Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3979 results about "Tourmaline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tourmaline ( /ˈtʊərməlɪn/, -/iːn/ TOOR-mə-lin, -leen) is a crystalline boron silicate mineral compounded with elements such as aluminium, iron, magnesium, sodium, lithium, or potassium. Tourmaline is classified as a semi-precious stone and the gemstone comes in a wide variety of colors.

an air purifier

InactiveCN103861421BLarger than surface and uniformGood adsorption and decomposition effectOther chemical processesDispersed particle separationActivated carbonHazardous substance

Owner:QINGDAO CHUANSHAN NEW MATERIALS

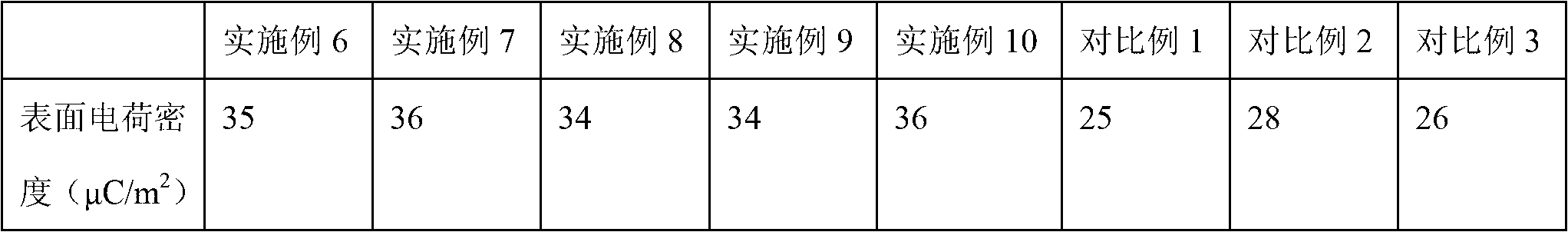

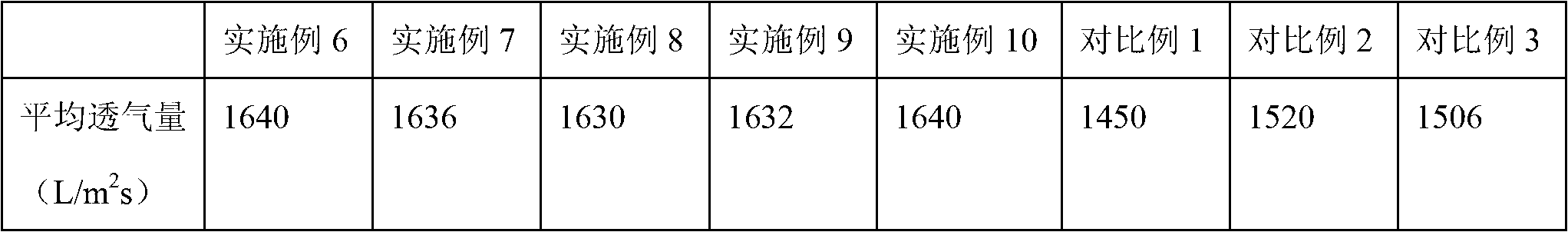

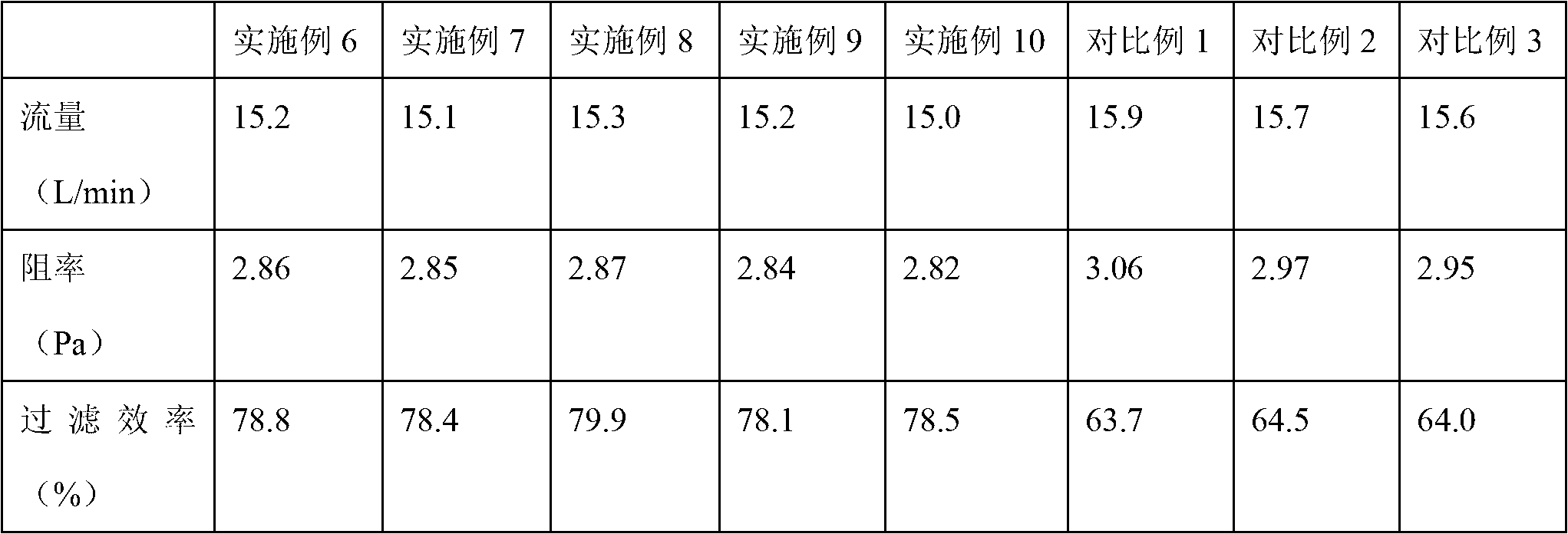

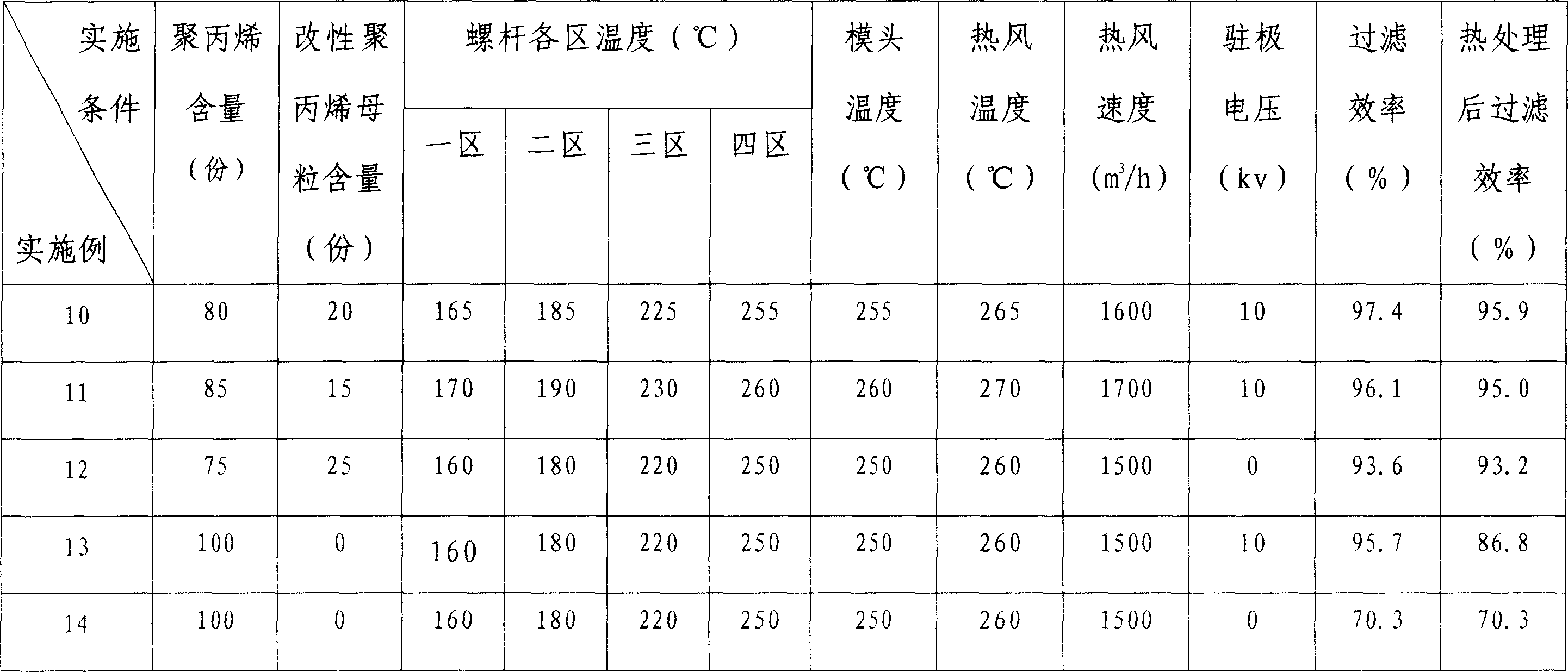

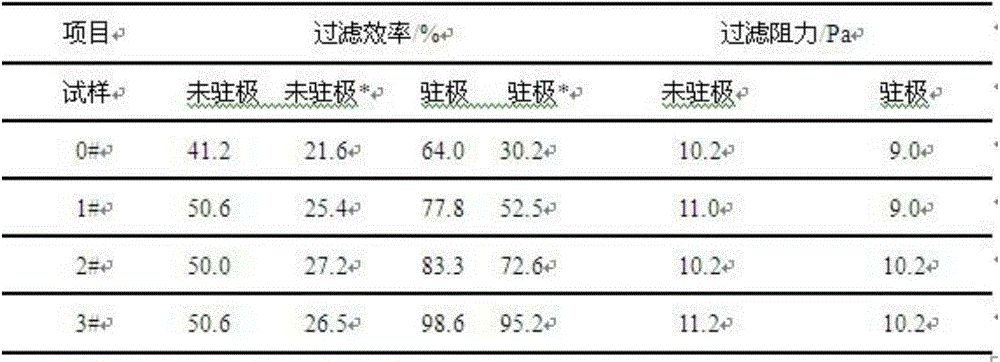

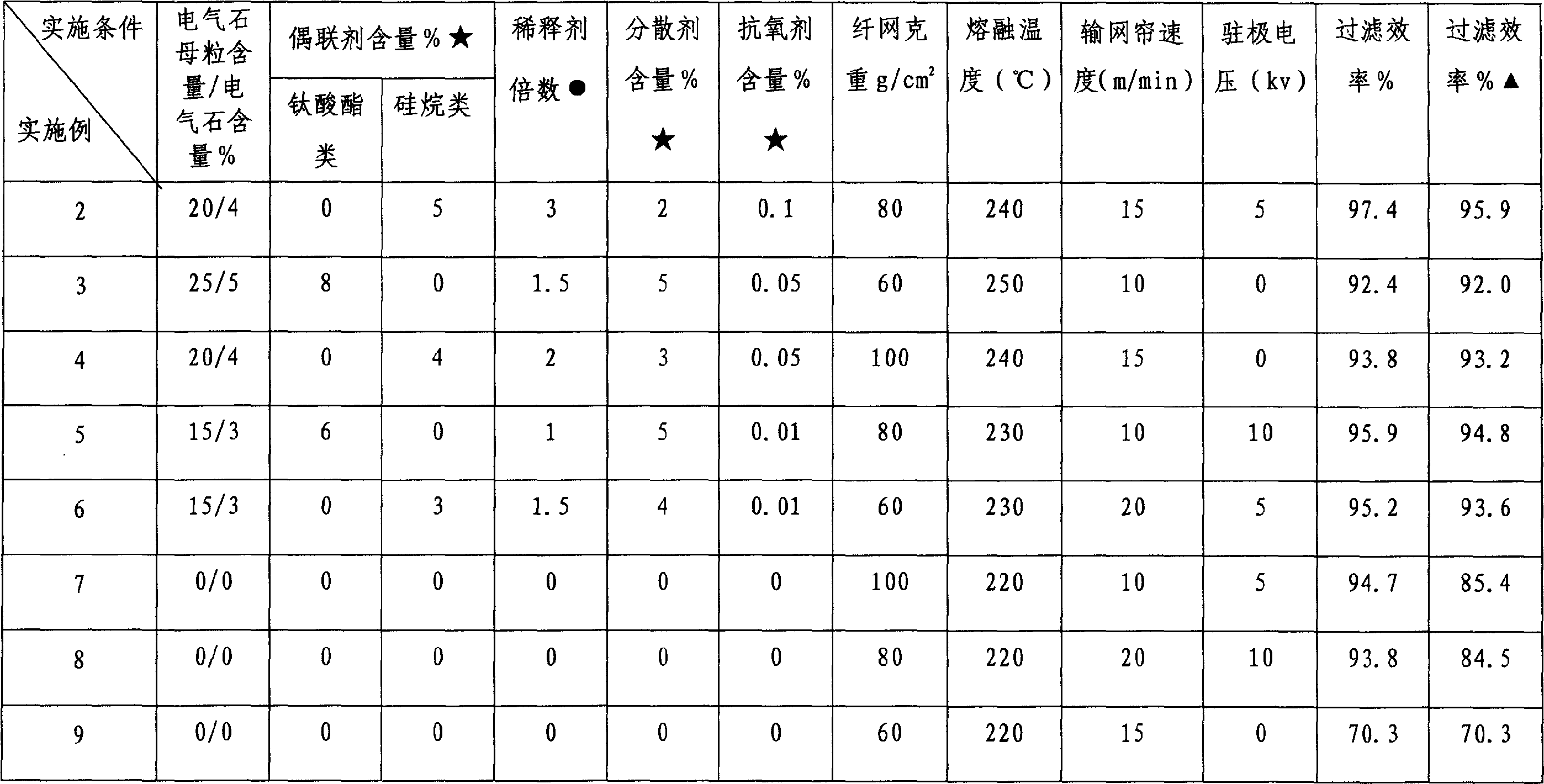

Antibacterial polypropylene melt-blow non-woven filter material and preparation method thereof

ActiveCN102836594AImprove filtering effectImprove filtration efficiencyFiltration separationNon-woven fabricsPolymer sciencePolypropylene

The invention relates to a polypropylene melt-blow non-woven filter material, in particular to an antibacterial polypropylene melt-blow non-woven filter material and a preparation method thereof. The polypropylene melt-blow non-woven filter material is prepared from the following raw materials in parts by weight: 85-95 parts of melt-blow polypropylene slices, 1-5 parts of nanometer tourmaline, 1-3 parts of nanometer titanium oxide, 1-3 parts of nanometer zinc oxide, 0.1-3 parts of a coupling agent, 0.1-2 parts of a dispersing agent and 0-0.5 part of an antioxidant. According to the antibacterial polypropylene melt-blow non-woven filter material prepared with the method, a formula and a preparation process are improved, so that the electret polarity time of the prepared filter material can be up to 5-6 years, and the antibacterial performance is superior to the prior art.

Owner:XINGNUO ECONOMIC & TRADE DEV SHANGHAI

Method for producing health ceramic brick capable of releasing negative ion

The production process of health ceramic brick capable of releasing negative ion includes introducing nanometer negative ion powder comprising tourmaline 20-40 wt%, dravite 10-20 wt%, nanometer TiO2 20-40 wt% and composite RE salt 5-12 wt%, making the nanometer negative ion powder combined well with ceramic base and sintering at 1080-1200 deg.c inside roller hearth kiln. The health ceramic brick has stable negative ion releasing function in health level and radiation performance index meeting relevant requirement.

Owner:GUANGDONG TIDIY CERAMICS

Anion powder

InactiveCN102702833APurify waterPurifying airAntibacterial agentsCosmetic preparationsSolubilitySesquioxide

The invention discloses anion powder which includes the following components: by weight, 10-15 parts of coral fossil, 10-15 parts of tourmaline, 30-50 parts of opal, 5-10 parts of serpentine, 2-4 parts of medical stone, 2-4 parts of odd ice stone, 2-4 parts of radiobarite, 2-4 parts of king stone, 3-6 parts of shell, 15-25 parts of diatomite, 2-4 parts of iron sesquioxide, 2-4 parts of aluminium sesquioxide, 2-4 parts of zirconium oxide and 2-4 parts of zirconium phosphate. Air ions generated by the anion powder prepared is high in solubility and is not easy to modify at high temperature and long in effects, and original characters of products cannot be modified when used with other functional materials.

