Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7609 results about "Alloy steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low alloy steels and high alloy steels. The difference between the two is disputed. Smith and Hashemi define the difference at 4.0%, while Degarmo, et al., define it at 8.0%. Most commonly, the phrase "alloy steel" refers to low-alloy steels.

Anti-sulfur well mouth valve body welding repair method

ActiveCN107520526AImprove carrying capacityAvoid softening problemsArc welding apparatusWelding/cutting media/materialsCarbon alloyTungsten

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

A welding repair method for anti-sulfur wellhead valve body

ActiveCN107520526BMeet the requirements of low temperature impact absorption energy greater than 27JAvoid softeningArc welding apparatusWelding/cutting media/materialsMachined surfaceMixed gas

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

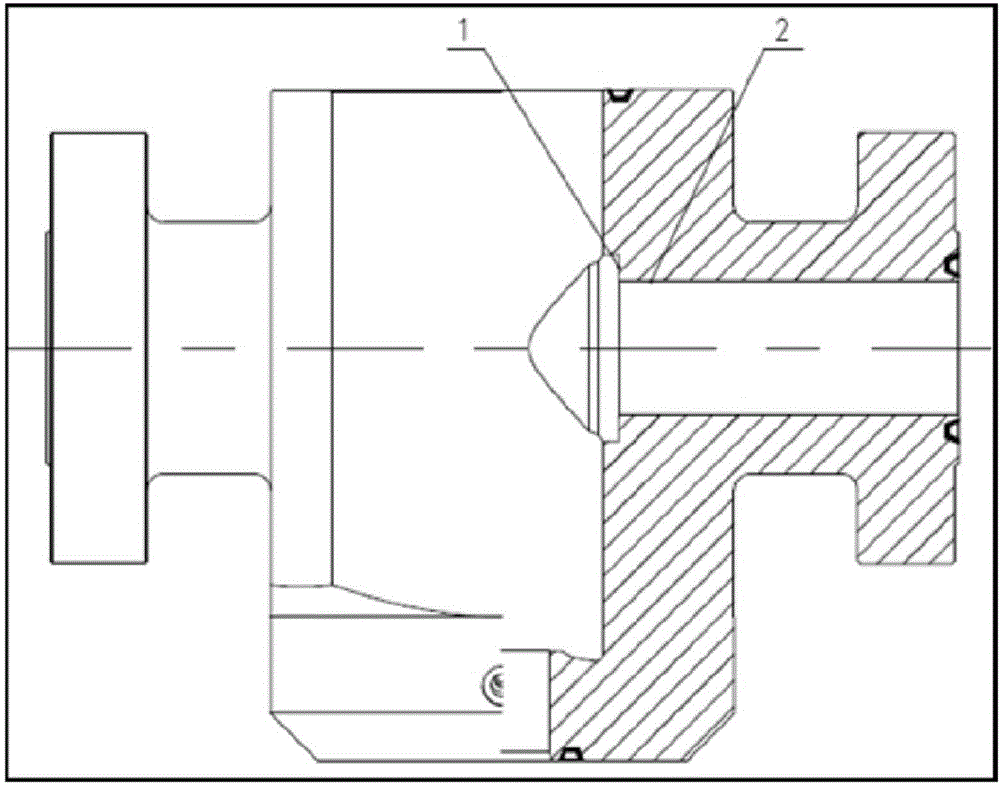

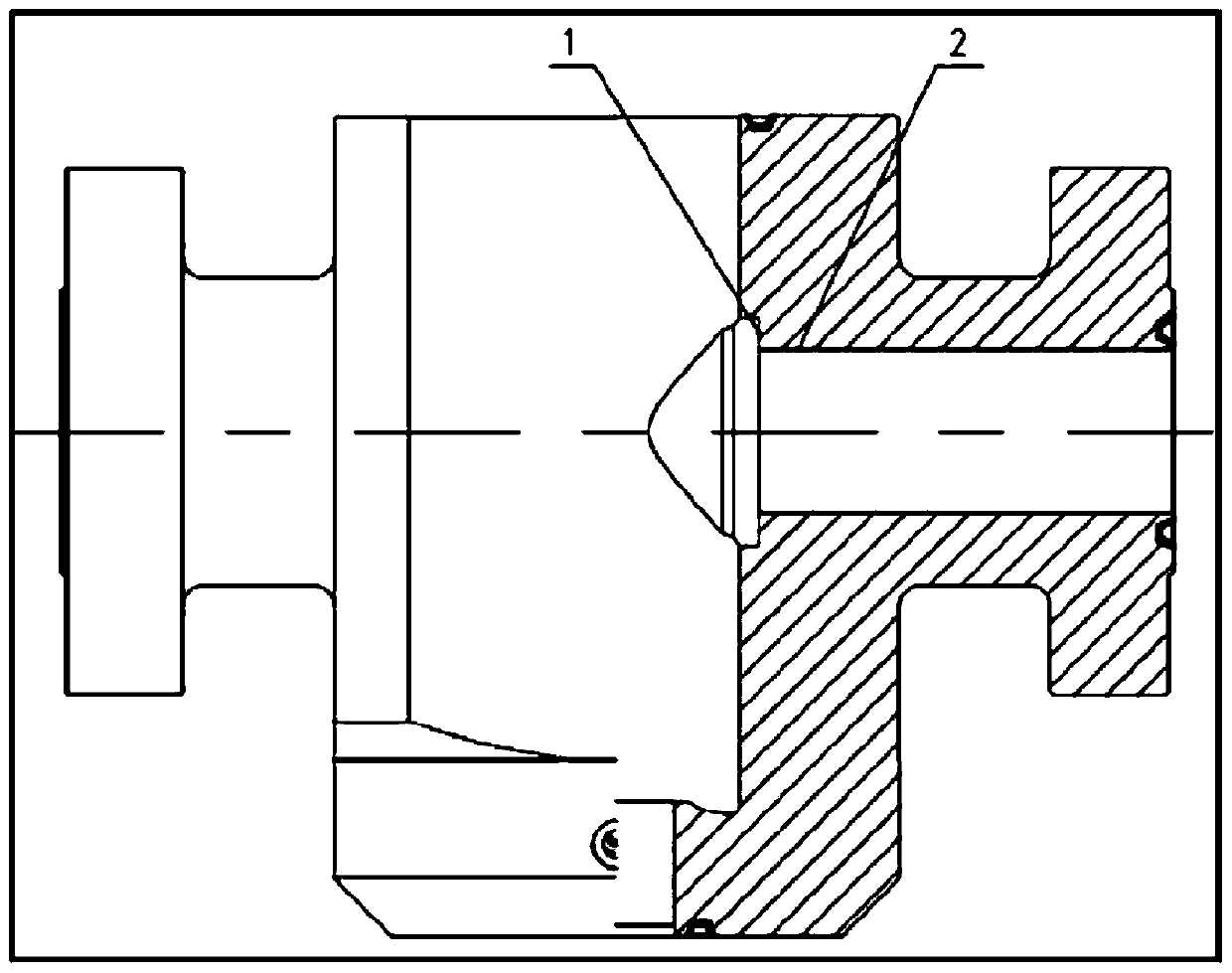

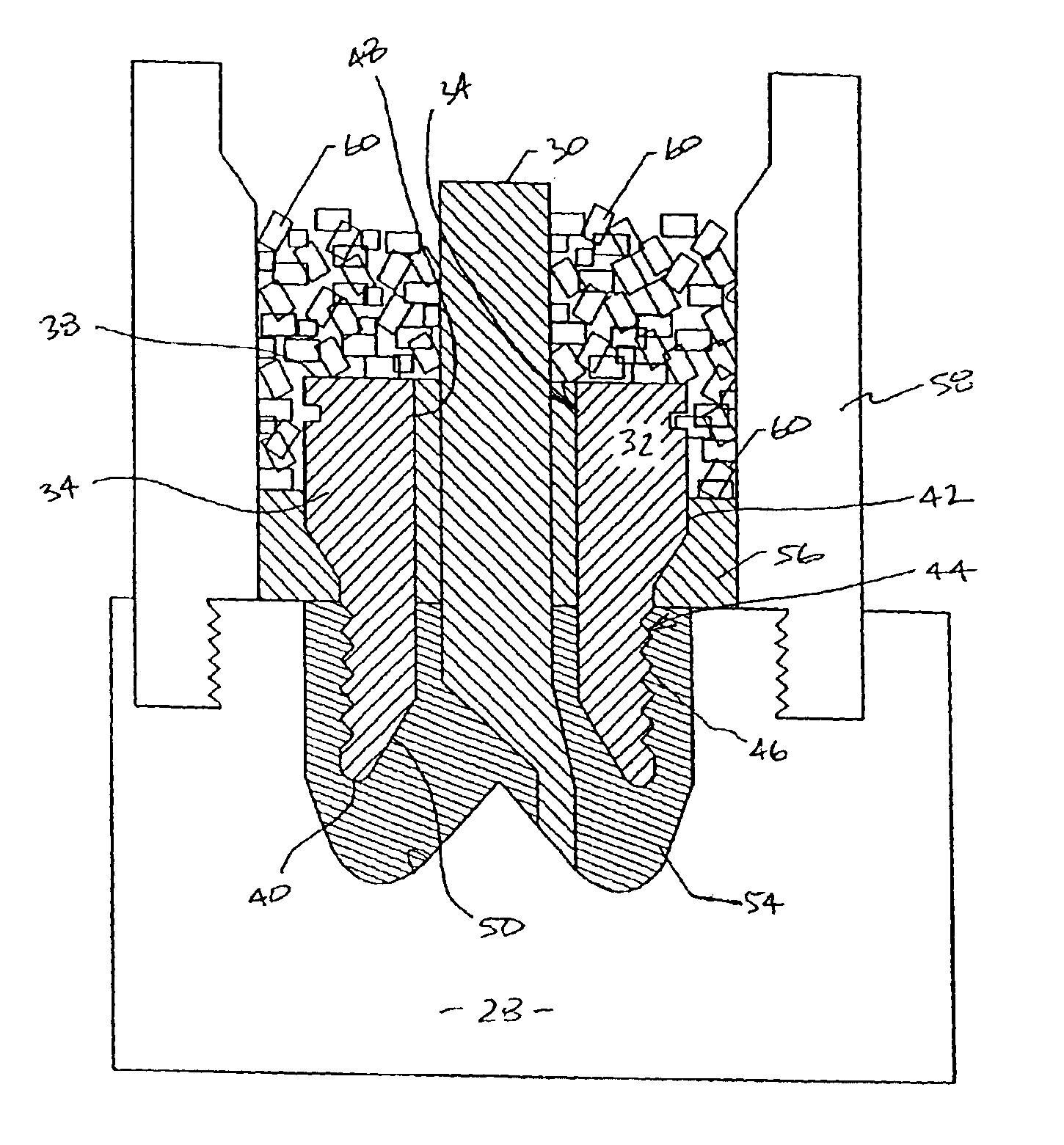

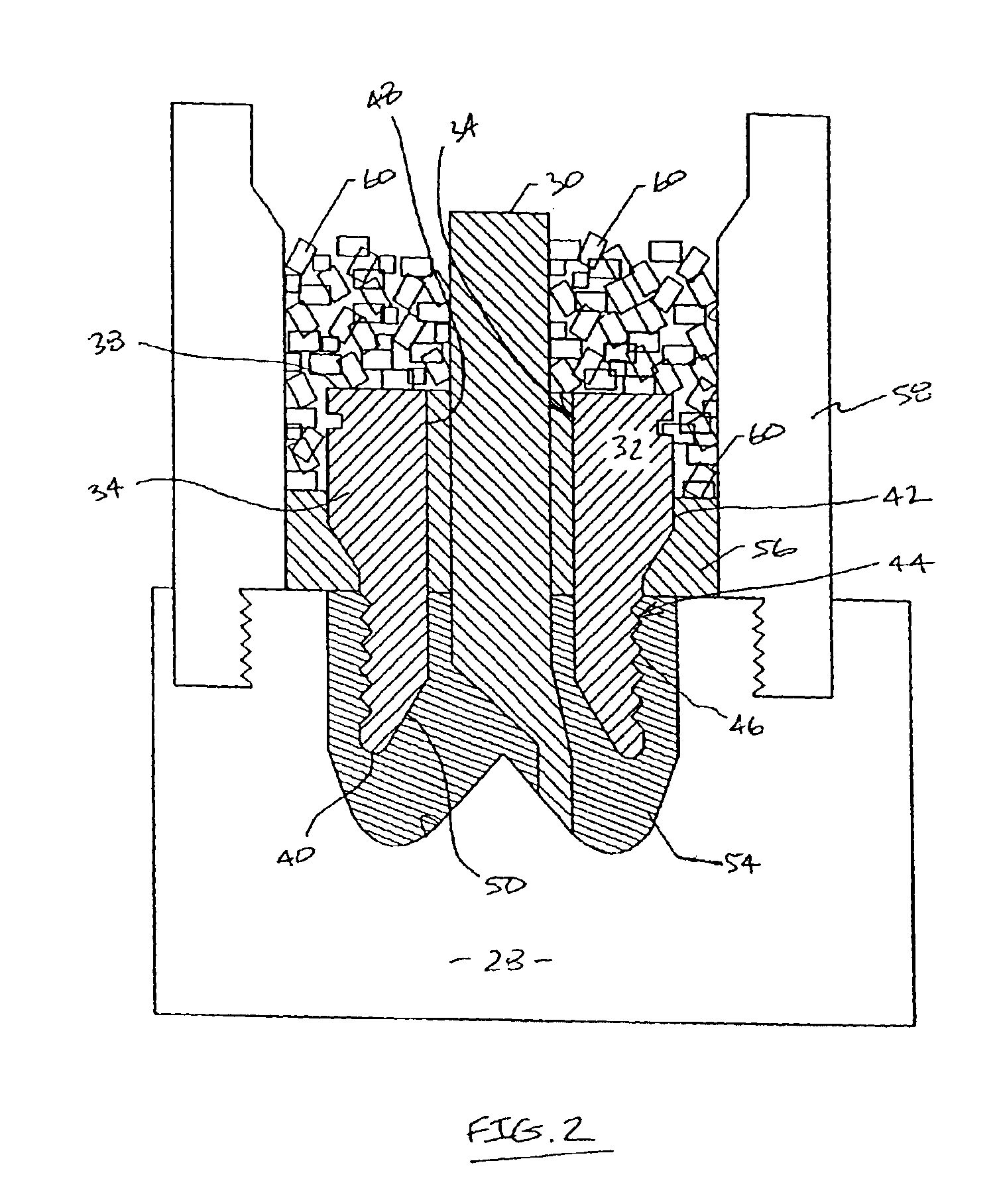

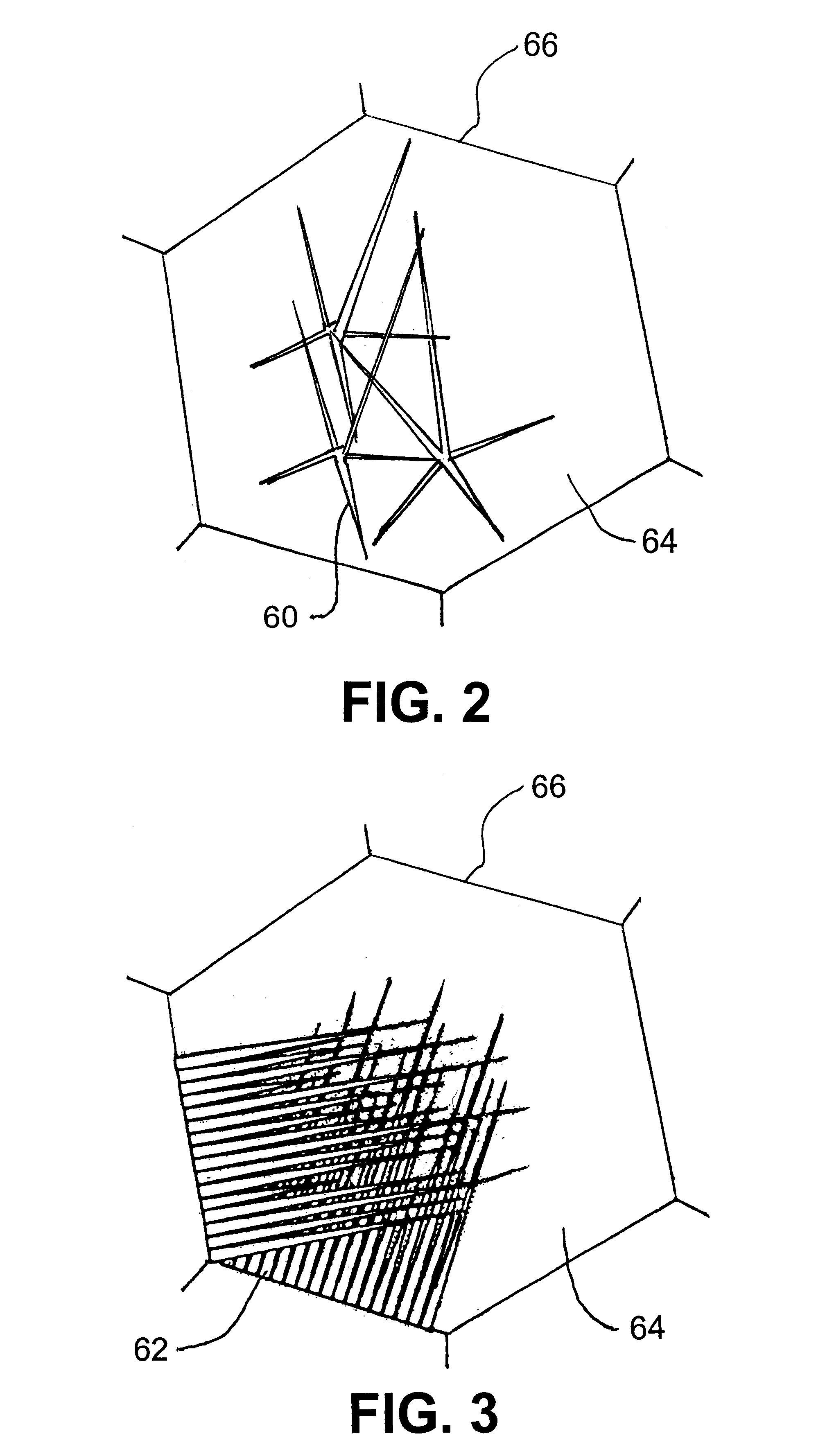

High-strength/high-toughness alloy steel drill bit blank

Drill bit reinforcing members or blanks of this invention are formed from high-strength steels having a carbon content less than about 0.3 percent by weight, a yield strength of at least 55,000 psi, a tensile strength of at least 80,000 psi, a toughness of at least 40 CVN-L, Ft-lb, and a rate of expansion percentage change less than about 0.0025% / ° F. during austenitic to ferritic phase transformation. In one embodiment, such steel comprises in the range of from about 0.1 to 0.3 percent by weight carbon, 0.5 to 1.5 percent by weight manganese, up to about 0.8 percent by weight chromium, 0.05 to 4 percent by weight nickel, and 0.02 to 0.8 percent by weight molybdenum. In another example, such steel comprises in the range of from about 0.1 to 0.3 percent by weight carbon, 0.9 to 1.5 percent by weight manganese, 0.1 to 0.5 percent by weight silicon, and one or more microalloying element selected from the group consisting of vanadium, niobium, titanium, zirconium, aluminum and mixtures thereof.

