Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6398results about How to "Improve construction progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

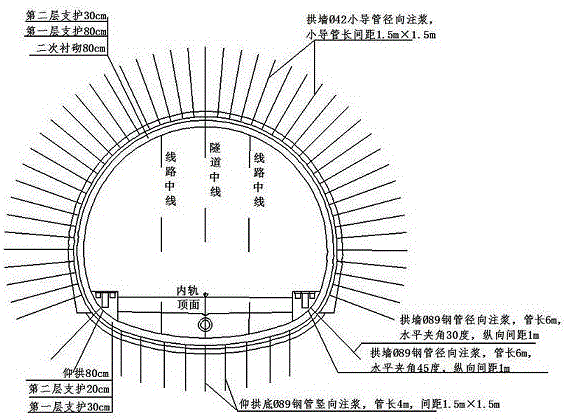

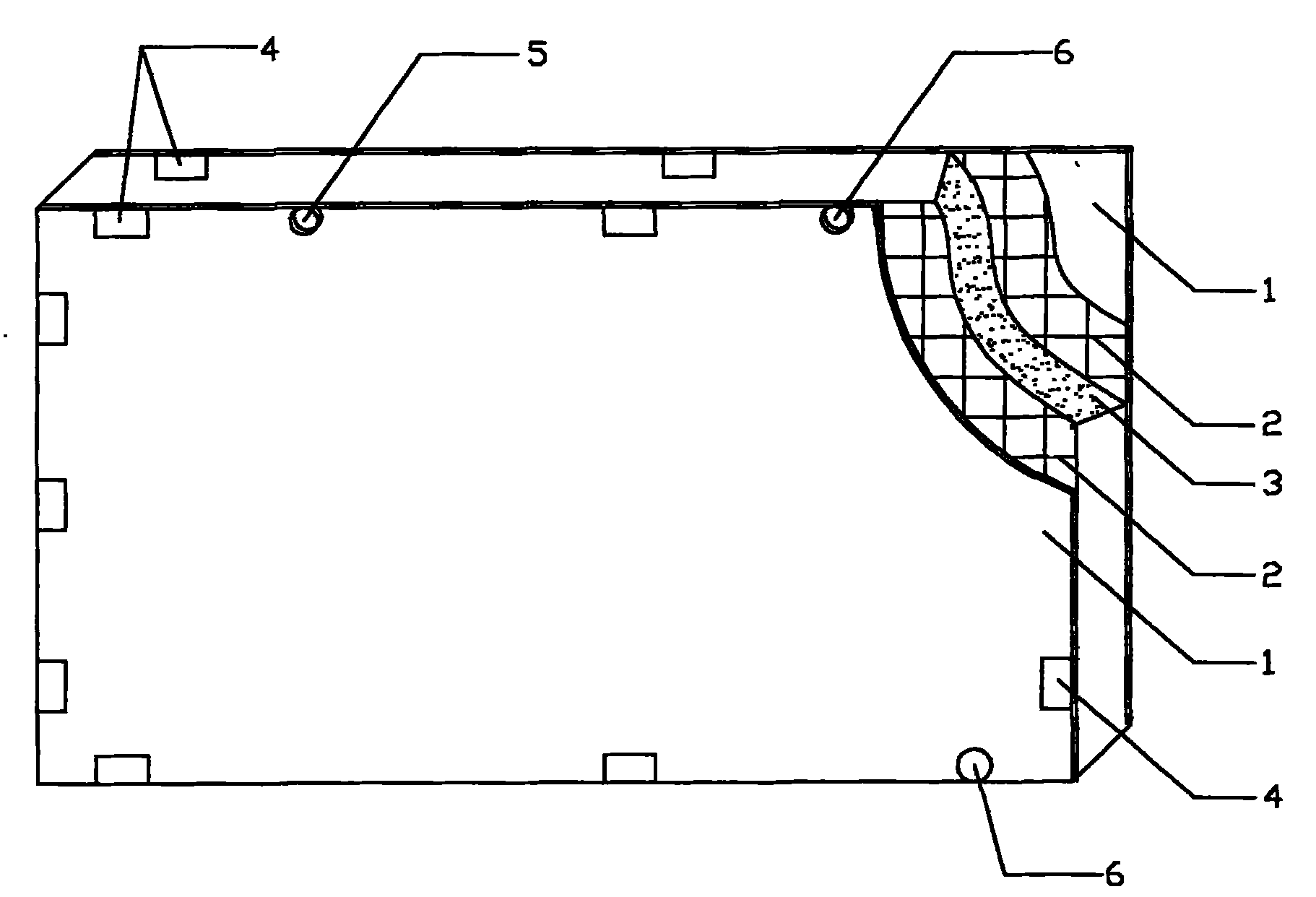

Construction method of V-level surrounding rock tunnel

InactiveCN101614125AAvoid defects such as cavity collapseRealize safe constructionUnderground chambersTunnel liningRock tunnelTunnel wall

The invention relates to a construction method of a V-level surrounding rock tunnel, comprising the following steps: (1) making a drill guiding I-beam steel lagging jack, i.e. mounting an I-beam steel lagging jack, a groove steel trimming beam, a lock pin anchor rod, a guiding steel pipe, a longitudinal connection steel rib and face injecting concrete in sequence; and (2) construction and support in the tunnel, i.e. drilling pipe shelter steel pipe holes, mounting pipe shelter steel pipes, filling slurry inwards. The earthwork construction of a pilot tunnel comprises earthwork construction, primary support, injecting concrete on a pilot tunnel wall, suspending steel bar nets, casting concrete basis, mounting I-beam steel lagging jack, groove steel trimming beam, steel pads, I-shaped steel inclined strut and lock pin anchor rods, welding longitudinal connection steel bar, injecting concrete on the face and removing core soils; mounting a first-level step temporary inverted arch comprises: constructing lower-level earthwork, performing primary support in the pivot tunnel, mounting the second-level step temporary inverted arch, constructing the following level of earthwork, performing primary support, casting and filling inverted arch, and casting lining concrete at a time inside the pivot tunnel. The invention has the advantage of rapid penetration speed and safe construction.

