Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6930 results about "Steel bar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steel bar, also called slide, play bar and bottleneck, is a musical apparatus which is used to play on steel guitars. The steel bar can be wound around the fingers or just held in the hand. Instead of pressuring the strings on the neck of the guitar, the steel bar slides over the strings, which produces a glissando effect.

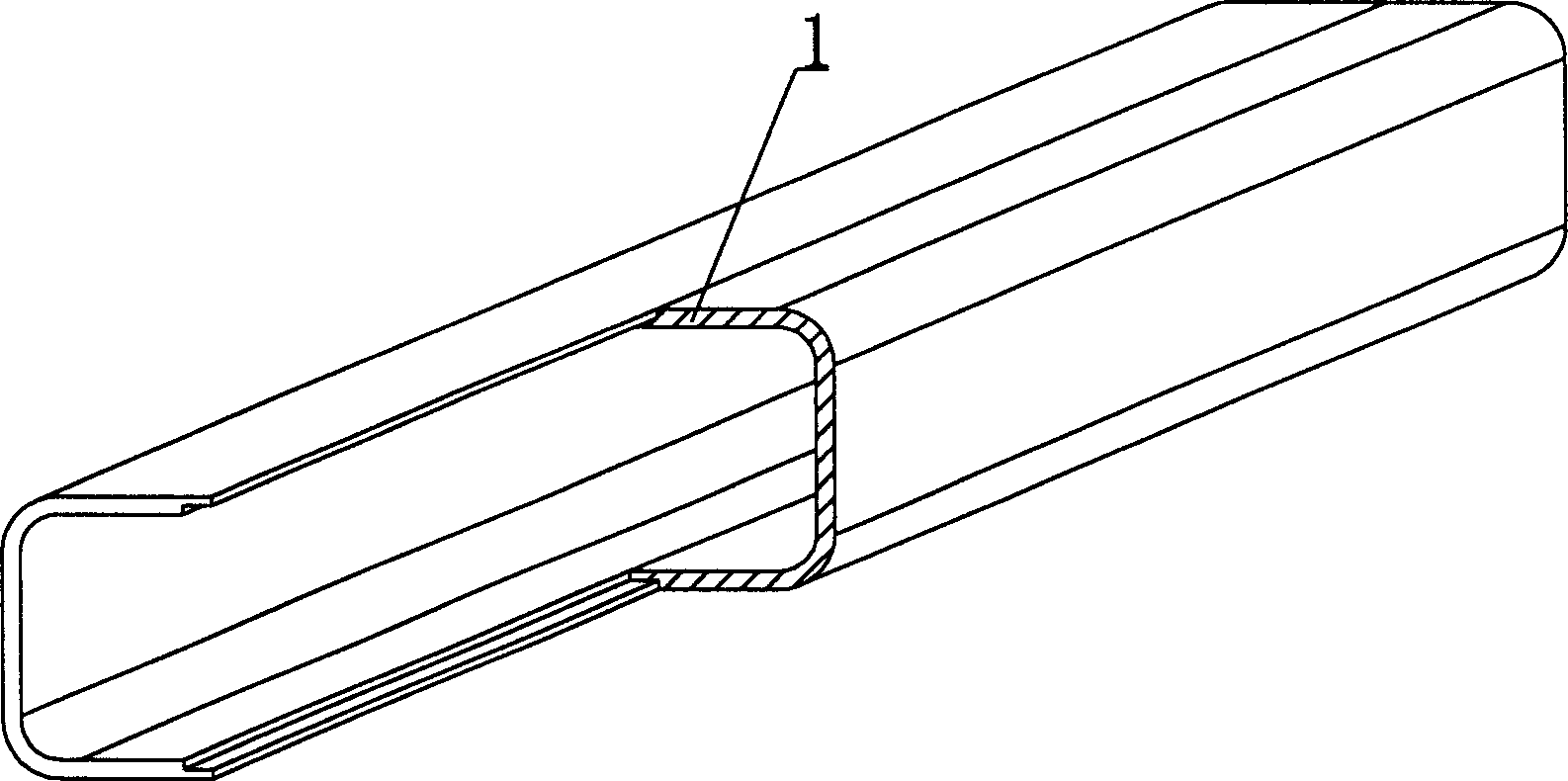

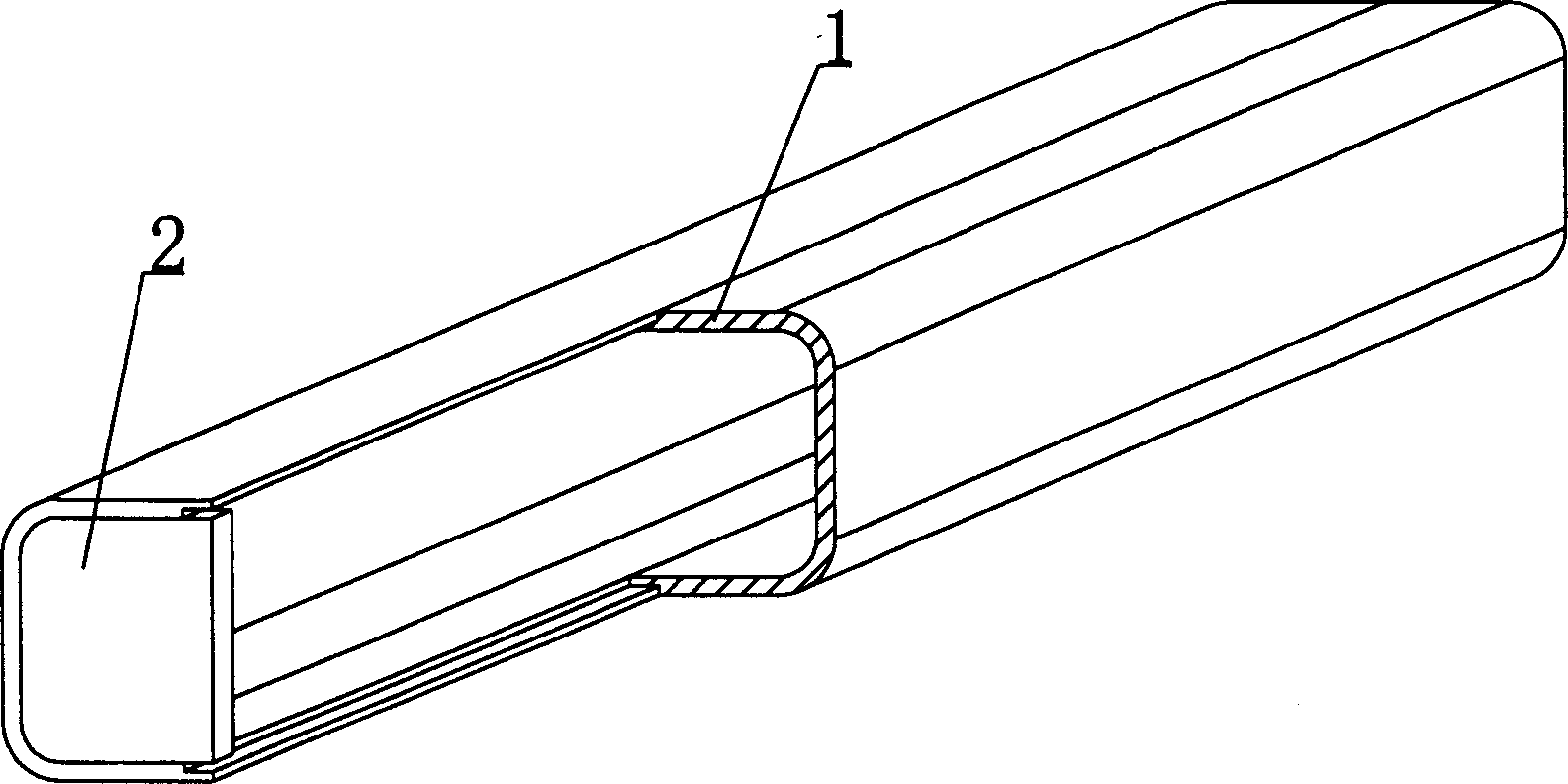

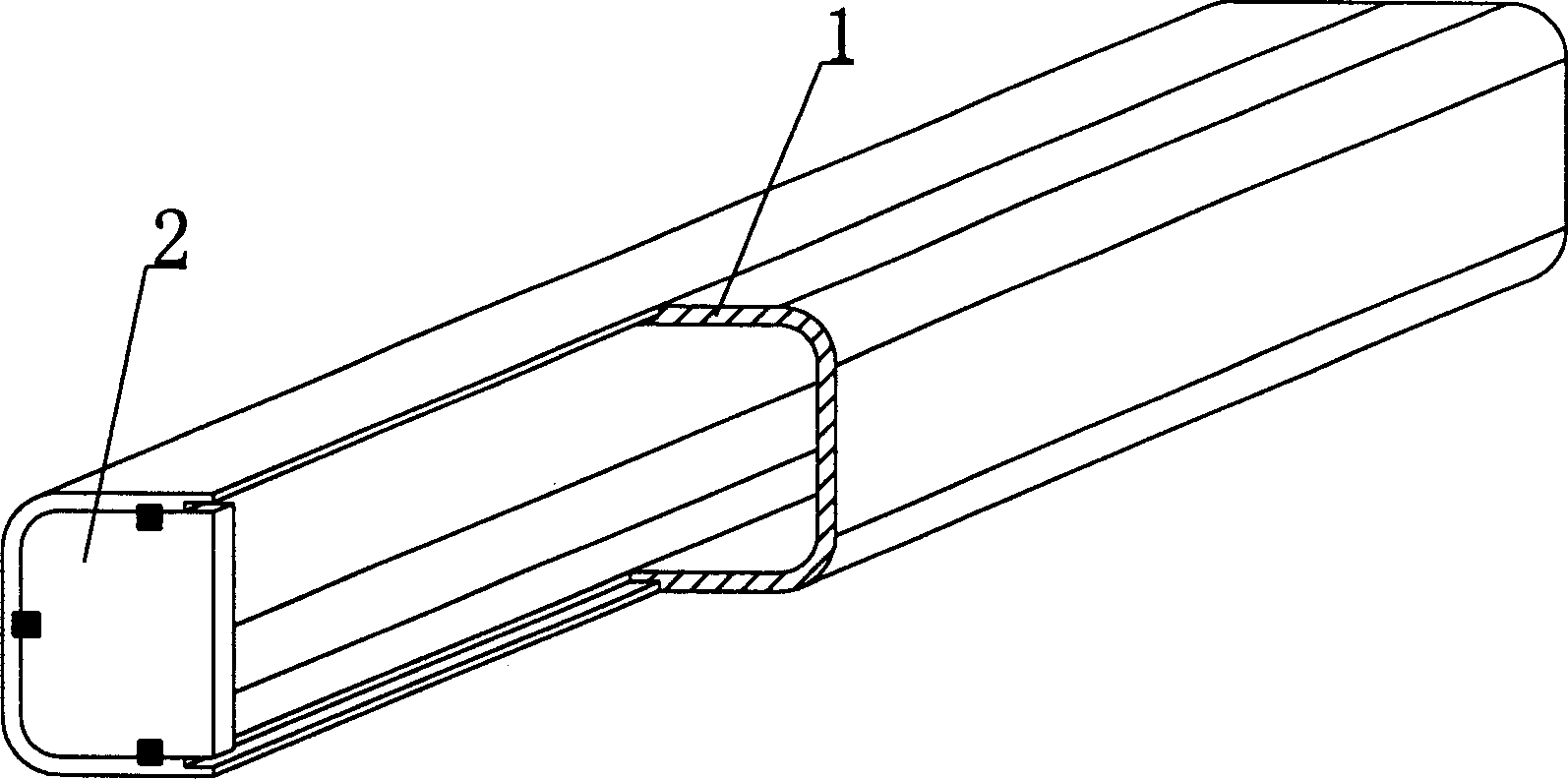

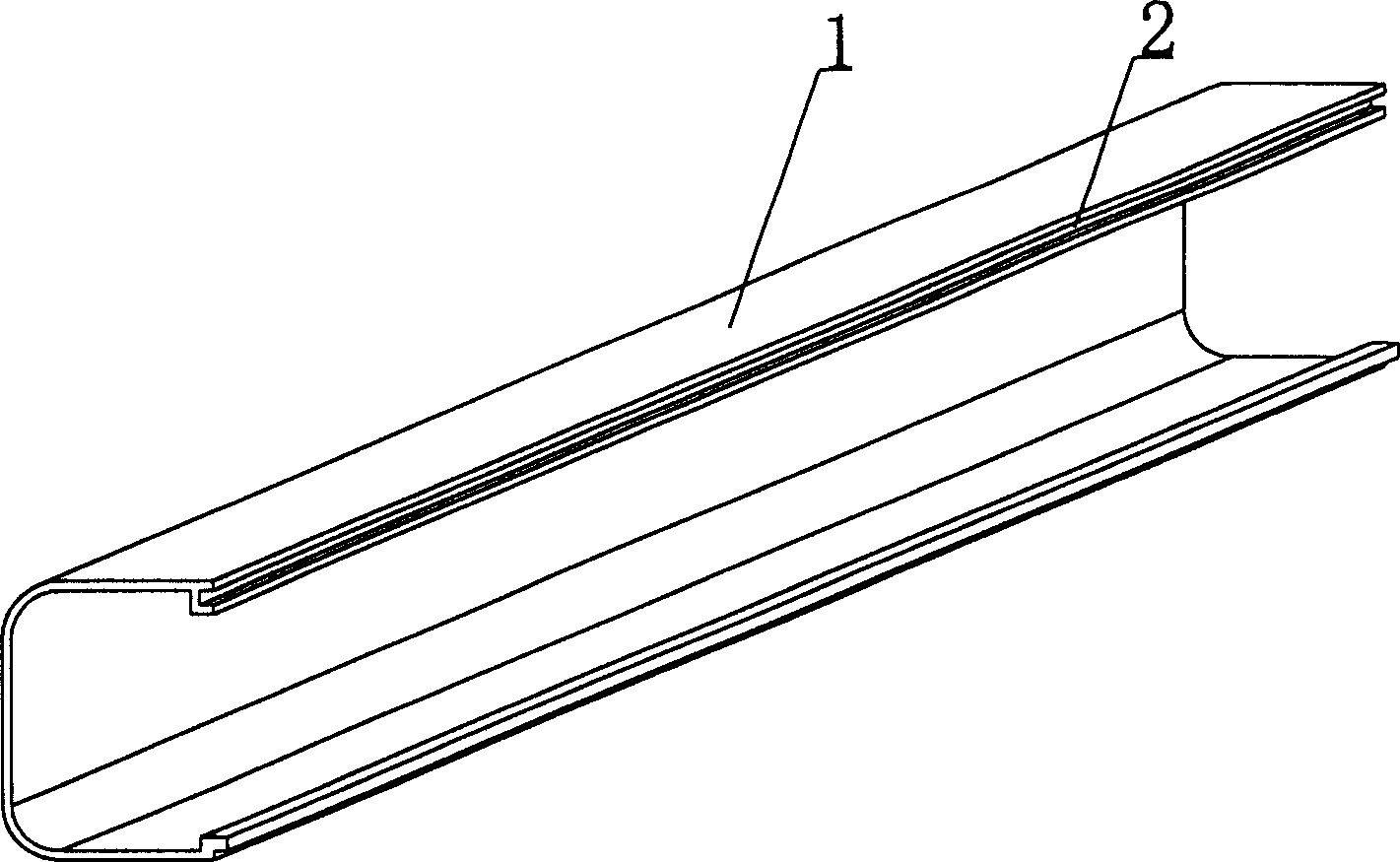

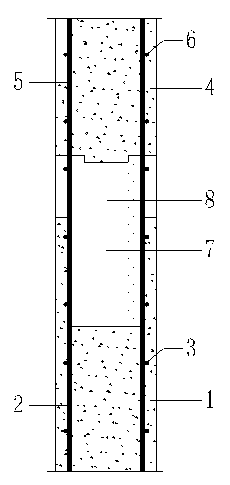

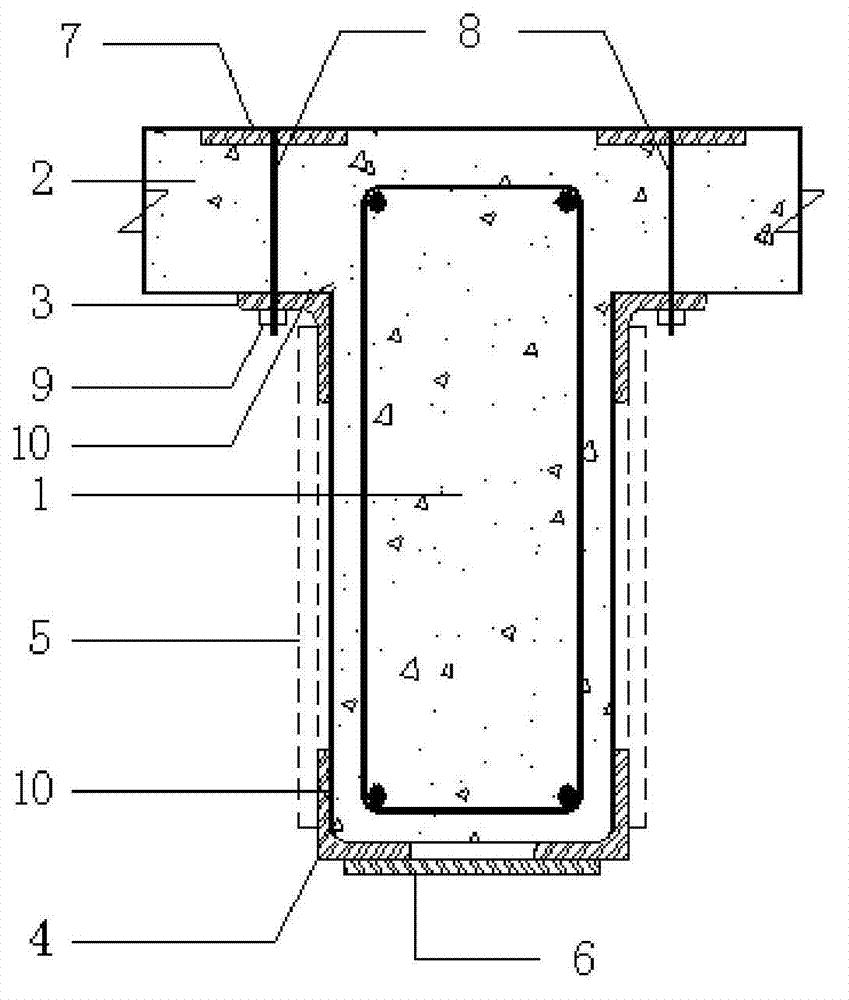

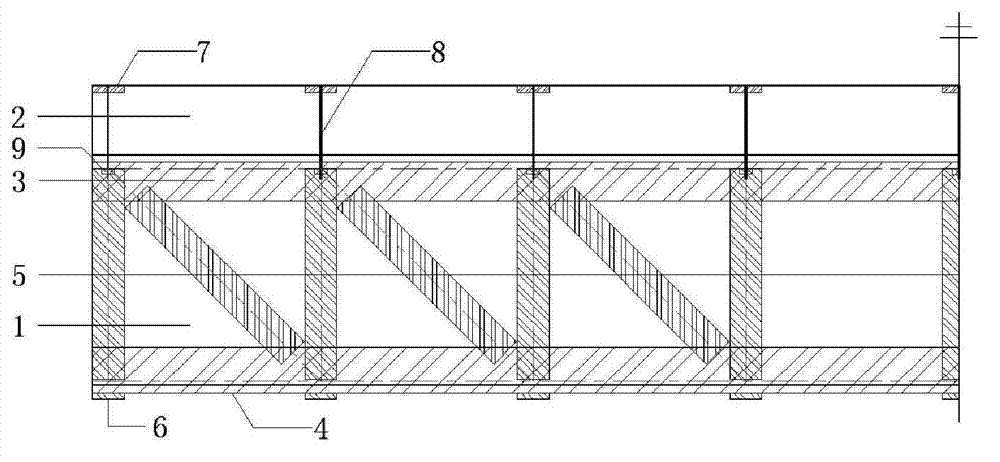

Member for cast-in-situ steel reinforced concrete

A member for in-situ casting the reinforced concrete is composed of two halves, which are fastened together to form a hollow thin-wall member used for in-situ casting hollow floor slab, roof, wall, etc. Said member is made up by die pressing. Its advantages are high strength, low cost, and convenient transportation.

Owner:湖南邱则有专利战略策划有限公司

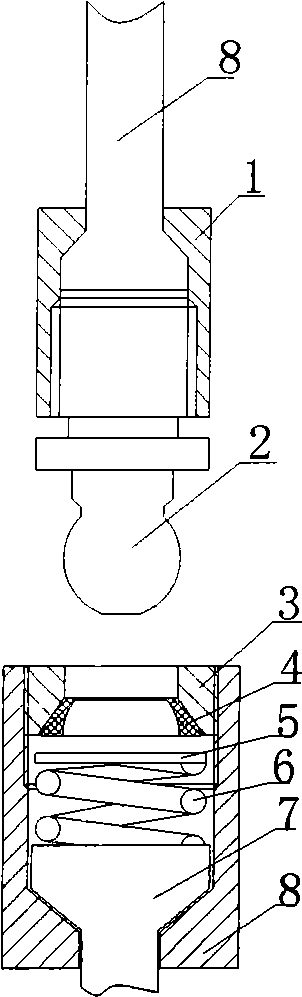

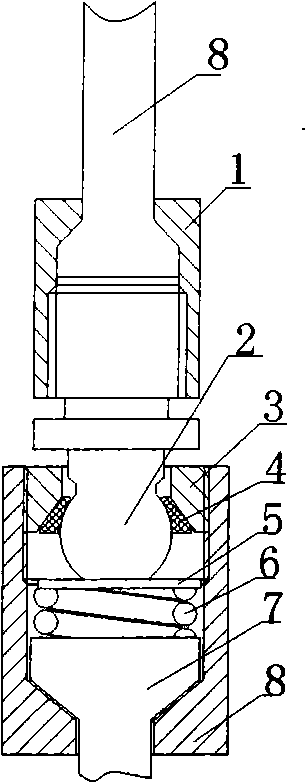

Cutting-free fast tearing butt coupler and butt joint piece

ActiveCN101519876AReliable dockingFirmly connectedCeramic shaping apparatusBulkheads/pilesButt jointSteel bar

The invention relates to a cutting-free fast tearing butt coupler and a butt joint piece, as well as a fabricated part formed by the cutting-free fast tearing butt coupler, a fabricated part formed by the cutting-free fast butt coupler, and butt joint structure between the fabricated parts, and the invention consists of a raising-pulling screw cap, a support-pulling screw cap and a fabricated part longitudinal bar which are positioned at the two ends of the fabricated parts, wherein the raising-pulling screw cap and the support-pulling screw cap have the internal thread structure, the internal thread is tearing screw thread, the center of the cap bottom is provided with a steel bar hole, the periphery of the steel bar hole is a steel bar upset head clamping table, the two ends of the fabricated part longitudinal bar are upset into the upset head which is clamped and connected on the upset head clamping table, a pressure spring is positioned inside the support-pulling screw cap, one end of the pressure spring is positioned on the steel bar upset head, the other end thereof is provided with a tapered sleeve formed by two or a plurality of pieces, a screw thread sleeve is rotatably connected inside the support-pulling screw cap and locates the displacement on the tampered sleeve, the tail part of a connection-peg is connected with the internal thread of the raising-pulling screw cap, and the head part of the connection-peg has the ball-lacking shape and is matched with the tampered sleeve in an elastic joint way.

