Cold-rolled sheet rolling emulsified oil containing modified nano copper and preparation method thereof

A cold-rolled thin plate and nano-copper technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of single components and weak synergy of components, and achieve good surface quality, good lubricating effect, and good detergency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

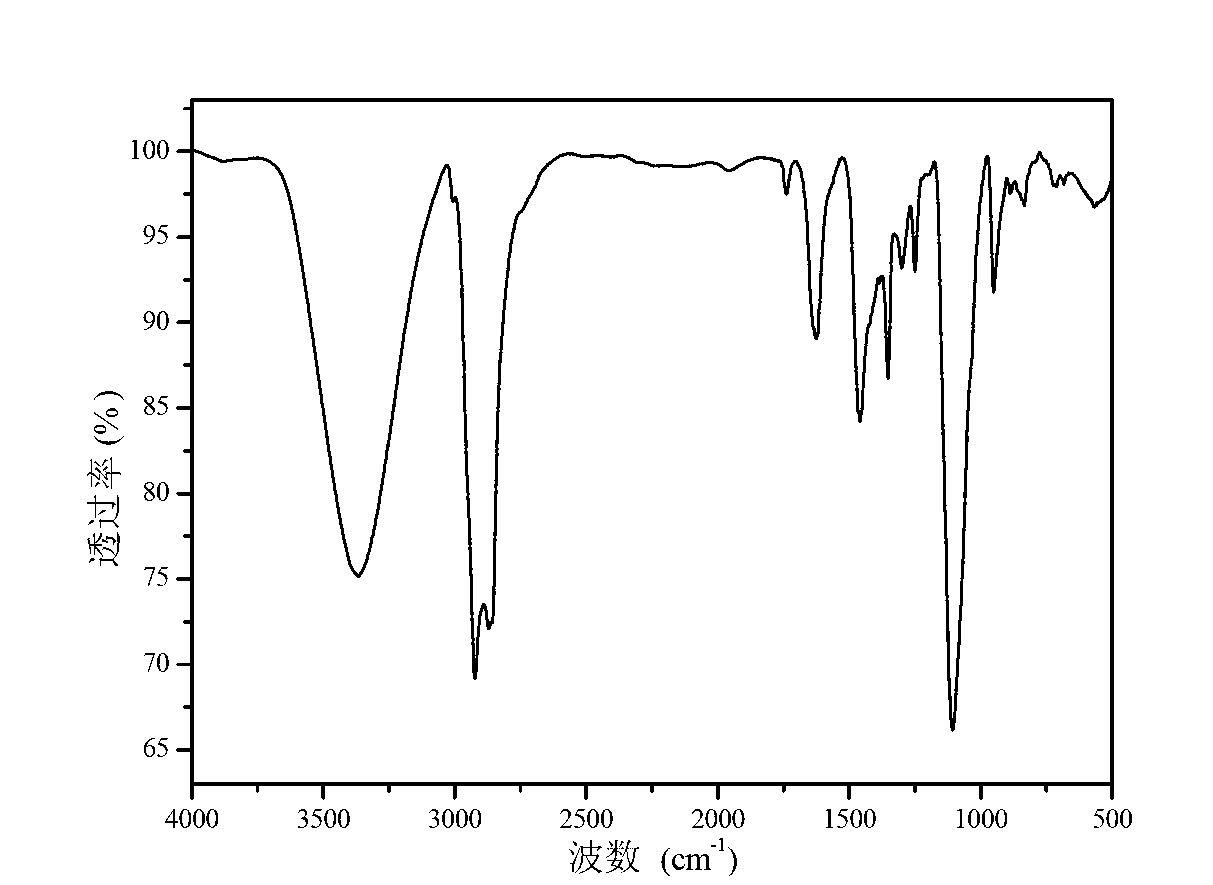

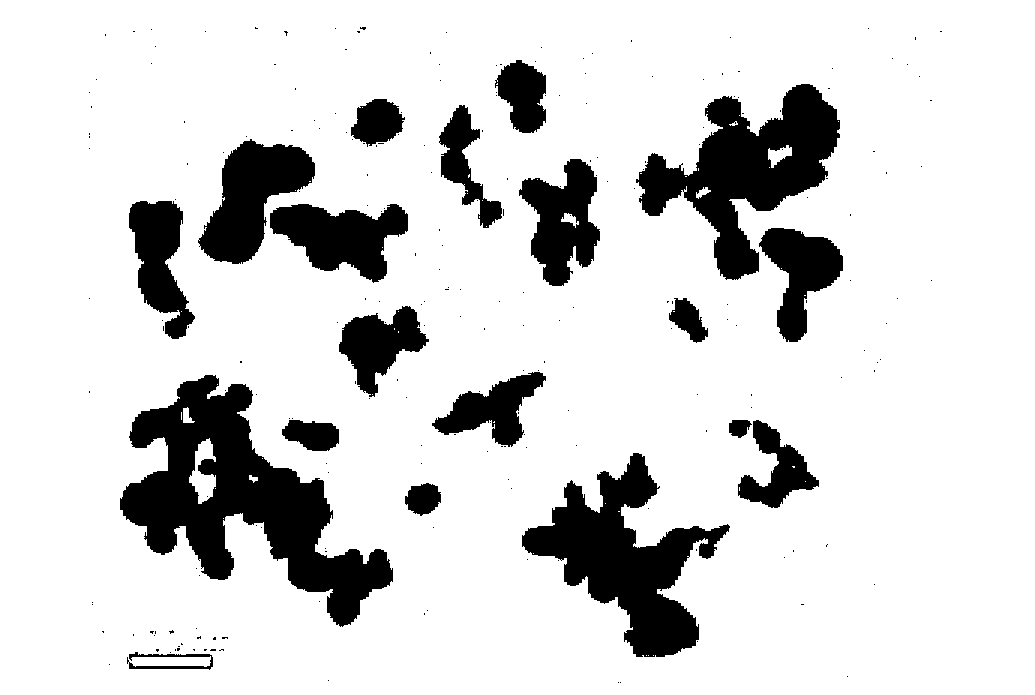

[0051] Modified Nano Copper C 1 Preparation of:

[0052] (1) Add 50nm nano-copper particles prepared by the gas condensation method into a three-necked flask filled with ethanol. The volume ratio of the amount of nano-copper particles to ethanol is 0.5mol / l; In a beaker filled with 95% ethanol, the volume ratio of silane coupling agent to ethanol is 0.1mol / L; the molar ratio of nanometer copper to silane coupling agent is 5:0.01, and the diluted silane coupling agent Add it into the dropping funnel, slowly drop it into the three-necked flask, and the three-necked flask is under 40KHz, 400w ultrasonic field and mechanical stirring, and react at a constant temperature of 30°C for 12 hours, and remove the solvent by vacuum filtration to obtain the intermediate M 1 ;

[0053] (2) In the autoclave, add the intermediate M 1 and catalyst, the added intermediate M 1 The molar ratio to nano-copper particles is 2:5, and the amount of catalyst added is 0.05% of the total weight of na...

Embodiment 2

[0064] Modified Nano Copper C 2 Preparation of:

