Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14360 results about "Continuous casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots. Since then, "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency. It allows lower-cost production of metal sections with better quality, due to the inherently lower costs of continuous, standardised production of a product, as well as providing increased control over the process through automation. This process is used most frequently to cast steel (in terms of tonnage cast). Aluminium and copper are also continuously cast.

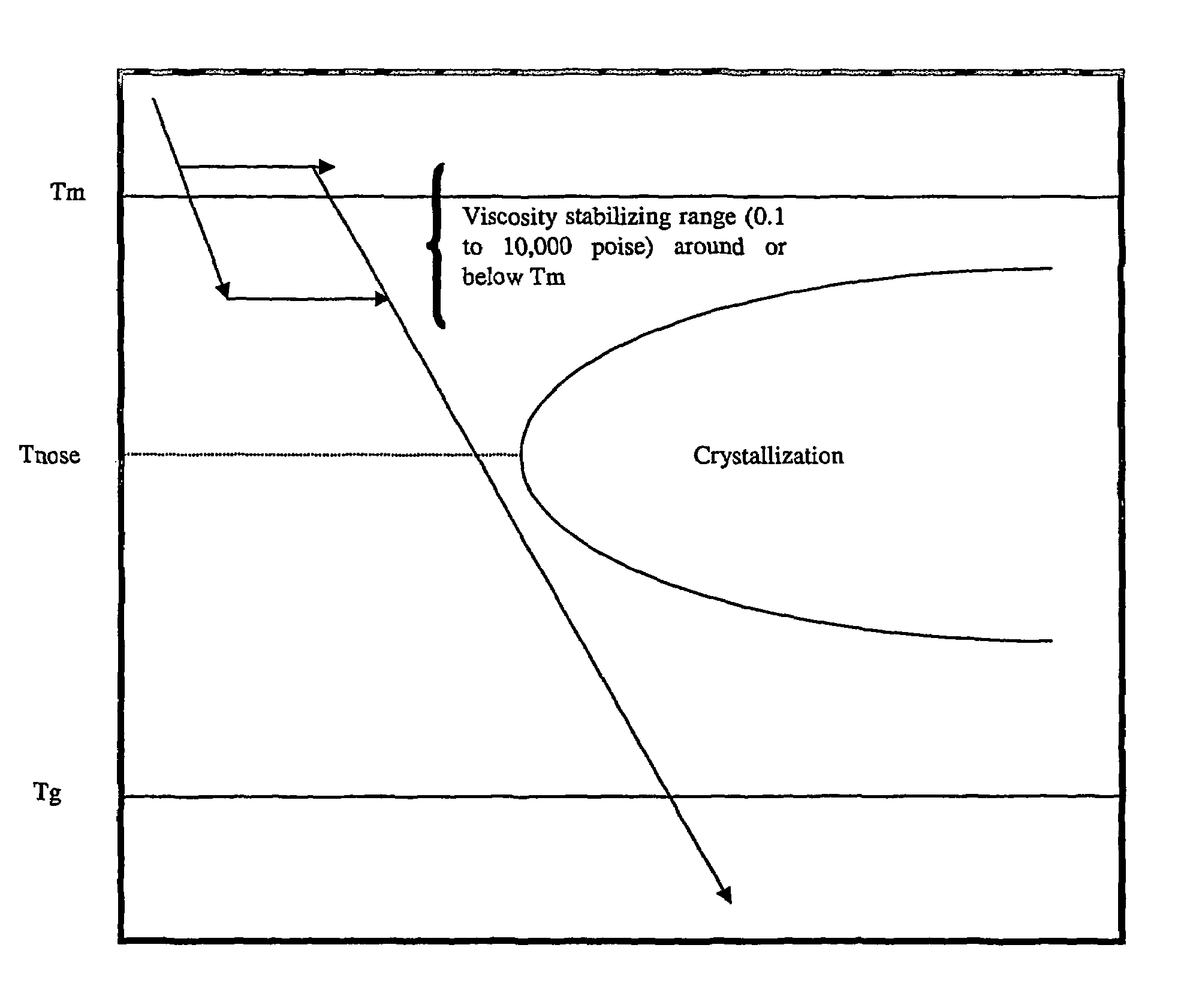

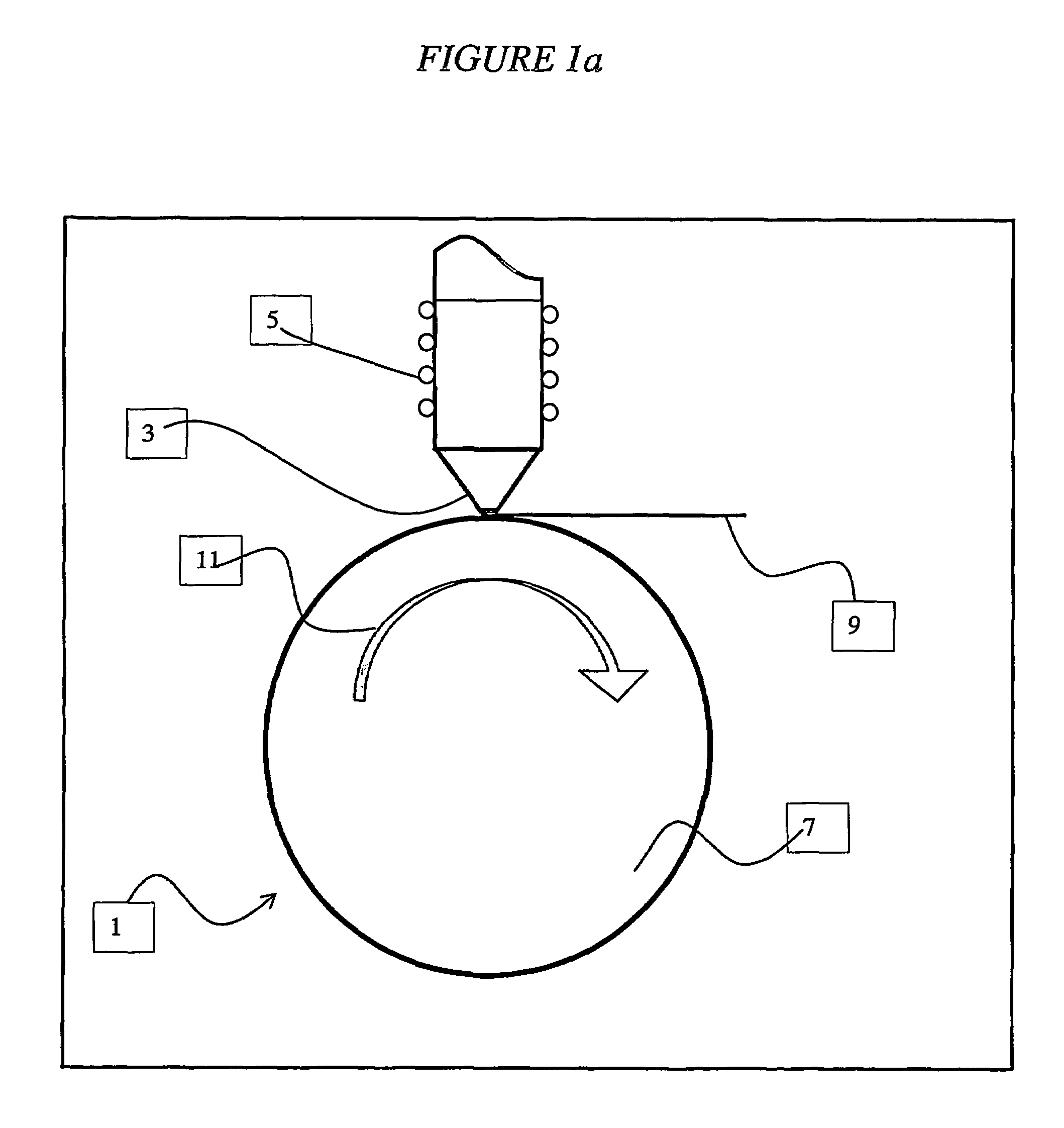

Continuous casting of bulk solidifying amorphous alloys

Owner:CRUCIBLE INTPROP LLC

Method for improving performance of 700MPa grade V-N micro-alloying high-strength weathering steel

InactiveCN101161849AImprove low temperature impact toughnessGood formabilityTemperature control deviceMetal rolling arrangementsChemical compositionHigh intensity

The invention discloses a method for improving the performance of 700 MPa grade V-N microalloyed high strength weathering steel. The method is specific to the characteristics of the sheet billet continuous casting and tandem rolling technology and metallurgy component, and adopts an electric furnace or a revolving furnace to smelt, refine, continuously cast sheet billet which directly enters into a roller hearth to heat after a casting blank concretes, or soaking furnace, hot rolling, laminar flow cooling and wind-up process flow. The chemical composition of molten steel is :C occupies less than or equal to 0.08Wt. percent, Si occupies from 0.25 to 0.75Wt. percent, Mn occupies from 0.2 to 2.0Wt.percent, P occupies less than or equal to 0.025Wt. percent, S occupies less than or equal to 0.040Wt. percent, Cu occupies from 0.25 to 0.60Wt. percent, Cr occupies from 0.30 to 1.25 Wt.percent, Ni occupies less than or equal to 0.65Wt. percent, V occupies from 0.02 to 0.20Wt. percent and N occupies from 0.015 to 0.030 Wt. percent. The invention takes full advantages of the characteristics of the sheet billet continuous casting and tandem rolling short flow process and adopts the V-N microalloyed technique to produce 700 MPa grade high strength weathering steel under the thinning function of VN and V (C, N) nanometer scale precipitate on crystal grain in casting blank of the sheet billet continuous casting and tandem rolling flow and the theory of precipitation strength. By the optimization design of the metallurgy component of V-N microalloyed 700MPa grade high strength weathering steel, the invention increases the low temperature impact ductility of coil of strip and improves the shaping property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Super-soft aluminum alloy conductor and preparation method thereof

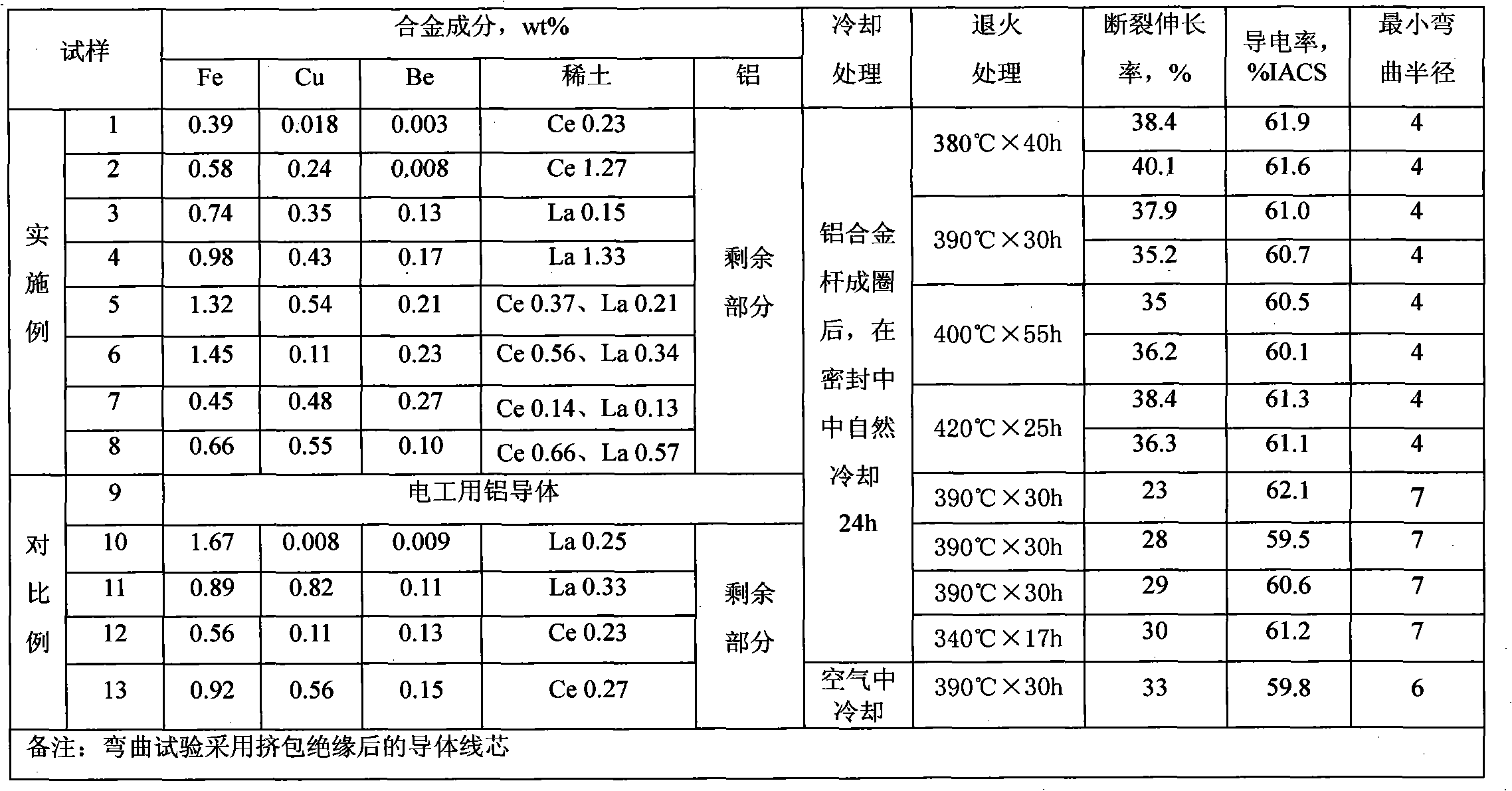

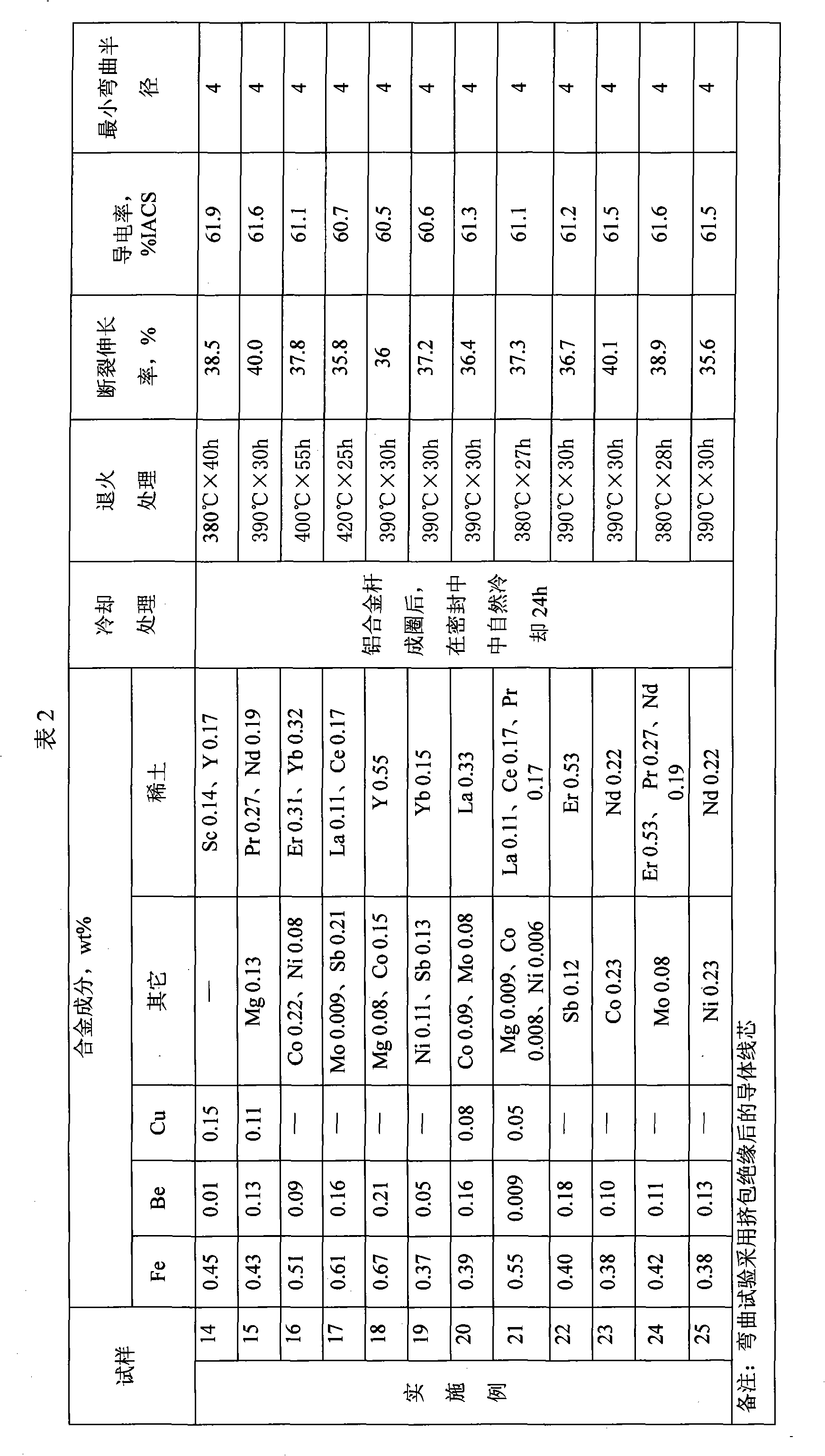

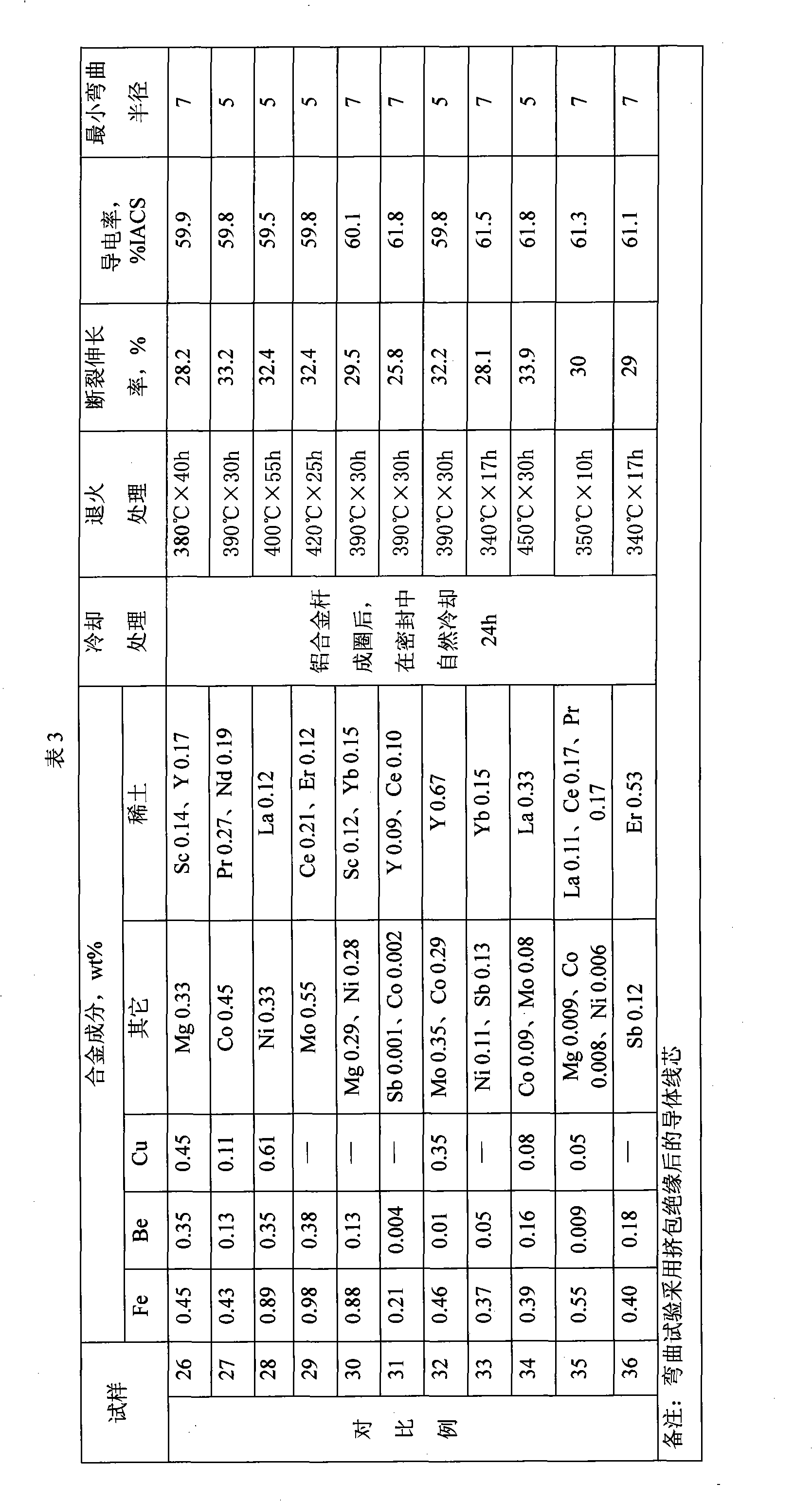

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

Production technique of copper strips for solar modules

InactiveCN101719527AHigh purityImprove conductivityFinal product manufactureSemiconductor devicesElectrolysisLiquid surfaces

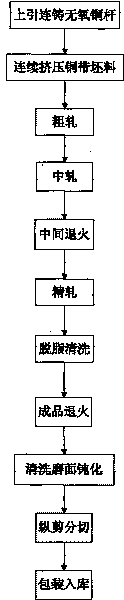

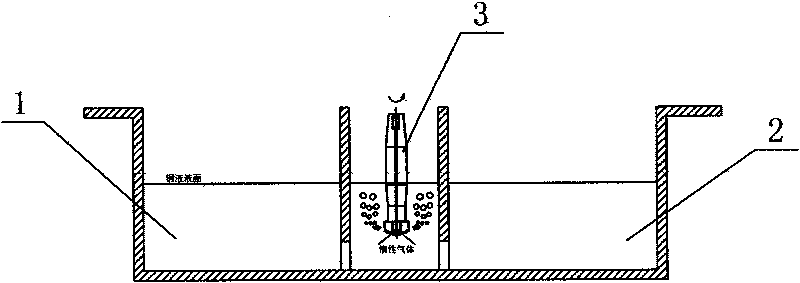

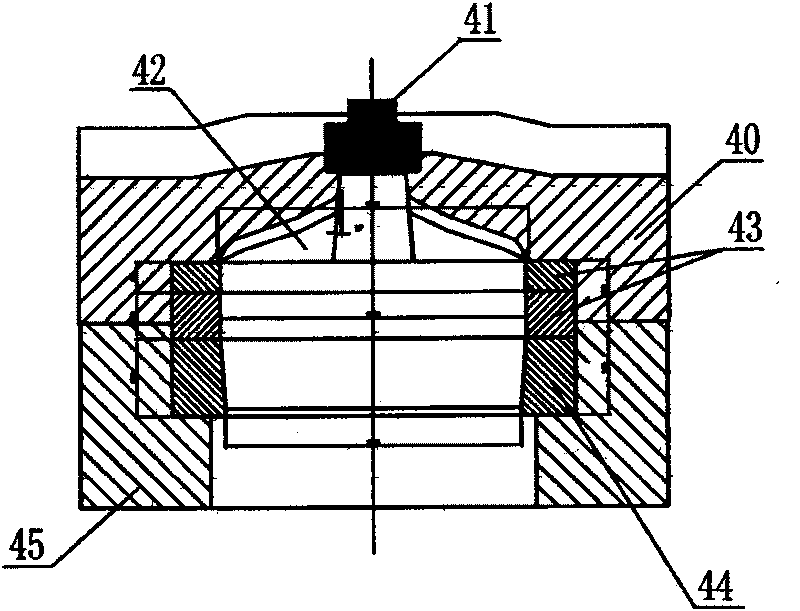

The invention discloses a production technique of copper strips for solar modules, which belongs to the technical field of nonferrous metal processing and comprises the following steps: drawing-up of continuous-casting oxygen-free copper bar: using high-quality electrolytic copper as the raw material, melting at 1150+ / -10 DEG C, keeping the temperature, covering the copper liquid surface with charcoal and graphite scales to ensure the vacuum state during melting, degassing on line, deoxidizing, stirring, and drawing up the copper bar with a tractor set in an on-off vacuum way; continuous extrusion of copper strip blanks: using oxygen-free copper rods as the raw material, producing copper strip blanks by using a continuous extruder set, cooling the extruded copper strip blanks through a vacuum oxidation-resisting pipe and a water tank, drying and coiling; and rough-rolling the copper strip blanks, medium-rolling, interstage annealing, finish rolling, degreasing, washing, annealing the finished product, washing, grinding the surface to passivate, and longitudinally cutting to obtain the finished product. The product of the invention has the advantages of high purity, low oxygen content and high electrical conductivity.