Owner:周兆弟

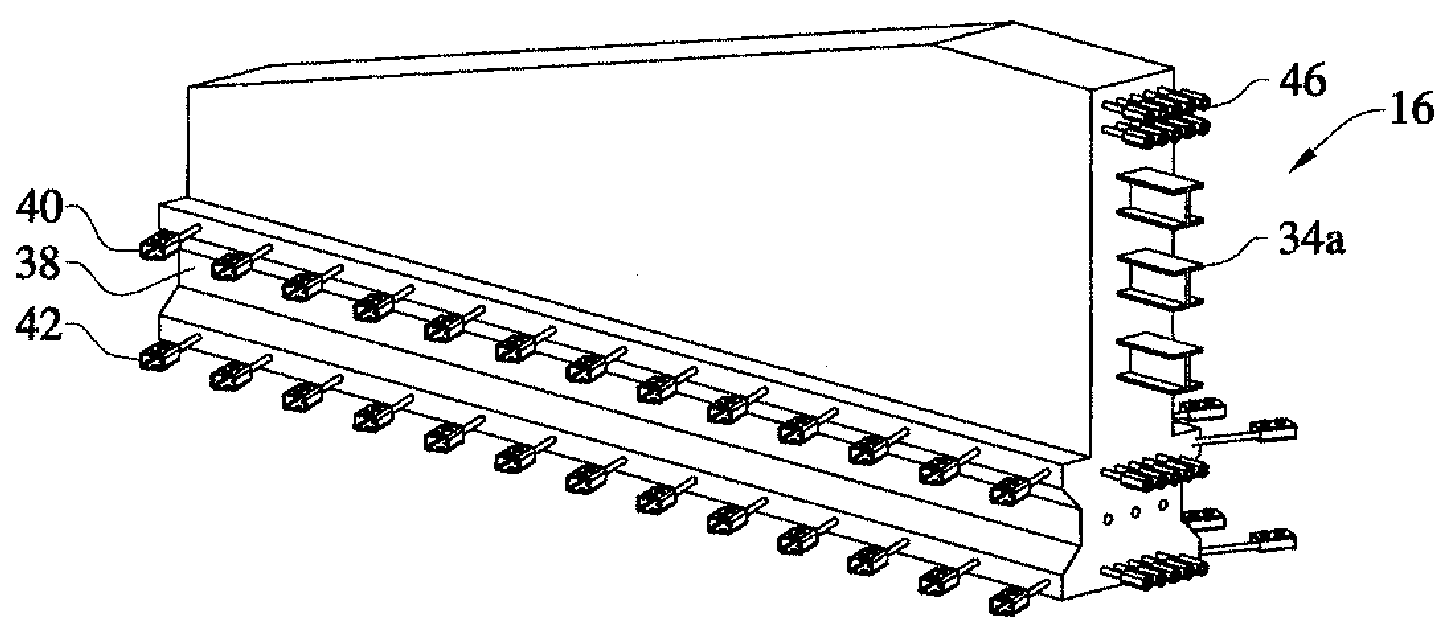

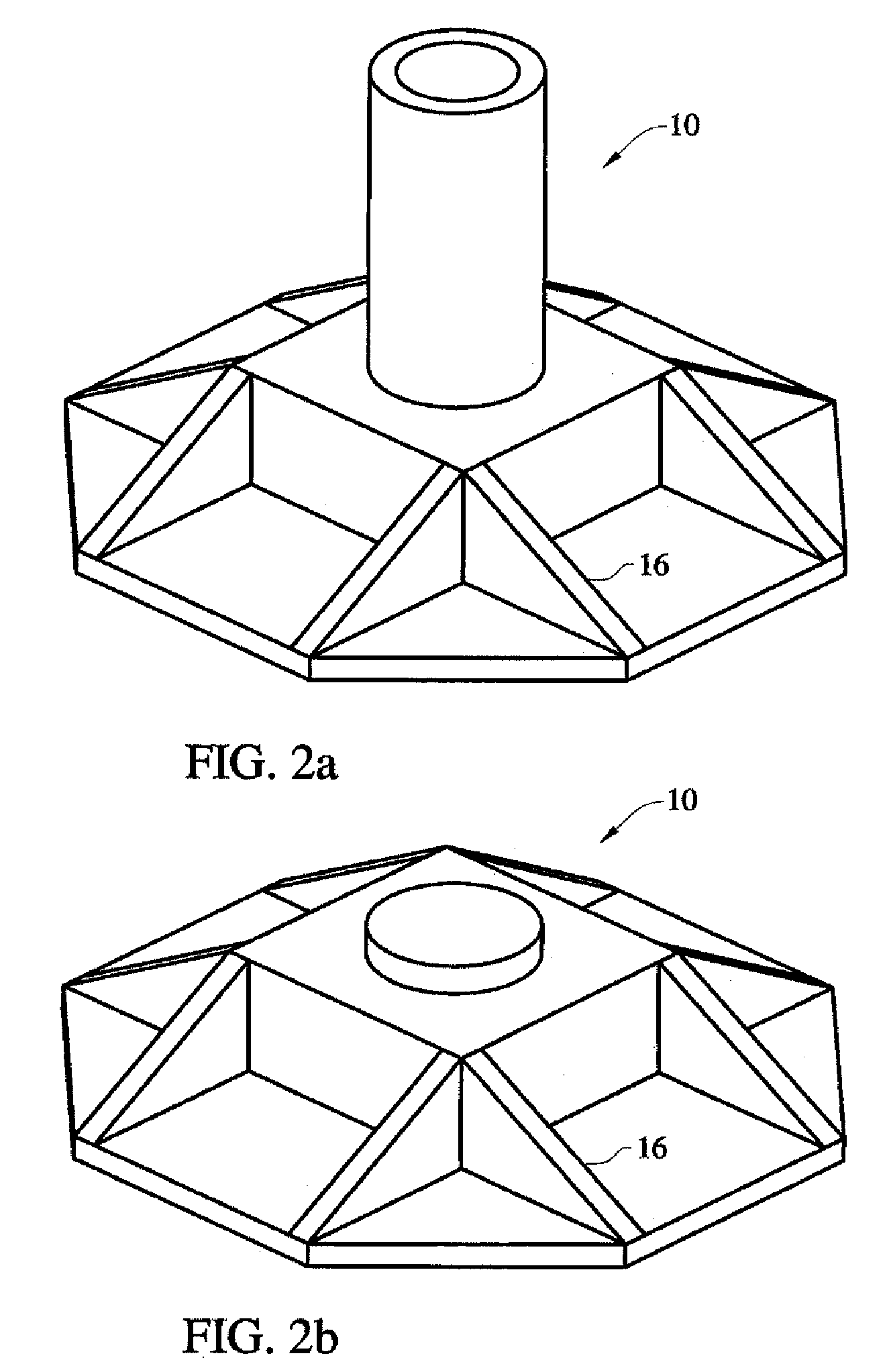

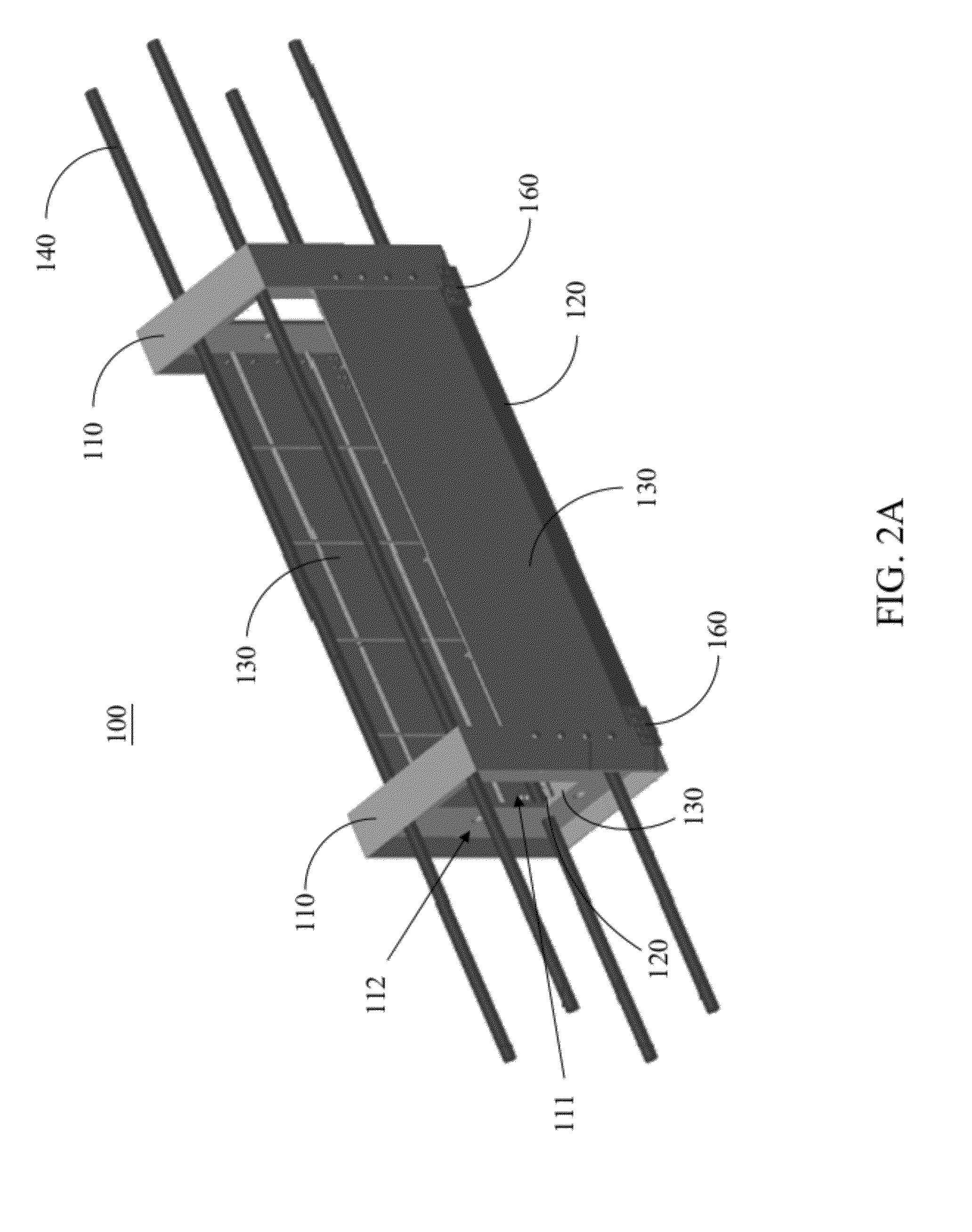

Partially prefabricated modular foundation system

InactiveUS20080072511A1Reliable and readily available designReduce engineering workEngine manufactureFinal product manufactureSteel barTurbine

A wind turbine foundation having a central pedestal, a bottom support slab, and a plurality of prefabricated radial reinforcing ribs. The pedestal and support slab are poured in situ at the site. When the concrete cures the support slab is united to the prefabricated ribs and the ribs are also united to the pedestal. The result is a continuous monolithic foundation wherein loads are carried across the structure vertically and laterally through the continuous structure by doweled and spliced reinforcing steel bars which are integrally cast into the pedestal, ribs and support slab. The slab thus behaves structurally as a continuous slab reducing deflections, improving fatigue conditions and increasing the stiffness of the foundation as well as allowing for the benefits of an economical design.

Owner:AHMED PHULY ENG & CONSULTING

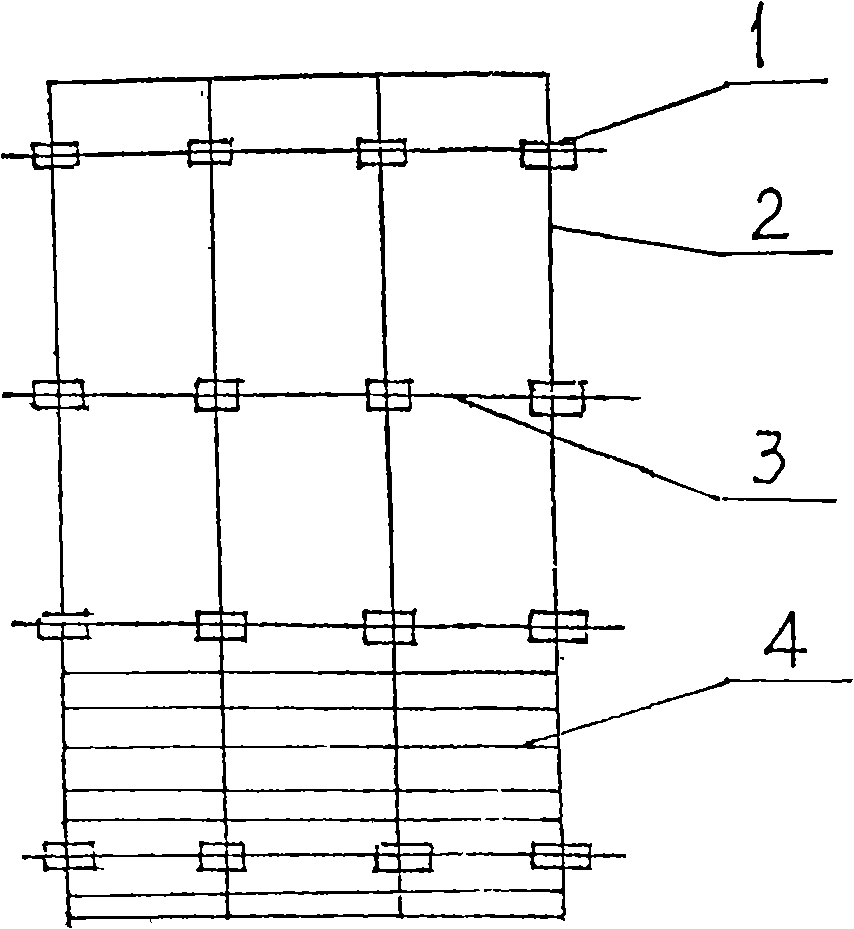

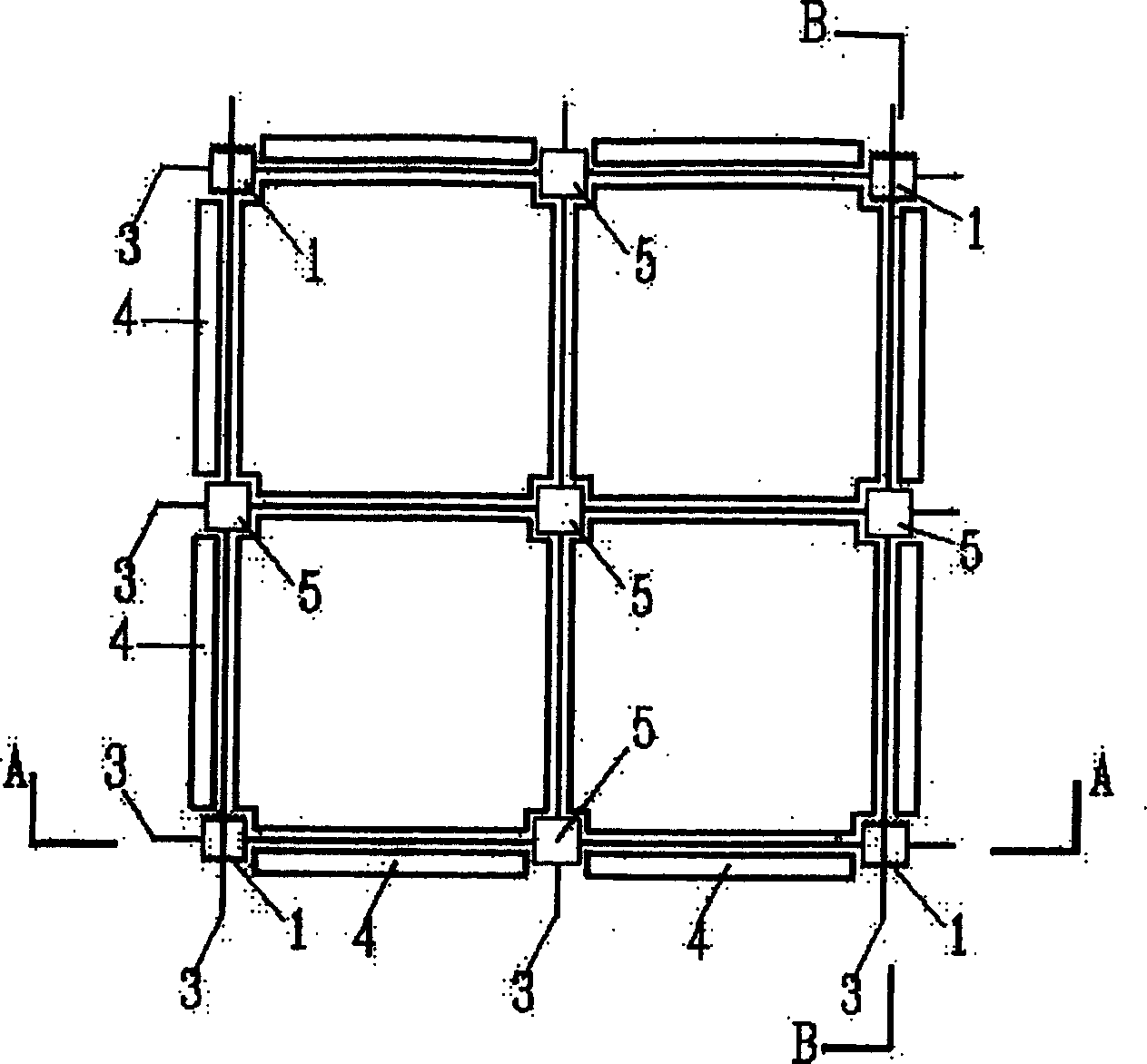

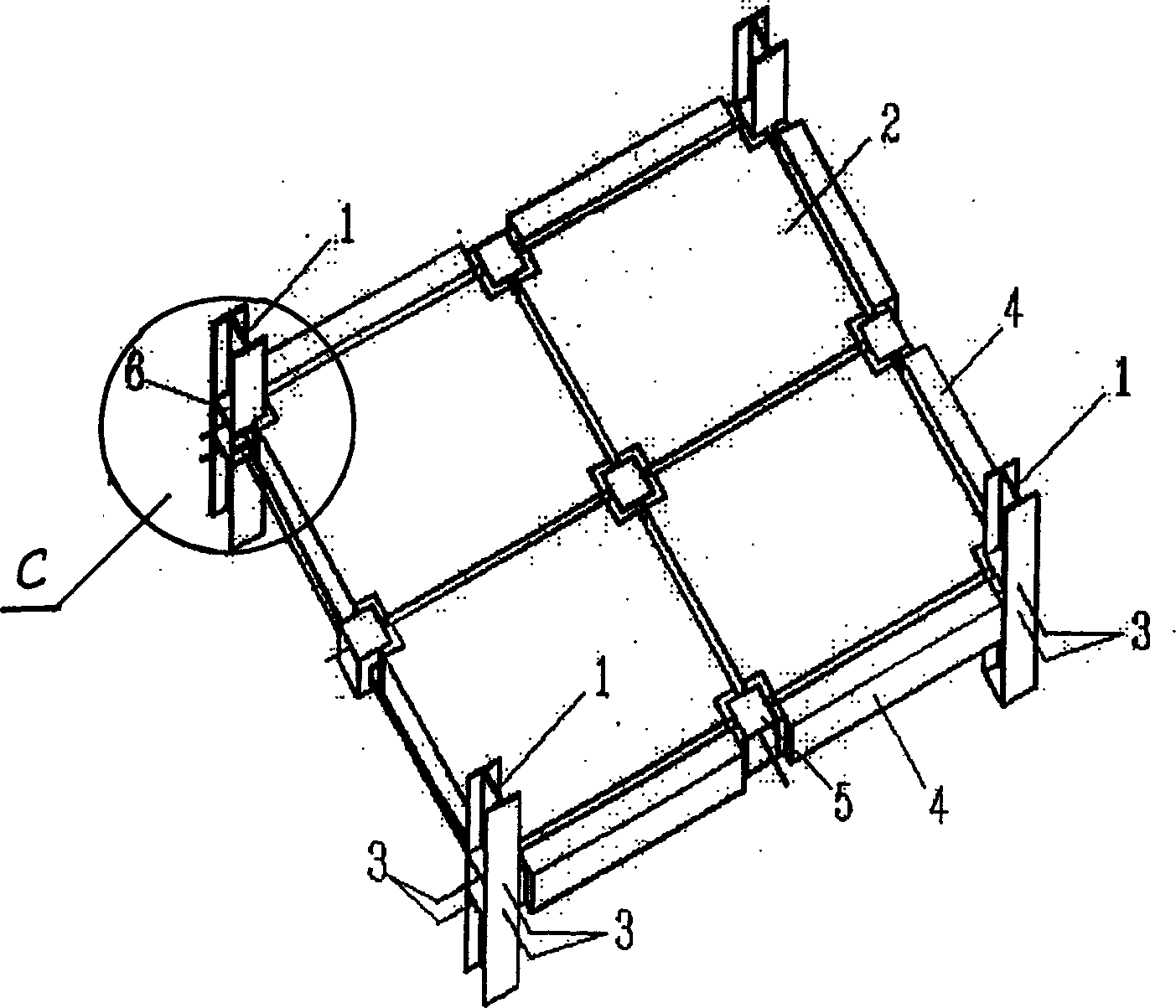

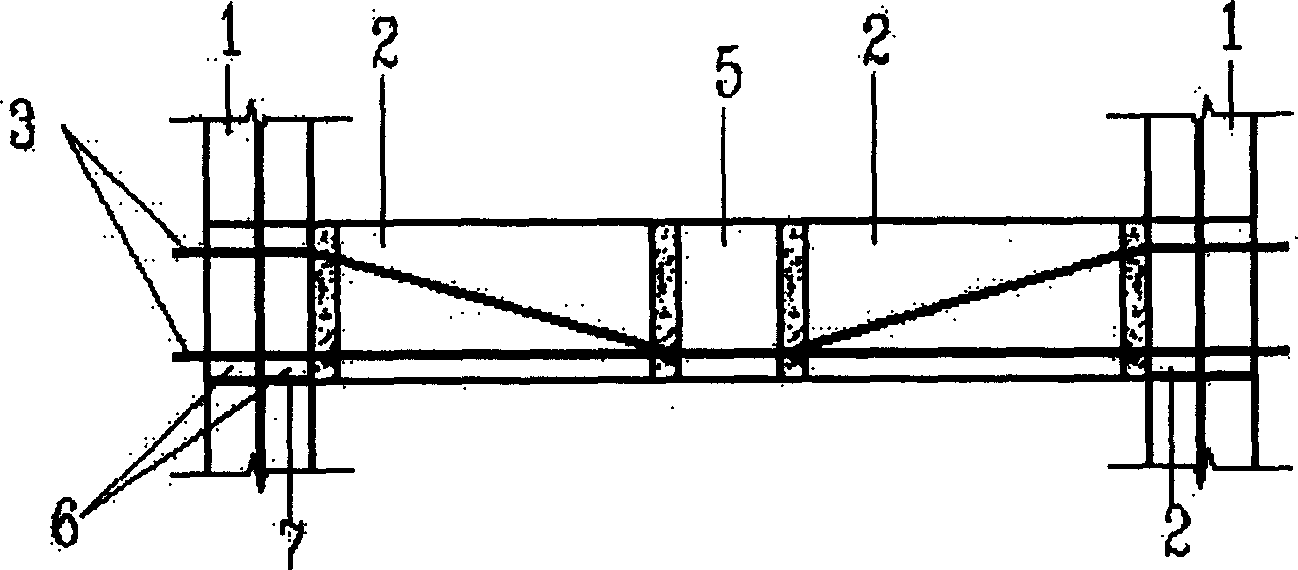

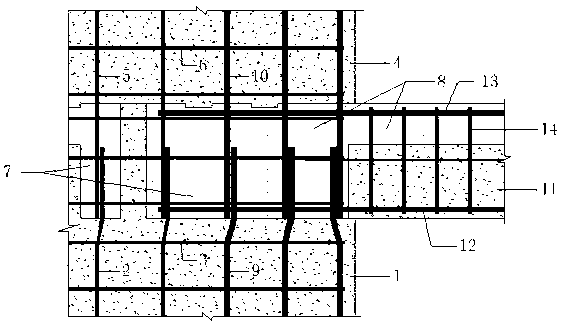

Multi-rib structure system and its connection construction method

InactiveCN1804263AAchieve graded releaseMeet the energy-saving requirements of light buildingsWallsFloor slabPre stressing

The invention relates to a ribbed structure which comprises a ribbed composite wall plate, a hidden frame and a floor. Wherein, the ribbed composite wall plate is a network construction element formed by reinforced steel concrete and light material and divided by the reinforced steel concrete beam as rib beam and rib post in small sections with embedding light material stuffing blocks into the grid; the ribbed composite wall plate also comprises the goatee bar extending from the rib beam and rib post, which is four steel bars with certain anchoring length extending from each rib beam and post and is longitude steel bar whose end is a hook in connection to hook hidden frame; or else the goatee bars are two U-shape closed ring extending from each rob beam an post and is inserted with longitude steel bars in connection; the hidden frame is formed by outer frame post, connection post, and hidden beam which are embedded outside the ribbed composite wall plate while using common concrete, profiled bar concrete or steel structural beam and post; the stuffing material is made from light material with certain strength, volume weight and little elastic modulus; and the floor can select on-situ irrigating concrete, on-sit or prefabricated ribbed composite floor, pre-stress layered floor or special-shaped pre-stress hollow floor.

Owner:姚谦峰

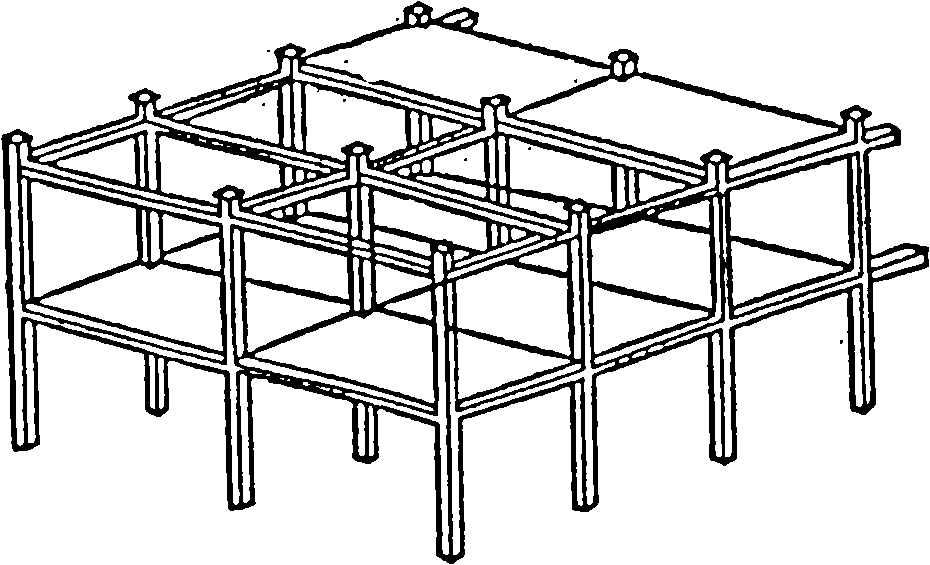

Novel method for quickly assembling low-cost energy-saving house with prefabricated pole, beam, plate

InactiveCN101294419ANo wasteReduce the amount of manual laborBuilding constructionsReinforced concrete columnHigh density

A novel method for rapidly assembling a low-cost energy-saving house with precast columns, beams and slabs comprises the steps of preparing house columns, beam molds and built-in reinforcing steel bars or profiled steel bars, pouring concrete grout into the molds, high-speed rotating in a centrifuge, curing, and demolding to obtain precast reinforced concrete columns and beam components; and inserting the precast columns on a cup foundation element, passing the precast beams through the preformed pores on the precast column, lapping precast floor slabs on the precast beams, and embedding wall slabs inside the embedding grooves of the precast beams, so as to form the major structure of the rapidly assembled low-cost energy-saving house. The inventive method has the advantages of application to industrial production, no air holes in components, high density, high strength, long service life, standardized production, low production cost, low time and raw materials consumption, rapid house construction speed, and high quality; and is a novel energy-saving house construction method in the construction field.

