Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7180 results about "Calcium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium hydroxide (traditionally called slaked lime) is an inorganic compound with the chemical formula Ca(OH)₂. It is a colorless crystal or white powder and is produced when quicklime (calcium oxide) is mixed, or slaked with water. It has many names including hydrated lime, caustic lime, builders' lime, slack lime, cal, or pickling lime. Calcium hydroxide is used in many applications, including food preparation, where it has been identified as E number E526. Limewater is the common name for a saturated solution of calcium hydroxide.

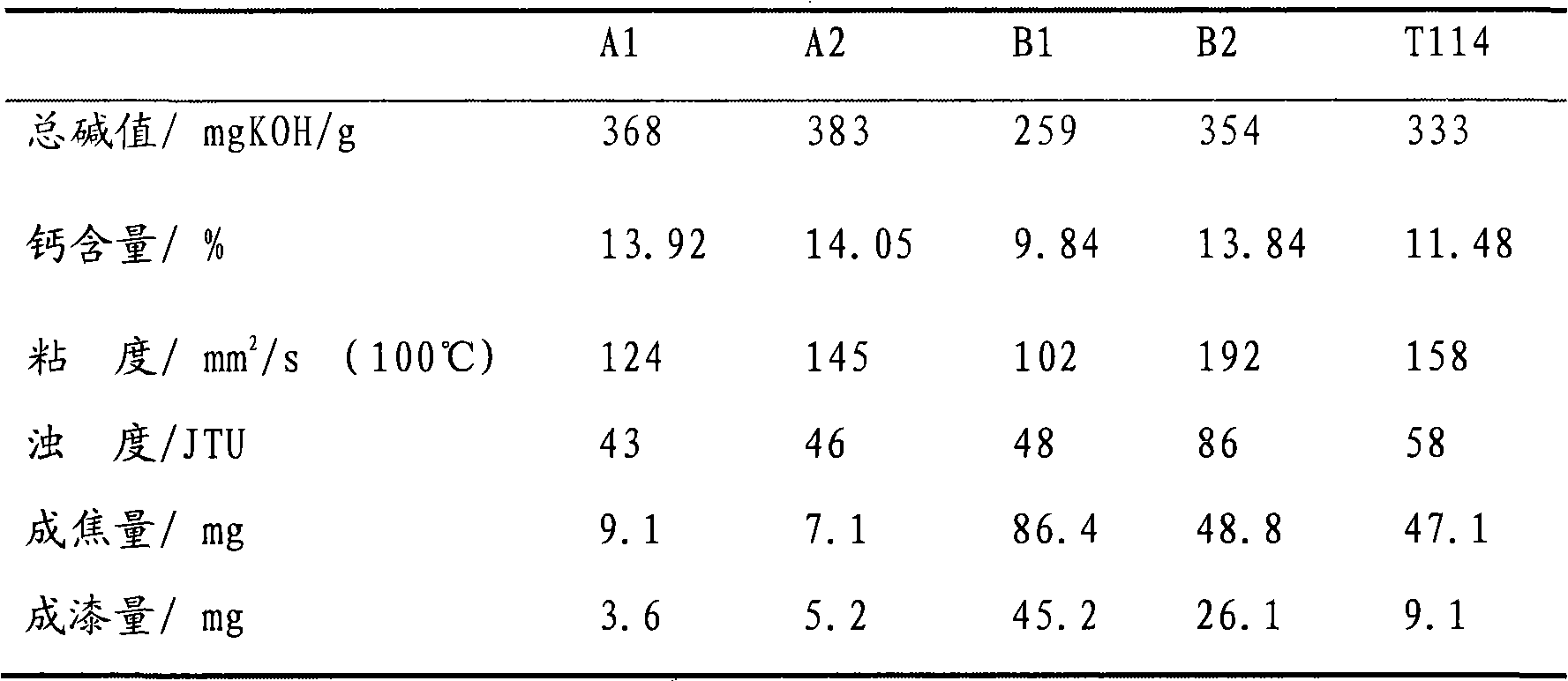

Preparation method for high-alkaline calcium naphthenate

ActiveCN101885677AAvoid aggregation and sedimentationHelps neutralize the reactionAdditivesCarboxylic acid salt preparationCalcium hydroxideAlkaline water

The invention relates to a preparation method for high-alkaline calcium naphthenate. In the method, calcium hydroxide and calcium oxide are taken as calcifying agents, pure water is replaced by alkaline aqueous solution, and a mode of multiple addition is adopted to prepare a calcium naphthenate product with the base number of more than or equal to 350 mgKOH / g. The product has the advantages of low viscosity and turbidity and better high temperature cleanliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

