Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

460 results about "Hot work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot work is a process that can be a source of ignition when flammable material is present or can be a fire hazard regardless of the presence of flammable material in the workplace. Common hot work processes involve welding, soldering, cutting, brazing burning and the use of powder-actuated tools or similar fire producing operations outside of designated hot work areas. When flammable materials are not present, industrial processes such as grinding and drilling become cold work processes.

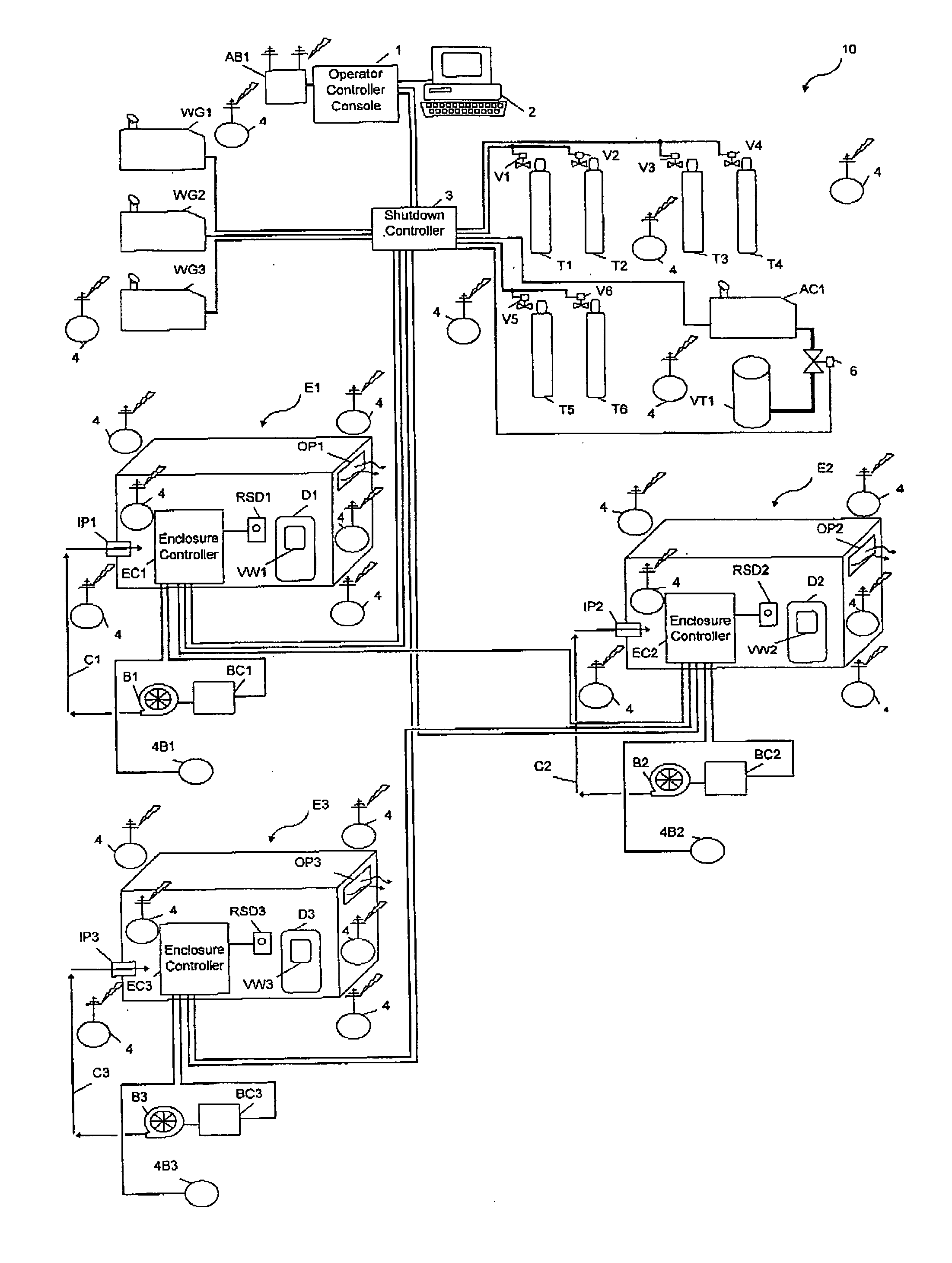

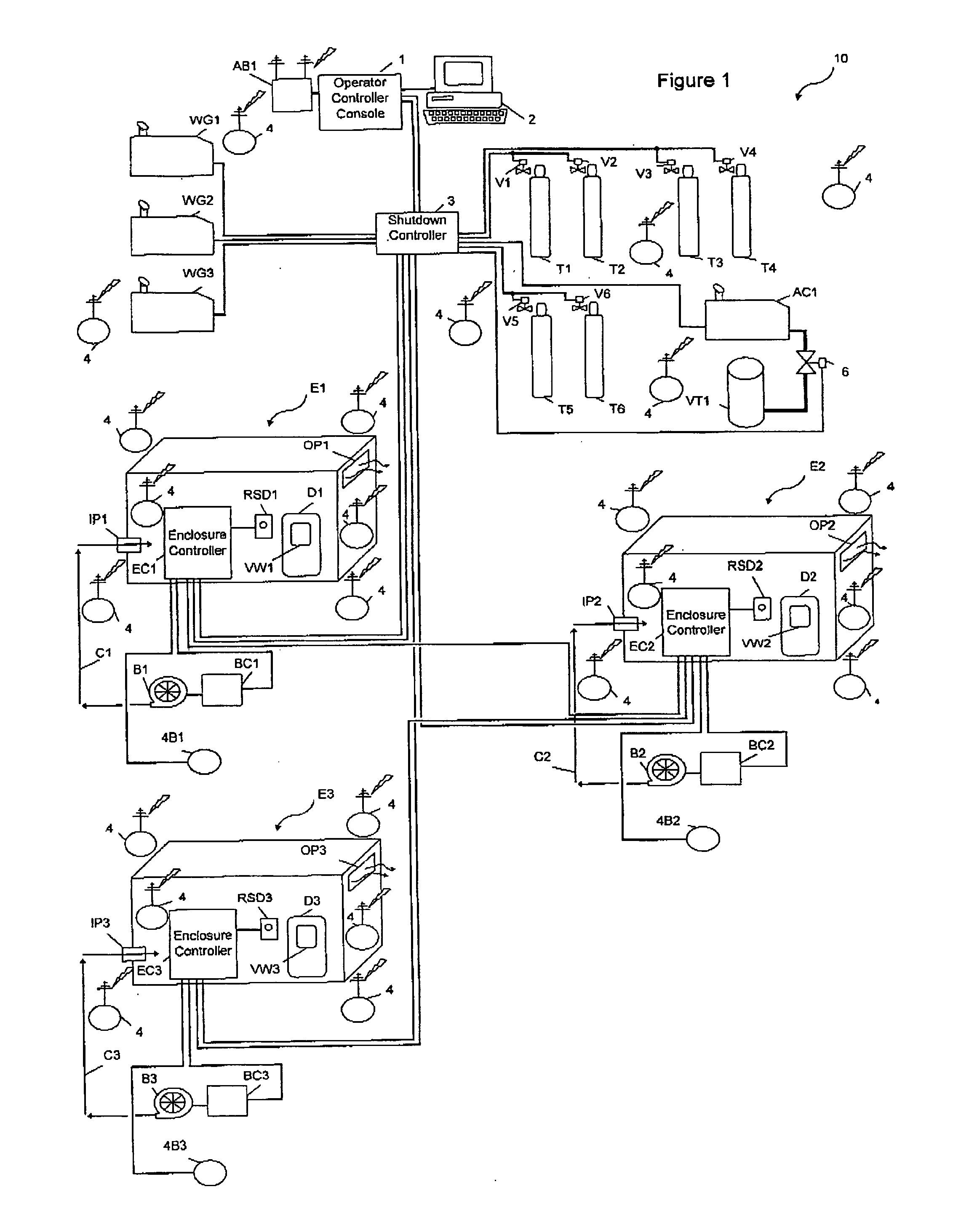

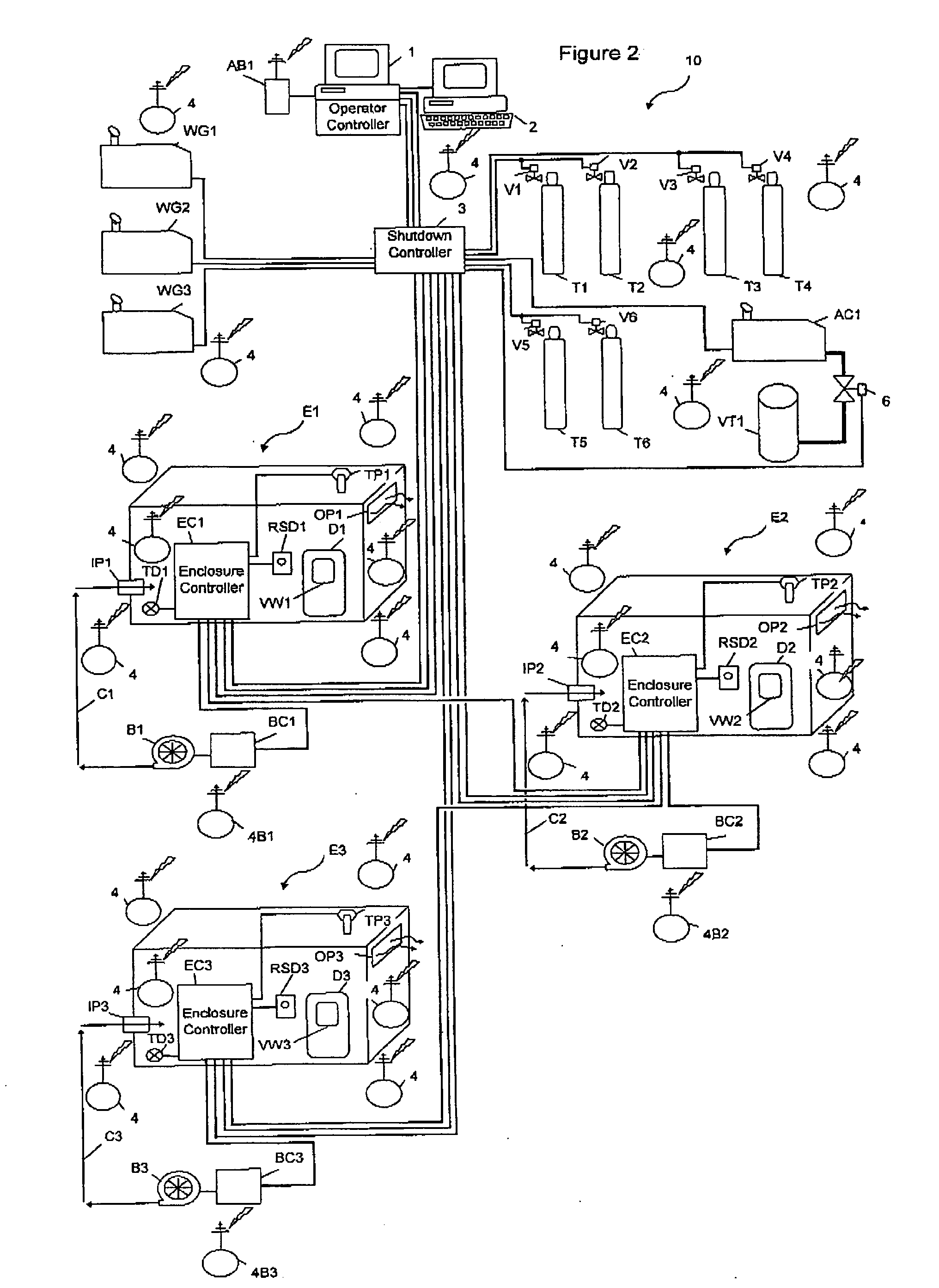

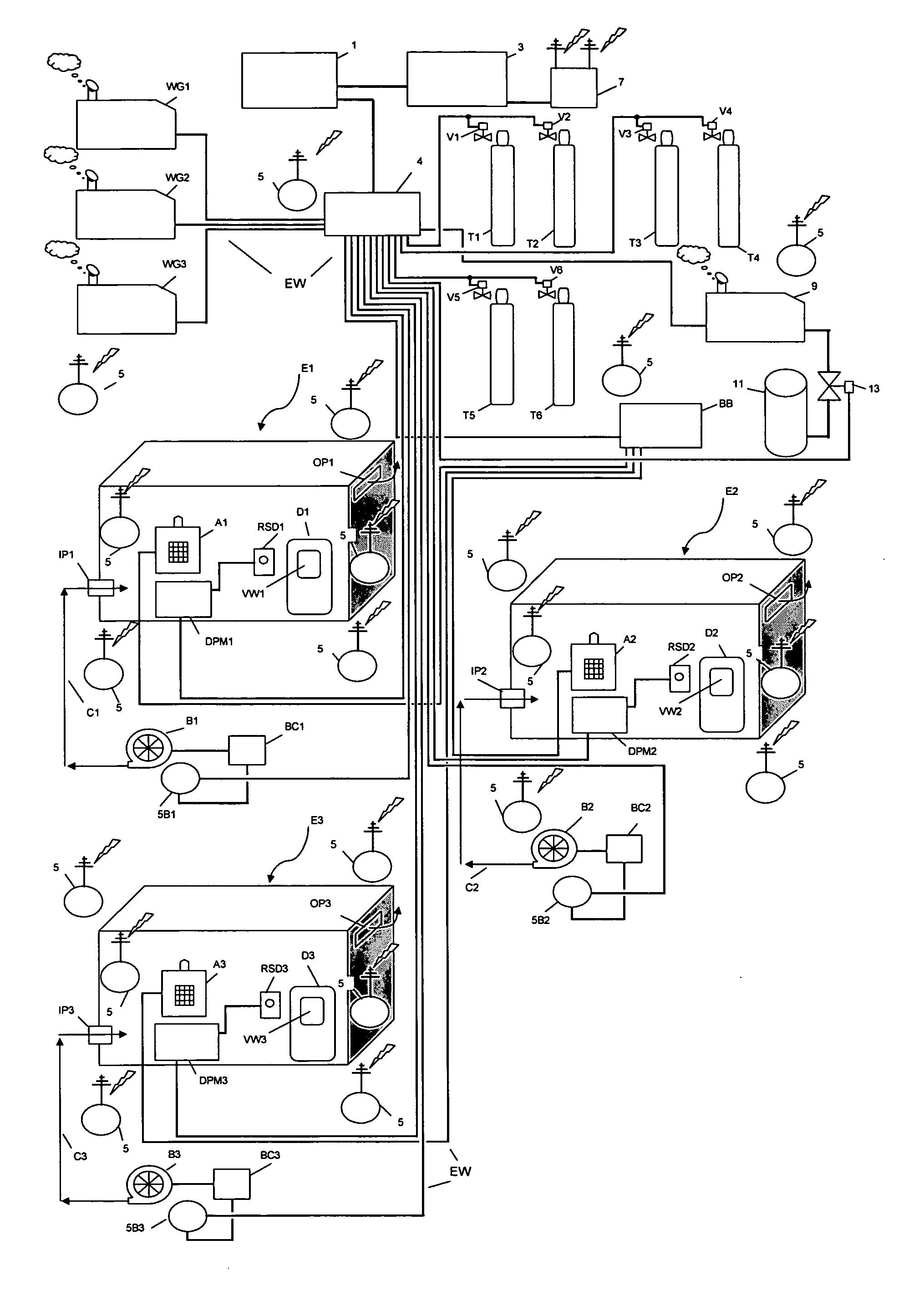

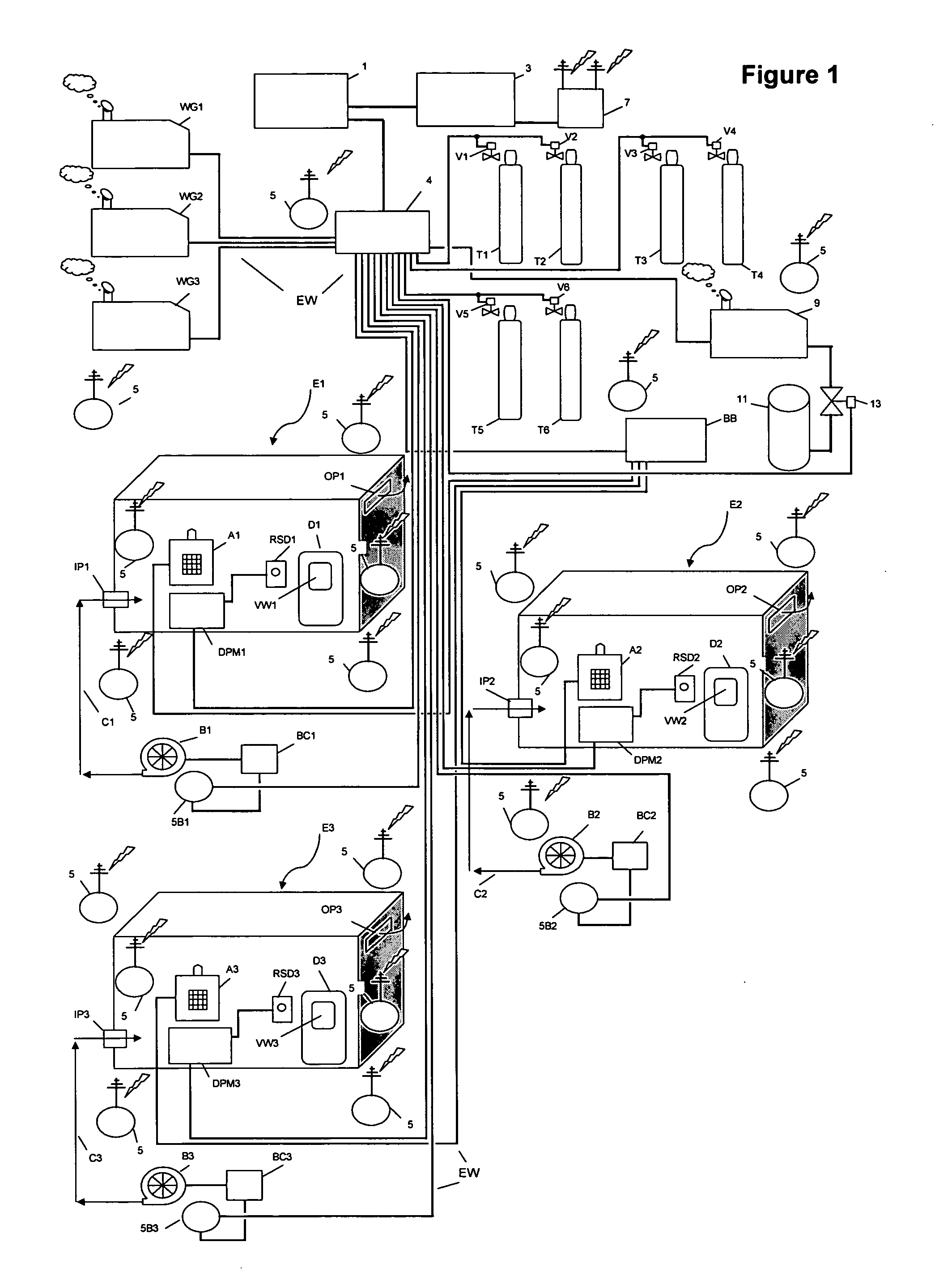

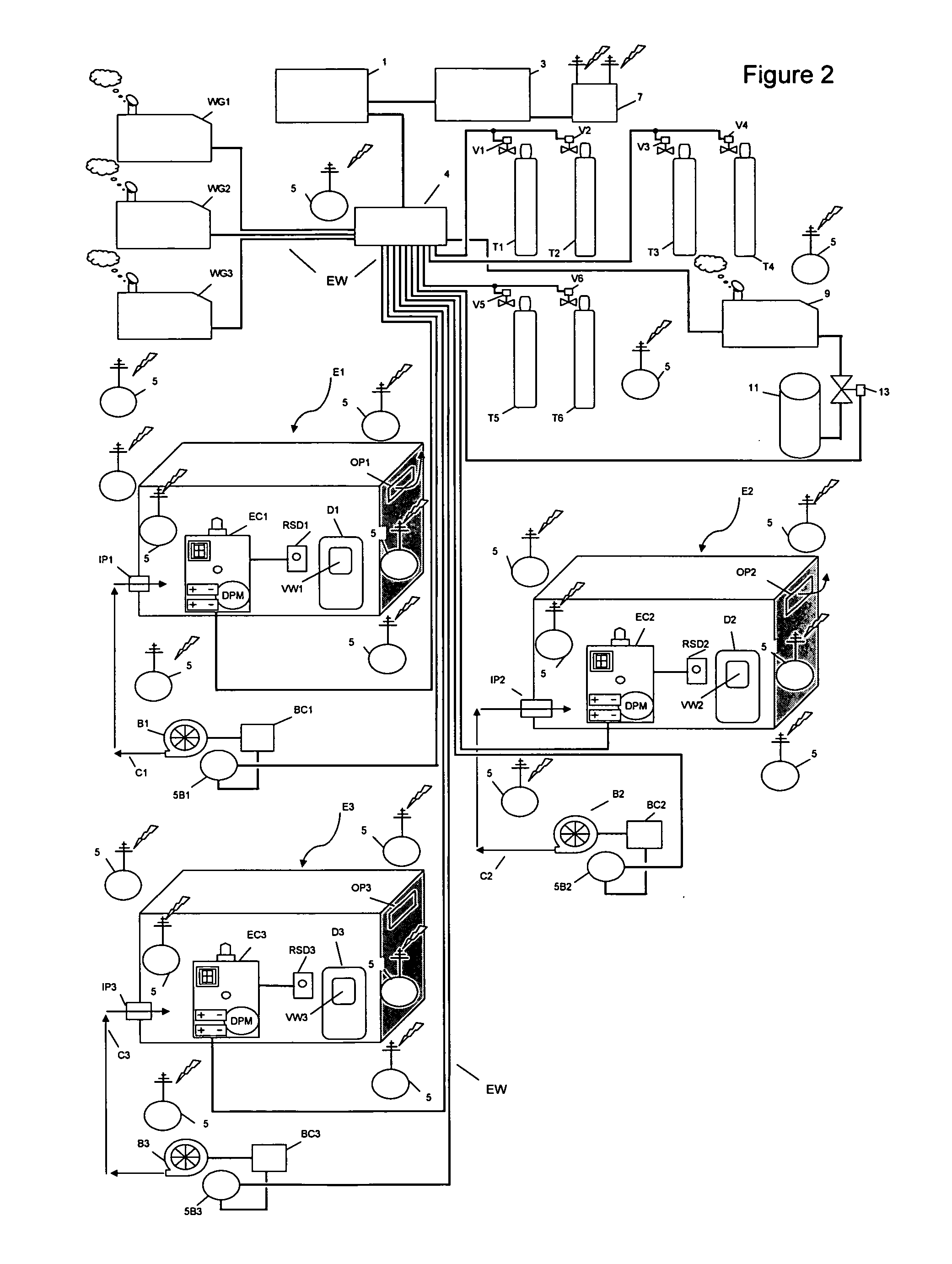

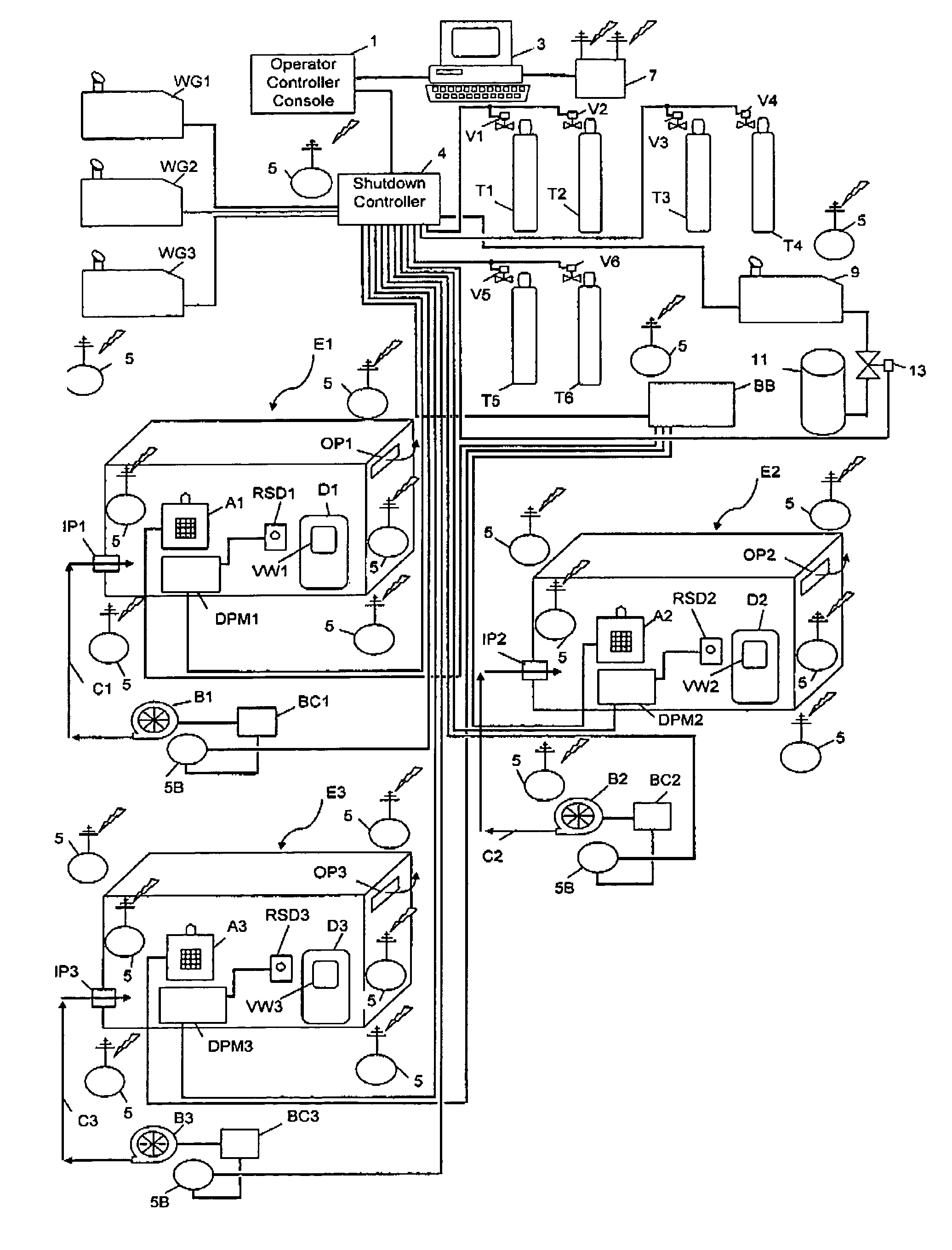

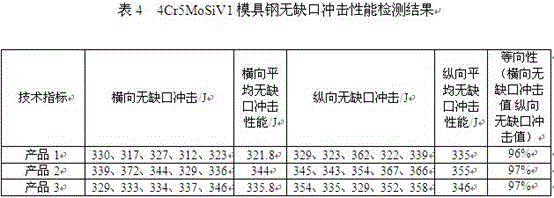

Enclosure system allowing for hot work within the vicinity of flammable and combustible material

InactiveUS20070052543A1Welding/cutting auxillary devicesElectric testing/monitoringCompound (substance)Hot work

An enclosure constructed around an area at which hot work is to be performed at a facility containing flammable or combustible material. Hot work includes such things as welding, torch cutting, grinding and the like. Facilities include petroleum drilling and production platforms, oil tankers, petroleum and chemical plants, and petroleum tank farms. Gas detection monitoring apparatuses are used with the enclosure which will automatically simultaneously shutdown one or more enclosures.

