Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3971 results about "Ceramic membrane" patented technology

Efficacy Topic

Property

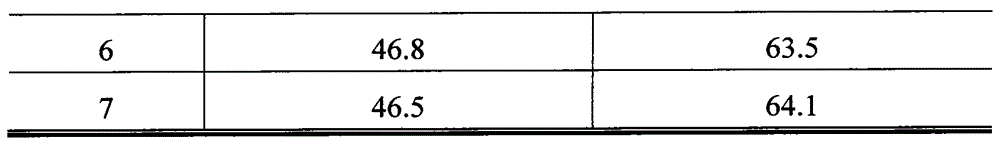

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic membranes are a type of artificial membranes made from inorganic materials (such as alumina, titania, zirconia oxides, silicon carbide or some glassy materials). They are used in membrane operations for liquid filtration.

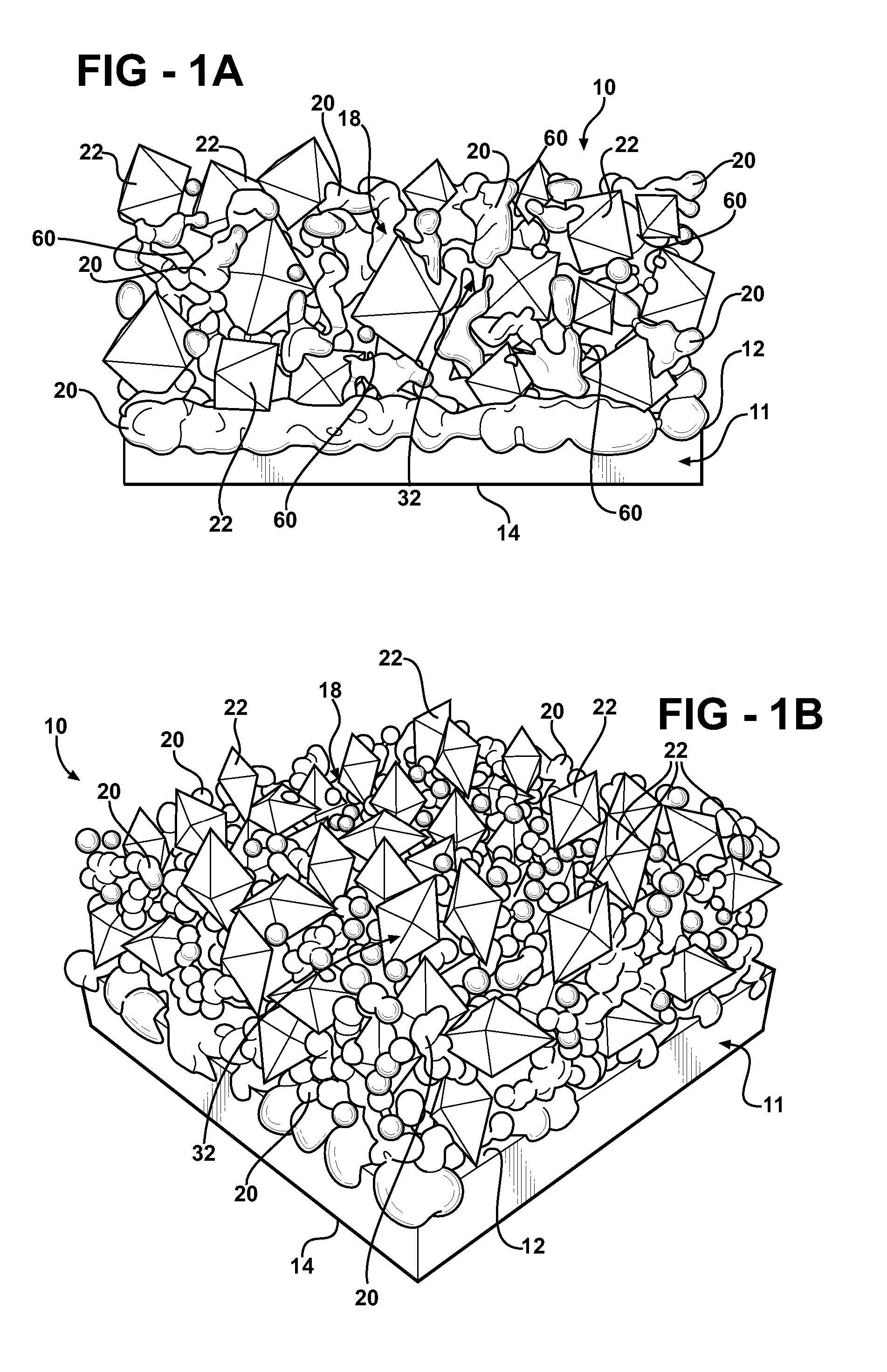

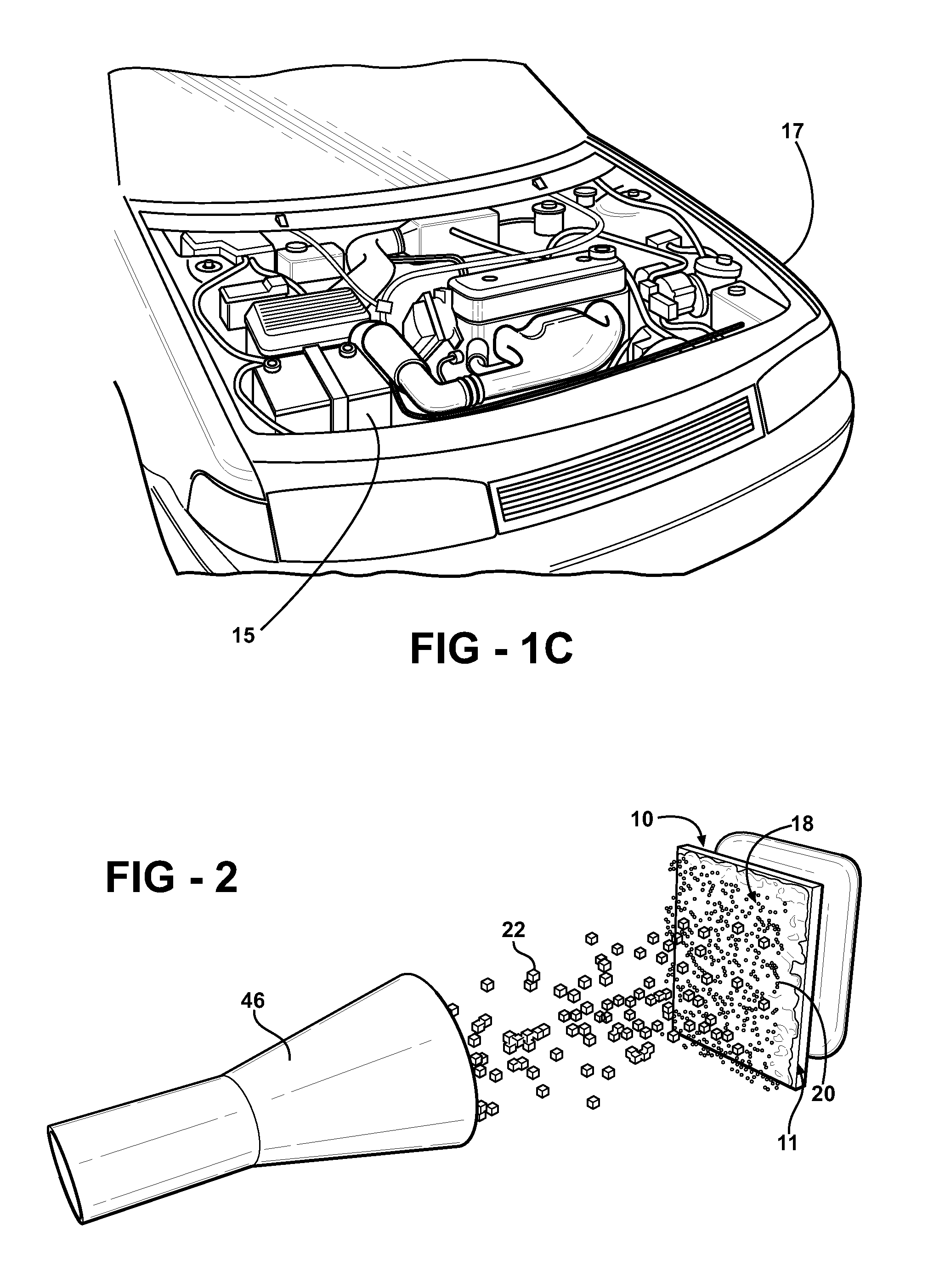

Nanoantenna arrays for nanospectroscopy, methods of use and methods of high-throughput nanofabrication

ActiveUS20130148194A1Large scaleStrong and enhanced couplingMaterial nanotechnologyDecorative surface effectsLithographic artistSurface plasmon

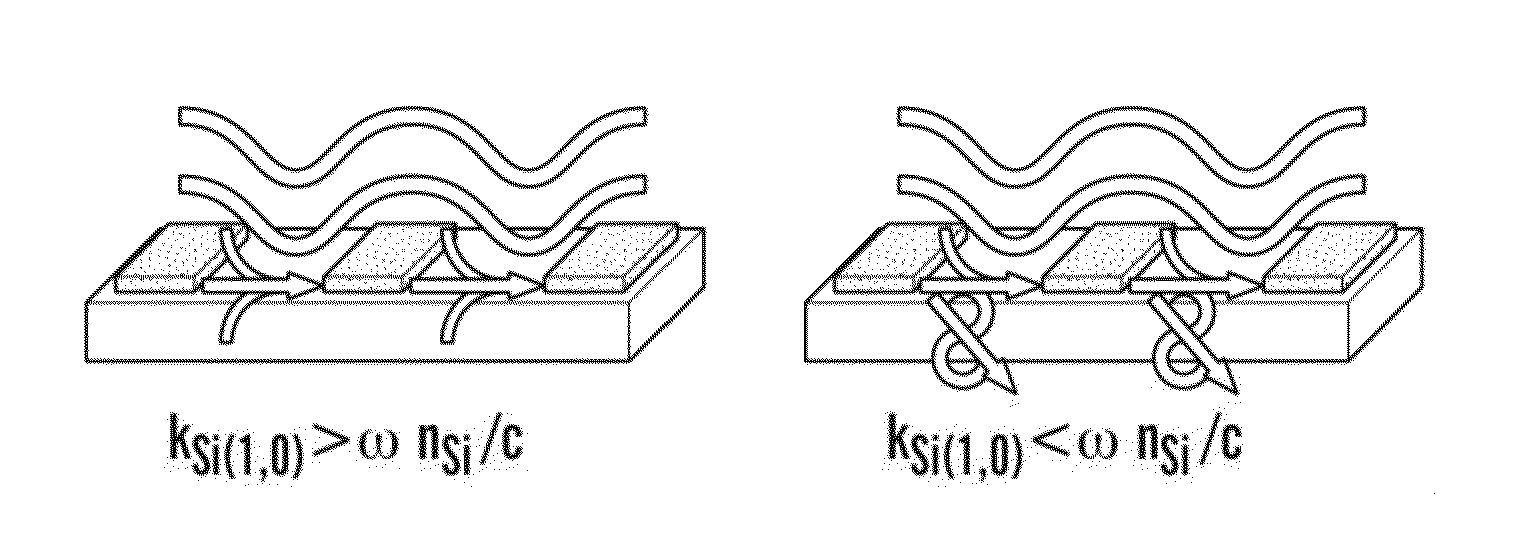

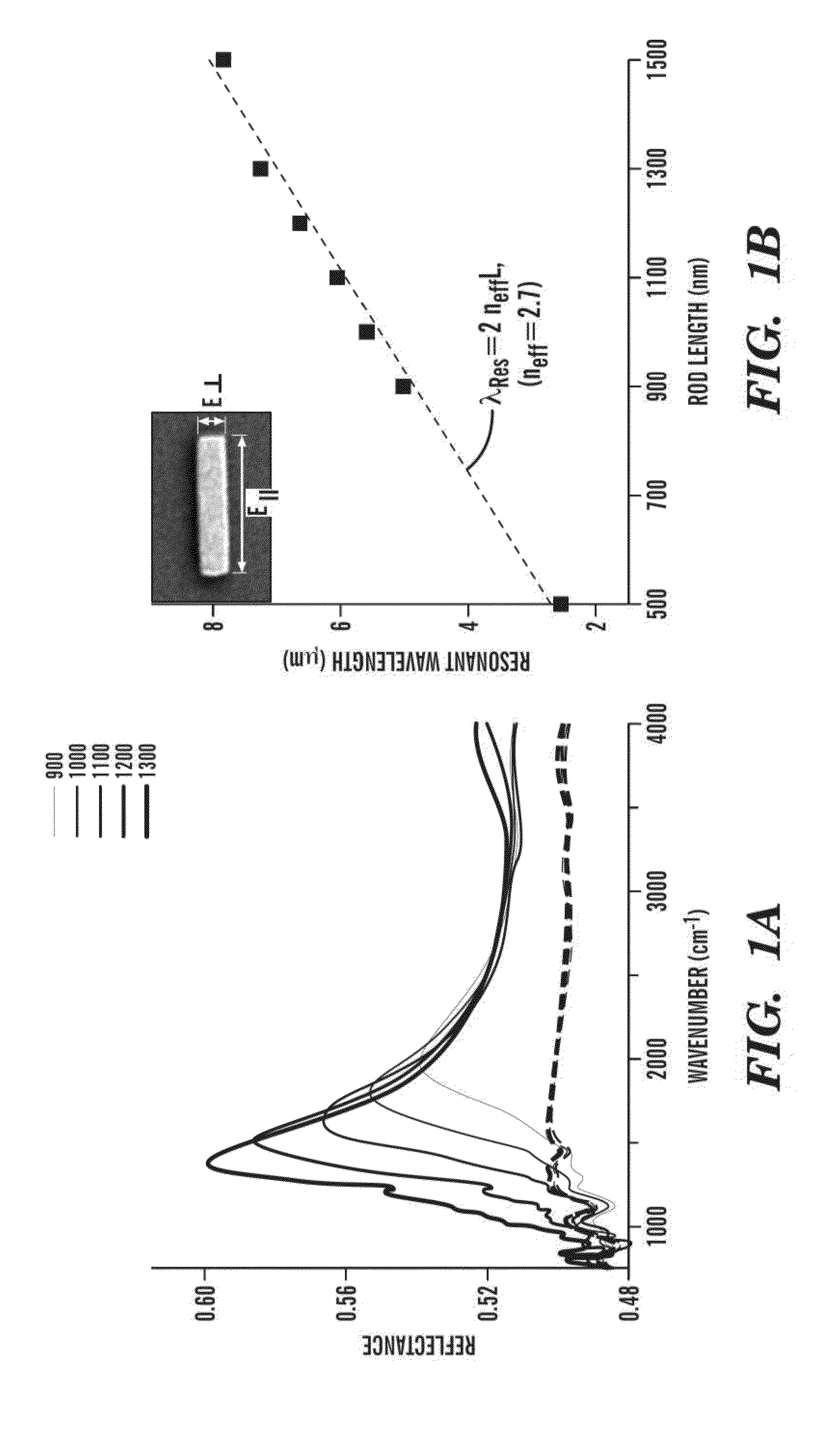

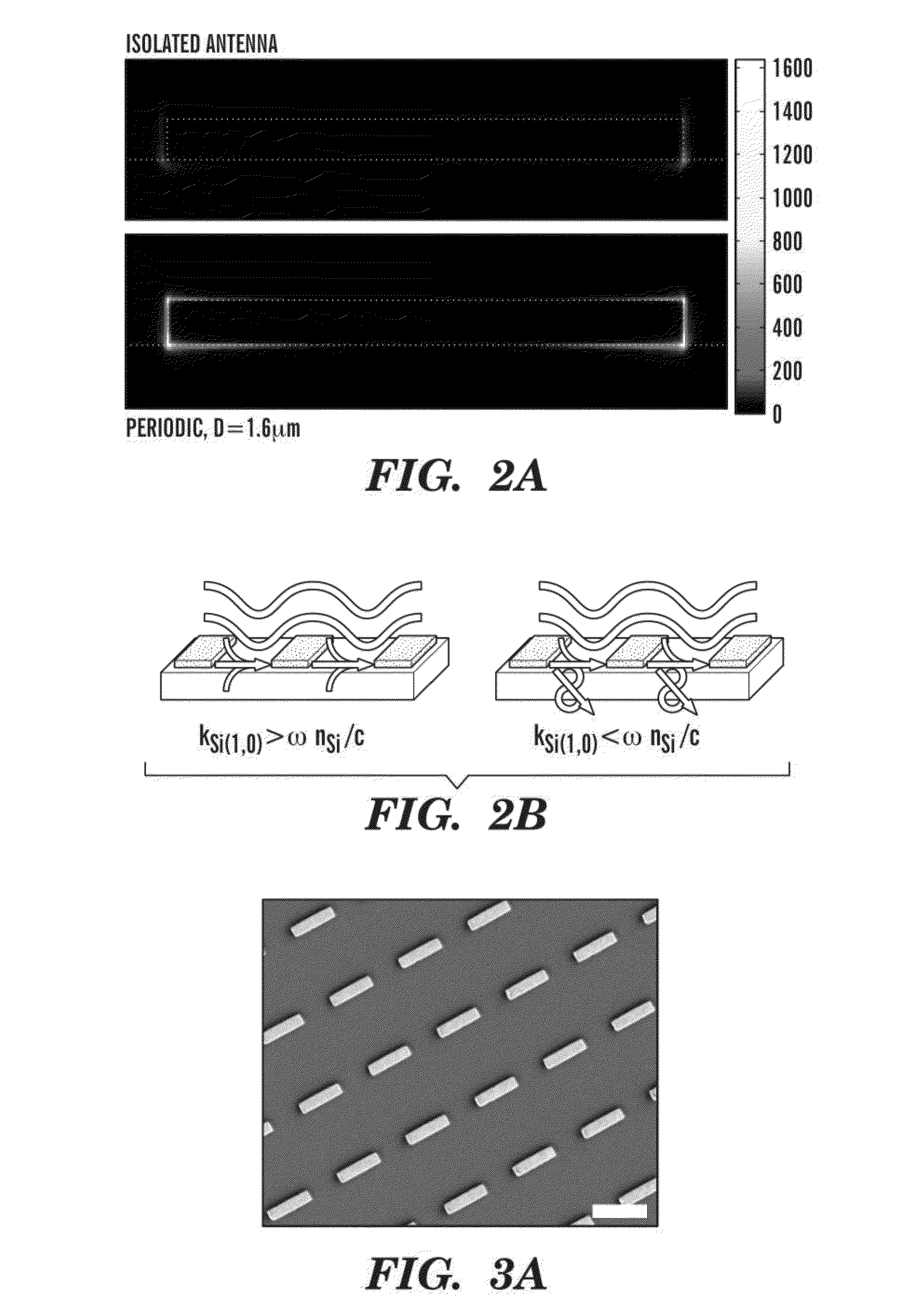

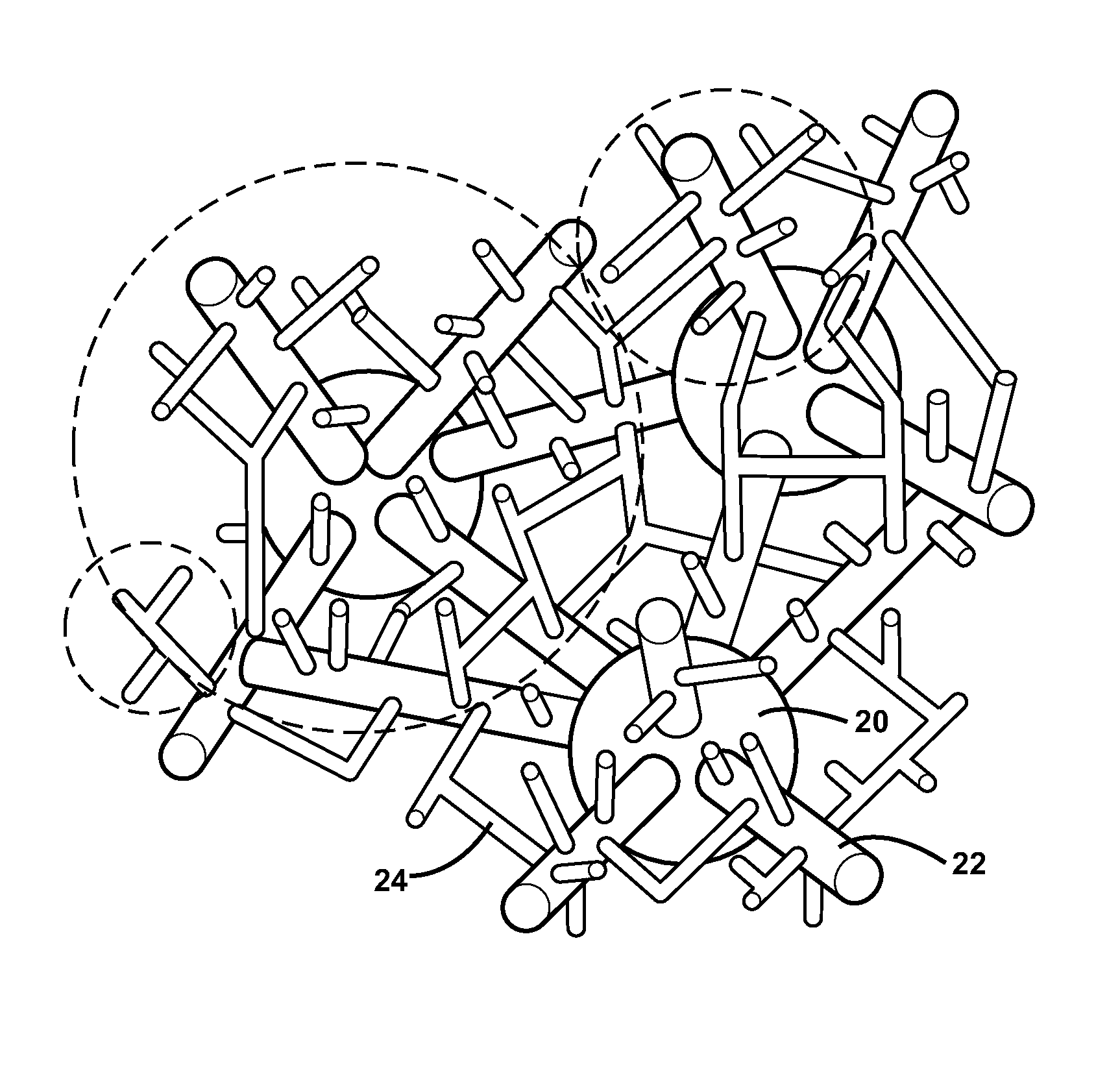

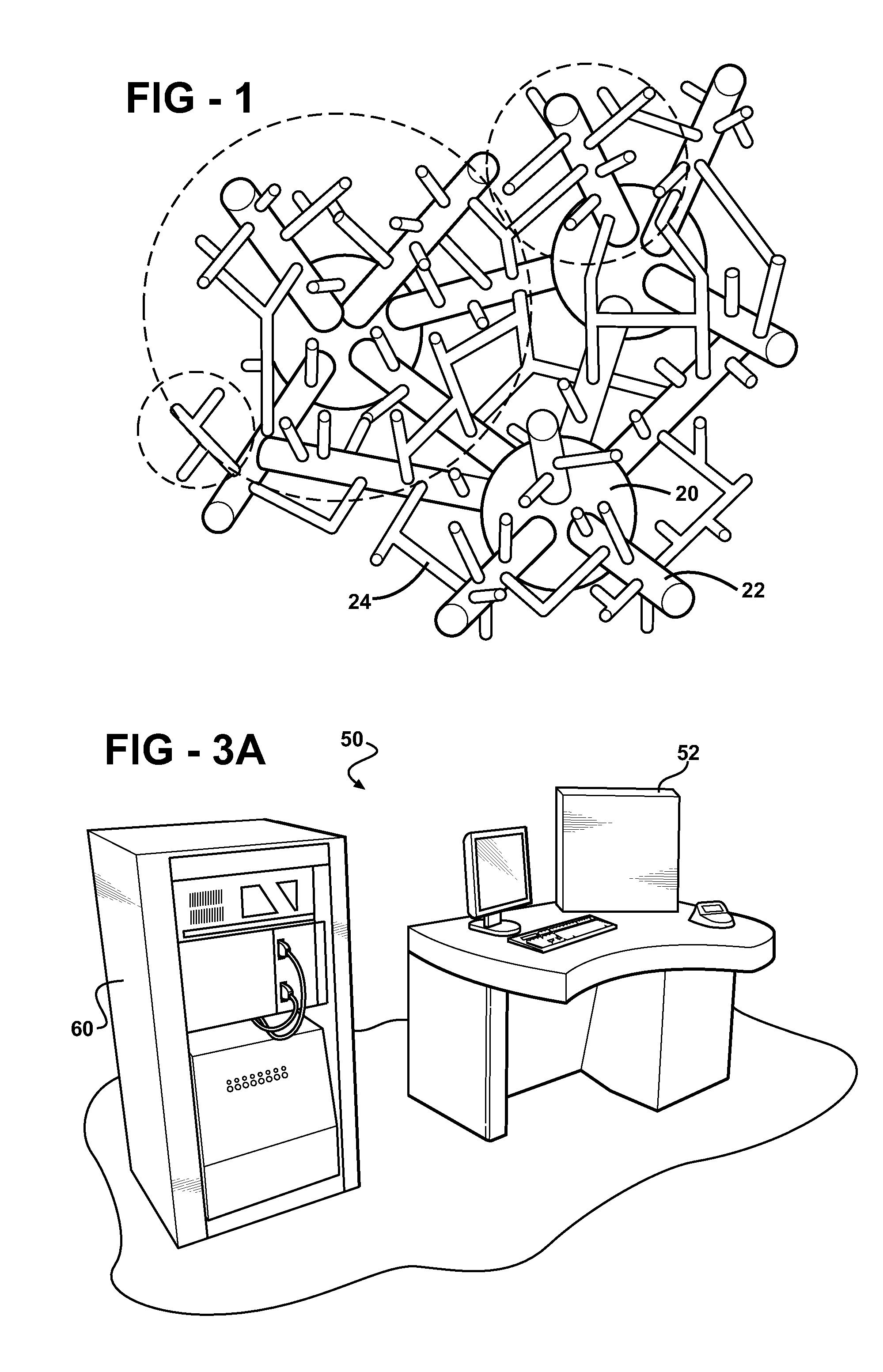

The present invention generally relates to nanoantenna arrays and methods of their fabrication. In particular, one aspect relates to nanoantenna arrays comprising nanostructures of predefined shapes in predefined patterns, which results in collective excitement of surface plasmons. In some embodiments the nanoantenna arrays can be used for spectroscopy and nanospectroscopy. Another aspects of the present invention relate to a method of high-throughput fabrication of nanoantenna arrays includes fabricating a reusable nanostencil for nanostensil lithography (NSL) which provides a mask to deposit materials onto virtually any support, such as flexible and thin-film stretchable supports. The nanostencil lithography methods enable high quality, high-throughput fabrication of nanostructures on conducting, non-conducting and magnetic supports. The nanostencil can be prepared by etching nanoapertures of predefined patterns into a waffer or ceramic membrane. In some embodiments, a nanoantenna array comprises plasmonic nanostructures or non-plasmonic nanostructures.

