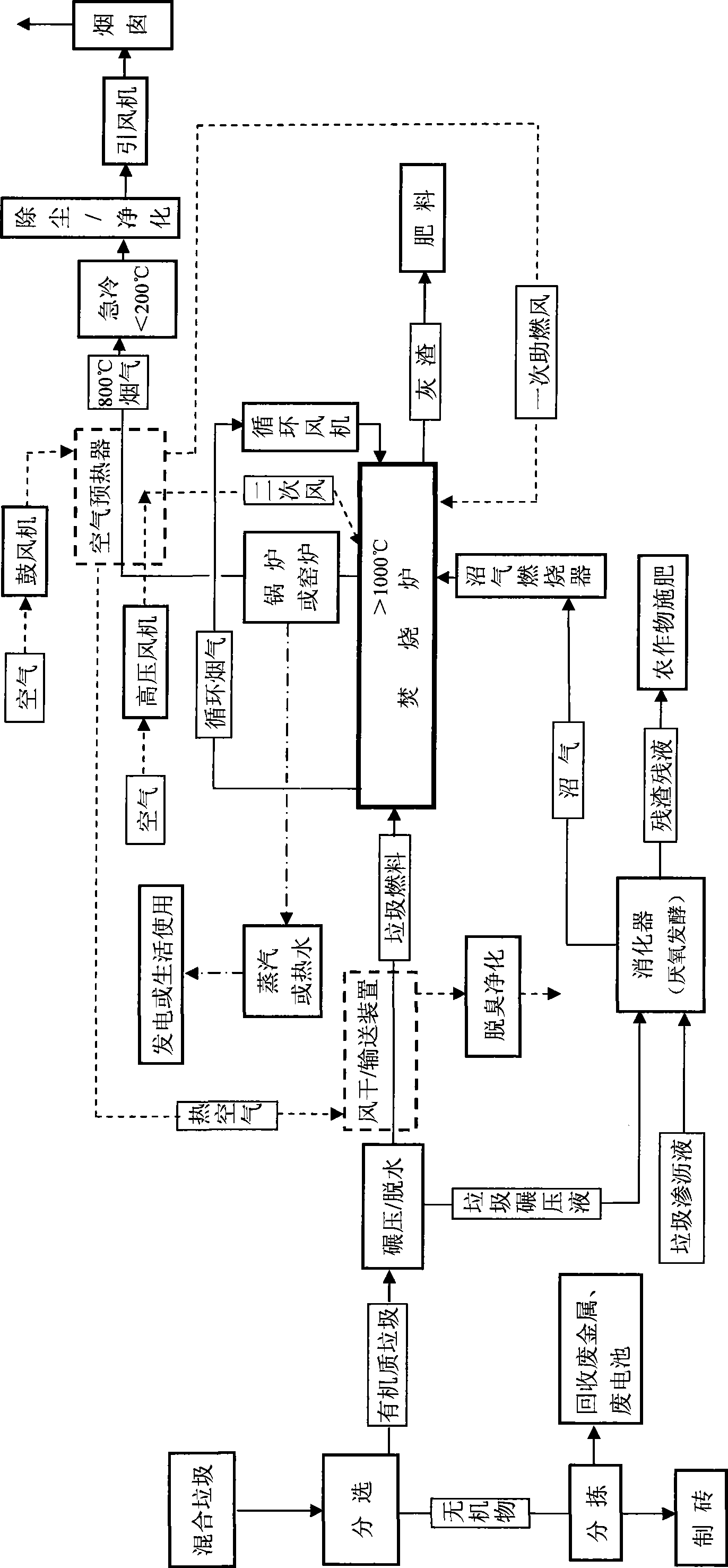

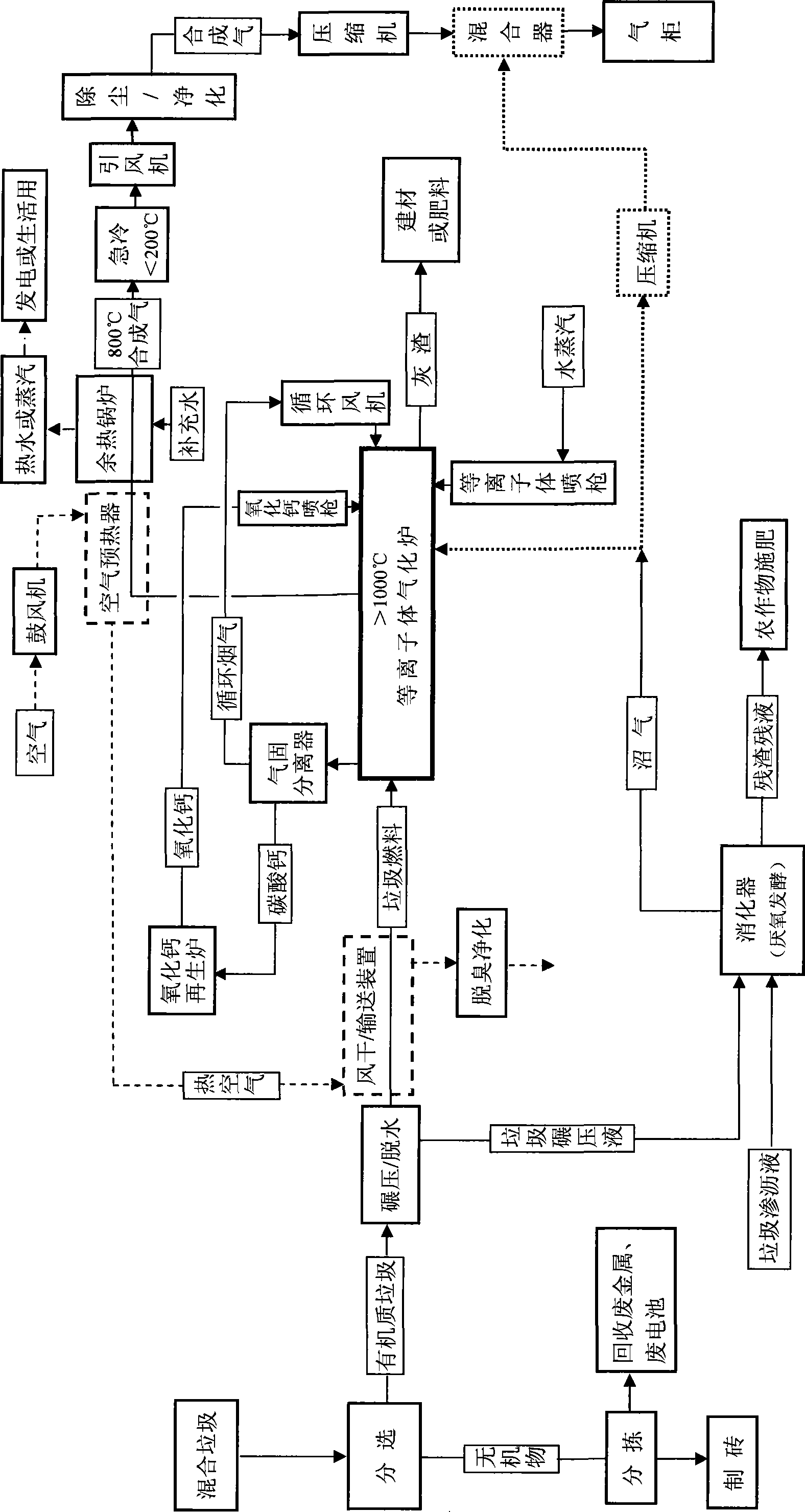

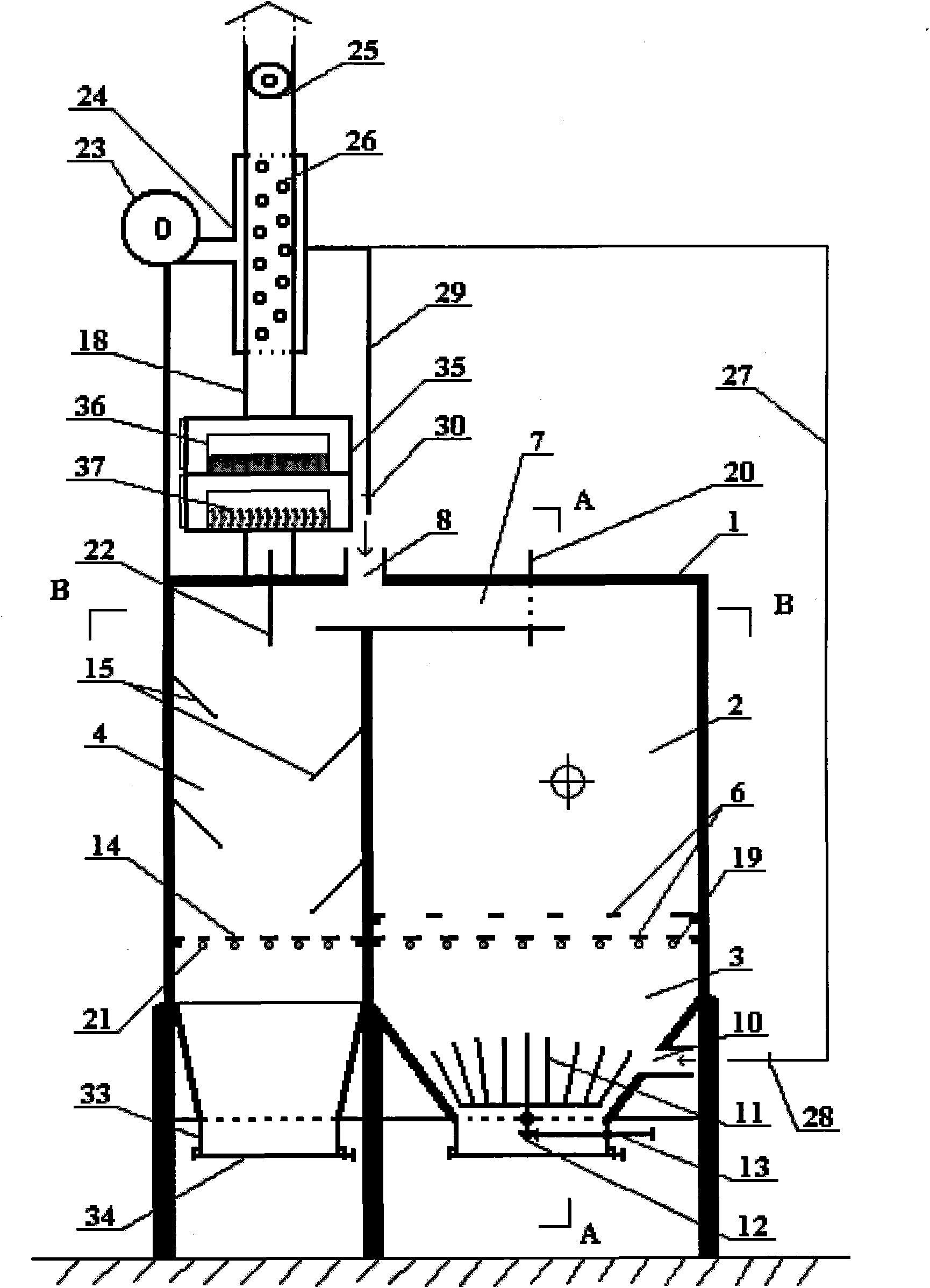

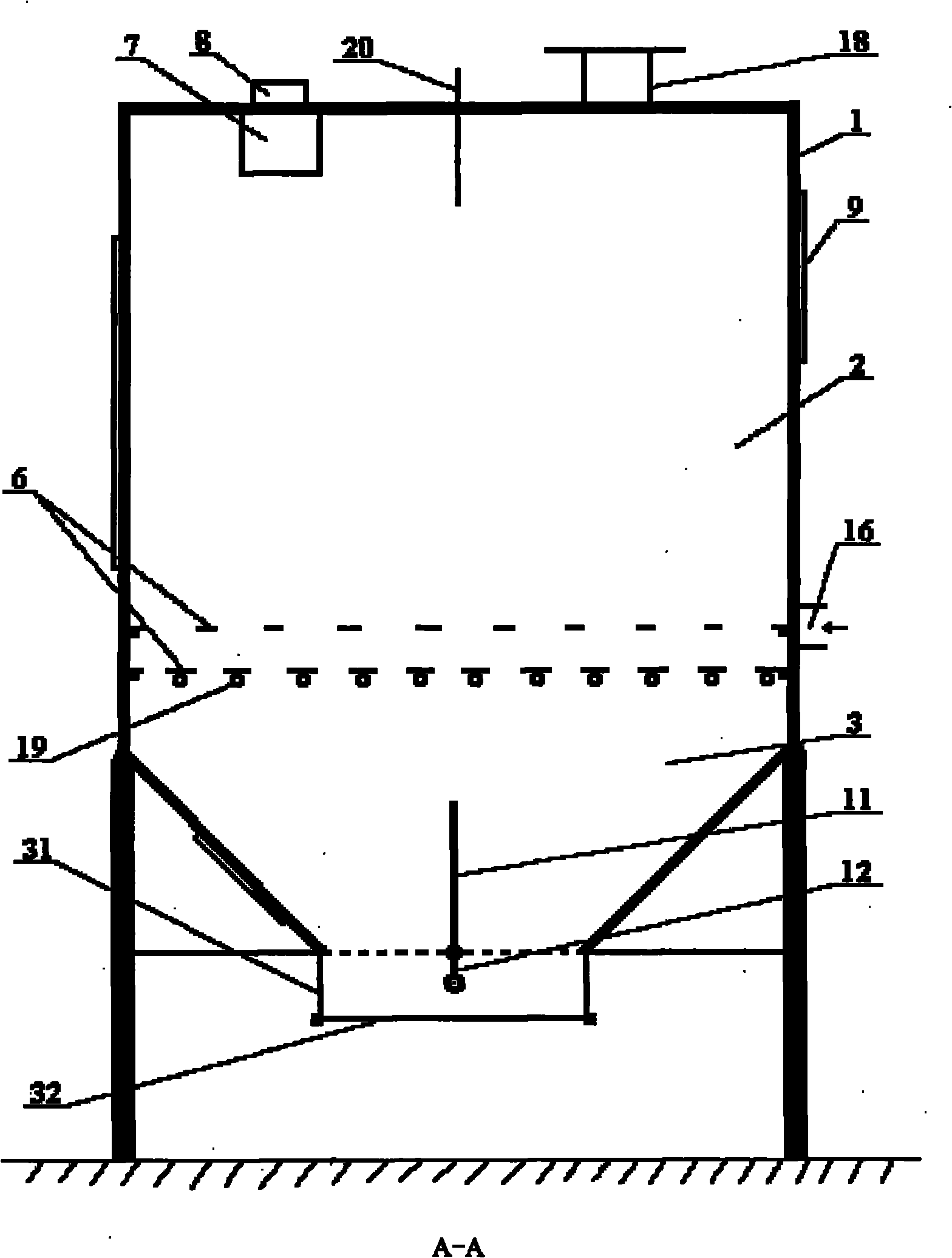

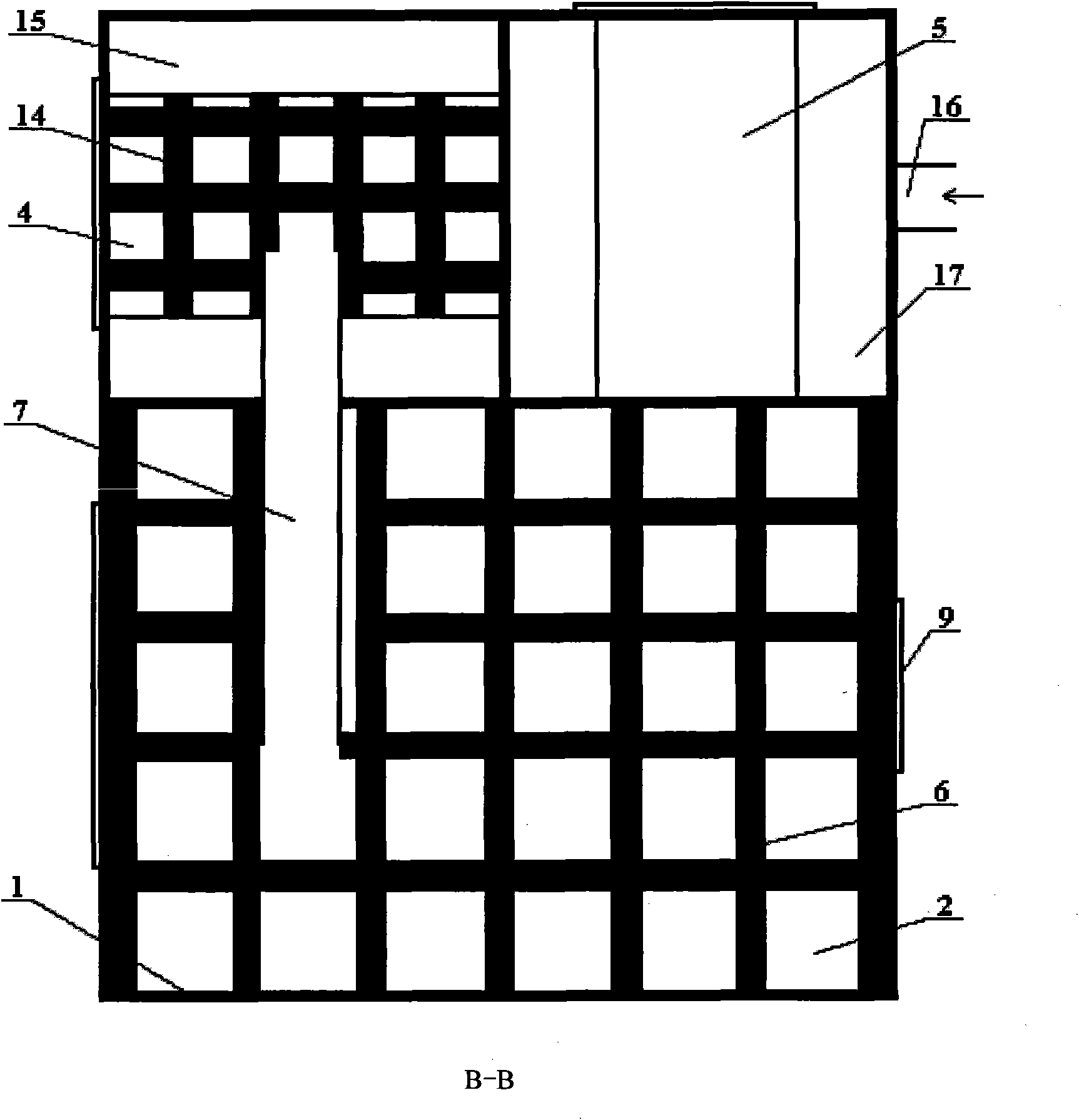

Domestic garbage transformation technique, system and apparatus without conventional fuel for combustion supporting

