Combination beam

A technology of composite beams and prefabricated beams, applied in the field of composite beams, can solve problems such as slow construction progress, large material loss, and small material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

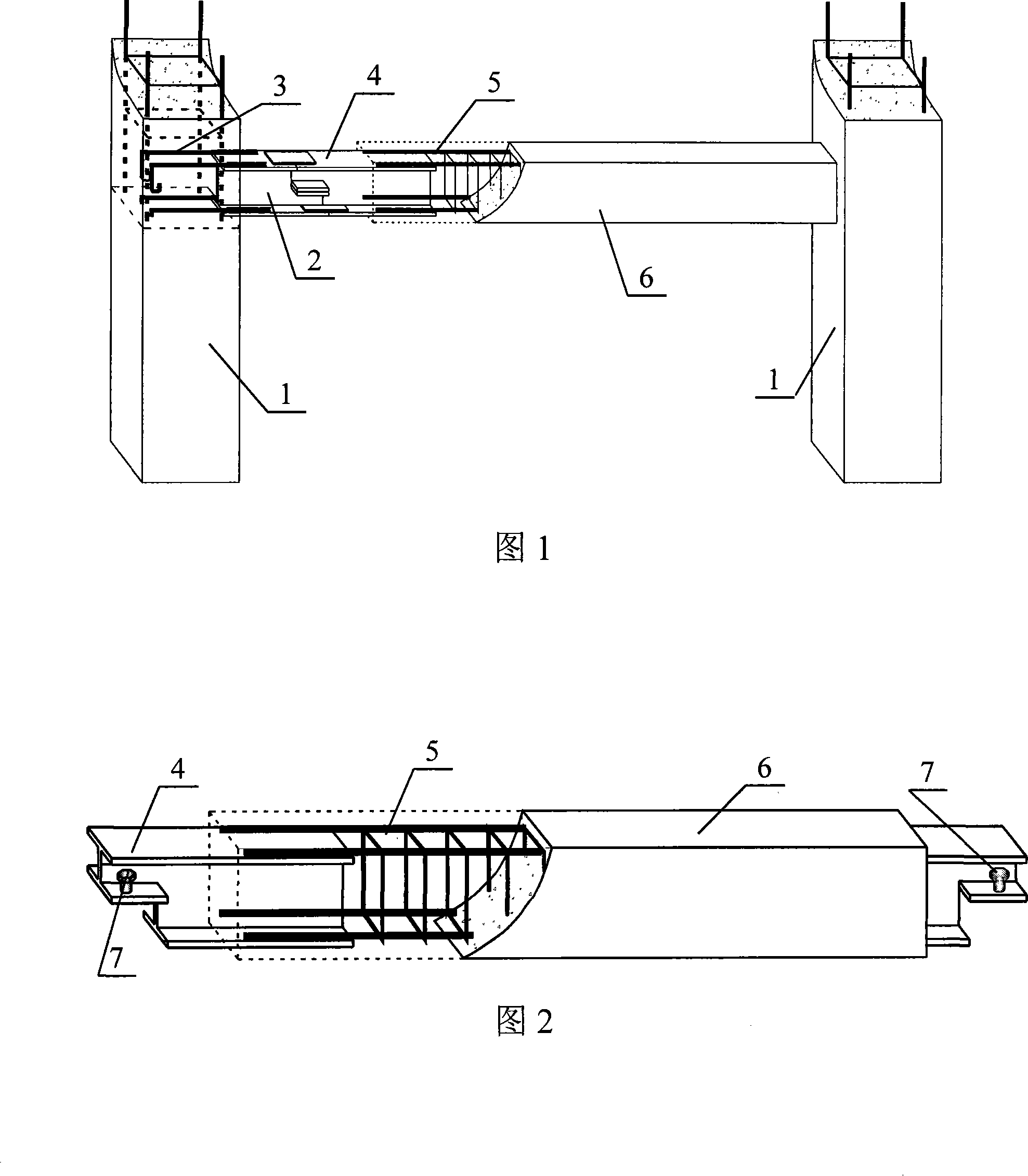

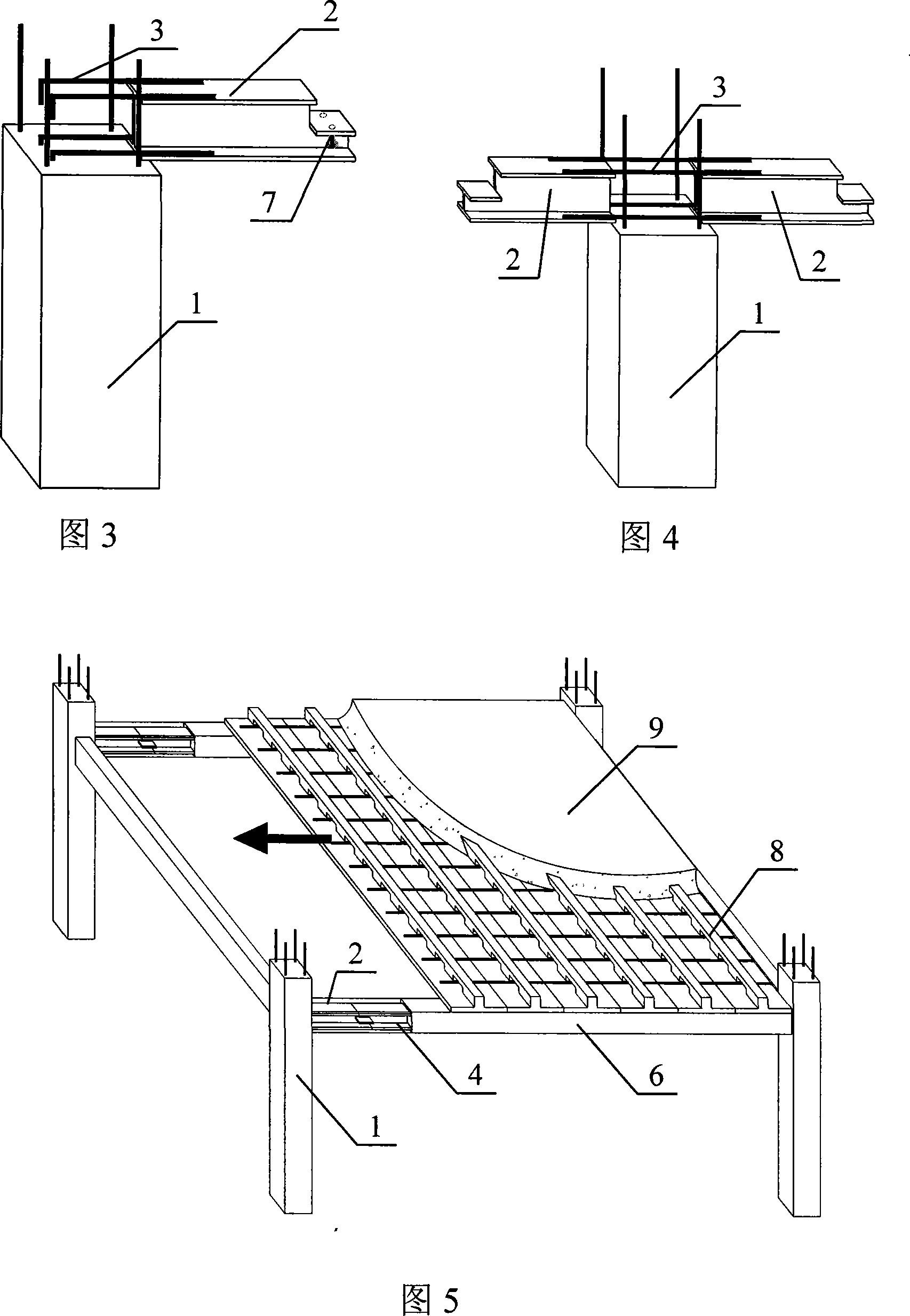

[0012] Referring to Fig. 1-Fig. 5, the composite beam is composed of reinforced concrete prefabricated beam 6 and profiled steel joint 2, and profiled steel 4 is connected to steel bars 5 at both ends of reinforced concrete prefabricated beam 6, and one end of profiled steel joint 2 is pre-embedded in wall column 1 In the concrete, it is connected with the steel bar 3 buried in the wall column 1, and the other end is left outside the concrete of the wall column 1. The two ends of the prefabricated beam 6 are connected with the section steel 4 and the section steel joint 2 to form a composite beam. The section steel 4 and the section steel joint 2 are used I-beam, square steel, channel steel and their combination can be used. Adjusting bolts 7 are installed on the shaped steel joint 2 or the shaped steel 4 at the end of the prefabricated beam 6 to adjust the flatness of the prefabricated beam 6 placed on the shaped steel joint 2. Welding, riveting, bolting and other connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com