Owner:浙江力博实业股份有限公司

Method for continuous casting of steel

A method of continuous casting of a steel employs a mold power having a viscosity of 0.5-1.5 poise at 1,300° C. and a solidification temperature of 1,190-1,270° C., in which the mass ratio of CaO to SiO2 is 1.2-1.9, and casting is carried out under the following conditions: casting speed is 2.5-10 m / minute; mold oscillation stroke is 4-15 mm; and specific cooling intensity in secondary cooling of a slab is 1.0-5.0 liter / kg-steel.

Owner:SUMITOMO METAL IND LTD

High-strength cold-rolled plate with favorable forming property and preparation method thereof

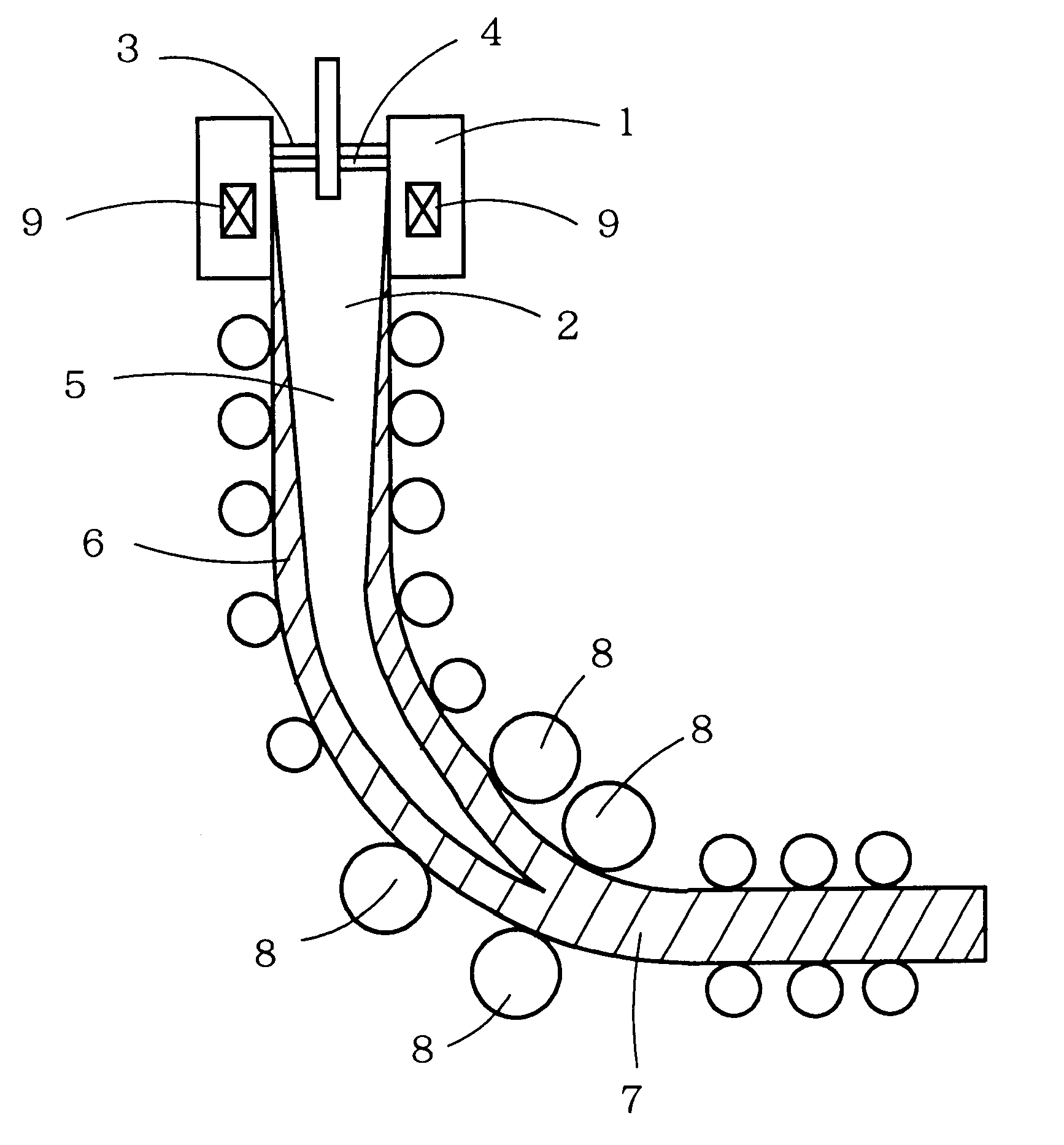

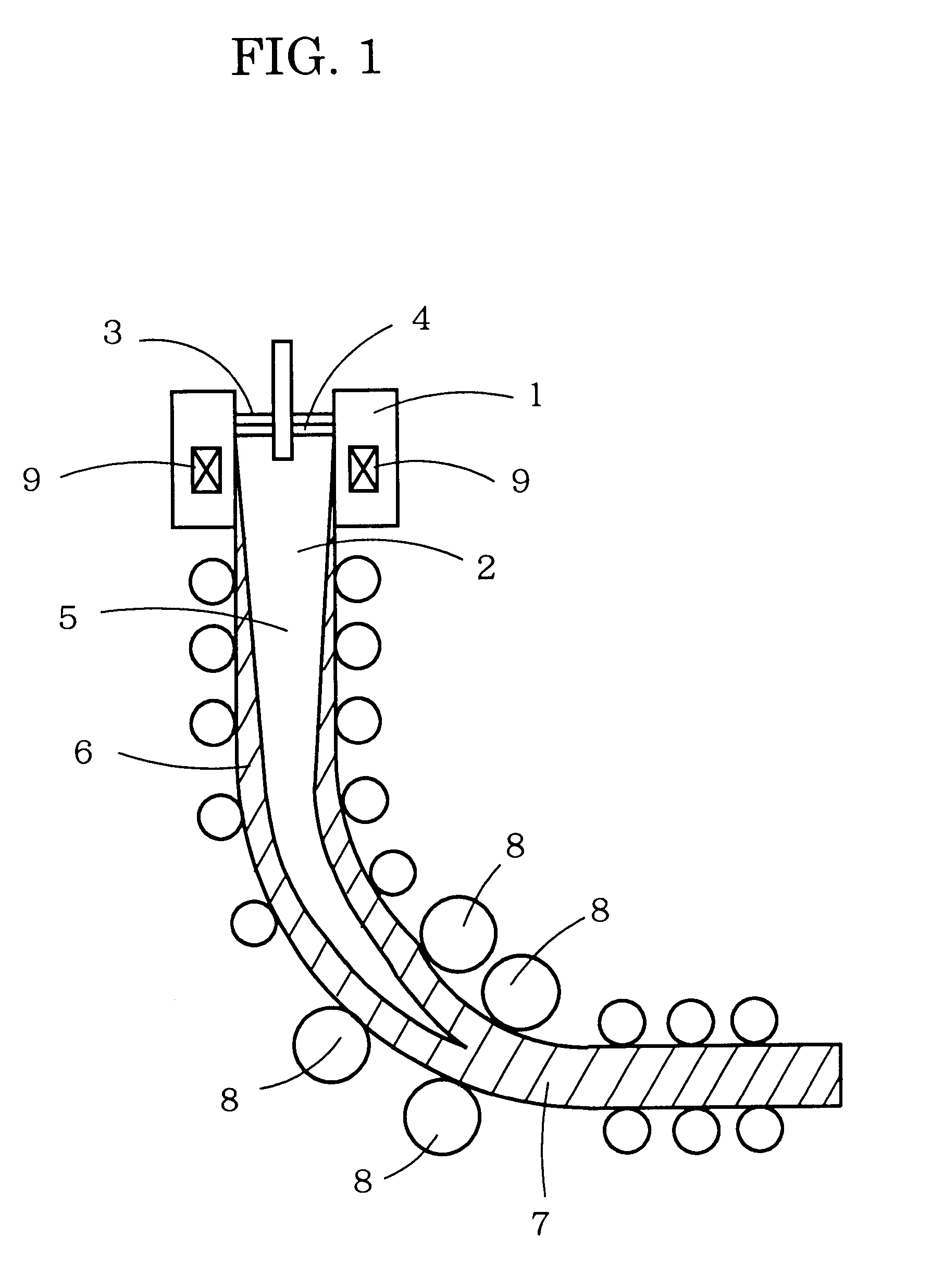

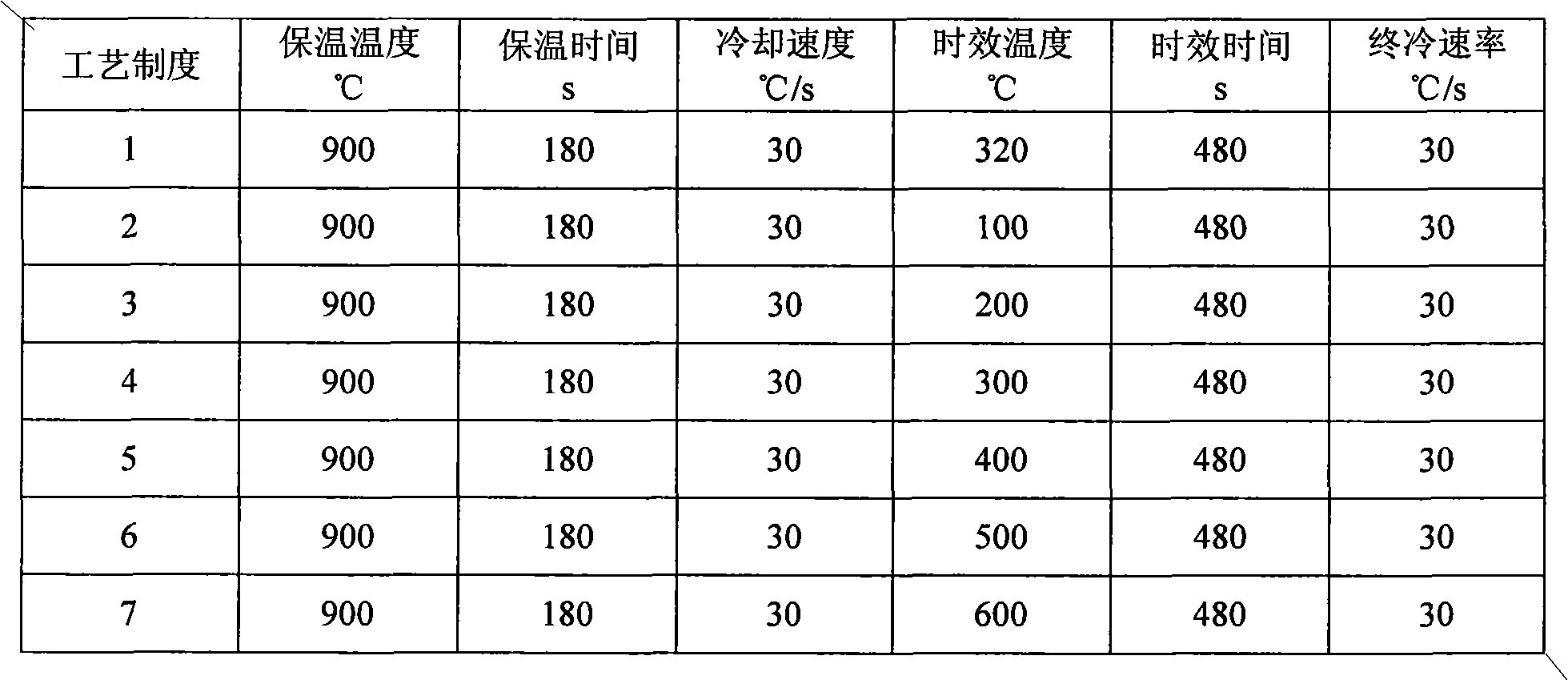

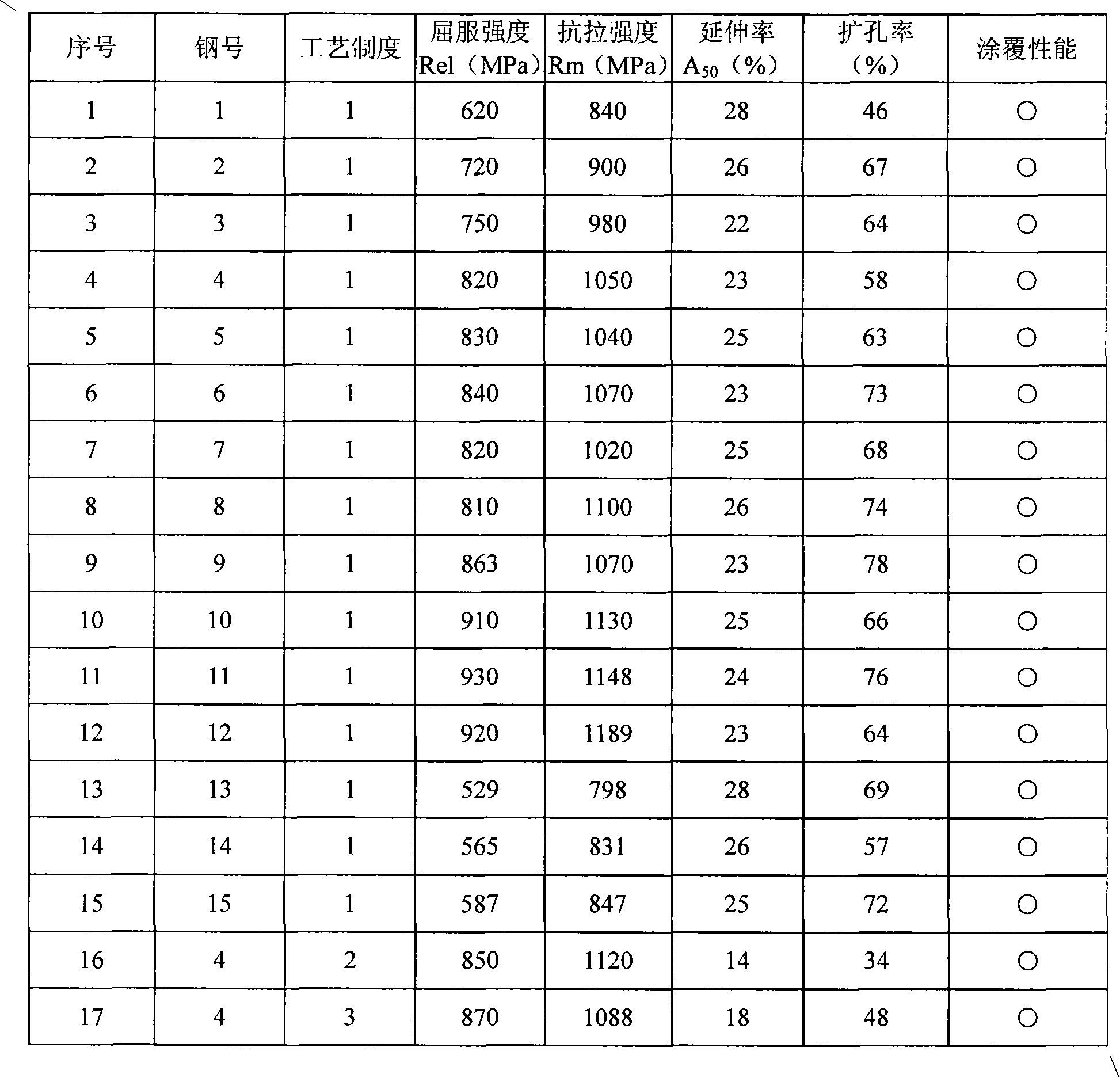

The invention provides a high-strength cold-rolled plate with favorable forming property and a preparation method thereof. The high-strength cold-rolled plate comprises the following chemical components: 0.05-0.6% of C, being more than or equal to 0.3% and being less than 0.8% of Si, 0.5-4.0% of Mn, being more than ore equal to 0.2% of P, being more than or equal to 0.002% of S, being more than or equal to 0.1% of Al, being more than or equal to 0.01% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, continuous-casting, hot-rolling, cold-rolling and continuous-annealing, wherein annealing temperature is higher than that of Ac3, holding time is 3-30 minutes; quickly cooling to 100-600 DEG C at the rate of 30-100 DEG C / s, keeping the temperature for 3-30 minutes, and finally cooling to room temperature at the rate of 5-30 DEG C / s. The invention adopts low-silicon low-aluminum component design and heat treatment technique; the strength level of the produced bainite TRIP steel is greater than 780 MPa; and the produced bainite TRIP steel has favorable strength, plasticity, extensibility, chambering property and coating property.

