Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4637 results about "Silicate Cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A relatively hard, translucent, restorative material used primarily in anterior teeth. (From Boucher's Clinical Dental Terminology, 4th ed, p50)

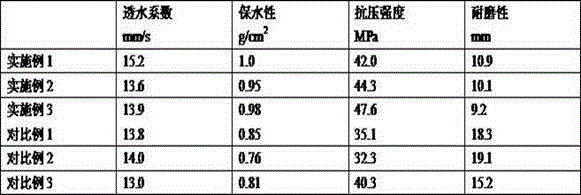

Corrosion resistant water permeable brick

ActiveCN105016765AHigh permeability coefficientHigh compressive strengthCeramicwareCompressive resistanceBrick

The present invention relates to a corrosion resistant water permeable brick, and belongs to the technical field of building materials. The corrosion corrosion resistant water permeable brick comprises 20-25wt% of Portland cement, 1.0-1.2wt% of anhydrite powder, 15.0-20.0wt% of slag pellets, 10-12wt % of cenospheres, 1.5-2.1wt% of admixtures, and the balance of quartz sand. Under the premise that the porosity and water permeability coefficient of the corrosion resistant water permeable brick are significantly higher than that of a water permeable brick, the compressive strength of the corrosion resistant water permeable brick is still higher than that of the conventional water permeable brick, the corrosion resistant water permeable brick has good corrosion resistance, and service life is significantly increased.

Owner:江苏溧阳建设集团有限公司

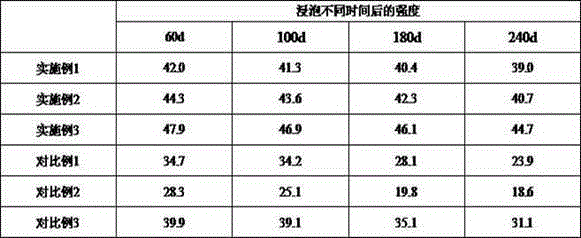

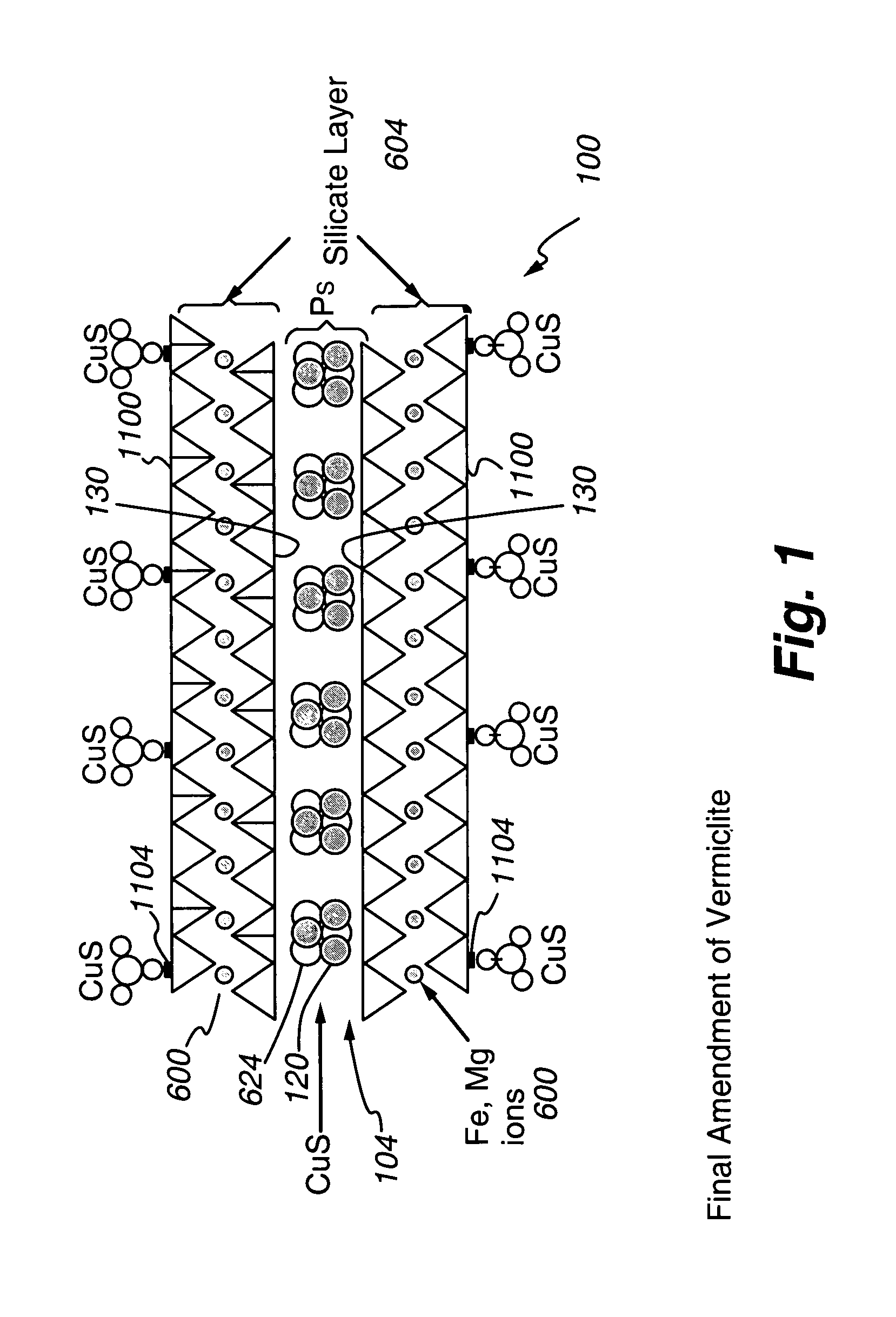

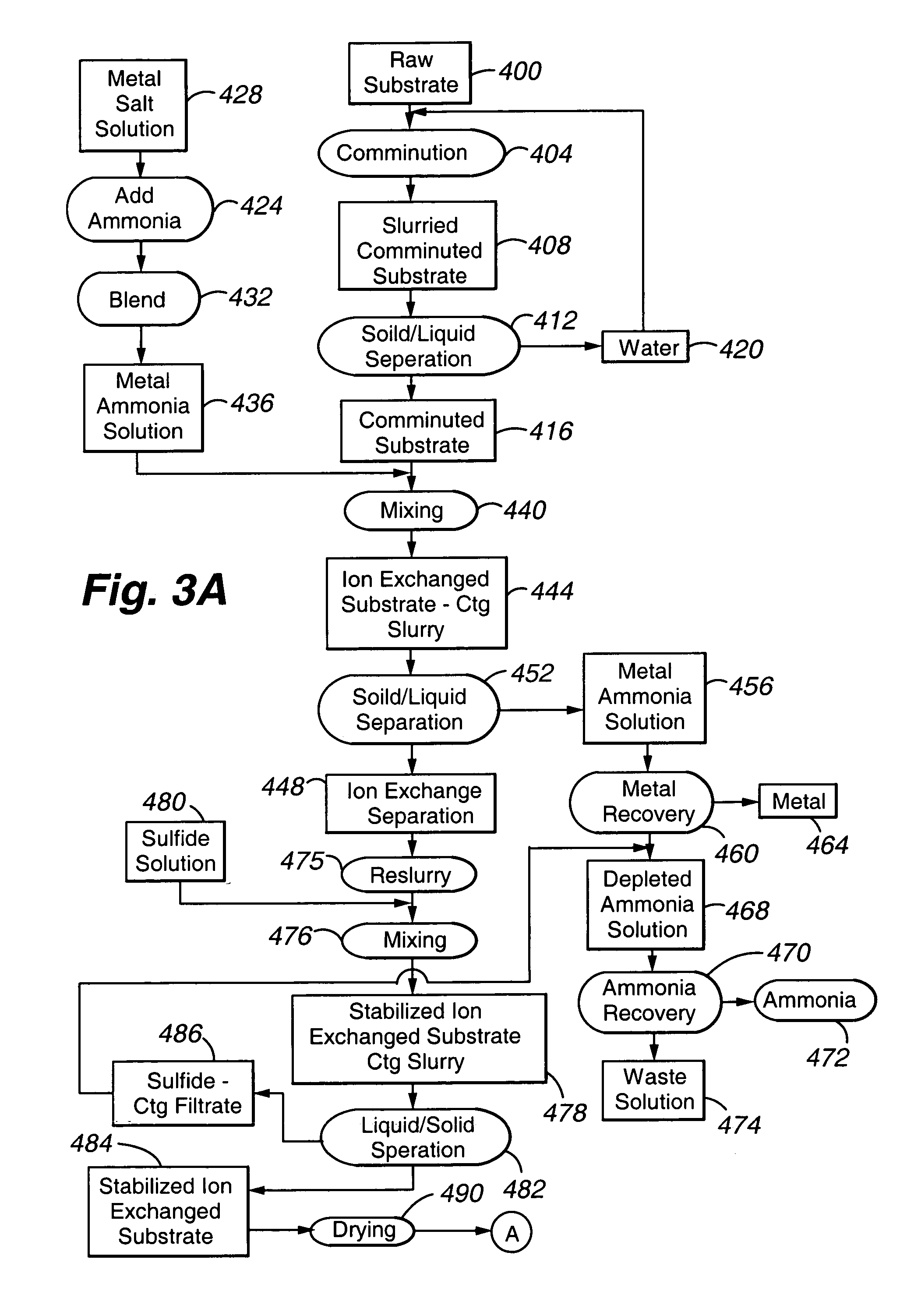

Chemically-impregnated silicate agents for mercury control

ActiveUS7048781B1Improved and cost-effective controlLower unit costGas treatmentUsing liquid separation agentIon exchangeMontmorillonite

