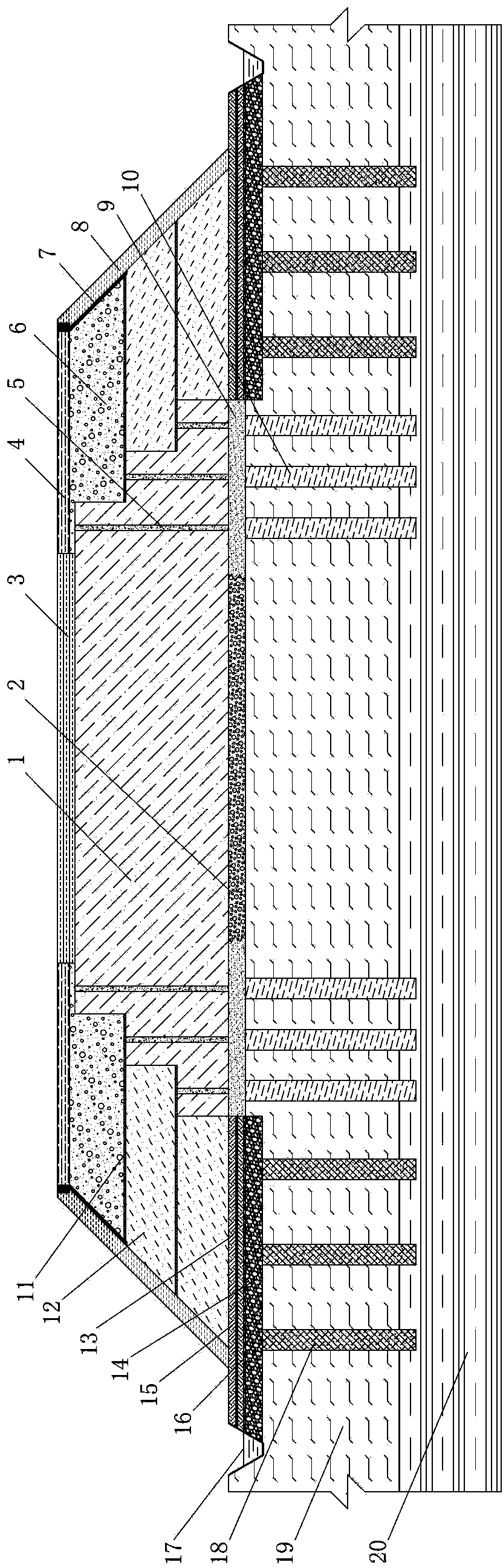

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2012 results about "Mesh reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

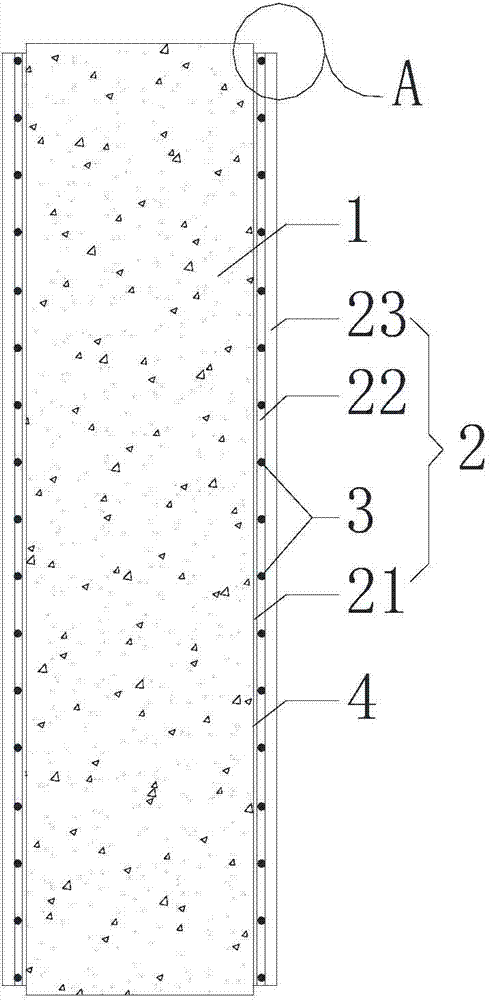

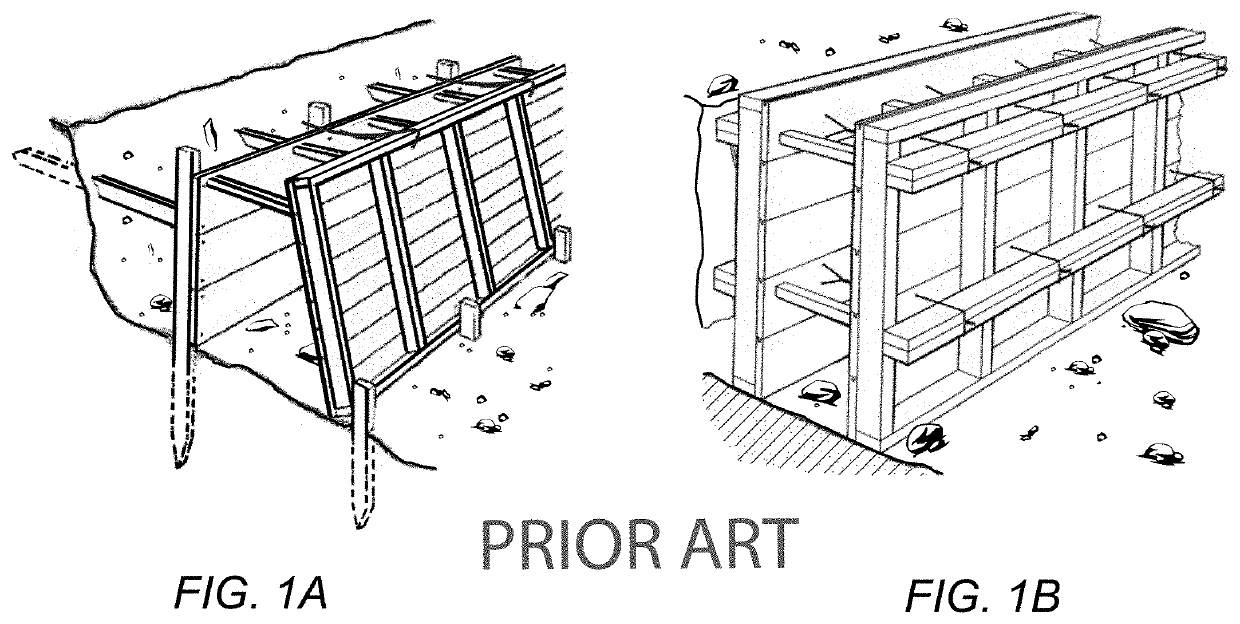

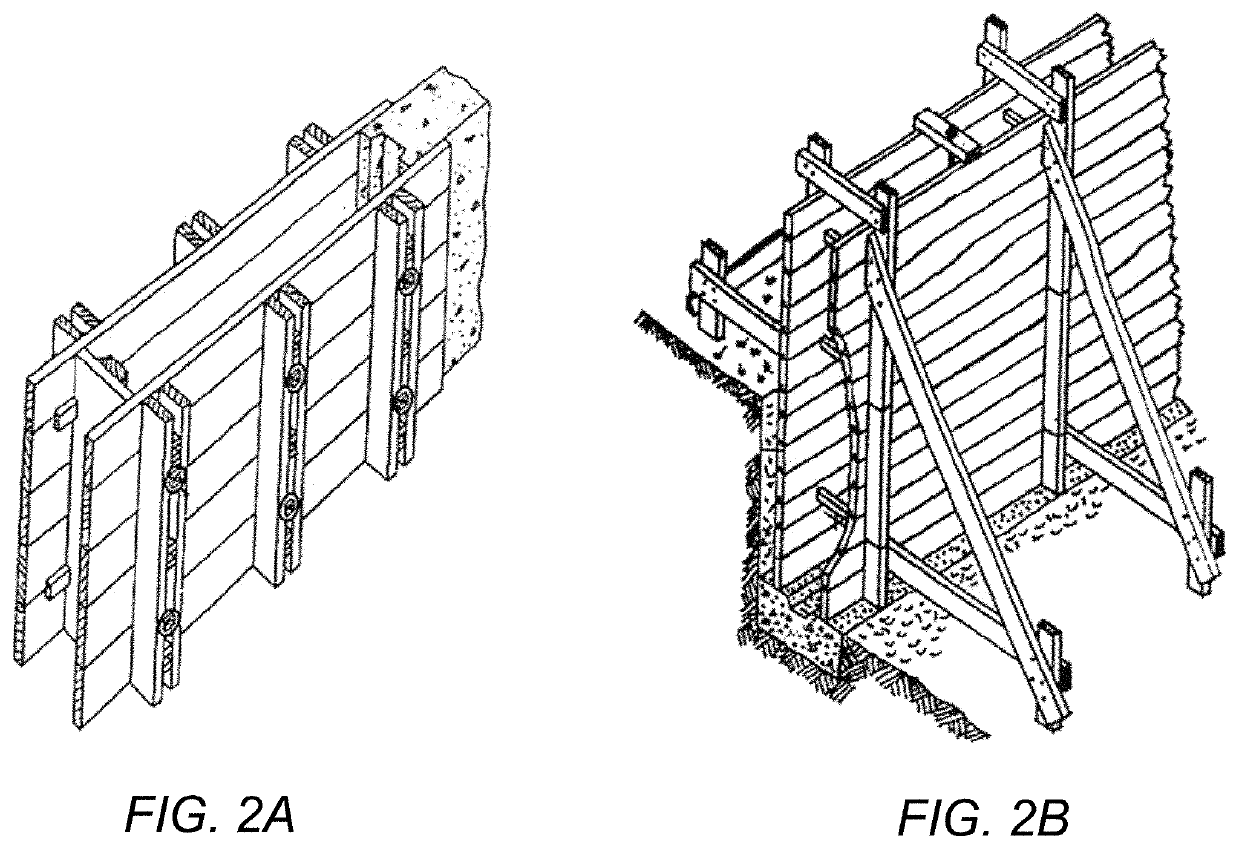

Gypsum wood fiber structural insulated panel arrangement

InactiveUS20080245007A1Low costHigh tensile strengthBuilding componentsMesh reinforcementCellulose fiber

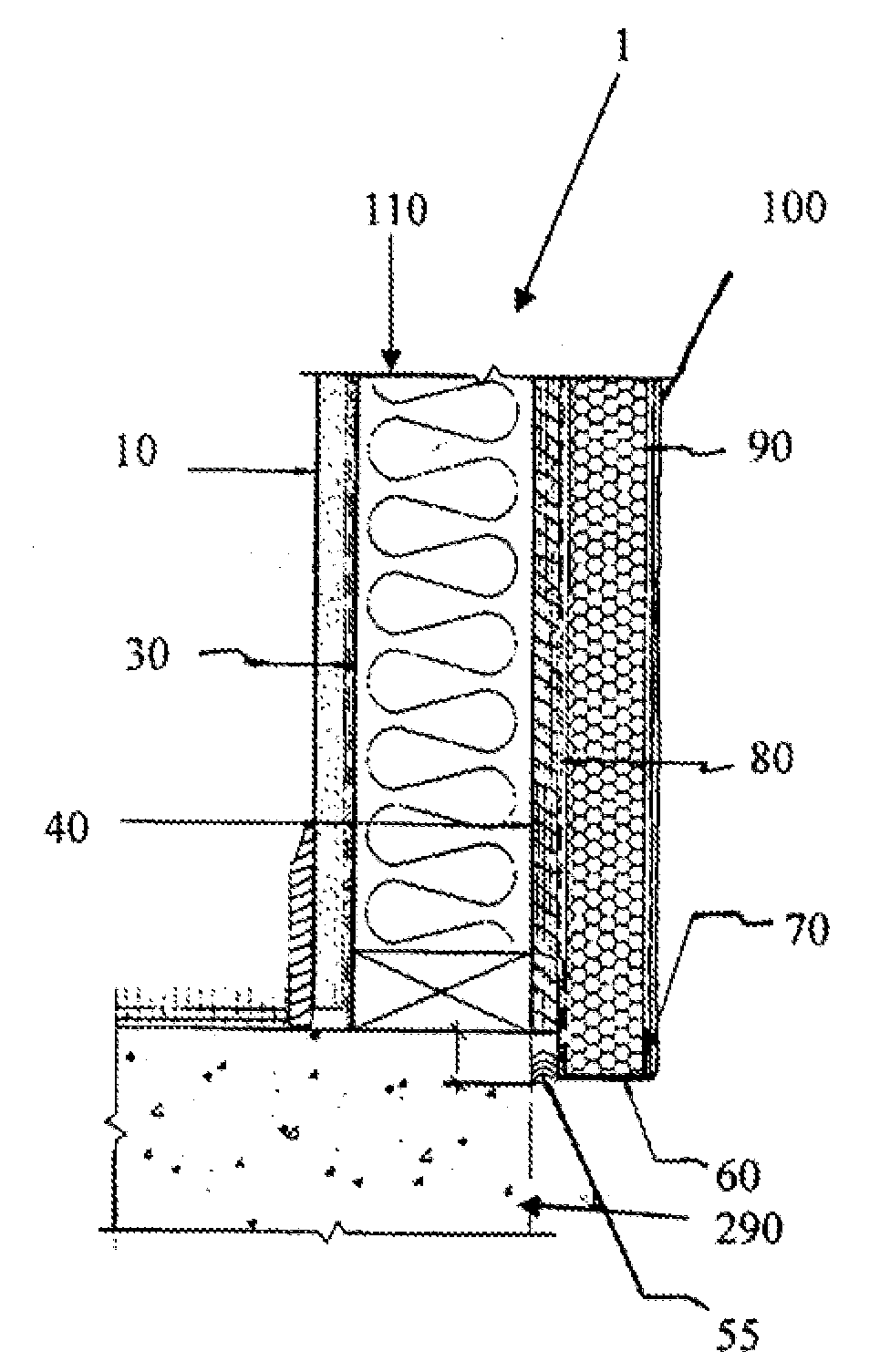

A generally planar, structural insulated panel for building construction includes a pair of outer facings disposed on opposed surfaces of a plastic foam core. Both of the outer facings are gypsum cellulose fiber board such as gypsum wood fiber board. Disposed on the exterior surface of the gypsum wood fiber board on the exterior surface and between another expanded polystyrene insulation panel is a weather resistant barrier that is fastened to the gypsum wood fiber board. The exterior surface of the second insulation panel is fastened to the gypsum wood fiber board by mechanical fasteners. The insulation panels are then coated with a basecoat which has an embedded mesh reinforcement and then a finishing coat is applied to the base coating. Vinyl or aluminum metal siding can be fastened to the structural assembly by G screw fasteners or other mechanical fasteners.

Owner:UNITED STATES GYPSUM CO

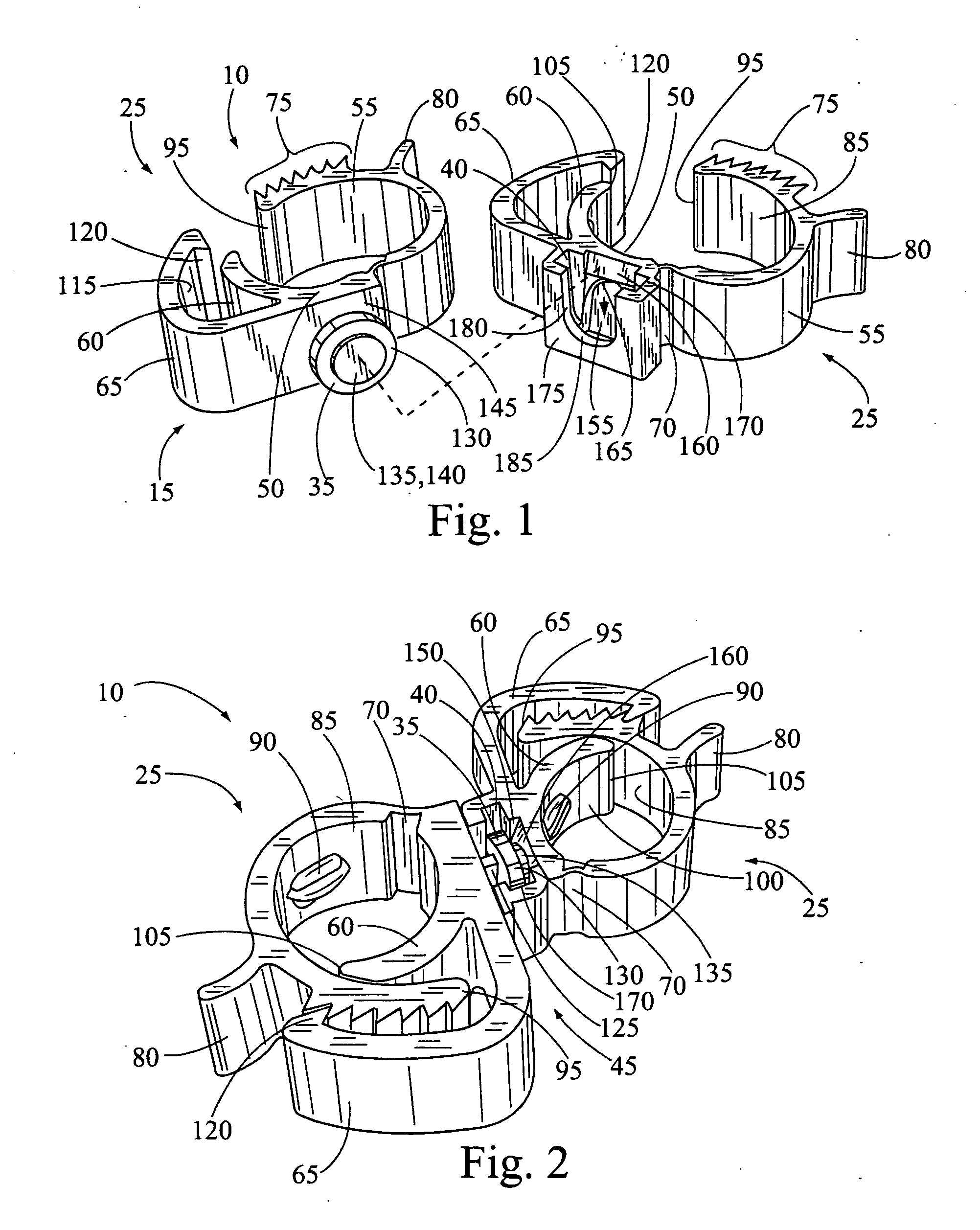

Swiveling rebar fastener

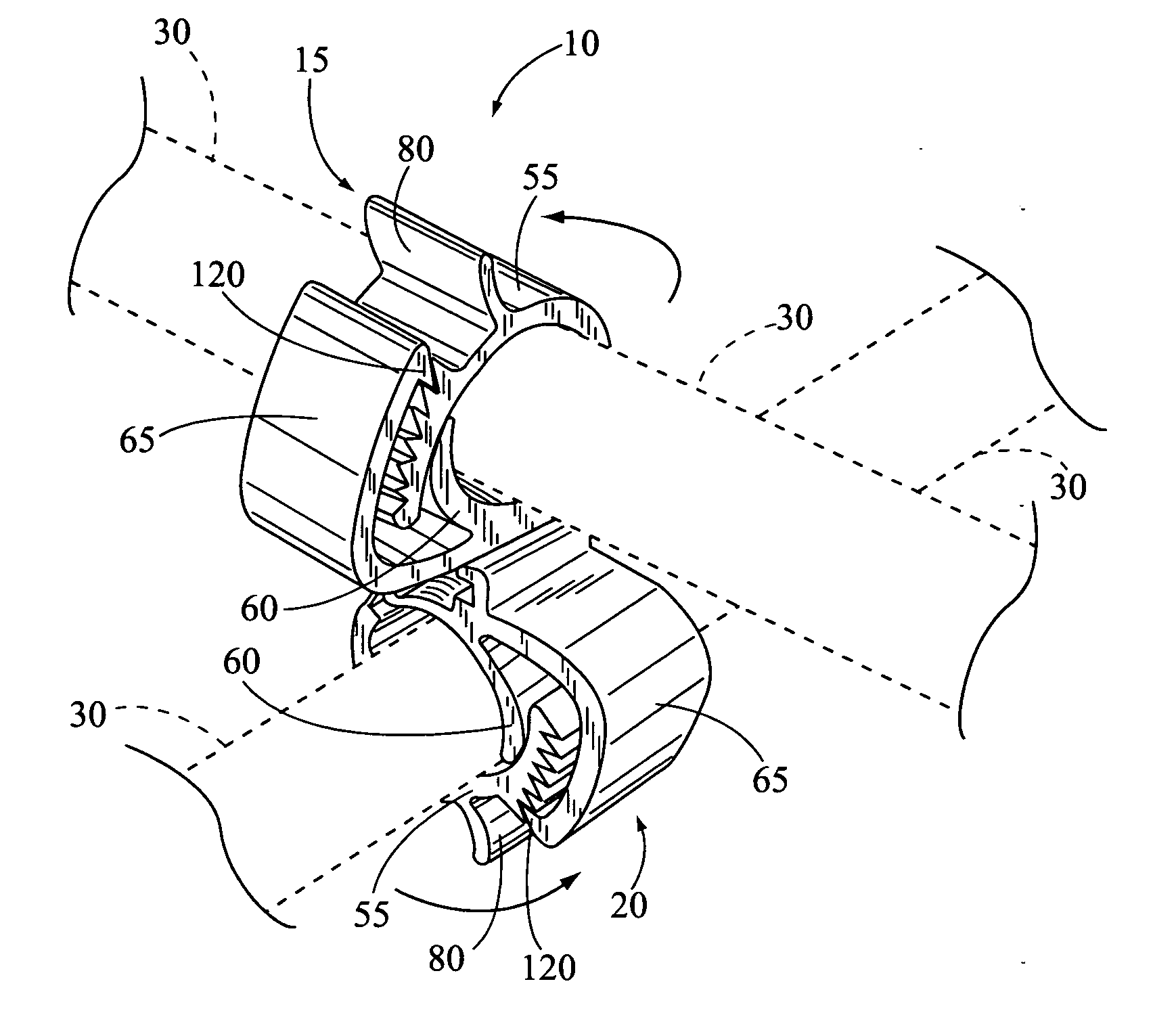

A fastener for joining two pieces of rebar together in a rebar grid used to reinforce subsequently poured concrete is described. The fasteners include two clamp pieces that in certain embodiments completely wrap around a piece of rebar and are tightly secured thereto. Further, each clamp piece can swivel or rotate up to 360 degrees relative to the other clamp piece such that two rebar pieces intersecting at any angle can be coupled together.

