Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2246 results about "Porous film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air permeable pressure-sensitive adhesive tapes

InactiveUS20060154546A1Convenient to to manufactureEasy to useLamination ancillary operationsLayered product treatmentEngineeringPlastic film

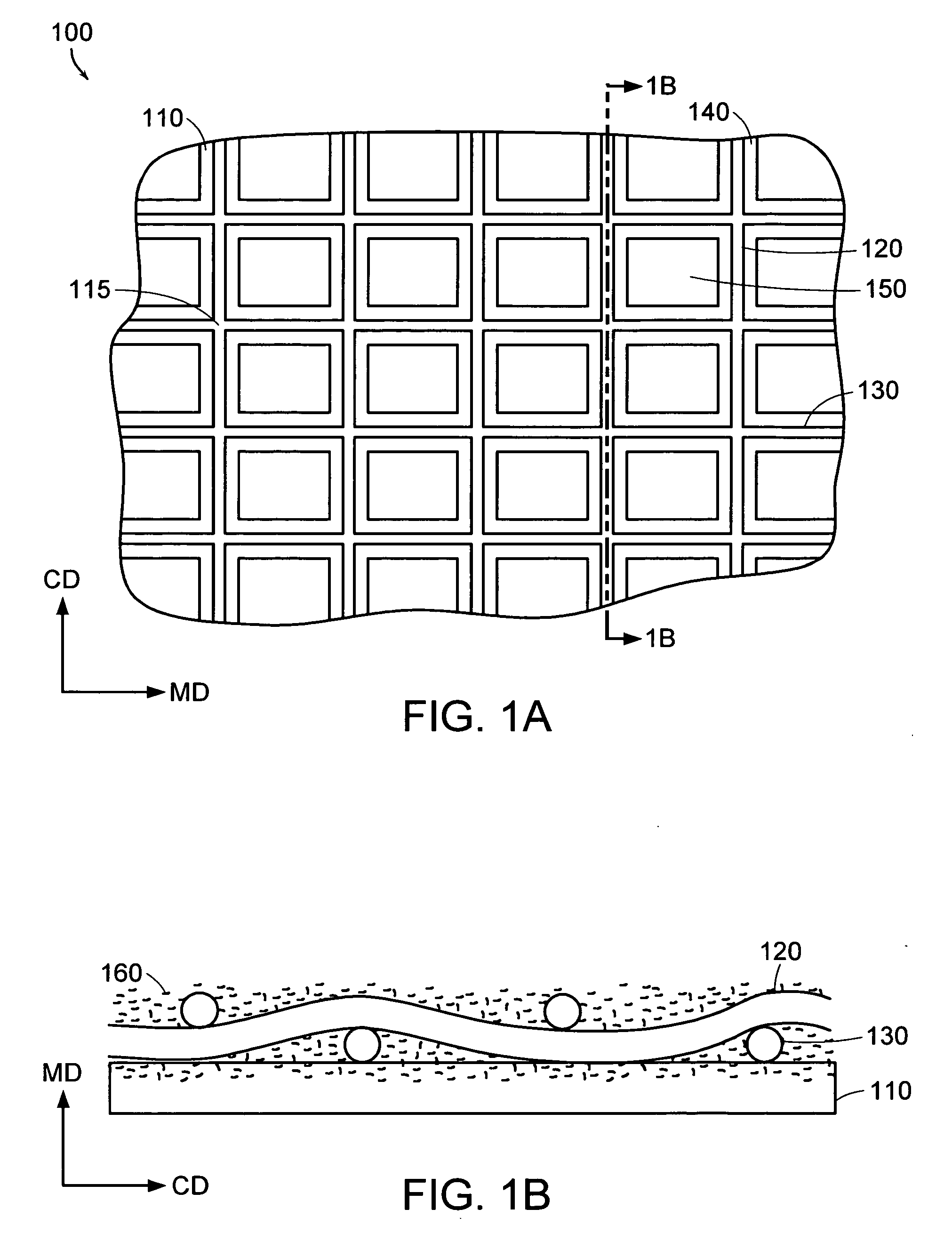

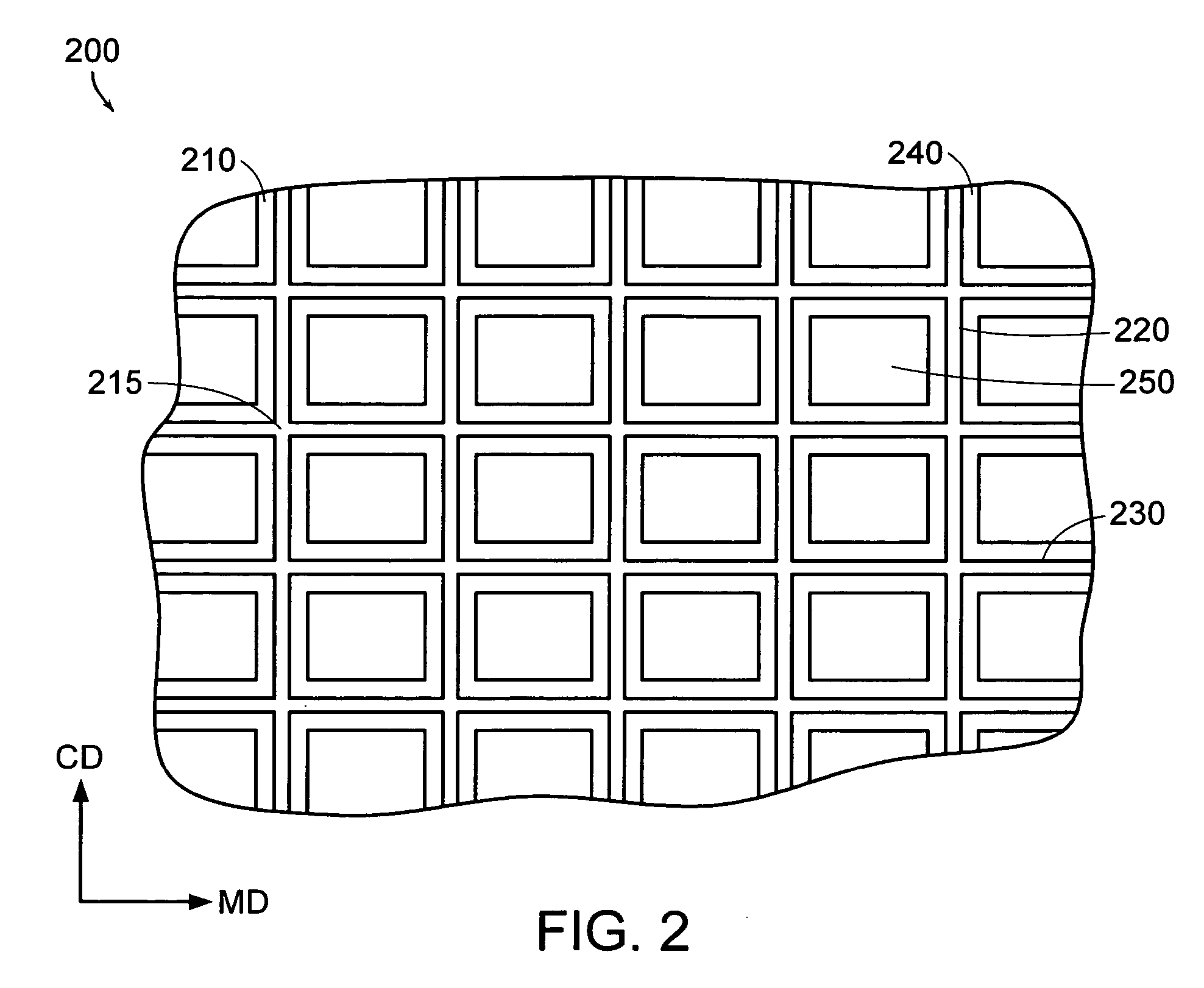

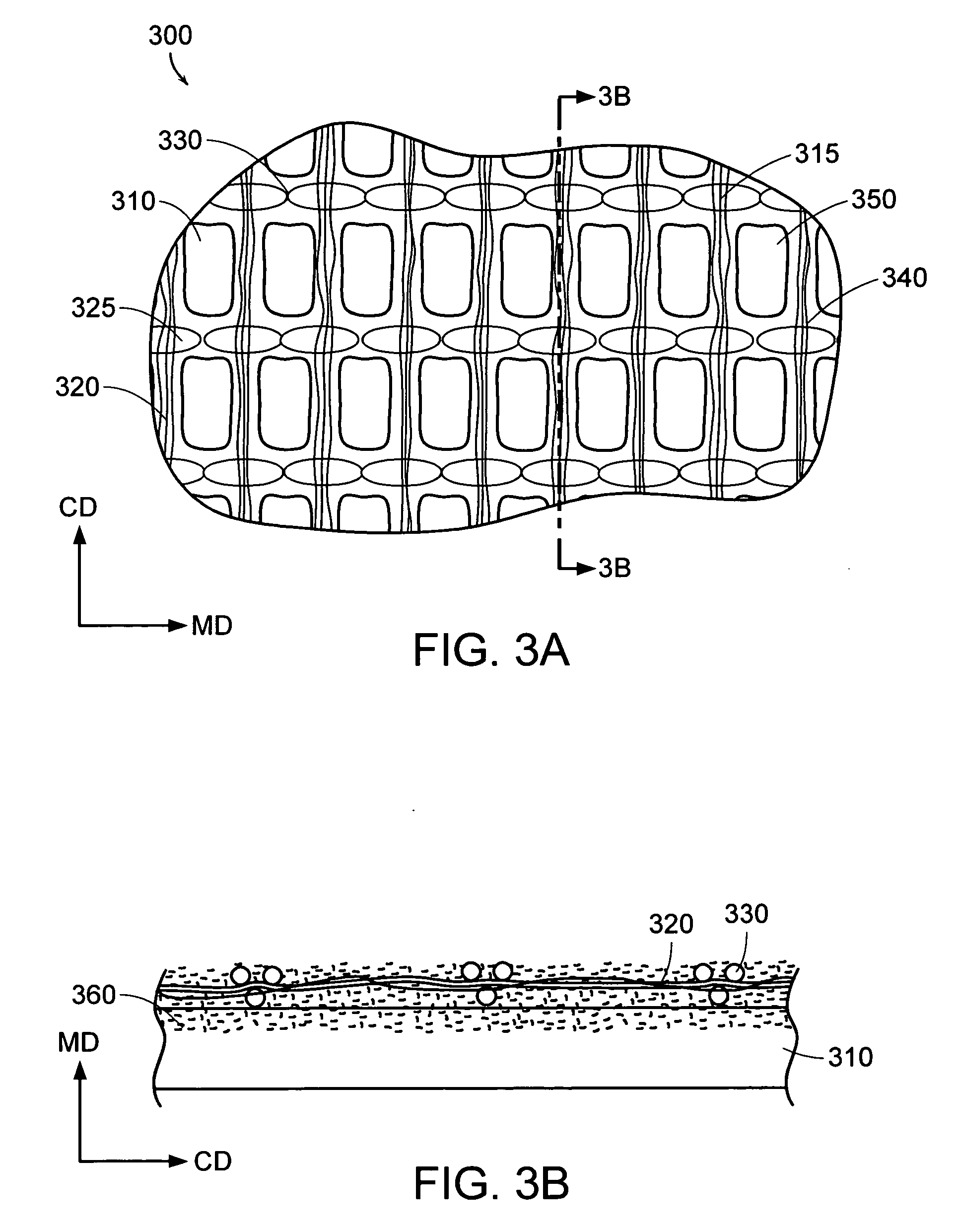

A vapor permeable article includes a porous backing substrate and an open fabric applied to one surface of the backing substrate. The open fabric has a greater porosity than that of the backing substrate. The open fabric may be a woven fabric comprising warp (MD) yarns and weft (CD) yarns, and the warp yarns may be of a lower denier than the weft yarns, so as to facilitate hand-tear of the assembled article. The open fabric is coated with an adhesive in such a manner that the open fabric remains porous and vapor permeable. The backing substrate can be a woven, knit or non-woven fabric, or a porous film, such as an apertured plastic film.