Owner:ALFORD SAFETY SERVICES

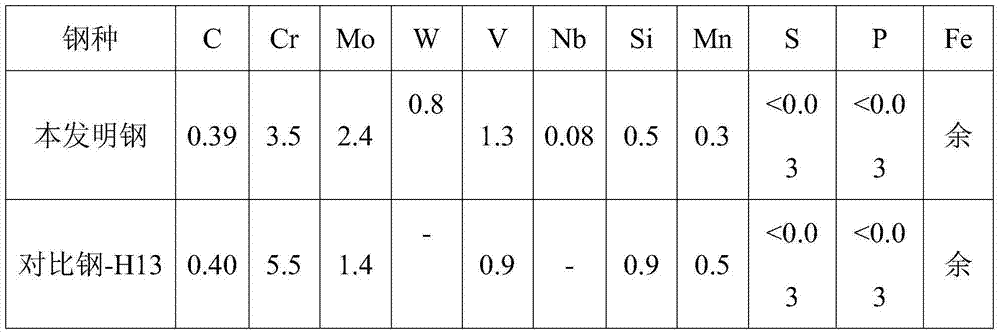

High-hot-strength spray-formed hot work die steel and preparation method thereof

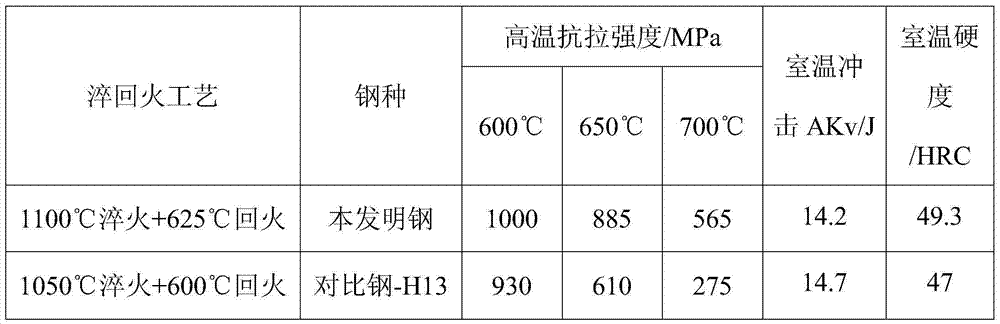

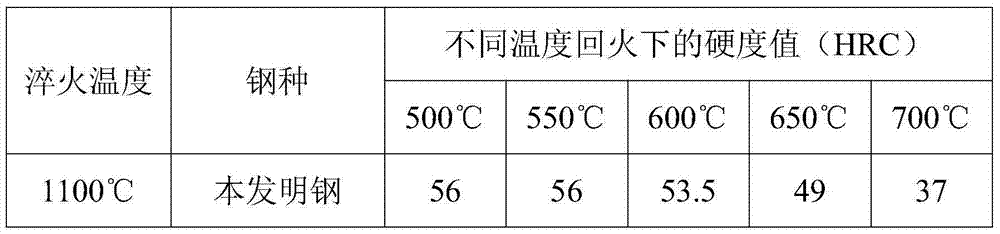

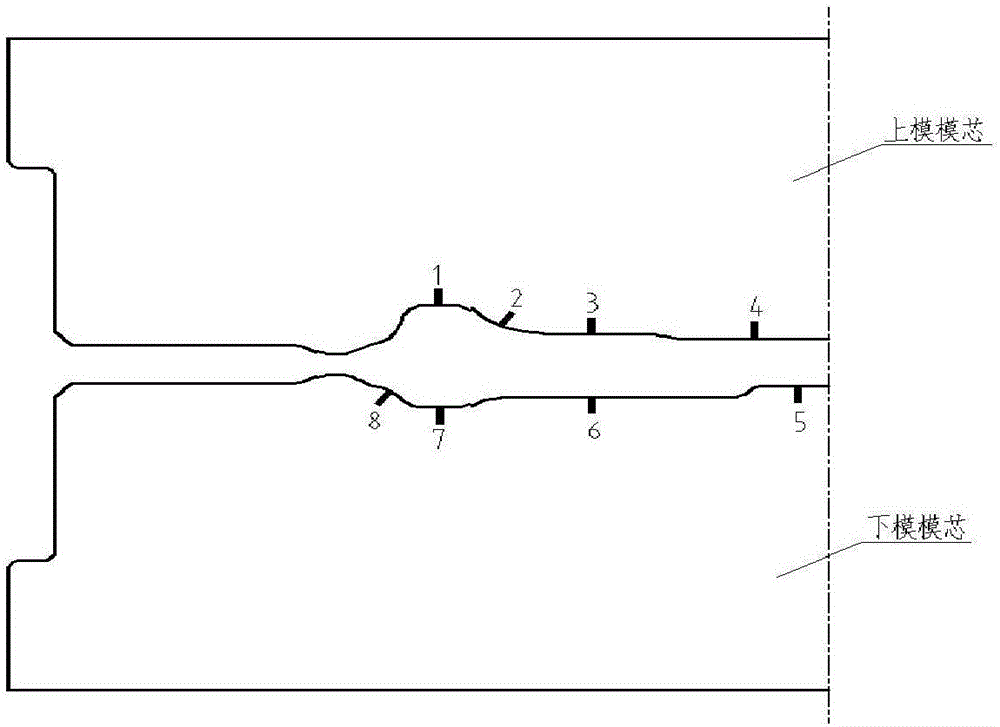

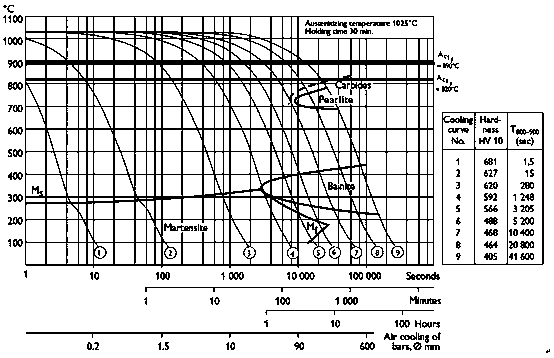

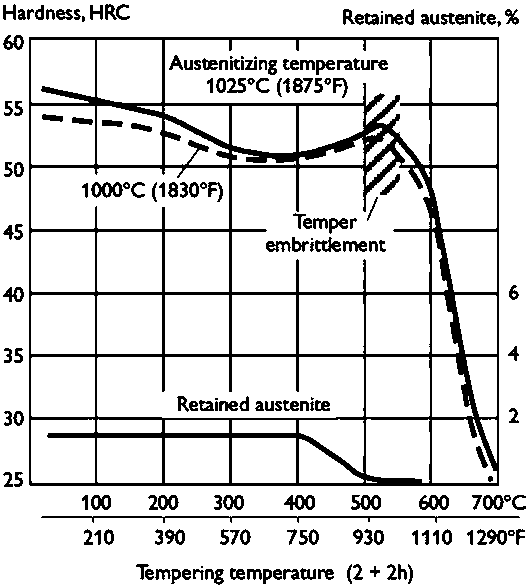

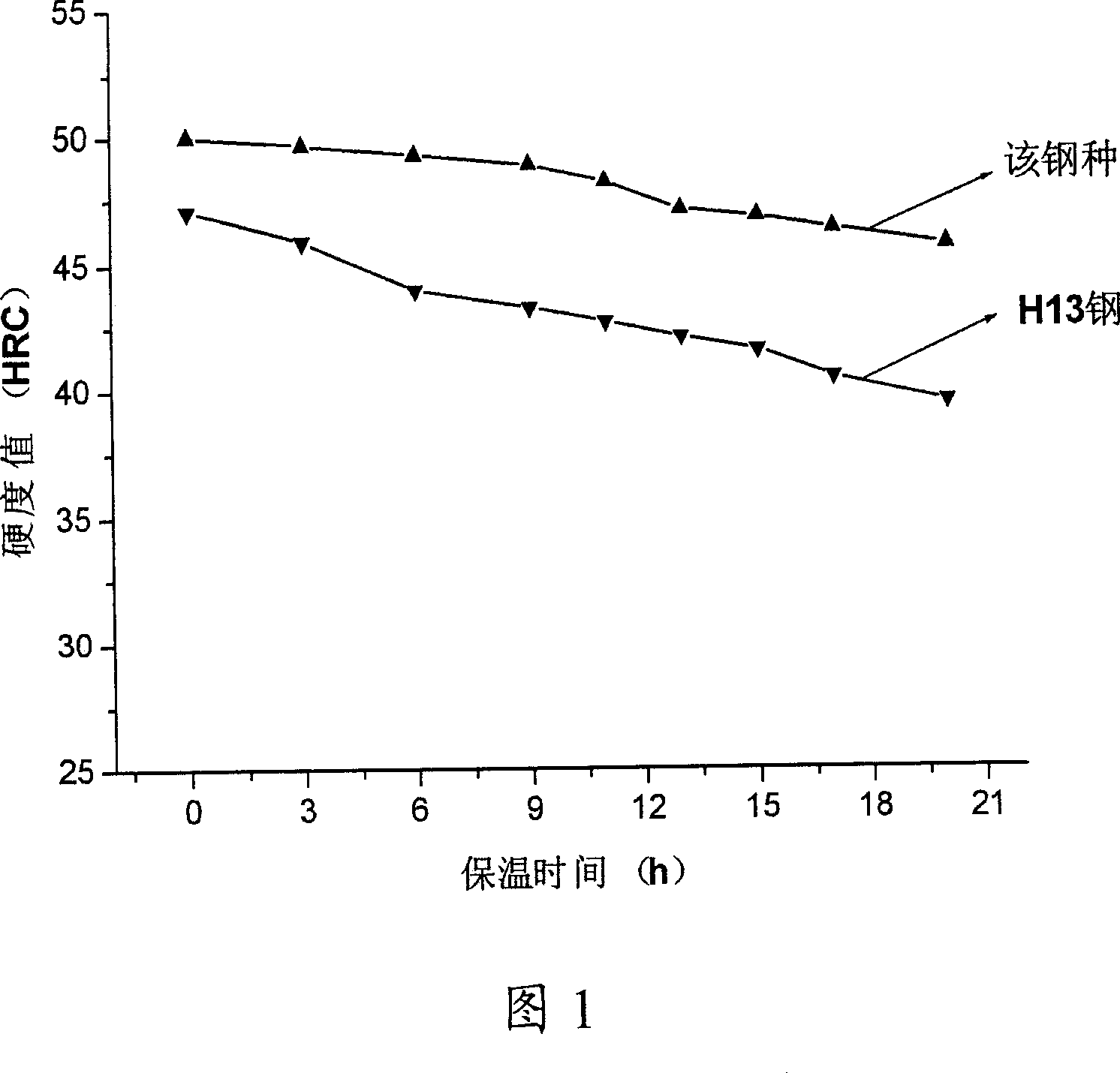

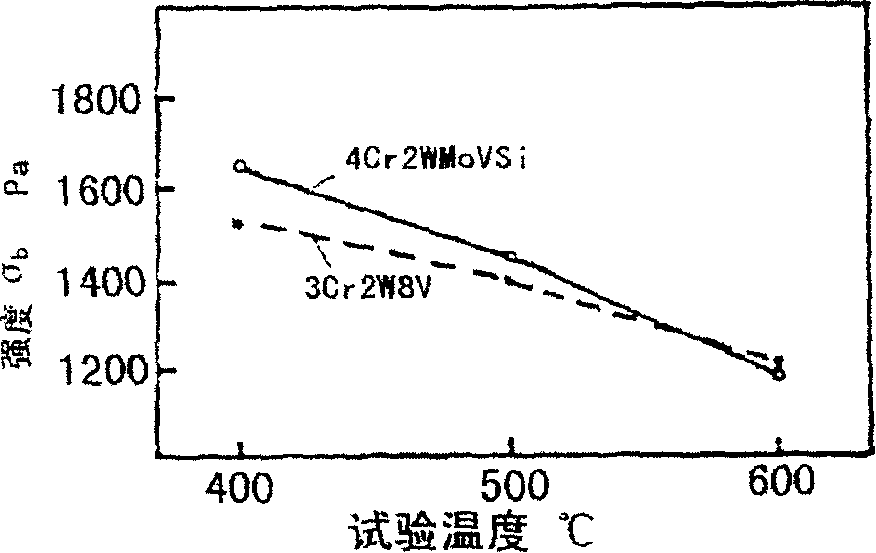

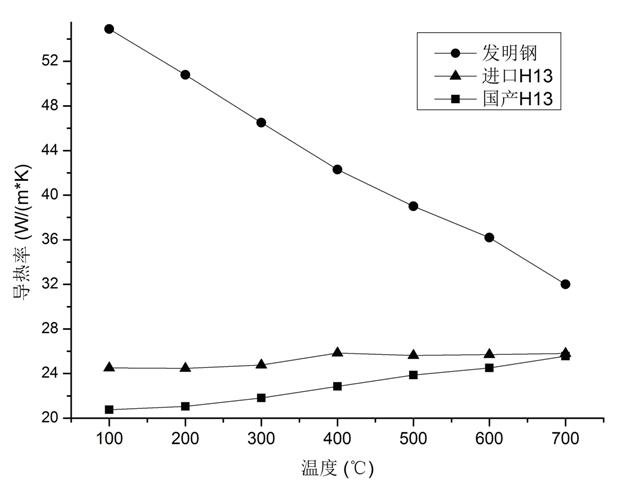

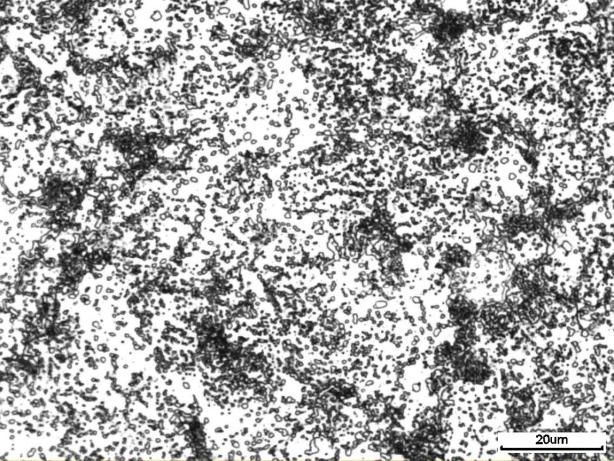

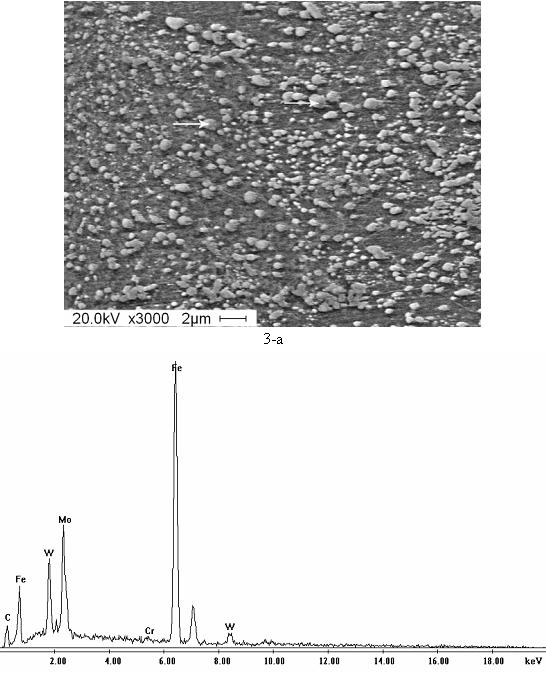

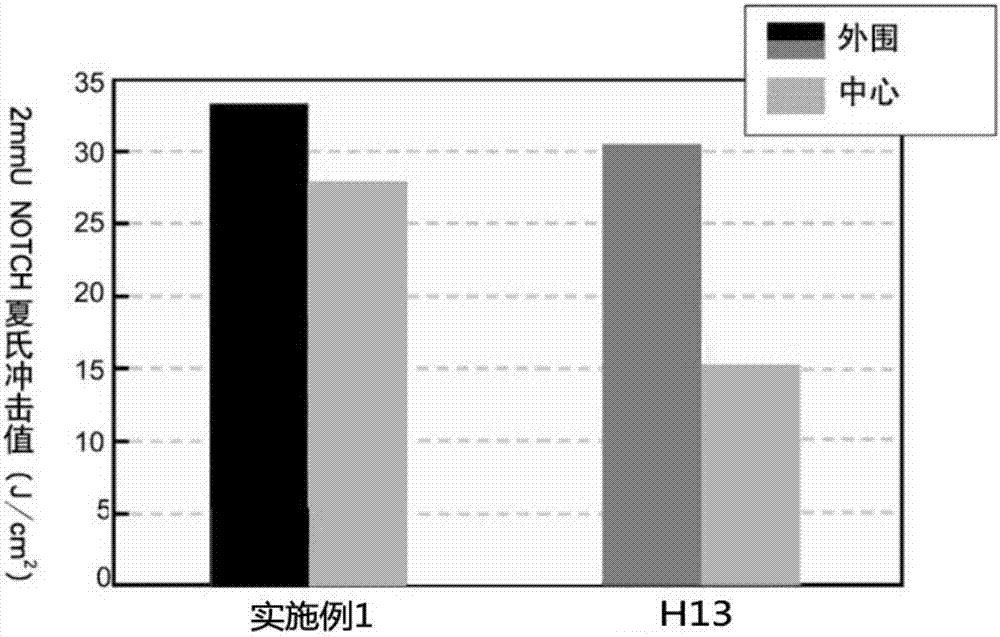

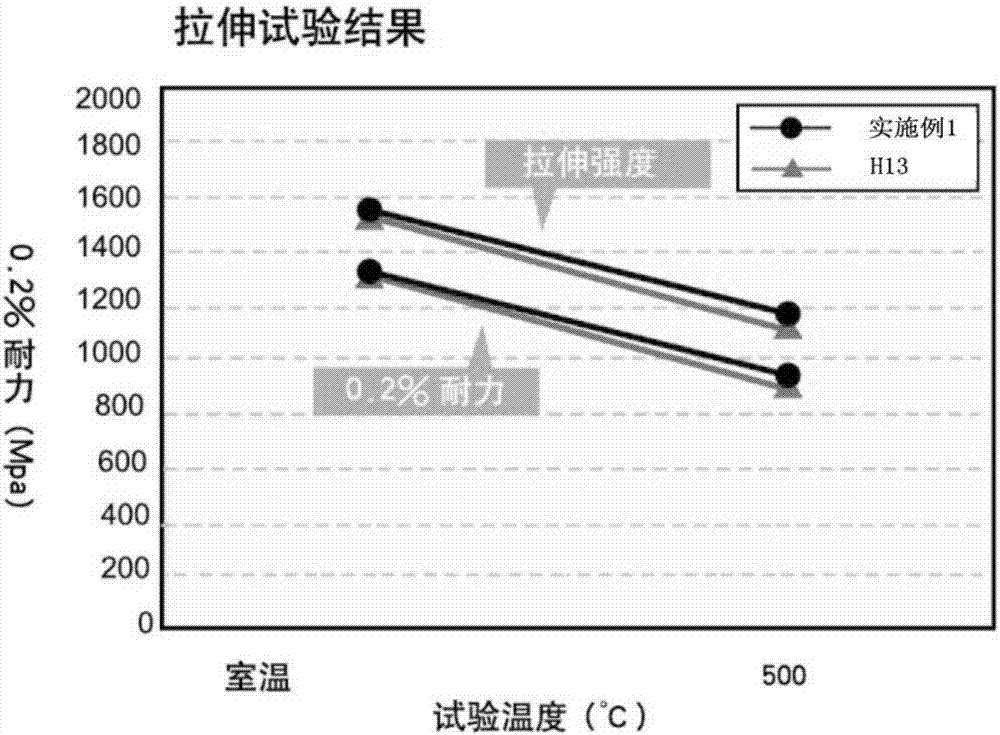

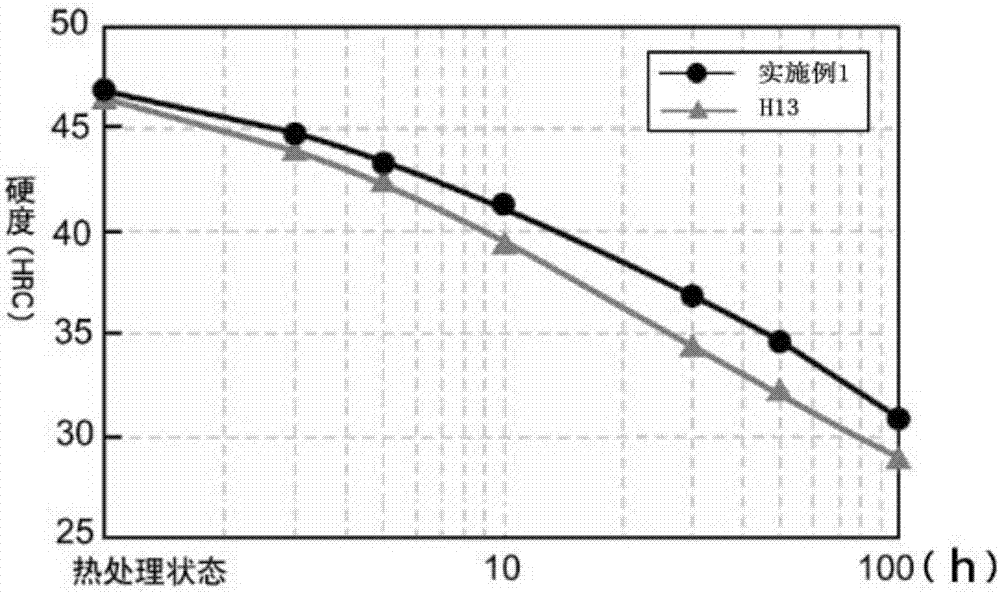

The invention discloses high-hot-strength spray-formed hot work die steel and a preparation method thereof, belonging to the technical field of hot work die steel. The die steel comprises the following components of 0.3-0.5 of C, 3.0-5.0 of Cr, 1.5-3.5 of Mo, 0.4-1.0 of W, 0.3-0.8 of Si, 0.3-0.5 of Mn, 0.8-1.5 of V, 0.03-0.10 of Nb, less than or equal to 0.03 of S, less than or equal to 0.03 of P and the balance of Fe. The preparation method comprises the process routes of spray forming, hot forging and heat treatment; different comprehensive mechanical properties are obtained by adjusting the quenching and tempering temperatures in a way of controlling process parameters and hot forging temperature in the spray forming process, so that the requirements of different working conditions are met. The compatibility of alloy elements is reasonably optimized according to the characteristic of a spray forming process and the special requirement of the hot work die steel for high-temperature performance, so that the high-hot-strength spray-formed hot work die steel has favorable high-temperature performance, good heat stability and tempering resistance, relatively high impact toughness and excellent comprehensive performance, and the service life of the hot work die steel is greatly prolonged.

Owner:UNIV OF SCI & TECH BEIJING

Cr5 series hot work die steel

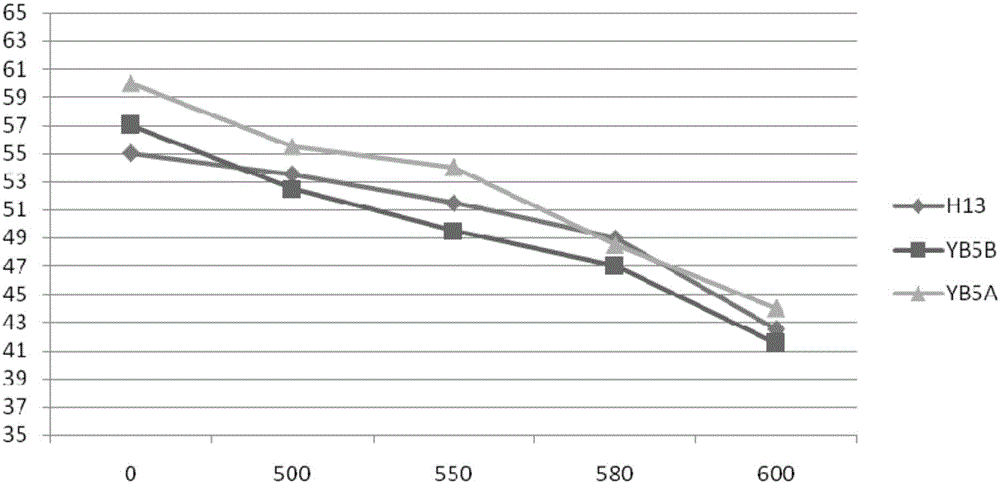

The invention provides Cr5 series hot work die steel which comprises, by weight, 0.40-0.48% of C, 0.20-1.2% of Si, 0.40-0.80% of Mn, no more than 0.020% of P, no more than 0.010% of S, 4.80-5.50% of Cr, 1.40-2.0% of Ni, 0.80-1.50% of Mo, 0.50-0.70% of V, 0.50-1.00% of W, 0-0.75% of Co, 0.01-0.20% of Al, 0.02-0.20% of Nb, and the balance Fe. The chemical composition formula of the novel Cr5 series hot work die steel provided by the invention is recorded as the YB5 series, and compared with existing Cr5 series (H13) hot work die steel, the YB5 series die steel is higher in C content and Mn content and lower in Si content (YB5A and YB5C), Mo content and V content, and Ni, W, Co (YB5C) and Al (YB5A and YB5C) are added. Accordingly, the toughness of the steel is improved, and the high-temperature strength and creep resistance are improved.

Owner:YINGKOU SPECIAL STEEL FORGING

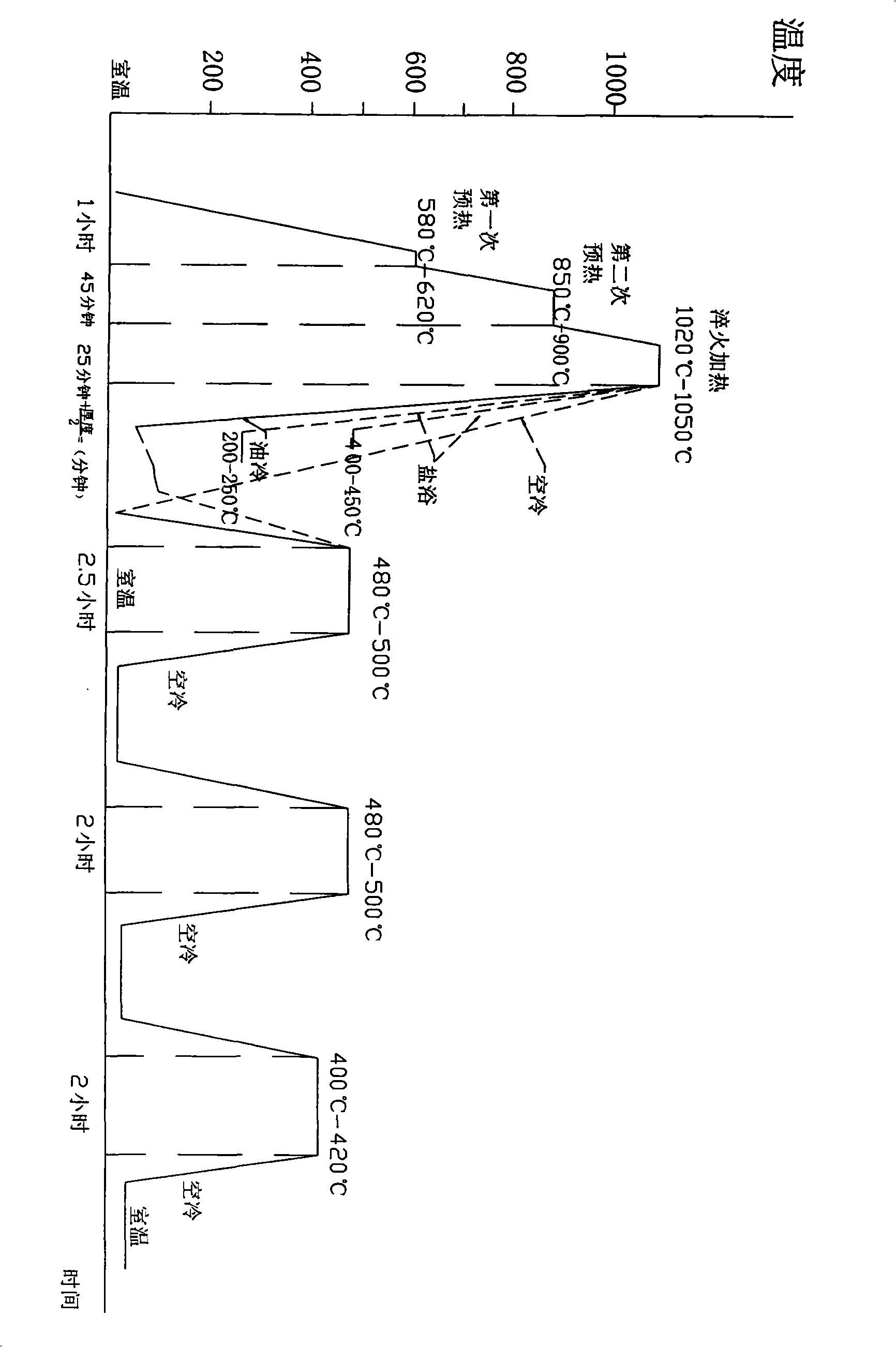

Novel chromium system hot die steel and thermal treatment process thereof

