Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223 results about "Felted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Felted is a term variously applied to hairy or otherwise filamentous material that is densely packed or tangled, forming felt or felt-like structures. Apart from fibres in felted fabric manufactured by humans, the term "felted" may apply to the condition of hair such as in the pathological condition known as felted hair, or it may apply to the tangled threads of the tissue of certain fungi, to matted fibres in animal connective tissue, or to the felted outer coat of certain plants. To say that something is felted need not imply that any processes of matting, condensing and pressing fibres have been applied as in the processes for artificial production of felt fabric. Depending on the nature of the felted material, it might rely purely on the scaly or barbed texture of the matted fibres to prevent unraveling, but commonly it will include clayey or sticky materials for its structural integrity, or for increased density.

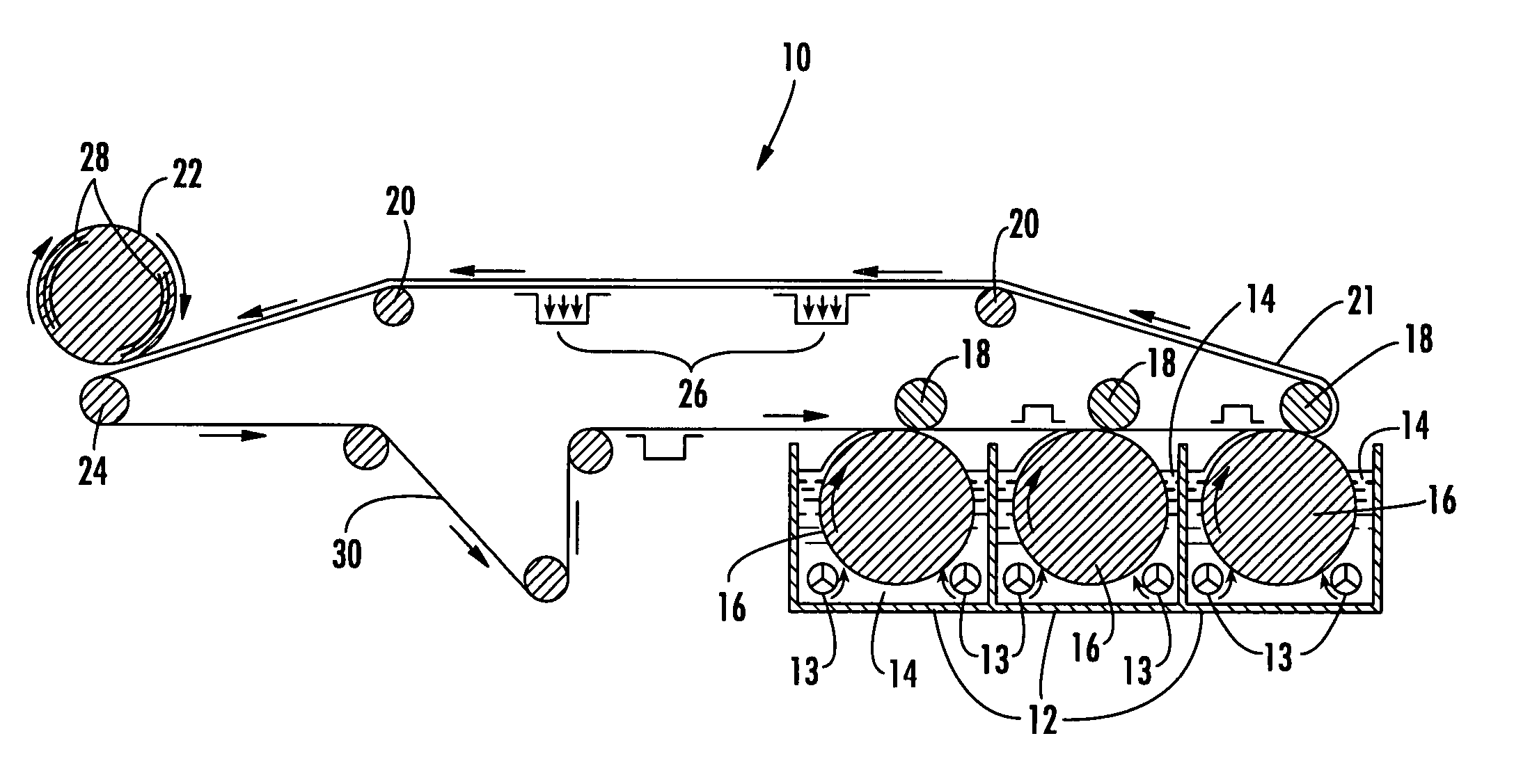

Impingement air dry process for making absorbent sheet

InactiveUS20020088577A1Easy to appreciateNon-fibrous pulp additionNatural cellulose pulp/paperPolymer sciencePapermaking

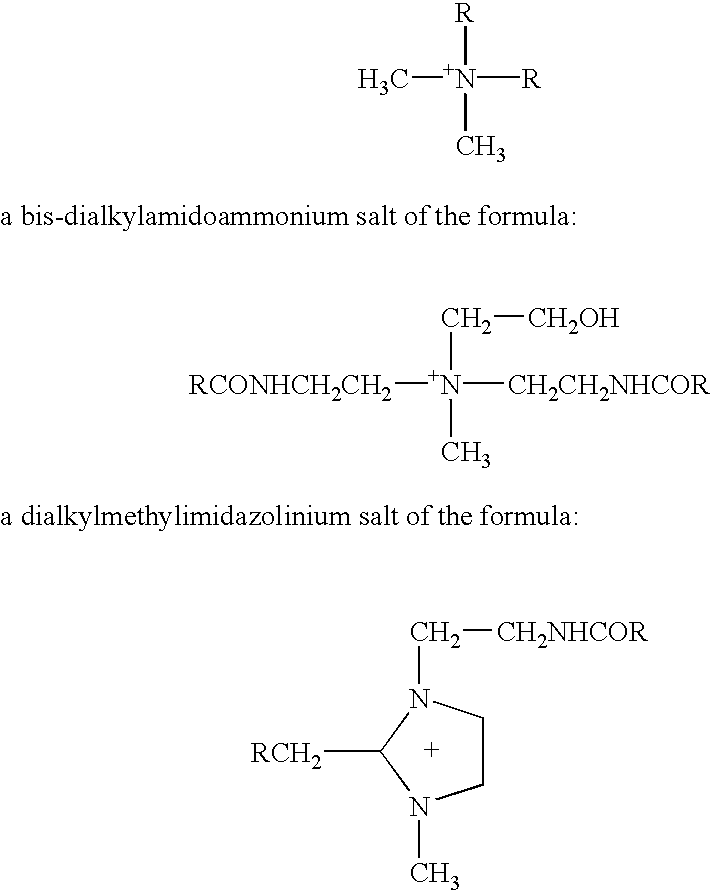

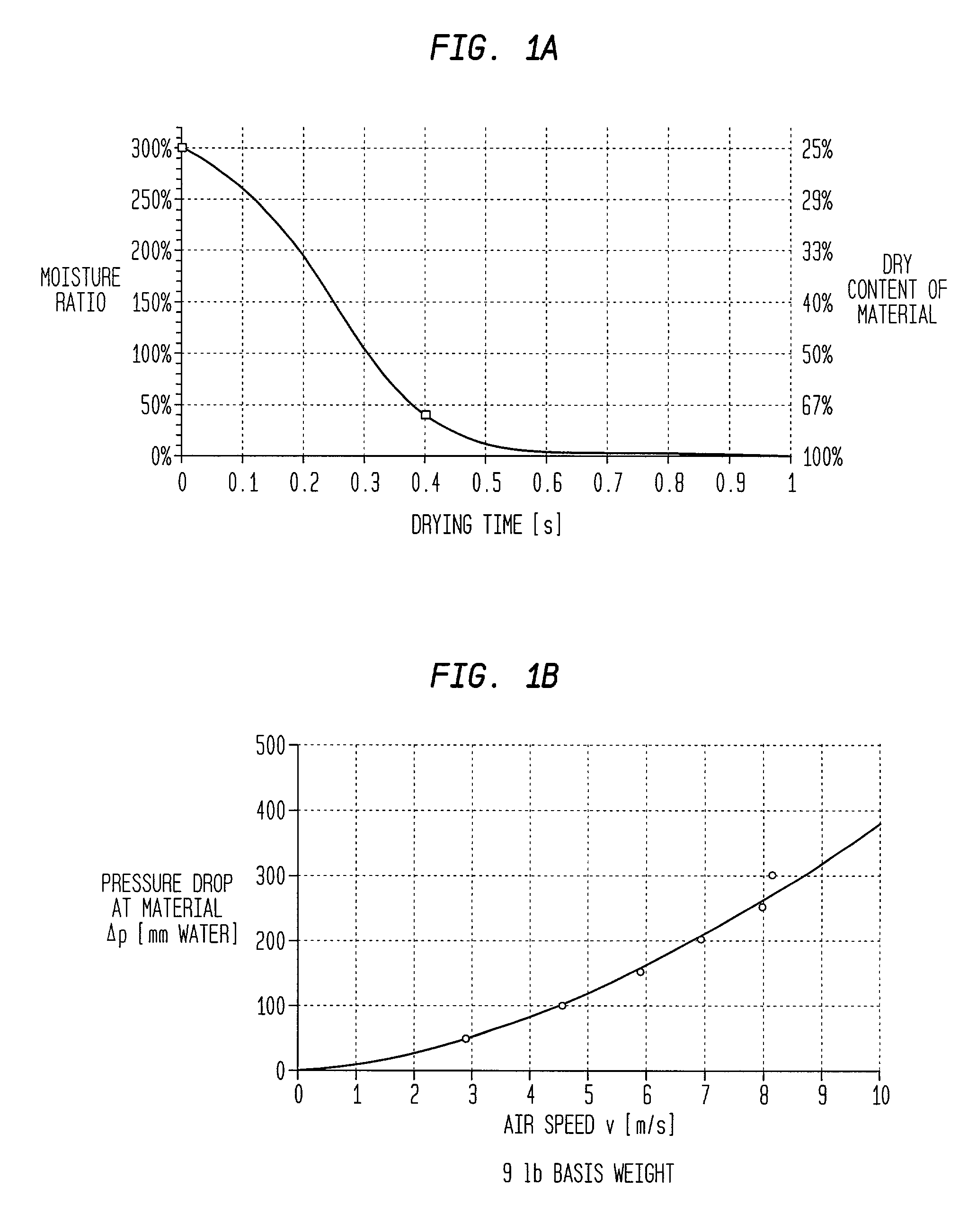

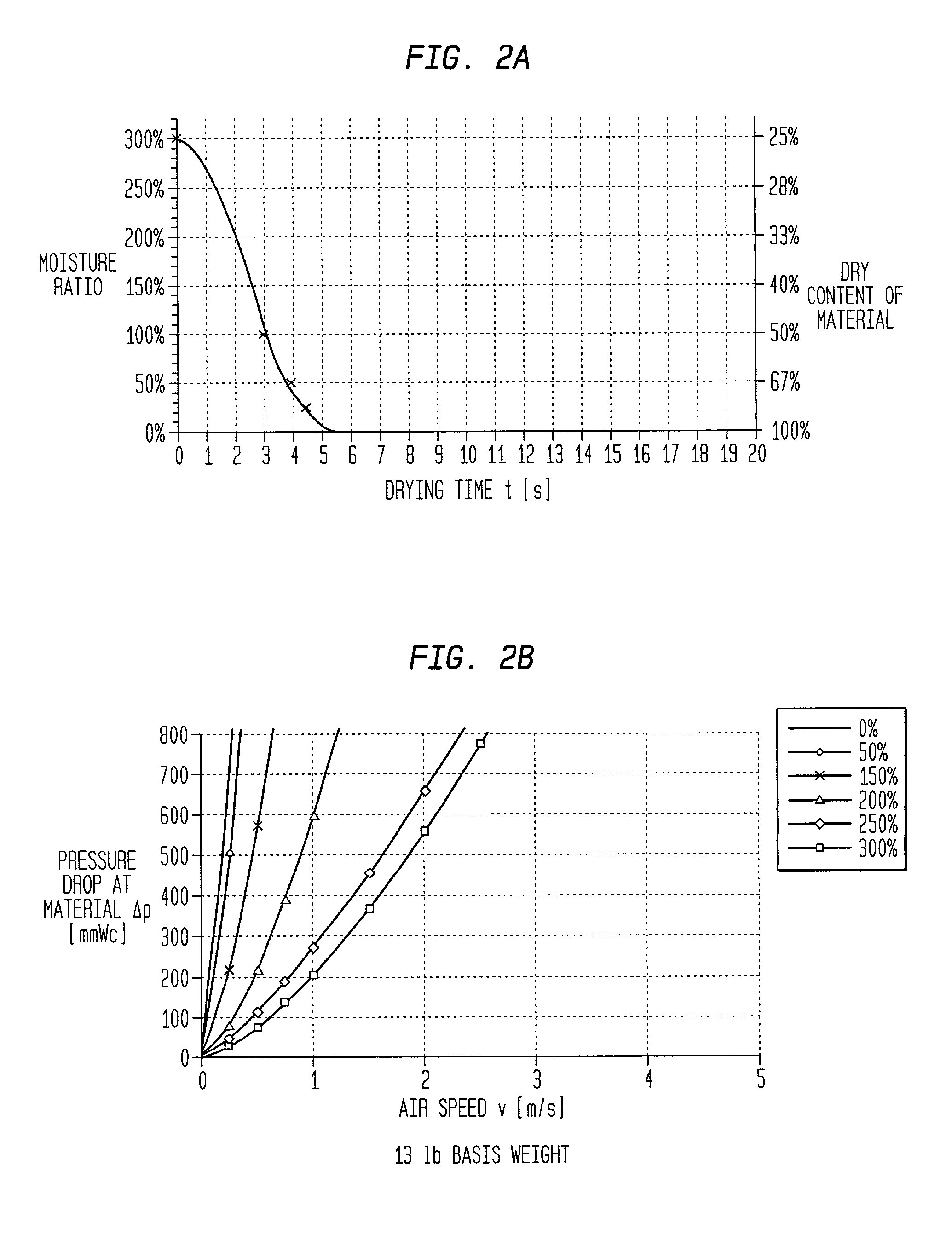

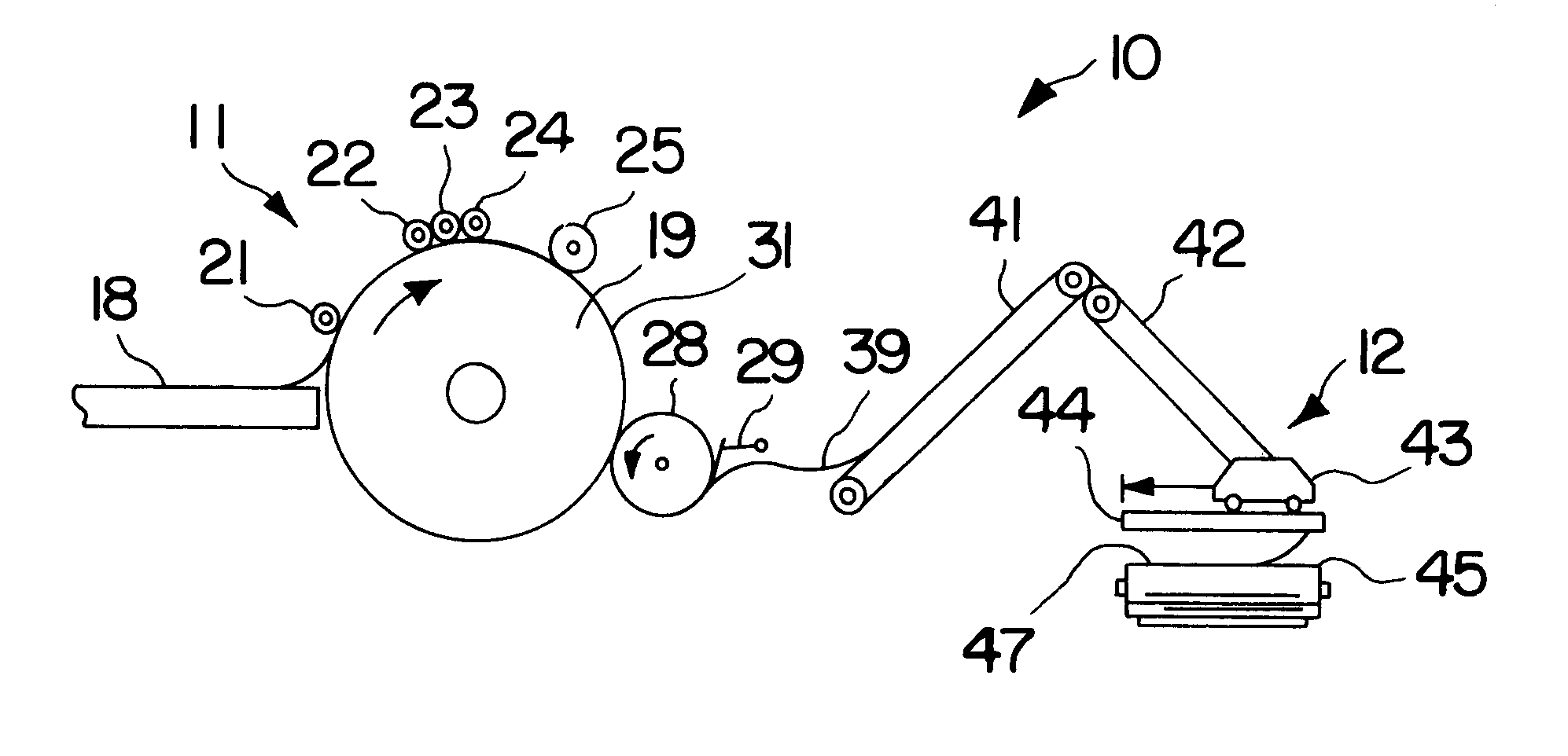

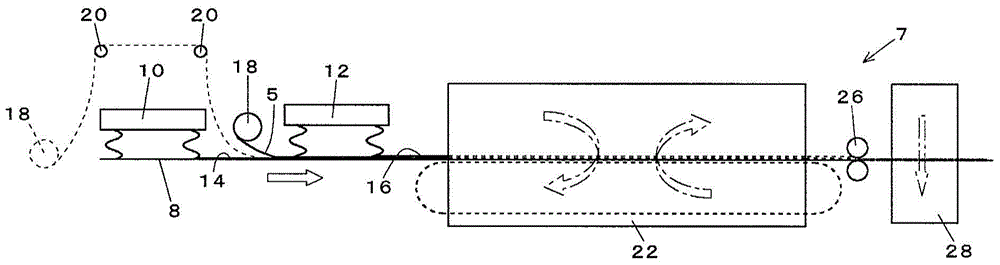

A process for making absorbent sheet includes: (a) depositing an aqueous furnish of cellulosic fiber on a forming fabric; (b) dewatering the wet web to a consistency of from about 15 to about 40 percent; (c) transferring the dewatered web from the forming fabric to another fabric traveling at a speed of from about 10 to about 80 percent slower than the forming fabric; (d) wet-shaping the web on an impression fabric whereby the web is macroscopically rearranged to conform to the surface of the impression fabric; and (e) impingement air drying the web. The process is particularly suitable for making high bulk products form difficult to process furnishes such as recycle furnishes and for making high basis weight products without compressive dewatering with a papermaking felt.

Owner:GPCP IP HLDG LLC

Non-woven fibrous batts, shaped articles, fiber binders and related processes

InactiveUS6296795B1Improve effectivenessImprove satisfactionWood working apparatusFlat articlesFiberParticulates

A process for producing a shaped article from a bonded, non-woven, fibrous batt of fibers comprising a number of steps. There is first provided (A) a dry, solid, heat-responsive fiber-binder; and (B) a moisture-responsive fiber-binder which is a dry, solid, particulate, raw, ungelled starch which swells and becomes sticky upon contact with moisture. The heat-responsive fiber-binder is contacted with the fibers to form a raw batt with the heat-responsive fiber-binder loosely adhering to the fibers of the batt. The moisture-responsive fiber-binder is contacted with the fibers to form a raw batt with the moisture-responsive fiber-binder loosely adhering to the fibers of the batt. The batt is heated to a temperature above the binding temperature of the heat responsive fiber-binder but below the scorching or melting point of the fibers thereby activating the heat-responsive fiber-binder whereupon the heat-responsive fiber-binder engages the intersections of the fibers binding the fibers together at their intersections thereby converting the raw batt into a partially cured batt. The partially cured batt is contacted with steam, thereby causing the moisture-responsive fiber binder to swell, become sticky and further bind the fibers. Fiber binders and shaped articles are described.

Owner:BUCK GEORGE S

Humidity control device

A device for controlling relative humidity in an environment with a solidified humectant composition. The solidified humectant composition is made from a humectant salt, water, and a carrier. The solidified humectant may be formed into a tablet with the aid of a binder, or it may be contained within a thermoformed felt material, a sachet, or a water permeable canister. In a preferred embodiment, the sachet is made of a micro-perforated polyester / paper / polyethylene material. Preferred humectant salts include CaCl2, K2CO3, LiCl2, NaCl, K2SO4, and combinations thereof. A preferred embodiment of the present invention includes the use of one or more of: an antimicrobial agent, activated carbon, a volatile organic, a moisture adsorber and an oxygen absorber, in combination with the solidified humectant salt.