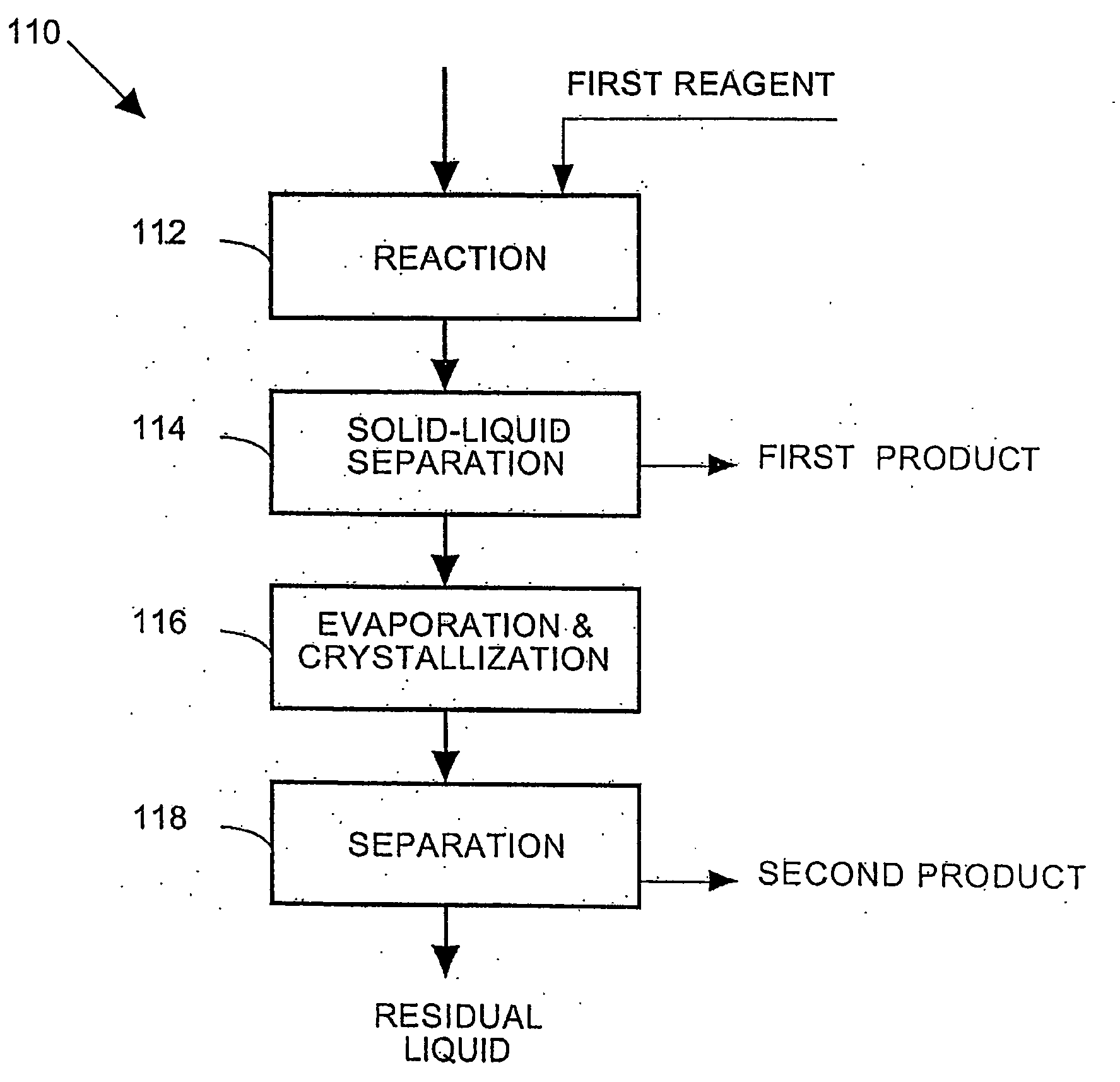

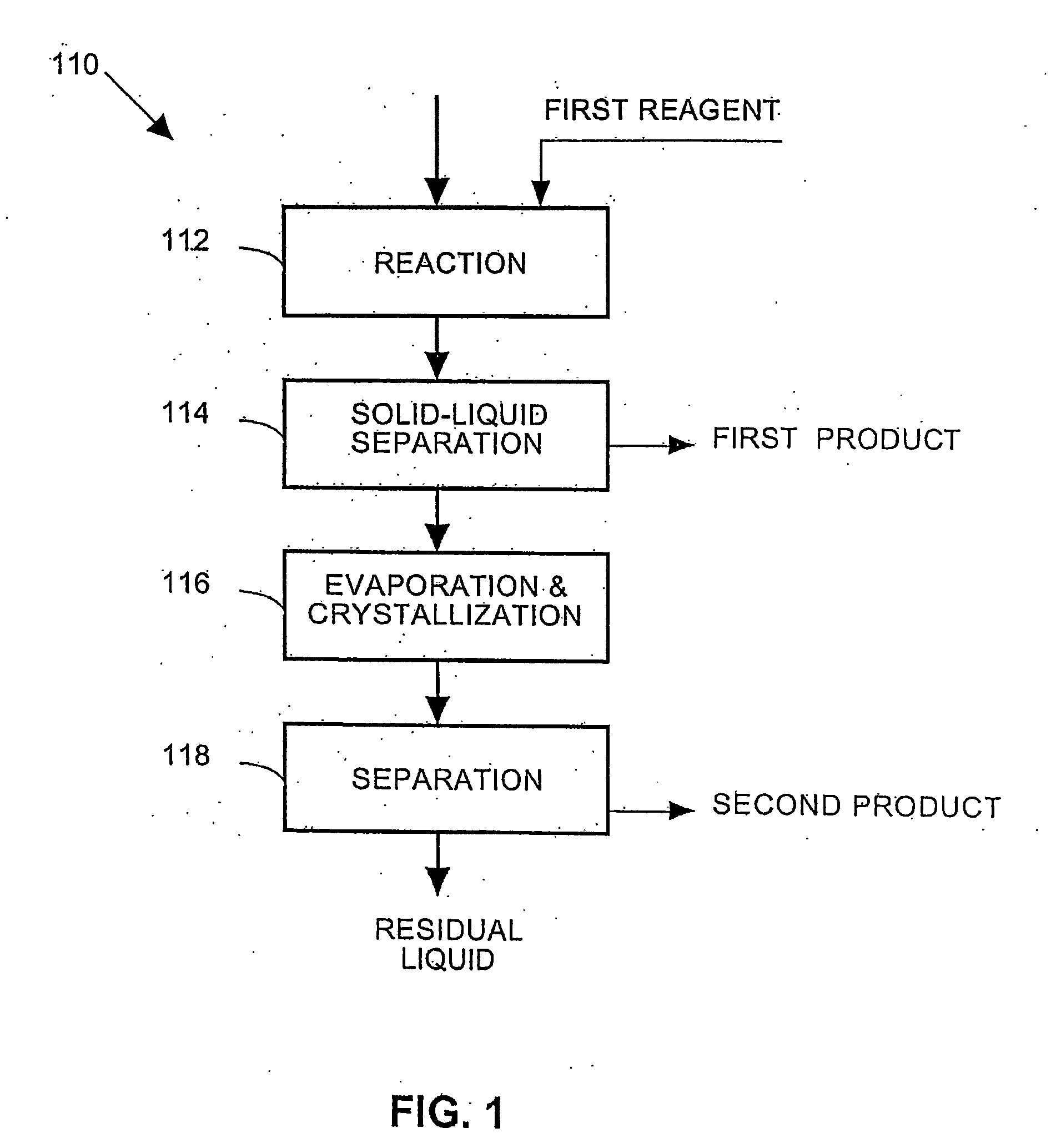

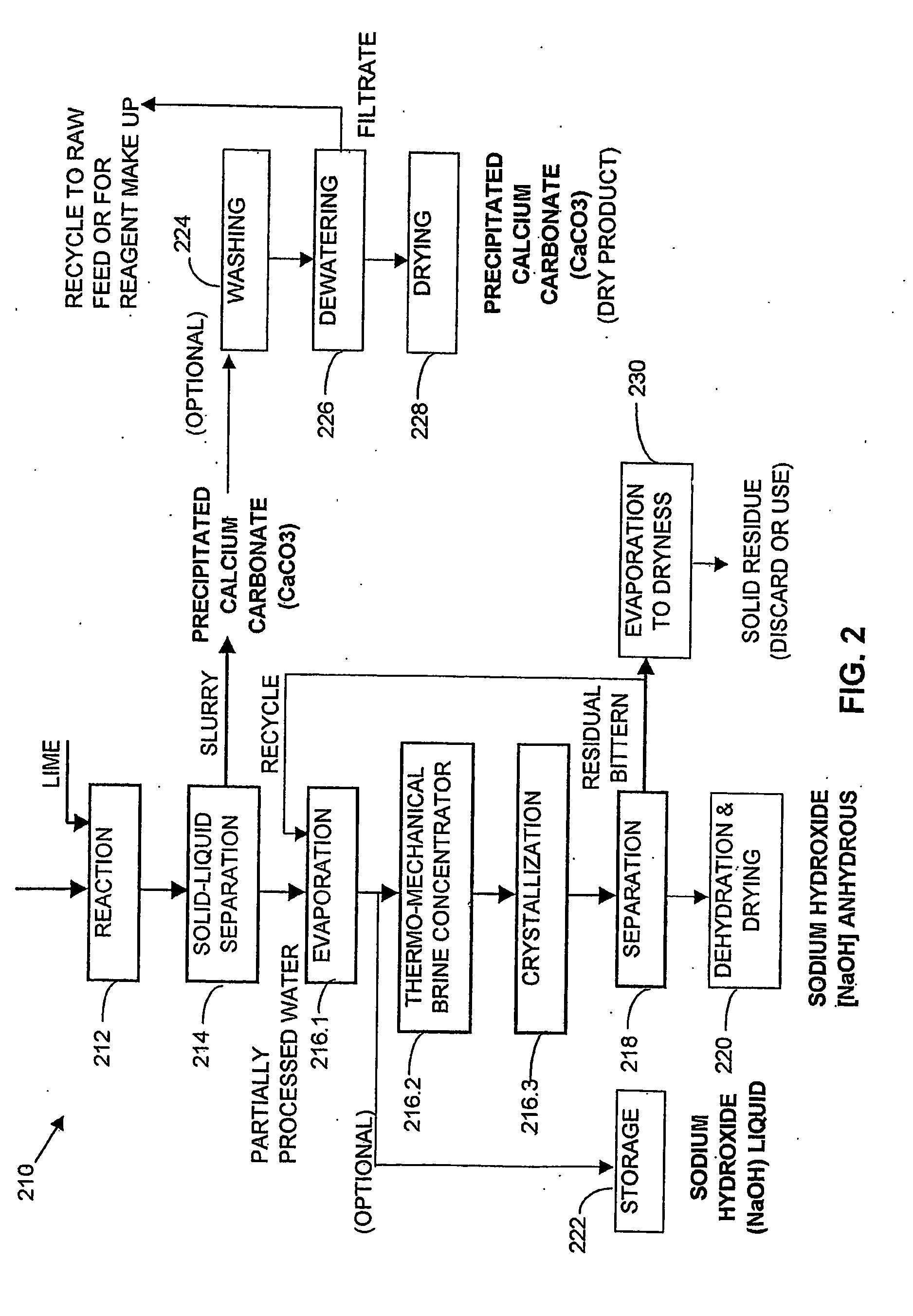

Process and apparatus for the treatment of saline water

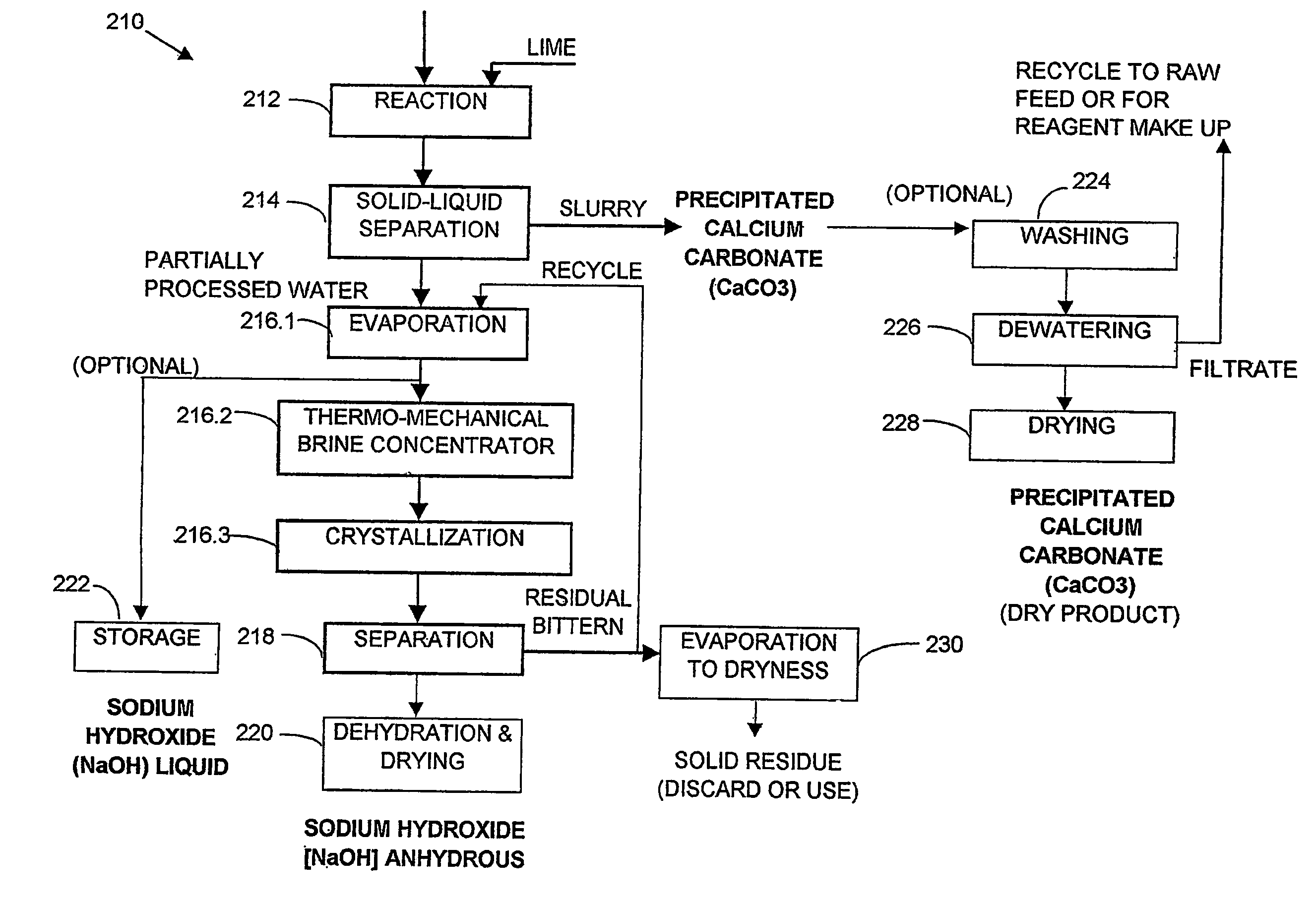

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

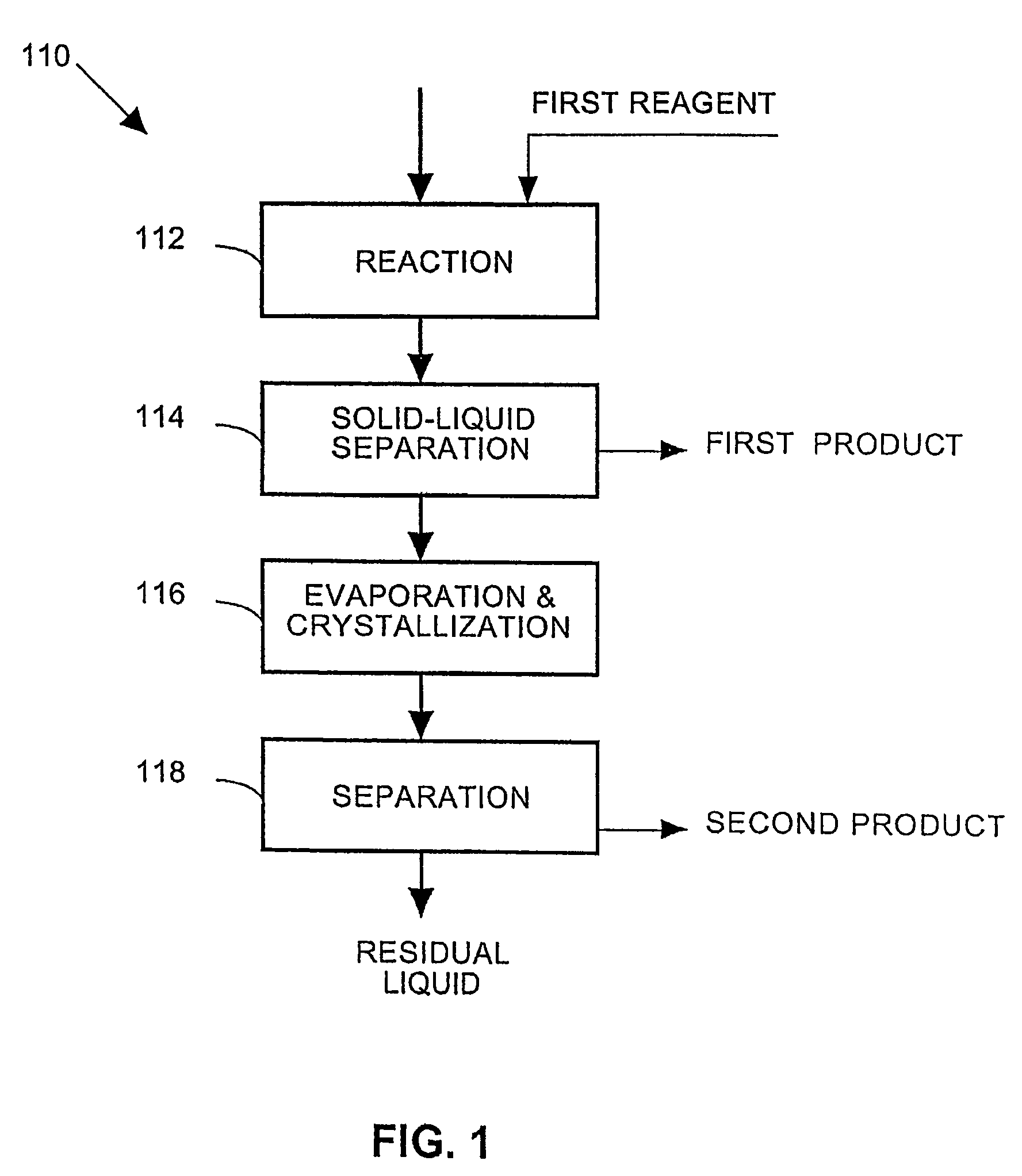

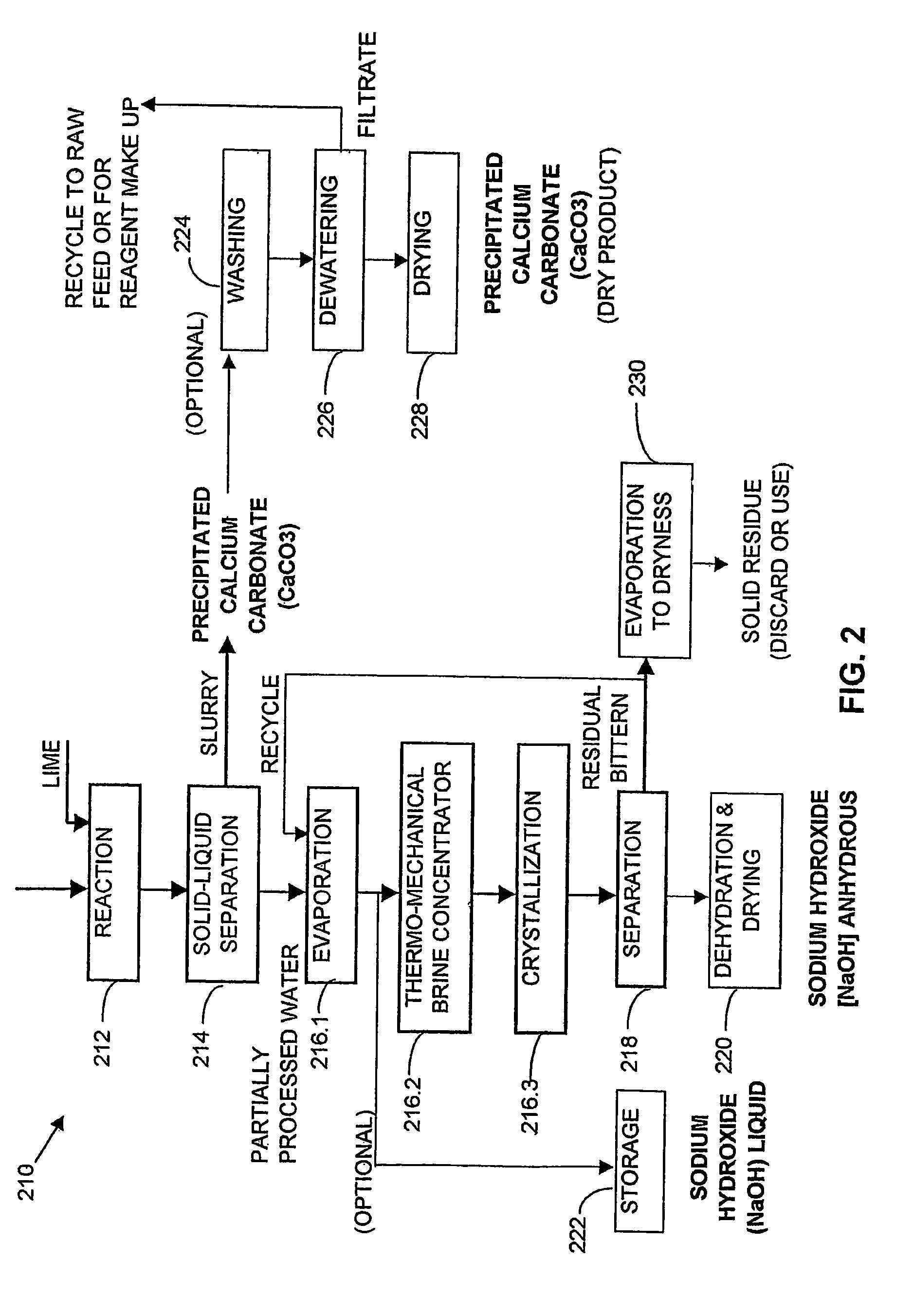

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

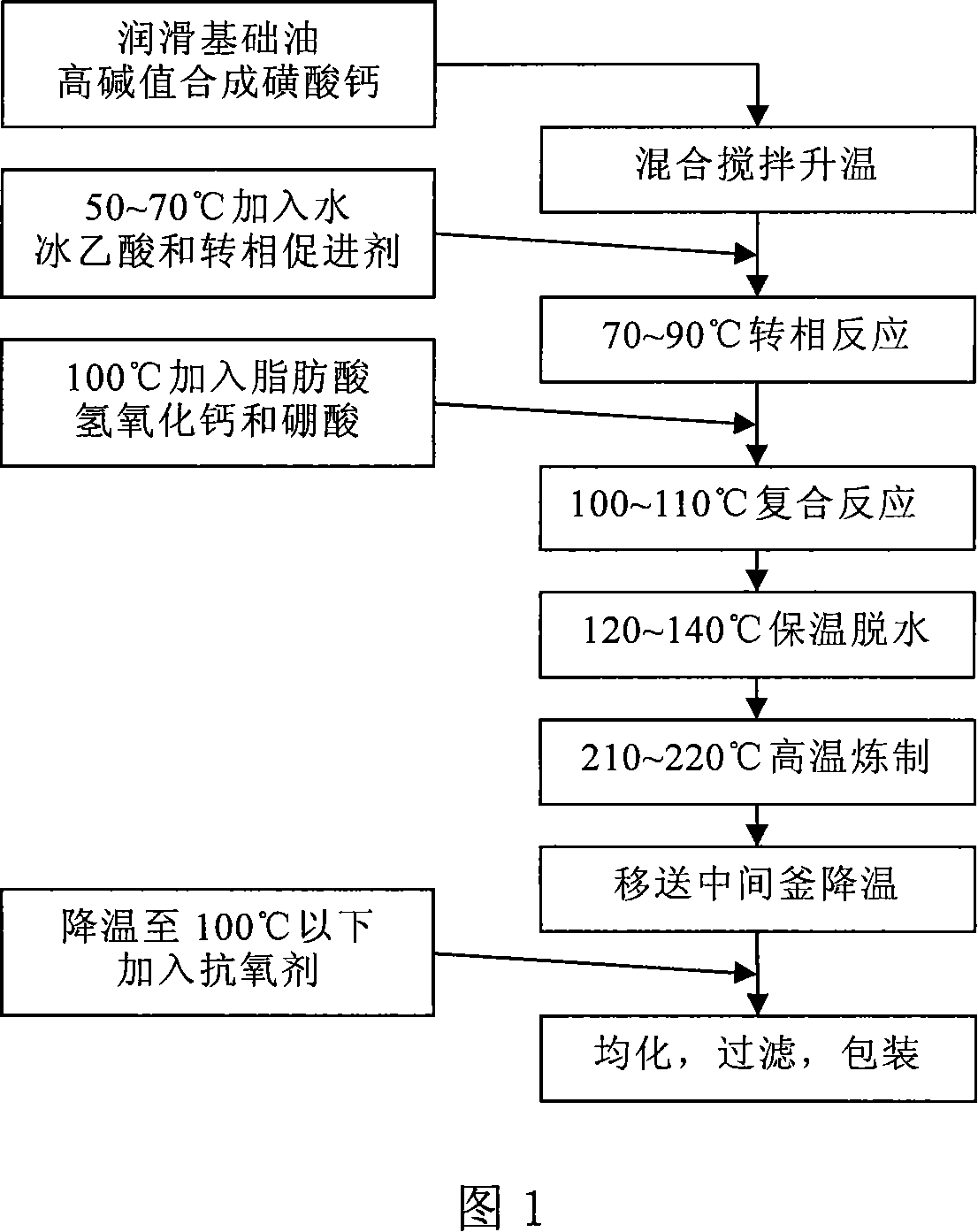

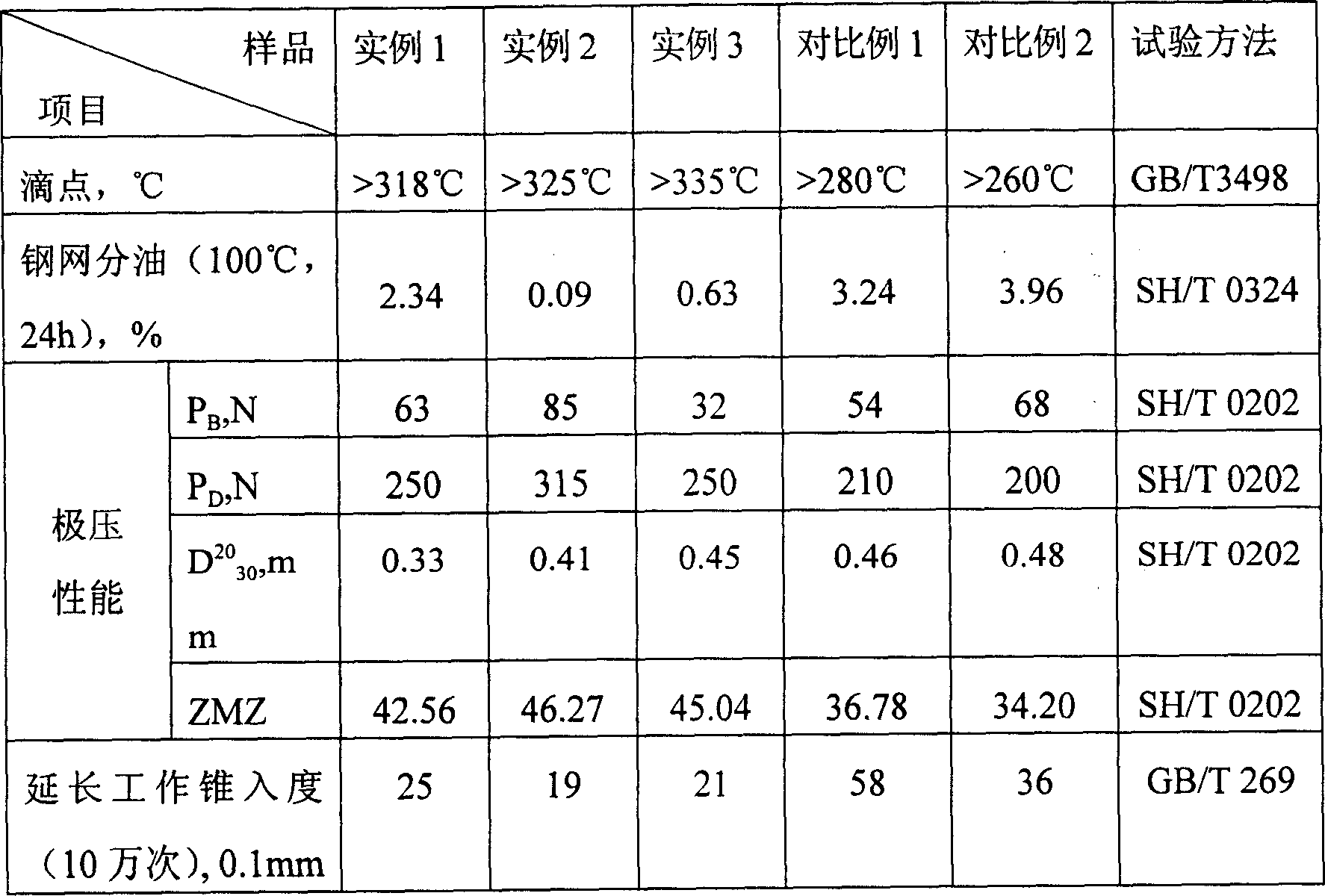

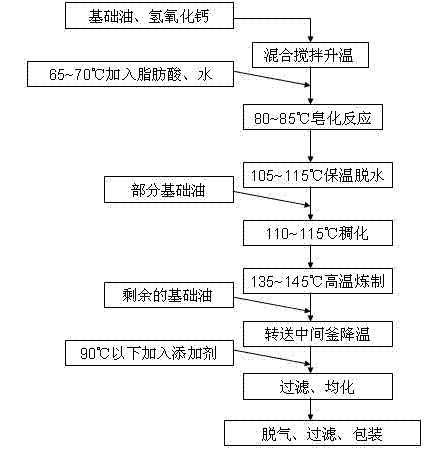

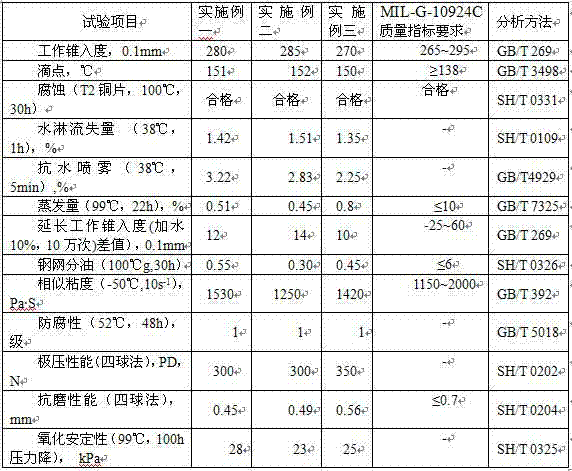

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

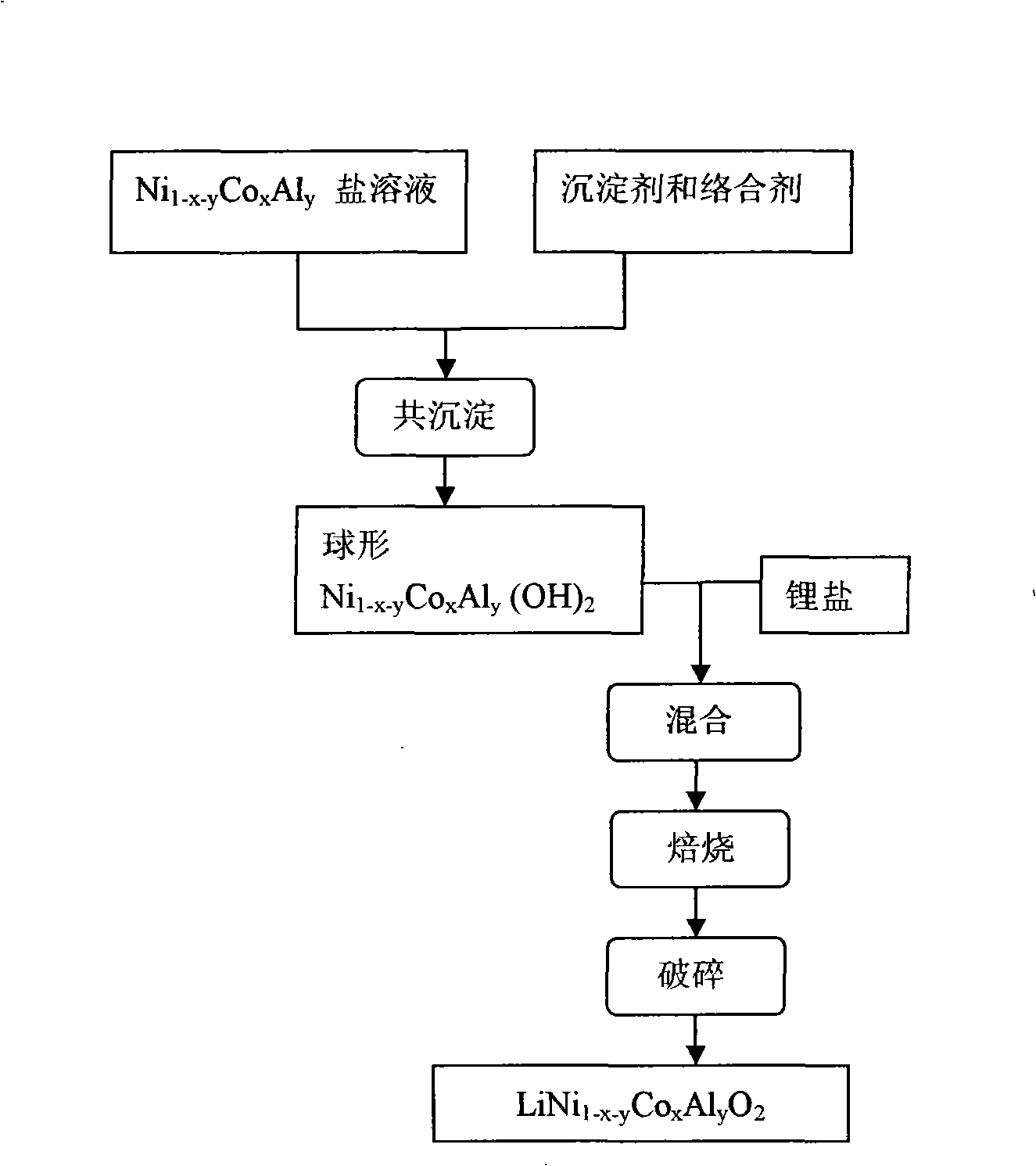

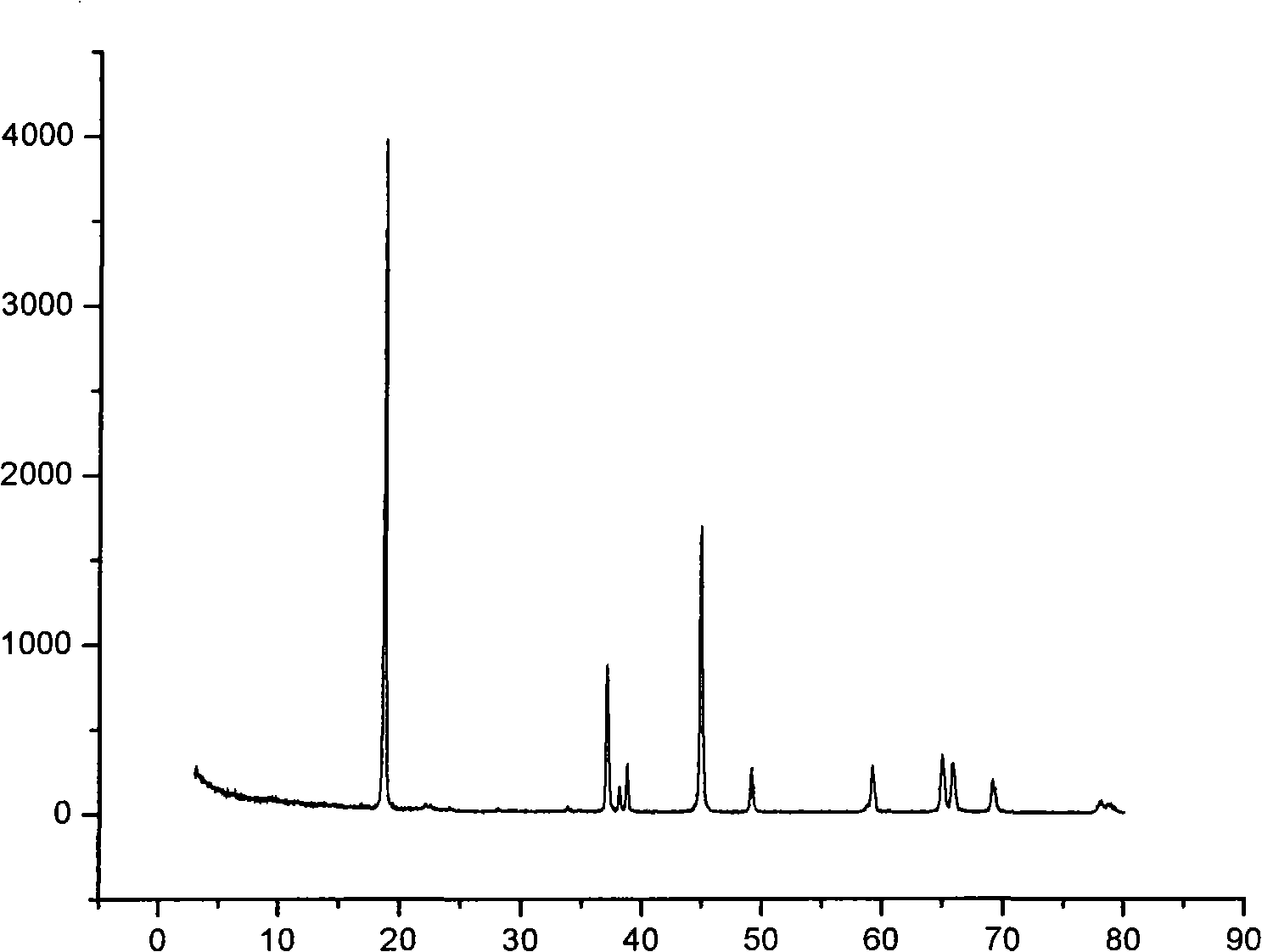

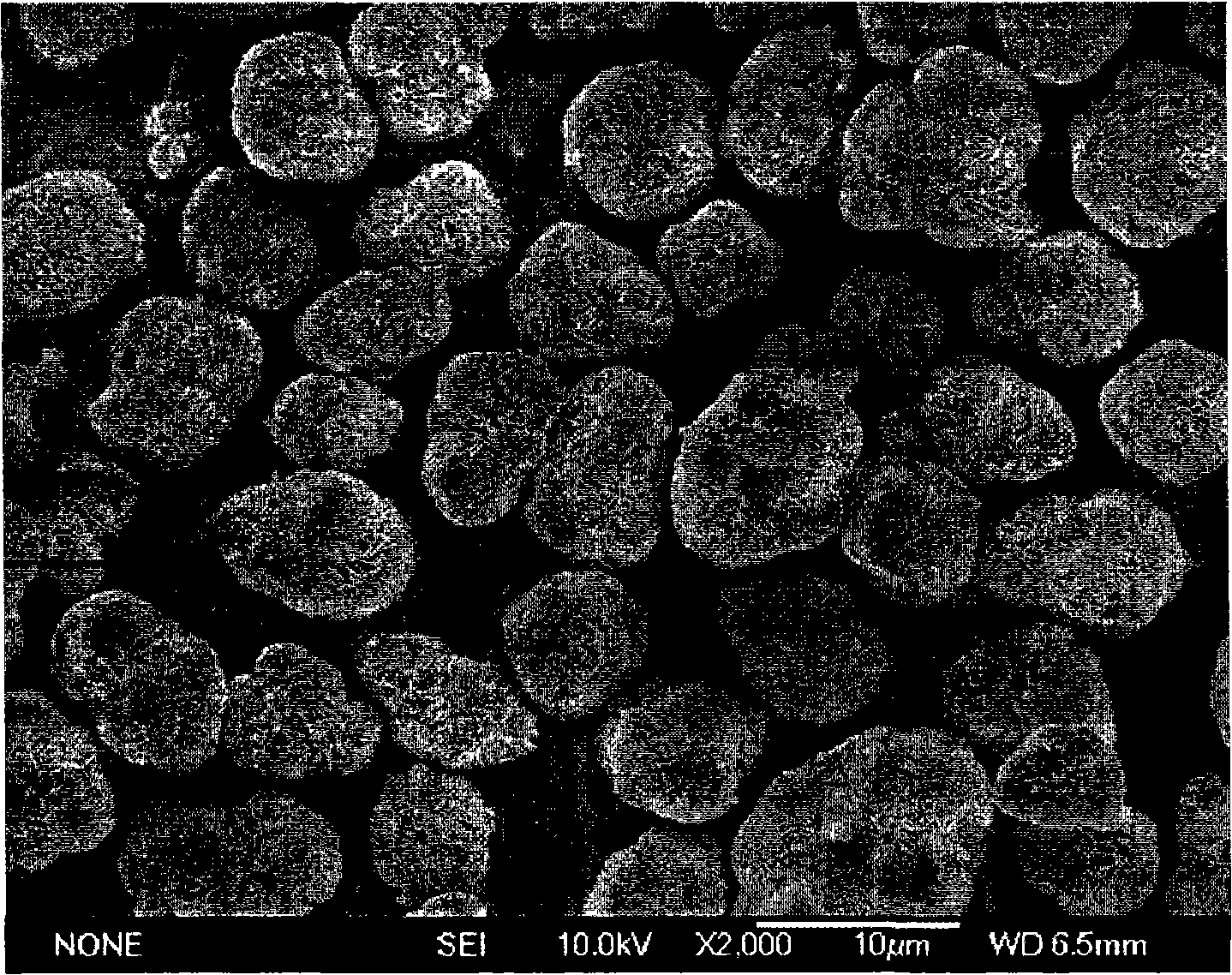

Spherical aluminum-doped nickel cobalt lithium for lithium ion battery and its making method

ActiveCN101262061AImprove liquidityImprove charge and discharge cycle stabilityElectrode manufacturing processesLithium compoundsDischarge efficiencyHigh rate

The invention discloses a preparation method of a spherical doped Al-Ni lithium cobalt oxide for lithium-ion battery. The preparation steps are that: first, sulfate, nitrate or chlorate of Al-Ni-Co react with strong alkali that is added with complex agent in liquid phase; the pH value, the temperature and the feeding speed of the reaction solution are controlled so as to produce a spherical precursor of Al-Ni-Co hydroxide; then the spherical precursor of Al-Ni-Co hydroxide is dried and evenly mixed with lithium hydroxide, lithium nitrate or lithium carbonate and dried; the obtained mixture is roasted into a spherical doped Al-Ni lithium cobalt oxide. The spherical doped Al-Ni lithium cobalt oxide has comparatively high tap density and remarkable cycle