Process for manufacturing type alpha+beta titanium alloy rod bar for rotor impeller vane

A technology for rotor blades and manufacturing processes, which is applied in the field of manufacturing process of titanium alloy bars for rotor blades, can solve the problems of uneven structure, unfavorable overheating structure of titanium alloy, and no introduction of process parameters, so as to improve the uniformity of structure and the The yield, the method is stable and reliable, and the effect of eliminating quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

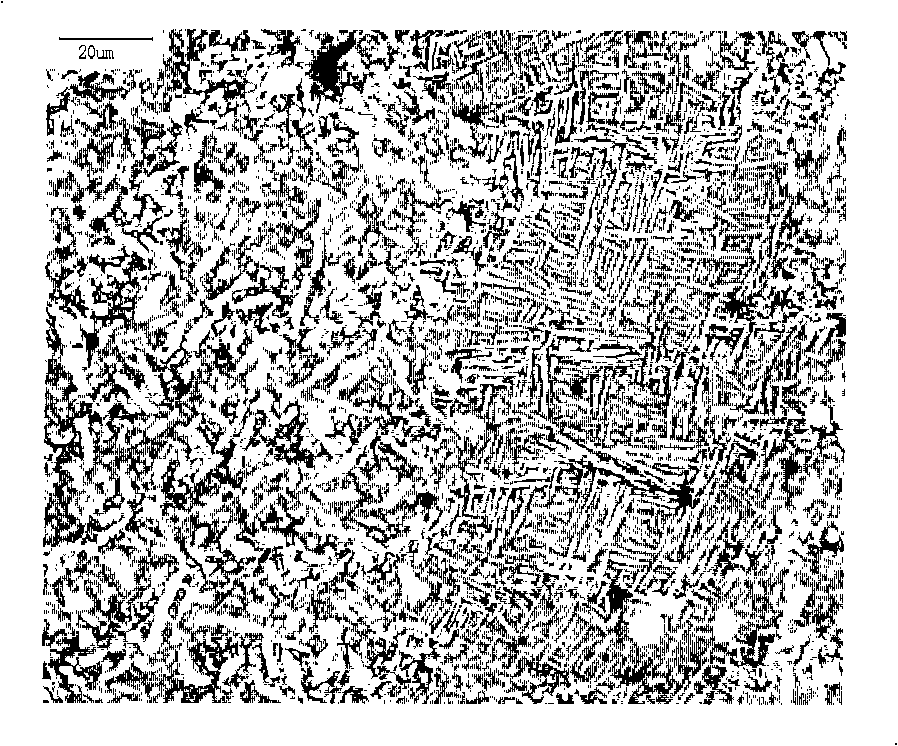

[0028] The surface of the ingot is uniformly coated with a special paint, and then the components are homogenized in a micro-oxidation atmosphere furnace. The furnace is lower than 800 °C, preheated for 30 minutes, and then the temperature is uniformly raised to 40 °C above the phase transition point at 100 °C / hour. Heat preservation for 13 hours; use fast forging machine to open the billet in the β area by pier drawing process, and then forge at 910°C to 160 octagonal, keep the 160 octagonal billet at 20°C above the phase transition point for 4 hours, and water quench immediately after coming out of the furnace , the operation time does not exceed 30 seconds; after that, the radial forging machine is used for forging, the forging temperature is 900°C, the deformation is controlled at 30-50%, the elongation coefficient of each pass is controlled at 1.2-1.3, forging to 90 square meters, and finally Rolled to a φ28mm bar on a rolling mill at a rolling temperature of 910°C, the pr...

