Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64982 results about "Steel plates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

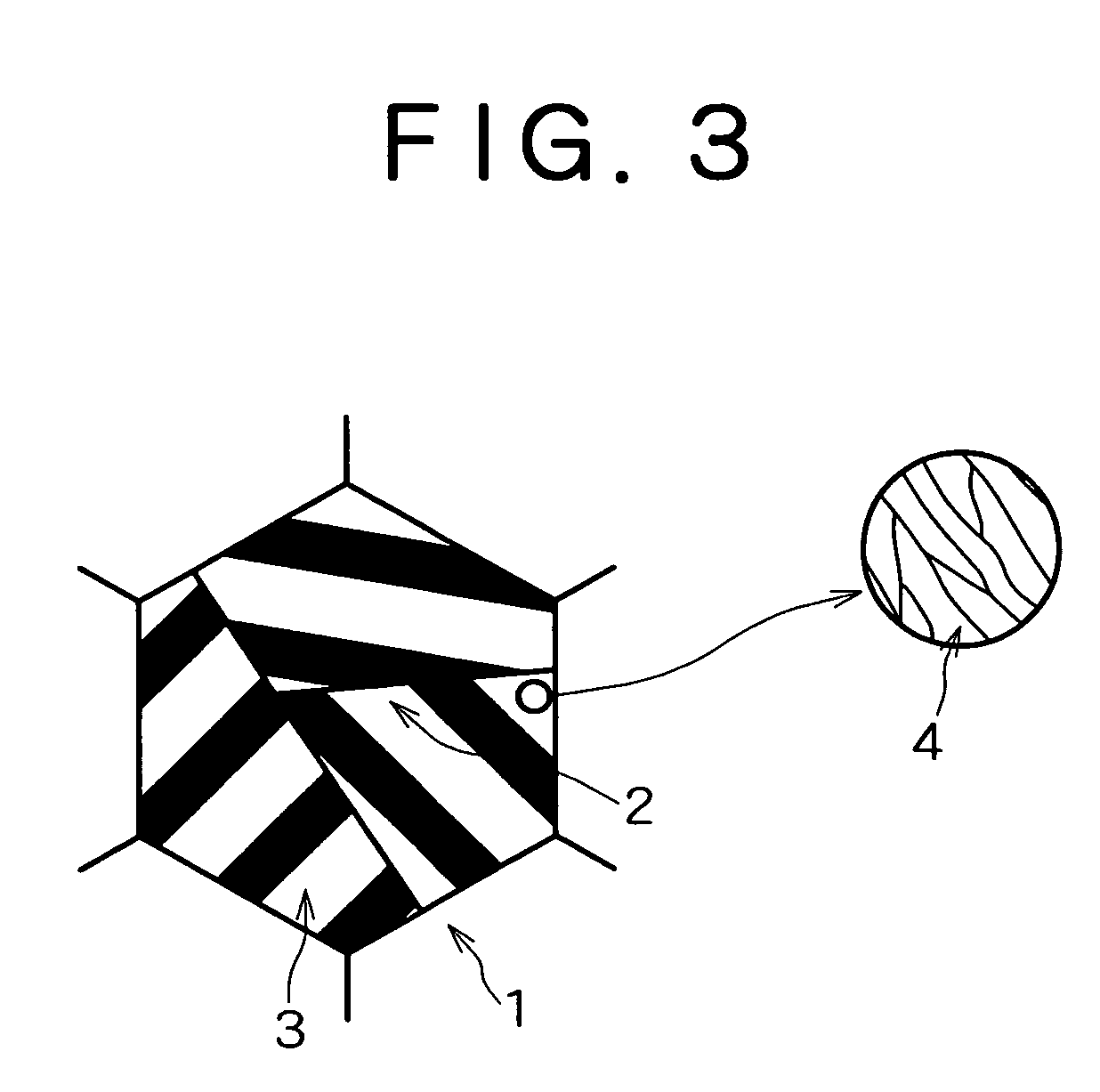

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Automobile steel with low cost and high strength ductility balance and preparation method thereof

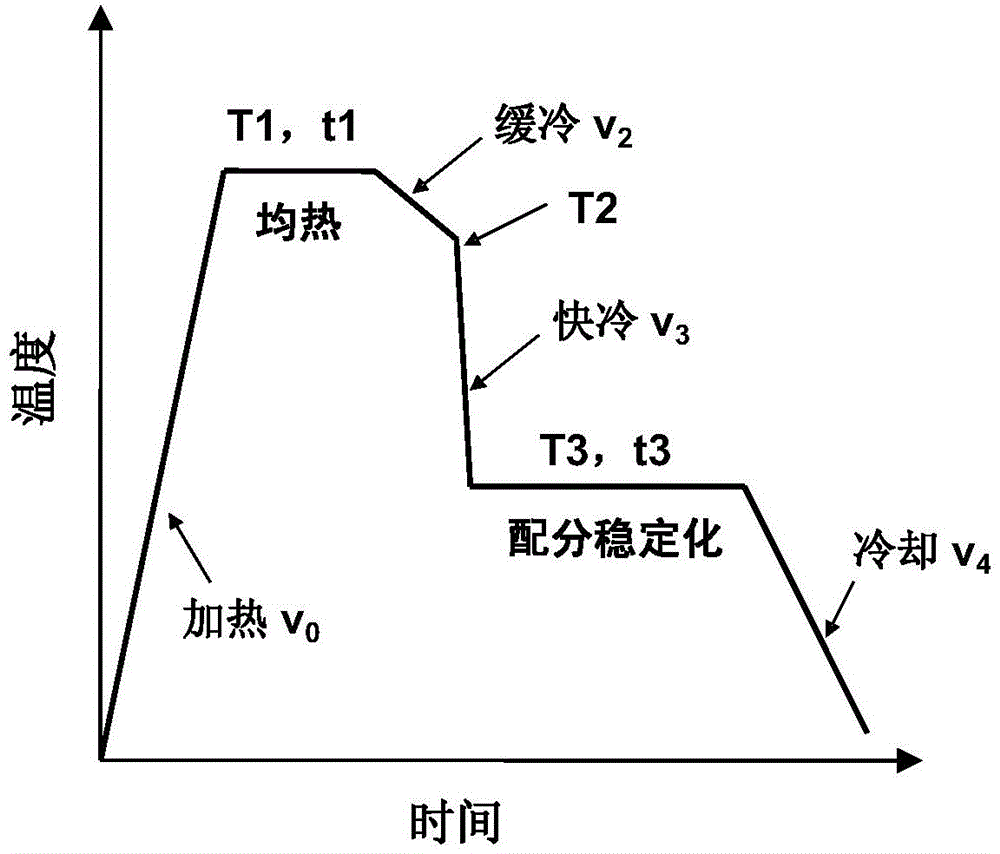

The invention provides automobile steel with low cost and high strength ductility balance and a preparation method thereof, belonging to the technical field of automobile steel. A multiphase, metastable and multiscale M<3> type organization structure is obtained based on reasonable design of chemical composition and partition of alloy elements and crucially based on the control of martensite phasetransformation, the repartition of solute such as C / Mn and the like and the austenite inverse phase transformation. The invention is characterized in that the martensite structure is obtained by using 0.02-0.50 wt%C and 3.50-9.00 wt%Mn in the cooling process of the inductrial production of steel plates and steel coils and the like; and superfine adverse transformation austenite and alpha phase substrate can be obtained through the partition of Mn and C in the heat preserving process between 100 DEG C below Acl and Acl, thus realizing the industrial production of hot rolled sheets and cold rolled sheets with high strength ductility balance used in automobiles. The invention has the advantages that the intensity is 0.7-1.3 GPa, the extension rate is 55-30% and the strength ductility balanceis 35-55 GPa%.

Owner:CENT IRON & STEEL RES INST

Corrosion protective cleaning agent for tin-plated steel

InactiveUS6060122ASignificant positive effectGood effectOther chemical processesPretreated surfacesTitaniumNonionic surfactant

PCT No. PCT / EP96 / 01137 Sec. 371 Date Sep. 24, 1997 Sec. 102(e) Date Sep. 24, 1997 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 30558 PCT Pub. Date Oct. 3, 1996The invention concerns an aqueous corrosion-protective cleaning solution for tin-plated steel, in particular for tin-plated steel cans, the solution containing complex fluorides of the elements boron, titanium, zirconium, and hafnium; non-ionic surfactants; and corrosion inhibitors and having a pH within the range from 3 to 6. The invention also concerns an aqueous concentrate for preparing the solution by dilution with water and a method of cleaning tin-plated cans using the solution.

Owner:HENKEL KGAA

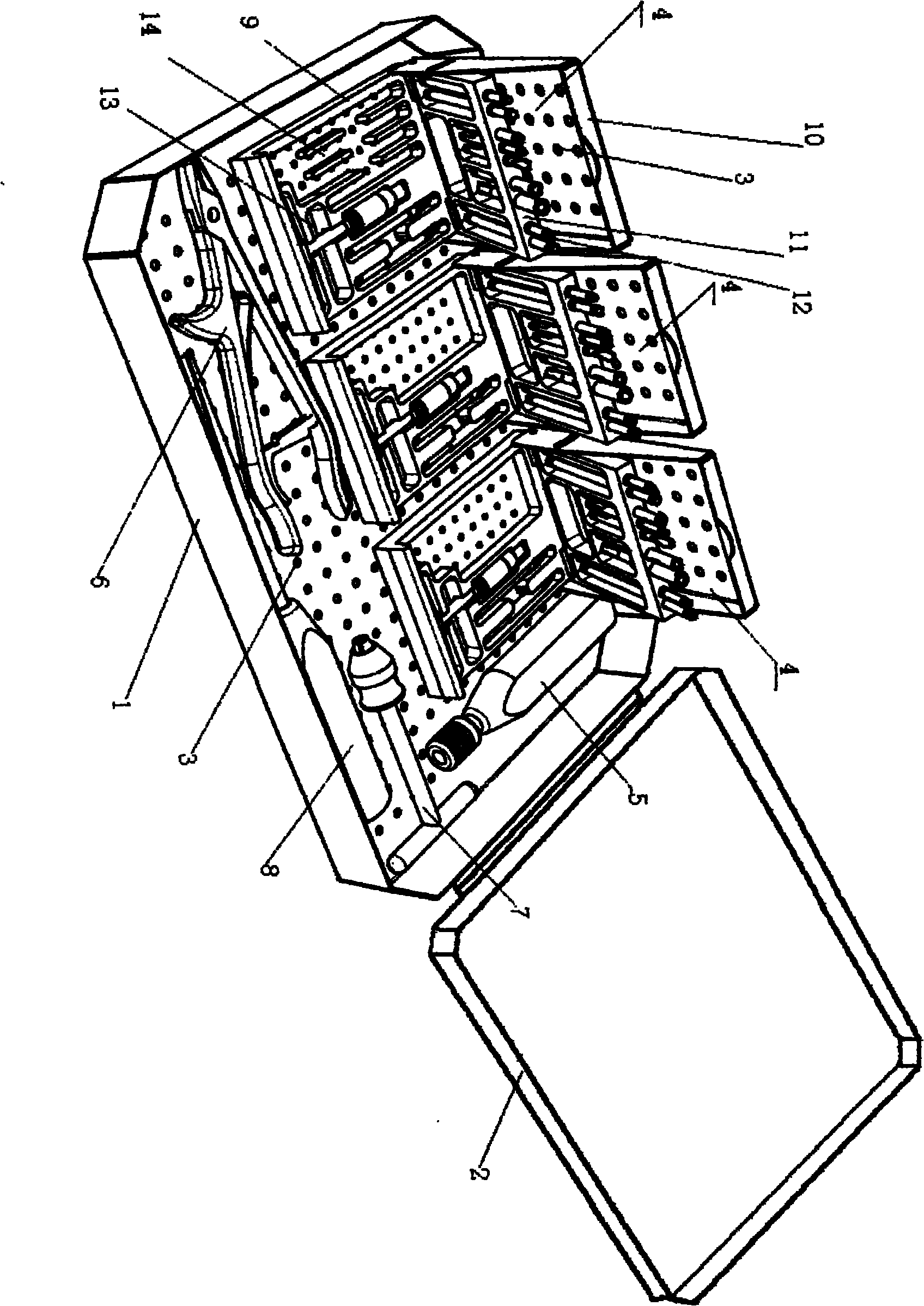

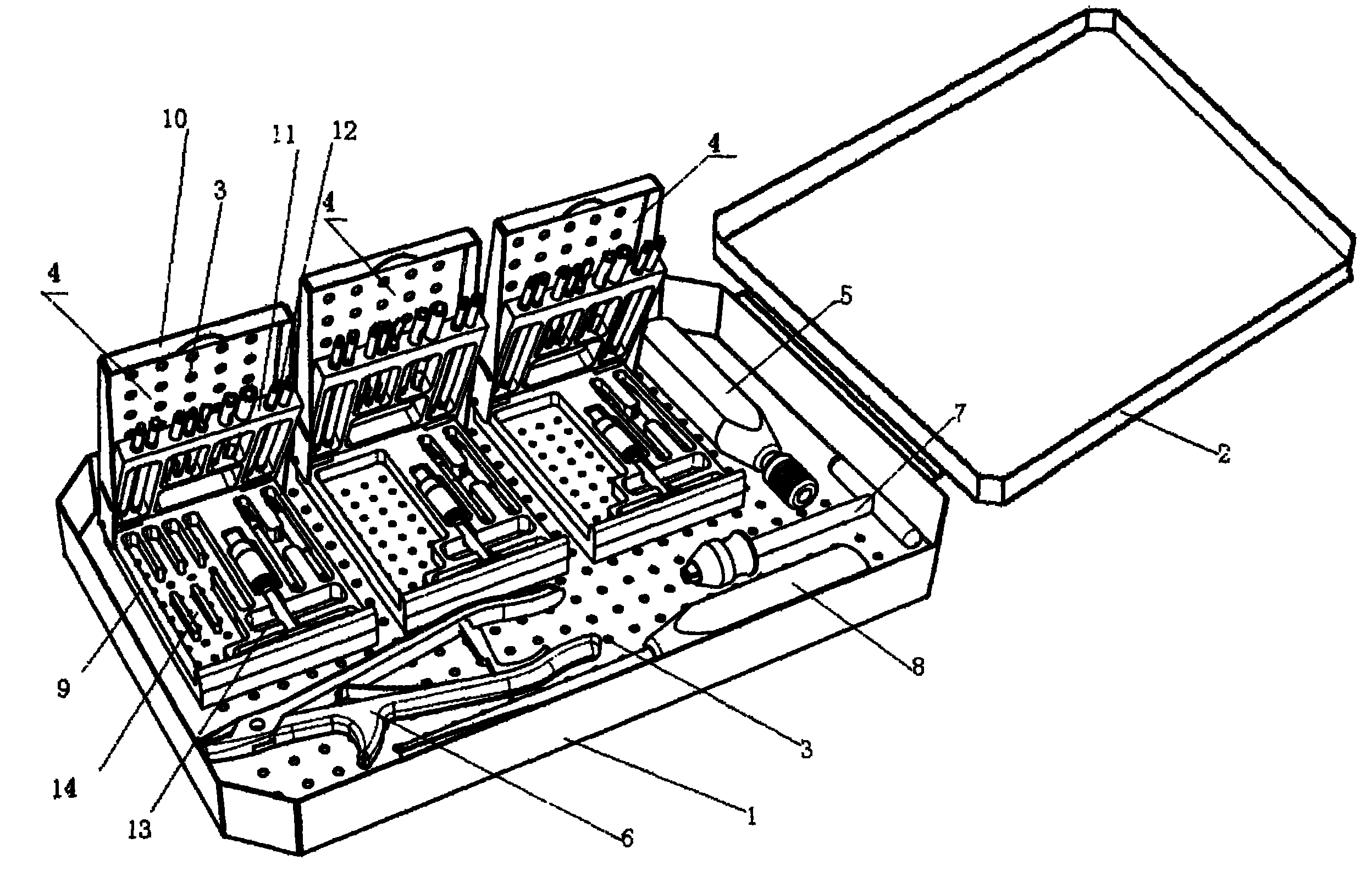

Orthopaedic universal appliance box

InactiveCN102038553AReasonably placedConvenient remote medical treatmentSurgical furnitureDiagnosticsEngineeringInternal fixation

The invention discloses an orthopaedic universal appliance box which comprises a box body and an upper cover, wherein the upper end of the bottom surface of the box body is uniformly fixed with a plurality of screw take-out device boxes; the left side of the leftmost screw take-out device box is provided with a vertical quick-change straight-handle groove; the left side of the lower end of the bottom surface of the box body is provided with a transverse A-shaped broken-screw take-out embedding groove, and the right side is provided with a transverse T-shaped quick-change handle groove; and the lower side of the A-shaped broken-screw take-out embedding groove and the T-shaped quick-change handle groove is provided with a transverse osteotome groove. The invention solves the problem that the standby tools of orthopaedic surgical appliances are not unified and not convenient to carry, which is common in the clinical work. The overall structure of the orthopaedic universal appliance box is compact. By reasonably putting a set of orthopaedic steel plates and surgical universal appliances of a nail-stick internal fixation system and a bracket external fixation system in the box body, the orthopaedic universal appliance box meets the use requirements during surgery.

