Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4673results about "Cell seperators/membranes/diaphragms/spacers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

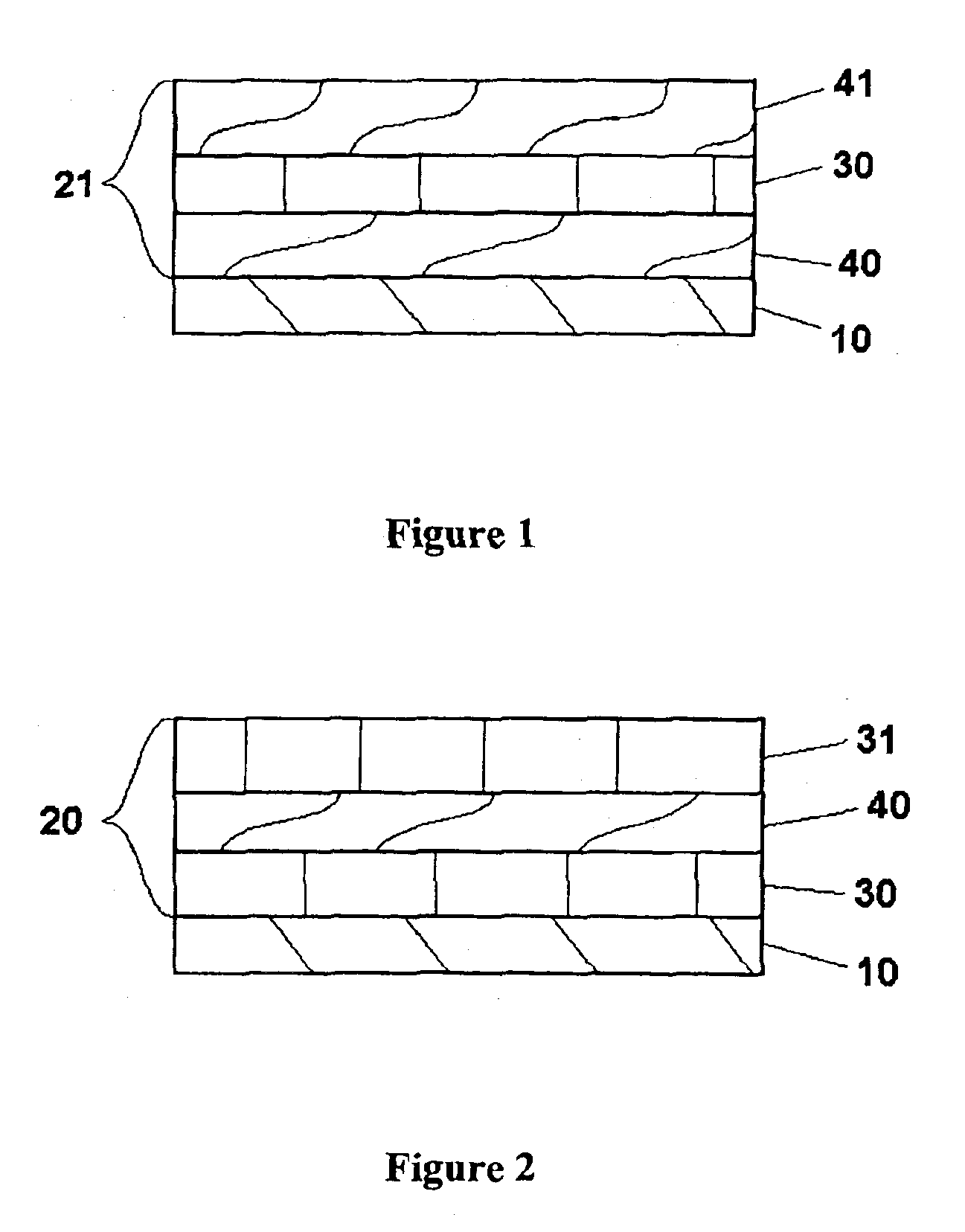

Separator for a high energy rechargeable lithium battery

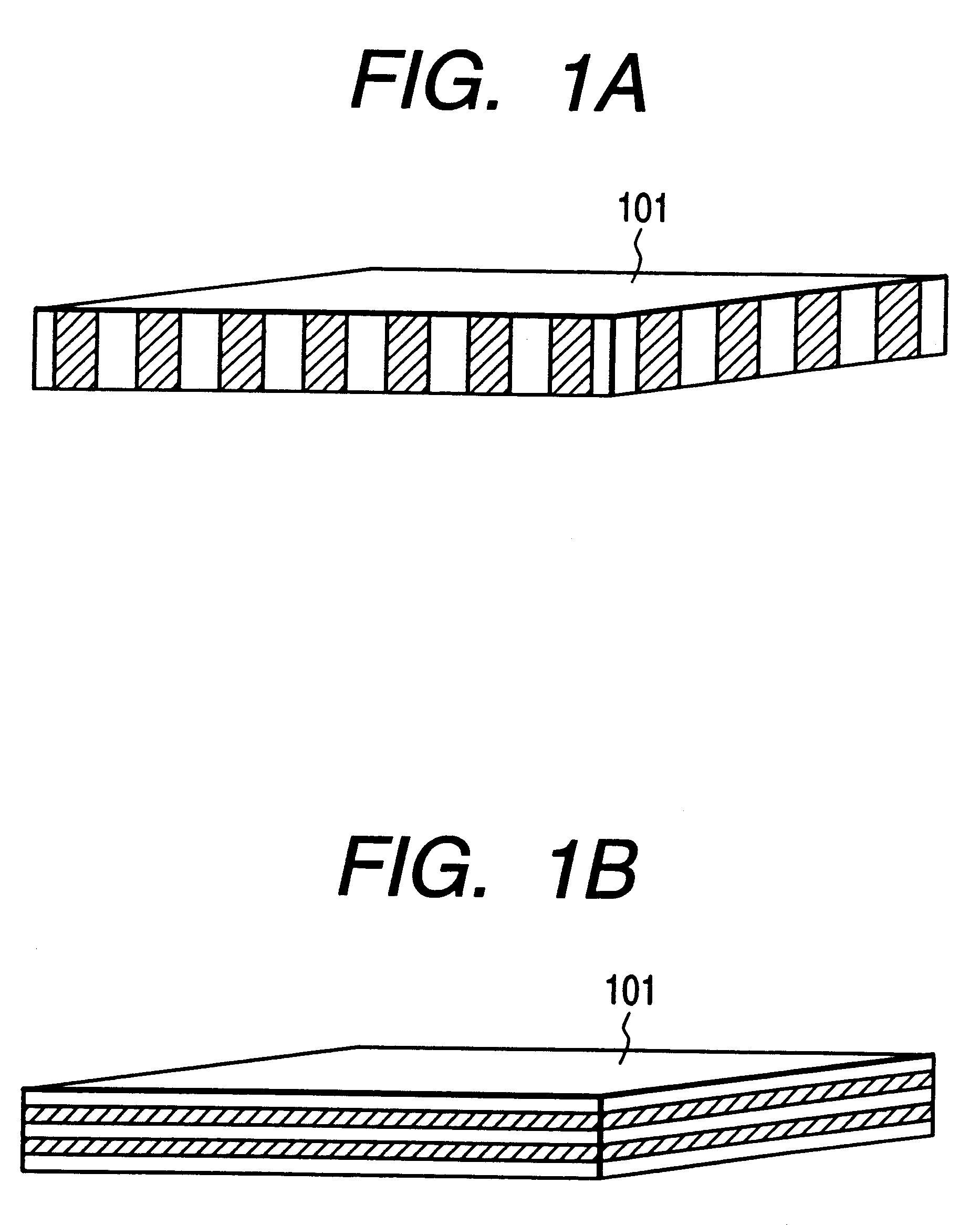

InactiveUS6432586B1Cell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte accumulator electrodesCeramic compositeMetallurgy

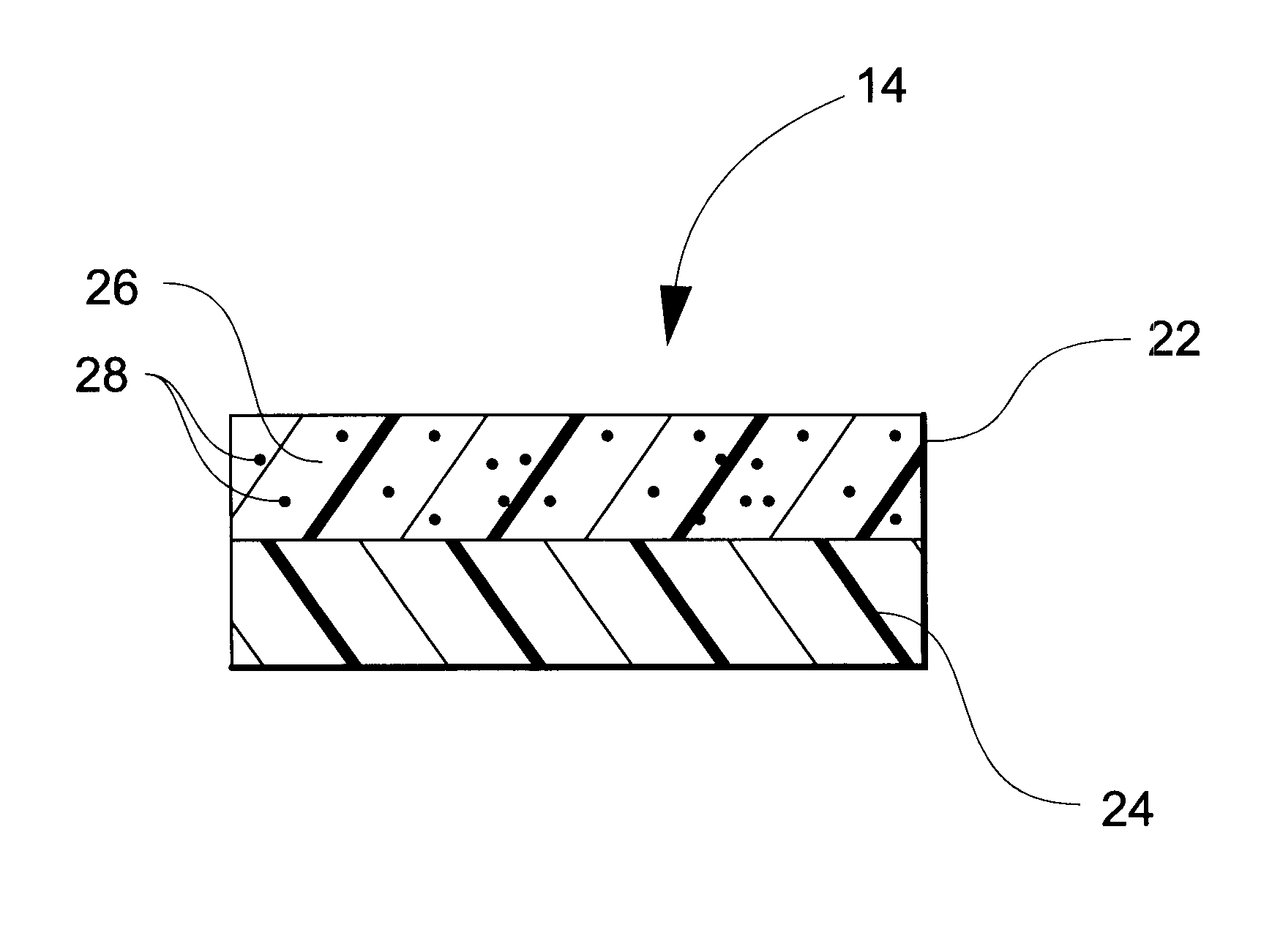

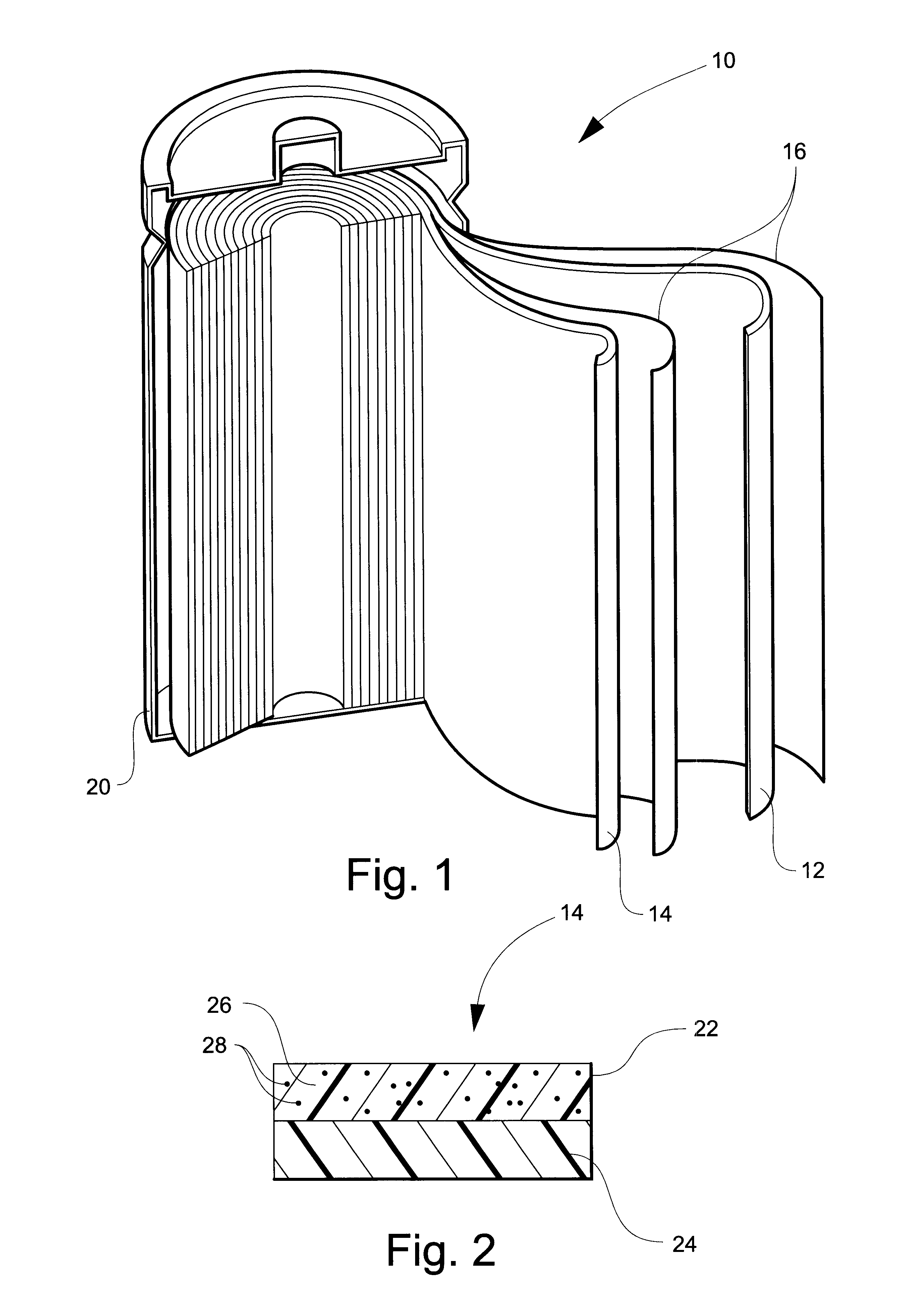

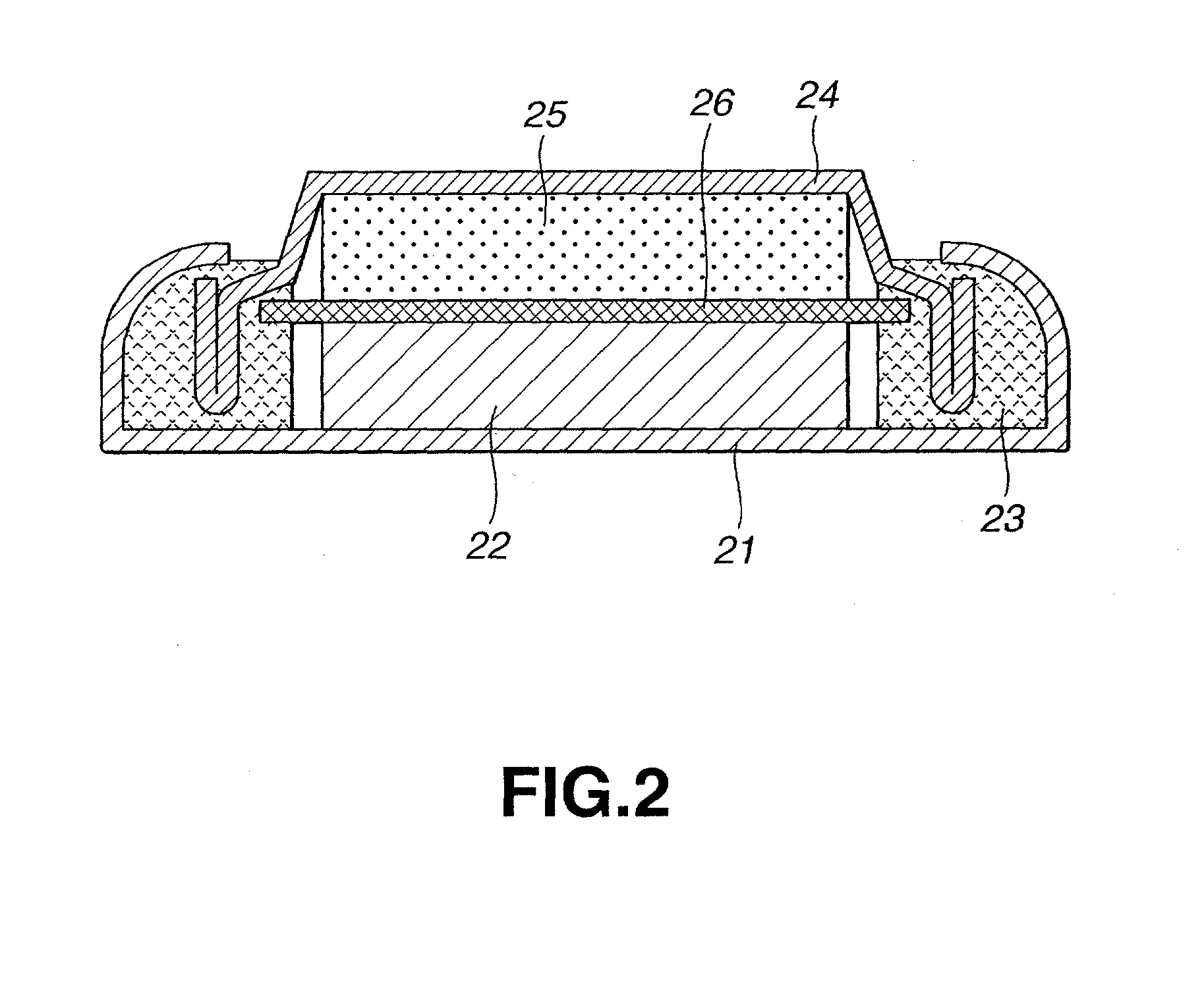

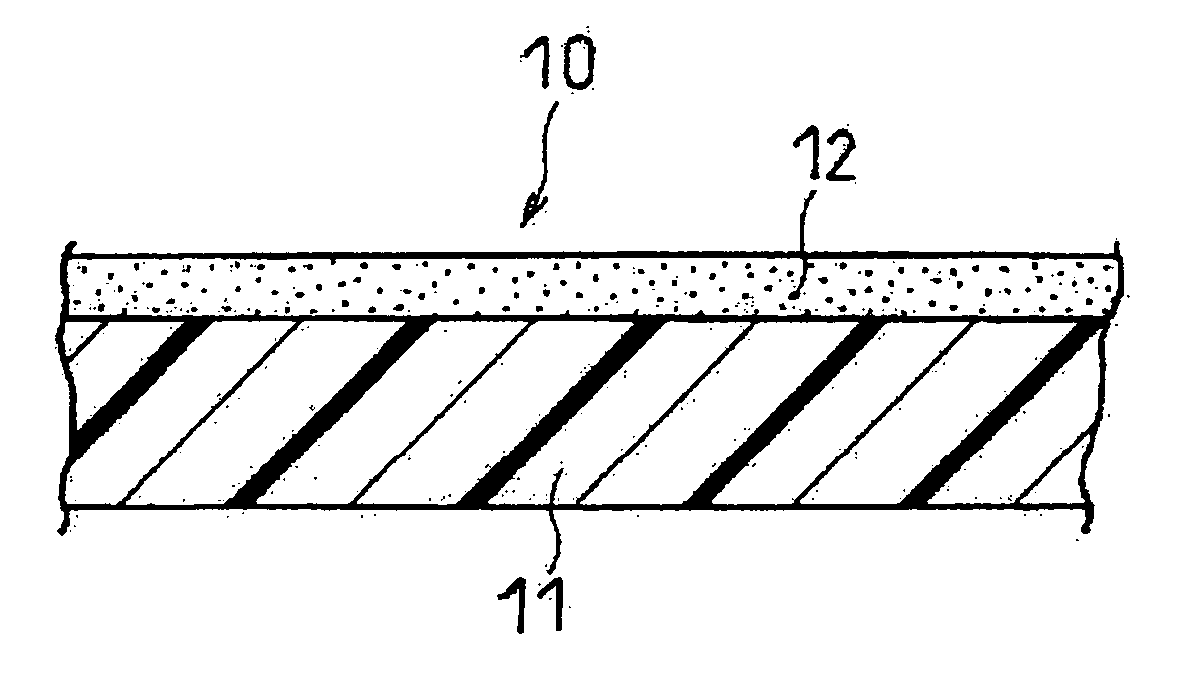

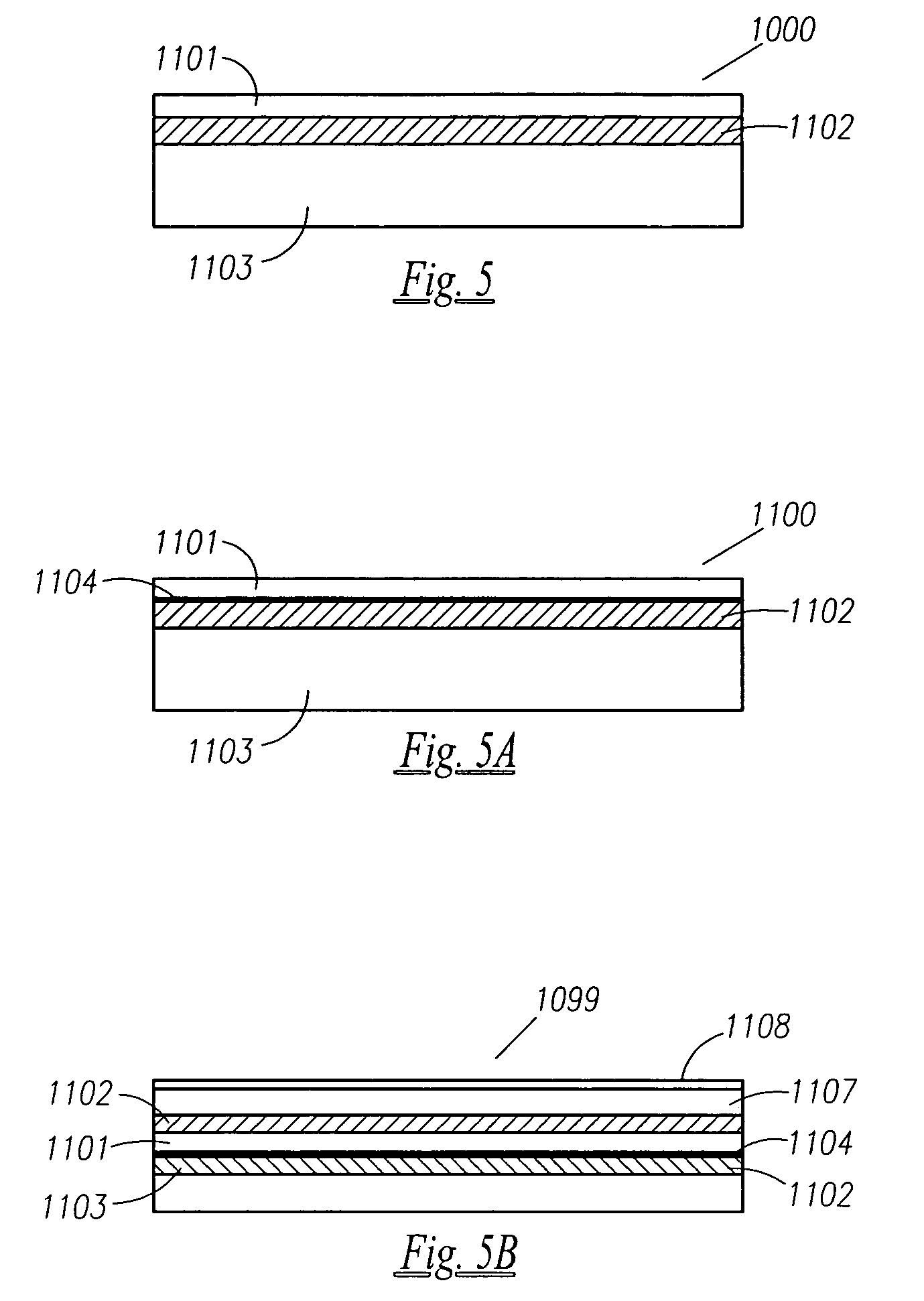

The instant invention is directed to a separator for a high energy rechargeable lithium battery and the corresponding battery. The separator includes a ceramic composite layer and a polymeric microporous layer. The ceramic layers includes a mixture of inorganic particles and a matrix material. The ceramic layer is adapted, at least, to block dendrite growth and to prevent electronic shorting. The polymeric layer is adapted, at least, to block ionic flow between the anode and the cathode in the event of thermal runaway.

