Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

292 results about "Broaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

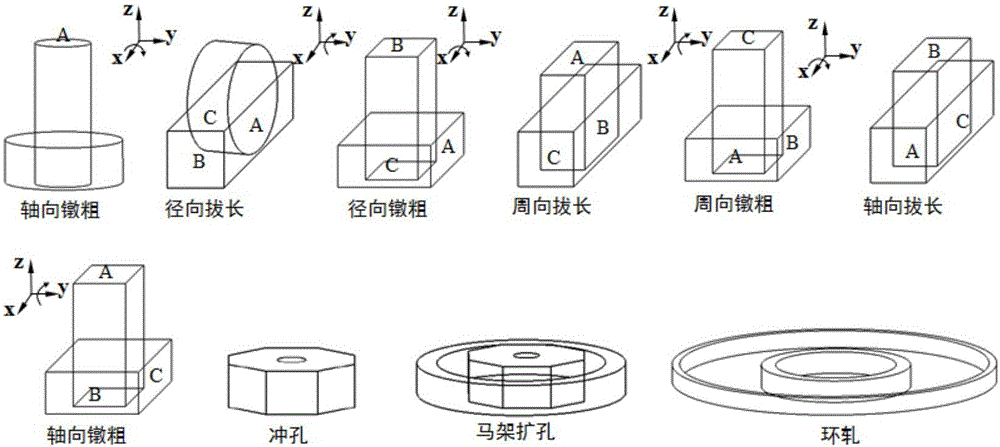

Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: linear and rotary. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to effect the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to broach. In rotary broaching, the broach is rotated and pressed into the workpiece to cut an axisymmetric shape. A rotary broach is used in a lathe or screw machine. In both processes the cut is performed in one pass of the broach, which makes it very efficient.

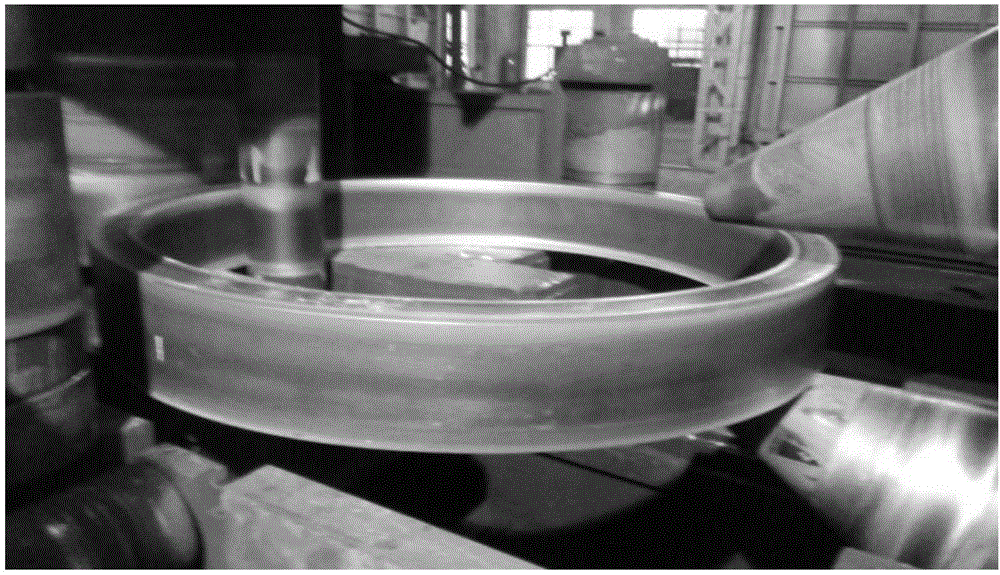

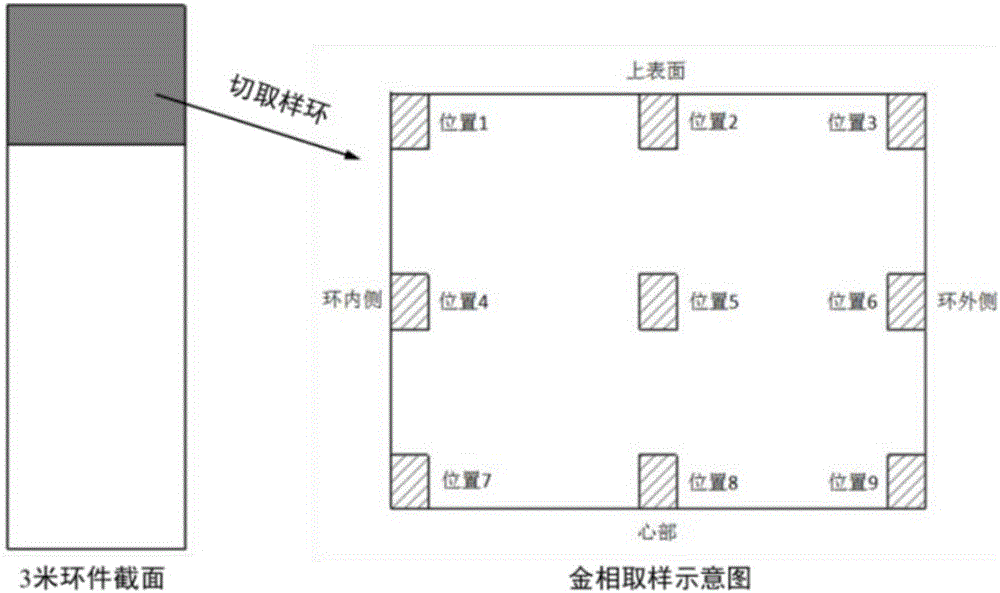

Process method for improving comprehensive mechanical property of 2219 aluminum alloy ring piece

The invention relates to the technical field of metal material deformation heat treatment processes and discloses a process method for improving the comprehensive mechanical property of a 2219 aluminum alloy ring piece so that coarse residual crystalline phases of the large-size 2219 aluminum alloy ring piece can be fully crushed and crystalline grains can be refined and equiaxed, thus, the strength and the plasticity of the 2219 aluminum alloy ring piece are improved at the same time, and the anisotropy is decreased. The process method comprises the steps of multi-directional forging, punching, mandrel supporter broaching, piecewise rolling and heat treatment. In the multi-directional forging step, the heating temperature of a blank is 500 DEG C-520 DEG C, and the final forging temperature is higher than or equal to 380 DEG C. Piecewise rolling comprises the steps that in the first stage, the ring blank is heated to 420 DEG C-460 DEG C and subjected to hot rolling on a ring rolling machine, and the hot rolling deformation quantity is 30%-40%; and in the second stage, the ring piece subjected to hot rolling is air-cooled to 240 DEG C-280 DEG C and is continuously subjected to medium and low temperature rolling on the ring rolling machine, and the deformation quantity is 15%-25%.

Owner:湖南中创空天新材料股份有限公司

Main spindle box for milling and drilling machine

InactiveCN102328098AMeet the needs of milling and drilling combined processingMeet the needs of compound processingOther manufacturing equipments/toolsMaintainance and safety accessoriesDrive shaftGear wheel

The invention relates to a main transmission box for a milling and drilling machine. The main transmission box comprises a sealed cavity composed of a box body and a box cover, and an input shaft component, a transmission shaft component and an output shaft component are mounted in the sealed cavity. The main transmission box is characterized in that a gear shaft is rotatably mounted in the sealed cavity, a main shaft motor is mounted on the sealed cavity, an output shaft of the main shaft motor is connected with the gear shaft; the transmission shaft can be rotatably mounted in the sealed cavity, and a high-low-drive gear set is assembled on the transmission shaft in a sliding manner; a large transmission gear in the high-low-drive gear set is always engaged with a gear shaft in the input shaft component; the main shaft can be rotatably mounted in the sealed cavity, a large output gear and a small output gear are mounted on the main shaft; a main shaft broaching-loosening cutter is arranged in the main shaft for firmly grasping a cutter. The transmission shaft box has rational and clever structure, and can meet a high output torque demand of the main shaft milling processing and a high output rotation speed demand of the drilling processing, can effectively meet the milling-drilling composite processing demands of parts. By the adoption of the transmission shaft box, the working efficiency can be obviously improved and the processing precision can be ensured.

Owner:无锡桥联数控机床有限公司

Ultrasonic broaching tool, high-efficiency precise ultrasonic broaching device and broaching process thereof

ActiveCN109967789AExtended service lifeImprove broaching efficiencyBroaching accessoriesBroaching toolsGratingUltrasonic sensor

The invention discloses an ultrasonic broaching tool, a high-efficiency precise ultrasonic broaching device and a broaching process thereof. An existing broaching tool and an existing broaching machine are not provided with integrated information acquisition devices and are short in service life. The ultrasonic broaching tool comprises an ultrasonic transducer, a detection assembly and a broachingtool body. The detection assembly comprises a detection substrate, a laser transceiving belt, an image sensor, an axial pressure sensor, a first radial pressure sensor and a second radial pressure sensor. The high-efficiency precise ultrasonic broaching device comprises a broaching machine body, an optical grating and the ultrasonic broaching tool. The broaching machine body comprises a broachingmachine drive assembly, a broaching machine body, a broaching machine guide rail and a fast positioning and clamping device. A broaching tool three-directional vibration value, a broaching tool axialtensile force, a broaching tool displacement value, and a workpiece dimension based on an image are measured. Real-time detection data is provided for a working condition feedback loop and a stop control loop of a control system. The service life of the broaching tool can be effectively prolonged.