Owner:JIFFY CLIP

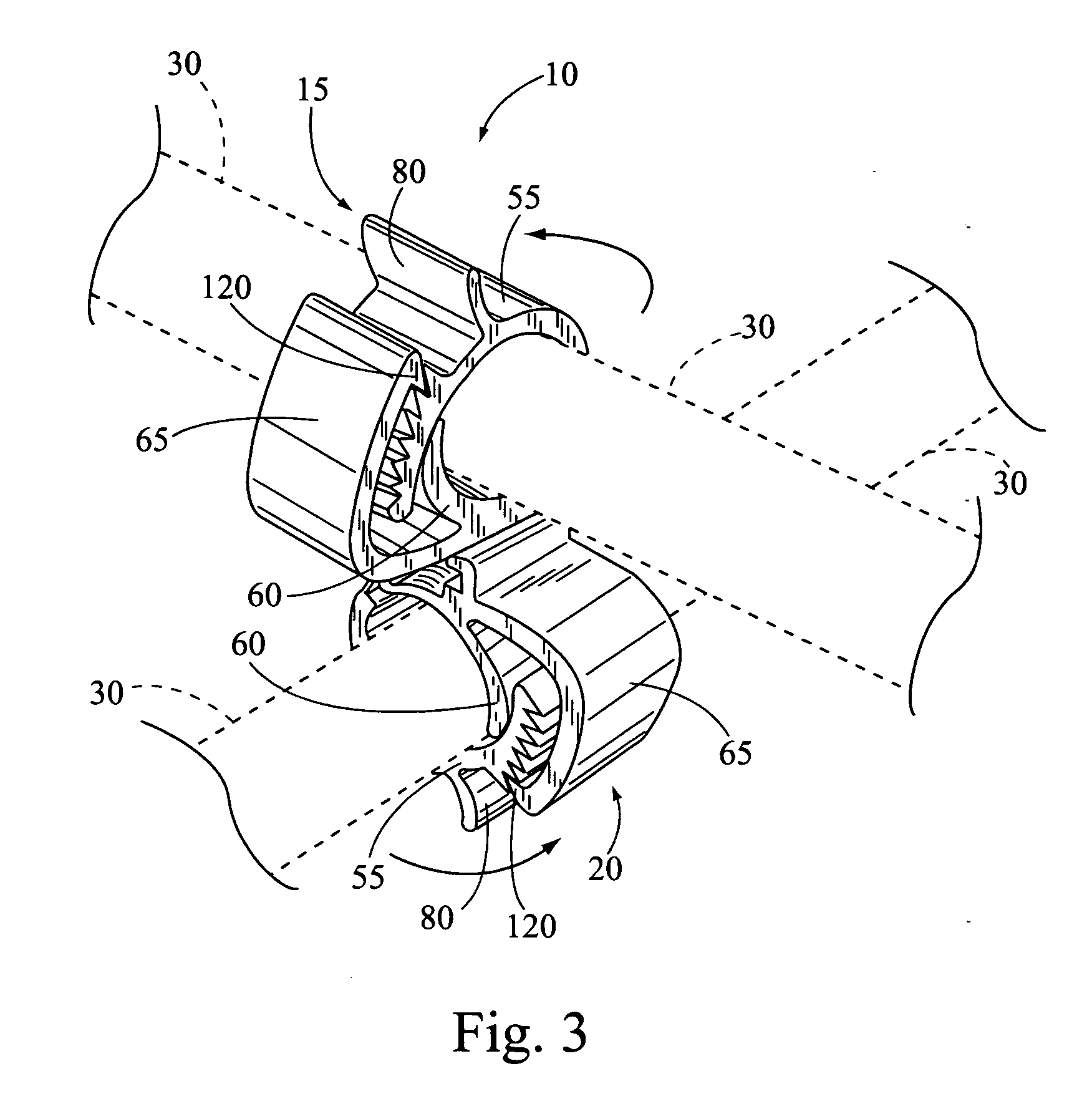

3-D construction modules

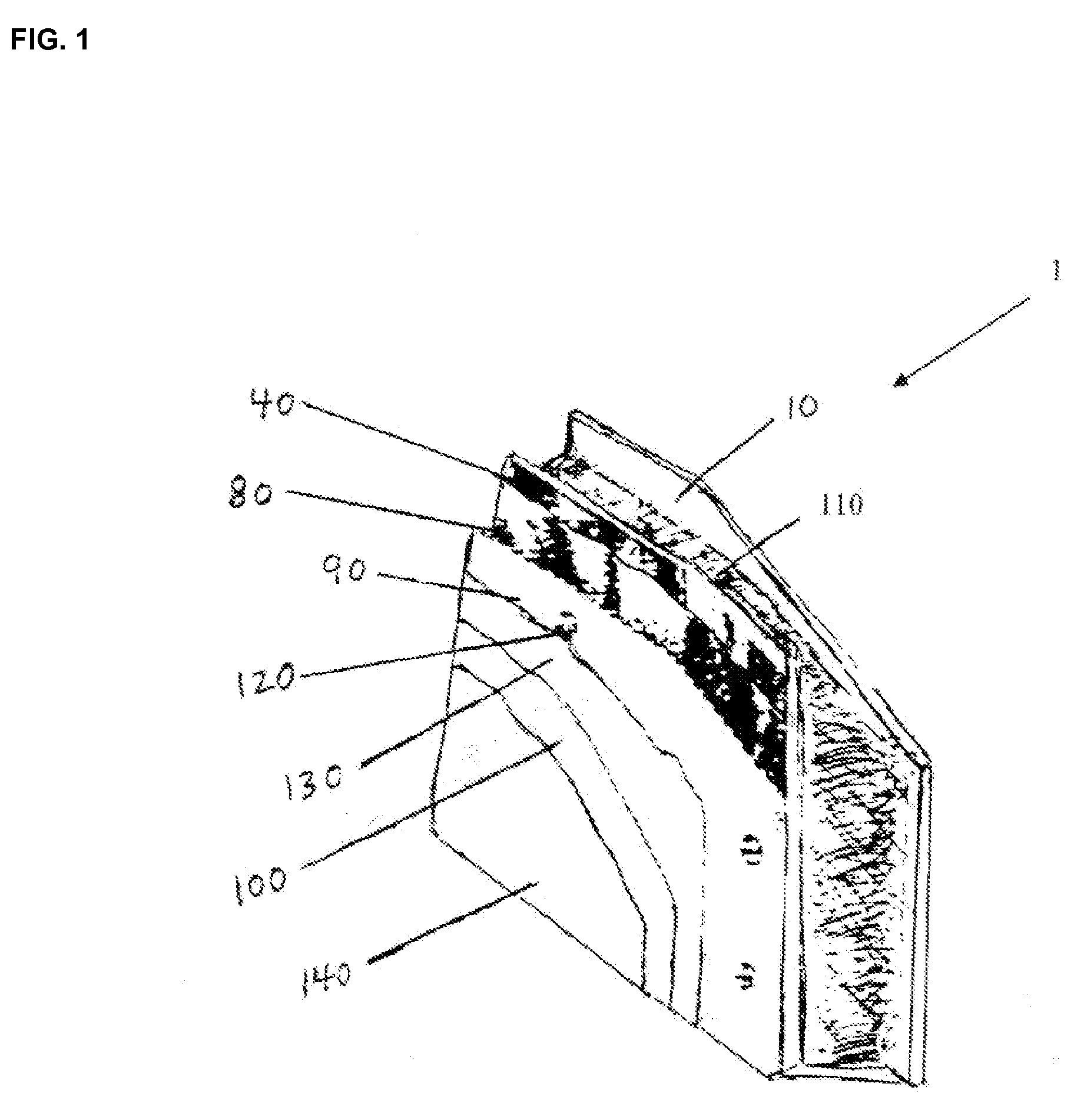

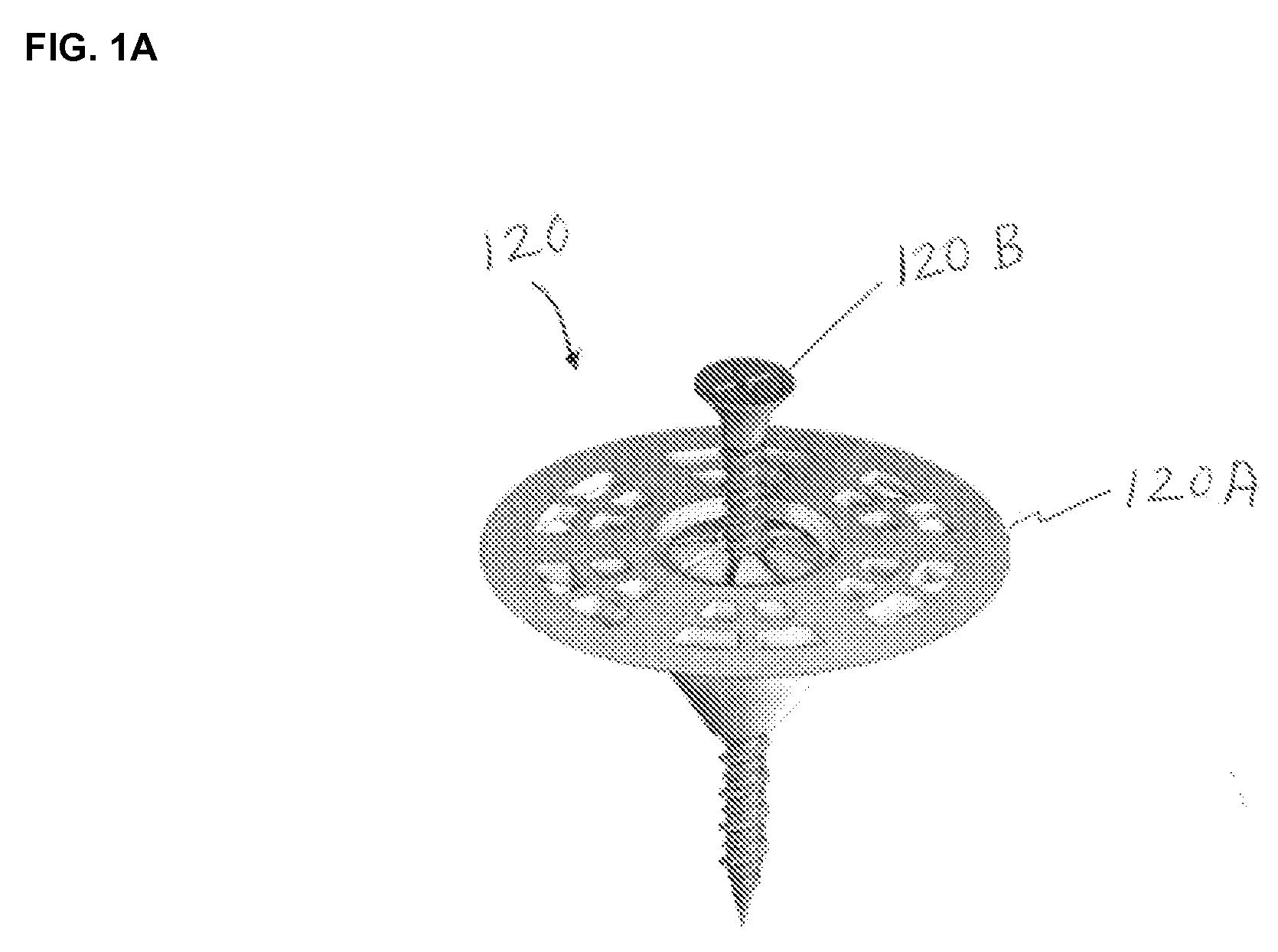

A 3D construction module comprising at least one vertically upstanding panel with first and second mesh layers oriented generally transversely and longitudinally. The first and second mesh layers have at least one rod member mounted to said panel and are vertically spaced from each other. The rod members form a first horizontally projected retention cell to restrict translation of a bar held in said retention cell between said first and second mesh layers. A third mesh can also be provided to form a second retention cell between said second and third mesh layers. The first and second retention cells restrict translation movement longitudinally and transversely of a vertical reinforcement member held in said first and second retention cells, and restrict rotation of the vertical reinforcement member about both a longitudinal axis and a transverse axis of the said 3D construction module. Horizontal reinforcement meshes are features of the invention. Other features of the invention include a trough for holding melted panel material, connectors for connecting rods to panels and associated stopper members. Also included are bracers for joining connectors and other devices related to panel connections.

Owner:BRAVINSKI LEONID G

Novel highway embankment widened structure and construction method

InactiveCN104278608ACoordinated settlement deformationImprove carrying capacityRoadwaysClimate change adaptationMesh reinforcementSoil cement

The invention relates to a novel highway embankment widened structure. The original roadbed slope of the structure is trimmed into a step shape, a high pressure jet grouting pile is disposed below an original roadbed slope cushion layer, pressurized continuous grouting is employed at an original roadbed cushion layer to form a slurry solid bearing plate, parts of pore cavities of the original roadbed are recharged with fine aggregate concrete or mortar; foundation treatment piles are employed to reinforce the foundation of a widened area, a drainage cushion layer is laid throughout the top of the foundation treatment piles; an earthwork cloth is laid on the drainage cushion layer, a cement soil plate is disposed on the earthwork cloth, high strength reinforcing mesh sheets are disposed in the cement soil plate; and the widened area embankment is formed by layered filling of excavation soil and light filler in a construction process. The structure provided by the invention can reinforce the bearing capacity of roadbed soil on both sides of the widened area and the original roadbed slope strength, and enhance the integrality of the embankment structure, reduce longitudinal cracks induced by differential settlement and the like at the juncture of new and old roadbeds, thus having good technical and economic benefits. The invention also discloses a construction method of the novel highway embankment widened structure.

