Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about How to "Meet manufacturing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

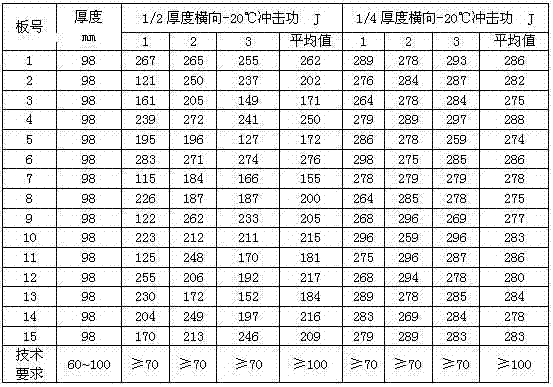

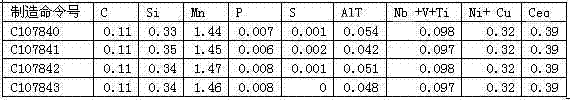

Method for producing super-thick steel plate

ActiveCN102409236AMeet manufacturing requirementsReduce manufacturing costRoll mill control devicesFurnace typesThick plateContinuous casting

The invention discloses a method for producing a super-thick steel plate. The method comprises the following production process steps of: performing pretreatment on molten iron; making steel by using a convertor; performing external refining; continuously casting; heating; rolling; cooling in an accelerated way; normalizing; controlling a cold condition; finishing; inspecting performance; and performing ultrasonic flaw detection. In the method, a low-C high-Mn component system is utilized, and Ni and Cu alloy elements are added into the steel in combination with micro-alloying treatment of Nb, V and Ti. The steel comprises the following chemical components in percentage by weight: less than or equal to 0.12 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.50 percent of Mn, less than orequal to 0.008 percent of P, less than or equal to 0.003 percent of S, 0.03 to 0.06 percent of AlT, less than or equal to 0.10 percent of Nb, Ti and V, less than or equal to 0.80 percent of Cu and Ni, less than or equal to 0.40 percent of Ceq and the balance of Fe and inevitable impurities. By the method, a continuous casting blank is used for producing high-performance Q345R steel plates with the thickness of 60 to 100mm, so that production cost is reduced, and the requirement of manufacturing containers with high parameter pressure is met; the low-C high-Mn component system is used for a component design, so that the requirement that the material Ceq is less than or equal to 0.40 percent is met; and the continuous casting blank is used for producing a high-performance Q345R super-thick plate, so that the method has a simple process, the process is easy to realize, and the plate can be produced by a common wide and thick plate factory.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process

InactiveCN1888120ARaise Strength IndexMeet manufacturing requirementsRoll mill control devicesHeat treatment process controlHeat sensitiveUltimate tensile strength

The present invention discloses one kind of ultra-high strength steel with excellent corrosion resistance and fatigue resistance and its making process. The ultra-high strength steel consists of C 0.05-0.12 wt%, Si 0.05-0.50 wt%, Mn 1.10-1.70 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Nb 0.025-0.070 wt%, V 0.005-0.080 wt%, Mo 0.20-0.50 wt%, Ni 0.30-0.80 wt%, Ti 0.005-0.025 wt%, Cu 0.25-0.80 wt%, B 0.0005-0.0020 wt%, and Cr 0.10-0.70 wt%, except Fe and inevitable impurities. It has carbon equivalent not lower than 0.65 % and heat sensitive coefficient not lower than 0.30 %. Its making process includes the steps of smelting, desulfurizing molten iron, combined blowing in converter, vacuum treatment, casting into plate blank, etc. It has yield strength not lower than 880 MPa, tensile strength not lower than 980 MPa and V-shaped notch Charpy absorbed-in-fracture energy at -20 deg.c not lower than 100J.

Owner:武钢集团有限公司

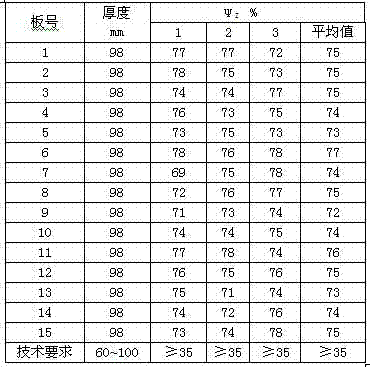

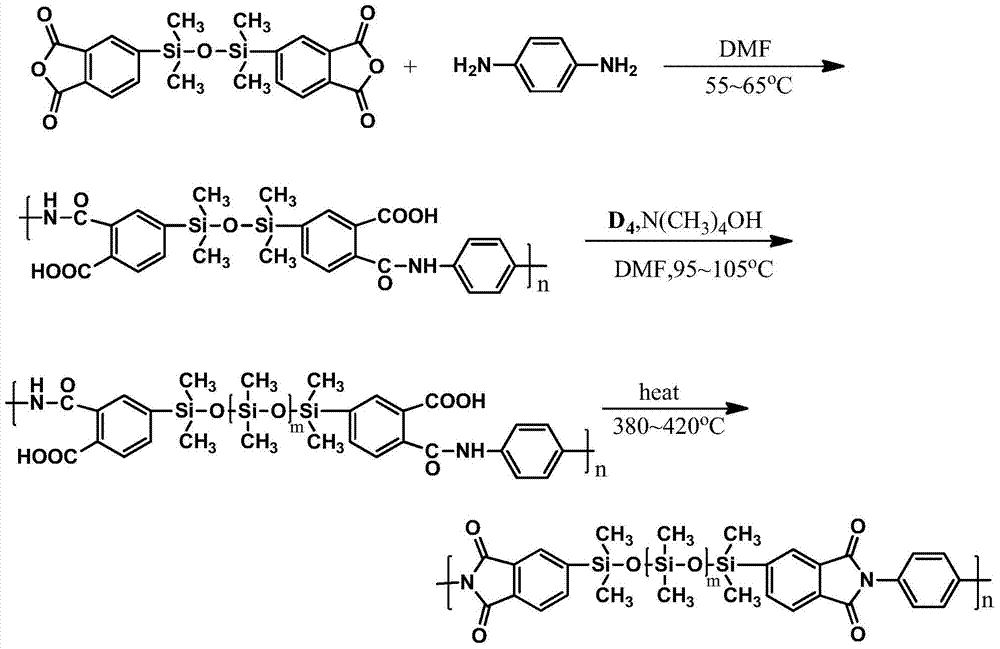

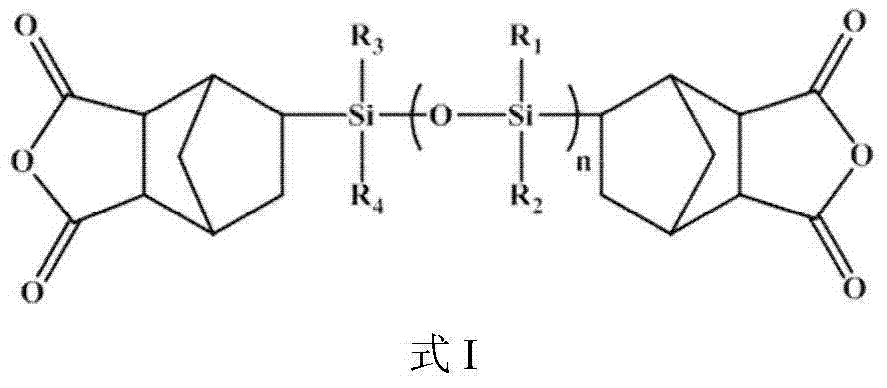

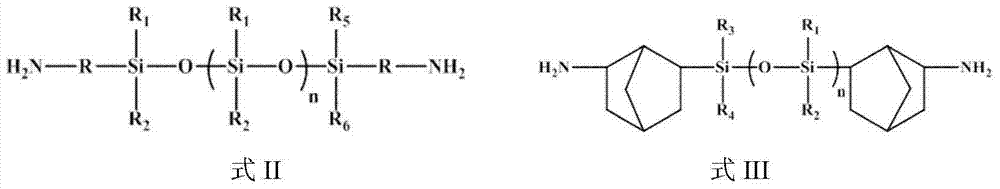

Novel electronic-grade polyimide film with low linear expansion coefficient and production method thereof

The invention relates to a preparation method of an electronic-grade polyimide film with low linear expansion coefficient. The method comprises the following steps that (1) the step-by-step condensation polymerization technology is used for obtaining polybasic block copolymerization polyamide acid glue solutions comprising one or more bar-shaped rigid chain sections containing para-benzene or biphenyl and one or more soft chain sections containing ether bonds or silicon-oxygen bonds and the like; (2) polyamide acid comprising one or more bar-shaped rigid chain structures containing para-benzene or biphenyl and polyamide acid comprising one or more soft chain structures containing ether bonds or silicon-oxygen bonds are independently compounded, and the two or more polyamide acid glue solutions different in rigidity and softness are mixed and compounded; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, casting filming, bidirectional stretching, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

Novel electronic-grade polyimide film with low linear expansion coefficient and manufacturing method thereof

The invention relates to a manufacturing method of an electronic-grade polyimide film with low linear expansion coefficient. The method is characterized by comprising the steps that (1) the step-by-step condensation polymerization technology or the blending compounding technology is used for obtaining two or more polyamide acid glue solutions comprising rigid structures and soft structures at the same time and are different in rigidity and softness; (2) ultrafine inorganic whiskers, like zinc oxide whiskers, silicon carbide whiskers and zirconium tungstate whiskers, which are subjected to surface organic modification already and / or nanoparticle materials are smashed and cavitated through high-energy-density supersonic waves, and then the functional fillers are compounded with polybasic polyamide acid in an in-situ micro-nano mode; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, extrusion casting filming, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

High low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and production method thereof

ActiveCN102605297AImprove strength and toughnessMeet manufacturing requirementsFurnace typesHeat treatment furnacesHydrogenWater flow

Disclosed are high low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and a production method thereof. The production method includes the steps: firstly, smelting and casting; secondly, heating plate blanks at 1070-1210 DEG C and rolling the plate blanks according to a compression ratio of 2.7-6.4; thirdly, normalizing within an austenitization temperature range; fourthly, accelerated cooling with water for 4-15 minutes; and fifthly, tempering at 700-750 DEG C; and sixthly cooling, wherein the steel plates comprise, in weight percentage, 0.10-0.15% of C, 0.50-0.60% of Si, 0.40-0.60% of Mn, not more than 0.010% of P, not more than 0.003% of S, 1.25-1.50% of Cr, 0.45-0.65% of Mo, 0.08-0.18% of Cu, 0.07-0.17% of Ni, 0.020-0.045% of Al, not more than 0.003% of Sn, not more than 0.003% of Sb, not more than 0.003% of As, 0.0020-0.0070% of N, the balance of Fe and unavoidable impurities, low-pressure section water flow of a pressure quenching machine is 18-38m<3> / min, top-to-bottom water volume ratio of each steel plate is 1:1.0-1.3, and the surface temperature of the steel palate at an outlet of the pressure quenching machine is not more than 120 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

Blue-ray-proof lens and resin raw material thereof

InactiveCN106674852ARealize coating modificationGood dispersionOptical filtersOptical partsHigh energySilanes

The invention relates to the field of a lens and specifically relates to a blue-ray-proof lens and a resin raw material thereof. A substrate polymer and a blue-ray-proof additive are contained in the lens; a nanometer rare earth oxide subjected to surface modification treatment is served as the blue-ray-proof additive; 3-methacryloxy trimethoxy silane and polymethyl methacrylate are contained in a modifying material used for the surface modification treatment. According to the invention, the nanometer rare earth oxide subjected to surface-cladding treatment is added into the substrate polymer, so that the lens has a better converting absorbing function for the 400-470nm high-energy blue ray; the high transparency and low haze of the lens can be guaranteed; the lens can meet the manufacturing requirements of the myopic lens, presbyopic glasses and sun glasses; the lens has wide adaptability.

