Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1936results about "Hydrogen separation using solid contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

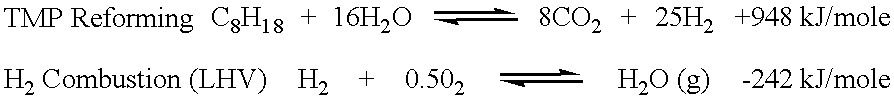

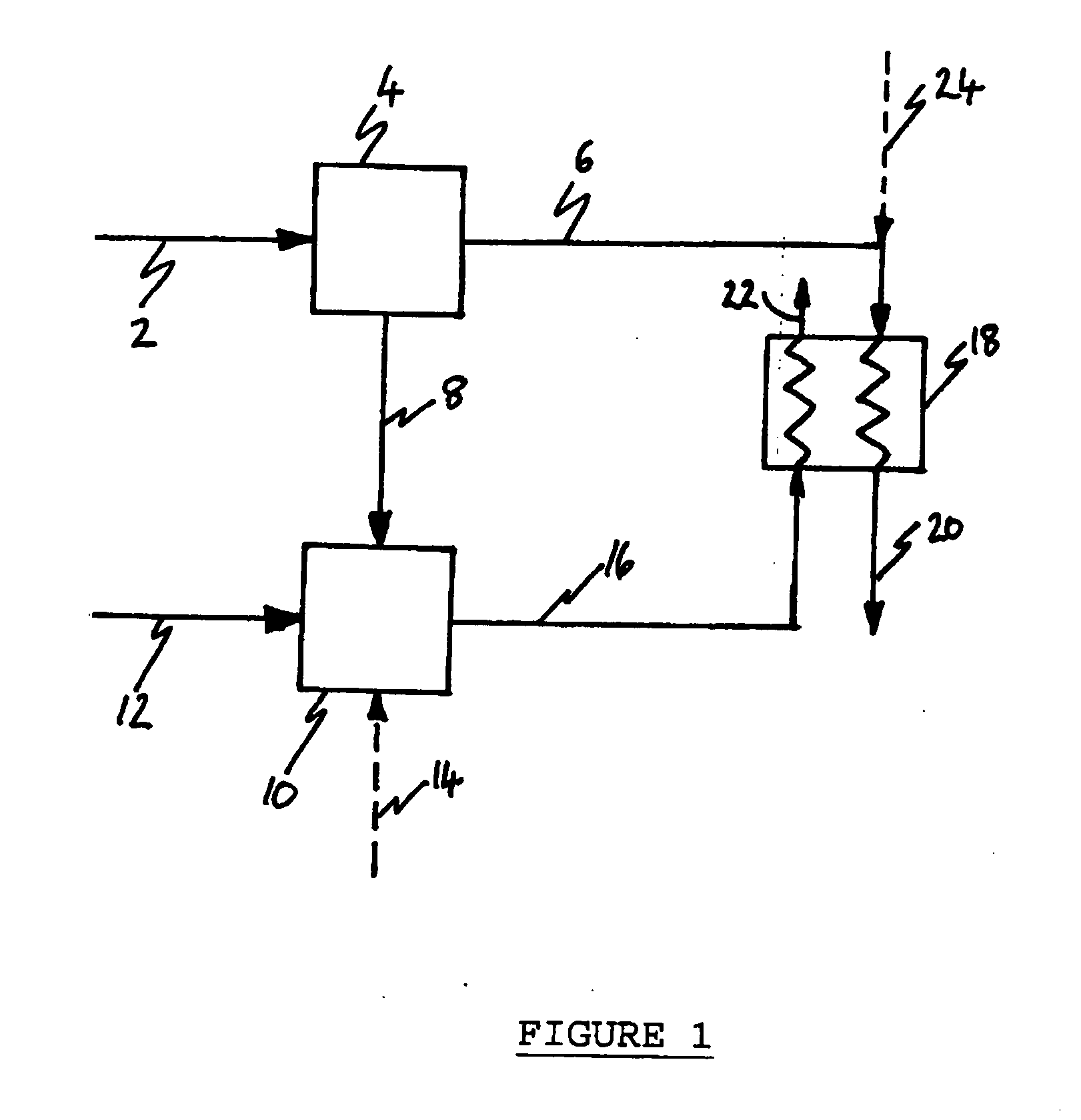

Method and system for supplying hydrogen for use in fuel cells

InactiveUS6348278B1Reduce hydrogen concentrationImprove concentrationElectricity cogenerationRegenerative fuel cellsHydrogenCombustor

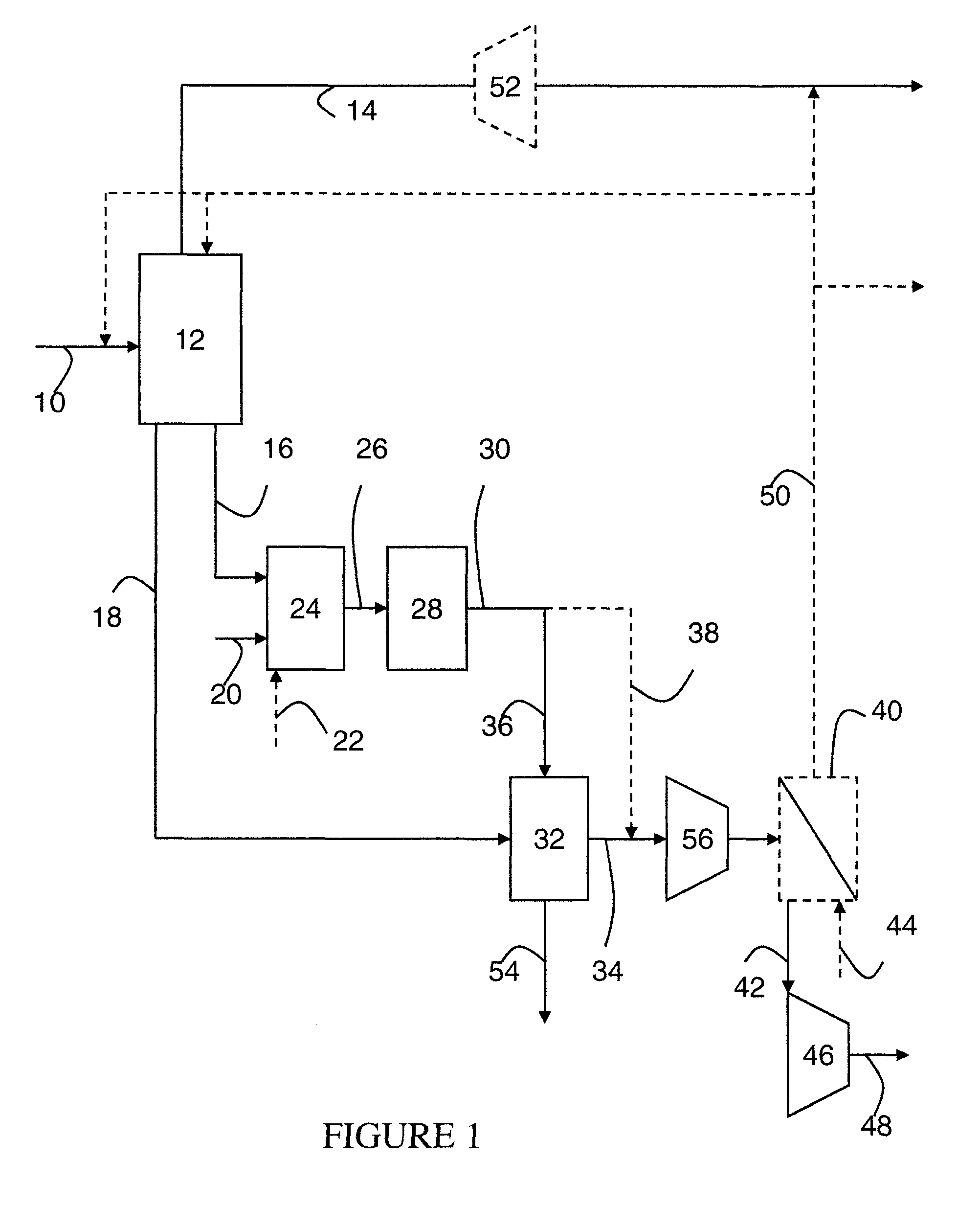

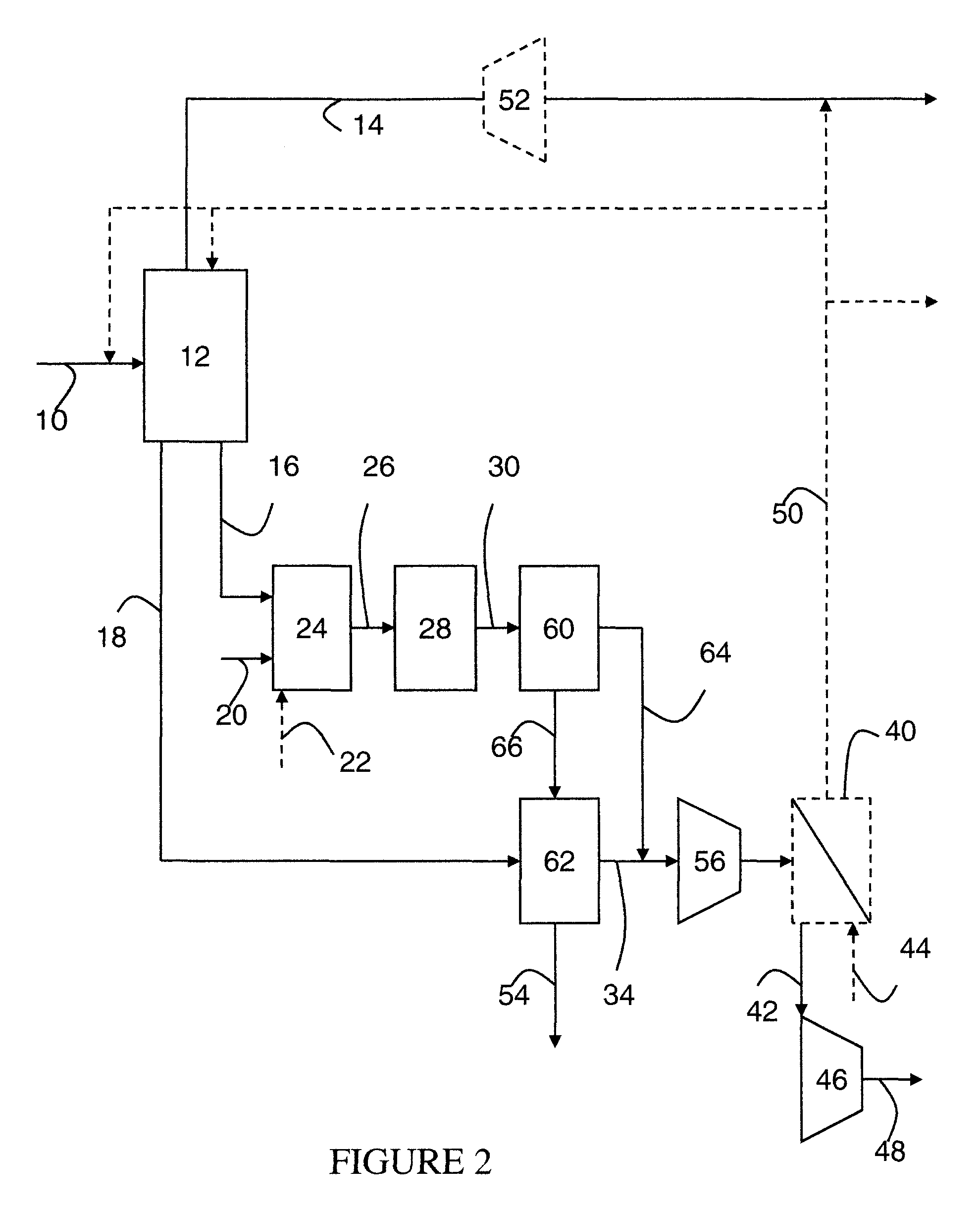

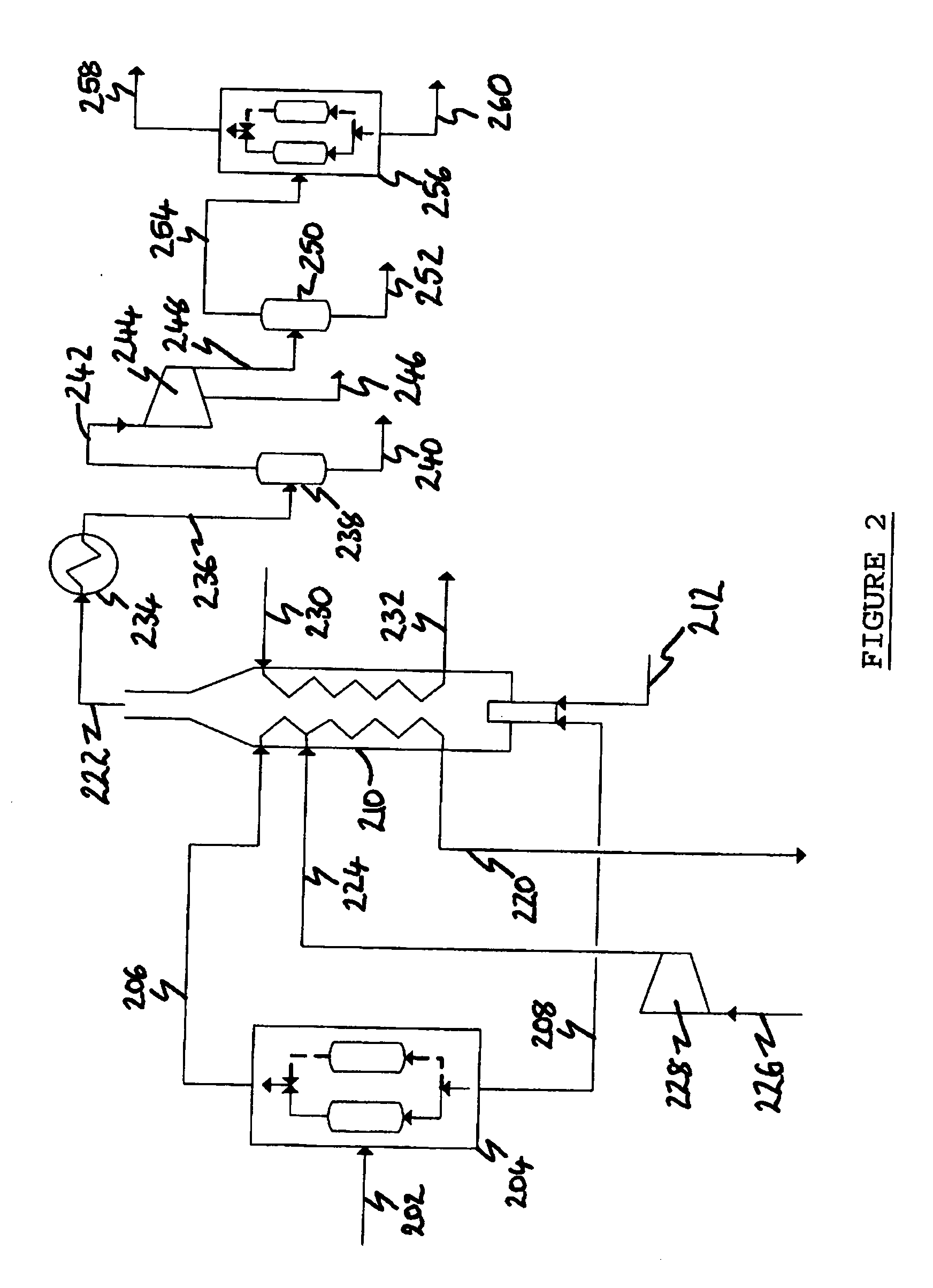

The present invention provides a method and system for efficiently producing hydrogen that can be supplied to a fuel cell. The method and system of the present invention produces hydrogen in a reforming reactor using a hydrocarbon stream and water vapor stream as reactants. The hydrogen produced is purified in a hydrogen separating membrane to form a retentate stream and purified hydrogen stream. The purified hydrogen can then be fed to a fuel cell where electrical energy is produced and a fuel cell exhaust stream containing water vapor and oxygen depleted air is emitted. In one embodiment of the present invention, a means and method is provided for recycling a portion of the retentate stream to the reforming reactor for increased hydrogen yields. In another embodiment, a combustor is provided for combusting a second portion of the retentate stream to provide heat to the reforming reaction or other reactants. In a preferred embodiment, the combustion is carried out in the presence of at least a portion of the oxygen depleted air stream from the fuel cell. Thus, the system and method of the present invention advantageously uses products generated from the system to enhance the overall efficiency of the system.