Owner:ANDOVER HEALTHCARE

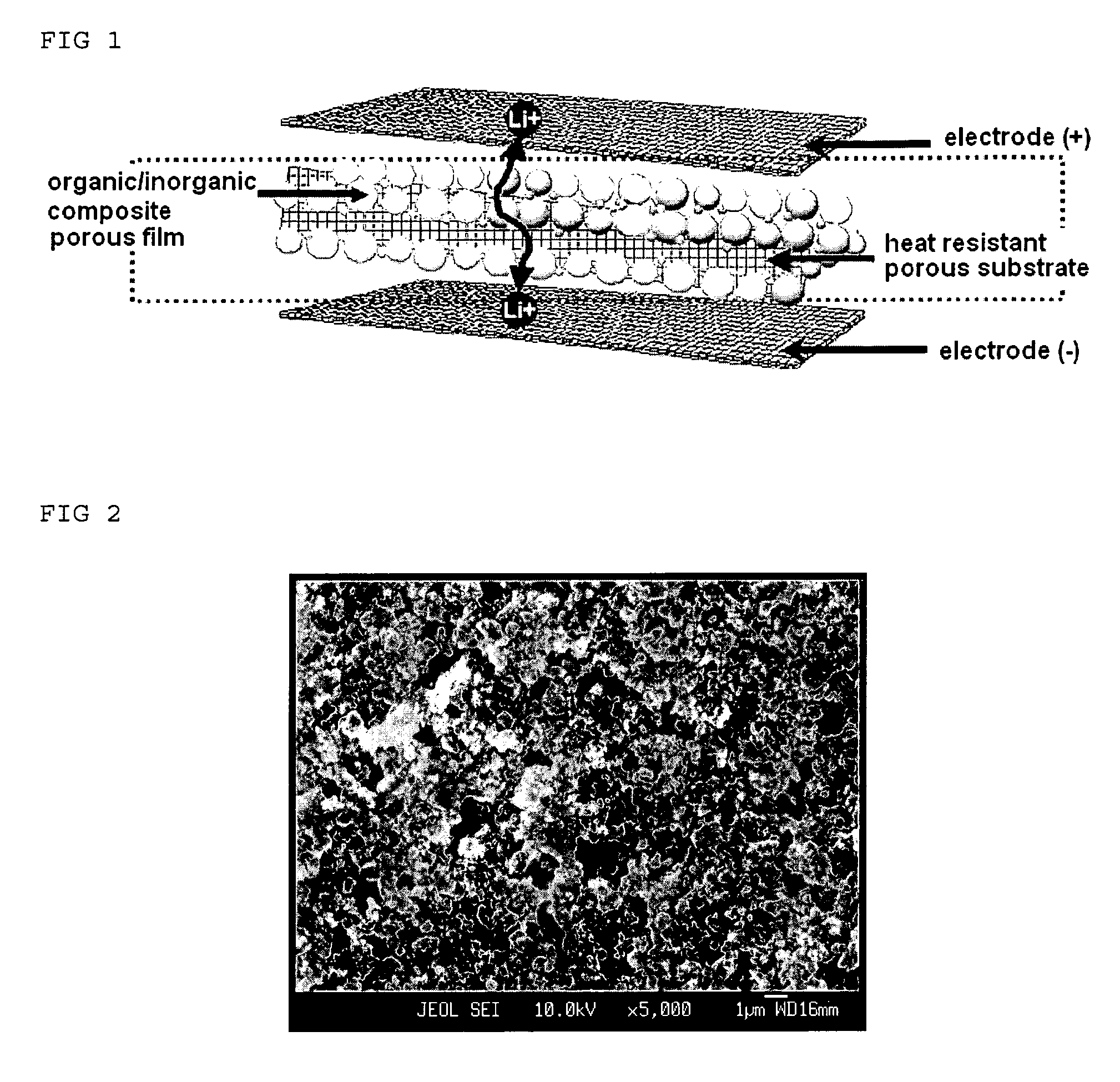

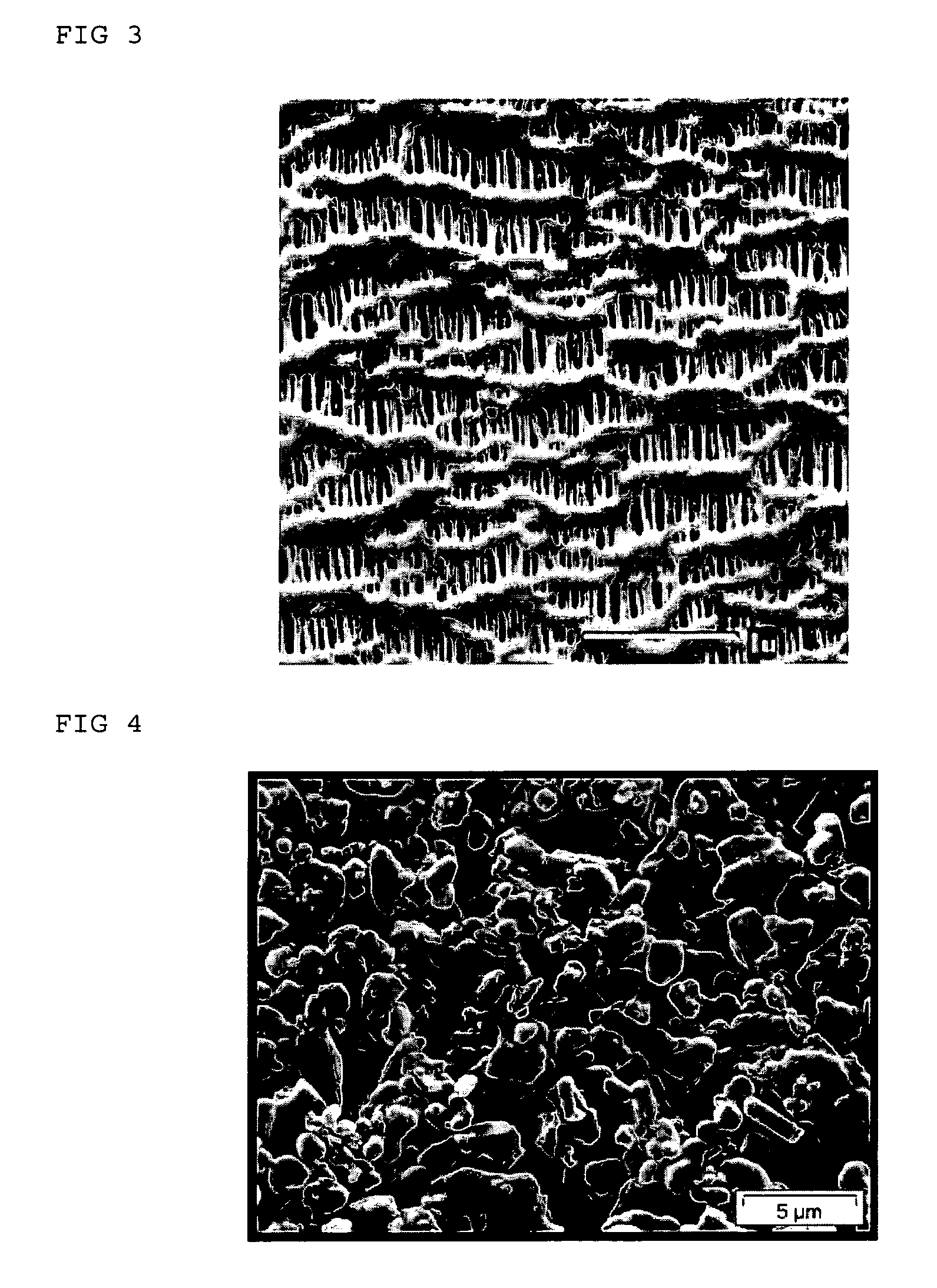

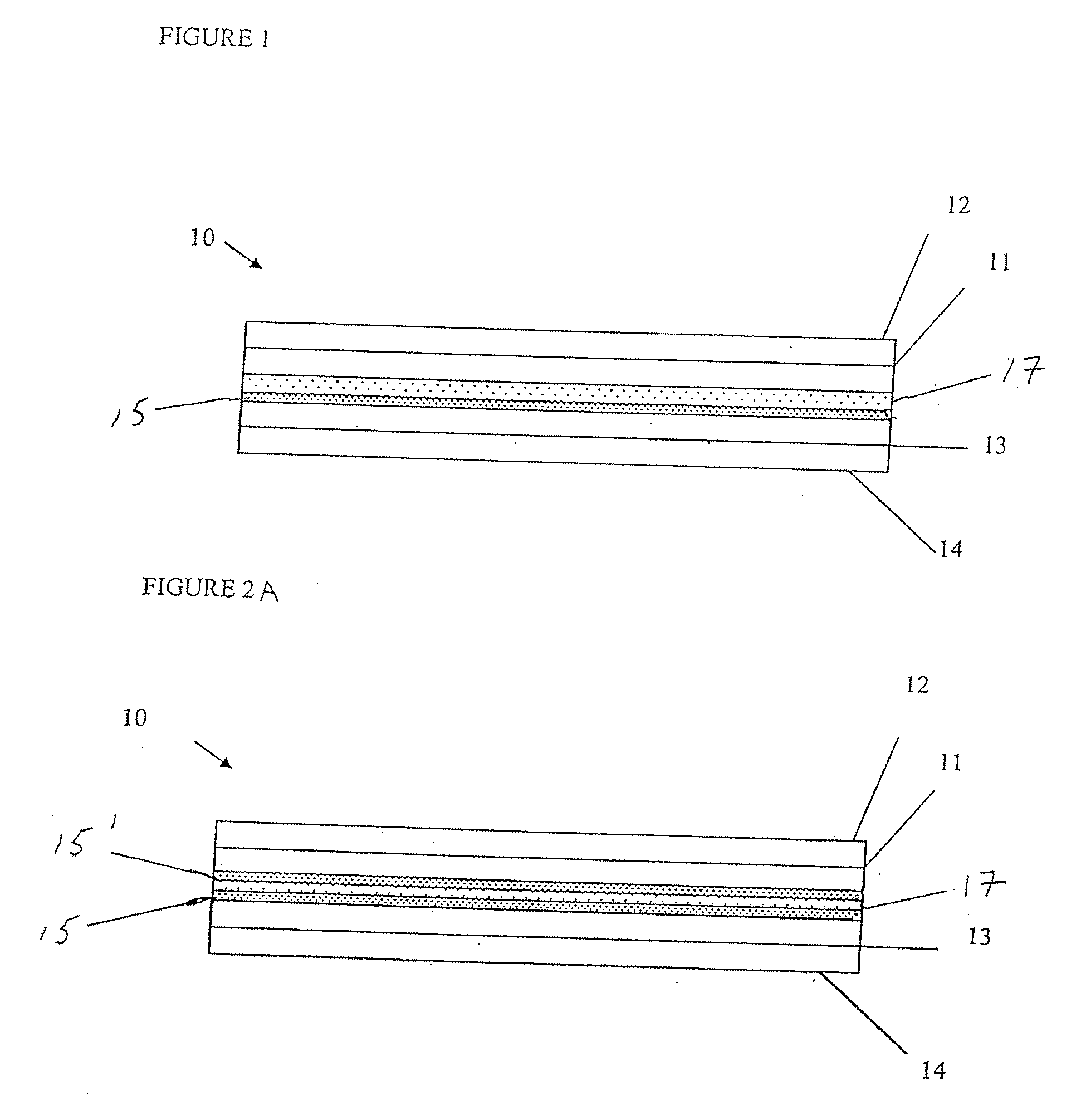

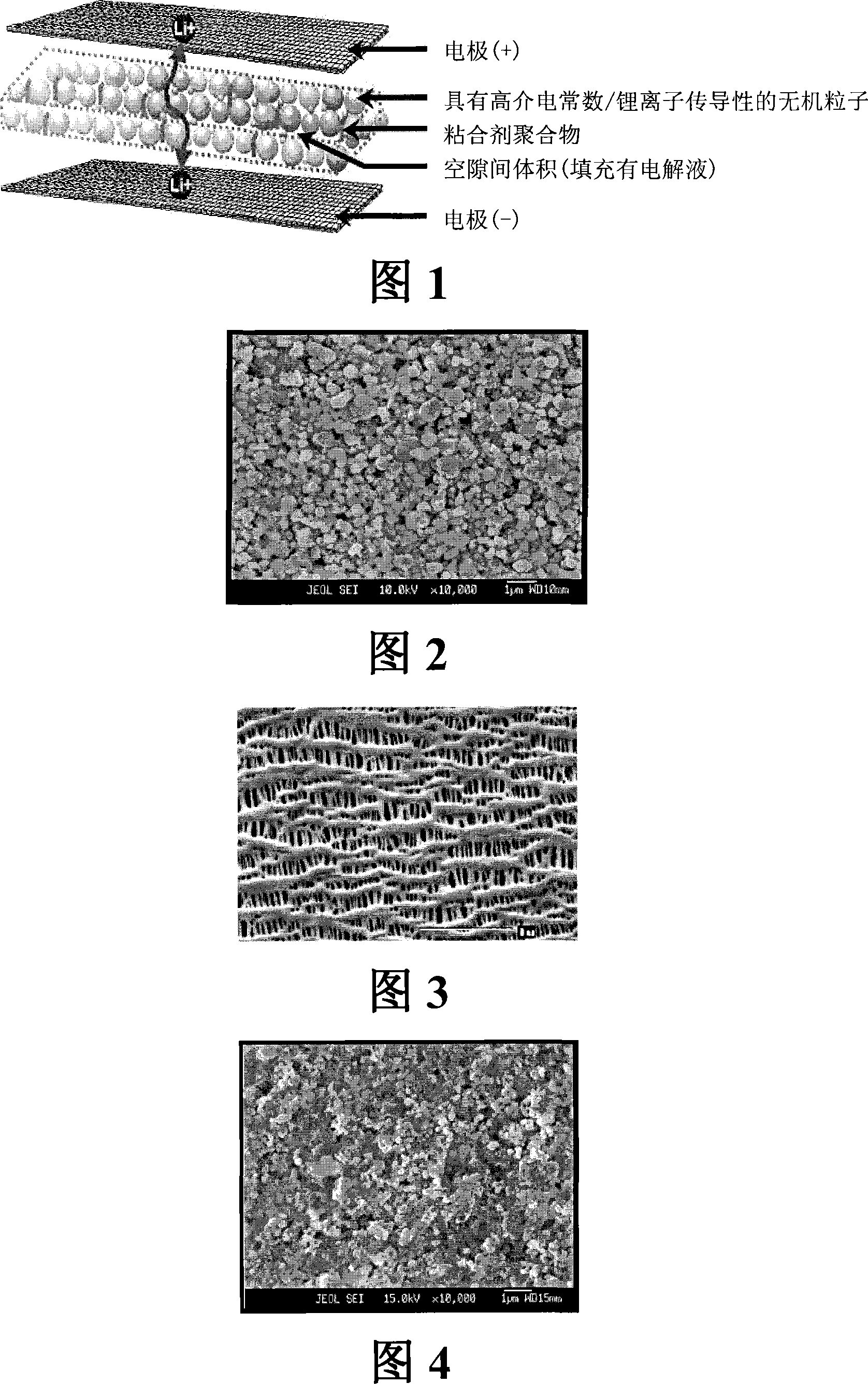

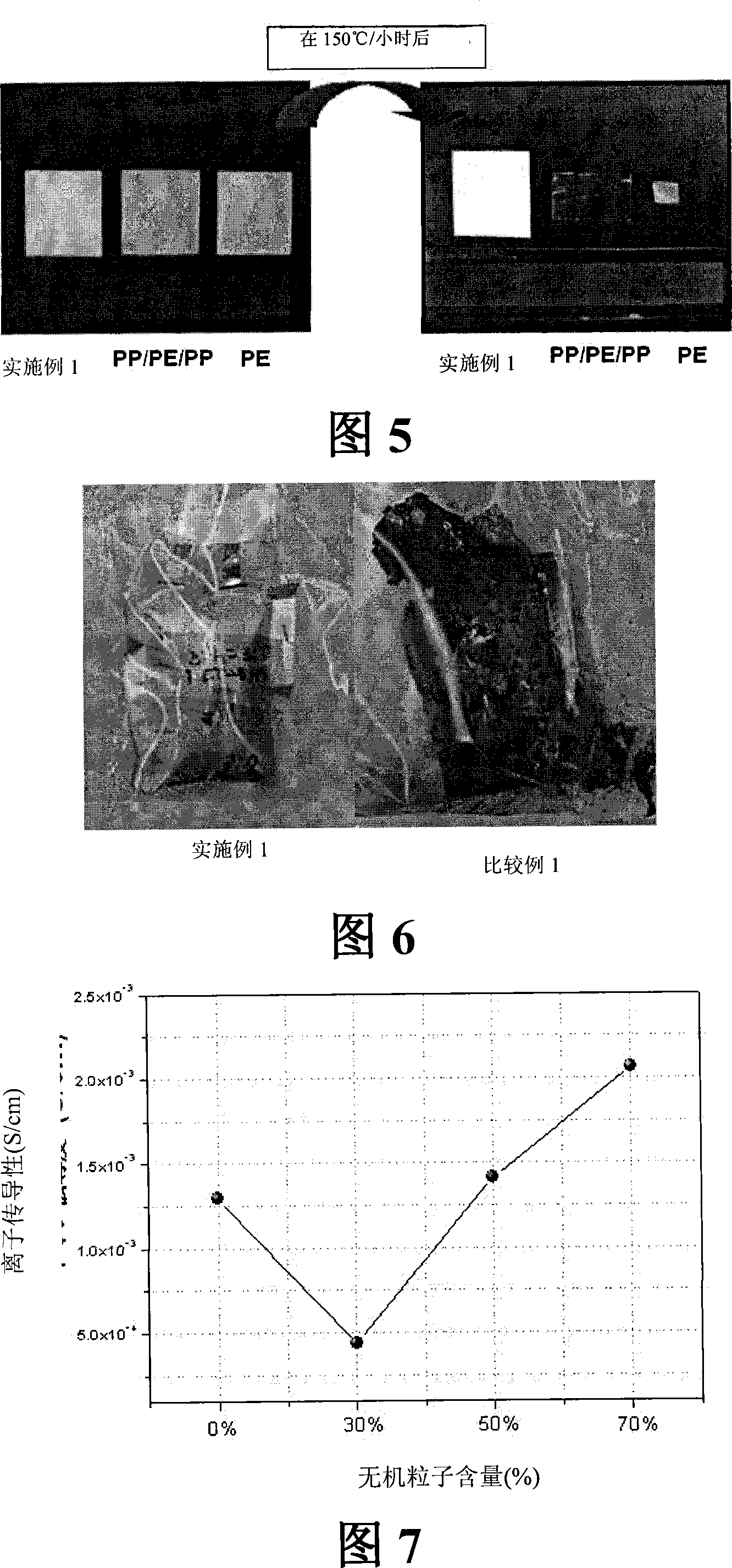

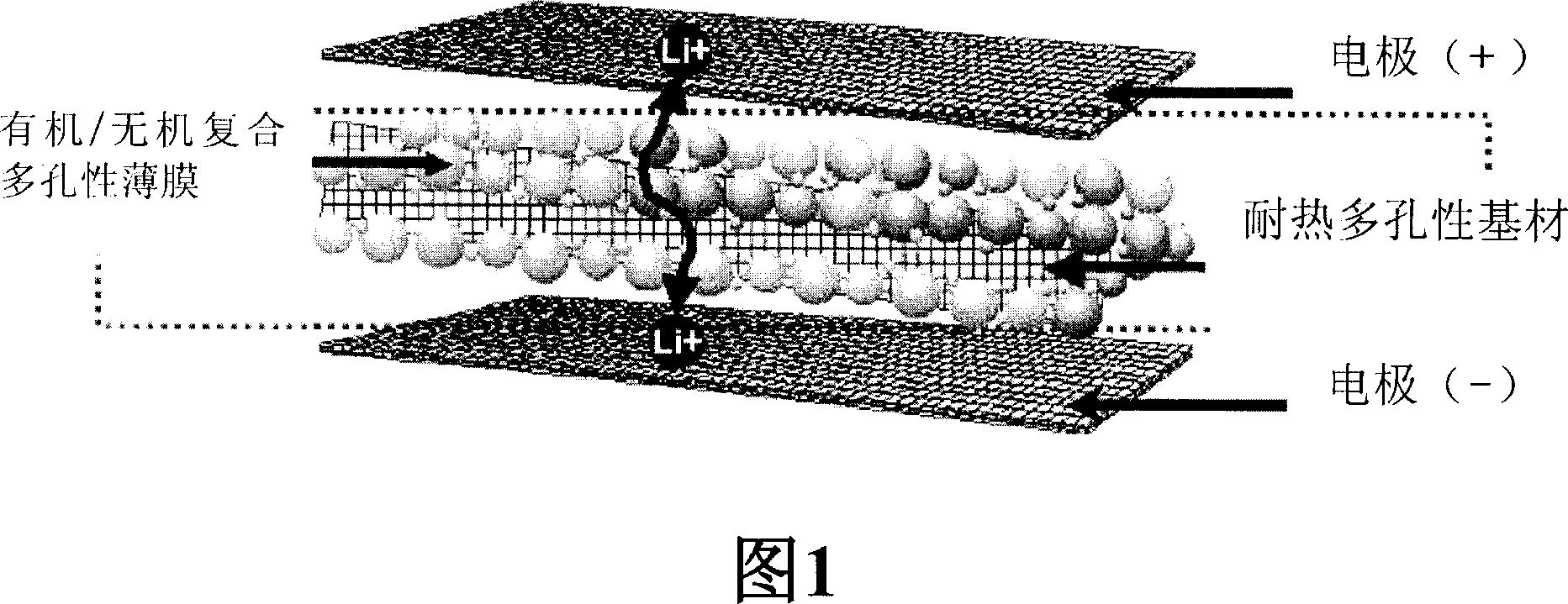

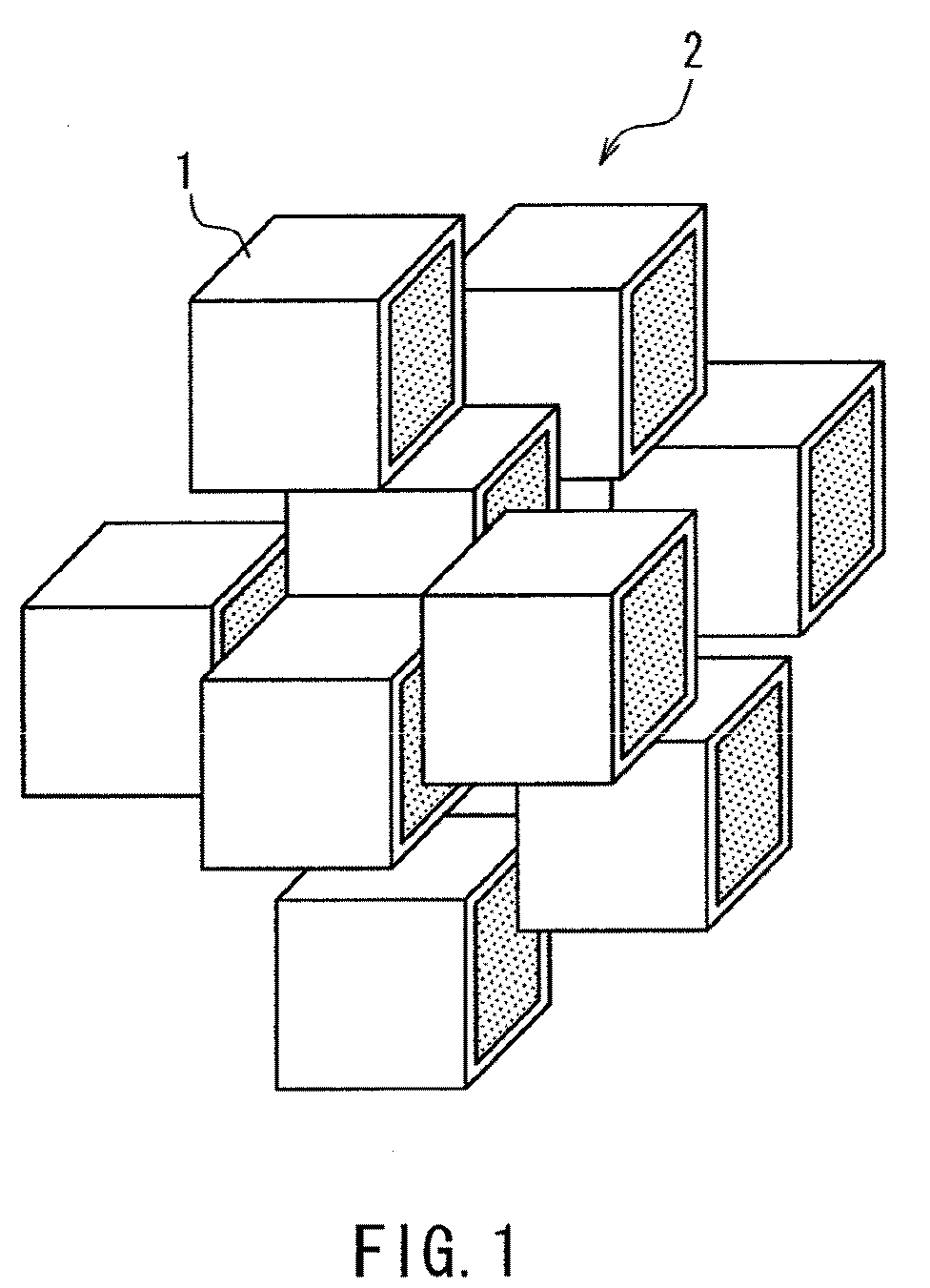

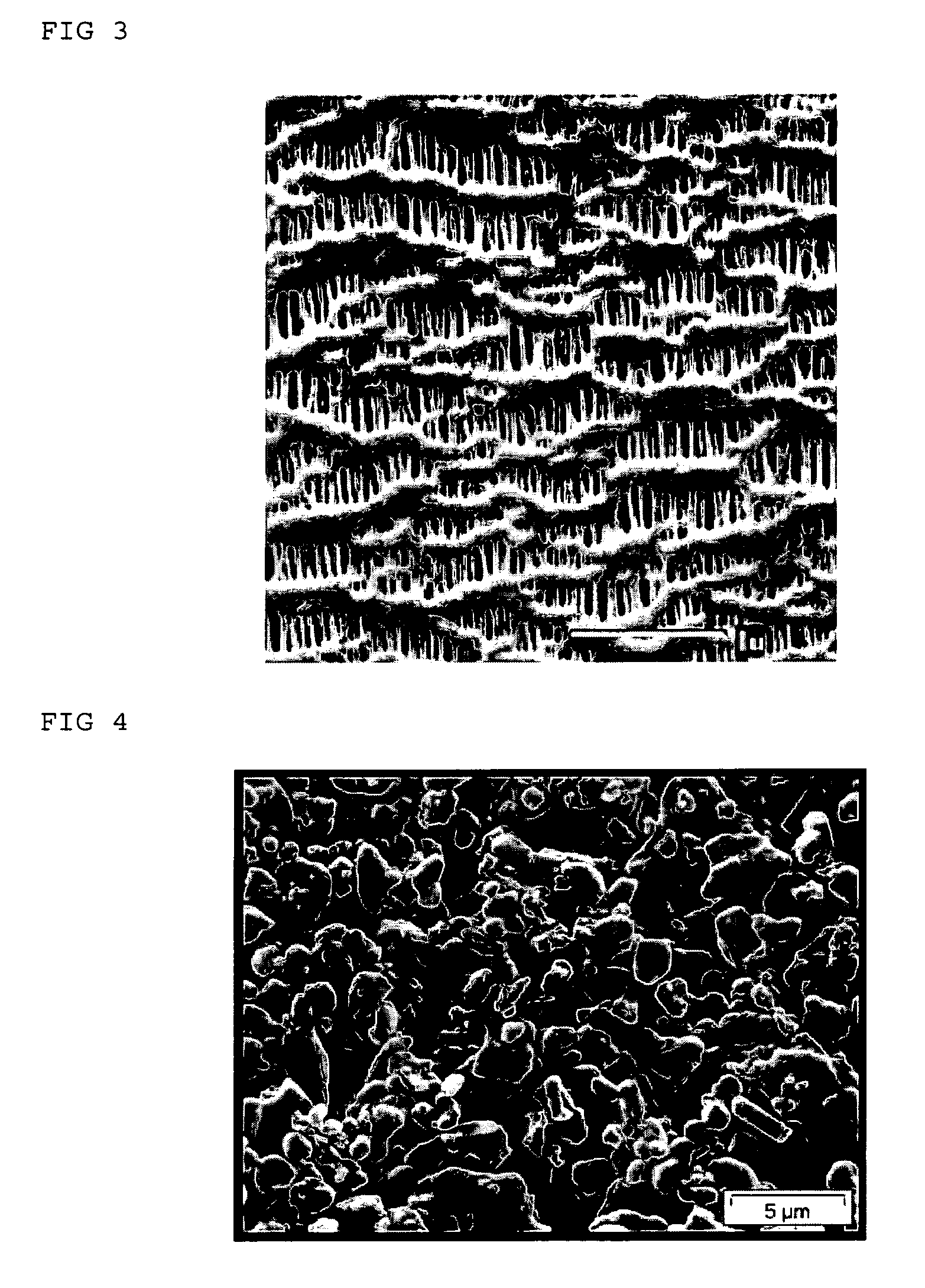

Organic/inorganic composite porous film and electrochemical device prepared thereby

ActiveUS20060008700A1Improve thermal safetyImprove adhesionSolid electrolytesLi-accumulatorsPorous substrateInorganic particle

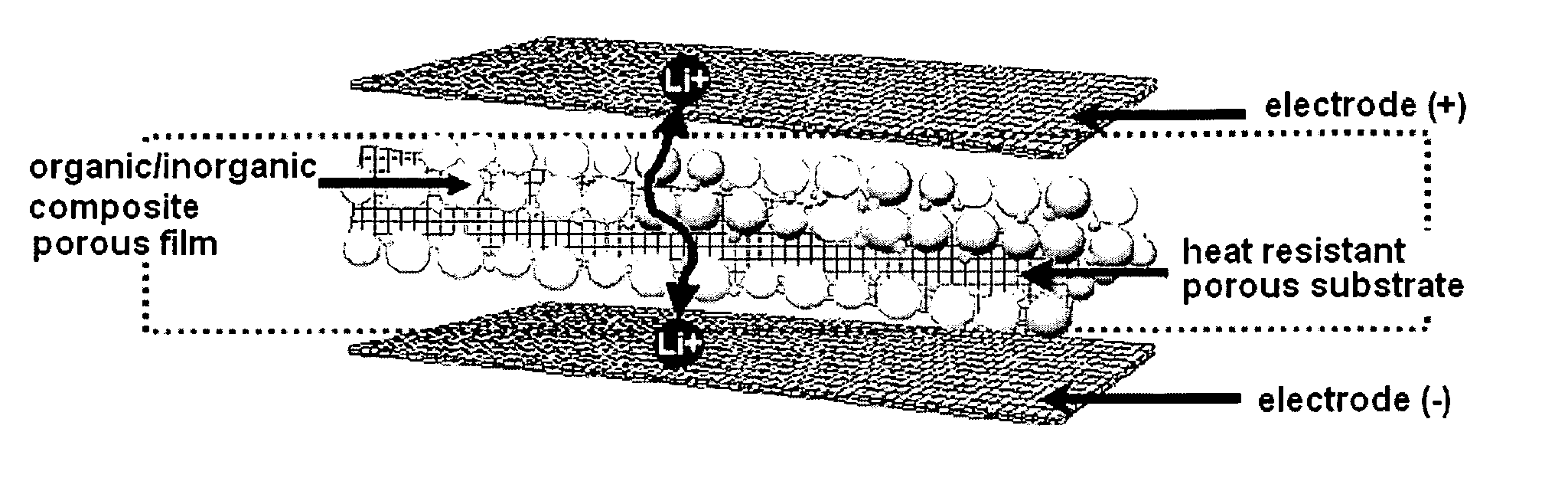

Disclosed is an organic / inorganic composite porous film comprising: (a) a porous substrate having pores; and (b) an active layer formed by coating a surface of the substrate or a part of the pores in the substrate with a mixture of inorganic particles and a binder polymer, wherein the inorganic particles in the active layer are interconnected among themselves and are fixed by the binder polymer, and interstitial volumes among the inorganic particles form a pore structure. A method for manufacturing the same film and an electrochemical device including the same film are also disclosed. An electrochemical device comprising the organic / inorganic composite porous film shows improved safety and quality, simultaneously.