stability in the process of high-rate charge / discharge cycle, which improves over charge performance of Ni-Co substance and first obviously enhances charge / discharge efficiency; in addition, the preparation method of the spherical doped Al-Ni lithium cobalt oxide has the advantages of being simple, controllable and suitable for industrialized production with low energy consumption, high efficiency, short reaction time and low cost.

Owner:成都巴莫科技有限责任公司

Composite heavy metal polluted soil in-situ fixing method

ActiveCN102303041APromote mineralization reactionQuick fixContaminated soil reclamationWater insolubleMagnesium sulfite

The invention discloses a composite heavy metal polluted soil in-situ fixing method. The method comprises the following steps of: preparing a heavy metal polluted soil restoration agent by using 80 to 90 weight parts of bentonite or kaolin serving as a filling agent, 0.5 to 15 weight parts of ferrous sulfide, 0.5 to 5 weight parts of magnesium sulfate, 1.5 to 8 weight parts of magnesium sulfite, 1 to 5 weight parts of magnesium oxide, 2 to 10 weight parts of calcium hydroxide and 1 to 5 weight parts of phosphorus-containing preparation; and mixing the components and heavy metal polluted soil according to the weight ratio of 1:(5-20), and uniformly stirring to make the humidity of the soil kept between 15 and 30 percent, wherein heavy metal ions in the polluted soil are converted into water-insoluble metal sulfides, hydroxides, multi-metal co-precipitates, basic carbonates and phosphate minerals, the biological activity of heavy metal is lost, and the heavy metal is fixed in the soil. The restored soil meets the requirement of second-level standard values of 'Environmental Quality Standard for Soil' (GB 15618-1995) in China.