Owner:MULTISORB TECH INC

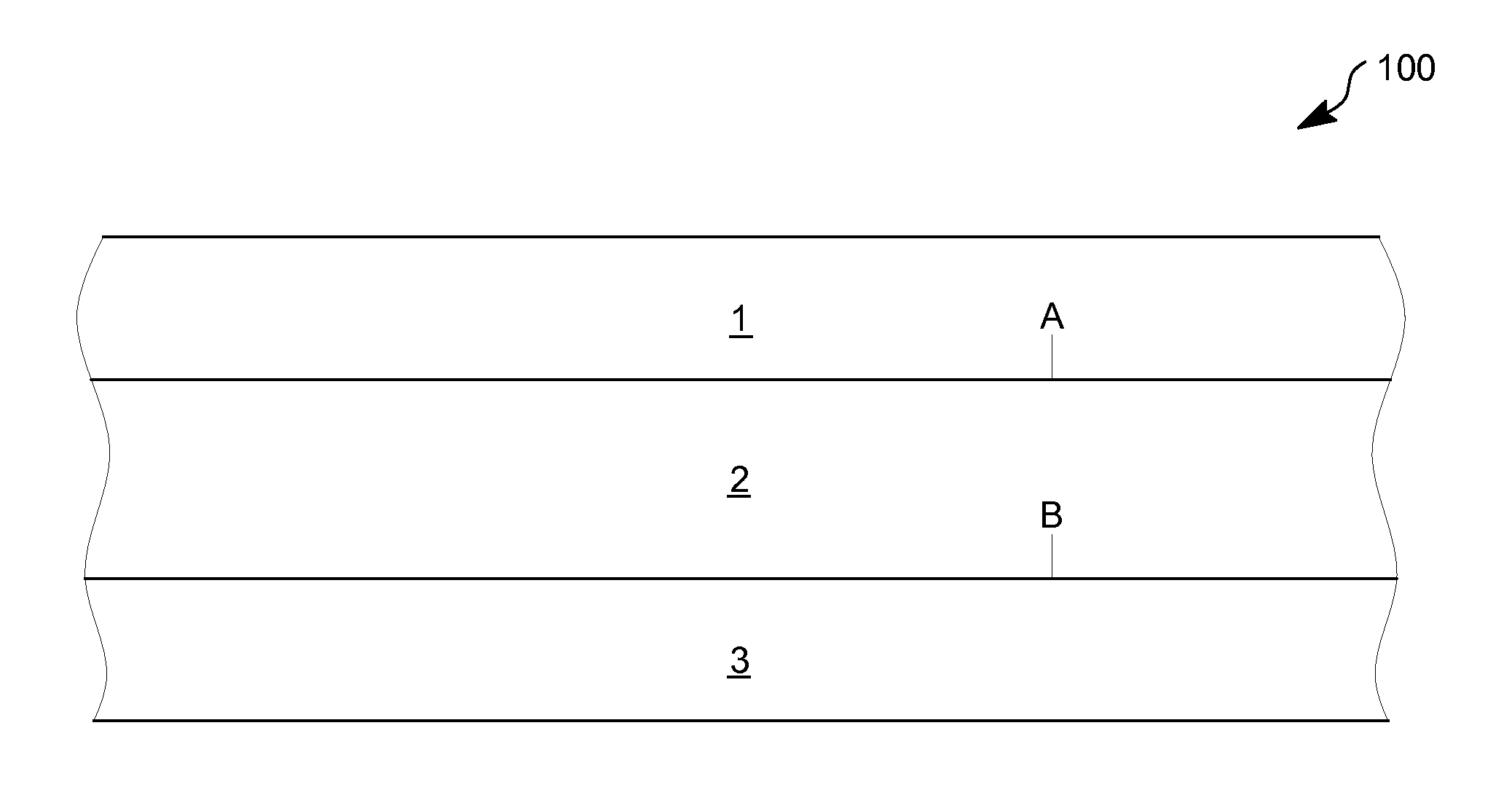

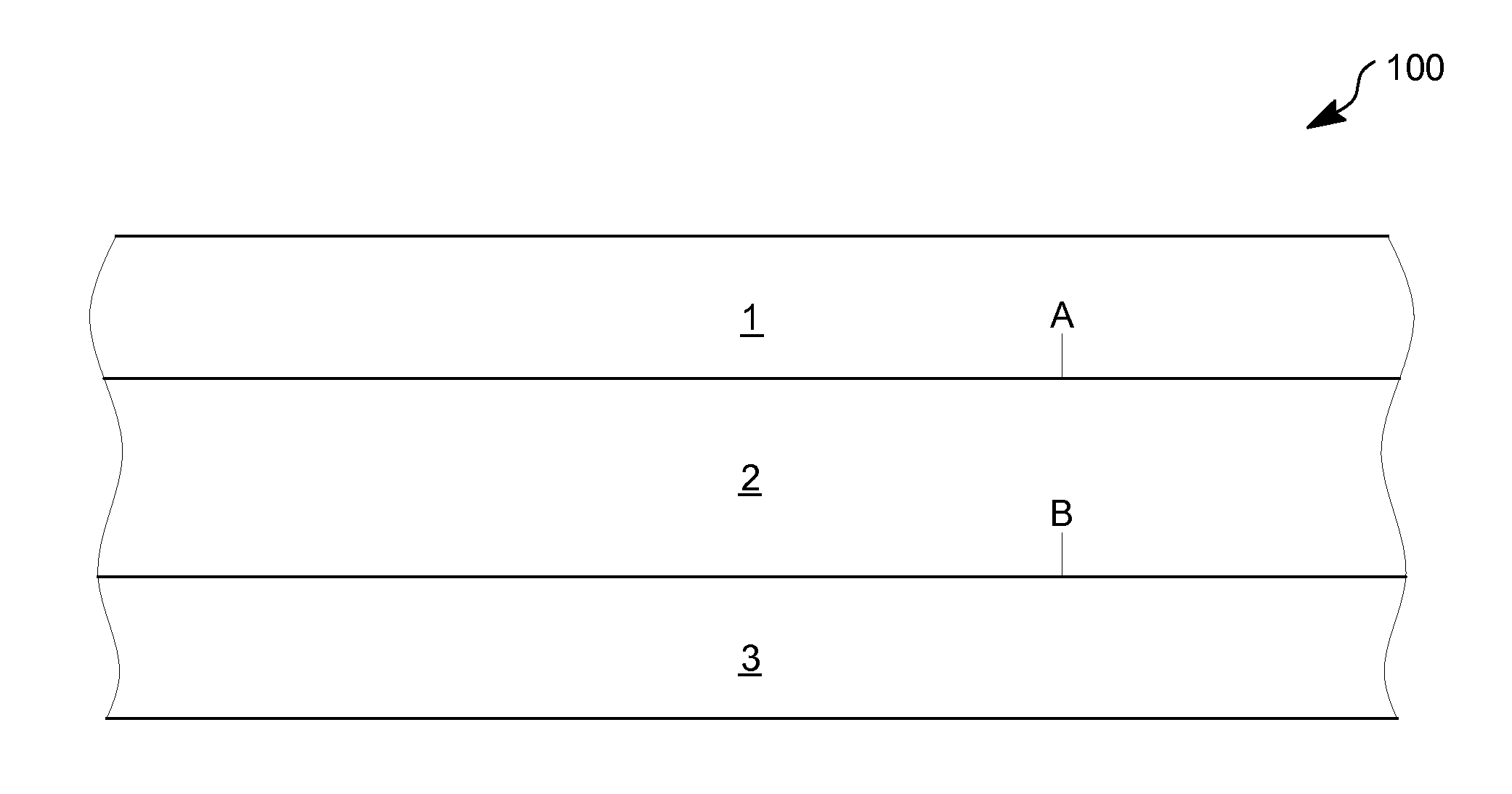

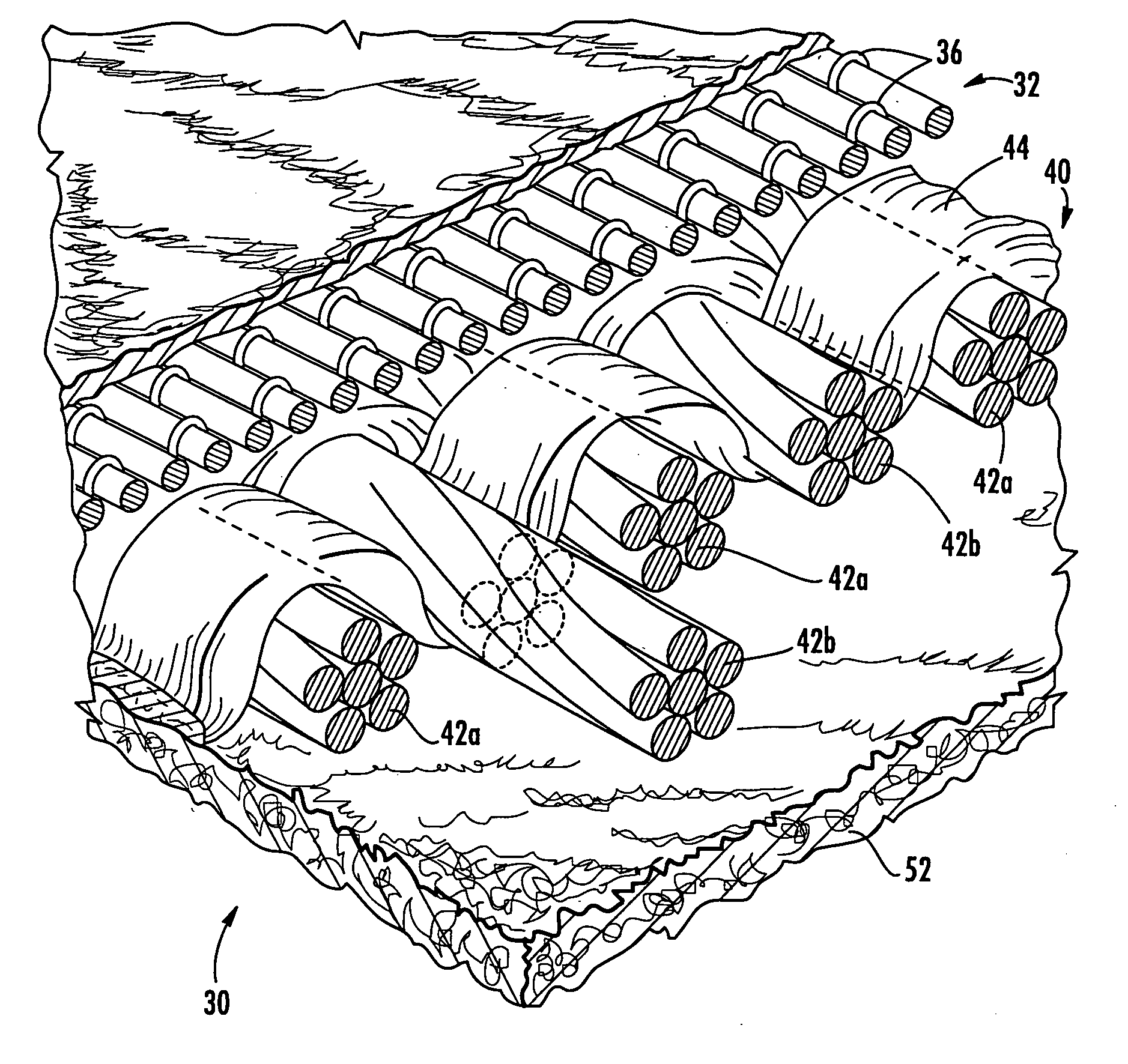

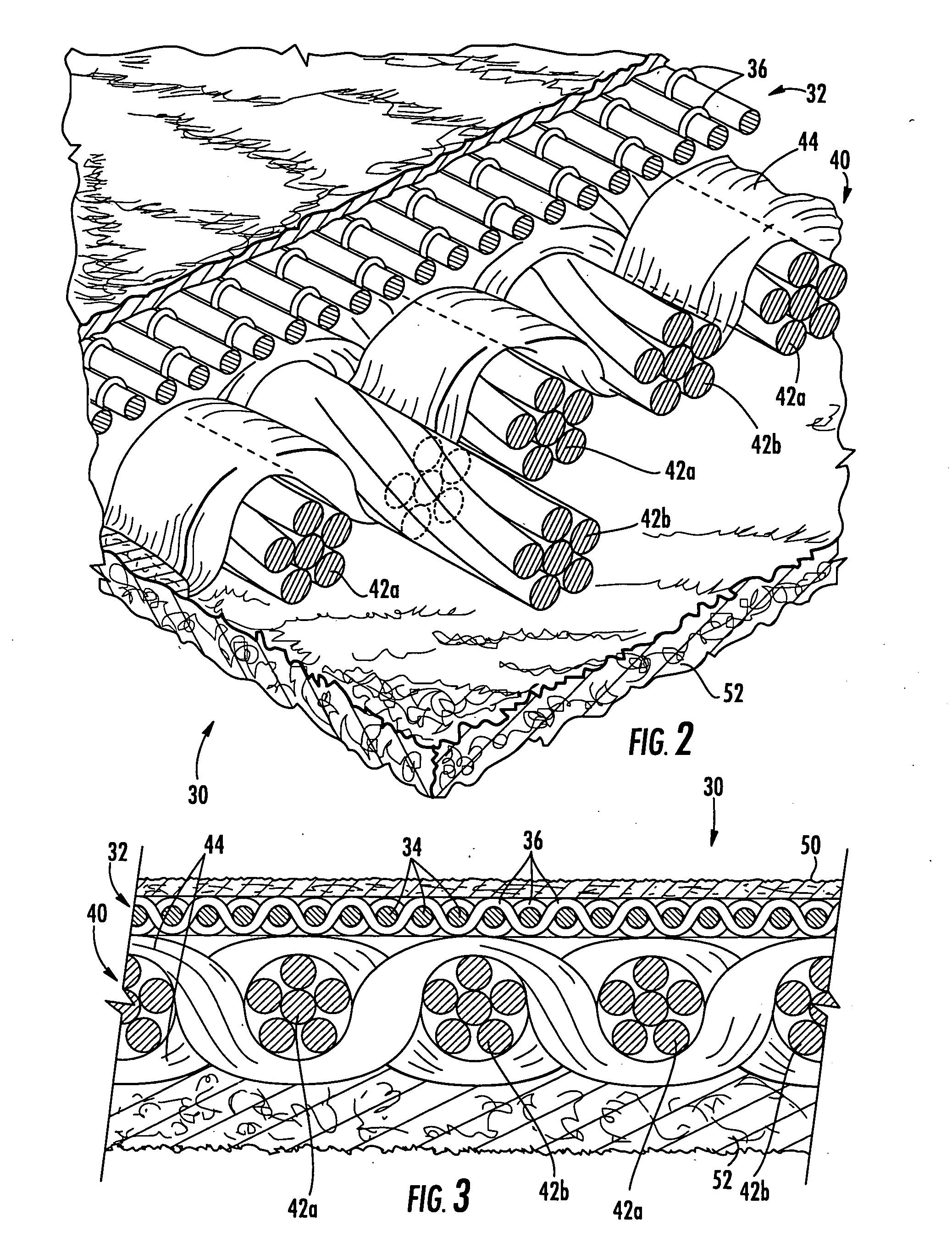

Ballistic shield composites with enhanced fragment resistance

ActiveUS8080486B1Good protectionHigh mobility/maneuverabilityArmourProtective equipmentFibrous layerWoven fabric

Consolidated, layered composites having high penetration resistance to both bullets and fragments are described. The composites comprise, in order, a first non-woven fabric comprising one or a plurality of unidirectionally oriented high tenacity fibrous layers, a felt material comprising high tenacity felt fibers, and a second non-woven fabric comprising one or a plurality of unidirectionally oriented high tenacity fibrous layers. The non-woven fabrics and intermediate felt material are consolidated at facing lateral surfaces.

Owner:HONEYWELL INT INC

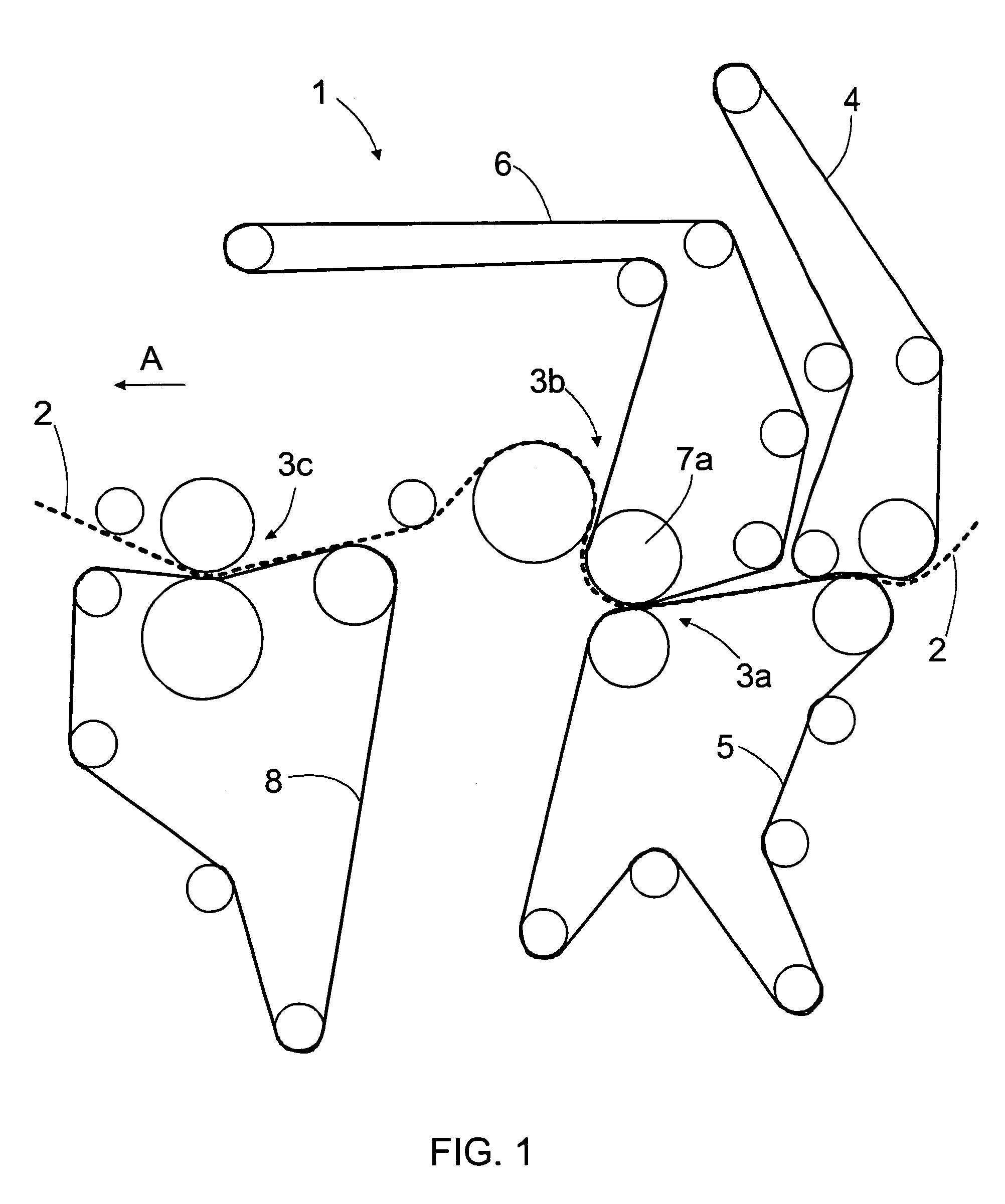

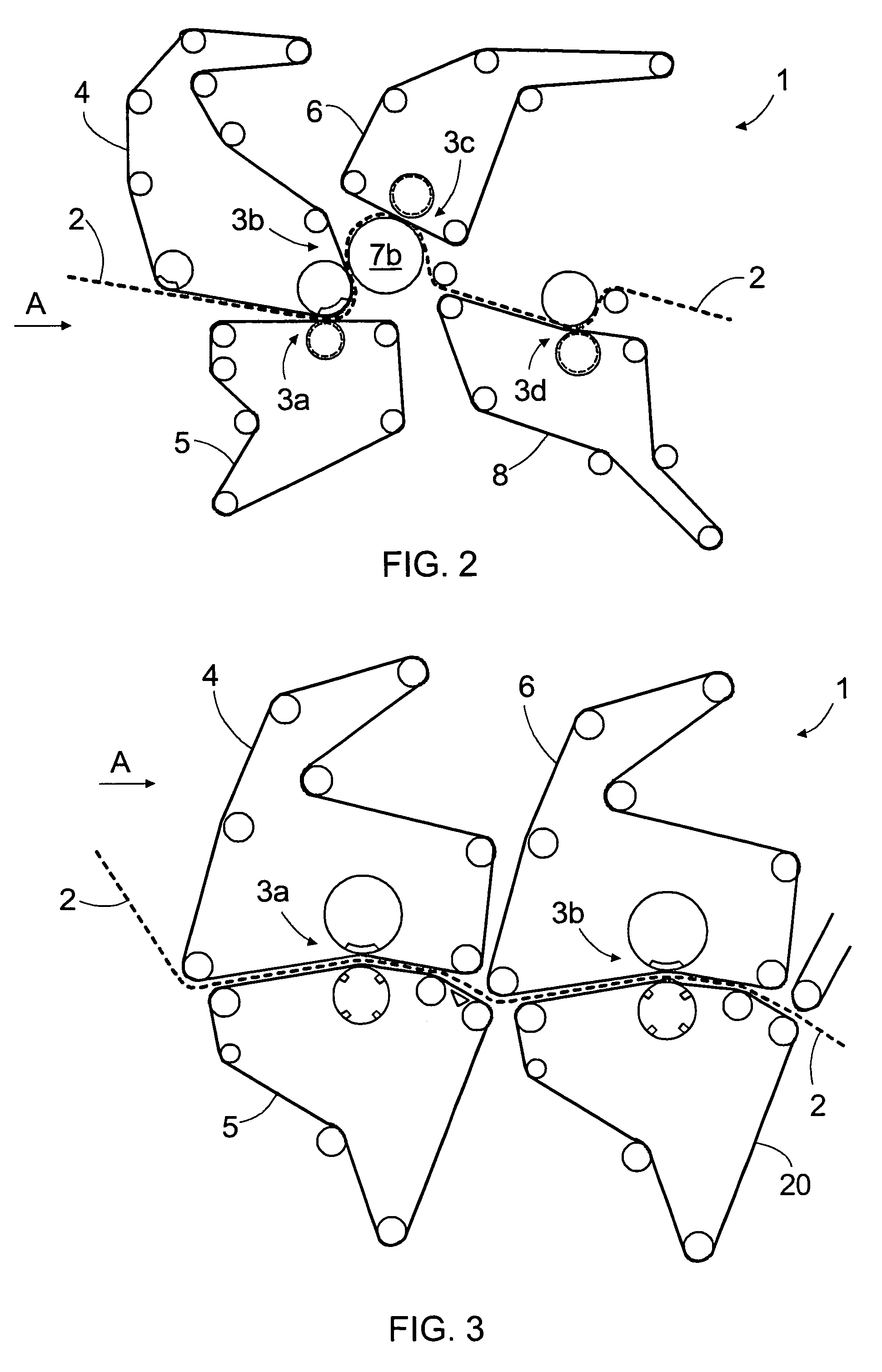

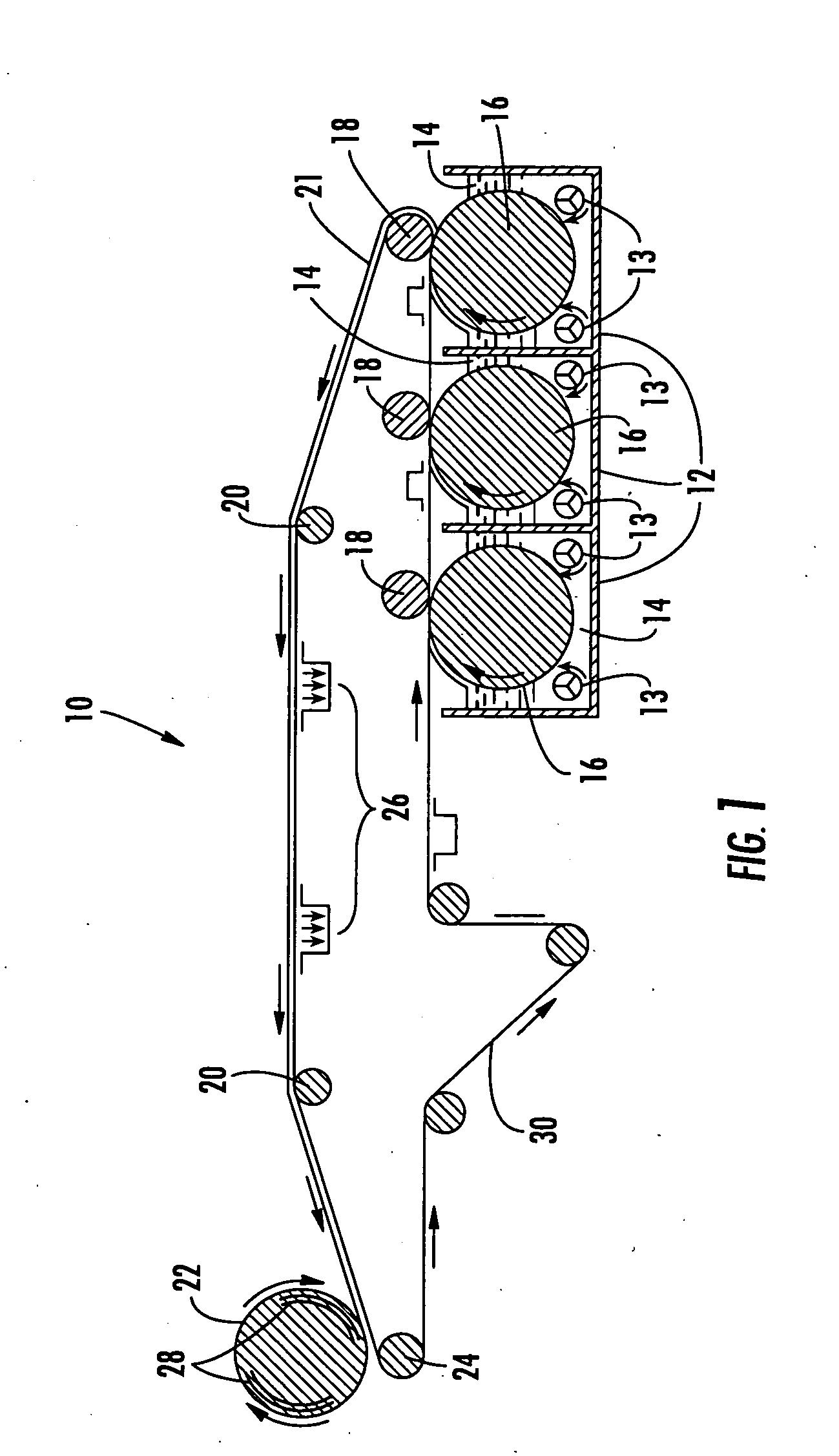

Nonwoven webs with enhanced loft and process for forming such webs

InactiveUS20140072767A1Good flexibilityImprove loftSynthetic resin layered productsNon-woven fabricsEngineeringFelted

The present invention relates to a process of forming a soft bulky nonwoven web from a batt using thermobonding and to a soft bulky nonwoven web with a bond impression pattern and shape. The process comprises several steps including feeding a batt to a nip between first and second surface of first and second roller, where at least the first of the surfaces comprises spaced apart bonding protrusions surrounded by recessed areas. The bonding protrusions and the bond impression shape in the web exhibit a ratio of the greatest measurable width to the greatest measurable length of at least 1:2.5 and the perimeters thereof comprise a convex portion. The bonding protrusions are symmetric and / or have a certain angle to the machine direction.

Owner:PEGAS NONWOVENS

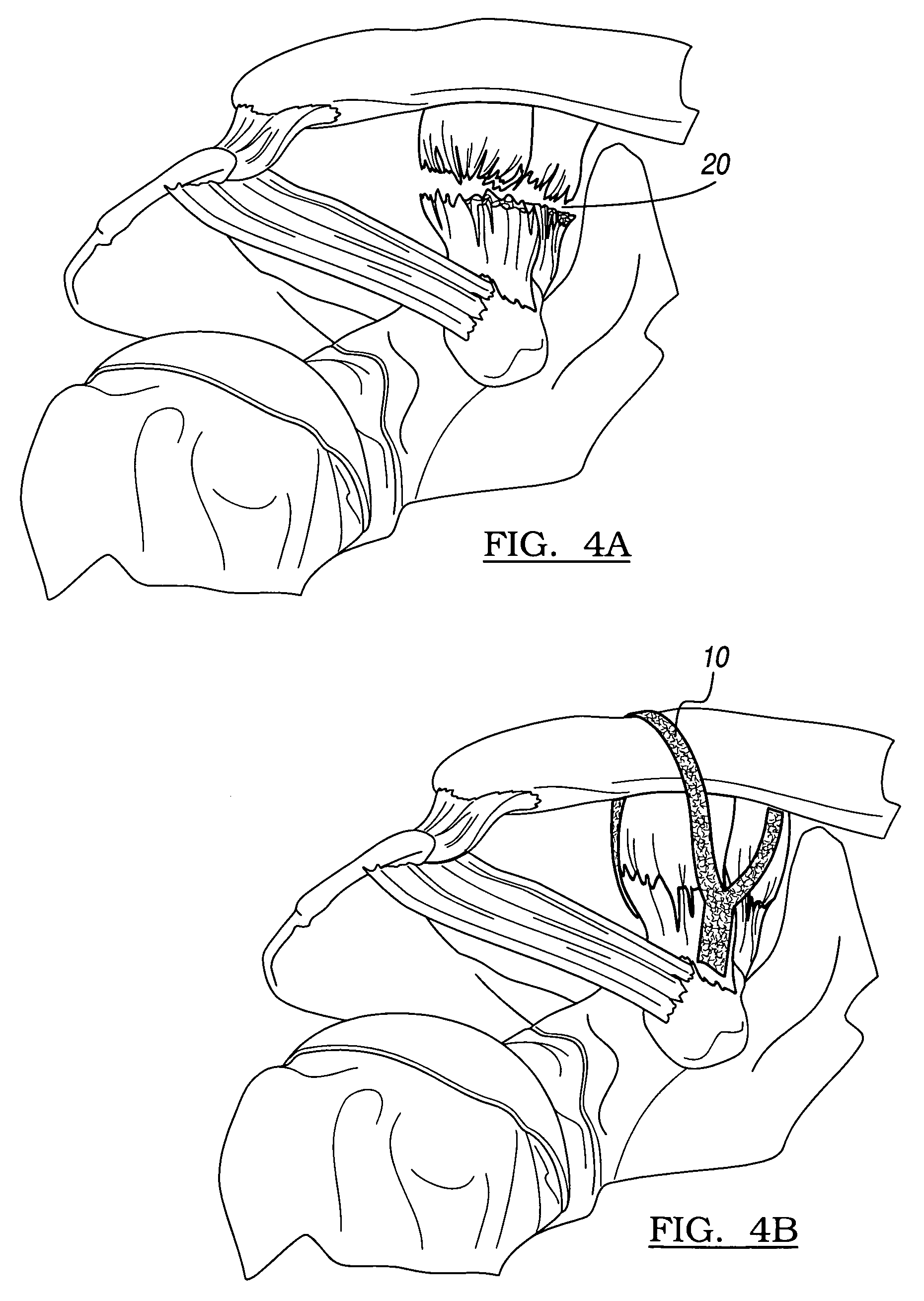

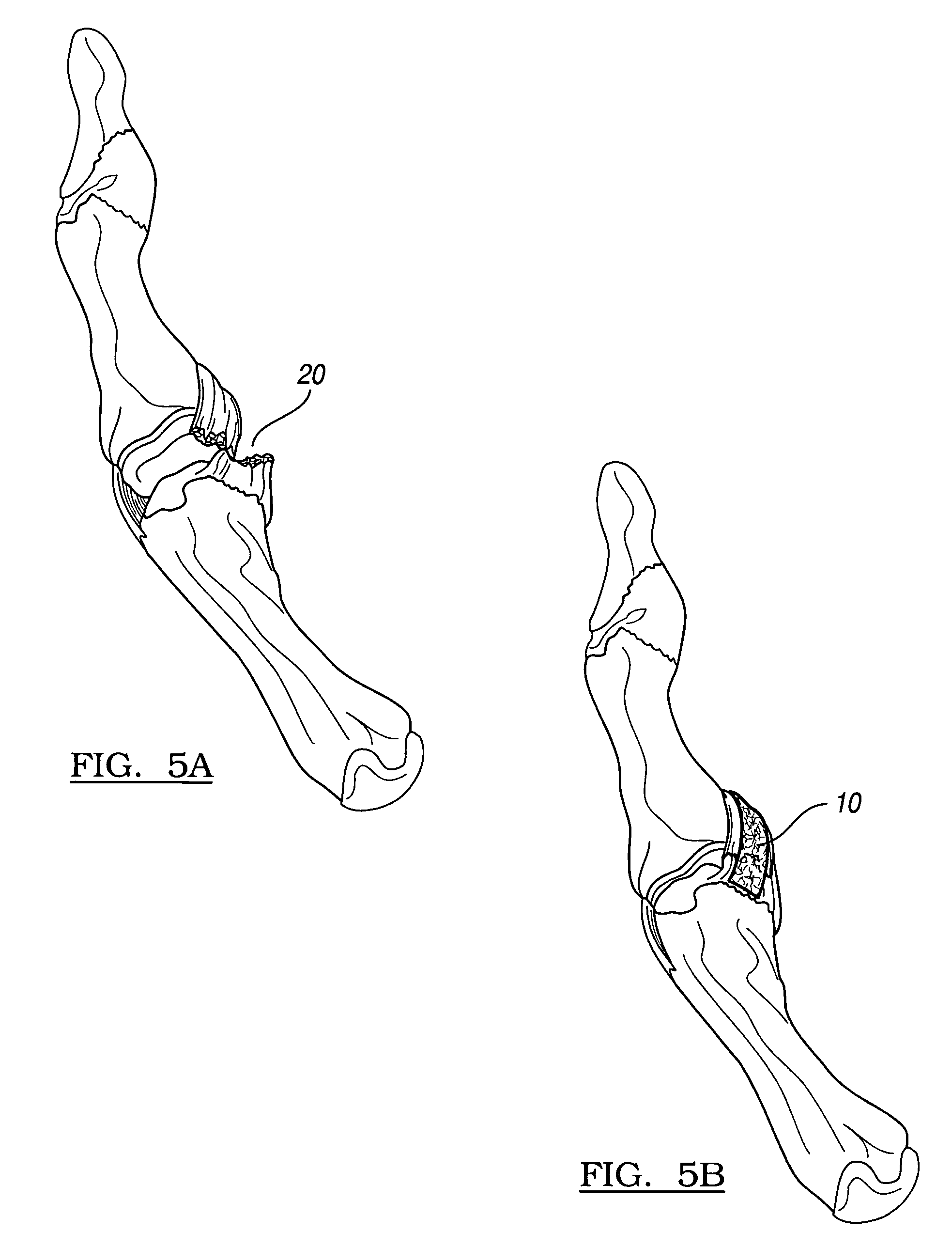

Composite collagen material and method of forming same

A felt for repairing soft tissue defects comprising a membranous collagen substrate and a bioresorbable fiber felted onto the collagen substrate. Methods of preparing a felt and methods of repairing soft tissue damage with a felt are also provided.