The present invention is directed to a contaminant removal agent comprising a polyvalent metal sulfide on the surface of an inert substrate. The substrate can be a layered silicate, such as vermiculite, an aluminosilicate such as montmorillonite, or a nonlayered silicate such as a zeolite. The agent removes mercury from process streams. The ion exchange to deposit the polyvalent metal on the substrate is preferably performed at a pH above the pHZPC.

Owner:ENVIRONMENTAL ENERGY SERVICES

Preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and preparation method thereof

ActiveCN101602589AWide variety of sourcesSimple preparation processSolid waste managementMixing operation control apparatusNeutral phPre stress

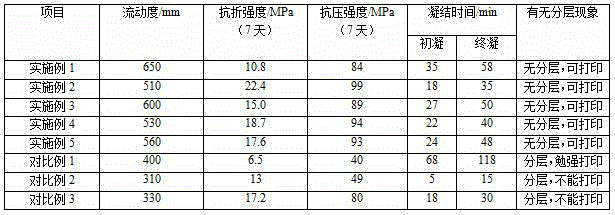

The invention discloses a preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and a preparation method thereof. The preformed material includes the following components by weight percent: 65 to 95 percent of silicate cement, 0.01 to 3 percent of high-range water-reducing agent, 0 to 1 percent of stabilizing agent, 0.05 to 5 percent of retarding agent, 1 to 20 percent of expanding agent, 0.2 to 2 percent of corrosion inhibitor, 0.01 to 1 percent of air entraining agent and 0 to 30 percent of mineral materials, wherein by uniformly and proportionally mixing the silicate cement, the high-range water-reducing agent, the stabilizing agent, the retarding agent, the expanding agent, the corrosion inhibitor, the air entraining agent and the mineral materials, the post-tensioned prestressing pipeline vacuum grouting or mudjacking preformed material can be obtained. After being uniformly mixed and stirred with water with neutral pH value according to the water cement ratio ranging from 0.24 to 0.32, the preformed material can be used, the obtained grouting material has the advantages of low water cement ratio, favorable flowability, no water bleeding and delamination, and favorable pumpability; meanwhile, the preparation method of the preformed material is simple and the raw material sources of the preformed material are wide.

Owner:HUBEI CHIDGE TECH

Concrete base sound absorption material for road sound screen and method of manufacturing the same

The invention relates to a cement-matrix sound-absorption material used in road noise barriers and a preparation method thereof; the sound-absorption material is a noise barrier material which can be used in airports, high-speed railways, expressways, urban viaducts, subways and light rails; the components and weight ratios are as follows: 15.4 to 62.3 percent of Portland cement, 0.1 to 15.7 percent of mineral admixture, 18.9 to 79.9 percent of lightweight porous aggregate, 0.013 to 0.078 percent of foaming agents, 0.1 to 0.7 percent of water reducing agent and 0.4 to 2.6 percent of fiber. The sound-absorption material and the preparation method thereof have the advantages of large sound absorption coefficient, high strength, good anti-impact performance, excellent durability, fire resistance, moisture resistance, anti-corrosion and self-clean function; at the same time, the sound-absorption material is wide in sources of raw materials, convenient in preparation and processing, suitable for large-scale production, low in cost, environment-friendly and good in decorativeness.

Owner:SOUTHEAST UNIV +1

A novel masonry cement

The invention discloses a novel type of masonry cement, which comprises silicate cement clinker aggregate, mixed material, gypsum, cellulose ether, grinding aid, dispersant emulsion powder, water reducing agent, air-entrainer, quick-setting agent, retarders, instant coagulant, thixotropy lubricating agent, defoaming agent, hydrophobing agent, starch ether, plumping agent, shrinkage reduction agent, exciting agent, pigment and fabric.

Owner:SOUTH CHINA UNIV OF TECH

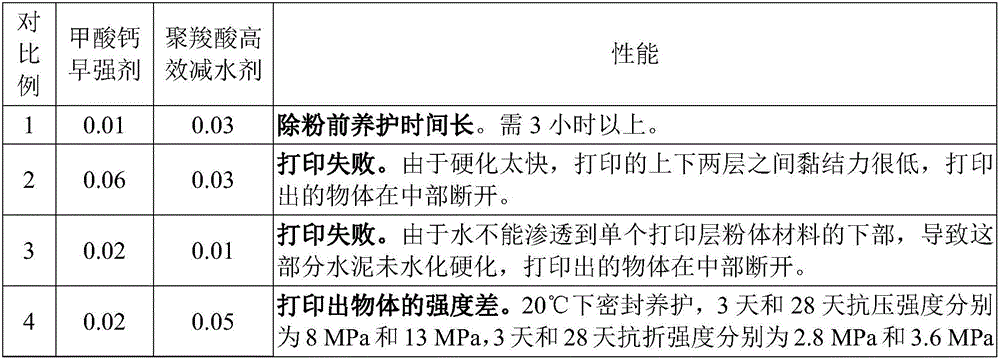

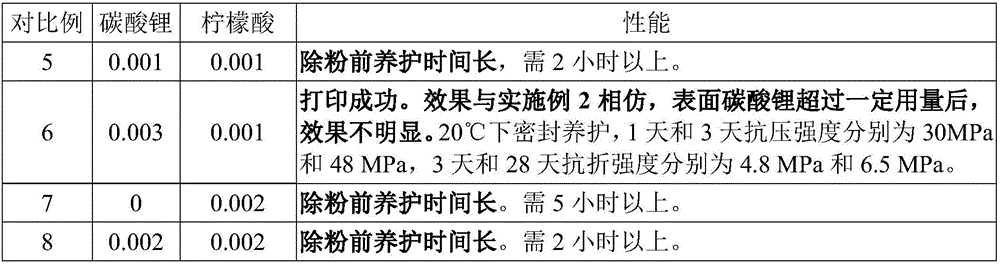

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

Cement-base dual-liquid slip-casting material

The invention relates to a kind of pair-slurry affusing material prepared with cement as basic raw material. It is comprised of two kinds of dry powdery mixed materials A and B of affusing slurry pair-liquid formed after adding water. Their weight percents are respectively: mixed material A: sulfur aluminate cement 30% - 98.1%, retarder citric acid 0.1% - 0.5%, flocculant polyacrylamide 0% - 0.8%, water-reducing agent FDN 0.6% - 1.5% and inorganic padding pulverized coal ash 0% - 69.1%; mixed material B: Portland cement 20% - 88%, land plaster 6% - 15%, flocculant UWN 0% - 0.7%, accelerator lithium carbonate 0.4% - 1.0%, water-reducing agent FDN 0.5% - 1.3%, calcareousness 2.0% - 5.0% and inorganic padding pulverized coal ash 0% - 70.8%.

Owner:张振秋

High performance cement-base self-leveling mortar

The invention discloses a high performance cement-base self-leveling mortar. The mortar is characterized by comprising cement, an auxiliary gel material, fine aggregate, a filling material, an additive, and water; wherein the cement is common silicate cement and sulphoaluminate-silicate cement, the auxiliary gel material comprises mineral slag, fly ash, silica fume, and gypsum, and the ratio of common silicate cement to sulphoaluminate-silicate cement to gypsum is equal to 1:0.2-0.6:0.1-0.4. The mortar has a self-leveling function without vibration, so the surface flatness is very high. The curing speed of the mortar is very quick, and after two hours, the strength of the mortar can meet the requirements of subsequent construction. Moreover the mortar has the advantages of low contraction rate, good volume stability, good surface wear resistance, and high compression strength.