Owner:山东天宇圣邦涂料有限公司

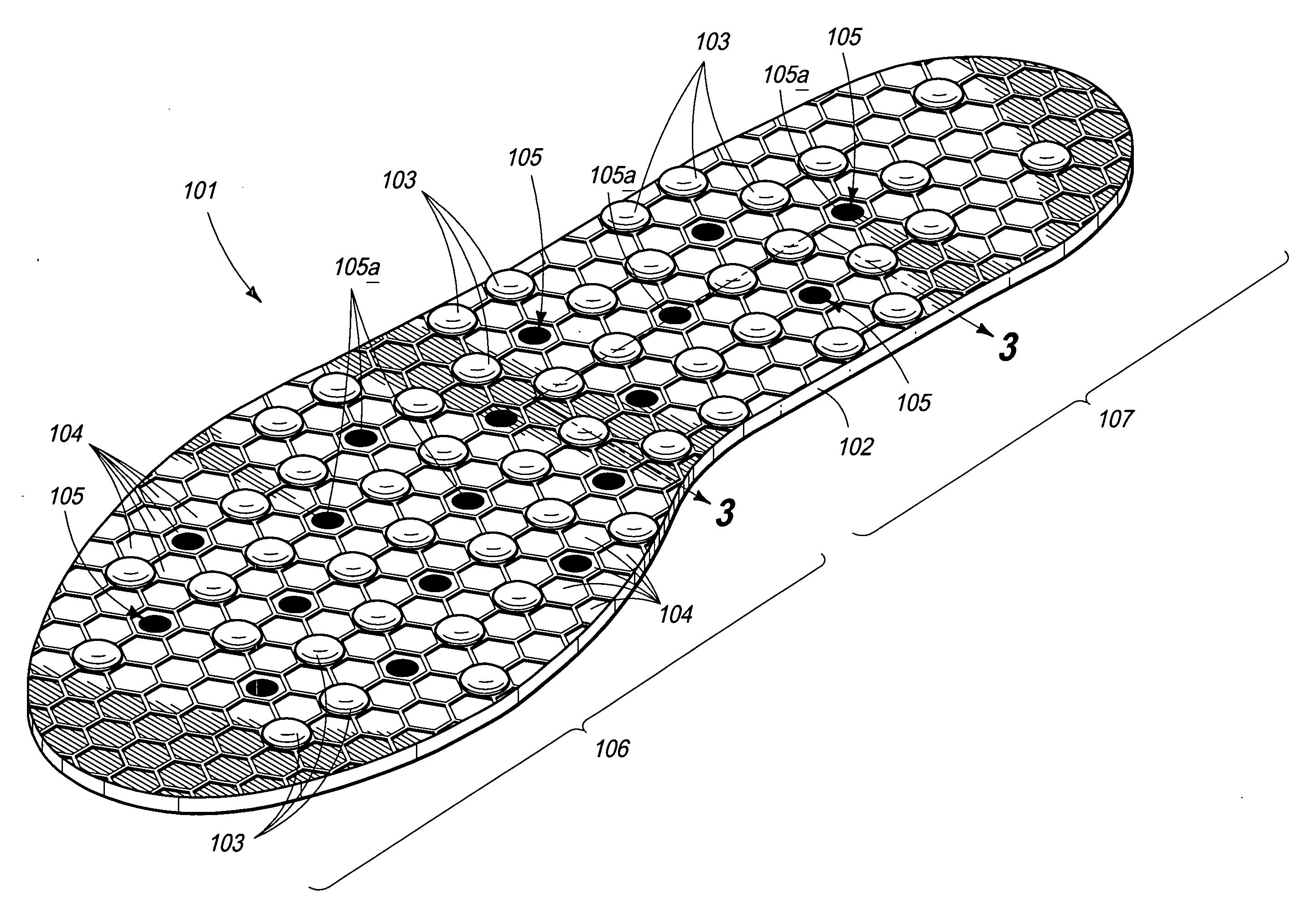

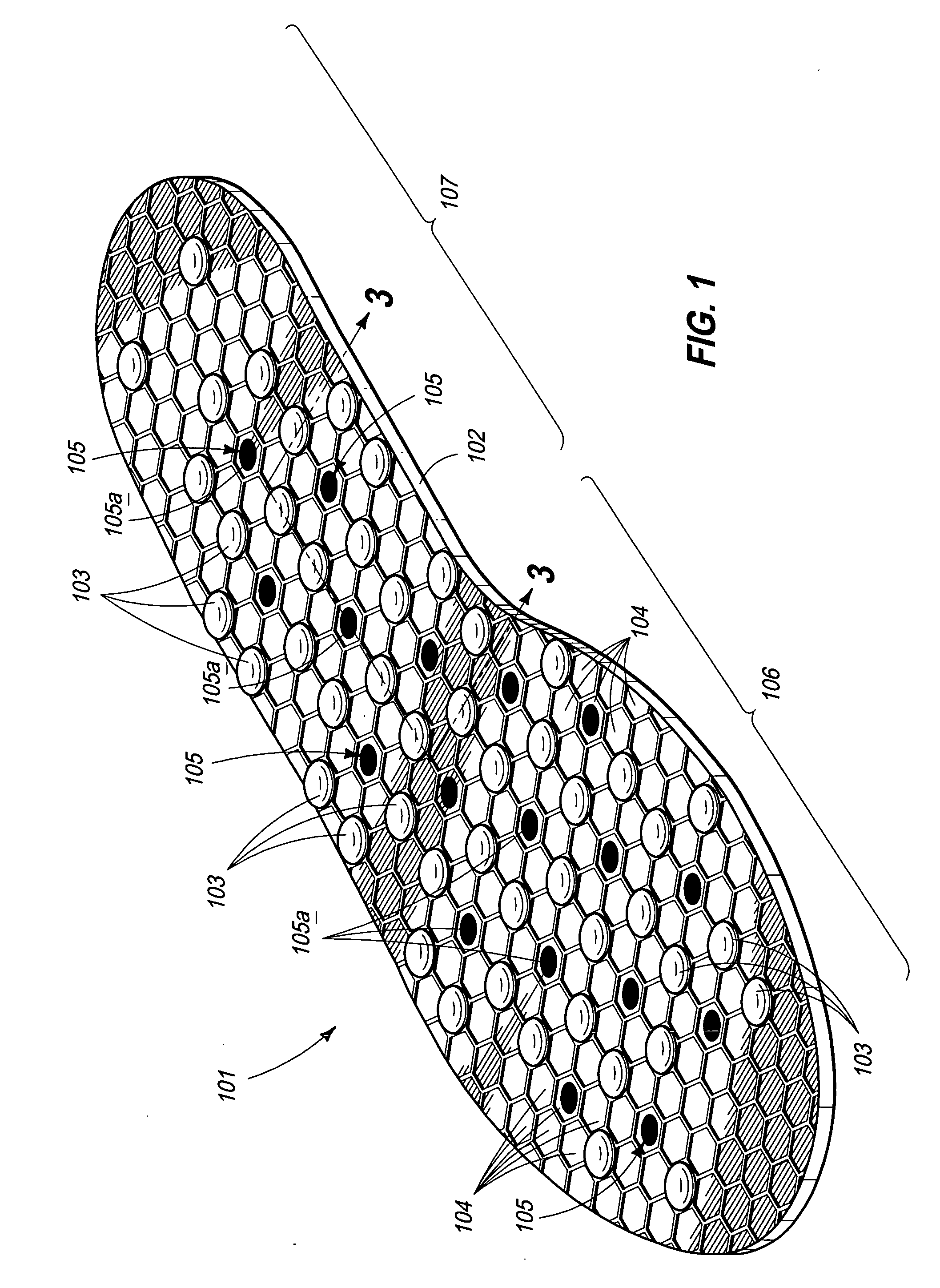

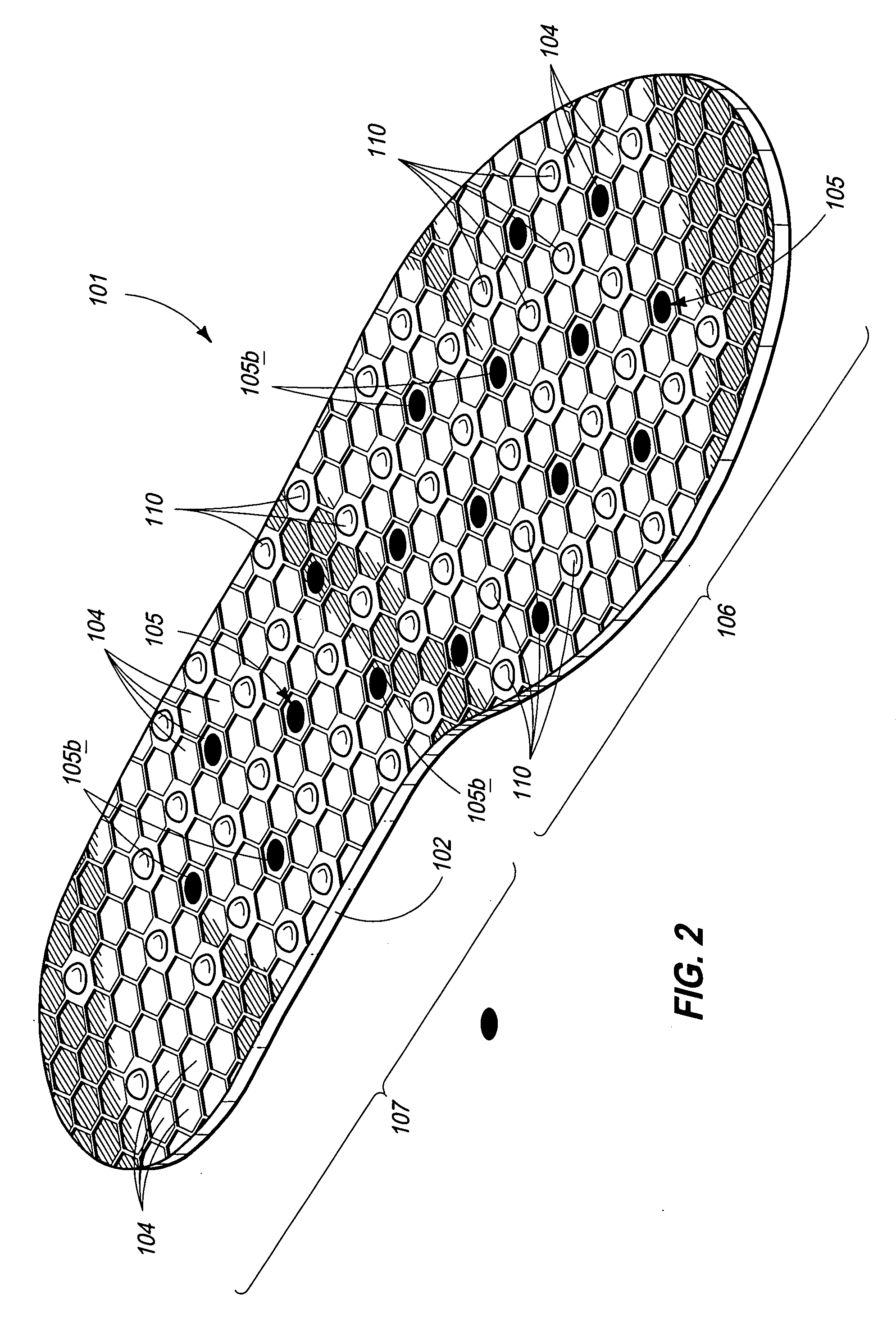

Shoe sole system providing a negative ion environment

This invention includes embodiments which disclose a shoe sole base system wherein there are a plurality of magnets embedded within a shoe base and a plurality of spheres containing tourmaline, also embedded within the shoe base. In further embodiments, the angle of the magnetic axis of each of the plurality of magnets to other magnets in the plurality of magnets is random in both two and in three dimensions and / or the spheres containing tourmaline may emit negative ions and / or far infrared rays.