The invention relates to novel chrome hot work die steel belonging to hot work die steel, particularly relating to the hot work die steel with low content of tungsten and the thermal treatment process thereof. The hot work die steel comprises 0.35-0.7 percent of C, 0.3-1.3 percent of Si, 0.3-1.3 percent of Mn, 7.0-11.0 percent of Cr, 0.4-1.2 percent of W, 0.4-1.2 percent of Mo, 0.4-1.2 percent of V, 1.0 percent of Ni, 0.005 percent or less of S, 0.030 percent or less of P, 0.03 percent of-0.10 percent of B, equal to or more than 0.02 percent and equal to or less than 0.20 percent of nitride, equal to or more than 0.02 percent and equal to or less than 0.10 percent of N, and the rest of Fe by weight percent. The steel of the invention has finer crystal grain, generates greatly increased heat resistance, toughness and compressive strength and has more than three times of durable frequencies than the existing die steel. The invention further provides the thermal treatment process with relatively low steel quenching temperature of 1020-1050 DEG C.

Owner:周向儒

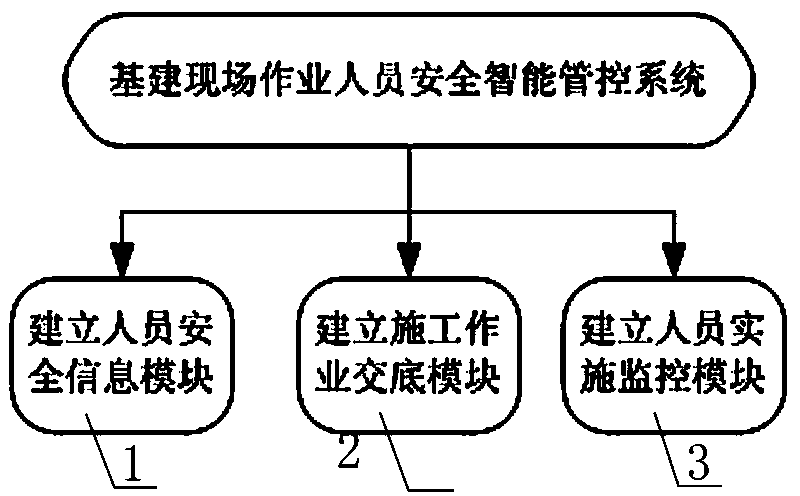

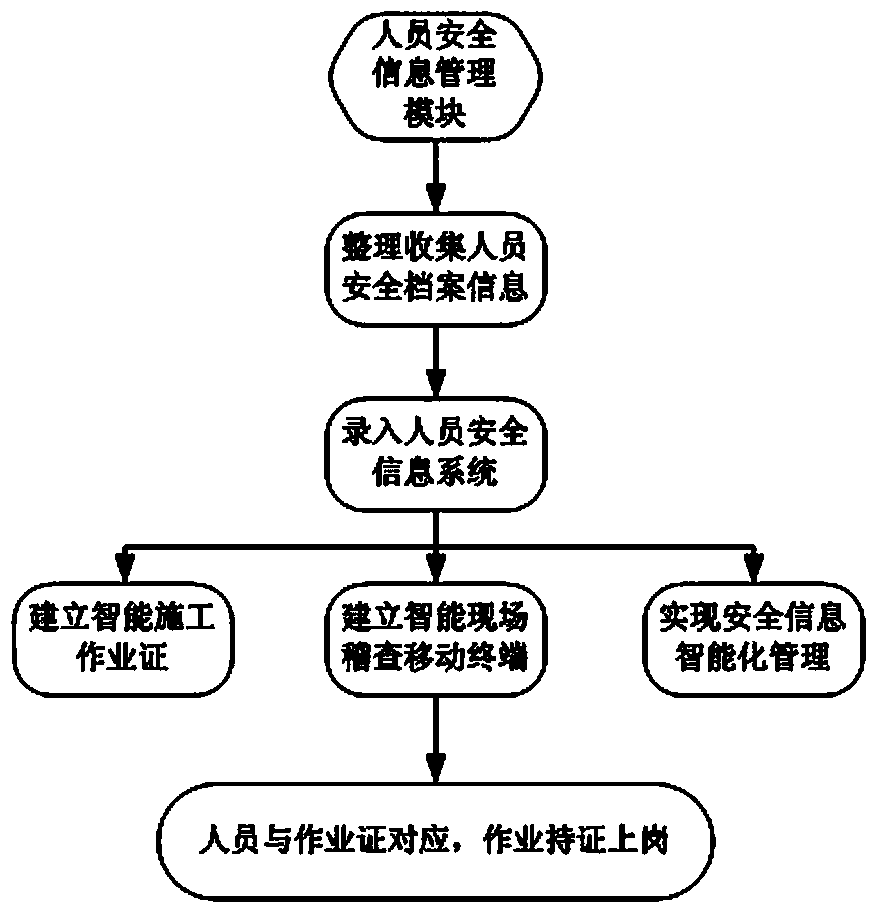

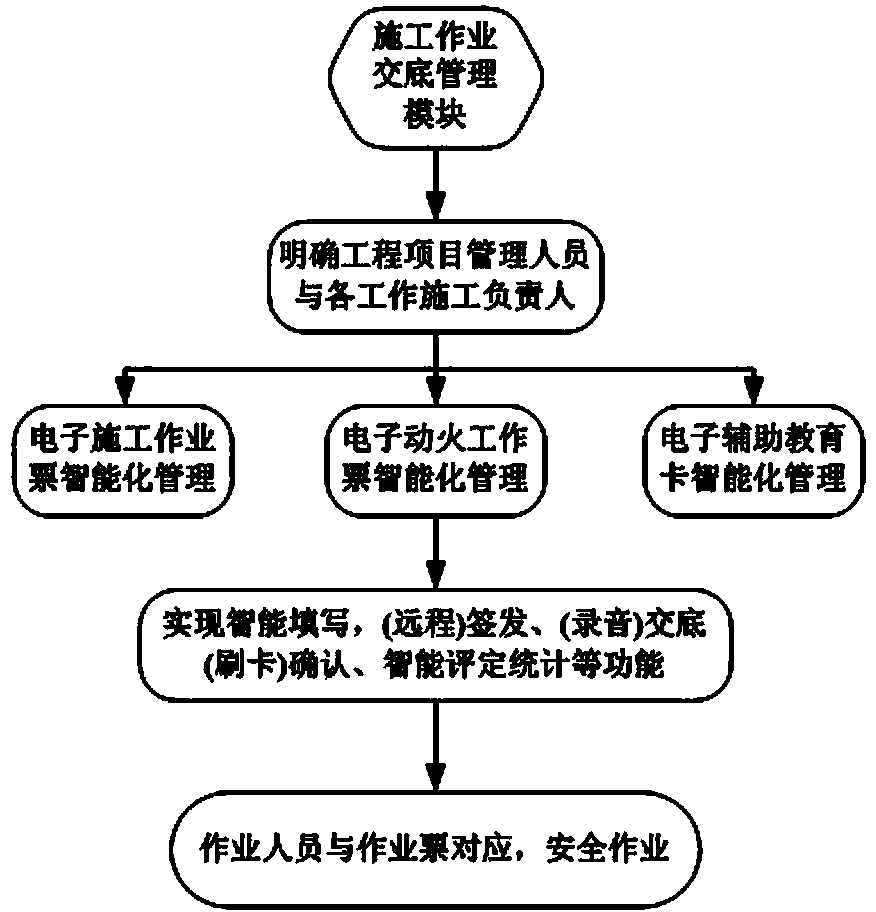

Intelligent security control method of electric power field operating personnel

InactiveCN103729712AAchieve normalizationRealize intelligent construction safety inspectionResourcesControl engineeringHot work

An intelligent security control method of electric power field operating personnel is mainly established based on the following three modules of a constructor safety information module, an intelligent construction operation disclosure module and a construction operating personnel real-time monitoring module. The constructor safety information module is used for achieving intelligent management of operating personnel safety information. The intelligent construction operation disclosure module is used for achieving intelligent compiling, signing and issuing, disclosing and statistic making of construction operation tickets, hot work operation tickets, auxiliary personnel education cards and the like. The construction operating personnel real-time monitoring module is used for achieving real-time monitoring of working site images, real-time monitoring of entrance and exit of the operating personnel and real-time positioning of the operating personnel. The constructor safety information management module mainly comprises a server including construction enterprise unit information, construction enterprise personnel information and labor subcontracting personnel information. The intelligent construction operation disclosure module carries out the following three sorts of intelligent management, namely construction operation ticket intelligent management, hot work operation ticket intelligent management and auxiliary education card establishing intelligent management. The construction operating personnel real-time monitoring module comprises two modes, one mode is that power transformation engineering is performed at a closed construction site so that directional recognizing and monitoring can be conducted, and the other mode is that a line project is performed at an opened construction site so that omni-directional recognizing and monitoring can be conducted.