Owner:广东省建筑工程监理有限公司

Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

InactiveCN101255698AHigh strengthImprove water stabilitySolid waste managementUnderground chambersWater blockCement slurry

The present invention discloses a running sand layer and sandy gravel layer dynamic-water double-liquid high-pressure slurry-injecting water-shutoff construction method which comprises the following construction steps: drilling a hole, flushing the hole, executing double-liquid high-pressure slurry-injecting operation and sealing the hole. The running sand layer and sandy gravel layer slurry-injecting liquid adopts an ordinary portland cement (P.O.42.5) and 40''Be sodium silicate as material for preparing the slurry, according to the weight proportion of water: cement, namely the cement slurry is prepared with the water cement ratio for 0.5-1.2:1. Then the slurry-injecting liquid is prepared with the volume ratio of cement slurry: sodium silicate for 1:0.08-0.15. The sodium silicate is taken as additive for regulating the initial setting time of the slurry-injecting liquid. The cement slurry can also be doped with fly-ash with cement consumption (weight proportion) for 10%-15%. The invention executes water-insulating construction aiming at the characteristics of large pressure of the underground dynamic water and high flowing velocity in the running sand layer and sandy gravel layer, and can obtain the maximal application sphere and optimum water-shutoff effect.

Owner:HUNAN CONSTR ENG GRP COR

High-performance powder concrete for 3D (three-dimensional) printing

The invention relates to high-performance powder concrete for 3D (three-dimensional) printing. The concrete is prepared from the following raw materials in parts by weight: 500-900 parts of ordinary Portland cement, 250-350 parts of active mineral admixture, 800-1,300 parts of inert filler, 10-20 parts of composite efficient water reducing agent powder, 2-5 parts of thickener, 4-10 parts of self-curing agent, 2-10 parts of fast setting time regulator, 145-230 parts of water, 3 parts of organic fiber and 40-200 parts of copper plated fiber. The concrete material for 3D printing has the characteristics of ultrahigh strength and toughness, good durability, long full life cycle, high curing rate, good flowing property and easiness in pumping and lifting and is suitable for constructing 3D-printed building structural materials in all kinds of engineering.

Owner:黄贺明

Thermal insulation building mortar and preparation process thereof

InactiveCN101759416AWith thermal insulationWith phase change energy storageCement mixing apparatusSodium BentoniteThermal insulation

The invention discloses a thermal insulation building mortar. The thermal insulation building mortar is prepared by the mixing portland cement, pulverized fuel ash, calcium bentonite, re-scattering glue powder, hypromellose, polyacrylamide powder, polypropylene fibre, wood fiber, permeating crystal waterproof agent, air entraining agent, vitrified micro-bead, sizing phase-change material and hollow glass bead. A preparation process thereof comprises the steps of: a) preparing the sizing phase-change material, b) preparing the permeating crystal waterproof agent and c) preparing the thermal insulation building mortar. The mortar of the invention is characterized by the functions of thermal insulation, phase-change energy storage, temperature control, water resistance and energy saving, the wide application scope and low cost. The mortar is widely applied in thermal insulation work inside or outside the buildings and has a broad prospect.

Owner:唐山市思远涂料有限公司

Quick-setting cement-based capillary crystalline self-repairing waterproofing material and preparation method therefor

ActiveCN106946518AAchieve waterproof effectImprove flexural and compressive capacityIon contentBULK ACTIVE INGREDIENT

The invention discloses a quick-setting cement-based capillary crystalline self-repairing waterproofing material and a preparation method therefor. The quick-setting cement-based capillary crystalline self-repairing waterproofing material is prepared from the following ingredients in parts by weight: 55-75 parts of silicate cement, 25-45 parts of quartz sand, 3-10 parts of buffering agent, 4-12 parts of active ingredient A, 4-15 parts of active ingredient B, 2-6 parts of expanding agent, 1-12 parts of calcium ion supplement and 1-4 parts of water reducing agent. The waterproofing material disclosed by the invention is prepared by a simple physical mixing method, is short in initial setting time and low in chloride ion content and can infiltrate into the interior of a cement-based material to form crystals so as to block up microcracks, thus, the folding and compressing resistance and secondary infiltrating resistance are improved, and meanwhile, the cement-based material is endowed with long-lasting self-repairing performance and good waterproof and durable performance. In addition, the preparation method for the quick-setting cement-based capillary crystalline self-repairing waterproofing material is simple, has low requirements on equipment and processes and has very high application power.

Owner:SOUTH CHINA UNIV OF TECH +1

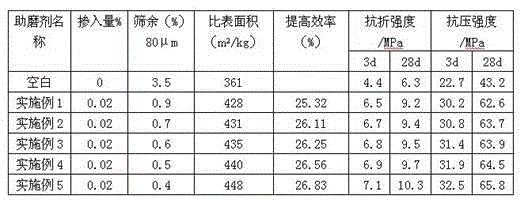

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

Porous phosphorus removing ceramic granules with function of slowly releasing alkali and preparation method thereof

ActiveCN101935195AImprove plasticityLarge specific surface areaSilicon compoundsWater/sewage treatment by sorptionFiberPorosity

The invention discloses porous phosphorus removing ceramic granules with a function of slowly releasing an alkali and a preparation method thereof. The prepared ceramic granules are an environmental material for efficiently removing phosphorus from municipal sewage and industrial wastewater. Based on the basic chemical properties of the phosphorus in water and a phosphorus removing mechanism by chemical absorption, the preparation method of the ceramic granules comprises the following steps of: mixing 20 to 40 mass percent of ordinary portland cement (42.5 level), 10 to 20 mass percent of bentonite, 10 to 20 mass percent of fly ash, 10 to 15 mass percent of calcium oxide, 15 to 25 mass percent of nitrocellulose, 14 to 30 mass percent of xonotlite fiber particle and 0.1 to 0.5 mass percent of pore-creating agent; adding water for stirring the mixture according to a water-solid ratio of 0.35 to 0.45; granulating the mixture into granules with required grain sizes; and after the granules are foamed and solidified, curing the granules by using high-temperature steam to obtain the ceramic granules. The method has the advantages of simple preparation process, readily available raw materials, low cost and wide application prospect in the field of the removing of the phosphorus in water bodies. The prepared ceramic granules have the characteristics of capacity of slowly releasing the alkalis, silicic and calcareous textures, porosity, capacity of continuously and efficiently absorbing and removing the phosphorus and suitability for phosphorus removing systems of the municipal sewage and the industrial wastewater.

Owner:郑俊 +1

Composite cementitious material and ground self-leveling mortar using same

The invention provides a ground self-leveling mortar comprising gelatinization materials, fine sand and an additive. The gelatinization materials comprise sulphate aluminium cement, silicate cement and plaster. The self-leveling mortar comprises the components by weight percentage of: 30% of sulphate aluminium cement, 12.6% of silicate cement, 46.15% of fine sand, and 4.75% of additive. The plaster is a natural hard plaster or reverse 8-type hymihydrate plaster. The additive comprises: redisperse emulsion powder, early strength agent, a retarder, a super-plasticizer, a defoamer and a stabilizer. The ground self-leveling mortar uses the sulphate aluminium cement to replace aluminate cement to be combined with the silicate cement and the plaster, so as to solve the problems that the aluminate cement is high in price and difficult to purchase, and overcome the contradiction between shrinkage and expansion, thus avoiding the self-leveling floor hollowing and cracking and ensuring the bonding strength, folding and compressingresistance strength as well as wearing resistance to reach the optimized level.

Owner:广东龙湖科技股份有限公司

Cement-based self-leveling mortar

The invention relates to cement-based self-leveling mortar, which is prepared from the following raw materials in percentage by weight: 35 to 40 percent of No.425 ordinary portland cement, 10 to 15 percent of No.42.5 rapid hardening sulphoaluminate cement, 15 to 18 percent of heavy calcium carbonate, 0.45 to 1 percent of high polymer, 0.15 to 0.3 percent of water reducing agent, 0.15 to 0.3 percent of early strength agent, 0.15 to 0.3 percent of retarder, 0.15 to 0.3 percent of thickener and the balance of fine river sand with the fineness modulus of 1.2 to 1.5. Compared with other traditional cement self-leveling mortar, the self-leveling mortar has the characteristics of higher fluidity, higher leveling property, high early strength and the like.