Owner:BIOMET MFG CORP

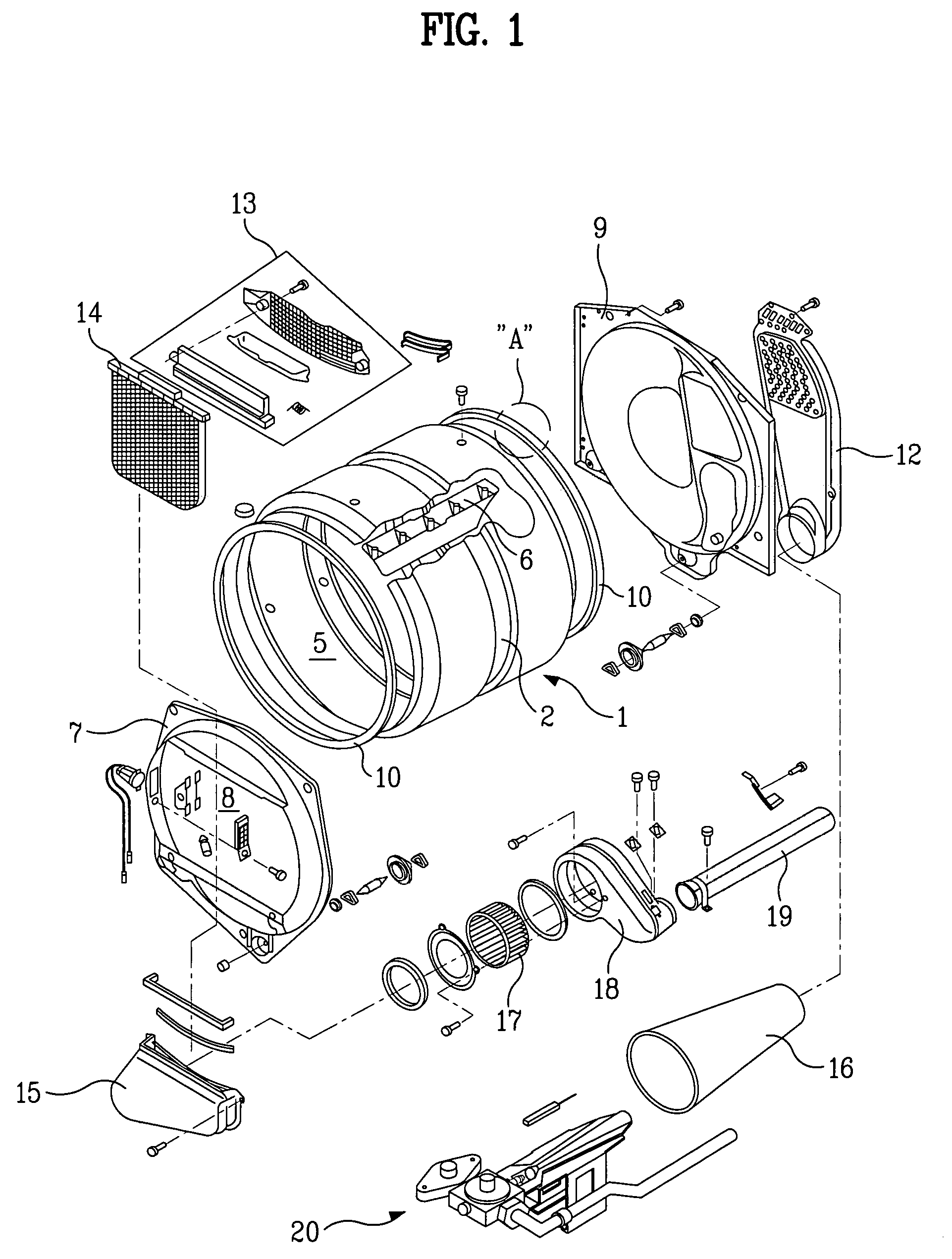

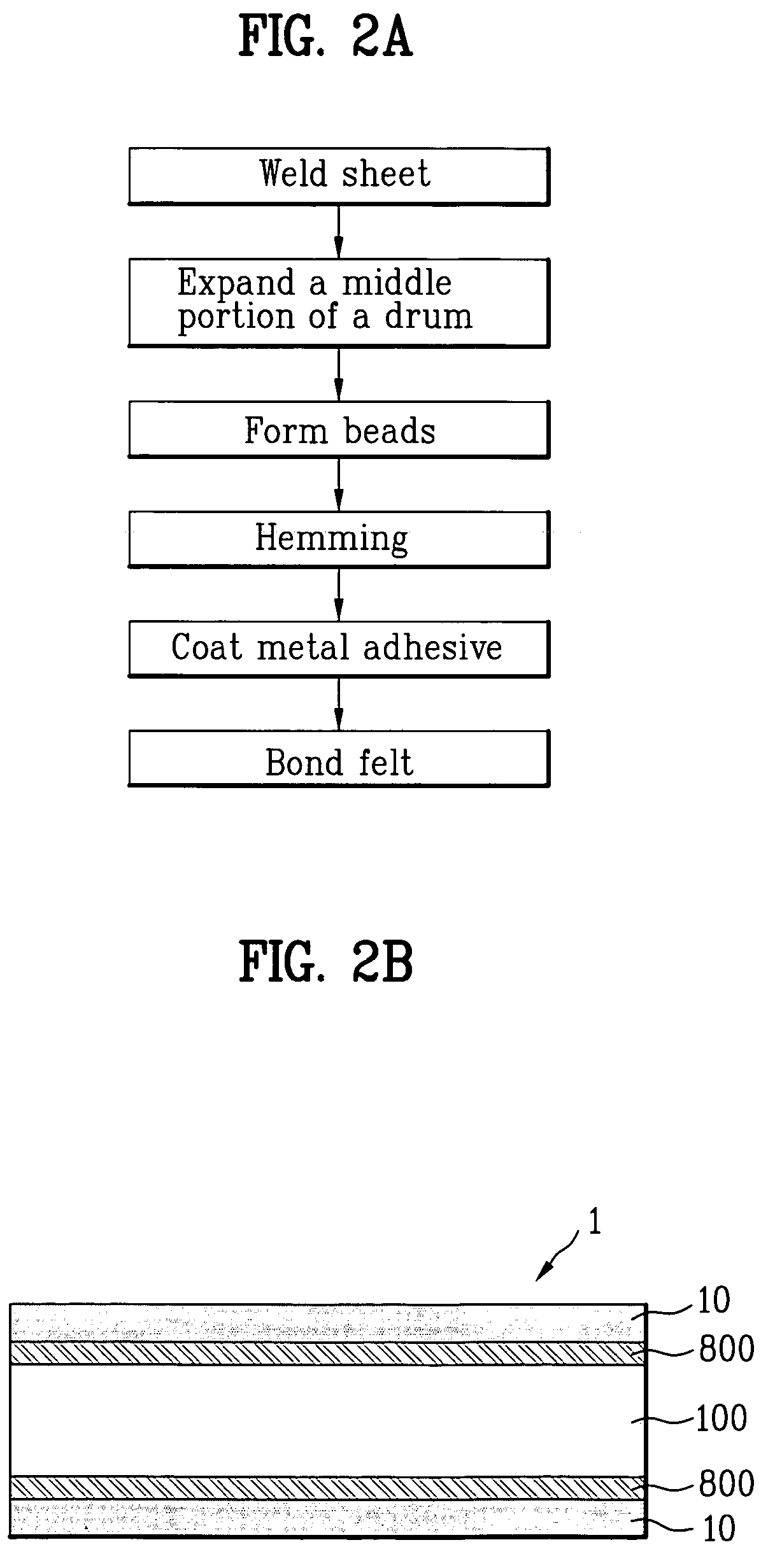

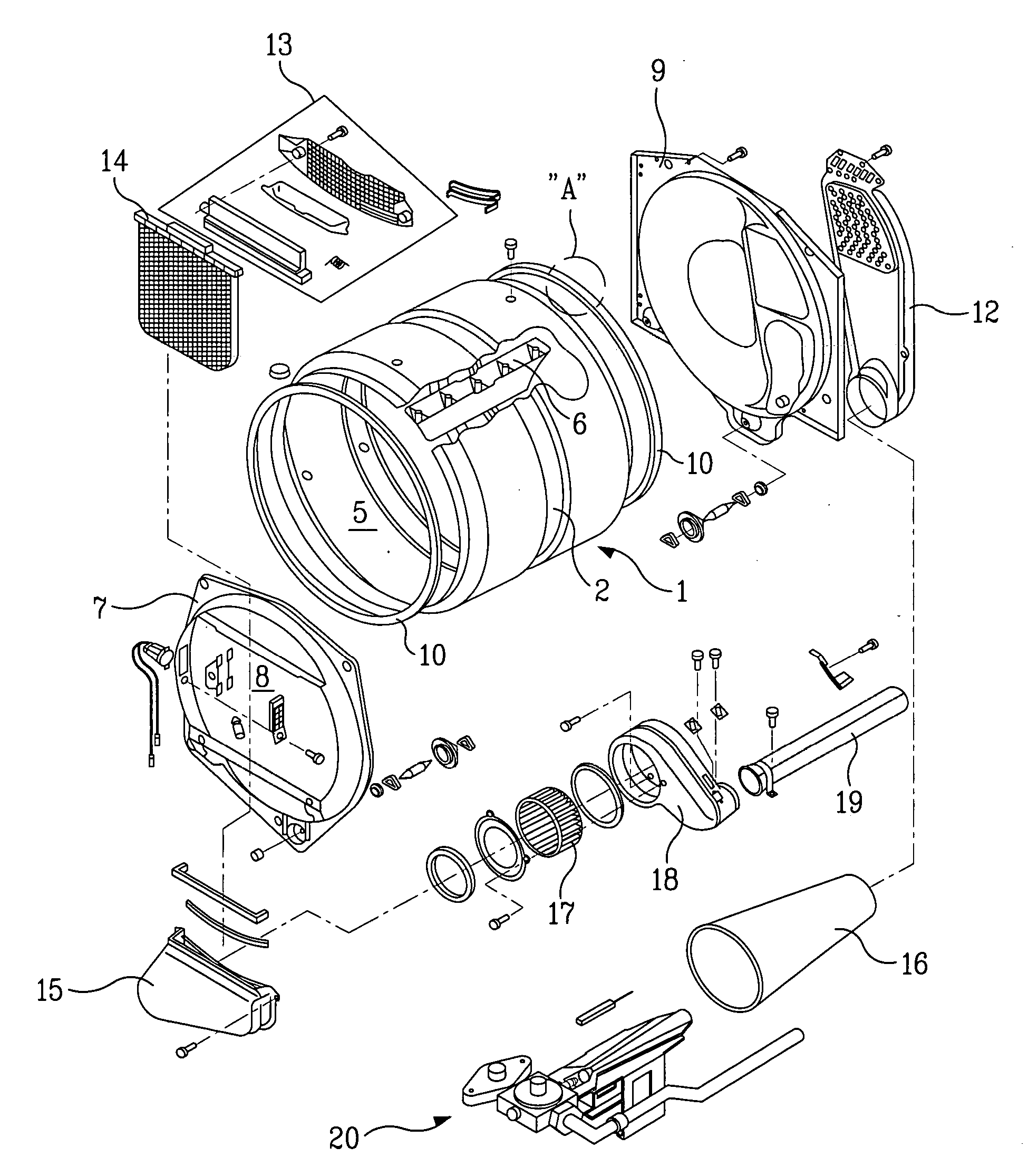

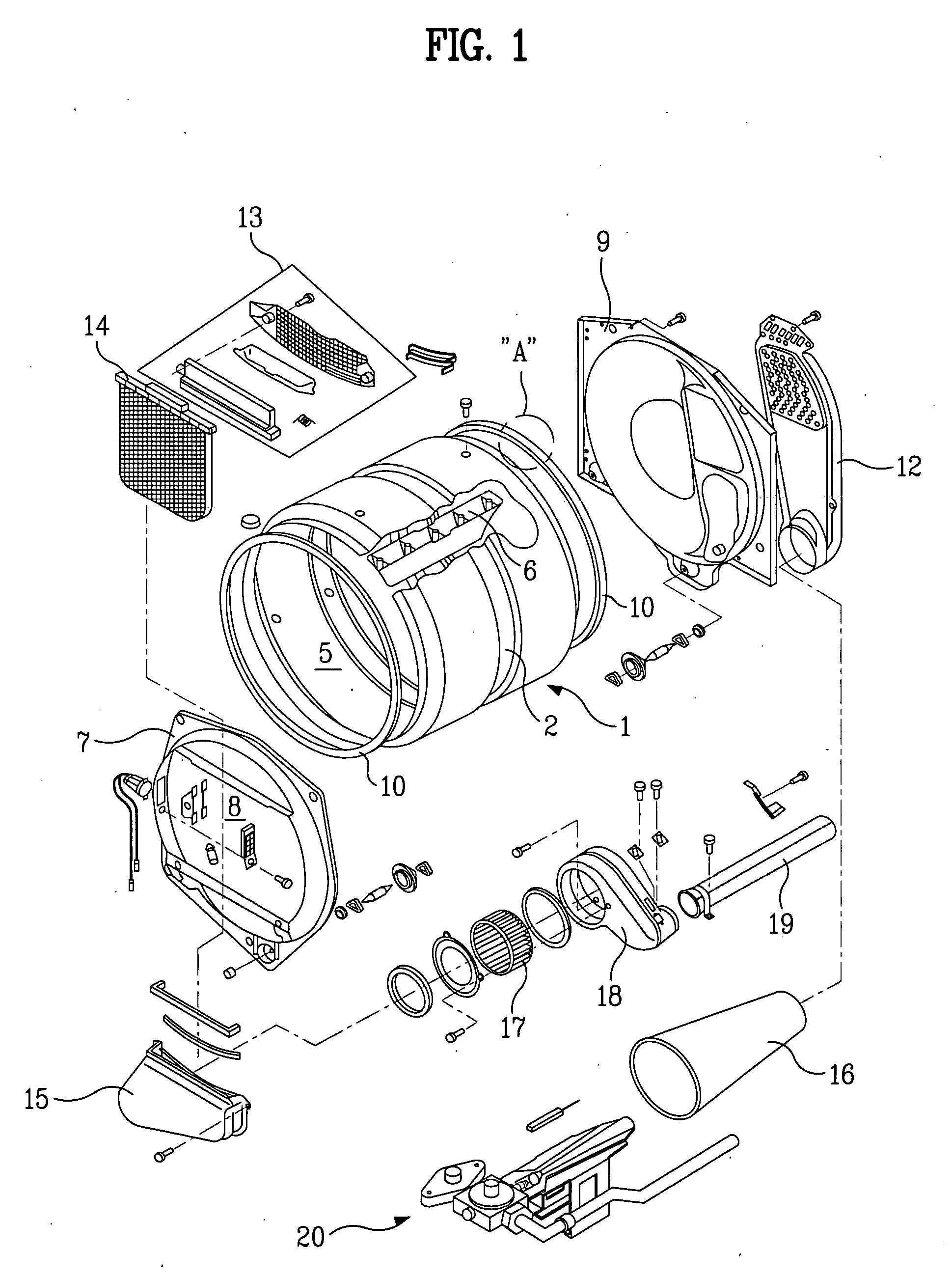

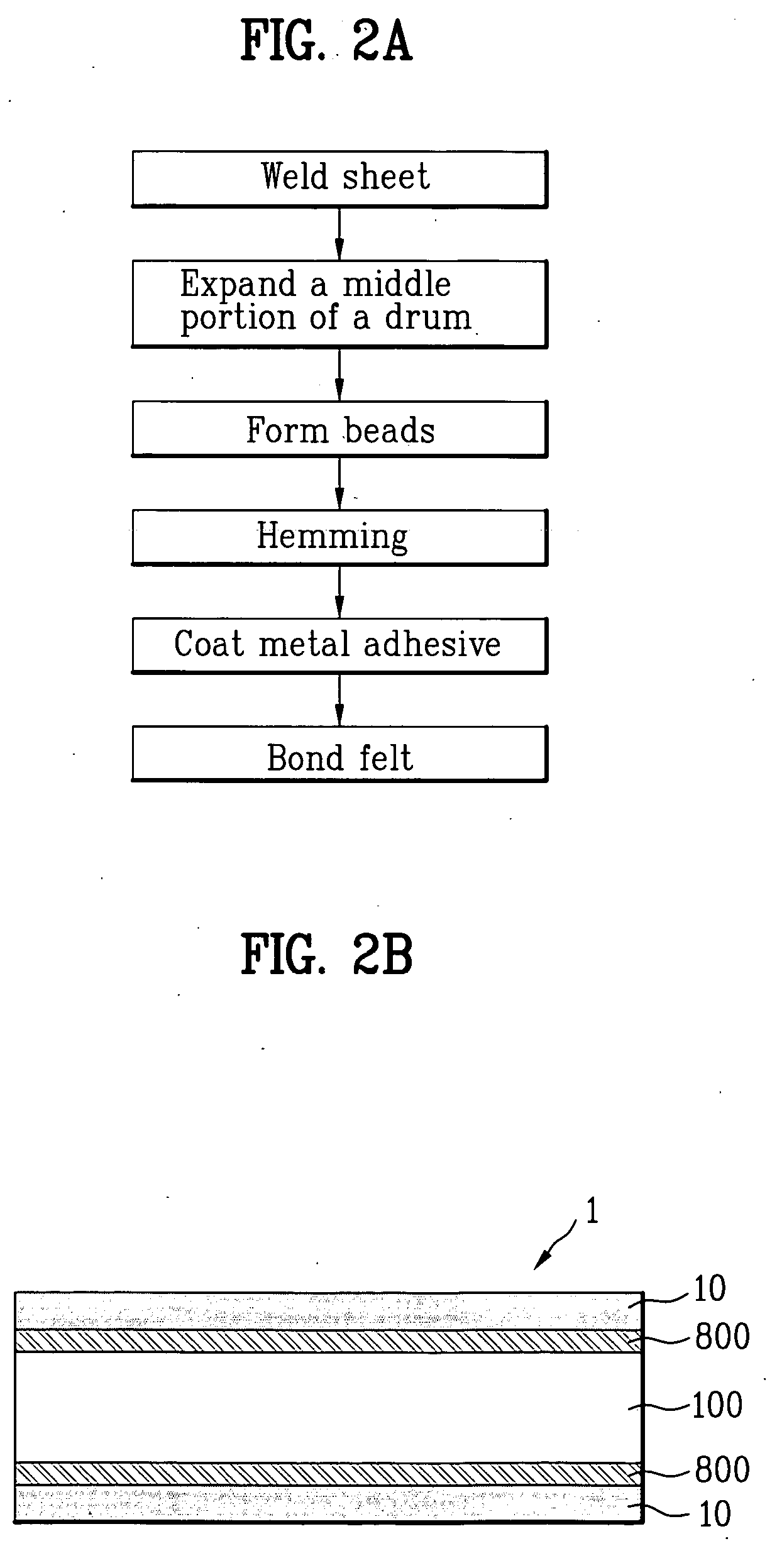

Drum in dryer and method for fabricating the same

ActiveUS7340849B2Low costHigh bonding strengthDrying machines with non-progressive movementsTextiles and paperEngineeringMetal sheet

Owner:LG ELECTRONICS INC

Absorbent Non-Woven Felt Material And Method Of Making Same

InactiveUS20080124533A1Promote absorptionReadily containsLayered productsAbsorbent padsNonwoven fabricFelted

Owner:BOUCKAERT INDAL TEXTILES

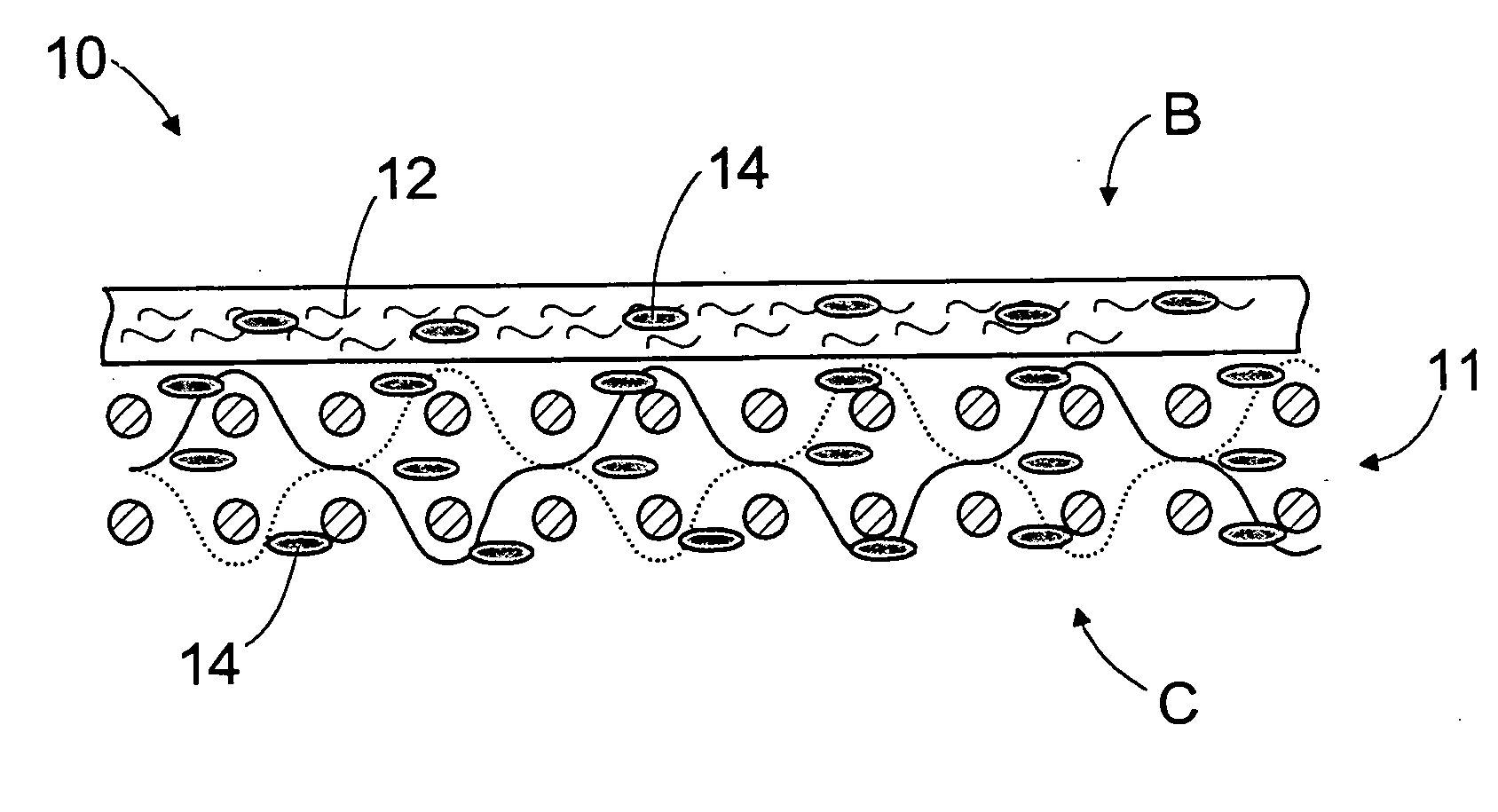

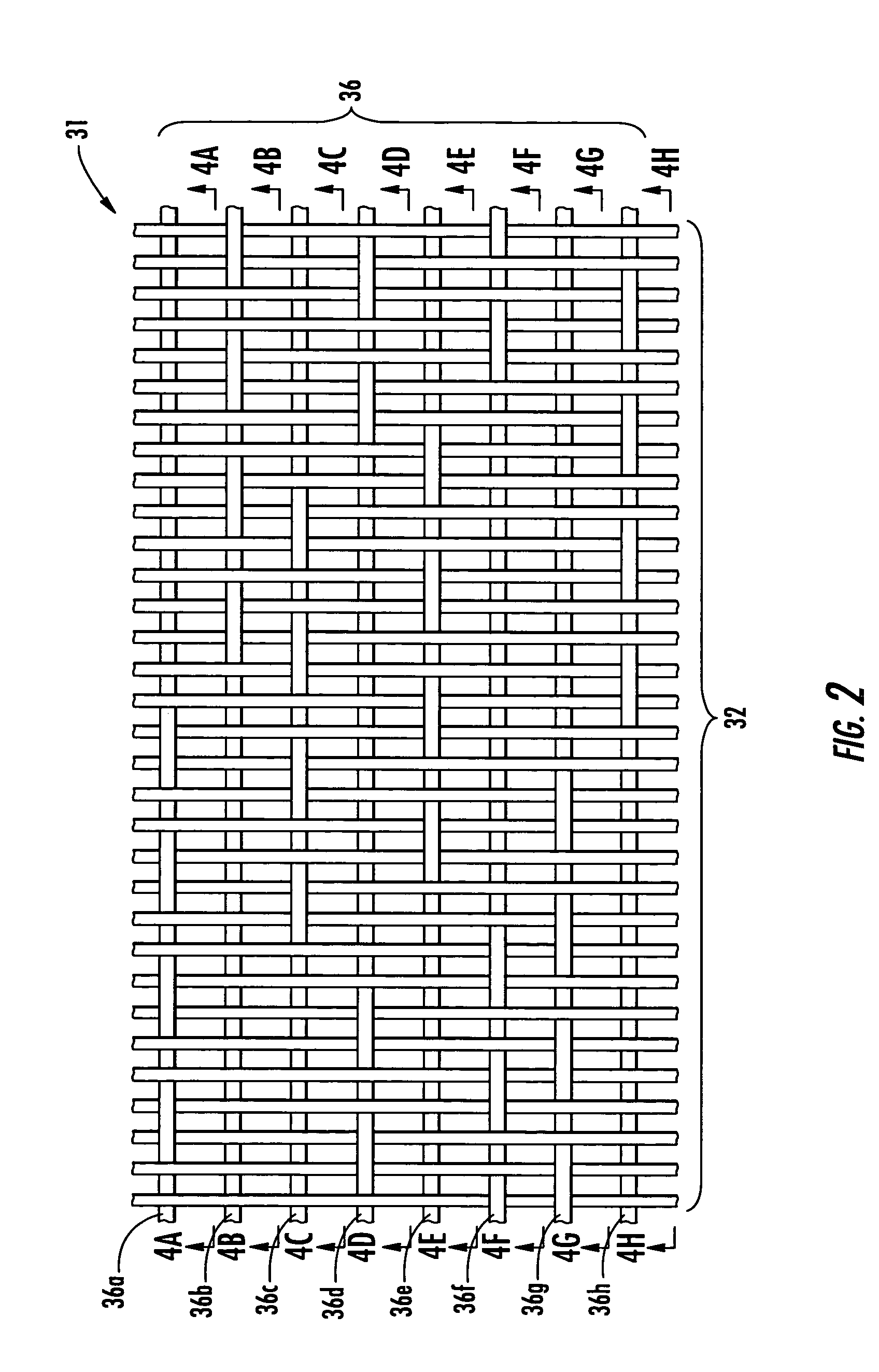

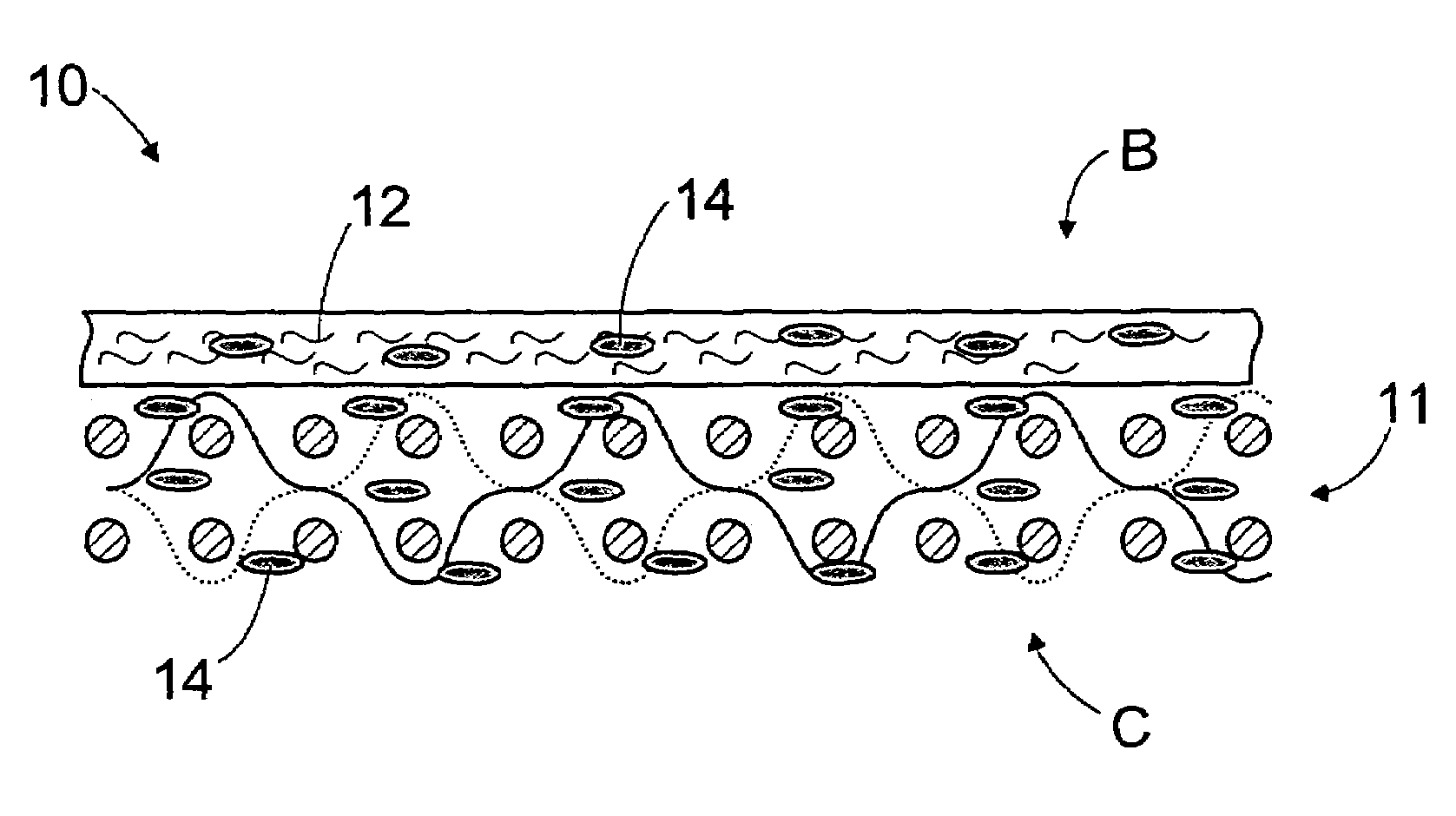

Press felt

InactiveUS20050124248A1Reduce basis weightImprove efficiencyLayered productsPaper/cardboardFiberEngineering