Owner:MOBIL OIL CORP

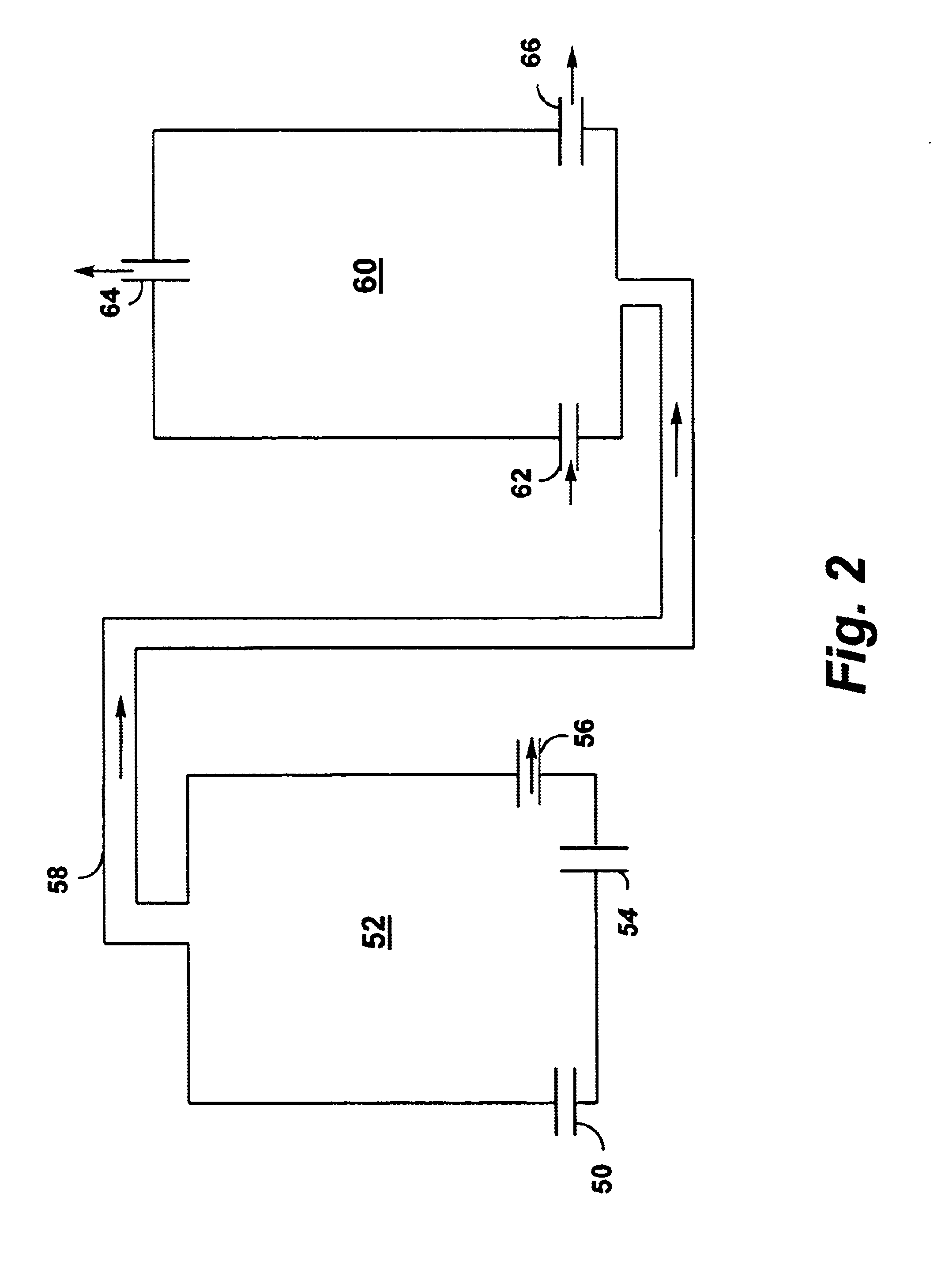

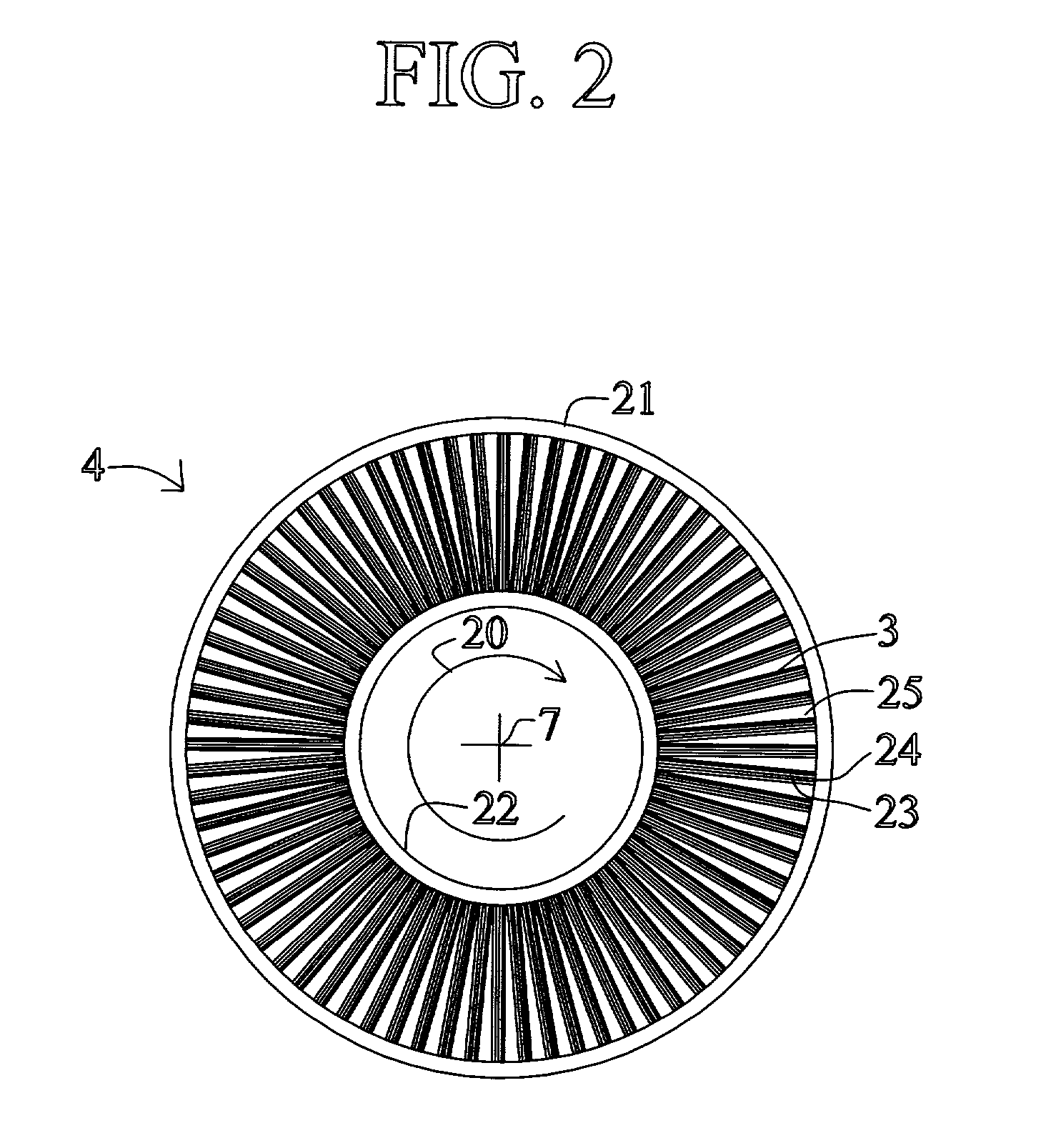

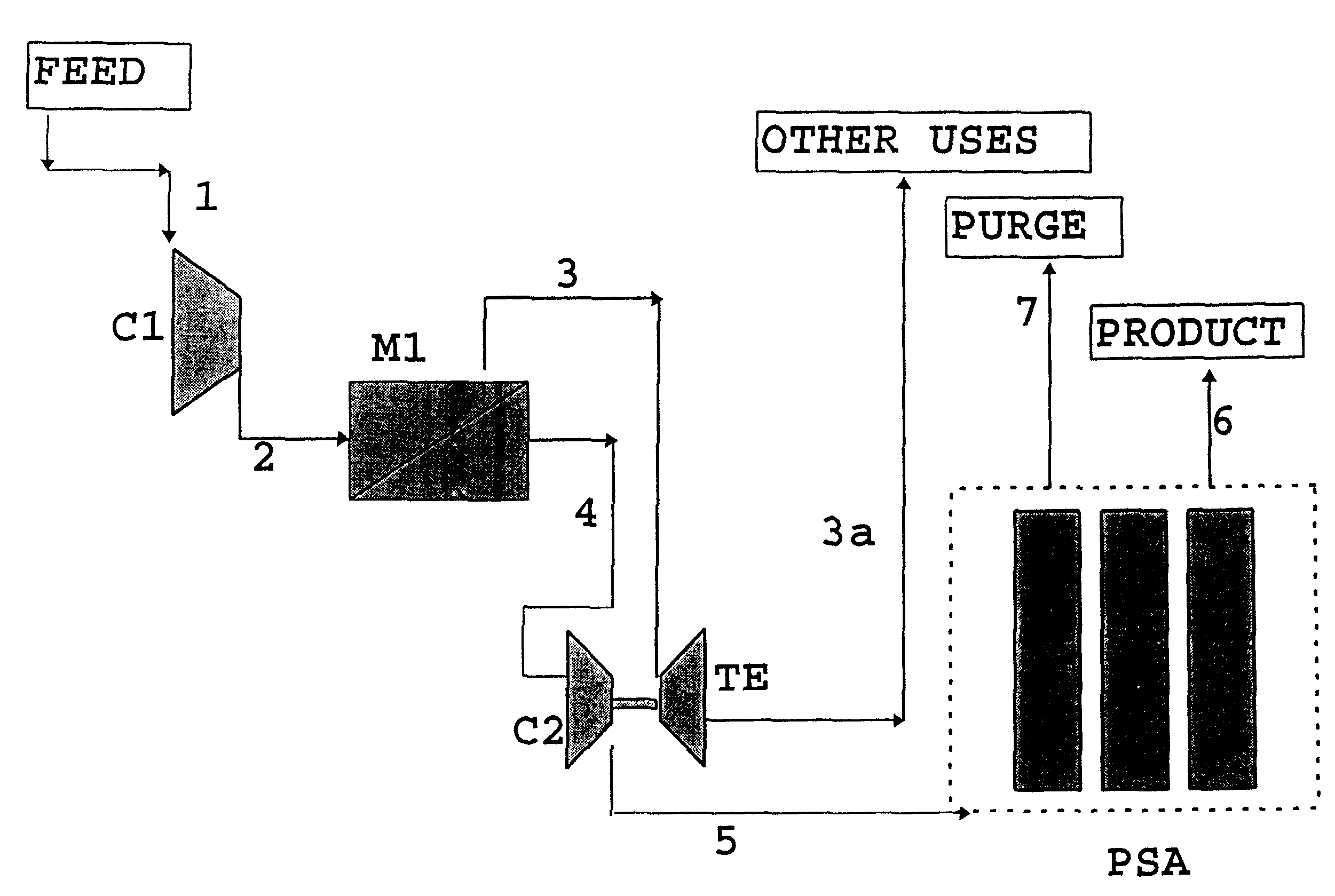

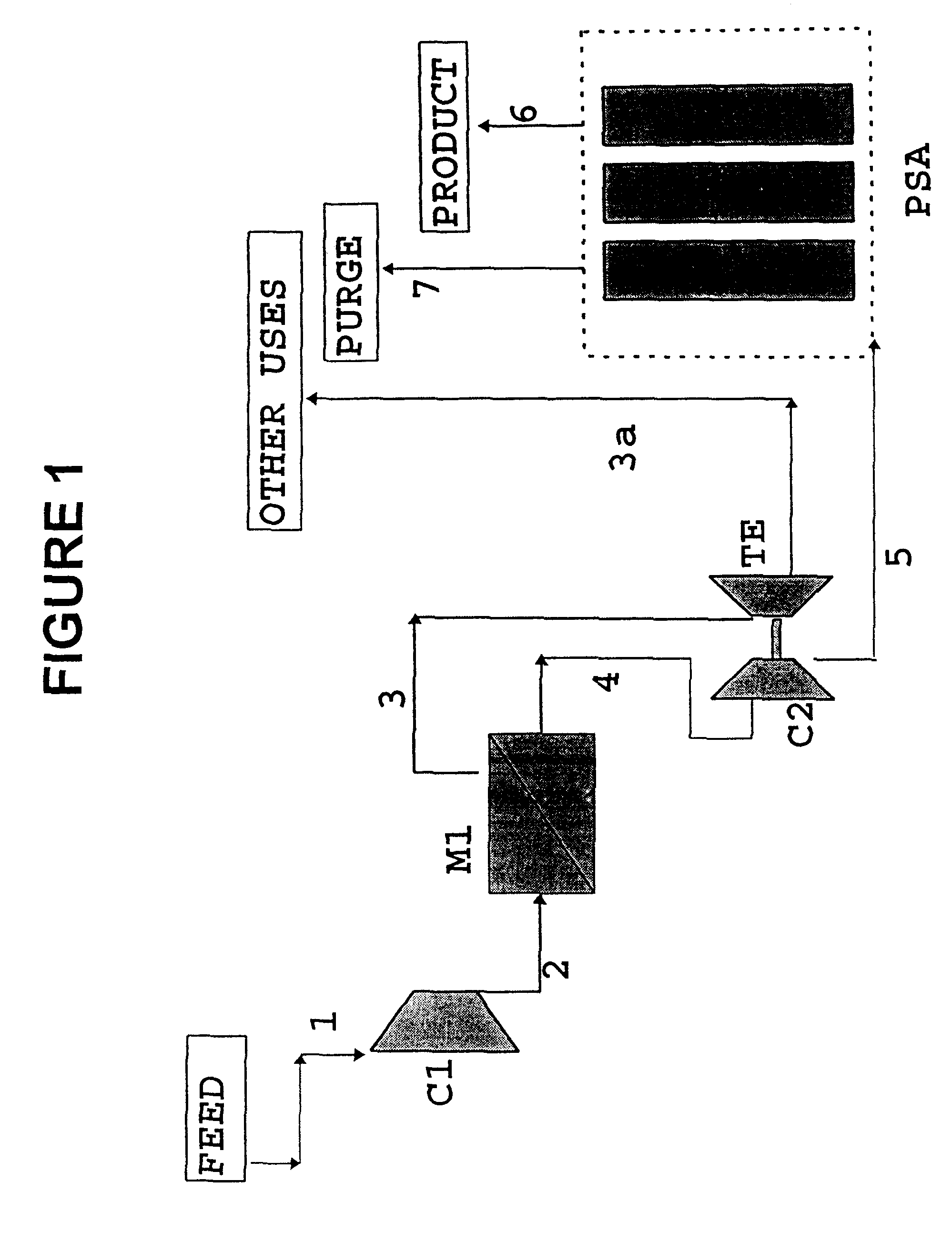

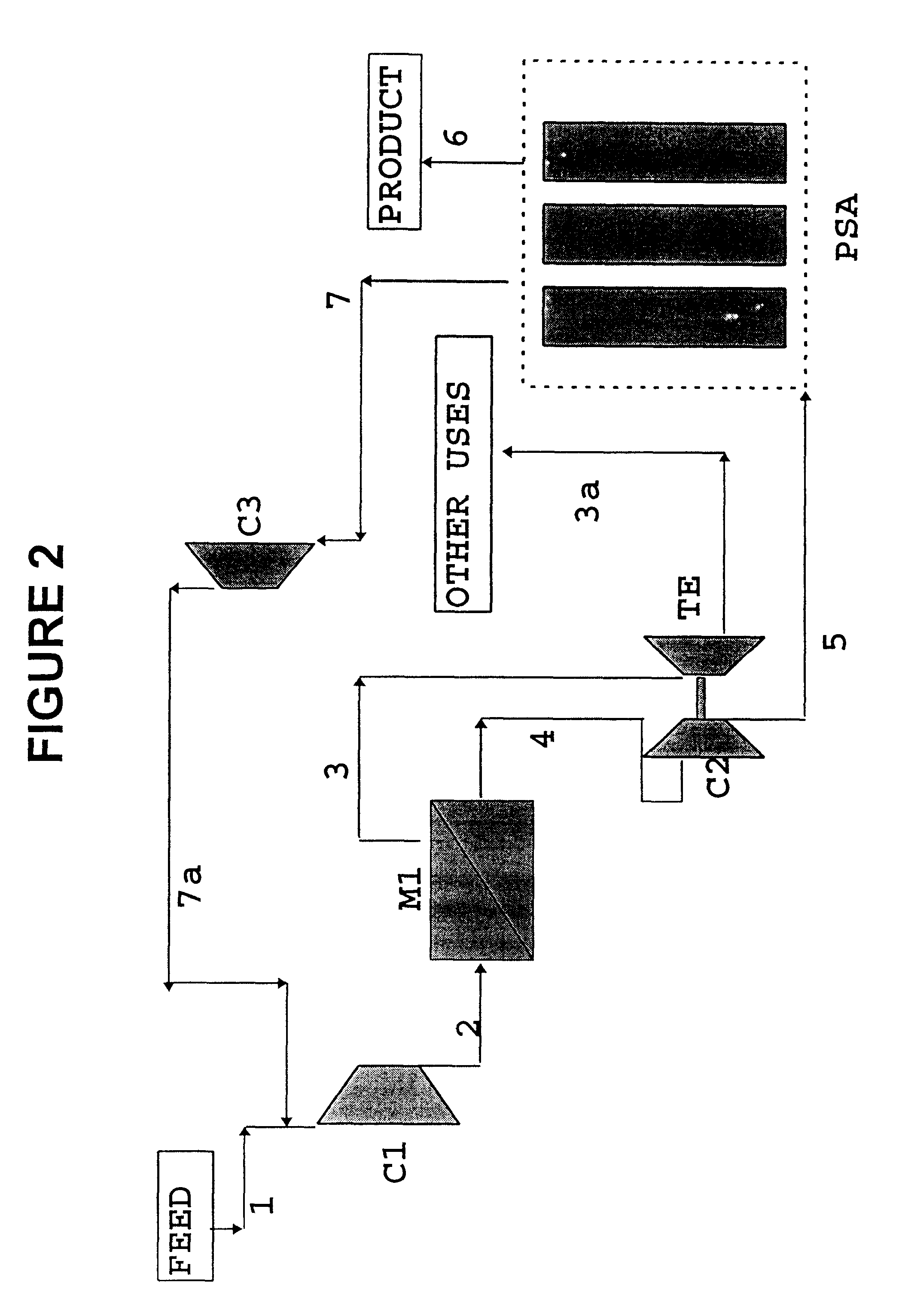

Flow regulated pressure swing adsorption system

InactiveUS6063161AAvoid damageGas treatmentHydrogen separation using solid contactSystem pressureProcess engineering