Owner:ANGANG STEEL CO LTD

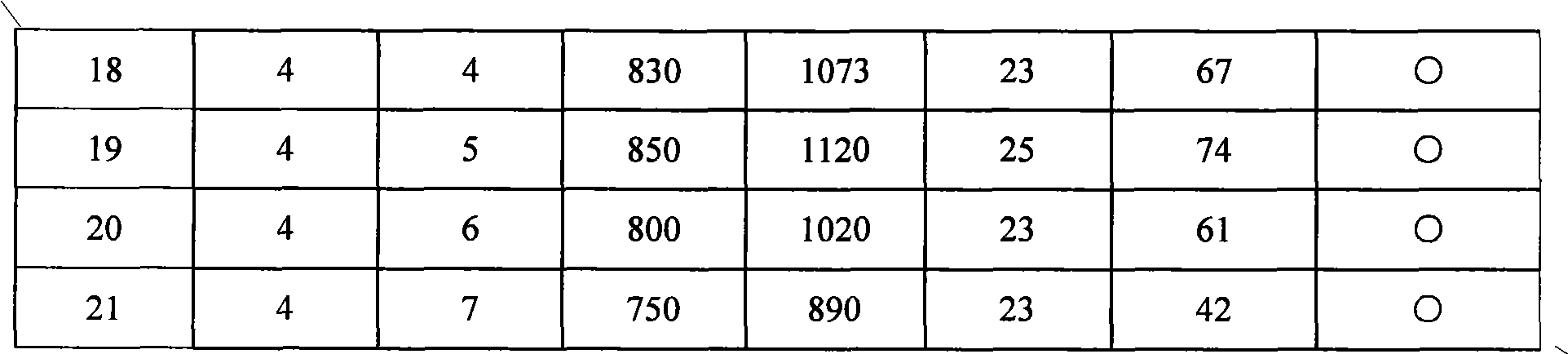

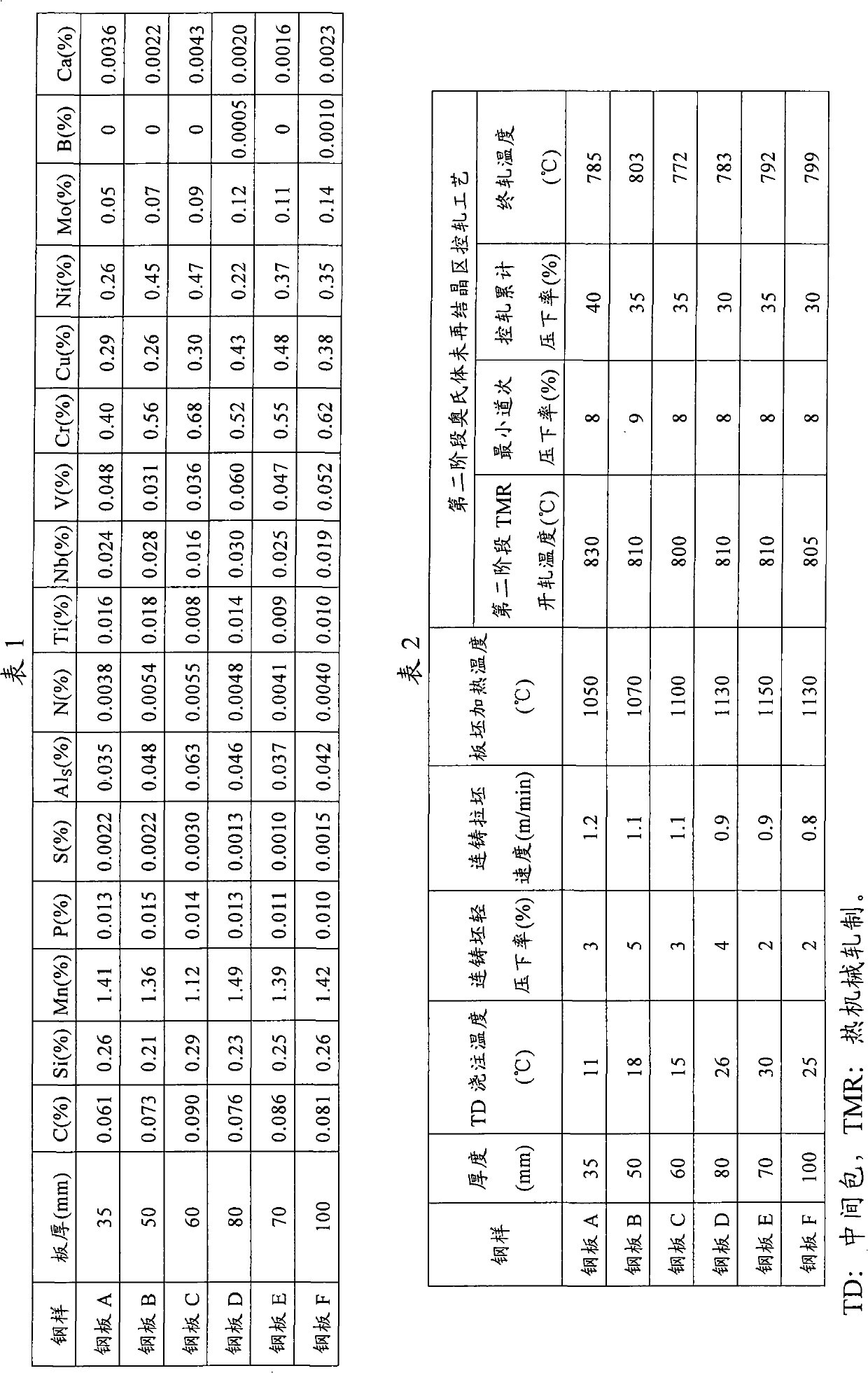

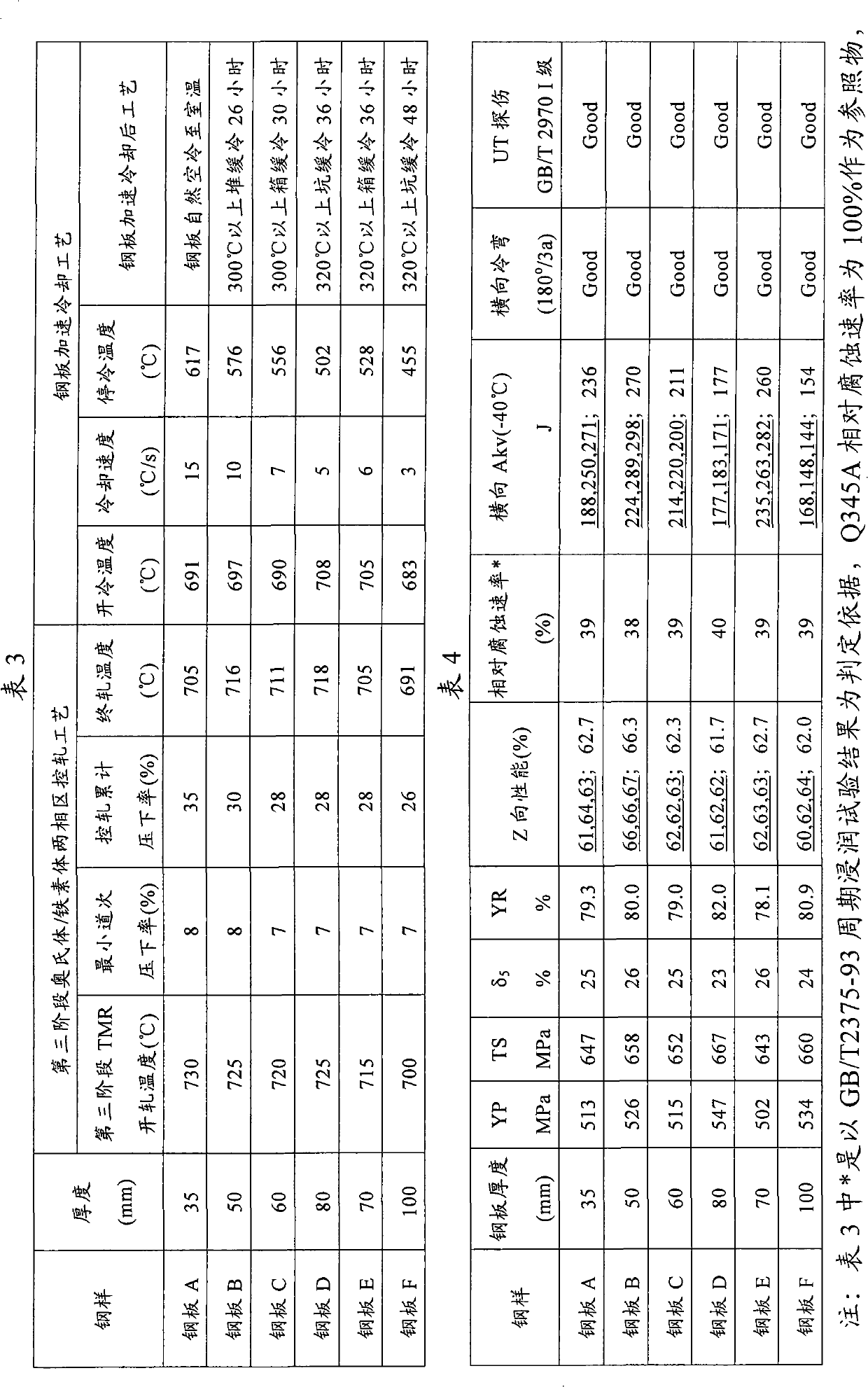

Weather resistant thick steel plate and manufacturing method thereof

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

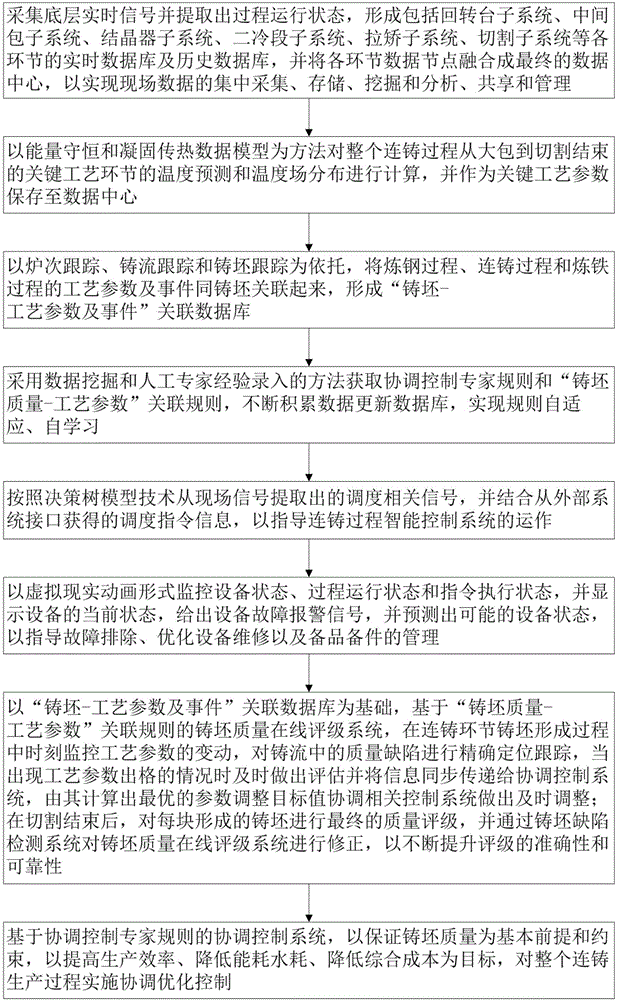

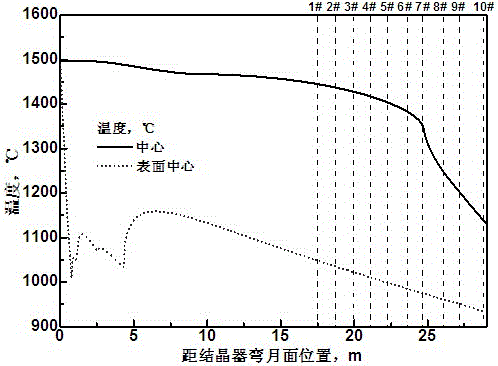

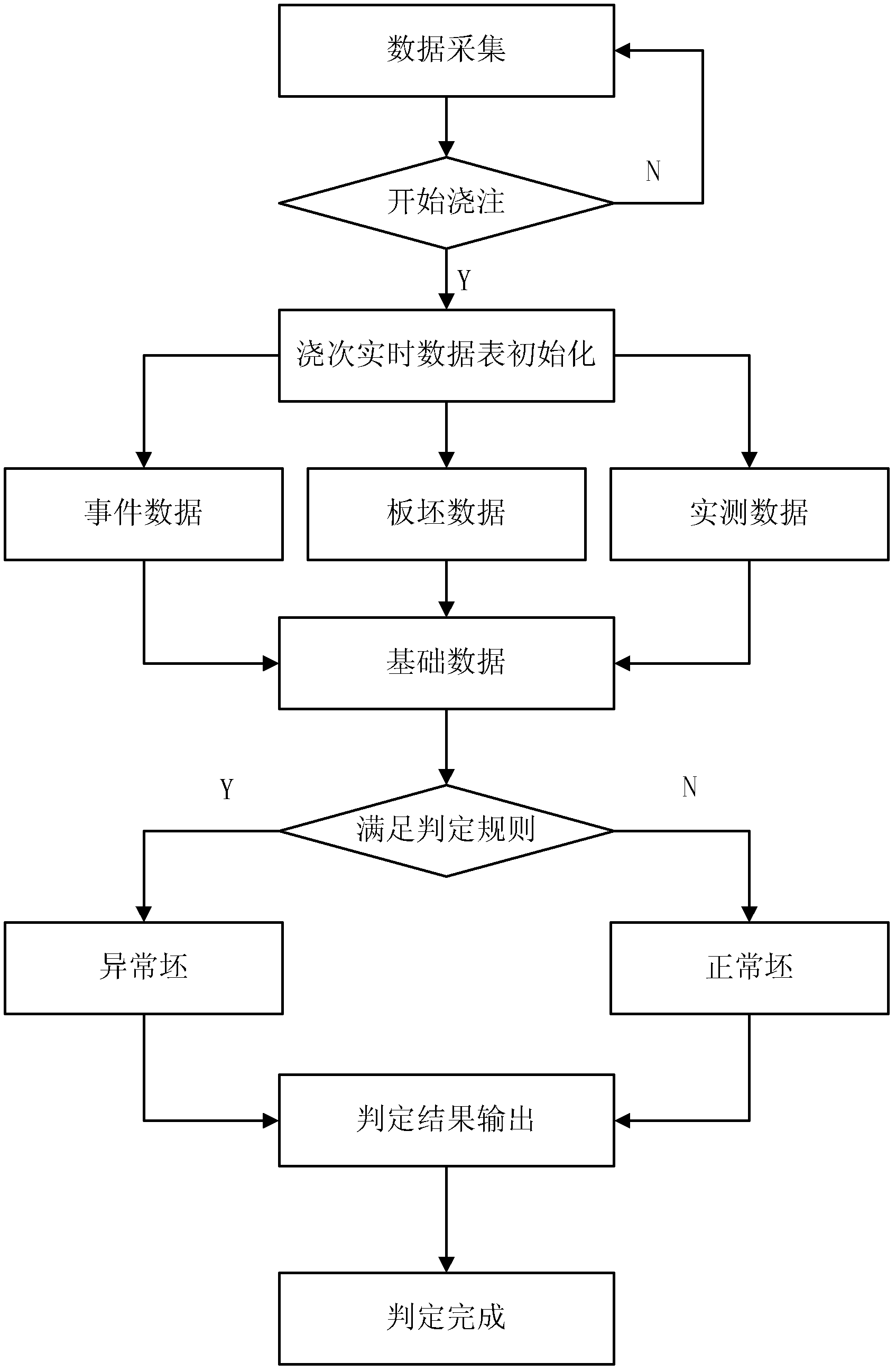

System method for intelligent control over continuous-casting process

The invention discloses a system method for intelligent control over the continuous-casting process. Firstly, signals are collected to form a data center; then a temperature field model is designed to calculate the temperatures of continuous-casting key process nodes, and the temperatures of the continuous-casting key process nodes are stored into the data center; then logistics tracking of the continuous-casting process is achieved, and a 'casting blank-technological parameter and event' related database is formed; then rules and dispatching command information are obtained through data mining and artificial expertise, and virtual reality animation displaying of the equipment state, process operation state and command execution state is conducted; then a casting blank quality online grading system is built and casting blank grading is achieved; and finally, a coordination control system is built, energy consumption and water consumption are optimized, and large-closed-loop quality control and underlying loop control are achieved. Energy conservation and consumption reduction are achieved by optimizing the related parameters of energy consumption and water consumption while the effects that the continuous casting blank quality is stable and the quality is improved continuously are ensured, so that the yield is improved, the cost of per ton of steel is reduced, the comprehensive production cost is reduced continuously, and normal and efficient operation of continuous casting is ensured.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

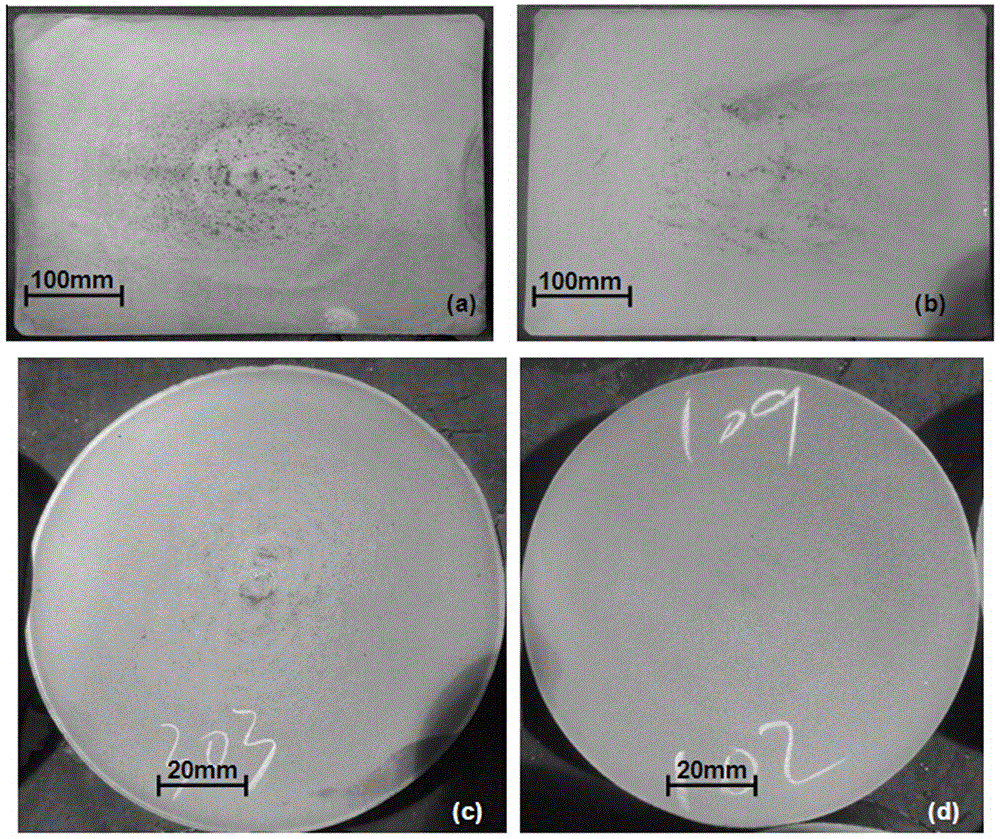

Method for continuous casting billet two-stage continuous and dynamic heavy downward pressing

The invention belongs to the field of continuous casting production, and particularly relates to a method for continuous casting billet two-stage continuous and dynamic heavy downward pressing. The method for the c two-stage continuous and dynamic heavy downward pressing is provided for the characteristics of a bloom caster and a wide and thick plate continuous casting machine. A specific process parameter design method of heavy downward pressing process implementation is given and includes downward pressing interval section and division and downward pressing amount design. The casting billet segregation defect is overcome in the first stage of downward pressing, the looseness defect of casting billets is overcome in the second stage of continuous downward pressing, and therefore the synchronous improvement of casting billet segregation and looseness is achieved.

Owner:NORTHEASTERN UNIV

Production process of cold rolled orientation-free electrical steel plate with low iron loss and high magnetic induction

ActiveCN1887512ALow investment costReduce operating costsOther manufacturing equipments/toolsElectrical steelImpurity