Owner:SMITH INT INC

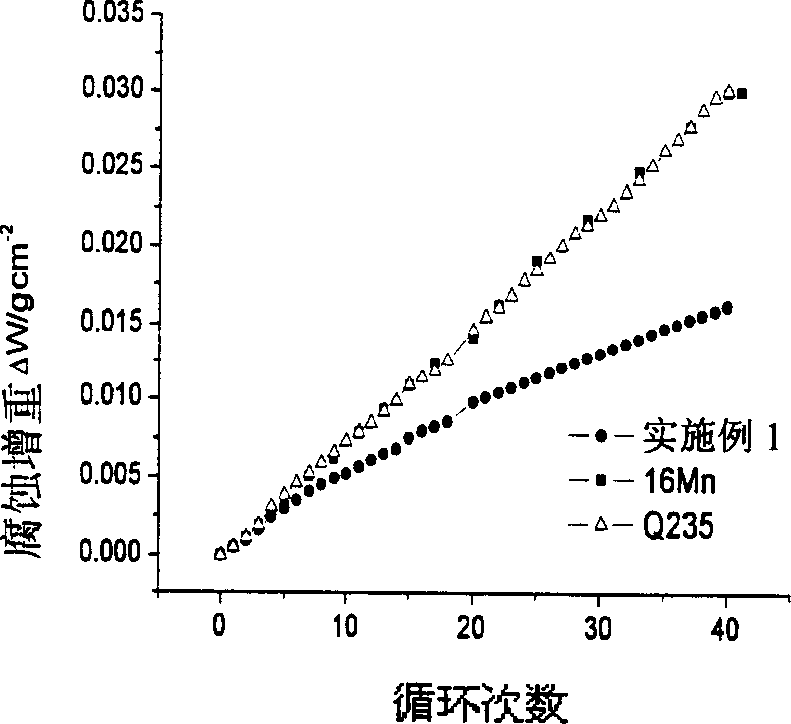

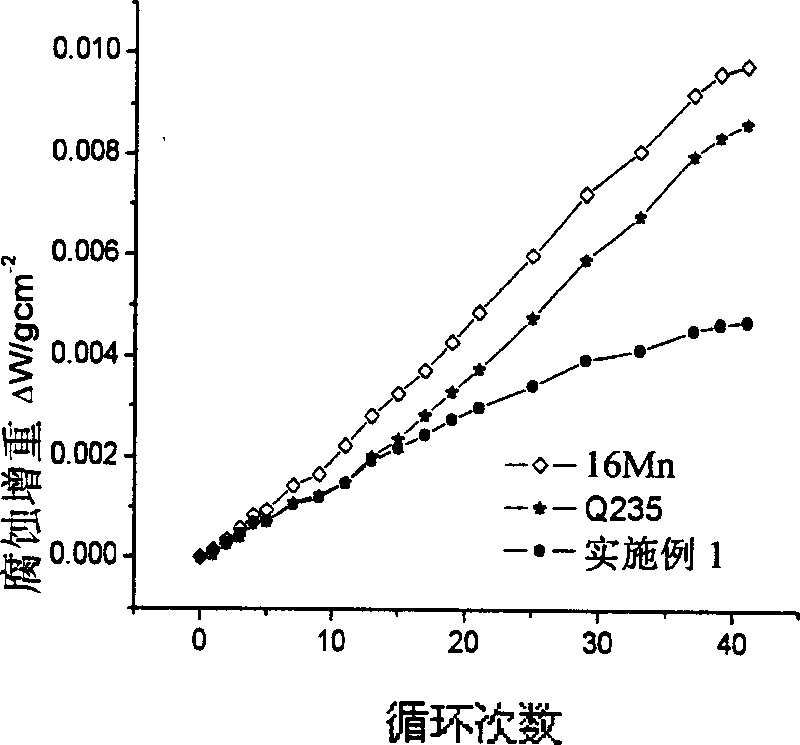

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

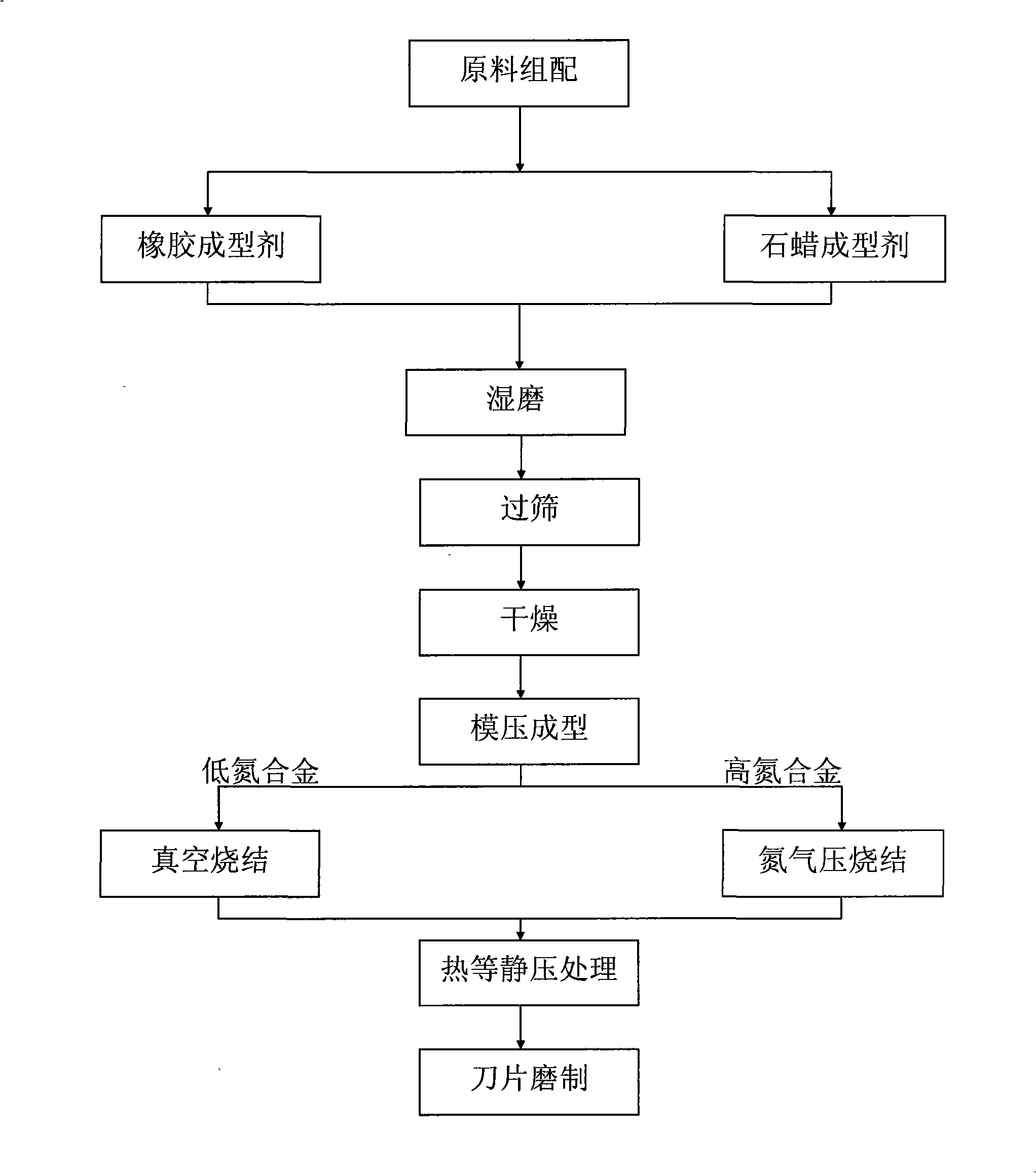

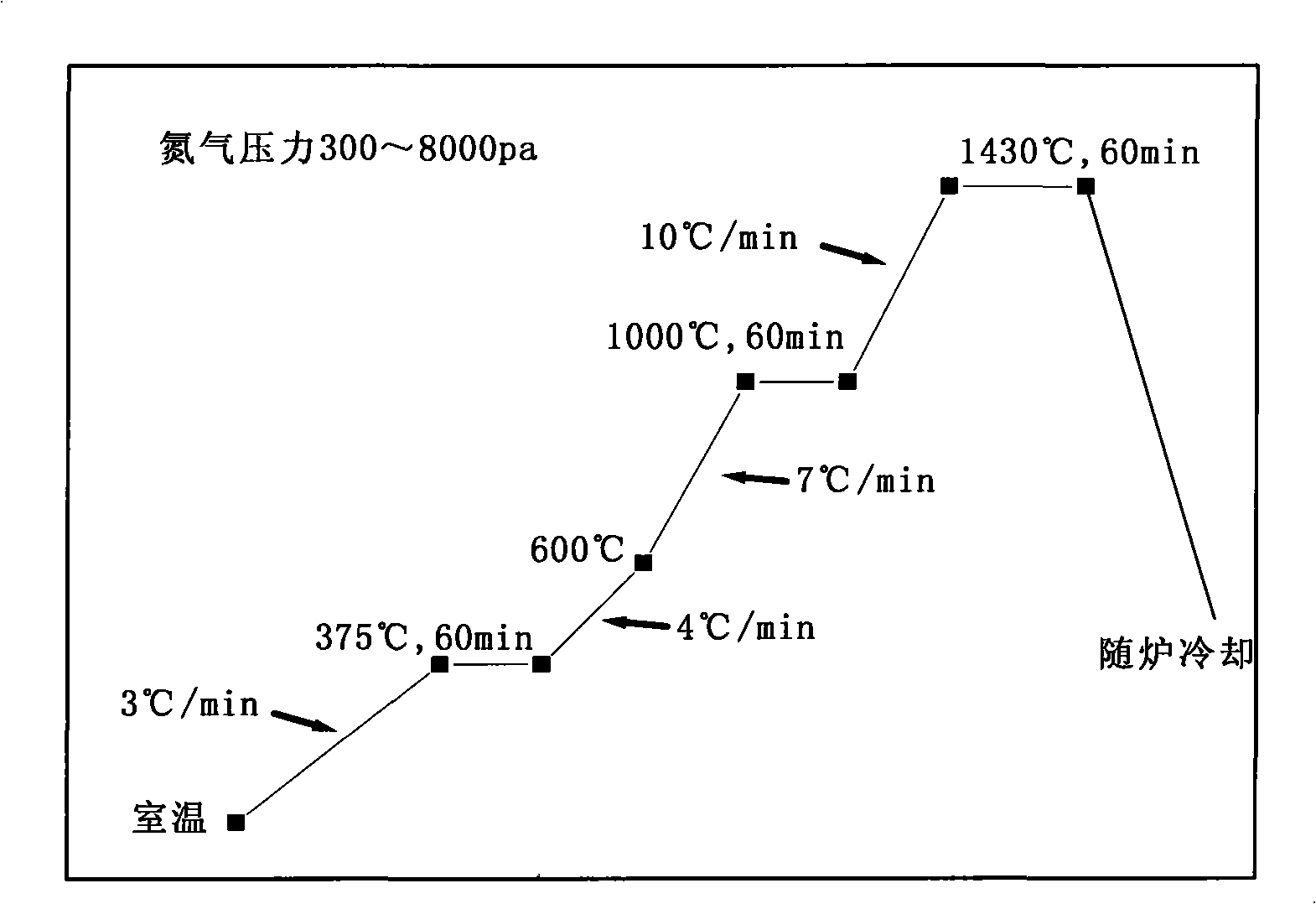

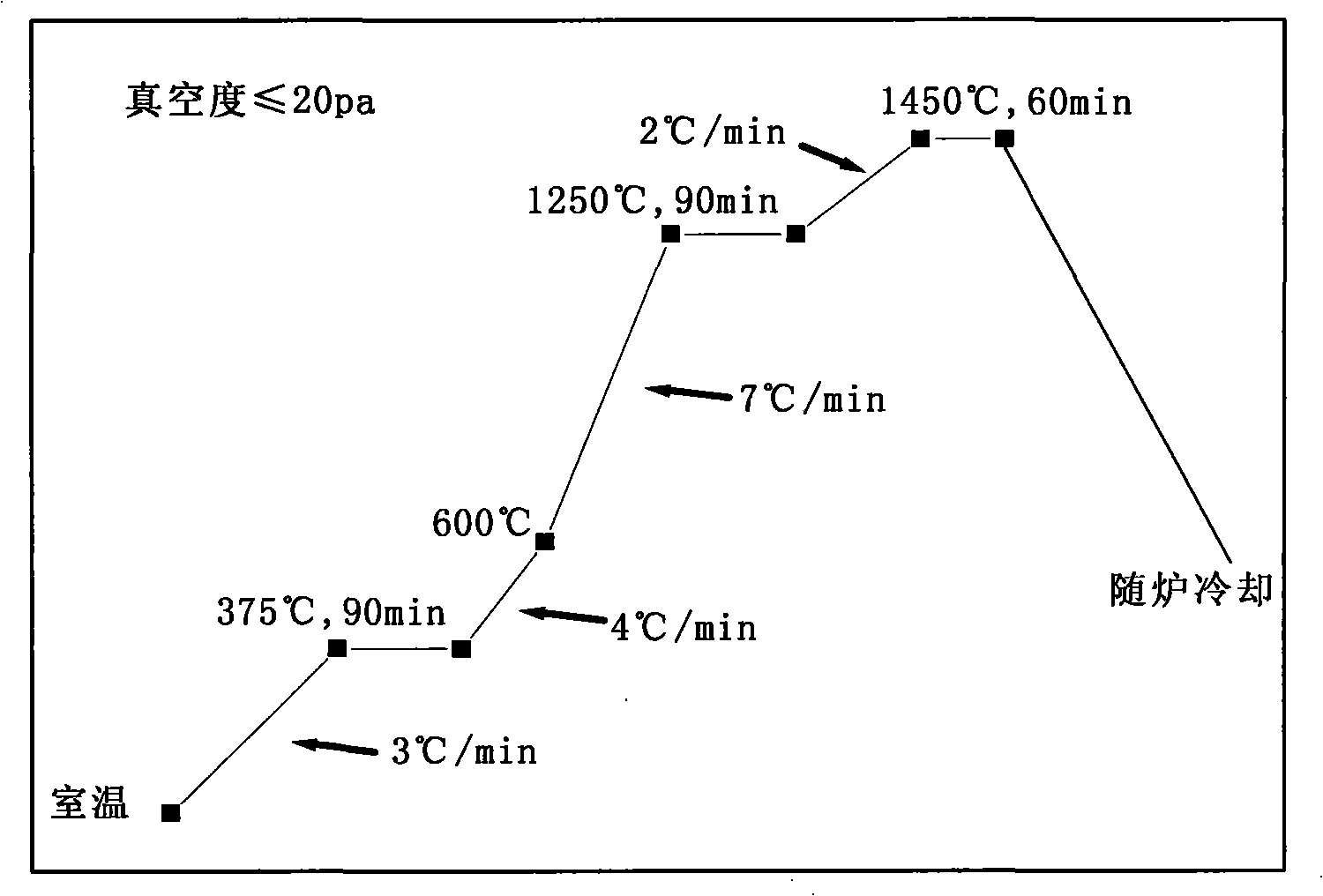

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

Acicular constituent high strength weathering resistant steel and producing method thereof

InactiveCN1609257AThe ingredients are designed to be simpleGood weather resistanceWeather resistanceAlloy steel

The present invention relates to high strength high weather resistance steel with needle structure and its production process, and belongs to the field of low alloy steel making. The present invention adopts very low carbon content to result in normal temperature dissolvability in alpha-Fe not higher than 0.0218 wt%, adds Cu, Cr, Ni, Mo, Nb, Ti, Al, Zr, RE and Ca, and ensures the main structure is needle-like structure for excellent weather resistance. The steel of the present invention is produced by means of hot rolling technology and relaxation-separation control technology and has low production cost and short production period. It has excellent weather resistance, excellent toughness, and excellent weldability needing no preheating before welding and heat treatment after welding, and may be used widely in bridge, building, traffic facility, sea platform, etc.

Owner:武汉钢铁有限公司 +1

Wear-resisting alloy steel with high boron, high chrome and low carbon and preparation method thereof

ActiveCN101660097AReduce manufacturing costElectric furnaceProcess efficiency improvementSilicon alloyCerium

The invention discloses a wear-resisting alloy steel with high boron, high chrome and low carbon and a preparation method thereof, which comprises the following chemical constituents in weight percent: 0.1-0.5% of C, 3-26% of Cr, 0.5-1.2% of Si, 0.5-1.5% of Mn, 0.3-2.8% of B, 0.3-2.6% of Cu, 0.2-0.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.02-0.15% of Mg, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. The method comprises the following steps: melting steel scrap and chromium iron in an electric furnace; adding copper plates, ferrosilicon, ferromanganese into the melted steel scrap and chromium iron, heating the melt to 1560-1620 DEG C after the constituents are adjusted to be qualified in stokehold; adding calcium-silicon alloy and aluminium deoxidation into the melt; and then adding ferrotitanium and ferroboron in sequence, melting and discharging; roasting the compound inoculant composed of granular rare earth magnesium alloy with the diameter being less than 12mm and cerium metal, Si3N4, VN, Nb and K; placing the roasted compound inoculant at the bottom ofa steel ladle; carrying out modification and inoculation processes on the smelted liquid steel by pour-over method in the steel ladle, wherein, the pouring temperature of the liquid steel is 1400-1450DEG C; heating castings to 920-1150 DEG C and preserving heat for 2-4 hours; and air cooling the castings to room temperature to obtain the alloy steel in the invention. The alloy steel of the invention has the advantages of high strength, rigidity and toughness, good thermal fatigue resistance property, wear resistance, and low manufacture cost.