[0065] (1) Add 20nm nano-copper particles prepared by the gas condensation method into a three-necked flask filled with ethanol. The volume ratio of the amount of nano-copper particles to ethanol is 0.5mol / l; In a beaker filled with 95% ethanol, the volume ratio of silane coupling agent to ethanol is 0.1mol / L; the molar ratio of nanometer copper to silane coupling agent is 5:1, and the diluted silane coupling agent Add it into the dropping funnel, slowly drop it into the three-necked flask, and the three-necked flask is under 20KHz, 150w ultrasonic field and mechanical stirring, and react at a constant temperature of 70°C for 5 hours, and remove the solvent by vacuum filtration to obtain the intermediate M 2 ;

[0066] (2) In the autoclave, add the intermediate M 2 and catalyst, the added intermediate M 2 The molar ratio to nano-copper particles is 2:5, and the amount of catalyst added is 0.45% of the total weight of nano-c...

Embodiment 3

[0073] Modified Nano Copper C 3 Preparation of:

[0074] (1) Add the nano-copper particles prepared by the gas condensation method into a three-necked flask filled with ethanol. The volume ratio of the added amount of nano-copper particles to ethanol is 0.5mol / l; In the beaker in ethanol, the volume ratio of the amount of silane coupling agent added to ethanol is 0.25mol / L; the molar ratio of nanometer copper to silane coupling agent is 5:0.5, and the diluted silane coupling agent is added to the dropping funnel In the three-necked flask, the three-necked flask was reacted at a constant temperature of 50°C for 8 hours under 40KHz, 400w ultrasonic field and mechanical stirring, and the solvent was removed by vacuum filtration to obtain the intermediate M 3 ;

[0075] (2) In the autoclave, add the intermediate M 3 and catalyst, the added intermediate M 3 The molar ratio to nano-copper particles is 2:5, and the amount of catalyst added is 0.15% of the total weight of nano-cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com