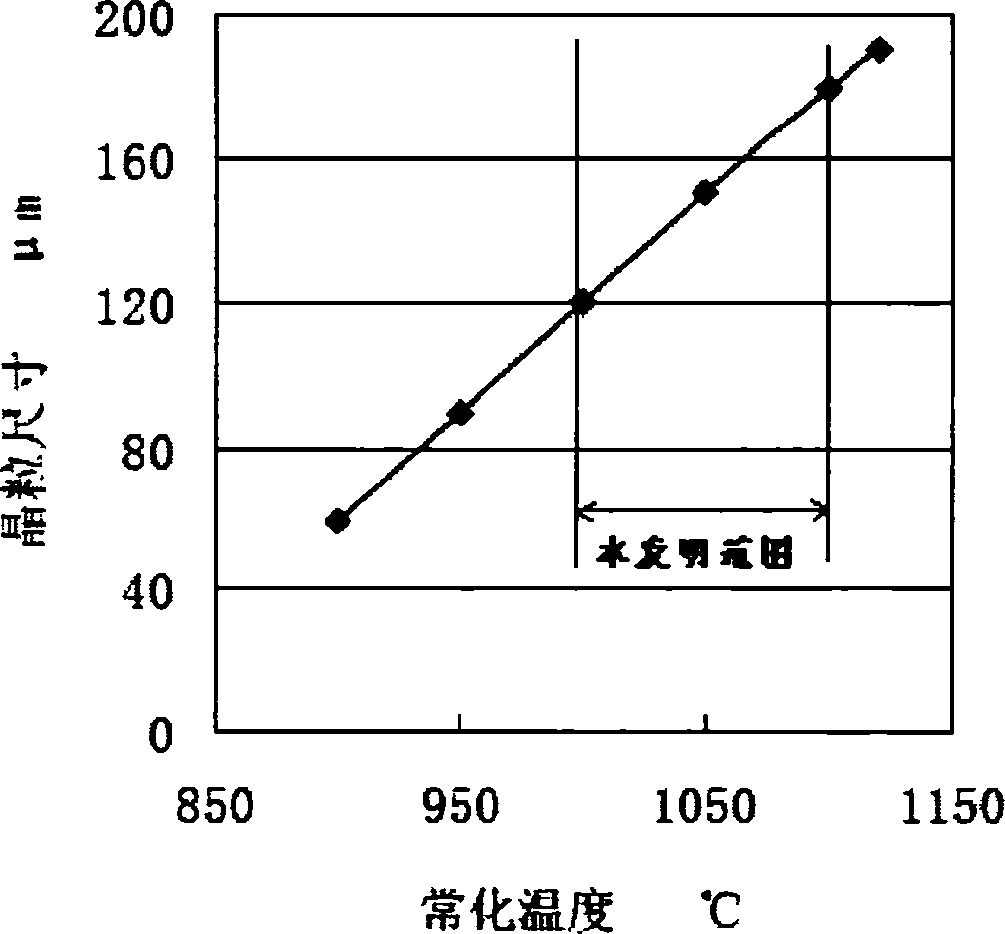

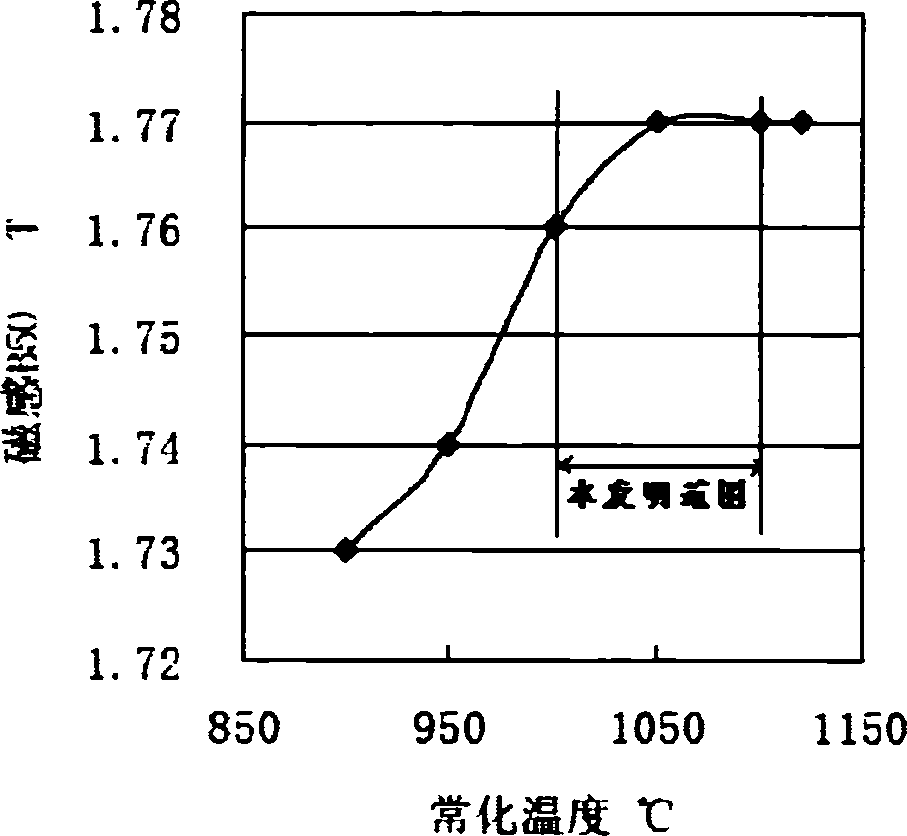

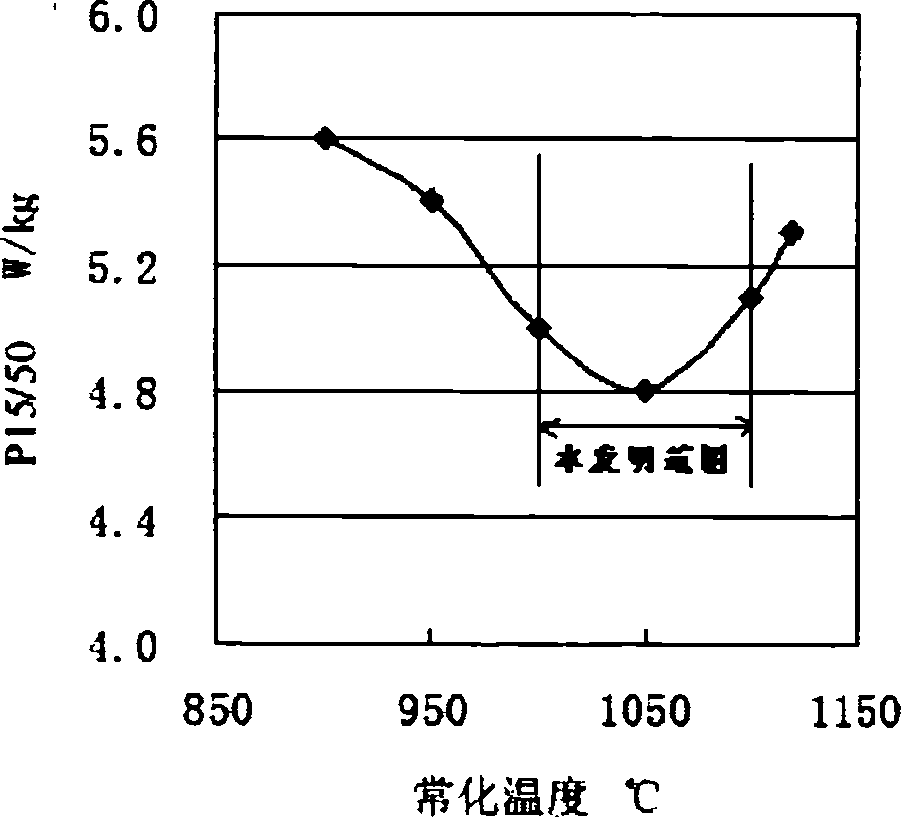

The production process of cold rolled non-orientation electric steel plate comprising C not more than 0.0050 wt%, Si not more than 2.50 wt%, Al not more than 1.0 wt%, Si+2Al not more than 2.50 wt%, Mn 0.10-1.50 wt%, P not more than 0.20 wt%, S not more than 0.005 wt%, N not more than 0.0025 wt%, Sn+Sb not more than 0.2 wt%, and Fe and inevitable impurities for the rest includes the following steps: 1. smelting, continuous casting and rolling; 2. normalizing treatment of the hot rolled plate through heating at heating rate of 5-15 deg.c / s to over Ac1, heat soaking at 1100 deg.c below for 10-90 s, cooling in two stages including cooling at the cooling rate belw 15 deg.c / s to below 650 deg.c and cooling at the cooling rate capable of ensuring the plate form to below 80 deg.c; 3. cold rolling; and 4. final annealing to form the cold rolled non-orientation electric steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

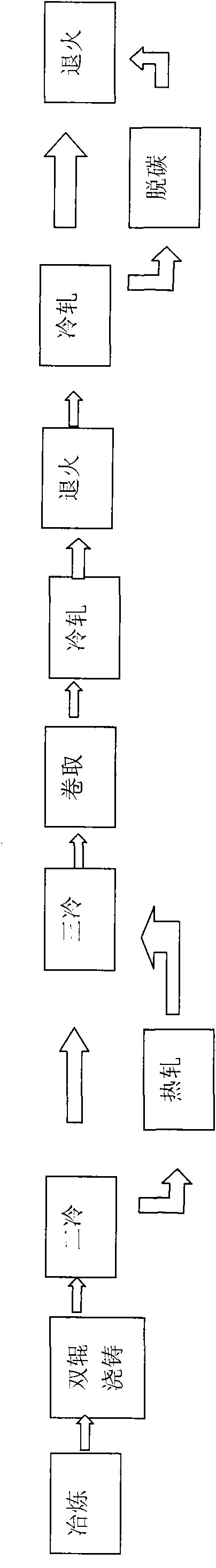

Method for manufacturing cold-rolled orientation-free electrical sheet

This is about the manufacturing method of cold-rolled non-oriented electrical steel, including the following steps: a) the continuous casting of blanks: the liquid steel is continuously cast into a blank of 120-170mm at a pulling speed of 2-3 m / min; b) hot rolling: the blanks are directly hot-rolled or heated into the hot-rolled plate of 900-1150 deg.C and the thickness of the blank is hot-rolled to 0.8-4mm with finishing temperature 800-900deg.C and coiling temperature 500-900deg.C; c) cold rolling: the hot-rolled band undergoes annealing or non annealing treatment and acidwashing, and then the first cold-rolling or the second cold-rolling with annealing until the goal thickness reaches. When the finishing annealing is carried out, the non-oriented electrical steel is produced.

Owner:BAOSHAN IRON & STEEL CO LTD

600MPa level quake-proof twisted steel and manufacturing method thereof

The invention discloses 600MPa level quake-proof twisted steel and a manufacturing method of the steel. The twisted steel comprises one or the combination of more than two of the following components in percentage by weight: 0.21-0.26% of C, 0.61-0.80% of Si, 1.30-1.60% of Mn, 0.15-0.21% of V, 0.001-0.050% of Nb, 0.001-0.050% of Ti, 0.10-0.50% of Cr, 0.0001-0.0050% of B, 0.001-0.010% of Mo and the balance of Fe and unavoidable impurities, wherein the components of C, Si, Mn and V are basic components, and the components of Nb, Ti, Cr, B and Mo are optional components. A short-flow process of converter or electric furnace smelting and small billet continuous casting and rolling and cold bed cooling is adopted by the manufacturing method of the twisted steel. The tensile strength of the twisted steel produced by adopting the components and the method is more than 730MPa, the yield strength is more than 600MPa, the percentage elongation after fracture is more than 14%, the maximum force percentage of total elongation is more than 9%, and the yield ratio is more than 1.25, so the international requirement of quake resistance on the twisted steel can be met.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

