Continuous pickling and wiredrawing process of brass wire

A brass wire and pickling technology, applied in wire drawing dies and other directions, can solve the problems of poor operating environment for employees, environmental pollution by waste liquid and harmful gases, and environmental pollution, and achieve less processing and circulation process, good gloss and consistency , the effect of improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

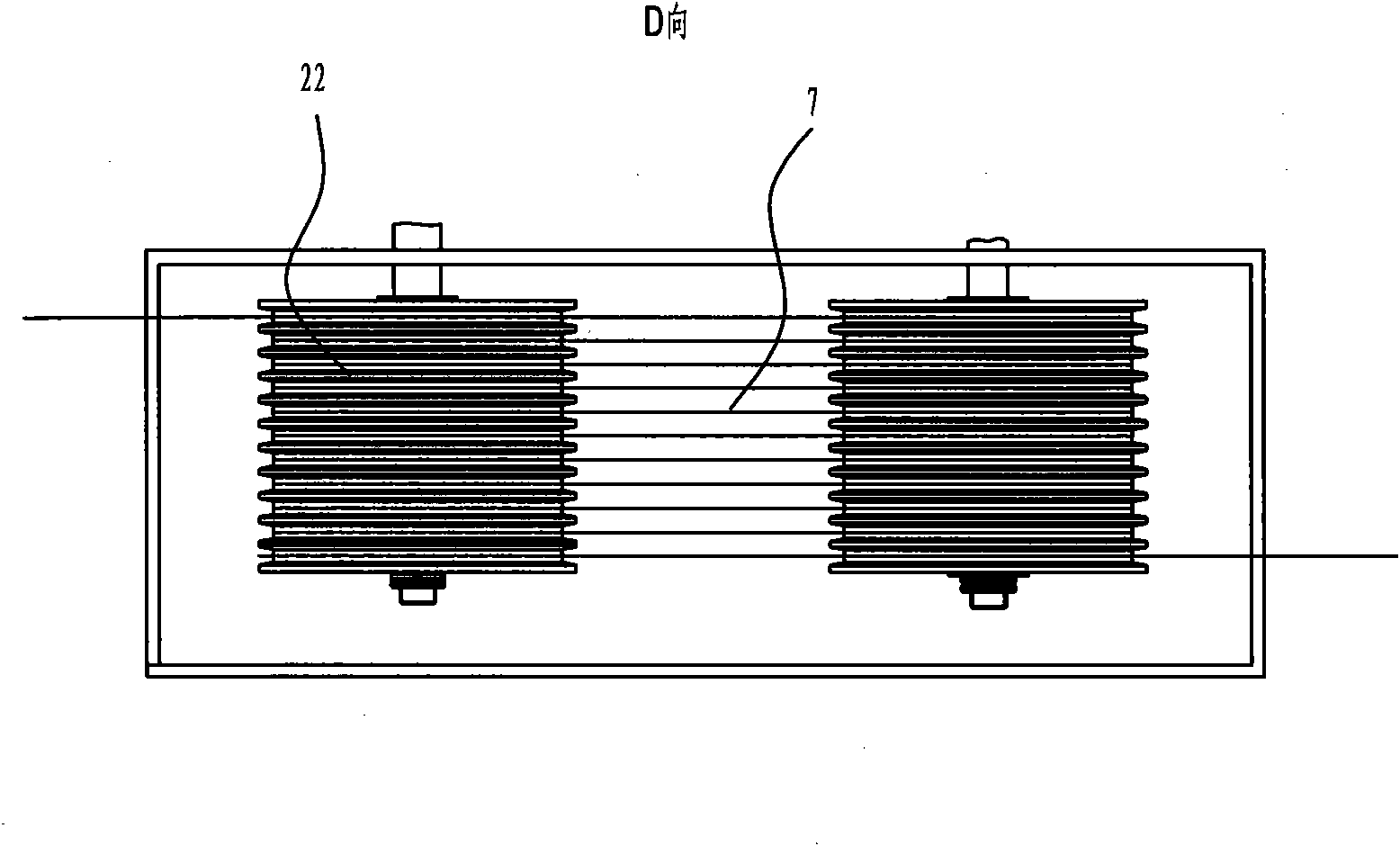

[0026] Such as figure 1 As shown, the annealed brass wire blank 7 is placed on the pay-off reel 1, and the brass wire blank 7 is manually passed through the pickling roller 22 in the pickling tank 2. During the threading process, the brass wire blank 7 is The copper wire blank 7 is wound in the wedge-shaped groove 23 of two pickling rollers 22, and then the wire blank 7 passes through the neutralization tank 3, the tensioner 4, the scrubbing tank 5, the cleaning tank 6, and then passes through the wire drawing die 8 , wind up on the wire drawing roller 9, open the wire drawing machine, and pull the brass wire billet to move toward the direction of the winding machine 9. Under the action of the traction force, the brass wire blank 7 on the pay-off reel 1 is drawn out and enters the pickling tank 2, which is filled with a sulfuric acid solution 21 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com