Owner:CHINA RAILWAY NO 9 GRP

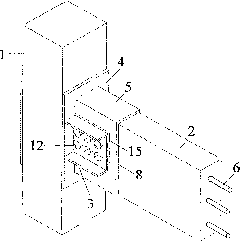

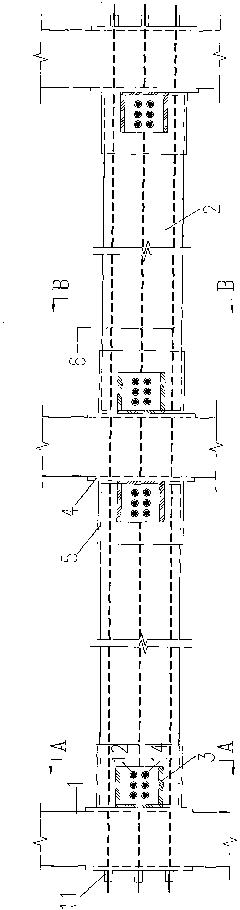

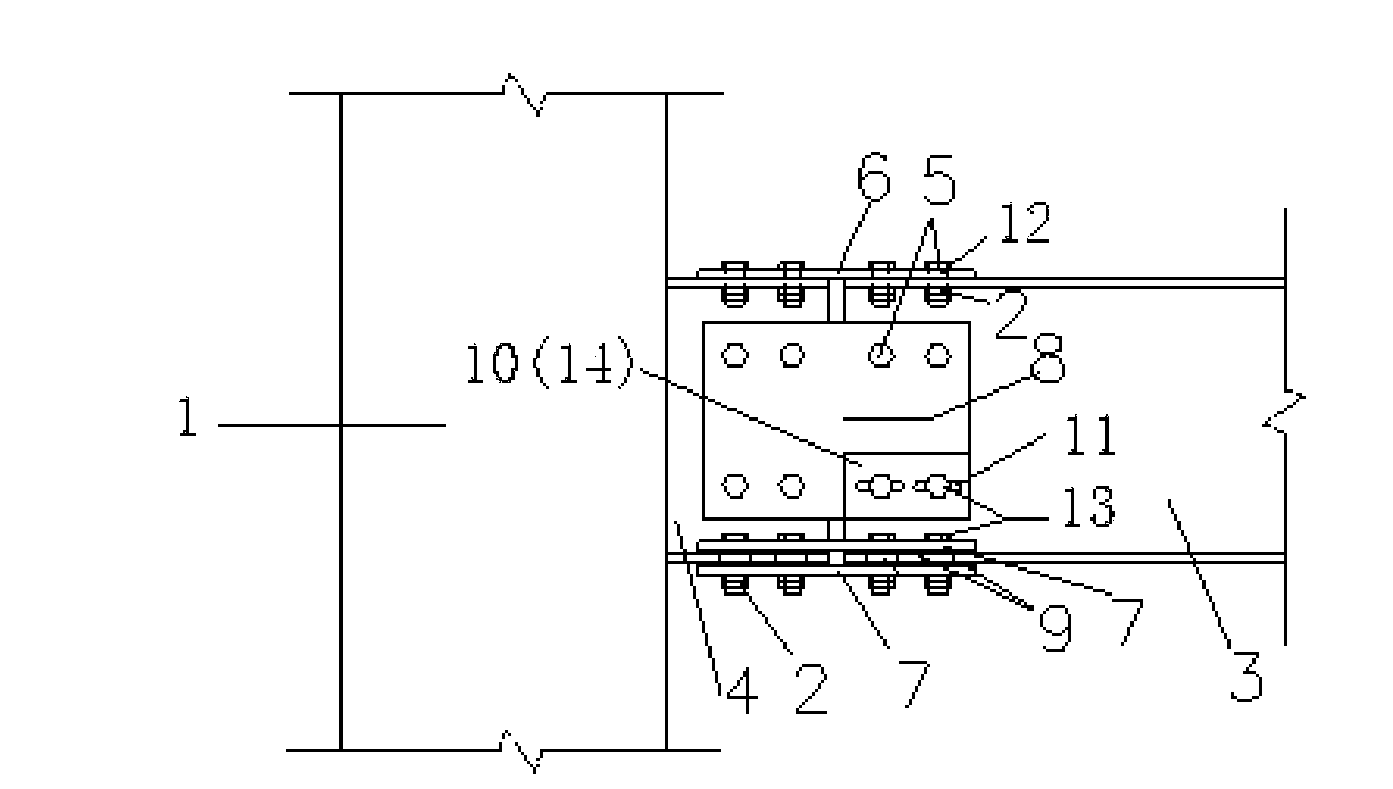

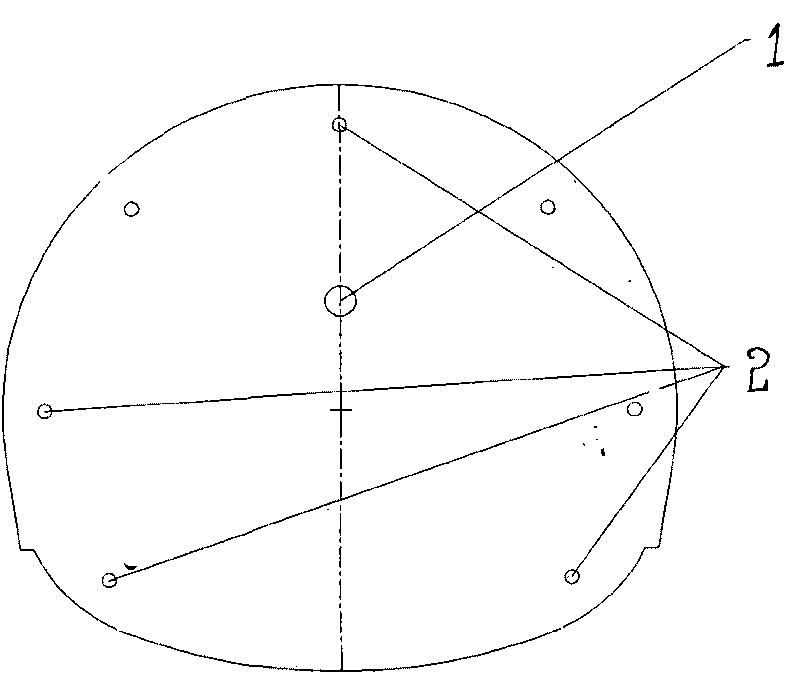

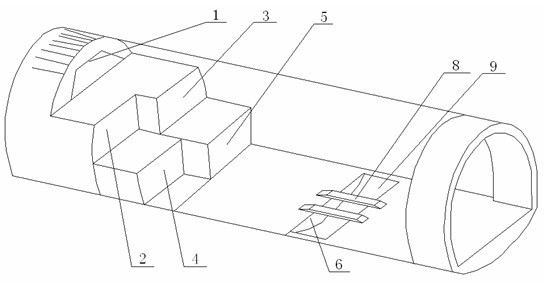

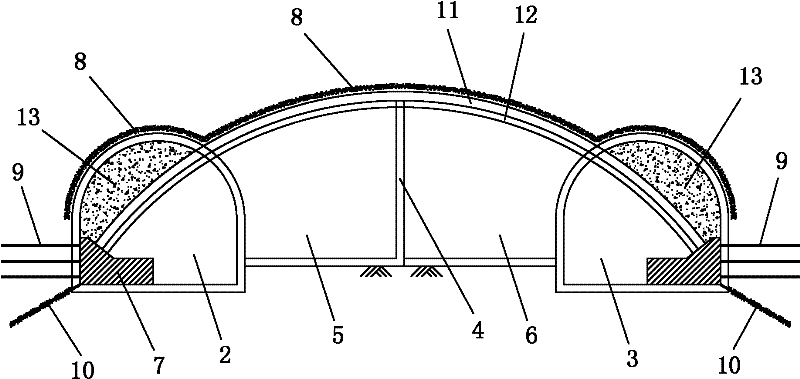

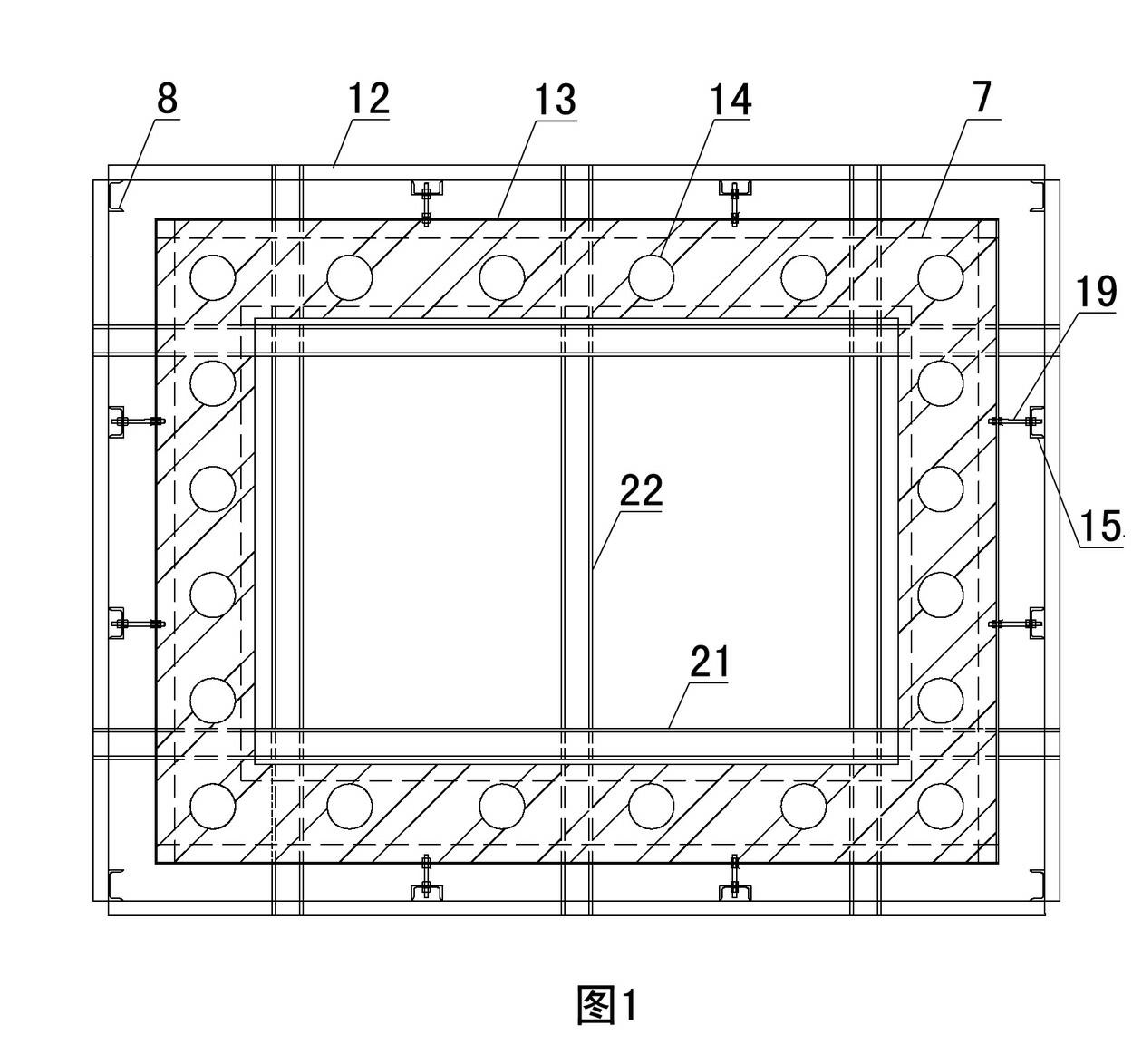

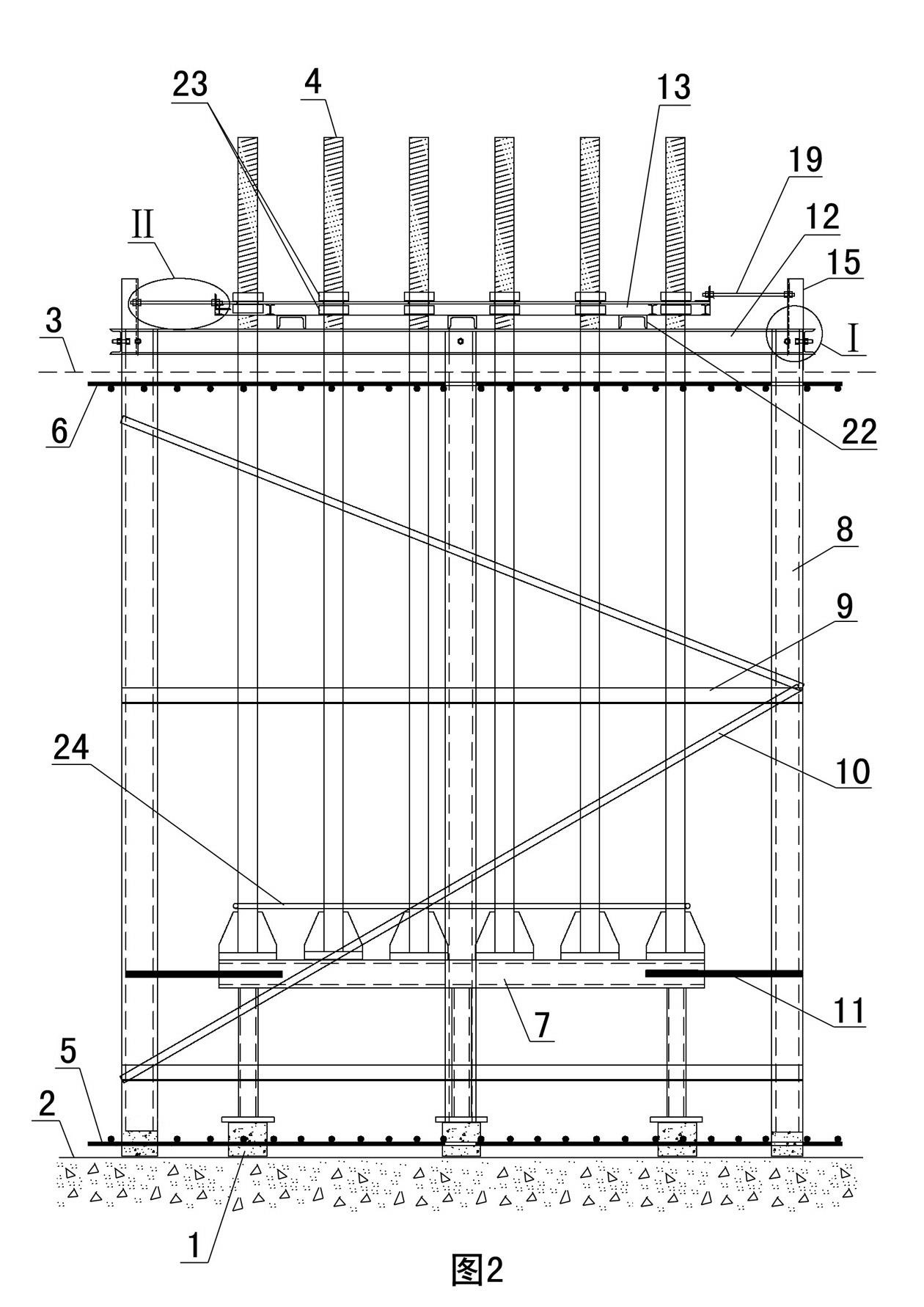

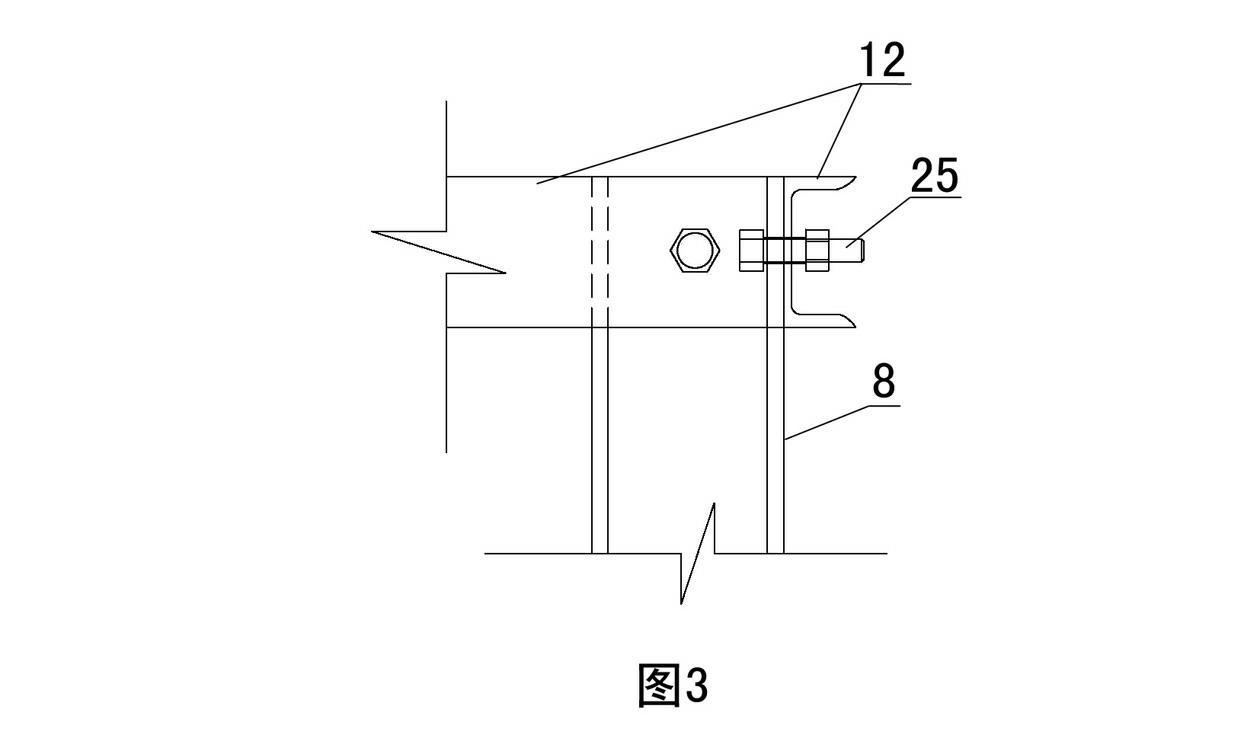

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

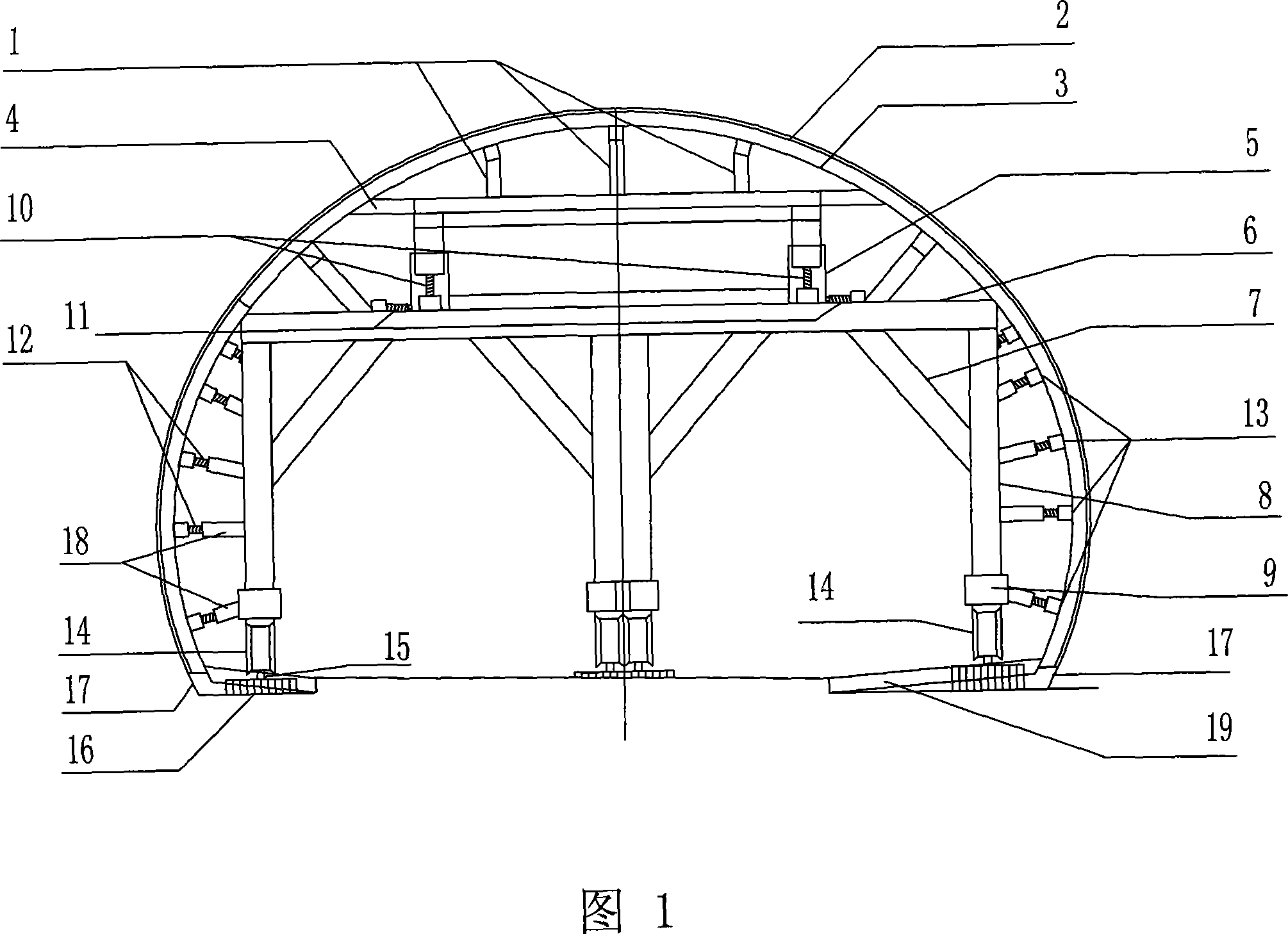

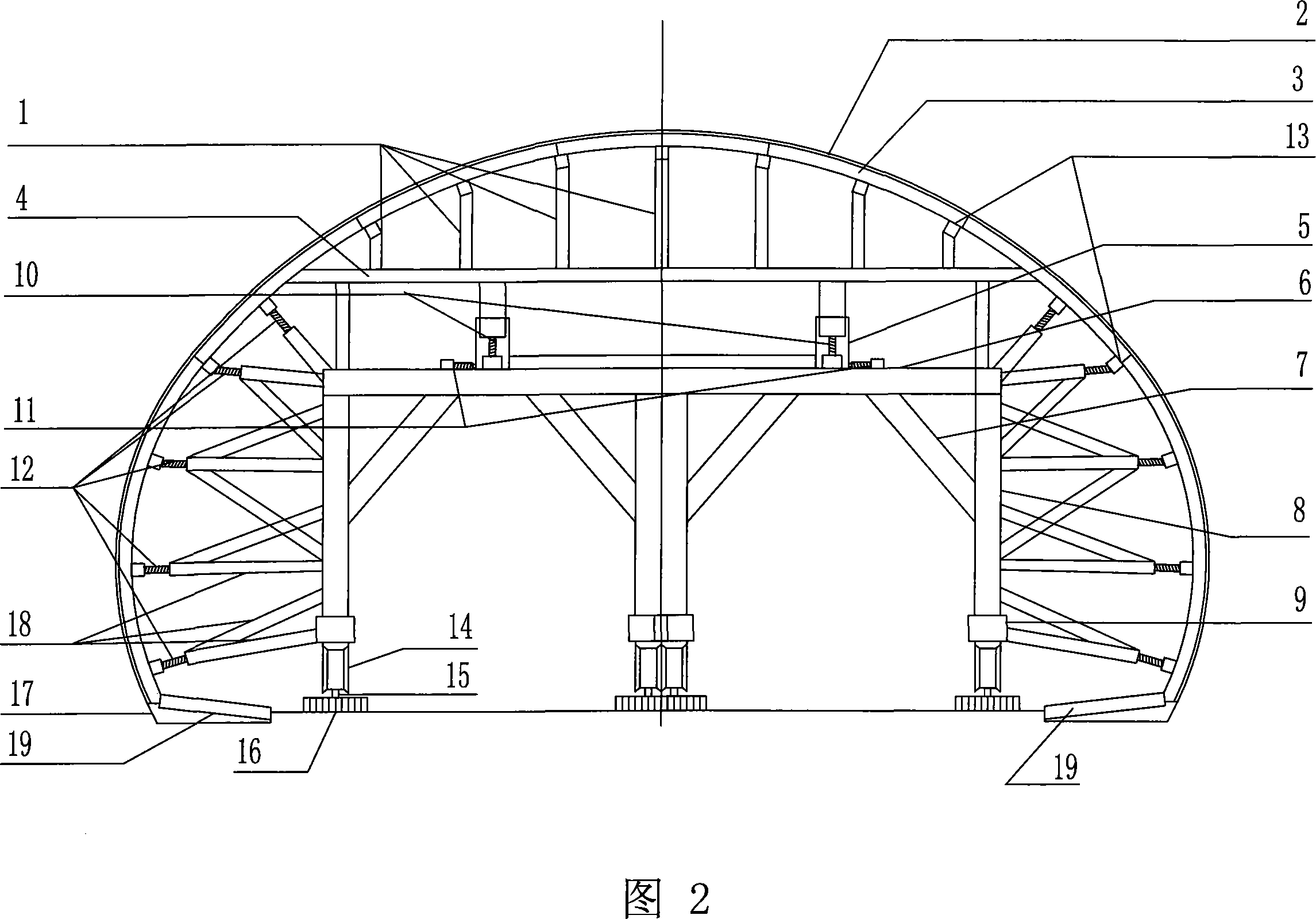

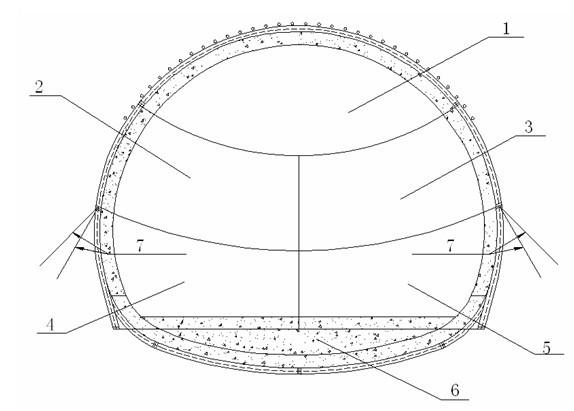

Construction method for large section and multiple sections tunnel lining

ActiveCN101230785AImprove construction progressQuick disassemblyUnderground chambersTunnel liningAssembly lineConstruction management

The invention discloses a large cross-section and multiple cross-section tunnel lining construction method. Combined type lining trolleys are chosen to carry through the trolley assembly lining to the cross-section, and adding a gantry mounting on the basis of a normal trolley single gantry mounting can form an assembled and detachable lining trolley. Steel molding plates, road wheels, main gantry mountings, etc. are listed in unchanged components in the process of the assembly trolleys with different cross-sections, and lateral adjusting driving screws, upper platform chord members, upper platform upright posts, lining steel arches, etc. are listed in adjustable components. In the process of the construction from one cross-section to another cross-section, the unchanged components do not change, and only the changeable components are carried through the refitting and assembly. The construction method has the characteristics of fast construction progress, low cost, easy control of site construction management, etc., can save a great deal of manpower, physical resources and financial resources and obtain good technical economic effect, and has the remarkable economic, social and environmental benefits; the invention is especially adapted to the large cross-section and multiple cross-section type lining construction of tunnels and underground constructions.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

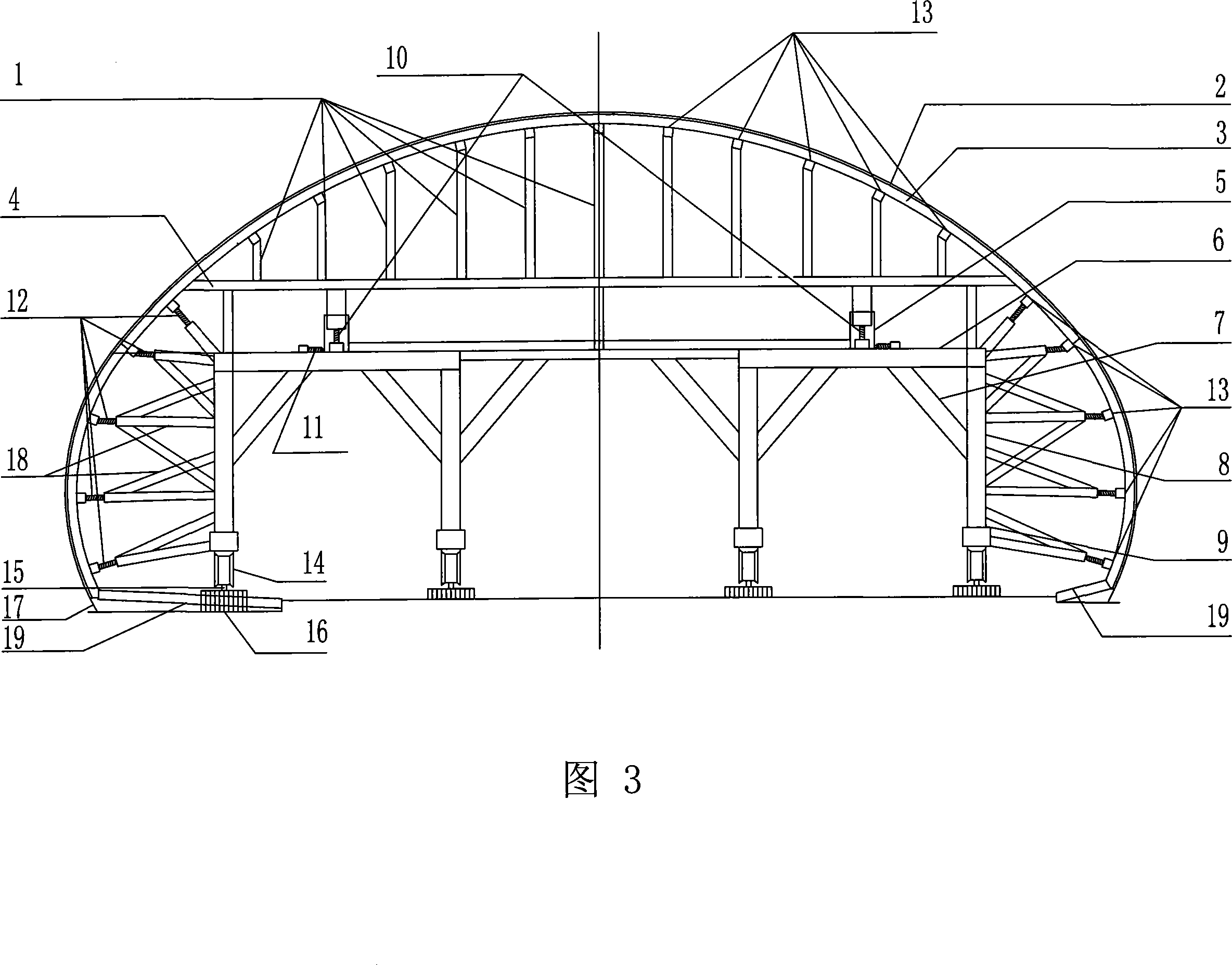

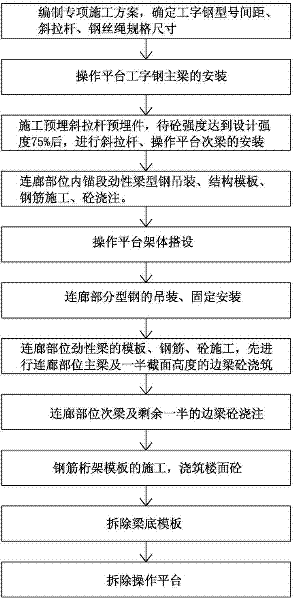

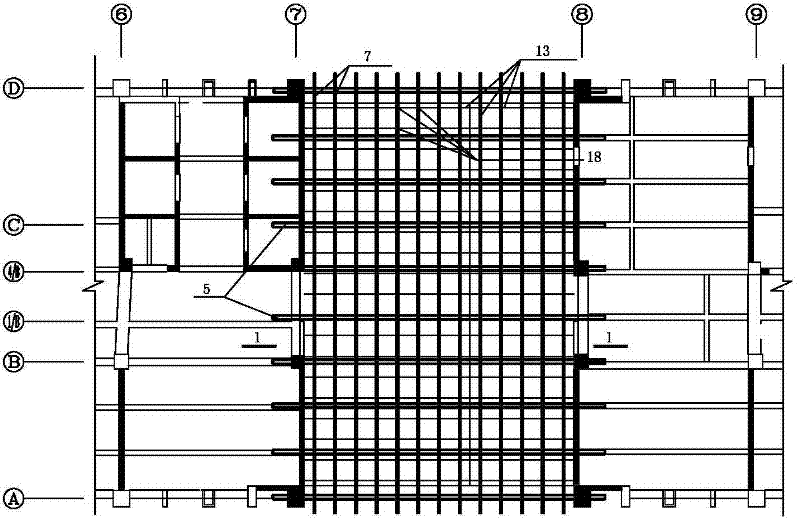

High-altitude long-span overhanging corridor type reinforced concrete structure and construction method

InactiveCN102444203ASave turnover materialsReduce construction costsBuilding material handlingSteel platesReinforced concrete

The invention relates to a high-altitude long-span overhanging corridor type reinforced concrete structure and a construction method, wherein the corridor part is a stiff beam structure; with own bearing capacity of a profile steel, a beam template supporting system is a hung template supporting system in such a manner of fixing a square steel by means of a U-shaped screw and a nut; a floorslab is a self-supporting steel bar truss template which is welded to a pre-embedded steel plate on the stiff beam by means of a pin; and a steel platform is arranged on a corresponding floor at the lower part of the corridor as an operating and safety protection platform for template support construction. The high-altitude long-span overhanging corridor type reinforced concrete structure and the construction method have the advantages that: the template supporting construction method, according to which the operating platform is built from H-steel or profile steel beams, the stiff beam is hung and is self-supported and the floorslab is self-supported, is employed, so that the problem of difficult template supporting of the high-altitude long-span overhanging corridor structure, the revolving materials are greatly saved, the construction cost is reduced, the construction progress is accelerated and the safety is ensured; and the steel plate is pre-embedded on the stiff beam, so that the floor bearing plate is effectively connected with the stiff beam and the floor bearing plate and the stiff beam are capable of acting together to ensure the safety of the structure.

Owner:浙江城建建设集团有限公司

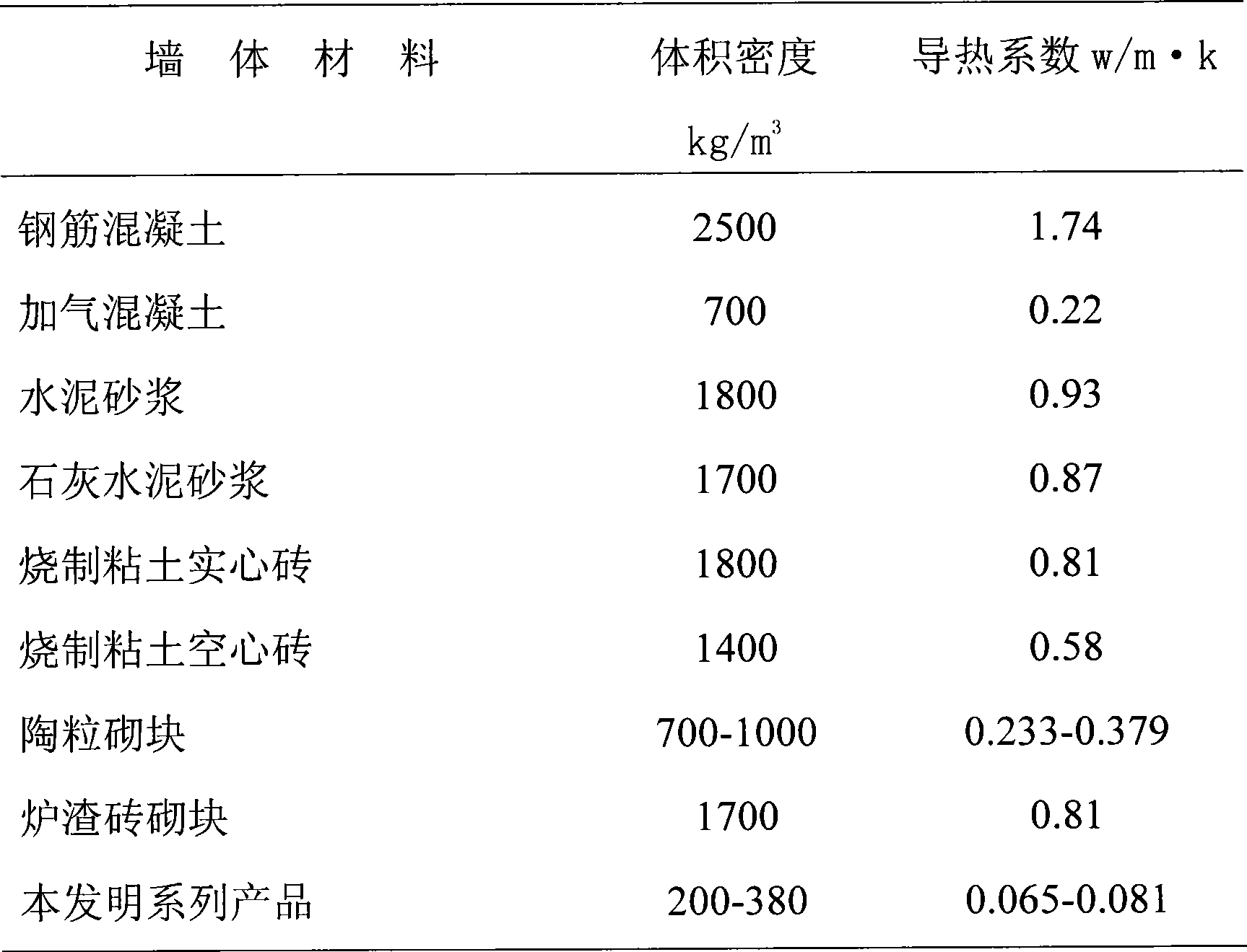

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

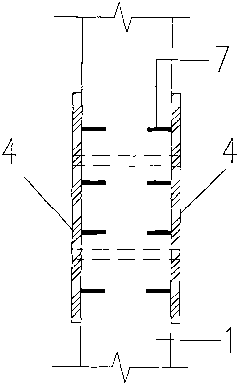

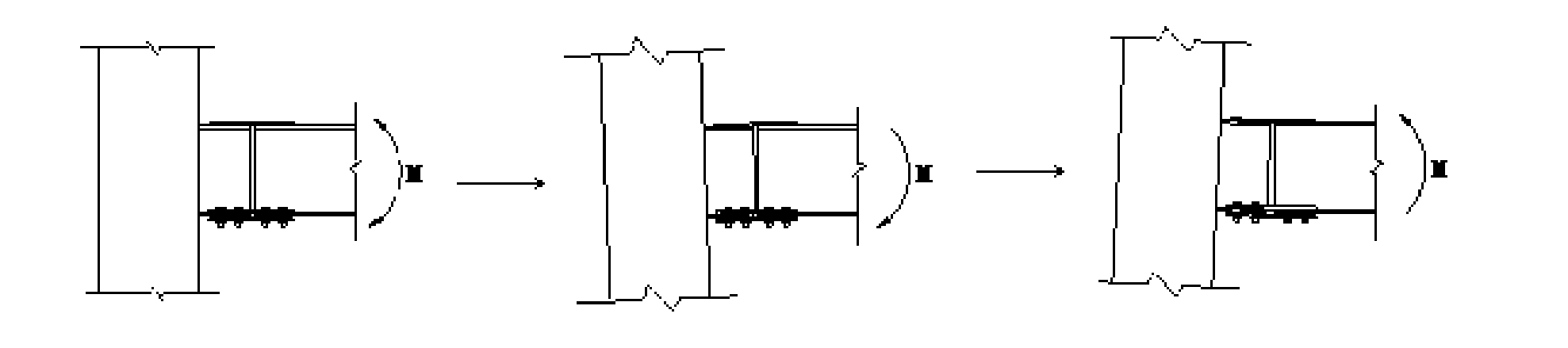

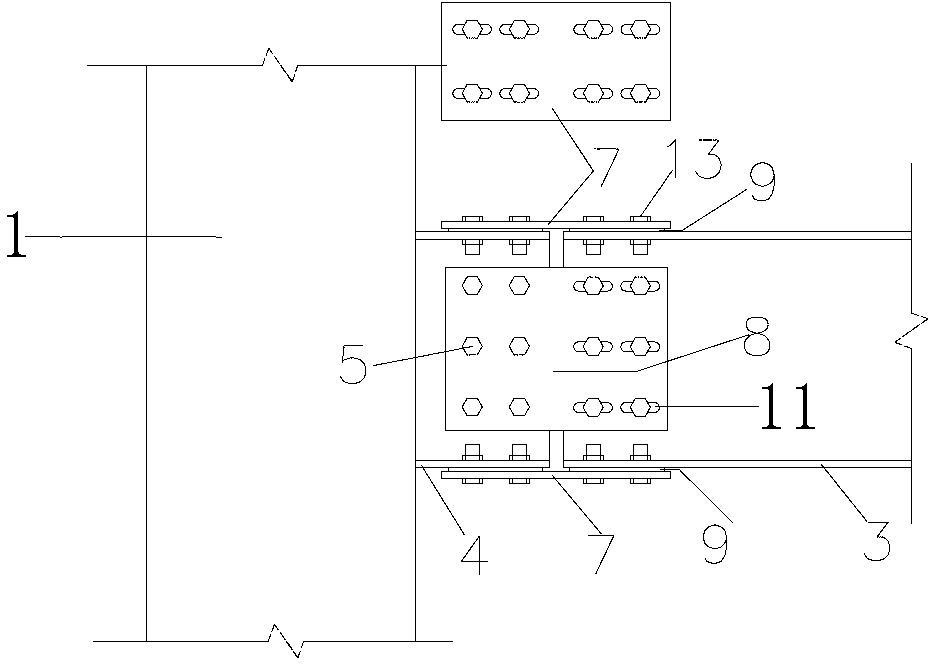

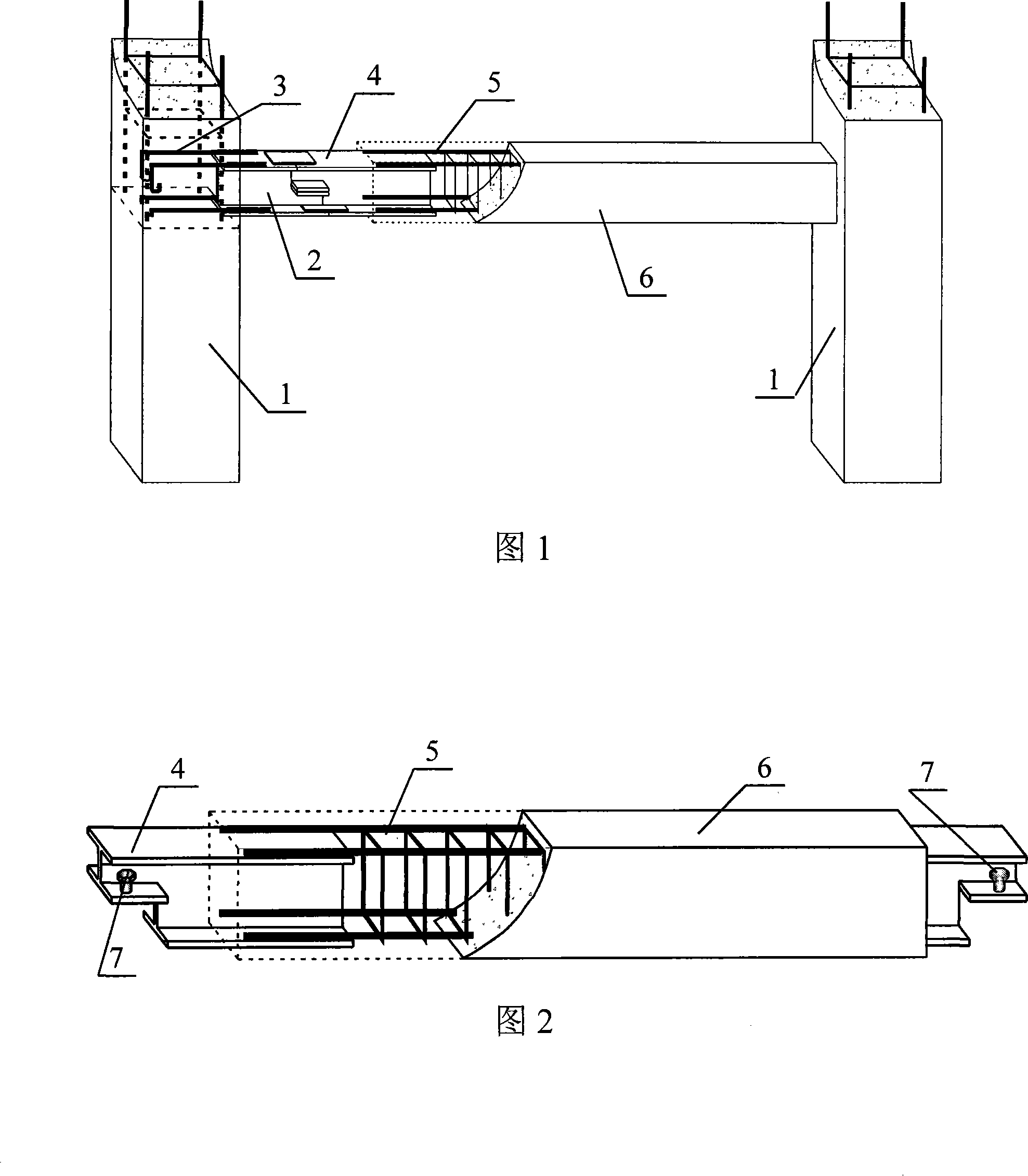

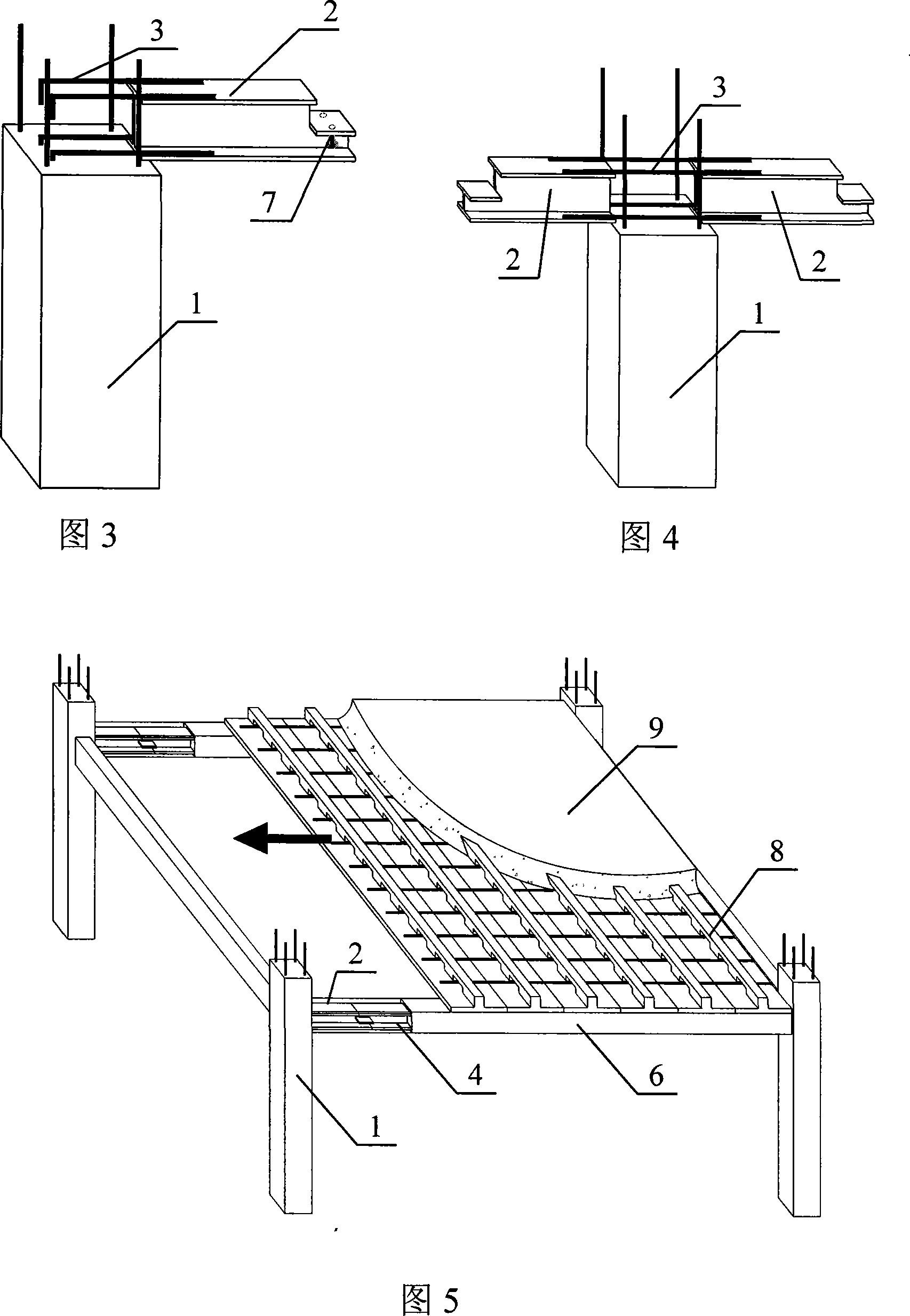

Fabricated concrete column-steel beam energy dissipation type panel point connecting device

ActiveCN103243819ARaise the damage thresholdReduce damageBuilding constructionsStructural elementAdverse effect

The invention discloses a fabricated concrete column-steel beam energy dissipation type panel point connecting device. The fabricated concrete column-steel beam energy dissipation type panel point connecting device is composed of a beam-beam bolt connection component and a friction energy dissipation device, and comprises a prefabricated concrete column, a pre-buried steel beam, a middle steel beam and a combination connection steel piece, wherein transversal surfaces of the pre-buried steel beam and the middle steel beam are both H-shaped, webs of the pre-buried steel beam and the middle steel beam are connected through a web cover plate, and flanges of the pre-buried steel beam and the middle steel beam are connected through a connection cover plate. Earthquake energy is dissipated by using friction plates attached inside a combination steel piece and through a friction energy dissipation mechanism. Compared with the prior art, the connecting device can reduce adverse effects on a floor and achieve a beam hinge yielding mechanism by moving a plastic hinge outward, the energy dissipation device can improve fabricated structure energy dissipation and reduce damages of main structural members, connection parts and the steel beams can be conveniently maintained, replaced and dismantled for reuse, and simultaneously, the fabricated concrete column-steel beam energy dissipation type panel point connecting device is produced by using a whole prefabricated industrialization standard, and installed only through bolts on site, and has strong engineering practicability.