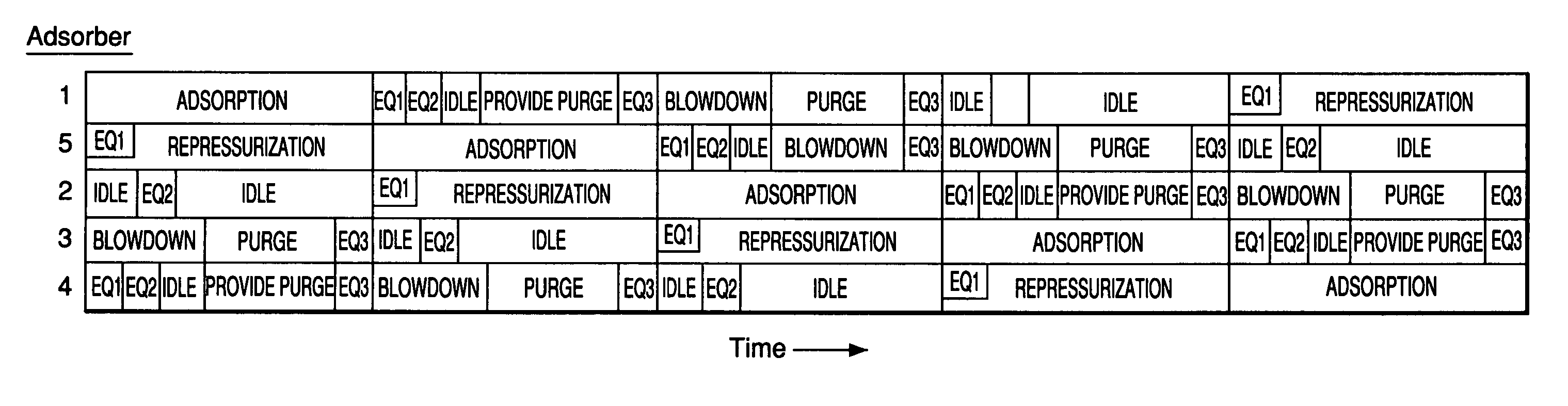

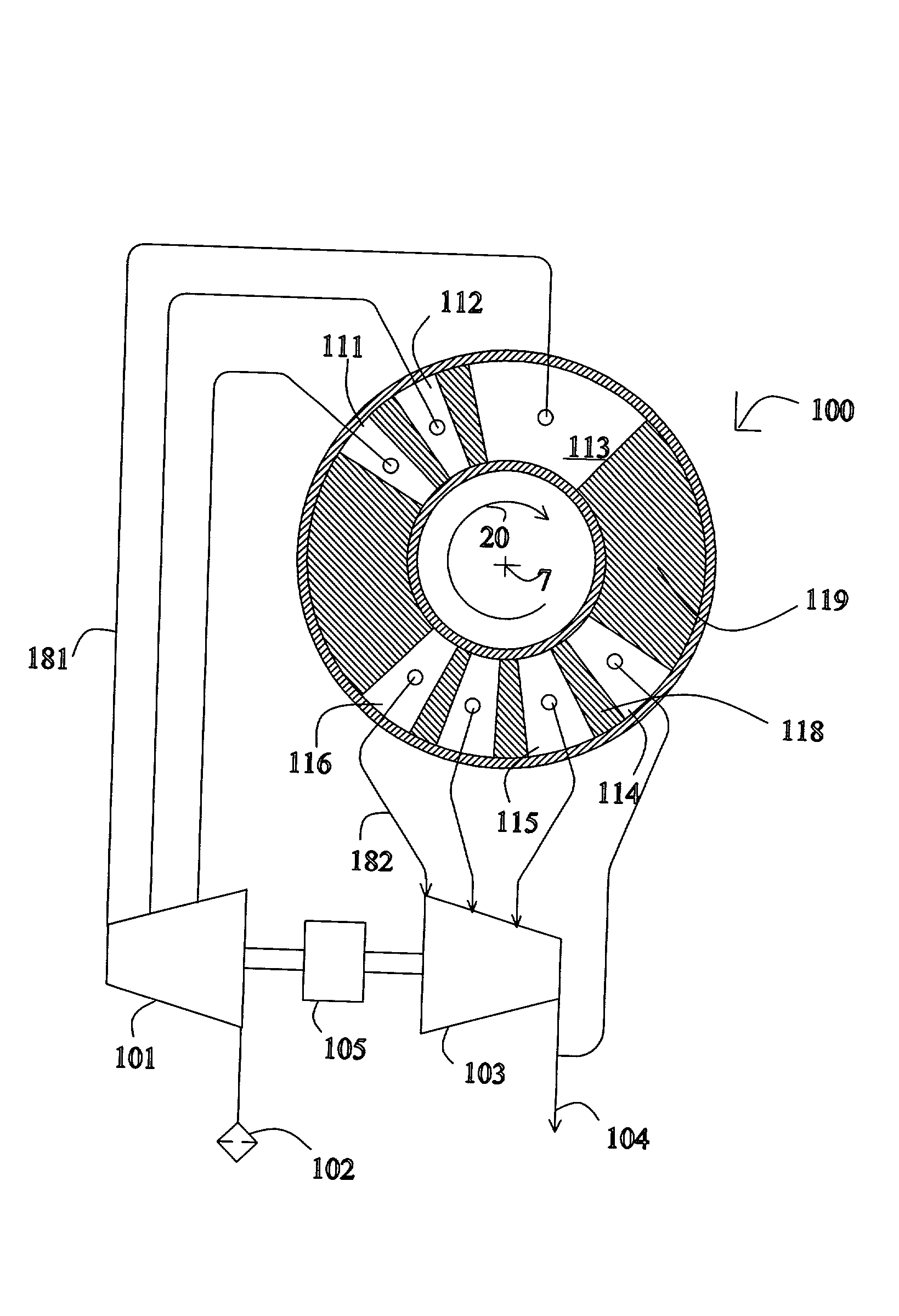

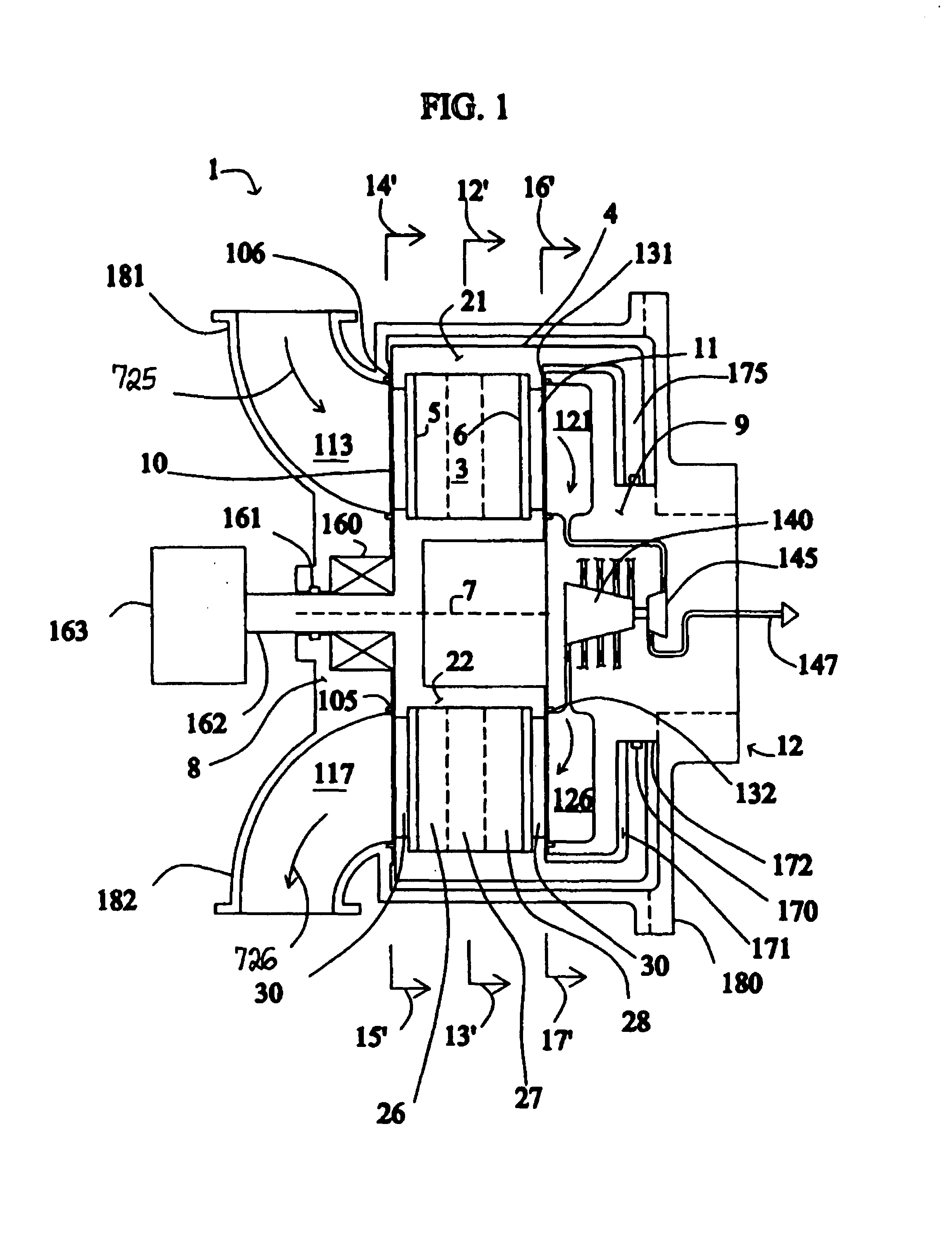

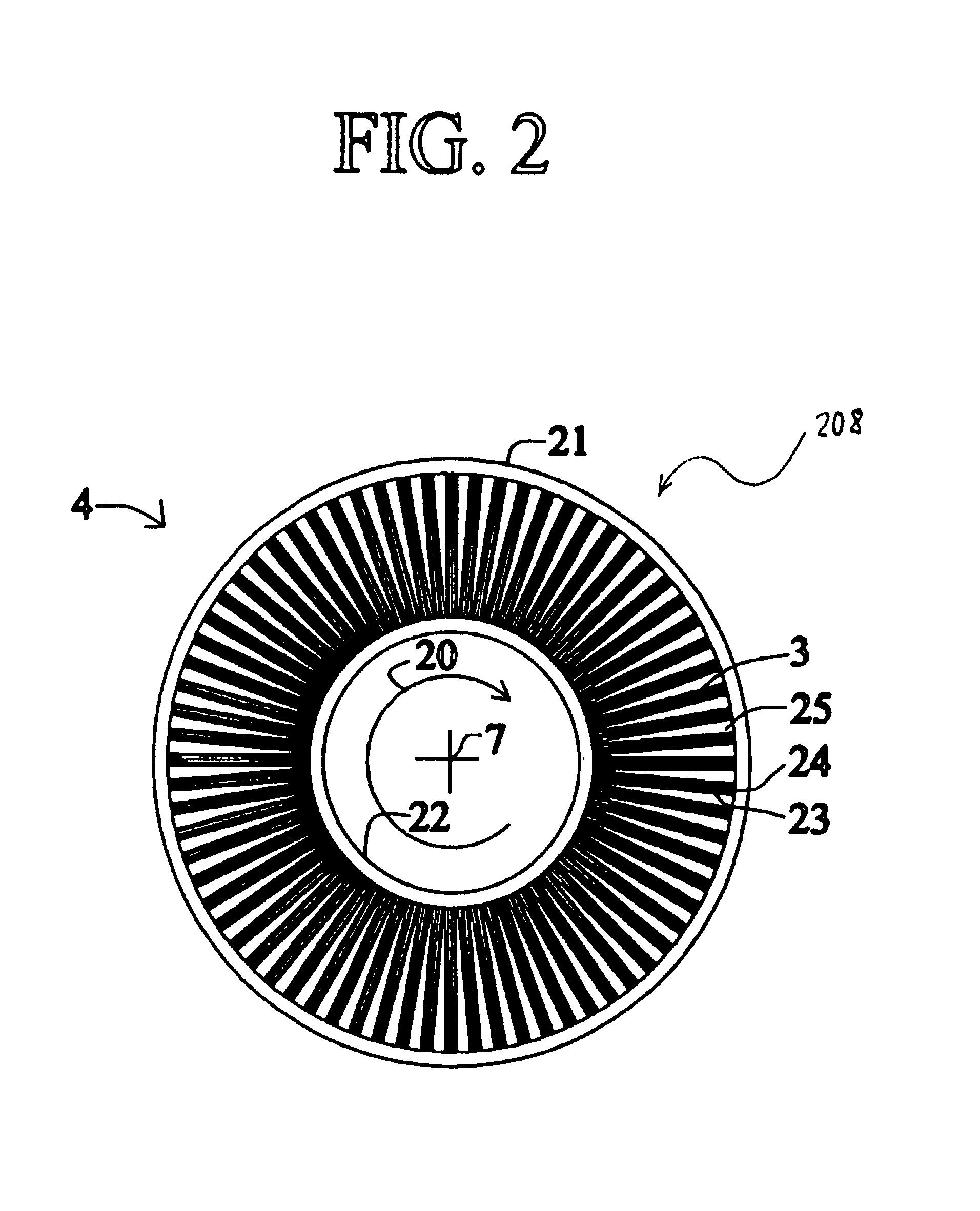

Pressure swing adsorption (PSA) separation of a gas mixture is performed in an apparatus with a plurality of adsorbent beds. The invention provides rotary multiport distributor valves to control the timing sequence of the PSA cycle steps between the beds, with flow controls cooperating with the rotary distributor valves to control the volume rates of gas flows to and from the adsorbent beds in blowdown, purge, equalization and repressurization steps.