Owner:刘阳生

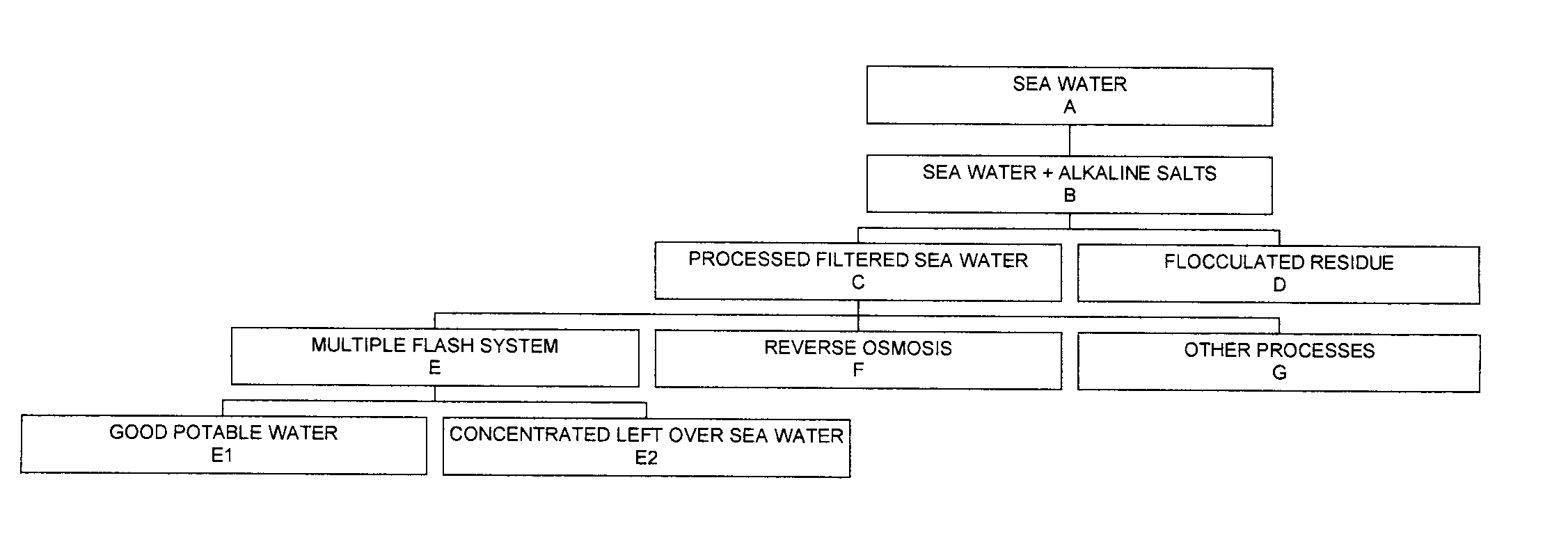

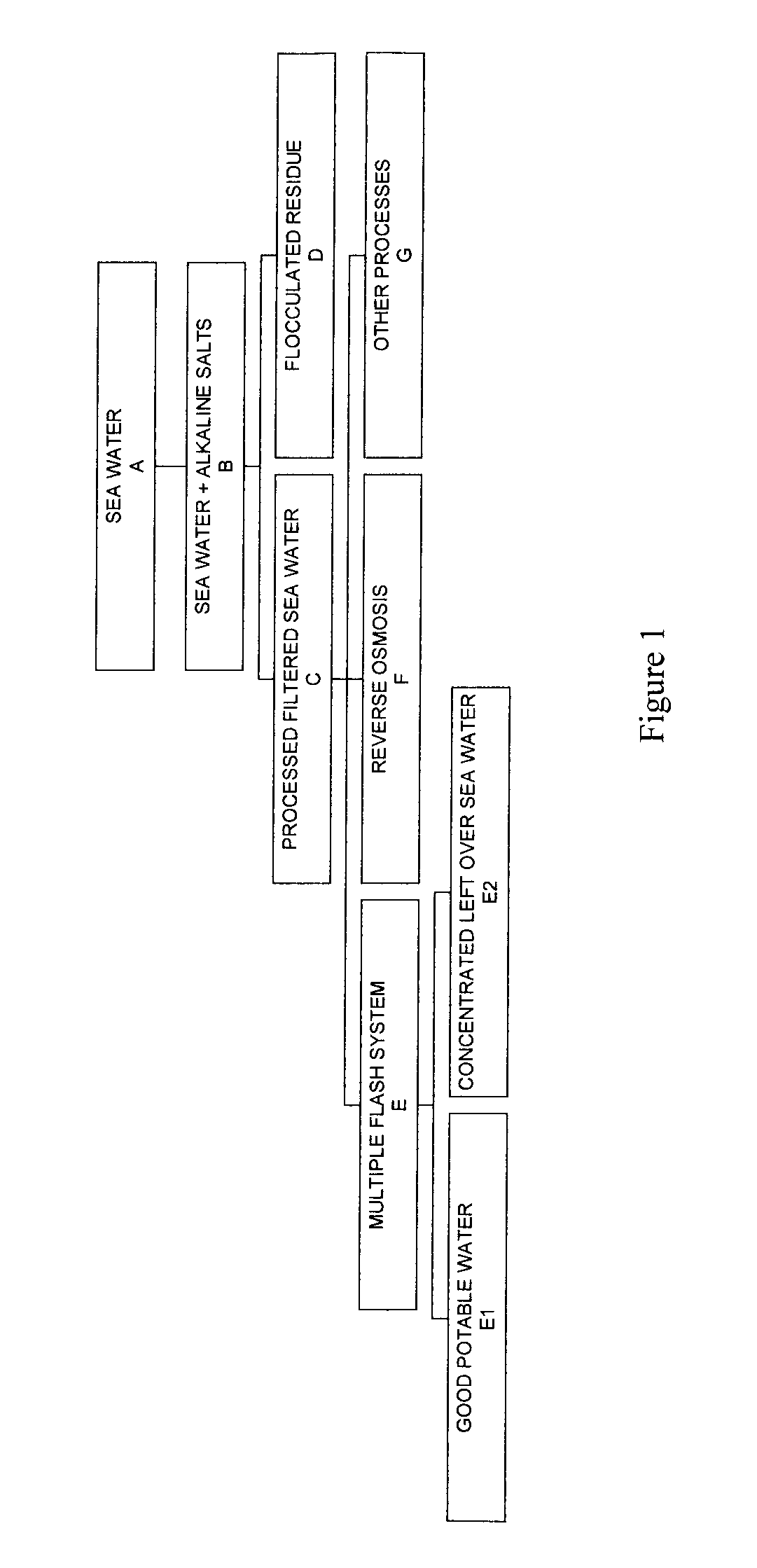

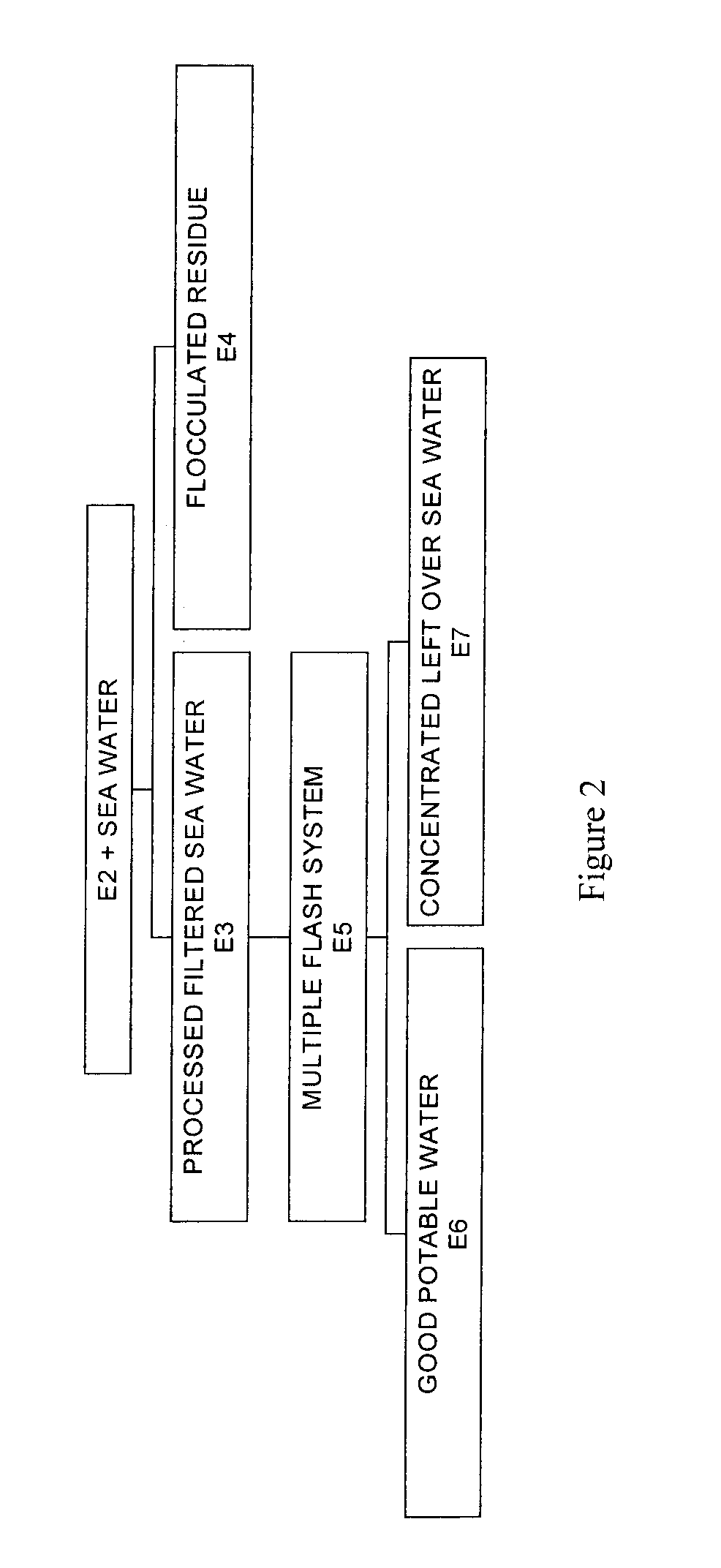

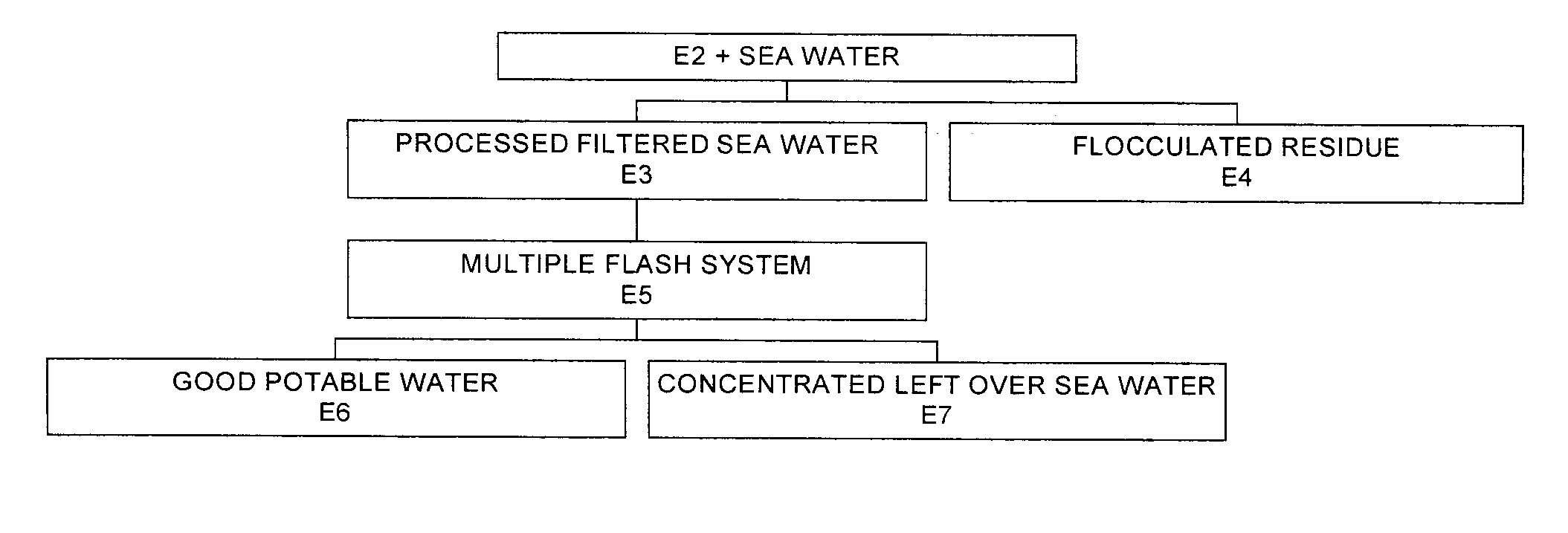

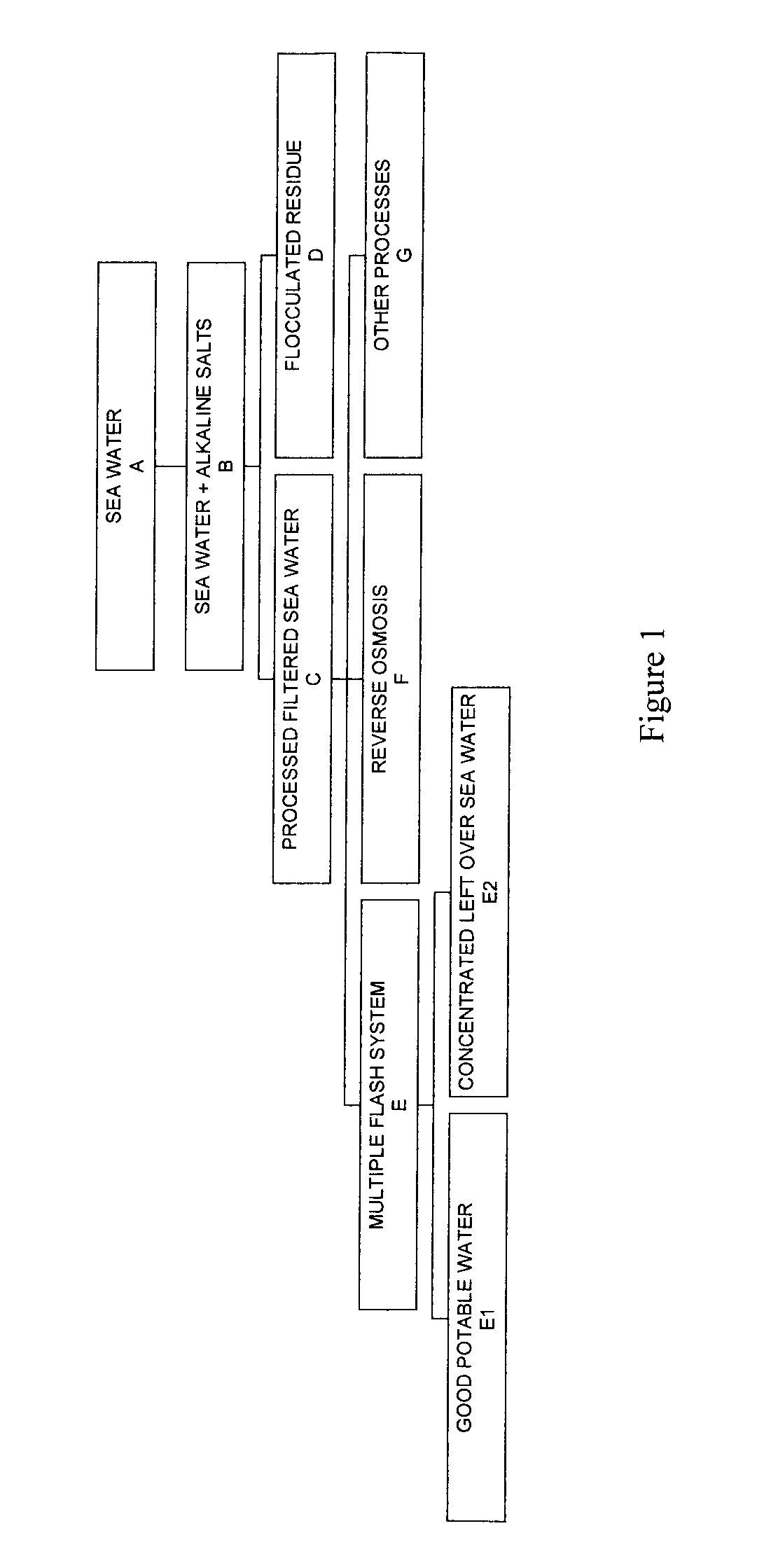

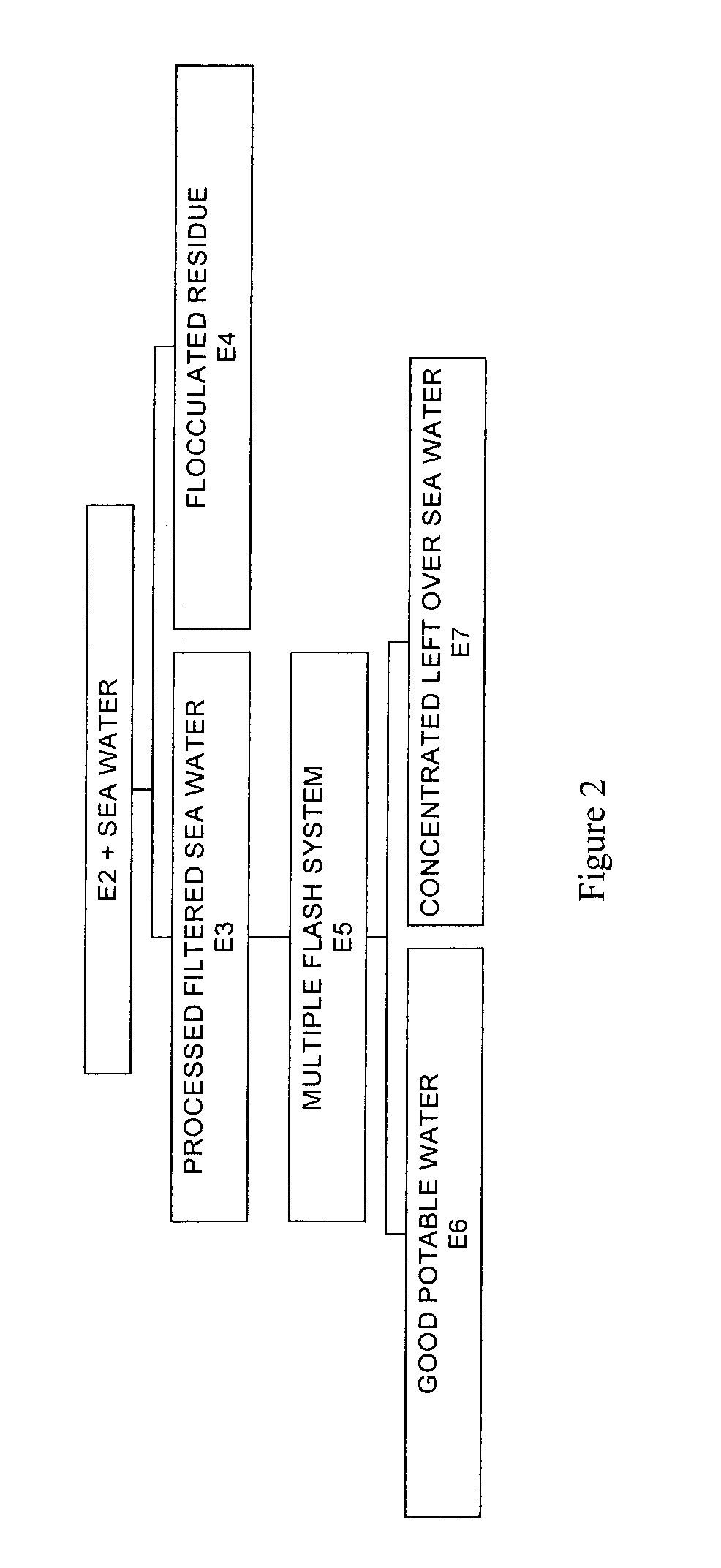

Process for pre-treating and desalinating sea water

ActiveUS20050098499A1Reduce maintenanceExtend equipment lifeGeneral water supply conservationSeawater treatmentCalcium bicarbonatePotassium hydroxide

Water containing dissolved salts, such as calcium sulfate, calcium chloride, magnesium sulfate, magnesium chloride, sodium carbonate, sodium chloride, sodium sulfate, calcium bicarbonate, and mixtures thereof, is treated to reduce the concentration of those salts. About 0.1 to about 60 g / L of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide, calcium carbonate, aluminum hydroxide, aluminum sulfate, aluminum potassium sulfate, and mixtures thereof is added to the water, whereby a precipitate forms in the water. The precipitate is separated from said water and the water is desalinated using reverse osmosis, flash evaporation, or another method. The process is preferably performed by first adding calcium oxide or calcium hydroxide, separating the precipitate that forms, then adding sodium hydroxide and sodium carbonate to form a second precipitate.

Owner:HUSSAIN MOHAMMED AZAM

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

Process for pre-treating and desalinating sea water

ActiveUS7198722B2Extend equipment lifeReduce maintenanceGeneral water supply conservationSeawater treatmentCalcium bicarbonateReverse osmosis

Owner:HUSSAIN MOHAMMED AZAM

Foamed fly ash cement compositions and methods of cementing

InactiveUS20050133221A1Easy to optimizeEasily fracturedDrilling compositionCoatingsCalcium hydroxideSlurry

Methods of cementing and low density foamed cement compositions therefor are disclosed. A low density foamed cement composition of the invention comprises fly ash comprising calcium oxide or calcium hydroxide, water present in an amount sufficient to form a slurry, a foaming and foam stabilizing surfactant or a mixture of surfactants present in an amount sufficient to facilitate foam and stabilize the foamed cement composition, and sufficient gas to foam the foamed cement composition.

Owner:HALLIBURTON ENERGY SERVICES INC

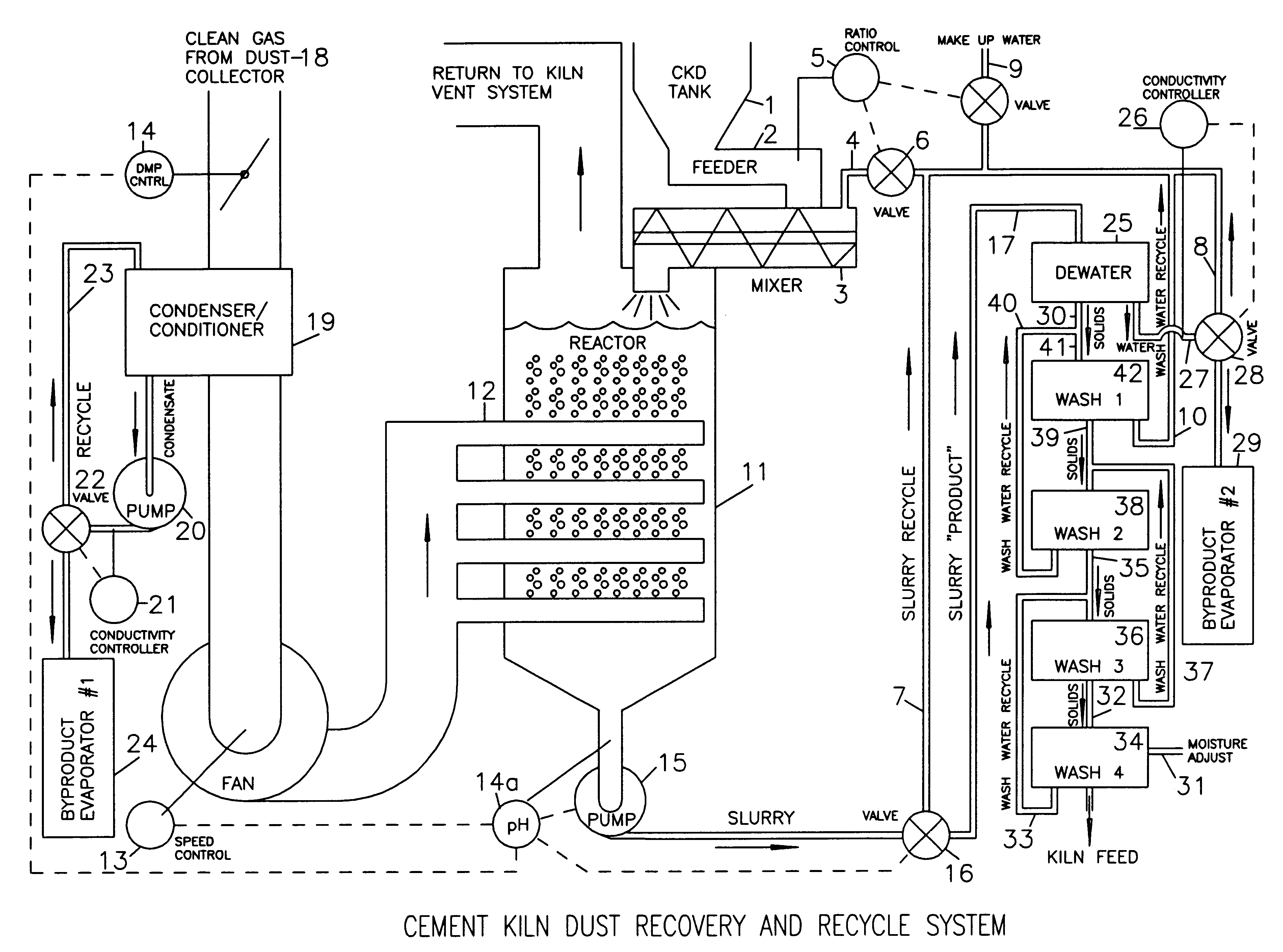

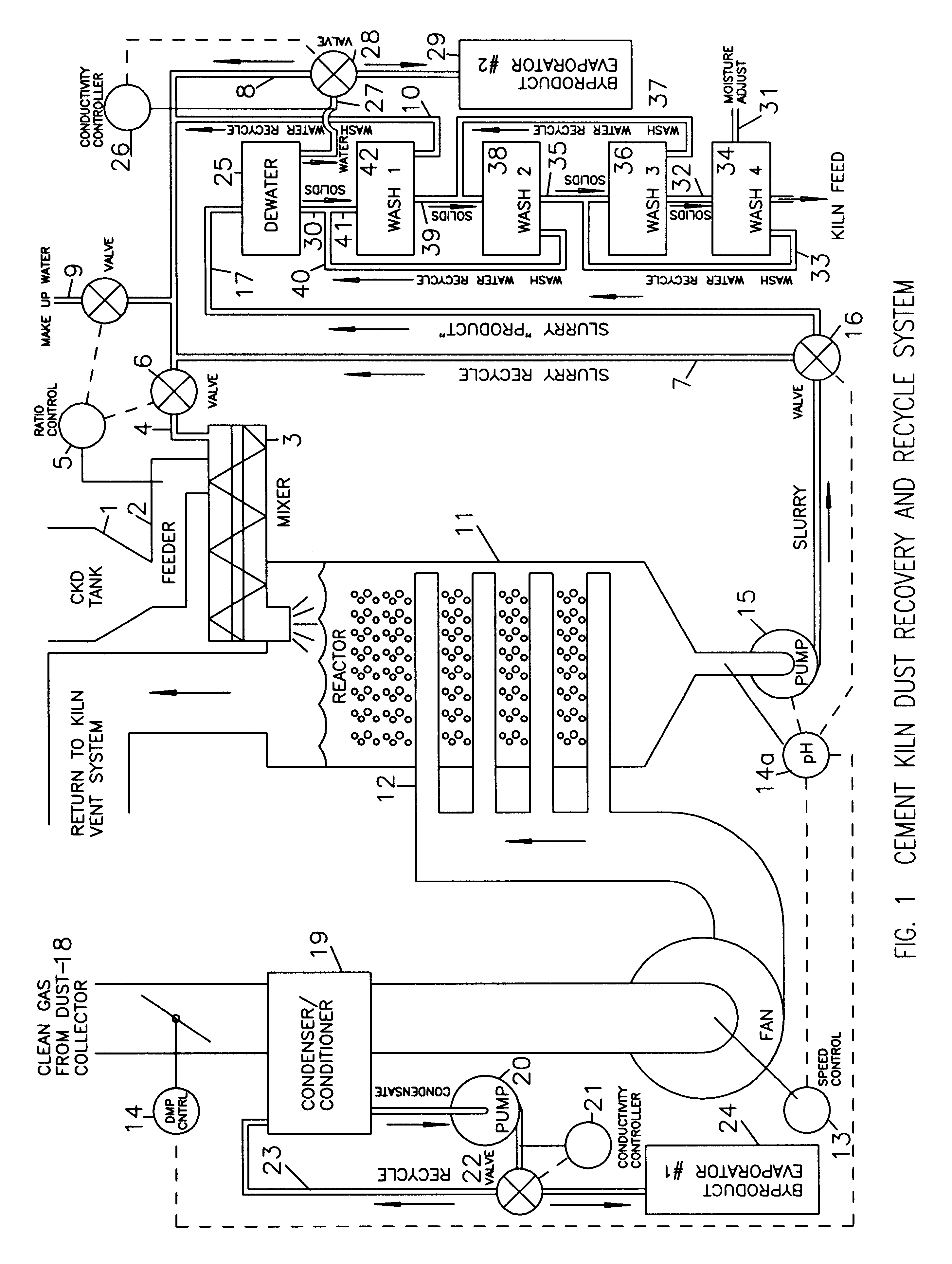

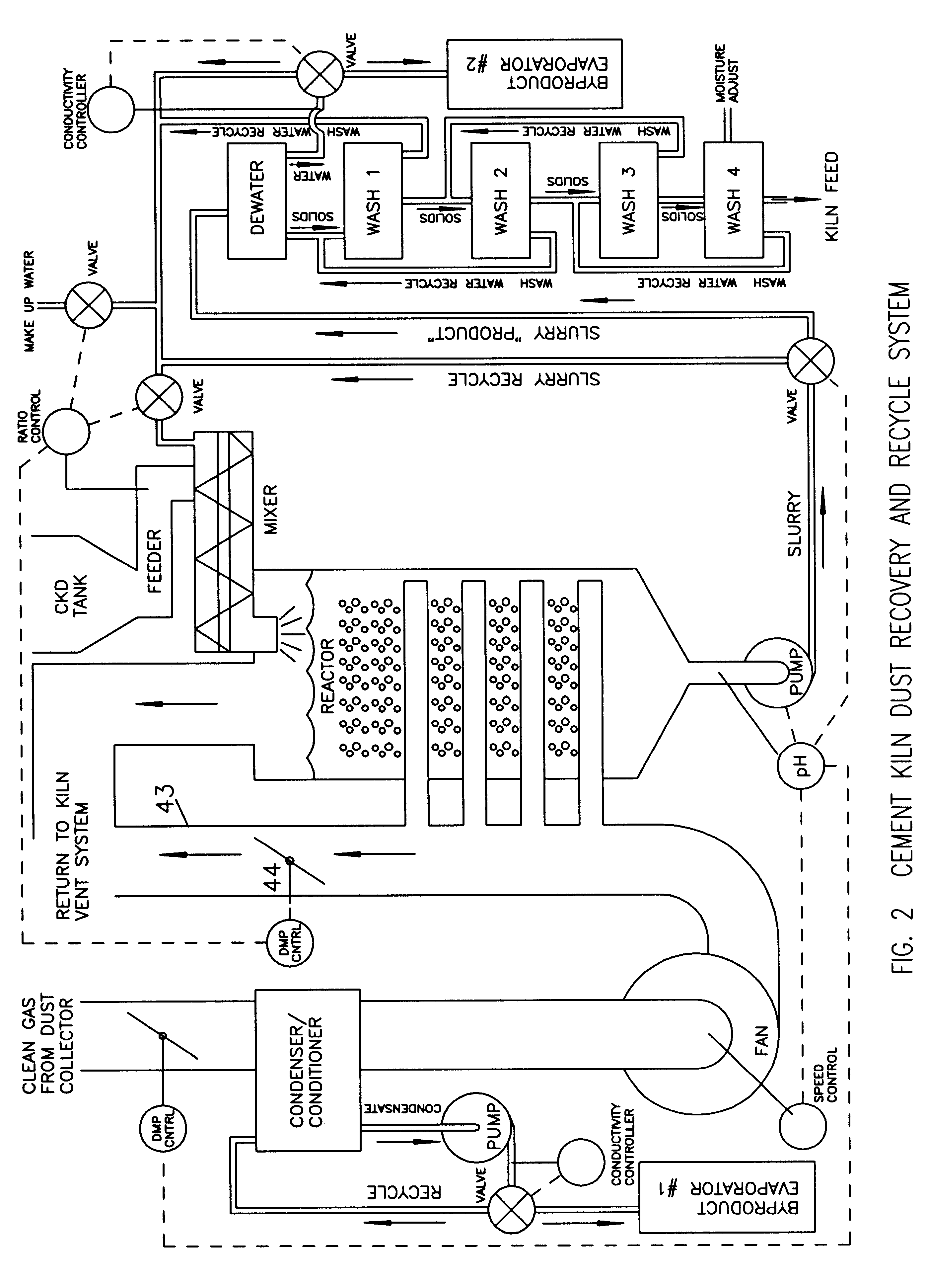

Method of treating cement kiln dust for recovery and recycle

Fresh or stockpiled cement kiln dust is moistened with sufficient water so that the amount of total free and combined water relative to dust is about 3 parts water to 1 part dust by mass, or less. The wet solids are treated with carbon dioxide to convert compounds, such as calcium hydroxide, to carbonates, such as calcium carbonate. The degree of carbonation is controlled so that the solubility of calcium becomes minimum for the dust being treated; this is also when hydroxyl and bicarbonate ions in solution are about at their minima. As the carbonation reactions occur, the water combined in hydroxides is released as free water so that the mixture becomes a slurry and the potentially soluble alkalies and sulfate (and any chlorides present) are released to the liquid phase. The solids are separated from the liquid, and the solids, which may be washed, provide a material suitable for return as feed to the kiln. The liquid, which contains the dissolved alkali compounds, is recycled to reclaim additional dust or treated to recover alkali salts when the alkali salts are sufficiently concentrated.While any source of carbon dioxide may be used, the preferred source is exit gases from the kiln. The gases are conditioned by condensation of water and removal of ammonium compounds, such as sulfate and chloride. The conditioning condensate may be treated to recover useful byproduct salts.