Owner:江苏德丰建设集团建筑科技有限公司

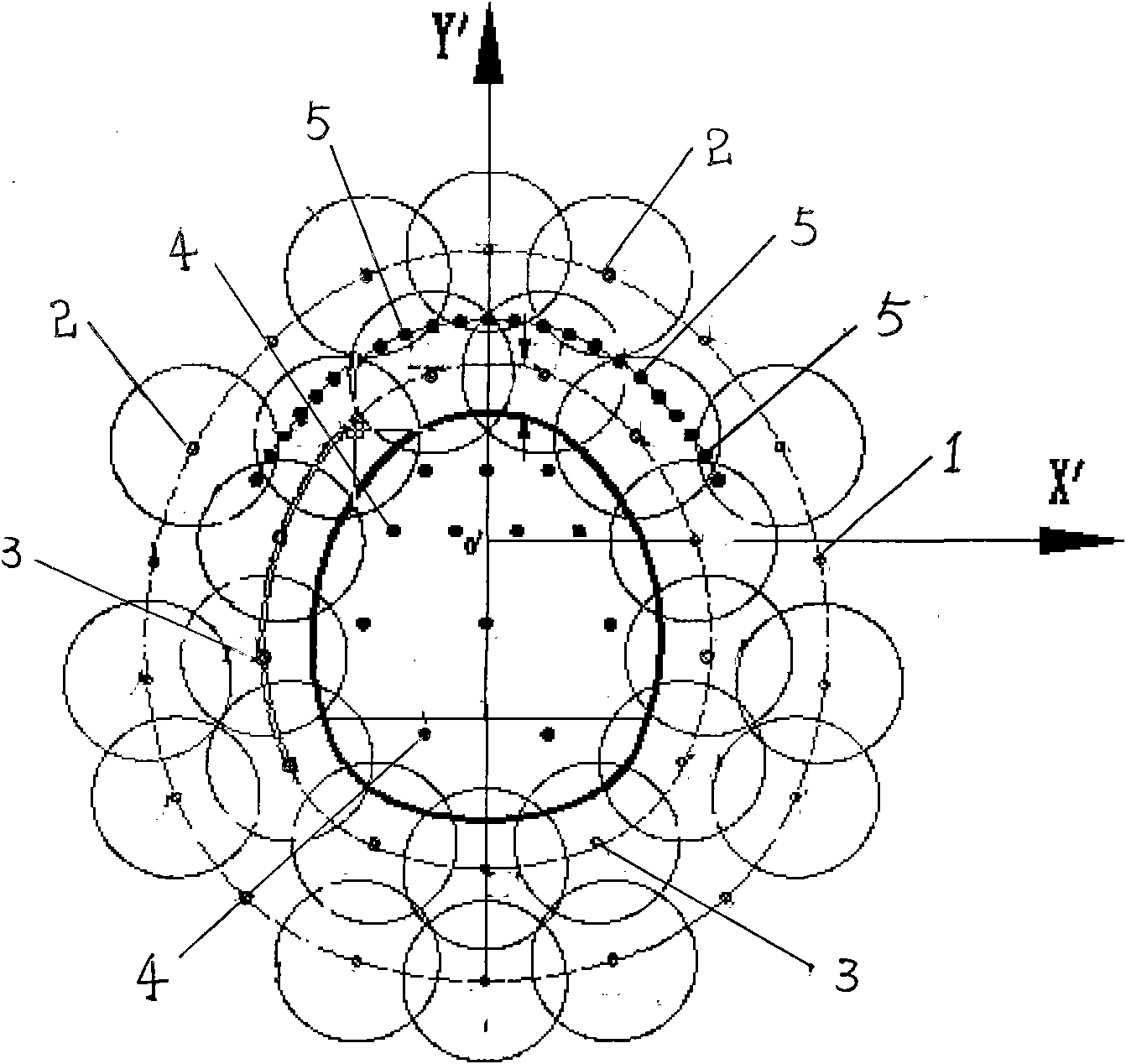

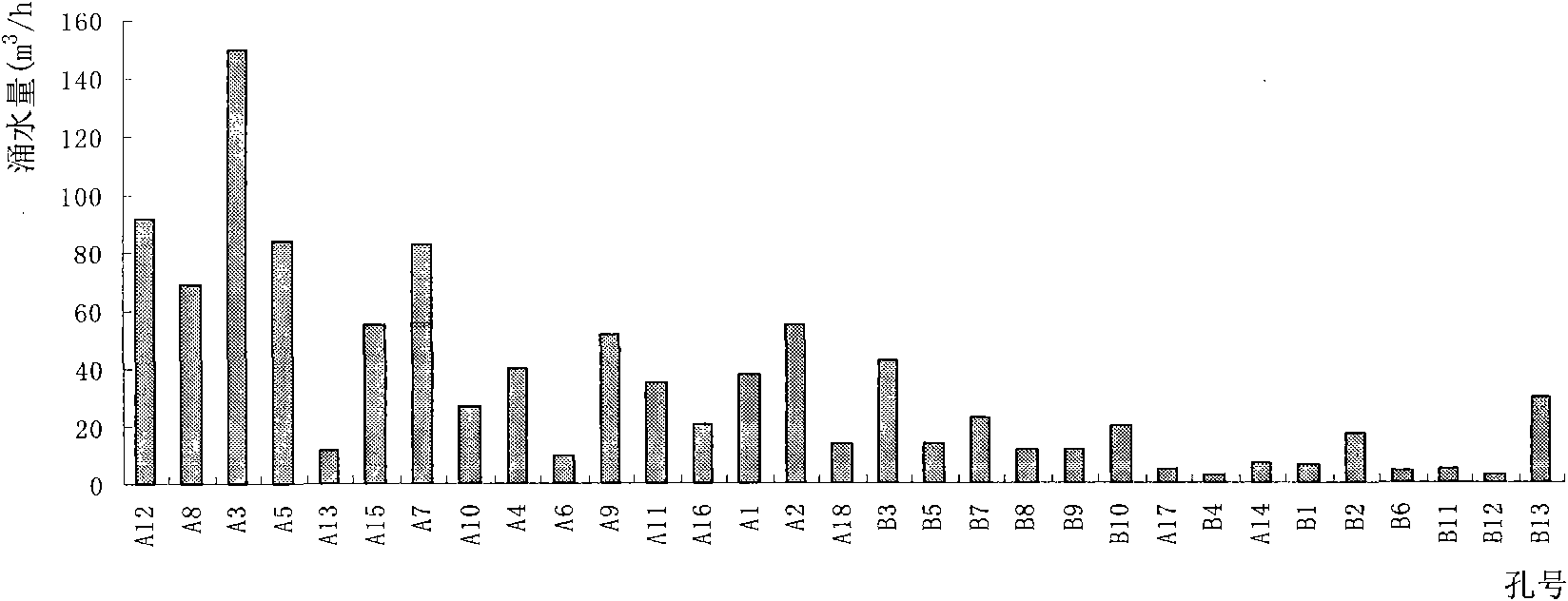

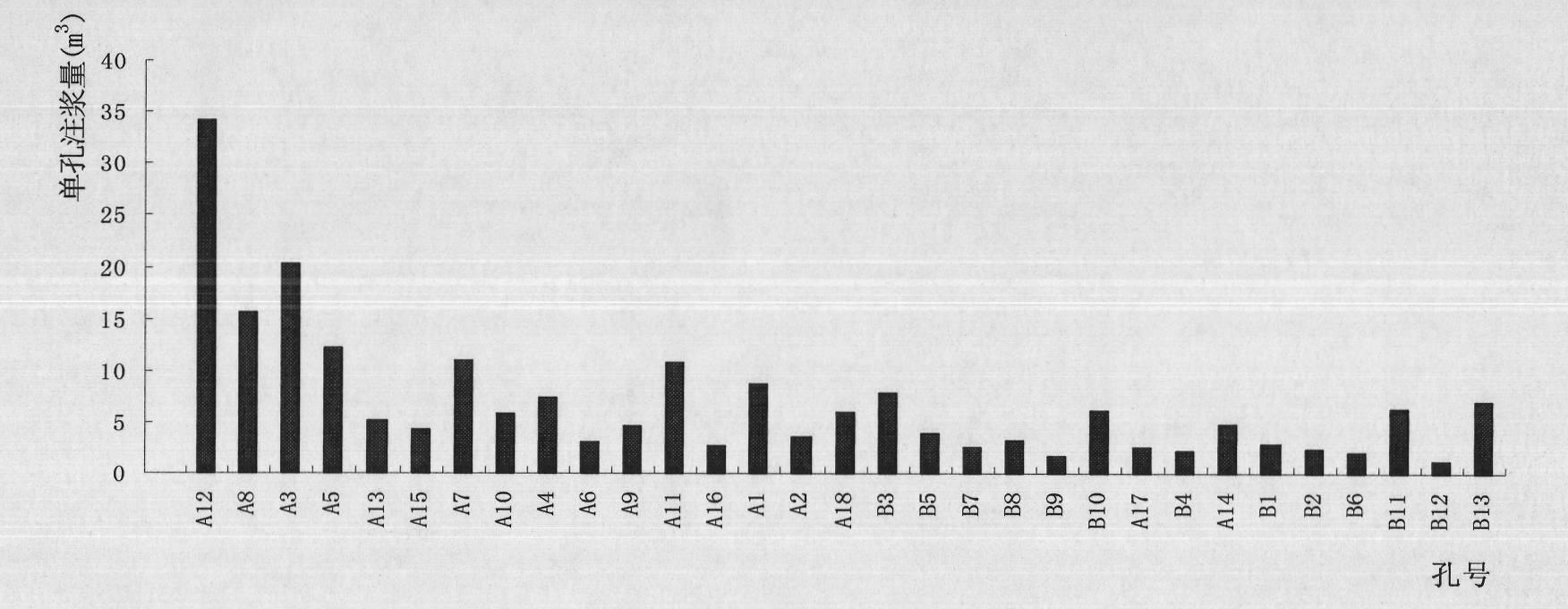

Tunnel information tracing accurate grouting method

ActiveCN101832142AOptimizing the Number of Grouting HolesReduce the amount of waterUnderground chambersTunnel liningGlass fiberGeomorphology

The invention relates to the field of tunnel grouting, in particular to a tunnel information tracing accurate grouting method, which solves the problems of thick reinforcing ring, large number of drilled holes, long construction period and the like of the traditional curtain grouting method adopted in current tunnel grouting. The method comprises the processes of grout stopping wall building, arrangement of orifice tubes and grouting tubes, measurement of the water burst of a drill hole, packer test, hole arrangement, drilling operation and grouting, wherein the hole arrangement and the grouting are performed according to the sequence from an advance geological drill hole to other outer ring holes to an inner ring hole to a working surface stabilizing hole to an access hole to a pipe-shed hole; and steps such as advance big pipe-shed construction of a working chamber and working surface stabilization by using a glass fiber anchor rod are saved. In the invention, a break through is made in the conventional construction philosophy, grouting design and geological change are tightly combined together, a grouting mechanism of 'crack blocking, water reduction, surrounding rock fixation and stratum stabilization' is adopted, the grouting holes are reduced by 30 to 40 percent, grouting quality is improved, the safe and quick construction is guaranteed, major water burst and mud burst accidents are eliminated, and the environment is protected maximally.

Owner:CHINA RAILWAY 12TH BUREAU GRP

Unmodified high-toughness low-temp steel for high-energy line welding and its production method

A high-toughness low-temp steel for high-energy linear welding contains C, Si, Mn, P, S, Al, Ti, N, B, Fe, and one or more of Cu, Ni, Nb, V, Mo and RE. The compound Ti-B oxide is used to obtain high welding performance under high linear energy (greater than 50 KJ / cm). Its low content of C and impurities can improve its toughness. Its advantags are high weld performance and low-temp toughness, andlow cost. It is suitable for low-temp spherical tank and large containers.

Owner:武钢集团有限公司

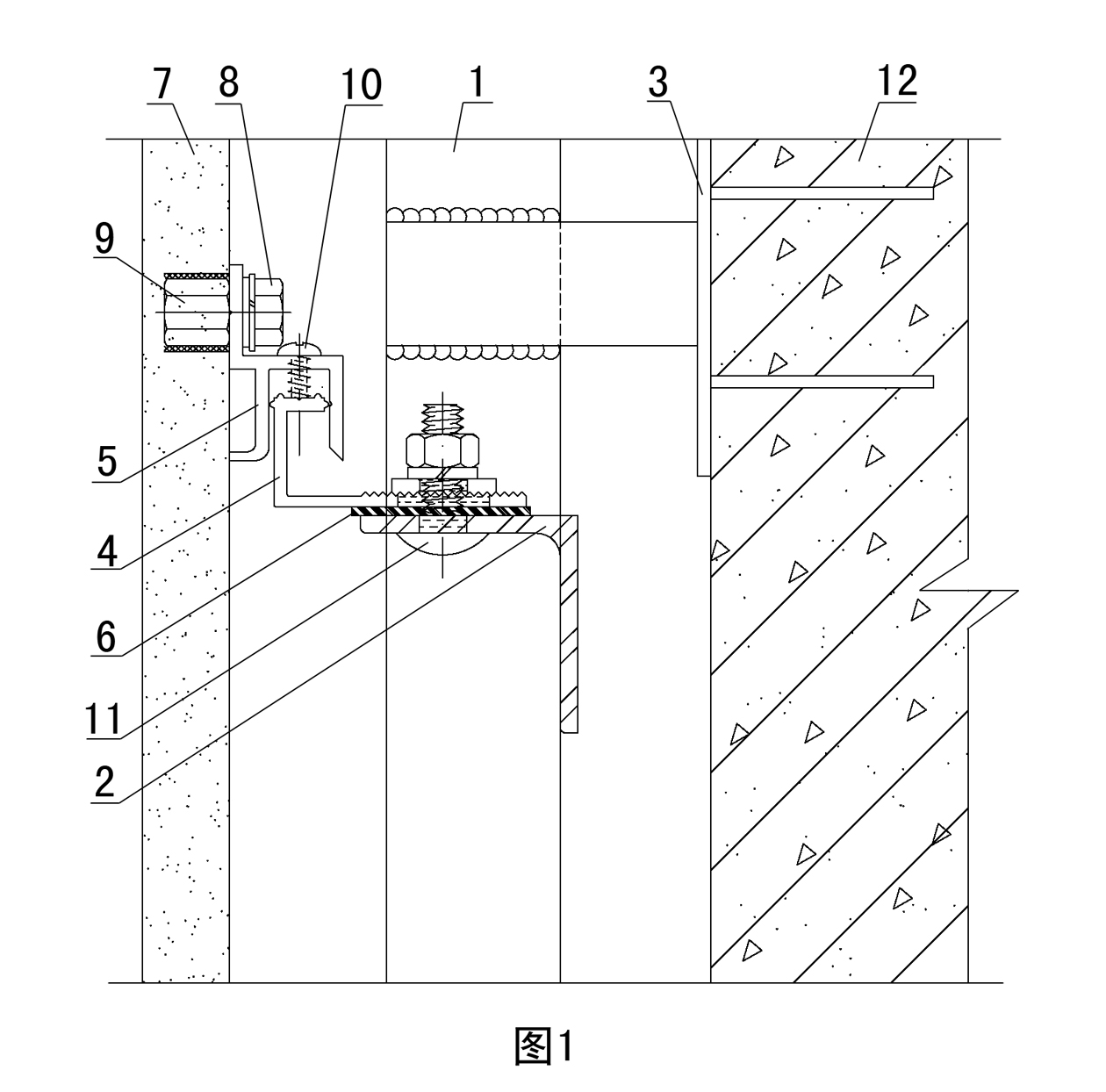

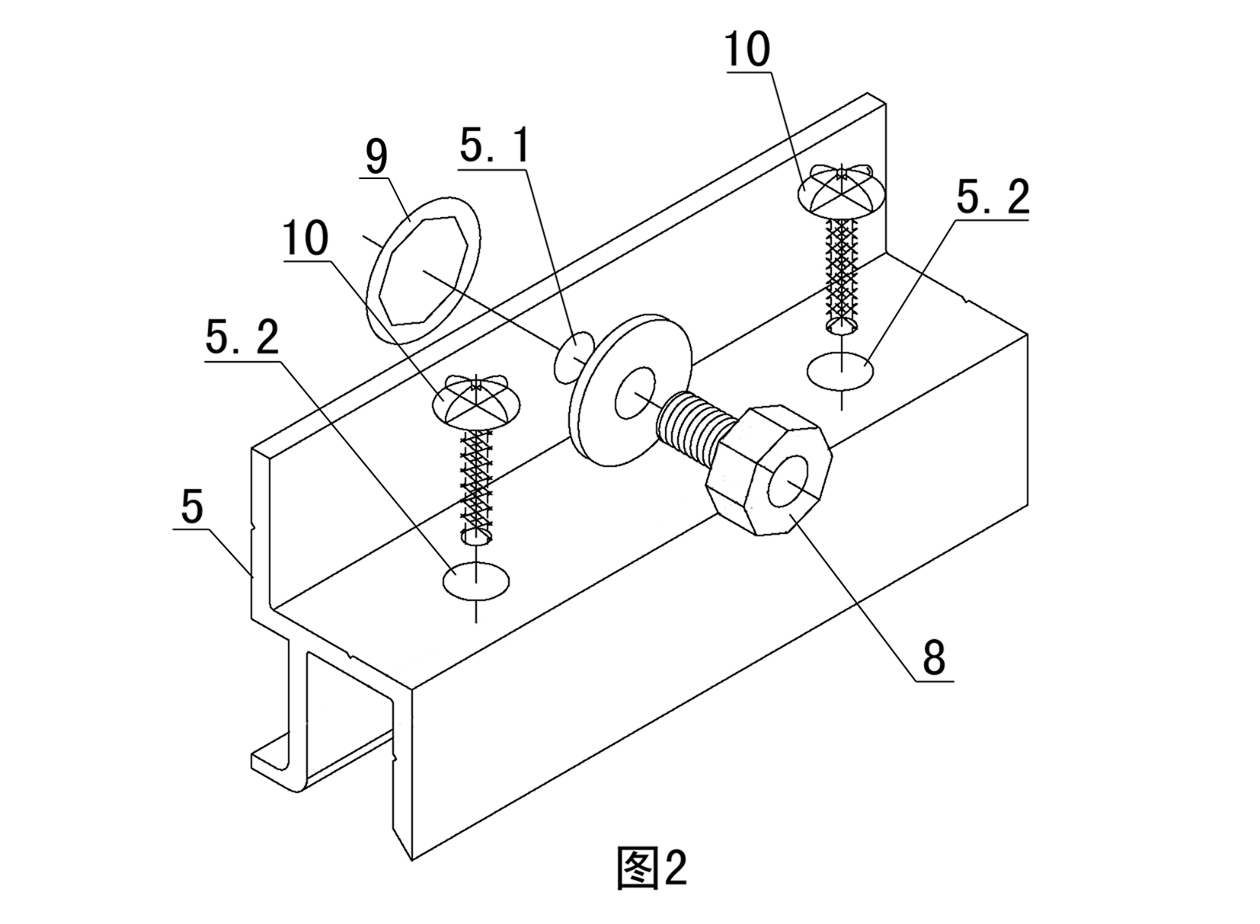

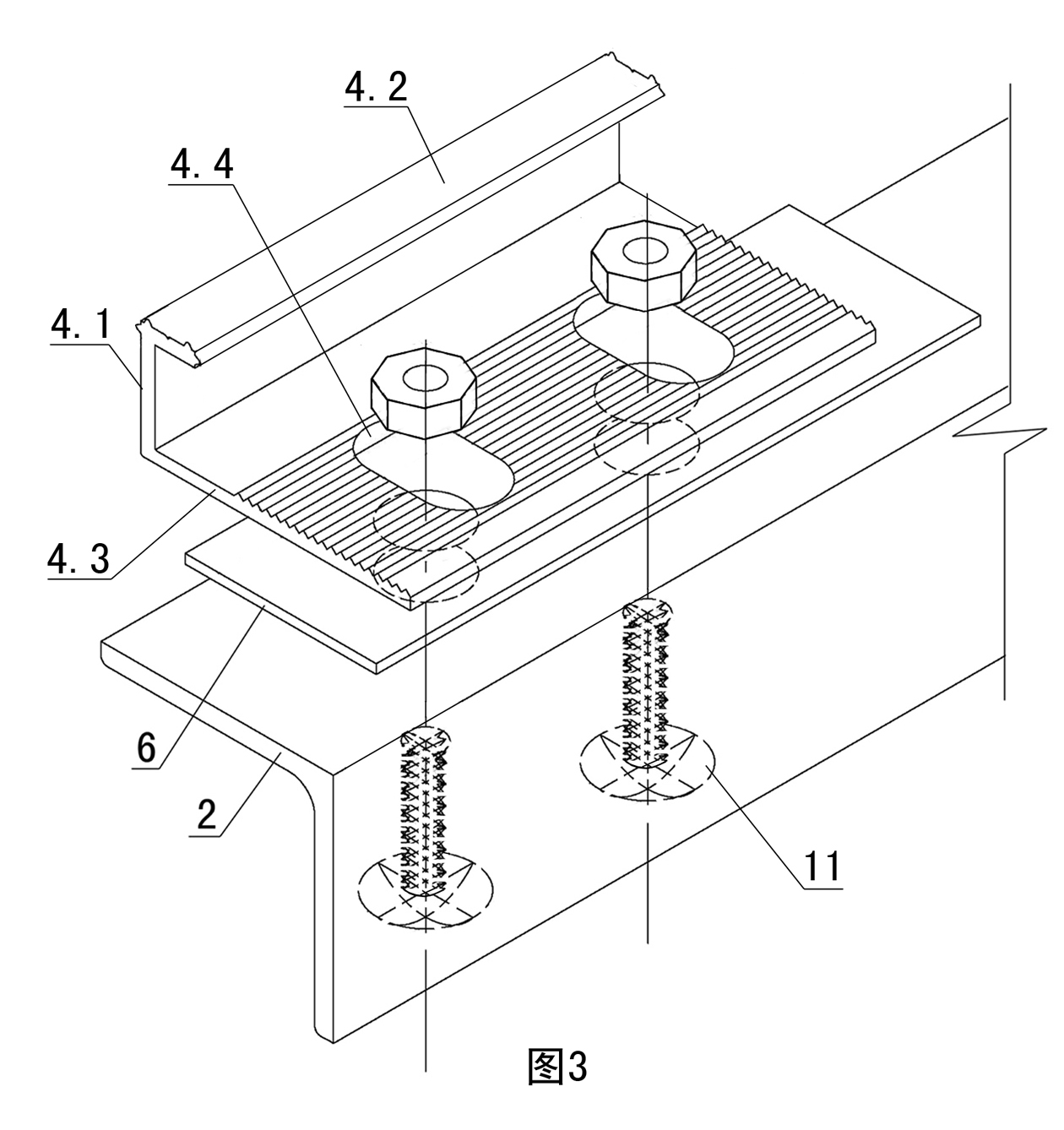

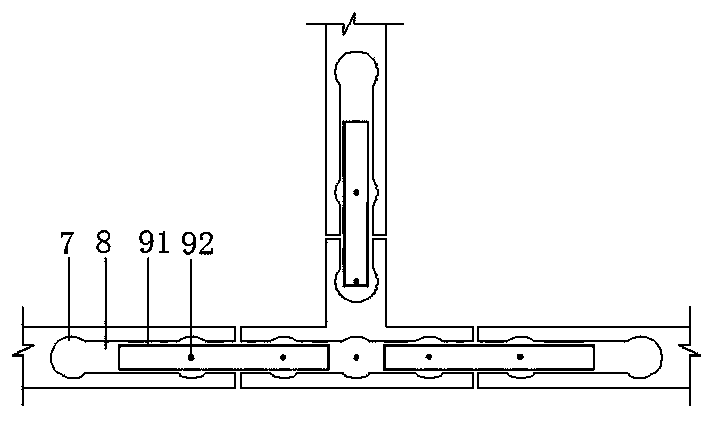

Three-dimensionally adjustable disconnectable curtain wall connecting device and construction method thereof

ActiveCN101956438ASolve the adjustmentSolve the different size of the board seamCovering/liningsWallsVertical deflectionKeel

The invention relates to a three-dimensionally adjustable disconnectable curtain wall connecting device. In the three-dimensionally adjustable disconnectable curtain wall connecting device, the section of a back pendant has a chair shape; a back bolt hole is formed at the back of the chair and is in threaded connection with an embedded nut at the back of each curtain wall plate through a back bolt; the back chair legs have L shapes and are propped against the back of each curtain wall plate; a jackscrew bolt hole is formed on the chair surface and is connected with an adjustable supporting piece of which the upper end is embedded between the front and back chair legs through a jackscrew bolt; the adjustable supporting piece is formed by connecting a supporting plate, a vertical plate and an adjusting plate to be a whole; the supporting plate is in top contact connection with the jackscrew bolt; the thread height of the jackscrew bolt is more than the longitudinally adjusting distance of each curtain wall plate; and a long round hole vertical to the wall body is formed on the adjusting plate. The device solves the problems that the position of each curtain wall plate cannot be adjusted, the plate gaps are different in sizes, the curtain wall plates are staggered with one another and the like so as to guarantee the appearance of the curtain wall and overcomes the defect that the installation of the traditional curtain wall plates completely depends on the control level and the vertical deflection of keels at the same time, so that the construction quality can be controlled easily.