Owner:HEFEI WIYE OPTICAL TECH CO LTD

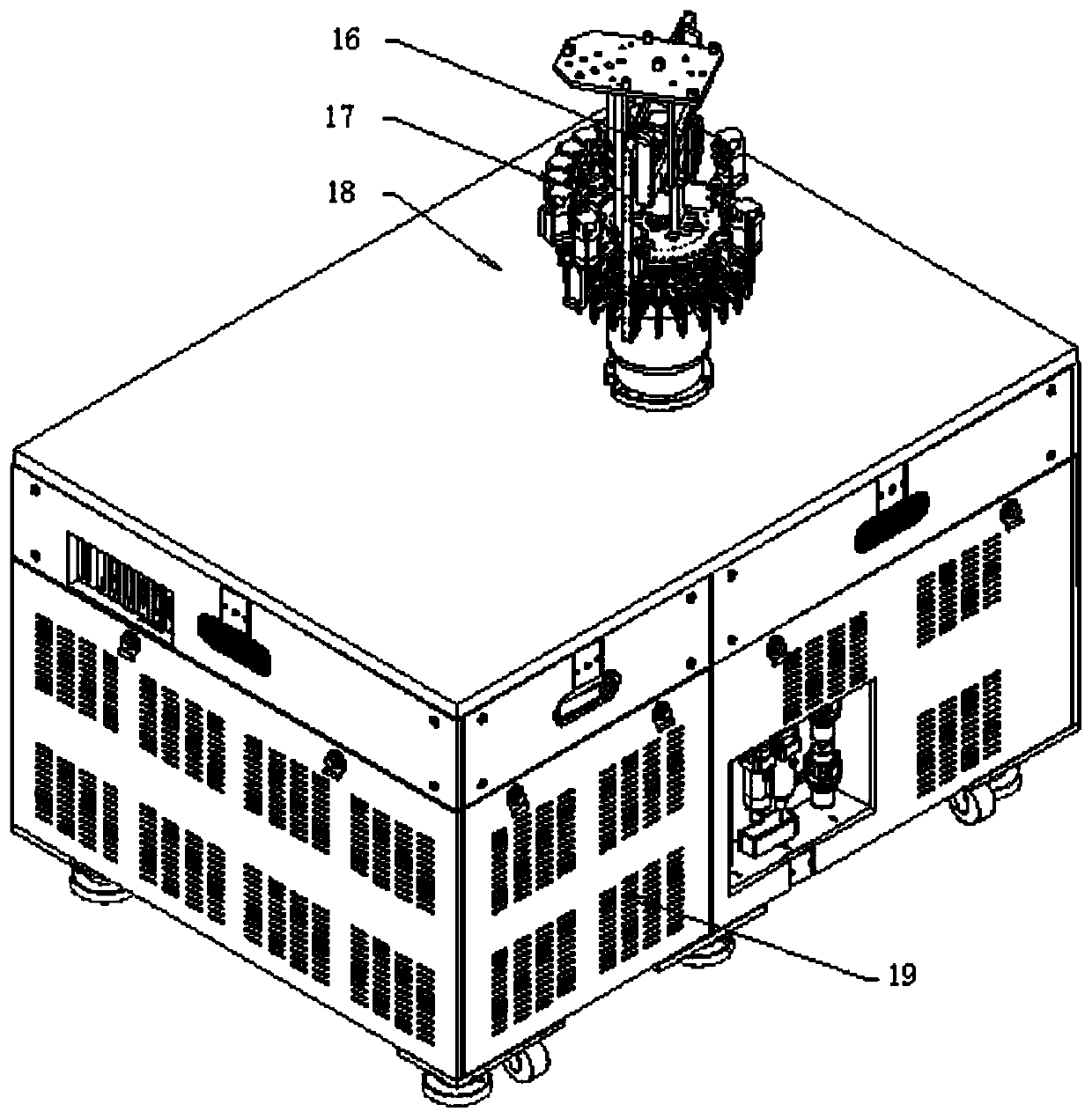

Photosensor testing sorting machine

The invention discloses a photosensor testing sorting machine which comprises a main tower rotating disc system, a feeding screening module and a feeding transfer device. The main tower rotating discsystem performs systematic control over module devices, a loading disc containing a device is placed on a product launching loading platform of the feeding screening module, a vision CCD device of thefeeding screening module recognizes the device, a device taking and placing suction nozzle selects a product of a correct directional surface from the loading disc, and the product is transferred toa device positioning reverse mold of the feeding transfer device; the feeding transfer device transfers the product to the portion under the working position of a vacuum suction nozzle of the main tower rotating disc system; the existing production mode that workers perform manual testing under the special environment and workers perform appearance inspection under a microscope is changed into themode that machine equipment intelligently and automatically selects a qualified product, and unqualified products are classified concentratedly; in this way, the production efficiency is high, the error rate is low, the mode can be popularized to mass production, the labor cost is greatly reduced, and the working efficiency is improved.

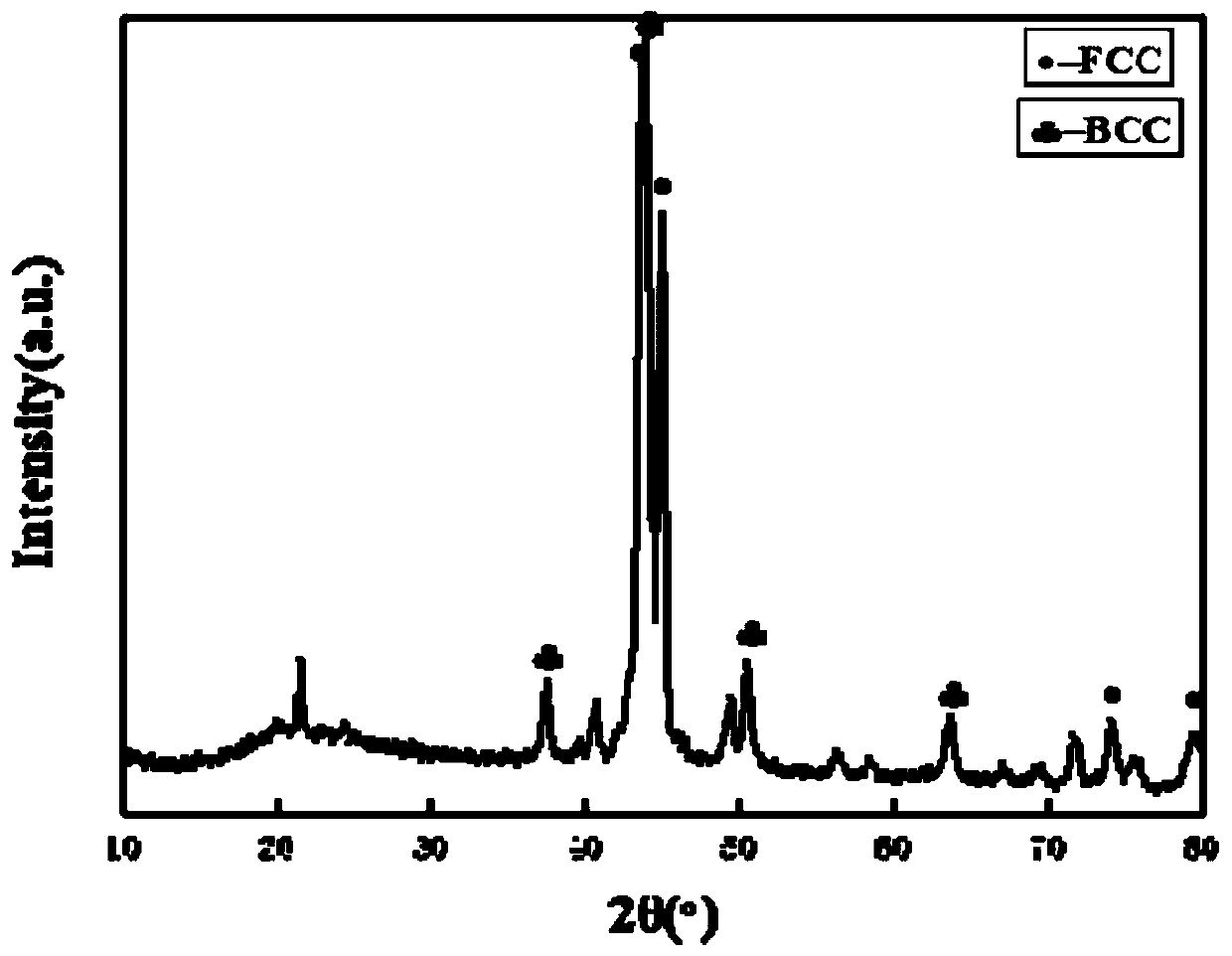

FeCrCuTiV high-entropy alloy powder for laser melting deposition manufacturing and preparation method of FeCrCuTiV high-entropy alloy powder

ActiveCN109957700AModerated coefficient of thermal expansionModerate differences in modulus of elasticity, etc.Additive manufacturing apparatusTransportation and packagingHigh entropy alloysThermal expansion

The invention discloses FeCrCuTiV high-entropy alloy powder for laser melting deposition manufacturing and a preparation method of the FeCrCuTiV high-entropy alloy powder. The high-entropy alloy powder is prepared from the following components in percentage by weight: 17-20% of Cr, 22-25% of Cu, 16-19% of Ti, 17-20% of V and 19-22% of Fe. The differences of the thermal expansion coefficient, the melting point, the elastic modulus and the like of a tungsten / steel interface can be effectively relieved through the solid solution effect of alloy elements such as Ti, V and Cu of a high-entropy alloy, the level of residual stress at a heterogeneous interface in the laser melting deposition preparation process can be reduced, precipitation of a Laves phase is avoided, and the manufacturing requirements of tungsten steel heterogeneous parts for a fusion reactor can be met.

Owner:SUZHOU UNIV

Bimetal opening mold for glass mold and preparation method of bimetal opening mold

ActiveCN102775047BImprove bindingAvoid crackingGlass blowing apparatusOxidation resistantEnergy source

The invention relates to a bimetal opening mold for a glass mold and a preparation method of the bimetal opening mold and belongs to the field of a glass mold and a preparation method of the glass mold. The bimetal opening mold comprises an opening mold base body and a nickel base alloy embedding block, wherein the nickel base alloy embedding block is combined into an inner cavity as an independent component, in addition, a group of tenons are formed at one side of the nickel base alloy embedding block backing to the nickel base alloy embedding block cavity, the group of tenons form a whole with the inner cavity of the opening mold base body in a mortise-tenon matching mode during the opening mold base body forming, the opening mold base body is copper alloy, the opening mold base body consists of the following chemical ingredients including aluminum, zinc, nickel, silicon, manganese, iron and the balance copper, and the nickel base alloy embedding block consists of the following chemical elements including carbon, silicon, chromium, copper, vanadium, boron, iron and the balance nickel. The bimetal opening mold has the advantages that the ideal high temperature resistance, oxidation resistance, creepage resistance, instant heat impact resistance and wear resistance performance can be realized, the service life of the opening mold is ensured, the manufacture requirements of the high-machine-speed glass container manufacture is met, the industrial production requirement is met, the energy sources are saved, the operation intensity of workers is reduced, and the influence caused by artificial factors is avoided.