Owner:CELGARD LLC

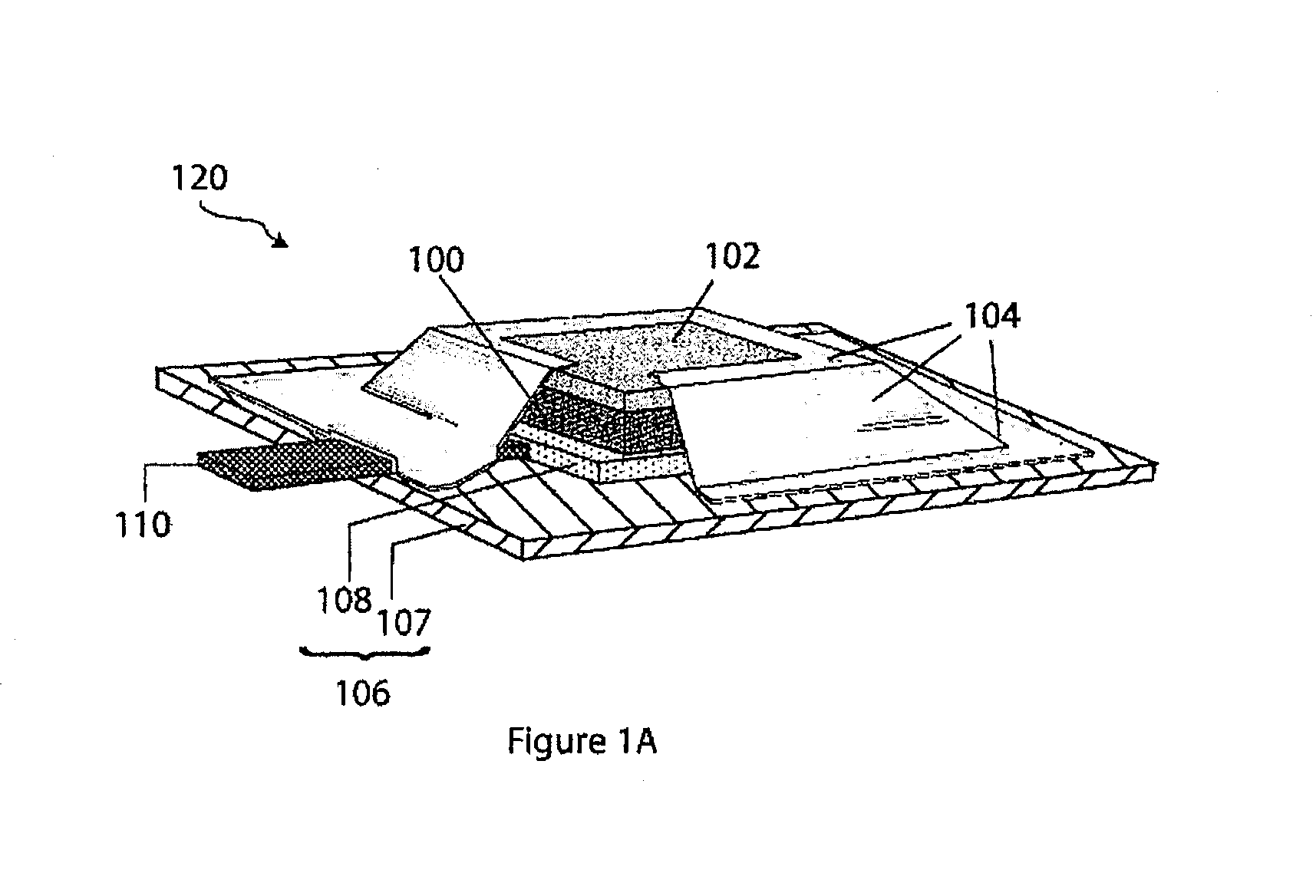

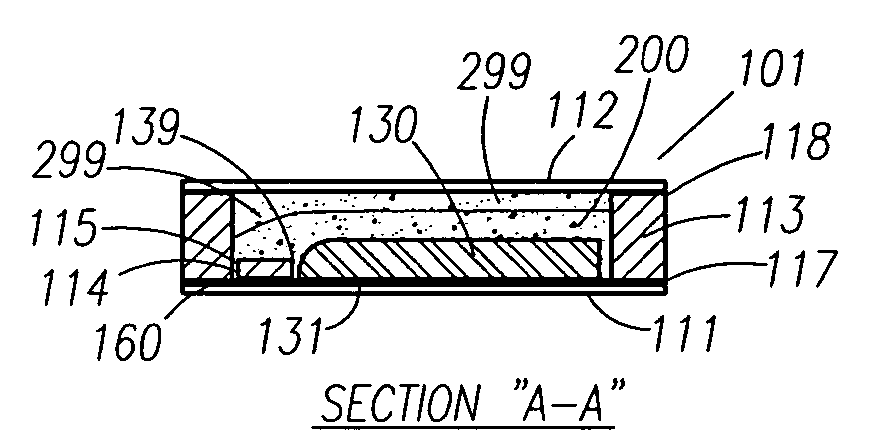

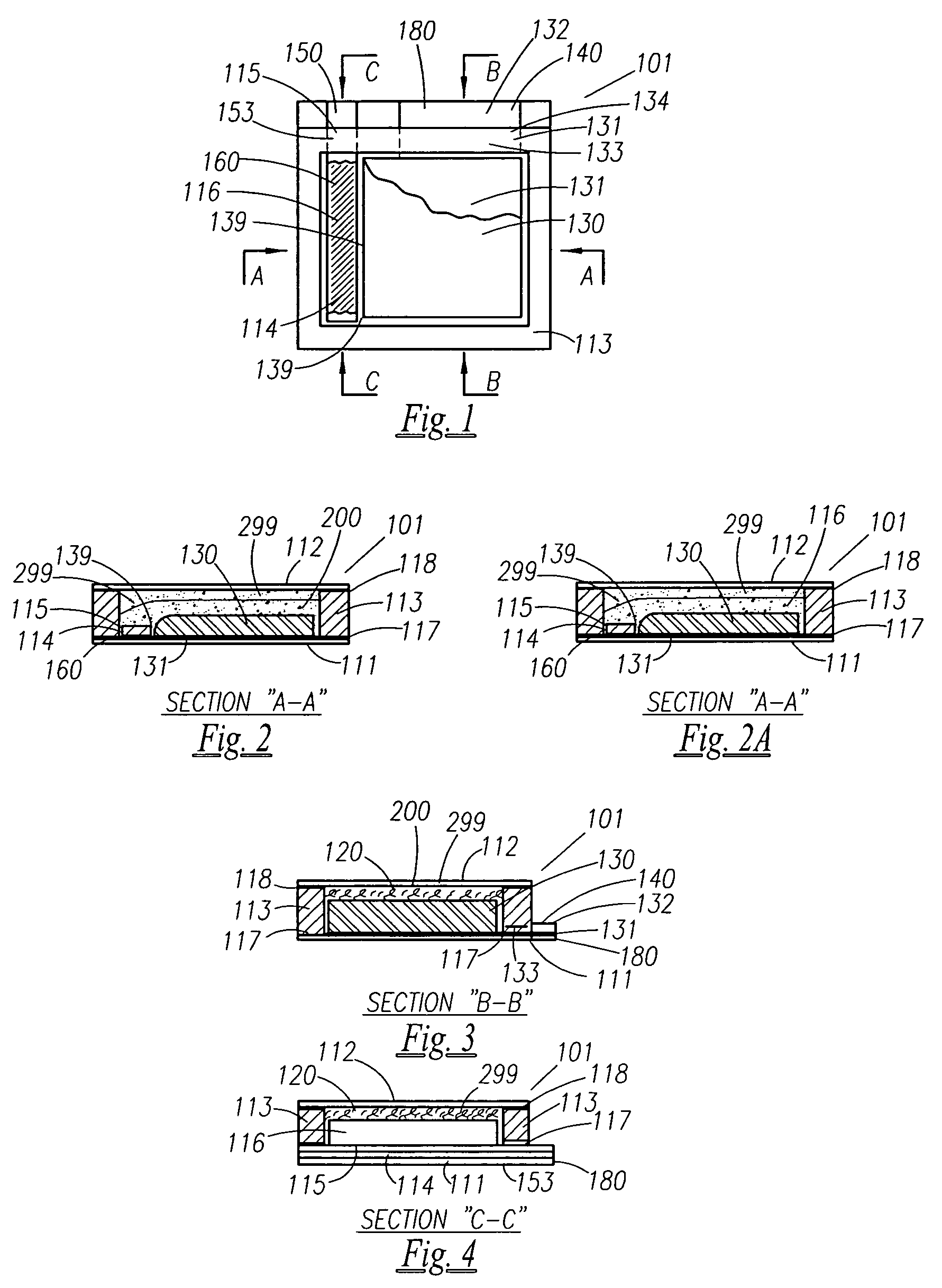

Compliant seal structures for protected active metal anodes

ActiveUS20070037058A1Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

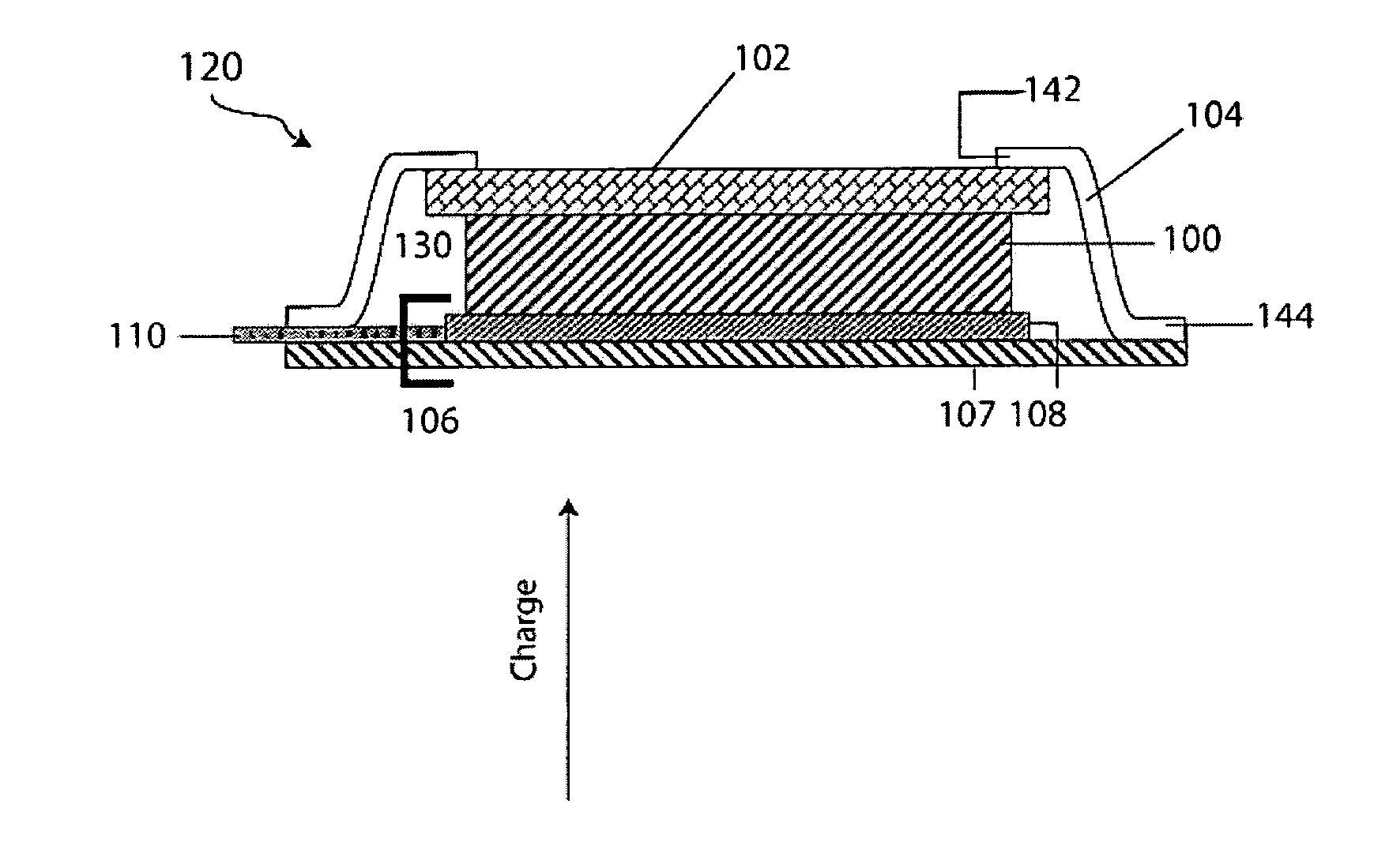

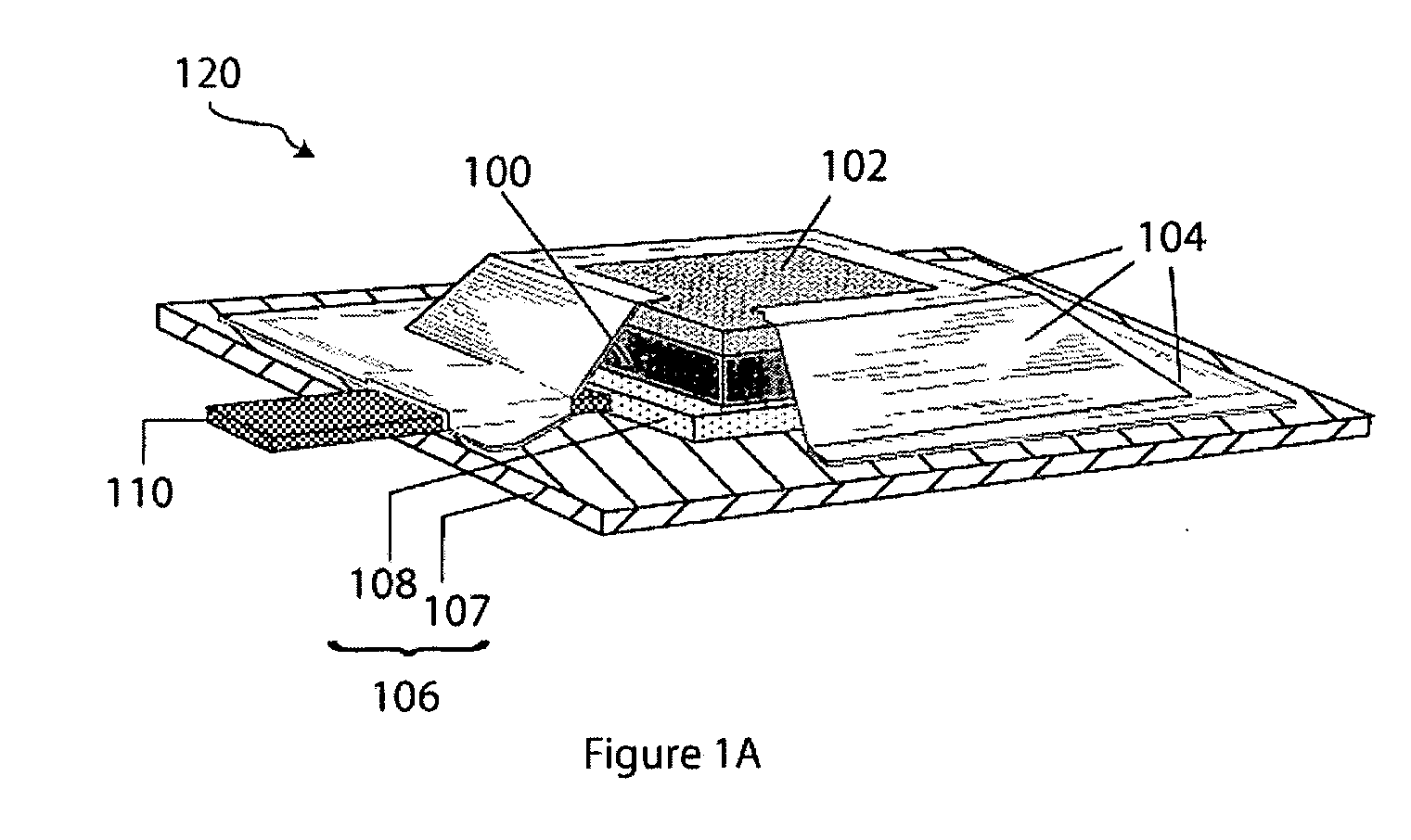

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

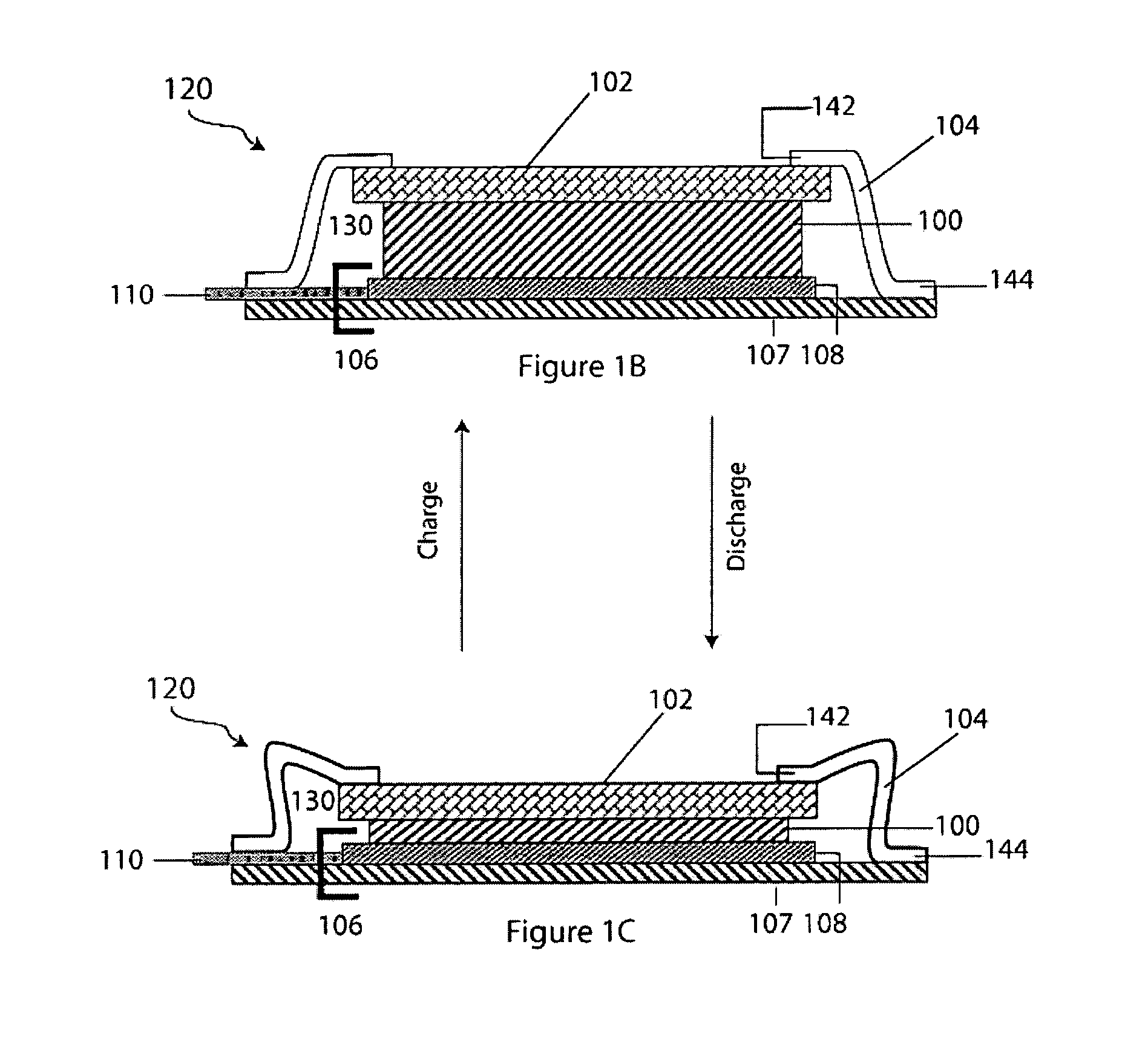

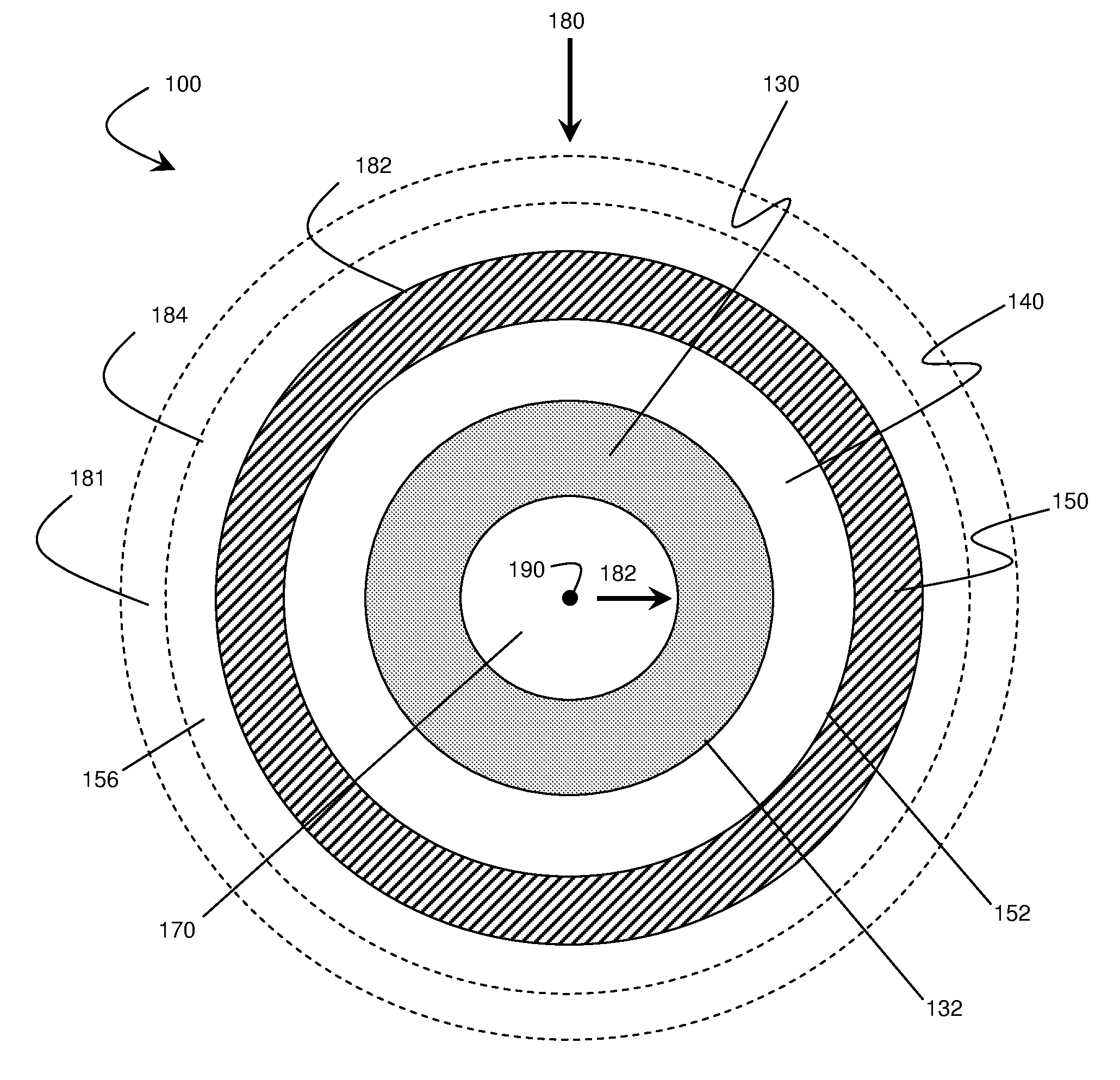

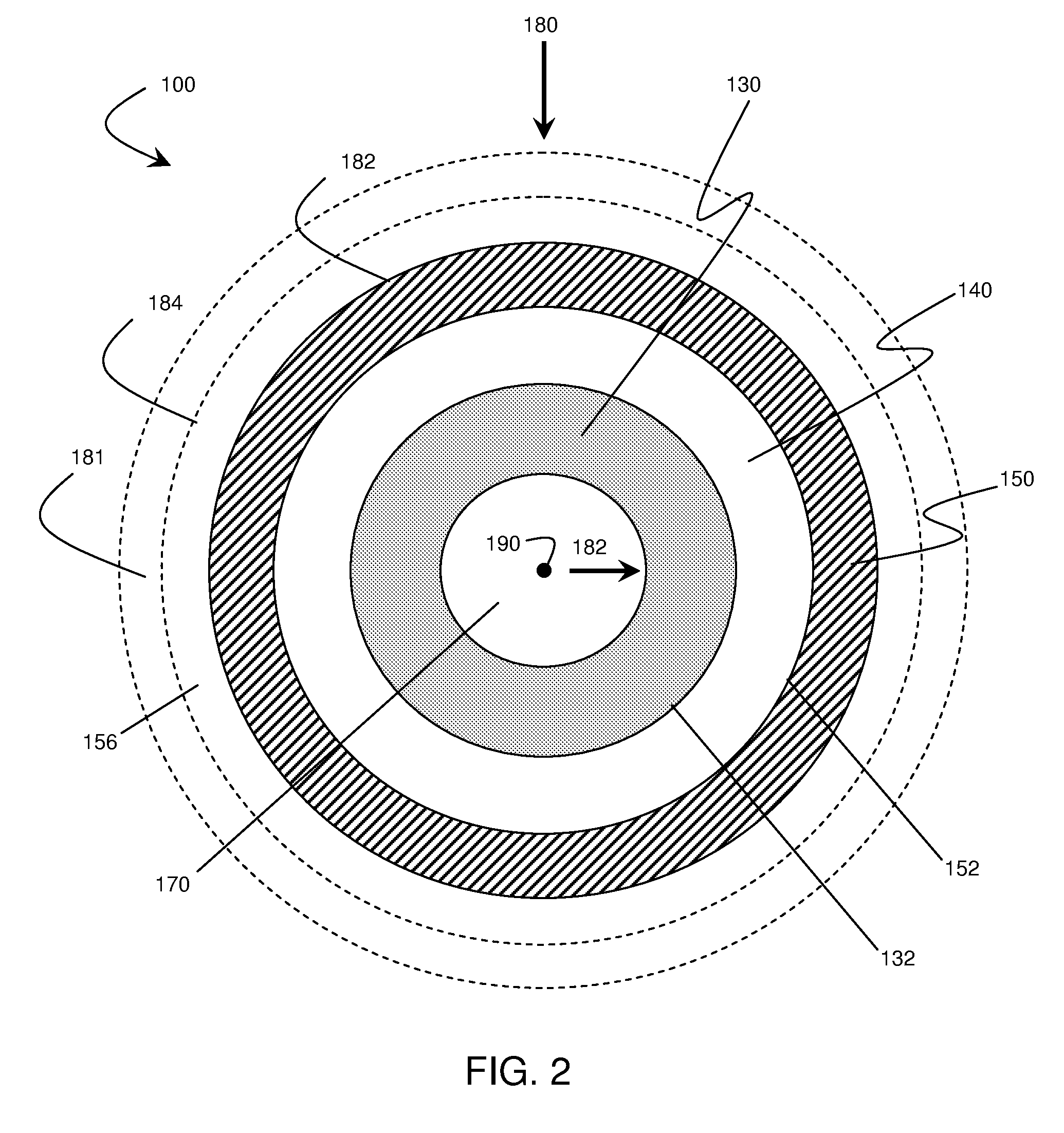

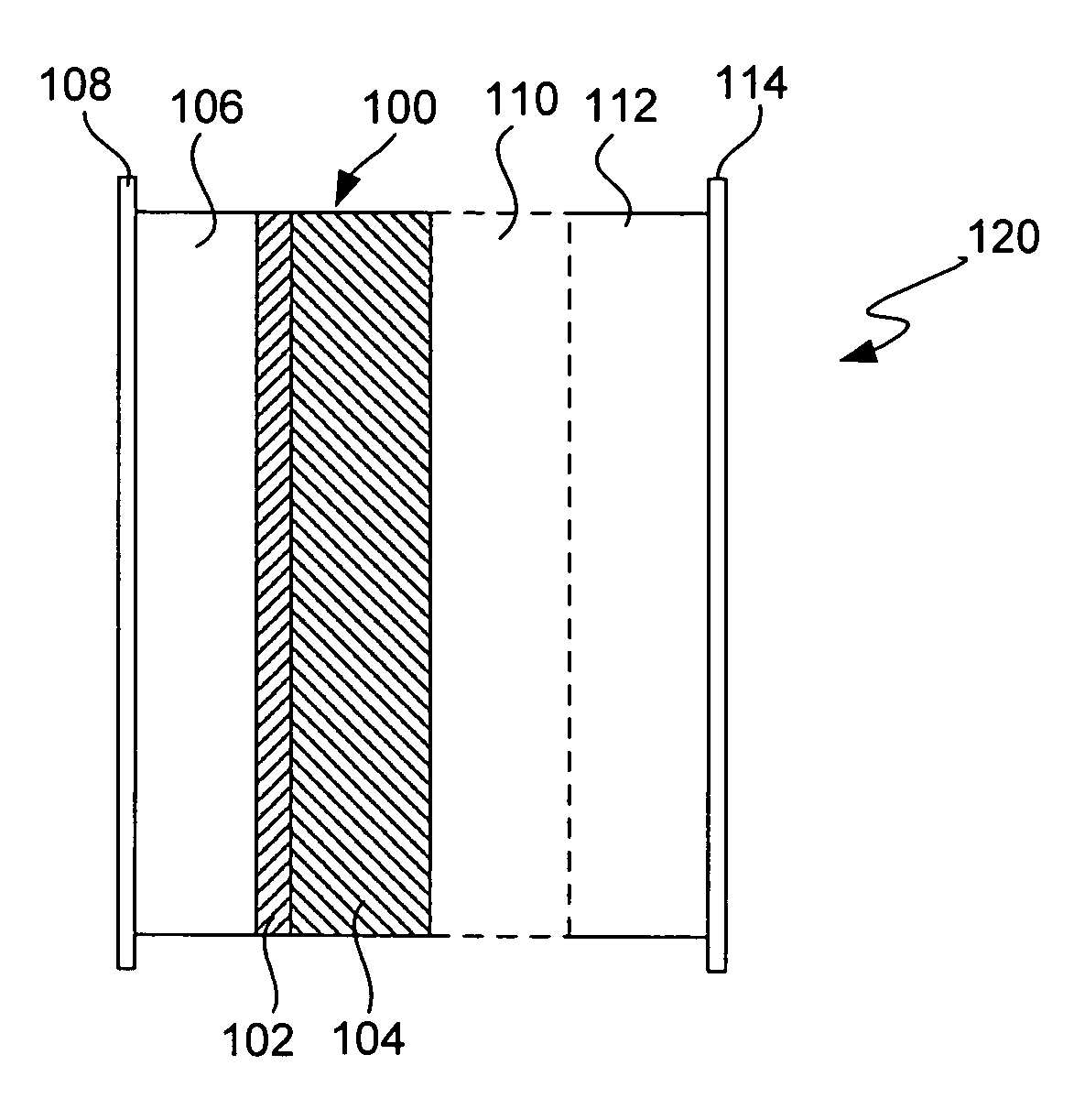

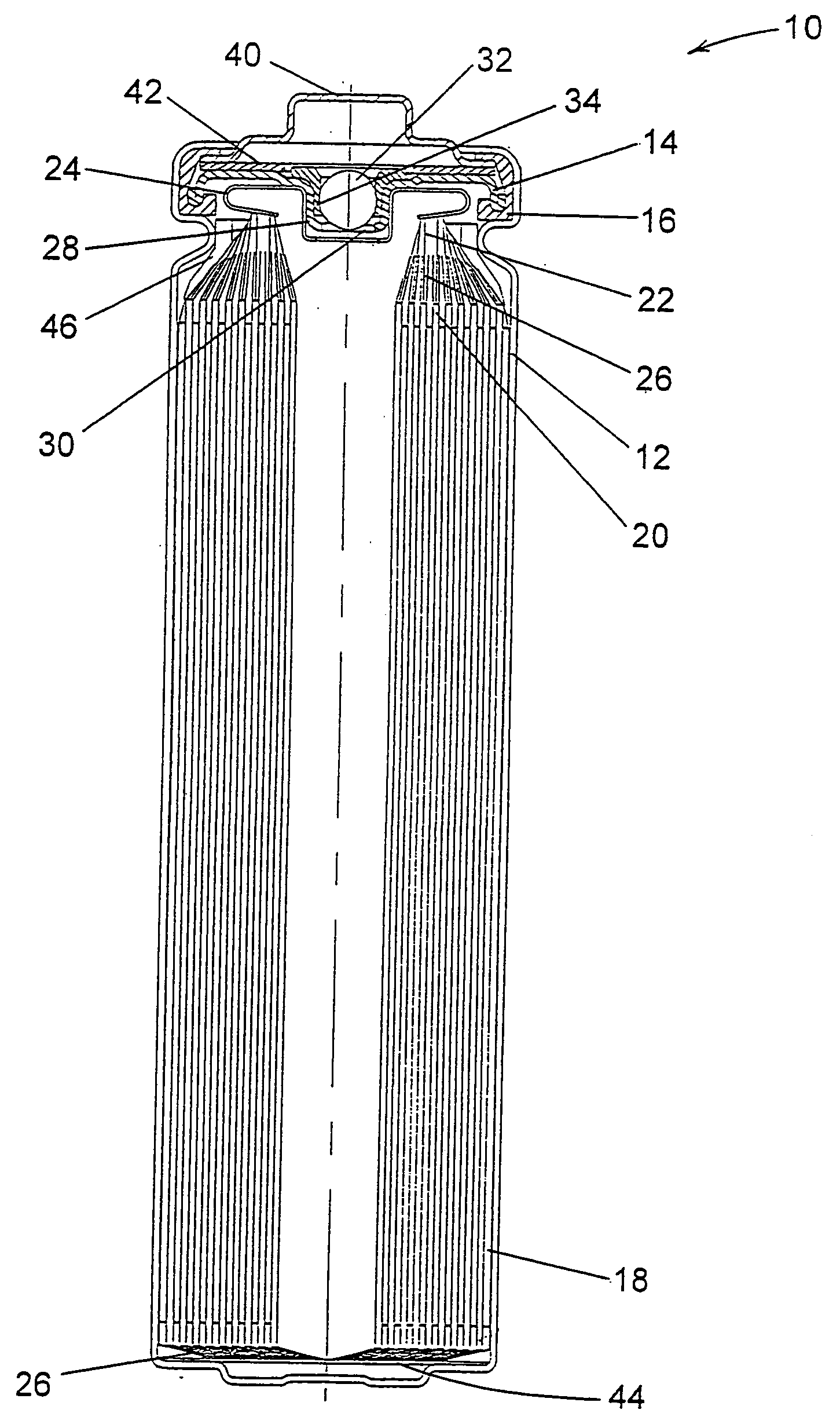

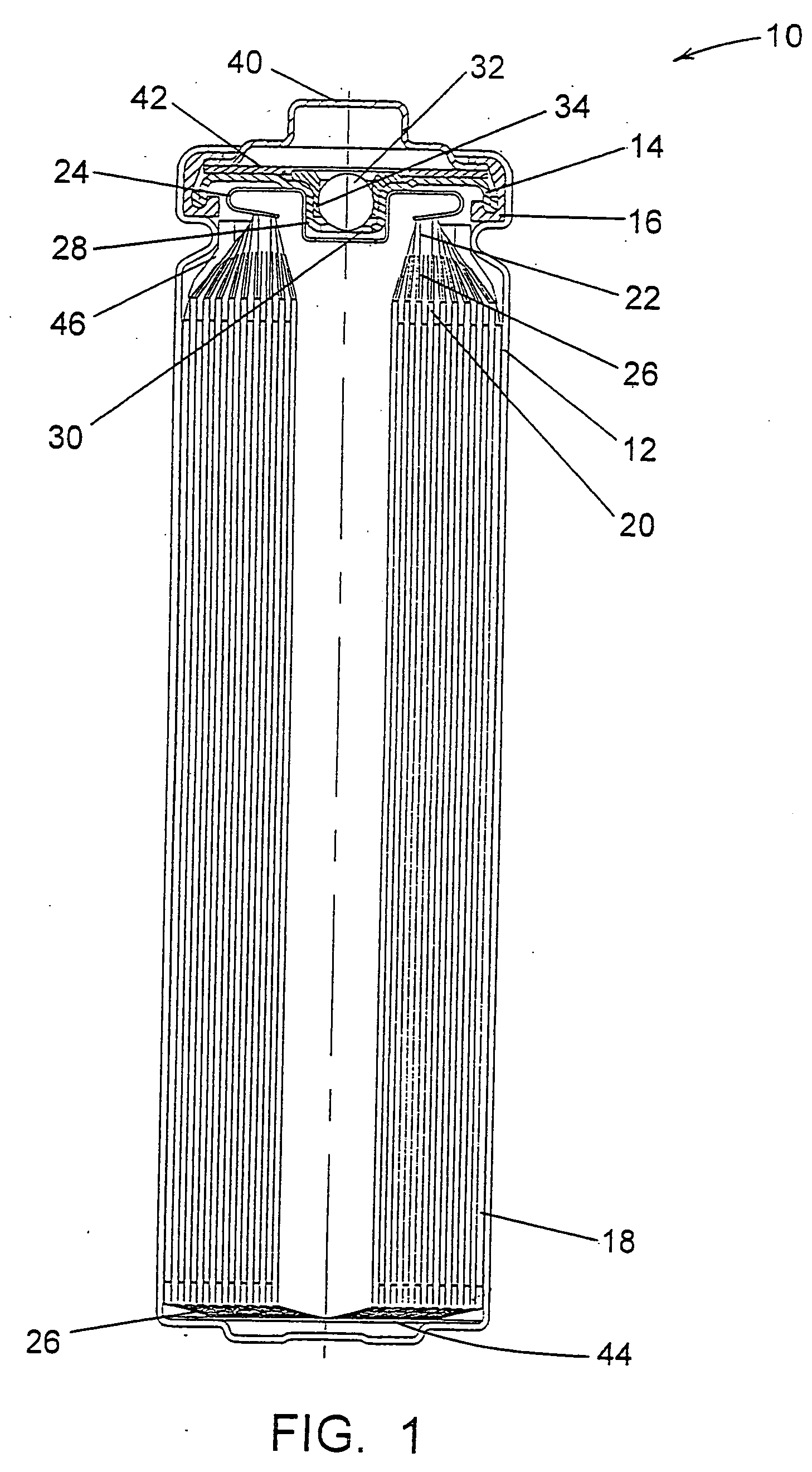

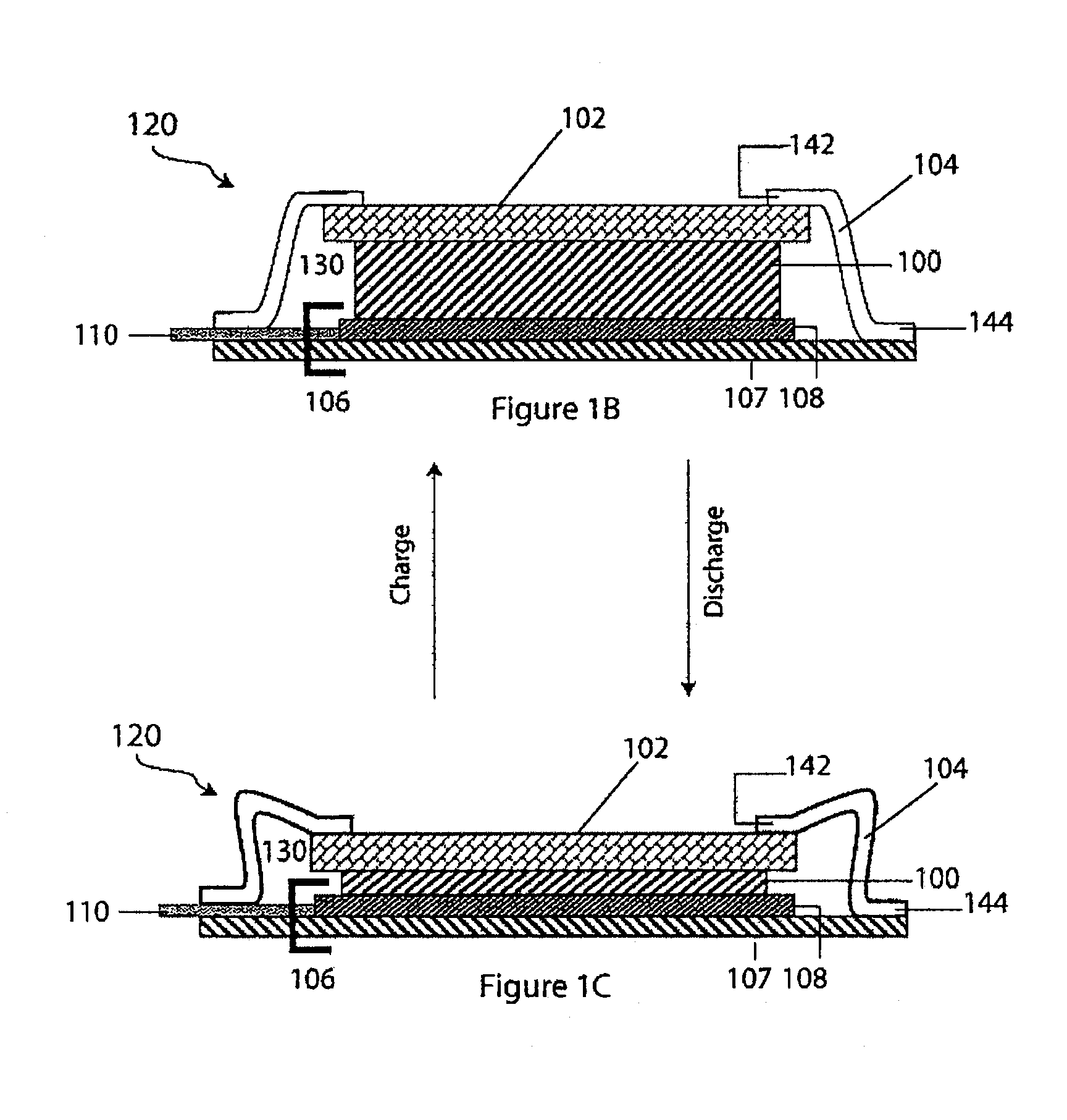

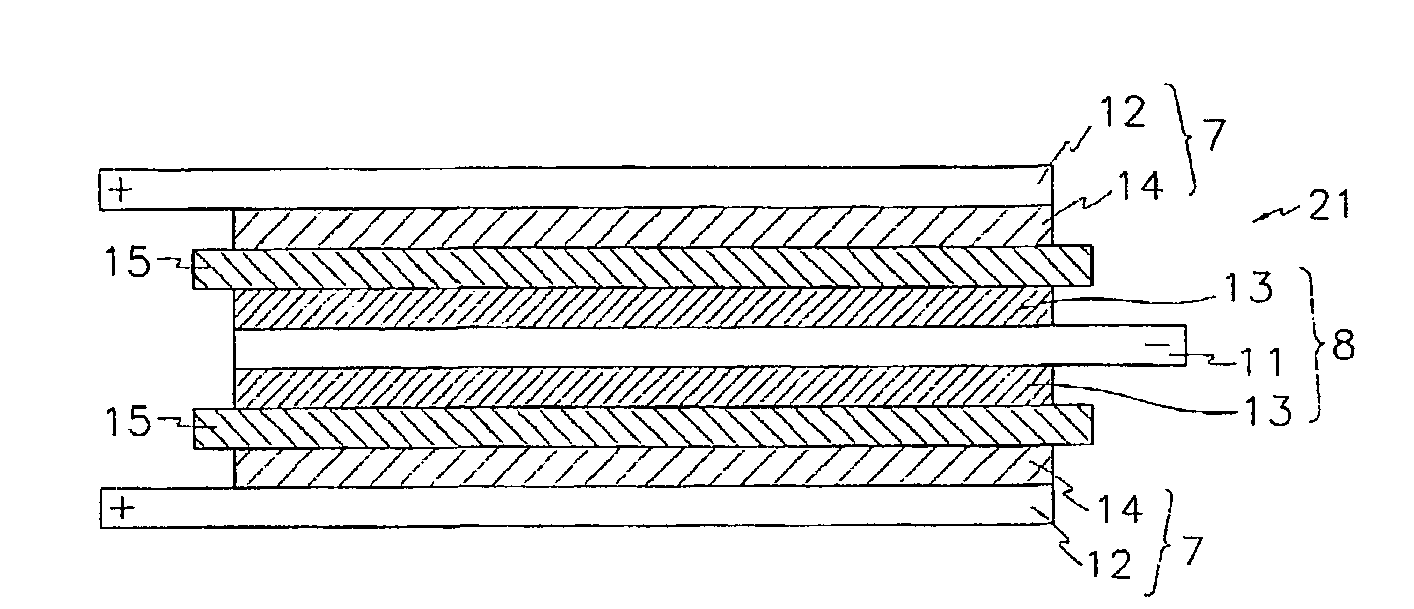

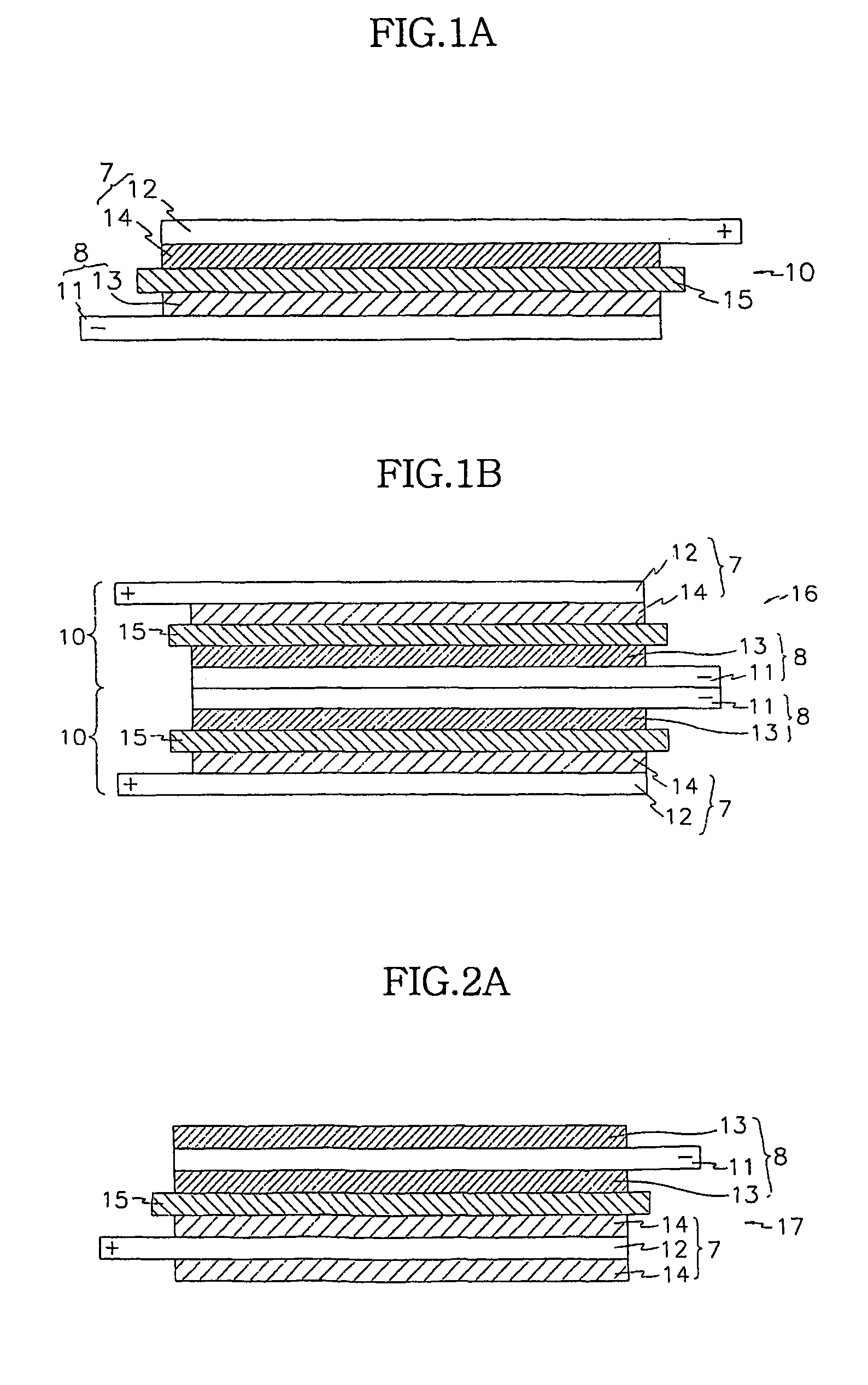

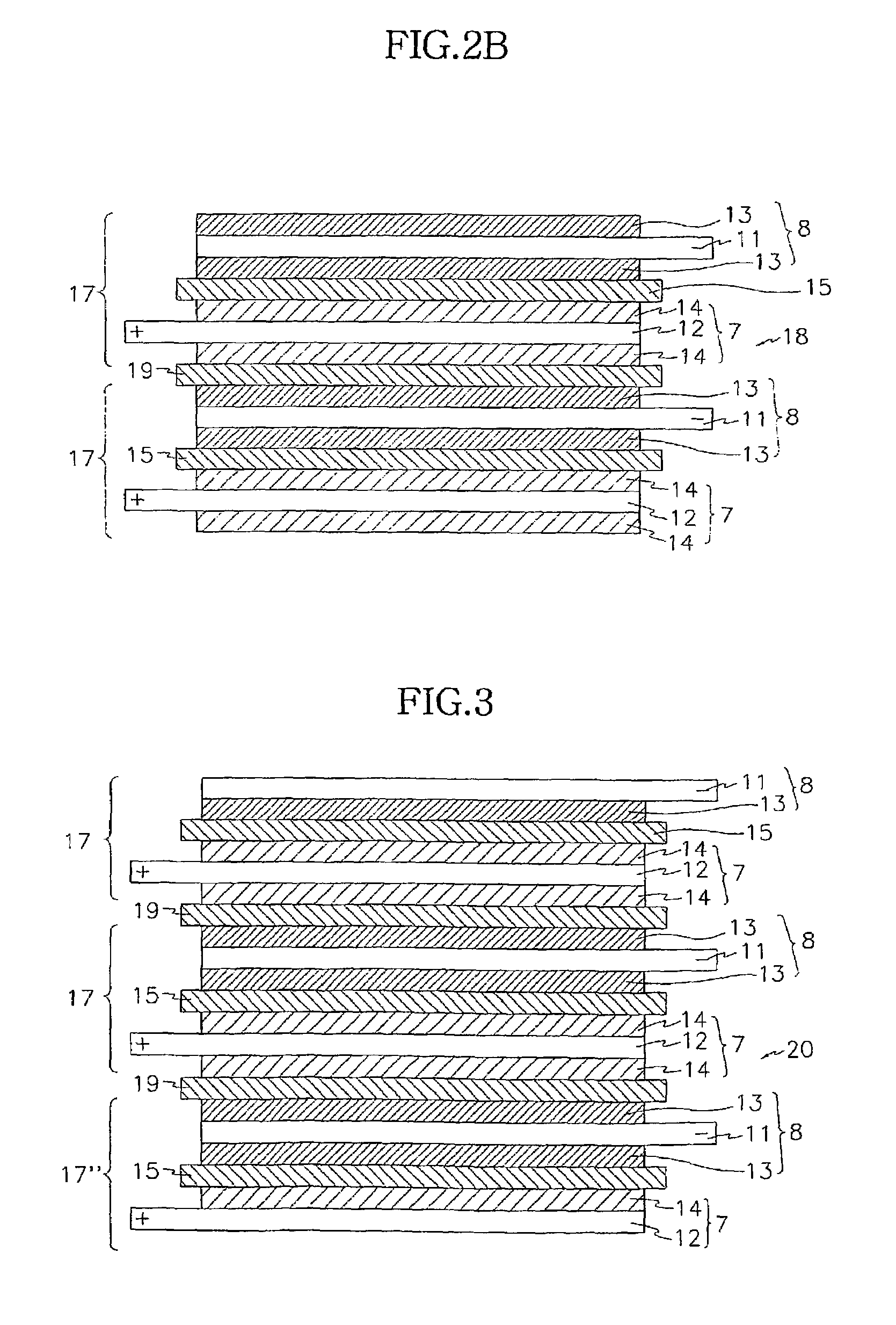

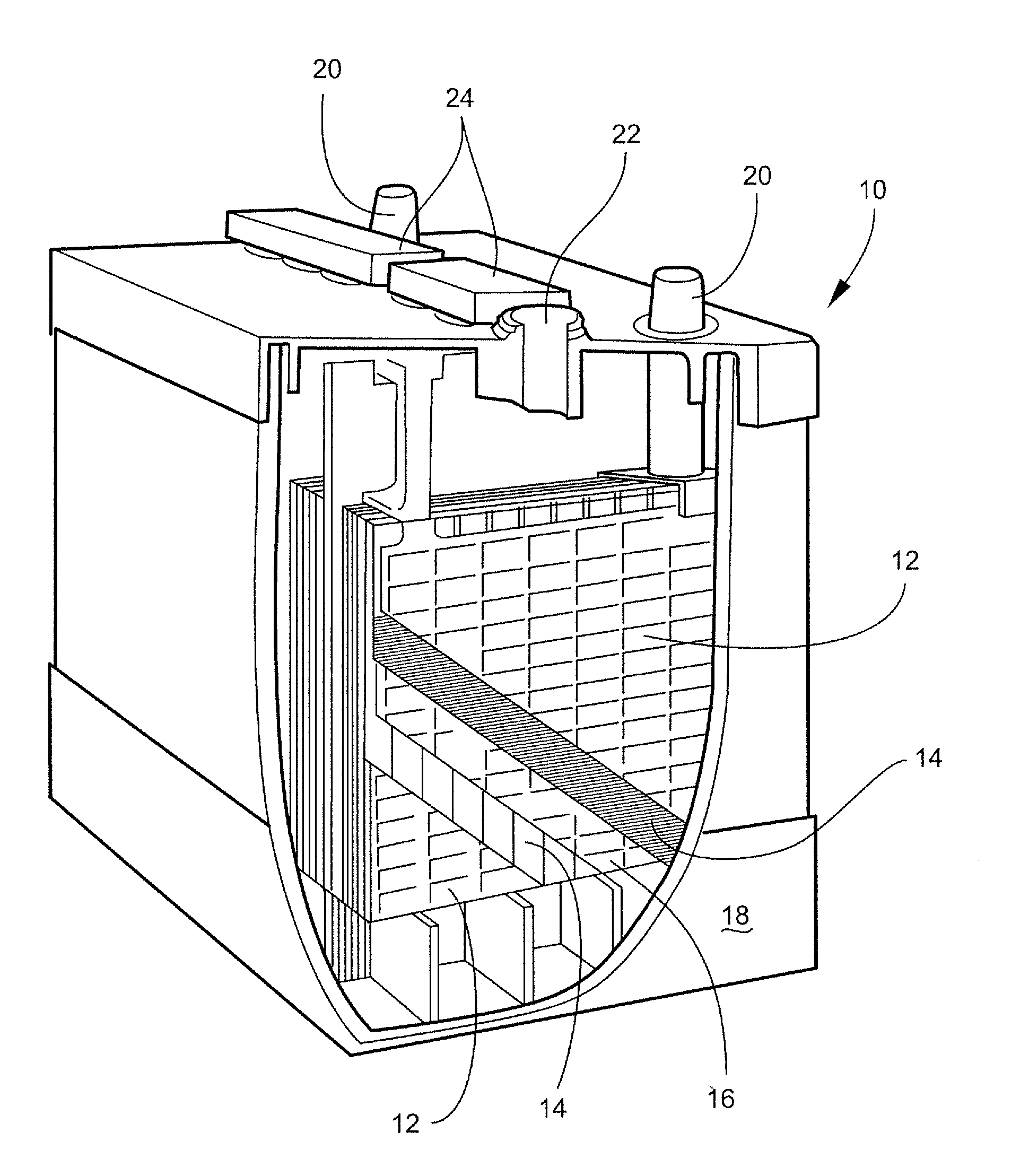

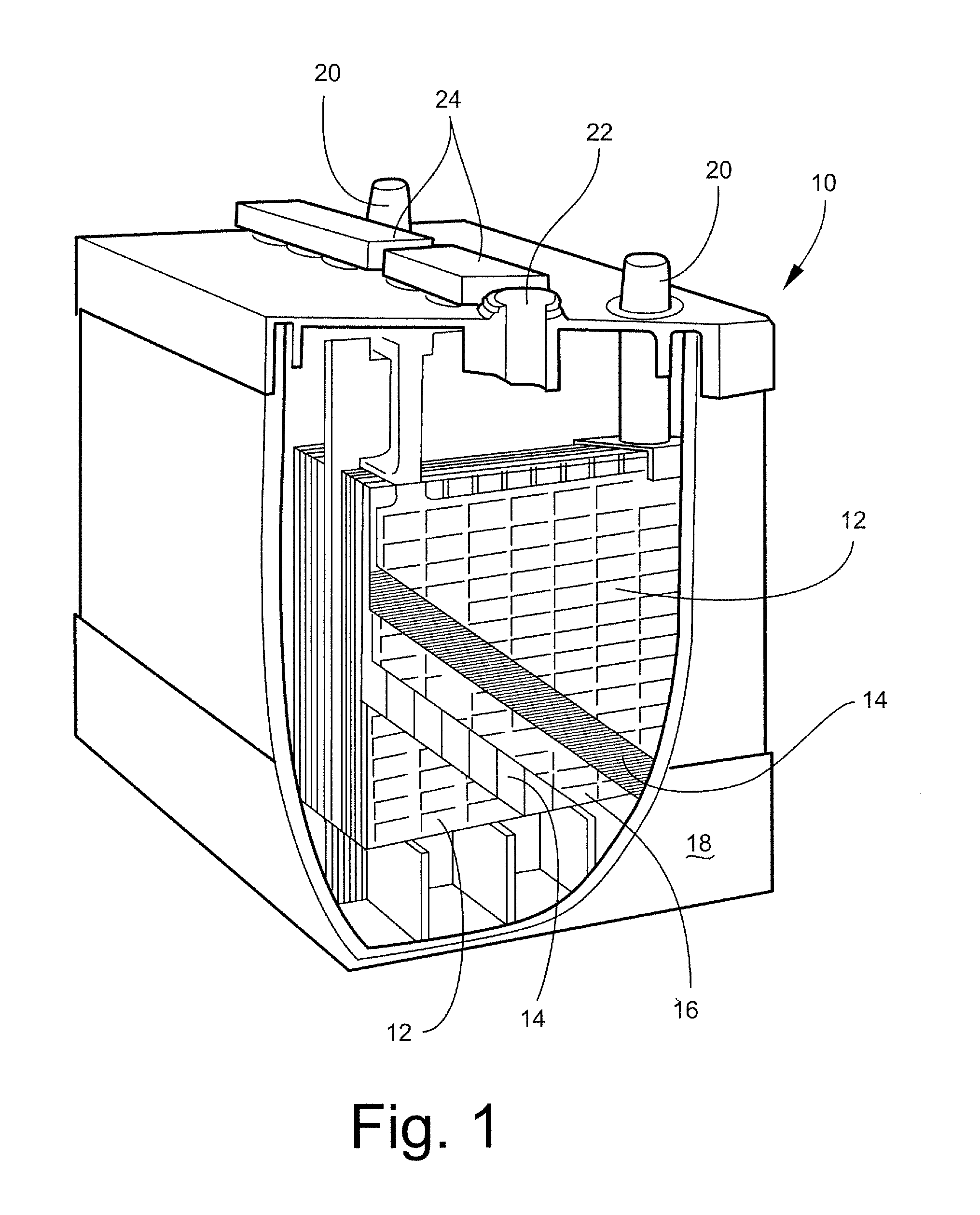

Application of force in electrochemical cells

ActiveUS20100035128A1Improve performancePrimary cell to battery groupingCell seperators/membranes/diaphragms/spacersRough surfaceChemical reaction

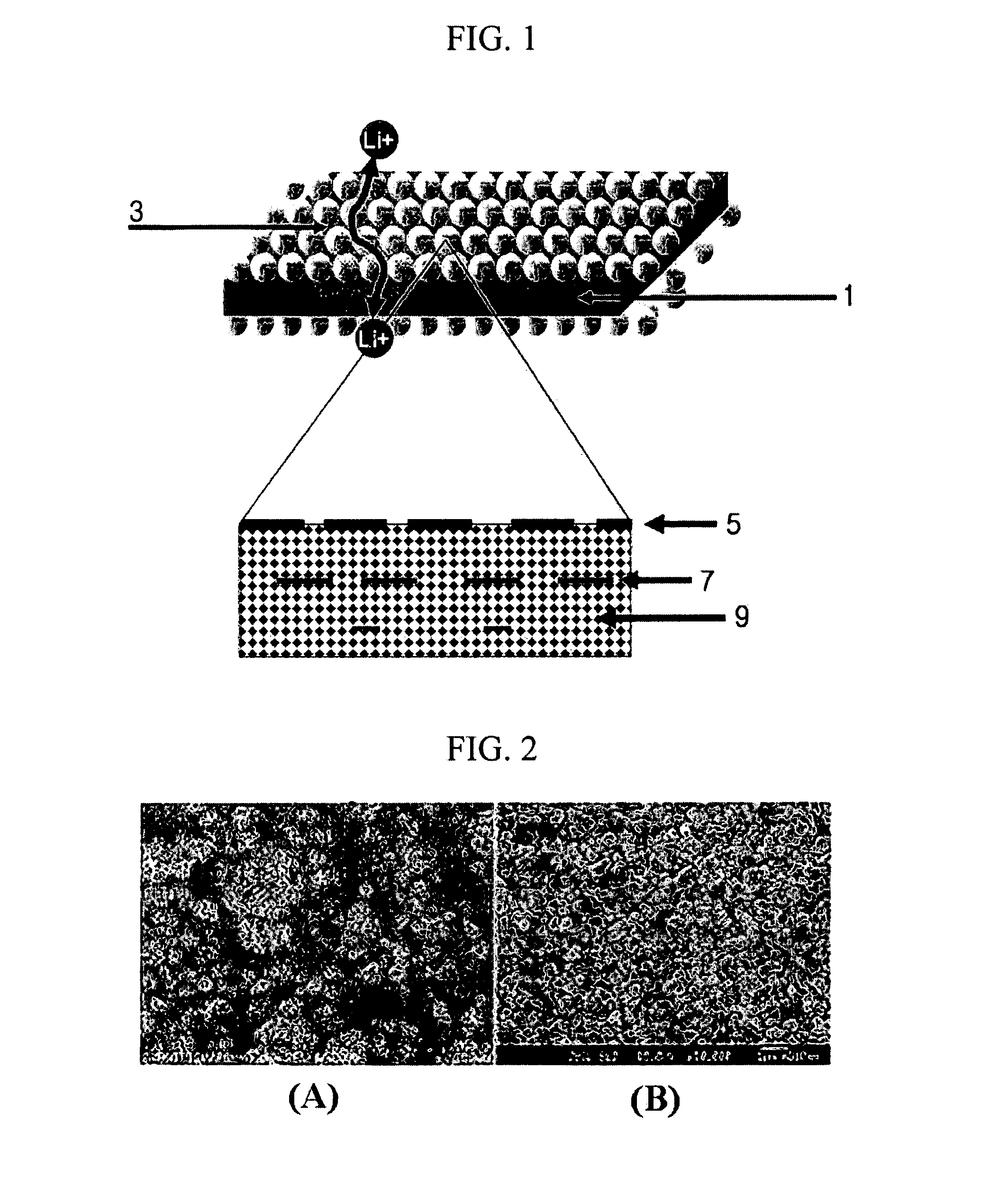

The present invention relates to the application of a force to enhance the performance of an electrochemical cell. The force may comprise, in some instances, an anisotropic force with a component normal to an active surface of the anode of the electrochemical cell. In the embodiments described herein, electrochemical cells (e.g., rechargeable batteries) may undergo a charge / discharge cycle involving deposition of metal (e.g., lithium metal) on a surface of the anode upon charging and reaction of the metal on the anode surface, wherein the metal diffuses from the anode surface, upon discharging. The uniformity with which the metal is deposited on the anode may affect cell performance. For example, when lithium metal is redeposited on an anode, it may, in some cases, deposit unevenly forming a rough surface. The roughened surface may increase the amount of lithium metal available for undesired chemical reactions which may result in decreased cycling lifetime and / or poor cell performance. The application of force to the electrochemical cell has been found, in accordance with the invention, to reduce such behavior and to improve the cycling lifetime and / or performance of the cell.

Owner:SION POWER CORP

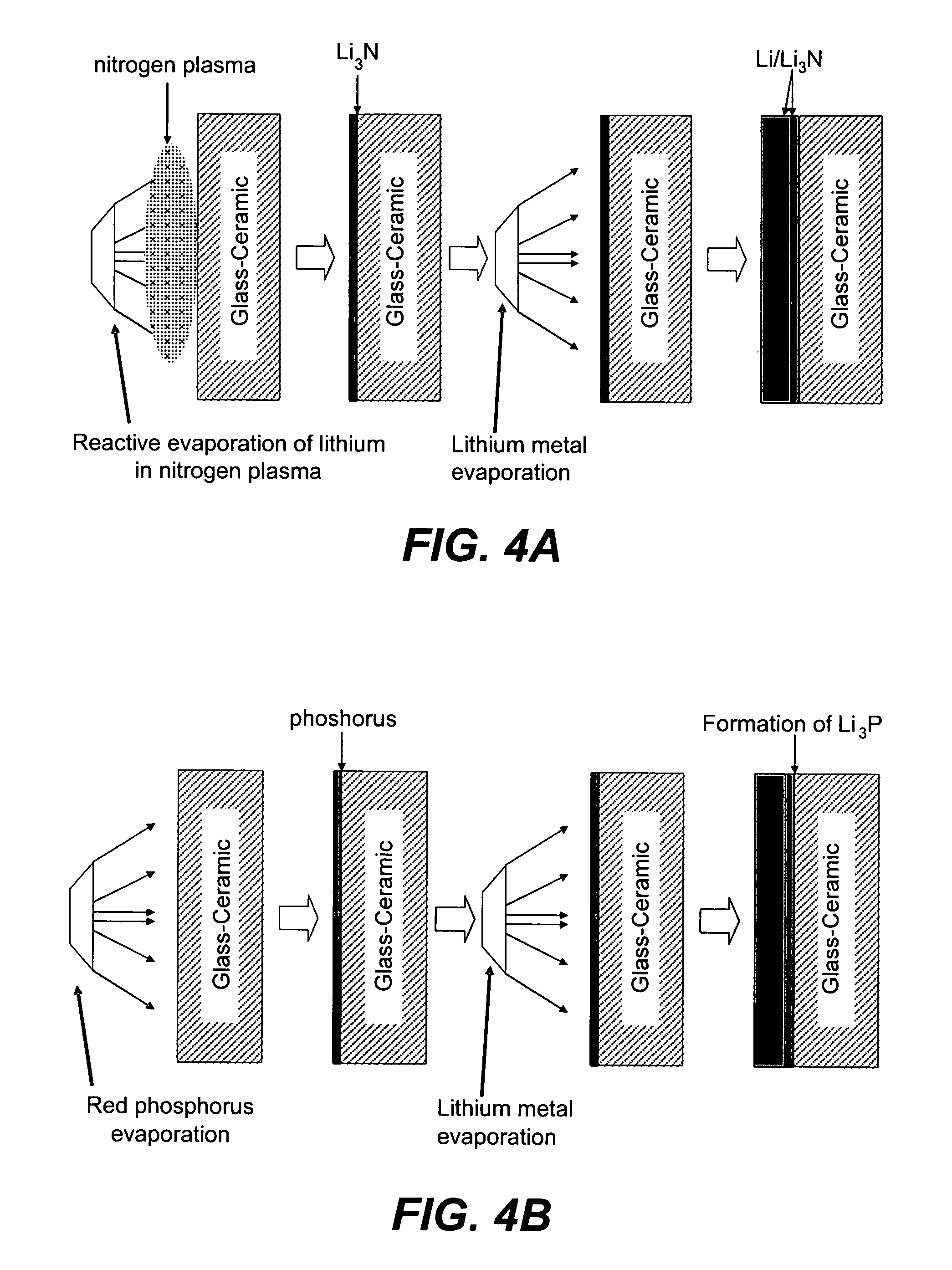

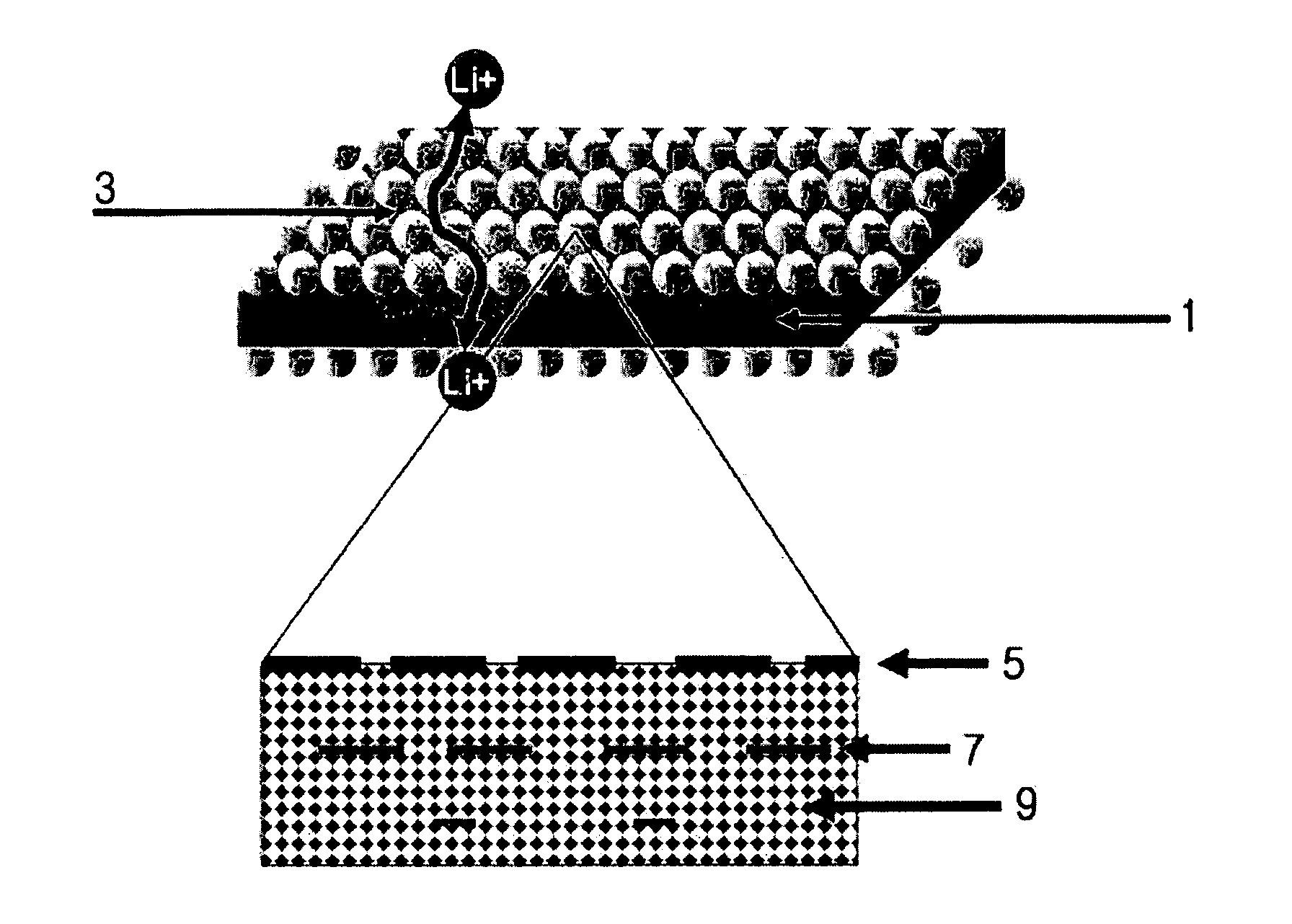

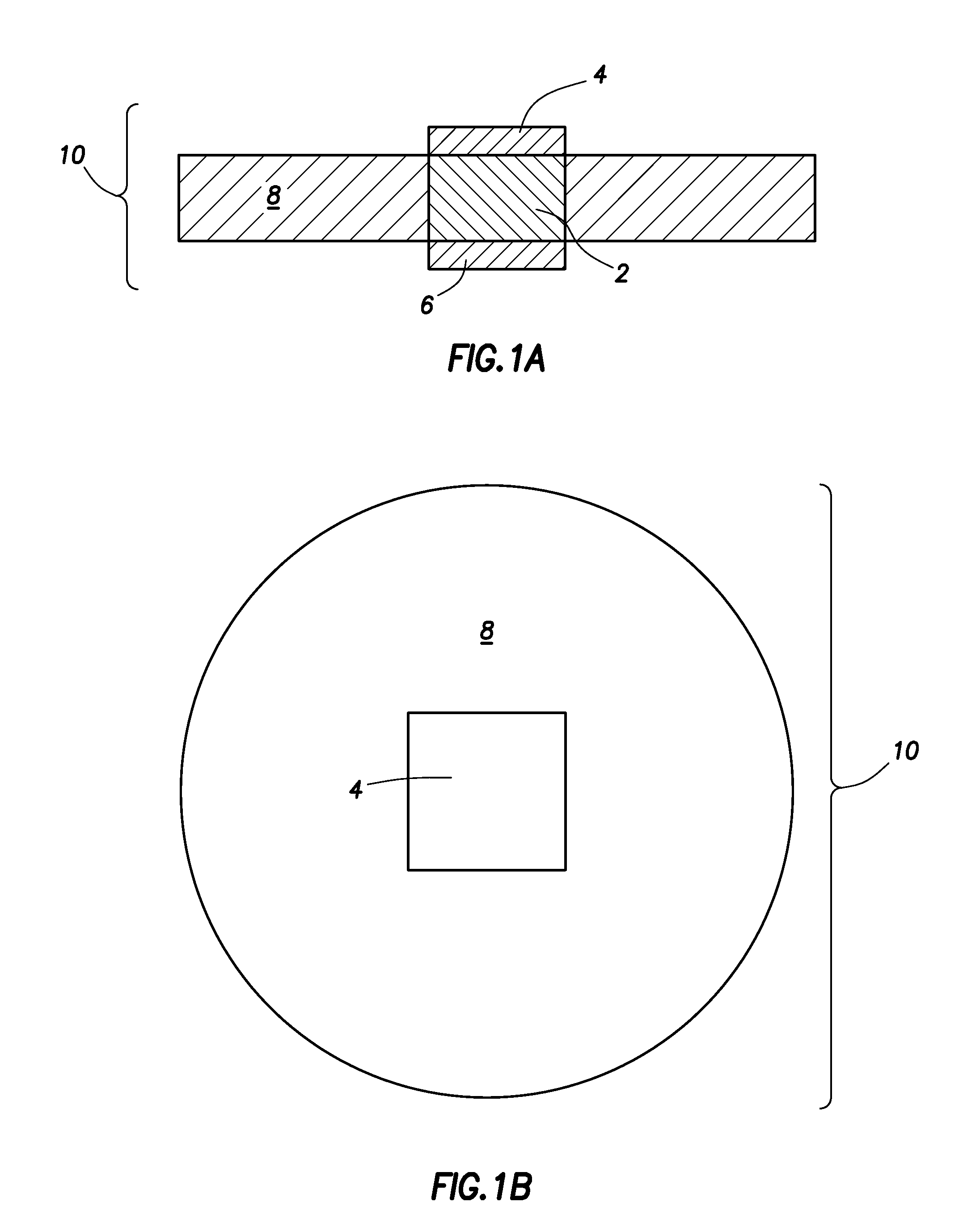

Ionically conductive composites for protection of active metal anodes

ActiveUS7282302B2Good chemical stabilityImprove ionic conductivitySolid electrolytesCell seperators/membranes/diaphragms/spacersChemical stabilityBattery cell

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

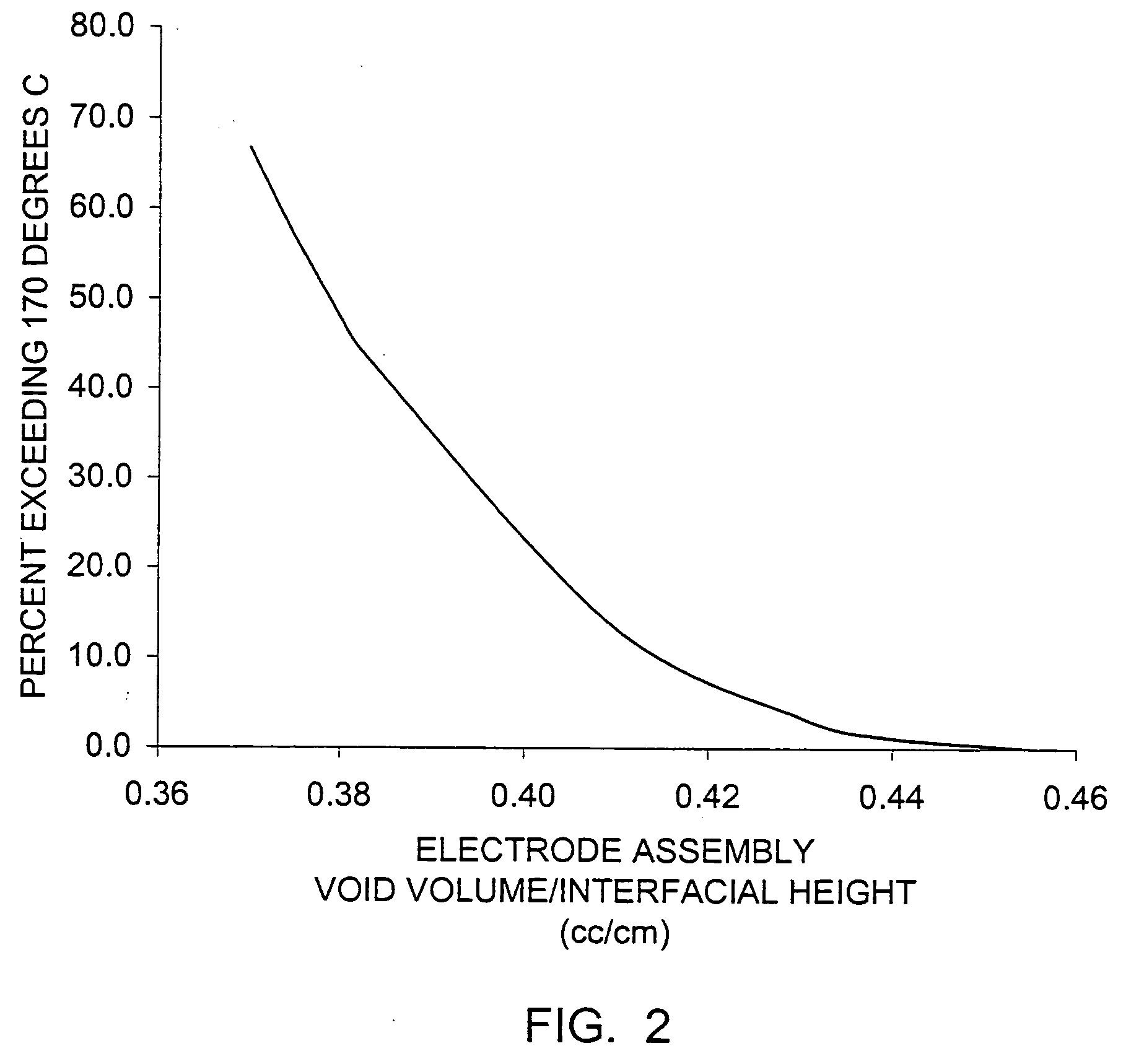

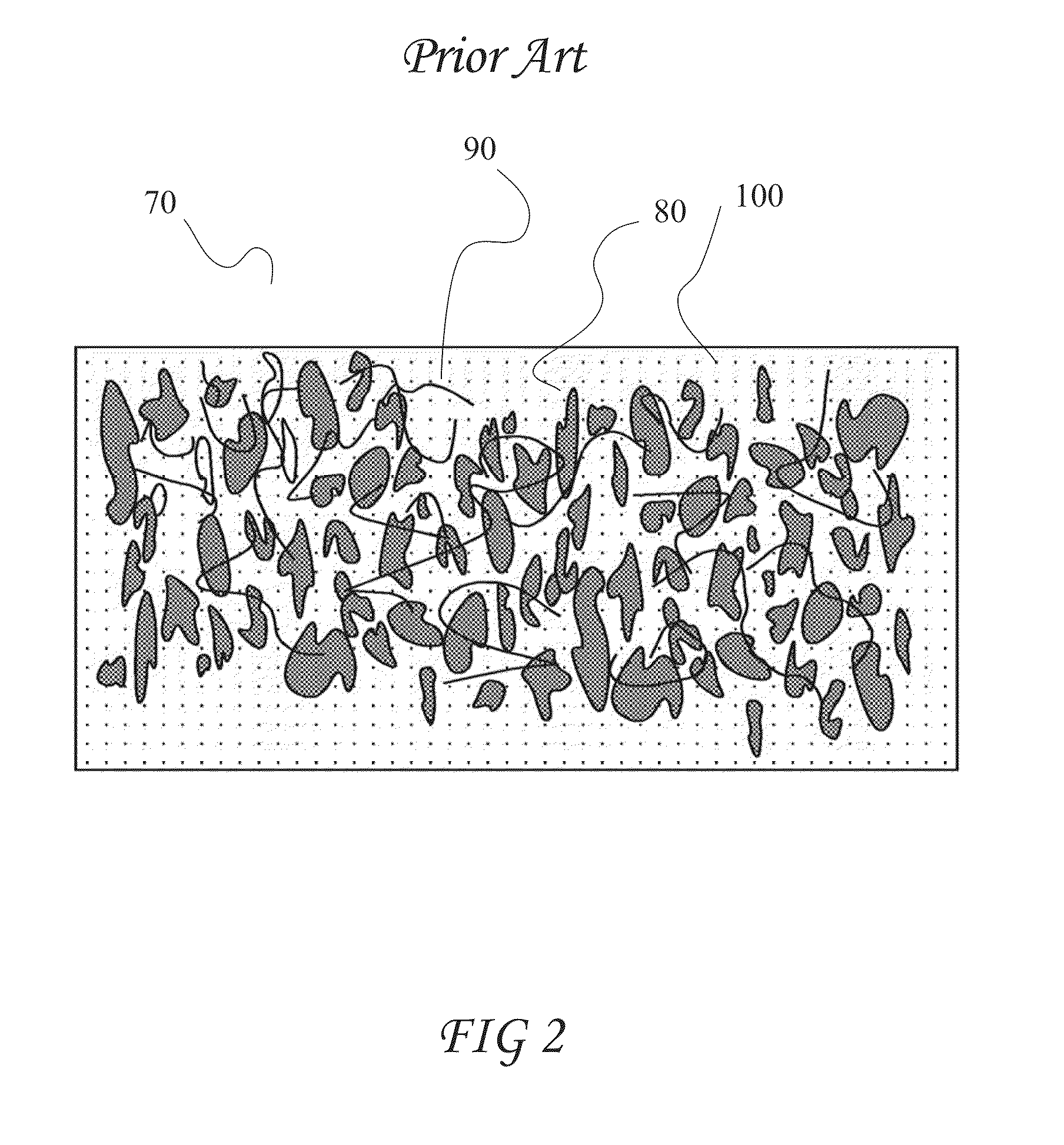

High discharge capacity lithium battery

InactiveUS20050233214A1Improve discharge performanceIncrease energy densityFinal product manufactureOrganic electrolyte cellsHigh rateIron disulfide