Owner:丁公权 +1

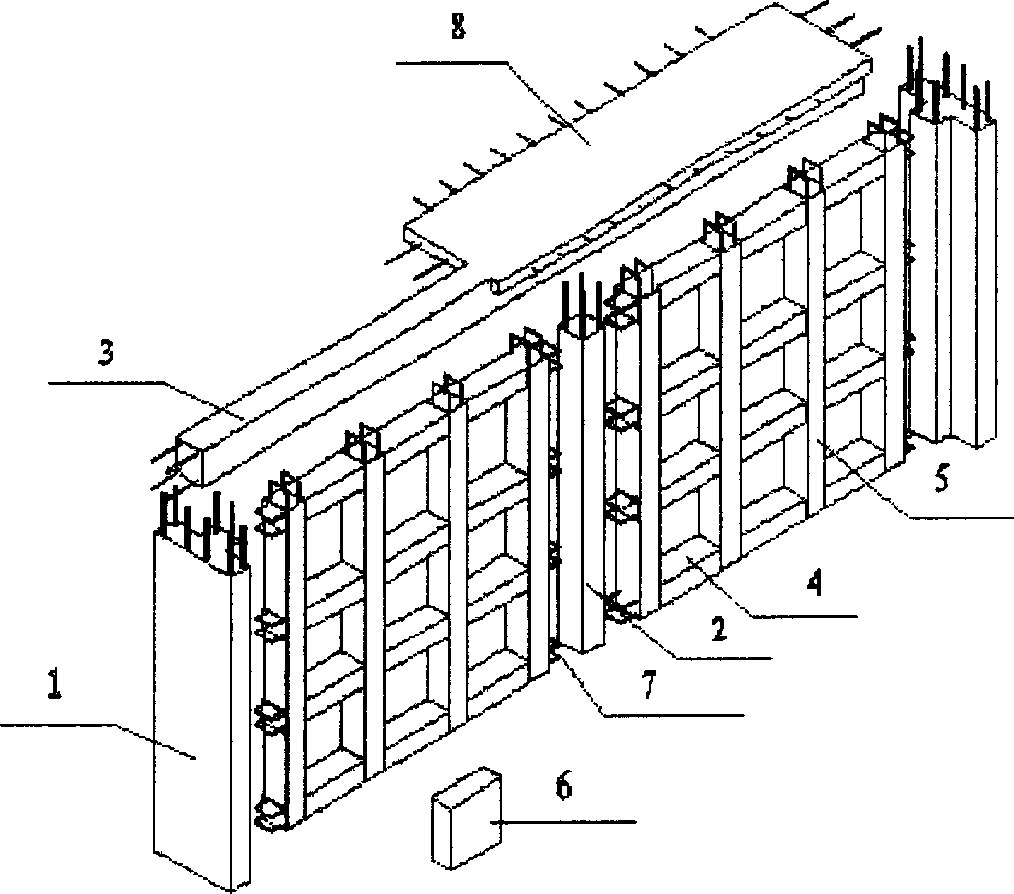

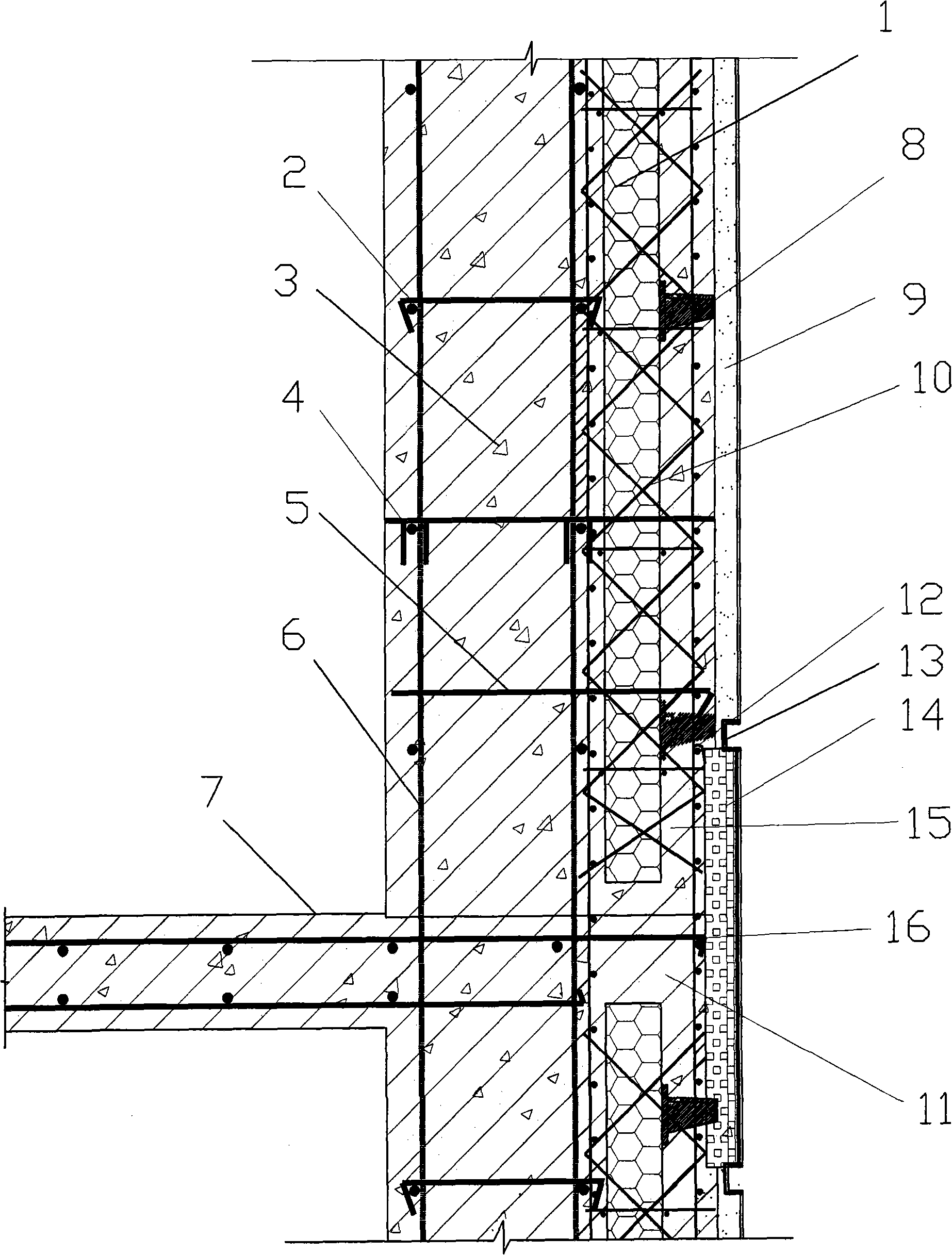

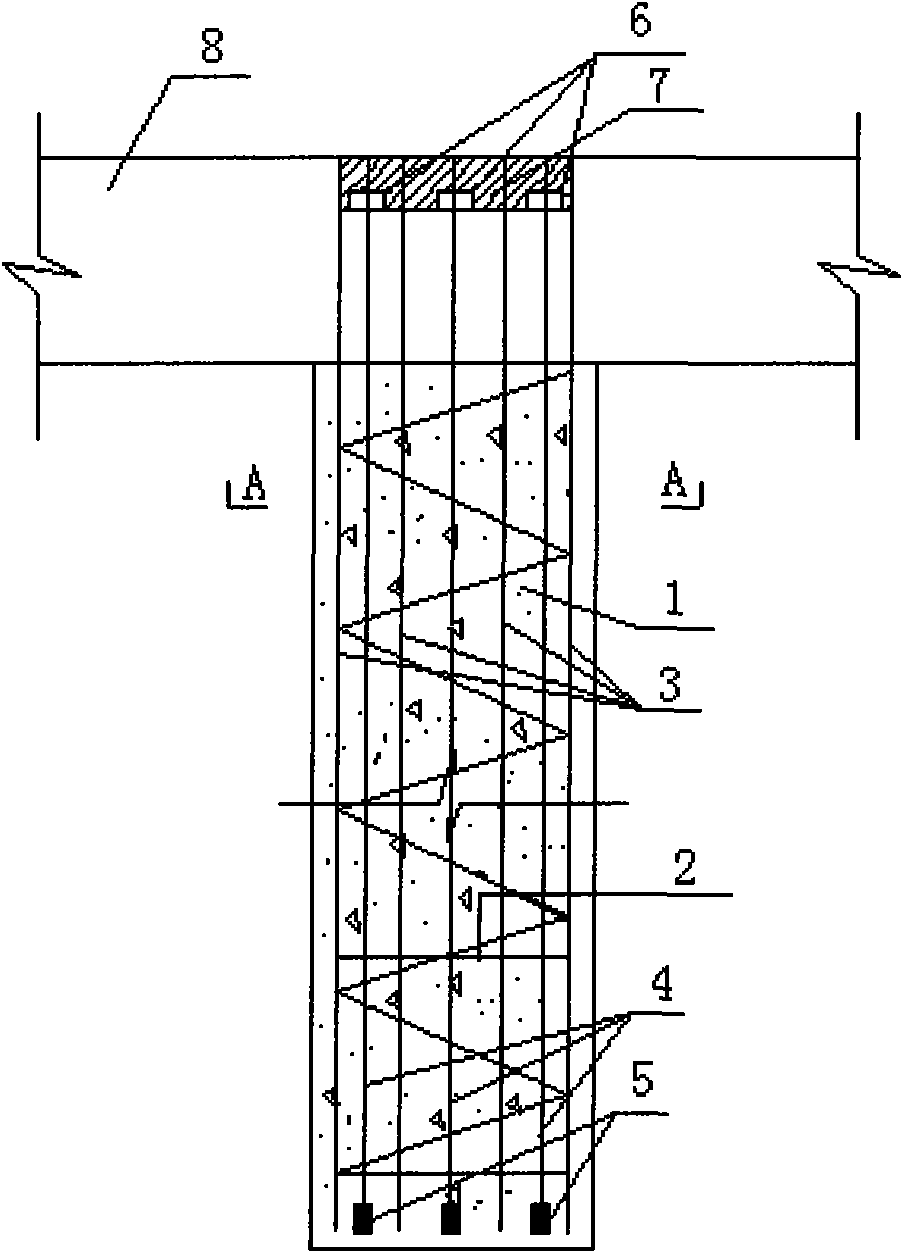

Externally reinforced concrete irrigated and heat preservation wall structure embedded energy-saving system and its construction method

ActiveCN101319525ANovel structureImprove thermal insulation performanceWallsClimate change adaptationInsulation layerSteel bar

The invention relates to an energy-saving system for a reinforced concrete outer-casting built-in heat insulation wall body structure and a construction method thereof, which can effectively solve the problems of external wall heat insulation of a high-rise building with high heat insulation requirement and cracking and falling of a heat insulation layer. The system is produced by a wall body and reinforcing steel bars in the wall body which are cast by concrete. The method comprises the following steps that: a reinforcing steel bar frame of the wall body is produced and arranged, namely parallel vertical reinforcing steel bars and indoor floor-connecting board tie bars perpendicular to the parallel vertical reinforcing steel bars are bound together, a grid board is hoisted and externally suspended outside the vertical reinforcing steel bars of the wall body, and is bound with the vertical reinforcing steel bars of the wall body by hooked bars and binding steel bars as well as framework positioning bearing bars, then a framework is arranged on the framework positioning bearing bars and is firmly bound with reinforcing steel bars of beams and boards of a floor, lapping bars are reserved, a heat insulation grid board is firstly arranged, then reinforcing steel bars of corbel brackets of a balcony and an air conditioning board external wall are bound, finally the concrete is cast, the curing is performed, and the framework is removed to repair the structure. The system has good heat insulation effect, energy conservation, environmental protection, simple method, and huge economic benefit and social benefit.

Owner:HENAN JINYUAN CONSTR

Architectured reinforcement structure

InactiveUS20120304584A1Easy constructionReduced isolationTowersBuilding constructionsReinforced concreteHoneycomb

This invention presents a modified reinforced concrete structure, which has a steel structure composed of a beam steel box unit, column steel box unit, and beam-column joint steel box unit with lap jointing reinforced steels. The side plate and / or end plate of the steel box has through holes for concrete flowing therebetween. In this way, the workability of concrete grouting and tamping are improved, and the phenomena of hive, segregation, or floating can be avoided. It can also enhance the performance of beam-column joints (e.g. with better confinement ability, etc.). Applying the invention, the efficiency and accuracy of constructing beam-column joints can be increased, and in addition to better ensure the structural safety, it can also reduce construction manpower and schedule.

Owner:NAT TAIWAN UNIV OF SCI & TECH

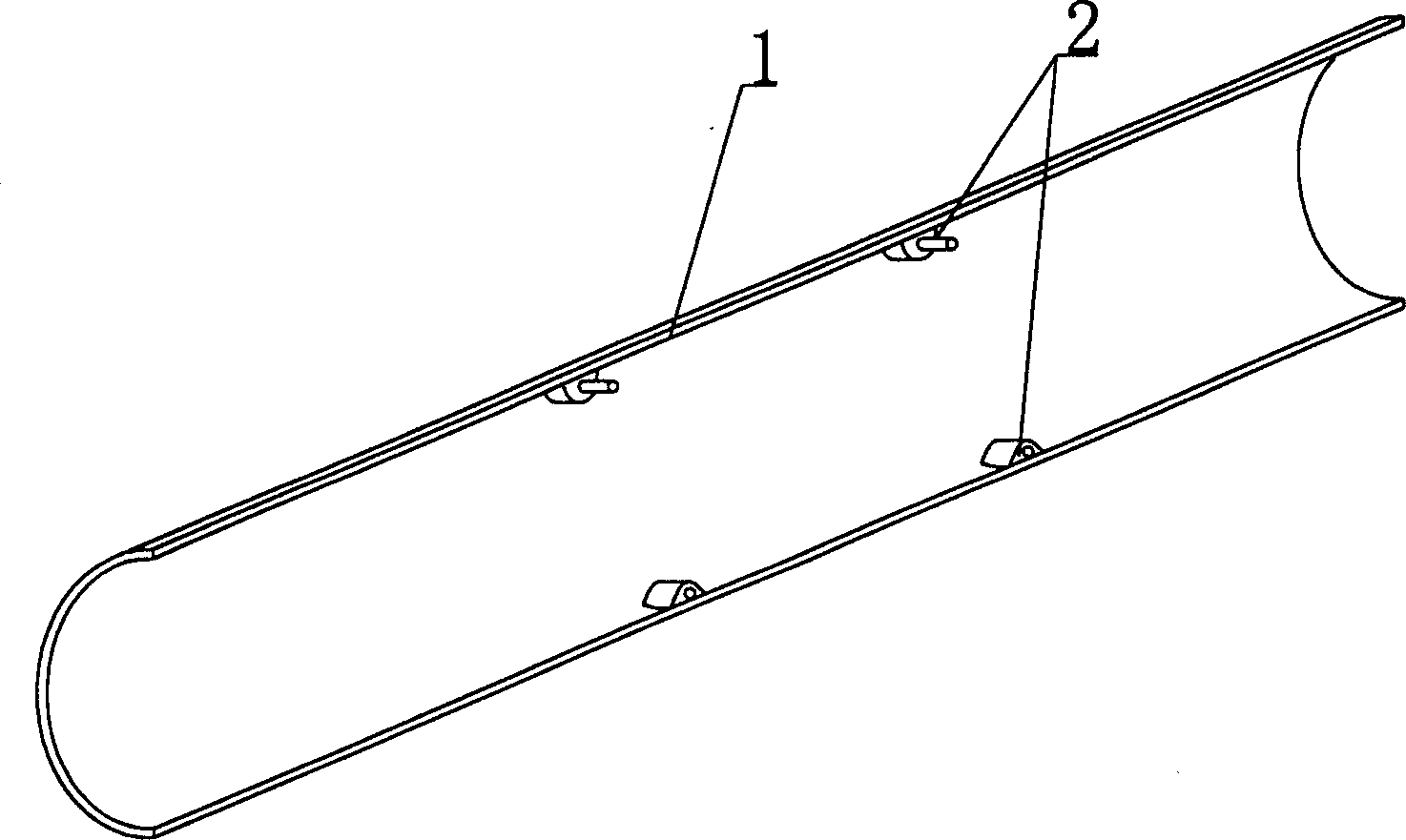

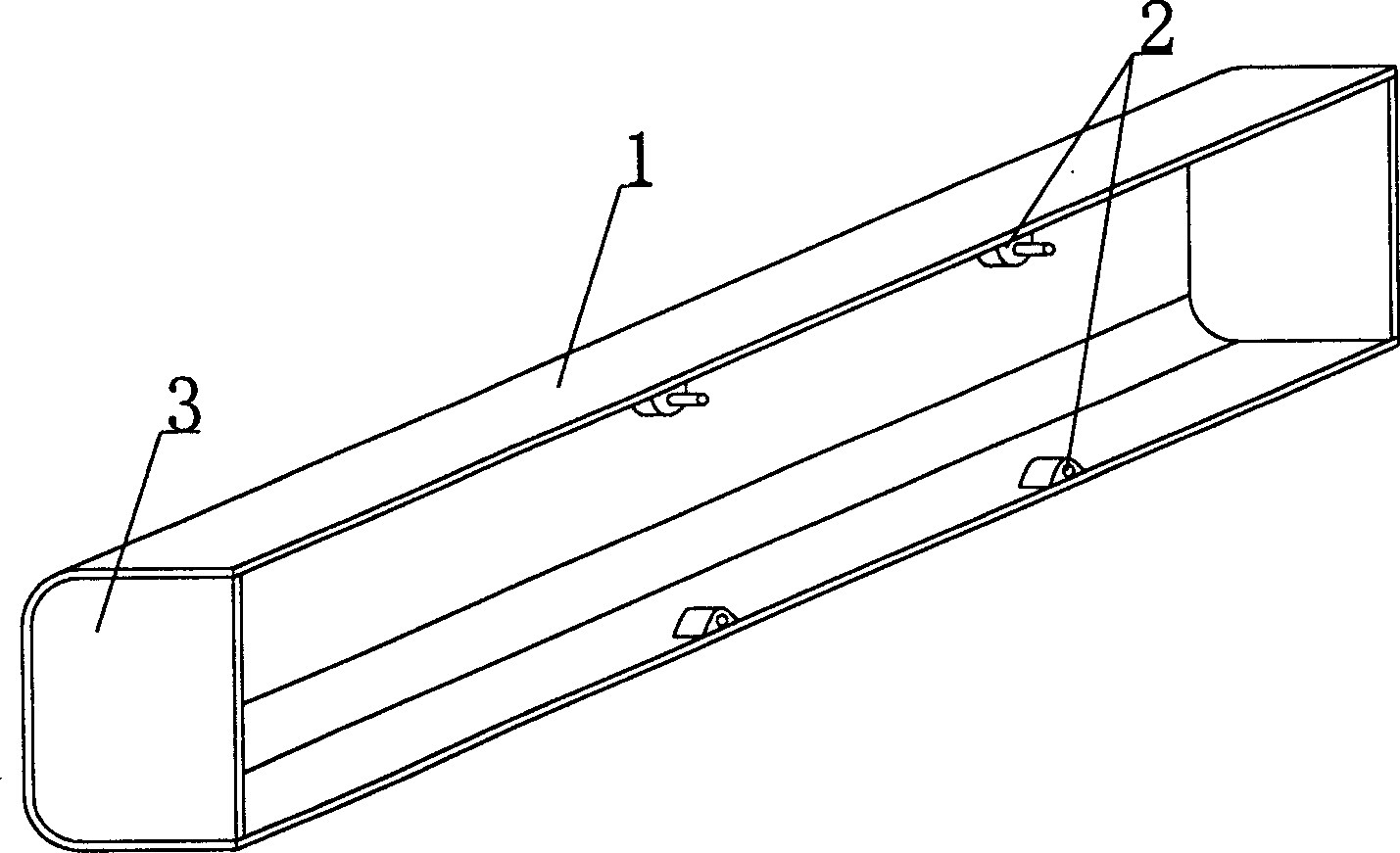

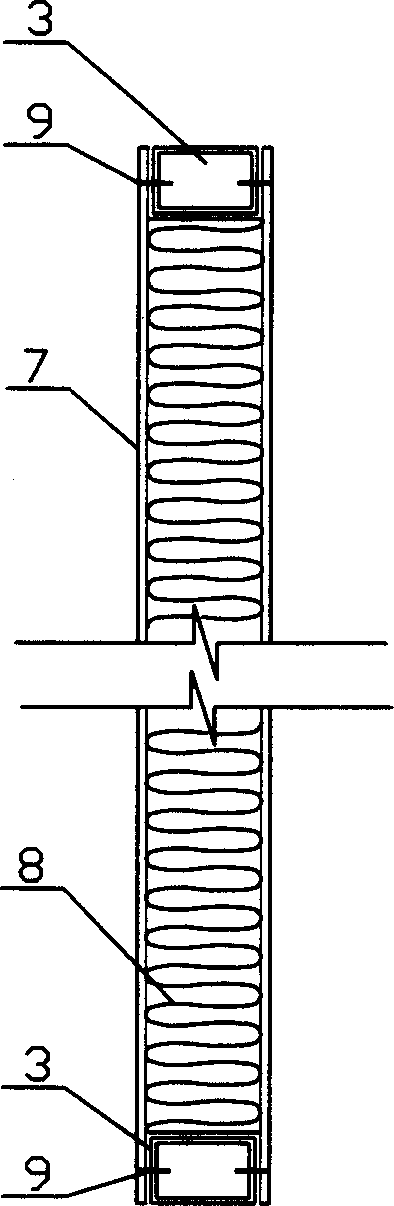

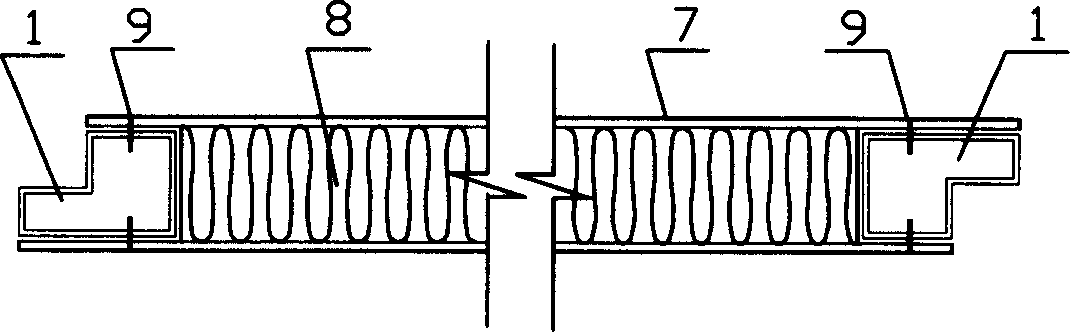

Hole constructing component for in situ cast steel bar reinforced concrete

A hole-forming member for in-situ casting the reinforced concrete is such a one used to combine a whole cavity. The connecting parts are used to combine two or more said members to form a hollow thin-wall member. Its advantages are high strength, low cost and high construction speed.

Owner:湖南邱则有专利战略策划有限公司

Cast-in-place hollow floor system with holes composed of steel meshes and organic objects

InactiveCN104005501AEnhanced resistance to construction loadsAnti-leakage preventionFloorsBraced frameReinforced concrete

The invention provides a cast-in-place hollow floor system with holes composed of steel meshes and organic objects. The cast-in-place hollow floor system is composed of a main beam, ribbed beams, an upper frange plate, a lower frange plate and a frame formed by the steel meshes and the organic objects; the main beam is a reinforced concrete composite beam or a structural steel beam; the frame formed by the steel meshes and the organic objects is formed by interaction of the steel meshes and the organic objects; the top surface of the frame, the bottom surface of the frame and the two lateral walls of the lateral faces of the frame are formed by the steel meshes; the top surface of the frame is formed by overlapping the head ends and the tail ends of the steel meshes, and the overlapping amount is smaller than or equal to the area of the top surface of the frame; the organic objects comprise an air sac or a polyphenyl block; the other two lateral walls of the lateral faces of the steel mesh frame are formed by the organic objects, and the organic objects are supported between the top surface of the frame and the bottom surface of the frame to conduct height control over the steel mesh combined frame. The steel meshes and the organic objects are combined, blocking of the other two lateral walls of the lateral faces of the frame and supporting of the inner hollow height between the top surface of the frame and the bottom surface of the frame are effectively achieved, and the cast-in-place hollow floor system is easily obtained.