Owner:STATE GRID CORP OF CHINA +2

Hot die steel for die-casting

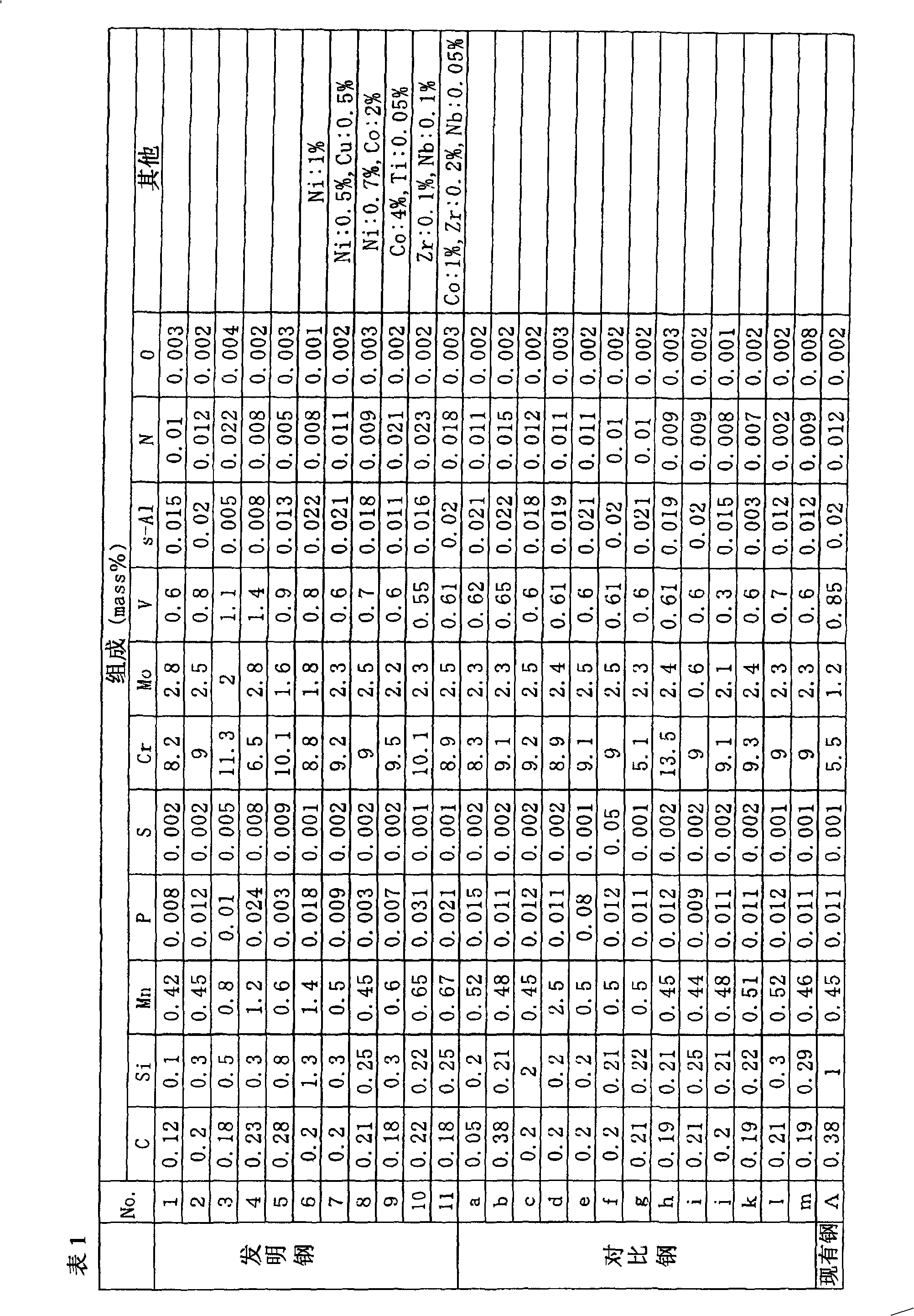

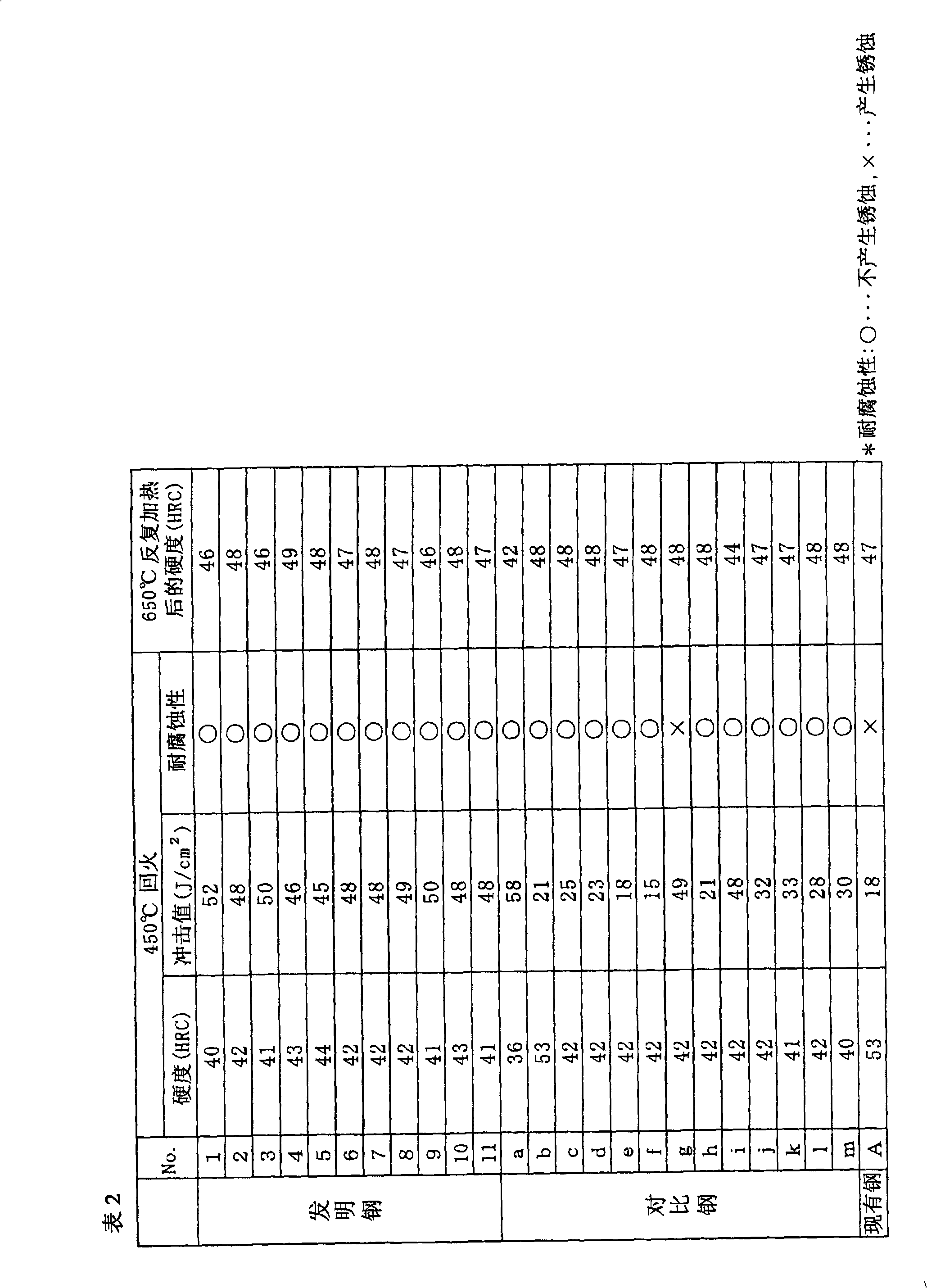

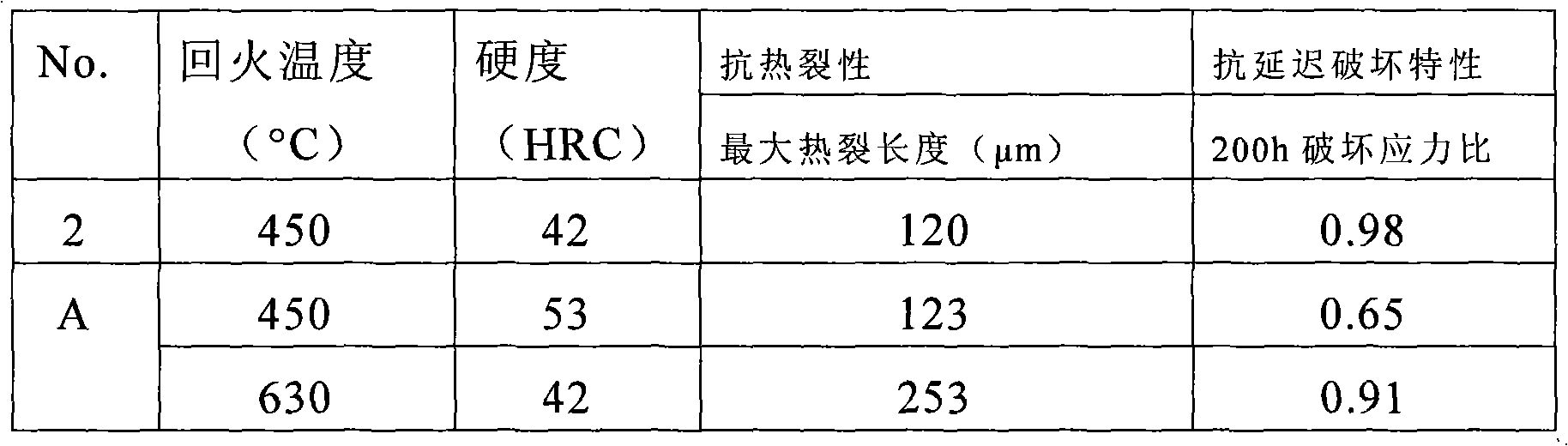

The invention provides a hot work die steel used for die-casting, which is obtained through temper under the temperature that is less than or equals to 500 DEG C after the following steels are quenched. The steels contain the components by mass percent as follows: C is 0.1 to 0.3 percent, Si is 0.1 to 1.5 percent, Mn is 0.3 to 2 percent, Cr is 6 to 12 percent, P is less than or equals to 0.05 percent, S is less than or equals to 0.01 percent, Mo is 1 to 3 percent, V is 0.5 to 1.5 percent, s-Al is 0.005 to 0.025 percent, N is 0.005 to 0.025 percent, O is less than or equals to 0.005 percent, and the residual components are Fe and ineluctable impurities.