Owner:QUSIR TECH +1

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

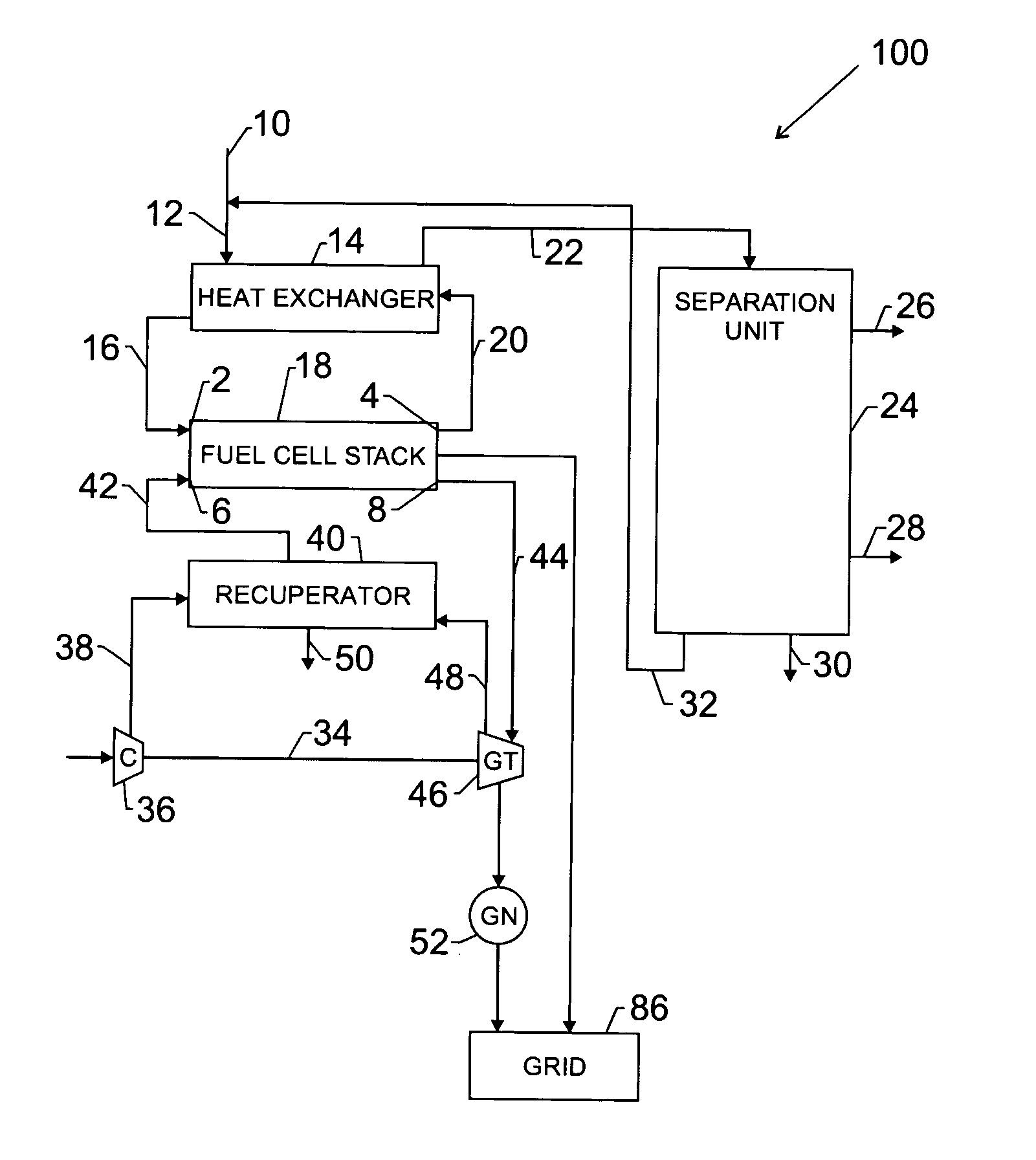

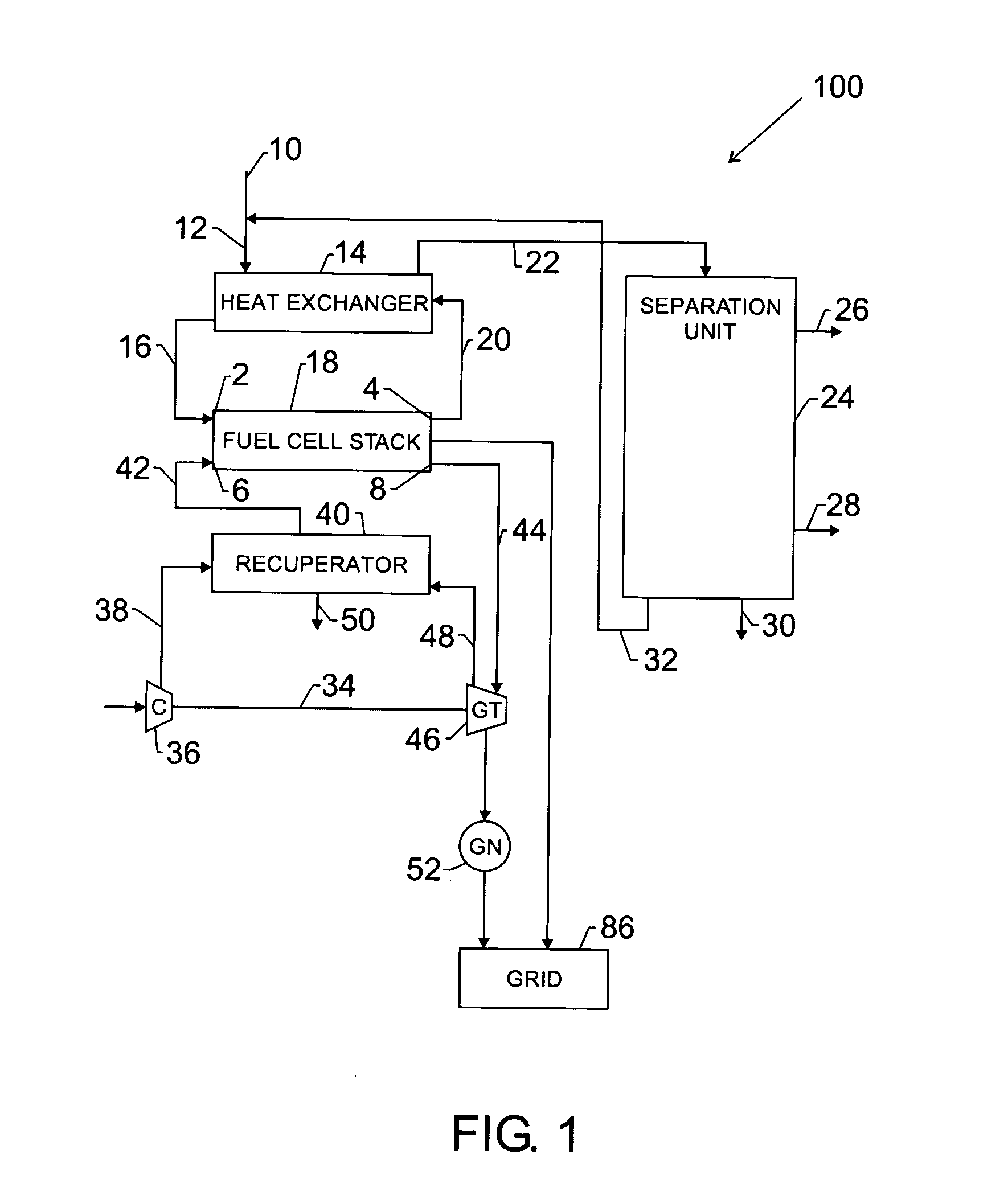

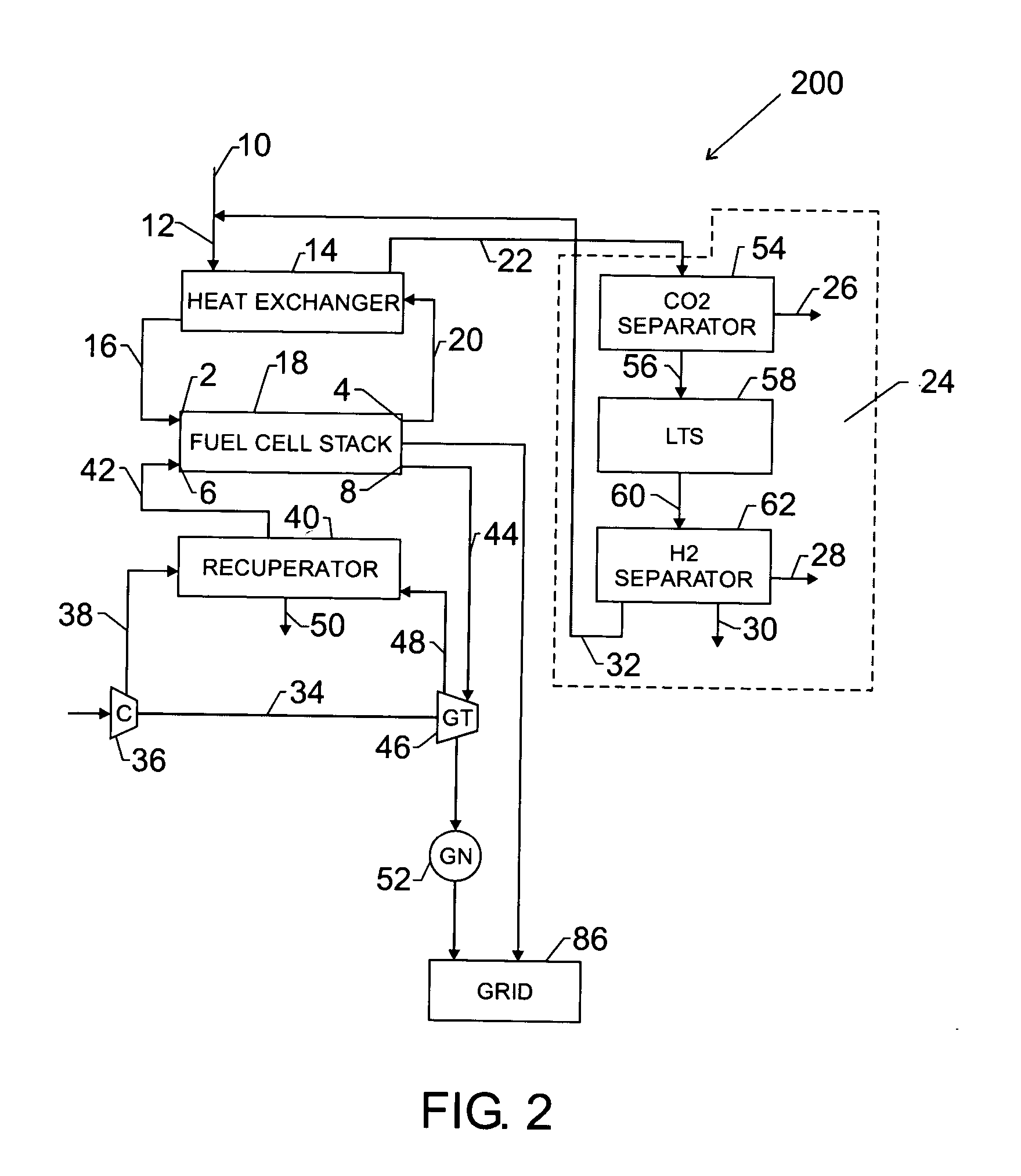

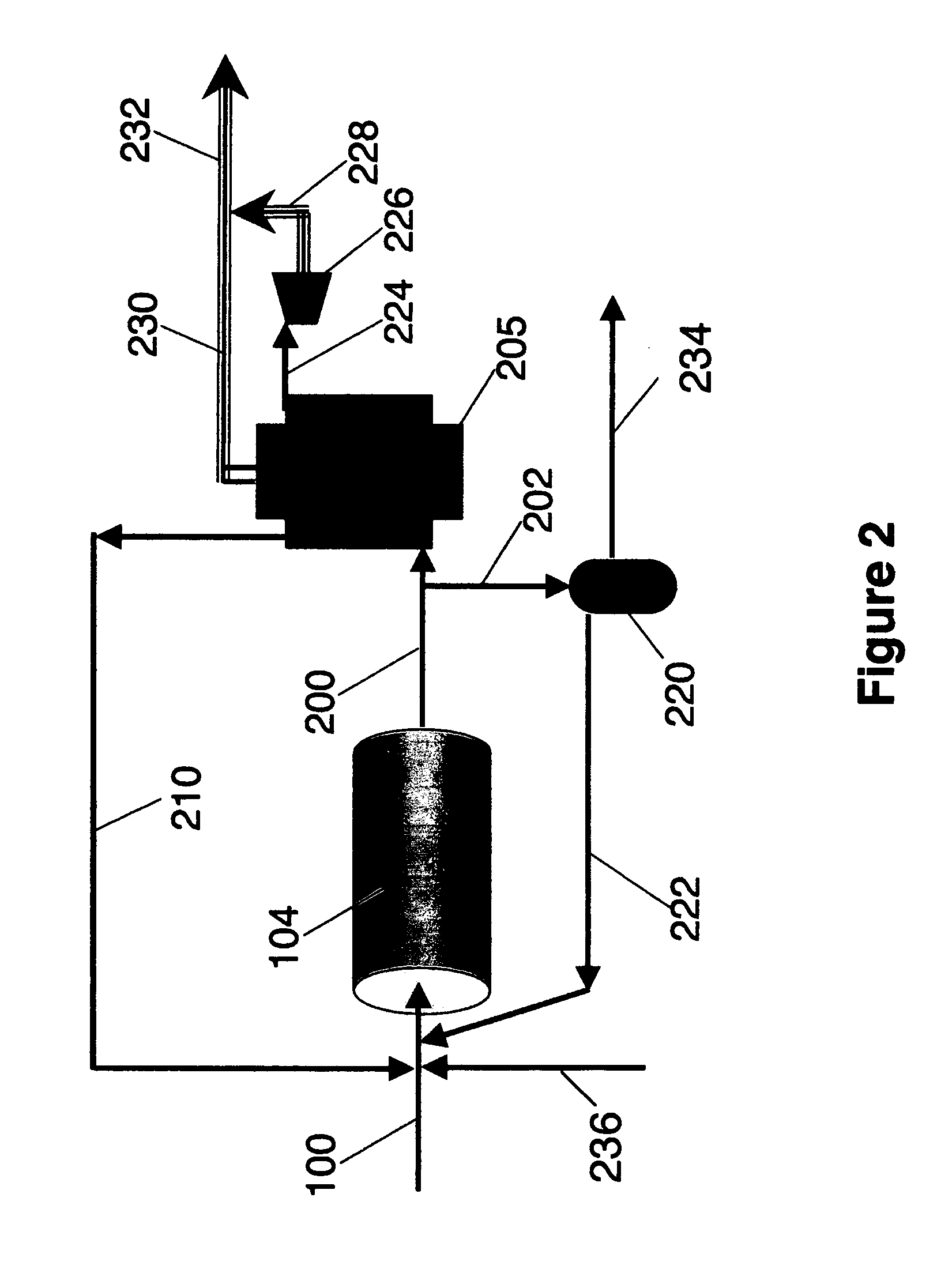

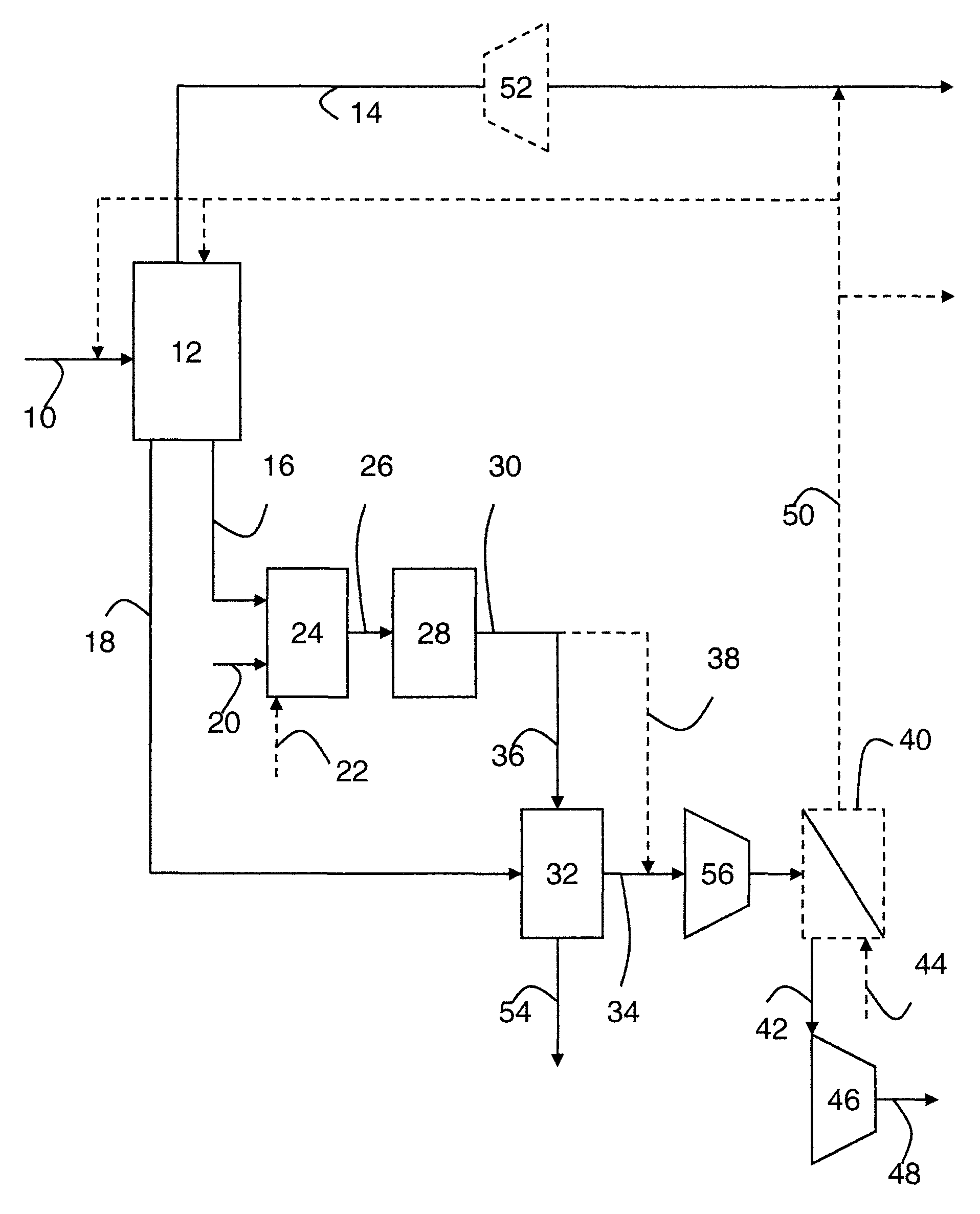

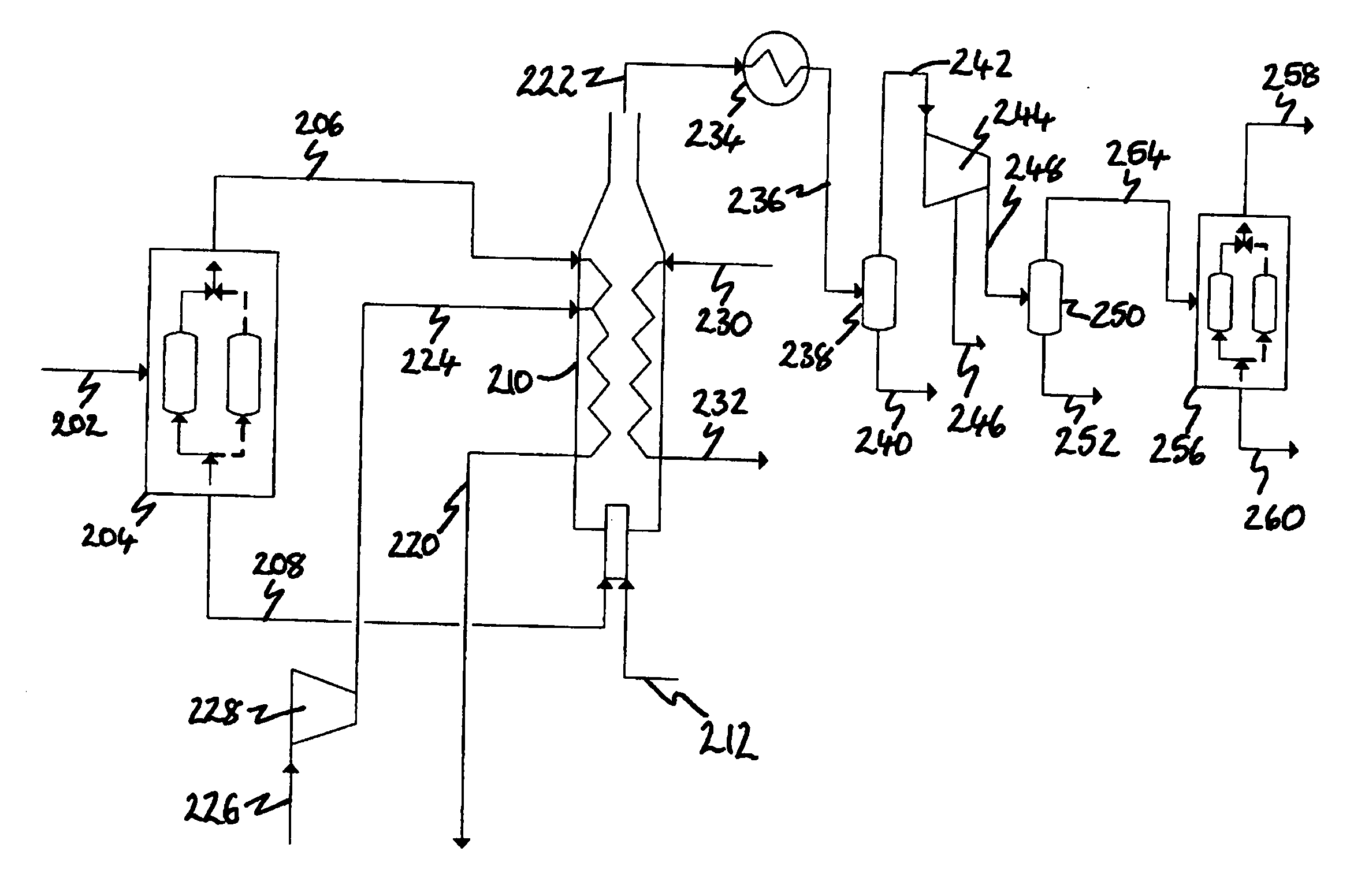

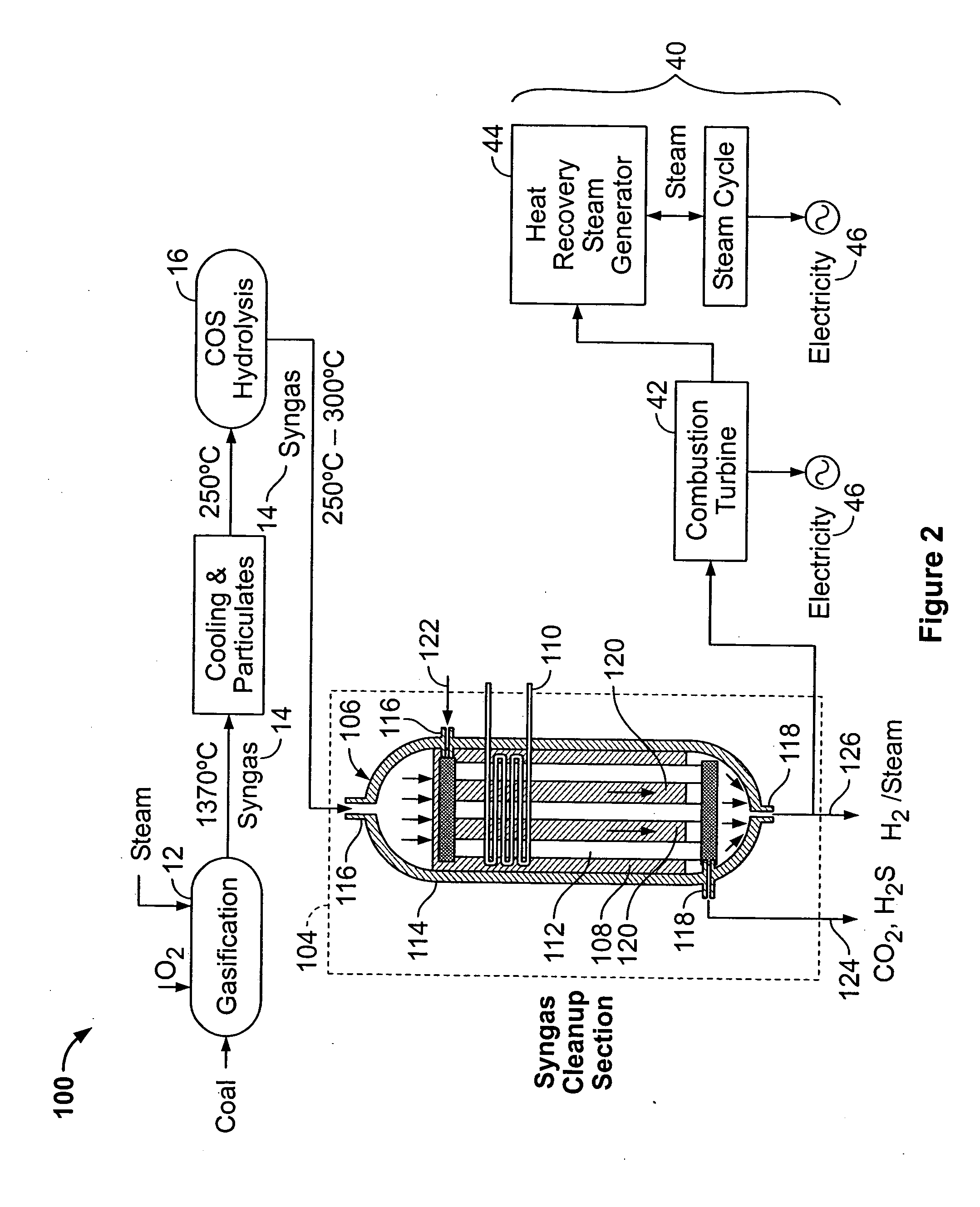

System and method for co-production of hydrogen and electrical energy

InactiveUS20050123810A1Fuel cell combinationsHydrogen separation at low temperatureHydrogenFuel cells

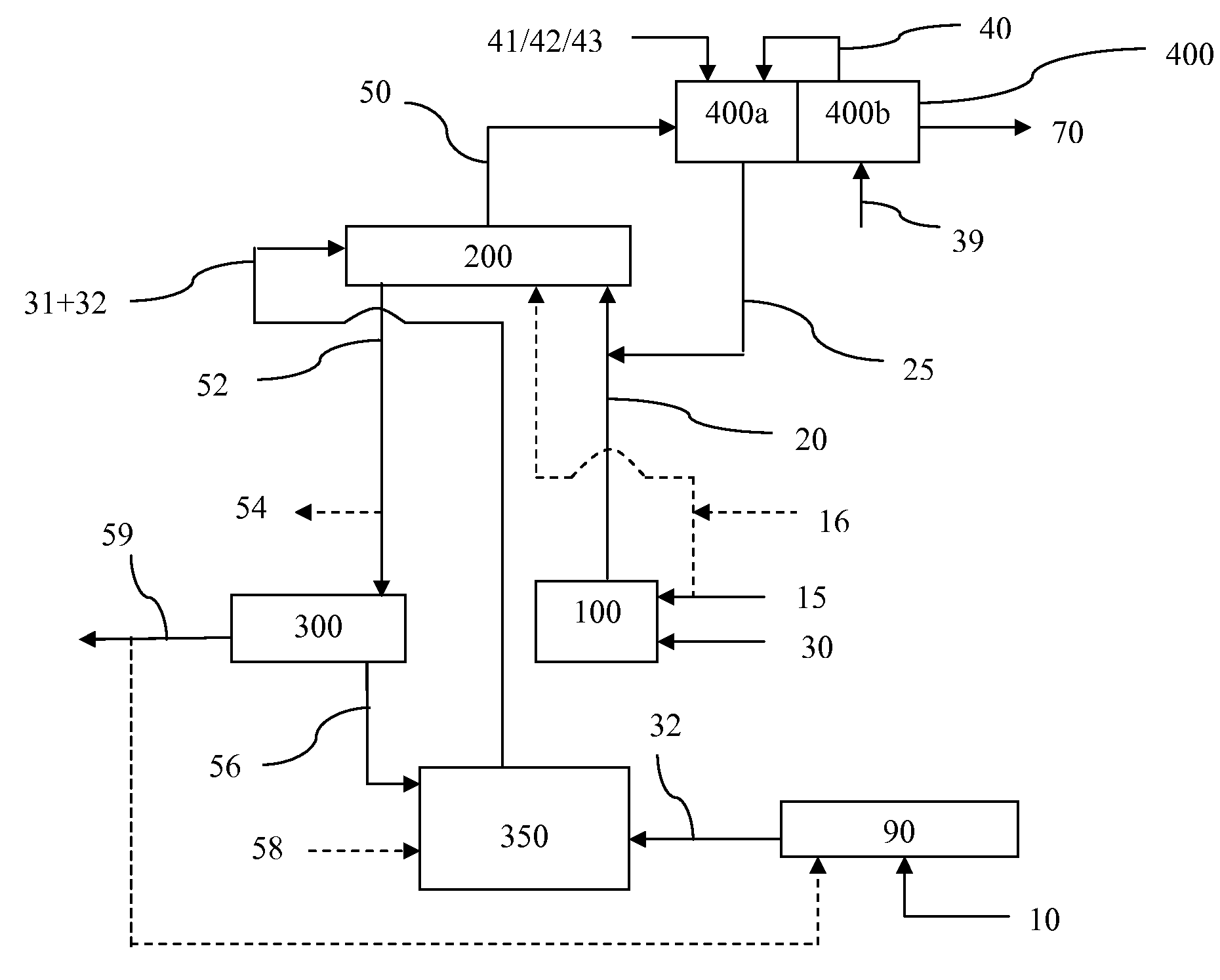

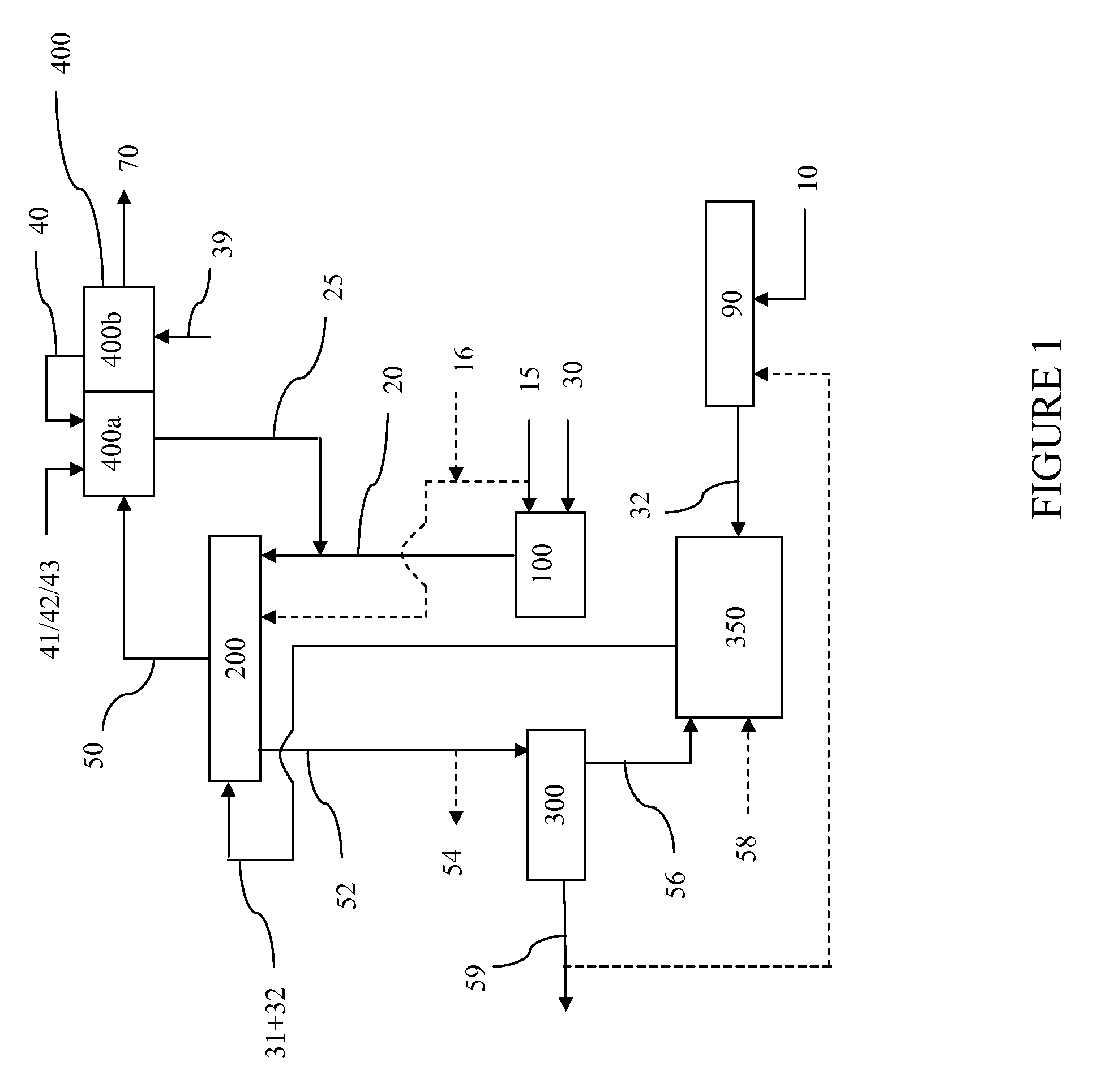

A system and method for co-production of hydrogen and electrical energy. The system comprises a fuel cell assembly comprising a plurality of fuel cells. The fuel cells further comprise a cathode inlet for receiving a compressed oxidant, an anode inlet for receiving a fuel feed stream, an anode outlet in fluid communication with an anode exhaust stream and a cathode outlet in fluid communication with a cathode exhaust stream. At least a portion of the fuel feed stream reacts with the oxidant to produce electrical power. The anode exhaust stream comprises hydrogen. The co-production system further comprises a separation unit in fluid communication with the fuel cell assembly. The separation unit is configured to receive the anode exhaust stream from the fuel cell assembly to separate hydrogen from the anode exhaust stream.

