Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1267results about "Drawing dies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

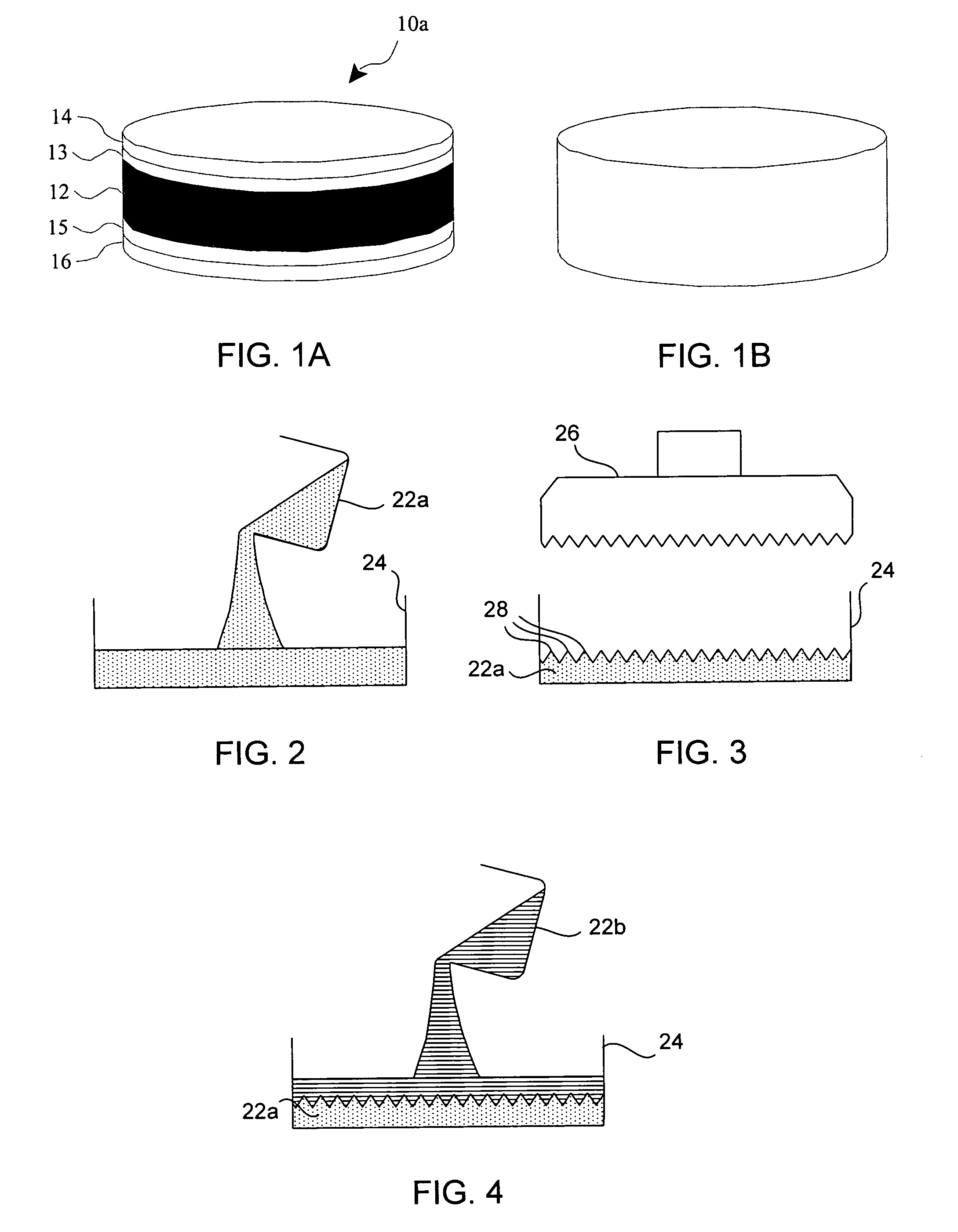

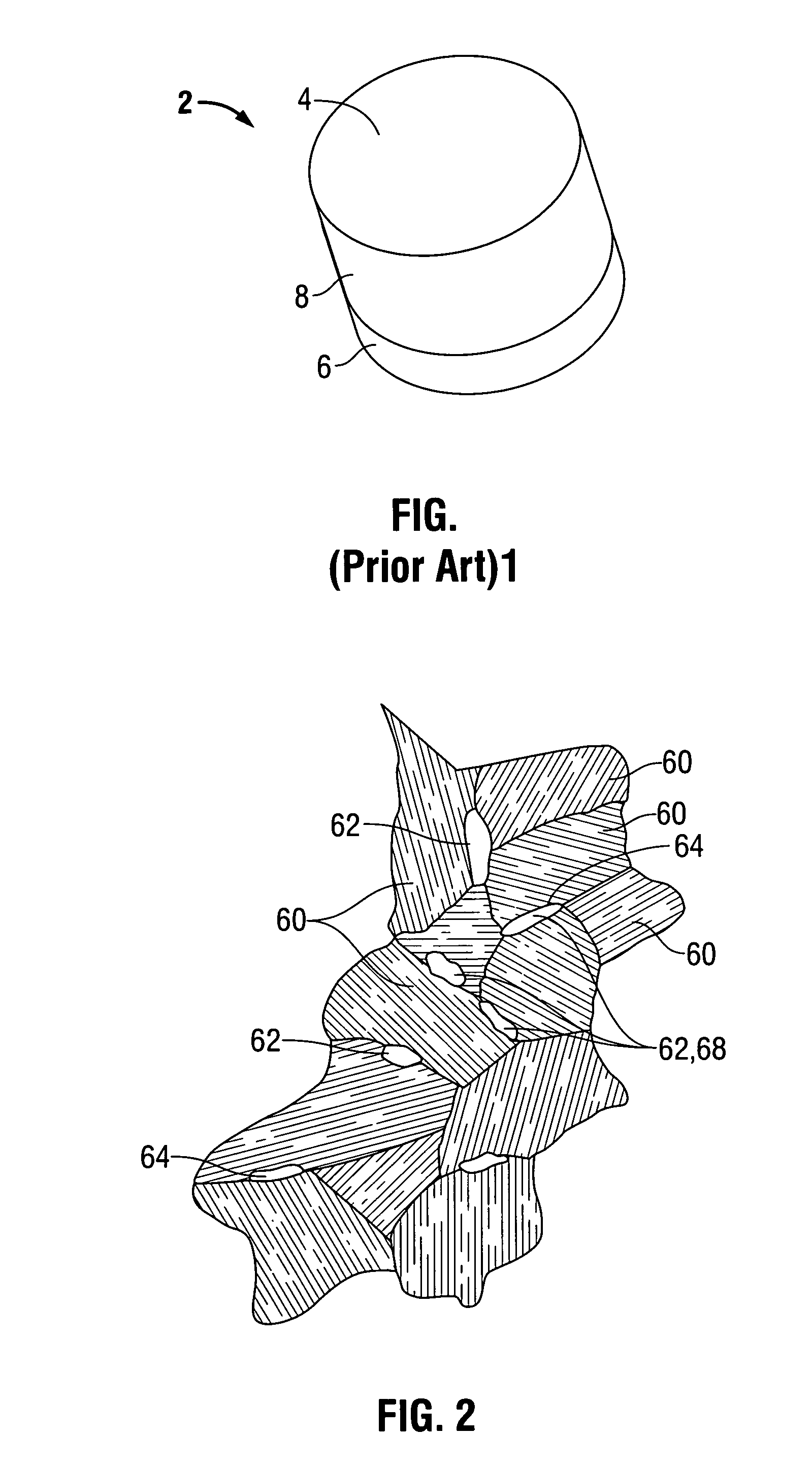

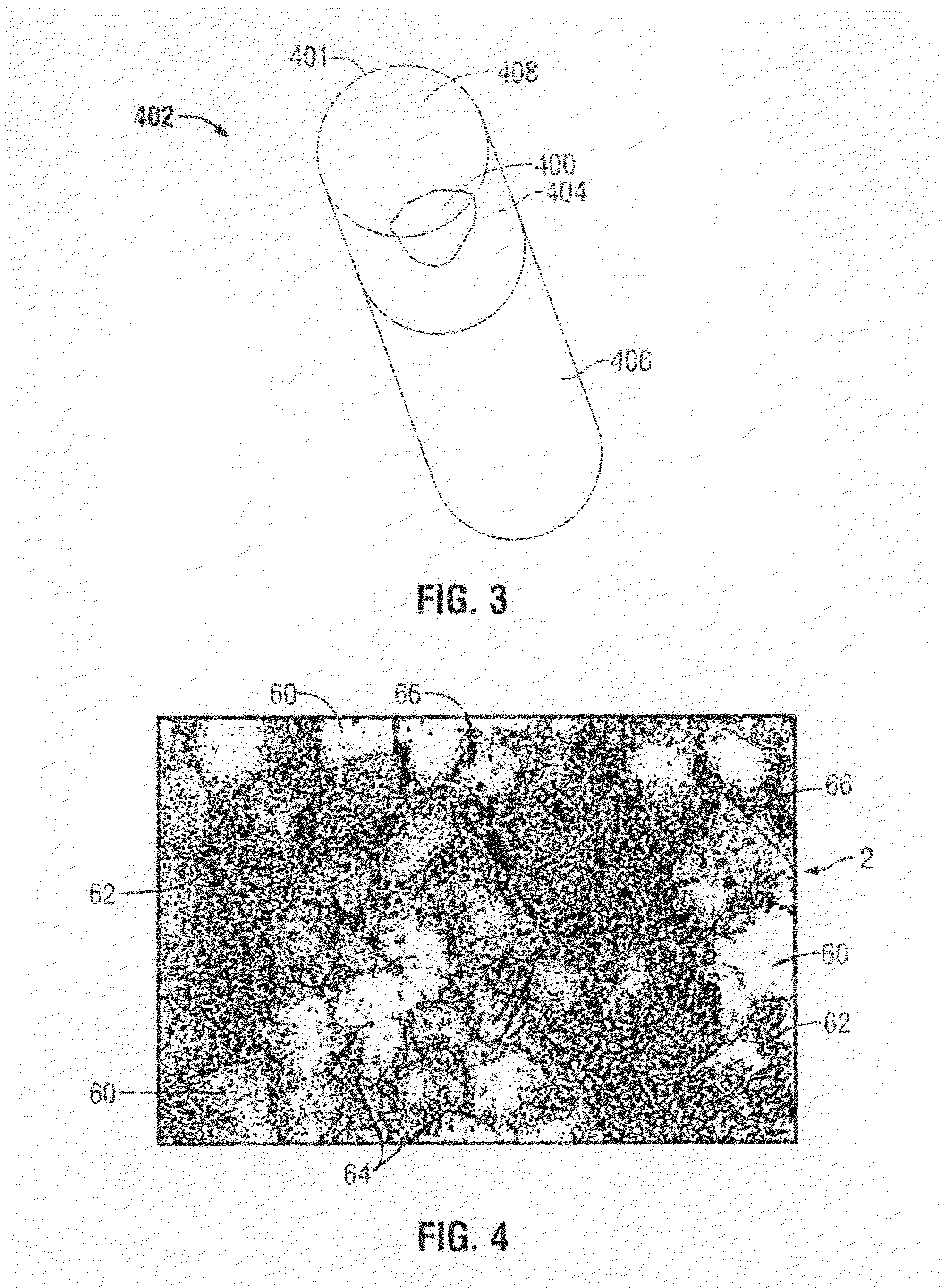

Nanodiamond PCD and methods of forming

InactiveUS20050019114A1Improve high temperature performanceReduce manufacturing costMaterial nanotechnologyPigmenting treatmentDiamond crystalPolycrystalline diamond

A nanodiamond tool, including a mass of sintered nanodiamond particles can be produced having improved mechanical, thermal, and electrical properties. The sintered mass can contain greater than about 95% by volume nanodiamond and greater than about 98% by volume carbon. Such nanodiamond tools can be formed by assembling a mass of nanodiamond particles and sintering the mass of nanodiamond particles to form a sintered mass. Prior to sintering, the mass of nanodiamond particles can be substantially free of non-carbon materials such as metal binders, sintering aids or the like. Upon sintering, the nanodiamond particles sinter together at high pressures and lower temperatures than those typically required in producing polycrystalline diamond compacts with diamond crystals of a larger size. The absence of non-carbon materials improves the high temperature performance and reliability of the nanodiamond tools of the present invention.