Owner:TRUSTEES OF BOSTON UNIV

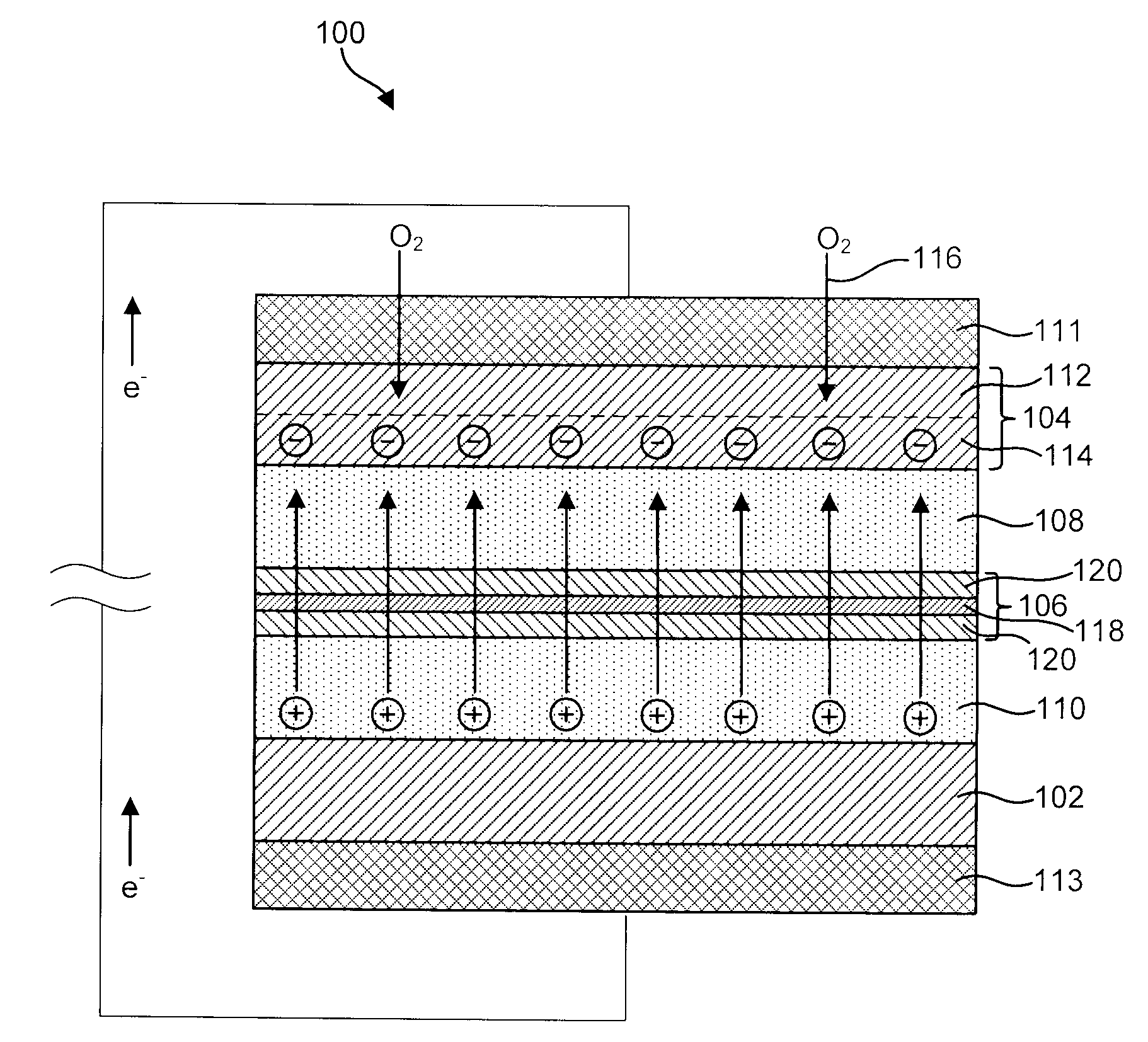

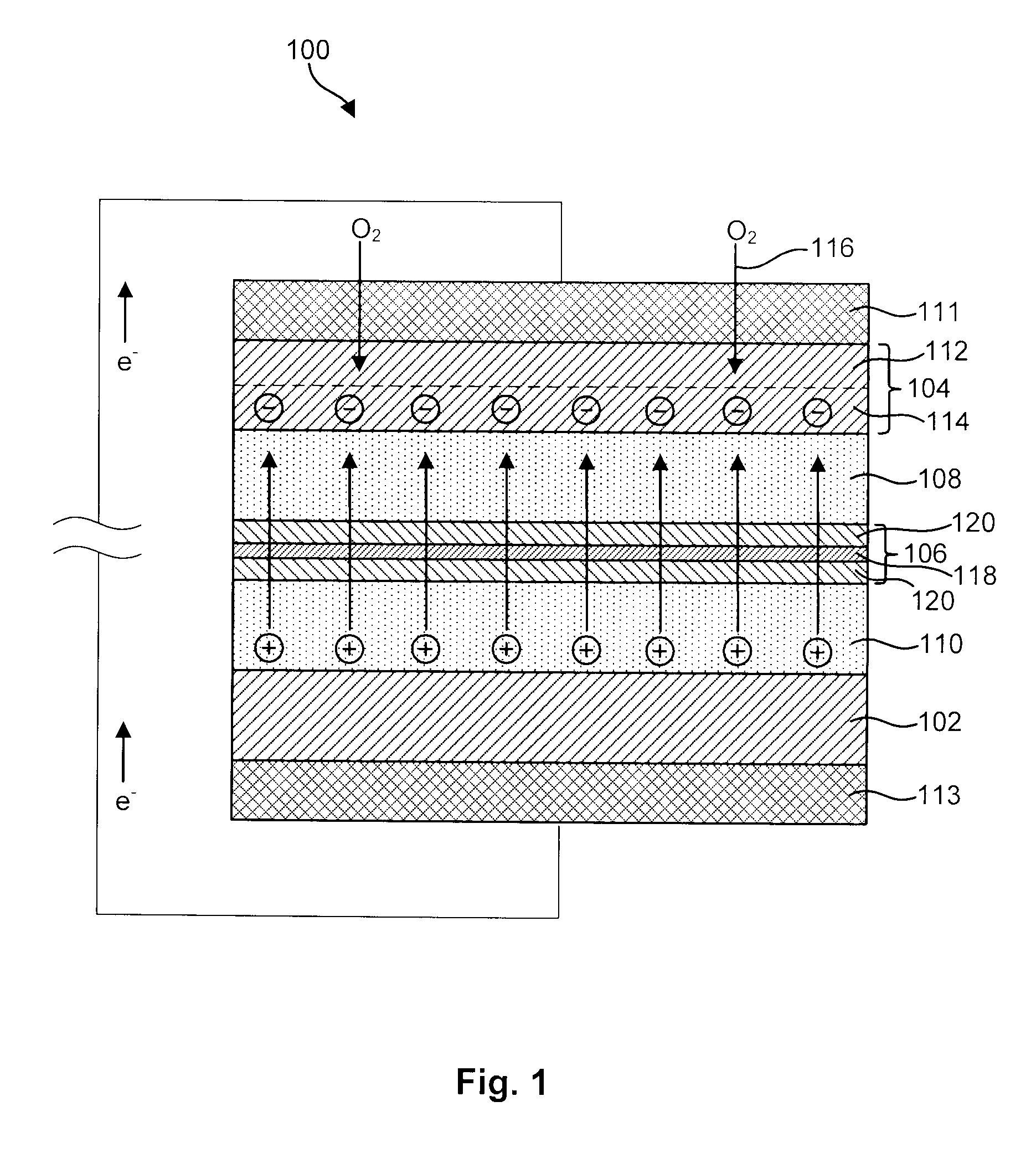

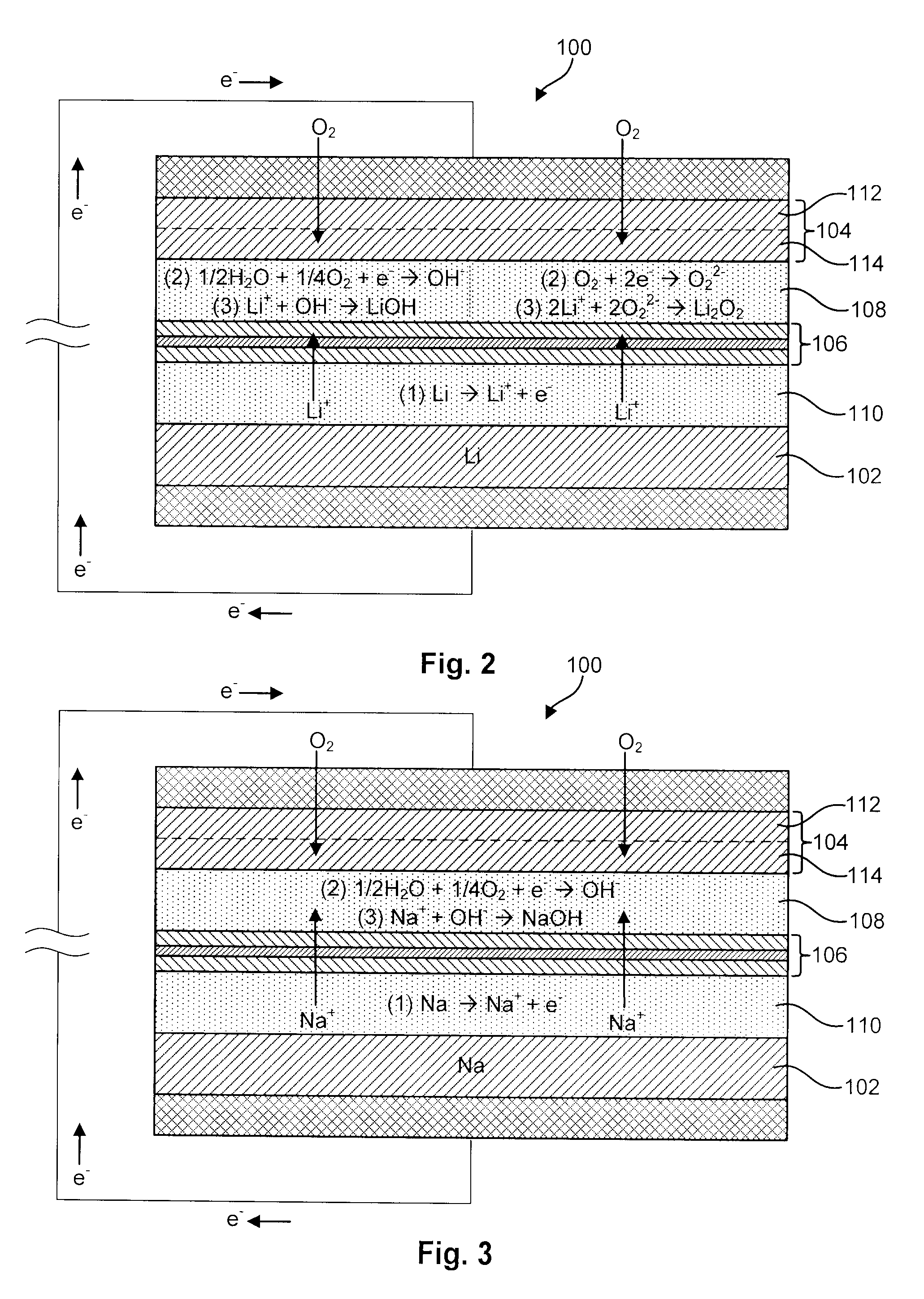

Advanced Metal-Air Battery Having a Ceramic Membrane Electrolyte Background of the Invention

ActiveUS20080268327A1Reduce oxygenReduce layeringFuel and primary cellsSolid electrolytesOxygenCeramic membrane

A metal-air battery is disclosed in one embodiment of the invention as including a cathode to reduce oxygen molecules and an alkali-metal-containing anode to oxidize the alkali metal (e.g., Li, Na, and K) contained therein to produce alkali-metal ions. An aqueous catholyte is placed in ionic communication with the cathode to store reaction products generated by reacting the alkali-metal ions with the oxygen containing anions. These reaction products are stored as solutes dissolved in the aqueous catholyte. An ion-selective membrane is interposed between the alkali-metal containing anode and the aqueous catholyte. The ion-selective membrane is designed to be conductive to the alkali-metal ions while being impermeable to the aqueous catholyte.

Owner:FIELD UPGRADING USA INC

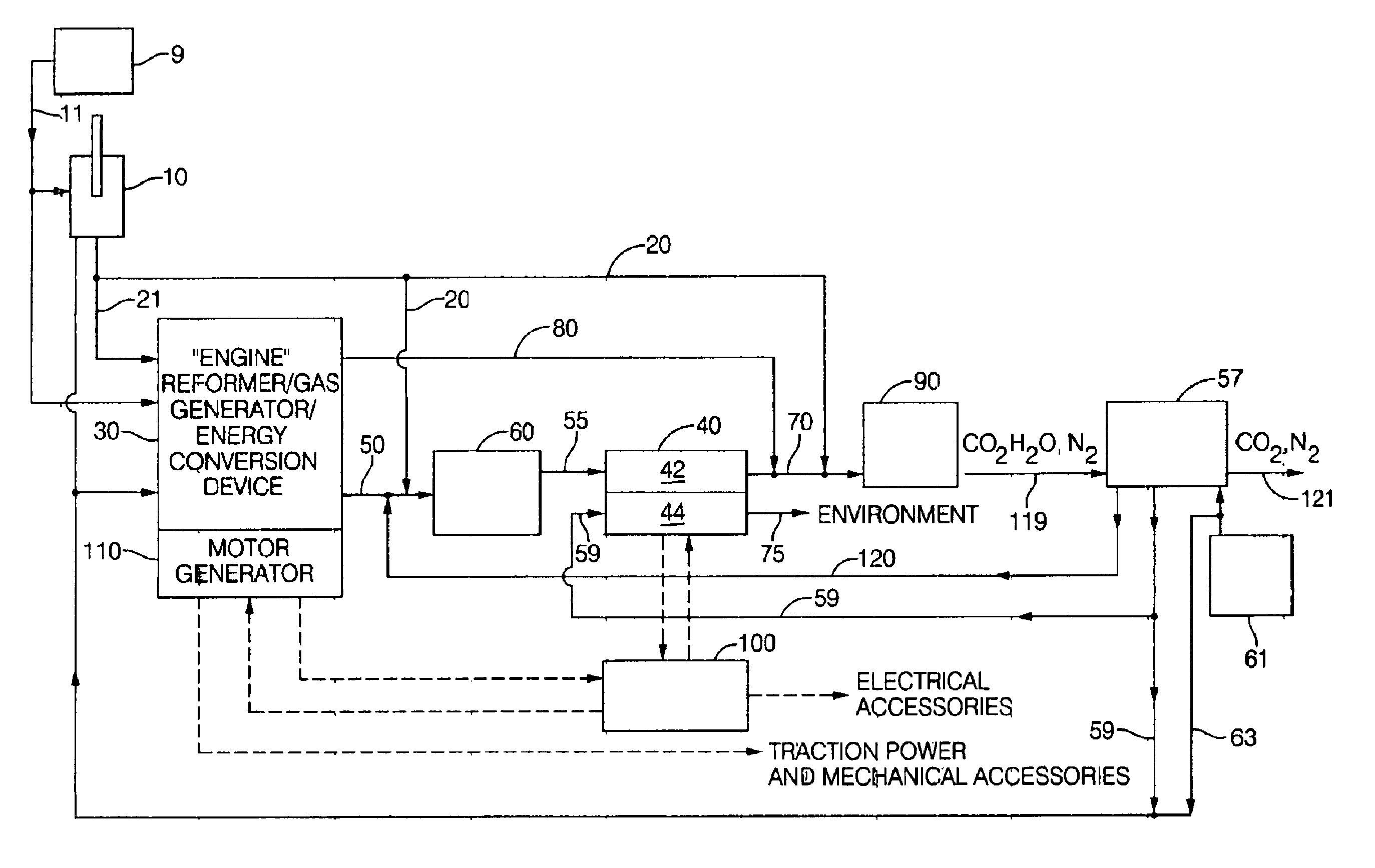

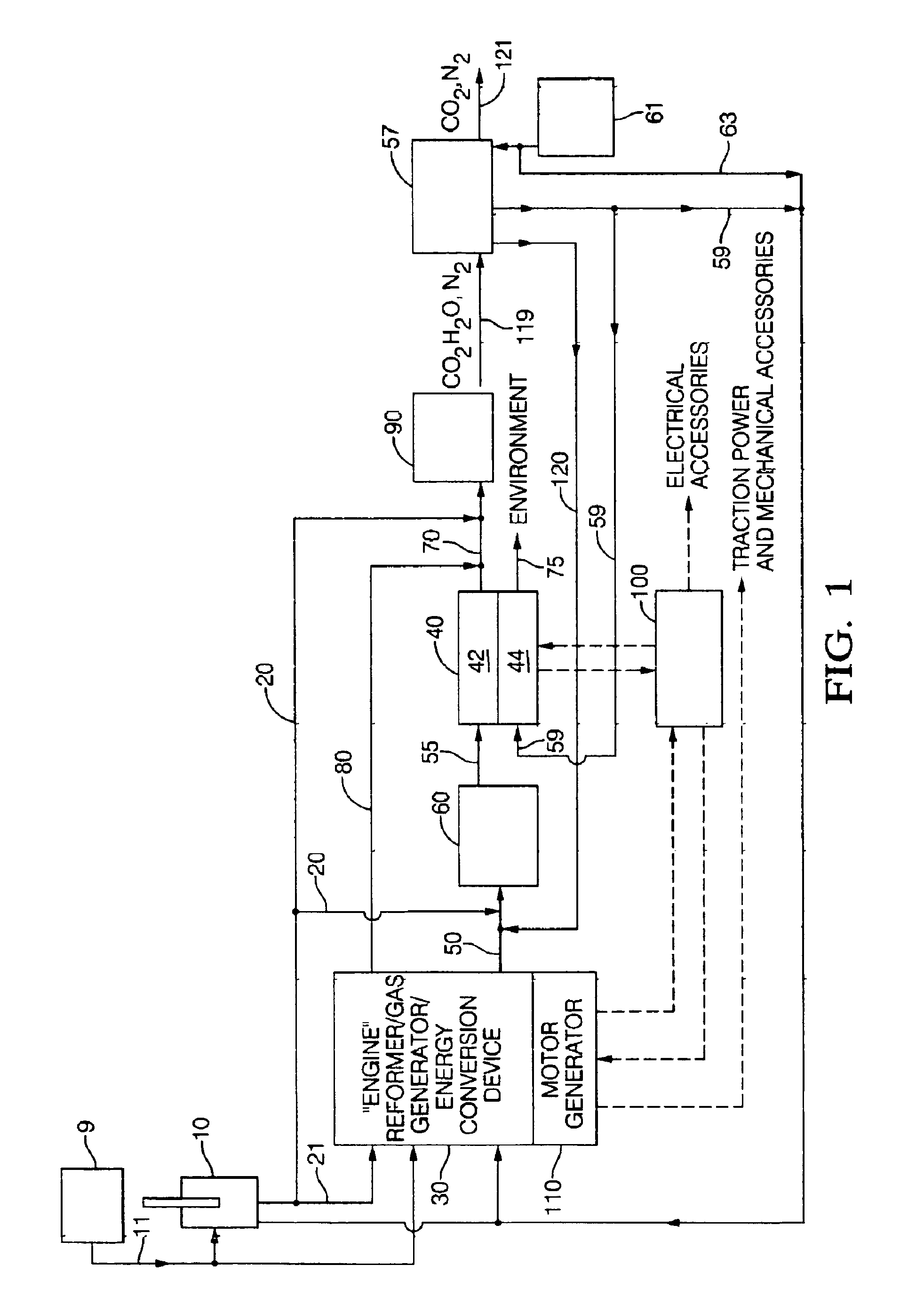

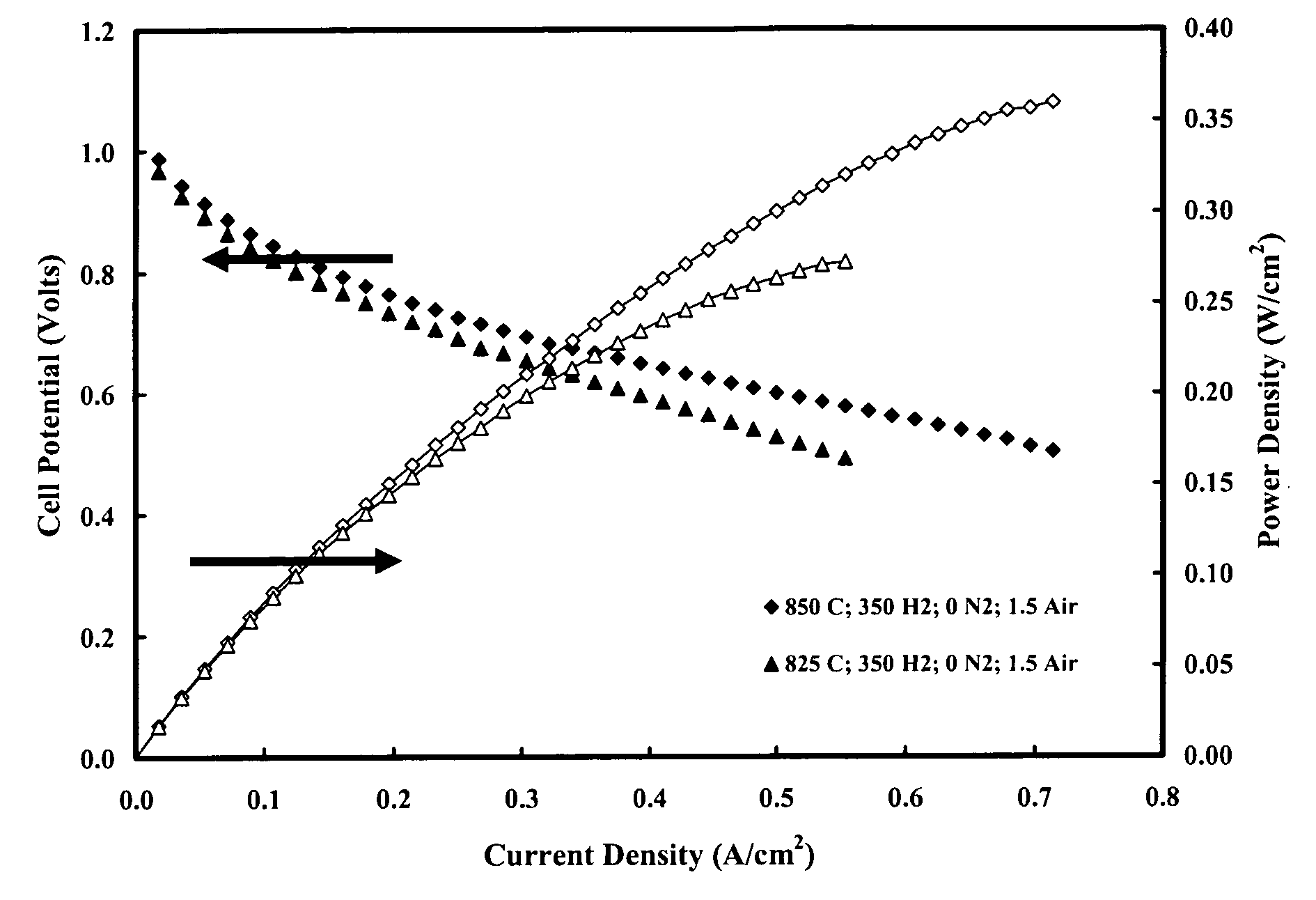

Power generation system and method

InactiveUS6915869B2Internal combustion piston enginesElectric propulsion mountingInternal combustion engineFuel supply

A power generation system and method providing an engine configured to produce hydrogen rich reformate to feed a solid oxide fuel cell includes an engine having an intake and an exhaust; an air supply in fluid communication with the engine intake; a fuel supply in fluid communication with the engine intake; at least one solid oxide fuel cell having an air intake in fluid communication with an air supply, a fuel intake in fluid communication with the engine exhaust, a solid oxide fuel cell effluent and an air effluent. Engines include a free piston gas generator with rich homogenous charge compression, a rich internal combustion engine cylinder system with an oxygen generator, and a rich inlet turbo-generator system with exhaust heat recovery. Oxygen enrichment devices to enhance production of hydrogen rich engine exhaust include pressure swing absorption with oxygen selective materials, and oxygen separators such as an solid oxide fuel cell oxygen separator and a ceramic membrane oxygen separator.

Owner:DELPHI TECH INC

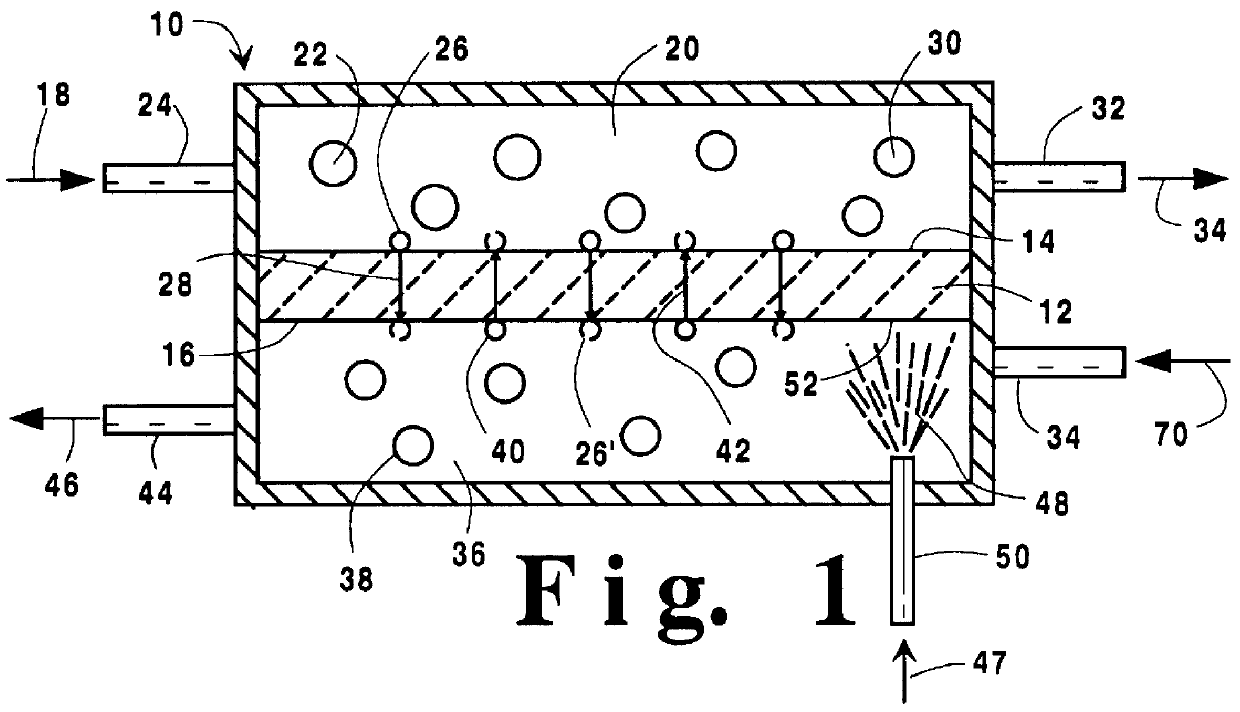

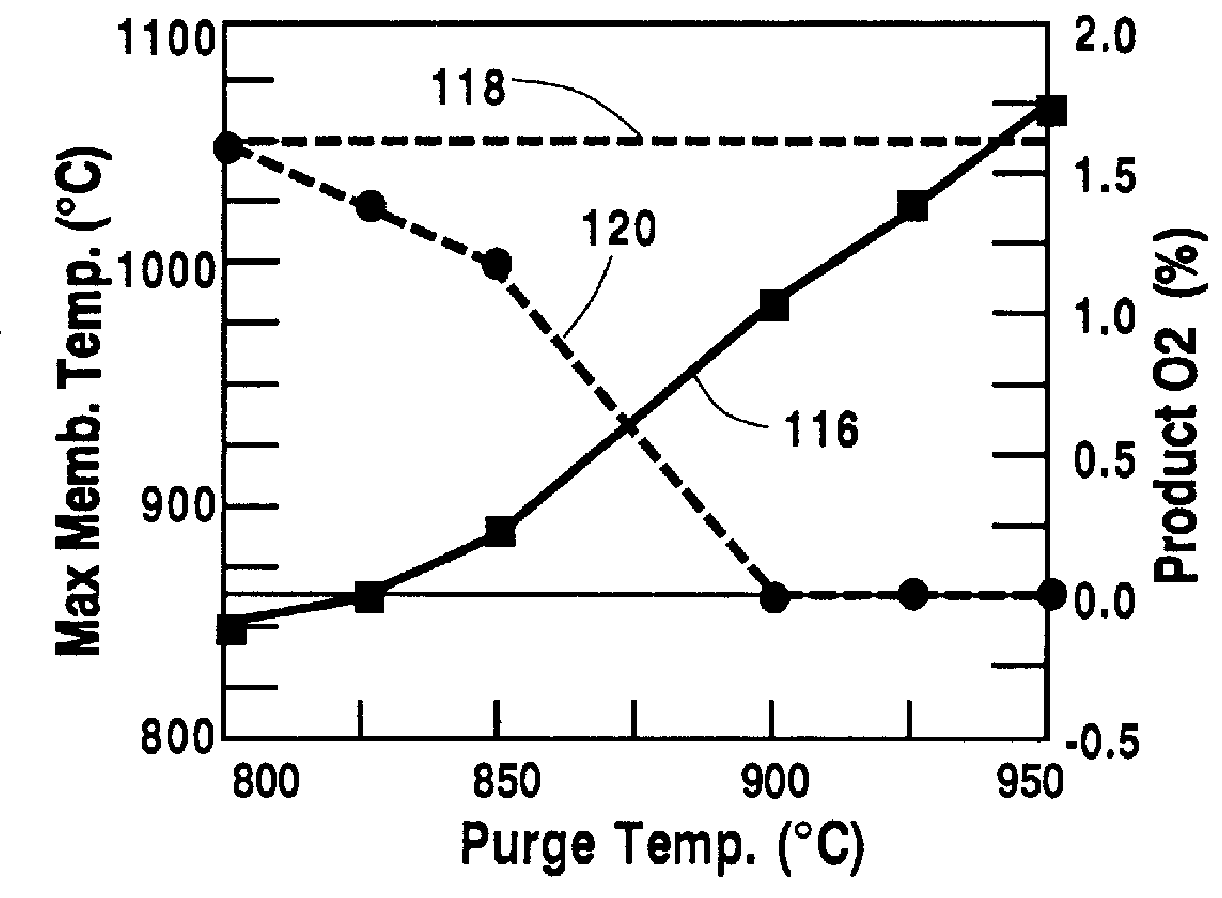

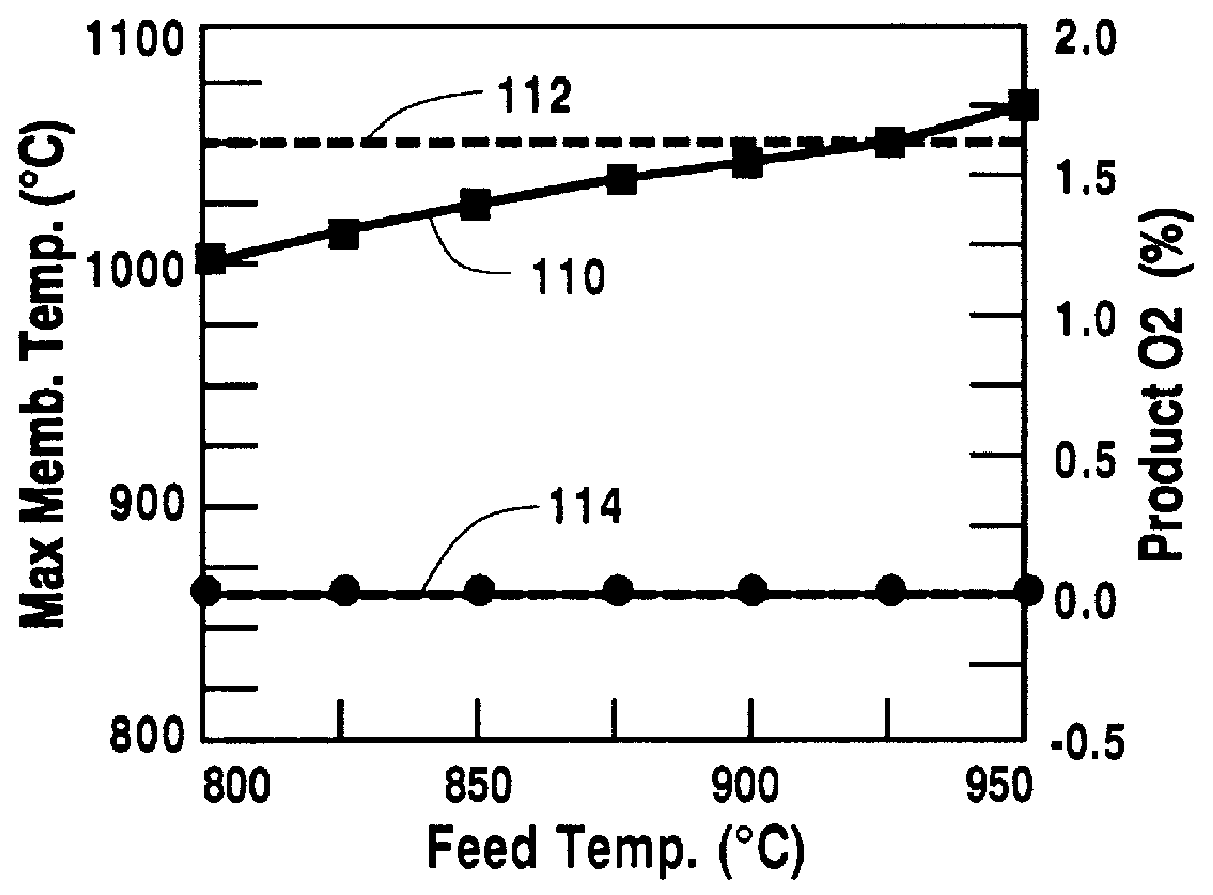

Temperature control in a ceramic membrane reactor

InactiveUS6010614AEnhance exchangeFine surfaceHydrogenLiquid separation by electricityTemperature controlOxygen ions

A method for maintaining the temperature of an oxygen-selective ion transport membrane within a desired temperature range includes providing an ion transport reactor with the oxygen-selective ion transport membrane. An oxygen-donating feed gas is delivered to a cathode side at a first temperature, at a first rate, and at a first oxygen partial pressure and a reactant gas is supplied to an anode side at a second temperature and a second rate. A physical condition is then established within the ion transport reactor that favors the transport of elemental oxygen through the oxygen selective ion transport membrane as oxygen ions. One or more process variables are then regulated to maintain the temperature of the oxygen selective ion transport membrane within the desired range.