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:EVEREADY BATTERY CO INC

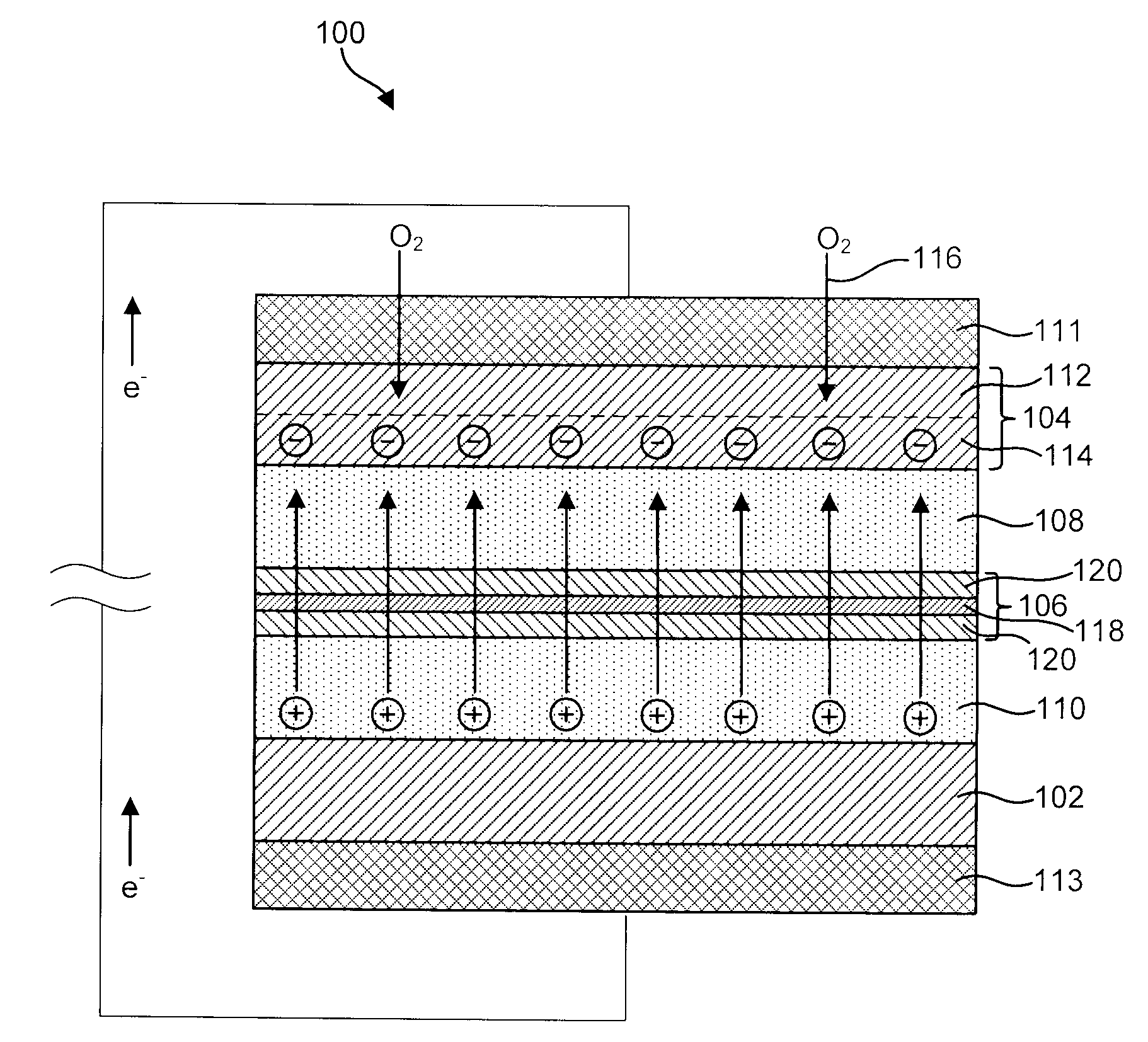

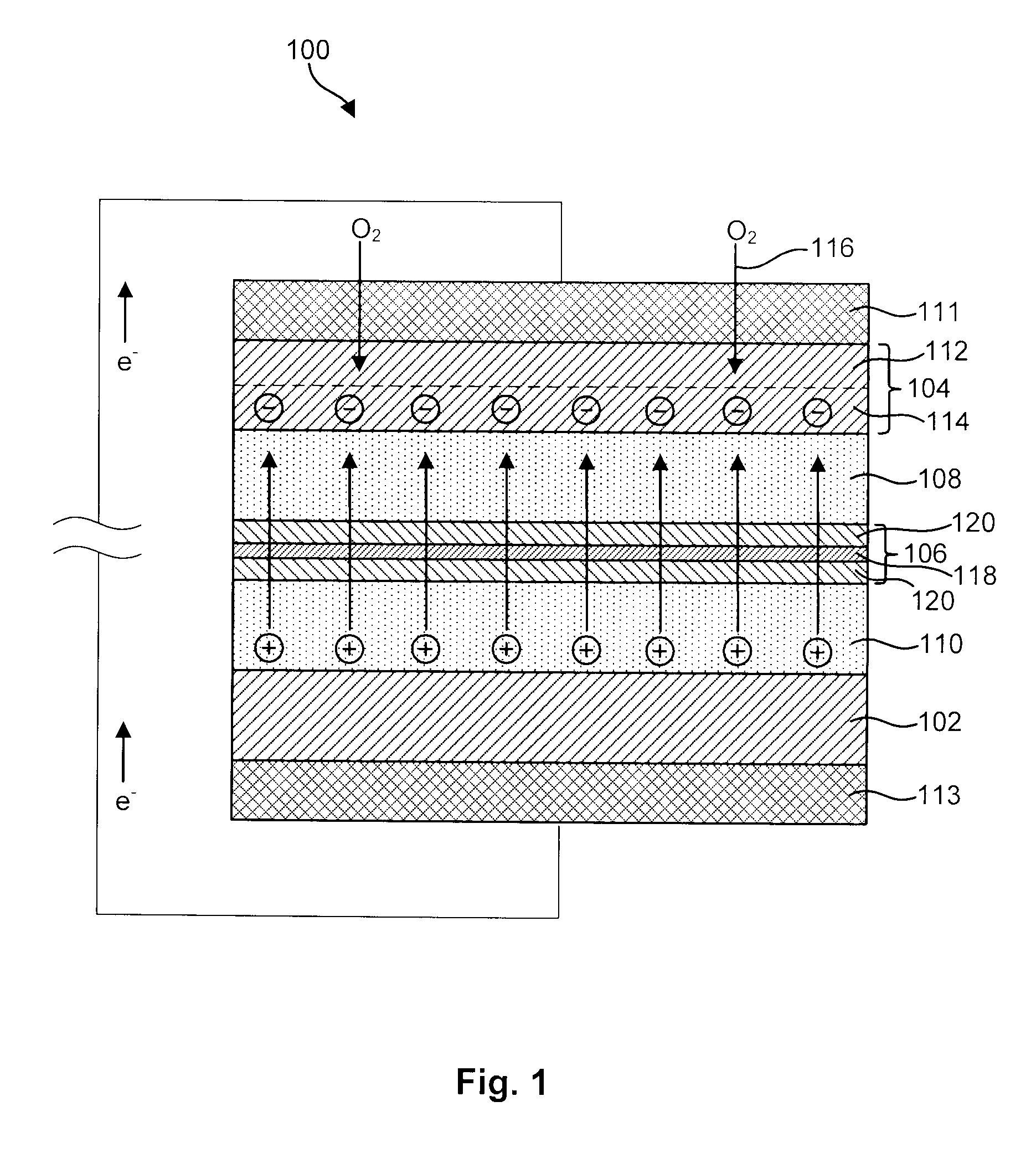

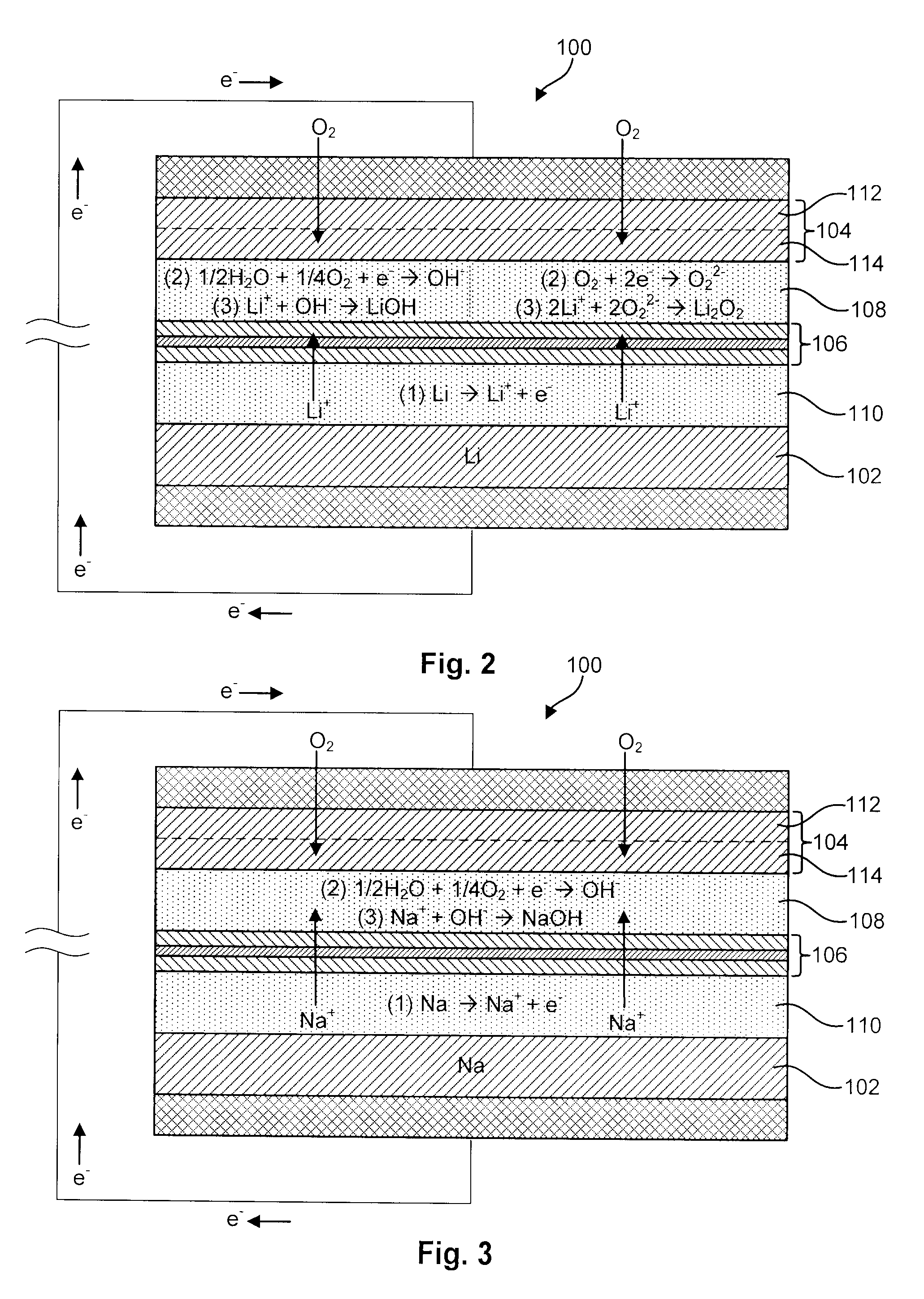

Advanced Metal-Air Battery Having a Ceramic Membrane Electrolyte Background of the Invention

ActiveUS20080268327A1Reduce oxygenReduce layeringFuel and primary cellsSolid electrolytesOxygenCeramic membrane

A metal-air battery is disclosed in one embodiment of the invention as including a cathode to reduce oxygen molecules and an alkali-metal-containing anode to oxidize the alkali metal (e.g., Li, Na, and K) contained therein to produce alkali-metal ions. An aqueous catholyte is placed in ionic communication with the cathode to store reaction products generated by reacting the alkali-metal ions with the oxygen containing anions. These reaction products are stored as solutes dissolved in the aqueous catholyte. An ion-selective membrane is interposed between the alkali-metal containing anode and the aqueous catholyte. The ion-selective membrane is designed to be conductive to the alkali-metal ions while being impermeable to the aqueous catholyte.

Owner:FIELD UPGRADING USA INC

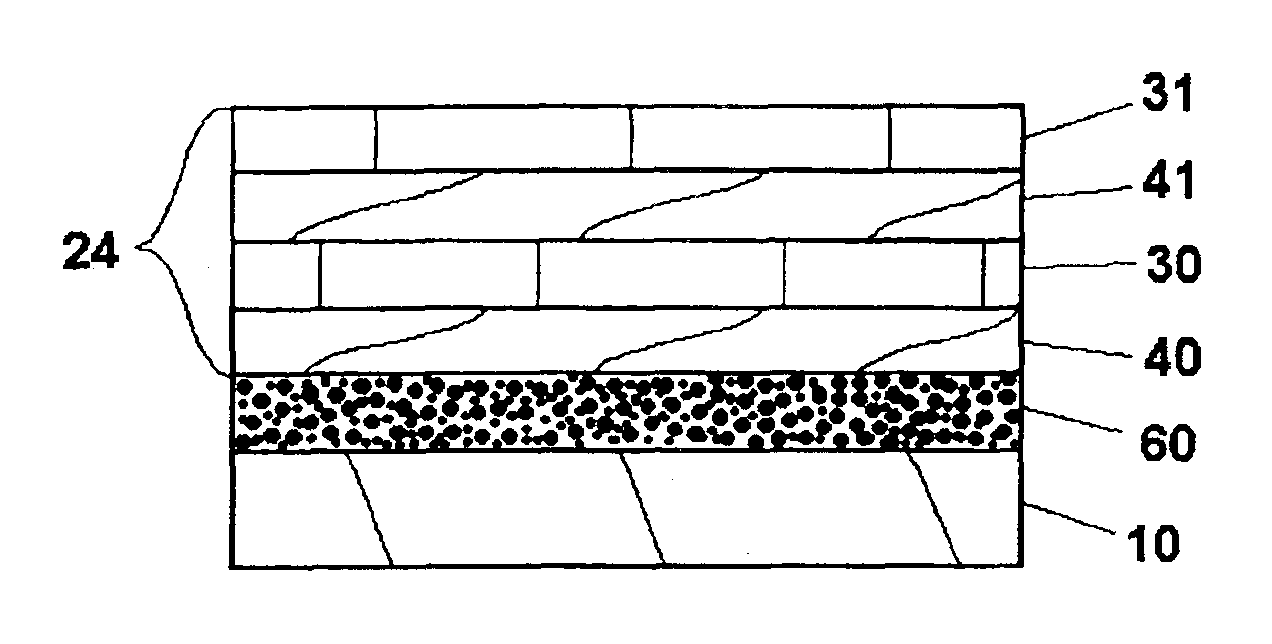

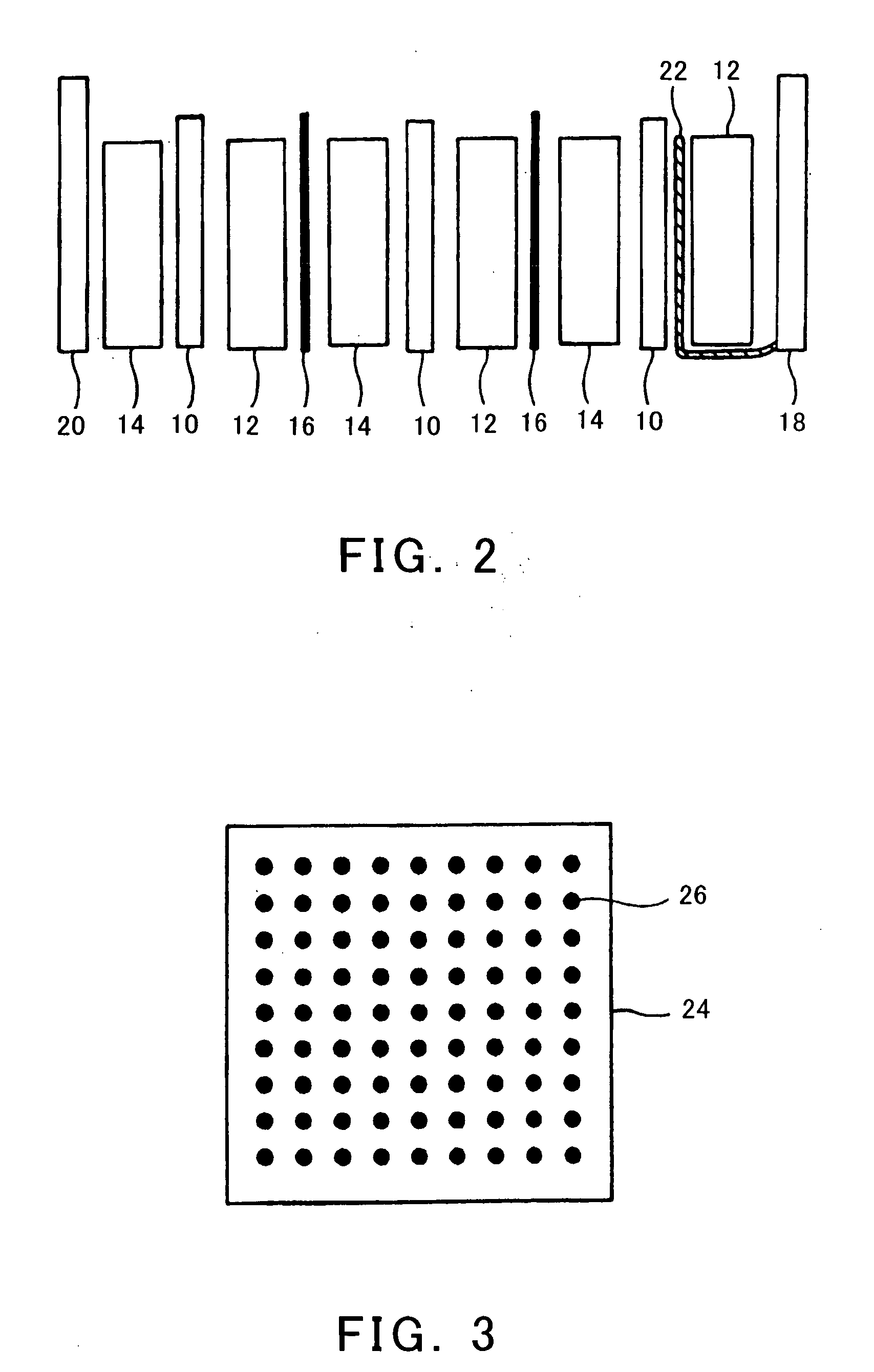

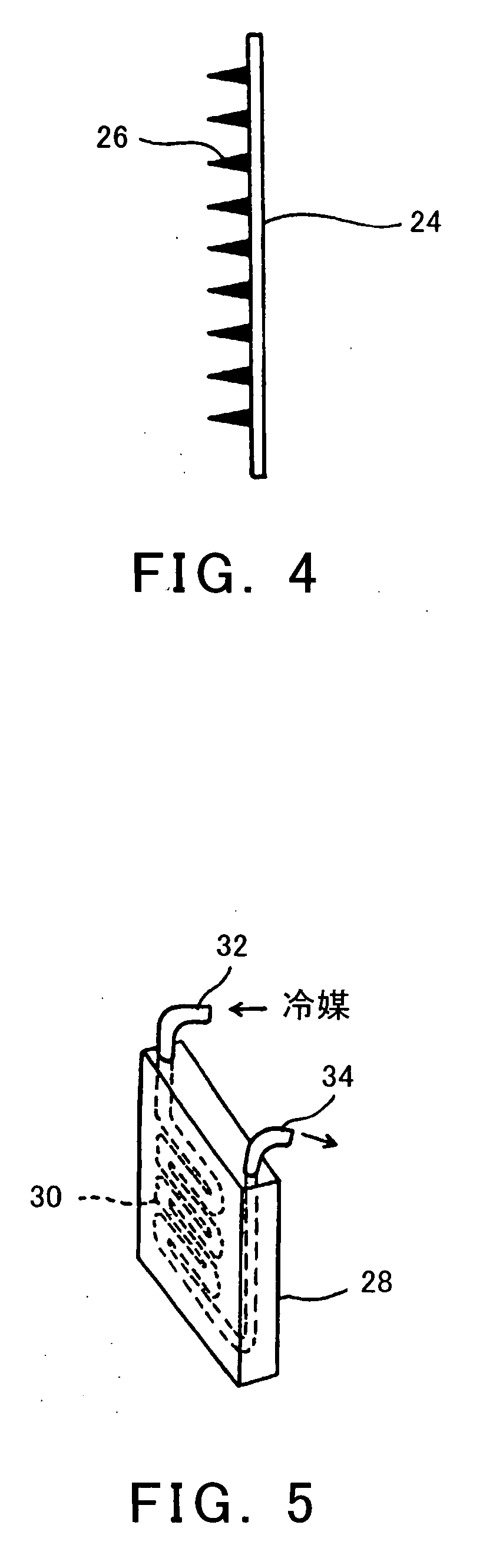

Methods and systems for making electrodes having at least one functional gradient therein and devices resulting therefrom

InactiveUS20110123866A1Improve performanceElectrode manufacturing processesElectric shock equipmentsHigh fluxEngineering

The invention disclosed herein provides for methods and apparatuses that yield electrodes having at least one functional gradient therein. In many embodiments, the electrodes comprise an electrode matrix having a plurality of layers, where at least two of the layers differs functionally, in composition, structure, or, organization. High-throughput electrode screening apparatuses are disclosed that include array formers and testers. Electrodes and battery cells arising from the methods and apparatuses disclosed herein are likewise disclosed. The methods, apparatuses, and resulting electrode and cell devices are, in some embodiments, ideally suited for use in lithium-ion batteries.

Owner:MOLECULAR NANOSYST

Lithium anodes for electrochemical cells

InactiveUS6936381B2Cell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsLithium metalCrosslinked polymers

Owner:SION POWER CORP

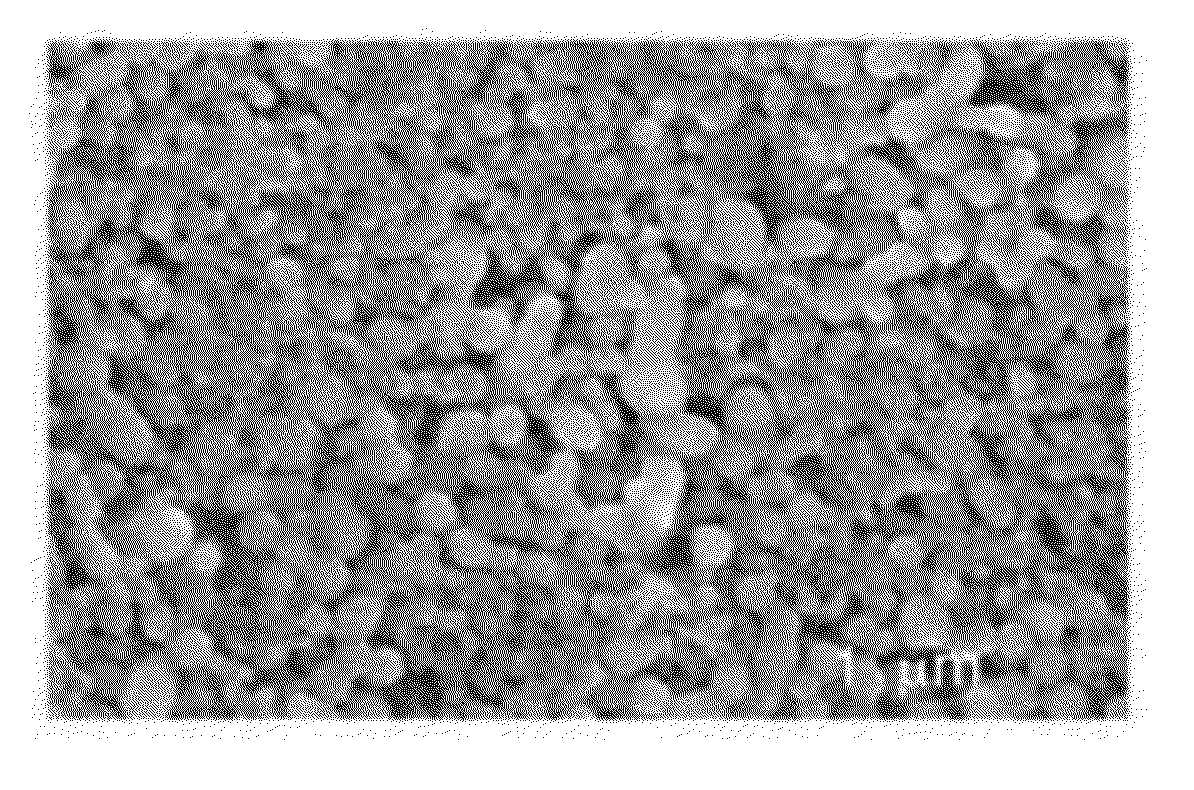

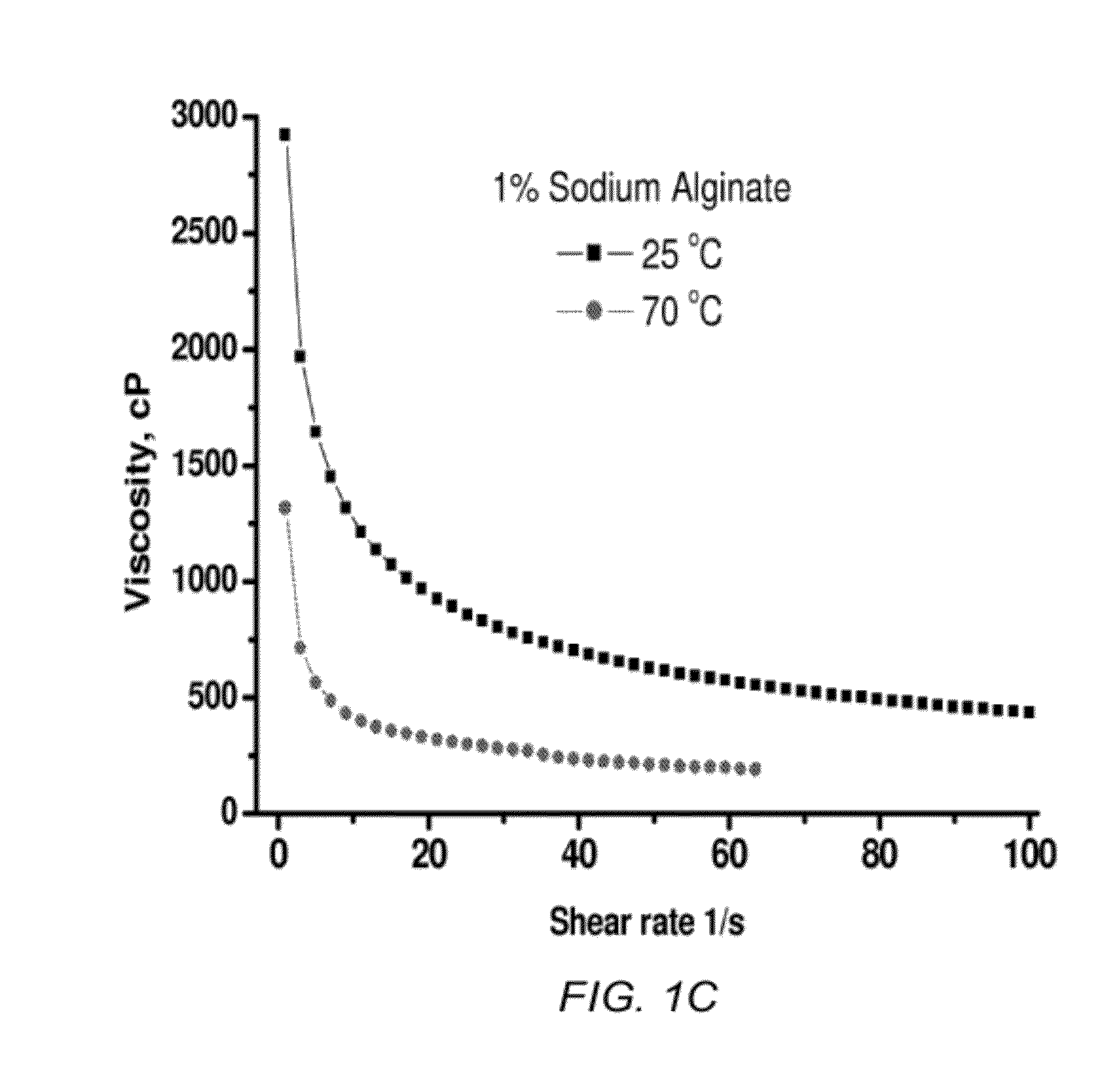

Alginate-containing compositions for use in battery applications

ActiveUS20120088155A1Material nanotechnologyCell seperators/membranes/diaphragms/spacersHydrogenMaterials science

A silicon-based anode comprises an alginate-containing binder. The many carboxy groups of alginate bind to a surface of silicon, creating strong, rigid hydrogen bonds that withstand battery cycling. The alginate-containing binder provides good performance to the anode by (1) improving the capacity of the anode in comparison to other commercially-available binders, (2) improving Columbonic efficiency during charging and discharging cycles, and (3) improving stability during charging and discharging cycles.