Owner:LG ENERGY SOLUTION LTD +1

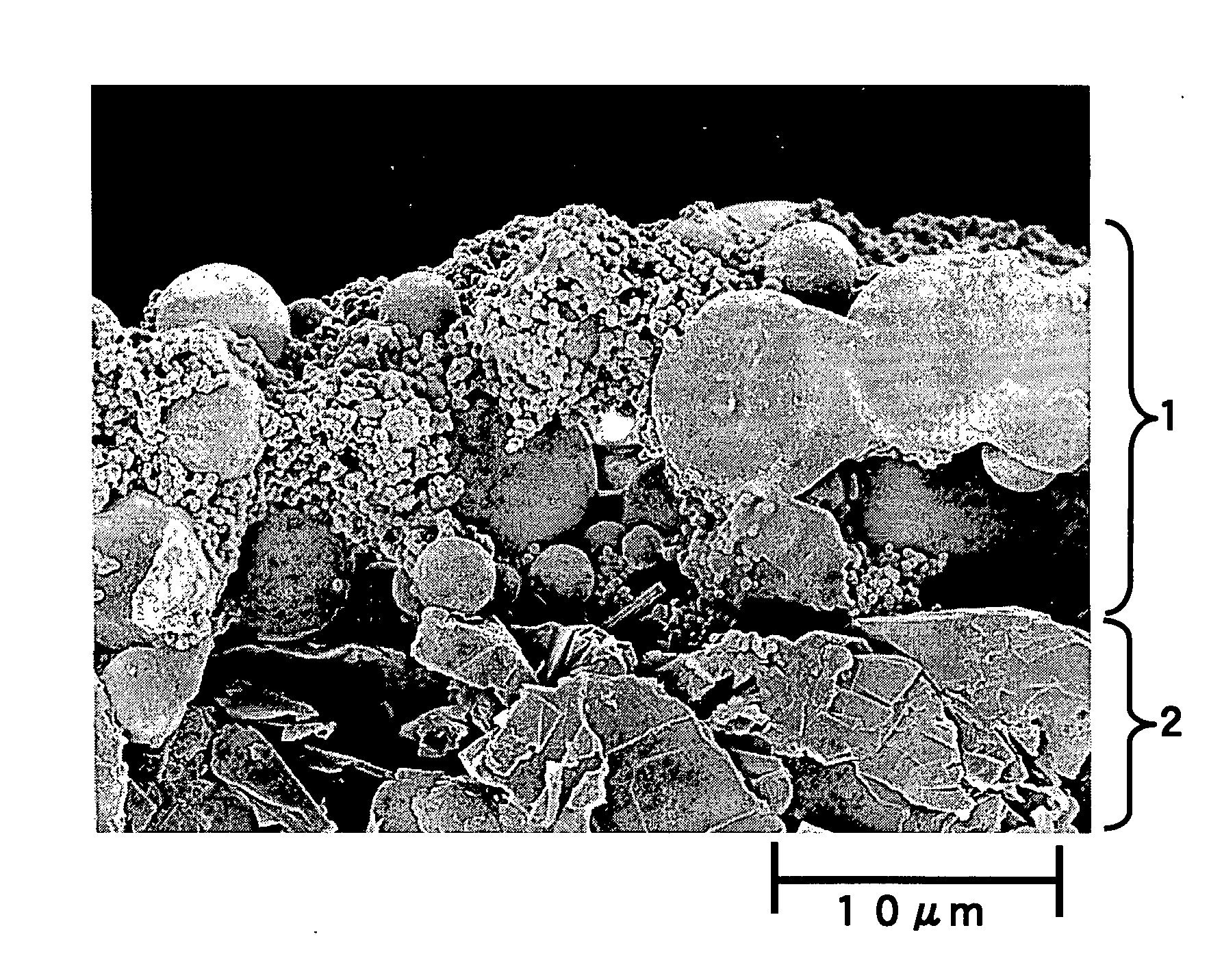

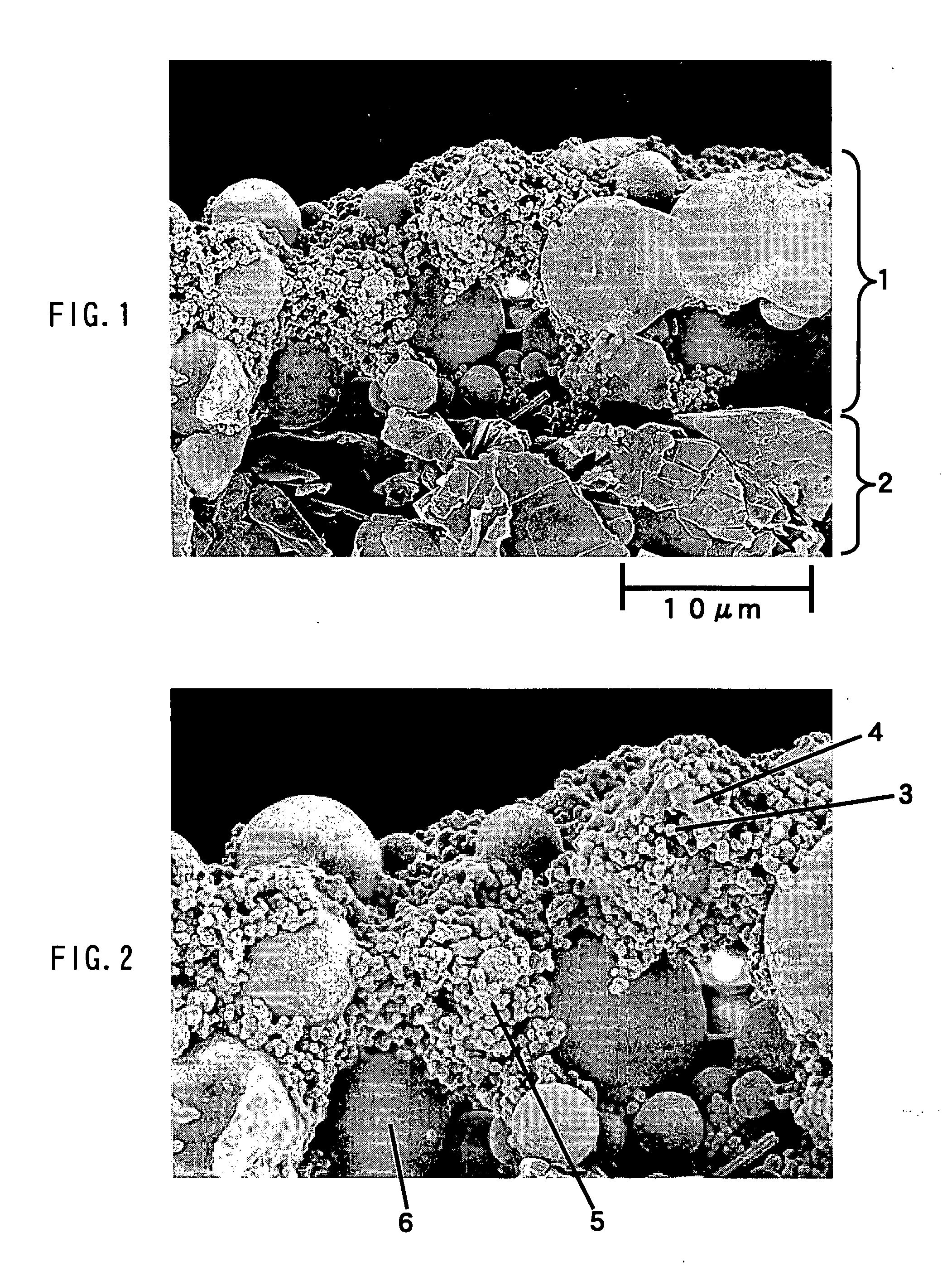

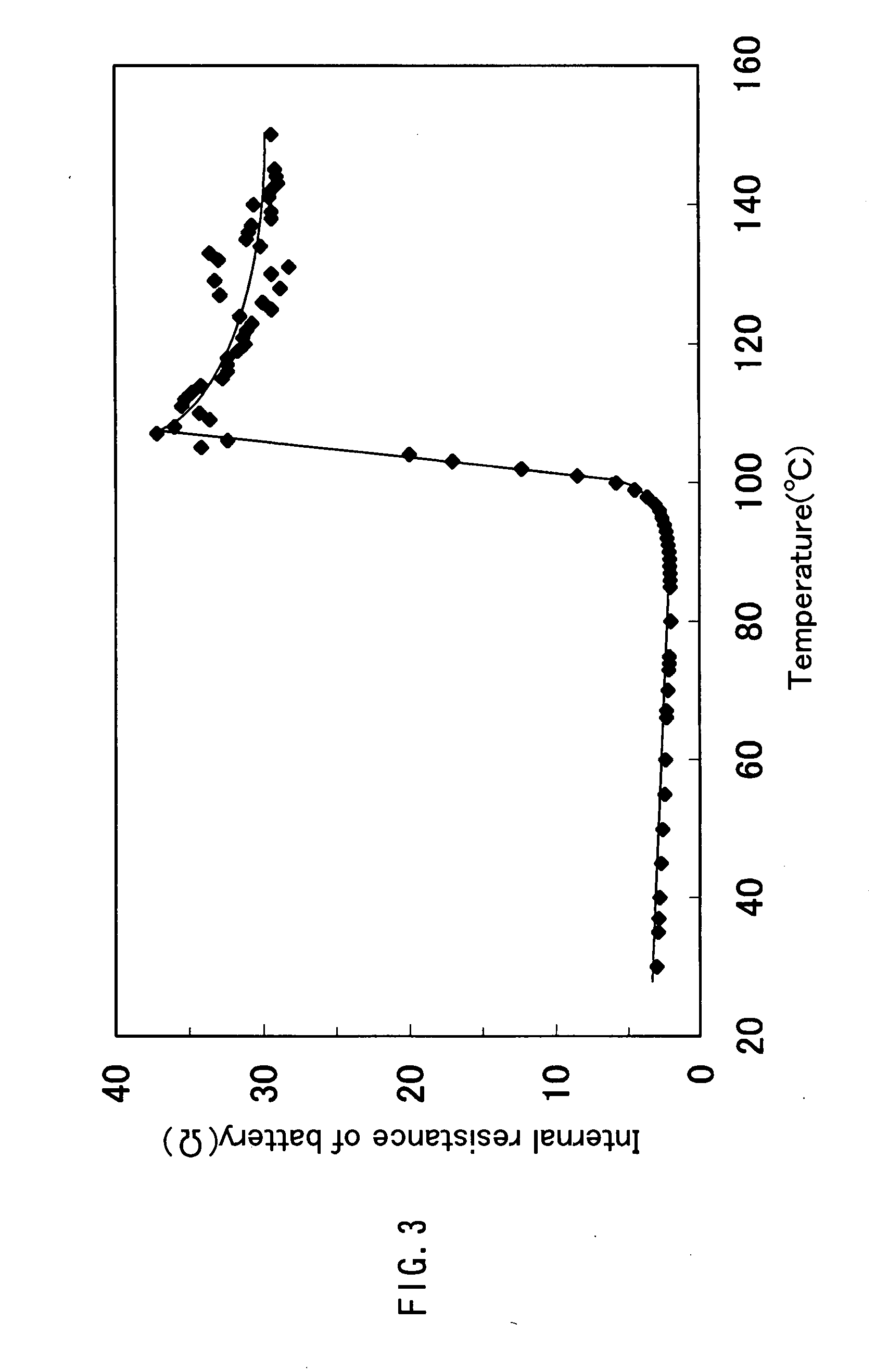

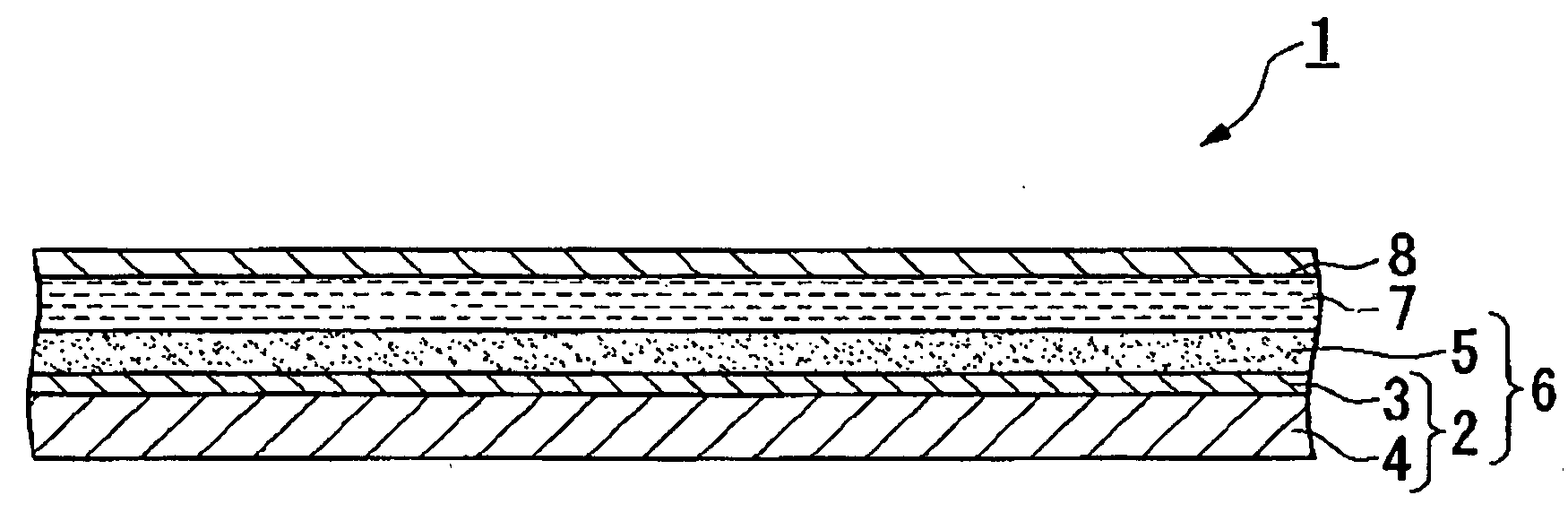

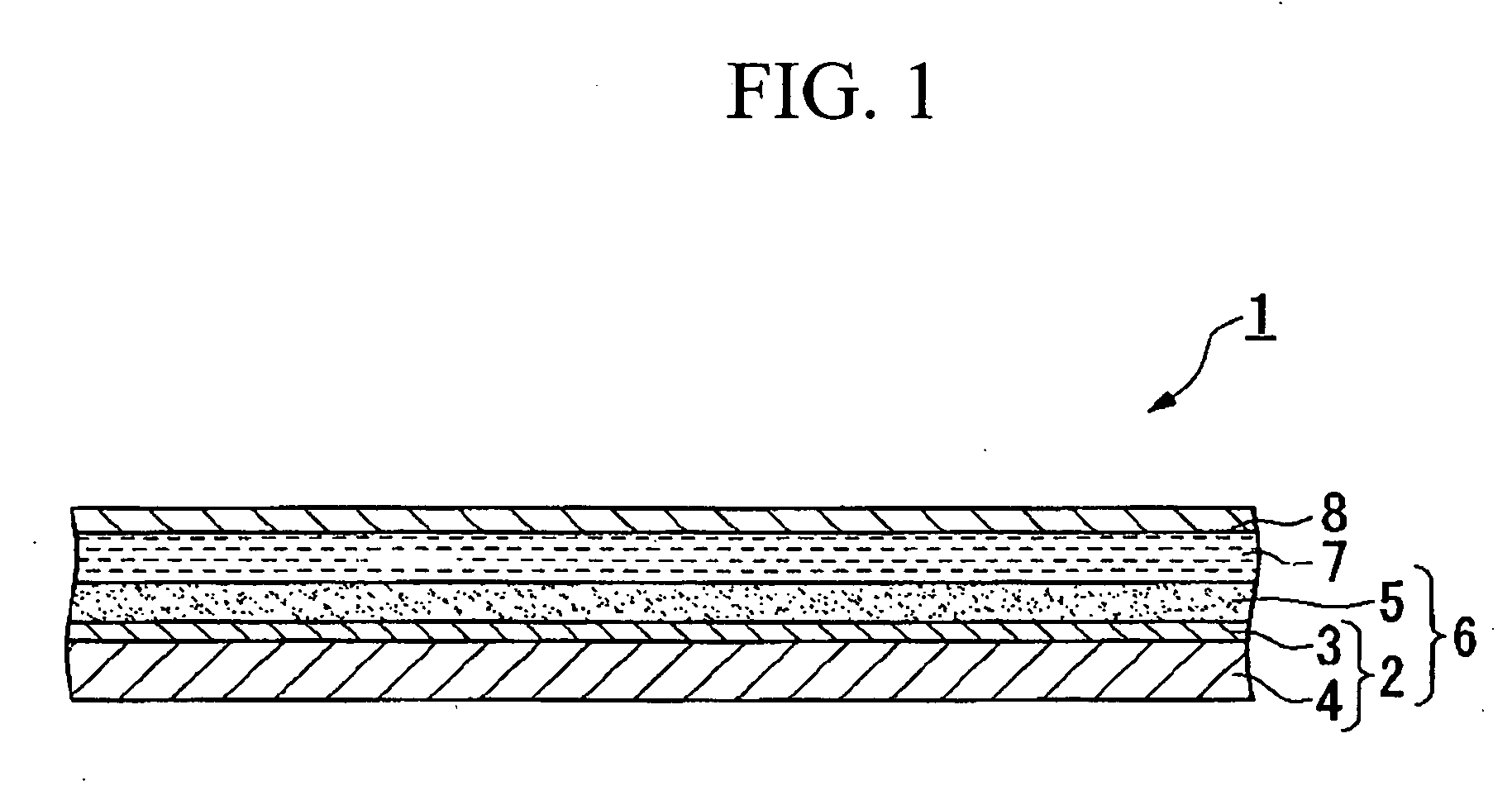

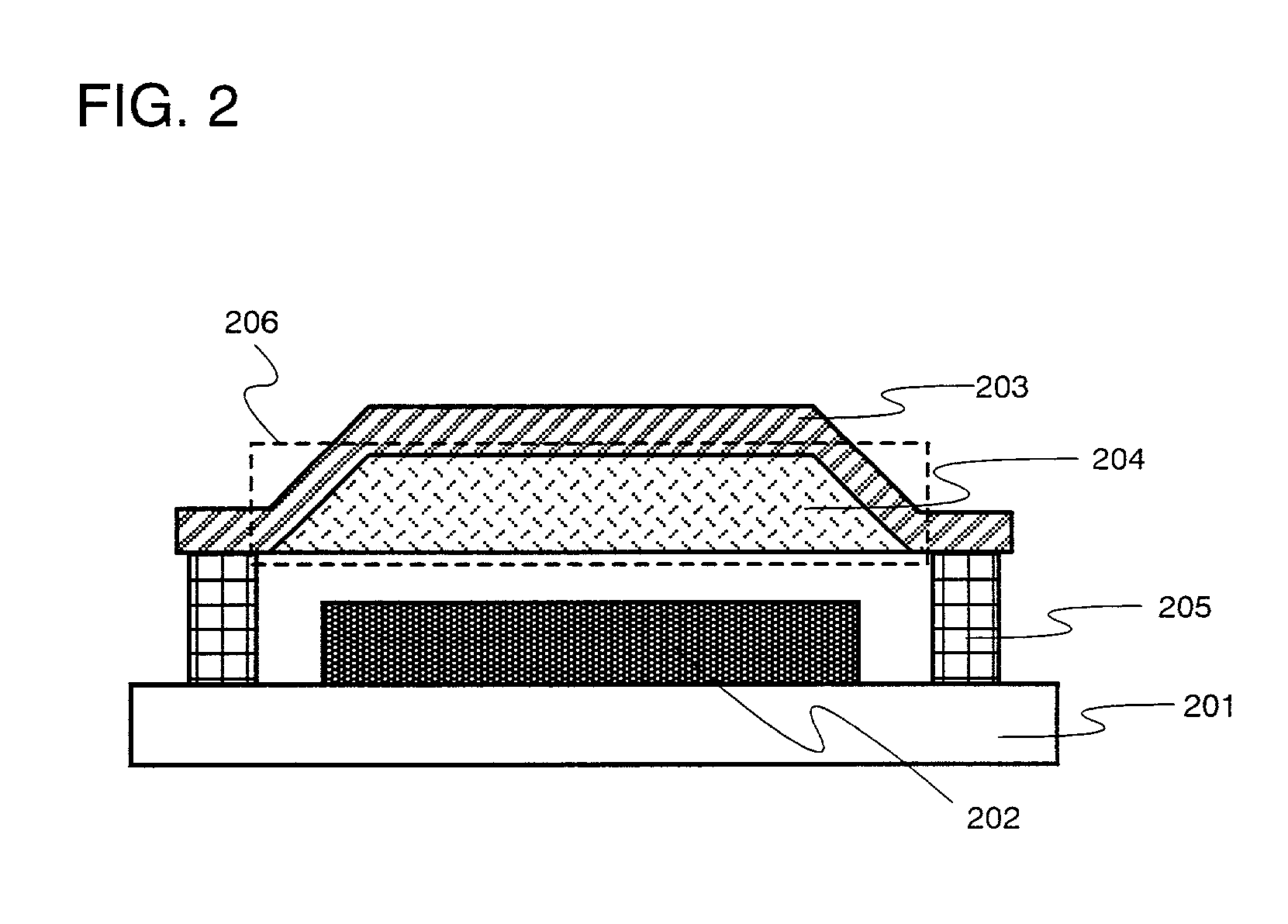

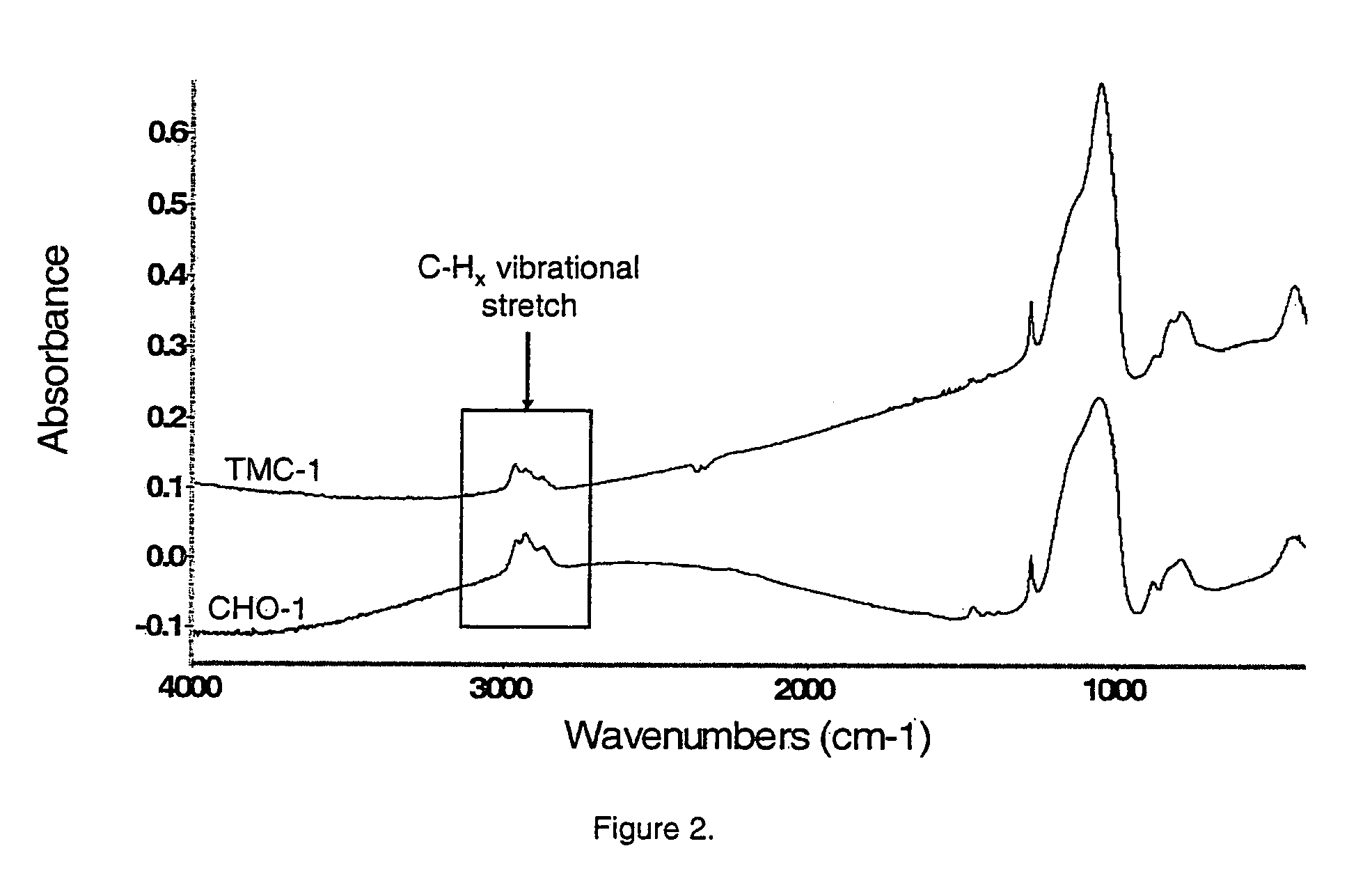

Separator for Electrochemical Device, and Electrochemical Device

ActiveUS20070264577A1Improve securityCell electrodesSecondary cellsPhysical chemistryElectrochemistry

An electrochemical device having excellent safety at high temperature is provided by using a separator for an electrochemical device, which is made of a porous film comprising: a porous base (5) having a heat-resistant temperature of 150° C. or higher and including filler particles (3); at least one kind of shutdown resin (6) selected from the group consisting of resin A that has a melting point in a range of 80° C. to 130° C. and resin B that absorbs an electrolyte and swells due to heating, and the swelling degree is increased as the temperature rises; and a binder (4).

Owner:MAXELL HLDG LTD

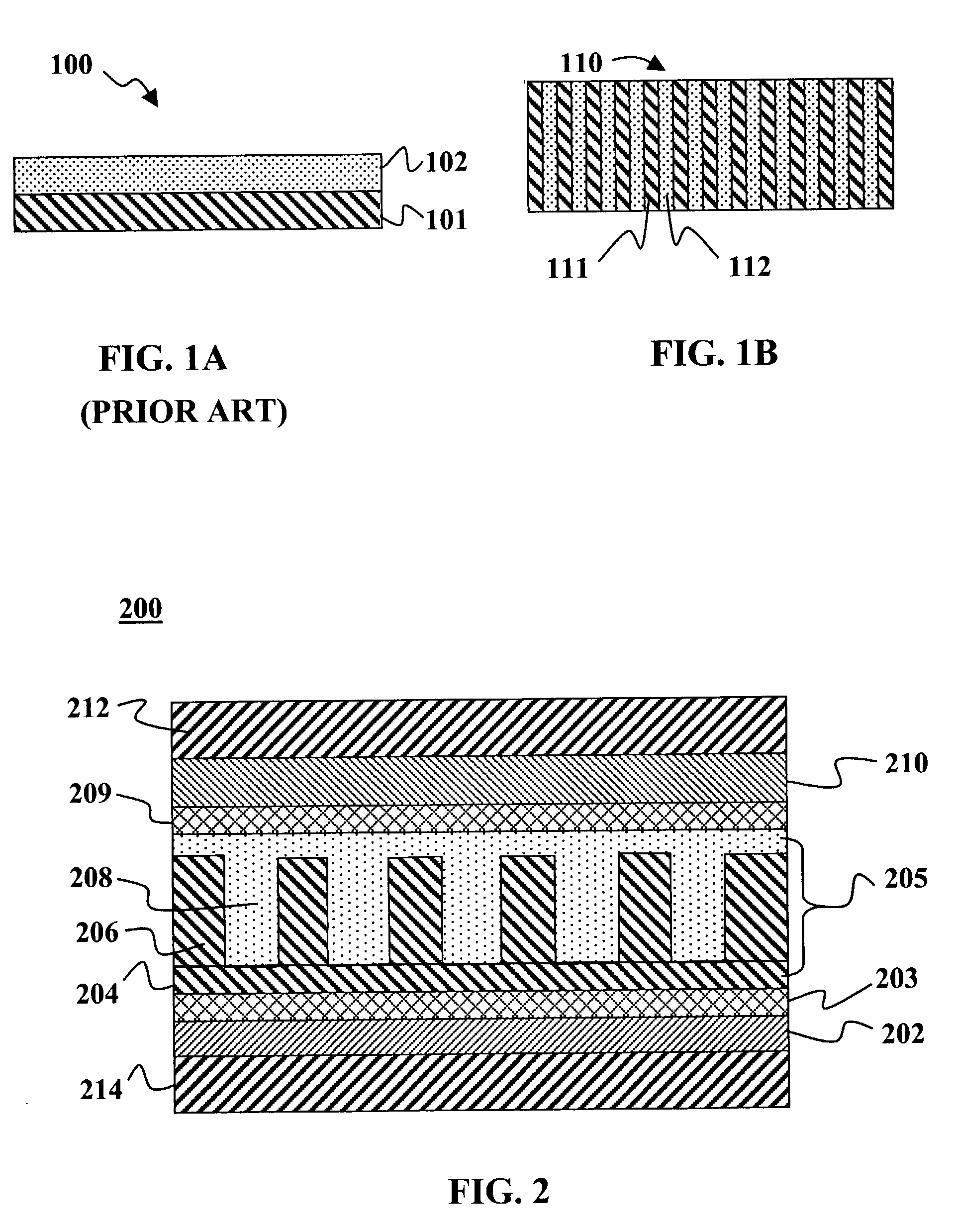

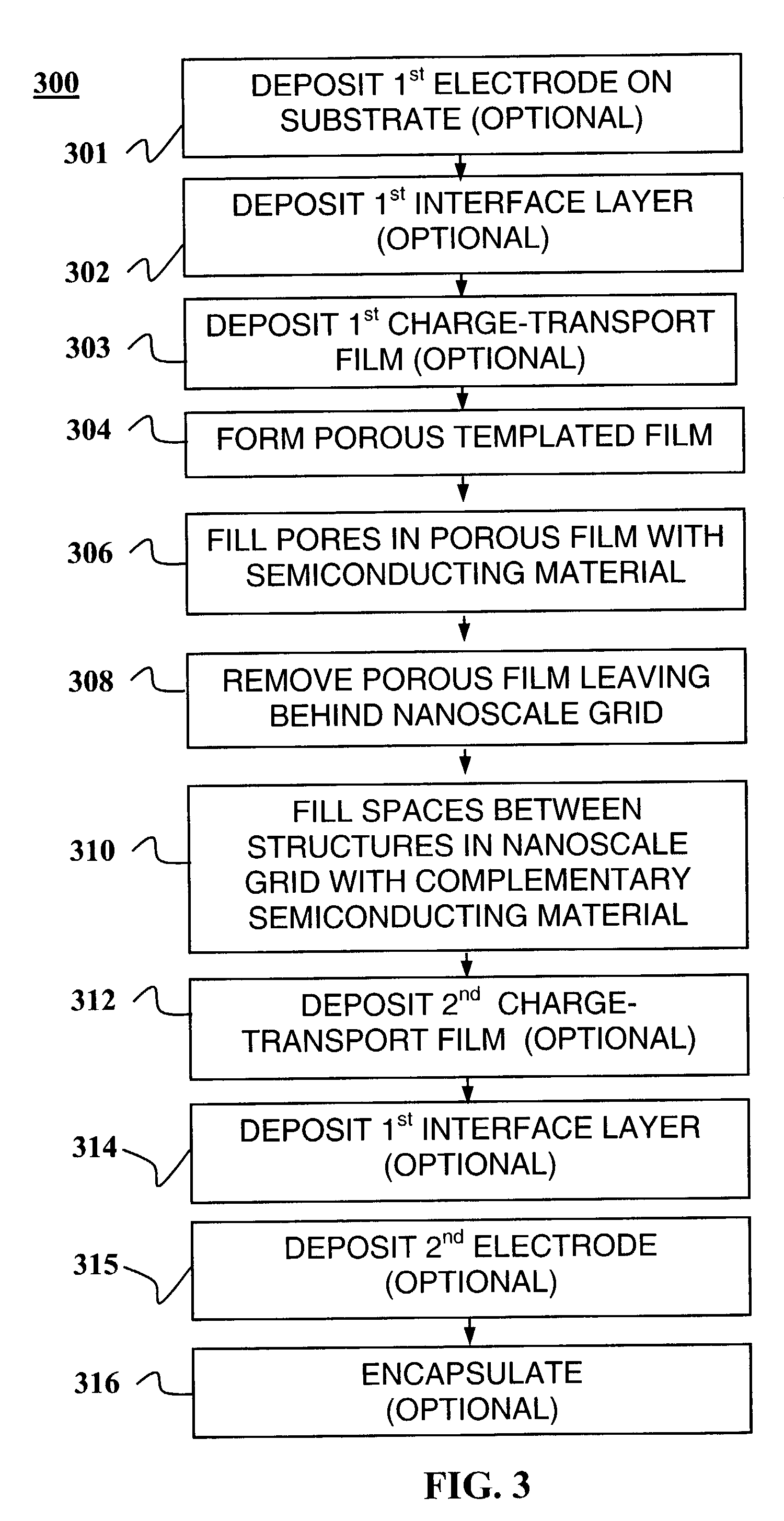

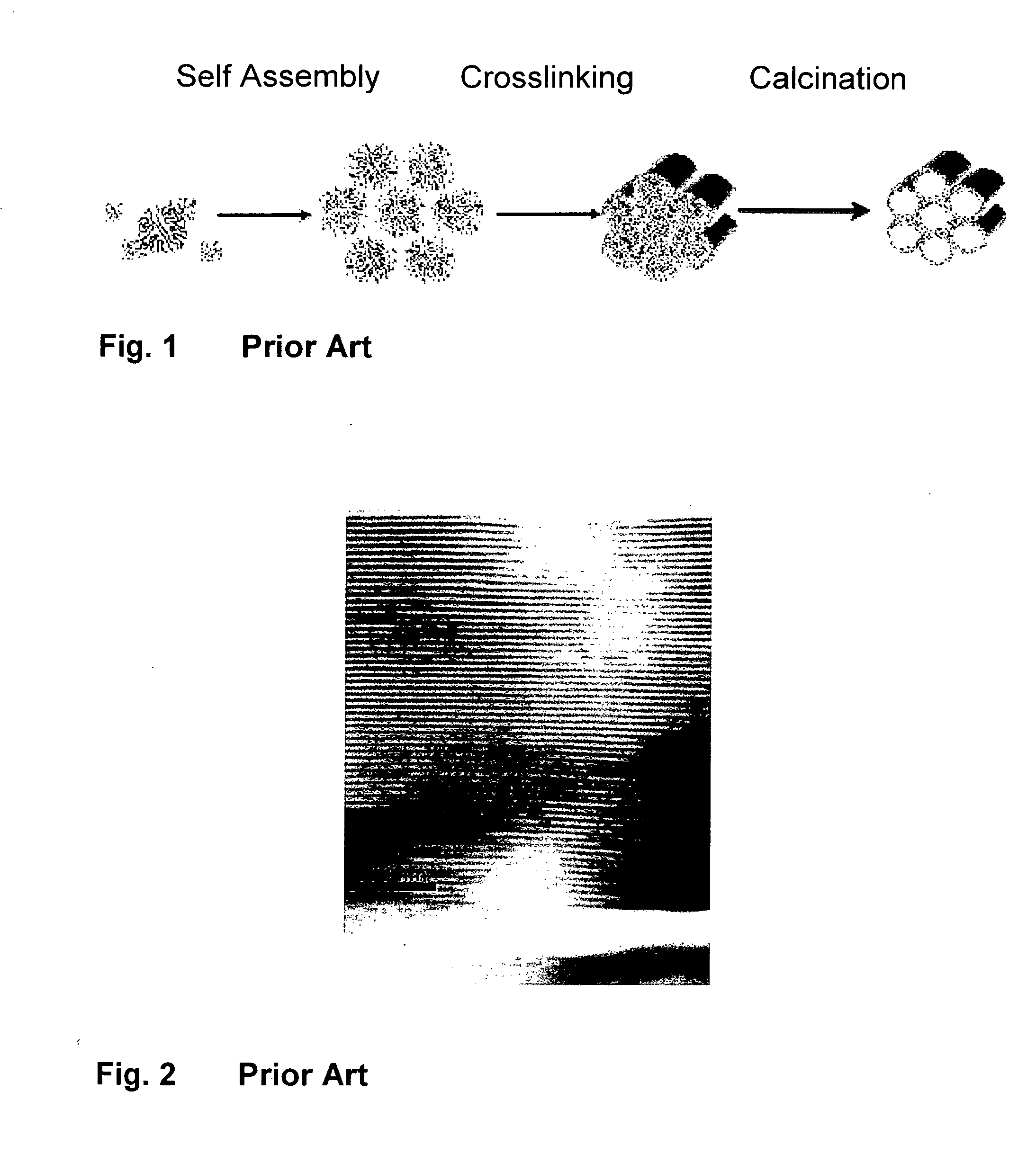

Molding technique for fabrication of optoelectronic devices

InactiveUS7253017B1Large scaleMaterial nanotechnologyPV power plantsSemiconductor materialsNanostructure