Owner:SUNG CHIEN MIN

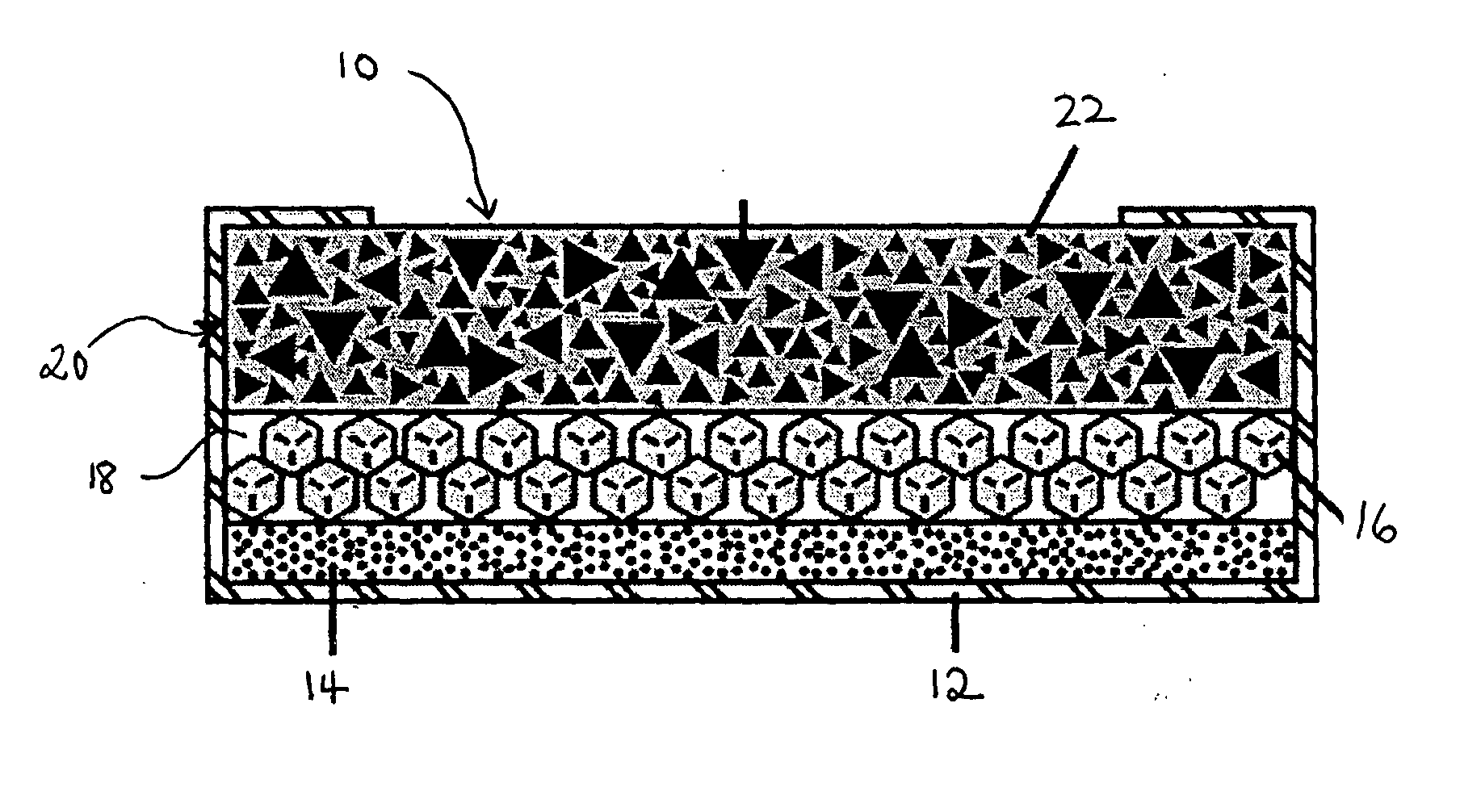

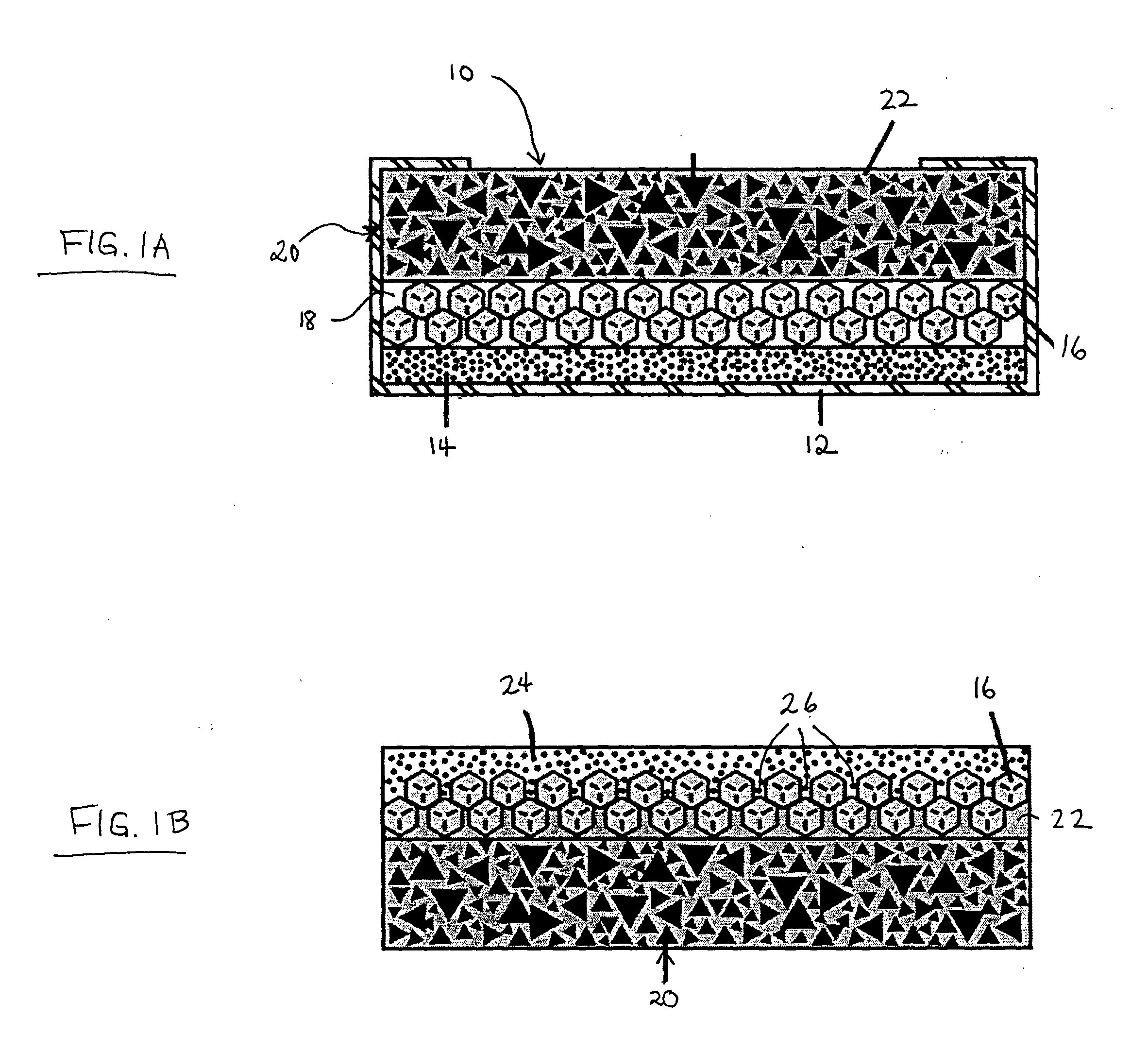

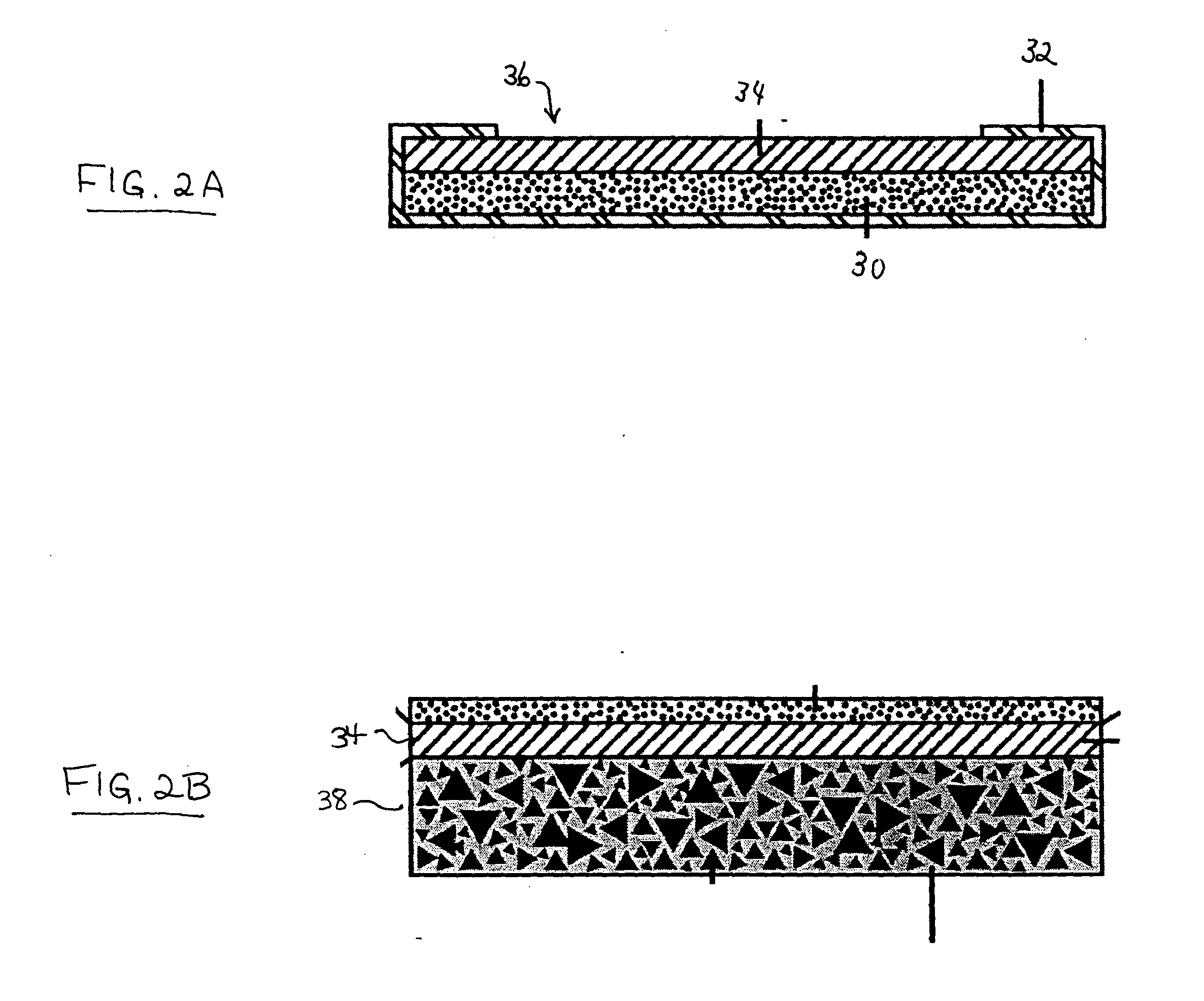

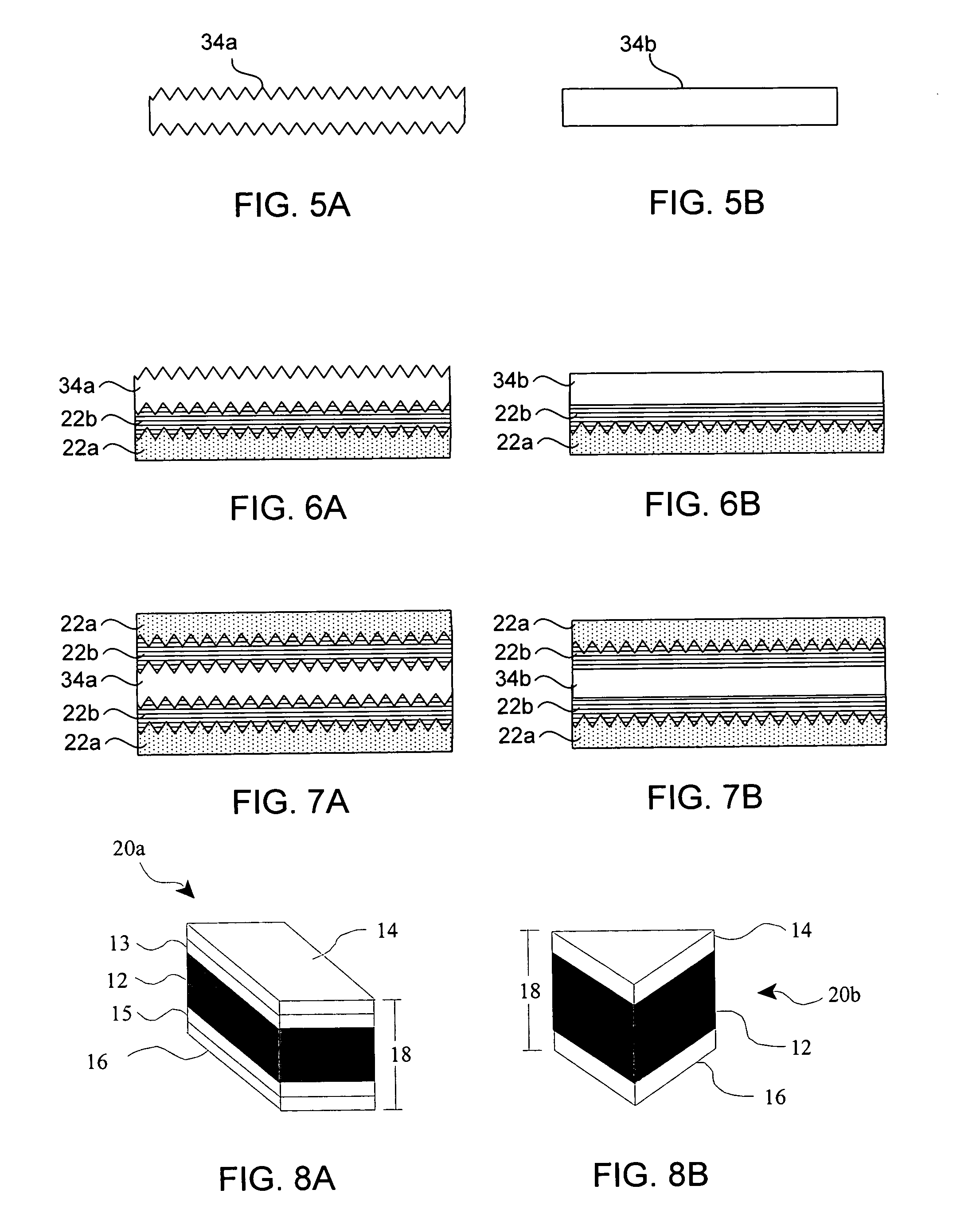

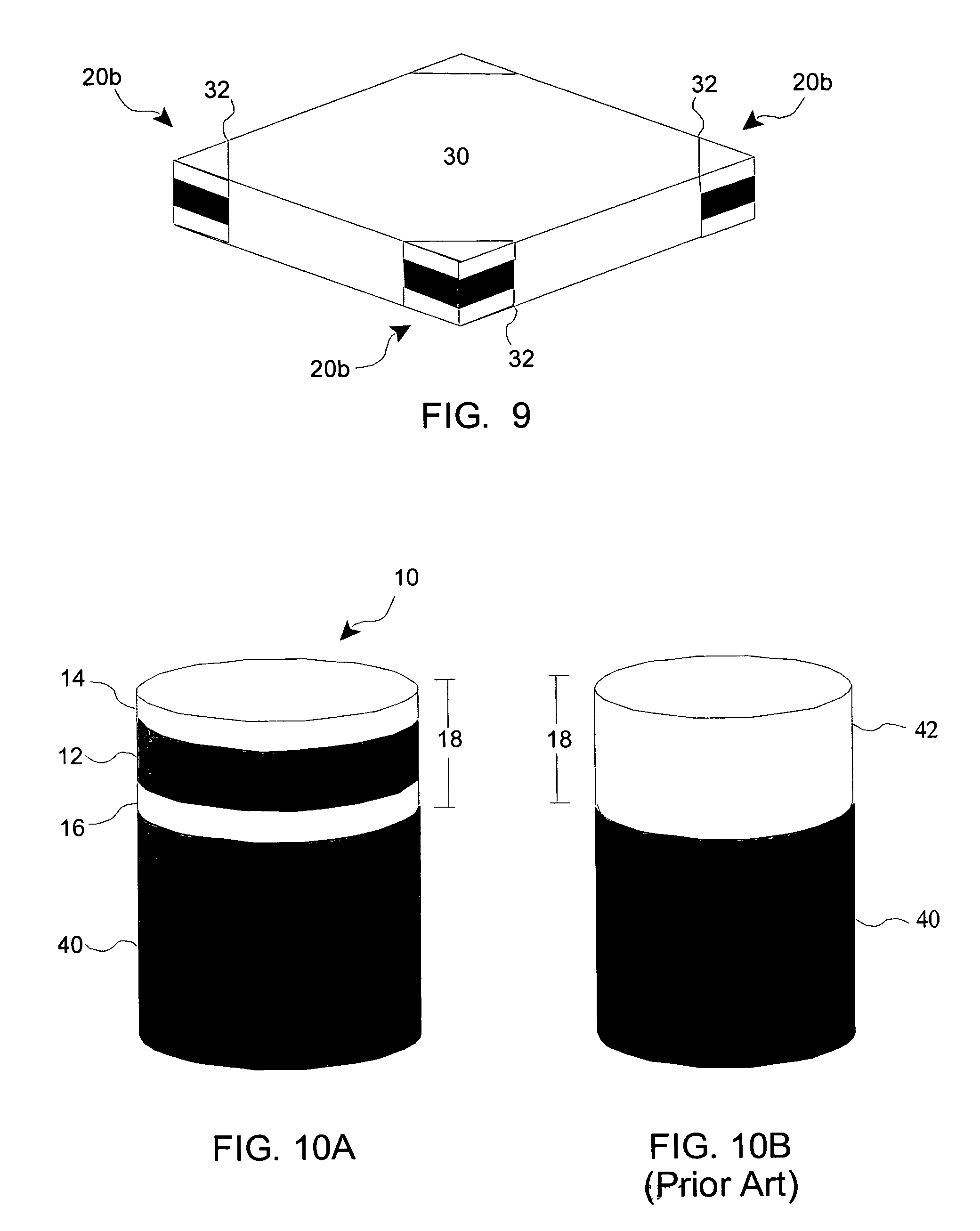

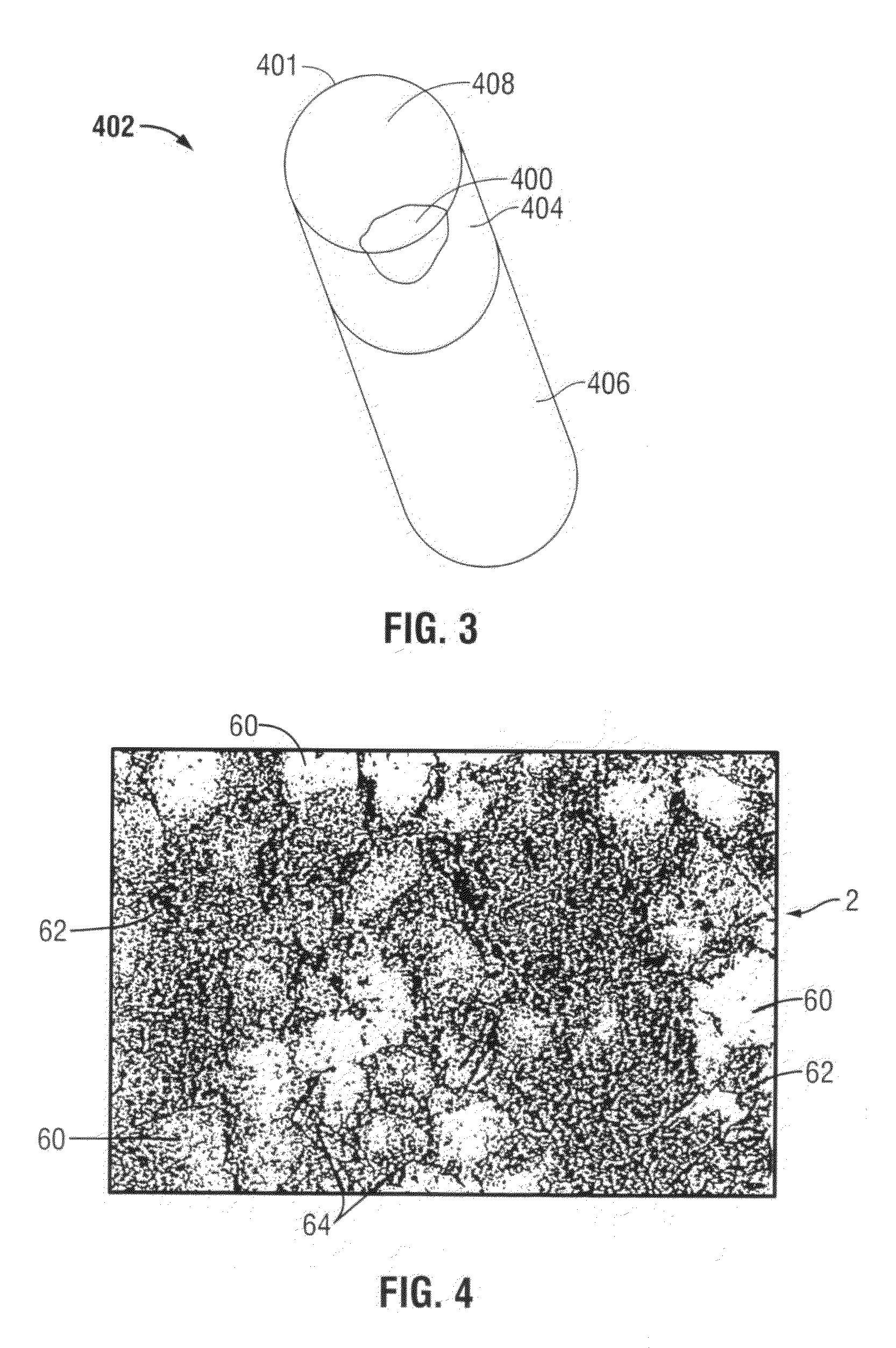

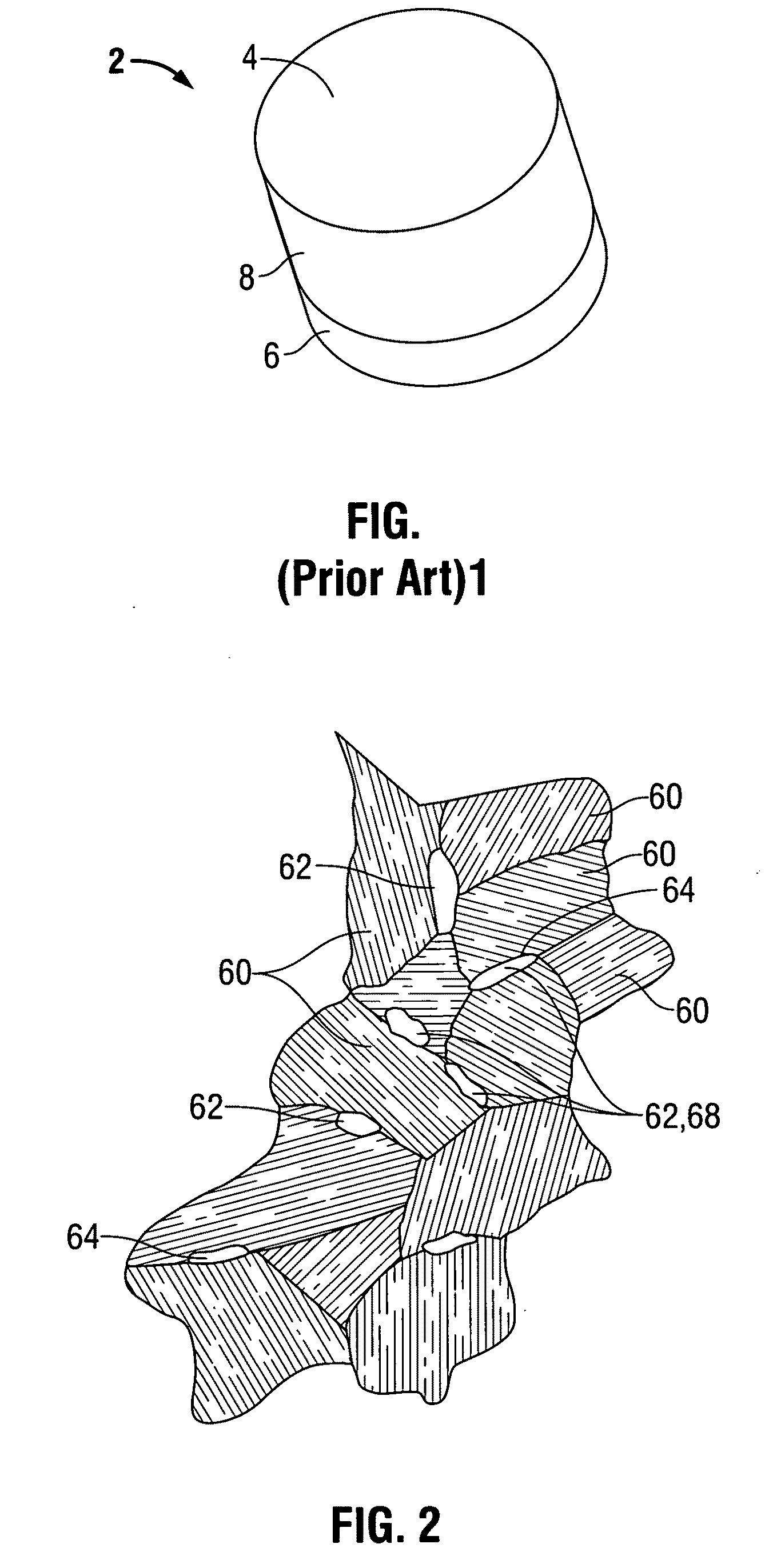

Doubled-sided and multi-layered PCBN and PCD abrasive articles

InactiveUS20050210755A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionWear particleHigh pressure

A doubled-sided PCBN and / or PCD compact can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools, decreased delamination, and increased useful service life. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can be attached to the substrate via an intermediate layer containing superabrasive particles. Such double-sided PCBN and PCD compacts allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided PCBN and PCD compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

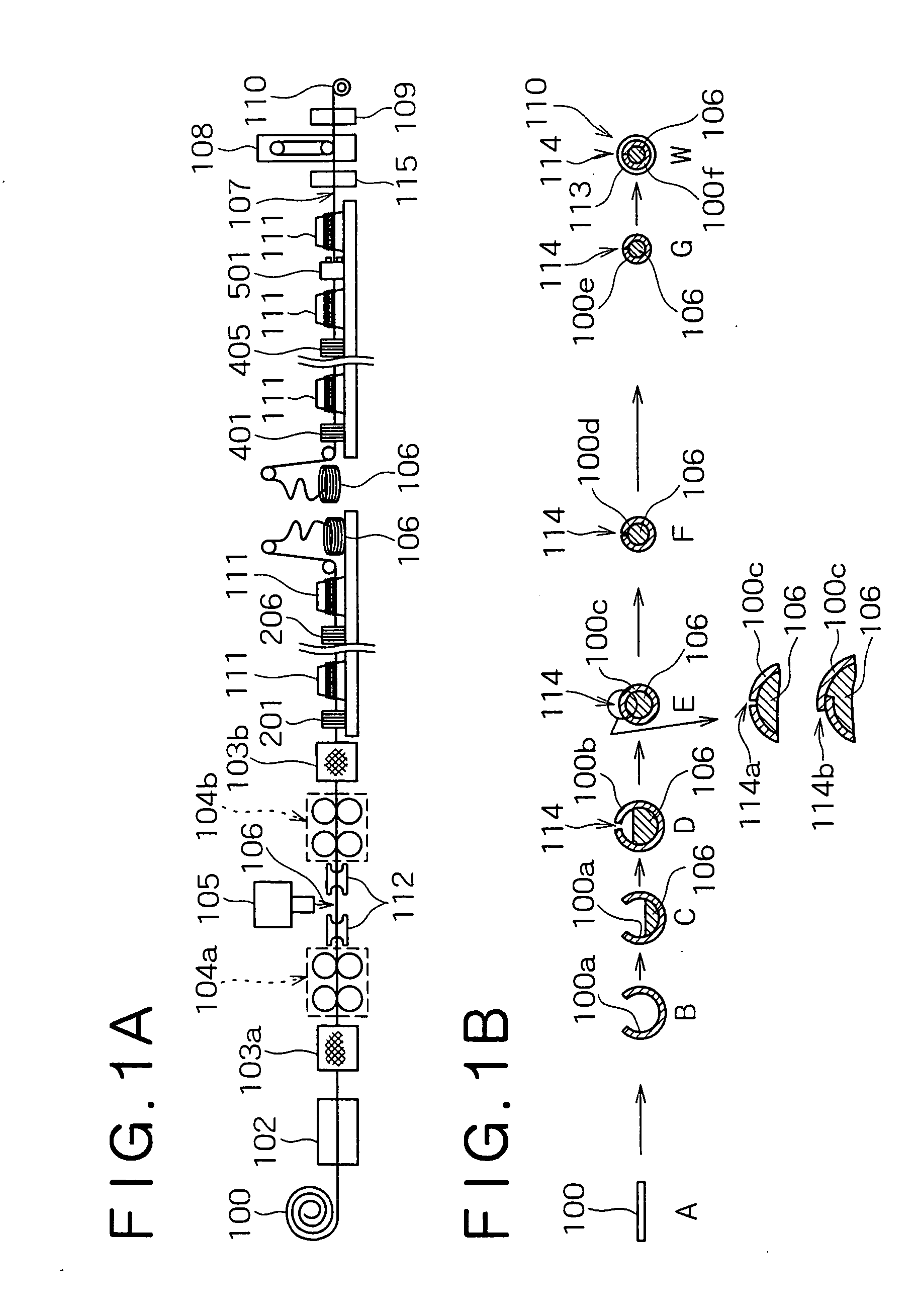

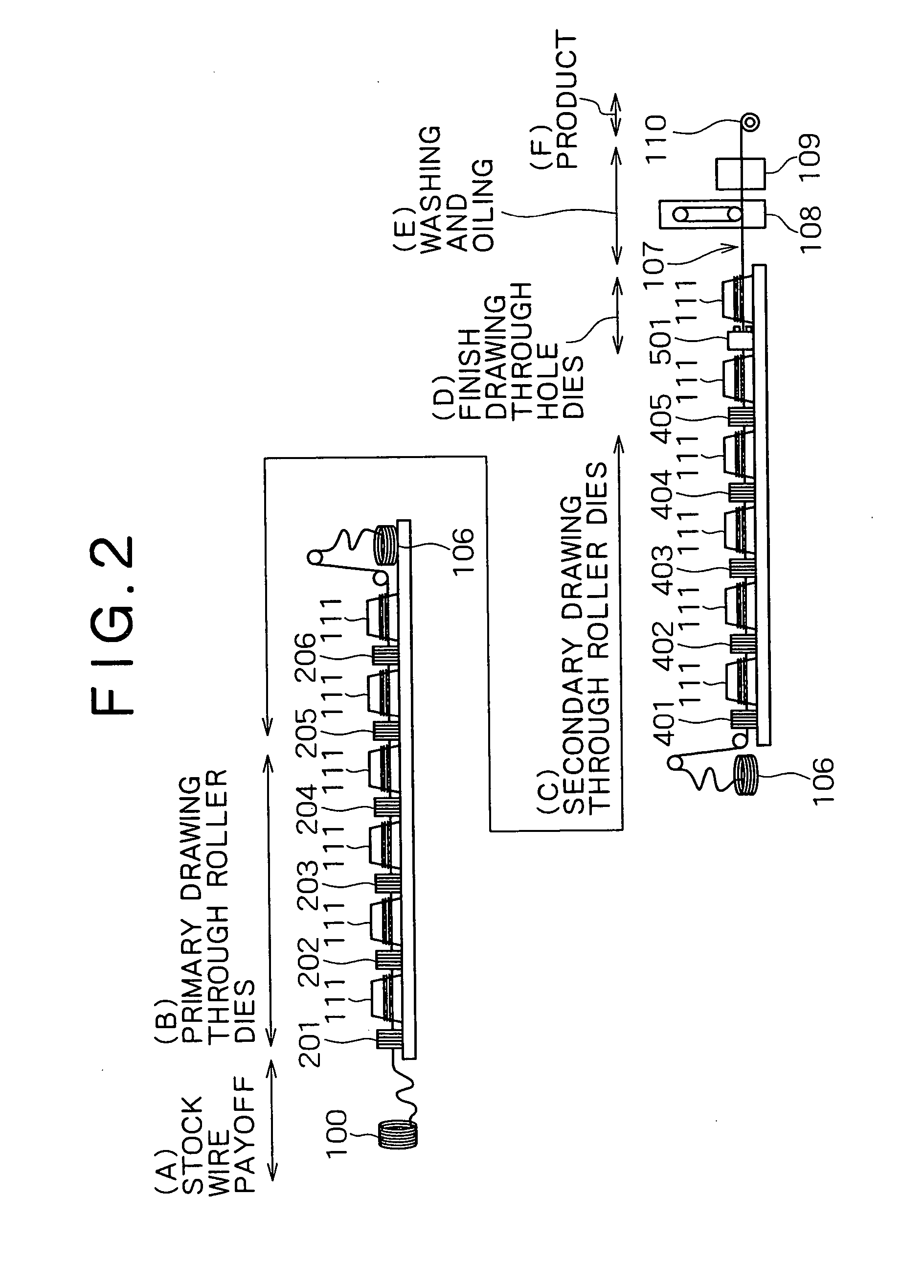

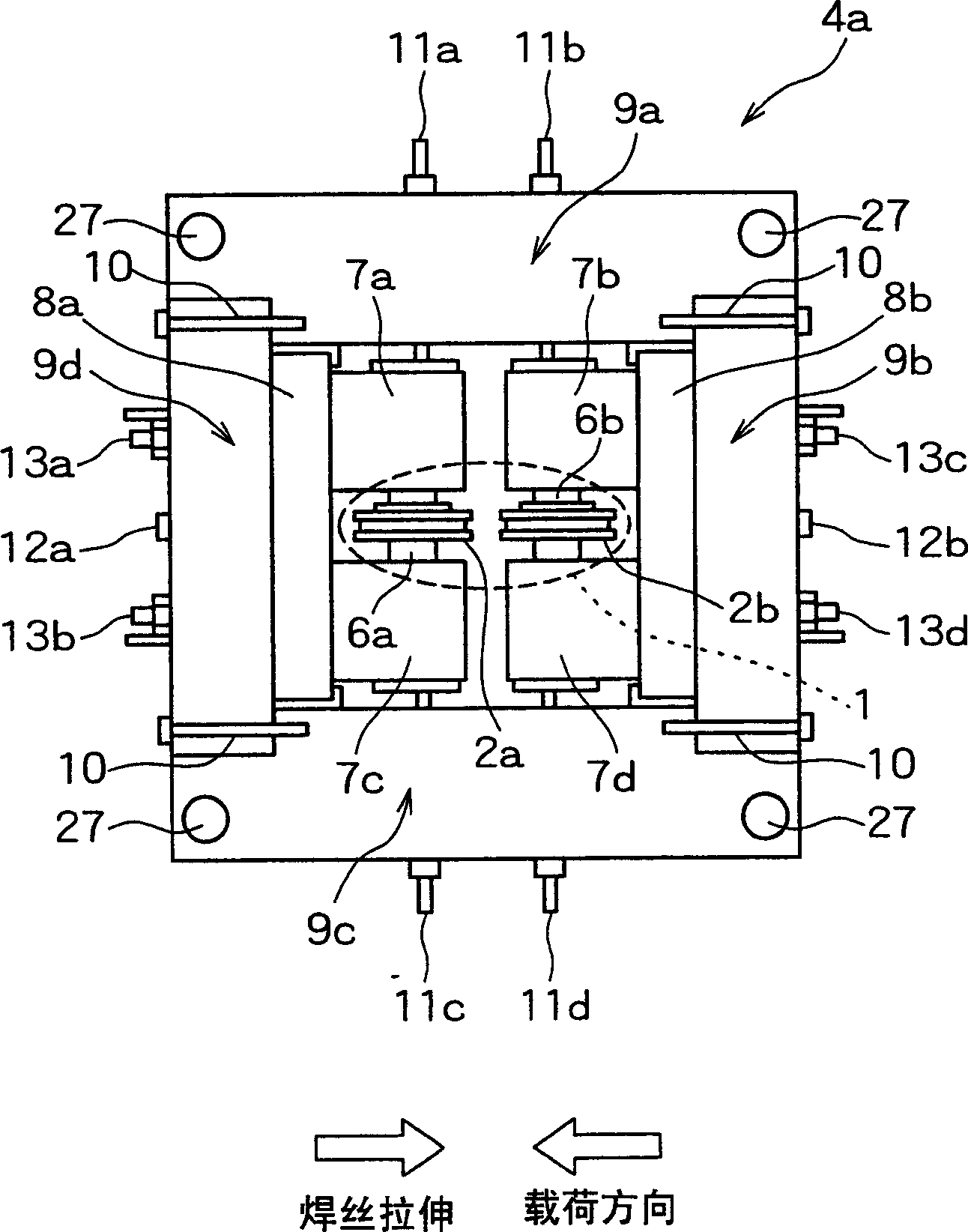

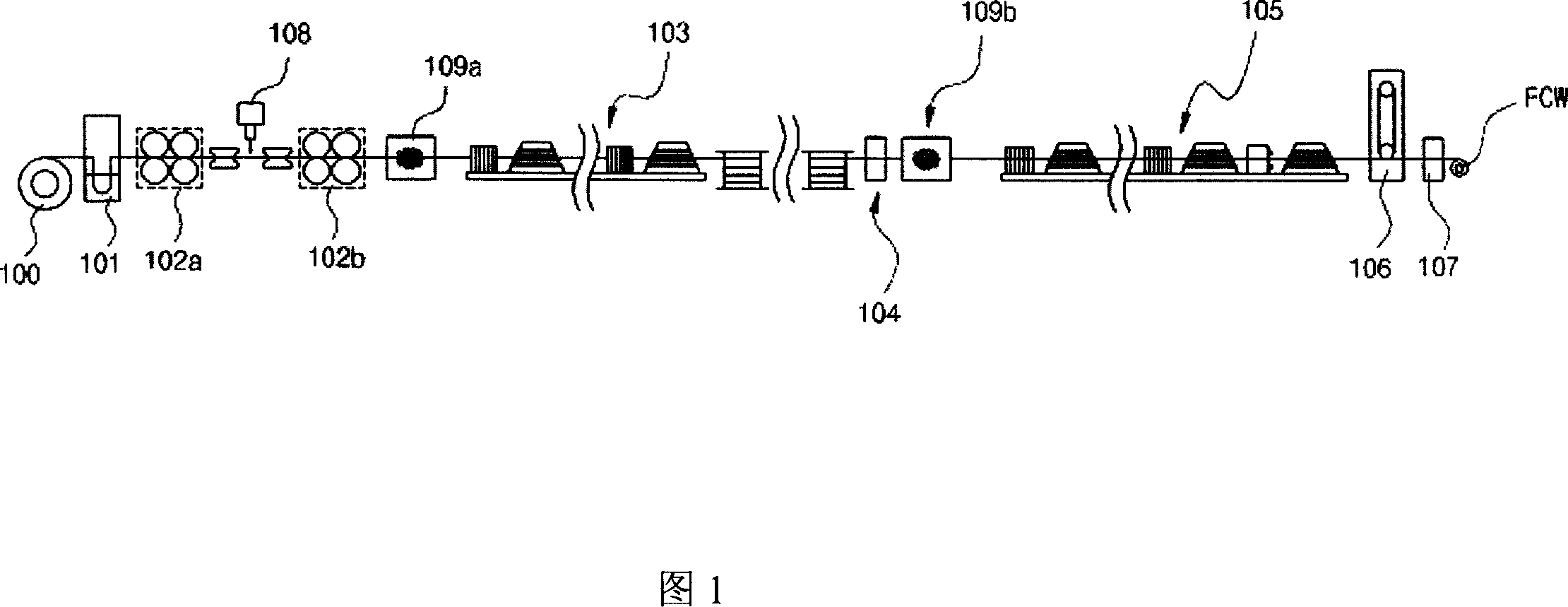

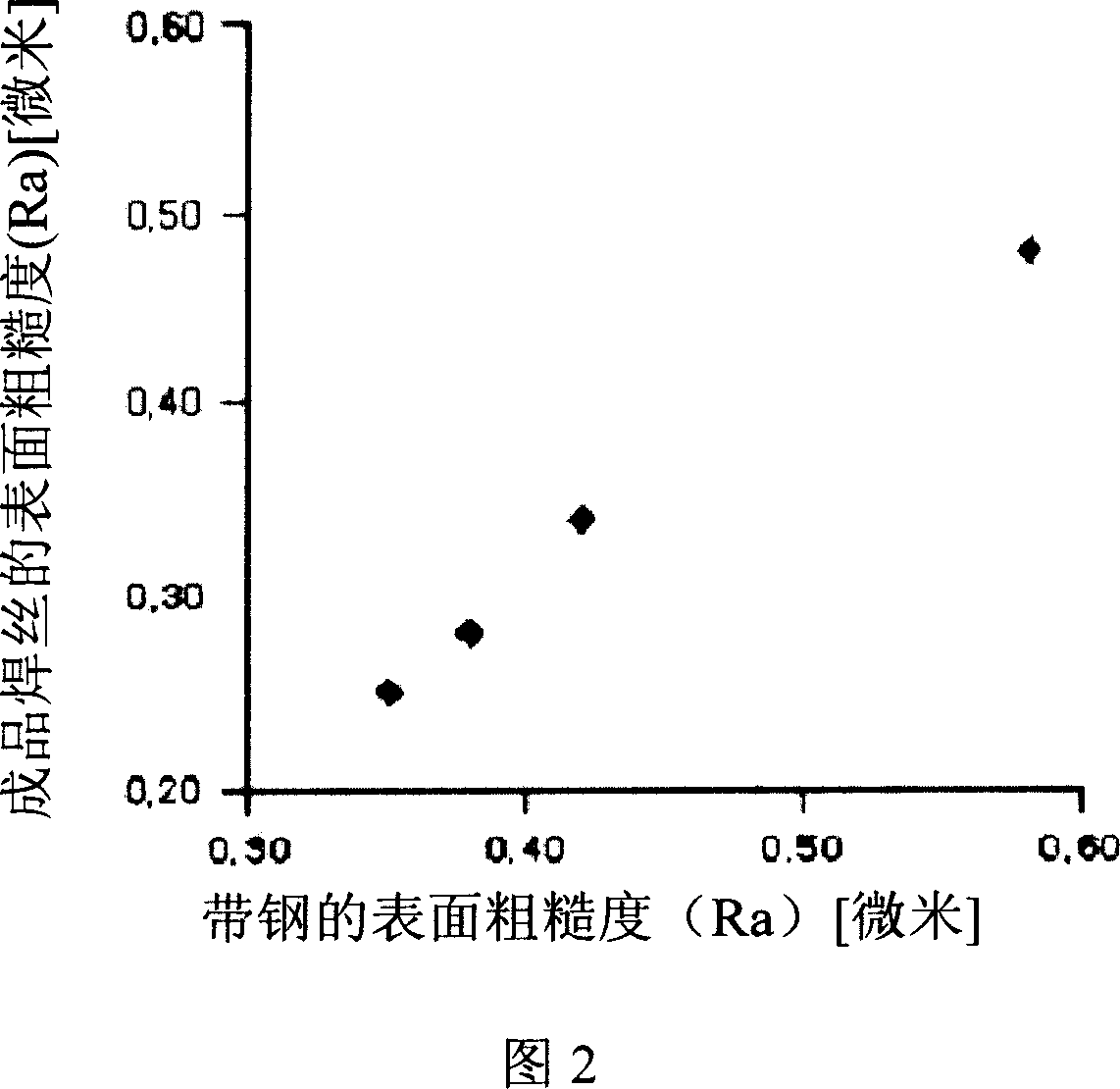

Method for manufacturing seamed flux-cored welding wire

ActiveUS20050044687A1Improve feeding effectReduce contentDrawing diesWelding/cutting media/materialsWire rodSulfur

Disclosed herein is a manufacturing method, excellent in wire drawability, of a seamed flux-cored welding wire having both favorable feedability and low hydrogen content characteristic. The method for manufacturing a seamed flux-cored wire, comprises the steps of: drawing a tube-like formed wire including a flux filled therein using a lubricant; removing the lubricant from the drawn wire by a physical means; and coating a lubricant (coating an oil) for wire feeding on the wire surface. The respective steps are carried out in an in-line manner. In the wire drawing step, a wire drawing lubricant containing a sulfur-bearing high-pressure lubricant is used, and the overall wire drawing from the tube-like formed wire to a roughly product-diameter wire is carried out by means of a roller die.