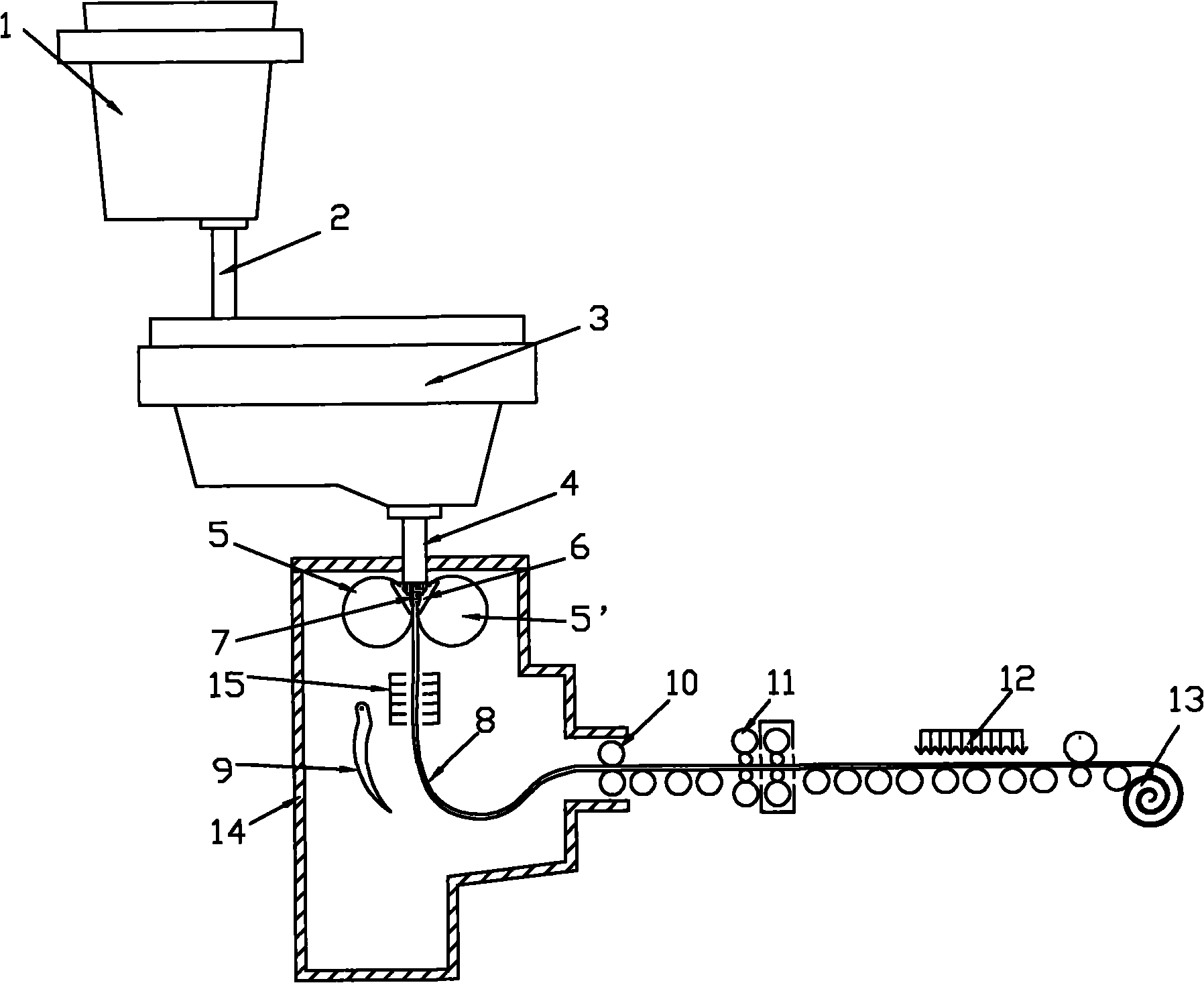

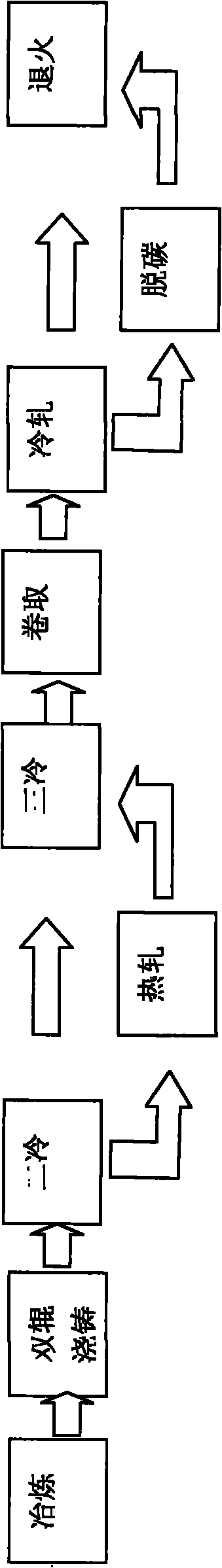

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

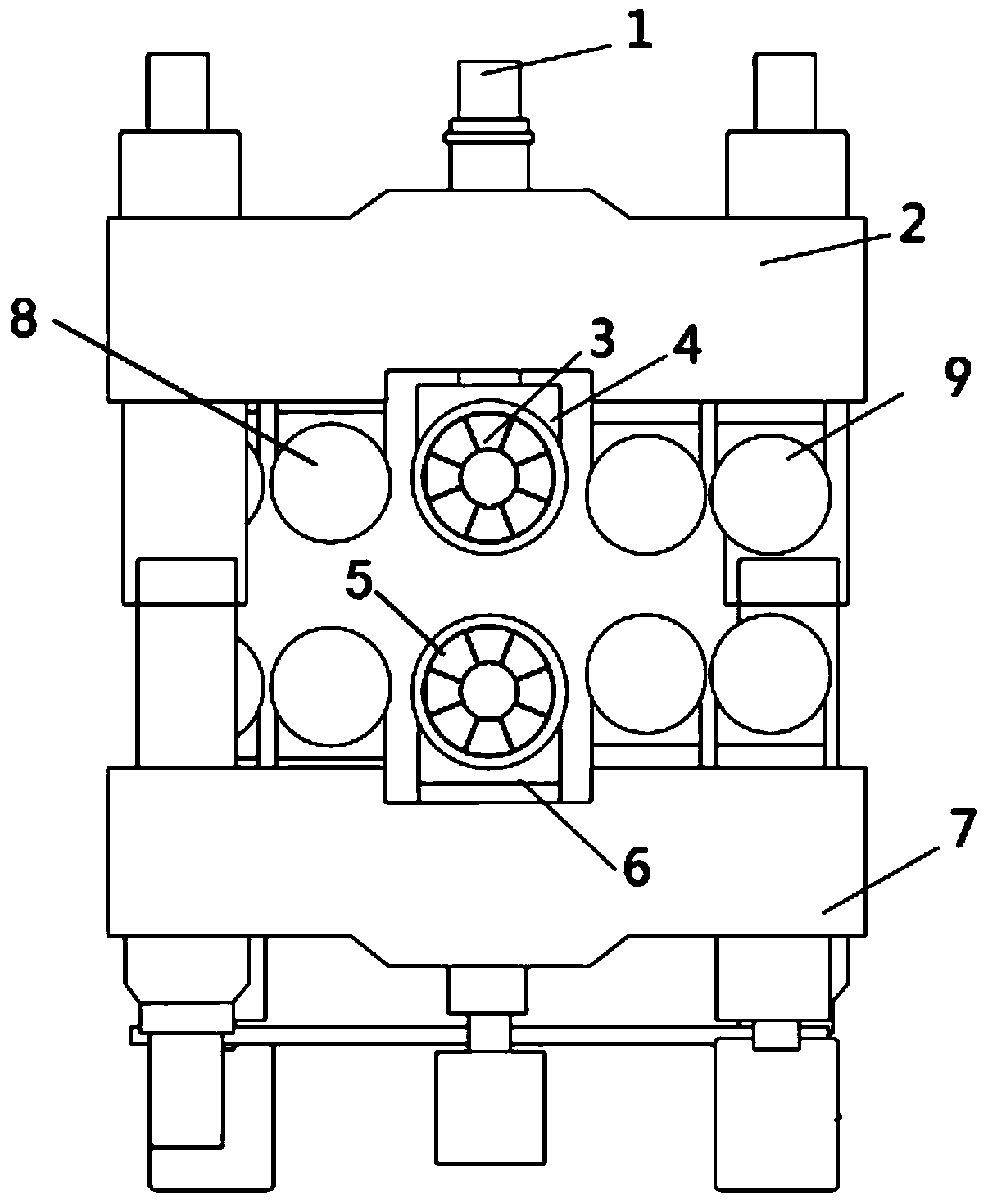

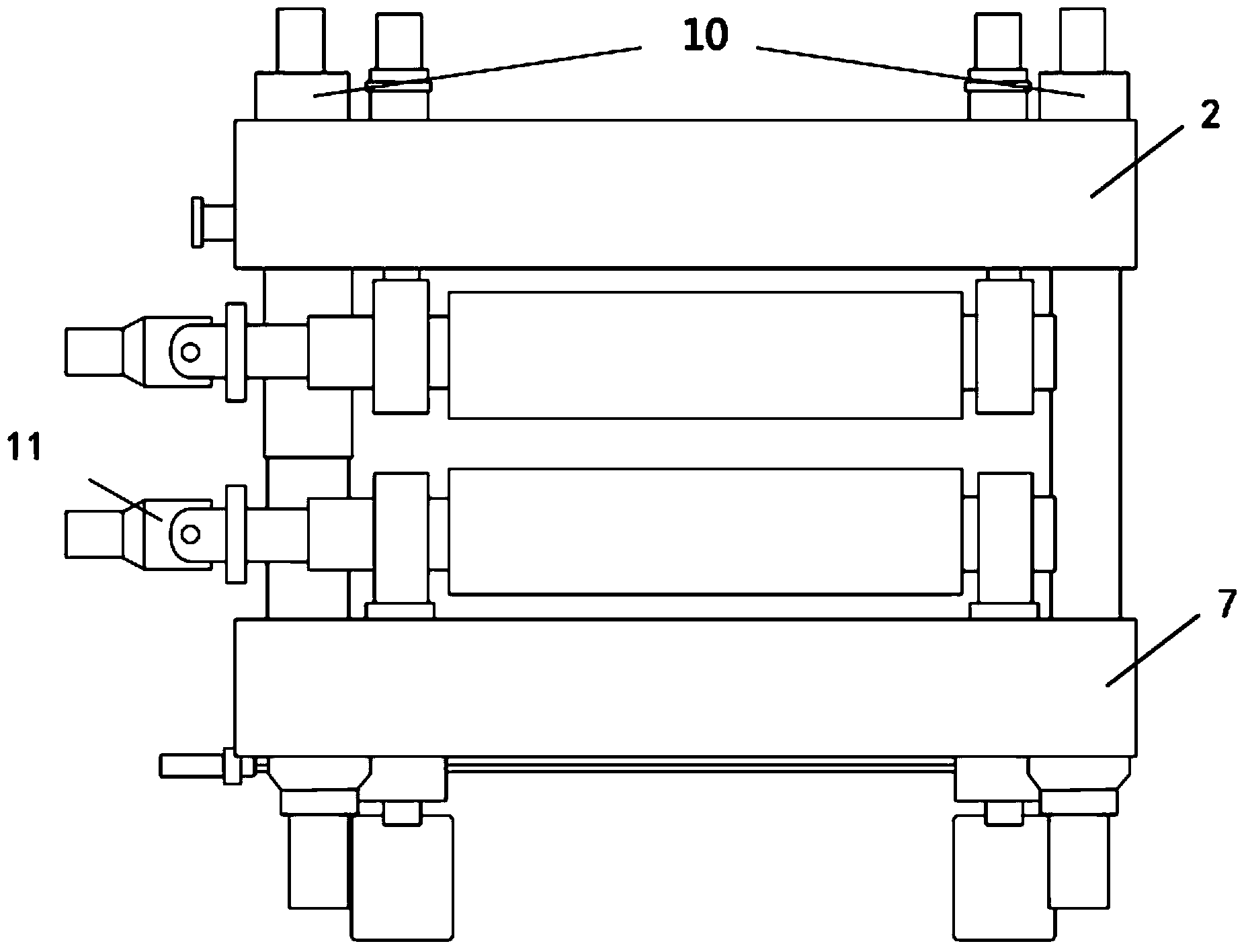

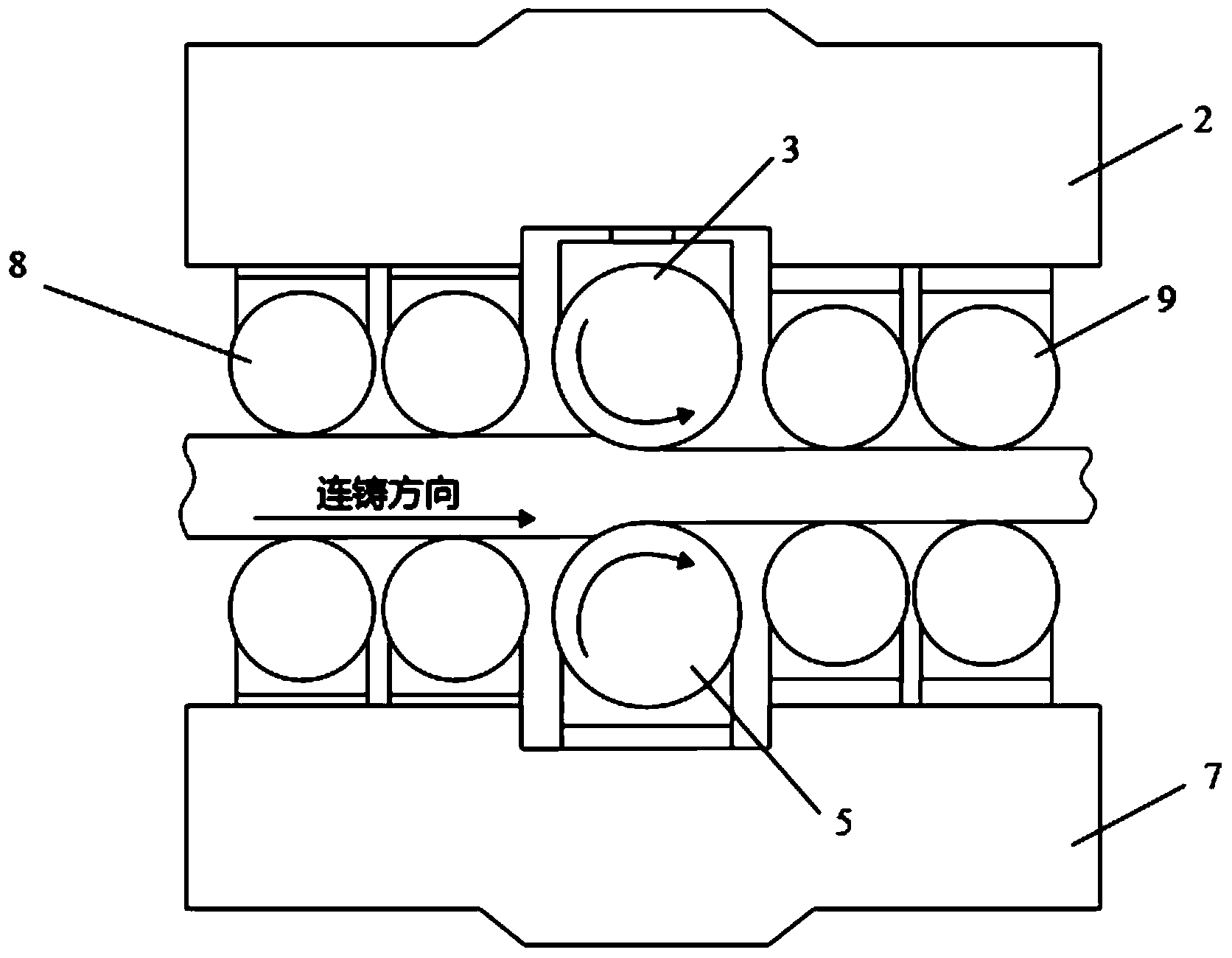

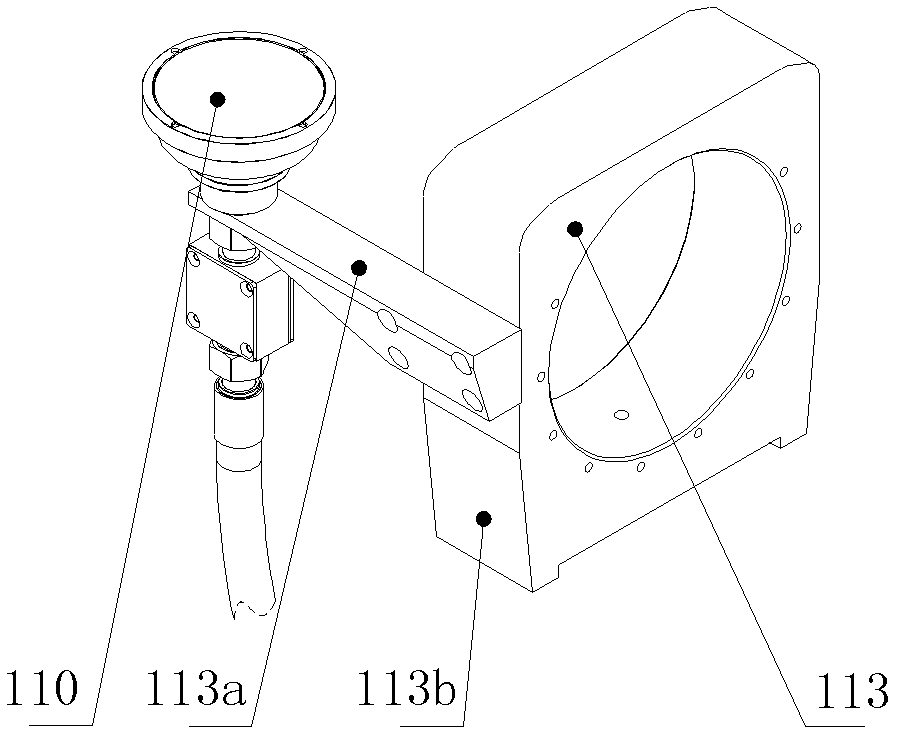

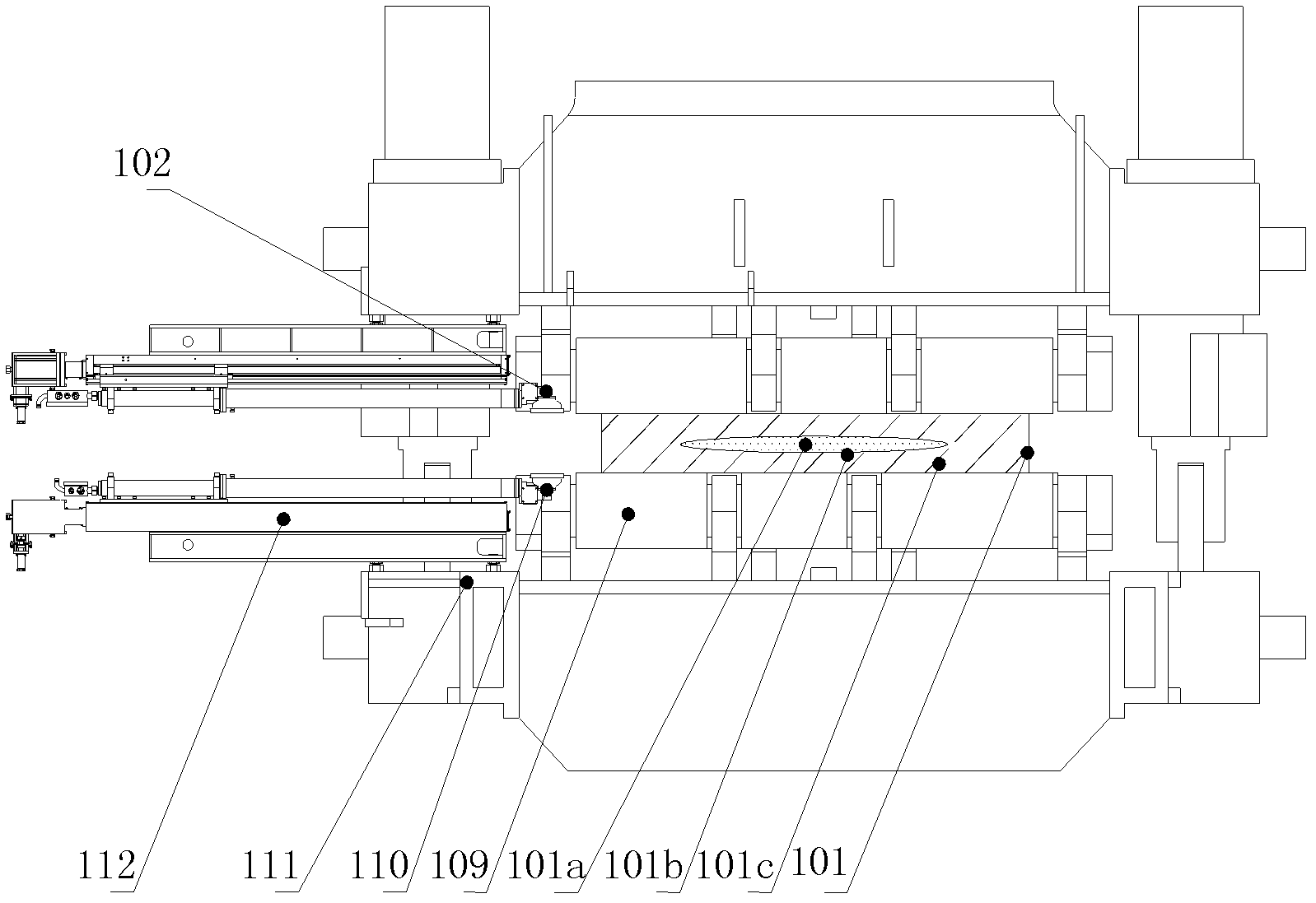

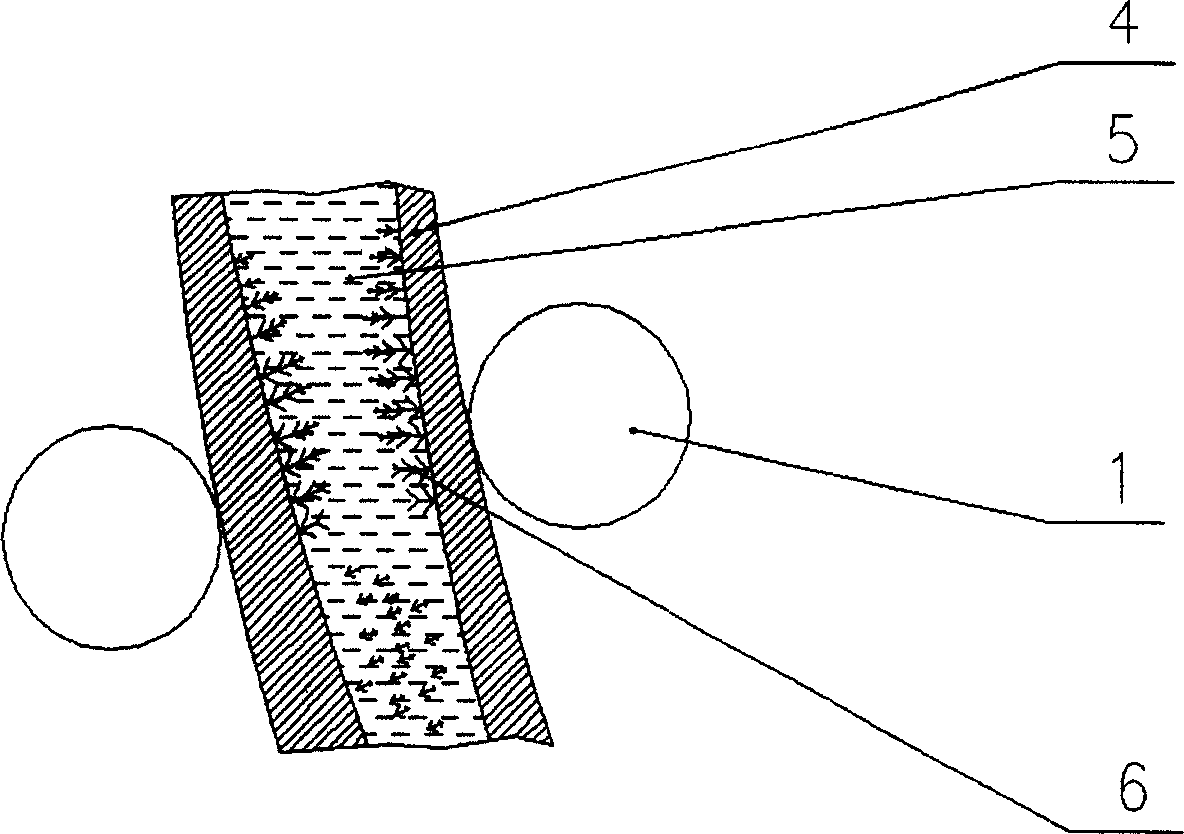

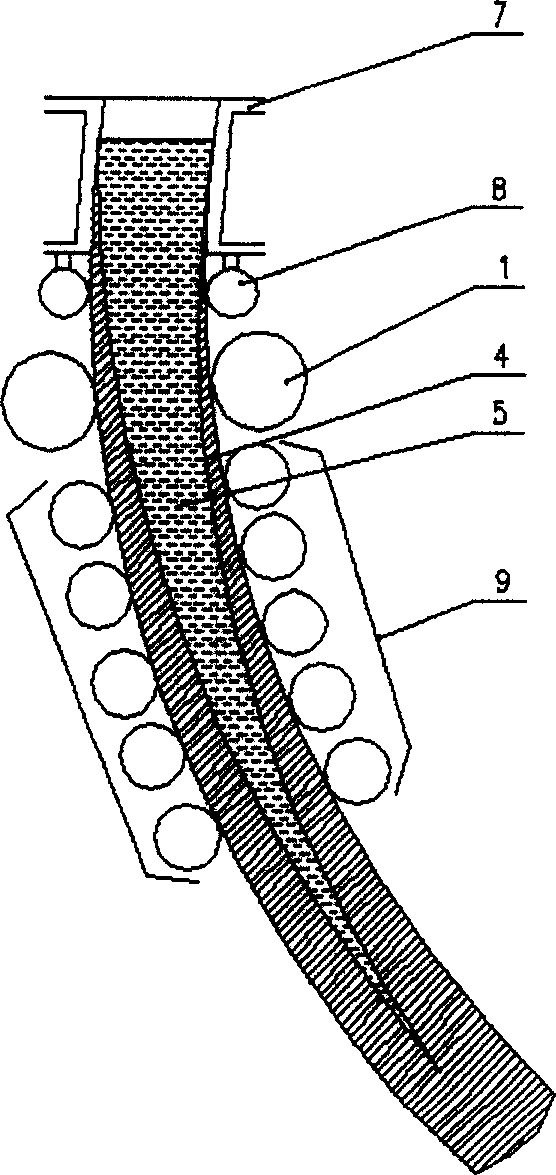

Continuous casting machine sector section for deep pressing of continuous casting blank solidification tail end and deep pressing method of continuous casting machine sector section

ActiveCN104057049AReduced plastic deformation contact areaTotal Deformation Force ReductionMaterials scienceContinuous casting

The invention provides a continuous casting machine sector section for deep pressing of the continuous casting blank solidification tail end and a deep pressing method of the continuous casting machine sector section. The continuous casting machine sector section comprises an upper frame, a lower frame, an upper driving roll, a lower driving roll, a left driven roll set, a right driven roll set, a pressing device and a clamping cylinder, wherein the upper frame, the lower frame, the upper driving roll, the lower driving roll, the left driven roll set, the right driven roll set, the pressing device and the clamping cylinder are arranged on the sector section; the clamping cylinder is used for clamping the upper frame and the lower frame to be kept in a certain set gap; the upper driving roll is connected with the pressing device and connected to the upper frame through a bearing base, the lower driving roll is connected to the lower frame through a bearing base, the left driven roll set and the right driven roll set are located on the two sides of the driving rolls respectively, the left driven roll set is used for clamping a casting blank before pressing, the right driven roll set is used for clamping the casting blank after pressing, and the radio of the diameter of each driving roll to the diameter of each driven roll is 1.1:1 to 2:1. According to the continuous casting machine sector section for deep pressing of the continuous casting solidification tail end and the deep pressing method of the continuous casting machine sector section, the deformation permeability is improved, deformation achieved through the continuous casting machine sector section is equivalent to that achieved by one rolling pass of a twin rolling mill with the large rolling diameter, and the improvement in loosening and segregating of a central zone of the casting blank is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

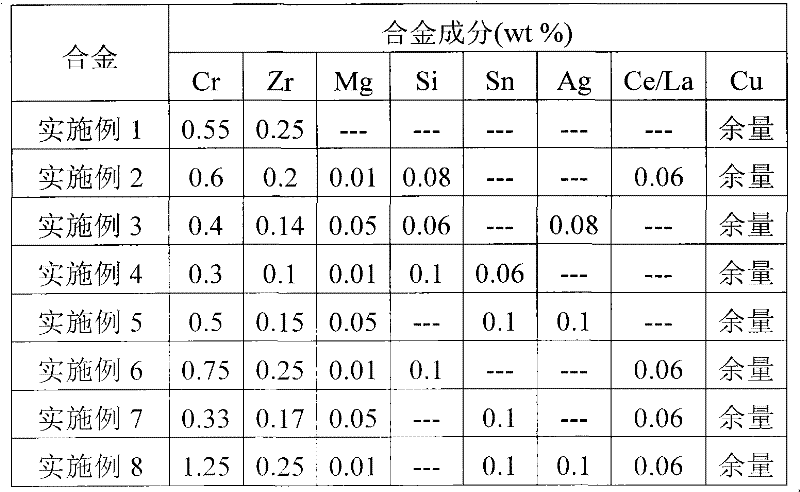

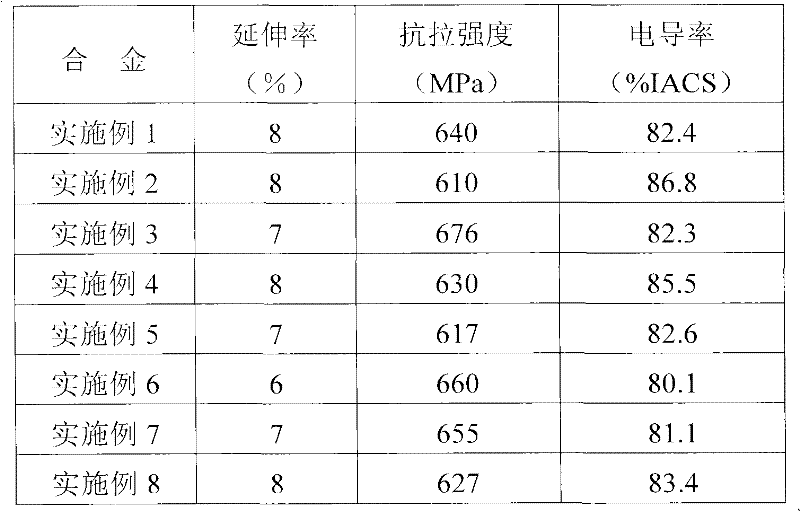

CuCrZr alloy with high strength and high conductivity, and preparation and processing method thereof

The invention relates to a CuCrZr alloy with high strength and high conductivity, and a preparation and processing method thereof. The alloy comprises the basic ingredients in percentage by mass: 0.3 percent to 1.4 percent of Cr, 0.02 percent to 0.25 percent of Zr and the balance Cu, wherein the ingredients in the CuCrZr alloy are needed to meet the following requirements: (a) Cr / Zr is less than or equal to 5 and is greater than or equal to 1.9; and (b) Cr+Zr is less than or equal to 1.5 percent and is greater than or equal to 0.4 percent. The preparation and processing method comprises the following steps of: a, compounding, feeding, smelting and casting according to mass percent; b, surface milling; c, hot rolling; d, solution treatment; e, primary cold rolling; f, primary aging; g, secondary cold rolling; and h, secondary aging. The CuCrZr alloy has the tensile strength sigma b being 600-700 MPa, the plasticity elongation rate delta being 4-10 percent, and the conductivity being greater than 80 percent of IACS (International Annealed Copper Standard), can be widely applied to occasions with high strength and high conductivity for preparing resistance welding electrodes, liners of crystallizers of continuous casting machines, integrated circuit lead frame and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

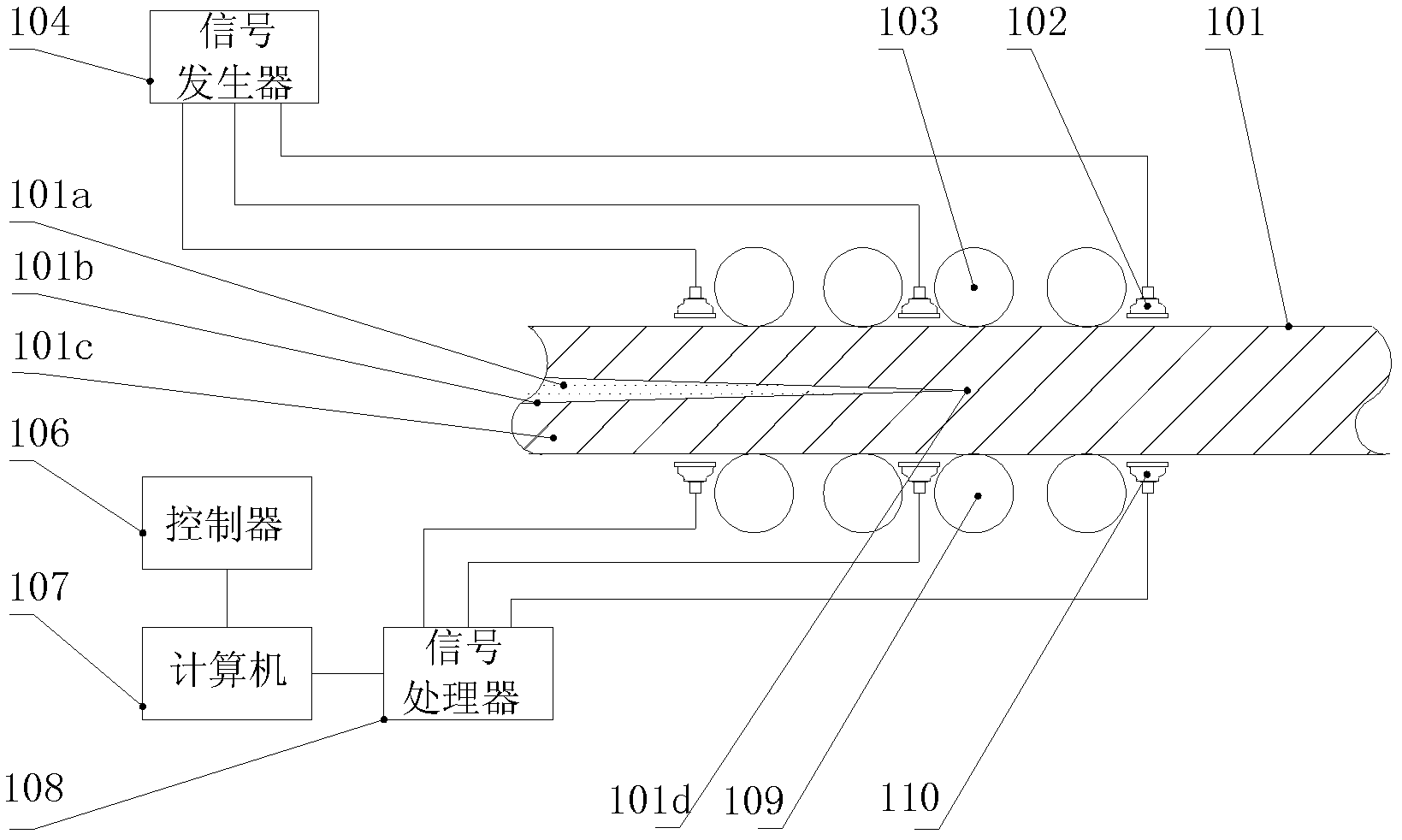

Online detection system for solid-phase internal boundaries and solidification end positions of continuous casting blanks and method

ActiveCN102500747AImprove signal-to-noise ratioIncrease distanceUltrasonic sensorSignal-to-noise ratio (imaging)

The invention discloses an online detection system for internal boundaries and solidification end positions of continuous casting blanks and a method. The system comprises a signal generator, electromagnetic ultrasonic sensors, a signal processor, a computer and a controller, wherein the electromagnetic ultrasonic sensors are arranged in dynamically slightly stressed regions in a casting direction of a continuous casting blank and set positions of various fan-shaped sections of local zones of the upstream and the downstream which are adjacent to the regions, and the end area of the end, which faces to the surface of the detected continuous casting blank, of a magnet in each electromagnetic ultrasonic sensor is larger than the end surface of the end, which is far away from the surface of the continuous casting blank, of the magnet in the electromagnetic ultrasonic sensor. In the system, the end area of the end, which faces to the surface of the detected continuous casting blank, of the magnet in each electromagnetic ultrasonic sensor is larger than the end surface of the end, which is far away from the surface of the detected continuous casting blank, of the magnet in the electromagnetic ultrasonic sensor, and accordingly, the signal to noise ratio of electromagnetic ultrasonic waves can be improved. In addition, electromagnetic ultrasonic signals are processed by the computer in screening, shifting, adding and averaging modes, so that the signal to noise ratio of the electromagnetic ultrasonic waves can be greatly increased.