Owner:GENERAL ELECTRIC CO

Energy efficient gas separation for fuel cells

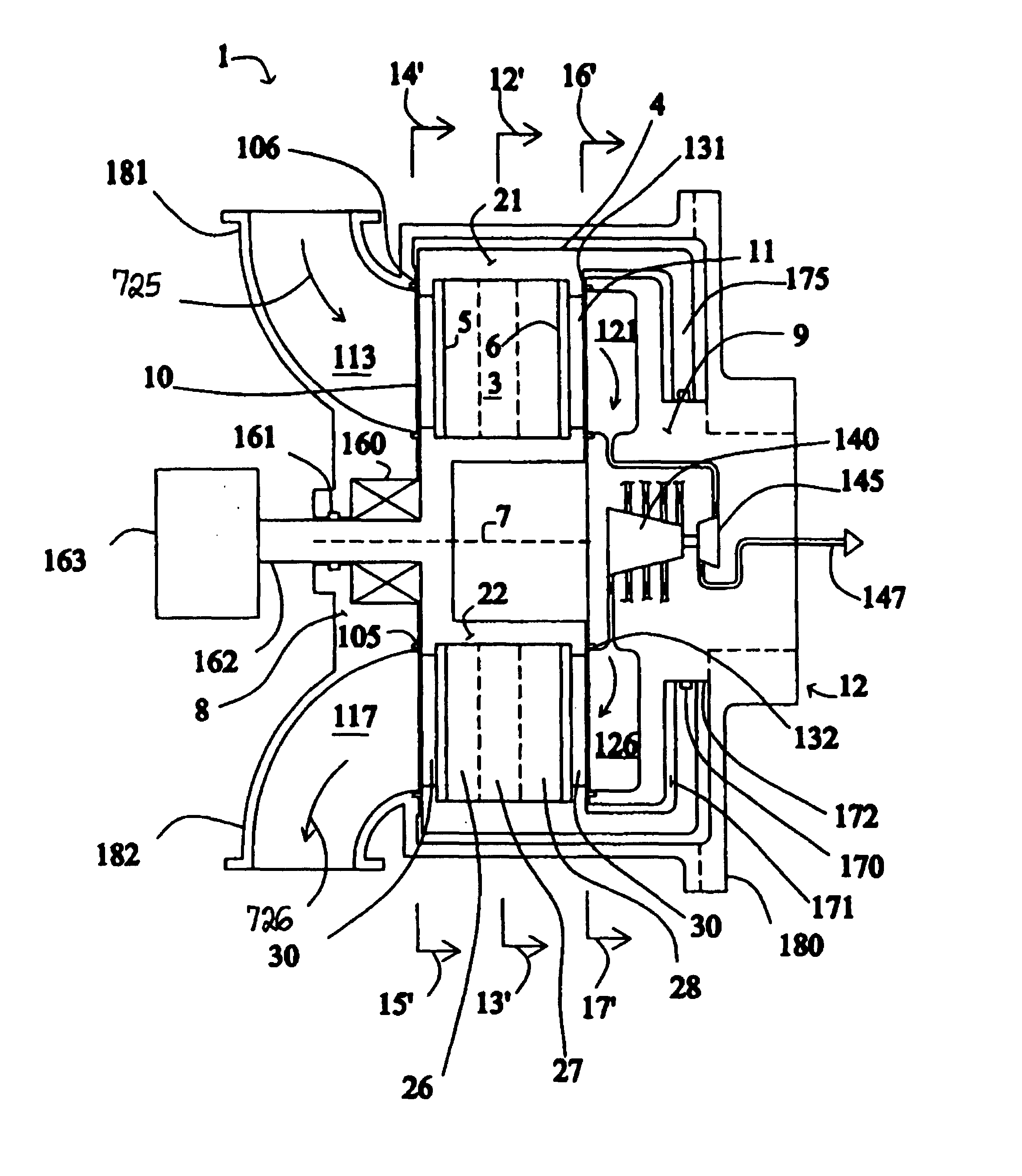

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

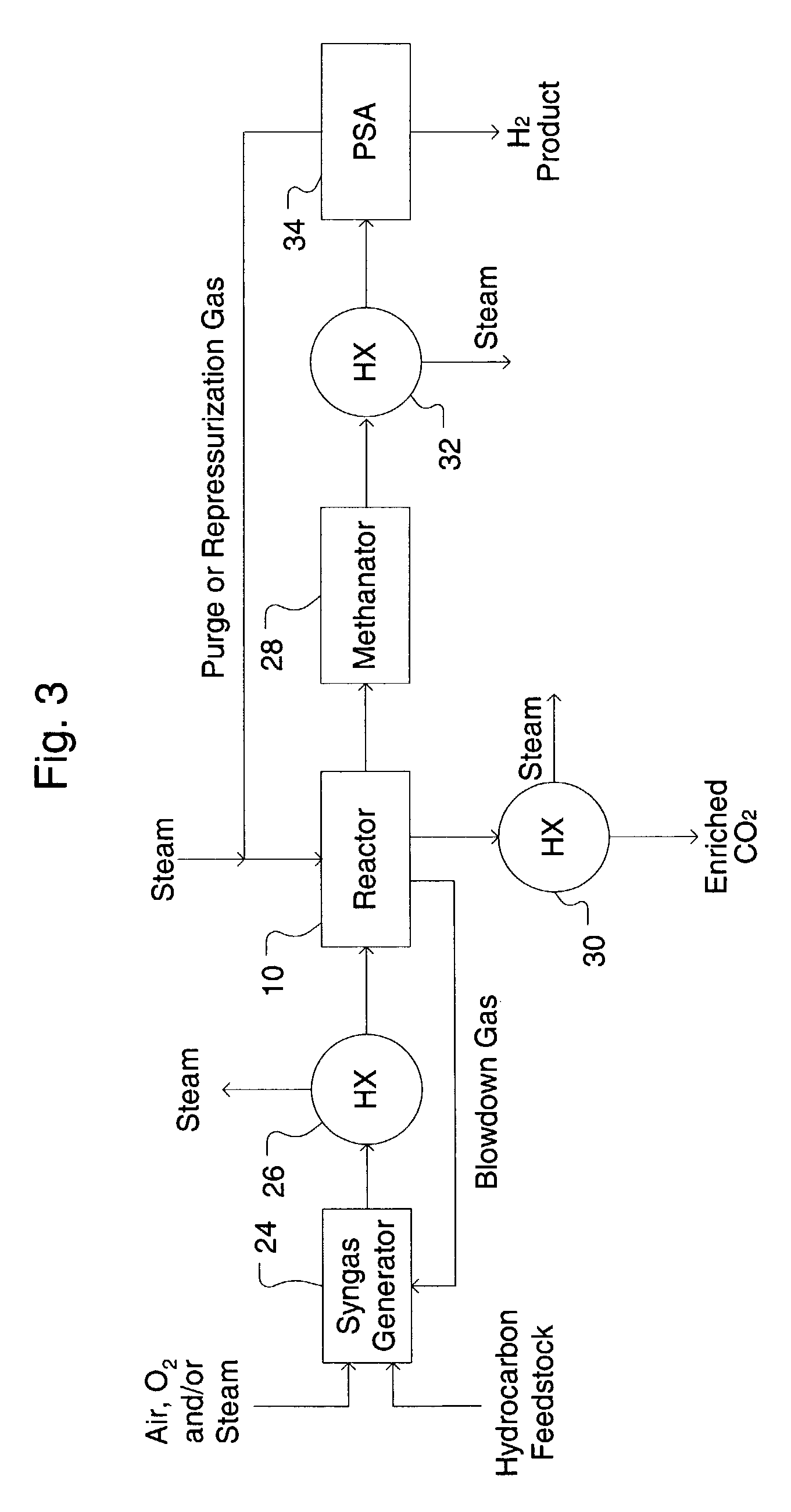

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

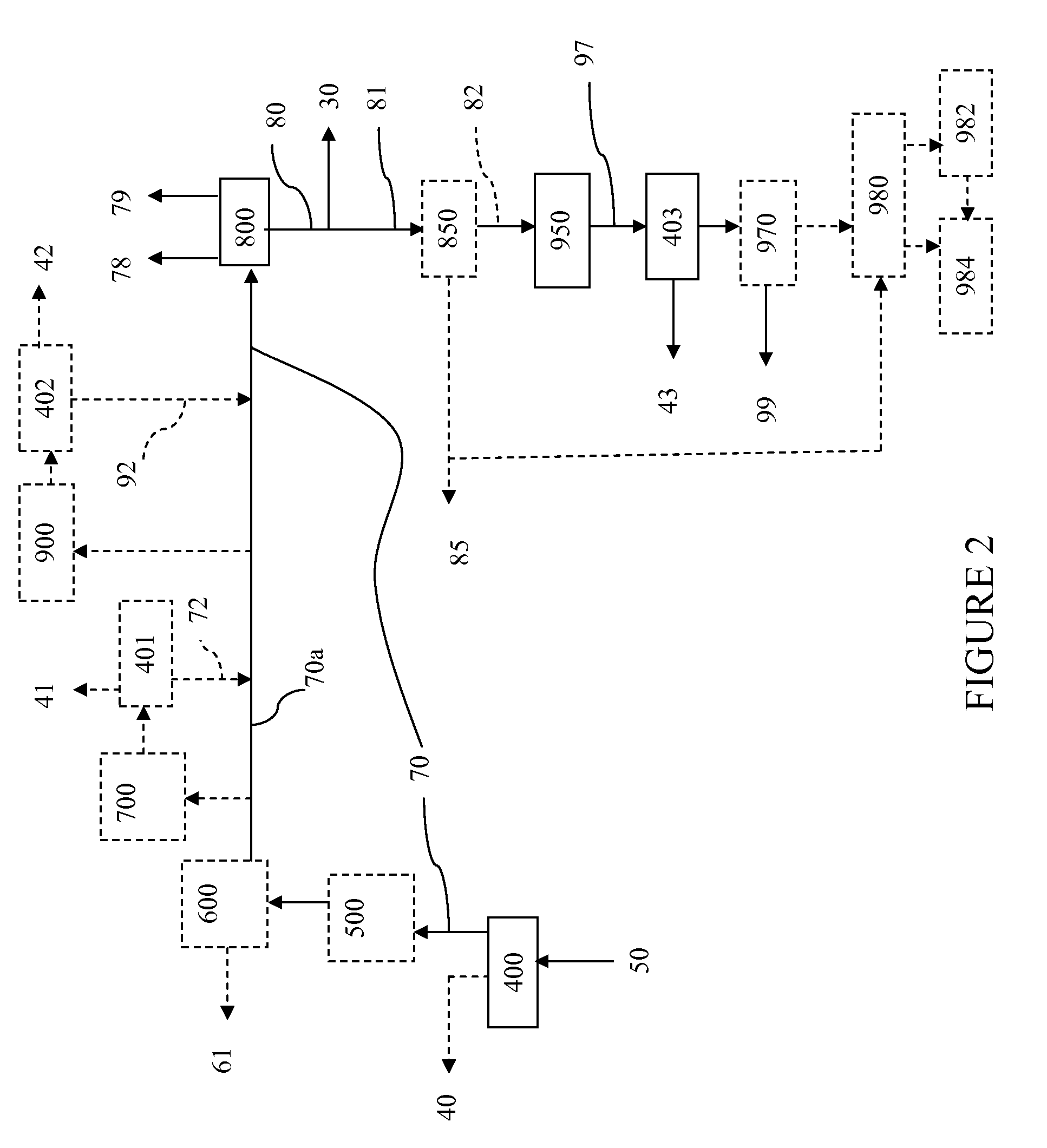

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

Process for the separation/recovery of gases

InactiveUS6179900B1Low costHigh purityNitrogen purification/separationGas treatmentHydrogenHigh pressure

A process for the separation / recovery of gases is described where the desired component to be separated from the gaseous mixture is present in low / very low molar amount and / or low / moderate pressure, the process comprising contacting the gaseous mixture with a separation membrane unit containing high permeability / medium selectivity membranes which separate the feed stream into a permeate stream, enriched in the desired component and at a lower pressure and a retentate stream lean in the desired component and at a higher pressure. The retentate stream is made to convey its pressure to the permeate stream which then is directed to an adsorption PSA unit for further purification of the permeate stream so that the effluent stream from the PSA unit which contains the purified component has a purity of up to 99.90%. The process is useful for separating hydrogen from refinery off gases such as FCC gases and can also be applied to other gases such as helium and any other valuable gases present in gaseous streams in low to very low molar contents and low to moderate pressures.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH +1

Method and apparatus for treating a sour gas

Owner:AIR PROD & CHEM INC

Steam methane reforming method

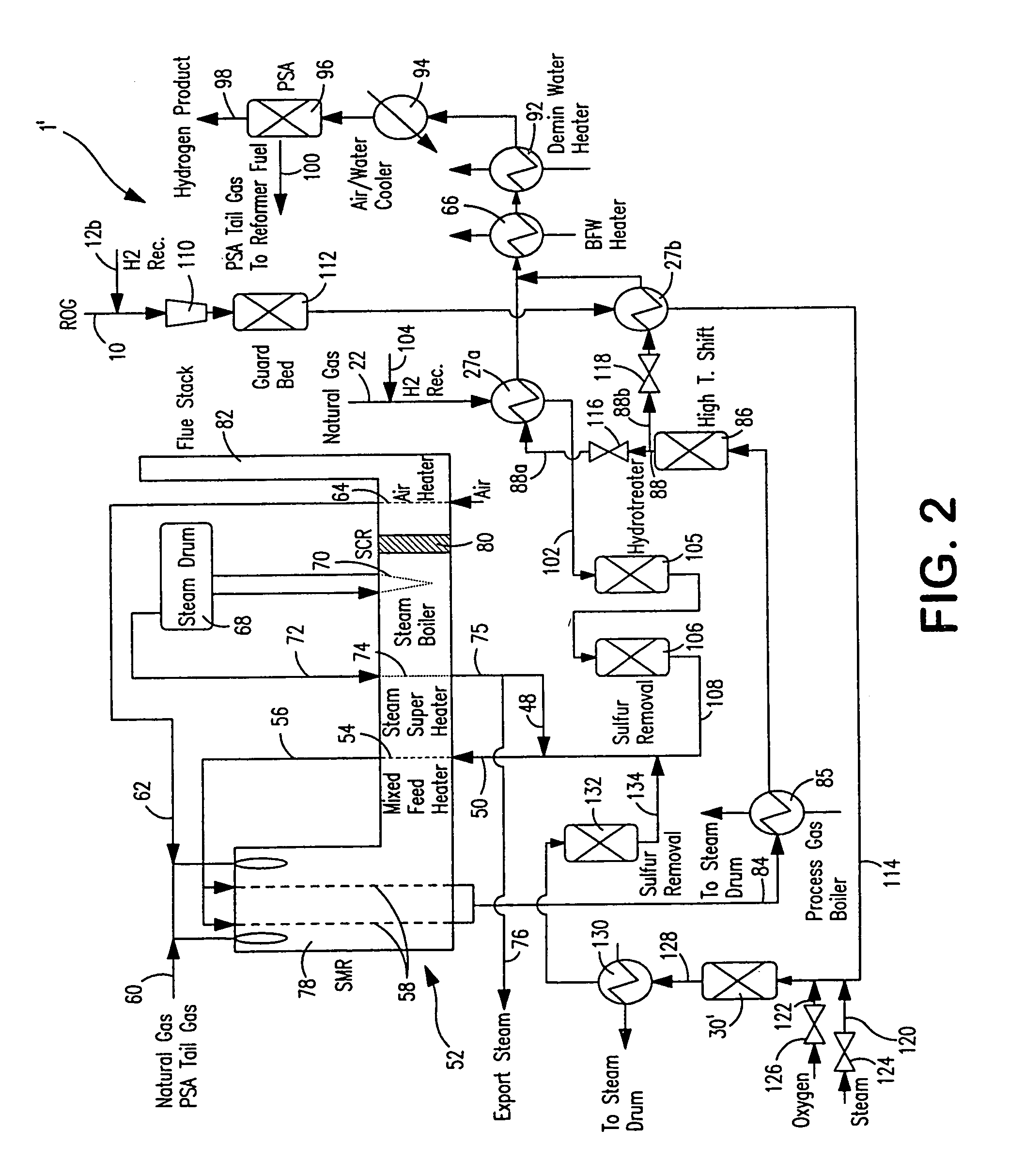

ActiveUS7037485B1Reduce fuel usageReduce firing rateHydrocarbon from carbon oxidesHydrogen separation using solid contactMethane reformerAlkane

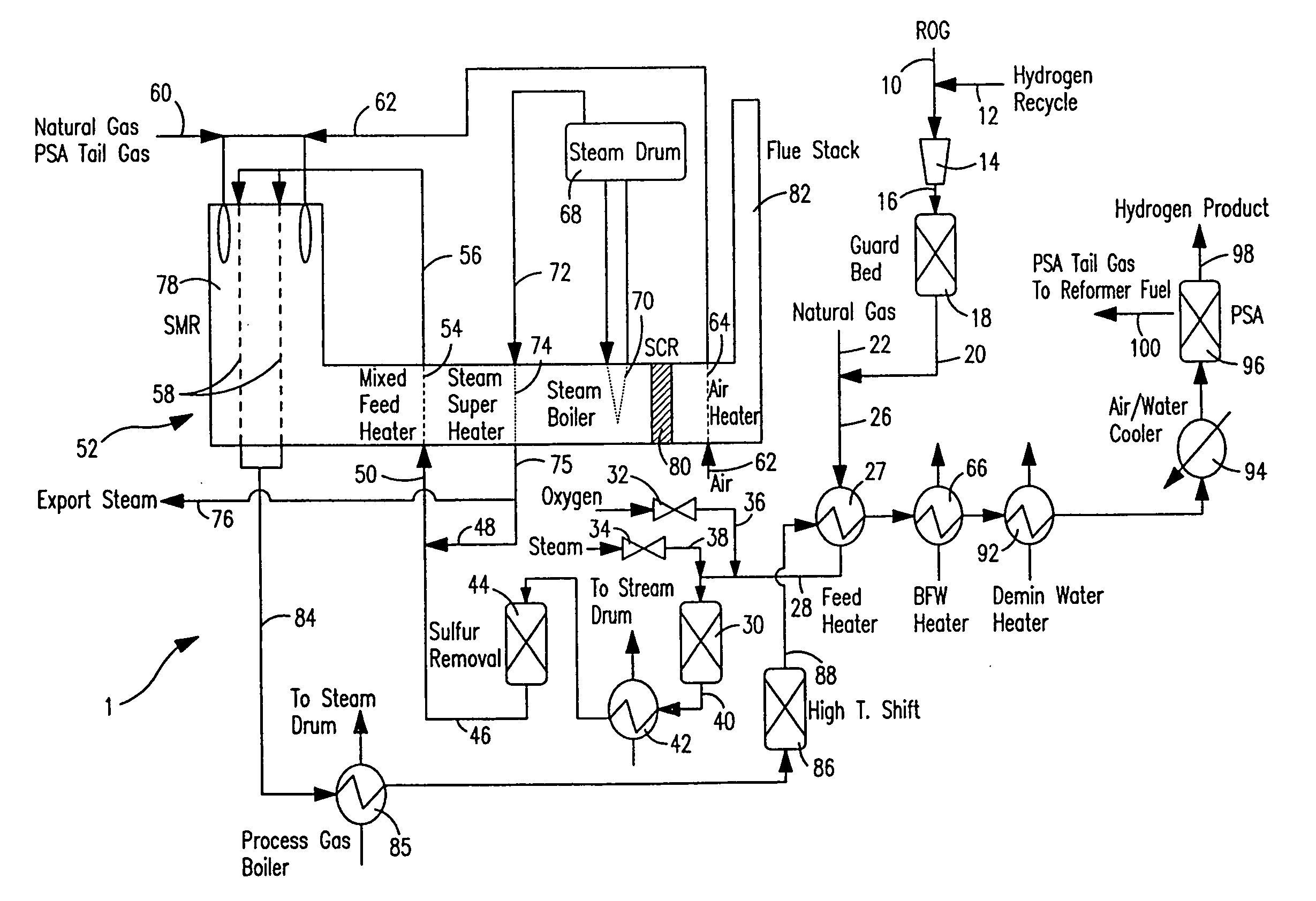

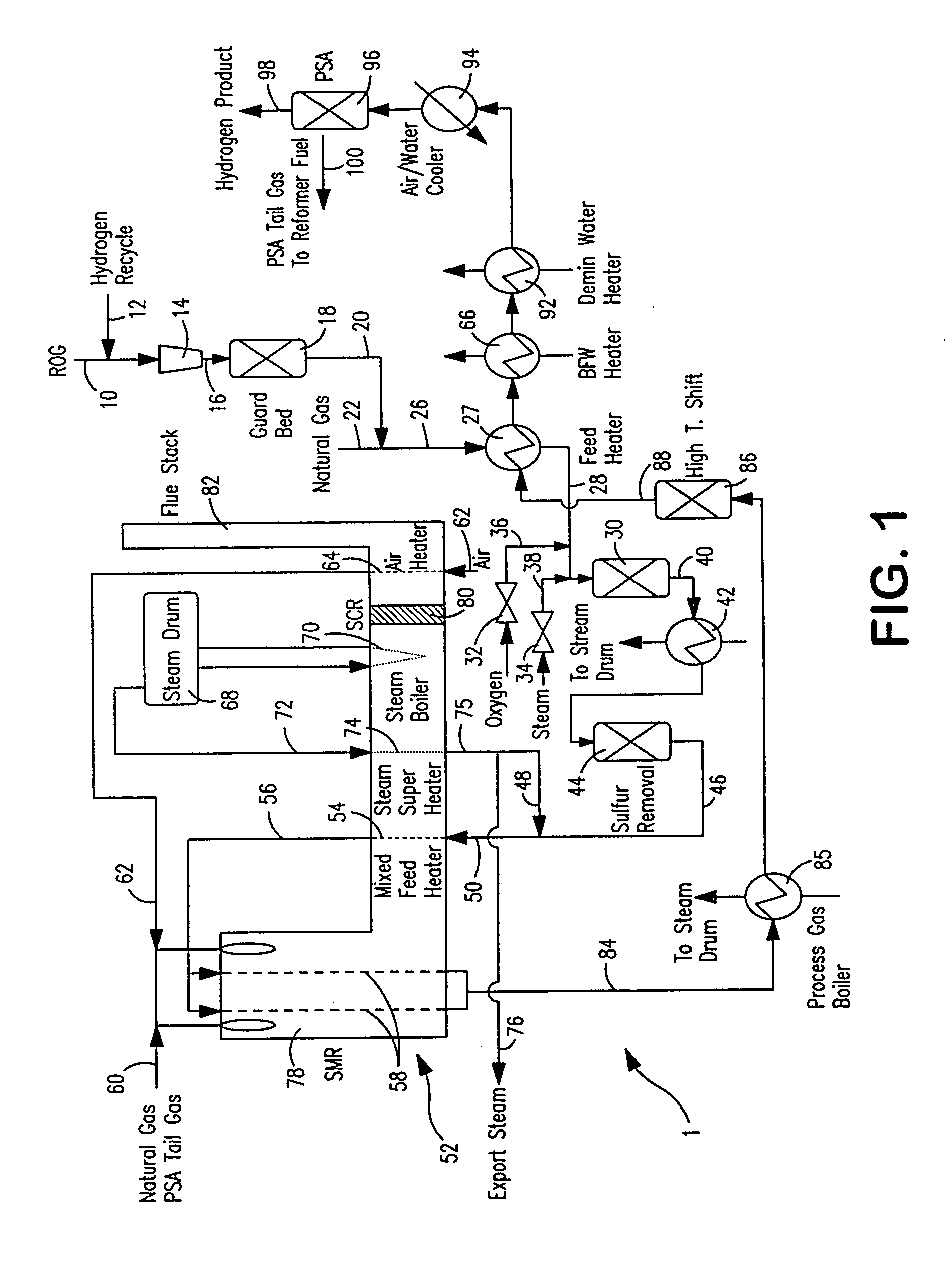

A steam methane reforming method in which a feed stream is treated in a reactor containing a catalyst that is capable of promoting both hydrogenation and partial oxidation reactions. The reactor is either operated in a catalytic hydrogenation mode to convert olefins into saturated hydrocarbons and / or to chemically reduce sulfur species to hydrogen sulfide or a catalytic oxidative mode utilizing oxygen and steam to prereform the feed and thus, increase the hydrogen content of a synthesis gas produced by a steam methane reformer. The method is applicable to the treatment of feed streams containing at least 15% by volume of hydrocarbons with two or more carbon atoms and / or 3% by volume of olefins, such as a refinery off-gas. In such case, the catalytic oxidative mode is conducted with a steam to carbon ratio of less than 0.5, an oxygen to carbon ratio of less than 0.25 and a reaction temperature of between about 500° C. and about 860° C. to limit the feed to the steam methane reformer to volumetric dry concentrations of less than about 0.5% for the olefins and less than about 10% for alkanes with two or more carbon atoms.