InactiveCN101468789AReduce pollutant contentLow investment costBio-organic fraction processingSolid waste disposalBrickClean energy

The invention provides a process, a system and equipment for converting household garbage without support combustion of the prior fuels, which relates to a process and equipment for processing garbage. The process is characterized in that the household garbage is sent into a gasification furnace or an incinerator after separating, dehydrating by rolling compaction and air-drying treatment; garbage fuel is converted in the furnace by a mode of gasification or incineration, and is subjected to baking, pyrogenation, gasification and carbon residue burn-out in the furnace; the converted synthesis gas is used for cleaning energy; waste heat of incineration is absorbed by heat-exchange equipment for reclamation; garbage rolling liquid is sent into a digesting machine for anaerobic fermentation so as to produce biogas, the biogas is used as auxiliary fuel of the incinerator, and the digested residue and residual liquid are used for fertilizing crops; and inorganic substances separated from the garbage are used as raw materials to manufacture bricks, and clinker discharged from the incinerator or the gasification furnace is used for producing cement or fertilizer. The process, the system and the equipment comprehensively utilize the garbage so as to achieve complete dissolving treatment, and the equipment has a simple structure and low investment cost, and is easy to popularize..

Owner:周开根

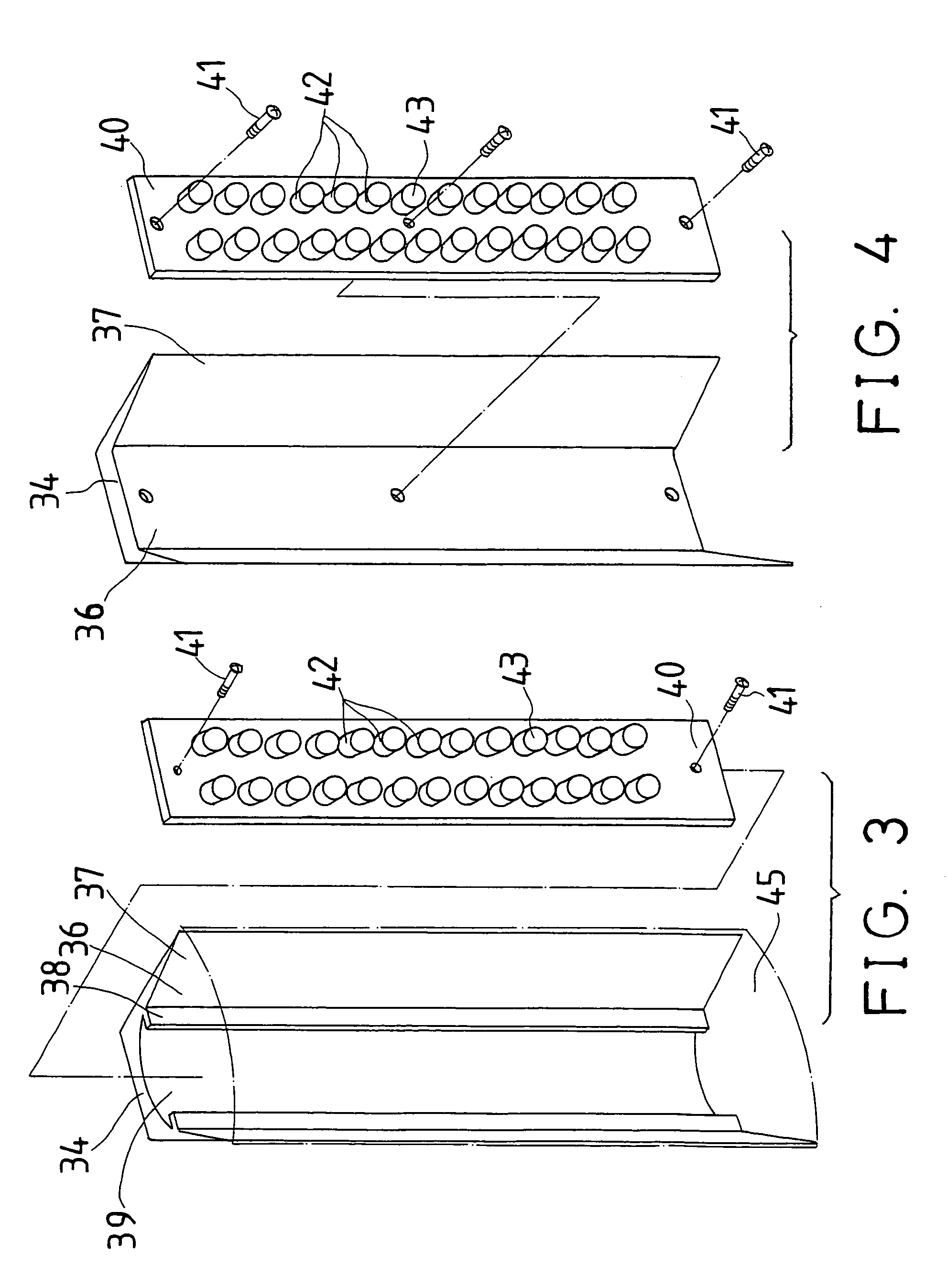

Light device having changeable light members

InactiveUS7014337B2Easy to changeEasy to replaceLighting applicationsNon-electric lightingEngineeringLED lamp

Owner:CHEN CHIA YI

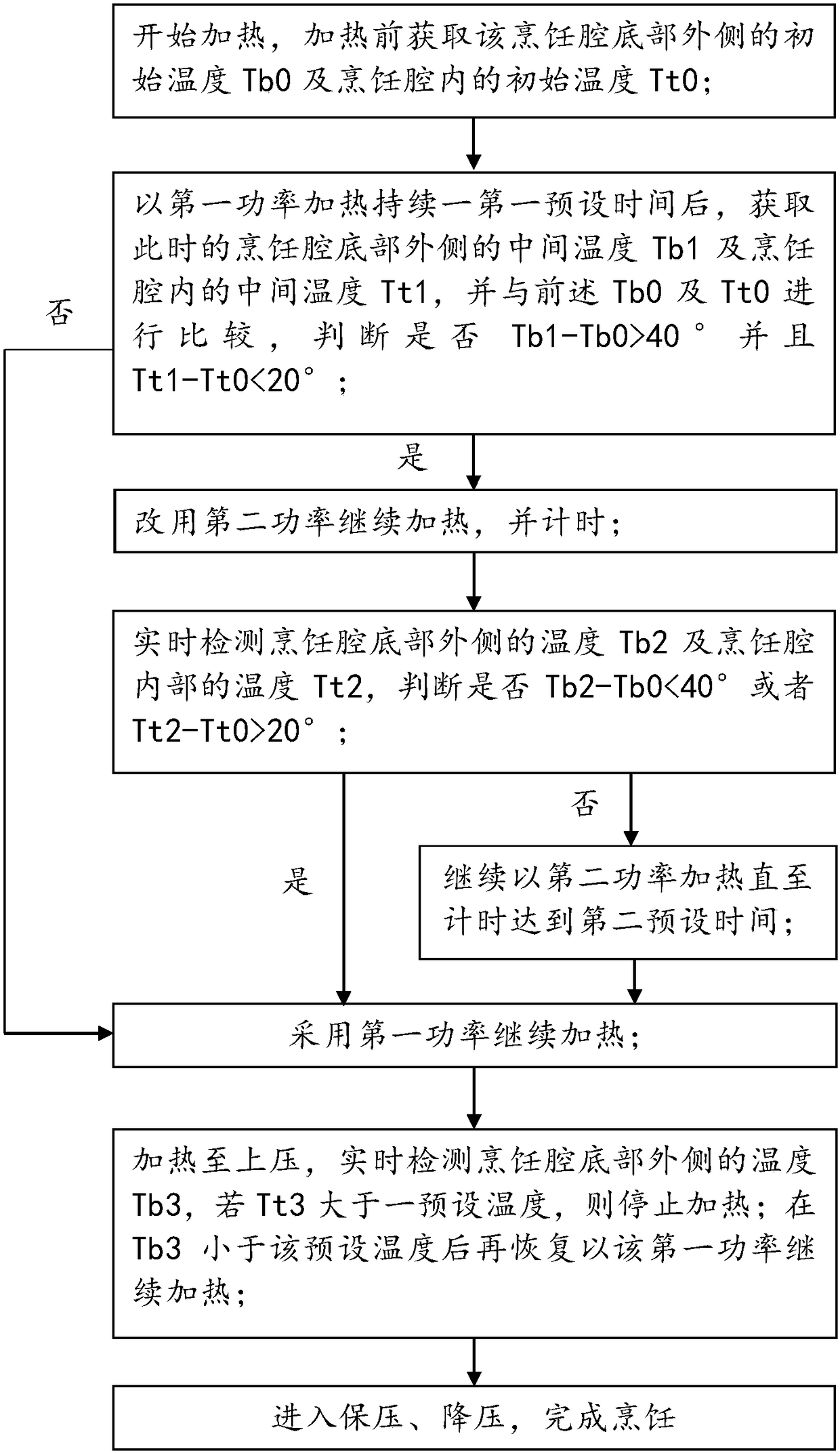

Cooking method and electric pressure cooker adopting cooking method

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

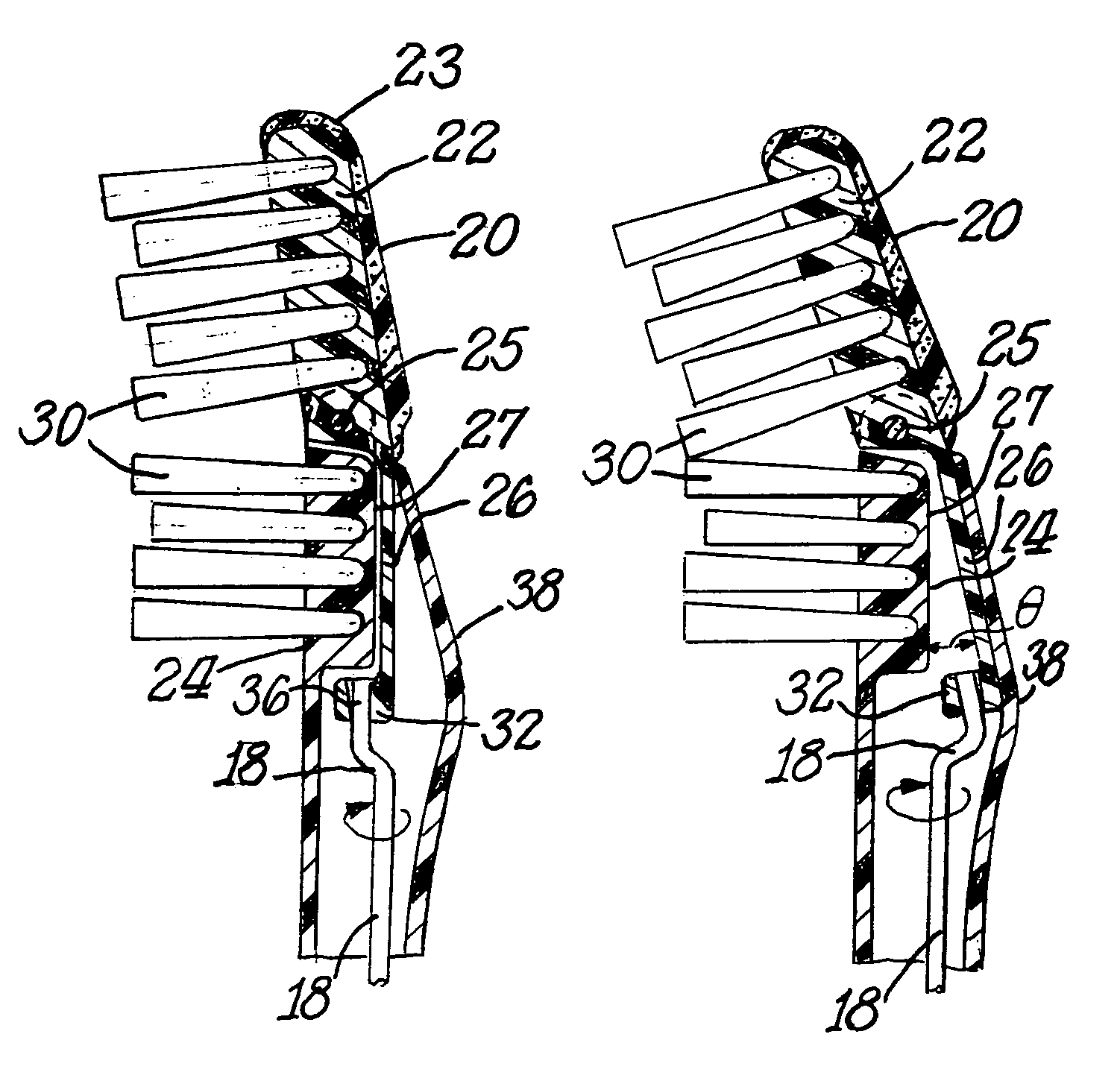

Powered toothbrush

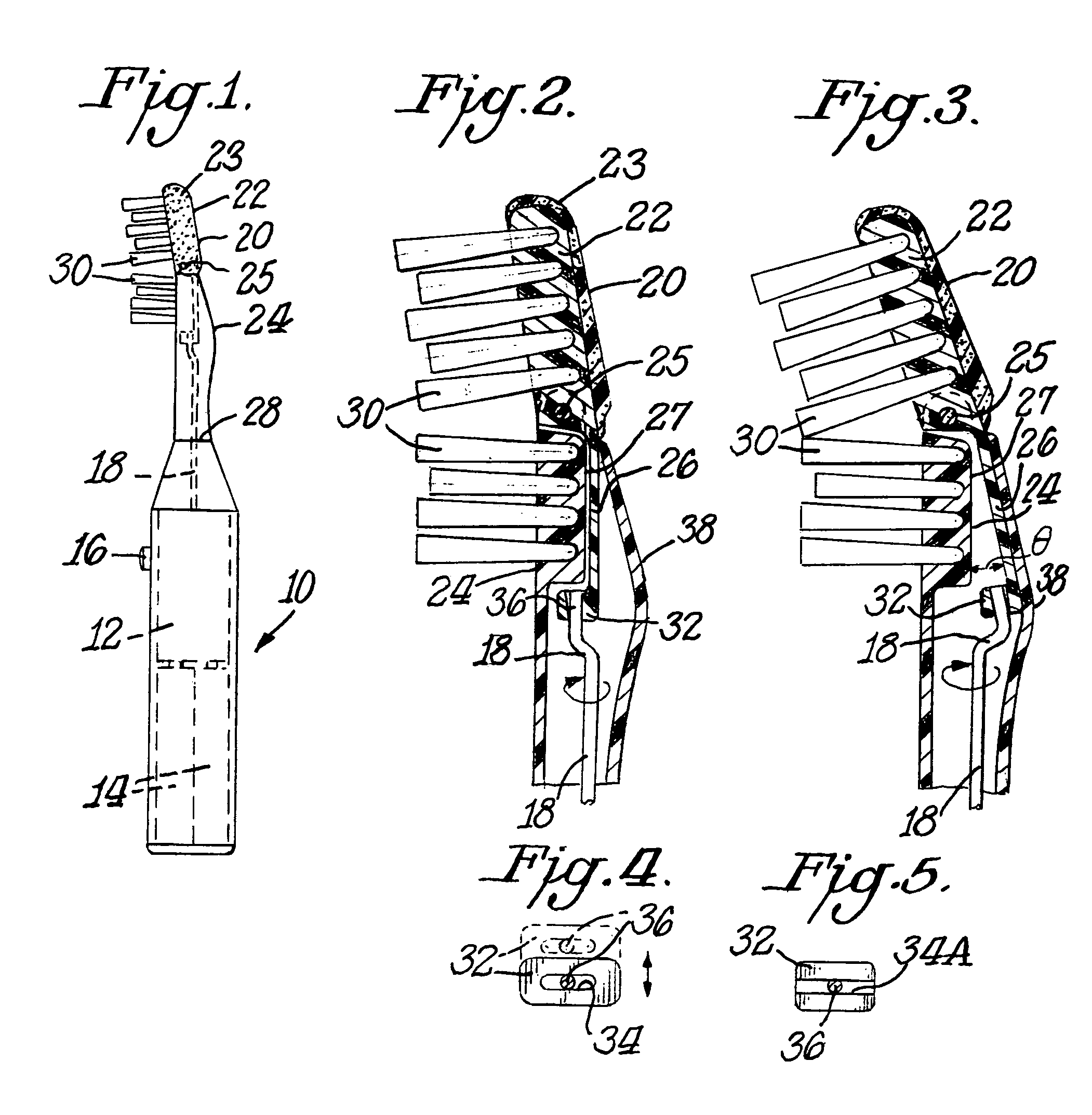

InactiveUS7007332B2Limit its operationLow profileCarpet cleanersBrush bodiesReciprocating motionDrive shaft

A powered toothbrush is disclosed wherein portion of the toothbrush head is movable about a hinge. The movable portion of the head reciprocates about that hinge through the interaction of a flexible extension of that portion containing a slot. Movable within the slot is an offset end of a rotating drive shaft connected to the power source in the toothbrush. Translation of rotation movement of the drive shaft to reciprocating movement of the hinged head is achievable in a manner that the power source is not stalled or burned out if movement of the toothbrush head is prevented or limited.