Owner:HANGZHOU HUASHUI MUNICIPAL ENG

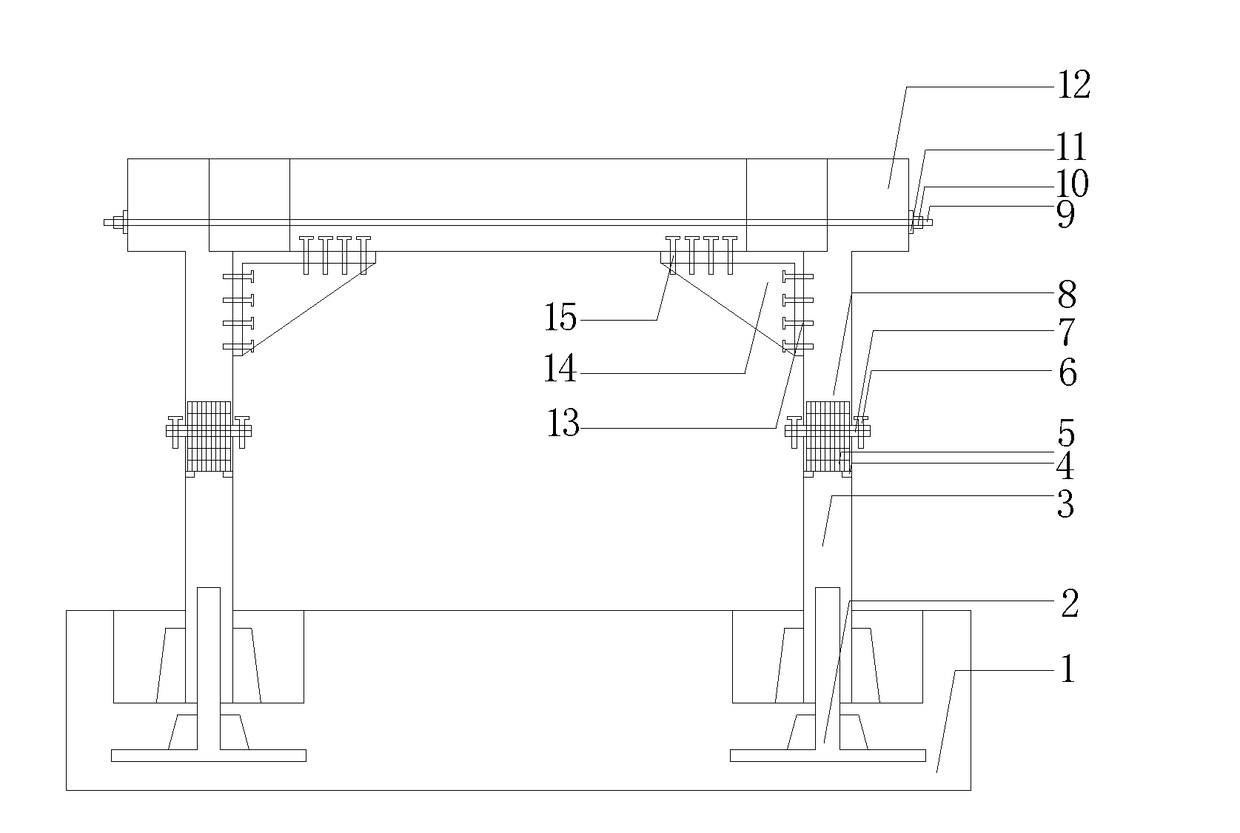

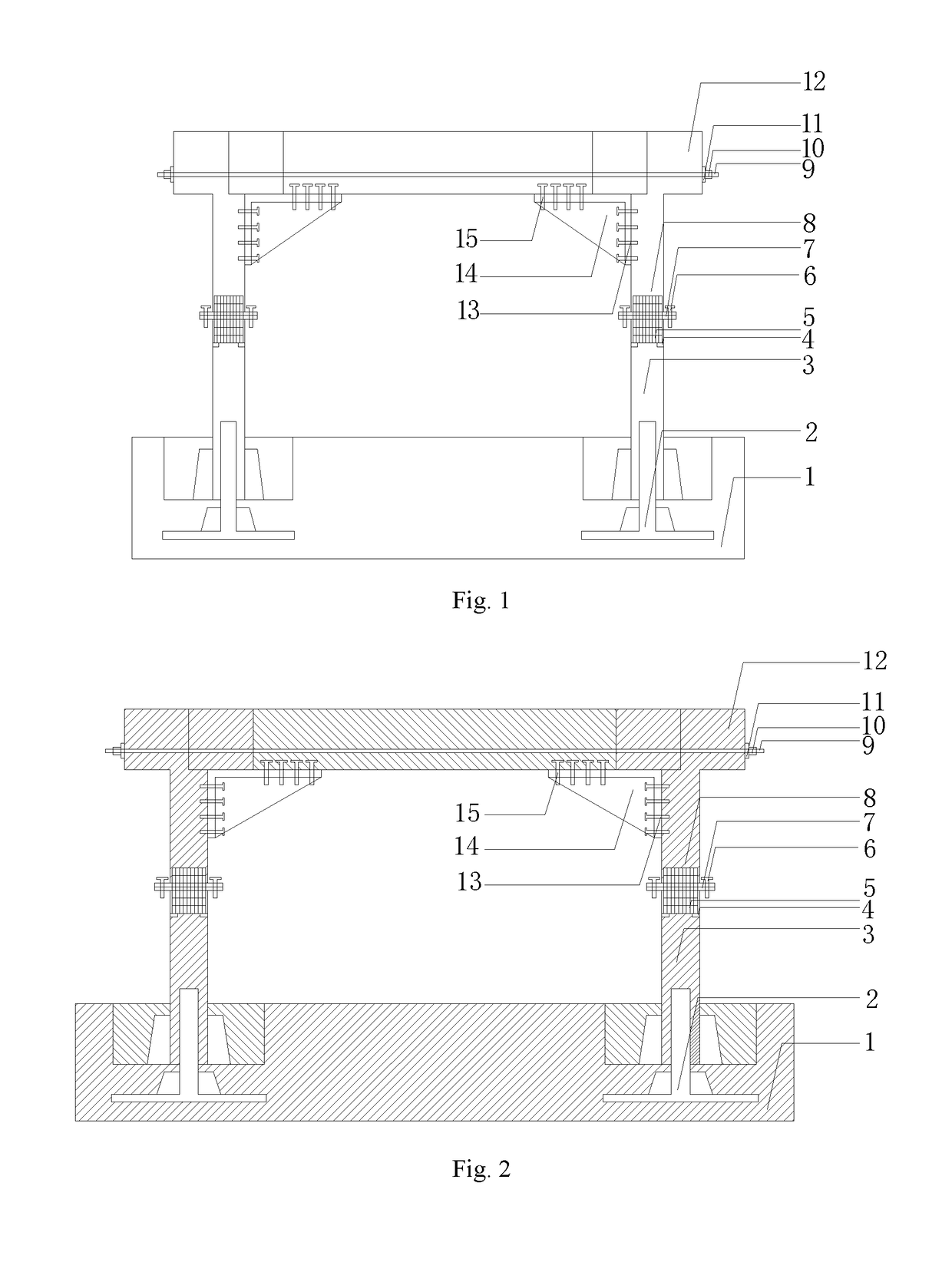

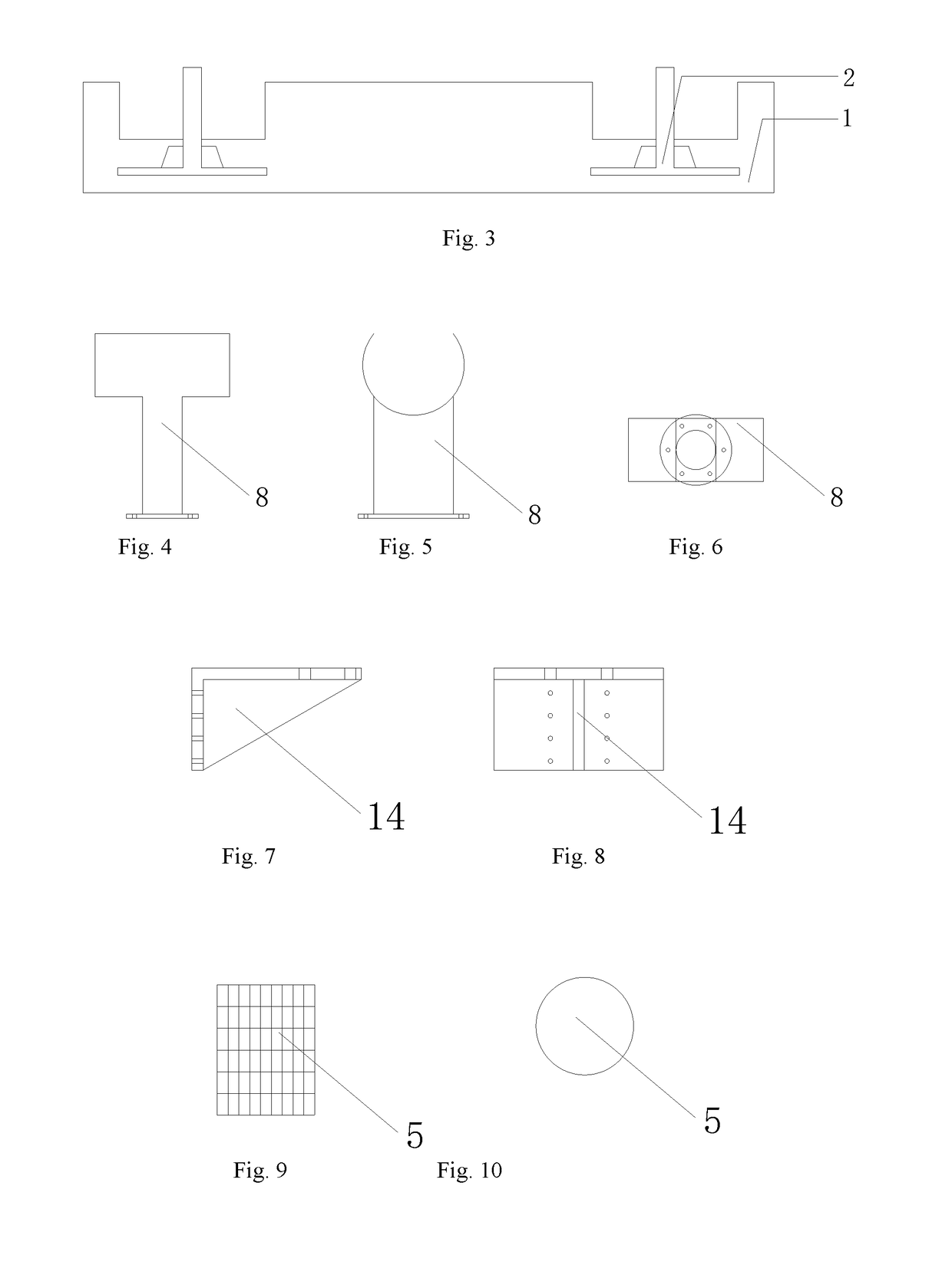

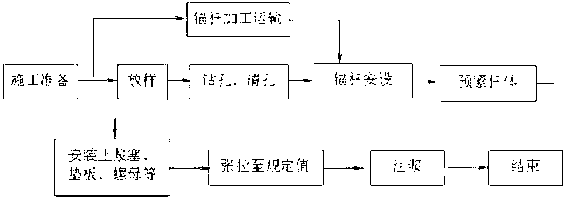

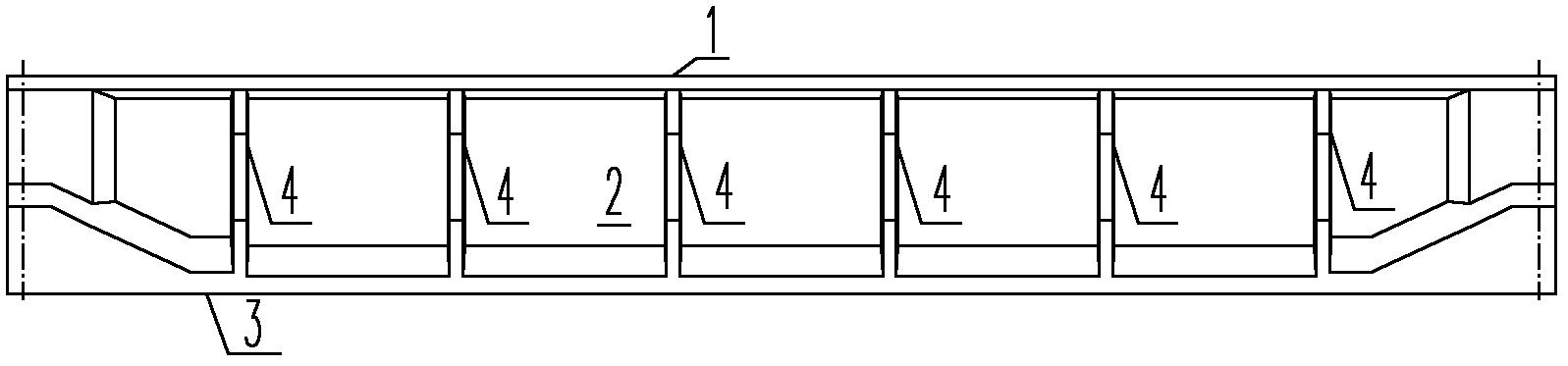

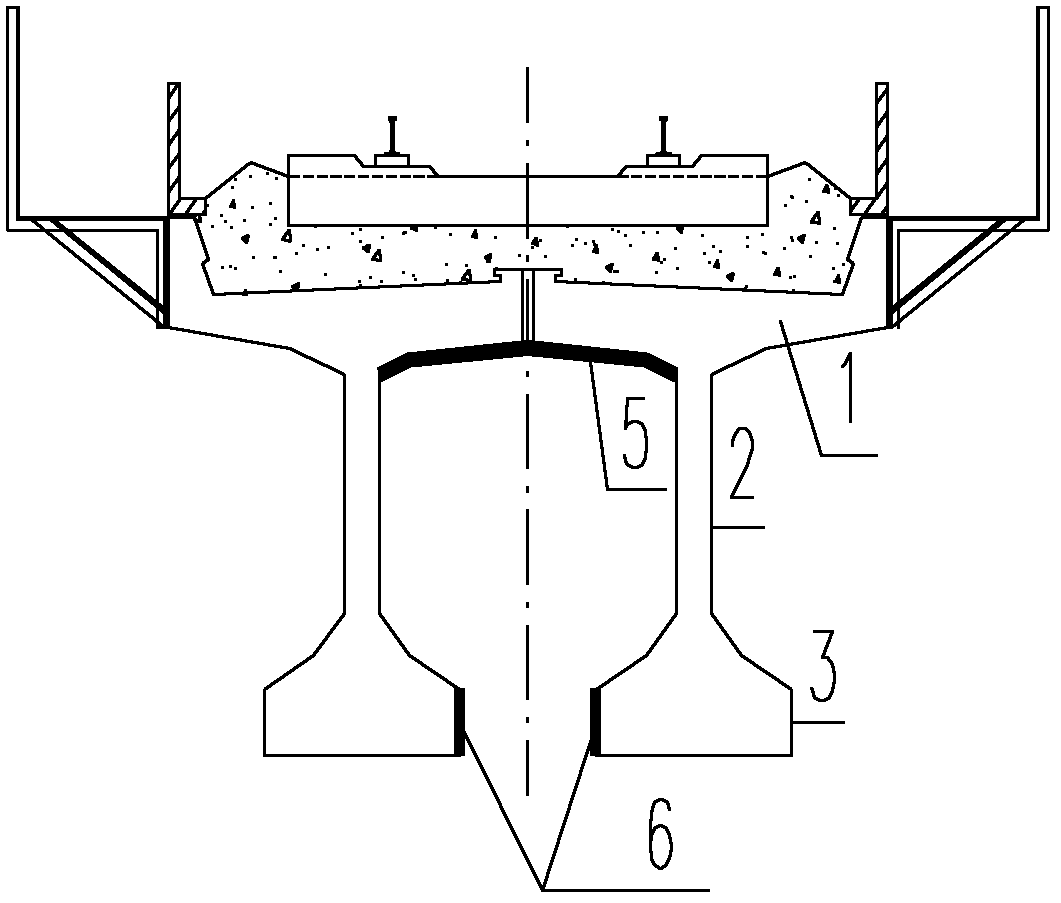

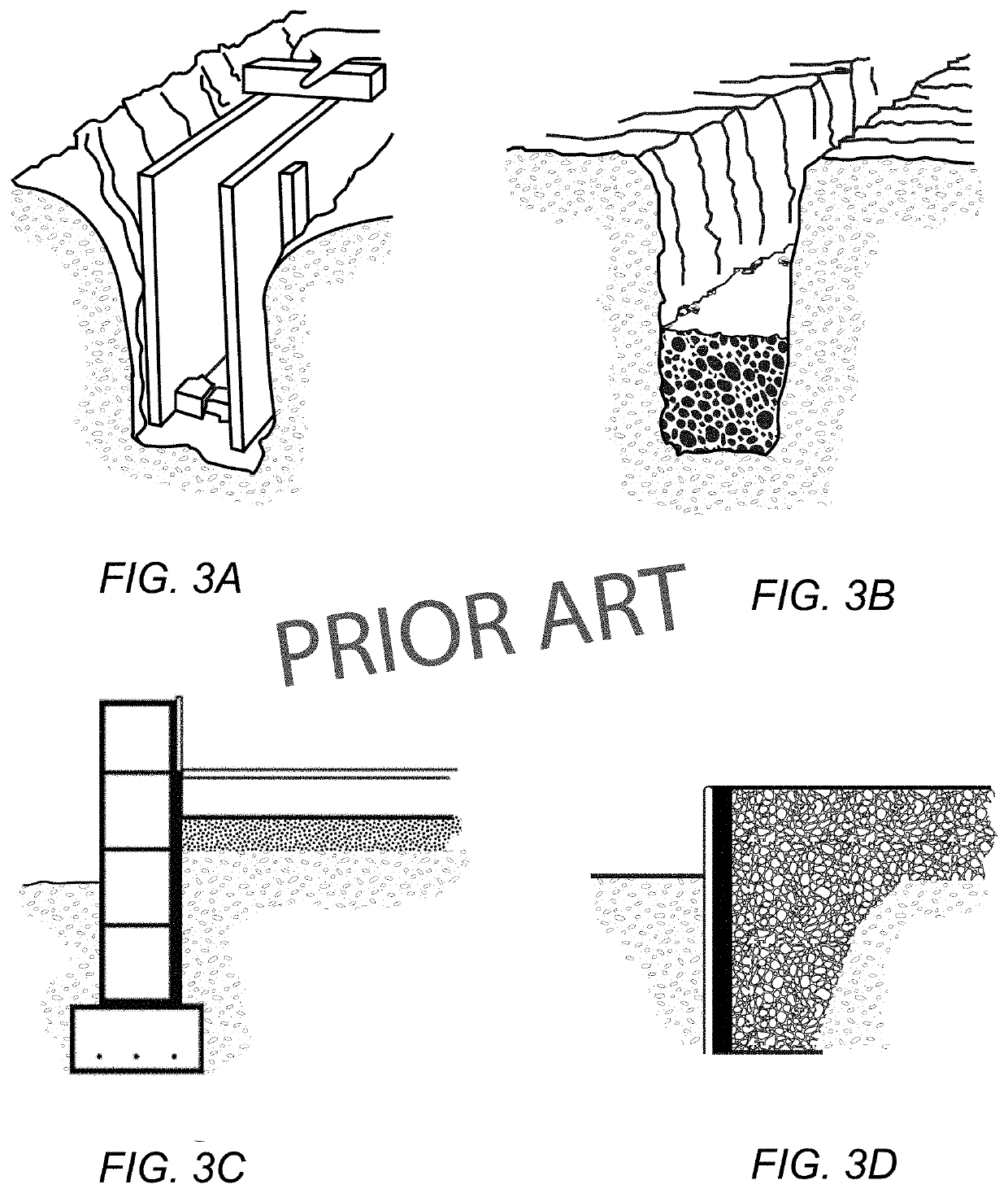

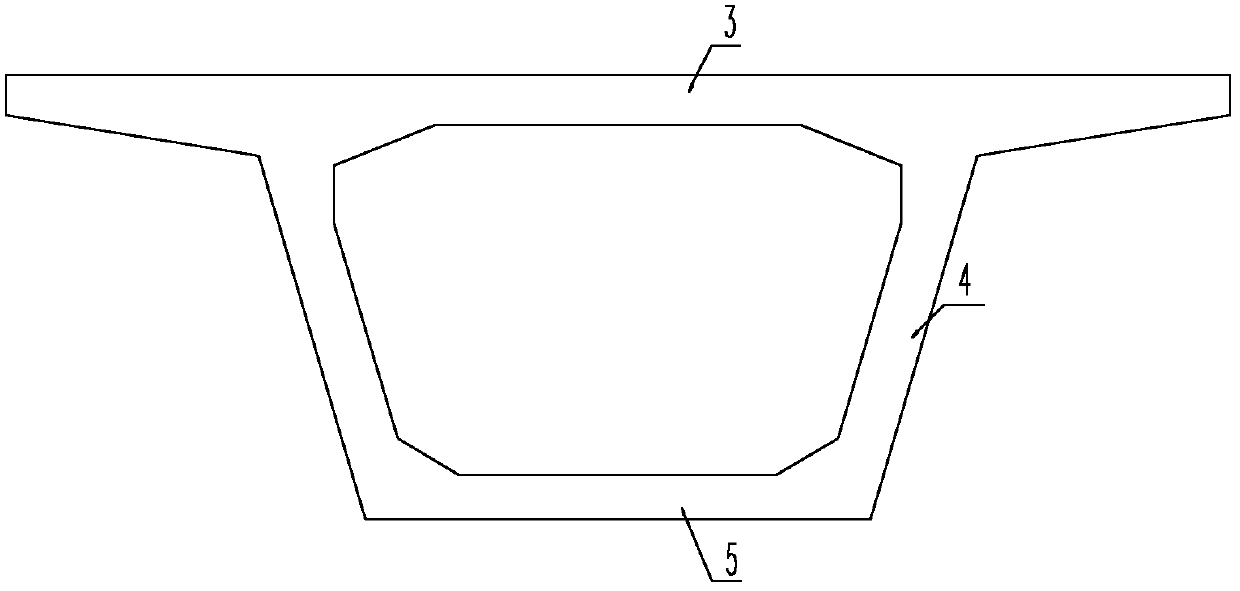

Assembled type pier column member with steel-concrete composite structure

InactiveUS20170356144A1Improve construction progressReasonable and convenient to constructBridge structural detailsBridge erection/assemblyPile capPre stress

A segment-assembled type pier column member with a steel-concrete composite structure includes a reinforcement tube embedded in a pile cap, wherein the reinforcement tube is connected with a bottom of a lower segment of a hollow steel tube pier and is poured with concrete, and pier columns in upper and lower segments are reinforced by means of segment connecting and being embedded with local reinforcing meshes. A steel cross beam is connected with an upper segment of the hollow steel tube pier in an assembled way. A pre-stressed tensioning duct is reserved between the steel cross beam and the pier column in the upper segment.

Owner:HOHAI UNIV

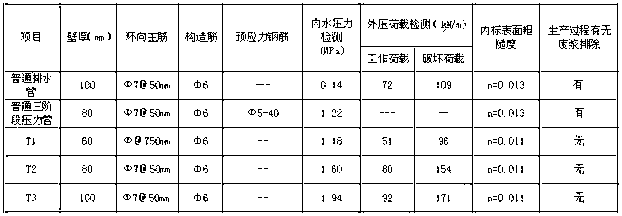

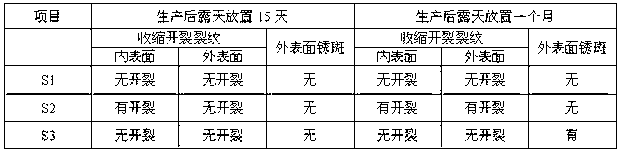

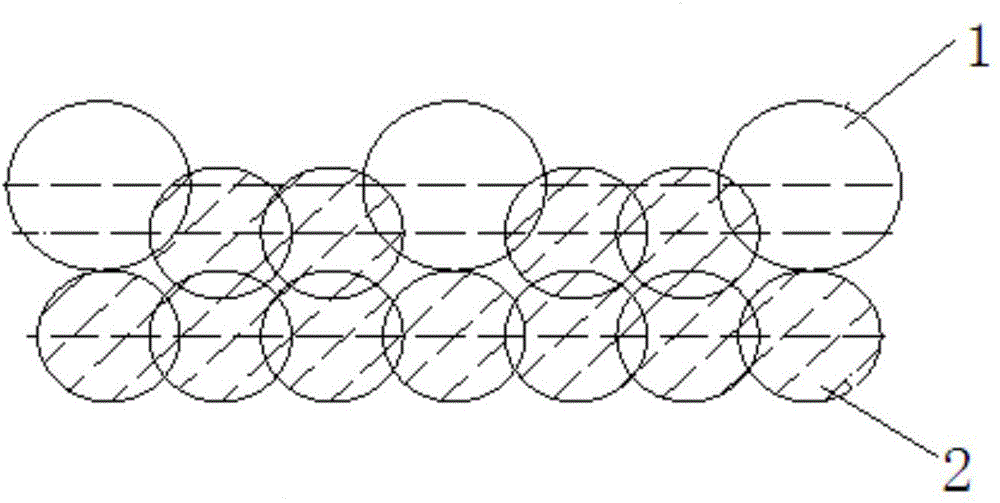

Green environmentally-friendly powder reinforced concrete water delivery pipe

ActiveCN103224356ALow costReduce pollution treatment costsCeramic shaping apparatusSlagMesh reinforcement

The invention belongs to the field of water delivery engineering and relates to a green environmentally-friendly powder reinforced concrete water delivery pipe. The green environmentally-friendly powder reinforced concrete water delivery pipe is manufactured by uniform distribution of concrete on a reinforcement mat. The concrete is prepared from 450 to 500 weight parts of ordinary portland cement or low-alkaline portland cement having the average grain diameter of 30 to 60 microns, 90 to 130 weight parts of silica fume having the average grain diameter of 0.18 microns and SiO2 content greater than or equal to 85%, 100 to 130 weight parts of I-grade coal ash having the average grain diameter of 10 to 20 microns, 130 to 160 weight parts of more than S95 grade of slag powder having the average grain diameter of 10 to 30 microns, 520 to 600 weight parts of quartz sand having the grain diameter of 0.16 to 1.63 millimeters, 800 to 880 weight parts of crushed stone having the grain diameter of 5 to 14 millimeters, 12 to 20 weight parts of a composite high-efficiency water reducer having a water-reducing rate more than 30%, 7 to 12 weight parts of a corrosion inhibitor, 45 to 50 weight parts of a high-efficiency expanding agent, 130 to 150 weight parts of water, 0.8 to 1.2 weight parts of polypropylene fibers, and 80 to 160 weight parts of copper-coated steel fibers having the diameter of 0.18 to 0.25 millimeters and the length of 10 to 15 millimeters. The reinforcement mat is manufactured by weaving hard-drawn wires having the diameter of 4.0 to 6.0 millimeters as reinforcements and cold-rolled ribbed bars having the diameter of 5.0 to 10.0 millimeters as hoop reinforcements.

Owner:黄贺明

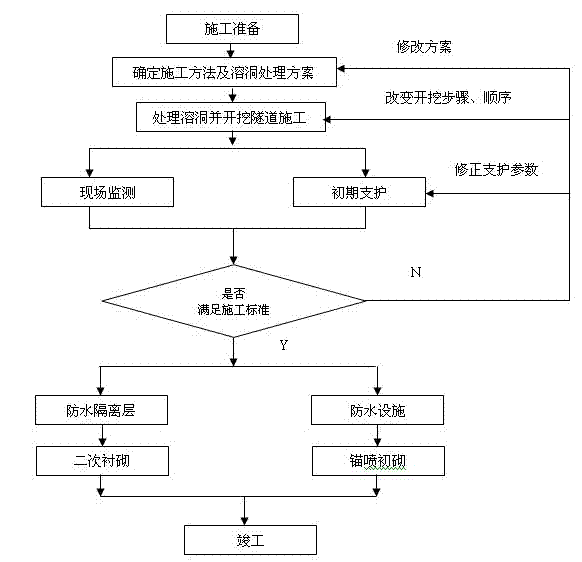

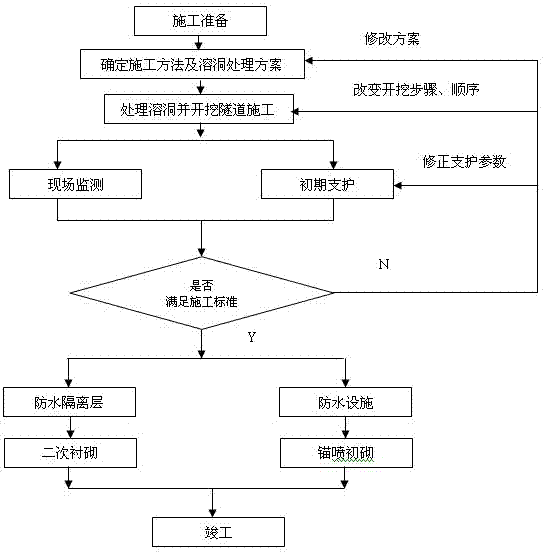

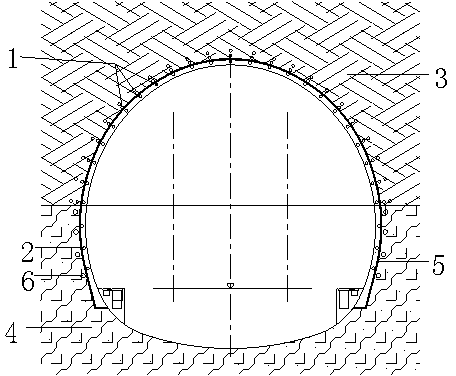

Construction technology for allowing tunnel to pass through ultra-large karst cave

ActiveCN102383806ADo not delay the construction periodQuality assuranceUnderground chambersFoundation engineeringShotcreteMesh reinforcement

The invention relates to a construction technology for allowing a tunnel to pass through a karst cave, and in particular relates to a construction technology for allowing a tunnel to pass through an ultra-large karst cave. The technology at least comprises the following steps of: 1) performing simple bridge treatment on the underground part of the karst cave; 2) performing primary support, namelyarranging a support wall at one side of the karst cave; 3) forming parallel guide holes; 4) performing bottom treatment; 5) treating the tunnel hole body at the inlet section of the karst cave; 6) filling C25 early strength sprayed concrete within 1 meter at the top of the support wall, and arranging phi 50 small grouting conduits with the lengths of 3 meters in the concrete, wherein the distancebetween the small conduits is 1.5 meters; 7) supporting the arch part and the side wall surrounding rock of the karst cave by adopting phi 22 cartridge anchor rods arranged in a plum blossom shape and at a distance of 150cm*150cm, hanging phi6 reinforcing meshes at a distance of 15cm*15cm, and spraying C25 early strength concrete with the thickness of 15 centimeters; 8) treating the accumulation of the karst cave; and 9) monitoring and measuring when the tunnel passes through the ultra-large karst cave. The construction technology for allowing the tunnel to pass through the ultra-large karst cave is simple in process, convenient for construction, low in cost, scientific, effective, energy-saving and environmentally-friendly.

Owner:CCCC SHEC DONGMENG ENG CO LTD

Section steel concrete- punched steel plate-concrete combined shear wall and method for producing the same

InactiveCN101457560AIncreased shear capacityIncrease the usable areaWallsShock proofingRebarSteel plates

The invention relates to a shear wall, in particular to a profile steel concrete-punching steel plate-concrete combined shear wall and a manufacturing method thereof. The shear wall is limited by a profile steel concrete column and formed by a steel plate combination structure which is covered with concrete outside and provided with holes; the shear wall is provided with the steel plate, and then two sides of the steel plate are configured with a reinforcing mesh formed by reinforcing steel bars which are distributed transversely and longitudinally, and a drawknot rib that passes through the holes is used for connecting the reinforcing meshes at the two sides of the steel plate together; finally, the concrete is poured. The profile steel concrete-punching steel plate-concrete combined shear wall can improve the carrying capacity, reduce the attenuation speed of rigidity and carrying capacity, lead the later period shakeproof performance of the wall to be relative stable, and weakens the damage caused by cutting and gliding at the bottom.

Owner:BEIJING UNIV OF TECH

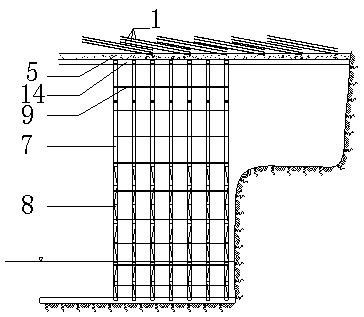

Preliminary bracing construction method for tunnel with surrounding rocks containing collapsible loess and soft rocks

InactiveCN103410527AEasy to operateEconomically reasonableUnderground chambersTunnel liningShotcreteMesh reinforcement

The invention discloses a preliminary bracing construction method for a tunnel with surrounding rocks containing collapsible loess and soft rocks. The method includes the following steps that a plurality of layers of advanced pipe sheds are arranged on a collapsible loess layer, and a single layer of advanced pipe shed is arranged on a soft rock layer; after the advanced pipe shed is set up, a working face is closed through sprayed concrete, a system anchor bolt is arranged on the soft rock layer, a foot locking small guide pipe is arranged at the arch springing position of the tunnel, and grouting is conducted on the rocks through permeation of the system anchor bolt and the foot locking small guide pipe; a pre-fabricated reinforcing mesh is paved on a concrete initial spraying layer formed by concrete initial spraying in a fluctuation mode, and a reinforcing mesh arranged at the collapsible loess layer is encrypted; a steel arch support is set on the collapsible loess layer, a reinforcing steel bar grid is set up at the soft rock layer, and the connecting position of the reinforcing steel bar grid and the steel arch support is welded; repeated spraying is conducted by adopting concrete spraying, and construction of tunnel preliminary bracing is finished. By means of the method, stress releasing and deformation coordination of two layers of surrounding rocks can be well controlled, operability is good, construction cost is low, and the safety is good.