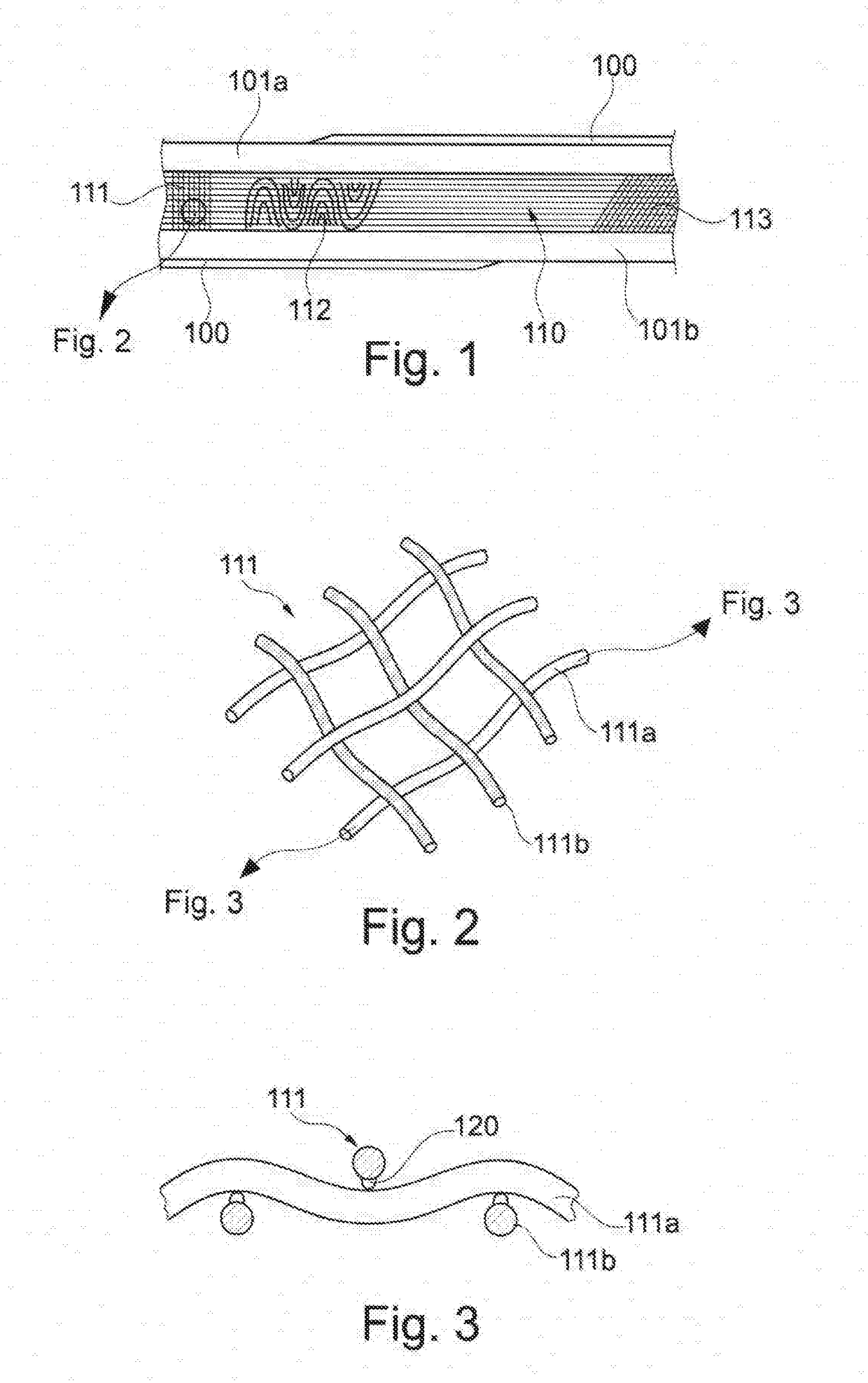

A method of manufacturing a press felt, a press section, and a press felt. The press felt comprises a base structure (11), a batt fibre layer (12) being attached to a first, web-side surface (B) of the base structure. Further, the structure of the press felt is compacted by treating it with a polymer material at least on the side of the first felt surface (B). After the polymer treatment, the surface of the felt is ground smooth.

Owner:TAMFELT PMC OY

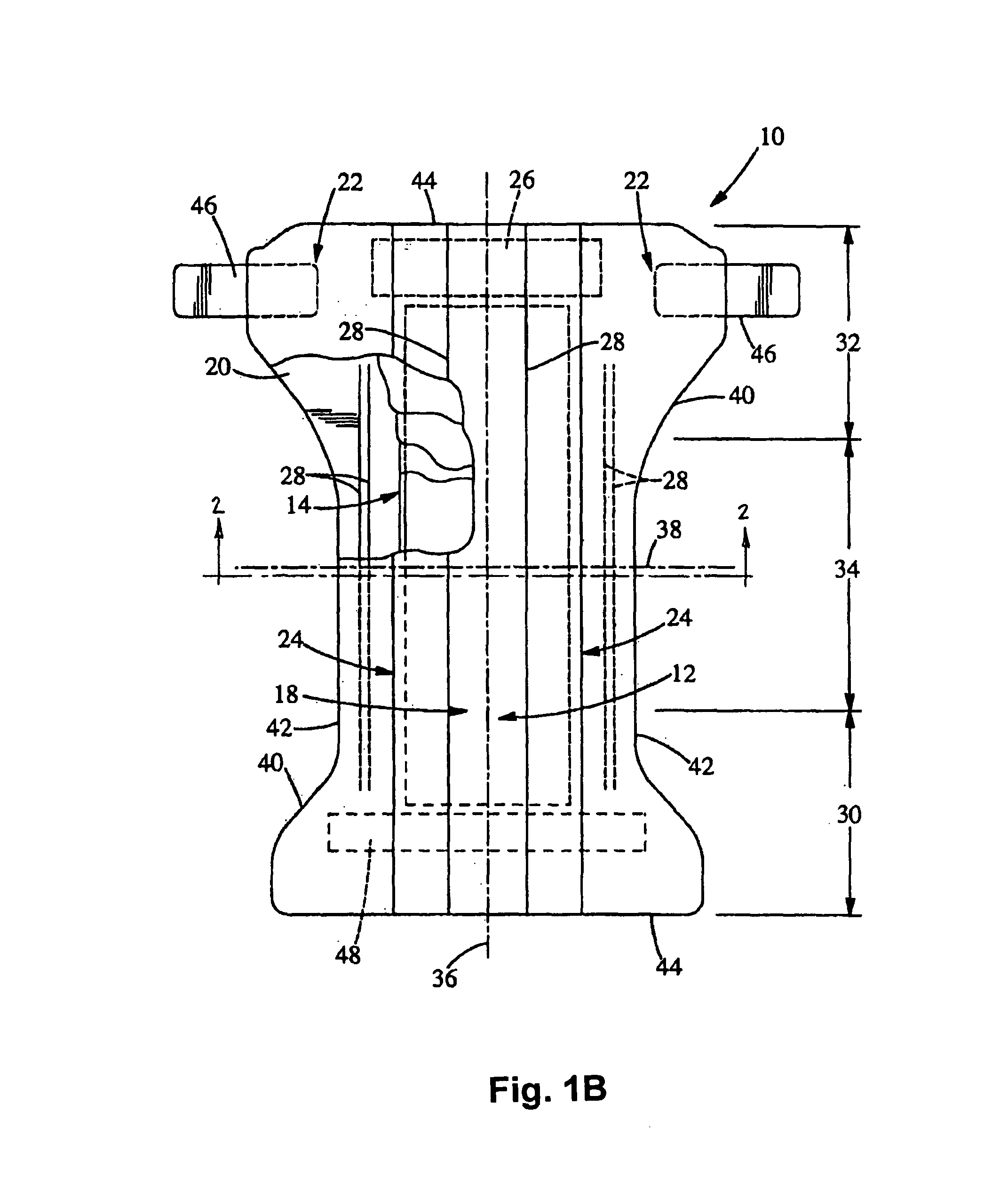

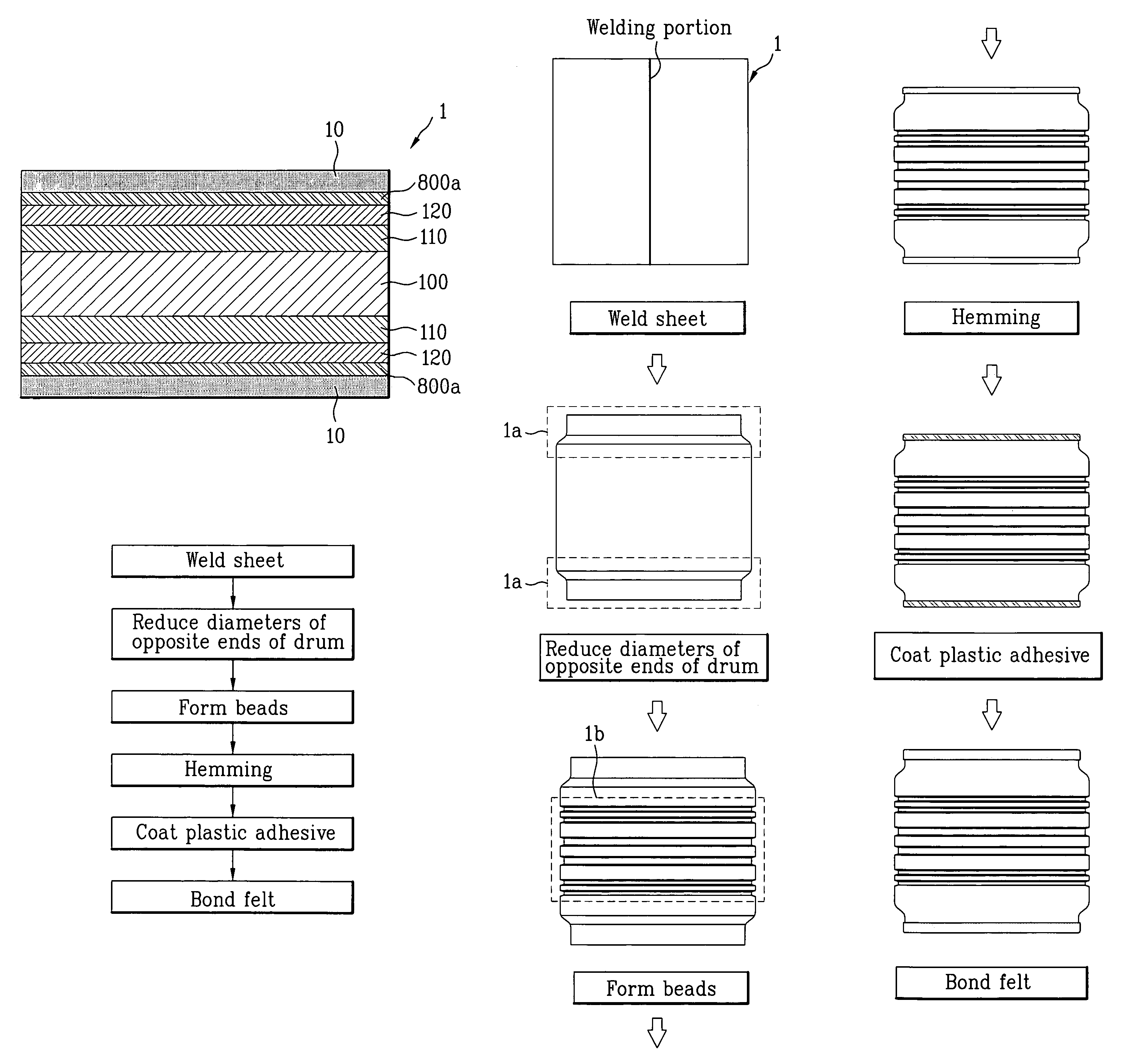

Drum in dryer and method for fabricating the same

ActiveUS20060005418A1Low costHigh bonding strengthDrying machines with non-progressive movementsTextiles and paperEngineeringMetal sheet

Drum in a laundry dryer, and method for fabricating the same, wherein the drum in a dryer including a steel layer which forms a base, anti-corrosive metal film on the steel layer, and an organic film on the metal film, and the method includes the steps of providing a metal sheet having a steel layer, a metal film thereon, and an organic film thereon, rolling the metal sheet into a cylinder, and welding abut joining parts, to form a cylindrical drum, reducing diameters of opposite ends of the cylindrical drum, forming beads in a middle portion of the cylindrical drum except the reduced diameter portions, and hemming opposite edges of the cylindrical drum of the reduced diameter portions, to fold the opposite edges, respectively, thereby reducing production cost significantly, preventing easy visibility of dents in an inside circumferential surface of the drum with naked eyes different from the related art, preventing occurrence of rust, and improving bonding strength of the felt which is a sealing material.

Owner:LG ELECTRONICS INC

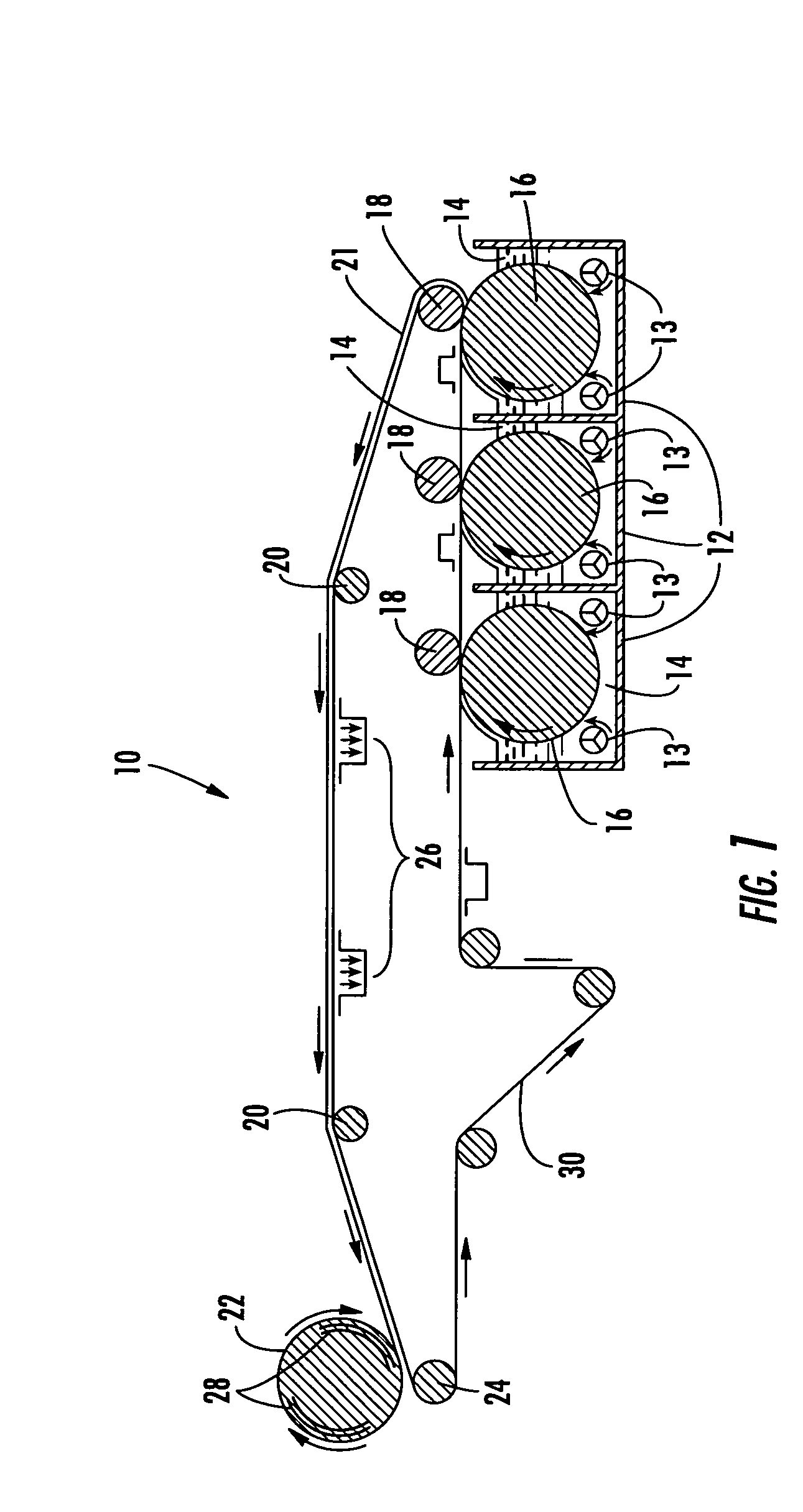

Felt for forming fiber cement articles with multiplex base fabric

A fiber cement felt includes a fabric and a batt layer. The fabric includes: a set of fine top machine direction yams; a set of coarse bottom machine direction yarns; and a set of fine cross machine direction yams interwoven with the top and bottom machine direction yams in a plurality of repeat units. The batt layer overlies and is attached to the set of top machine direction yams of the fabric. The fineness of the yams of the top machine direction yams and the cross machine direction yams can improve the surface achieved with other fiber cement felts

Owner:WEAVEXX

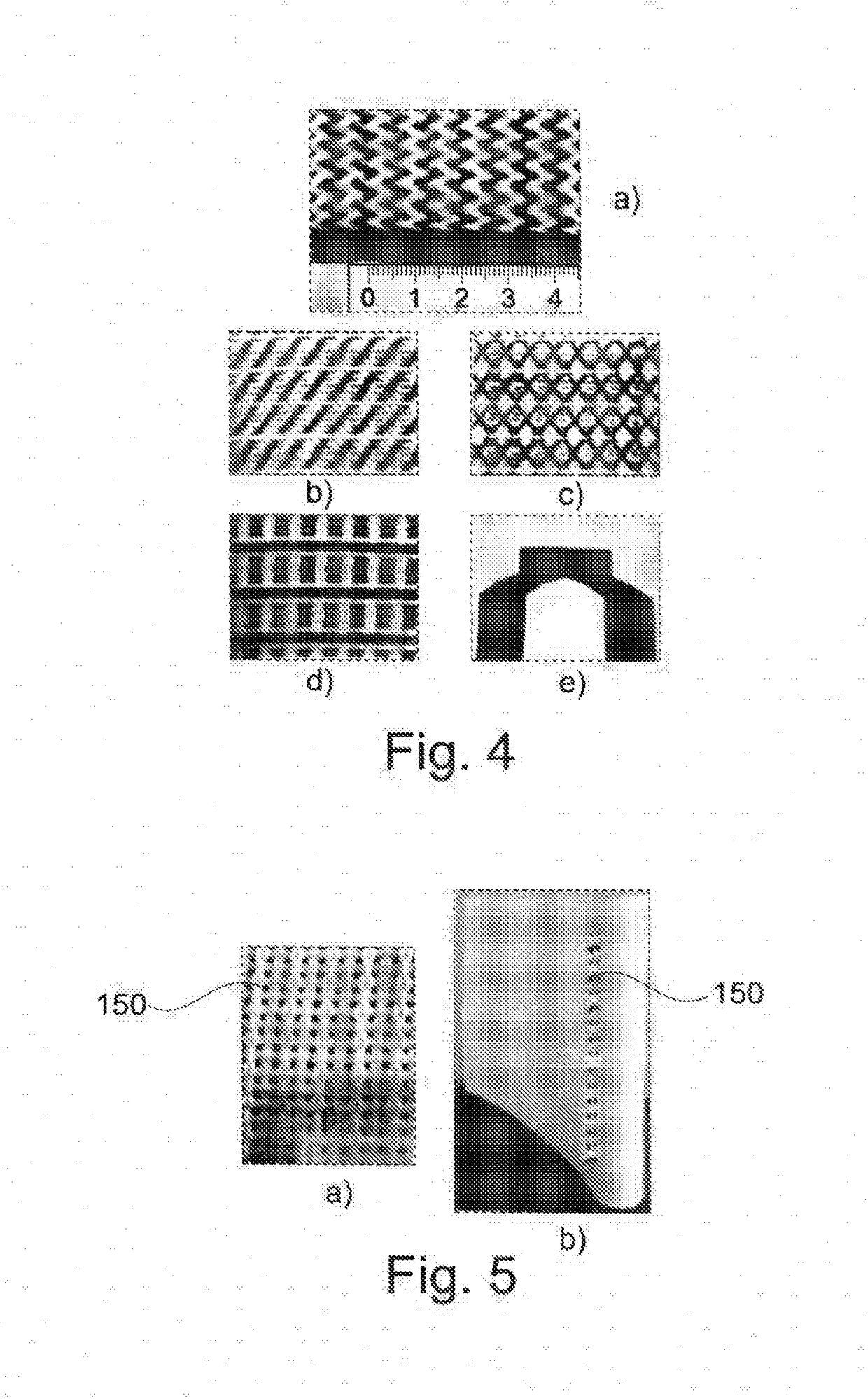

Sandwich arrangement with ceramic panels and ceramic felts

InactiveUS20180065337A1Easily withdrawnCorrect positionBlade accessoriesEfficient propulsion technologiesCeramicAdhesive

The disclosure relates to a sandwich arrangement having at least two peripheral disposed ceramic panels and a ceramic felt which is inserted between a first and second ceramic panel, The material of the first ceramic panel is equal or different to the material of the second panel, wherein the ceramic felt is formed by a textile structure with a regularly or quasi-regularly structured woven fibres. The fibres are made of at least one material and / or composition, wherein at least one adhesive is provided between an underside of the panels and adjacent fibres.