Owner:PRAXAIR TECH INC

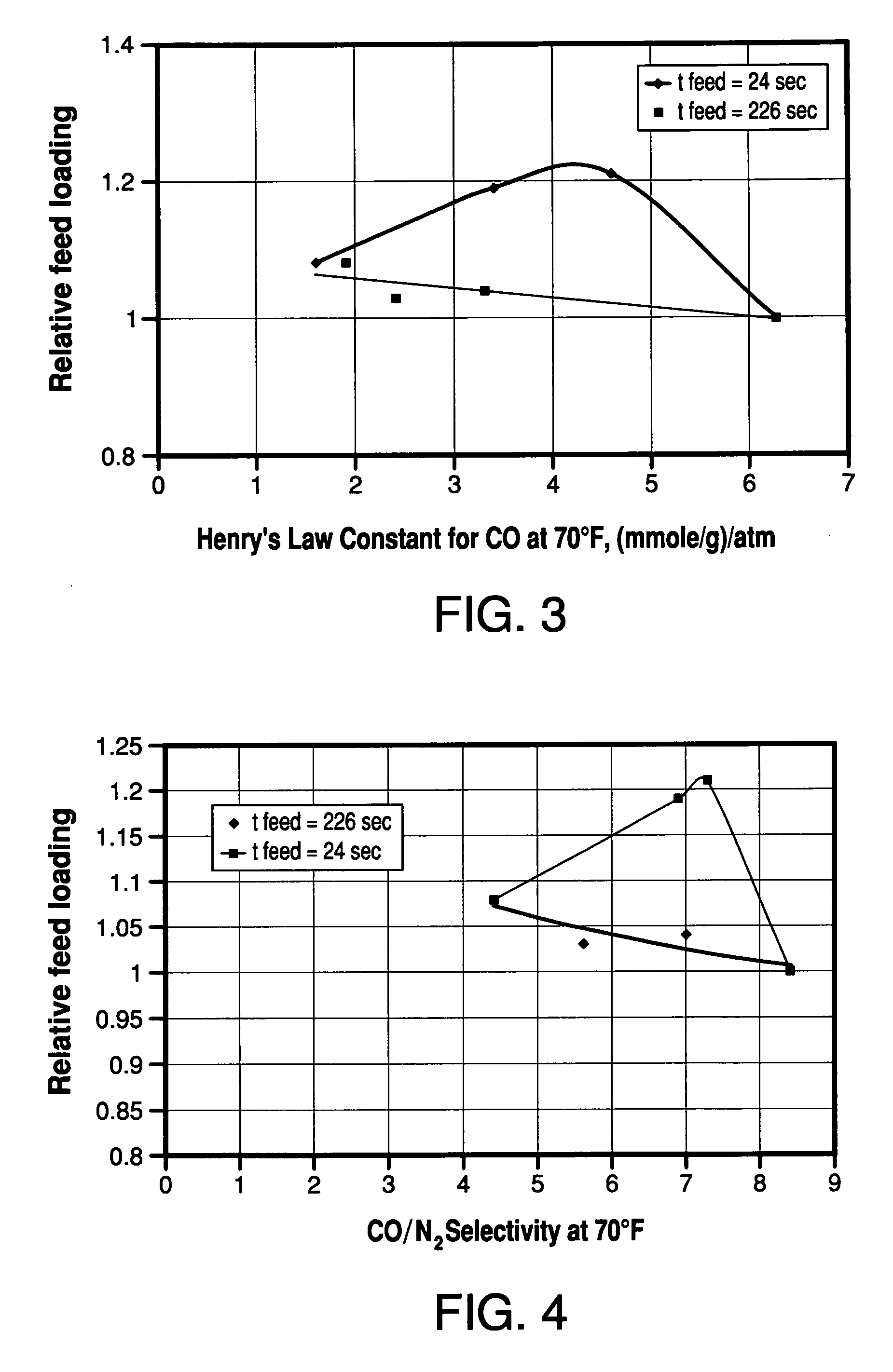

Adsorbents for rapid cycle pressure swing adsorption processes

Method for the separation of a gas mixture comprising providing a PSA system with at least one adsorber vessel containing adsorbent material that is selective for the adsorption of carbon monoxide and nitrogen, passing a feed gas mixture containing at least hydrogen and carbon monoxide and optionally containing nitrogen through the adsorbent material in a feed step and withdrawing a purified hydrogen product from the adsorber vessel, wherein the feed step has a duration or feed time period of about 30 seconds or less. The adsorbent material is characterized by any of (1) a Henry's law constant for carbon monoxide between about 2.5 and about 5.5 (mmole / g) / atm; (2) a carbon monoxide heat of adsorption between about 6.0 and about 7.5 kcal / gmole; (3) a Henry's law constant for nitrogen greater than about 1.5 (mmole / g) / atm; and (4) a selectivity of carbon monoxide to nitrogen between about 5.0 and about 8.0.

Owner:AIR PROD & CHEM INC

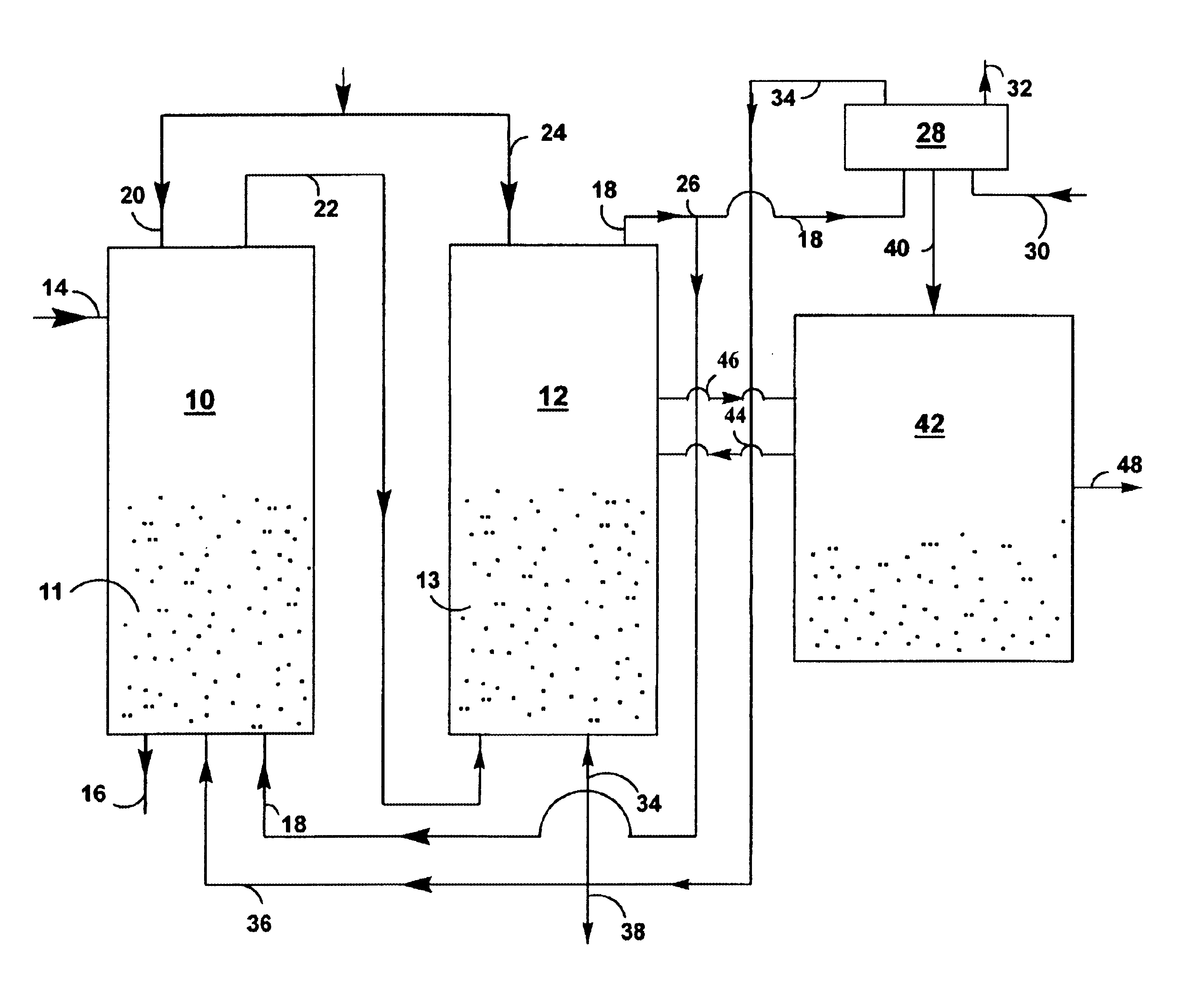

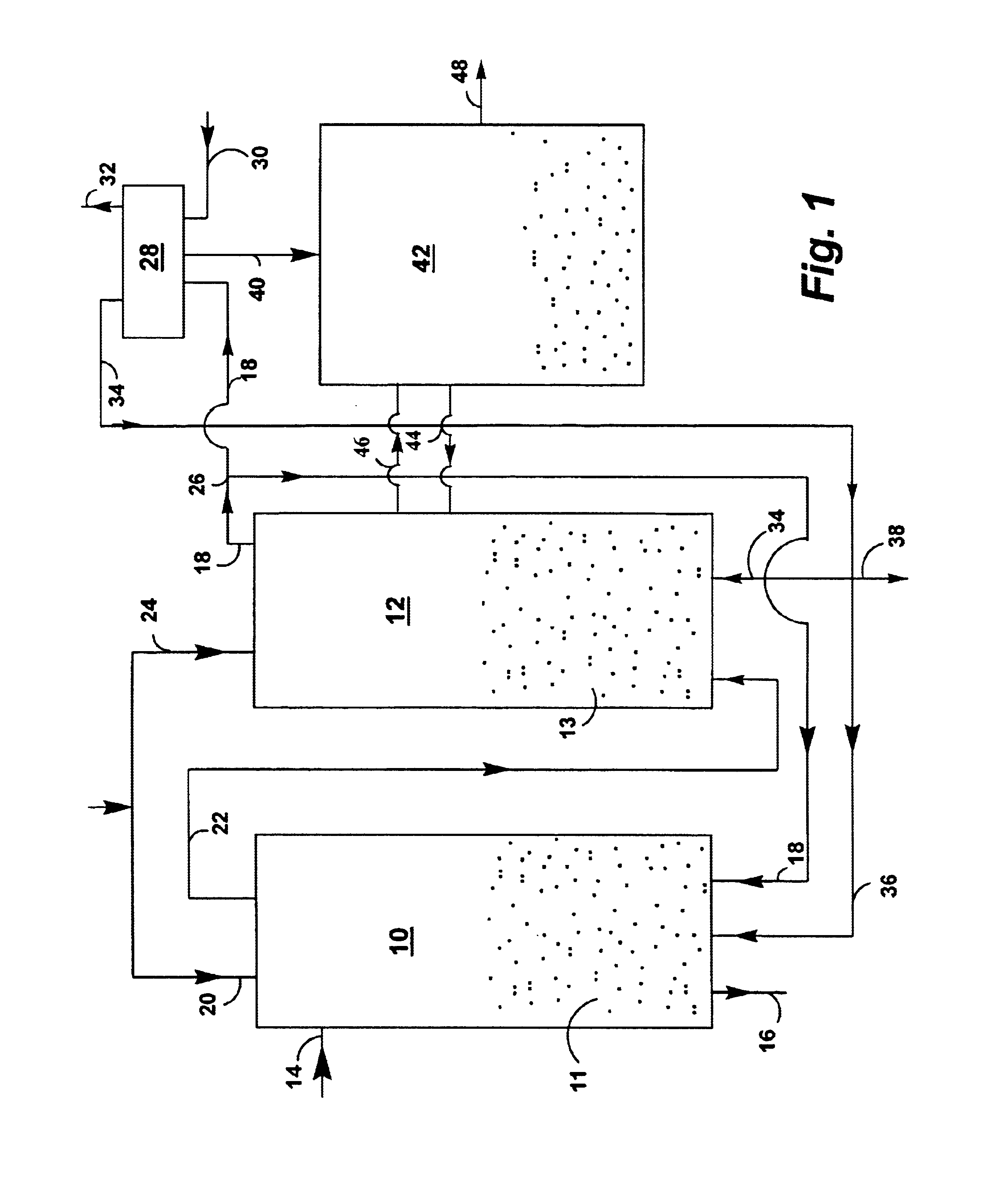

Systems and processes for providing hydrogen to fuel cells

InactiveUS20020098394A1Minimized in sizeMaximize energy efficiencyFuel cell auxillariesHydrogen/synthetic gas productionFuel cellsInternal combustion engine

A process and system for providing a hydrogen-containing gas stream to a fuel cell anode that includes providing a hydrogen-containing gas stream that includes carbon monoxide, introducing the hydrogen-containing gas stream into a pressure swing adsorption module that includes at least one carbon monoxide-selective adsorbent to produce a purified hydrogen-containing gas stream, and introducing the purified hydrogen-containing gas stream to the fuel cell anode. The pressure swing adsorption module can also include a second adsorbent and / or catalyst. Also disclosed is a fuel cell system coupled to an internal combustion engine and a fuel cell system that utilizes fuel cell waste heat for vaporizing a hydrocarbon / water mixture.

Owner:AIR PROD & CHEM INC

Method of treating a gaseous mixture comprising hydrogen and carbon dioxide

Hydrogen (H2) gas and crude carbon dioxide (CO2) gas are separated from a gaseous mixture thereof. Combustible gas(es) in the crude CO2 gas are combusted to produce heat, at least a portion of which is recovered by indirect heat exchange with at least a portion of the separated H2 gas or a gas derived therefrom. The invention may be integrated with coal-fired power stations to reduce or eliminate emission of harmful components into the atmosphere.

Owner:AIR PROD & CHEM INC

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287836A1Hydrogen separation at low temperatureCarbon compoundsMethanationHydromethanation

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen and a hydromethanation catalyst.