Owner:KOBE STEEL LTD

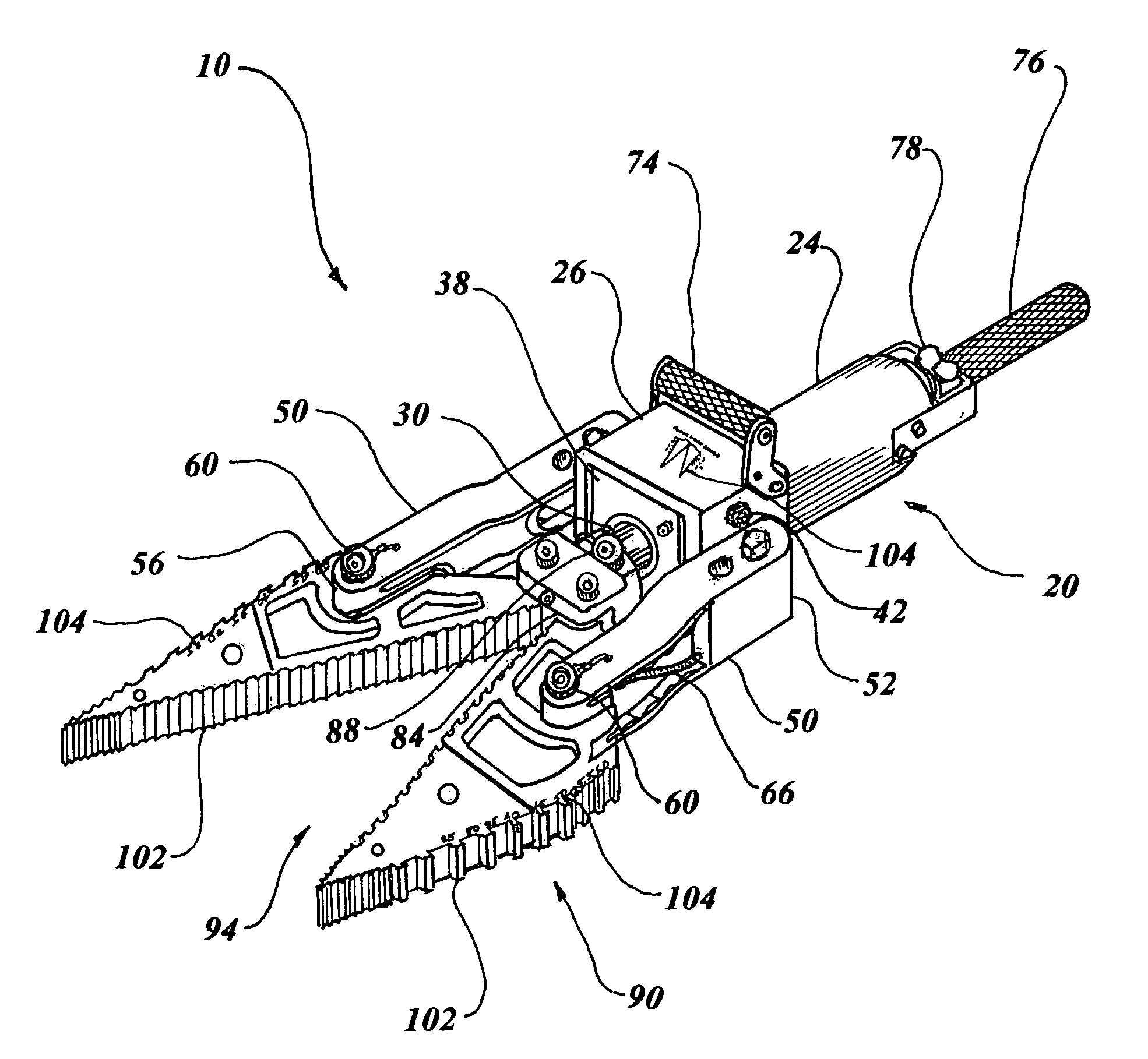

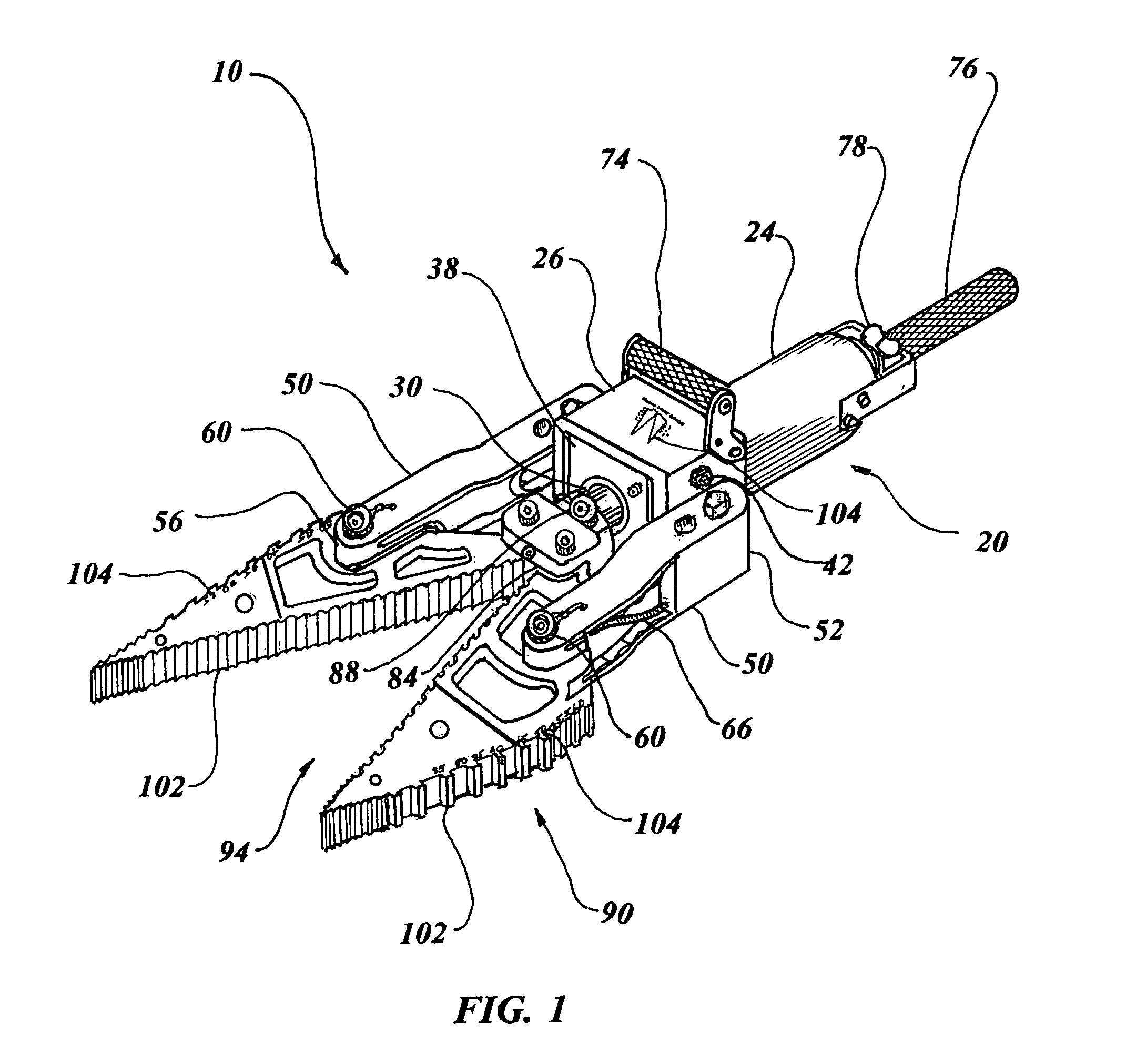

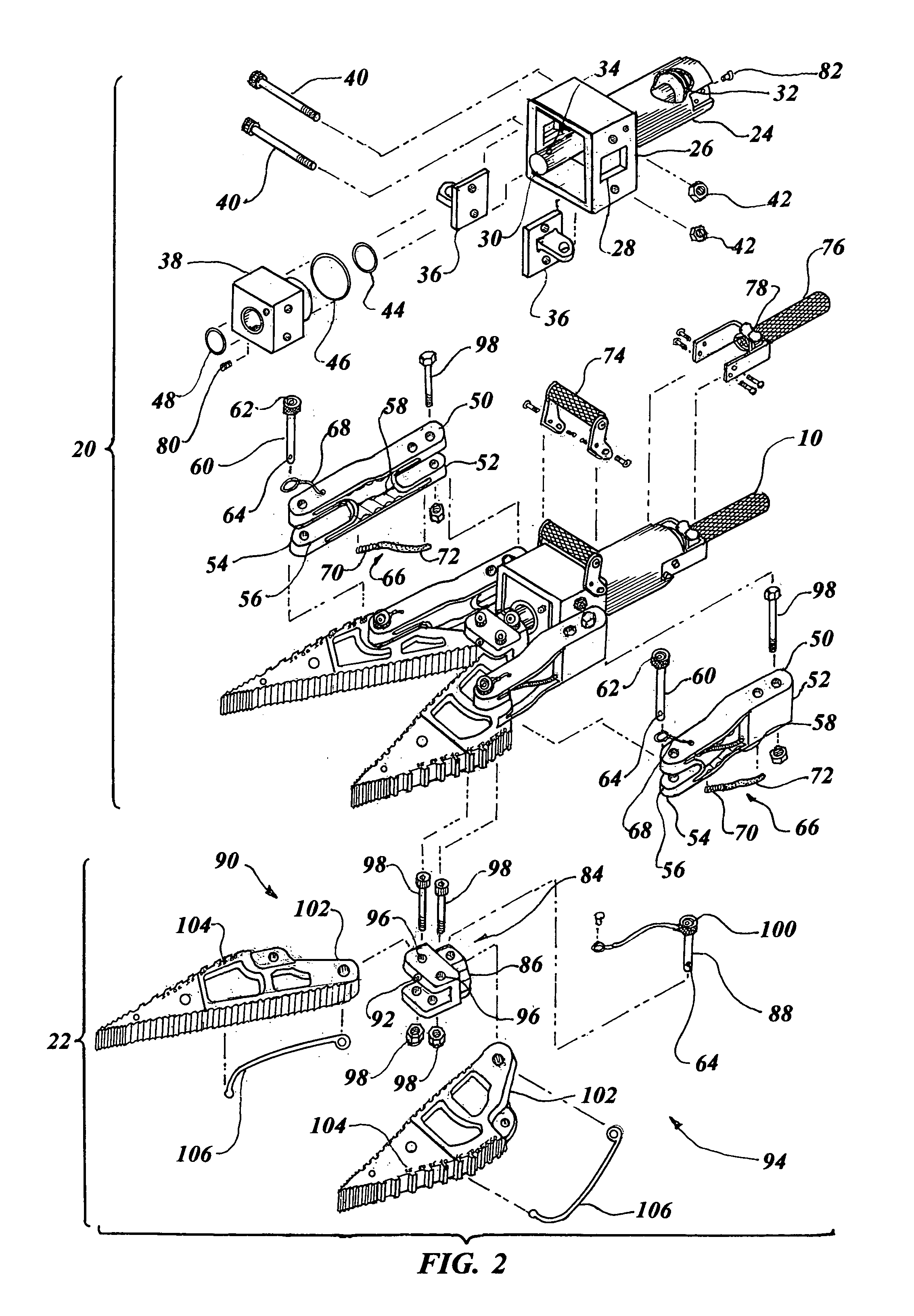

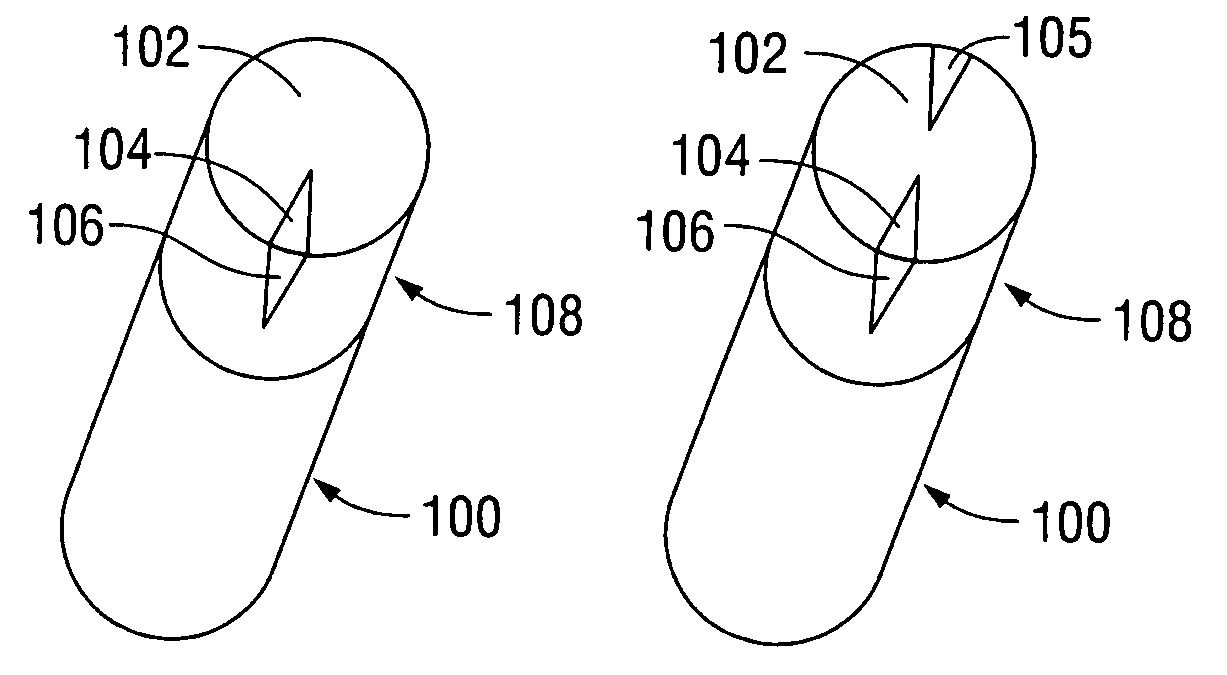

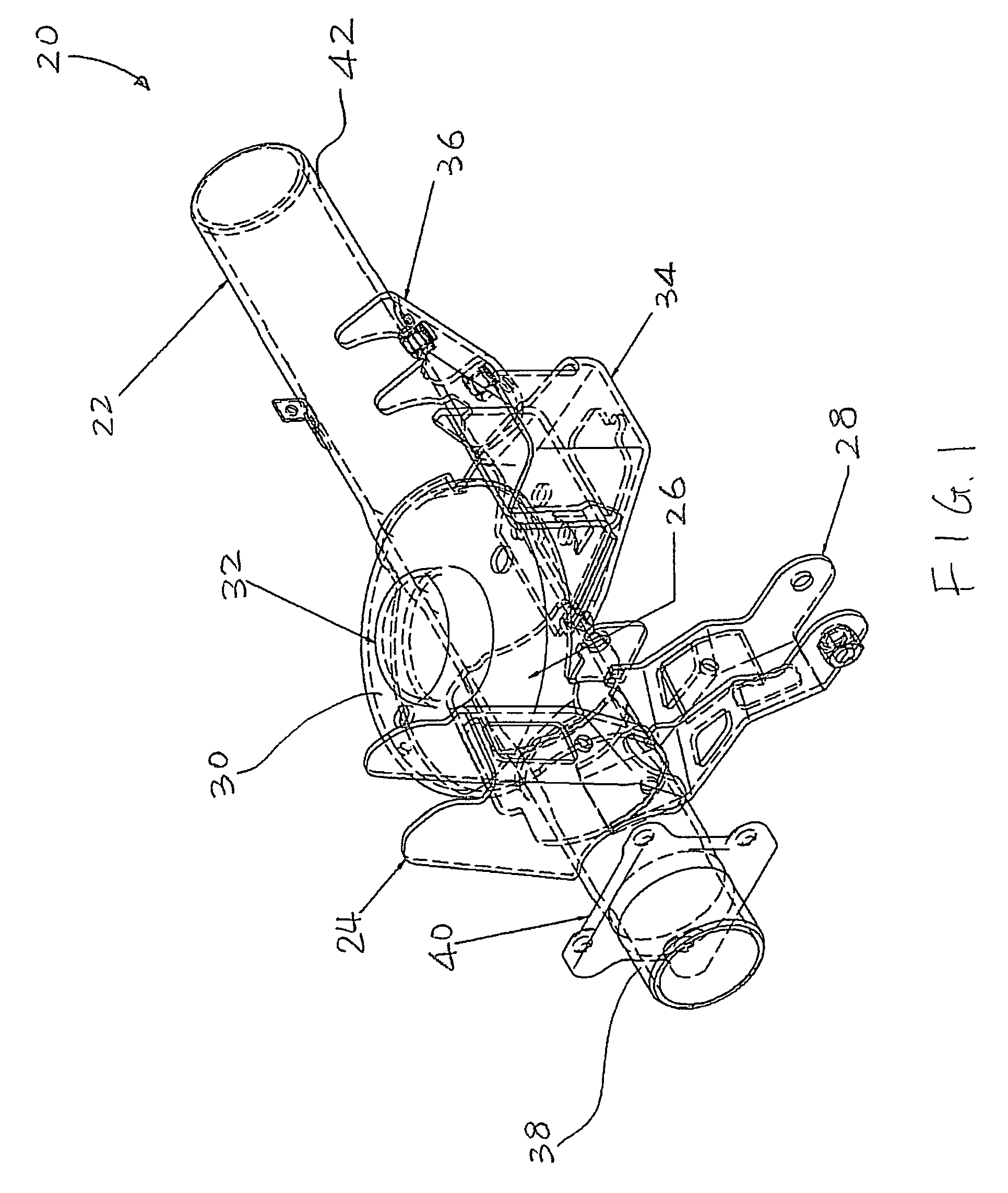

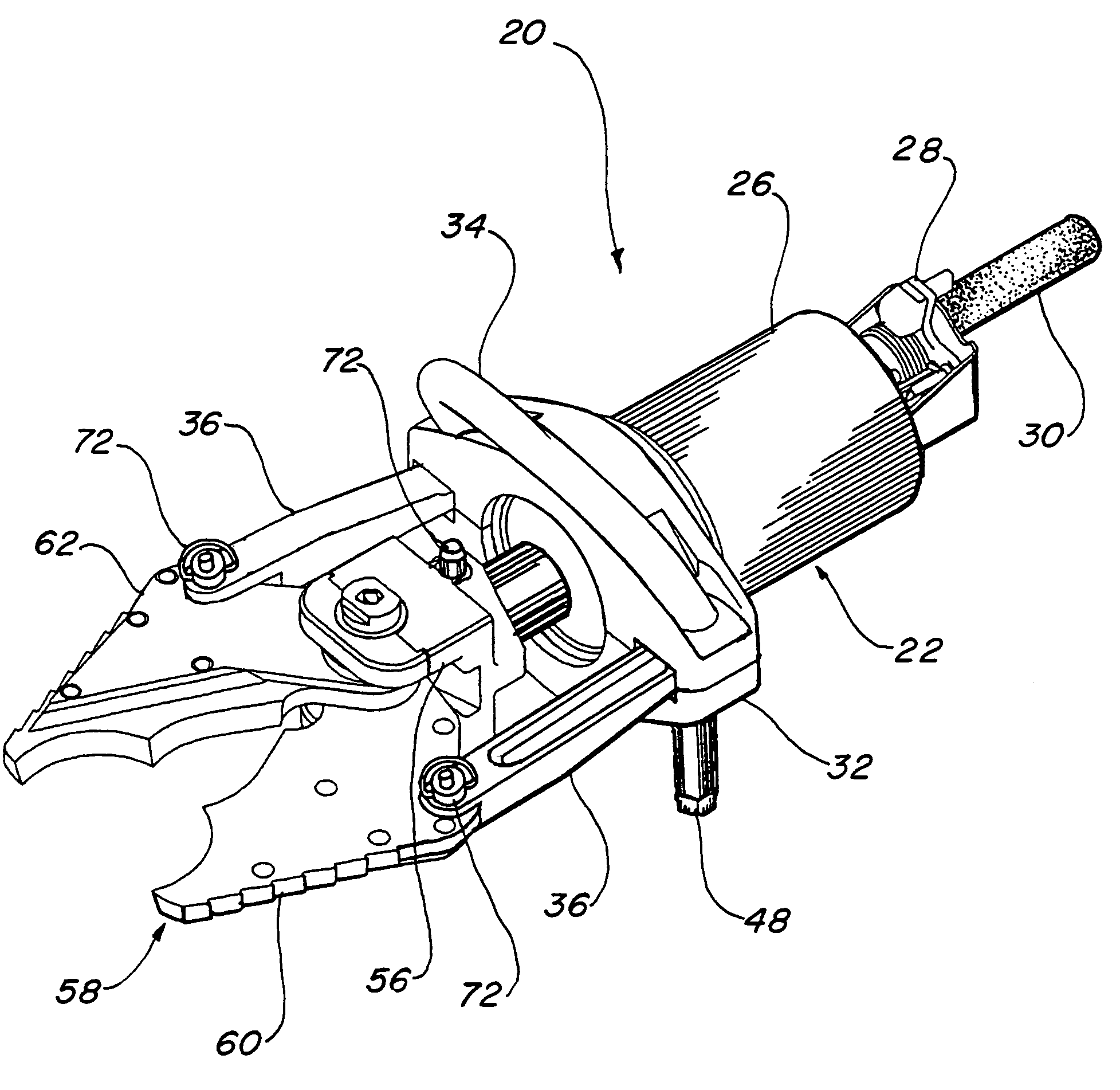

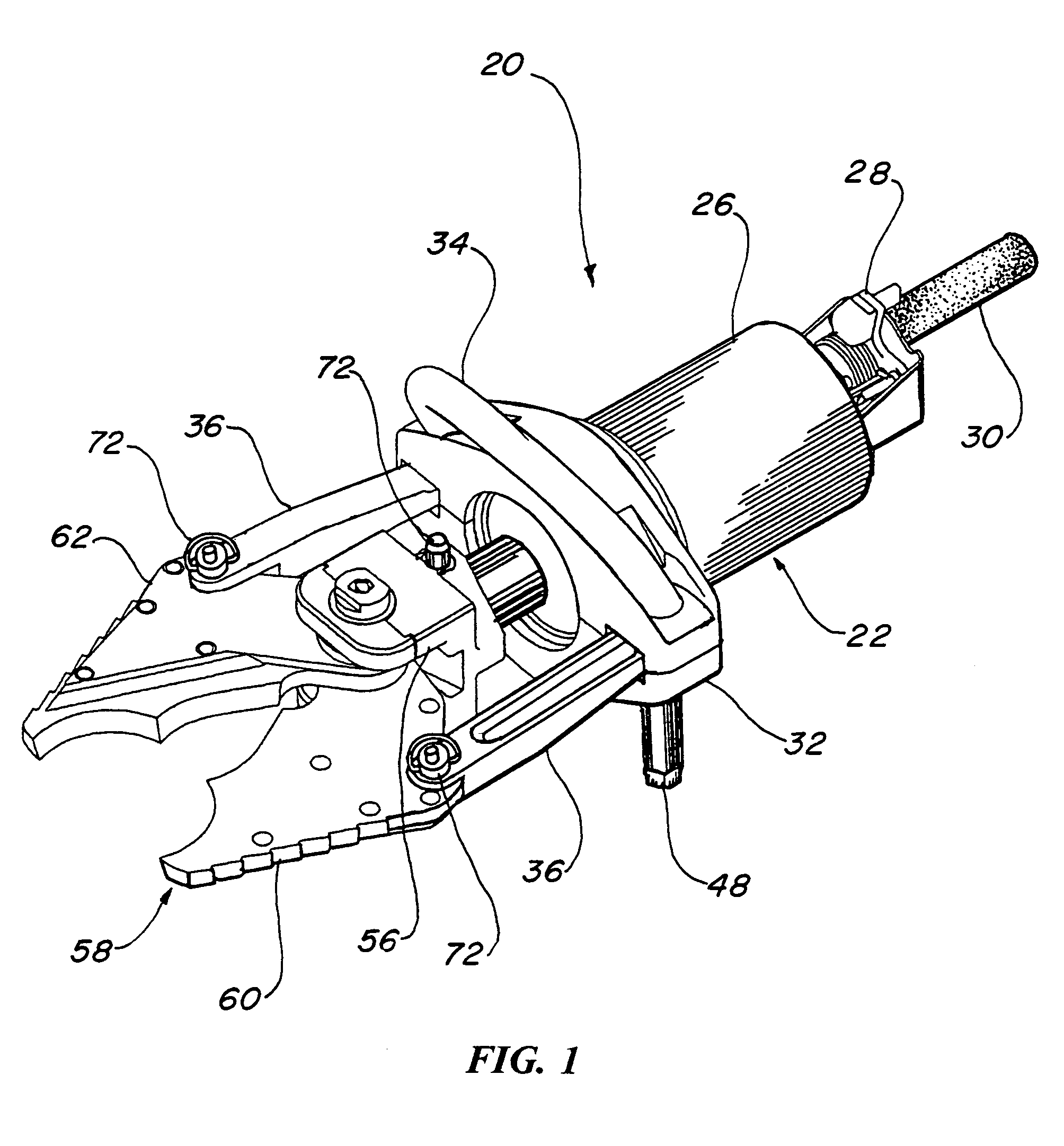

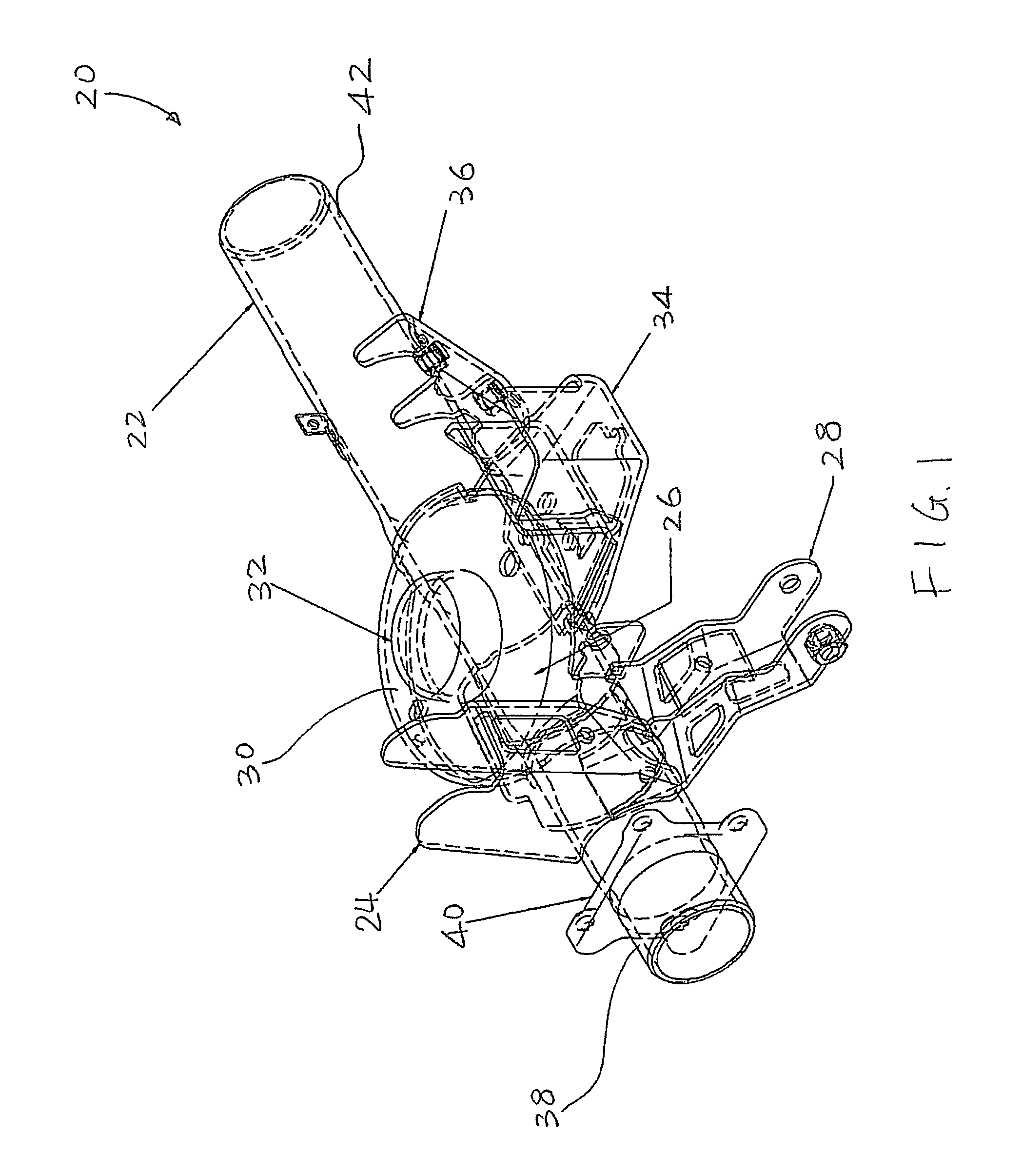

Hydraulic rescue tool

InactiveUS7568372B1Preventing pressurizationLimit hydraulic pressureDrawing diesBuilding rescueHydraulic cylinderThreaded fastener

A hydraulic rescue tool (10) is comprised of a hydraulic thrust apparatus (20) consisting of a hydraulic cylinder body (24) having slots (28) within a hollow end and interlocking ears (36) protruding from the slots. A gland (38) is interfaced between the ears, with the gland and ears connected to the cylinder hollow end with threaded fasteners (98). A connecting link (50) is attached to each interlocking ear and a quick disconnect implement unit (22) is attached to each link and to a piston rod (30) within the cylinder body (24). Six dissimilar embodiments of implement units, each having quick disconnect capabilities and different vehicle structure separating utility are attached to the hydraulic thrust apparatus (20).

Owner:FIVE STAR IP HLDG

Method and apparatus for selectively leaching portions of PDC cutters used in drill bits

A polycrystalline diamond compact (PDC) cutter having a body of diamond crystals containing a catalyzing material is coated with a material impervious to a given acid. After the coating has dried, a segment of the coating is removed and acid is supplied to the diamond crystal body through the template in the coating to leach out the catalyzing material contained within the body of diamond crystals.

Owner:TERCEL IP

Continuous pickling and wiredrawing process of brass wire

ActiveCN101961736AImprove surface qualityReduce labor intensityDrawing diesCompression injuryProduction line

The invention relates to a continuous pickling and wiredrawing process of a brass wire, which is characterized in that: after being drawn out of a wire releasing disc, a brass wire blank is subjected to continuous processes of pickling, neutralizing, brushing, cleaning and wiredrawing. A continuous producing mode is used for connecting the pickling process and the drawing process of the brass wire together, namely that after an annealed brass wire blank is arranged on a wire releasing frame by one end of a production line, a finished product of the fine-drawn brass wire can be generated from the other end, therefore, the continuous producing mode has few processing and flowing processes and stops scrapes and compression injuries in the flowing process; pickled products are wiredrawn in a shorter period to ensure better brightness and consistency of product appearance and obviously increase the surface quality of the finished product of the brass wire; the processing process has high automation degree, reduces labor intensity of staffs and increases production efficiency; when the brass wire is in the pickling process, an oxide layer on the surface of the brass wire only needs to be loosened; and therefore, when the brass wire is pickled, nitric acid does not need to be added, the usage amount of acid liquor is greatly reduced, and the production cost is reduced.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Tubular articles with varying wall thickness and method of manufacturing same

Owner:AAM INT S A R L

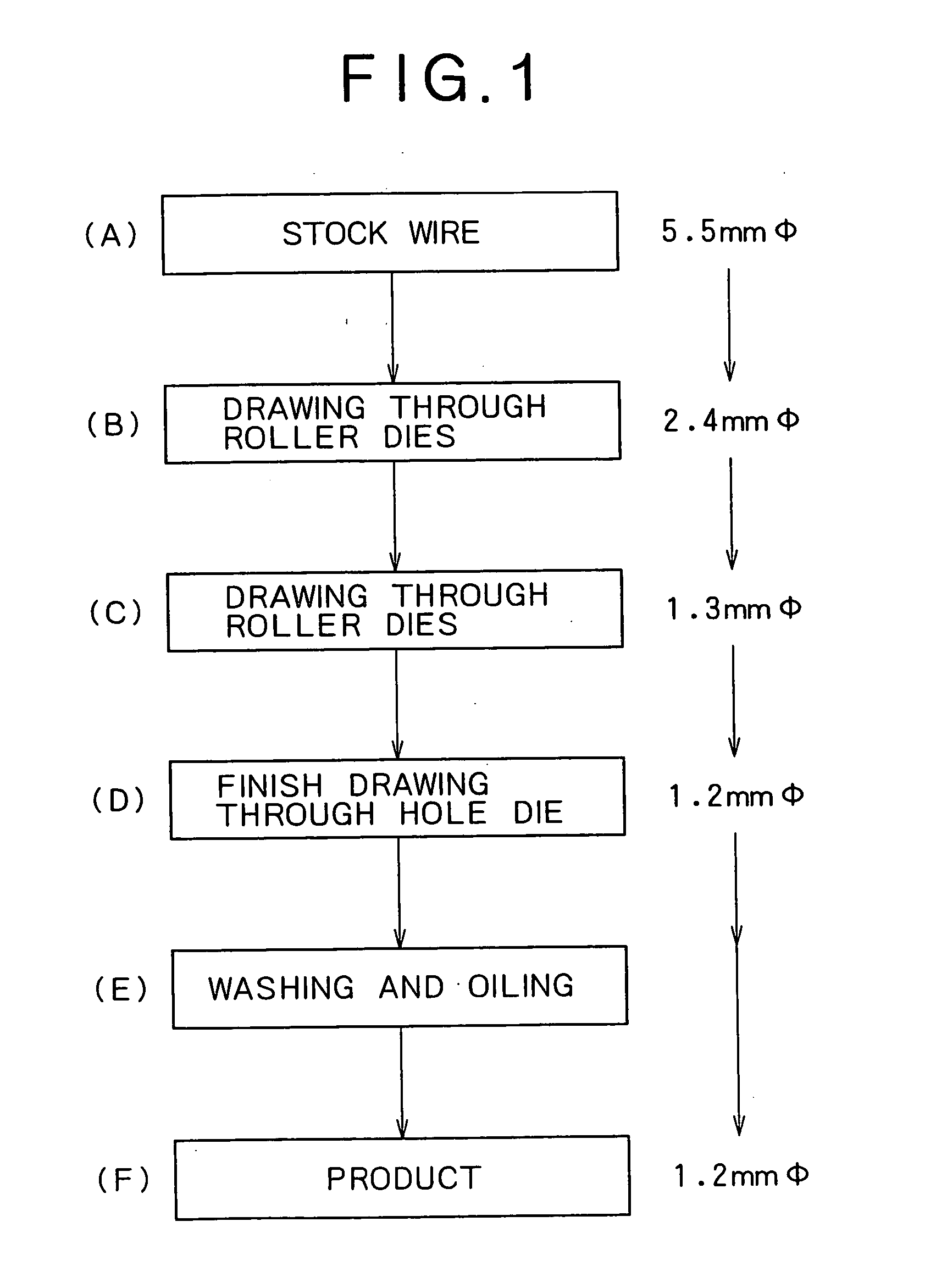

Method of producing solid wire for welding

ActiveUS20050045699A1Uniform applicationEfficient weldingDrawing diesArc welding apparatusCopper platingSodium stearate

A method for efficient production of a welding solid wire free of copper plating. The method consists of drawing by means of roller dies with the help of a dry solid lubricant for drawing which is at least either of sodium stearate or potassium stearate, removing the lubricant from the wire surface by means of a washing device, and applying a lubricant for wire feeding to the surface of the drawn wire by means of an oiling device. High-speed drawing by means of roller dies makes a stock wire into a welding solid wire having the diameter of the finished wire or nearly finished wire. The drawing step is followed by the washing step and the lubricant applying step, which are all accomplished in-line.

Owner:KOBE STEEL LTD

Method and apparatus for selectively leaching portions of PDC cutters used in drill bits

A polycrystalline diamond compact (PDC) cutter having a body of diamond crystals containing cobalt is coated with Teflon which is impervious to hydrofluoric acid. After the Teflon coating is dried, a segment of the Teflon coating is removed and a mixture of 50% hydrofluoric acid and 50% nitric acid is supplied to the diamond crystal body through the template in the Teflon coating to leach out the cobalt catalyzing material contained within the body of diamond crystals. In an alternative embodiment, a similar process is used to coat a PDC drill bit and the PDC cutters mounted in the PDC drill bit. After the Teflon dries, a segment of the coating is removed and the acid mix is applied through the templates in the cutters to leach out the cobalt in each of the bodies of diamond crystals. In another alternative embodiment, a tube is placed over the PDC cutter, the tube having one or more templates exposing only the segment or segments of the cutting surface to the acid mix.

Owner:TERCEL IP

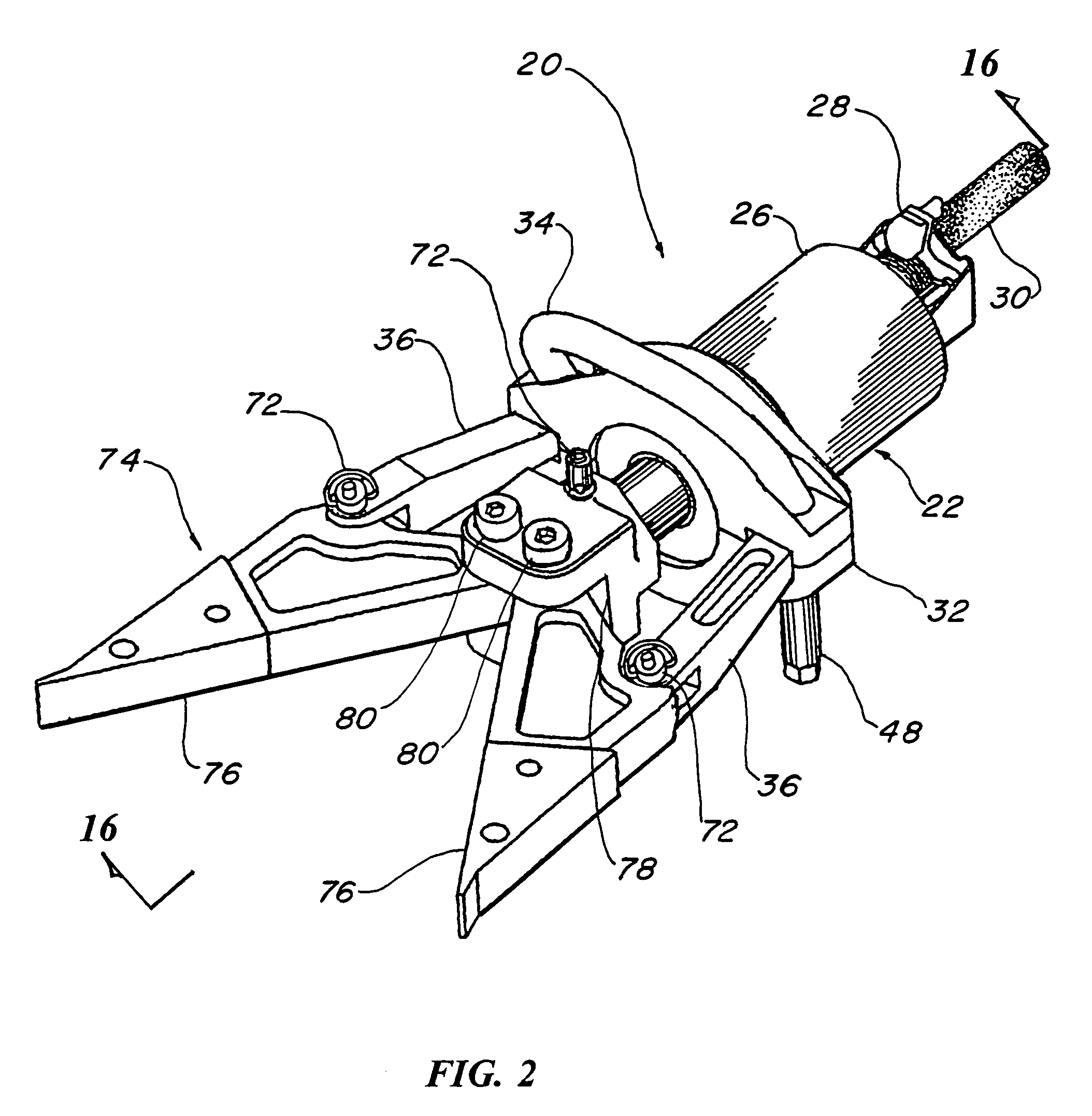

Hydraulic rescue tool

InactiveUS7107812B1Increase the areaIncrease surface areaDrawing diesBuilding rescueHydraulic cylinderPreventing injury

A hydraulic rescue tool (20) that utilizes a hydraulic cylinder (22) having a piston rod (24) that is movably disposed within the housing of the cylinder to provide linear driving means for the rescue tool. A cylinder yoke (32) is rotatably attached to the hydraulic cylinder housing and includes a front handle bar (34) for manipulating the tool. Rotation of the cylinder yoke (32) relative to the cylinder (22) prevents injury to an operator in the event that the tool binds and torques. An implement unit (50), which is either a cutter (54) or a spreader (74), is detachably disposed onto the piston rod (24). Pivotal links (36) connect the unit (50) to the cylinder yoke (32), with the unit used for cutting or spreading metal during a rescue. A plurality of quick release pins (72) attach the implement unit (50) to the piston rod (24) and pivotal links, thus providing a rapid release of the implement unit (50) from the piston rod (24) and links (36) for replacement or repair. The piston rod (24) has a rebated diameter (82) on its internal end that is at least two times smaller than the piston. This reduction in diameter provides additional surface area for hydraulic pressure when retracting an attached implement unit.