Owner:ANSALDO ENERGIA IP UK LTD

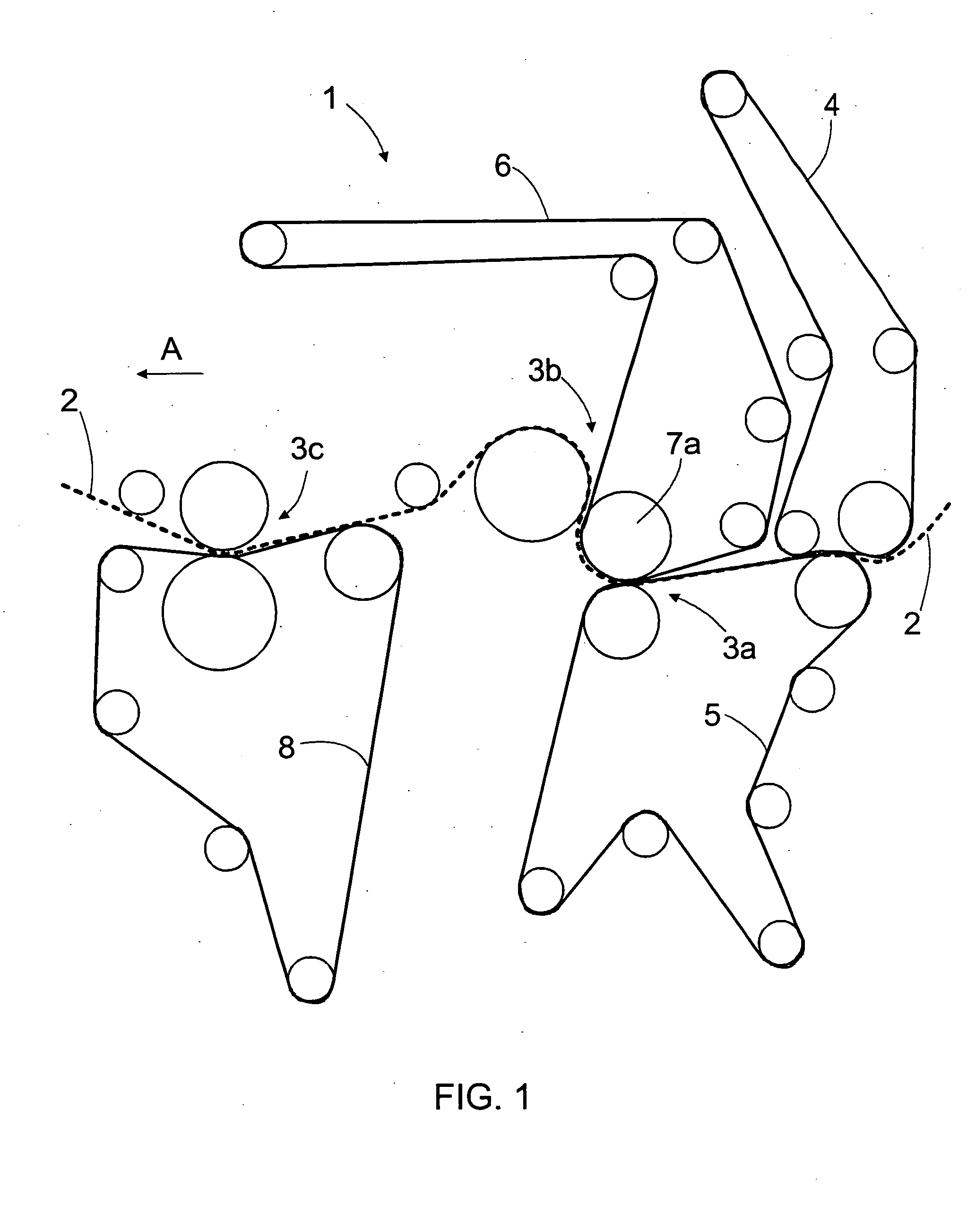

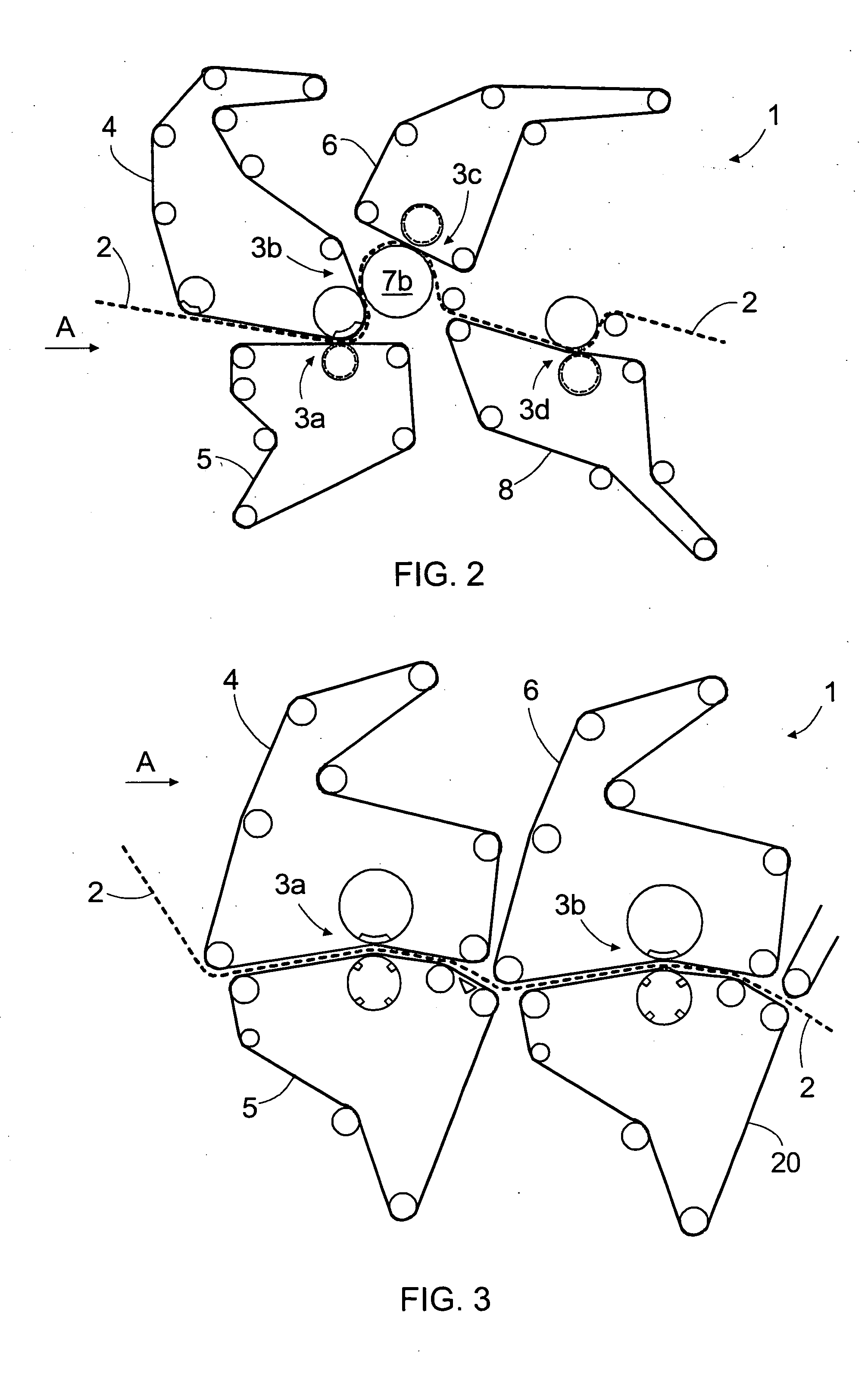

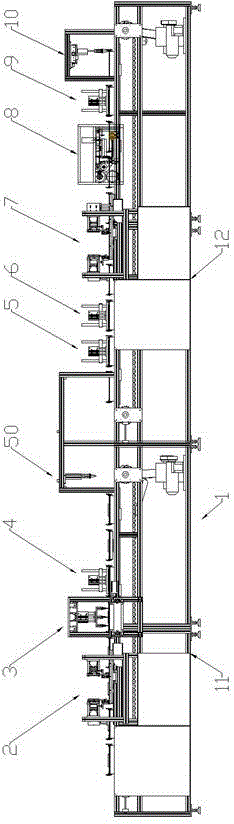

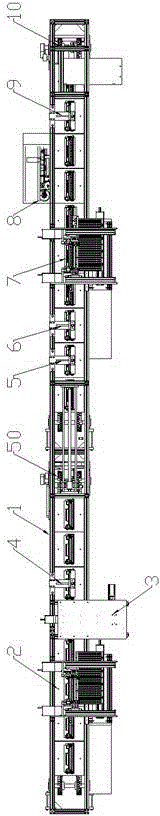

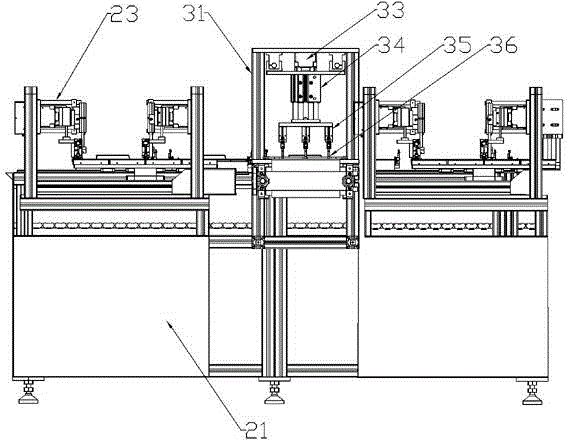

Automatic pasting production line for scrapers, sponges and felts

The invention discloses a production line used for automatically pasting scrapers, sponges and felts, and aims at providing an automatic pasting production line for the scrapers, the sponges and the felts. The automatic pasting production line is high in production efficiency, low in labor cost and good in pasting effect. The automatic pasting production line comprises a main base (1), a controller, a transmission belt arranged on the main base (1) and a motor, and the motor is in transmission connection with the transmission belt and is electrically connected with the controller. A short sponge pasting mechanism (2), a long sponge pasting mechanism (3), a long sponge pressing mechanism (4), a short sponge pressing mechanism (5), a first gluing mechanism (6), a felt pasting mechanism (7), a scraper pasting mechanism (8), a second gluing mechanism (9) and a discharging mechanism (10) are sequentially arranged on the base body (1) in the conveying direction of the transmission belt. The production line is applied to the technical field of automatic pasting production of the scrapers, the sponges and the felts of toner cartridges.

Owner:PROSPECT IMAGE PROD LIMITED OF ZHUHAI

Press felt

InactiveUS7306704B2Reduce basis weightImprove efficiencyLayered productsPaper/cardboardFiberEngineering

A method of manufacturing a press felt, a press section, and a press felt. The press felt comprises a base structure (11), a batt fibre layer (12) being attached to a first, web-side surface (B) of the base structure. Further, the structure of the press felt is compacted by treating it with a polymer material at least on the side of the first felt surface (B). After the polymer treatment, the surface of the felt is ground smooth.

Owner:TAMFELT PMC OY

Felted hydrophilic ester polyurethane foams

InactiveUS6841586B2Good wicking characteristicImprove water holding capacityChemical treatmentCellulose

An ester polyurethane foam is prepared by reacting a mixture of one or more polyester polyols with one or more isocyanates and one or more silicone surfactants in the presence of a blowing agent, such as water, and other additives, such as catalysts. The cured foam is chemically treated in a caustic solution and is then felted (compressed under heat and pressure) to form a hydrophilic ester polyurethane foam having a water absorption rate of at least 30 pounds of water per square foot per minute (1.44 kPa / min). The foam also has greater water holding capacity and wet strength than cellulose.

Owner:MP FOAM DIP

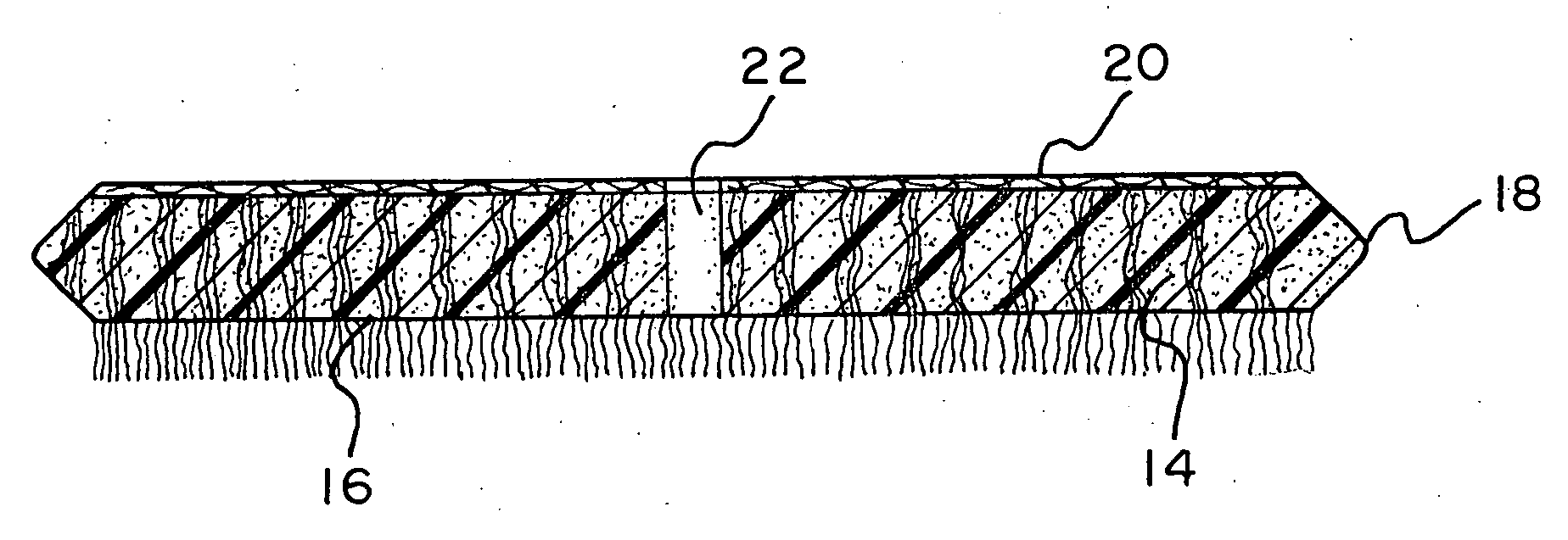

Nonwoven fabric, method for producing the same, and filter formed with the same

ActiveUS20130193063A1High hardnessIncrease stiffnessFibre mixingMembrane filtersFilter mediaEngineering

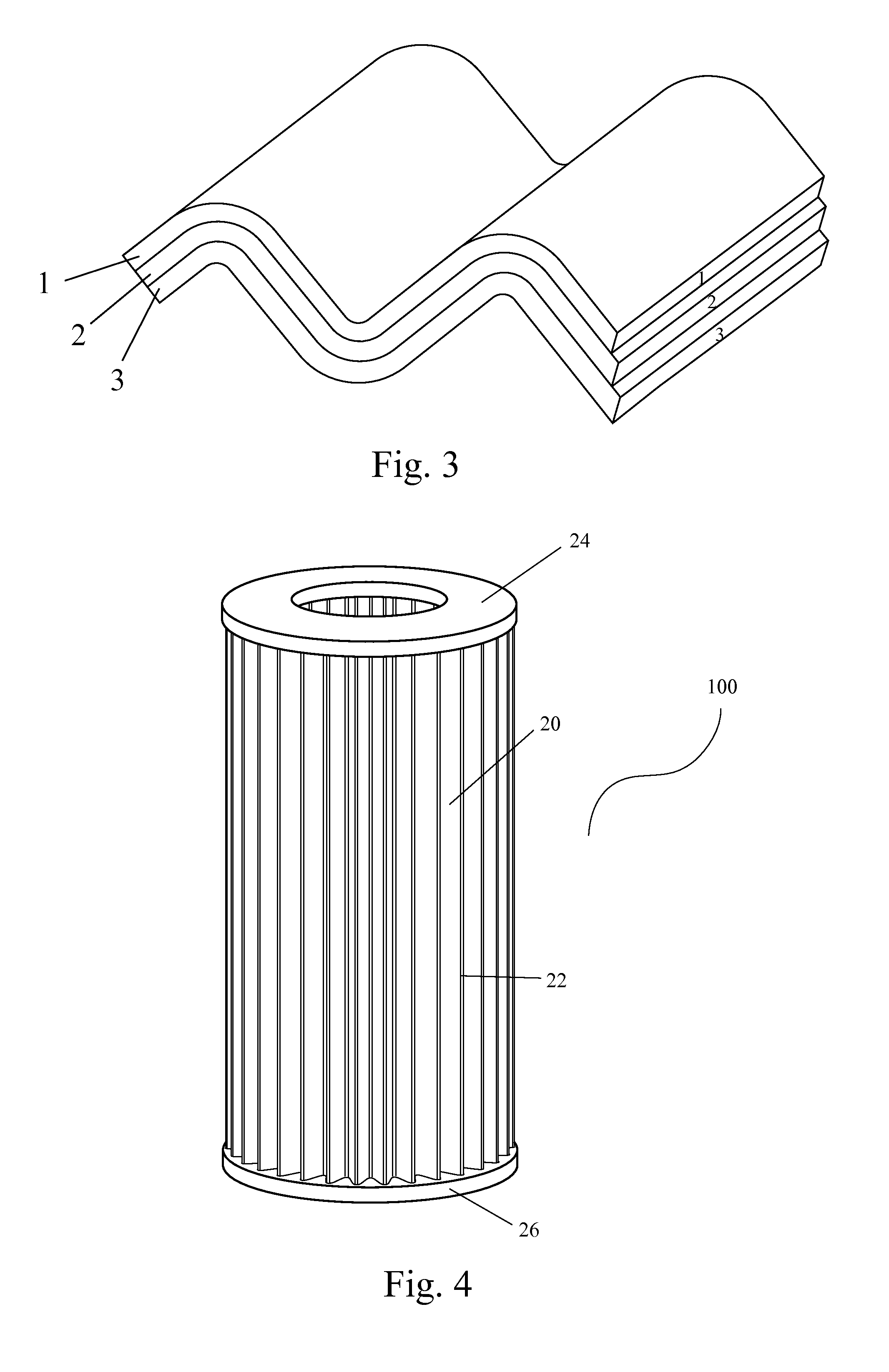

The present invention provides a novel nonwoven felt fabric, which is made of at least one low-melting-point short fiber and at least one high-melting-point short fiber of same type or different types, wherein the fabric is stiff enough to be self-sustaining and have the ability of shape maintenance. The felt fabric exhibits excellent pleatability, moldability and compressive strength. The invention also provides a method for producing the felt fabric, and a filter comprising the felt fabric used as the material of a filter medium of the filter, wherein the filter medium requires no support structure to stand alone and persistently retains its shape.

Owner:FAIRTECH INVESTMENT

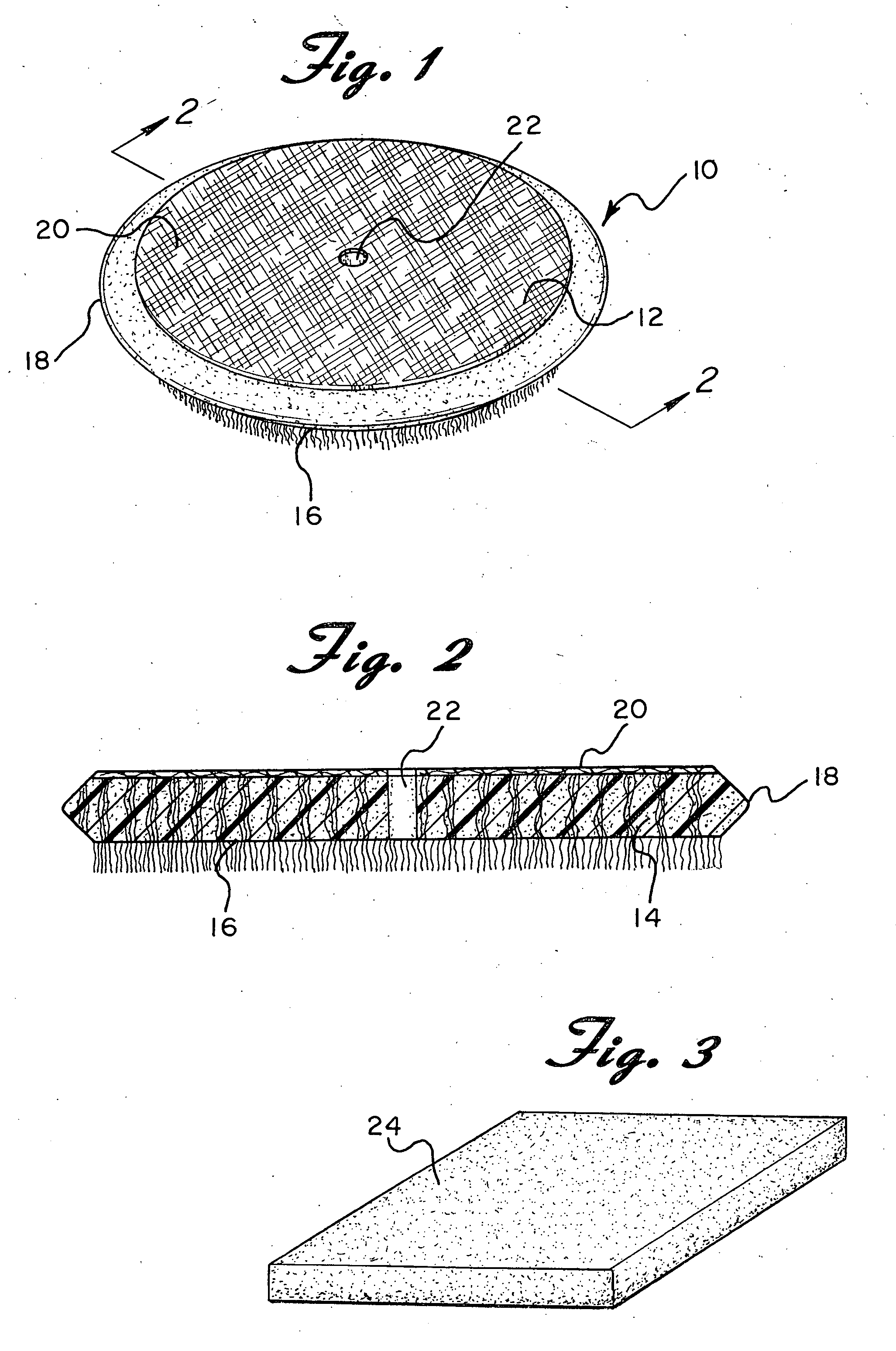

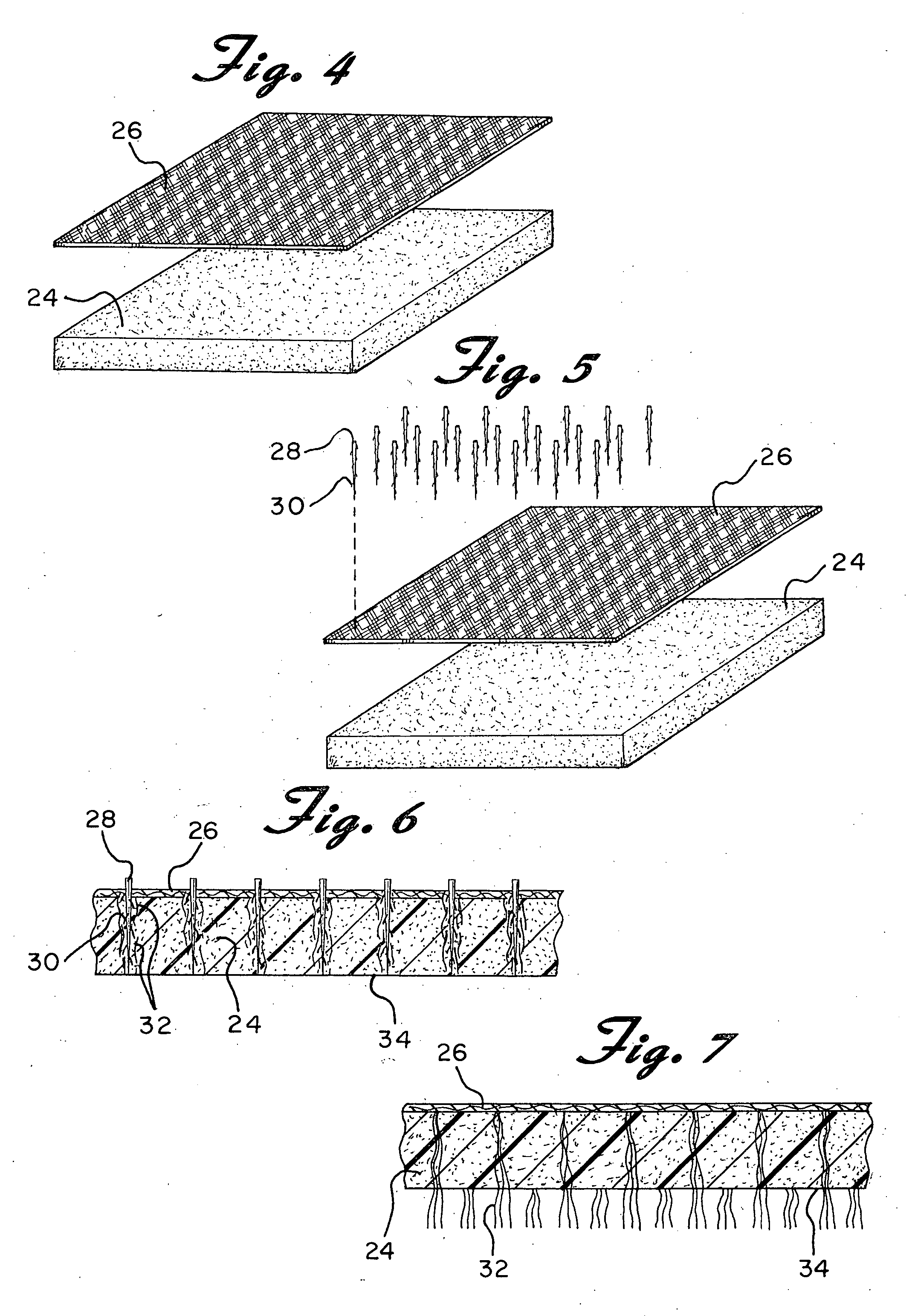

Hybrid fiber-foam buffing pad

InactiveUS20060107482A1Increase speedLiquid surface applicatorsSuction cleanersNeedle penetrationEngineering

A buffing pad primarily for automobiles includes a foam layer and filaments of textile material interspersed throughout the foam layer and extending passed or exposed at the working surface of the pad. The filaments are needle punched through the foam layer. The filaments may be felt fiber such as wool fiber, cotton fiber, or the like.

Owner:3M INNOVATIVE PROPERTIES CO

Method and device for processing fabric surface functionality

ActiveCN102828368AEffective control of permeabilityEffective control of suction volumeLiquid/gas/vapor textile treatmentTextile treatment rollersSprayerCombined method

The invention provides a method and a device for processing fabric surface functionality. According to the method and the device, a diluted surface treatment solution is sprayed on the front face and the back face of the fabric by means of a special device by using a spraying and rolling combined method; the special device comprises a fabric conveying roller, a winding roller, a pair of extruding roller, and a plurality of sprayers arranged on and below the extruding rollers; a layer of hair felt or cellulose needled felt, which has excellent hygroscopicity or capillary core absorbing function and is capable of absorbing and maintaining a certain amount of diluted surface treatment liquid, is coated on the surface of each extruding roller; the fabrics run through the extruding rollers in an open-width status. By controlling the fabric speed, the spraying amount and the pressure of the extruding rollers, the surface treatment liquid is enabled to permeate into the front face and the back face of the fabric under the control. The fabrics processed by the method provided by the invention are unlikely to harden after being dried, and the original softness, the air permeability and the hygroscopicity of the fabrics can be held.