Owner:CHENGDU JIAXIN TECH

Energy-saving type concrete crack repairing agent

The invention discloses an energy-saving type concrete crack repairing agent which comprises the following components in parts by weight: 12-18 parts of sand, 5-10 parts of a quartz powder, 20-35 parts of ordinary portland cement, 10-18 parts of sulphoaluminate cement, 6-12 parts of sodium silicate, 5-9 parts of a polyvinyl acetate emulsion powder, 3-7 parts of silica fume, 7-10 parts of a slag powder, 6-9 parts of fly ash, 8-10 parts of an expansive agent, 0.4-0.6 part of a polycarboxylic acid type high-efficiency water-reducing agent, and 0.2-0.4 part of polypropylene fiber. The concrete repairing agent has high bonding strength, and significantly improves the binding force between a new concrete interface and an old concrete interface; the concrete repairing agent is short in congealing curing time, fast in development of strength after congealing, and suitable for rapid repairing; the concrete repairing agent has the advantages of environmental protection, no toxicity, no smell, harmlessness to human bodies, single-component construction, and no pollution to the environment; and the concrete repairing agent can be used for repairing of concrete cracks, holes, honeycombs and pock marks, and drawing repairing of seams of face bricks and mosaic.

Owner:HUNAN CONSTR ENG GRP COR +1

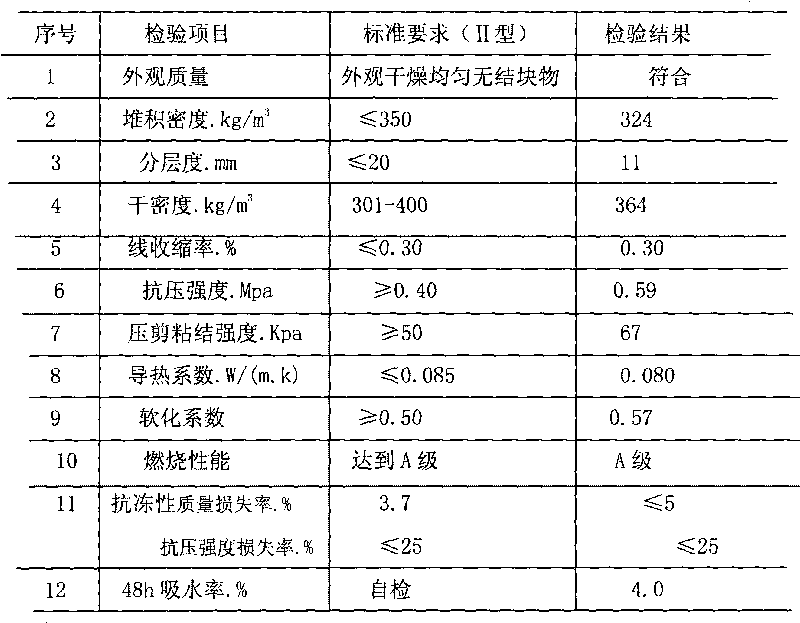

Sepiolite fiber modified vitrification bead thermal insulation mortar

InactiveCN101549978AThermal conductivity can be adjusted over a wide rangeLarge adjustment rangeSolid waste managementThermal insulationBuilding material

The invention belongs to the building material field, relates to vitrification bead, thermal insulation mortar and preparation method thereof. A sepiolite fiber modified vitrification bead thermal insulation mortar has the following components of the mass percentages of: 52.5R common portland cement 35-55% fly ash5-15%, heavy calcium powder 1-5%, vitrification bead 35-55%, redispersable latex powder 0.5-2%, cellulose ether 0.1-0.3%, starch ether 0.025-0.07%, air-entrainer 0.01-0.02%, and sepiolite fiber 0.5-2%; wherein, the grades and proportions of the sepiolite fiber are: 3-5mm 30-40%, 5-10mm 40-50%, 10-15mm 20-30%. The epiolite fiber modified vitrification bead thermal insulation mortar of the present invention achieves the advantages of excellent construction performance, no-cracking, good bonding performance to wall, high strength, good thermal insulation performance and low cost.

Owner:TONGJI UNIV

Inorganic powder capillary crystalline waterproof coating material

InactiveCN101362867AImprove impermeabilityImprove permeabilityAntifouling/underwater paintsPaints with biocidesWater reducerQuartz

The invention discloses an inorganic powder infiltration crystalline water-proof material which consists of 45 to 55 portions of 600#silicate cement, 20 to 25 portions of ultra-thin quartz sands, 25 to 30 portions of master batches, 1 to 5 portions of effective retarding water reducers and 1 to 5 portions of macromolecular tougheners and is manufactured by feeding the materials into a stirrer to be uniformly stirred. The inorganic powder infiltration crystalline water-proof material is characterized by having the advantages of secondary anti-permeability capacity, durable water-proof performance, high sticking performance, acid resistance and alkali matter resistance; besides, the inorganic powder infiltration crystalline water-proof material have the capacity of growing an insoluble crystal in the pores and the micro cracks of a concrete substrate to plug the pores and the micro cracks, thereby improving the anti-permeability capacity of the concrete and achieving the goals of anti-permeability and anti-leakage. The inorganic powder infiltration crystalline water-proof material can be broadly applied to the water-proof projects of railways, roads, ports and docks, culverts, dams and pools as well as large underground projects.

Owner:天津市耀新科技发展有限公司

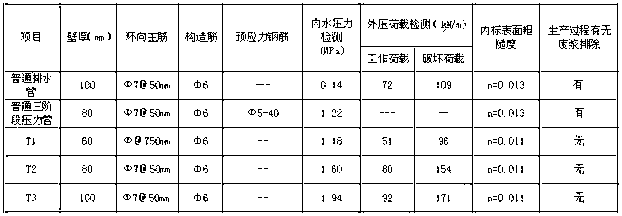

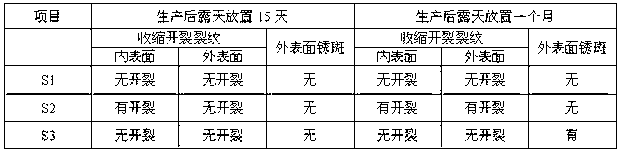

Green environmentally-friendly powder reinforced concrete water delivery pipe

ActiveCN103224356ALow costReduce pollution treatment costsCeramic shaping apparatusSlagMesh reinforcement

The invention belongs to the field of water delivery engineering and relates to a green environmentally-friendly powder reinforced concrete water delivery pipe. The green environmentally-friendly powder reinforced concrete water delivery pipe is manufactured by uniform distribution of concrete on a reinforcement mat. The concrete is prepared from 450 to 500 weight parts of ordinary portland cement or low-alkaline portland cement having the average grain diameter of 30 to 60 microns, 90 to 130 weight parts of silica fume having the average grain diameter of 0.18 microns and SiO2 content greater than or equal to 85%, 100 to 130 weight parts of I-grade coal ash having the average grain diameter of 10 to 20 microns, 130 to 160 weight parts of more than S95 grade of slag powder having the average grain diameter of 10 to 30 microns, 520 to 600 weight parts of quartz sand having the grain diameter of 0.16 to 1.63 millimeters, 800 to 880 weight parts of crushed stone having the grain diameter of 5 to 14 millimeters, 12 to 20 weight parts of a composite high-efficiency water reducer having a water-reducing rate more than 30%, 7 to 12 weight parts of a corrosion inhibitor, 45 to 50 weight parts of a high-efficiency expanding agent, 130 to 150 weight parts of water, 0.8 to 1.2 weight parts of polypropylene fibers, and 80 to 160 weight parts of copper-coated steel fibers having the diameter of 0.18 to 0.25 millimeters and the length of 10 to 15 millimeters. The reinforcement mat is manufactured by weaving hard-drawn wires having the diameter of 4.0 to 6.0 millimeters as reinforcements and cold-rolled ribbed bars having the diameter of 5.0 to 10.0 millimeters as hoop reinforcements.

Owner:黄贺明

Slag antiseizing spraying material for desulfurization hot-metal bottle

The invention discloses an antiseize slag spraying material for sulfur removal hot iron tank, which comprises the following steps: allocating mass percent with 70-90% carbonaceous fireproof material waste brick, 4-8% alumina cement, 1-3% silicate cement, 1-3% silicon micronized quartz powder, 2-13% clay, 0-5% soil carbite, 0. 5-3% inorganic staple fiber and 0. 1-0. 5% phosphate; getting the product. This invention possesses wide raw material source, low cost and good using effect.