Owner:CENT SOUTH UNIV

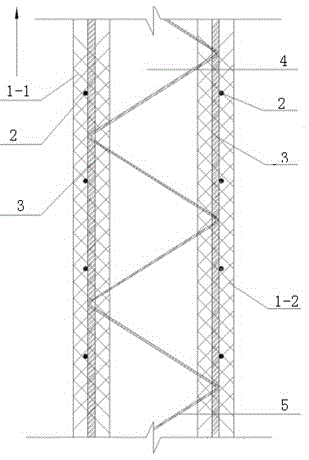

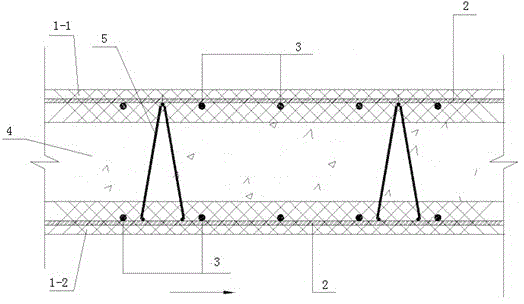

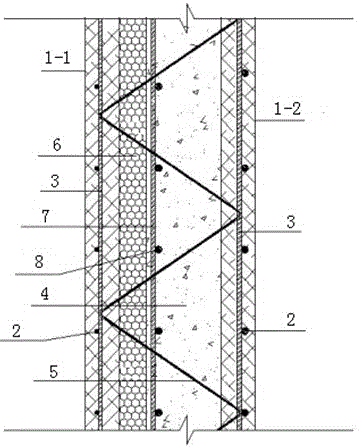

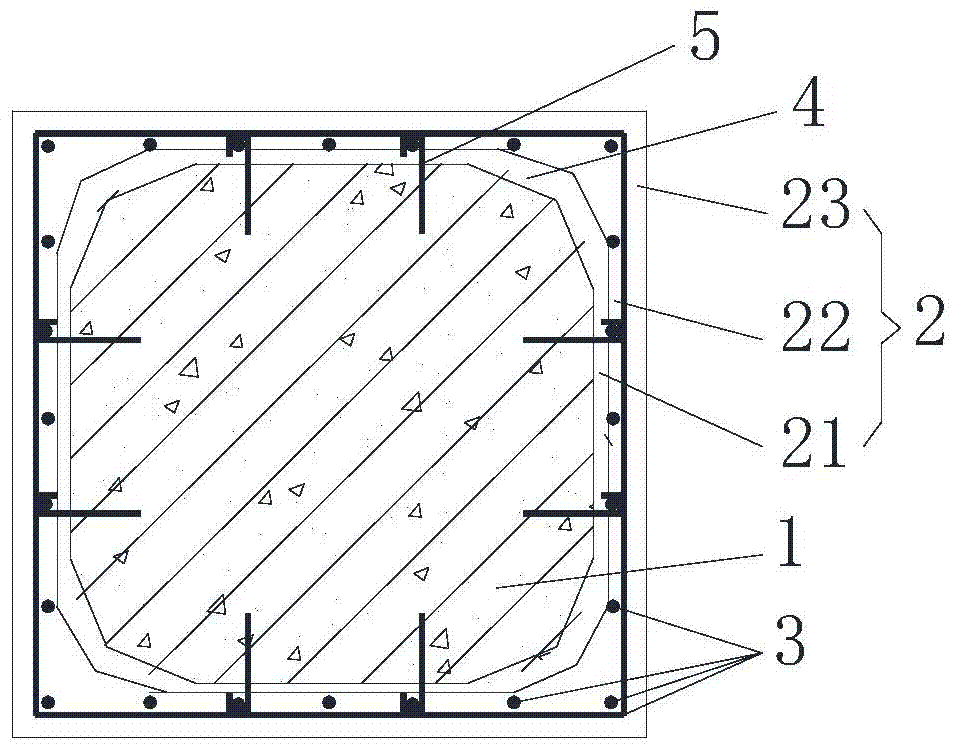

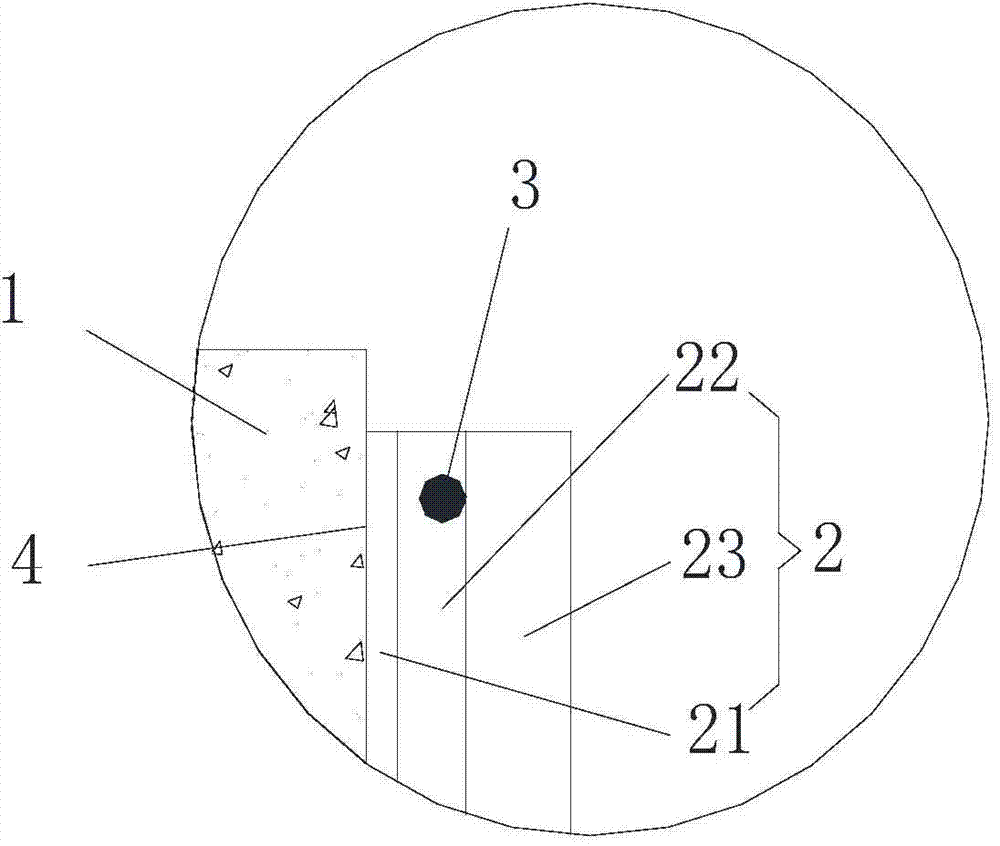

Double-board laminated type concrete shear wall and production process thereof

InactiveCN102720284AAvoid wastingImprove seismic performanceWallsHeat proofingEngineeringLayer thickness

The invention discloses a double-board laminated type concrete shear wall which comprises a laminated wallboard prefabricated part and a laminated wallboard truss steel reinforcement and laminated wallboard field-poured part, wherein the laminated wallboard prefabricated part comprises an external wallboard and an inner wallboard, an insulating layer is formed inside the external wallboard, and a steel reinforcement net is arranged inside the insulating layer. The production process comprises the steps of: (1) cleaning surface of a steel template; (2) automatically drawing, supporting the template and spraying a stripping agent; (3) placing a protective layer thickness spacer; (4) placing the steel reinforcement net of the external wallboard; (5) placing a truss; (6) placing an embedded part in the external wall; (7) pouring concrete; (8) installing an insulating material; (9) maintaining; (10) installing the steel reinforcement net inside the insulating layer; (11) repeating the steps 1 to 3; (12) installing steel reinforcement of the inner wallboard; (13) placing the embedded part of the inner wall; (14) pouring inner wall concrete; (15) laminating the external wall and inner wall; (16) conveying to a maintaining room for maintaining; and (17) hoisting and stacking. According to the invention, the materials are saved and the work efficiency is improved.

Owner:张钟元

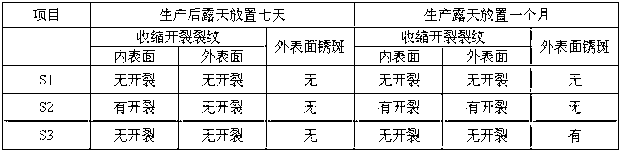

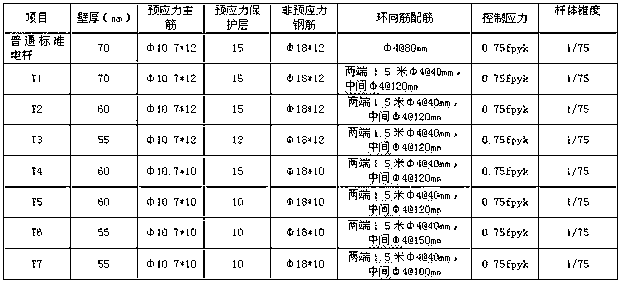

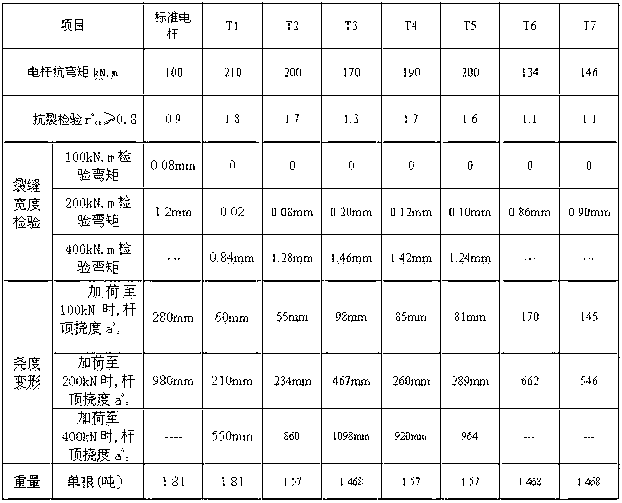

Environment-friendly concrete pole

ActiveCN103225439ASmall electric fluxNo weight lossCeramic shaping apparatusTowersSlagMesh reinforcement

The invention relates to the field of transmission equipment, in particular to a concrete pole. Concrete is uniformly distributed on a reinforcing steel bar mesh, so that the pole is formed. The concrete comprises raw materials in parts by mass as follows: 480-550 parts of low-alkaline Portland cement or ordinary Portland cement with an average grain diameter of 30-60 mu m, 120-140 parts of silica fume with an average grain diameter of 0.18 mu m and the SiO2 content of no less than 85%, 80-110 parts of I-level pulverized fuel ash with an average grain diameter of 10-20 mu m, 110-140 parts of slag powder with the level higher than S95 and an average grain diameter of 10-30 mu m, 510-550 parts of quartz sand with a grain diameter of 0.16-1.63 mm, 860-920 parts of cobbles with a grain diameter of 5-14 mm, 14-18 parts of a compound high-efficiency slushing agent with a water-reducing rate higher than 30%, 7-12 parts of a corrosion inhibitor, 120-140 parts of water, 70-110 parts of a copper plating steel fiber with a diameter of 0.18-0.25 mm and a length of 10-15 mm and 0.8-1.5 parts of a polypropylene fiber. Prestressed wires with a diameter of 4.8-10.7 mm and taken as main bars and high-strength hard-drawn wires with a diameter of 3.0-5.0 mm and taken as circular structural bars are woven, so that the reinforcing steel bar mesh is formed.

Owner:黄贺明

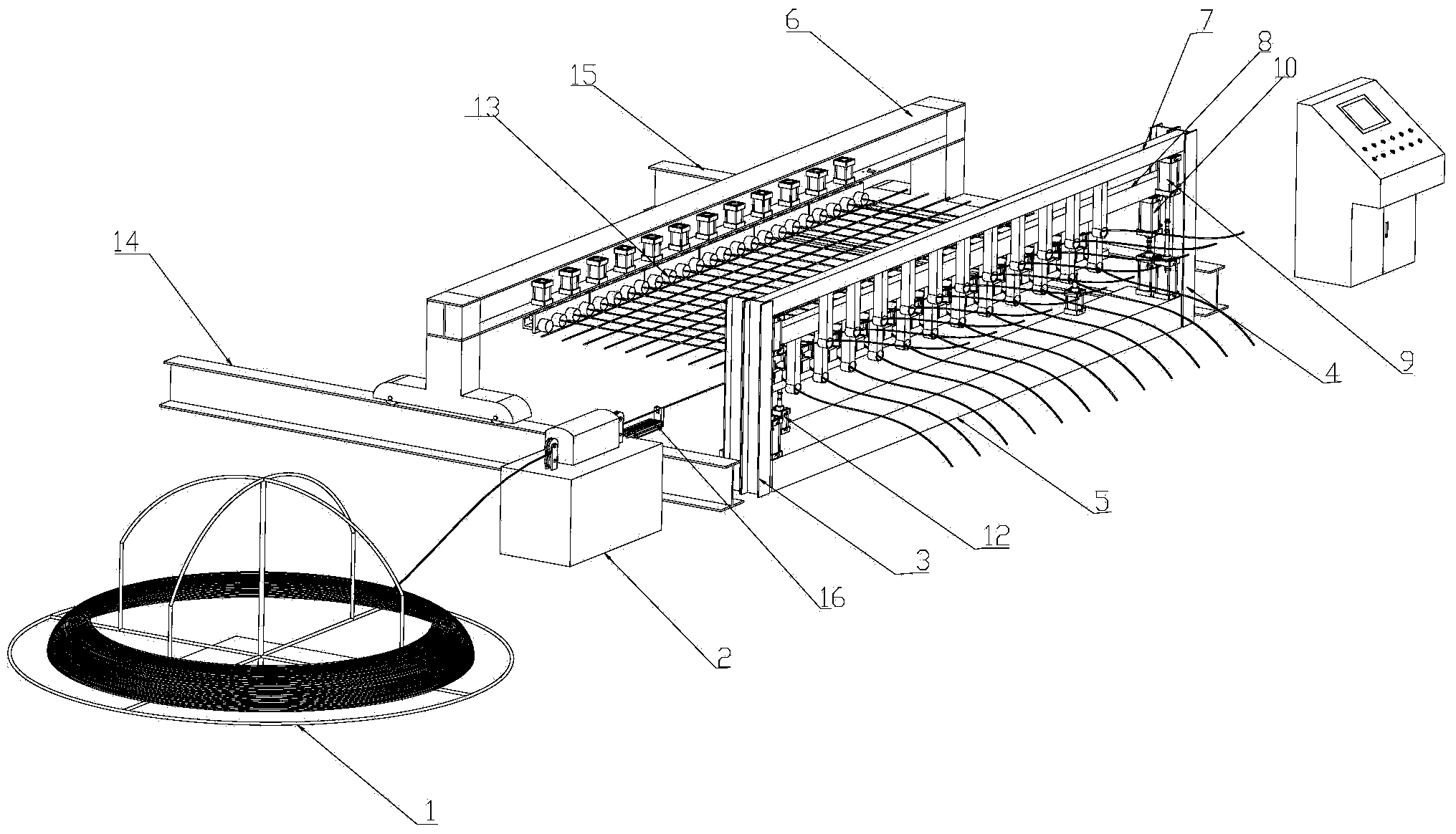

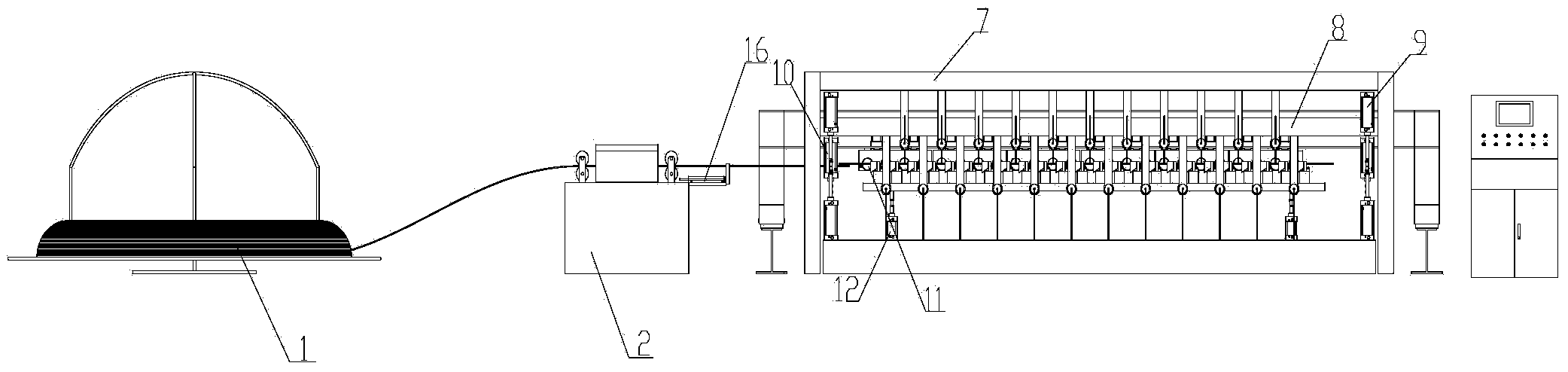

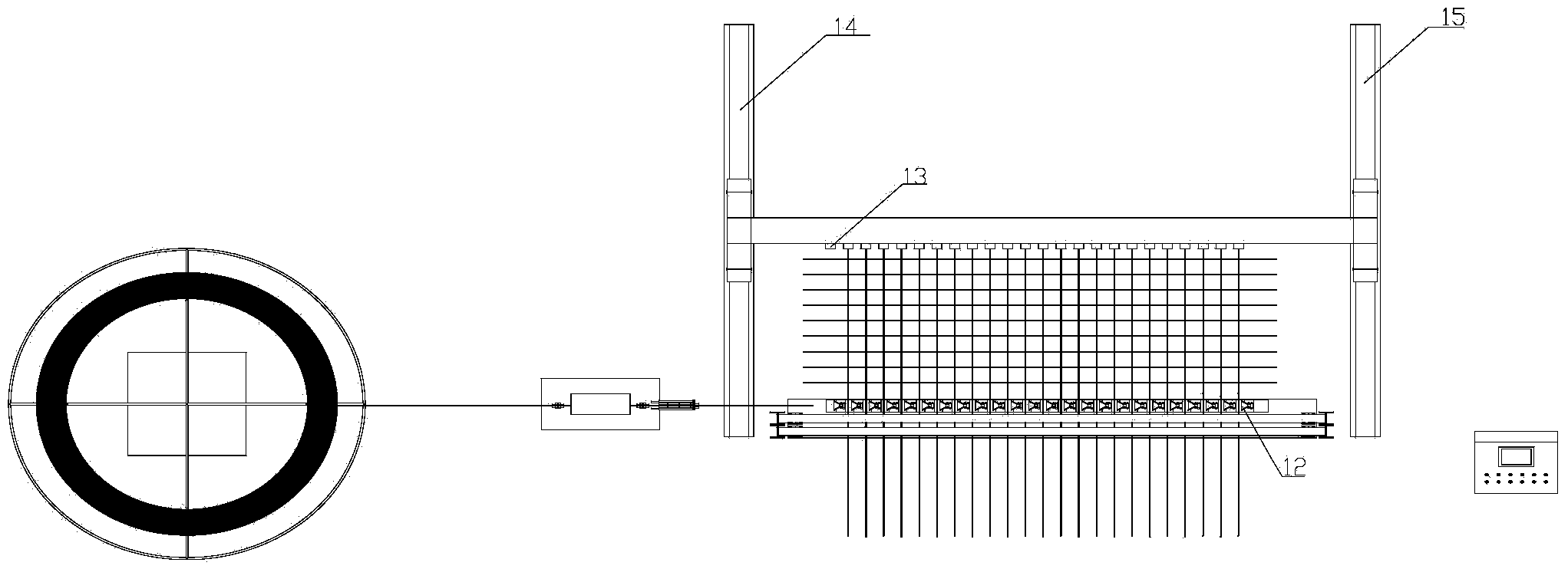

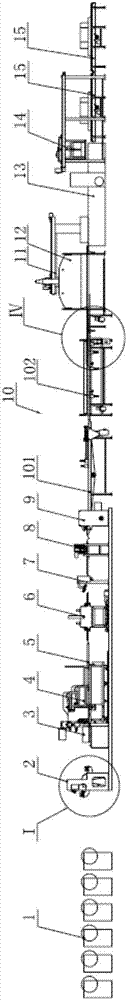

Rebar mesh knitting unit

The invention discloses a rebar mesh knitting unit which comprises rebar disc elements, a fixed-length shearing machine and a rebar knitting machine main body, wherein outgoing lines of the rebar disc elements, an inlet-outlet of the fixed-length shearing machine and a transverse guide wheel belt-shaped mechanism are located on the same horizontal line, and the height of the inlet-outlet of the fixed-length shearing machine is the same as that of the transverse guide wheel belt-shaped mechanism, when a lifting air cylinder is under an initial state. According to the rebar mesh knitting unit, automatic induction and clamping can be achieved, the spacing distance of rebar grids can be regulated, a knitted mesh is high in precision, and rebar is not easily loosened.

Owner:TIANSHUN GROUP

Reactive powder fiber concrete reinforced concrete column and reinforcement method

InactiveCN103590616ALight weightSelf-respect and high strengthBuilding repairsReinforced concrete columnFiber

The invention discloses a method for reinforcing a reactive powder fiber concrete reinforced concrete column. The method includes the steps that firstly, cleaning treatment is carried out on the surface of an original concrete column so that a concrete structure layer of the original concrete column can be exposed, and then impurity removal and dabbing are carried out till a new surface is exposed and an aggregate surface of the concrete structure layer is reached; secondly, positioning, lining and drilling are carried out on the surface of the column, shear pins are embedded into drilled holes through rib embedding glue, and a reinforcing mesh is bound at the lining position; thirdly, interface agents are applied, specifically, reactive powder fiber concrete is applied with the interface agents in a layered mode, joints between the layers are made staggered, and reinforcement of the concrete column is completed after the processes of flattening, burnishing and maintenance. The reinforced concrete column obtained through the method mainly comprises the original concrete column structure layer and a reactive powder fiber concrete reinforced layer, and the reactive powder fiber concrete reinforced layer is formed by mutually overlaying multiple unit reinforced layers with the reactive powder fiber concrete as a base material and the reinforcing mesh as a reinforcing material. The reactive powder fiber concrete reinforced concrete column has the advantages of being small in sectional dimension change, good in durability, long in service life, easy and convenient to construct, high in construction efficiency and the like.