Owner:中国人民解放军第一零五医院

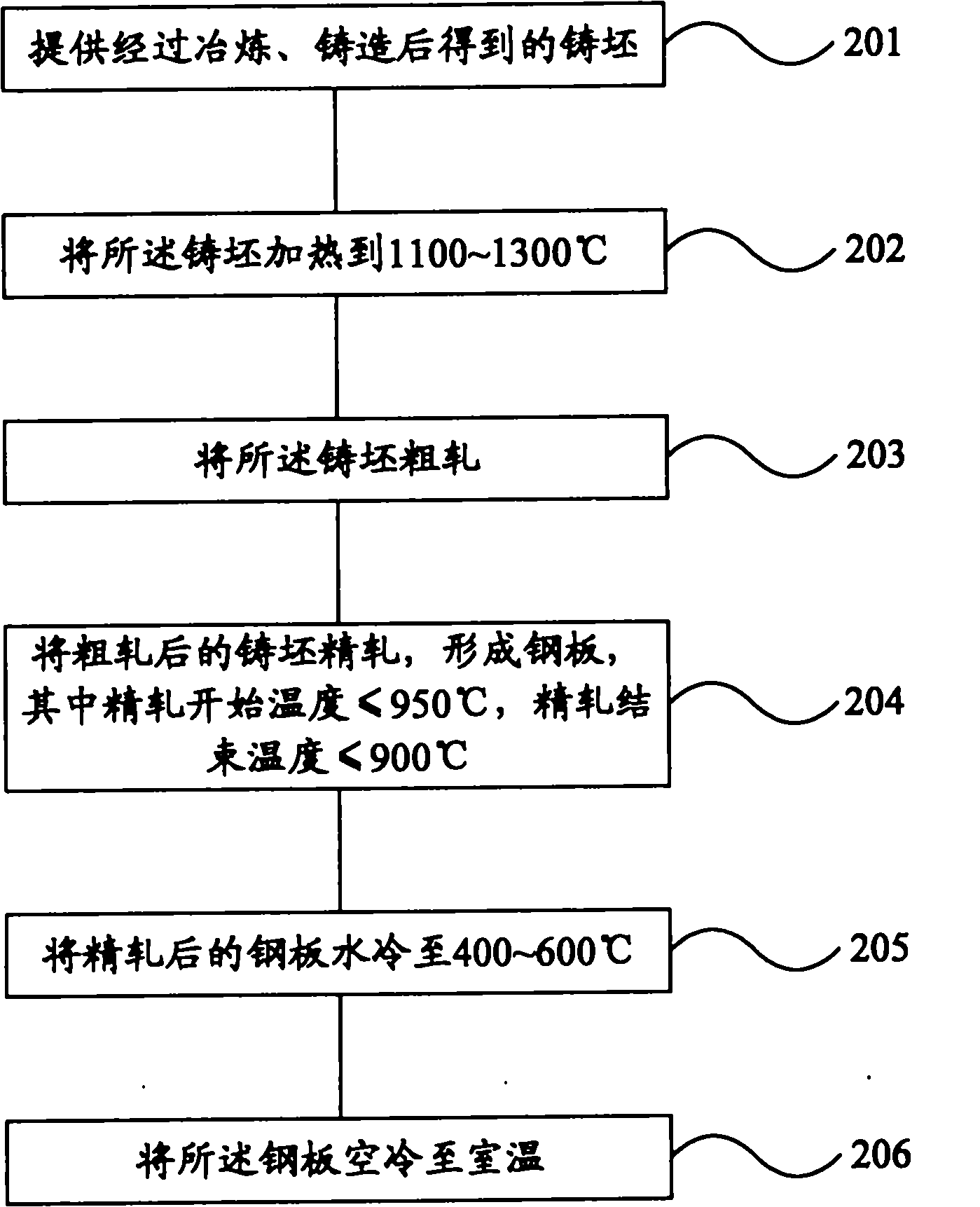

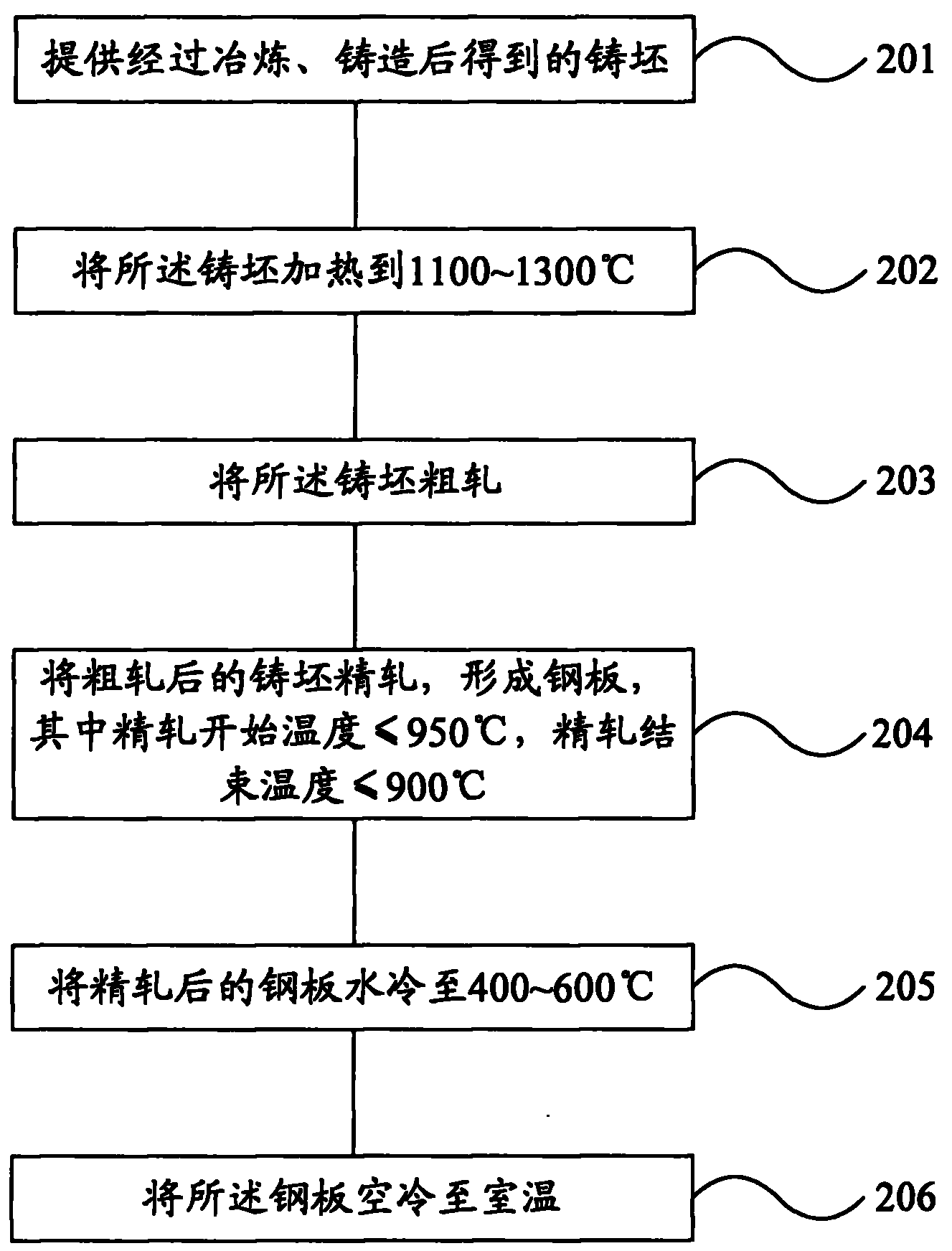

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Superhigh strength steel plate with yield strength more than 1100Mpa and method for producing same

The invention provides a super-strength steel plate comprising the following constituents (by weight percent): C 0.10-0.20%, Si<=0.6%, Mn 0.5-2.5%, Al <=0.03%, N 0.001-0.006%, B 0-0.0025%, Ca 0-0.006%, P<=0.015%, S<=0.005%, Ni 0.2-1.2%, Cr 0-0.8%, Cu 0-0.5% and Mo 0-0.6%, Ti 0.01-0.03%, V 0-0.1%, Nb 0.01-0.1%, balancing Fe and unavoidable foreign substance.

Owner:BAOSHAN IRON & STEEL CO LTD

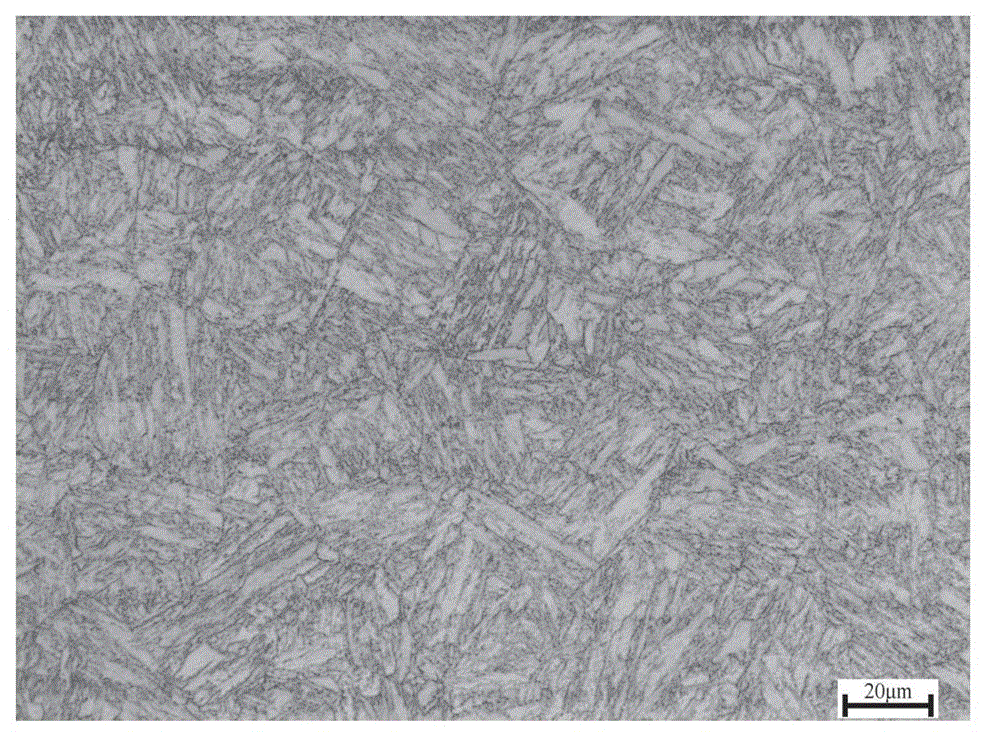

High-strength plastic accumulation TRIP (Transformation-Induced Plasticity) steel plate and preparation method thereof

The invention discloses a high-strength plastic accumulation TRIP (Transformation-Induced Plasticity) steel plate and a preparation method thereof, wherein the high-strength plastic accumulation TRIP steel plate consists of the following elements: 0.08%-0.5% of C, 0.4%-2.0% of Si, 3%-8% of Mn, smaller than or equal to 0.10% of P, smaller than or equal to 0.02% of S, 0.02%-4% of Al, smaller than or equal to 0.01% of N, 0-0.5% of Nb, 0-0.5% of V, 0-0.5% of Ti, 0-2% of Cr, 0-1% of Mo, and the balance of Fe and unavoidable impurities. In a microstructure, martensites account for 30%-90% by area occupation ratio, austenites account for 5%-30% by volume fraction, and the remaining is few ferrites and cementites. The hot rolling heating-up temperature is 1100-1250 DEG C, the holding time is more than or equal to 2 hours, the initial rolling temperature is higher than or equal to 1100 DEG C, the final rolling temperature is 850-950 DEG C, and the coiling temperature is lower than 720 DEG C; a hot rolled plate is 2-4mm in thickness; and the cover annealing is furnace heating for heat preservation at 550-750 DEG C for 1-20 hours and then furnace cooling.

Owner:ANGANG STEEL CO LTD

High strength steel sheet having excellent formability and method for production thereof

InactiveUS7090731B2Good molding effectHigh strengthHot-dipping/immersion processesFurnace typesHigh intensityHardness

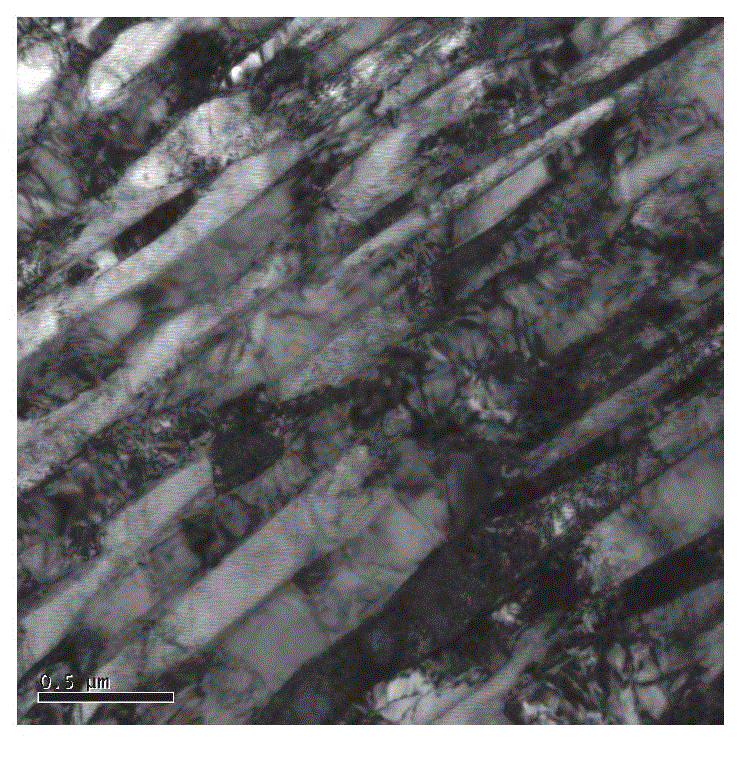

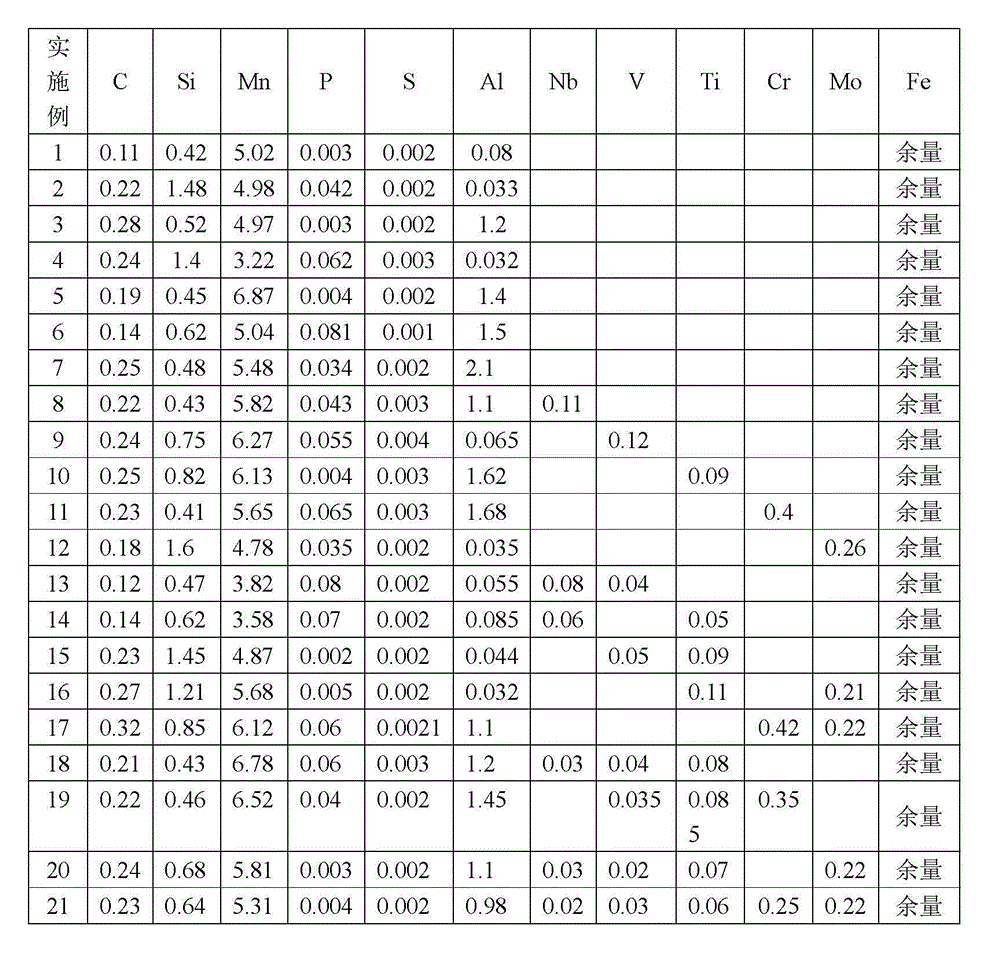

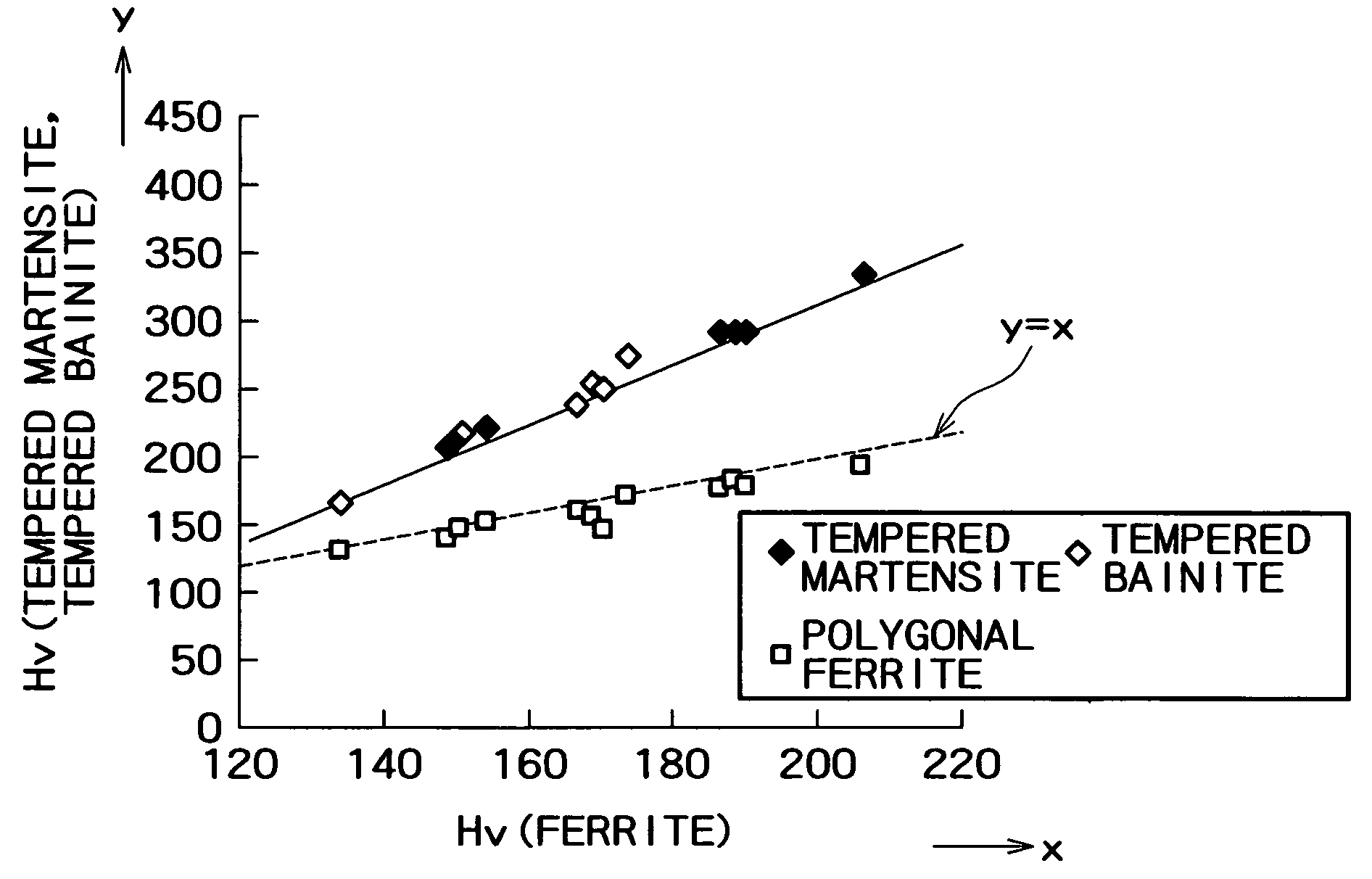

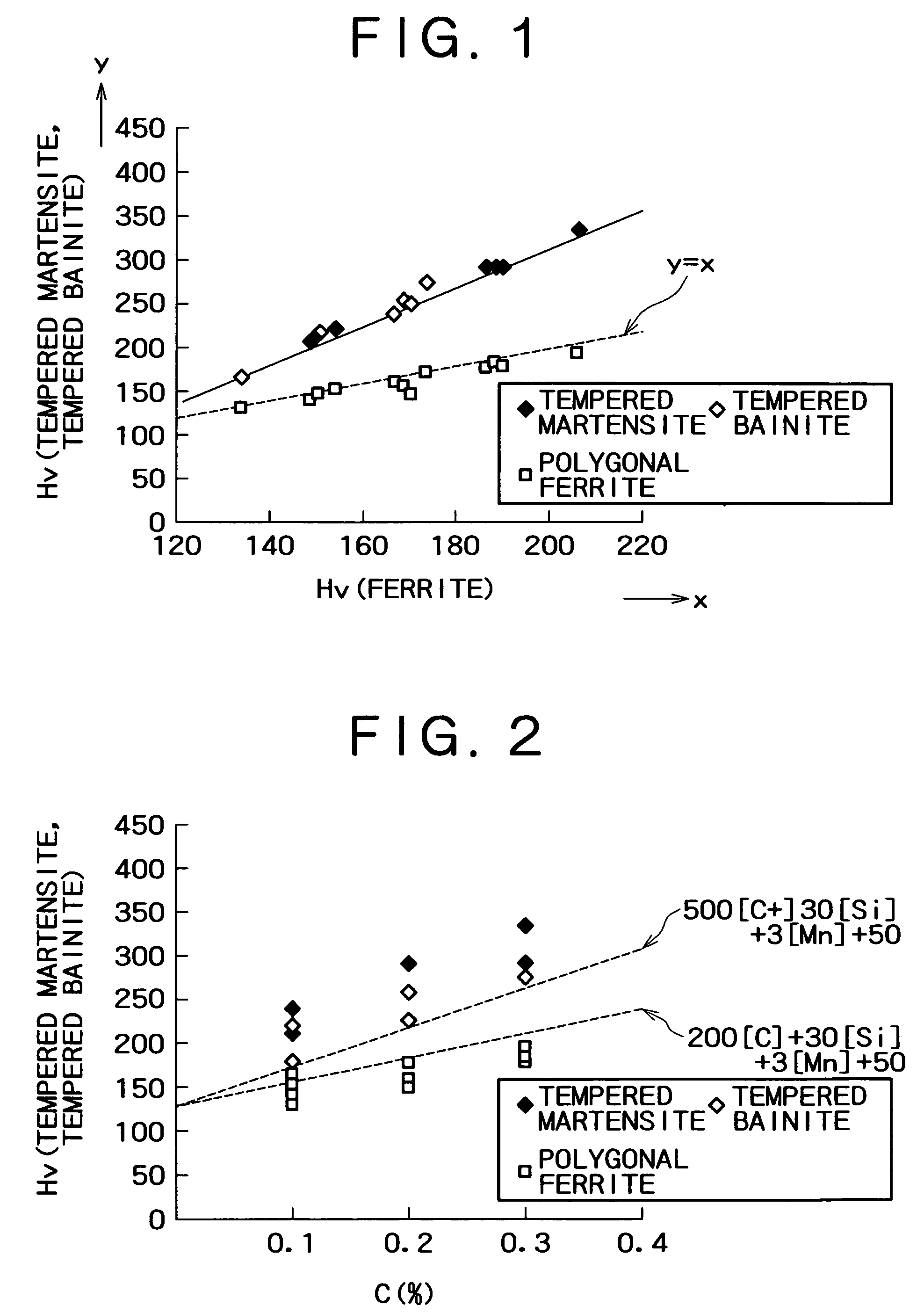

A high strength steel sheet having (2-1) a base phase structure, the base phase structure being tempered martensite or tempered bainite and accounting for 50% or more in terms of a space factor relative to the whole structure, or the base phase structure comprising tempered martensite or tempered bainite which accounts for 15% or more in terms of a space factor relative to the whole structure and further comprising ferrite, the tempered martensite or the tempered bainite having a hardness which satisfies the relation of Vickers hardness (Hv)≧500[C]+30[Si]+3[Mn]+50 where [ ] represents the content (mass %) of each element, and (2-2) a second phase structure comprising retained austenite which accounts for 3 to 30% in terms of a space factor relative to the whole structure and optionally further comprising bainite and / or martensite, the retained austenite having a C concentration (CγR) of 0.8% or more.