Owner:U S WAX & POLYMER +1

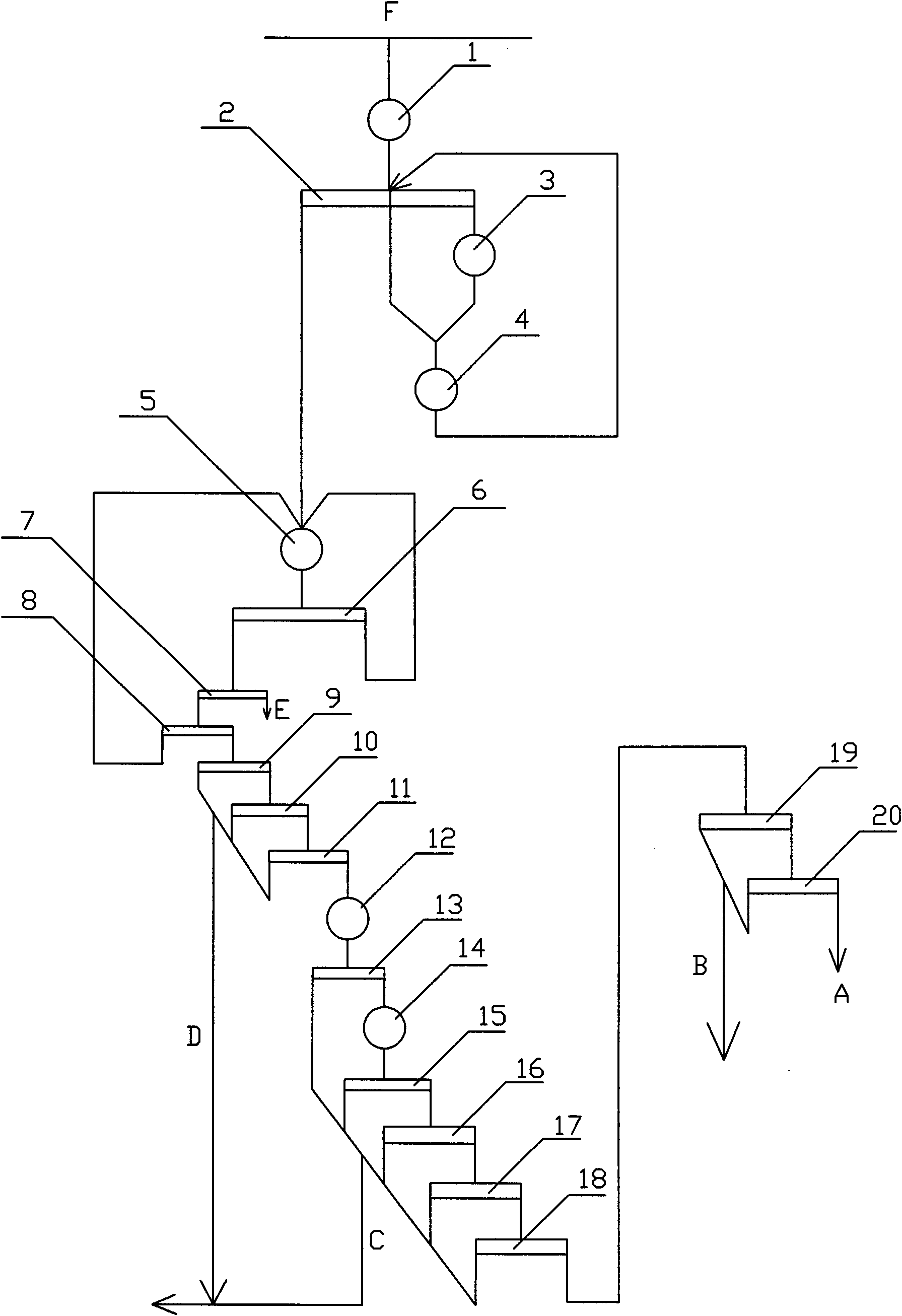

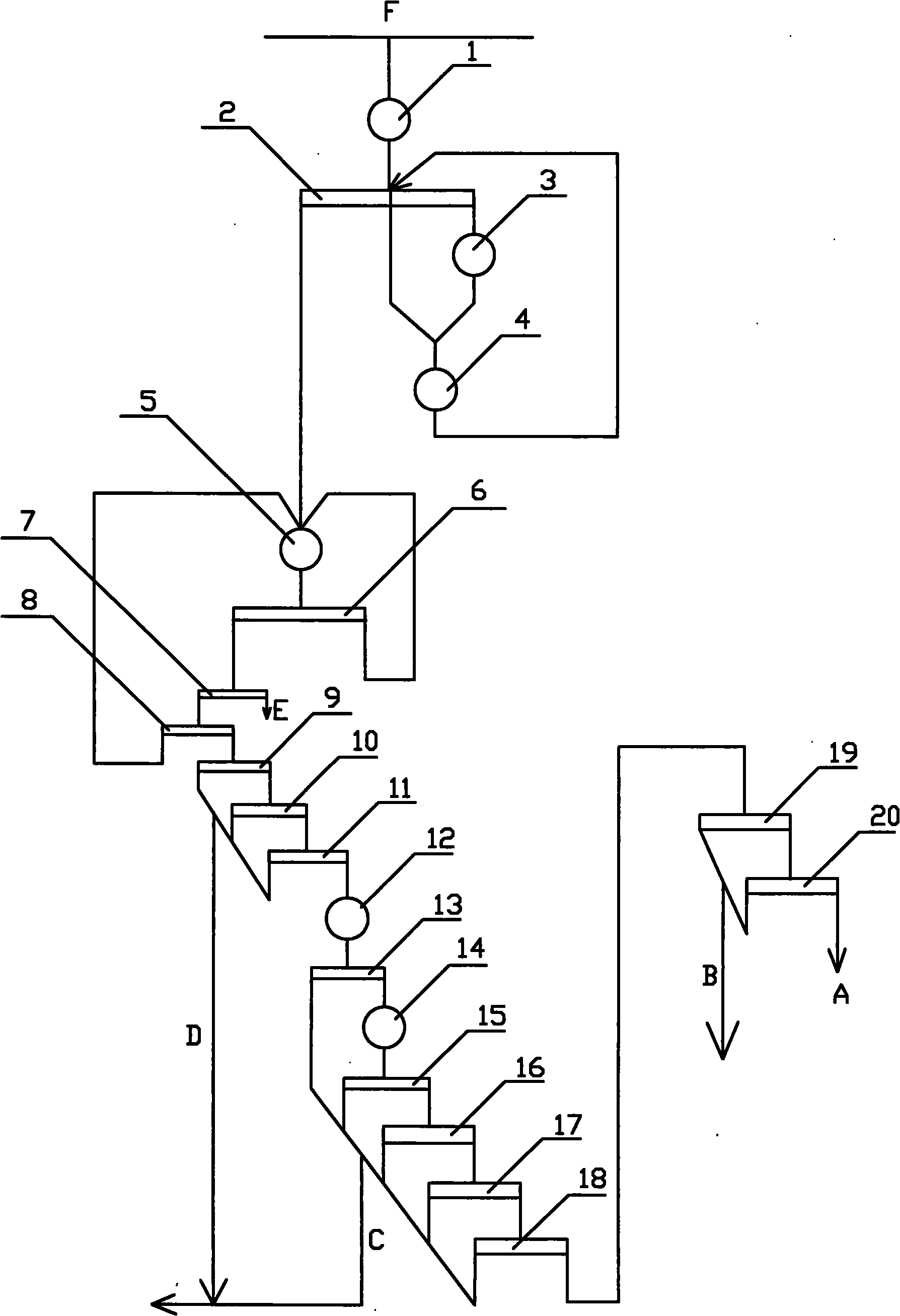

Beneficiation method for removing long quarry impurities by adopting strong magnetic flotation

InactiveCN101898168AIncrease production capacityImprove grinding efficiencyFlotationMagnetic separationEngineeringBall mill

The invention relates to a beneficiation method for removing long quarry impurities by adopting strong magnetic flotation, comprising the steps of crushing, grinding, sieving, desliming, strong magnetically floating, floating, concentrating and dewatering. The concrete beneficiation method comprises the following steps of: breaking and grinding ore in a ball mill; grading ground minerals by a spiral grader and a hydraulic hydrocyclone twice; combining with the ball mill into a closed cycle; respectively mounting high-frequency linear vibration sieves in overflows graded twice; respectively removing impurities over 3 mm and 1 mm, such as mica, grass-roots bark, and the like; removing most of muddy substances from minerals through desliming equipment after the impurities are removed; removing mechanical iron, weakly magnetic iron ore, tourmaline and partial mica in a strong magnetic flotation machine; floating the minerals passing through the strong magnetic flotation machine again to remove residual iron minerals, mica and black minerals; and finally, concentrating and dewatering the minerals to form a product.

Owner:衡阳县湘雁矿业有限公司

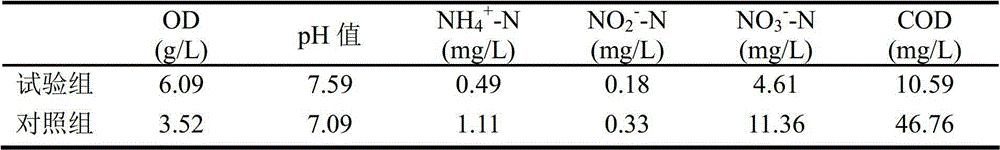

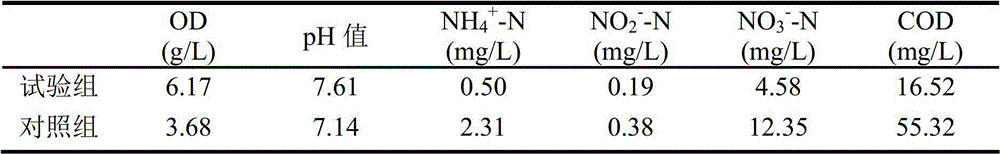

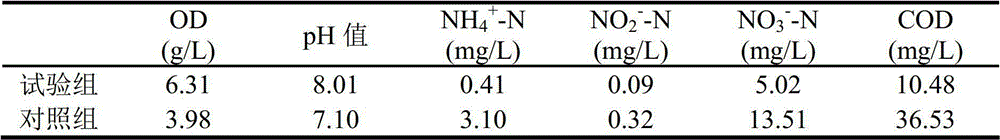

Nano-biological water body remediation agent for aquaculture and preparation method thereof

ActiveCN102718327AIncrease dissolved oxygenEfficient decompositionBiological water/sewage treatmentHazardous substanceAdditive ingredient

The invention discloses a nano-biological water body remediation agent for aquaculture and a preparation method thereof. The nano-biological water body remediation agent comprises a carrier and complex bacteria attached to the carrier, wherein the carrier comprises the following ingredients in percentage by weight: 10-70 wt% of nano tourmaline, 10-70 wt% of nano titanium dioxide, 10-70 wt% of modified zeolite and 10-50 wt% of montmorillonite, and the complex bacteria comprise photosynthetic bacteria, denitrifying bacteria, nitrifying bacteria and phosphorus accumulating bacteria. The nano-biological water body remediation agent for aquaculture, disclosed by the invention, is economical and environment-friendly and is simple and convenient to prepare; the adsorption characteristics of the natural mineral materials are cooperated with the degradation characteristics of the microorganisms, so that organics in a water body can be efficiently adsorbed and degraded, and the remediation efficiency of water quality is higher; and the microorganisms can increase the dissolved oxygen in the water body while harmful substances, such as ammonia nitrogen and hydrogen sulfide, are efficiently decomposed, excellent-quality baits can be supplied to aquatic livestock through the propagation of the microorganisms, and the secondary pollution on the water body cannot be caused.

Owner:浙江皇冠科技有限公司

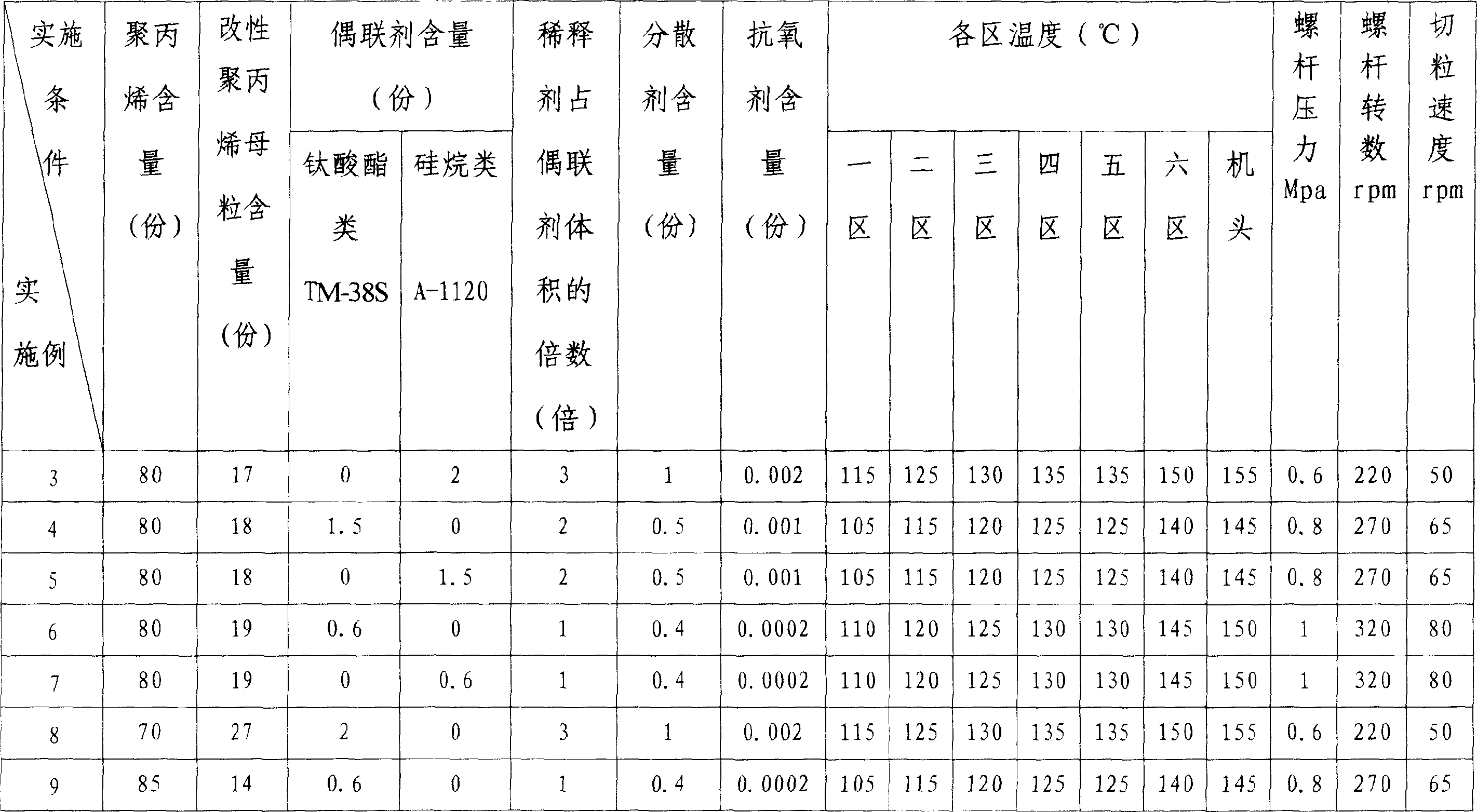

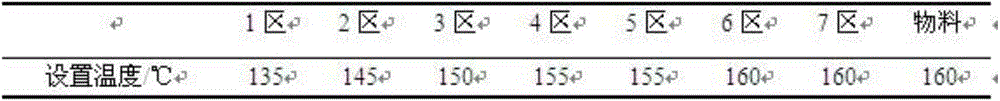

Modified polypropylene mother particle for melt spray, its preparation method and use

The present invention relates to a modified polypropylene mother granule for melt-blowing process, its preparation method and application technique. Its composition contains (by wt %) 70-85% of polypropylene, 14-27% of tourmaline and 1-3% of adjuvant. The described polypropylene is a low molecular weight melt-blowing polypropylene resin, the average grain size of tourmaline is less than 0.5 microns, and the adjuvant includes coupling agent, dispersing agent and antioxidant. Its preparation method includes the steps of surface modification of tourmaline, vacuum drying and meltblending and granulating, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Composite material with anti-bacterial and purifying functions and preparation method of composite material

ActiveCN104607039AImprove adsorption capacityImprove decomposition rateWater/sewage treatment by irradiationDispersed particle separationDecompositionRare earth

The invention relates to a composite material with anti-bacterial and purifying functions and a preparation method of the composite material, and belongs to the technical field of environmental-friendly materials. The composite material with the anti-bacterial and purifying functions comprises raw materials in parts by weight as follows: 70-95 parts of a mineral composite adsorption material, 3-25 parts of a photocatalytic degradation material, 2-15 parts of a rare earth inorganic anti-bacterial material and 1-10 parts of an additive, wherein the mineral composite adsorption material is prepared from sepiolite, diatomite, medical stone and attapulgite; the photocatalytic degradation material is prepared from titanium oxide, tourmaline and far infrared ceramic powder; the rare earth inorganic anti-bacterial material is prepared from zinc oxide, cerium oxide and silver oxide; the additive is a mixture of activated carbon, carboxymethylcellulose and pumice powder. The composite material with anti-bacterial and purifying functions has high adsorption and decomposition rate, can be resistant to water and damp and has excellent anti-bacterial effect. Meanwhile, the invention provides the preparation method. According to the preparation method, the cost is low, the amount of produced wastewater is low, and powder is simple and convenient to apply.