Owner:GEBHARDT RONALD FR

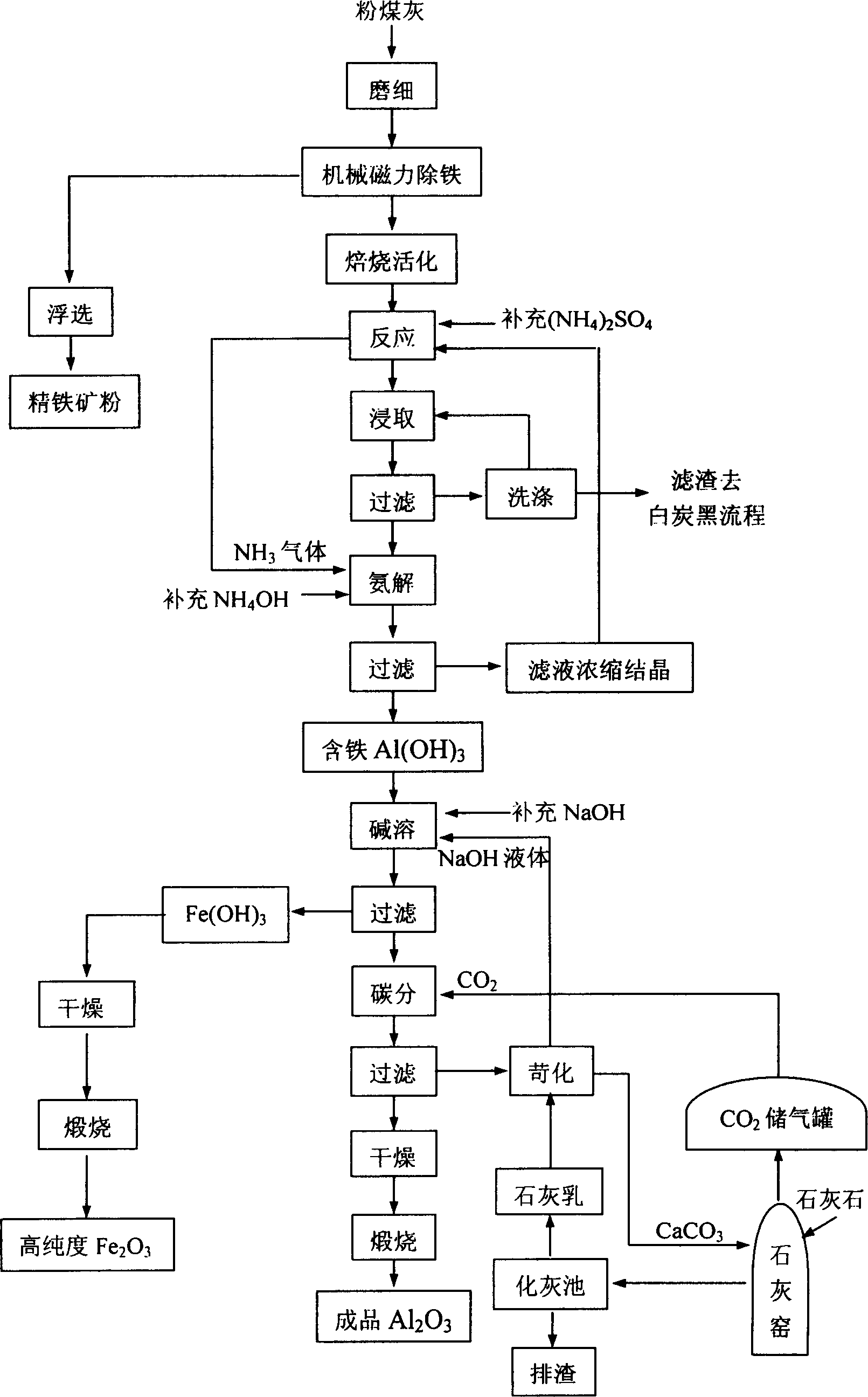

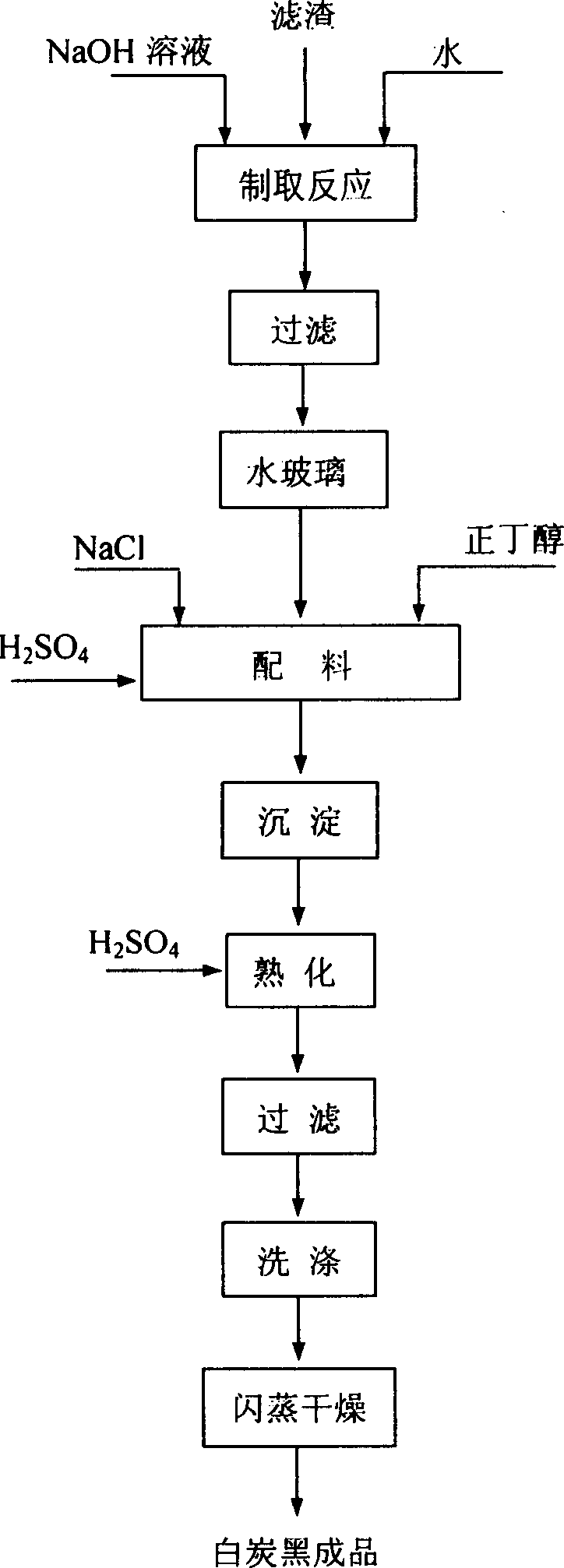

Method of extracting aluminium oxide from fly ash and simultaneously producing white carbon black

InactiveCN1868884AHigh activityUniform particle sizeSilicaAluminium oxides/hydroxidesAluminium hydroxideCoal

A process for extracting alumina from powdered coal ash while generating white carbon black includes such steps as grinding powdered coal ash, activating, adding ammonium sulfate, reacting, adding water, filtering, filling ammonia gas into the filtered liquid to obtain the deposited mixture of aluminum hydroxide and iron hydroxide, adding the solution of sodium hydroxide to dissolve the aluminum hydroxide deposit, adding carbon to obtain pure aluminum hydroxide, and calcining to obtain Al2O3.

Owner:NORTH UNITED POWER CO LTD

Preparation method of polyurea-composite calcium lubricating grease

InactiveCN1493673APrevent volatilizationImprove high temperature performanceAdditivesCalcium hydroxideOrganic acid

A lubricating polyureas-composite calcium grease is prepared through proportionally mixing basic oil, calcium hydroxide (oxide), water and C1-C20 organic acid together, heating to 30-100 deg.C, adding diisocyanate and organic amine, draining water, saponifying, heating to 210-230 deg.C, cooling and homogenizing. Its advantages are high refractory performance, stability and extreme-pressure antiwear nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of aerated concrete

ActiveCN101823864AIncreased durabilityExcellent mechanical propertiesSolid waste managementCeramicwareCalcium hydroxideFoaming agent

The invention discloses a manufacturing method of aerated concrete, which comprises the following steps of: preparing liquid feed liquid; precuring; mixing an amorphous silicon material and water to prepare amorphous silicon material slurry; then mixing the amorphous silicon material slurry, the liquid feed liquid, a crystalline silicon material, one of calcined lime or calcium hydroxide or lime milk, dihydrate gypsum or semi-hydrated gypsum, ordinary portland cement, feldspar materials, strength intensifier, calcined lime digestion regulator, bubble regulator, lubrication tackifier, water repellent, a foaming agent and water; stirring the mixture at the speed of between 800 and 1,500rpm for 3 to 7 minutes to prepare foam slurry; and performing standing curing and still kettle curing to prepare the aerated concrete. The product obtained by the manufacturing method has the characteristics of light weight, high strength, flame retardance, heat preservation, heat insulation, hydrophobic property, long service life, impact resistance, small shrinkage, and the like; moreover, the material sources are wide, and the products are simple and convenient to process and manufacture.

Owner:吴智深 +2

Flue Gas Scrubbing

ActiveUS20110123422A1Reduce its mercury concentrationGas treatmentMolecular sieve catalystsCalcium hydroxideFlue gas

Herein is disclosed a flue gas scrubbing composition, a method of using the flue gas scrubbing composition, and a method of entombing mercury collected with the flue gas scrubbing composition. The flue gas scrubbing composition includes an admixture of a mercury sorbent material that comprises a clay, copper, and sulfur; and lime that comprises calcium oxide and / or calcium hydroxide. The method of collecting mercury from a flue gas includes injecting the flue gas scrubbing composition of any one of the preceding claims into a flue duct comprising the flue gas; reacting the mercury sorbent material with mercury in the flue gas to form a mercury-sorbed material and thereby reducing the concentration of mercury in the flue gas; reacting the lime with SO2, SO3, and / or HCl in the flue gas to form a calcium sulfate and / or a calcium chloride; and collecting a mixture that includes the mercury-sorbed material. The method of entombing mercury includes mixing the collected mixture of any one of claims 6 to 9 with water to form a freshly mixed concrete; and casting the freshly mixed concrete into a form.