Owner:PRAXAIR TECH INC

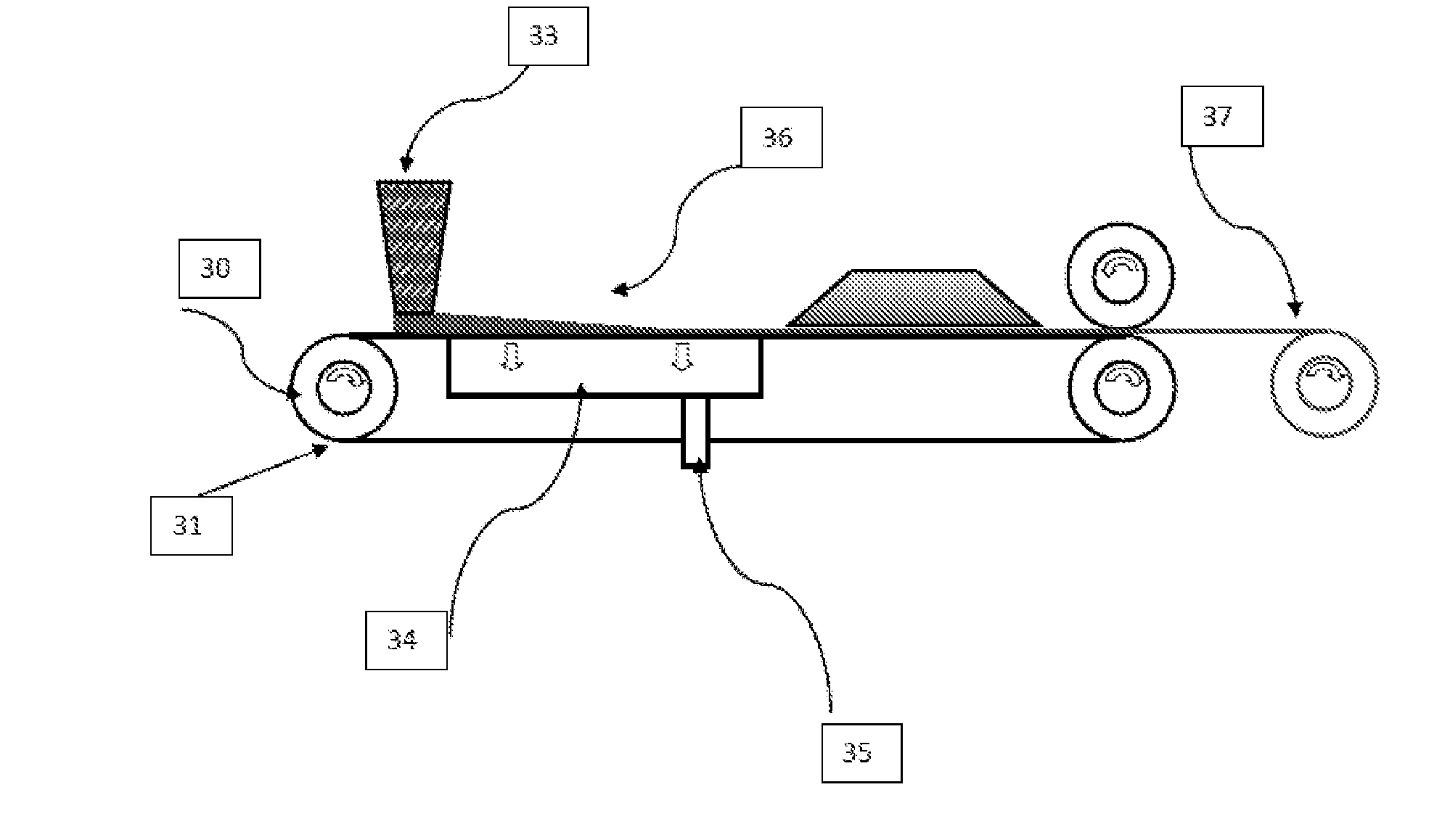

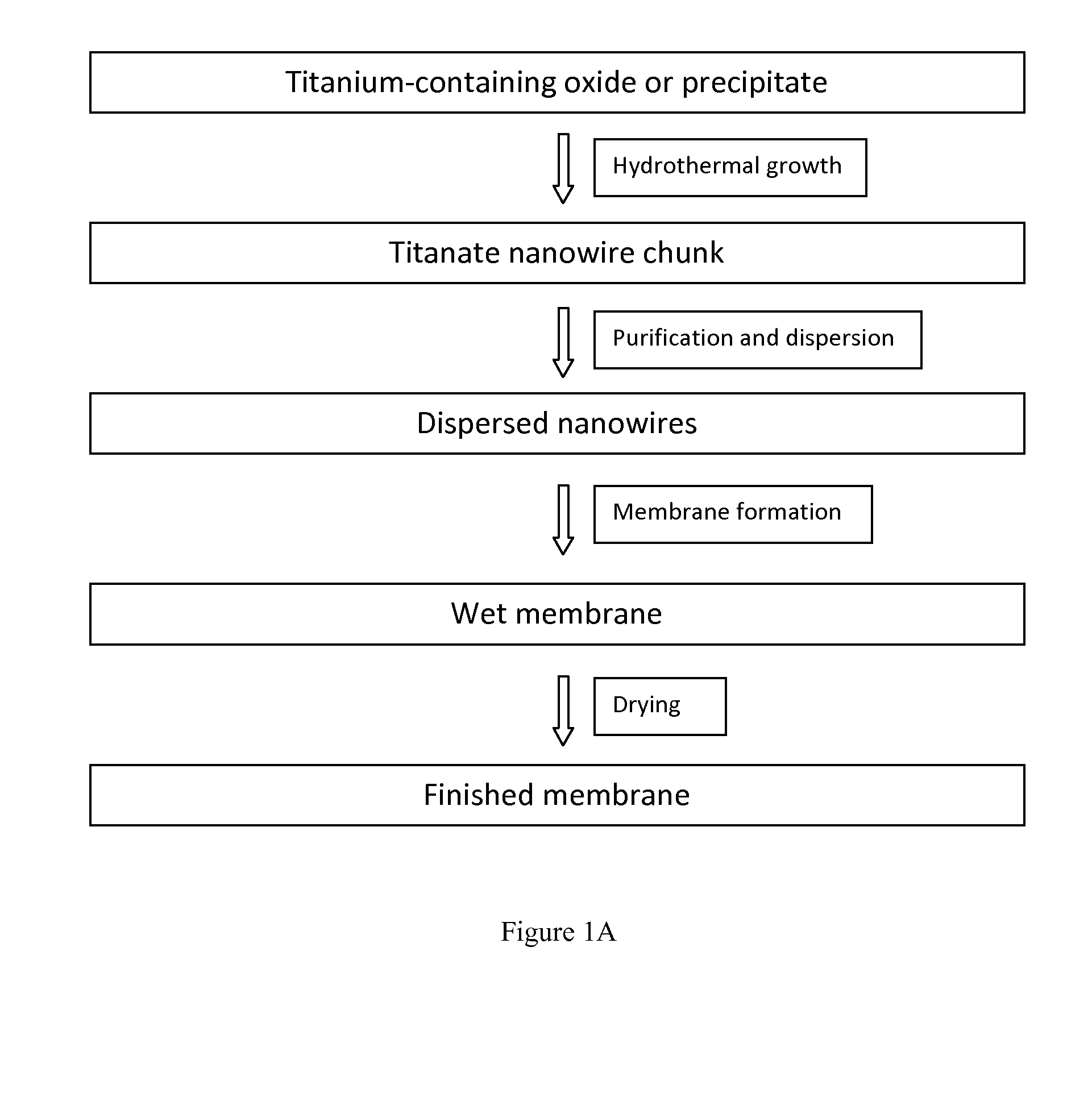

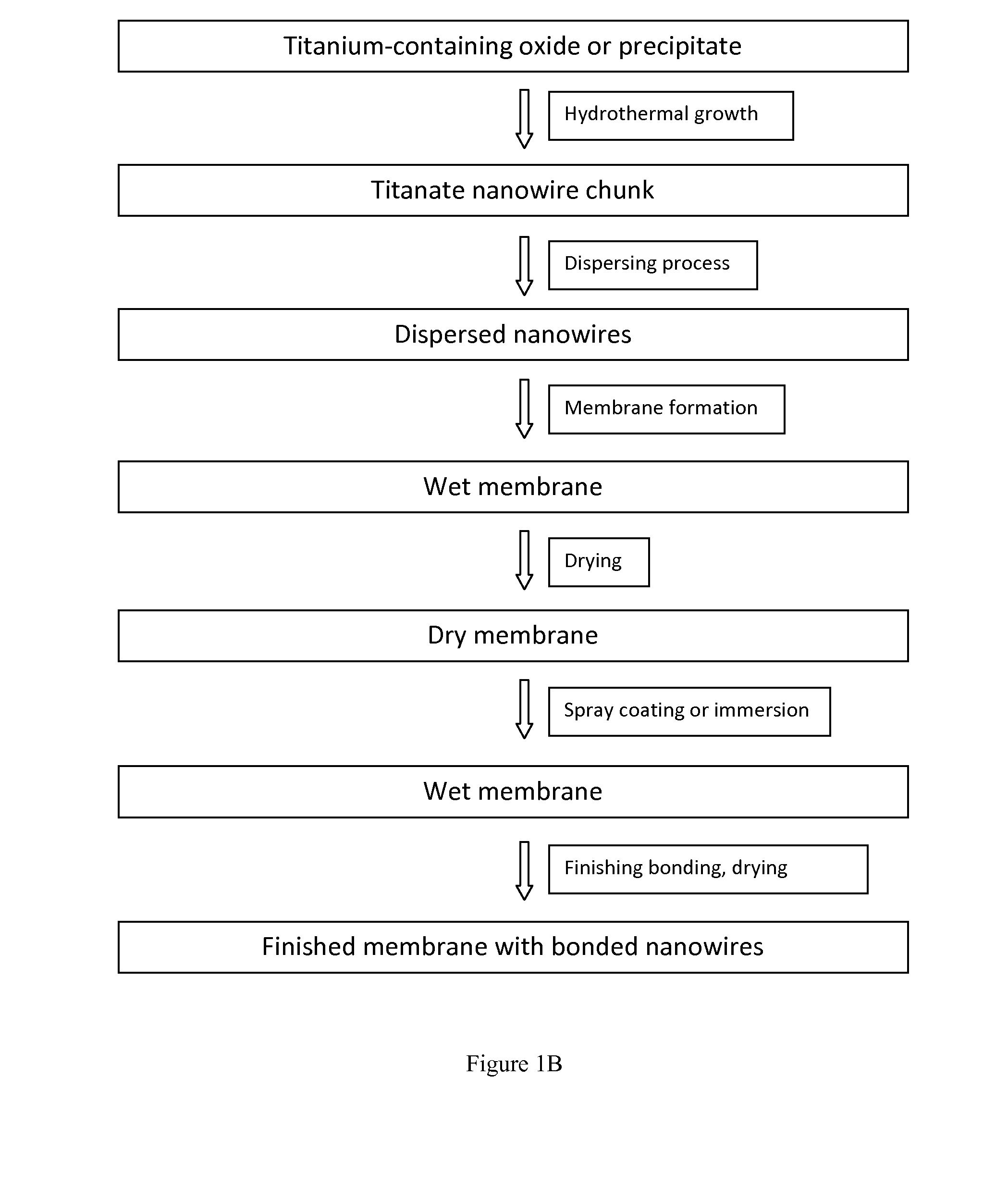

Ceramic nanowire membranes and methods of making the same

InactiveUS20130270180A1StrongStrong membraneSemi-permeable membranesMembranesNanowireCeramic membrane