Owner:田志恒

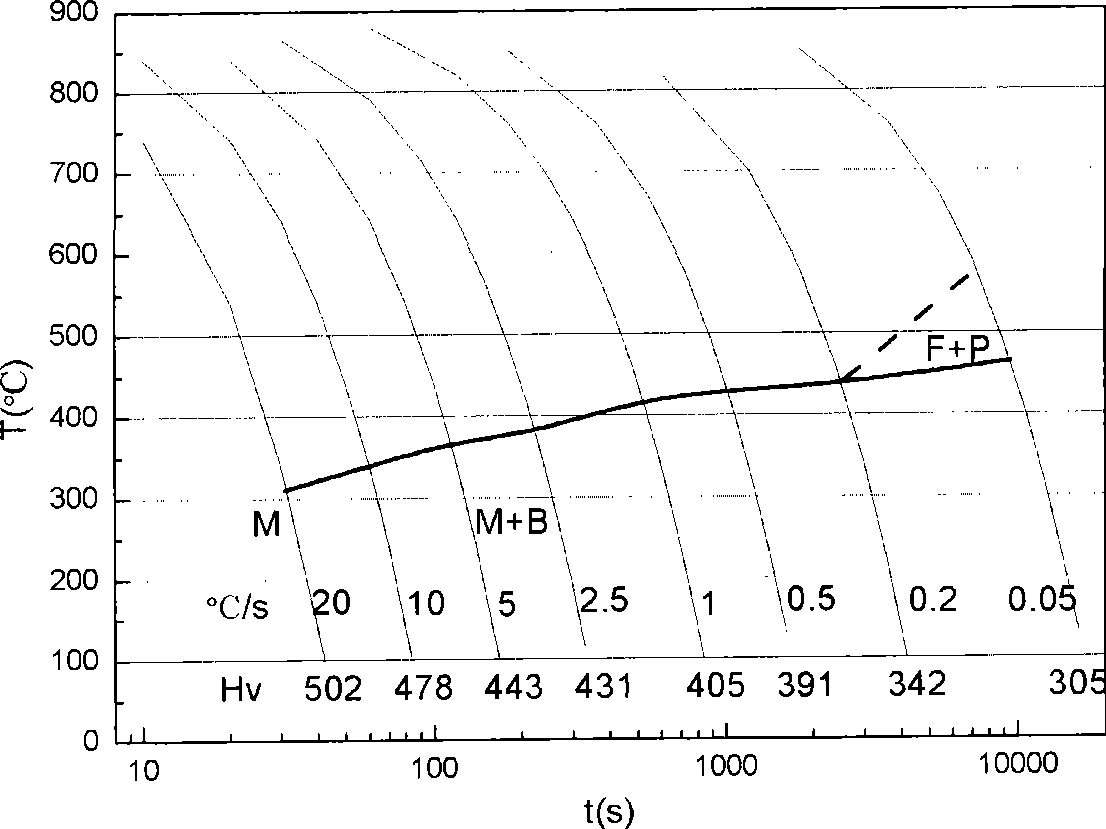

High-performance marine mooring chain steel and manufacturing method thereof

InactiveCN101519751AGood weather resistanceImprove corrosion resistanceMetal rolling arrangementsIngotHeating furnace

The invention relates to high-performance marine mooring chain steel and a manufacturing method thereof. The method comprises the following steps: a. tapping compositions comprise the following by weight percentage: C: 0.16 to 0.27, Mn: 0.40 to 1.45, Si: 0.15 to 0.50, Cr: 1.25 to 2.50, Ni: larger than 0 and less than 1.20, Mo: 0.20 to 0.60, Al: 0.01 to 0.06, N: 0.004 to 0.015, S: not larger than 0.005, P: not larger than 0.015, Cu: larger than 0 and less than 0.50, and the balance of Fe; b. a steel ingot or a continuous casting billet is casted after the steps of primary smelting in an electric stove or a converter, external refining and vacuum degassing; c. the charging temperature of a heating oven is not larger than 900 DEG C, the heating rate is not larger than 150 DEG C / h; when being raised to 1100 to 1300 DEG C, the temperature is kept for more than 40 minutes, cogging bloom or rolling by a finisher is carried out, and the finishing temperature is not larger than 1050 DEG C; and d. after heated at the temperature of 1000 to 1250 DEG C, the cogged ingot is hot-rolled or forged into round steel, the finishing temperature is not larger than 1050 DEG C, and after rolling, the steel is air-cooled, slow cooled or softening heat-treated at the temperature of not less than 600 DEG C. The performance of finished products achieves or exceeds the requirement of level 4.5 and level 5 of mooring chain steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Method for producing silicon for use in solar cells

InactiveUS6090361AAvoid energy wasteAvoid material lossPolycrystalline material growthSiliconElectrical batteryZone melting

Method for producing highly purified silicon for use in solar cells by a single solidification purification, pouring silicon into a mold and gradually fractionally solidifying it while solidifying the liquid surface, followed by purifying the solidified silicon by zone melting or continuous casting using an electromagnetic mold, or by zone melting in combination with continuous casting, and optionally causing directional solidification to concentrate impurities, leaching and recycling.

Owner:KAWASAKI STEEL CORP

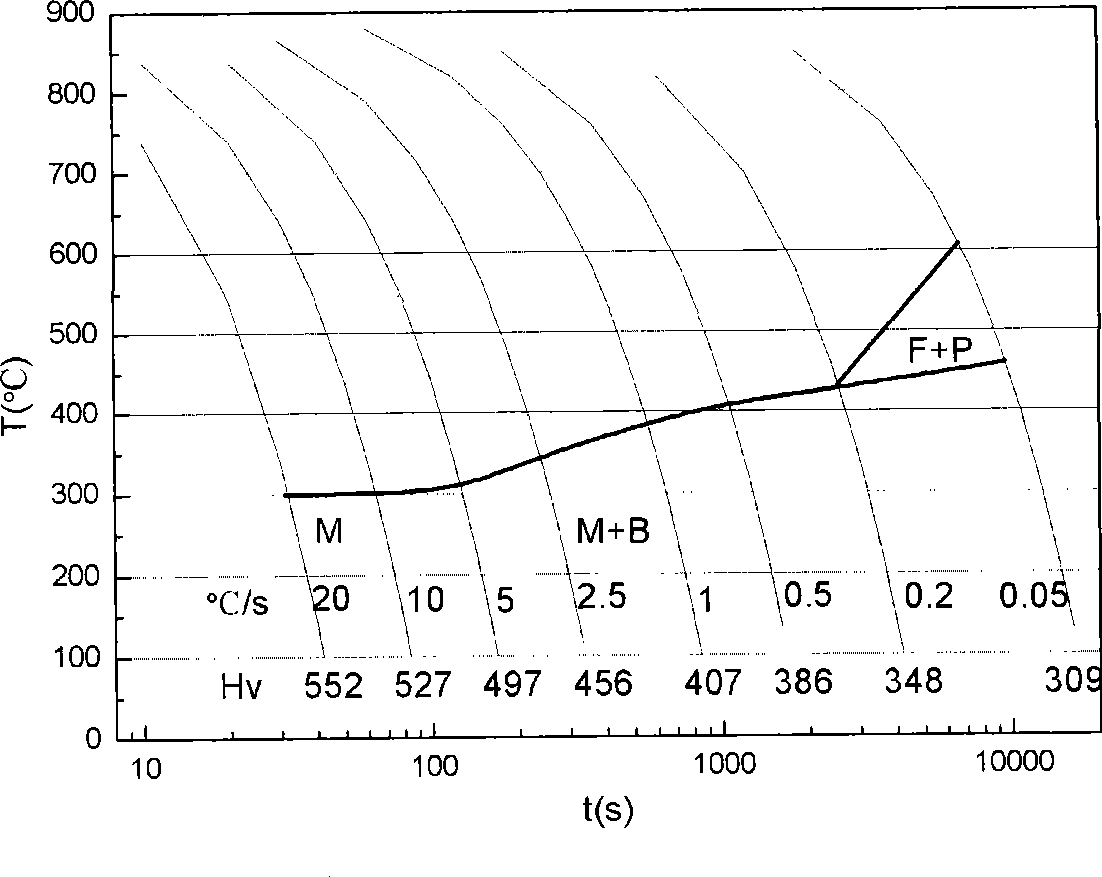

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

High strength cold-rolled plate with excellent formability and production method thereof

The invention provides a high strength cold-rolled plate with excellent formability, containing: no more than 0.0040% of C, 0.02-0.15% of Si, 0.20-1.00% of Mn, 0.02-0.09% of P, 0.015-0.06% Ti, 0.01-0.05% of Nb, and the rest being Fe. The production method comprises: smelting, continuous casting, hot-rolling, cold rolling and continuous annealing, wherein the heating temperature of the hot-rolled billet is 1170-1270 DEG C, the finishing temperature of hot-rolling is 850-960 DEG C, and the coiling temperature is 650-760 DEG C; the cold rolling reduction percent is 60-82%; the annealing temperature is 760-880 DEG C, the thermal insulation time is 60-210s, the slow-cooling segment temperature is 630-700 DEG C, and the fast-cooling exit temperature is 300-500 DEG C; and the levelling elongationrate is 0.5-1.0%. The high strength steel plate containing phosphorus of the invention has the features of low carbon, microalloying and purity. The steel added with a certain amount of Nb and Ti hashigher plasticity. Using relevant rolling and annealing technique, the indexes of performance of the steel achieves the demand of high strength automobile stamping parts.

Owner:ANGANG STEEL CO LTD

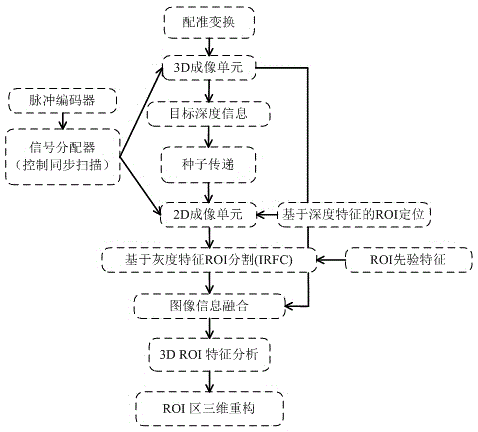

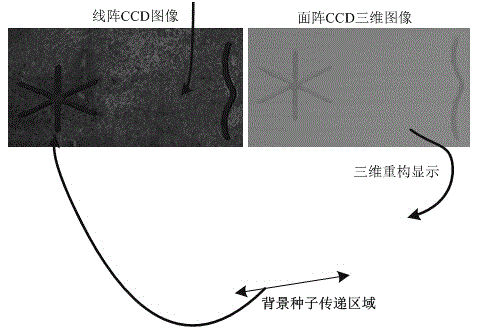

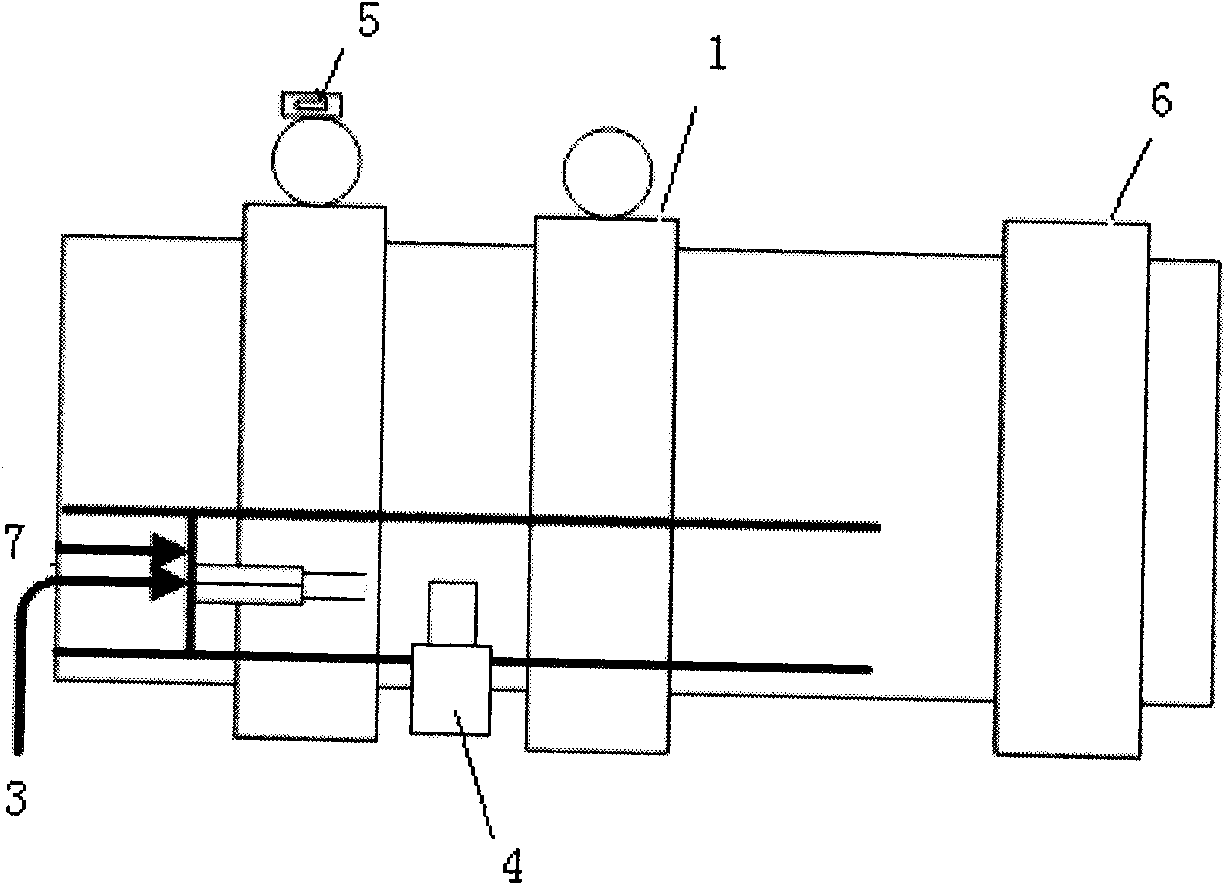

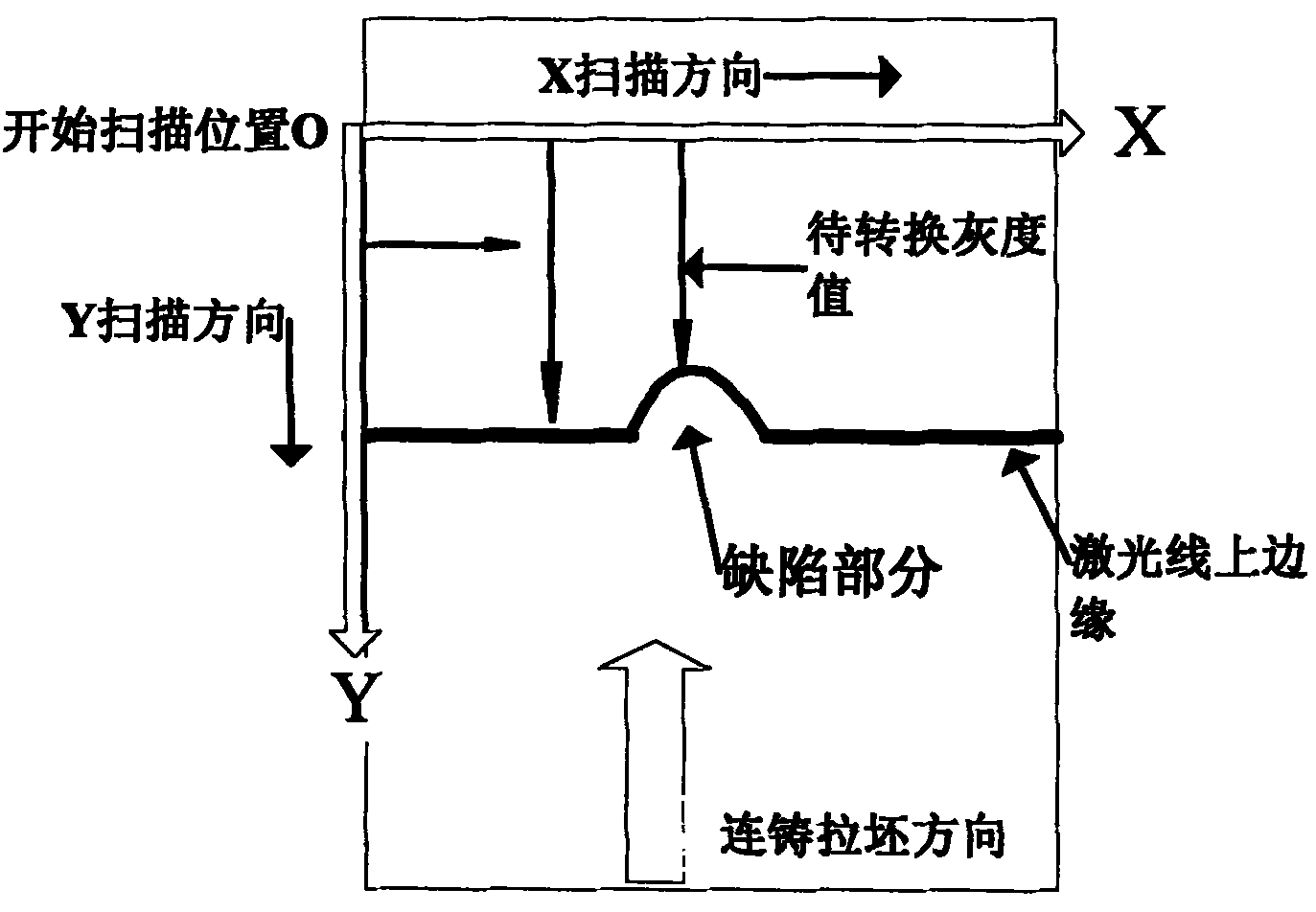

Dual-CCD (Charge Coupled Device) scanning imaging detection method for continuous casting slab surface defects

InactiveCN104020177AImprove accuracyHigh degree of automationOptically investigating flaws/contaminationLaser transmitterCcd camera

The invention discloses a dual-CCD (Charge Coupled Device) scanning imaging detection method for continuous casting slab surface defects. The dual-CCD scanning imaging detection method comprises the following steps: (1) mounting a linear array CCD camera, an area array CCD camera and a linear laser transmitter on a continuous casting slab; (2) scanning by the linear array CCD camera and the area array CCD camera according to a synchronous frame frequency and line frequency manner to obtain a two-dimensional image and a three-dimensional image of the surface of the continuous casting slab; (3) registering the acquired two-dimensional image and three-dimensional image; and (4) carrying out information fusion processing on the registered two-dimensional image and three-dimensional image in one area on the surface of the continuous casting slab, analyzing area-of-interest features of the two images, and extracting a final area-of-interest to be identified on the surface of the continuous casting slab by combining the feature fusion processing result of the two images, thus reserving reliable defect information of the surface of the casting slab and detecting the surface defects of the continuous casting slab. According to the dual-CCD scanning imaging detection method provided by the invention, the structure is simple and convenient; the method is high in detection precision, great in real-time property and capable of automatically eliminating interference information.