Embodiment 2

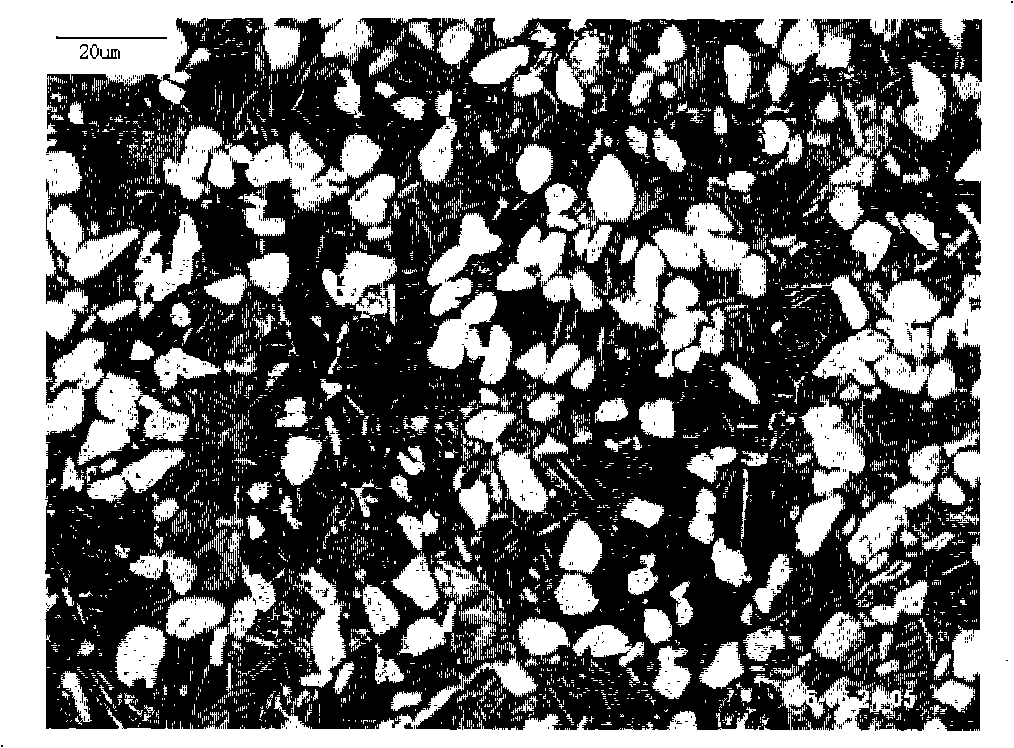

[0030]The surface of the ingot is evenly coated with a special paint, and then the components are homogenized in a micro-oxidation atmosphere furnace. The furnace is lower than 800 °C, preheated for 30 minutes, and then the temperature is uniformly raised to 50 °C above the phase transition point at 100 °C / hour. Heat preservation for 15 hours; use fast forging machine to open the billet in the β area by pier drawing process, and then forge at 920°C to 180 octagonal, keep the 180 octagonal billet at 30°C above the phase transition point for 5 hours, and water quench immediately after coming out of the furnace , the operation time does not exceed 30 seconds; after that, the radial forging machine is used for forging, the forging temperature is 910°C, the deformation is controlled at 30-50%, the elongation coefficient of each pass is controlled at 1.2-1.3, forging to 110 square meters, and finally in Rolled to φ32mm bars on the rolling mill, the rolling temperature is 920°C, the p...

Embodiment 3

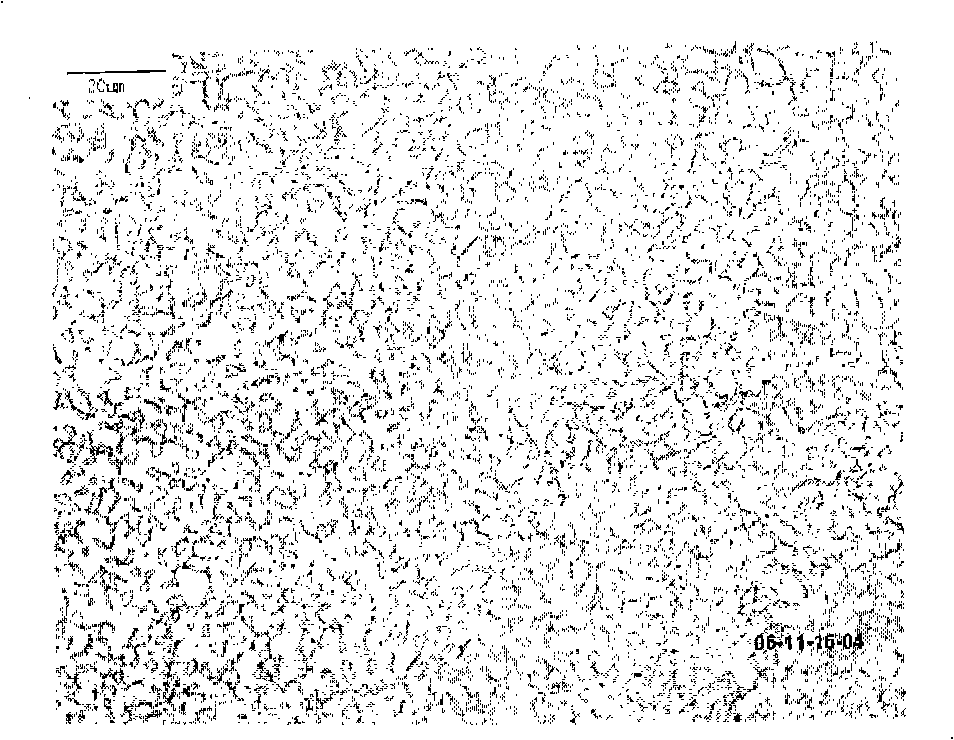

[0032] The surface of the ingot is uniformly coated with a special paint, and then the components are homogenized in a micro-oxidizing atmosphere furnace. The furnace is lower than 800 °C, preheated for 30 minutes, and then the temperature is uniformly raised to 60 °C above the phase transition point at 100 °C / hour. Heat preservation for 17 hours; use fast forging machine to open the billet in the β area by pier drawing process, and then forge at 930°C to 190 octagonal, keep the 190 octagonal billet at 40°C above the phase transition point for 6 hours, and water quench immediately after coming out of the furnace , the operation time does not exceed 30 seconds; after that, the radial forging machine is used for forging, the forging temperature is 920°C, the deformation is controlled at 30-50%, the elongation coefficient of each pass is controlled at 1.2-1.3, forging to 120 square meters, and finally in Rolled to φ36mm bars on the rolling mill, the rolling temperature is 930°C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com