Owner:NOVARIALS CORP

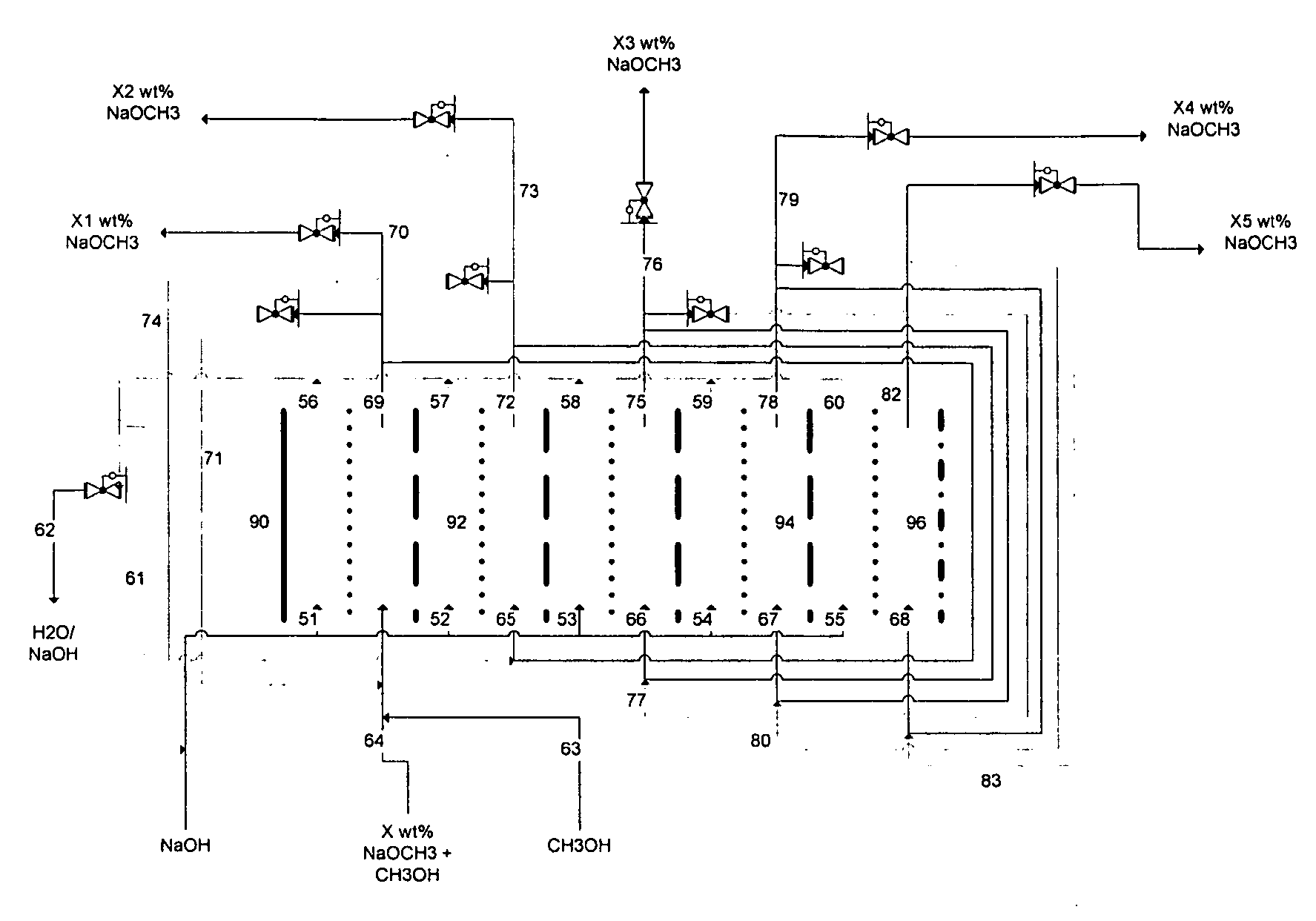

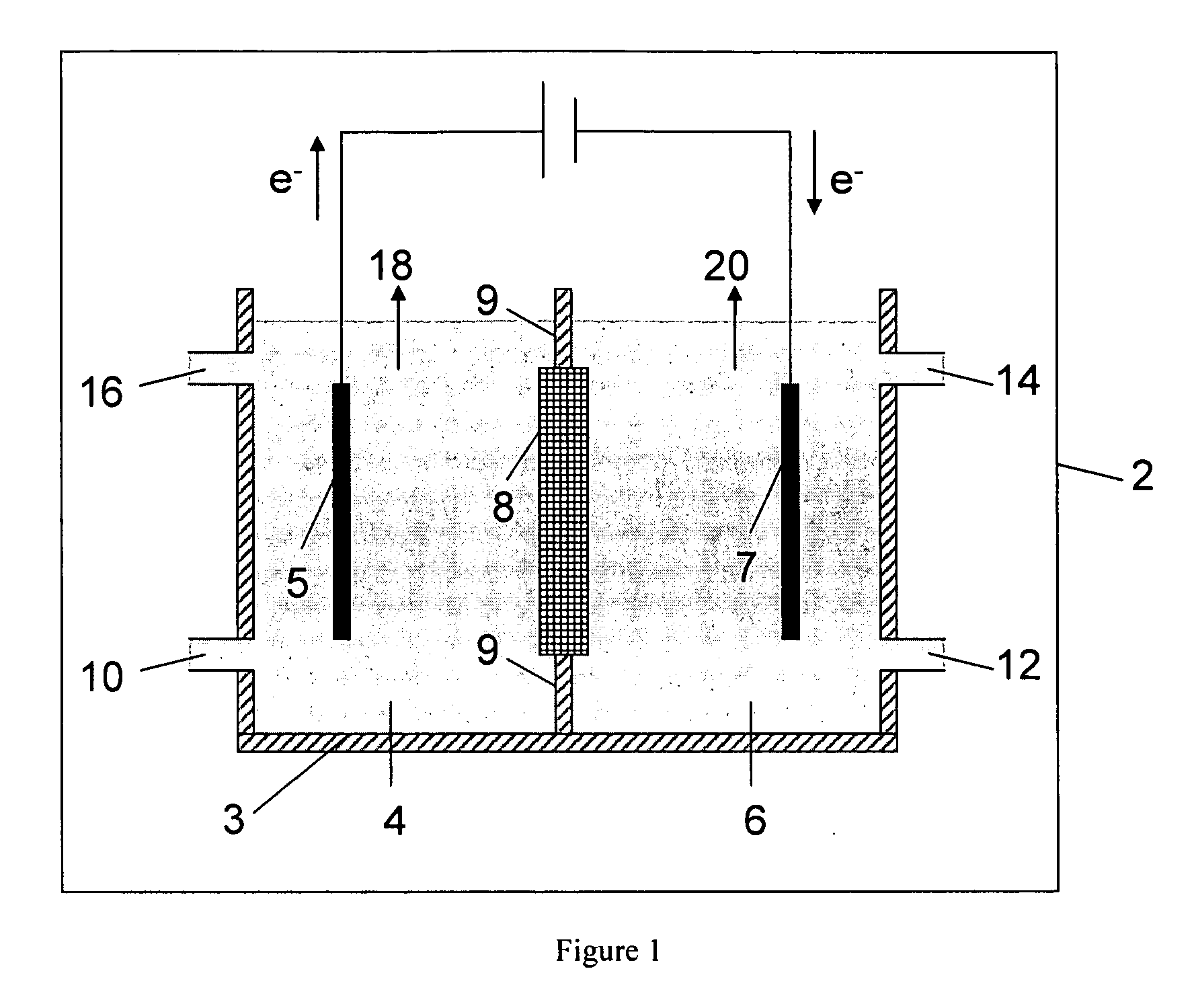

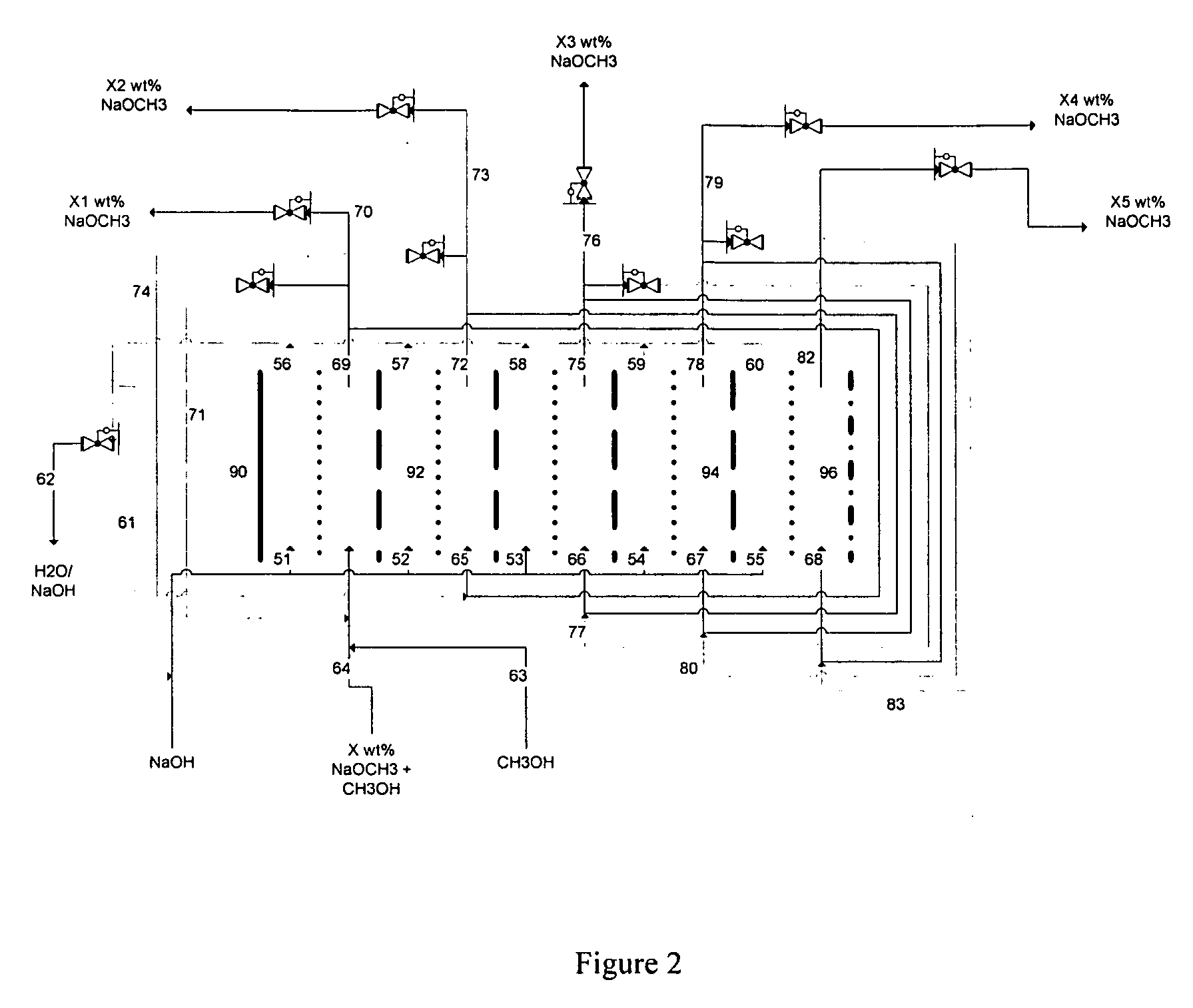

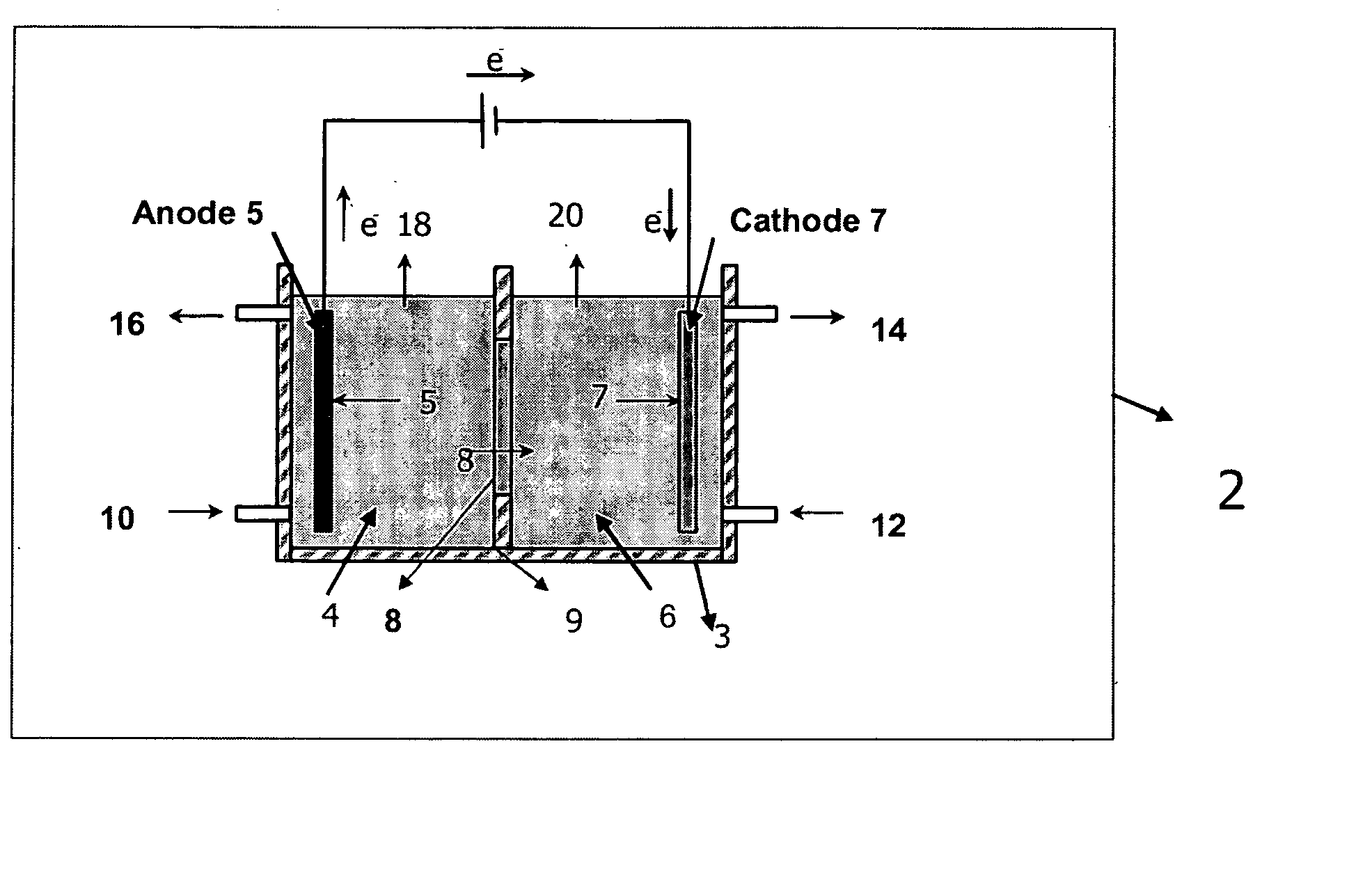

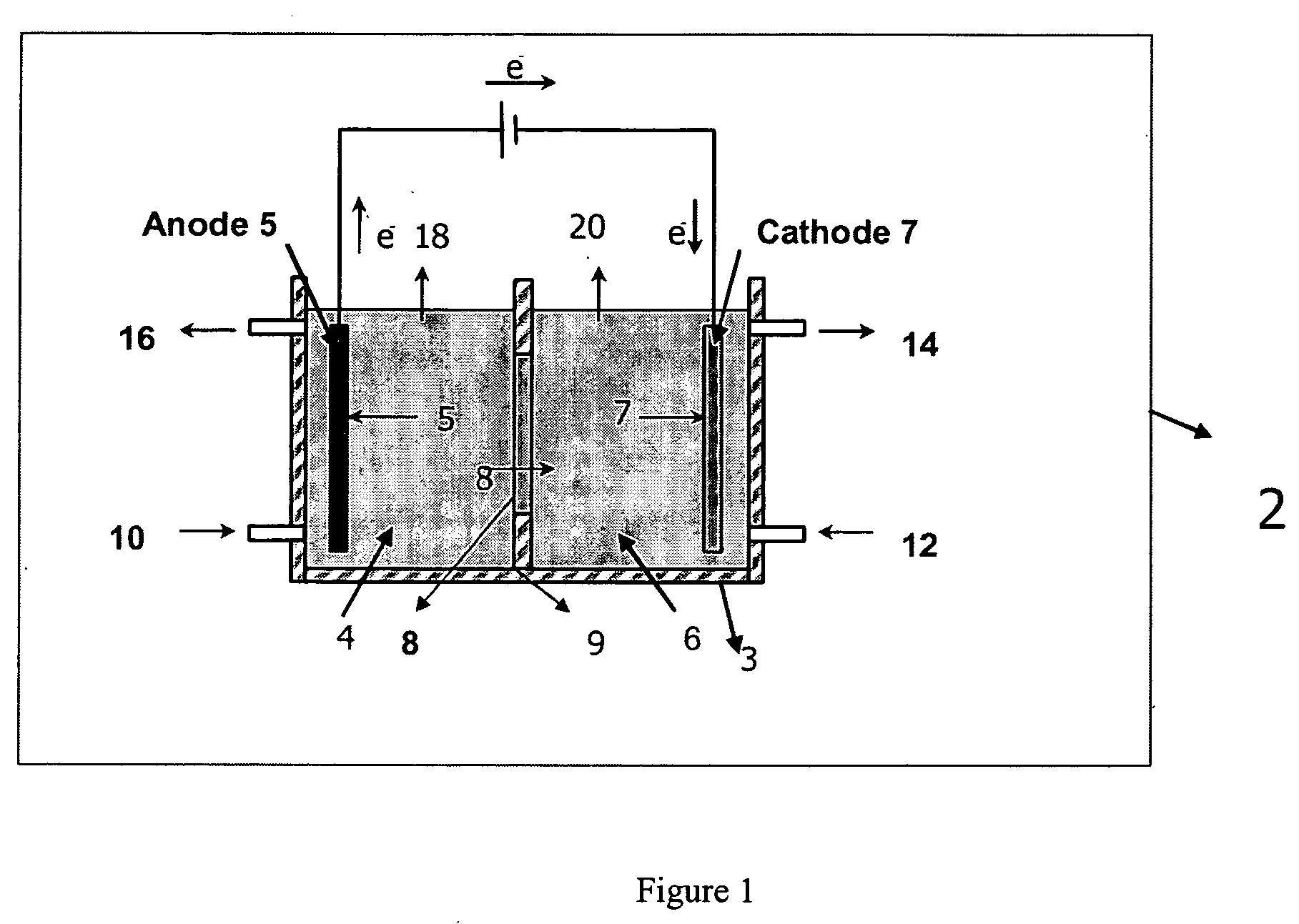

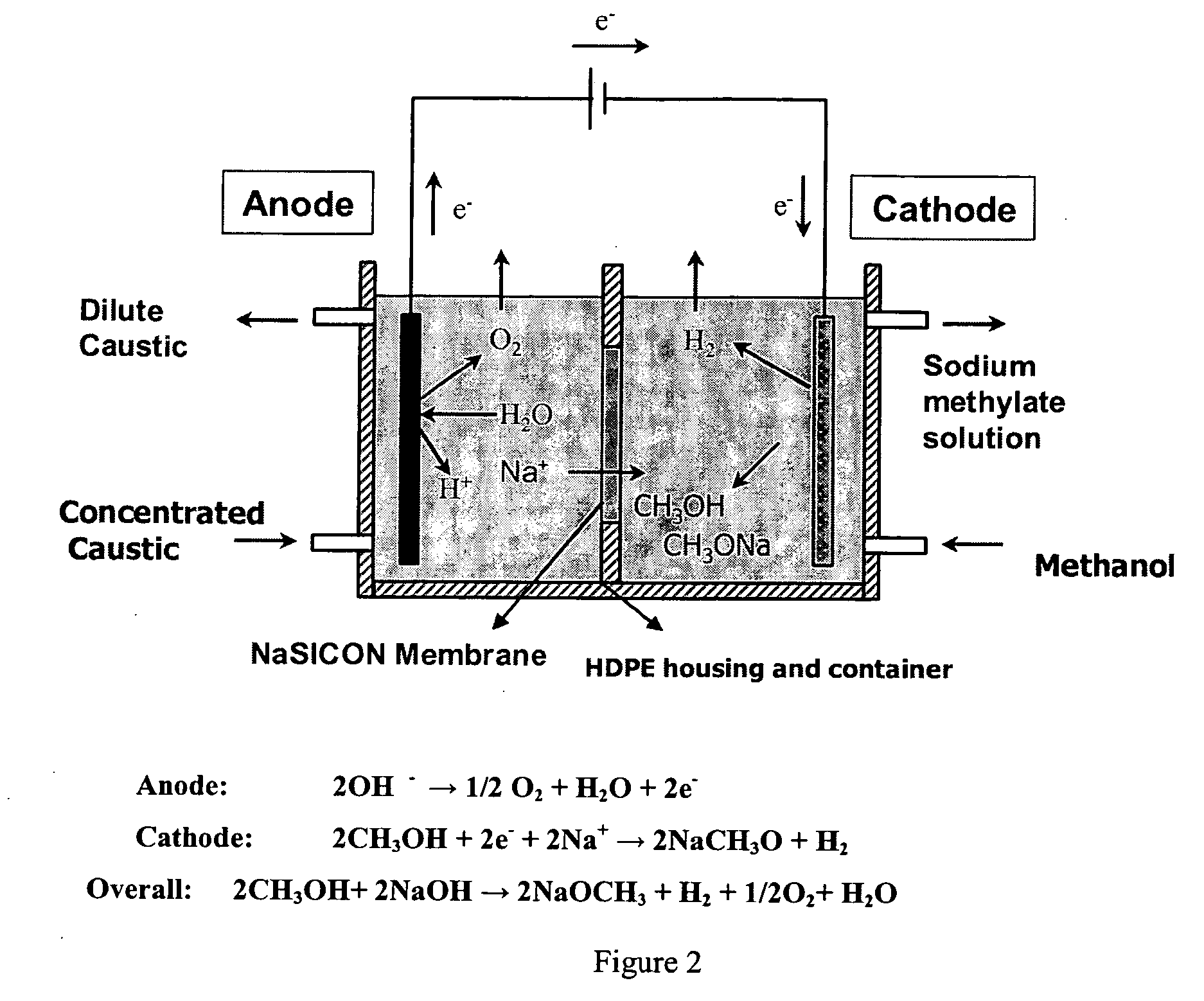

Electrolytic method to make alkali alcoholates using ceramic ion conducting solid membranes

Disclosed are processes of making solutions of alkali alkoxides in their corresponding alcohols using an electrolytic process. In one embodiment, sodium methoxide in methanol is made from methanol and aqueous sodium hydroxide solution, where the aqueous sodium hydroxide solution is present in the anolyte compartment and a solution of sodium methoxide in methanol is present in the catholyte compartment, the two compartments are separated by a ceramic membrane that selectively transports sodium ions under the influence of an electric potential, and wherein the composition of the solution of sodium methoxide in methanol in the catholyte compartment of the electrolytic cell comprises between at least about 2% by weight sodium methoxide and at most about 20% by weight sodium methoxide.

Owner:ENLIGHTEN INNOVATIONS INC

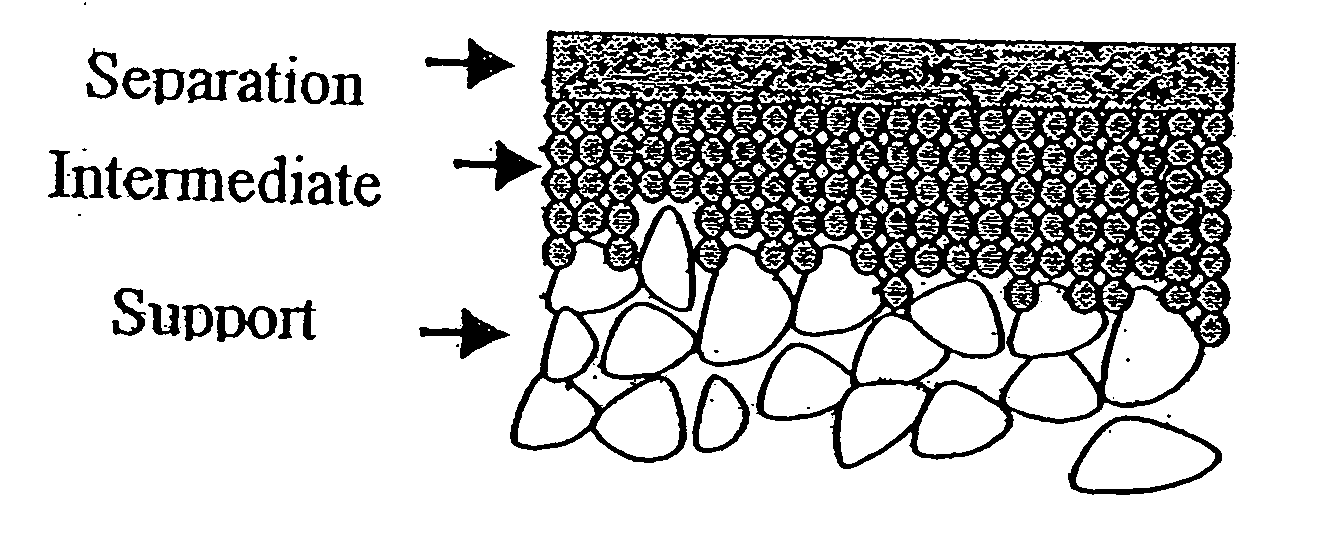

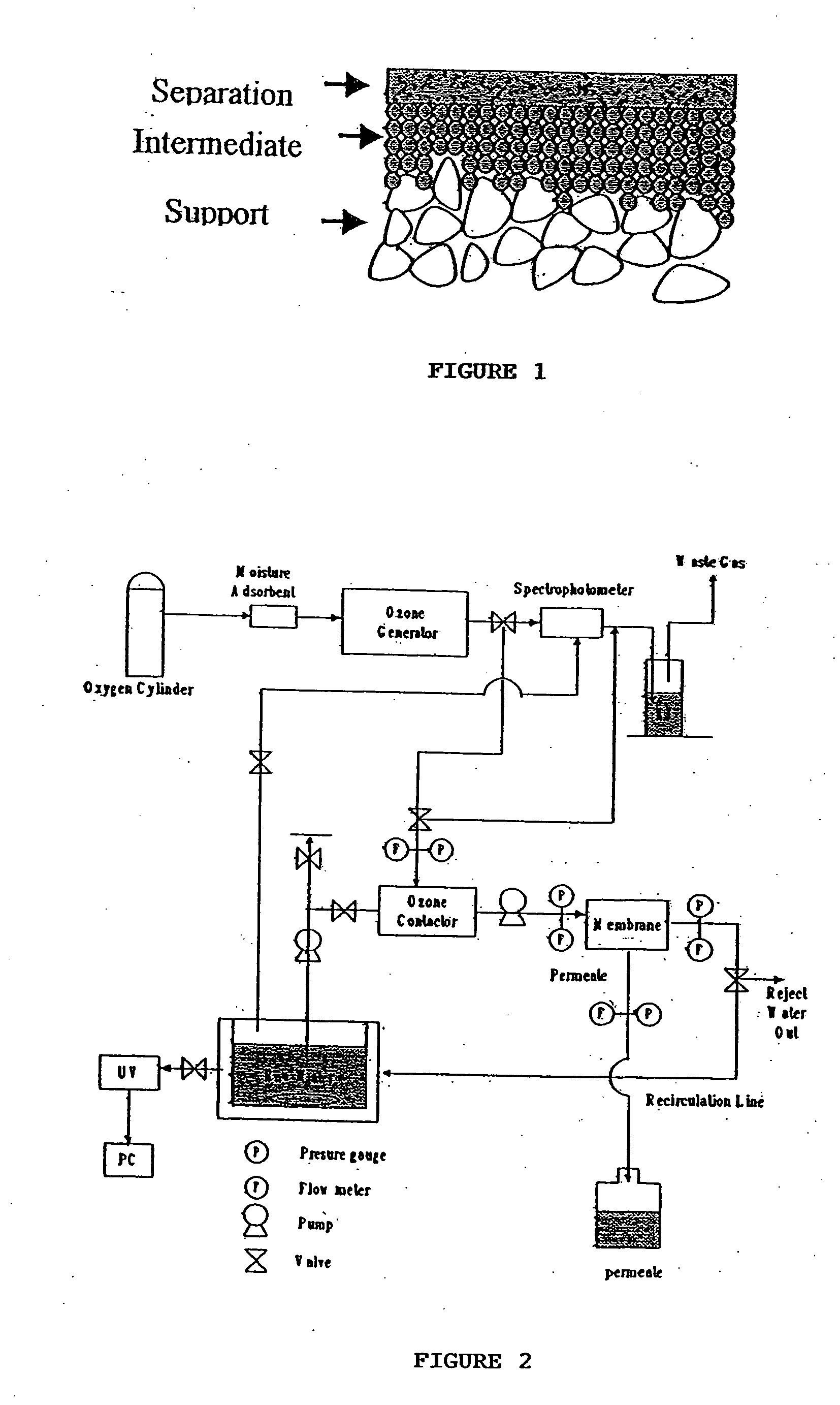

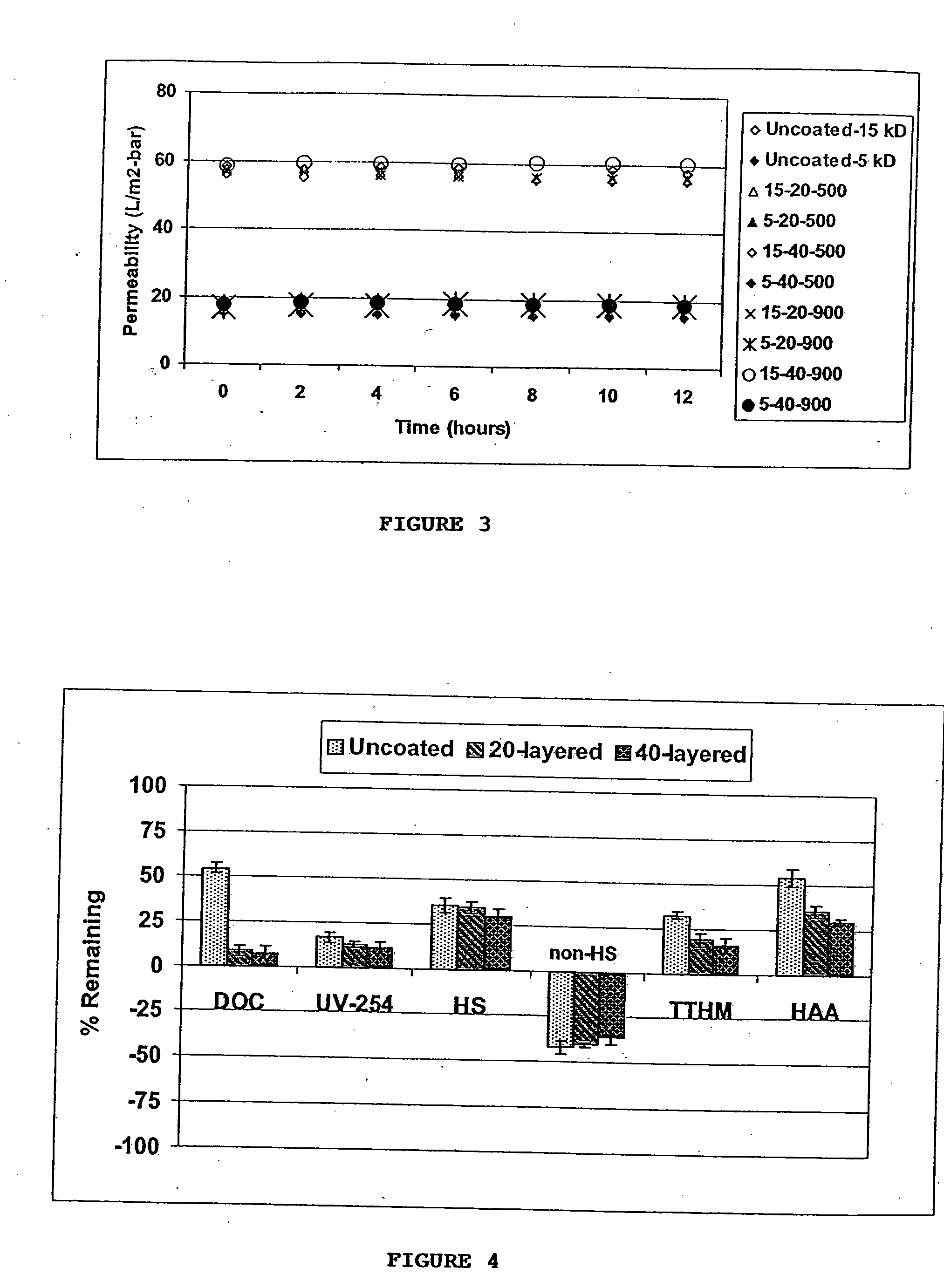

Ceramic membrane water filtration

A process for combined ozone degradation and filtration using a multi-layered, nanocrystalline, sintered ceramic, metal oxide catalyst and ceramic membrane filter is described. The process reduces fouling of the membrane and degrades ozone remaining in the water from ozonation of water to kill microorganisms.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Electrolytic method to make alkali alcoholates using ceramic ion conducting solid membranes

Disclosed are processes of making solutions of metal alcoholates in their corresponding alcohols using an electrolytic process. In a preferred embodiment, sodium methylate in methanol is made from methanol and sodium hydroxide solution. The sodium hydroxide solution is placed in the anolyte compartment and the methanol is placed in the catholyte compartment, and the two compartments are separated by a ceramic membrane that selectively transports sodium under the influence of current. In preferred embodiments, the process is cost-effective and not environmentally harmful.