Charge splitting networks for optoelectronic devices may be fabricated using a nanostructured porous film, e.g., of SiO2, as a template. The porous film may be fabricated using surfactant temptation techniques. Any of a variety of semiconducting materials including semiconducting metals and metal oxides (such as TiO2, CdSe, CdS, CdTe, or CuO) may be deposited into the pores of the porous template film. After deposition, the template film may be removed by controlled exposure to acid or base without disrupting the semiconducting material leaving behind a nanoscale network grid. Spaces in the network grid can then be filled with complementary semiconducting material, e.g., a semiconducting polymer or dye to create a exciton-splitting and charge transporting network with superior optoelectronic properties for an optoelectronic devices, particularly photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

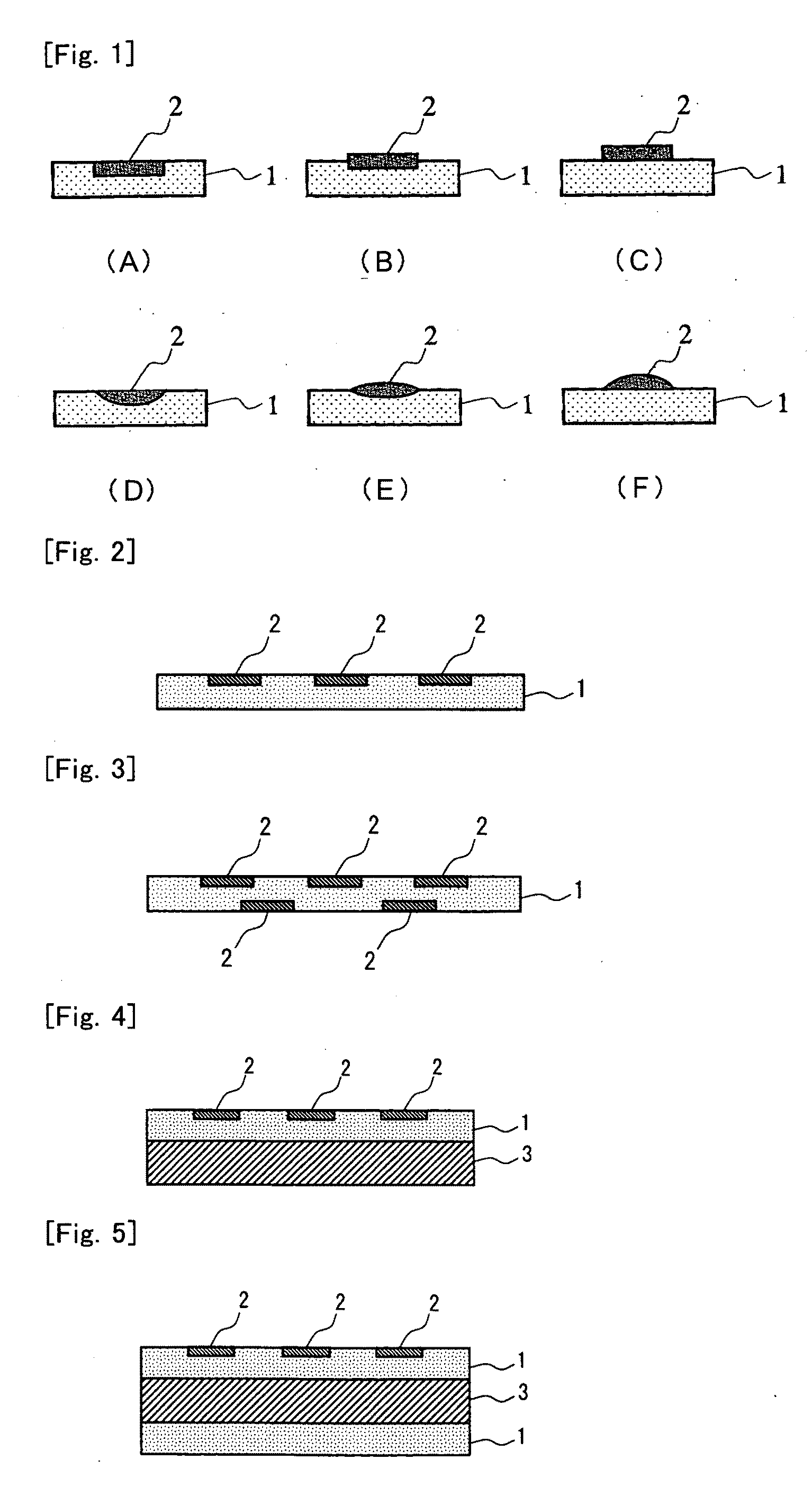

Porous Film and Multilayer Assembly Using the Same

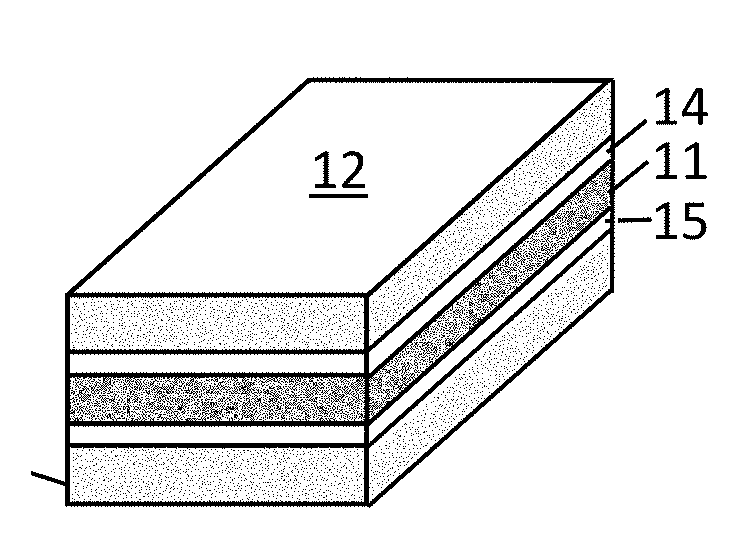

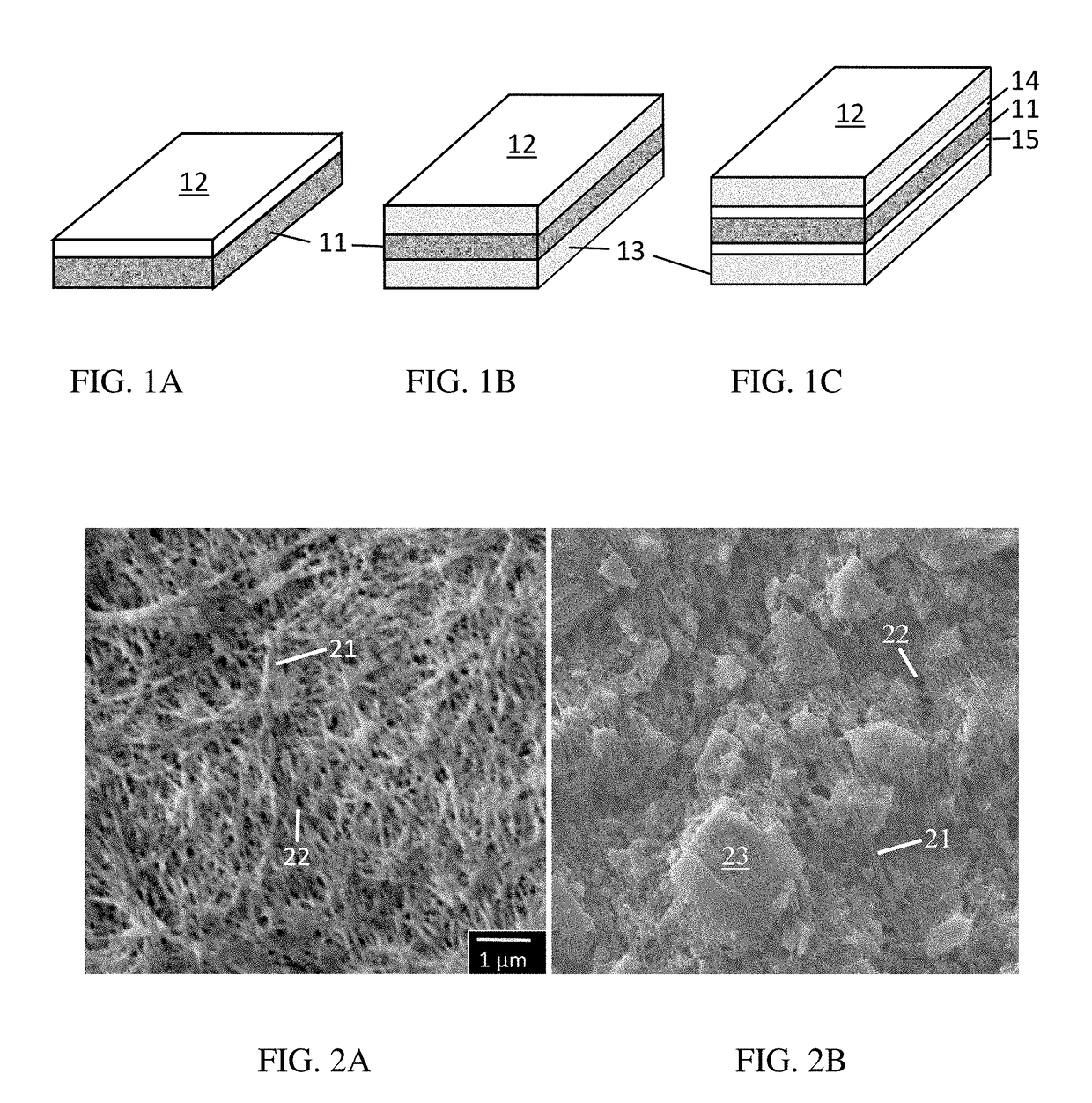

InactiveUS20090008142A1Satisfactorily flexibleImprove porosityVacuum evaporation coatingSputtering coatingInterfacial delaminationPorous layer

[Object] To provide a multilayer assembly that excels in pore properties, is flexible, and is satisfactorily handled and processed; and a method of producing the multilayer assembly.[Solving Means] A multilayer assembly includes a base and, arranged on at least one side thereof, a porous layer and has a large number of continuous micropores with an average pore diameter of 0.01 to 10 μm. The multilayer assembly suffers from no interfacial delamination between the base and the porous layer when examined in a tape peeling test according to the following procedure:Tape Peeling TestA 24-mm wide masking tape [Film Masking Tape No. 603 (#25)] supplied by Teraoka Seisakusho Co., Ltd. is applied to a surface of the porous layer of the multilayer assembly and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf to give a sample; and the sample is subjected to a T-peel test with a tensile tester at a peel rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

Dissolvable Nano Web Porous Film and Method of Preparing the Same

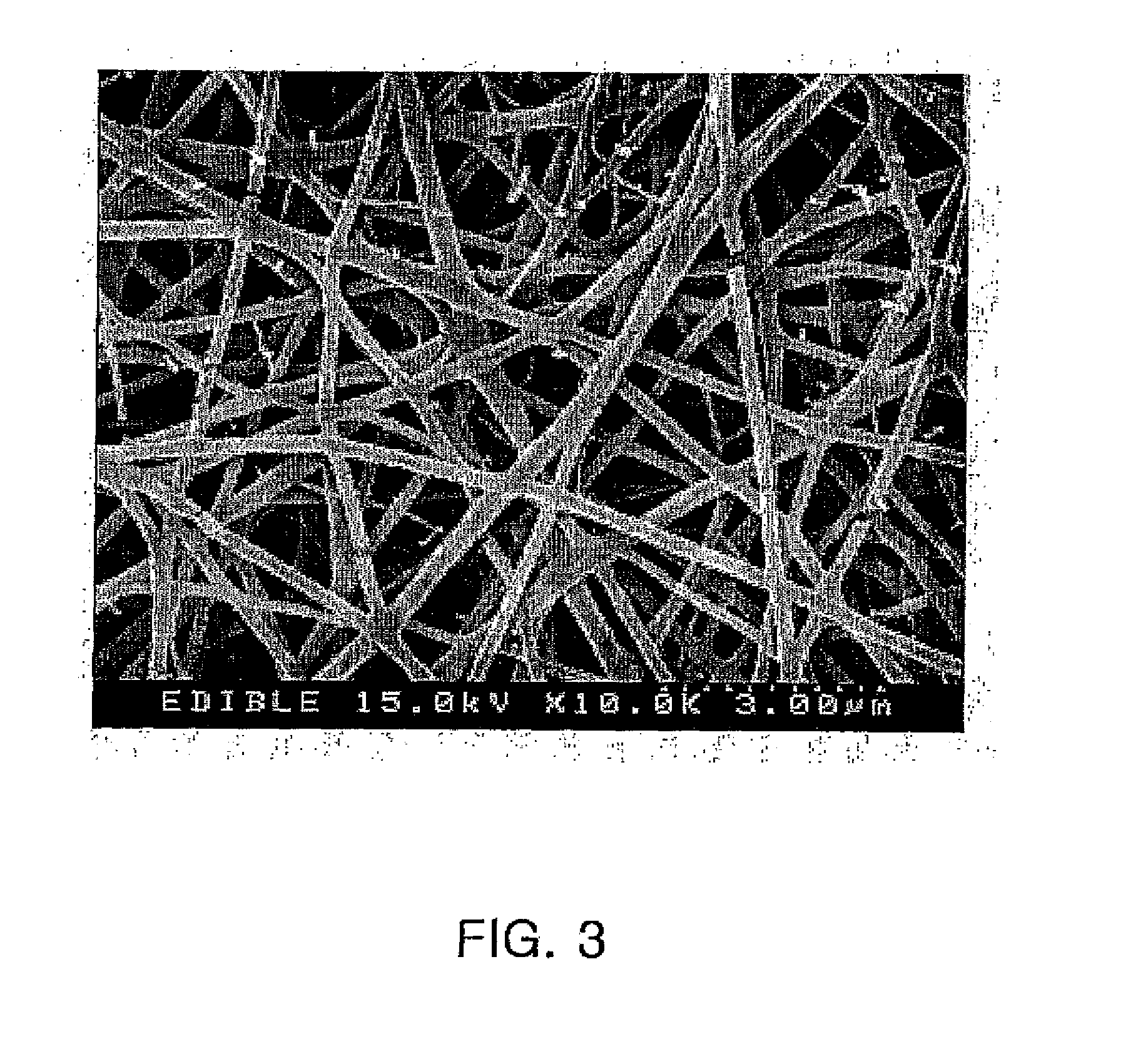

InactiveUS20110250256A1Excellent in dissolvabilityImprove solubilityBiocideElectric discharge heatingSolubilityFiber

A dissolvable nano web porous film has a network structure and a large specific surface area. The network structure is formed by stacking nano fibers that have a thickness of 10˜50,000 nm. The nano fibers are formed of a composition comprising nano fiber forming polymer, a gelling agent, a plasticizer, an optional active component and an optional additive. A method of preparing a dissolvable nano web film comprises producing a polymer melt or solution formed of a composition that comprises a nano fiber forming polymer, a gelling agent, a plasticizer, an optional active component and additives, spinning the melt or solution to form a nano web porous film having nano webs stacked in a network structure, drying the nano web porous film, and stabilizing the nano web porous film. The porous film has a 5˜5000 times higher specific surface area and a 2˜20 times faster dissolving time than a conventional film. The dissolvable nano web porous film has excellent dissolvability and solubility.

Owner:GENIC

Separator for nonaqueous electrolyte batteries, nonaqueous electrolyte battery using it, and method for manufacturing separator for nonaqueous electrolyte batteries

InactiveUS6511774B1High tear strengthEnhanced penetration strengthNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersHigh energyEngineering

The present invention provides a separator for non-aqueous electrolyte batteries which neither breaks nor slips off at the time of fabrication of battery, gives excellent battery fabricability, causes no internal short-circuit caused by contact between electrodes even if the electrodes are externally short-circuited, can inhibit ignition of battery and produces high energy density and excellent cycle life, and further provides a non-aqueous electrolyte battery using the separator and a method for manufacturing the separator. That is, the present invention relates to a separator for non-aqueous electrolyte batteries which comprises a porous base containing at least one member selected from a porous film, a woven fabric or nonwoven fabric containing an organic fiber and a paper and an organometallic compound applied to the porous base; a method for the manufacture of the separator for non-aqueous electrolyte batteries which comprises allowing said porous base to contact with a solution of organometallic compound by impregnation, coating or spraying, followed by drying or curing with heating to apply the organometallic compound to the porous base; and a non-aqueous electrolyte battery using the separator.

Owner:MITSUBISHI PAPER MILLS LTD

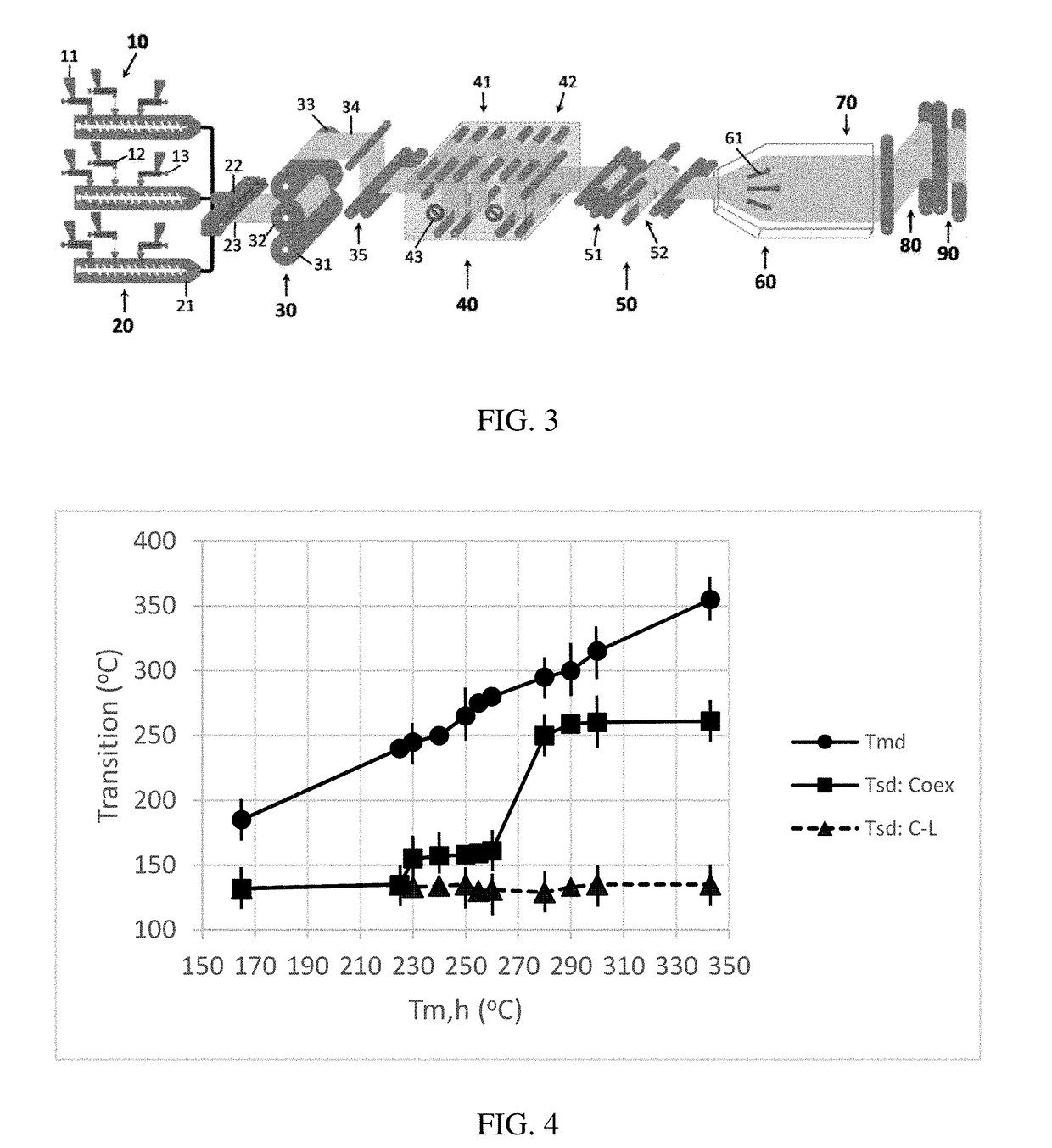

Oriented Multilayer Porous Film

PendingUS20180043656A1Improve conductivityImprove insulation effectHybrid capacitor separatorsElectrolytic capacitorsFiltrationLithium sulfur

Provided is an oriented multilayer porous film comprising at least one layer comprising: a heat, solvent, and degradation resistant matrix polymer; a plurality of interconnecting pores; and a porosity less than 90%. The film is made by a dry and / or wet method, with its multilayer structure constructed by coextrusion, lamination, and coating. The film of this disclosure finds a wide range of applications as a permselective medium for use in energy harvesting and storage, filtration, separation and purification of gases and fluids, CO2 and volatile capture, electronics, devices, structural supports, packaging, labeling, printing, clothing, drug delivery systems, bioreactor, and the like. The film is preferably used as a separator of lithium-ion, lithium-sulfur, lithium-air, metal-air, and nonaqueous electrolyte batteries.

Owner:LISO PLASTICS L L C

Electrolyte compositon, photoelectric converter and dye-sensitized solar cell using same

ActiveUS20060174932A1Improve conductivityDecrease in flowabilityMaterial nanotechnologyLight-sensitive devicesElectrolyte compositionPhotoelectric conversion

An electrolyte composition containing an ionic liquid and conductive particles as main components, an electrolyte composition containing an ionic liquid, and oxide semiconductor particles or oxide semiconductor particles, and conductive particles, and an electrolyte composition containing an ionic liquid and insulating particles are provided. Furthermore, a photoelectric conversion element comprising: a working electrode, the working electrode comprising an electrode substrate and an oxide semiconductor porous film formed on the electrode substrate and sensitized with a dye; a counter electrode disposed opposing the working electrode; and an electrolyte layer made of these electrolyte compositions is provided.

Owner:THE FUJIKURA CABLE WORKS LTD

Separator for lithium secondary battery, method for producing the same, and lithium secondary battery including the same

InactiveUS20070281206A1Suppress occurrenceIncrease energy densityCell temperature controlPretreated surfacesPorous layerMolecular materials

A separator for a lithium secondary battery includes a high molecular porous film with a shut-down function and a heat-resistant porous layer integrally formed on each side of the high molecular porous film. The heat-resistant porous layers contain a heat-resistant high-molecular material and a ceramic filler. By using the separator, the occurrence of a short-circuit due to the melting and shrinkage of the high molecular porous film is prevented. Also, in the event of a short-circuit and the generation of heat higher than the melting point of the material of the high molecular porous film, the expansion of the short-circuit is prevented, so that the safety of the lithium secondary battery is improved.

Owner:PANASONIC CORP

Batteries having inorganic/organic porous films

ActiveUS20090087728A1Low costImprove performanceFinal product manufactureSecondary cellsLithiumSolvent

An electrochemical cell, such as Li-Ion, having (a) a positive electrode; (b) a negative electrode, (c) a porous inorganic / organic composite layer interposed between the positive electrode and the negative electrode, and (d) an electrolyte comprising a lithium salt and a non-aqueous solvent. The composite layer includes inorganic nanoparticles and a binder to form a nanocomposite separator (NCS). In addition to the composite layer, the electrochemical cell includes a porous separator.

