Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

627 results about "Anhydrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anhydrite, or anhydrous calcium sulfate, is a mineral with the chemical formula CaSO₄. It is in the orthorhombic crystal system, with three directions of perfect cleavage parallel to the three planes of symmetry. It is not isomorphous with the orthorhombic barium (baryte) and strontium (celestine) sulfates, as might be expected from the chemical formulas. Distinctly developed crystals are somewhat rare, the mineral usually presenting the form of cleavage masses. The Mohs hardness is 3.5, and the specific gravity is 2.9. The color is white, sometimes greyish, bluish, or purple. On the best developed of the three cleavages, the lustre is pearly; on other surfaces it is glassy. When exposed to water, anhydrite readily transforms to the more commonly occurring gypsum, (CaSO₄·2H₂O) by the absorption of water. This transformation is reversible, with gypsum or calcium sulfate hemihydrate forming anhydrite by heating to around 200 °C (400 °F) under normal atmospheric conditions. Anhydrite is commonly associated with calcite, halite, and sulfides such as galena, chalcopyrite, molybdenite, and pyrite in vein deposits.

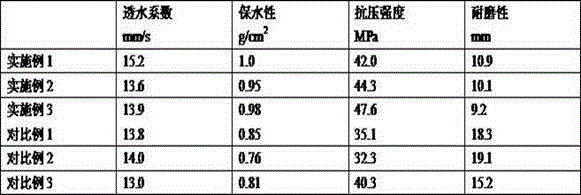

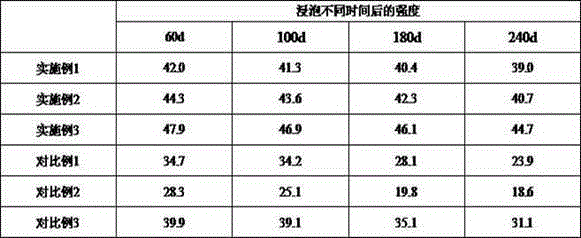

Corrosion resistant water permeable brick

ActiveCN105016765AHigh permeability coefficientHigh compressive strengthCeramicwareCompressive resistanceBrick

The present invention relates to a corrosion resistant water permeable brick, and belongs to the technical field of building materials. The corrosion corrosion resistant water permeable brick comprises 20-25wt% of Portland cement, 1.0-1.2wt% of anhydrite powder, 15.0-20.0wt% of slag pellets, 10-12wt % of cenospheres, 1.5-2.1wt% of admixtures, and the balance of quartz sand. Under the premise that the porosity and water permeability coefficient of the corrosion resistant water permeable brick are significantly higher than that of a water permeable brick, the compressive strength of the corrosion resistant water permeable brick is still higher than that of the conventional water permeable brick, the corrosion resistant water permeable brick has good corrosion resistance, and service life is significantly increased.