Owner:泛华建设集团有限公司

Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

InactiveCN105781571AGuaranteed carrying capacityGuaranteed integrityUnderground chambersTunnel liningEngineeringLarge deformation

The invention provides a construction method for a soft rock deformation tunnel lining support dismantling-replacing arch. One-time whole section integral dismantling and replacing of a lining support is achieved. The construction method has the advantages that before dismantling and replacing, a lining which loses bearing capacity is subjected to grouting reinforcement treatment first, then a temporary cover arch is additionally arranged outside for reinforcement, and afterwards, the lining support is dismantled step by step, so that potential safety hazards caused by dismantling or removing of a temporary platform frame are avoided, and some security risks are avoided effectively. According to the construction method, the construction difficult problem of soft rock large deformation occurs during construction of a tunnel in special and complex geology is solved. Through the created novel construction method, the construction difficult problem of second lining cracking deformation needing remediation due to weak surrounding rock large deformation is solved. Through the construction method, safe, fast and economic treatment and remediation of the lining support and arch replacing construction are achieved, and the tunnel structure stability and construction safety are ensured effectively.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

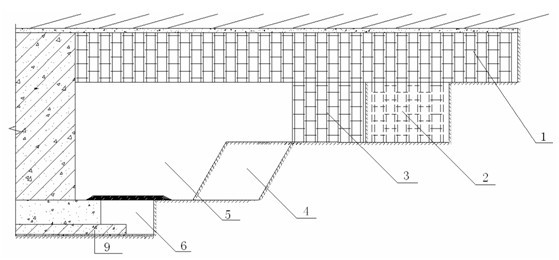

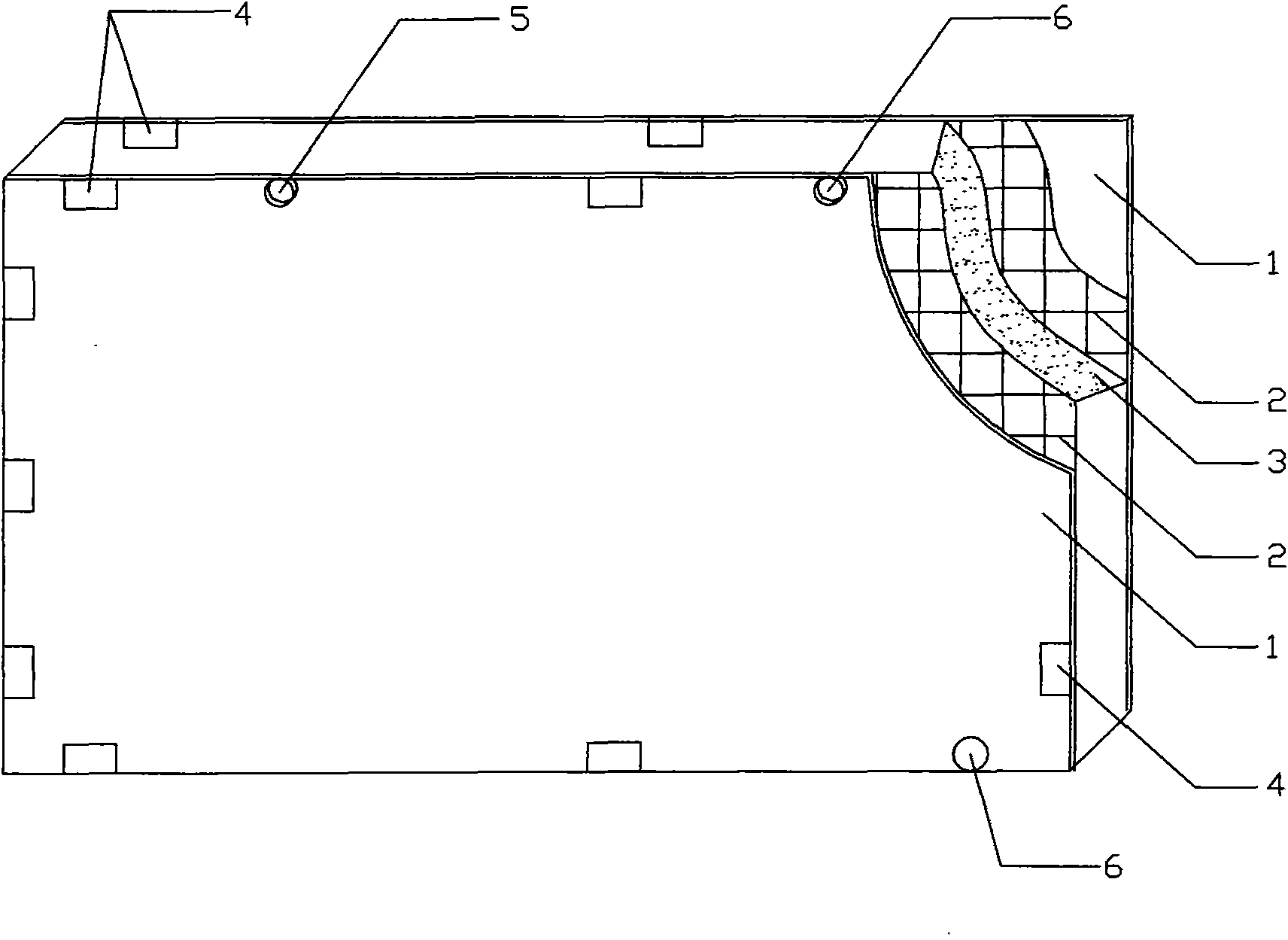

Method and system for basement engineering water proof and water drain

InactiveCN101298782AFree from buoyancyFrom erosionArtificial islandsProtective foundationBasementLine tubing

A basement engineering waterproof and drainage method is provided. The wall footing of the outside wall in basement engineering is embedded in watertight or micro-watertight soil rock layer or cement soil layer. The wall footing intercepts water by a thin-part structure. The cushion of the basement engineering soleplate and the falling layer of the top board are composed of combined water-proof layers. The late poured band, the movement joint and the horizontal construction joint at the lower part of the outside wall are treated by a water-proof structure combined with waterproofing measures. The basement engineering is provided with a drainage system. The groundwater and surface water at the soleplate are drained into city drainage pipelines via a soleplate part of the drainage system. The rainwater of overburden layer bottom of the top board is then drained into city drainage pipelines via the indoor part of the drainage system. The invention is designed by adopting a one-body method of arranging the basement engineering waterproofing, drainage and anti-floating as well as underground engineering space enclosing structure and pipelines, thereby shortening the construction period, reducing the engineering cost, increasing the durability and reliability of underground building space enclosing structure and waterproof layer as well as pipelines.

Owner:朱邃科 +2

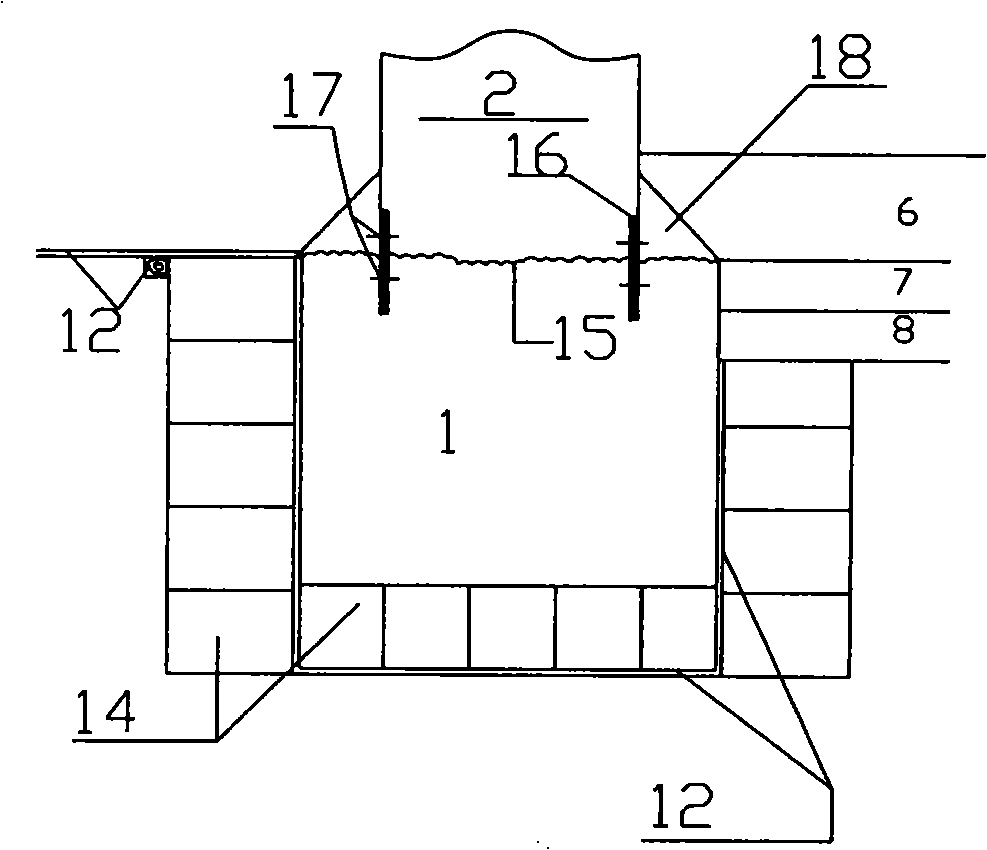

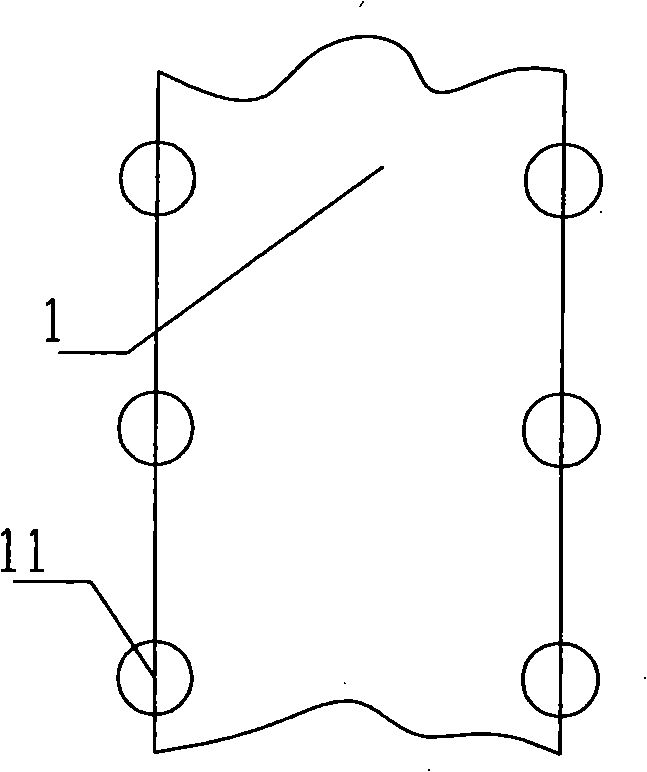

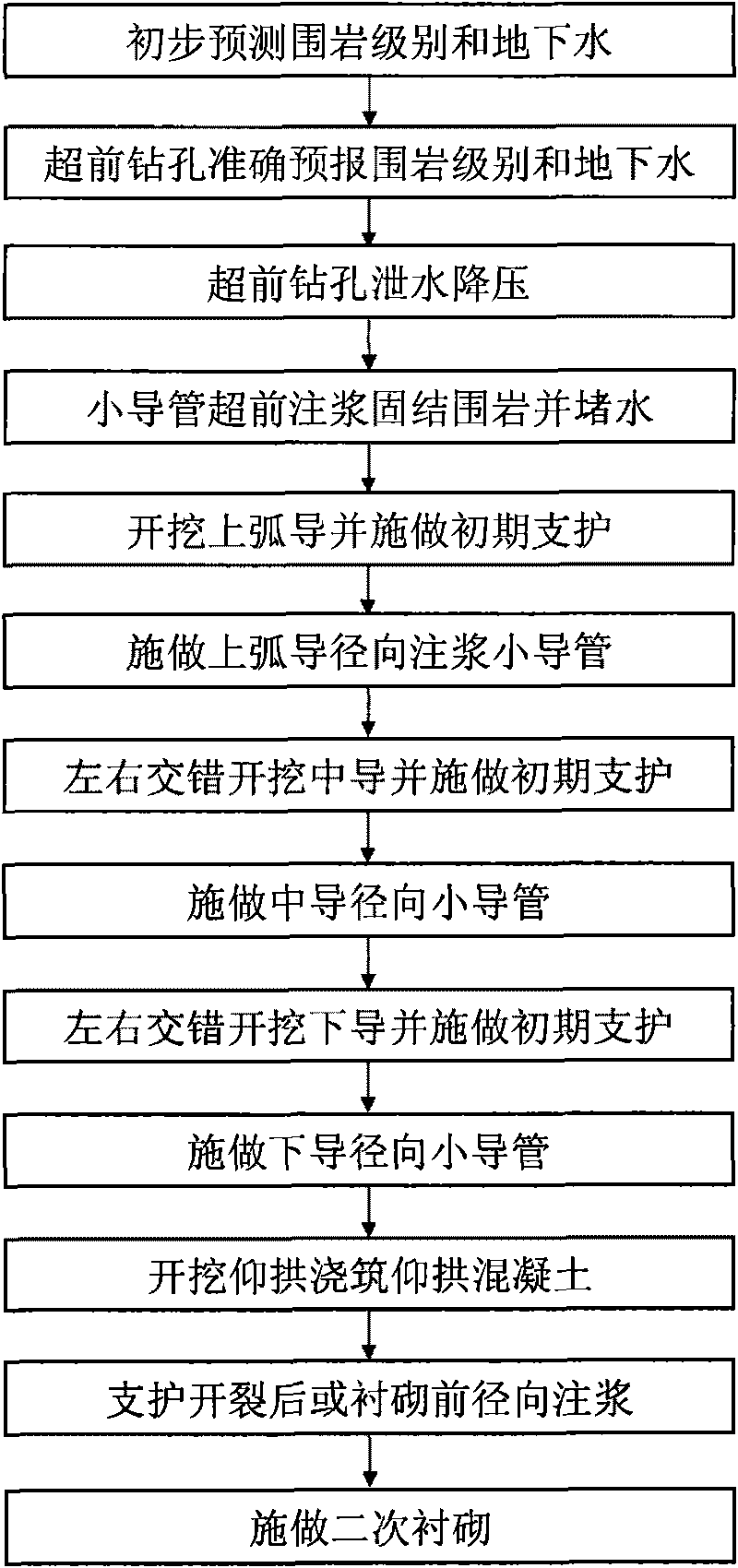

Method for constructing metamorphic rock confined water tunnel

ActiveCN101761346AImprove self-stabilization abilityReduce disturbanceUnderground chambersTunnel liningTunnel constructionConfined water

The invention relates to the field of tunnel construction, in particular to a method for constructing a metamorphic rock confined water tunnel, which solves the problems of the current method that geological disaster is easily initiated, the digging outline is difficult to control, timbering at initial stage is easy to transform and craze and the collapse is easy to occur. The method comprises the steps of: preliminarily forecasting surrounding rock level and underground water developing condition, accurately forecasting the geologic condition and the underground water developing condition by an advanced prospect hole, draining and decreasing water pressure by an advanced borehole, fixing the surrounding rock and plugging water by grouting via an advanced ductile, choosing a digging manner of tunnel trunk, determining the timbering form at initial stage, constructing a radial ductile, digging an inverted arch, pouring inverted arch concrete, and constructing a secondary lining. The construction method of the invention can efficiently control the digging outline, decrease the collapse frequency and the scale, efficiently control the transformation and cracking of the timbering at initial stage and can almost avoid the tunnel collapse by secondarily exchanging arch. The cost is decreased and the construction quality and the construction safety are efficiently promoted so as to bring excellent social benefit.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY

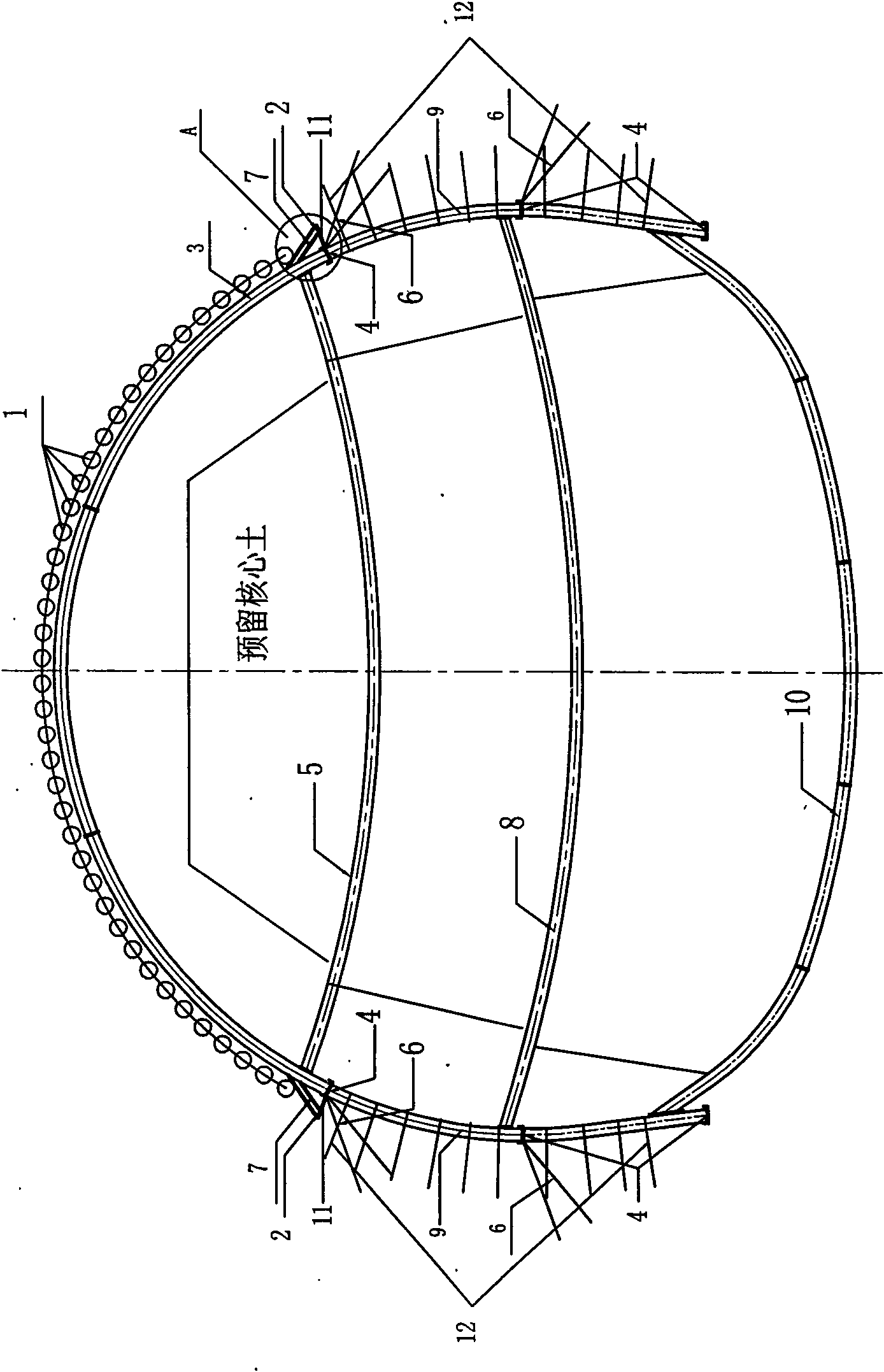

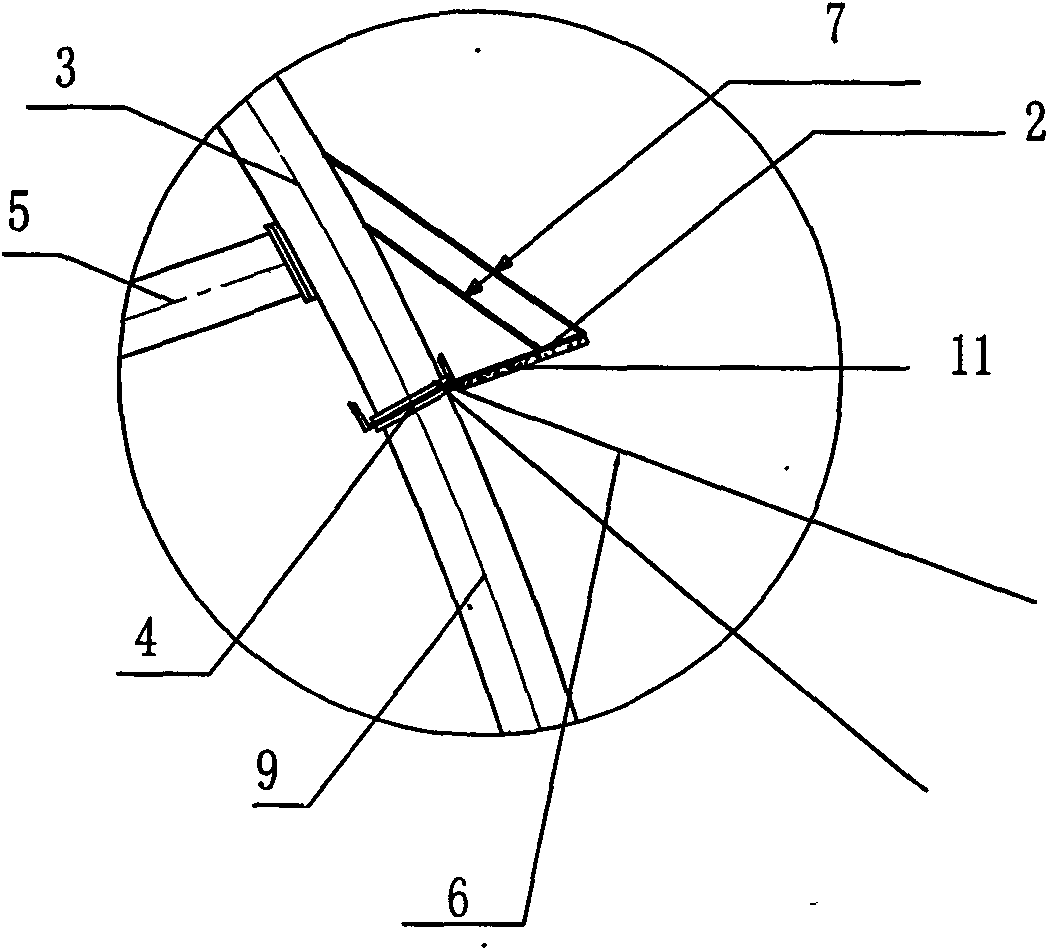

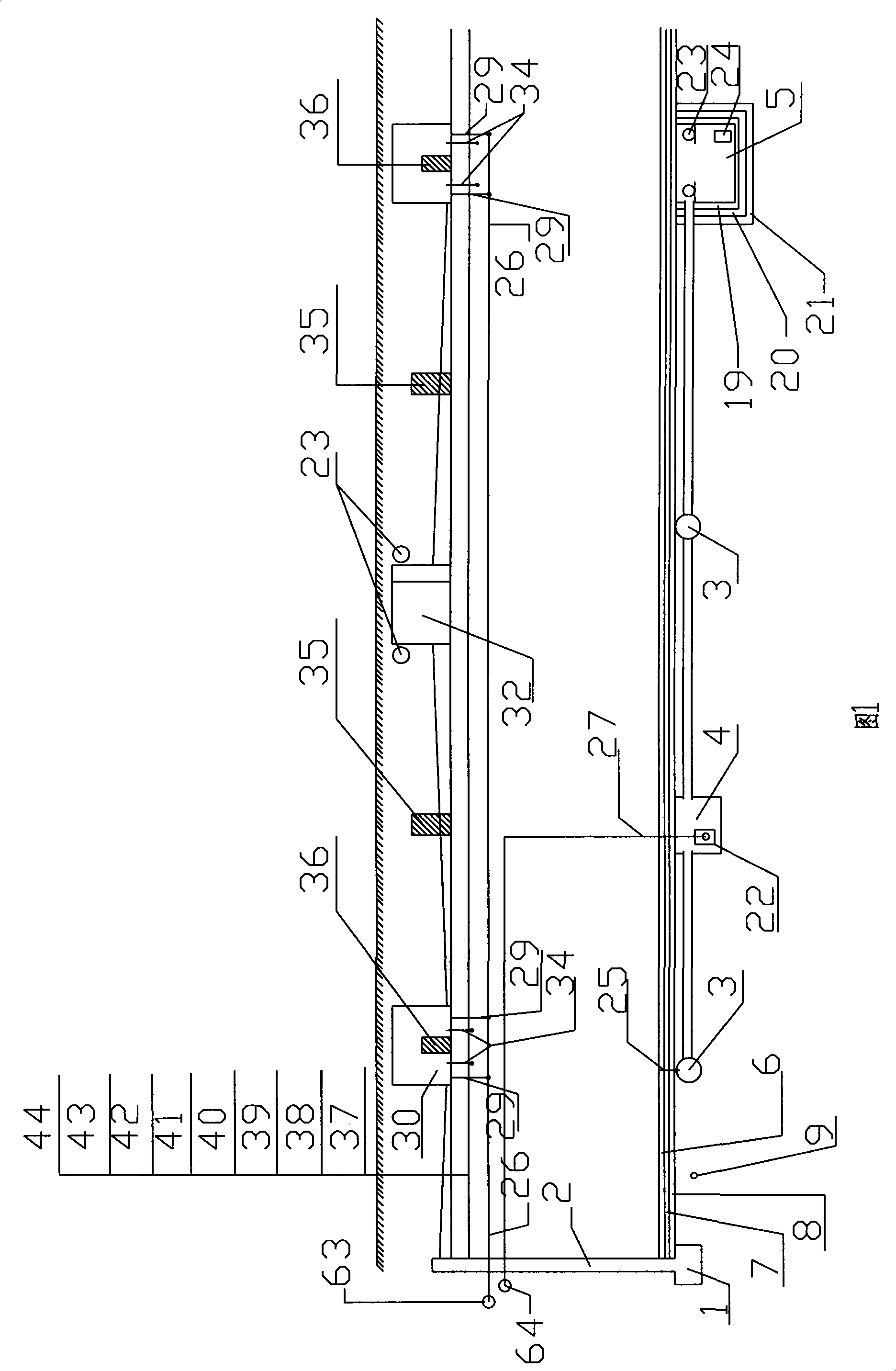

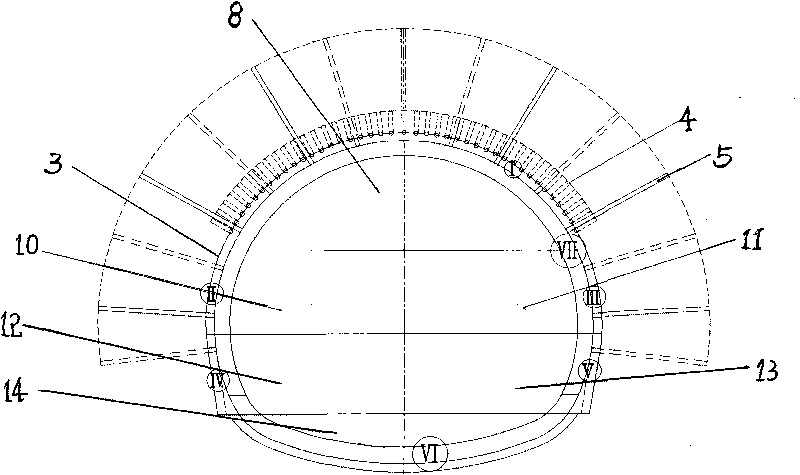

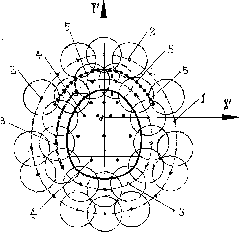

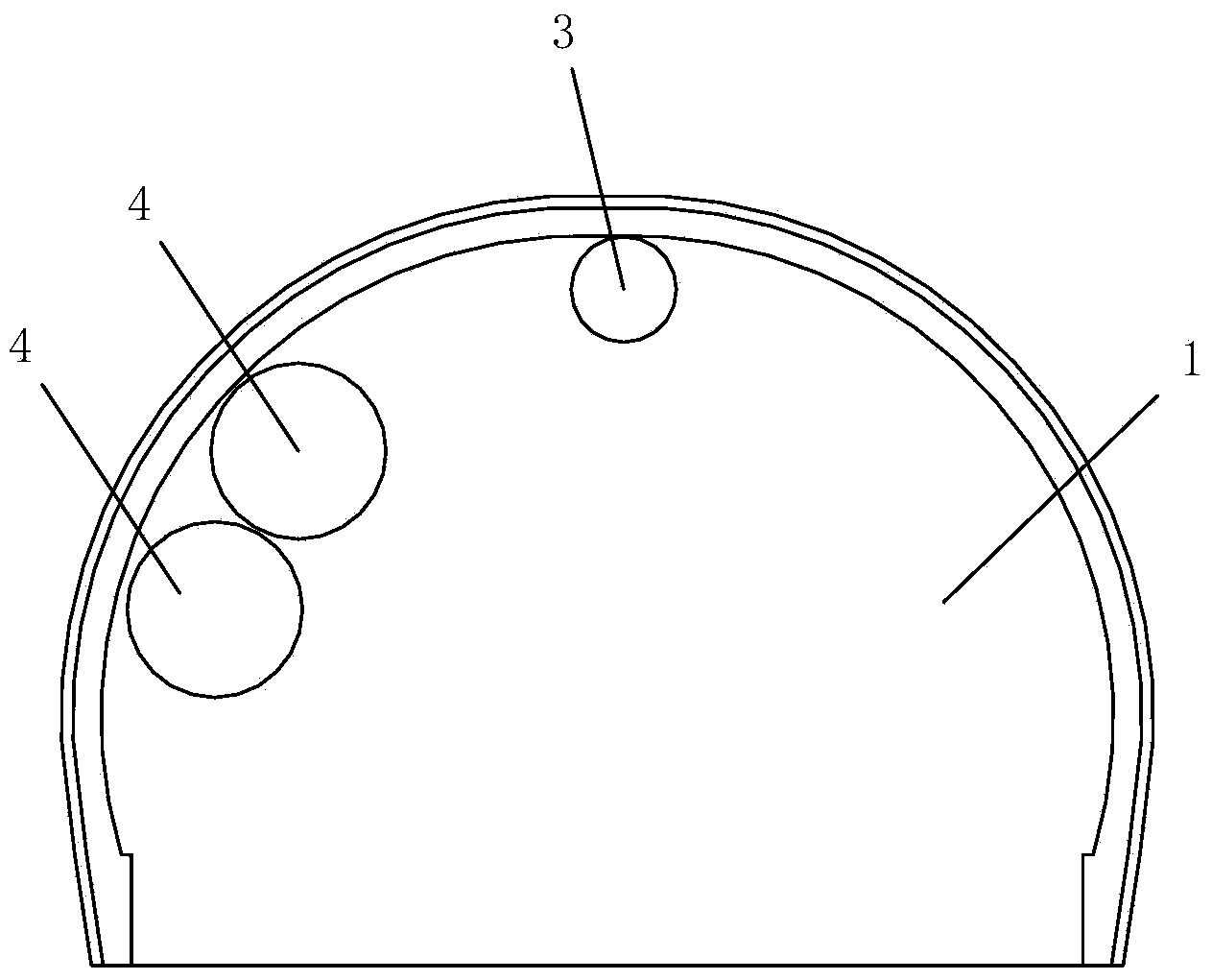

Large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method

ActiveCN102562075AMeet the requirements for enhanced controlsSpeed up early closure timesUnderground chambersTunnel liningShortest distanceRock tunnel

The invention discloses a large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method, which comprises the steps as follows: (1) annularly excavating an upper step of an upper part arc pilot tunnel, transferring excavated earthwork of the upper step to a lower step; (2) excavating a left part of a middle step about 4.5-5 meters behind the upper step, and transferring excavated earthwork to the lower step; (3) excavating a right part of the middle step about 3-4 meters behind the left part of the middle step, and transferring excavated earthwork to the lower step;(4) excavating a left part of the lower step about 6-8 meters behind the left part of the middle step or about 3-4 meters behind the right part of the middle step, and conveying excavated earthwork of the left part of the lower step out of the tunnel; (5) excavating a right part of the lower step about 3-4 meters behind the left part of the lower step, and conveying excavated earthwork of the lower step out of the tunnel; and (6) excavating the rest part of the tunnel bottom about 20-25 meters behind the right part of the lower step, excavating continuously according to the steps in a circulating and interlacing manner, and finally realizing tunnel excavating construction. The method can be used for building a large cross-section tunnel in a safe, rapid and economic manner.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

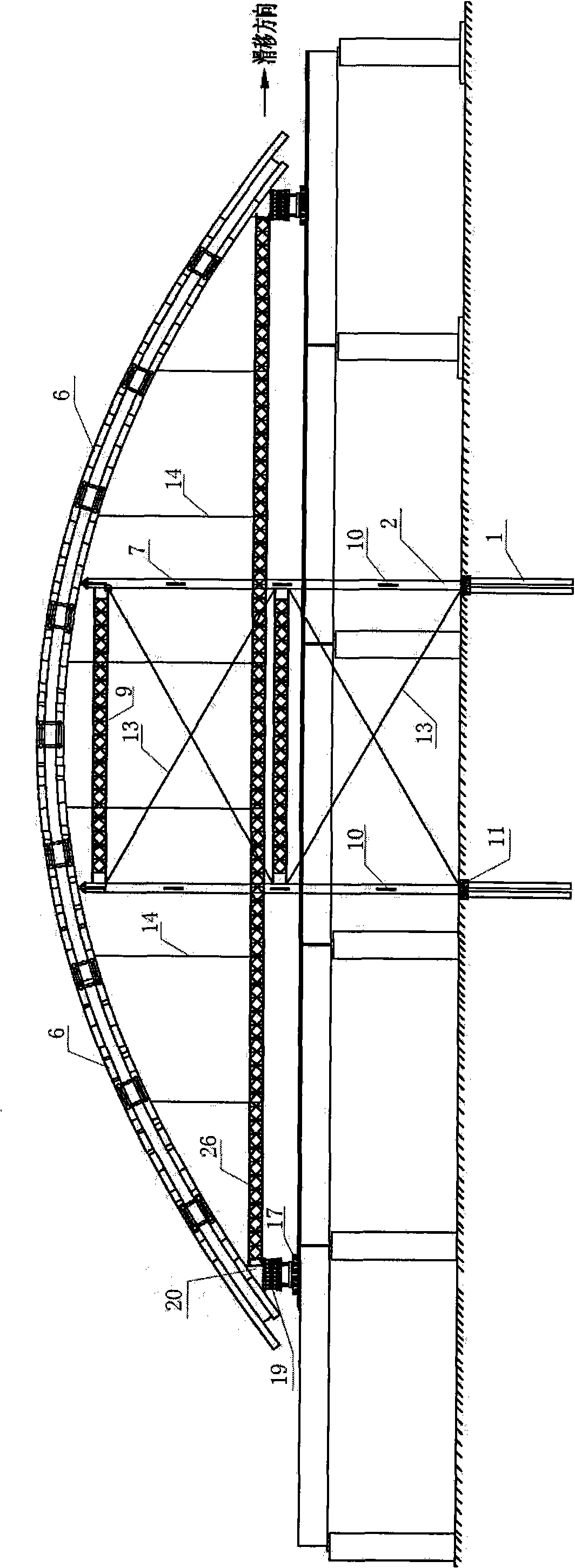

Construction method for integrally sliding large-span steel pipe arch of curved bridge

ActiveCN101935987AReduce occupancyReduce in quantityBridge erection/assemblyBridge engineeringConcrete beams

The invention relates to a construction method for integrally sliding a large-span steel pipe arch of a curved bridge, belonging to the field of bridge engineering construction. The method comprises the following steps: firstly, carrying out on-site splicing and welding on the manufacturing and installing sections of a steel pipe arch to form a large hoisting section; then installing a temporary arch-splicing support on a bridge-site longitudinal splicing site position, arranging arch ribs on the temporary arch-splicing support, and adopting an arch springing restraint device to preload arch springings after finishing splicing the steel pipe arch, thus enabling the steel pipe arch to form a stressed entirety; and finally, dismantling the temporary arch-splicing support, and adopting a pushing power system to realize integrally sliding the whole steel pipe arch into a proper position. The construction method of the invention has the advantages of small site occupation, integral hoisting of large sections, less hoisting subsection and less arch-splicing support amount, thus the construction cost is economical, the high-altitude welding quantity is less, the welding quality is ensured, the arch axis linetype control is easy, the steel pipe arch splicing and a concrete beam can be simultaneously constructed, arch splicing is carried out on an ectopic bridge site, the underbridge navigation is not influenced, the construction is safe and the construction progress can be quickened.

Owner:CHINA FIRST HIGHWAY ENG +1

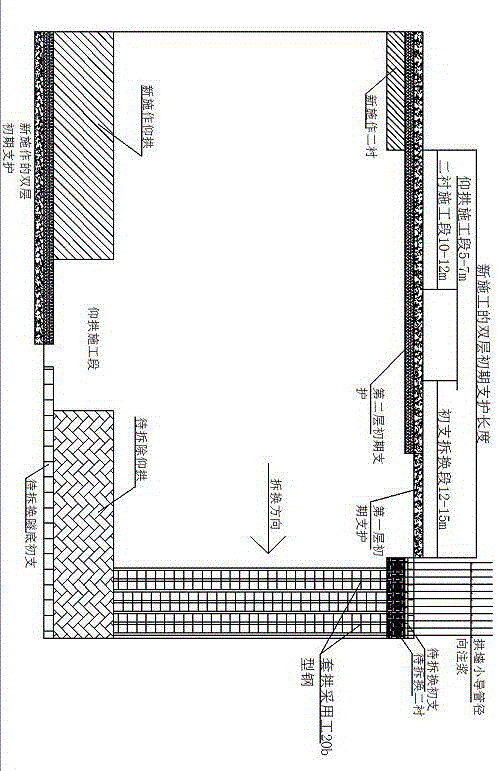

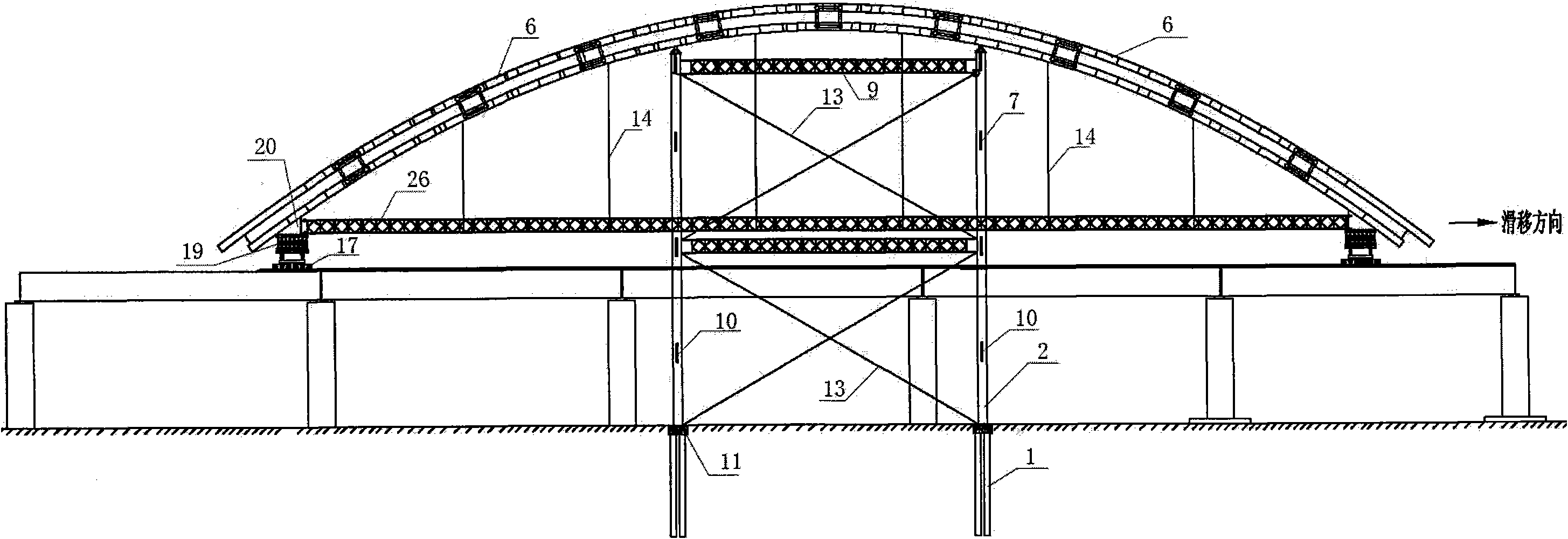

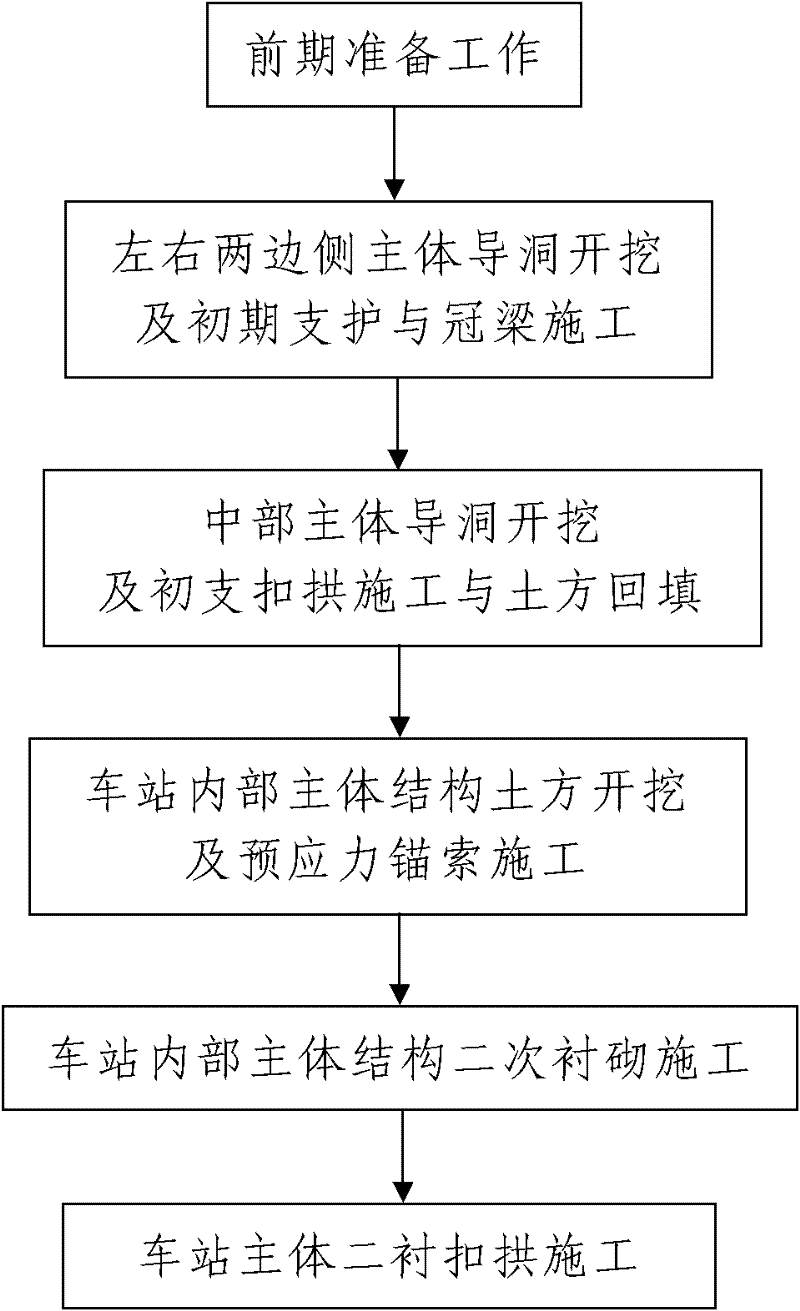

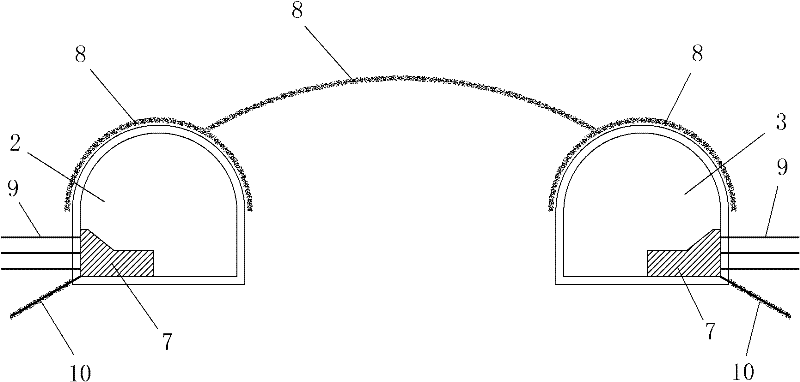

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Steel series with high linear energy and low weld crack sensitivity and its preparing process

InactiveCN1396294ALow weld crack susceptibilityGood welding performanceUltimate tensile strengthPhase point

A high-strength steel as low-alloy steel contains low-C, Ti, Nb, B and two or more of Ni, V, Cu, Mo, Zr and RE, and is prepared through rolling and modifying heat-treatment to obtain high-toughness tempered sorbite texture and the high-smelting-point second-phase points and compound educed phase to suppress growth of welding coarse crystal region. Its advantages are high linear energy (60-70 kg) and low sensitivity to weld cracking.

Owner:武钢集团有限公司

Combination beam

InactiveCN101215855AImprove integrityEasy to make nodesBuilding constructionsReinforced concreteMaterial consumption

The invention discloses a composite beam, which comprises reinforcement concrete prefab beam and section steel joints, wherein both ends of reinforcements of the reinforcement concrete prefab beam are connected with section steels, one end of section steel joint is pre-imbedded into the wall pier concrete and is connected to the reinforcement inside the wall pier, the other end of the section steel joint is remained outside the wall pier, both ends of section steel of the prefab beam and the section steel joints are connected to form the composite prefab beam. Due to the composite beam, the section steel joints and the wall piers are integrated with good connection integration property of the beams and simple process, wherein both ends of the section steel is connected with the section steel joints of the prefab beam to form composite beam, the connection between the prefab beam end and the section steel joints adopts welding, bolt connection type, and the like, the composite beam production can be industrialized, needs no framework, has small materials consumption and rapid construction progress.