Owner:ORI MOLD TECH SUZHOU

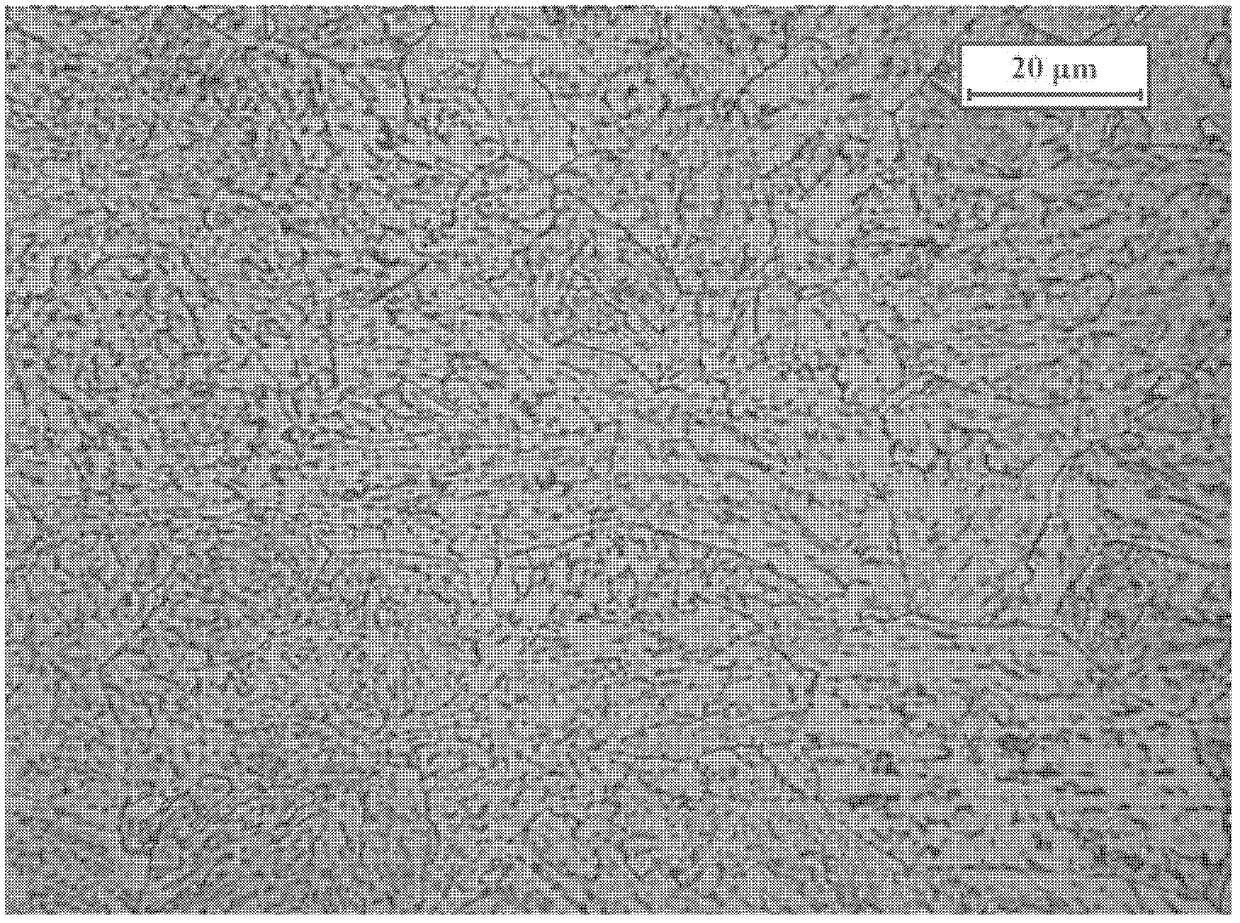

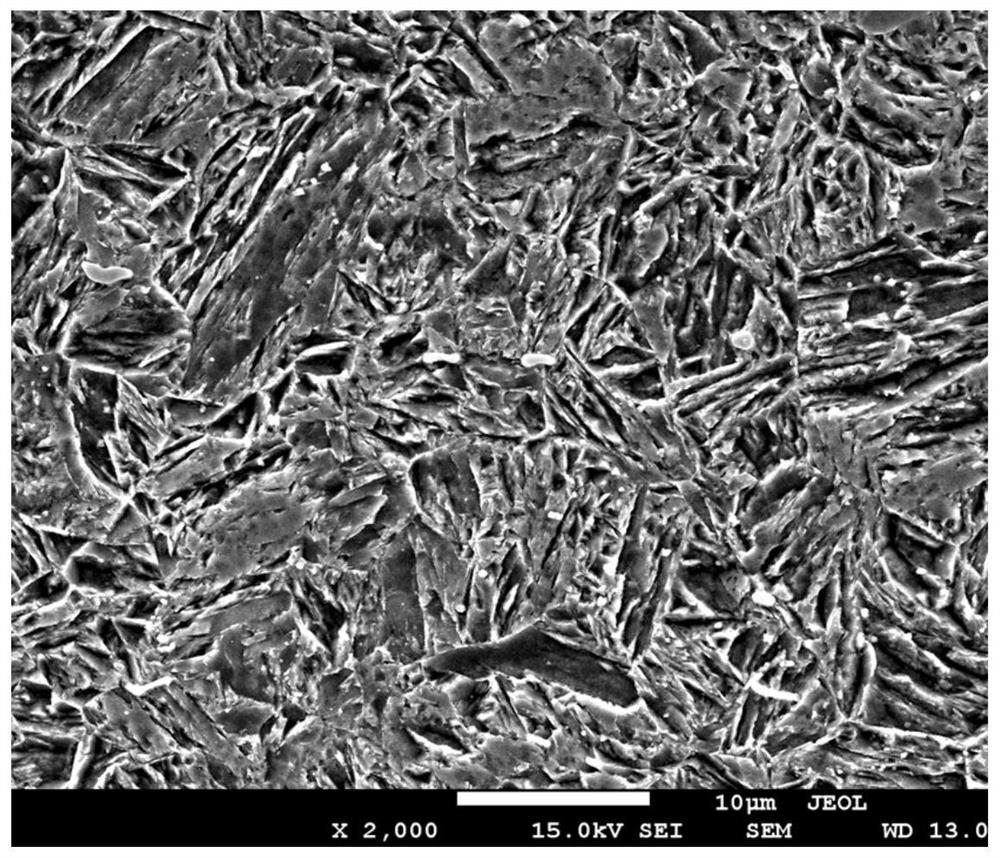

TiC-reinforced martensite wear-resistant steel plate with high toughness and good bending performance and manufacturing method thereof

The invention relates to a TiC-reinforced martensite wear-resistant steel plate with high toughness and good bending performance and a manufacturing method thereof. The TiC-reinforced martensite wear-resistant steel plate comprises the following elements including 0.18 to 0.30% of C, less than or equal to 0.30% of Si, 0.60 to 1.20% of Mn, 0.20 to 0.40% of Ti, 0.04 to 0.08% of Al, less than or equal to 0.10% of Ni, less than or equal to 0.10% of Cu, 0.20 to 1.00% of Cr, 0.10 to 0.60% of Mo, 0.0010 to 0.0040% of B, 0.001 to 0.005% of Ca, less than or equal to 0.015% of P, less than or equal to 0.003% of S, less than or equal to 0.0015% of O, less than or equal to 0.0030% of N, less than or equal to 0.0002% of H and the balance of Fe, and C-Ti / 4 is more than or equal to 0.13 and less than orequal to 0.25, so that the hardness of a martensite matrix reaches 400-480 HB after TiC is formed; the carbon equivalent CEV is smaller than or equal to 0.65%, and the machining welding performance can meet the manufacturing requirement of high-abrasion-resistance equipment. The technological process comprises the steps of converter or electric furnace steelmaking, LF refining, vacuum degassing, Ca treatment, continuous casting, heating, hot rolling, quenching and low-temperature tempering; the elongation A50 is greater than or equal to 8%; the low-temperature impact toughness Akv at -40 DEG Cis larger than or equal to 20 J, and the cold bending performance d of the steel plate d is equal to 5a and the steel plate does not crack after 90-degree cold bending; and the wear resistance is 1.4times or more than 1.4 times that of low-alloy martensite wear-resistant steel NM450.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Medium-strength nitric acid corrosion-resistant titanium alloy

The invention discloses a medium-strength nitric acid corrosion-resistant titanium alloy. The titanium alloy is composed of the following components of, in percentage by mass, 5.0-7.0% of Ta, 0.7-1.5%of Al, 0.2-2% of Zr, 0.6-1.5% of Mo, 0.2-2% of Nb, and the balance Ti and inevitable impurities. The tensile strength of the annealed titanium alloy subjected to annealing treatment is 670-750 MPa, the yield strength of the annealed titanium alloy is 520-650 MPa, and the corrosion rate of the annealed titanium alloy in a boiling nitric acid solution with the concentration of 6 mol / L is not higherthan 0.08 mm / a. According to the medium-strength nitric acid corrosion-resistant titanium alloy, through adjusting the content of each element in the titanium alloy, the medium-strength nitric acid corrosion-resistant titanium alloy has excellent tensile strength, yield strength, corrosion resistance and impact toughness, also has excellent cold and hot processing properties, can be prepared intovarious processed products, and is suitable for manufacturing related equipment in the fields of nuclear industry and chemical industry.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

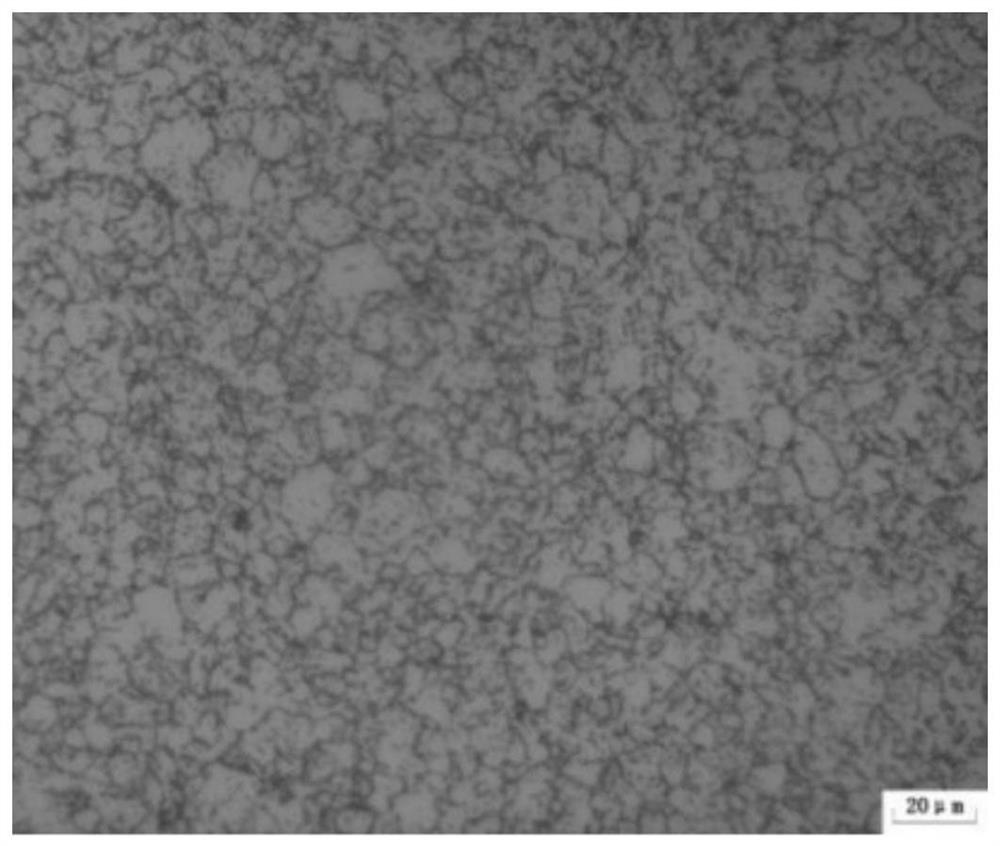

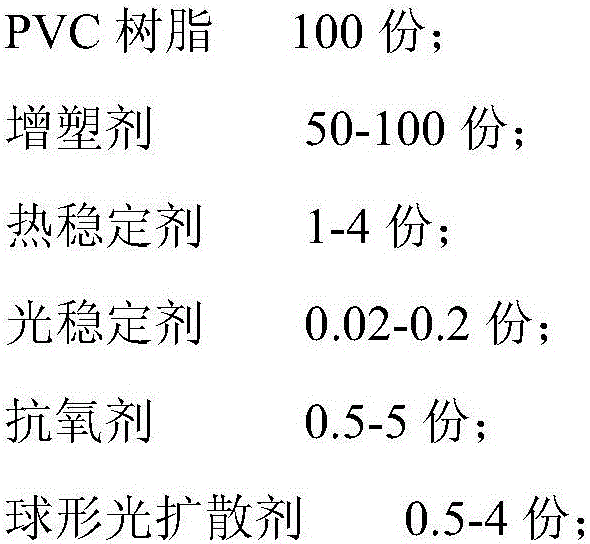

Photodiffusion-type flexible colored PVC (polyvinyl chloride) composition and application thereof

The invention relates to the technical field of high-polymer materials, and discloses a photodiffusion-type flexible colored PVC (polyvinyl chloride) composition and application thereof in photodiffusion-type flexible colored LED (light-emitting diode) decorative lamp bars. The composition comprises the following components in parts by weight: 100 parts of PVC resin, 50-100 parts of plasticizer, 1-4 parts of heat stabilizer, 0.02-0.2 part of light stabilizer, 0.5-5 parts of antioxidant, 1-4 parts of photodiffusant agent and 1-8 parts of transparent toner. The composition is prepared by the following steps: uniformly dispersing and mixing the components in a high-speed mixing machine, and carrying out screw extrusion granulation while controlling the screw temperature at 120-180 DEG C. The thickness of the rubber strip extruded by the extruder is 2mm, the haze is greater than or equal to 90%, and the light transmittance is greater than or equal to 70%. By using the high-yield low-price PVC resin as the main material and adding the cheap plasticizer and the composition composed of the heat stabilizer, light stabilizer, antioxidant, spherical photodiffusant, transparent toner and other aids, the prepared photodiffusion-type flexible PVC rubber strip has the advantages of low price and bright color, and overcomes the defects in PC (polycarbonate), PMMA (polymethyl methacrylate) and PS (polystyrene).