Owner:江苏溧阳建设集团有限公司

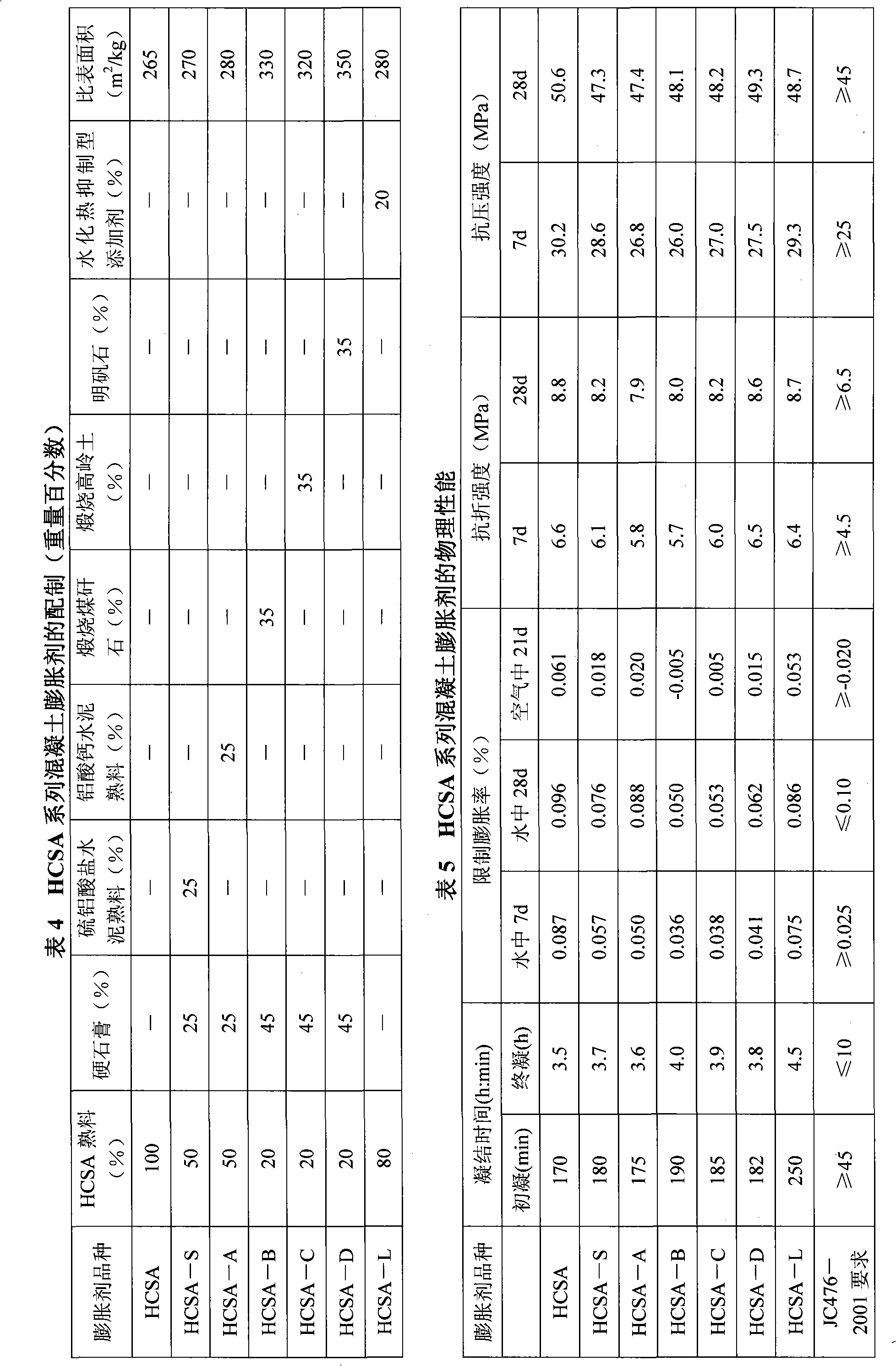

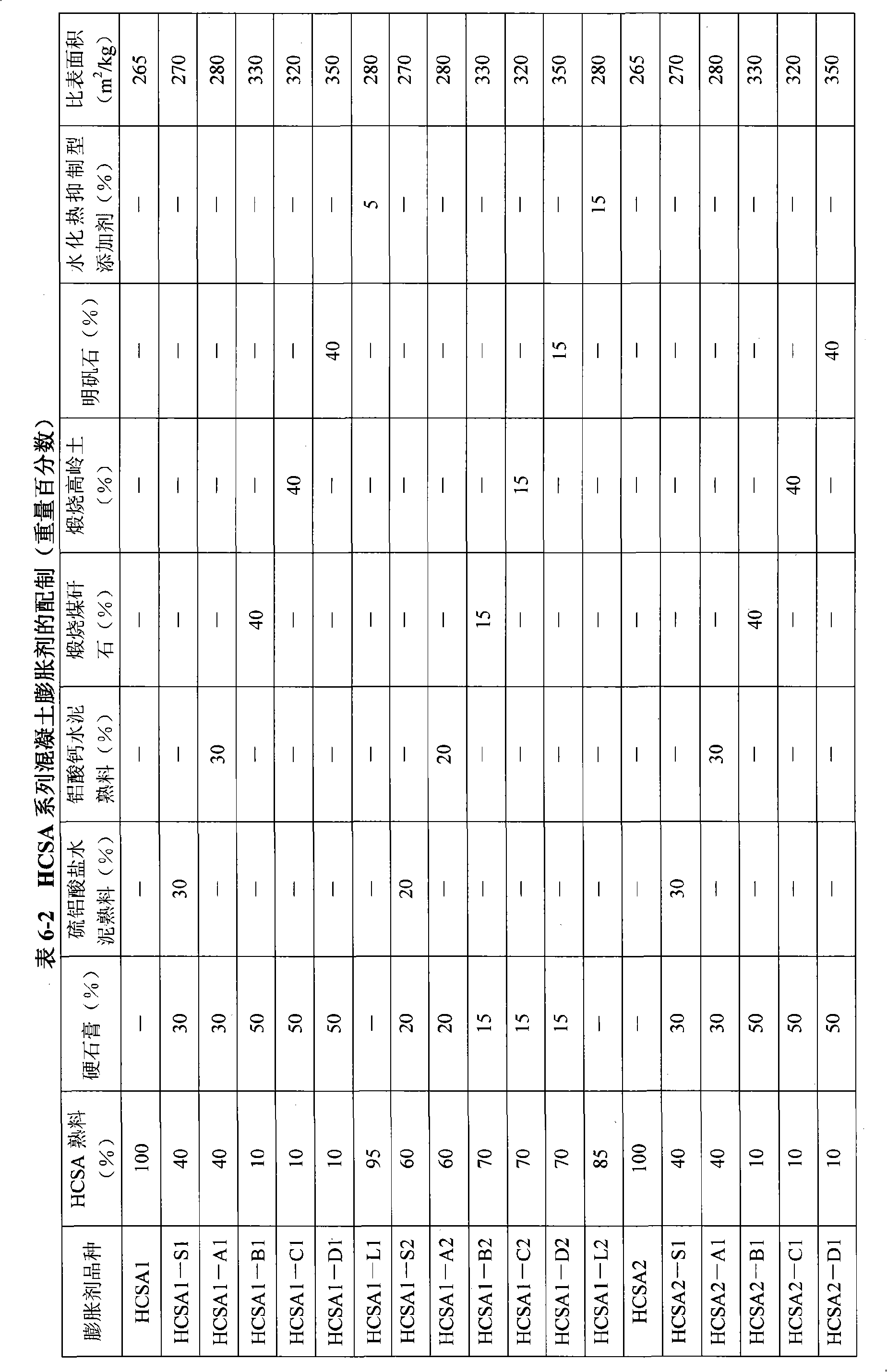

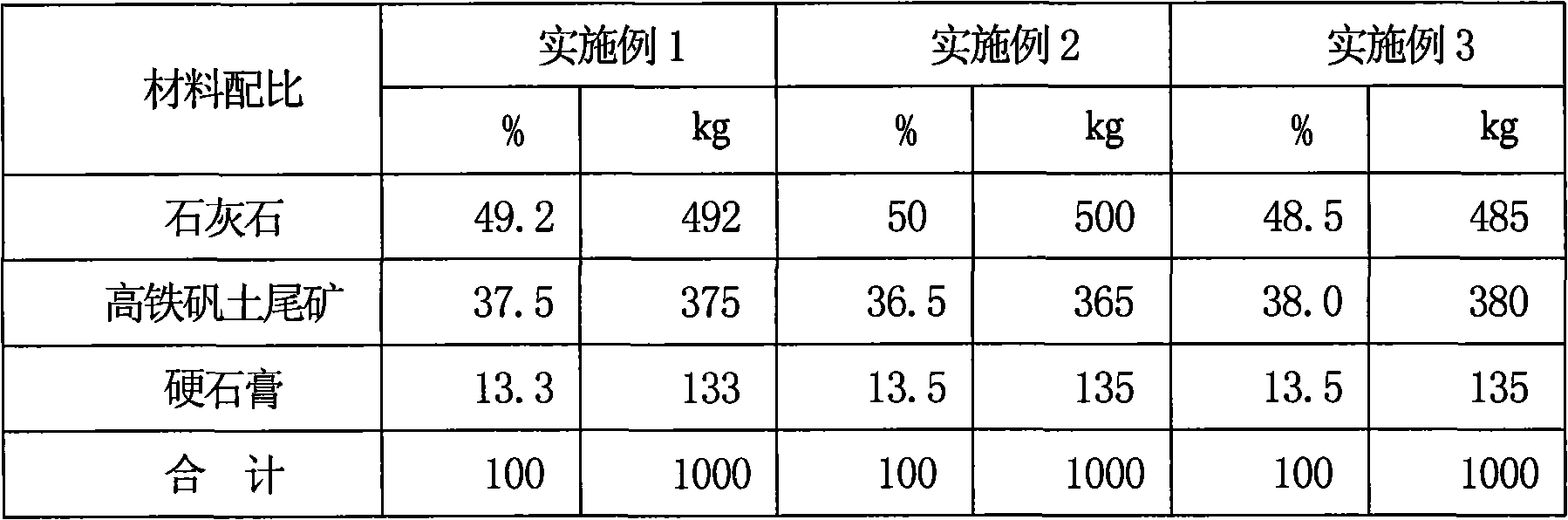

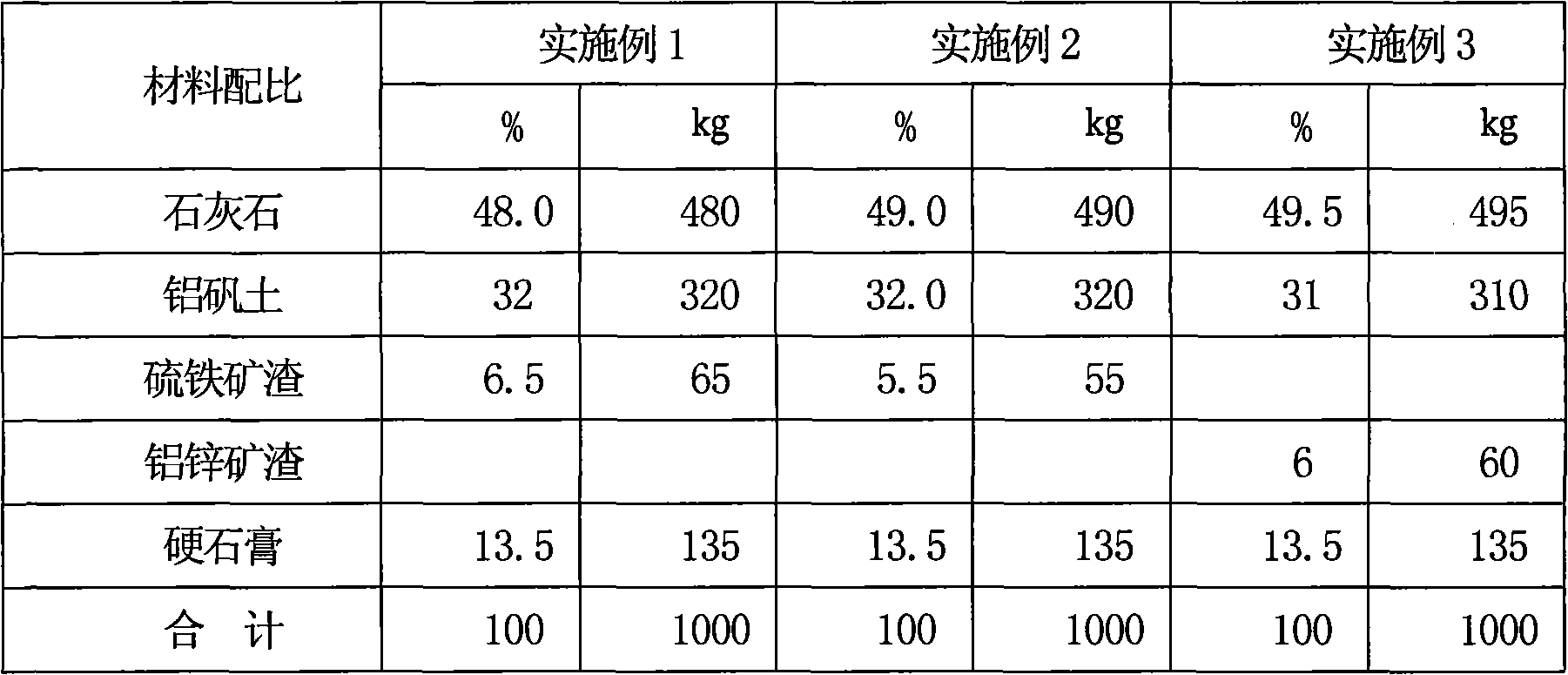

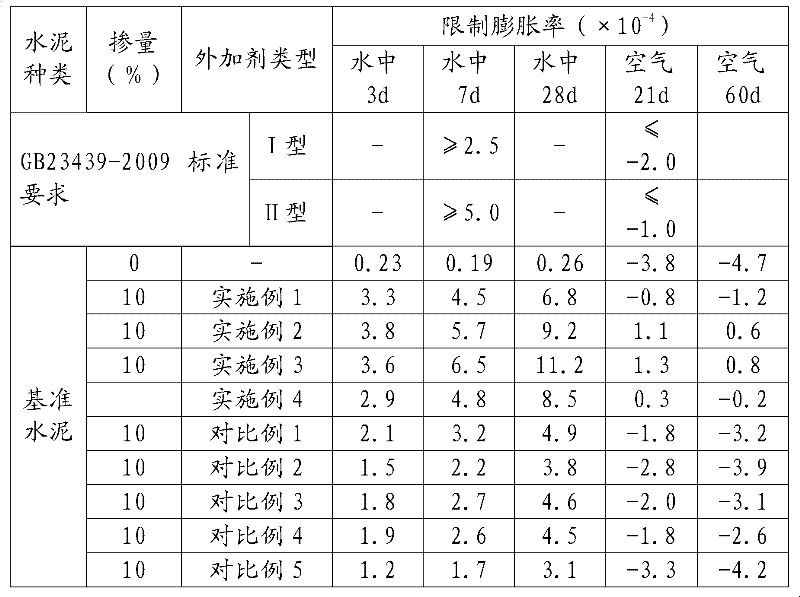

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

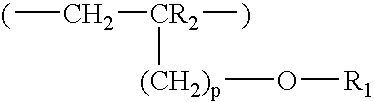

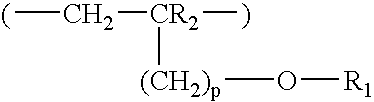

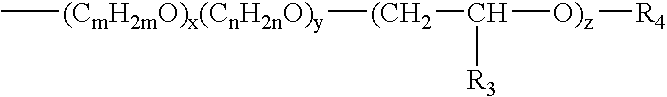

Polyether-containing copolymer

Owner:BASF CONSTR SOLUTIONS

Polyether-containing copolymer

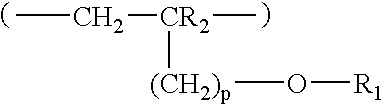

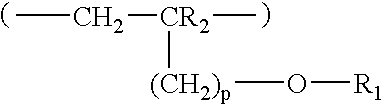

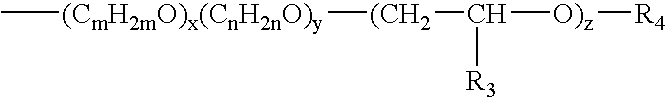

Copolymers include two monomer components, a) an olefinic unsaturated monocarboxylic acid comonomer or an ester or a salt thereof of an olefinic unsaturated sulfuric acid comonomer or a salt thereof, and b) an ether comonomer of the general formula (I) Components a) and b) are present in amounts of from 30 to 90 mol-% and from 70 to 10 mol-%, respectively, and comonomer component a) is selected from the group consisting of acrylic acid, methacrylic acid, crotonic acid, isocrotonic acid, allylsulfonic acid, vinylsulfonic acid and a salt thereof or an alkyl or hydroxyalkyl ester. Compositions including a hydraulic binder such as cement, gypsum, lime and anhydrite and the copolymer are also disclosed. The copolymer can be used as superplasticizer or dispersant for non-hardened (wet) and a hydraulic binder containing compositions.

Owner:BASF CONSTR POLYMERS

High-moisture filling material and preparation method thereof

The invention discloses a high-moisture filling material and a preparation method thereof. The high-moisture filling material comprises a composition A and a composition B, wherein the composition A comprises 52.4 to 95 by weight percent of sulfo-aluminate cement clinkers, 2.7 to 39 by weight percent of aluminate cement clinkers, 0.3 to 2 by weight percent of setting retarder, and 1.5 to 8 by weight percent of suspending agent; the composition B comprises the following ingredients: 40 to 80 by weight percent of anhydrite, 10 to 30 by weight percent of lime, and 10 to 36 by weight percent of compound additives. The high-moisture filling material has the advantages of easily-available raw materials, low price, good stability, high long-term strength and no risk of surface efforescence.

Owner:CCTEG CHINA COAL RES INST

Slope artificial soil conditioner with water retention role

InactiveCN101391930ALow costStrong targetingClimate change adaptationExcrement fertilisersRevegetationSodium Bentonite

The invention provides a conditioner for artificial soil on a slope with the function of water retention, which is prepared by the following raw materials according to weight percentage by compounding and mixing: 10 to 25 percent of livestock manure, 25 to 50 percent of super absorbent resin, 5 to 15 percent of ground phosphorite, 1 to 5 percent of anhydrite powder, 20 to 35 percent of humic acid, 5 to 10 percent of zeolite powder, 1 to 10 percent of chitosan, 0 to 10 pecent of bentonite, 0 to 5 percent of phosphate ester and 0 to 5 percent of citrate acid. The conditioner has obvious effects of enhancing the water retention of soil, reducing the water loss and soil erosion, improving the physical and chemical properties of soil and promoting the revegetation.