Owner:CHONGQING UNIV

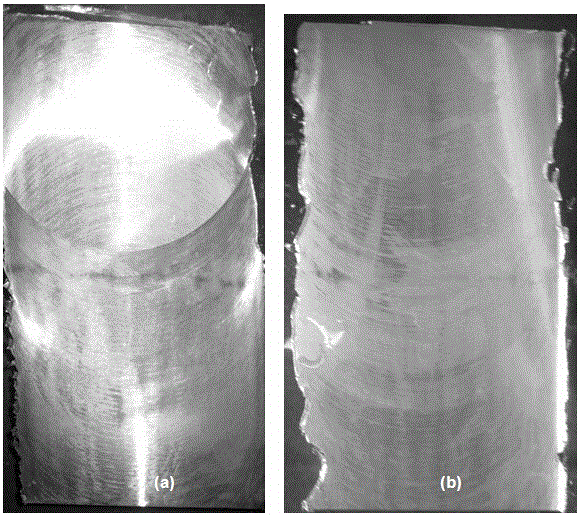

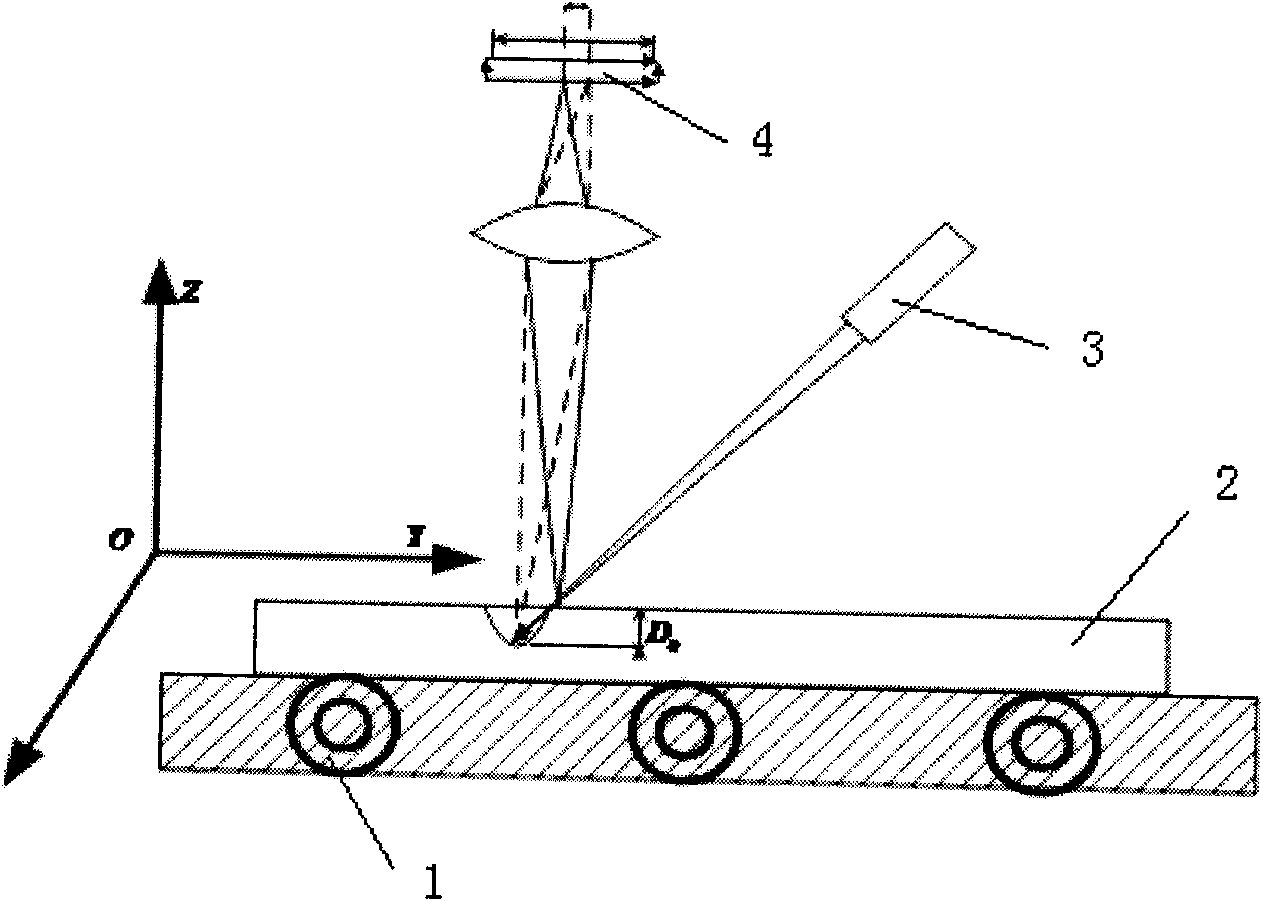

Laser scanning imaging nondestructive inspection method for hot continuous casting blank surface defects

InactiveCN101871895ASuppress interferenceAccurate identificationMaterial analysis by optical meansUsing optical meansLaser transmitterDot matrix

The invention discloses a laser scanning imaging nondestructive inspection method for hot continuous casting blank surface defects, comprising the following steps: 1) transversely irradiating a casting blank by a laser emitter to obtain a laser line; 2) scanning the laser line by utilizing an area array CCD image sensor; 3) extracting information representing the defect depths from the laser line so as to obtain a one-dimensional distance dot matrix formed by assembling the defect depths of the casting blank at the transverse position; and 4) mapping the one-dimensional distance dot matrix into gray level images with different gray levels; 5) splicing the gray level images at different transverse positions of a hot blank so as to obtain a whole gray level image; and 6) identifying the defects on the surface of the casting blank and reconstructing a casting blank surface tri-dimensional topographic image. The intention can effectively inhibit interference from a flaky scale on the high temperature casting blank surface which is not a defect but presents a defect state and water films so as to avoid the pseudo-defects from influencing detection precision, accurately identify defect target images and realize quantized detection of the defect depths, thereby realizing online detection of the defect states and depths of the surface of the casting blank under a high temperature state.

Owner:CHONGQING UNIV

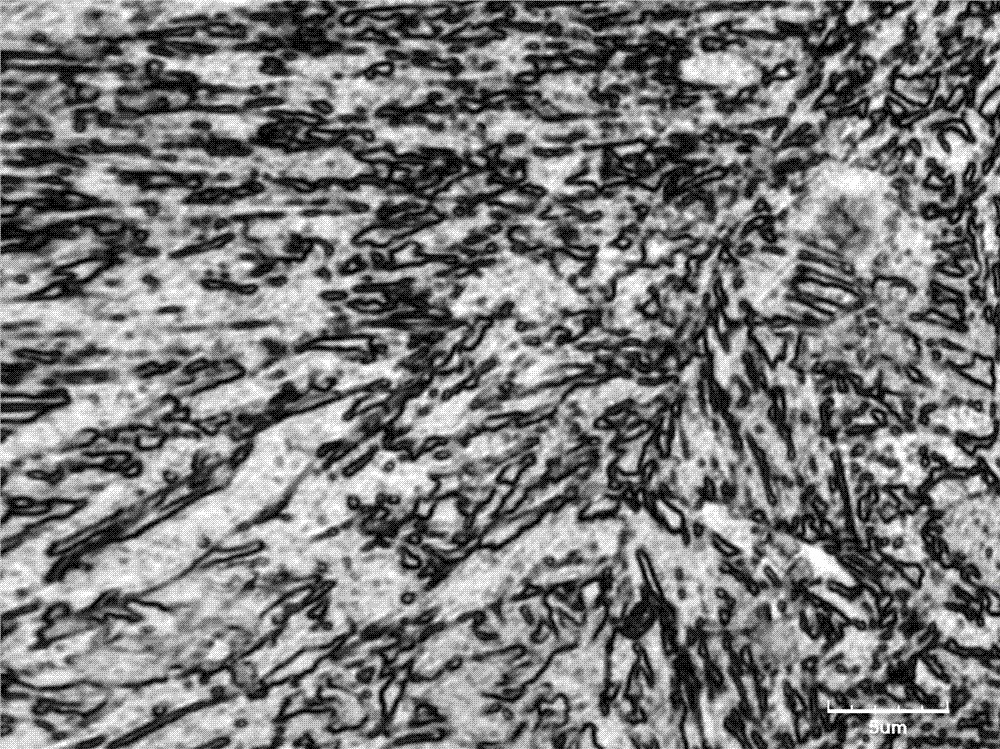

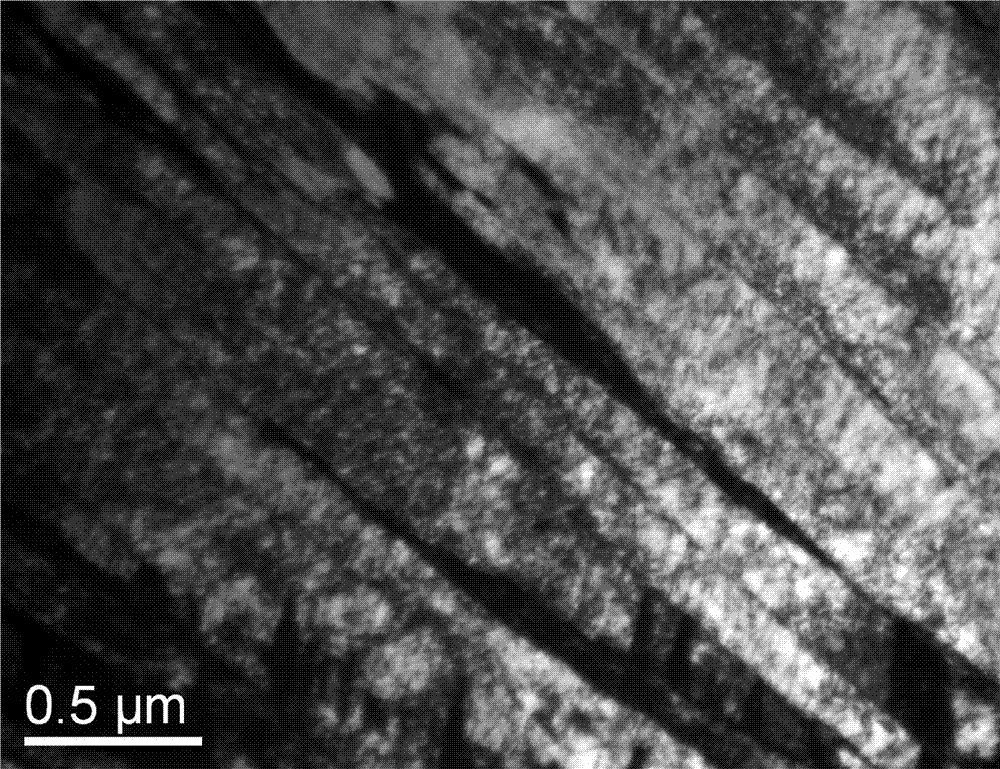

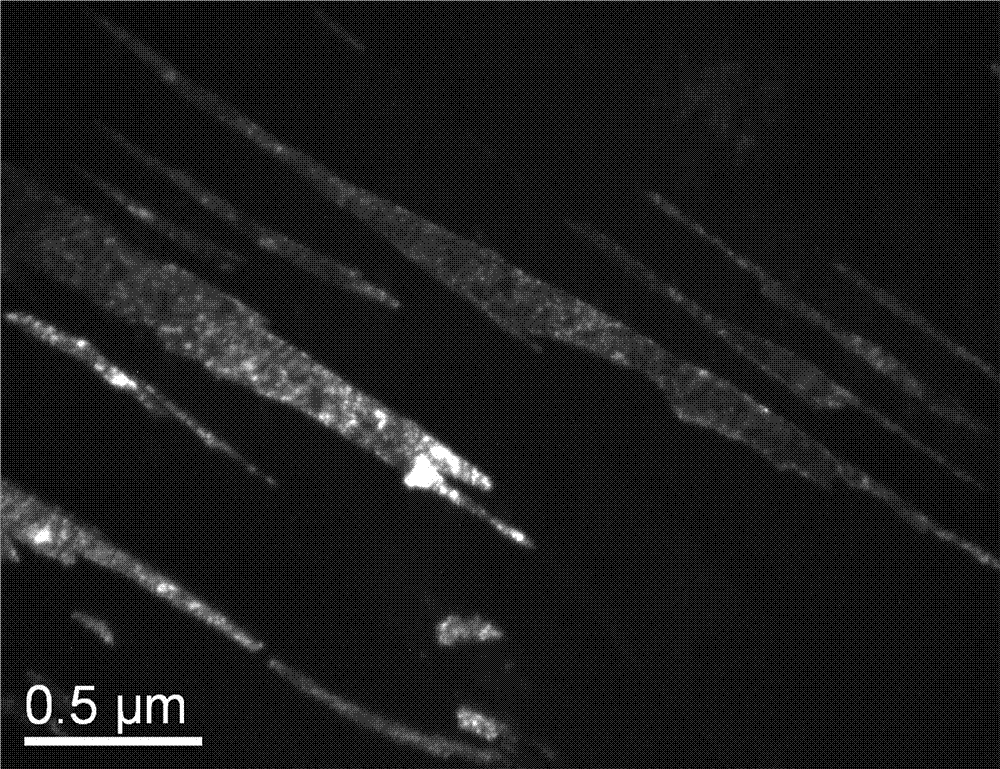

High-strength, high-toughness and high-plasticity martensitic stainless steel and preparation method thereof

ActiveCN103614649AImprove the level of toughness and plasticityImprove stabilityMartensitic stainless steelRoom temperature

The invention discloses high-strength, high-toughness and high-plasticity martensitic stainless steel, and belongs to the technical field of metallurgy. The martensitic stainless steel comprises the following components in percentage by weight: 0.15 to 0.4 percent of C, 0 to 0.12 percent of N, 0.2 to 2.5 percent of Si, 0.4 to 3.0 percent of Mn, less than or equal to 0.02 percent of S, less than or equal to 0.02 percent of P, 13.0 to 17.0 percent of Cr, 0 to 5.0 percent of Ni, 0 to 2.0 percent of Mo, 0 to 0.3 percent of V, 0 to 0.2 percent of Nb, 0 to 0.05 percent of Ti, 0 to 0.8 percent of Al and the balance of Fe and inevitable impurities. A preparation method comprises the following steps of (1) smelting molten steel according to the set components, and solidifying the molten steel to form an ingot blank by using a continuous casting machine or a casting mold; (2) hot-rolling the ingot blank to form a hot-rolled plate blank; (3) heating the hot-rolled plate blank to 950 to 1100 DEG C, preserving heat for 0.5 to 2 hours, cooling the plate blank to 25 to 200 DEG C, heating the plate blank to 350 to 500 DEG C, preserving heat for 10 to 60 minutes, and air-cooling the plate blank to room temperature. According to the martensitic stainless steel prepared by the method, dispersed remaining martensite is introduced into a microscopic structure, so that the strength, toughness and plasticity of the martensitic stainless steel are greatly improved.