Owner:A123 SYSTEMS LLC

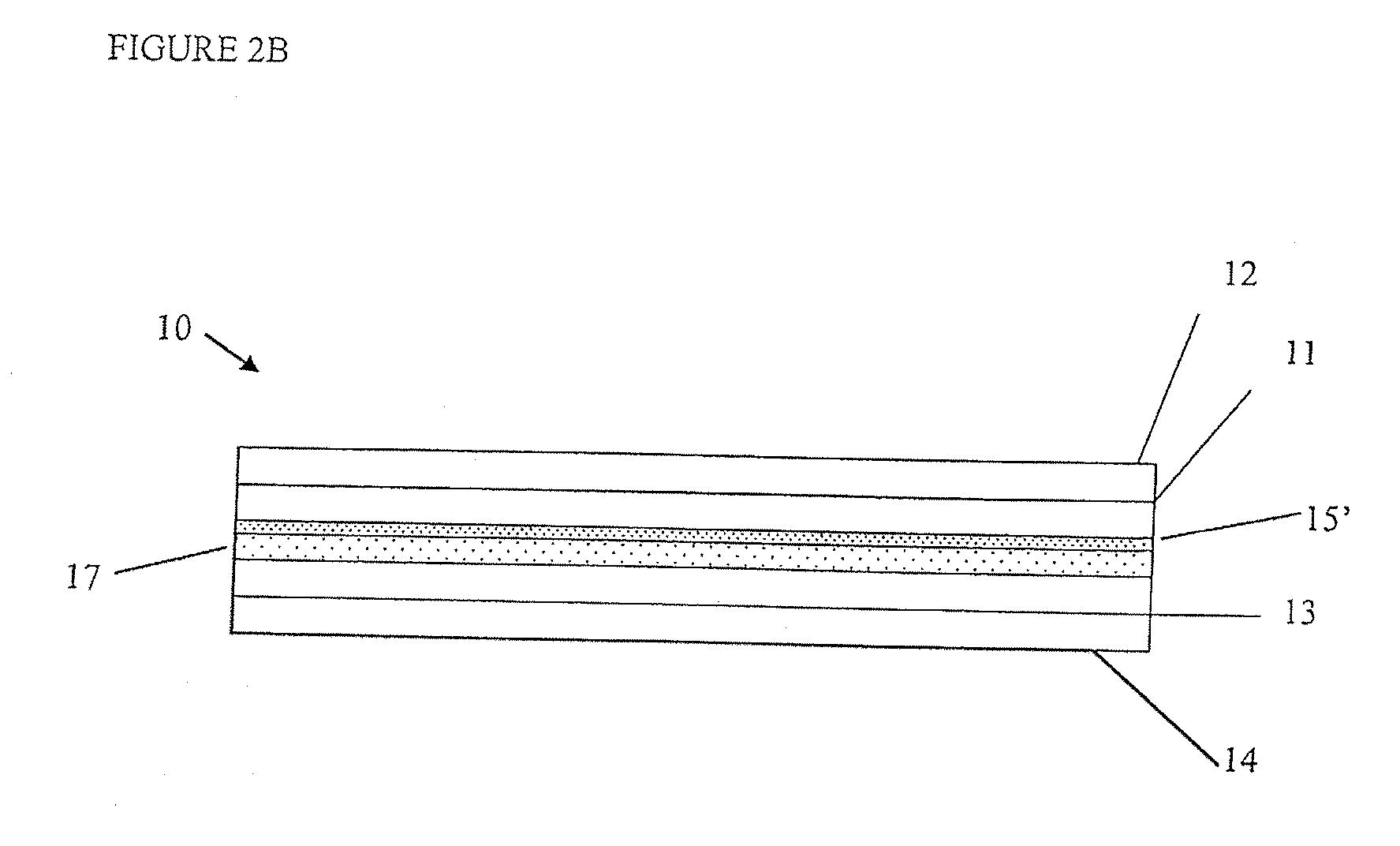

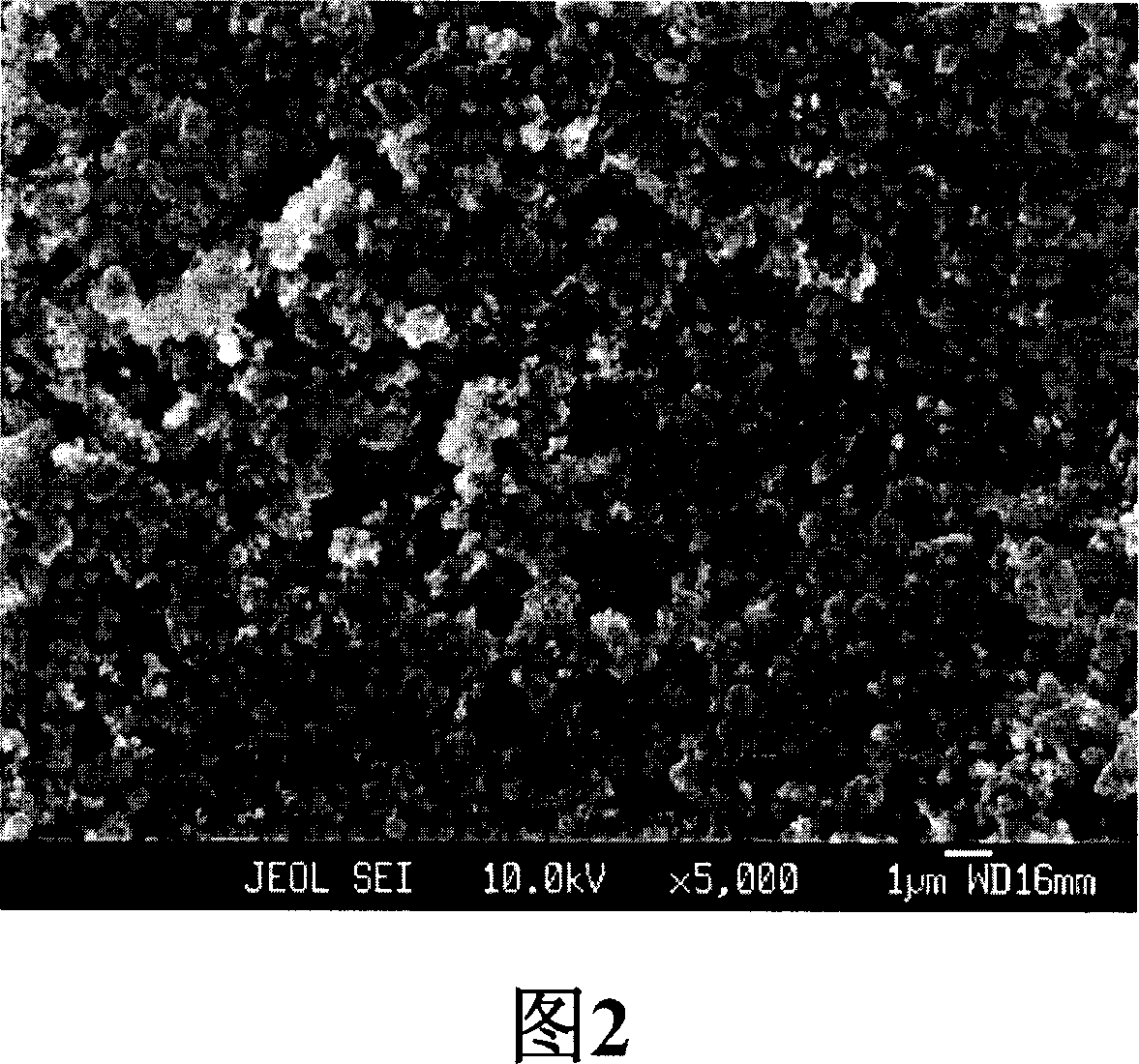

Organic/inorganic composite porous film and electrochemical device prepared thereby

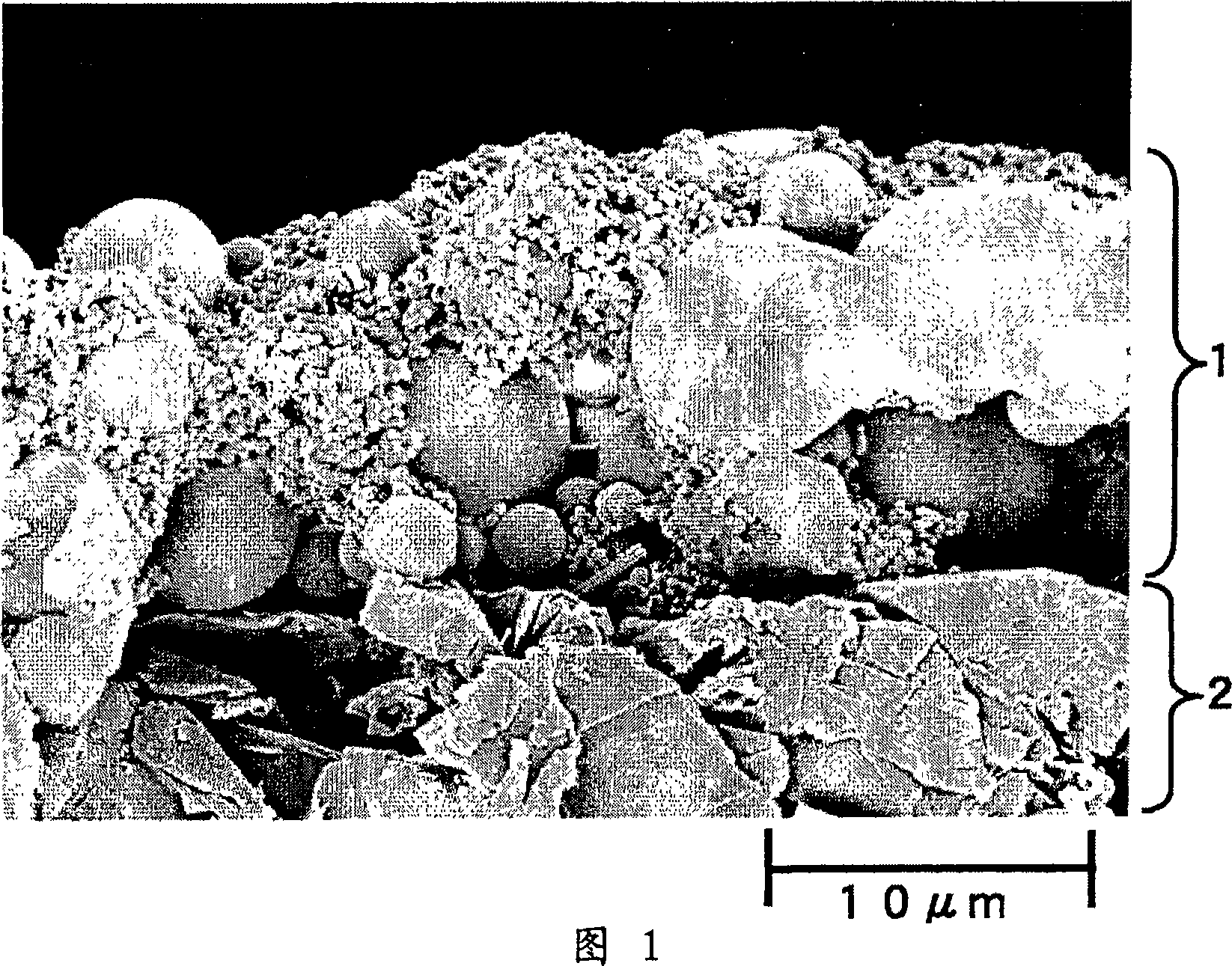

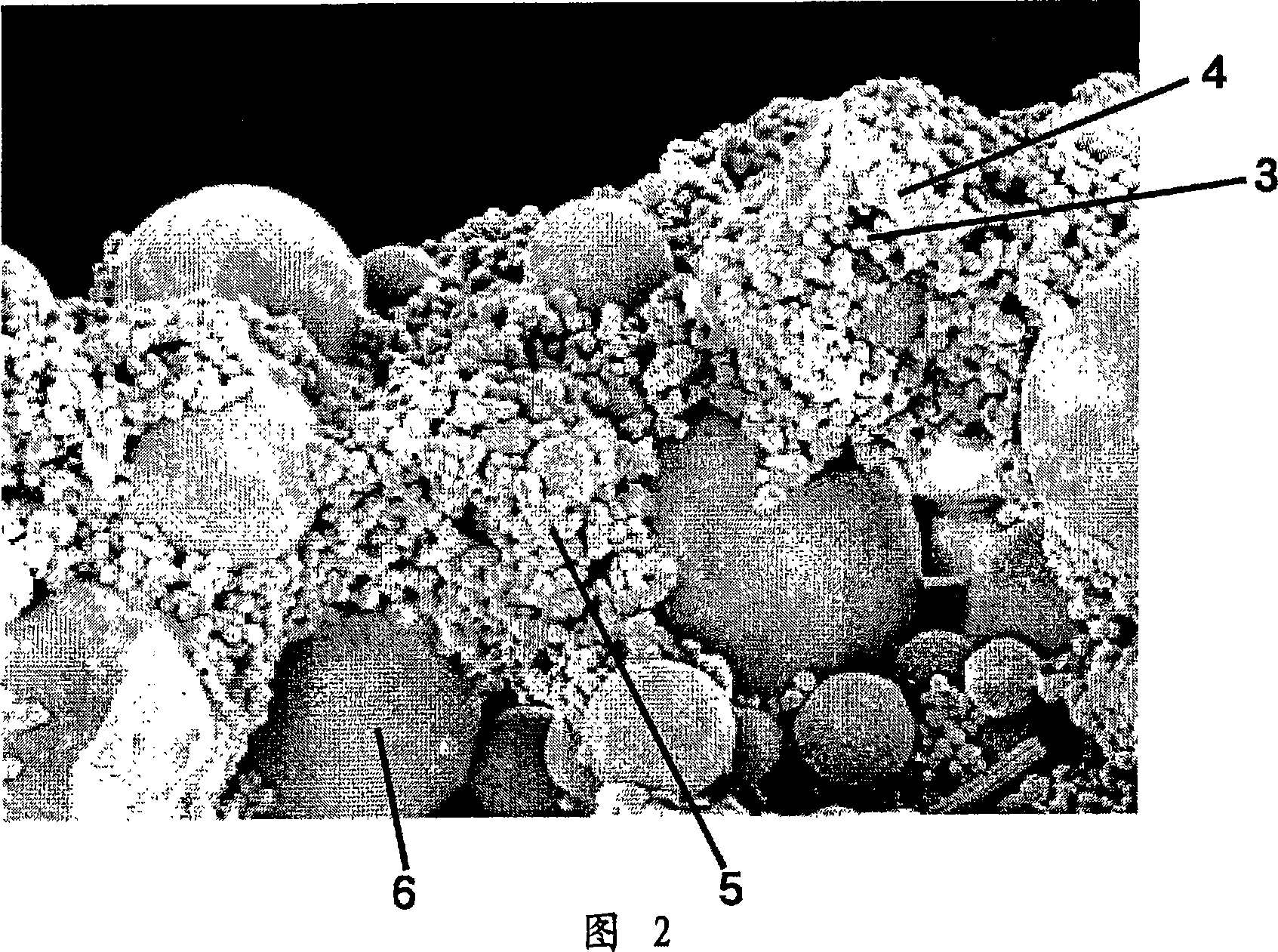

ActiveCN101002347AImprove thermal safetyImprove performanceLi-accumulatorsCell component detailsInorganic particleInorganic particles

Disclosed is an organic / inorganic composite porous film comprising: (a) inorganic particles; and (b) a binder polymer coating layer formed partially or totally on surfaces of the inorganic particles, wherein the inorganic particles are interconnected among themselves and are fixed by the binder polymer, and interstitial volumes among the inorganic particles form a micropore structure. A method for manufacturing the same film and an electrochemical device including the same film are also disclosed. An electrochemical device comprising the organic / inorganic composite porous film shows improved safety and quality.