Owner:SICHUAN UNIV

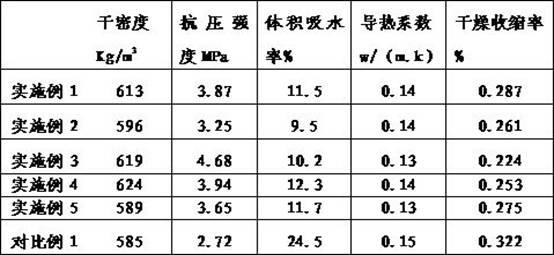

Flame retardant heat-insulation foam concrete and preparation method thereof

The invention discloses flame retardant heat-insulation foam concrete which consists of the materials by mass as follows: 30-60 parts of cement; 30-70 parts of coal ash; 10-40 parts of mineral powder; 0.05-1. 0 part of water reducing agent; 0.02-0.2 part of cellulose ether; 0.05-1.0 part of water repellent; 1-10 parts of anhydrous anhydrite; 0.06-0.2 part of polypropylene fiber; 0.1-0.4 part of foaming agent; and 0.30-0.60 part of water. The advantages are as follows: the foam concrete has high strength, low shrinkage and good water repellent property; the heat insulation performance is good and can meet different heat-insulation requirements of buildings; the preparation technology is simple; and industrial wastes such as coal ash, mineral powder and the like are utilized fully, and the flame retardant heat-insulation foam concrete has excellent environment-protection effects of utilizing waste, saving energy and the like, as well as better economic benefit.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

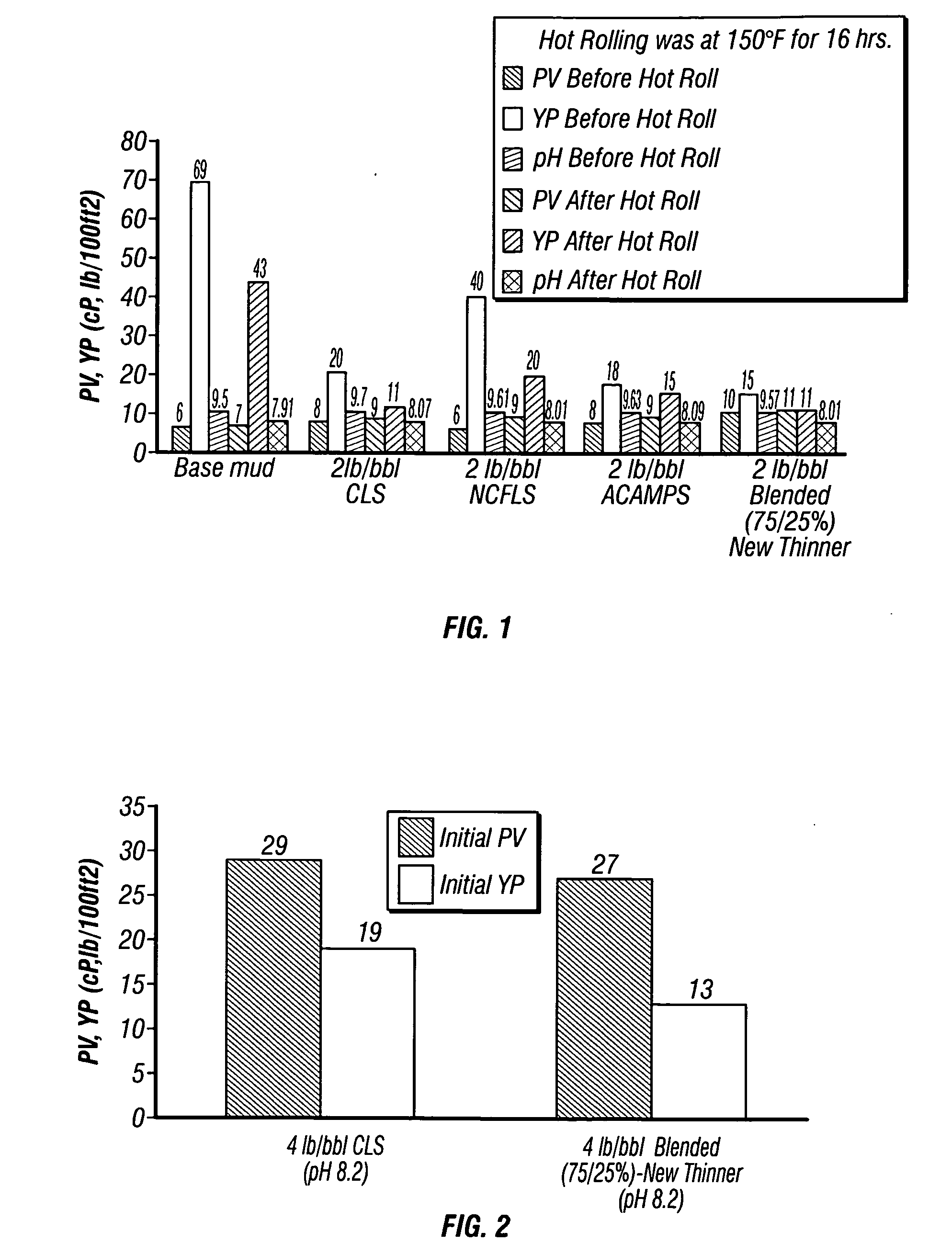

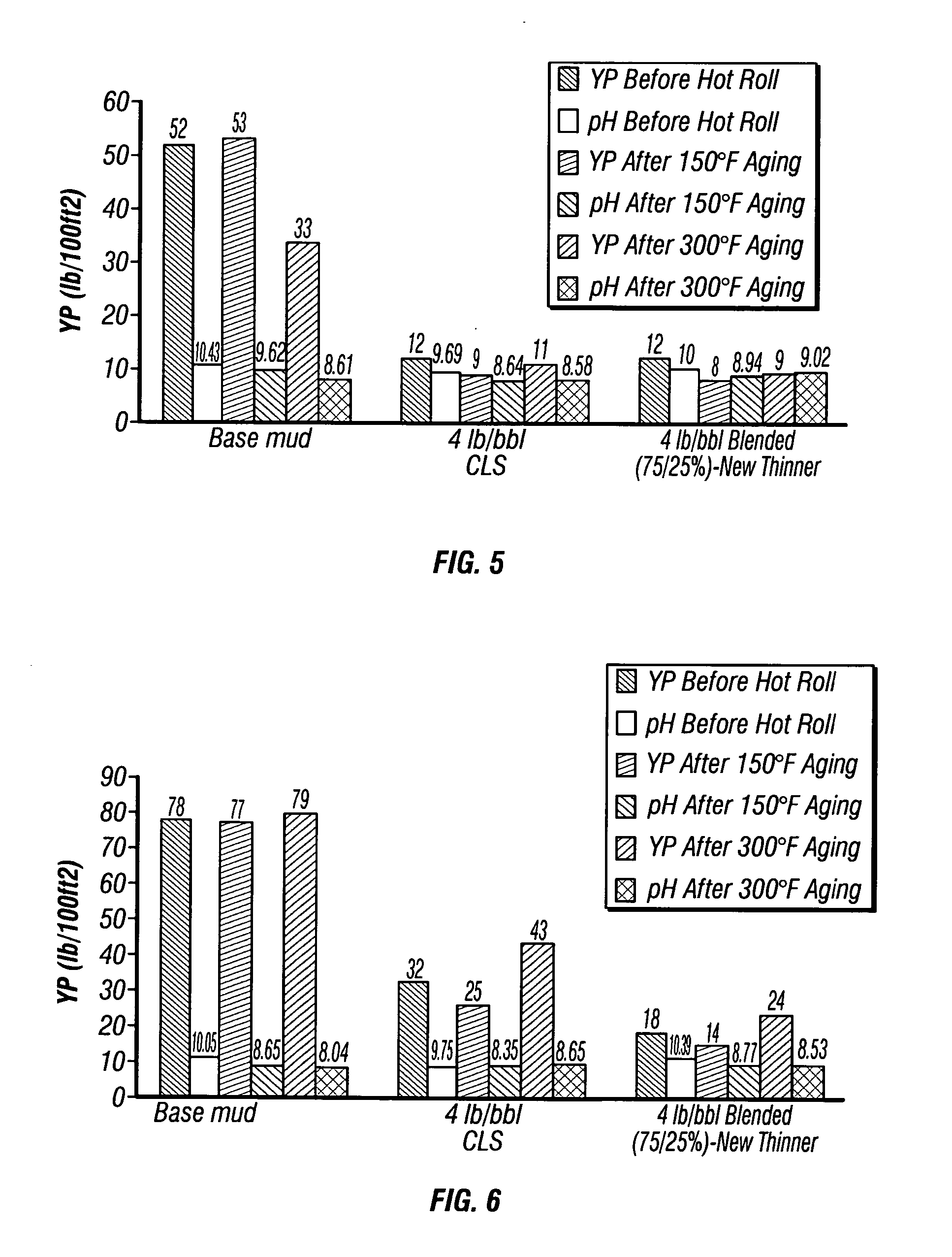

Environmentally friendly water based mud deflocculant/ thinner

Methods and compositions for use in such methods are provided for drilling, running casing in, and / or cementing a borehole in a subterranean formation using aqueous based drilling fluids. The drilling fluids are thinned or dispersed with a blend of non chrome, ferro lignosulfonate and acrylate copolymer with one or more acrylo amido propane sulfonate functional groups, at a pH in the range of about 8.0 to about 10.5. The drilling fluids do not contain heavy metals and are rheologically tolerant to contaminants such as cement, anhydrite and sodium and temperatures as high as about 350° F.

Owner:HALLIBURTON ENERGY SERVICES INC

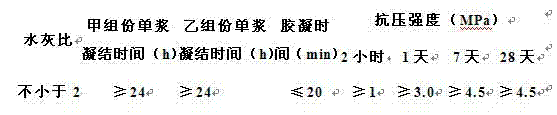

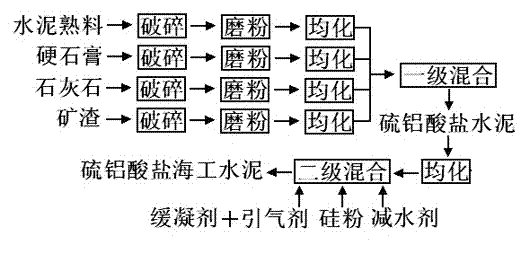

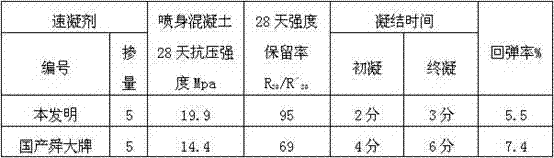

Sulphoaluminate maritime work cement and preparation method thereof

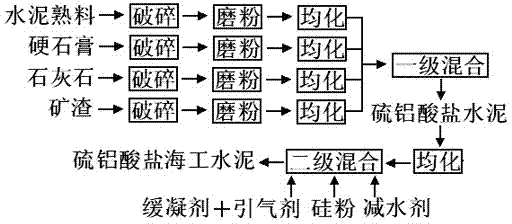

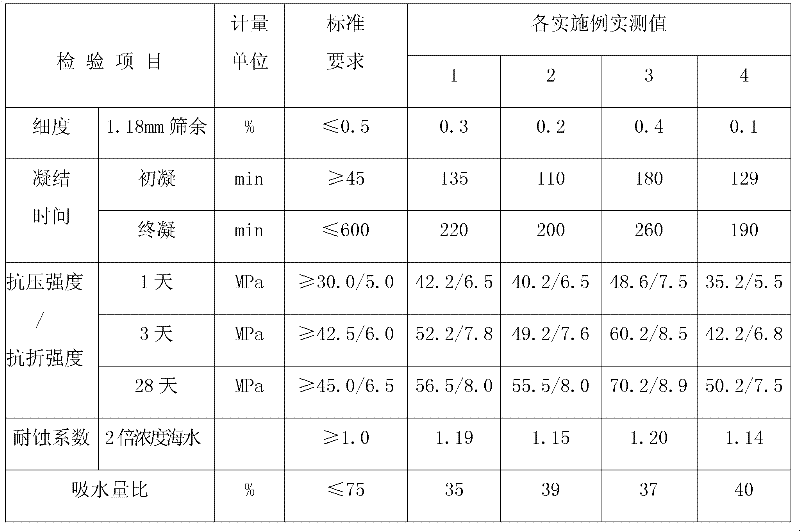

The invention discloses sulphoaluminate maritime work cement and a preparation method thereof. The sulphoaluminate maritime work cement comprises the following main raw materials in parts by weight: 50-80 parts of cement clinker, 8.0-20 parts of anhydrite, 0-30 parts of limestone, 0-30 parts of slag, 0.1-0.5 part of water reducing agent, 0.001-0.005 part of air entraining agent, 0.1-0.5 part of retarder and 2-5 parts of silicon powder. The preparation method comprises the following steps of: respectively smashing, grinding and homogenizing the sulphoaluminate cement clinker, the anhydrite, the limestone and the slag; then, burdening at a ratio, and evenly mixing; adding the water reducing agent, the air entraining agent, the retarder and the silicon powder; and mixing and homogenizing to obtain the product. The concrete mixed by the sulphoaluminate maritime work cement has the advantages of small bleeding rate and high slurry viscidity. The slurry has strong covering and supporting action on aggregate. The concrete keeps good homogeneity and has the advantages of hard and quick early strength, continuously-increased later strength, good slurry structure compactness and high volume stability and is convenient to use and operate for constructing.