Owner:广东中联新材科技有限公司

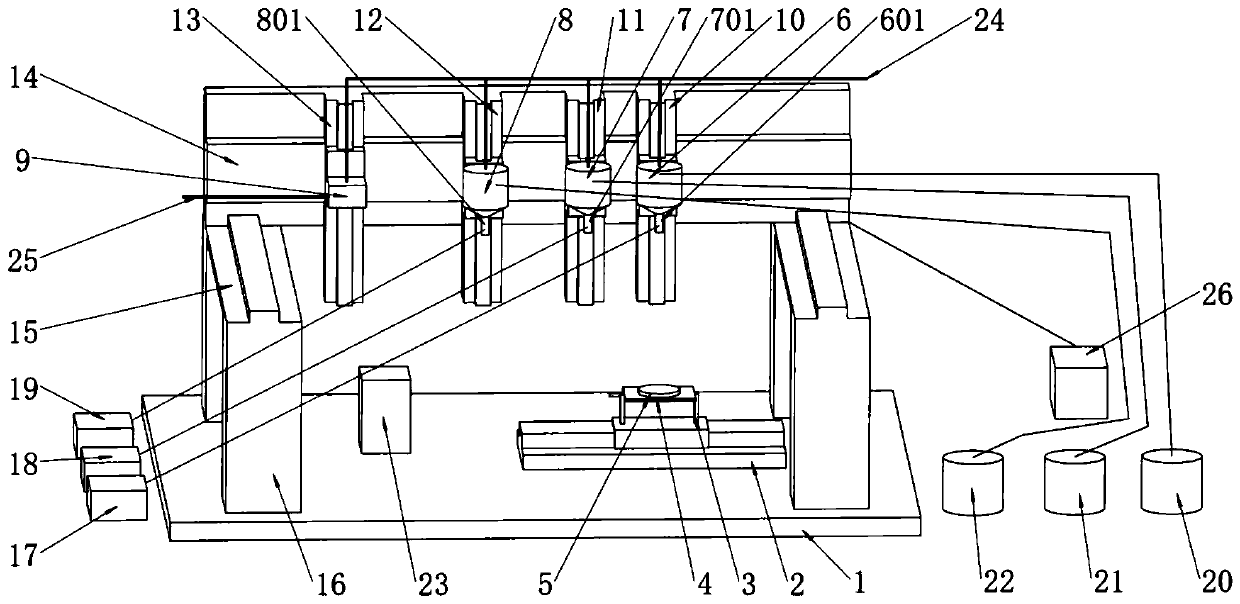

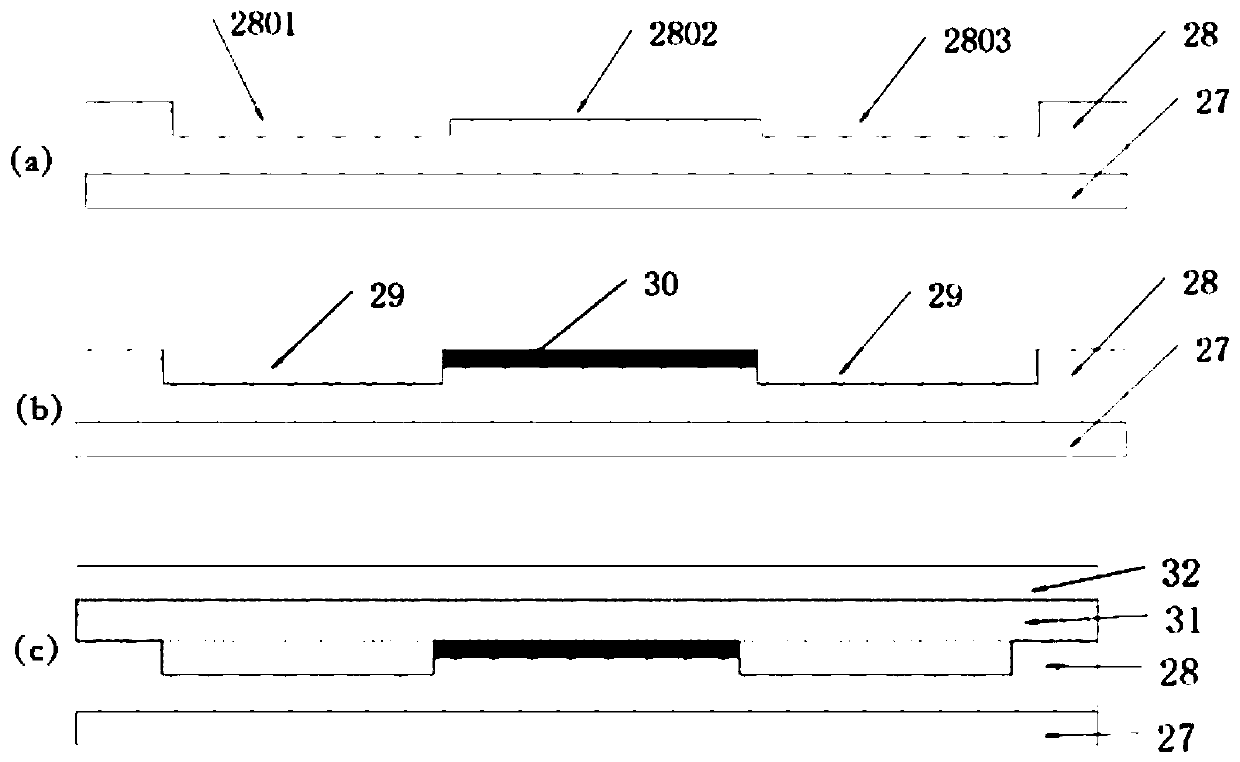

Multi-material 3D printing device for integrally manufacturing stretchable electronic product and working method

PendingCN109732900AAchieving heat curingReduce printing timeManufacturing platforms/substratesManufacturing heating elementsStretchable electronicsMulti material

The invention provides a multi-material 3D printing device for integrally manufacturing a stretchable electronic product and a working method. The device comprises a base and a control module; the base is provided with a three-dimensional workbench, a placing platform, a swing table and a printing bed, wherein the printing bed is arranged on the swing table, and the swing table drives the printingbed with vacuum adsorption and electric heating functions to swing and rotate; and the three-dimensional workbench comprises at least four Z-direction workbenches, the first Z-direction workbench isprovided with a mechanical arm used for grabbing and placing electronic elements, and each of the remaining Z-direction workbenches is provided with a printing nozzle. Movement of the three-dimensional workbench, the swinging table, the mechanical arm and a feeding module are controlled, each printing nozzle executes printing of a flexible base plate, a protective layer, a connecting circuit, an embedded electronic element and a packaging layer of the stretchable electronic product according to a set sequence, and thus integrated manufacturing is realized.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

Preparation method of thermosensitive film for NTC powder and graphene compound plane

ActiveCN108515713ALower the resistance valueImprove photoelectric conversion efficiencyNegative temperature coefficient thermistorsFlat articlesFiberSheet film

The invention relates to a preparation method of a thermosensitive film for an NTC powder and graphene compound plane. An NTC powder material and graphene for forming the general formula are compounded to prepare a film shape, the NTC powder material is coated or superimposed with graphene to form a sheet film, and the total resistance value of the compounded film is reduced. In order to better absorb solar radiation energy, graphene and the NTC powder material with various ratios can be compounded to respectively prepare films, then the films are superimposed to form a film with a microscopicgradient structure, and the internal resistance value is anisotropic according to different electrode connecting directions and positions, so that a better heat absorbing effect is realized, the self-resistance is reduced, the electrical conductivity is good, and the resistance value also can be set artificially. A single film or a superimposed film and a polymer film or a polymer fiber porous film are pressed again to be compounded into a new compound film, so that the toughness and the strength are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Header of 620-DEG C steam parameter ultra supercritical unit boiler

InactiveCN105066098AReduce wall thicknessMeet manufacturing requirementsBoiler drums/headersSuperheaterEngineering

The invention relates to a header of a 620-DEG C steam parameter ultra supercritical unit boiler. The header of the 620-DEG C steam parameter ultra supercritical unit boiler comprises a header main body and a pipe seat, wherein one end of the pipe seat is welded with the header main body, and the other end of the pipe seat is welded with a final-stage superheater or final-stage reheater pipe. The header is characterized in that the header main body is made by a 9Cr-3W-3Co large-diameter pipe, the pipe seat is made by a 9Cr-3W-3Co small-diameter pipe, the inner diameter of the pipe seat is larger than 35mm, and Ni-based alloy is welded on the inner wall of the pipe seat except the region which is 15-20mm away from the header. The header provided by the invention is a novel superheater outlet header or reheater outlet header applied to the 620-DEG C steam parameter ultra supercritical unit boiler, and the 9Cr-3W-3Co large-diameter pipe is used as the material. The high-temperature oxidation performance of the material is great, and the practical value is high.

Owner:SHANGHAI BOILER WORKS

Bimetal opening mold for glass mold and preparation method of bimetal opening mold

ActiveCN102775047AImprove bindingAvoid crackingGlass blowing apparatusOxidation resistantEnergy source

The invention relates to a bimetal opening mold for a glass mold and a preparation method of the bimetal opening mold and belongs to the field of a glass mold and a preparation method of the glass mold. The bimetal opening mold comprises an opening mold base body and a nickel base alloy embedding block, wherein the nickel base alloy embedding block is combined into an inner cavity as an independent component, in addition, a group of tenons are formed at one side of the nickel base alloy embedding block backing to the nickel base alloy embedding block cavity, the group of tenons form a whole with the inner cavity of the opening mold base body in a mortise-tenon matching mode during the opening mold base body forming, the opening mold base body is copper alloy, the opening mold base body consists of the following chemical ingredients including aluminum, zinc, nickel, silicon, manganese, iron and the balance copper, and the nickel base alloy embedding block consists of the following chemical elements including carbon, silicon, chromium, copper, vanadium, boron, iron and the balance nickel. The bimetal opening mold has the advantages that the ideal high temperature resistance, oxidation resistance, creepage resistance, instant heat impact resistance and wear resistance performance can be realized, the service life of the opening mold is ensured, the manufacture requirements of the high-machine-speed glass container manufacture is met, the industrial production requirement is met, the energy sources are saved, the operation intensity of workers is reduced, and the influence caused by artificial factors is avoided.

Owner:ORI MOLD TECH SUZHOU

Method for preparing and transferring magnetic nanometer array

InactiveCN103708414AMeet manufacturing requirementsSimple processNanostructure manufactureNanoholeMicro electrical mechanical systems

The invention provides a method for preparing a magnetic nanometer array and transferring the magnetic nanometer array to a metal substrate. The method includes the steps that a secondary anode oxidation method is utilized to prepare an aluminum oxide porous die plate which is not through, magnetic nano materials are deposited in holes of the die plate, the length of a deposited nanowire is controlled to make a certain unfilled depth reserved in the holes of the die plate, metal is deposited on the surface of the die plate, a continuous metal film with the nano holes is formed, thermocompression bonding is conducted on the continuous metal film and the metal substrate under certain temperature and pressure, and eventually the die plate is dissolved, and the goal of transferring the magnetic nanowire to the metal substrate is achieved. The method is simple in process and convenient to operate, compatible with the micro-electronic processing process, particularly, low-temperature bonding is achieved by the utilization of the nanoscale effect of a formed porous nanometer metal film layer, and the method has wide application prospect in the field of manufacturing of magnetic sensors based on a micro electro mechanical system.

Owner:河南省科学院应用物理研究所有限公司

Interactive wiring method

ActiveCN110968983AFirmly connectedEnsure consistencyComputer aided designSpecial data processing applicationsSoftware engineeringObstacle avoidance

An interactive wiring method comprises the following steps: 1) setting interactive wiring parameters; 2) selecting a connection graph, generating a connection point according to the graph attribute, and selecting a wiring width; 3) selecting a turning point and a jump layer obstacle avoidance point for orthogonal and oblique wiring; and 4) determining the wiring result and performing interactive wiring. According to the interactive wiring method, the graph of the starting point can be automatically detected, and the hierarchy and the width of the interactive wiring can be dynamically set, andthe starting point of the interactive wiring can be adjusted, and the consistency of the interactive wiring can be guaranteed, and the manufacturing requirement can be met.