Owner:泰州海天机械配件有限公司

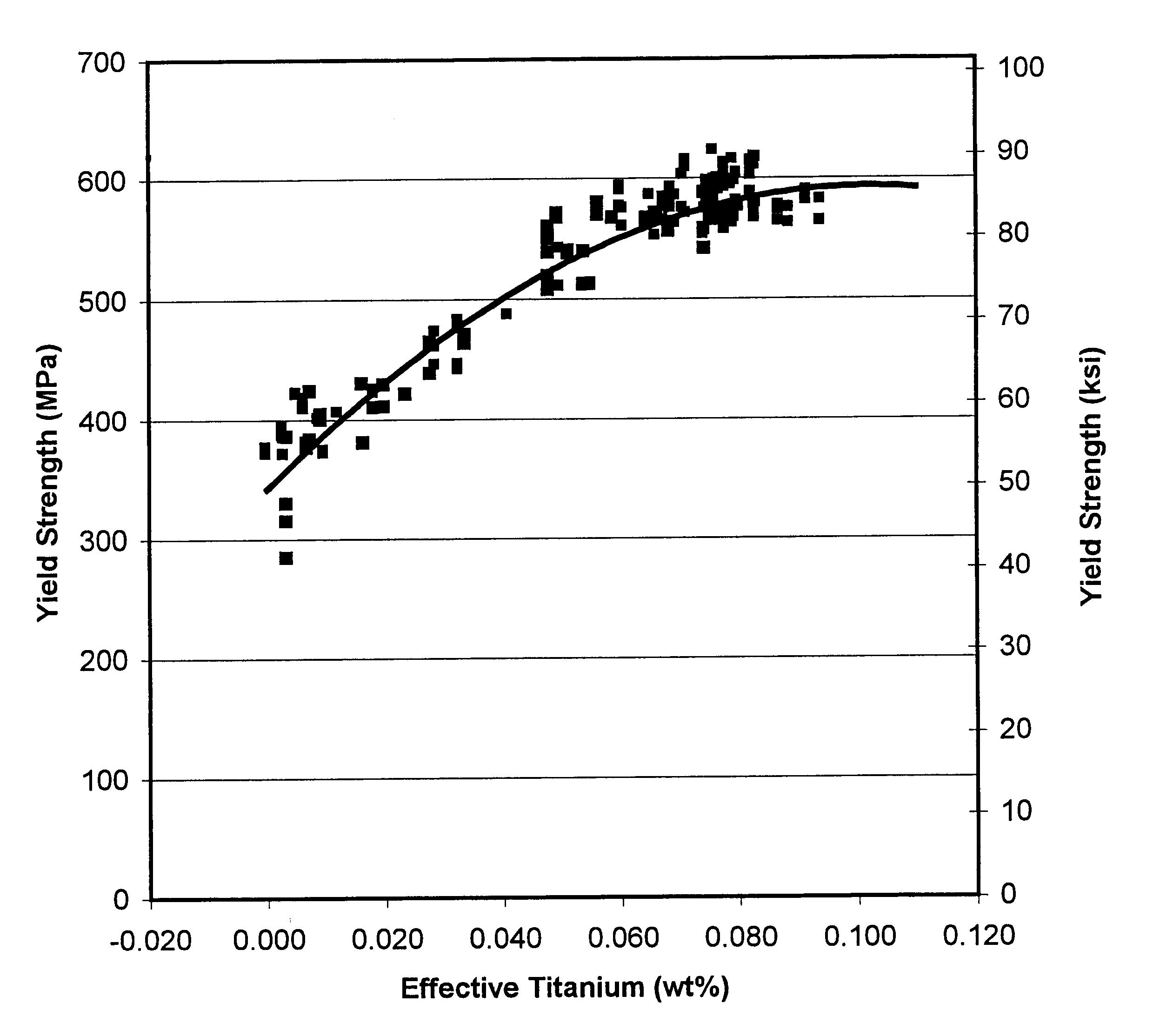

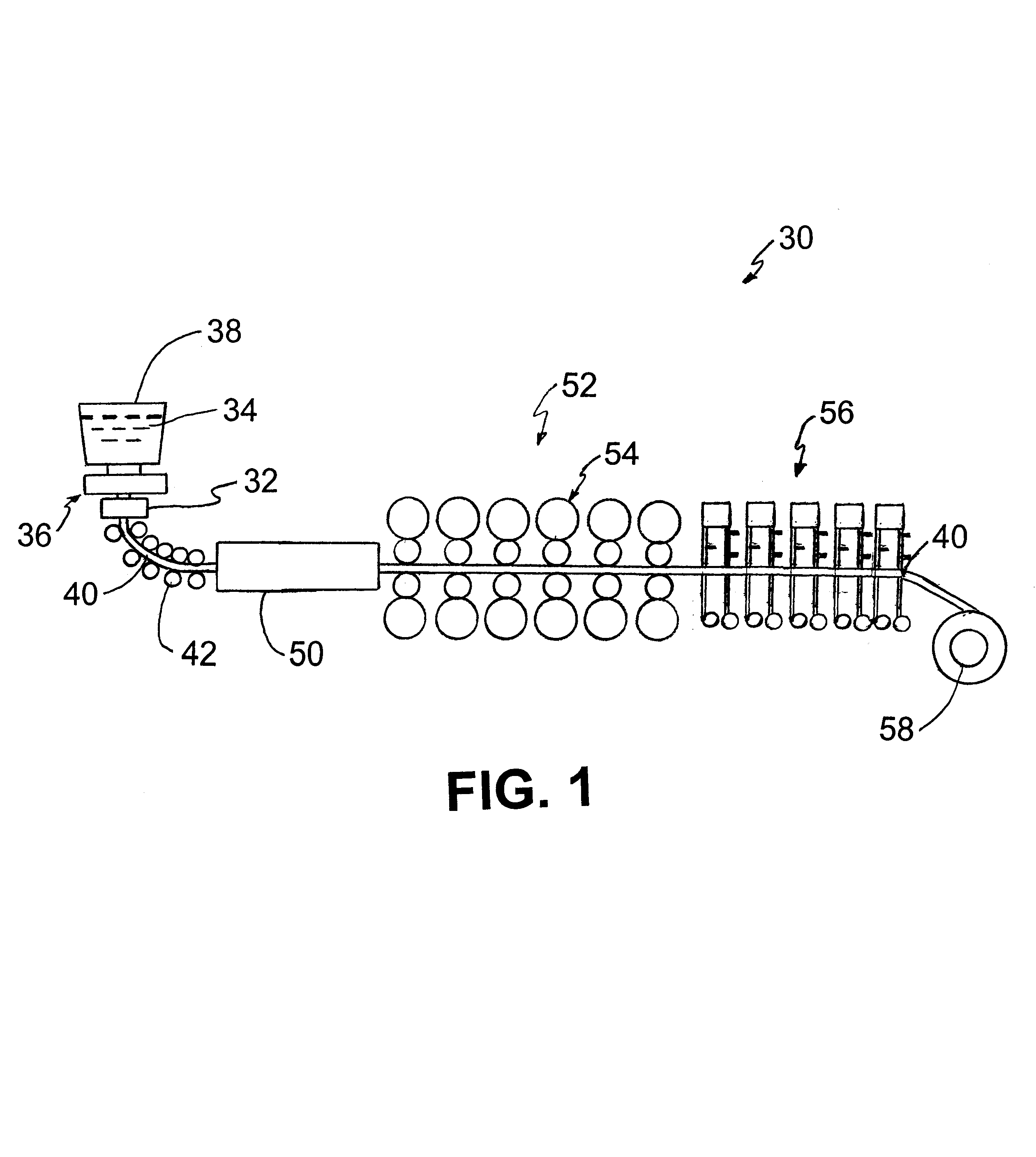

Method for producing titanium-bearing microalloyed high-strength low-alloy steel

A composition and method of making a high-strength low-alloy hot-rolled steel sheet, strip, or plate bearing titanium as the principal or only microalloy strengthening element. The steel is substantially ferritic and has a microstructure that is at least 20% acicular ferrite. The steel has a minimum yield strength of at least 345 MPa (50 ksi) and even over 621 MPa (90 ksi) adding titanium as the lone microalloy element for strengthening, with elongation of 15% and more. Addition of vanadium, niobium, or a combination thereof can result in yield strengths exceeding 621 MPa (90 ksi). Effective titanium content, being the content of titanium in the steel not in the form of nitrides, oxides, or sulfides, is in the range of 0.01 to 0.12% by weight. The manufacturing process includes continuously casting a thin slab and reducing the slab thickness using thermomechanical controlled processing, including dynamic recrystallization controlled rolling.

Owner:NUCOR CORP

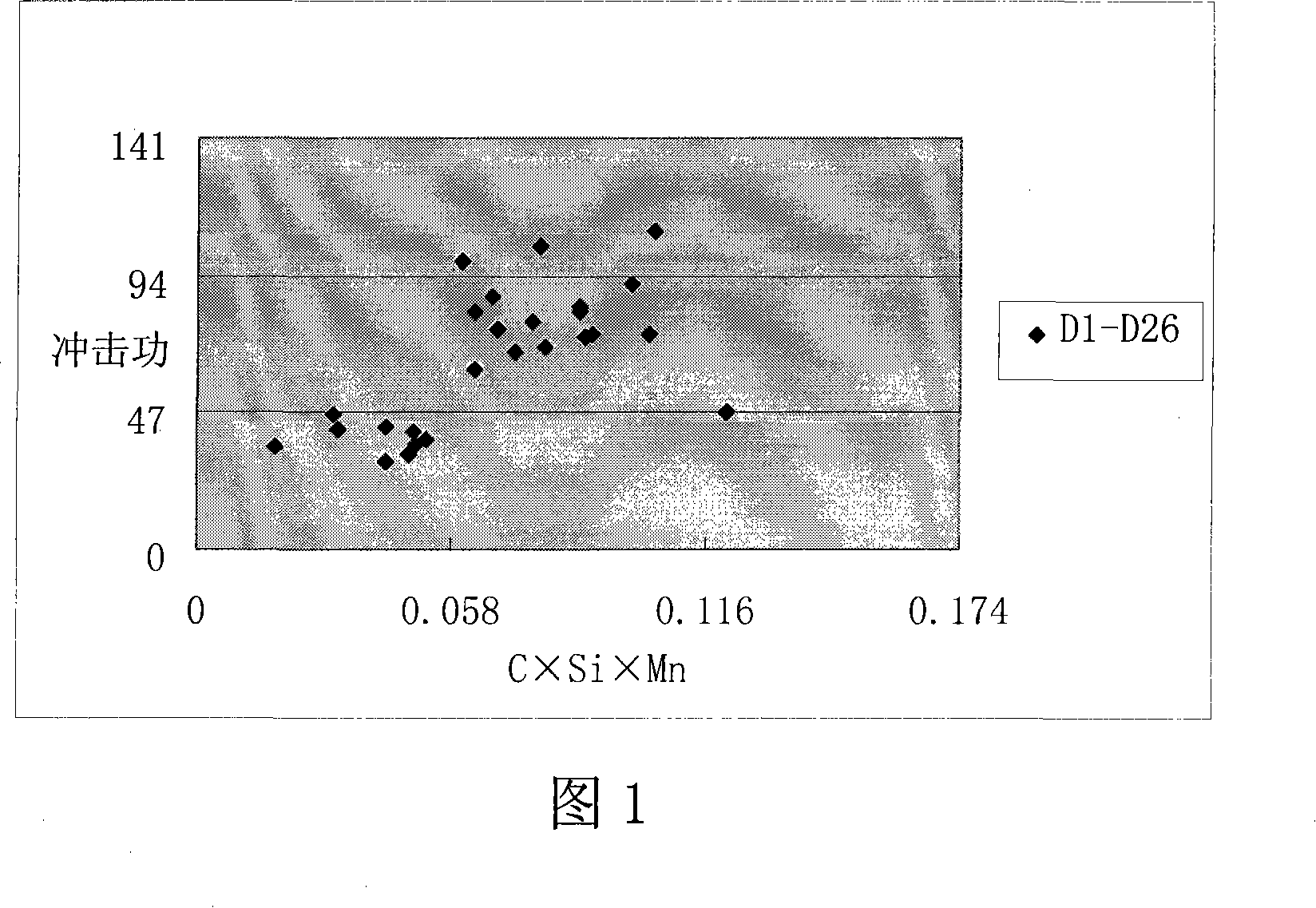

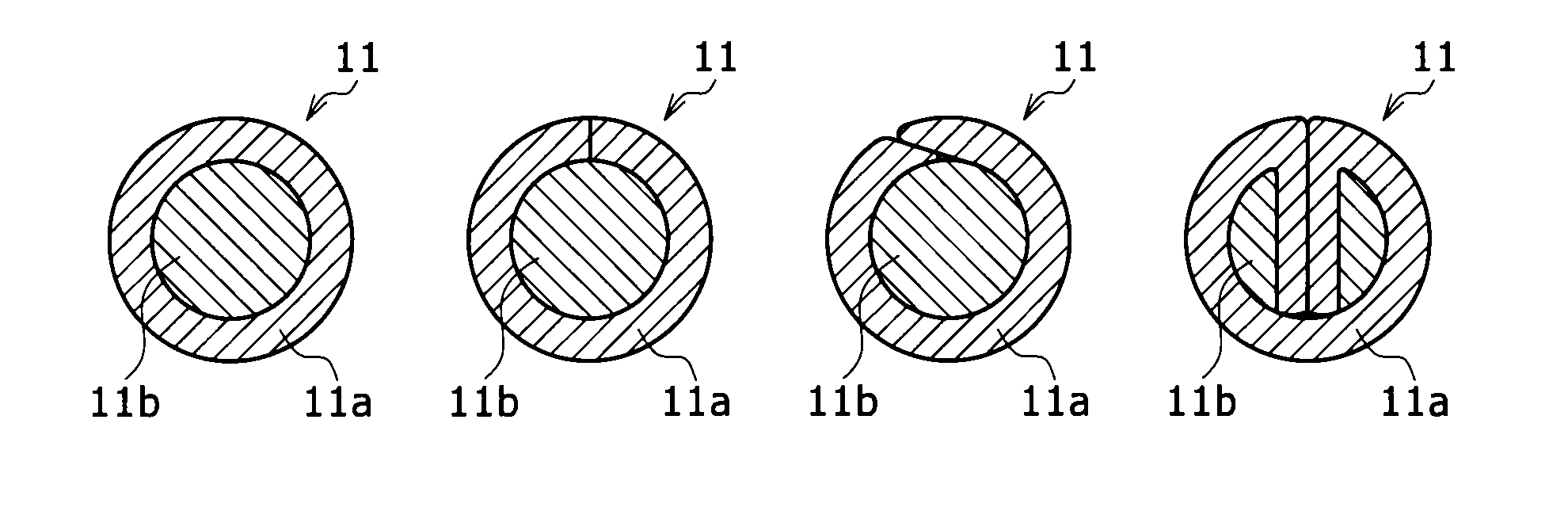

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

High-strength weathering steel and method of manufacturing same

InactiveCN1970818AReduce control requirementsUniform microstructureRoll mill control devicesHeat treatment process controlSolubilityMetallurgy

The invention discloses a high-strength weatherabile steel and manufacturing method in the low-alloy steel making domain, which is characterized by the following: adding low-carbon and Cu-Cr-Ni-Mo-Nb into two or more composite additives; controlling carbon content with maximum solubility in the alpha-Fe at 0.0218% under normal temperature; reducing carbon-permeating evolution; affirming main control tissue evenly.

