Architectural interior anion waterproof putty powder and preparation method thereof

A technology of water-resistant putty and negative ion powder, which is applied in filling slurry and other directions, can solve the problem of excessive radioactivity of putty powder, etc., and achieve the effects of improving removal rate, water resistance and drawing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

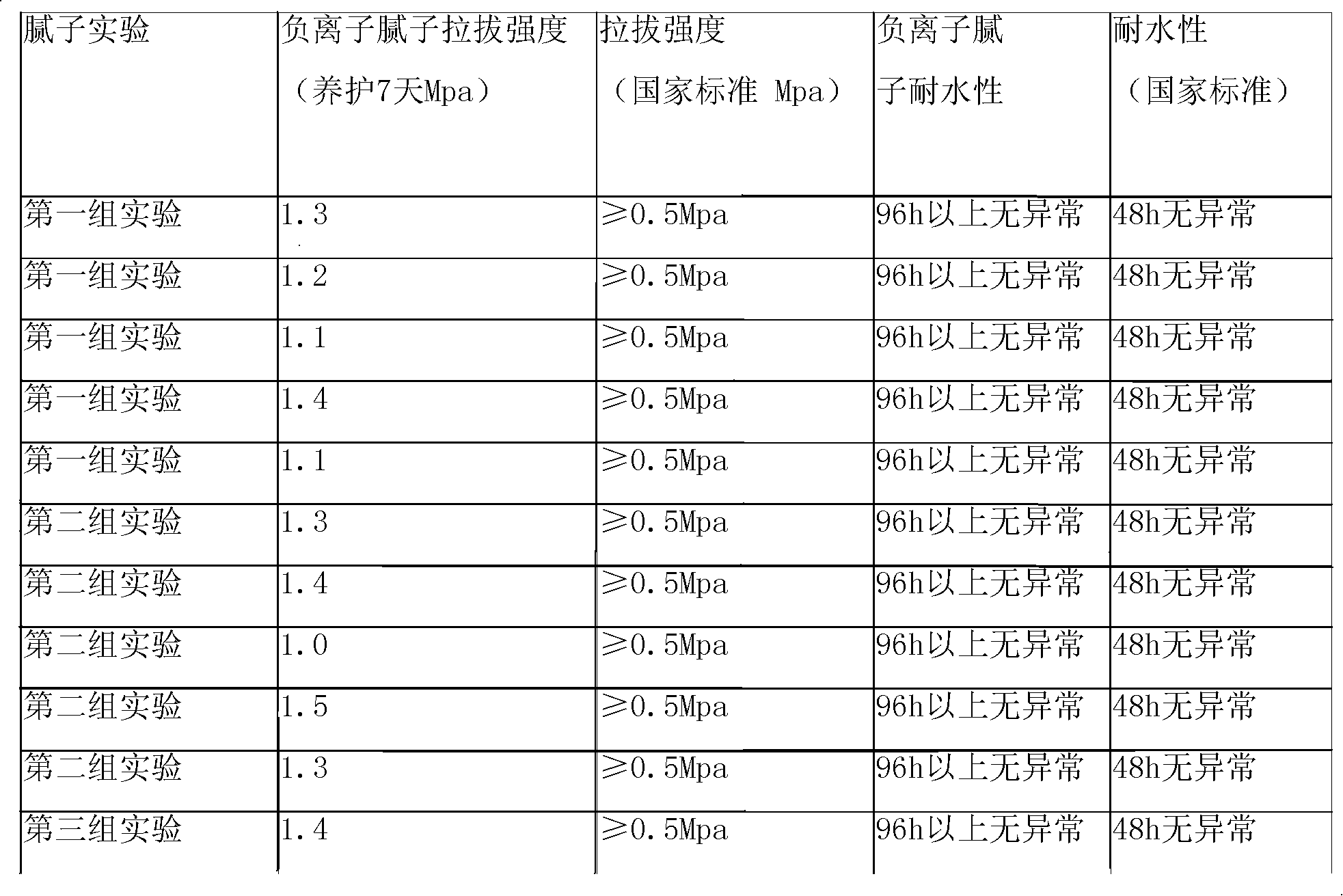

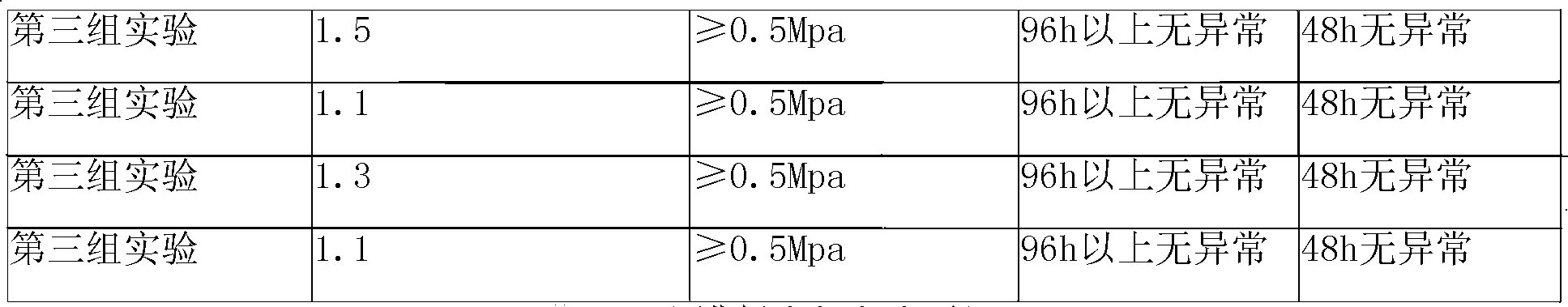

Examples

Embodiment 1

[0045] Embodiment one, this building interior wall negative ion water-resistant putty powder is according to the following proportions by weight:

[0046] Active calcium powder: 100-300 parts;

[0047] Calcium carbonate powder: 200-700 parts;

[0048] Negative ion powder: 50-200 parts;

[0049] Organic gelling material: 1 to 10 parts;

[0050]Cellulose: 1 to 5 parts;

[0051] The above negative ion powder is a mixed powder of tourmaline tourmaline powder and physical adsorption material, wherein the ultrafine tourmaline powder has a fineness of more than 2.6 μm and a purity of more than 95%; the physical adsorption material is one of diatomite and modified activated carbon. The weight of the physical adsorption material accounts for 25% to 30% of the total weight of the negative ion powder. The diatomite accounts for 2-5 parts of the total weight of the putty powder, and the modified activated carbon accounts for 1-3 parts of the total weight of the putty powder.

[0052]...

Embodiment 2

[0058] Ash calcium powder: 100 parts;

[0059] Double fly powder: 200 copies;

[0060] Tourmaline tourmaline powder 45 parts;

[0061] 15 parts of diatomaceous earth;

[0062] Starch: 2 parts;

[0063] Methylcellulose: 1 part.

Embodiment 3

[0065] 150 parts of the mixture of gray calcium powder and calcium hydroxide powder;

[0066] Large white powder: 300 parts;

[0067] Tourmaline tourmaline powder 70 parts;

[0068] 30 parts of modified activated carbon;

[0069] Gelatinized starch: 4 parts;

[0070] Methylcellulose: 2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com