Owner:PATTON HYDRAULICS

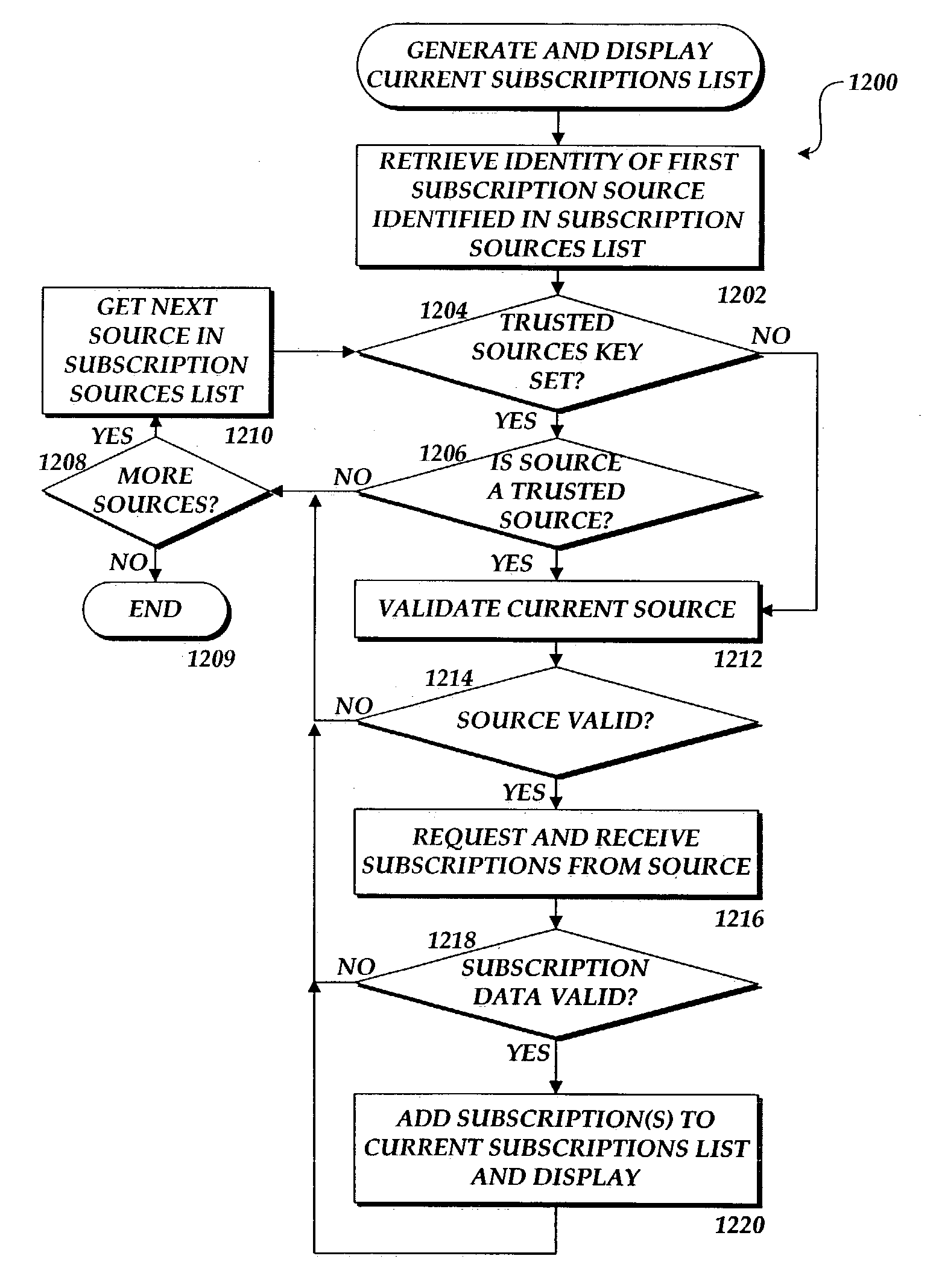

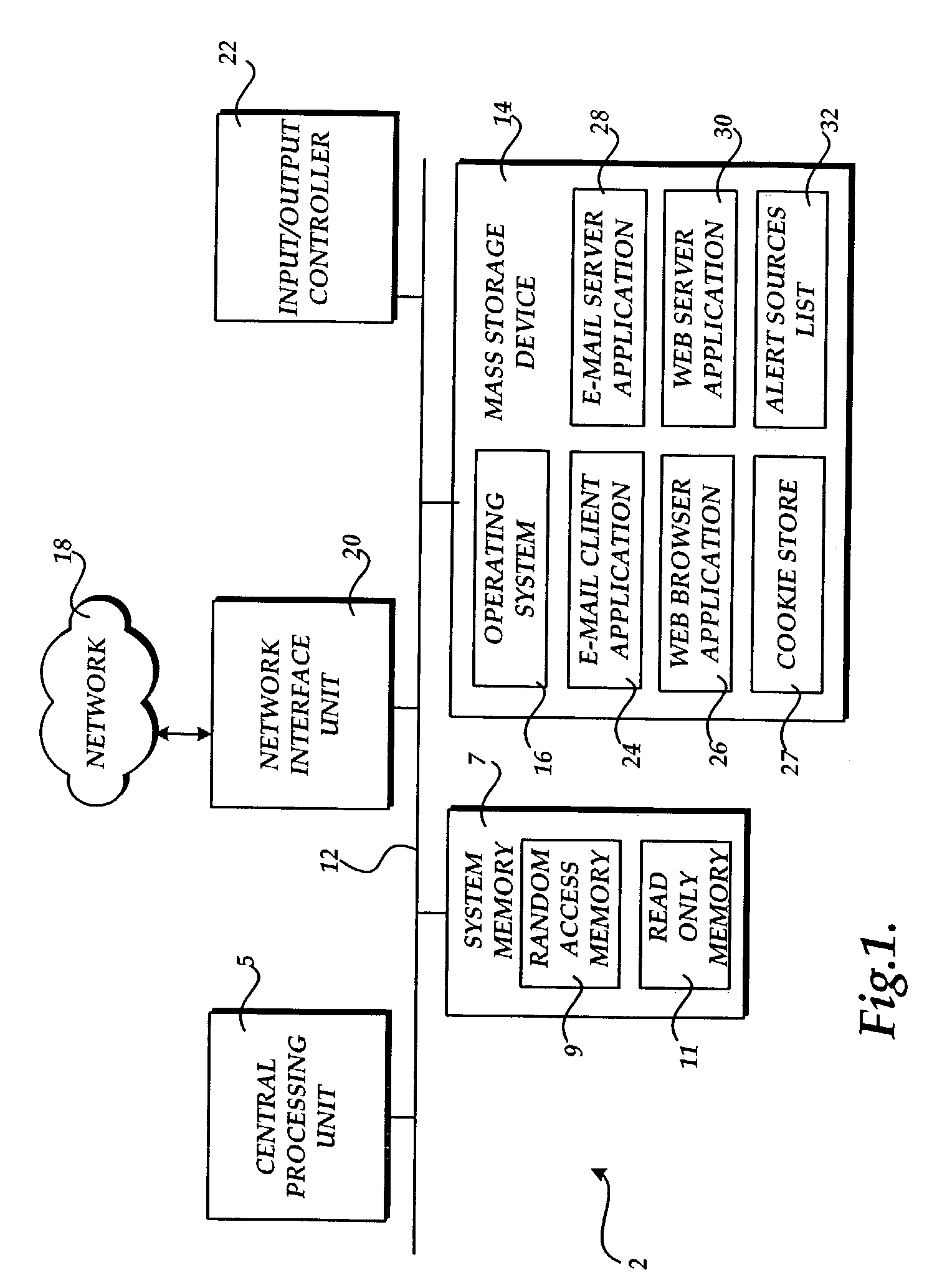

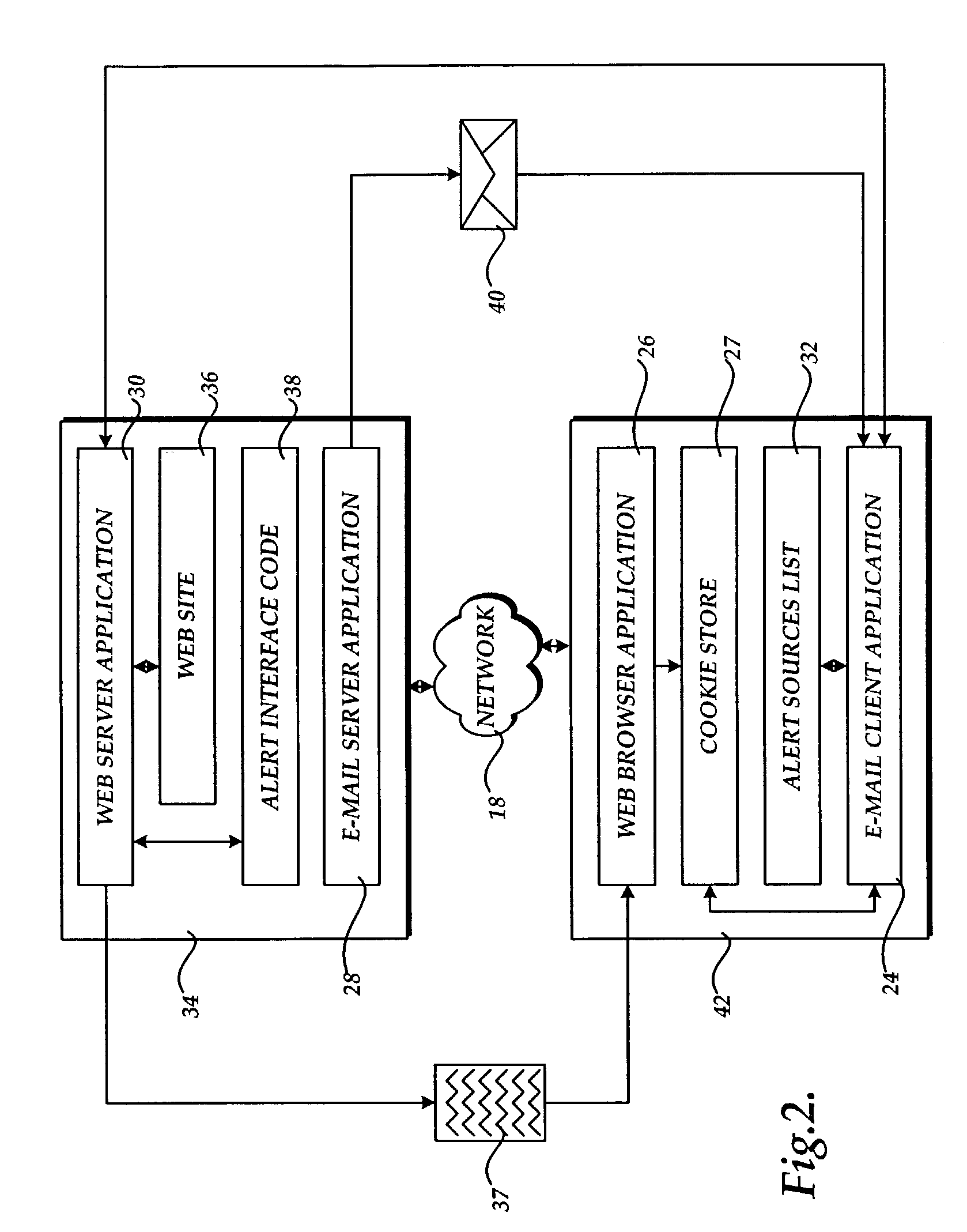

Method, apparatus, and user interface for managing electronic mail and alert messages

InactiveUS7467183B2Easy to manageEasy to addHand manipulated computer devicesDrawing diesNetwork addressingNetwork address

A method, apparatus, system, and user interface are provided for managing e-mail rules and alert subscriptions from multiple sources. Alert messages and persistent state objects, such as cookies, are examined to determine whether they relate to an alert subscription. If an e-mail message or persistent state object is determined to relate to an alert subscription, a network address for a subscription source identified by the contents of the e-mail message or state object are added to a list of subscription sources. A request may then be received to manage one or more alert subscriptions. In response to the request, each subscription source identified in the list of subscription sources is validated. Each validated subscription source is added to a current subscriptions list, which is displayed to a user. Each subscription in the current subscriptions list may be modified or deleted by the user through a unified user interface for managing e-mail rules and alert subscriptions. Schema and data structures are also provided for communication between an e-mail and alert subscription client and a subscription source.

Owner:MICROSOFT TECH LICENSING LLC

Method for manufacturing seamed flux-cored welding wire

ActiveCN1590009AGuaranteed modifiabilityImproved wire feedabilityDrawing diesWelding/cutting media/materialsSulfurHydrogen content

Disclosed herein is a manufacturing method, excellent in wire drawability, of a seamed flux-cored welding wire having both favorable feedability and low hydrogen content characteristic. The method for manufacturing a seamed flux-cored wire, comprises the steps of: drawing a tube-like formed wire including a flux filled therein using a lubricant; removing the lubricant from the drawn wire by a physical means; and coating a lubricant (coating an oil) for wire feeding on the wire surface. The respective steps are carried out in an in-line manner. In the wire drawing step, a wire drawing lubricant containing a sulfur-bearing high-pressure lubricant is used, and the overall wire drawing from the tube-like formed wire to a roughly product-diameter wire is carried out by means of a roller die.

Owner:KOBE STEEL LTD

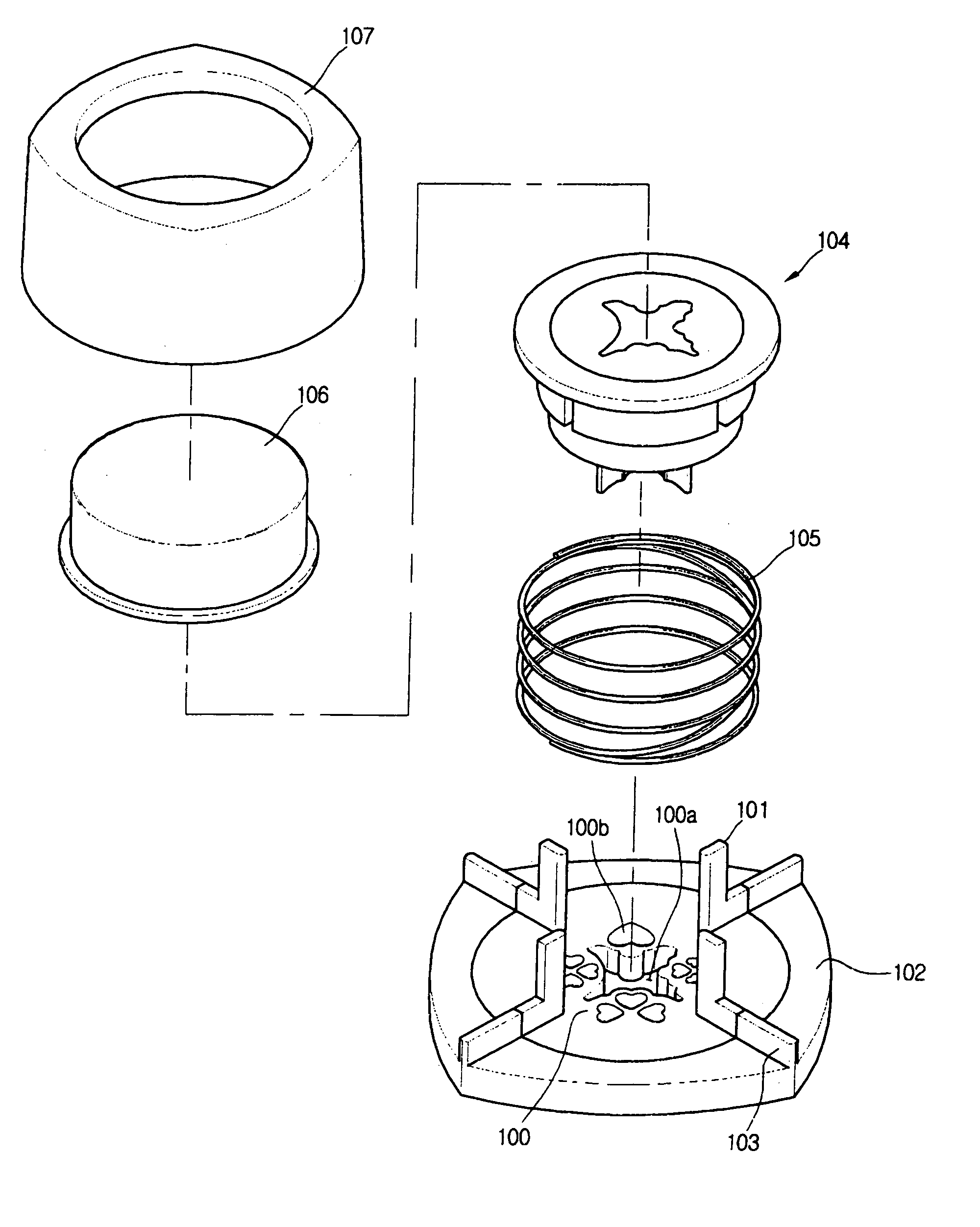

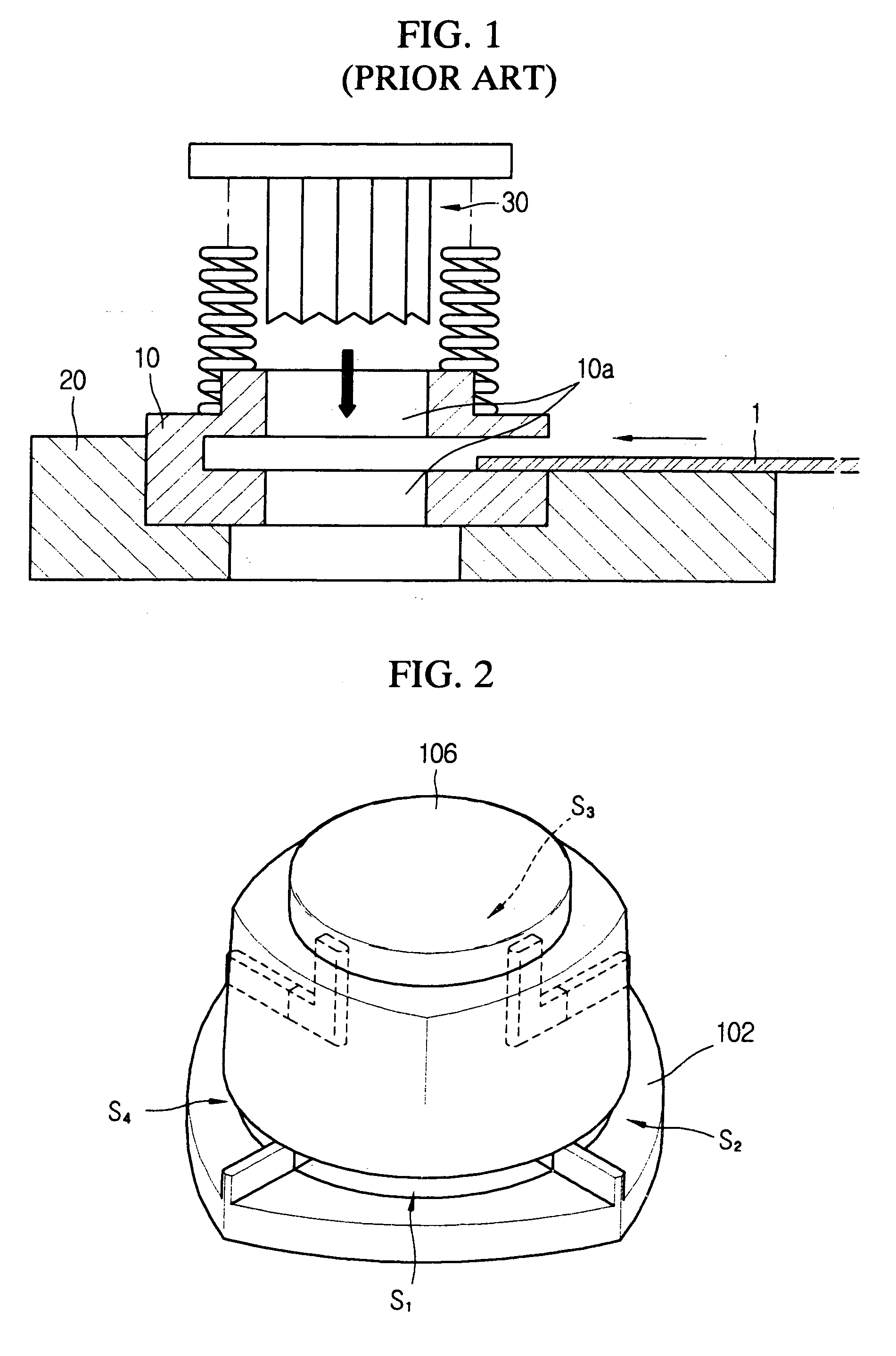

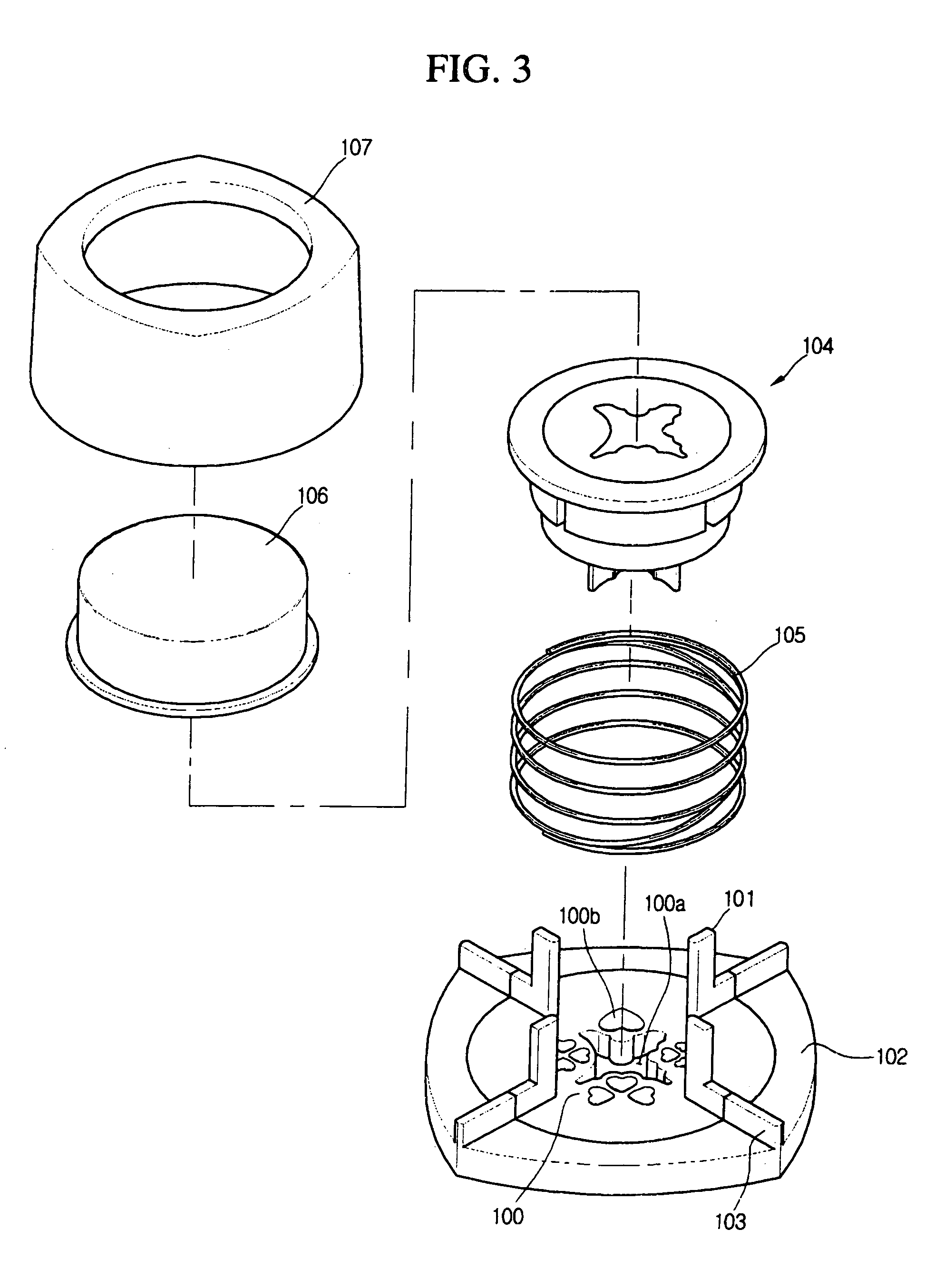

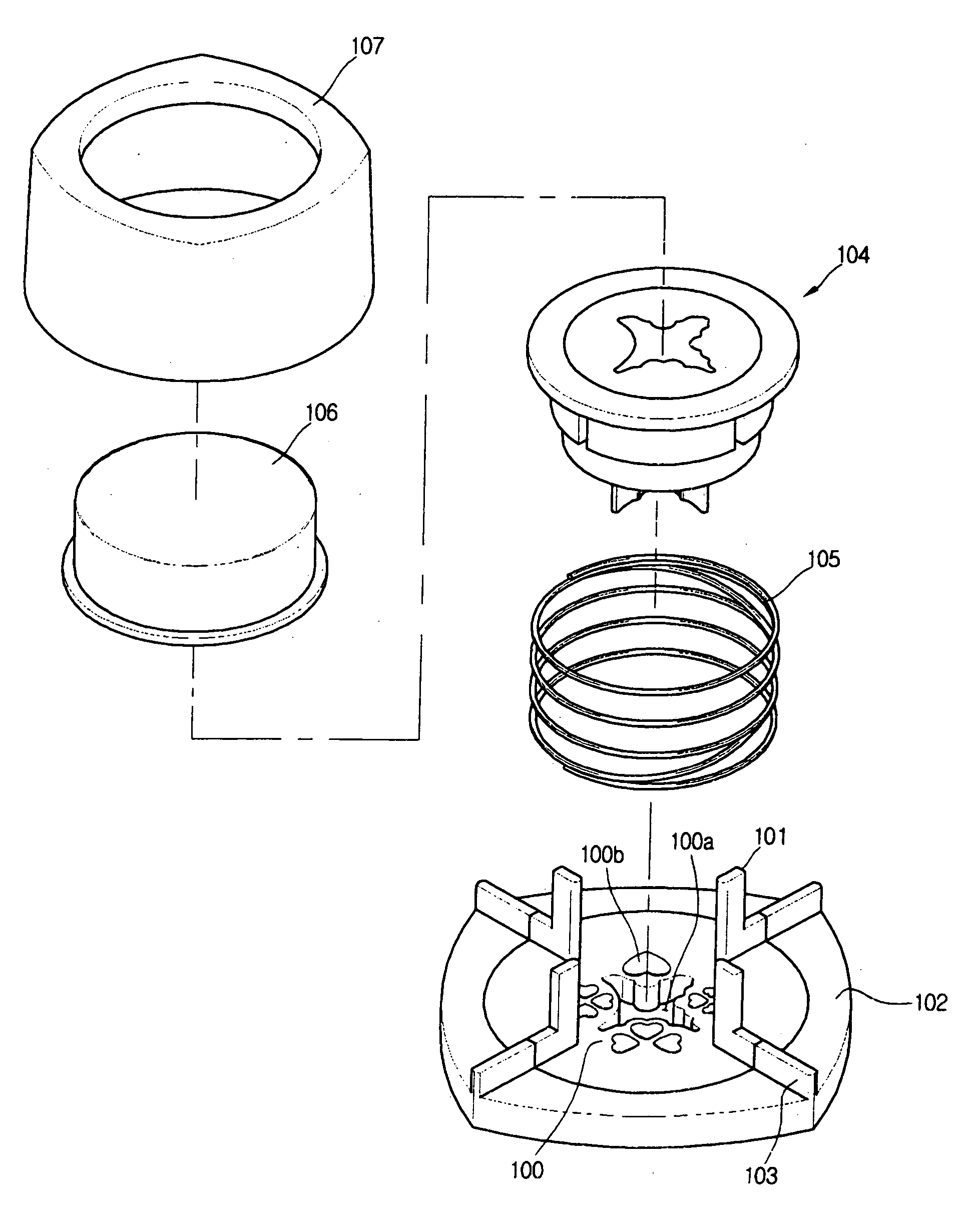

Punch capable of punching an object at four directions

InactiveUS7201101B2Simple structureEasy to useMechanical working/deformationLeather manufacturingPunch pressEngineering

A punch includes a jig having four punching regions, each punching region having a pattern hole and a concave embossment; guide columns extended upward from a border of the punching regions on the jig; a base for fixing the jig; a punching member punching and embossing the rectangular corner of a sheet member with vertically moving against the jig by guidance of the guide columns; and an elastic body to elastically bias the punching member upward.

Owner:DN CRAFT

Preparation process of red copper square pipe material

ActiveCN105562456APrevent oxidationReduce operational processingDrawing mandrelsDrawing diesSurface oxidationChain type

The invention provides a preparation process of a red copper square pipe material. The process comprises the following flow processes of casting, cast ingot sawing and cutting, water seal extrusion, sawing and cutting, straightening, rolling, chain type drawbench circular drawing, circular transition to square pipe material hollow pulling, square pipe material hollow pulling, shaping drawing, finishing, bright annealing and packaging; the diameter shaping drawing is firstly performed after the rolling; the transition to the square pipe material is realized; the diameter shaping hollow pulling is performed; finally, a finished product is fed onto a core head to be subjected to shaping drawing; the goal that the radius R of the circular corner is gradually reduced until the radius R conforms to the requirement is achieved; the outer dimension center part back arching is avoided; the inner dimension is enabled to conform to the requirements; the water seal decrustation processing mode is used in the extrusion process; the pipe blank surface oxidation can be prevented; the process processing process is reduced; the product quality is further ensured.