Owner:WUHAN IRON & STEEL (GROUP) CORP

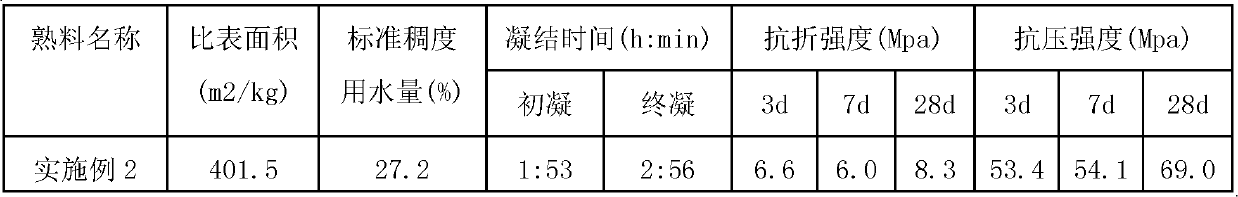

Active belite-sulphate aluminum cement clinker and preparation method for active belite-sulphate aluminum cement clinker

ActiveCN102584045AChange work performanceReduce manufacturing costCement productionAmorphous phaseMaceral

The invention discloses active belite-sulphate aluminum cement clinker, which comprises the following mineral compositions in weight percentage: 25-30 percent of beta-type C2S, 25-30 percent of a-type C2S, 28-40 percent of C4A3S`, 4-12 percent of C4AF and 4-8 percent of amorphous-phase substance. The control of different forms and the change of number of the C2S in the clinker are controlled mainly through special setting on clinker ingredient rate values. The invention also discloses a preparation method for the active belite-sulphate aluminum cement clinker. Compared with traditional common silicate cement clinker, the active belite-sulphate aluminum cement clinker has the advantages that more industrial solid waste residues are used in raw materials by the active belite-sulphate aluminum cement clinker, and thereby, the production cost is reduced, the use proportion of limestone is greatly reduced, and the carbon dioxide emission in clinker production is obviously reduced. Under the condition that the water demand and the setting time of the obtained clinker are basically the same as that of the common silicate cement clinker, the strength of the obtained clinker is superior to that of the common silicate cement clinker.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Composite cement with large amount of coal gangue and its preparation method

InactiveCN1546410AImprove performanceFull play of water activity and hardnessSolid waste managementHigh intensityMaceral

The invention discloses a large mixing amount coal gangue composite cement comprising coal gangue, silicate cement clinker aggregate, exciting agent, gypsum coagulation regulating agent, mineral admixture by right weight portion through a finite process, wherein the content of coal gangue is 20-80% wt. The composite cement according to the invention can be used for making various concrete structure, in particular mass concrete structure.

Owner:TONGJI UNIV

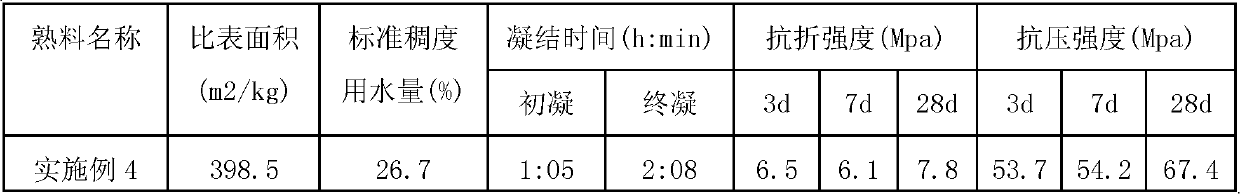

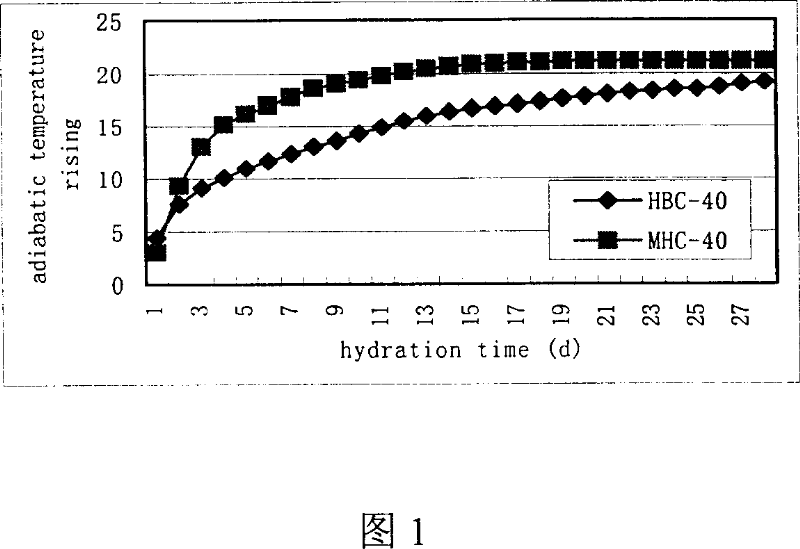

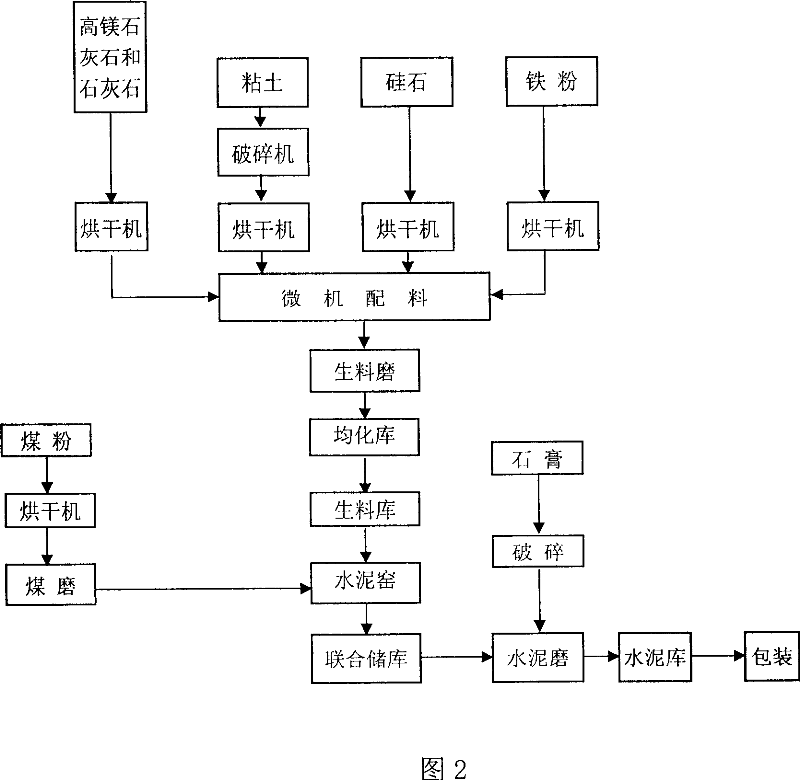

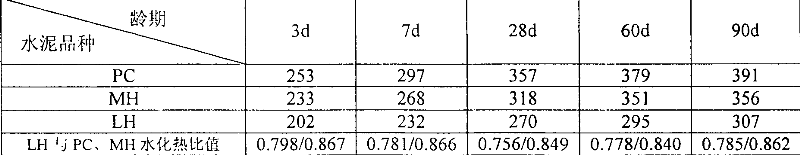

High-magnesium low-heat portland cement clinker aggregate and preparation method thereof

InactiveCN101041560AImprove crack resistanceLow heat of hydrationClinker productionHigh magnesiumPortland cement

The invention discloses a high-magnesium lower thermal silicate cement clinker, making mineralogical composition at (mass percent): 40 -65% C2S, 15-40% C3S, 1-8% C3A, 10-25% C4AF and content of MgO at 2.0-6.0%. The invention also discloses a preparing method of high-magnesium lower thermal silicate cement clinker, including indispensable steps of producing cement clinker with raw materials and controlling content of MgO of cement clinker at 2.0-6.0%.