Owner:武钢集团有限公司 +1

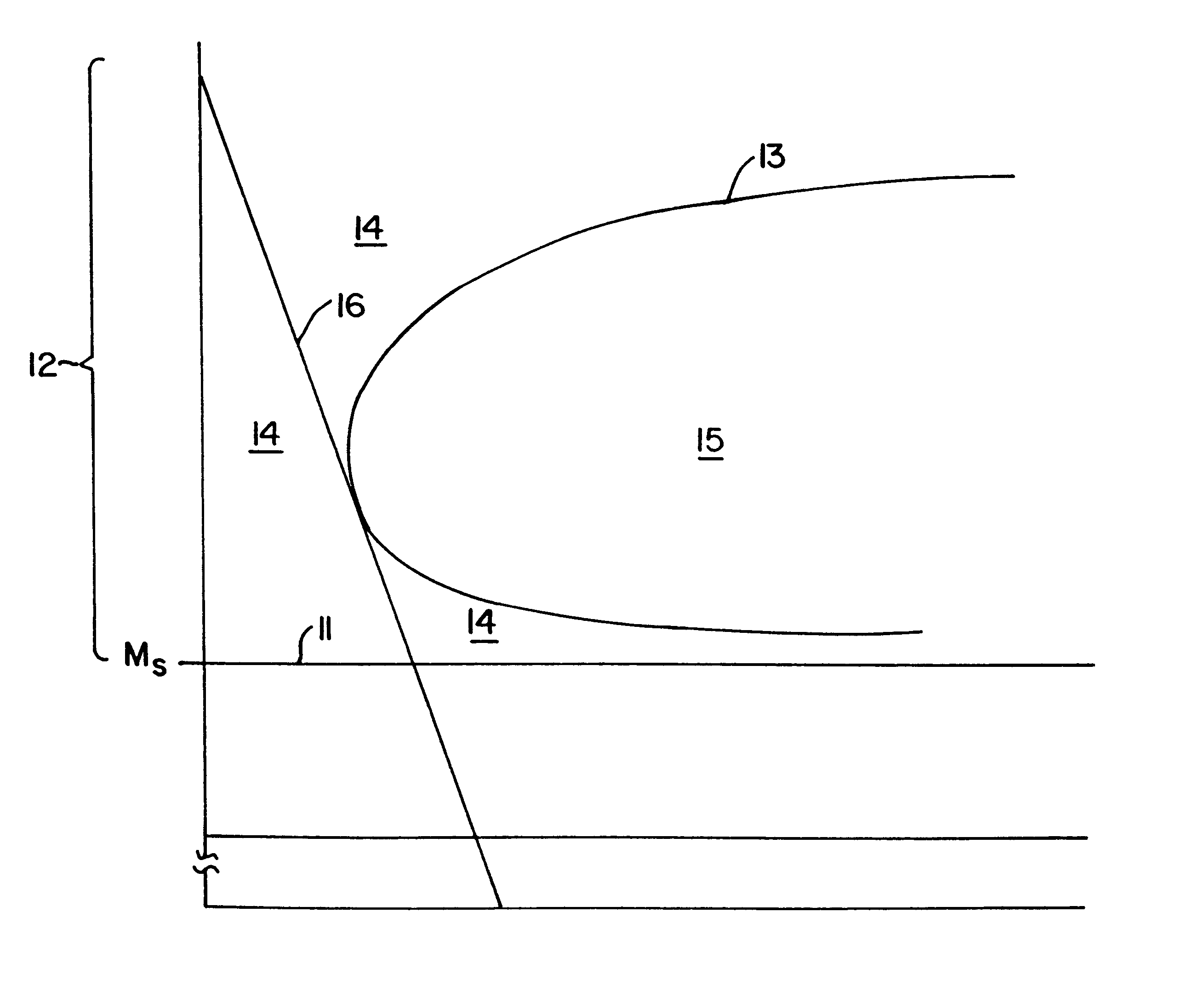

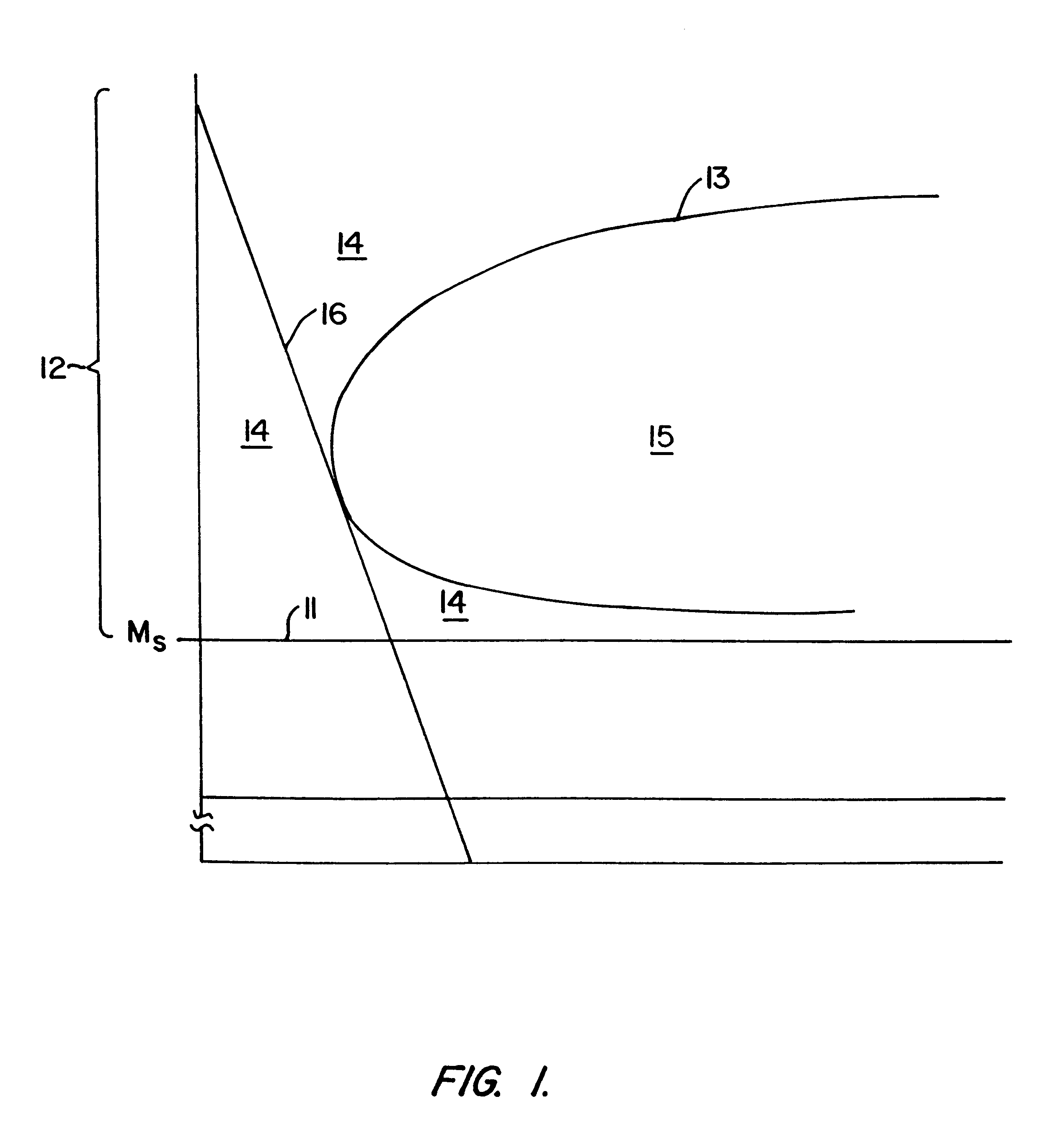

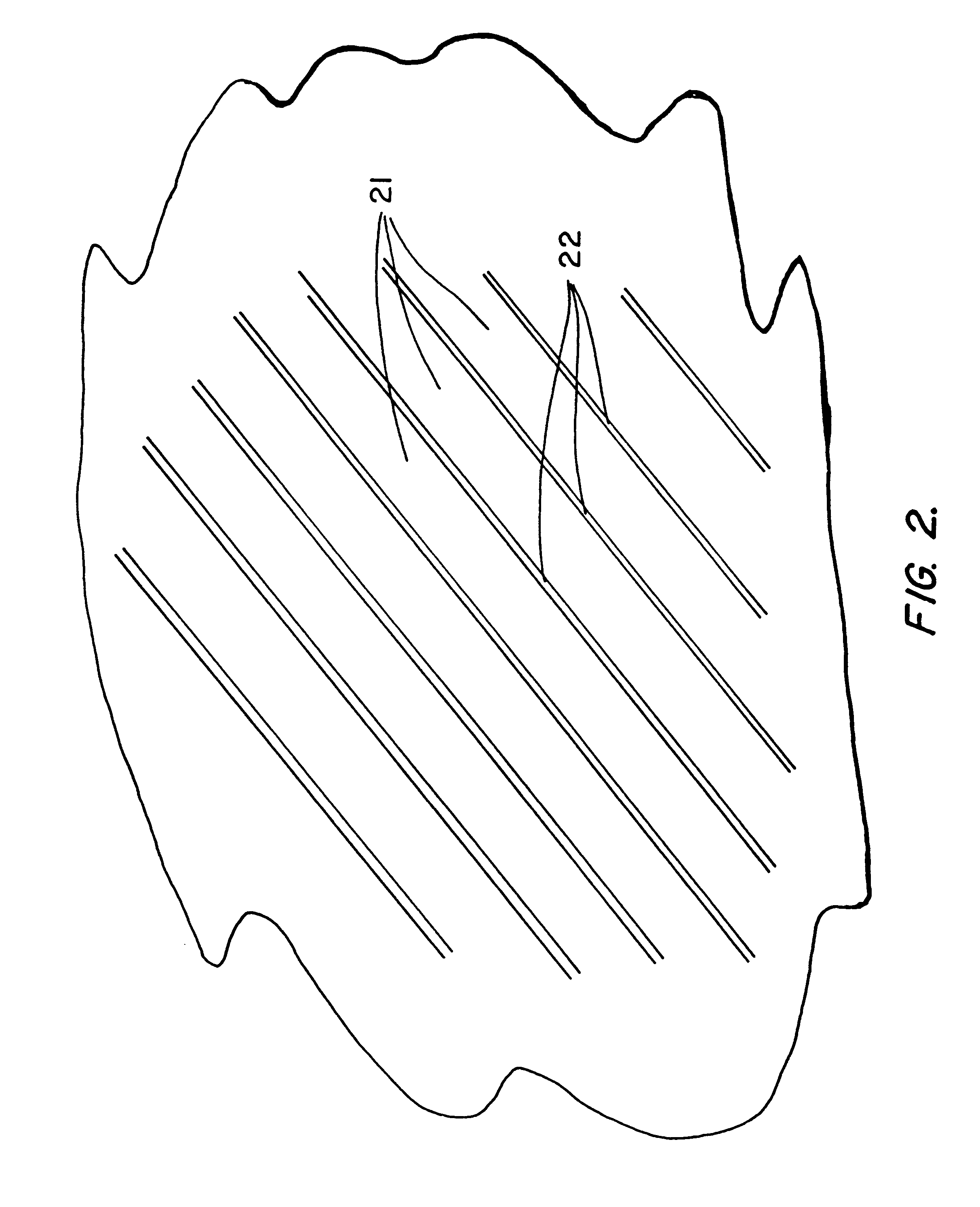

Low-carbon steels of superior mechanical and corrosion properties and process of making thereof

InactiveUS6273968B1Simple structureAccelerated corrosionFurnace typesHeat treatment furnacesCrystal twinningCarbide

Alloy steels that combine high strength and toughness with high corrosion resistance are achieved by a dislocated lath microstructure, in which dislocated martensite laths that are substantially free of twinning alternate with thin films of retained austenite, with an absence of autotempered carbides, nitrides and carbonitrides in both the dislocated martensite laths and the retained austenite films. This microstructure is achieved by selecting an alloy composition whose martensite start temperature is 350° C. or greater, and by selecting a cooling regime from the austenite phase through the martensite transition region that avoids regions in which autotempering occurs.

Owner:CMC STEEL FABTORS

Economy type weathering-resistant steel

The invention relates to economic air corrosion prevention low-alloy carbon constructional steel in the field of low-alloy constructional steel. It is mainly used in the steel structure which is used in air such as railroad, carriage, bridge and tower and so on. The alloying component and the percentage by weight of the weather fastness steel is as following: C: 0.12-0.21, Si: 0.2-2.0, Mn: 0.7-2.0, S <=0.036, P<=0.034, Cu: 0.10-0.40, Al<0.2, and other iron and impurity elements.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Acid-cleaning inhibiter for cleaning boiler and use method thereof

ActiveCN101634030ASlow down the dissolution rateIncrease activation energyBoiler cleaning apparatusThioureaPhosphoric acid

The invention discloses an acid-cleaning inhibiter for cleaning a boiler and a use method thereof. The acid-cleaning inhibiter comprises the following components by weight percent: 2.0%-10.0% of acid liquor, 0.08-0.25% of urotropine, 0.04-0.15% of dimethylbenzene thiourea or thiourea, 0.01-0.05% of thiocyanate, 0.03-0.12% of dodecyl-cetyl phenmethyl chloride or bromide, 0.05-0.12% of a surface active agent and the balance of water. Acids suitable for the acid-cleaning inhibiter include hydrochloric acid, citric acid, sulphuric acid, hydrofluoric acid, aminosulfonic acid and phosphoric acid, which are suitable for boiler steel, mild steel, alloy steel and steam steel. The inhibition effect of the invention is over 98% with less toxicity under the boiler chemical cleaning condition, the value of LD50 (orally taken by mice) is 5.74 g / kg. The invention can be stored for 2 years, resistant Fe<3+> ion is 800 mg / kg in the acid cleaning. The preparation method has simple steps, easily obtained raw materials and convention operation.

Owner:湖南省湘电试验研究院有限公司 +2

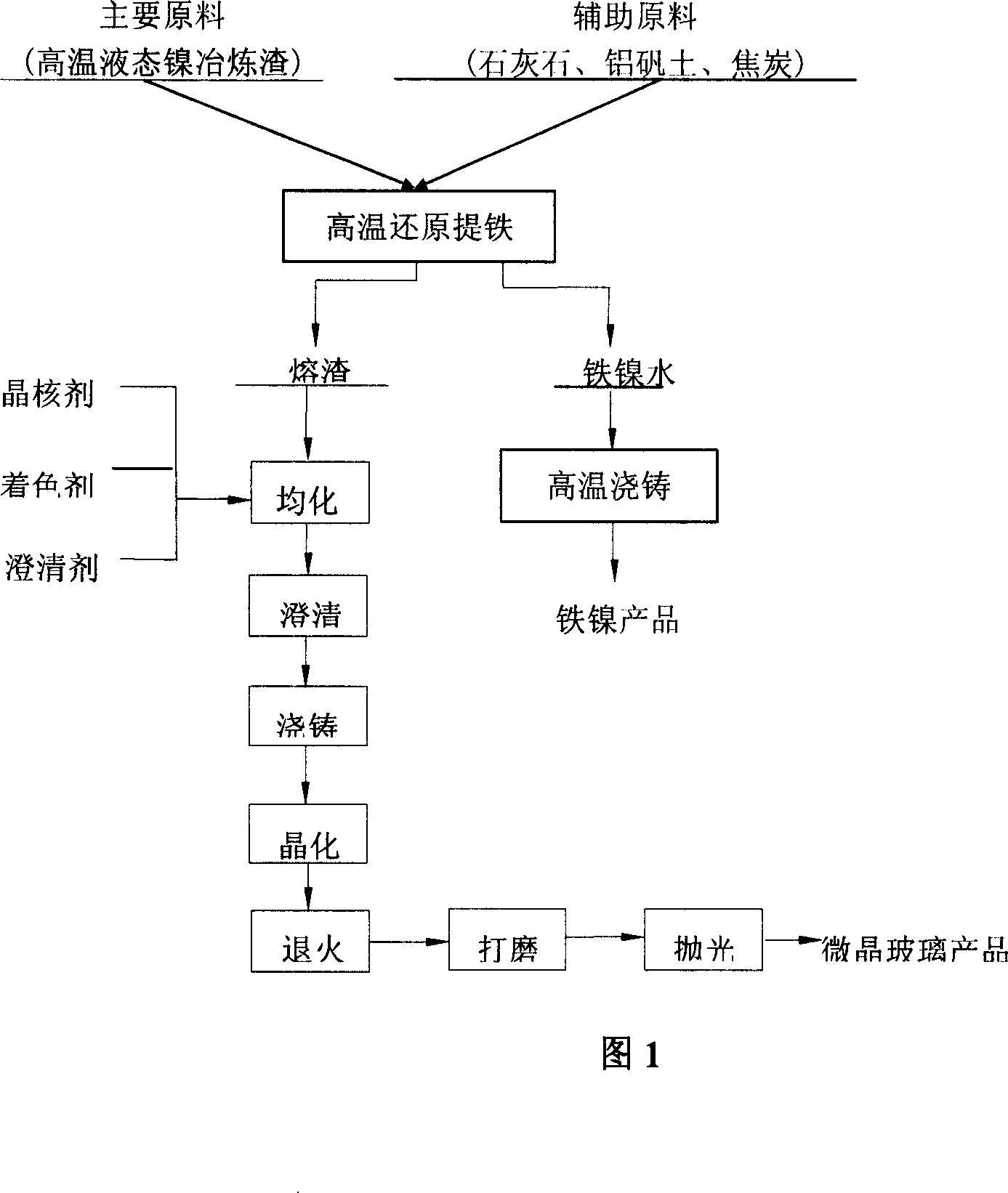

Process of comprehensively utilizing high temperature nickel smelting slag

The present invention relates to process of comprehensive utilization of smelting slag, and is especially technological process of comprehensively utilizing high temperature nickel smelting slag in extracting iron and producing microcrystal glass. The present invention features that the nickel smelting slag is first reduced in high temperature molten state to reduce its metal iron and nickel so as to obtain ferronickel alloy or alloy steel, and the residual molten silicate slag is heat maintained, homogenized, clarified, cast and microcrystallized to obtain microcrystal glass product. The process of the present invention utilizes nickel smelting slag in high temperature molten state, and has saving in secondary heating cost and high value utilization of nickel smelting slags.

Owner:JINCHUAN GROUP LIMITED +1

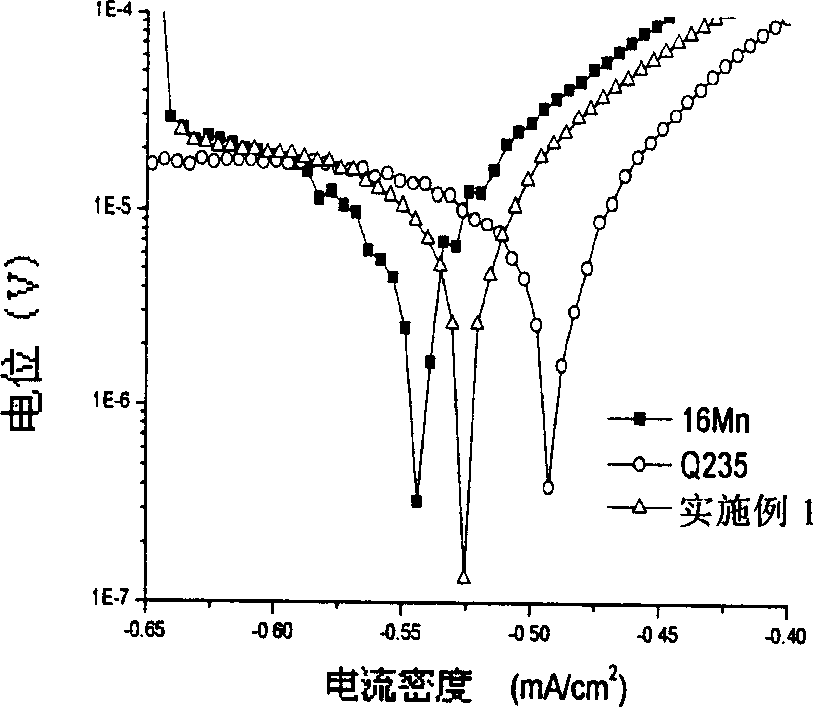

Low alloy steel resisting CO2 and H2S corrosion

The present invention is one kind of low alloy steel capable of being used in oil well pipe to resist CO2 and H2S corrosion. Chemically, its consists of C 0.01-0.30 wt%, Si 0.10-1.0 wt%, Mn 0.10-2.0, Cr 0.50-3.0 wt%, Mo 0.01-1.0 wt%, Ce 0.01-0.25 wt%, V 0.005-0.1 wt%, Cu 0.05-1.0 wt%, Al 0.01-0.10 wt% and small amount of Nb if necessary, except Fe and inevitable impurity, with impurity elements being less than 0.05 wt%. The alloy steel of the present invention after hardening and tempering has mechanical performance reaching the requirement on API 80 and 90 level steel but obviously improved CO2 and H2S corrosion resistance, and is economic oil well pipe steel with moderate cost.

