Mo-V-Ni high temperature steels, articles made therefrom and method of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preliminary Studies

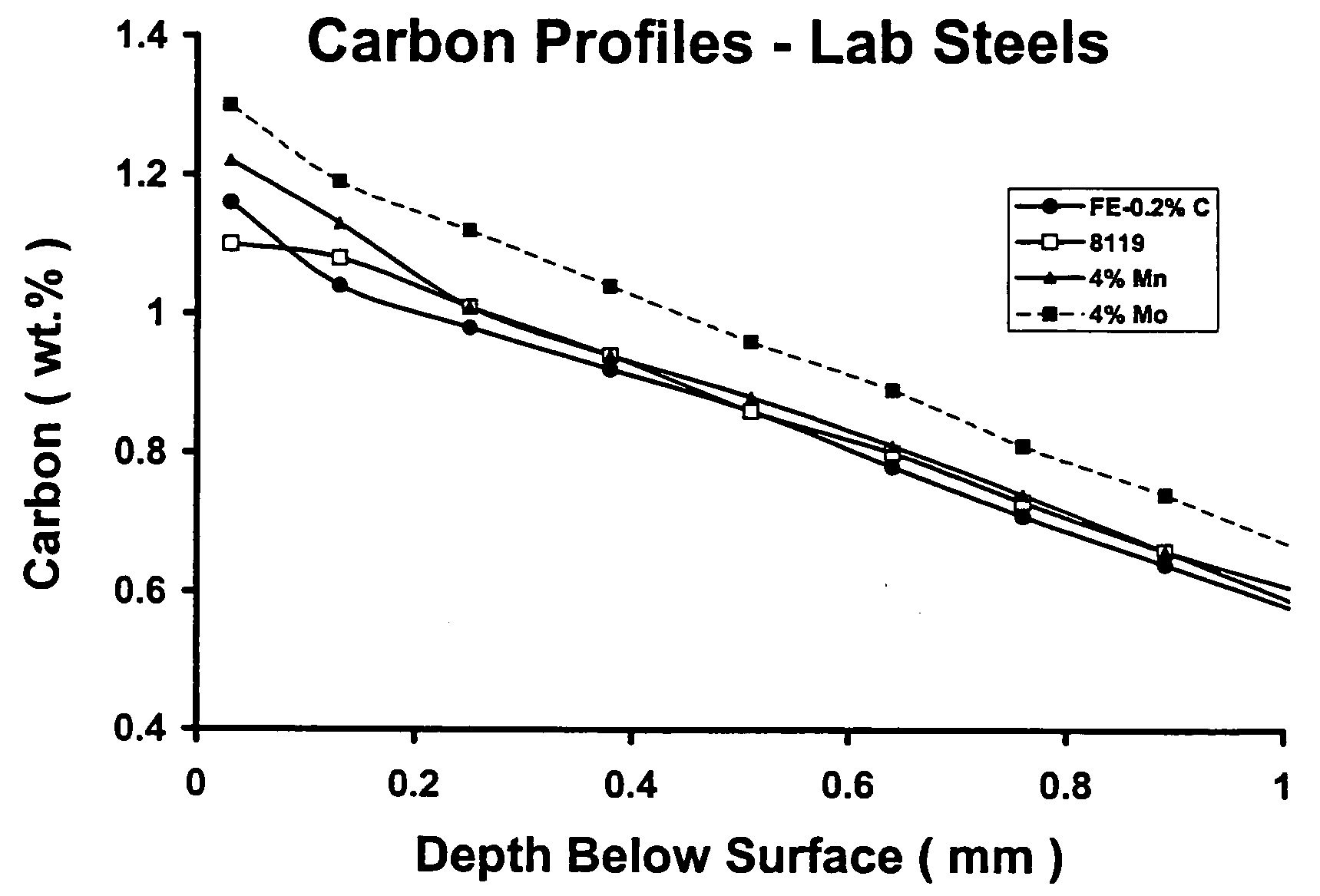

[0073]The initial research pertaining to the present invention examined several alloy steels presently used in various applications and determined how they could be carburized with respect to a laboratory alloy containing just 0.20% carbon and the balance iron. Specimens of the iron −0.20% C alloy (Heat 2128) and laboratory heats of 8119 (Heat 2132), CBS 400 (Heat 2124) and CBS 600 (Heat 2126) were carburized using normal production cycles, Table 3. As indicated by measuring the carbon content of the specimens at different depths, the results for 8119 and the 0.20% carbon alloy (Heat 2128) were similar, FIG. 5. However, the CBS 400 and CBS 600 alloys did not contain as much carbon per test depth as the specimen without alloy additions. This suggests that the various combinations of the alloy constituents present in CBS 600 and CBS 400 actually impede the diffusion of carbon into the specimens. Another group of specimens were carburized at the same time as these sp...