Owner:王本淼 +2

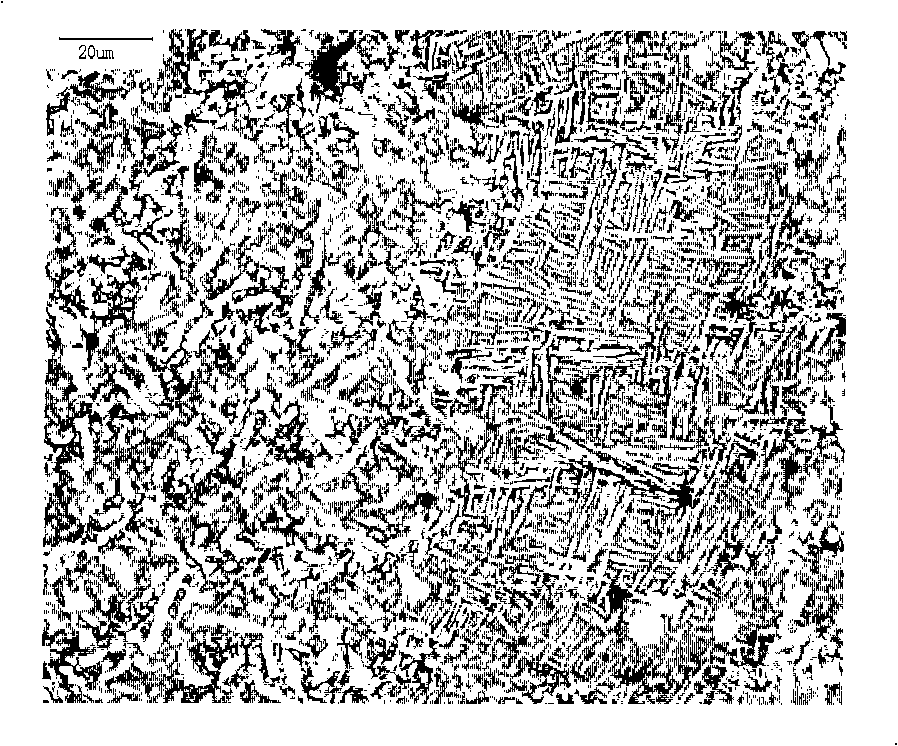

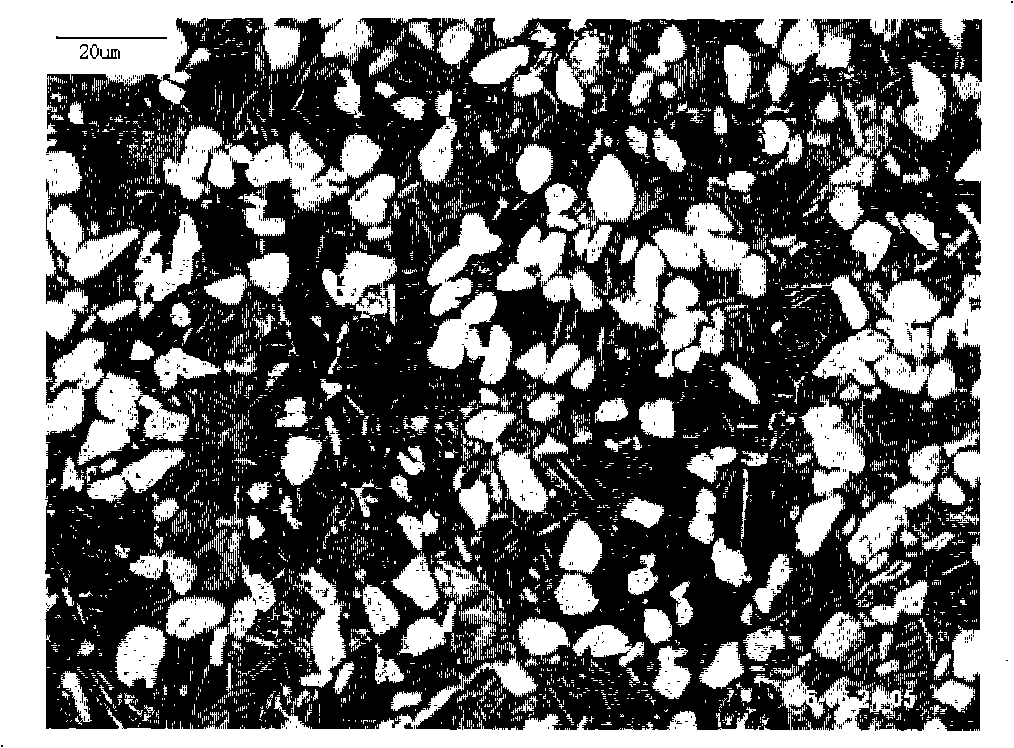

Process for manufacturing type alpha+beta titanium alloy rod bar for rotor impeller vane

InactiveCN101294264AEliminate surface oxidationPrevent surface oxidationTemperature control deviceBlade accessoriesImpellerIngot

The invention relates to an Alpha+Beta type titanium alloy steel bar fabrication technology used on a rotor vane, which comprises the following steps: (1) a cast ingot is heated, and the temperature is risen to 40 to 60 DEG C above a Beta transformation point after entering in a furnace, and the temperature is kept for 10 to 20 hours; (2) the cast ingot is processed through cogging and smithing, each pier drawing deformation amount is controlled between 30 percent to 40 percent; the smithing is performed in a two phase region after the pier drawing, and the total deformation amount is more than or equals to 90 percent; (3) the cast ingot is heated until the temperature reaches 20 to 40 DEG C above the transformation point after returning to the furnace, the temperature is preserved, and then the water quench is performed; (4) after the water quench, stocks are returned to the furnace and heated, and then are heat-preserved in the two phase region; the two phase region smithing is performed in a radial forging machine after the stocks reach a certain temperature, and the lengthening coefficient is controlled between 1.2 to 1.3; (5) after the radial smithing, the stocks is returned to the furnace and heat continuously and then is heat-preserved in the two phase region, then the stocks is rolled on a rolling mill, and the rolling temperature ranges from 910 to 940 DEG C. The Alpha+Beta type titanium alloy steel bar fabrication technology eliminates the figures on a macrostructure and the Beta spots on a microstructure of the heat strong two-phase titanium alloy caused by the hot work, and obtains a small-size two-phase titanium alloy steel bar with a fine and uniform equiaxed two-state structure.

Owner:BAOSHAN IRON & STEEL CO LTD

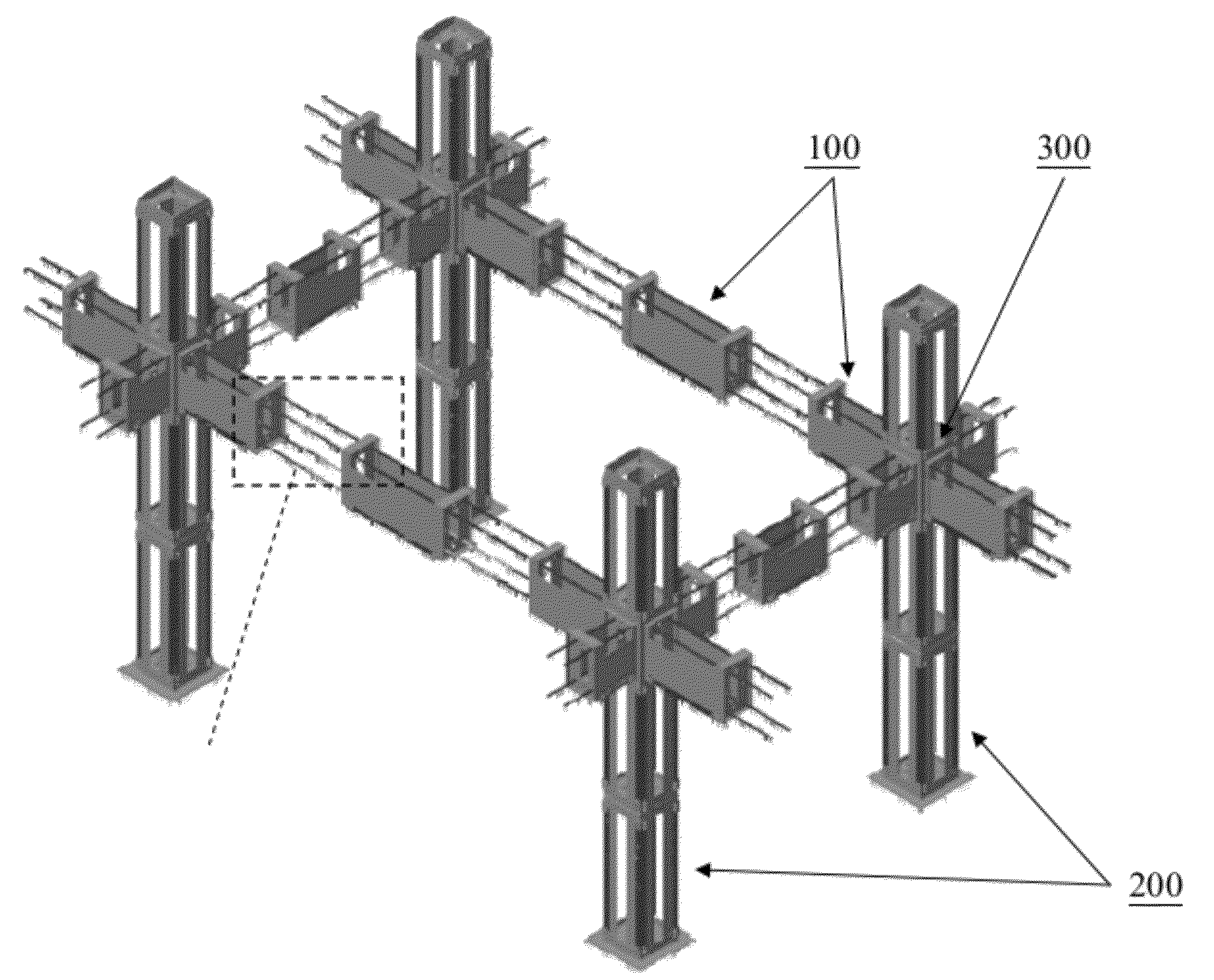

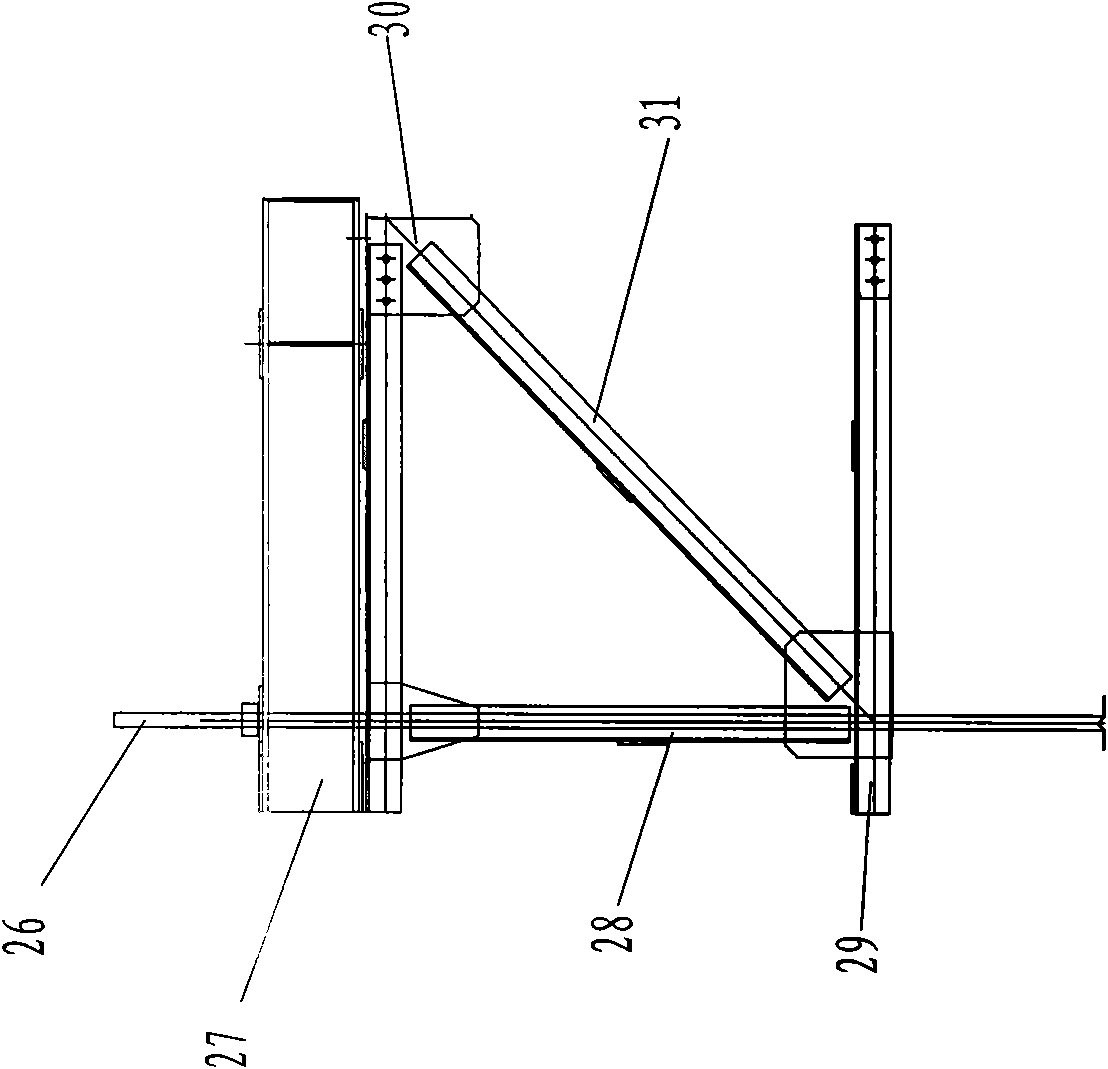

Splitting and assembling structure and assembling connecting method of assembled type concrete frame-shear wall

ActiveCN102900168ASplit location is reasonableEasy to manufactureWallsBuilding material handlingSteel barEngineering

The invention relates to the field of concrete structures, in particular to a splitting and assembling structure and an assembling connecting method of an assembled type concrete frame-shear wall. The splitting and assembling structure comprises prefabricated pillars, prefabricated beams, prefabricated shear walls and cast-in-situ joints, wherein sleeves are embedded at the lower ends of the prefabricated pillars, mutually embedded with protruding reinforcing steel bar sections which extend from the upper ends of lower layer pillars and are integrally connected with the lower layer pillars by filling mortar; longitudinal prefabricated beam reinforcing steel bars extend into a joint core area to be anchored or connected with side beam ribs in a mechanical manner; a cast-in-situ zone is arranged between the prefabricated pillars and the prefabricated shear walls so as to carry out the connection of the embedded ribs of the pillars and the walls; and the embedded reinforcing steel bar sleeves at the lower ends of the prefabricated shear walls are mutually embedded with protruding reinforcing steel bar sections which extend upwards from the walls at the lower layer and are integrally connected with the walls at the lower layer by filling the mortar. The through connection of the vertical reinforcing steel bars of the share walls at the upper and lower layers is realized by filling the mortar into the through holes and the sleeves at the upper ends of the prefabricated shear walls and the prefabricated beams, so that the key problem that the vertical reinforcing steel bars of the share walls are hard to be continuous because of the isolation of the prefabricated beams is solved.