Owner:CLEMSON UNIV RES FOUND +1

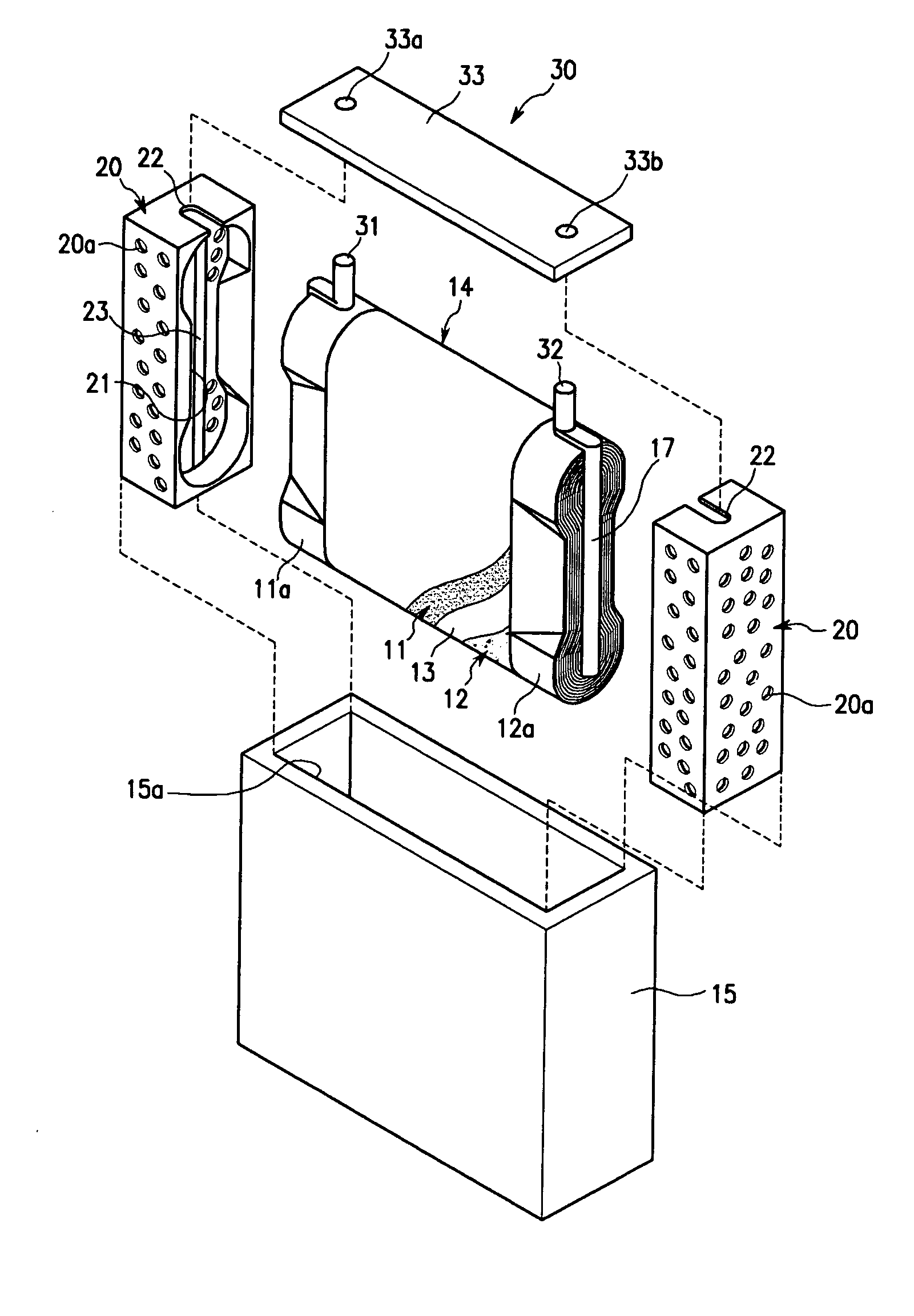

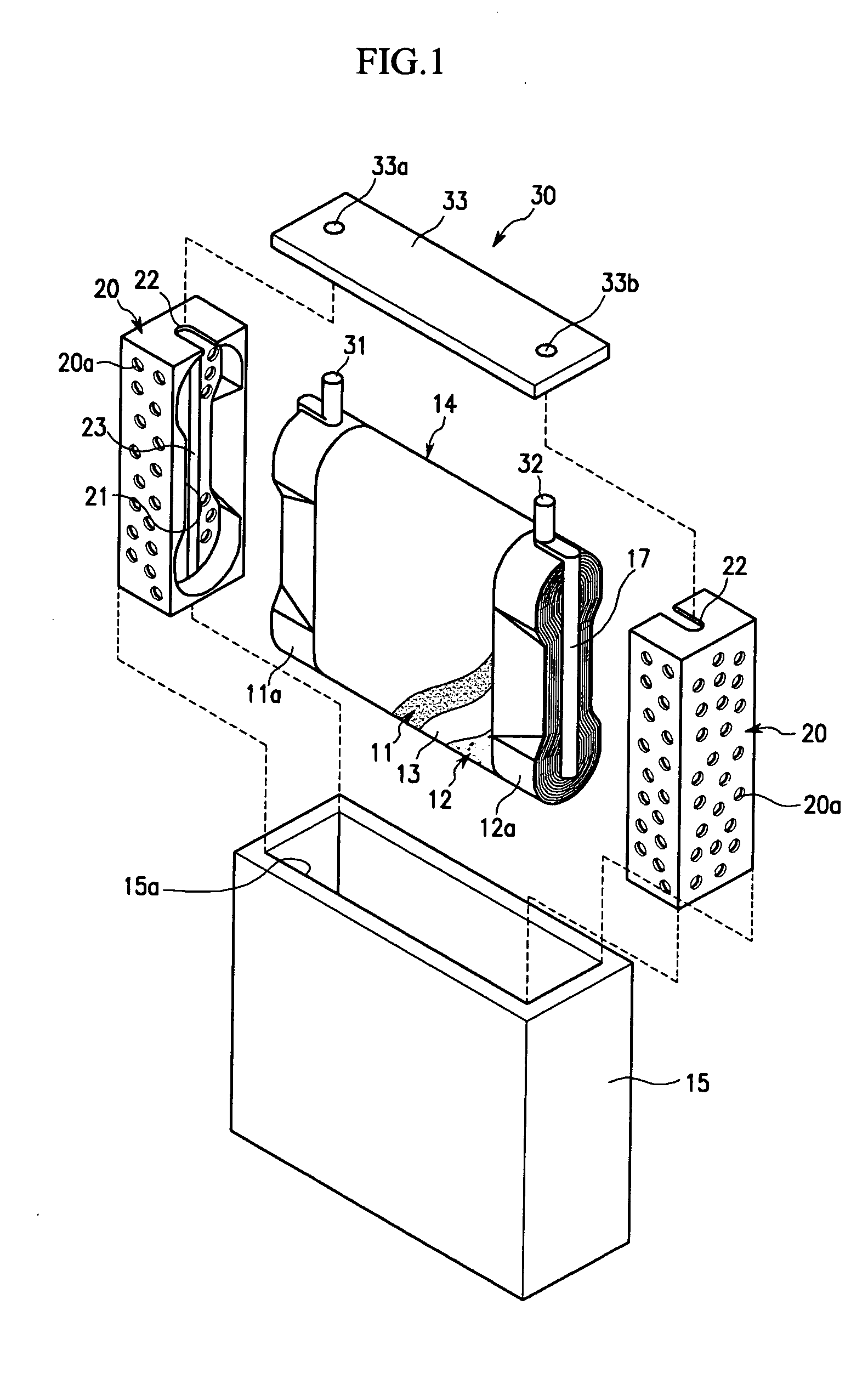

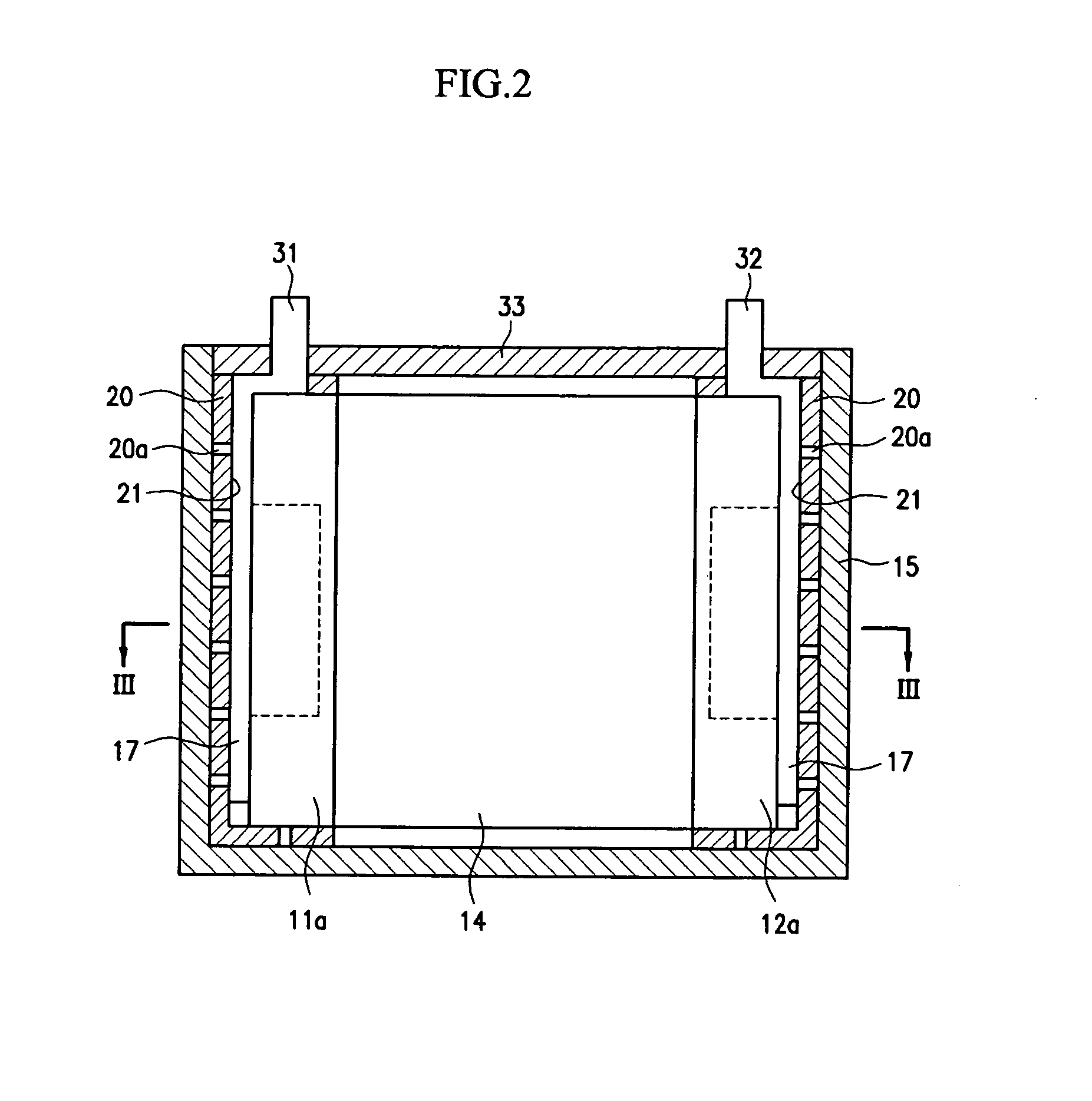

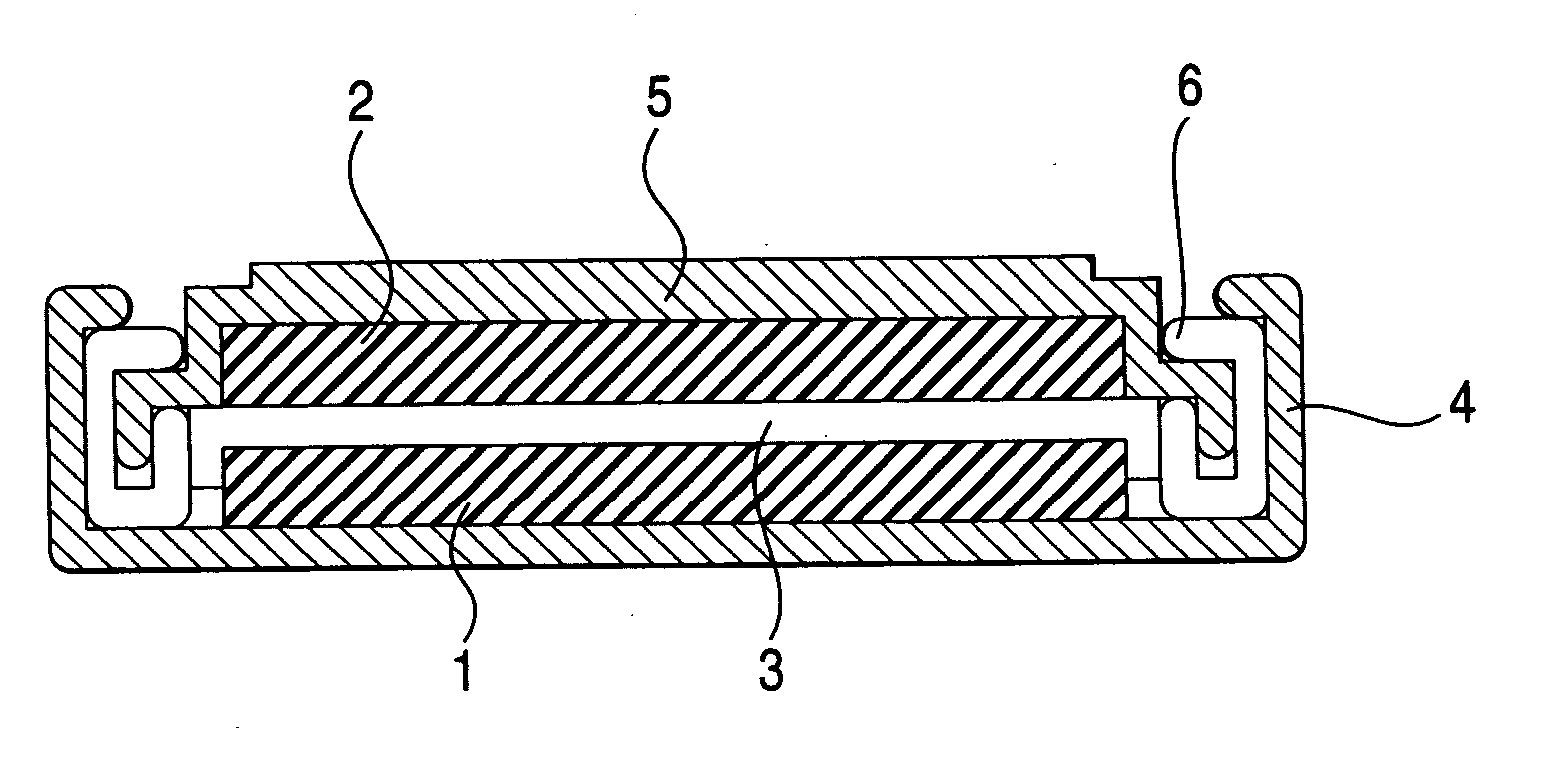

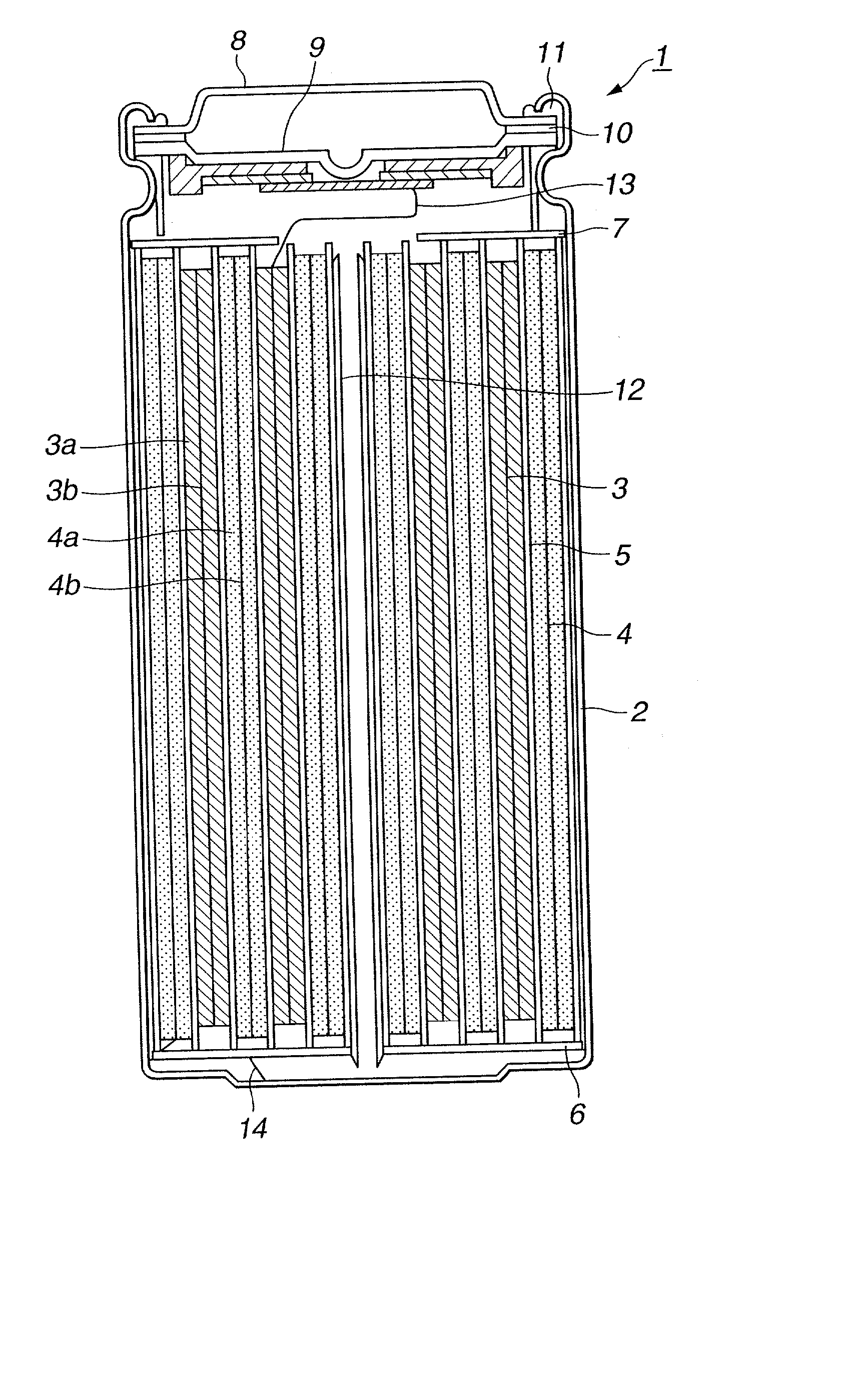

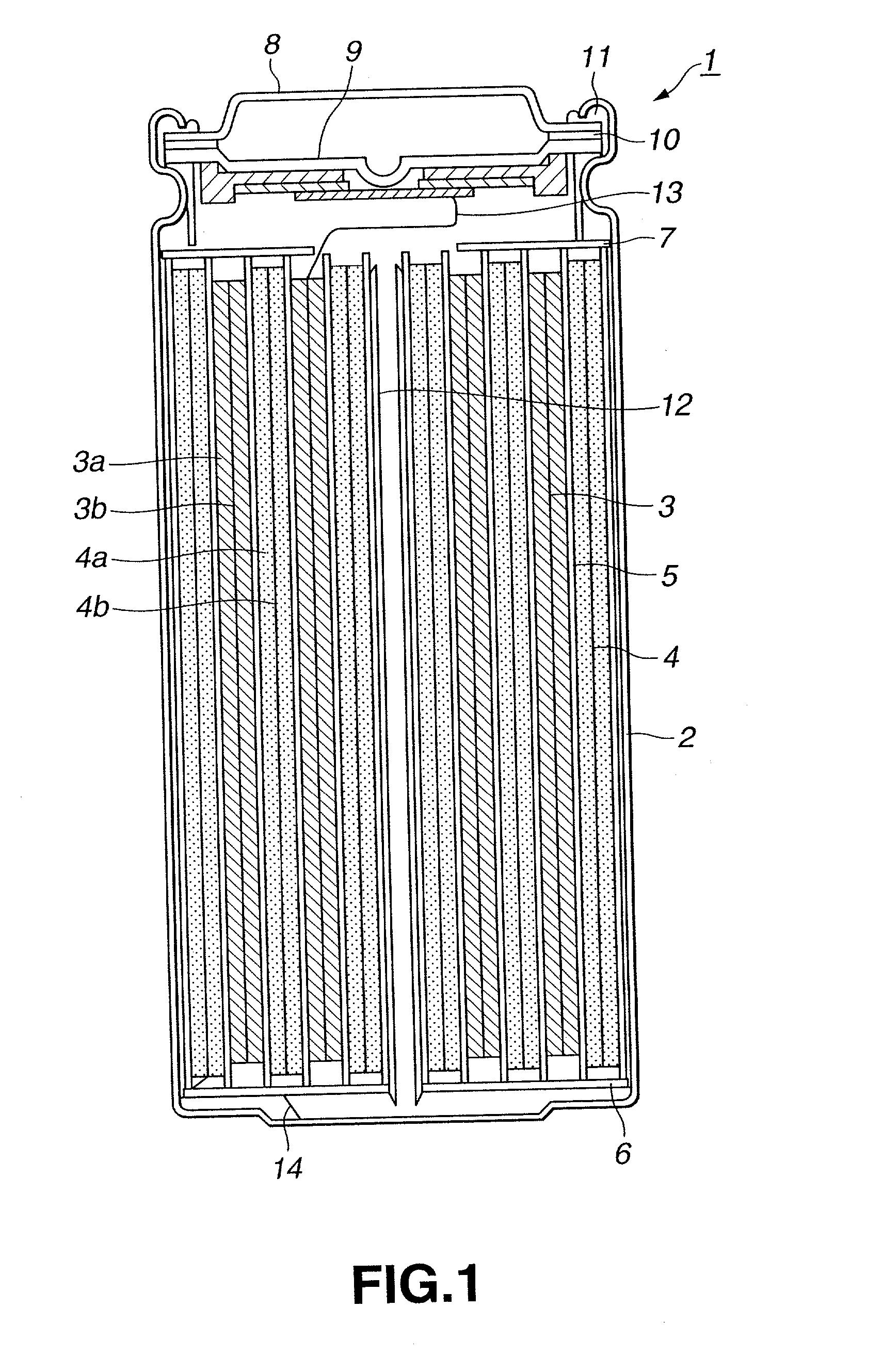

Secondary battery

ActiveUS20060024578A1Reduced durabilityIncreased durabilityCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrical and Electronics engineeringElectrode

A secondary battery comprising an electrode assembly having a positive electrode plate, a negative electrode plate, and a separator between the positive and negative electrodes is provided. The secondary battery further comprises a case for containing the electrode assembly, and a cap assembly connected to the case. The cap assembly comprises positive and negative terminals electrically connected to the positive electrode plate and the negative electrode plate, respectively. Lead connectors are electrically connected to the positive and negative electrode plates and the positive and negative terminals. A support is connected to each end of the electrode assembly and surrounds the lead connectors. The supports are adapted to fit between the electrode assembly and the case.

Owner:SAMSUNG SDI CO LTD

Electrochemical methods, devices, and structures

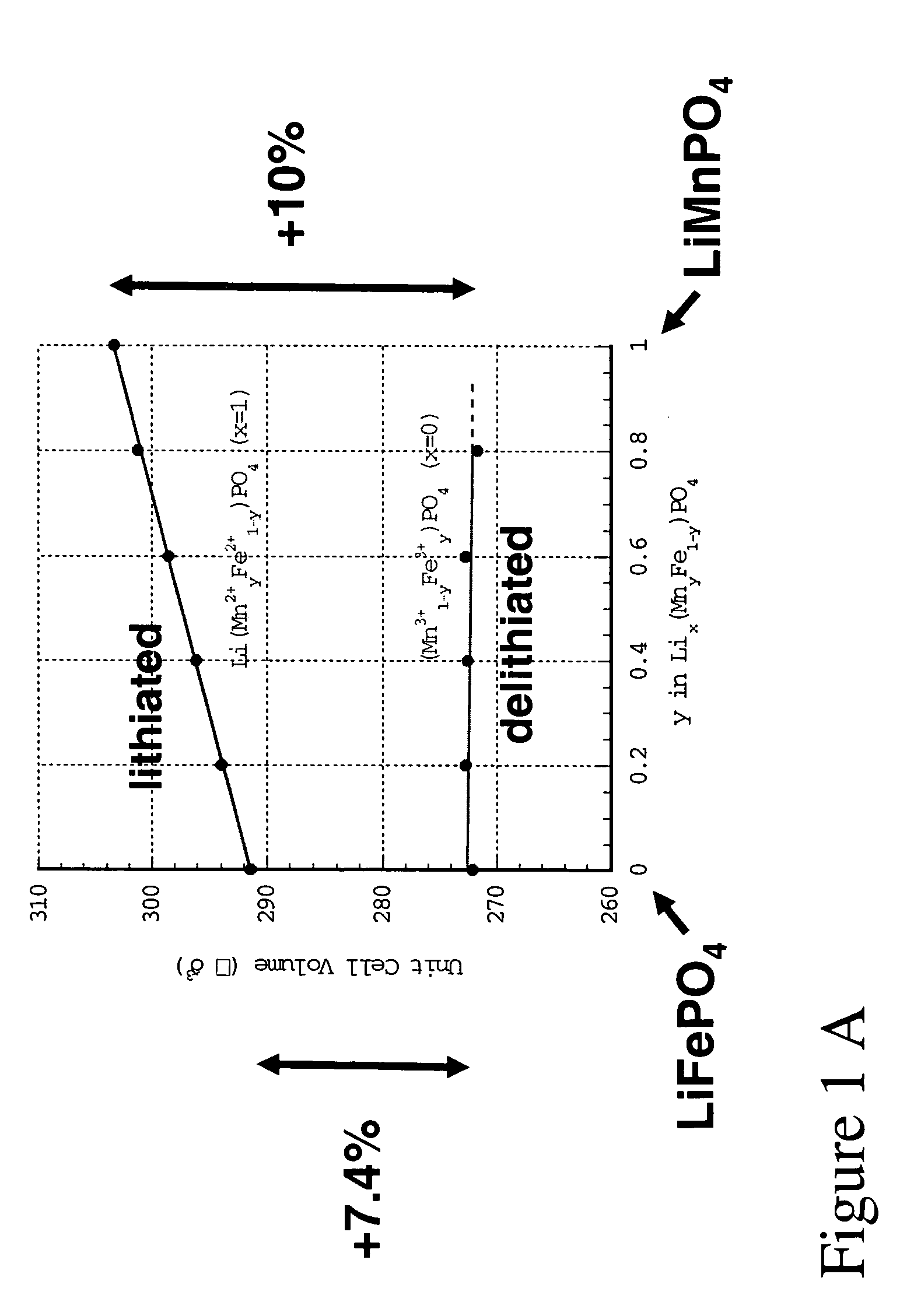

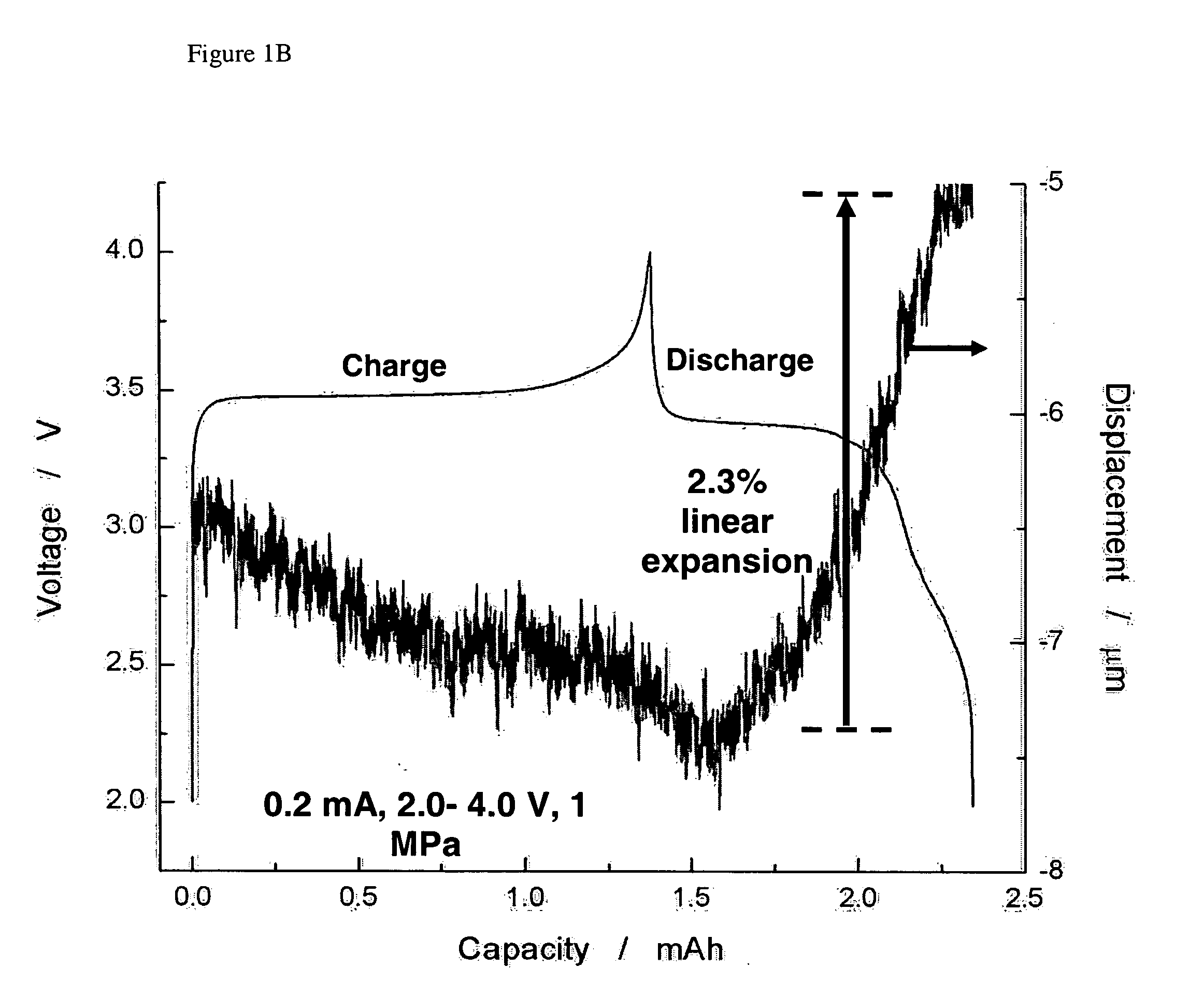

ActiveUS20060102455A1Increase strainDeferred-action cellsCell seperators/membranes/diaphragms/spacersInorganic compoundElectrochemistry

The present invention provides devices and structures and methods of use thereof in electrochemical actuation. This invention provides electrochemical actuators, which are based, inter-alia, on an electric field-driven intercalation or alloying of high-modulus inorganic compounds, which can produce large and reversible volume changes, providing high actuation energy density, high actuation authority and large free strain.

Owner:MASSACHUSETTS INST OF TECH

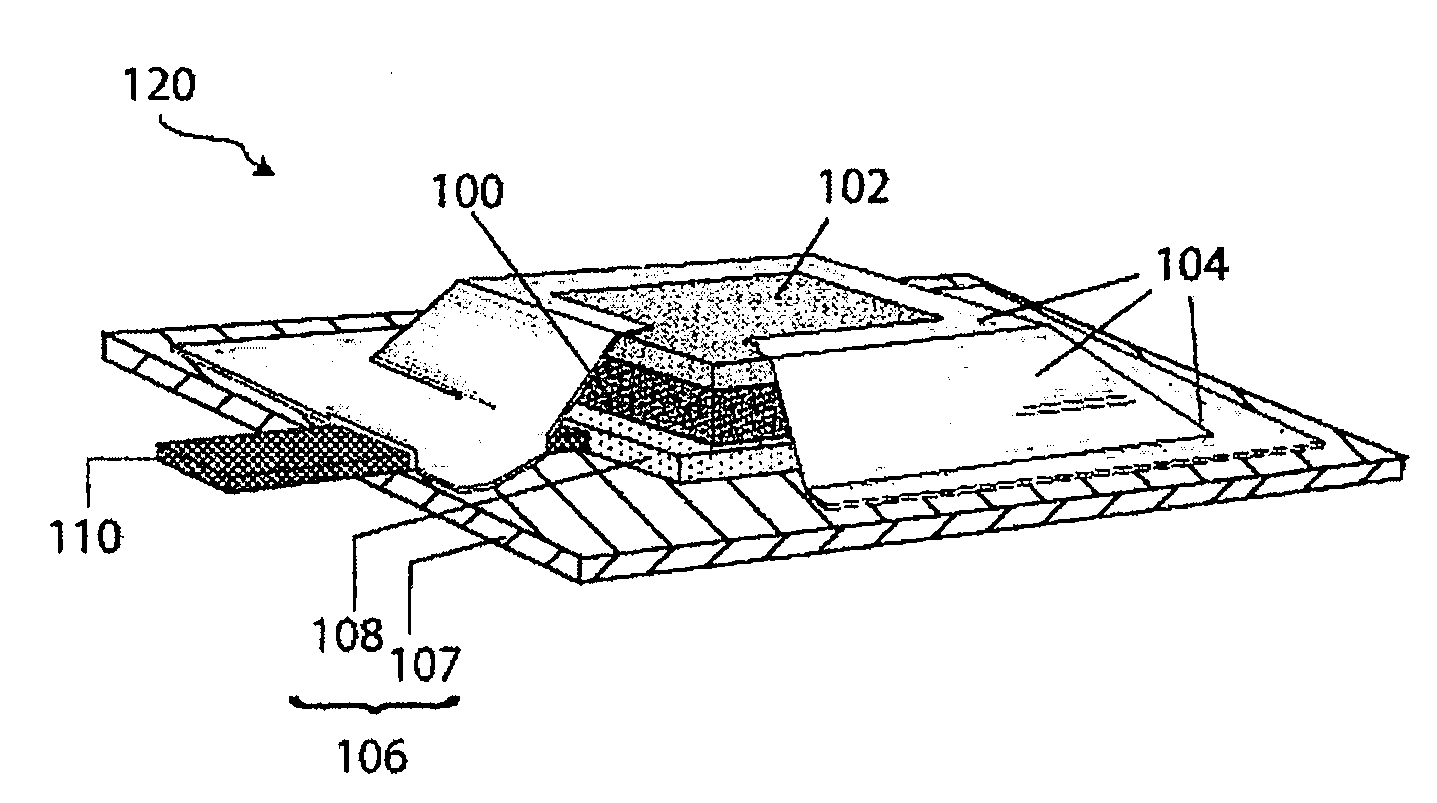

Compliant seal structures for protected active metal anodes

ActiveUS20100112454A1Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

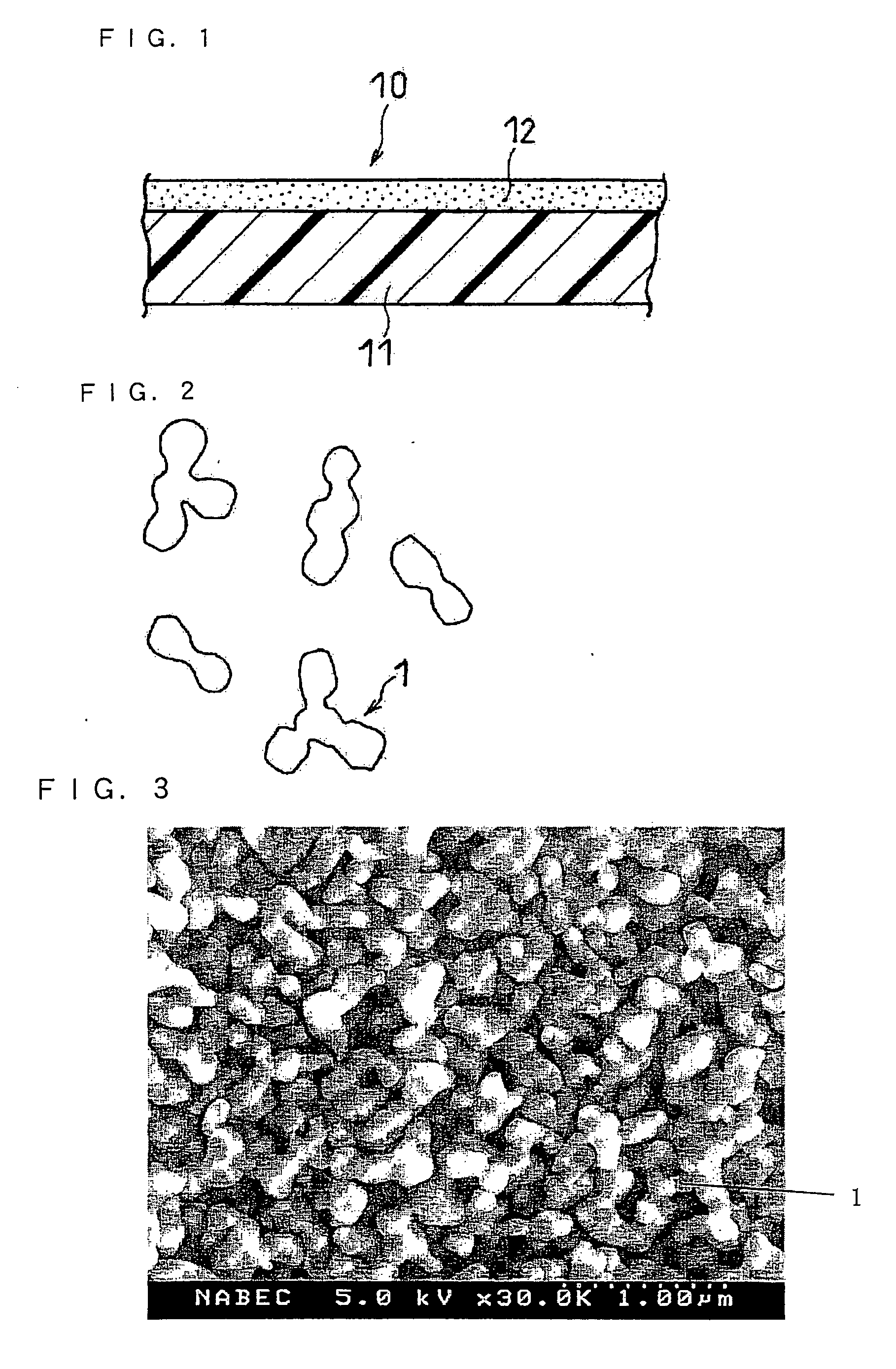

Separator for nonaqueous electrolyte batteries, nonaqueous electrolyte battery using it, and method for manufacturing separator for nonaqueous electrolyte batteries

InactiveUS6511774B1High tear strengthEnhanced penetration strengthNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersHigh energyEngineering

The present invention provides a separator for non-aqueous electrolyte batteries which neither breaks nor slips off at the time of fabrication of battery, gives excellent battery fabricability, causes no internal short-circuit caused by contact between electrodes even if the electrodes are externally short-circuited, can inhibit ignition of battery and produces high energy density and excellent cycle life, and further provides a non-aqueous electrolyte battery using the separator and a method for manufacturing the separator. That is, the present invention relates to a separator for non-aqueous electrolyte batteries which comprises a porous base containing at least one member selected from a porous film, a woven fabric or nonwoven fabric containing an organic fiber and a paper and an organometallic compound applied to the porous base; a method for the manufacture of the separator for non-aqueous electrolyte batteries which comprises allowing said porous base to contact with a solution of organometallic compound by impregnation, coating or spraying, followed by drying or curing with heating to apply the organometallic compound to the porous base; and a non-aqueous electrolyte battery using the separator.

Owner:MITSUBISHI PAPER MILLS LTD

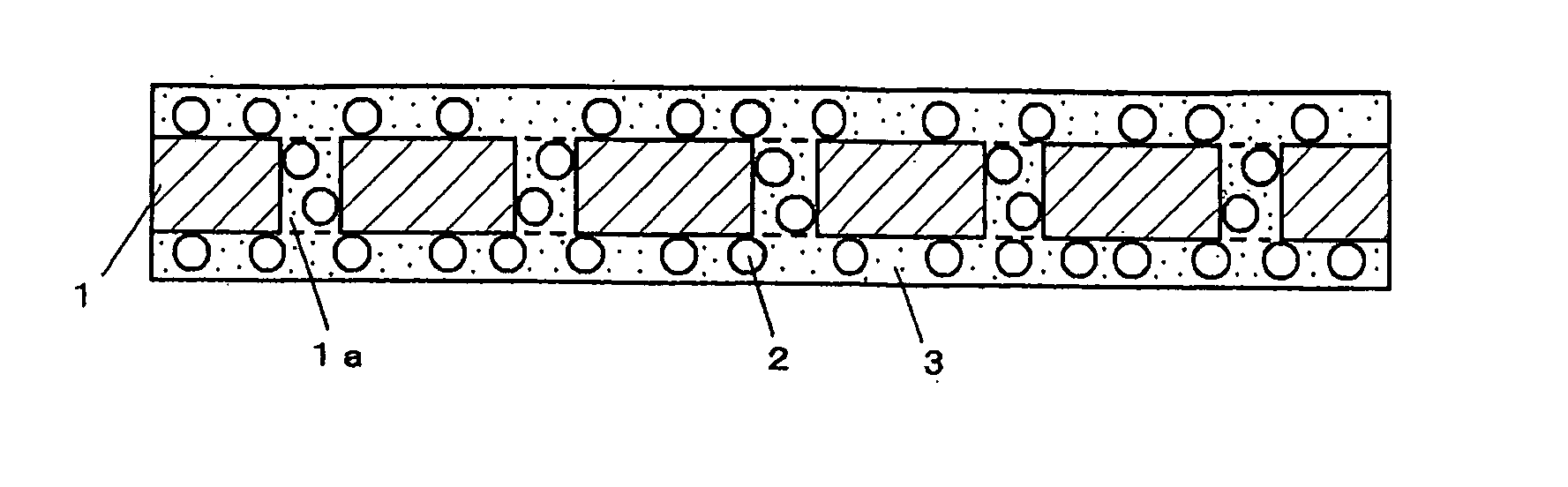

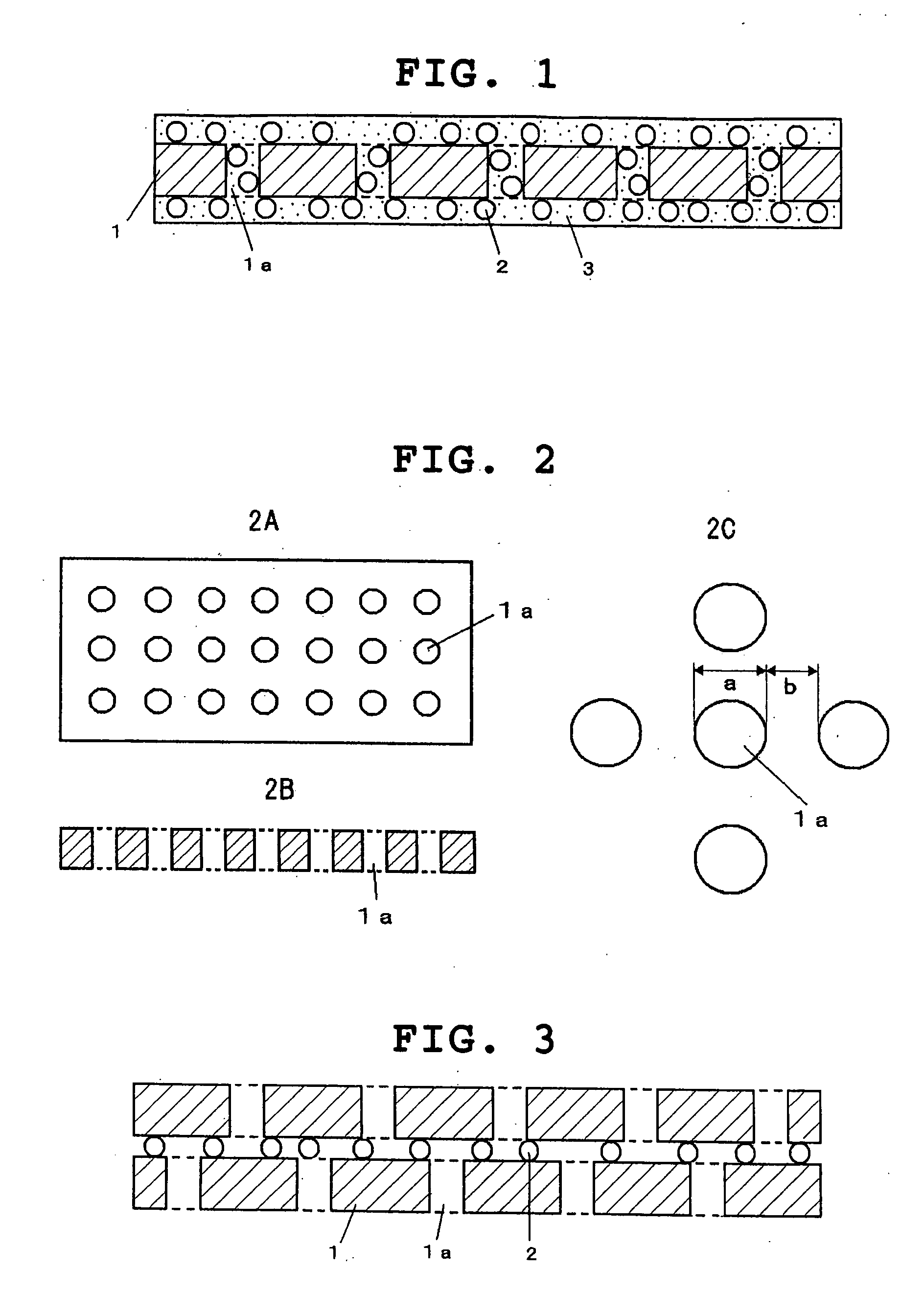

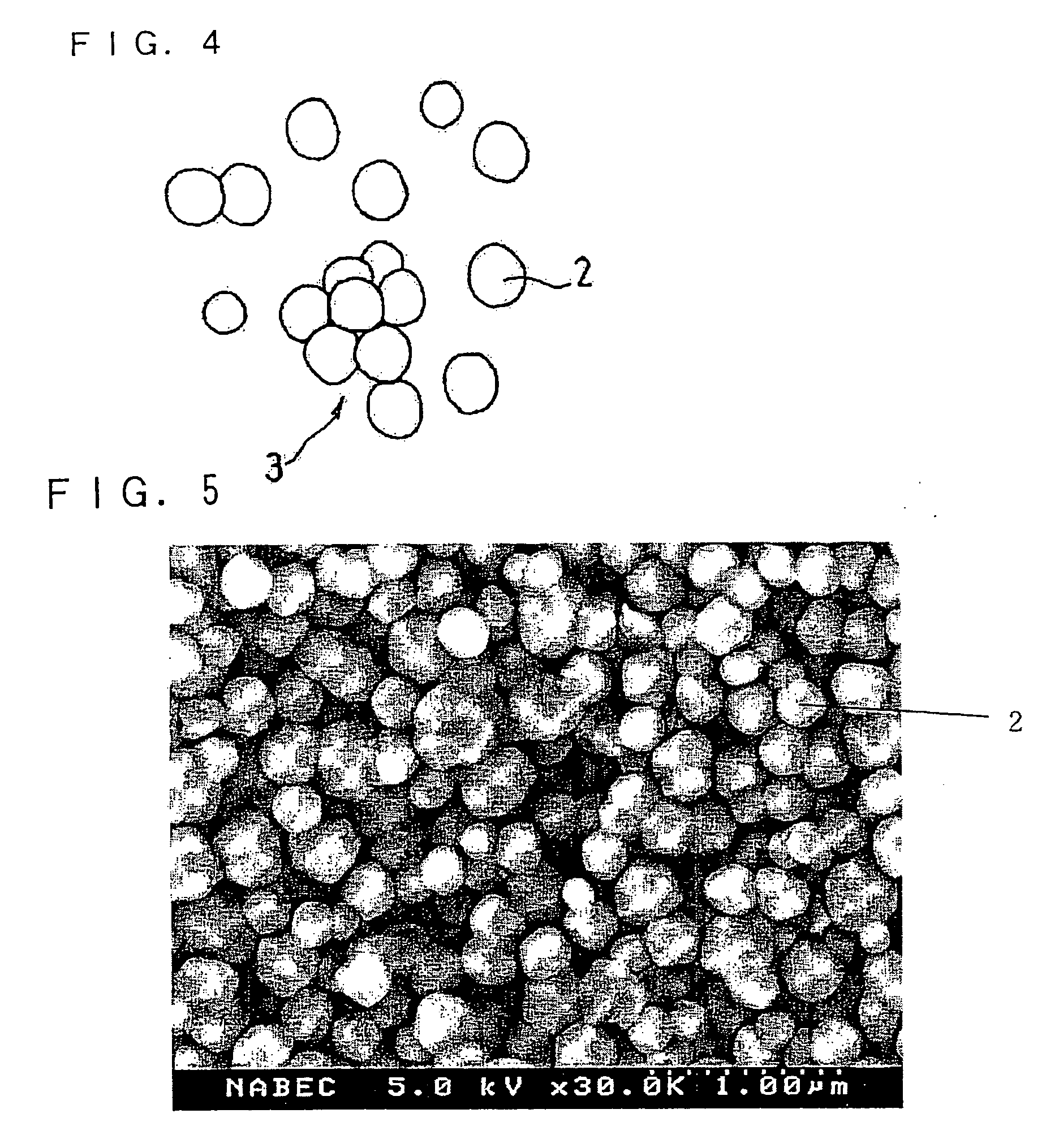

Electronic component separator and method for producing the same

InactiveUS20050208383A1Improve reliabilityImprove machinabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumElectronic component

The present invention provides a separator that, when used in a lithium ion secondary battery, polymer lithium secondary battery, aluminum electrolytic capacitor or electric double-layer capacitor, offers desired levels of various practical characteristics, undergoes minimal heat shrinkage even when overheated, and exhibits high reliability and excellent workability. The electronic component separator proposed by the present invention comprises a porous base made of a substance having a melting point of 180° C. or above, and a resin structure provided on at least one side of and / or inside the porous base, and the porous base and / or resin structure contains filler grains.