Owner:HANGZHOU DIANZI UNIV

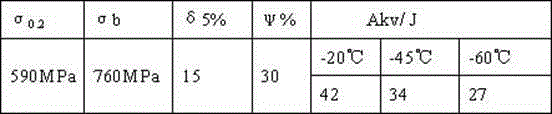

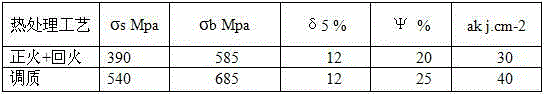

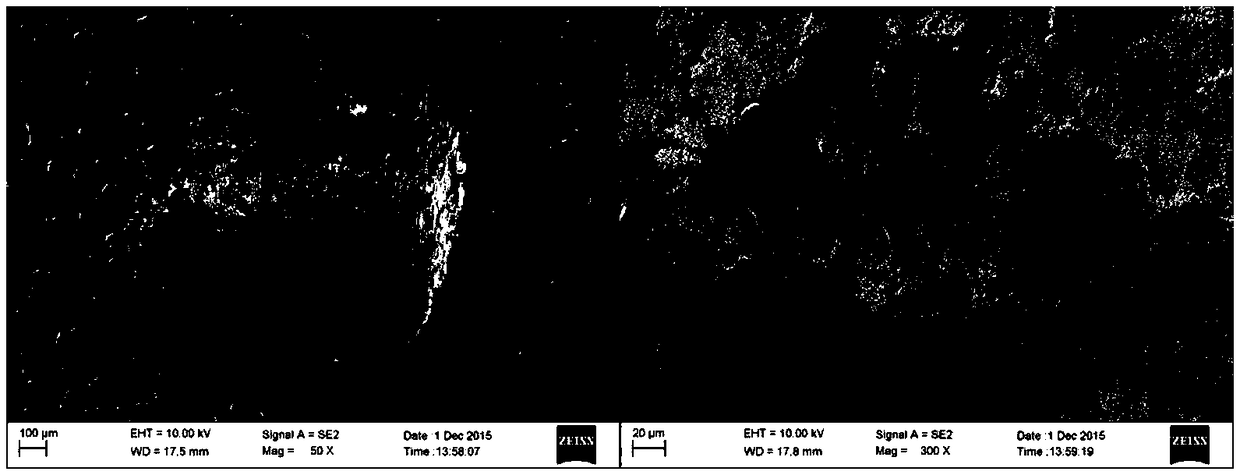

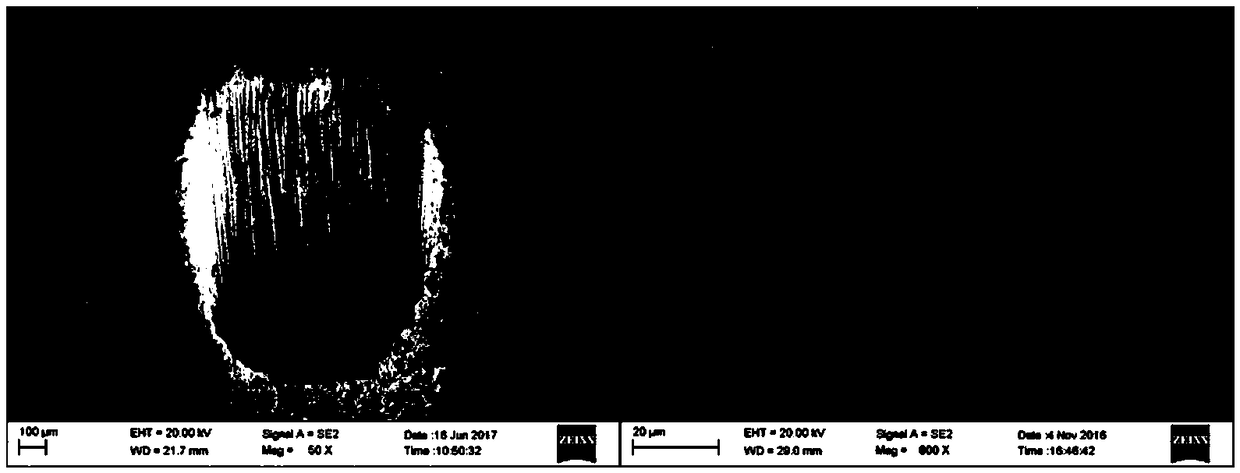

Manufacture technique of tap shells for polar drill rigs

The invention discloses a manufacture technique of tap shells for polar drill rigs. The manufacture technique incudes: (1) for forging, performing forging via upsetting, punching, broaching and forming to guarantee a forging fiber flow line under the conditions that heating temperature is 1270-1310 DEG C, initial forging temperature is 1100-1250 DEG C and terminal temperature is not lower than 850 DEG C, performing annealing after forging under the condition that the heating temperature is 880+ / -20 DEG C, and performing furnace cooling to enable tapping temperature not higher than 300 DEG C; (2) for heat treatment, normalizing at temperature of 880-900 DEG C prior to air cooling, quenching at temperature of 840-860 DEG C prior to oil cooling or cooling with a PAG quenching medium, tempering at temperature of 580+ / -40 DEG C prior to air cooling, performing subcritical quenching at temperature of 790+ / -10 DEG C prior to oil cooling or cooling with the PAG quenching medium, and tempering at temperature of 520-600 DEG C prior to air cooling; (3) for non-destructive inspection, finishing prior to machining a product according to size, and performing ultrasonic inspection and magnetic particle inspection, wherein the qualified level conforms to API Specification 8C standards. Compared with the prior art, the manufacture technique has the advantages that the tap shells manufactured with the technique have high strength to guarantee enough safety factor, adapt to polar regions (at the temperature of minus 60 DEG C) and meet the requirement on enough low temperature impact toughness so as to resist to the low-temperature environment of the polar regions.

Owner:RG PETRO MACHINERY GROUP

Special-shaped hole machining method and special-shaped hole

InactiveCN109175732AHigh shape accuracyHigh dimensional accuracyLaser beam welding apparatusGalvanometerNanosecond pulse

The invention discloses a special-shaped hole machining method and a special-shaped hole and relates to the technical field of laser machining. According to the method, femtosecond or picosecond or nanosecond pulse laser is adopted, and a mode completely based on scanning galvanometer filling machining is provided. The method comprises the steps that firstly, a through hole smaller than the hole diameter requirement is machined so that gasification objects and fusion objects formed in the machining process can be discharged and re-coagulation objects are prevented from depositing; then, roughmachining of a special-shaped hole diffusion section is conducted; then, the laser focusing position is adjusted, broaching is conducted on the basis of a dust discharge through hole, and a cylindrical through hole meeting the hole diameter requirement is machined; and finally, the focus position is precisely adjusted, and the diffusion section is machined layer by layer. By means of the special-shaped hole machining method and the special-shaped hole, heat-induced defects such as recasting layers, microcracks, coating collapse and the like generated in the process that in the prior art, a special-shaped hole is machined, and in particular, the special-shaped hole is machined in a workpiece with the surface coated with a thermal barrier coating are avoided; and in addition, the shape and dimension precision of the special-shaped hole are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Gear ring support machining technique

The invention provides a gear ring support machining technique. The machining technique comprises the following steps of (1) blank detection, (2) rough turning, (3), tempering and shot blasting, (4) semi-extractive turning, (5) quenching, (6) gear broaching, (7) large end face and groove turning, (8) hole drilling and notch milling, (9) hobbing, (10) orifice chamfering, and (11) cleaning and packaging. The machining technique of an inner gear ring is simple in procedure, the hardness of an obtained gear ring support is high and can reach 700-850 HV, the effective hardness depth can reach 0.50 mm, the precision is high, and the abrasion resistance is good.

Owner:江苏金卡汽车部件有限公司

Extruding molding method of austenitic stainless steel seamless pipe for hydrogenation cracking furnace

The invention relates to an extruding molding method of an austenitic stainless steel seamless pipe for a hydrogenation cracking furnace. The method comprises the following steps of I, preparing a pipe blank, wherein the specification of the pipe blank is phi250mm to 450mm, and a central through hole is phi40mm to 100mm; II, preheating the pipe blank, wherein the temperature of the furnace when the pipe blank enters a furnace mouth is 750 DEG C plus or minus 10 DEG C, the target temperature of an annular furnace is 1000 DEG C plus or minus 10 DEG C, a heat homogenizing time lasts for 25min to 30min, the surface temperature of the pipe blank when the pipe blank is discharged from the furnace is 1000 DEG C plus or minus 10 DEG C; III, primarily heating in an induction manner, wherein the target induction temperature is 1150 DEG C plus or minus 10 DEG C, and the total time of the heating and heat preserving lasts for 3min to 5min; IV, broaching, namely, placing the pipe blank after being lubricated by glass powder into a broaching machine, and completing the broaching by utilizing a broaching cone; V, secondarily heating in the induction manner, wherein the pipe blank enters a second induction furnace, the target temperature is 1200 DEG C plus or minus 10 DEG C, and heat homogenizing time lasts for 1min to 2min; VI, extruding, namely, preheating an extrusion tube to be more than 300 DEG C, placing the pipe blank into an extruder after being lubricated by the glass powder, and performing water cooling on the pipe blank after the extrusion is completed. By adopting the extruding molding method of the stainless steel pipe, the thermoplasticity is good in molding, and a crack hard to occur in the heating machining process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Formed reinforced complex phase steel and preparation method thereof

The invention provides formed reinforced complex phase steel, and belongs to the field of cold-rolled ultrahigh-strength steel production and manufacturing. The formed reinforced complex phase steel is prepared from the chemical components including, by mass, 0.17%-0.21% of C, 0.2%-0.7% of Si, 1.8%-2.5% of Mn, less than or equal to 0.01% of P, less than or equal to 0.005% of S, 0.4%-0.8% of Al, 0.1%-0.39% of Cr, 0.02%-0.04% of Nb, at least one of 0.01%-0.04% of Ti and 0.03%-0.1% of Cu, and the balance Fe. The tensile strength of the complex phase steel is higher than 980 MPa, and meanwhile, the complex phase steel has good broaching performance and forming performance and is particularly applicable to automobile parts which have flanging and broaching design and need certain forming capacity. The invention further provides a preparation method of the formed reinforced complex phase steel.

Owner:SHOUGANG CORPORATION

Axial force controllable surgical bone drill with stepped bit

The invention relates to an axial force controllable surgical bone drill with a stepped bit. The axial force controllable surgical bone drill with the stepped bit is high in control precision and capable of effectively preventing injury to brain tissues, and comprises a drill body and the bit, a direct-current motor is arranged in a casing of the drill body and is connected with an intelligent integrated control system and a direct-current power supply, an output shaft of the direct-current motor is connected with a gear transmission device which is connected with a drill chuck through a transmission shaft, and the bit is mounted on the drill chuck. A thrust bearing is arranged at the joint of the drill chuck and the transmission shaft and clings to a deformation element, the deformation element is closely attached onto the casing and is positioned by an elastic element, a resistance strain gauge is adhered to the inner surface of the deformation element and is further connected with the intelligent integrated control system, and a sealing device is arranged between the drill chuck and the casing. A first portion of the bit is a guide portion, a twist drill serves as a bit body, a second portion of the bit is a transition portion, a third portion is a broaching portion, and diamond grains are arranged on spiral surfaces of the transition portion and the broaching portion.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

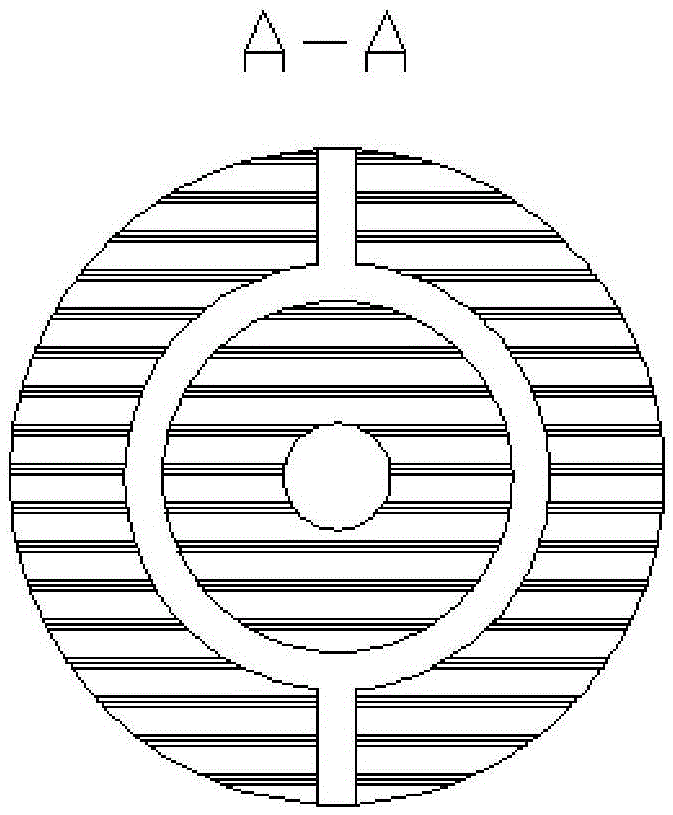

Spiral bevel gear broaching method and gear broaching machine tool

ActiveCN103624332AAvoid shockEfficient processingDriving apparatusGear-cutting machinesGear wheelEngineering

The invention relates to a spiral bevel gear broaching method. The spiral bevel gear broaching method includes the following steps that firstly, a gear to be machined is clamped on an indexing device and kept still, an initial cutter tooth of a gear broaching cutter rotates at the initial speed to enter a machining portion to conduct gear broaching; secondly, subsequent cutter teeth sequentially rotate at a machining speed to enter the machining portion to conduct machining till the final cutter tooth rotates out of the machining portion; thirdly, indexing fan sections of the gear broaching cutter rotate corresponding to the machining portion at an indexing speed, the indexing device drives the gear to be machined to rotate so that indexing can be completed, wherein the rotating speed of the initial cutter tooth of the gear broaching cutter in the machining portion and the rotating speed of the indexing fan sections of the gear broaching cutter in the machining portion are lower than the rotating speed of other cutter teeth in the machining portion; fourthly, executing the first step, the second step and the third step to machine a next gear. The invention further relates to a gear broaching machine tool special for implementing the spiral bevel gear broaching method. The rotating speed of the initial cutter tooth of the gear broaching cutter in the machining portion and the rotating speed of the indexing fan sections of the gear broaching cutter in the machining portion are lower than the rotating speed of other cutter teeth in the machining portion, and therefore machining safety is ensured, and machining efficiency is improved.