Owner:SHENYANG JIANZHU UNIVERSITY

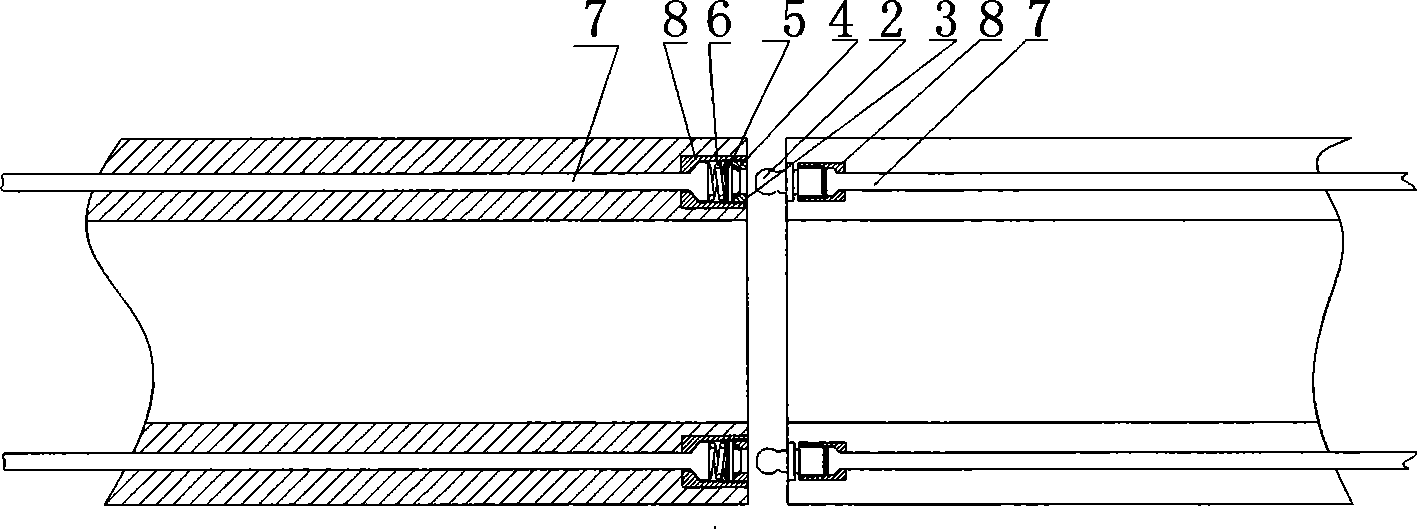

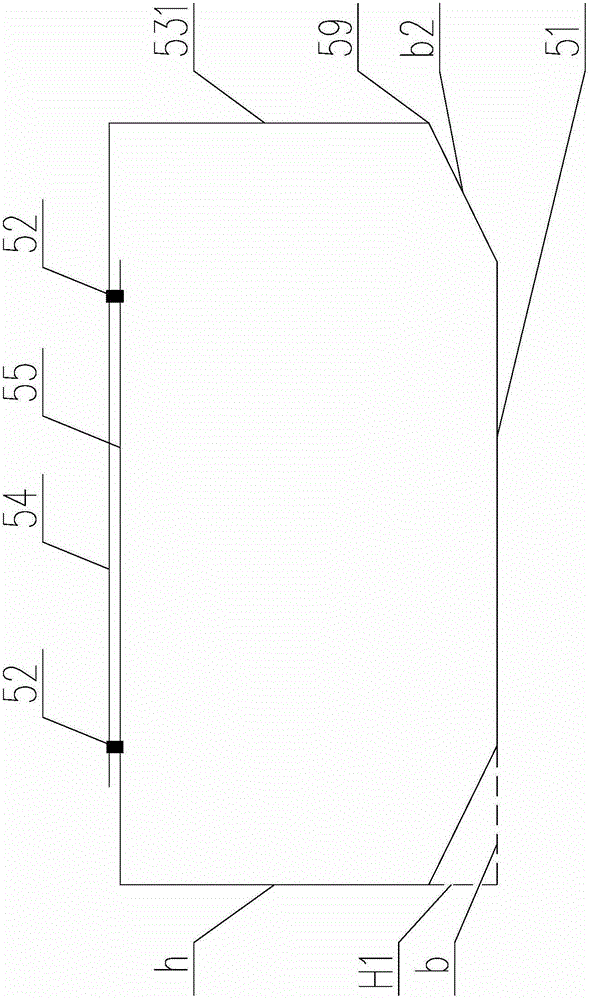

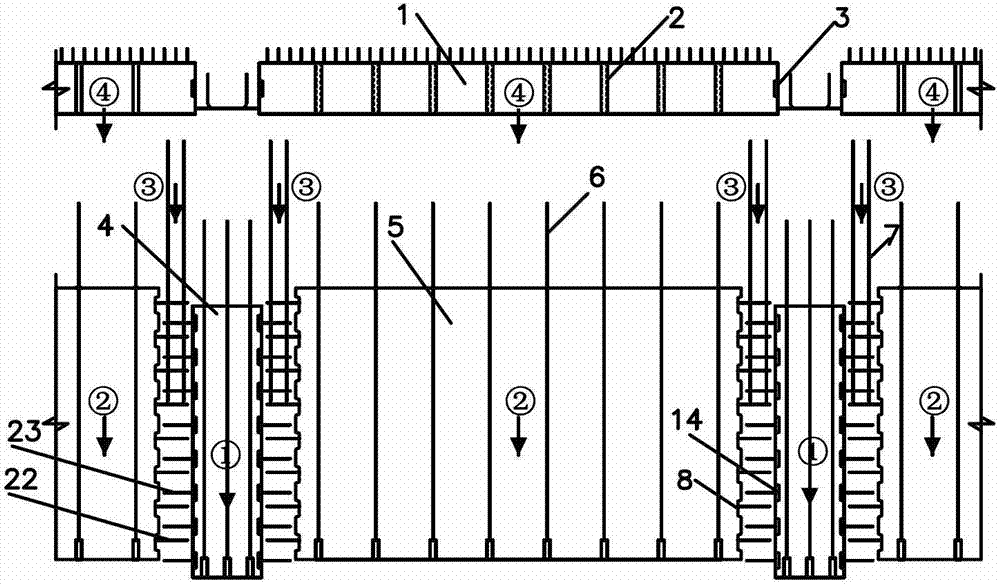

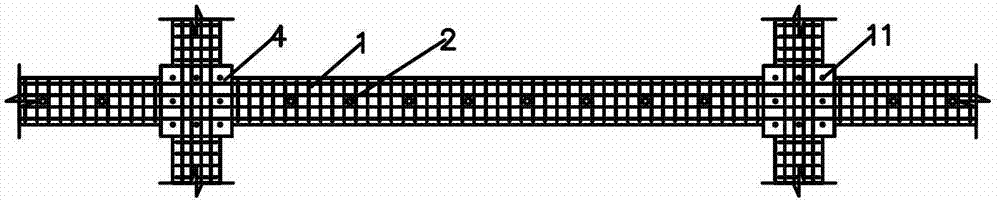

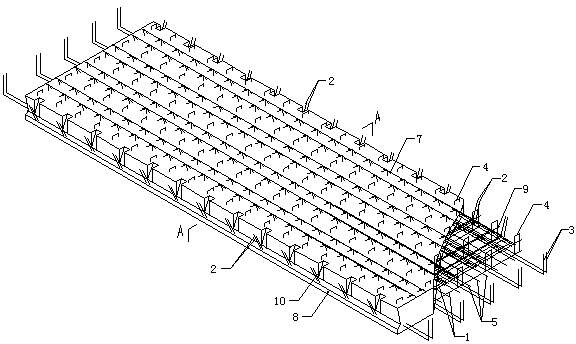

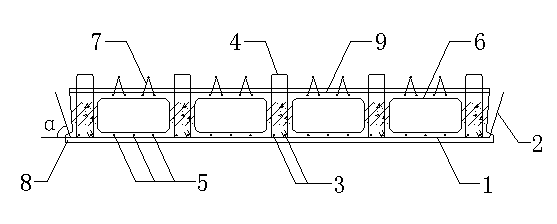

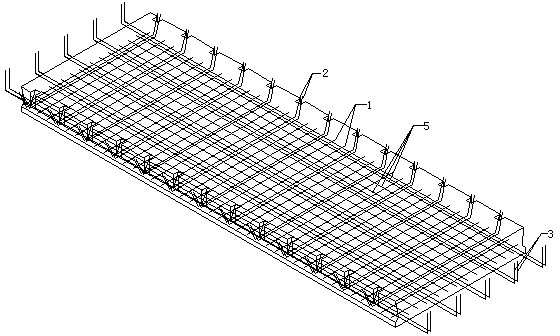

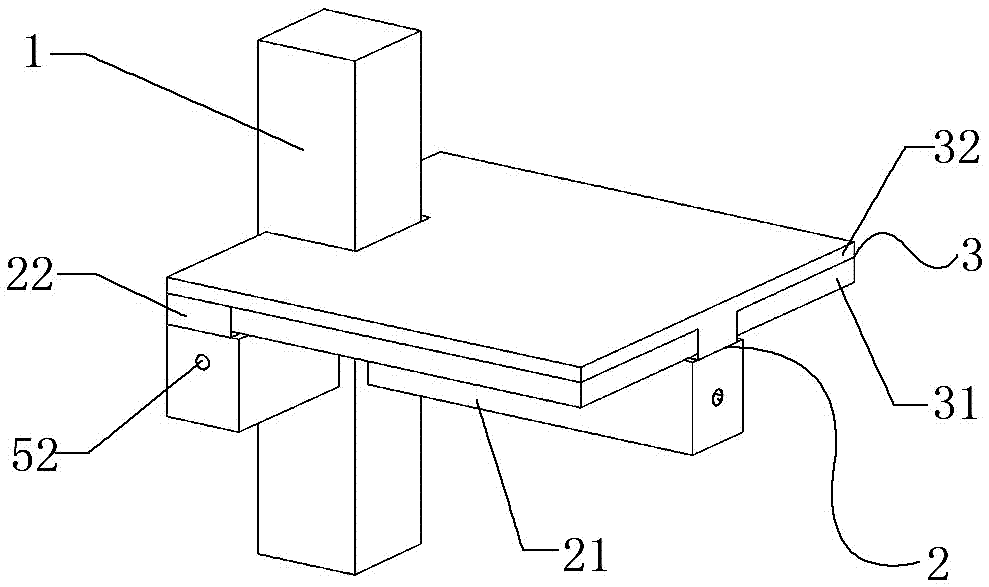

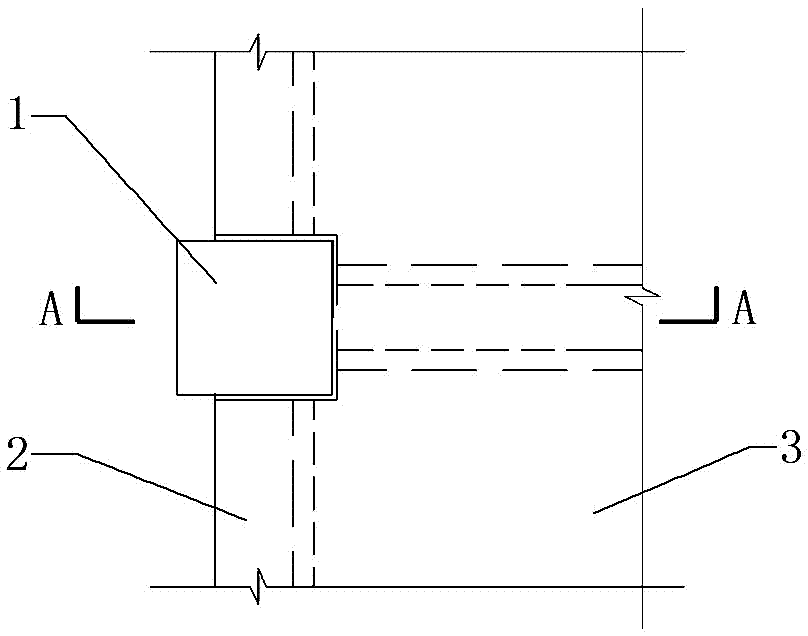

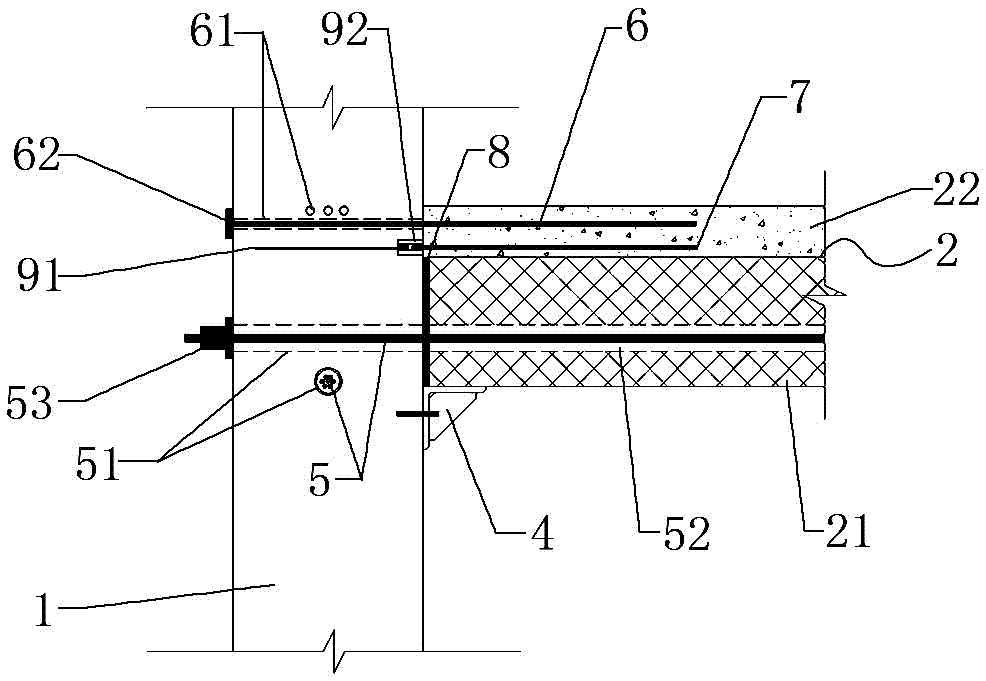

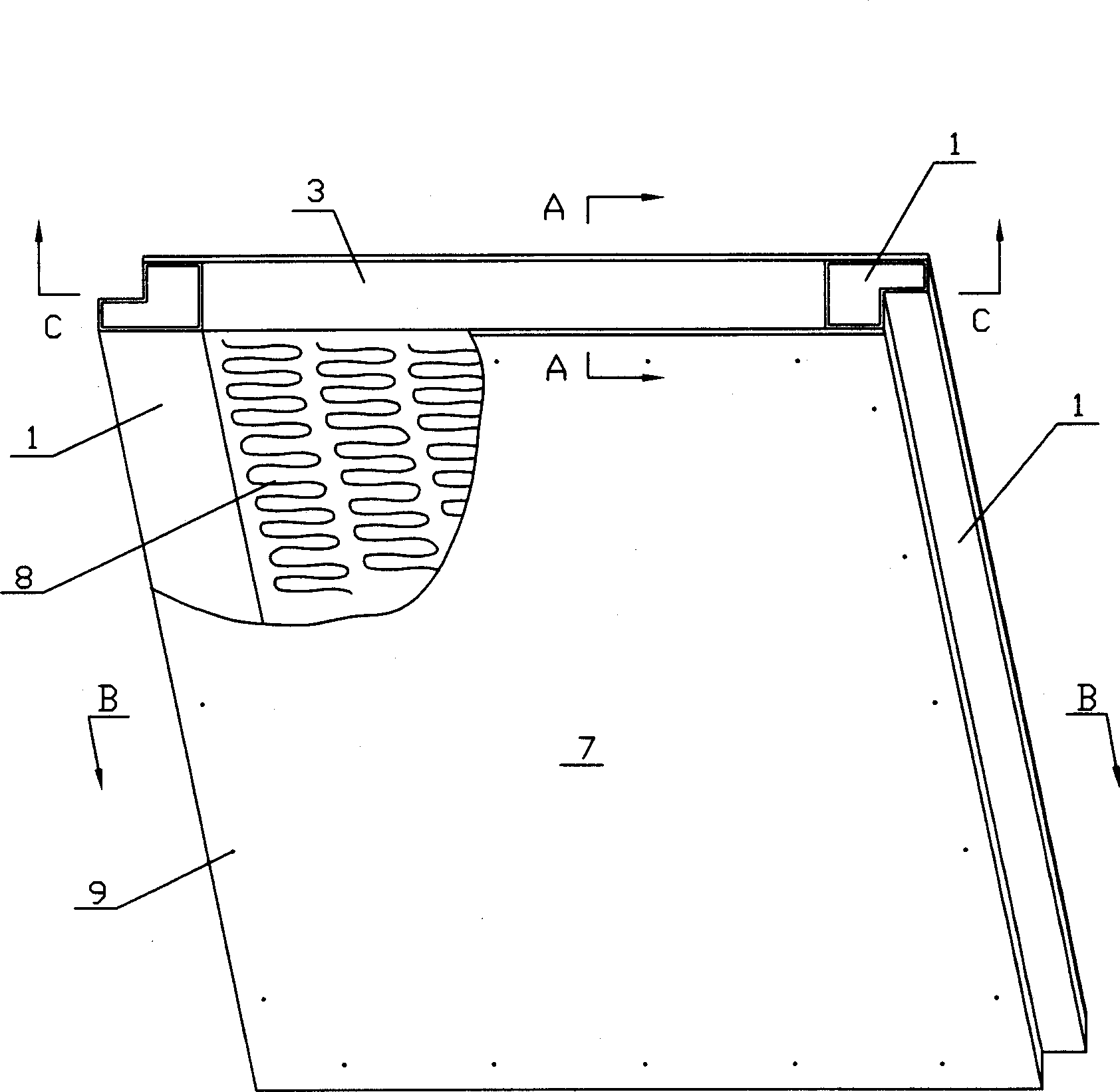

Integrally fabricated box-shaped multi-ribbed composite floor

The invention relates to an integrally fabricated box-shaped multi-ribbed composite floor, and belongs to a prefabricated concrete structural component. The integrally fabricated box-shaped multi-ribbed composite floor is characterized in that the composite floor mainly comprises bottom transverse reinforcement bars, bottom linkage reinforcement bars, lower ribbed beam longitudinal ribs, ribbed beam stirrups, bottom longitudinal reinforcement bars, shutterings, truss ribs, flanges, top transverse reinforcement bars, wedge-shaped grooves and a concrete layer, wherein the bottom linkage reinforcement bars, the bottom transverse reinforcement bars, the lower ribbed beam longitudinal ribs, the bottom longitudinal reinforcement bars, the ribbed beam stirrups, the top transverse reinforcement bars and the truss ribs form a steel reinforcement framework of the composite floor; the concrete layer is poured with a conventional concrete pouring method, the flanges are arranged at the bottoms of the front side and the rear side of a concrete slab body, the connecting position of two composite floors forms a U-shaped groove by the flanges, and crack pouring of post-poured concrete is facilitated; and the wedge-shaped grooves are formed in the front side part and the rear side part of the concrete slab body at intervals respectively, the wedge-shaped grooves between every two adjacent composite floors form shear keys, and the shearing resistance between the composite floors is increased.

Owner:CHINA MCC17 GRP

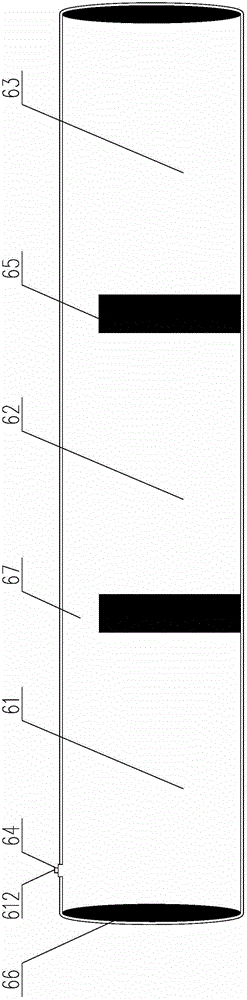

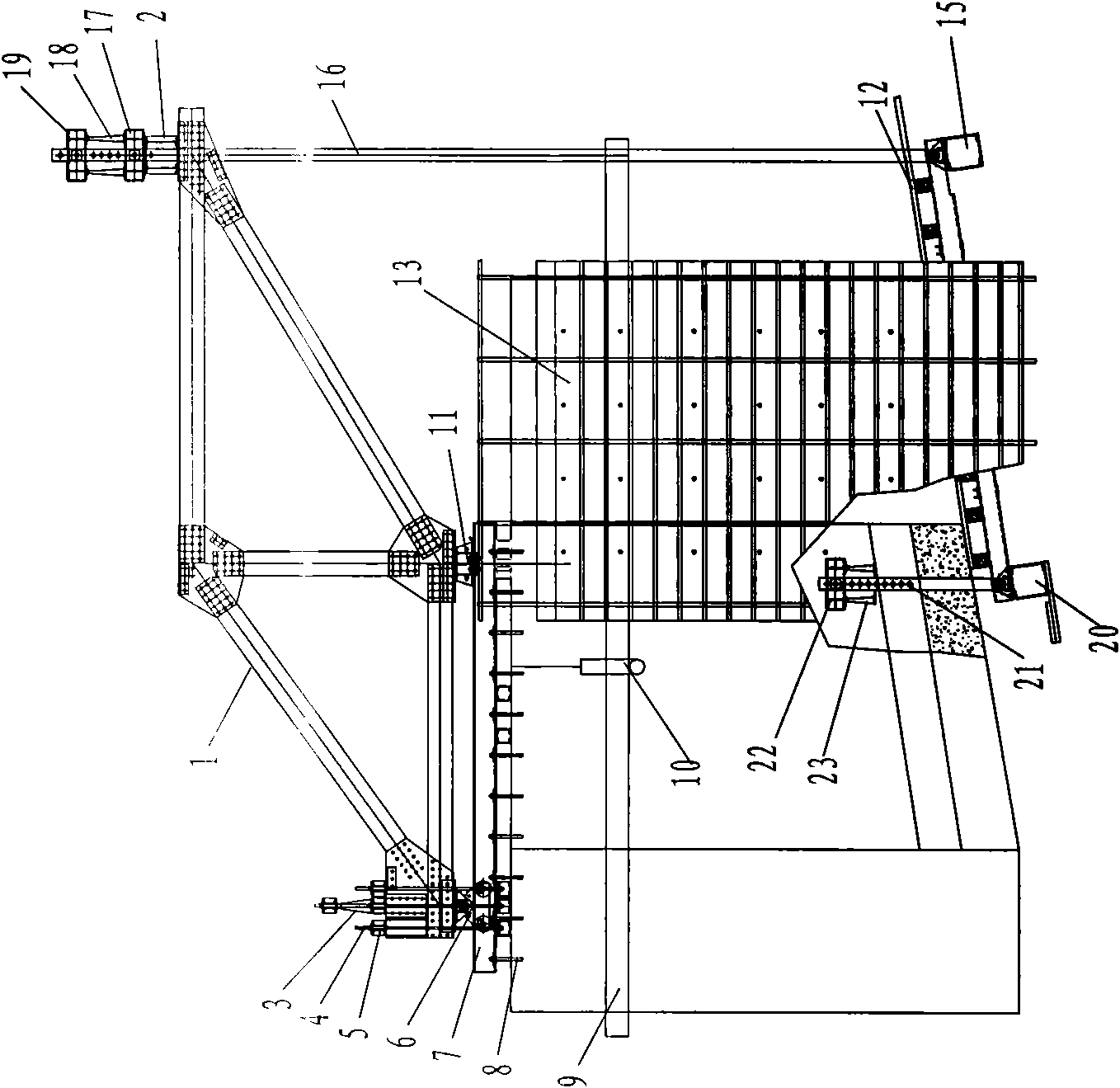

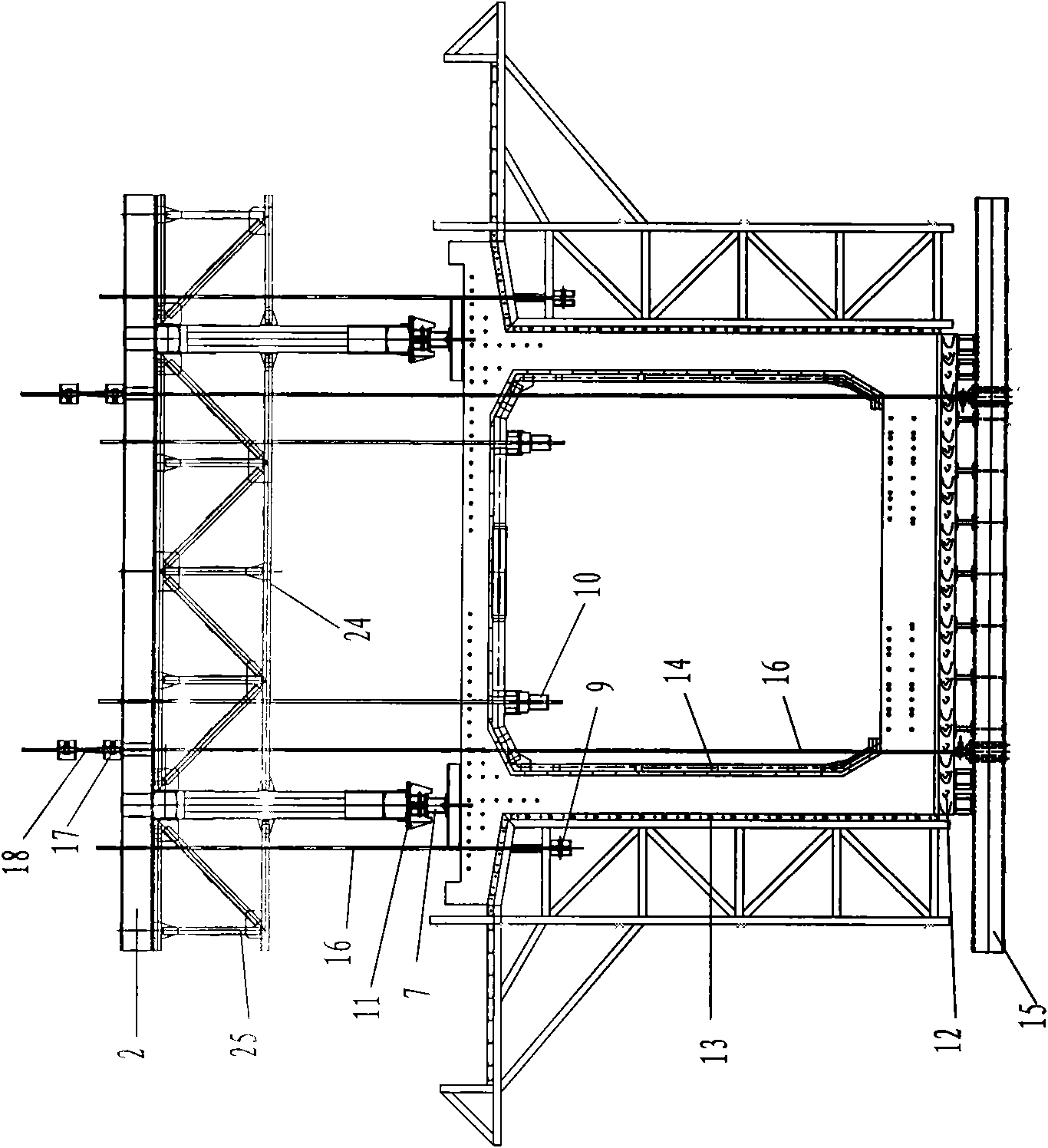

Receding construction method of cradle of continuous girder bridge made of prestressing concrete

The invention relates to a receding construction method of a cradle of a continuous girder bridge made of prestressing concrete, which is characterized in that the bridge surface of a bridge prefabricated by concrete is provided with a track and a door-shaped truss traveling device, and the width of a ceiling girder inside the door-shaped truss traveling device is wider than that of the bridge surface by 90cm-110cm; a front bottom cross beam and a rear bottom cross beam must extend to the outer side of an external mold by 45cm-55cm to form a main cradle truss, and an overhanging auxiliary door frame is additionally arranged outside the main cradle truss, after the construction of a closure segment of the bridge prefabricated by concrete is finished, and precise rolling deformed steel bars with the diameter of 32 outside a box girder positioned on the overhanging auxiliary door frame are connected with the rear bottom cross beam to disassemble a rear hanging strip; a bottom mold frame is separated from a beam body by utilizing a manual spiral type jack to loose the precise rolling deformed steel bars positioned on the door frame and the front bottom cross beam; a leading chain or a hoist are utilized to drive the main cradle truss so that the cradle recedes in a slideway to a first cast-in-situ segment; and a bottom mold and the external mold are fallen by the leading chain or the hoist to disassemble the main truss.

Owner:NO 1 ENG CO LTD OF CR11BG +1

Pre-stressing-force fabricated concrete-frame-joint connecting structure and construction method thereof

PendingCN107165272AImprove integrityImprove energy consumptionGirdersProtective buildings/sheltersFloor slabPre stress

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Dry type joggle frame structure

The invention relates to a dry type joggle frame structure. The structure comprises beam node components, each beam node component comprises a prefabricated column and a prefabricated beam which are cast into one piece, the prefabricated column and the prefabricated beam are prefabricated reinforced concrete components, the upper and lower ends and the column connection points of the prefabricated column are provided with reserved steel bars, the upper-end column connection point is provided with a column head, the lower-end column connection point is provided with a column cap in cooperation muff-coupling with the column head, the column head and the column cap are connected with the preserved steel bars; two ends of the prefabricated beam and the beam connection points are provided with joggle heads which are connected with the steel bar in the prefabricated beam. During the assembly process, the dry type joggle frame structure is environmentally friendly, and the construction noise and the building dust can be effectively reduced. The economic performance is excellent, the man power, materials and time are saved, the application range is wide, and the dry type joggle frame structure can be used both in industrial and civil buildings.

Owner:HUAIHAI INST OF TECH

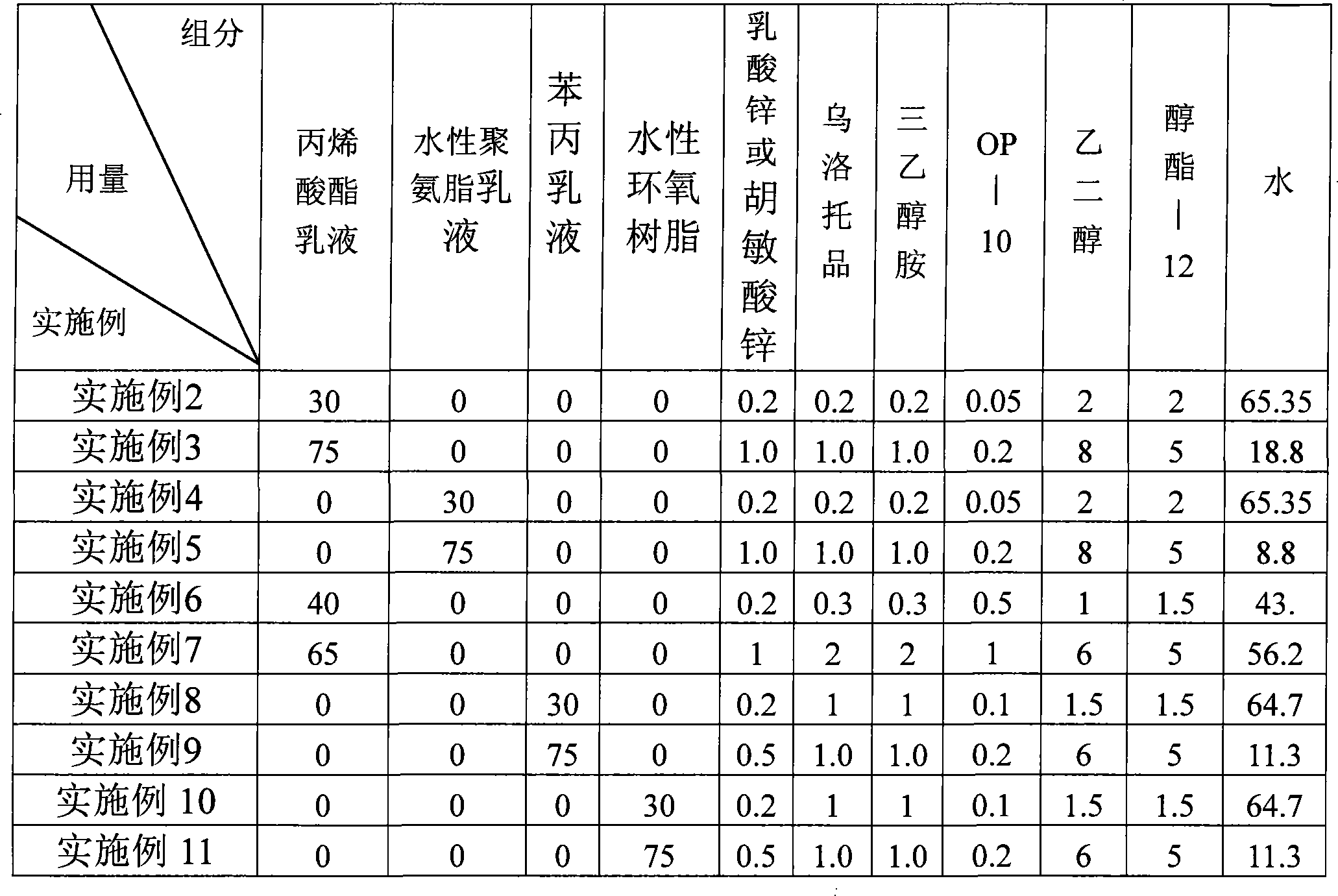

Water-based antirust agent

InactiveCN101240141AImprove bindingStay the sameLiquid surface applicatorsAnti-corrosive paintsWater basedWater vapor

The invention discloses a water-base anti-rust agent composed of 30% to 75% film-forming agent, 0.5% to 6.0% inhibitor, 2% to 16% accessory ingredient and water. Bonding force of film layer to basal body is improved by adopting acrylic ester emulsion or water-base polyurethane emulsion as film-forming substance associated with components of inhibitor, accessory ingredient, etc. The water-base anti-rust agent is brushed on steel surface to form continuous compact protection layer, isolating steel surface from oxygen and water vapor effectively, for long lasting rust prevention. The anti-rust period of steel piece might be more than one year. The protecting film is quite compact, which maintains fundamental color of steel piece invariable. User can process next step of treatment directly without removing the protecting film, which reduces tiresome process of removing anti-rust coat. Operation modes include soaking, spraying, brush coating, etc. The invention is incombustible, nontoxic and environment-friendly. Contents of free formaldehyde, heavy metal and volatile organic meet qualified criteria. Bond strength of twice-brushed deformed steel bar to concrete is more than non-brushed test piece.

Owner:焦占付

Steel-steel concrete fully prefabricated assembling structure

InactiveCN1554839AEnsure safetyImprove bearing capacityBuilding constructionsHigh strength concreteFloor slab

The fully prefabricated assembled steel-steel concrete structure includes two kinds of assembling forms. The first one is fully prefabricated assembled steel column-steel concrete structure, and its prefabricated steel column consists of H-shaped steel column, reinforcing concrete ribs, supporting steel plate and prestress-shearing force friction nodes with shear resisting strips. The second one is fully prefabricated assembled prefabricated steel pipe-concrete column-steel concrete structure, and the prefabricated steel pipe-concrete column consists of steel pipe with square cross section, micro expanding high strength concrete cast inside the steel pipe and shear resisting strips attached to the outer wall of the steel pipe to form preshearing force-friction type nodes. The present invention has raised antiseismic performance, area utilization, construction efficiency, fireproof performance, low cost and small member size, and is suitable for various buildings.