Owner:广西云燕特种水泥建材有限公司

Self-levelling material and preparation method thereof

The invention provides a self-levelling material, which comprises the following components by weight: 250 to 300 grams of ordinary Portland cement, 20 to 100 grams of high-alumina cement, 450 to 500 grams of quartz sand, 40 to 60 grams of anhydrite, 100 to 120 grams of ground calcium carbonate, 0.1 to 1 gram of lithium carbonate, 0.1 to 1 gram of tartaric acid, 0.5 to 1.5 grams of cellulose ether, 5 to 30 grams of latex powder and 1 to 1.5 grams of polycarboxylate water reducer. A preparation method comprises the following steps of: adding the ordinary Portland cement, the high-alumina cement and the quartz sand, stirring uniformly, adding the anhydrite, the ground calcium carbonate, the lithium carbonate, the tartaric acid, the cellulose ether, the latex powder and the polycarboxylate water reducer sequentially, and stirring fully and uniformly. The self-levelling material has high self-levelling performance, stable quality and high construction effect and is easy to construct and manage, and the construction is easy to perform designedly.

Owner:CHINA ACAD OF BUILDING RES

Novel tailing consolidator and preparation method thereof

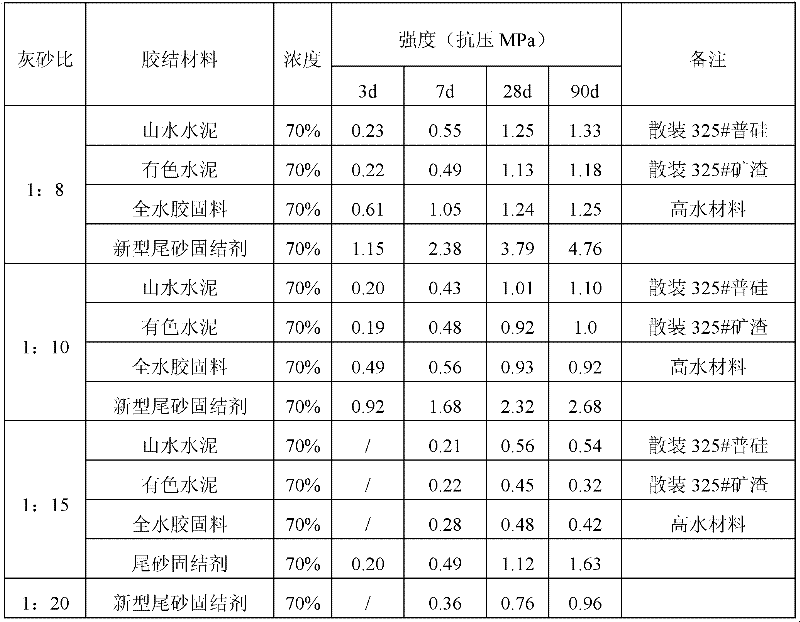

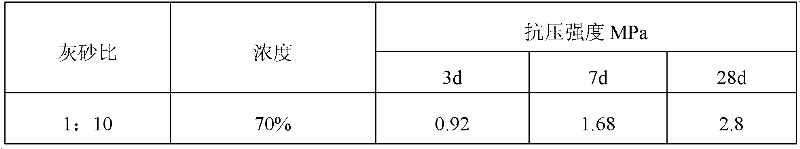

The invention concretely relates to a novel tailing consolidator which uses fine powder ground from blast furnace water quenching slag as a main raw material and a preparation method of the consolidator. The consolidator is characterized in that the consolidator comprises, by mass concentration, 9 % to 17.54% of portland cement clinker, 10% to 17.54% of anhydrite, 6% to 10% of quicklime, 0.2 to 6 thousandths of Na2SO4, 0.2 to 0.5 thousandths of carboxymethyl cellulose, 5% to 10% of coal ash and 43.65% to 69.96% of the fine powder ground from the blast furnace water quenching slag. Each above component is dried by a dryer, put in a mixer to be evenly stirred, and conveyed to a bowl mill by a belt conveyer to be ground. The blast furnace slag discharged from a smeltery is used as the main raw material in the invention to reduce the cost and solve slag processing, so the consolidator has the advantages of low production cost, simple processing, and agile and convenient usage. A usage amount of the consolidator in the present invention is half or less than the usage amount of common cement under the same conditions with the same backfilling intensity.

Owner:淄博乾耀固结材料有限公司

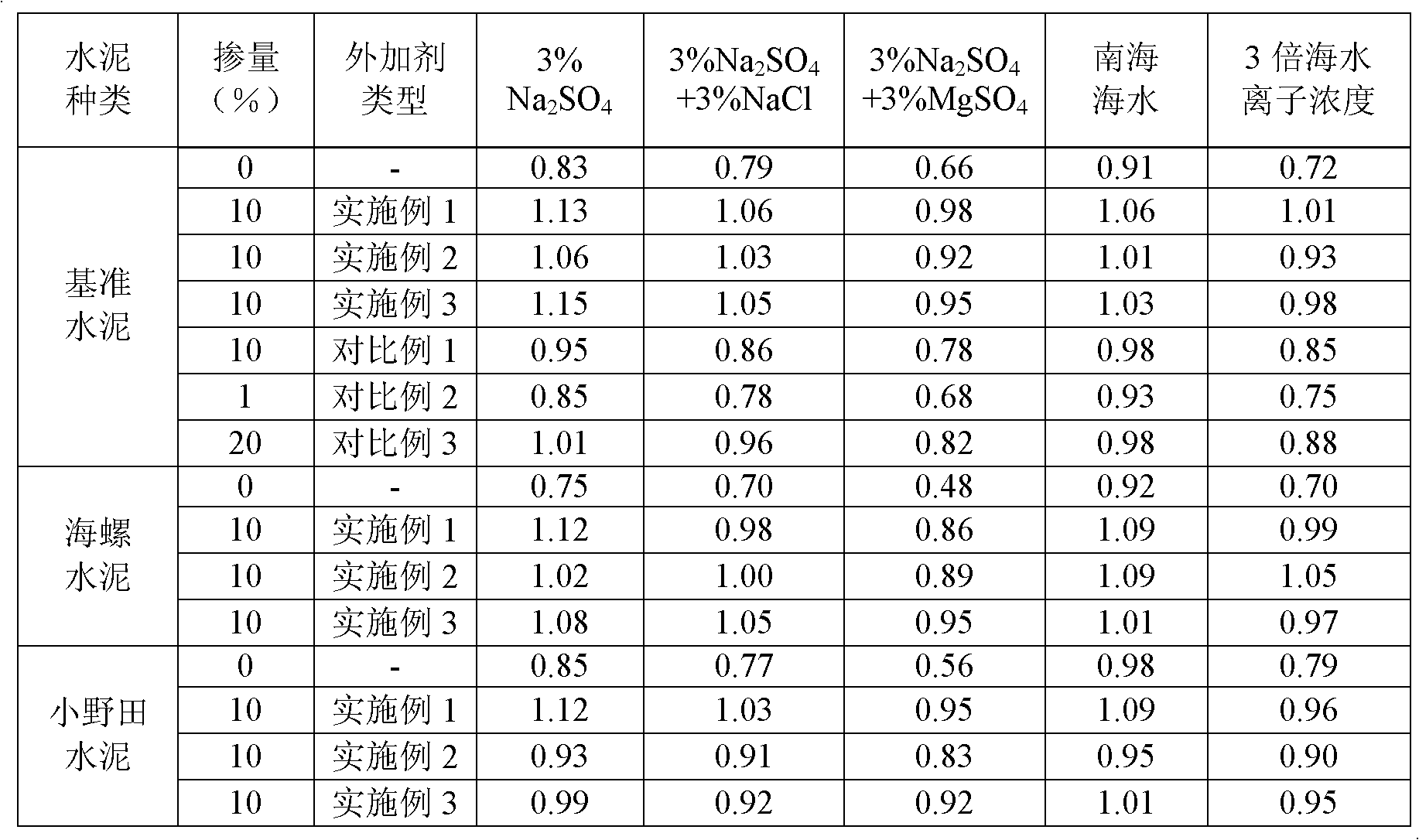

Seawater corrosion resisting mineral additive for concrete, and preparation method thereof

The invention discloses a seawater corrosion resisting mineral additive for concrete, and a preparation method thereof. The seawater corrosion resisting mineral additive for concrete comprises components of, by weight: 15 to 40% of calcium sulphoaluminate mineral, 10 to 40% of anhydrite, 10 to 30% of calcined diatomite, 10 to 30% of natural volcanic ash, 5 to 25% of quartz powder, and 2 to 8% of an auxiliary agent. The seawater corrosion resisting mineral additive provided by the invention has good corrosion resisting capacities against corrosion media such as Na2SO4, NaCl, and MgSO4. The corrosion resisting coefficient is higher than 0.9. Therefore, the mineral additive can be used for preparing high-strength high-performance seawater corrosion resisting concrete, or underwater concrete placed in corrosion media. The mineral additive can also be used in water conservancy and hydropower projects for improving the corrosion medium resisting performances of buildings, wherein in the corrosion media comprise sulfate, chloridion, and the like. With the mineral additive, cracks of buildings can be reduced or eliminated, and the service lives of the buildings can be prolonged.