Owner:洛阳越格数控设备有限公司

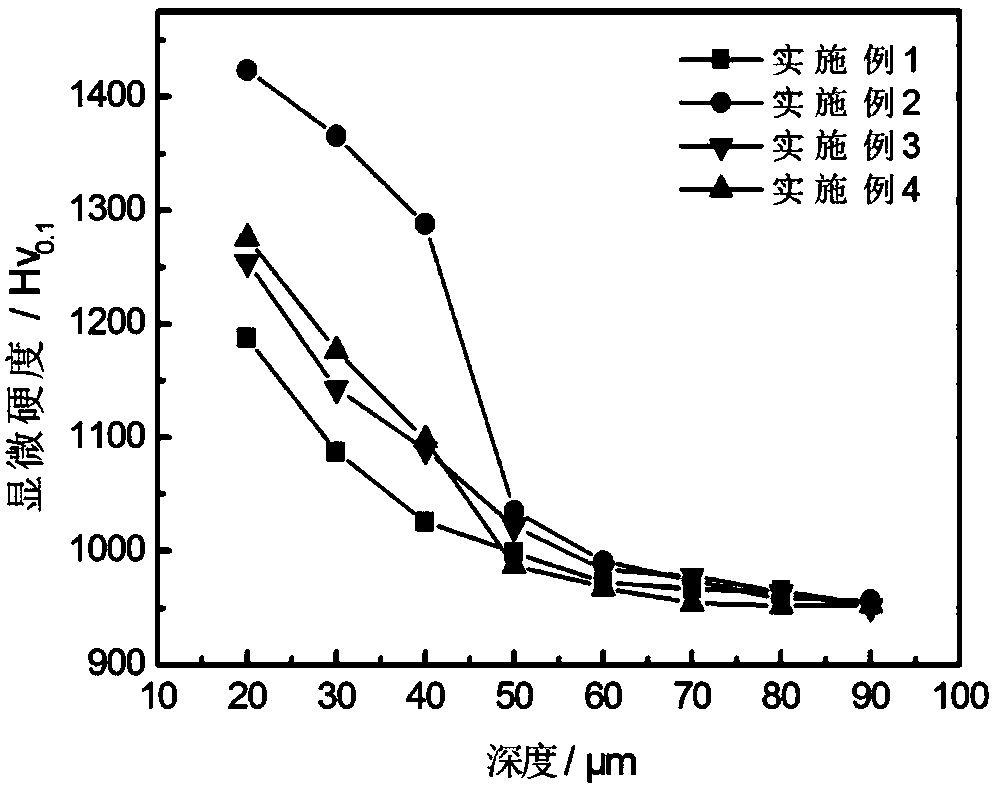

Strength-toughening treatment method of W6Mo5Cr4V2 high-speed steel broaching tool

ActiveCN108359785AHigh hardnessGuaranteed toughnessSolid state diffusion coatingFurnace typesTime rangeRoom temperature

The invention discloses a strength-toughening treatment method of a W6Mo5Cr4V2 high-speed steel broaching tool, and belongs to the technical field of alloy tool steel heat treatment technology. The method specifically comprises the following steps that the W6Mo5Cr4V2 high-speed steel broaching tool is subject to graded quenching in a salt bath; high-temperature tempering is carried out two times;salt bath nitrogen carbon co-cementation treatment is carried out, the temperature ranges from 540 DEG C to 550 DEG C, and time ranges from 20 min to 40 min; finally, liquid oxidizing treatment is carried out, the temperature ranges from 350 DEG C to 380 DEG C, time ranges from 20 min to 30 min, and discharge cooling to the room temperature is achieved; salt bath nitriding and liquid oxidizing arerepeated for multiple times, and the diffusion layer depth is increased. The strength tightening of the W6Mo5Cr4V2 high-speed steel broaching tool is improved, the impregnating layer depth is obviously increased, the surface hardness of the broaching tool is effectively improved, the service life of the broaching tool can be prolonged by two to four times, in addition, after the broaching tool isused for a while, the blade regrinding property is better than that of existing one-time nitriding treatment.

Owner:YANCHENG INST OF TECH

Up and down hole combined cutting-well-free slot broaching method

ActiveCN111441774AReduce clamping effectSufficient space for blasting compensationUnderground miningBlastingRock cuttingEngineering

The invention provides an up and down hole combined cutting-well-free slot broaching method. The method comprises the steps that inclined down holes are constructed in corresponding positions of an upper layering rock chiseling roadway and a lower layering cutting transverse roadway through a down-the-hole drill, after the down holes are arranged and constructed, a lower ore roof falling zone andthe lower layering cutting transverse roadway serve as blasting free faces, and blasting is carried out to obtain a first blasting space; up slot broaching holes are mounted and constructed in the lower layering cutting transverse roadway, first blasting space formed through down hole blasting and the lower layering cutting transverse roadway serve as free faces, and segmented blasting is carriedout to form a complete cutting vertical slot. The down holes and up holes are combined to carry out slot broaching, the up holes take the blasting space formed by the down holes as the free faces, segmented blasting is carried out, the process is simple and reliable, and the method is safe and economic. The method is suitable for breaking ores, construction of a cutting well is not needed, high danger and cost of construction of the cutting well in fractured ore rock can be reduced, and giant application prospects can be achieved.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Valve hole ream-extrude working method

InactiveCN1775463AImprove stabilityEnsure consistencyTurning toolsReaming toolsEngineeringMachine tool

The present invention discloses a method for machining valve hole by simultaneously adopting reaming and extruding processes. Said method process includes broaching-semifinishing boring-reaming and extruding hole; selecting cutting parameters (cutting speed Vc=5.9m / min, feeding rate f=0.084mm / r and cutting depth ap=0.1mm) and extrusion quantity (0.01-0.02mm). the broaching process adopts broaching cutter, semi-finishing boring process adopts boring cutter with two edges and reaming-extruding process adopts reaming-extruding cutter.

Owner:贵州凯星液力传动机械有限公司

Radius highly synchronous and precise broaching processing method for double bearing bushes and automation device

ActiveCN102873398AEven by forceGuaranteed positioning accuracyOther manufacturing equipments/toolsMetal working apparatusEngineeringAutomation

The invention discloses a radius highly synchronous and precise broaching processing method for double bearing bushes and an automation device on the basis of the method. The processing method comprises processes of automatic loading and feeding, clamping and positioning and broaching processing of the bearing bushes; before the clamping and positioning process, a floating preset positioning process of the double bearing bushes is added; and in the clamping and positioning process, a full floating structure clamping seat and two elastic-expansion three-point positioning pressure heads are adopted. According to the automation device, the technical difficult problem of simultaneously clamping and positioning the double bearing bushes is solved; the processing efficiency is improved; and the automation device has high precision degree and good safety performance.

Owner:SHIJIAZHUANG DONGFANG BEARING

Heating-wiredrawing-finish broaching shaping-cooling wire manufacturing method

ActiveCN105642688AImprove plasticityAvoid the effects of performance degradationWire straightening devicesDrawing diesWire rodShielding gas

The invention discloses a heating-wiredrawing-finish broaching shaping-cooling wire manufacturing method. A device related to the method mainly comprises an induction heating mechanism, a wiredrawing die, a finish broaching shaping treatment mechanism, a cooling mechanism, shield gas grooves and sealing rings. The wiredrawing device is suitable for manufacturing high-strength welding wires and metal wires. Non-contact induction heating is adopted so that wires to be drawn or line materials to be drawn can be rapidly heated to a certain temperature, the plasticity and toughness of the wires to be drawn or the line materials to be drawn are improved, and wiredrawing is convenient. Gas shield can be provided through the device, and the wires are effectively prevented from being oxidized in the heating and drawing process. By means of the wire manufacturing method, induction heating, wiredrawing, finish broaching shaping, tissue control and other functions are integrated.

Owner:JIANGSU SHUOSHI WELDING SCI & TECH

Processing technology for plate hub of driven plate assembly and mould component adopted in the processing technology

InactiveCN102554572AIncrease profitMeet the use requirementsMetal working apparatusSheet steelPunching

The invention relate to a processing technology for a plate hub of a driven plate assembly. The plate hub comprises a plate hub sheet and a plate hub core, wherein the plate hub sheet is formed by processing steel plates through material shearing, punching, leveling and thermal treatment; the plate hub core is formed by processing blank plate hub core materials through surface turning, groove lathing, gear punching and thermal refining; then the plate hub cores form an integral body through assembling and riveting treatment; after inner hole turning, shot blasting, spline broaching and rust prevention treatment, the whole processing procedure of the plate hub is completed, and the finished product plate hub is produced. A mould component adopted in the processing technology comprises a lower mould template, an upper mould and an upper mould template, wherein a lower mould universal female seat is mounted on the lower mould template; and a work lower mould is mounted in the lower mould universal female seat. For the processing technology, the machining allowance is small, the material utilization ratio is high, the verticality of the plate hub is guaranteed, the production efficiency is improved, and the performance requirement on deflection of the driven plate assembly is met, so that the torsion property is more stable. Due to the adoption of the universal female seat, the mode that specific work components are replaced is adopted, so that the use requirements of different products on the mould are met, the mould replacement time is prolonged, the number of moulds is reduced, and the manufacturing and managing costs of the mould are reduced.