Owner:DAIDO STEEL CO LTD

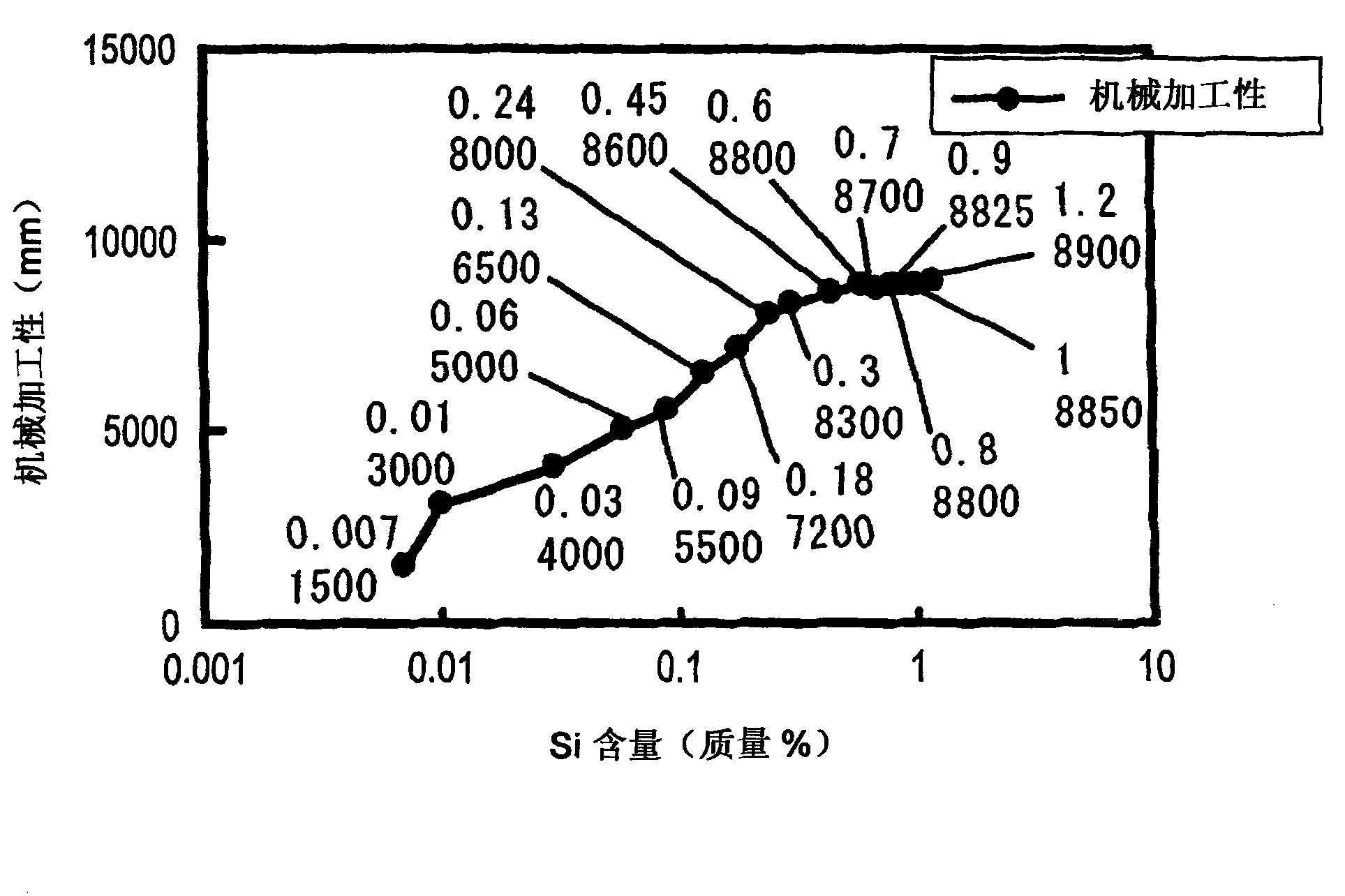

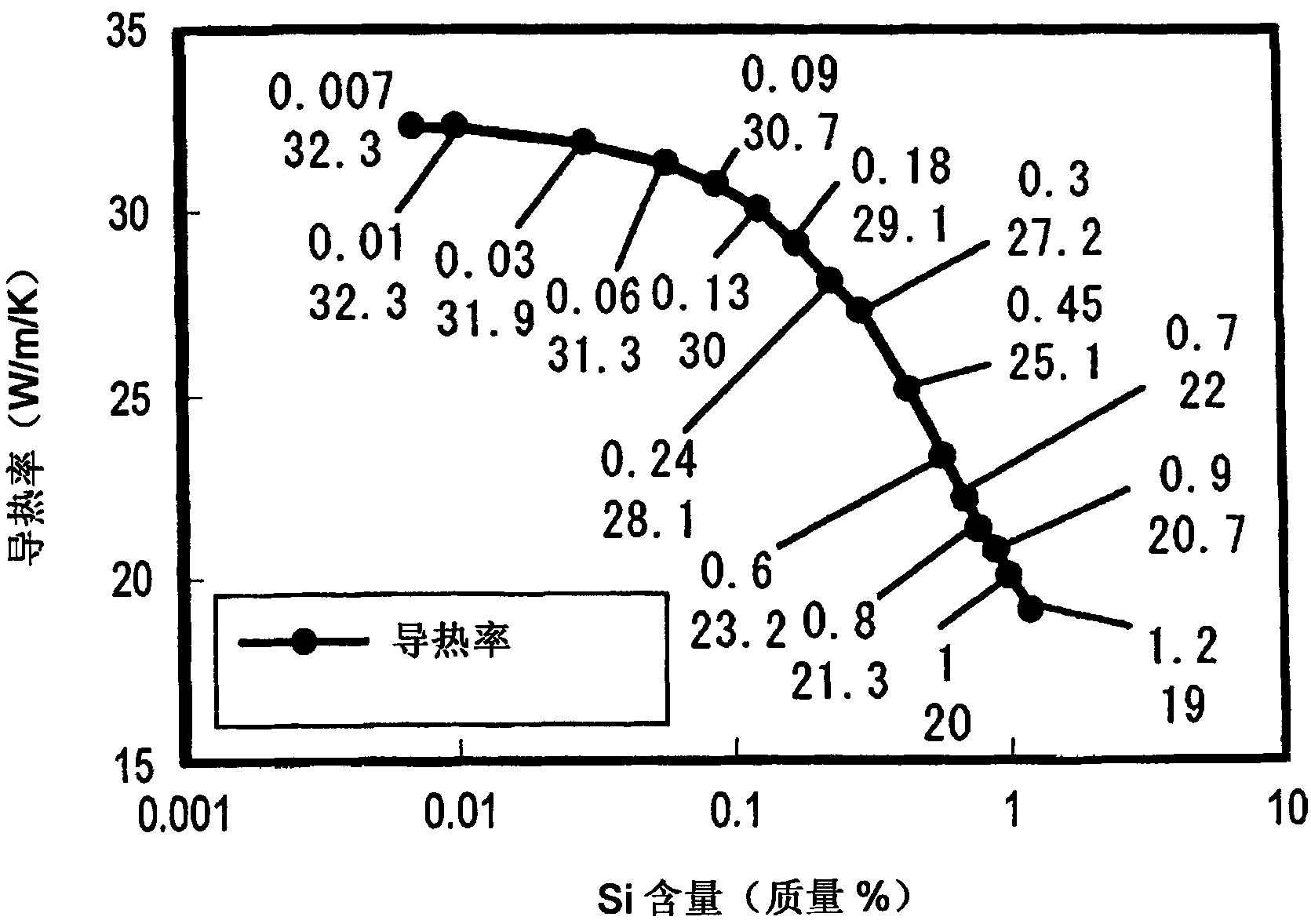

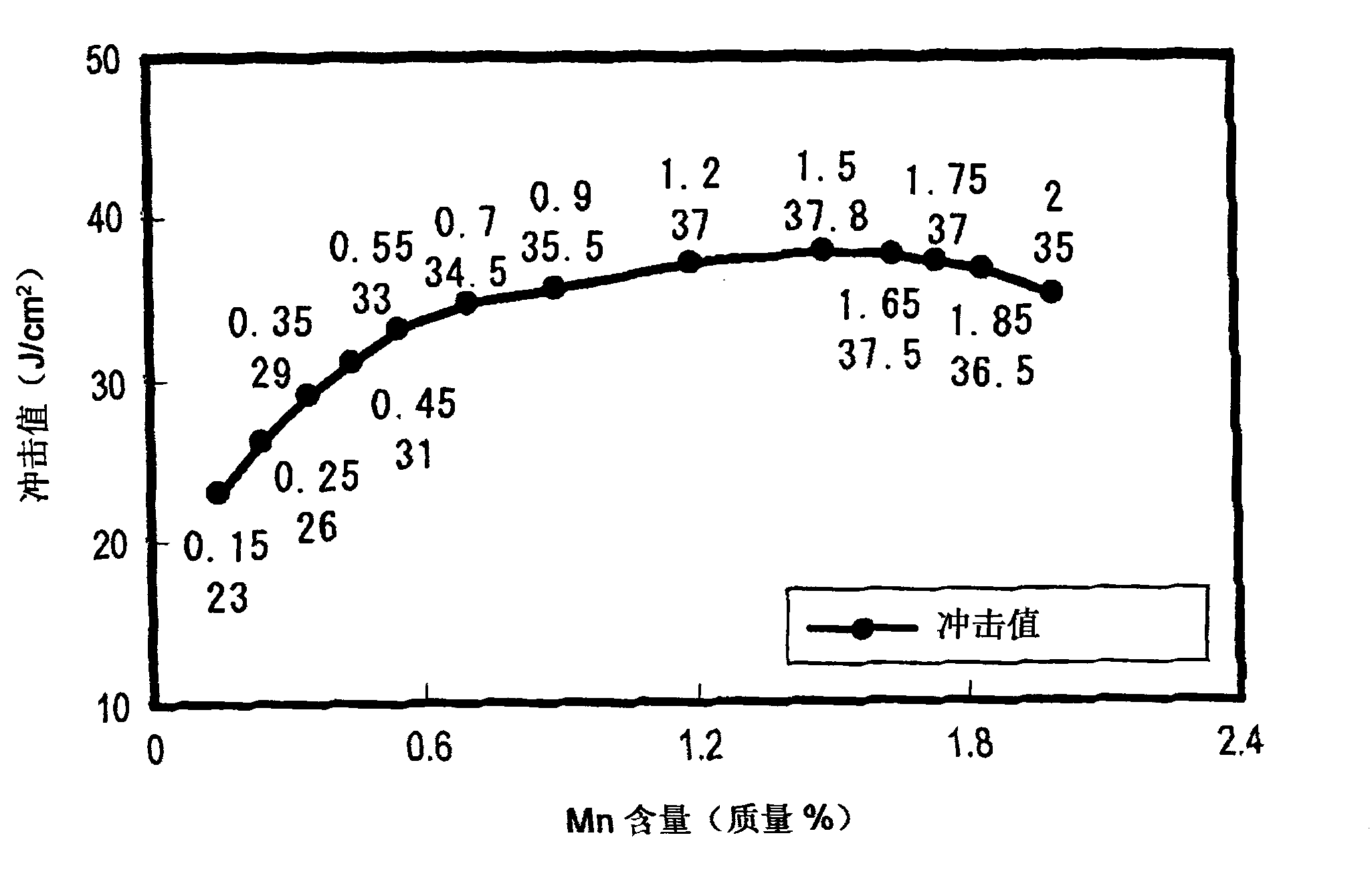

Hot work tool steel and steel product using the same

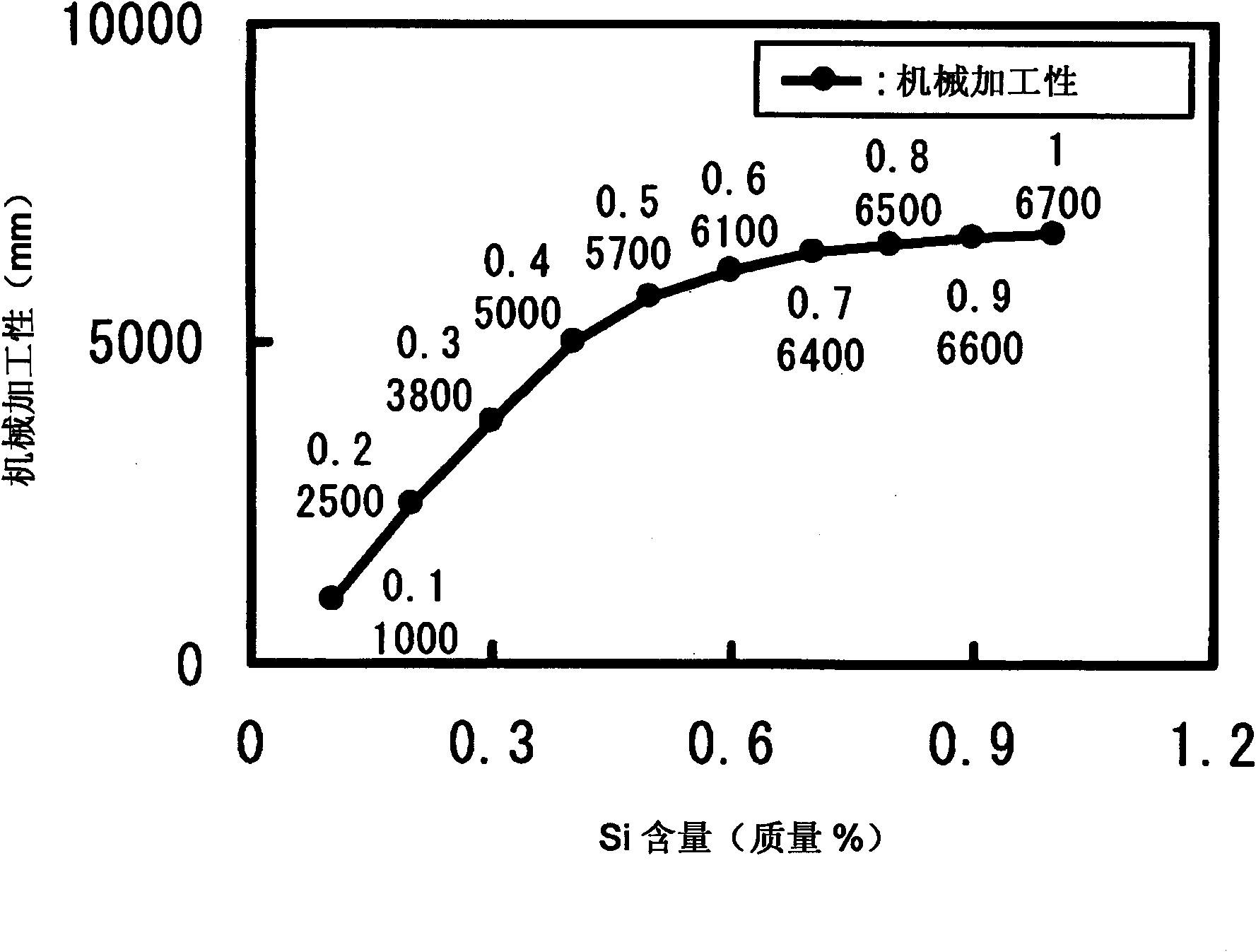

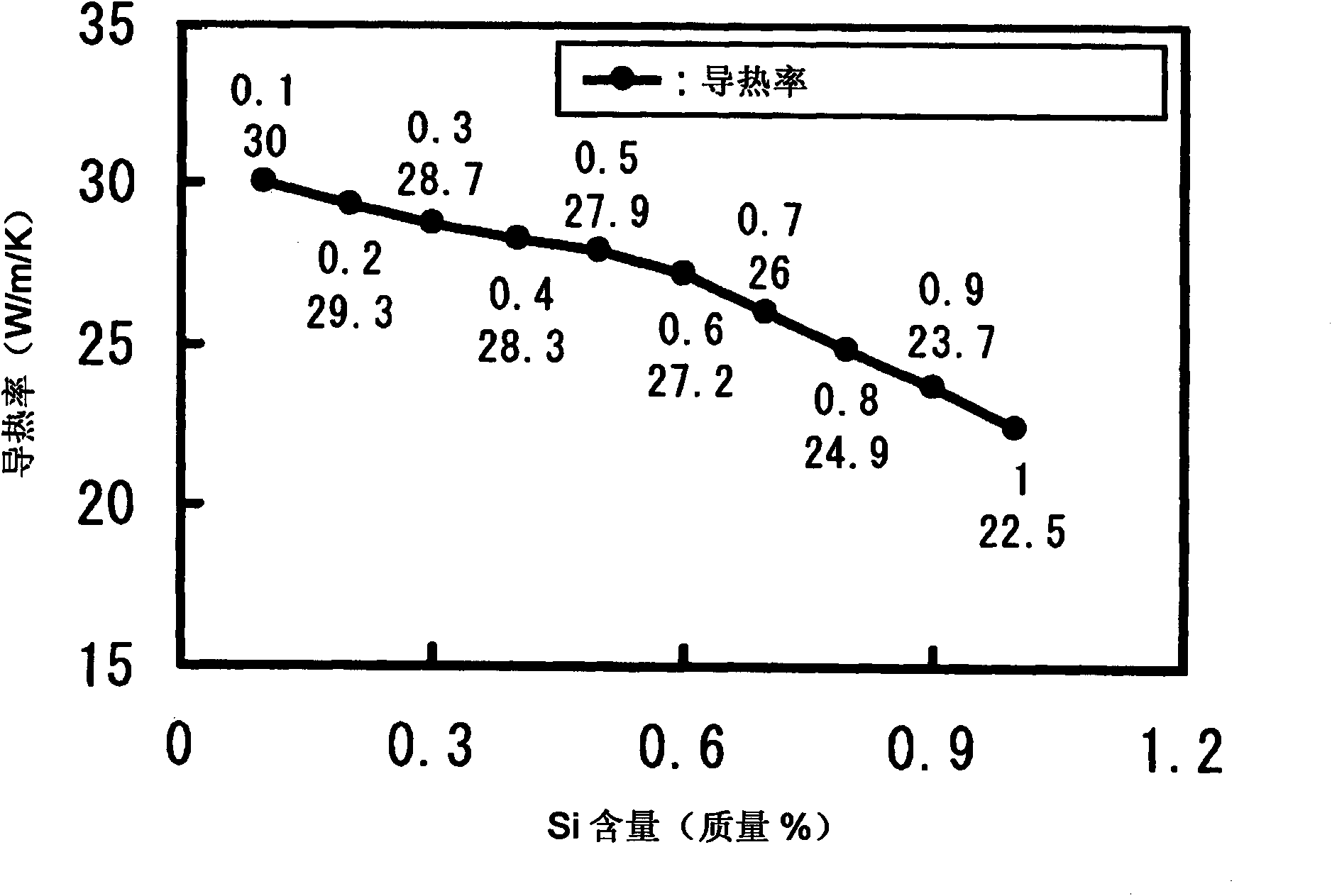

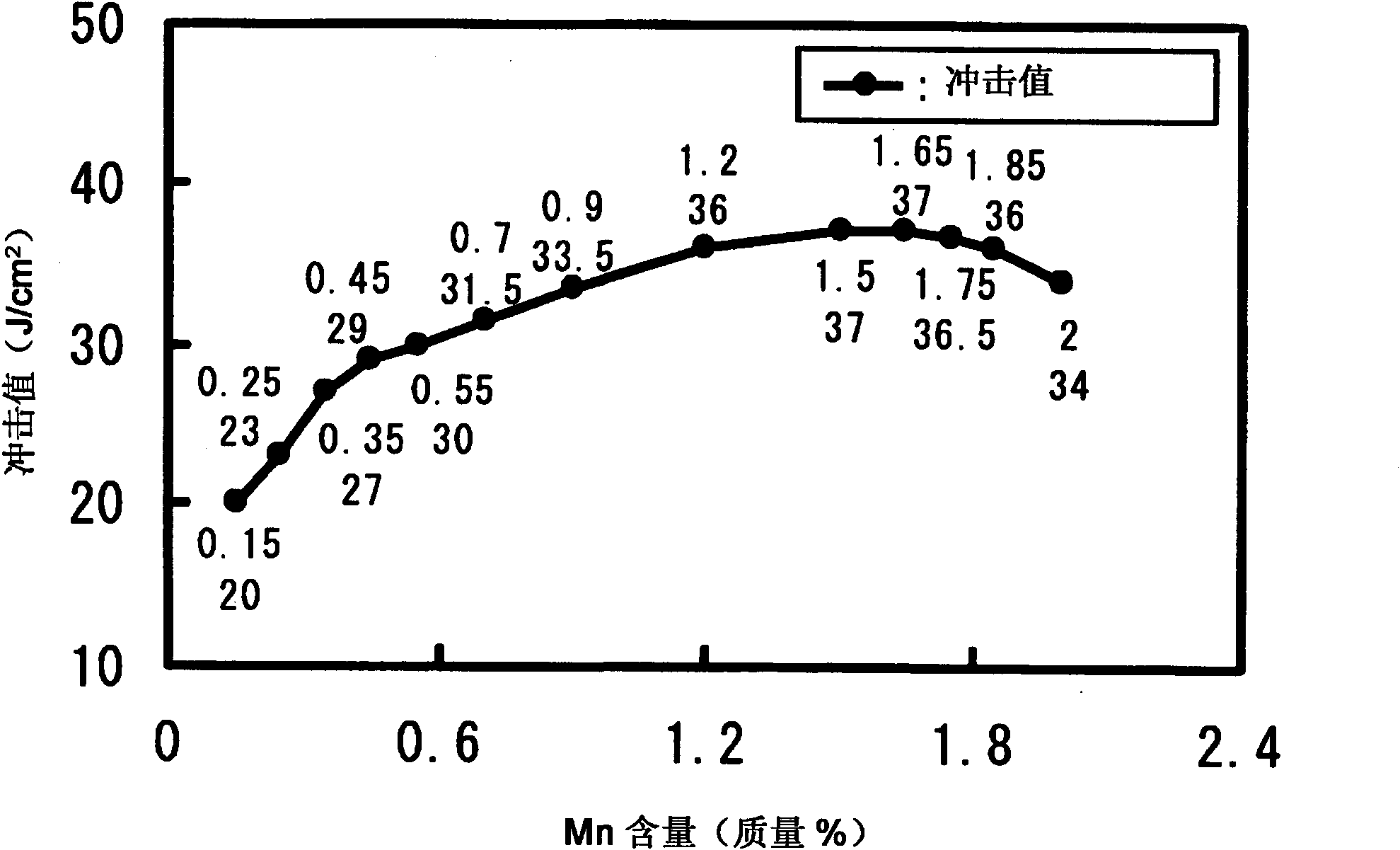

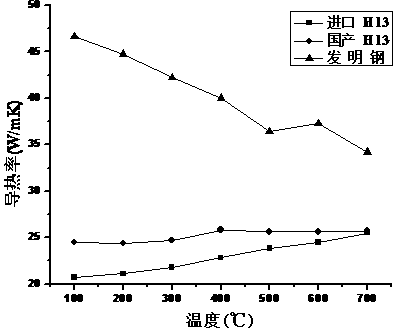

The present invention provides a hot work tool steel containing: 0.20 C 0.50 mass%, 0.01 Si 0.25 mass%, 0.50<Mn 1.50 mass%, 5.24<Cr 9.00 mass%, 1.24<Mo<2.95 mass%, and 0.30<V<0.70 mass%, with the balance being Fe and unavoidable impurities; and a steel product using the hot work tool steel. The hot work tool steel of the present invention is assured of machinability industrially allowing for working into a die shape and enhanced in the thermal conductivity and impact value as compared with general-purpose die steel (for example, JIS SKD61).

Owner:DAIDO STEEL CO LTD

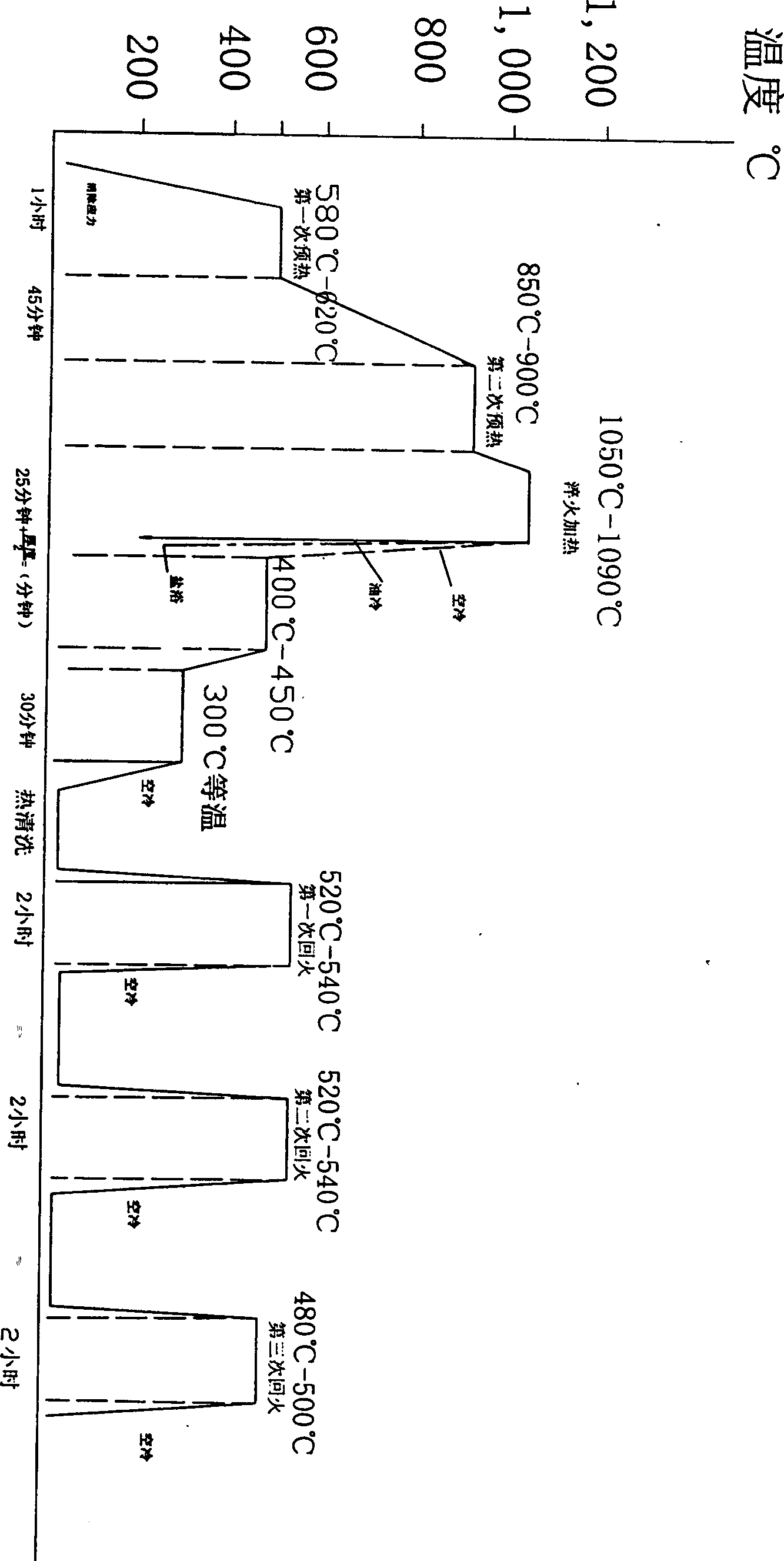

Novel chromium system hot die steel and thermal treatment process thereof

InactiveCN101368247AReduce contentSolve the problem of poor thermal brittleness and easy crackingQuenchingChromium

The invention relates to chromium hot work die steel which belongs to hot work die steel, in particular to hot work die steel containing lower tungsten and a thermal processing technique thereof. Counted by weight percentage, the die steel includes 0.3 to 0.8 percent of C, 0.2 to 0.8 percent of Si, 0.2 to 0.8 percent of Mn, 6.0 to 8.0 percent of Cr, 1.0 to 2.4 percent of W, 0.8 to 2.0 percent of Mo, 0.3 to 1.0 percent of V, 0.3 to 8.0 percent of Co, 0.3 to 1.5 percent of Ni, equal to or less than 0.005 percent of S, equal to or less than 0.030 percent of P and 0.03 to 0.10 percent of B; the content range of a nitride is as follows: the nitride is equal to or more than 0.02 percent, or equal to or less than 0.20 percent; the content range of N is as follows: the N is equal to or more than 0.02 percent, or equal to or less than 0.10 percent; and the rest is Fe. The grains of the steel are thinner; the effects of greatly increased heat resistance, toughness and anti-pressing intensity are generated; the rigidity is between 55 and 61HRC which is more than three times than the durable times of the existing die steel. The invention also provides a thermal processing technique with a lower quenching temperature between 1050 and 1090 DEG C for the steel.

Owner:周向儒

Powder metal rotating components for turbine engines and process therefor

InactiveUS20070020135A1Reduce rateReduce yield lossTurbinesTransportation and packagingMechanical propertyPrecipitation

A process for producing turbine rotors and other large rotating components of power-generating gas turbine engines using powder metallurgy techniques. The process involves forming a powder of a gamma prime or gamma double prime precipitation-strengthened nickel-based superalloy whose particles are about 0.100 mm in diameter or smaller. The powder is placed in a can and consolidated to produce an essentially fully dense consolidation, which is then hot worked to produce a billet of a size sufficient to form a forging of at least 2300 kg. The billet is forged at a temperature and strain rate to produce a forging with a uniform fine grain of ASTM 10 or finer. Thereafter, the forging may undergo a heat treatment to achieve a desired balance of mechanical properties while retaining a uniform grain size of ASTM 10 or finer.

Owner:GENERAL ELECTRIC CO

Hot work tool steel and steel product using the same

The present invention provides a hot work tool steel containing: 0.20 C 0.50 mass%, 0.40<Si<0.75 mass%, 0.50<Mn 1.50 mass%, 5.24 Cr 9.00 mass%, 1.08<Mo<2.99 mass%, and, 0.30<V<0.70 mass%, with the balance being Fe and unavoidable impurities; and a steel product using the hot work tool steel. The hot work tool steel is capable of improving the thermal conductivity as compared with general-purpose die steel (JIS SKD61) and has a higher impact value than that of general-purpose die steel while maintaining machinability at a level equal to or higher than that of general-purpose die steel.

Owner:DAIDO STEEL CO LTD

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

Metamorphic hot-work die steel

The present invention relates to one kind of novel denatured hot work die steel material. The hot work die steel material consists of C 0.200-0.350 wt%, Cr 7.000-13.000 wt%, Mo 0.800-2.000 wt%, Ni 0.600-1.500 wt%, V 0.300-1.200 wt%, Mn 0.200-0.600 wt%, Si 0.700-1.500 wt%, S not more than 0.040 wt%, P not more than 0.040 wt%, N 0.005-0.100 wt%, Ti 0.050-0.200 wt%, Ca 0.001-0.050 wt%, Ce 0.000-0.100 wt% and Y 0.000-0.100 wt%, except Fe. The hot work die steel has very long service life.

Owner:JILIN UNIV

High-performance hot work die steel and manufacturing technology thereof

InactiveCN109280849AImprove thermal stabilityReduce carbon contentManufacturing technologyHeat stability

The invention relates to high-performance hot work die steel and manufacturing technology thereof. The high-performance hot work die steel comprises, by mass percent, 0.20%-0.30% of C, 0.40%-0.80% ofSi, 0.40%-0.80% of Mn, 3.10%-4.00% of Cr, 1.60%-2.00% of Mo, 0.5%-1.00% of W, 0.10%-0.30% of V, smaller than 0.010% of P, smaller than 0.005% of S and the balance Fe. The manufacturing process of thedie steel includes the following steps that burdening, smelting and pouring are conducted; then electroslag remelting is conducted; high-temperature diffusion heat treatment is conducted, then multidirectional forging hot working is conducted, and controlled cooling is conducted after forging; then secondary carbide refining heat treatment and isothermal annealing treatment are conducted; and finally, quenching and tempering heat treatment are conducted. The high-performance hot work die steel and manufacturing technology thereof have the beneficial effect that the quenching degree, the heat stability, the impact toughness and the thermal fatigue performance of the hot work die steel are superior to H13 steel, the hot work die steel can be machined into large die casting dies with the weight of the single piece reaching 5 tons or higher, and the good use performance is achieved; and in addition, the steel ingot smelting cost can be reduced, and the service life of dies is prolonged.