Owner:北京华大九天科技股份有限公司

Manufacturing method for rear case body of gear case

InactiveCN106583661AOptimizing recycled sand processMeet manufacturing requirementsFoundry mouldsMould handling/dressing devicesSurface cleaningCoating

The invention discloses a manufacturing method for a rear case body of a gear case. An upper box and a lower box are adopted for modeling. The manufacturing method includes the following steps of precoated sand manufacturing, modeling, mould assembling, smelting, pouring, sand shakeout, pouring gate removing, surface cleaning, heat treatment, descaling, polishing, test and acceptance, primer coating and drying. According to the manufacturing method, the core setting process is simplified, a cavity core and the lower box are directly made together, and therefore the core manufacturing process and the core setting process in the modeling procedure are omitted, and a series of resulting problems and hidden dangers are prevented; and meanwhile, the precoated sand process and the reclaimed sand process are optimized, and the manufacturing requirements of the high-quality gear case can be met through the whole manufacturing method.

Owner:CHANGZHOU XINLIAN FOUNDRY IND CO LTD

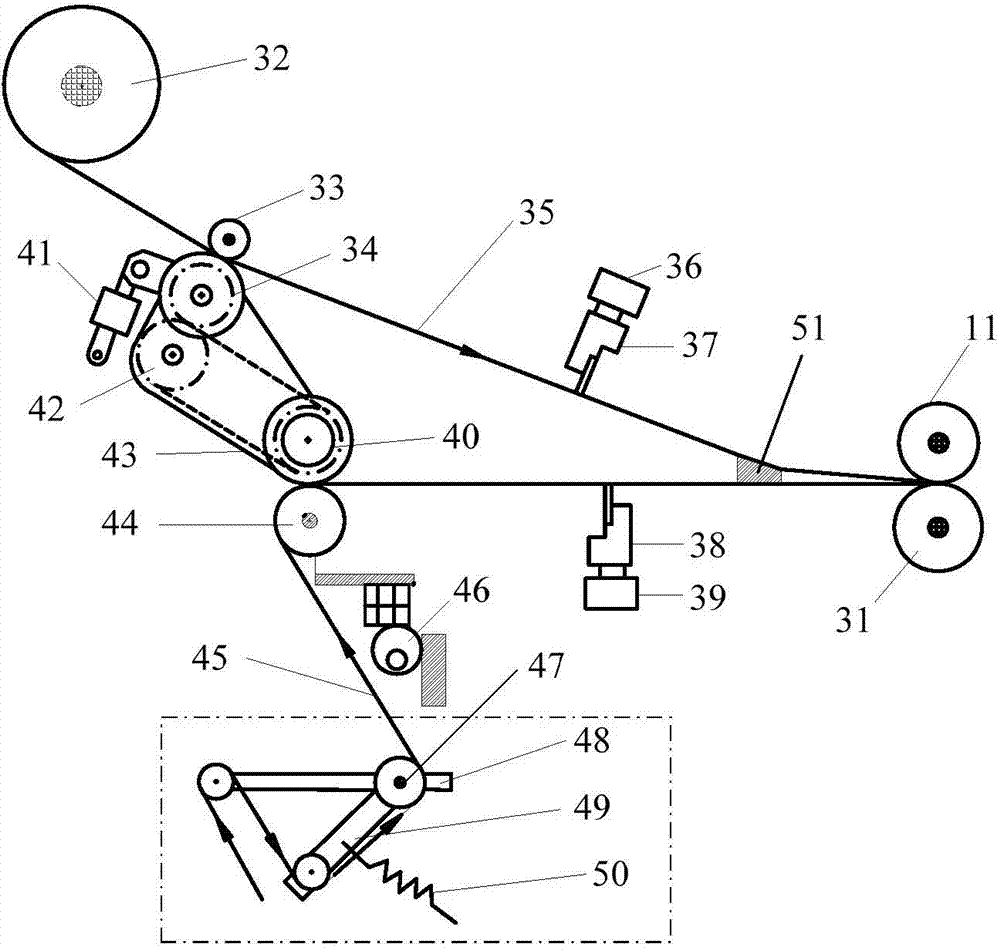

High-efficiency winding machine for flexible graphite metal spiral wound gasket

The invention relates to a high-efficiency winding machine for a flexible graphite metal spiral wound gasket, which mainly comprises a transmission mechanism and a winding feeding mechanism. In the transmission mechanism, an electric motor is connected with a speed reducer; an output shaft of the speed reducer is provided with a coupling and is connected with a compression wheel shaft; the compression wheel shaft is supported on a fixed support by adopting a bearing through a compression wheel shaft right end cover; a guide round rod is welded on the peripheral plane of an end cover support; the upper end of the guide round rod is welded with a welding block; a steel wire rope passes across a pulley on a fixing device; and the other end of the steel wire rope is connected with a counter weight. In the winding feeding mechanism, a graphite ribbon is connected between a compression wheel and a graphite ribbon reel; a guide block is arranged at the position between the graphite ribbon and a metal belt; the metal belt passes across an A wheel to be connected with a fixed arm arranged below the A wheel; and an eccentric mechanism is arranged between the A wheel and the fixed arm. According to the invention, quality of a domestic spiral wound gasket can be improved, so that the domestic spiral wound gasket meets more and more harsh working conditions in large-scale chemical production equipment; and the high-efficiency winding machine for the flexible graphite metal spiral wound gasket has more complete functions and a higher automation degree.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

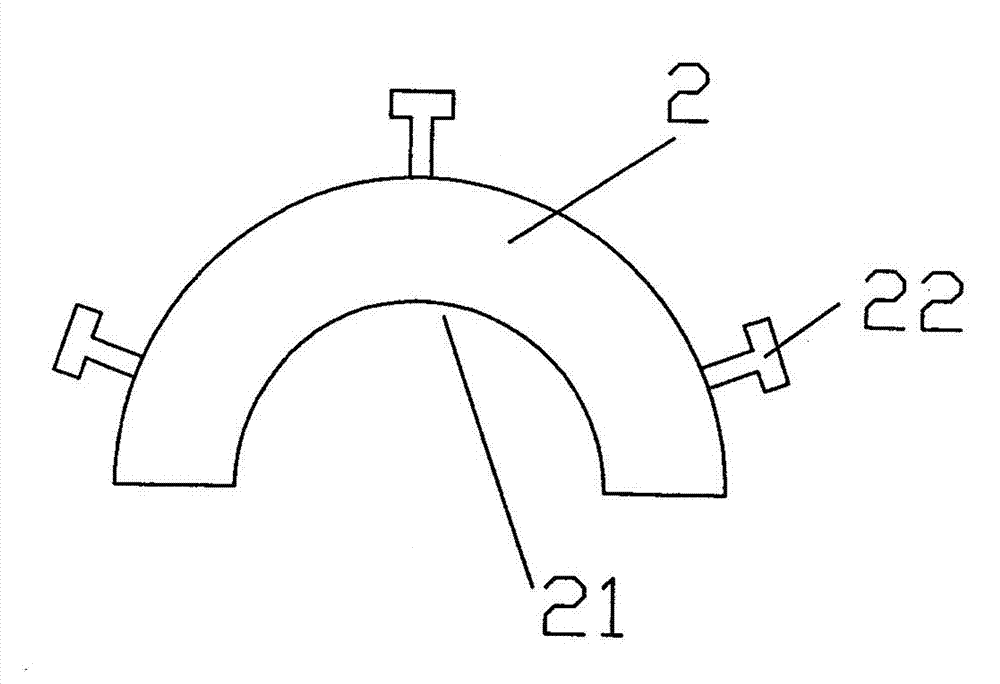

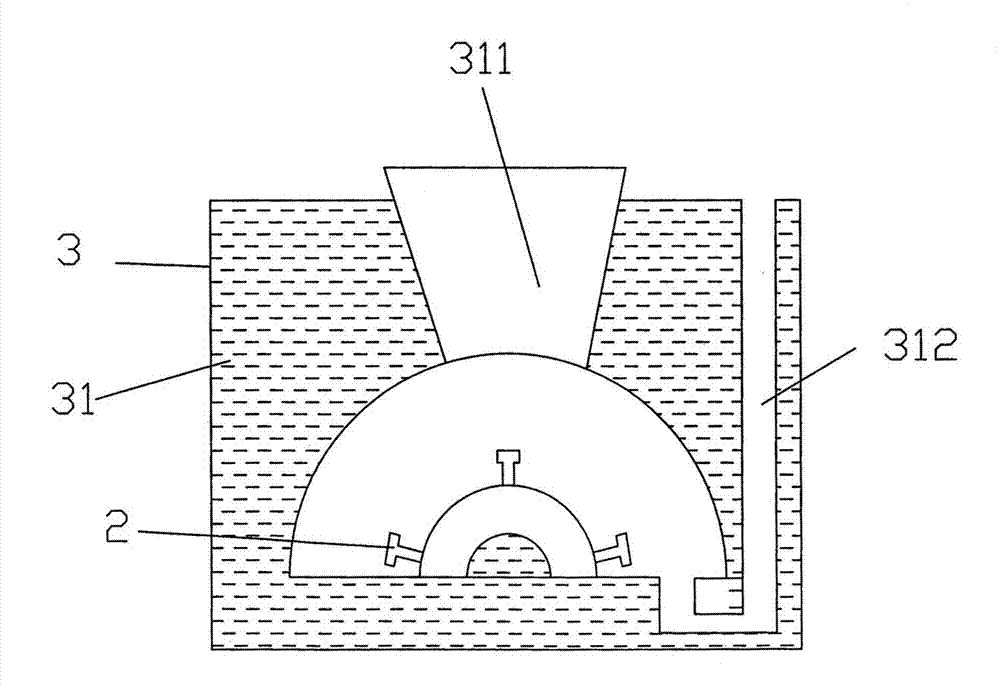

Bamboo joint pile mold

InactiveCN105619592AMeet production needsMeet manufacturing requirementsMouldsEngineeringThick section

Disclosed is a bamboo joint pile mold. The bamboo joint pile mold comprises an outer mold body and an inner mold body. The outer mold body comprises a bottom mold plate, side mold plates and a supporting pull rod which is disposed at the top ends of the side mold plates. The exterior of the inner mold body is provided with fixing supporting grooves or connected with supporting nuts. Screw mounting holes are formed in the side mold plates. The inner mold body is fixed to the inside of the outer mold body through screws or supporting rods. The inner mold body includes at least two joints and comprises inner mold body thick sections and inner mold body thin sections, and the inner mold body thick sections and the inner mold body thin sections are arranged in an intersection mode. According to the design of the bamboo joint pile mold, the inner mold body and the outer mold body are combined, and moreover the inner mold body is fixed to the inside of the outer mold body through the supporting rods and the screws so that the function of replacing different inner mold bodies can be achieved and the production demand for bamboo joint piles with different shapes can be met; adjusting plates are mounted between the side mold plates of the outer mold body and L-shaped turnover plates so that the size adjustment of outer mold plates can be achieved, the manufacturing requirement for pipe piles with different sizes and specifications is met, and repeated investment is avoided; and the included angles of the L-shaped turnover plates are larger than 90 degrees, so that the mold and the pipe piles are conveniently taken out, and the work efficiency is improved.