Owner:SURE CHAMPION INVESTMENT LTD

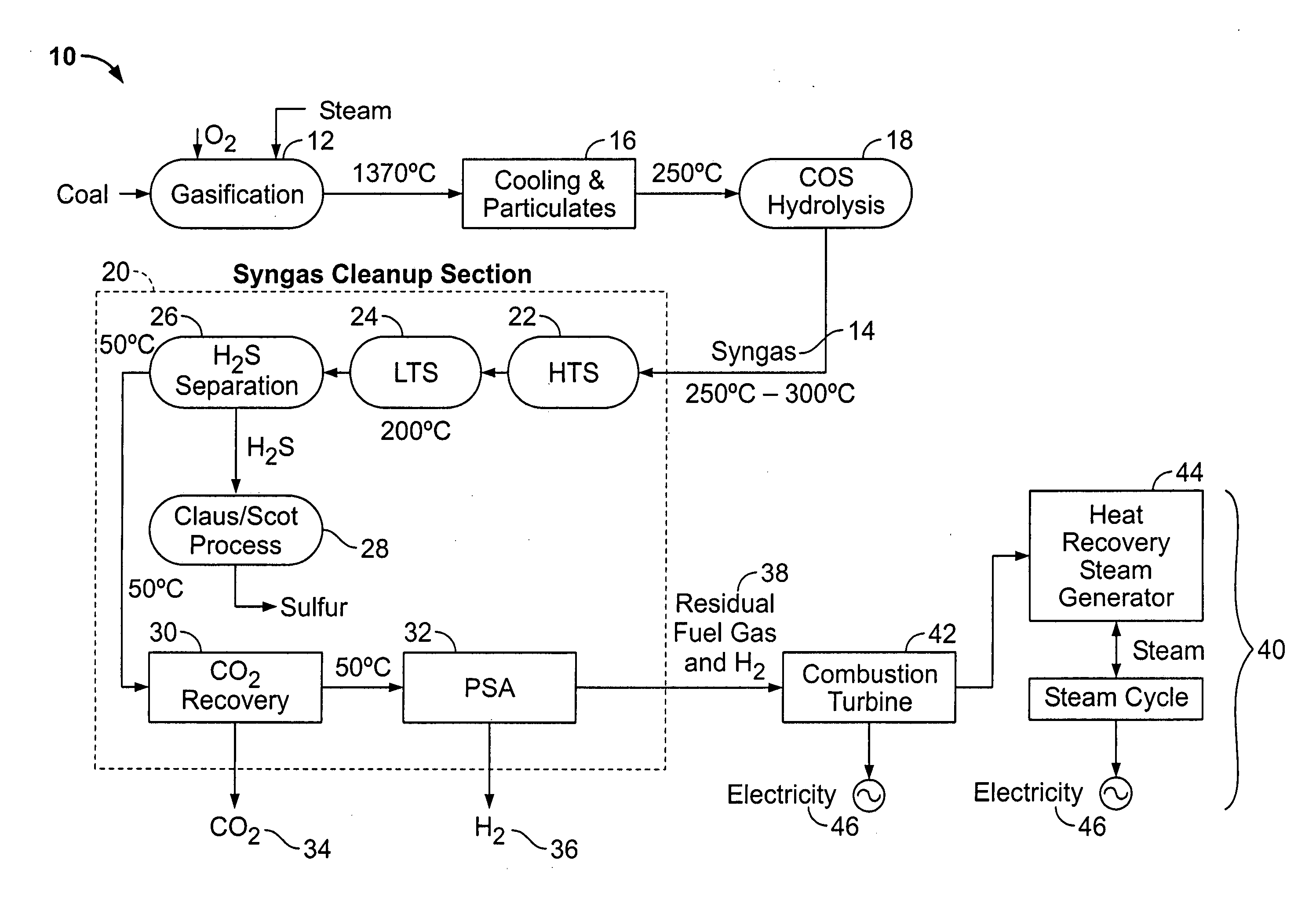

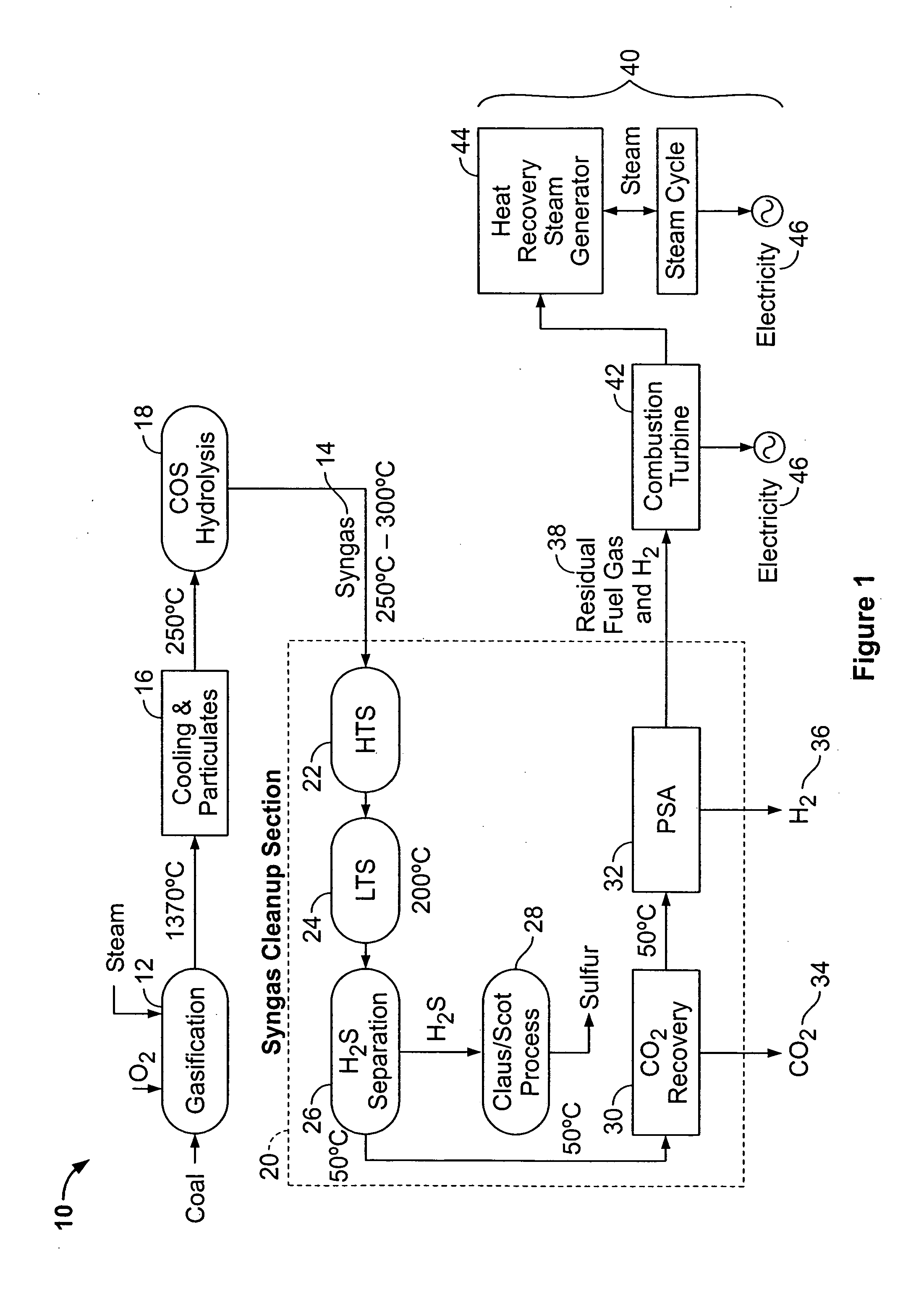

Carbon dioxide production method

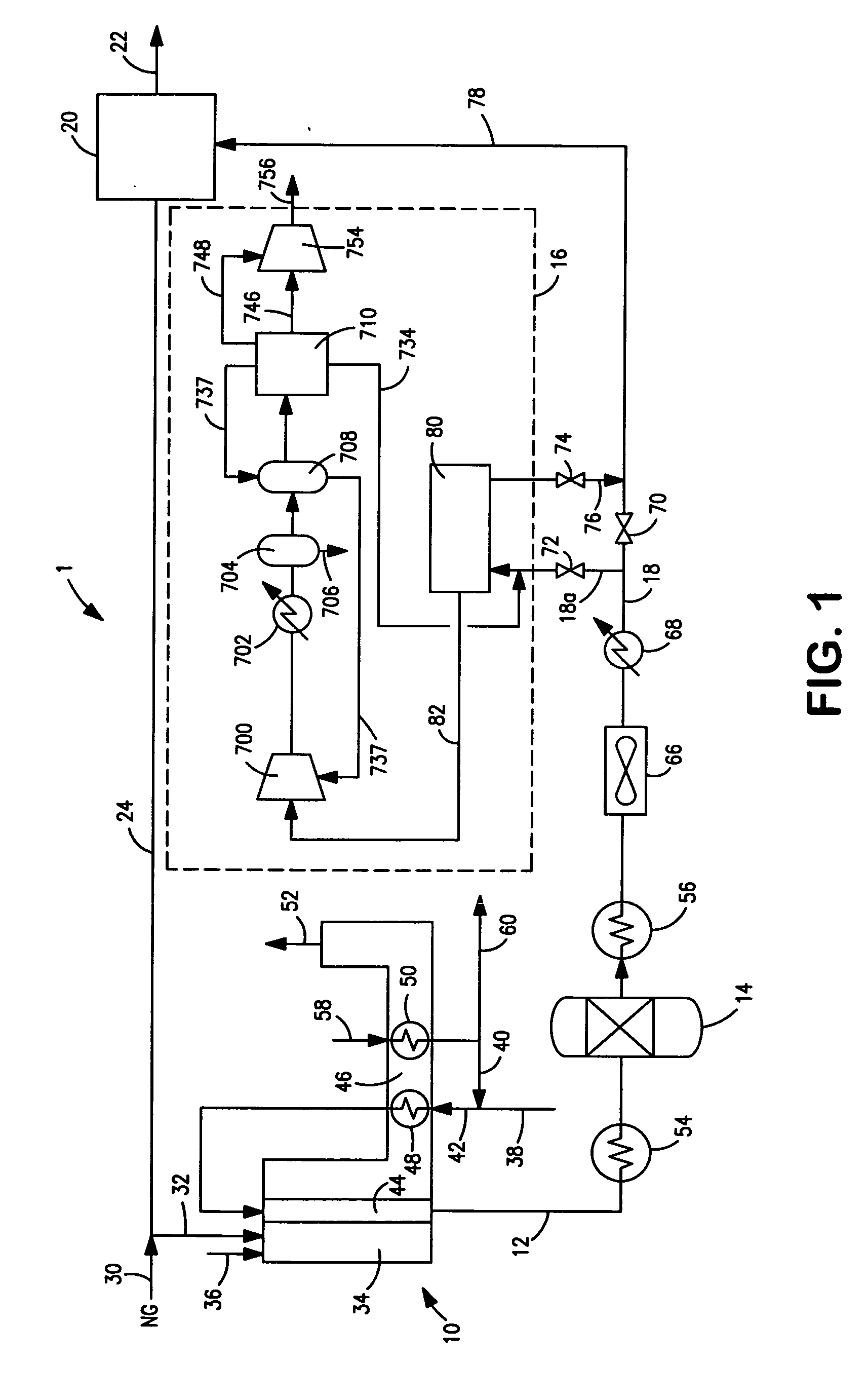

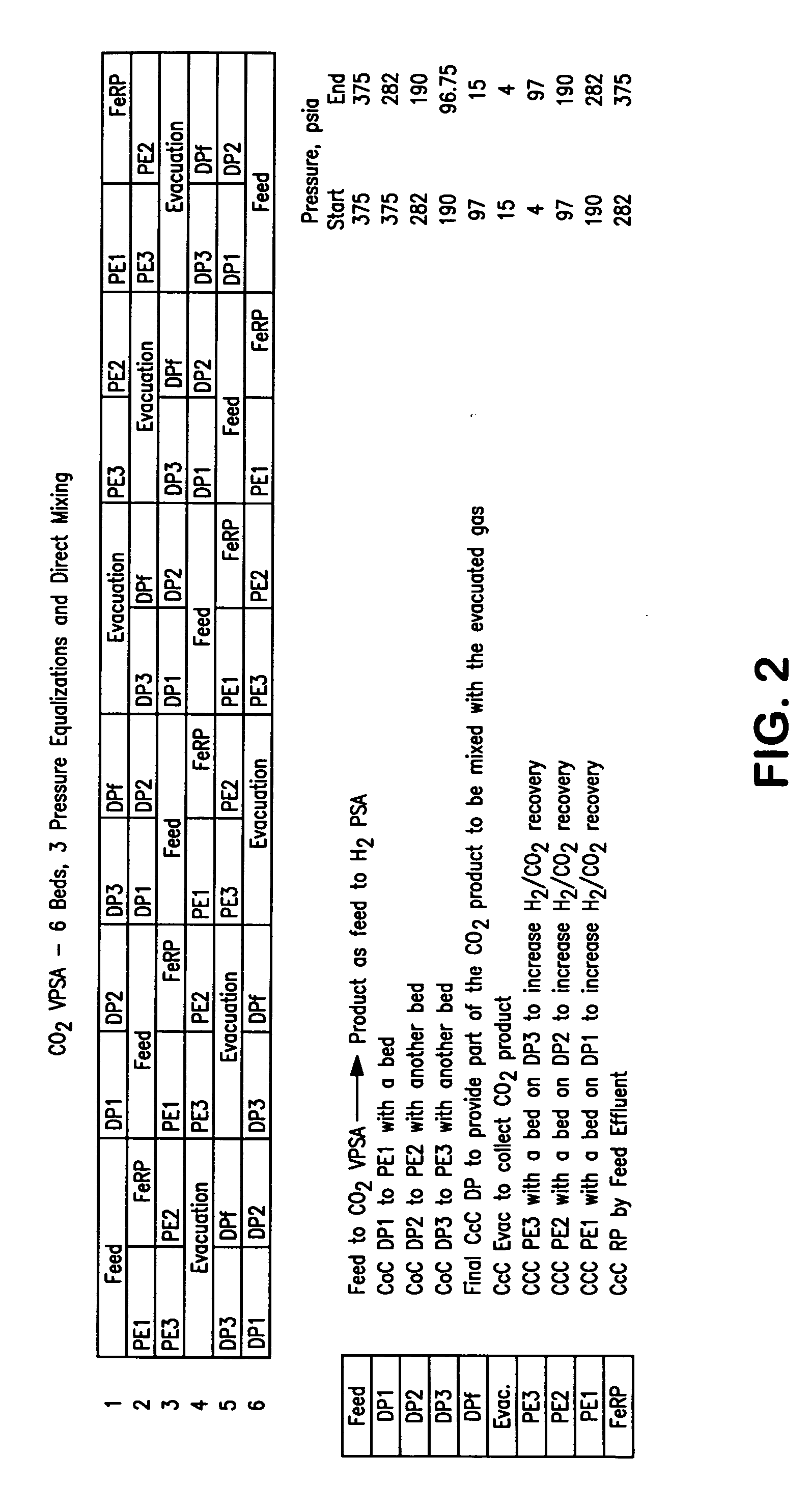

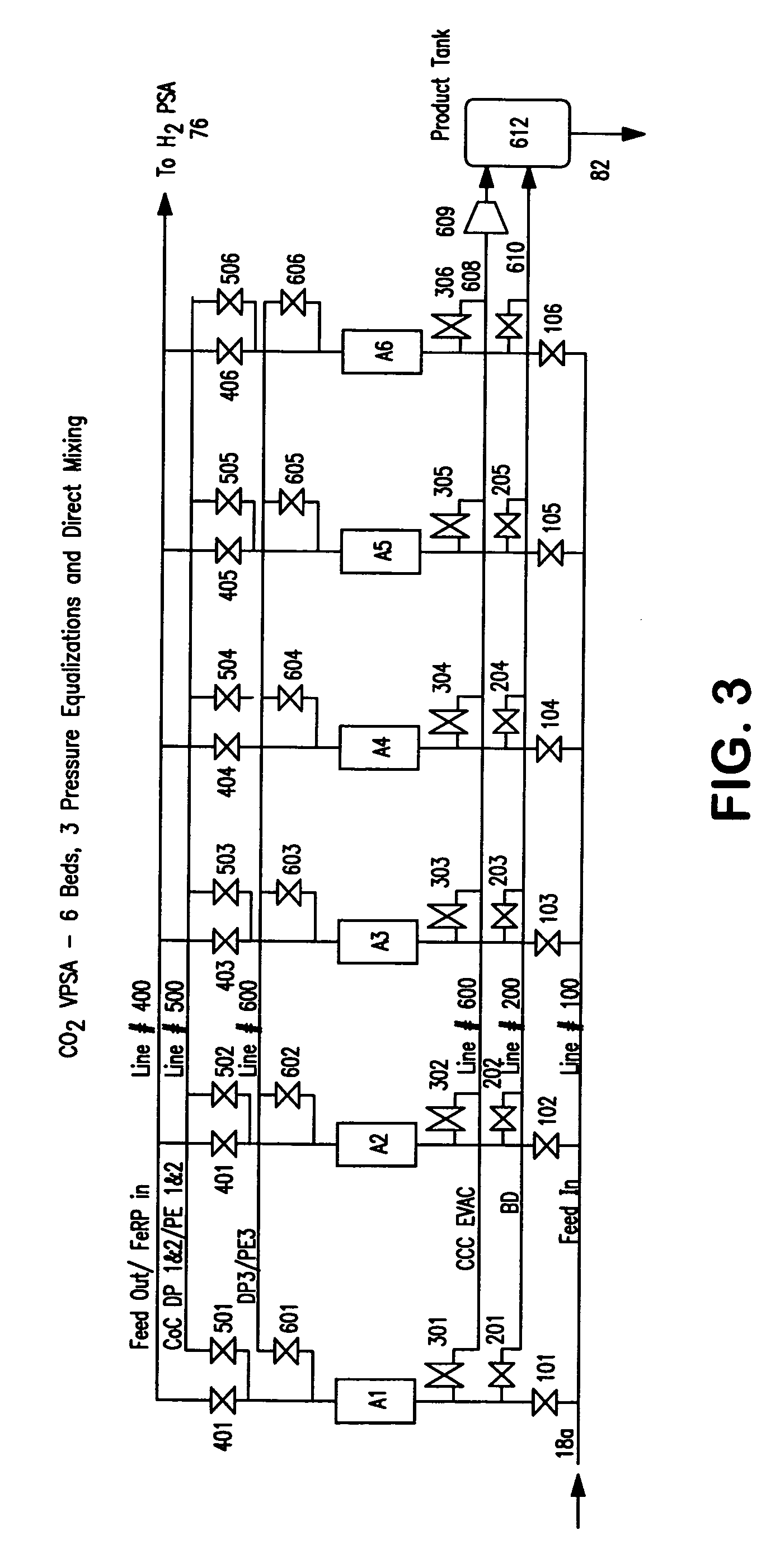

ActiveUS20070232706A1Increased hydrogen recoveryPromote recoverySolidificationLiquefactionVacuum pressureCarbon dioxide production

A method of producing a carbon dioxide product stream from a synthesis gas stream formed within a hydrogen plant having a synthesis gas reactor, a water-gas shift reactor, located downstream of the synthesis gas reactor to form the synthesis gas stream and a hydrogen pressure swing adsorption unit to produce a hydrogen product recovered from the synthesis gas stream. In accordance with the method the carbon dioxide from the synthesis gas stream by separating the carbon dioxide from the synthesis gas stream in a vacuum pressure swing adsorption system, thereby to produce a hydrogen-rich synthesis gas stream and a crude carbon dioxide stream and then purifying the crude carbon dioxide stream by a sub-ambient temperature distillation process thereby to produce the carbon dioxide product. A hydrogen synthesis gas feed stream to the hydrogen pressure swing adsorption unit is formed at least in part from the hydrogen rich stream.

Owner:PRAXAIR TECH INC

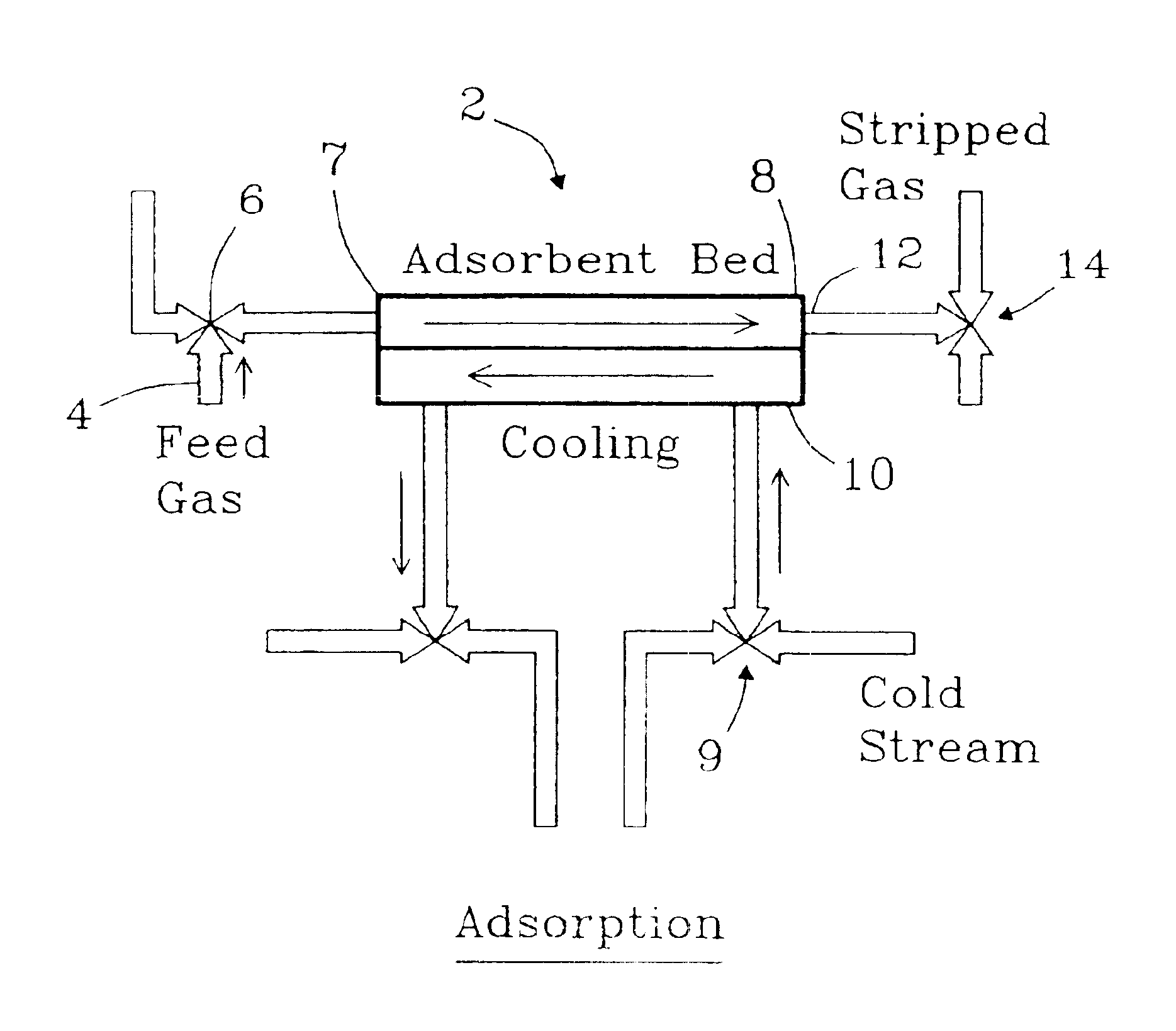

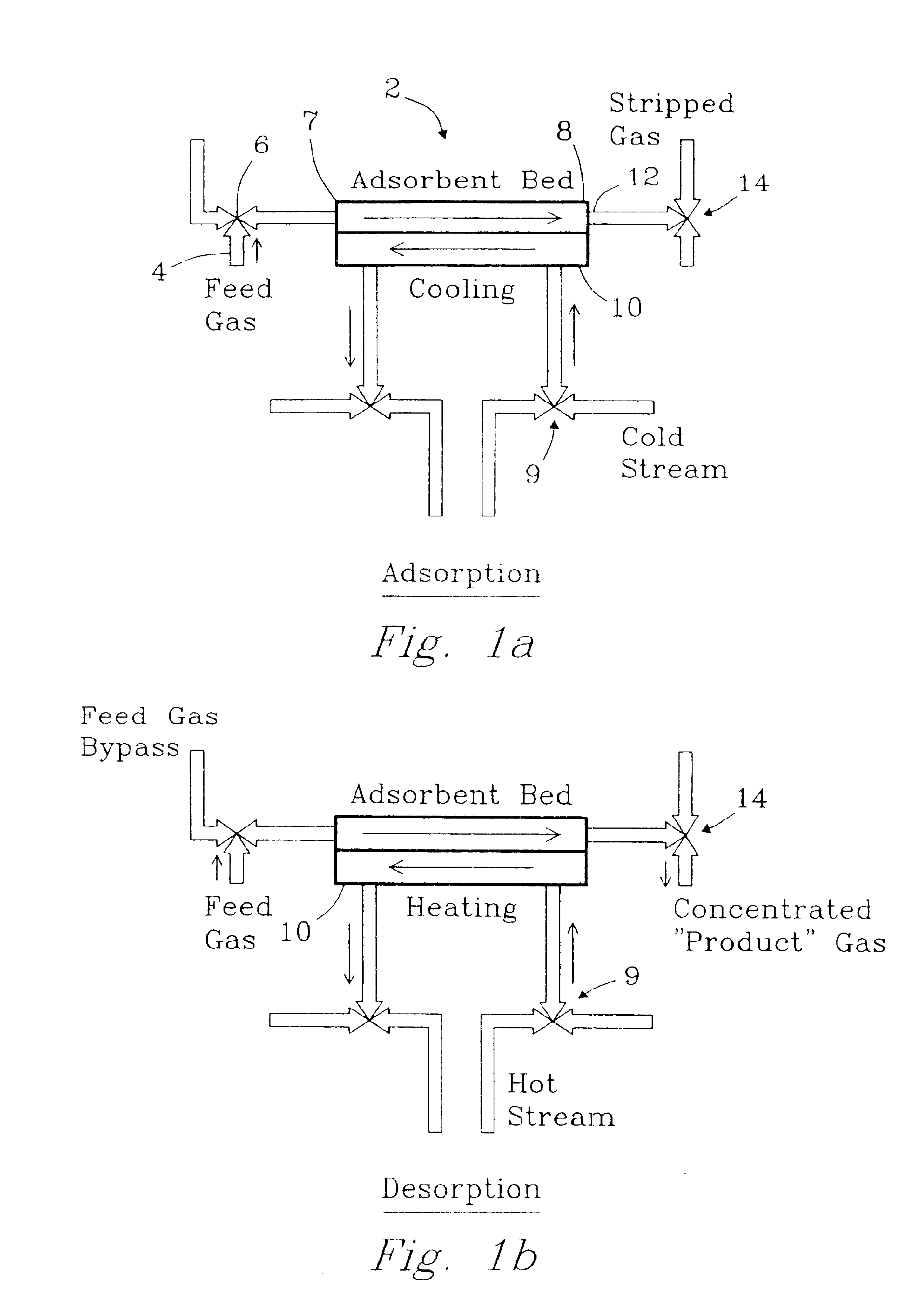

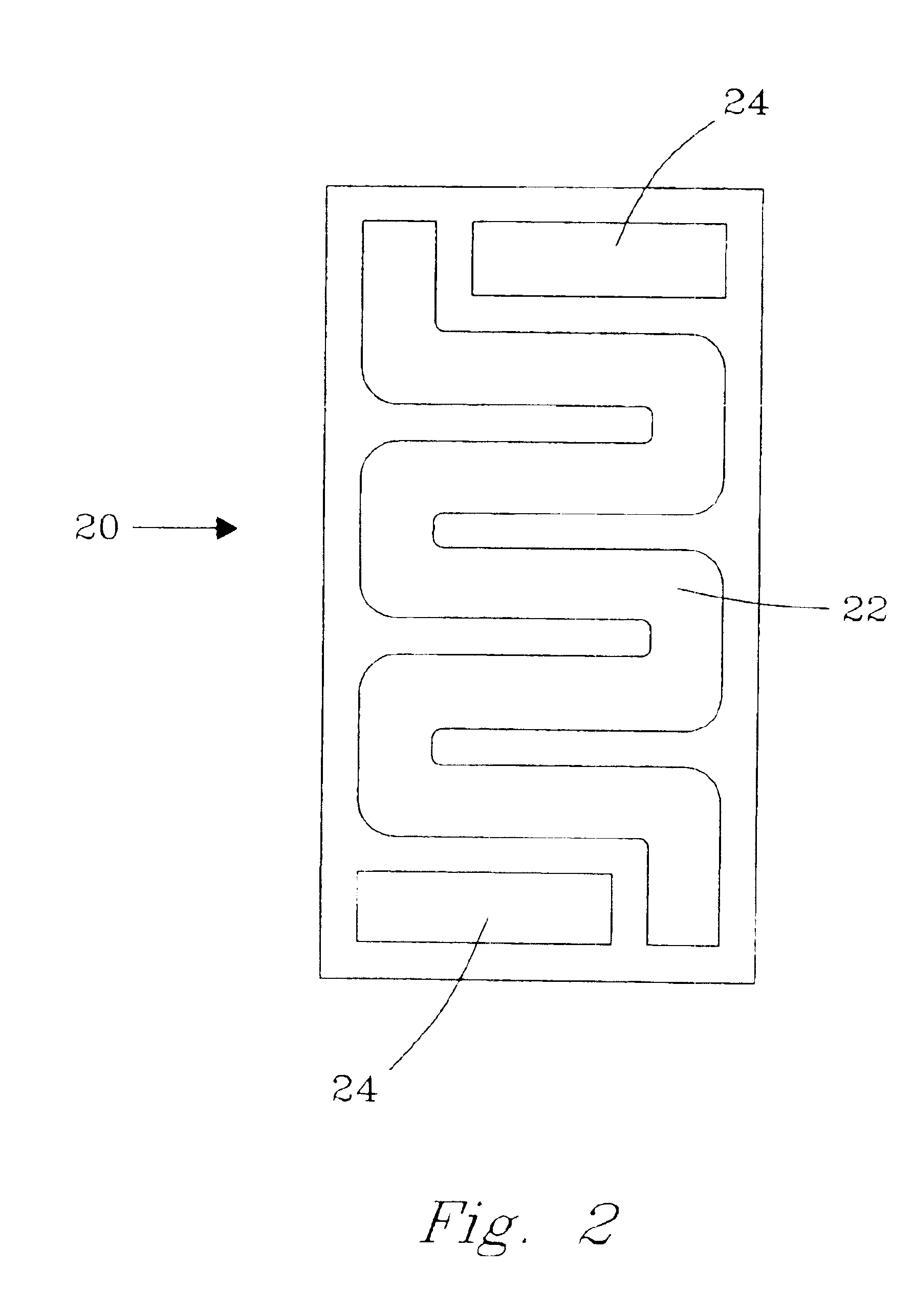

Apparatus for thermal swing adsorption and thermally-enhanced pressure swing adsorption

The present invention provides compact adsorption systems that are capable of rapid temperature swings and rapid cycling. Novel methods of thermal swing adsorption and thermally-enhanced pressure swing adsorption are also described. In some aspects of the invention, a gas is passed through the adsorbent thus allowing heat exchangers to be very close to all portions of the adsorbent and utilize less space. In another aspect, the adsorption media is selectively heated, thus reducing energy costs. Methods and systems for gas adsorption / desorption having improved energy efficiency with capability of short cycle times are also described. Advantages of the invention include the ability to use (typically) 30-100 times less adsorbent compared to conventional systems.