Owner:淄博木齐新材料科技有限公司

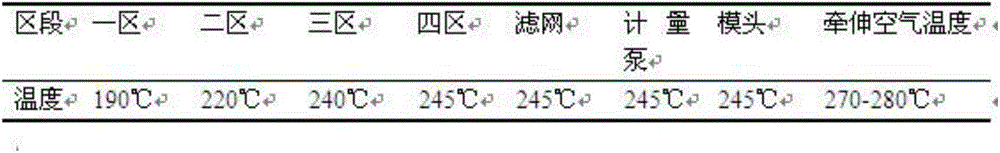

Tourmaline electret polylactic acid melt-blown non-woven cloth and manufacture method

InactiveCN103061038AGood dispersionHigh softening temperatureUltrasonic/sonic fibre treatmentNon-woven fabricsFiberFilter effect

The invention relates to tourmaline electret polylactic acid melt-blown non-woven cloth and a manufacture method. The tourmaline electret polylactic acid melt-blown non-woven cloth is manufactured through tourmaline modified polylactic acid melt-blown ultrafine fibers, wherein the diameter of the fiber ranges from 1 mu m to 10 mu m, and the tourmaline modified polylactic acid melt-blown ultrafine fiber is made of polylactic acid, tourmaline and assistant. The mass of the tourmaline is 1-3% of the mass of the polylactic acid, the assistant comprises coupling agent, dispersing agent and diluent, the mass of the coupling agent occupies 2-3% of that of the tourmaline, the mass of the dispersing agent occupies 1-3% of the mass of the tourmaline, and the mass of the diluent is three times as that of the coupling agent. The tourmaline electret polylactic acid melt-blown non-woven cloth is good in filtering effect, non-toxic, harmless and environment-friendly.

Owner:ZHEJIANG SCI-TECH UNIV

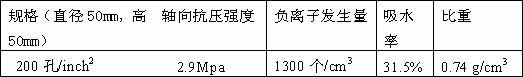

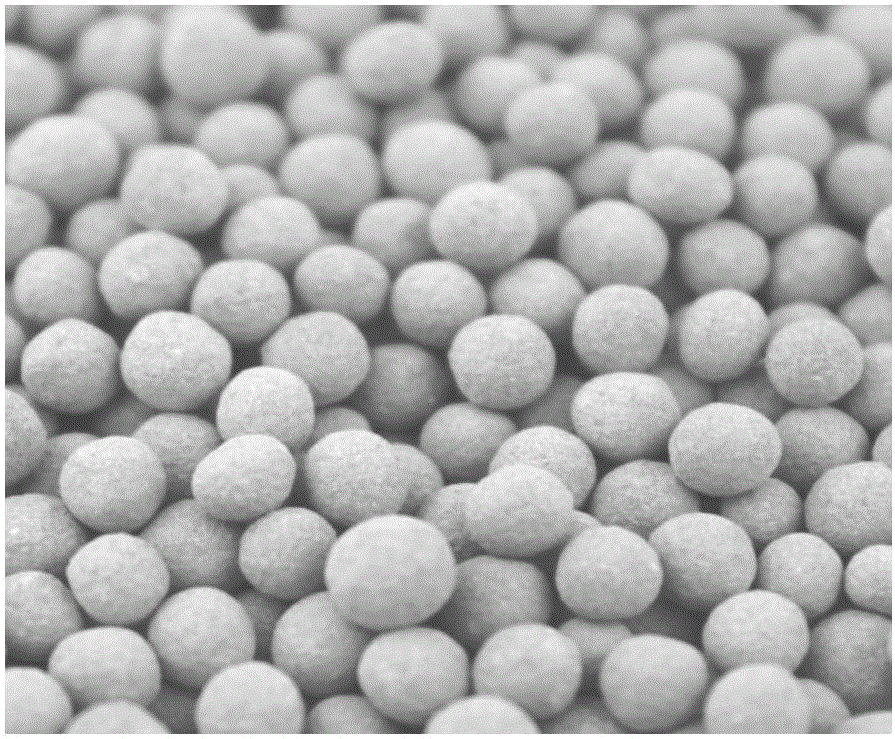

Tourmaline monolithic honeycomb ceramic and preparation method thereof

ActiveCN102285816AImprove adsorption capacityEnhance the efficacy of toxic and harmful substances in liquidsCeramicwareMicrowaveHoneycomb

The invention discloses a tourmaline integral honeycomb ceramic and the ceramic mainly comprises the following components by weight percent: 10-75% of tourmaline, 2-20% of clay, 2-40% of fluxing agent and 1-30% of auxiliary material. The preparation method of the tourmaline integral honeycomb ceramic comprises the following steps: adding tourmaline, clay, the fluxing agent, the auxiliary materialand a dry powder forming agent in a medium mill in proportion to grind and mix so as to obtain a mixture, then adding a appropriate amount of water and a liquid forming agent in the mixture to knead and obtain mud, granulating the mud, aging, extruding to obtain mud sections, moulding the mud sections, performing microwave forming, drying to prepare a semi-finished product, and placing the semi-finished product in a kiln at 500-850 DEG C to fire. Compared with the existing tourmaline products, the characteristics of the existing honeycomb ceramics, namely large specific surface area and porescan be ensured, the effect of tourmaline can be extremely exerted, the amount of tourmaline can be greatly reduced and the ceramic has good energy-saving effect. The energy consumption of the tourmaline integral honeycomb ceramic is one tenth of the energy consumption of the tourmaline ball fired at the same temperature.

Owner:曹南萍

Oil emulsion

[Object] To provide an oil emulsion which can be readily ignited using a conventional, commercially available burner without need of a specific type of device and which has a high ratio of water to an oil and is inexpensive.[Solving Means] An oil emulsion is obtained by mixing under agitation an oil, an emulsifier and a specific type of water obtained by initially passing water through an ion exchange resin, passing either tourmaline or a silicon dioxide-rich rock selected among igneous rocks and further passing the other. The oil emulsion obtained by mixing the oil, the emulsifier and the water is inexpensive and is able to maintain a stable emulsified state.

Owner:FUKAI TOSHIHARU

Ultra-fine highly effective anion powder material and its preparation method

The invention relates to an ultrafine high-effect negative ion powder material, which comprises: 60~95% natural negative ion releasing material, 2~30% activated material, and 3~25% energy transfer material. Wherein, using dry way and wet way to ultrafine break the material and obtain the product. This material increases the ion releasing ability more than twenty times to pure natural tourmalin and three times to the material theoretic value, and has high far-infrared radiation function without toxin.

Owner:深圳市金士吉康复用品科技有限公司

Negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and manufacturing method thereof

InactiveCN107083579AWith far infrared heating performanceAntibacterial and anti-mite effectMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and a manufacturing method thereof. The compound polyester fibers are added with a negative-ion additive, a far-infrared additive and an antibacterial and anti-mite additive, wherein the negative-ion additive, the far-infrared additive and the antibacterial and anti-mite additive respectively account for 2%, 5% and 6% by mass in the compound polyester fibers; the negative-ion additive comprises an additive carrier and tourmaline negative-ion powder; the far-infrared additive comprises an additive carrier, Tai Chi stone powder, ZrO2 nano-powder, nano-silicon dioxide, nano-aluminum oxide, nano-manganese oxide and nano-calcium oxide; the antibacterial and anti-mite additive comprises an additive carrier, nano-Cu-ZnO compound particles, nano-titanium dioxide, nano-zinc oxide and nano-silicon dioxide; and the additive carrier is TiO2 hollow spheres.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

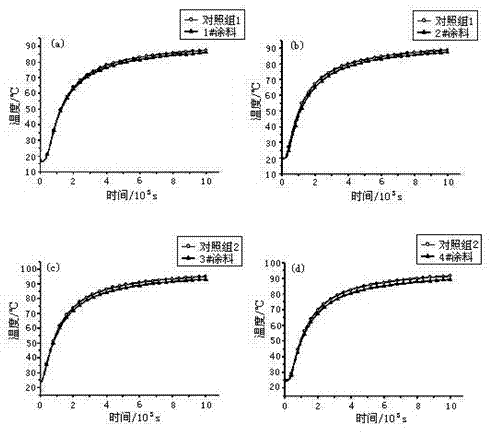

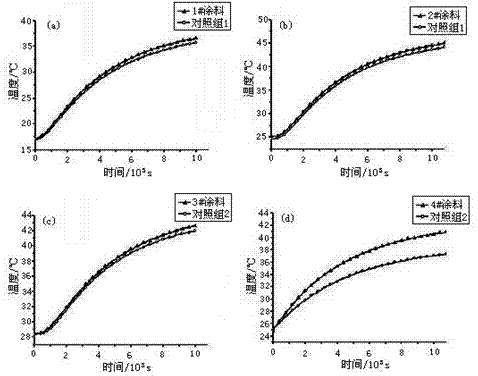

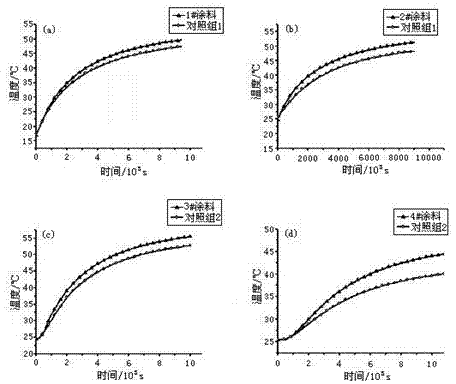

Composite intensified heat dissipation coating containing graphene or graphene oxide and preparation method of coating

ActiveCN102964972AHigh infrared emissivityIncrease the areaPolyester coatingsComparative testTemperature resistance

The invention discloses a composite intensified heat dissipation coating containing graphene or graphene oxide and a preparation method of the coating. The performances of the coating are combined with the performances of infrared ray radiation of tourmaline and transition metal oxide, larger specific surface areas and high thermal conductivity coefficients of the graphene and the graphene oxide, excellent adhesive property of resin, high strength and excellent high-temperature resistance. The functional powder and the graphene or the graphene oxide are dispersed in the resin under the synergistic effect of various auxiliaries so as to prepare the composite intensified heat dissipation coating. In the preparation method, the graphene or the graphene oxide wraps the surface of the infrared emission powder by a reflux method; based on the higher thermal conductivity coefficient of the graphene or the graphene oxide, the thermal resistance of infrared particles can be lowered effectively and the infrared emissivity of the infrared particles is improved; in comparative test with the normal heat dissipation coating, the infrared emissivity of the coating provided by the invention can be 0.96 and is improved by 6.6%, 6.37% of energy is saved, and better energy-saving effect is realized.