Owner:KUNMING UNIV OF SCI & TECH

Post-tensioned prestressing cast pile and construction method thereof

InactiveCN101629418AImprove the way of reinforcementHigh application strengthBulkheads/pilesSocial benefitsPre stress

The invention discloses a post-tensioned prestressing cast pile comprising a construction reinforcing cage arranged in a concrete pile body. A plurality of common principle bars and a plurality of prestressing steel strands are arranged in the construction reinforcing cage, wherein each prestressing steel strand is a retarded adhesive prestressing steel strand or an adhesive-free prestressing steel strand; the top of the concrete pile body is provided with a pile top tension anchorage, and the bottom of the concrete pile body is provided with a pile bottom fixing end anchorage. The invention is a construction technology of firstly placing the reinforcing cage tied up with the prestressing steel strands and the common principle bars in a pile hole, and then casting concrete; the reinforcing cage does not deform, and the prestressing steel strands have high perpendicularity and stable position and are easy to tense. The prestressing tension is utilized to generate compressive pre-stress on the concrete, thereby increasing the durability of the concrete under harsh work conditions. As the tensile strength of the adopted prestressing steel strands is 5 times that of HRB400-grade steel bars, the steel usage can be saved by more than 50%, thus being beneficial for energy saving and emission reduction and generating obvious economic benefits and social benefits.

Owner:TIANJIN RES INST OF BUILDING SCI

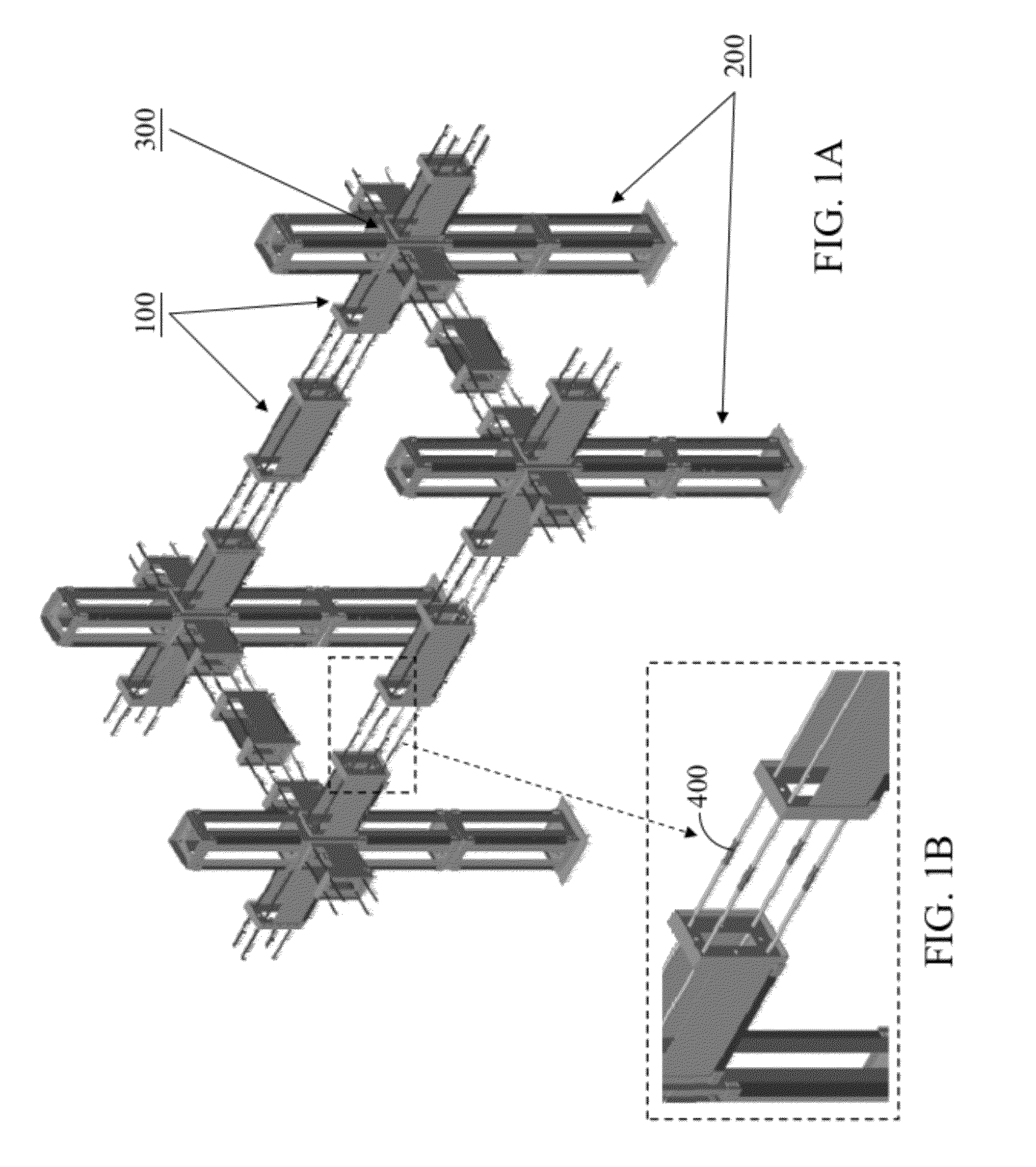

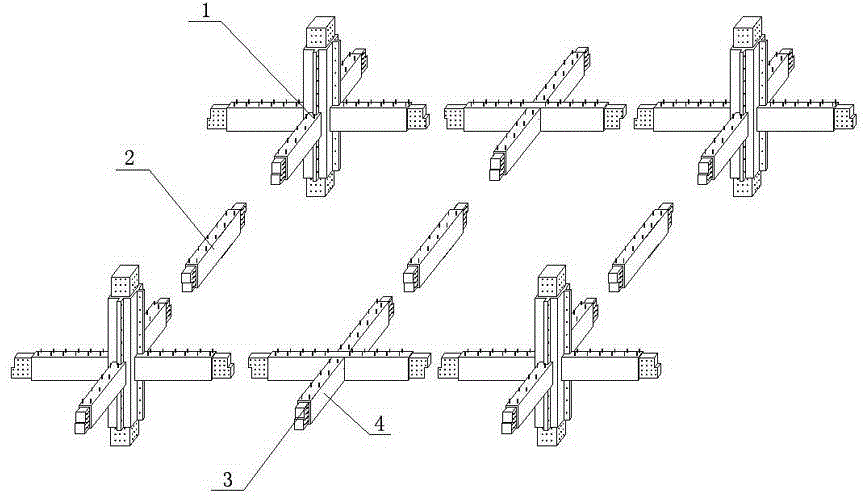

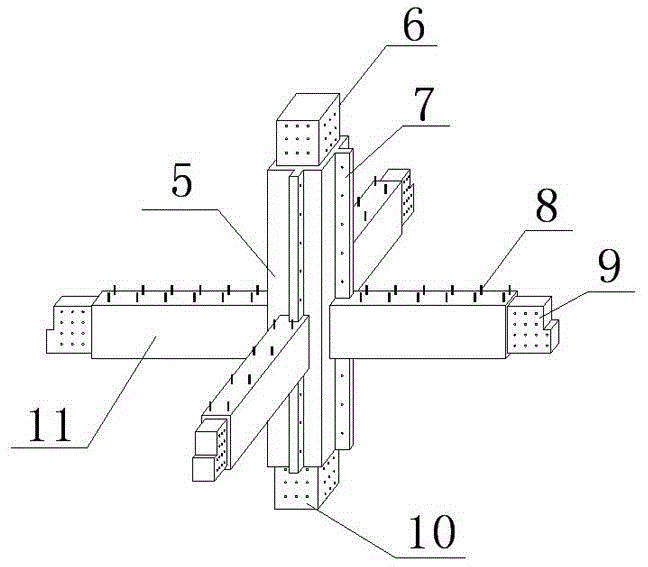

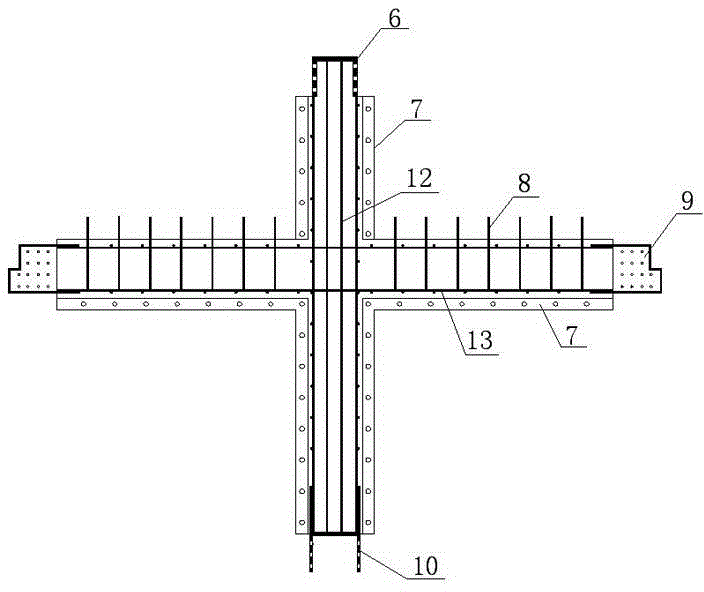

Integrally-assembled concrete structural system adopting steel bar lapping mode

InactiveCN102995745AIn line with construction industrializationMeet the requirementsBuilding constructionsReinforced concreteSteel bar

The invention provides an integrally-assembled concrete structural system adopting a steel bar lapping mode and relates to a concrete part system. Effective lapping degree of parts is reserved according to common cast-in-place steel bar concrete calculation and design, designed common concrete filling (pouring) is adopted after prefabricated parts are installed in place in the field construction process, the lapping length of the parts is required to be considered when the parts are dismantled, steel bars and steel bar plugging-in grooves with considered lapping length are reserved according to the design and construction requirements when the parts are manufactured, the parts are arranged in place in construction and installation according to the requirements after the prefabricated parts are transported to a field, and concrete is filled (casted) according to the design requirement under the condition that the parts are ensured to be stable. Additional sleeves, spiral bars and the like are not required, accurate aligning between the steel bars and preserved holes of the parts is not required, part processing difficulty and construction installing difficulty are reduced greatly, construction cost is reduced, and a construction period is shortened.

Owner:沈阳易筑建材经销有限公司 +2

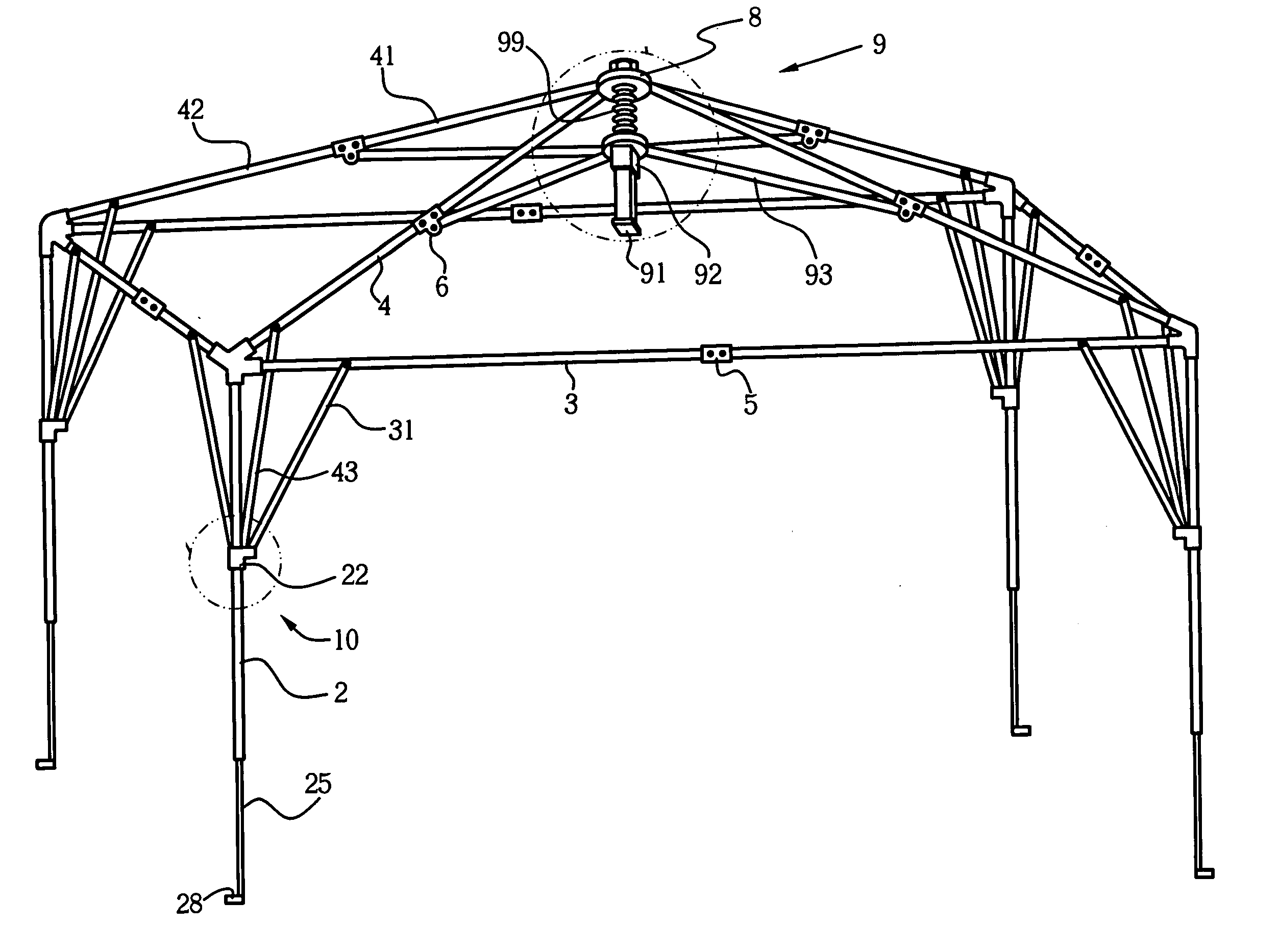

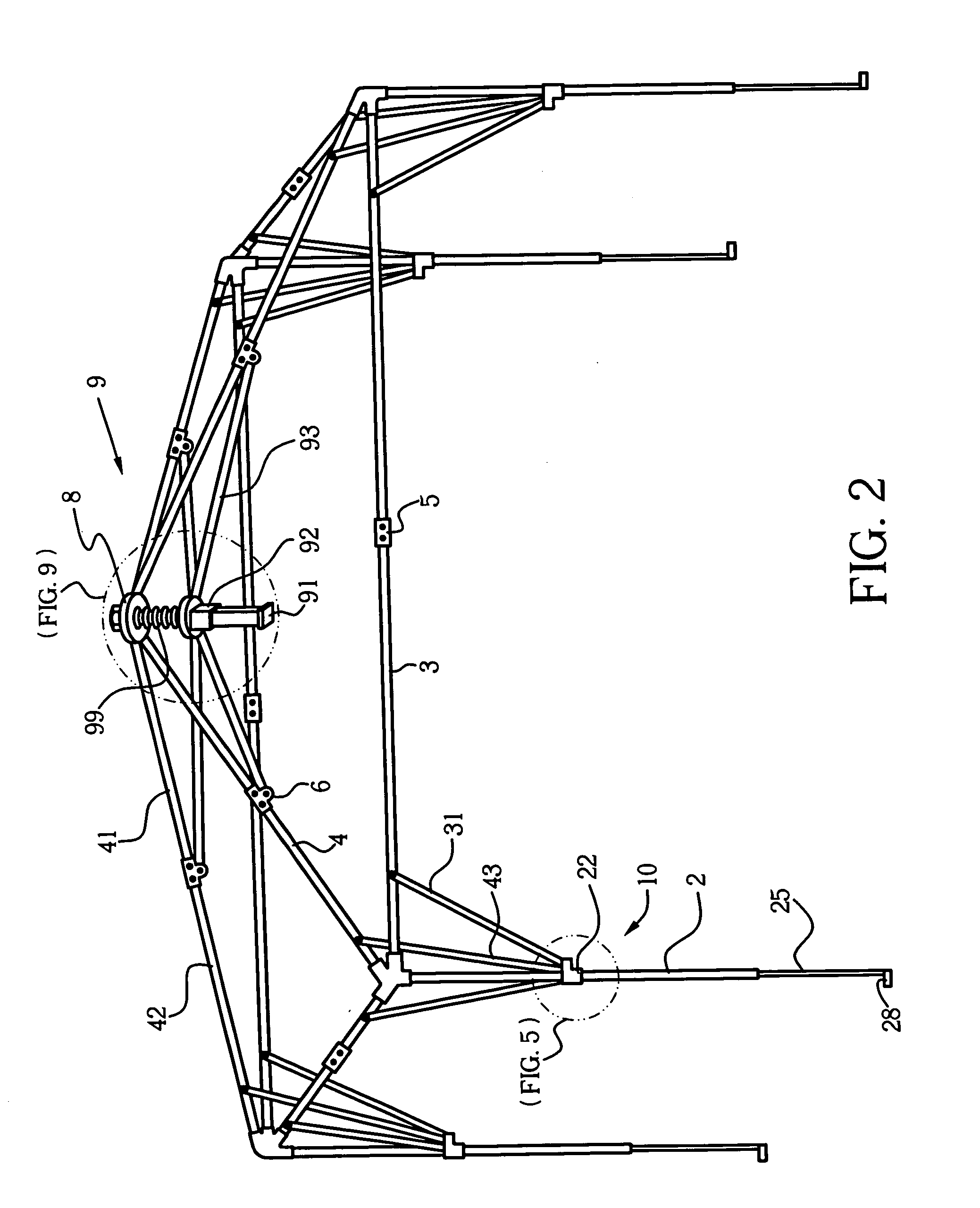

Portable collapsible tent

A portable collapsible tent includes a cover, a roof frame with a central pole, inclined roof ribs and spreaders, extensible legs, and cross bars. The ribs and spreaders are pivotally and movably jointed at the central pole. A locking unit secures the roof frame when the tent is pitched. Each leg has at one end a fixed corner member that provides a four-way connection and a multi-way support member that movably engages and locks onto the leg to support two cross bars and an inclined rib connected thereto with three diagonal braces. A spring is positioned on the central pole to enable the collapsed tent to be opened easily. A lateral projecting foot member enables each leg to be anchored on the ground. Reinforcement ropes further secure the tent to the ground via the four-way connectors. The portable collapsible tent can be easily set up and collapsed without tools and has a strong structural integrity, able to withstand substantial stress and direct / indirect forces.

Owner:WU WEIDAN

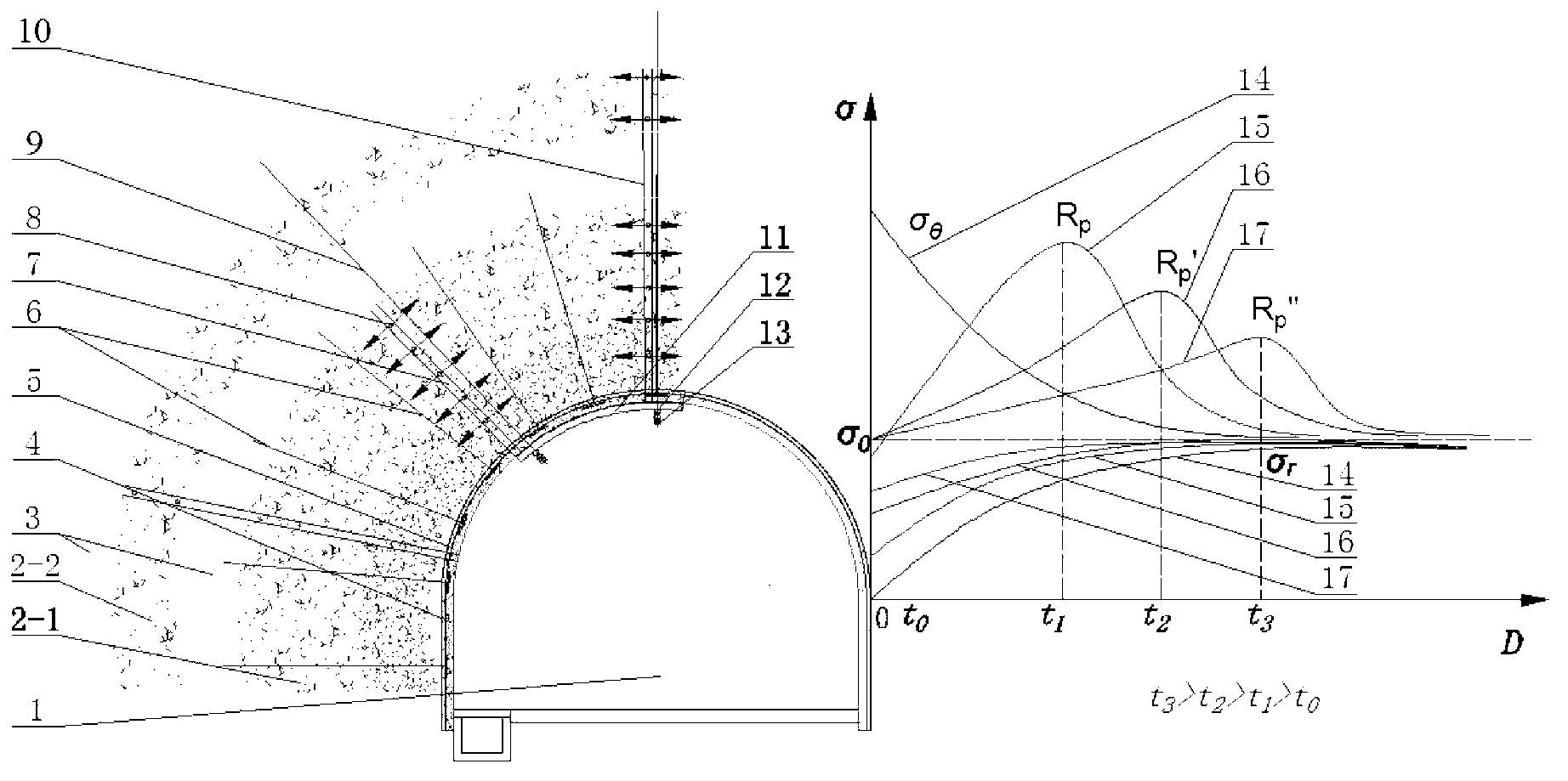

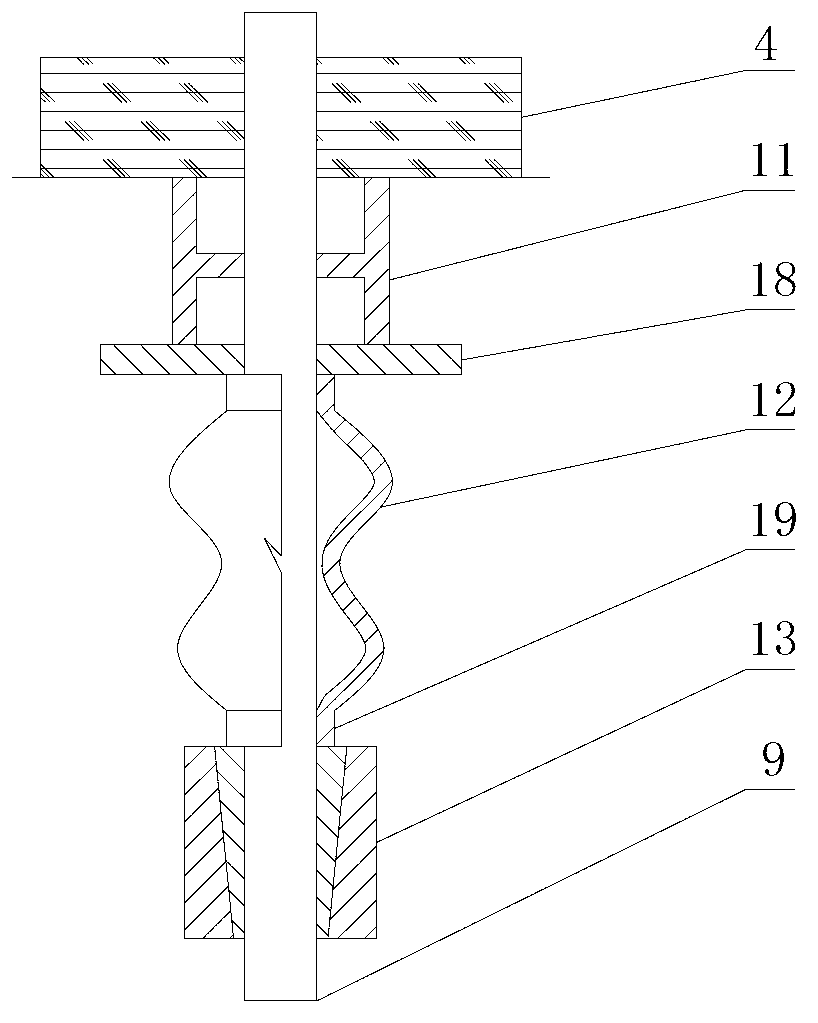

Bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock

The invention specifically discloses a bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock, and the method comprises the following steps of: (1) after the roadway is excavated, immediately shotting concrete to close the surrounding rock, employing a high-pretightening force overstrength anchor bolt for supporting in the first disintegration zone, and arranging a steel bar net on the inner wall of the roadway surrounding rock and shotting concrete again; (2) applying a pretightening force anchor cable on the top plate of the roadway surrounding rock such that the anchoring end of the anchor cable is located in the deep intact rock mass, arranging a steel I-beam closely to the surrounding rock, passing the anchor cable through the shotcrete, the steel I-beam and a yielding ring and fixing the anchor cable on the inner wall of the roadway surrounding rock by using an anchor cable lock, thereby realizing coupling and supporting of the anchor bolt and the anchor cable; and (3) according to the monitoring result of the zonal disintegration of the surrounding rock, performing the delayed anchor bolt support for about 20-30 days, and performing grouting reinforcement on each disintegration zone by virtue of long and short combined injection pipes or a hollow sectional spiral grouting anchor bolt. The bolting-grouting integrated support method is capable of effectively performing bolting-grouting integrated reinforcement on the disintegrated surrounding rock of the deep roadway and thereby obviously enhancing the stability of the roadway.