Owner:COLGATE PALMOLIVE CO

Coefficient of thermal expansion filler for vanadium-based frit materials and/or methods of making and/or using the same

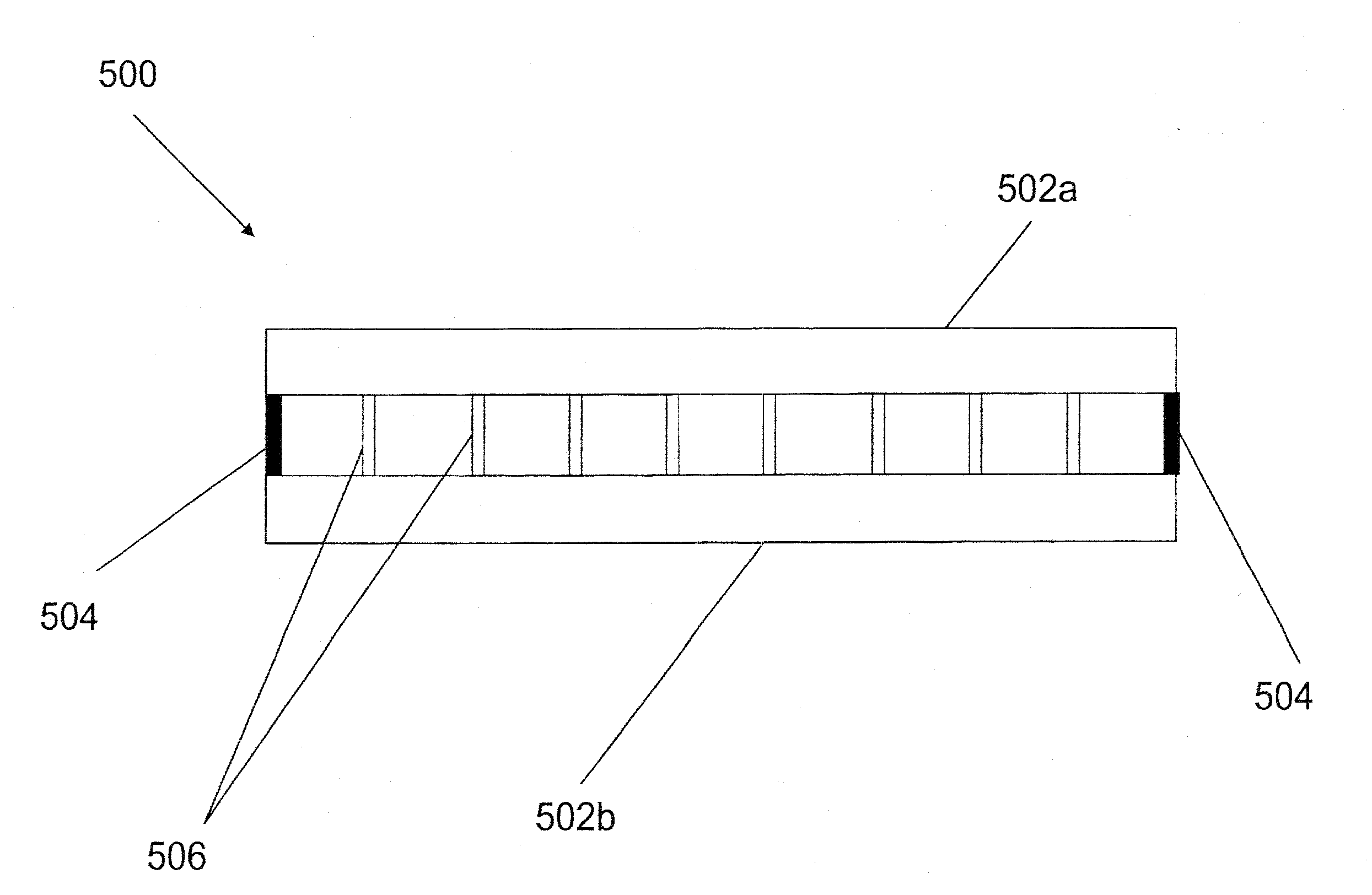

ActiveUS20120213954A1Improve sealingReduce sealClimate change adaptationWindows/door improvementMetal chlorideFrit

Certain example embodiments relate to seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a composition may be combined with a binder solution that substantially or completely burns out by the time the composition is melted. In certain example embodiments, a CTE filler is included with a frit material. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

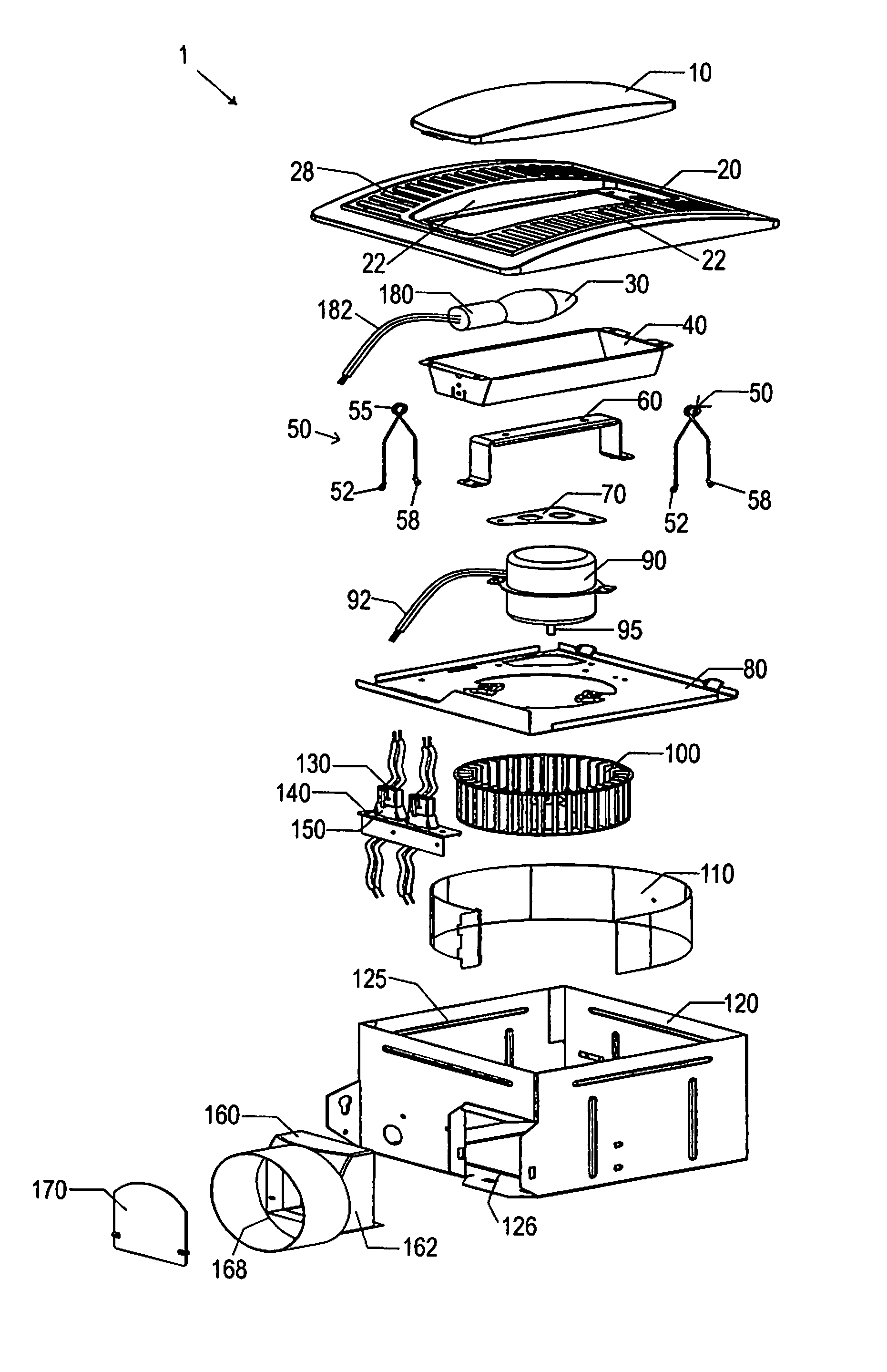

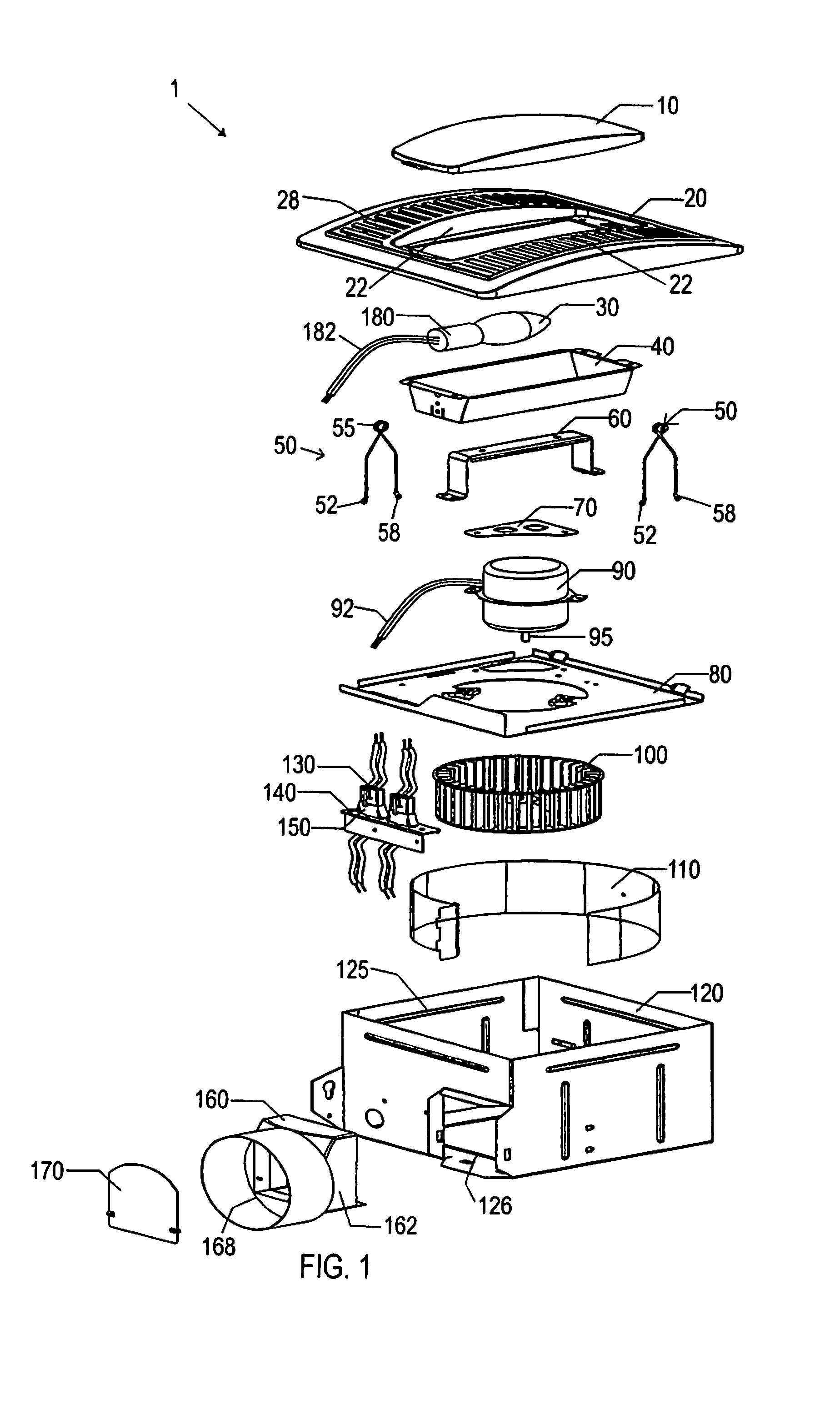

50 CFM bath fans with lens cover and flaps/ears that allow housings to be mounted to joists

InactiveUS9028212B1Minimize excess noiseEasy to disassemblePump componentsEngine componentsImpellerJoist

Apparatus, systems and methods of 50 CFM exhaust and ventilation fans for bathrooms with grill covers having removable light lens covers, and flaps / ears that allow the housings to mount directly to joists and / or other structural members inside of a ceiling or inside of a wall. The housing can include a mounting plate having a motor with attached impeller thereon, wherein the mounting plate with motor and attached impeller and electrical connectors can be removed as a single unit from the housing for accessing and inspecting interior wire connections during inspection and for ease in replacing parts such as burned out motors overtime.