Owner:深圳市德宜新材料科技有限公司

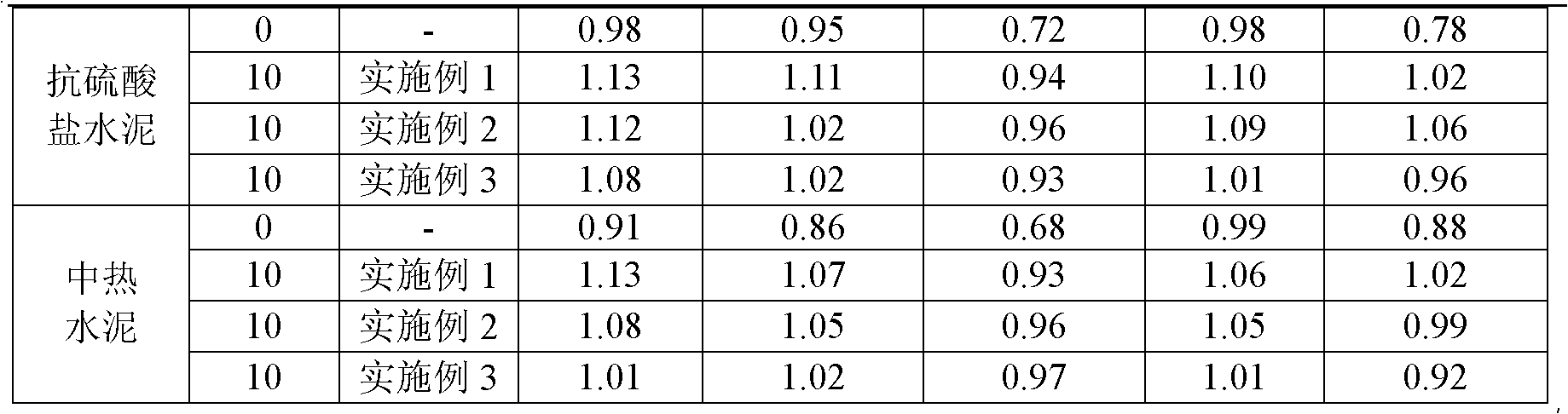

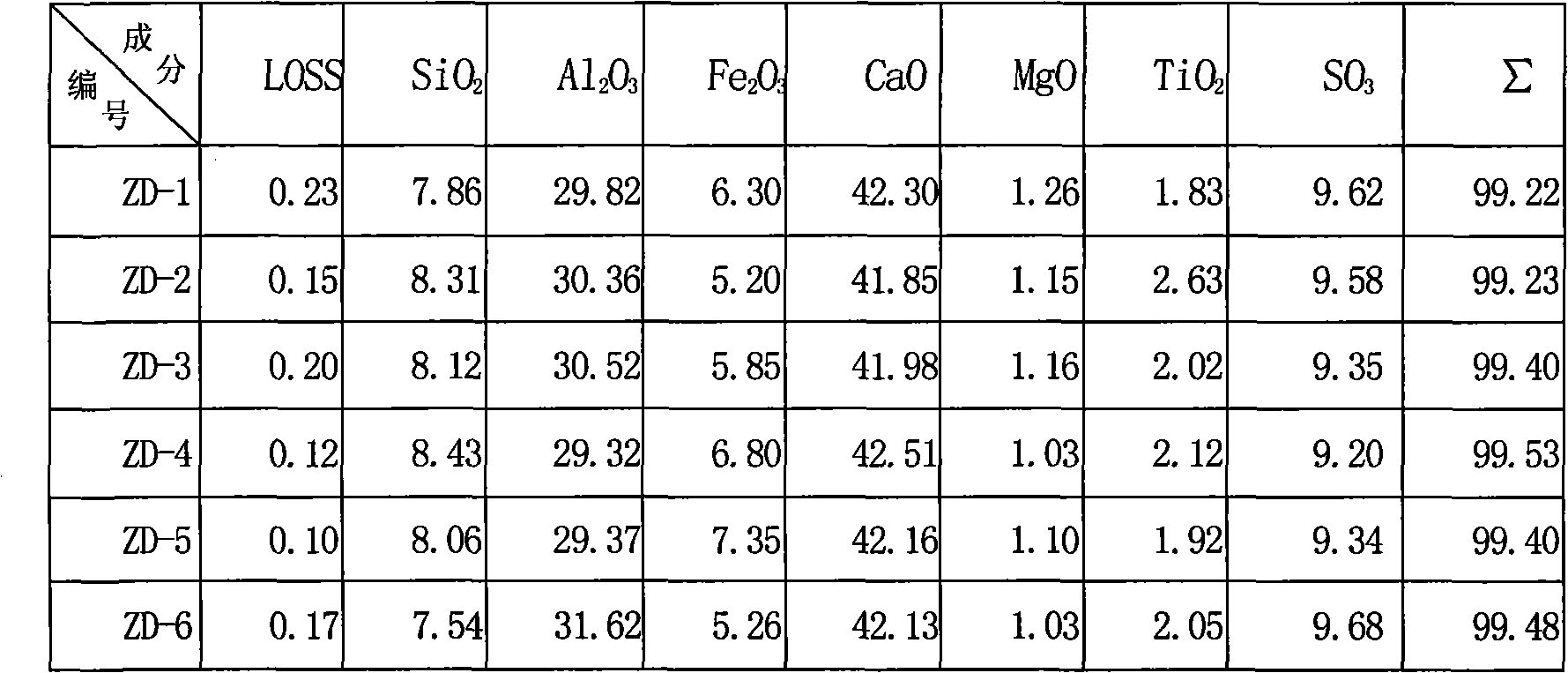

Rapid-setting and hardening, high-belite sulfoaluminate cement clinker as well as application and production process thereof

ActiveUS20170050882A1Increase heightHigh-strength rapid-hardeningSolid waste managementCement productionChemical compositionSlag

The invention discloses a rapid-hardening high-belite calcium sulfoaluminate cement clinker and relates generally to a rapid-hardening high-belite calcium sulfoaluminate cement clinker and methods to use and to manufacture the clinker. The clinker of the present invention comprises 20% to 35% by weight of C4A3S 3% to 9% by weight of C4AF, 37% to 47% by weight of C2S, 0.5% to 4.6% by weight of f-Ca° and 14% to 26.3% by weight of CaSO4. The chemical compositions of the clinker are 12.9% to 16.1% by weight of SiO2, 12% to 19% by weight of Al2O3, 1% to 3% by weight of Fe2O3, 49% to 54% by weight of CaO and 12% to 18.43% by weight of SO3. It is manufactured by calcining, at a temperature of 1300° C.±50° C. in a rotary kiln, the raw meal, comprising 33% to 62% by weight of limestone, 10.5% to 28% by weight of fly ash, and 19% to 45% by weight of FGD gypsum. A group of rapid-hardening high-strength cements of various strength classes can be manufactured by mixing and grinding 26% to 97% by weight of clinker, 3% to 19% by weight of anhydrite and 0% to 55% by weight of granulated blast furnace slag.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

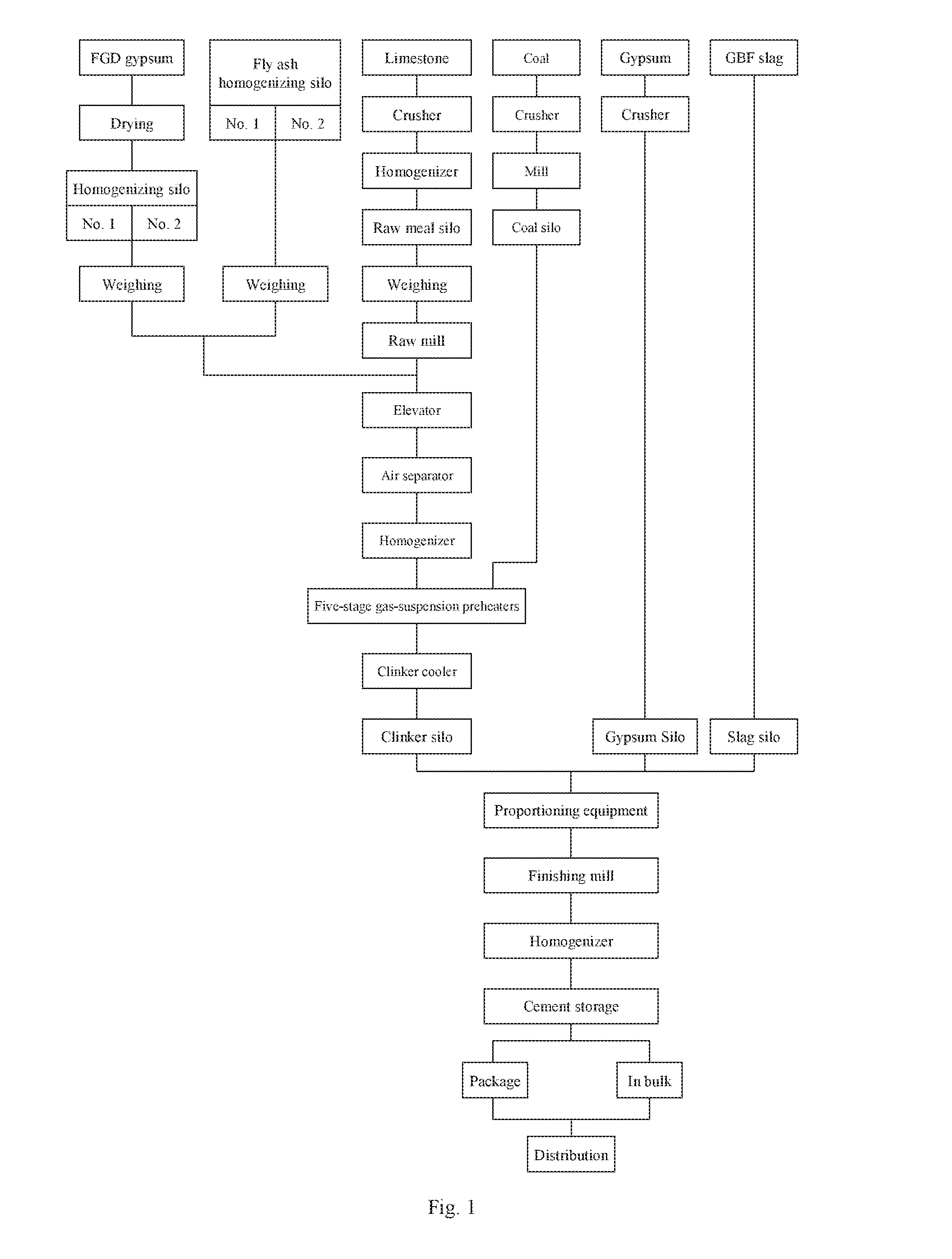

White fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and application and production technology thereof

The invention relates to a white fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and also relates to an application and a production technology thereof. The mineral component of the cement clinker comprises 0.5-4.6% of f-CaO; the chemical component of the cement clinker comprises 12.9-16.1wt% of SiO2, 12-19wt% of Al2O3, 0.15-1.0wt% of Fe2O3, 49-53wt% of CaO and 12-18.5wt% of SO3; and the clinker rate range Cm is 1.01-1.137, and P is 0.62-1.44. The clinker is produced through calcining 30-50wt% of limestone, 26-46wt% of slag powder and 21.1-40wt% of desulfurized gypsum in a rotary kiln at 1250-1350DEG C. 26-97% Of the clinker, 3-19% of anhydrite and 0-55% of the slag powder, or 5-25% of the clinker, 14.4-19.0% of the anhydrite and 55.8-79% of the slag powder are mixed and ground to form white fast-setting, fast-hardening and high-belite sulphoaluminate cement and high-late strength and high-belite sulphoaluminate cement.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL +1

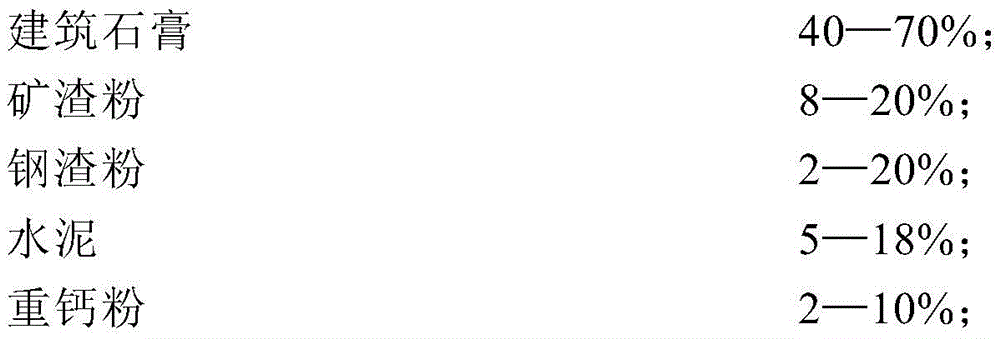

Modified gypsum-based self-leveling mortar and preparation and application thereof