example 2

Series 1—Room Temperature Design Matrix; 1% Carbon and Carburized 0.2% C Alloys

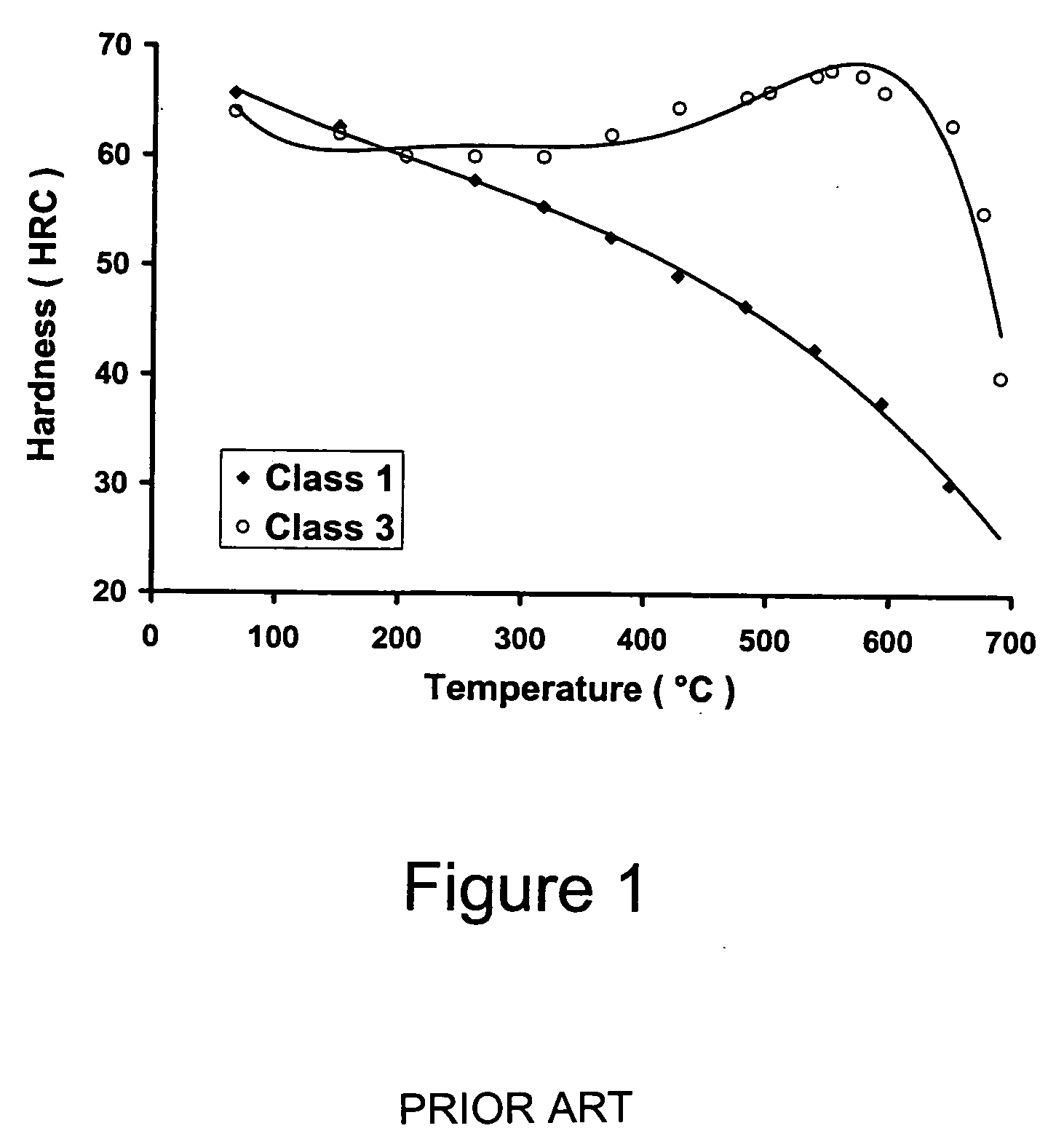

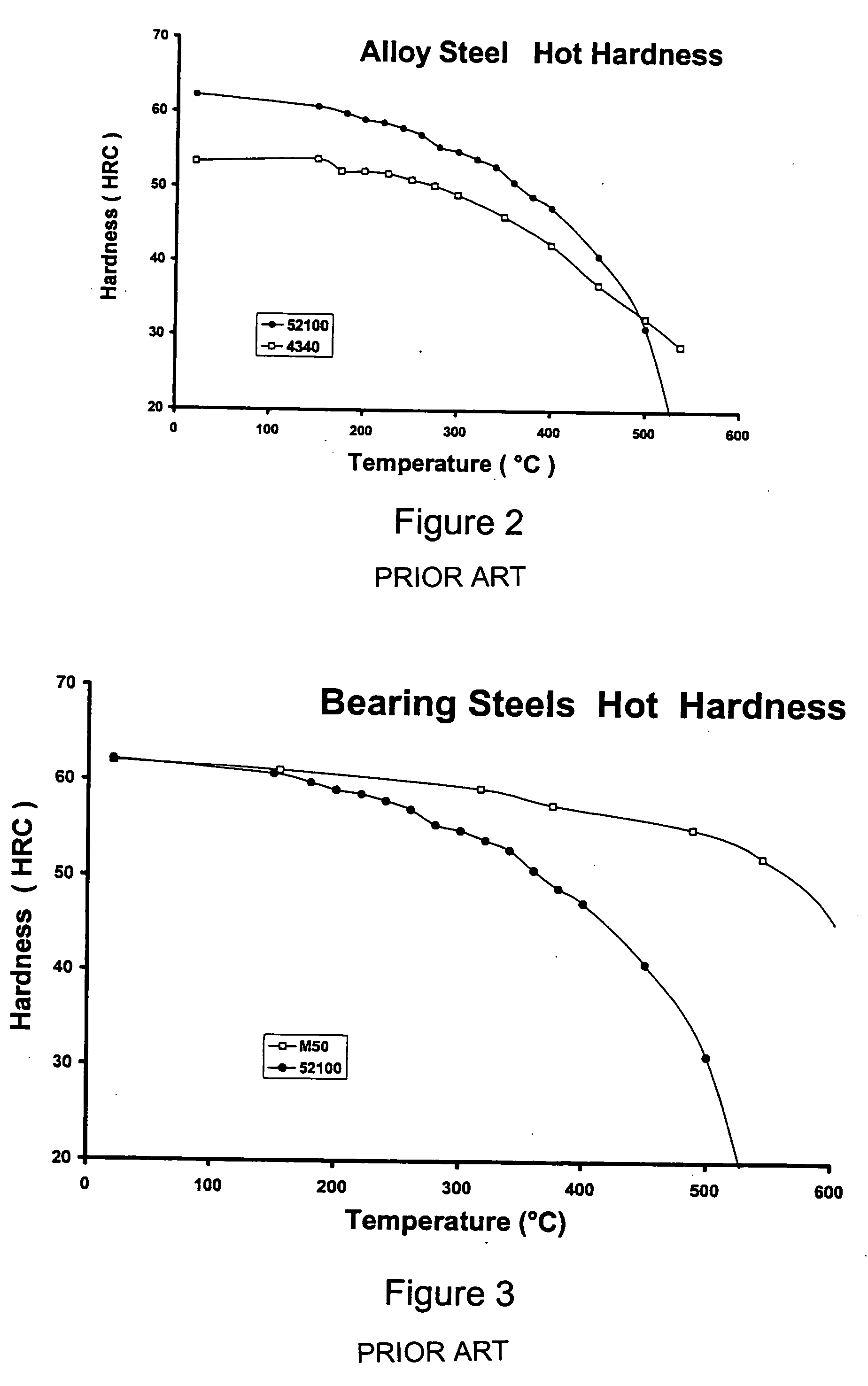

[0078]The first design matrix, referred to as Series 1, used for alloy development was composed of the following elements: Approximately 1% Cr was included in each laboratory alloy. Chromium increases the hardenability of alloy steels, and at the 1% level, it has been shown not to be detrimental to the carburizing process. Approximately 0.40% Mn was included in each alloy. This level was chosen for the improvement in hardenability given by Mn and by its enhancement of the carburizing process. However, the level of Mn was not made larger because, as mentioned above, Mn does not significantly improve the hot hardness of alloy steels. Less than 0.20% Si was included in the experimental steels so as to avoid detrimental effects on carbon diffusion in austenite. A low silicon content was also desirable in preventing the formation of low melting point carbides in the test alloys. Various amounts of Mo, V and Ni...

example 3

Series 2 and 3—Room Temperature Design Matrix; 1% Carbon and Carburized 0.2% C Alloys

[0079]Based on the results obtained from the alloys in Series 1, two additional groups of alloys were melted, processed and evaluated. As with Series 1, the additional heats of steel (Series 2) were split into two groups. For the steels of Series 2, the nominal carbon contents were 1.25% (through hardening) and 0.20% (carburizing). The molybdenum content of these steels ranged from 2.9% through 6.8%, Tables 6 and 7. For the steels of Series 3, the nominal carbon contents were 1.0% (through hardening) and 0.20% (carburizing), and the nominal molybdenum content was 3%. The vanadium content of these alloys ranged from 0% through 1%, and the Ni content ranged from 1% through 3%, Tables 8 and 9.

TABLE 6Composition and room temperature hardness of Series 2 throughhardened steels. For all heats, Cr ≈ 1.0%, V ≈ 1.0%, Mn ≈ 0.40% andSi ≈ 0.12%.Composition (wt. %)Hardness (HK)HeatCMoVNiγ830° C.*γ1190° C.**24691...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com