Owner:吴方伯

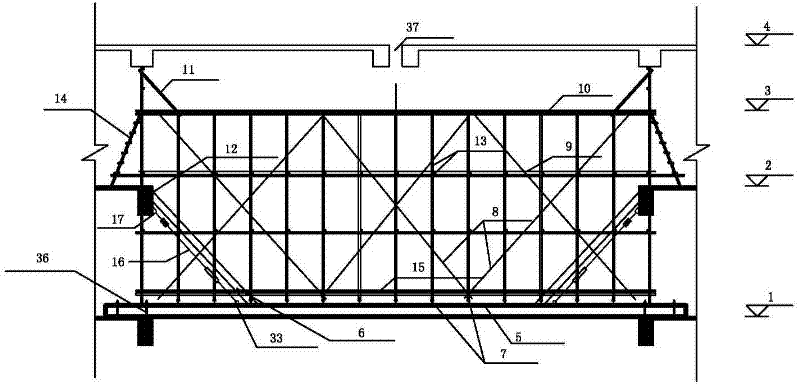

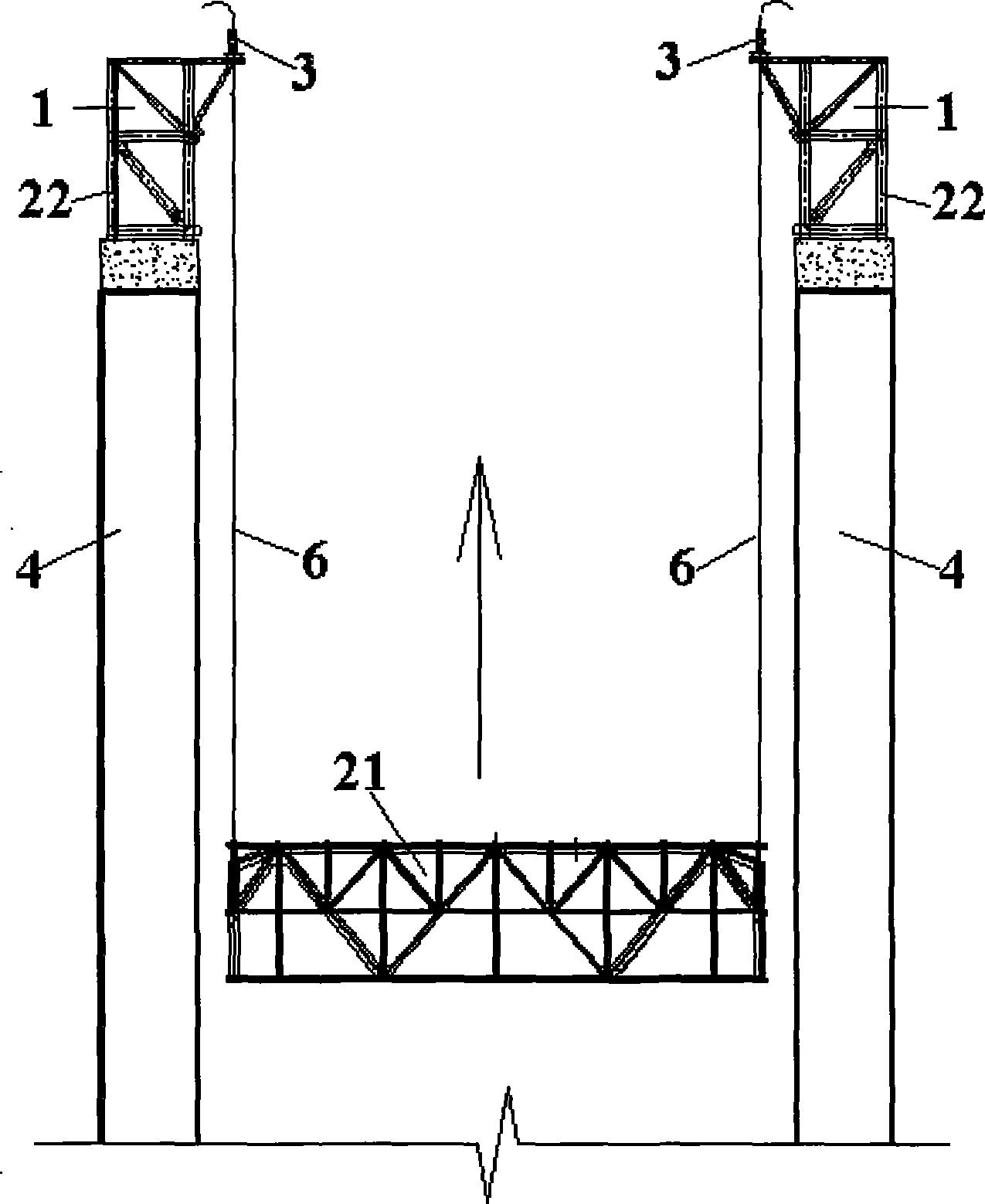

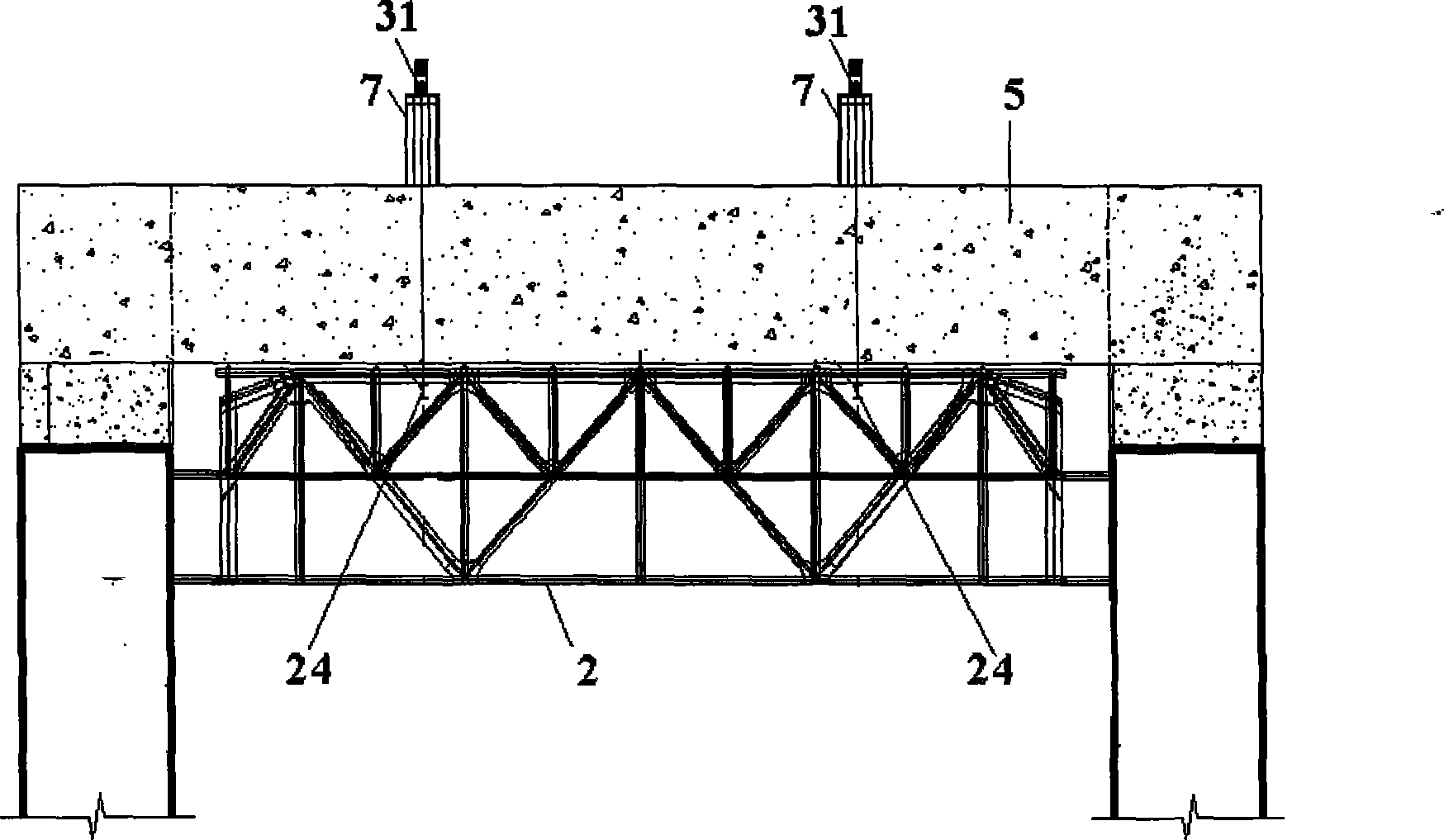

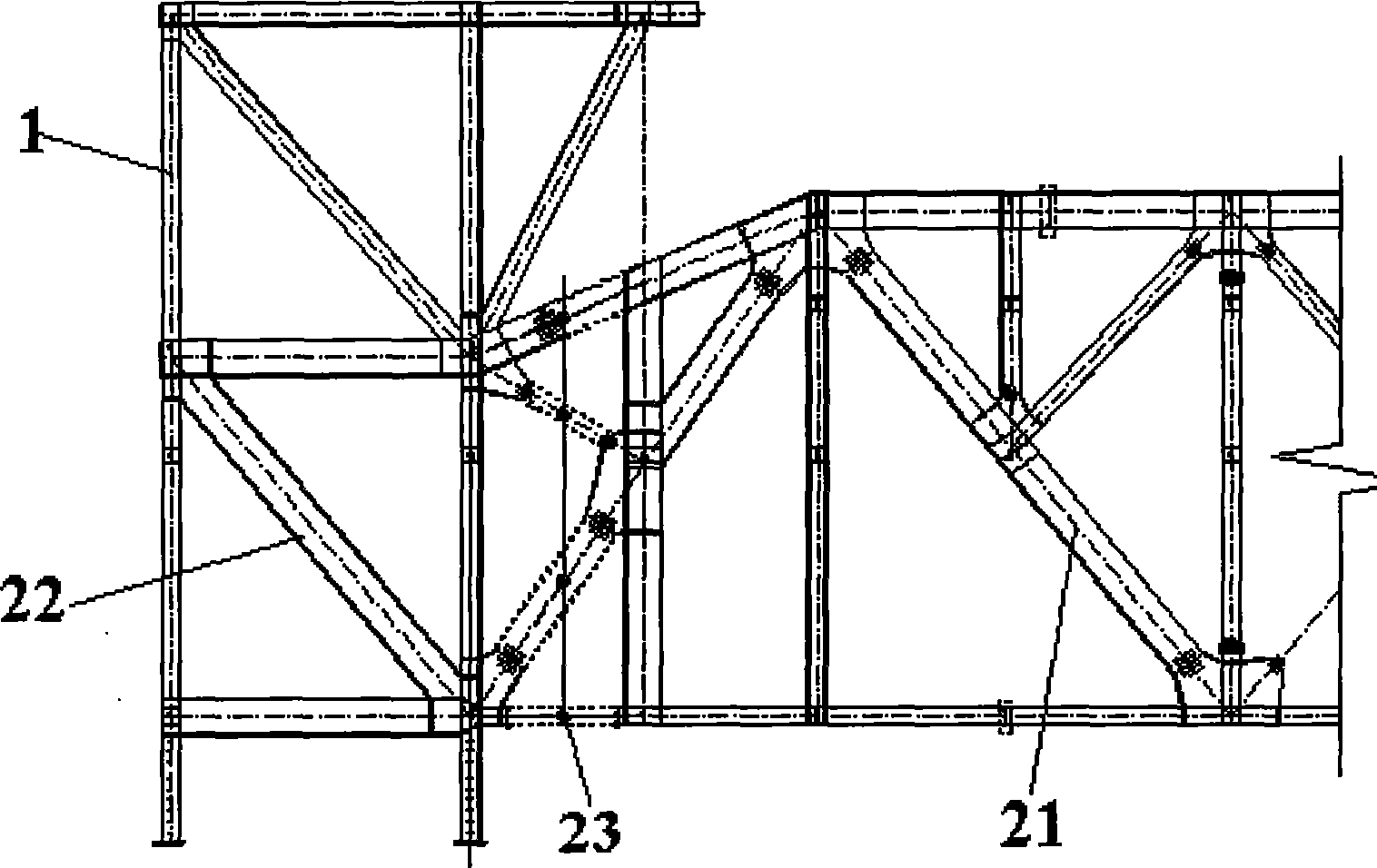

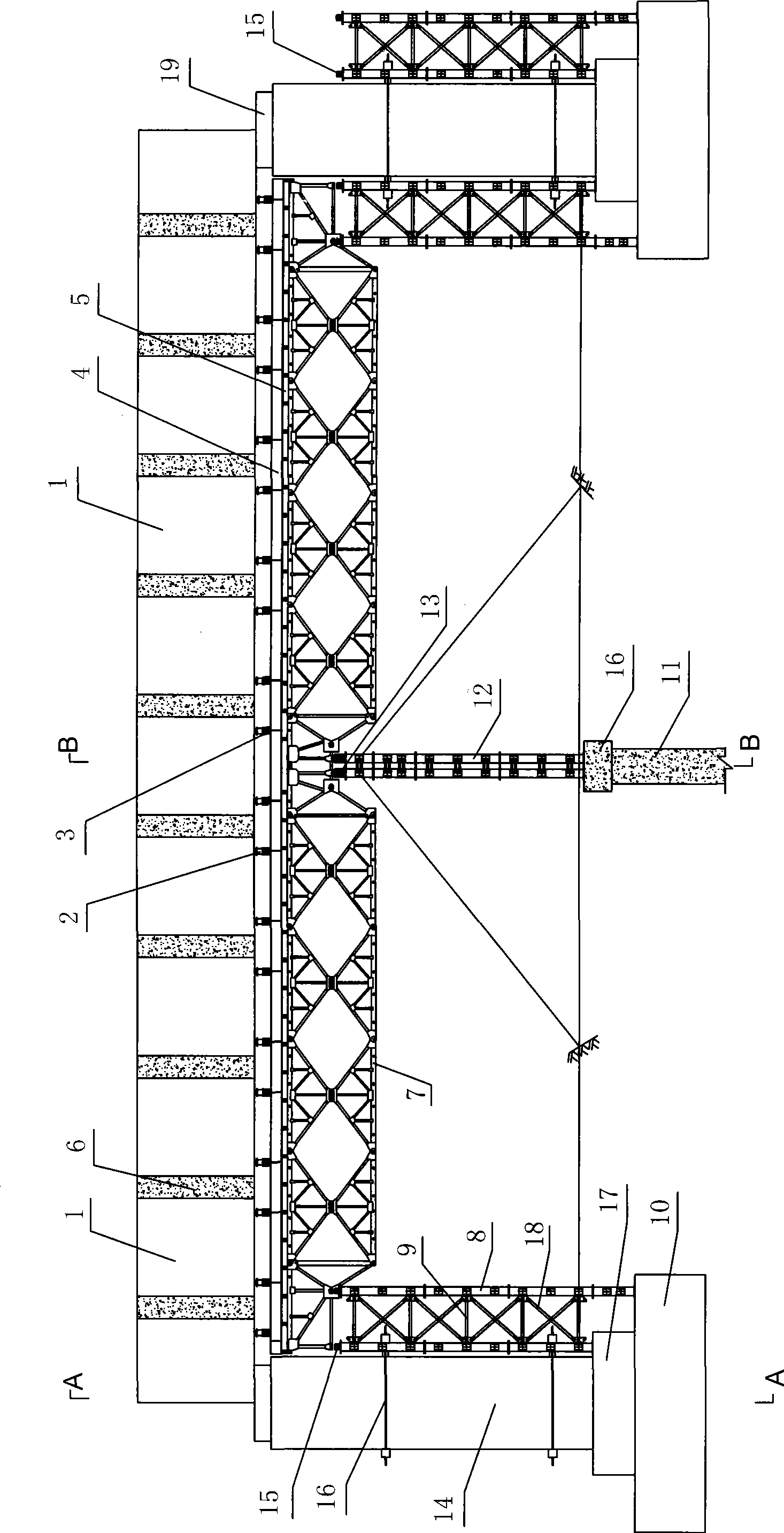

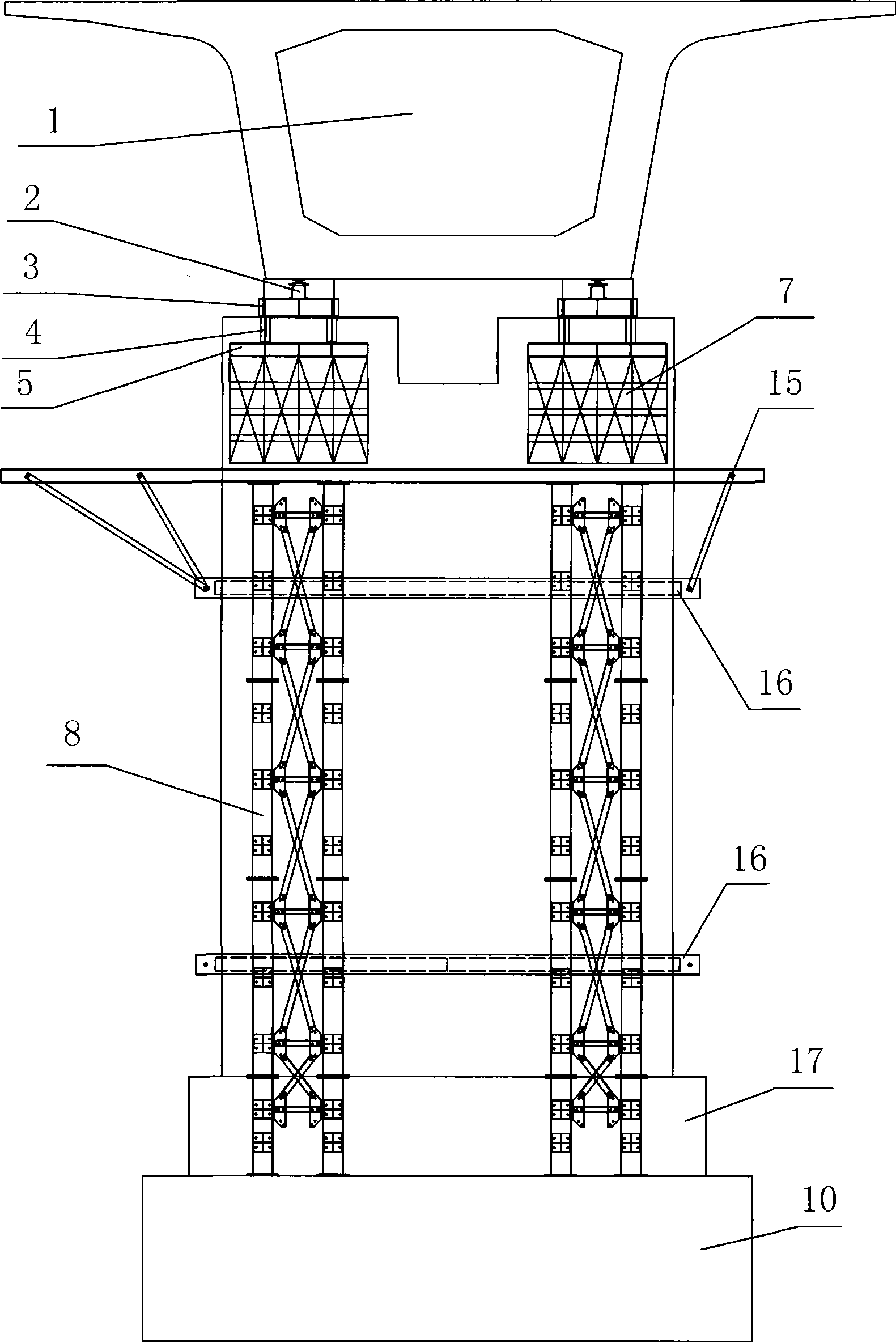

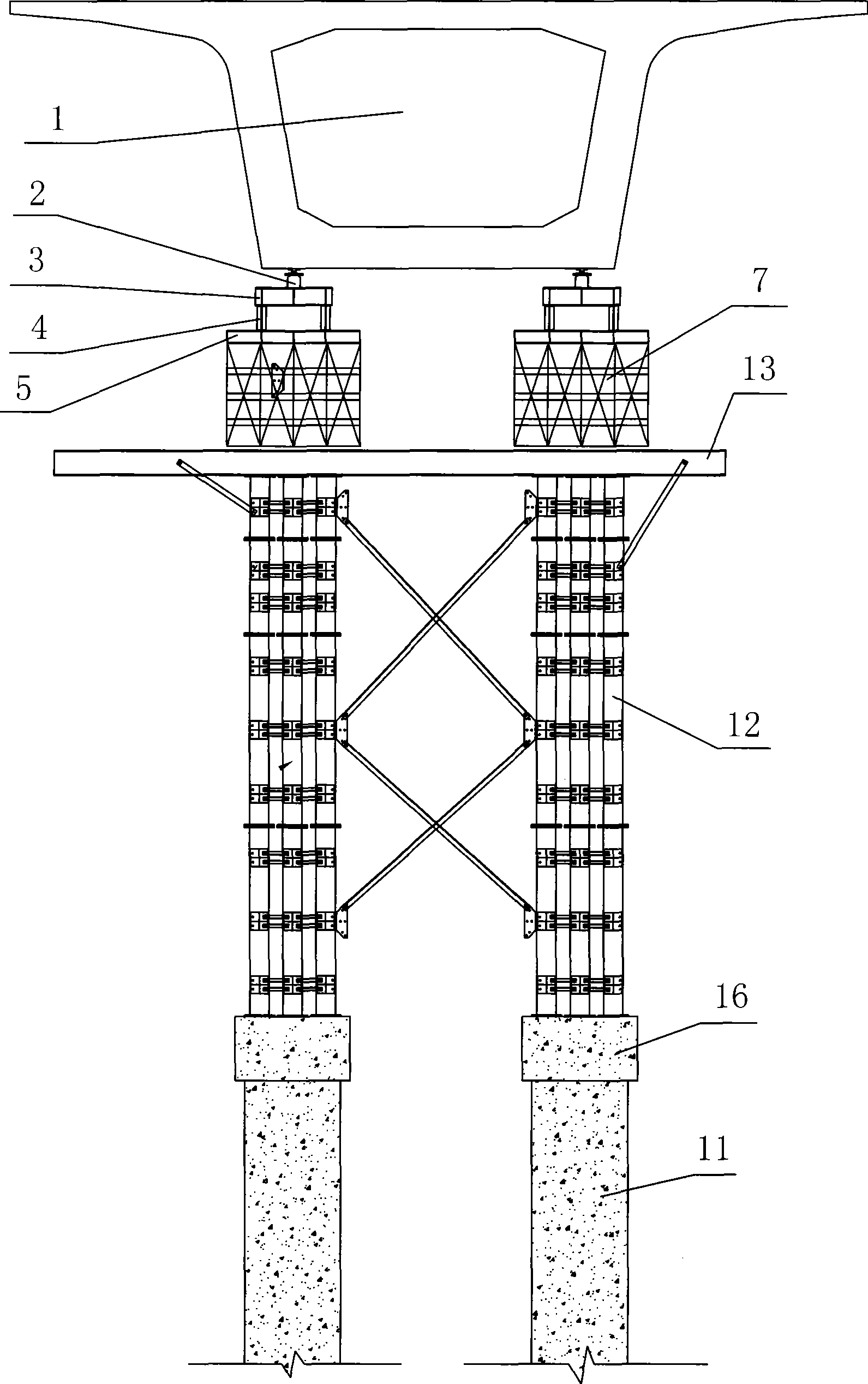

Integral hoisting system for superaltitude overlong jumbo beam by truss method and construction method thereof

InactiveCN101446135AImprove construction progressReduce safety hazards of falling objectsBridge erection/assemblyBuilding material handlingLow altitudeFalling Objects

Owner:SHANGHAI CONSTR NO 1 GRP

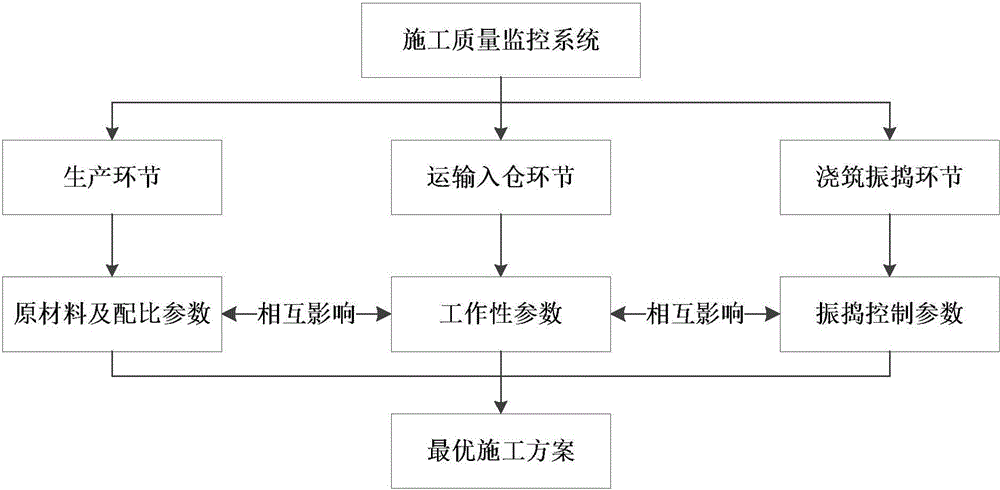

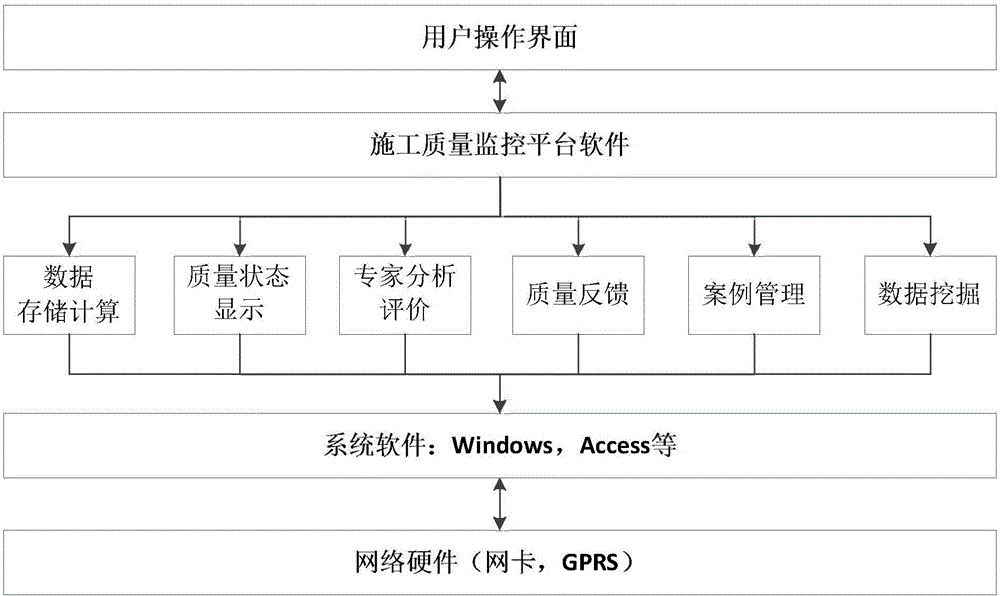

Concrete construction quality intelligent visualized monitoring system based on cloud technology platform

ActiveCN104898622AAutomatic and efficient storage and calculationImprove real-time performanceTotal factory controlProgramme total factory controlData informationMonitoring system

The invention discloses a concrete construction quality intelligent visualized monitoring system based on a cloud technology platform. Quality information parameters of each process of concrete construction production, transportation and pouring are acquired by the system via corresponding equipment and wirelessly transmitted to a quality real-time monitoring platform in a cloud-end server, the construction quality state of each technological link is analyzed through cloud storage, computing and display, and feedback regulation scheme information is timely transmitted to the related operators. The cloud technology is applied in the system so that a problem of insufficient local storage capability of wireless terminal equipment is solved and infinite data information can be processed within a few seconds. Besides, construction quality state information can be accessed, inquired and uploaded by all project participants so that interaction and sharing of the construction quality information can be realized and thus high-efficiency management and control of construction quality can be enhanced.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

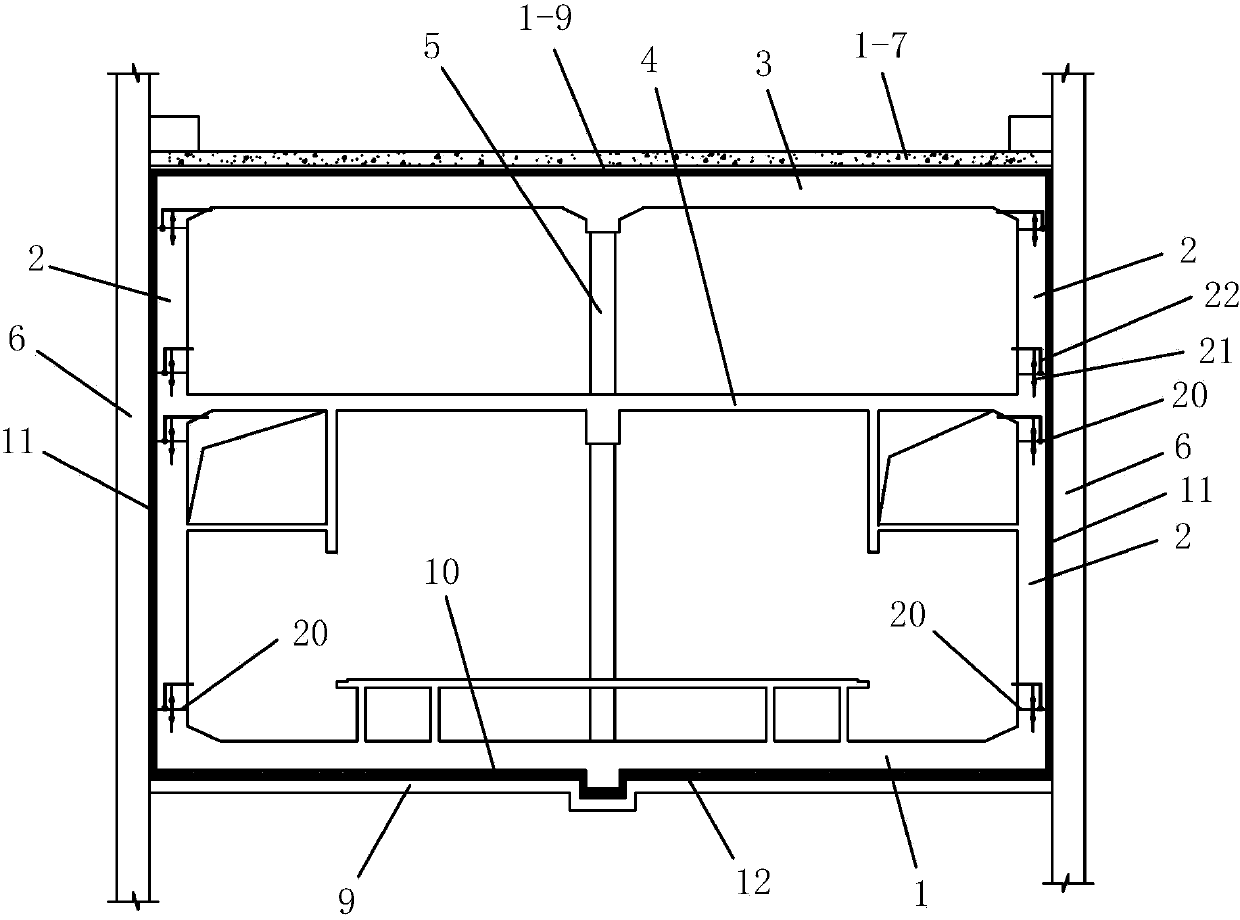

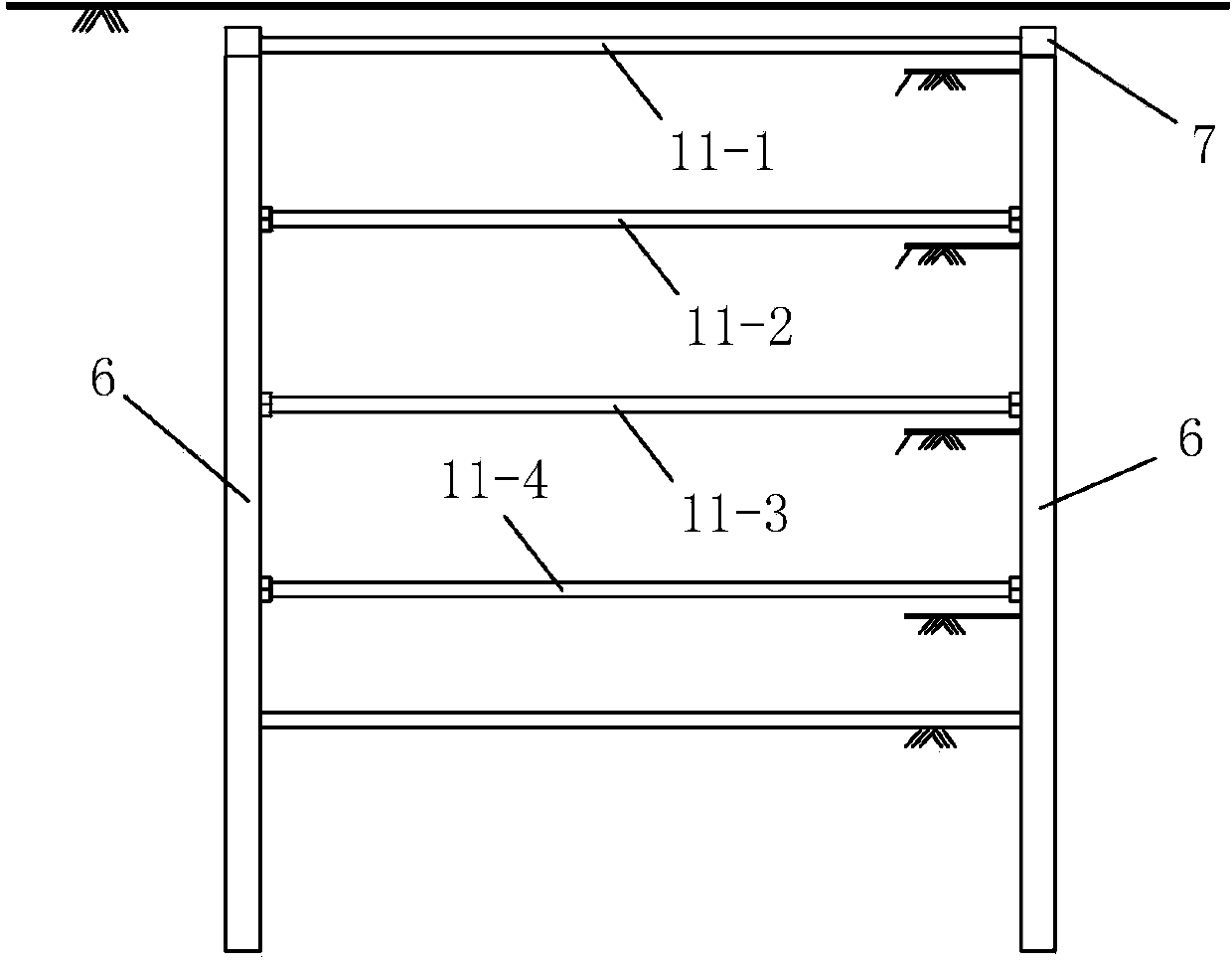

Segment-assembling simply supported box girder movable falsework construction method

The invention discloses a segment assembled simple box girder movable trestle construction method. The required construction simple box girder has single hole or multiple holes, and is assembled by a plurality of longitudinal (i.e. along bridge direction) segment box grinders; the method comprises the following steps: prefabricating all the segment box girders for assembling the simple box girder in concentration; assembling and erecting the first hole grinder, which comprises the steps of: assembling and erecting the trestle (i.e. assembling platform), hanging the segments on to the assembling platform according to the assembling sequence and adjusting the arch degree, line style and position accurately, constructing the segments on the assembling platform by segment assembling construction technology until complete the whole hole grinder construction, and dismounting the trestle and moving to the next hole grinder; and performing the subsequent hole grinders in order according to the construction steps of the first hole grinder. the invention achieves the advantages of simple steps, low construction difficulty, short construction cycle and low onetime fund investment; can solves the practical problems existing in the segment assembling construction process of current large-span bridge fabrication machine.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Construction method for mounting outdoor embedded high-density polyethylene double-wall corrugated drain pipe

InactiveCN101565964AReduce weightConstruction and transportation are convenientSewerage structuresSewer pipelinesLow speedDouble wall

The invention relates to a construction method for mounting an outdoor embedded high-density polyethylene double-wall corrugated drain pipe (CPP).The method is characterized by comprising the following processes of foundation trench digging, pipe mounting and backfilling, wherein the foundation trench digging technical process comprises measuring and setting out, mechanical grooving, levelling and tamping of a groove bottom, grit gravel cushioning and foundation sanding; the pipe mounting technical process comprises pipe mounting, well chamber building and rendering; and the backfilling technical process comprises soil filling for a chest, a water tight test, soil backfilling and tamping. The method solves the problems of discharge of rainwater and sewage of current municipal engineering, industrial wastewater discharge, subdistrict drain engineering, low speed for cement and metal pipe construction in the engineering of pipelines preburying and the like, heavy pipe weight, inconvenience for conveying and carrying, large labor intensity, high mounting cost and the like, and is applicable to the discharge of the rainwater and the sewage of the current municipal engineering, the industrial wastewater discharge, the subdistrict drain engineering, and the construction for mounting engineering drain pipes such as the pipelines preburying and the like.