Owner:ENLIGHTEN INNOVATIONS INC

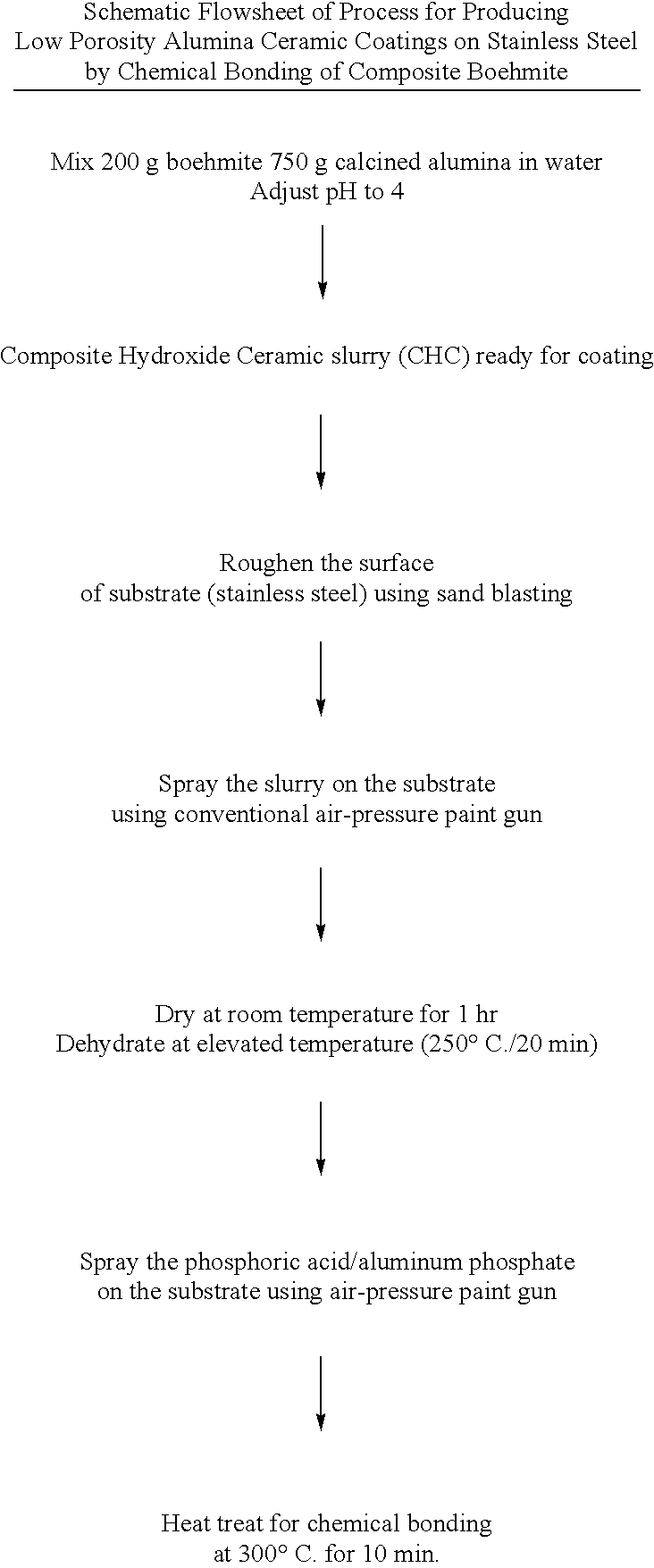

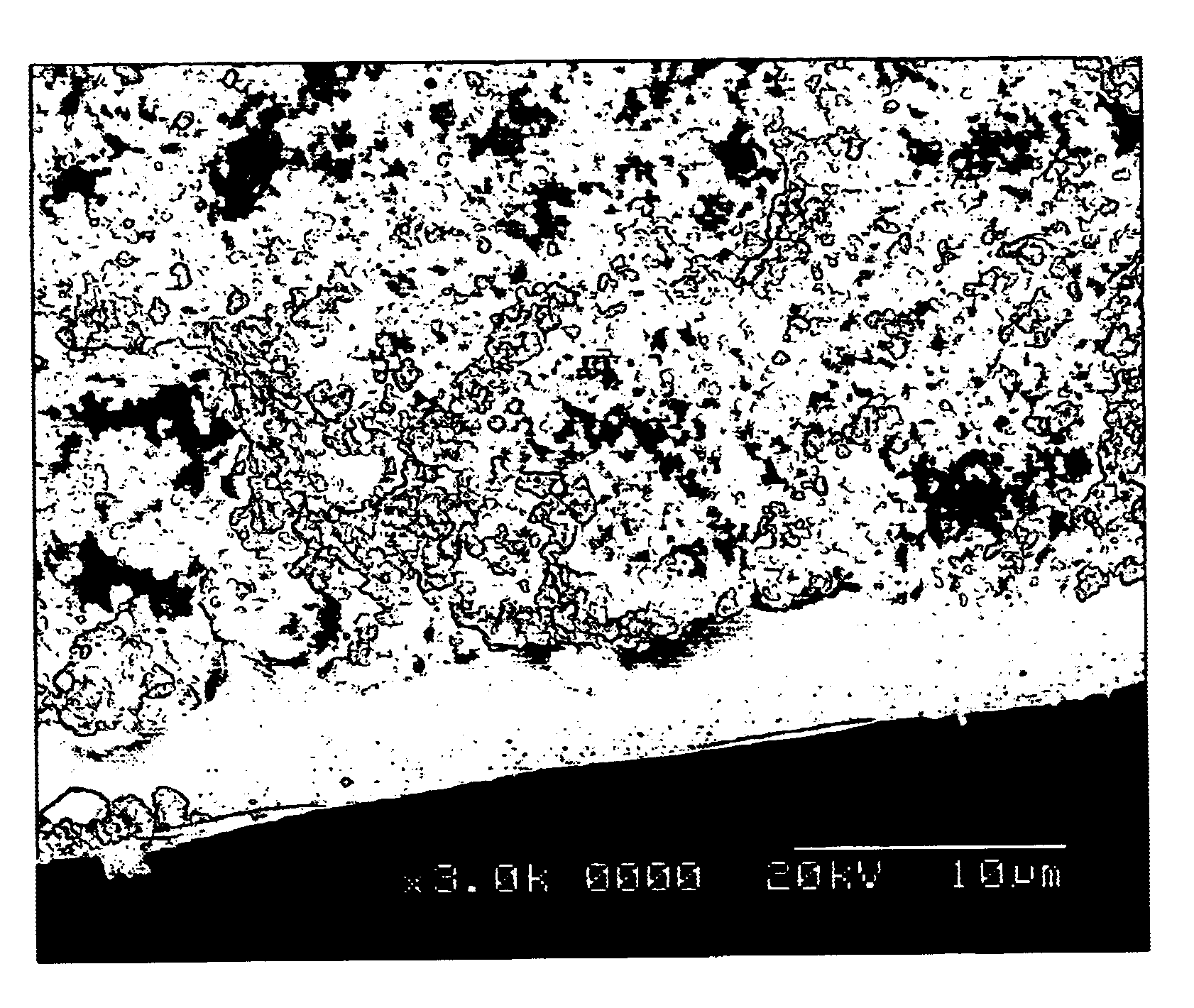

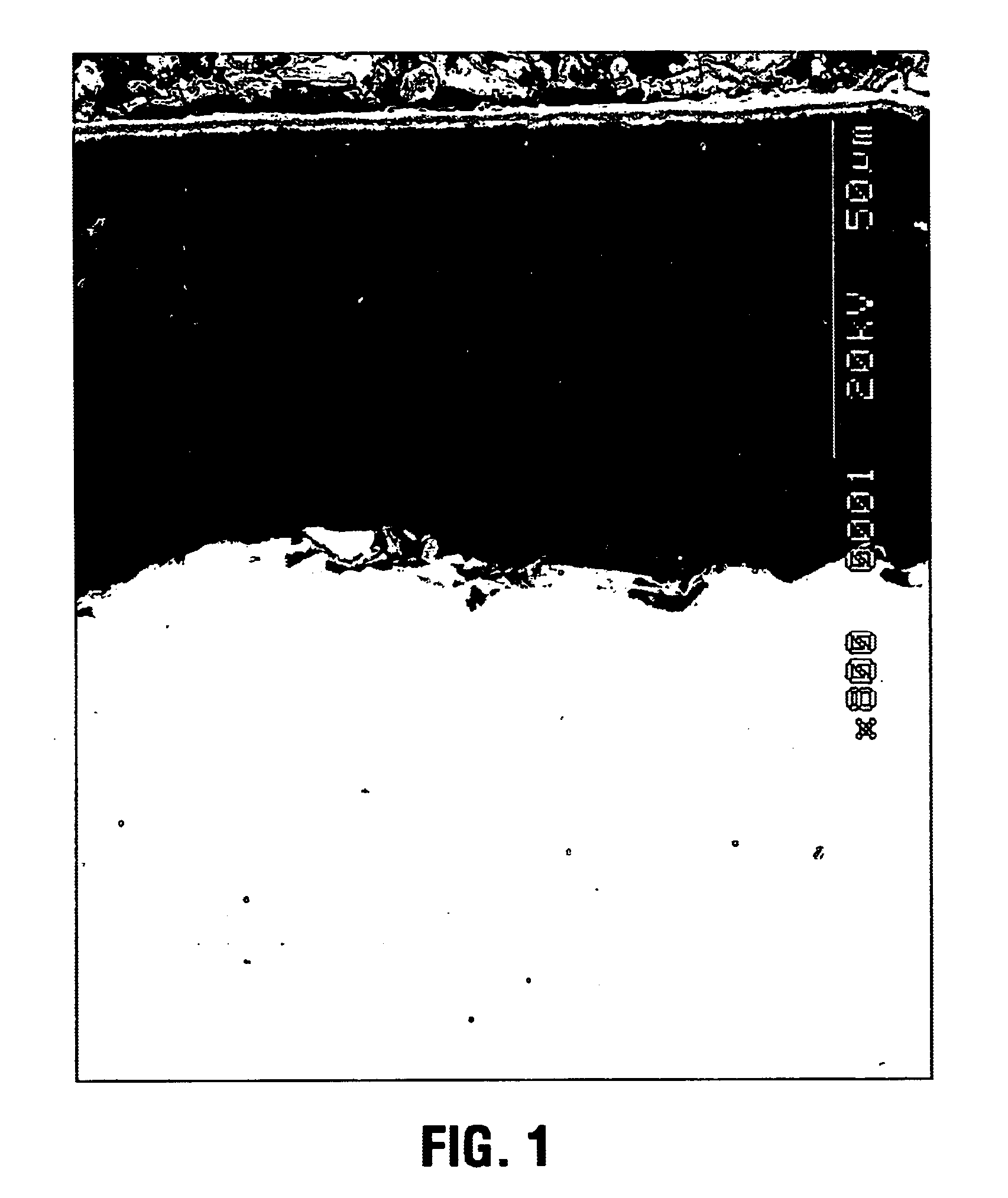

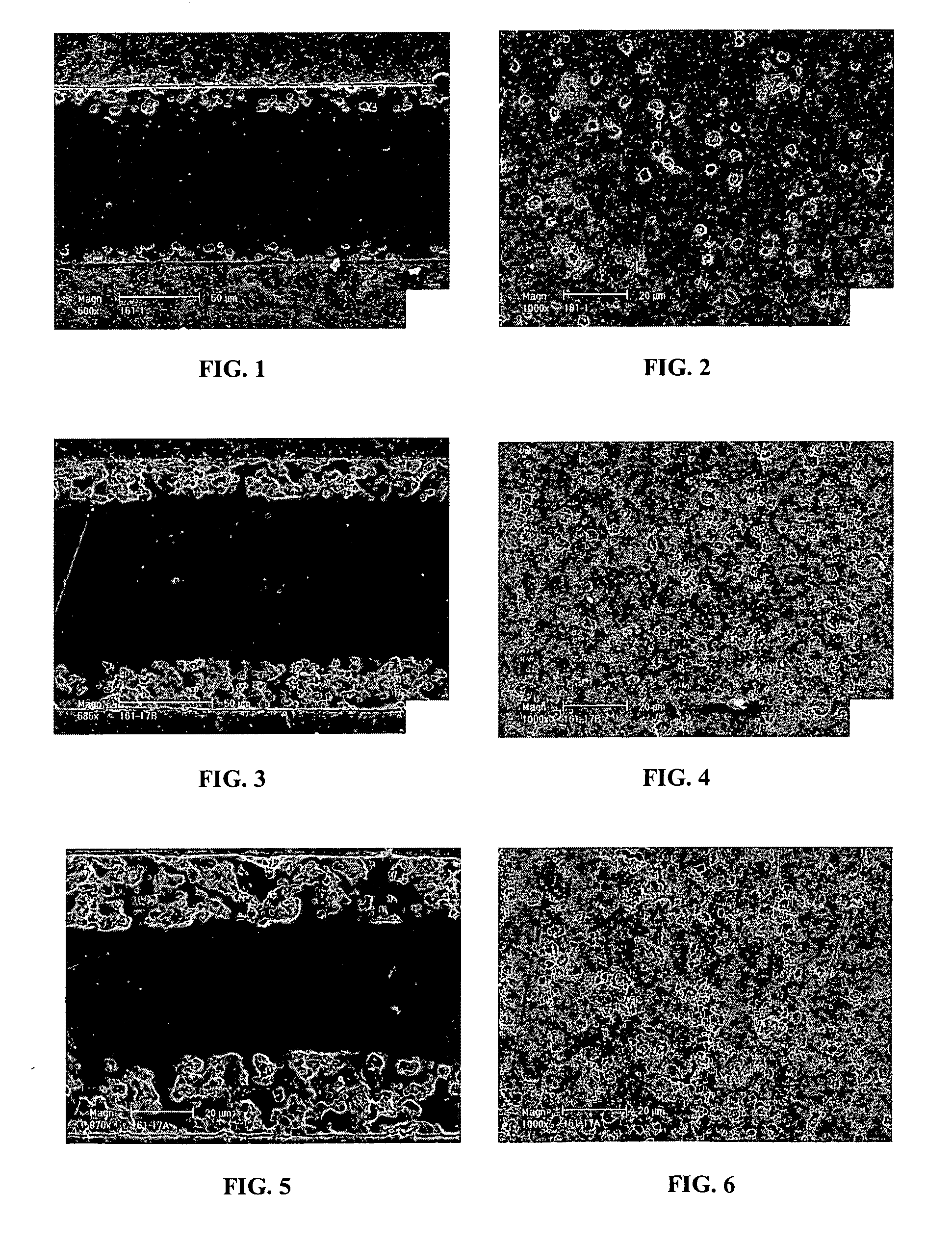

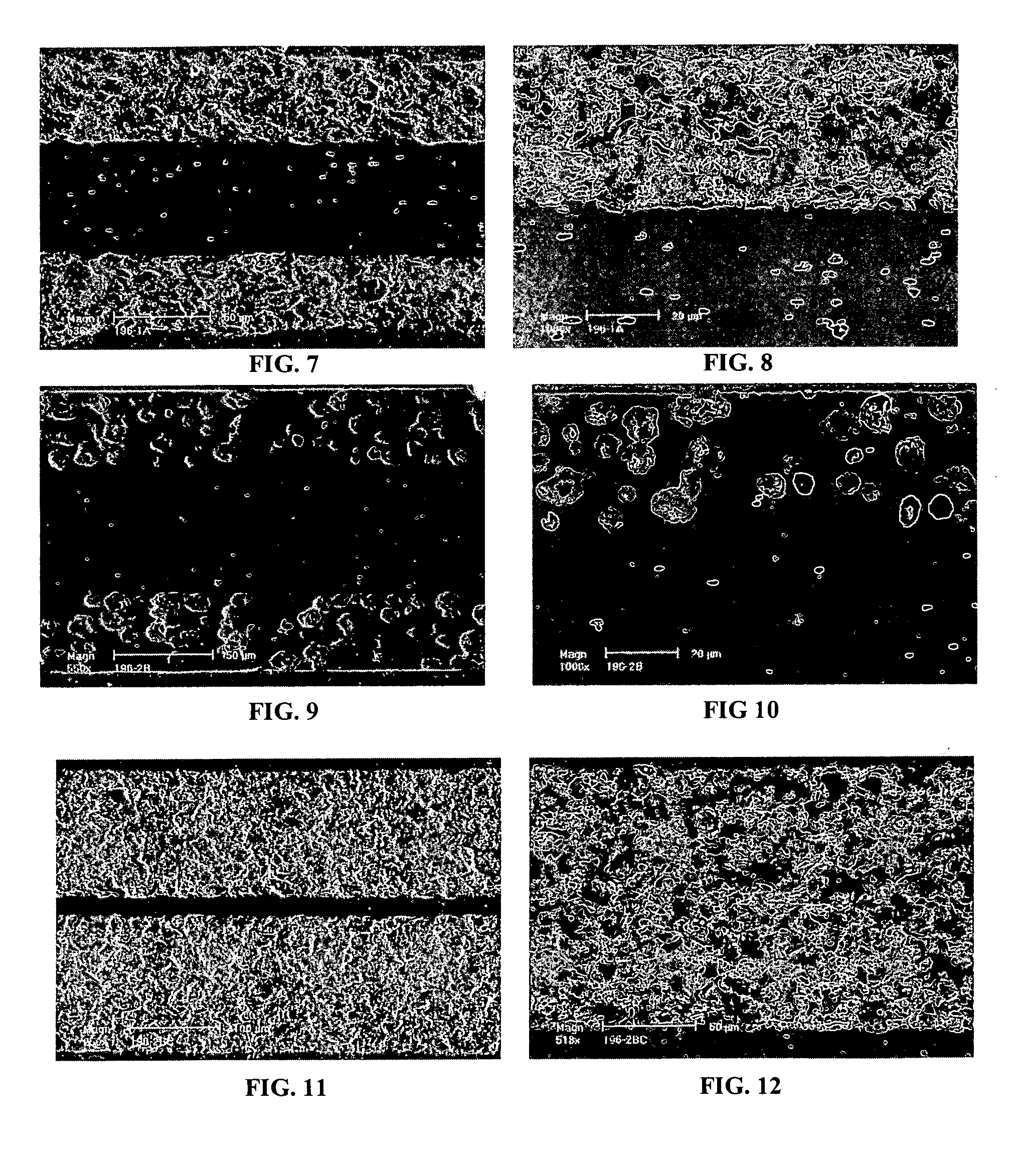

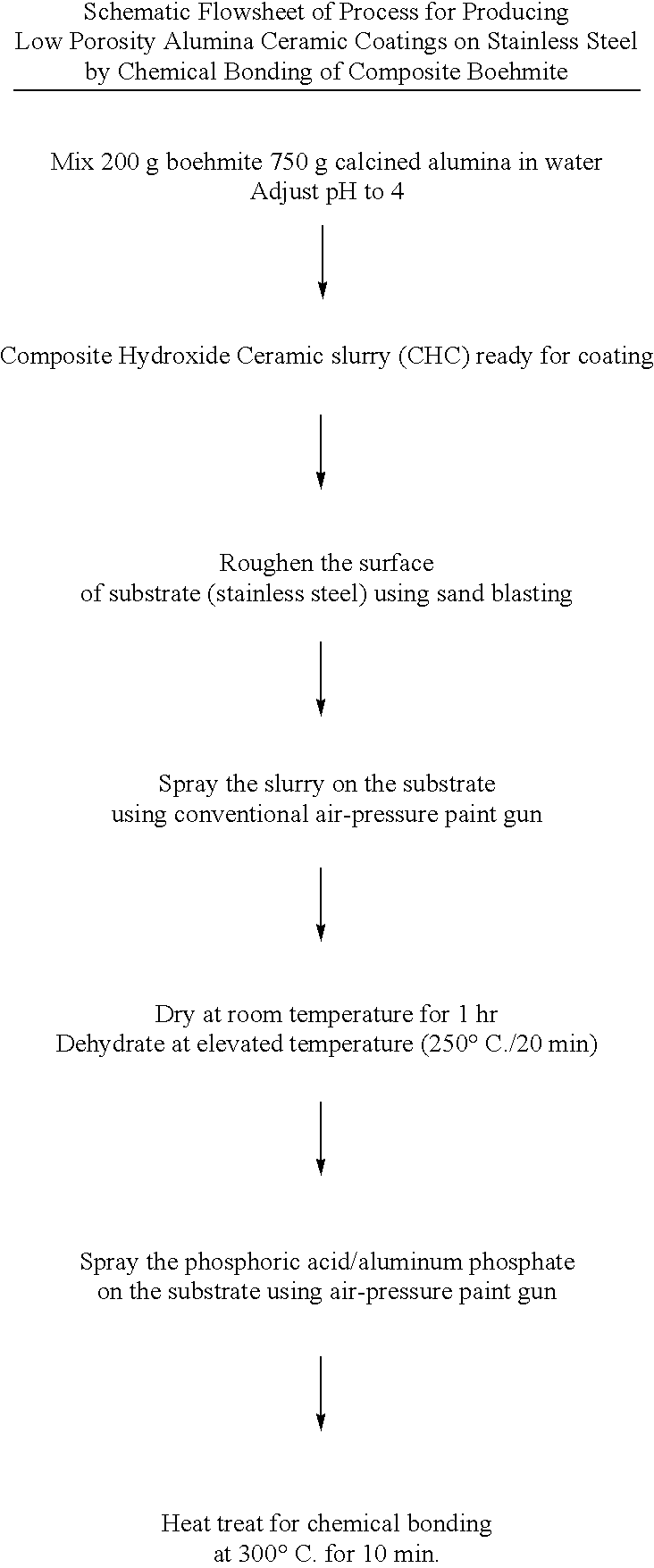

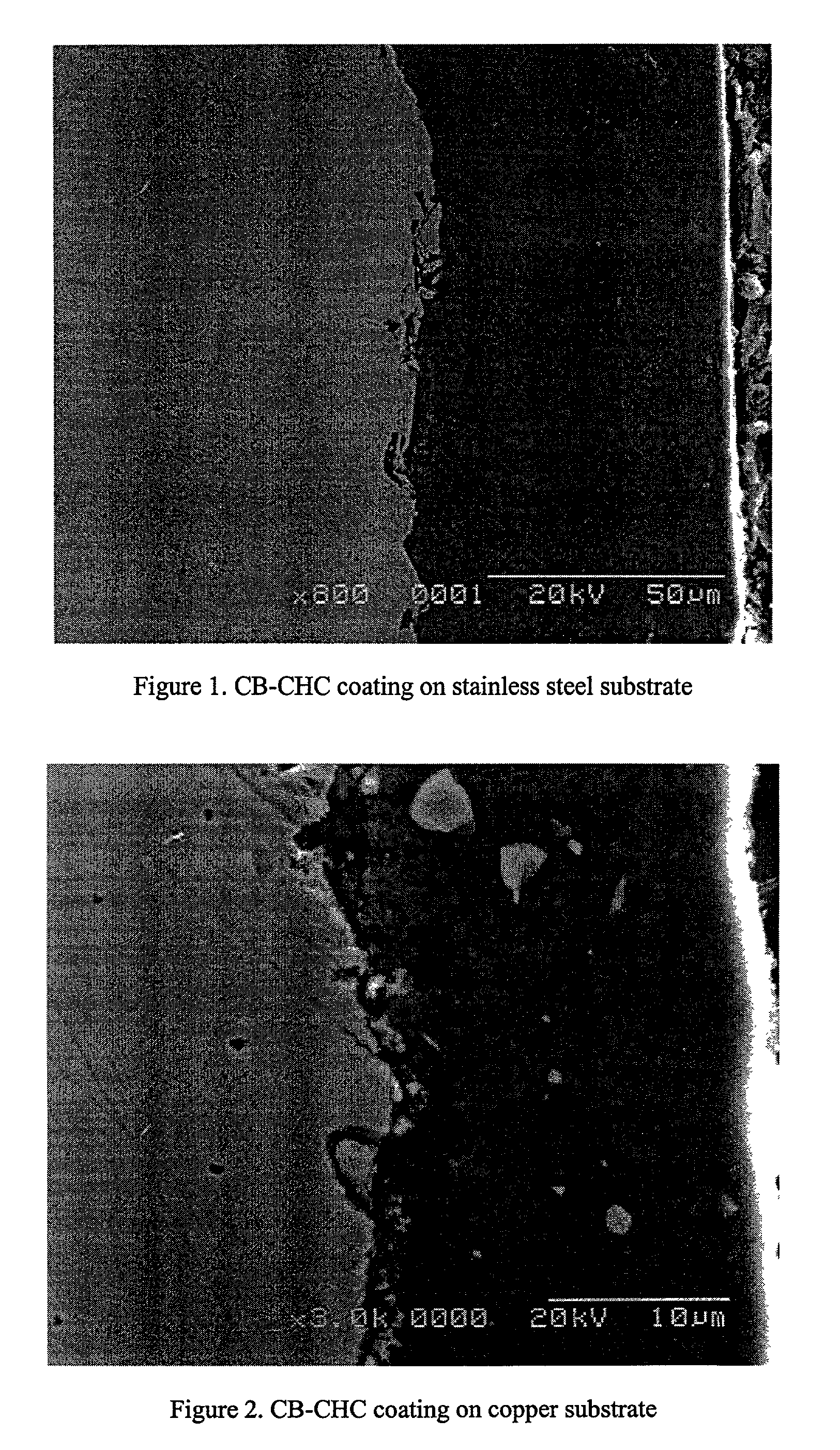

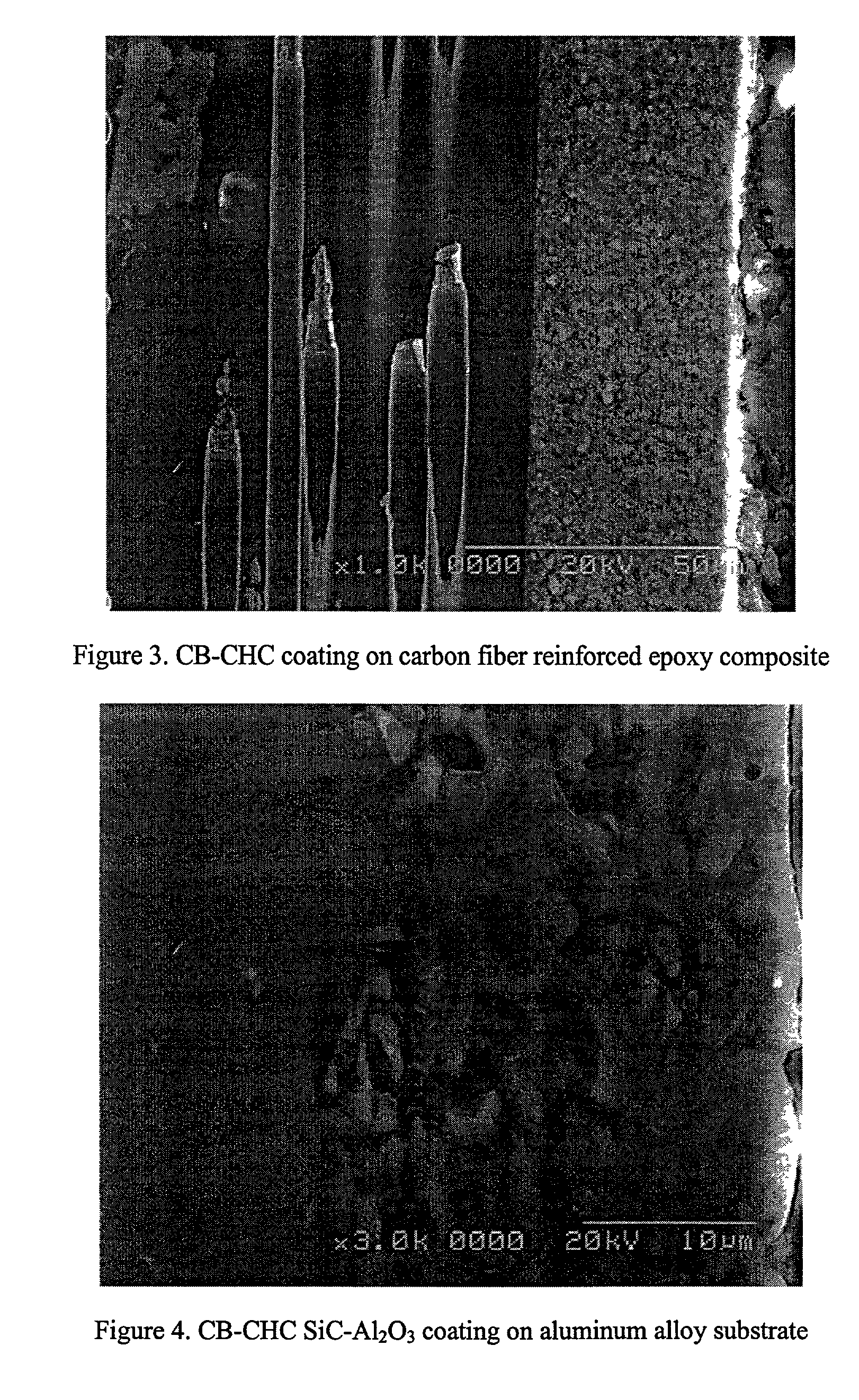

Process for making chemically bonded composite hydroxide ceramics

InactiveUS6770325B2Reduce reactivityMinimizes shrinkageImpression capsPretreated surfacesPhosphateCeramic coating

This invention relates to novel process of preparing chemically bonded composite hydroxide ceramics by exposing a thermally treated hydroxide ceramic to phosphate reagent and subsequent heat treating the resulting system to initiate a rapid chemical bonding reaction. Such combined hydroxide / chemical bonding process can be used to fabricate ceramics or ceramic coatings for a variety of high and low temperature applications, including corrosion protection, wear resistance, dielectric properties, metal reinforced ceramics, ceramic membranes, non-sticky surfaces, bio-active ceramics, thermal barrier ceramics, non-wetted surfaces, and others.

Owner:THE UNIV OF BRITISH COLUMBIA

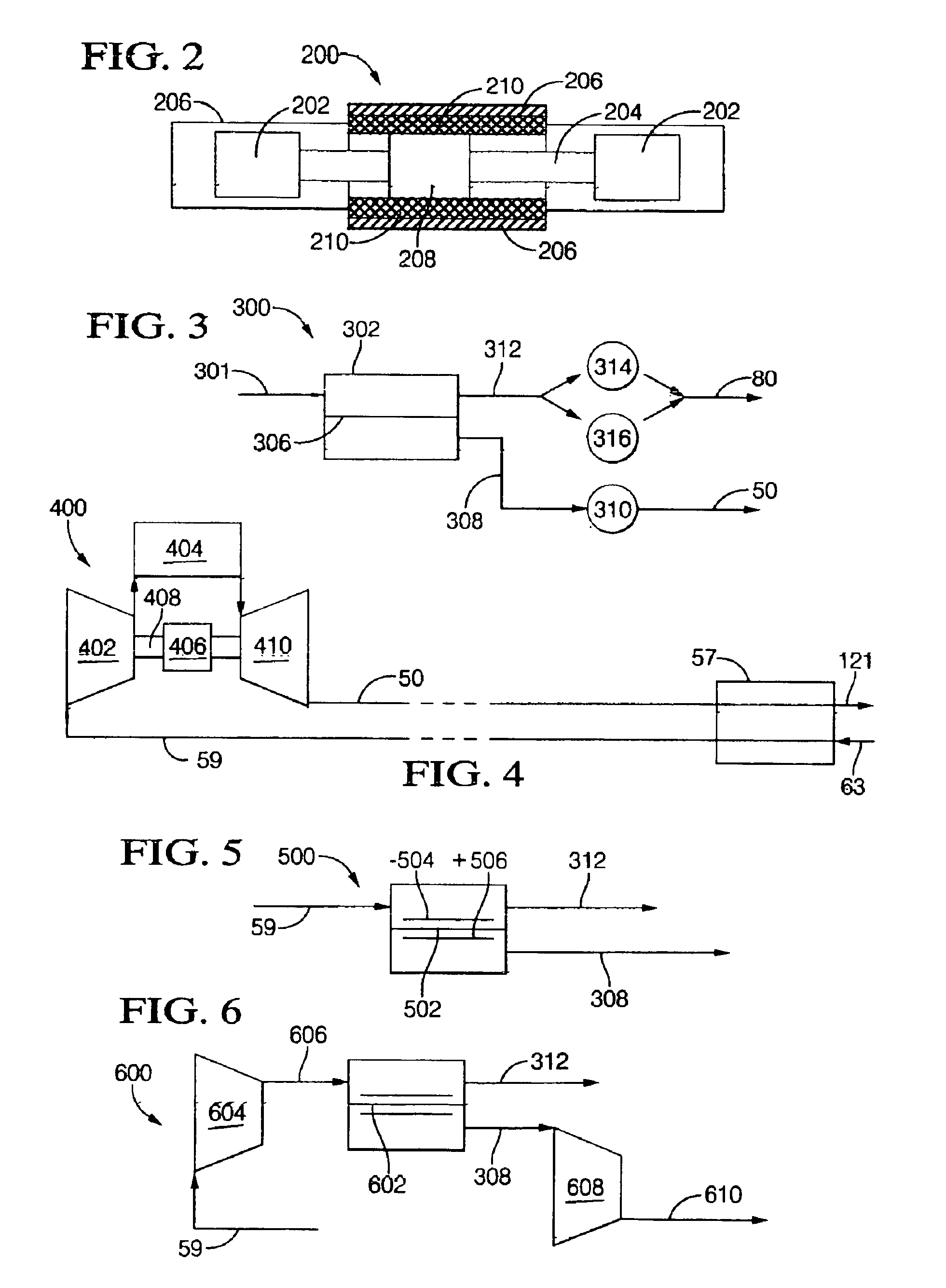

Supported ceramic membranes and electrochemical cells and cell stacks including the same

InactiveUS20060269813A1Advantage in processingAdvantage in mechanical integrityFuel cells groupingFinal product manufacturePorous ceramicsMaterials science

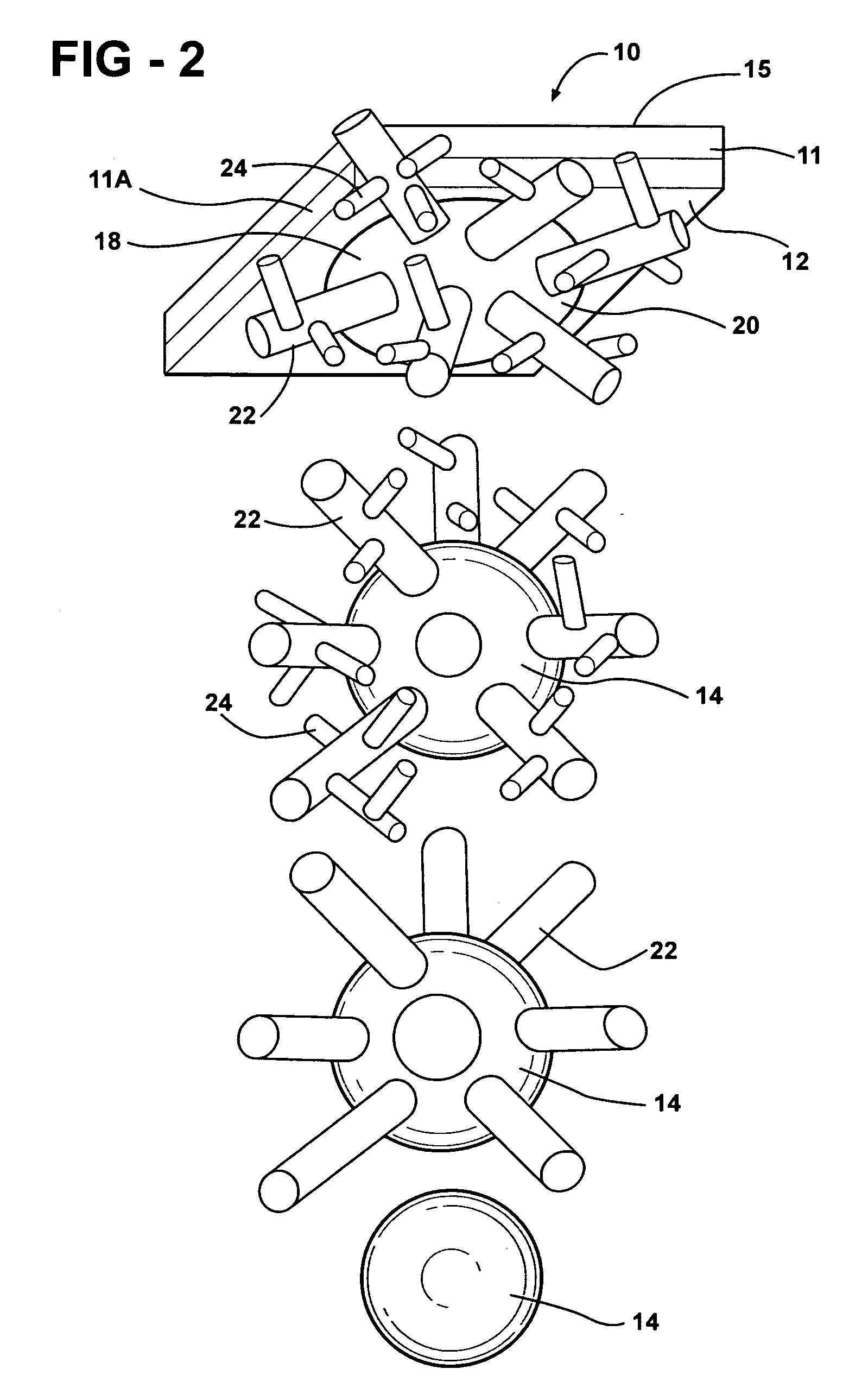

A dense ceramic electrolyte membrane supported by symmetrical porous ceramic electrolyte layers. The thin (t<100 microns) electrolyte layer is sandwiched between two fugitive-containing electrolyte support layers that become highly porous after firing. The heat treated fugitive-containing support layers form a skeletal structure of strongly adhered electrolyte with an interpenetrating network of pores that extends well always from the electrolyte surface. The porous layers can be infiltrated with a range of electrode materials or precursors to form a solid oxide fuel cell or other electrochemical cell as well as electrochemical cell stacks. The supported ceramic membrane provides electrochemical performance advantages and reduces warpage during sintering compared to conventional structures.

Owner:NEXTECH MATERIALS

Ceramic membranes with improved adhesion to plasma-treated polymeric supporting material and their production and use

InactiveUS20080190841A1Overcome disadvantagesMembranesSemi-permeable membranesCeramic coatingCarbon chain

Owner:EVONIK DEGUSSA GMBH

Oxidative reactions using membranes that selectively conduct oxygen

InactiveUS6730808B2Eliminate the problemNot possibleAlkali metal oxides/hydroxidesFunctional group formation/introductionLanthanideOxygen

Reactor membranes for used in oxidation reactions of hydrocarbons involving oxygen comprising a selective oxidation catalyst on a mixed conducting, oxide ion selective ceramic membrane of the composition (Sr1-xCax)1-yAyMn1-zBzO3-delta, whereA is Ba, Pb, Na, K, Y, an element of the lanthanide group or a combination thereof,B is Mg, Al, Ga, In, Sn, an element of the 3d or 4d period or a combination thereof,x is from 0.2 to 0.8,y is from 0 to 0.4,z is from 0 to 0.6, anddelta is a number, dependent on x, y and z, that renders the composition charge neutral.