Owner:中铝洛阳铜加工有限公司

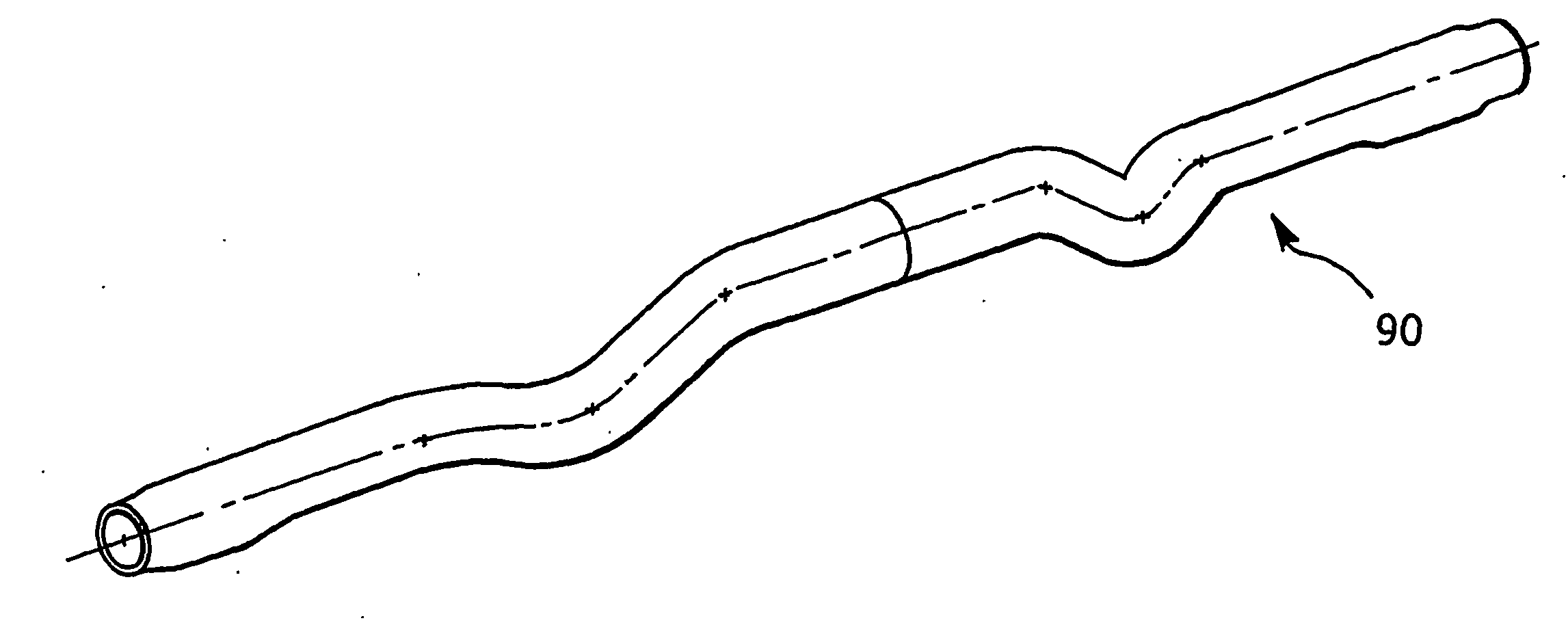

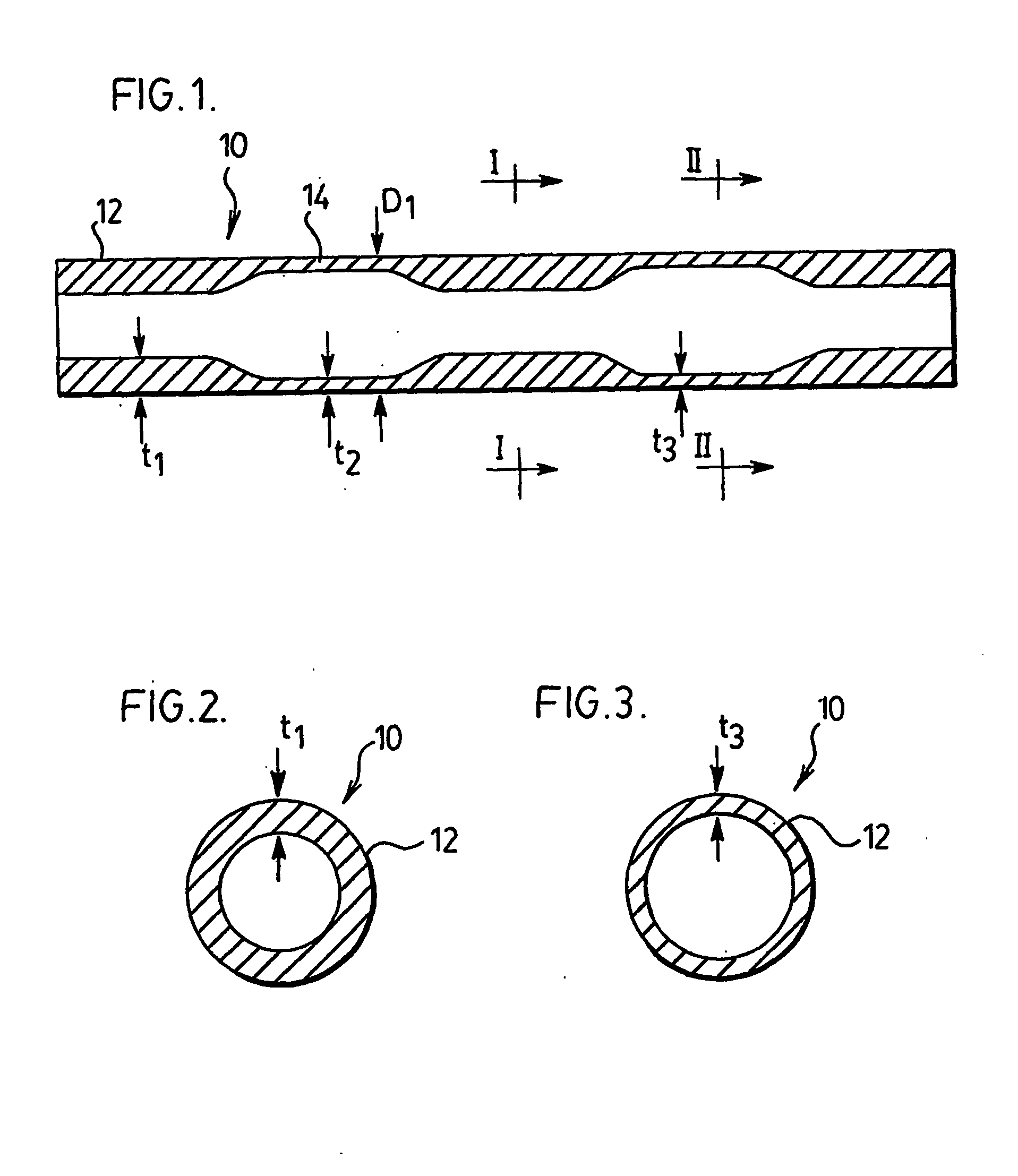

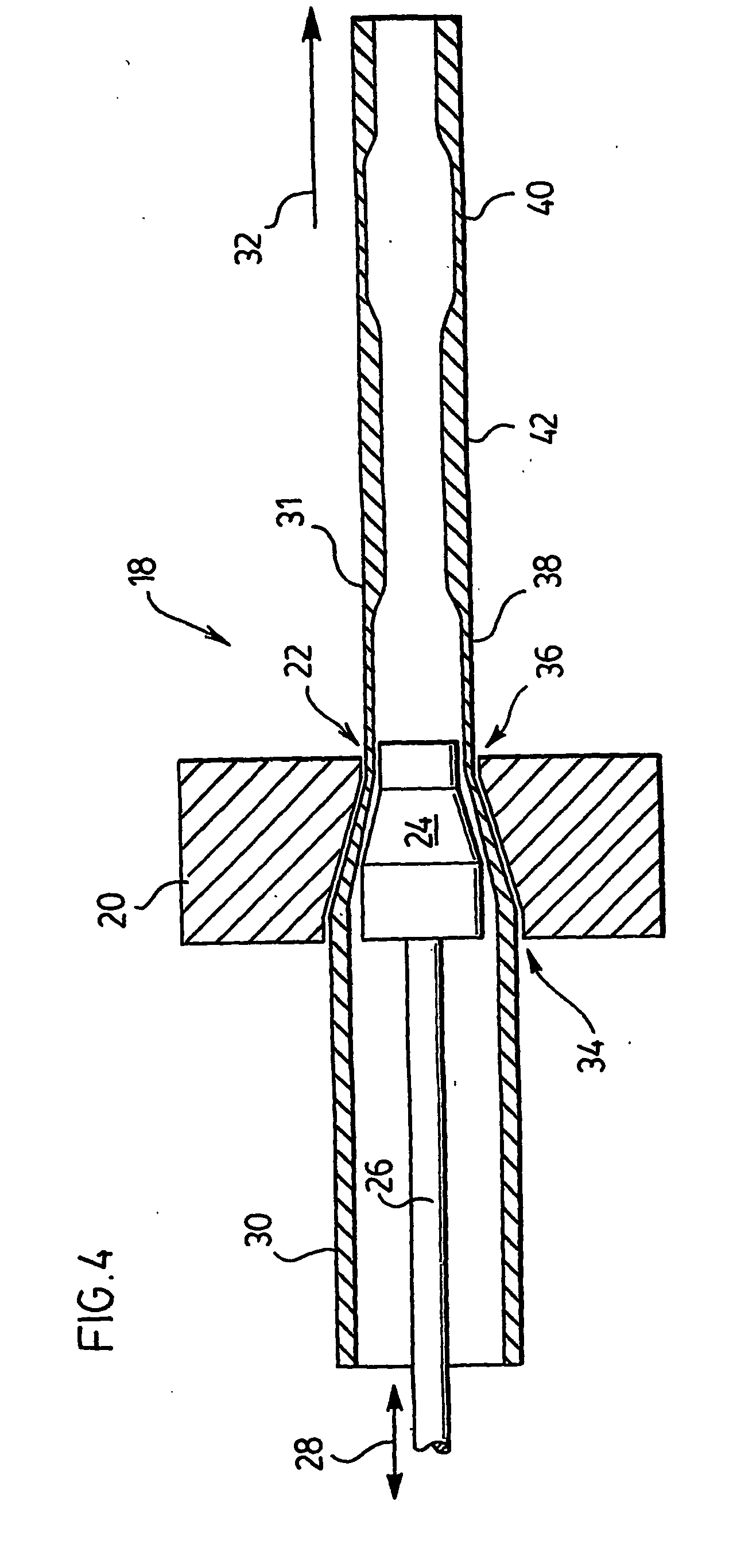

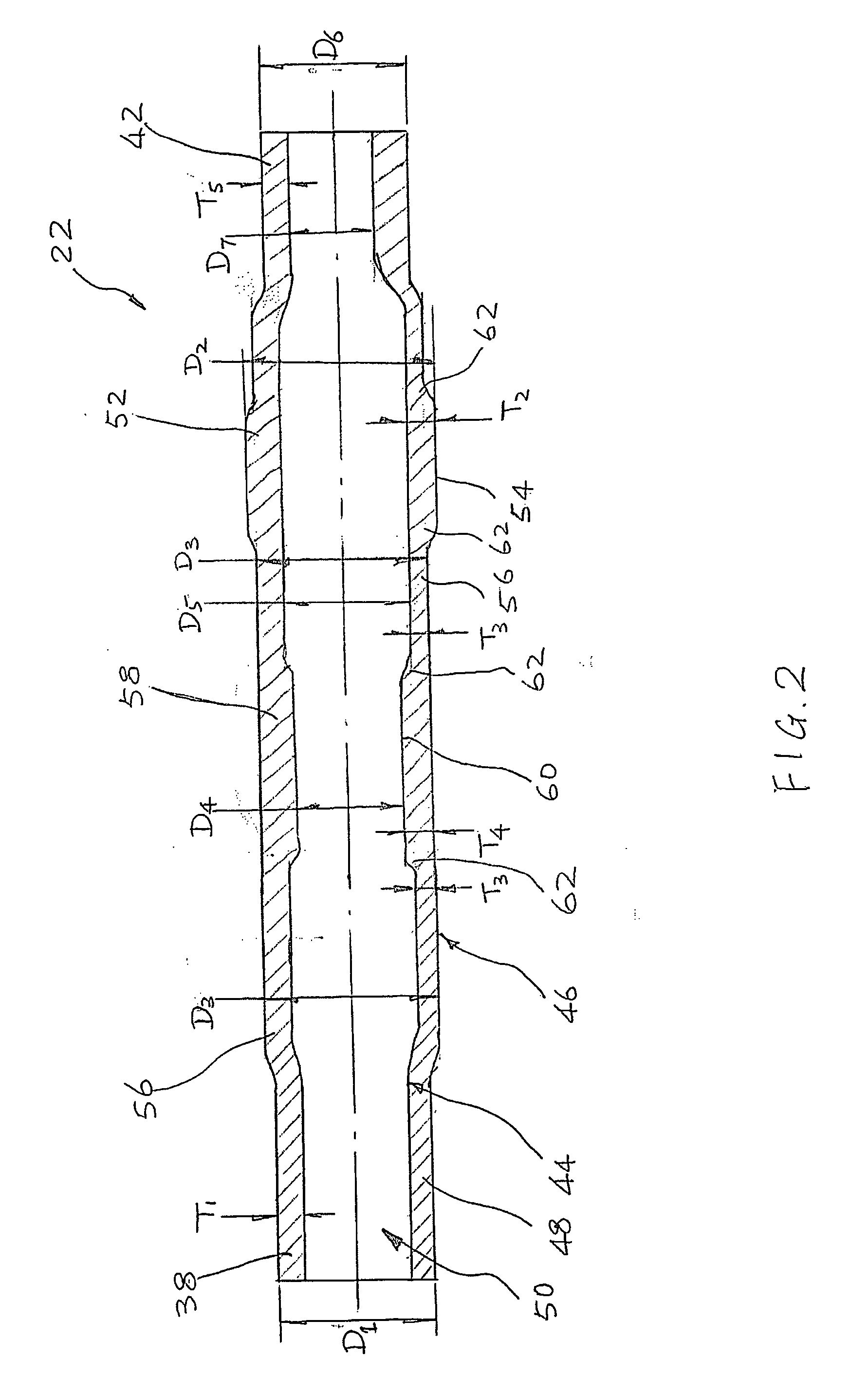

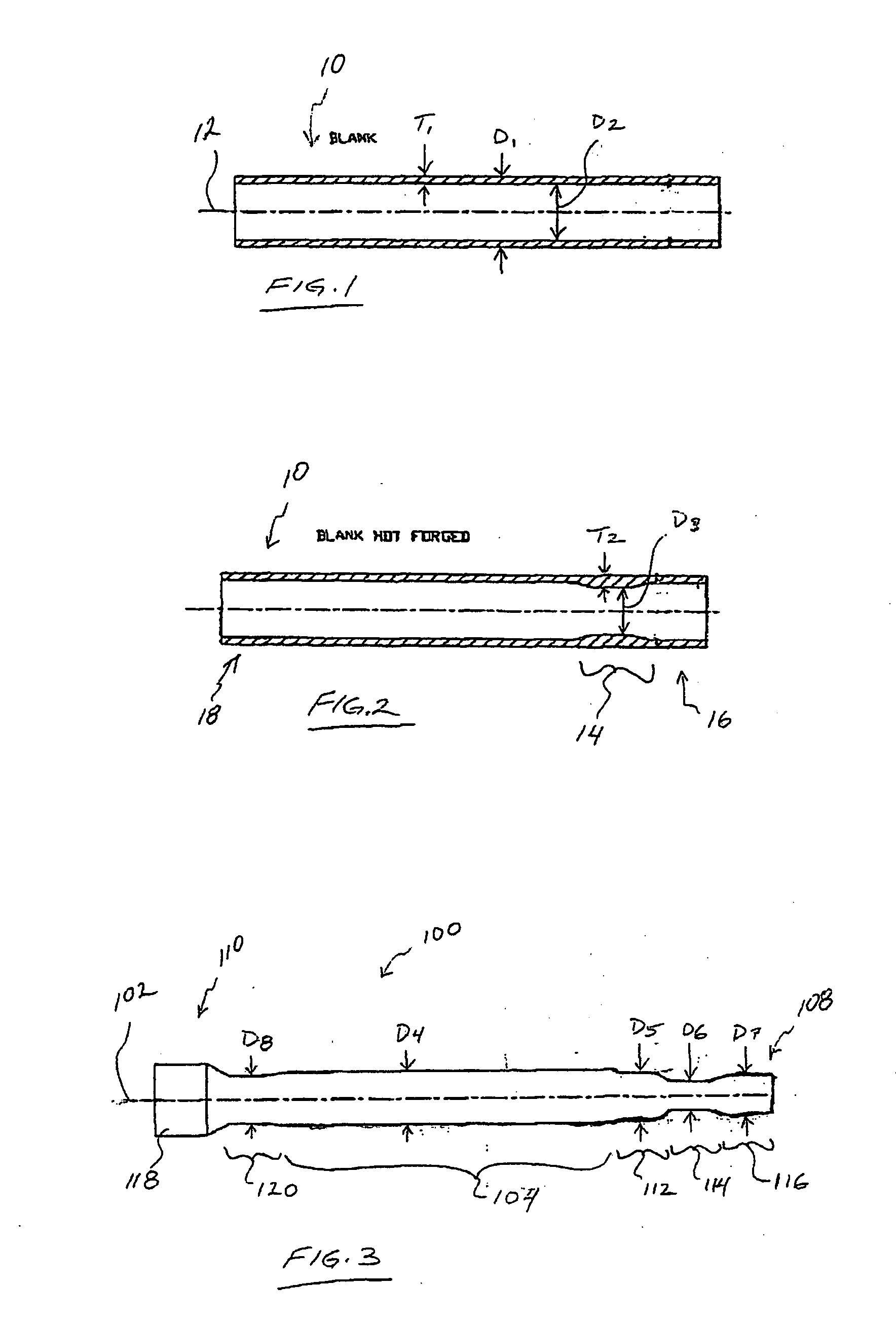

Method of manufacturing structural components from tube blanks of variable wall thickness

A method for forming a tubular structural member includes the steps of cold forming a tube blank (10) to have a longitudinally variable but circumferenfially constant wall thickness (t1, t2, t3) and forming the blank into the desired structural member (90). Preferably, the forming step involves hydroforming.