Owner:LG ENERGY SOLUTION LTD +1

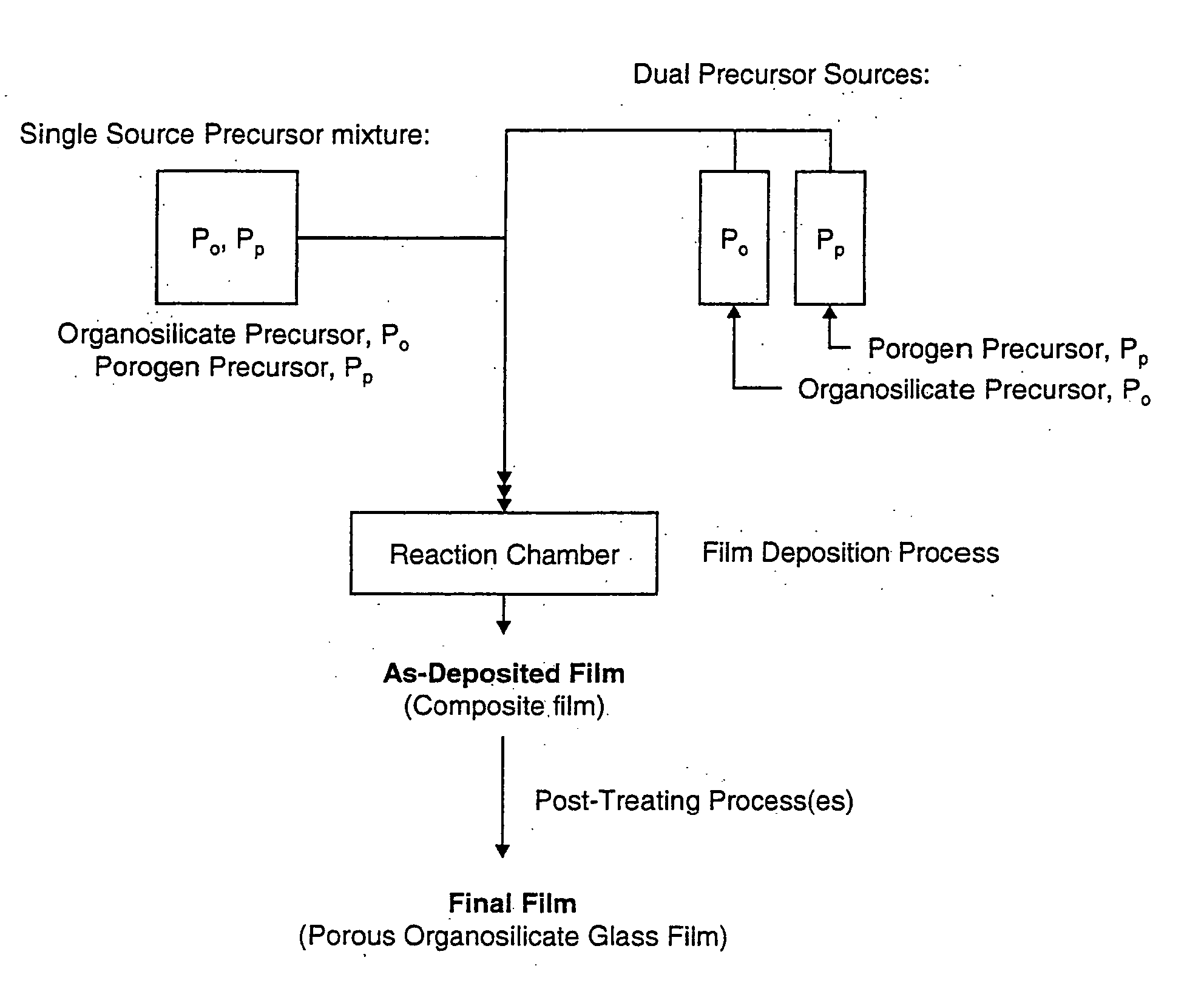

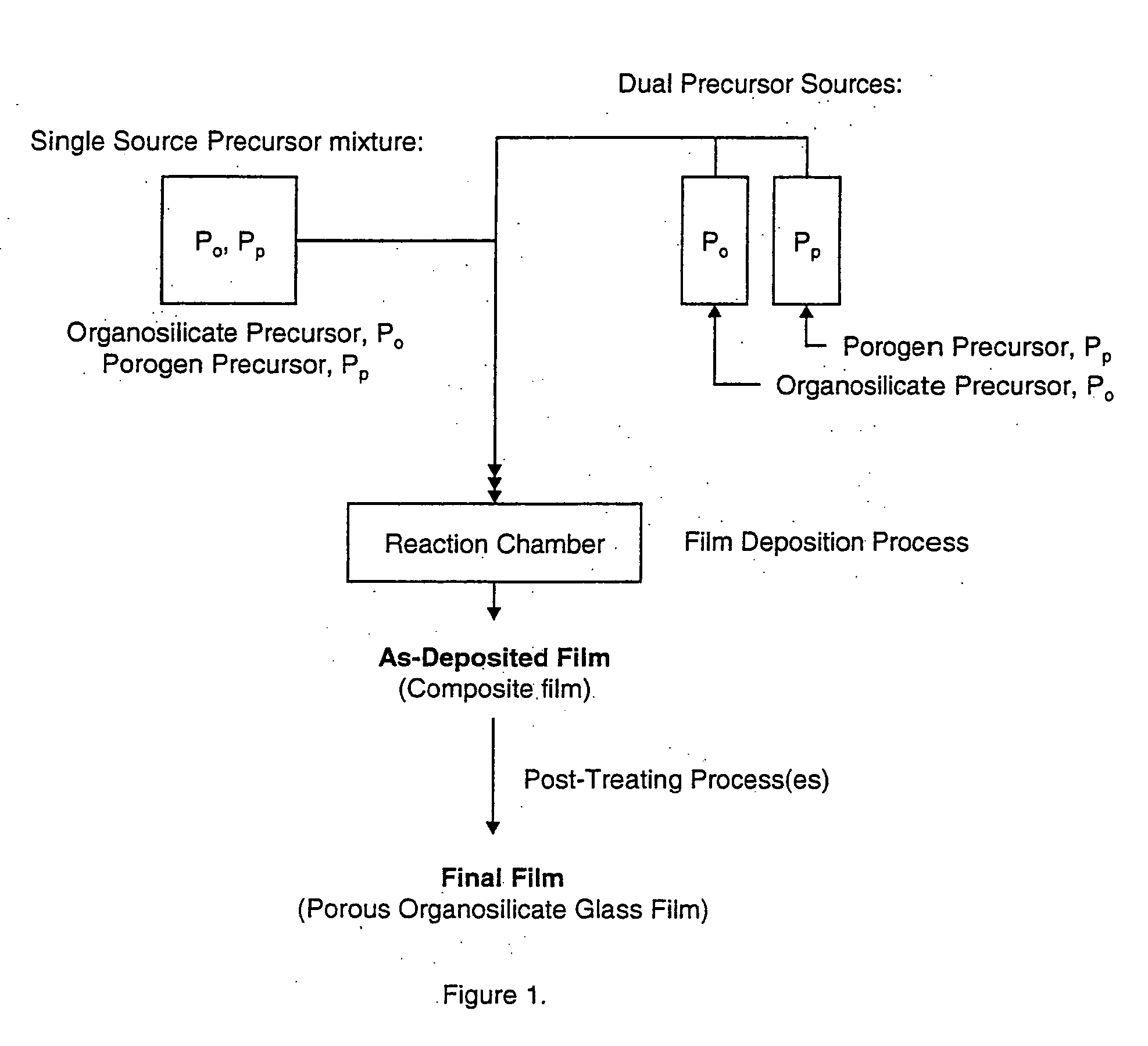

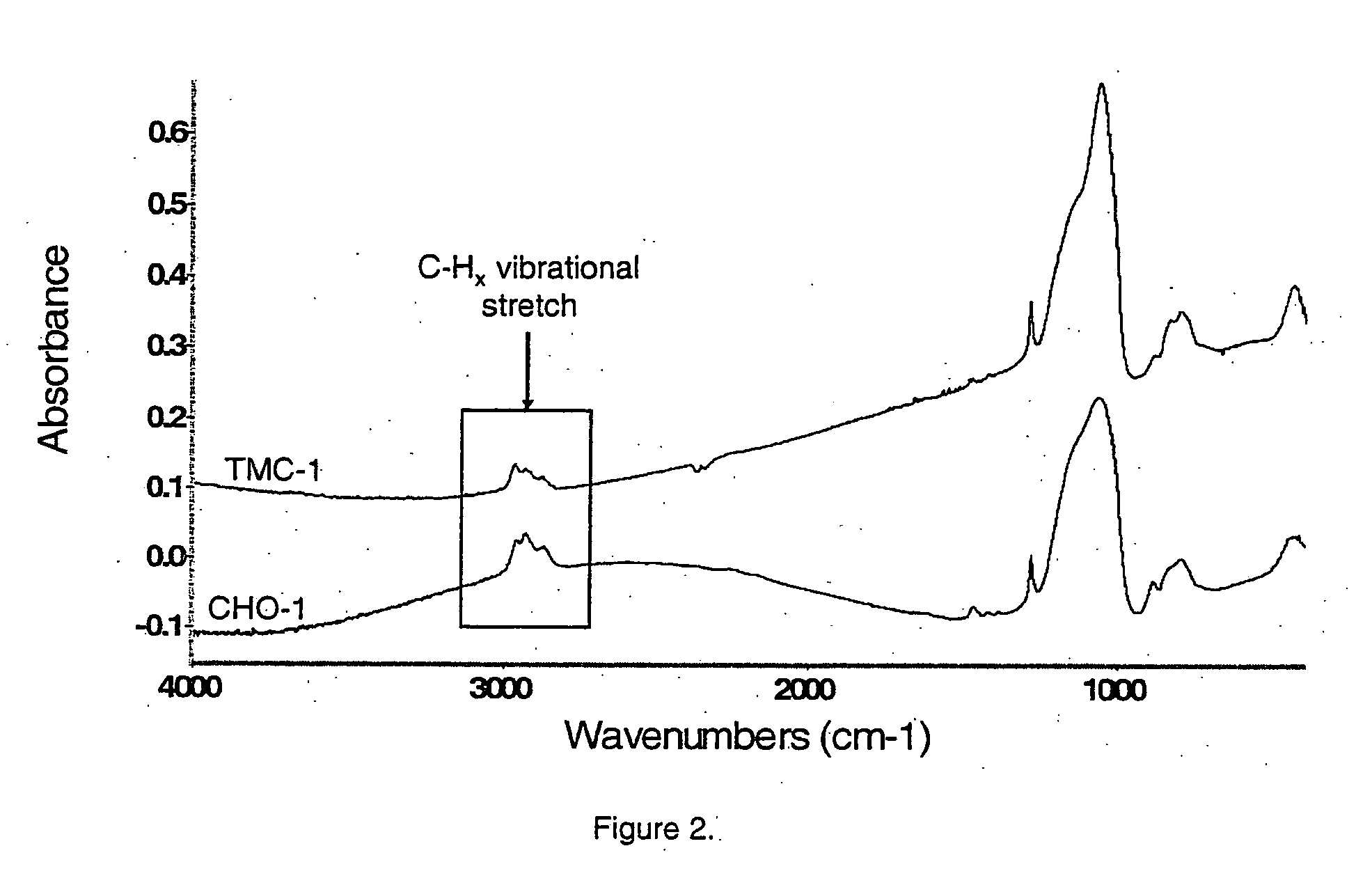

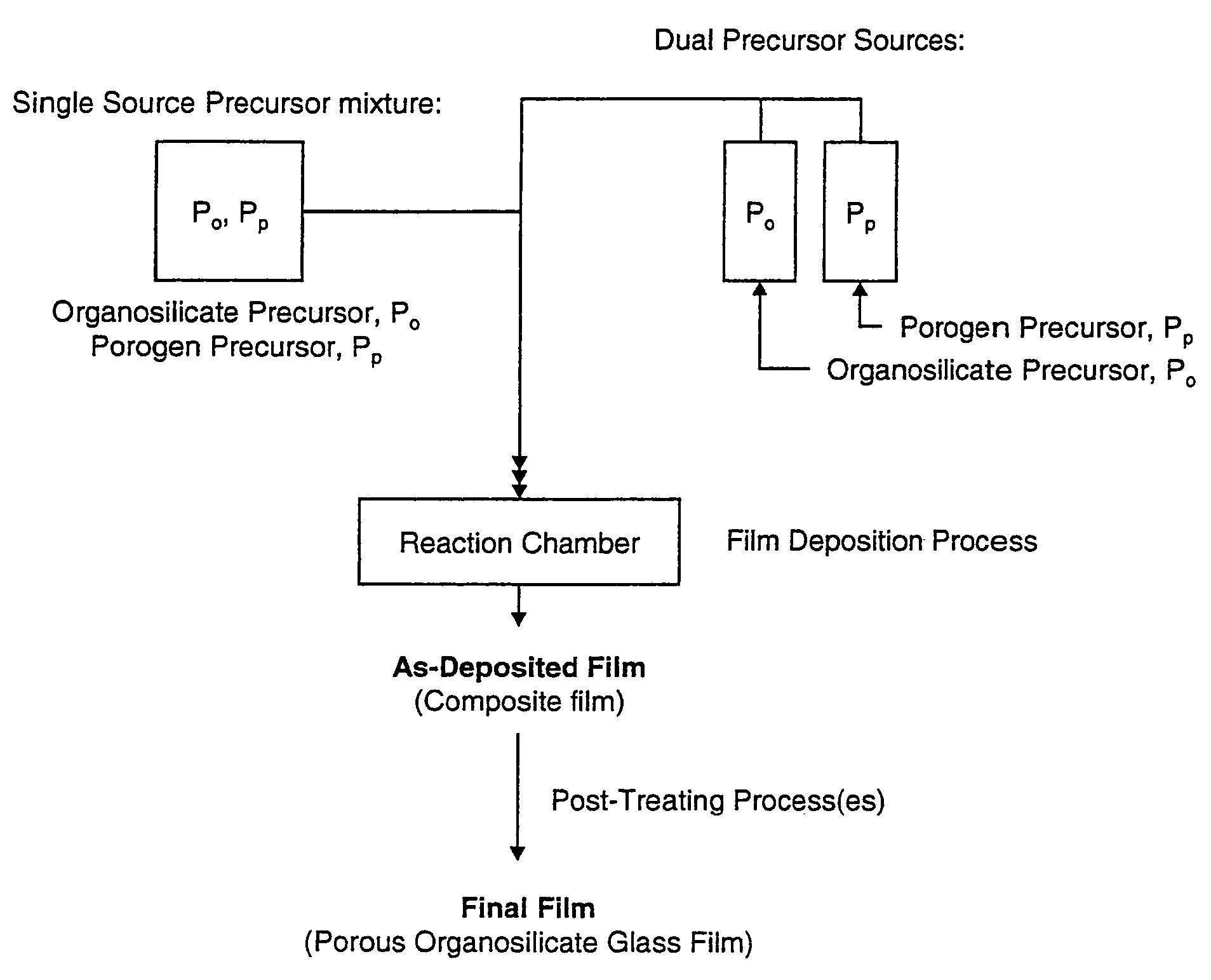

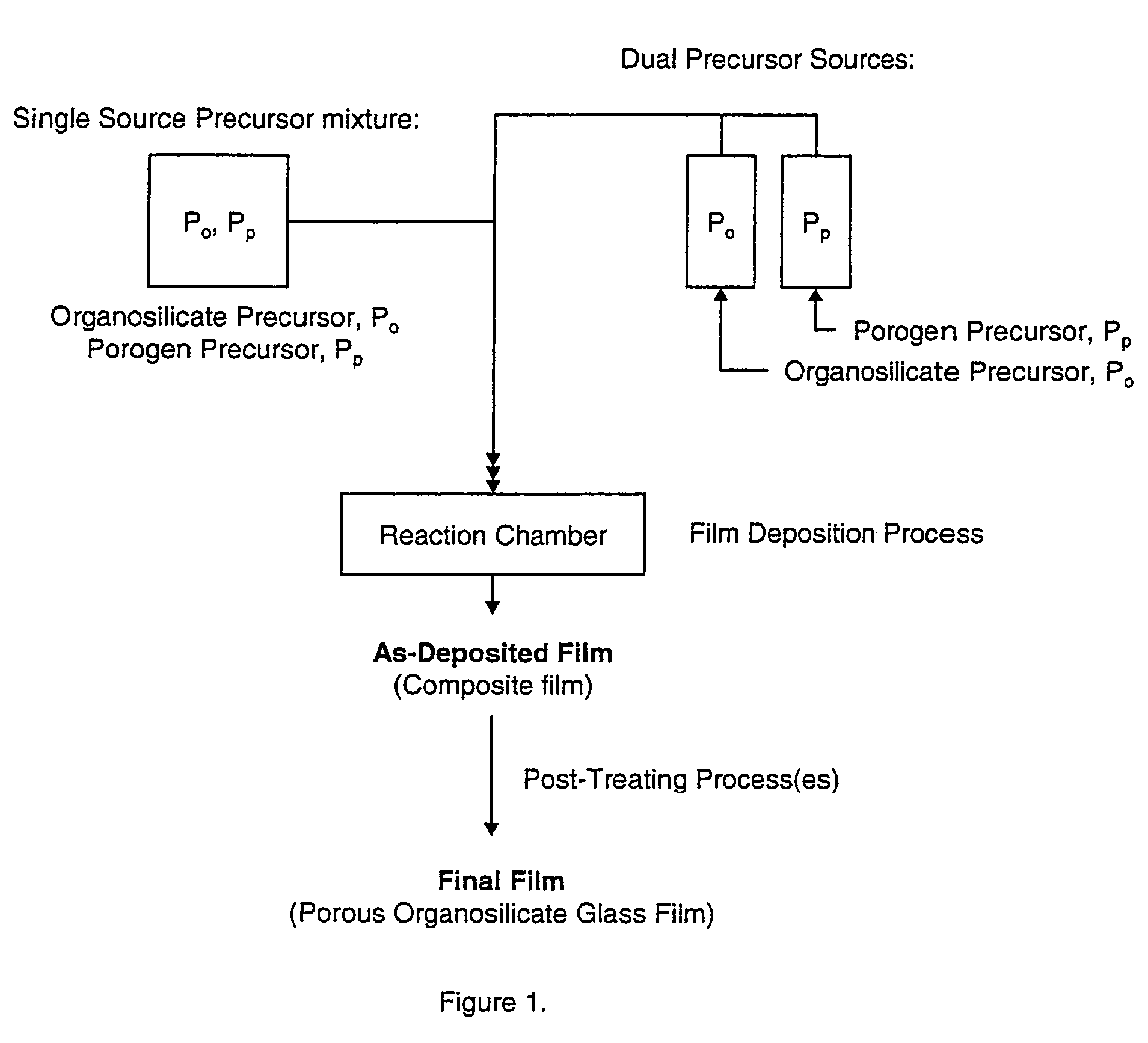

Porous low dielectric constant compositions and methods for making and using same

ActiveUS20060078676A1Semiconductor/solid-state device manufacturingPretreated surfacesConstant compositionCarboxylic acid

A porous organosilicate glass (OSG) film: SivOwCxHyFz, where v+w+x+y+z=100%, v is 10 to 35 atomic %, w is 10 to 65 atomic %, x is 5 to 30 atomic %, y is 10 to 50 atomic % and z is 0 to 15 atomic %, has a silicate network with carbon bonds as methyl groups (Si—CH3) and contains pores with diameter less than 3 nm equivalent spherical diameter and dielectric constant less than 2.7. A preliminary film is deposited by a chemical vapor deposition method from organosilane and / or organosiloxane precursors, and independent pore-forming precursors. Porogen precursors form pores within the preliminary film and are subsequently removed to provide the porous film. Compositions, film forming kits, include organosilane and / or organosiloxane compounds containing at least one Si—H bond and porogen precursors of hydrocarbons containing alcohol, ether, carbonyl, carboxylic acid, ester, nitro, primary amine, secondary amine, and / or tertiary amine functionality or combinations.

Owner:VERSUM MATERIALS US LLC

Nonaqueous-electrolyte secondary battery

ActiveUS20070048607A1Good effectIncrease capacityNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersLithiumParticulates

A subject for the invention is to improve the cycle characteristics of a high-capacity secondary battery containing an active material packed at a high density, by using a particulate active material having a low aspect ratio. The invention relates to a nonaqueous-electrolyte secondary battery comprising a negative electrode and a positive electrode each capable of occluding / releasing lithium, a separator, and a nonaqueous electrolyte solution comprising a nonaqueous solvent and a lithium salt, characterized in that the separator comprises a porous film made of a thermoplastic resin containing an inorganic filler, and at least either of the following is satisfied: the active material contained in the negative electrode is a particulate active material having an aspect ratio of from 1.02 to 3; and the active material contained in the positive electrode is a particulate active material having an aspect ratio of from 1.02 to 2.2.

Owner:MITSUBISHI CHEM CORP

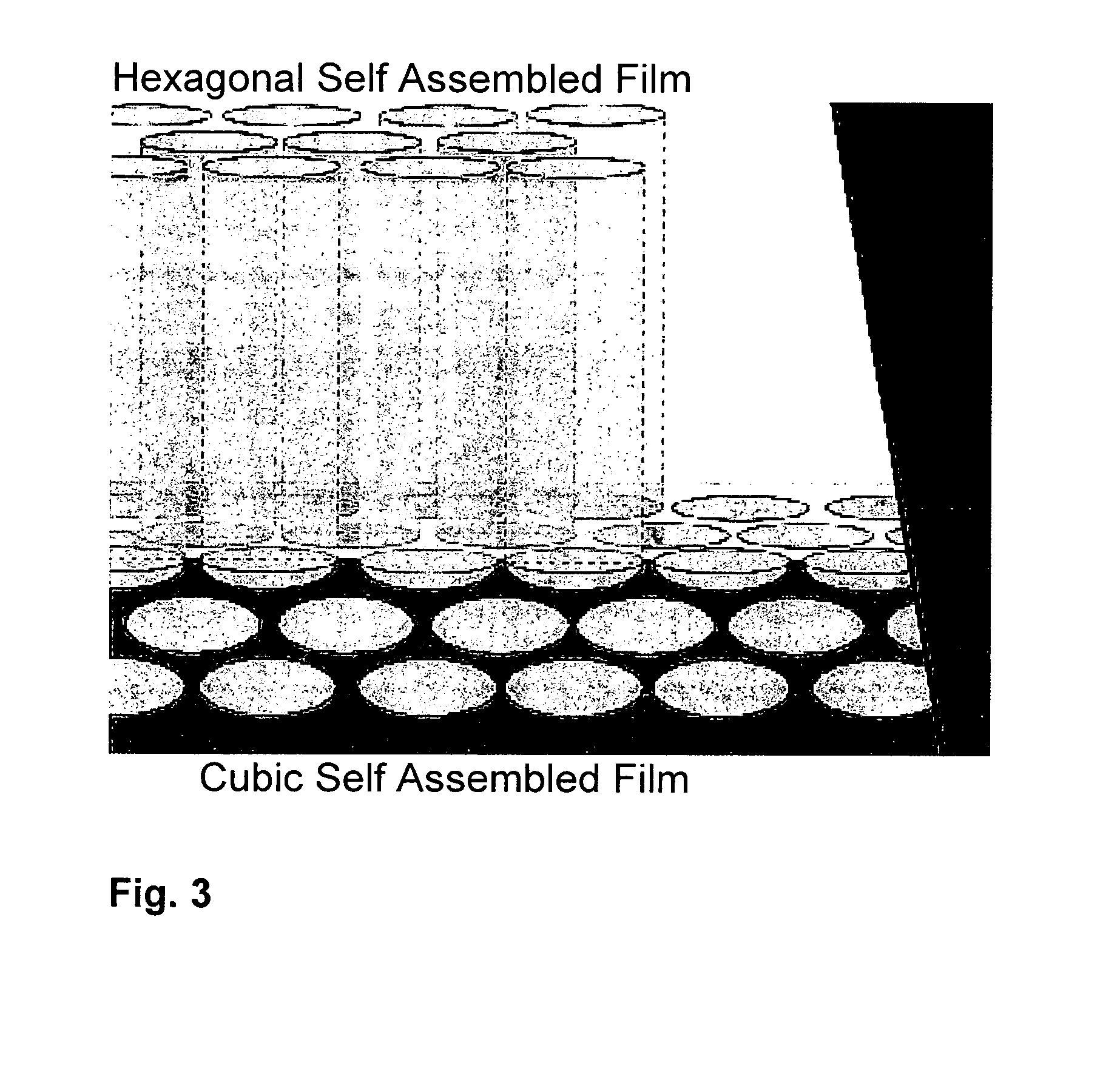

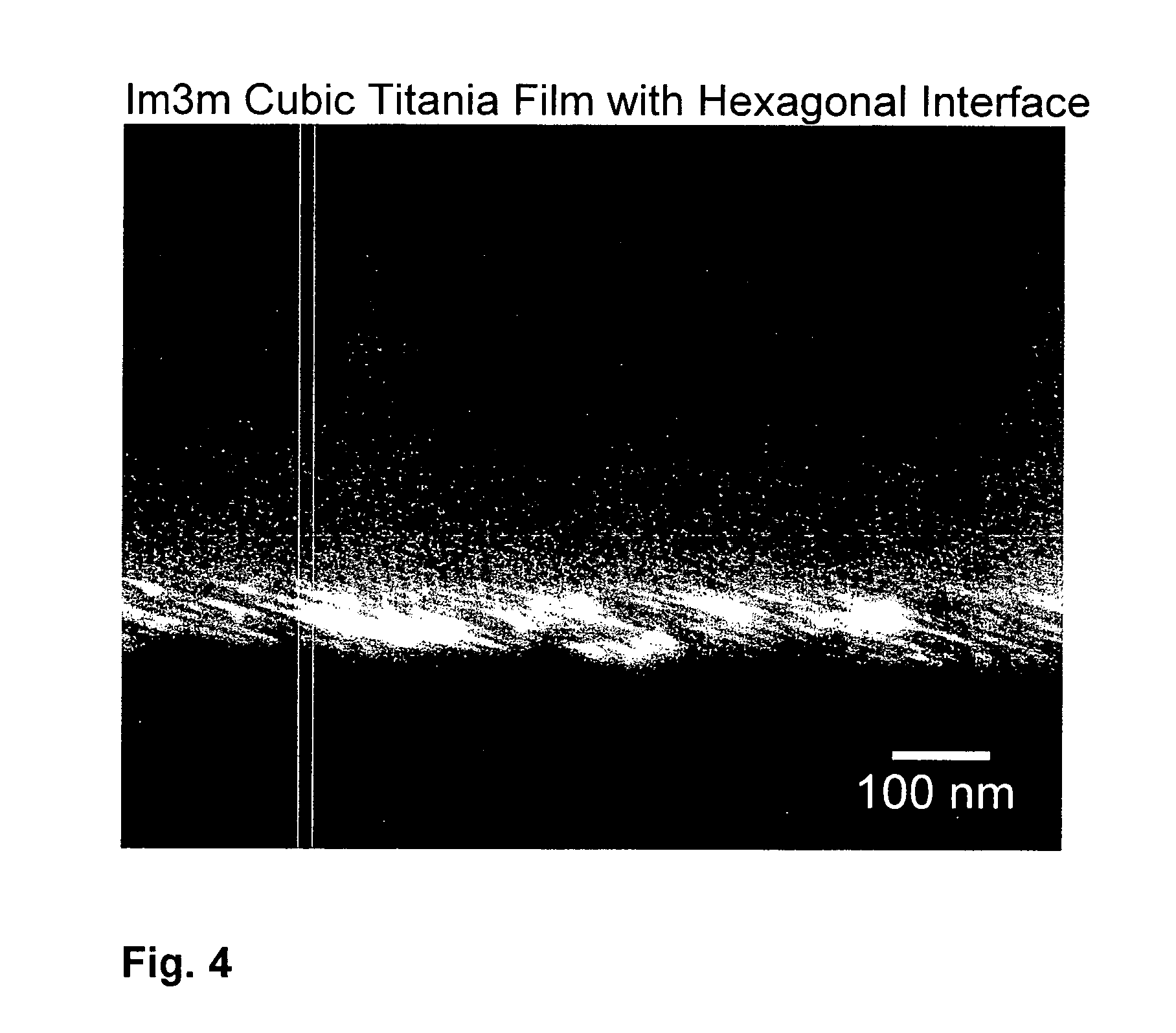

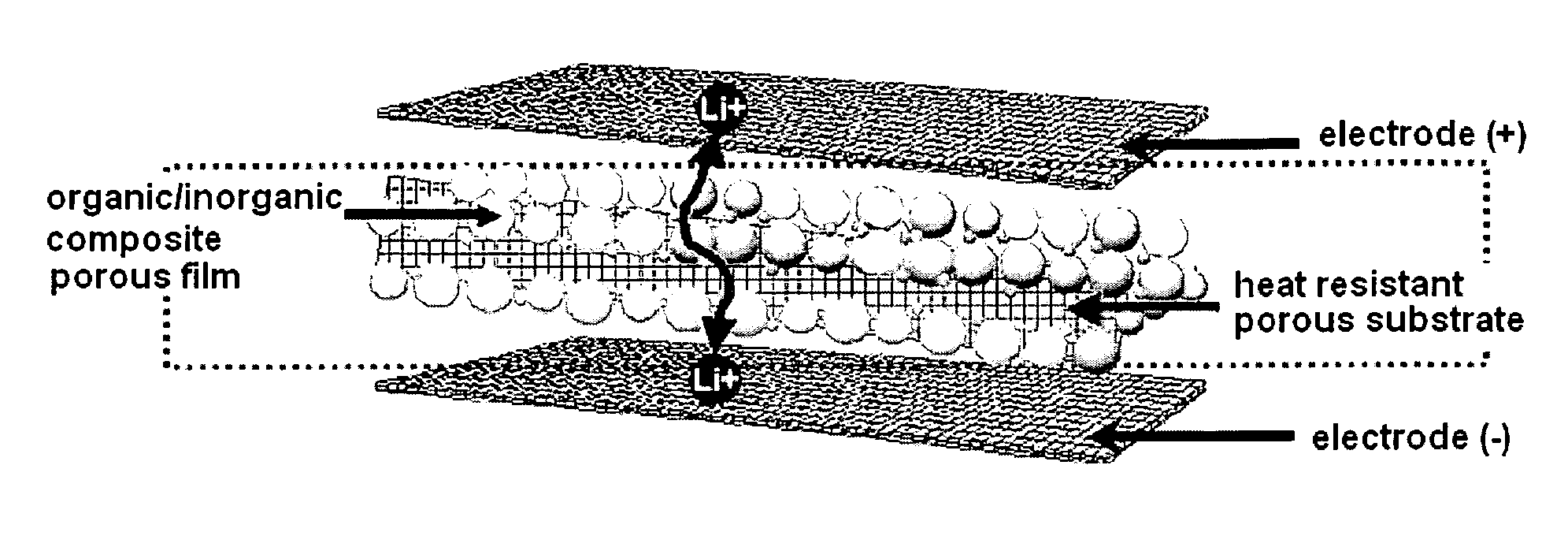

Ordered vertically oriented porous inorganic films produced through solution processing

InactiveUS20060278158A1Easy to produceFrom gel statePhotosensitive materialsPatterned substrateSelf-assembly

Porous films with straight pores oriented normal to the plane of the films are produced through solution processing techniques. The production takes advantage of inorganic-surfactant or inorganic-polymer co-assembly and a patterned substrate. The patterned substrate, which is also produced via solution phase self-assembly, forces vertical orientation in a hexagonal cylinder system with no practical limits in substrate size or type. This provides a route to vertically oriented inorganic pores with a pitch ranging from 3 nm to over 15 nm and pore sizes ranging from 2 nm to over 12 nm. The size is tuned by choice the choice of organic templating agents and the deposition conditions. The pores can be produced with or without a capping layer which can be used to seal the nanopores.

Owner:RGT UNIV OF CALIFORNIA

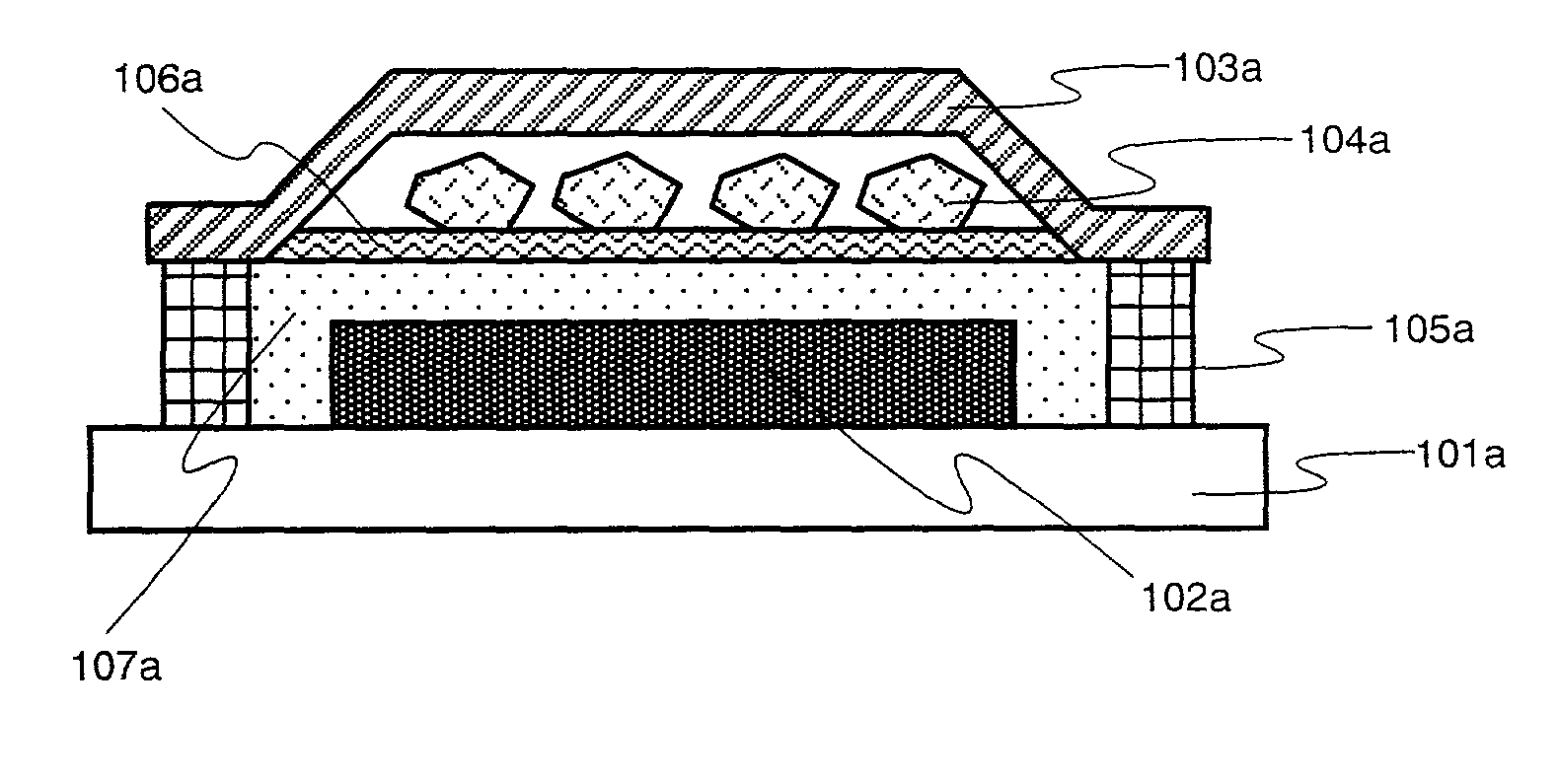

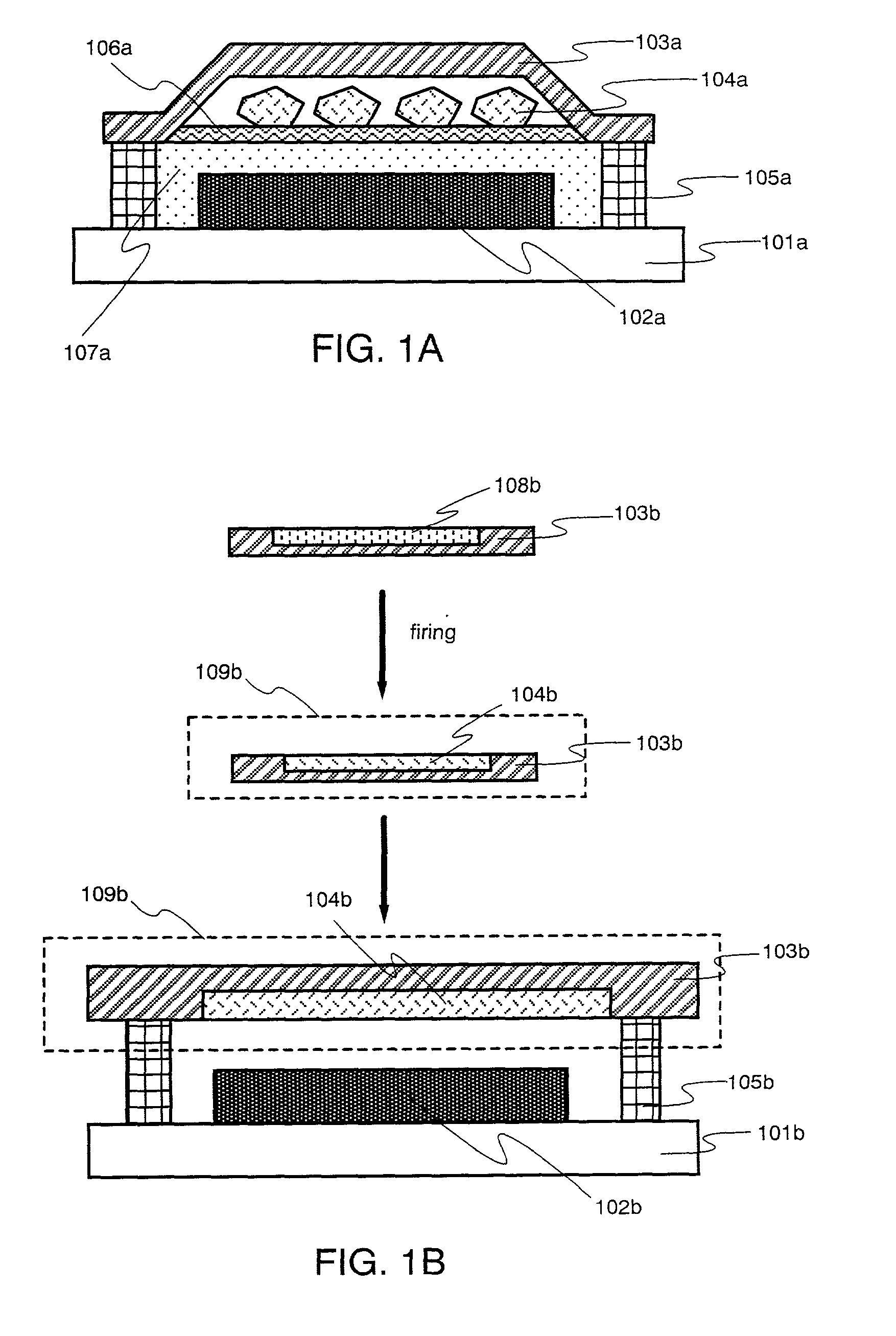

Light emitting device

InactiveUS20020057565A1Discharge tube luminescnet screensElectroluminescent light sourcesDesiccantEngineering

A drying agent enclosed in an organic EL element is sealed with a shape with which particulate contamination becomes less than that of a conventional shape, while still capable of showing a moisture absorption capacity similar to that of a fine powder. A light emitting device, and an electronic device, having long life and having less particulate contamination than in a device manufactured by conventional processes, are provided by using the organic EL element. The drying agent, made from a compound capable of chemically absorbing moisture, is formed as a bulk porous body or a porous film, and is formed along with the organic EL elements within a container cut off from the atmosphere. In addition, the light emitting device and the electronic device are manufactured using the organic EL elements.

Owner:SEMICON ENERGY LAB CO LTD

Nonaqueous electrolyte solution secondary battery separator and nonaqueous electrolyte solution secondary battery using the same

ActiveUS20060127753A1Improve battery performanceImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryPore diameter

An object of this invention is to improve battery performance such as a rate capability of a nonaqueous electrolyte solution secondary battery using a separator constituting a thermoplastic resin-based porous film containing a filler. This invention provides a nonaqueous electrolyte solution secondary battery separator which is formed from a porous film containing a thermoplastic resin and a filler contained in the thermoplastic resin and has a ratio of an average pore diameter (μm) to a maximum pore diameter (μm) defined by ASTM F316-86 of 0.6 or more as well as relates to a nonaqueous electrolyte solution secondary battery using this separator.