Owner:CHINA BUILDING MATERIALS ACAD

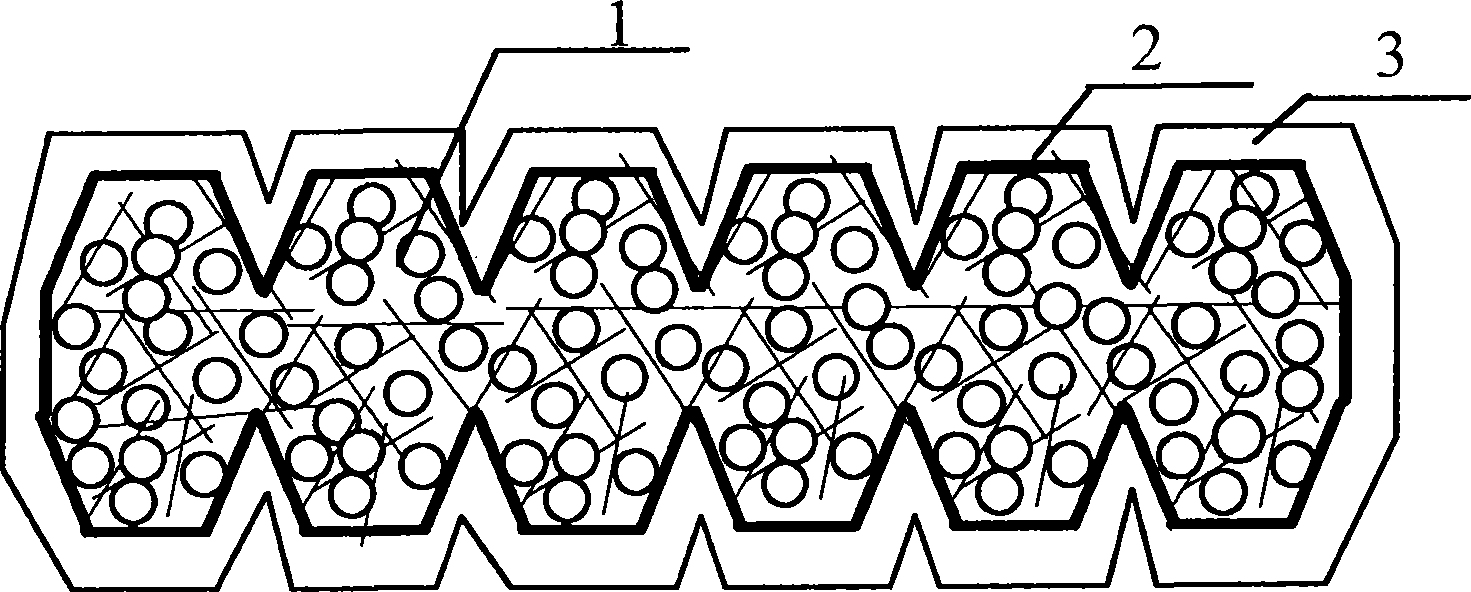

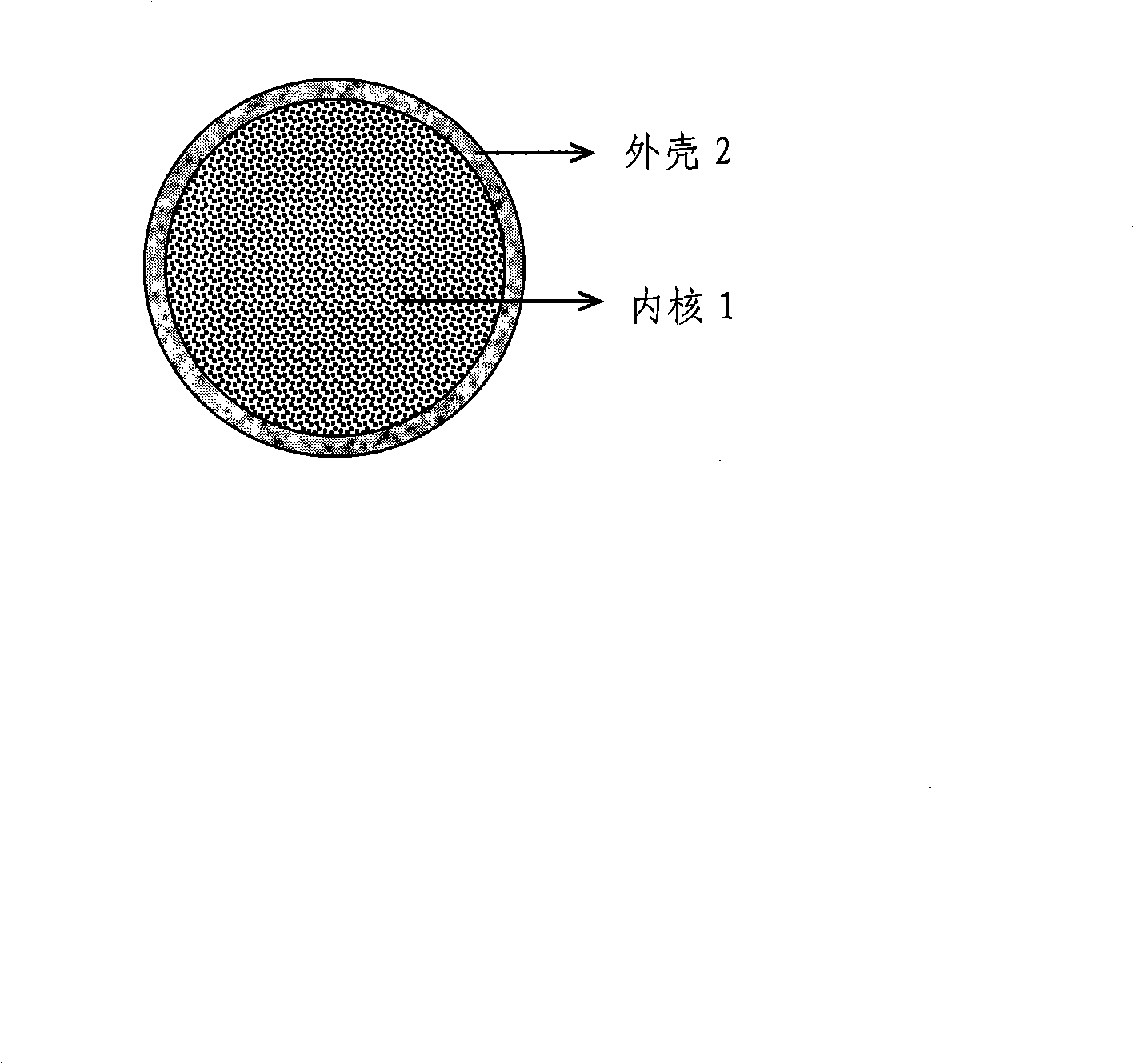

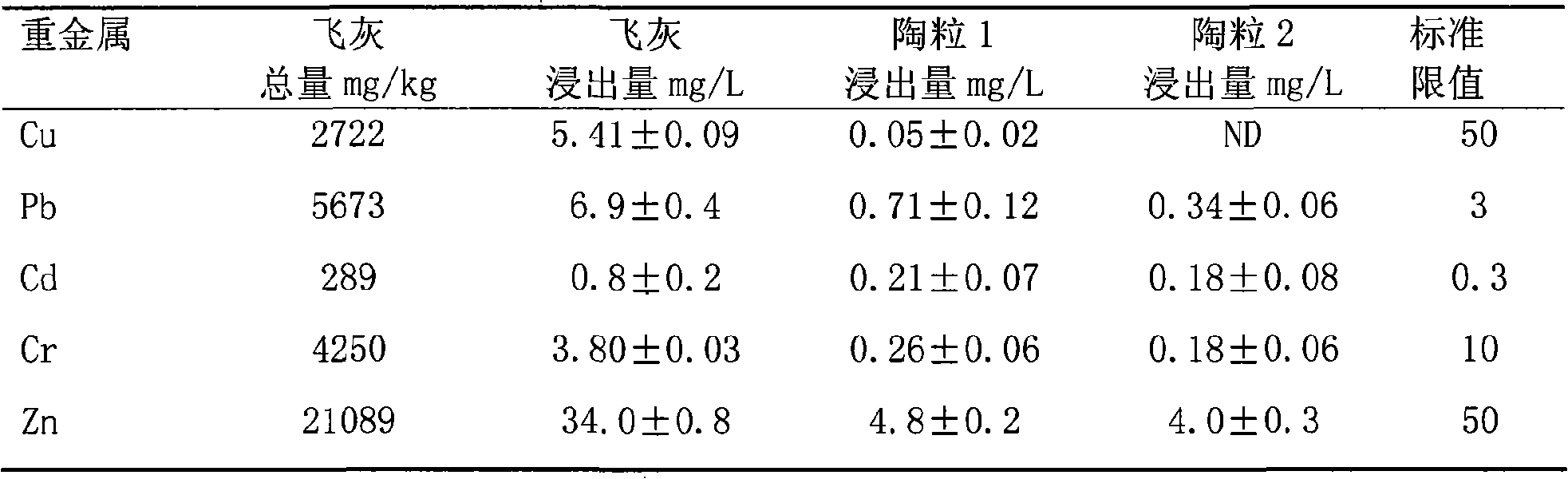

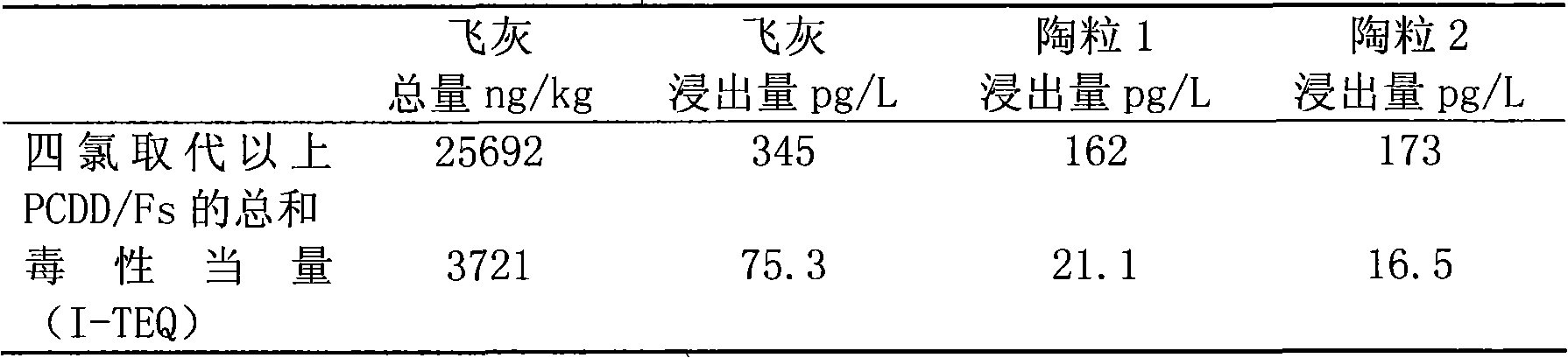

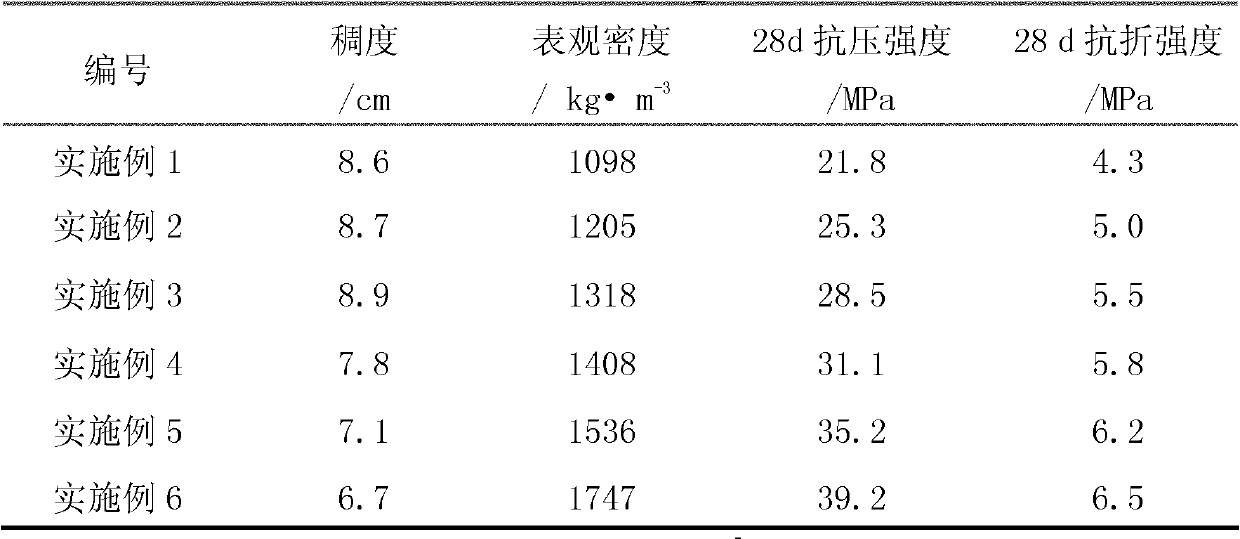

Baking-free type refuse burning flyash haydite and manufacturing method thereof

ActiveCN101357840ALow costNo need to worry about secondary pollutionSolid waste managementDry weightResource utilization

The invention provides a non-burned porcelain granule which adopts fly ash generated by waste incineration as the main raw material and a manufacturing method thereof; the non-burned porcelain granule comprises a spherical inner core 1 and a shell 2 attached outside; wherein, the components (dry weight) of the inner core 1 are as follows: 50 to 70 parts of fly ash generated by waste incineration, 25 to 50 parts of portland cement, 0 to 15 parts of coal ash and 0.2 to 0.5 part of heavy metal stabilized agent; the shell 2 adopts ordinary portland cement or lime. The method includes the following steps: firstly, the agent stabilization treatment is carried out on the fly ash generated by waste incineration; then the fly ash is mixed with the portland cement and coal ash to be granulated, thus manufacturing the inner core 1; finally, the inner core 1 is coated on the shell 2 in a pan granulator for natural curing. The method adopts the fly ash which is the dangerous waste as the raw material of the porcelain granule for resource utilization, realizes the harmlessness of the whole treatment process and has the advantages of economy, environmental protection and less investment of one-off equipment.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