Owner:ARCELORMITTAL TUBULAR PRODS CANADA

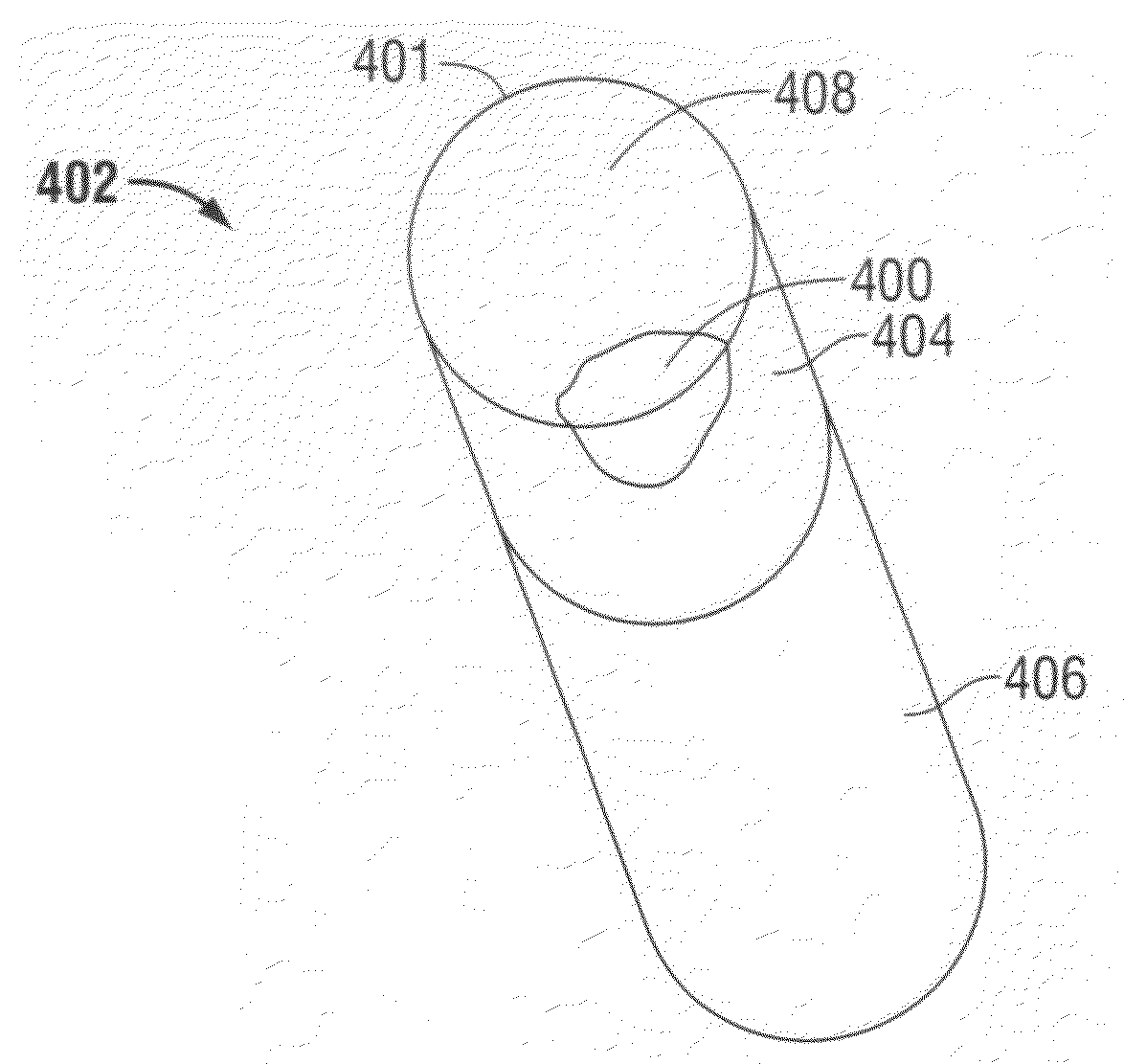

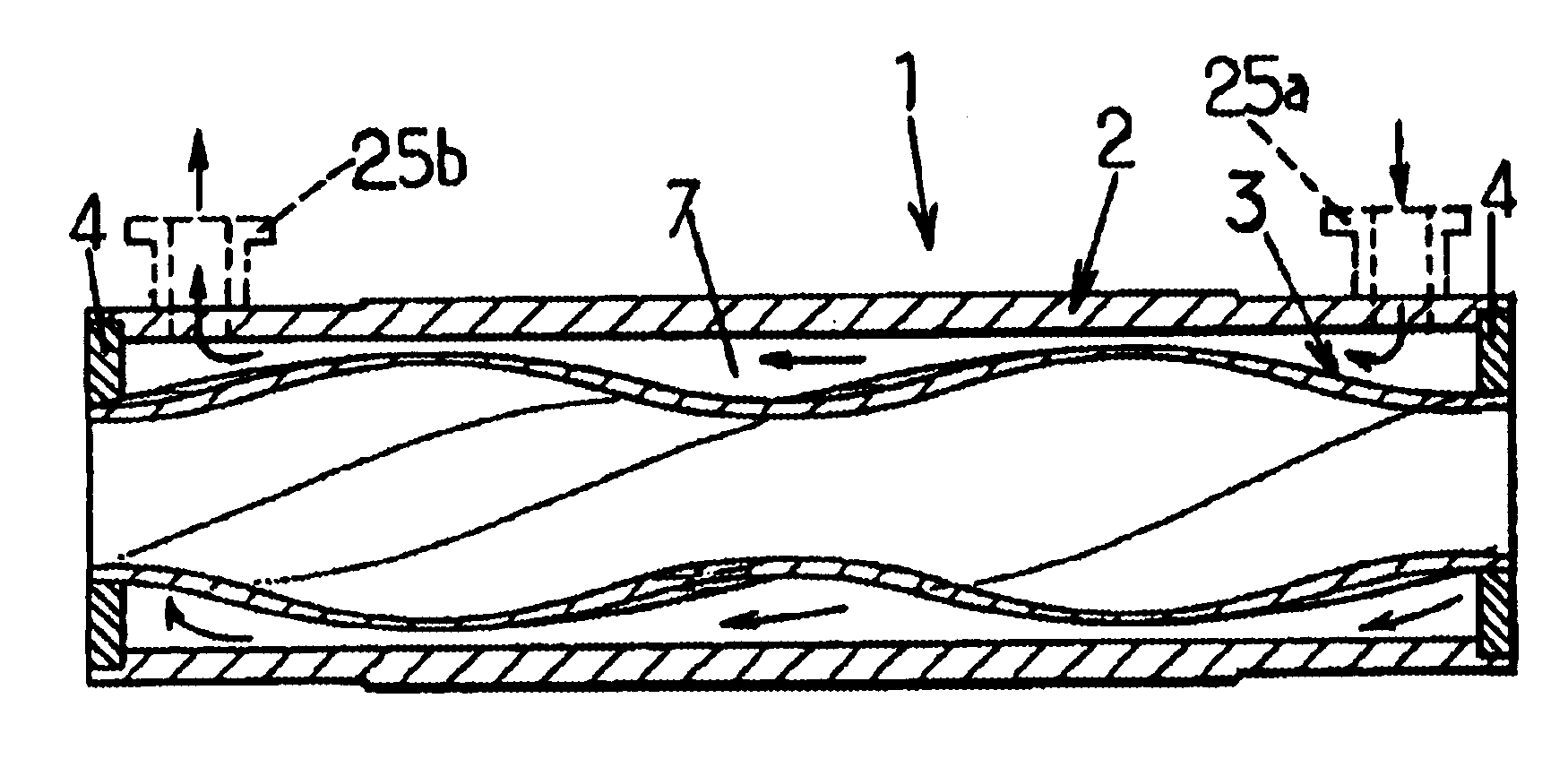

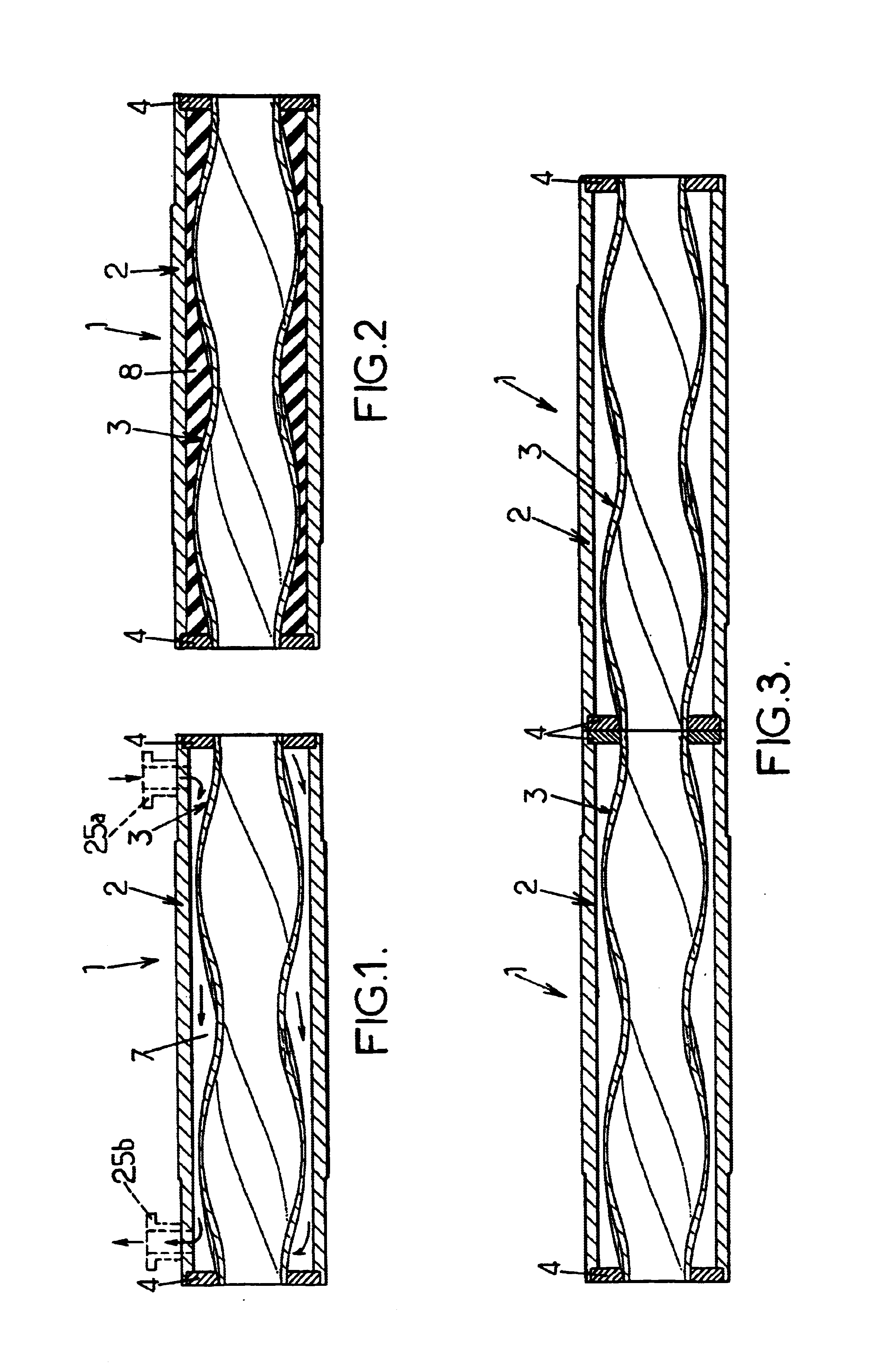

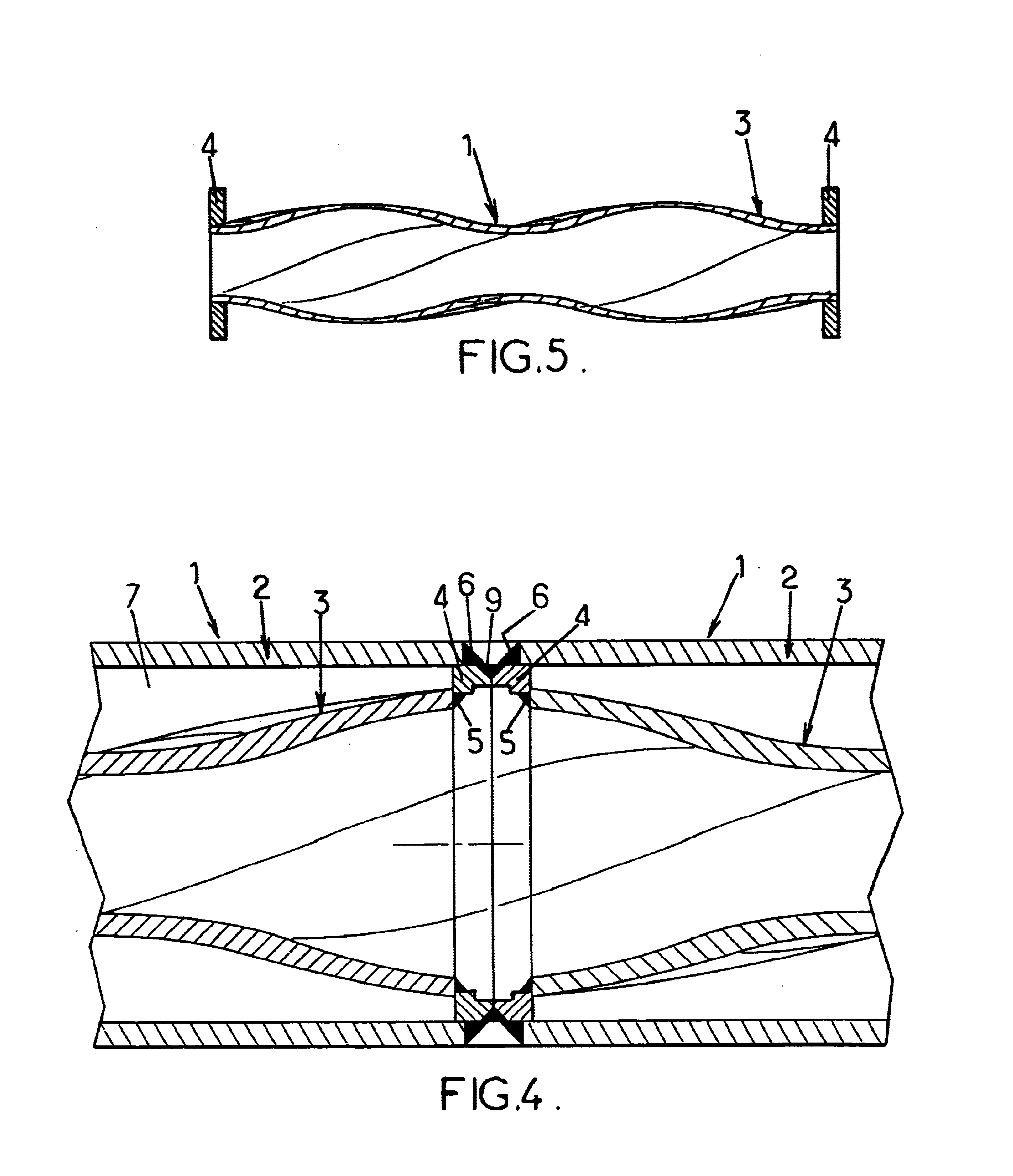

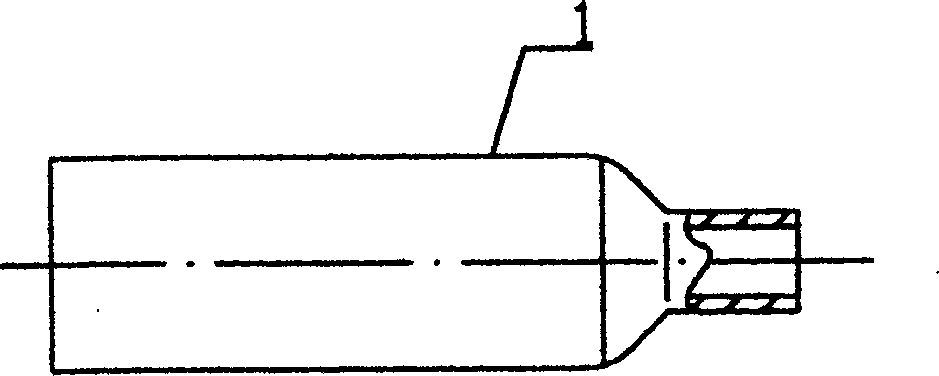

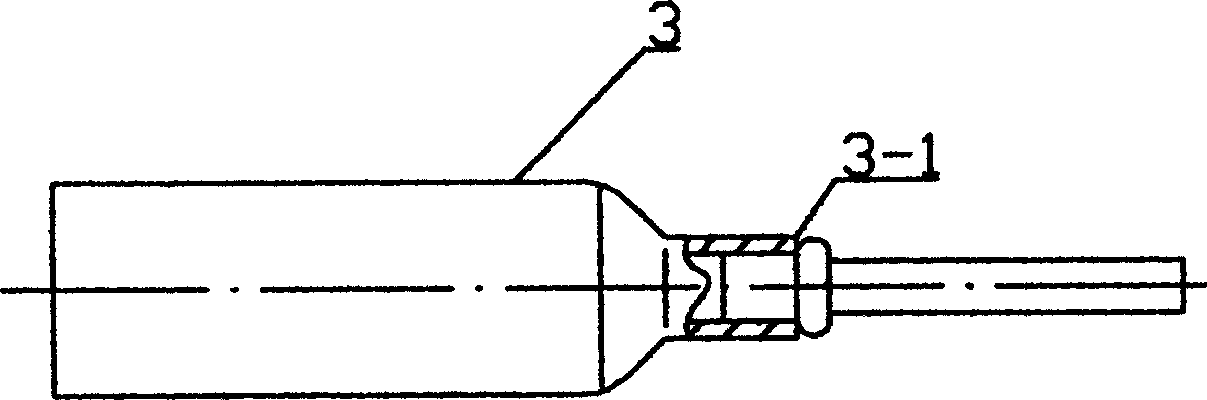

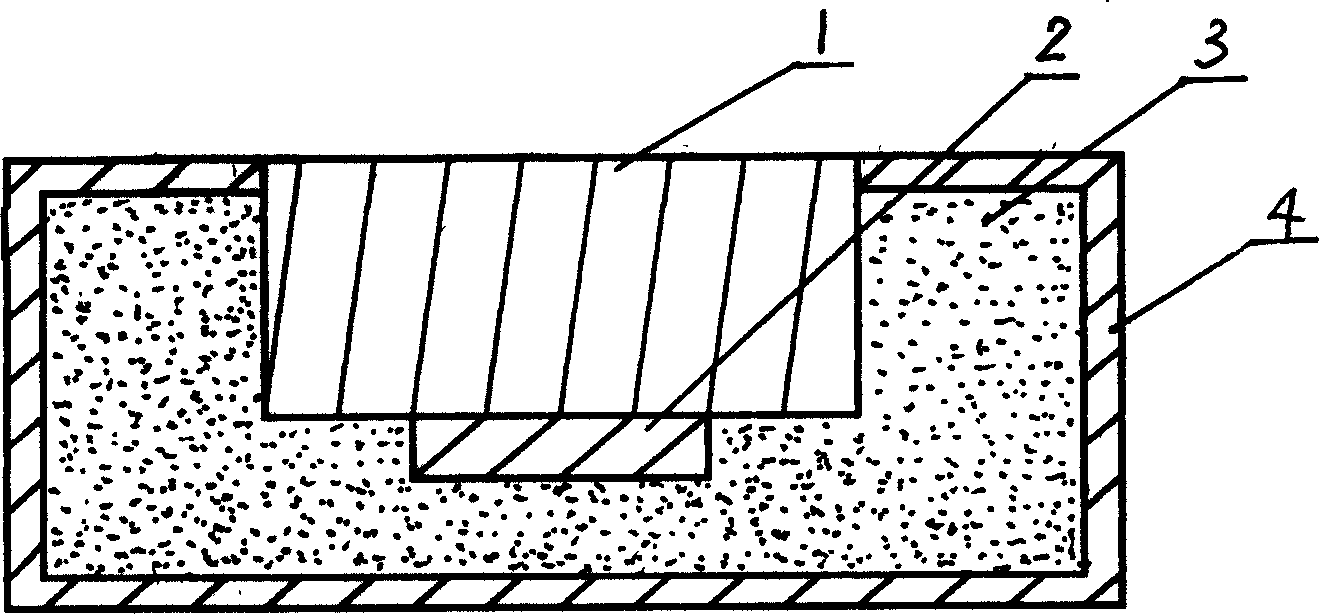

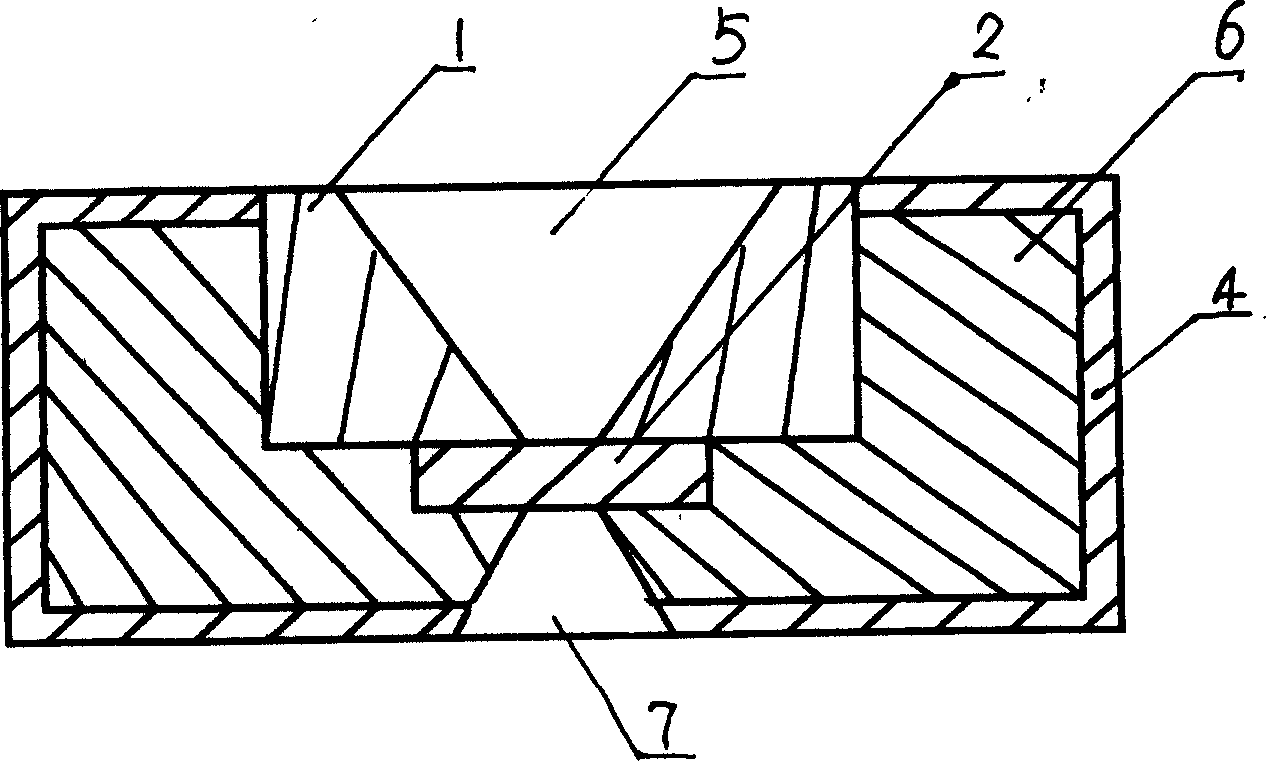

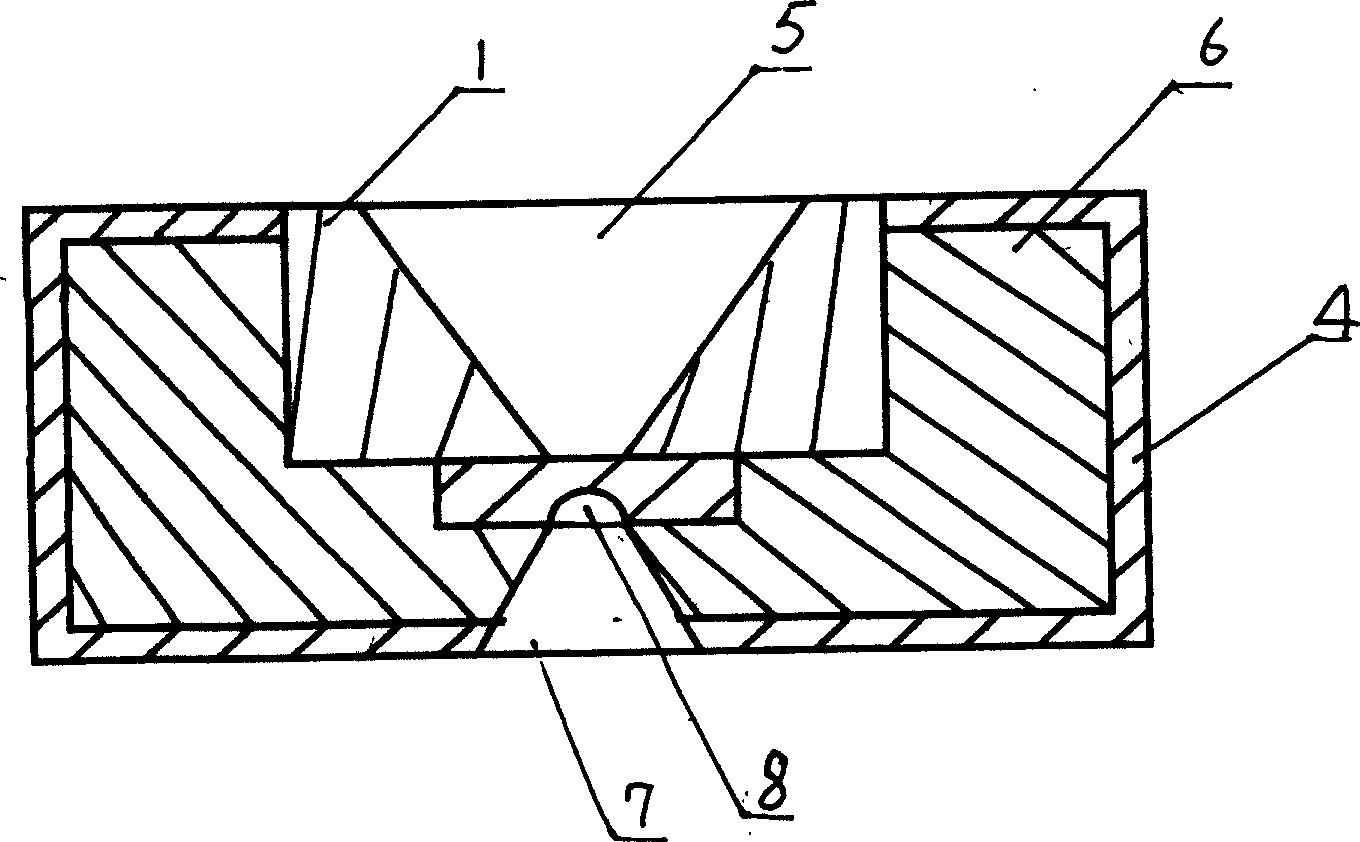

Method for making a moineau stator and resulting stator

InactiveUS6872061B2Easy to assembleLow costDrawing diesOscillating piston enginesGear pumpRigid wall

The invention concerns a Moineau type gear pump stator (1), comprising a stator cavity with global axial extension inside an elongated body, characterised in that the stator cavity is defined by a rigid-walled metal tubular element (3) having internall the shape and dimensions of the stator cavity such that, when it is assembled with a rotor, a positive clearance with the rotor is obtained.

Owner:PCM TECH

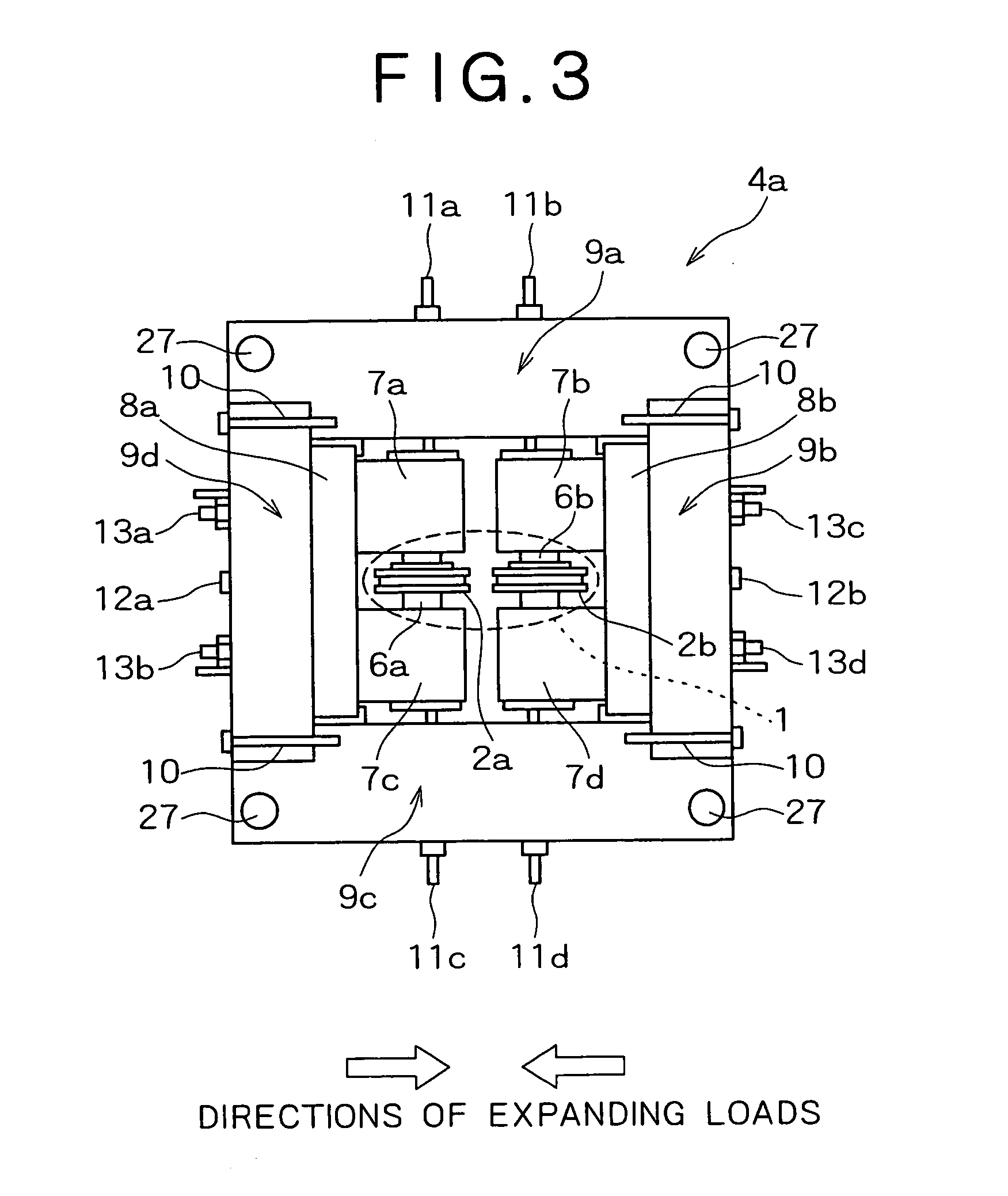

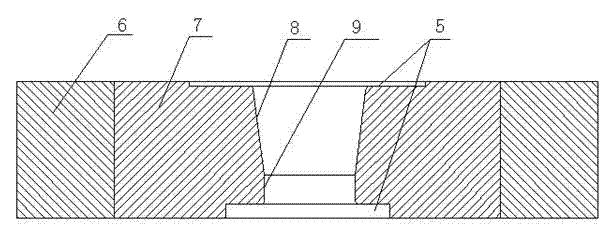

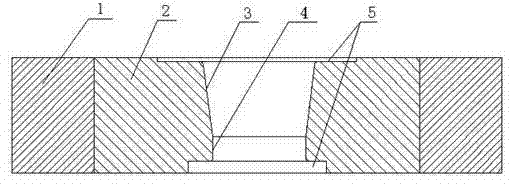

Method and apparatus for manufacturing reducing pipe

InactiveCN1528542ASleek appearanceIncrease productivityDrawing diesEngine componentsControl systemThin walled

The invention relates variable aperture tube making method and device, including tube end rotary forging and draw stretching. It first forges one end of the tube on the rotary forger into a smaller-aperture technical tube, which makes the stretching mould through to be clamped by the clamping module; using a hydraulic control system to drive clamping base and clamping module; inserting core rod with mould head in the copper tube to stretch by the stretching mould. It includes rotary forger and draw-stretching device. The clamping module, the stretching mould and the core rod makes up a stretching process line. The position of the core rod is adjustable and the stretching effect is good. The hydraulic control system is installed with travel switch to control stretching travel. It is applied to the control of thin-wall small-aperture copper tube and widely applied to cryogen pipeline in refrigerating industry.

Owner:广州冠华金属精工制造有限公司

Titanium alloy wire production method

The invention discloses a titanium alloy wire production method. A titanium alloy wire is prepared by carrying out multi-die continuous cold-drawing on a titanium alloy wire blank by using a polycrystalline wire drawing die or high-crystalline wire drawing die, wherein calcium-based wire drawing powder or sodium-based wire drawing powder is used as a lubricating agent. By using the titanium alloy wire production method, the size precision and the surface quality of a finished product of the titanium alloy wire are ensured, the production efficiency is increased, and the environment of a working site is improved.

Owner:BAOJI TITANIUM IND CO LTD

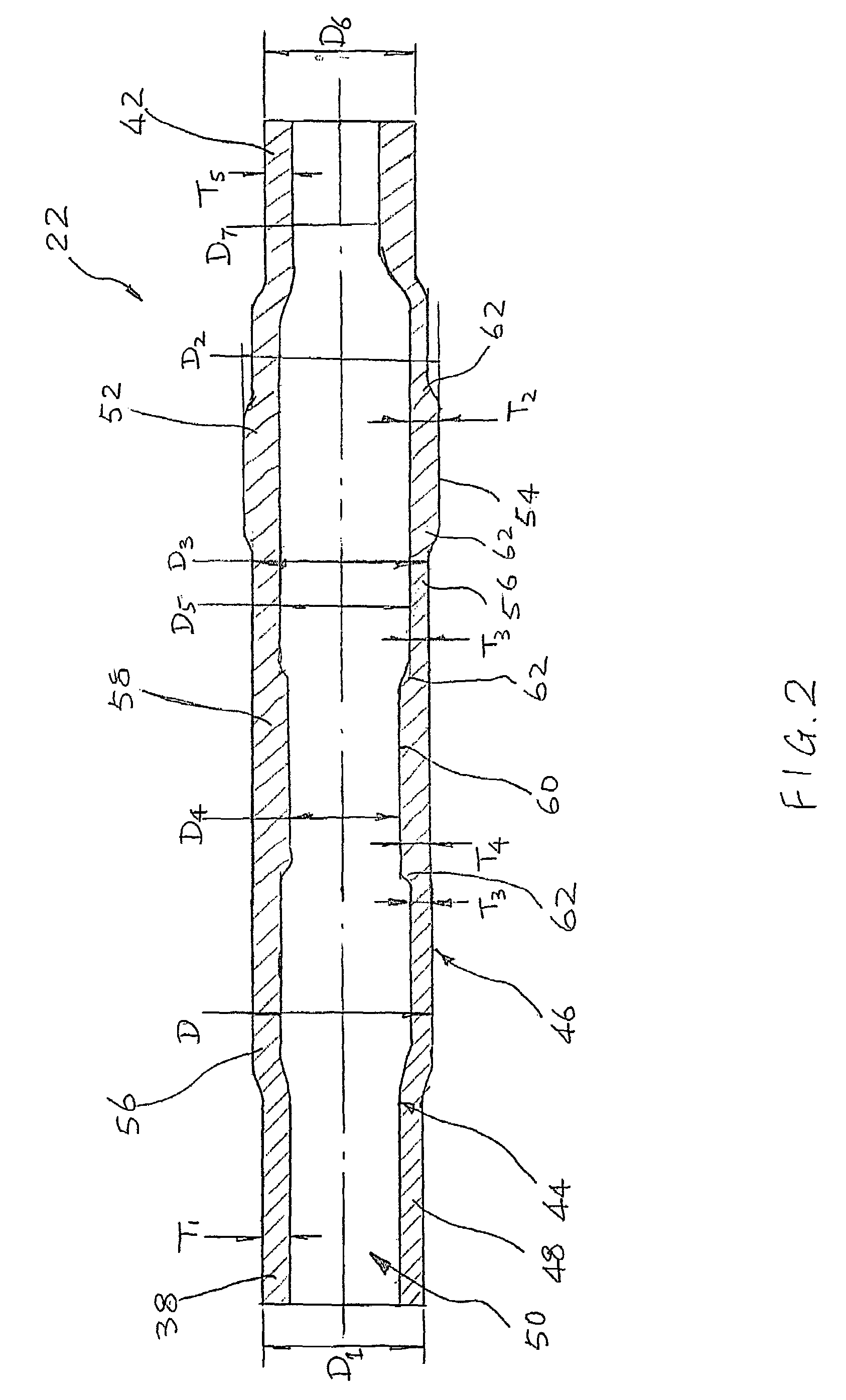

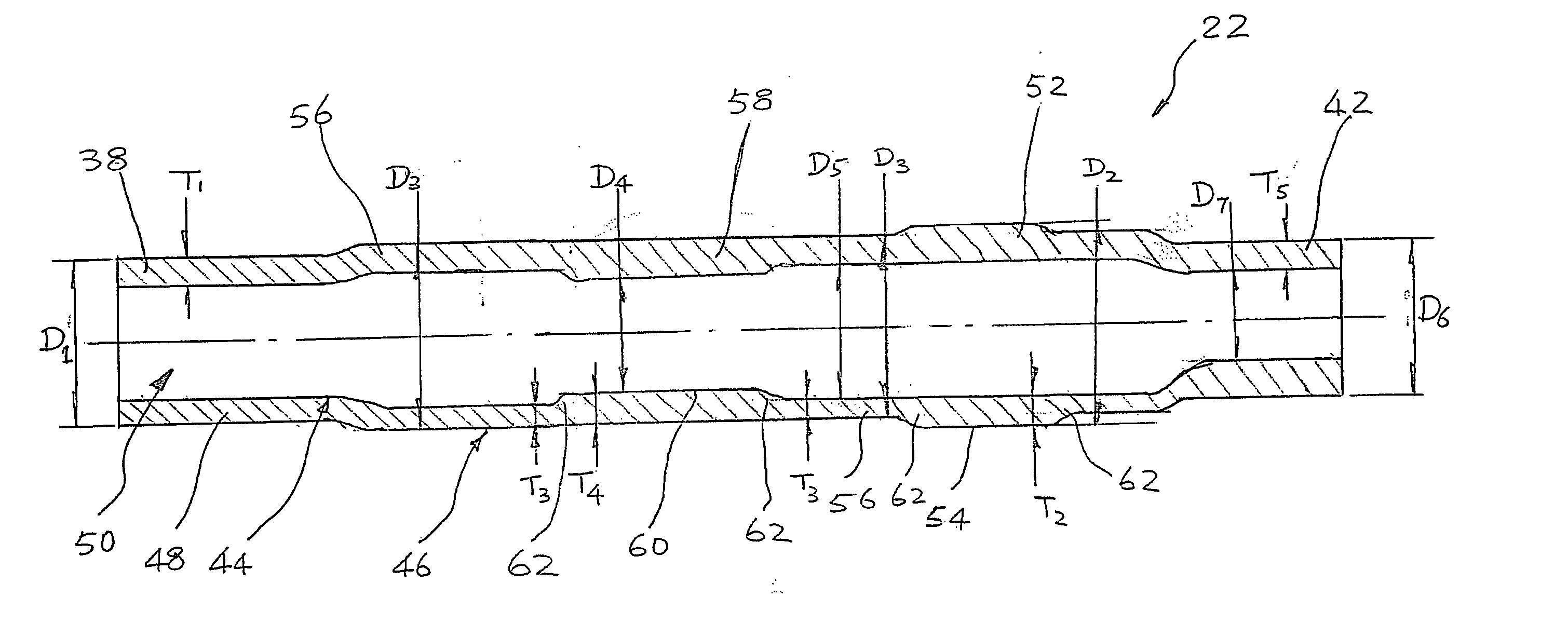

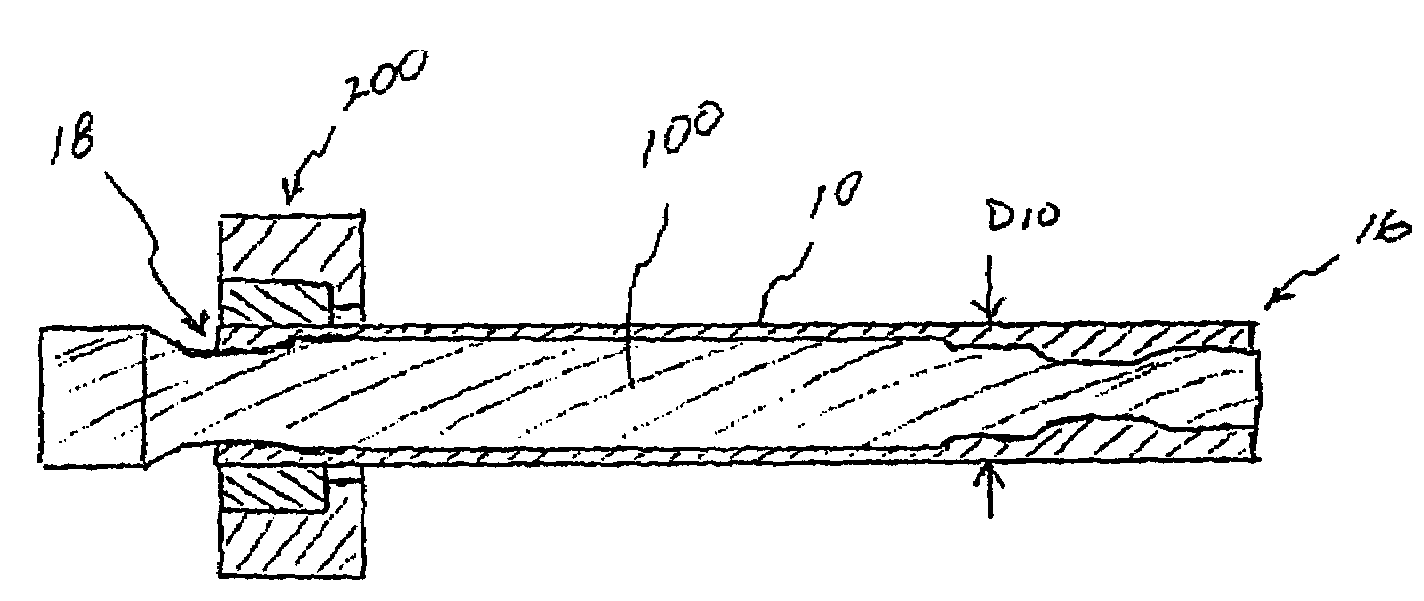

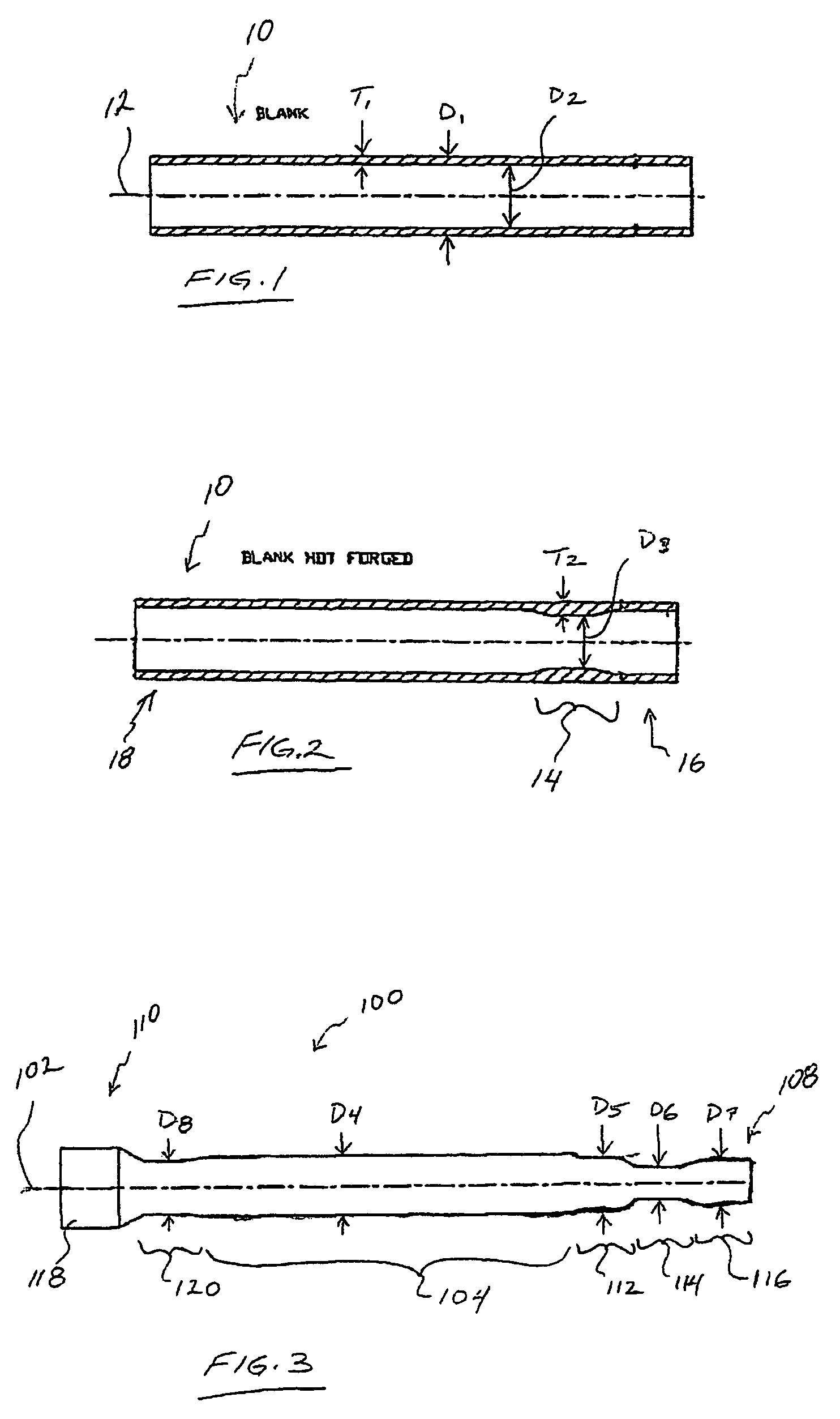

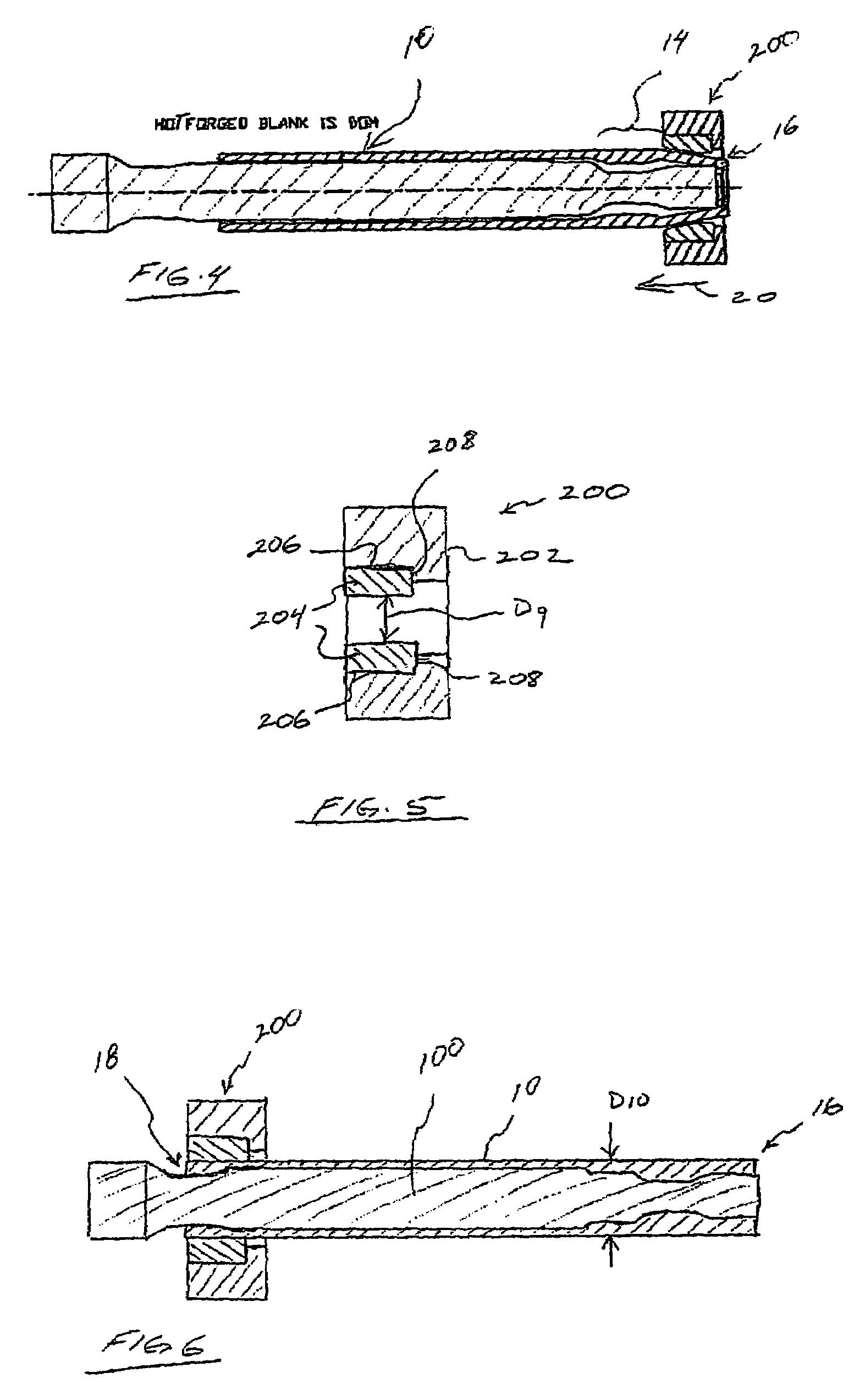

Tubular articles with varying wall thickness and method of manufacturing same

A method for manufacturing a one-piece axle tube housing with localized sections of increased wall thickness includes providing a tube blank, inserting a mandrel having a reduced diameter profile, passing the tube through an extrusion die to conform the tube to the shape of the mandrel; and extraction of the mandrel from the tube to cause outward deformation of the tube at specific locations. A further reducing step may be used to form the final desired profile, including reduced inner and outer diameters along sections of the axle tube housing.