Owner:CHIEN LUEN INDS

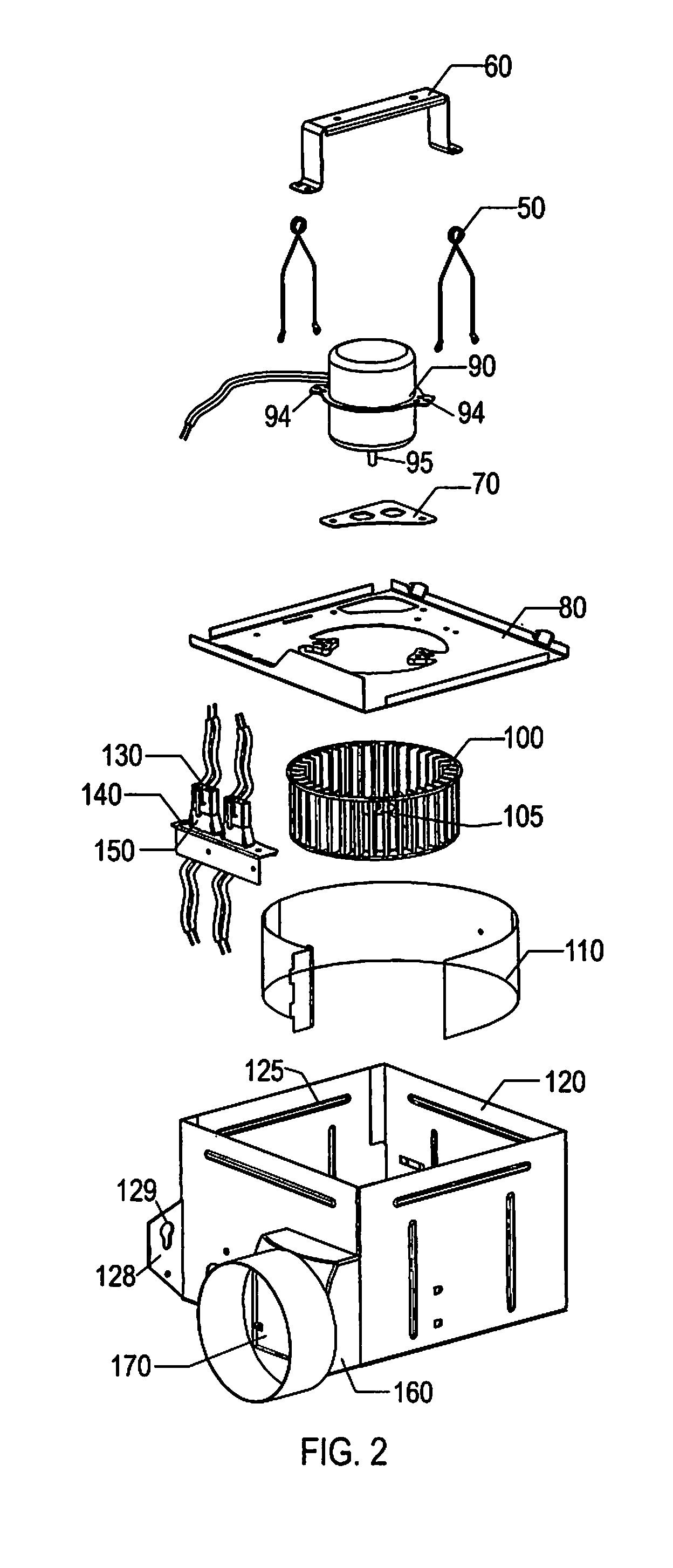

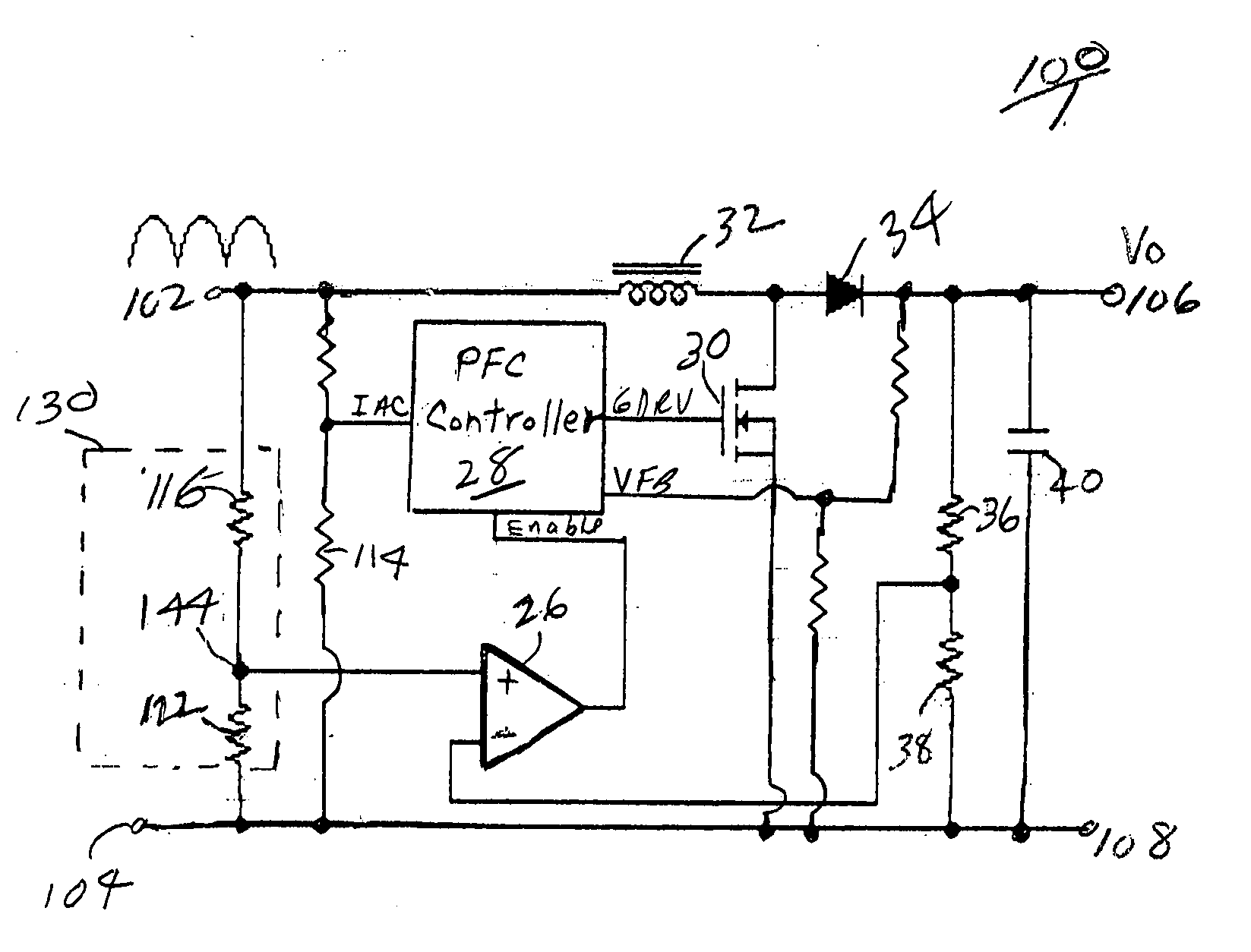

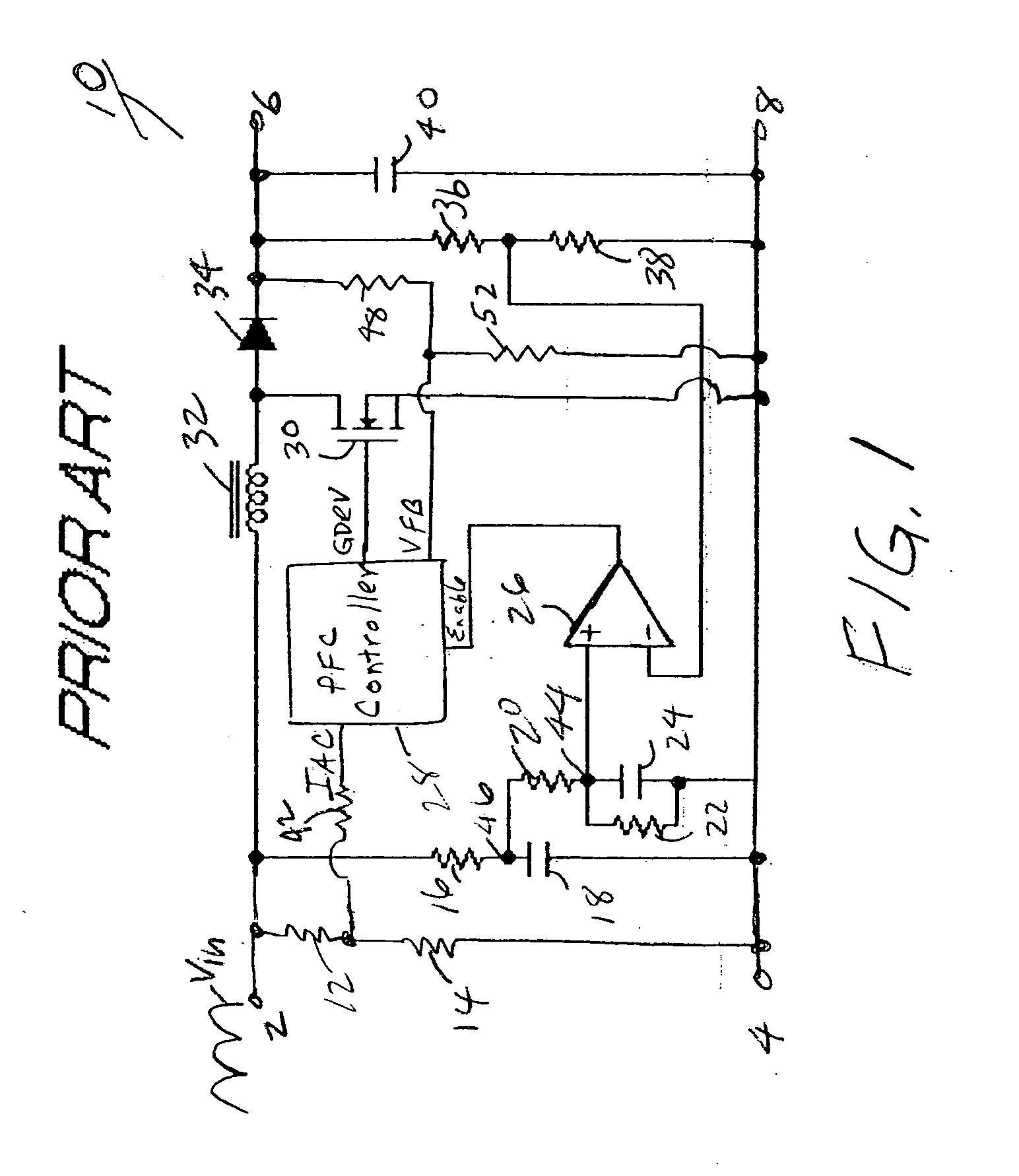

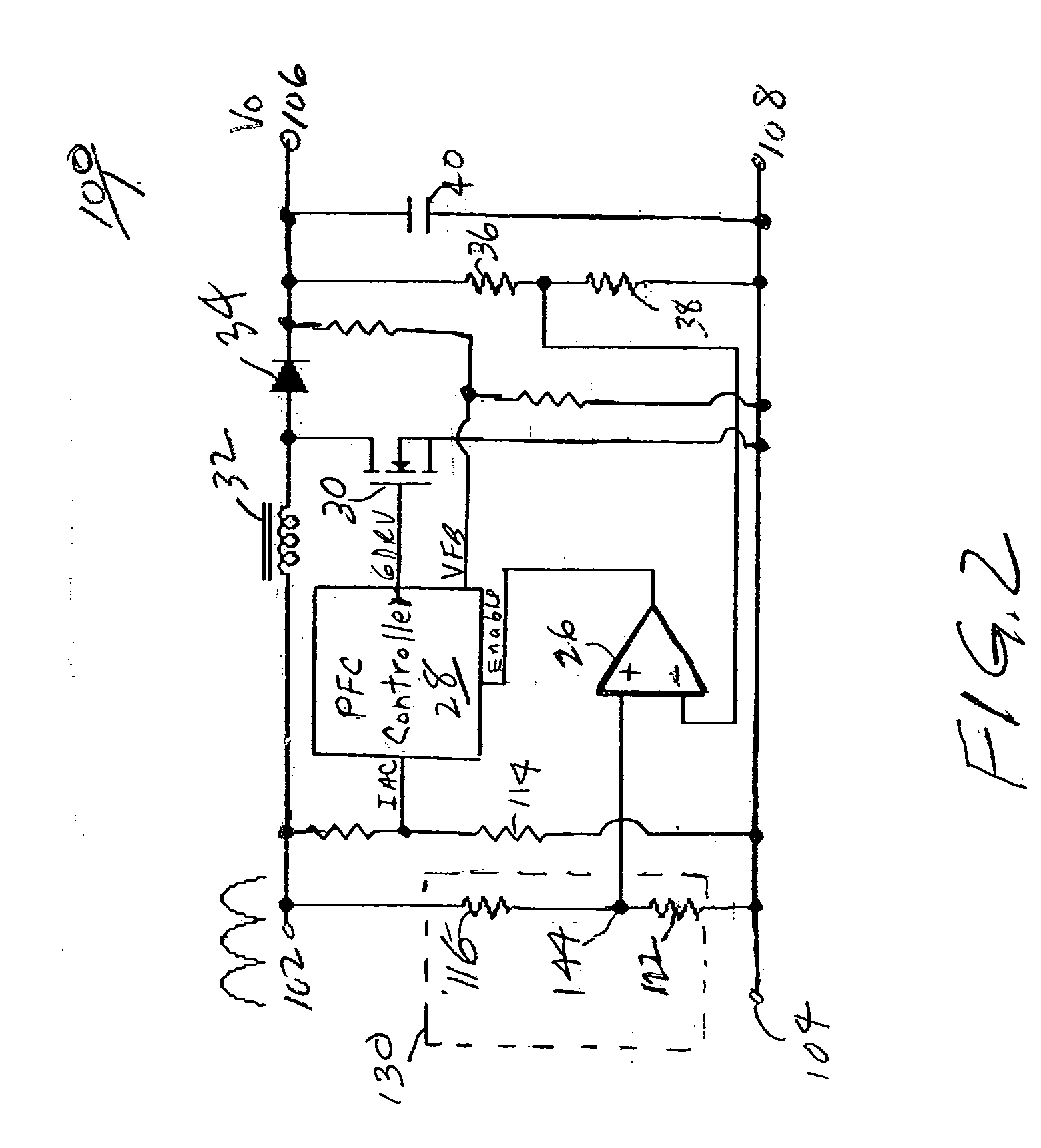

Real-time voltage detection and protection circuit for PFC boost converters

InactiveUS20050269999A1Avoid unnecessary down timeOvercomes drawbackEnergy industryElectric variable regulationPower factorPeak value

A circuit for protection of the operation of power factor correction (PFC) converters from conditions such as input voltage surges that can otherwise cause failure, and to prevent unnecessary down time of the boost converter after a power failure or on startup. The circuit detects the real time rectified input voltage and provides real time comparison of the detected input voltage and the output voltage. The boost function of the PFC is controlled as a function of the output of the comparison circuit so as to quickly inhibit the boost function of the PFC controller thereby disabling boost and protecting the circuit from burning out. The circuit enables the PFC to starts and restart more quickly, even before the output voltage becomes stabilized, since boost is permitted as soon as the output voltage exceeds the real time sampled input voltage. By enabling boost during this period, the circuit eliminates the need to wait at least a few cycle times until the output voltage is higher than the peak of rectified input voltage. In a preferred embodiment, a complementary protection circuit having a voltage clamp is also provided to prevent unnecessary shutdown of the converter.

Owner:ASTEC INT LTD

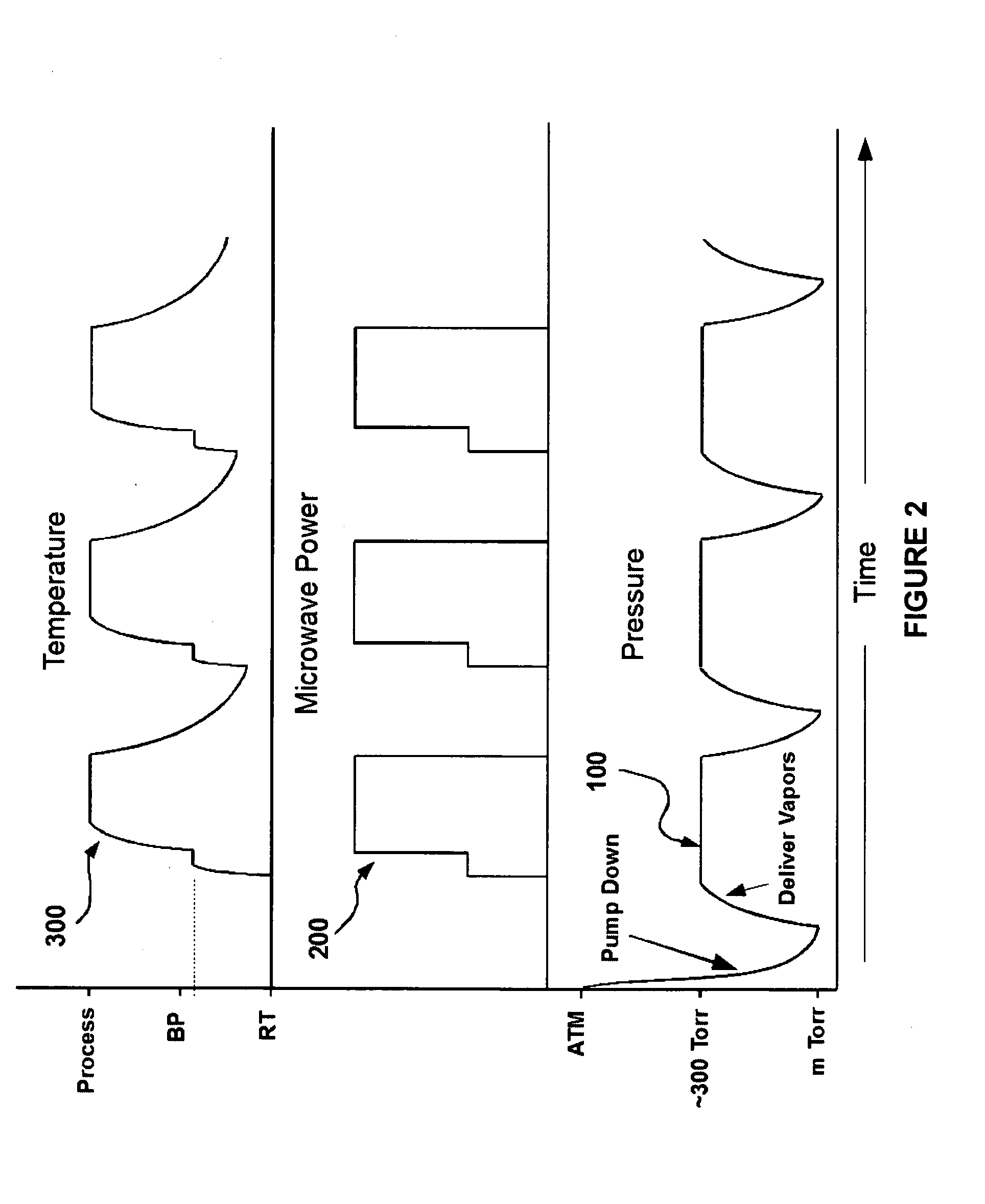

Method and apparatus for microwave treatment of dielectric films

ActiveUS20140322921A1Semiconductor/solid-state device manufacturingMicrowave heatingPorosityBoiling point

A method for processing a dielectric film on a substrate comprises: depositing a porous dielectric film on a substrate; removing the porogen; stuffing the film with a protective polymeric material; performing at least one intermediate processing step on the stuffed dielectric film; placing the film in a microwave applicator cavity and heating to a first temperature to partially burn out the polymeric material; introducing a controlled amount of a polar solvent into the porosity created by the partial burn out; applying microwave energy to heat the film to a second selected temperature below the boiling point of the solvent to clean away remaining polymeric material; and applying microwave energy to heat the film to a third temperature above the boiling point of the solvent to completely burnout the residues of polymeric material. The interaction of the polar solvent with the microwaves enhances the efficiency of the cleaning process.