Owner:TOMOEGAWA PAPER CO LTD

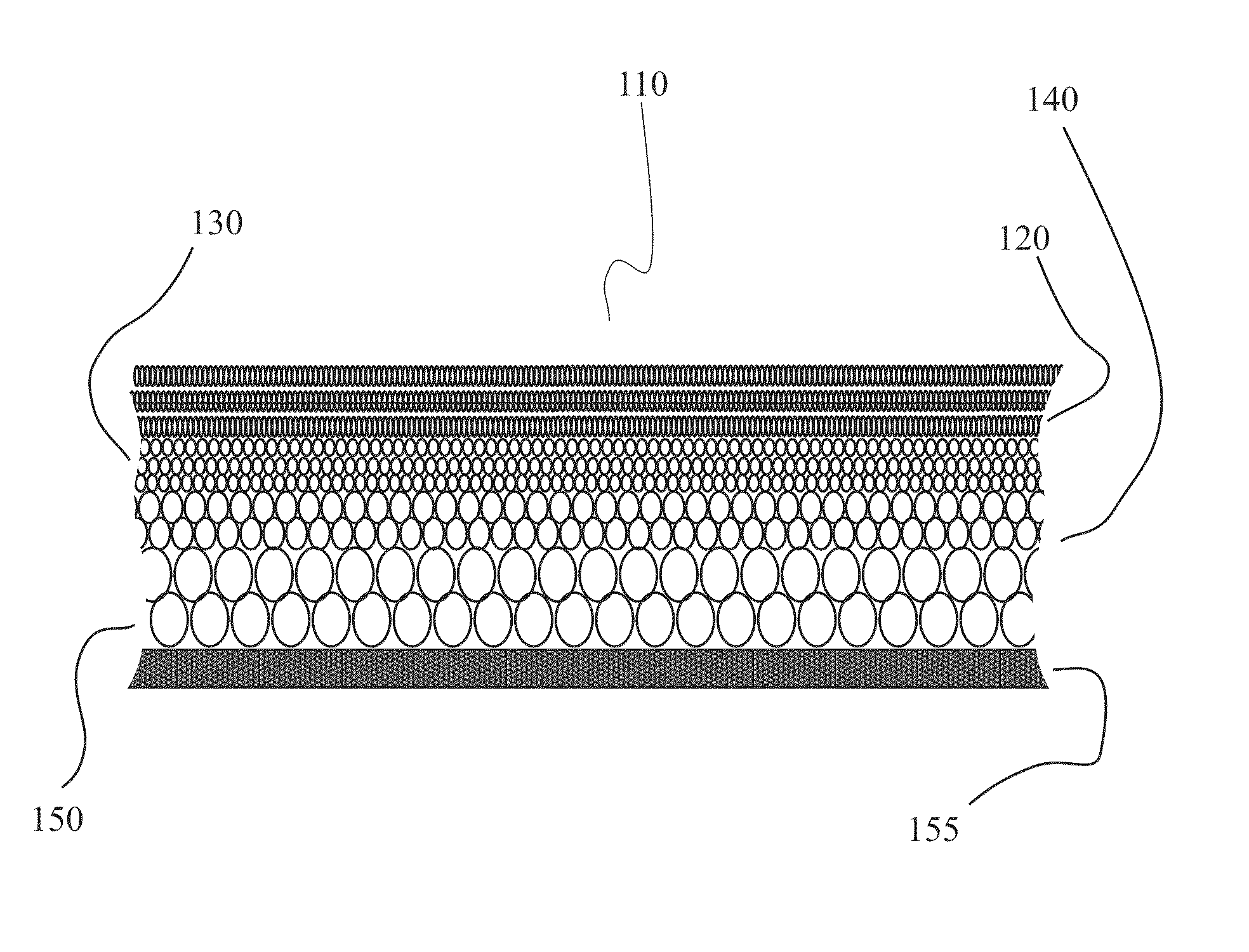

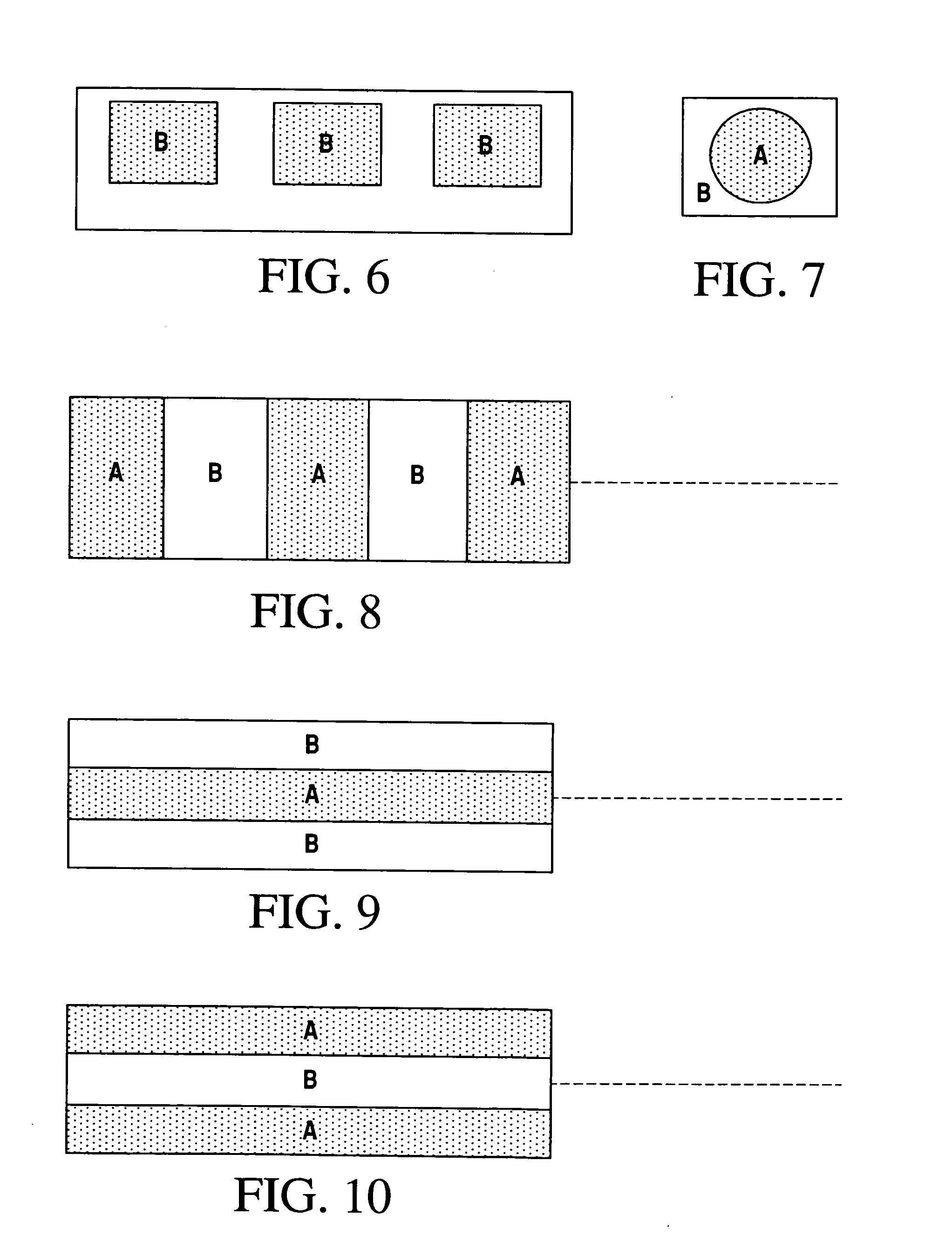

Organic/Inorganic Composite Separator Having Morphology Gradient, Manufacturing Method Thereof and Electrochemical Device Containing the Same

ActiveUS20080292968A1Improve featuresSolve Porosity InsufficiencyCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous substrateSurface layer

Disclosed is an organic / inorganic composite separator including: a porous substrate having pores; and a porous active layer containing a mixture of inorganic particles and a binder polymer with which at least one surface of the porous substrate is coated. The organic / inorganic composite separator of the present invention may be useful to enhance peeling and scratch resistances and improve a lamination characteristic by introducing a porous active layer onto a porous substrate having pores, the porous active layer having heterogeneity of morphology toward a thickness direction in which a content ratio of the binder polymer / inorganic particles present in a surface layer is higher than that of the binder polymer / inorganic particles present inside the surface layer. Accordingly, the stability and performances of a battery can be improved together since the detachment of inorganic particles from the porous active layer may be reduced during the assembly process of the electrochemical device.

Owner:TORAY BATTERY SEPARATOR FILM +1

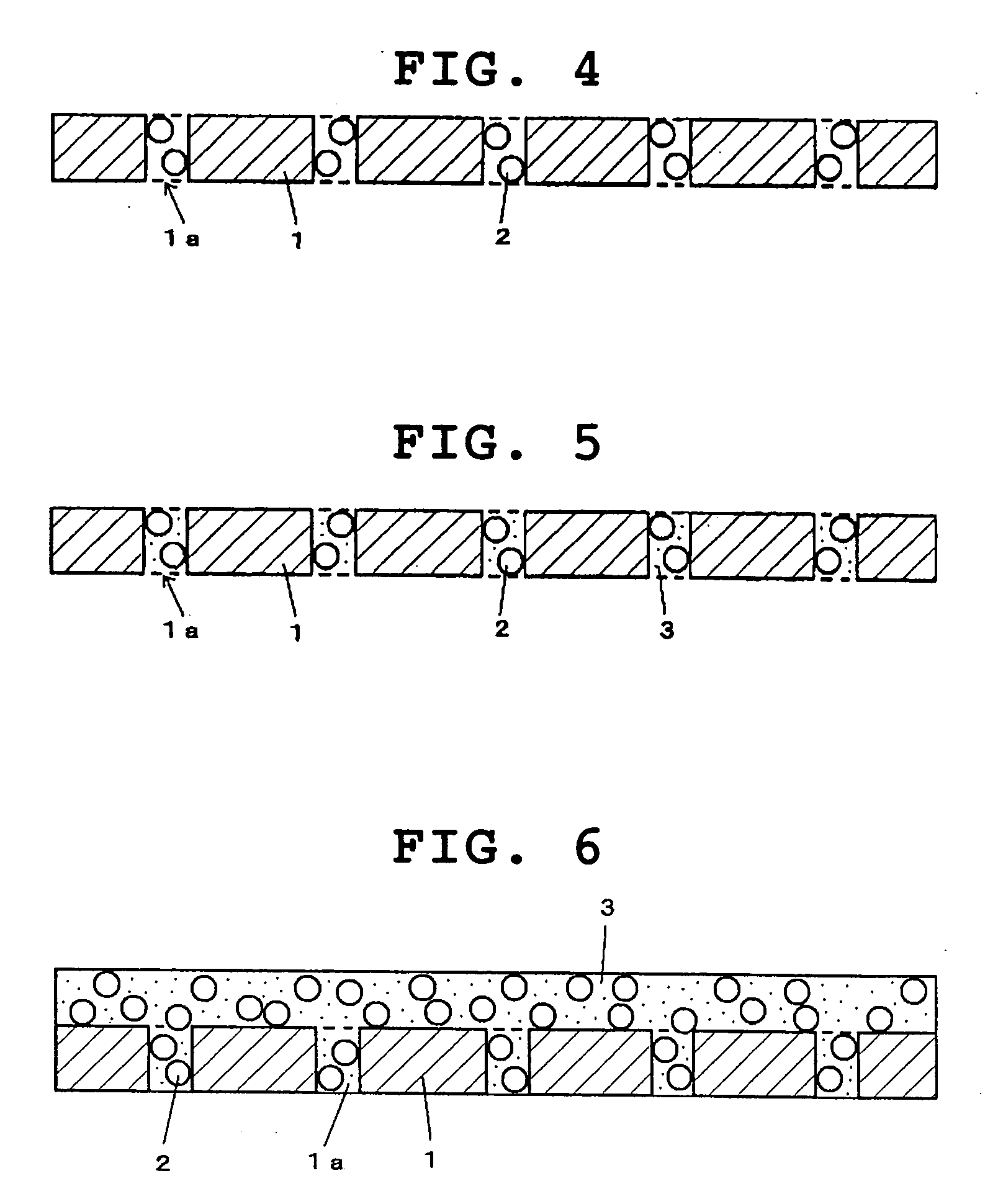

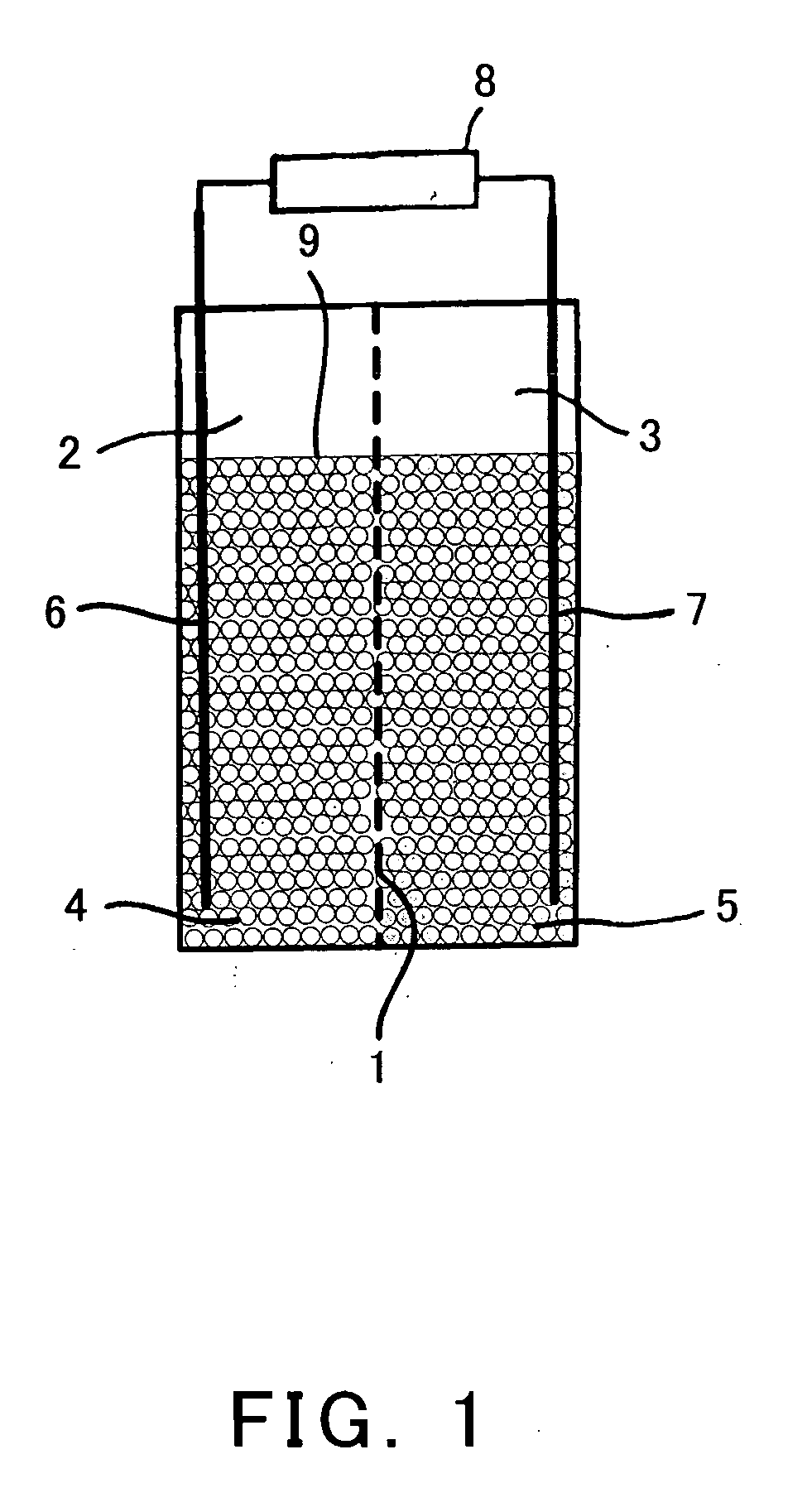

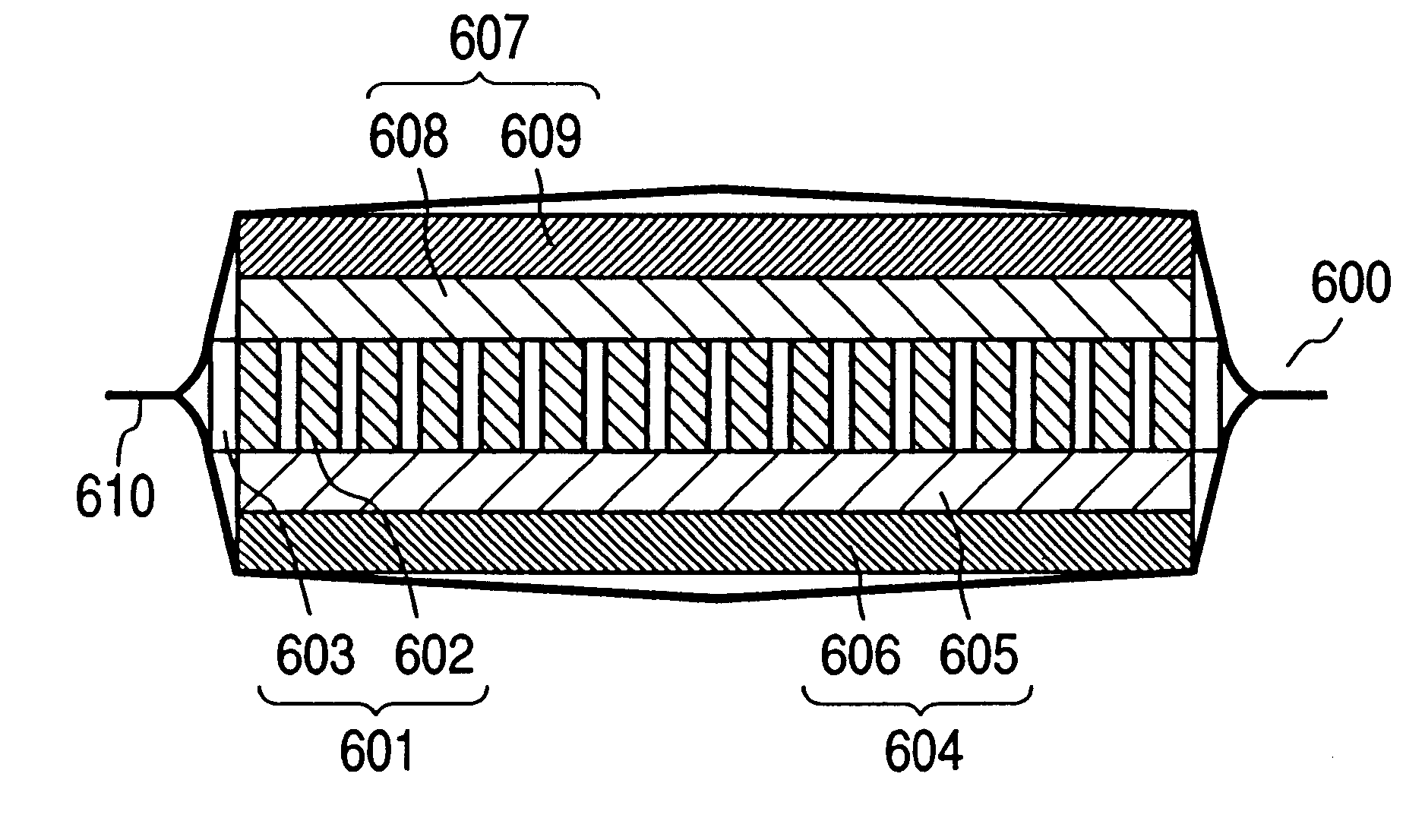

Three-dimensional cell and its electrode structure and method for manufacturing electrode material of three-dimensional cell

InactiveUS20040241540A1Easy to specifyEasy to getCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesEngineeringElectrode material

When producing an electrode for use in a three-dimensional battery, an active material is combined with at least one of a separator, a dividing wall, and a current collector for simultaneous formation. Both the dividing wall and the current collector are planar or are so formed as to have projected portions in needle, plate, wave, particle, or the like form. Both the dividing wall and the current collector may be provided with a cooling structure. As an additional current collector, an ion permeable current collector, which has voids therein, permits passage of ions, and exhibits electrical conductive properties, is provided.

Owner:KAWASAKI HEAVY IND LTD +1

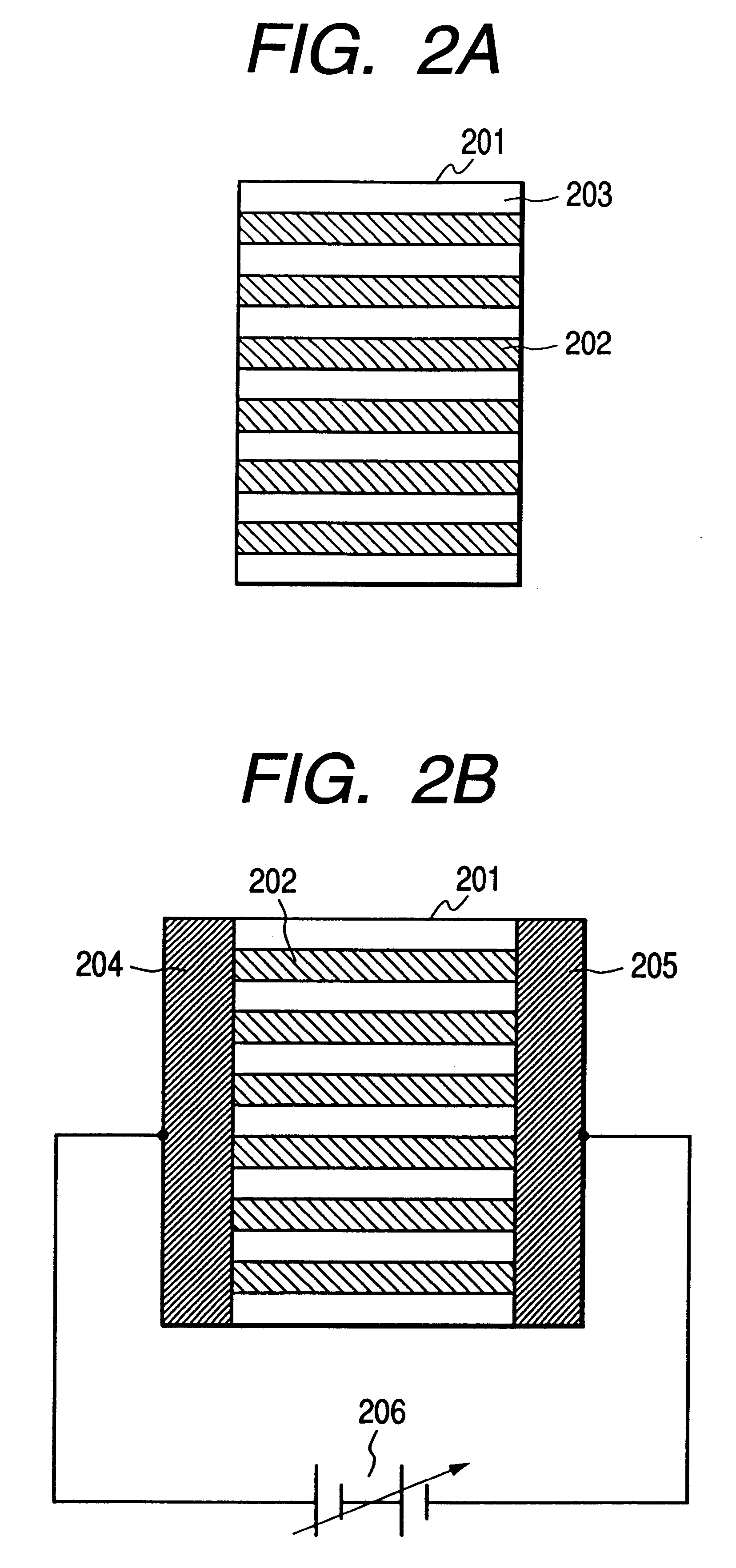

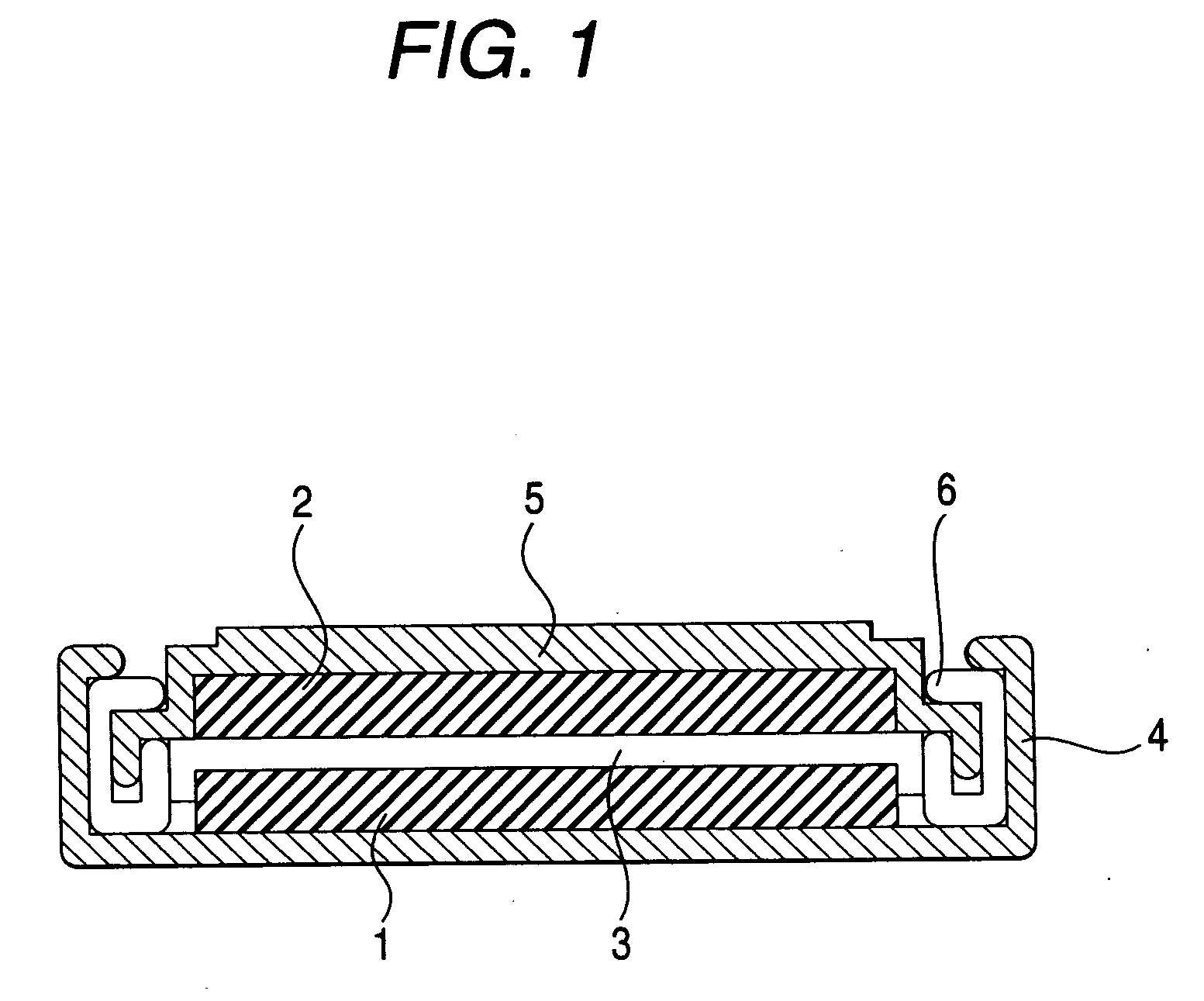

Secondary battery having an ion conductive member and manufacturing process thereof

InactiveUS6372387B1Cell seperators/membranes/diaphragms/spacersOrganic electrolyte cellsEngineeringIon channel

Owner:CANON KK

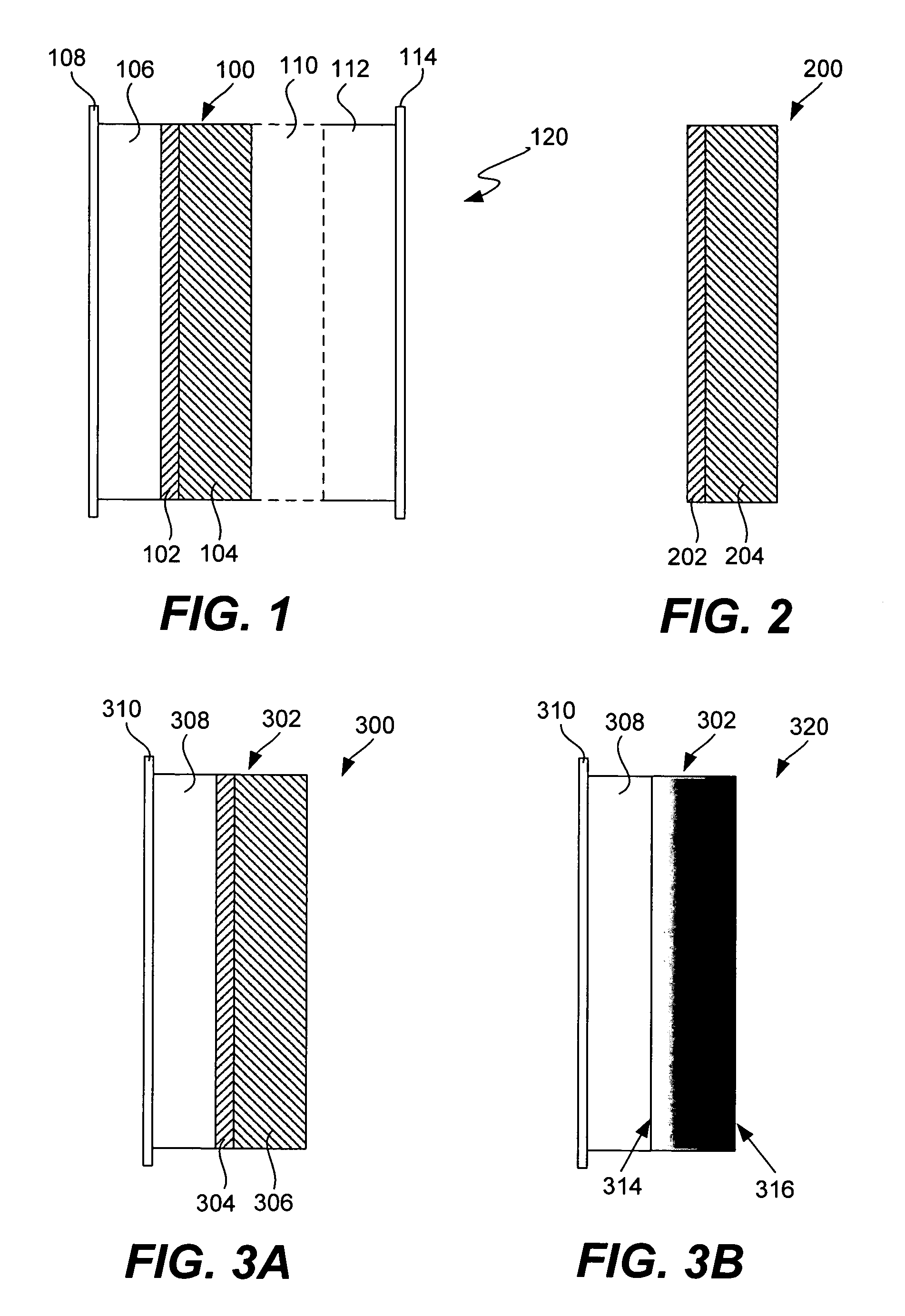

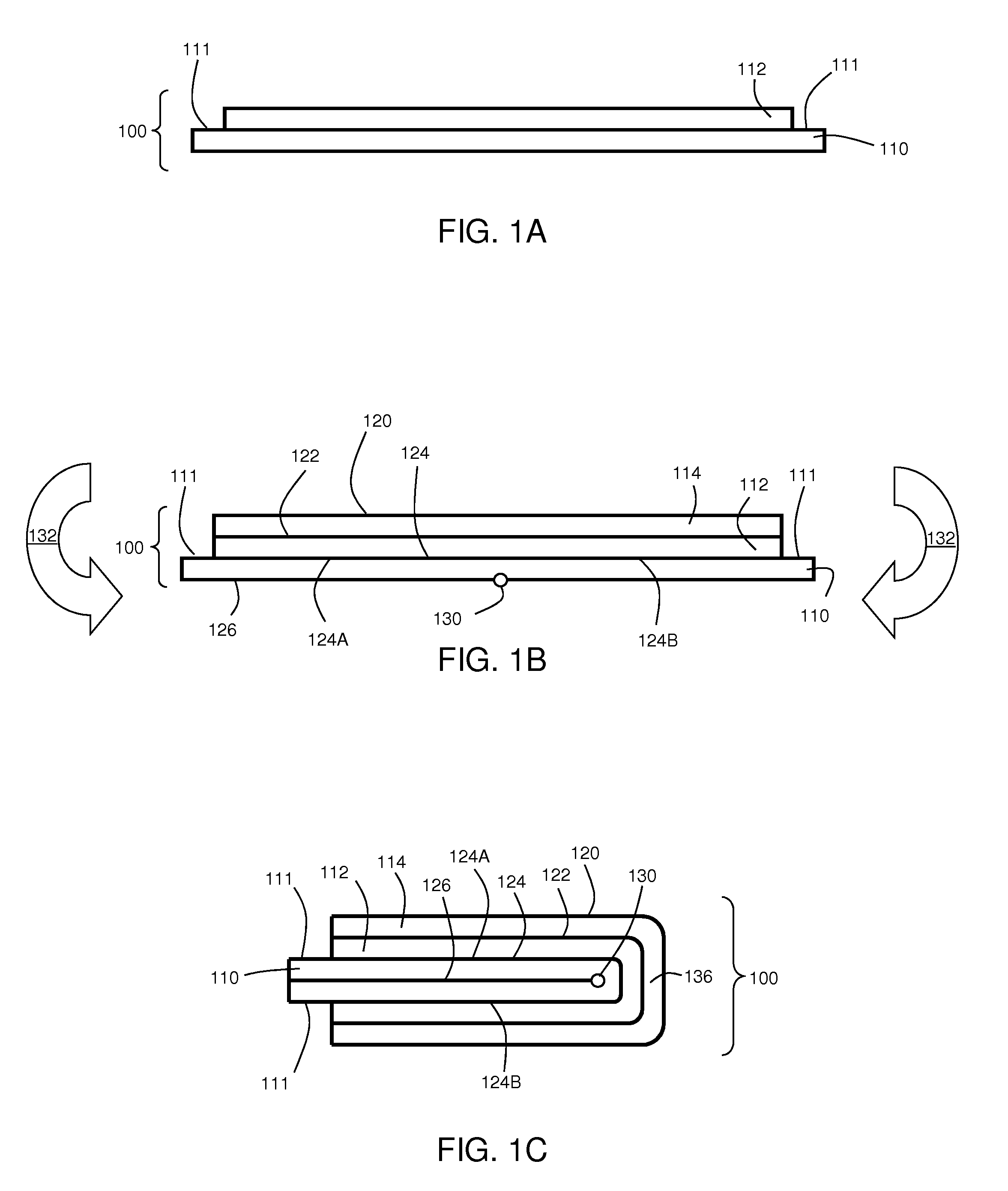

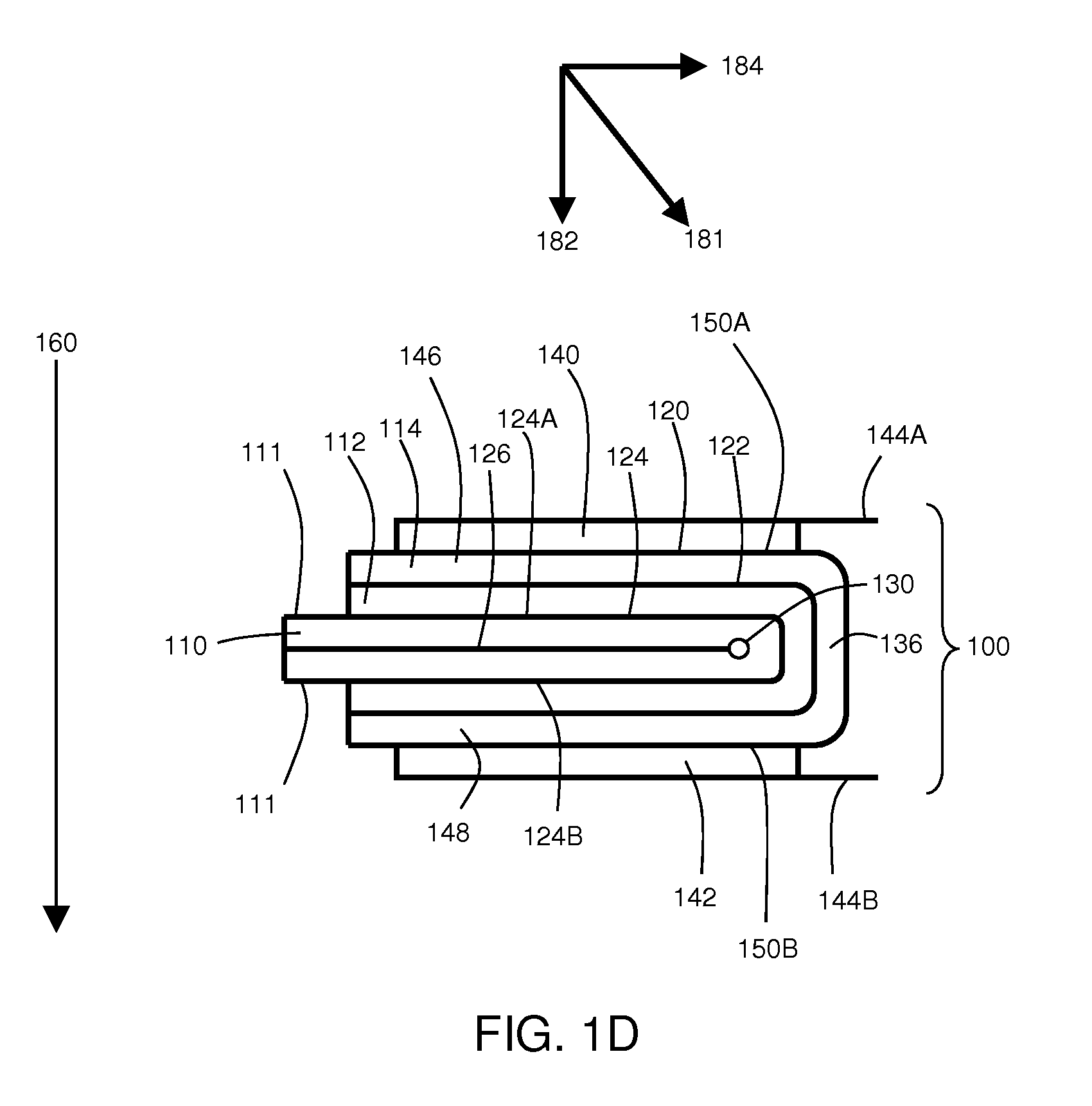

Electrically non-conductive materials for electrochemical cells

Articles, systems, and methods related to the configuration of electrically non-conductive materials and related components in electrochemical cells are generally described. Some inventive electrochemical cell configurations include an electrically non-conductive material (e.g., as part of the electrolyte) that is configured to wrap around the edge of an electrode to prevent short circuiting of the electrochemical cell. In some embodiments, the electrically non-conductive material layer can be arranged such that it includes first and second portions (one on either side of an electrode) as well as a third portion adjacent the edge of the electrode that directly connects (and, in some cases, is substantially continuous with) the first and second portions. The electrically non-conductive material layer can be relatively thin while maintaining relatively high electrical insulation between the anode and the cathode, allowing one to produce an electrochemical cell with a relatively low mass and / or volume. The arrangements described above can be formed, for example, by forming a multi-layer structure comprising an electrode and an electrically non-conductive material layer (e.g., as a coating), and folding the multi-layer structure such that the electrically non-conductive material covers the convex surface portion of the resulting crease.