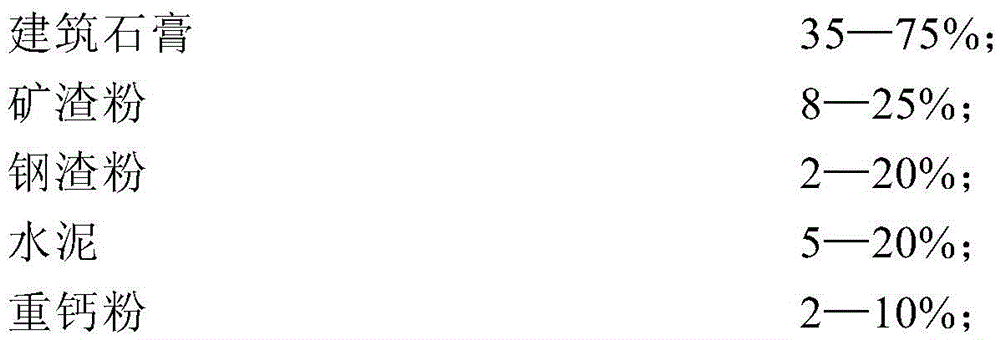

The invention discloses modified gypsum-based self-leveling mortar and preparation and application thereof. The mortar can be taken as a self-leveling mortar material for use in indoor ground leveling, and is prepared from modified gypsum, graded sand and a proper quantity of building additives. A method of adding a proper quantity of inorganic materials such as ground steel slag and ground slag and relevant additives is adopted, so that the water consumption of the modified gypsum is lowered, the density of a material is increased, and the water resistance and the mechanical property of the material are improved while high bonding performance of the gypsum-based material is kept. Scarce alpha gypsum or natural anhydrite is not adopted, raw materials are stable and reliable in supply, and more superior cost performance is achieved; wastes such as gypsum of power plants, ardealite, ground steel slag and ground slag are made full use for making a cementing material, so that general recycling of waste resources is realized, environmental pollution is lowered, and meanwhile a tremendous economic benefit is achieved.

Owner:上海每天生态科技发展有限公司

Low cost cement self-leveling mortar

The invention relates to a low cost cement self-leveling mortar, which does not contain redispersible emulsion, and is doped with zeolite powder, wollastonite powder and fly ash on the basis of a three-phase system containing silicate cement, quick hardening cement and quick hardening anhydrite so as to meet practical engineering needs. The zeolite powder, the wollastonite powder and the fly ash, under the excitation of a cement hydrate, not only have self-maintenance and crack resistance, but also play a role in replacing the cement partially so that the performance of the prepared cement self-leveling mortar is superior to that of the self-leveling mortar added with a large amount of polymer rubber powder, and the cost of the prepared cement self-leveling mortar is comparatively lower.

Owner:北京联合荣大工程材料股份有限公司

Modified low-alkalinity sulphoaluminate cement

InactiveCN101671133ASimple production processEasy qualitySolid waste managementClinker productionCrack resistanceCarbonization

The invention discloses modified low-alkalinity sulphoaluminate cement, which is a hydraulic cementing material prepared by the following steps: forging raw materials including proper elements to obtain 55-70% of clinker which takes anhydrous calcium sulphoaluminate (C3A3S), dicalcium silicate (C2S) and tetracalcium aluminoferrite (C4AF) as main mineral elements, using 5-10% of lithium residues asa modifier, adding a proper amount of 8-15% of anhydrite, 15-20% of mixing material and 0.05-0.2% of adjusting setting agents, and grinding to prepare the cement. The invention has the advantages ofsimple preparation technique, easily guaranteed quality, industrial waste residue recycle, low energy consumption, low cost, environment protection, good performances of low alkalinity, early and highstrength, microdilatancy, cracking resistance, freezing resistance, impermeability, anti-carbonization, abrasion resistance, flushing resistance, good adhering capability, adjustable primary time offinal setting, good slurry fluidity, good coherence in water and wide application range.

Owner:YONGZHOU ZHONGDA SPECIAL CEMENT

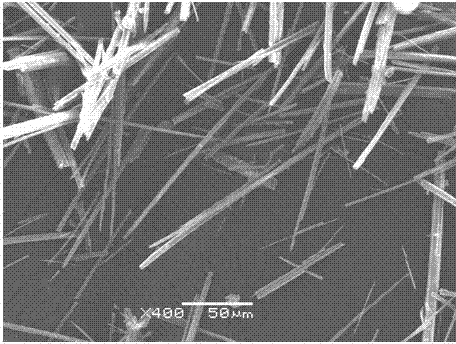

Method for preparing calcium sulfate crystal whisker in low cost

InactiveCN102965721AIncrease profitReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateHigh pressure

The invention discloses a method for preparing calcium sulfate crystal whisker in low cost and relates to a method for preparing the calcium sulfate crystal whisker. The method comprises the following steps of: crushing raw materials consisting of ground limestone and anhydrite, treating the crushed ground limestone and anhydrite by a sulfuric acid solution, adding a crystal growth substance to prepare a mixture solution, preparing calcium sulfate hemihydrate crystal whisker with higher length-diameter ratio by a hydrothermal synthesis method at high temperature under high pressure, and carrying out filtering, washing and high-temperature crystal water removing steps on the calcium sulfate hemihydrate crystal whisker to obtain high-quality anhydrous calcium sulfate crystal whisker products. The calcium sulfate crystal whisker prepared by the method disclosed by the invention can be applied to high polymer material such as plastic and rubber to improve the performances of polymer materials by serving as a reinforcing material. The method disclosed by the invention has the advantages of low production cost, simple operation and high additional value of products.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Self-leveling terrace powder mortar composite

The invention provides a self-leveling terrace powder mortar composite and the composite comprises the following components in parts by weight: 250-350 parts of ordinary silicate cement, 50-100 parts of aluminate cement, 250-550 parts of quartz sand, 50-250 parts of heavy calcium carbonate, 10-30 parts of anhydrite and 40-80 parts of zeolite graft re-dispersible emulsion powder. The invention adopts zeolitic inner hole adsorption principle to disperse zeolite evenly in mortar; solid zeolite is crosslinked with graft zeolite inside and outside; in the hydration process of silicate cement, the dense doping among anhydrite, heavy calcium carbonate and crosslinked zeolite changes the lattice of cement so as to ensure the stable long-term strength of mortar and eliminate the phenomenons such as the efflorescence of the self-leveling terrace mortar in later period, sand-stripping and cracking and the like; in addition, aluminum powder is added to increase the wearability and antishrinking property of the terrace mortar and the flexibility of the polymer is increased to improve the breaking strength of the mortar.

Owner:常熟市金龙装饰有限责任公司

Impermeable anti-cracking concrete

The invention discloses an impermeable anti-cracking concrete which comprises the following components in parts by weight: 180-280 parts of cement, 50-70 parts of ore powder, 50-80 parts of fly ash, 920-980 parts of gravel, 700-750 parts of scrap, 100-200 parts of sand, 170-200 parts of water, 0.5-0.9 part of water reducing agent, 0.3-0.7 part of air entraining agent, 1-2 parts of polyacrylamide, 0.05-0.1 part of sodium alkyl benzene sulfonate, 0.2-0.4 part of ethylene glycol, 0.05-0.1 part of sodium carboxymethyl cellulose, 1.3-1.7 parts of commercial aluminum sulfate, 0.2-0.5 part of high-strength steel-wire-like fiber, 0.01-0.04 part of lauryl sodium sulfate, 0.7-1.3 parts of silica fume, 3.45-4.5 parts of anhydrite, 2.3-3 parts of sulfoaluminate clinker, 0.3-0.7 part of activator, 10-35 parts of hydrogen polypropylene fiber, 18-42 parts of graphite particle and 4.5-7 parts of foaming agent. The impermeable anti-cracking concrete has the advantages of high earthquake resistance, high shock resistance, high cracking resistance, high impermeability and high durability, and has the functions of fire resistance, sound insulation and thermal insulation.

Owner:CHANGAN UNIV

Polyvinyl chloride (PVC) composite electrical sleeve

InactiveCN102977498AImprove heat resistanceImprove light resistancePolyvinyl chlorideShock resistance

The invention relates to a polyvinyl chloride (PVC) composite electrical sleeve which comprises the following raw materials in parts by weight: 100 parts of PVC resin, 2-60 parts of natural anhydrite, 3-10 parts of titanium white, 0.01-15 parts of surface modifier, 1-20 parts of toughener, 0.5-2 parts of MBS (methyl methacrylate-butadiene-styrene) resin, 1-3 parts of PE (polyethylene) wax, 1-15 parts of stabilizer and 0.1-15 parts of lubricant, wherein the mesh number of the natural anhydrite is more than 400 meshes. The PVC composite electrical sleeve is a composite pipe made of PVC / natural anhydrite and other materials, has the advantages of high temperature resistance, high voltage resistance, high strength, shock resistance and the like, and can be used as various guide pipes for wire protection, guide pipes for wiring protection, pipes for postal service, telecommunication and network cabling and threading carriers for auxiliary electric / data transfer cables.