Owner:SUZHOU VOCATIONAL UNIV

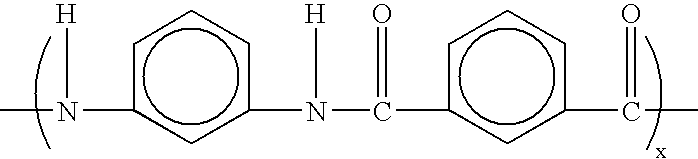

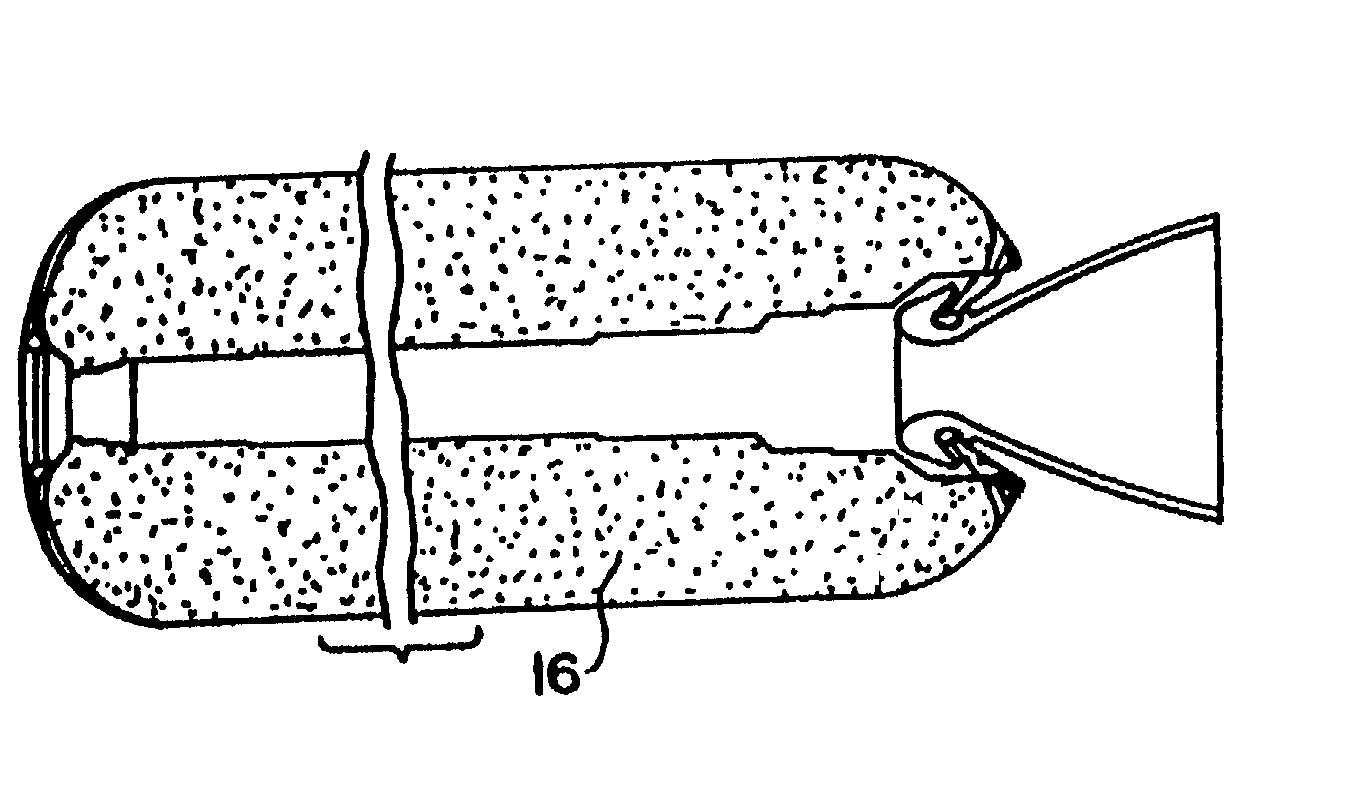

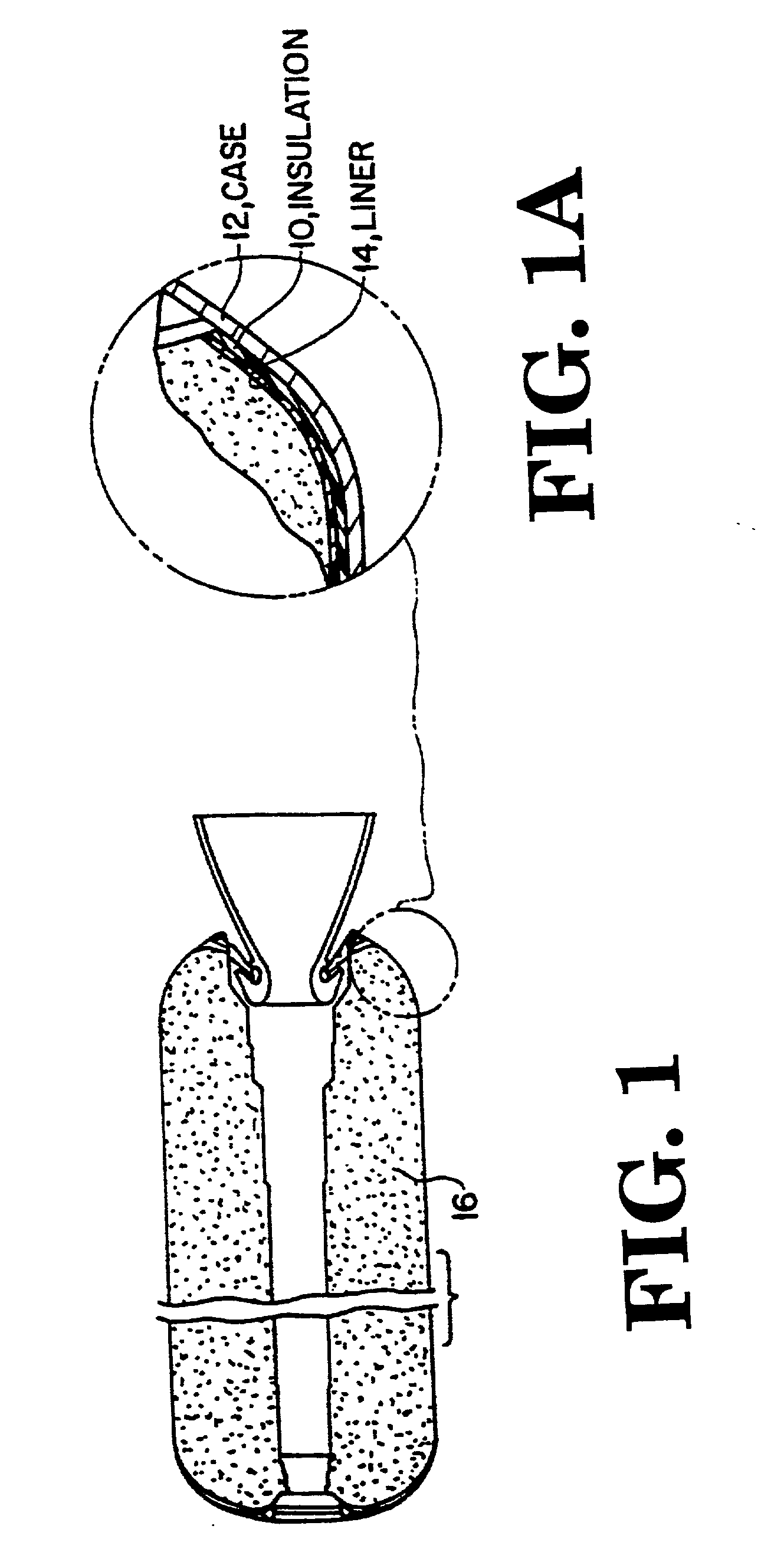

Rocket assembly ablative materials, and method for insulating or thermally protecting a rocket assembly

InactiveUS20030200656A1Reduce processing timeReduces production expenseCosmonautic vehiclesWriting implementsYarnAramides

A rocket motor ablative material (e.g., an insulation liner, bulk material, or the like) of this invention is formed from, as a precursor of the carbon reinforcement structure, one or more polyarylamides configured as a suitable reinforcing structure, such as a yarn, flock, and / or felt. Aramid yarns can be prepared by twisting / spinning aramid filaments, and / or by carding and yarn-spinning staple aramid fibers. In particular, the insulation may be used, for example, for a rocket motor nozzle or as a rocket motor heat shield subjected to conditions comparable to those of continuous filament viscose rayon.

Owner:ORBITAL ATK INC

Sheath-core type low-melting-point copolyamide composite fiber and preparation method thereof

InactiveCN104894686AHigh tensile strengthImprove tear resistanceArtificial thread manufacturing machinesFilament/thread formingPolymer sciencePolyolefin

The invention relates to a sheath-core type low-melting-point copolyamide composite fiber and a preparation method thereof. The sheath of the composite fiber is copolyamide, the core is polyolefin, the melting point of the sheath ranges from 90 DEG C to 130 DEG C, the melting point of the core ranges from 130 DEG C to 190 DEG C, the breaking strength is in a range of 1.8-3.4 cN / dtex, and the elongation at break is in a range of 50%-90%. The preparation method of the composite fiber comprises steps as follows: copolyamide slices and polyolefin slices are dried and molten respectively and then ejected by a same composite assembly to form filaments, and the composite fiber is prepared through cooling, oiling, draft setting and winding into rolls. The sheath can be molten at the lower temperature through heat setting or ironing and plays a role in bonding and fixing the fiber, and the core is the polyolefin and can keep certain strength and flexibility at the temperature; compared with single-component low-melting-point fibers, the fiber has the advantages that the core is the polyolefin, the production cost can be reduced, and the economic benefit can be increased. The composite fiber can be applied to shoe upper fabric, felt, curtain fabric, garment cuffs and collars, the paper industry, automobile interiors and the like.

Owner:CTA HIGH TECH FIBER +2

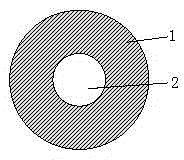

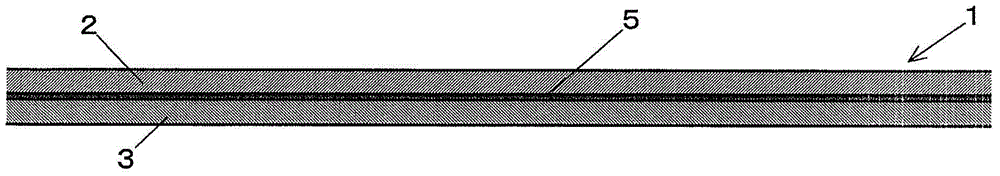

Lightweight felt material

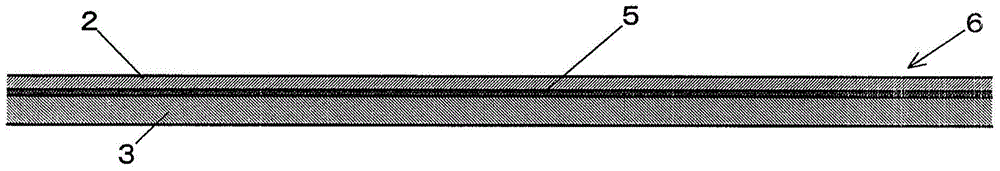

This invention addresses the problem of providing a lightweight felt material that is soft, highly sound-absorbent and flame-retardant, and suitable as an interior material for an automobile or other vehicle, industrial material, clothing material, or another such material. This lightweight felt material (1) has a nonwoven sheet (5) interposed between two hard cotton layers (2, 3) so as to integrate the overall material, wherein: 20-80% of an ultrafine fiber having a fineness of 1.1 dtex or less, 10-60% of a hollow fiber for imparting bulkiness, and 10-60% of a low-melting-point fiber which melts when the overall material is thermally treated are fiber-blended in each of the two hard cotton layers (2, 3); and the nonwoven sheet (5) has a fiber diameter of 2-20 μm and a basis weight of 20-100 g / m2.

Owner:株式会社富士工

Felt for forming fiber cement articles having stretch-resistant yarns

InactiveUS20070155272A1Improved stretch-resistance and tenacityCeramic shaping apparatusConstructions elementsYarnFelted

A fiber cement felt includes: a base fabric including a set of machine direction (MD) yarns and a set of cross machine direction (CMD) yarns interwoven with the MD yarns in a plurality of repeat units, wherein between about 5 and 95 percent of the MD yarns are stretch-resistant yarns; and a batt layer overlying and attached to the fabric. A fiber cement felt of this configuration can exhibit improved stretch-resistance and tenacity.

Owner:WEAVEXX

Noise-absorbing heat-insulating flame-proof compound material for automobile as well as technique and method for producing the same

InactiveCN101376275AImprove insulation performanceGood noise prevention and sound insulation effectLamination ancillary operationsLaminationAdhesiveWhole body

The invention provides a sound-absorption heat-insulation flame-retardant composite material used for a vehicle. The material comprises rubber, felt, non-woven fabric and aluminum foil. The rubber, the felt, the non-woven fabric and the aluminum foil are combined as a whole body by bonding and pressing at a high temperature in sequence. The manufacturing process comprises the following steps: firstly bonding the rubber, the felt and the non-woven fabric in sequence through a wood glue adhesive, then conducing the pressing at the high temperature, and pressing and shaping with the aluminum foil at the high temperature. The main control conditions are as follows: (1) material thickness: the thickness of the rubber is 1 to 3mm, the thickness of the felt is 12-18mm, the thickness of the non-woven fabric is 1-2.5mm, and the thickness of the aluminum foil is 0.6-1.0mm; and (2) the control indexes of high temperature pressing: the temperature of an upper plate of the mould is 140 DEG C to 220 DEG C, the temperature of a lower plate of the mould is 130 DEG C to 190 DEGC, the pressure of a main cylinder is 16MPa, the control pressure is 4-6MPa, the slide stroke is 320-360mm, the holding time is 190-290s, the decompression time is 1.5-2.5s, and the whole shaping period is 300-450s.

Owner:吴全强

High temperature-resistant felt and making method thereof

InactiveCN101275364AAvoid the disadvantage of easy separationReduce abnormal wear and tearTextiles and paperEngineeringWear resistance

The invention discloses a high temperature resistant carded felt and manufacturing method thereof, wherein, the high temperature resistant carded felt is composed of a basal layer, and a working layer which is formed by needling and combining multiple layer of base cloth fabric nets, the base cloth fabric net includes base cloth, and the surface of the base cloth is needled with a fabric net. The manufacturing method of the high temperature resistant carded felt includes the following steps: 1 manufacturing base cloth; 2 manufacturing a fabric net; 3 needling the fabric net onto the surface of the base cloth using needling mechanical or felting needle, to form a base cloth fabric net; 4 integrally compounding the base cloth fabric net with a ring shaped nonwoven needling technique, selecting a plurality of layers of base cloth fabric net according to the required thickness of the carded felt to complete the needling and combining molding on the basal layer; 5 using the mechanism and mold to manufacture the base cloth fabric net carded felt formed by needling and combining into the high temperature resistant carded felt. The inventive high temperature resistant carded felt has advantages of good antifriction property, low cost and environment protection.