Owner:KOBE STEEL LTD

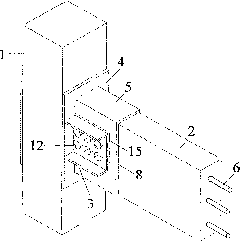

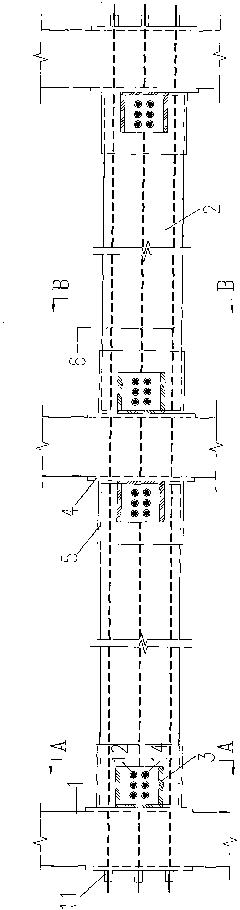

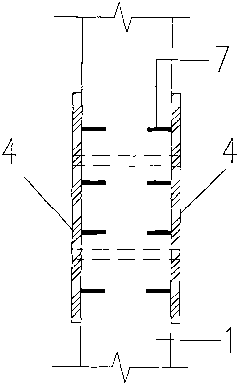

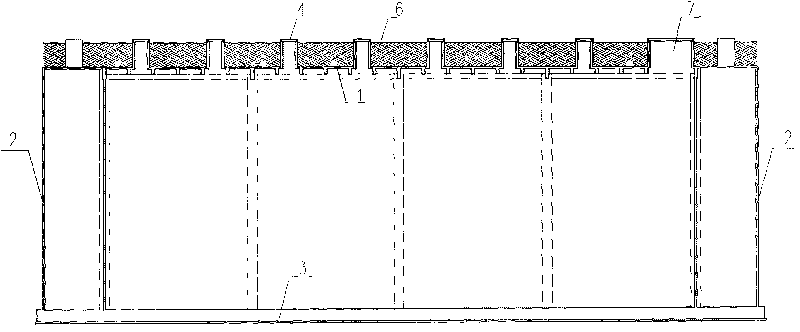

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

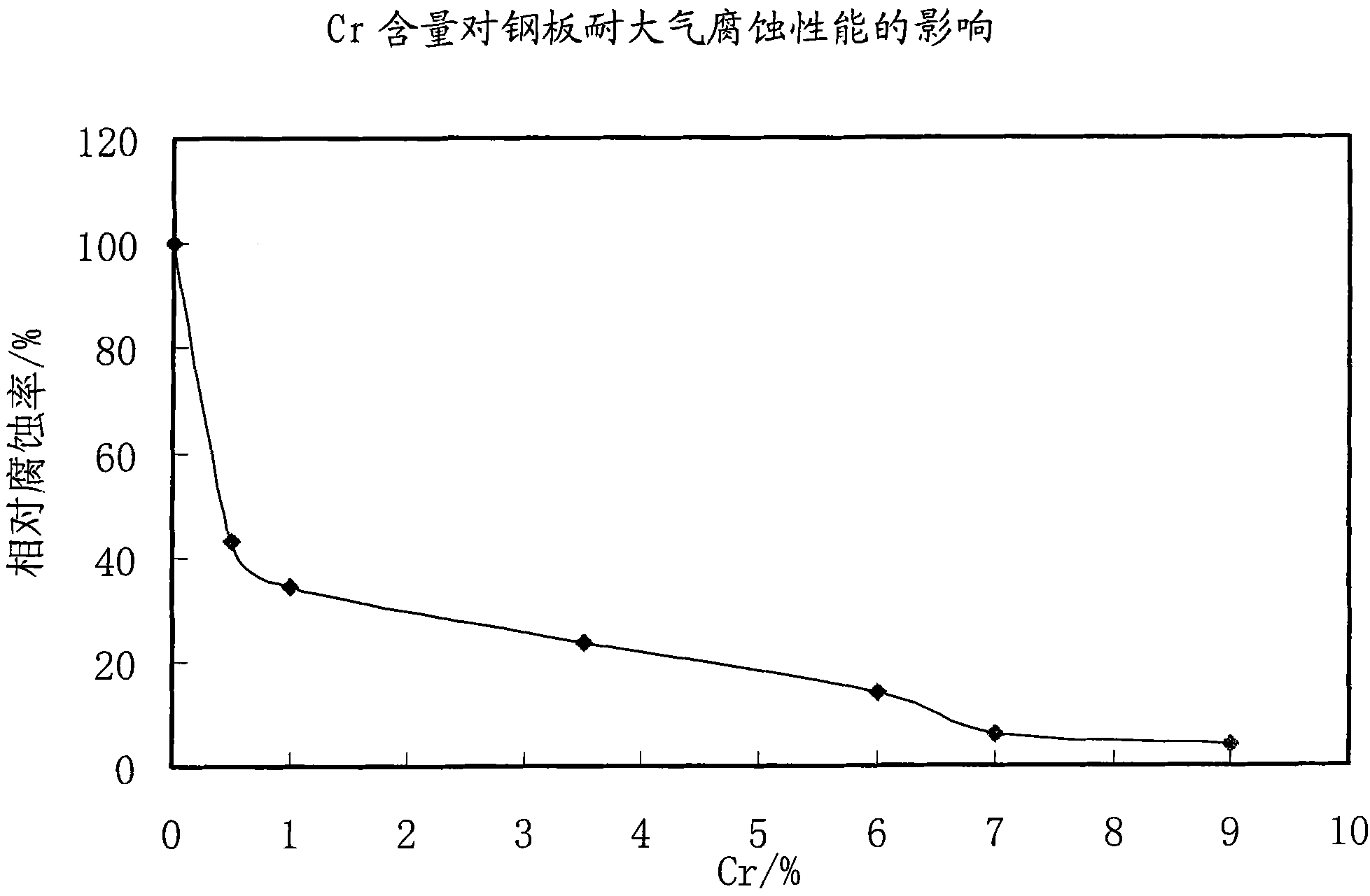

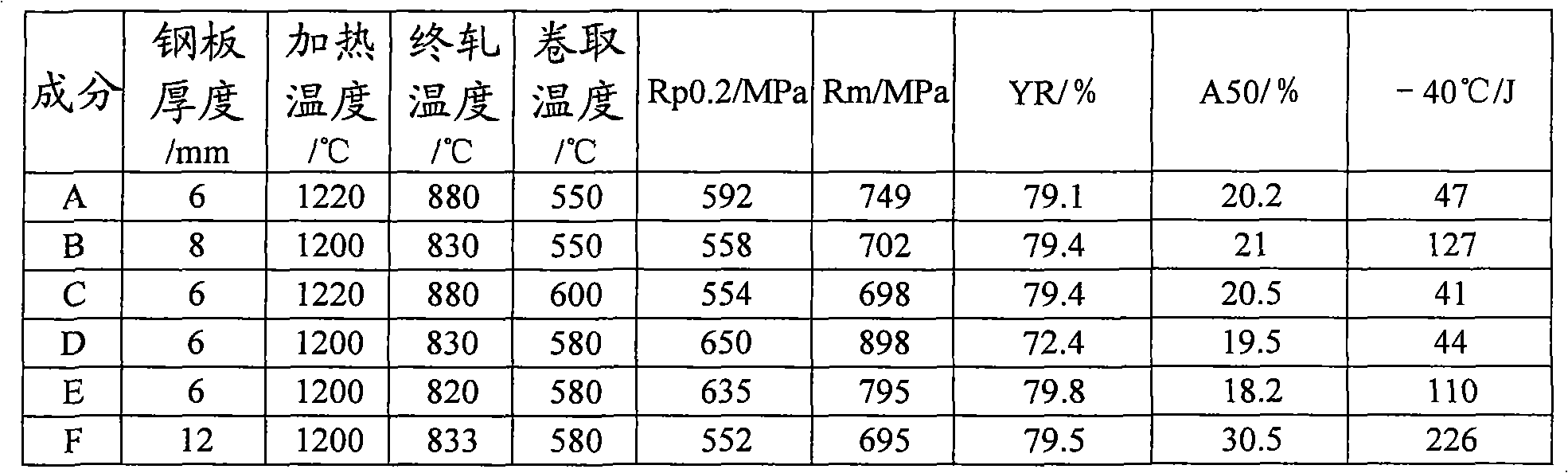

Weathering steel with yield strength of 550MPa level and manufacturing method thereof

InactiveCN101994064AMeet the requirements of reducing the self-weight of componentsMeet the requirements of self-respectTemperature control deviceSheet steelUltimate tensile strength

The invention relates to weathering steel with the yield strength of 550MPa level and the advantages of excellent toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components: 0.02 to 0.08wt% of C, 0.15 to 0.55wt% of Si, 0.2 to 1.0wt% of Mn, less than or equal to 0.01wt% of P, less than or equal to 0.006wt% of S, 0.2 to 0.5wt% of Cu, 2.5 to 7.0wt% of Cr, 0.2 to 1.2wt% of Ni, 0.02 to 0.06wt% of Nb, 0.01 to 0.05wt% of Al, less than or equal to 0.05wt% of N, 0.01 to 0.10wt% of Ti and the balance of Fe and the unavoidable impurities. The steel plate made of the steel has the yield strength more than 550MPa and excellent toughness, and the relative corrosion rate is simultaneously reduced by one time on the basis of the traditional weathering steel so as to satisfy the requirement of enhancing the corrosion resistance of the steel for railway vehicles and reach the purposes of prolonging the service duration and reducing the maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

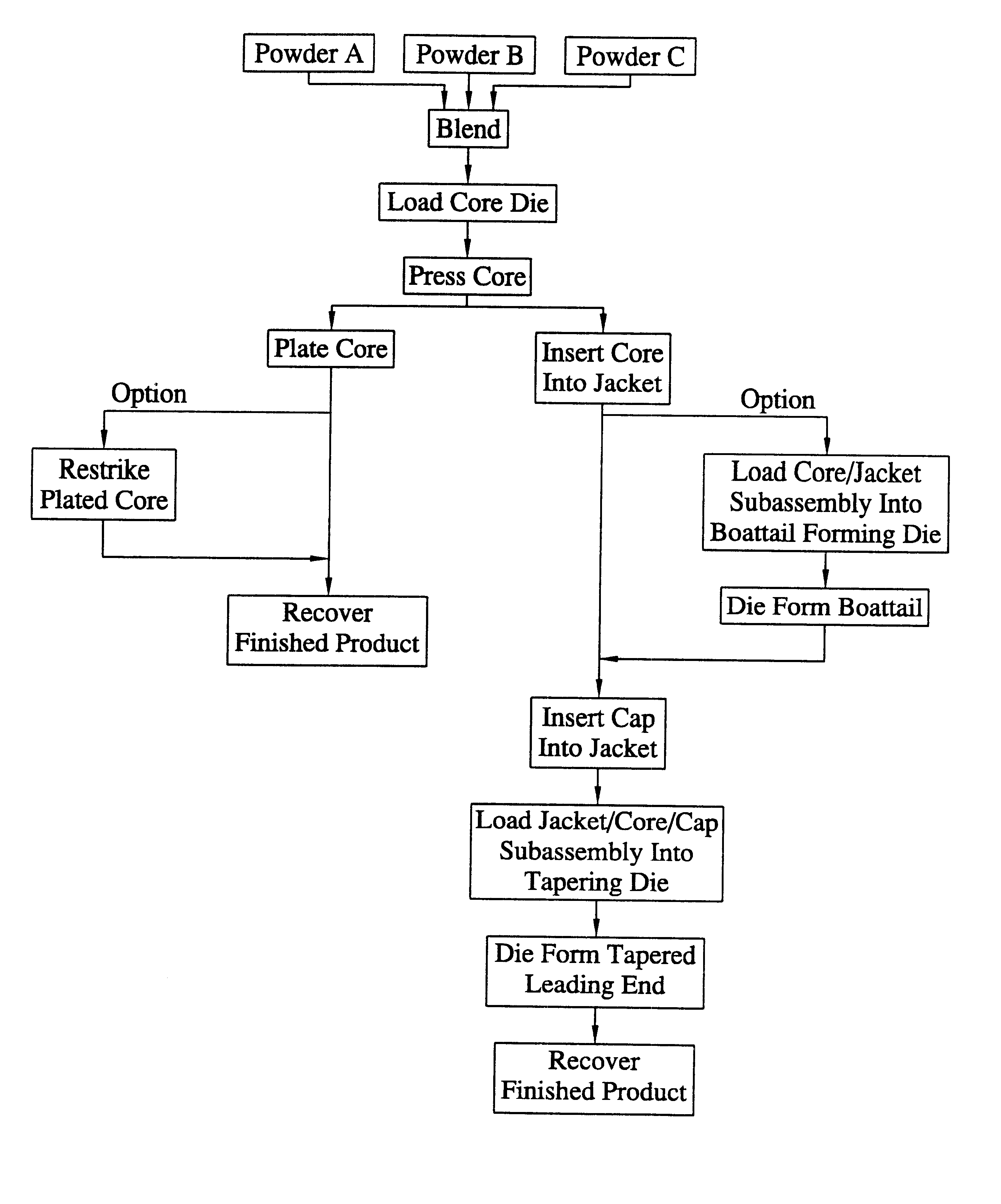

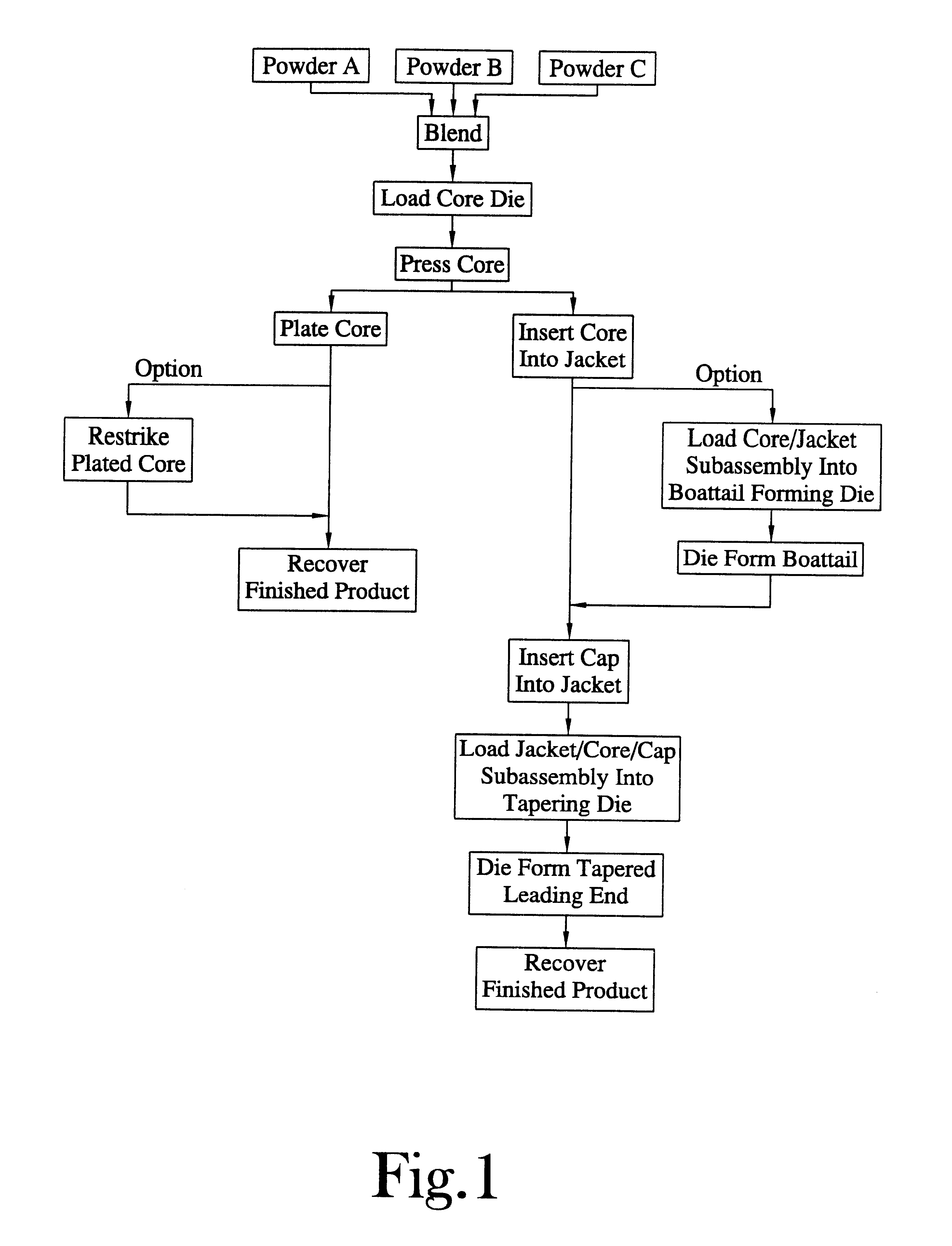

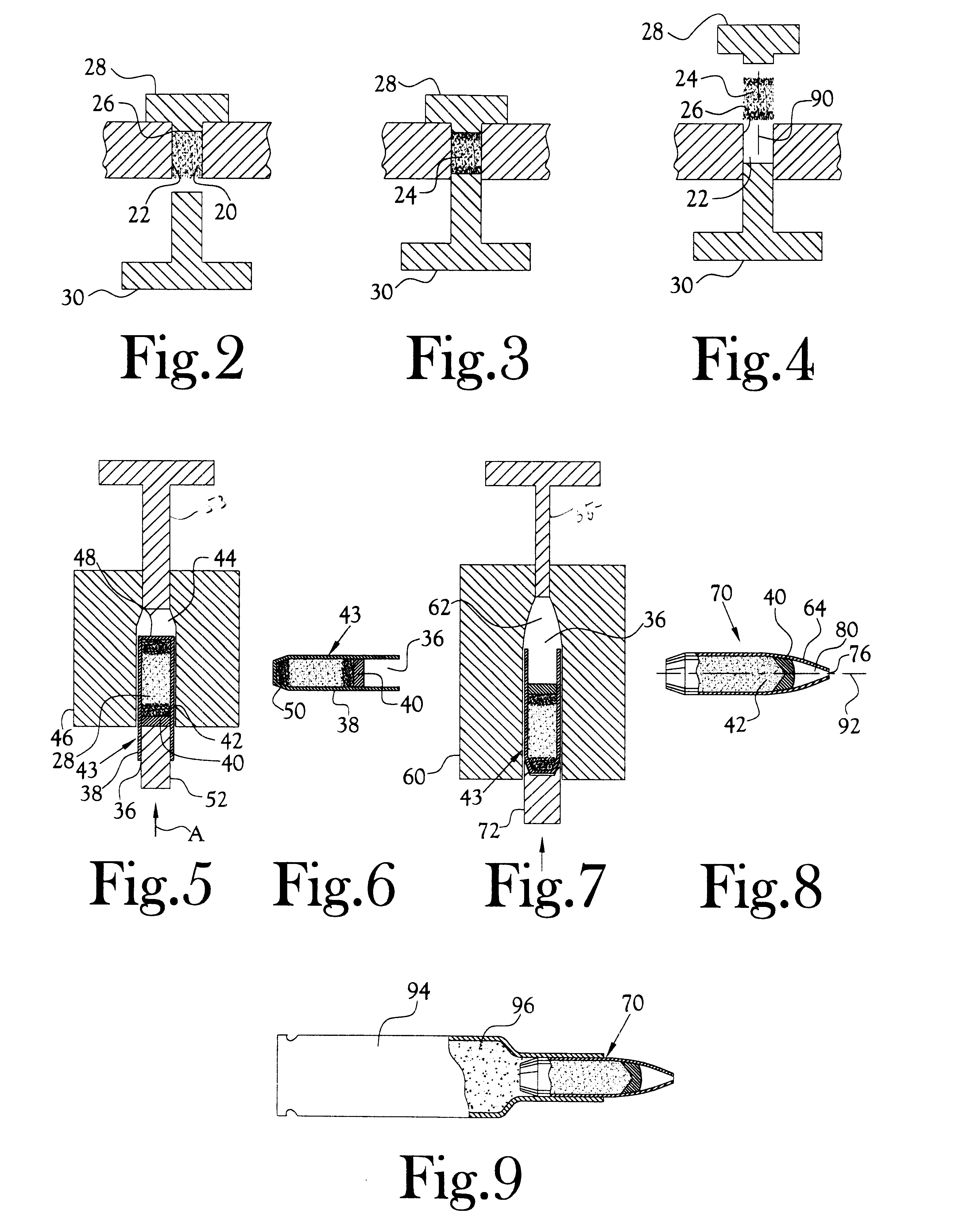

Method for the manufacture of a frangible nonsintered powder-based projectile for use in gun ammunition and product obtained thereby

InactiveUS6457417B1Easy and inexpensive to manufactureAmmunition projectilesTraining ammunitionSemi solidRicochet

A method for the manufacture of heavy metal powder-based frangible projectiles which are relatively easy and inexpensive to manufacture and which exhibit a selectable variety of desirable physical and / or performance properties. The projectiles of the present invention are powder-based, preferably including predominately tungsten powder as a heavy metal, particularly a tungsten powder which includes a predominate portion of finely sized particles. Lighter metal powders, also preferably having a predominate portion of finely sized particles, may be employed in combination with the tungsten to achieve certain desired results. Importantly, the present inventor has found that inclusion of a non-metal matrix powder, also of finely sized particles, in a mixture of a heavy metal powder, such as tungsten powder, and a light metal powder, may be employed in a variety of combinations to produce a projectile which is fully frangible upon striking a target (no ricochet), or which is frangible after either partial or full penetration of a selected target, either a semi-solid (e.g., a gel block) or a solid (e.g., a ¼ inch thick cold rolled steel plate at an angle of about 90 degrees).