Owner:AMCOL INTERNATIONAL CORPORATION

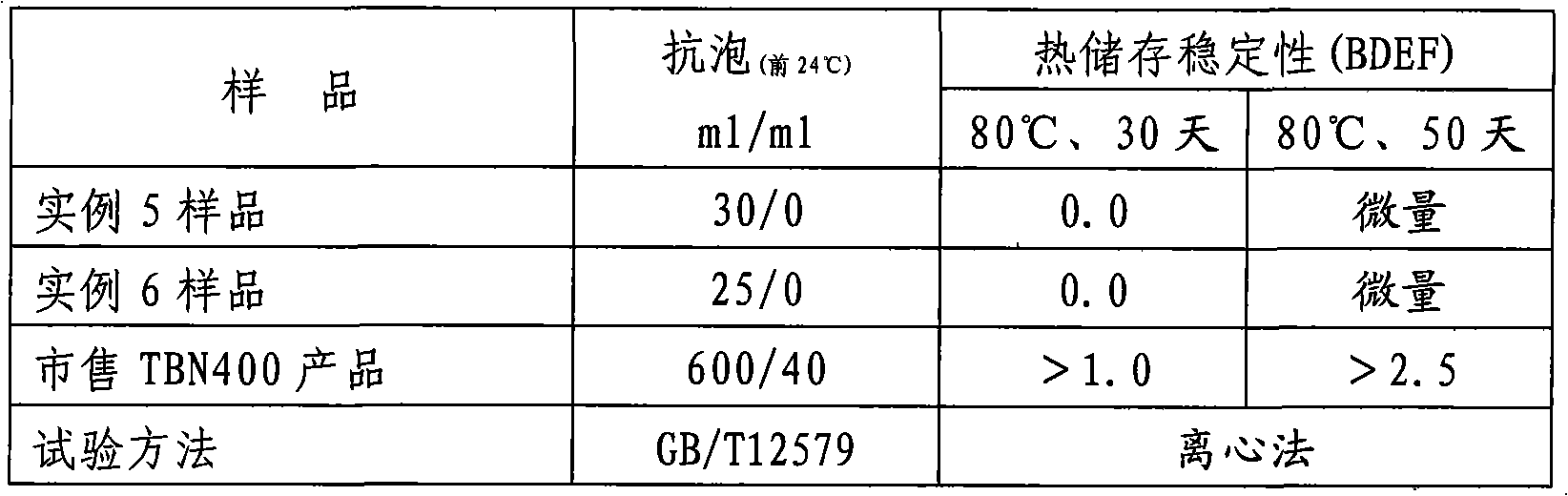

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

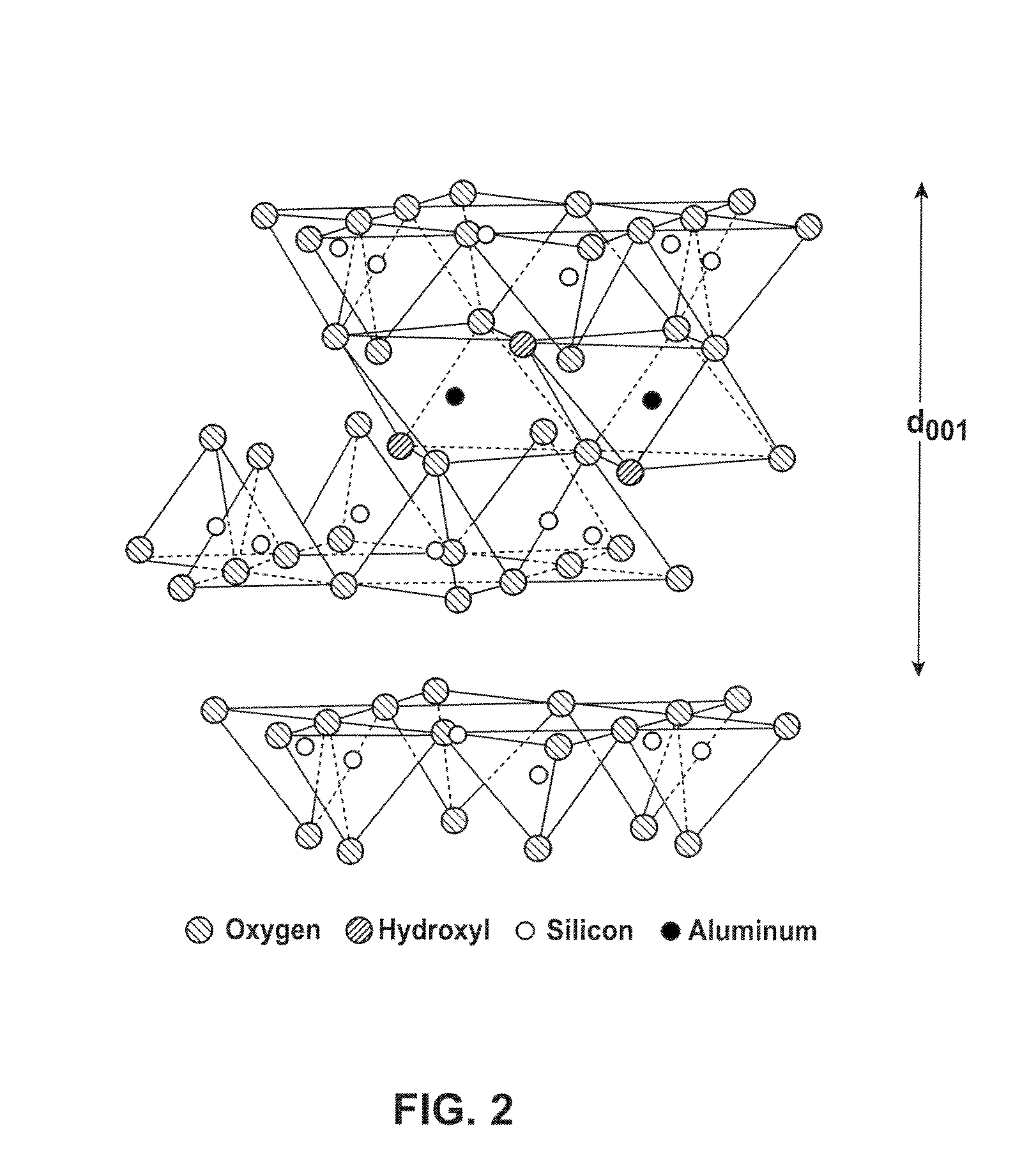

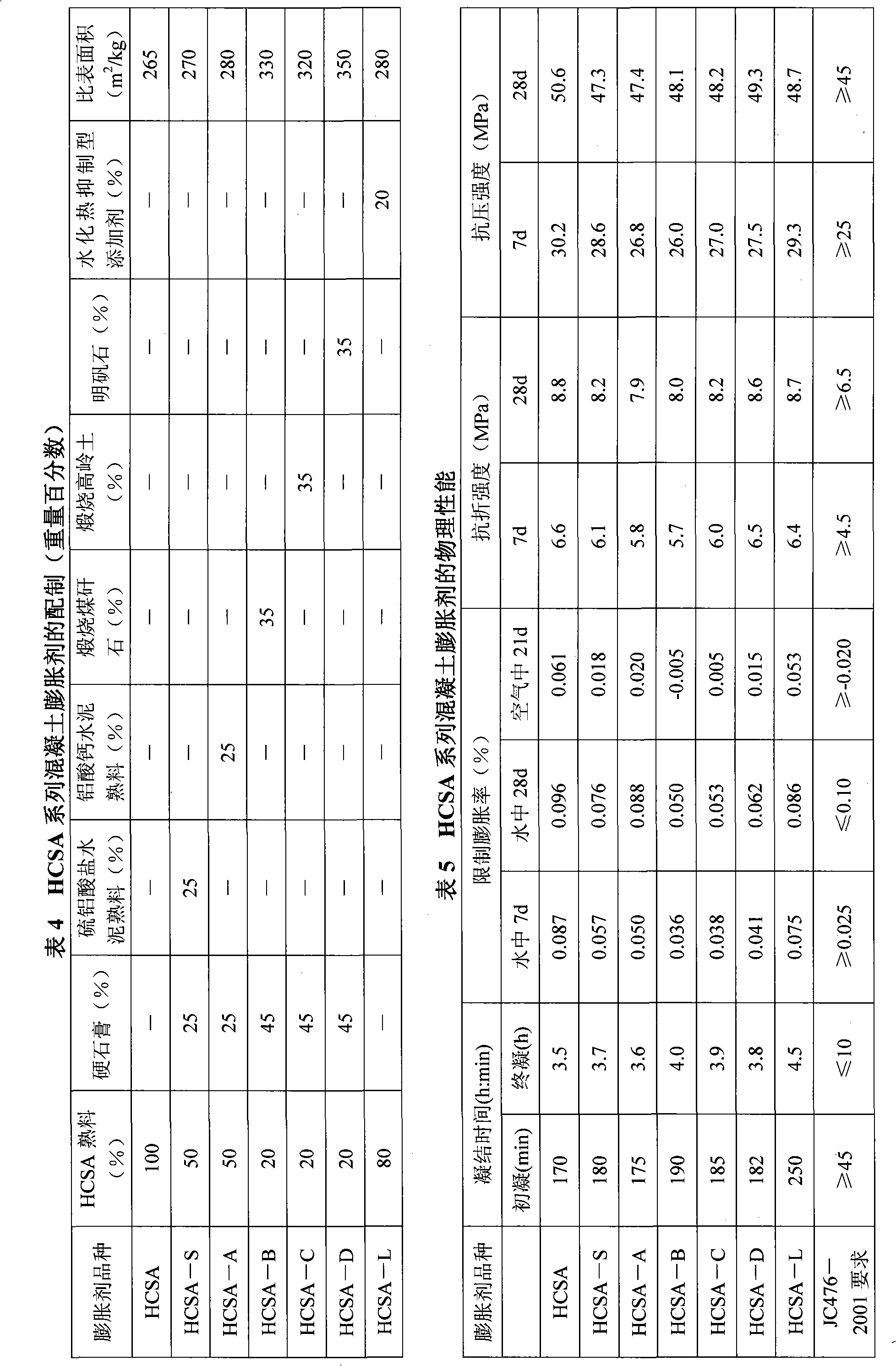

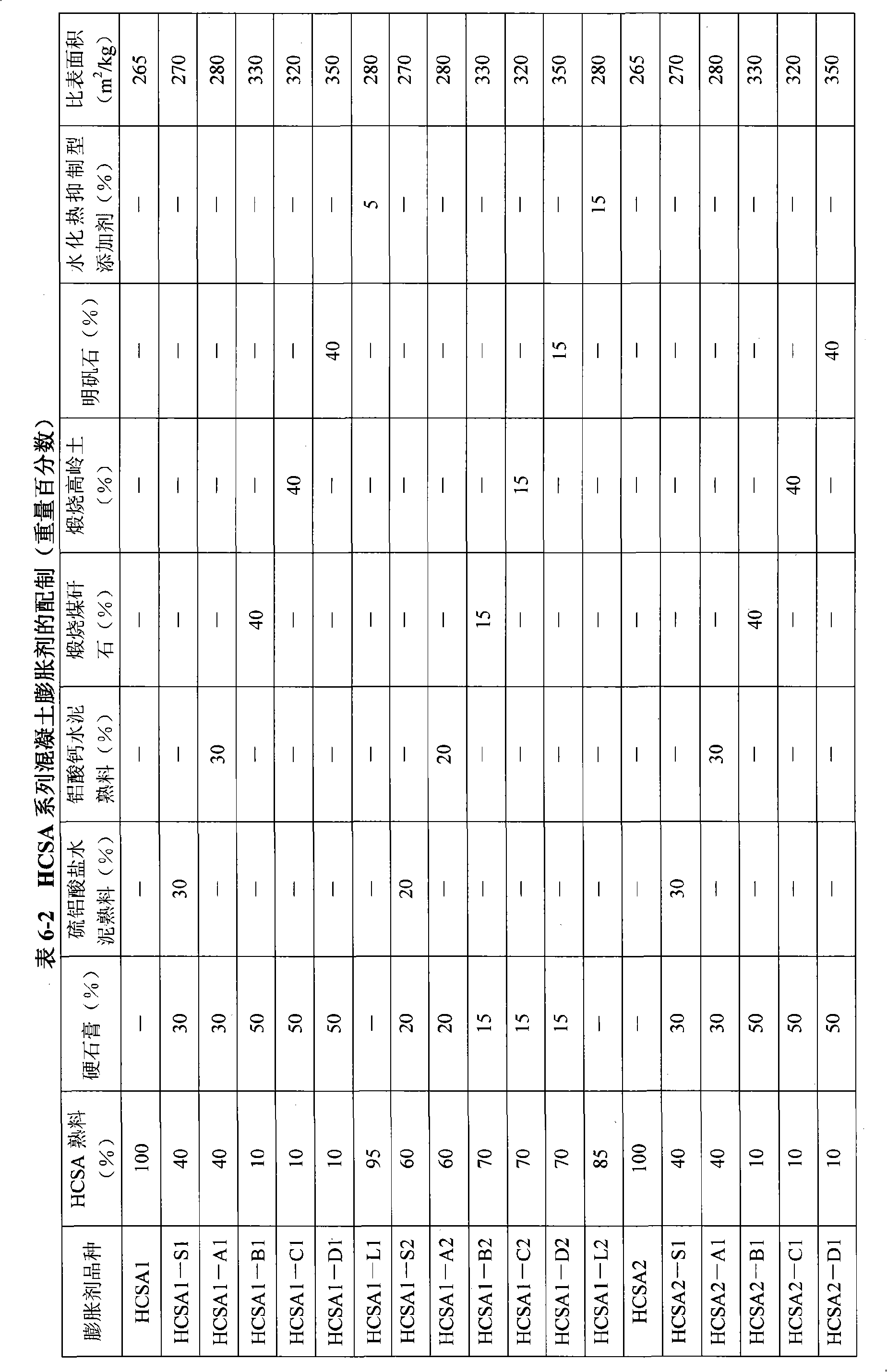

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

Anhydrous albany grease and preparation method thereof

ActiveCN102757847AMeet the requirements of wide temperature rangeExcellent water shear stabilityLubricant compositionChemical industryCalcium hydroxide

The invention belongs to the technical field of the chemical industry, and relates to grease and a preparation method thereof, in particular to anhydrous albany grease and the preparation method thereof. The anhydrous albany grease and the preparation method comprises the following components by weight: 82-90% of base oil, 1-4% of calcium hydroxide, 6-15% of fatty acid, 0.3-1% of antioxygen, 0.5-1.5% of rust inhibitor, and 0.5-3% of extreme pressure antiwear additive. The anhydrous albany grease and the preparation method have the benefits as follows: the grease is simple in preparation process and easy to control; and the prepared product has better water erosion resistance, favorable metal adhesivity and extreme pressure abrasion resistance, and can provide outstanding lubrication and abrasion resistance protection for wheel bearings and chassis.

Owner:JIANGSU LOPALTECH

Calcium Carbonate Based Sulfonate Grease Compositions and Method of Manufacture

ActiveUS20130109602A1Saving expenseShorten the timeThickenersAdditivesCalcium carbonateCalcium hydroxide

An overbased calcium sulfonate grease composition comprising a reduced amount of overbased calcium sulfonate, added calcium carbonate, base oil, one or more converting agents, and one or more complexing acids if a complex grease is desired. The calcium sulfonate grease composition improves thickener yield and expected high temperature utility as demonstrated by dropping point. The calcium carbonate may be used to react with complexing acids when making a complex grease, such that the addition of calcium oxide or calcium hydroxide is not required. A method of making the composition comprising the steps of mixing the overbased calcium sulfonate and base oil, adding the calcium carbonate, adding one or more converting agents, and adding one or more complexing acids. All or a portion of one or more of the complexing acids may be added with or prior to the one or more converting agents.

Owner:NCH CORP

Plugging flexibilizer

ActiveCN103740346AImprove flexural strengthGood toughening effectDrilling compositionCellulosePetroleum

The invention discloses a plugging flexibilizer, comprising the components in parts by weight: 5-12 parts of polypropylene fiber, 20-30 parts of rubber particles, 1-5 parts of high molecular polyacrylamide, 2-8 parts of toughened nylon, 2-8 parts of asbestos section, 5-12 parts of plant fibers, 4-7 parts of calcium hydroxide, and 0.1-0.4 part of polyanionic cellulose PAC-HV. A preparation method of the plugging flexibilizer comprises the following steps: orderly adding the components in parts by weight to a kneading machine according to a conventional preparation method at constant temperature and constant pressure; evenly mixing and stirring; and crushing into a 0.05-1mm granular product. The plugging flexibilizer has the characteristics of being wide in material source, free of toxicity and pollution, simple and convenient in construction technology, good in rheological property, good in pillar-forming property, strong in tenacity, not easy to fragilely fall off, high in plugging success rate and the like, does not easily generate a rupture and a brittle fracture in the drilling process after plugging, and is widely applied to pressure-loaded plugging engineering of low-pressure fractured formation, large cracks, large caves, subterranean rivers and serious voidage formation in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

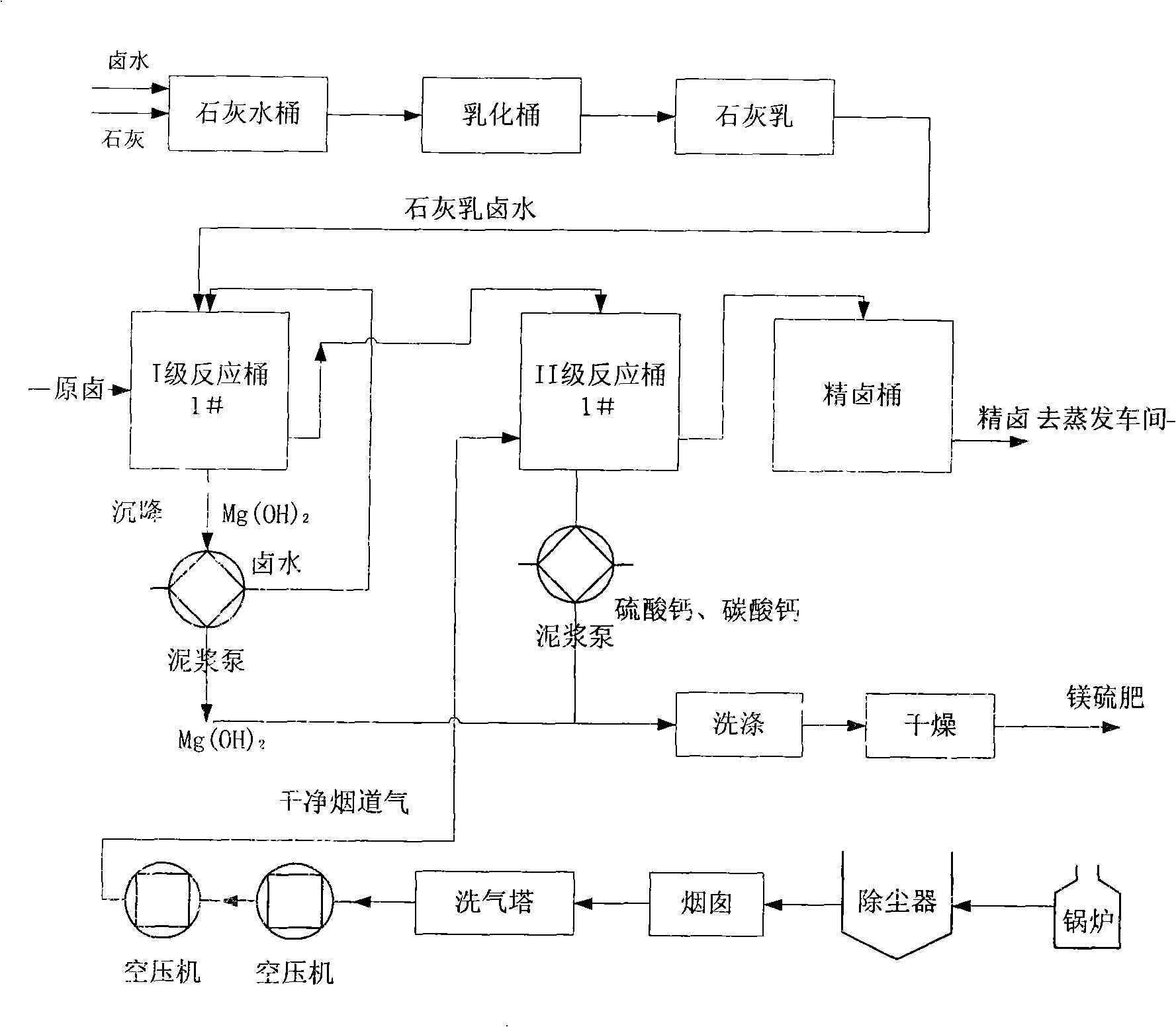

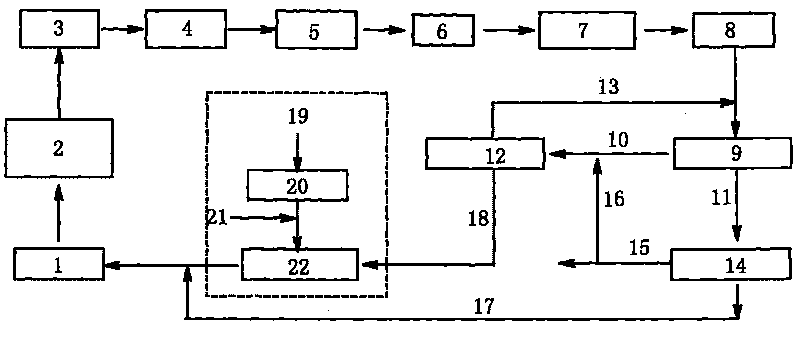

Technological process for purifying bittern

InactiveCN101289200AReduce purification costsImprove purification qualityAlkali metal chloridesSlurryCalcium carbonate precipitation

The invention provides a brine purification technical method which comprises that: a first step is that limewater is added into brine so that reaction happens to calcium hydroxide in the limewater and magnesian ion in the brine to generate magnesium hydrate sedimentation, the magnesian ion in the brine is removed, excessive calcium hydroxide is used for causticizing the sodium sulfate in the brine into sodium hydroxide; a second step is that flue gas is put into the brine after the magnesian ion is removed for carrying out reaction between carbon dioxide in the flue gas and the sodium hydroxide causticized in the brine to generate sodium carbonate which reacts with calcium ion in the brine to generate calcium carbonate sedimentation, the calcium ion in the brine is removed; a third step is that slurry produced in the first step and the second step is collected; and a fourth step is that refined brine after being treated by the first step and the second step is recycled. The technical method can reduce the pollution to environment, can save energy, and can reduce the consumption of raw brine and the purification cost of the brine at the same time, thereby conforming to the requirements of the strategy of sustainable development.

Owner:CHINA NATIONAL SALT INDUSTRY CORPORATION +1

Method for preparing vanadium pentoxide

InactiveCN1843938AMeet the needs of domestic chemical productionVanadium oxidesCalcium hydroxideSodium aluminate

The invention relates to a method for preparing vanadic anhydride. It comprises following steps: employing ammonium vanadate, vanadic anhydride of technical grade or waste catalyst discharged in sulfuric acid preparation process; treating with ammonium hydroxide, sulfuric acid and ammonium chloride, washing with water; getting fine active vanadic anhydride; removing foreign matter with ammonium hydroxide, calcium hydroxide, sodium aluminate, sodium silicate, sulfuric acid and ammonium chloride; washing with water again; drying; calcing at 670 Deg. C and getting high-purity vanadic anhydride. The invention is characterized in that it makes use of current material to prepare chemical materials urgently needed by industrial production, and saves a large amount of foreigh exchange.

Owner:宿素满

Nano-zinc oxide coated sericite powder composite material and preparation method thereof

InactiveCN104017393AImproves UV resistanceImprove antibacterial propertiesCosmetic preparationsInorganic pigment treatmentCalcium hydroxideOrganic solvent

The invention discloses a sericite / nano-zinc oxide composite material and a preparation method thereof. The composite material is characterized in that the surface of sericite powder is coated with nano-zinc oxide. The preparation method comprises the following step: adding calcium hydroxide or calcium oxide into a mixed system of the sericite powder and zinc sulfate solution so as to directly obtain the nano-zinc oxide coated sericite powder composite material. According to the method, the sericite which is taken as a base material is a natural mineral, so that the raw material is easily available, free of pollution and low in cost; the preparation process is simple, safe, reliable and easy to control; the obtained composite material is stable in quality, and has the good dispersibility in an organic solvent and also has the excellent ultraviolet resistance and the excellent antibacterial and deodorant performance. Thus, the composite material can be applied to the field of coatings, cosmetics and the like. The method has a good potential application value in the field of synthesis of the composite material or other related sciences.

Owner:ANHUI HENGHAO SCI & TECH

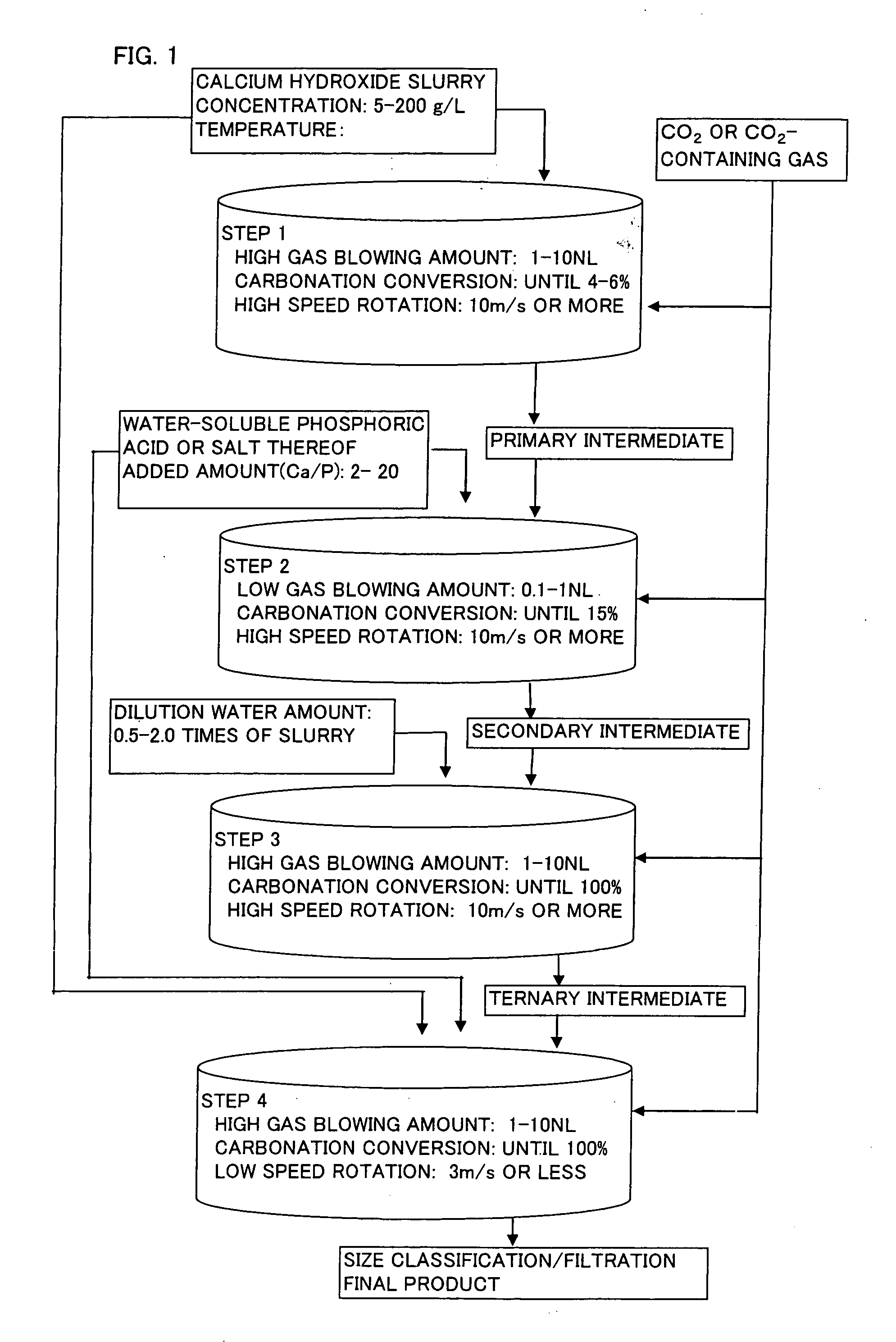

Spherical calcium carbonate and method for producing thereof

InactiveUS20060165583A1Inferior physical propertyLow blowing rateCalcium/strontium/barium carbonatesCosmetic preparationsCalcium hydroxideO-Phosphoric Acid

When spherical calcium carbonate is produced by blowing a carbon dioxide gas or a carbon dioxide-containing gas into an aqueous suspension containing calcium hydroxide to react them, after start of the reaction, an aqueous solution or suspension of a water-soluble phosphoric acid compound or a water-soluble salt thereof is added to the reaction mixture when carbonation ratio reaches 2 to 10%, and the reaction is further allowed to continue at a low gas blowing rate of 1.0 NL / minute or lower (step (a)). Subsequently, an aqueous suspension containing calcium hydroxide and an aqueous solution or suspension of a water-soluble phosphoric acid compound or a water-soluble salt thereof are added to the reaction mixture, and a carbon dioxide gas or a carbon dioxide-containing gas is introduced to allow to react and thereby produce spherical calcium carbonate having a mean particle diameter of 10 μm or larger. This production method is performed under high velocity revolution from the start of the reaction to the end of the step (a) This method provides calcite type spherical calcium carbonate showing high brightness and small friction coefficient, and having a shape comparatively close to a true sphere and a mean particle diameter of 10 μm or larger.