Owner:AAM INT S A R L

Punch capable of punching an object at four directions

InactiveUS20050211036A1Simple structureEasy to useDrawing diesLeather manufacturingPunch pressEngineering

A punch capable of punching an object at four directions is disclosed. The punch includes a jig having four punching regions radially symmetrical to each other on the basis of a punching center, each punching region having a pattern hole and / or a concave embossment; guide columns extended upward from a border of the punching regions on the jig; a base for fixing the jig and giving a supply surface so that a rectangular corner of a sheet member to be punched is supplied between the adjacent guide columns; a punching member having a punch pin and / or a convex embossment corresponding to the pattern hole and / or the concave embossment, and punching and / or embossing the rectangular corner of the sheet member with vertically moving against the jig by guidance of the guide columns; and an elastic body interposed between the punching member and the jig to elastically bias the punching member upward.

Owner:DN CRAFT

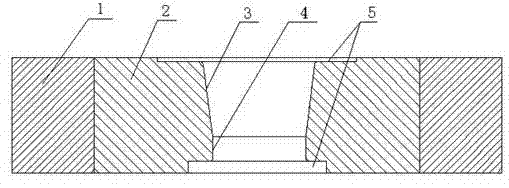

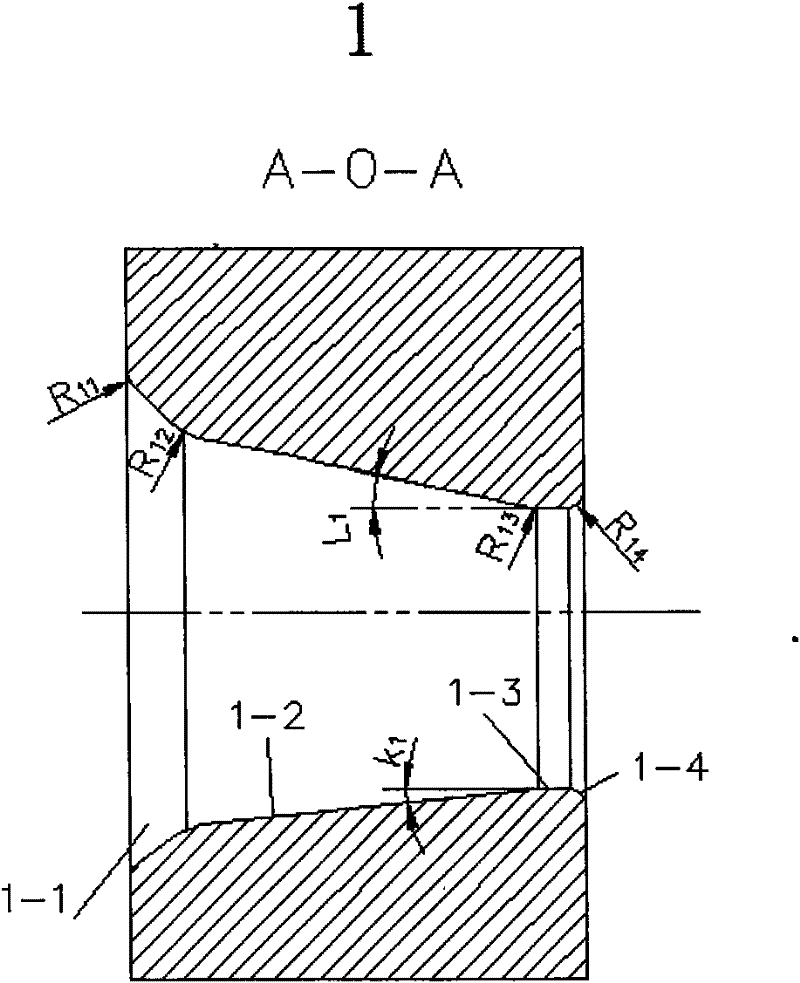

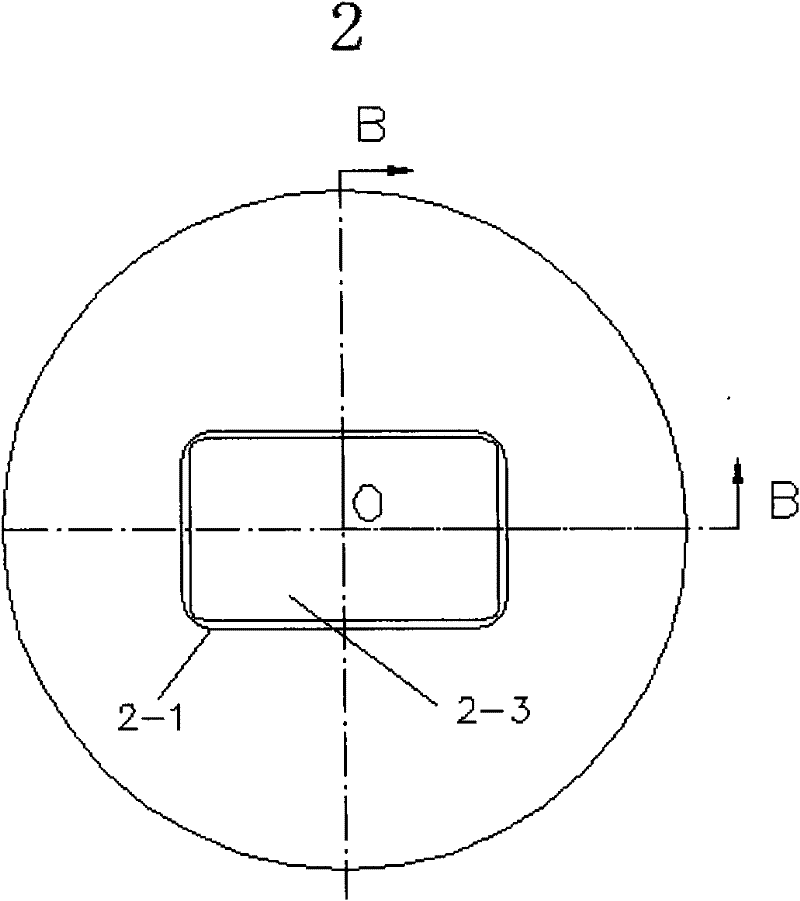

Cold drawing method and die for special-shaped pipes

InactiveCN102189379AImprove surface qualityPorousDrawing diesMetal working apparatusProcess engineeringEngineering

The invention discloses a cold drawing method and a die for special-shaped pipes. A heat exchanger for a waste heat boiler is formed by closely arranging and welding the omega-shaped special-shaped pipes produced by the method, the pipes are convenient to weld, welding cost is low, and the pipes can resist impact during use and have long service life. The effective heating area of the omega-shaped special-shaped pipe heat exchanger is about two times that of a round pipe heat exchanger, so that heat exchange efficiency is greatly improved, the volume of the waste heat boiler is greatly reduced, and manufacturing cost and occupied area are reduced.

Owner:ZHANGJIAGANG FREE TRADE ZONE HENGLONG STEEL TUBE

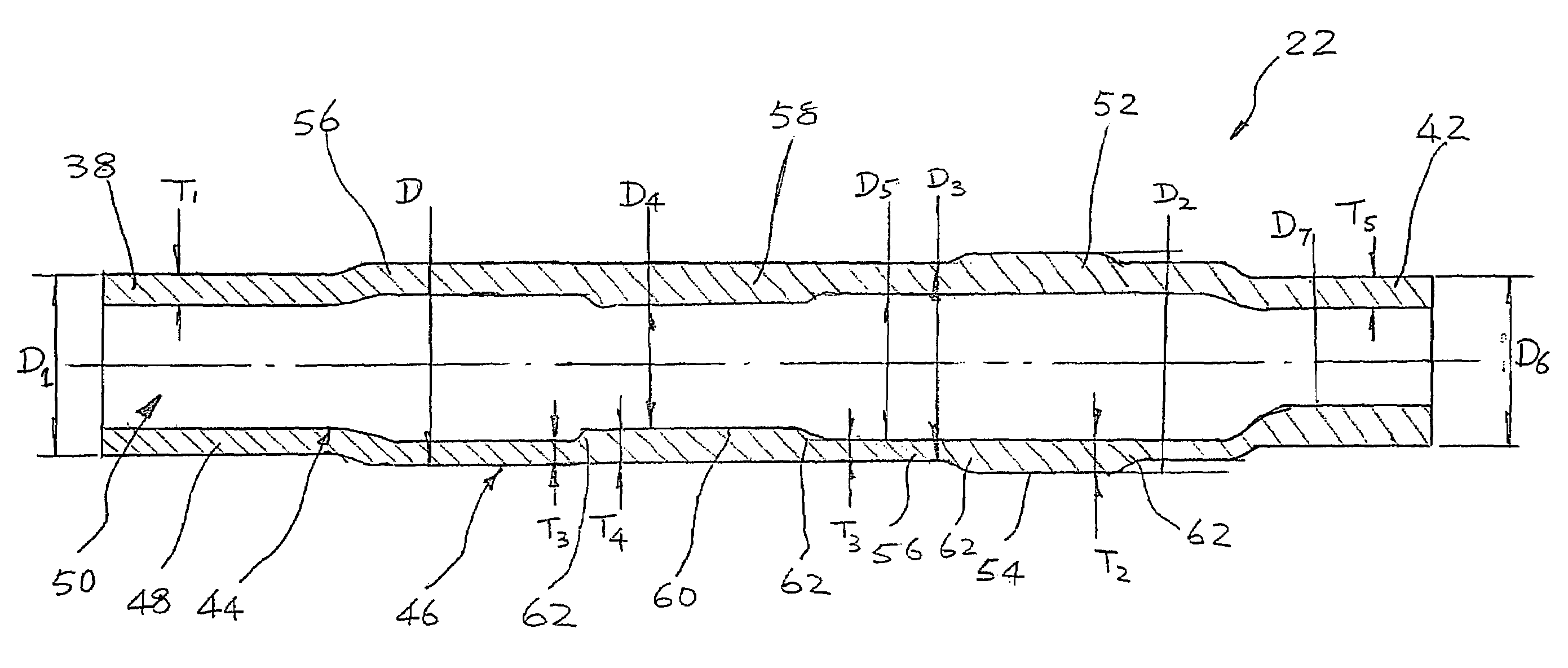

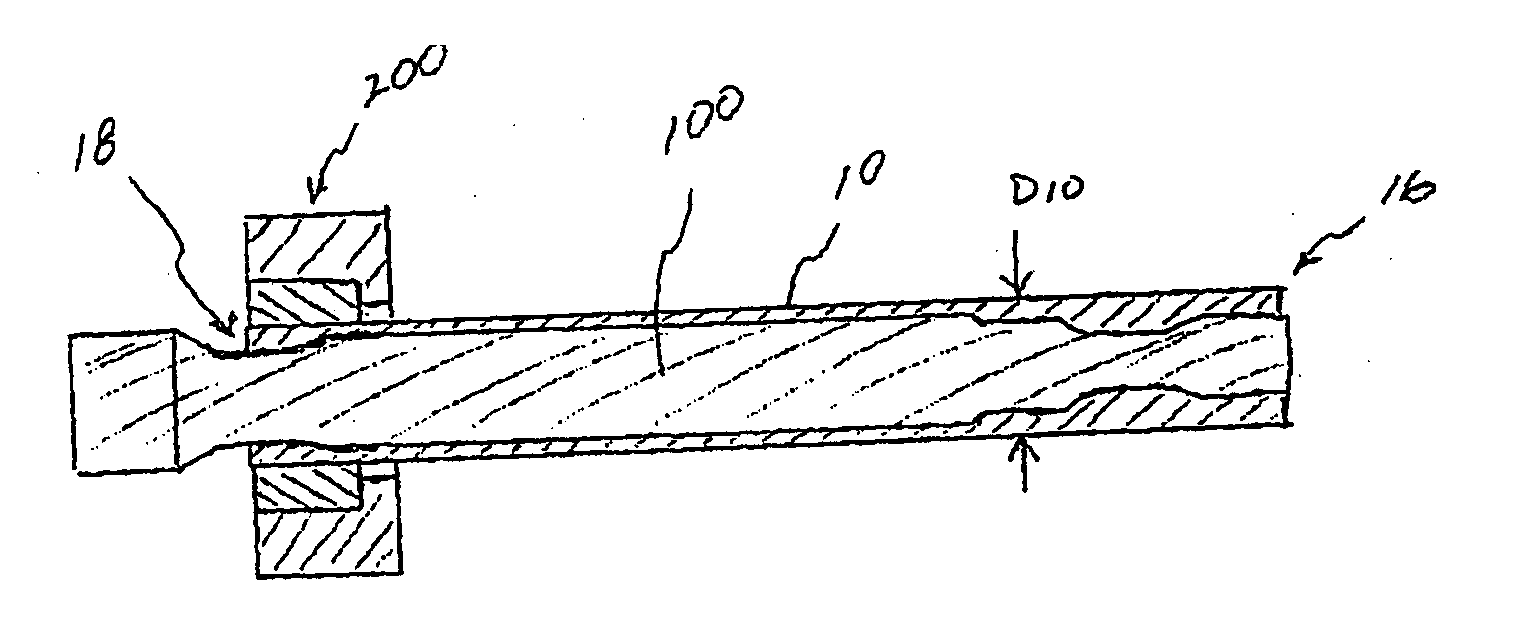

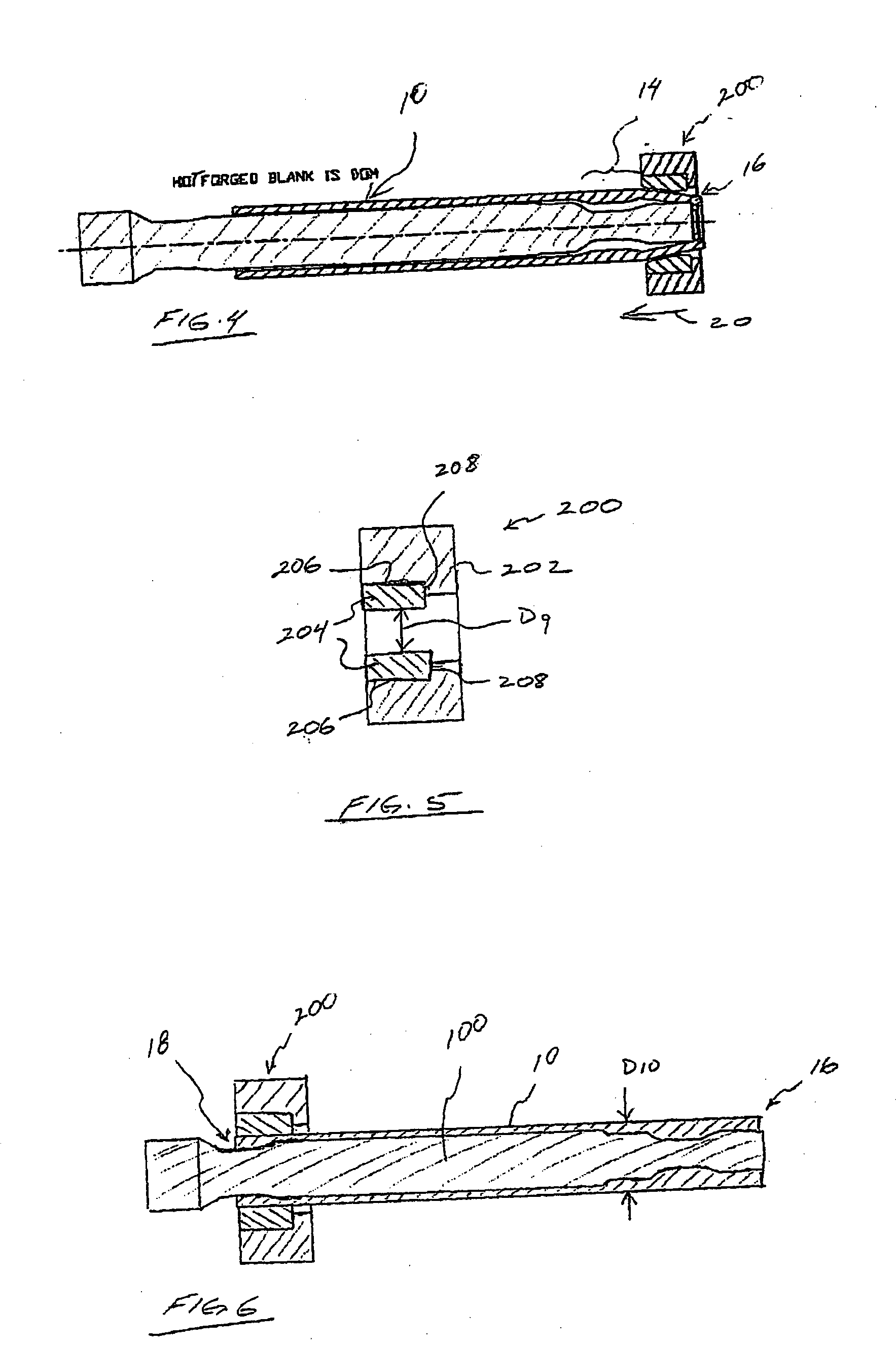

Unitary rear axle housing and method for manufacturing same

ActiveUS20070062241A1Increase wall thicknessDrawing diesEngine componentsStructural engineeringMechanical engineering

A method for manufacturing a one piece axle tube housing with an integral spindle includes providing a tube blank, providing the blank with a region of increased thickness, inserting a mandrel having a reduced diameter profile, passing a reducing die over the tube to conform the tube to the shape of the mandrel; and extraction of the mandrel from the tube to cause outward deformation of the tube at specific locations. A further swaging step may be used to form the final spindle structure.

Owner:AAM INT S A R L

Diamond die production process

The invention discloses a diamond wire drawing die producing technique, including: 1) select diamond: selecting good-quality diamond; 2) grinding diamond: grinding the diamond out of surfaces; 3) insert in a case: inserting the well-ground diamond in a stainless steel die case added with metallic powder, then covering a covering plate and sending in heat-press sintering machine for sintering and obtaining a crude die case; 4) process the die case:; 5) punch by laser; 6) mould. It better saves the diamond, and largely reduces production cost, completely suitable for producing diamond wire drawing dies.

Owner:张安

Unitary rear axle housing and method for manufacturing same

ActiveUS7681426B2Increase wall thicknessDrawing diesEngine componentsStructural engineeringMechanical engineering

A method for manufacturing a one piece axle tube housing with an integral spindle includes providing a tube blank, providing the blank with a region of increased thickness, inserting a mandrel having a reduced diameter profile, passing a reducing die over the tube to conform the tube to the shape of the mandrel; and extraction of the mandrel from the tube to cause outward deformation of the tube at specific locations. A further swaging step may be used to form the final spindle structure.

Owner:AAM INT S A R L

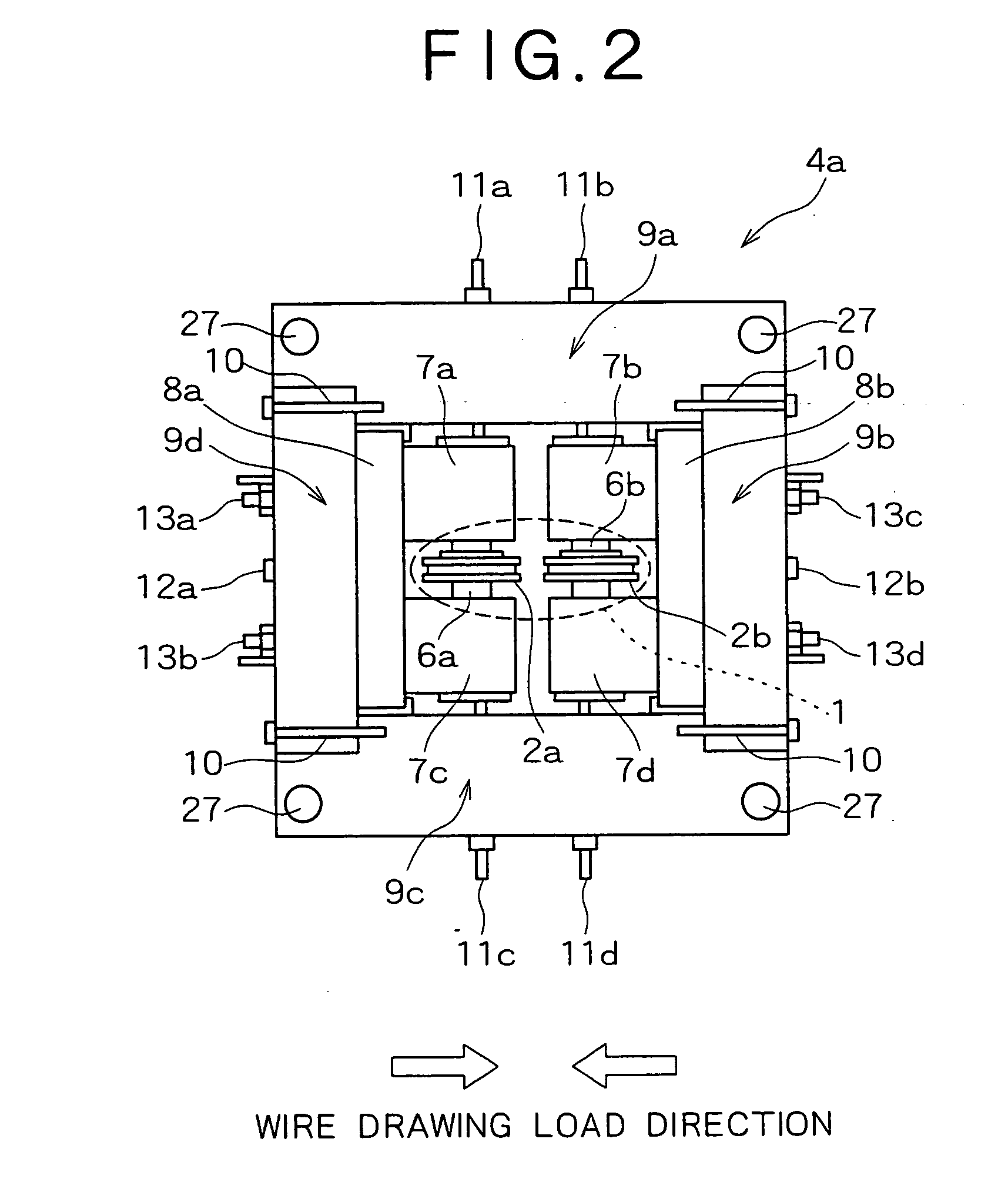

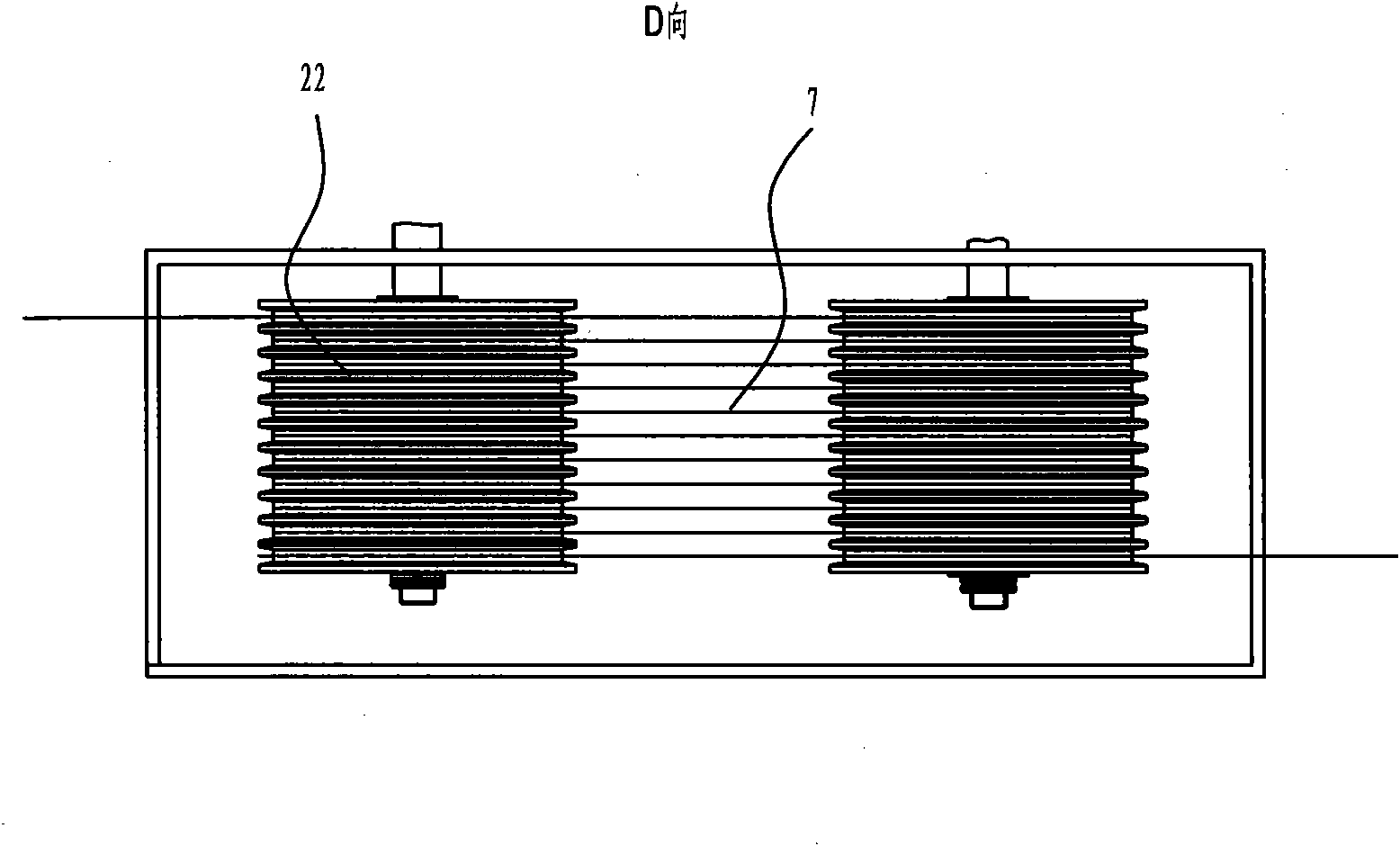

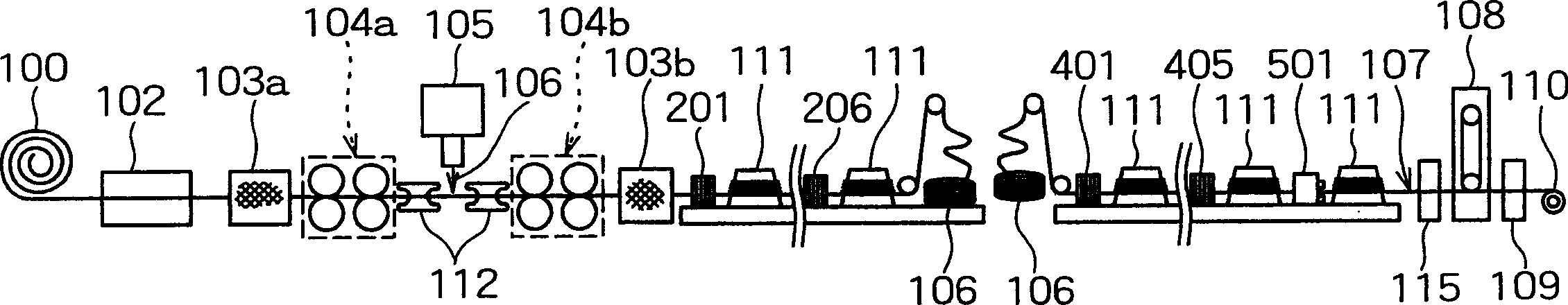

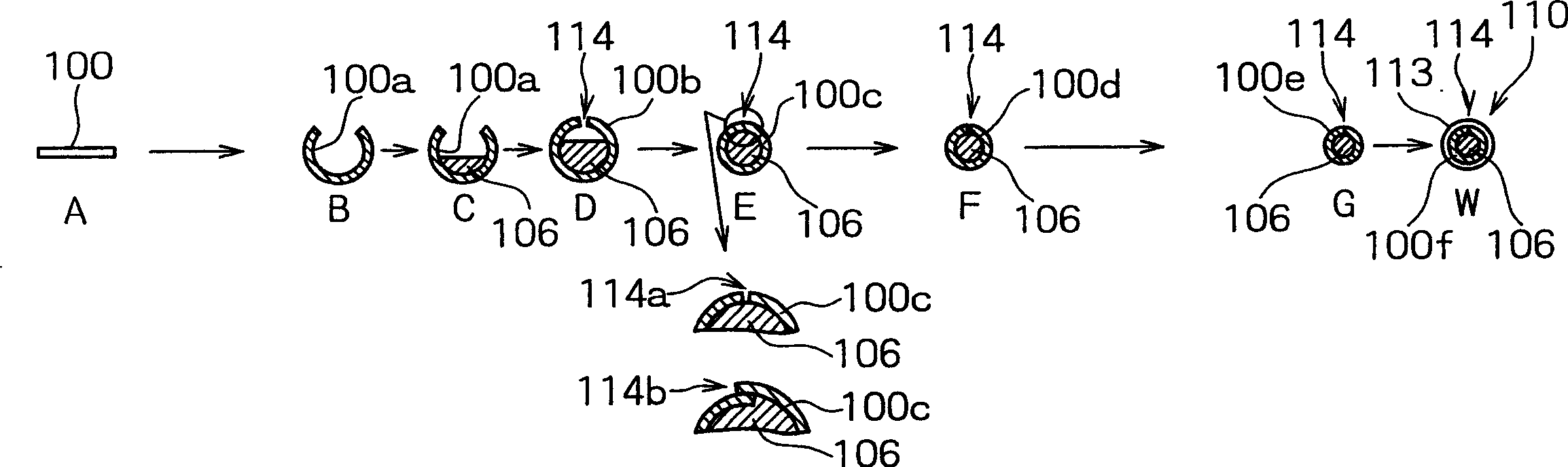

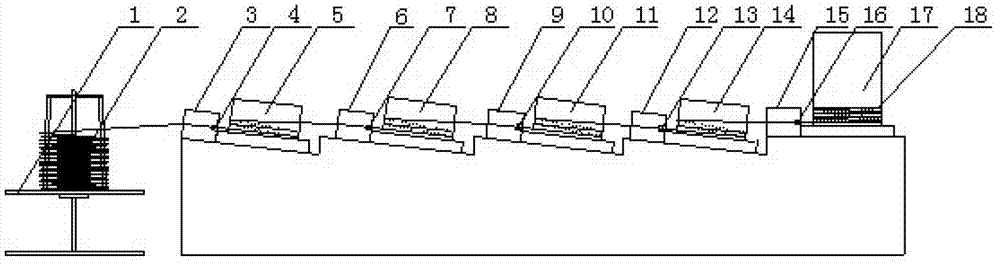

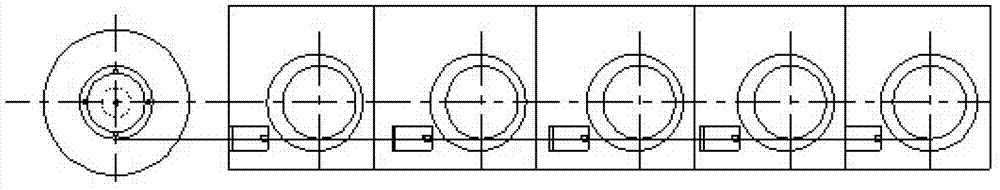

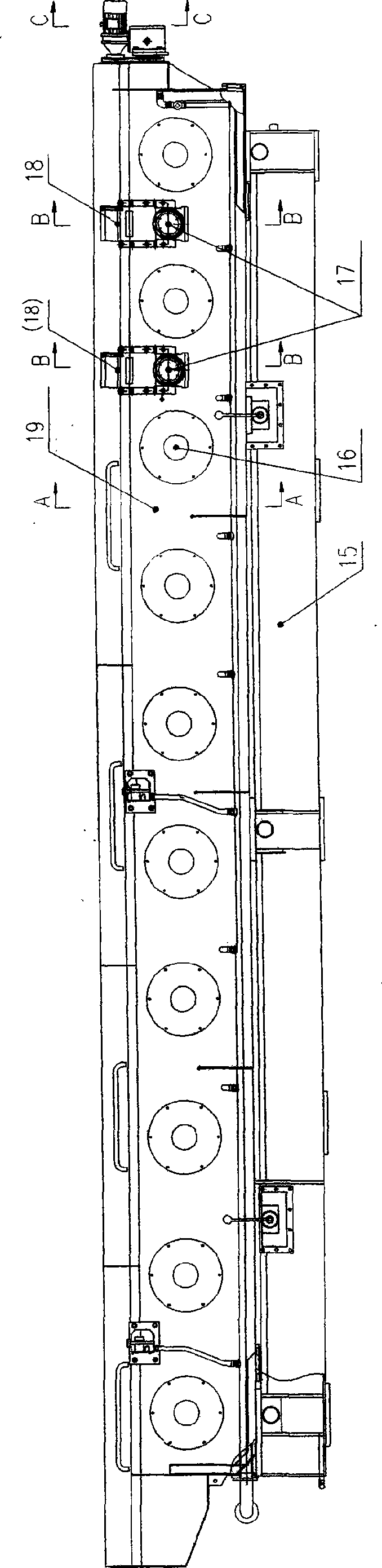

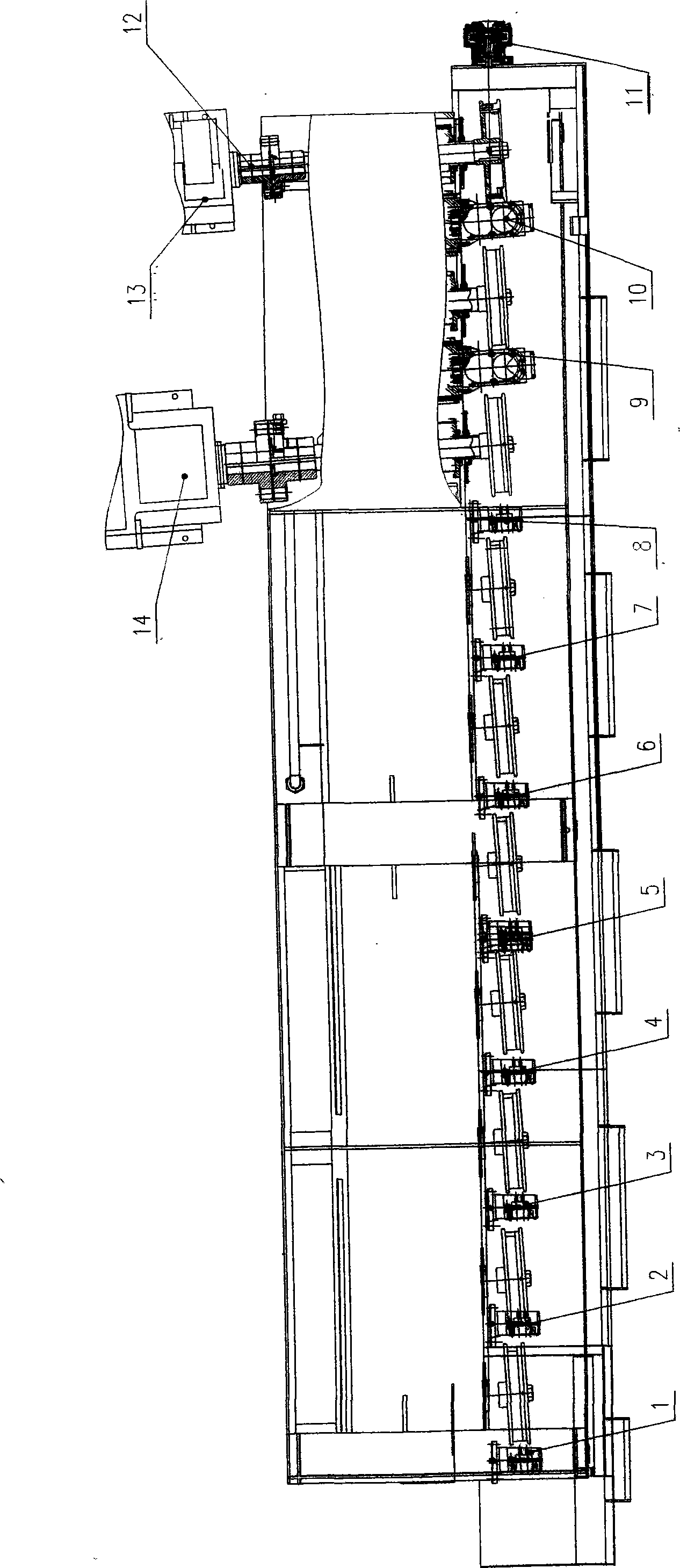

Technology and apparatus for manufacturing shaped conductor

InactiveCN101510455AMeet the requirements of flow productionOut of line fastDrawing diesSingle bars/rods/wires/strips conductorsFiberEngineering

The invention relates to a shaped conductor manufacturing technique and a device thereof, wherein, the manufacturing technique comprises payingoff step, lead-forming step and lead-drawing step and is characterized in that the lead-forming step adopts the technique of combing drawing and rolling; the section of a lead is shaped by rolling; the sectional area of the lead meets requirement by drawing; the device comprises a payingoff device, a shaped conductor forming device and a lead-drawing device which are sequentially arranged, wherein, the shaped conductor forming device is provided with a shaped groove roller device. The technique ensure the quality of products, greatly improves producing efficiency and meets the production requirement of compound carbon fiber aluminum stranded conductors required by ultra-high and super-high power transmission.