Owner:APPLIED MATERIALS INC

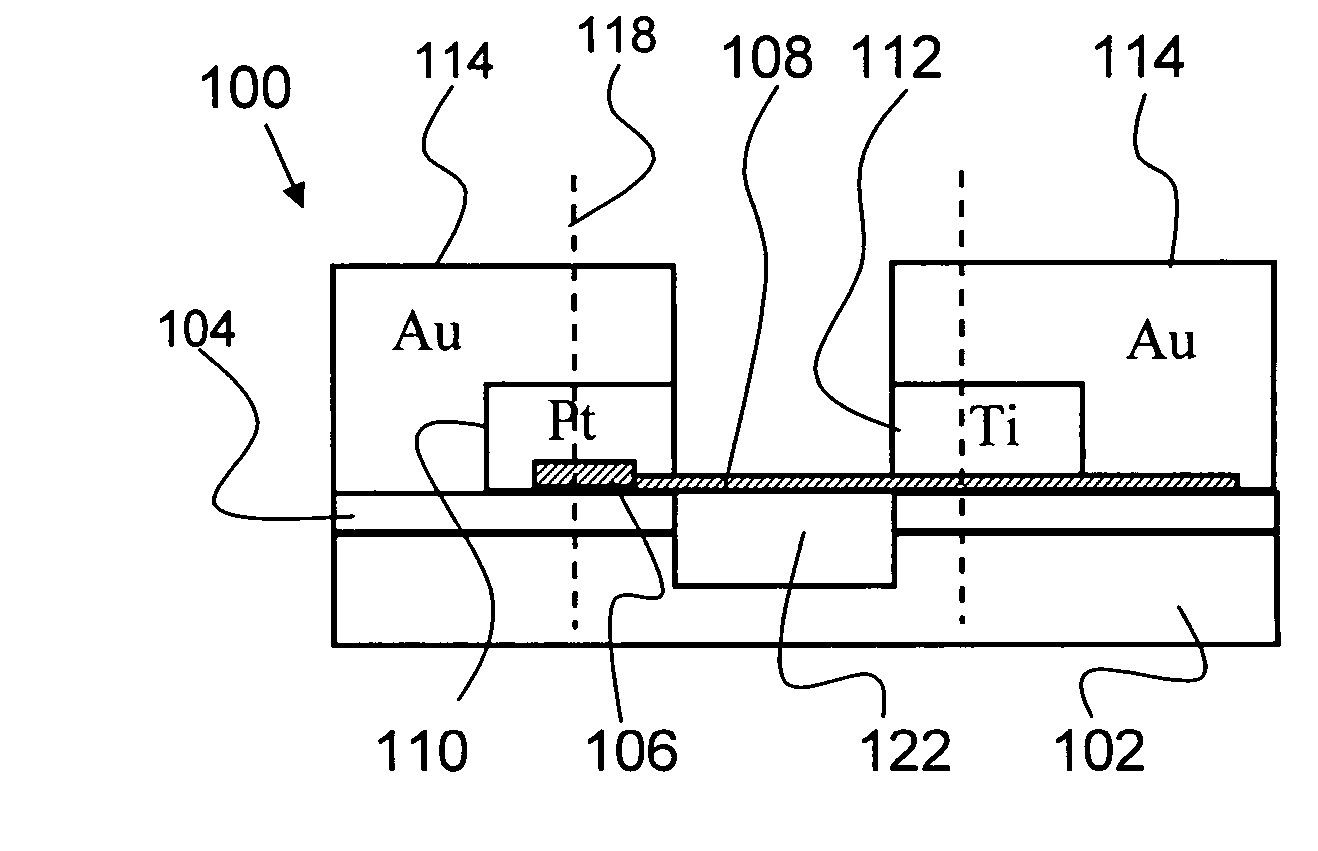

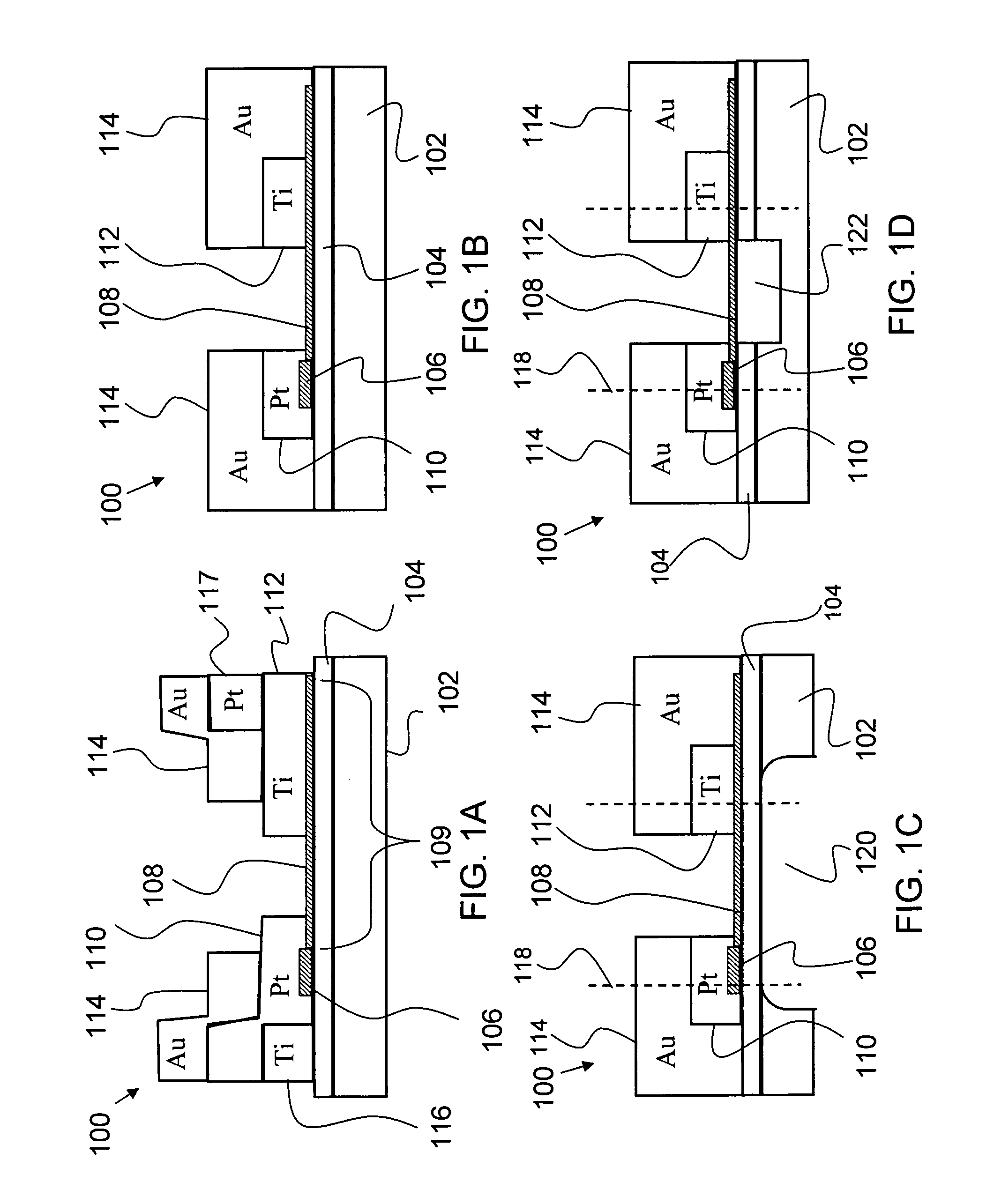

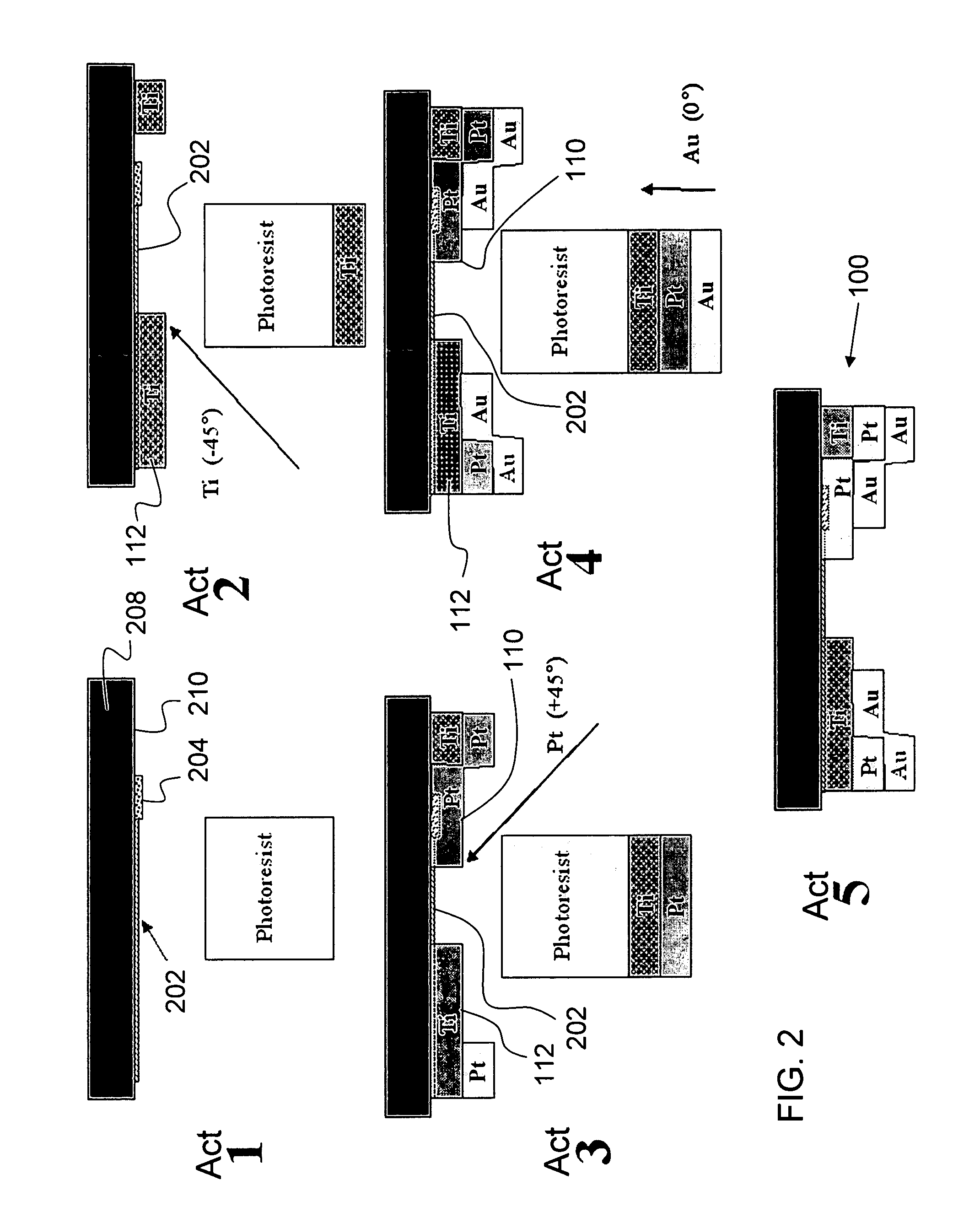

Nanotube Schottky diodes for high-frequency applications

InactiveUS20060261433A1Lower work functionImprove work functionNanoinformaticsSemiconductor/solid-state device manufacturingEvaporationNanotube

Described is a Schottky diode using semi-conducting single-walled nanotubes (s-SWNTs) with titanium Schottky and platinum Ohmic contacts for high-frequency applications. The diodes are fabricated using angled evaporation of dissimilar metal contacts over an s-SWNT. The devices demonstrate rectifying behavior with large reverse-bias breakdown voltages of greater than −15 V. In order to decrease the series resistance, multiple SWNTs are grown in parallel in a single device, and the metallic tubes are burnt-out selectively. At low biases, these diodes showed ideality factors in the range of 1.5 to 1.9. Modeling of these diodes as direct detectors at room temperature at 2.5 terahertz (THz) frequency indicates noise equivalent powers (NEP) comparable to that of the state-of-the-art gallium arsenide sold-state Schottky diodes, in the range of 10-13 W / square-root (√) Hz.

Owner:CALIFORNIA INST OF TECH

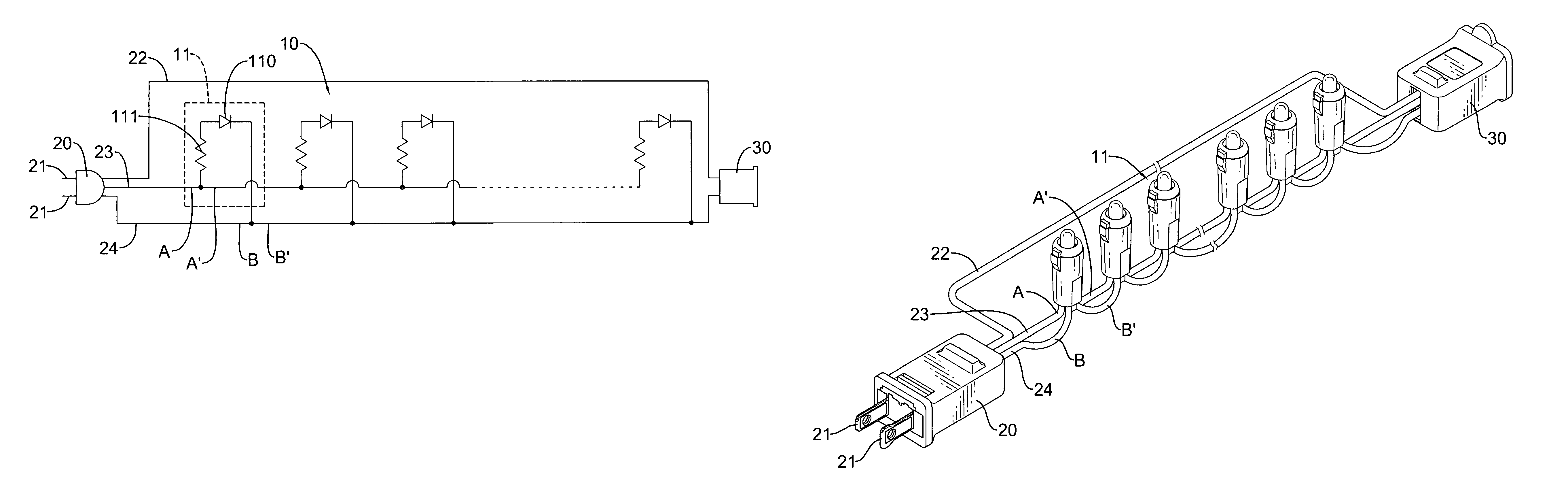

LED-based christmas light string assembly with parallel-wired lighting units

An LED light string assembly has a plug for providing a low DC voltage, an extension socket, a light string connected between the plug and the extension socket. The light string has multiple LED Christmas bulbs connected in parallel. Each LED Christmas bulb includes an LED and a resistor connected in series. Even one of the LED Christmas bulb burns out, all the remaining LED Christmas bulb of the light string will not be affected and still can be normally turned on as required to generate light.