Owner:COVE CORP +1

Steel plate having superior toughness in weld heat-affected zone and welded structure made therefrom

Owner:POHANG IRON & STEEL CO LTD

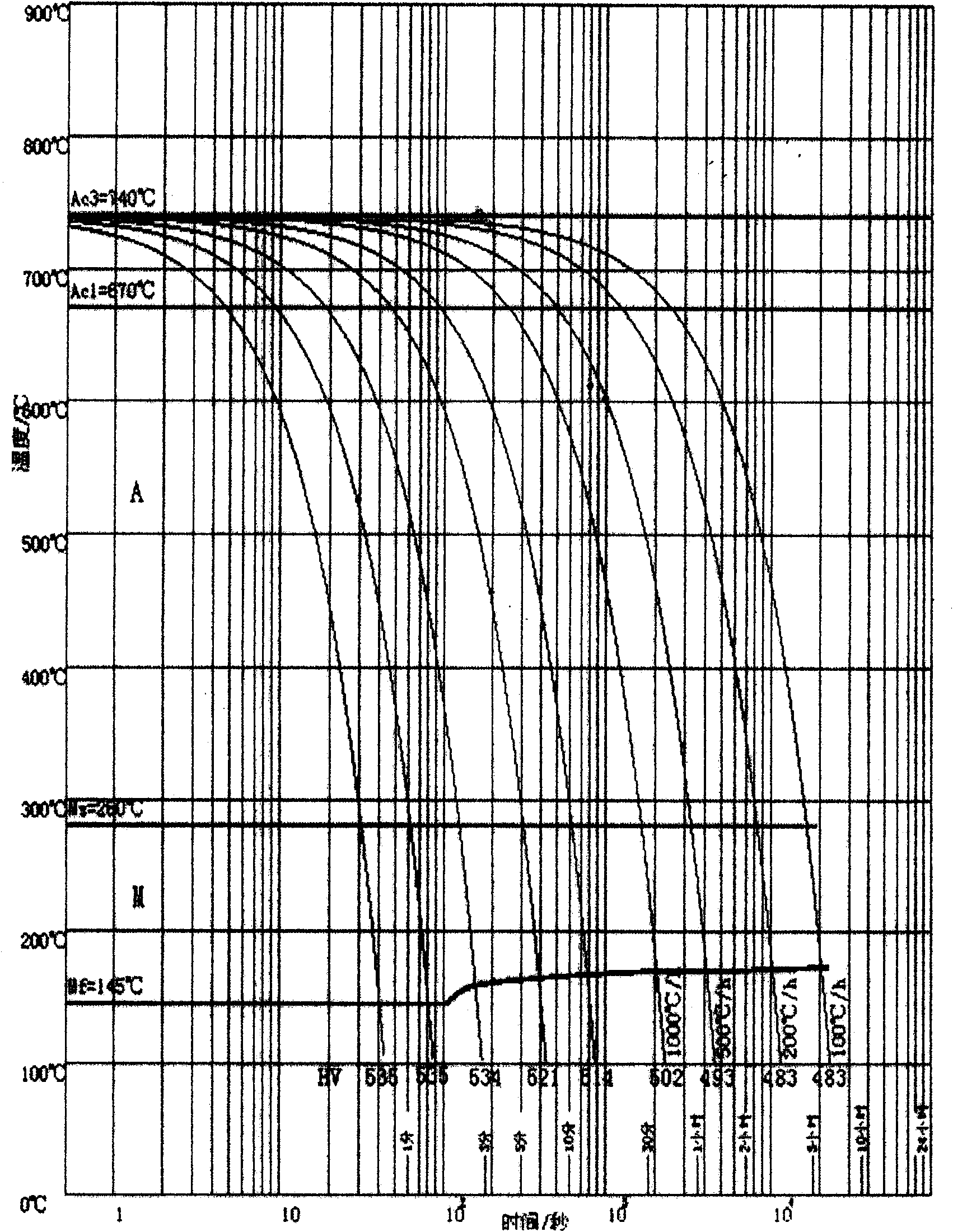

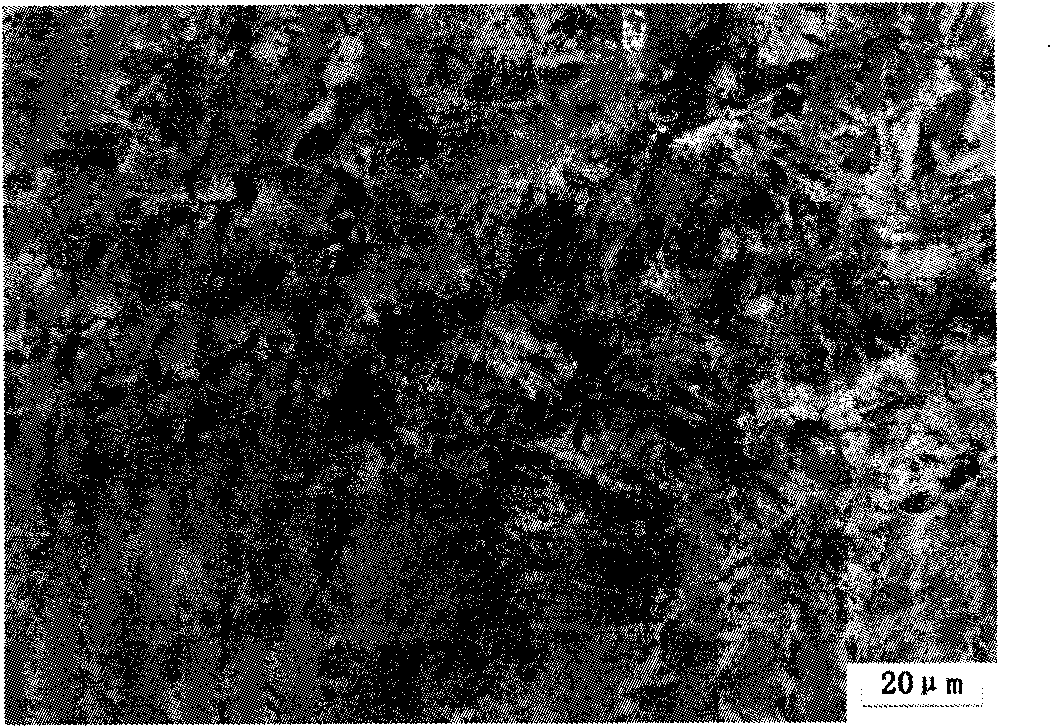

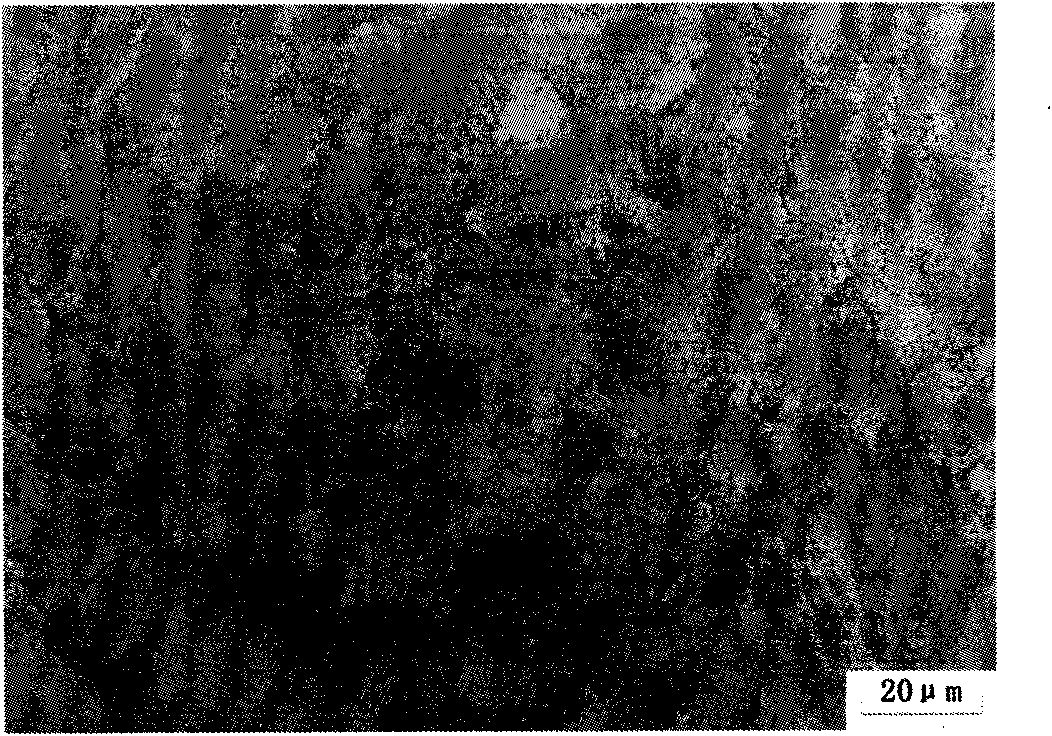

Superhigh strength steel plate with yield strength more than 960Mpa and method for producing same

ActiveCN1840724AEasy to implementEasy to controlFurnace typesHeat treatment furnacesAusteniteForeign substance

The invention provides a super-strength steel plate comprising the following constituents (by weight percent): C 0.08-0.18%, Si<=0.6%, Mn 0.5-2.0%, Al <=0.018%, N<=0.008%, B<=0.0025%, Ca 0-0.006%, P<=0.015%, S<=0.005%, Ni <=1.0%, Cr<=0.8%, Cu<=0.5%, Mo<=0.6%, Ti 0.01-0.03%, V<=0.1%, Nb 0.01-0.1%, balancing Fe and unavoidable foreign substance. The invention also provides the preparing process.

Owner:BAOSHAN IRON & STEEL CO LTD

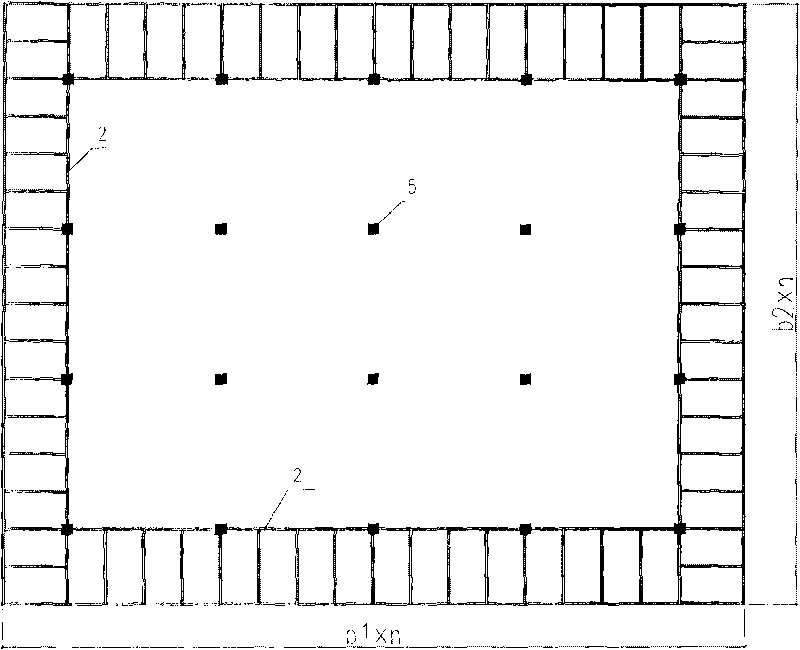

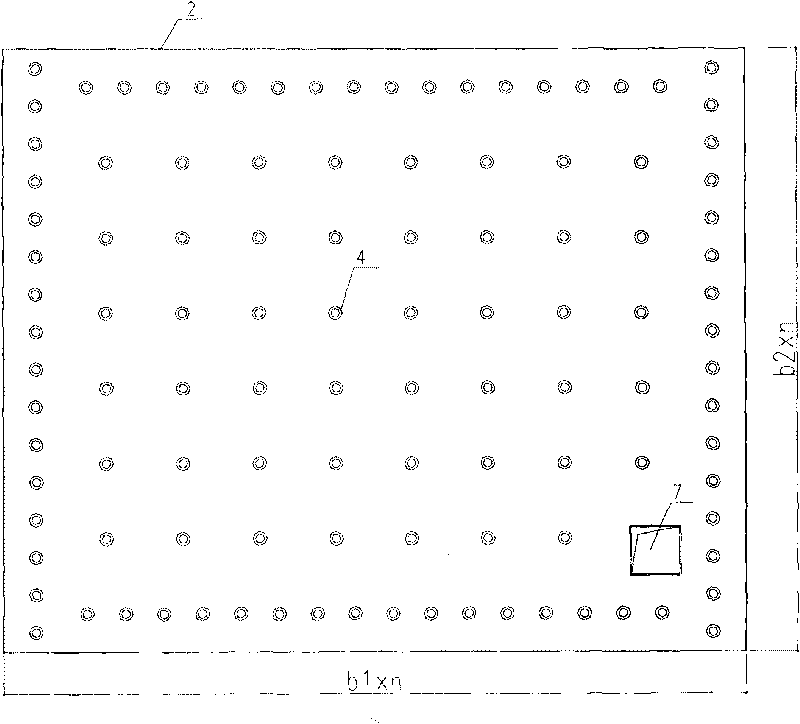

Water-proof and damp-proof underground granary

InactiveCN101705755ASolve the waterproof and moisture-proof problemLow construction costBulk storage containerStructural engineeringSquare cylinder

Owner:HENAN UNIVERSITY OF TECHNOLOGY

High-toughness and ultrahigh-strength wear-resistant steel plate and production method thereof

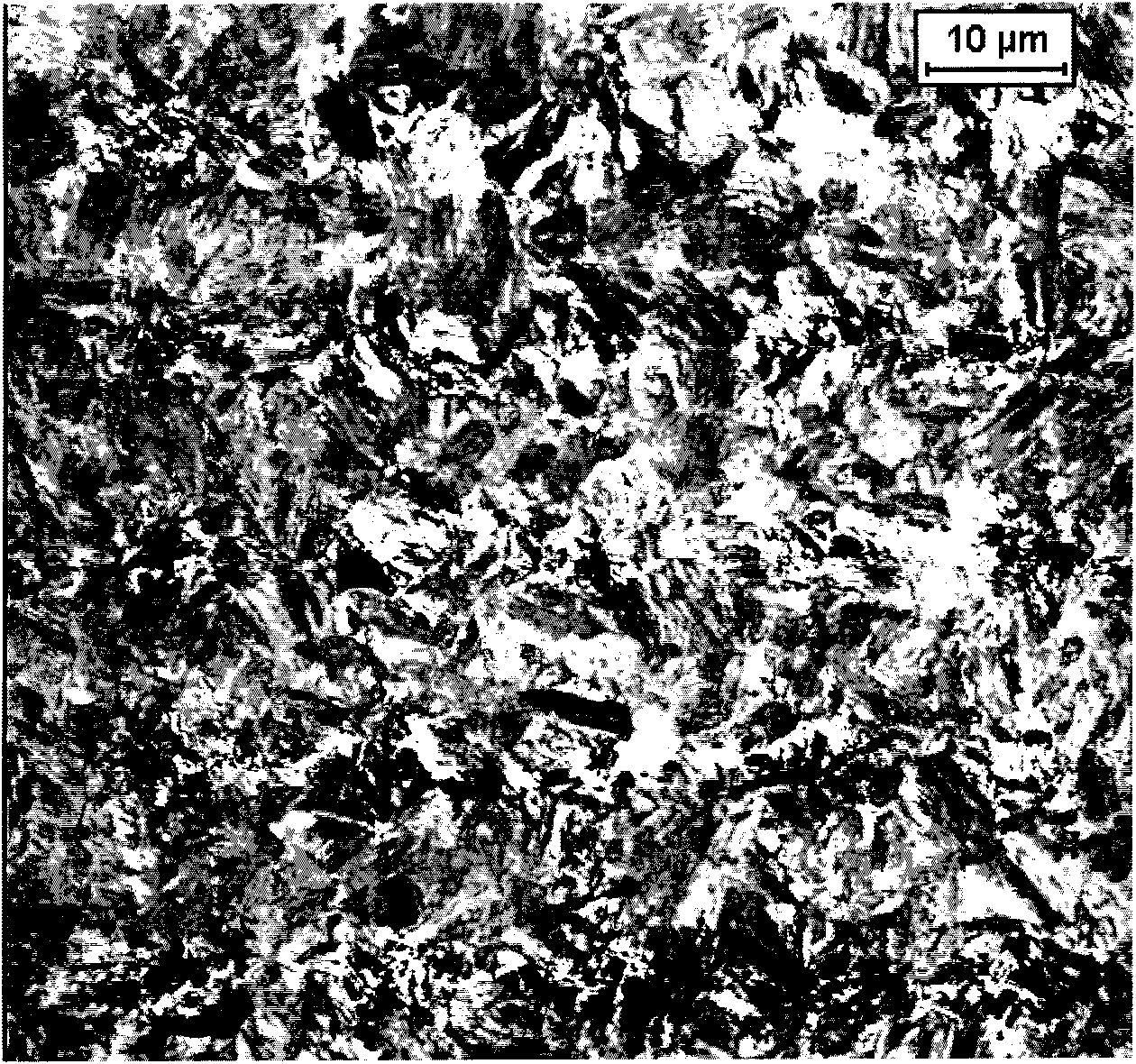

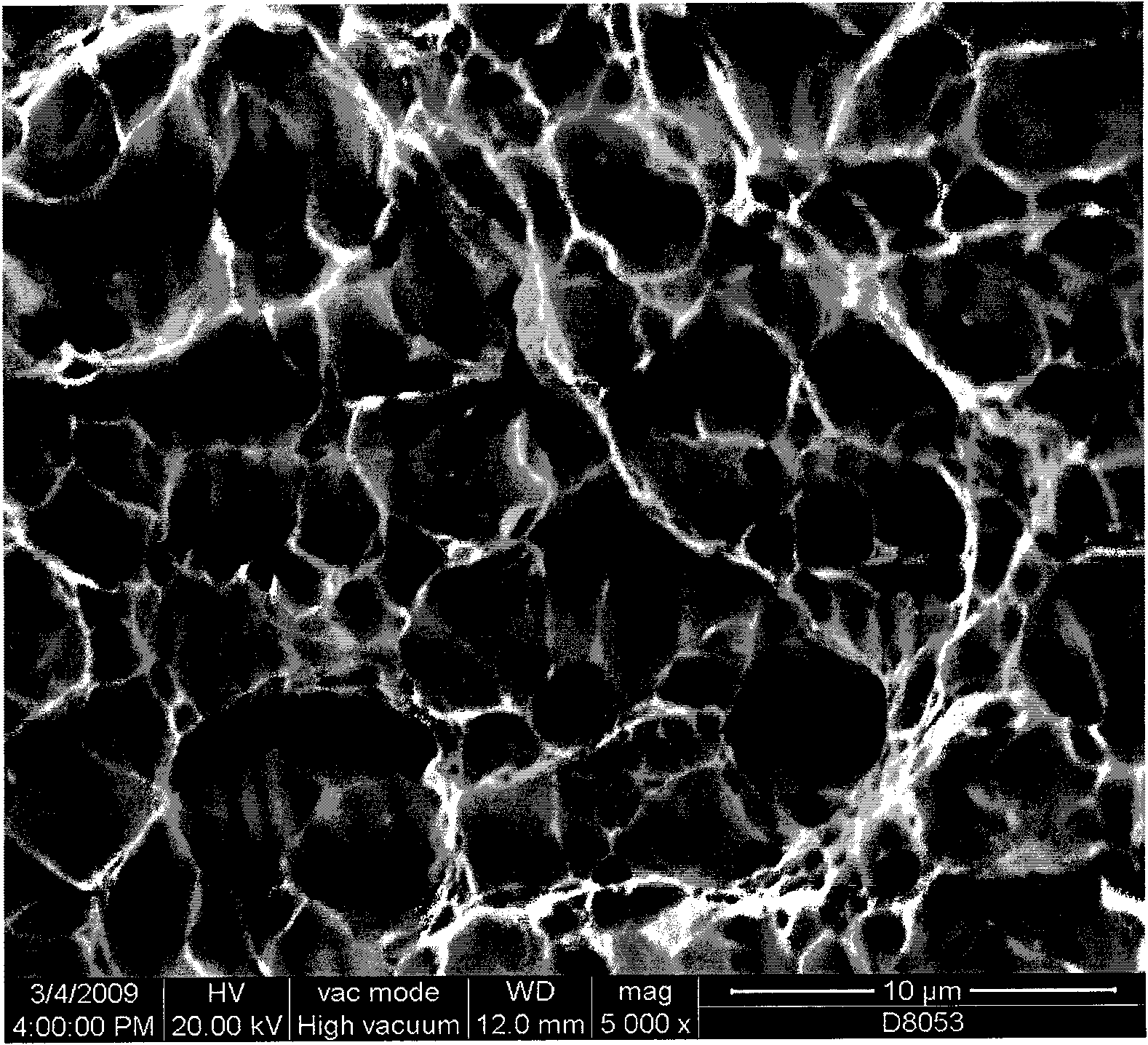

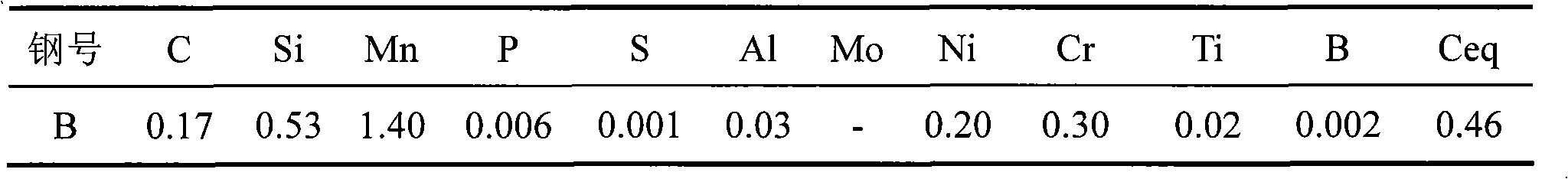

InactiveCN101638755AGood toughness matchGood welding performanceManufacturing convertersChemical compositionWear resistant

The invention provides a high-toughness and ultrahigh-strength wear-resistant steel plate and a production method thereof. The steel comprises the following chemical compositions by mass percent: 0.15-0.26% of C, 0.20-0.55% of Si, 1.0-1.60% of Mn, P less than or equal to 0.020%, S less than or equal to 0.010%, 0.00-0.60% of Mo, 0.00-0.50% of Ni, 0.20-1.00% of Cr, 0.01-0.05% of Ti, 0.02-0.04% of Als, 0.0005-0.004% of B and the balance Fe and inevitable impurities. The production method of the steel comprises the following steps: high clean steel smelting, hot metal desulphurizing, converter top-bottom blowing, vacuum processing and blank casting, in particular to plate blank heating, rough rolling, finish rolling and heat treatment technology parameter controlling. The chemical compositionsof the steel contain no V, Mo or Ni, or contain less Mo and Ni, therefore, the steel plate is low in alloy content and fine in toughness and can be widely applied to the mines and construction machinery products, which feature bad working conditions and have high requirements on steel properties.