Owner:浙江华信汽车零部件有限公司

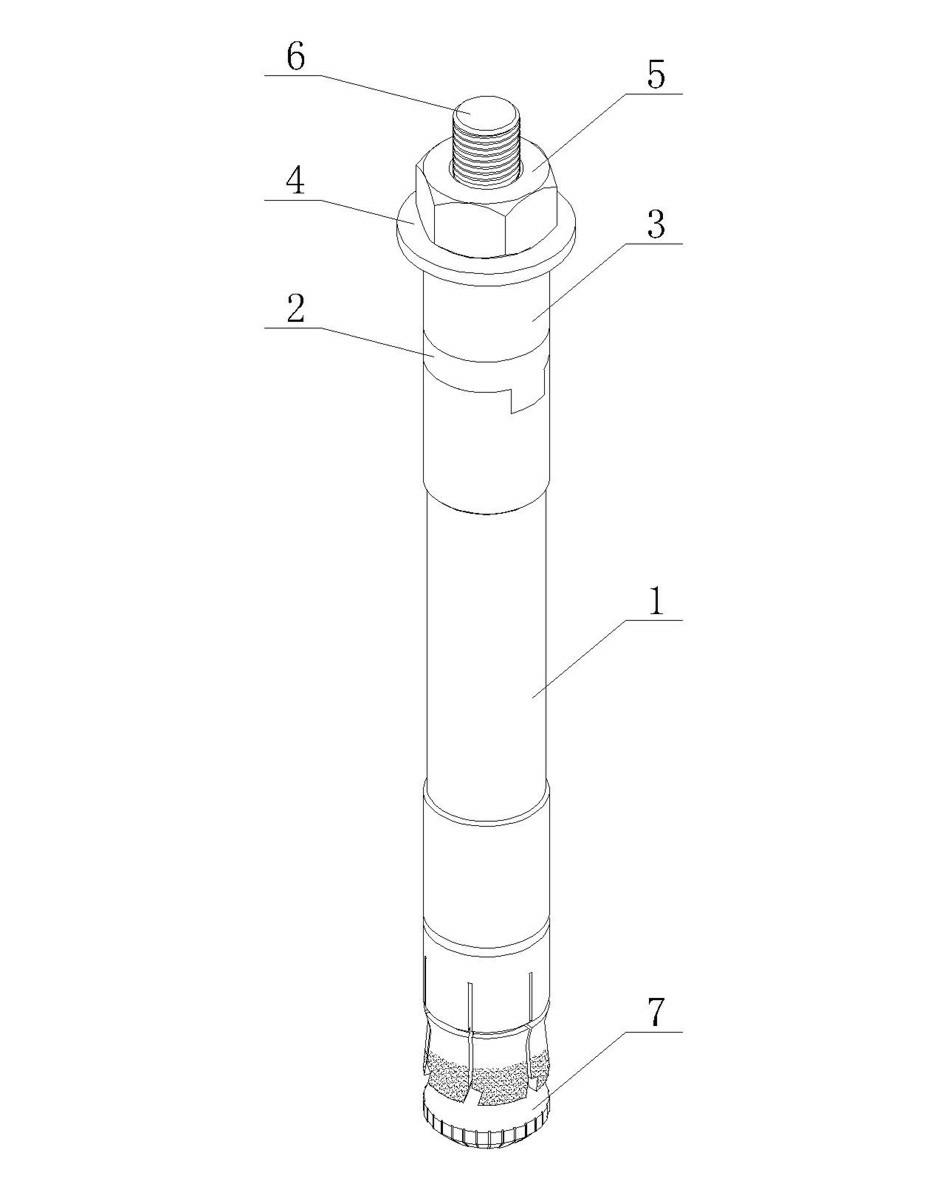

Self-tangency broaching anchor bolt

InactiveCN102635616AImprove horizontalImproved Longitudinal Milling PerformancePortable percussive toolsDowelsMilling cutterAlloy

The invention discloses a self-tangency broaching anchor bolt comprising a sleeve, wherein the lower end of the sleeve is provided with an expansion structure, the upper end of the sleeve is provided with a clamp groove which is embedded with an installing tool, the expansion structure comprises a plurality of expansion pieces, the lower end of the expansion structure is provided with a milling structure, the milling structure comprises a plurality of cutter teeth which are peripherally and evenly distributed around the axis of the sleeve, one sides, which face to a sleeve rotating direction, of the cutter teeth are provided with cutting edges, the cutting edges are slantwise arranged opposite to the end face of the sleeve, and the bottom ends of the cutting edges are convex towards the sleeve rotating direction; and the cutter teeth are directly machined by the lower end of the expansion structure, a hard material wear layer is arranged on the working faces of the cutter teeth or the cutting edges are provided with hard alloy blocks, or the cutter teeth are wholly formed by the hard alloy and are fixed at the lower end of the expansion structure. The self-tangency broaching anchor bolt uses the milling principle of a milling cutter, so that the cutting edges are matched with the hard alloy or hard material wear layer, therefore, the transverse and lengthways milling performance can be greatly improved when the anchor bolt is expanded.

Owner:王春华

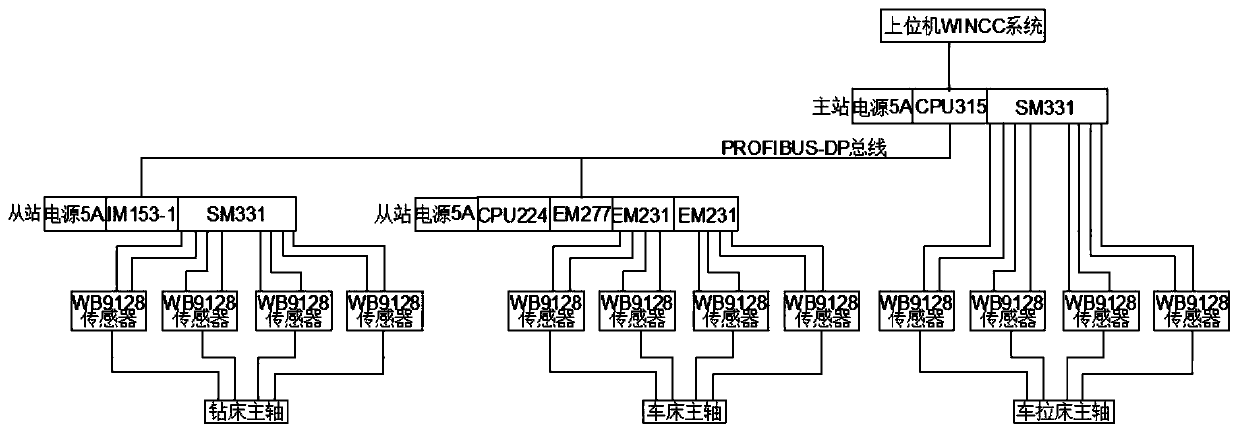

Numerically controlled machine tool electrical parameter collection system and method

PendingCN109753021ARealize human-computer interaction and coordination workEasy to analyzeProgramme controlComputer controlElectrical and Electronics engineeringNumerical control

The invention belongs to the technical field of the numerically controlled machine tool, and discloses a numerically controlled machine tool electrical parameter collection system and method. A hardware platform is constructed by Siemens PLC200, Siemens PLC300 and WB9128 power collectors, three WB 9128 power collectors are used for respectively collecting a turn-broaching numerically controlled machine tool electrical parameter, a drilling machine electrical parameter and a numerically controlled lathe electrical parameter, and then an electrical parameter analog signal is transmitted to analog input modules of S1-300 and S7-200 through a WB9128 sensor analog quantity output OUT, and then the PLC program is compiled to collect and process the analog quantity data; the WINCC configuration software is utilized to communicate with the PLC through a PROFIBUS-DP bus, and the electrical parameters are saved, and the process filing is performed; and the intelligent control of the numericallycontrolled lathe is realized.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