Owner:湖南大兴加固改造工程有限公司

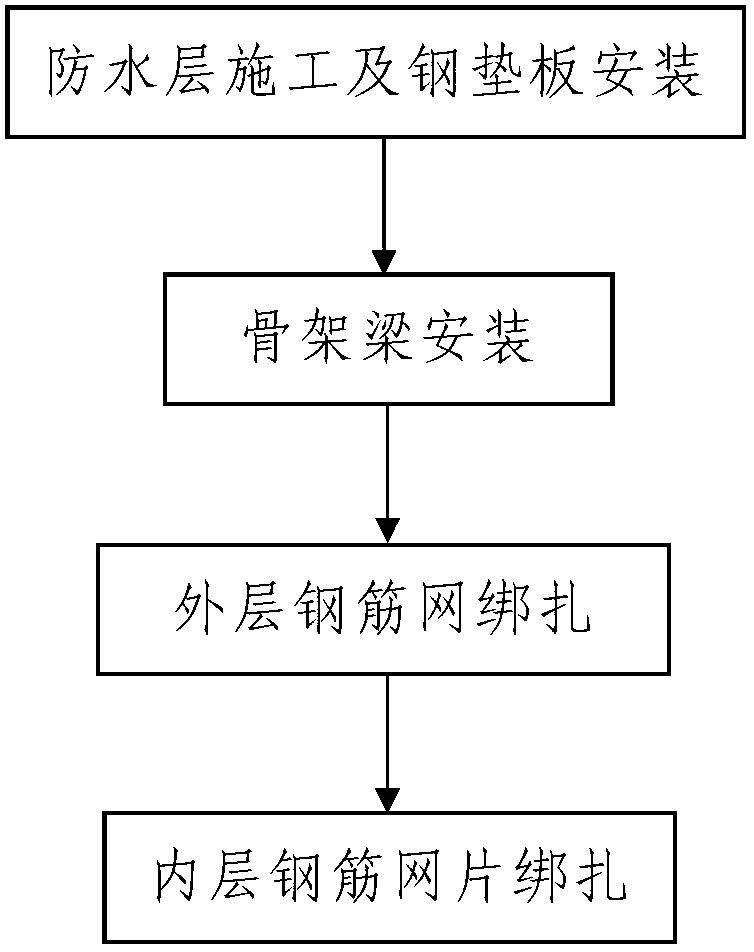

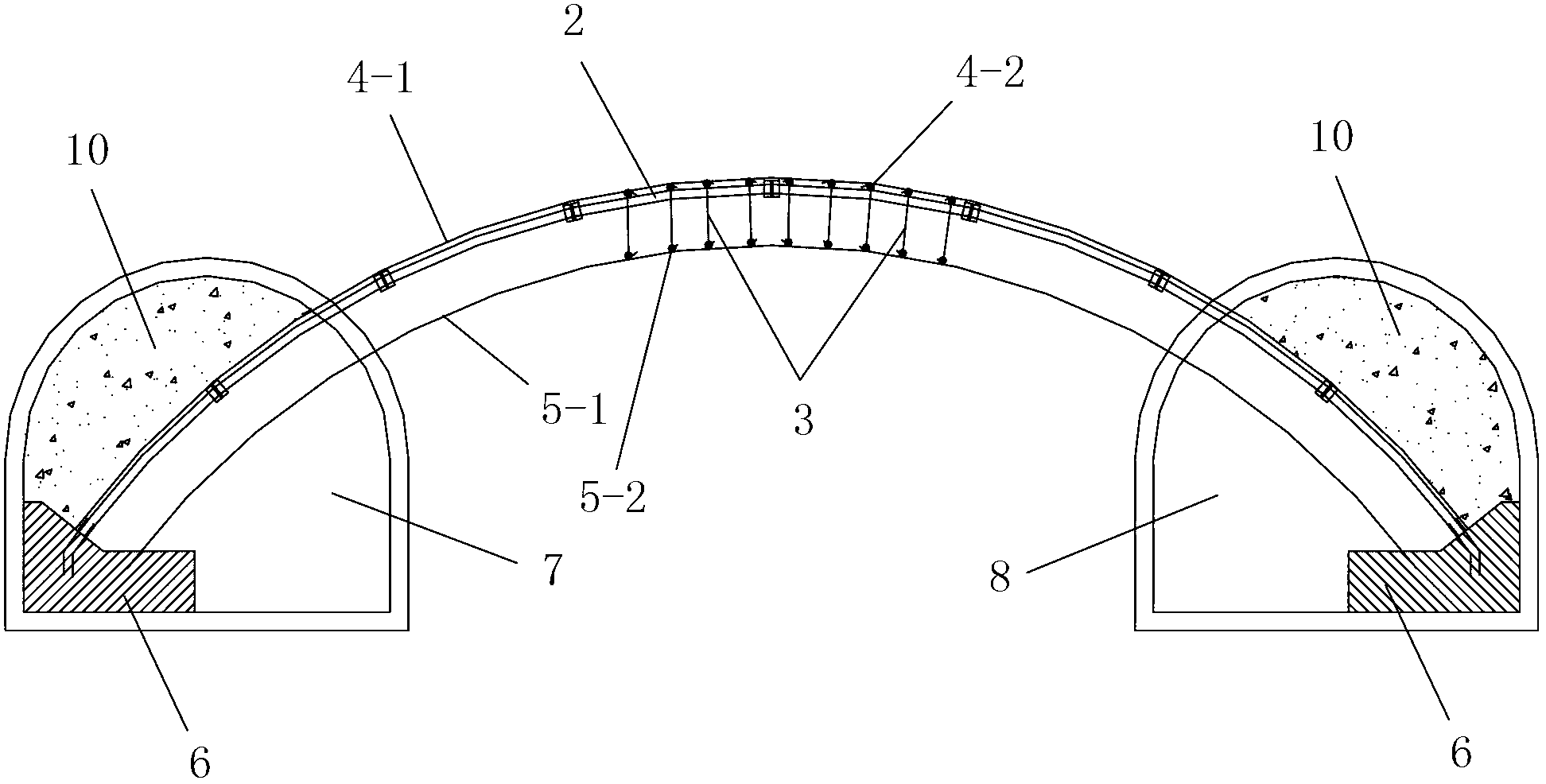

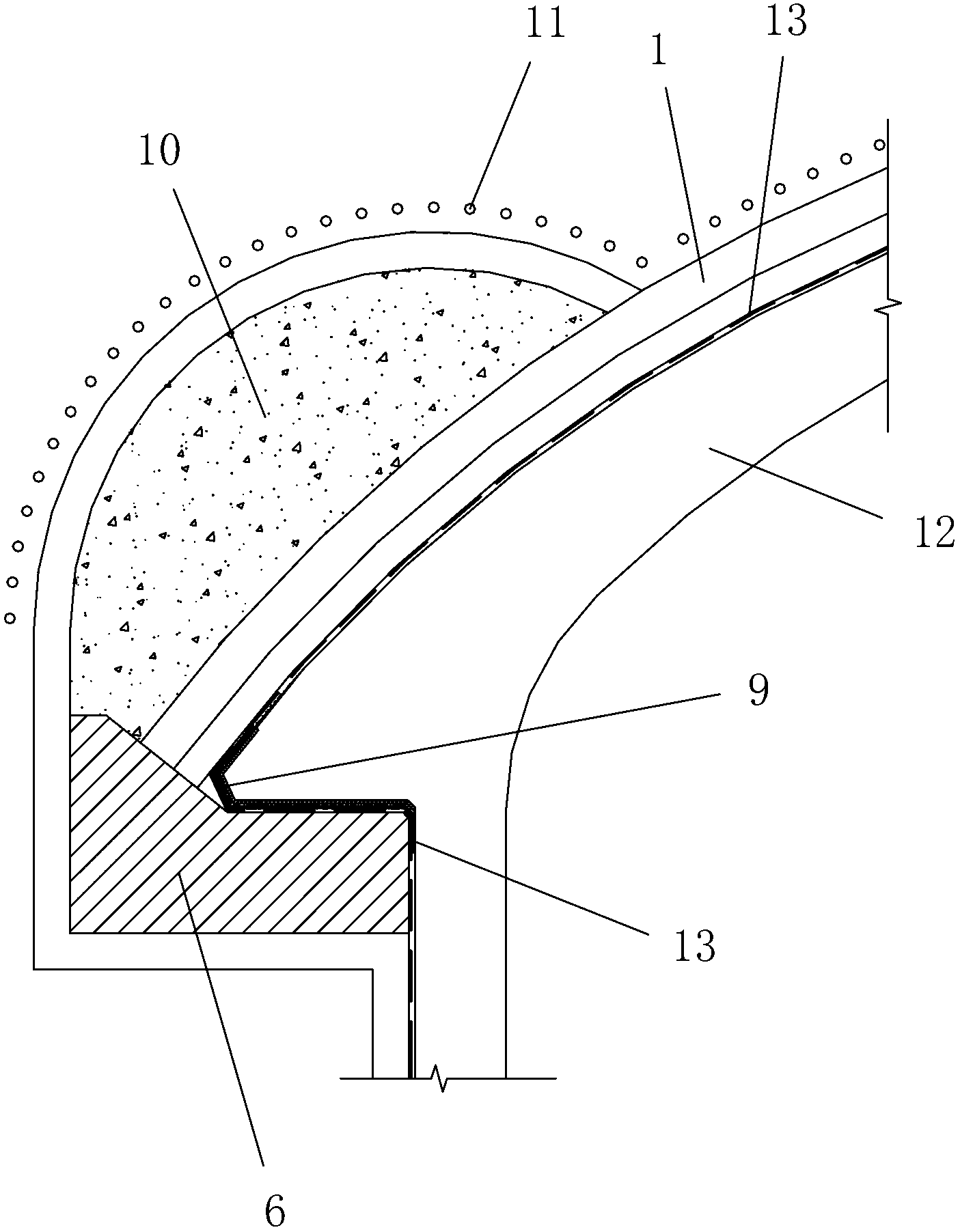

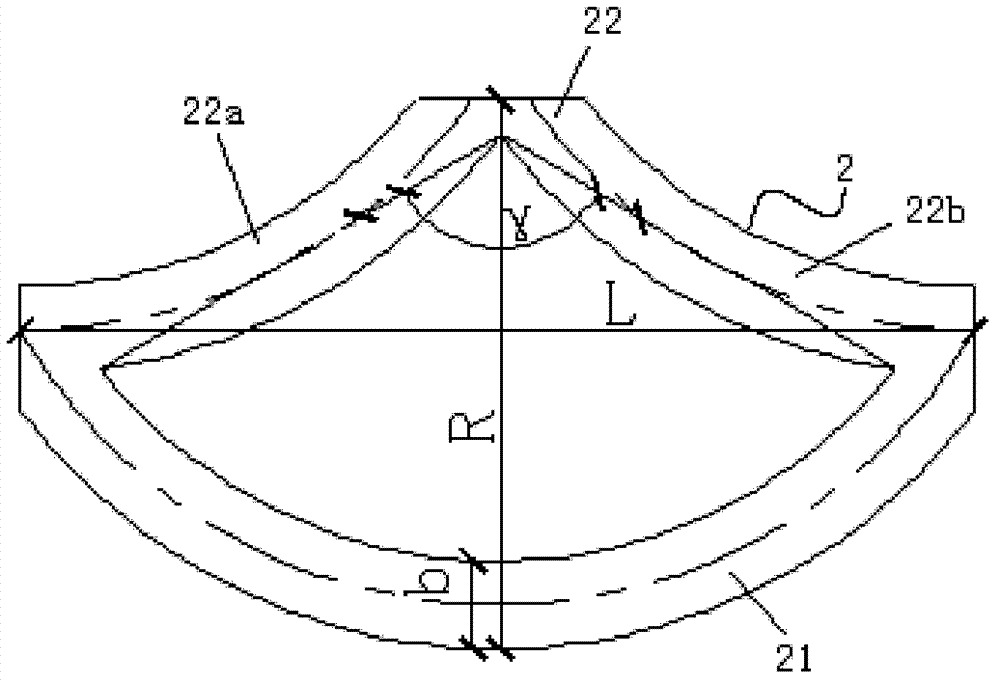

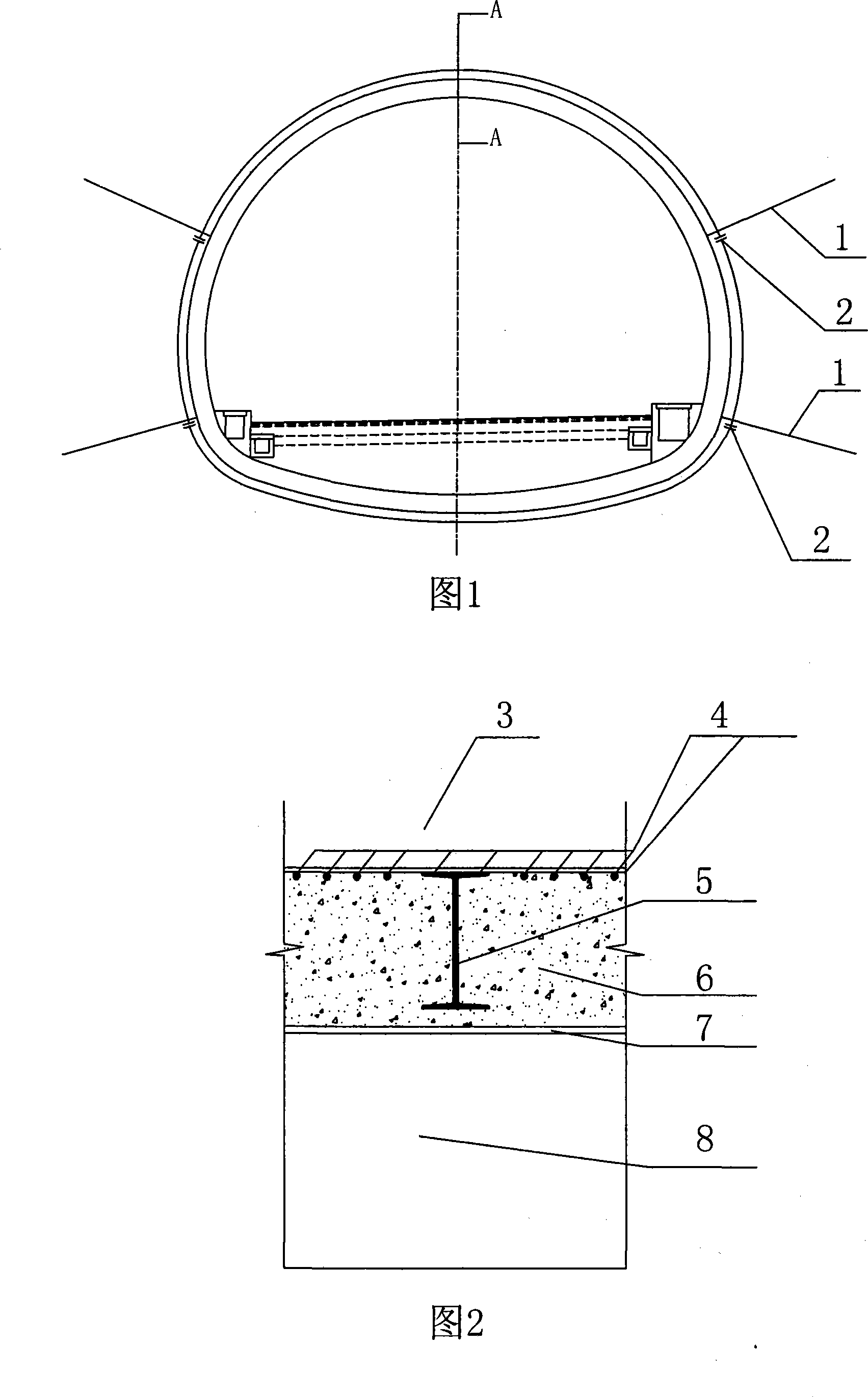

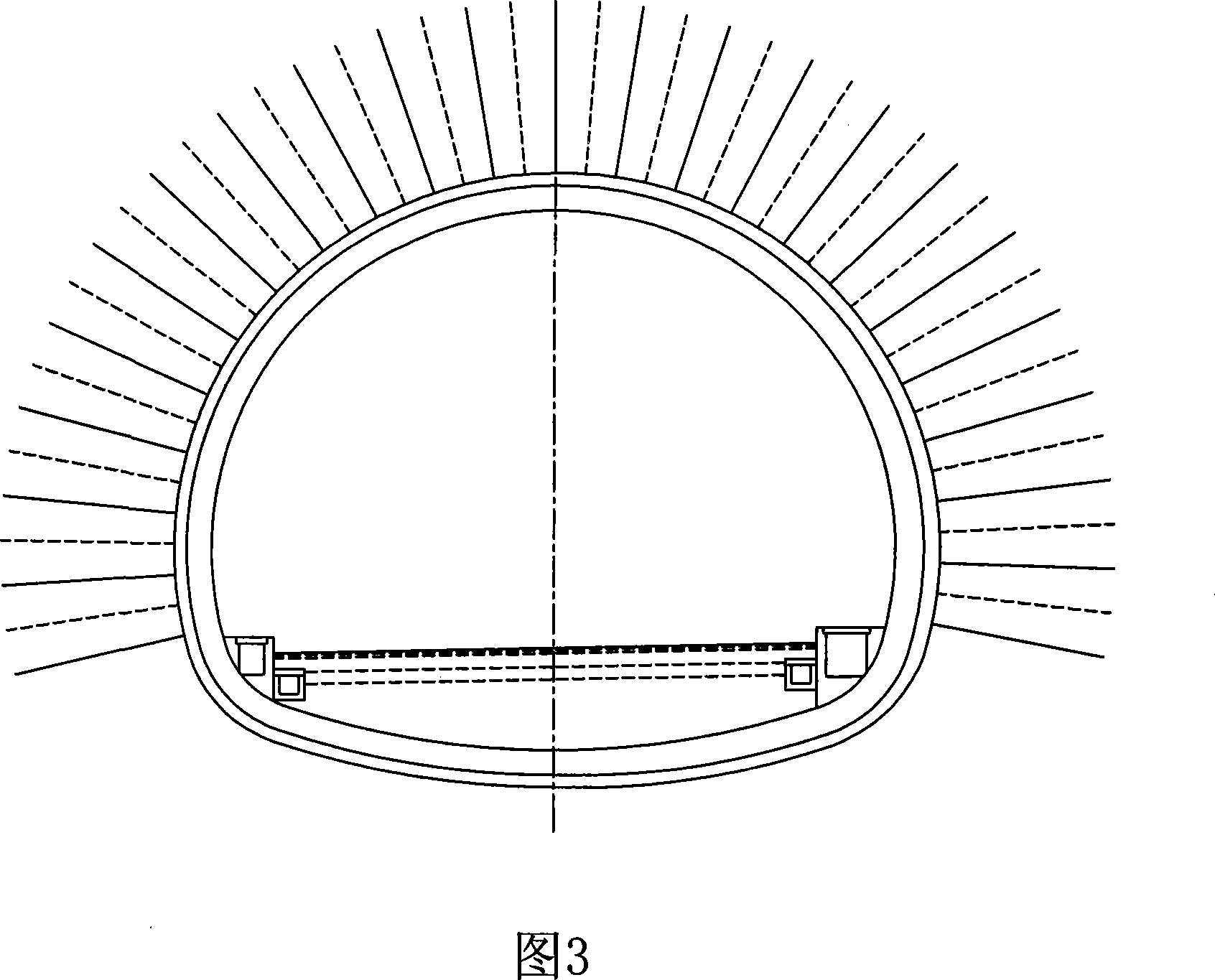

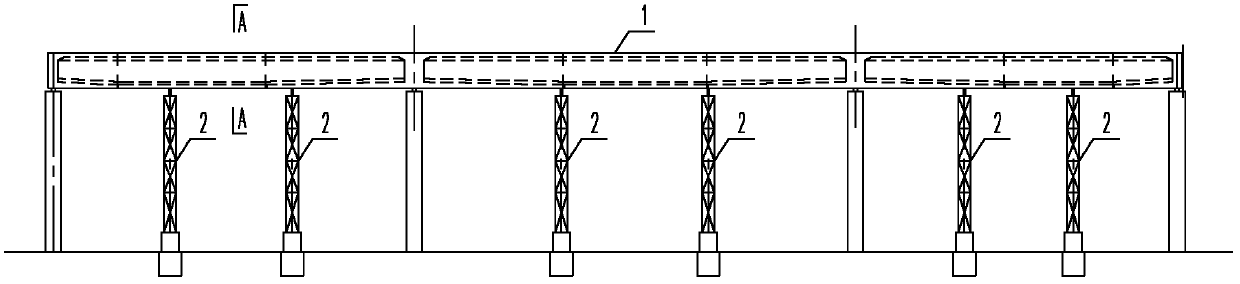

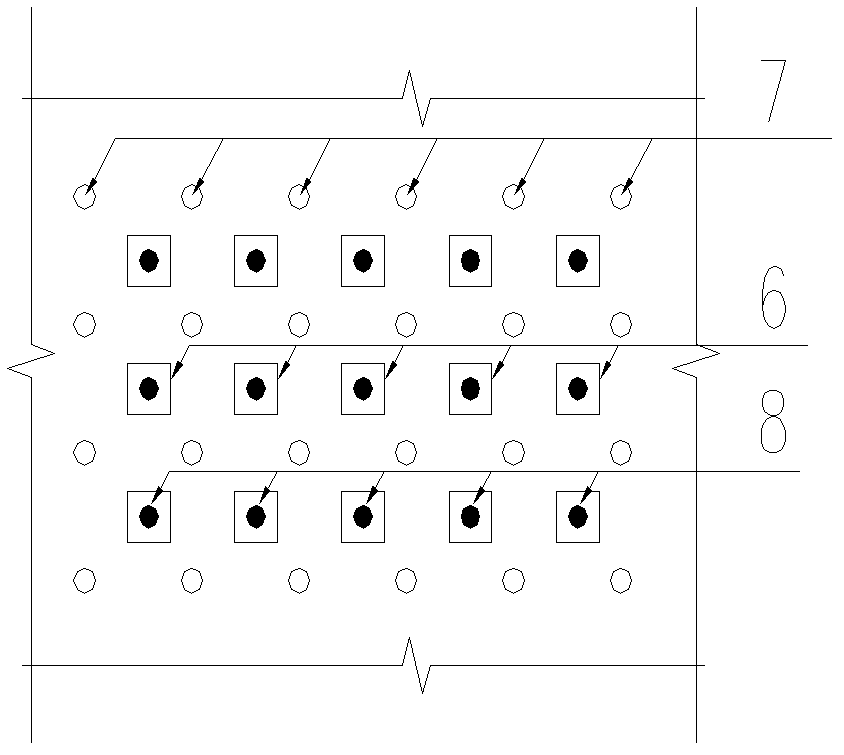

Large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams

The invention discloses a large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams. A bound tunnel arch secondary lining steel bar comprises an outer layer reinforcement mat, an inner layer reinforcement mat and a vertical connecting bar for connecting the outer layer reinforcement mat with the inner layer reinforcement mat. The construction method comprises the following steps of: arranging skeleton beam: arranging a plurality of skeleton beams below a tunnel arch primary supporting structure from front to back, wherein the skeleton beams are arch-shaped beams of which the radiuses are the same as that of the outer layer reinforcement mat, and the plurality of skeleton beams construct a load bearing structure of a tunnel arch secondary lining steel bar; and II, binding the tunnel arch secondary lining steel bar: binding the outer layer reinforcement mat on the upper parts of the plurality of skeleton beams, and suspending the inner layer reinforcement mat on the outer layer reinforcement mat through the vertical connecting bar. The method has the advantages of simple construction process, convenience in constructing, good use effect, high practical value, no damage to a paved waterproof structure and easiness and convenience in controlling the deflection of a large-span station arch secondary lining steel bar.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Method for preparing antiskid wearable lightweight steel box girder bridge floor paving layer

ActiveCN101234876AWear-resistantWith wear resistanceSolid waste managementWear resistantMesh reinforcement

The invention relates to an anti-sliding, wear-resistant and light steel box girder bridge deck pavement and a preparation method thereof, which is characterized in that the method includes the following steps: 1) preparation of high toughness and high strength lightweight aggregate concrete and cement paste on a basalt bare stone surface layer: a. the high toughness and high strength lightweight aggregate concrete is prepared; b. the cement paste on the basalt bare stone surface layer is prepared; 2) pretreatment of the steel box girder bridge deck; 3) welding of shear key: the shear key is welded on the steel box girder bridge deck one by one according to mutual spacing of the shear keys with (30-60)cm plus (30-60)cm; the shear key is stud; 4) lashing of mesh reinforcement; 5) paving of the high toughness and high strength lightweight aggregate concrete layer: thickness of the high toughness and high strength lightweight aggregate concrete layer is 50-80cm; 6) paving of the surface layer of the basalt bare stone; then maintenance is carried out. The bridge deck pavement prepared by the method can effectively prevent disease occurrence of the steel box girder, prolong service life of the bright deck and simultaneously has the functions of anti-sliding, wear-resistant and noise reduction and has good pavement performance.