Owner:YANG CHEN SHENG

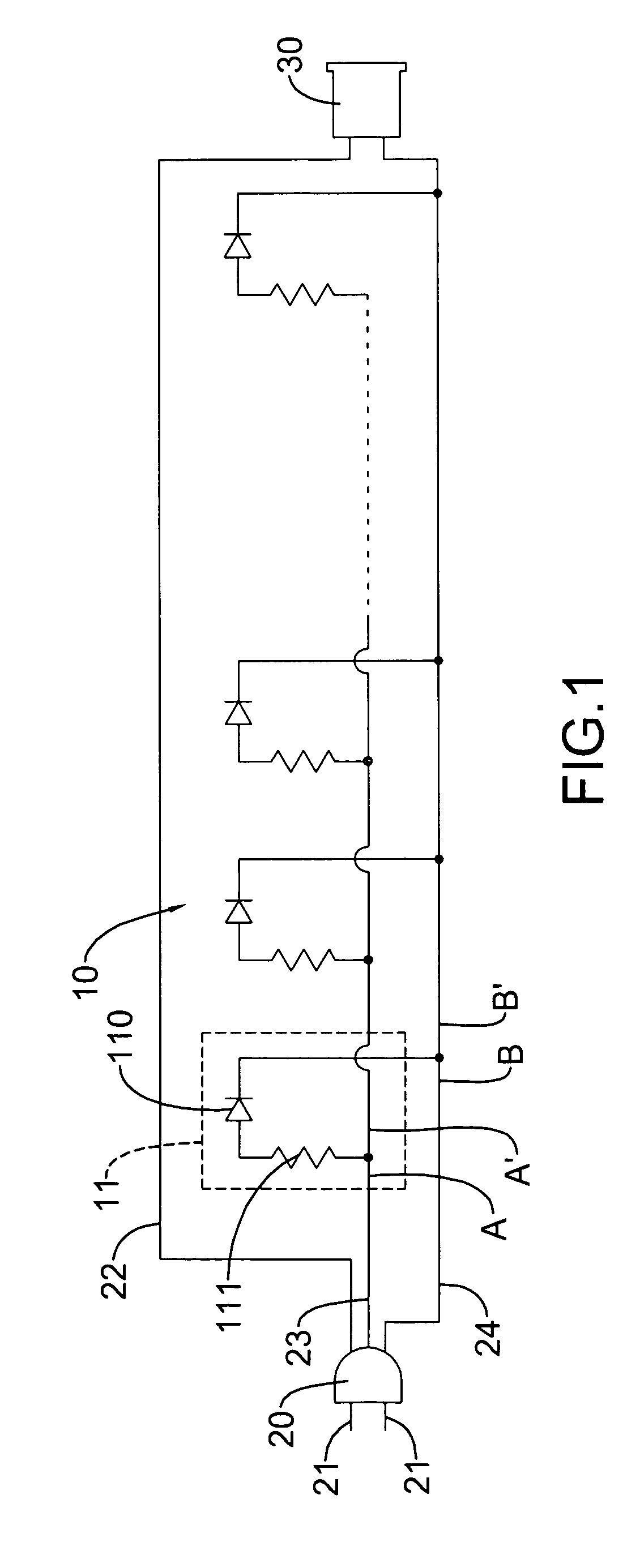

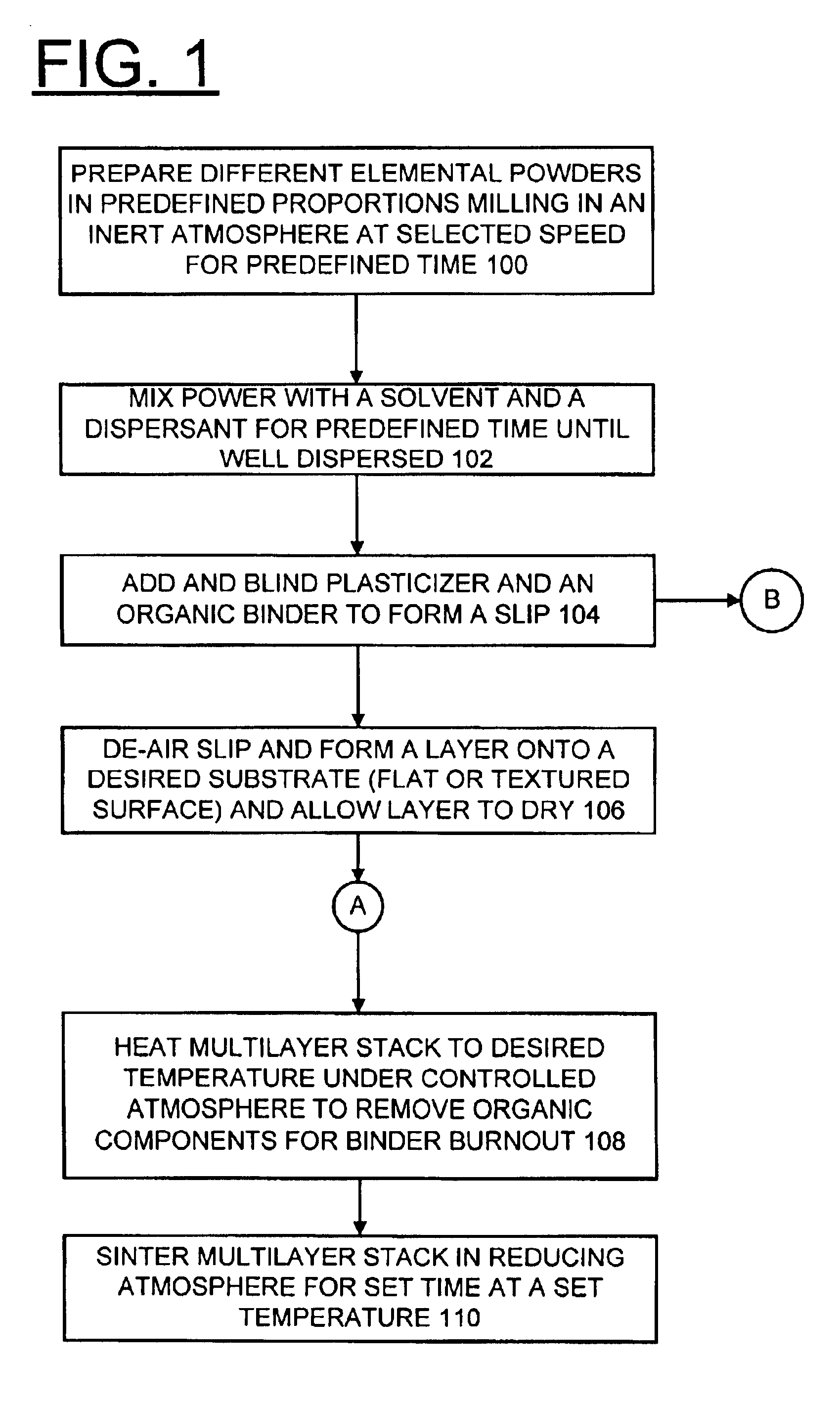

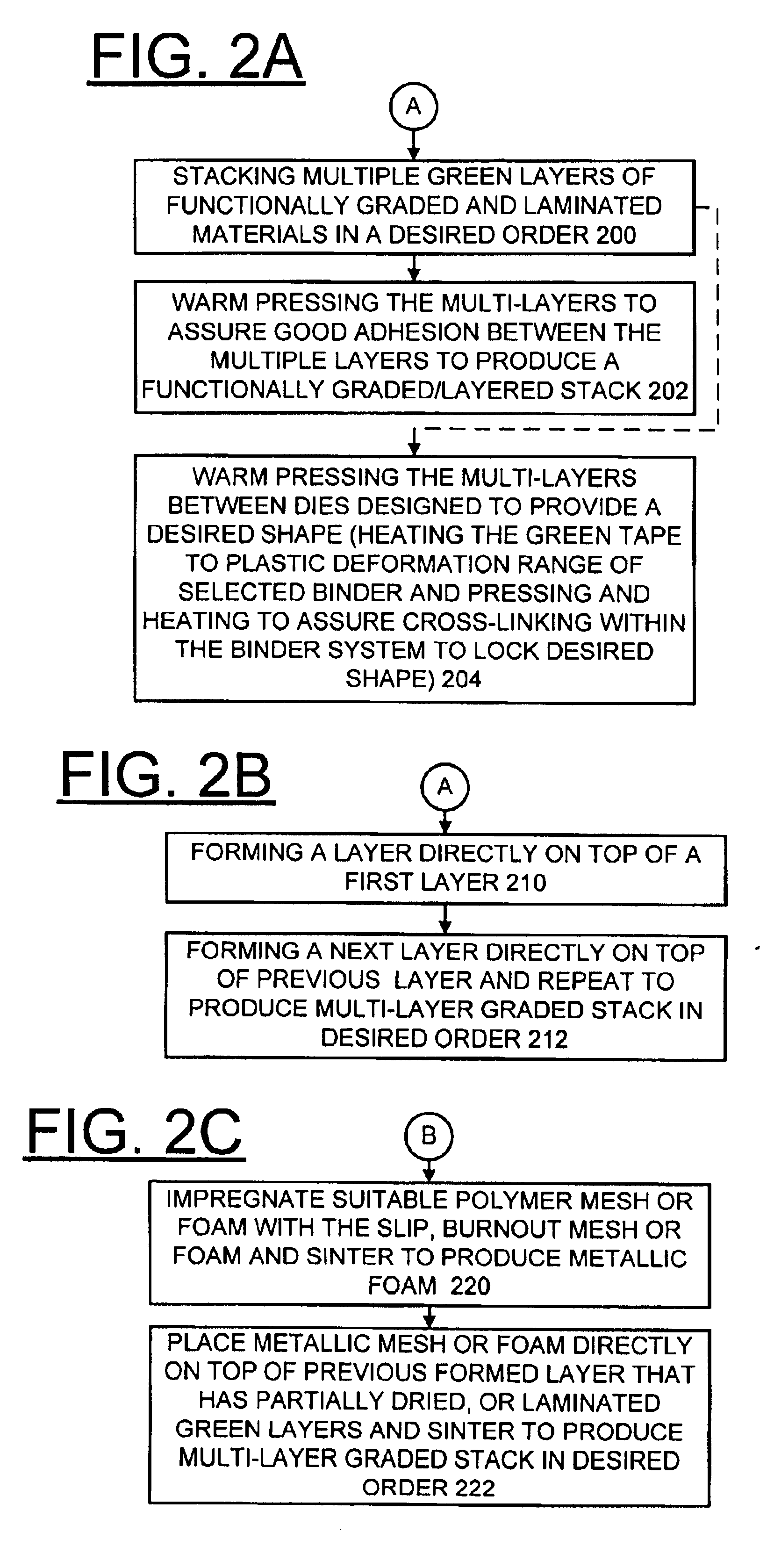

Compositionally graded metallic plates for planar solid oxide fuel cells

A method for preparing compositionally graded metallic plates and compositionally graded metallic plates suitable for use as interconnects for solid oxide fuel cells are provided. The method of the invention, utilizing powder metallurgy, enables making metallic plates of generally any desired composition to meet the corrosion requirements of fuel cells and other applications, and enables making metallic plates of graded composition from one surface of the plate to the other. A powder of the desired alloy composition is obtained, then solvents, dispersants, a plasticizer and an organic binder are added to form a slip. The slip is then formed into a layer on a desired substrate that can be flat or textured. Once dried, the layer is removed from the substrate and the binder is burned out. The layer is sintered in a reducing atmosphere at a set temperature for a predefined duration specific to the materials used and the desired final properties.

Owner:UCHICAGO ARGONNE LLC +1

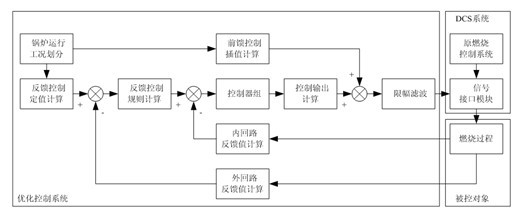

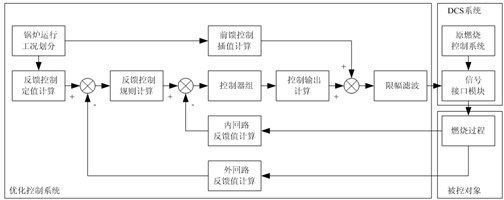

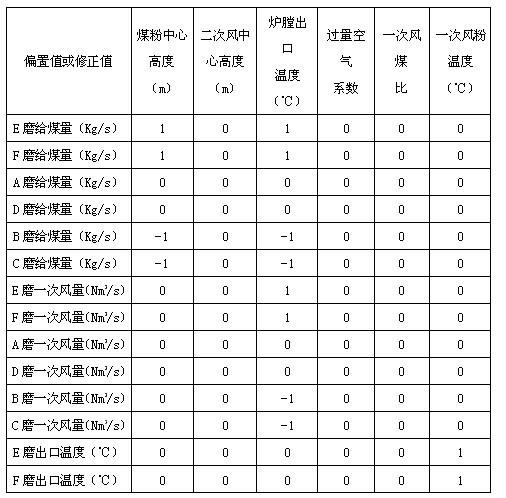

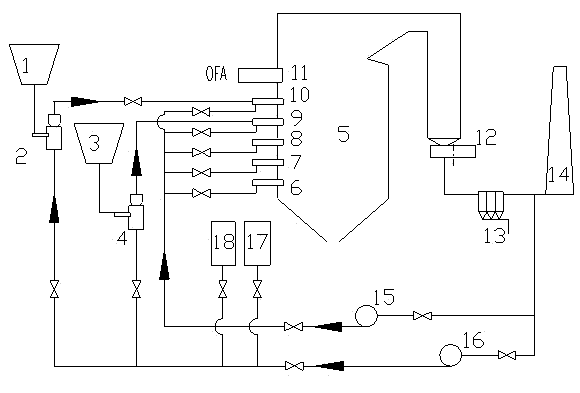

Combustion feedforward and feedback composite optimization controlling method for pulverized coal fired boiler

InactiveCN102425807AImprove combustion efficiencyEmission reductionCombustion regulationCombustorComposite optimization

The invention discloses a combustion feedforward and feedback composite optimization controlling method for a pulverized coal fired boiler. The method is used for realizing dynamic accurate proportioning of wind and coal under a full working condition and in the full combustion process. According to the technical scheme, the method comprises the following steps of: determining feedforward signals according to combustion adjusting experiment data or operation personnel experience, determining feedback signals according to the thermodynamic properties and laws of the boiler, and automatically and accurately adjusting the coal quantity proportion of each burner, the primary air quantity proportion of each coal mill, the outlet temperature of each coal mill and the secondary air quantity and burning-out air quantity proportion of each burner under different working conditions to keep the burning efficiency and the NOX discharge of the boiler in an optimal state. By the method, the advantage of coexistence of a plurality of independent adjusting means of the large pulverized coal fired boiler and the advantages of high dynamic response speed of feedforward control and high static precision of feedback correction control are fully exerted, the pulverized coal fired boiler is close to the optimal state under various working conditions, the burning efficiency of the boiler is improved, and the discharge of NOX is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Infrared humidification device and control method

ActiveCN105650794ASolve the problem of high water quality requirementsAvoid burnsMechanical apparatusSpace heating and ventilation safety systemsWater storage tankWater quality

The invention discloses an infrared humidification device and a control method. The device comprises a plurality of infrared light sources, a lampshade, a water storage structure, a water inlet structure, a water level switch and a controller. The water storage structure comprises a water storage tank, an overflow valve and a drainage pipe. The water inlet structure comprises a water inlet pipe, a water inlet electromagnetic valve and a water injection pipe. On-off of a power supply circuit of the multiple infrared light sources is controlled by the controller, a current transformer is arranged in the power supply circuit of the infrared light sources and used for collecting current values, and the current values are transmitted to the controller. According to the infrared humidification device and the control method, radiant energy of the infrared light sources is adopted for heating and evaporating water, the requirement for water quality is not high, and the application range is wide; the water storage tank is automatically cleaned, the daily maintenance workload is reduced, and the maintenance cost is reduced; and the current values are collected by the current transformer and transmitted to the controller, the controller controls on-off of the power supply circuit of the infrared light sources according to the current values, and the situation that the infrared light sources are burnt out due to abnormal current is avoided, so that the safety and stability of the whole device are improved.