Owner:NORTHEASTERN UNIV

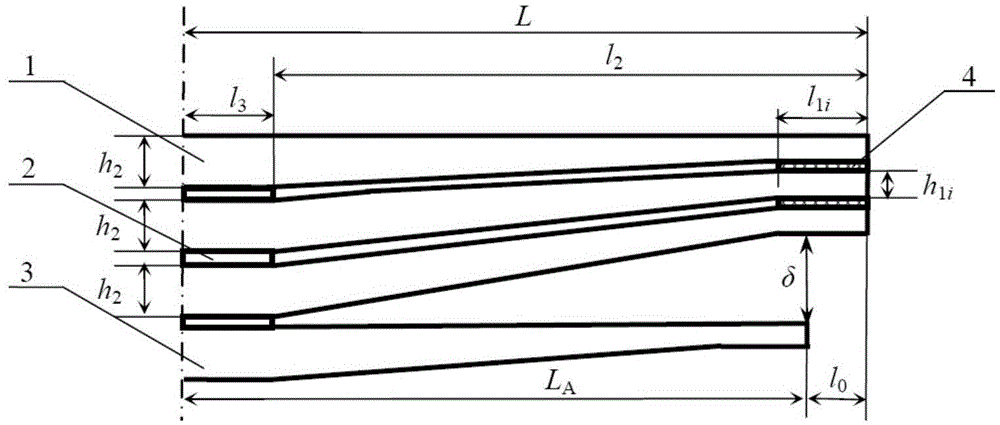

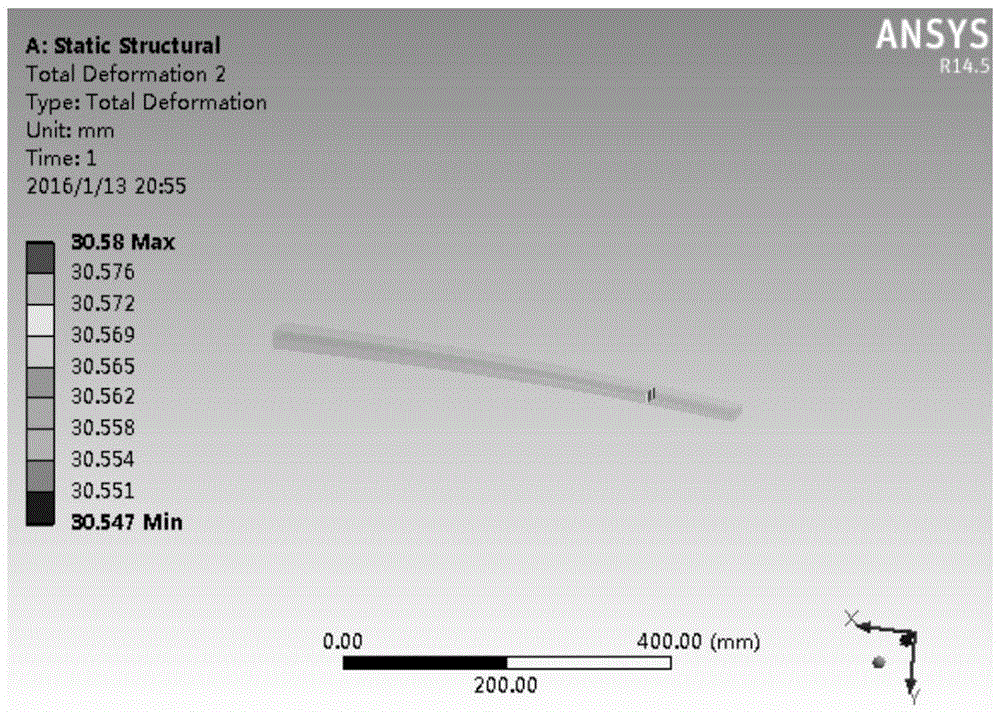

Method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs

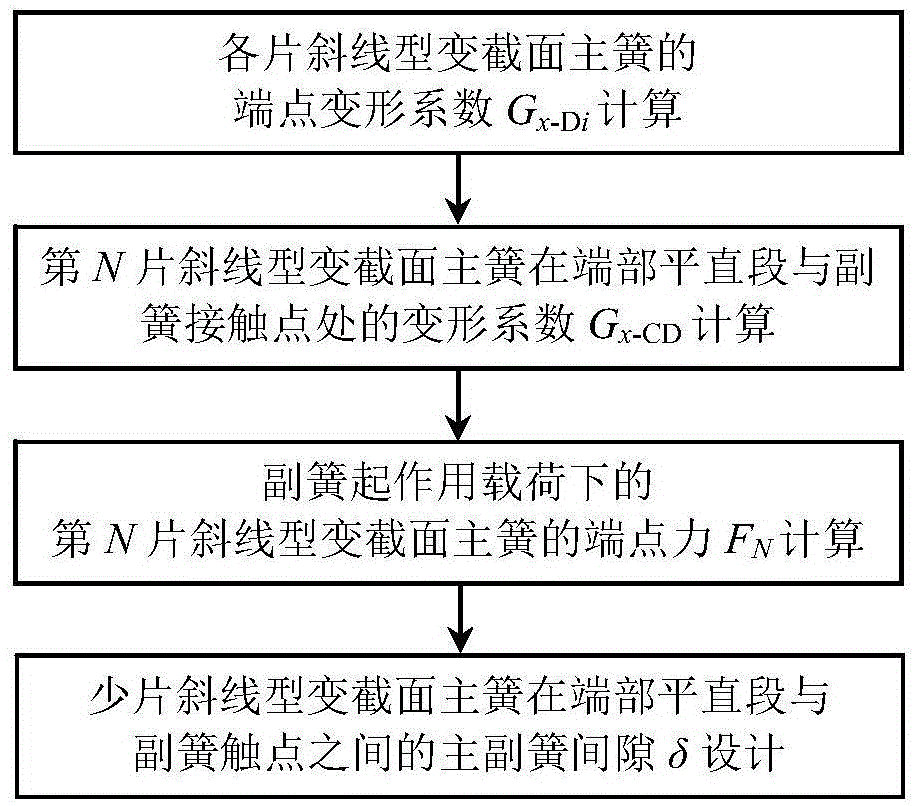

ActiveCN105526290AExact design valueReliable design valueGeometric CADLeaf springsEngineeringDesign values

The invention relates to a method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs, and belongs to the technical field of suspension steel plate springs. The method includes determining endpoint deformation coefficients of the various main springs and deformation coefficients G<x-CD> of contact points of the end straight sections of the N main springs and the auxiliary springs according to structure sizes and elastic modulus of the various diagonal variable-section main springs; acquiring endpoint force F<N> of the N main springs according to acting load of the auxiliary springs and the endpoint deformation coefficients of the various main springs; designing the main and auxiliary spring gaps between contact points of the end straight sections of the main springs and the auxiliary springs according to the thicknesses h<2> of roots of the N main springs, the endpoint force F<N> and the deformation coefficients G<x-CD>. The method has the advantages that as known from simulation verification, design values of the gaps of the end straight sections of the diagonal few-leaf variable-section main springs and the auxiliary springs can be accurately and reliably obtained by the aid of the method, and accordingly the product design level and performance and the vehicle ride comfort can be improved; the design and experiment costs can be reduced, and the product development speeds can be increased.