Owner:WUHAN MUNICIPAL CONSTR GROUP

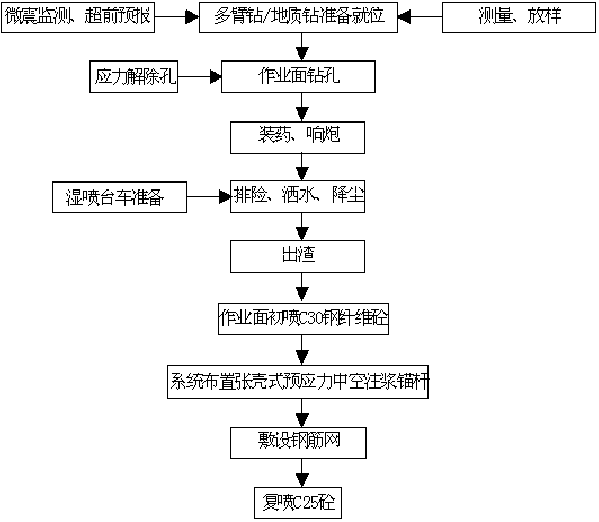

Construction method for microseisms monitoring and stress relieving of strong rockburst tunnel

The invention discloses a construction method for microseisms monitoring and stress relieving of a strong rockburst tunnel. The construction method comprises the steps that firstly, a microseisms monitoring system is installed, and microseisms monitoring and rockburst predicting are performed; secondly, specific positions where rockburst possibly happens, the scale and the intensity of the rockburst are obtained through the microseisms monitoring system; thirdly, a stress relieving hole is drilled through a drilling jig; fourthly, an explosive is loaded and detonated; fifthly, the treatment of danger eliminating, water spraying and dust falling are performed, and slag is discharged; sixthly, primary concrete spraying is performed on a working face; seventhly, shell-expansion type prestress hollow grouting anchor rods are arranged systematically; eighthly, a reinforcing rib mesh is arranged in a laying mode, and concrete is sprayed again. The construction method for microseisms monitoring and stress relieving of the strong rockburst tunnel overcomes the defects that in a traditional stress releasing process, drilling and explosion are blind and a stress releasing effect is poor. According to the construction method for microseisms monitoring and stress relieving of the strong rockburst tunnel, prediction of a stress concentrating portion is accurate, stress releasing is in place, a detecting result of a releasing effect is reliable, rockburst prevention pertinence is strong, and the construction method for microseisms monitoring and stress relieving of the strong rockburst tunnel is simple, practical, strong in operability and good in effect.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG

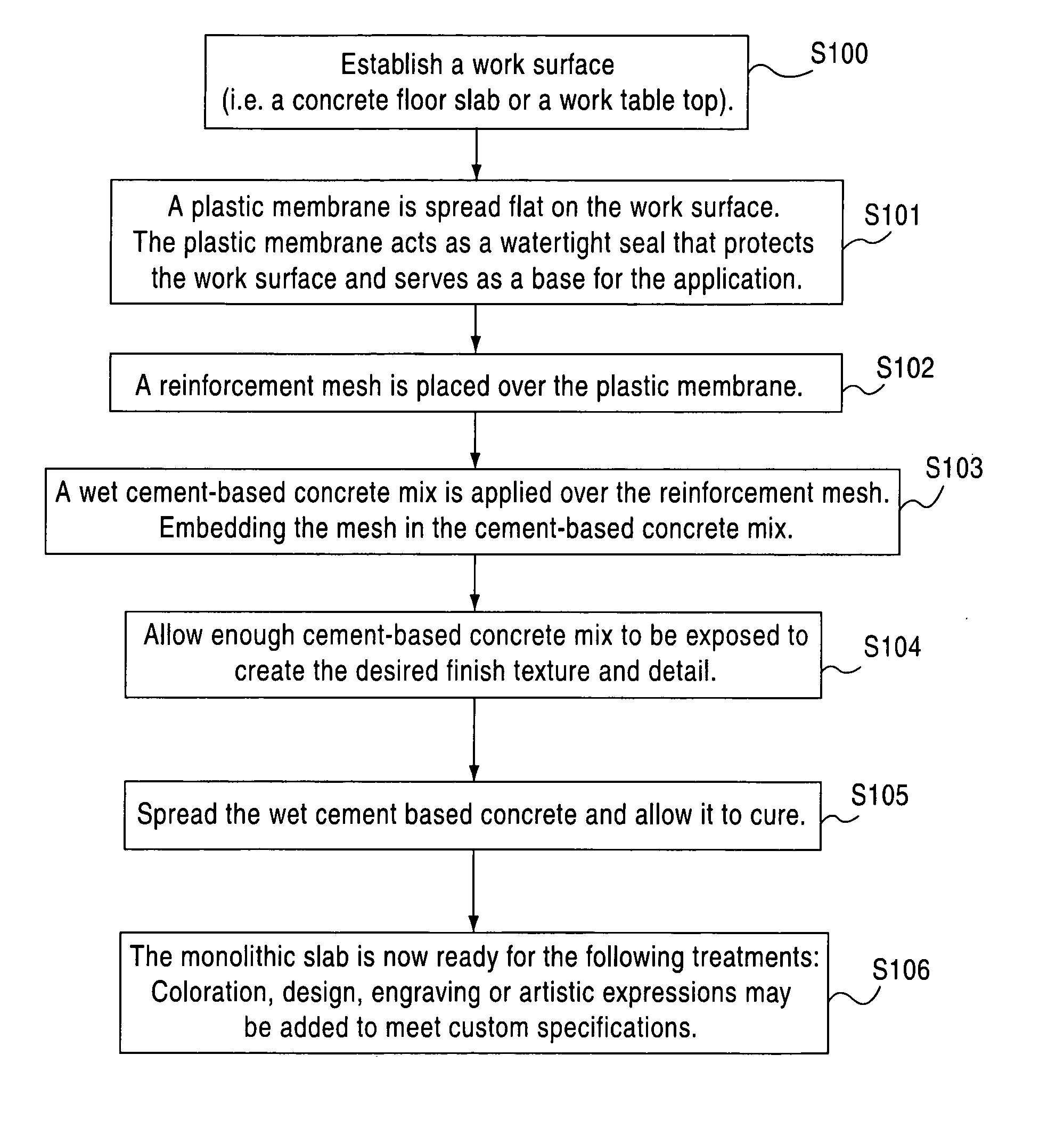

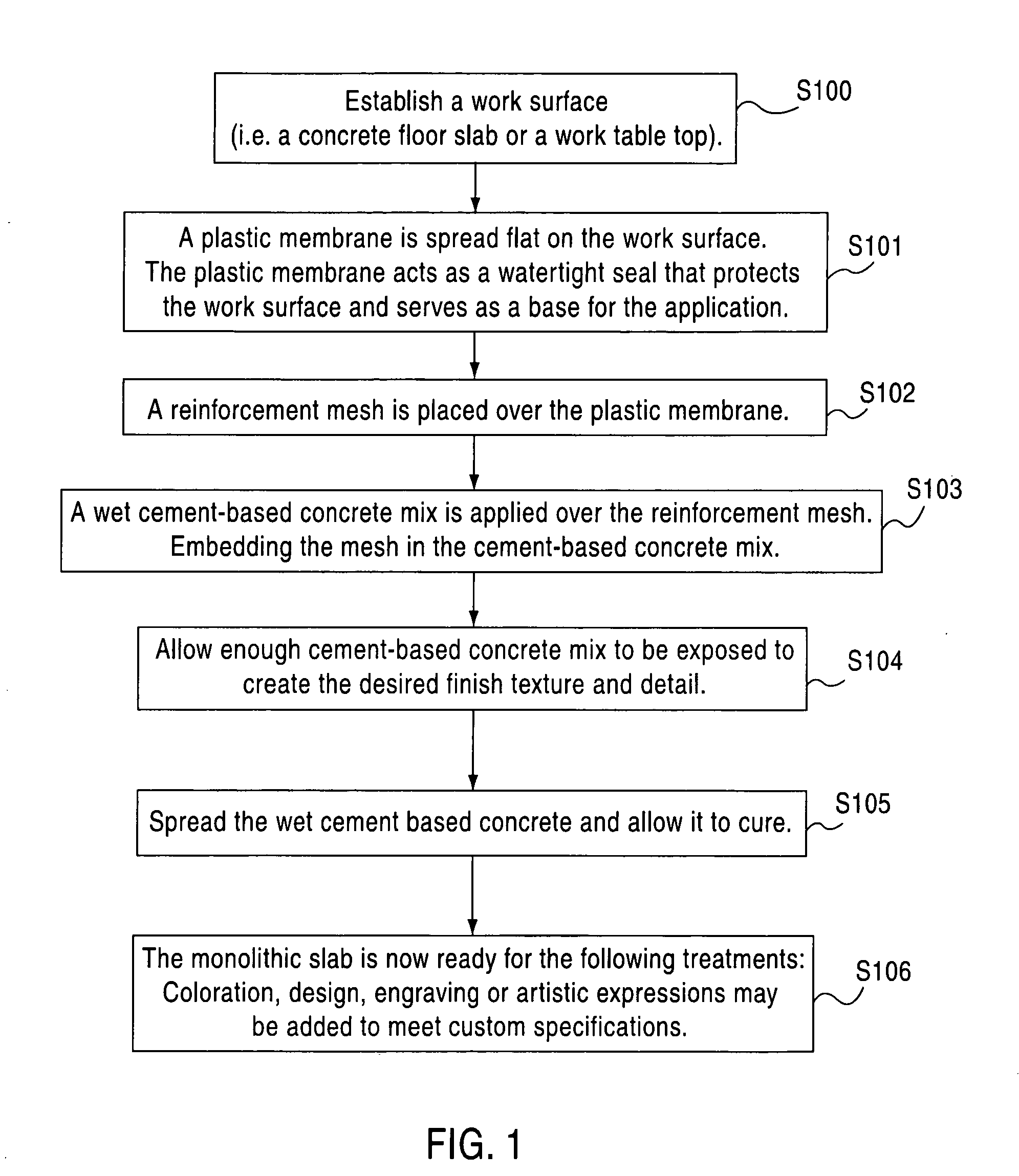

Cement-based, mesh reinforced concrete tiles with integral color and design

A method of manufacturing and installing cement-based concrete tiles, composed of portland cement, polymer-modified cement admixtures, sand, additional ingredients and color pigments integrated with reinforcement mesh for support and strength. The cement-based concrete mix may be dispersed and formed into a single layer cement-based concrete slab configuration with the reinforcement mesh completely embedded within. The cement-based concrete mix is distributed to achieve the desired texture, thickness and finish to form the cement-based concrete slab. After curing, any desired custom designs, engravings, additional colorations and wearing surface sealers are added to render the designs an embodiment of the cement-based concrete slab and thus an embodiment of the cement-based concrete tiles. The concrete slab is then cut into concrete tiles of custom dimensions. The cement-based concrete tiles are identified in sequential order to establish correct placement during the installation process. The custom cement-based concrete tiles may be from ⅛ inch thick to 2 inches thick, and may be installed on floors, walls, counter tops, interior, exterior and at any grade level using excepted professional installation procedure. The cement-based concrete tiles may be custom designed subject to the specifications of the end user.

Owner:BAILEY WAYNE EDWARD

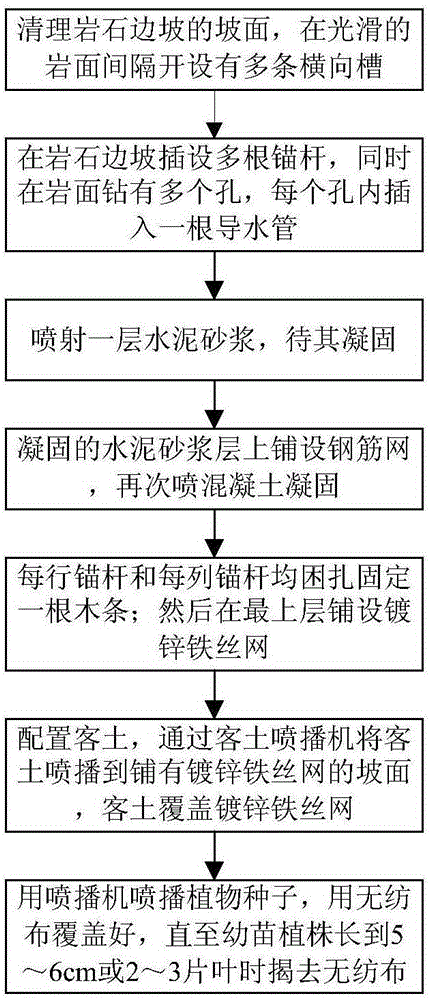

Rock slope ecological protection method

InactiveCN105220698AAchieve coverageAchieve plant coverageClimate change adaptationCoastlines protectionComing outEcological environment

The invention discloses a rock slope ecological protection method and relates to the field of rock slope ecological protection. The method includes that a slope surface of a rock slope is cleaned; multiple anchor rods are inserted into the rock slope, meanwhile, multiple holes are formed in a rock surface through drilling, and one water guide pipe is inserted into each hole; a layer of cement grout is sprayed; a steel mesh reinforcement is laid on the layer of solidified cement grout, and concrete is sprayed again for solidification; a batten is fixedly tied to each row of anchor rod and each column of anchor rod outside the solidified concrete layer; then a galvanized wire mesh is laid on the uppermost layer; borrowed soil is prepared and sprayed to the slope surface where the galvanized wire mesh is laid so as to cover the galvanized wire mesh; plant seeds are sprayed and seeded and then covered by non-woven fabrics, and the non-woven fabrics can be removed when seedlings grow to 5-6cm or 2-3 leaves come out. By means of the rock slope ecological protection method, plants are planted to cover the rock slope, the phenomena of loosening and rock scattering are avoided, potential safety hazards are eliminated, and the ecological environment is advantageously maintained.

Owner:武汉沃田生态科技有限公司

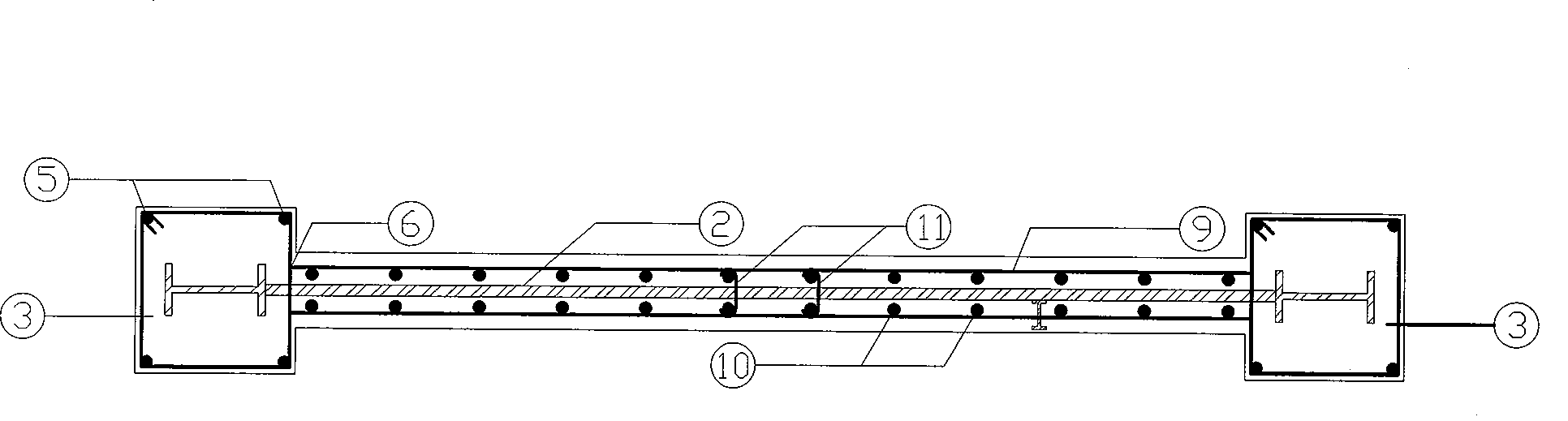

Method for reinforcing bridge structure separated steel-concrete combined truss

The invention relates to a method for reinforcing a bridge structure separated steel-concrete combined truss. The method is characterized by comprising the following steps of: 1, processing an interface at the joint of upper and lower flanges of a concrete beam; 2, planting steel bars in concrete at the joint of the upper and lower flanges of the concrete beam; 3, manufacturing steel plates (10),low-height steel box girders (12) and welding studs (9); 4, binding steel bar meshes (11), and installing in place; 5, manufacturing and installing upper and lower chord node plates (17) and connecting members thereof; and coating a structural adhesive on pouring joint surfaces of the steel plates (10) and the low-height steel box girders (12), and scattering fine sand; 6, installing the steel plates (10) and the low-height steel box girders (12) of the upper and low flanges, vertical rods (16), an external cable (14) and an anchoring tool; 7, manufacturing and installing truss diagonal web rods (15); 8, constructing a truss support; 9, mixing, spraying and curing self-compacting concrete; and 10, tensioning the external cable (14) to obtain an external prestressed steel-concrete combinedtruss reinforced structure. The method has the advantages that: vehicle operation is not influenced, external prestressed bars can be replaced and repeatedly tensioned, a beam body has superior overall working performance and high durability, the process is simple, the combined truss is convenient to maintain and cure, and the like.

Owner:SHUOHUANG RAILWAY DEV +3

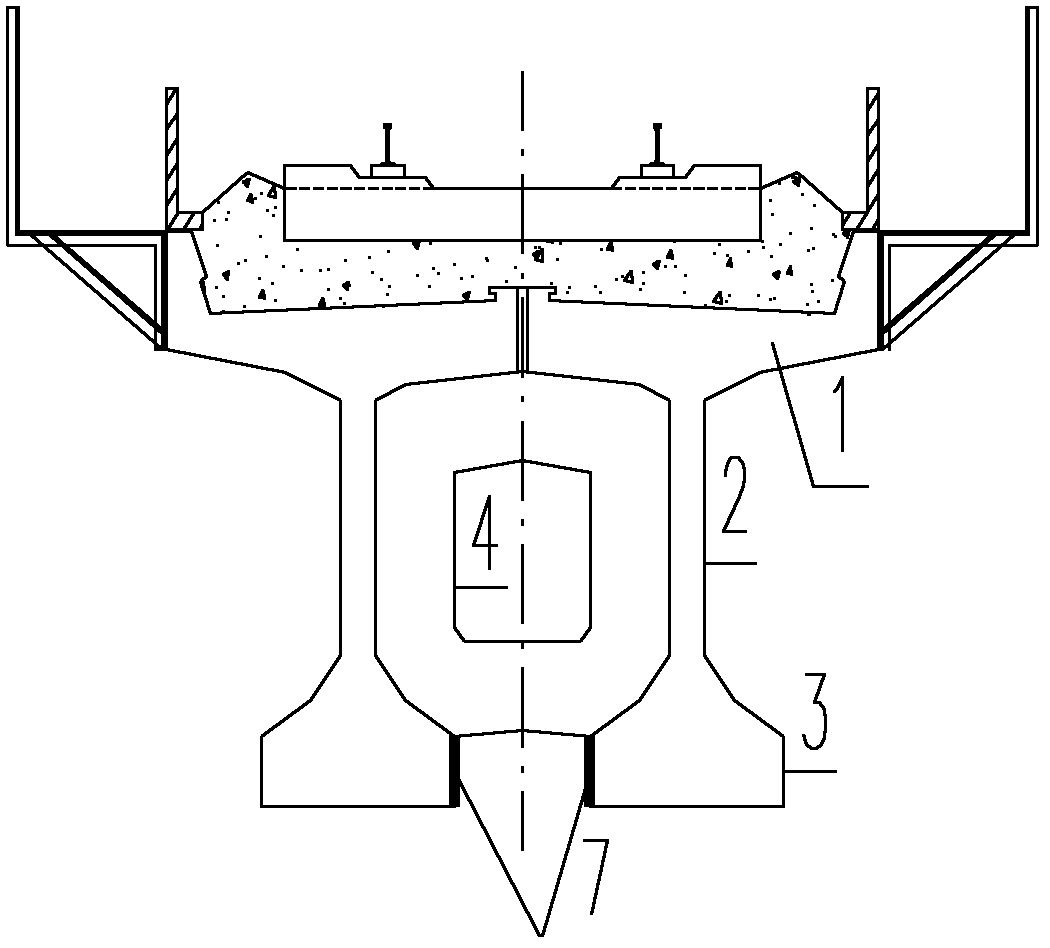

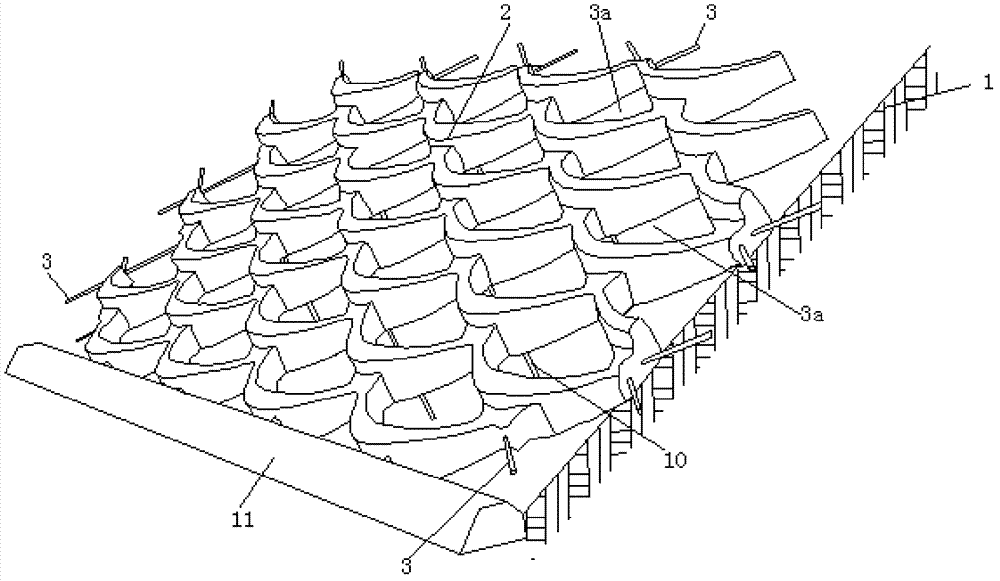

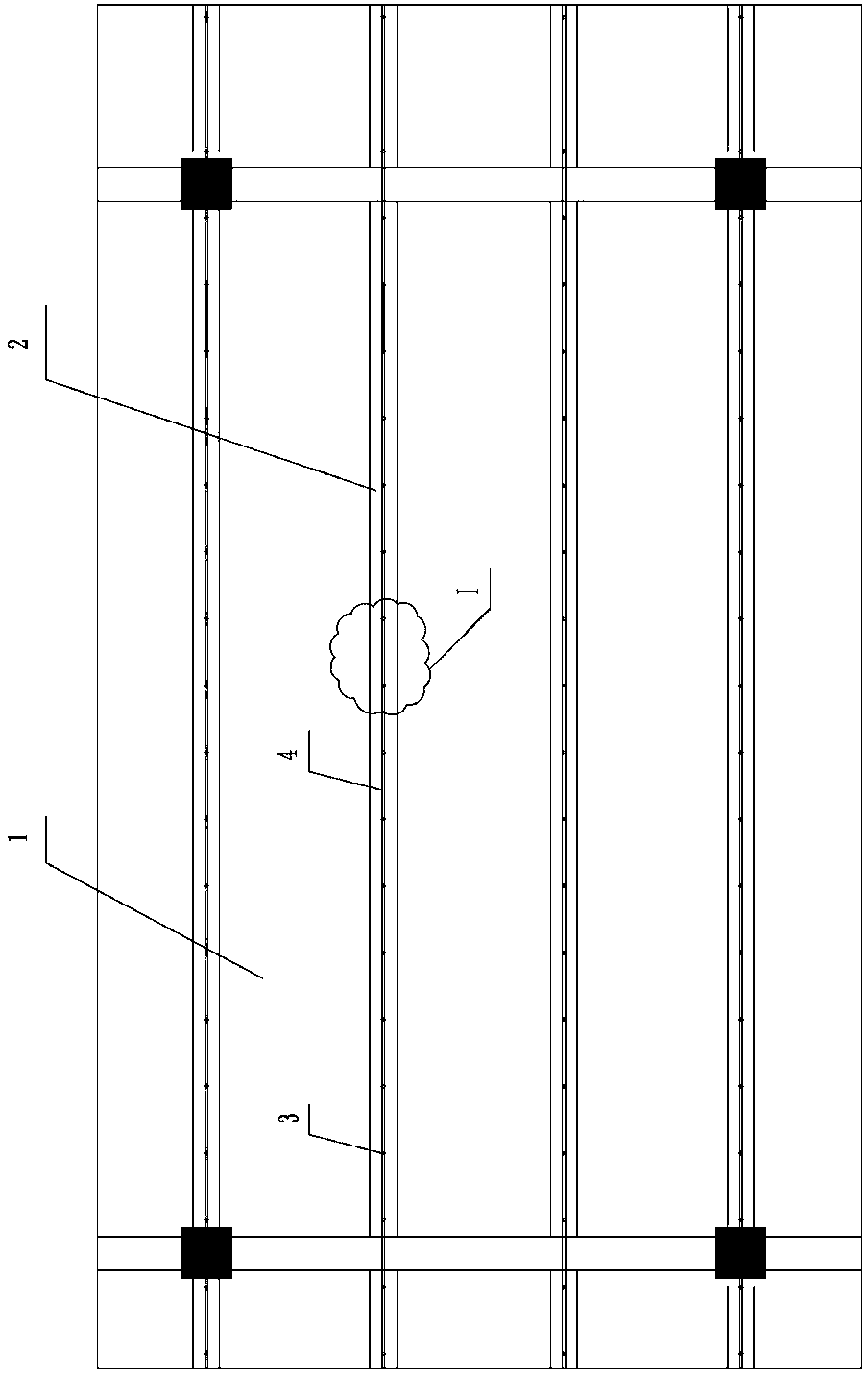

Cast-in-place ecological slope protection and construction method thereof

The invention discloses a cast-in-place ecological slope protection and a construction method thereof. The construction method is characterized by including the steps of firstly, mounting anchor bolts (10) on a slope (1); secondly, laying a plurality of reinforcing steel bars (3) on the slope in a staggering manner, and forming a reinforcing steel bar mesh with a plurality of meshes; thirdly, fixing two of the reinforcing steel bars (3) at each joint of each mesh together, and fixedly connecting the reinforcing steel bar mesh with the anchor bolts (10); fourthly, disposing a mould (5) in each mesh to allow all the adjacent moulds on the reinforcing steel bar mesh to enclose to form cavities mutually communicated through side plates of the moulds; and fifthly, pouring concrete into the cavities so that a plurality of mesh beams (2) are formed on the slope (1), wherein the mesh beams (2) are connected to form a mesh protection slope with a plurality of meshes to be planted. Pouring of the mesh beams is achieved in the field of a side slope, and accordingly the mesh beams are integrally connected mutually. In addition, the mesh beams are fixedly connected with the side slope, and accordingly a foundation for greening of the side slope is laid while the structure of the slope protection is stable.