Owner:BAOSHAN IRON & STEEL CO LTD

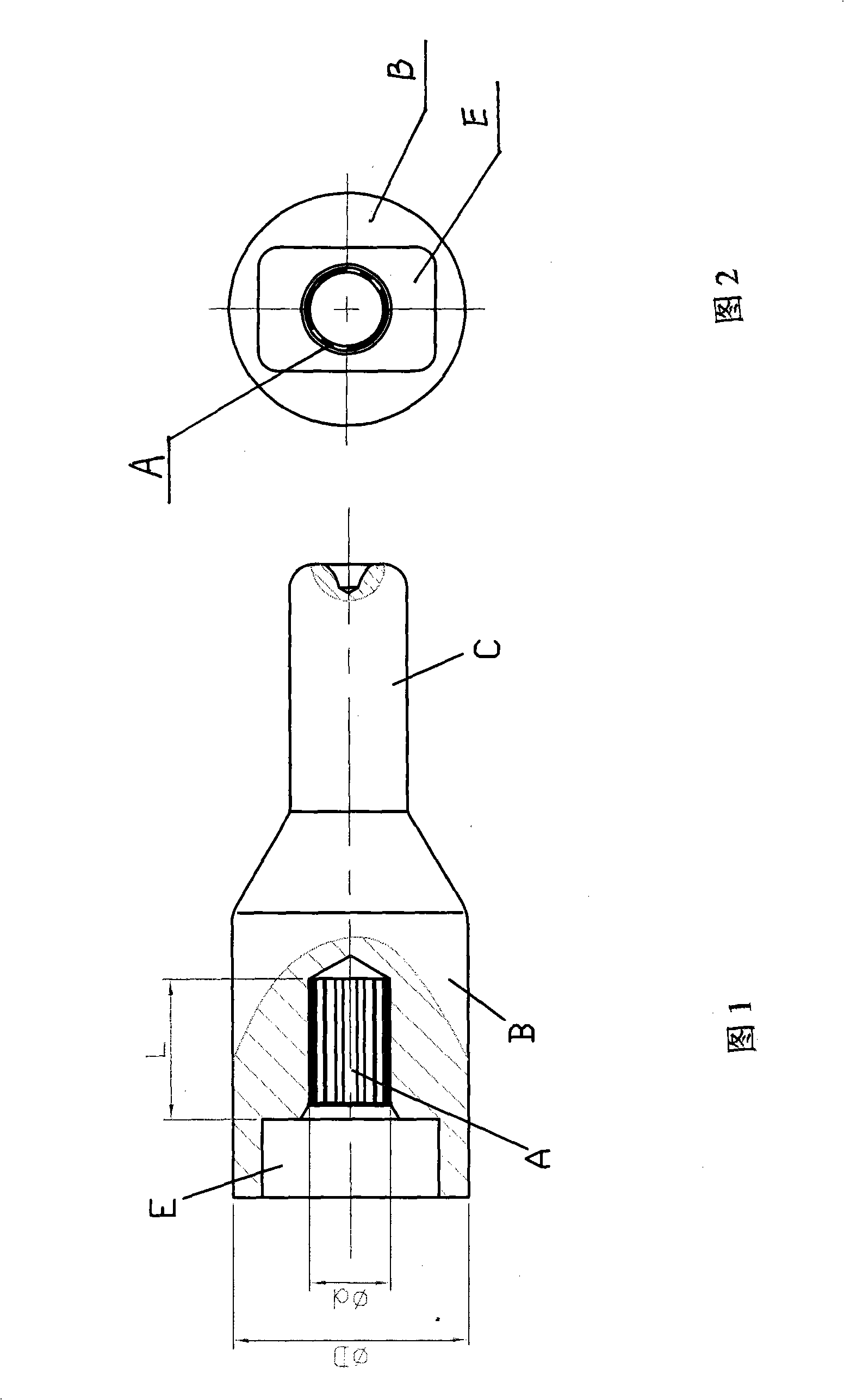

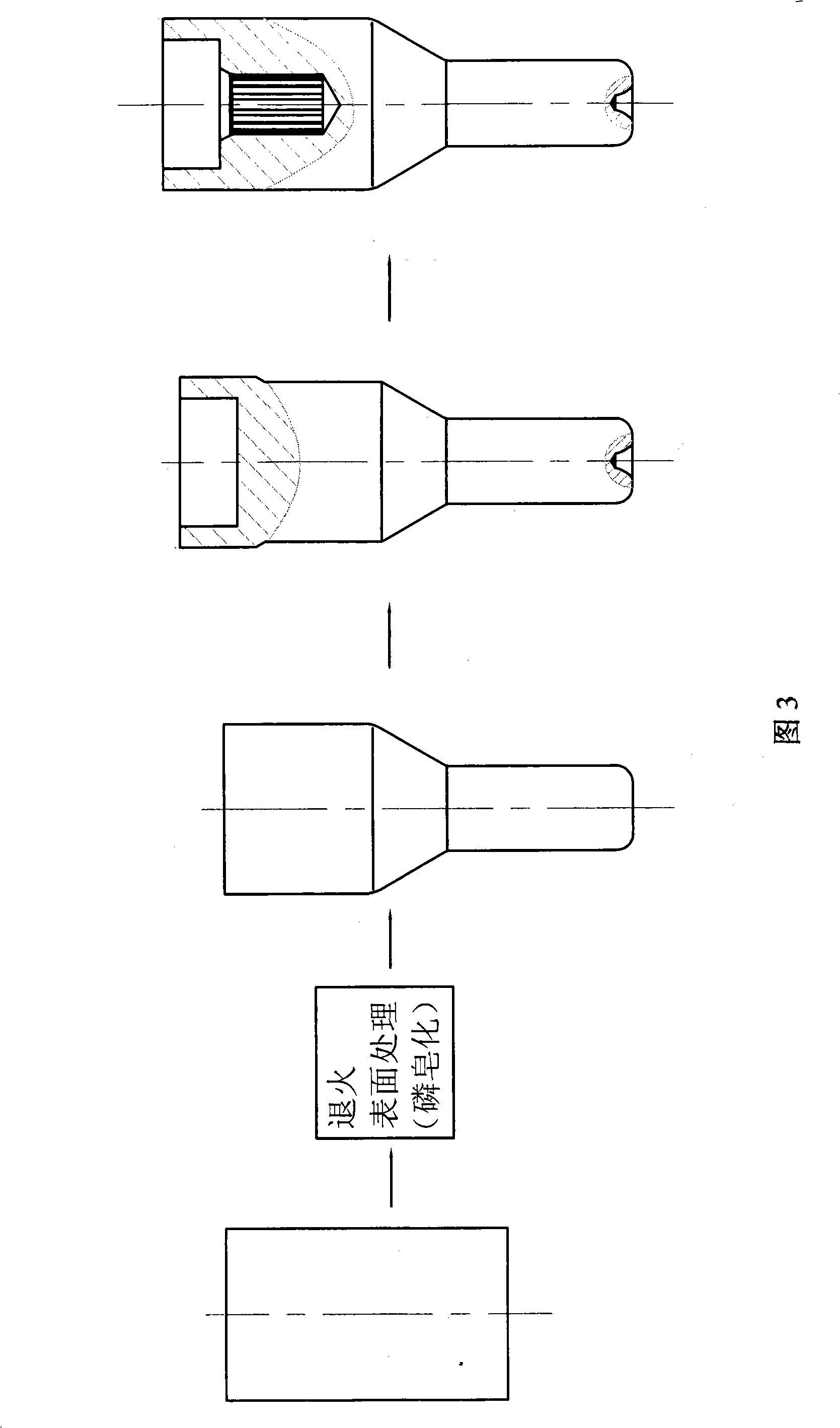

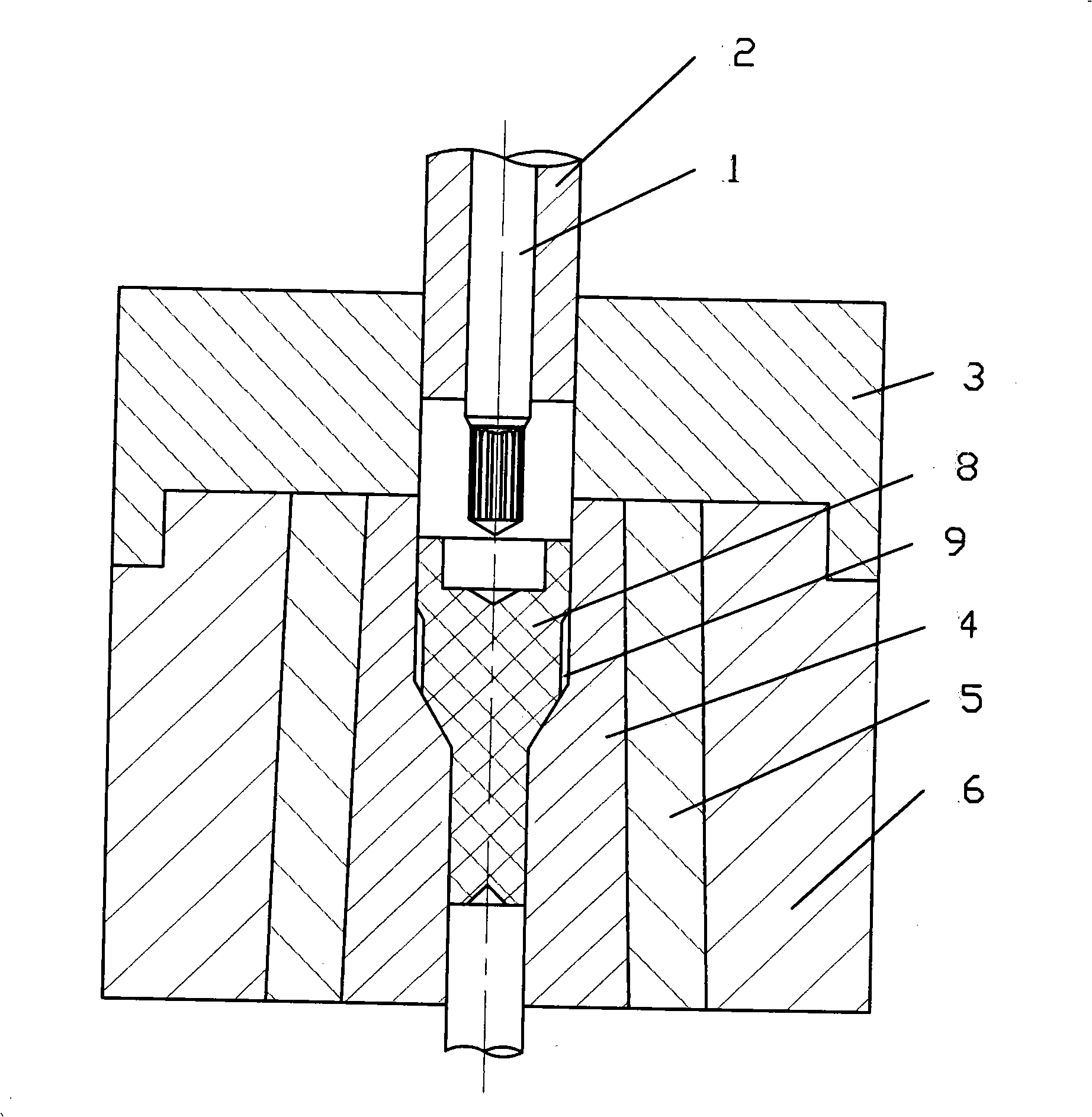

Cold-forging technique of gear shaft

InactiveCN101332488ALow flow resistanceReduce the bearing unit extrusion forceForging/hammering/pressing machinesMetallic material coating processesGear wheelPre stress

The invention relates to a cold forging technology for a gear shaft; the cold forging technology is characterized in that a new technology of the cold forging forming of the inside and outside and split flow forging, a volume split flow space is arranged between the gear shaft diameter and a concave die, the metal flow resistance is reduced and the unit extruding force carried by the die is lowered by split flow; high-strength die steel and split structure are adopted to produce a gear hole forming die; the concave die is produced by adopting three-layer sleeve prestressed structure so as to improve the compression resistance of the die; a punch is made from an alloy steel material and used for the cold forging and precision forming of a complex gear form blind hole, which improves the forming quality and production efficiency of the gear hole, and lowers the consumption of the raw materials markedly. The cold forging technology of the invention has the advantages of achieving the smooth forming of the gear form blind hole, improving the production efficiency greatly, and improving the quality of the gear hole and the qualification rate of the product markedly.

Owner:SHANGHAI DONGFU COLD FORGING MFG

Unmodified high-toughness low-temp steel for high-energy line welding and its production method

A high-toughness low-temp steel for high-energy linear welding contains C, Si, Mn, P, S, Al, Ti, N, B, Fe, and one or more of Cu, Ni, Nb, V, Mo and RE. The compound Ti-B oxide is used to obtain high welding performance under high linear energy (greater than 50 KJ / cm). Its low content of C and impurities can improve its toughness. Its advantags are high weld performance and low-temp toughness, andlow cost. It is suitable for low-temp spherical tank and large containers.

Owner:武钢集团有限公司

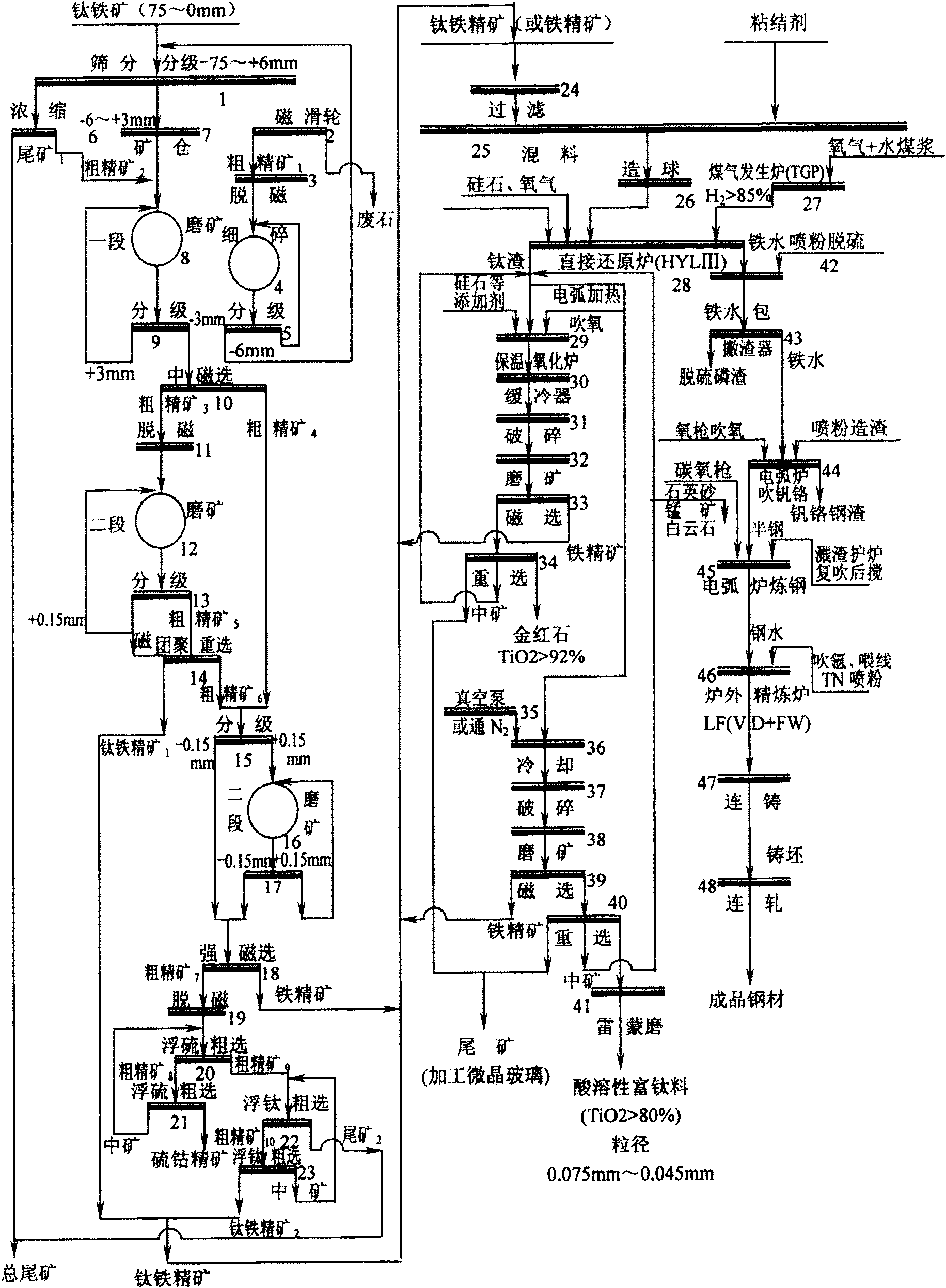

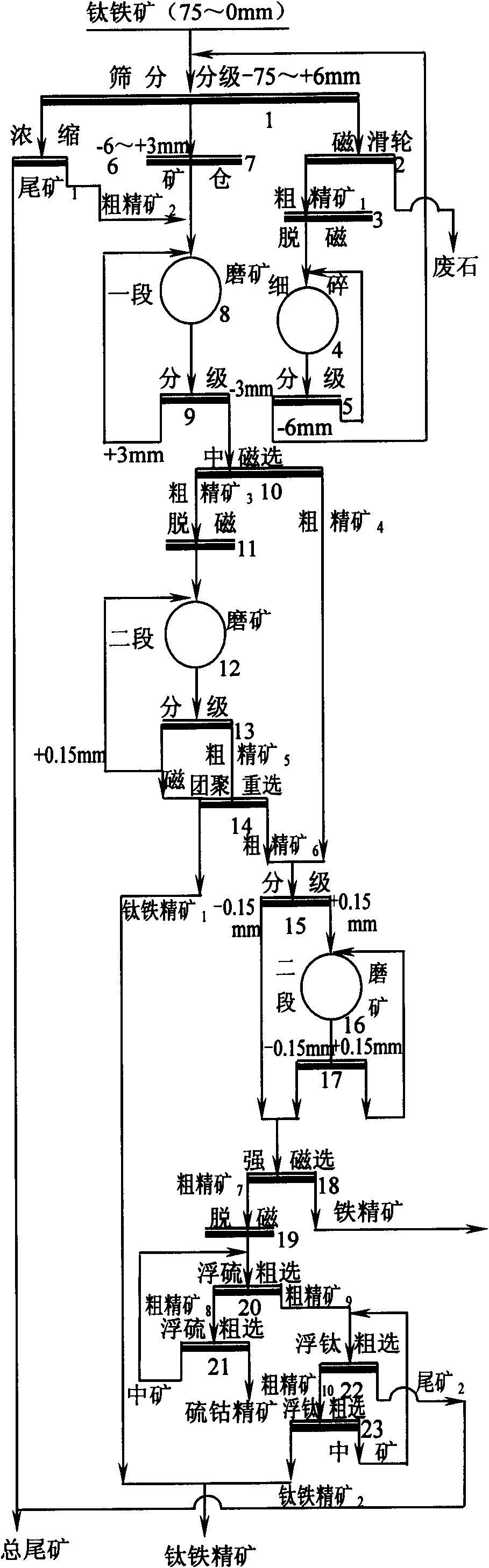

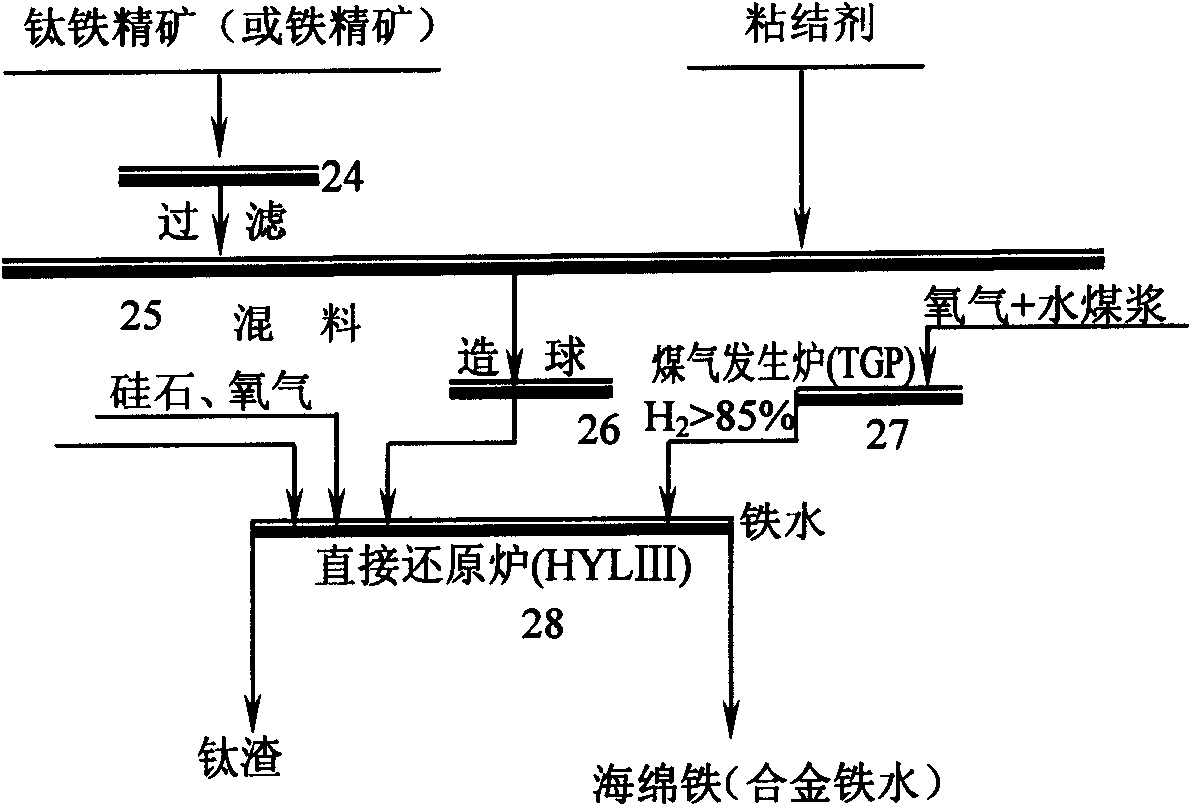

Method for producing titanium and steel products by utilizing titanium and iron ores

InactiveCN101613825AIncrease profitHigh recovery rateProcess efficiency improvementElectric furnaceRutileContinuous rolling

The invention discloses a method for producing titanium and steel products by utilizing titanium and iron ores, which belongs to the field of technical innovation of mining, dressing and smelting full process flow of the titanium and iron ores. Ordinary blast furnaces are not suitable for the smelting of high-titanium and medium-titanium schreyerite; and schreyerite mining, dressing and smelting enterprises in Panxi region extract rich parts and discard poor parts, and discard weathered ore of submarginal ore which accounts for over 95 percent of that of raw ore and is taken as mining mullock. The method comprises the following step: directly reducing titaniferous iron concentrate dressed from the mining mullock (TiO2 is over 5 percent, and TFe is over 13 percent) of the schreyerite, electric furnace melt producing titanium slag and molten water with electric furnace melt components, and producing a titanium-rich material and rutile with the titanium slag through mineral dressing by a fire method; producing alloy molten iron with the molten iron through electric smelting and vanadium-chrome steel slag blowing; and producing various alloy steel products the alloy molten iron in a continuous casting and continuous rolling mode through the electric smelting. The recovery rates of titanium, iron and vanadium are improved to 80 percent from 3.86 percent, improved to 70 percent from 34.5 percent and improved to 70 percent from 20.90 percent respectively.