Owner:山东恒日悬架弹簧股份有限公司

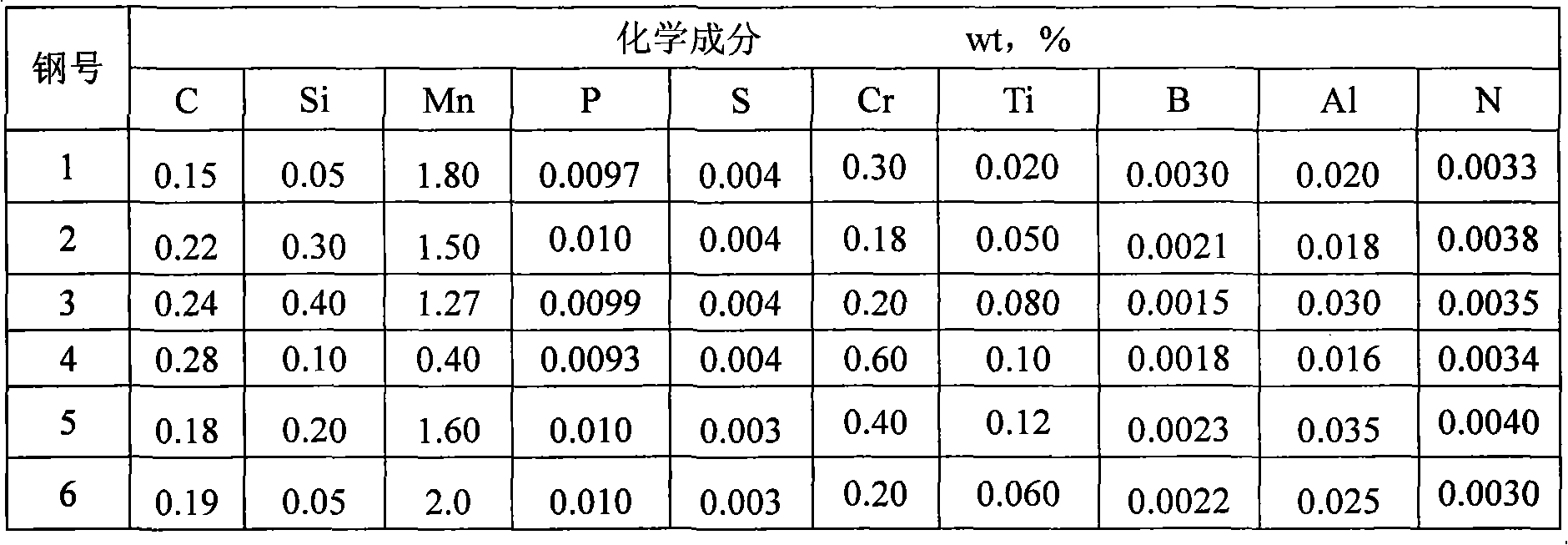

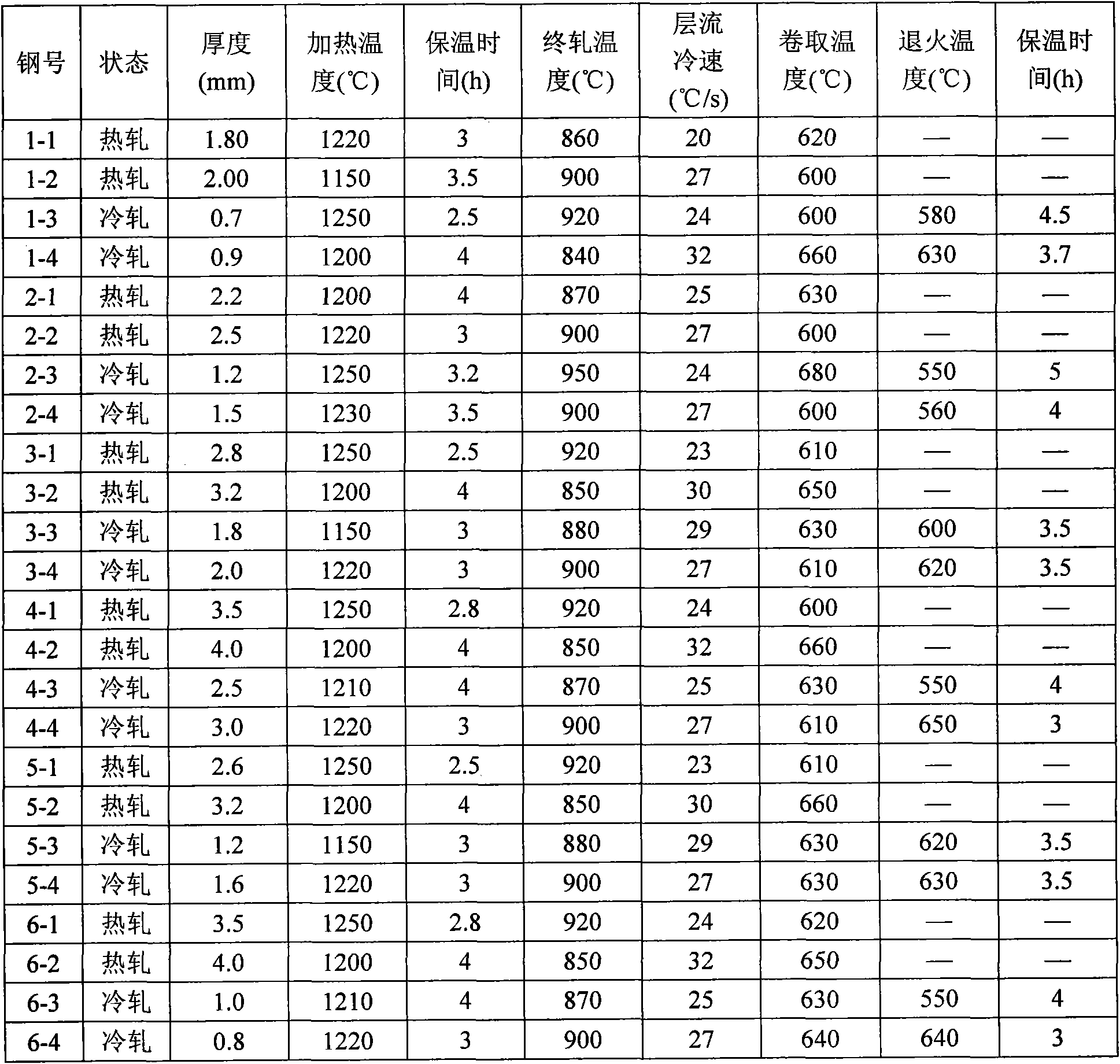

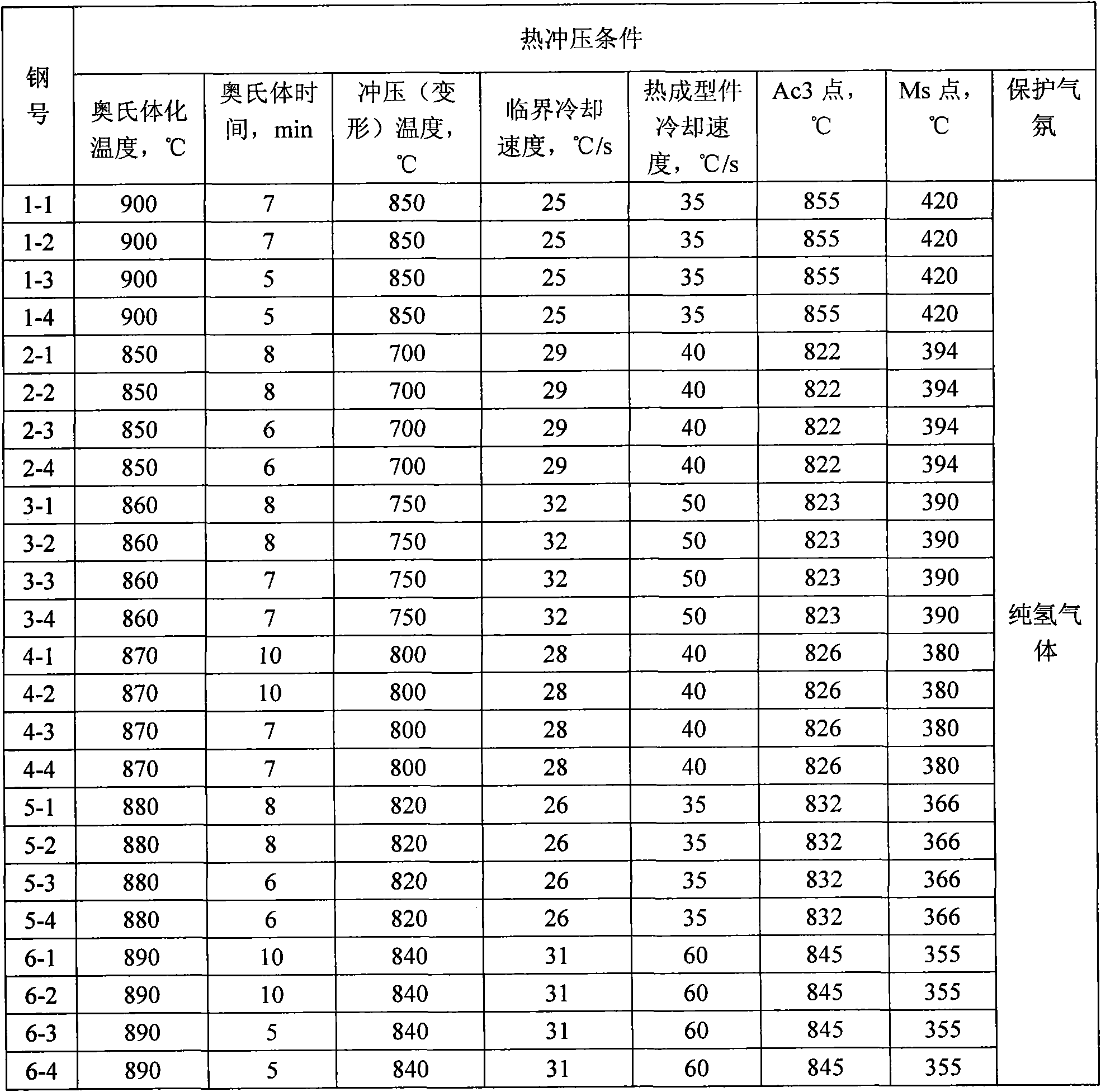

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

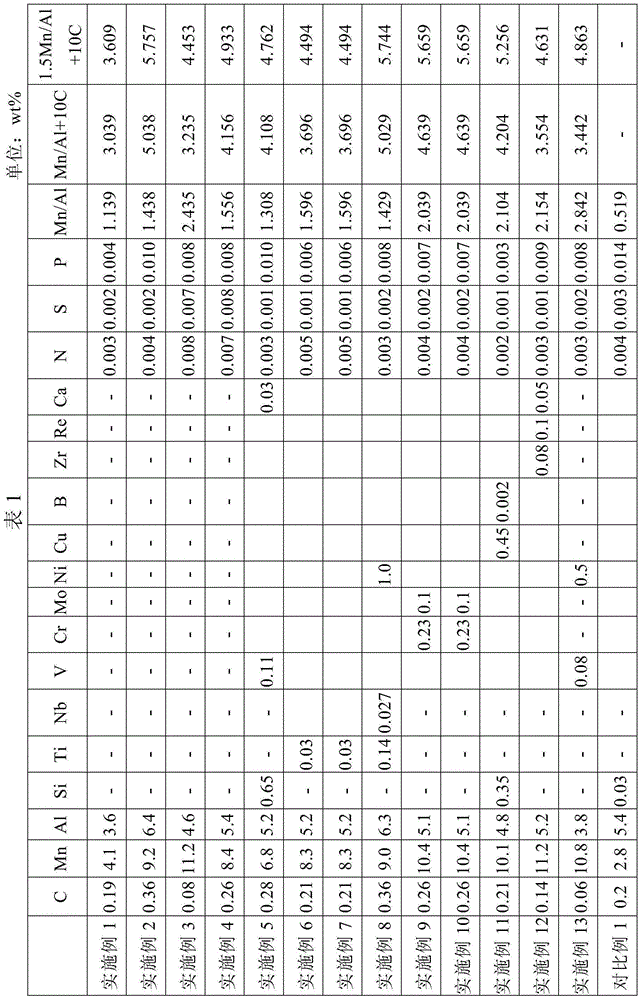

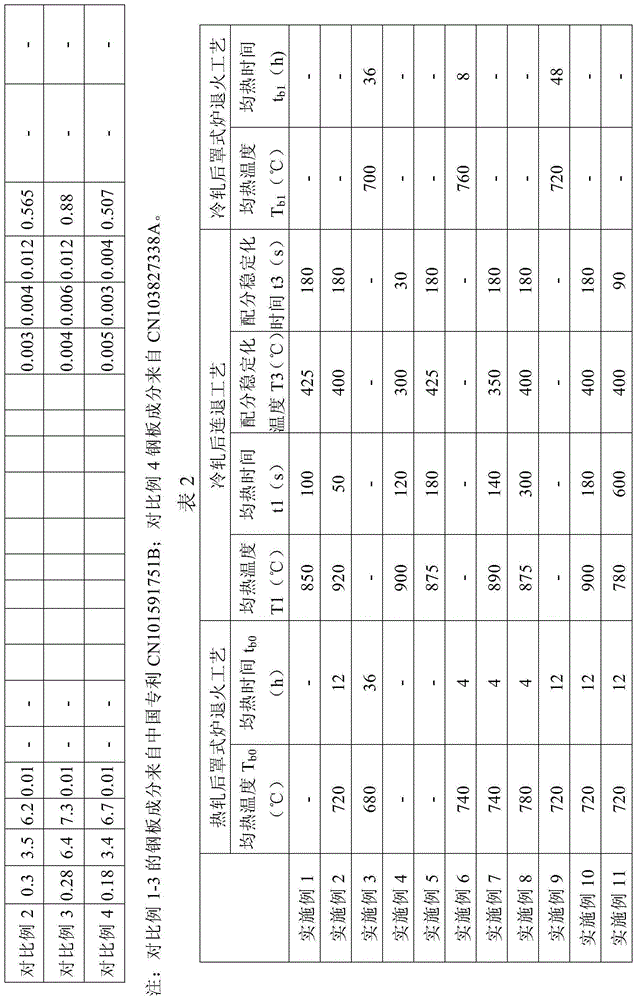

Ferrite low-density high-strength steel and manufacturing method thereof

A ferrite low-density high-strength steel and manufacturing method thereof. The ferrite low-density high-strength steel chemical comprises the following chemical components composition by mass percentage: 0.05-0.40% of C, 4.0-12.0% of Mn, 3.0-7.0% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.01% of N, and the balance of Fe and inevitable impurity elements. The above elements satisfy the following relationship: 1.0<Mn / Al, 3.5 <1.5Mn / Al+10C, and Mn / Al + 10C <5.2 The manufacturing method comprises hot rolling, annealing, pickling, cold rolling and annealing to prepare the low-density high-strength steel plate. In addition to ferrite, the microstructure of the steel plate also contains 6-40% of residual austenite. The low-density high-strength steel plate has tensile strength no less than 800MPa, elongation no less than 25%, and density less than 7500kg / m<3>.

Owner:BAOSHAN IRON & STEEL CO LTD

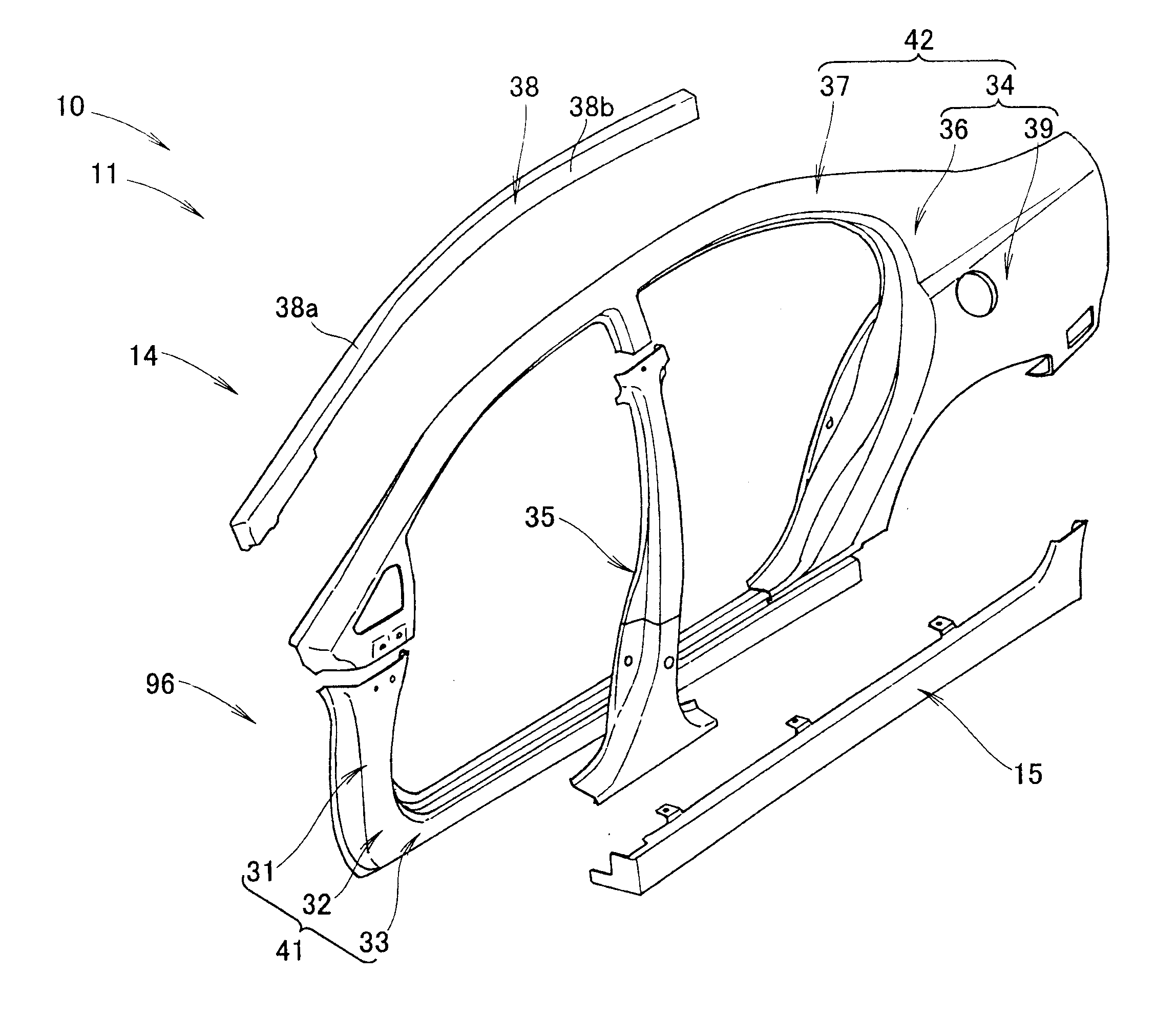

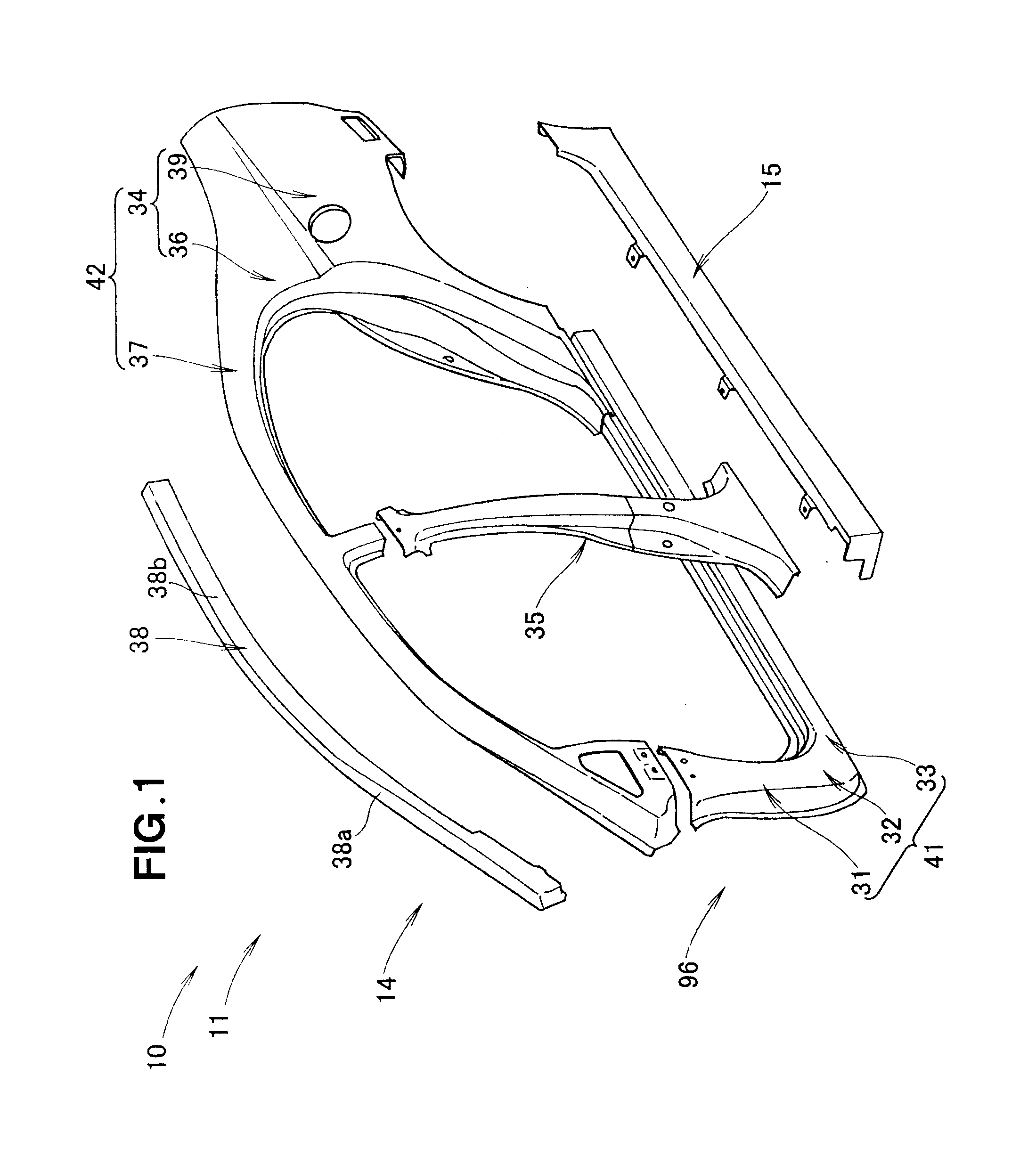

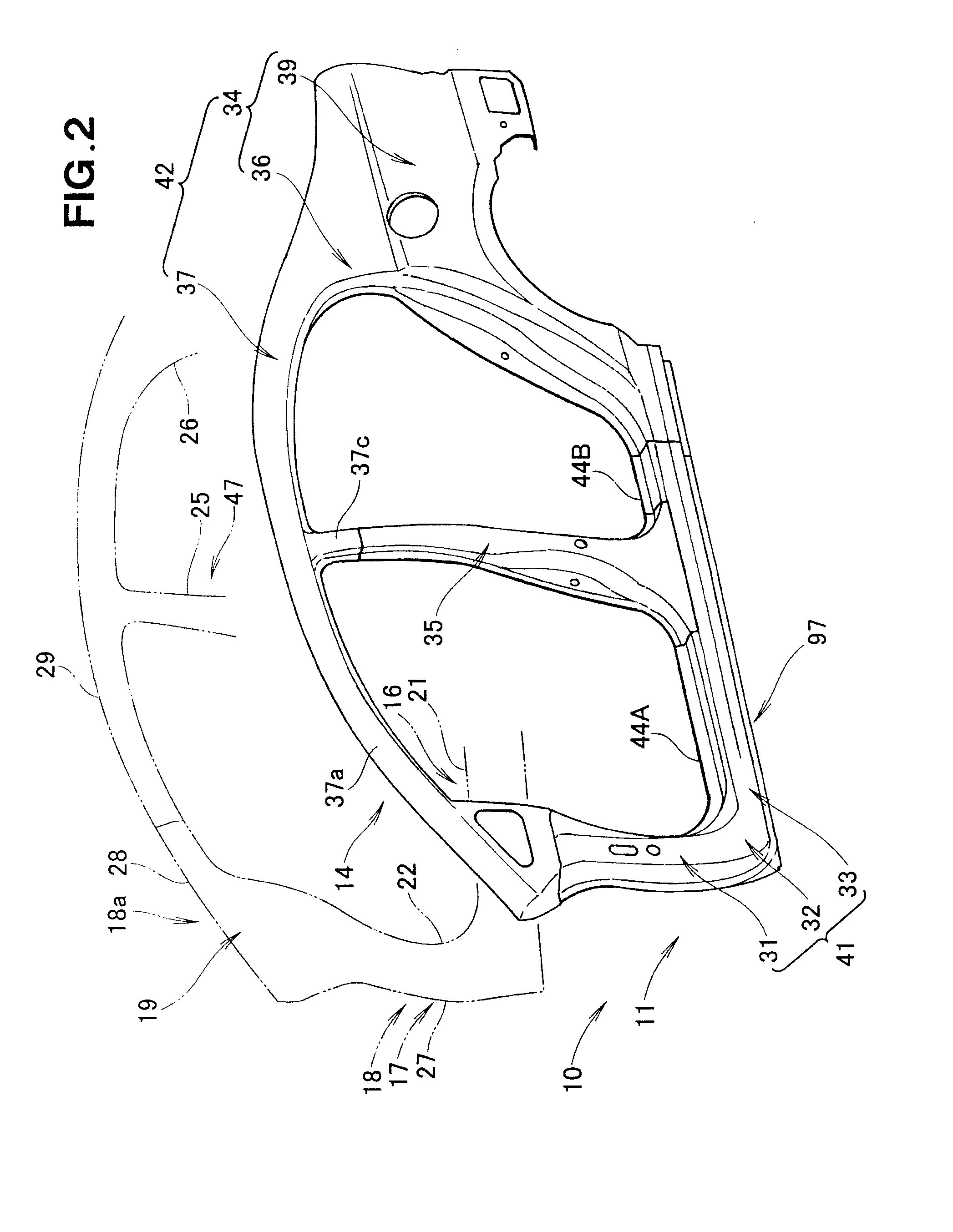

Vehicle side body structure

ActiveUS20110233970A1Reduce weightGood lookingVehicle seatsSuperstructure subunitsSteel platesHigh intensity