Owner:内蒙古山水绿景生态科技有限公司

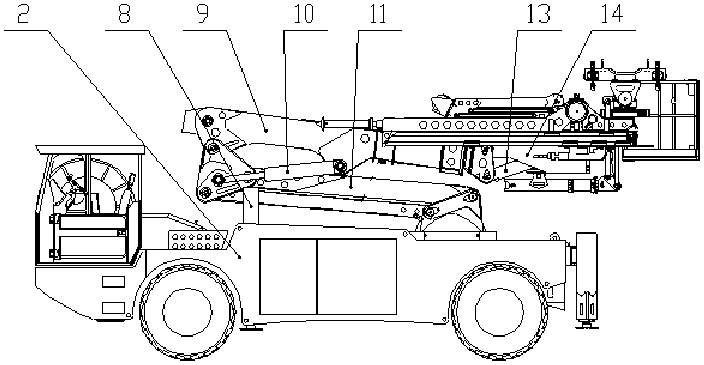

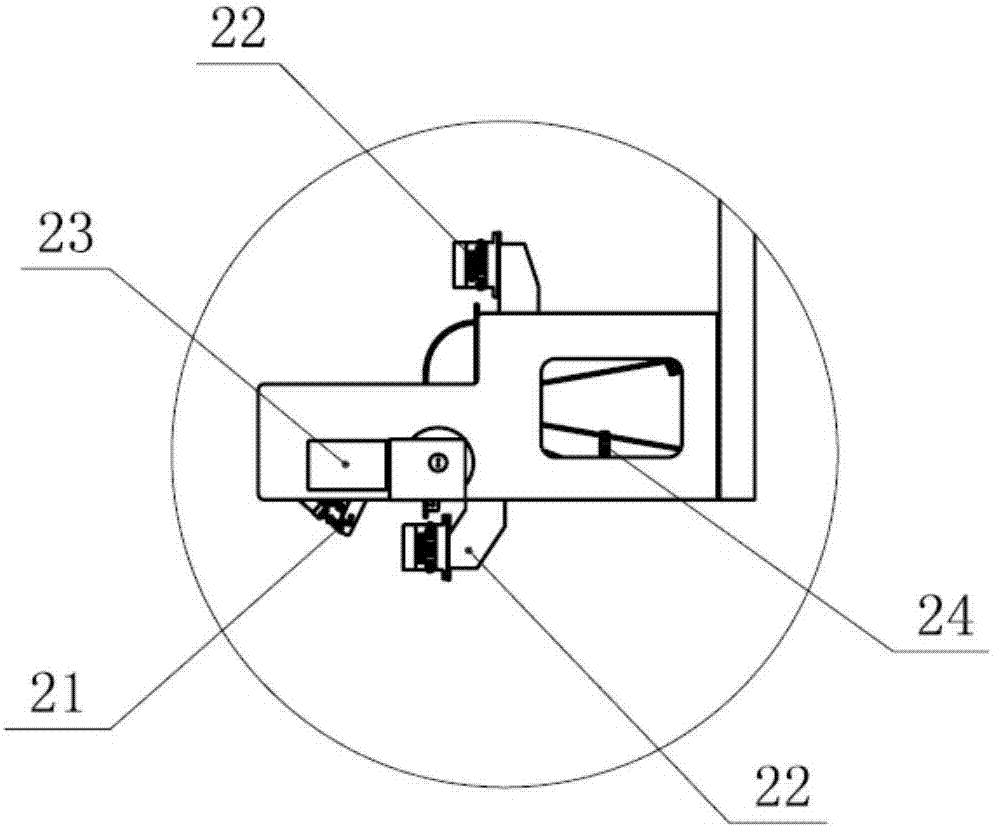

Multi-function tunnel rock drilling and arching all-in-one machine

PendingCN107842311AGrow fastSolve the problem that the vehicle cannot be retracted and the vehicle is too long and has a large turning radiusUnderground chambersDerricks/mastsEngineeringDrilling machines

A multi-function tunnel rock drilling and arching all-in-one machine comprises a host platform (2) which is arranged on a basal disc (1); two arm frames (6) are arranged at the rear portion of the host platform by a rotation seat (5), and the arm frames can be folded and stored in a driving or static state; the front end of a forearm is rotationally provided with an arch grabbing device (18), a rock drilling device (19), a manned platform (24), and a truck crane (23). The multi-function tunnel rock drilling and arching all-in-one machine can perform the arch support operation during full section, two-step and three-step excavating of a tunnel. Through the coordination of the two arm frames and the above working devices, the arch frame transported by car, the installation of the arch, the hanging of the reinforcing mesh, the welding of the transverse reinforcement and the installation of a bolt and a drill hole of leading small tube can be realized; the efficiency is far higher than that of the manual operation.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

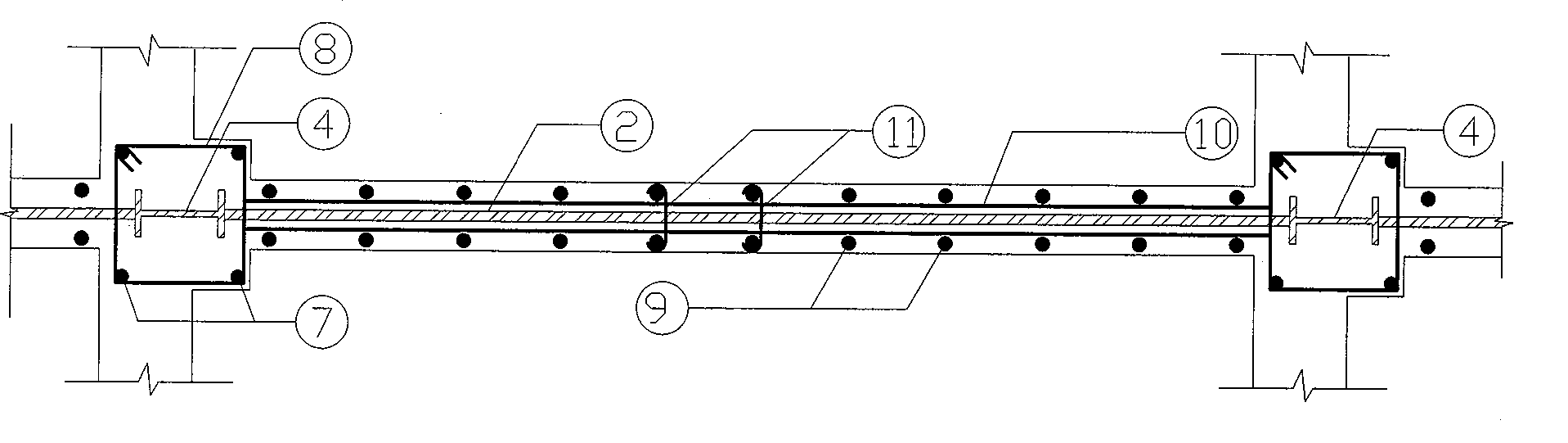

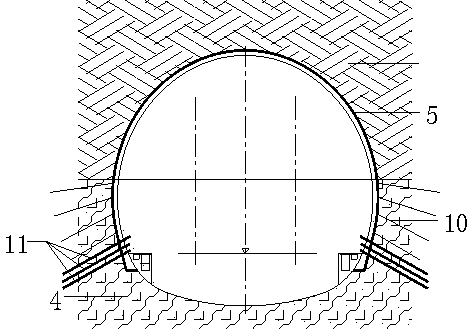

Tunnel steel arch frame lock foot anchoring stock net-spraying composite structure

InactiveCN101230784AShorten the construction periodClose earlyUnderground chambersTunnel liningShotcreteMesh reinforcement

The invention relates to a tunnel steel arch locking bolt mesh spraying combined structure, which can greatly shorten the construction period, lower the construction difficulty, benefit for the construction safety and the structure stabilization and obviously lower the construction cost. The invention comprises steel arches, wherein, a steel mesh is arranged on the steel arches; the joint point of the steel arches is provided with a locking bolt (anchor pipe); the periphery of the steel arches is provided with a sprayed concrete layer; a formworking concrete layer is arranged outside the sprayed concrete layer; a waterproof layer is arranged between the sprayed concrete layer and the formworking concrete layer.

Owner:CHANGAN UNIV

Apparatus For Reinforced Cementitious Construction By High Speed 3D Printing

InactiveUS20210107177A1Reduces and eliminates random internal crackingReduces and eliminates and or deformationAdditive manufacturing apparatusConstruction materialBrickReinforced concrete

The present invention relates to methods and apparatuses for an automated reinforced concrete construction system for onsite slip-form molding and casting a variety of cementitious mixes in a cast in place leave in place externally moldable flexible reinforced containment sleeve providing a wide variety of interchangeable full-scale molding configurations simultaneously optimizing a wide variety of cementitious mix curing characteristics, further having optional internal reinforcement net(s), for layer wise interlocking additive printed brick deposition providing improved slip-form mold casting of a wide variety of reinforced concrete structures; the present invention further includes a variety of operating platforms suitable for on and offsite constriction as disclosed herein.

Owner:ARMATRON SYST LLC

Steel plate-concrete composite structure reinforcement method of structural negative moment region

ActiveCN102561213AEnhanced interface connection reliabilityImprove connection reliabilityBridge erection/assemblyBridge strengtheningPrestressed concrete beamT-beam

A steel plate-concrete composite structure reinforcement method of a structural negative moment region is characterized in that the method comprises the steps of: (1) carrying out interface treatment of a negative moment region of a concrete box girder top plate 3; (2) planting bars on the surface of the negative moment region of the concrete box girder top plate 3; (3) manufacturing a steel plate 9, a welding stud 8 and a corrugated steel plate 14: (4) forming a self-compacting concrete pouring hole 13 and a location leveling hole 17 on the steel plate 9; (5) erecting a reverse ejection support 2 and unloading reverse ejection; (6) binding a reinforcing mesh 10 and installing in position; (7) applying a structural adhesive on the steel plate 9 and spreading fine sands; (8) installing and leveling the steel plate 9 to the design position, applying a pre-stress to the top of the steel plate 9 through a pre-installed apparatus; (9) mixing and pouring self-compacting concrete; and (10) releasing the pre-stress, removing the corrugated steel plate 14, curing concrete, constructing a pavement layer, and removing the reverse ejection support 2. The novel steel plate-concrete composite structure negative moment region reinforcement method can be widely used for negative moment region reinforcement of concrete box girder, T-beam, hollow plate girder, common reinforced concrete beam, and pre-stressed concrete beam, and can be used in the bridge reinforcement with the advantages of almost no reduction of the headroom below the bridge, no requirement for surface levelness of the original structure, low cost, no influences on the appearance, and so on. The steel plate-concrete composite structure reinforcement method is economic, safe, and practical, is easy to ensure the project quality and has wide application prospect.

Owner:CENT SOUTH UNIV +2

Deep foundation pit combination retaining and protecting construction method for geology with high water level and large particle size sand gravel

ActiveCN104631470ARapid Construction SupportImprove piling efficiencyExcavationsBulkheads/pilesEngineeringHigh pressure

The invention discloses a deep foundation pit combination supporting construction method for geology with high water level and large particle size sand gravel. High pressure jet grouting pile construction is conducted outside a foundation ditch retaining and protecting system, by means of a triple placing method, cement paste is injected into underground soil filling layer and sand gravel gaps, after solidifying, secant pile wall and retention wall are formed, the underground water is prevented outside the periphery the foundation ditch retaining and protecting system, and conditions are created for the construction of a support pile; when the strength of outer side jet grouting pile meets design requirements, a long auger drilling cast-in place pile begin to be constructed close to the inner side of the jet grouting pile; after perfusion pile beings maintained for 15 days, jet grouting pile construction begins to conduct to make up partial failure of waterproof curtain of the jet grouting pile in construction of retaining and protecting pile, and retaining and protecting strength and water interception effect of the retaining and protecting system are increased; at last, in an earth excavation process, bar-mat reinforcement sprayed concrete slope protection and construction of dewatering well, open trench and water-collecting well in the foundation ditch are completed well, multiple retaining and protecting forms are used for combining construction and interaction. Accordingly, the problems of retaining and protecting the geology with high water level and large particle size sand gravel and processing the geology are solved.