Owner:BASF AG

Process for making chemically bonded composite hydroxide ceramics

InactiveUS20020107133A1Minimizes shrinkagePromote environmental protectionImpression capsPretreated surfacesPhosphateCeramic coating

This invention relates to novel process of preparing chemically bonded composite hydroxide ceramics by exposing a thermally treated hydroxide ceramic to phosphate reagent and subsequent heat treating the resulting system to initiate a rapid chemical bonding reaction. Such combined hydroxide / chemical bonding process can be used to fabricate ceramics or ceramic coatings for a variety of high and low temperature applications, including corrosion protection, wear resistance, dielectric properties, metal reinforced ceramics, ceramic membranes, non-sticky surfaces, bio-active ceramics, thermal barrier ceramics, non-wetted surfaces, and others.

Owner:THE UNIV OF BRITISH COLUMBIA

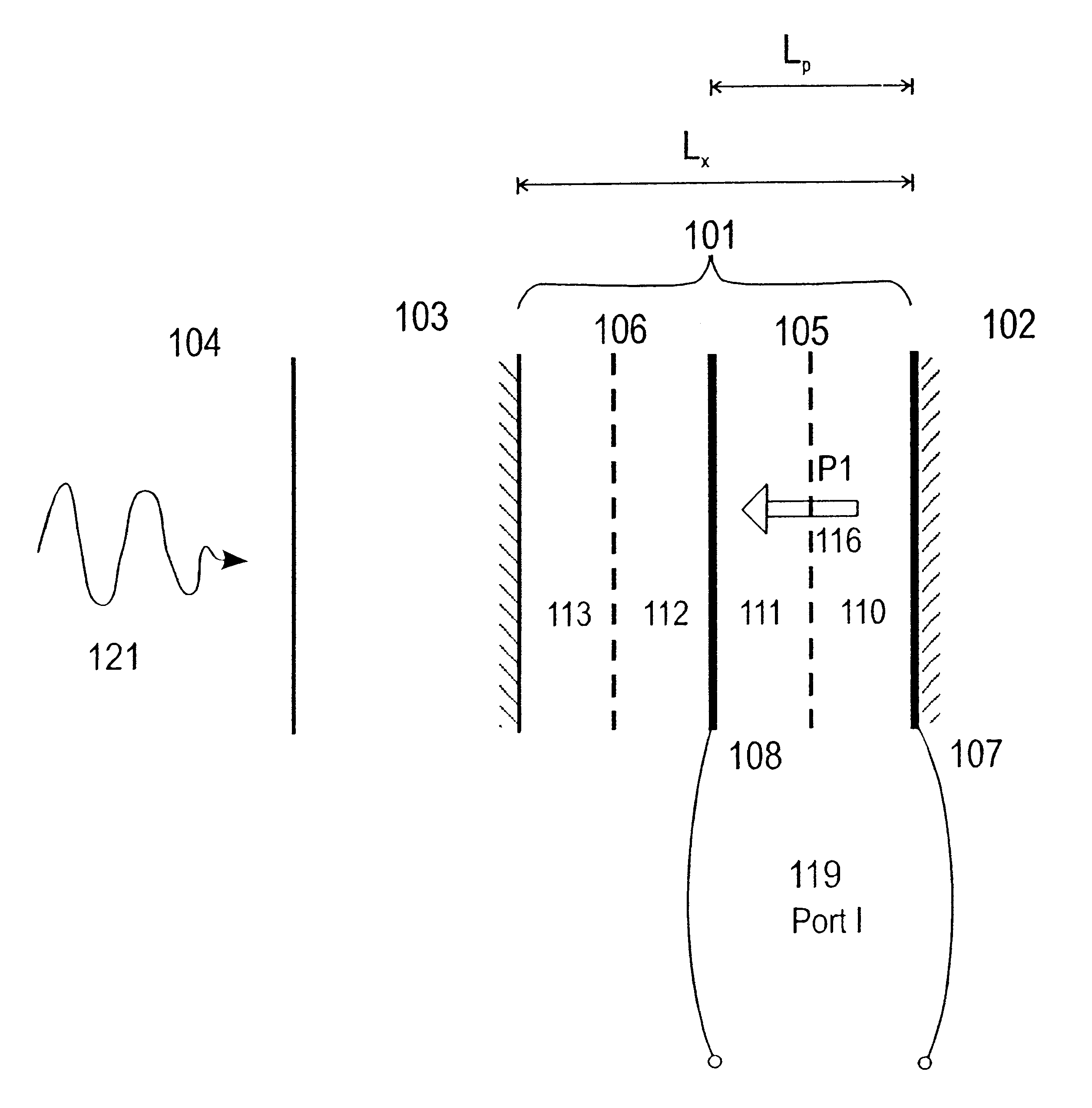

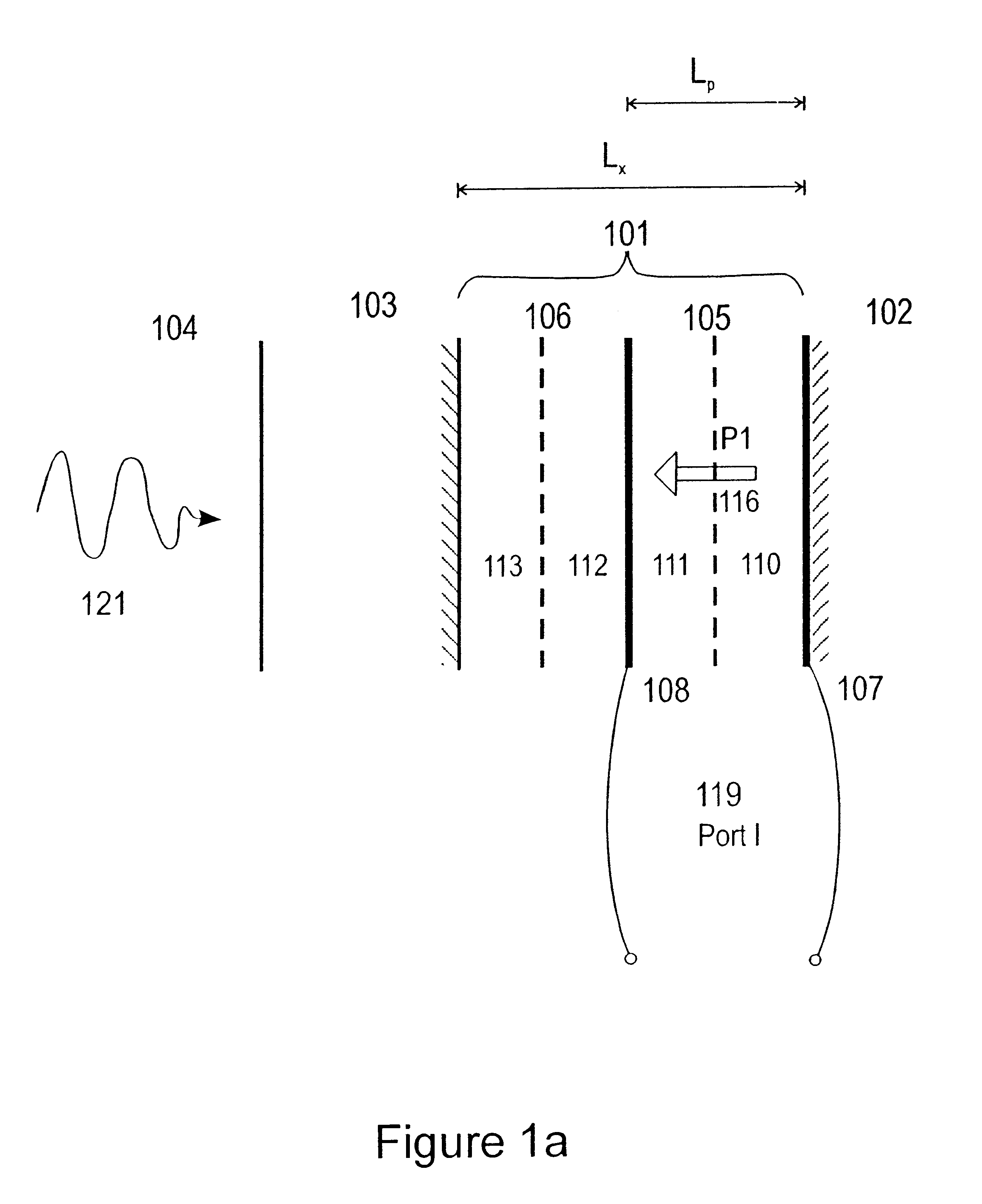

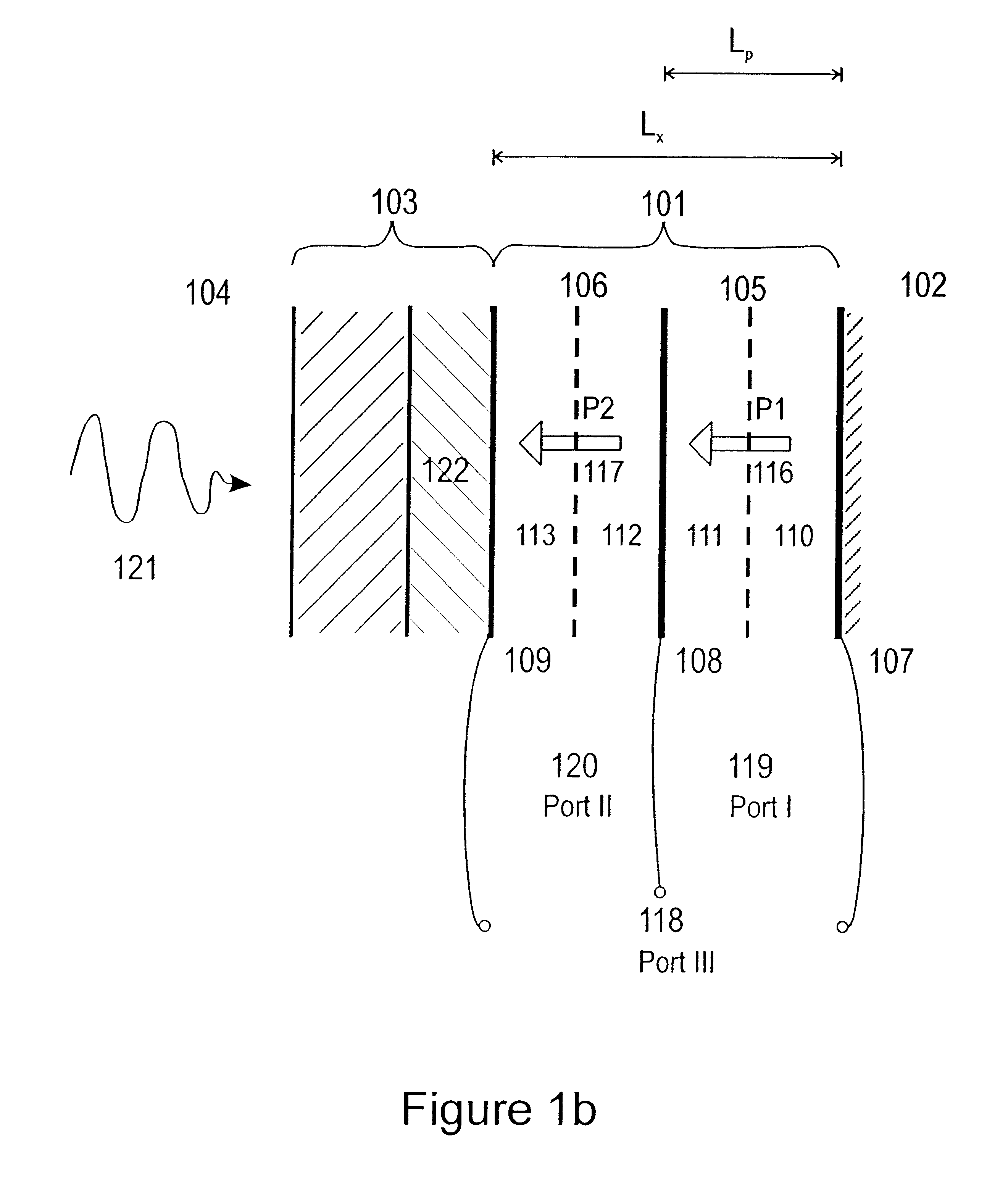

High frequency and multi frequency band ultrasound transducers based on ceramic films

InactiveUS6761692B2Maximizing electromechanical couplingImprove stabilityUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesMulti bandTransceiver

A design and a manufacturing method of ultrasound transducers based on films of ferro-electric ceramic material is presented, the transducers being particularly useful for operating at frequencies above 10 MHz. The designs also involve acoustic load matching layers that provides particularly wide bandwidth of the transducers, and also multiple electric port transducers using multiple piezoelectric layers, for multi-band operation of the transducers over an even wider band of frequencies that covers ~4 harmonics of a fundamental band. A transceiver drive system for the multi-port transducers that provides simple selection of the frequency bands of transmitted pulses as well as transmission of multi-band pulses, and reception of scattered signals in multiple frequency bands, is presented. The basic designs can be used for elements in a transducer array, that provides all the features of the single element transducer for array steering of the focus and possibly also direction of a pulsed ultrasound beam at high frequencies and multi-band frequencies. The manufacturing technique can involve tape-casting of the ceramic films, deposition of the ceramic films onto a substrate with thick film printing, sol-gel, or other deposition techniques, where manufacturing methods for load matching layers and composite ceramic layers are described.

Owner:PREXION

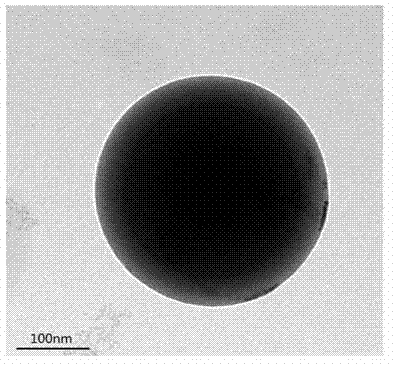

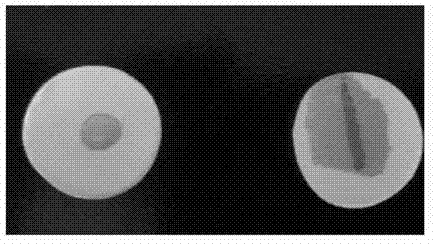

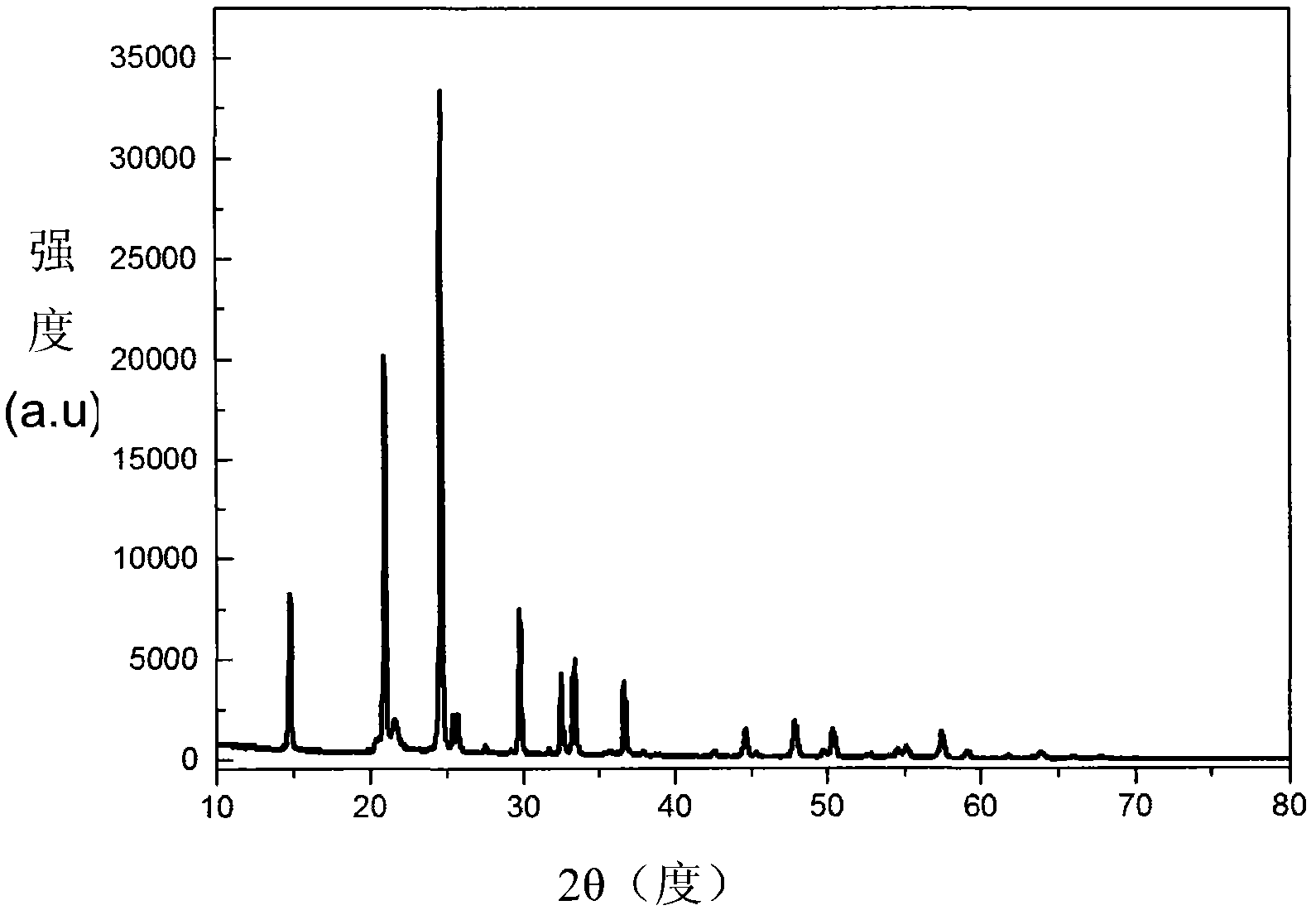

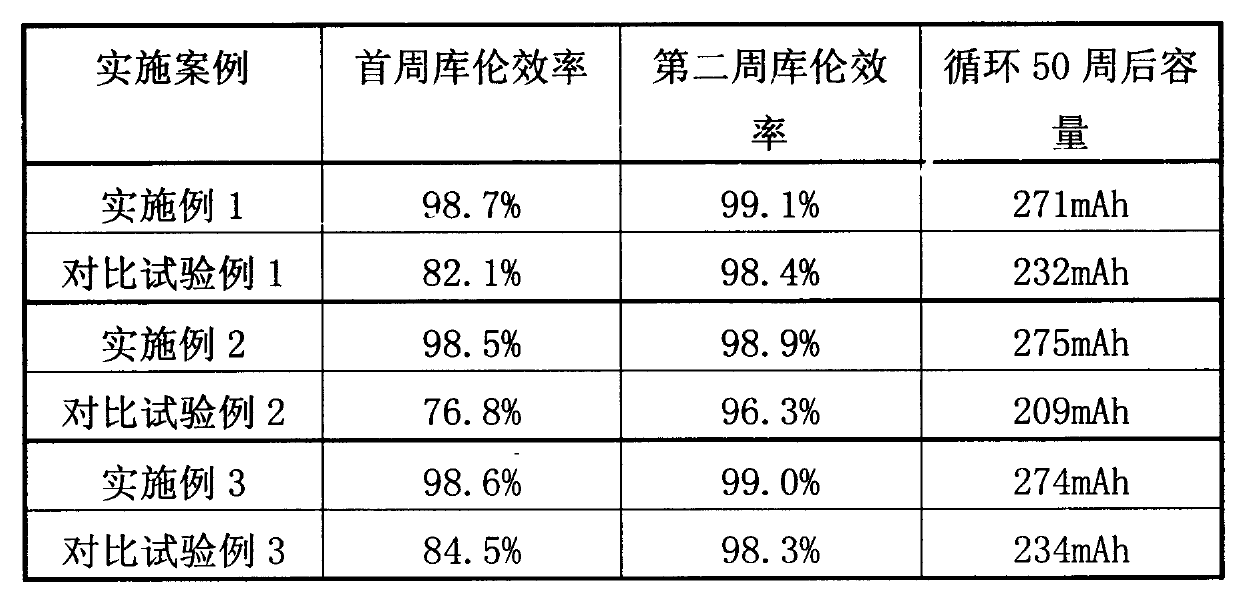

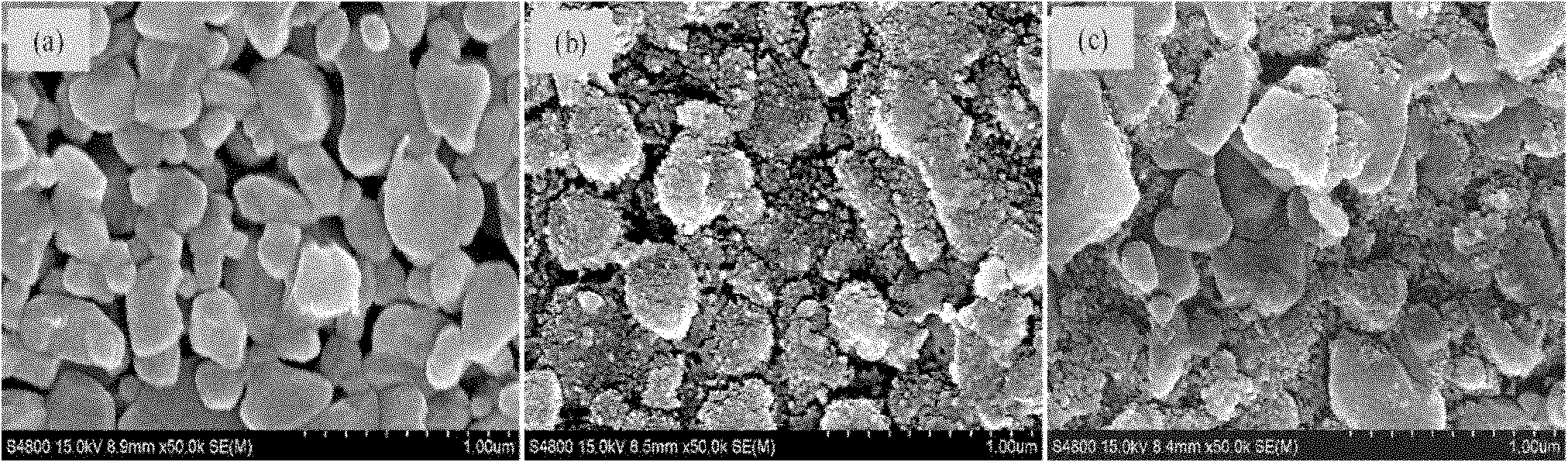

Ceramic membrane, application of ceramic membrane to battery and battery comprising ceramic membrane

ActiveCN103035866AFast conductionImprove cycle performanceCell component detailsMetallurgyHeat stability

The invention belongs to the field of electrochemistry and in particular relates to a ceramic membrane. Particularly, the invention also relates to a ceramic membrane with a core-shell structure and prepared by substituting an organic-inorganic composite for ceramic powder. The invention further relates to application of the ceramic membrane to a chemical power supply system such as a lithium ion battery and a battery comprising the ceramic membrane. The ceramic powder with the core-shell composite structure is favorable for improvement of the electrolyte adsorbing and maintaining ability of the ceramic membrane. The ceramic membrane can serve as a high-safety membrane material of secondary batteries such as a lithium ion battery, and has excellent electrochemical performance and heat stability. According to the invention, the operability is high; the cost is low compared with that of other methods; the reproducibility is high; and the obtained product quality is stable.

Owner:XIAMEN UNIV +1

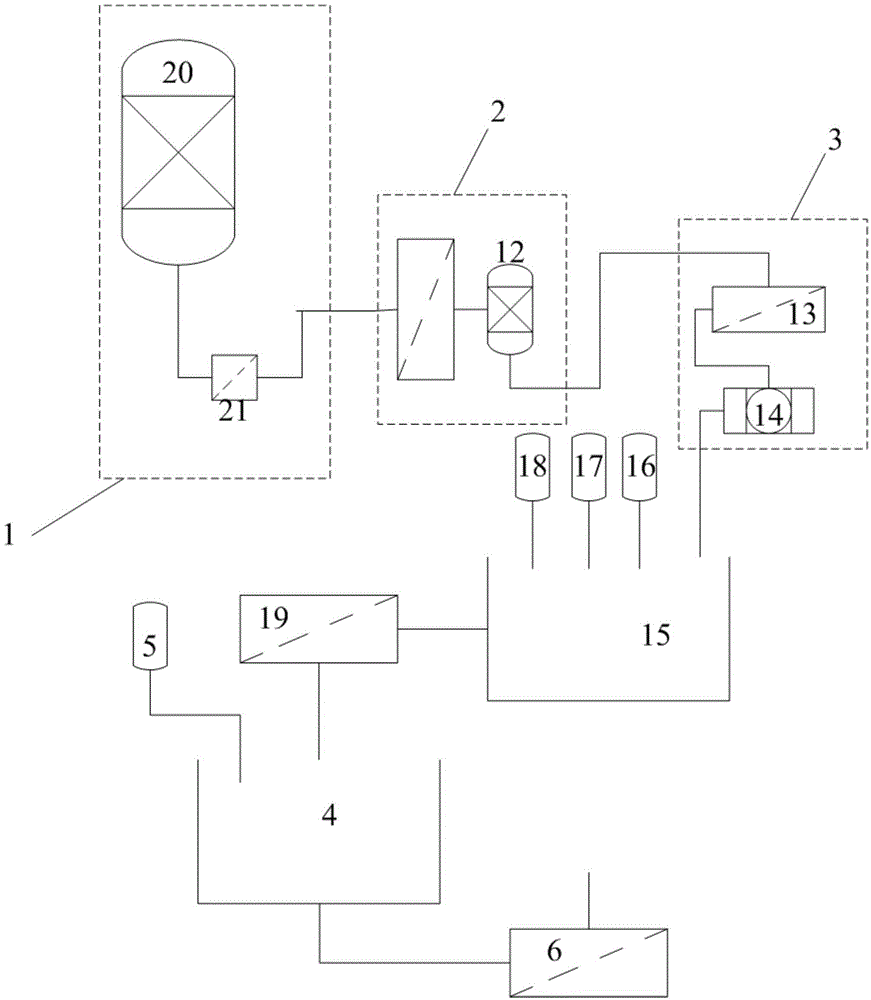

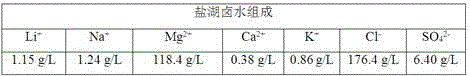

Process and device for extracting battery grade lithium from brine

ActiveCN104310446AIncrease the concentration factorHigh yieldLithium carbonates/bicarbonatesPhysical chemistryReverse osmosis

The invention relates to a process and a device for extracting battery grade lithium from brine. The process comprises the following steps: adding an adsorbent into the brine to adsorb lithium ions in the brine, intercepting the adsorbent by using a ceramic membrane filter, performing plate-frame pressure filtration on the ceramic membrane concentrated solution to obtain an adsorbent filter cake, washing and desorbing the adsorbent filter cake so as to obtain a desorption solution; removing magnesium in the desorption solution through a nanofiltration membrane system, entering the nanofiltration membrane permeate into an ion exchange resin tower for performing deep magnesium removal, concentrating through a reverse osmosis membrane, performing deep concentration in a DTRO membrane or electrodialysis equipment, evaporating the concentrated solution, adding BaCl2, Na2CO3 and NaOH into the solution, stirring, filtering in a ceramic membrane filter, performing plate-frame pressure filtration on the ceramic membrane filtrate, adding Na2CO3 into the clear liquid, preparing Li2CO3, washing Li2CO3 through a ceramic membrane, centrifuging, and drying, thereby obtaining the finished battery grade Li2CO3 product.