Owner:RUGAO HONGMAO HEAVY FORGING

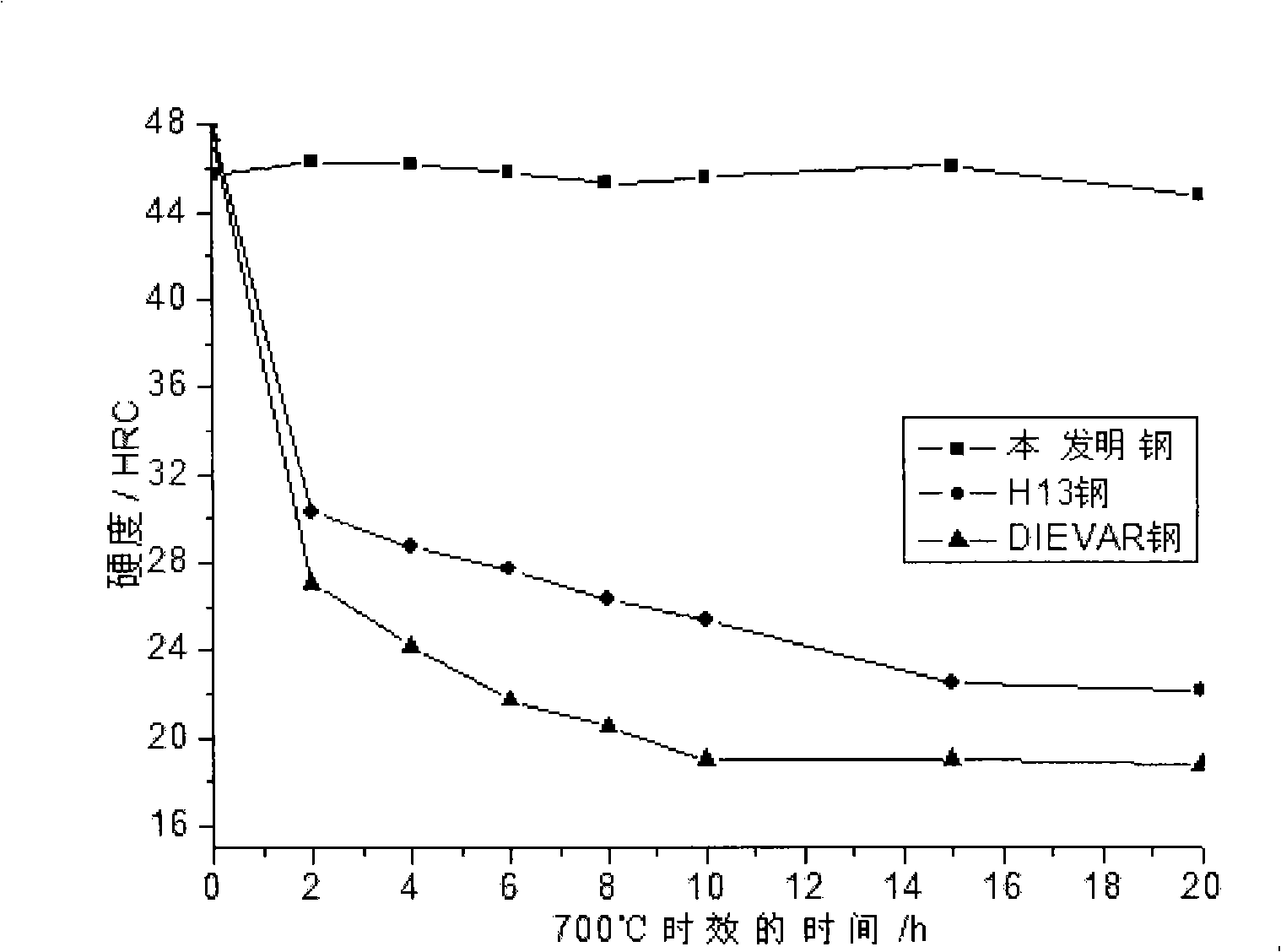

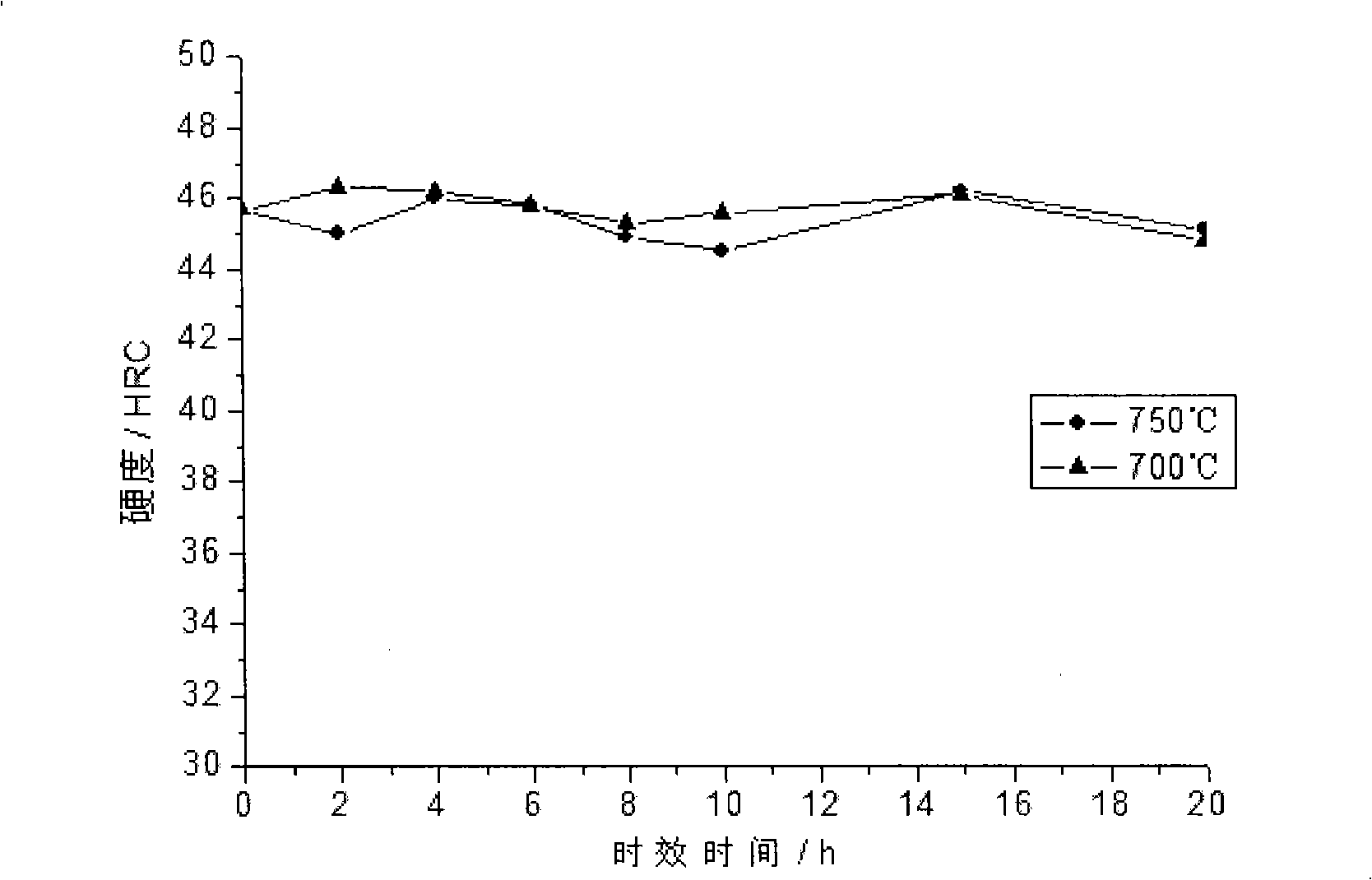

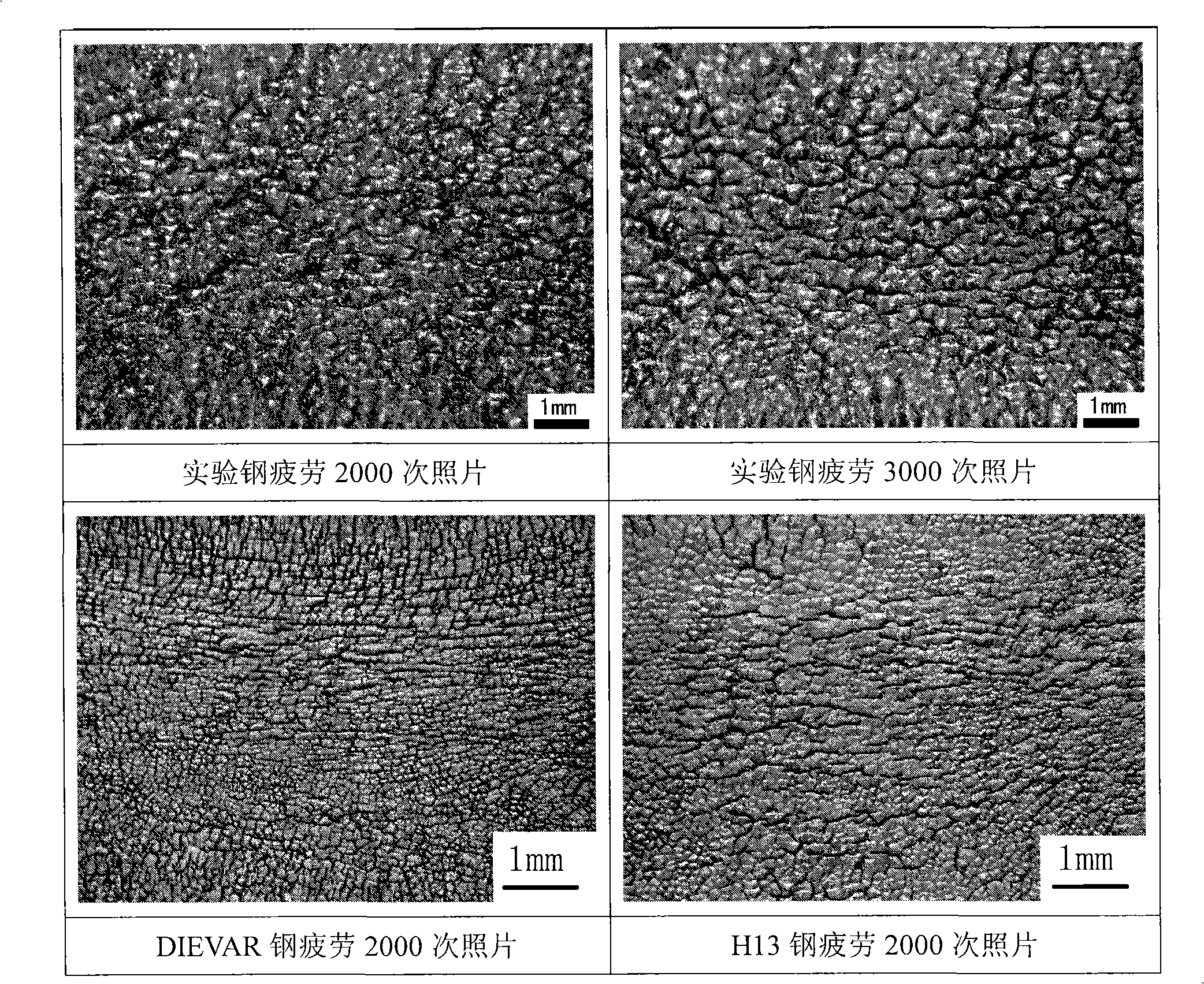

High heat-intensity hot-work die steel material

ActiveCN1924069AImprove metallurgical qualityImprove organizationHeat treatment process controlSlagHot work

The invention discloses a heat mould steel material in the alloy steel material manufacturing technological domain, which comprises the following parts: 3.5-4.0%Cr, 2.0-2.5% Mo, 1.0-1.5% V,1.0-1.5% W , 0.1-0.5% Mn, 0.1-0.25% Ni, 0.3-0.35% C, 0.1-0.5% Si, 0.005-0.01% S, 0.01-0.02% P and Fe. The preparing method comprises the following steps: (1) fusing; (2) refusing electric slag; (3) evening at high temperature; (4) forging; (5) annealing; (6) forging blank; (7) annealing to obtain the product with hardness between 48-54HRC and impaction flexibility more than 300J.

Owner:SHANGHAI UNIV

Enclosure system for hot work within the vicinity of flammable or combustible material

One or more enclosures constructed about one or more objects at which hot work is to be performed at a facility containing flammable and / or combustible material. Hot work includes such things as welding, torch cutting, grinding and the like that produces heat, spark, slag or flame. The one or more enclosures are capable of being simultaneously and independently controlled and monitored by a single control and monitoring system.

Owner:ALFORD SAFETY SYST +1

Hot work die steel and its preparation method

ActiveCN1912165AReasonable compositionEasy to useMetal-working apparatusHeat treatment process controlSteelmakingHot work

The invention relates to hot-work die steel and its manufacturing method. It includes the following alloying element: 0.40-0.48wt% C, 0.60-1.00wt% Si, 0.30-0.80wt% Mn, less than 0.030wt% P, S, 2.20-2.70wt% Cr, 0.90-1.20wt% W, 0.80-1.00wt% Mo, 0.70-1.00wt% V, rest Fe and impurity. The method includes the following steps: adopting common steel facility, common medium steel smelting technology to smelt as the given constituent; forging; heat processing; making hot-work die. It has the advantages of reasonable alloy element composition, simplifying technology, lowering the cost. And it is fit for making tool die at 400-650 degree centigrade, such as cutting edge etc.

Owner:MAANSHAN IRON & STEEL CO LTD

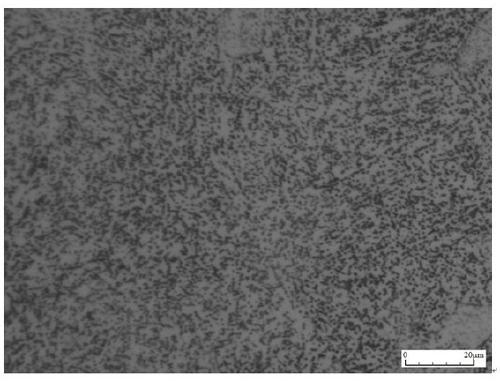

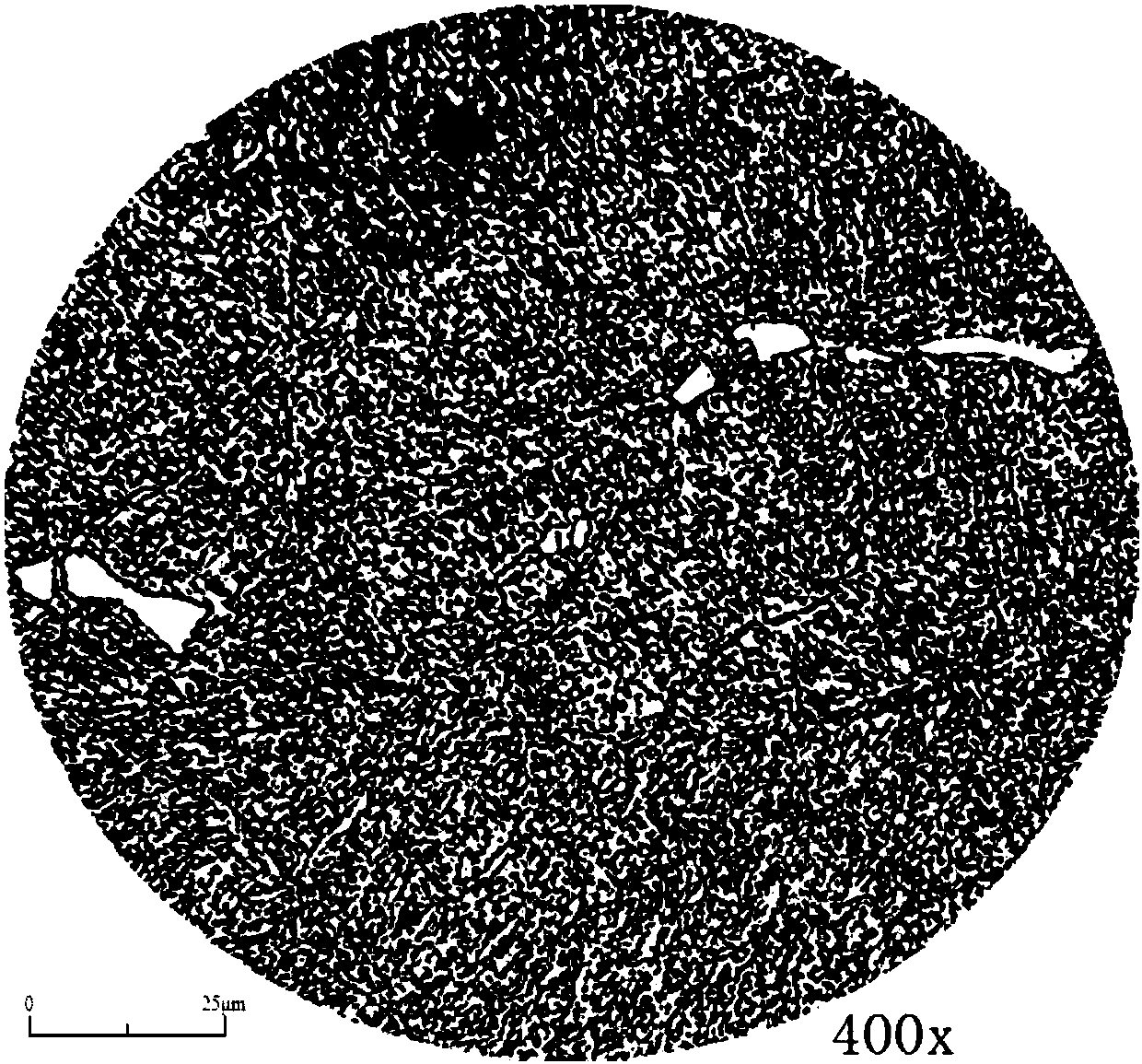

Manufacturing technology of hot work die steel forge piece

ActiveCN107686878AReduce contentOligodendrite segregationMetal-working apparatusSolution treatmentManufacturing technology

The invention relates to a manufacturing technology of a hot work die steel forge piece. The manufacturing technology comprises the steps including forging, high-temperature normalization, high-temperature tempering, ultrafine solution treatment, spheroidizing and sampling inspection. Through the procedures and related heat treatment, chemical components in the hot work die steel forge piece tendto be consistent, the structure inheritance is effectively cut off, and accordingly the purposes of refining grains and homogenizing structures are achieved. After spheroidizing, a spherical pearlitewith fine-particle-shaped carbide evenly distributed on a ferrite base body is obtained. An excellent organization structure is provided for final heat treatment.

Owner:山西同航特钢有限公司

Enclosure system for hot work within the vicinity of flammable or combustible material

Owner:ALFORD SAFETY SYST +1

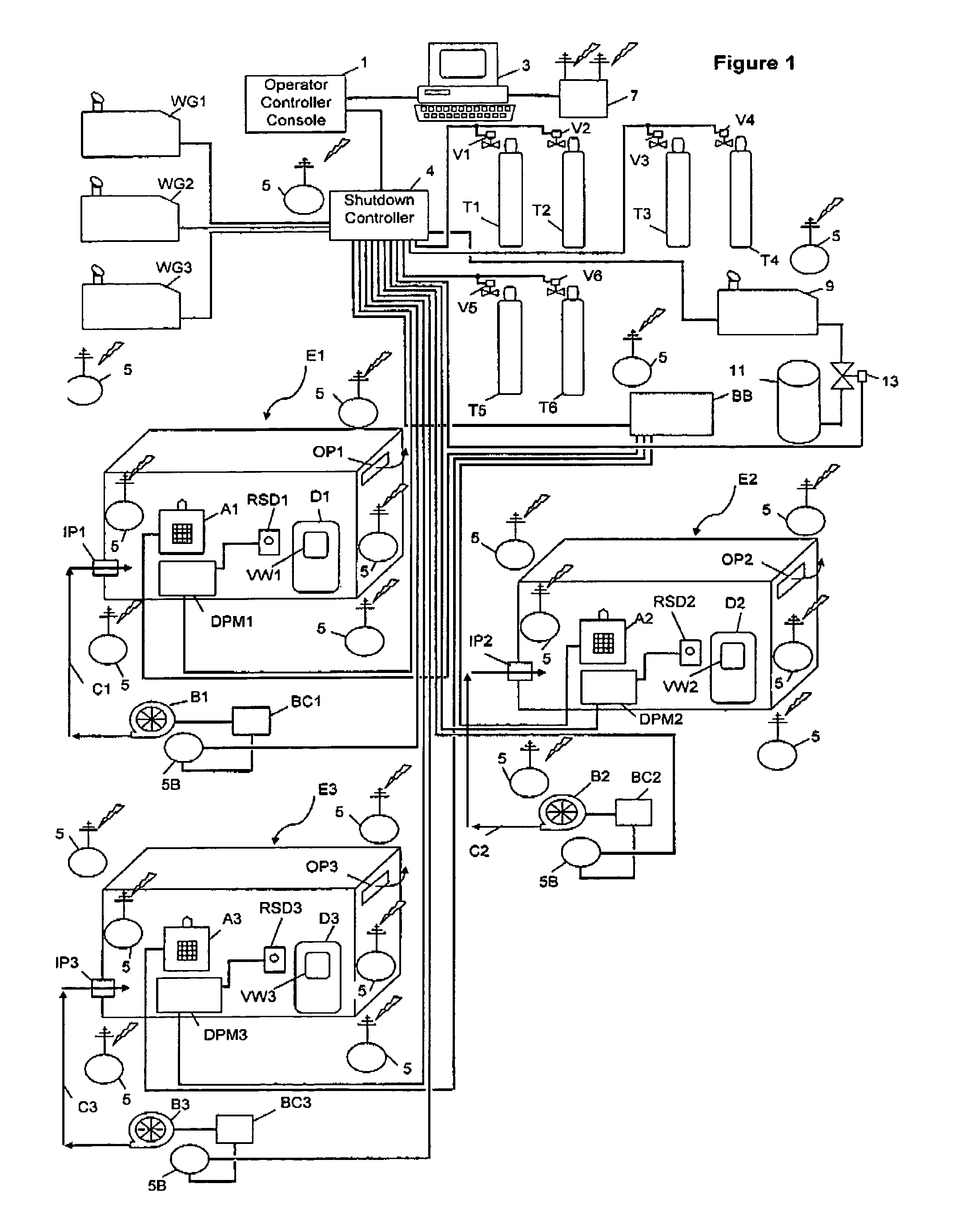

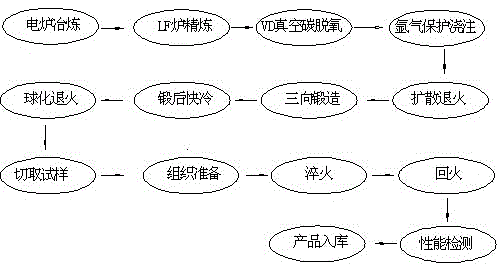

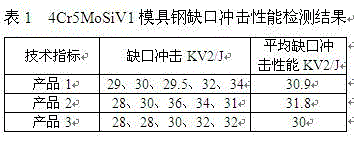

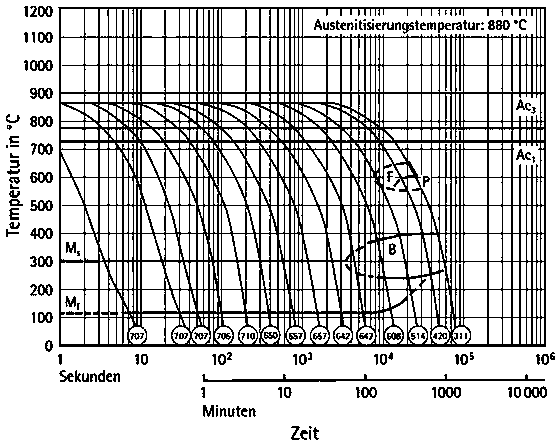

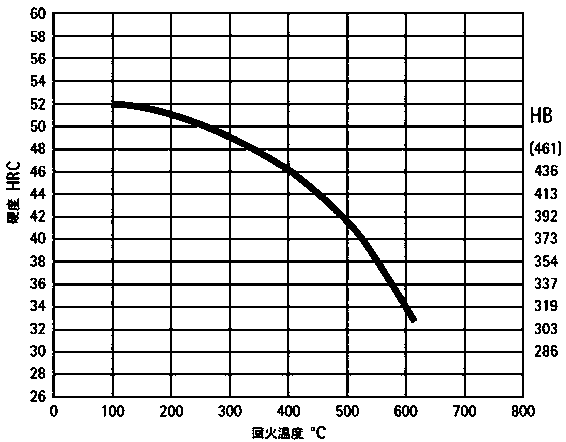

Preparation method for improving performance of 4Cr5MoSiV1 hot work die steel

ActiveCN105525078ALow steel total oxygen contentReduce oxygen contentHeating/cooling devicesSlagHot work

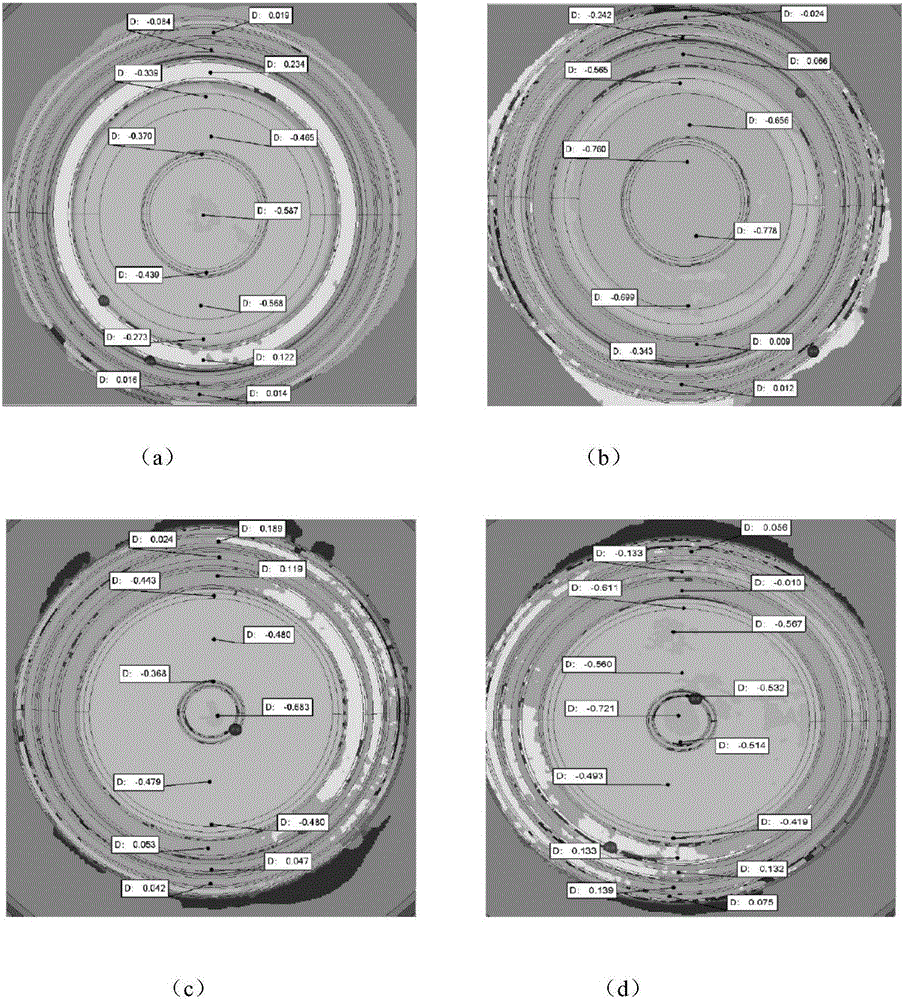

The invention relates to 4Cr5MoSiV1 hot work die steel, in particular to a preparation method for improving the performance of the 4Cr5MoSiV1 hot work die steel. The preparation method comprises the steps of producing highly-clean steel ingots with the total oxygen content being 12 ppm by adopting electric furnace smelting, vacuum carbon deoxidizing and slag surface diffusing and deoxidization refining, adding the pure rare earth La and Ce on the oxygen control condition and carrying out argon shield pouring; carrying out diffusing and homogenizing annealing on the steel ingots and upsetting and drawing forging on the steel ingots in the three-dimensional directions three times, fast cooling the steel ingots through water and air alternately after forging, carrying out the processes of fast cooling after ultrahigh-temperature austenitizing and spheroidizing annealing before quenching, carrying out tempering with the temperature not lower than 590 DEG C 2-3 times after quenching, and finally obtaining the stable tempered structure of the 4Cr5MoSiV1 hot work die steel. According to the invention, the single notched impact property KV2 of the 4Cr5MoSiV1 hot work die steel is greater than or equal to 25 J, the average notched impact property KV2 is greater than or equal to 30 J, the single non-notched impact energy is greater than or equal to 280 J, the average non-notched impact energy is greater than or equal to 320 J, the ratio of the transverse non-notched impact energy to the longitudinal non-notched impact energy is greater than or equal to 93%, and the isotropy is excellent.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

High-performance hot stamping die steel and manufacturing process thereof

The invention relates to high-performance hot stamping die steel and a manufacturing process thereof. The high-performance hot stamping die steel comprises the following components of, in percentage by mass, 0.66% - 0.80% of C, 0.80% - 1.20% of Si, 0.20% - 0.50% of Mn, 5.00% - 6.50% of Cr, 1.50% - 2.00% of Mo, 0.40% - 0.80% of V, less than 0.015% of P, less than 0.015% of S and the balance Fe. Themanufacturing process of the die steel comprises the following steps of carrying out burdening, smelting, casting, electroslag remelting; carrying out high-temperature diffusion thermal treatment, multi-direction forging and hot machining and cooling control after forging; then carrying out secondary carbide refining thermal treatment and isothermal annealing treatment; and finally carrying out quenching and tempering thermal treatment. The high-performance hot stamping die steel and the manufacturing process thereof has the advantages that the hardenability, the thermal stability, the wear resistance and the thermal fatigue performance of the hot-work die steel are superior to the hardenability, the thermal stability, the wear resistance and the thermal fatigue performance of H13 steel,and the hot-work die steel can be machined into a large-scale hot stamping die with the single-piece weight reaching 5 tons or above, and the usability is good.