Owner:NORTHEASTERN UNIV

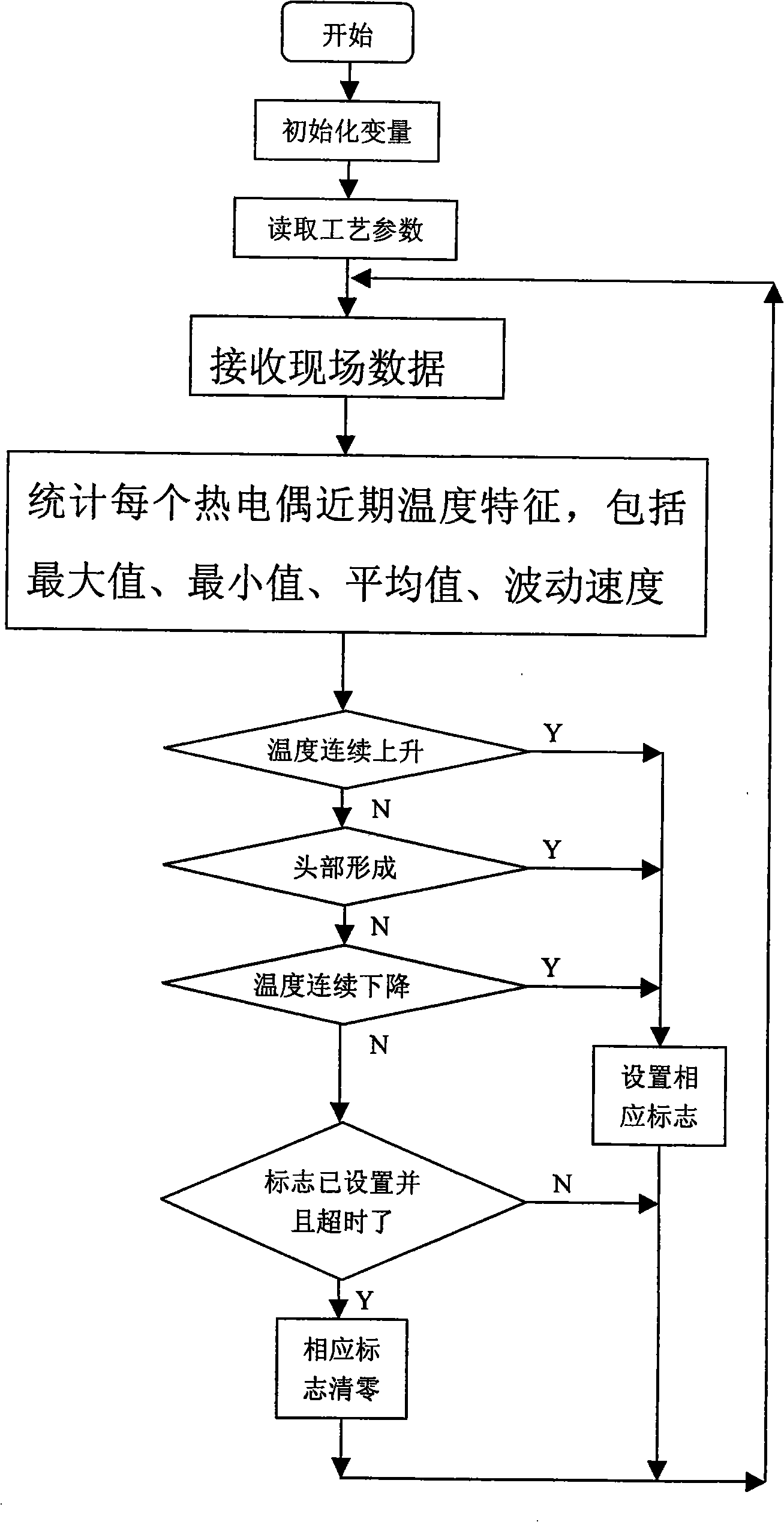

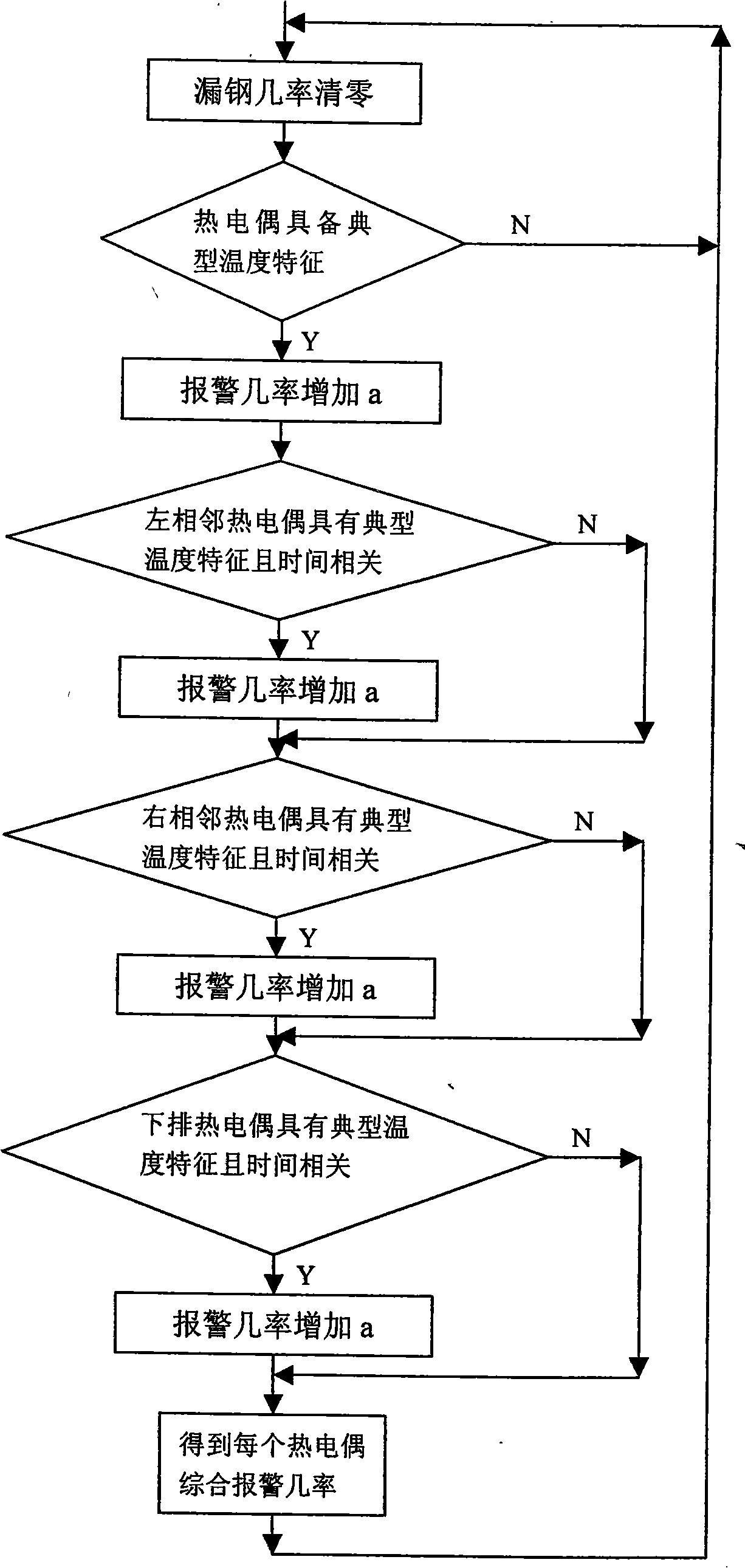

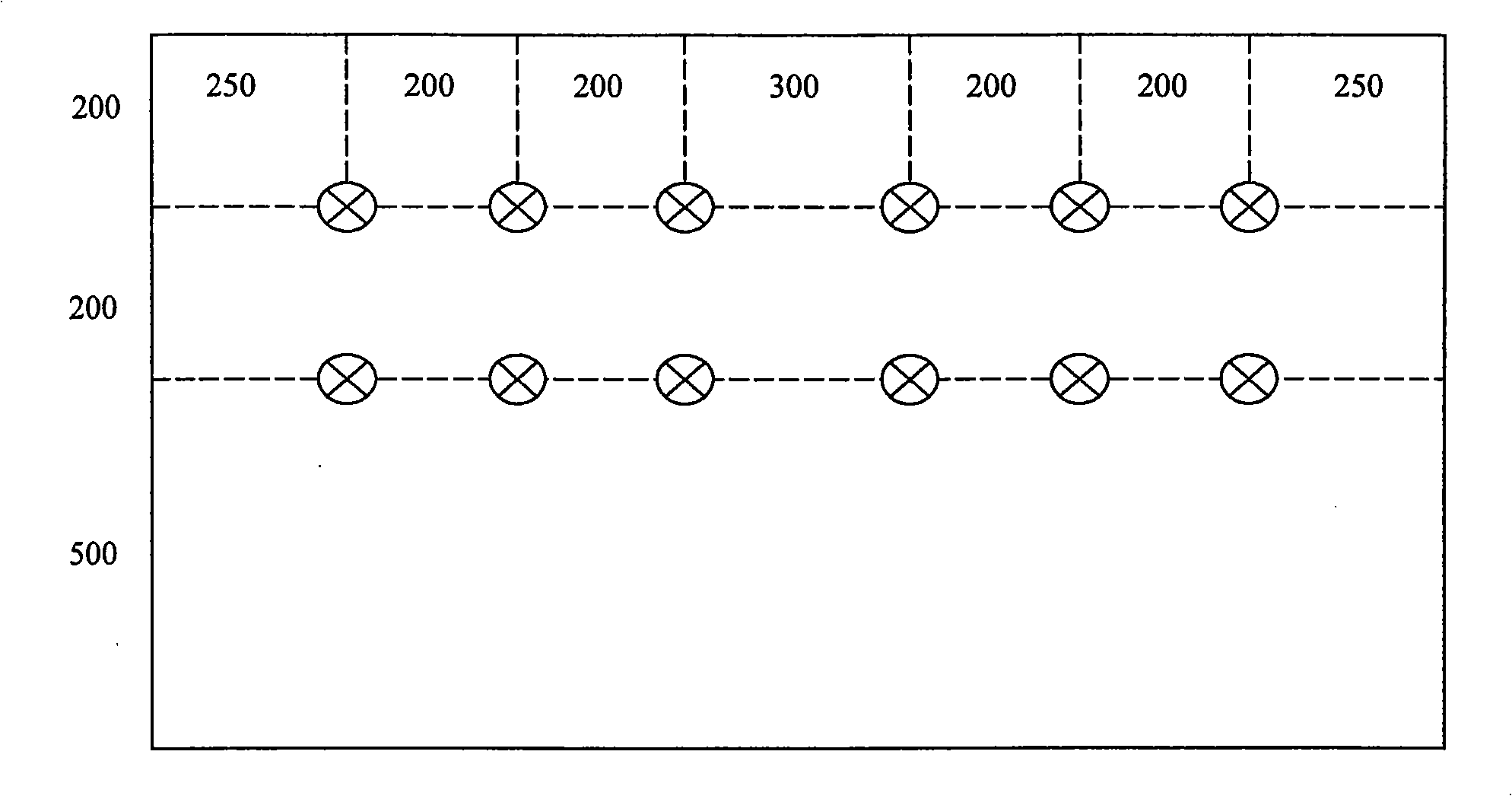

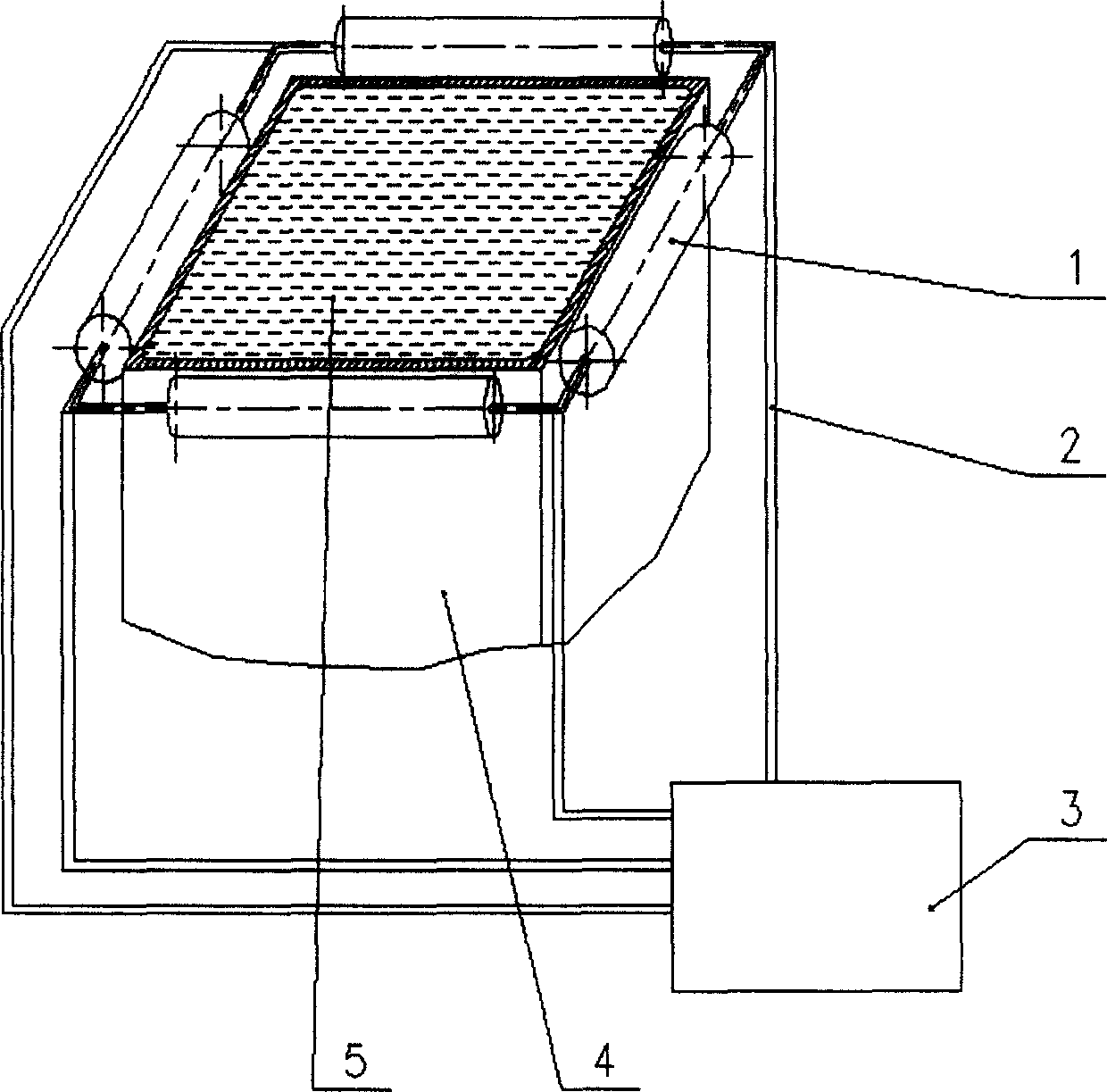

Slab continuous-casting bleedout forecast control method

The invention relates to a method for predicting and controlling slab continuous casting breakout, in particular to a method for preventing sticking breakout according to the temperature variation condition of a thermocouple in a crystallizer in the process of slab continuous casting. The method mainly aims at solving the technical problems that the existing various breakout prediction methods can not compressively consider interference factors and can not predict small-scale sticking and slag entrapment in time. The technical proposal of the invention is that the method for predicting and controlling the slab continuous casting breakout comprises the step that lines of thermocouples are arranged on the crystallizer, and the method is characterized by comprising the following steps: a. capture of typical temperature characteristics: the typical temperature characteristics of each thermocouple is determined according to the crystallizer parameters and the installment location of the crystallizer on the thermocouple; b. determination of breakout probability: the breakout probability of each thermocouple is determined according to the typical temperature characteristics of the adjacent thermocouples as well as the characteristics of the breakout thermal conductance and abnormal temperature distribution; c. control of casting speed: when the breakout probability of the thermocouples is up to 95%, the casting is stopped. The method is mainly used for warning continuous casting breakout.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for improving continuous casting blank quality and vibration support roller device

The present invention belongs to the field of continuous metal blank casting technology, and is especially the method of raising continuous cast blank quality and the vibrating support roller apparatus. While the vibrating support roller closely contacting the casing of the continuously cast blank casing rotates synchronously with cast blank, it vibrates in the direction perpendicular to the cast blank thickness or in the direction parallel to the blank drawing under the drive of the vibration source, and the vibration is transferred to the solidifying shell of the liquid core via contact. The vibrating support roller apparatus consists of vibrating support roller, vibration transferring pipeline and vibration generating source. The present invention can improve the quality of the continuous cast blank obviously.

Owner:CENT IRON & STEEL RES INST

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

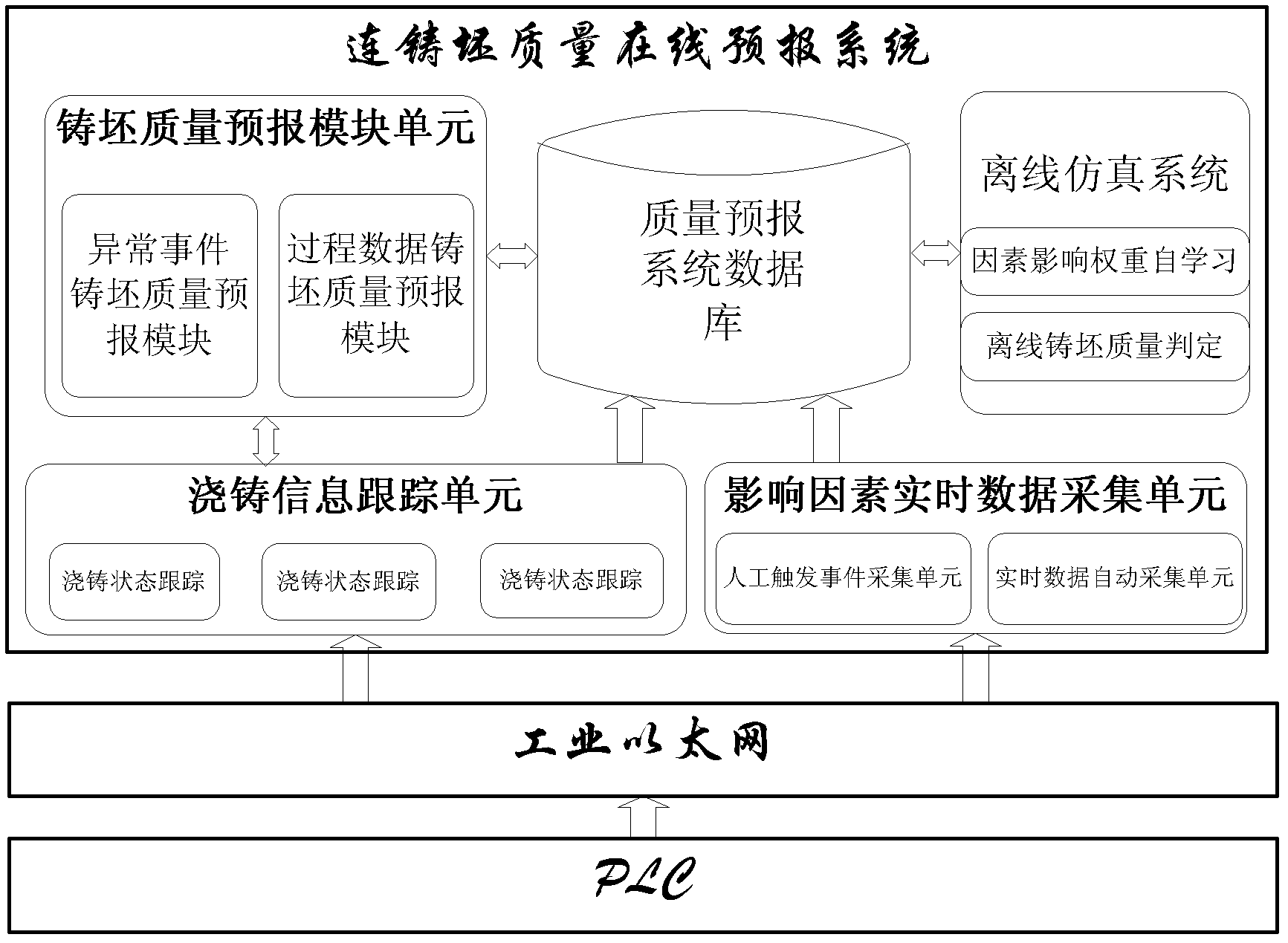

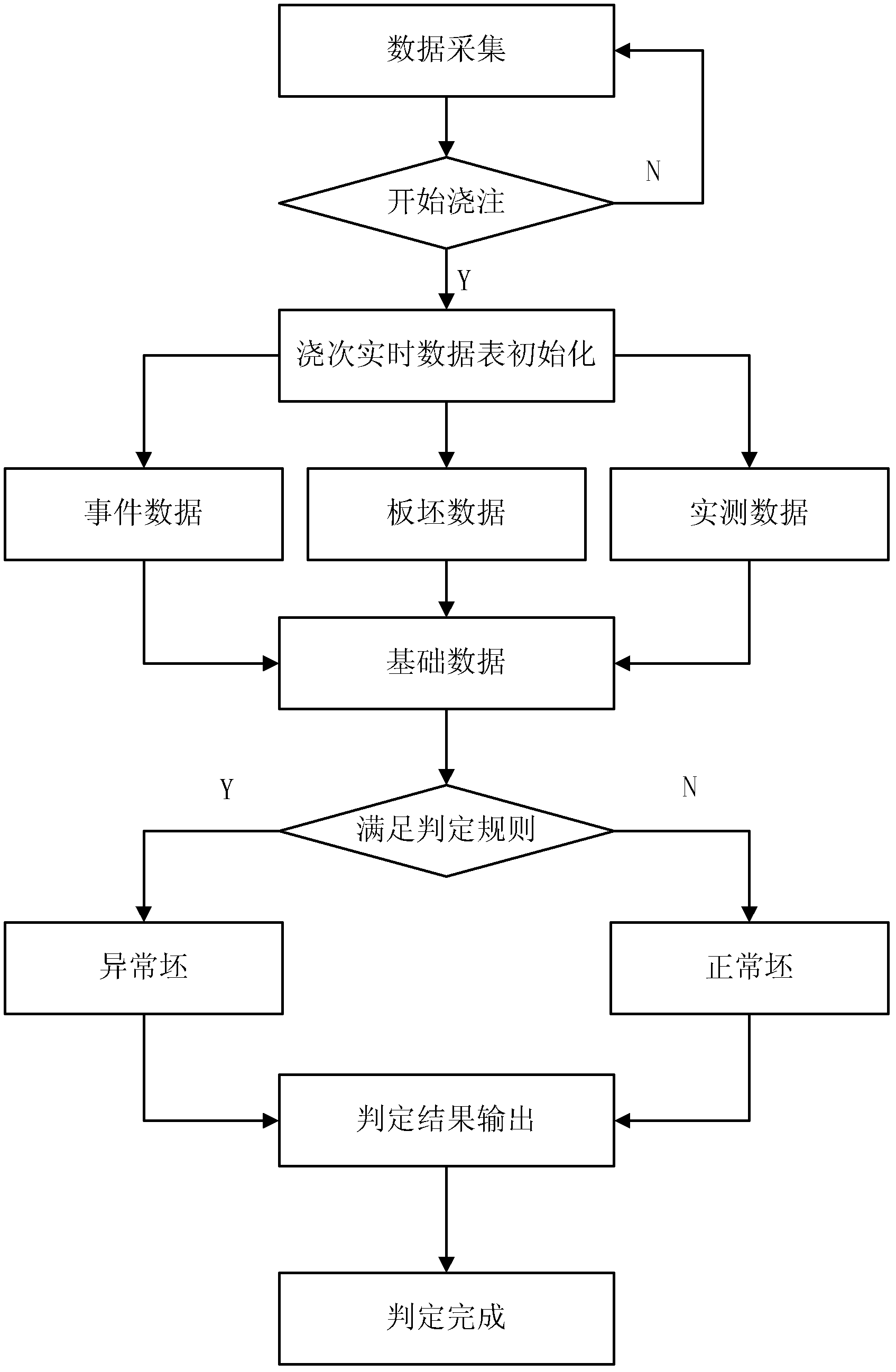

Method for controlling on-line prediction of continuous casting blank quality

The invention discloses a method for controlling on-line prediction of continuous casting blank quality, which belongs to the field of metallurgical automation control. In the method, a comprehensive quality prediction rule based on an expert system, mathematical statistics and a neural network is programmed by secondary control software, and data communication is performed by the secondary control software and a primary basic automatic control system, so that the automatic prediction of casting blank quality in the continuous casting production process is realized; and a quality judgment system overall framework comprises an influence factor real-time data acquisition module, a casting state and casting information tracking module, an abnormal event and casting blank quality prediction module, an off-line simulation system, a quality prediction system database, a primary communication interface module and a system human-machine interface (HMI) picture. The method has the advantage that the on-line automatic prediction of the casting blank quality in the continuous casting production process is realized.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

Method for smelting ultra-low carbon steel

ActiveCN102719593AHigh carbon contentReduce carbon contentManufacturing convertersProcess efficiency improvementHigh carbonSlag

The invention provides a method for melting ultra-low carbon steel. The method adopts a desulfuration of molten iron-converter-RH-continuous casting process, wherein a sulfur content in the molten iron is 0.002%-0.006% after desulphurization; converter smelting controls oxygen blowing time, an oxygen gun flow, a bottom-blowing intensity and a smelting period, adopts slag-stopping tapping, steel tapping with a content of C being 0.06%-0.08% and with a temperature of 1650-1680 DEG C, and an oxygen content in the molten iron is 0.03%-0.05%; an RH adopts forced decarburization with a highest vacuum degree of 67-100 MPa and decarburization time of 15-27 min, and a carbon content in the molten iron is 0.0010%-0.0020% and a dissolved oxygen content in the molten iron is 0.025%-0.040% after the decarburization; the molten iron is recycled for 3-5 min after deoxidation by adding aluminium and recycled for another 3-5 min after adding other alloys; a nitrogen content in the molten iron is 0.0015%-0.0035%, and the temperature is 1590-1640 DEG C; and killed steel treatment is carried out for 10-30 min. The method adopts converter tapping with a high carbon and low oxygen content, can use less or not use slag modified agents during the tapping process, accelerates the production rhythm, makes the molten steel cleaner, and reduces the production cost.

Owner:ANGANG STEEL CO LTD

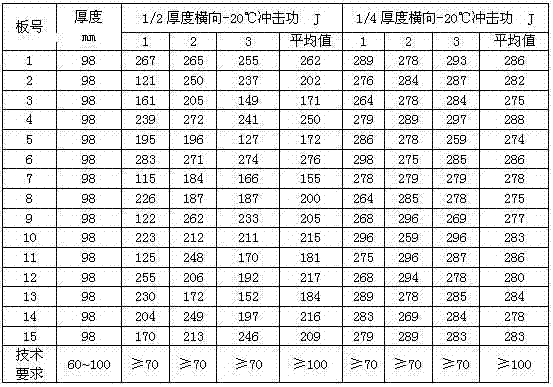

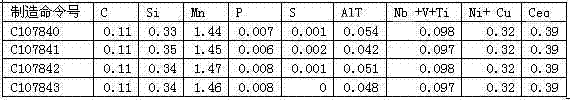

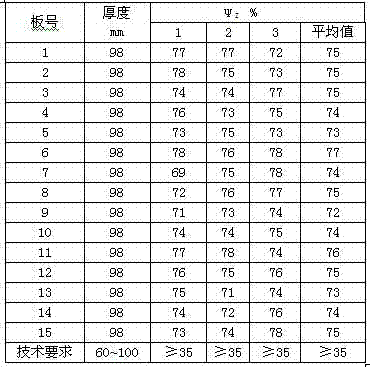

Method for producing super-thick steel plate

ActiveCN102409236AMeet manufacturing requirementsReduce manufacturing costRoll mill control devicesFurnace typesThick plateContinuous casting

The invention discloses a method for producing a super-thick steel plate. The method comprises the following production process steps of: performing pretreatment on molten iron; making steel by using a convertor; performing external refining; continuously casting; heating; rolling; cooling in an accelerated way; normalizing; controlling a cold condition; finishing; inspecting performance; and performing ultrasonic flaw detection. In the method, a low-C high-Mn component system is utilized, and Ni and Cu alloy elements are added into the steel in combination with micro-alloying treatment of Nb, V and Ti. The steel comprises the following chemical components in percentage by weight: less than or equal to 0.12 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.50 percent of Mn, less than orequal to 0.008 percent of P, less than or equal to 0.003 percent of S, 0.03 to 0.06 percent of AlT, less than or equal to 0.10 percent of Nb, Ti and V, less than or equal to 0.80 percent of Cu and Ni, less than or equal to 0.40 percent of Ceq and the balance of Fe and inevitable impurities. By the method, a continuous casting blank is used for producing high-performance Q345R steel plates with the thickness of 60 to 100mm, so that production cost is reduced, and the requirement of manufacturing containers with high parameter pressure is met; the low-C high-Mn component system is used for a component design, so that the requirement that the material Ceq is less than or equal to 0.40 percent is met; and the continuous casting blank is used for producing a high-performance Q345R super-thick plate, so that the method has a simple process, the process is easy to realize, and the plate can be produced by a common wide and thick plate factory.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com