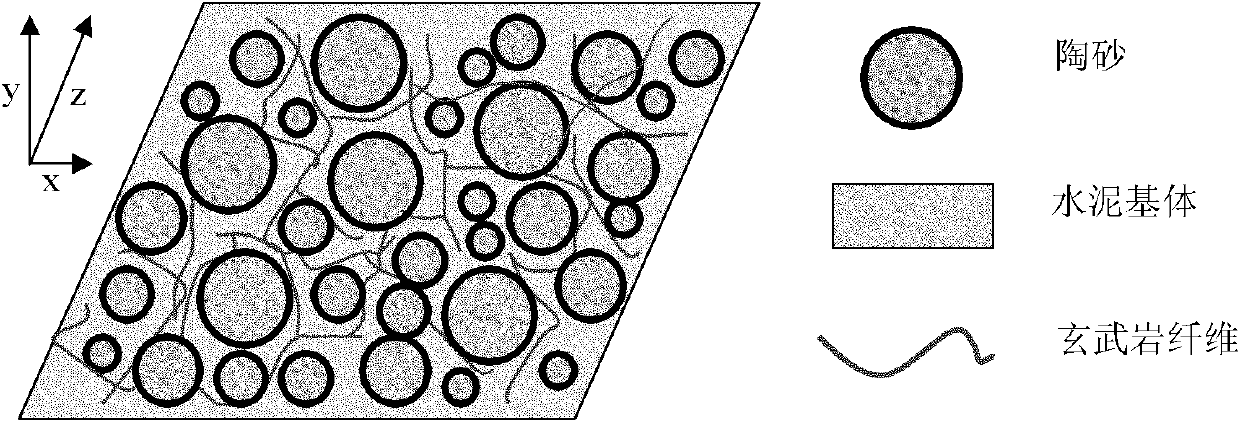

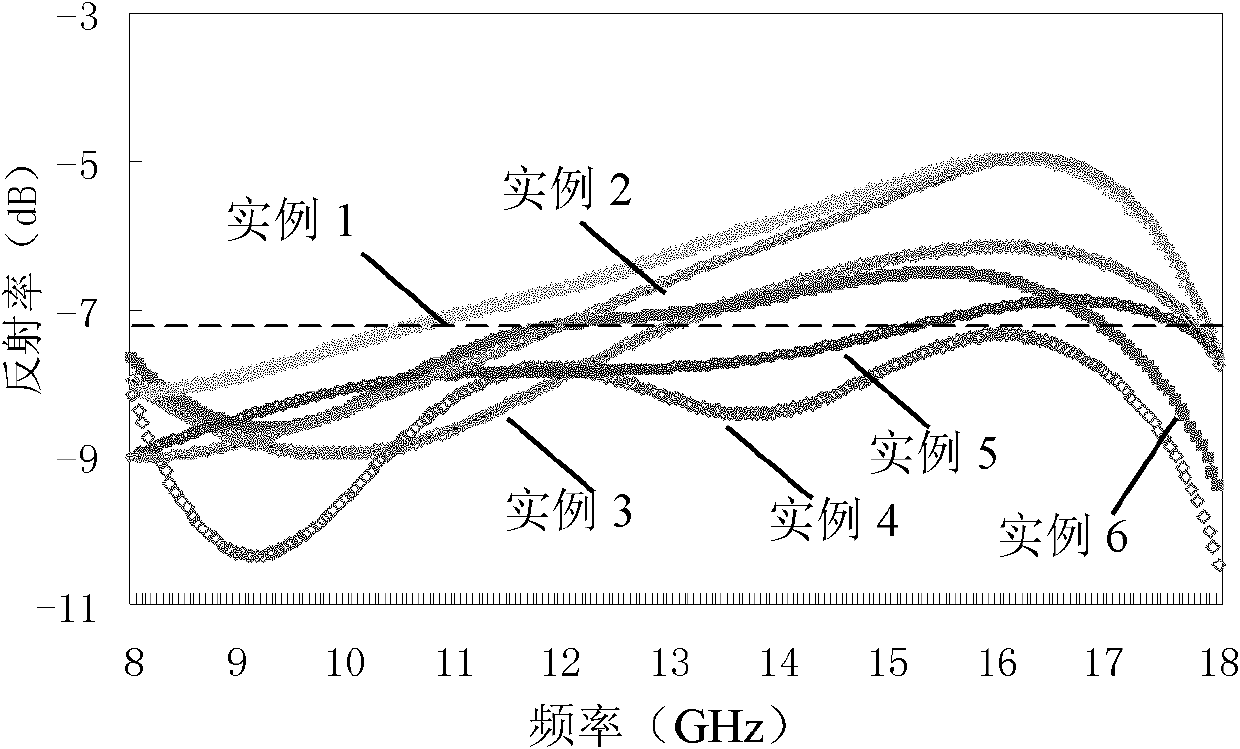

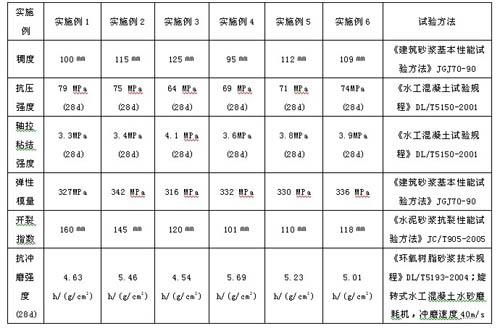

High-iron ground steel slag lightweight high-toughness wave absorption concrete and preparation method thereof

The invention relates to wave absorption concrete and a preparation method thereof. High-iron ground steel slag lightweight high-toughness wave absorption concrete is characterized in that the concrete is prepared from powder, aggregate and admixture, wherein the powder consists of silicate cement, fly ash and high-iron ground steel slag; the aggregate is ceramic sand; the admixture consists of efficient water reducing agent, basalt fiber and water; and the concrete comprises the following raw materials in a ratio (kg / m<3>): 110 to 300 kg / m<3> of silicate cement, 80 to 120 kg / m<3> of fly ash, 70 to 140 kg / m<3> of high-iron ground steel slag, 600 to 1,500 kg / m<3> of ceramic sand, 3.0 to 4.5 kg / m<3> of efficient water reducing agent, 30 to 50 kg / m<3> of basalt fiber and 150 to 180 kg / m<3> of water. The wave absorption concrete has the characteristics of energy conservation, environmental protection and low price.

Owner:WUHAN HAIJIAN ENVIRONMENTAL PROTECTION MATERIALS CO LTD

Dry powder mortar of mine tailings

InactiveCN101560083ALow costEmission reductionSolid waste managementEcological environmentResource utilization

The invention relates to dry powder mortar of mine tailings, which comprises the following components in portion by weight: 40 to 60 portions of copper tailing sand or iron tailing sand, 20 to 30 portions of river sand, 10 to 30 portions of low-clinker silicate cement, and 0.5 to 1.5 portions of water-retaining thickening agent. The dry powder mortar is suitable for masonry, plastering, ground and common waterproof engineering. By using the low-clinker cement to replace the prior common silicate cement and using the tailing sand to partially replace the river sand, the dry powder mortar reduces the discharge of carbon dioxide and the consumption of sand river resources, realizes the resource utilization of solid wastes such as mine refuses, steel slag, tailings and the like, and protects the ecological environment.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Anti-impact and wear-resistant mortar

The invention discloses an anti-impact and wear-resistant mortar, belonging to the field of a repairing material in water-power engineering. The difficulty that the constructions in the conventional water-power engineering is difficult to repair after being damaged by rushing and abrading with water with sands and stones can be solved. The anti-impact and wear-resistant mortar comprises the following components in parts by weight: 39-48 parts of silicate cement, 45-50 parts of graded hard fine aggregate, 0.05-0.25 parts of water reducing agent, 0.05-0.3 parts of de-foaming agent and 0.05-1.5 parts of nanometer material. The anti-impact and wear-resistant mortar provided by the invention has the advantages of high anti-impact and wear-resistant strength, low elasticity modulus and good anti-crack property, and is a finished product material with a higher application value for repairing through irrigation works.

Owner:POWERCHINA CHENGDU ENG +1

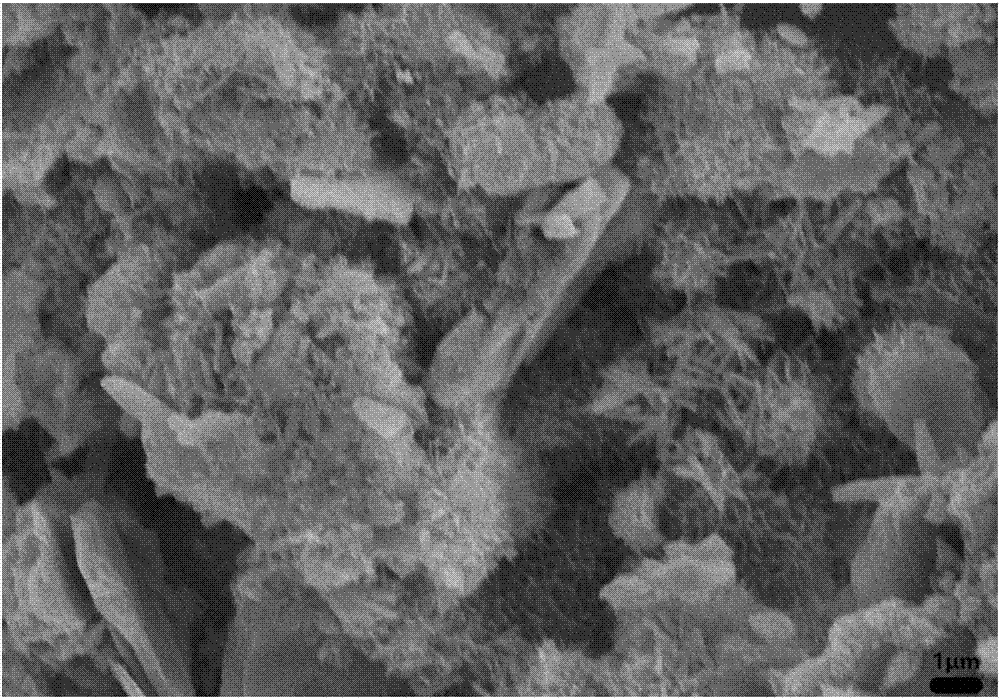

Cement-based nanocomposite material and preparation method thereof

The invention relates to an inorganic nanocomposite material and a preparation method thereof and in particular relates to a cement-based nanocomposite material and a preparation method thereof. The invention provides a cement-based nanocomposite material in order to improve the mechanical property of a cement-based material. The cement-based nanocomposite material comprises the following raw materials in parts by weight: 1 part of silicate cement, 0.15-0.25 part of silicon ash, 0.003-0.006 part of nano CaO, 0.01-0.02 part of nano CaCO3, 0.005-0.01 part of nano Al2O3, 0.01-0.02 part of fibrous nano calcium silicate or 0.001-0.002 part of carbon nanofibers, 0.3-0.4 part of 325-mesh quartz powder or glass powder, 0.45-0.55 part of quartz sand with a particle diameter of 0.4-0.6mm, 0.4-0.6 part of steel fiber, 0.015-0.025 part of a high-performance water reducer and 0.18-0.25 part of water. The mechanical property of the cement-based nanocomposite material is improved to a great extent.

Owner:HUNAN MINGXIANG TECH DEV

Ultra-thin wearing layer of pavement

The invention belongs to the technical field of a building material used in road engineering, and specifically relates to drainage asphalt mixture for an ultra-thin wearing layer. The mixture comprises aggregated material, stuffing, high-performance asphalt and warm mixing additive; the maximal nominal size of the mixture is 6.7mm; the thickness of a pavement layer is 10-20mm; the aggregated material is basalt or dolerite; the used stuffing is mixture of limestone powder and common silicate cement, and the used high-performance asphalt is prepared from general modified asphalt by adding waste tire rubber powder which is 20-28% of weight of the asphalt and modifying. An ultra-thin finishing coat and low-temperature construction are realized by the asphalt mixture by adding the warm mixing additive; the ultra-thin wearing layer has the advantages of low construction cost, convenience in construction and the like, and is suitable for building of an asphalt concrete pavement and function-improving works of the pavement.

Owner:上海砼仁环保技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com