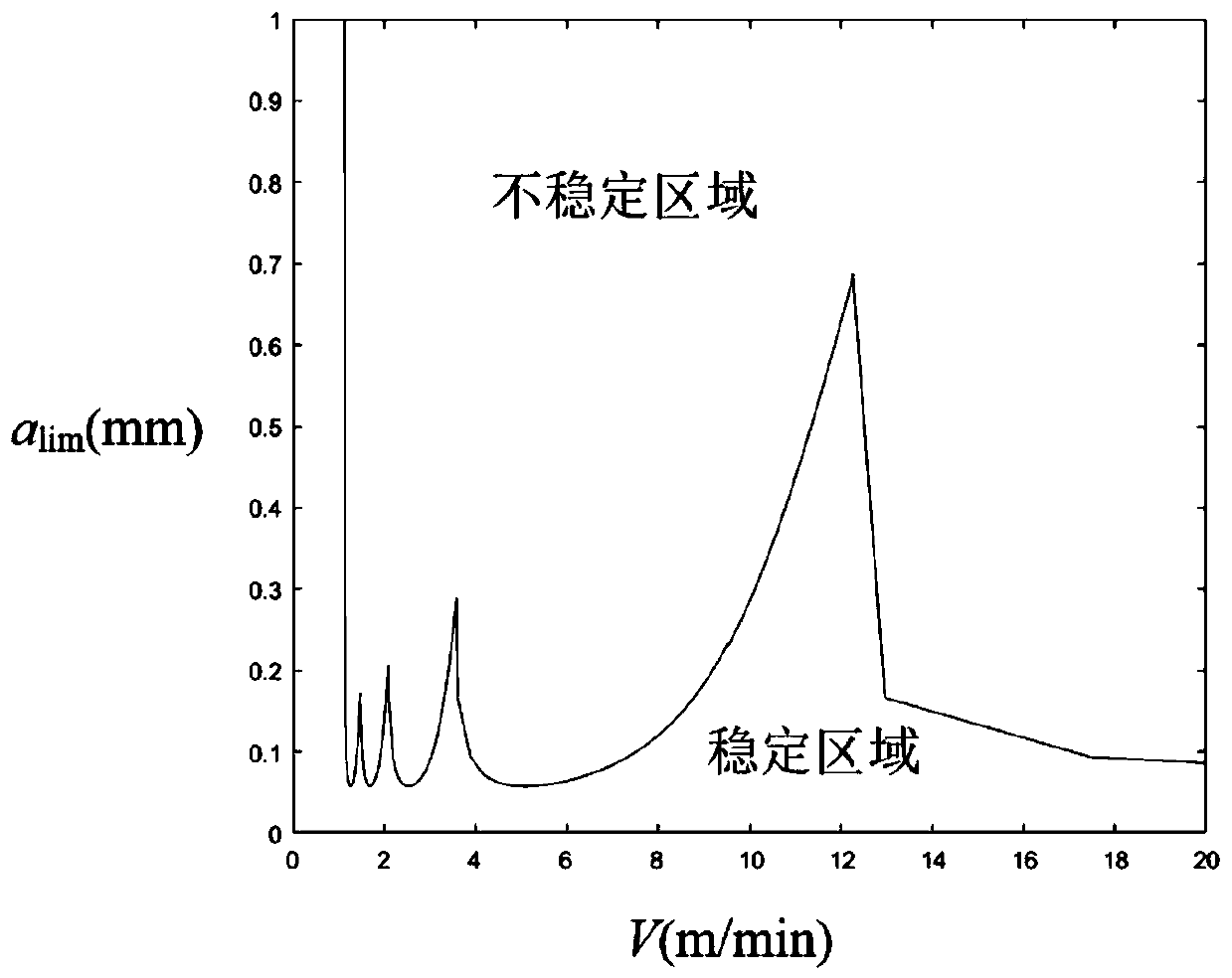

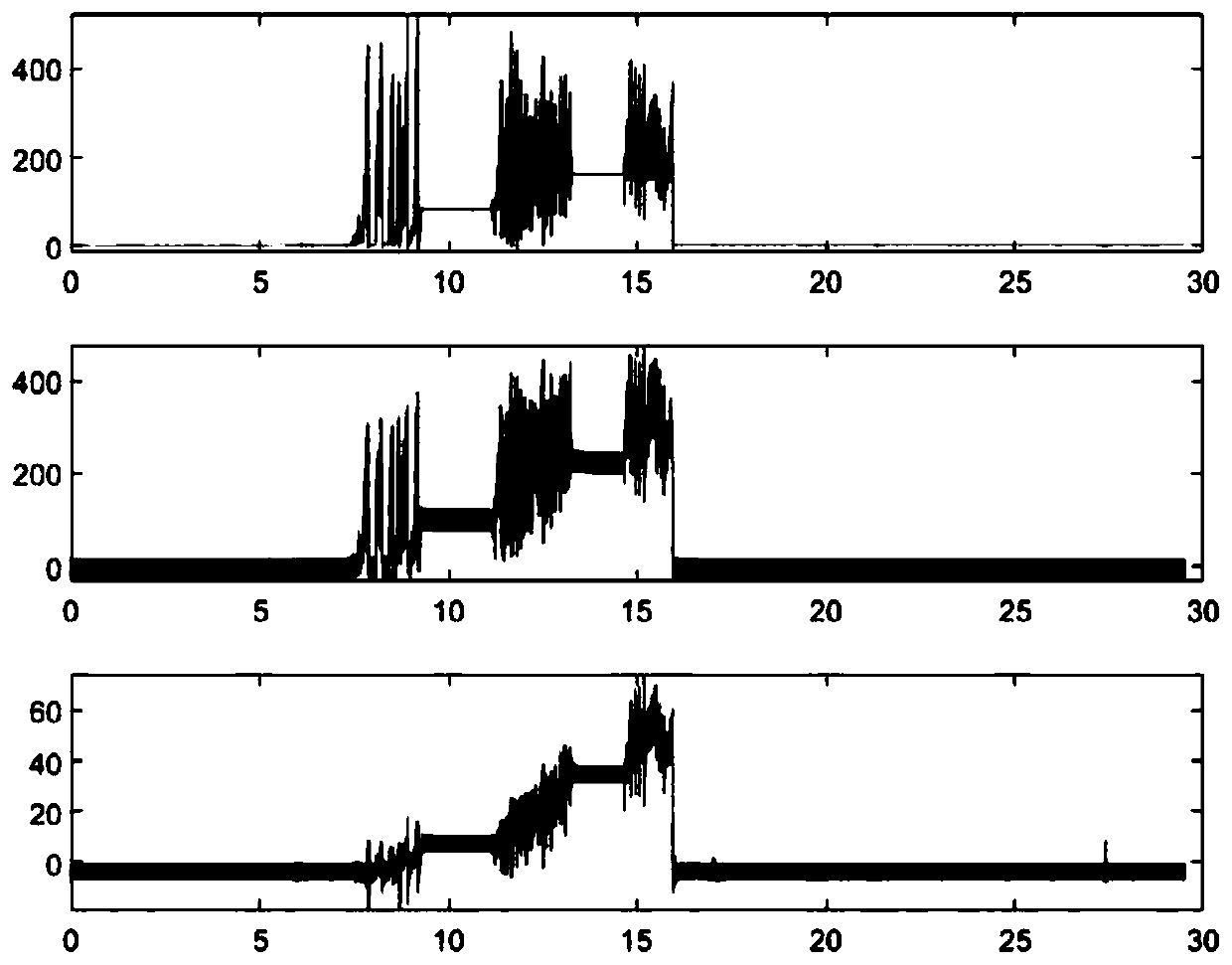

Clamp system and machining method for high-speed precision broaching machining of turbine disc mortise

ActiveCN111069941AEasy to processReal-time monitoring of processing statusMeasurement/indication equipmentsPositioning apparatusVibration accelerationEngineering

The invention discloses a clamp system and a machining method for high-speed precision broaching machining of a turbine disc mortise. The clamp system comprises a pressure sensor, a vibration acceleration sensor, signal collecting and processing equipment and a clamp for clamping a workpiece. The clamp comprises a clamp body, a pressing plate, an upper plate and pressing bolts, the pressure sensorand the vibration acceleration sensor are electrically connected with the signal collecting and processing equipment, and the pressing plate and the upper plate are connected to form a space containing the workpiece through the pressing bolts. The upper plate is arranged on the clamp body, the pressure sensor is arranged in the clamp body, and the vibration acceleration sensor is arranged in theupper plate. The clamp system can monitor the machining state such as tool abrasion, abnormal vibration, cutting force and other parameters in real time, through the method, the machining strategy canbe adjusted through monitoring of the tool state, and optimal machining of the turbine disc mortise is achieved.

Owner:CENT SOUTH UNIV

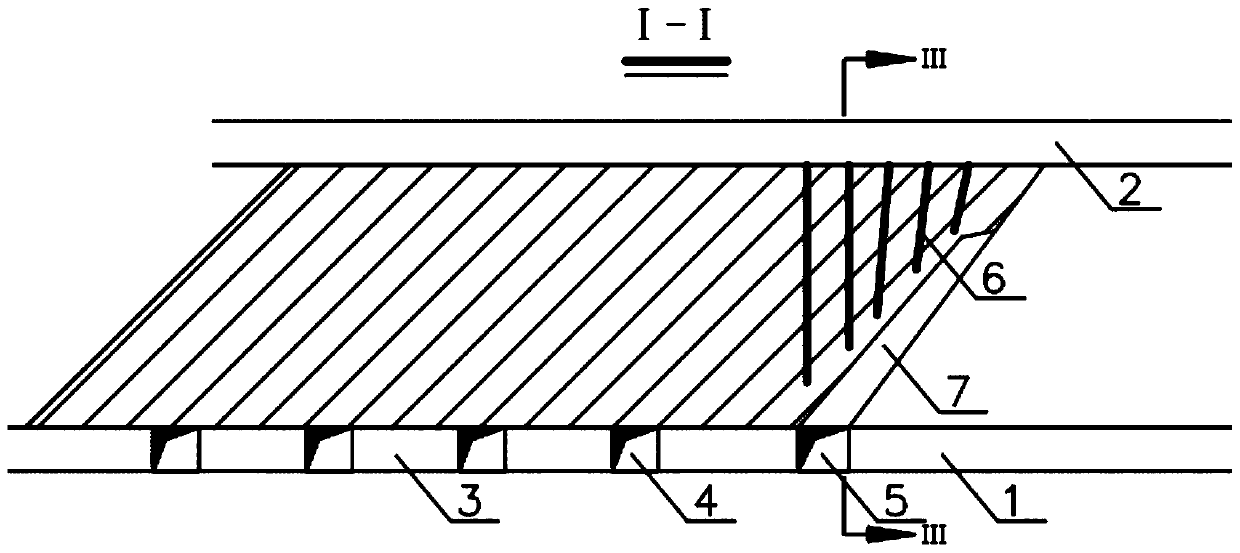

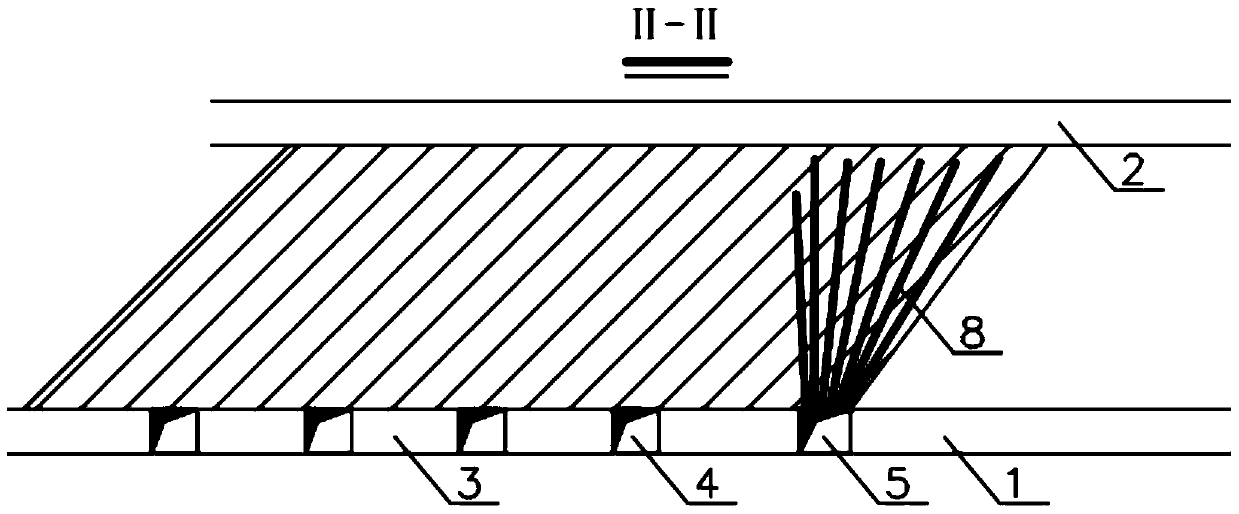

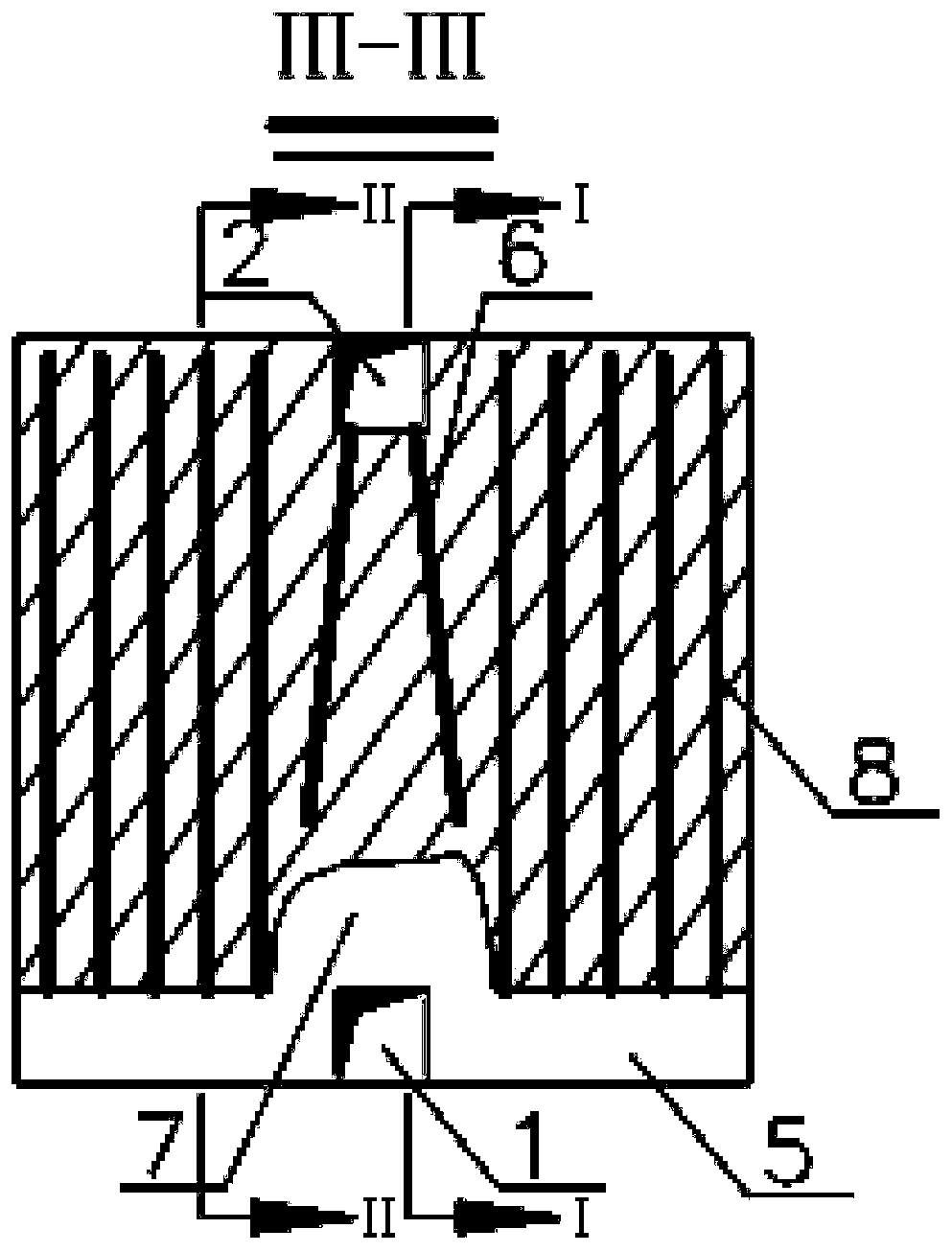

Gear broaching key positioning fixture

InactiveCN103831467AEasy loading and unloadingQuick loading and unloadingPositioning apparatusBroaching machinesGear wheelDetent