Owner:HEBEI UNIV OF TECH

Element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles

InactiveCN102400238AMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentTextile fiberSlurry

The invention relates to element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles. The invention belongs to the technical field of textile fiber fabric production of vehicle-use nano-grade decorative fabric with functions of refreshing and air-purifying. The fabric is a nano-grade functional healthy textile. The nano-grade fabric provided by the invention is produced form chitosan, which is a natural high polymer extracted from shells of shellfishes, crabs and shrimps; a natural antibiotic humectant SCJ-920; a high-efficiency mite-preventing antibacterial agent SCJ-998; nano-grade negative-ion powder SCJ-900; negative-ion far infrared healthcare slurry 700; a fire retarding finishing agent ATF; an aromatic finishing agent SCM; electromagnetic-wave-preventing ferrites Fe2O3, Fe3O4, and Fe; substances such as TiO2, Al2O3, and ZnO used for providing far infrared radiation; an Ag-embedded nano-TiO2 (AT) antibacterial agent; nano-grade selenium or organic selenium which is rare on earth; organic germanium, Chinese herbal medicines, essential oil, maifanite, tourmaline nano-grade powder and other materials. A mixture of the materials is added to cotton, linen, wool, silk, polyamide fiber, acrylic fiber, terylene or viscose fiber spinning liquid, and the nano-grade fabric is produced through weaving.

Owner:丁一

Ceramal material for manufacturing hydrogen-enriched water and preparing method and application thereof

The invention belongs to the technical field of new environment-friendly materials, and particularly relates to a ceramal material for manufacturing hydrogen-enriched water and the preparing method and application thereof. The ceramal material is prepared from, by weight, 30-85 parts of base material component, 20-60 parts of hydrogen-enriched component, 2-25 parts of anti-microbial component, and 3-30 parts of binder. The base material component is prepared from tourmaline, serpeggiante, silicon oxide, calcium oxide and zeolite. The hydrogen-enriched component is prepared from magnesium metal powder, magnesia powder and KDF alloy powder. The anti-microbial component is prepared from zinc oxide, titanium oxide and cerium oxide. The binder is prepared from one or more of high-purity distilled water, carboxypropyl cellulose and bentonite. The ceramal material can be used for manufacturing alkalescent water, negative-potential water and hydrogen-enriched water and also has an anti-microbial function and a water activating function. The invention further provides the preparing method and application of the ceramal material. The technology is simple and easy to realize. The ceramal material can be applied to products including water purifiers, water purifying kettles and cups.

Owner:山东木齐健康科技有限公司

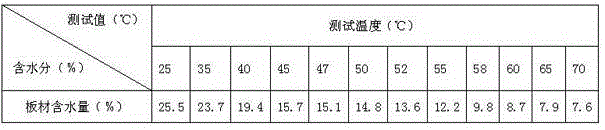

Healthcare plate material capable of generating anions and far infrared rays and composite healthcare plate

The invention discloses a healthcare plate material capable of generating anions and far infrared rays. The plate material comprises the following raw material components in percentage by weight: 70-80 percent of saw dust, 3-5 percent of eaglewood, 5-9 percent of tourmaline powder, 5-9 percent of anion powder, 1-3 percent of preservative, 2-4 percent of adhesive and 1-3 percent of antibacterial agent. The invention further discloses a composite healthcare plate material with the healthcare plate material capable of generating the anions and the far infrared rays. According to the healthcare plate material, healthcare materials beneficial to a human body such as the eaglewood, the anion powder and the tourmaline are adopted, and healthcare plate materials which are pressed under different pressures according to different using functions and are different in hardness and thickness can have different purposes. The healthcare plate material can release negative oxygen ions, the far infrared rays and a magnetic field, and the fitness and the immunity of a human body are unconsciously improved in the life and work of people by virtue of the fragrance of the eaglewood. Meanwhile, the practicality of the healthcare plate material is improved, so that the using function of the healthcare plate material is diversified, and the healthcare plate material is convenient to commonly use and popularize.

Owner:王文娟

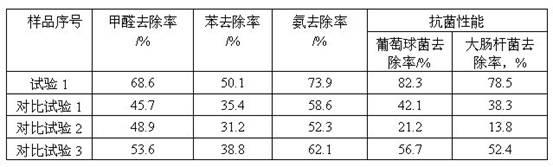

Diatomite-based environmentally friendly glaze for interior wall tiles and interior wall tiles prepared using the glaze

The invention belongs to the technical field of inorganic materials and in particular relates to a kieselguhr-based environmentally-friendly glaze material for an inner wall brick and the inner wall brick prepared by using the same as well as a preparation method. The kieselguhr-based environmentally-friendly glaze material for the inner wall brick comprises kieselguhr, a nano TiO2 / tourmaline composite material, a sintering adjuvant, ceramic pigment, a dispersing agent and water, wherein the weight ratio of kieselguhr to nano TiO2 / tourmaline composite material to sintering adjuvant to ceramic pigment to dispersing agent to water is (40-92):(6-40):(2-15):(0-8):(0.1-4):(60-250). According to the invention, a functional raw material nano TiO2 / tourmaline composite material is introduced in the environmentally-friendly glaze material for the inner wall brick, and the functional raw material has multiple functions of obviously dispelling poisonous and harmful gases such as formaldehyde, ammonia, benzene, volatile organic compound (VOC) and the like which are released by various decoration and finishing materials, furniture and the like, releasing negative ions, resisting bacterium and the like.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Light-transmitting, breathable and static electricity repellent PM2.5 air filter membrane and preparation method thereof

ActiveCN104906970AHigh retention rateReduced resistance pressure dropSemi-permeable membranesFibre treatmentAir filterEngineering

The invention discloses a light-transmitting, breathable and static electricity repellent PM2.5 air filter membrane and the preparation method thereof. The air filter membrane is characterized by being provided with at least one layer of non-woven fabric base material or screen net and at least one layer of ultrathin electrostatic spinning nano fiber layer. The preparation method comprises the steps of impregnating the non-woven fabric base material, the screen net or the ultrathin electrostatic spinning nano fiber layer in a tourmaline nano-particle containing suspension or spraying the tourmaline-containing nano particle suspension on the on-woven fabric base material, the screen net or the ultrathin electrostatic spinning nano fiber layer and drying, wherein the mass percentage of tourmaline nano particles in the suspension is 1-30%, the suspension further comprises a bonding agent, so that the tourmaline nano particles can be wrapped on the surface of the non-woven fabric base material, the screen net or the ultrathin electrostatic spinning nano fiber layer. The air filter membrane applied in a window screen is prepared by adopting the nano fiber technique and electrostatic repulsion and fine particulate matter PM2.5 is guaranteed to be blocked outside when a window is opened for ventilation.

Owner:上海展恒环保科技有限公司

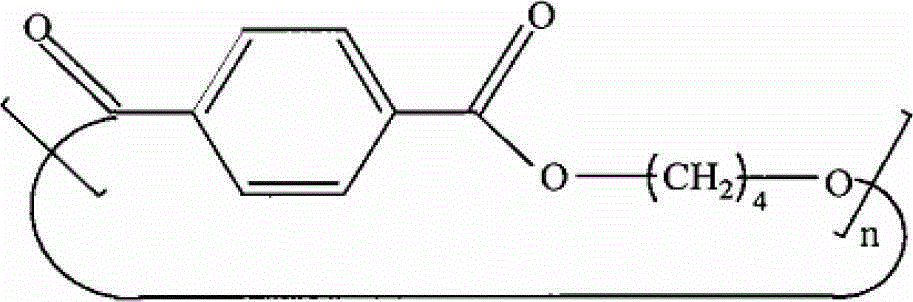

Preparation method of functional polyester fibers

ActiveCN102719932AHigh crystallinityImprove mechanical propertiesFilament forming substance formingMelt spinning methodsPolytetramethylene terephthalatePolyethylene glycol

The invention provides a preparation method of functional polyester fibers. The preparation method mainly comprises the following two steps of: firstly, mixing functional powders, polybutylene terephthalate cyclic oligomer (CBT) and a dispersing agent, performing reactive extrusion on the mixture by double screws to prepare a polybutylene terephthalate (PBT) functional master batch, wherein the functional powders are one of or several of a carbon nano tube, nano titanium dioxide, tourmaline powders, a nano-silver antibacterial agent, a nano silicon oxide and fluorescent powders; and secondly, blending and spinning the master batch, the PBT, polyethylene glycol terephthalate (PET) or polytrimethylene terephthalate (PTT) to prepare the functional polyester fibers. According to the method, the reactive extrusion process is adopted, the operation is simple and convenient, the process flow is shortened greatly, the obtained PBT functional master batch contains 30wt%-40wt% of the functional powders, and can be well dispersed in a base body, the compatibility of the obtained functional master batch and polyester polymer is good, and the fiber obtained by the method has an obvious functional effect.

Owner:ZHOUSHAN XINXIN CHEM FIBER

Electret polypropylene melt-blown nonwovens and method for preparation

InactiveCN1544724AMature technologyWell mixedElectroconductive/antistatic filament manufactureFibre treatmentHigh humidityPolymer science

The invention relates to an electret polypropylene melt-spray nonwoven cloth and its making method, the components in weight percent: polypropylene 95-97%, and tourmaline 3-5% with average particle size not greater than 0.5mum; its making method: (1) uniformly mixing and fusing the tourmaline particles and the polypropylene slices to make particles; the assistants of making the tourmaline particles in weight percent: coupling agent 3-10%; dispersant 2-5% and chemical inhibitor 0.01-0.1%; (2) uniformly mixing, fusing and extruding the particles with the polypropylene slices, stretching under the high-speed hot air flow to make the product. The product has better adaptability to high temperature and high humidity environment, can be used in filtering liquid; the making method has the characters of simple technique, no special devices, easy industrialized implementation, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Formaldehyde-removal nano compound and preparation method thereof

ActiveCN103706337ALow costConvenient for daily useMaterial nanotechnologyOther chemical processesCyclodextrinGraphene

The invention is applicable to the field of air processing, and provides a formaldehyde-removal nano compound and a preparation method thereof. The method comprises the steps of preparing nano aerogel from photocatalyst-composite nano titanium dioxide, ultra-absorptive graphene, nano negative-ion tourmaline and cyclodextrin-cladding biological polyphenol through a supercritical carbon dioxide technology, extracting biological polyphenol from plants such as aloe and natural lauraceae, and preparing the formaldehyde-removal nano compound through a polymer polymerization method. The formaldehyde-removal nano compound has the functions of removing formaldehyde and adsorbing PM2.5 for a long time; moreover, the cost is low, and convenience in daily use can be realized.