Owner:HONDA MOTOR CO LTD

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

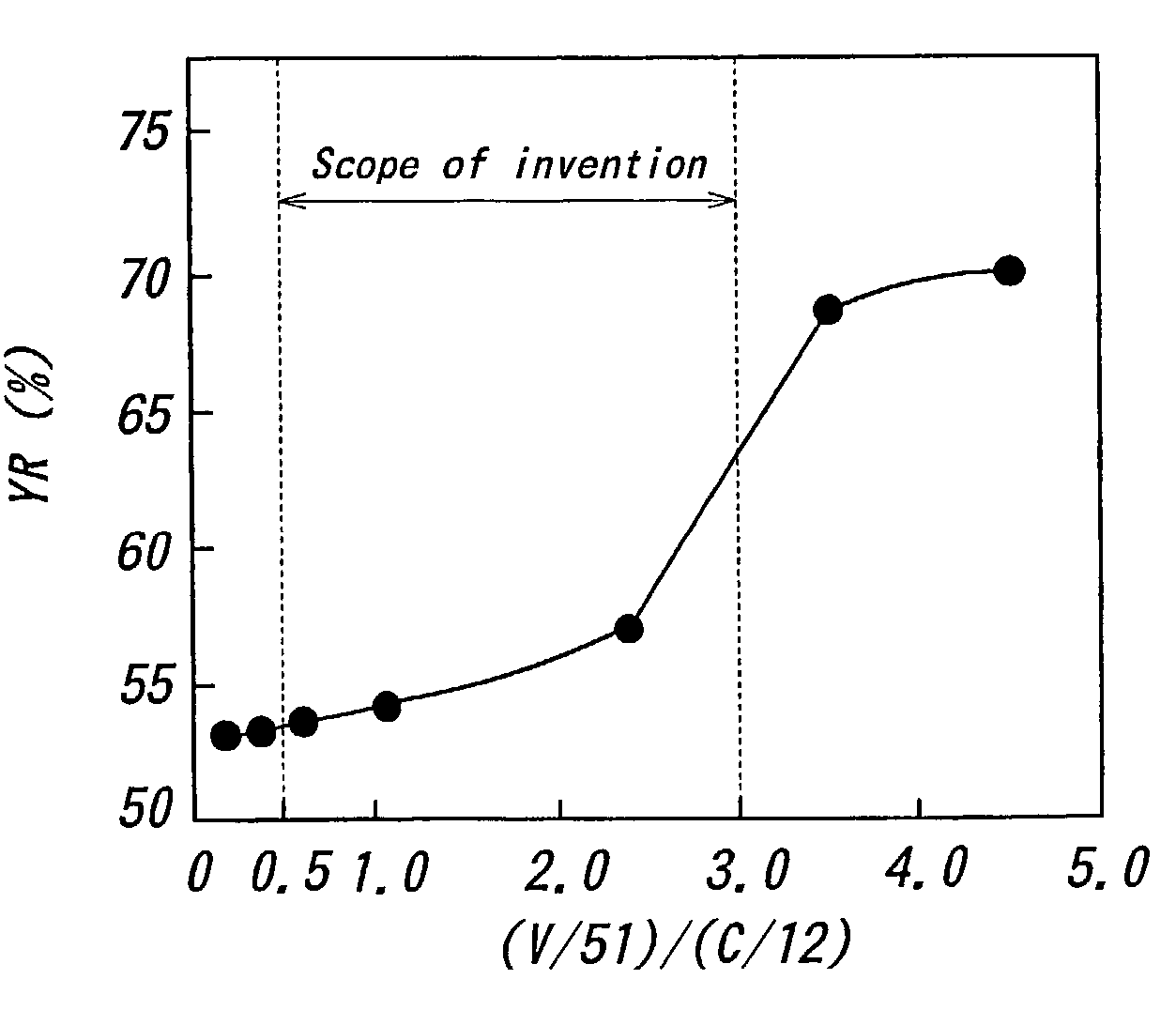

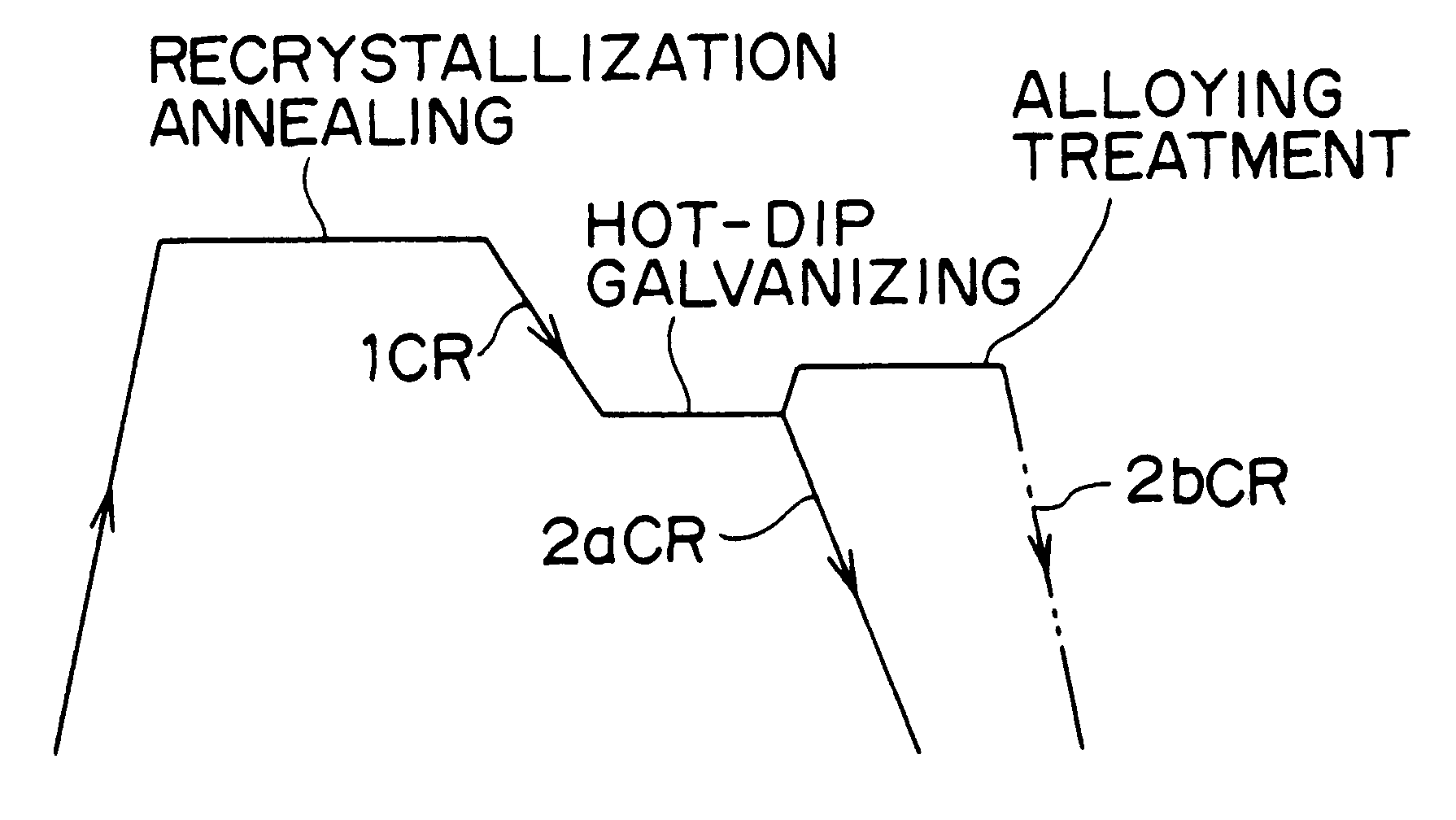

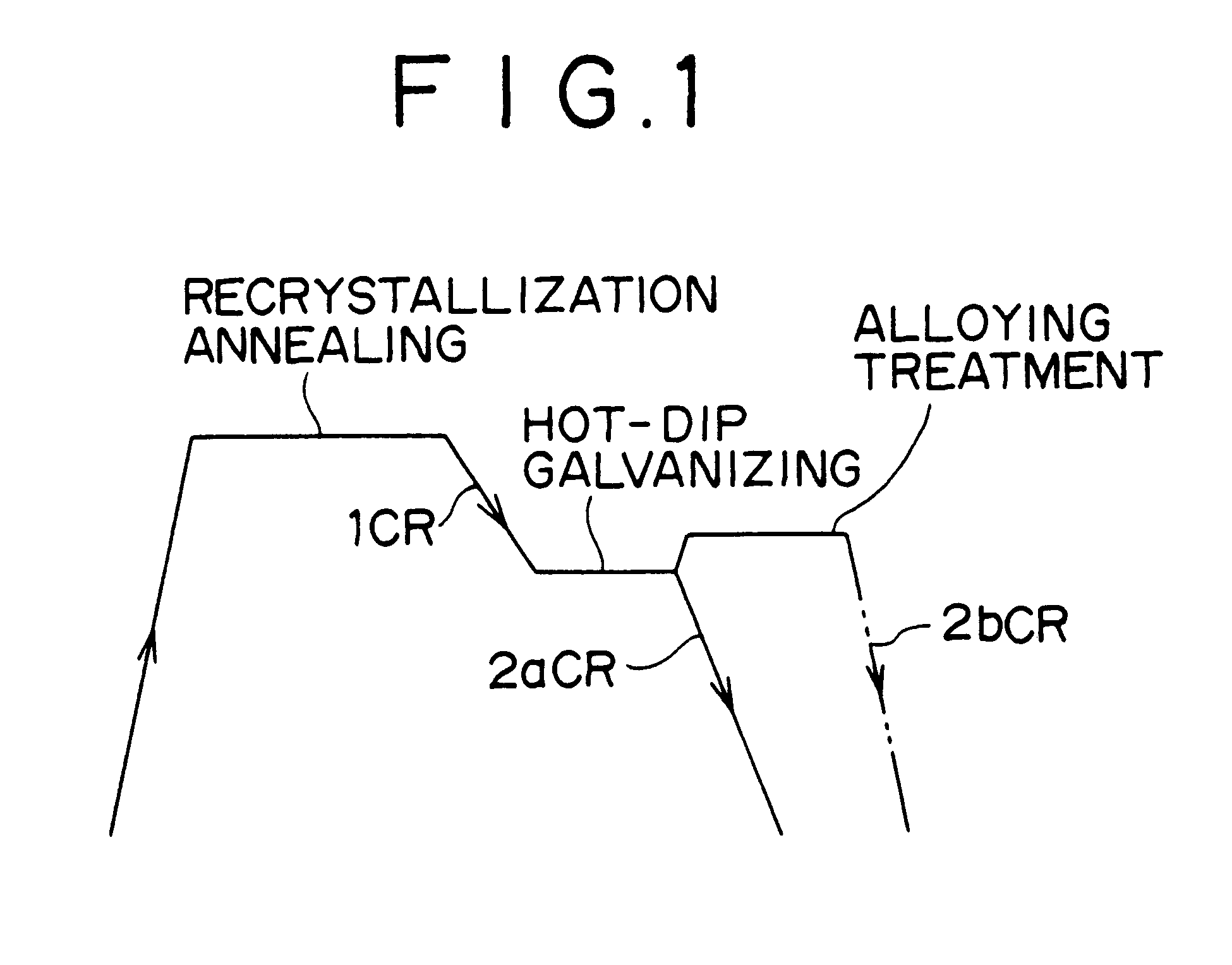

Composite structure type high tensile strength steel plate, plated plate of composite structure type high tensile strength steel and method for their production

InactiveUS20030129444A1Lower yield stressImprove ductilityHot-dipping/immersion processesThin material handlingSheet steelHigh intensity

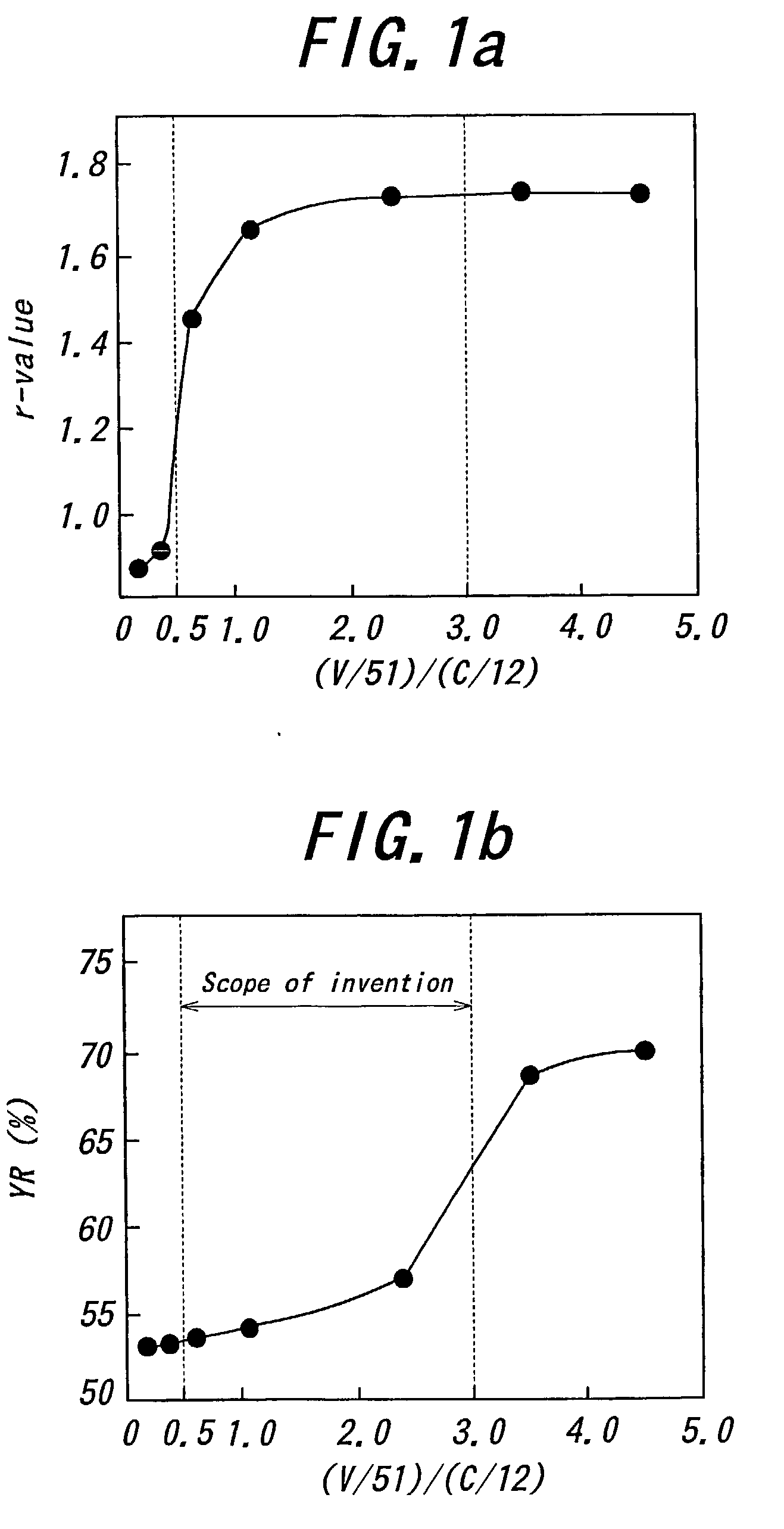

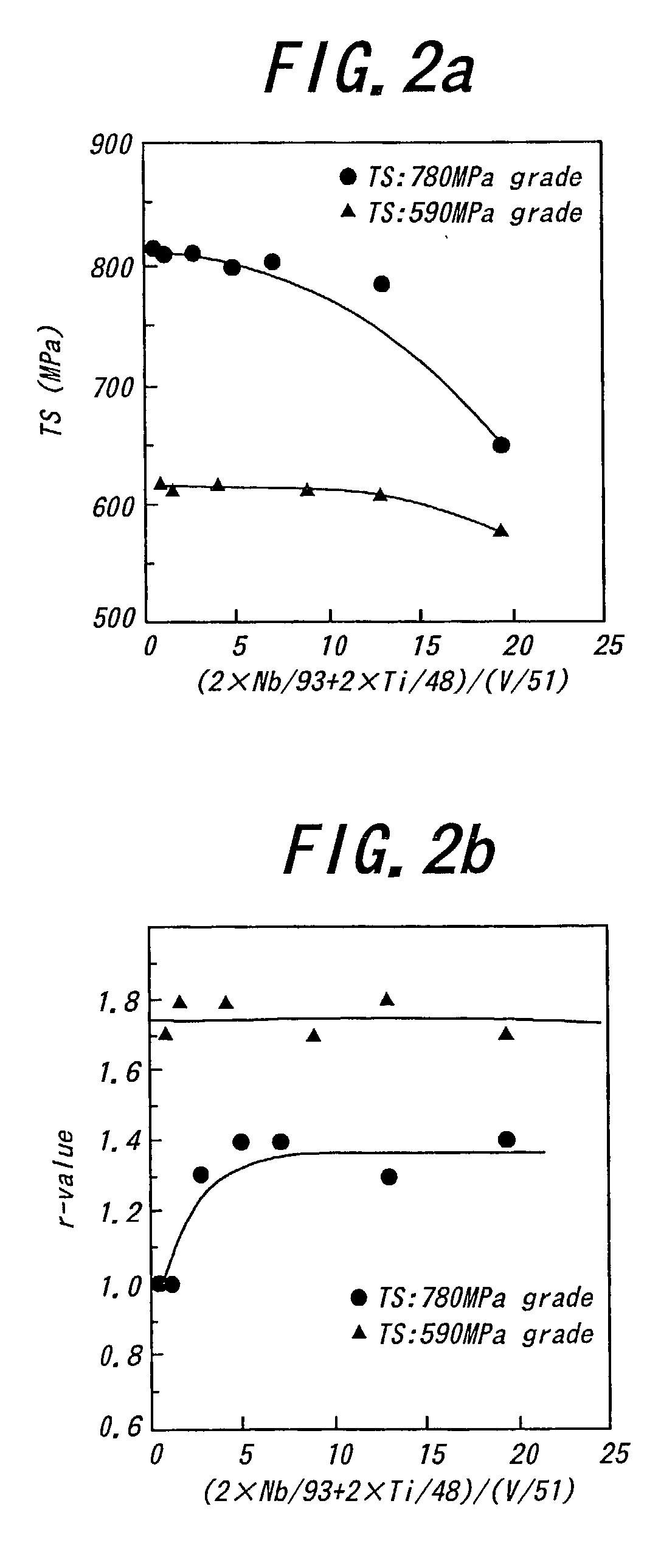

The invention proposes a high-strength dual-phase cold rolled steel sheet having an excellent deep drawability, wherein the steel sheet has a composition comprising C: 0.01-0.08 mass %, Si: not more than 2.0 mass %, Mn: not more than 3.0 mass %, P: not more than 0.10 mass %, S: not more than 0.02 mass %, A1: 0.005-0.20 mass %, N: not more than 0.02 mass % and V: 0.01-0.5 mass %, provided that V and C satisfy a relationship of 0.5xC / 12<=V / 51<=3xC / 12, and the remainder being Fe and inevitable impurities, and has a microstructure consisting of a ferrite phase as a primary phase and a secondary phase including martensite phase at an area ratio of not less than 1% to a whole of the microstructure and a high-strength dual-phase galvanized steel sheet comprising a galvanized coating on the above steel sheet as well as a method of producing the same.