Owner:青岛海信网络能源股份有限公司

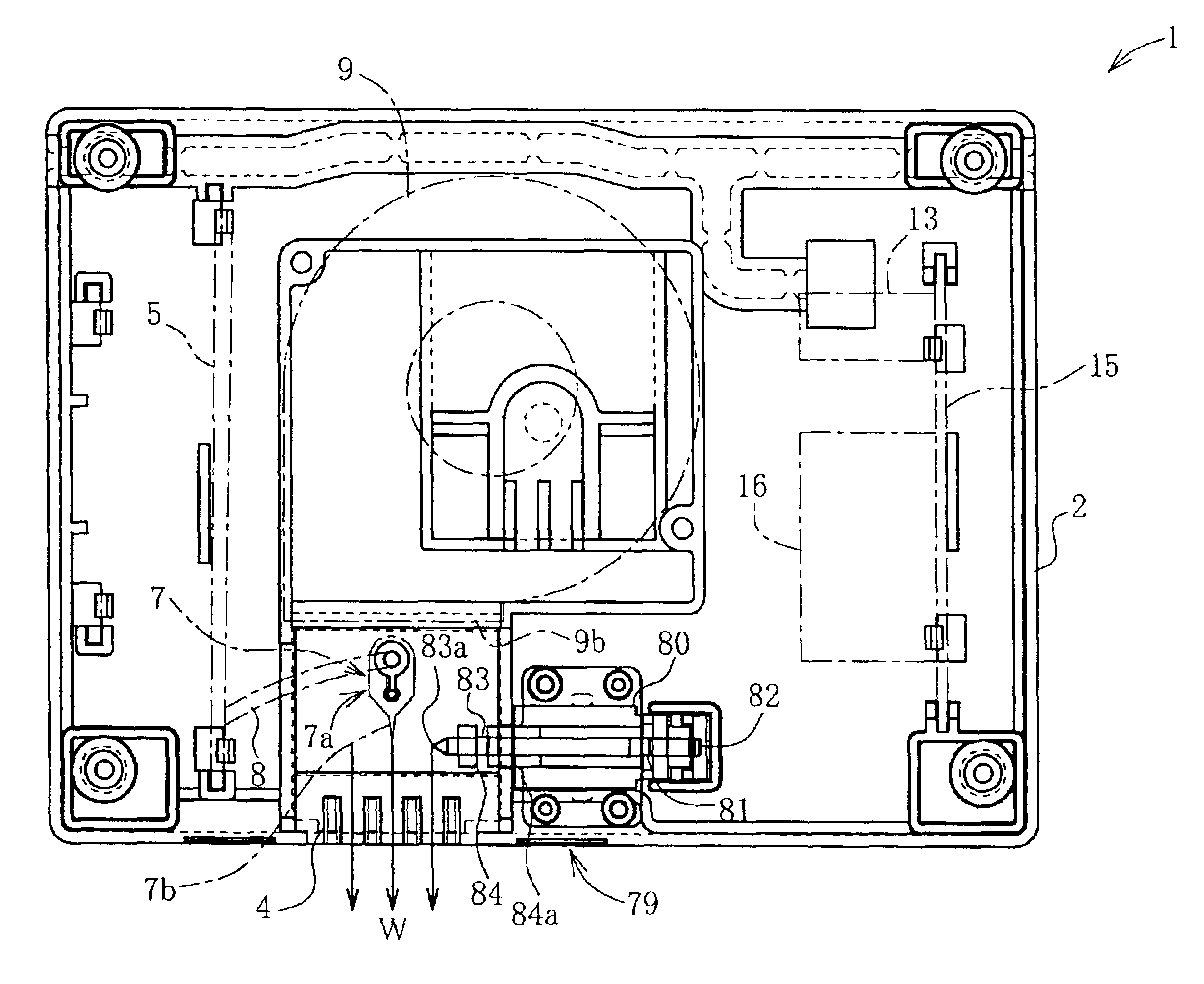

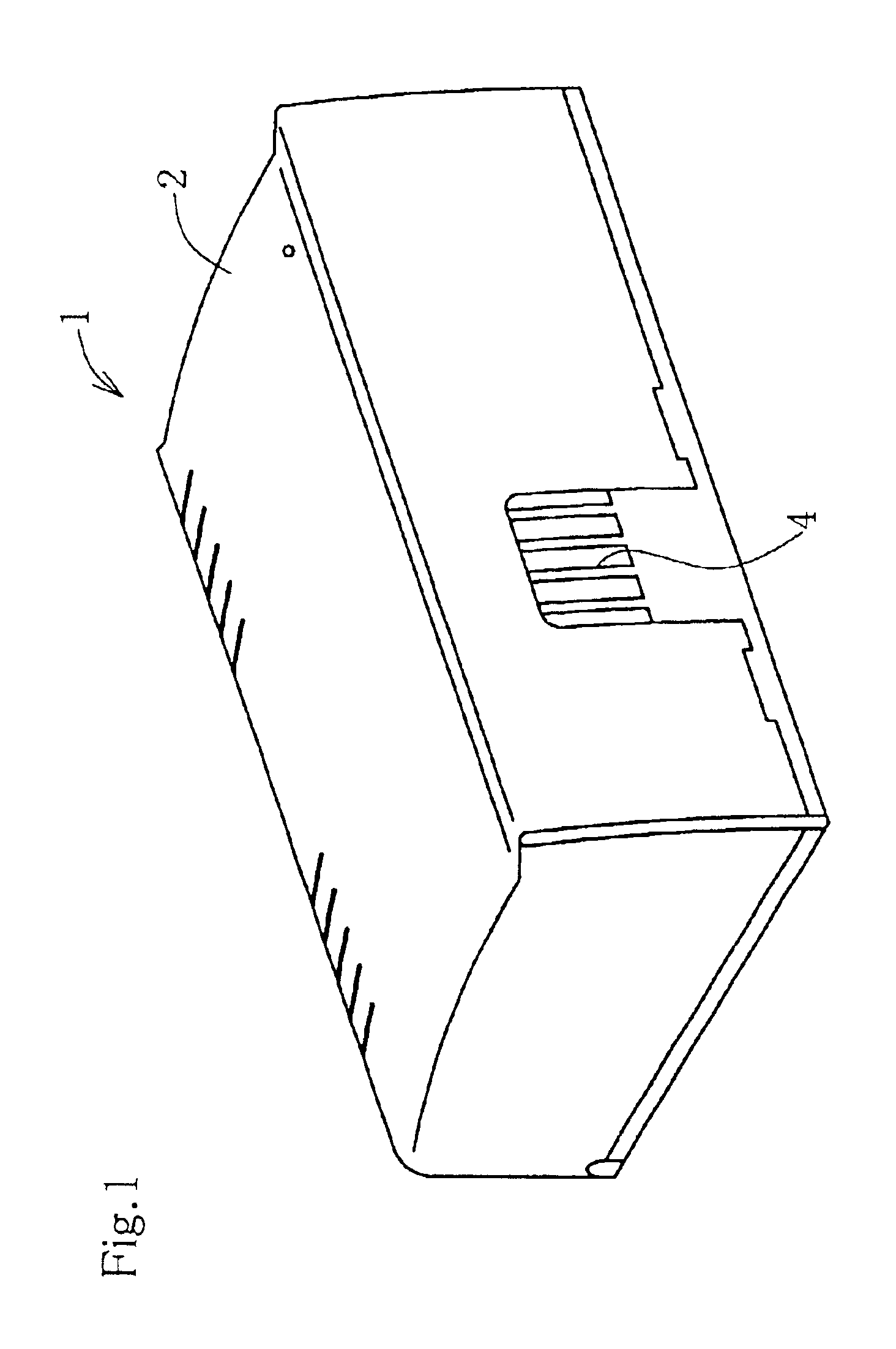

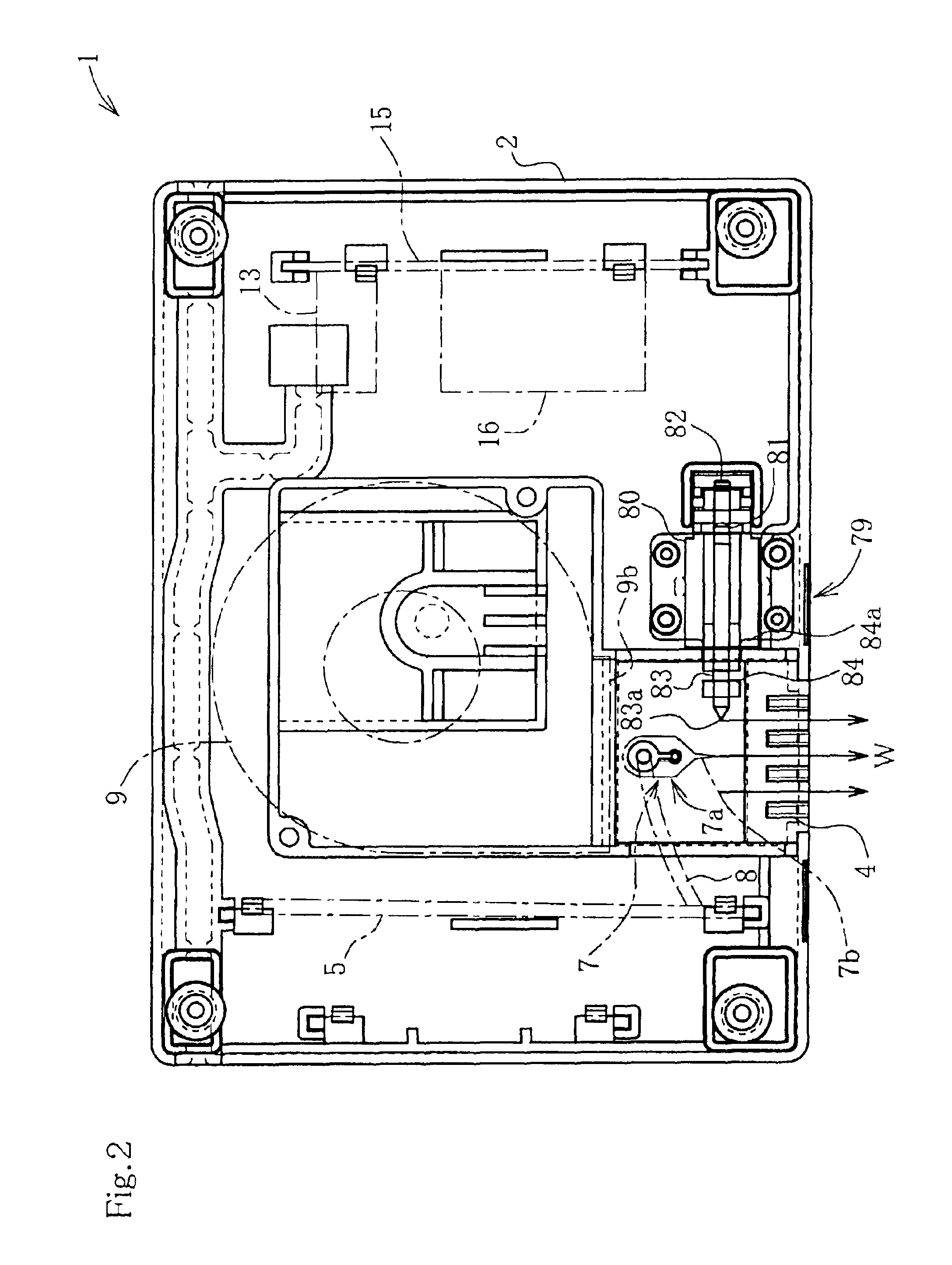

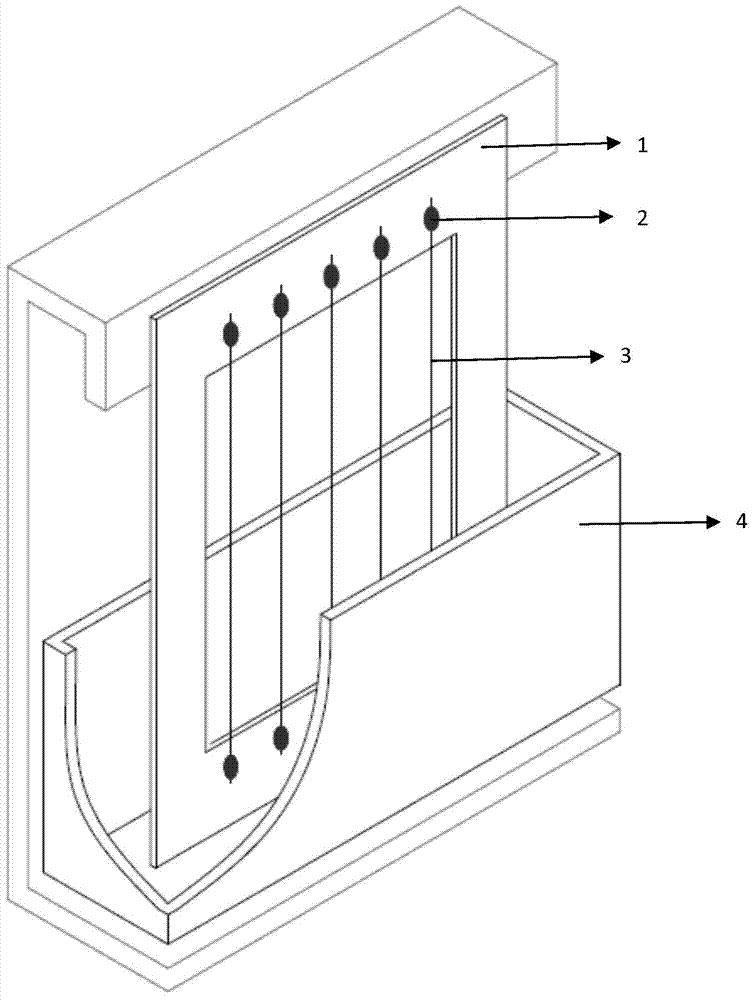

Ion generating apparatus

InactiveUS6791814B2Simple wayAvoid efficiencyLighting and heating apparatusAlternating current plasma display panelsElectricityEngineering

An ion generating apparatus 1 has an electric cleaning mechanism 79 for burning out attachment adhered on an ion generating electrode 7 by electric heating. Adhesion of dirt and the like onto the end portion of the electrode where an electron generation field concentrates will considerably ruin the ion generation efficiency. So that burning out of attachment adhered onto the end portion 7a of the ion generating electrode 7 using the electric cleaning mechanism 79 is extremely effective in terms of avoiding such nonconformity. Object of the cleaning will be attained to a sufficient degree if only the dirt adhered onto the sharpened end portion of the electrode 7, which is responsible for the ion generation, is selectively removed, which is also advantageous in simplifying the apparatus since there is no need to excessively raise the electric heating capacity of the electric cleaning mechanism 79.

Owner:NIHON PACHINKO PARTS

Method for combusting fuel reburning low-nitrogen oxide

ActiveCN102252324AImprove the mixing effectLong reduction reaction timeCombustion apparatusLow nitrogenEvaporation

The invention discloses a method for combusting a fuel reburning low-nitrogen oxide and belongs to a clean combustion method for a coal-fired boiler. Secondary medium air is used as a powder conveying medium of a combustor on the upper layer of the main combustion area of the boiler, coal powder used as a reburning fuel is conveyed into the boiler, the secondary medium air is used as distributed air of the combustor, the secondary air of the combustor on the upper layer is reduced correspondingly, the distributed air in the reburning area is reduced correspondingly, low excess air combustion is formed, the distributed air in a hearth is not enough, and finally over fire air (OFA) complements the required air; and the mixed medium of air and fuel gas is used as the conveying medium of the coal powder of the combustor of the upper layer, and the coal powder with the conventional fineness is conveyed into the boiler from the combustor on the upper layer by using a coal mill and a powder making system and is re-burnt and denitrated, and is burnt out by OFA. The problem that the reburning fuel and the fuel gas are not mixed uniformly, the reduction time is short, and the denitration efficiency is low is solved, the original design working conditions of maximum continuous evaporation capacity of the boiler and the like are not influenced, transformation is easy to realize, and the running cost is low.

Owner:徐州燃烧控制研究院有限公司

Processing method of warp knitting plush fabrics with burning out printing terylens

InactiveCN101876121AImprove the three-dimensional effectIdeal embossing effectPattern makingHeating/cooling textile fabricsPolyesterEngineering

The invention relates to a processing method of warp knitting plush fabrics with burning out printing terylens. The processing method comprises the following steps of: materials selection: selecting DTY (Draw Textured Yarn) terylen low stretch yarns from 75 D to 150 D as felted yarn materials and selecting FDY (Fully Drawn Yarn) semi-dull polyester yarns from 50 D to 100 D as ground yarn materials, wherein the DTY terylen low stretch yarns account for 60-80% of the fabrics by weight percent, and the FDY semi-dull polyester yarns account for 20-40% of the fabrics by weight percent; weaving or slitting after weaving; thermally forming or pretreating after thermally forming; brushing and cropping the front surface or brushing and cropping the back surface, cropping the back surface and pilling; post-forming; burning out printing: carrying out burning out printing on grey fabrics subjected to the post-forming by using a burning out printing alkali slurry; steaming; post-treating; and forming a finished product. By the technical scheme, the fabrics can achieve the advantages of strong third dimension of patterns, ideal sculptured pattern effects and favorable shininess, residues does not generate in the weaving process, which is beneficial to protecting warp knitting machines.

Owner:CHANGSHU XINXIN WARP & KNITTING

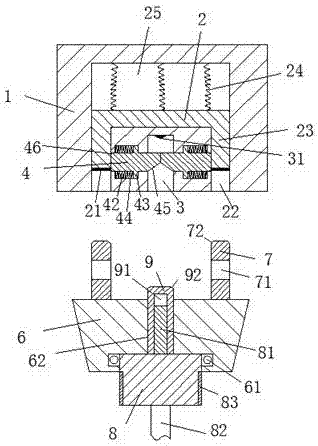

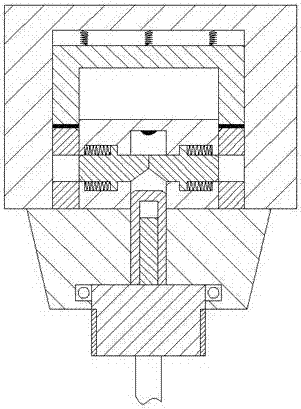

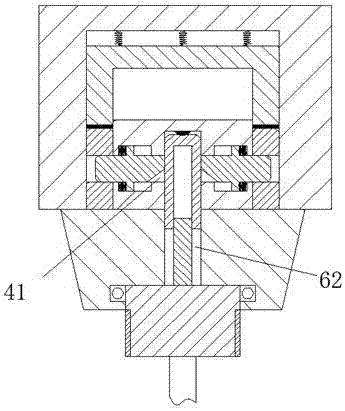

Hand-operated power supply plugging connecting device

ActiveCN107154551AImprove stability and securityAvoid Electric Shock AccidentsCoupling device detailsElectric shockBurning out

The invention discloses a hand-operated power supply plugging connecting device. The hand-operated power supply plugging connecting device comprises a power supply body and a plug connected with the power supply body in a cooperated way. The power supply body comprises two plugging grooves, which are in a left-right symmetric arrangement, and have openings facing forwards; and a power supply groove, which is disposed between the two plugging grooves, and has an opening facing forward. The rear end wall of the power supply groove is provided with a power supply contact connected with a power supply. The rear ends of the two plugging grooves are communicated with a sliding groove, A sliding block capable of sliding forwards and backwards is disposed in the sliding groove. The hand-operated power supply plugging connecting device is advantageous in that a structure is simple, production costs are low, power supply is safe and stable, and connecting and disconnecting operation steps are simple, and therefore electric shock accidents in a daily life are effectively reduced, life safety of users is guaranteed, occurrence of electrical equipment power-off accidents caused by wrong kicking and wrong colliding is prevented, the burn-out rate of the electrical equipment is reduced, and popularization and application are facilitated.