Owner:CHENGDU TEXTILE COLLEGE

Non-toxic anti-pollution paint for sea and method for preparing same

InactiveCN101333348AEasy to buyEasy to synthesizeAntifouling/underwater paintsPaints with biocidesHypochloriteElectrolysis

Nontoxic marine anti-fouling dope and a preparation method thereof are disclosed, belonging to technical fields of anti-fouling dope and underwater dope. The nontoxic marine anti-fouling dope contains film forming matter, nontoxic antifouling compound, dye, addition agent and water. The nontoxic antifouling compound is pre-dispersed slurry prepared by adding super-fine tourmaline powder and nano zinc oxide powder into 10 times amount of water, coating with sodium alkylbenzene sulfonate while heating and stirring. The nontoxic marine anti-fouling dope can be prepared through the steps of adding the nontoxic antifouling compound into ethanol aqueous solution, adjusting pH value to be 9-12, adding silicon ester ethanol solution to react for 2-4h, bathing in water and separating, and drying. The tourmaline of the nontoxic anti-fouling dope automatically develops an electric field on the surface of the dope in the seawater to enable the seawater to electrolyse to produce hypochlorite ions, which can prevent halobios to adhere or grow on the boat and the structure. The ion membrane is approximately 10 microns and causes no environment pollution. The nontoxic marine anti-fouling dope is mainly suitable for underwater fouling prevention.