The invention discloses a gear broaching key positioning fixture. By the adoption of the gear broaching key positioning fixture, the precision of a key groove can be guaranteed, and the angle between the key groove and teeth can reach the standard. According to the technical scheme, the left end of a fixture body (1) of the gear broaching key positioning fixture is connected with a horizontal broaching machine, and a mandrel at the right end of the fixture body (1) is matched with an inner hole of a gear (4); a guiding body (2) is connected and clamped to the fixture body (1) through screws (7) and positioning pins (8), grooves are formed in the middle of the fixture body (1) and in the middle of the guiding body (2), and a broaching tool (5) reciprocates along the grooves to machine the gear; a positioner (3) is installed on the fixture body (1), the position where the positioner (3) is fixed is adjusted according to the angle of a gear which is machined firstly until the angle between the key groove (6) and a marking tooth (9) is within the range of + / -10 minutes, and then the positoiner (3) is tightened. The gear broaching key positioning fixture has the advantages that the manufacturing cost is low, and using is easy and convenient; readjustment is not needed after adjustment is conducted once, and the stability is high; the gear can be assembled and disassembled conveniently, rapidly and efficiently, and the average time for assembling or disassembling a part is only five seconds.

Owner:大连创新齿轮箱制造有限公司

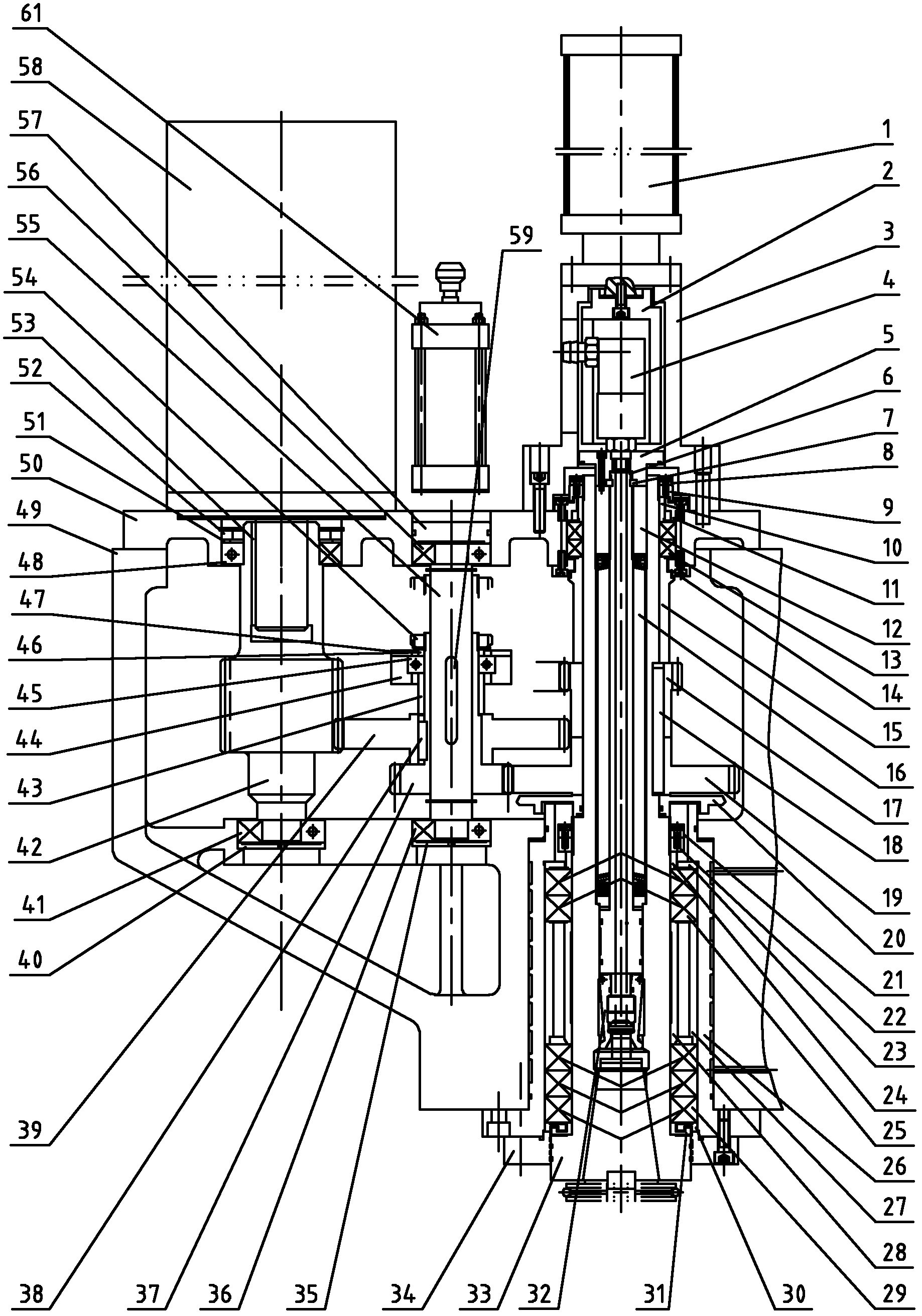

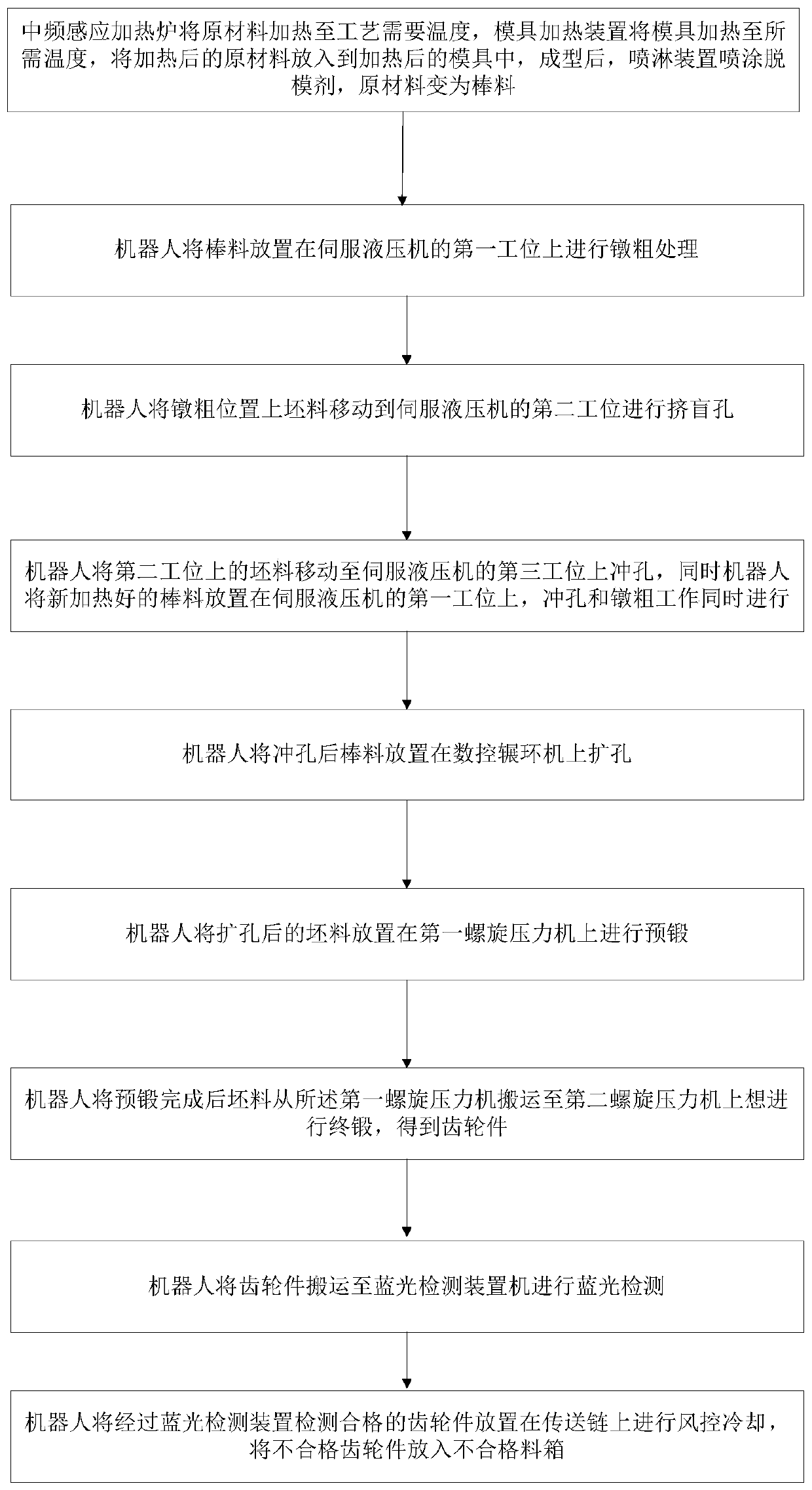

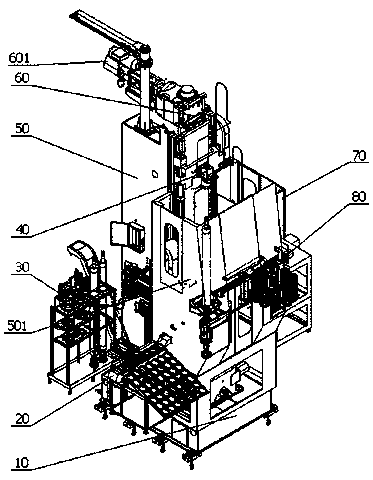

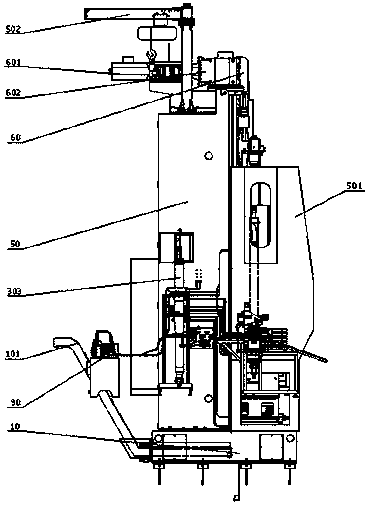

Automatic forging system and method for annular gear blank

PendingCN111036831APrevent possible errors caused by manual operationHigh sorting accuracyMetal-working apparatusGear wheelsNumerical controlAutomatic control

The invention discloses an automatic forging system and method for annular gear blanks. The system comprises a sawing machine, a medium-frequency induction heating furnace (2), a robot (3), an annularpiece multi-station blank manufacturing servo hydraulic machine (4), a numerical control ring rolling machine (6) and a screw press (7) which are connected in sequence. The annular piece multi-station blank manufacturing servo hydraulic machine (4) is provided with a first station, a second station and a third station, wherein the first station is used for conducting upsetting treatment on a bar,the second station is used for conducting blind hole extrusion treatment on the bar subjected to upsetting treatment, and the third station is used for conducting punching on the blank subjected to blind hole extrusion treatment; and a gear blank can be obtained after ring rolling, broaching and die forging are conducted. With the system and method adopted, a large number of unqualified productsare avoided, and meanwhile, harm of high temperature to human bodies during traditional manual detection is avoided; full-automatic control over discharging, heating, multi-station blank manufacturing, broaching, pre-forging, finish forging and size detection is achieved; and unmanned and intelligent gear forging production is achieved.