Owner:黄乐军

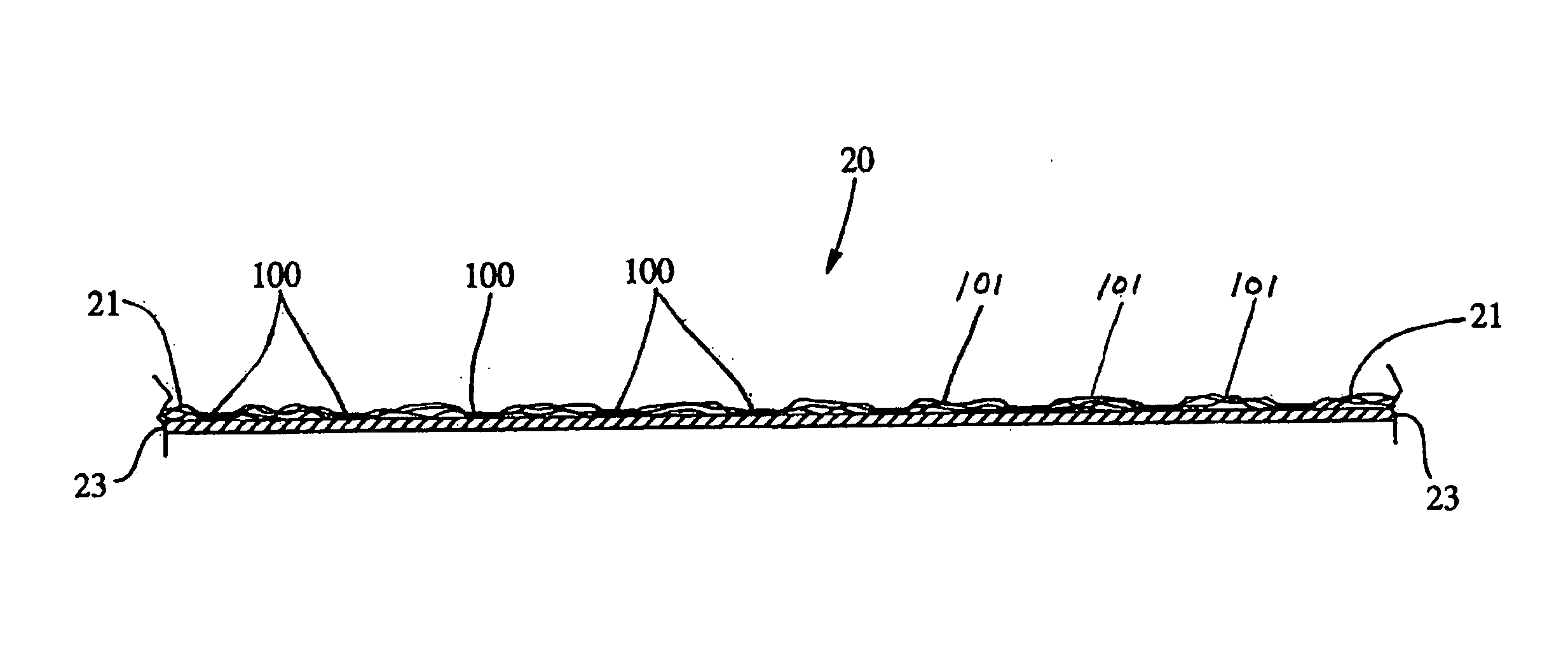

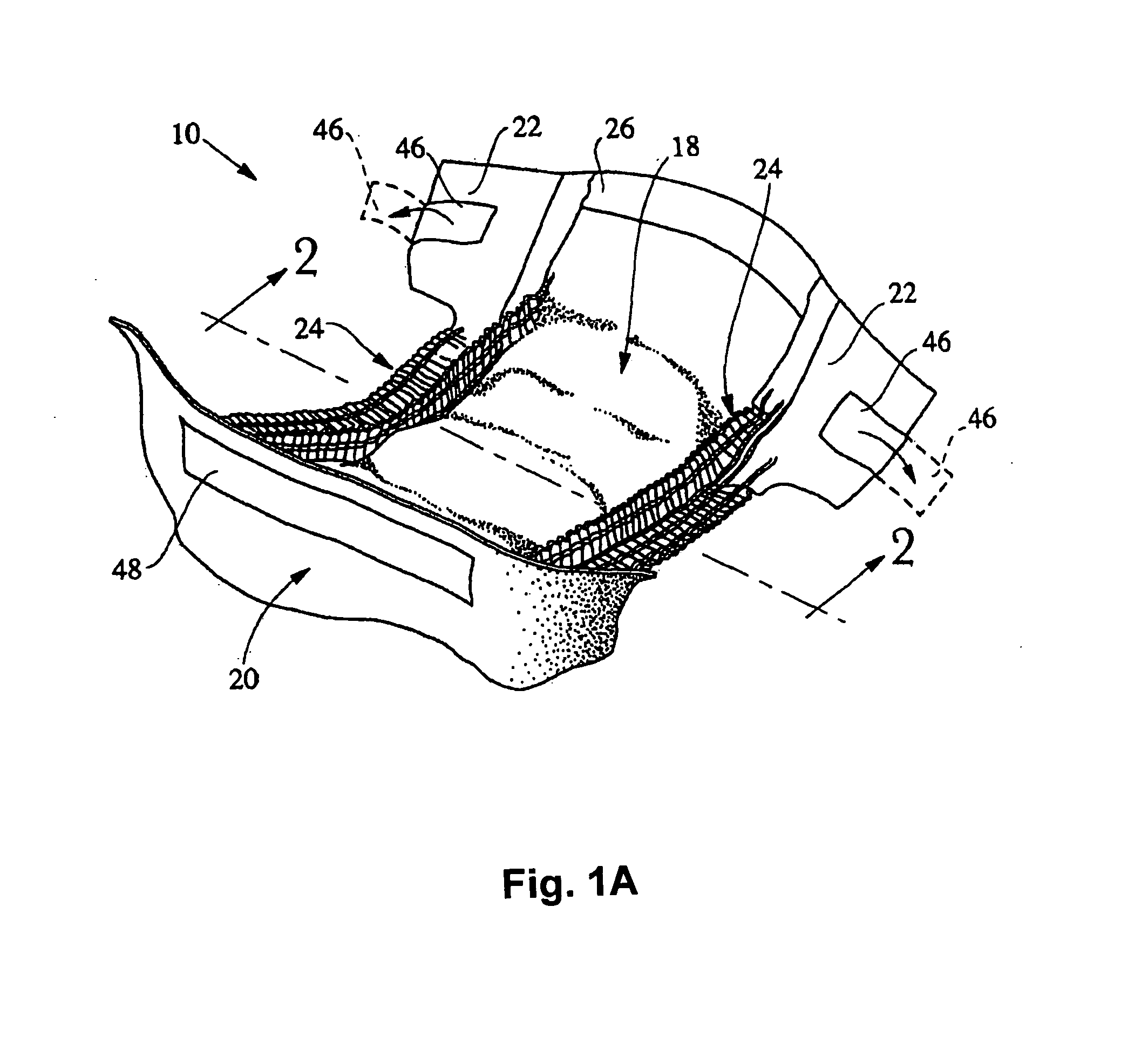

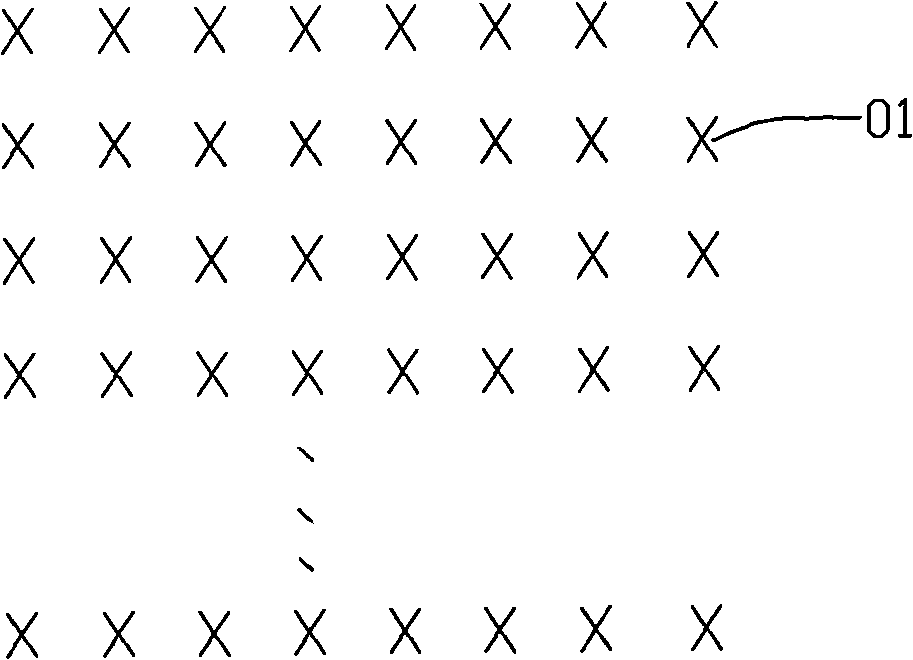

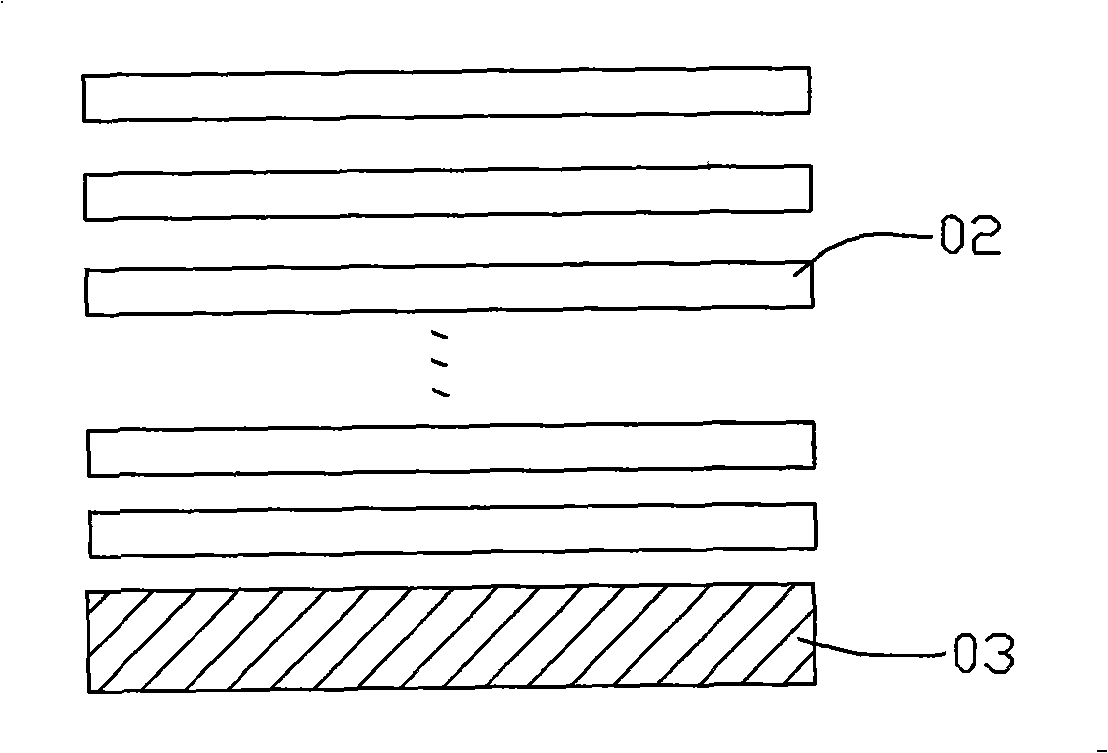

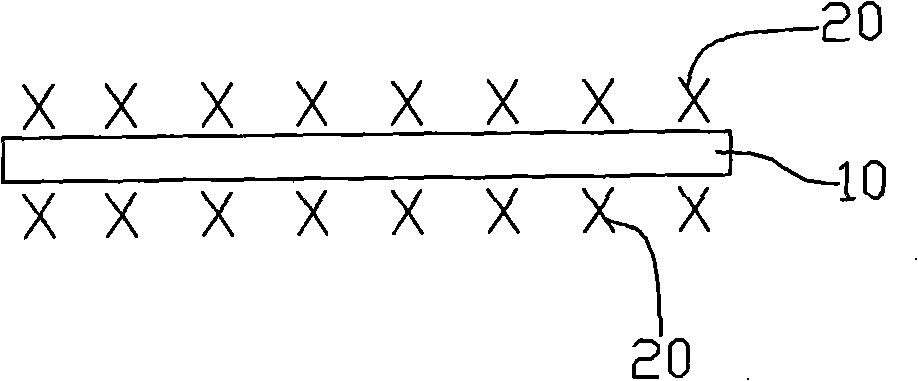

Light emitting tufted carpet

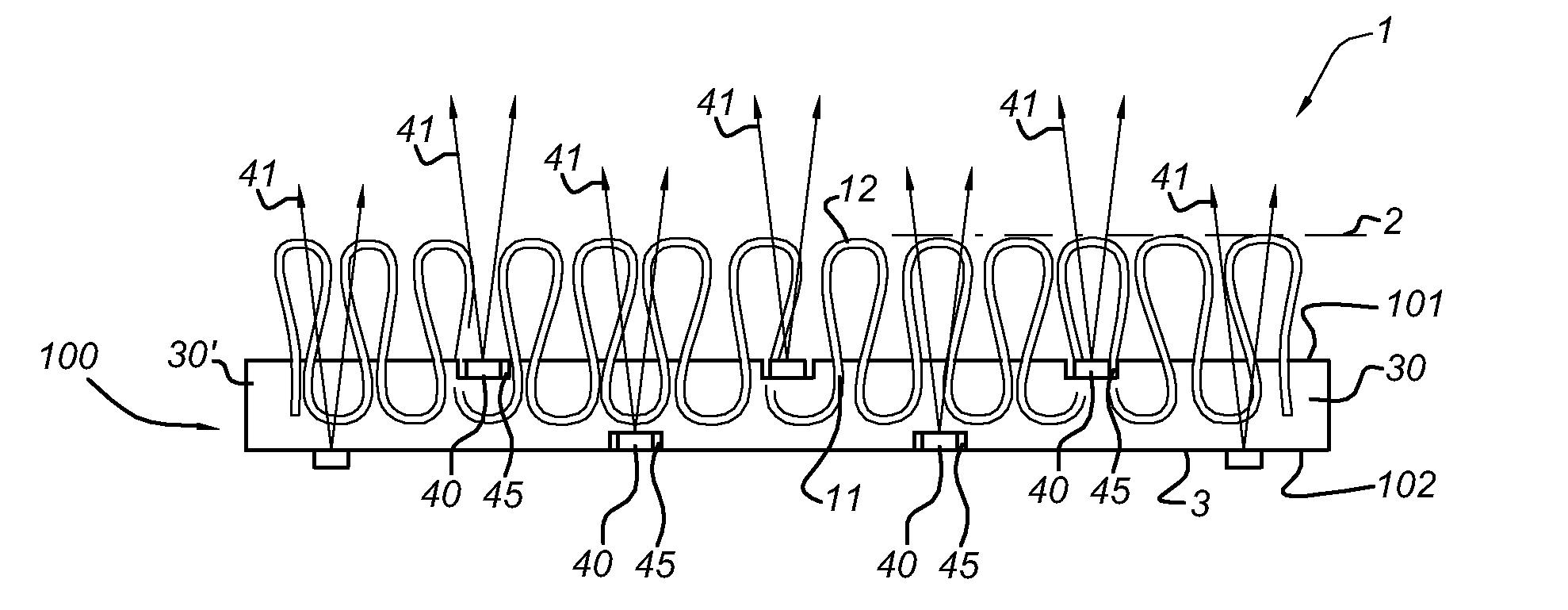

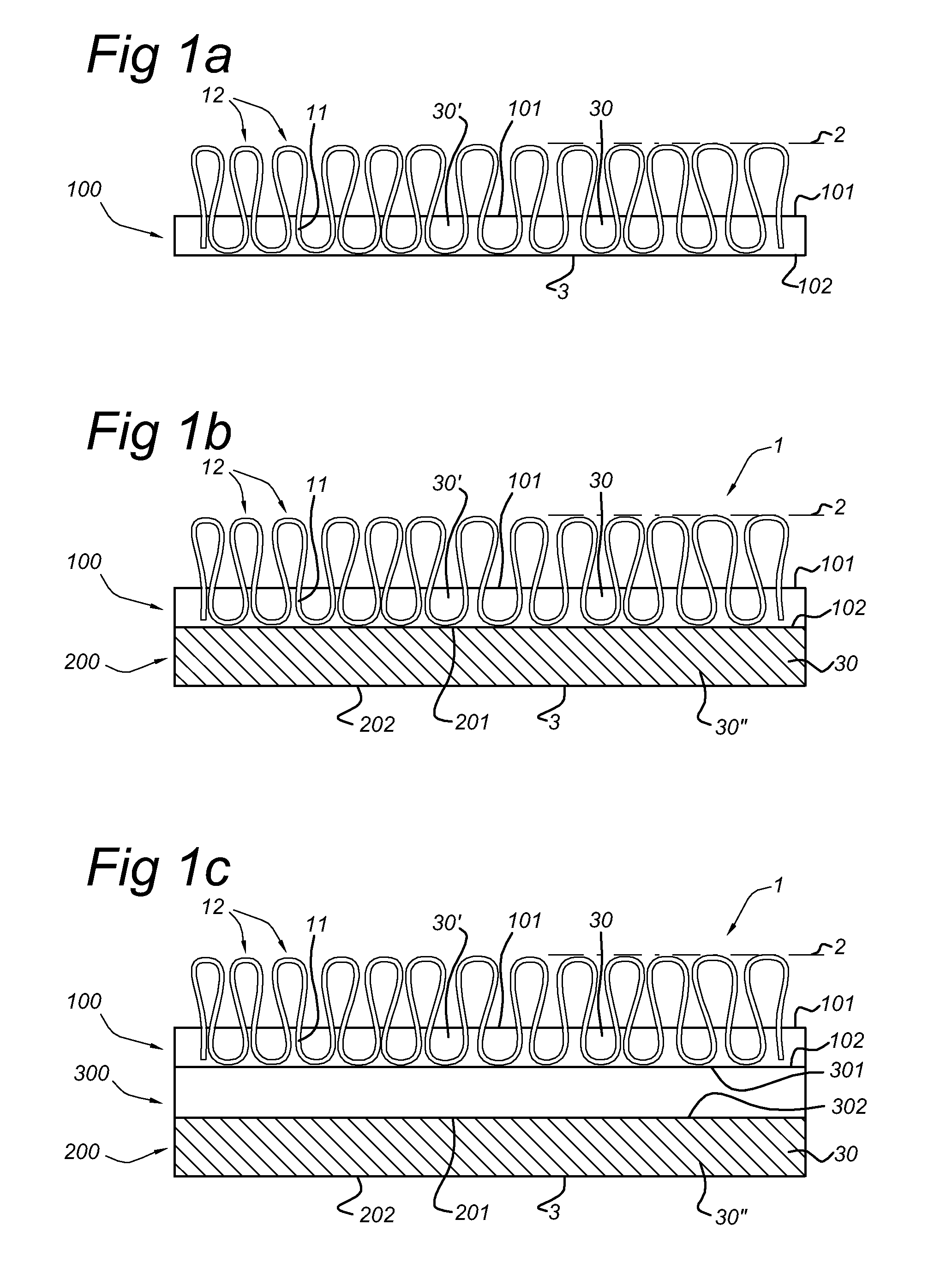

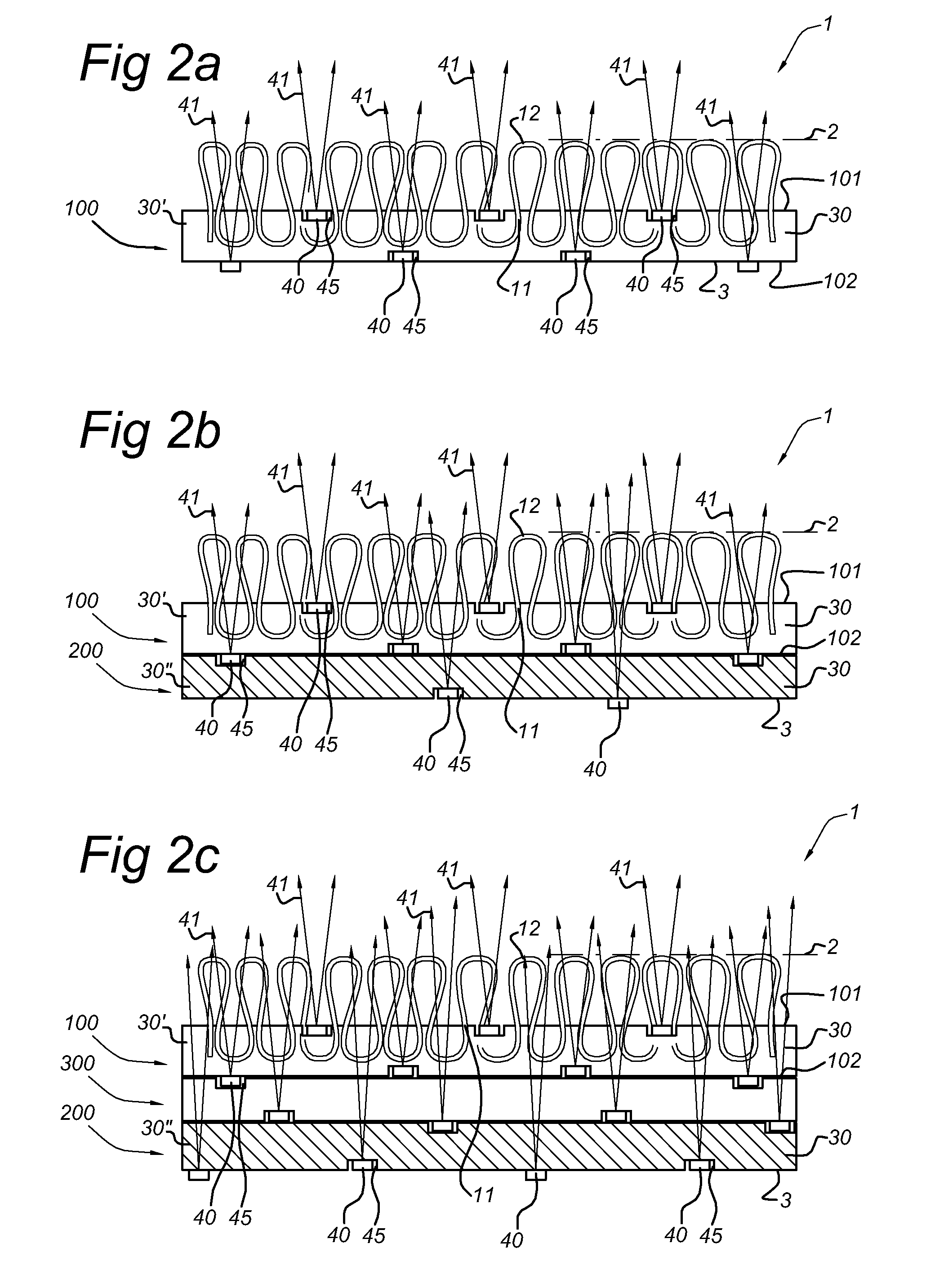

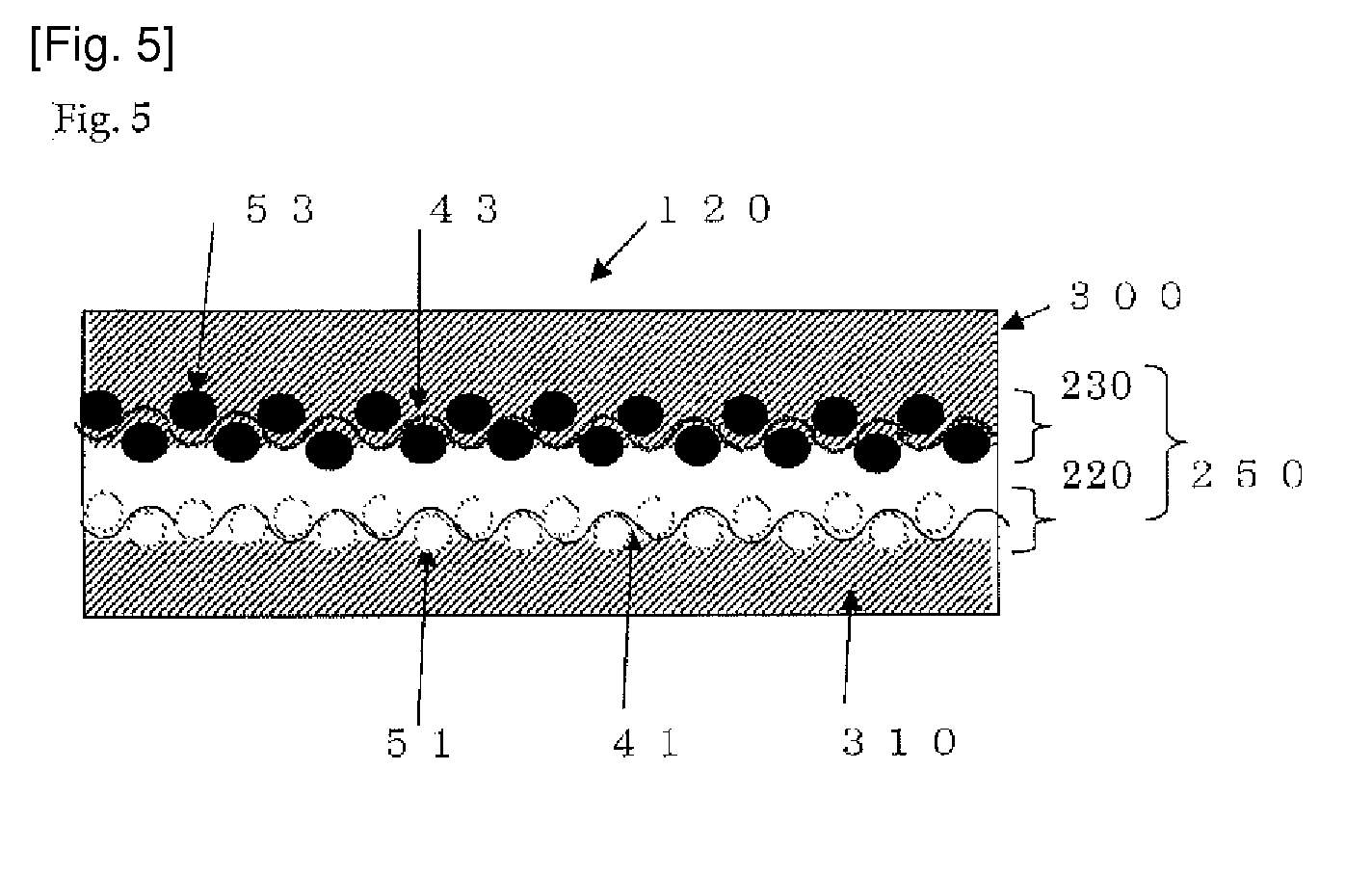

InactiveUS20100254141A1Provide strengthLow costCoupling device connectionsVehicle arrangementsEngineeringFelted

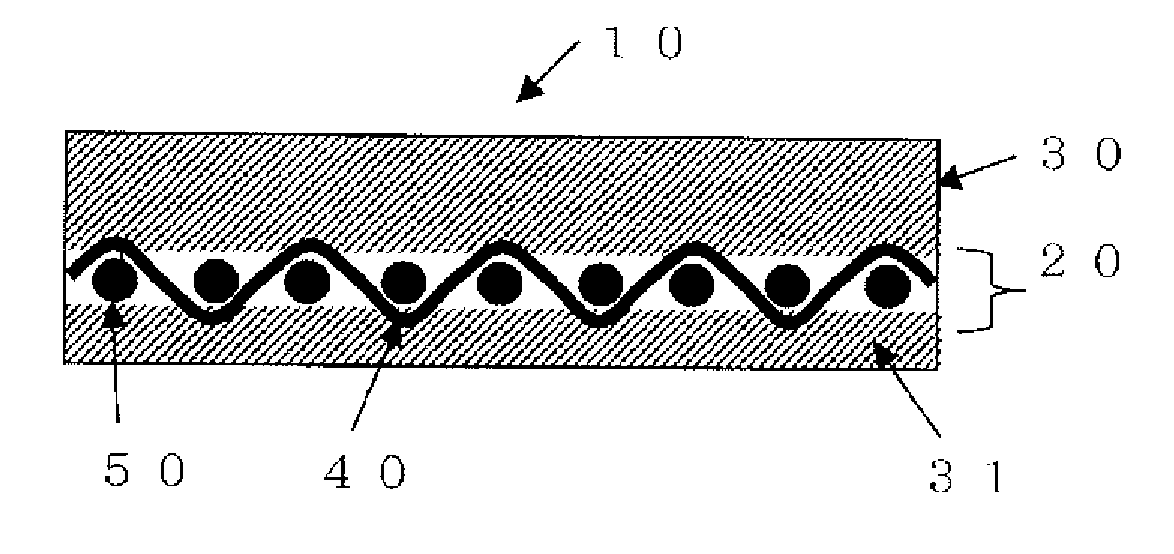

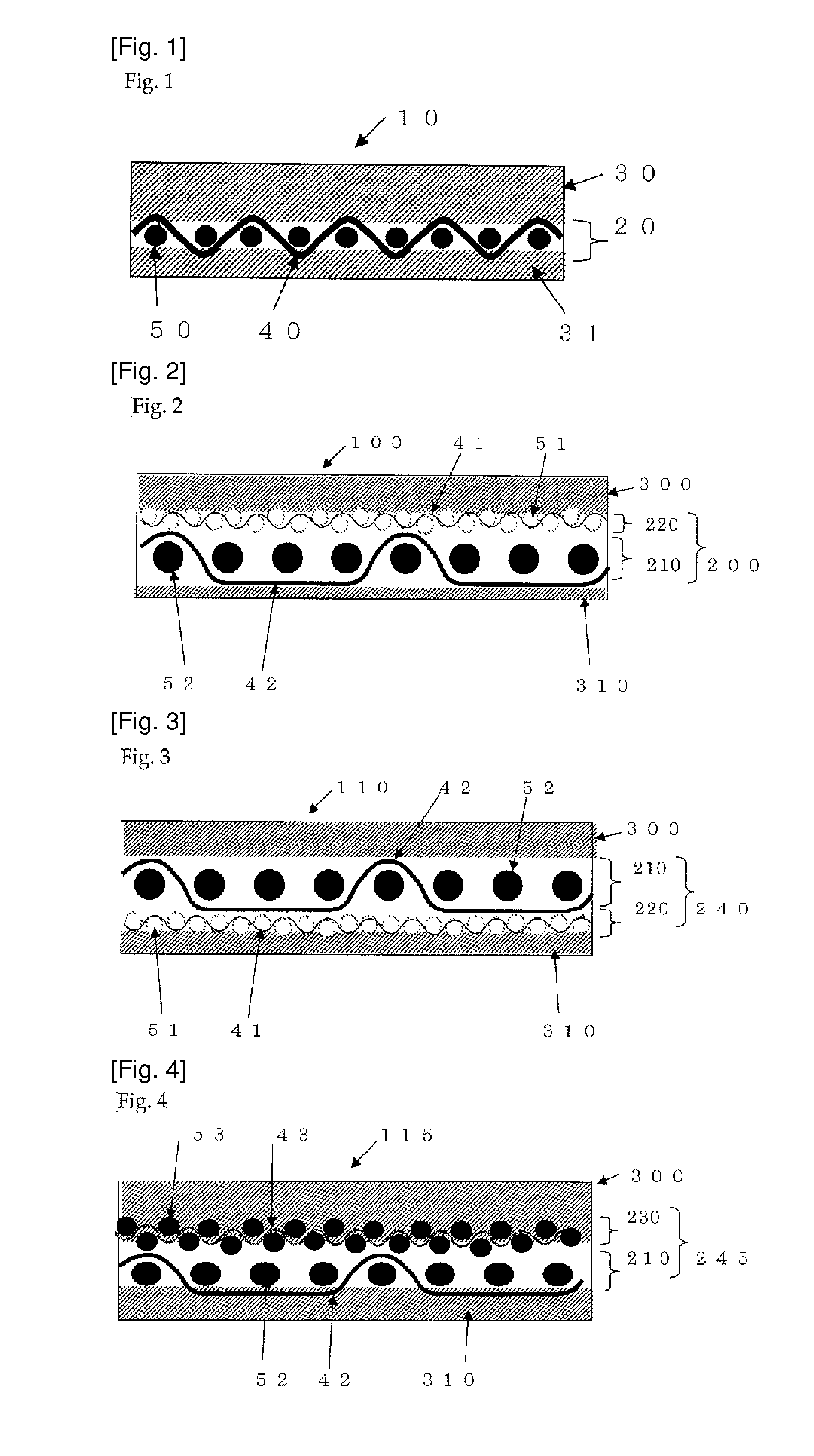

The invention provides a light emitting tufted carpet (1). The carpet (1) comprises a primary backing layer (100), an optional secondary backing layer (200), an optional adhesive layer (300), a plurality of carpet integrated LEDs (40) arranged to generate carpet light (41), and a first electric conductor (10) and a second electric conductor (20). The first electric conductor (10) and the second electric conductor (20) are arranged to provide power from a power source (50) to the LEDs (40). The primary backing layer (100) comprises a first felt layer (30′), or the optional secondary backing layer (200) comprises second felt layer (30″), or both the primary backing layer (100) and the optional secondary backing layer (200) comprise felt layers (30′,30″). One or more of the first electric conductor (10) and the second electric conductor (20) are at least partially integrated in one or more of the first felt layer (30′) and the second felt layer (30″).

Owner:SIGNIFY HLDG BV

Manufacturing method of novel negative-ion self-cleaning active carbon fiber

InactiveCN103846077AWith far infrared functionHigh Filtration AdsorptionPhysical/chemical process catalystsOther chemical processesYarnCarbon fibers

The invention discloses a manufacturing method of a novel negative-ion self-cleaning active carbon fiber. The manufacturing method comprises the following steps: adding nano titanium dioxide powder into common plant cellulose pulp; simultaneously, adding nano tourmaline powder bodies into the common plant cellulose pulp; weaving the pulp added with the titanium dioxide powder and the nano tourmaline powder bodies into long yarns or short yarns according to conventional process; weaving functional long yarns into plant cellulose cloth, and needling the short yarns into a felt or non-woven cloth form; and carrying out functional fiber carbonization and activated nano-pore opening treatment on the manufactured plant cellulose cloth and the felt or non-woven cloth, so as to obtain the novel nano active carbon fiber. The manufacturing method disclosed by the invention has the advantages that the novel active carbon fiber with the high filtering and absorption, a far-infrared function and capabilities of releasing negative ions and catalyzing and decomposing organisms adhered to the surface is obtained by adding the nano tourmaline powder bodies capable of generating the negative ions and the nano titanium dioxide powder with the photocatalytic action in the manufacturing process of the nano active carbon fiber.

Owner:VIOLET HOME TEXTILE TECH

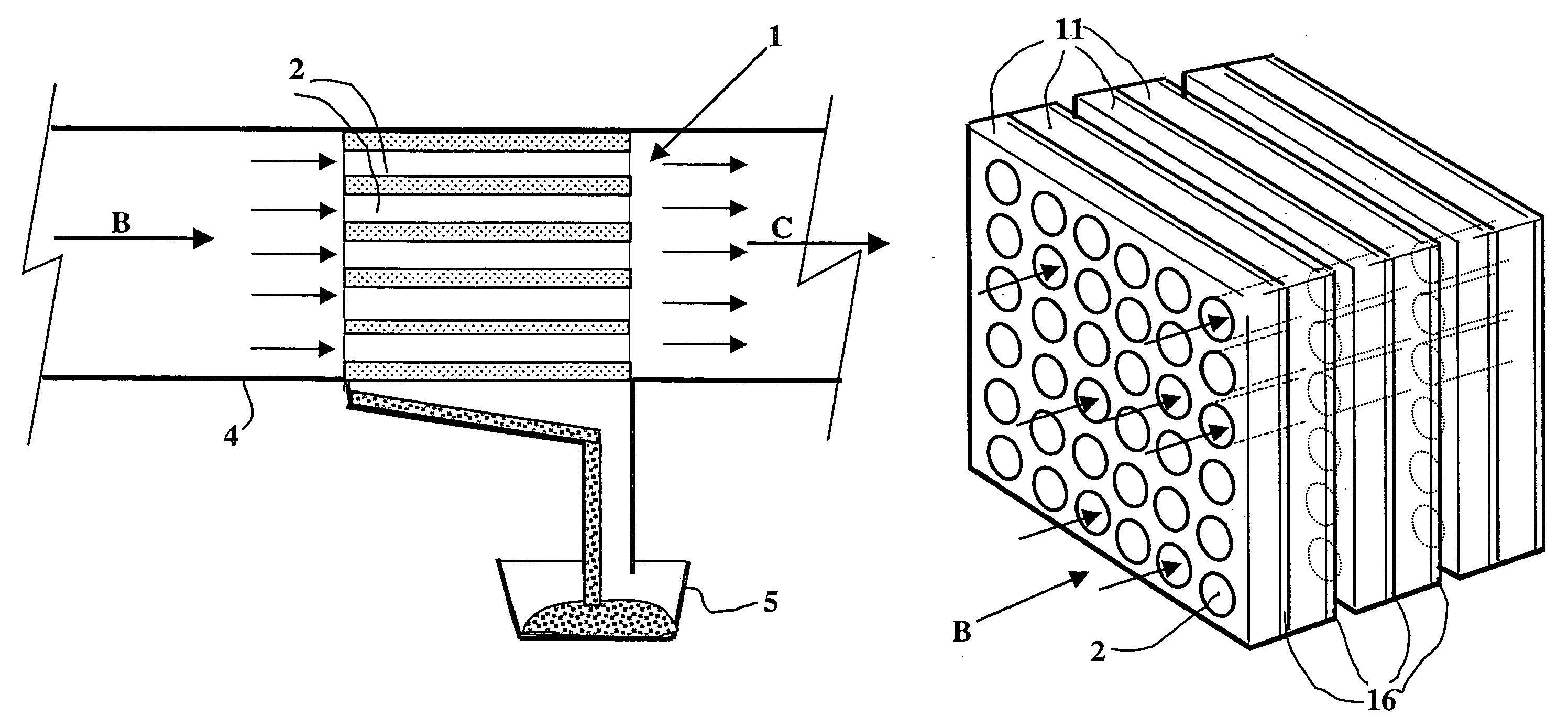

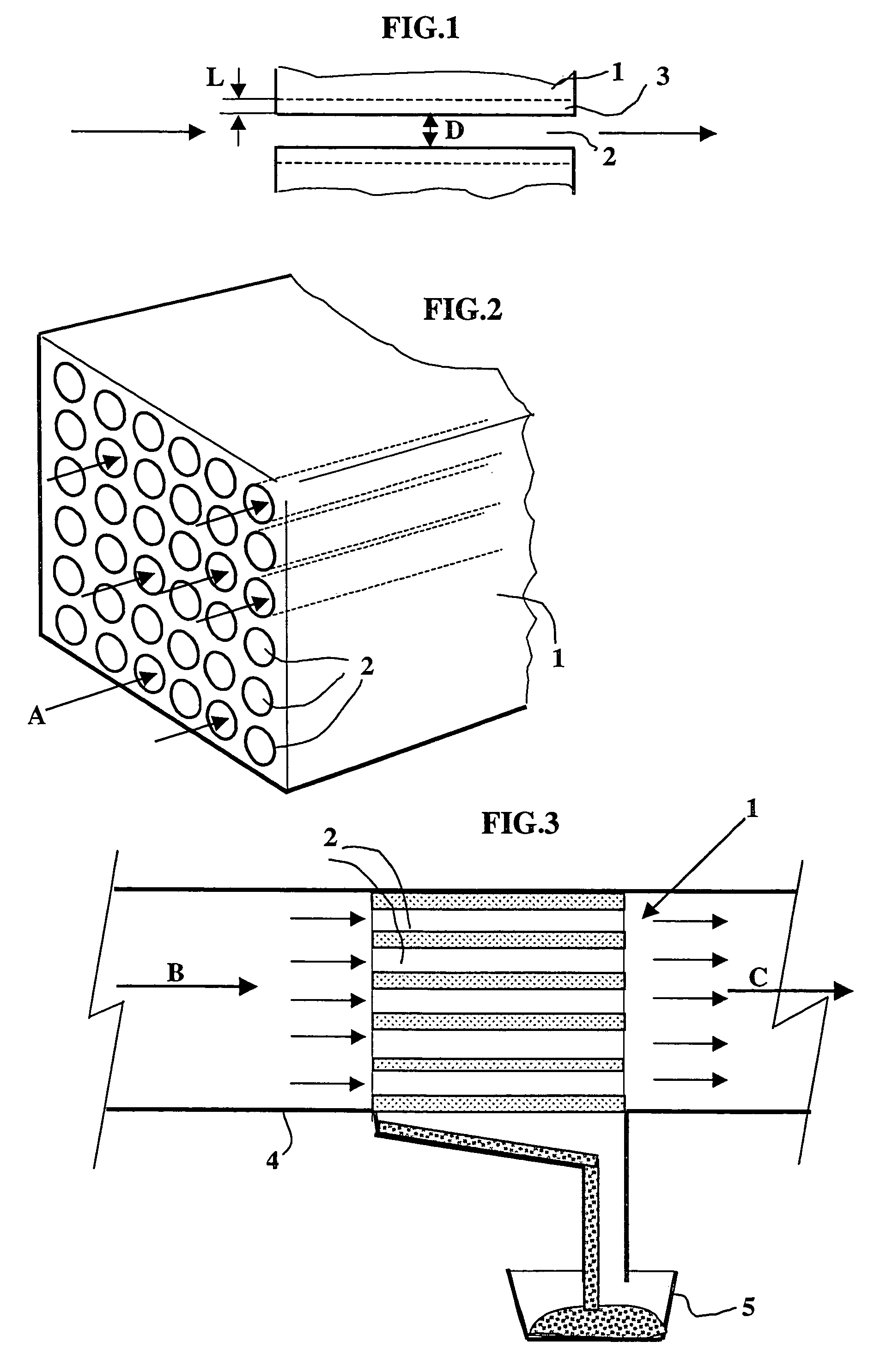

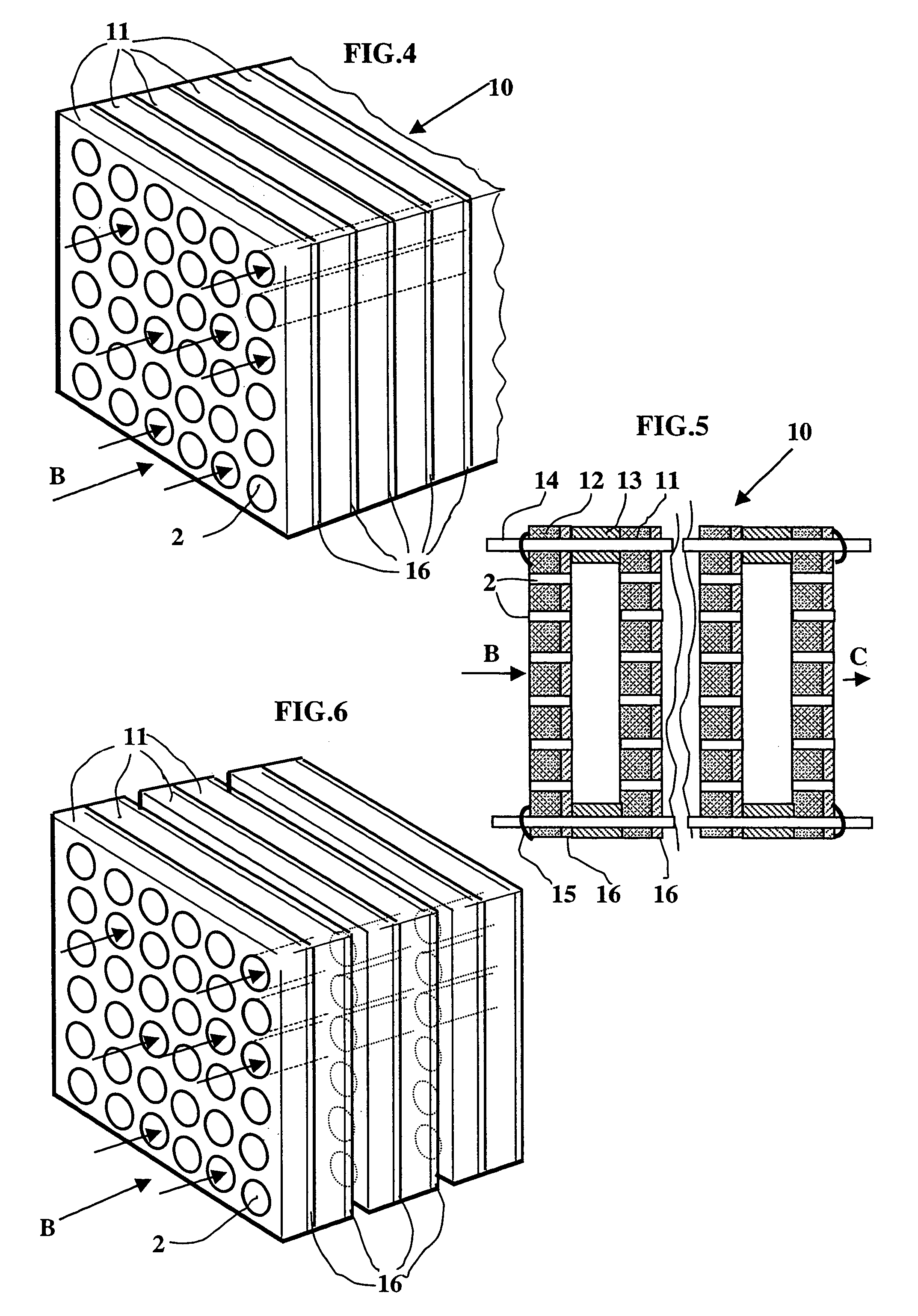

Separator made of a fibrous porous material such as a felt

A separator is made of a porous material and is intended to treat gaseous effluents which contain particles whose size is substantially less than one micrometer or of the order of one micrometer. The porous material includes channels. The channels are delimited by a fibrous porous material such as batting.