Owner:DALIAN MARITIME UNIVERSITY +1

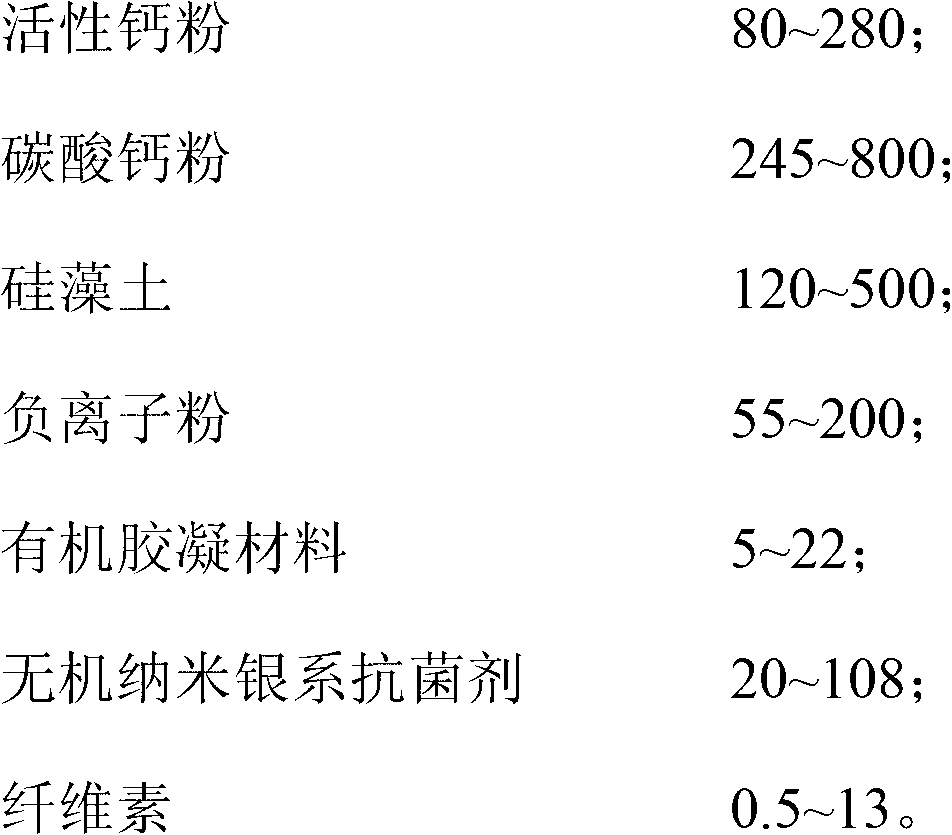

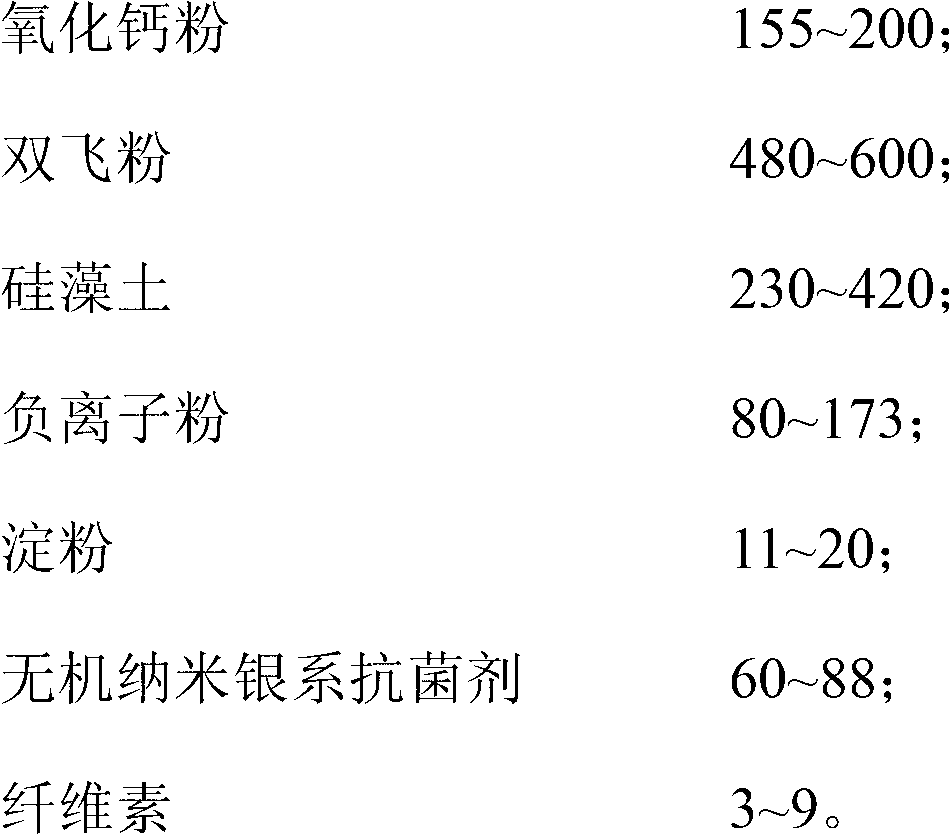

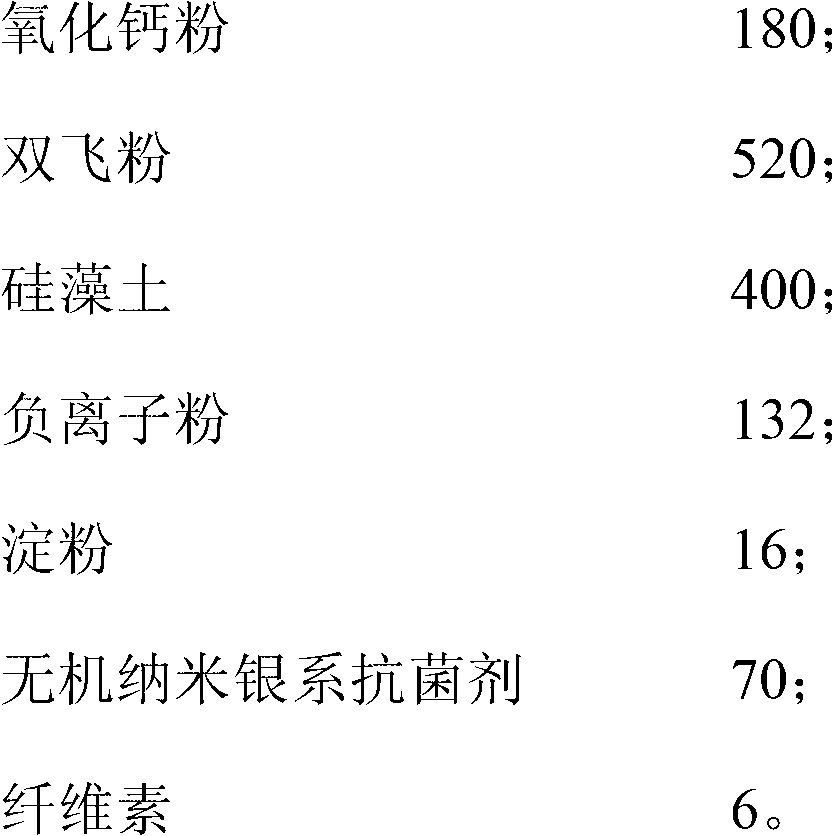

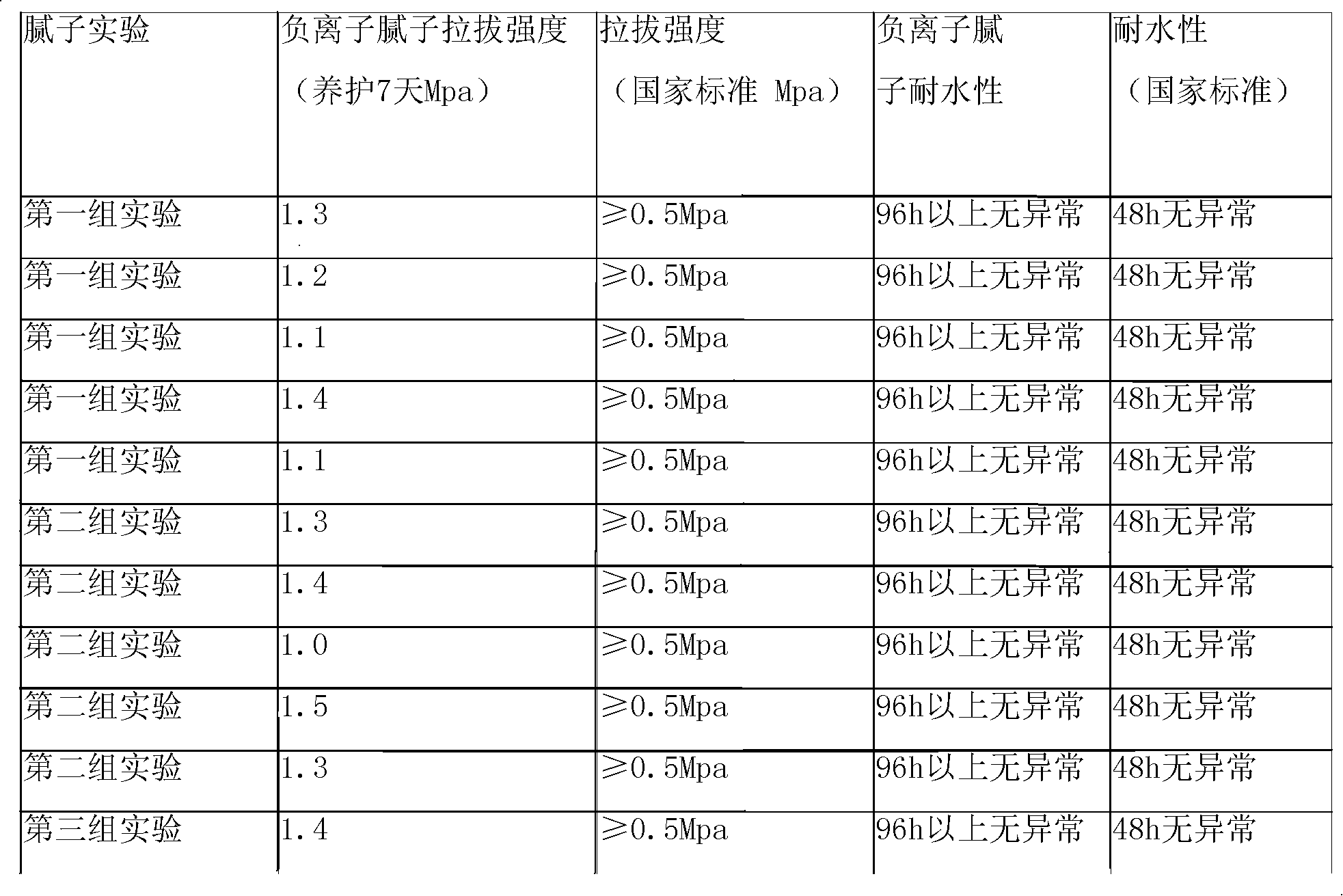

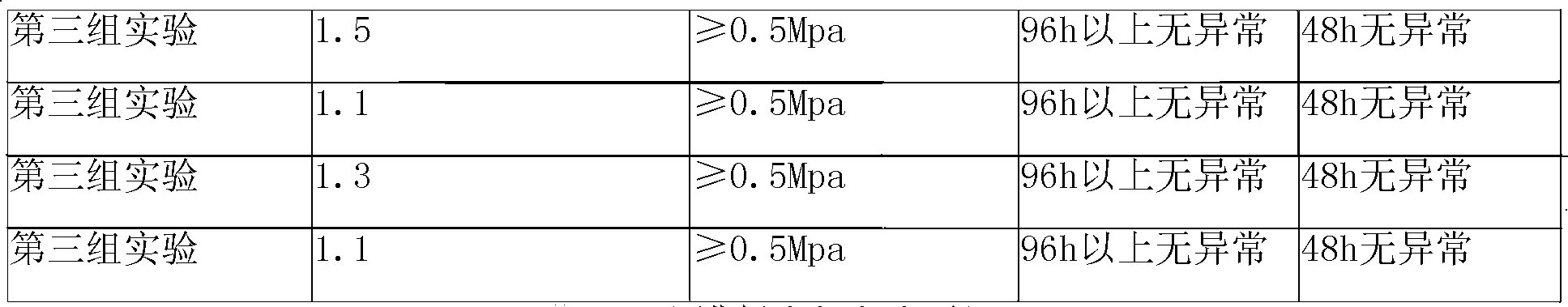

Antibacterial negative ion putty powder

The invention relates to antibacterial negative ion putty powder. The putty powder mainly comprises the following components: active calcium powder, calcium carbonate powder, kieselguhr, negative ion powder, an organic binding material, an inorganic nano-silver germicide and cellulose. The negative ion powder, provided by the invention, comprises the following components: tourmaline powder, cerium oxide, yttrium oxide, neodymium oxide and titanium dioxide. The antibacterial negative ion putty powder, provided by the invention, has an effect of purifying the air, and is mainly manifested in absorbing and neutralizing the positive ions in the air, eliminating toxic and harmful gas such as formaldehyde, ammonium, benzene and the like, which is released in indoor decoration and decoration materials, inhibiting growth of bacterium and mildew, and enhancing antibacterial performance of the putty powder.

Owner:TIANCHANG JULONG TRAVEL PAINT

Fabric multifunctional foaming material and preparation method and application thereof

ActiveCN101892590AImprove sleep qualityImprove microcirculationFibre treatmentScreen printingAntibiosis

The invention relates to a fabric multifunctional foaming material with the functions of magnetism, far infrared, anion, traditional Chinese medicine, aroma, antibiosis, adsorption and the like. The invention mainly solves the technical problems that the conventional fabric products have single function, have side effect on a human body and the like. The fabric multifunctional foaming material is prepared by mixing NdFeB powder microcapsules, nano silver powder microcapsules, tourmaline powder microcapsules, Chinese medicinal powder microcapsules, plant essential oil microcapsules, a foaming base material, a wetting agent and a diluent. The preparation method comprises the step of uniformly mixing the raw materials according to a certain proportion. The fabric multifunctional foaming material can be applied to slurry for screen printing of fabrics. The foaming material is applied to the fabrics, so the fabrics have the functions of magnetism, far infrared, anion, traditional Chinese medicine, aroma, antibiosis, adsorption and the like, have no harm to a human body and improve the quality of life of people.

Owner:太原伦嘉生物科技股份有限公司

Architectural interior anion waterproof putty powder and preparation method thereof

InactiveCN101225261AHigh removal rateImprove water resistanceFilling pastesLight energyWater resistant

The invention relates to a building interior anionic water resistant putty powder. The weight ratios of the components are 100 to 300 portions active calcium powder, 200 to 700 portions calcium carbonate powder, 50 to 200 portions anion powder, 1 to 10 portions cementing material and 1 to 5 portions cellulose; wherein, the anion powder is the mixed powder of ultrafine tourmaline powder and physical adsorption materials, the fineness of the ultrafine tourmaline powder is more than 2.6 Mum and the purity of the ultrafine tourmaline powder is more than 95 percent, the physical adsorption material is diatomite or modified active carbon and the weight of the physical adsorption material is 20 to 35 percent the total weight of the anion powder. The building interior anionic water resistant putty powder has the advantages that: the preparation method does not need the excitation of light energy sources and has not the danger of over standard radioactivity, so the removal ratios of formaldehyde and toluene is increased greatly, the putty powder plays the role of eliminating pollution and purifying air, meanwhile, the water resistant performance of the putty powder are enhanced.