Owner:PANZHIHUA JINTAI HI TECH

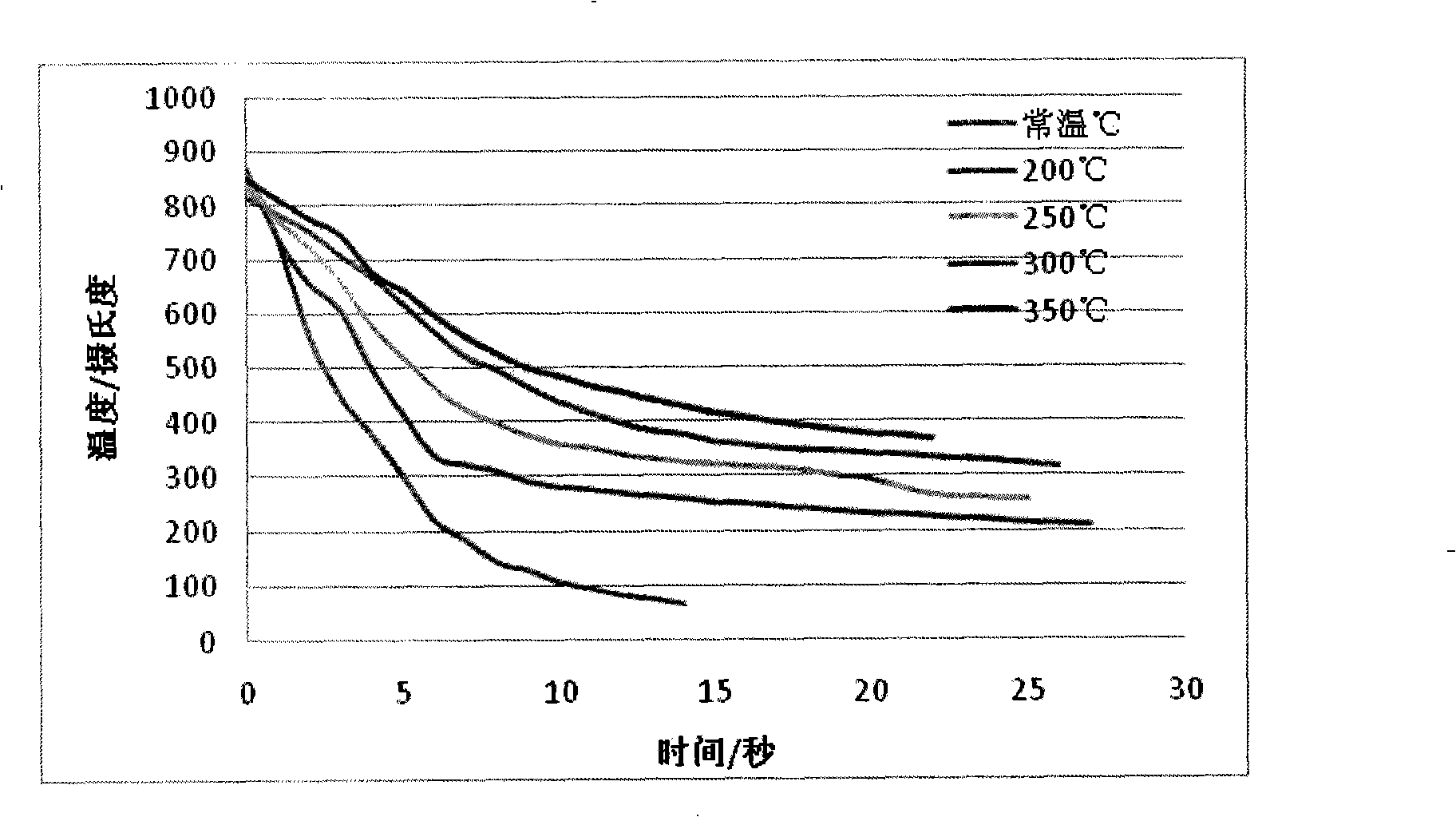

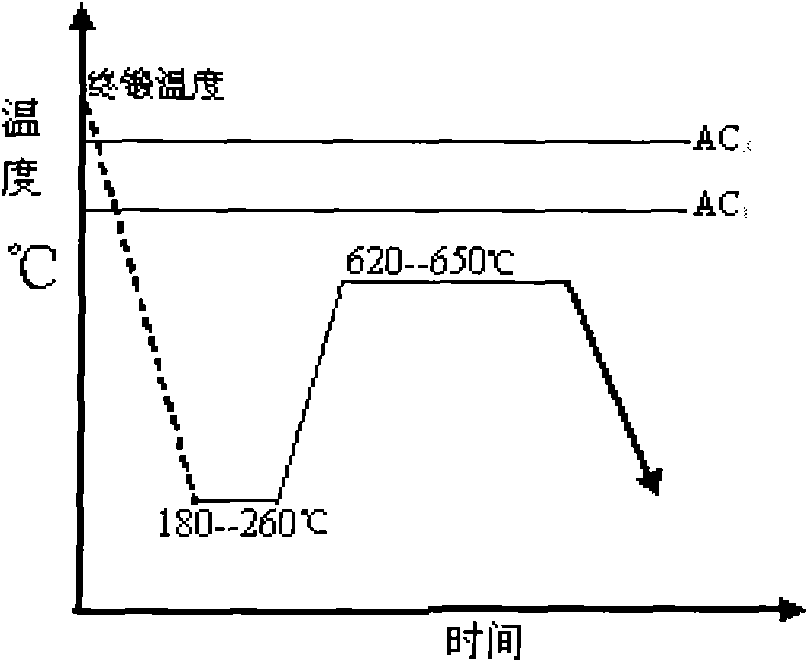

High-safe high-precision producing method of thermoforming martensitic steel parts

InactiveCN101280352AGuaranteed Hardenability RequirementsLow yield ratioShaping toolsHot stampingSheet steel

The invention provides a high security, high accuracy and thermal forming martensite steel part preparing method, which belongs to the field of obtaining controlling and cooling technology of the hot stamping forming part of the alloy steel plate, the martensite works as the matrix structure of the alloy steel plate. The method adopts the processes as follows: a steel plate is heated to 20 to 250 DEG C above the Ac3 temperature, therefore an austenite structure can be obtained, then the steel plate is transferred to the stamping die for forming by stamping; simultaneously, the temperature of the stamping die is controlled in a range of 100 to 400 DEG C, 5 to 60 seconds later after stamping forming, the formed component parts can be taken out of the stamping die. The method has the advantages that a well ductility and security can be obtained, and the anti-susceptibility of the steel can be greatly enhanced.

Owner:CENT IRON & STEEL RES INST

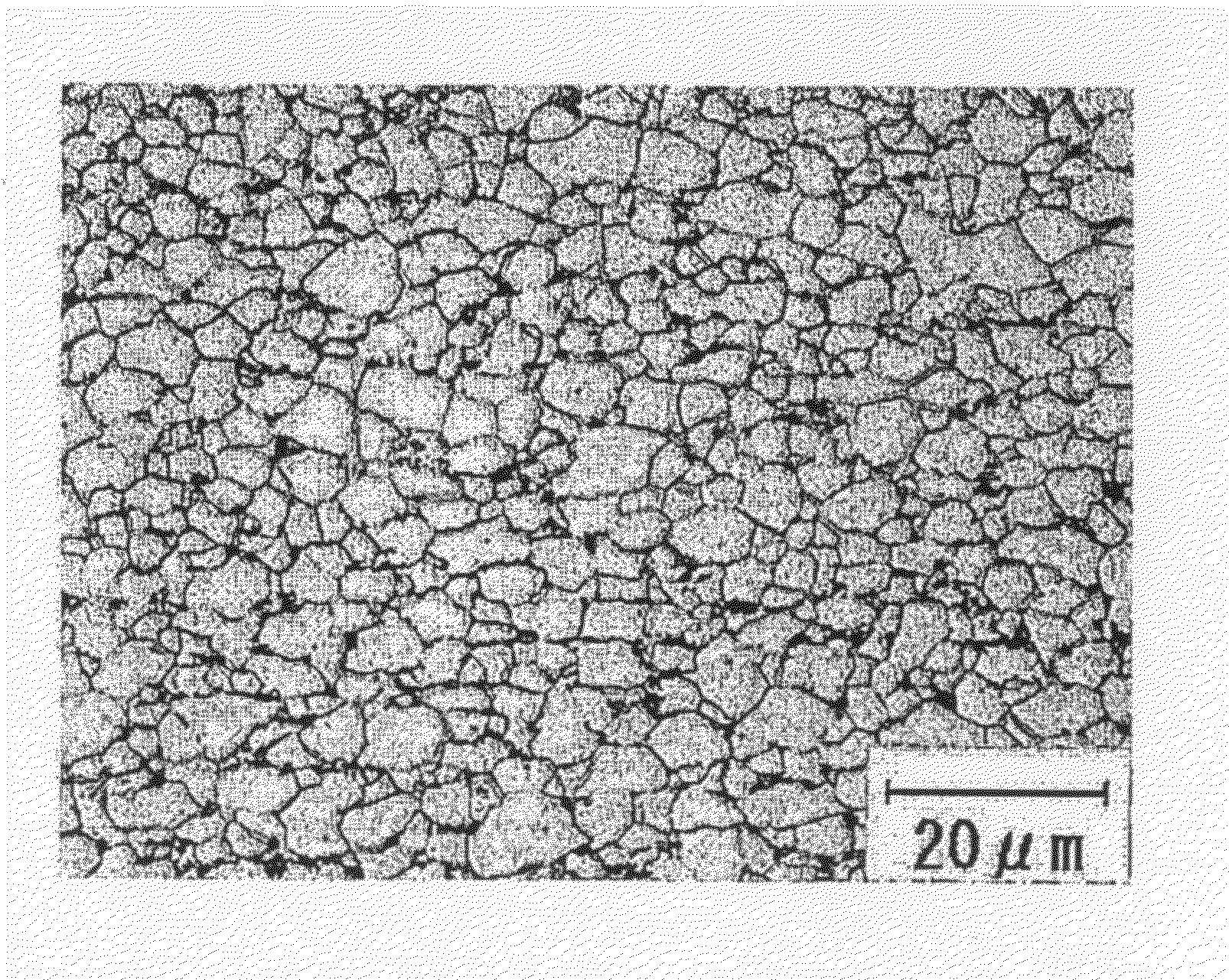

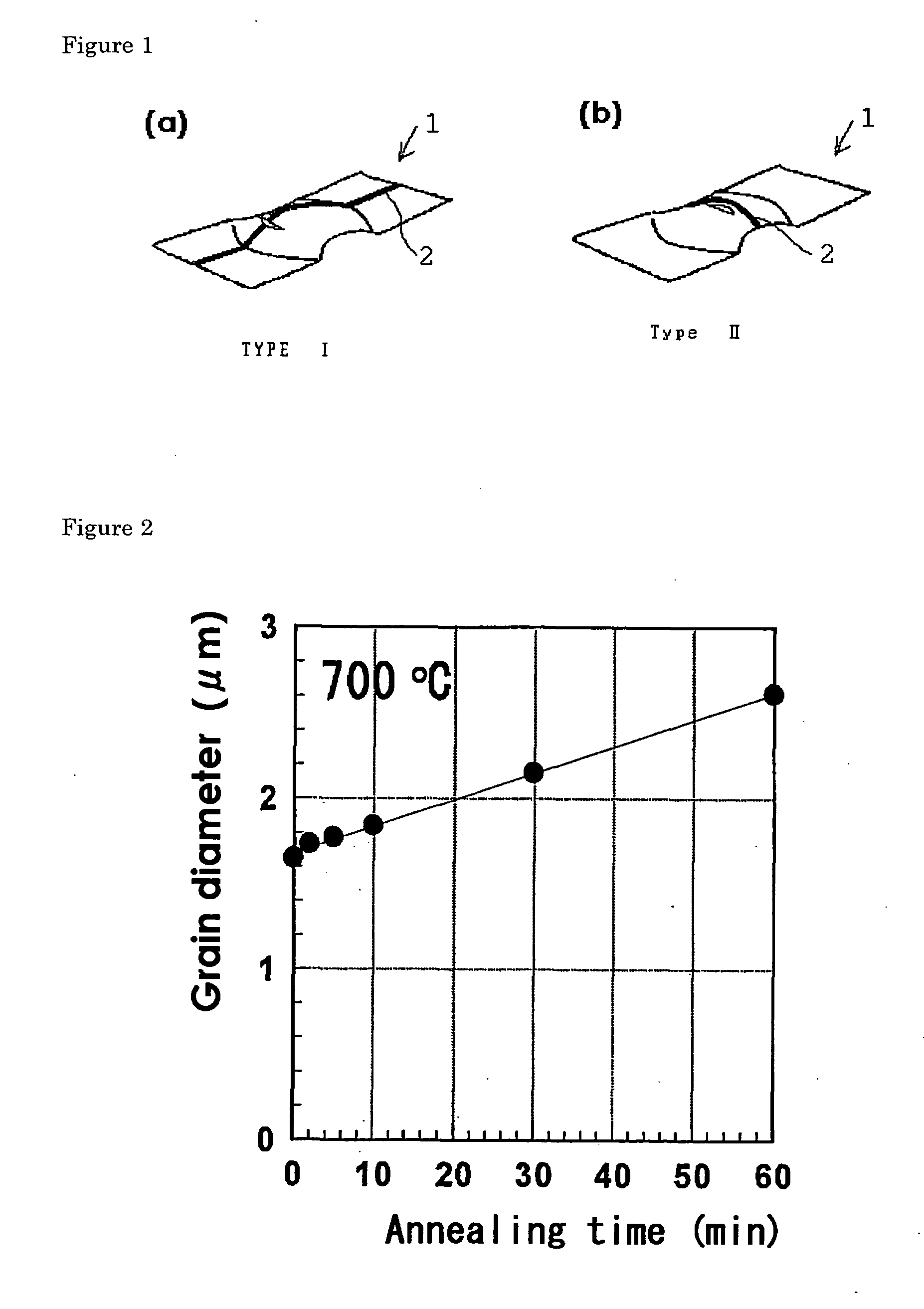

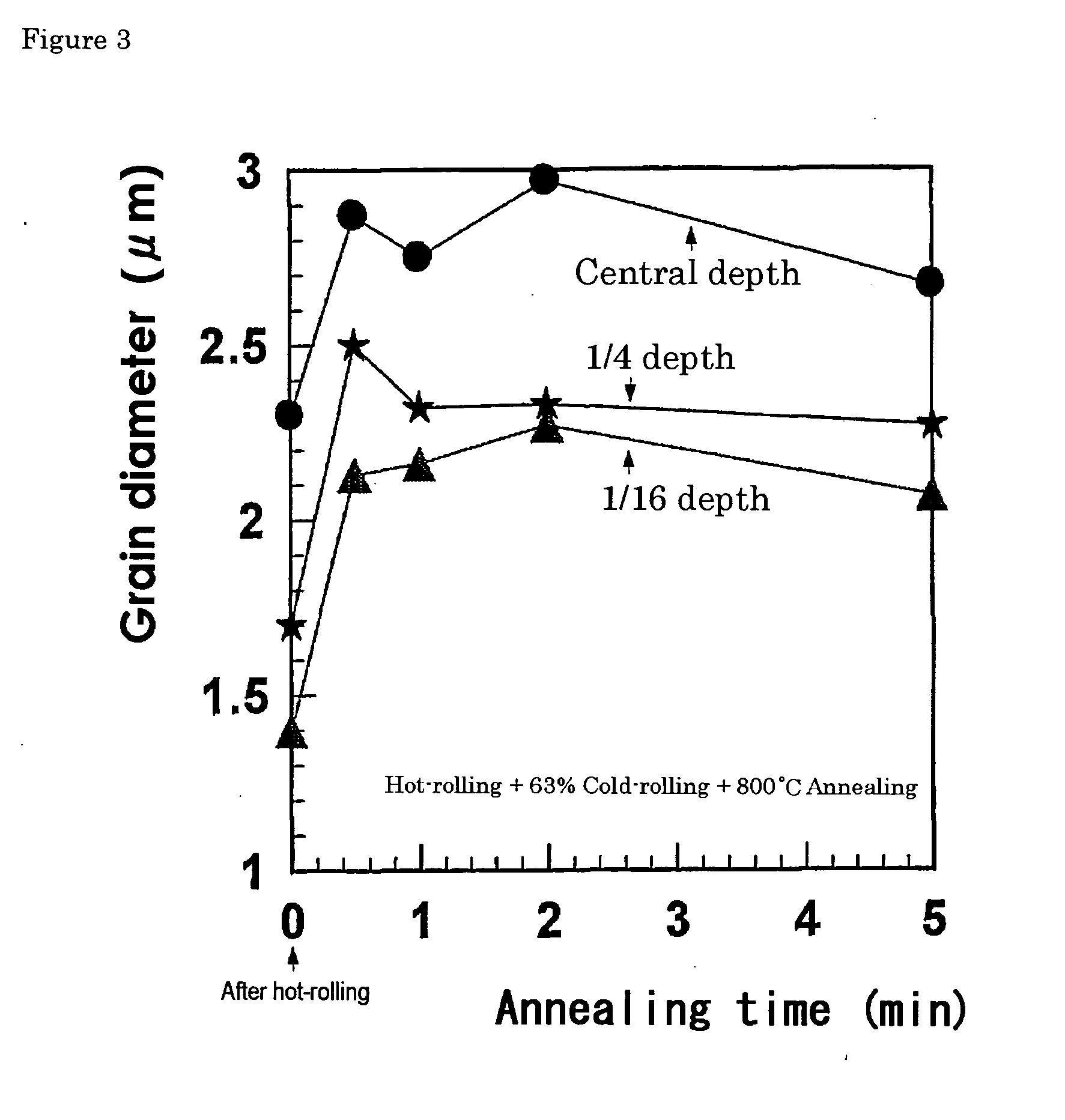

Hot-rolled steel sheet and cold-rolled steel sheet and manufacturing method thereof

InactiveUS20080202639A1Excellent mechanical propertiesLower transition temperatureHot-dipping/immersion processesFurnace typesMaterials scienceRaw material

A steel sheet excellent in mechanical strength, workability and thermal stability and suited for use as a raw material in such fields of manufacturing automobiles, household electric appliances and machine structures and of constructing buildings, and a manufacturing method thereof. are provided.The steel sheet is a hot-rolled steel sheet of carbon steel or low-alloy steel, the main phase of which is ferrite, and is characterized in that the average ferrite crystal grain diameter D (μm) at the depth of ¼ of the sheet thickness from the steel sheet surface satisfies the relations respectively defined by the formulas (1) and (2) given below and the increase rate X (μm / min) in average ferrite crystal grain diameter at 700° C. at the depth of ¼ of the sheet thickness from the steel sheet surface and said average crystal grain diameter D (μm) satisfy the relation defined by the formula (3) given below:1.2≦D≦7 formula (1)D≦2.7+5000 / (5+350·C+40·Mn)2 formula (2)D·X≦0.1 formula (3)wherein C and Mn represent the contents (in % by mass) of the respective elements in the steel.