Owner:MITSUBISHI CHEM CORP

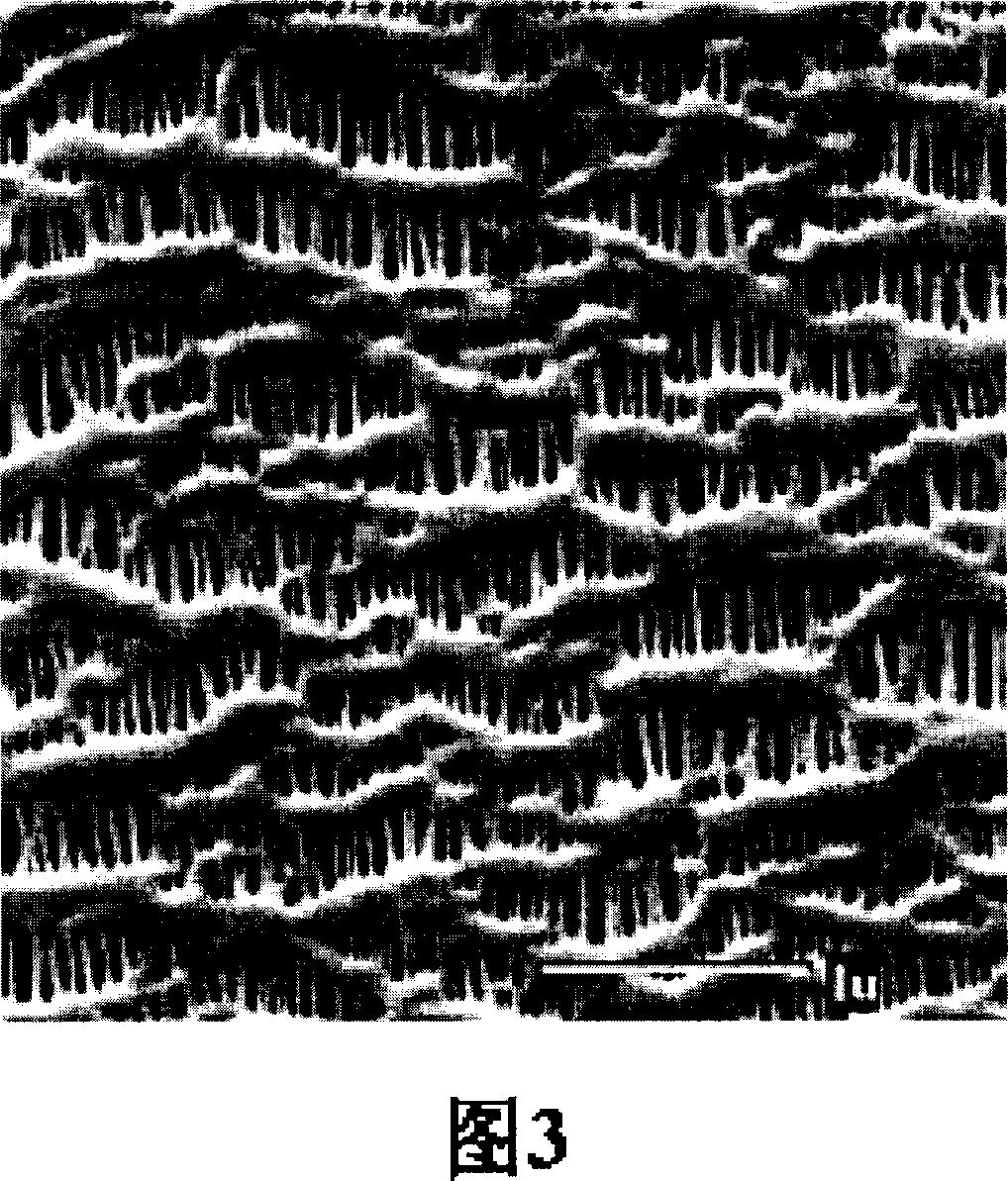

New organic/inorganic composite porous film and electrochemical device prepared thereby

ActiveCN1969407AImprove brittlenessImprove interfacial adhesionLi-accumulatorsCell component detailsPorous substrateInorganic particle

Disclosed is an organic / inorganic composite porous film comprising: (a) a porous substrate having pores; and (b) an active layer formed by coating a surface of the substrate or a part of the pores in the substrate with a mixture of inorganic particles and a binder polymer, wherein the inorganic particles in the active layer are interconnected among themselves and are fixed by the binder polymer, and interstitial volumes among the inorganic particles form a pore structure. A method for manufacturing the same film and an electrochemical device including the same film are also disclosed. An electrochemical device comprising the organic / inorganic composite porous film shows improved safety and quality, simultaneously.

Owner:LG ENERGY SOLUTION LTD +1

Separator for electrochemical device, electrode for electrochemical device, and electrochemical device

ActiveUS20100015530A1Improve reliabilityImprove load characteristicsHybrid capacitor separatorsHybrid capacitor electrodesPhysical chemistryPolyresin

A separator for an electrochemical device of the present invention includes a porous film including: a filler; an organic binder; and at least one resin selected from resin A that has a melting point of 80 to 140° C. and resin B that absorbs a non-aqueous electrolyte and swells upon heating and whose swelling degree increases with increasing temperature, and the filler contains boehmite having a secondary particle structure in which primary particles are connected.

Owner:MAXELL HLDG LTD

Porous film and preparation method of porous film

The invention discloses a porous film and a preparation method of the porous film, which can easily achieve high porosity and guarantee the formability during the preparation, and are simple and practical in preparation process. The thickness of the porous film is 200-1500[mu]m, the average aperture of the porous film is 0.05-100[mu]m, and the porosity of the porous film is 25-75%. The preparation method includes (1) acquiring a support film which has a porous first material, and forming primary pores in the first material; (2) preparing slurry containing a powder-like second material; (3) coating the support film with the slurry to prepare a base substrate; (4) sintering the base substrate, generating a porous third material through the reaction between the first material and the second material during the sintering, and further generating secondary pores communicated with the primary pores; and (5) cooling the base substrate to obtain the porous film after the sintering. The porous film at least contains the primary pores and the secondary pores, so that the porous film is easy to achieve high porosity.

Owner:CHENGDU INTERMENT TECH

Organic/inorganic composite porous film and electrochemical device prepared thereby

ActiveUS7704641B2Improve securityIncrease space volumeSolid electrolytesPrimary cellsPorous substrateInorganic particle

Disclosed is an organic / inorganic composite porous film comprising: (a) a porous substrate having pores; and (b) an active layer formed by coating a surface of the substrate or a part of the pores in the substrate with a mixture of inorganic particles and a binder polymer, wherein the inorganic particles in the active layer are interconnected among themselves and are fixed by the binder polymer, and interstitial volumes among the inorganic particles form a pore structure. A method for manufacturing the same film and an electrochemical device including the same film are also disclosed. An electrochemical device comprising the organic / inorganic composite porous film shows improved safety and quality, simultaneously.

Owner:LG ENERGY SOLUTION LTD +1

Porous low dielectric constant compositions and methods for making and using same

Owner:VERSUM MATERIALS US LLC

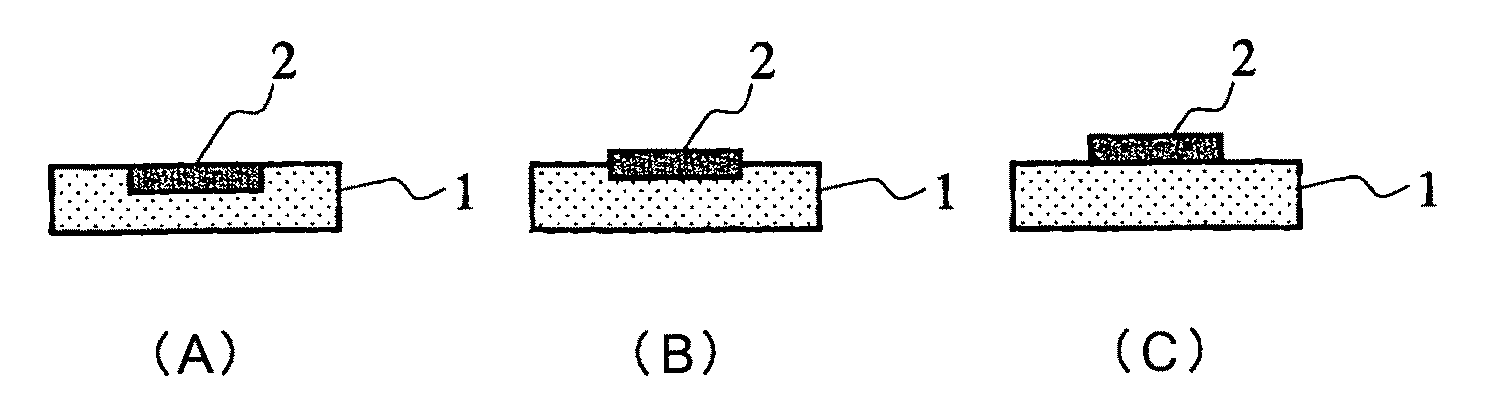

Lithium ion secondary battery

ActiveUS20060194116A1Improve securityAvoid deformationCell seperators/membranes/diaphragms/spacersFinal product manufactureWater insolubleDecomposition

A lithium ion secondary battery includes a positive electrode capable of absorbing and desorbing lithium ion, a negative electrode capable of absorbing and desorbing lithium ion, a porous film interposed between the positive electrode and the negative electrode, and a non-aqueous electrolyte, the porous film being adhered to a surface of at least the negative electrode. The porous film includes an inorganic filler and a first binder: The content of the first binder in the porous film is 1.5 to 8 parts by weight per 100 parts by weight of the filler: The first binder includes a first rubber including an acrylonitrile unit: The first rubber is water-insoluble and has a decomposition temperature of 250° C. or higher. The negative electrode includes a negative electrode active material capable of absorbing and desorbing lithium ion and a second binder, and the second binder includes a second rubber particle and a water-soluble polymer.

Owner:PANASONIC CORP

Heat-resistant separator, electrode assembly and secondary battery using the same, and method for manufacturing secondary battery

InactiveUS20130236766A1Improve stabilityAvoid dendrite formationElectric shock equipmentsCell seperators/membranes/diaphragms/spacersFiberInorganic particle

A porous polymer web layer of ultrafine fibers, and a non-porous film layer made of a material that is swellable and allows conduction of electrolyte ions in an electrolyte solution, are integrally provided on one surface or both surfaces of a positive electrode or a negative electrode, and a short circuit between the positive electrode and the negative electrode by the inorganic particles contained in polymer web is prevented although a battery is overheated. The electrode assembly includes: a positive electrode; a negative electrode; and a separator that separates the positive electrode and the negative electrode. The separator comprises: a first non-porous polymer film layer; and a porous polymer web layer that is formed on the first non-porous polymer film layer and is made of ultrafine fibers of a mixture of a heat-resistant polymer and inorganic particles or a mixture of a heat-resistant polymer, a swellable polymer, and inorganic particles.