Owner:INST FR DU PETROLE +1

Papermaking felt

InactiveUS20110312239A1Increase resistanceImprove rendering capabilitiesLayered productsWoven fabricsYarnPapermaking

A papermaking felt which, in a papermaking machine, has good water squeezing capability (water permeability) and durability with regard to flattening and which also has excellent wet paper web smoothing properties and resistance to fiber loss. The papermaking felt is made by stacking and intertwiningly integrating by needling a substrate, a first batt fiber layer disposed on the wet paper web side of the substrate, and a second batt fiber layer disposed on the machine side of the substrate; wherein the substrate is made from a plurality of reinforcing materials, the reinforcing materials include a spunyarn, and due to the intertwining with a batt fiber layer, the spunyarn is integrated to such a degree that the yarn shape disappears.

Owner:ICHIKAWA ELECTRIC CO LTD

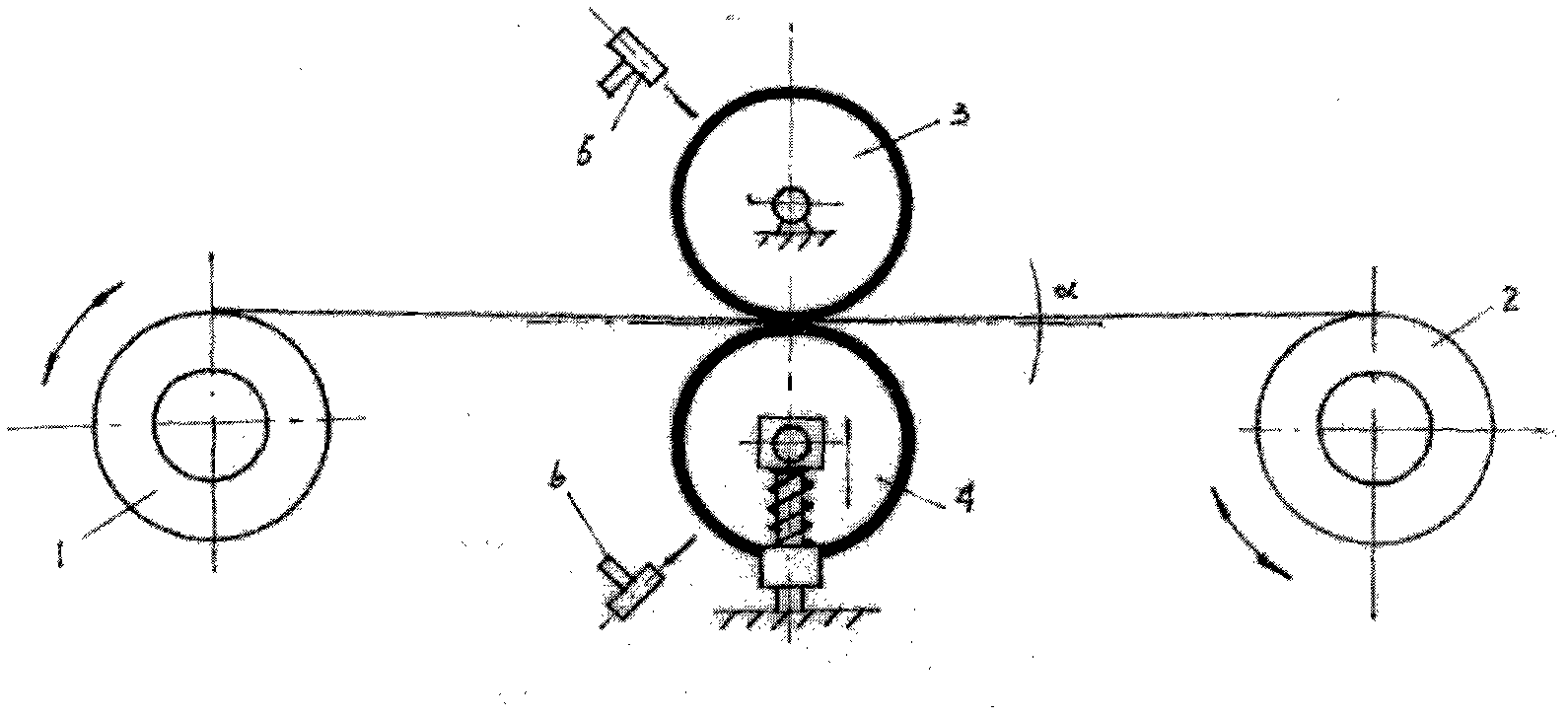

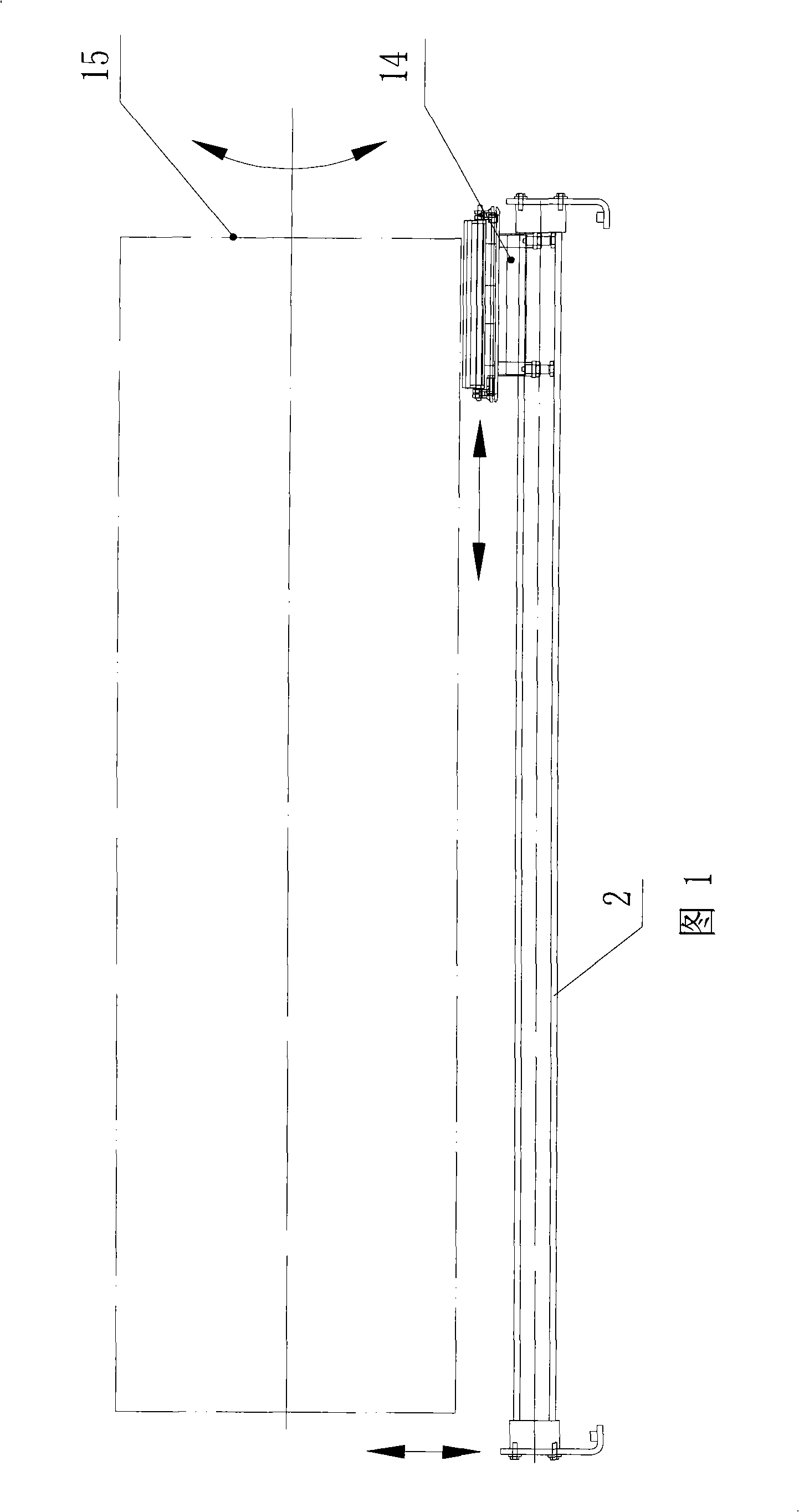

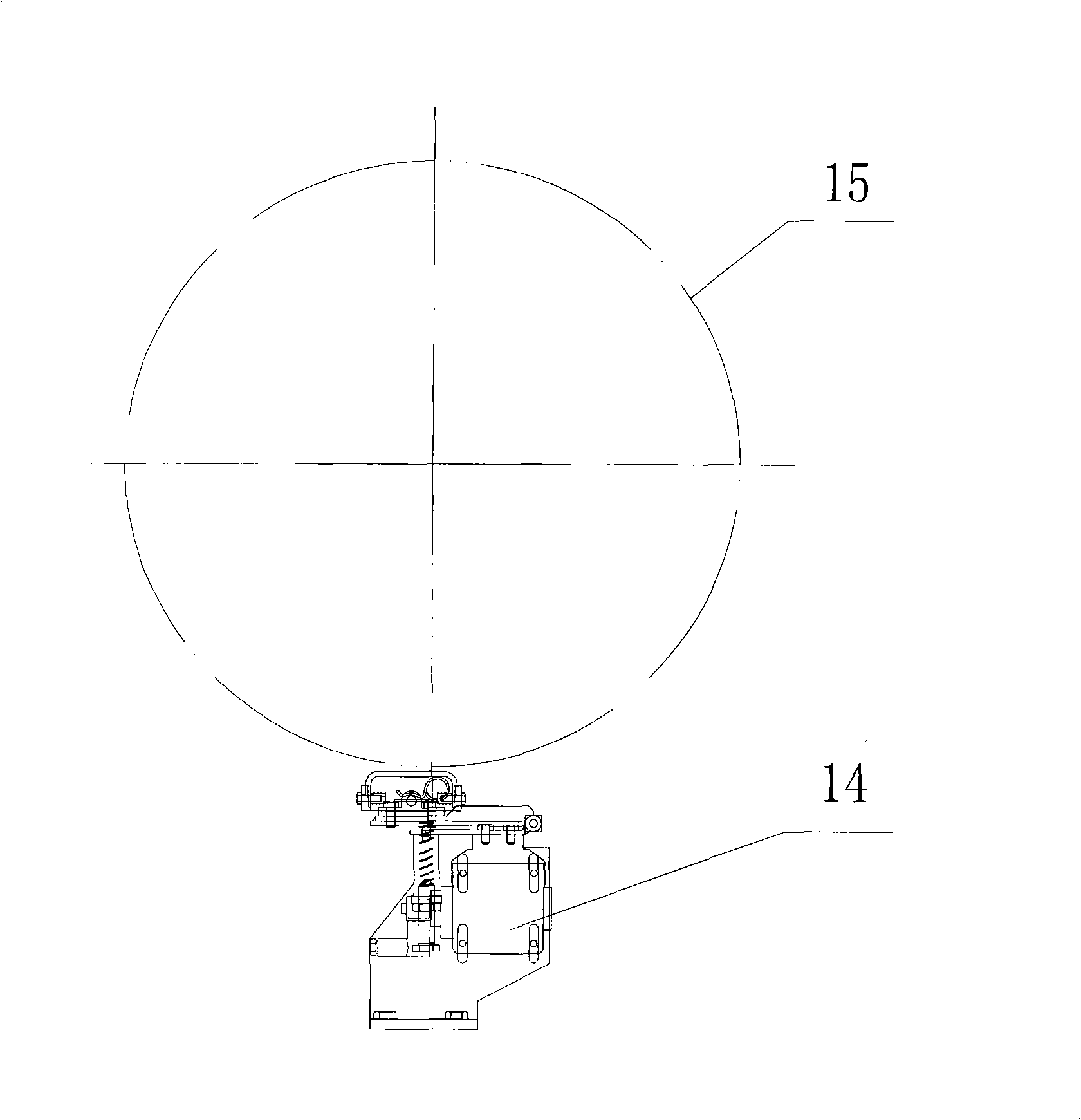

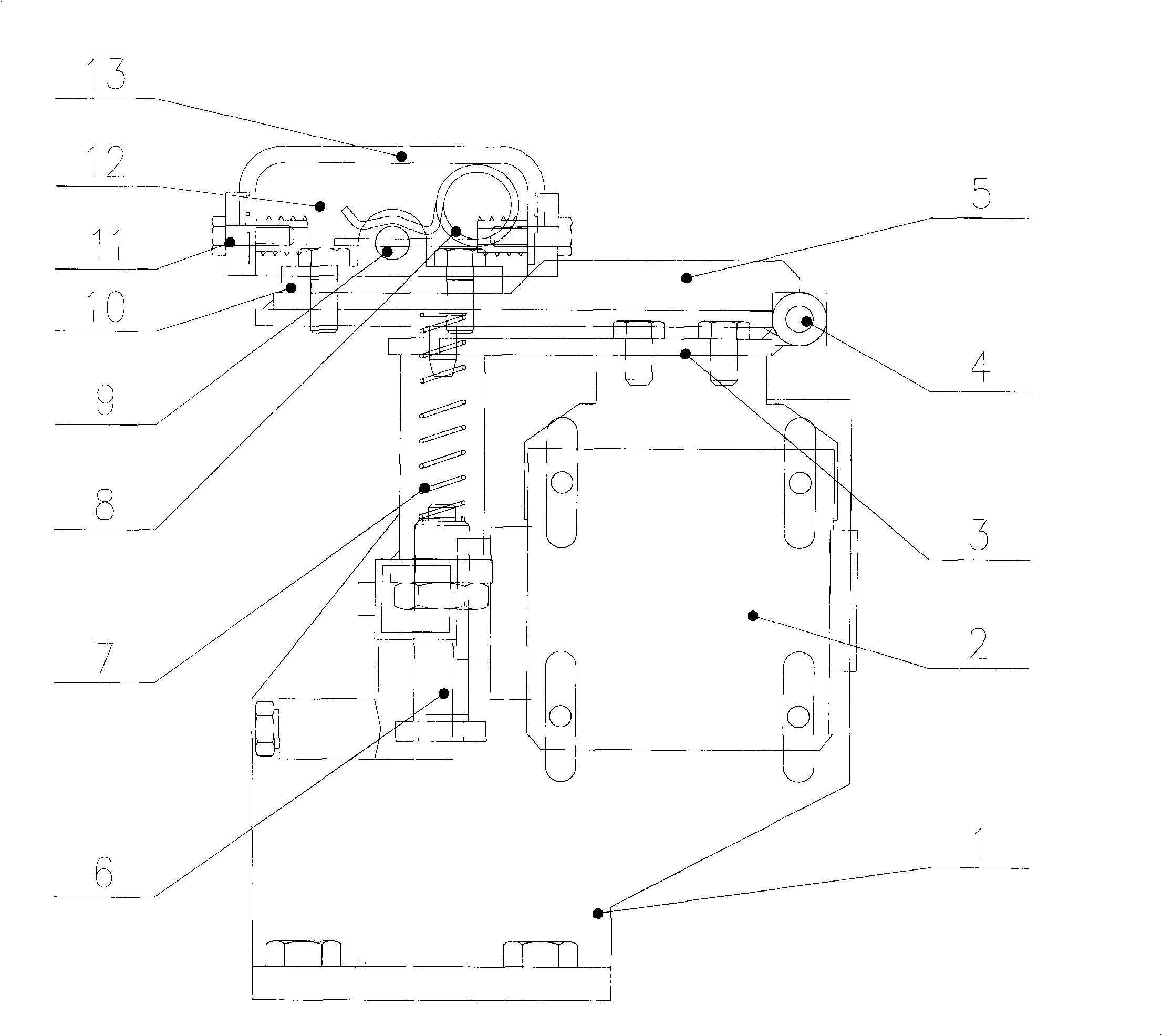

Roll surface cleaning method and device

InactiveCN101491805AEasy to cleanReduce labor intensityCleaning using toolsSurface cleaningReciprocating motion

The invention relates to a roll surface cleaning method and a device therefore, which are mainly applied to metal plate and strip production machine sets. The roll surface cleaning method is characterized by comprising that: a roll to be cleaned is compressed with a wiping clock of which the outside is covered with felt or non-woven fabrics (and the compression is realized by lifting the roll or swinging the wiping block); the roll begins to rotate; the felt or the non-woven fabrics reciprocates linearly under the driving of a transverse shift driving mechanism; and through the rotation of the roll and linear reciprocation of the felt and the non-woven fabrics, the felt or the non-woven fabrics can contact various positions on the roll surface so as to complete cleaning of the roll surface. The invention frees laborers from the production, uses machines to replace manpower, can effectively clean the roll surface, lighten labor intensity of workers, and improve work efficiency and product quality, and has high cleaning efficiency. The roll surface cleaning device has a simple and reliable structure.

Owner:WISDRI ENG & RES INC LTD

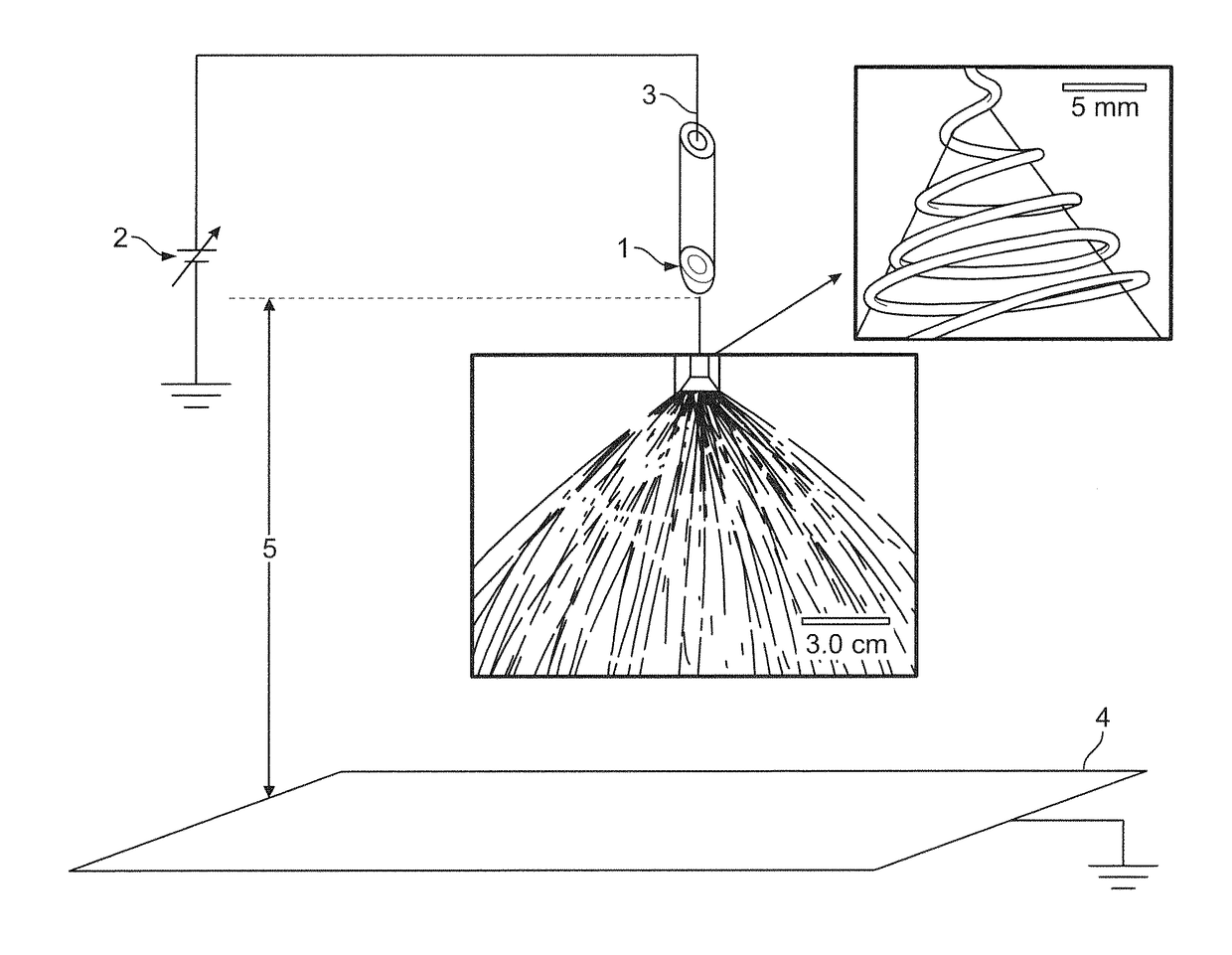

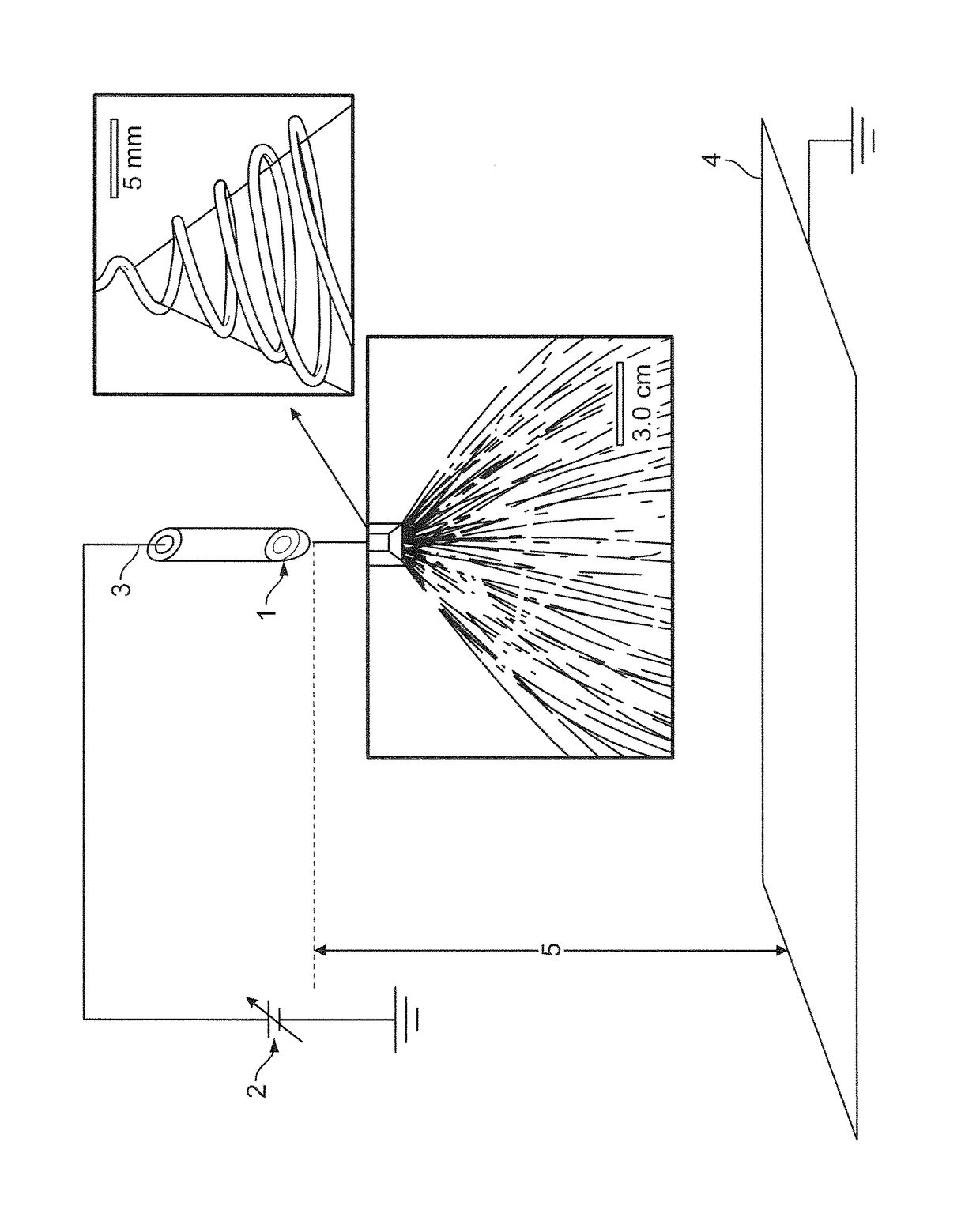

Hybrid felts of electrospun nanofibers

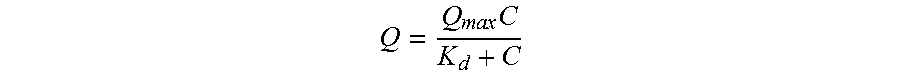

The present invention relates generally to compositions for use in biological and chemical separations, as well as other applications. More specifically, the present invention relates to hybrid felts fabricated from electrospun nanofibers with high permeance and high capacity. Such hybrid felts utilize derivatized cellulose, and at least one non-cellulose-based polymer that may be removed from the felt by subjecting it to moderately elevated temperatures and / or solvents capable of dissolving the non-cellulose-based polymer to leave behind a porous nanofiber felt having more uniform pore sizes and other enhanced properties when compared to single component nanofiber felts.

Owner:NANOPAREIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com