Owner:德阳东佳港智能装备制造股份有限公司

Methods for manufacturing flux cored wire for welding stainless steel and products thereof

Disclosed is a method for manufacturing a flux cored wire for welding stainless steel of 0.9-1.6 mm in diameter having a seamed portion, which the method includes the steps of: forming a hoop (stainless steel 304L or 316L) into a U-shape and filling the hoop with a flux mixture, thereby forming a tube having a seamed portion; performing a primary drawing process on the tube shaped wire using a lubricant; performing a bright annealing process to relieve work hardening of the primarily drawn wire; performing a secondary drawing process on the wire until an accumulated reduction ratio after the bright annealing process falls within the range of 38-60%; physically removing a lubricant residue on the surface of the secondarily drawn wire; and coating the wire with a surface treatment agent.

Owner:KISWEL LTD

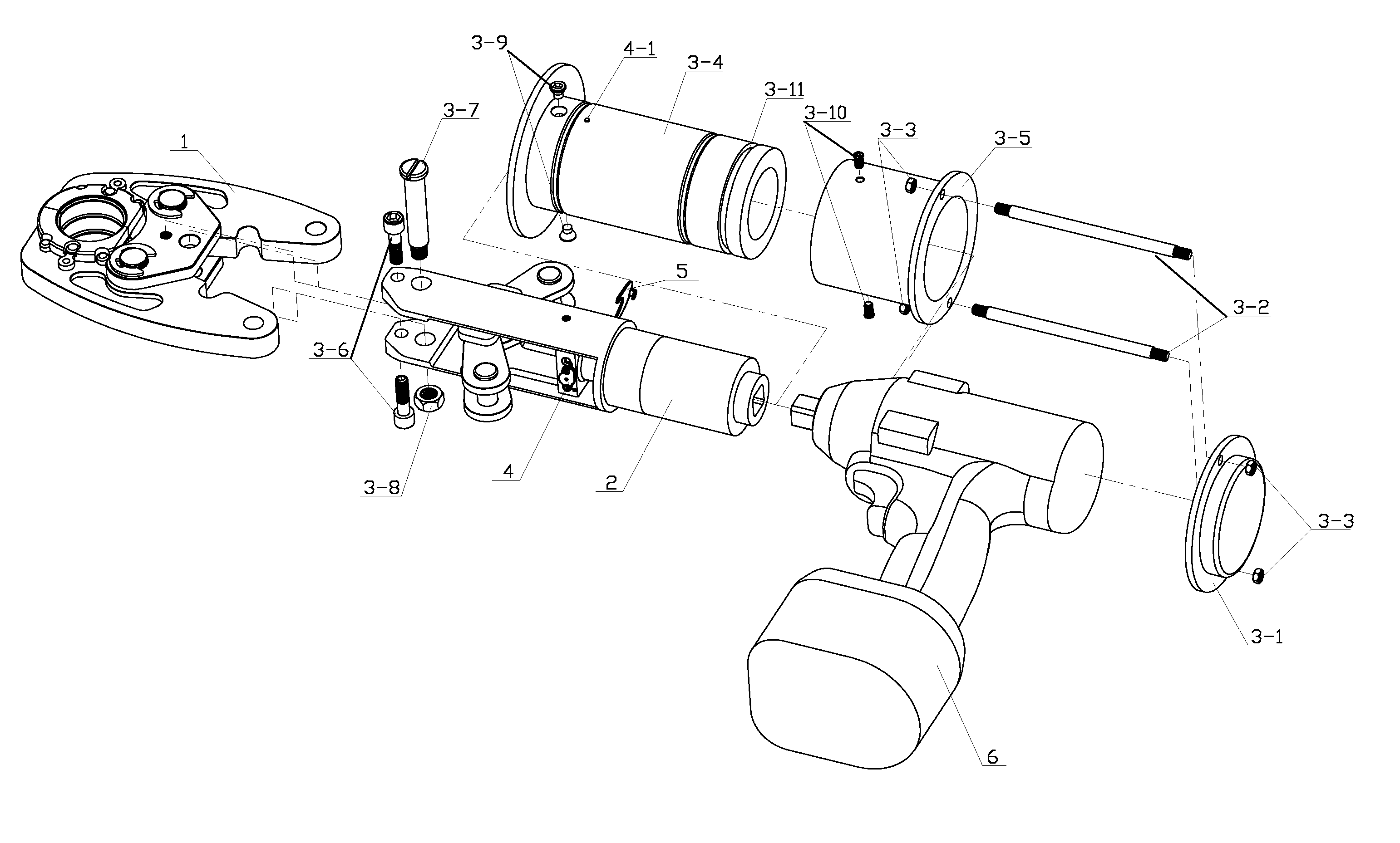

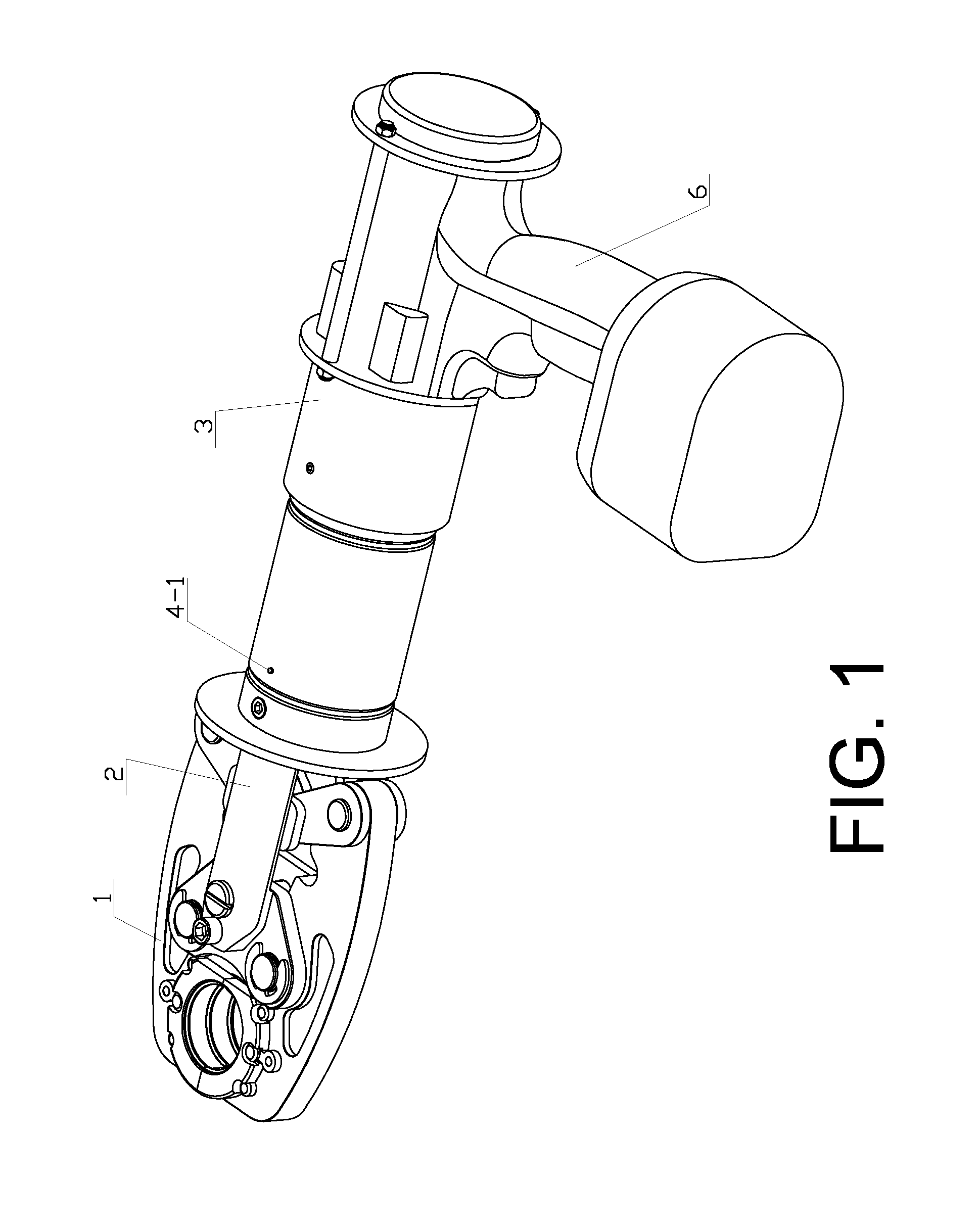

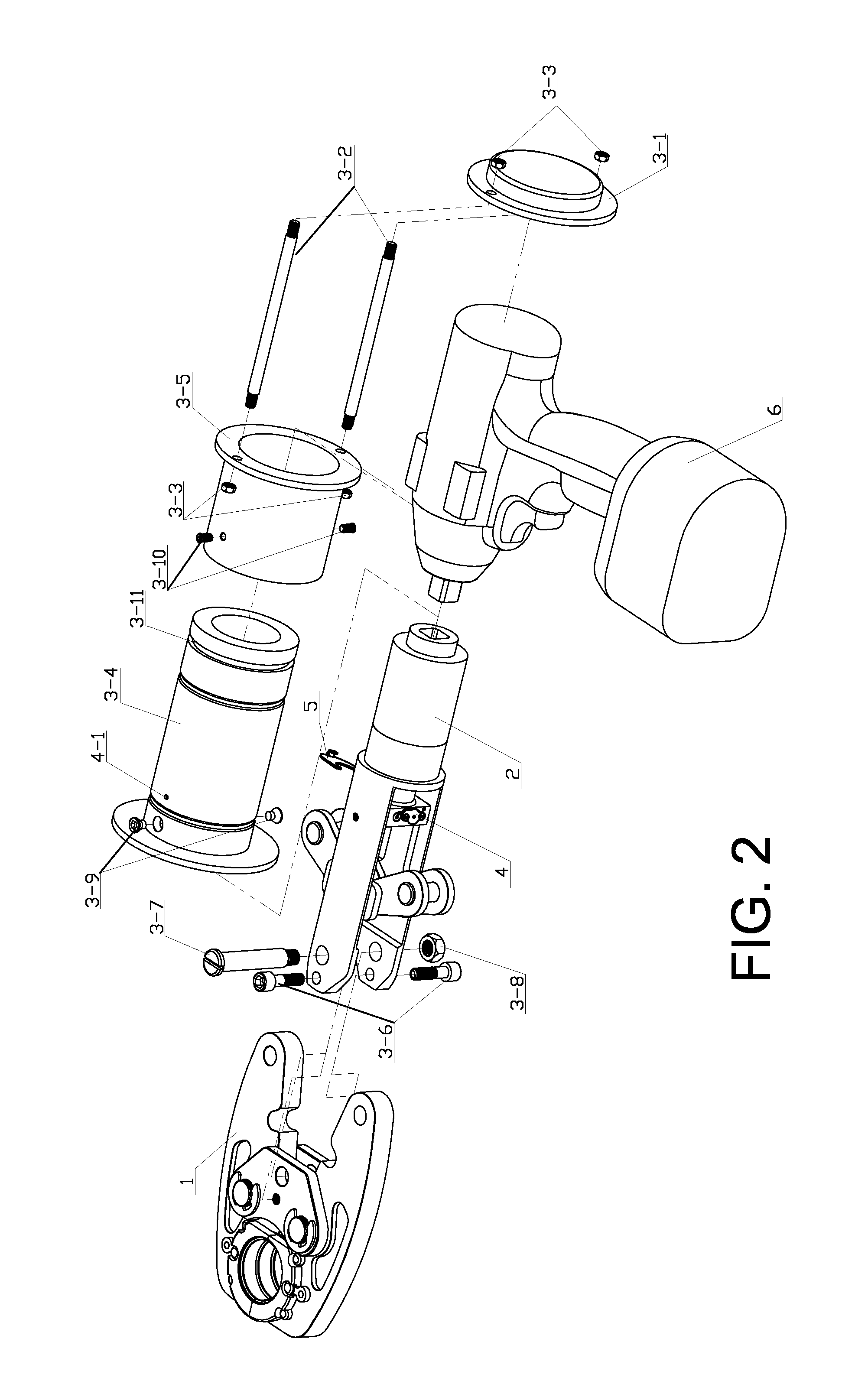

Crimping/cutting working head for impact wrench

InactiveUS8342001B2Quickly and conveniently replacedPracticalLine/current collector detailsDrawing diesImpact wrenchWrench

A power operated crimping / cutting tool driven by any type of impact wrench, with a crimping or cutting working head, includes a transmission unit, a connection unit, a process indication device and an adjustment device, wherein the transmission unit includes a jaw device and a transmission device, the jaw device is detachable, both the process indication device and the adjustment device are mounted on the transmission unit, the connection unit is sleevedly mounted at the impact wrench. The present invention can replace the jaw device according to different requirements.

Owner:LINK TECH TIANJIN METAL PROD

Phi 0.03m special titanium filament processing process

InactiveCN101844158AImprove the lubrication effectImprove adhesionDrawing diesFurnace typesTitaniumFriction force

The invention discloses a 0.03m special titanium filament processing process, belonging to the field of metal fine machining. The processing process mainly comprises wire drawing, heat treatment and oxidizing scale treatment; a method for fixing a framework and two ends of a wiredrawing shaft is adopted in two times of wire drawing; by adopting a special lubricating agent, the friction force of the surface of a titanium wire and a calibrating strap part of a wiredrawing film can be reduced; different heat treatment temperatures or annealing points are adopted in two heat treatment processes and the uniform line velocity can be kept; the problems of low tensile strength and poor elongation percentage can be solved; and by adopting a single-line multi-head continuous cleaning method in the treatment process of oxidation scale, the resistance for the titanium wire to pass through a wire release rack, a rinsing tank and leaching pond and to be subjected to drying, taking up and other links can be reduced. The invention has the advantages of simple process and high processing efficiency; the processed titanium wire has high tensile strength and favorable elongation percentage; and the processing of a 0.03mm titanium wire can be realized.

Owner:SHANGHAI GIORAY METAL MATERIAL

High-strength steel wire excelling in resistance to strain aging embrittlement and longitudinal cracking, and method for production thereof

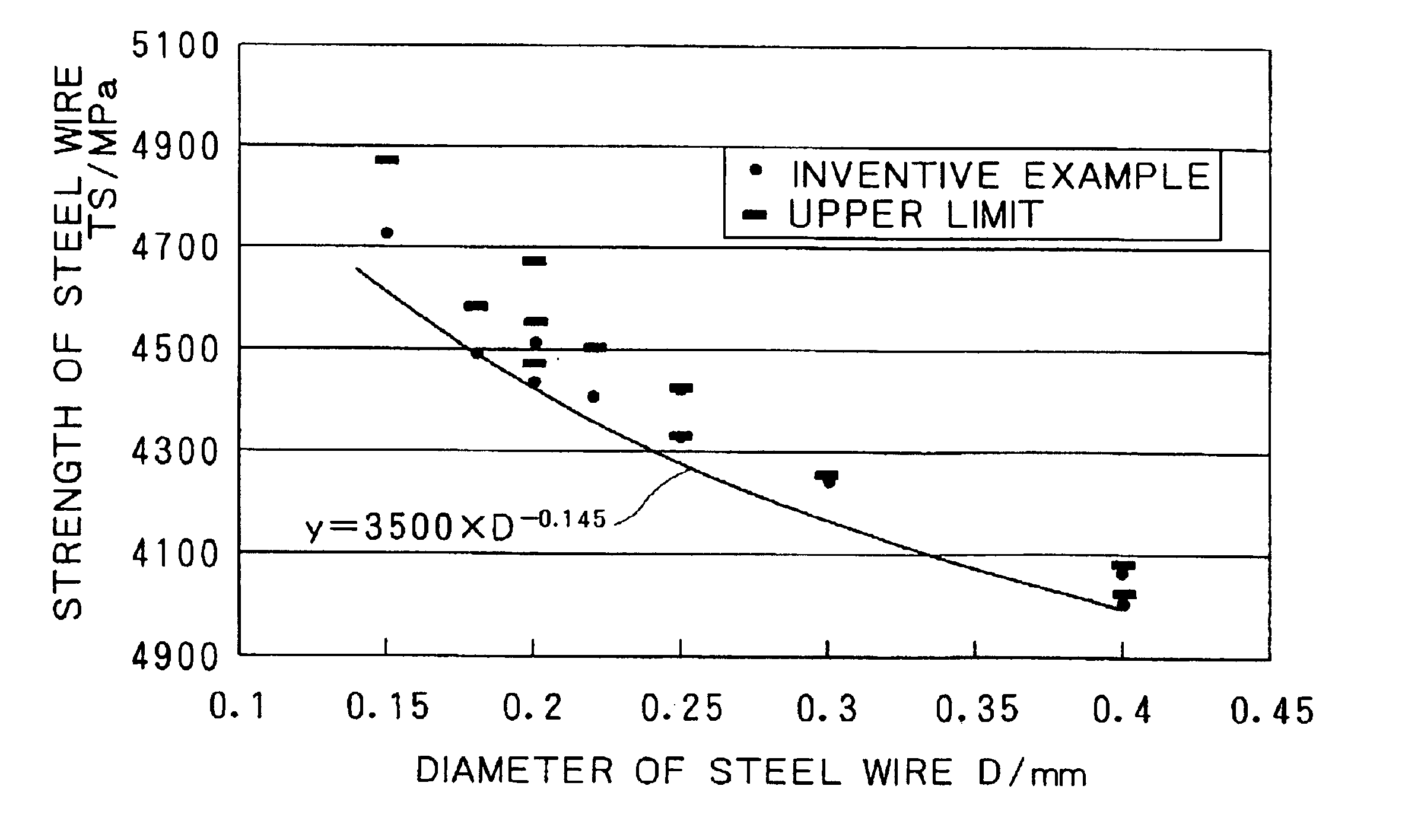

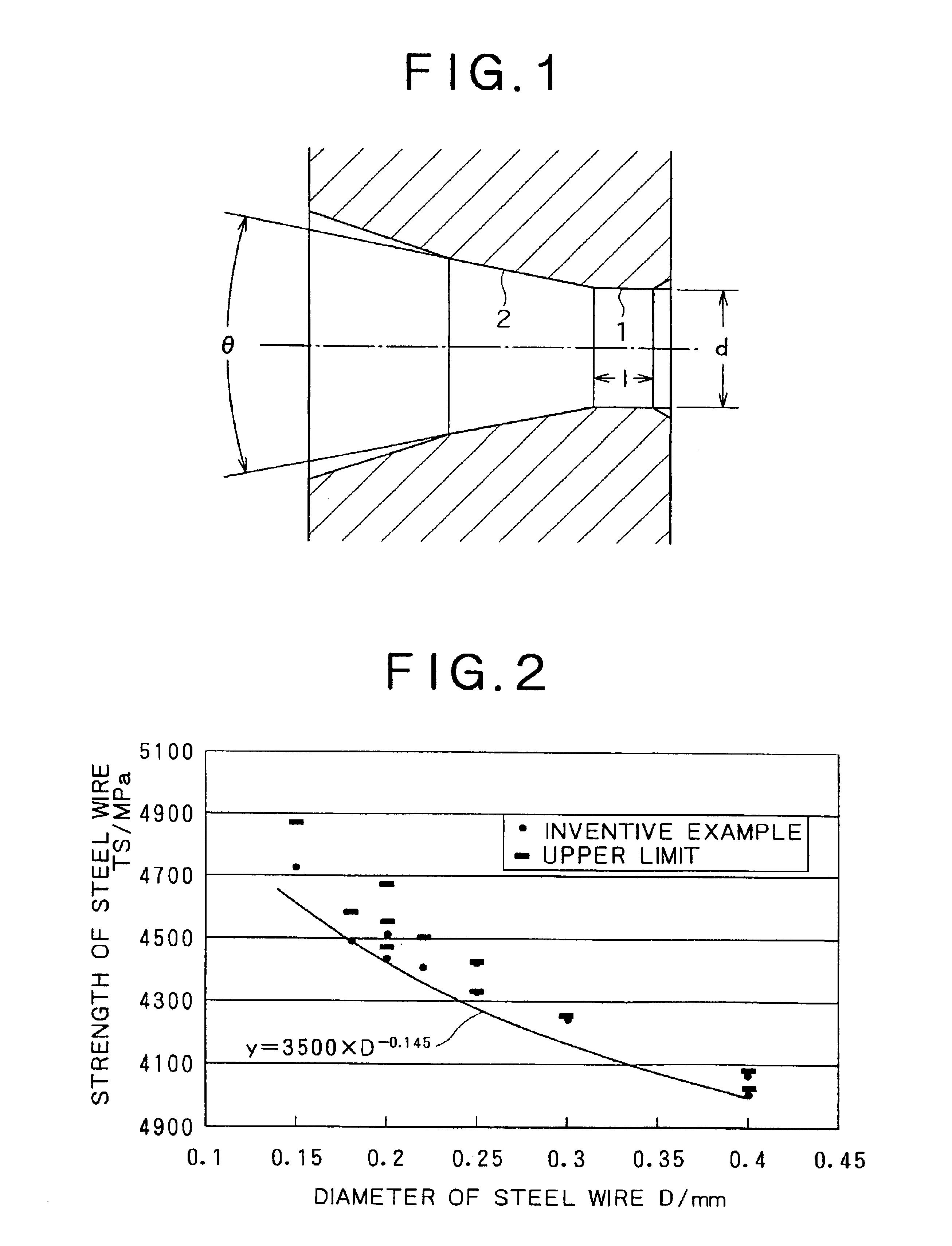

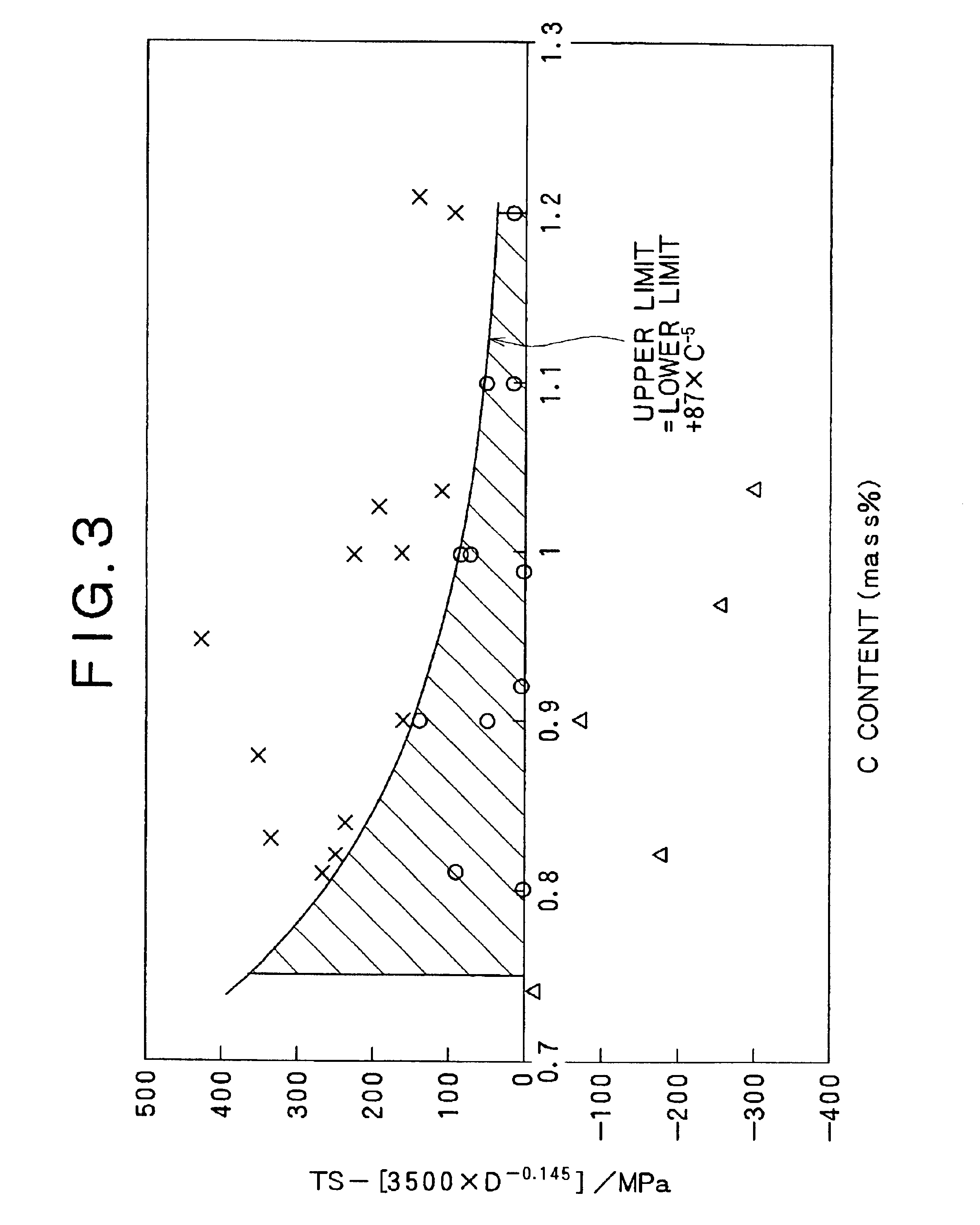

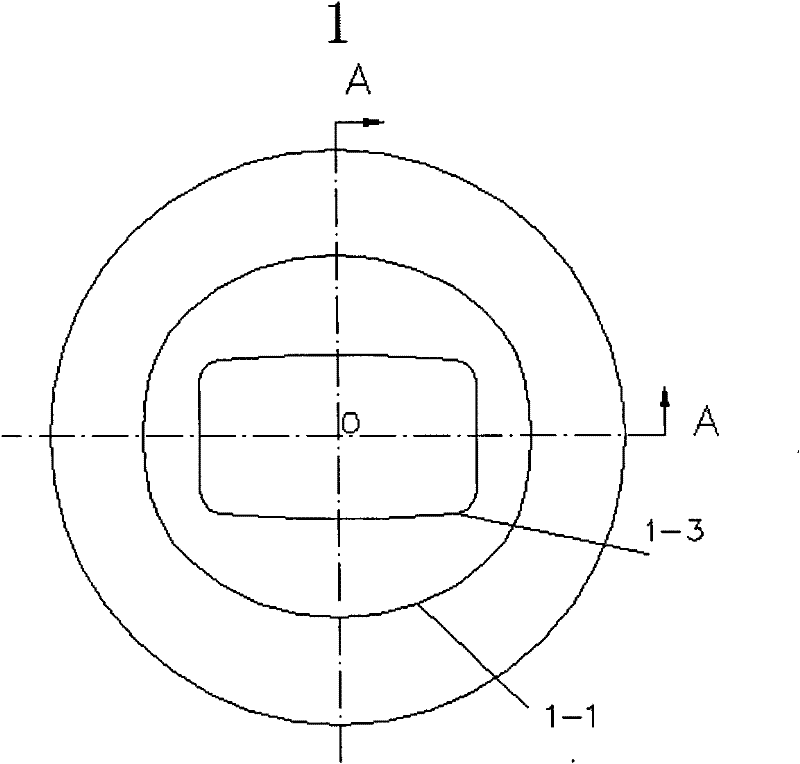

Disclosed herein is a high-strength high-carbon steel wire which, owing to its high strength as well as good ductility, is excellent in resistance to strain aging embrittlement and longitudinal cracking.The steel wire is characterized by having a chemical composition (in mass %) including C: 0.75-1.20%, Si: 0.1-1.5%, Mn: 0.3-1.2%, P: no more than 0.02%, S: no more than 0.02%, Al: no more than 0.005%, and N: no more than 0.008%, with the remainder being Fe and inevitable impurities. The steel wire is further characterized by having worked pearlite structure containing lamellar cementite in amorphous form, a diameter (D) ranging from 0.15 to 0.4 mm, a metal lubricating film as the surface layer whose main phase is composed of at least one of Cu, Ni, and Zn or an alloy thereof, and tensile strength no lower than (3500xD<-0.145>) MPa and no higher than (3500xD<-0.145>+87x[C]<-5>) MPa, where [C] denotes C content in %.

Owner:KOBE STEEL LTD

High-precision aluminum alloy rectangular tube forming method

The invention discloses a high-precision aluminum alloy rectangular tube forming method which comprises the following steps: a) heating the prepared No.6061 aluminum alloy ingot over uniform fire to 415+ / -5 DEG C, and keeping for 1-2 hours; b) performing hot extrusion on an extrusion shunting mould with a preheating temperature of 400 DEG C to obtain an initial tube blank; c) performing annealingtreatment in salt bath; d) performing cold rolling on the tube blank obtained in the step c) to obtain a round tube; e) soaking the round tube obtained in the step d) in a 38# cylinder oil for 24 hours; f) performing non-mandrel drawing on the tube blank obtained in the step e) to obtain an approximately rectangular tube; g) performing mandrel drawing on the approximately rectangular tube obtained in the step f) through a rectangular correction mould to obtain a rectangular tube; and h) performing mandrel drawing of the rectangular tube obtained in the step g) to obtain the finished tube. Through the invention, the size precision and surface quality of the finished tube are improved, the problems that the tube blank is drawn apart in the drawing process and obvious transverse cracks appear at the corner are solved, and the operational performance and service life of the product are remarkably improved.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com