Owner:JIANGSU JIUWU HITECH

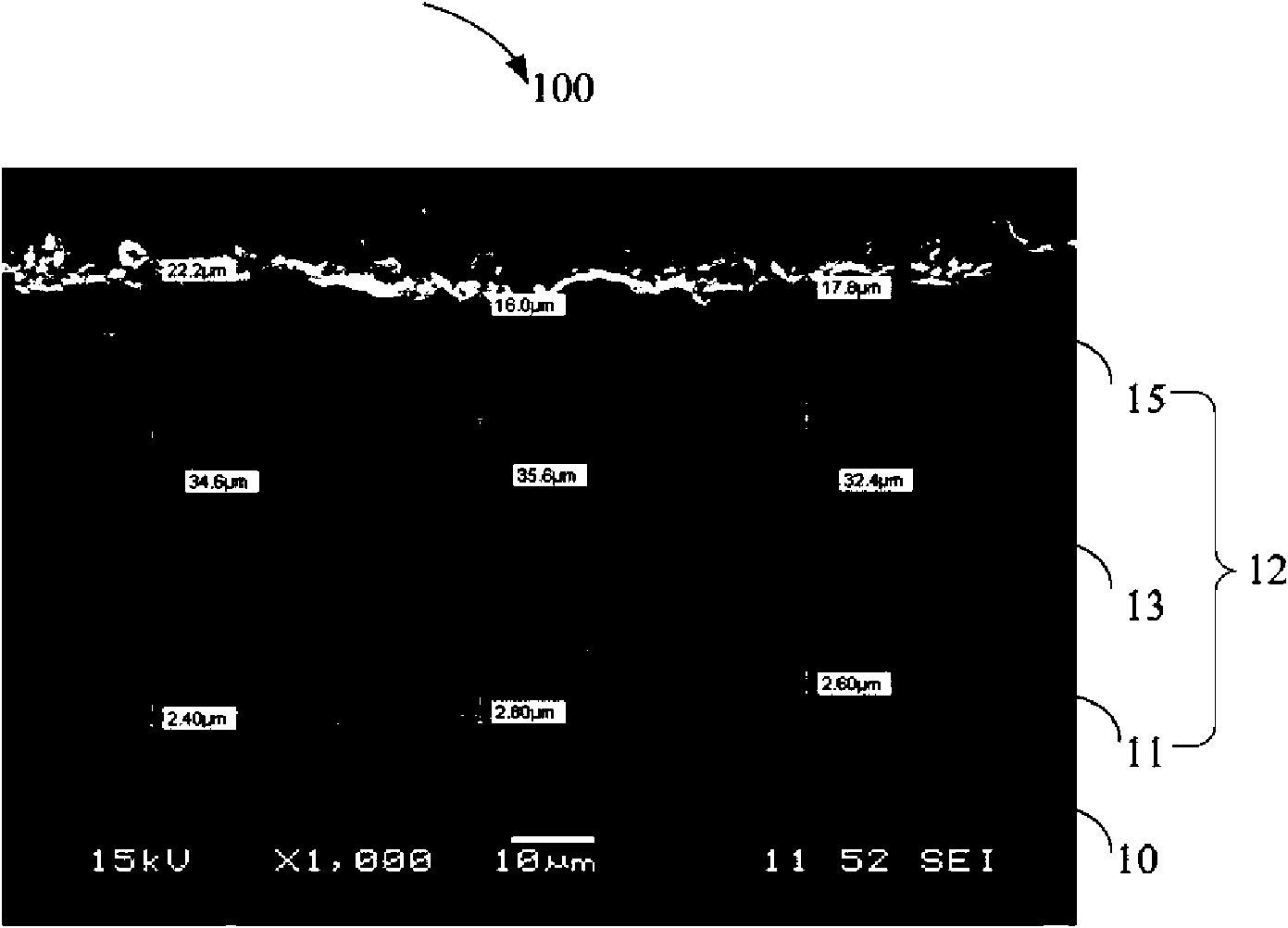

Ceramic membrane layer on metal surface and preparation method thereof

InactiveCN103014706AIncreasing the thicknessSolving problems in applications requiring high wear resistanceAnodisationSuperimposed coating processMicro arc oxidationPlasma electrolytic oxidation

Owner:柯全

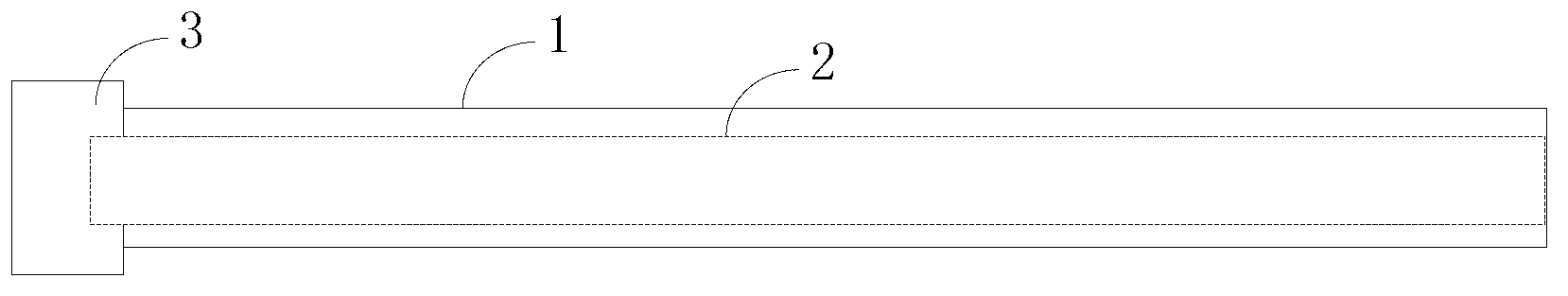

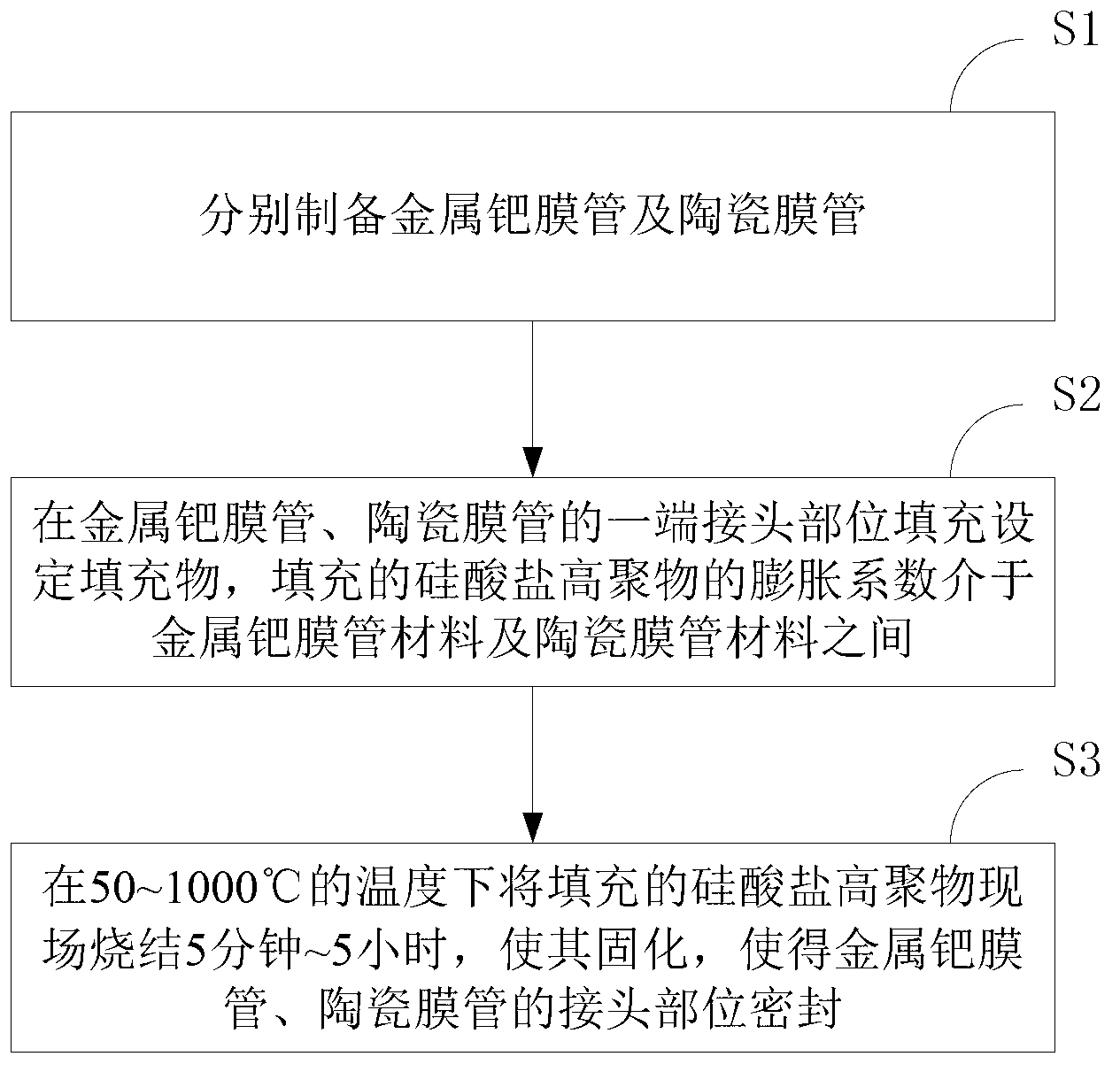

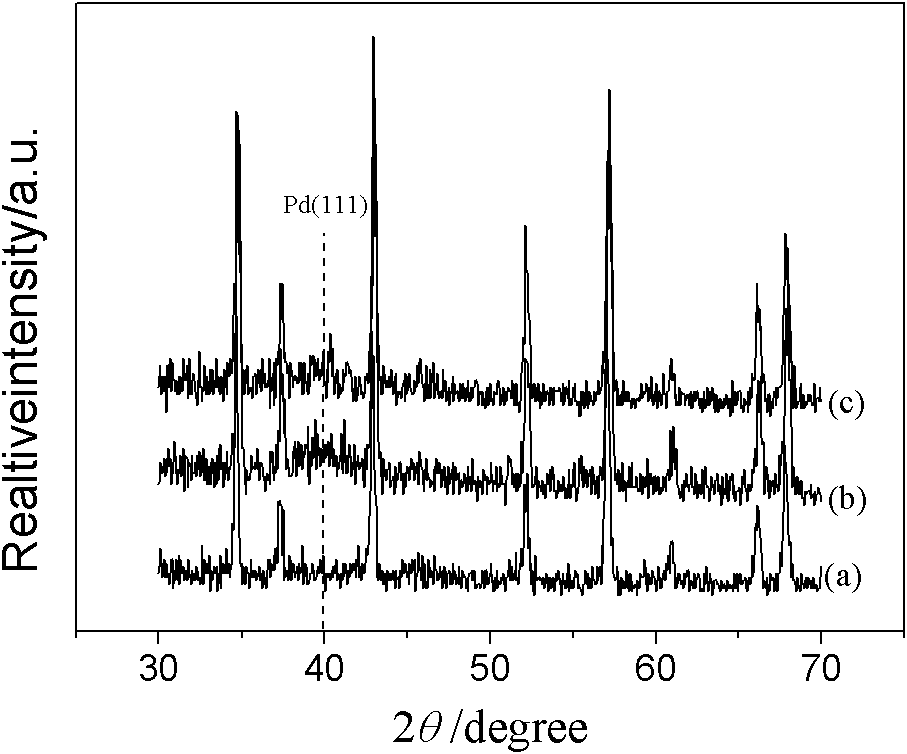

Membrane separator for methyl alcohol water hydrogen production equipment and fabrication method of membrane separator

ActiveCN103007697AImprove sealingGuaranteed preparation efficiencyHydrogen separation using solid contactDispersed particle separationAlcoholPhysical chemistry

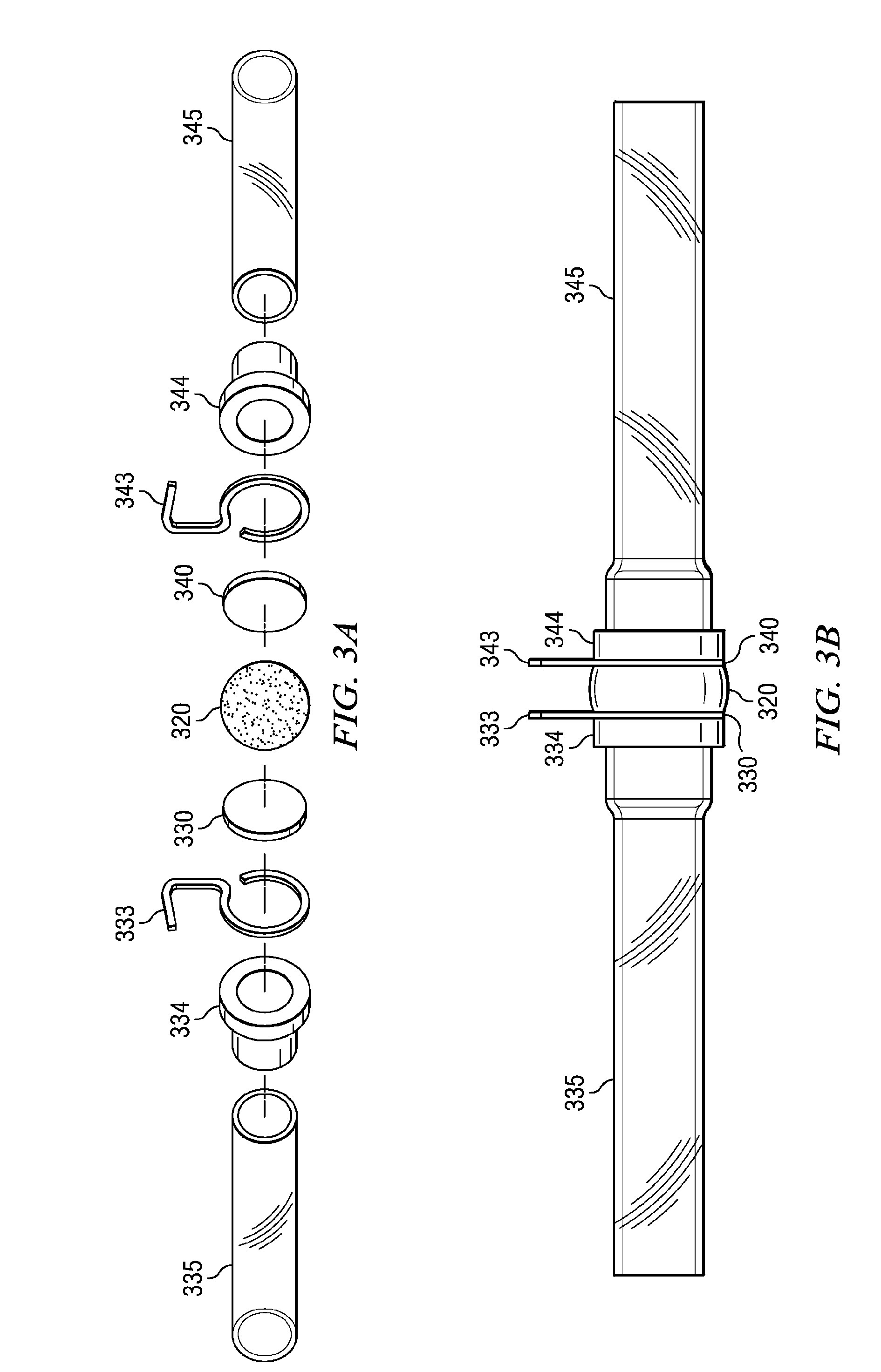

The invention discloses a membrane separator for methyl alcohol water hydrogen production equipment and a fabrication method of the membrane separator. The method comprises the following steps that Step S1, a metal palladium membrane tube and a ceramic membrane tube are fabricated respectively; Step S2, set packing is filled in joint parts at one end of the metal palladium membrane tube and one end of the ceramic membrane tube; an expansion coefficient of the packing falls in between those of a metal palladium membrane tube material and a ceramic membrane tube material; and Step S3, the packing is sintered on site at 50-1000 DEG C, and solidified; and the joint parts of the metal palladium membrane tube and the ceramic membrane tube are sealed. With the adoption of the fabrication method of the membrane separator for the methyl alcohol water hydrogen production equipment, the membrane separator with good sealability can be fabricated, so that the preparation efficiency of hydrogen is ensured.

Owner:SHANGHAI HYDROGEN MOBILE REFRMER INSTR

Ceramic hollow fibers made from nanomscale powder particles

The invention relates to a method for producing ceramic hollow fibers from nanoscale particles and to hollow fibers produced in such a manner. The inventive method is characterized in that the ceramic material has a solids content of >25% by volume, preferably >30% by volume and is processed by means of extrusion and spinning. The hollow fiber is sintered according to conventional sintering methods. A hollow fiber produced in this manner is used for metal, polymer and ceramic matrix reinforcements, for artificial organs, for microsystems technology components, for fiber optical waveguides, for ceramic membranes, for solid electrolyte in fuel cells (SOFC), for tissue engineering and for producing extremely light ceramic parts, such as heat shields or brake systems, that are subjected to temperature stresses. The inventive ceramic batch can also be processed by means of silk screening whereby resulting in the production of filigree structures over the ceramic silk screening.

Owner:ITN NANOVATION AG

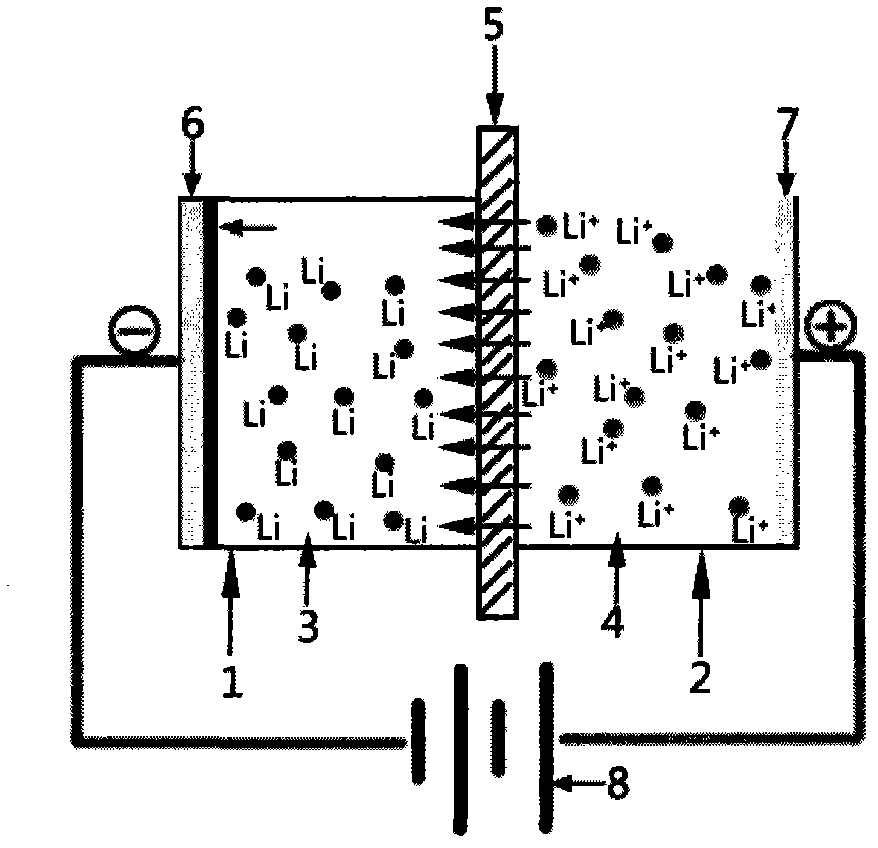

Preparation method of lithium metal through electrolysis

ActiveCN103031568AHigh purityWide variety of sourcesPhotography auxillary processesProcess efficiency improvementElectrical conductorSingle substance

The invention discloses a preparation method of lithium metal through electrolysis, which comprises the following steps: at normal temperature and normal pressure, applying direct current voltage on an anode current collector and a cathode current collector so that potassium ions in a water phase in an anode chamber penetrate through a diaphragm having lithium ion conductor characteristics under the driving of the voltage, an organic solvent in a cathode chamber is reduced to a metal lithium single substance which is deposited and enriched on the surface of the cathode current collector to obtain the product, wherein the anode chamber of an electrolysis cell is filled with an aqueous solution at least containing the lithium ions, the cathode chamber od the electrolysis cell is filled with the organic solvent having the lithium ion conductor characteristics, the diaphragm for separating the anode chamber from the cathode chamber is a lithium ion conductor ceramic membrane having the lithium ion conductor characteristics or a composite membrane of a lithium ion conductor and a polymer, and the cathode chamber is in inert gas atmosphere. The electrolysis preparation method for lithium metal avoids severe conditions which are required to prepare lithium metal by a traditional high temperature molten electrolysis process, and has the characteristics of low energy consumption, high lithium extraction efficiency and high product purity and is environment-friendly and wide in raw material sources.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for pre-lithiating electrode material of lithium ion battery

InactiveCN104201320AIncrease profitLow costFinal product manufactureCell component detailsElectrical conductorElectrical battery

The invention relates to an electrode material of a lithium ion battery, in particular to a method for pre-lithiating a cathode material. The method comprises the steps that an electrolytic cell cathode cavity is made of the electrode material such as a lithium ion cathode material and arranged in a lithium ion conductive organic electrolyte; an anode cavity is an aqueous solution containing lithium salt or an organic solution; the anode cavity is separated from the cathode cavity by a lithium ion conductor ceramic membrane or a composite membrane of lithium ion conductor ceramic and a high molecular material; an electric potential and current density are controlled by external circuit charge and discharge equipment to allow lithium ions to migrate to a cathode from an anode through the membrane; and an SEI (Solid Electrolyte Interphase) membrane is formed on the surface of the material; or the electrode material is pre-lithiated. According to the method, a cheap and safe lithium ion saline solution serves as a source of the lithium ion; the SEI membrane is generated for the cathode of the lithium ion battery in advance; or lithium is supplemented to the electrode material; the coulombic efficiency and cycling stability of the cathode material can be improved; a formation process in production of the lithium ion battery in the prior art is simplified; the electrode material and cost are saved; and the method is safe and efficient and has a large-scale application prospect.

Owner:赵前永

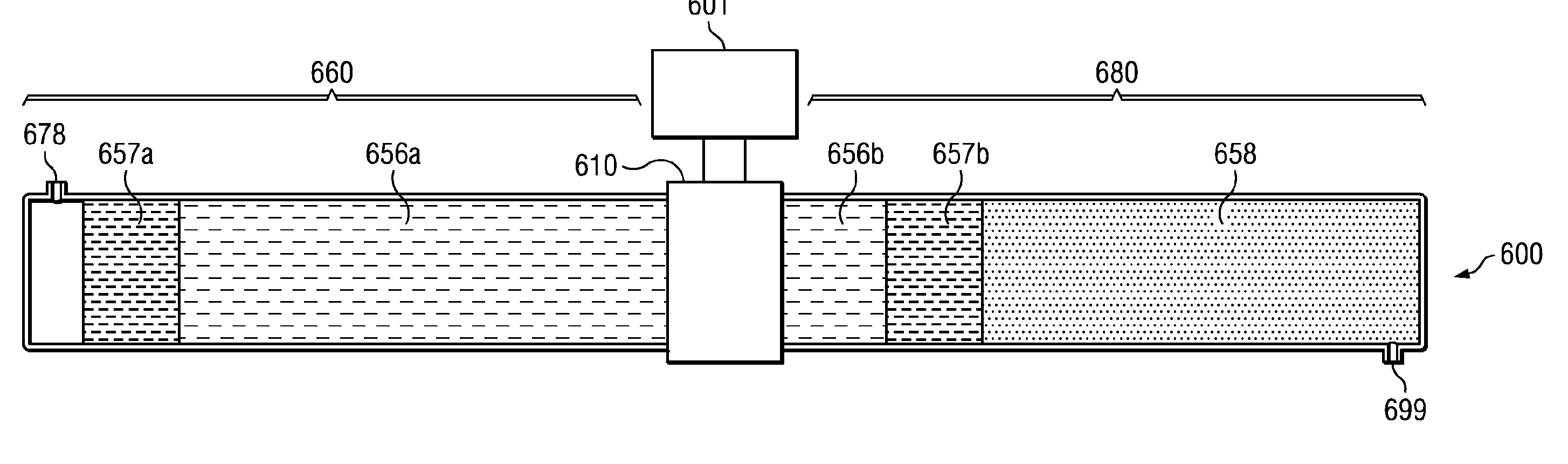

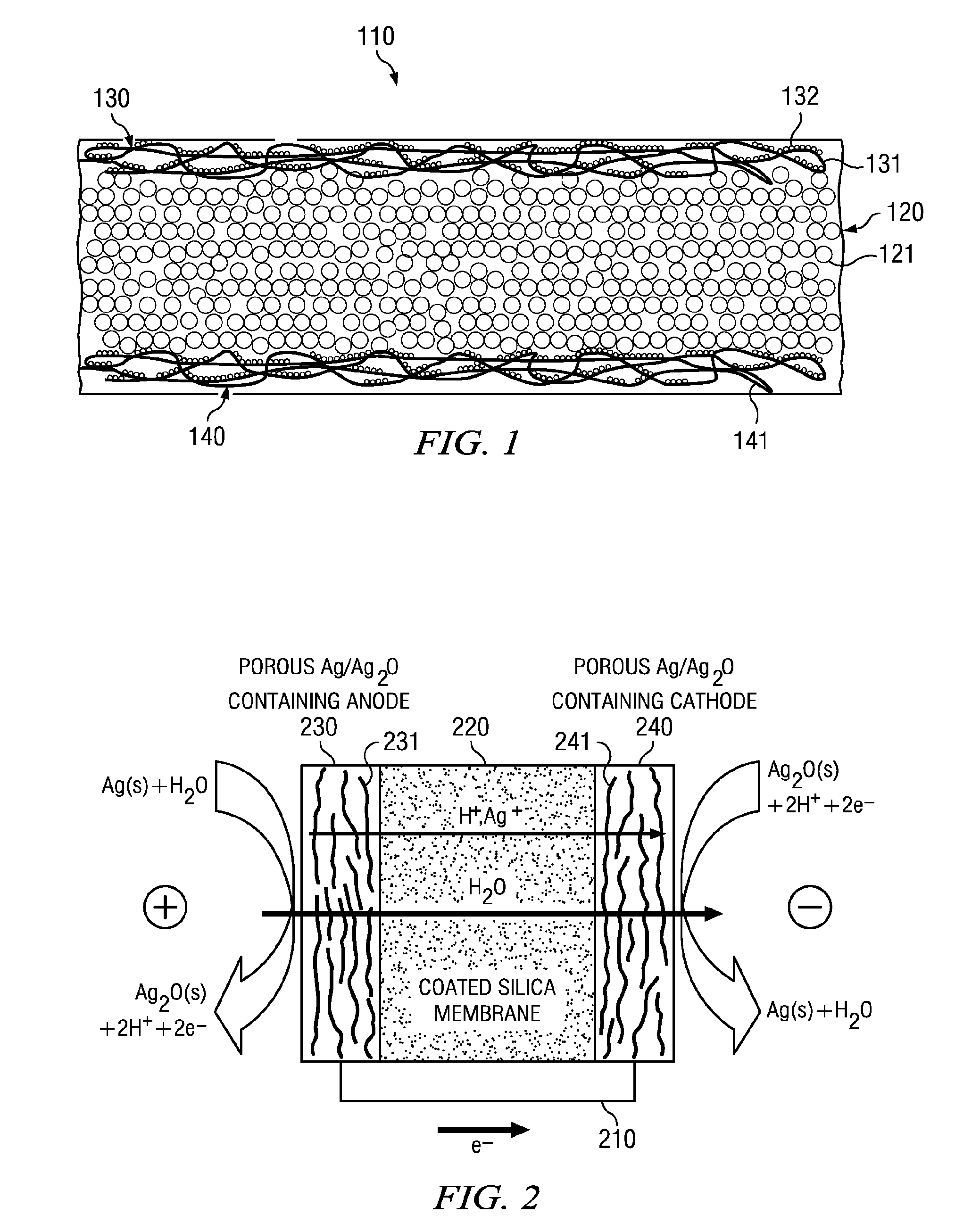

Electro-osmotic pumps, systems, methods, and compositions

The present disclosure relates, according to some embodiments, to compositions, methods, devices, and systems for delivering a composition (e.g., a fluid composition) to a subject. For example, the present disclosure relates to non-gassing, direct current (DC), electro-osmotic pumps in some embodiments. A pump may comprise an anode (e.g., a porous silver / silver oxide anode), a cathode (e.g., a porous silver / silver oxide cathode), and a membrane (e.g., a porous ceramic membrane) positioned at least partially between the anode and the cathode in some embodiments. A pump system may comprise an electro-osmotic pump, a reservoir comprising a pump fluid chamber in fluid communication with the electro-osmotic pump and a delivery fluid chamber in fluid communication with the electro-osmotic pump; a controller assembly in electrical communication with the anode and the cathode; and a cannula and / or a needle in fluid communication with the delivery fluid chamber. A pump fluid may comprise water and / or a delivery fluid may comprise a drug, in some embodiments.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Nanostructural Electrode and Method of Forming the Same

InactiveUS20070154807A1Improve adhesionLow costActive material electrodesLi-accumulatorsPorosityHigh rate

An electrode and method of forming the same of the present invention is used for the high-rate deposition of materials, such as carbon, silicon, metals, metal oxides, and the like, onto a metal substrate defined by a metal tape used as cathode or anode combined with a separator to form a fuel cell of a secondary battery, metal-ceramic membranes, film composite metal-ceramaic materials for electronic devices. The method is cost effective and is directed to form the electrode with improved and high porosity.