Owner:莱恩斯建材(北京)有限公司

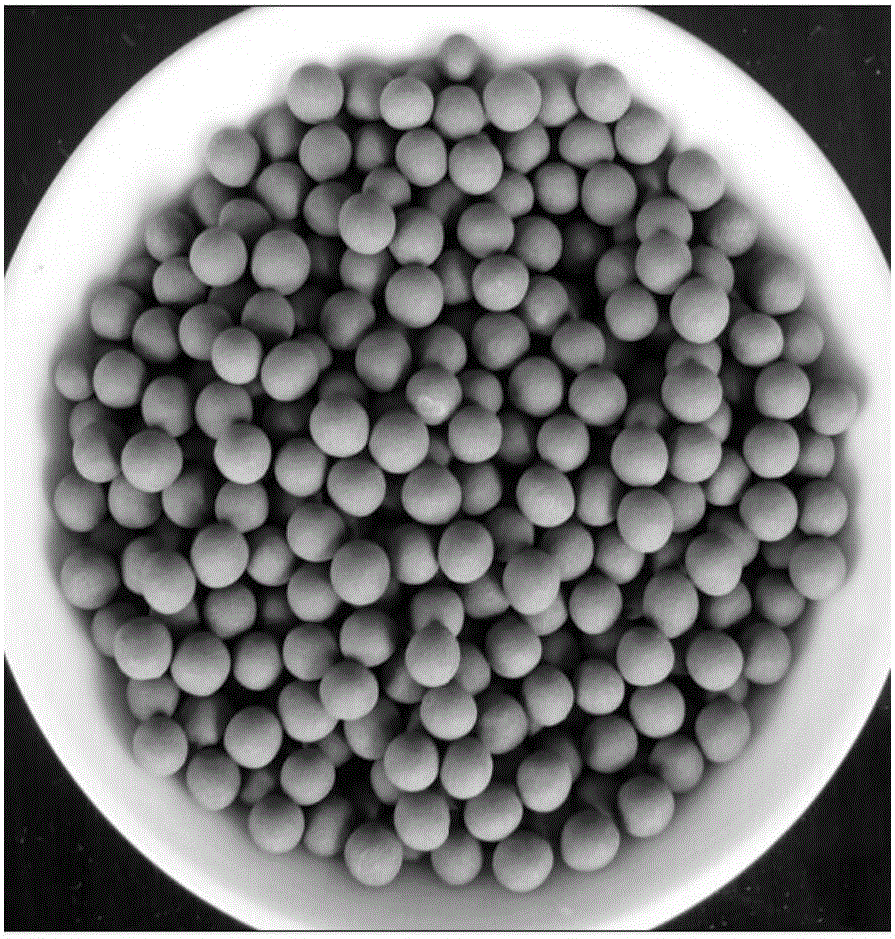

Porous ceramicite and preparation method and application thereof

InactiveCN101693631AHigh activityTo promote metabolismWater/sewage treatment by irradiationWater/sewage treatment using germicide/oligodynamic-processRare earthBiological activation

A porous ceramicite and a preparation method and an application thereof in the field of water purifying and filtering technologies, the porous ceramicite comprises the following components in percentage by weight: 2.5%-4.5% of titanium dioxide nanometer grade micro powder, 2%-4.5% of silicon dioxde nanometer grade micro powder, 2.5%-5.5% of zinc oxide nanometer micro powder, 12%-29% of polarity mineral tourmaline powder, 0.5%-1.5% of rare-earth activating agent, 1.5%-3% of ferric oxide red, 3%-10% of feldspar ores, 5%-8% of bergmeal ores, 15%-47% of light clay ores, and the other is water. The method ionizes water into negative ions through realizing infrared, cuts off hydrogen keys through resonance and splits the hydrogen keys into small water molecules (five-six), improves the activation, enables the small molecules into a body, can activate cells, prompts metabolism and acid-base balance, reduces the function of the oxidation-reduction potential ORP value of a water body, and the method can be used for processing water in cups and containers, such as tanks, tower pools, grooves and the like.

Owner:SHANGHAI JIAO TONG UNIV

Air purifying agent

InactiveCN103861421ALarger than surface and uniformGood adsorption and decomposition effectOther chemical processesDispersed particle separationActivated carbonHazardous substance

The invention relates to an air purifying agent which comprises the following raw materials by mass: kieselguhr powder, zeolite powder, medical stone powder, tourmaline powder, activated carbon power, sepiolite powder and titanium dioxide powder. The air purifying agent is prepared by the steps of (1) mixing the kieselguhr powder, the zeolite powder, the medical stone powder, the tourmaline powder, the activated carbon power, the sepiolite powder and the titanium dioxide powder; (2) granulating a mixture obtained in the step (1); and (3) drying the granulated mixture obtained in the step (2). The air purifying agent disclosed by the invention is large in specific surface area and uniform, has a good effect for adsorbing and decomposing harmful substances in air and is an ideal selected material suitable for environment purification in closed spaces such as a room and an automobile and for various air purifiers.

Owner:QINGDAO CHUANSHAN NEW MATERIALS

Functionalized polypropylene fibre and its preparation method

InactiveCN1766184AWith deodorizing functionSolve reunionMonocomponent polyolefin artificial filamentArtifical filament manufactureNatural substanceSilicon dioxide

The invention discloses a functional polypropylene fibre contained and fused a plurality of natural inorganic materials and polypropylene, which comprises: tourmaline, alumina, zirconium phosphate carried-Ag antibacterial agent, silicon dioxde, and titania. The preparation method comprises: breaking and mixing the materials, fusing and mixing said materials with polypropylene slice to obtain mother grain; then, using common fusion spinning method to treat said grain and slice. This product has well spinnability, high strength, and deodorization function.

Owner:上海依福瑞实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com