Porous ceramic membrane support with flat structure and preparation method thereof

A technology of ceramic membrane support body and porous ceramic membrane, which is applied in the direction of chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of acid and alkali resistance, low service life, and inability to backwash, etc., so as to avoid accumulation or The effect of strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

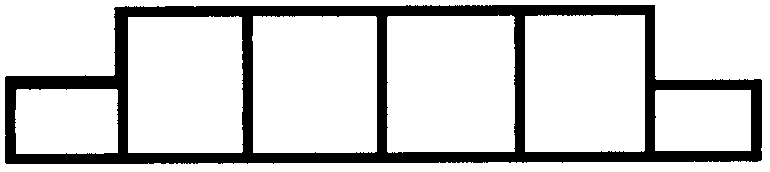

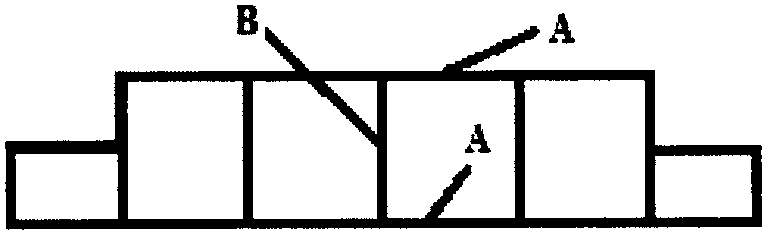

Image

Examples

Embodiment 1

[0029] Mullite (20 μm, 80wt%), starch (20 μm, 10wt%), methyl cellulose (molecular weight 50000, 10wt%) were ball-milled for 4 hours and mixed evenly, then water was added (the volume ratio of mixed powder to water was 1.5:1 ) Ball milled for 4h to make a uniformly dispersed slurry. Then the slurry was put into a mud refiner, and the relative vacuum was 95%, and the mud was refined 6 times. The molding process of the porous ceramic membrane support body can be extrusion molding. The extrusion temperature is 10° C., the extrusion speed is 0.2 m / min, and the extrusion pressure is 6 MPa. When the sintering temperature is 1500°C and the holding time is 2h, the average pore size of the flat ceramic membrane support is 10μm, the porosity is 60%, and the compressive strength is 20MPa. Under the pressure of 0.1MPa, the flux of pure water is 15m 3 / m 2 h.

Embodiment 2

[0031] ZrO 2 (10μm, 88wt%), graphite (10μm, 5wt%), polyvinyl alcohol (molecular weight: 170,000, 5wt%) ball milled for 6h and mixed evenly, then add water (the volume ratio of mixed powder and water is 1.8:1) ball milled for 8h Make a uniformly dispersed slurry. Then put the slurry into a mud refiner with a relative vacuum of 80%, and refine the mud twice. The molding process of the porous ceramic membrane support body can be extrusion molding. The extrusion temperature is 50° C., the extrusion speed is 2 m / min, and the extrusion pressure is 6 MPa. When the sintering temperature is 1550°C and the holding time is 2h, the average pore diameter of the flat ceramic membrane support is 8μm, the porosity is 40%, and the compressive strength is 25MPa. Under the pressure of 0.1MPa, the flux of pure water is 12m 3 / m 2 h.

Embodiment 3

[0033] Will Al 2 o 3 (5 μm, 91wt%), PMMA microspheres (15 μm, 3wt%), carboxymethyl cellulose (molecular weight is 17000, 6wt%) ball milling 8h mixes evenly, then adds water (the volume ratio of mixing powder and water is 1.5: 1 ) Ball milling for 6h to make a uniformly dispersed slurry. Then put the slurry into the mud refiner, the relative vacuum is 90%, and the mud is refined 4 times. The molding process of the porous ceramic membrane support body can be extrusion molding. The extrusion temperature is 30° C., the extrusion speed is 1 m / min, and the extrusion pressure is 8 MPa. When the sintering temperature is 1550℃ and the holding time is 4h, the average pore diameter of the flat ceramic membrane support is 15μm, the porosity is 50%, and the compressive strength is 28MPa. Under the pressure of 0.1MPa, the flux of pure water is 18m 3 / m 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com