Owner:WUHAN NEWWISH TECH

Gear broaching process for thin-wall internal spline shaft

The invention discloses a gear broaching process for a thin-wall internal spline shaft, and relates to the technical field of internal spline shaft machining. The gear broaching process specifically comprises the following steps that S1, firstly, a round steel material is selected for blanking, and the round steel material is cut into the size required by an internal spline shaft through cutting equipment according to the required workpiece size to form a workblank; and S2, rough turning is carried out on the workpiece, the cut workblank is polished through polishing equipment, after polishingis completed, the workpiece is clamped through a clamp, then rough machining is carried out on an inner hole, an outer circle and the length of the workpiece through a horizontal lathe, so that the workpiece is made to be close to the final shape and size, and 0.4mm - 1mm machining allowance is correspondingly reserved for the inner hole, the outer circle and the length of the workpiece after rough turning. According to the gear broaching process for the thin-wall internal spline shaft, the gear broaching process is adopted to replace a gear shaping process to machine an internal spline, theproduct machining precision is improved, the product quality is stabler, the product damage rate is reduced, the economic loss is reduced, and the loss of a cutter is small.

Owner:HUBEI JIANFENG TECH INC

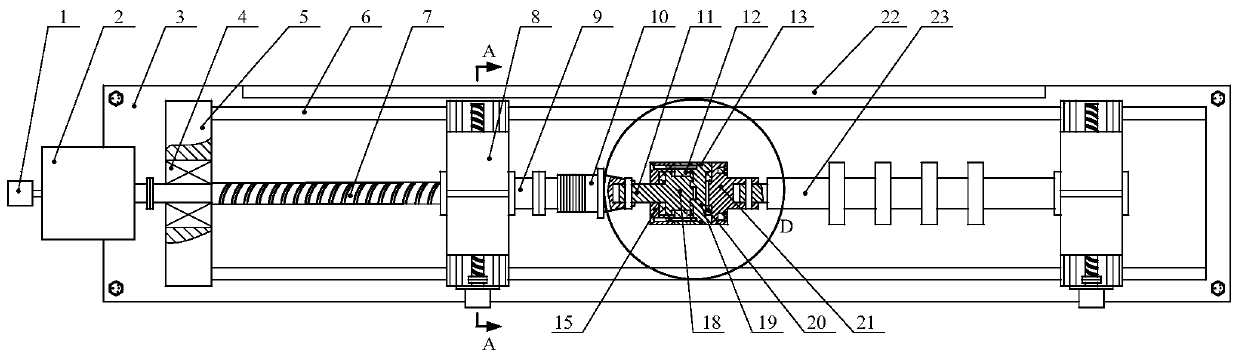

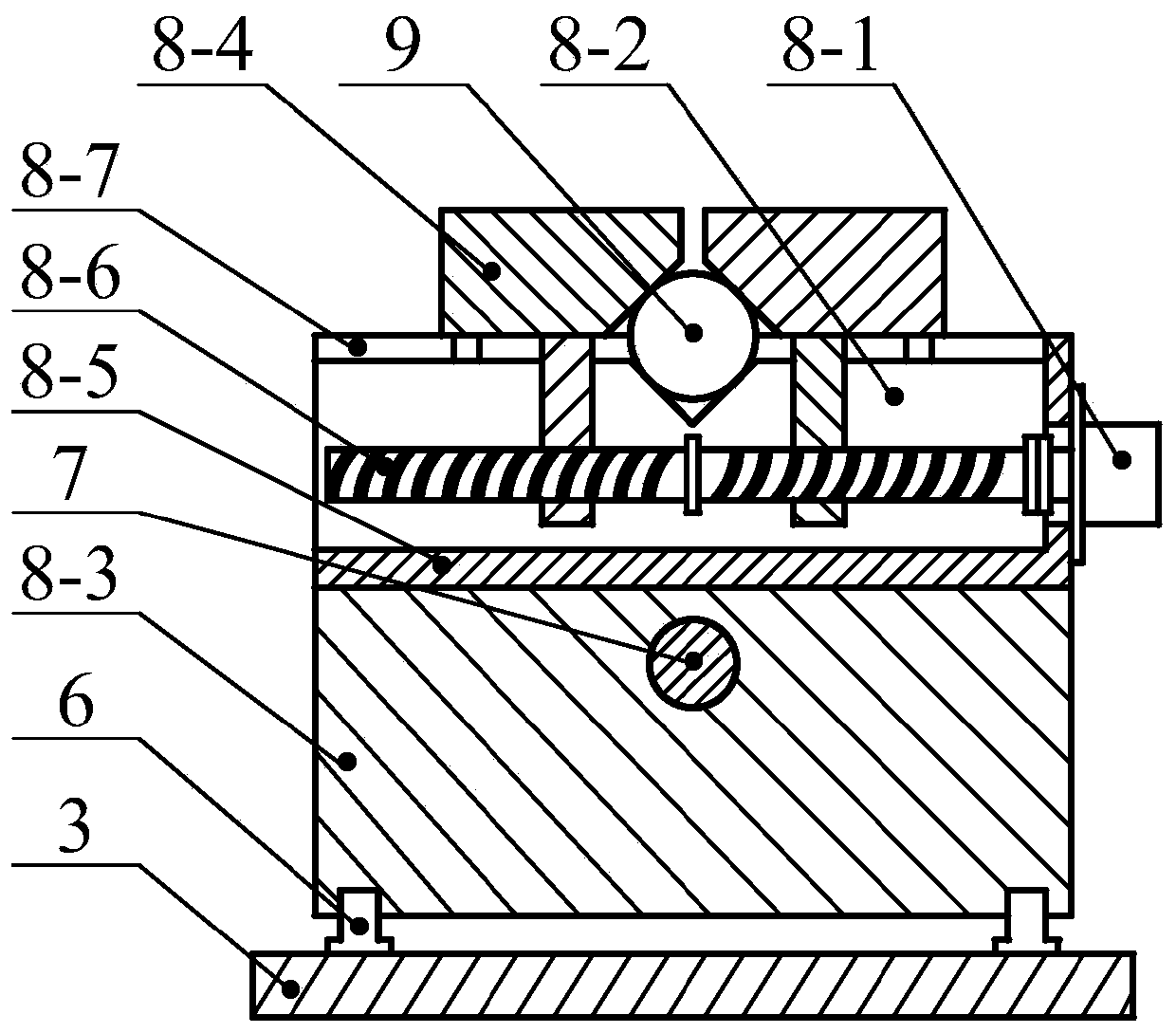

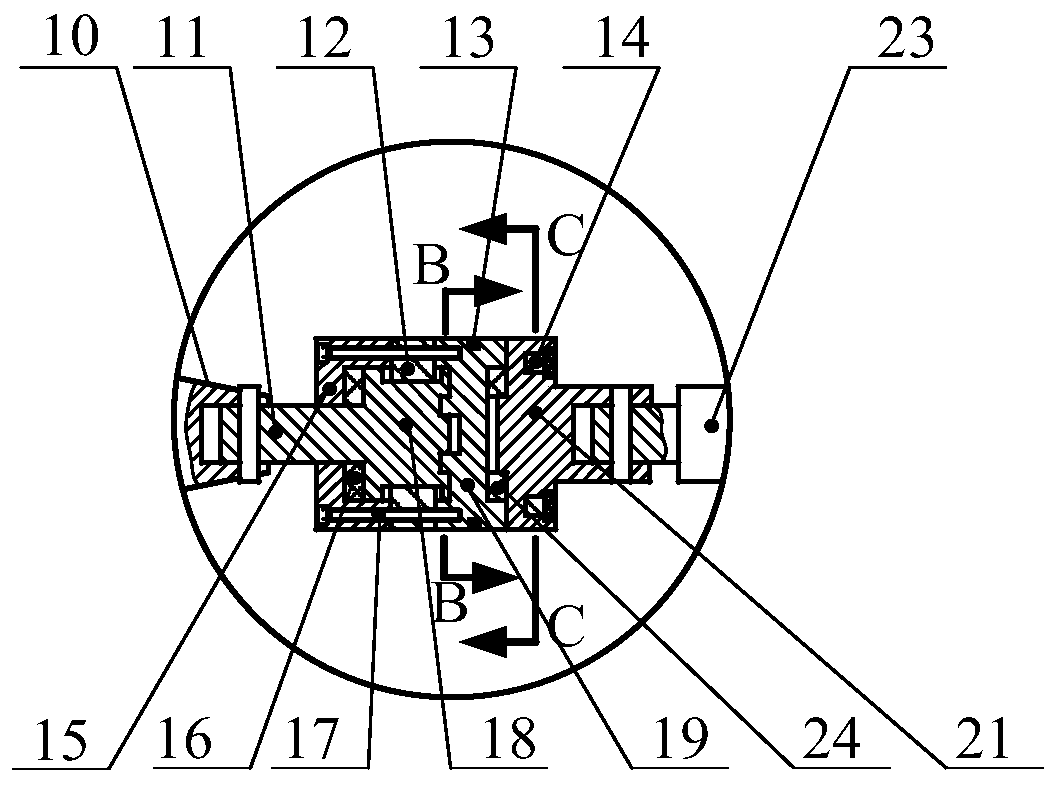

Large-tonnage helical broaching machine

PendingCN107900446AHigh broaching forceAvoid errorsMetal working apparatusBroaching machinesElectrical controlEngineering

The invention discloses a large-tonnage helical broaching machine. The large-tonnage helical broaching machine comprises a lathe body, a base, a main clamp cutter body, a broaching tool, a main sliding plate, a tool magazine, an automatic discharging mechanism, an automatic feeding mechanism, a pushing device, a workpiece pressing device, a cutter receiving and conveying mechanism, a servo drivingdevice, an electrical control cabinet and a hydraulic system, wherein the tool magazine is arranged at the rear side of the lathe bed, and the tool magazine comprises a tool magazine frame body, at least two broaching cutters and a positioning tool matched with the broaching cutters; the positioning tool comprises a clamping jaw, a pressing ring and a positioning plate; the broaching cutters areplaced on a tool holder arranged on one side of the tool magazine frame body, and the other side of the tool magazine frame body is sequentially provided with a clamping jaw frame for containing the clamping jaw, the pressing ring and the positioning plate, a pressing ring frame and a positioning plate frame from bottom to top; and the tool holder, the clamping jaw frame, the pressing ring frame and the positioning plate frame are each provided with a proximity switch internally, and the proximity switches are electrically connected with an alarm device. According to the large-tonnage helicalbroaching machine, large inner spiral gear rings in various heavy machinery fields can be machined, the broaching force is up to more than 25 tons, the stroke length can reach 2000mm, automatic feeding and discharging can be achieved, and the phenomenon of errors caused by manual tool taking can be effectively avoided.