Owner:SUQIAN BAOXIANG HEAVY IND

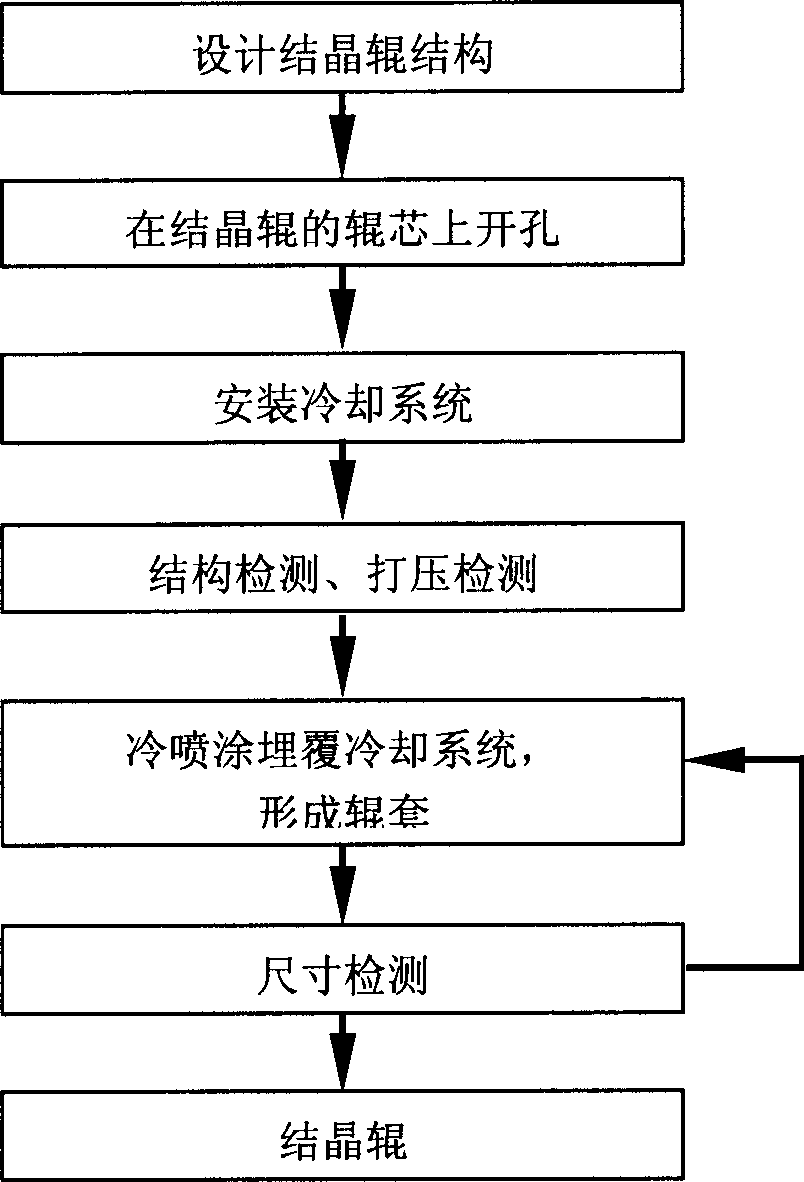

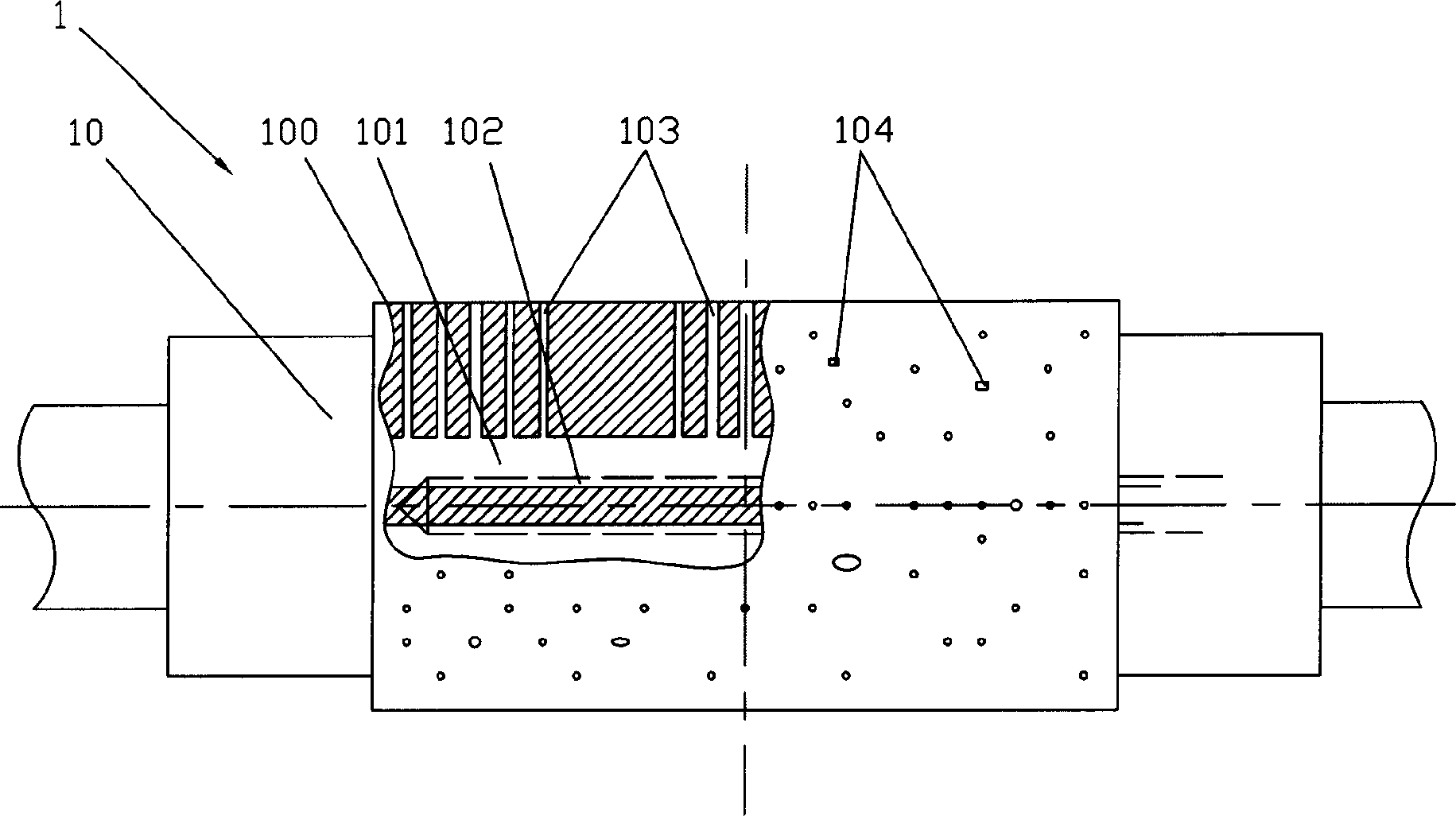

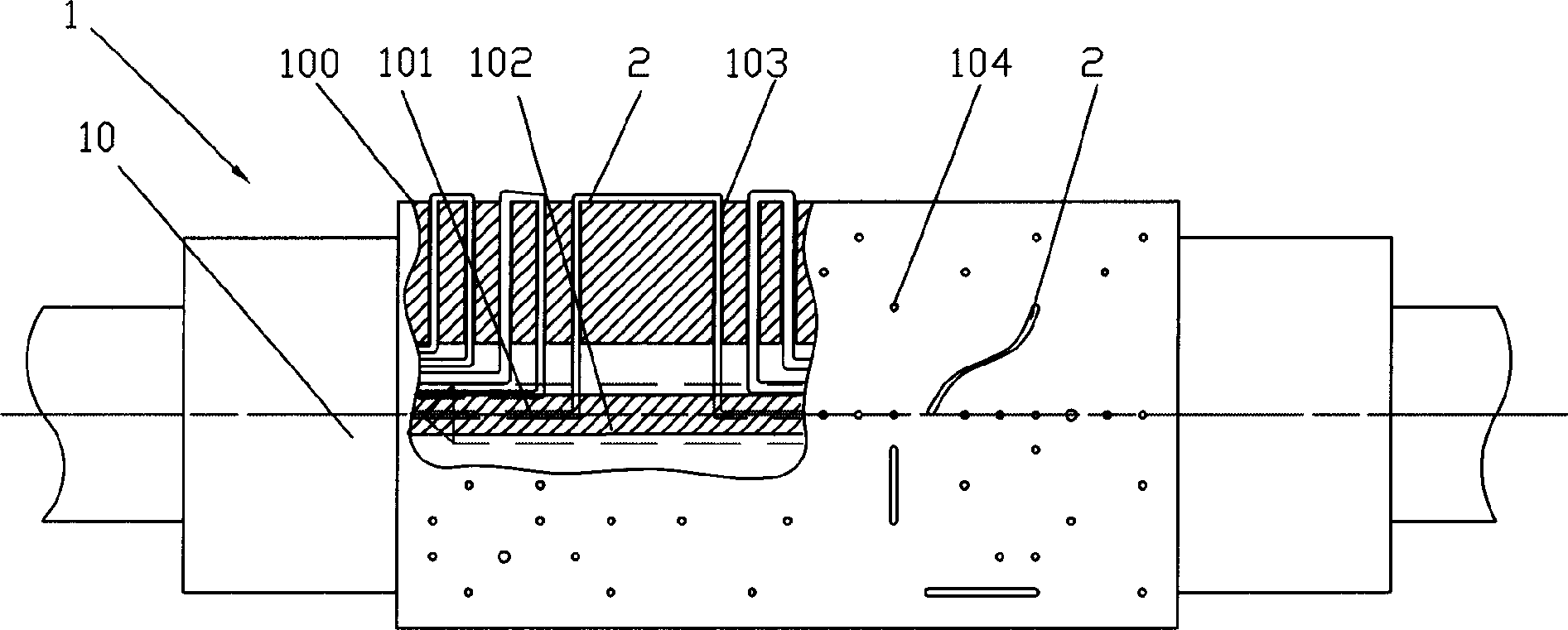

Method for producing continuous casting crystalli-zing roll

ActiveCN1781623AThe manufacturing method is simple and reliableEliminate the adsorbed oxygen layerNon-electric welding apparatusEngineeringMetal

The process of producing continuous casting crystallization roller includes the following steps: cutting axial water inlet hole and water outlet hole on roller core, and forming water guide hole on the core wall to communicate the water inlet hole and the water outlet hole with outside surface of the core; installing metal pipe outside the core to form crystallization roller cooling system with several cooling loops; and cold pneumatic spraying through driving metal grains with pressure over 1.0 MPa to bump the outer surface of the core at high speed so as to make metal grains deform sufficiently for adhering onto the surface of the core and the outer surface of the cooling loops, filling the gaps, forming coating in enough thickness to cover the cooling loops and forming roller sleeve in enough thickness.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparing method of high-pressure shell aluminum alloy die forging for submersible

ActiveCN107931498AMeet manufacturing requirementsMeet the standard requirementsHeating/cooling devicesIngotHigh pressure

The invention relates to a preparing method of a high-pressure shell aluminum alloy die forging for a submersible, and is applied to the aluminum alloy forging field. The method aims at solving the problems that the high-pressure shell aluminum alloy die forging for the submersible is poor in stress corrosion resistance, strength and breaking toughness. The method comprises the steps of firstly, aluminum alloy casting ingot heating, secondly, forging of a workblank for die forging molding, thirdly, lubricating mold pressing molding to obtain the forging, fourthly, corrosive washing and degreasing of the forging formed through die forming and neutralizing and whitening of the forging in an acid tank, fifthly, heat treatment and sixthly, metallographic structure detection and performance detection of the die forging obtained after heat treatment, and detection of qualified die forging. The standard requirements can be met, the pressure resistance of the shell is improved, strength, breaking toughness and other properties of the high-pressure die forging for the submersible can be improved, and the service life of the shell is prolonged.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Ultrawide and ultrafine gauge structural steel plate for bridges and production method thereof

ActiveCN102766806BImprove low temperature impact resistanceMeet manufacturing requirementsChemical compositionSheet steel

The invention provides an ultrawide and ultrafine gauge structural steel plate for bridges and a production method thereof. The ultrawide and ultrafine gauge structural steel plate for bridges consists of the following chemical components by weight: C: 0.12 to 0.17 percent; Si: 0.20 to 0.45 percent; Mn: 1.25 to 1.50 percent; S: 0.010 percent or less; P: 0.020 percent or less; Nb: 0.010 to 0.040 percent; Ti: 0.008 to 0.030 percent; Als (standing for acid-soluble aluminium): 0.015 to 0.050 percent; N: 40 multiplied by 10 negative 6 or less; O: 20 multiplied by 10 negative 6 or less; H: 2 multiplied by 10 negative 6 or less; and the balance of iron and inevitable impurities. According to the invention, the ultrawide and ultrafine gauge structural steel plate for bridges has excellent low-temperature impact resistance, can meet the construction requirements of high-speed multi-track railways and wide highway bridges, and also can be widely used in engineering structures such as buildings, traffic and ocean platforms.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