Owner:OKUTAMA IND

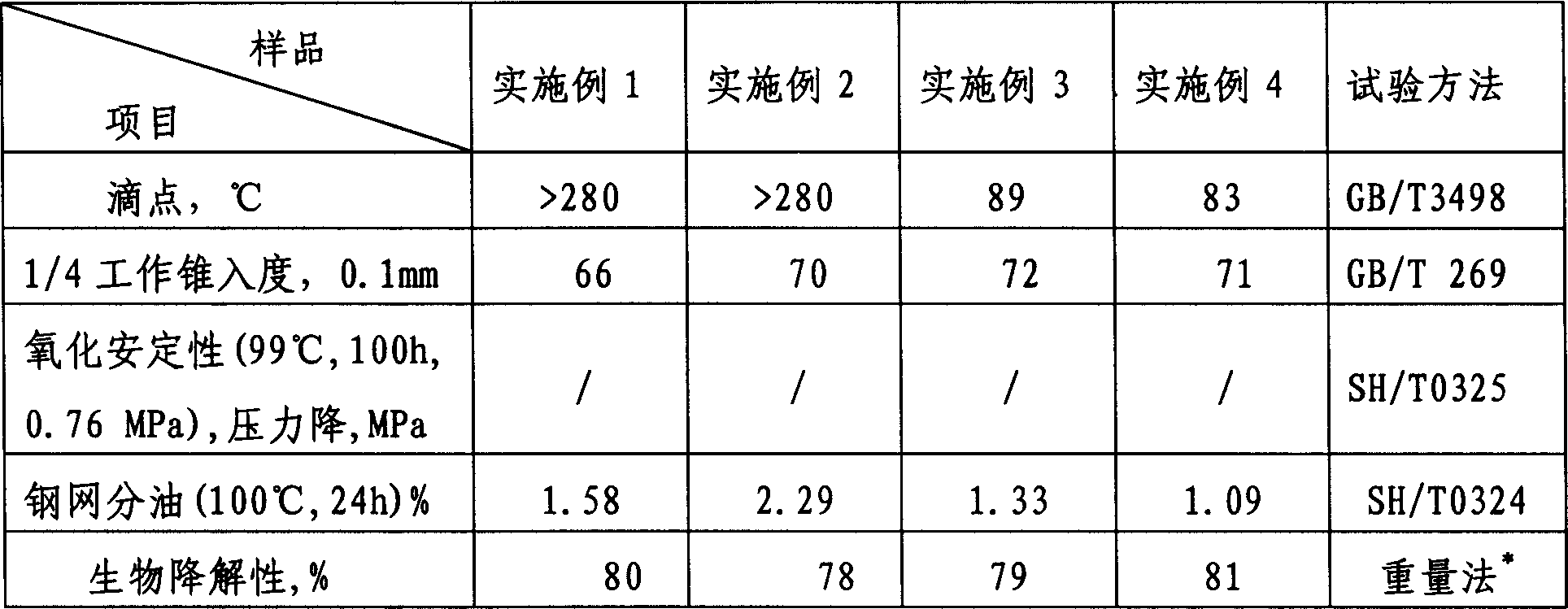

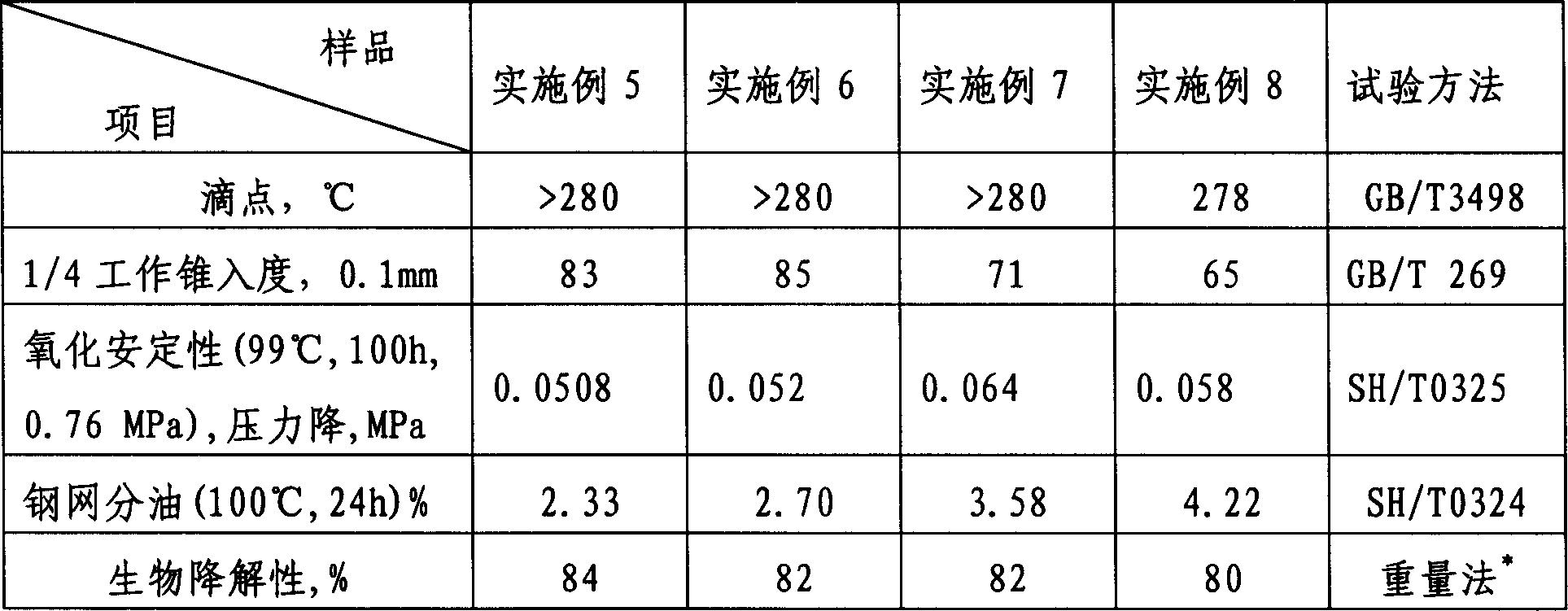

Biodegradable lubricating grease

InactiveCN1504552AExcellent conventional physical and chemical propertiesWill not polluteLubricant compositionLithium oxideVegetable oil

A biodegradable lubricating grease comprises (overall composition weight as benchmark) (1) 70-94% vegetable oil whose kinetic viscosity is 100-250 square mm per second, (2) 6-30% thickening agent, wherein the thickening agent is alta-mud, or single saponin or composite saponin produced through the reaction of C1-C20 organic acid with calcium hydroxide, calcium oxide, lithium hydroxide or lithium oxide, (3) 0-2% amine antioxidant or phenol and amine mixed anti-oxidant. The lubricating grease possesses both fine normal physical chemical properties and good bio-ecological characteristics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing propylene oxide

ActiveCN101735177AReduce investmentAchieve recyclingOrganic chemistryDispersed particle separationProcess designSodium hydroxide

The invention discloses a chemical production method, in particular a novel green production process for propylene oxide. In the method, the process design is carried out by using bipolar membrane, electrodialysis, antiosmosis, air flotation, heat exchange, oxidation, and other technology. In the production process, sodium hydroxide replaces the conventional calcium hydroxide and generates sodium chloride through reaction; the sodium chloride generates hydrochloric acid and sodium hydroxide by the bipolar membrane technology; and the hydrochloric acid is recovered, and the sodium hydroxide and water can be recycled. Therefore, no new sodium hydroxide is needed and no wastewater is discharged in the production of the propylene oxide. The sodium hydroxide is added at the preliminary stage of the production of the propylene oxide, and the input amount of the sodium hydroxide is controlled between 5 and 15 percent. The novel green production process for the propylene oxide has the advantages that: the recycling of the water, sodium chloride and sodium hydroxide is realized, the effects of zero discharge and input reduction of production materials are substantially achieved, and finally better social and economic benefits are achieved. The novel green production process for the propylene oxide can be widely applied to the chlorohydrin production in China.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

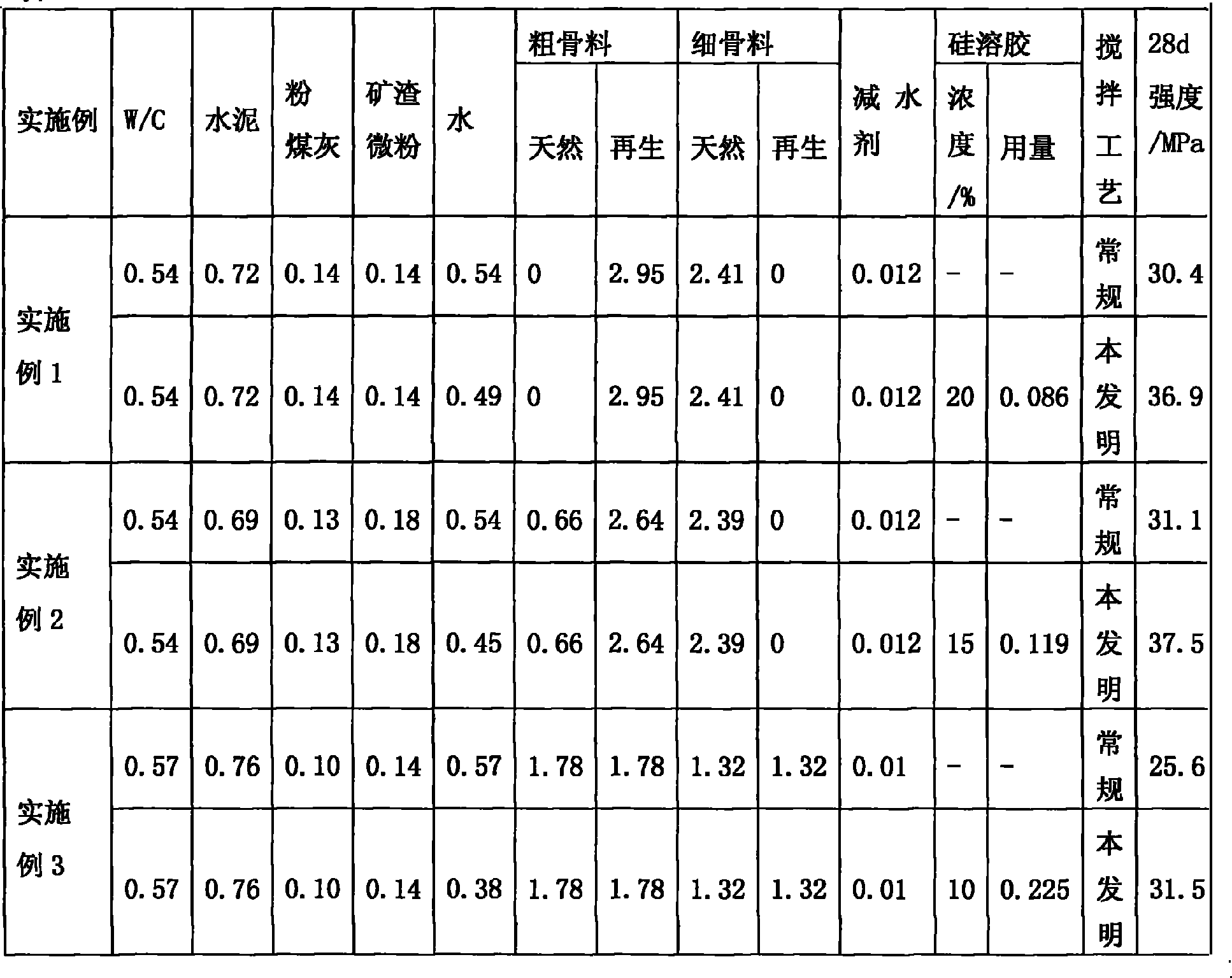

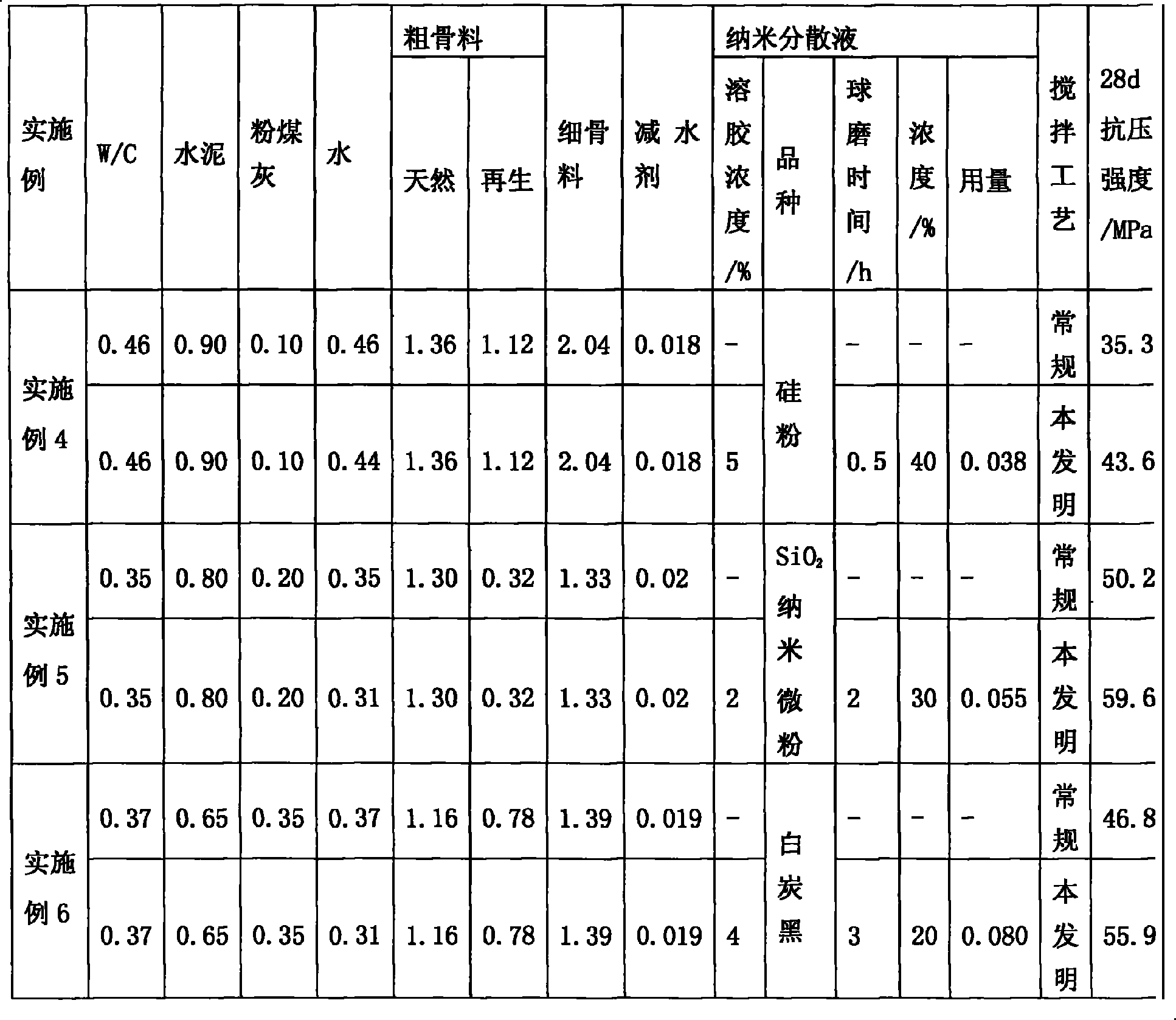

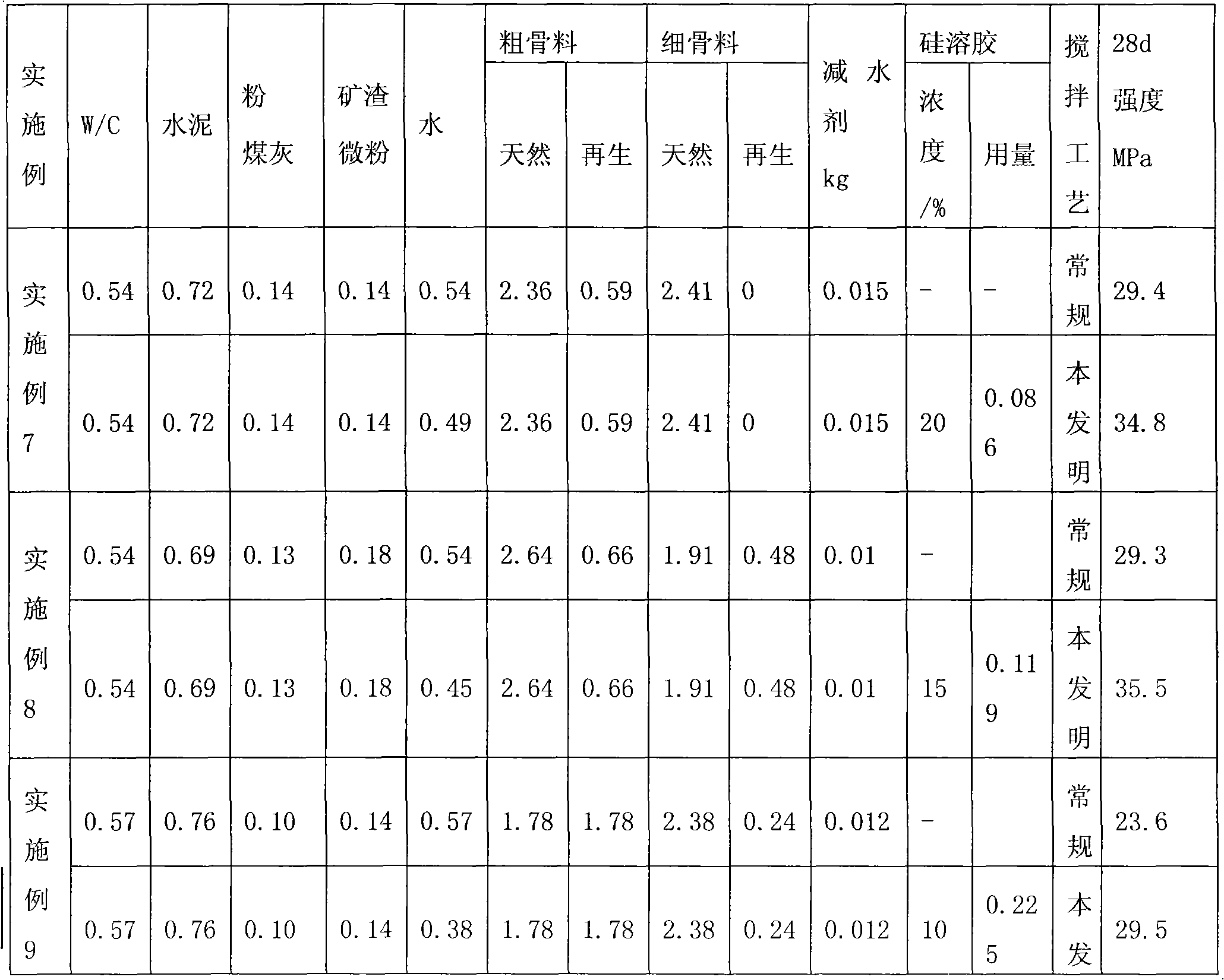

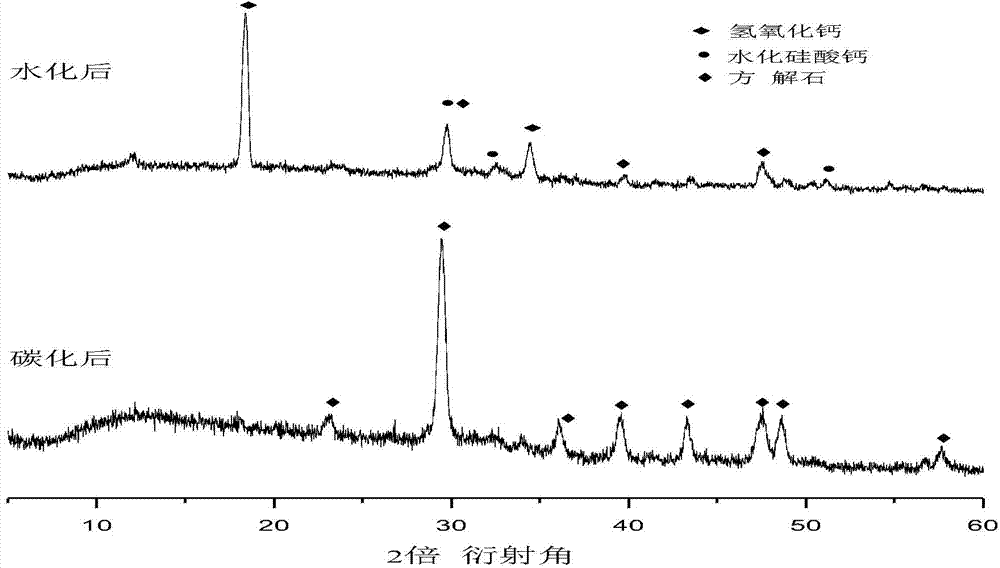

Nano reinforcing method for recycled aggregate concrete

InactiveCN102092993AHigh strengthImprove interfacial bond strengthSolid waste managementSuperplasticizerWater reducer