Owner:CHANGSHA SISHENG INTELLIGENT EQUIP

Super-high-strength hot-rolled steel plate and steel belt with good fatigue and broaching performance and manufacturing method of steel plate and steel belt

ActiveCN110643894AHigh strengthImprove hole reaming effectFurnace typesHeat treatment furnacesTensile fatigueBroaching

Owner:BAOSHAN IRON & STEEL CO LTD

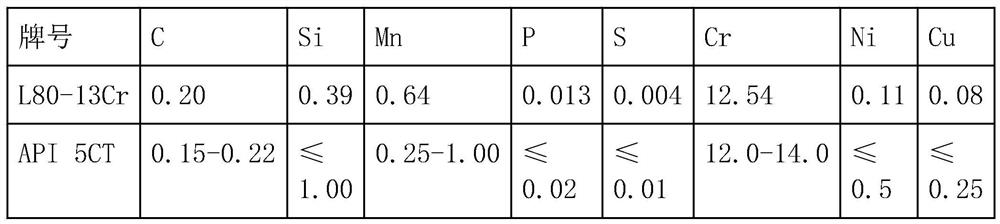

Method for forming L80-13Cr martensitic stainless steel seamless steel tube

PendingCN112317551AHigh yieldReduce lossesShaping toolsMartensitic stainless steelSS - Stainless steel

The invention relates to a method for forming a L80-13Cr martensitic stainless steel seamless steel tube. The process comprises the steps that 1, a 13Cr continuous casting billet is adopted; 2, the continuous casting billet is annealed; 3, the outer circle of the continuous casting billet is subjected to unilateral machining, and an outer surface oxide skin and a center loose layer are removed; 4,the treated continuous casting billet is uniformly heated to 1100 DEG C-1150 DEG C, and hot broaching is conducted; 5, hot extrusion is conducted on the continuous casting billet obtained after hot broaching; and 6, the hot-extruded steel tube is subjected to heat treatment to obtain the finished stainless steel seamless steel tube. According to the method, the continuous casting billet and hot extrusion forming process is combined, the problem that an existing production process is long in process flow and low in yield is solved, riser losses are reduced, the forging process is omitted, theyield of the martensitic stainless steel seamless steel tube can be increased, and the production cost is reduced.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Injection-molded flange gasket groove-spinning external-broaching device

ActiveCN111571689AIncrease productionFeatures that do not require laborious retrievalMetal working apparatusEngineeringBroaching

The invention relates to an external broaching device, in particular to an injection-molded flange gasket groove-spinning external-broaching device. The invention aims to provide the injection-moldedflange gasket groove-spinning external-broaching device with safety, less effort and high production output. The invention provides the technical implementation plan that the injection-molded flange gasket groove-spinning external-broaching device comprises a lower bracket, support rods I, an upper bracket, support rods II, an installation plate I, an intermittent mechanism and the like, wherein the four support rods I are fixedly connected to the lower bracket; the upper bracket is fixedly connected to the support rods I; the four support rods II are fixedly connected to the upper bracket; and the installation plate I is fixedly connected to the support rods II. According to the injection-molded flange gasket groove-spinning external-broaching device provided by the invention, through a clamping mechanism, the production output is improved; and through the intermittent mechanism, a rotary table and a groove-spinning mechanism, the effect on intermittently and automatically groove-spinning external-broaching the flange gasket can be achieved.

Owner:黄山耀瑞精密模塑科技有限公司

Gearbox parking gear manufacturing method

The invention discloses a gearbox parking gear manufacturing method. The manufacturing method comprises the steps of feeding, shot blasting, heating, warm forging, hardening and tempering, shot blasting, cold shaping, end face finish turning, internal spline broaching, induction surface quenching and flaw detection, wherein the warm forging machining process further comprises the steps of upsetting, pre-forming, final forming, punching and trimming. According to the gearbox parking gear manufacturing method, a gearbox parking gear is manufactured through the warm forging, the quenching and tempering, the cold shaping and the induction quenching of medium carbon steel, the tooth surfaces of parking teeth do not need to be machined subsequently after the warm forging, and the forging streamline of the tooth surfaces of the parking teeth is not cut off, so that a subsequent product keeps high mechanical strength; a core part of a product is quenched and tempered, the quenched and temperedsorbite structure can keep high strength and high toughness, the cold shaping is carried out after the hardening and tempering to correct thermal deformation of the hardening and tempering, and the surfaces of the parking teeth are subjected to high-frequency quenching, so that low thermal deformation and high surface hardness are kept; and the gearbox parking gear manufacturing method is reasonable in design, the process advantages of net forming forging, hardening and tempering and surface quenching are combined, the material utilization rate is increased, the machining and manufacturing cost is reduced, surface oxidation and thermal deformation of the product are effectively controlled, and the precision and quality of the product meet the use requirements.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

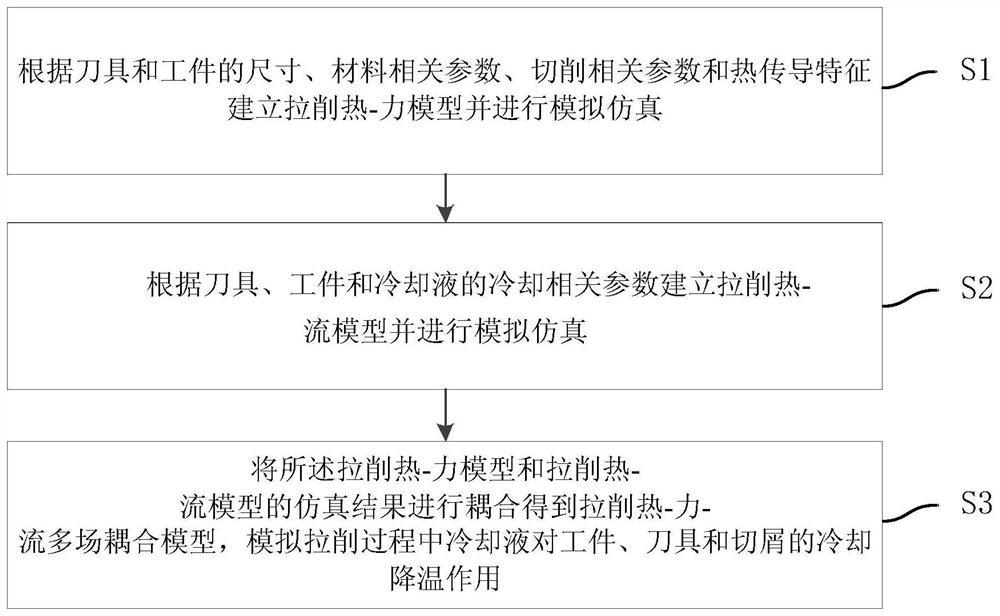

Mortise broaching process simulation analysis method based on heat-force-flow multi-field coupling

PendingCN112528535AVelocity fully consideredFully consider the temperatureGeometric CADDesign optimisation/simulationHeat flowThermal force

The invention discloses a mortise broaching process simulation analysis method based on thermal force flow multi-field coupling. The method comprises the steps of creating a broaching thermal force model according to the sizes of a cutter and a workpiece, material related parameters, cutting related parameters and heat conduction characteristics, and making analog simulation; establishing a broaching heat flow model according to the cooling related parameters of the cutter, the workpiece and the cooling liquid, and performing analog simulation; and coupling the simulation results of the broaching thermal force model and the broaching thermal flow model to obtain a broaching thermal force flow multi-field coupling model, and simulating the cooling effect of the cooling liquid on the workpiece, the cutter and the cuttings in the broaching process. The thermal force and thermal flow simulation analysis model in the broaching process is established, a data transmission platform among the models is established, coupling simulation analysis among three fields of broaching thermal force flow is achieved, the flow speed, temperature and impact pressure of cooling liquid are fully considered, and simulation precision is greatly improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

Automatic slot broaching machine for lock container and slot broaching process of automatic slot broaching machine

InactiveCN108188473AIncrease productivityHigh precisionFeeding apparatusLarge fixed membersProcess designMachining

The invention relates to the lock container machining field, in particular to an automatic slot broaching machine for a lock container. The automatic slot broaching machine comprises a horizontally arranged workbench; the top of the workbench is provided with a slotting mechanism which comprises a first driving device and a second driving device; the tops of the first driving device and the seconddriving device are provided with a first bearing block and a second bearing block correspondingly; a connection block is arranged between the first bearing block and the second bearing block; a firstslot broaching device is arranged at the middle position of the first driving device; a second slot broaching device is arranged at the middle position of the second driving device; a first feeding device is arranged on one side of the first driving device; a first moving and transporting device is arranged on the side wall of the first feeding device; a second feeding device is arranged on one side of the second driving device; a second moving and transporting device is arranged on the side wall, close to the second driving device, of the second feeding device; and the bottom of the workbench is provided with a first discharging device and a second discharging device. The automatic slot broaching machine is high in automation degree, the slot broaching efficiency of the lock container isimproved, the process design is ingenious, and 2 / 3 manual work is saved.

Owner:浙江慕来智能科技有限公司

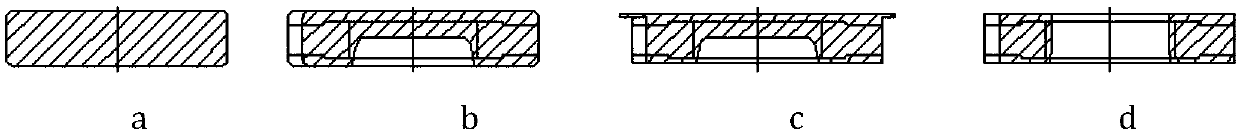

Broach for machining inner hexagonal connecting bolt and broaching method

InactiveCN110977018AImprove processing qualityExtended service lifeBroaching toolsStructural engineeringBroaching

The invention relates to a broach for machining an inner hexagonal connecting bolt and a broaching method. The broach comprises a tail handle, guide parts and a working part, and from right to left the front part is the machining reference of the rear part; and a groove connected with a machine tool is reserved in the tail handle, and the tail handle and the machine tool are clamped according to the half clamping design of a puller. The guide parts are respectively a front guide part and a rear guide part. The working part comprises rough cutting and shaping gradual cutting; the front cutter teeth and the rear cutter teeth are alternately arranged, and V-shaped chip breaker grooves are formed in the rough cutting cutter teeth; the cutter teeth of the working part are gradually cut and formed from right to left along with increase of the number of the teeth along with increase of the tooth rise amount; and the broach has an inverted cone size. The broach is long in service life, and thebroaching method is high in machining efficiency, easy to operate and high in reliability.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com