Owner:NIPPON STEEL CORP

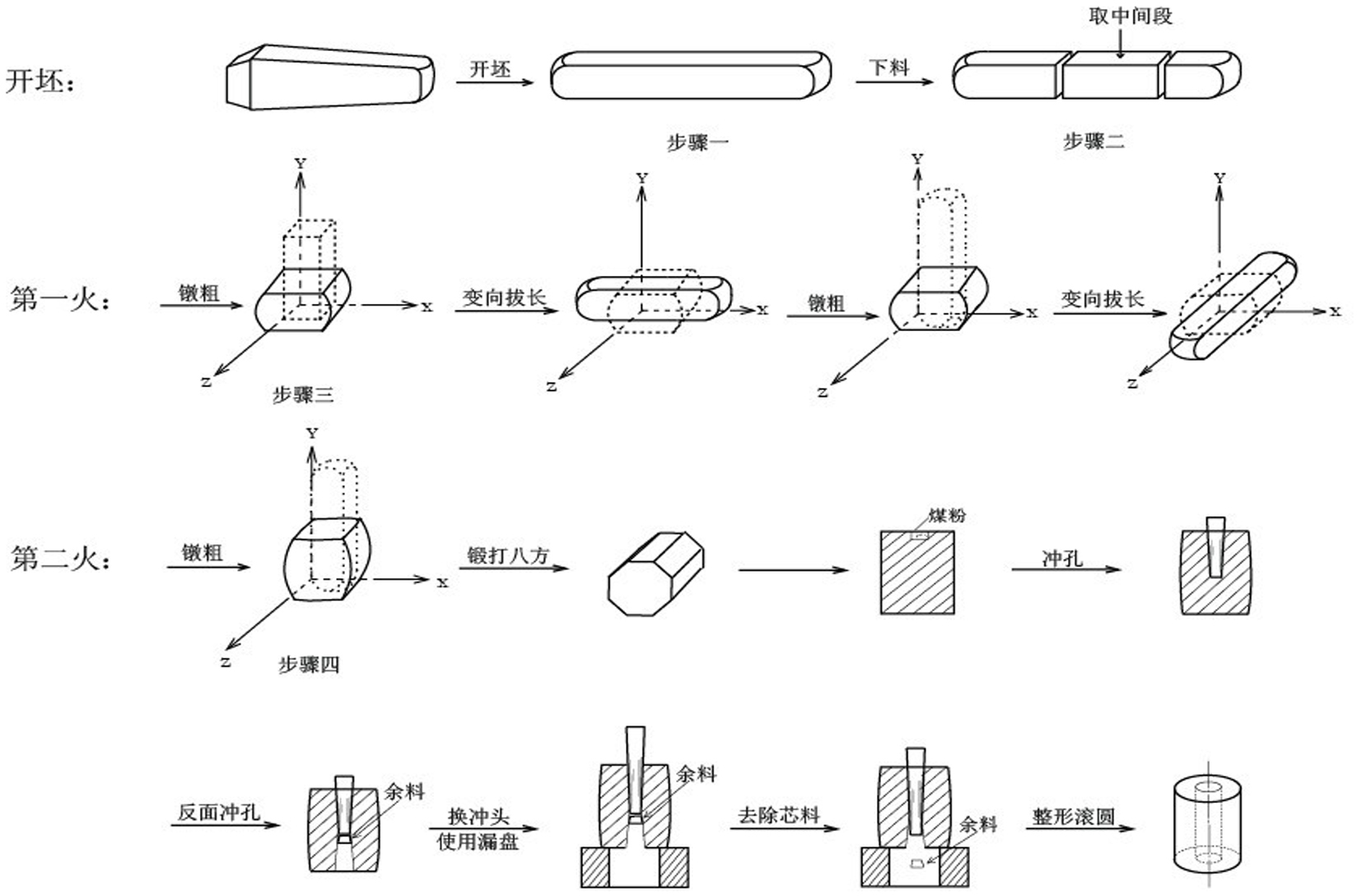

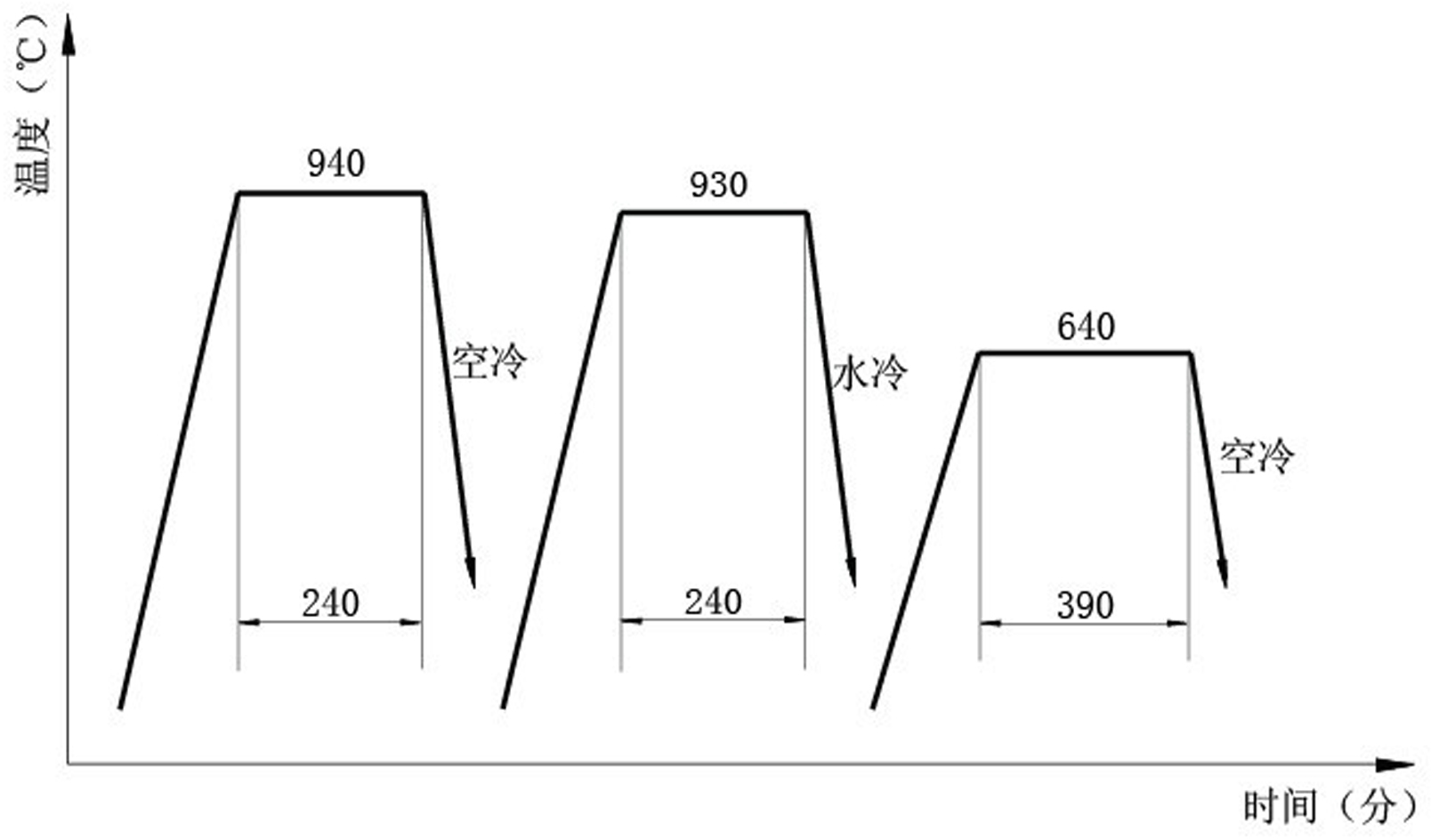

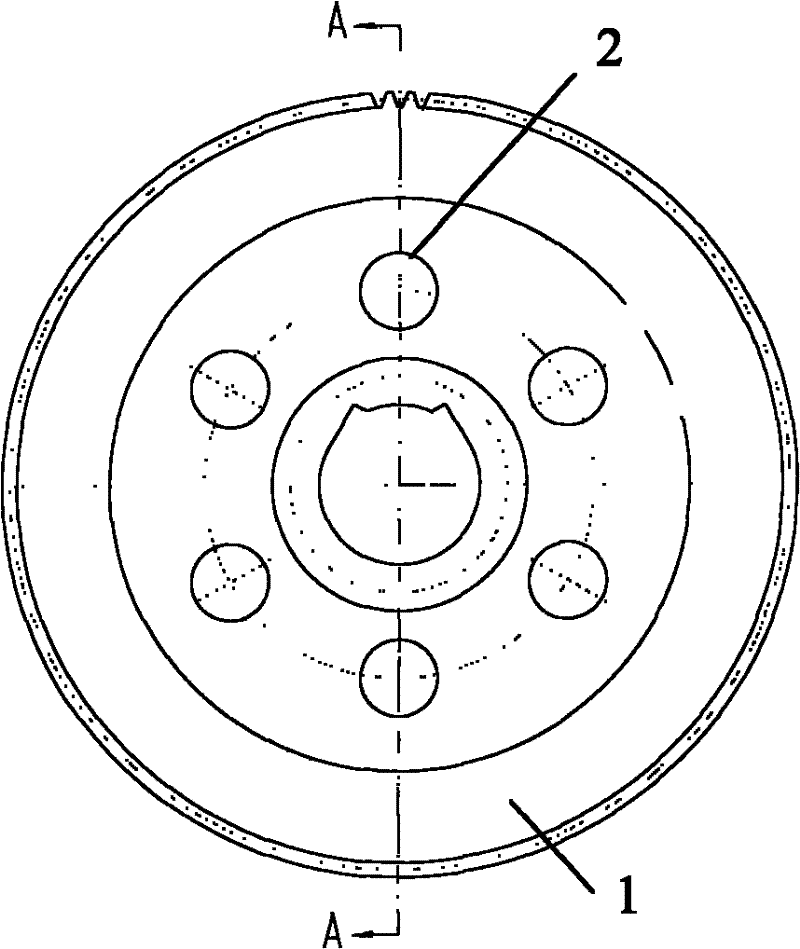

Steel forging manufacturing process for deep-sea Christmas tree equipment connectors

ActiveCN102071367AEliminate the problem of increased toughnessImprove forging qualityMetal-working apparatusPunchingEngineering

The invention relates to a steel forging manufacturing process for deep-sea Christmas tree equipment connectors, which comprises the following steps: (1) using chromium-nickel-molybdenum low-alloy steel as the blank material; (2) selecting square ingots, heating to 1220 DEG C, cogging, pulling out the material, sawing, and taking the middle section as the blank; (3) heating to the initial forging temperature, upsetting in the directions of three-dimensional coordinates, and drawing out to obtain the isotropic blank; (4) upsetting and forging the blank to obtain an octagonal prism, punching, circularly rolling and shaping to obtain a cylindrical forging stock with a hole; (5) carrying out rough machining on the cylindrical forging stock with a hole to obtain a cylindrical workpiece with a hole; (6) heating the cylindrical workpiece with a hole to 940 DEG C, and cooling in the air to room temperature; (7) heating the cylindrical workpiece with a hole subjected to the step (6), to 930 DEG C, and quenching with water; and (8) heating the cylindrical workpiece with a hole subjected to the step (7), to 640 DEG C, and cooling in the air to room temperature.

Owner:NANJING DEV ADVANCED MFG

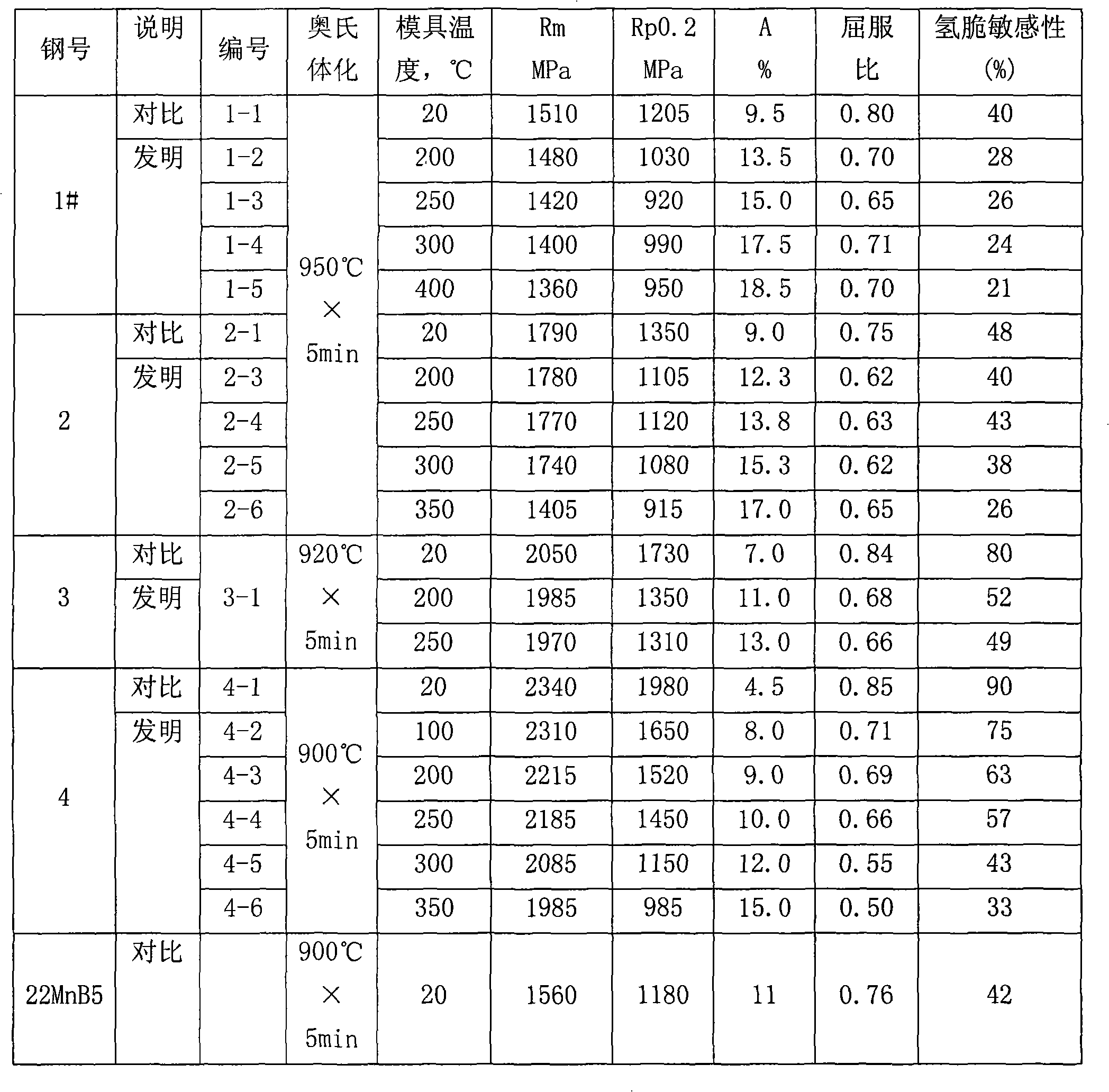

Hotforming martensitic steel

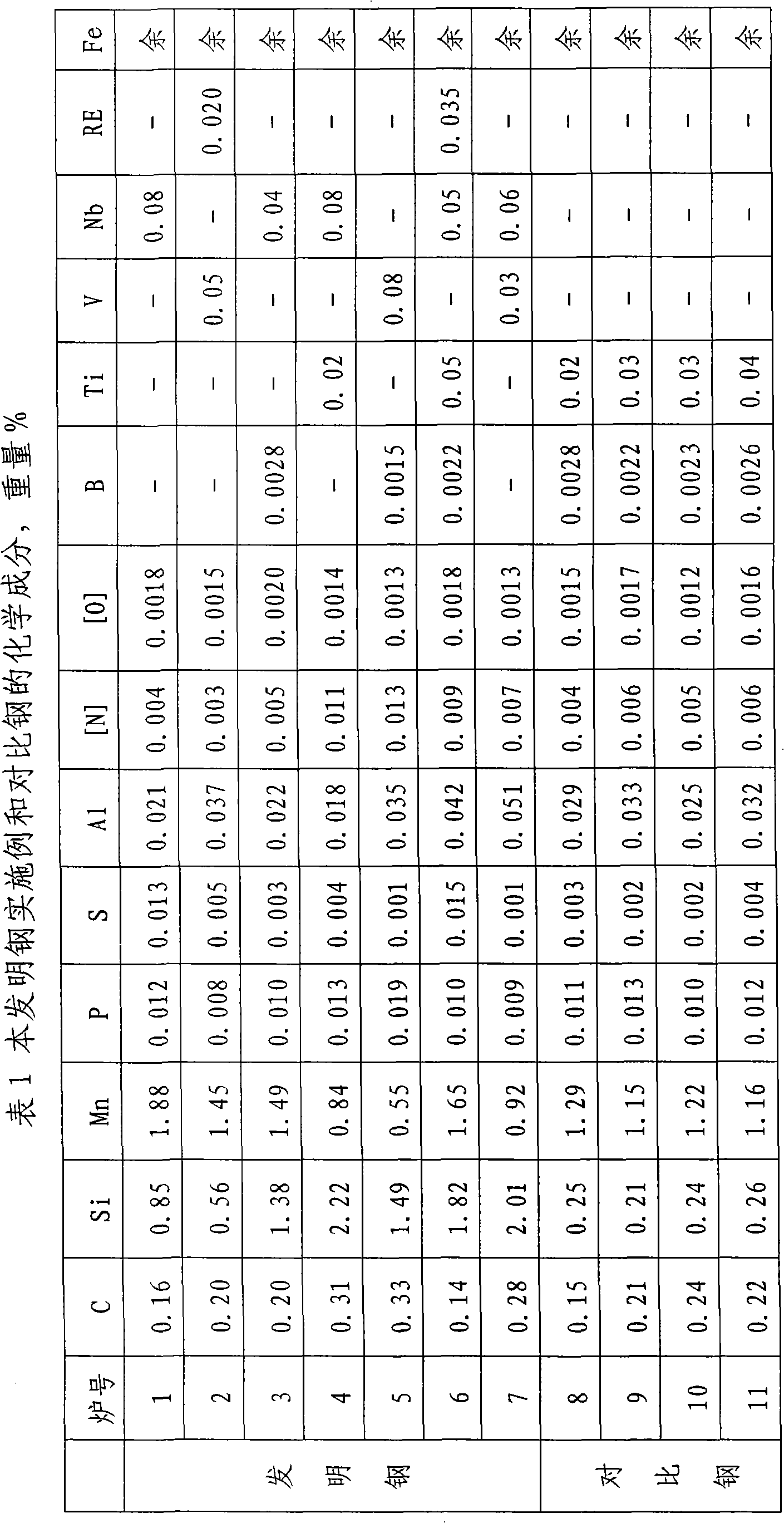

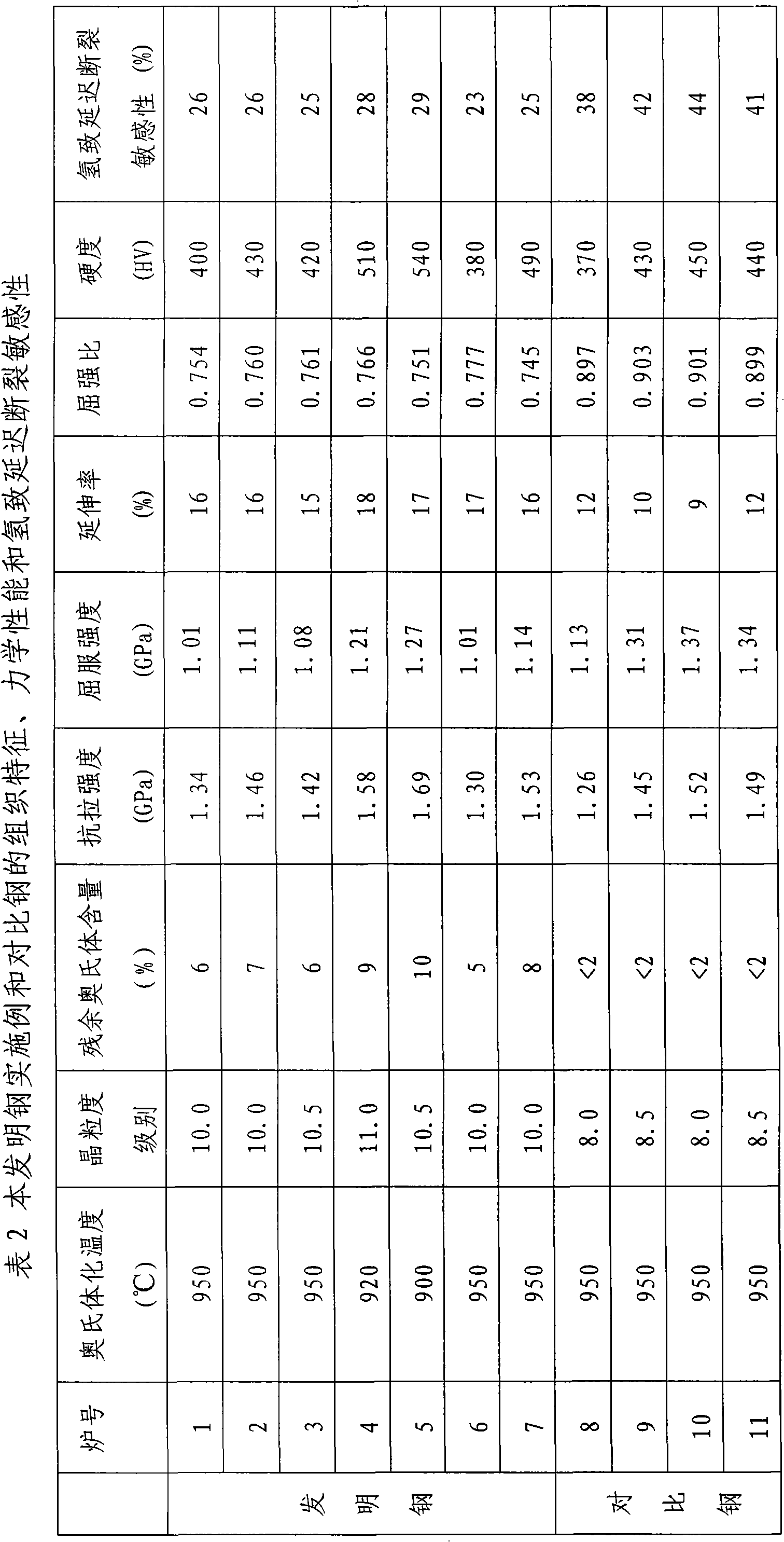

The invention belongs to the field of alloy steel, more particularly relates to thermal forming martensitic steel, which is mainly suitable for the steel for thermal punching forming accessory with thin thickness whose tensile strength ranges from 1.3 to 1.7GPa. The mainly chemical ingredients (weight %) of the steel are: C 0.10-0.33%, Si, 0.50-2.30%, Mn 0.50-2.00%, P <= 0.020%, S <= 0.015%, Al 0.015-0.060%, [O] <= 0.002%, [N] 0.002-0.015%, the rests are Fe and unavoidable impurities. In addition, the steel is also added with any or more than one of the group consisting of B 0.0005-0.0050%, Ti 0.02-0.10%, Nb 0.02-0.10%, V 0.02-0.15% and RE 0.001-0.050%. Compared with the current thermal forming martensitic steel 22MnB5, the steel of the invention not only has the tensile strength enhanced from 1.0-1.5GPa to 1.3 to 1.7GPa, but also has good plasticity, the coefficient of extension is more than 15%, and hydrogen-induced delayed fracture sensitivity is obviously reduced, thus making the vehicle having lighter weight and higher secure performances become true.