Owner:HEFEI CONSTR ENG GRP

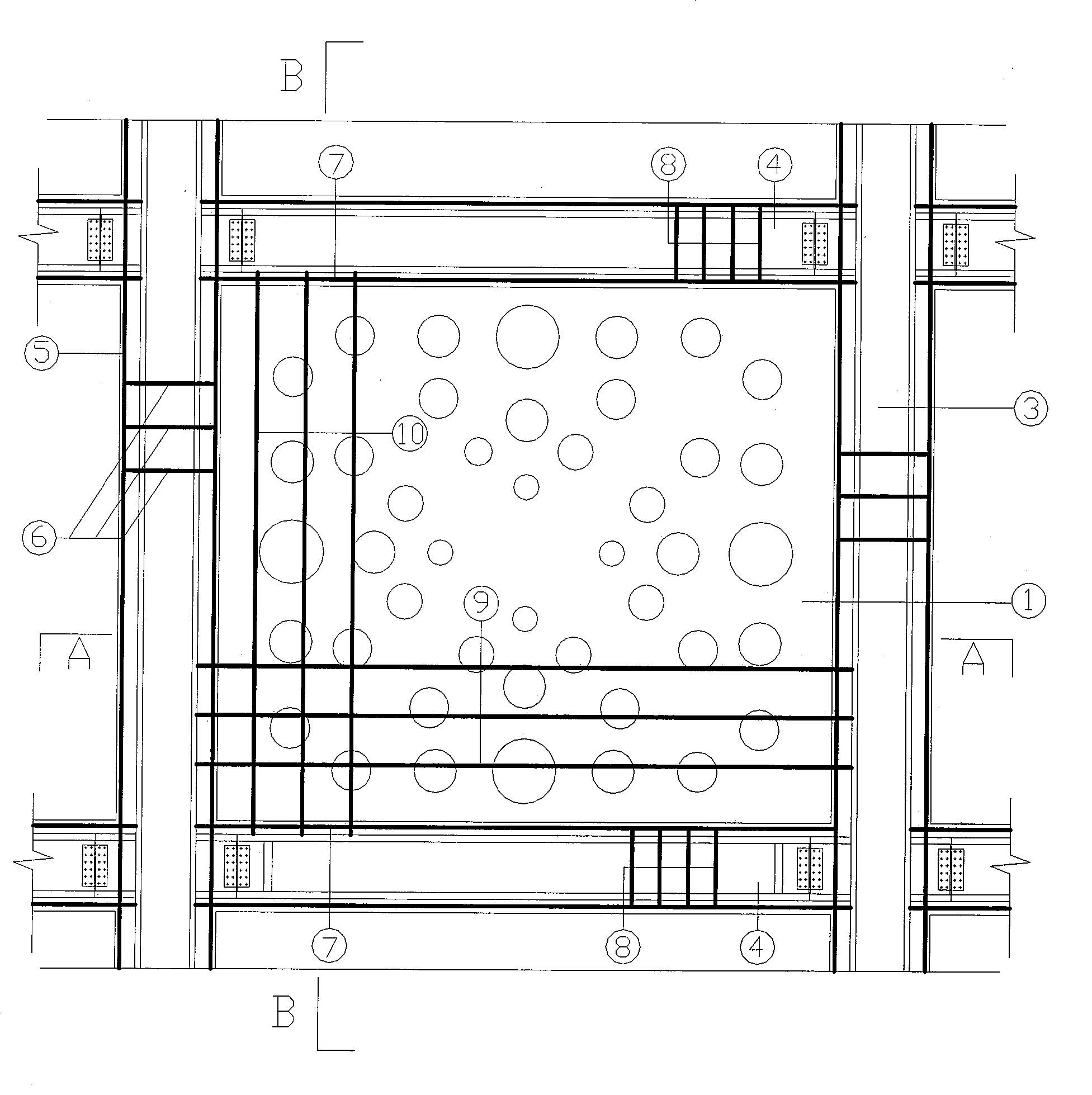

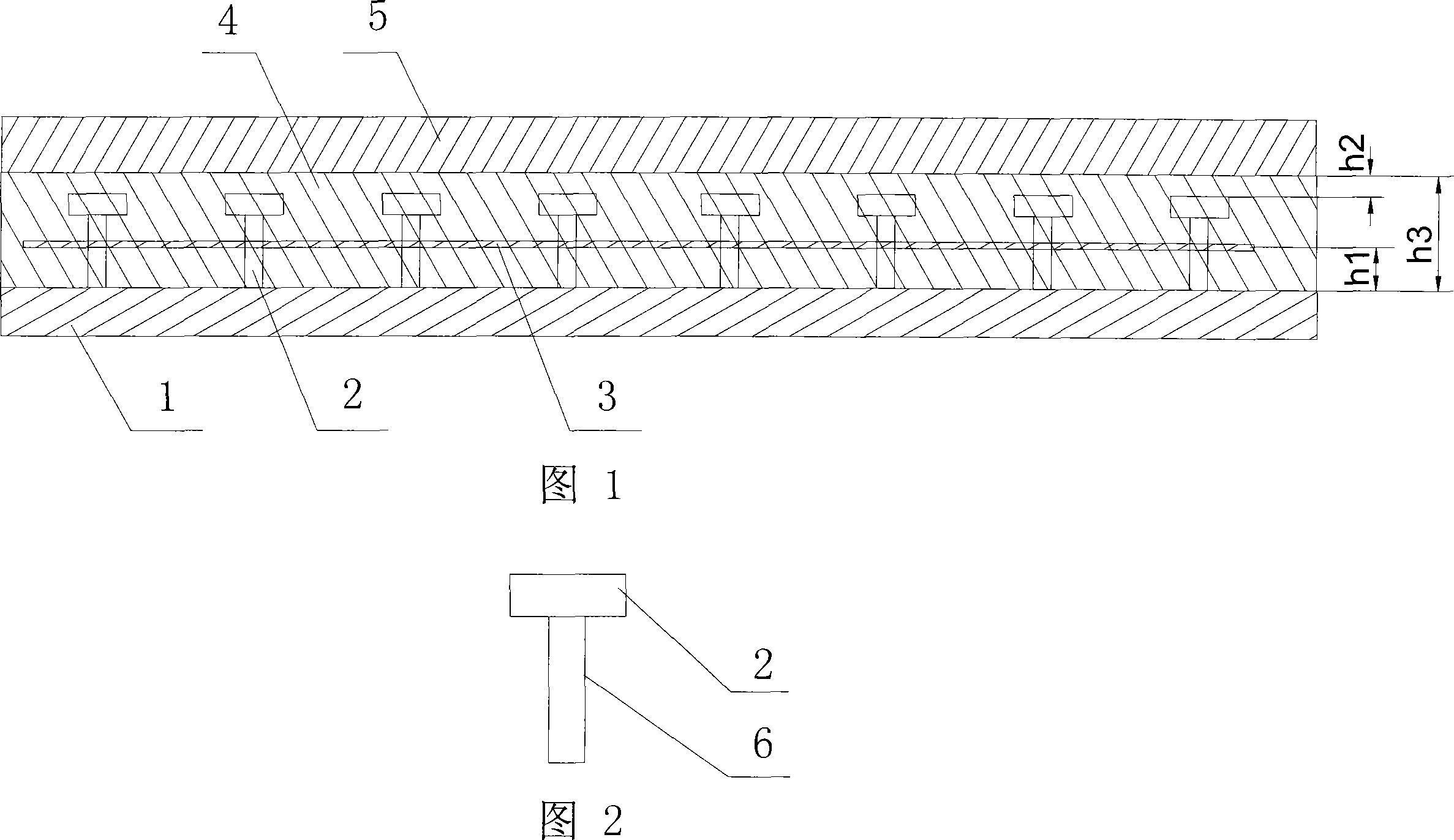

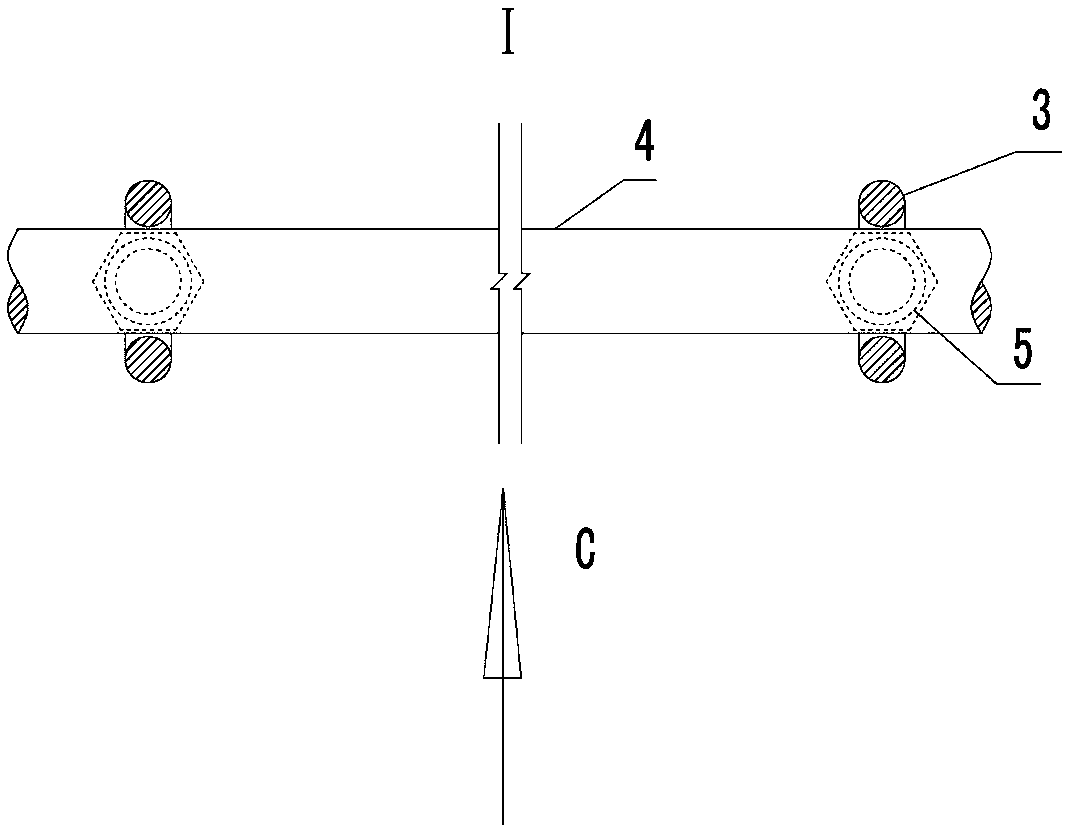

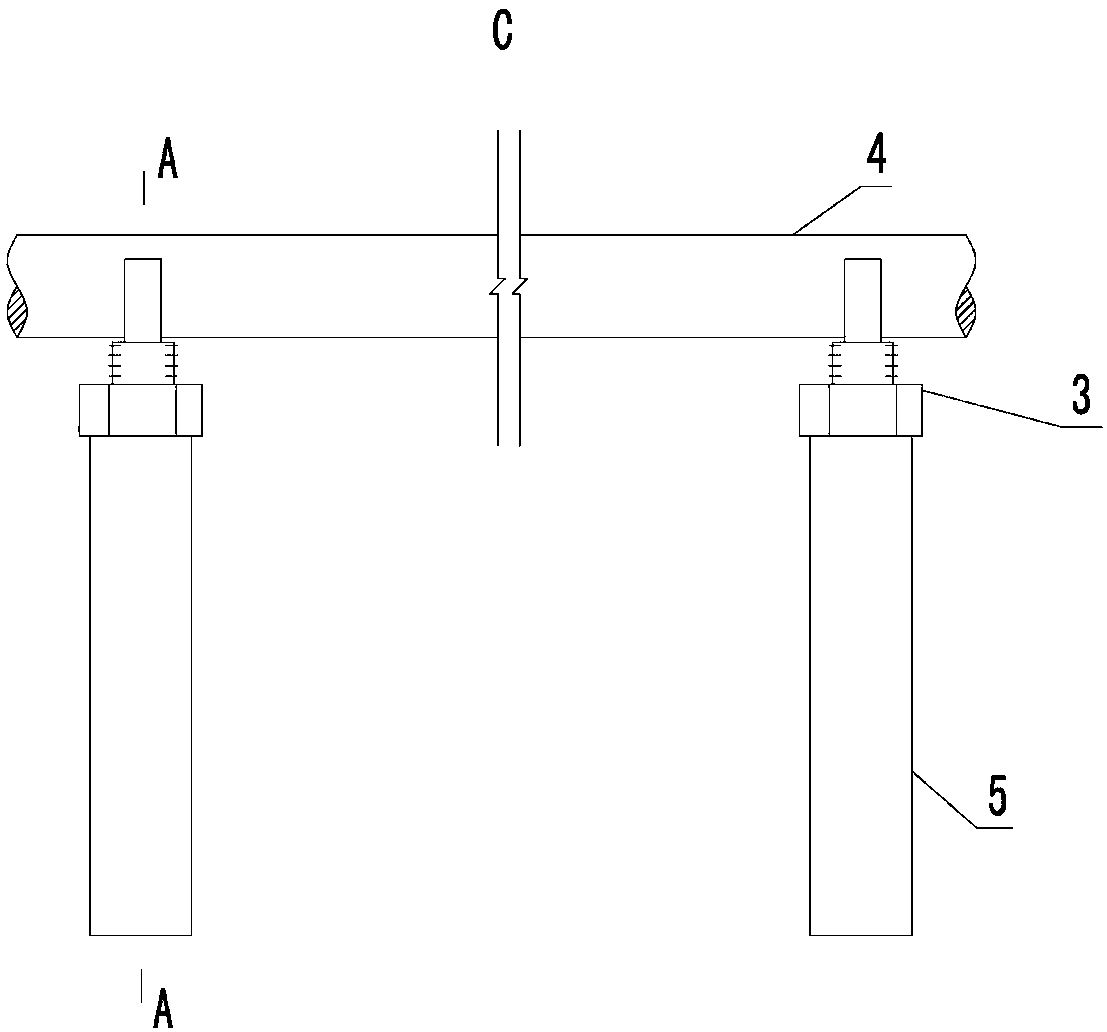

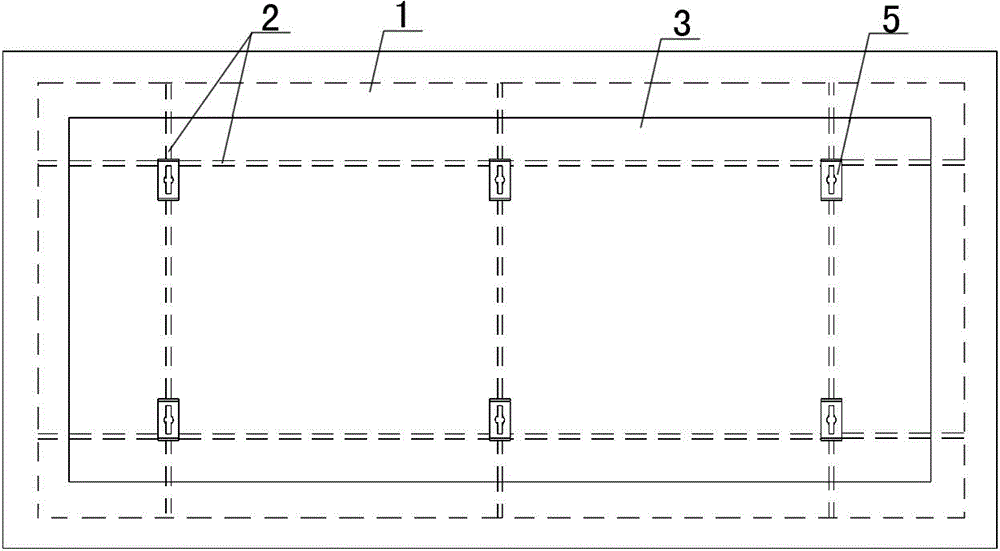

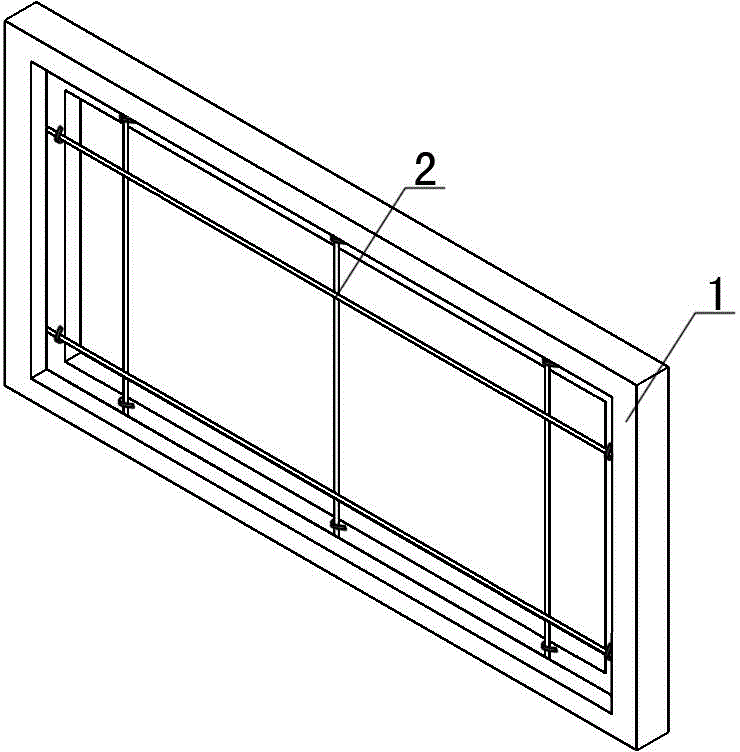

Accurate leveling device for cast-in-situ concrete flooring formed in one step and construction method

ActiveCN103184796ARaise the standard of flatnessImprove construction efficiencyBuilding material handlingMesh reinforcementRebar

The invention provides an accurate leveling device for cast-in-situ concrete flooring formed in one step and a construction method. The device comprises a structural slab form and the reinforcement frameworks of beams, wherein a plurality of leveling adjusting racks are uniformly distributed and welded on the longitudinal reinforcement of each beam; each leveling adjusting rack comprises a semicircular bracket, a screw rod, an adjusting screw nut and a steel pipe sleeve; and steel pipe guide rails are longitudinally supported on the leveling adjusting racks. All mesh reinforcements, the leveling adjusting racks and the steel pipe guide rails supported on the leveling adjusting racks together constitute the accurate leveling device for the cast-in-situ concrete flooring formed in one step. The heights of the steel pipe guide rails are adjusted by rotating the adjusting screw nuts, and an automatic leveling rotating laser level gauge is adopted to determine that the heights of the steel pipe guide rails are correct. The accurate leveling device has the advantages that the structure is simple, part of elements can be used repeatedly in a turnover manner, the cost is low, the operation is simple and convenient, and the construction efficiency is high. Through the method provided by the invention, ground level control and accurate concrete construction leveling can be conducted for cast-in-situ concrete of each layer of floor; and the method is used for leveling operation for cast-in-situ concrete of each layer of floor and improves the flatness standard of the flooring.

Owner:中国建筑土木建设有限公司

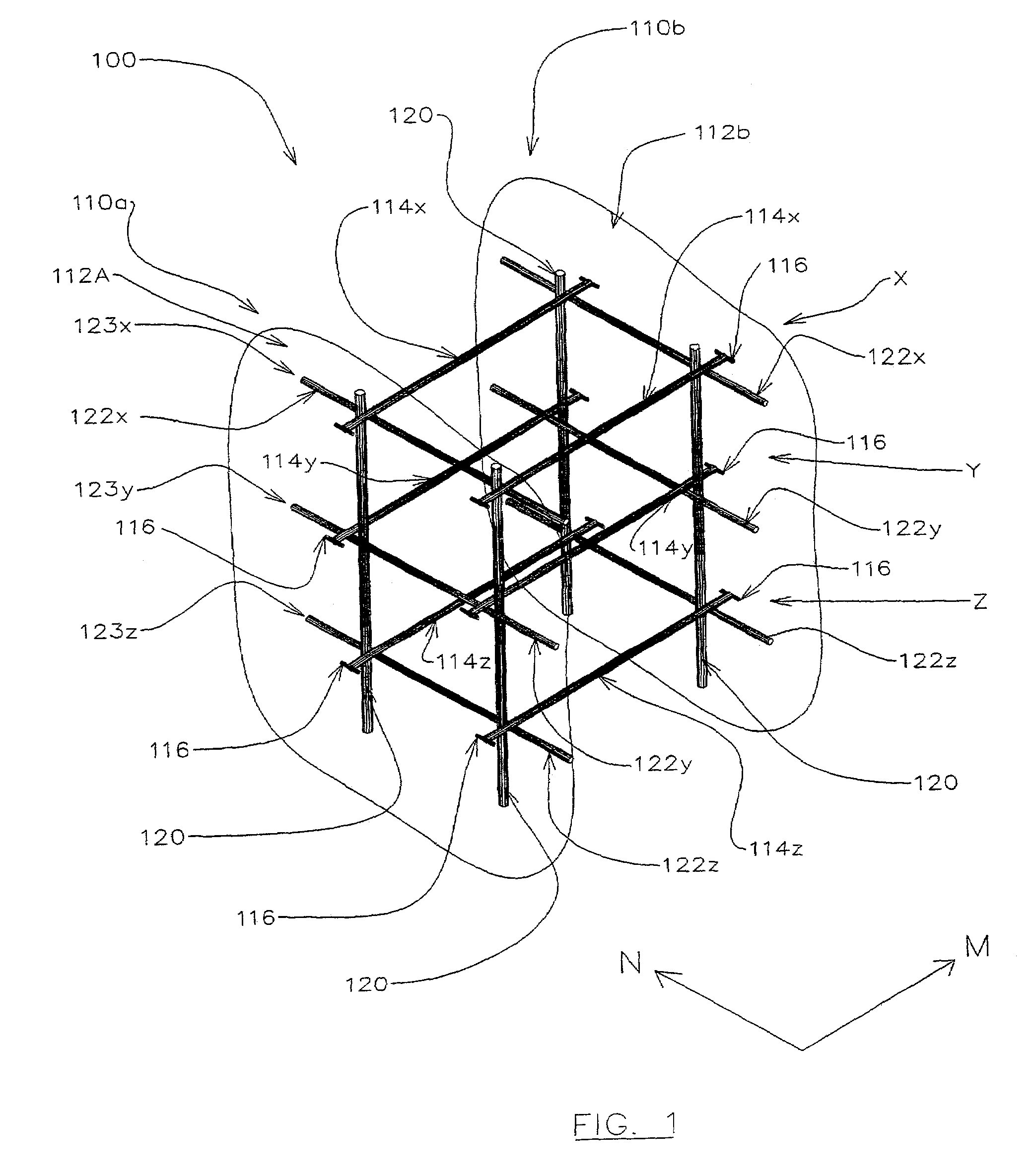

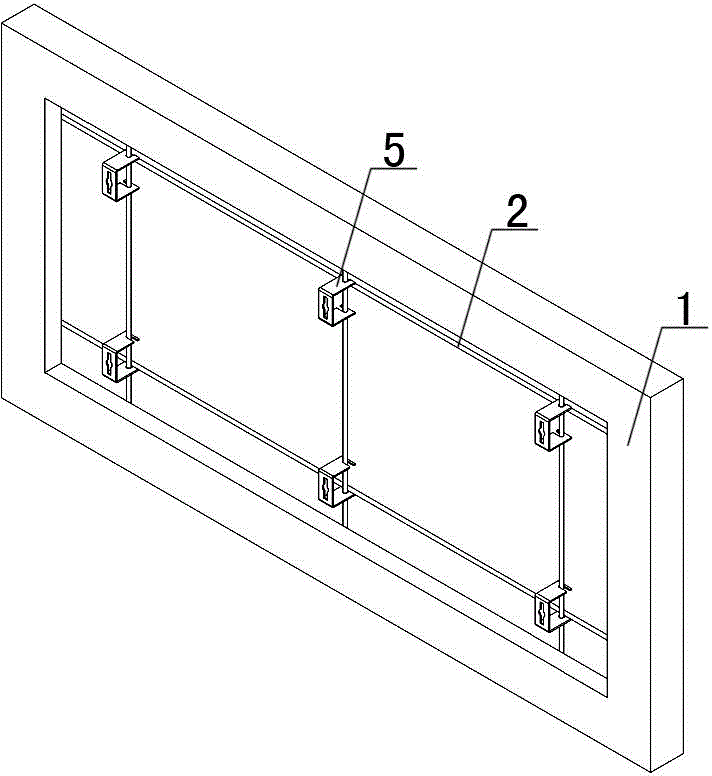

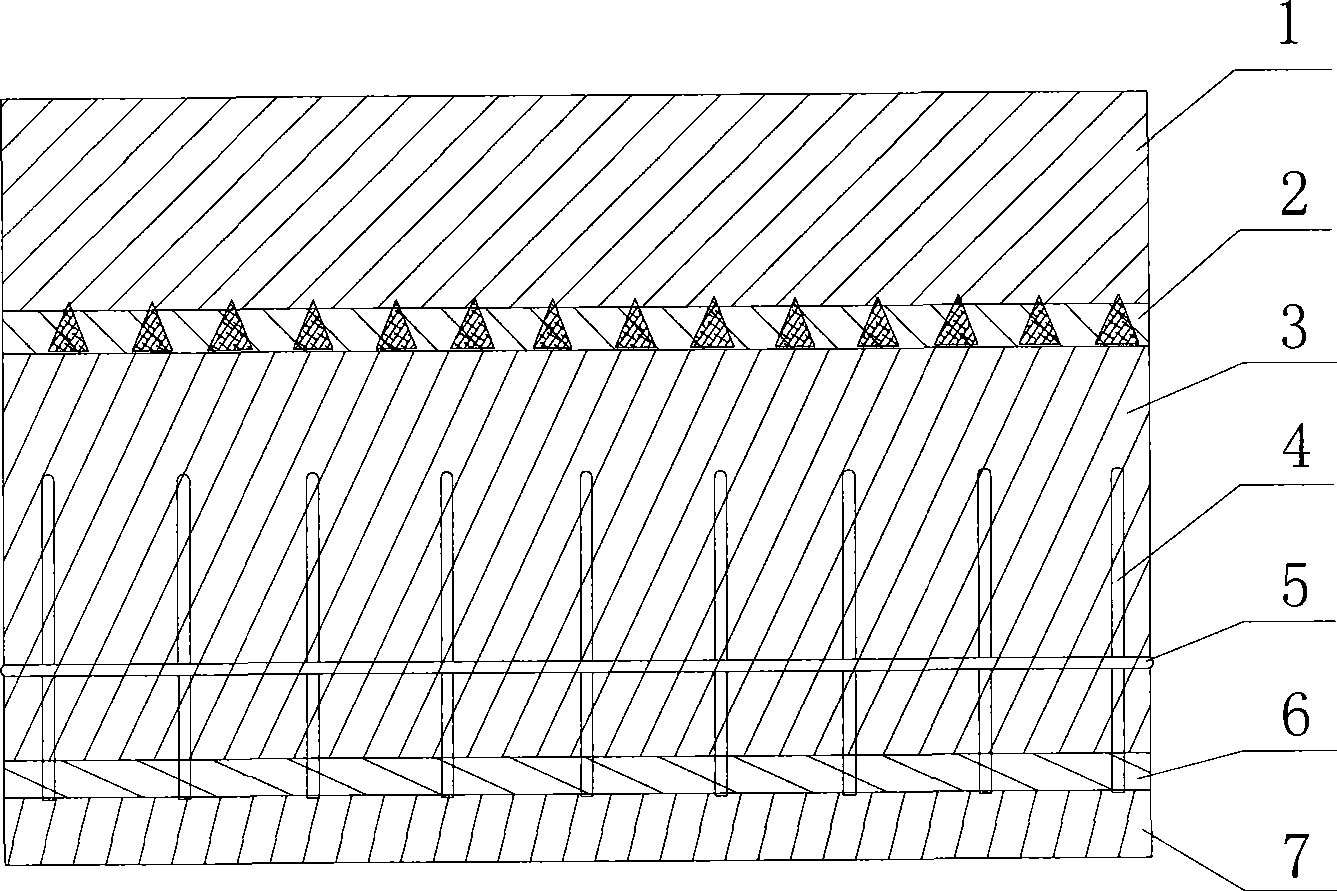

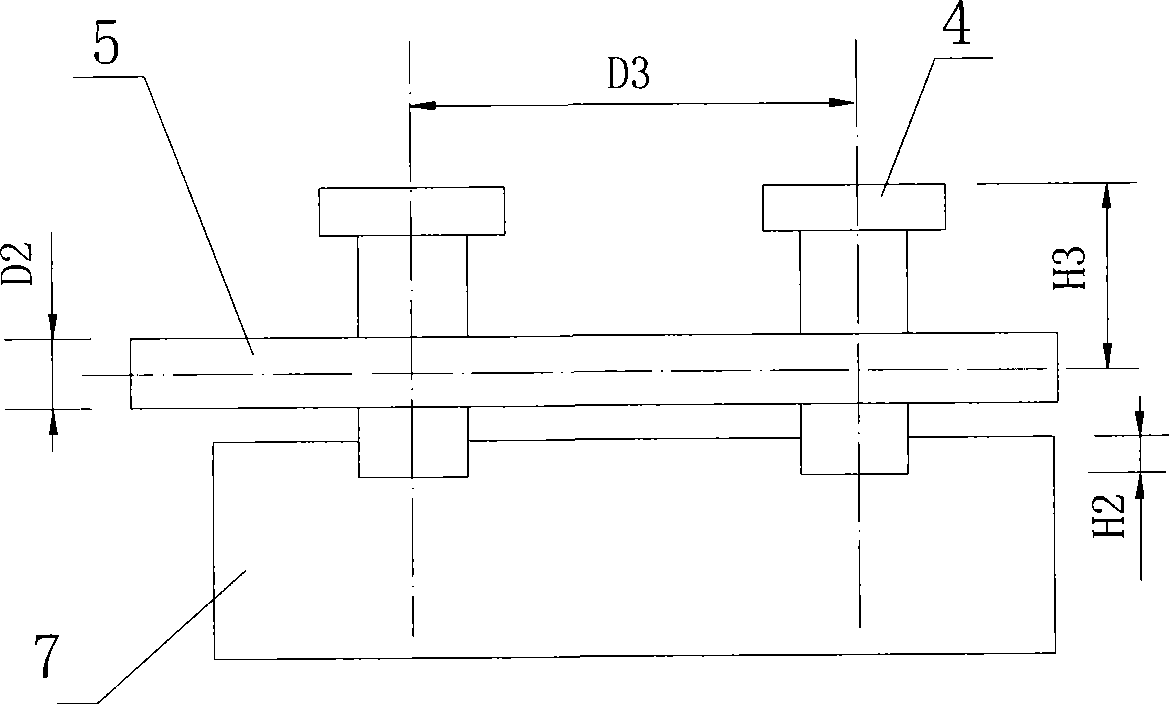

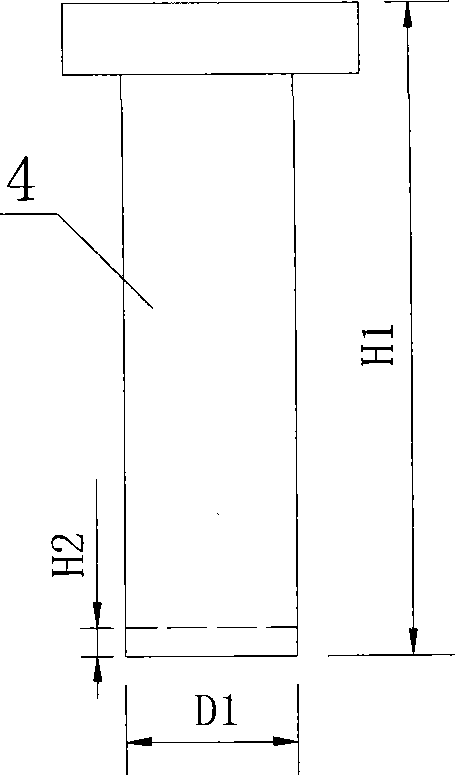

Non-dismantling die cast-in-place lightweight thermal insulation wall formboard, thermal insulation wall and construction method thereof

ActiveCN104674985AReduce the amount of constructionFast constructionWallsThermal insulationDie casting

Disclosed are a non-dismantling die cast-in-place lightweight thermal insulation wall formboard, a thermal insulation wall and a construction method thereof. The formboard comprises an inner formboard unit, an outer formboard unit and opposite-drawing connectors connecting the formboard units; the inner formboard unit comprises a formboard frame, steel bar grid frames connected between inner circles of the formboard frame, steel bar clamps connected to the cross points of the steel bars of the steel bar grid frames and a formboard core filling the inner side of the formboard frame; the inner formboard unit and the outer formboard unit are the same in structure and are connected at two ends of the opposite-drawing connector symmetrically; the steel bar clamps of the inner formboard unit and outer formboard unit are corresponded horizontally and are connected through the opposite-drawing connectors. The thermal insulation wall is simple in structure, by means of the double-layer wall formboard, the wall thickness consistence is guaranteed, the strength performance requirements are met, the thermal insulation wall is convenient to construct, the matching bar, core column and tie beam arrangement procedures are omitted, construction cost is lowered, constructing efficiency is improved, and the formboard can widely applied to wall construction.

Owner:北京振利节能环保科技股份有限公司

Pavement method for anti-movement composite structure of large-span steel box beam bridge deck

ActiveCN101368368AImprove bindingIncrease stiffnessIn situ pavingsBridge structural detailsSheet steelBridge deck

The invention relates to a method for paving combined anti-push structures on the surface of a large-span steel box girder bridge, including the following steps: 1) pretreating the armor plates of the large-span steel box girder bridge; 2), welding shear studs: welding shear studs on the armor plates of the large-span steel box girder bridge, with an interval at area of (35-45)cm X (35-45)cm between two shear studs; 3) colligating the reinforcement mats: fixing the reinforcement mats at specification of (95-105)cm X (95-105)cm on the shear studs; 4) mineral aggregate grading; 5)preparing and paving cast-type asphalt concrete; 6) paving a waterproof bond coat; and 7)paving anti-skid denoising wearing layer: paving a anti-skid denoising wearing layer at thickness of 3-5cm on the waterproof bond coat. The method has the advantages that cohesiveness at the interfaces is good, the paved layer and the armor plates are strong in coordinated deformability, and construction process is simple and convenient.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Integral-type mesh welding machine

ActiveCN107253053AMeet development needsIncrease productivityOther manufacturing equipments/toolsMetal working apparatusPunchingMesh reinforcement

The invention belongs to the field of steel bar mesh welding devices and discloses an integral-type mesh welding machine. The integral-type mesh welding machine is sequentially provided with a longitudinal bar conveying mechanism, a welding mechanism, a transverse bar blanking mechanism, a mesh pulling mechanism, a shearing mechanism, a conveying mechanism, a packaging machine, a stacking mechanism and a tray travelling mechanism according to the steel bar mesh machining sequence. A punching mechanism and / or a wire reversing mechanism and / or a mesh wiping mechanism capable of being selectively started are further arranged between the mesh pulling mechanism and the shearing mechanism. According to the integral-type mesh welding machine, through arrangement of all the mechanisms, welding, punching, wire welding and reversing, bending, stacking and packaging of a mesh piece can be automatically and integrally completed, and therefore a steel bar mesh with special requirements is machined; and the current development demands of machining industries are effectively met, and the production efficiency is improved.

Owner:TJK MACHINERY TIANJIN

Large-span steel box beam bridge deck pavement layer material gradient structure pavement construction method

InactiveCN104846740AAnti-shear and anti-transition propertiesSolve usabilityBridge structural detailsBridge erection/assemblyFiberMesh reinforcement

The invention discloses a large-span steel box beam bridge deck pavement layer material gradient structure pavement construction method. The method comprises the steps that 1, derusting by sandblast and cleaning processing are conducted on an interface of a steel bridge deck; 2, shearing force parts are welded between a steel plate and a concrete pavement layer; 3, steel rib meshes are paved, and the steel rib meshes are bound to the shearing force parts; 4, high-strength toughening light concrete is poured; 5, a DPS waterproof layer is sprayed; 6, a bond stress absorbing layer is paved; 7, high-viscosity high-elastic SMA-13 bituminous mixtures are paved. According to the large-span steel box beam bridge deck pavement layer material gradient structure pavement construction method, polymers and fibers are added, the light aggregate concrete mix proportion design is optimized, the strength, the toughness, the deformability and the anti-fatigue performance of the light aggregate concrete are strengthened, and an optimal design on the arrangement of the shearing force studs and the steel rib meshes and the reinforcement ratio is conducted.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com