Owner:SHANDONG UNIV

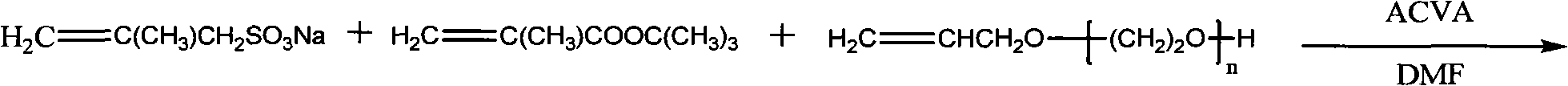

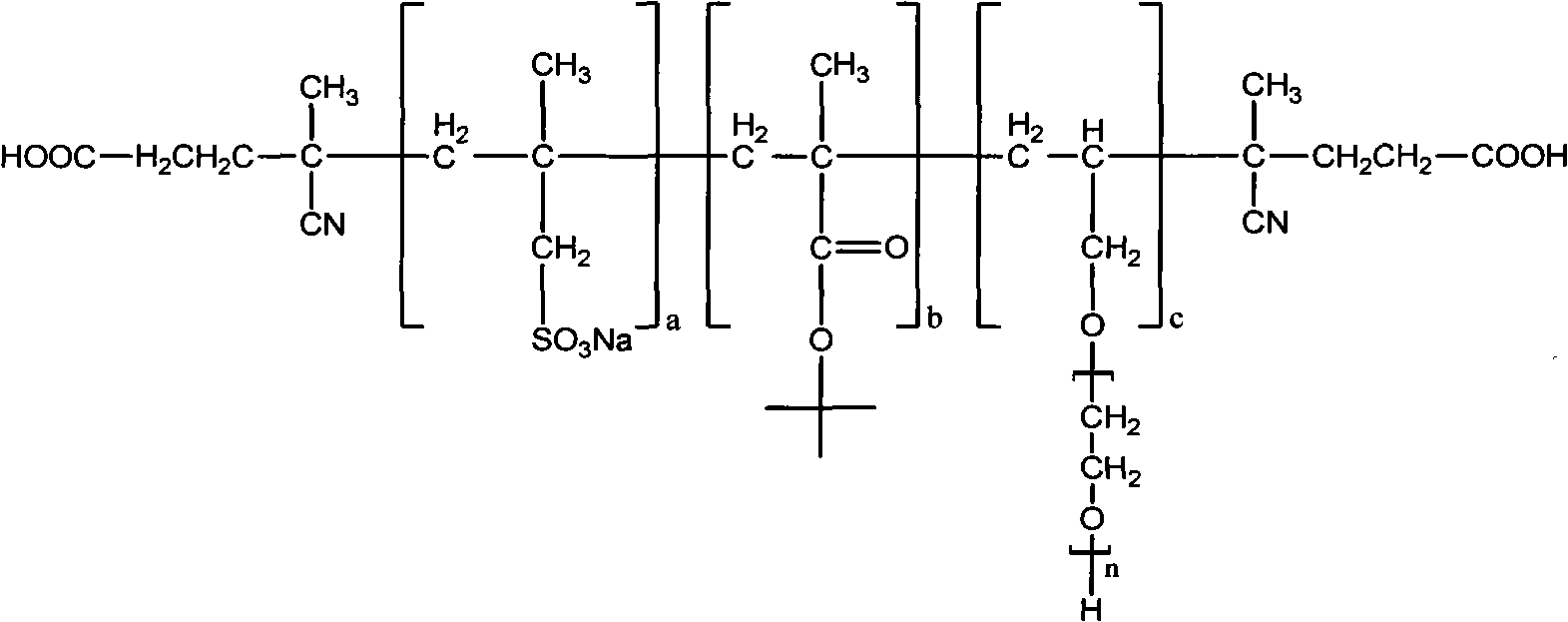

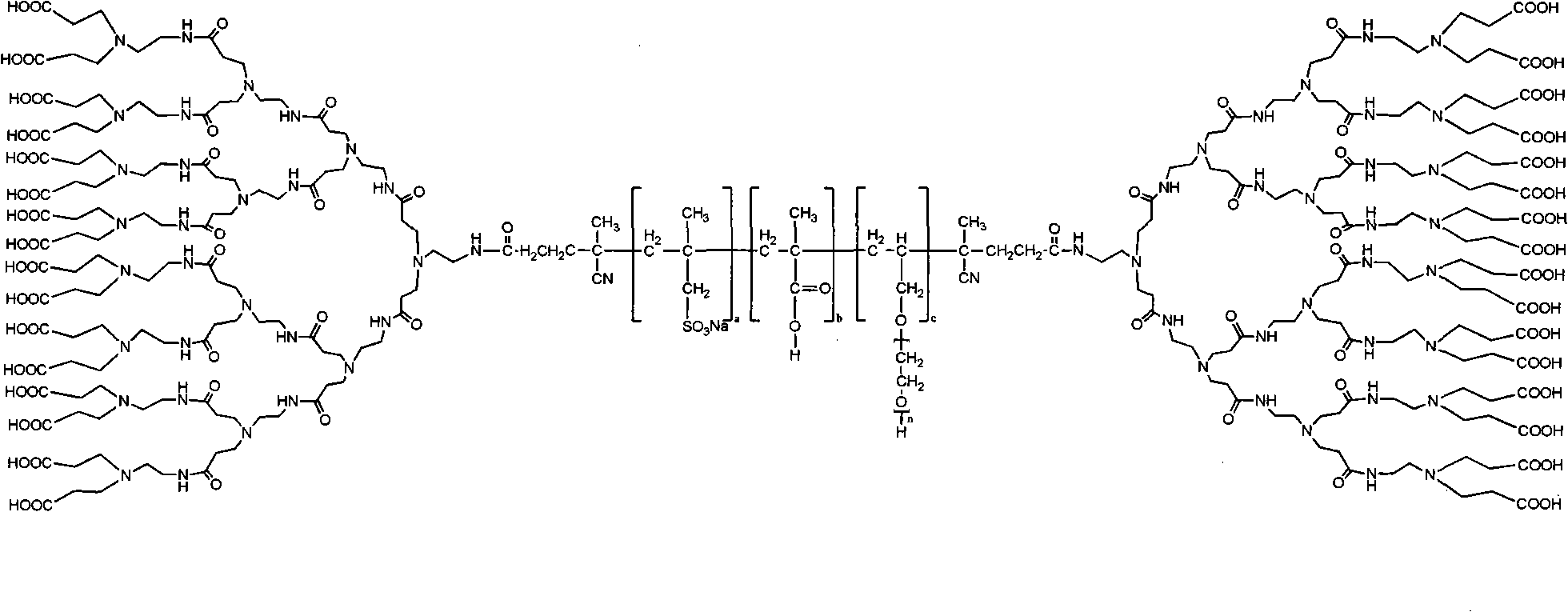

Hyper-branched polycarboxylate high-efficiency water reducing agent and preparation method thereof

The invention relates to a hyper-branched polycarboxylate high-efficiency water reducing agent and a preparation method thereof. The water reducing agent is prepared by polymerizing one of tert-butyl acrylate and methyl tert-butyl acrylate with sodium methyl-acryl sulfonate and allyl polyethenoxy ether to form a copolymer main chain, and then performing condensation polymerization on one of acrylic acid and methacrylic acid with ethylene diamine to form a hyper-branched polyamide structure which is grafted to two ends of the main chain. The preparation method comprises the following steps: (1) preparing the sodium methyl-acryl sulfonate into solution with DMF, and heating the solution in a nitrogen atmosphere; (2) dissolving the other two monomers and an initiating agent into the DMF to prepare mixed solution, and dripping the mixed solution into the step (1) to react for 1 to 20 hours; (3) adding a condensating agent CDI after the reaction and performing condensation reaction by using N-methyl morpholine as an organic base, the ethylene diamine and the acrylic acid as the monomers and the DMF as a solvent; and (4) performing vacuum distillation to remove the residual monomers and the solvent, and refluxing for 2 to 5 hours by using methylene chloride solution of trifluoroacetic acid to obtain the water reducing agent. The hyper-branched polycarboxylate water reducing agent has the advantages of low admixture, high water reducing rate, small slump loss, good compatibility with cement, no corrosivity to steel bars, strong frost resistance and the like.

Owner:厦门路桥翔通建材科技有限公司 +1

Control method of intelligent tension system and intelligent tension system

ActiveCN103526948AHigh measurement accuracyImprove construction efficiencyBuilding material handlingFrequency changerControl signal

The invention provides a control method of an intelligent tension system and the intelligent tension system. The method is characterized by including the steps that a loading speed control unit is built and used for detecting pressure of an oil inlet, and the pressure, monitored in real time, of the oil inlet is compared with preset pretightening force of each stage; a prestressing tendon extending amount control unit is built and used for detecting the displacement value of a prestressed steel bar in real time in the tensioning process and the displacement value of the prestressed steel bar in set holdup time after the prestressed steel bar reaches set tension force of each stage; tensioning values of different jacks are compared after first-stage tension; control signals of different stage conditions in the tensioning process are converted into electromagnetic motions and frequency converter rotation speed control requirements; according to signals fed back by a pressure sensor and a displacement sensor in the tensioning process, the related control commands undergo fuzzy conditioning. The control method and the system have the advantages of improving data measuring precision and construction efficiency, reducing labor intensity of construction workers, reducing cost, improving labor efficiency, eliminating safety hidden risks of the construction workers, and enabling the whole tensioning process to be finished at a time.

Owner:LIUZHOU QIAN BRIDGE ENG MATERIALS

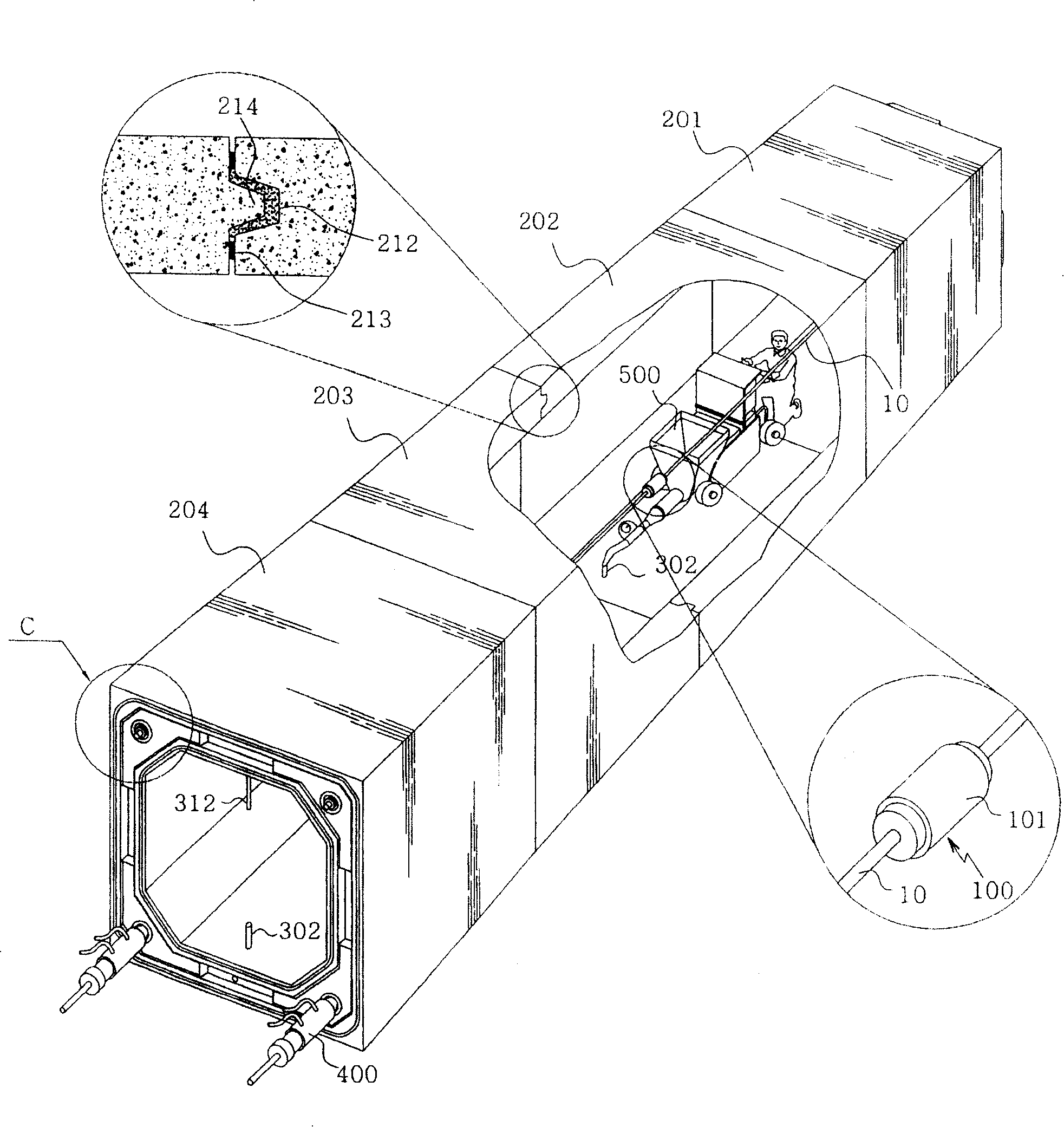

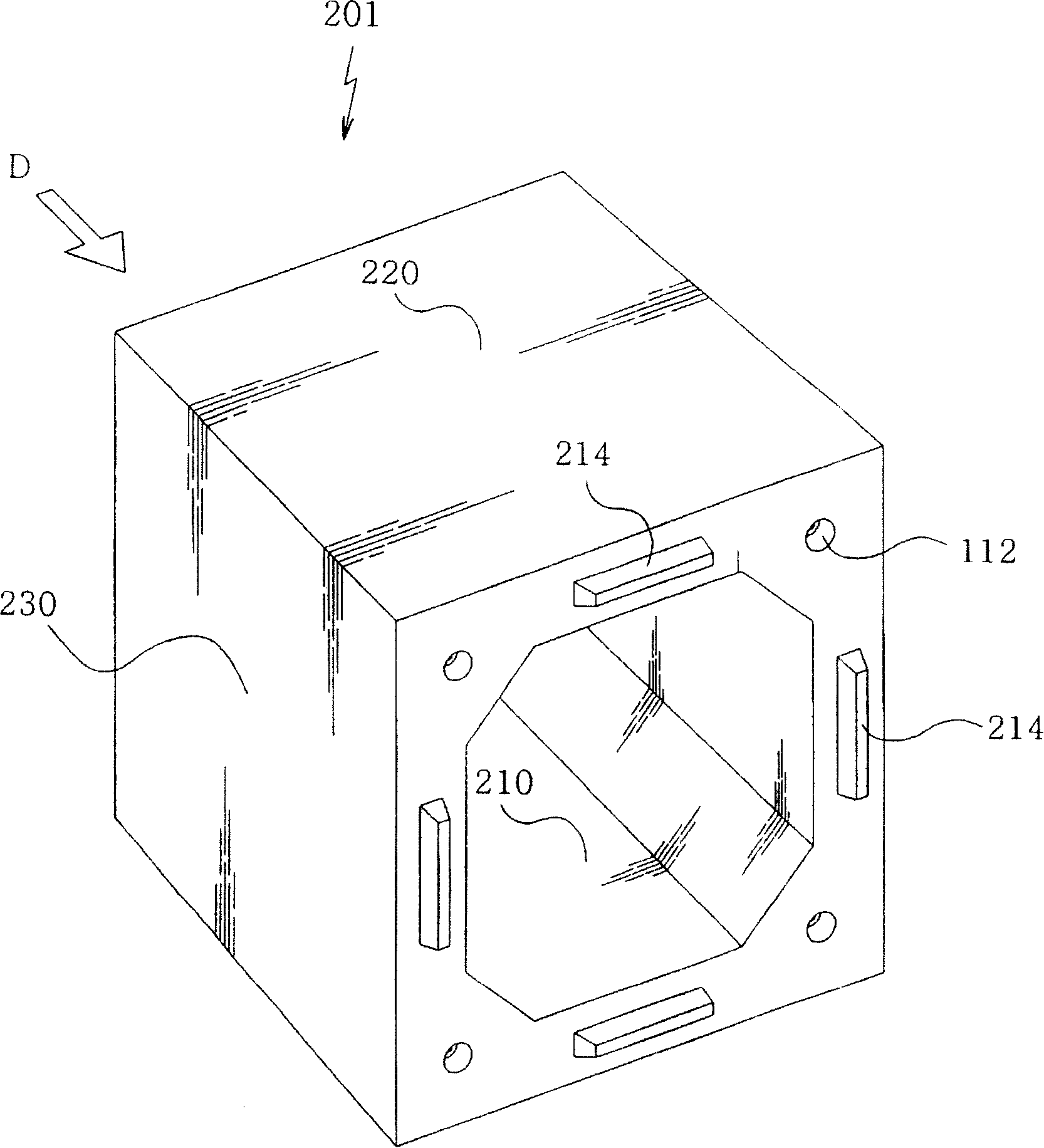

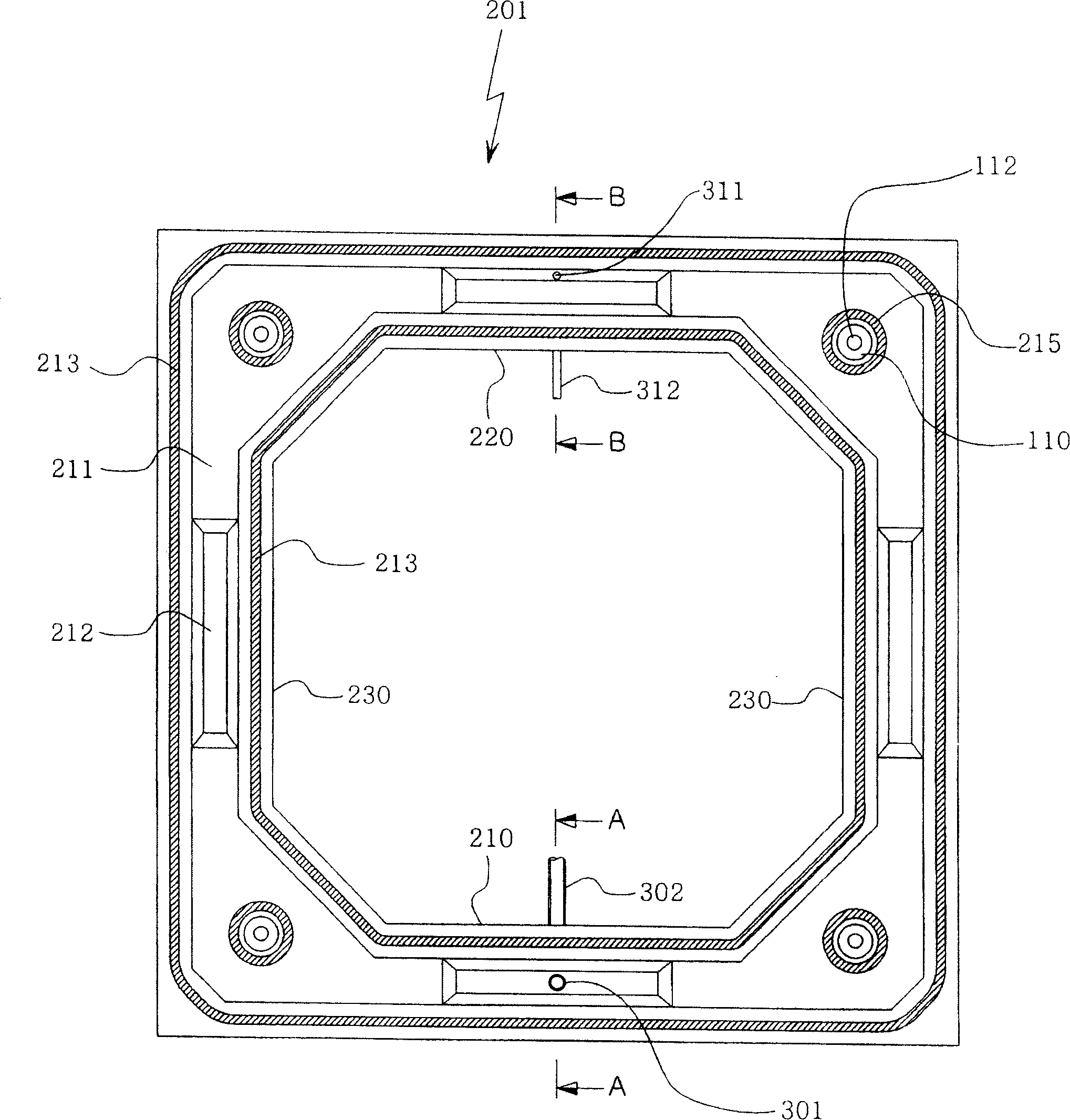

Prefabricated concrete box culvert using grouting method and bidirectional anchoring system as well as mounting structure and method thereof

InactiveCN101205724AAvoid damageReduce lossesArtificial islandsUnderground chambersAdhesion forcePre stress

The invention discloses a pre-fabricated concrete box culvert, the assembly structure thereof and an assembly method. The invention can ensure that the mortar is completely filled on a connecting surface of the pre-fabricated concrete box culvert, thereby furthest reducing the pre-stress damage caused by the sliding when the reinforcing steel bar is fixed, and allowing the pre-fabricated concrete box culvert to be assembled into a structure with extremely strong adhesion force, firmness and reliability, furthest reducing the loss of the bundled reinforcing steel bars and avoiding the damage to the structure.