The invention discloses a nano reinforcing method for recycled aggregate concrete, which belongs to the technical fields of recycling comprehensive utilization of waste and production of building materials, and is mainly characterized by comprising the steps of: mixing and stirring a recycled aggregate and a nano particle dispersion for 5-10s; after the surface of the recycled aggregate is in a moist state, further mixing the recycled aggregate with all admixtures for 5-10s; and mixing and stirring with cement, water and a high-efficiency water reducing agent for 20-45s to obtain a nano-reinforced recycled aggregate concrete mixture. The nano reinforcing method has a principle that by changing a stirring process and introducing the nano dispersion, nano particles can be adsorbed into the opening pores and microcracks of the recycled aggregate, an admixture enriched layer is further formed on the surface of the recycled aggregate, the nano particles permeating into the interiors of the opening pores of the recycled aggregate and the admixture enriched layer formed on the surface of the recycled aggregate are used for jointly absorbing calcium hydroxide enriched on the surface and the pores of the recycled aggregate in the strength development process of the recycled aggregate concrete, a gelling material with higher strength is generated through hydration, liquid-phase or solid-phase reactions so as to reinforce the recycled aggregate per se and an interface between the recycled aggregate and set cement, and thus, the strength of the recycled aggregate concrete is enhanced. After the nano reinforcement, the recycled aggregate concrete has the 28-day compression strength improved by around 15-20%.

Owner:ZHEJIANG UNIV +1

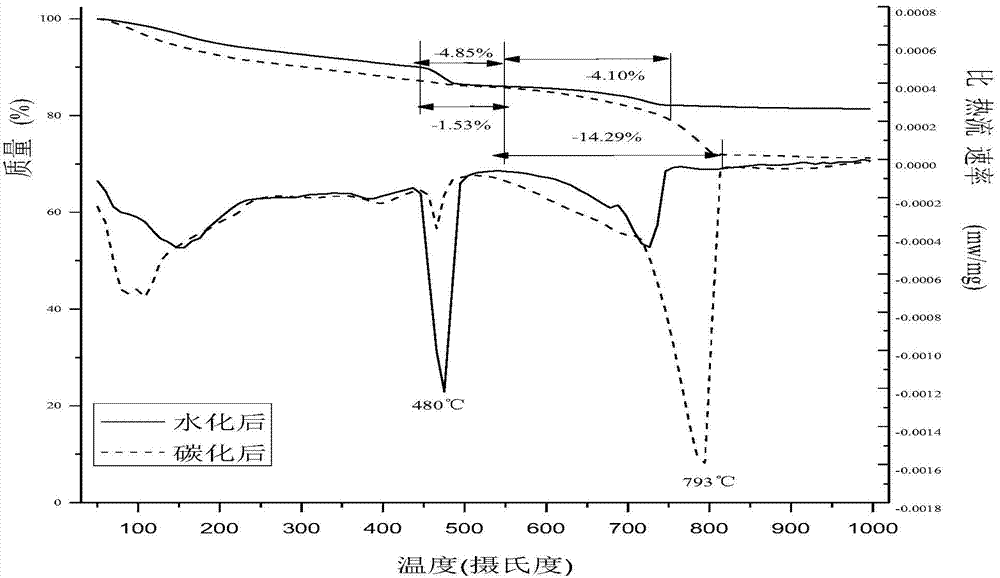

Method for preparing building material products through hydration-carbonation coupling technique

The invention belongs to the technical field of building materials, and provides a method for preparing building material products through processing industrial solid waste by hydration-carbonation coupling technique. The method comprises steps of uniformly mixing the industrial waste comprising at least one of calcium oxide, calcium hydroxide, dicalcium silicate, tricalcium silicate and tobermorite with alkaline excitation material and proper amount of water so as to prepare the blank of the building material product, wherein the industrial waste comprises steel slag, mineral waste residue, furnace slag, coal ash or coal gangue, the alkaline excitation material comprises carbide slag, lime, Portland cement or waste cement; maintaining for a period through hydration, then maintaining through carbonation so as to obtain the carbonate-based building material product. The coupling technique can effectively use the industrial solid wastes such as steel slag, mineral waste residue, furnace slag, coal ash, coal gangue, carbide slag and the like, so that emission of greenhouse gases is reduced, the greenhouse effect is relieved, furthermore, the method can be used for producing the building material products with good properties, effectively uses the waste and is environmentally friendly.

Owner:DALIAN UNIV OF TECH

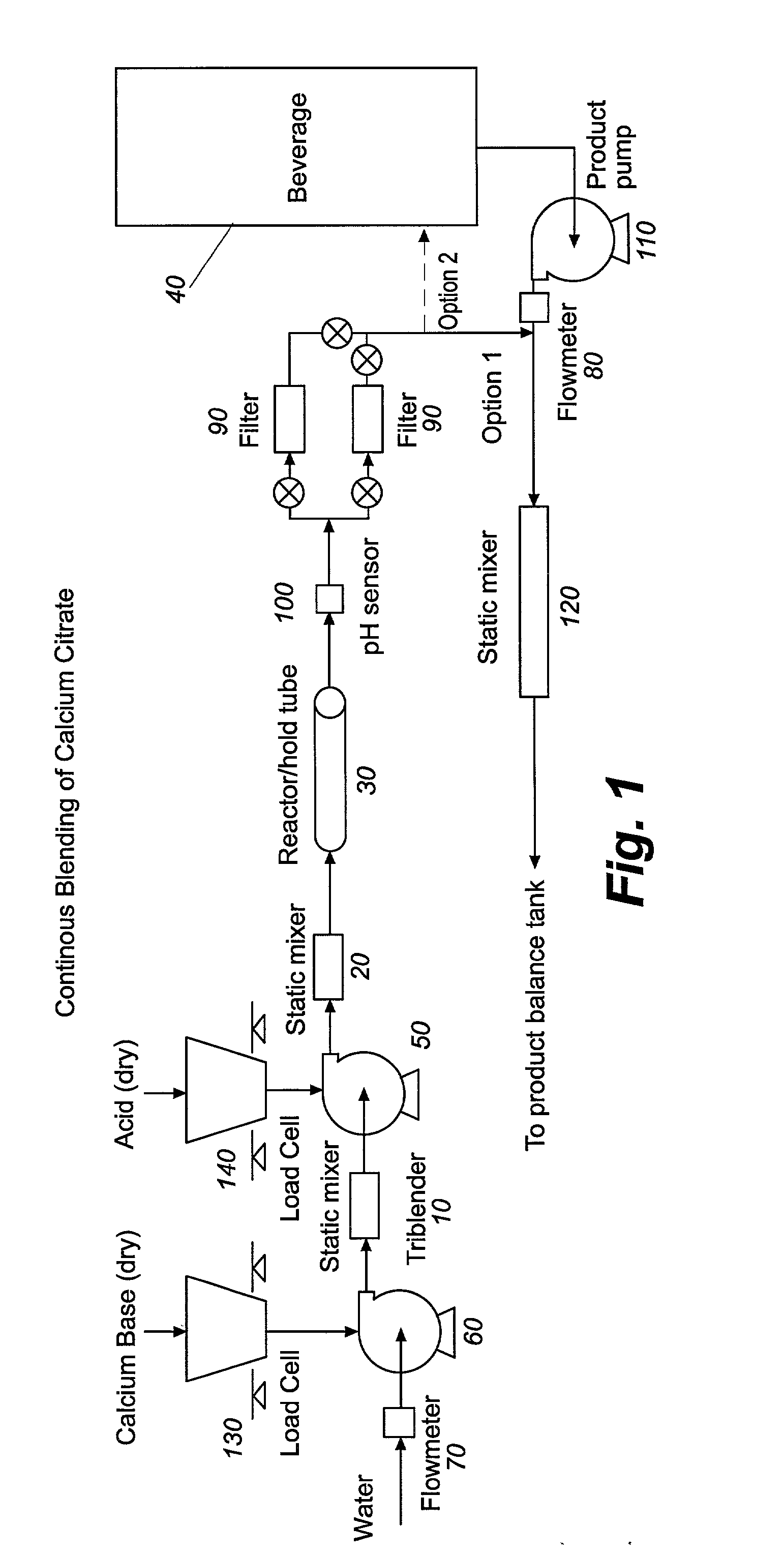

Process apparatus, and composition for calcium fortification of beverages

InactiveUS20020122866A1Inhibit productionReduce presenceFood ingredientsFood preparationCalcium hydroxideSufficient time

Process, apparatus and composition for calcium fortification of beverages are provided. The methods comprise continuously blending in water a calcium source, preferably calcium hydroxide, and an acid source for a time sufficient to produce soluble calcium salts, but with minimal precipitation. The acid source is preferably citric acid. The calcium salt solution remains in an in-line retaining reaction hold tube for the necessary period to produce calcium salt in solution without significant precipitation, and is then continuously and immediately added to a non-dairy beverage, such as orange juice, to calcium fortify the beverage. The pH of the calcium salt solution can be monitored to optimize the amount of soluble salt and minimize the amount of precipitate.

Owner:THE COCA-COLA CO

Process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt

InactiveCN103436720ASolve the problem of ammonia nitrogen pollutionRealize green miningProcess efficiency improvementAmmoniacal nitrogenCalcium hydroxide

The invention relates to a process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt. The process comprises the step of replacing ammonium salt by taking a mixture of calcium, magnesium and sodium salts as a leaching agent and taking non-ammonium salts, such as calcium hydroxide, magnesium hydrate or sodium hydroxide as a precipitator. According to the process disclosed by the invention, the ammonia nitrogen pollution problem in exploitation of ion-adsorption type rare earth is radically solved; environmental-friendly exploitation of the ion-adsorption type rare earth can be realized; the process disclosed by the invention has higher economic benefit and social benefit.

Owner:LONGNAN COUNTY NANYU RARE EARTH RESOURCES COMPREHENSIVE UTILIZATION CO LTD

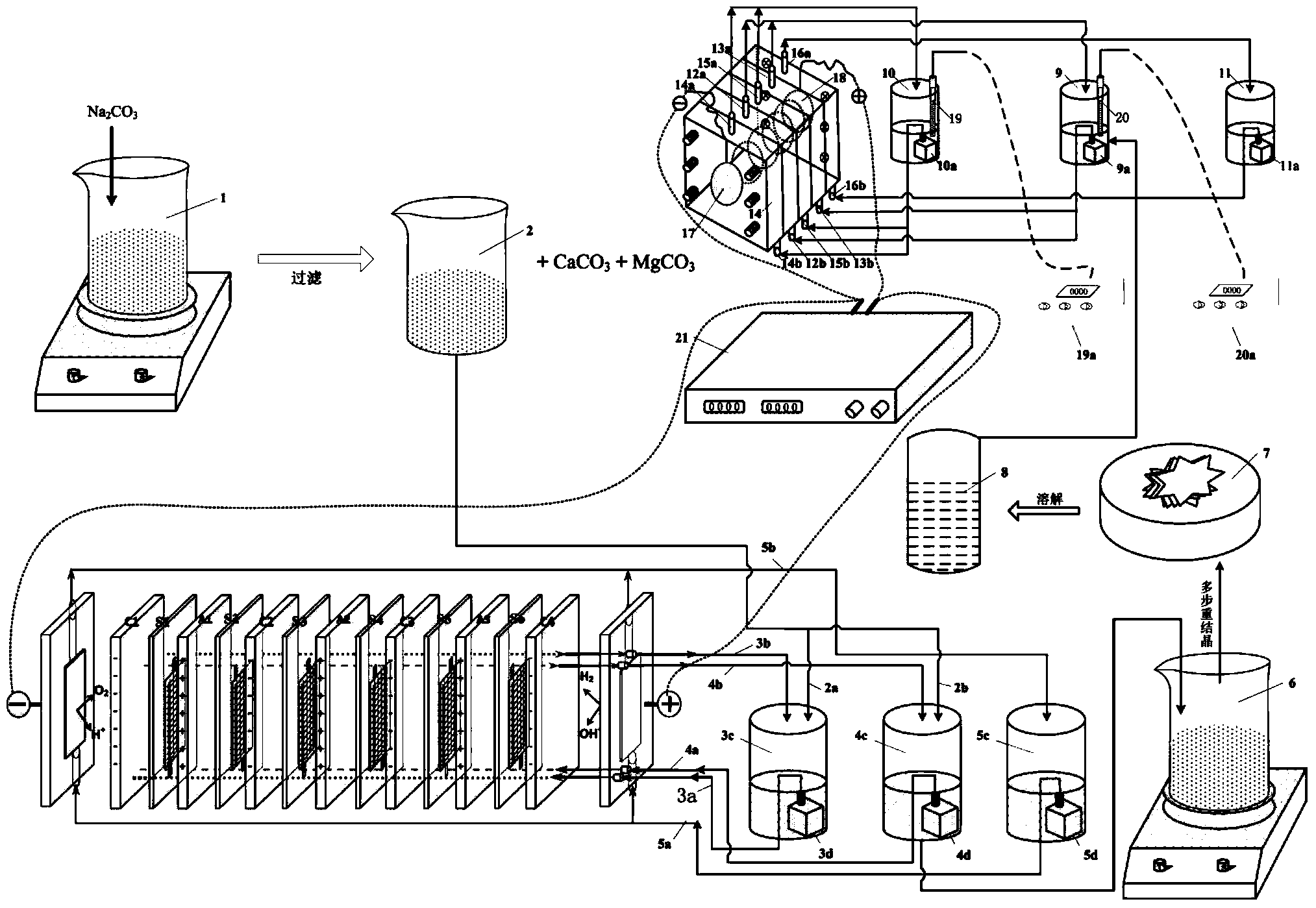

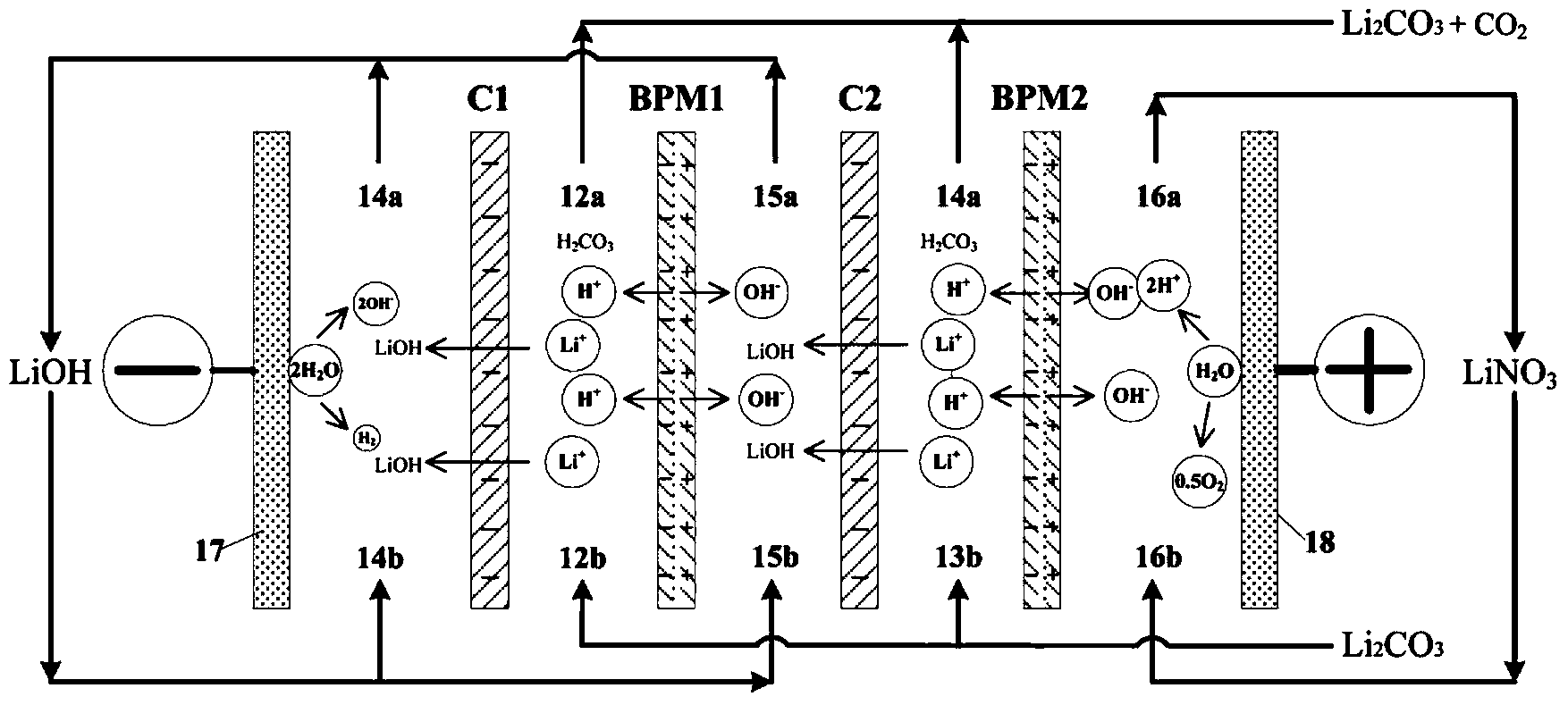

Method for extracting lithium hydroxide by salt lake brine

ActiveCN103864249AIncrease the concentration factorEasy extractionElectrolysis componentsMultistage water/sewage treatmentChemistryCalcium hydroxide

The invention discloses a method for extracting lithium hydroxide by salt lake brine. The method is characterized by comprising the following steps: firstly, removing calcium and magnesium ions in salt lake brine by adding sodium carbonate; concentrating the obtained brine with low lithium-magnesium ratio through ordinary electrodialysis to obtained concentrated brine; adding sodium carbonate to the concentrated brine and removing the calcium and magnesium ions again; adding sodium carbonate to obtain lithium carbonate through a multi-step crystallization method; preparing the lithium hydroxide by an electrolysis-bipolar membrane electrodialysis system after dissolving the lithium carbonate again. The traditional distillation process is replaced by ordinary electrodialysis, so that energy consumption is reduced, and the method is friendly to environment. In addition, the lithium hydroxide is produced by using an electrolysis-bipolar membrane electrodialysis technology, the defects of high energy consumption and low purity in the traditional lime method and electrolytic process are avoided, the capacity of the lithium hydroxide is improved, no waste residue is generated in the process, and the method is friendly to environment. Taken together, the method is simple to operate, low in energy consumption, friendly to environment, and expanded production is easy to achieve.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com