Owner:SION POWER CORP

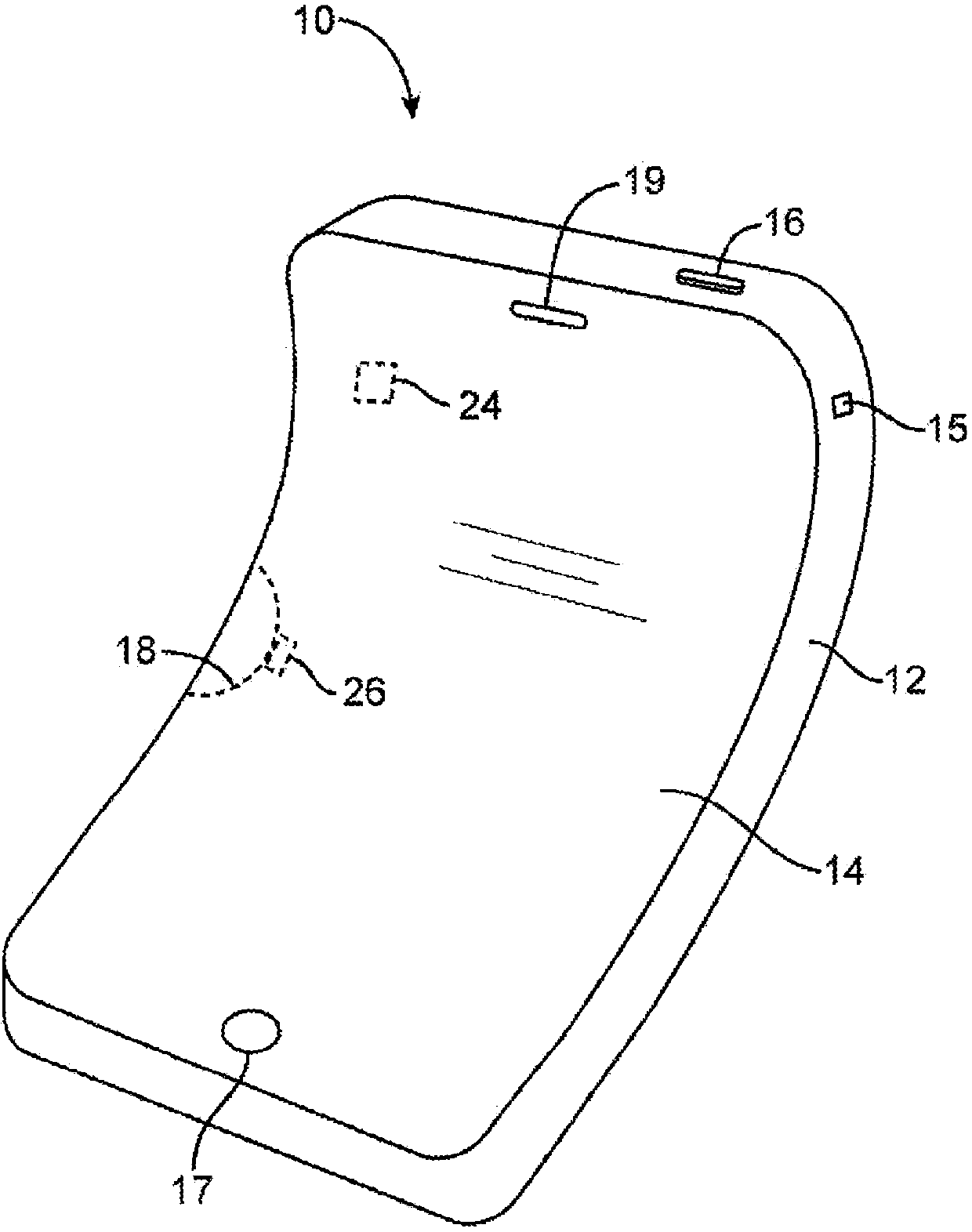

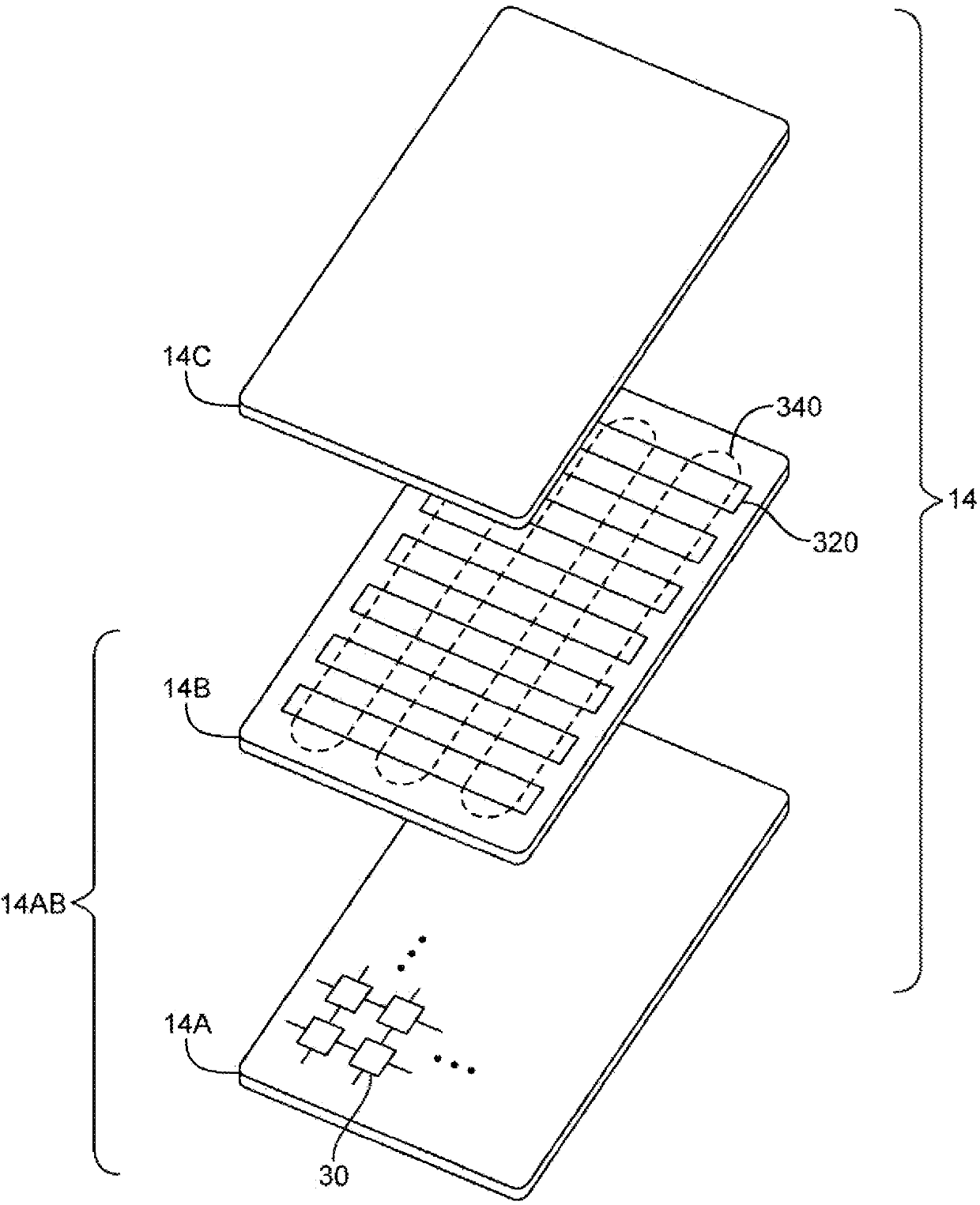

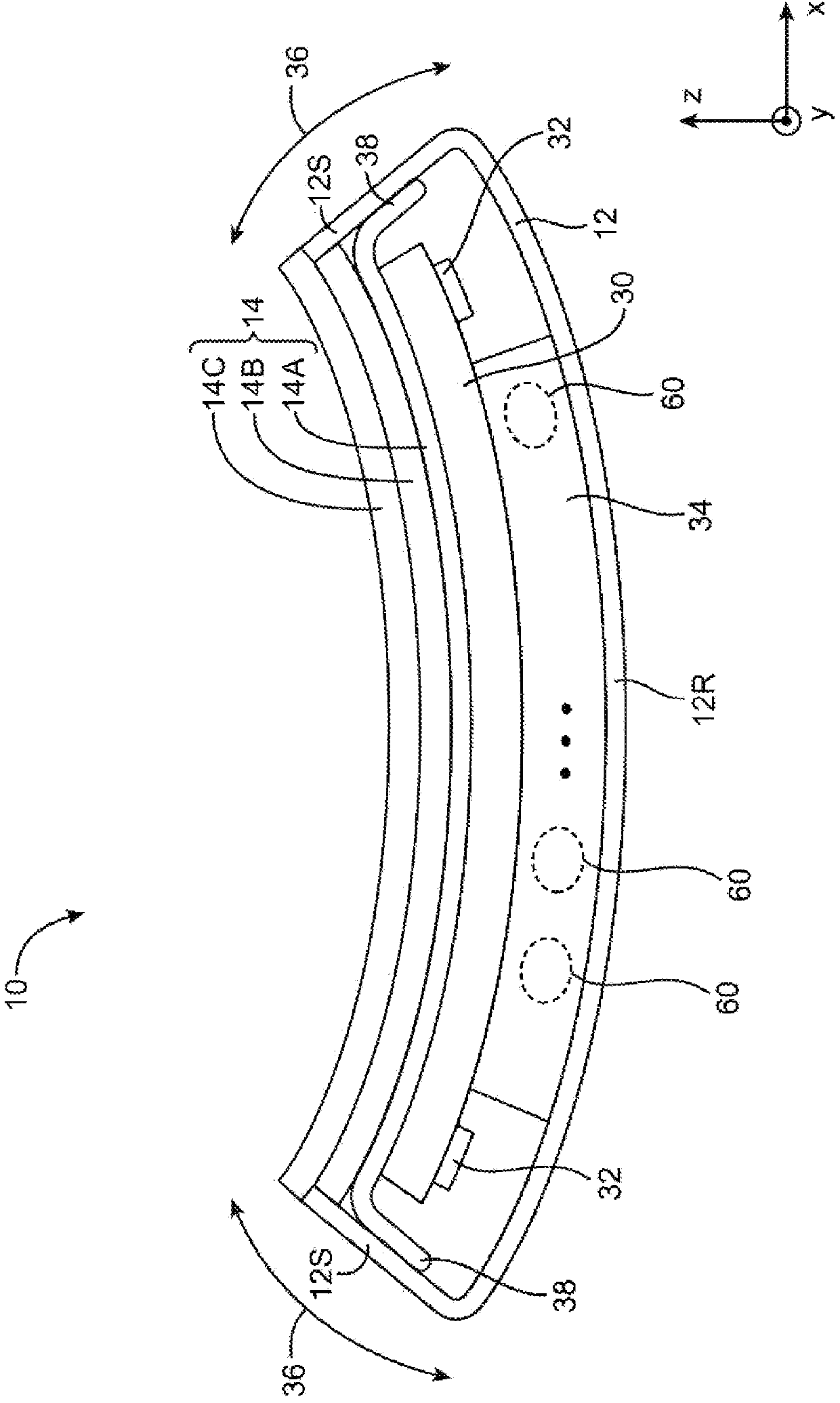

Flexible electronic devices

ActiveCN103827771ACell seperators/membranes/diaphragms/spacersStatic indicating devicesDisplay deviceEngineering

Flexible electronic devices may be provided. A flexible electronic device may include a flexible display, a flexible housing and one or more flexible internal components configured to allow the flexible electronic device to be deformed. Flexible displays may include flexible display layers, flexible touch-sensitive layers, and flexible display cover layers. The flexible housing may be a multi-stable flexible housing having one or more stable positions. The flexible housing may include a configurable support structure that, when engaged, provides a rigid support structure for the flexible housing. The flexible internal components may include flexible batteries, flexible printed circuits or other flexible components. A flexible battery may include flexible and rigid portions or may include a lubricious separator layer that provides flexibility for the flexible battery. A flexible printed circuit may include flexible and rigid portions or openings that allow some rigid portions to flex with respect to other rigid portions.

Owner:APPLE INC

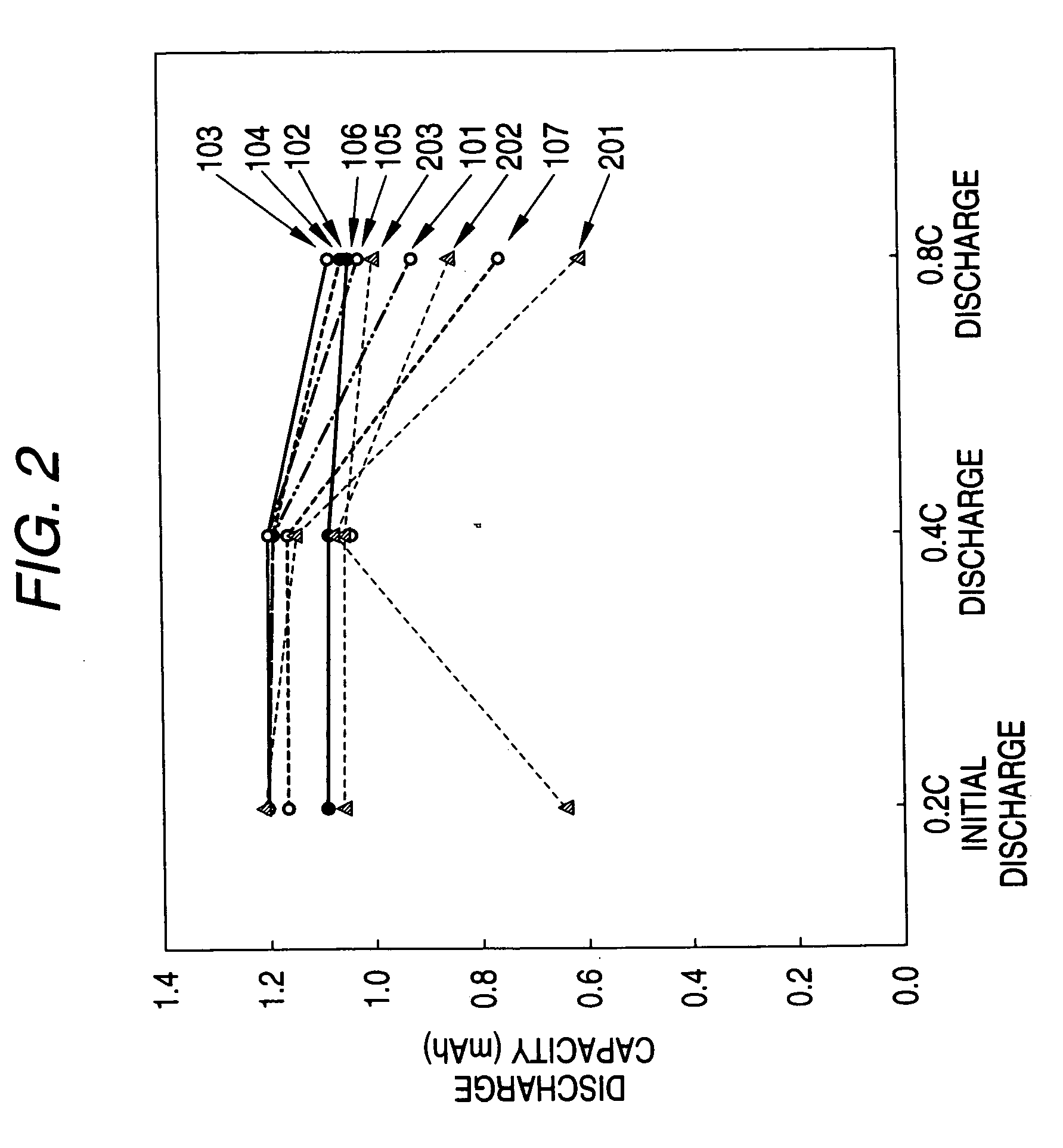

Non-aqueous electrolyte battery

InactiveUS20060068282A1Improve output performanceImprove cycle performanceNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersMolten saltNon aqueous electrolytes

A non-aqueous electrolyte battery that contains a molten salt electrolyte and has the enhanced output performances and cycle performances can be provided. The electrolyte has a molar ratio of lithium salt to molten salt of from 0.3 to 0.5, and the non-aqueous electrolyte battery has a positive electrode having a discharge capacity of 1.05 or more times that of a negative electrode thereof.

Owner:KK TOSHIBA

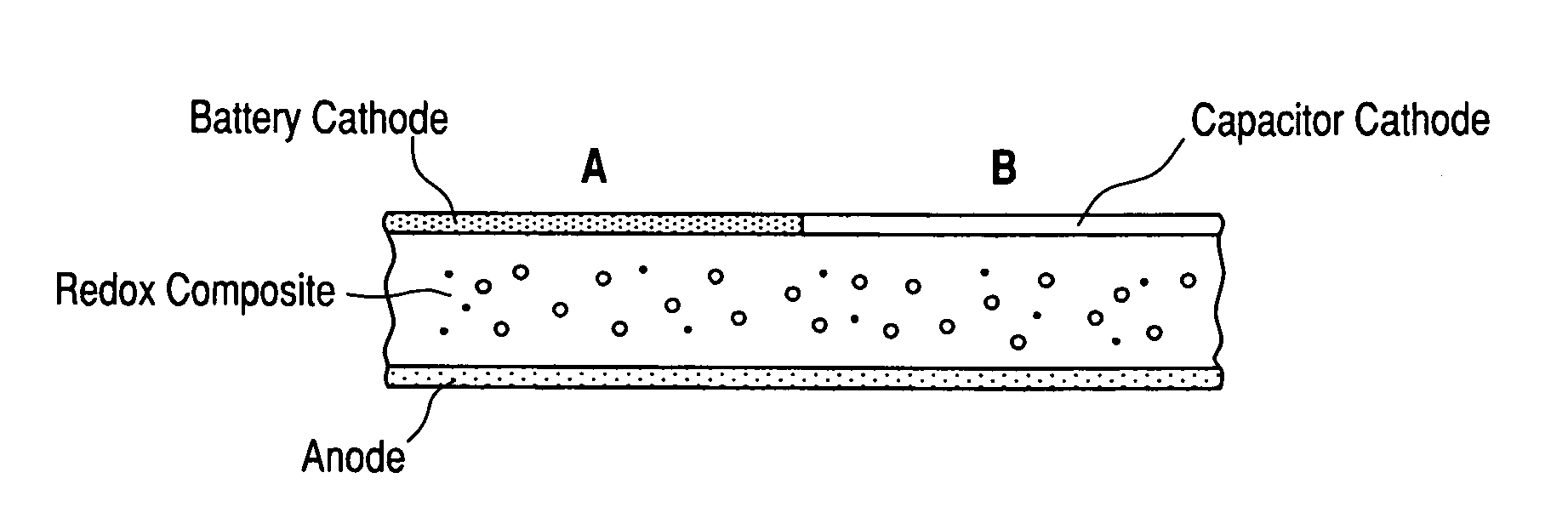

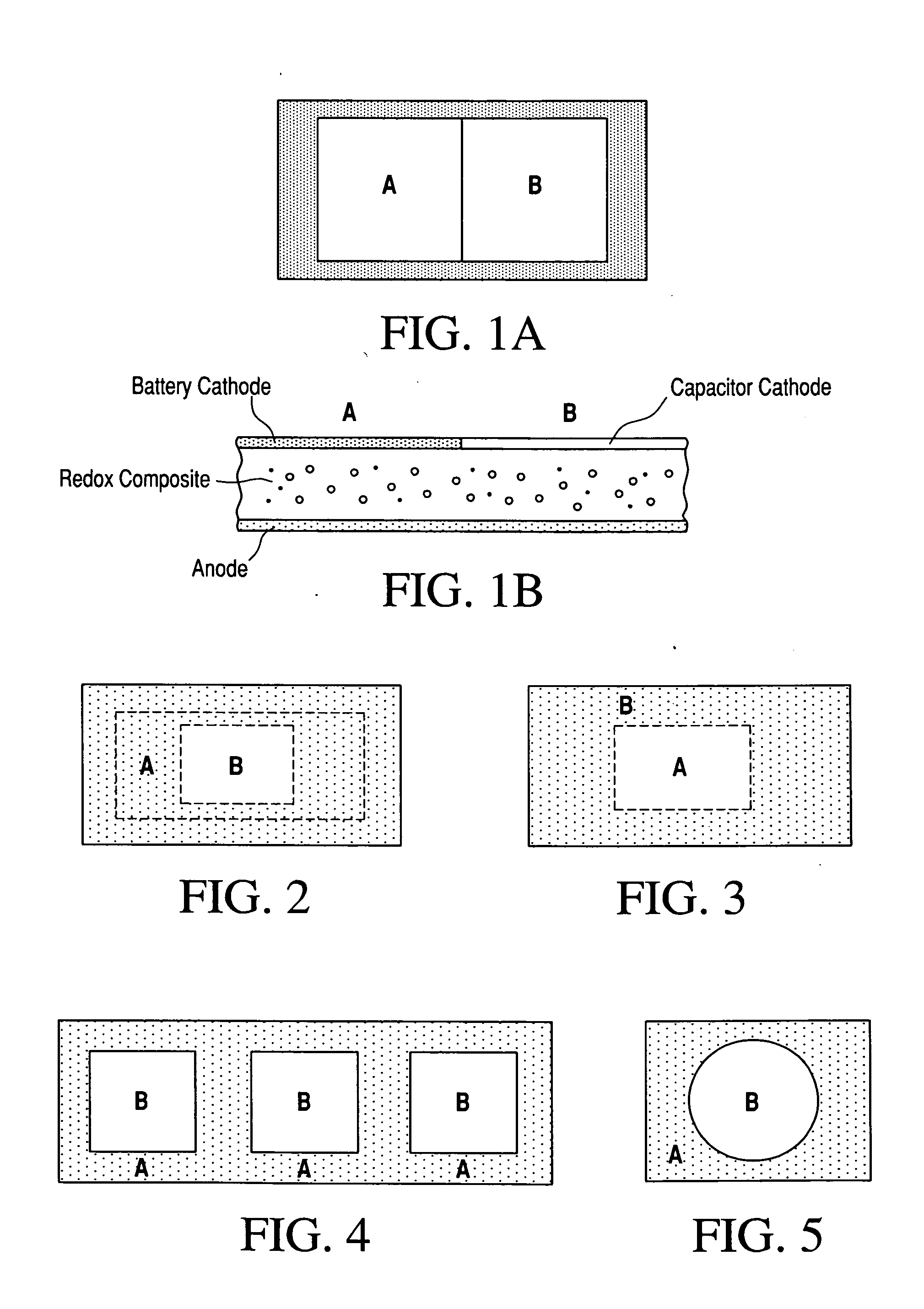

Composite ionic conducting electrolytes

InactiveUS20130026409A1High operating requirementsOptimize volumeFuel and primary cellsHybrid capacitor electrolytesComposite electrolyteConductive polymer

Ionically conducting, redox active additive composite electrolytes are disclosed. The electrolytes include an ionically conductive component and a redox active additive. The ionically conductive component may be an ionically conductive material such as an ionically conductive polymer, ionically conducting glass-ceramic, ionically conductive ceramic, and mixtures thereof. Electrical energy storage devices that employ the ionically conducting, redox active additive composite electrolytes also are disclosed

Owner:RECAPPING +1

Electrochemical device using multicomponent composite membrane film

InactiveUS7014948B2Easy to manufactureImprove adhesionMembranesSemi-permeable membranesPolymer scienceElectrochemistry

The present invention provides a electrochemical element, wherein a multi-component composite film comprising a) polymer support layer film and b) a porous gellable polymer layer which is formed on either or both sides of the support layer film of a), wherein the support layer film of a) and the gellable polymer layer of b) are unified with each other without an interface between them.

Owner:TORAY BATTERY SEPARATOR FILM +1

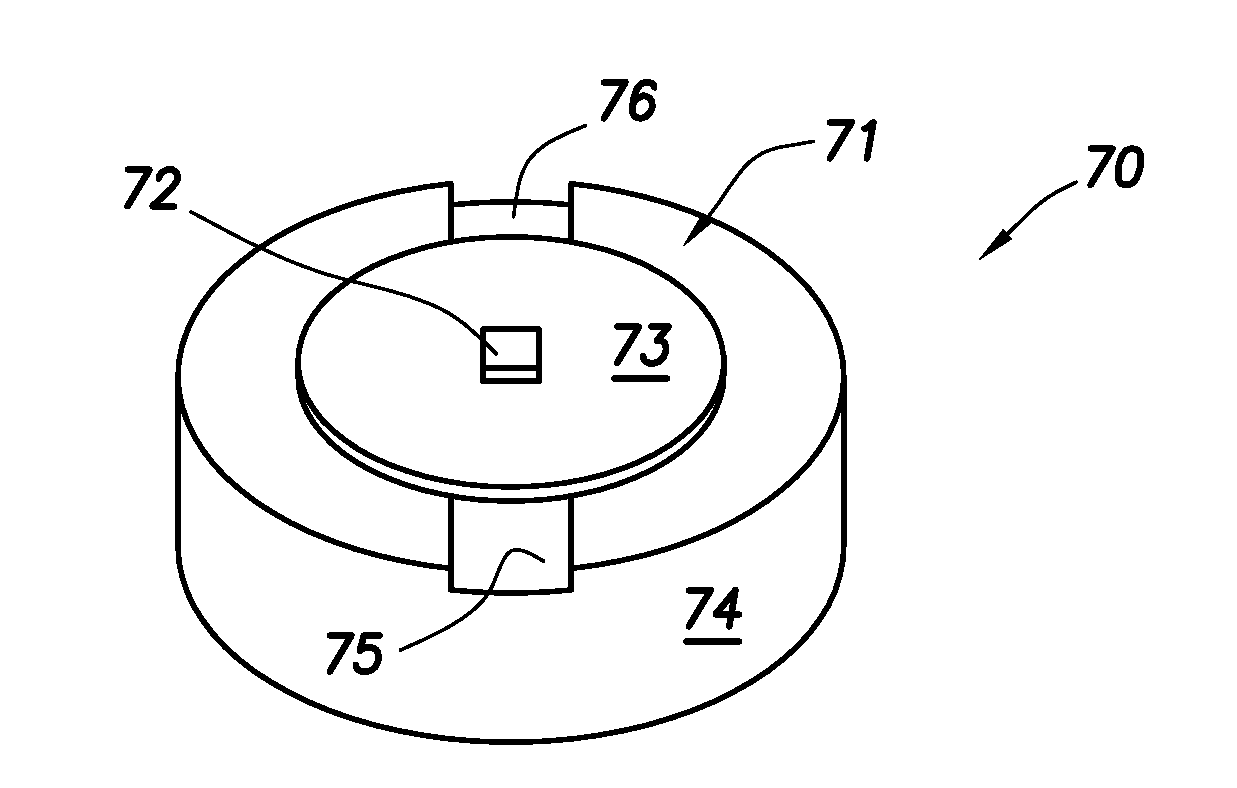

Highly reliable ingestible event markers and methods for using the same

ActiveUS20110054265A1Improve reliabilityTransmission systemsCell seperators/membranes/diaphragms/spacersDiagnostic agentActive agent

Ingestible event markers having high reliability are provided. Aspects of the ingestible event markers include a support, a control circuit, a first electrochemical material, a second electrochemical material and a membrane. In addition, the ingestible event markers may include one or more components that impart high reliability to the ingestible event marker. Further, the ingestible event markers may include an active agent. In some aspects, the active agent, such as a pharmaceutically active agent or a diagnostic agent may be associated with the membrane.

Owner:OTSUKA PHARM CO LTD

Anode active material and nonaqueous electrolyte secondary battery

InactiveUS20030008212A1Chemical deterioration of a nonaqueous electrolyte material is preventedAvoid destructionElectrode manufacturing processesPrimary cell maintainance/servicingFiberMaterials science

The present invention relates to an anode material excellent in its charging and discharging characteristics and a secondary battery excellent in its charging and discharging cyclic characteristics. An anode active material is used for a nonaqueous electrolyte secondary battery including an anode having the anode active material, a cathode having a cathode active material and a nonaqueous electrolyte. The capacity of the anode is expressed by the sum of a capacity component obtained when light metal is doped and dedoped in an ionic state and a capacity component obtained when the light metal is deposited and dissolved. The light metal includes an anode base material capable of doping and dedoping the light metal in an ionic state and a fibrous material having an electric conductivity.

Owner:SONY CORP

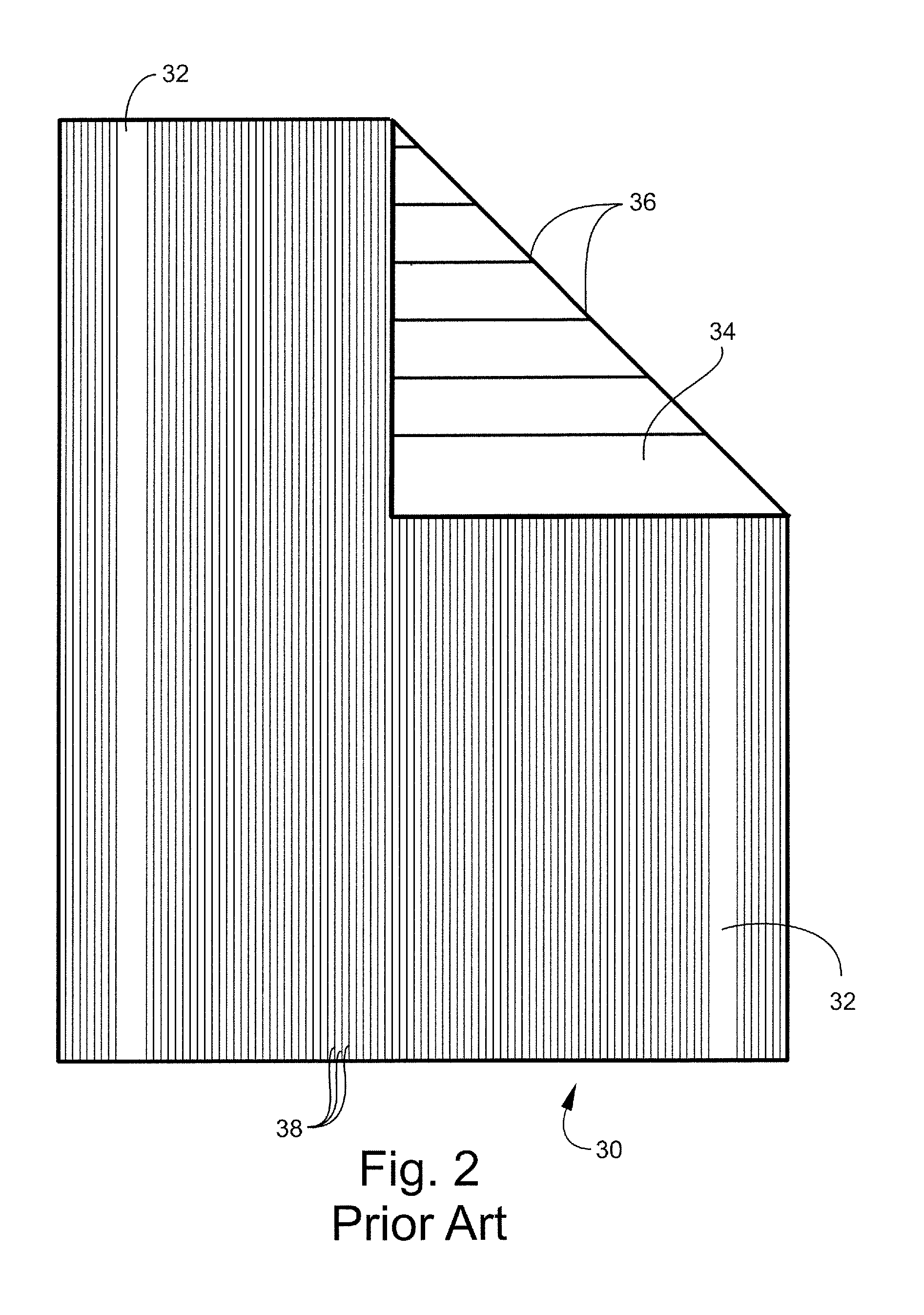

Battery separators with cross ribs and related methods

ActiveUS20110091761A1Increased bending stiffnessEasy to prepareCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous membraneBiomedical engineering

A separator for a lead acid battery is a porous membrane having a positive electrode face and a negative electrode face. A plurality of longitudinally extending ribs, a plurality of protrusions or a nonwoven material may be disposed upon the positive electrode face. A plurality of transversely extending ribs are disposed upon the negative electrode face. The transverse ribs disposed upon the negative electrode face are preferably juxtaposed to a negative electrode of the lead acid battery, when the separator is placed within that battery.