Owner:RUGAO HONGMAO HEAVY FORGING

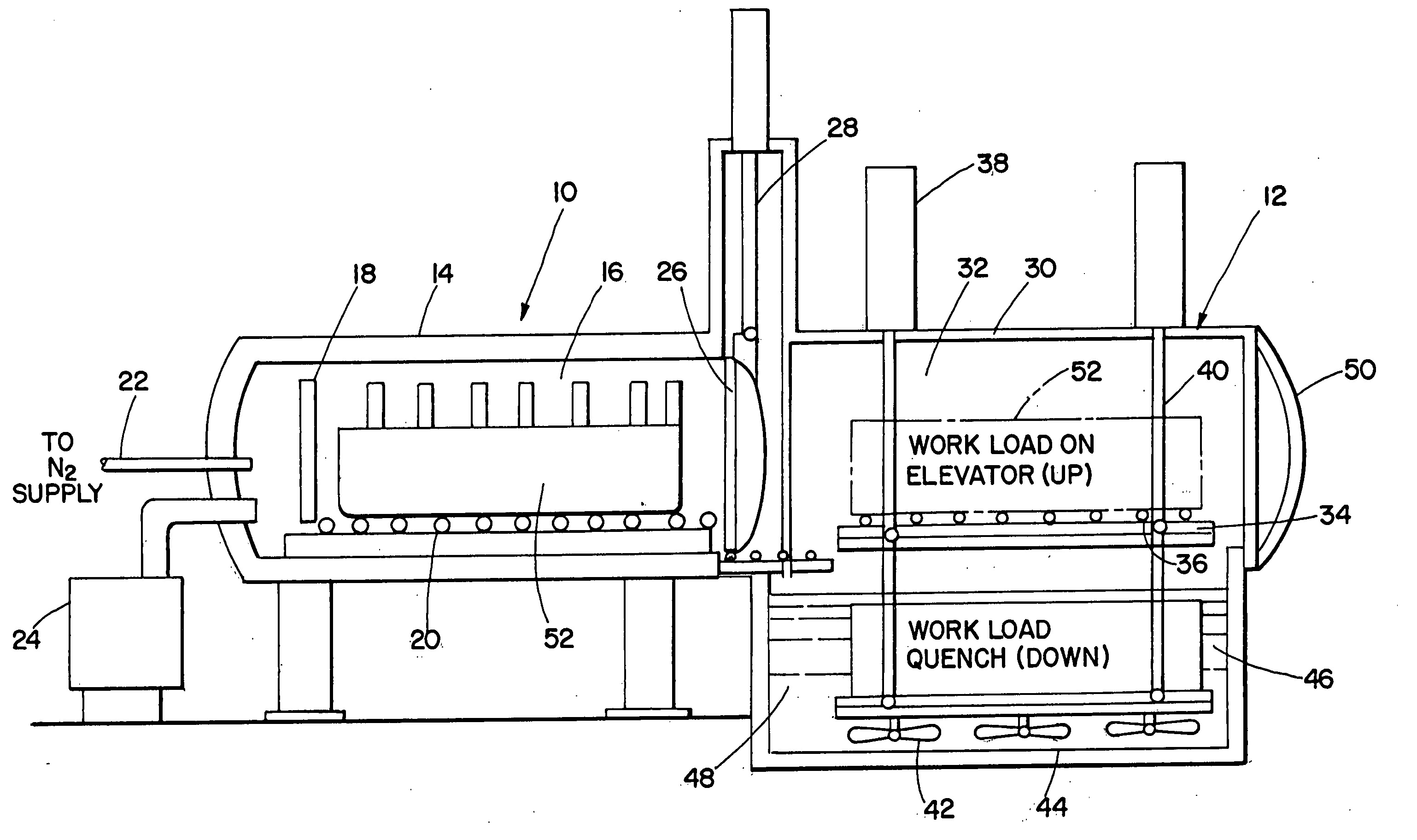

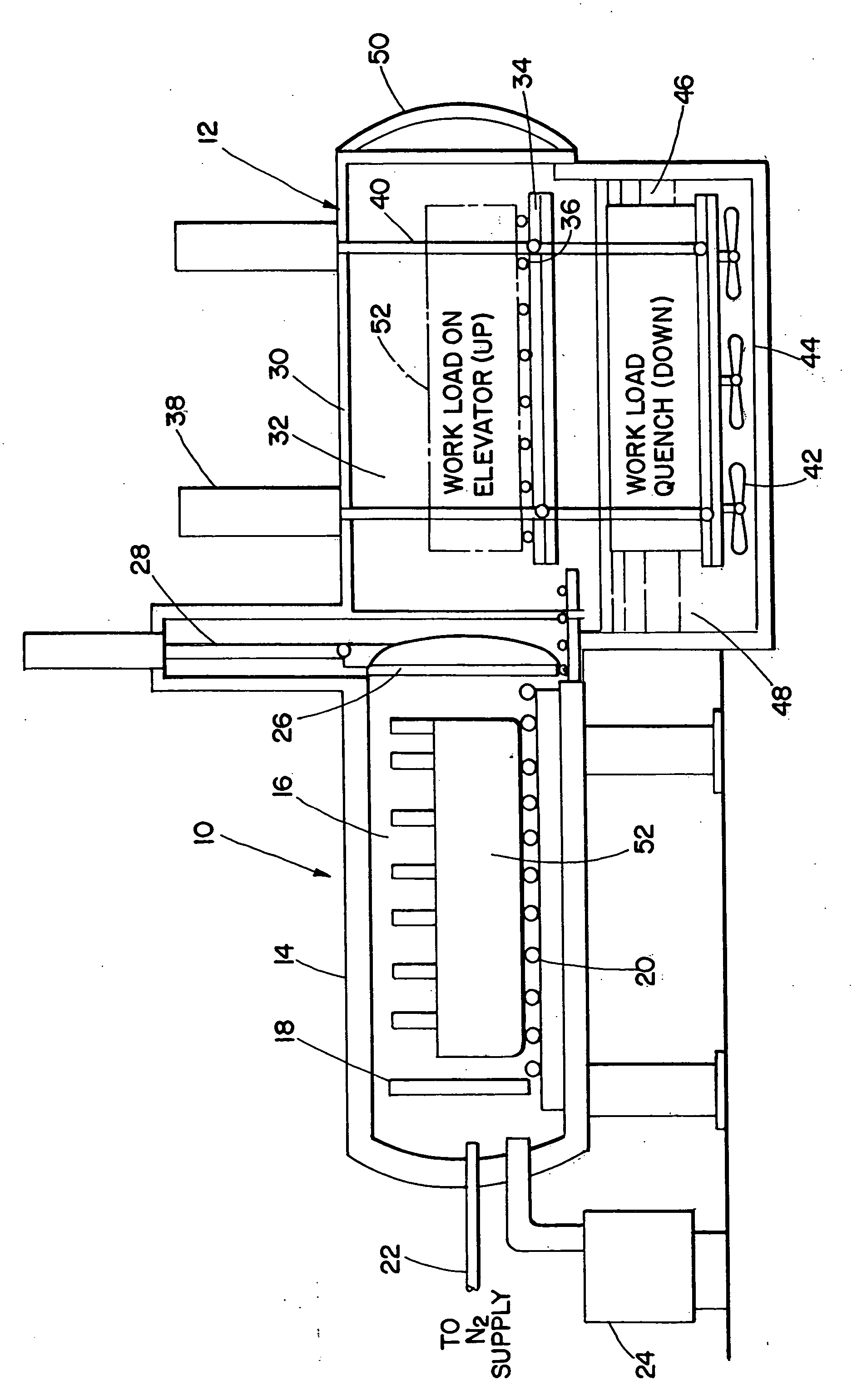

Vacuum furnace with pressurized intensive water quench tank

A heat treating furnace having a quenching chamber incorporated therein or associated therewith is disclosed. The heating chamber within the furnace is utilized to heat work-pieces to a desired temperature. When the heating cycle has been completed, the heating chamber and the quenching chamber are back-filled with an inert gas to a redundant pressure (over atmospheric). The work-pieces are then transferred into the quenching chamber and lowered into the intensively agitated water in the water quench tank by an elevator mechanism. High quenchant (water) agitation rates eliminate film boiling on the surface of the hot work-pieces. When the compressive stresses on the surface of the work-pieces are at a maximum and are at an optimum depth, or when the cooling recipes otherwise determine, the elevator mechanism in the quenching chamber lifts the work-pieces out of the water quench tank and into the inert gas blanket above the tank, thus interrupting the intensive quenching process. The cores of the work-pieces are then allowed to cool uniformly by conduction through their intensively quenched outer shells. After cooling, the work-pieces, having both high hardness and low distortion, are removed from the quenching chamber.

Owner:IQ TECH

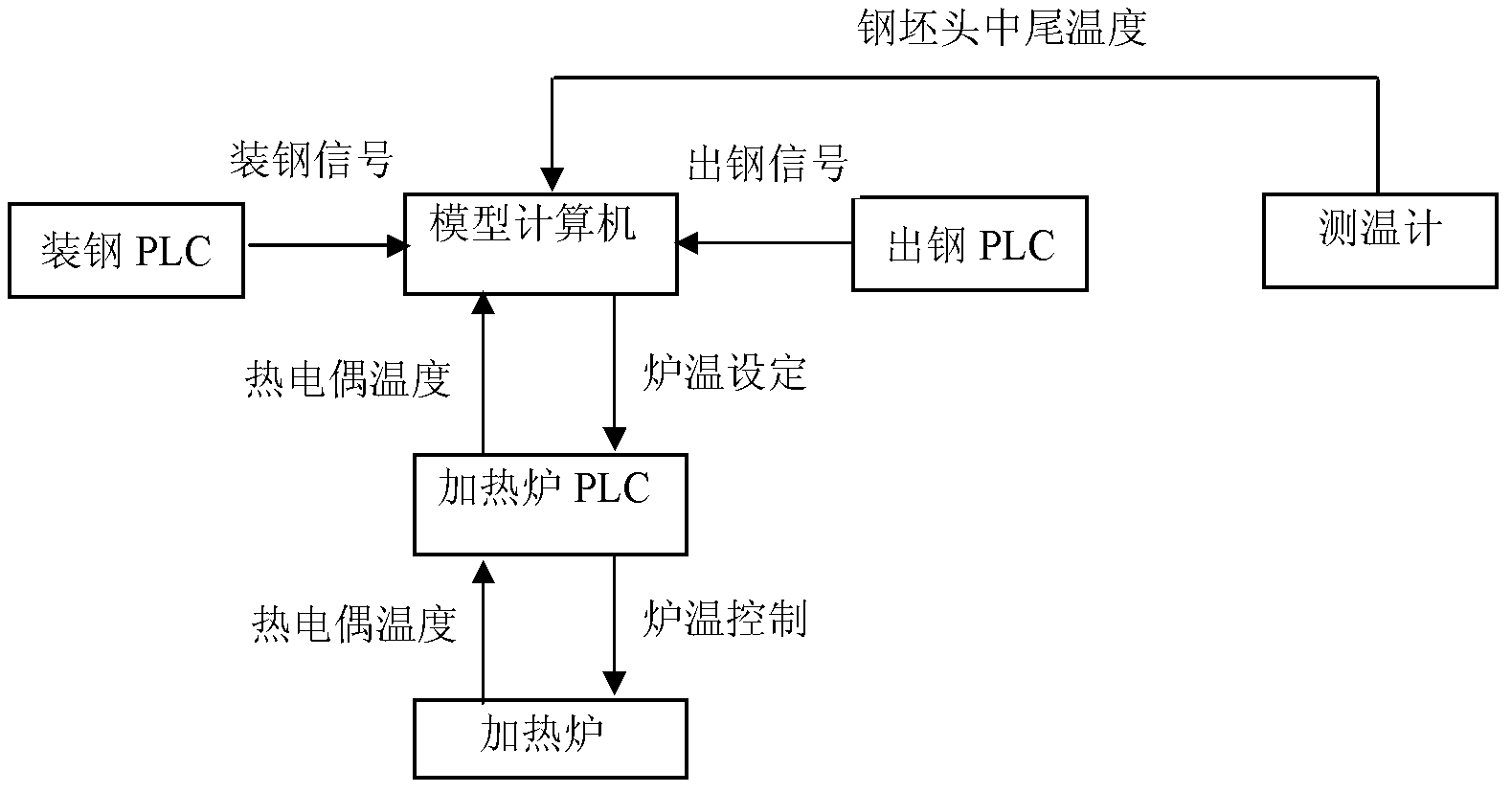

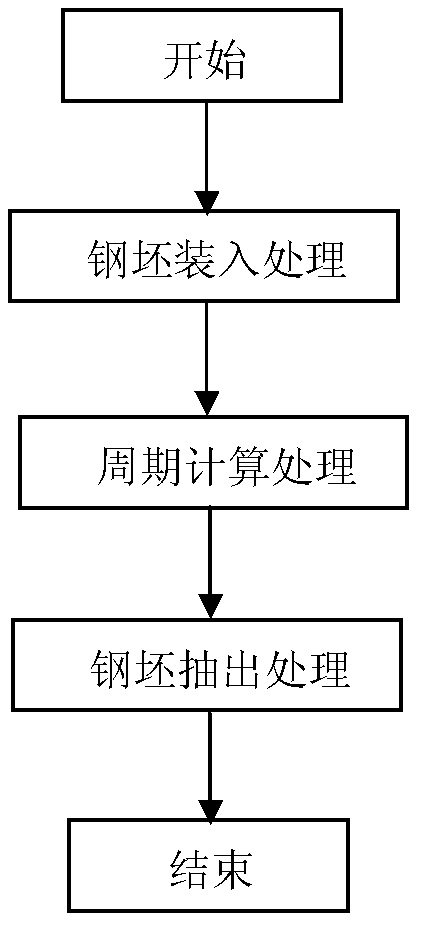

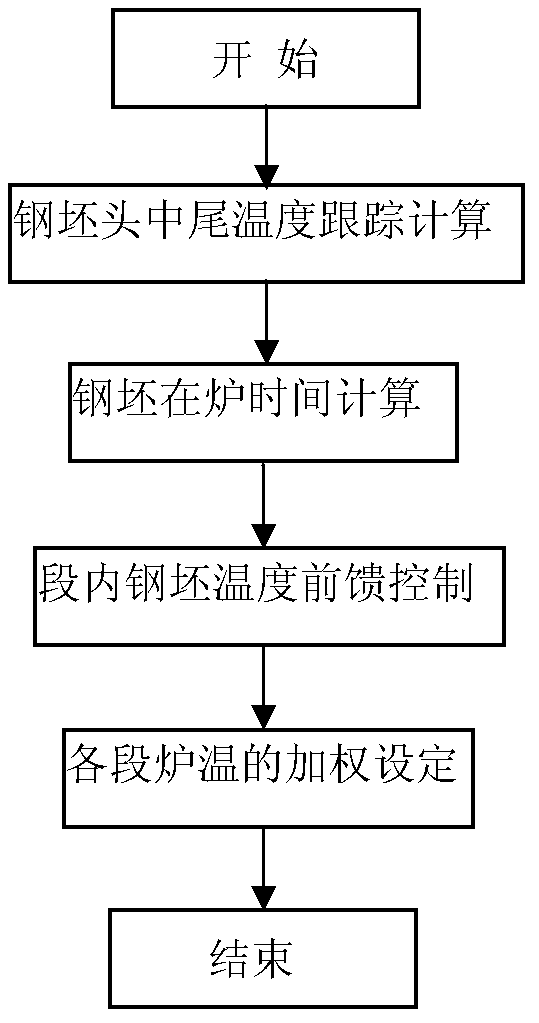

Rod and wire billet heating furnace model control method and apparatus

ActiveCN103225017AFast Stable Tracking OKPrecise control of head and tail temperature distributionFurnace typesHeat treatment process controlFurnace temperatureTemperature control

The invention relates to a rod and wire billet heating furnace model control method and an apparatus, which belongs to the metallurgy field. The control method is characterized in that PLC is used for zone control on furnace temperature of a heating furnace, the PLC comprises a steel loading PLC, a steel tapping PLC and a heating furnace combustion control PLC, a heating furnace is divided into a furnace tail segment, a preheating segment, a heating segment and an isothermal segment, the billet to be treated is passed through each segment of the heating furnace in order for being heated, three thermoelectric couples are respectively arranged on the heating furnace along the furnace width direction of each segment, the temperature of head part, intermediate part and tail part of the billet can be rapidly tracked and determined in a stable mode, furnace temperature control of each segment of the heating furnace can be realized, by combining a radiation pyrometer at a rough rolling inlet, the head and tail part temperature distribution of the billet can be accurately controlled, and the control precision of the temperature control along the billet length direction and the temperature distribution along the billet length direction enable real-time tracking and determination. The rod and wire billet heating furnace model control method and the apparatus have obvious effects for increasing the product quality, enhancing rolling stability, saving energy and reducing consumption, and can be widely used for the hot working or heat treatment field of the wire rod billet.

Owner:BAOSHAN IRON & STEEL CO LTD

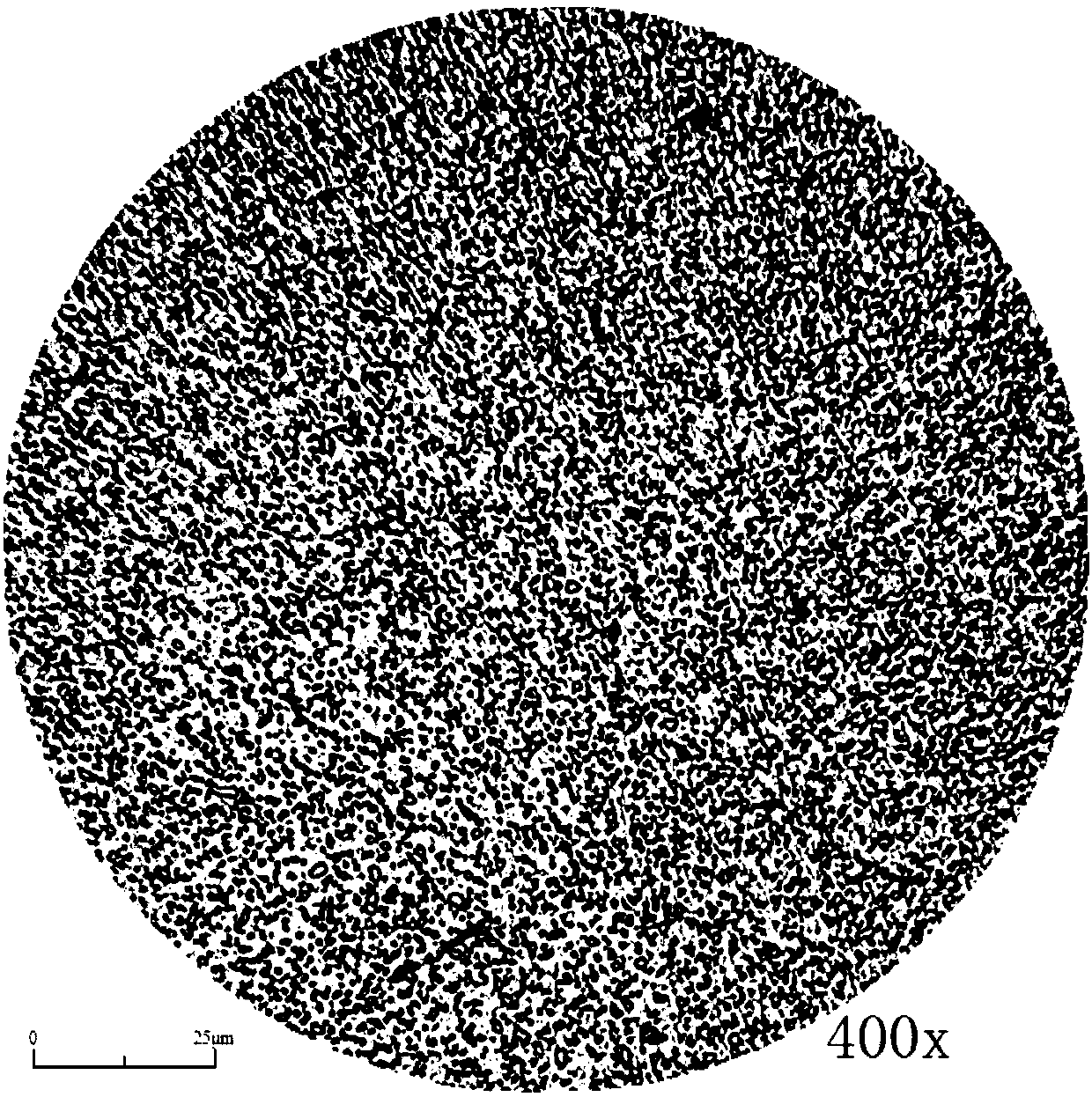

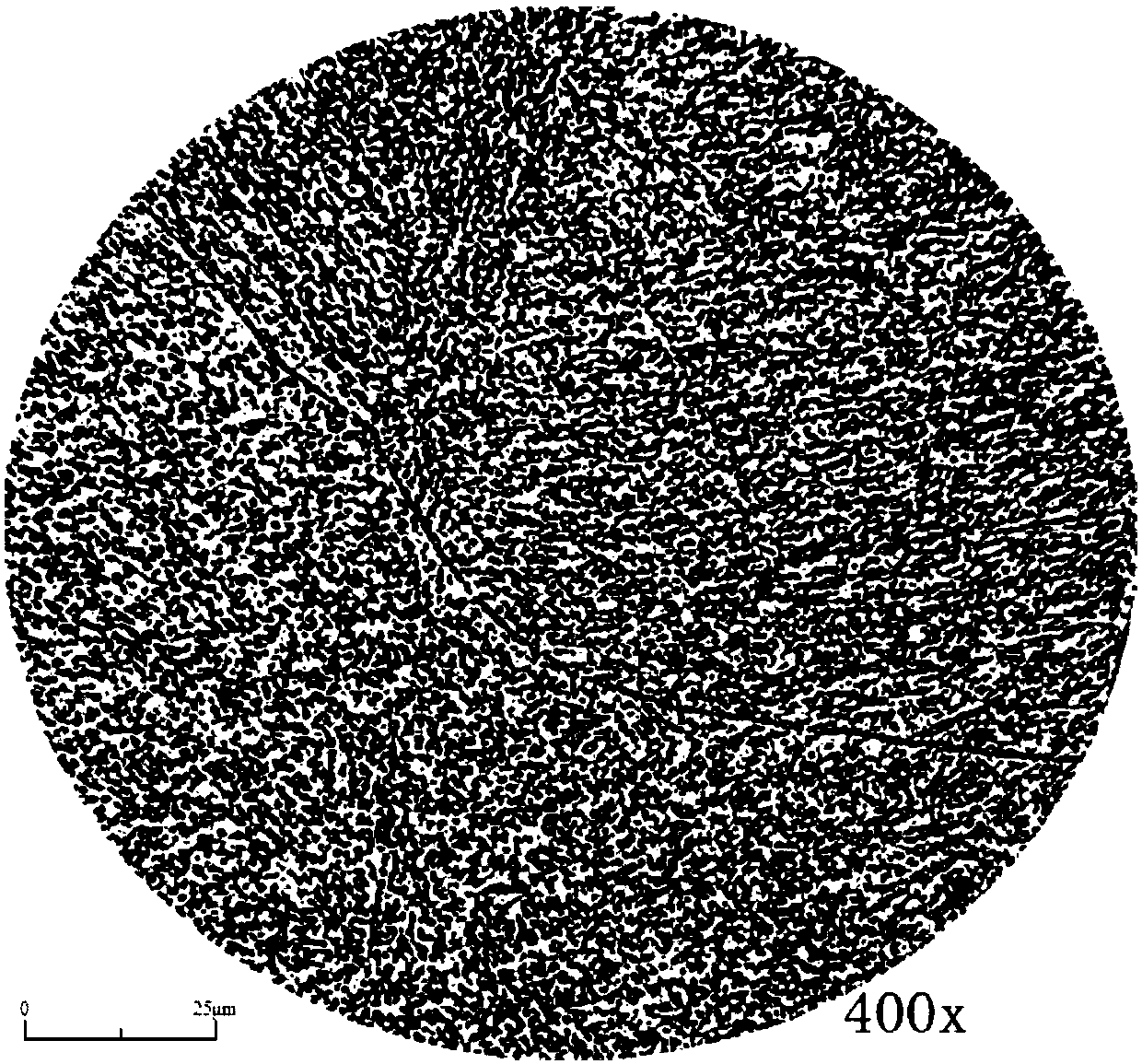

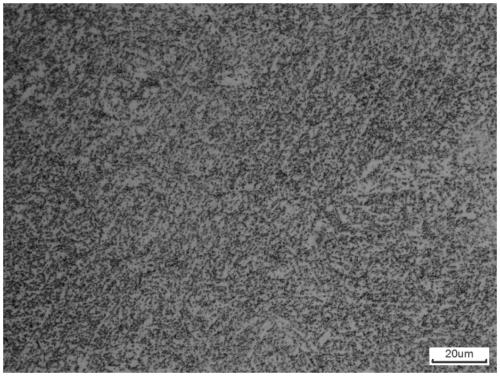

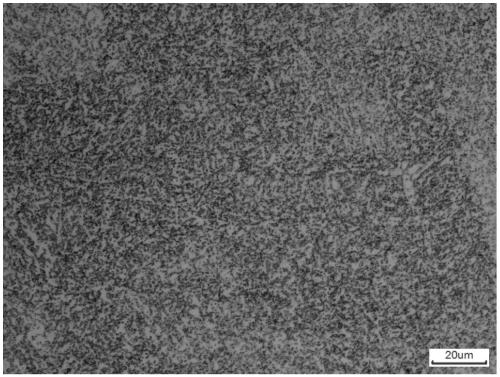

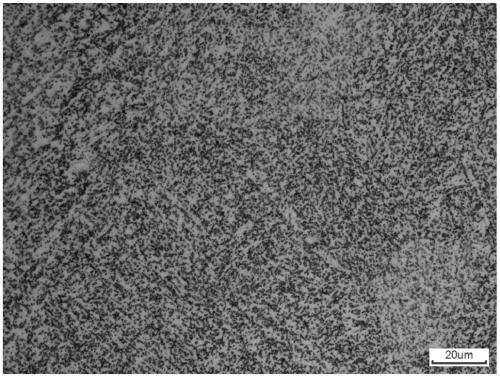

High-toughness and high-thermal-stability hot work die steel and preparation method thereof