Owner:QINGDAO HENGSHENGYUAN GROUP CONSTR

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930AReduce water pressure in tunnelReduce water and mud inrushUnderground chambersTunnel liningWorld classTunnel construction

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

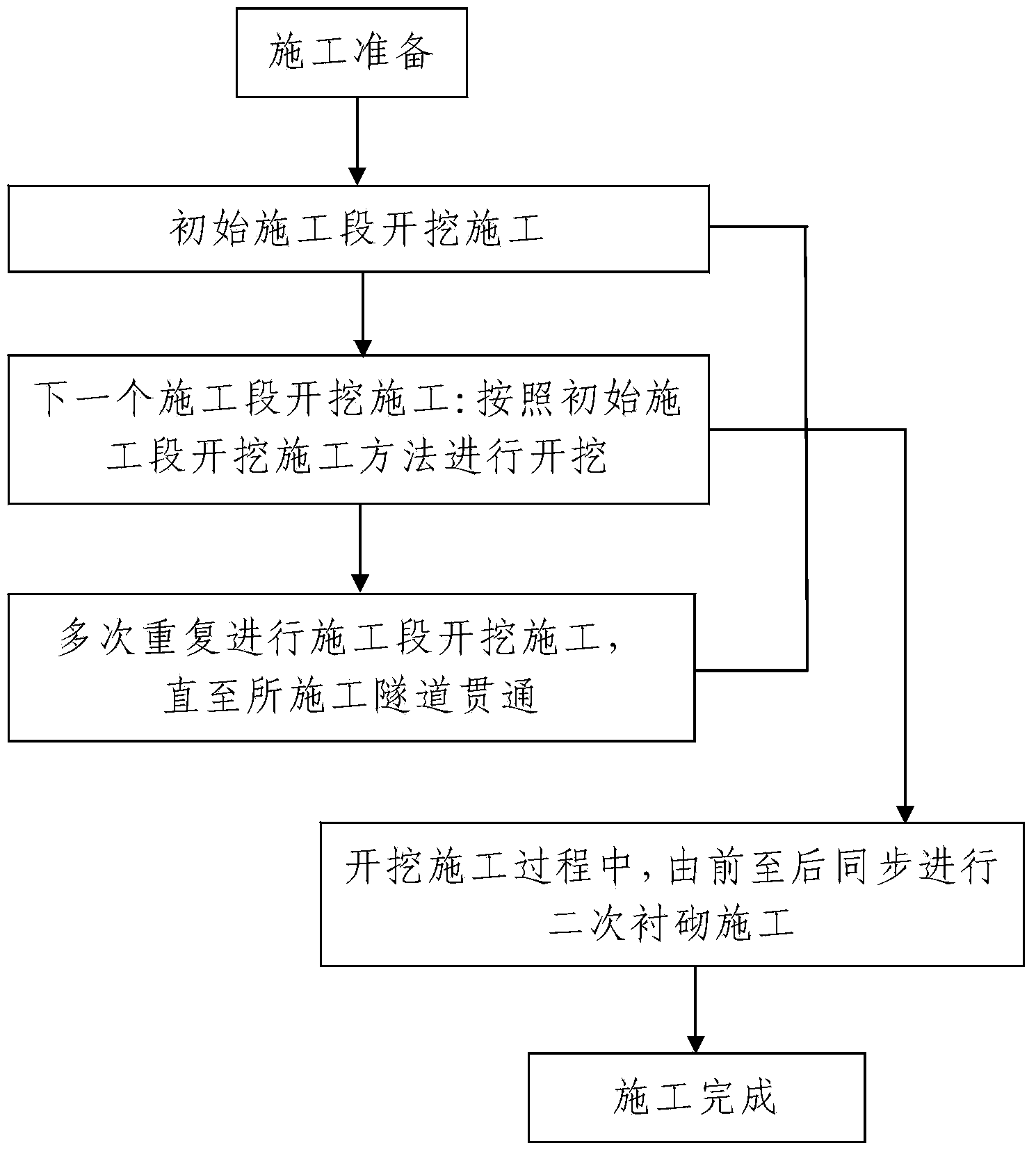

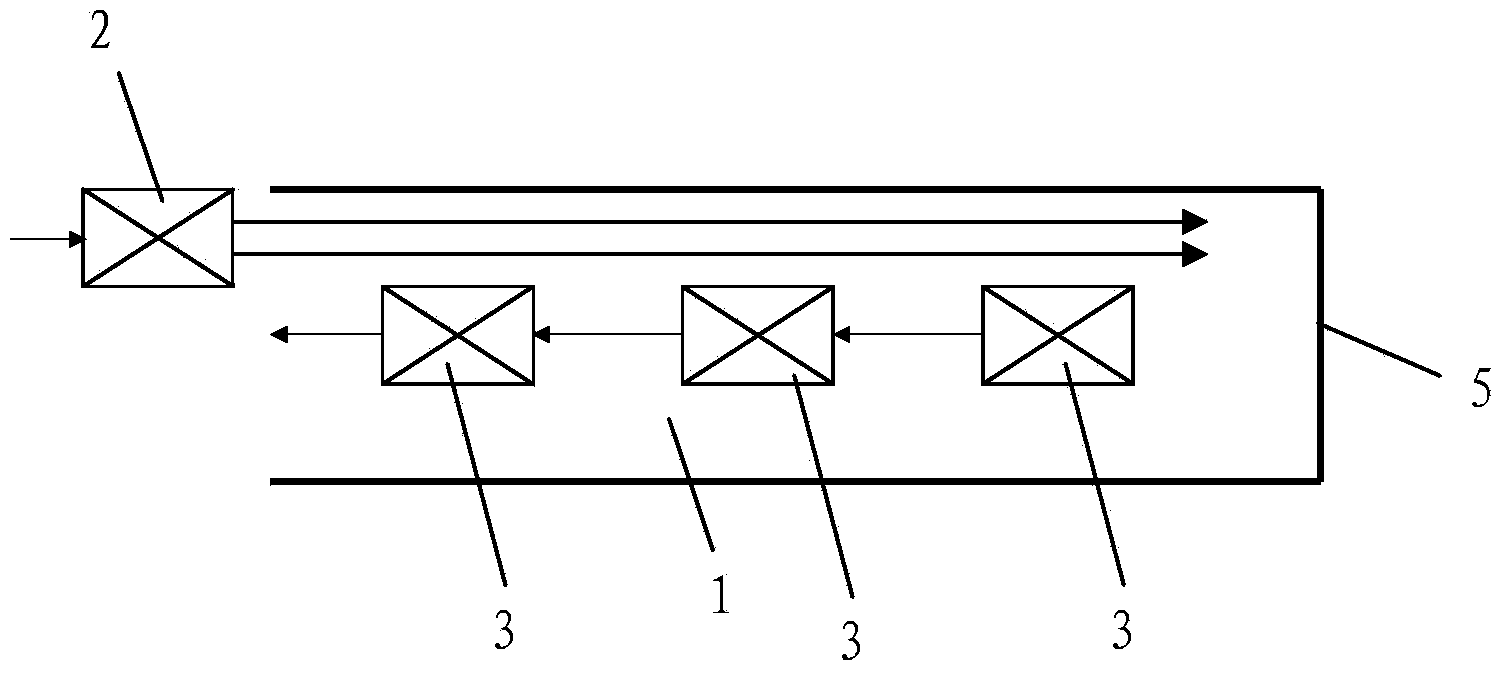

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

Construction method for cast-in-place integral light-weight partition wall

InactiveCN101858114AReduce crackingHigh tensile strengthWallsBuilding material handlingEarthquake resistanceKeel

The invention discloses a construction method for an interior partition wall. The construction of the partition wall is characterized by comprising the following steps: erecting templates at both sides of a wall body, and fixing the templates by using outside removable keels; and then casting light aggregate concrete or manufactured-in-place aerated concrete in the templates so as to cast the wall body into an complete whole, wherein the permanent templates can be made of thistle boards, plastic boards, cement boards or insulation boards; the casting of the light aggregate concrete is transferred by a booster pump; and the casting of the concrete can be started from the lower part, middle part or the upper part of the wall body until the concrete is spread all over the whole wall body. The wall body constructed by using the method meets the requirements of light weight, sound insulation and heat insulation for the traditional partition wall, and simultaneously, the common quality problems of plastering, wall surface cracking and poor earthquake resistance in the construction of the traditional partition wall are avoided or reduced because of the one-piece casting. Meanwhile, by erecting the permanent templates in the construction of the wall body, the molded wall surface is smooth and level, and the floated coat construction is omitted, thereby greatly raising the construction speed of the wall body, and lowering the construction cost.

Owner:段风雷

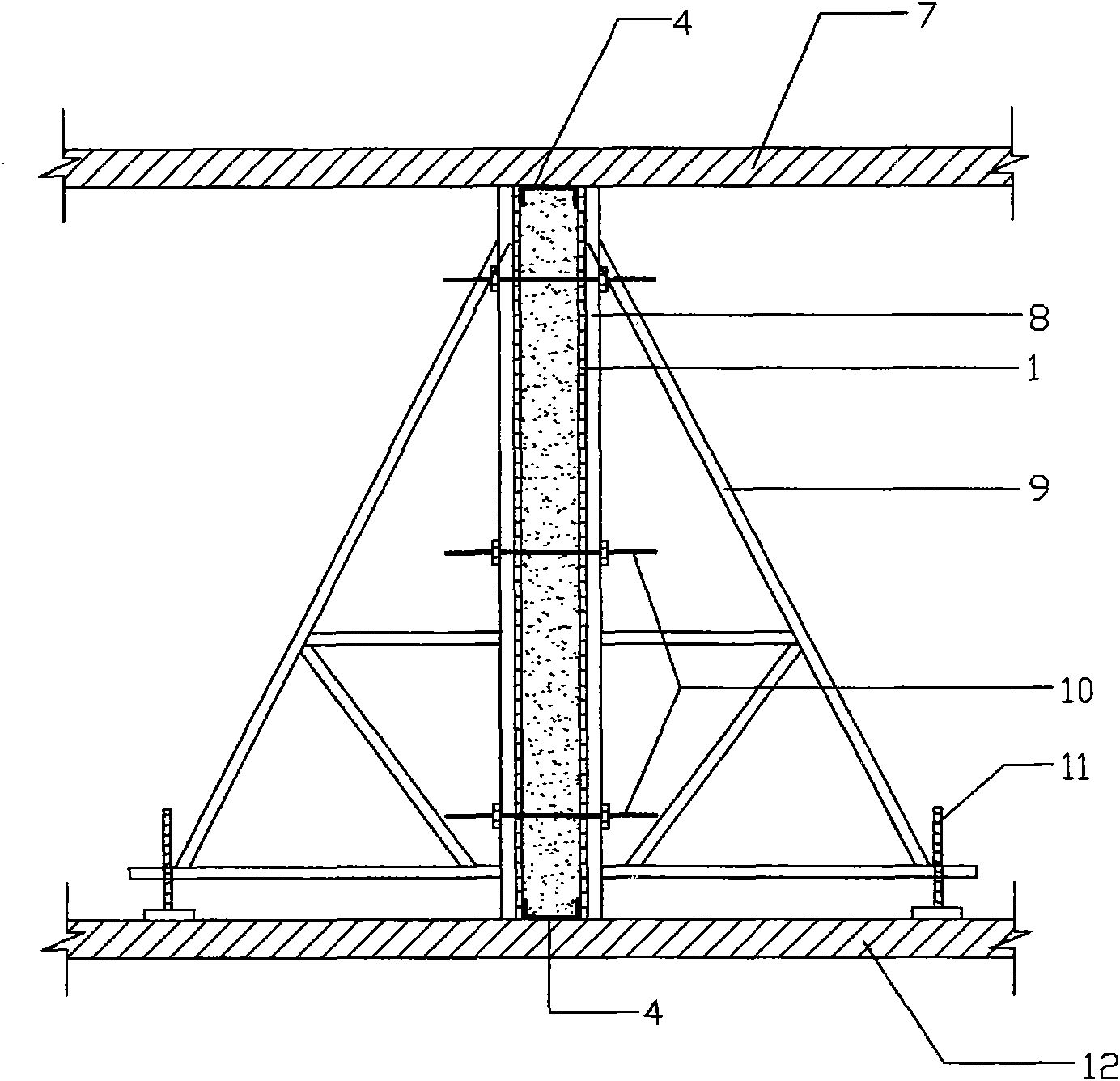

Precise positioning frame for large steel columns and equipment foundation fixing bolts and construction method of precise positioning frame

InactiveCN102561712AEasy to installGuaranteed installation accuracyFoundation engineeringBuilding material handlingBraced frameSteel columns

The invention discloses a precise positioning frame for large steel columns and equipment foundation fixing bolts and a construction method of the precise positioning frame. The precise positioning frame comprises a supporting frame for placing the fixing bolts; a profile steel bracket is surrounded at the outer side of the supporting frame; the profile steel bracket comprises vertical rods, connecting rods, a profile steel bracket top frame and a positioning sleeve frame placing platform, wherein the vertical rods are distributed at intervals, each connecting rod is connected between every two adjacent vertical rods, the profile steel bracket top frame is detachably connected between upper end parts of the vertical rods through a connecting bolt, and the positioning sleeve frame placing platform is connected on the profile steel bracket top frame; the fixing bolt positioning sleeve frame is laid on the positioning sleeve frame placing platform; and a positioning hole is arranged on the fixing bolt positioning sleeve frame. The positioning frame ensures that large steel structure column bolts or large equipment foundation fixing bolts are more precise to install, the defect that bolts can be adjusted and fixed only before concrete is cast and cannot be precisely adjusted during the casting of concrete in the traditional process is avoided, moreover, the positioning frame can be partly turned over to be operated, so that the construction cost is saved, and the construction progress is accelerated.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Corrugated steel webplate combined box girder floor system for cable-stayed bridge and construction method thereof

InactiveCN101864729AAvoid on-site molding processReduce wet work workloadCable-stayed bridgeBridge structural detailsCrack resistanceEngineering

The invention relates to a corrugated steel webplate combined box girder floor system for a cable-stayed bridge and a construction method thereof, and belongs to the technical field of bridge structures. The corrugated steel webplate combined box girder floor system comprises a precast concrete plank and a cast-in-place concrete seam, wherein the precast concrete plank is positioned on a steel box girder and is integrated with the steel box girder into a whole; the steel box girder is formed by welding a top flange steel plate, a corrugated steel webplate and a steel plate at the bottom of the box girder; a box girder baseplate stiffening rib and a diaphragm plate are welded in the steel box girder; the diaphragm plate comprises a top flange steel plate of the diaphragm plate and a steel webplate of the diaphragm plate; a toggle pin connecting piece is welded on the top flange steel plate and the top flange steel plate of the diaphragm plate; and a steel anchor pulling plate and a steel sleeve are welded on the top flange steel plate. The corrugated steel webplate combined box girder floor system simplifies the manufacturing process for the precast concrete plank, gives full play to the superior mechanical property of the corrugated steel webplate and the release action of the corrugated steel webplate on the creep effect of concrete shrinkage, improves the bearing capacity, stiffness and crack resistance of the structure, and improves the durability of the structure.