Owner:ANHUI KANGJIA PLASTIC BUILDING MATERIAL

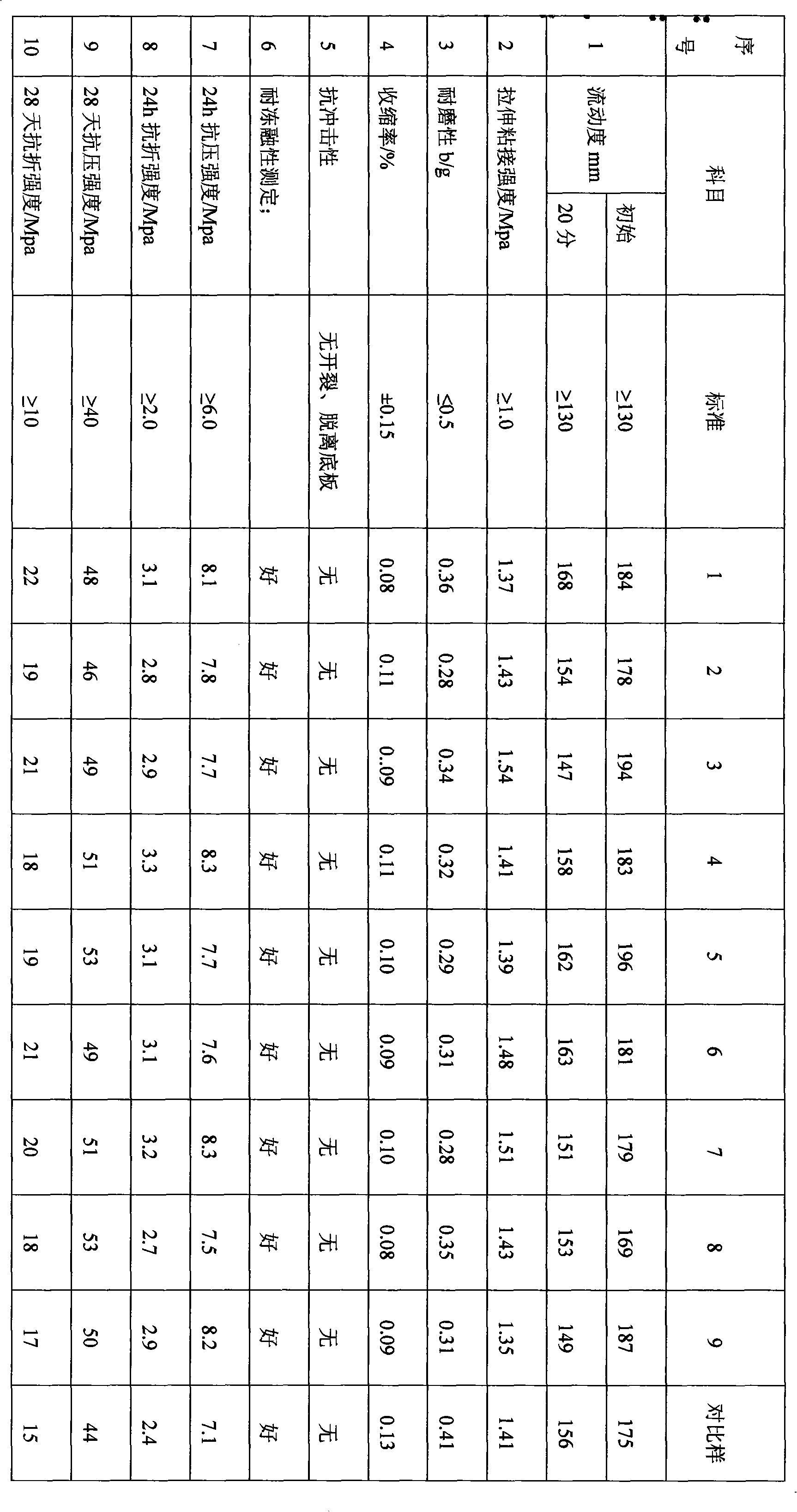

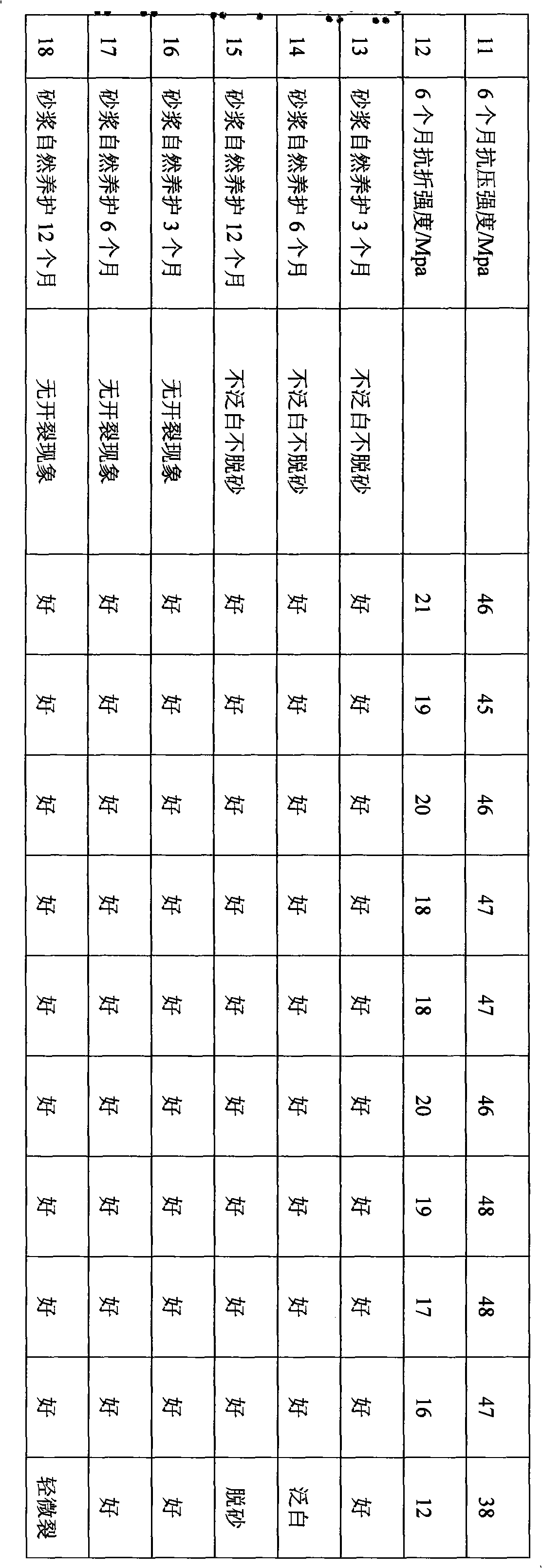

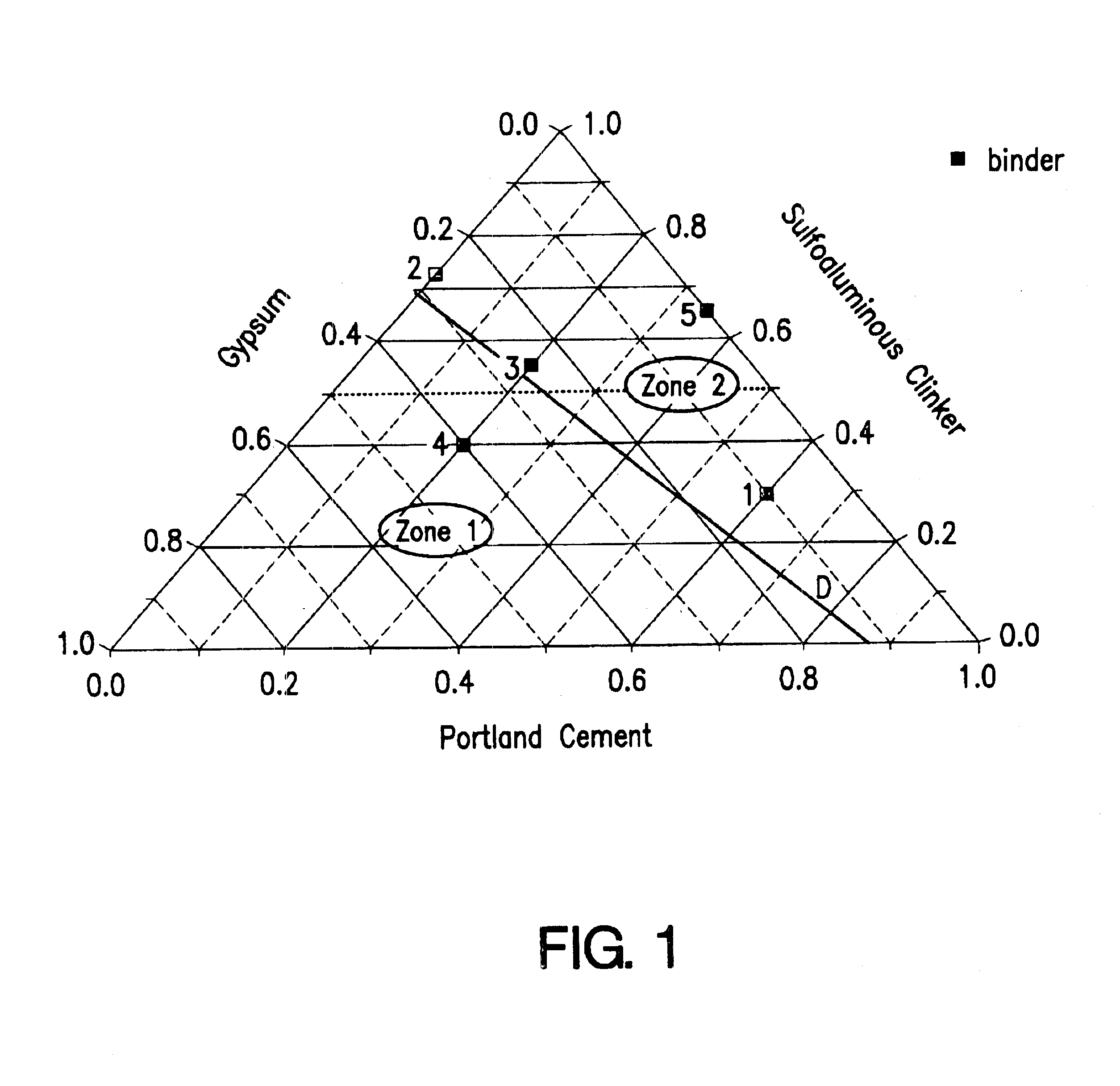

Sulfoaluminous clinker without iron and without free lime, its process of preparation and its use in white binders

The lightly colored sulfoaluminous clinker contains: more than 55% by weight of calcium sulfoaluminate phase (C4A3S), more than 10% by weight of belite phase (C2S), less than 10% by weight of anhydrite (C{overscore (S), and contains practically no ferrite phase, nor a gehlenite phase (C2AS), nor free lime. It is prepared by a process of roasting carried out at temperatures comprised between about 1250° C. and 1350° C. It can be used for a wide range of applications by combining it with a source of calcium sulfate and / or Portland cement, to obtain binders having specific properties (color, setup time, mechanical strength, expansion or contraction . . . ).

Owner:SOC DES CIMENTS FR

Polymer cement-based self-leveling mortar

InactiveCN101591160AImprove liquidityImprove early strengthSolid waste managementPortland cementCompressive strength

The invention relates to the field of building materials, in particular to polymer cement-based self-leveling mortar for leveling ground, which comprises the following materials in percentage: 20.0 to 30.0 percent of Portland cement, 5.0 to 8.0 percent of high-alumina cement, 8.0 to 12.0 percent of anhydrite, 1.0 to 4.0 percent of polymeric powder, 55.0 to 65.0 percent of mineral admixtures, 0.1 to 0.5 percent of water reducer, 0.5 to 1.0 percent of water-retentive thickening admixture, and 0.05 to 0.30 percent of retarder or 0.05 to 0.20 percent of coagulation accelerator. The polymer cement-based self-leveling mortar has the advantages that: the polymer cement-based self-leveling mortar has the performance characteristics of automatic leveling, high early flexural and compressive strength and high spreading degree on the ground, also has excellent performance of high bonding strength with base materials, high durability, high compactness, no crack and no reservation of expansion joints after construction, and the like, and can be used for automatically leveling the base of the ground, and repairing old ground, sand ground and the ground.

Owner:爱福家居(江苏)有限公司

Contraction-free cement grout material

The invention relates to the field of cement grout materials, in particular relating to a property-adjustable functional contraction-free cement grout material. The contraction-free cement grout comprises the following components in percentage by weight: 30.0%-6.0% of gelled material, 0%-5.0% of anhydrite, 4.0%-6.0% of expanding agent, 0.6%-1.5% of water reducing agent, 0%-0.09% of coagulant, 0%-2% of shrinkage agent, 0%-0.06% of thickener and 40.0%-65.0% of aggregate. The grout material has the advantages of good self-flowability, no sedimentation, no bleeding, minimum inflation and no obvious contraction phenomenon; the property of the grout material can be adjusted at random according to the requirement of a building, thus the grout material is wide in adaptability, low in cost, flexible to operate and convenient to use; and the grout material can be suitable for aid repair engineering with a high strength requirement at early period, can be used for a common grout material with a general requirement, and also can be used for a superfluid grout material with large flowability.