Owner:朴斗绪 +1

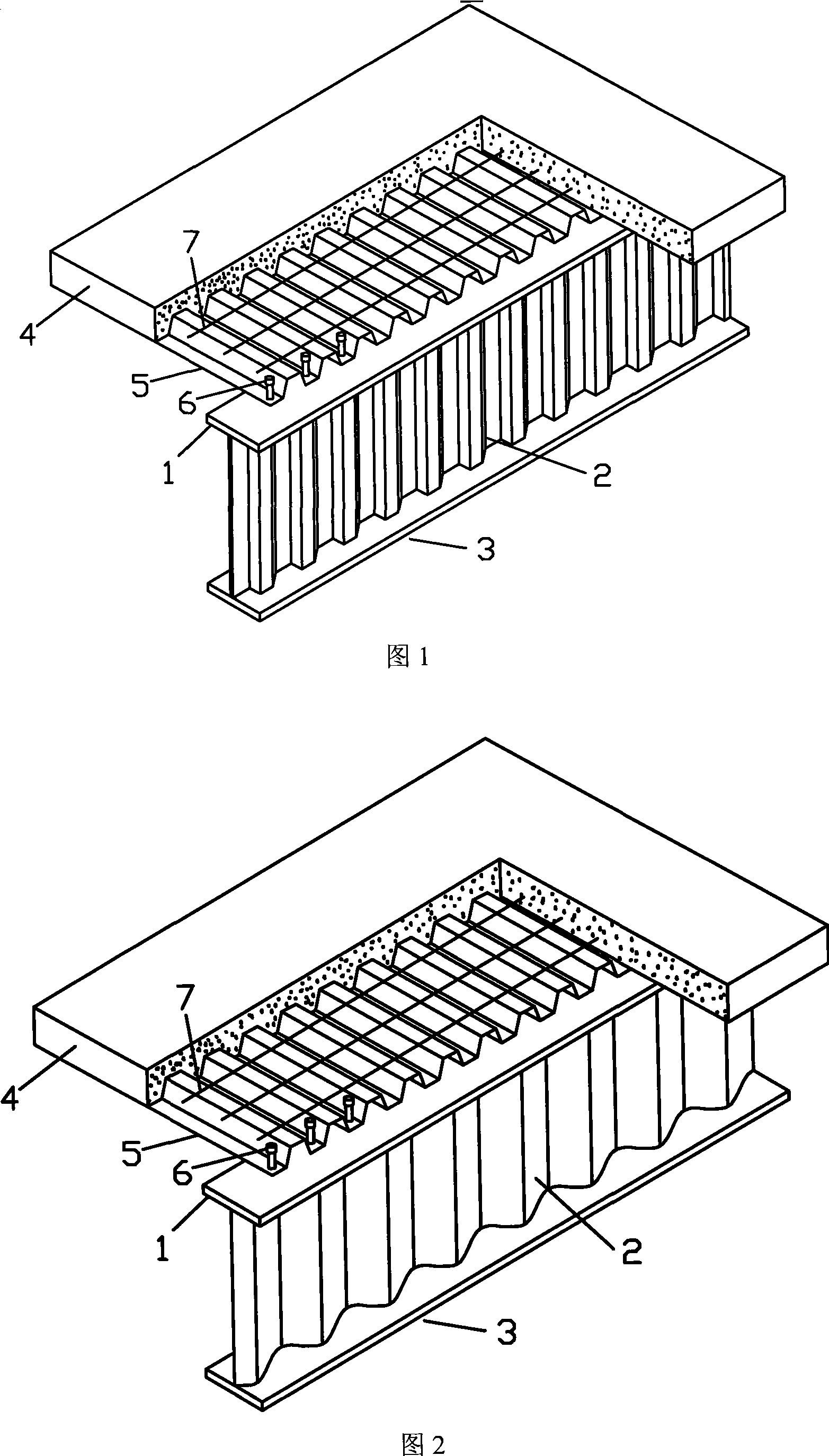

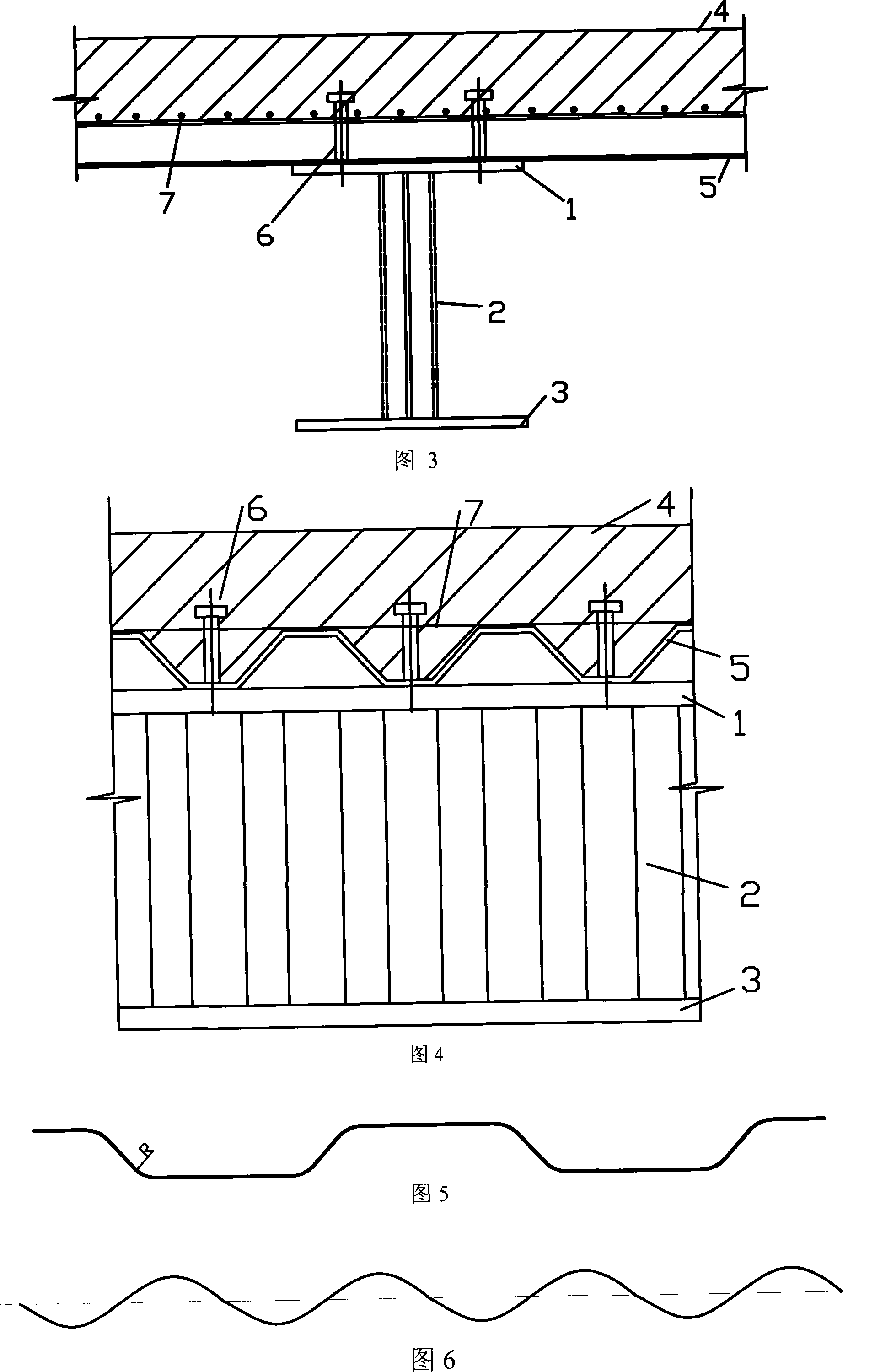

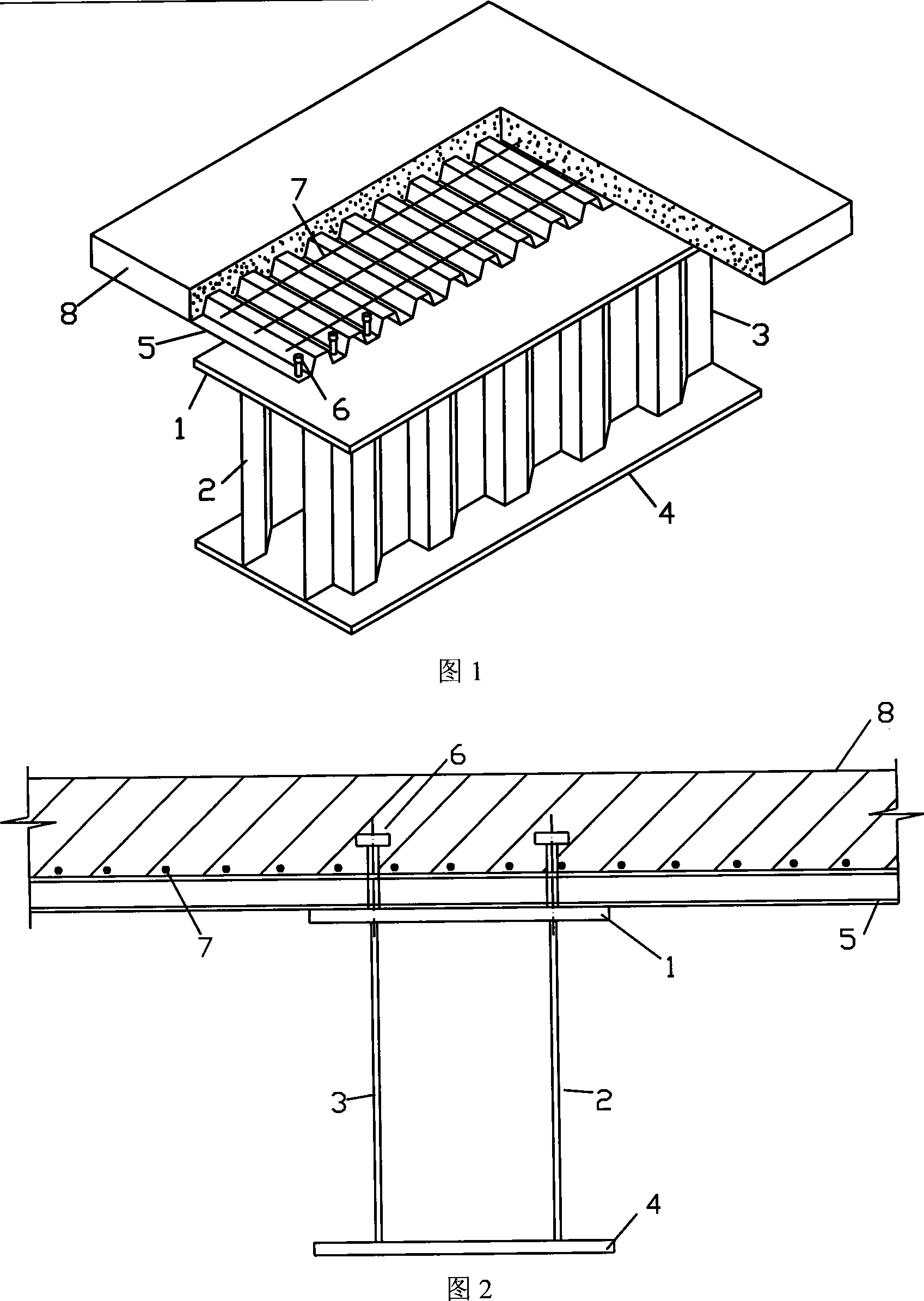

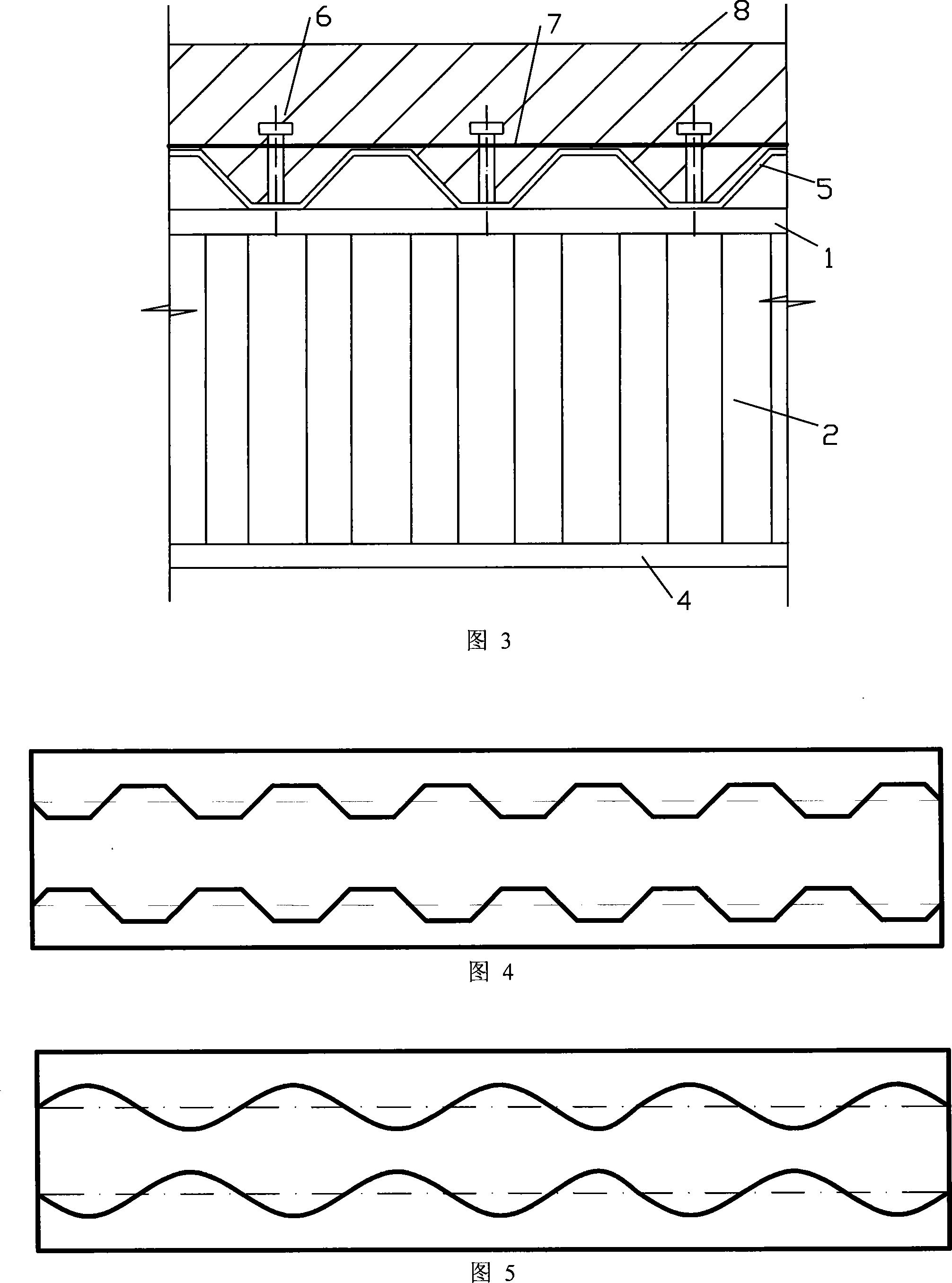

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

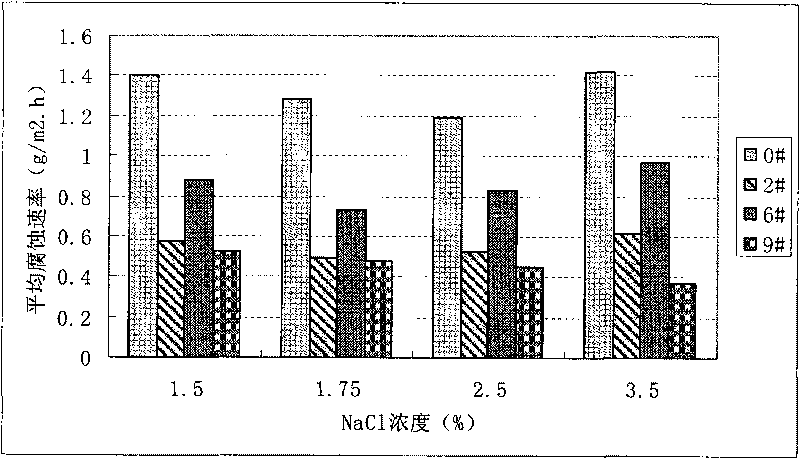

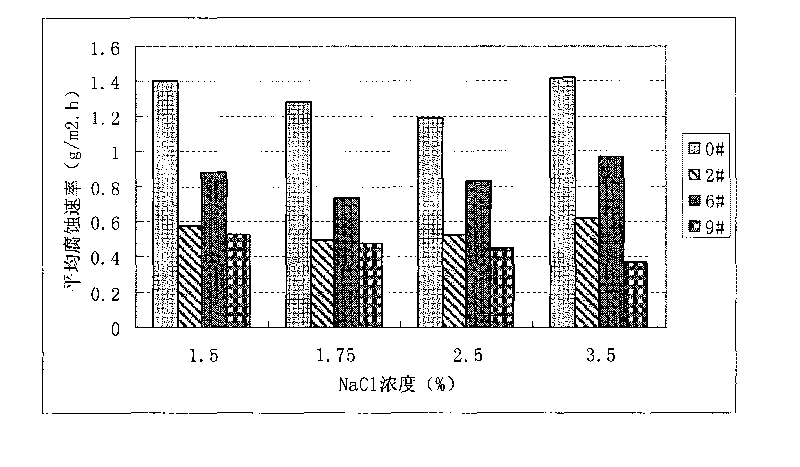

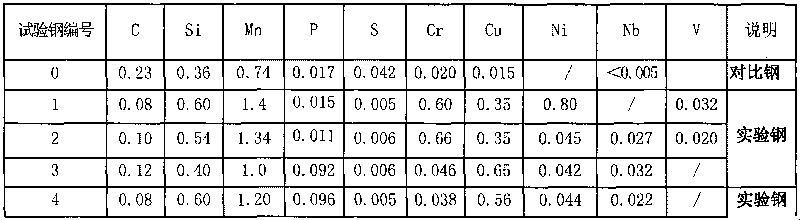

Cl- corrosion resistant high-strength low-alloy steel bar and production method thereof

InactiveCN101709434AAccelerated corrosionWith durability design requirementsTemperature control deviceSteel barPerformance index

The invention discloses a Cl- corrosion resistant high-strength low-alloy steel bar and a production method thereof, and belongs to the technical field of steel bars. The alloy in a basic alloy system comprises the following elements in percentage by weight: 0.08 to 0.25 percent of C, 0.35 to 1.1 percent of Si, 0.7 to 2.0 percent of Mn, 0.05 to 0.10 percent of P, 0.010 percent of S, 0.30 to 1.60 percent of Cr, 0.2 to 0.80 percent of Cu, 0.2 to 1.0 percent of Ni, and the balance of Fe and inevitable impurity elements; and one or more of micro alloy elements comprising V, Nb, Ti, B and the like can be added with trace according to the performance requirement of the steel bar, and the total amount of the micro alloy elements is controlled in a range of 0.01 to 0.5 percent. The steel bar has the advantage of economic and reasonable cost, and the Cl- corrosion resistance of the steel bar is obviously superior to that of carbon steel. The performance index of the steel bar meets the requirement of 400MPa-grade steel bars in GB1499-2007; and the steel bar has good welding performance and mechanical connection performance, and is applied to a concrete structure with durability design requirement under the marine environment condition.

Owner:CENT IRON & STEEL RES INST

Double-ripple ventral shield steel case built-up beam

InactiveCN101220697APrecise positioningImprove mechanical propertiesFloorsLoad-supporting elementsSteel barSpandrel

The invention belongs to the technical field of architectural profiles and particularly relates to a double corrugated web steel box composite beam. The sectional shape of the invention is composed of two symmetrically arranged corrugated webs, a top flange and a lower flange. The top flange is parallel with the lower flange, the web is vertical to the top flange and the lower flange, the web and the flange are connected by single-side fillet joint, and the web has periodically repetitive trapezoidal wave or sinusoid wave along the length direction. The top of the composite beam is a reinforced concrete wing plate and a profiling steel plate. The top flange, the reinforced concrete slab and the profiling steel plate are connected each other by male pins, and a transverse reinforcement can be additionally used for the connection between the reinforced concrete wing plate and the profiling steel plate. The invention can replace the traditional hot rolled flange beam, H-beam composite beam and welded steel box composite beam; furthermore, the invention has wider application than the flange beam and the H-beam composite beam, and can realize maximization to be used in special fields and special places, including the construction of wide-span industrial and civilian buildings and wide-span bridges, etc.

Owner:TONGJI UNIV

Assembled large-scale construction board with light frame and manufacturing process thereof

ActiveCN1884762AImprove structural performanceImprove seismic performanceBuilding componentsKeelEdge structure

The invention relates to an assembly light frame large-scale building sheet material and relative preparation, wherein said invention comprises: two plates and one core plate clamped between them; said core plate comprises a light frame at the edge to form sealed edge structure, and light thermal-insulated material filled into the chamber surrounded by said light frame; the plate and the light frame are connected via self-threading screw. And the preparation comprises filling type, rolling type and model compress type. The inventive sheet is preformed with light keel, which can confirm better structure of room, with anti-wind, anti-vibration and anti-theft functions (it arranges steel bar network inside the plate).

Owner:广州益群板业有限公司

Steel bar concrete beam reinforcing structure with partially restrained steel truss

The invention discloses a steel bar concrete beam reinforcing structure with a partially restrained steel truss, comprising upper angle steel, lower angle steels, a web batten plate, a bottom steel plate, an anchored steel plate, a shear resistant anchor bolt and a bolt, wherein the upper angle steel, the lower angle steels, the web batten plate and the bottom steel plate are spliced to form an opened steel truss for tightly hooping a beam to be reinforced, the lower angle steels are respectively arranged at two lower corners of the beam to be reinforced and are connected with each other by the bottom steel plate, the upper angle steel is mounted between the beam to be reinforced and a slab, and is connected with the lower angle steels by the web batten plate, the anchored steel plate is arranged in the slab and is connected with the shear resistant anchor bolt arranged in the slab, and the shear resistant anchor bolt is connected with the upper angle steel by the bolt in a pre-fastening mode. The steel truss and the steel bar concrete beam form two load bearing protection lines, so the bearing capacity of the steel bar concrete beam meets the reinforcing design requirement, and the safety of a member and a structure can be ensured.

Owner:NANJING UNIV OF TECH

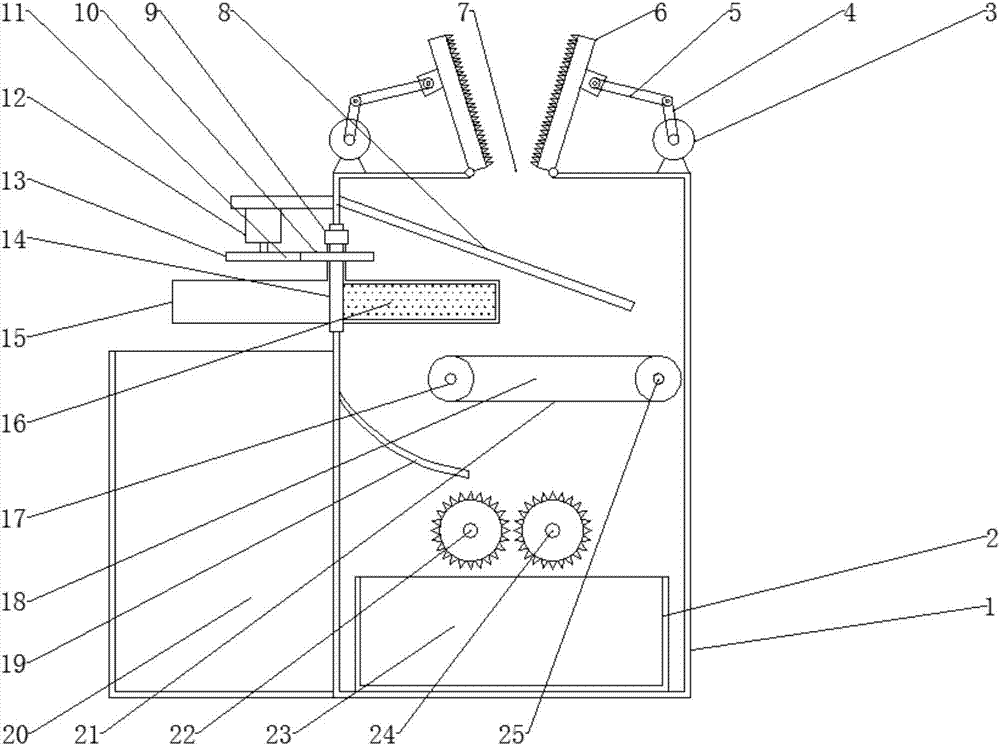

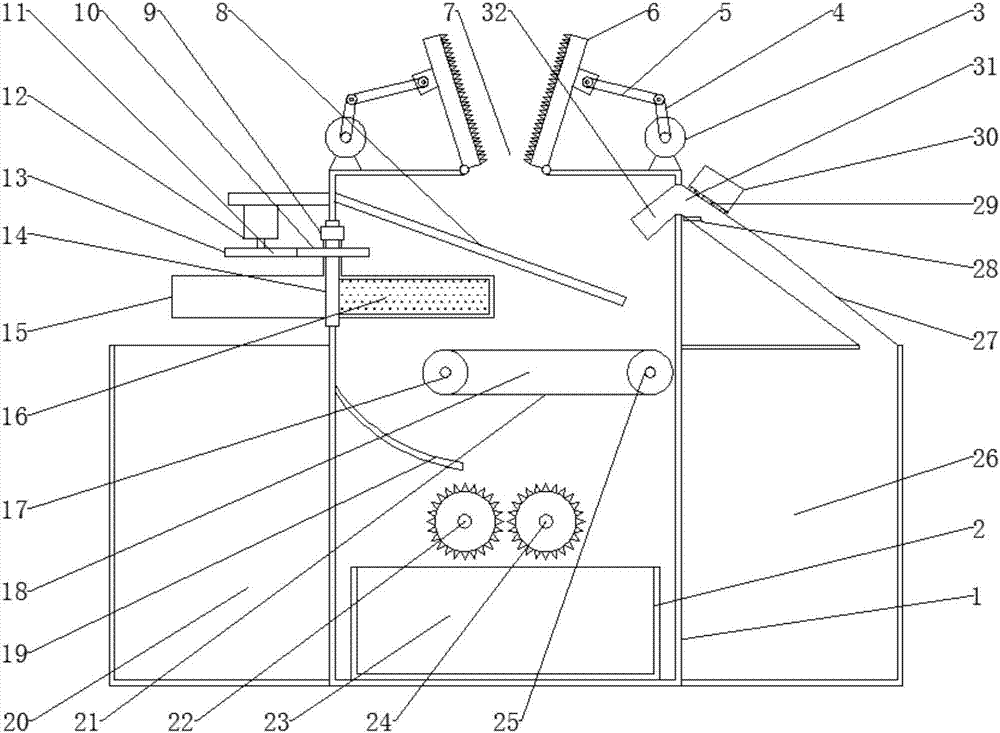

High-efficiency crushing device for construction waste recovery

InactiveCN106944182AEasy to reproduceAvoid affecting service lifeGas current separationMagnetic separationIron removalArchitectural engineering

The invention discloses a high-efficiency crushing device for recycling construction waste, which includes a machine body, a first motor, a first connecting rod, a second connecting rod and a movable jaw plate are symmetrically arranged on the top of the body, and the first motor is driven to connect the first connecting rod. The other end of the first connecting rod is hinged with the second connecting rod, and the other end of the second connecting rod is hinged with a movable jaw plate. The bottom of the movable jaw plate is connected to the top of the body through a hinge. An inclined plate is fixed in the lower part of the body, a conveying device is arranged under the inclined plate, an iron removal device is arranged above the conveying device, an arc-shaped plate is fixed under the left end of the conveying device, and a secondary crushing device is arranged under the right end of the arc-shaped plate. The invention is provided with a first motor, a first connecting rod, a second connecting rod and a movable jaw plate, which can pre-shred the construction waste, and is provided with an iron removal device to remove metals such as steel bars and steel bars in the construction waste to avoid Damage the device and affect the service life of the device.

Owner:合肥红蔻健康管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com