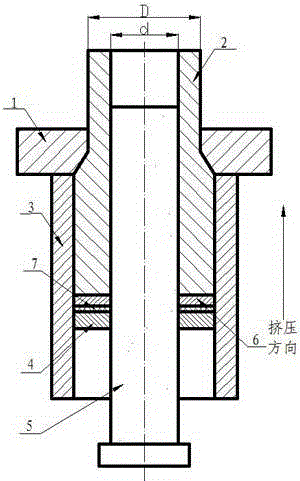

Extruding machine and method of utilizing extruding machine to manufacture large-diameter thick-wall seamless copper pipe

ActiveCN105268753ALittle change in sizeInhibit refluxExtrusion diesRams/plungersThermal insulationThick wall

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Method for rolling wide thin plates of wide and thick plate rolling machine

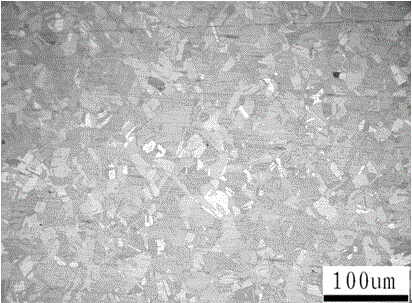

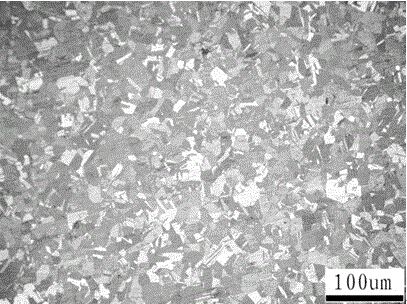

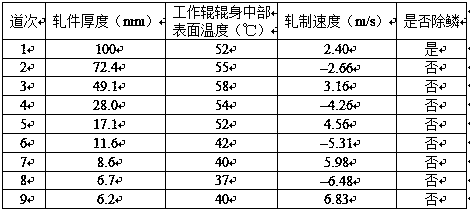

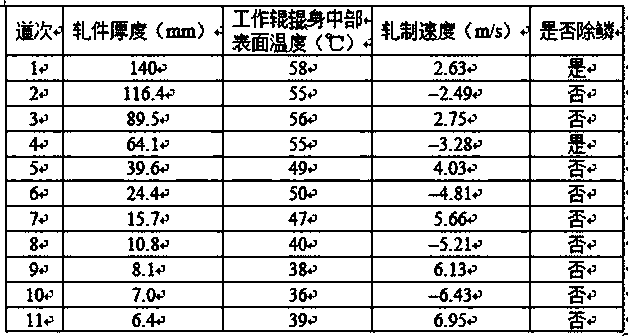

ActiveCN109513745AUniform performanceControl performanceTemperature control deviceRollsThick plateStrip mill

The invention provides a method for rolling wide thin plates of a wide and thick plate rolling machine. According to the method, by means of size and shape design of a blank, uniform high-temperatureheating, control over rolling roller type and roller face temperature, optimization of the rolling schedule, especially ensuring of the stability of the rolling state of the last two passes, and control over technology key points of straightening and pile cooling, the wide and thick plate rolling machine can roll wide and thin steel plates with the thickness of 6 mm and the width surpassing 2500 mm, the uneven degree of the steel plates can reach the range smaller than 3 mm / m, the thickness allowance meets the N type deviation allowed by the national standard GB / T 709-2006, the performance ofthe overall steel plate is uniform, the obdurability is good, and the steel plate can meet the manufacturing requirement of ship plates, bridges, buildings and other steel structures. The method solves the problem that in the production process of existing wide and thin steel plates, the plate shape and the performance are not stable, and the ability of the wind and thick plate rolling machine toproduce the wide and thin plates in batches can be achieved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

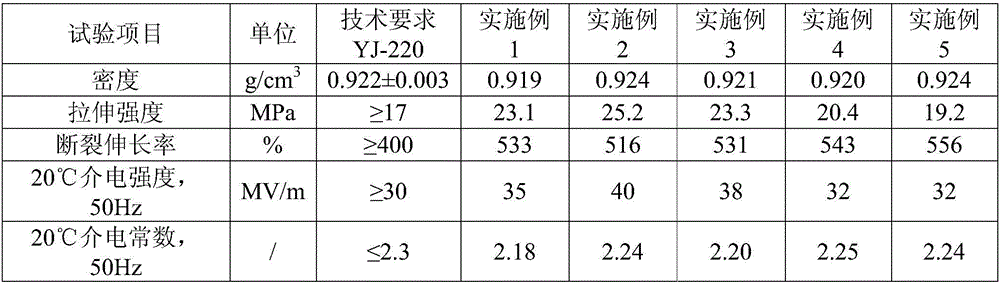

220 kV crosslinkable polyethylene insulating material with low by-product content and preparation method of 220 kV crosslinkable polyethylene insulating material

InactiveCN106279920AMeet manufacturing requirementsAvoid high levels of impuritiesPlastic/resin/waxes insulatorsLow-density polyethyleneAntioxidant

The invention relates to a 220 kV crosslinkable polyethylene insulating material with low by-product content and a preparation method of the 220 kV crosslinkable polyethylene insulating material. The raw material formula of the 220 kV crosslinkable polyethylene insulating material comprises components in parts by weight as follows: 100 parts of low-density polyethylene, 0.1-1 part of an antioxidant, 0.1-2.0 parts of a crosslinking agent and 1.0-3.0 parts of a crosslinking accelerator. By means of the formula formed by specific low-density polyethylene, the antioxidant, the crosslinking agent and the crosslinking accelerator, the problems of overhigh impurity content, appearance of pin holes inside and the like of prepared products can be solved, and requirements for manufacturing 220 kV cable insulating materials can be met.

Owner:ANHUI CHUZHO DEWEI NEW MATERIAL +3

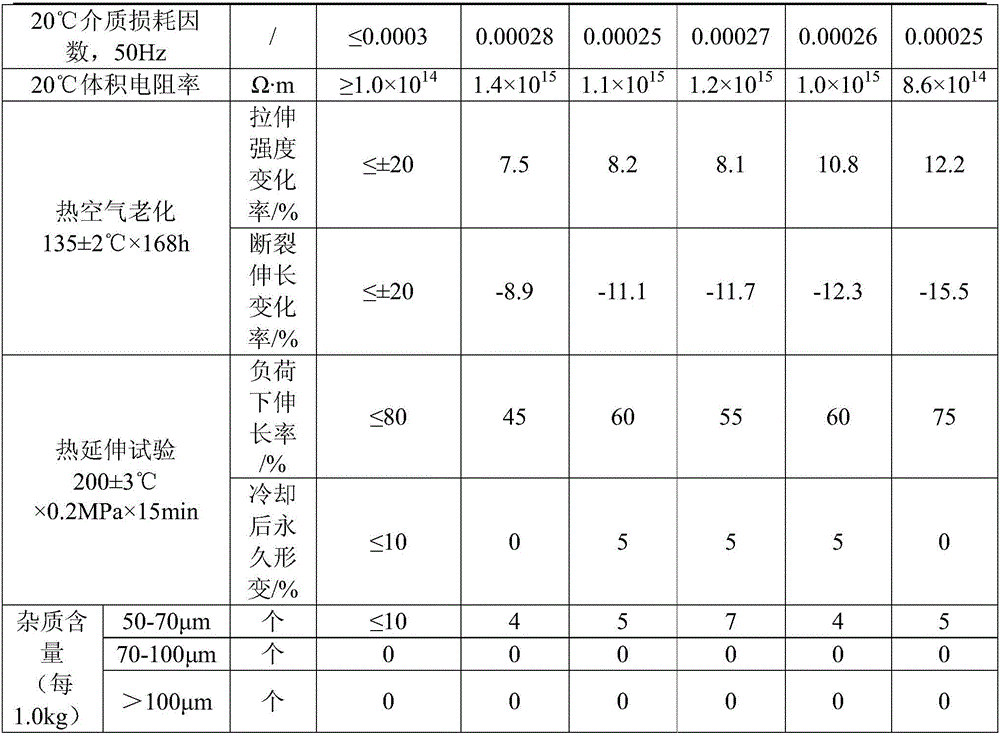

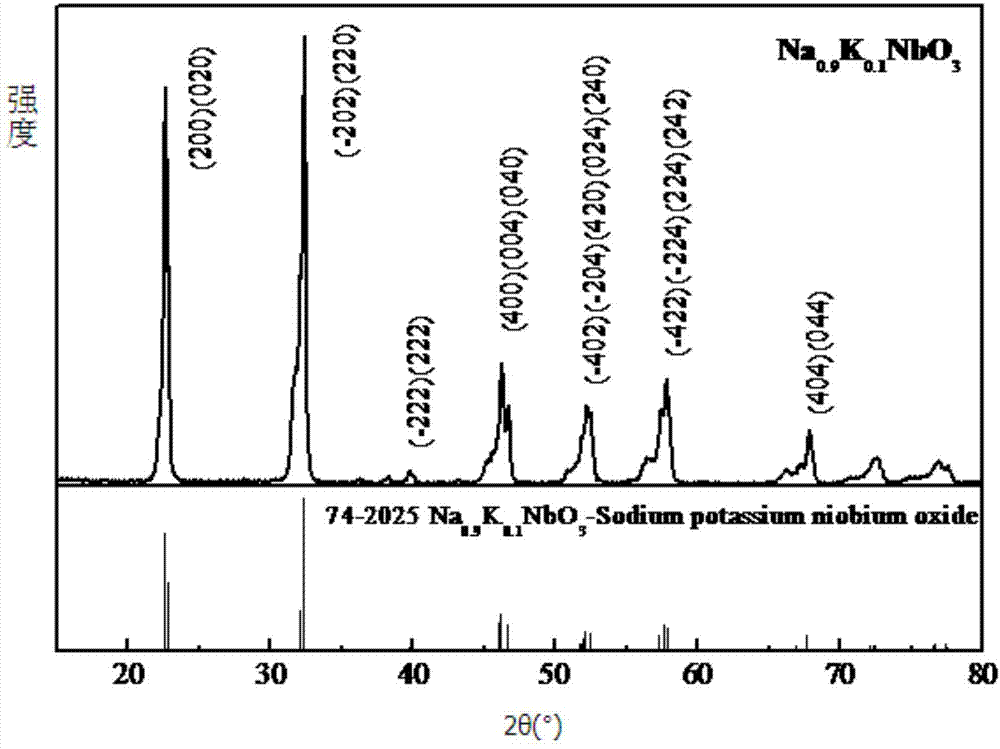

One-step method for synthesizing leadless piezoelectric K0.1Na0.9NbO3 powder by hydrothermal process

The invention relates to a preparation method of leadless piezoelectric ceramic K0.1Na0.9NbO3 powder, particularly a one-step method for synthesizing leadless piezoelectric K0.1Na0.9NbO3 powder by a hydrothermal process, which comprises the following steps: 1. respectively taking a 5 mol / L potassium hydroxide solution and a 5 mol / L sodium hydroxide solution, and uniformly mixing according to the KOH:NaOH mole ratio of (3-9):1 to form a mixed alkali solution xmol; 2. adding niobium pentaoxide into the mixed alkali solution according to the mixed alkali solution x:niobium pentaoxide mole ratio of (20-5):1, and magnetically stirring for 30-60 minutes to form an uniform precursor solution; carrying out hydrothermal reaction on the precursor solution at 180-220 DEG C for 6-10 hours, and cooling to room temperature to obtain a material D; and 3. flushing the material D with deionized water to a neutral state, and drying to obtain the K0.1Na0.9NbO3 powder. The method has the advantages of simple technique, favorable repetitiveness and lower requirements for reaction environment; and the prepared K0.1Na0.9NbO3 powder has the advantages of small grain size and high purity.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing torsion-exfoliation-resistant extra-high-strength steel wires with excellent fatigue resistance

The invention discloses a method for producing torsion-exfoliation-resistant extra-high-strength steel wires with excellent fatigue resistance. The method comprises the following steps: (1) dry-drawing until the steel wires are 1.8-2.2mm long; (2) performing sorbitizing heat treatment; (3) performing pinchbeck alloy electroplating; and (4) wet-drawing until the steel wires are 0.20-0.40 mm long. Ultra-high-strength steel wires produced according to the method has high strength, good toughness, torsion-exfoliation resistance and excellent fatigue resistance, the 100d of the steel wire has the torsion number being not less than 30 / 360 degrees, and the fracture after torsion test is an even fracture, that is to say, torsion without exfoliation can be realized. Based on the method for producing torsion-exfoliation-resistant extra-high-strength steel wires with excellent fatigue resistance, the torsion exfoliation of the steel wires is effectively controlled, the requirements of the steel wires on strength and toughness are met, and the requirements for manufacturing ultra-high-strength steel cords for low rolling resistance tyres are well met.