Owner:浙江五龙新材股份有限公司

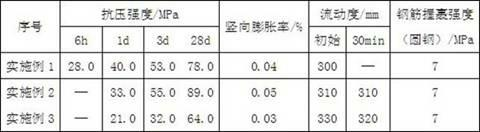

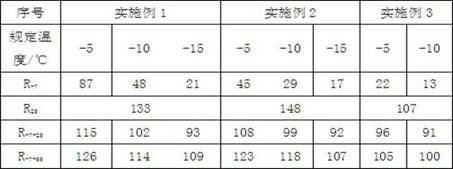

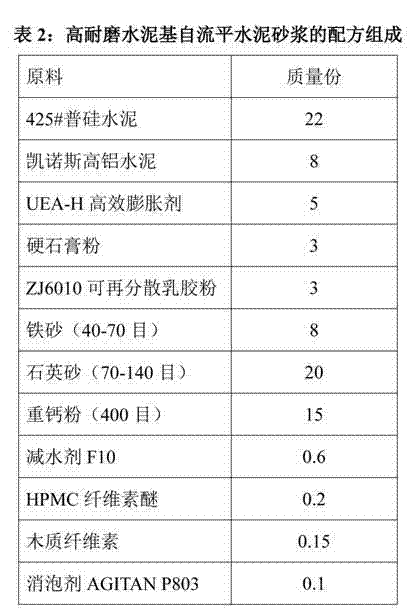

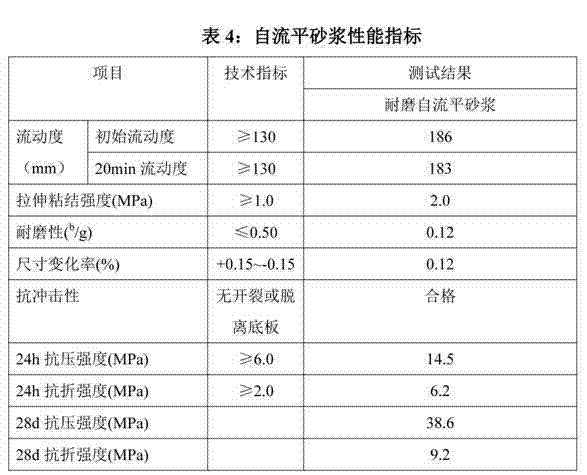

High-wear-resistant cement-based self-leveling mortar and preparation method thereof

The invention discloses high wear-resistant cement-based self-leveling mortar. The high wear-resistant cement-based self-leveling mortar is prepared from the following raw materials in parts by weight: 8-20 parts of iron sand, 22-32 parts of ordinary portland cement, 4-8 parts of high alumina cement, 4-8 parts of expansion agent, 3-6 parts of anhydrite powder, 2-4 parts of dispersible adhesive powder, 20-40 parts of quartz sand, 10-20 parts of heavy calcium carbonate, 0.5-0.8 parts of water reducing agent, 0-6 parts of early strength agent, 0.1-0.2s part of retarding agent, 0.1-0.2 parts of lignocellulose and 0.1-0.2 parts of defoaming agent. A method for preparing the high wear-resistant cement-based self-leveling mortar comprises the following steps: 1) performing rust prevention treatment on the iron sand, namely placing the iron sand in boiled alkali liquor for 10-20 minutes, further separating the iron sand and drying; and 2) uniformly mixing the iron sand after the rust prevention treatment with other components of the self-leveling mortar. The mortar prepared by the invention has better flowability; and simultaneously, a terrace formed by construction of the mortar disclosed by the invention has better surface wear resistance.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

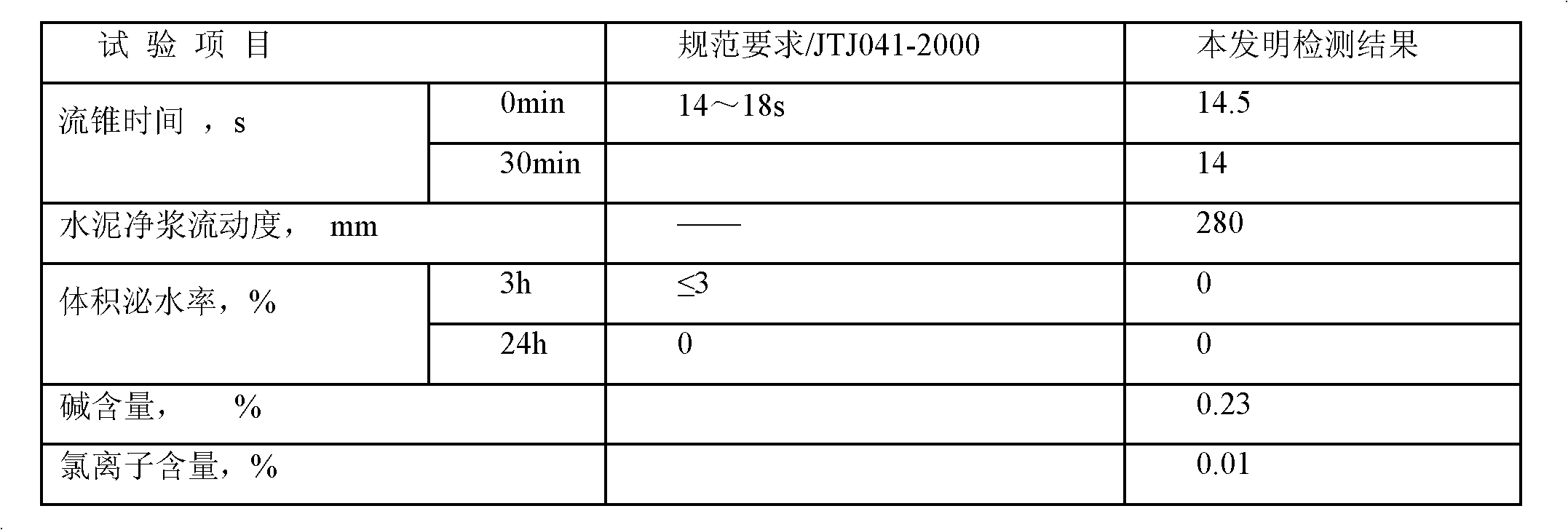

High-performance concrete expansion agent and preparation method thereof

The invention discloses a high-performance concrete expansion agent and a preparation method thereof. The high-performance concrete expansion agent comprises the following components by weight percentage: 30-70 percent of expansion clinker, 20-45 percent of anhydrite and 10-25 percent of other additives. The high-performance concrete expansion agent has functions of cracking prevention, seepage prevention, shrinkage compensation and the like. Compared with the expansion agent in the prior art, the early expansion is large, the later expansion is small, no harmful later expansion can be produced, harmful cracks of concrete structures caused by early shrinkage, dry shrinkage and cold shrinkage can be avoided, the seepage problem of the structures can be solved, and the durability of concrete can be improved greatly.

Owner:SHENZHEN ROCK INVESTMENT

Rapid hardening high-strength grouting material

InactiveCN101913840ASolve the problem of degraded perfusion qualityWith antifreeze functionSolid waste managementAnti freezingLithium carbonate

The invention discloses a rapid hardening high-strength grouting material, which consists of the following components in percentage by weight: 40 to 55 percent of fast hardening sulphoaluminate cement, 40 to 55 percent of quartz sand, 1 to 5 percent of silicon micro-powder, 2 to 5 percent of high-calcium powder, 0.6 to 1.0 percent of FDN water reducer, 1 to 3 percent of anhydrite powder, 0.02 to 0.14 percent of lithium carbonate, and 0.2 to 1.4 percent of sodium chloride. The components are uniformly mixed, and stirred with water in a water / cement ratio of 0.14-0.18, and the grouting material can be used after uniform stirring. The grouting material is suitable for low-temperature construction, and has the characteristics of early strength, high strength, good flowing performance, no shrinkage, good anti-freezing effect and the like.

Owner:刘茂平

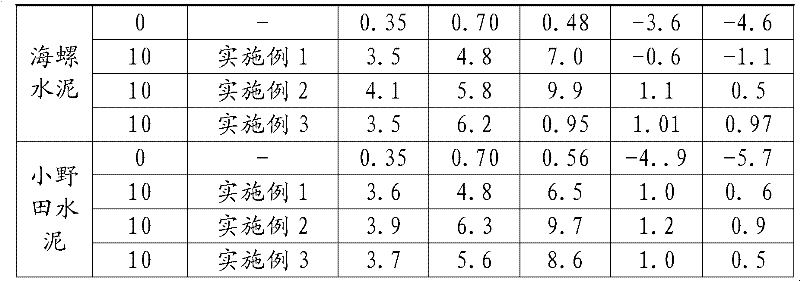

Cement concrete accelerator

The invention relates to a cement concrete accelerator. The accelerator comprises 50-65% of aluminium-oxygen clinker, 25-35% of calcined alunite, 3-8% of zinc sulfate and 6-8% of anhydrite. According to the accelerator, the resilience rate is low, the later strength is high, the compression strength retention rate for 28 days can reach more than 90%, and the alkali charge is low, and harm to an operating worker can be reduced greatly.

Owner:贵州遵辉环保科技有限公司

Compound high-performance expanding agent for cement-based material

The invention discloses a compound high-performance expanding agent for a cement-based material and belongs to the technical field of cement-based material additives. A plurality of materials such as panniculus adiposus lime, natural anhydrite, limestone, an azo compound and the like are selected as expanding components. The compound high-performance expanding agent provided by the invention is prepared by the following steps of: grinding panniculus adiposus lime, natural anhydrite and limestone according to a certain proportion to a certain fineness by a grinding machine, adding the azo compound and a dispersant in a certain proportion, and uniformly mixing. The expanding agent can be used to produce appropriate expansion of the cement-based material during plasticity and hardening phases, greatly raise dispersibility and fluidity of the prepared pulp and enhance rupture and compressive strength of the material. In addition, low alkali and microamount chlorine can raise endurance of the cement concrete construction.

Owner:中冶武汉冶金建筑研究院有限公司

Levelling mortar and ground construction process based on the same

The invention relates to a levelling mortar, comprising ingredients of, by weight, 20-30% of rapid hardening sulphoaluminate cement, 3-5% of ordinary portland cement, 3-5% of anhydrite, 30-40% of silica sand, 20-30% of calcium carbonate, 0.1-0.3% of water reducing agent, 0.02-0.1% of thickening agent, 0.02-0.1% of early strength agent, 0.1-0.8% of coagulation accelerator, 0.1-0.3% of retarder, 0.1-0.3% of antifoaming agent, 0.5-2% of shrinkage reducing agent, and 0.5-2% of redispersible emulsion powder. The invention also relates to a ground construction process based on the levelling mortar specified in the patent claim 1. The technology comprises steps of: (1) carrying out a base ground surface treatment; (2) finding out a highest point on the ground; (3) coating an interface agent; (4)setting horizontal control points; (5) setting levelling mortar casting segmenting plates; (6) stirring the levelling mortar; (7) casting the levelling mortar; (8) repeating the step (5), (6) and (7); (9) segmenting a work surface; (10) maintaining. The levelling mortar of the present invention and the construction process thereof have advantages of an accurate and controllable construction thickness of a levelling layer, convenient operation, small amount of material usage and high ground flatness after construction.

Owner:天津国成泰材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com