Owner:TSINGHUA UNIV

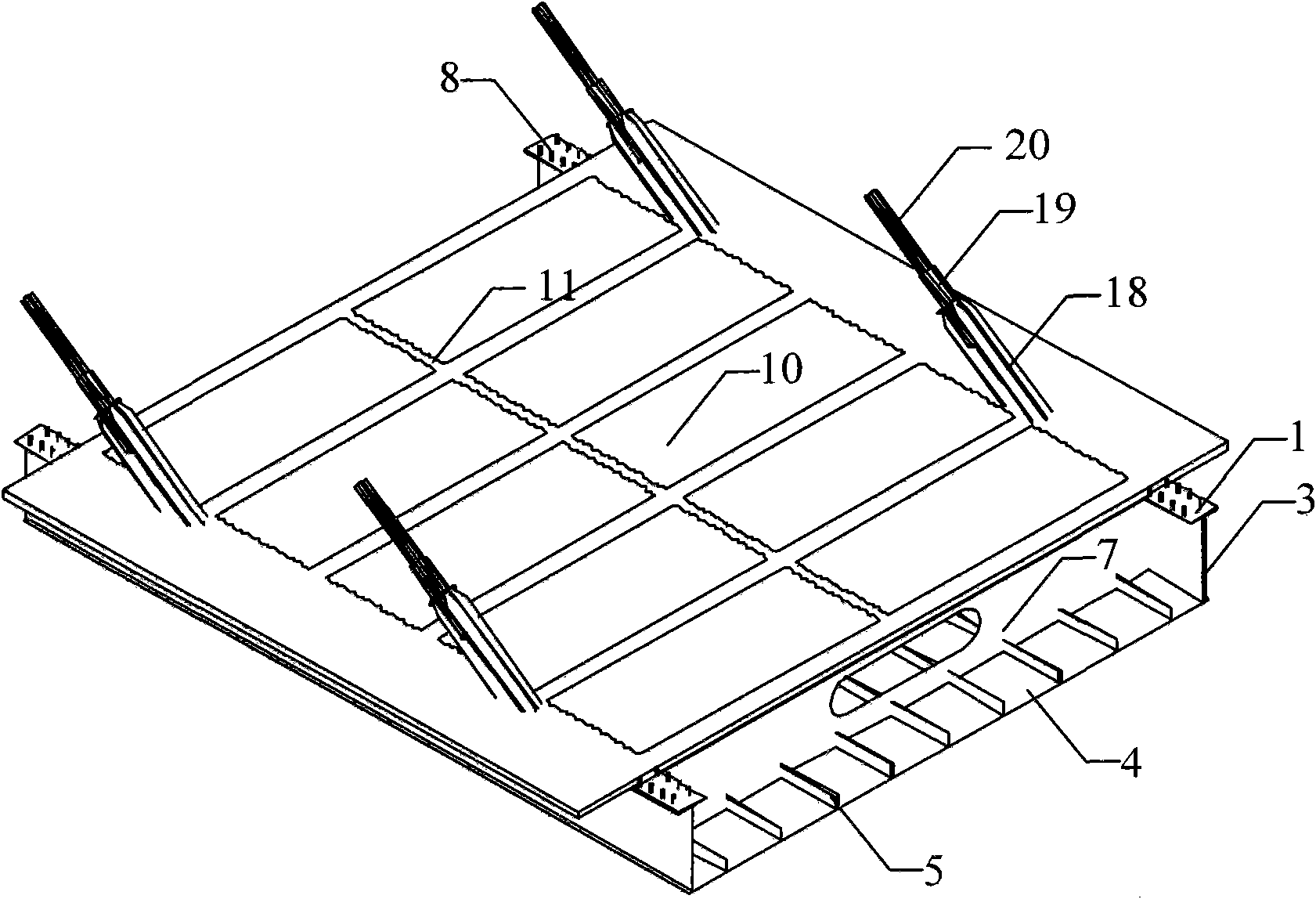

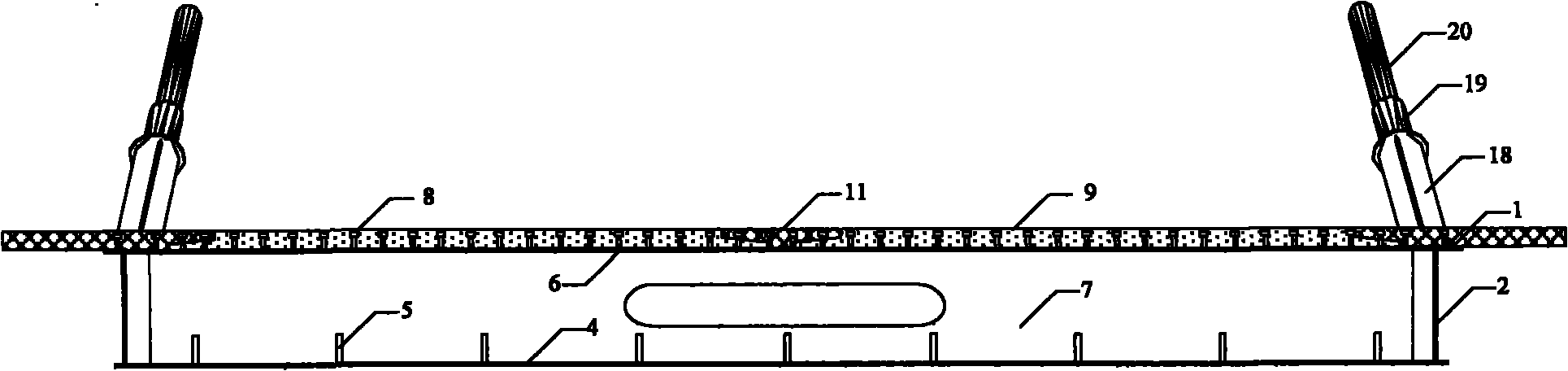

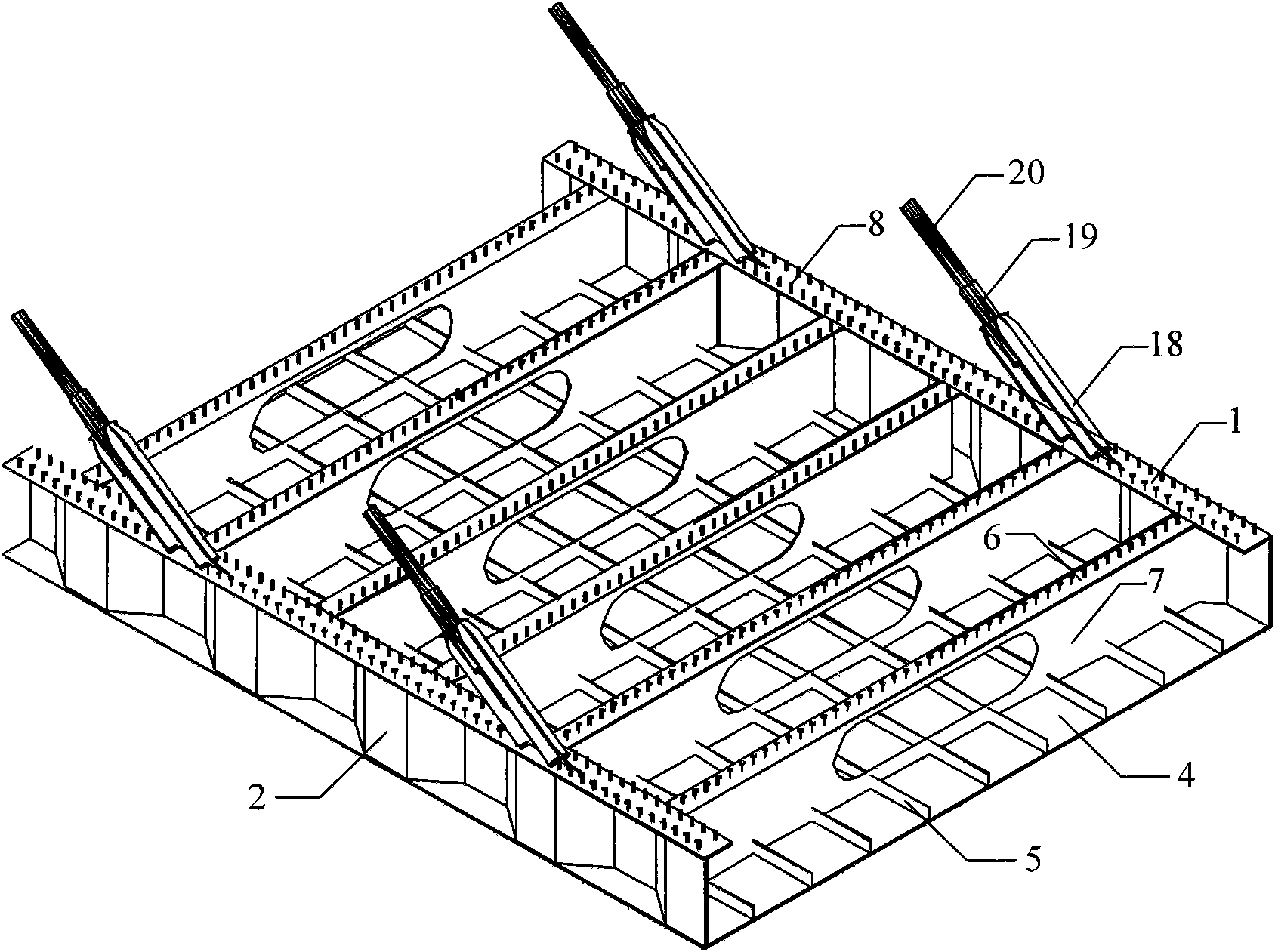

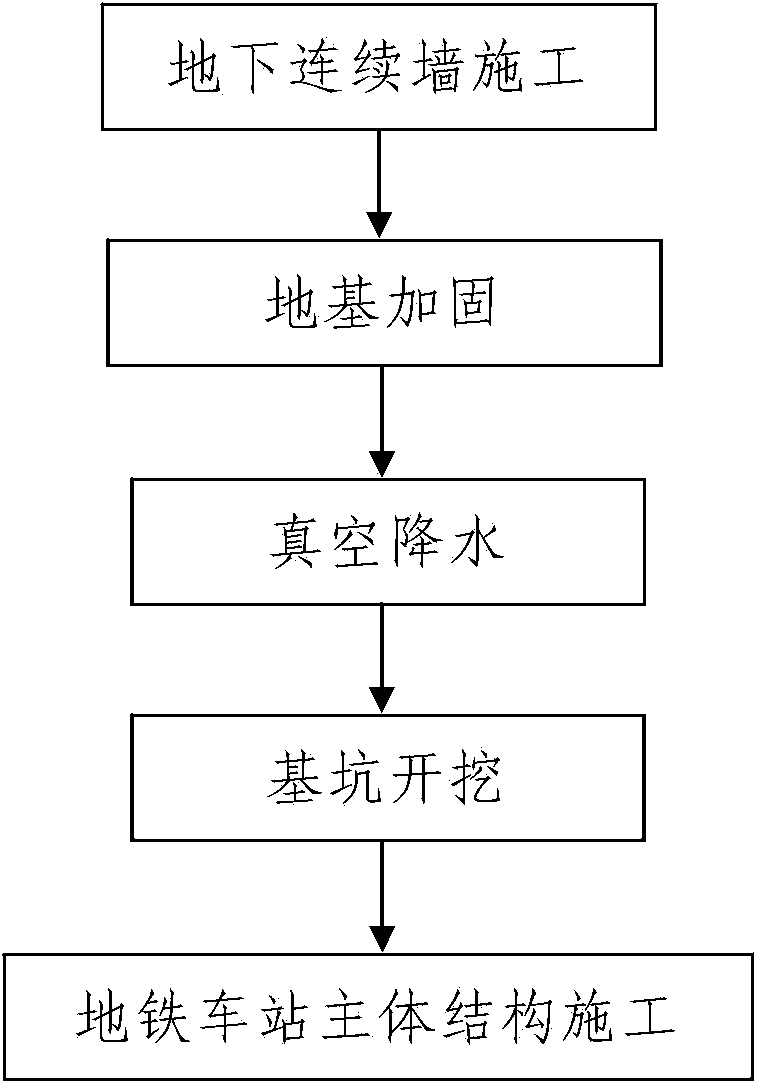

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

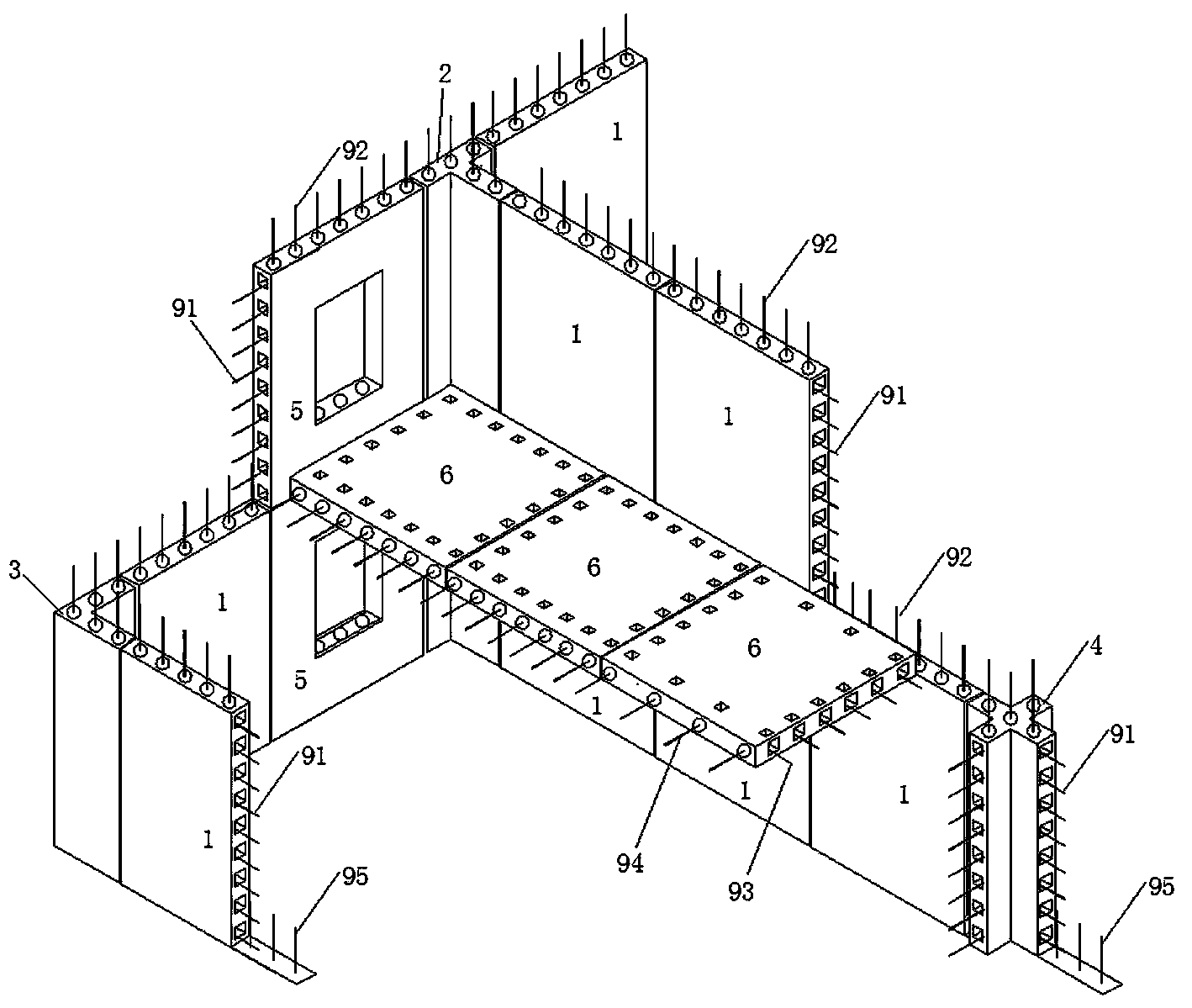

Assembly integral shear wall building structure and building method

ActiveCN103669559AImprove the level of industrializationIncrease productivityWallsBuilding material handlingRebarHigh rise

The invention relates to an assembly integral shear wall building structure and a building method and belongs to the field of buildings and construction technologies of the buildings. The shear wall building structure is formed by connecting prefabricated concrete hollow components through steel bars and cast-in-place concrete, wherein the prefabricated concrete hollow components include prefabricated wall body components, floor board components, T-shaped wall pillar components, L-shaped wall pillar components, cross-shaped wall pillar components and wall body components with holes. Multiple parallel lengthwise through holes are formed in the prefabricated hollow components in the length direction and multiple parallel transverse non-through holes communicated with the lengthwise through holes are formed in the prefabricated hollow components in the width direction. Horizontal anchor connection steel bars inserted into the transverse holes are arranged among the different prefabricated components. Lengthwise anchor connection steel bars are arranged in the lengthwise holes, wherein one end of each lengthwise anchor connection steel bar protrudes out of the surface of the corresponding prefabricated component by a certain length. The concrete is filled into the lengthwise holes and the transverse holes to form a layer of structural unit or a single-layer building structure. Multiple structure units are connected to form a multiple-layer or high-rise assembly integrated shear wall structure. The assembly integral shear wall building structure and the building method can be applied to the multiple-layer or high-rise shear wall building structures and frame-shear wall building structures. Thus, the industrial level of the building structures can be improved, stress performance can be improved and resources are saved.

Owner:初明进

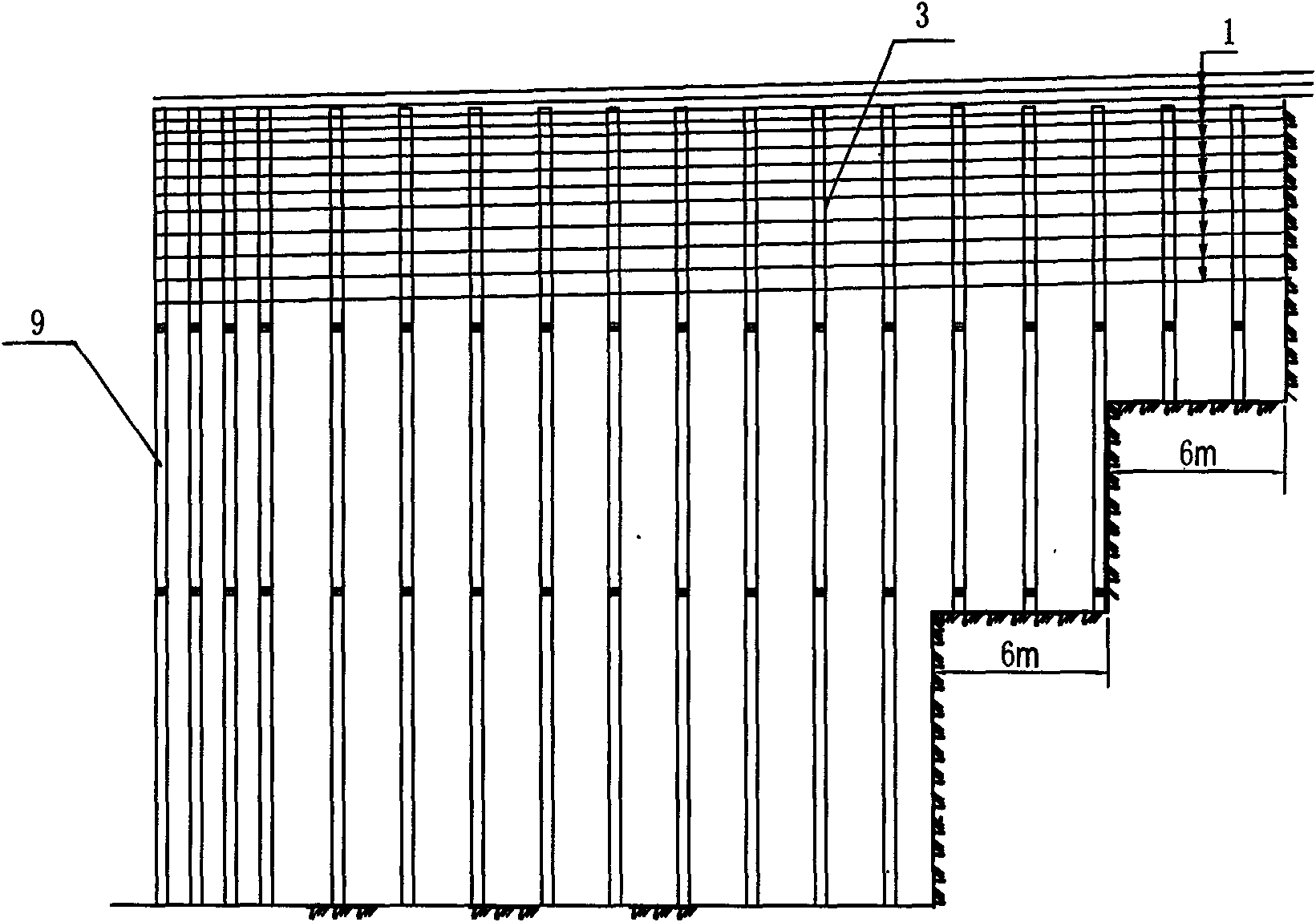

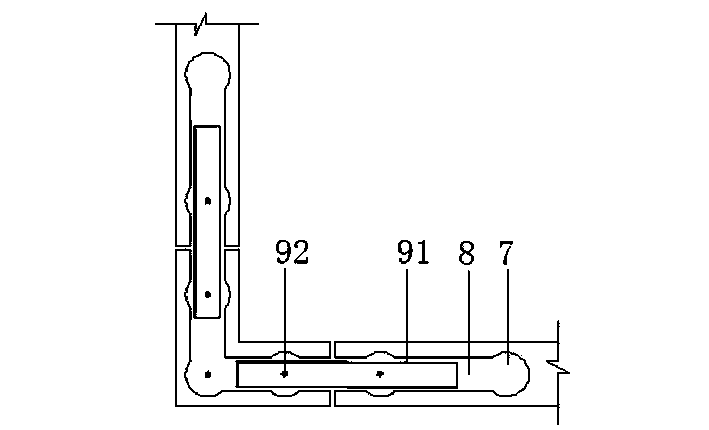

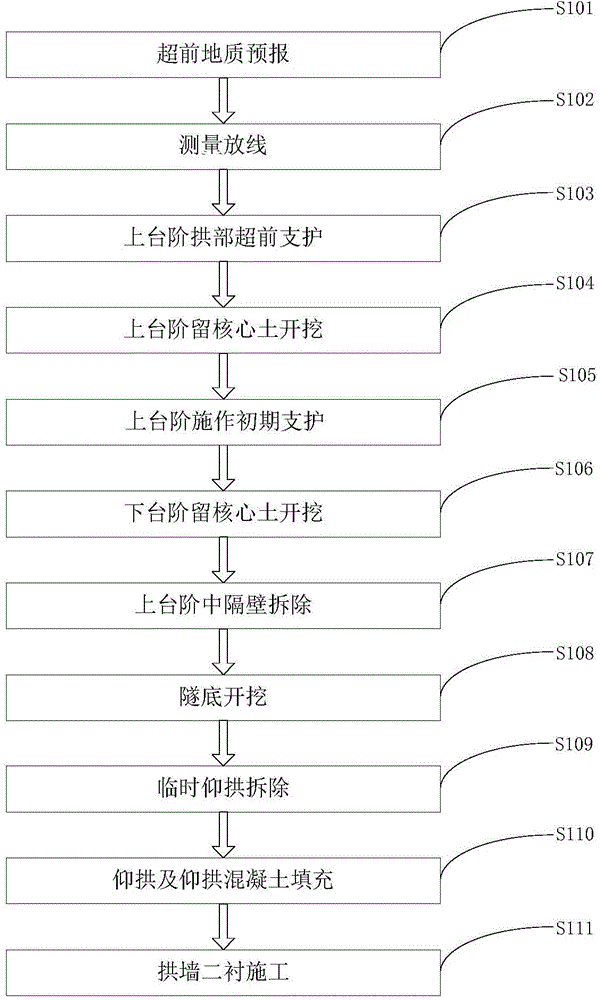

Method for constructing upper step middle partition wall of shallow-buried excavation tunnel

ActiveCN104612698ASuppression of extrusion displacementControl rear displacementUnderground chambersTunnel liningEconomic benefitsSupport materials

The invention discloses a method for constructing an upper step middle partition wall of a shallow-buried excavation tunnel. The method includes the steps of advanced geology forecast, measuring and setting-out, upper step arch advanced supporting, upper step excavation with core soil reserved, upper step application primary supporting, lower step excavation with core soil reserved, upper step middle partition wall detachment, tunnel bottom excavation, temporary inverted arch detachment, inverted arch and inverted arch concrete filling, and arch wall secondary lining construction. The method simplifies construction procedures, saves temporary supporting materials, accelerates the construction progress to 45-60 meters per month, reduces labor cost, effectively shortens the construction period, reduces engineering cost, solves various problems that the number of auxiliary procedures of shallow-buried excavation tunnel construction is large, construction process is slow and structure stress is complicate, reduces influences on surrounding environments, and achieves good social and economic benefits.

Owner:HANGZHOU TIANHENG INVESTMENT CONSTR MANAGEMENT +1

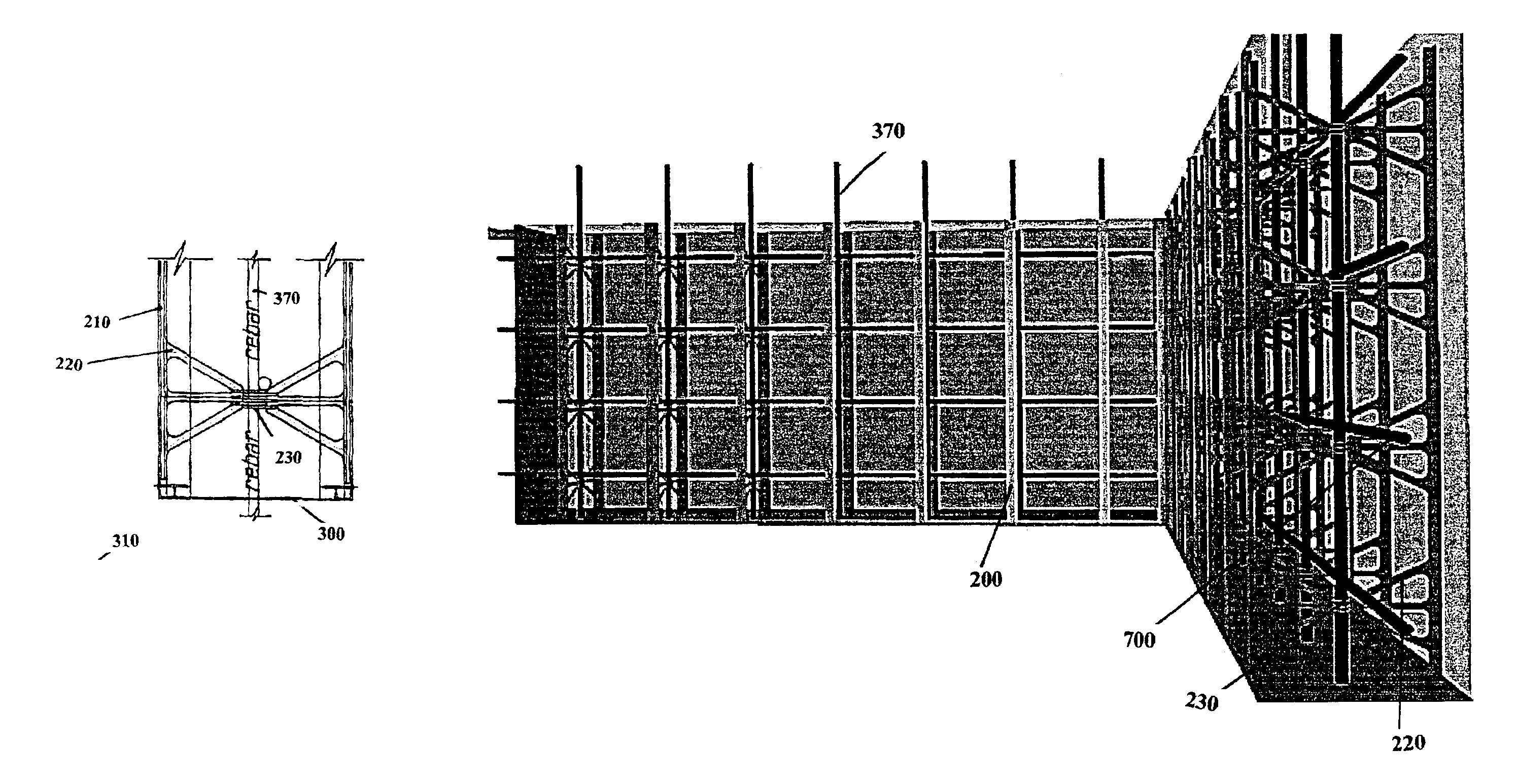

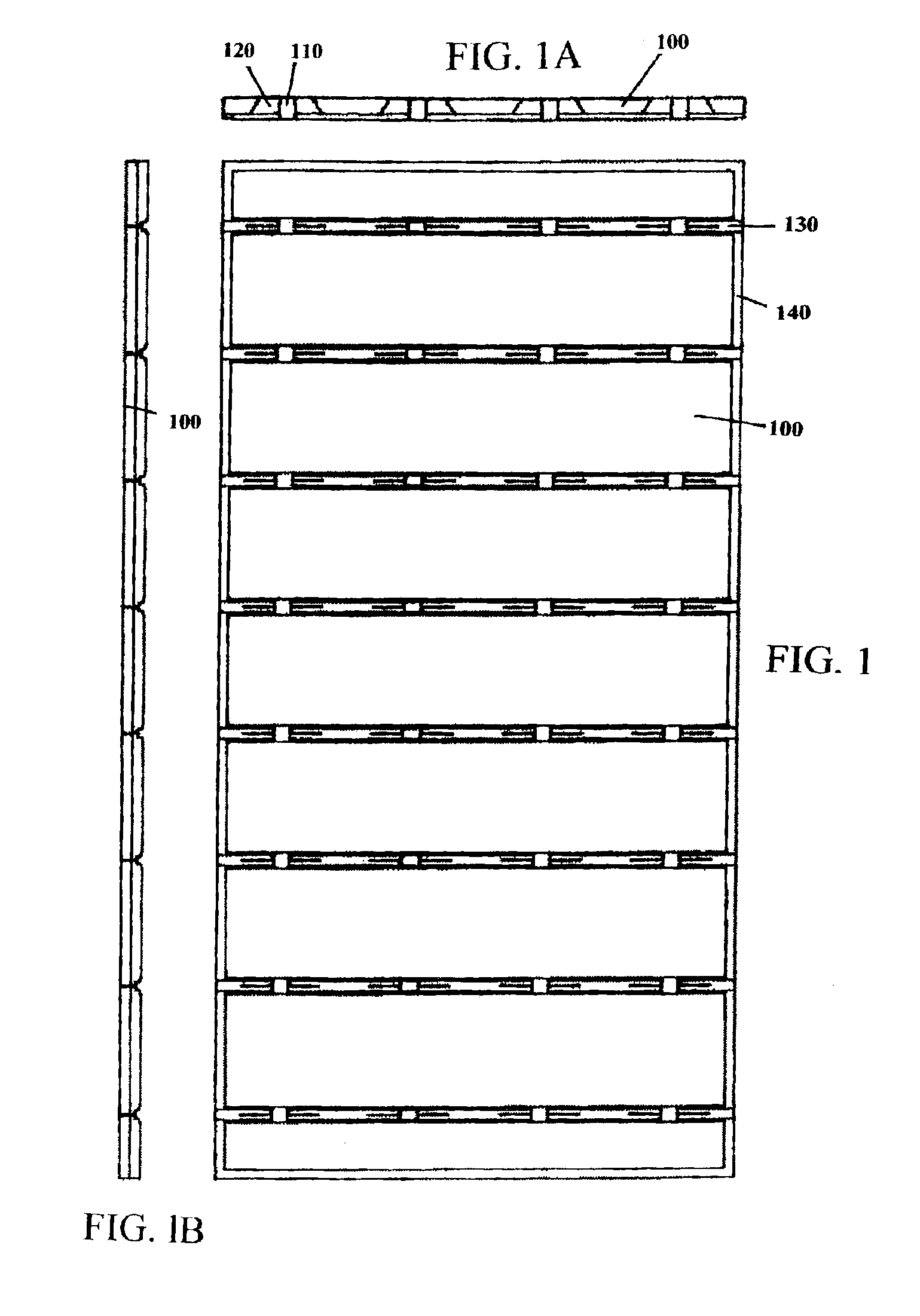

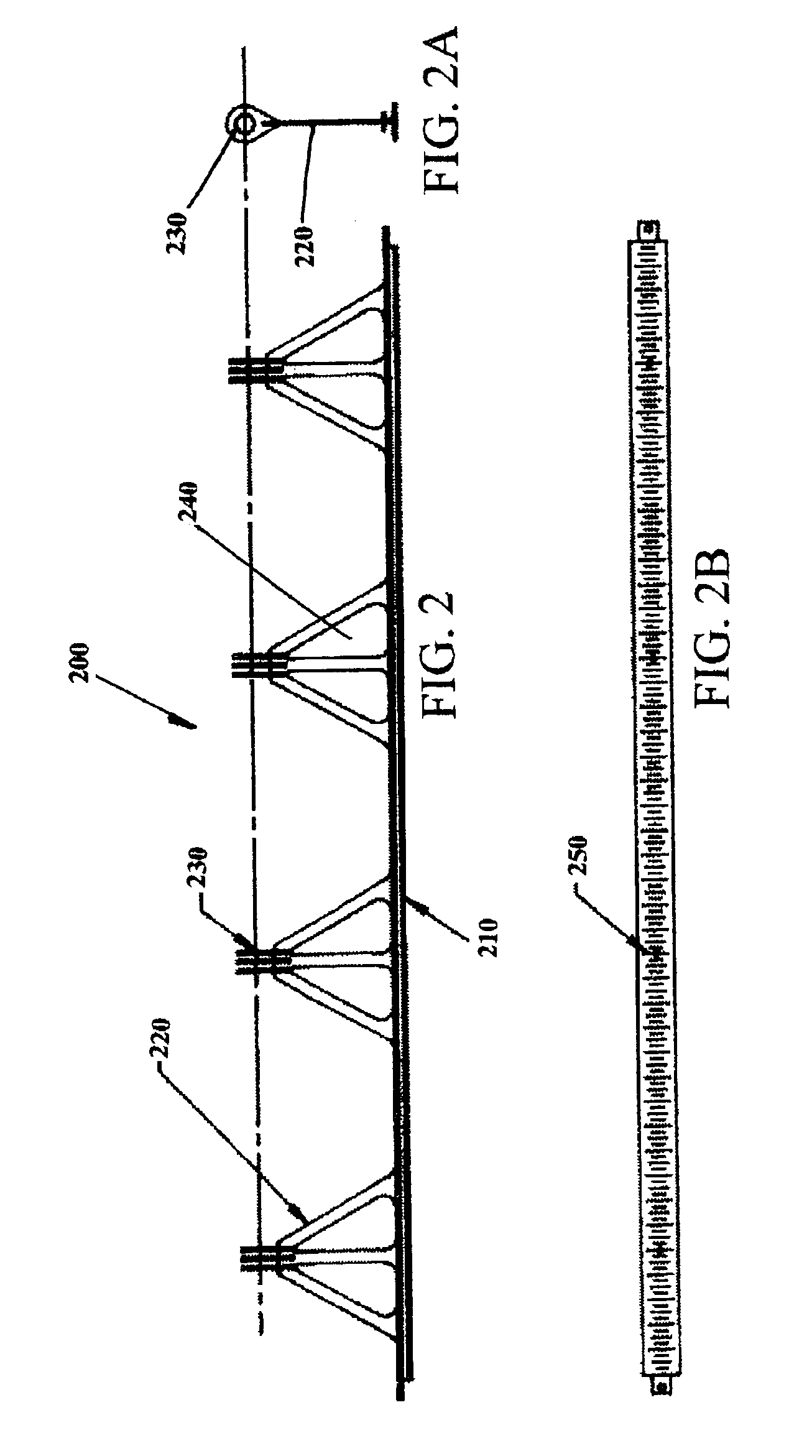

Concrete forming system and method

A system and method for forming concrete structures, using foam panels as forms, supported by vertical tracks with horizontal bridge pieces inserted through the forms. The bridge pieces are in the form of triangular webs with coaxial rings for supporting vertical rebars centrally between opposing forms. The coaxial rings on opposing bridge pieces key together to securely hold the vertical rebars. At the corners of the structure, corner retaining extrusions are used having fins for retaning the foam panels, and having various included angles such as 60°, 75°, 90°, 120°, 135°, 150° or 165°. Specific types of corner tie pieces for square, obtuse or acute corners are used to connect together the corner retaining extrusions at the inner and outer corners of the structure.

Owner:OLSEN TIMOTHY A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com