Owner:DARAMIC LLC

Battery separator

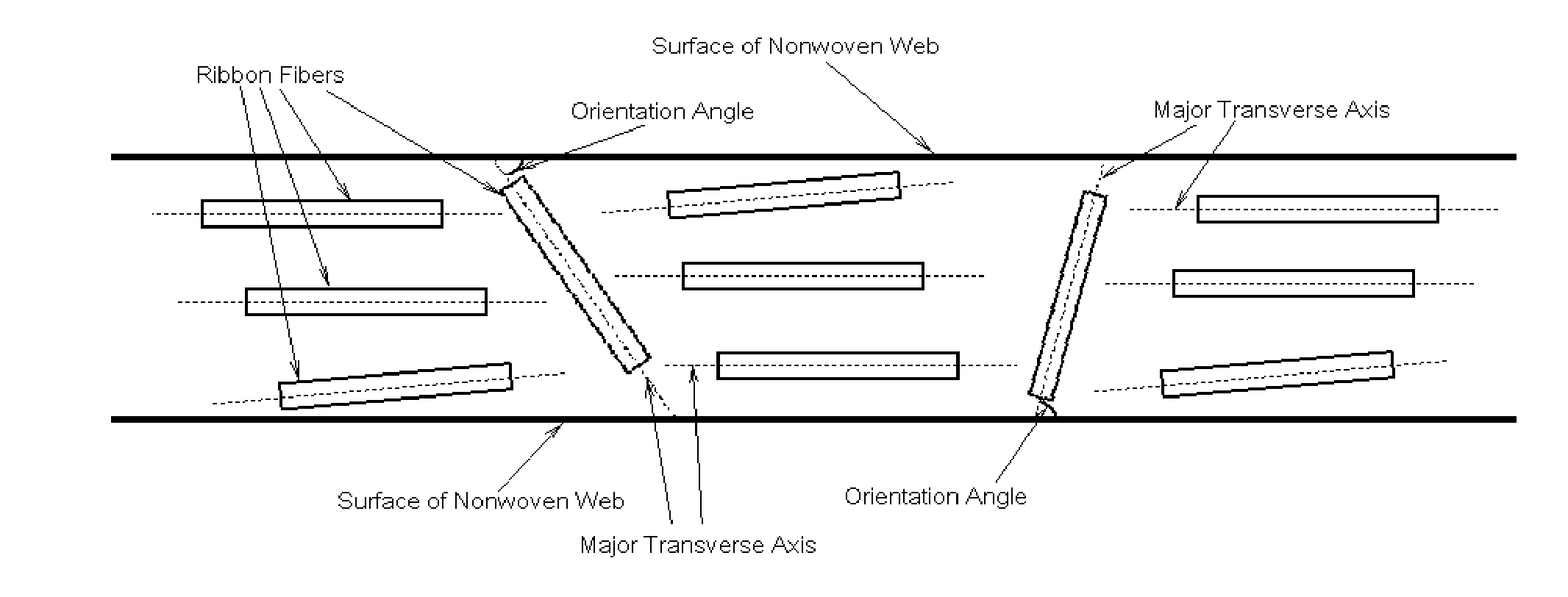

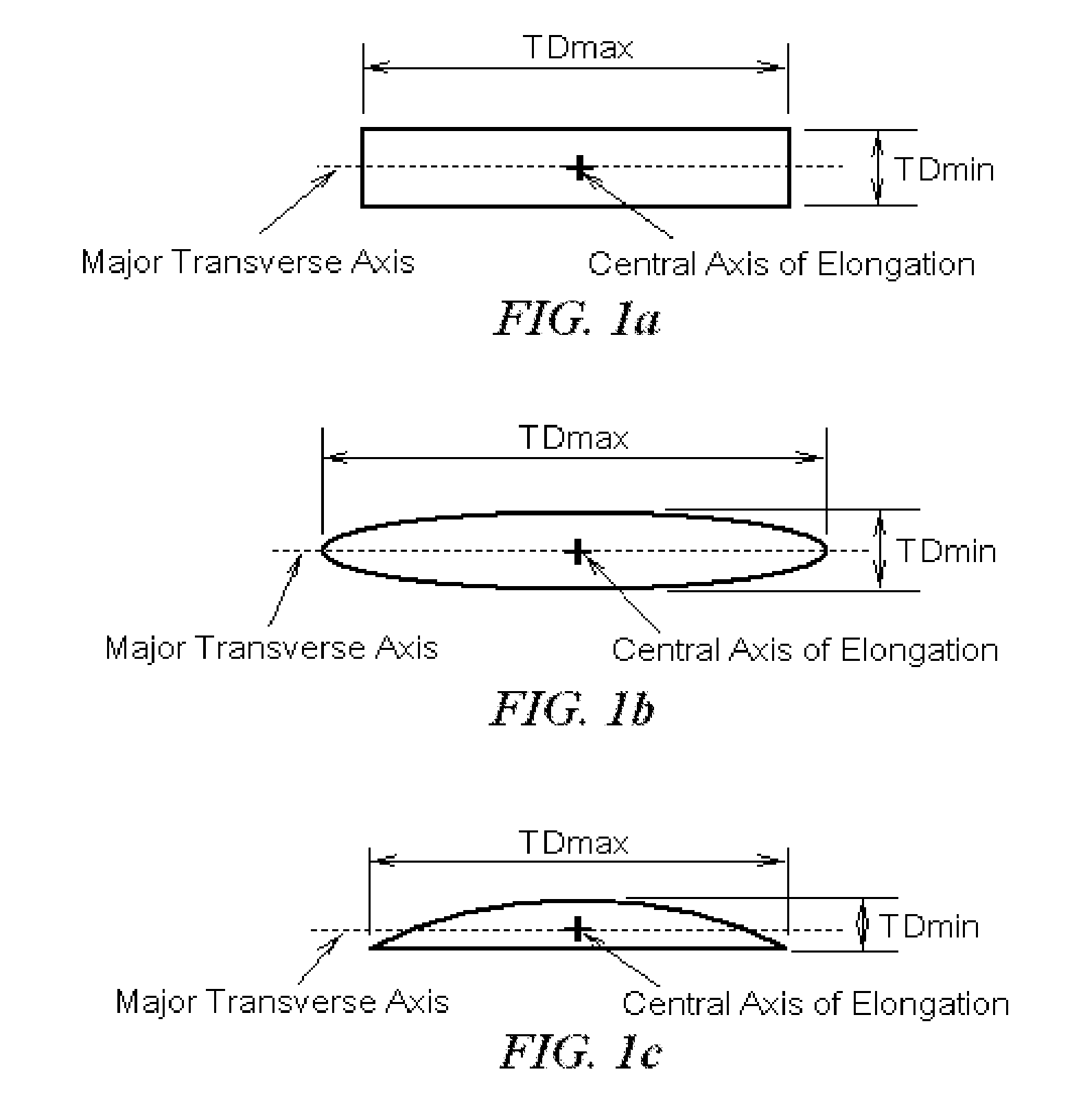

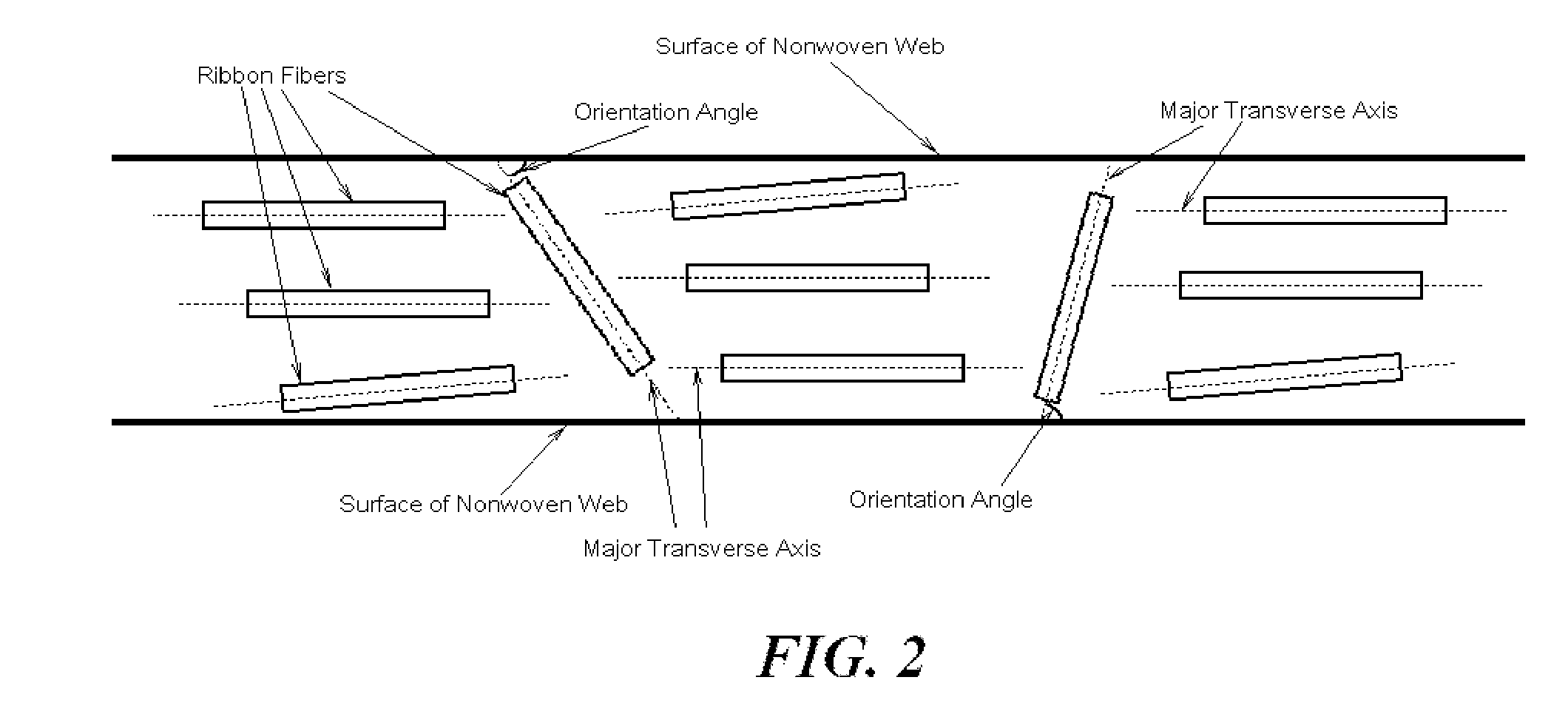

InactiveUS20120183862A1Cell seperators/membranes/diaphragms/spacersNon-woven fabricsFiberUltimate tensile strength

A battery separator comprising at least one nonwoven web layer is provided. The nonwoven web layer comprises a plurality of first fibers, a plurality of second fibers, and a binder. The first fibers comprise a water non-dispersible synthetic polymer and have a different configuration and / or composition than the second fibers. The first fibers have a length of less than 25 millimeters and a minimum transverse dimension of less than 5 microns. The nonwoven web layer comprises at least 10 weight percent of the first fibers, at least 10 weight percent of the second fibers, and at least 1 weight percent of the binder. The battery separator exhibits an enhanced combination of strength, durability, and ionic resistance.

Owner:EASTMAN CHEM CO

Separator and Non-Aqueous Electrolyte Secondary Battery Using Same

InactiveUS20080070107A1Improve securityImprove performanceNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersFine particulateMaterials science

A separator including at least a layer containing a fine particulate filler and a shutdown layer. The fine particulate filler includes a joined-particle filler that is in the form of a plurality of primary particles joined and bonded to one another. A non-aqueous electrolyte secondary battery including this separator exhibits improved safety, high performance and large current discharge capability particularly at low temperatures.

Owner:PANASONIC CORP

Thin printable electrochemical cell utilizing a "picture frame" and methods of making the same

A thin printed flexible electrochemical cell, and its method of manufacture, using a “picture frame” structure sealed, for example, with a high moisture and oxygen barrier polymer film and featuring, for example, a printed cathode deposited on an optional, highly conductive carbon printed cathode collector with a printed or a foil strip anode placed adjacent to the cathode. A viscous or gelled electrolyte is dispensed and / or printed in the cell, and a top laminate can then be sealed onto the picture frame. Such a construction could allow the entire cell to be made on a printing press, for example, as well as gives the opportunity to integrate the battery directly with an electronic application, for example.

Owner:BLUE SPARK INNOVATIONS LLC

Bipolar battery assembly

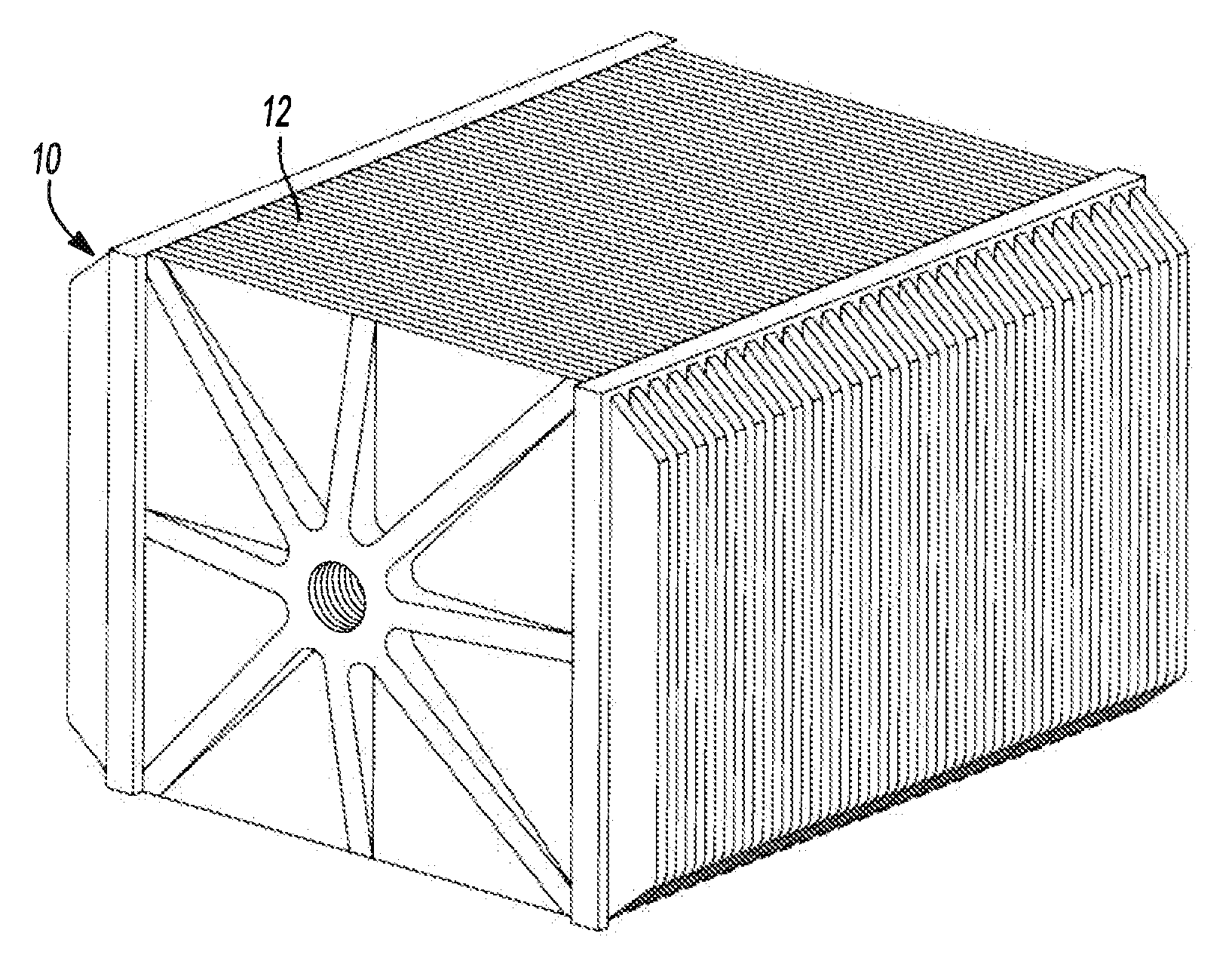

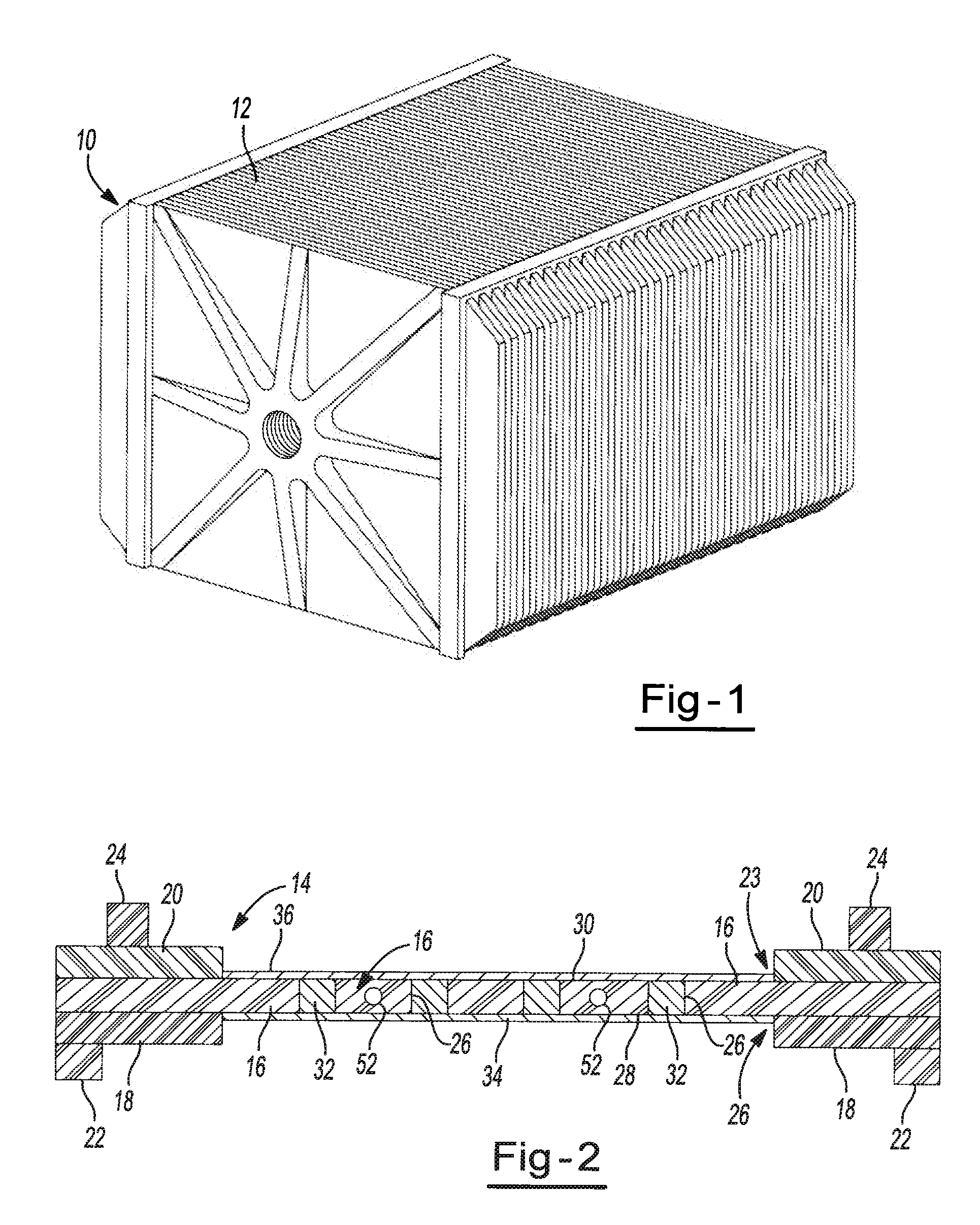

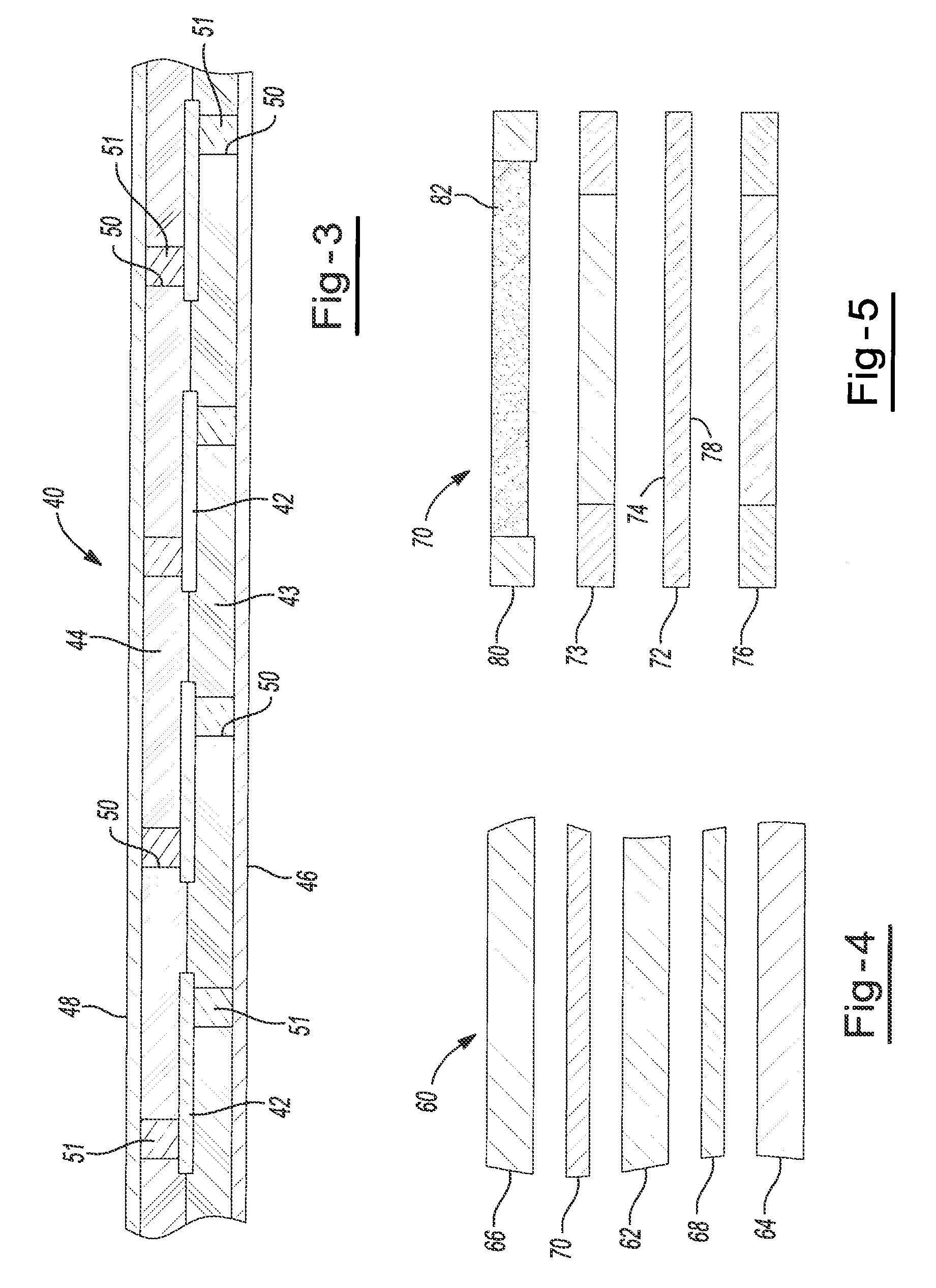

ActiveUS20100183920A1Easy constructionEffective distanceCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesConductive materialsPositive current

A bipolar battery construction is disclosed comprising a substrate, openings in the substrate, an electrically conductive material placed within the openings, a negative and positive current collector foil placed on opposing sides of the substrate and negative and positive pasting frame members. The electrically conductive material may have a melting point below the thermal degradation temperature of the substrate.

Owner:ADVANCED BATTERY CONCEPTS

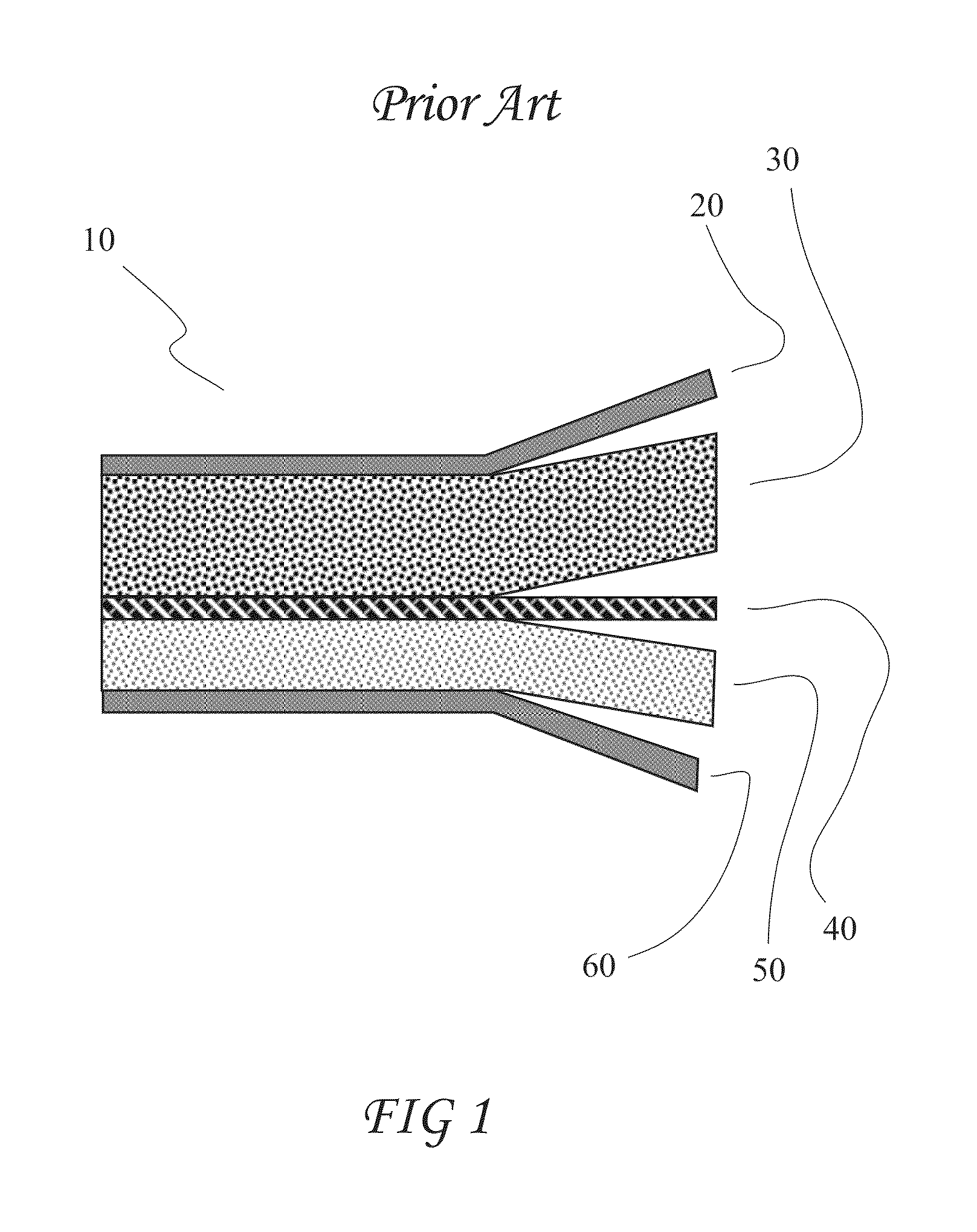

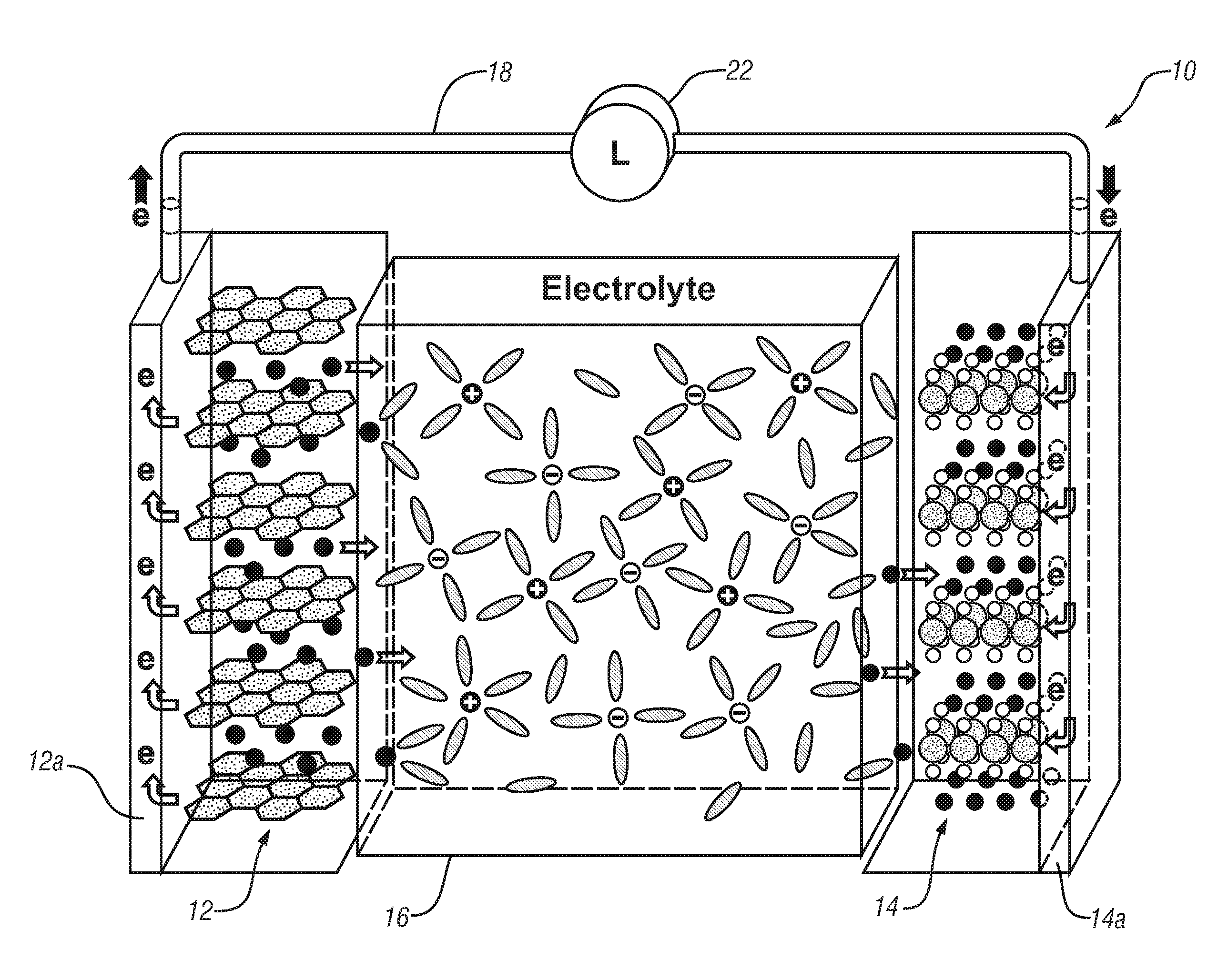

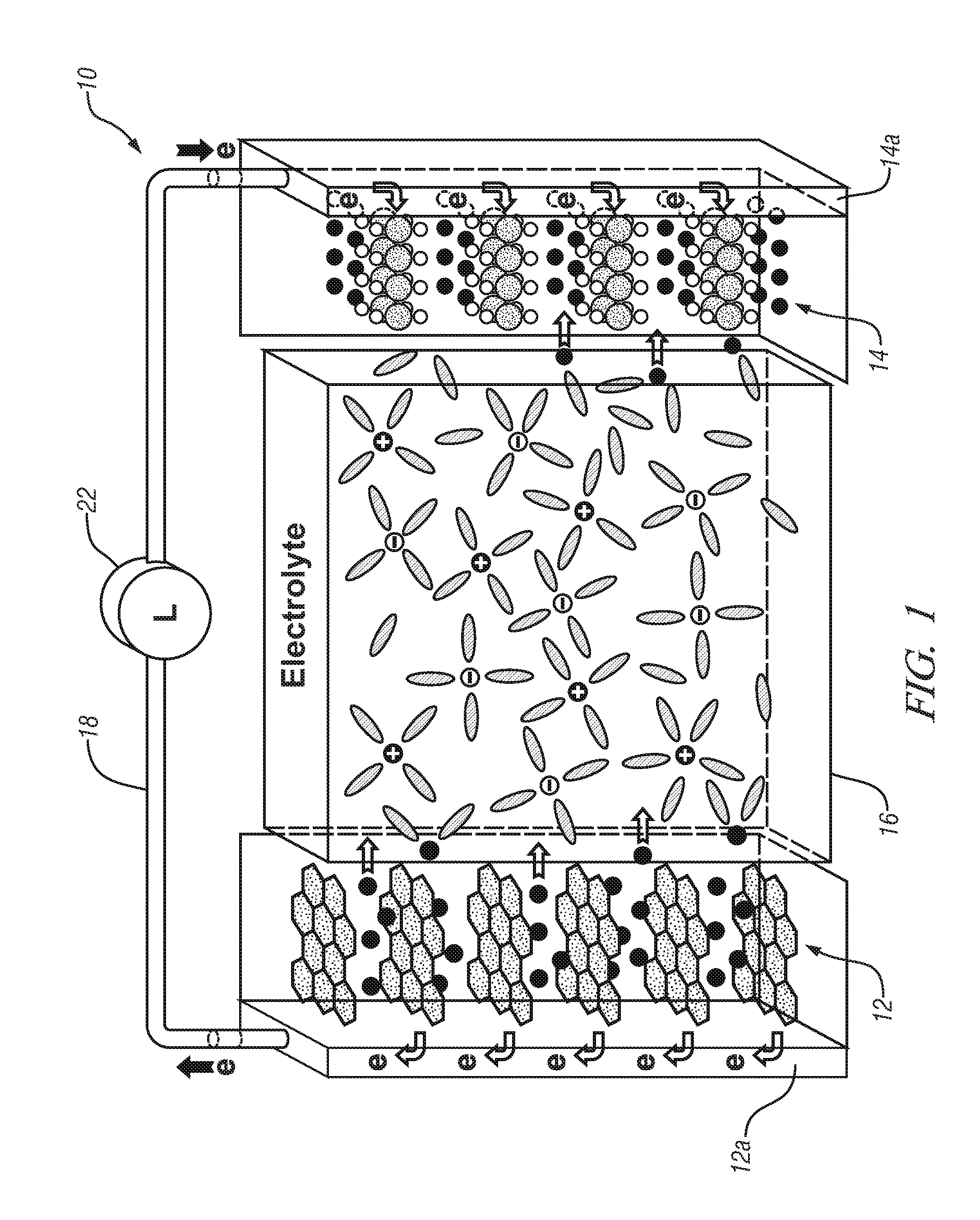

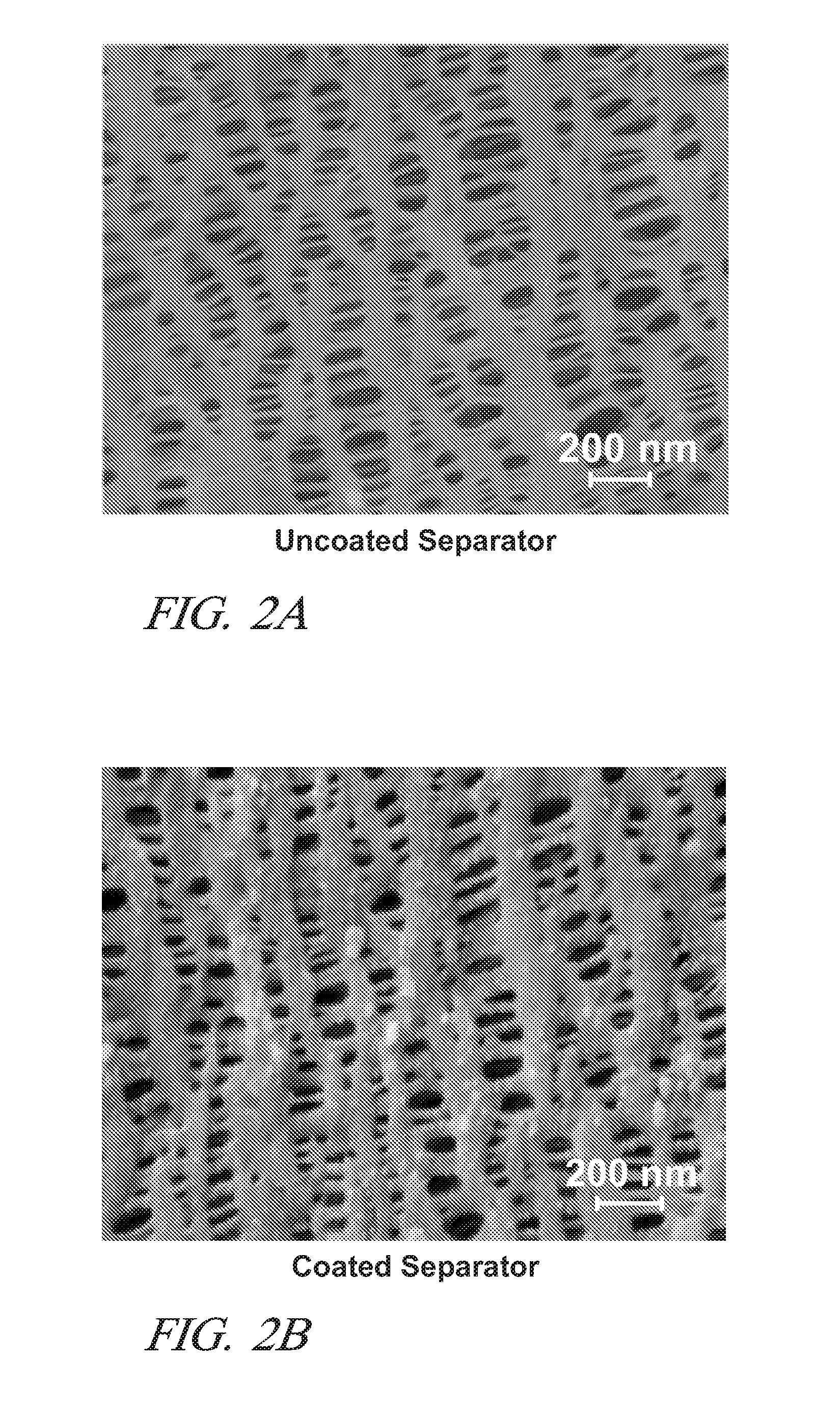

Lithium-ion batteries with coated separators

ActiveUS20110200863A1Low environmental impactThermal conductivityCell seperators/membranes/diaphragms/spacersLi-accumulatorsCoated membraneGas phase

A porous polymer sheet or membrane is provided with a thin coating of an electrically non-conductive ceramic composition and the coating conforms to all surfaces, including the pore surfaces, of the membrane. Such a coated membrane serves well, for example, as an intra-cell separator in a lithium ion battery. The coating increases the mechanical properties and thermal stability of the separator in battery operation and retains electrolyte. The coating may be formed by a two-step vapor-phase process in which atoms of one or more metals such as aluminum, calcium, magnesium, titanium, silicon and / or zirconium are deposited in a conformal layer on a workpiece surface. The metal atoms may then be reacted with ammonia, carbon dioxide, and or water to form their respective non-conductive nitrides, carbides, and / or oxides on the surface. The two-step process is repeated as necessary to obtain a ceramic material coating of desired thickness.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com