Owner:SHANDONG FENGYUAN CHEM CO LTD

Water-resistant and replaceable LED lamps

Disclosed is waterproof lamp assembly that allows easy assembly and disassembly. LED elements can be quickly and easily replaced if an LED element is defective or burns out. Extended connectors are used that extend beyond an overmolded lamp holder so that the lamp holder can be easily molded without covering the connectors with molding material. The connectors are made from a malleable metal so that the connectors can be folded into a central opening in the lamp holder.

Owner:SANTAS BEST

Method of making multilayer glass structures

ActiveUS20060260734A1Glass transportation apparatusCeramic layered productsCombustionAdditive ingredient

The present invention provides a method of making a decorated multilayer glass structure using a single firing step that includes that use of a crystallizing glass enamel composition that contains ingredients to ensure the complete burnout of the organic portion of the composition upon firing and bending of a mated pair of glass sheets. A benefit of the composition is that when applied to one sheet of a mated pair of glass sheets, it burns out completely during firing and bending of the pair. The presence of high levels of oxidizers in the composition ensures a supply of oxygen to enable combustion of the organic vehicle while firing the glass sheets and prior to the sintering of the enamel composition to only one glass sheet in a mated pair of decorated or colored glass sheets.

Owner:FERRO CORP

Regeneration method of catalyst for dehydrogenation of low-carbon alkanes

ActiveCN101940959AExtend the life cycleExtended service lifeCatalyst regeneration/reactivationHydrocarbonsAir atmosphereAlkane

The invention discloses a regeneration method of a catalyst for dehydrogenation of low-carbon alkanes, which comprises the following steps: firstly regenerating the catalyst in the air atmosphere at a lower temperature, burning out carbon deposits on the surface of the catalyst and most of carbon deposits in holes, and then preferably regenerating the catalyst further in a vapor-air mixed atmosphere at a temperature of 400-500 DEG C, so that the carbon deposits on the surface of the catalyst and in the holes can be completely removed, and simultaneously, the acid value and the acid distribution of the catalyst can be modulated so as to restore the crystal form and crystal phase composition of the deactivated catalyst to the original state of the fresh catalyst. Thus, the catalyst can be regenerated, and simultaneously, the physicochemical properties and the dehydrogenation activity of the regenerated catalyst are similar to those of the fresh catalyst, thereby prolonging the service cycle and life of the catalyst. The method has the advantages of moderate regeneration conditions and short regeneration time, and further lowers the production cost of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Small efficient medicinal rubbish pyrolysis incinerator

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

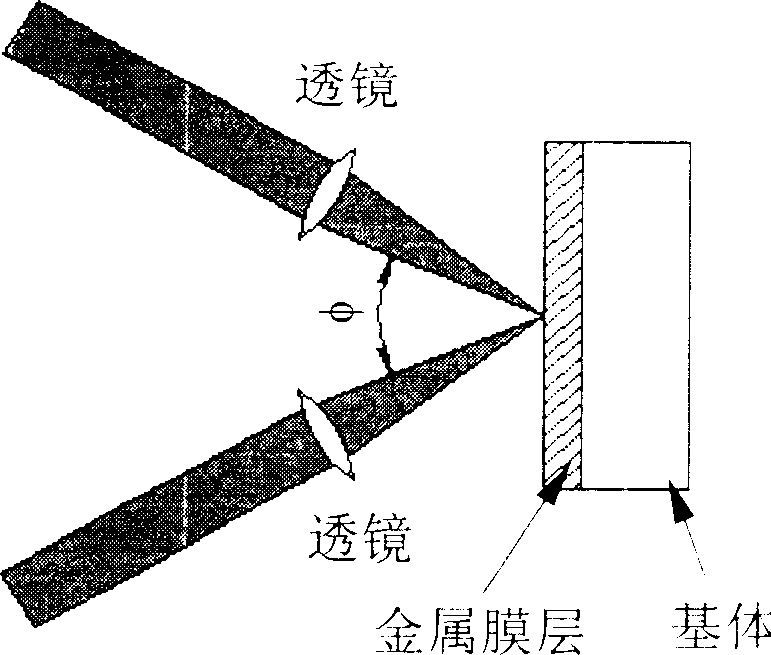

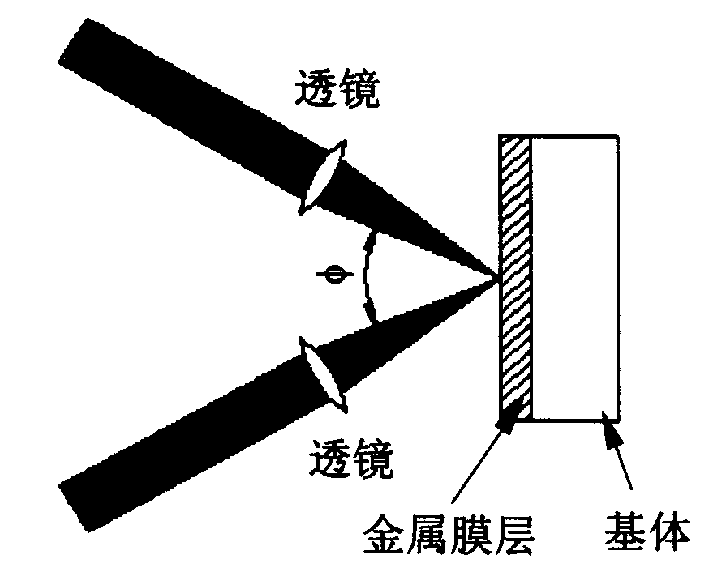

Method for preparing periodic microstructure on metallic film by femto second laser

InactiveCN1448755ASimple preparation processImprove efficiencyNon-linear opticsOptical elementsFemto second laserLaser beams

The laser beam produced by titanium jewel femto second laser is split into two beams and the two laser beams are focused by lenses to realize temporal and spatial coherent superposing before acting on metal film on quartz, common glass or silicon substrate. The laser pulse width, pulse frequency and single pulse energy are so controlled that the laser beam can burn out metal film and produce no damage of the substrate. The coherent laser beam is fixed and the sample on 3D platform is computer-controlled to move to prepare periodical microstructure of metal film.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

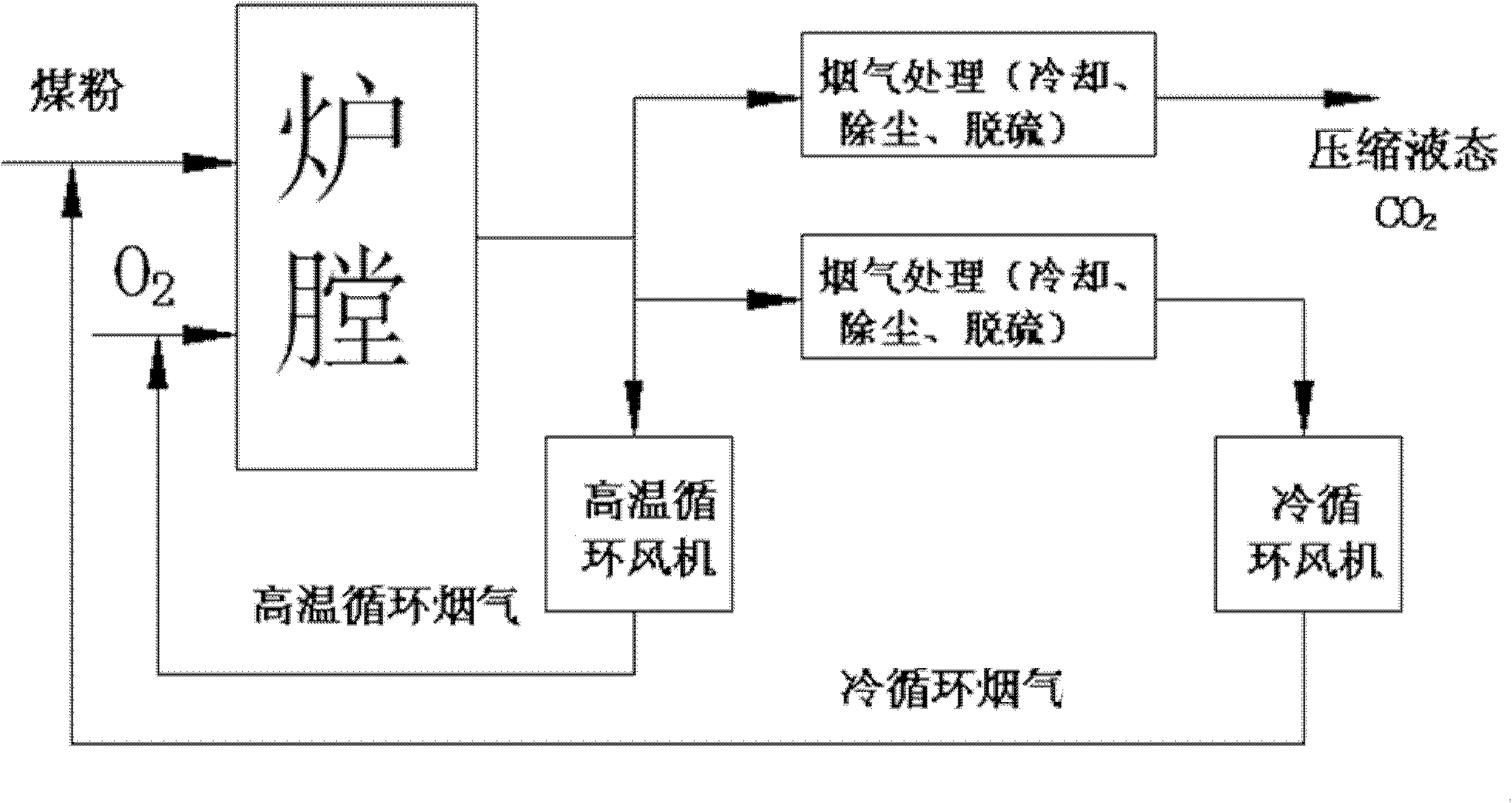

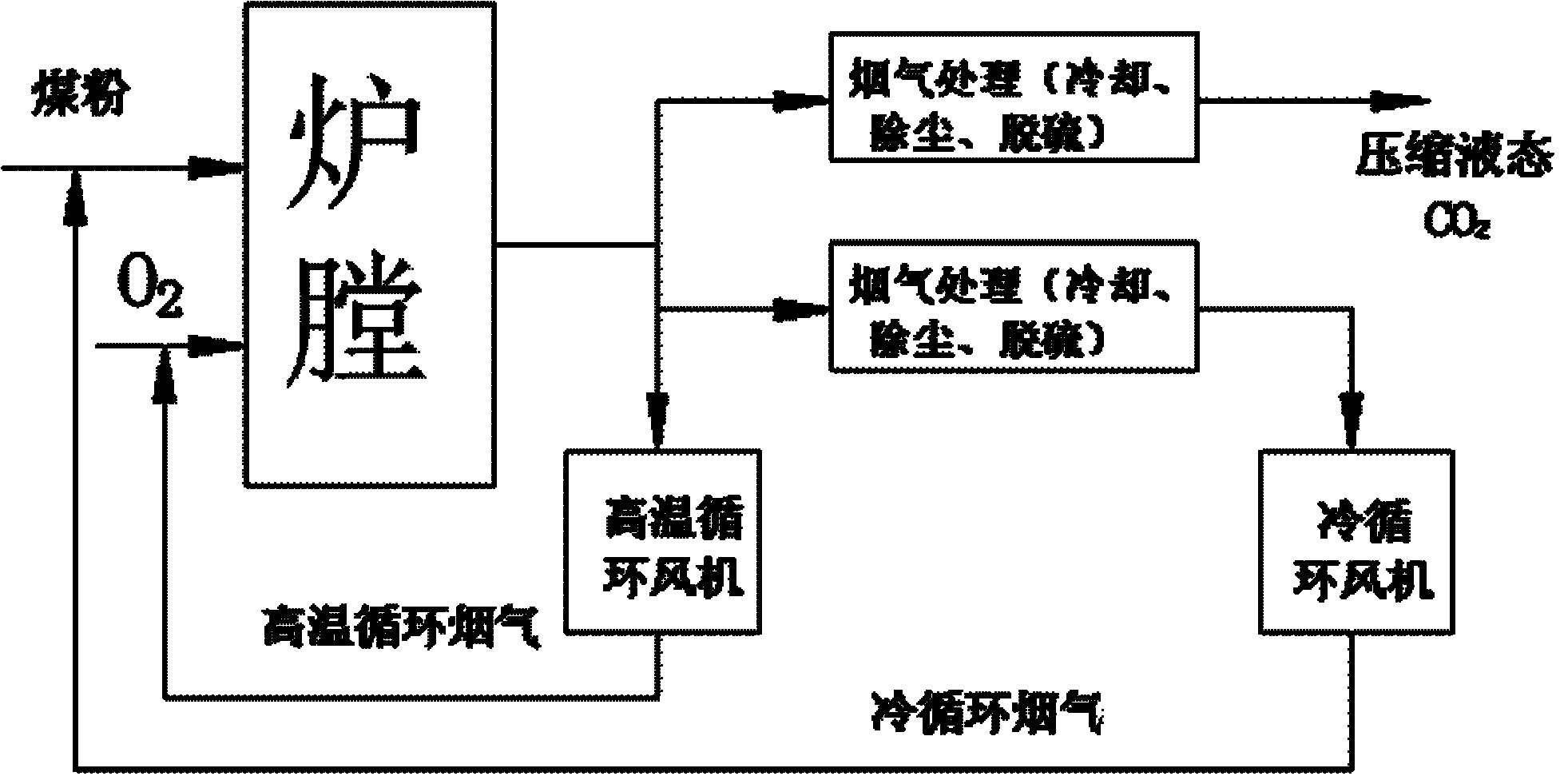

Method for re-circulating combustion of flue gas of pulverized coal fired boiler

InactiveCN101839474ASteam temperature increasedHigh thermal efficiencyFluidized bed combustionCarbon compoundsCO2 contentHearth

The invention provides a method for re-circulating combustion of flue gas of a pulverized coal fired boiler, belongs to a method for circulating combustion of oxygen gas (O2) and carbon dioxide (CO2) of pulverized coal, and aims to solve the problems of low heat efficiency and poor burn-out property existing in the conventional combustion method. The method comprises the steps of: 1,igniting and combusting: conveying the pulverized coal to a furnace hearth by using the circulation flue gas, and simultaneously conveying O2 to the furnace hearth for ignition; 2, circulating the flue gas: dividing the high-temperature flue gas generated by combustion into two parts, and performing cooling, dust removal and desulfurization compression on the first part to obtain liquid CO2; dividing the second part into two paths, conveying the first path to an entrance of the furnace hearth by using a high-temperature circulation fan, and mixing the first path of the flue gas and O2; and performing cooling, dust removal and desulfurization on the second path, and conveying the second path carrying the pulverized coal to the furnace hearth by using a cold circulation fan. The method has the advantages of adjusting the steam temperature of the boiler by using the high-temperature flue gas, enhancing convective heat transfer, increasing the steam temperature of the boiler, improving the heat efficiency of the boiler and the denitration rate, increasing the CO2 content after the high-temperature flue gas is cooled, reducing emission load of NOx, lowering CO2 capturing and collecting cost, and meeting the national energy conservation and environmental protection standard.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for producing a ceramic filter element

InactiveUS20070186911A1Easy to carryImprove filter characteristicsInternal combustion piston enginesDispersed particle filtrationMetallurgyInternal combustion engine

A method of producing a ceramic filter element suitable for use in an exhaust filter for an internal combustion engine, during which a combustible, non-ceramic support web is impregnated with a ceramic slip and formed into a desired geometric shape in either order, and then the impregnated and formed web is fired until the support web is burned out and a rigid ceramic filter body is formed.

Owner:MANN HUMMEL GMBH

Method for testing interfacial bonding strength of ceramic fiber-reinforced resin matrix composite material

ActiveCN104122202AImplement statistical measurementsSolve the fragileUsing mechanical meansMaterial analysisAdhesivePaperboard

The invention discloses a method for testing the interfacial bonding strength of a ceramic fiber-reinforced resin matrix composite material and relates to ceramic fibers. The method comprises the following steps: bonding the ceramic fibers to a hard paper frame by virtue of an instant adhesive, for straightening and solidifying the ceramic fibers; preparing an embedding mold, putting the ceramic fibers and the hard paper frame into the embedding mold, and introducing resin into the embedding mold; after the resin is solidified, cutting an embedded end together with the embedding mold so as to obtain a sample, and polishing; when the embedding depth of the sample is lower than 1mm, bonding the embedded end with a primary cut part by virtue of quick-dry resin after the polishing process; burning out two sides of the paper frame at an un-embedded end by virtue of naked flame, averagely cutting the upper end of the paper frame according to the quantity of the ceramic fibers, and bonding and reinforcing the paper frame by virtue of a hard paperboard with area equal to that of the cut paper frame; firstly fixing the embedded end at a lower clamp of a testing machine, and then fixing a reinforcing section to an upper clamp of the testing machine; carrying out a single-filament draw-out experiment; recording each withdrawal force value given by a testing machine; observing the shape of an withdrawn end, and measuring the maximal withdrawing length of the single fiber; and calculating the interfacial bonding strength between the fiber and the resin.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com