Owner:AMOGREENTECH CO LTD

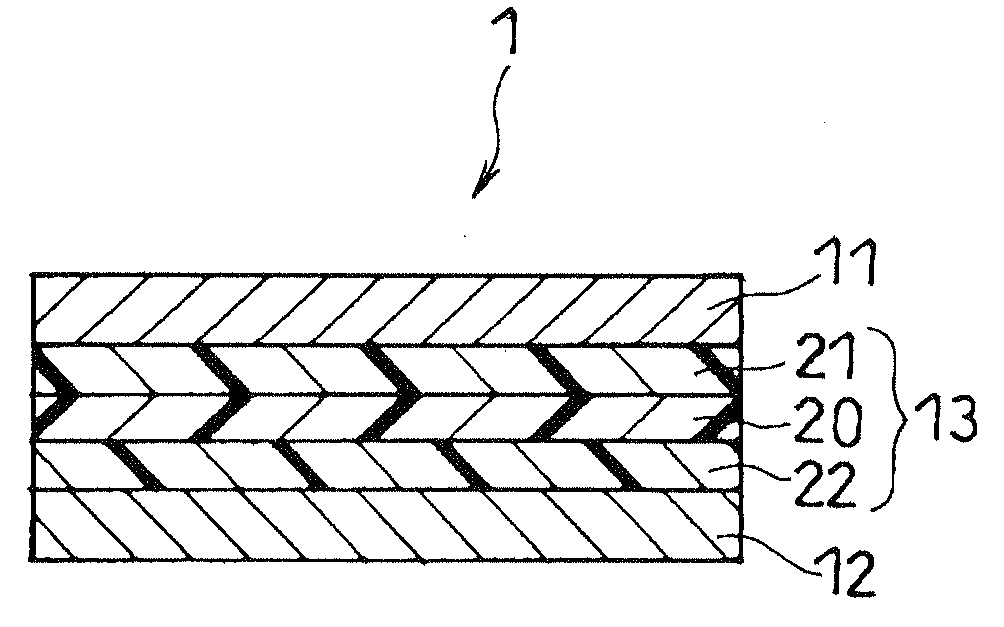

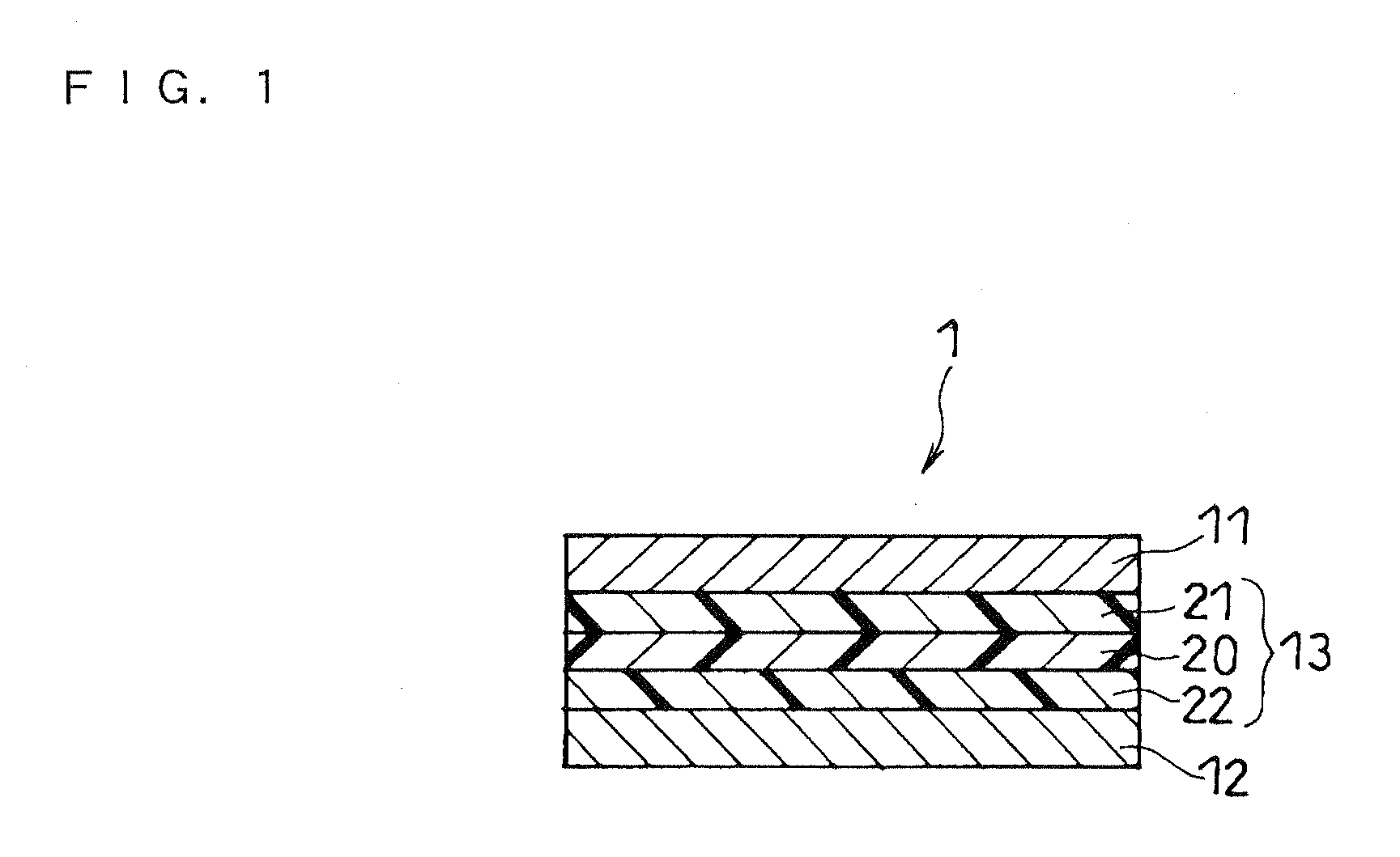

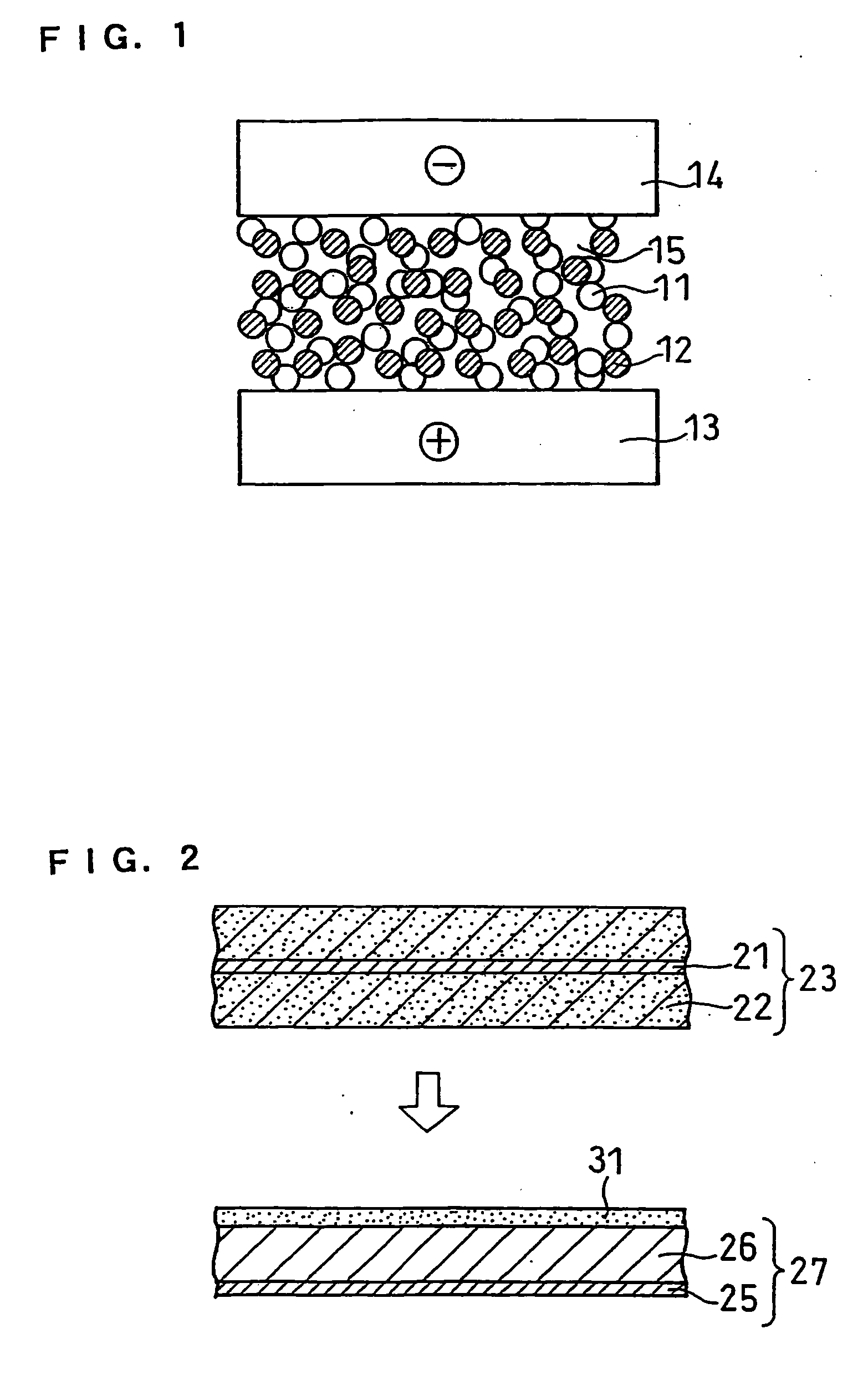

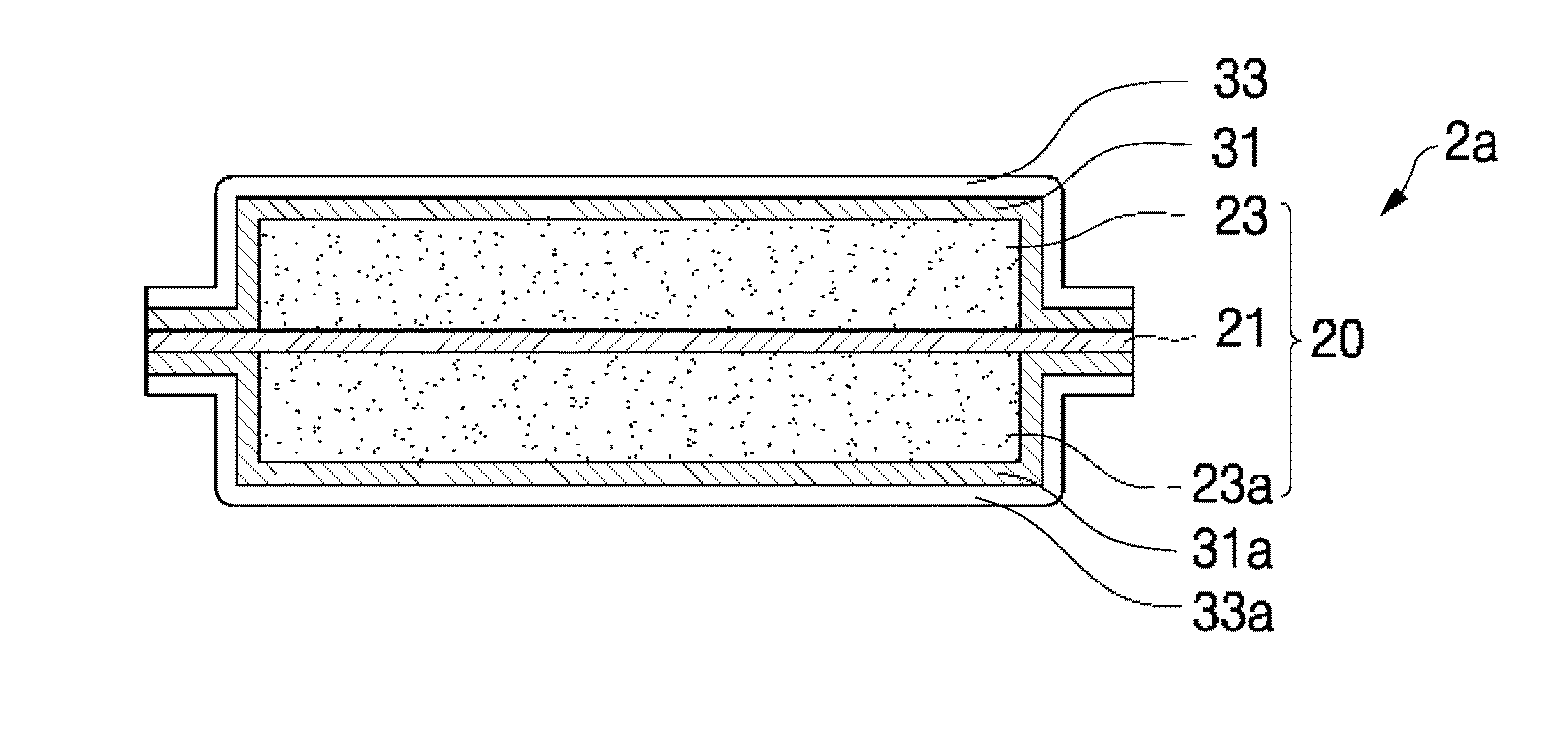

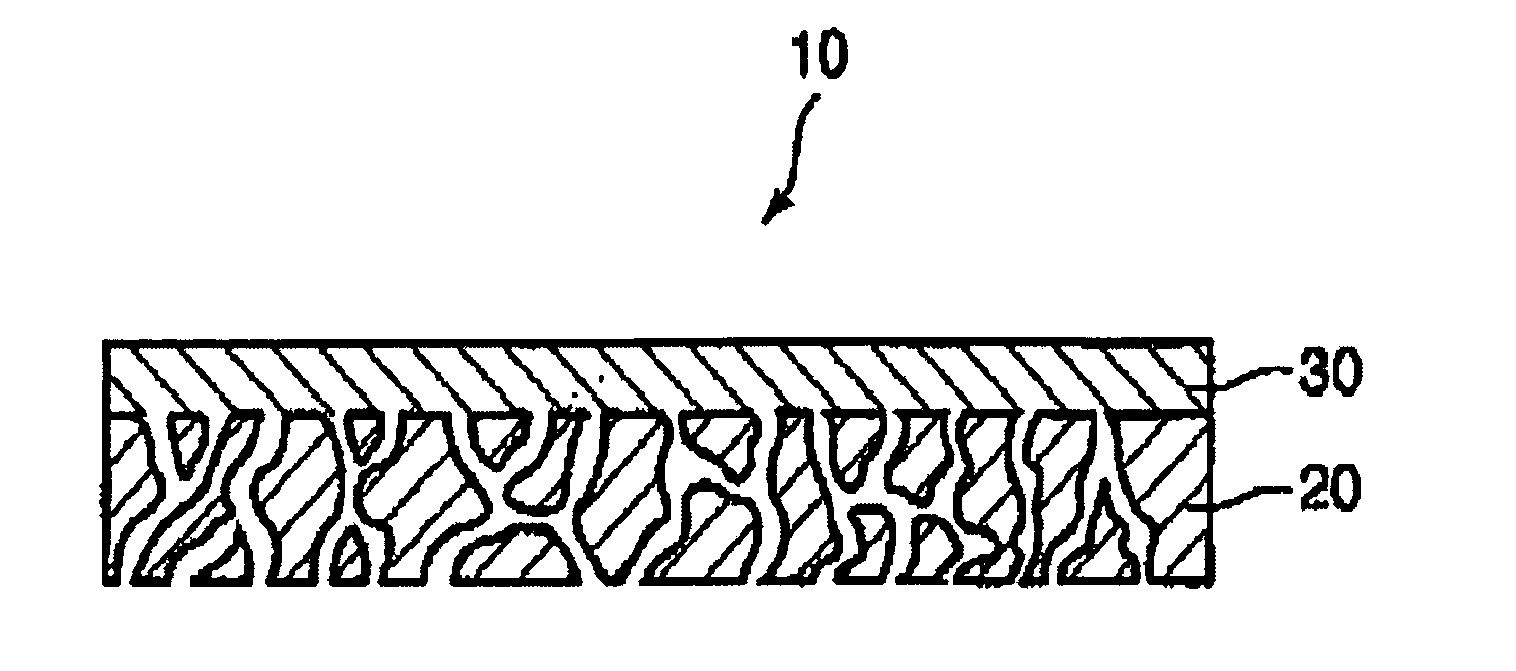

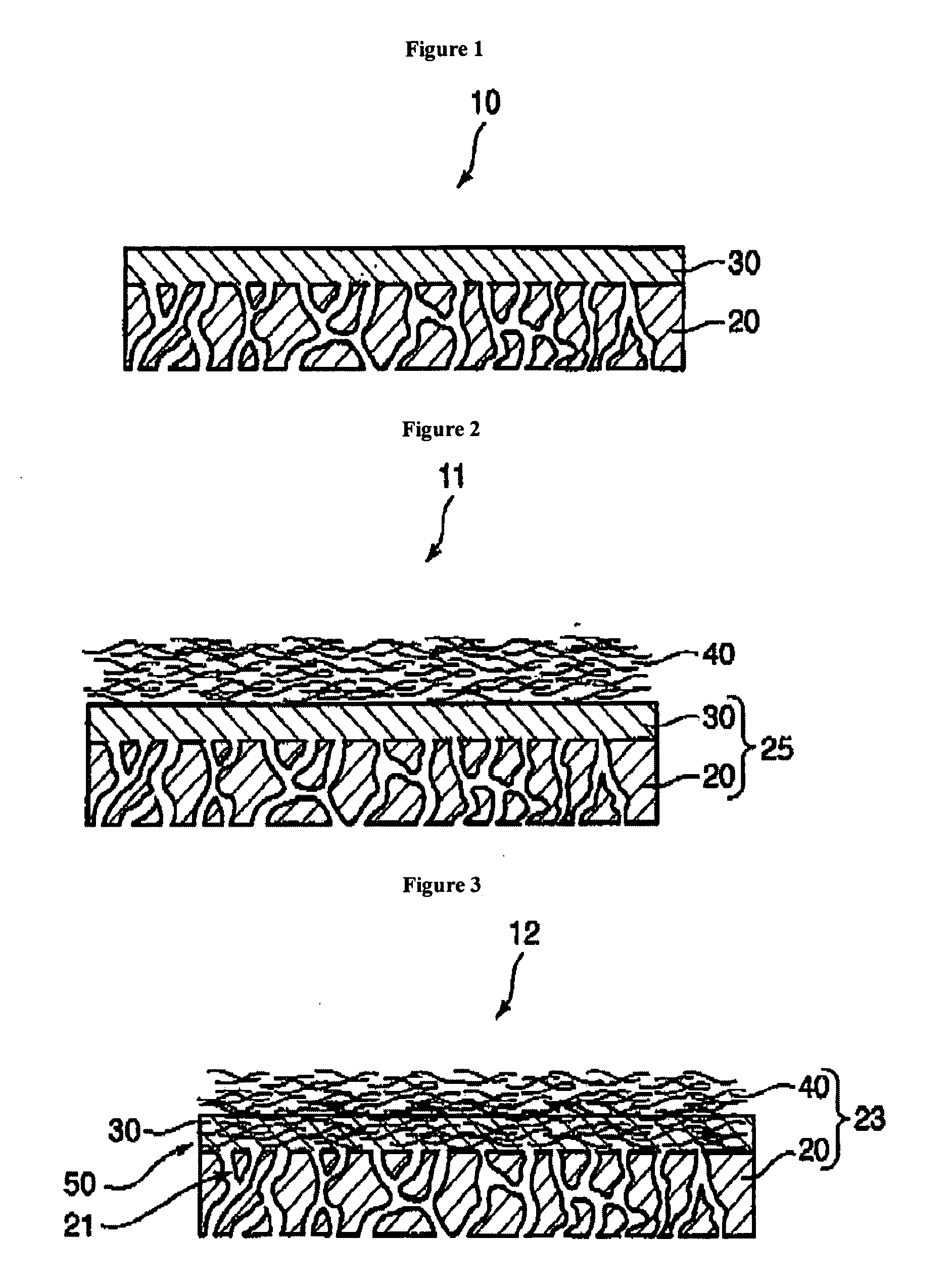

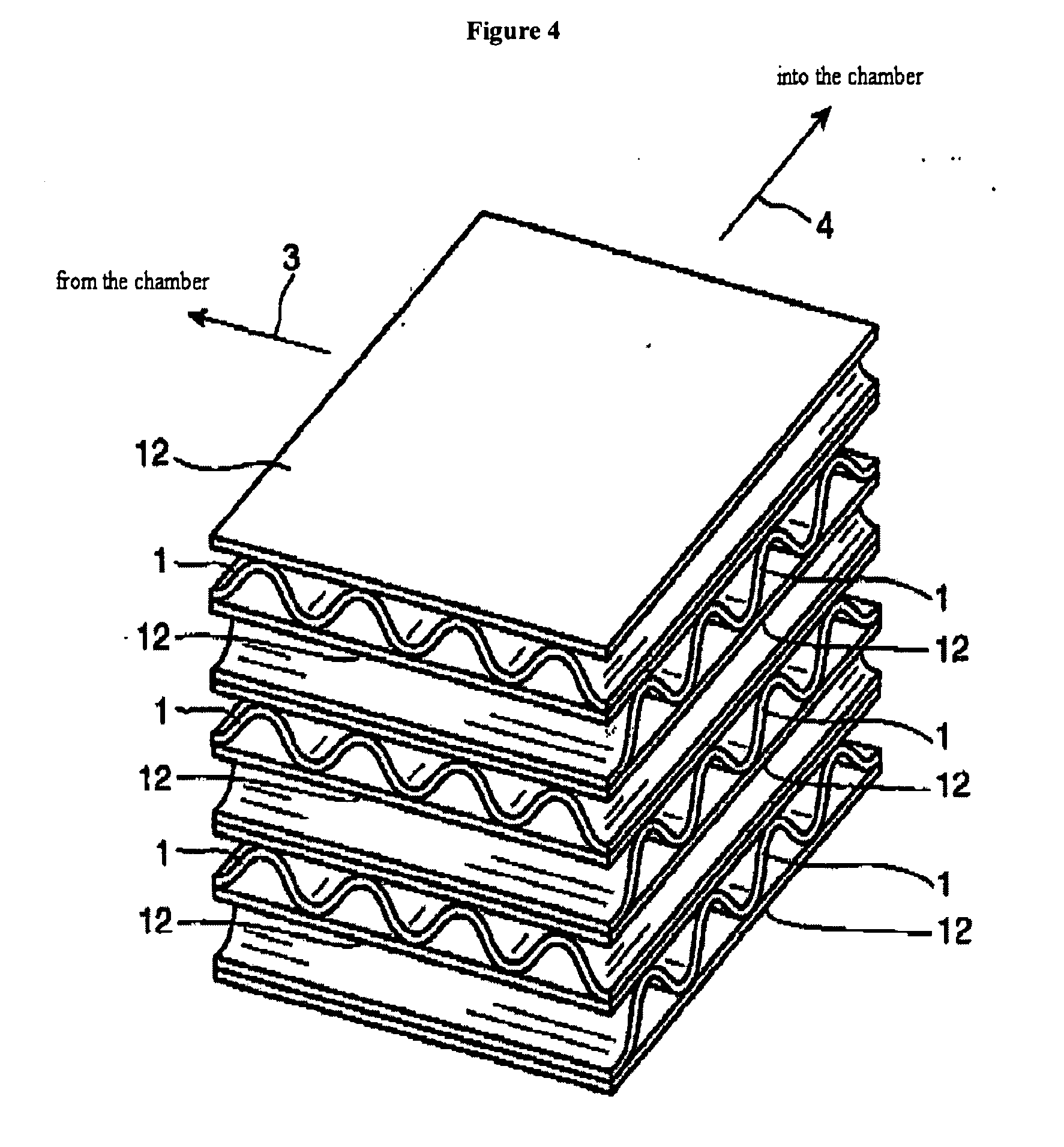

Membrane, method of making same and heat exchanger furnished with said membrane

ActiveUS20060090650A1Solid sorbent liquid separationPretreated surfacesPolyvinyl alcoholWater soluble

A membrane 12 that exhibits superior condensation resistance regardless of the type of moisture-permeable resin, that has satisfactory adhesion between a porous film and a reinforcing member, and that can be manufactured in a simple manner. The membrane 12 is a laminated article 23 containing a porous film 20 and a reinforcing member 40, and the reinforcing member 40 has a moisture-permeable resin layer 30 on the side of an interface 50 with the porous film 20. To reliably form the moisture-permeable resin layer (moisture-permeable resin film) 30, the average pore diameter of the porous film 20 is preferably 0.01 to 10 μm, and the porosity of the reinforcing member 40 is preferably 30 to 95%. According to the membrane 12 of the present invention, even if the moisture-permeable resin is water-soluble (for example, polyvinyl alcohol), condensation resistance is still satisfactory. If the difference between the critical surface tension γc2 of the reinforcing member 40 and the critical surface tension γc1 of the porous film 20 (γc2−γc1) is set in advance to −5 mN / m or greater, the moisture-permeable resin layer 30 can be disposed internally at a specific location.

Owner:JAPAN GORE TEX INC

Porous film-forming composition, patterning process, and porous sacrificial film

ActiveUS20050277756A1Improve wetting rateIncrease ratingsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusHydrogenOrganic solvent

A porous film-forming composition is provided comprising (A) a polymer obtained by hydrolytic condensation of a hydrolyzable silane having formula (1): R1n—Si—R24-n (1) wherein R1 is a monovalent organic group or hydrogen, R2 is a hydrolyzable group or a hydroxyl group and n is an integer of 0 to 3, a hydrolyzate thereof or a partial condensate thereof, with the proviso that at least one silicon compound having an organic crosslinkable group as R1 is included, the polymer being capable of crosslinking reaction by the organic crosslinkable group, and (B) an organic solvent. The composition has improved storage stability, filling properties, adhesion and coating uniformity sufficient to form a sacrificial film which is dissolvable in a stripping solution.

Owner:SHIN ETSU CHEM IND CO LTD

Surface-treated microporous membrane and electrochemical device prepared thereby

ActiveUS20090291360A1Improve adhesionAvoid breakingSecondary cellsCell component detailsPorous substrateElectrochemistry

Disclosed is a porous film comprising: (a) a porous substrate having pores; and (b) a coating layer formed on at least one region selected from the group consisting of a surface of the substrate and a part of the pores present in the substrate, wherein the coating layer comprises styrene-butadiene rubber. An electrochemical device using the porous film as a separator is also disclosed. The porous film is coated with a styrene-butadiene polymer, whose rubbery characteristics can be controlled, and thus provides improved scratch resistance and adhesion to other substrates. When the porous film is used as a separator for an electrochemical device, it is possible to improve the safety of the electrochemical device and to prevent degradation in the quality of the electrochemical device.

Owner:LG ENERGY SOLUTION LTD +1

Separator for electrochemical device, and electrochemical device

ActiveCN101048892AImprove securityLi-accumulatorsCell component detailsPhysical chemistryElectrochemistry

An electrochemical device having excellent safety at high temperature is provided by using a separator for an electrochemical device, which is made of a porous film comprising: a porous base ( 5 ) having a heat-resistant temperature of 150 DEG C. or higher and including filler particles ( 3 ); at least one kind of shutdown resin ( 6 ) selected from the group consisting of resin A that has a melting point in a range of 80 DEG C. to 130 DEG C. and resin B that absorbs an electrolyte and swells due to heating, and the swelling degree is increased as the temperature rises; and a binder ( 4 ).

Owner:MAXELL HLDG LTD

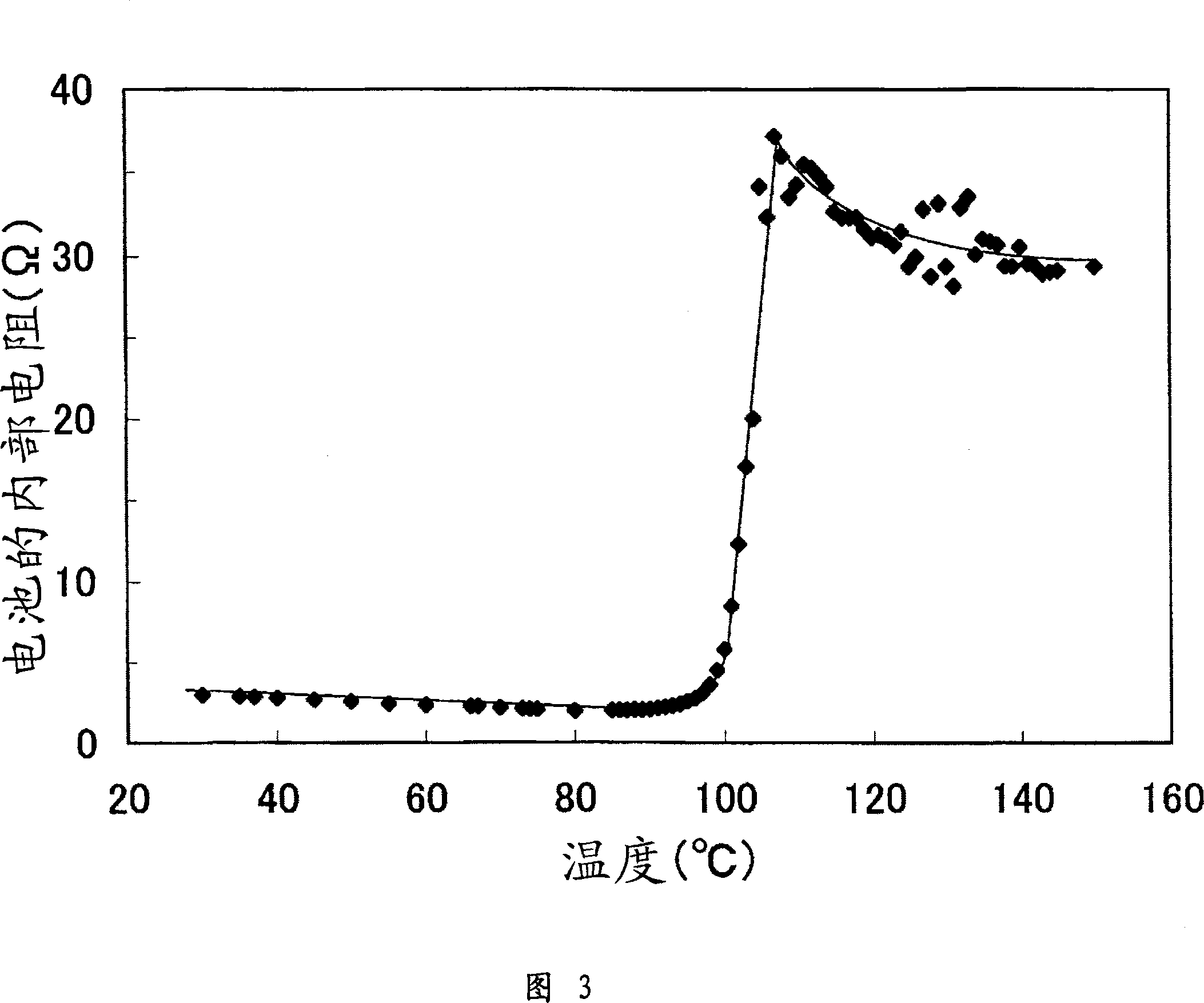

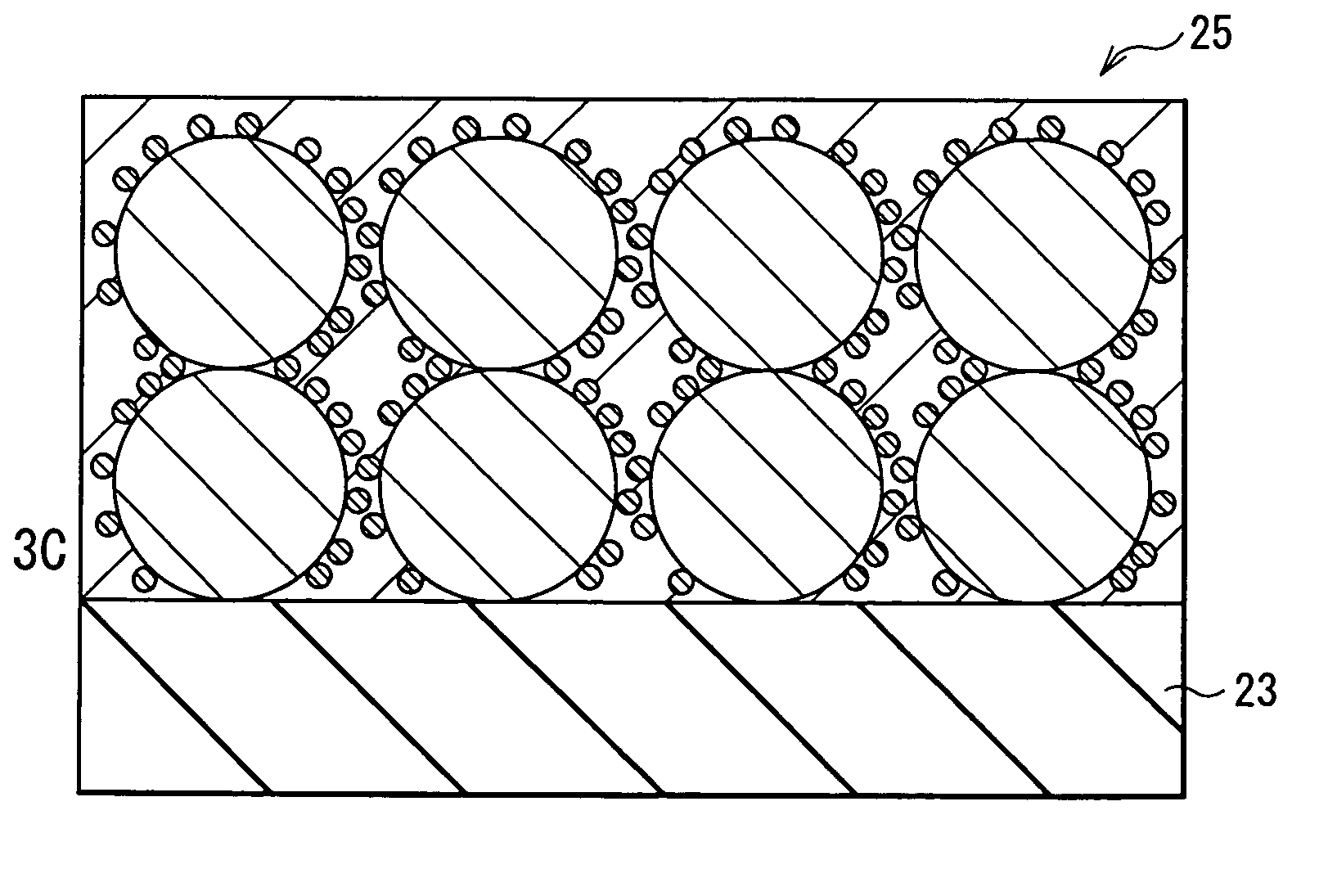

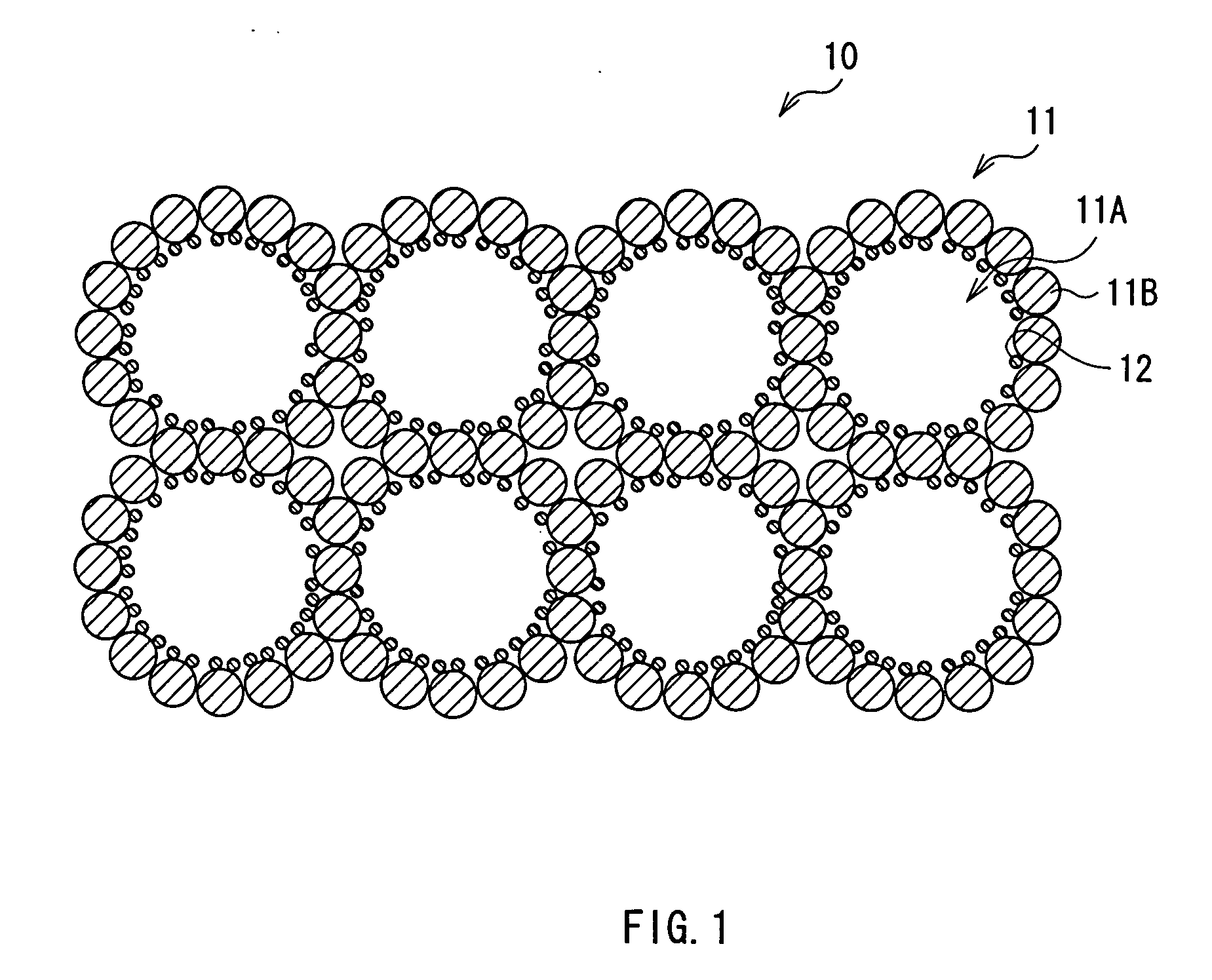

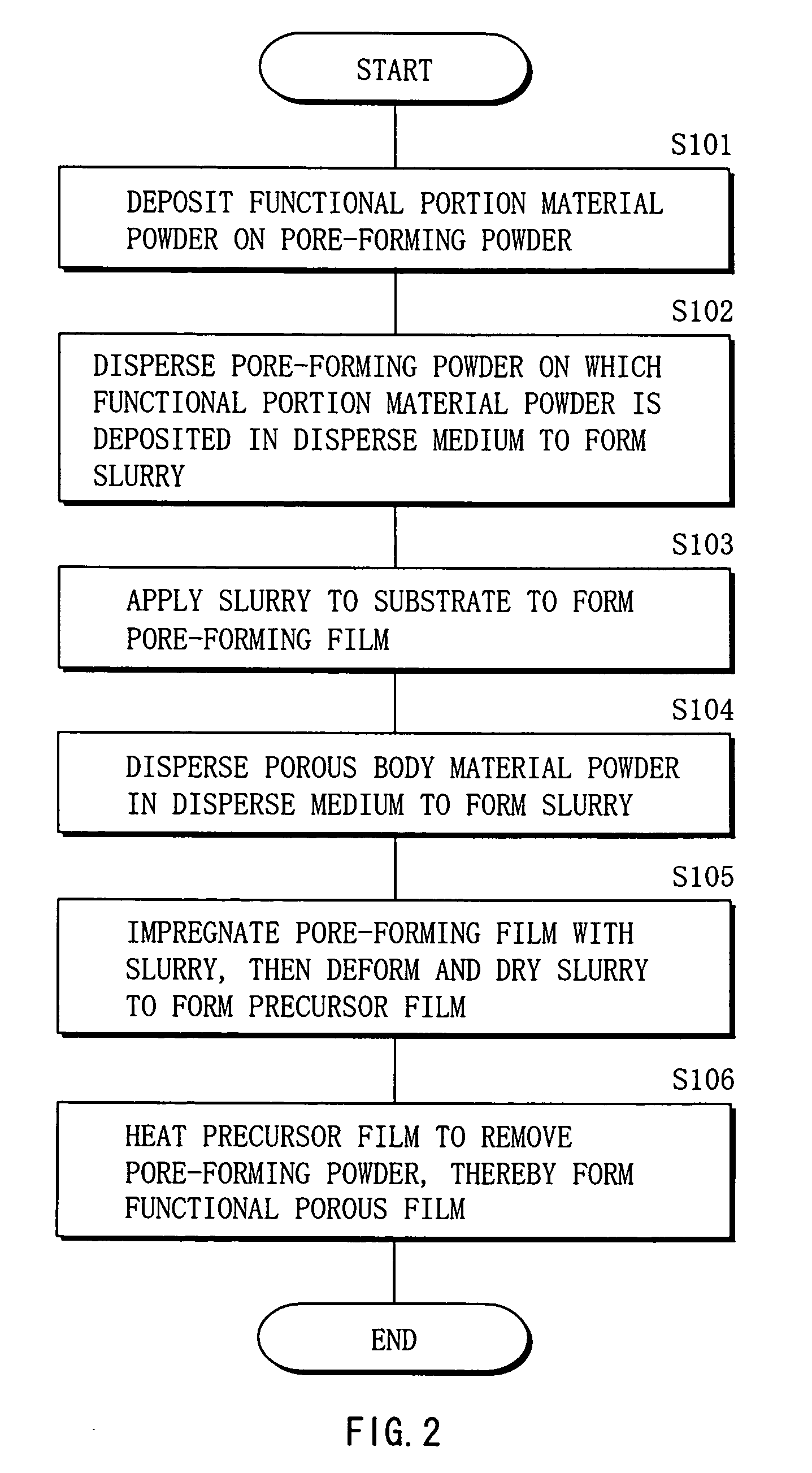

Functional porous film, sensor, method of manufacturing functional porous film, method of manufacturing porous metal film, and method of manufacturing sensor

InactiveUS20050109617A1Improve accuracyImprove precision controlCell electrodesMaterial electrochemical variablesMetallurgyPorous film

Provided are a functional porous film having a plurality of functions, a method of manufacturing the same, and a sensor using the same. In the functional porous film, a functional portion having a different function from a porous body is disposed on the inner wall of a pore of the porous body. The functional porous film is formed through forming a precursor film including a pore-forming powder such as an organic powder on which a material powder of the functional portion is deposited and a material powder of the porous body, and then heating the precursor film to remove the pore-forming powder and sinter the material powder of the porous body.

Owner:TDK CORPARATION

Method for characterizing porous low dielectric constant films

A method and apparatus for determining pore size distribution and / or the presence of at least one killer pore in at least a portion of a porous film deposited upon a substrate are disclosed herein. In one embodiment, there is provided a method for determining pore size distribution comprising: providing the substrate having the film deposited thereupon wherein the film comprises pores and wherein the pores have a first volume; exposing the film to an adsorbate at a temperature and a pressure sufficient to provide condensation of the adsorbate in pores and wherein the pores after the exposing step have a second volume; and measuring the difference between the first and the second volume using a volumetric technique; and calculating the pore size and pore volume using the change in the first and the second volume, the pressure, and a model that relates pressure to pore diameter.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com