ActiveCN111593257AImprove toughnessImprove thermal stabilityProcess efficiency improvementMaterials scienceMicrostructure

The invention relates to a preparation method of high-toughness and high-thermal-stability hot work die steel. The preparation method comprises the following steps of optimizing alloy components, andstrictly controlling the production process; and the specific process route is as follows, electric furnace smelting, ladle refining furnace refining, vacuum refining furnace refining, electrode blankcasting, protective atmosphere electroslag furnace remelting, forging, ultrafine treatment and spheroidizing annealing production processes are adopted at the same time. The invention further relatesto the high-toughness and high-thermal-stability hot work die steel prepared through the preparation method. The product has the advantages of uniform annealed microstructure, favorable spheroidizedstructure, fine and uniform grain distribution and uniform quenched and tempered structure, and the fine precipitated phases of the Mo and Cr carbides have the dispersion strengthening action in the use process, thereby enhancing the properties of the material and endowing the material with high toughness and high isotropy. The product can be widely used for manufacturing hot extrusion dies, mandrels, hammer dies of die forging hammers, dies of forging presses and dies for precision forging machines, and particularly can be used as a high-end die-casting die made of aluminum, copper and alloysthereof.

Owner:江苏宏晟模具钢材料科技有限公司

Steel with ultra-high thermal conductivity for hot-stamping die and preparation method of steel

The invention relates to a novel material with ultra-high thermal conductivity for a hot-stamping die. The steels in the market for the hot-stamping die are mainly various types of improved H13 and H11 high-alloy hot work die steels. The steel in the invention comprises the following compositions in percentage by mass: 0.150-0.35% of C, less than or equal to 0.25% of Si, 0.08-0.20% of Mn,1.0-2.0% of W,2.0-4.5% of Mo, less than or equal to 0.30% of Cr,less than or equal to 0.02% of V and the balance of Fe and inevitable impurity elements, wherein S in the impurity elements is less than or equal to 0.005%, P in the impurity elements is less than or equal to 0.01 and O in the impurity elements is less than or equal to 30 ppm (parts per million). The invention is characterized in that simple elements i.e. C, Mo and W are used as the main elements, and proper proportion of carbide is adopted; the contents of Mn and Cr are maintained low, and the content of Si is maintained ultra-low; the steel has superior machining property after being subjected to electro-smelting, electro-slag remelting, annealing, high-temperature homogenization, forging and annealing; through thermal treatment (1060-1100 DEG C quenching and high-temperature annealing), the toughness of the steel can reach the toughness of common hot-stamping die steel such as H13, and the hardness, annealing stability and the fatigue property of the steel are more superior; particularly, the steel with lower coefficient of thermal expansion and ultra-high thermal conductivity is more suitable for hot stamping.

Owner:SHANGHAI UNIV

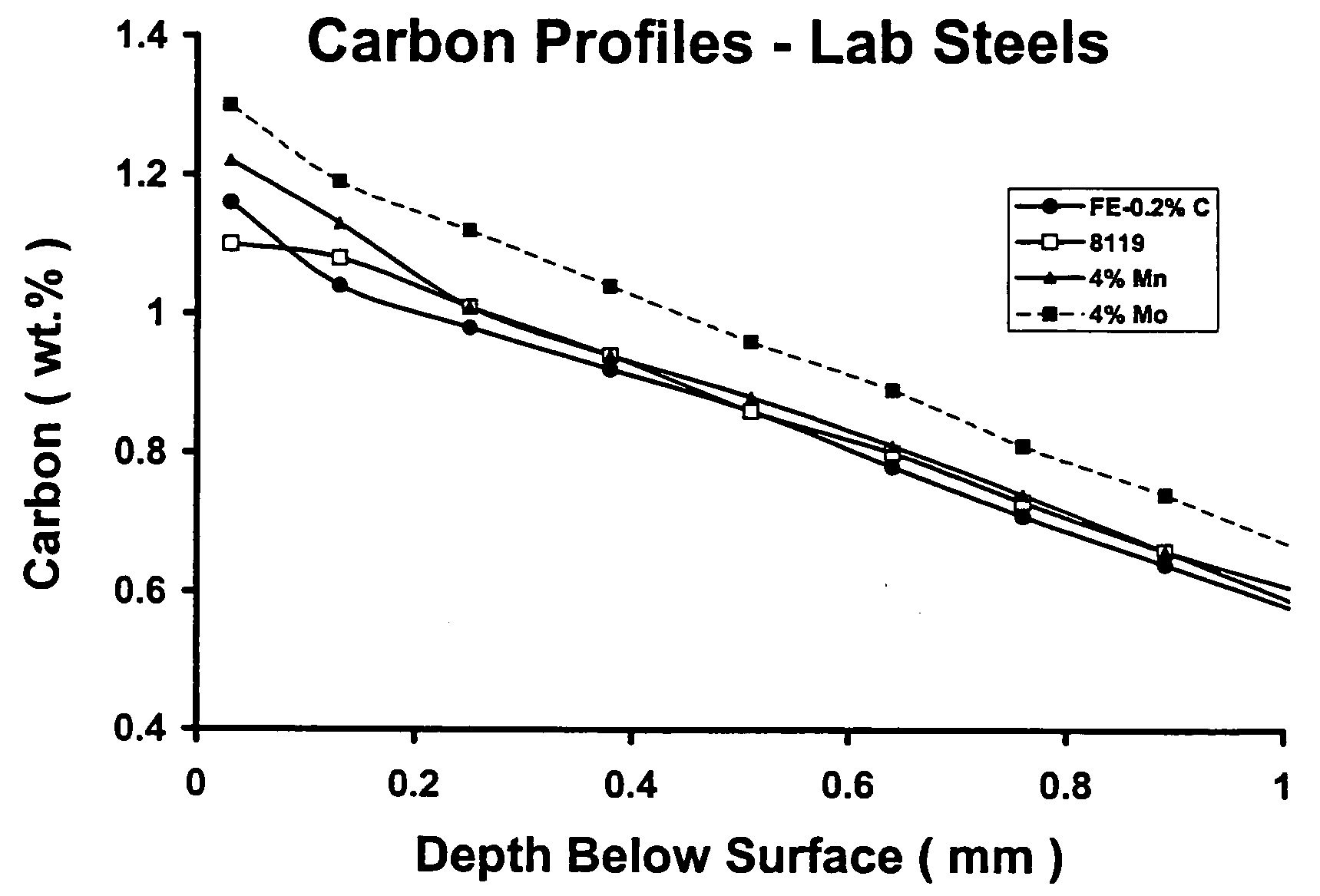

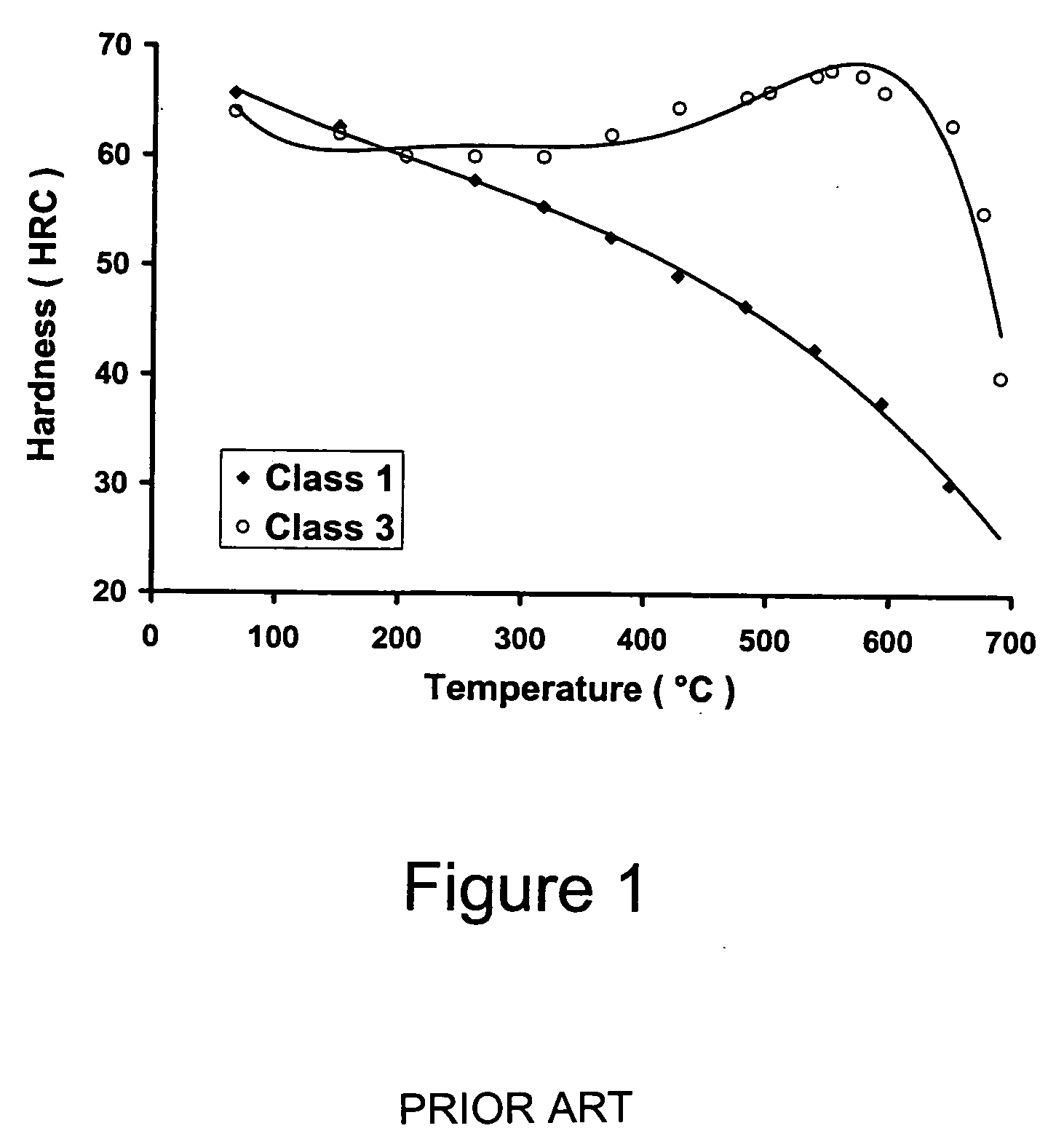

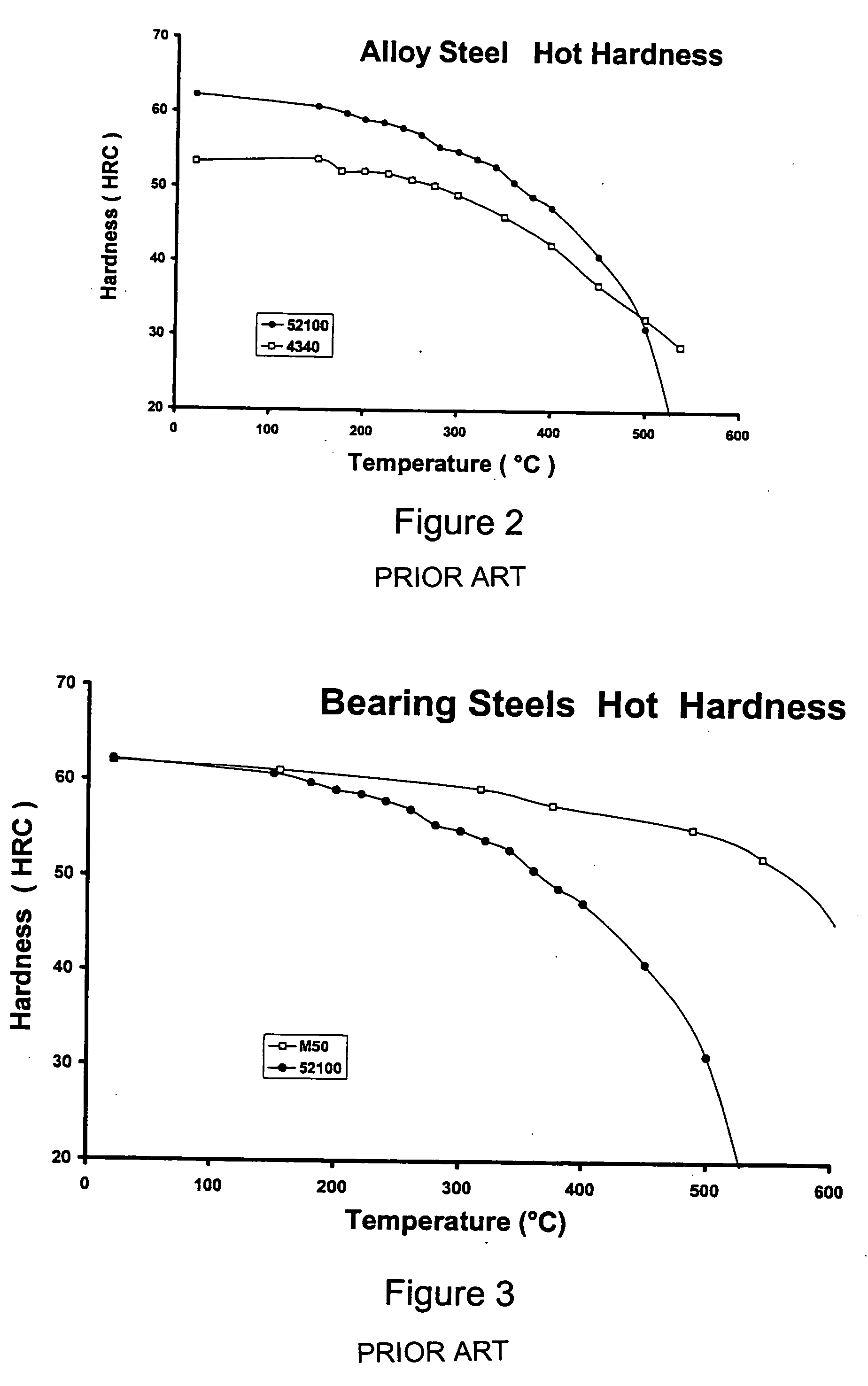

Mo-V-Ni high temperature steels, articles made therefrom and method of making

InactiveUS20080145264A1Good hot hardnessEnhance carbon diffusionSolid state diffusion coatingHigh carbonHardness

Low carbon carburizing (surface hardening) and higher carbon through hardening steels primarily containing molybdenum, vanadium and nickel and, to a lesser amount, chromium used for rolling contact bearings, gears and other similar applications where high hardness at elevated temperatures is required. The alloy steel includes, in % by weight: 0.05% to 1.25% C; up to 1.25% Cr; 0.40% to 4% Mn; up to 4.0% Mo; up to 2.0% V; 1.0% to 3.0% Ni; 4% to 8% (Mo+V+Ni+Cr); less than 0.20% Si; and balance Fe plus incidental additions and impurities. The method for providing a steel having improved hardness at elevated temperatures includes the steps of: (a) providing an alloy including, in % by weight: less than 1.25% Cr, 0.4% to 4% Mn, up to 4% Mo, up to 2% V, 1 to 3% Ni, 4% to 8% (Mo+V+Ni+Cr), less than 0.2% Si, a C content selected from one of 0.05% to 0.40% C defining a carburizing steel or greater than 0.40% to 1.25% C defining a through hardening steel, and the balance Fe plus incidental additions and impurities; (b) performing a step selected from the group consisting of (i) subjecting the carburizing steel to carburizing and quenching to provide a quenched carburized steel, or (ii) subjecting the high carbon steel to hot working to provide a wrought high carbon steel; (c) preheating the quenched carburized steel or wrought high carbon steel and then austenitizing said steel to provide an austenitized steel; (d)quenching the austenitized steel to provide quenched austenitized steel; and (e) tempering the quenched austenitized steel followed by air cooling.

Owner:THE TIMKEN CO

Die steel with high heat resistance, high stability and high tenacity and manufacturing technology thereof

ActiveCN106967930AExcellent central part cracking propertyImprove toughnessHigh resistanceManufacturing technology

The invention relates to die steel with high heat resistance, high stability and high tenacity and a manufacturing technology of the die steel. A base body of the die steel is prepared from 0.37-0.42% of C, 0.40-0.60% of Si, 0.38-0.55% of Mn, 4.50-5.50% of Cr, 0.08-0.20% of Ni, 1.40-1.80% of Mo, 0.40-0.80% of V, 0.01-0.03% of Nb, 0.02-0.05% of Ti, 0.01-0.03% of Os, 0.04-0.06% of La, 0.006-0.012% of Co, 0.005-0.010% of W, 0.06% or smaller of Cu, 0.005% or smaller of S, 0.015% or smaller of P and the balance Fe. The hot work die steel has the excellent center cracking property, is good in heat resistance and softening property, can keep high hardness for a long time, and is good in heat stability and heat conductivity.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

High-toughness hot work die steel and production method thereof

The invention relates to high-toughness hot work die steel and a production method thereof and belongs to the field of alloy steel manufacture. The die steel comprises the components: 0.36-0.45% of C, 0.8-0.95% of Si, 0.7-0.8% of Mn, 4.8-5.5% of Cr, 1.3-1.8% of Mo, 0.8-1.0% of V, 0.3-0.6% of W, 0.4-0.5% of Ni, 0.1-0.2% of Co, 0.08-0.12% of Nb, 0.008-0.012% of RE, less than or equal to 0.003% of S, less than or equal to 0.025% of P and the balance Fe. The production method is implemented according to the following steps: (1) smelting; (2) electroslag remelting; (3) high-temperature homogenizing; (4) forging; (5) blank forging; (6) annealing treatment; and (7) quench tempering. The high-toughness hot work die steel is high in hardness, low in production cost, long in service life and relatively high in toughness, wear resistance and durability.

Owner:辽宁乾金金属材料开发有限公司

Rare earth austenite hot work die steel and preparation thereof

The invention relates to a rare earth austenite type hot die steel material, belonging to the alloy steel manufacture technical field. The compositions in percentage by weight of the hot die steel are: 0.3 to 0.7 percent of C, 0.5 to 1 percent of Si, 10.5 to 15 percent of Mn, 2.0 to 6.0 percent of Cr, 1.5 to 3.5 percent of Mo, 0.5 to 2.0 percent of V, 0.01 to 0.02 percent of of P, less than 0.005 percent of S, 0.003 to 0.01 percent of rare earth elements, and the balance being Fe. A method for preparing the hot die steel comprises the following steps of dispensing materials, melting, casting, remelting electro slag, carrying out high temperature homogenization at a temperature of between 1240 and 1290 DEG C, forging roughly, forging a blank, annealing, carrying out solution treatment at a temperature of between 1140 and 1200 DEG C and carrying out aging treatment at a temperature of between 700 and 760 DEG C. The hot die steel is the rare earth adding austenite type hot die steel which is high in thermal stability, strength and toughness.

Owner:SHANGHAI UNIV

Process for producing H13 hot work die steel

The invention relates to a process for producing H13 hot work die steel, aiming to solve the problem that the present H13 hot work die steel universally has problems of 'good heat resistance and poor toughness or good toughness and poor heat resistance'. The chemical components of the 4Cr5MoSiV1(H13) hot work die steel are reasonably designed and adjusted to control the content of alloy elements such as Cr, Mo, V and Si and exert the interaction of the alloy elements, so that grains are thinned and distributed uniformly; meanwhile, by optimizing an electroslag remelting technology, a forging technology and a thermal treatment technology, the purity and compactness of the steel are improved, segregation is reduced, the mechanical property and isotropy of the steel are further improved, the heat uniformity of a forged part is ensured, a carbide ball structure with stable size and uniform distribution is obtained, and therefore the mechanical property and service life of a product are improved.

Owner:南平市双友金属有限公司

Preparation method for nanometer ceramic composite coating material on surface of hot work die steel

InactiveCN102650029AIncreased microhardnessImprove wear resistanceMolten spray coatingCeramic compositeNanoceramic

The invention relates to hot work die steel, in particular to a preparation method for a nanometer ceramic composite coating material on the surface of hot work die steel. The preparation method comprises the steps of preparing a spray feeding material, preprocessing an H13 steel basal body, preparing a transition layer and preparing a nanometer ceramic composite coating. The nanometer ceramic composite coating material and the preparation method thereof have the benefits as follows: (1) the nanometer ceramic composite coating has the characteristics of high microhardness and good wear resistance; (2) the oxidation resistance and the thermal shock resistance are better; and (3) the raw materials are cheap and general, the process is simple, and the cost is lower, so that the industrial production is facilitated. The prepared nanometer ceramic composite coating can take effect of repairing defects or enhancing the H13 steel basal body so as to recover and prolong the service life of the hot work die.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com