Owner:JIANGSU XINGDA STEEL TYPE CORD

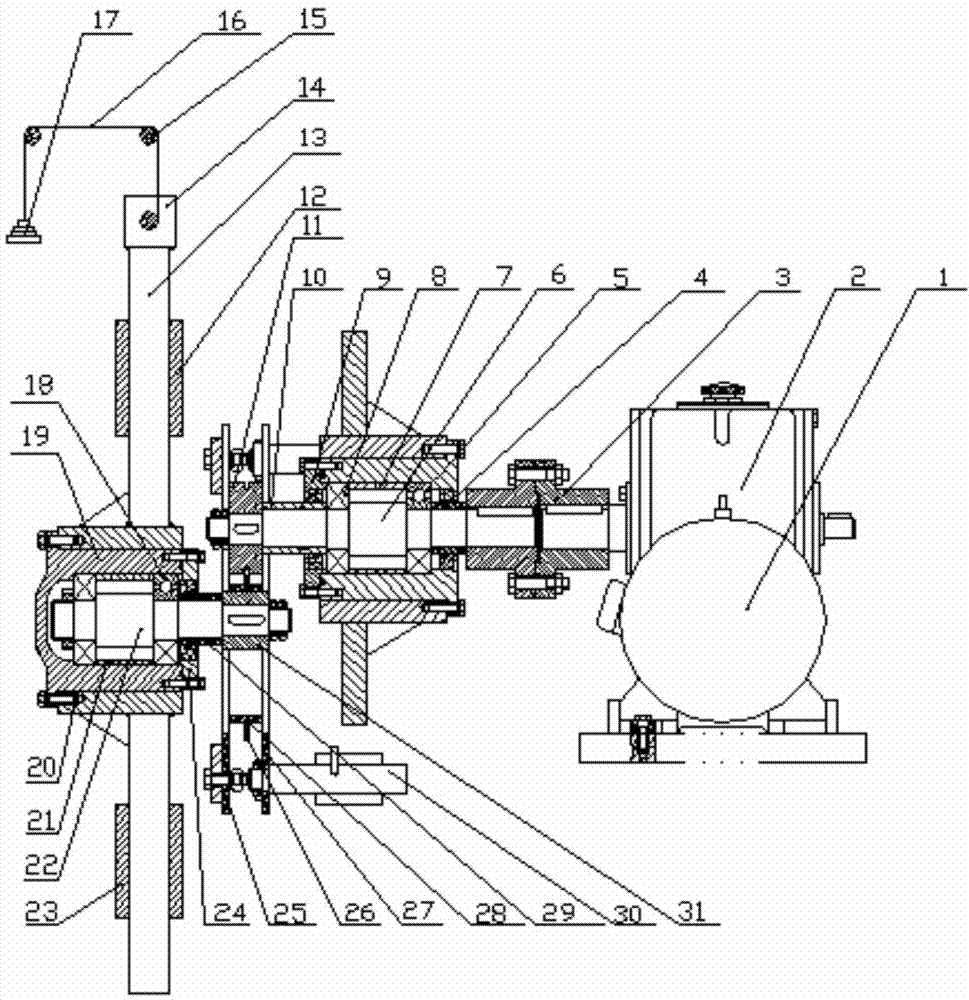

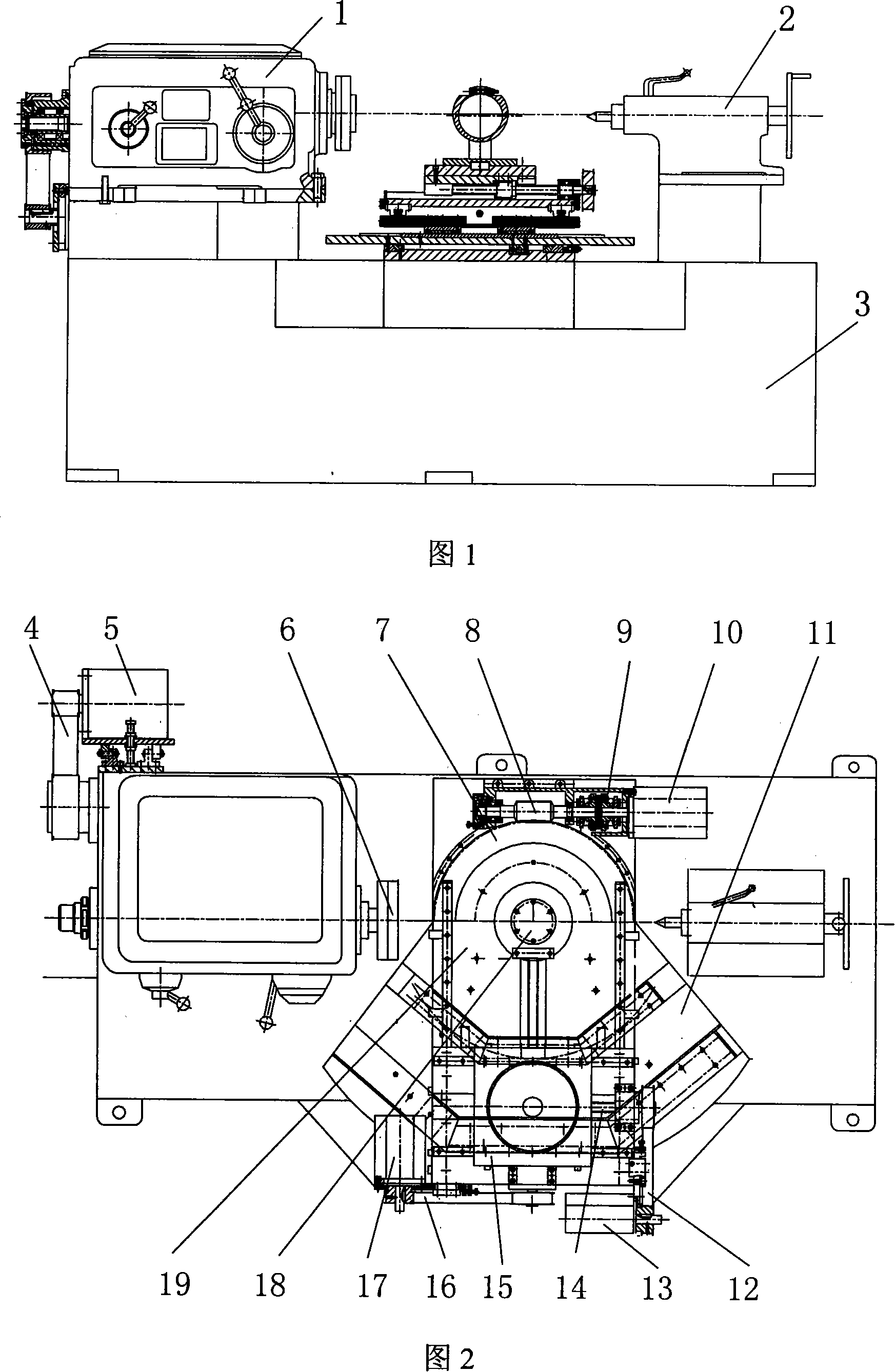

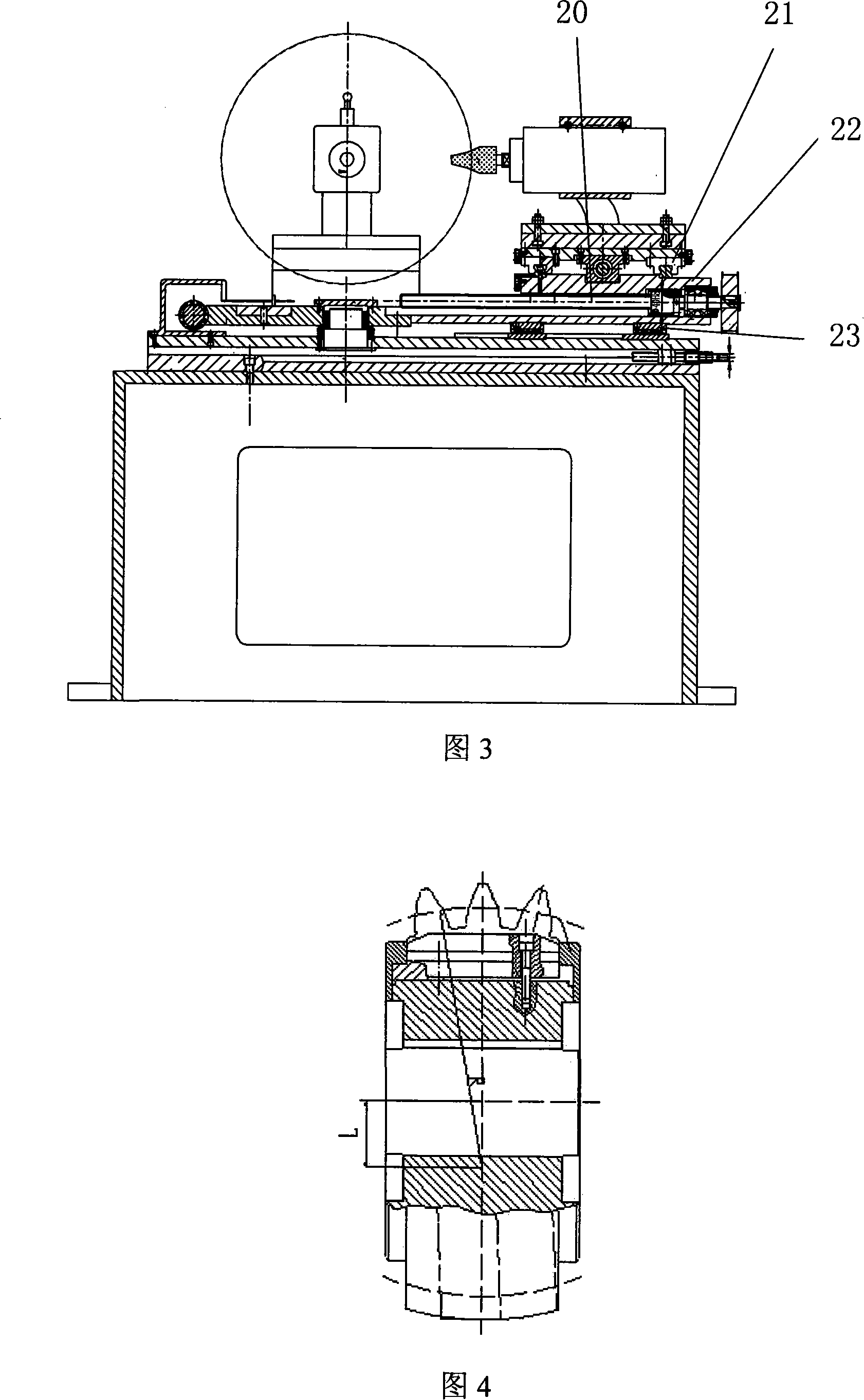

Four-shaft numerically controlled ellipsoidal and spherical hobbing cutter spade milling machine tool

InactiveCN101104245AFix production issuesCorrection of theoretical tooth pitch errorMilling cuttersHobbingTailstock

The invention discloses a 4-axis nc relief grinding machine tool for ellipsoidal and spherical hobs, which is characterized in that: a machine bed(3) is provided with an arc adjusting plate(11) whose position can be adjusted and a rotary plate(19) that can rotate around a rotary shaft(18) fixed on the arc adjusting plate(11).The rotary plate(19) is sequentially provided with a radial feeding knife frame(22), a tangential feeding knife frame(15) and a cutter from the lower part to the higher part. The rotary shaft (18) is perpendicular to the central lines of a spindle box (1) and a tailstock (2). An arc rolling guiding rail (23) is arranged between the rotary plate (19) and the arc adjusting plate (11). The lower parts of the radial feeding knife frame (22) and the tangential feeding knife frame (15) are respectively provided with a straight line rolling guiding rail (21). With the proposal adopted, the special machine tool for processing spherical and ellipsoidal internal gear hobs is provided, which solves the problems that the cutters of large diameters are difficult to be processed with difficult processing and low precision.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com