Owner:JFE STEEL CORP

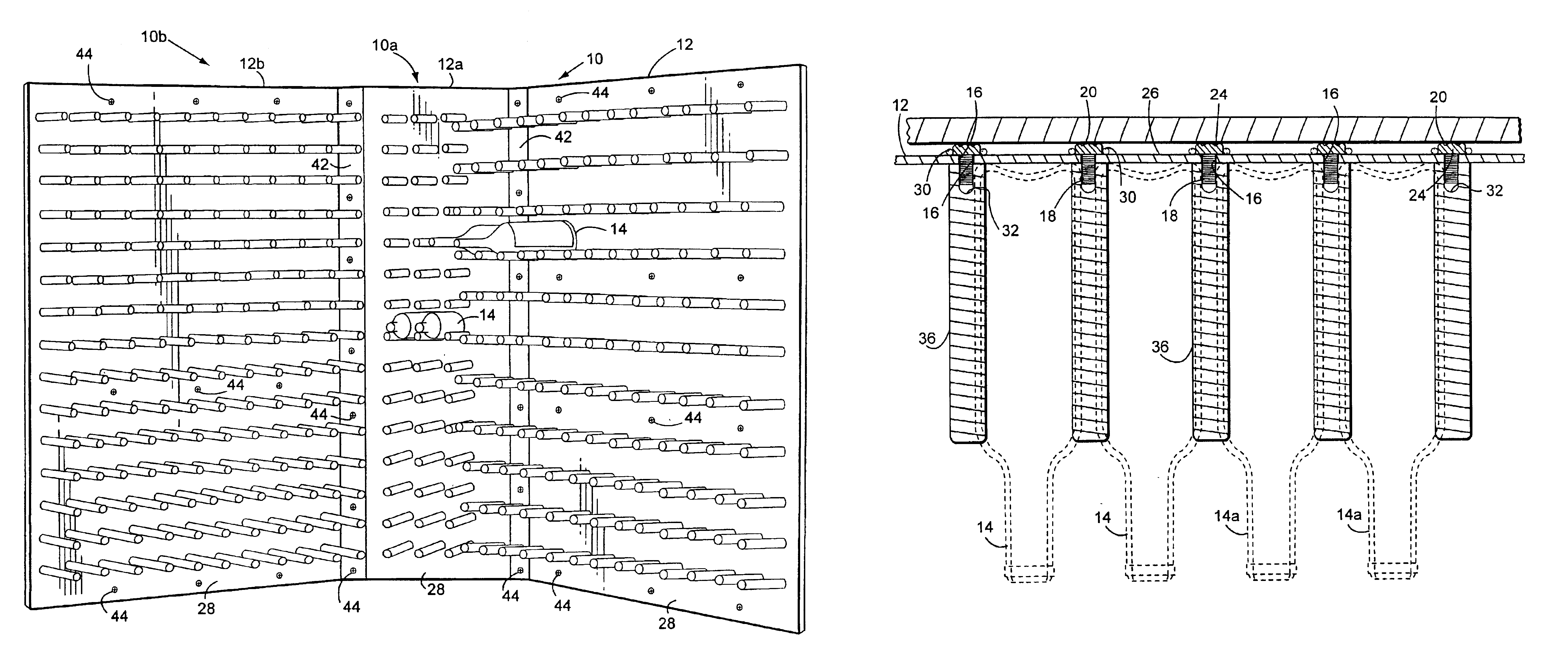

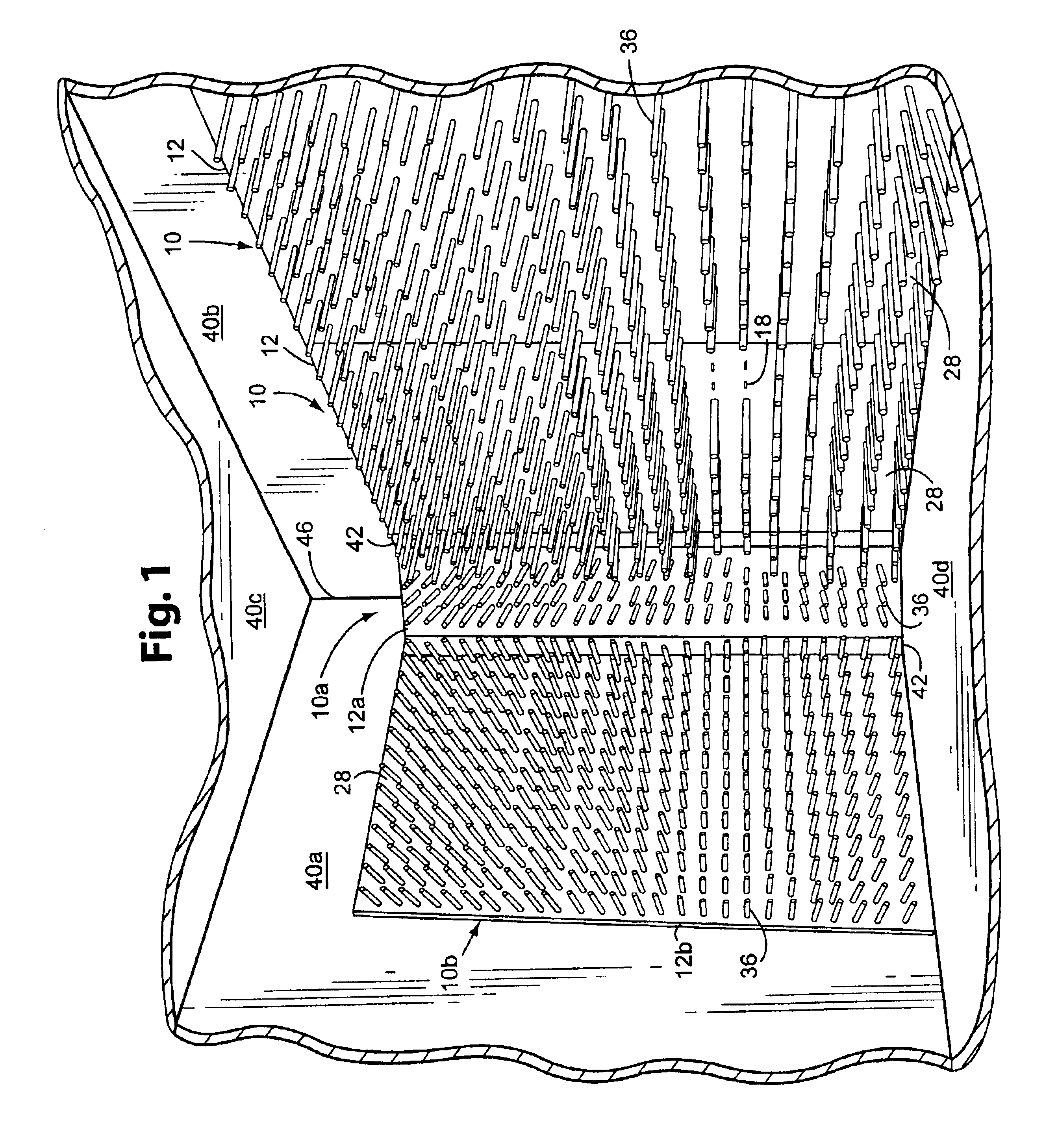

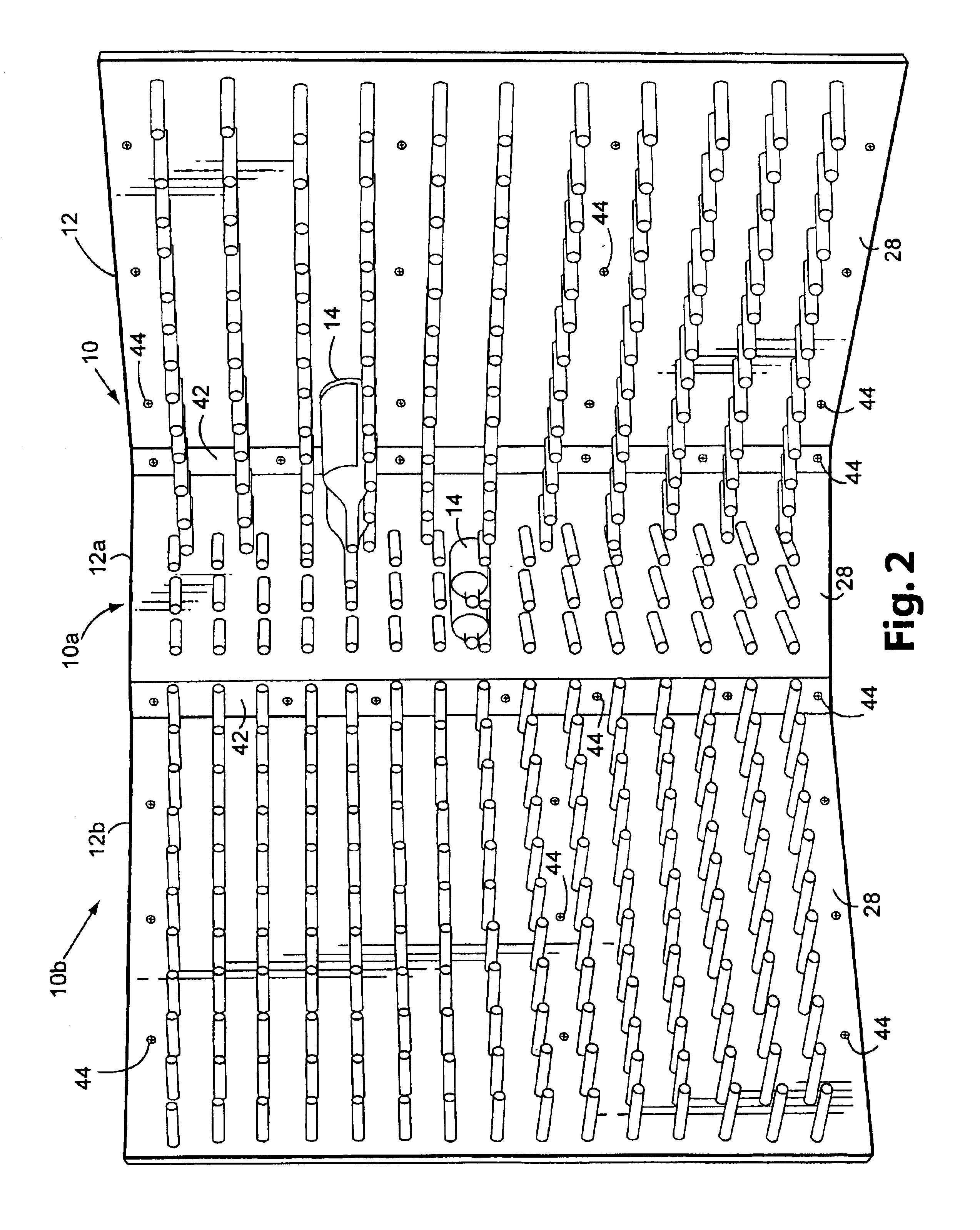

Wine rack and kit and method for its onsite assembly

InactiveUS6763956B2Readily and economically and expeditiously fabricated offsiteAssembled inexpensively and rapidlyBottle cupboardsFolding cabinetsSheet steelShortest distance

Disclosed is a wine rack, large versions of which are adapted to be installed against a wall of a room or as a free standing wall separated from the walls of a room, which is a monolithic flat rigid sheet to which has uniformly mounted in rows through holes therein a like number of wine bottle support rods which project perpendicularly and parallel to each other from one or both faces of the sheet so that two wine bottles of varying sidewall diameter can be stored on three of the rods without their side-walls touching and whose essential elements can be fabricated offsite by forming uniform rows of holes in a monolithic sheet of stainless steel; fitting in the holes machine bolts whose threaded shank ends project beyond a face of the steel sheet; bonding the heads of the bolts to the opposite face of the steel sheet so that their threaded ends project axially perpendicularly, rigidly and parallel to each other; and forming a female threaded cavity in one end of a plurality of wine bottle support rods. The thus-fabricated structural parts of the wine rack are then transported to the installation site, where the rods are coupled to the projecting ends of the bolts. A plurality of the thus-fabricated wine rack are mounted side-by-side vertically on a wall of a room at the installation site or one of them can be installed as free standing version which is stabilizing from bending or swaying at its base. A free standing version with wine bottle support rods projecting from both faces thereof can similarly be produced using short lengths of threaded steel rods which, when inserted in the holes in the steel sheet, its ends project a short distance beyond each face of the steel sheet so that the internally female threaded ends wine bottle support rods can be mounted on both ends thereof.

Owner:WOODS DANIEL

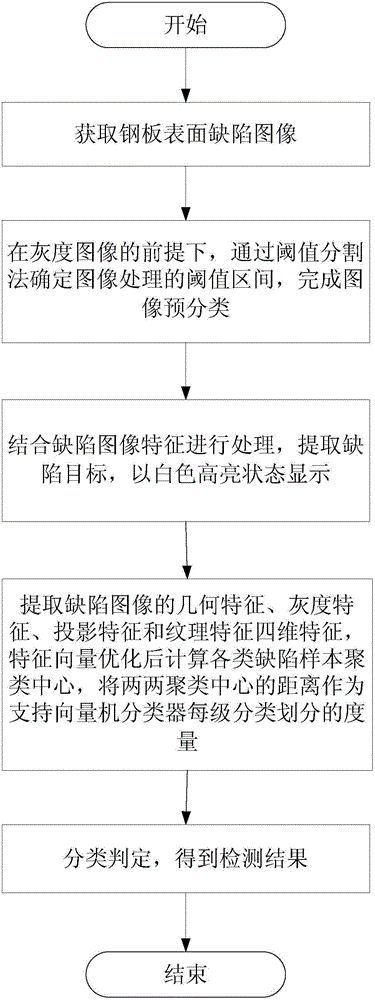

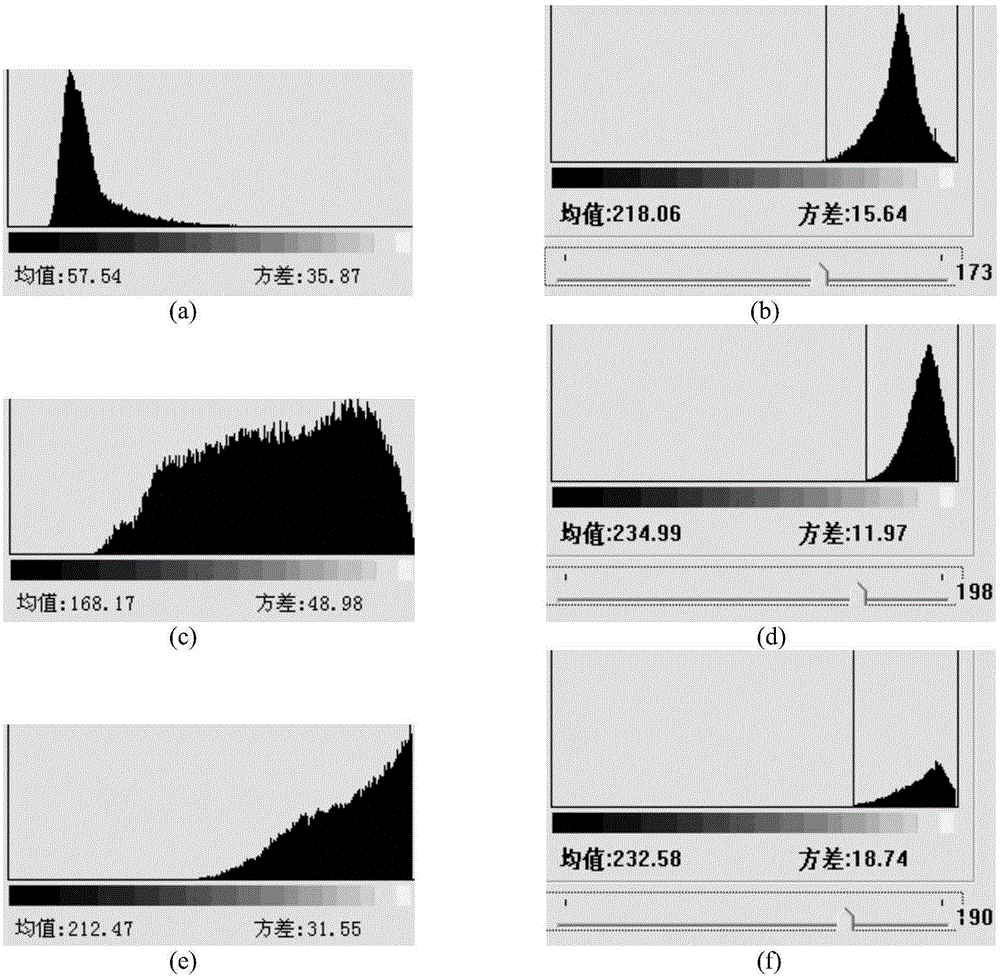

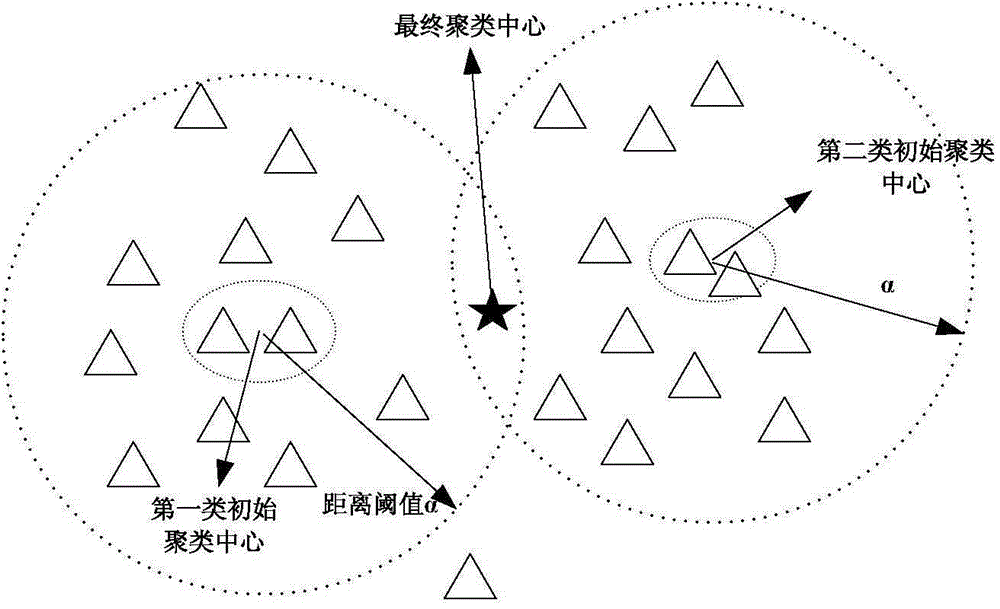

Fuzzy clustering steel plate surface defect detection method based on pre classification

InactiveCN104794491AFast classificationImprove accuracyImage analysisCharacter and pattern recognitionGray levelDimensionality reduction

The invention relates to the technical field of digital image processing and pattern recognition, discloses a fuzzy clustering steel plate surface defect detection method based on pre classification and aims to overcome defects of judgment missing and mistaken judgment by the existing steel plate surface detection method and improve the accuracy of steel plate surface defect online real-time detection effectively during steel plate surface defect detection. The method includes the steps of 1, acquiring steel plate surface defect images; 2 performing pre classification on the images acquired through step 1, and determining the threshold intervals of image classification; 3, classifying images of the threshold intervals of the step 2, and generating white highlighted defect targets; 4, extracting geometry, gray level, projection and texture characteristics of defect images, determining input vectors supporting a vector machine classifier through characteristic dimensionality reduction, calculating the clustering centers of various samples by the fuzzy clustering algorithm, and adopting the distances of two cluster centers as scales supporting the vector machine classifier to classify; 5, determining classification, and acquiring the defect detection results.

Owner:CHONGQING UNIV

Hot-dip galvanized steel sheet and process for production thereof

InactiveUS6306527B1Ductility deterioratesImprove ductilityHot-dipping/immersion processesLiquid surface applicatorsHot-dip galvanizationDuctility

A hot-dip galvanized steel sheet which is produced from a cold-rolled steel sheet, as a base steel sheet, consisting essentially of C: 0.010-0.06 wt %, Si: no more than 0.5 wt %, Mn: no less than 0.5 wt % and less than 2.0 wt %, P: no more than 0.20 wt %, S: no more than 0.01 wt %, Al: 0.005-0.10 wt %, N: no more than 0.005 wt %, Cr: no more than 1.0 wt %, Mn+1.3Cr: 1.9-2.3 wt %, Fe: remainder, and having a structure composed of ferrite and a second phase containing martensite, said second phase in the structure accounting for no more than 20% in terms of area and martensite in the second phase accounting for no less than 50%, and which has a zinc-plated layer formed on the surface thereof by hot-dip galvanizing or hot-dip galvannealing. A process for production of said hot-dip galvanized steel sheet. This steel sheet has a composite structure containing martensite and yet it has a low strength (no higher than 500 MPa) and also has good strength-ductility balance.

Owner:KOBE STEEL LTD

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

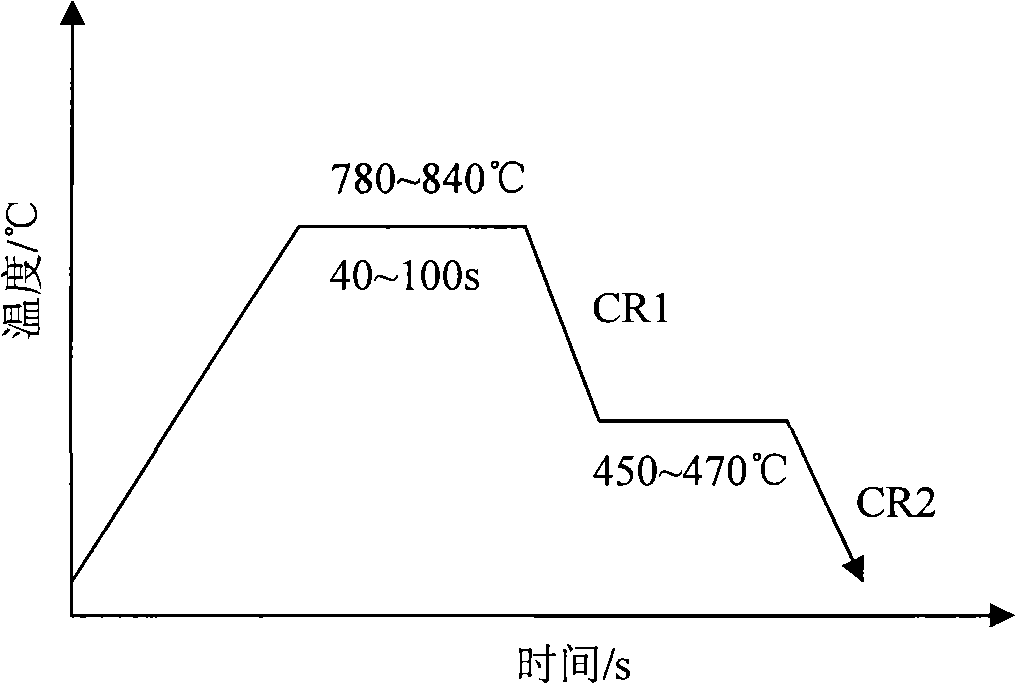

1000MPa grade cold rolling hot dip galvanizing two-phase steel and manufacturing method thereof

The invention provides 1,000 MPa cold-rolled hot-dip galvanized dual-phase steel and a manufacturing method thereof, belonging to the technical field of cold-rolled hot-dip galvanized high-strength steel plates. The chemical components in mass percentage of the cold-rolled hot-dip galvanized dual-phase steel are: 0.06 to 0.18 percent of C, less than or equal to 0.1 percent of Si, 1.2 to 2.5 percent of Mn,0.05 to 0.5 percent of Mo, 0.05 to 0.6 percent of Cr, 0.005 to 0.05 percent of Al, 0.01 to 0.06 percent of Nb, 0.01 to 0.05 percent of Ti, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.005 percent of N, the balance being Fe and inevitable impurities. The manufacturing method adopts Cr or Mo to replace Si, so as to enlarge an austenitic and ferritic two-phase region and improve the hardenability of the dual-phase steel, and meanwhile, the manufacturing method improves the strength of toughness of the steel by adding Nb or Ti refined grains, so as to ensure that the steel has good weldability and usability, and the strength grade of the steel can reach over 1,000 Mpa.

Owner:UNIV OF SCI & TECH BEIJING +1

Weather resistant thick steel plate and manufacturing method thereof

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

All-weather clean energy comprehensive electricity generating and energy saving method and facility manufacturing method thereof

InactiveCN104295448AHigh light transmittanceImprove efficiencyWind motor with solar radiationGeneral water supply conservationNew energyTransmitted power

The invention discloses an all-weather clean energy comprehensive electricity generating and energy saving method and a facility manufacturing method. In ten inventions, having at least one identical or corresponding specific technical characteristic and related to the total inventive concept, of solar gallery buildings, through graphene series facilities under solar gallery buildings, in a land field, a zero-carbon environment-friendly safe type raft-shaped basic-framed-tube-structured huge building group of a universal wind energy tower shape is established and new energy automobiles and trains are manufactured, wherein cheap wind power solids are established, photoelectric benzene expansion optical fibers are manufactured, lightning is utilized firstly for supplying power externally, various spaces are shared through building three-dimensional afforesting, and three-dimensional energy collection is achieved; in a water field, deep water self-floating buildings of a super steel concrete frame-tube structure (preferably, complete steel plates are adopted) are built, the deep water self-floating buildings are connected in series to form a global ocean water and electricity and agriculture and forestry extraction traffic network and a large lake and reservoir water and electricity and agriculture and forestry dredging dam water level traffic network, wherein the deep water automatic floating buildings are free of influences of earthquakes, tsunamis and wars, the Red Cross can rescue people in all-weather conditions; in a space field, multiple receiving and transmitting solar towers are first established on the equator of the earth and the equator of the moon, the receiving and transmitting solar towers are connected in series to operate in a timed mode in the specific direction and transmit power to the whole world through graphene cables which are all packaged with colored insulating films.

Owner:熊凌云 +6

HIGH STRENGTH STEEL PLATE WITH ULTIMATE TENSILE STRENGTH OF 900 MPa OR MORE EXCELLENT IN HYDROGEN EMBRITTLEMENT RESISTANCE AND METHOD OF PRODUCTION OF SAME

ActiveUS20120222781A1Reduce resistanceImprove plasticityHot-dipping/immersion processesSurface reaction electrolytic coatingCarbideUltimate tensile strength

High strength steel plate with an ultimate tensile strength of 900 MPa or more which is excellent in hydrogen embrittlement resistance characterized in that, in the structure of the steel plate, (a) by volume fraction, ferrite is present in 10 to 50%, bainitic ferrite and / or bainite in 10 to 60%, and tempered martensite in 10 to 50%, and (b) iron-based carbides which contain Si or Si and Al in 0.1% or more are present in 4×108 (particles / mm3) or more.

Owner:NIPPON STEEL CORP

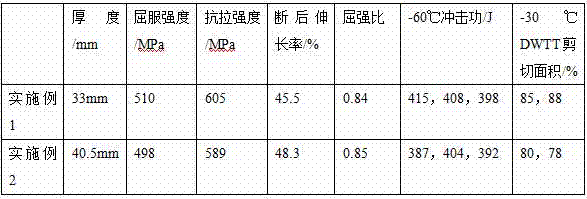

Extra-thick specification economical X70 pipeline steel plate used in ultra-low temperature environment and manufacturing method thereof

ActiveCN107502821AIncrease pass reduction rateFully refine the grain sizeChemical compositionUltimate tensile strength

The invention relates to an extra-thick specification economical X70 pipeline steel plate used in an ultra-low temperature environment. The steel plate comprises the following chemical components in percentages by mass: 0.02-0.08% of C, 0.2-0.4% of Si, 0.9-1.7% of Mn, 0.02-0.04% of Al, 0.02-0.08% of Nb, less than or equal to 0.05% of V, less than or equal to 0.2% of Cr, less than or equal to 0.2% of Ni, less than or equal to 0.1% of Mo, less than or equal to 0.2% of Cu, 0.01-0.02% of Ti, less than or equal to 0.0005% of B, less than or equal to 0.006% of P, less than or equal to 0.001% of Si, less than or equal to 0.002% of N, less than or equal to 0.0012% of O, less than or equal to 0.0001% of H, less than or equal to 100 ppm of P+S+[N]+[O]+[H], less than or equal to 0.19% of Pcm and the balance Fe and inevitable impurities. By means of a great compression ratio rolling technology, the effect of refined grains is intensified, strength and toughness loss caused by reduction of alloy elements are remedied, and the steel plate has a better economical benefit.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com