Owner:NANOENER

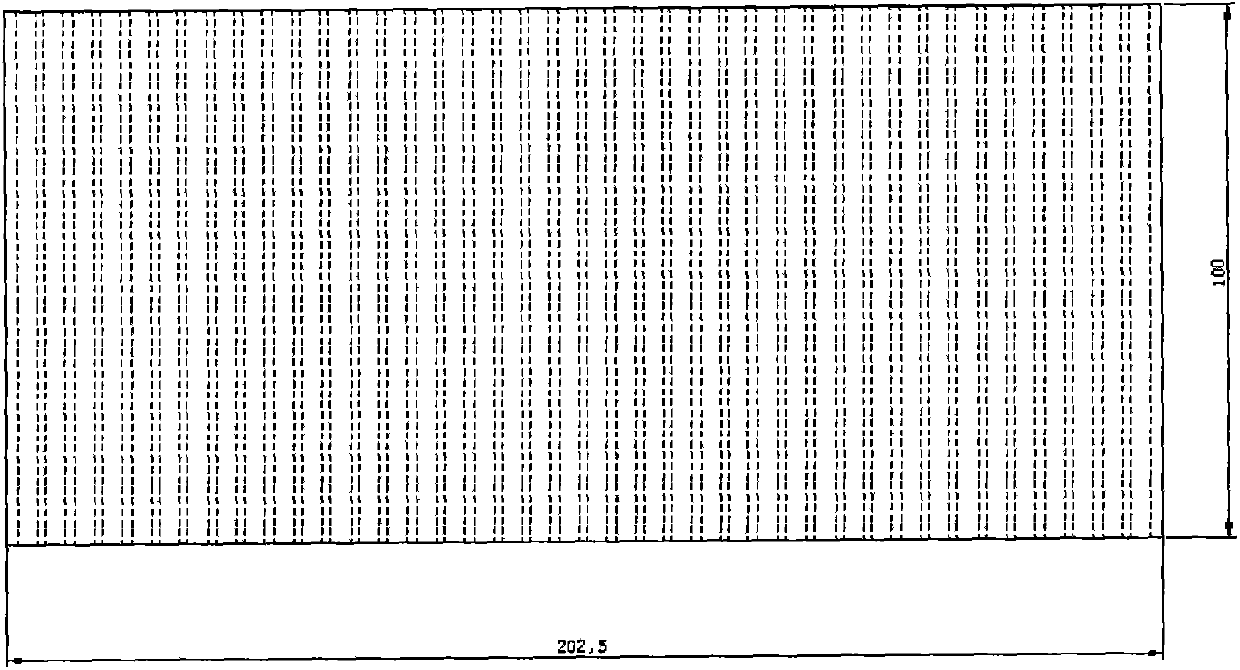

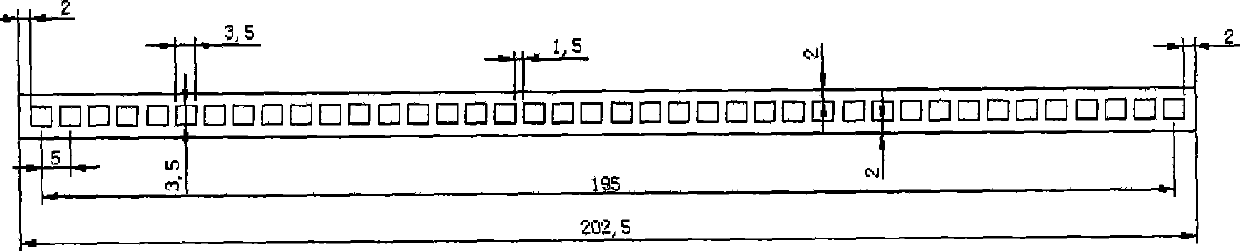

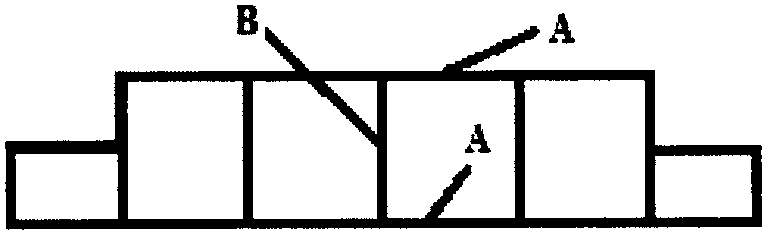

Preparation method of hollow flat plate structure type ceramic filter membrane element

ActiveCN103623711ALower sintering temperatureSmall filter resistanceSemi-permeable membranesAluminium hydroxideChemical separation

The invention provides a preparation method of a hollow flat plate structure type ceramic filter membrane element. The method comprises the following steps: (1) preparing a hollow structure type ceramic membrane supporting body by using an extrusion molding method, namely sintering aluminum hydroxide obtained by calcination at 600 DEG C as a main raw material to prepare the ceramic membrane supporting body; (2) preparing the ceramic filter membrane by using a plasma spray method. When the ceramic membrane supporting body is prepared, the selected and used raw material is calcined aluminum hydroxide, so that the sintering temperature of the ceramic membrane supporting body can be greatly reduced, and the sufficient strength of the supporting body can be guaranteed; when the ceramic filter membrane layer is prepared, the thickness of the filter membrane can be excellently controlled by using the plasma spray process, and the filter resistance is reduced; the membrane layer has the uniform pore size distribution and the high separation accuracy; the membrane layer is closely combined with the supporting body. The ceramic filter membrane is prepared by using plasma spraying without sintering, so that the process is simple, the production cost of the ceramic filter membrane can be effectively reduced, the production efficiency is improved, and the process can be widely applied to the fields of sewage treatment and filtration, solid-liquid chemical separation, and the like.

Owner:雅安沃克林环保科技有限公司

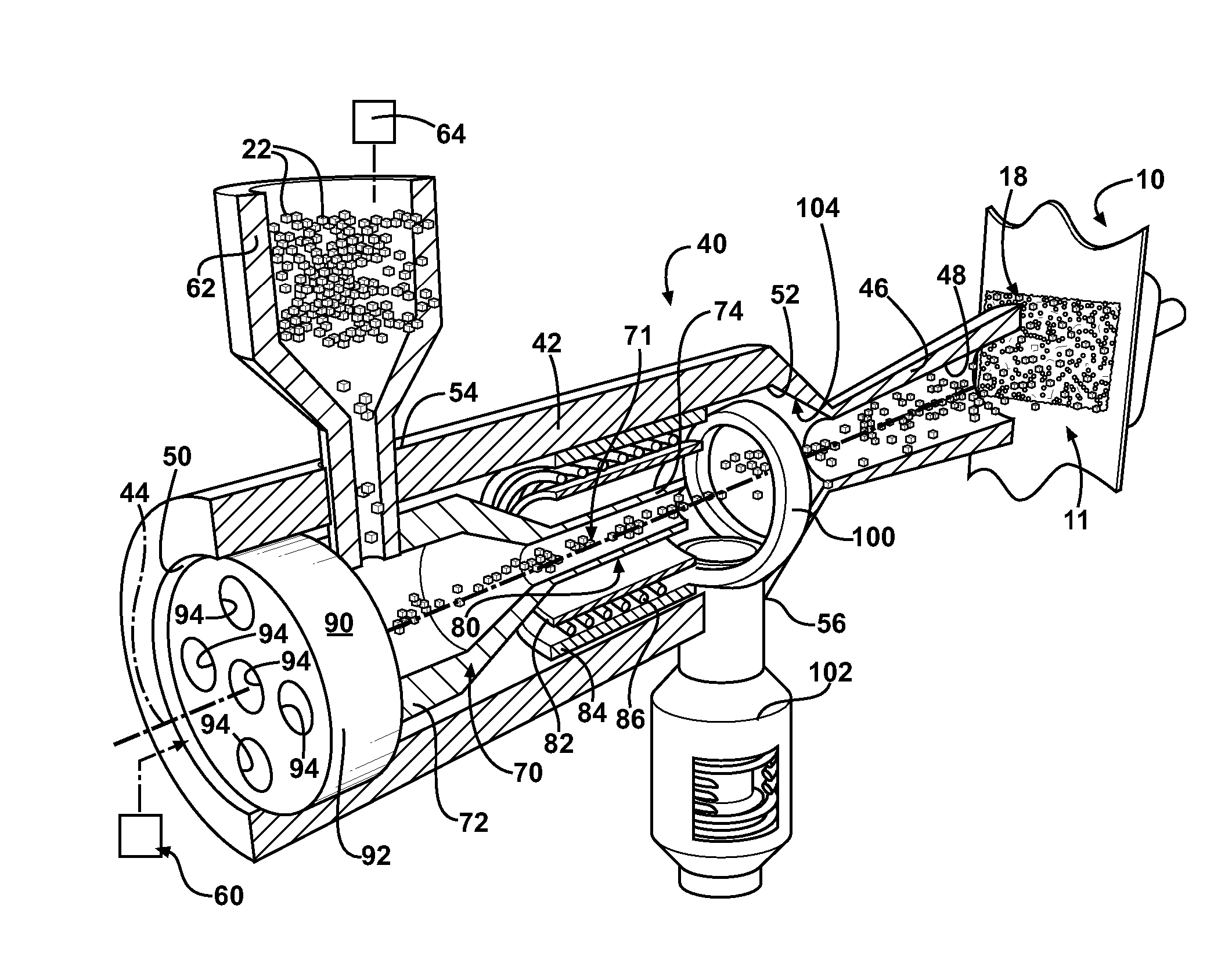

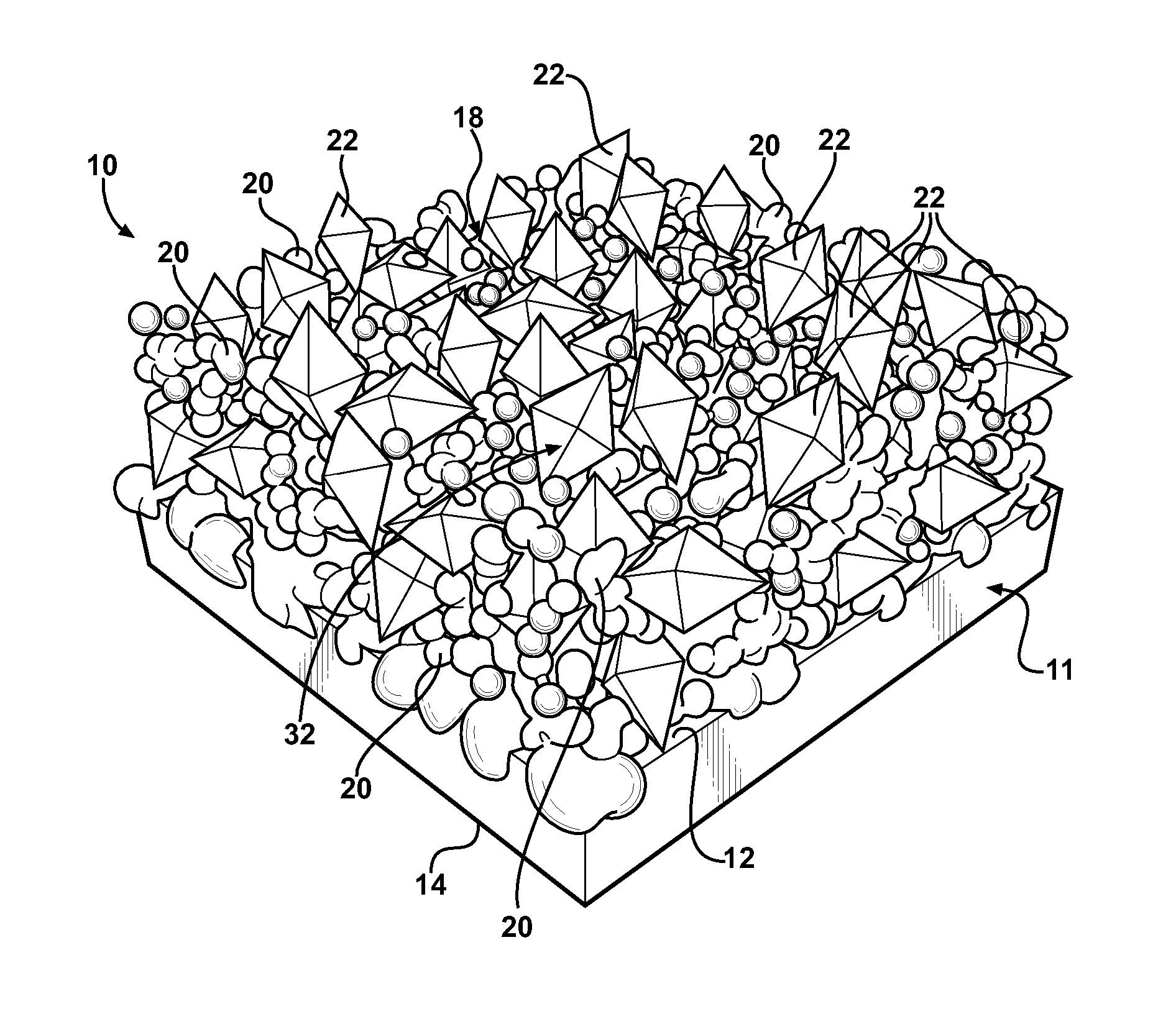

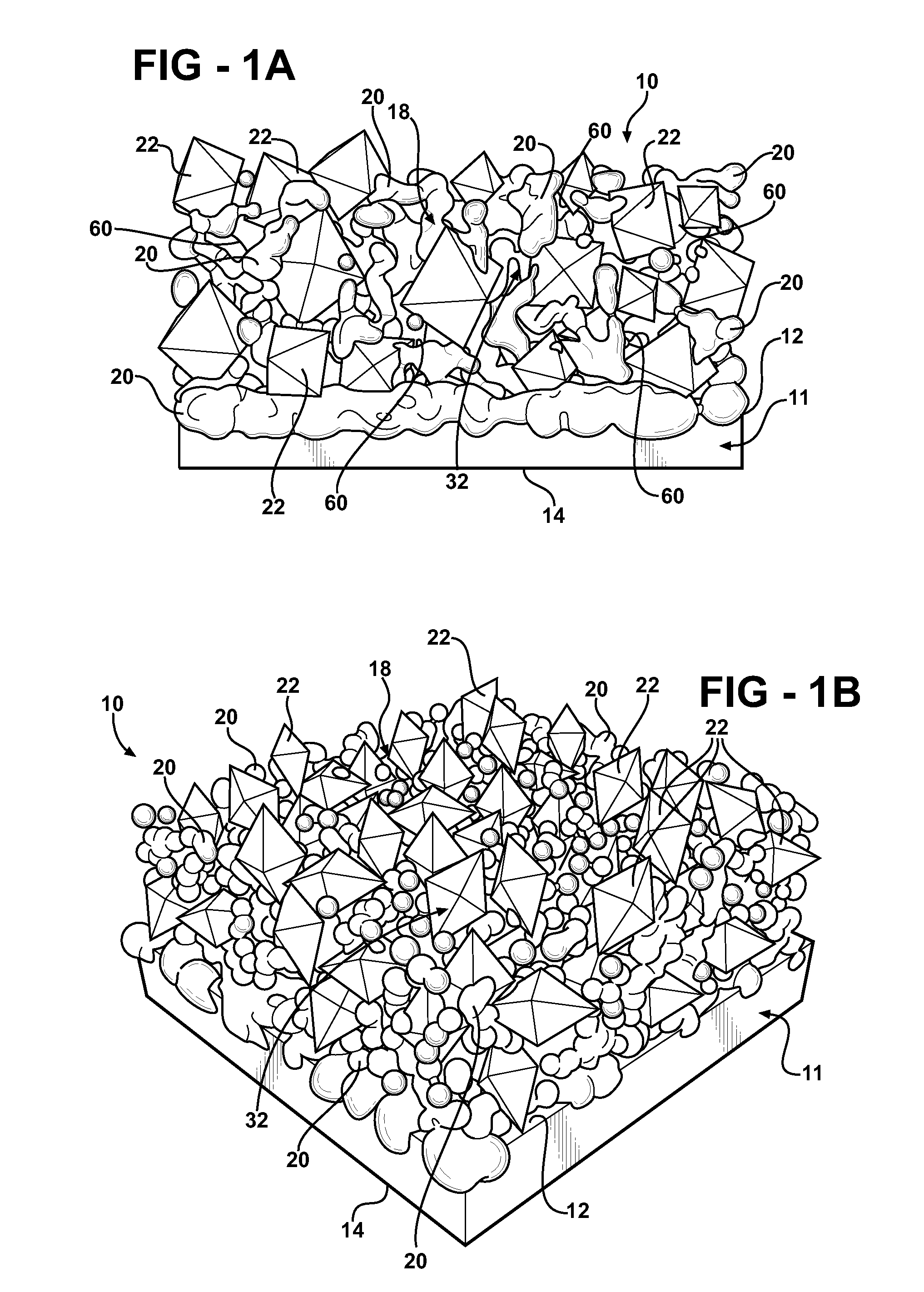

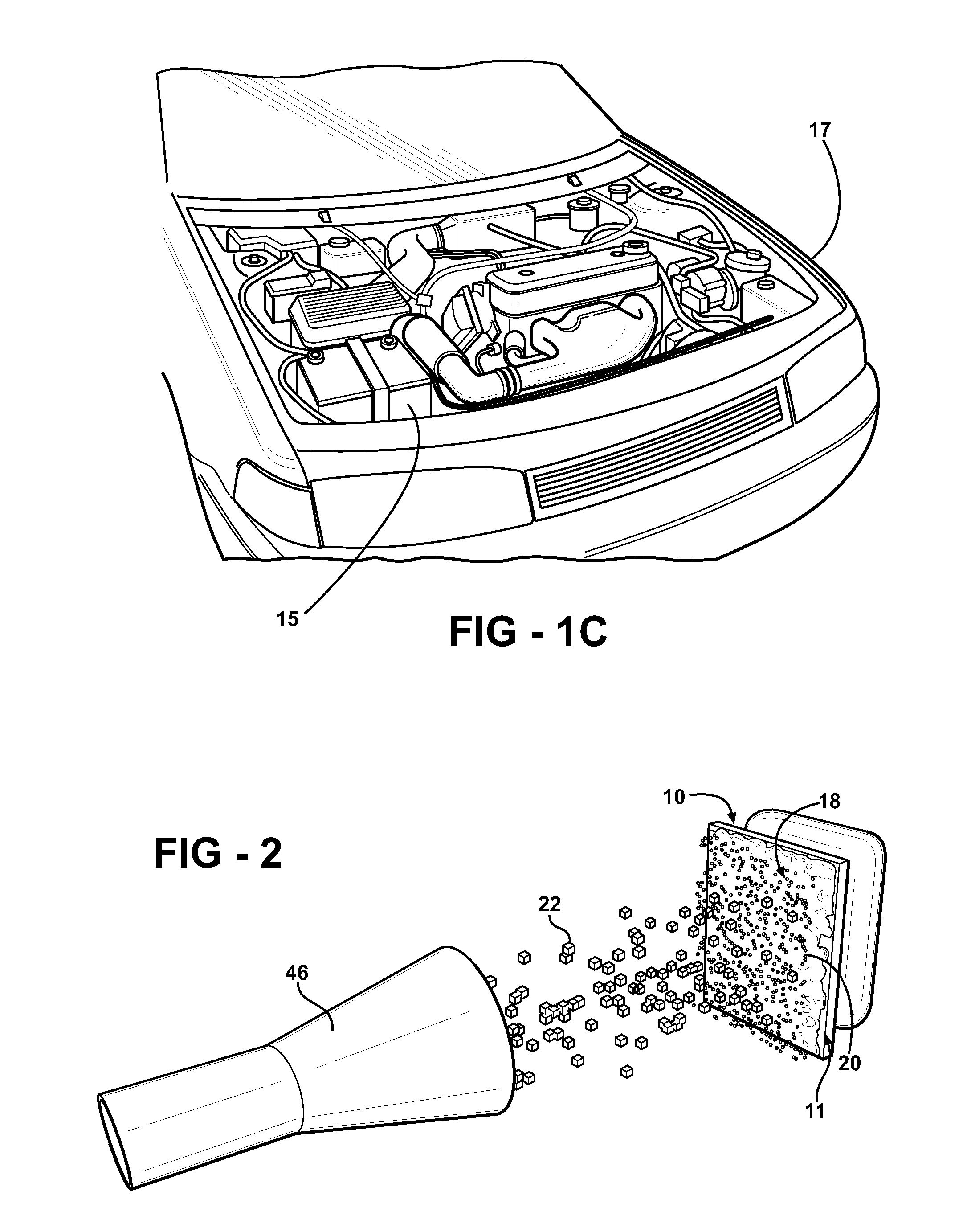

Apparatus for forming structured material for energy storage device and method

InactiveUS20070209584A1Improve adhesionLow costMolten spray coatingFinal product manufactureHigh rateHigh pressure

A method and an apparatus of the present invention is used for the high-rate deposition of materials, such as carbon, silicon, metals, metal oxides, and the like, onto a metal substrate defined by a metal tape. The particles of the material are mixed with fluid and are injected against the metal tape at a high pressure and high velocity. The particles of the material form a current collection surface of the metal tape. The metal tape is used as cathode or anode combined with a separator to form a fuel cell of a secondary battery, metal-ceramic membranes, film composite metal-ceramic materials for electronic devices.

Owner:NANOENER TECH INC +2

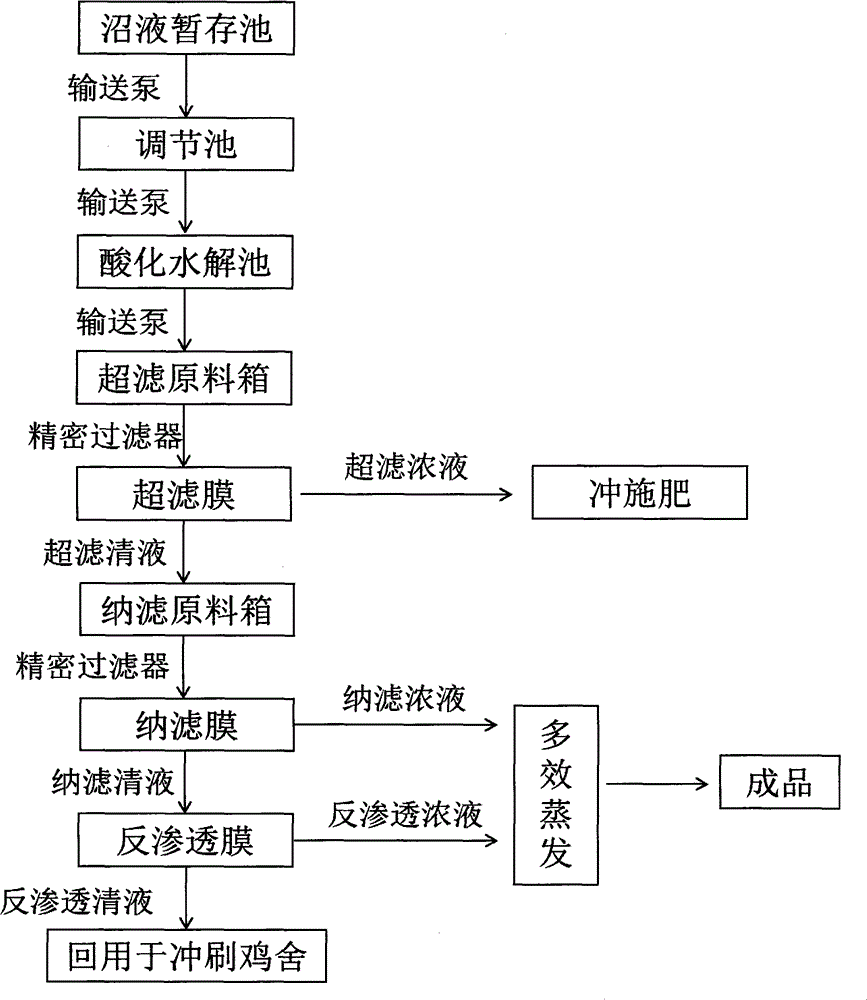

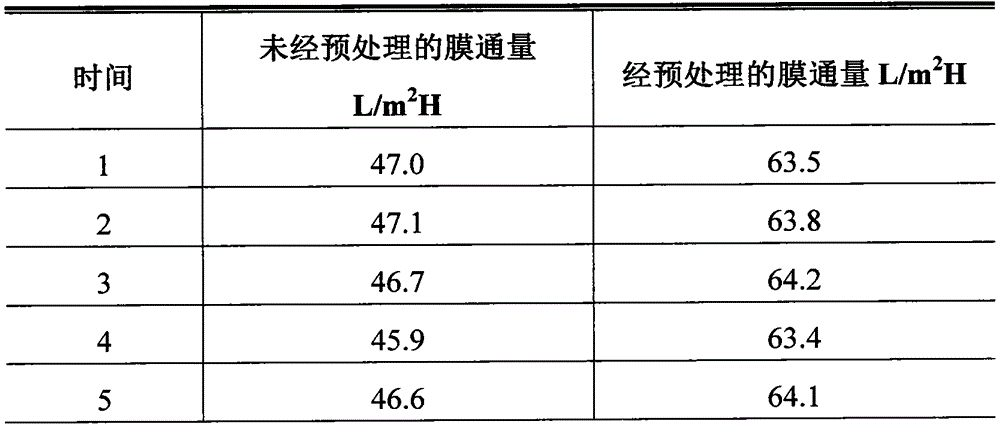

Biogas slurry concentrate and engineering preparation method

ActiveCN104058799AEasy to concentrateImprove throughputBio-organic fraction processingClimate change adaptationSolubilityResource utilization

The invention relates to a biogas slurry concentrate and an engineering preparation method, which belongs to the technical field of biogas slurry resource utilization. The method comprises the following steps: pretreating a membrane of a chicken manure biogas slurry, passing the pretreated biogas slurry through an ultrafilter membrane of an inorganic ceramic membrane for filtering impurity, passing through a nanofiltration membrane and a reverse osmosis membrane for interception and condensation, and final removing solid insoluble particles in the biogas slurry, the macro-molecule substance which is difficult to be absorbed by the crops, high power concentrated biogas slurry organic micromolecule nutrients. The method overcomes of disadvantages of easy membrane obstruction, severe damage, difficult high power condensation, difficult engineering stable operation in prior art, the obtained biogas slurry concentrate finished product is nano level organic state micromolecule substance, has the advantages of comprehensive and balanced nutrition, good water solubility, strong permeability, high activity, and high practical application value.

Owner:SHANDONG MINHE BIOTECHNOLOGY CO LTD

Porous ceramic membrane support with flat structure and preparation method thereof

ActiveCN102688700AReduce frictionAvoid accumulationSemi-permeable membranesPolyvinyl alcoholAdhesive

The invention relates to a porous ceramic membrane support with a flat structure and a preparation method thereof, and belongs to the technical field of ceramic membrane supports. The ceramic membrane support is flat and consists of two flat membrane supports; a certain space is reserved between the two flat membrane supports; at least one supporting column is distributed in the space; and at least one water outlet passage is formed in each flat membrane support, so that flowing resistance of filtrate in the support with the flat structure is reduced. The ceramic aggregate of the support is one or more of alumina, zirconia, silicon dioxide, silicon carbide, titanium oxide, mullite and cordierite; the pore-forming agent is starch, graphite, phenolic resin spheres and the like; and the adhesive is methylcellulose, polyvinyl alcohol and the like. The porosity of the prepared porous ceramic membrane support with the flat structure can reach 30 to 50 percent, the aperture is 20 to 200 nanometers, and the compressive strength can reach 20 to 40MPa; and the support can be used for substituting an organic hollow fiber membrane bioreactor, and has great potential application in the fields of sewage treatment, fine chemical industry and the like.

Owner:TSINGHUA UNIV +1

Catalyst for catalytic hydrogenation of p-nitrophenol and preparation method thereof

ActiveCN102091626AEasy to separateSimple production processCatalyst carriersOrganic compound preparationSilanesP-Aminophenol

The invention relates to a catalyst for preparing p-aminophenol through catalytic hydrogenation of p-nitrophenol, and a preparation method thereof, and belongs to the technical field of catalysis. The carrier of the catalyst is a ceramic membrane, and the preparation method comprises the following steps of: modifying the membrane surface by using aminosilane; immersing in salt solution of an active ingredient; and performing hydrazine hydrate reduction to prepare a catalytic membrane. The invention has the advantages that: nano-scale catalyst particles are supported on the surface of the ceramic membrane modified by silane, and the activity and stability of the catalyst are improved; moreover, a problem that the catalyst is hardly separated from the product subsequently is avoided. The catalyst is simple in preparation process and high in activity and stability and can be widely applied to preparing the p-aminophenol through catalytic hydrogenation of the p-nitrophenol.

Owner:NANJING UNIV OF TECH

Electrode for energy storage device and method of forming the same

InactiveUS20070218366A1Stay cohesiveLow costMolten spray coatingHybrid capacitorsHigh rateFuel cells

A method of the present invention is used for the high-rate deposition of materials, such as carbon, silicon, metals, metal oxides, and the like, onto a metal substrate defined by a metal tape. The particles of the material are mixed with fluid and are injected against the metal tape at high pressure and high velocity. The particles of the material form a current collection surface of the metal tape. The metal tape is used as cathode or anode combined with a spearator to form a fuel cell of a secondary battery, metal-ceramic membranes, film composite metal-ceramic materials for electronic devices.

Owner:NANOENER TECH INC +2

Aluminum alloy with micro-arc oxide ceramic membrane on surface and preparation method thereof

ActiveCN101608332AAvoid process problemsIncrease productivityAnodisationThin material handlingOxide ceramicPlasma electrolytic oxidation

The invention relates to an aluminum alloy which comprises an aluminum alloy matrix and a micro-arc oxide ceramic membrane formed on the surface of the matrix, wherein the ceramic membrane comprises a bottom transition layer, a middle compact layer and a surface compact layer. The preparation method of the aluminum alloy, which is used for forming the micro-arc oxide ceramic membrane without a loose layer on the surface of the aluminum alloy, comprises the following steps: putting the aluminum alloy matrix in an oxidation tank containing electrolyte; carrying out initial oxidation treatment for the aluminum alloy matrix by adopting constant current; and continuously applying oxidation treatment to the aluminum alloy matrix by adopting positive and negative bidirectional pulse voltage, wherein positive and negative voltage keeps constant after rising to the maximum value, wherein the maximum constant positive voltage is 450V-650V, the maximum constant negative voltage is 30V-200V, the width of positive and negative pulse is 1000-10000mus, the pulse interval is 300-2000mus, the continuous oxidation treatment time is 30-180min, and the treatment temperature is between 20 DEG C and 50DEG C.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com