Owner:CENT IRON & STEEL RES INST

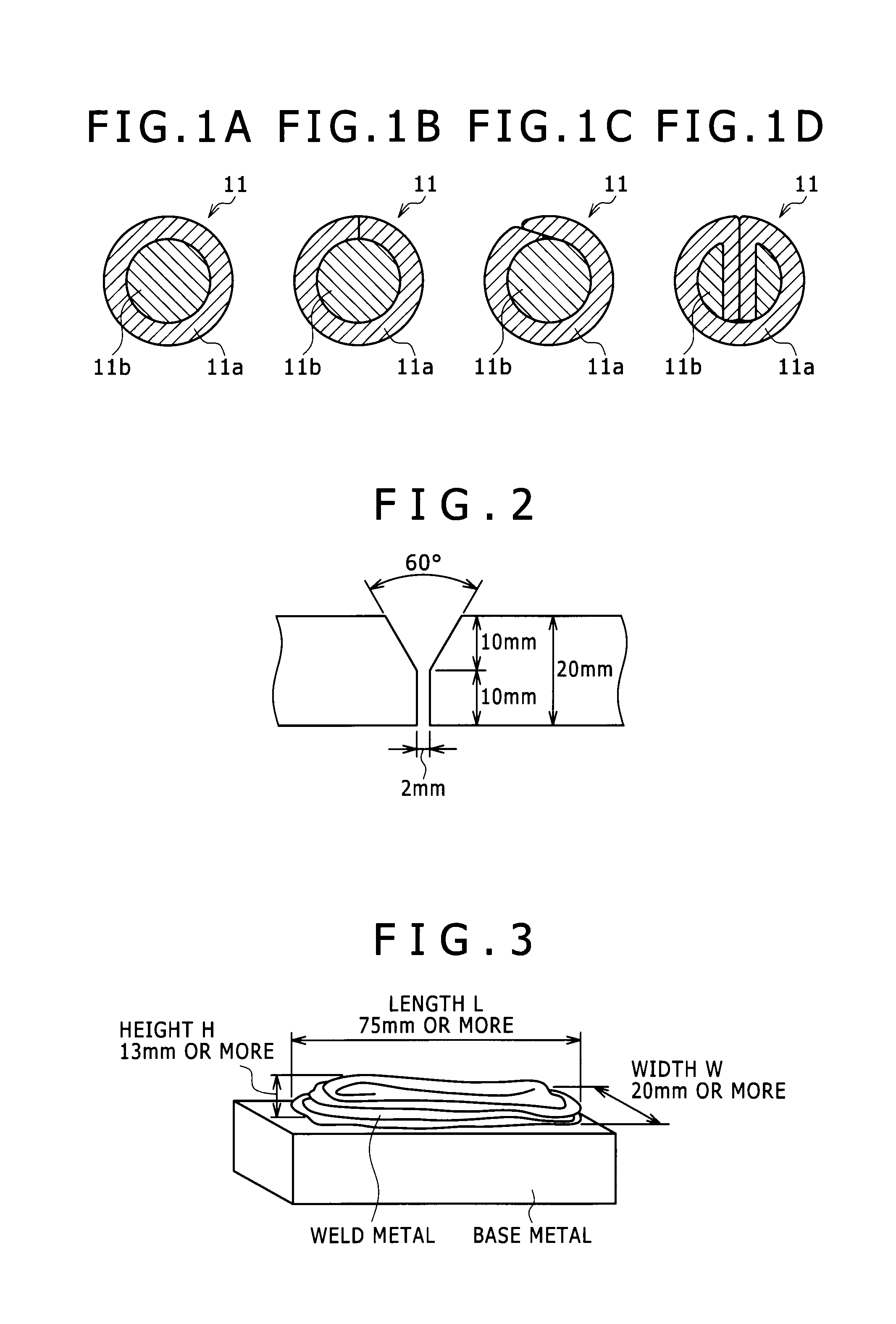

Nickel-based welding electrode for welding nickel-chromium-molybdenum alloy

ActiveCN102430876AExcellent heat crack resistanceEasy to useWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention relates to a nickel-based welding electrode which comprises the following component by weight percent (wt%): 50.0-68.0% of Ni, 18.0-23.0% of Cr, 6.0-11.0% of Mo, 3.0-6.0% of Nb, 2.50-9.00% of Fe, 0.01-0.1% of C, 0.10-1.00% of Mn, 0.010-0.10% of Si, 0.015% of S or less, 0.015% of P or less, 0.01-0.10% of Cu, 0.003-0.010% of Co and the balance of impurities. The coat of the nickel-based welding electrode comprises the following components by weight percent of the welding core: 12-18% of marble, 10-15% of fluorite, 12-18% of barium carbonate, 5.0-6.4% of rutile, 3.5-5.0% of ferroniobium, 3.3-4.5 of chromium metal powder, 0.45-0.65% of sodium carbonate, 0.45-0.65% of electrolytic manganese and 1.3-1.8% of zircon sand, and the adhesion agent is 10-20% of the total weight of the power. The nickel-based welding electrode is prepared by mixing, wrapping mixture on the welding core and baking at low and high temperature. The nickel-based welding electrode disclosed by the invention is used for nickel-chromium-molybdenum alloy steel welding, ensures that the excellent mechanical properties, the excellent corrosion resistance, the excellent thermal crack resistance and the hightensile strength of the welding seam match with those of the base material, has good welding process performance, guarantees attractive molding and can be used for the welding of the steel (with 9% of Ni) working at low temperature.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Steel series with high linear energy and low weld crack sensitivity and its preparing process

InactiveCN1396294ALow weld crack susceptibilityGood welding performanceUltimate tensile strengthPhase point

A high-strength steel as low-alloy steel contains low-C, Ti, Nb, B and two or more of Ni, V, Cu, Mo, Zr and RE, and is prepared through rolling and modifying heat-treatment to obtain high-toughness tempered sorbite texture and the high-smelting-point second-phase points and compound educed phase to suppress growth of welding coarse crystal region. Its advantages are high linear energy (60-70 kg) and low sensitivity to weld cracking.

Owner:武钢集团有限公司

Flying-shear main-transmission gearwheel steel and preparation method thereof

ActiveCN102162069AReduce the effect of heat treatment distortionOvercoming brittlenessGear grindingHobbing

The invention discloses a flying-shear main-transmission gearwheel steel and a preparation method thereof. The flying-shear main-transmission gearwheel steel comprises the following elements in percentage by mass: 0.10-0.20% of C, 2.00-3.00% of Cr, 2.50-3.50% of Ni, 0.4-1.00% of Mo, 0.10-0.40% of Si, 0.40-1.00% of Mn, at most 0.25% of Cu, at most 0.1% of Al, at most 0.020% of P, at most 0.015% ofS, at most 30ppm of O, at most 100ppm of N and at most 2ppm of H. The preparation method comprises the following steps: (1) smelting according to the percentage by mass to obtain a forging stock; (2)forging; (3) carrying out normalizing heat treatment; (4) carrying out gear hobbing; (5) carrying out surface carburization quenching heat treatment; and (6) carrying out gear grinding. The inventionenhances the bearing capacity and reliability of the gearwheel, and satisfies the production demands of high-carbon high-alloy steel and enhanced specifications, thereby having wide popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

Flux-cored nickel-based alloy wire

InactiveUS20110171485A1Improve solderabilityImprove pitting resistanceWelding/cutting media/materialsThin material handlingPotassiumLithium compound

A flux-cored nickel-based alloy wire contains, based on the total mass of the wire, 3 to 11 percent by mass of TiO2, 0.2 to 1.3 percent by mass of SiO2, 1 to 3 percent by mass of ZrO2, and 0.3 to 1.0 percent by mass of manganese oxides in terms of MnO2, contains of a total of 0.2 to 1.0 percent by mass in terms of Na, K and Li of sodium compounds, potassium compounds, and lithium compounds. The flux has a ratio (([TiO2]+[ZrO2]) / [SiO2]) of the total of the TiO2 and ZrO2 contents to the SiO2 content of 5.0 to 14.5, in which [TiO2], [SiO2] and [ZrO2] represent TiO2, SiO2 and ZrO2 contents. The wire shows excellent weldability in welding of all positions typically on 9% nickel steels and nickel-based alloy steels and gives a weld metal having good pitting resistance, bead appearance, and resistance to hot cracking.

Owner:KOBE STEEL LTD

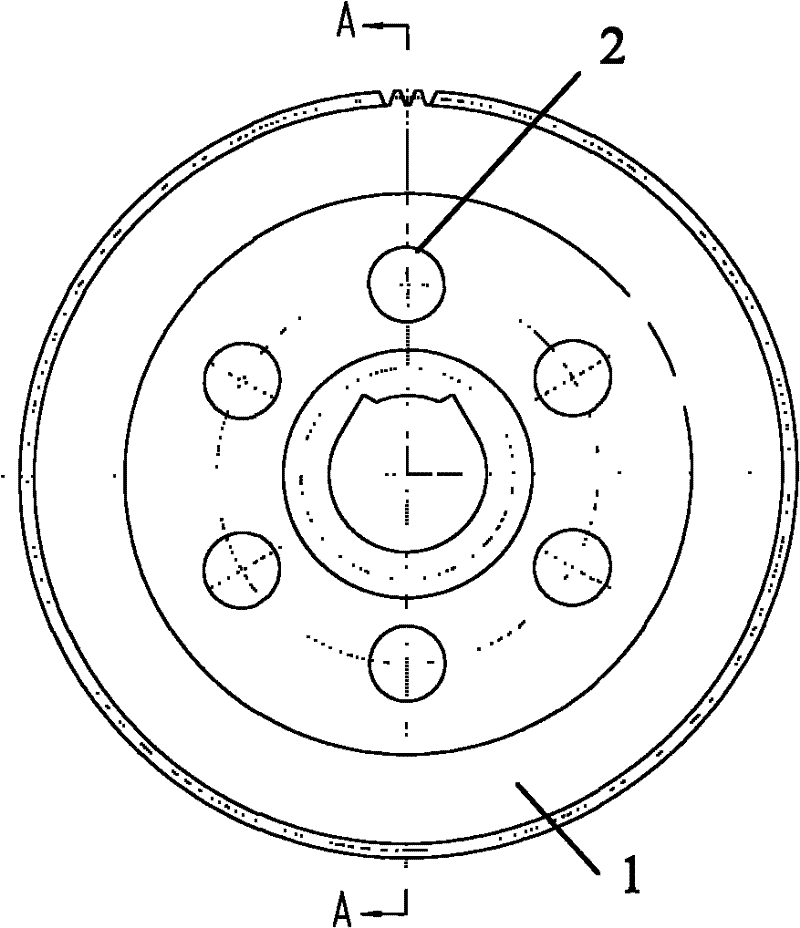

Wind power flange alloy steel and preparation technology of parts thereof

The invention discloses wind power flange alloy steel and a preparation technology of parts thereof. The alloy steel comprises the following chemical compositions: carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, vanadium, nickel, copper, nitrogen, oxygen, hydrogen, rare earth and the balance of iron and the inevitable impurities. The preparation technology of the alloy steel parts comprises the following steps: pretreating molten iron, smelting in a converter, performing external refining, casting steel ingots, performing flame cleaning, heating, forging, slowly cooling, performing heat treatment, machining, performing flaw detection, inspecting, packaging and warehousing. Compared with the existing alloy steel used in the wind power generation at home and aboard, the alloy steel disclosed by the invention has higher tensile strength, yield strength, elongation after fracture and reduction of area, particularly higher low-temperature impact toughness. The atmosphere corrosion resistance and the sea atmosphere corrosion resistance are increased by two levels.

Owner:江阴同庆机械制造有限公司

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

Roll sleeve of ultra-strong wear-resistant high alloy steel roll squeezer and manufacturing method roll sleeve

The invention relates to a roll sleeve of an ultra-strong wear-resistant high alloy steel roll squeezer and a manufacturing method of the roll sleeve, belonging to the technical field of casting in building material industry. The technical scheme is as follows: an outer layer adopts ultra-strong wear-resistant high alloy steel, an inner layer is formed by compounding low-carbon medium alloy steel, and the roll sleeve is manufactured through the process steps of melting the outer-layer ultra-strong wear-resistant high alloy steel, melting the inner-layer low-carbon medium alloy steel, centrifugally casting the compound roll sleeve and performing heat treatment on the compound roll sleeve. The roll sleeve and the manufacturing method thereof, disclosed by the invention, have the positive effects that: the preferential mixture ratio of the inner-layer material to the outer-layer material of the roll sleeve is adopted and a reasonable centrifugal compound casting process is adopted, thereby the inner layer and the outer layer are subjected to metallurgical bonding and a good bonding state is achieved. According to the characteristics of high alloy of the roll sleeve, the fracture toughness of the roll sleeve is enhanced by raising tempering temperature and performing multiple tempering processes. The outer layer of the roll sleeve disclosed by the invention has the hardness of 60-64HRC and the impact toughness of 12J / cm<2>, the inner layer has the hardness of 26-30HRC, the tensile strength of 800-900MPa and the yield strength of 730MPa, and the service life of the roll sleeve is prolonged by above 2 times in comparison with the traditional roll sleeve formed by forging and overlaying welding.

Owner:河北津西钢铁集团重工科技有限公司

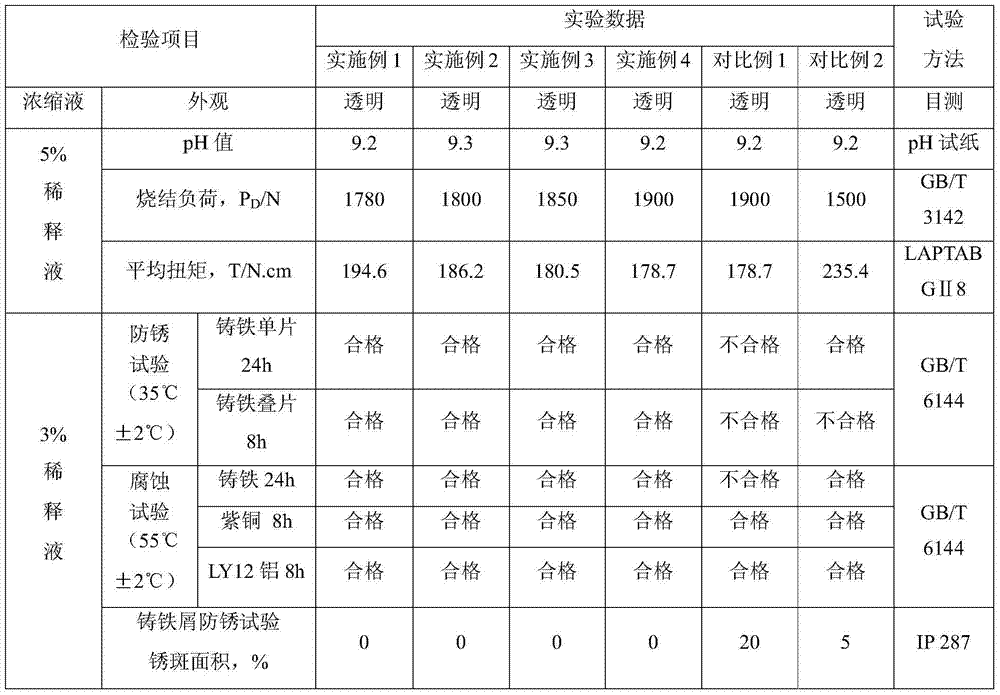

Heavy-load metal machining total synthesis cutting fluid as well as preparation method and application thereof

ActiveCN104277902AImprove the lubrication effectImprove extreme pressure performanceAdditivesMachine partsSuperalloy

The invention belongs to the field of metal machining fluids, and discloses a heavy-load metal machining total synthesis cutting fluid as well as a preparation method and an application thereof. The total synthesis cutting fluid comprises the following components in percentage by weight: 20%-30% of mixed alcohol amine, 6%-9% of anti-rust agents, 4%-6% of special amine, 6%-10% of lubricating agents, 15%-25% of extreme pressure agents, 6%-10% of cosolvents, 1%-2% of water-softening agents, 1%-3% of corrosion inhibitors and the balance of water. The total synthesis cutting fluid disclosed by the invention has excellent lubricating extreme pressure property, can meet the requirement for heavy-load machining, namely reaming, drilling, tapping, threading, broaching, thread machining and the like, of difficult-to-machine materials, namely high-temperature alloy steel, a titanium alloy and the like; a product is green and environment-friendly without containing boron, sodium nitrite, secondary amine, chlorine, phenol, formaldehyde, heavy metals and the like; in addition, the total synthesis cutting fluid disclosed by the invention has excellent anti-rust property, biological stability and machining property, and can enhance the surface quality of a machined part, prolong the service life of a cutter and reduce the rejection rate, thus improving the production efficiency.

Owner:广州国机润滑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com