Owner:BATTELLE MEMORIAL INST

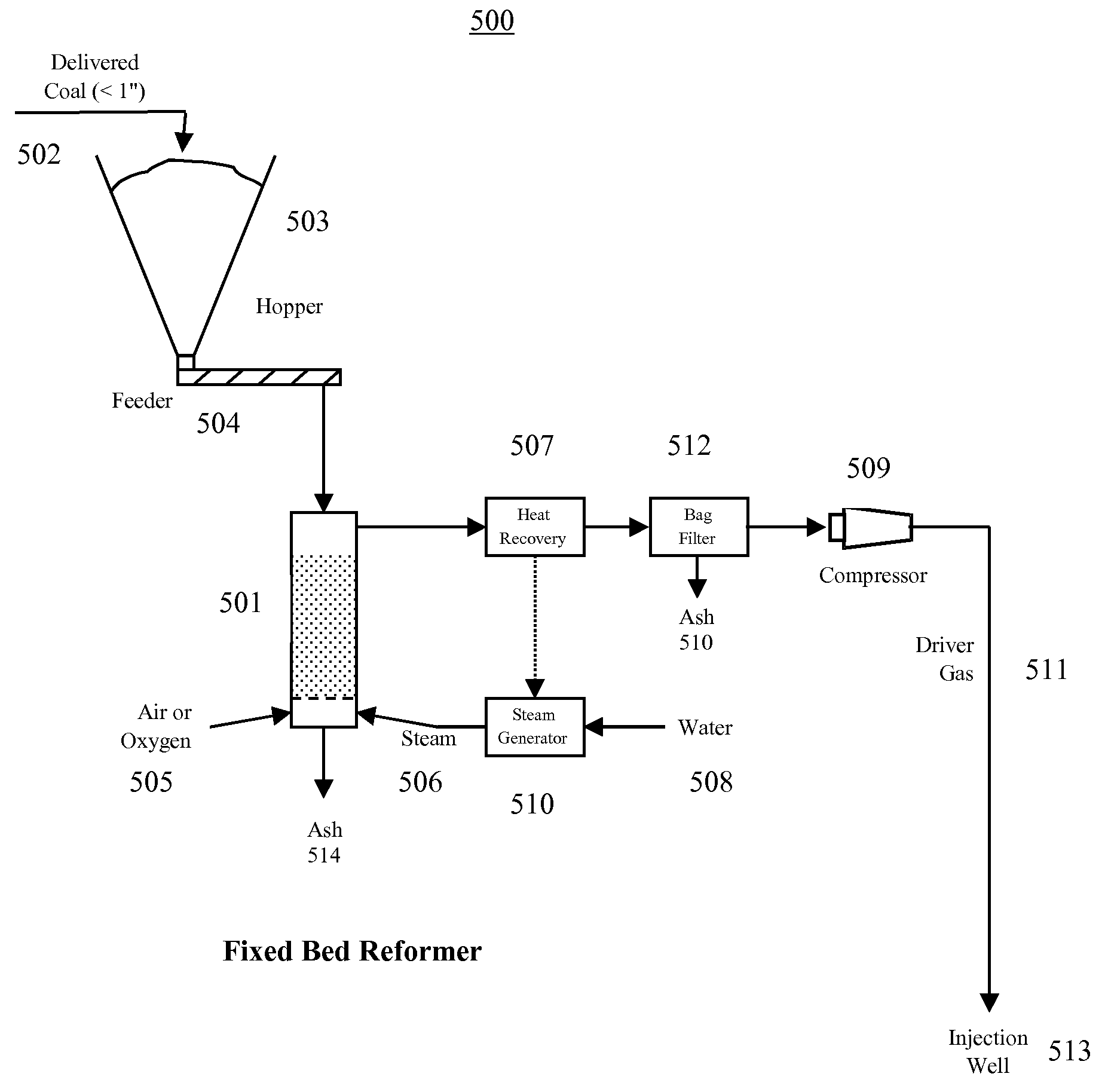

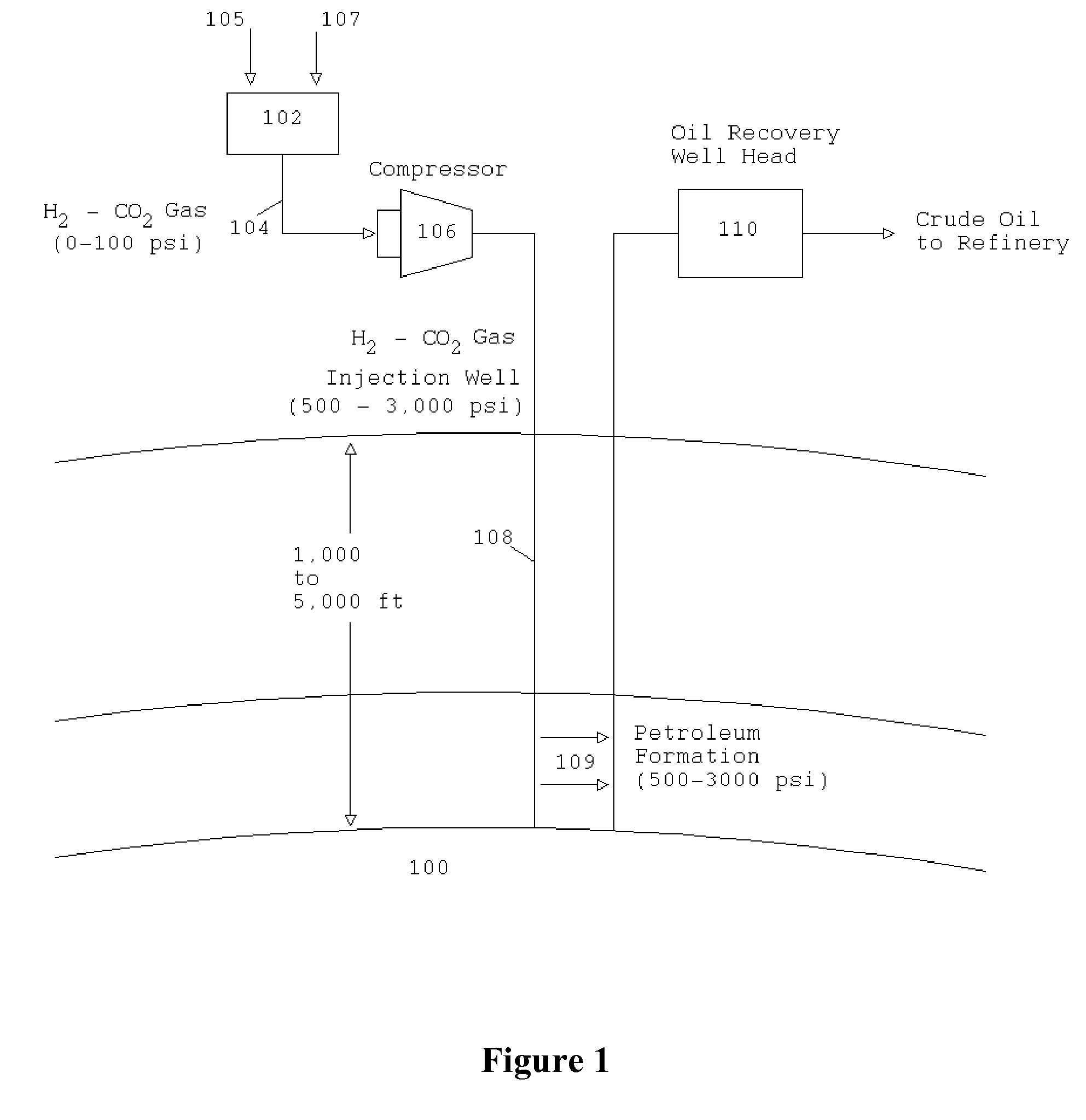

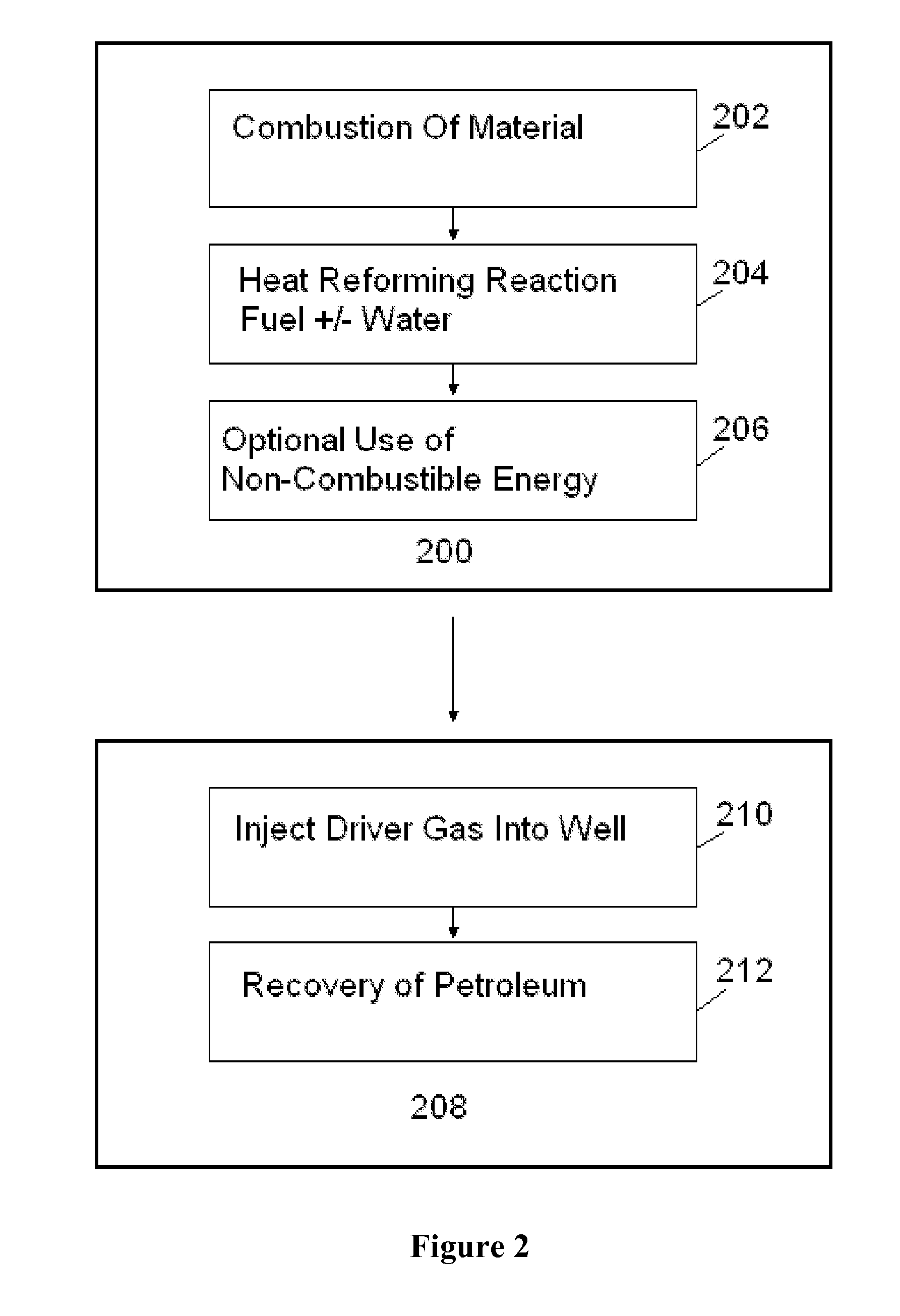

Apparatus, methods, and systems for extracting petroleum using a portable coal reformer

InactiveUS7654330B2Highly economicalVast supplyDrilling rodsHydrogen separation using solid contactPetroleumCoal

Apparatus, methods, and systems for extracting oil or natural gas from a well using a portable coal reformer. In one example, the method may include reforming coal by reaction with water to generate driver gas (comprising carbon dioxide and hydrogen gas), and injecting the driver gas into the well. The driver gas reduces the viscosity and pressurizes the oil to help extract the oil from the oil well. The coal reforming operation may include combusting coal or other combustible material with ambient oxygen to release energy, and heating coal and water with the energy released to a temperature above that required for the coal reforming reaction to proceed, thereby reforming coal and water into driver gas. The driver gas may be purified by filtering out particles and sulfur before injecting into the well. A portion of the hydrogen gas may be separated from the driver gas and used to generate electrical power.

Owner:PIONEER ENERGY

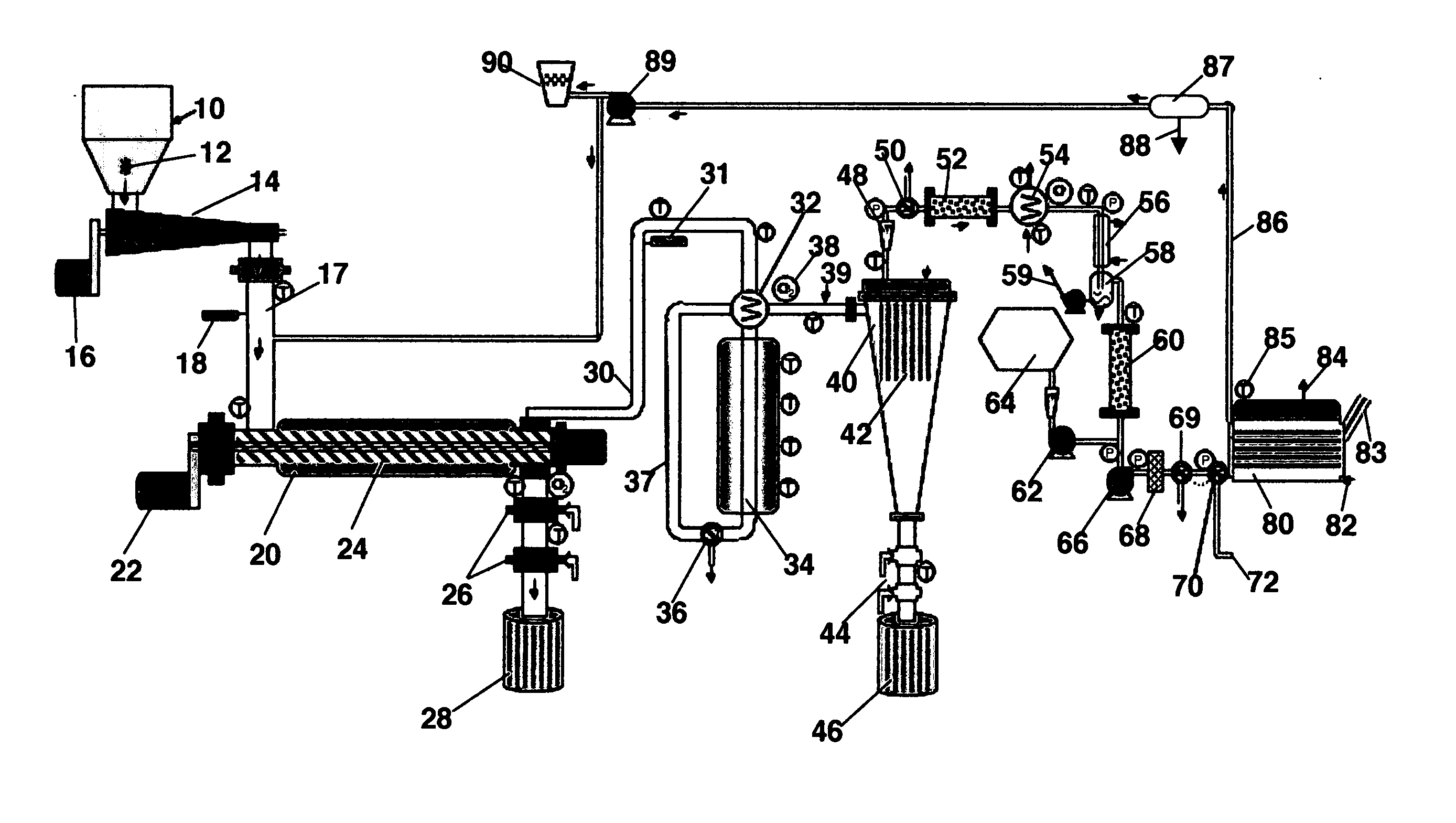

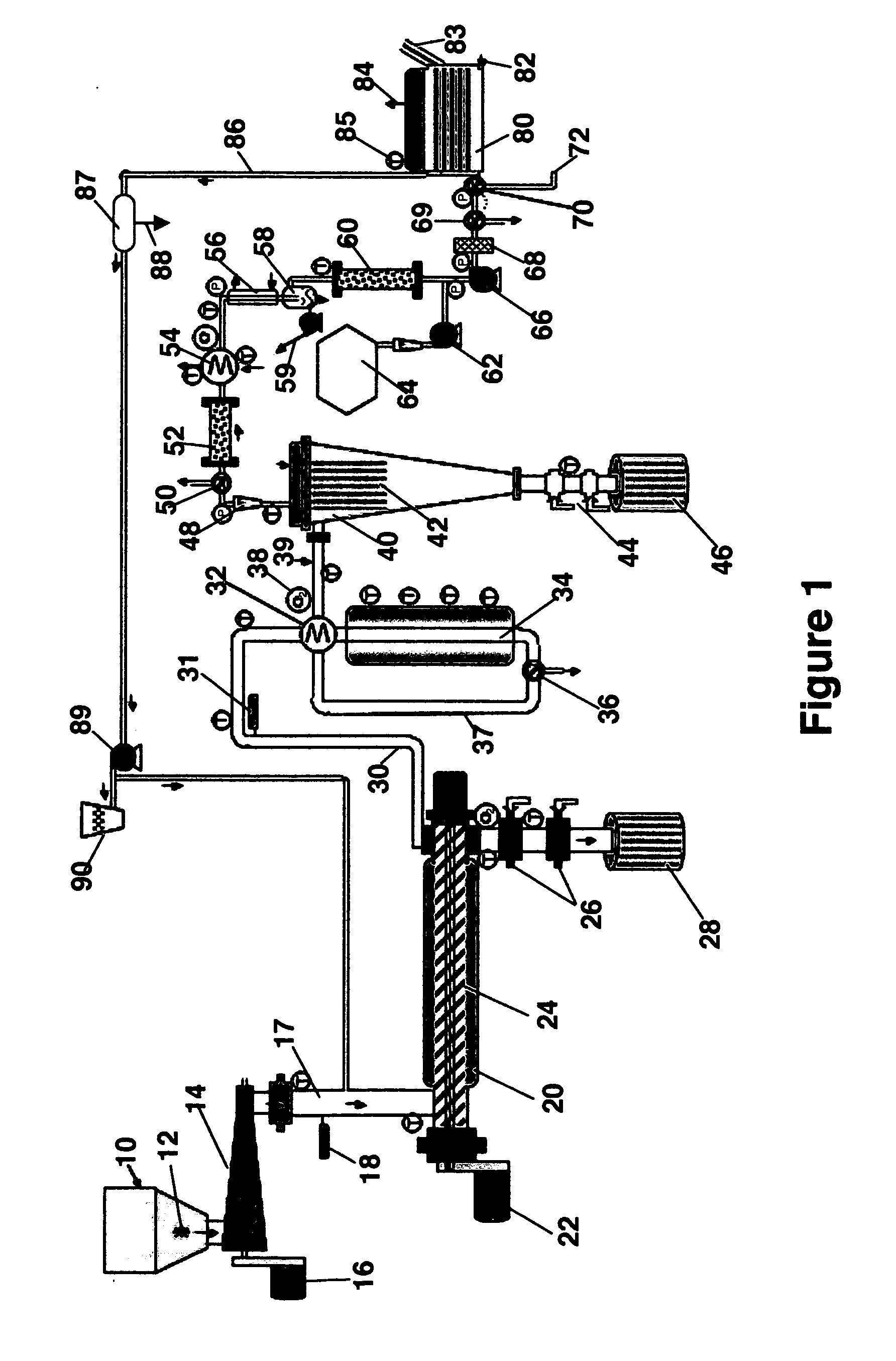

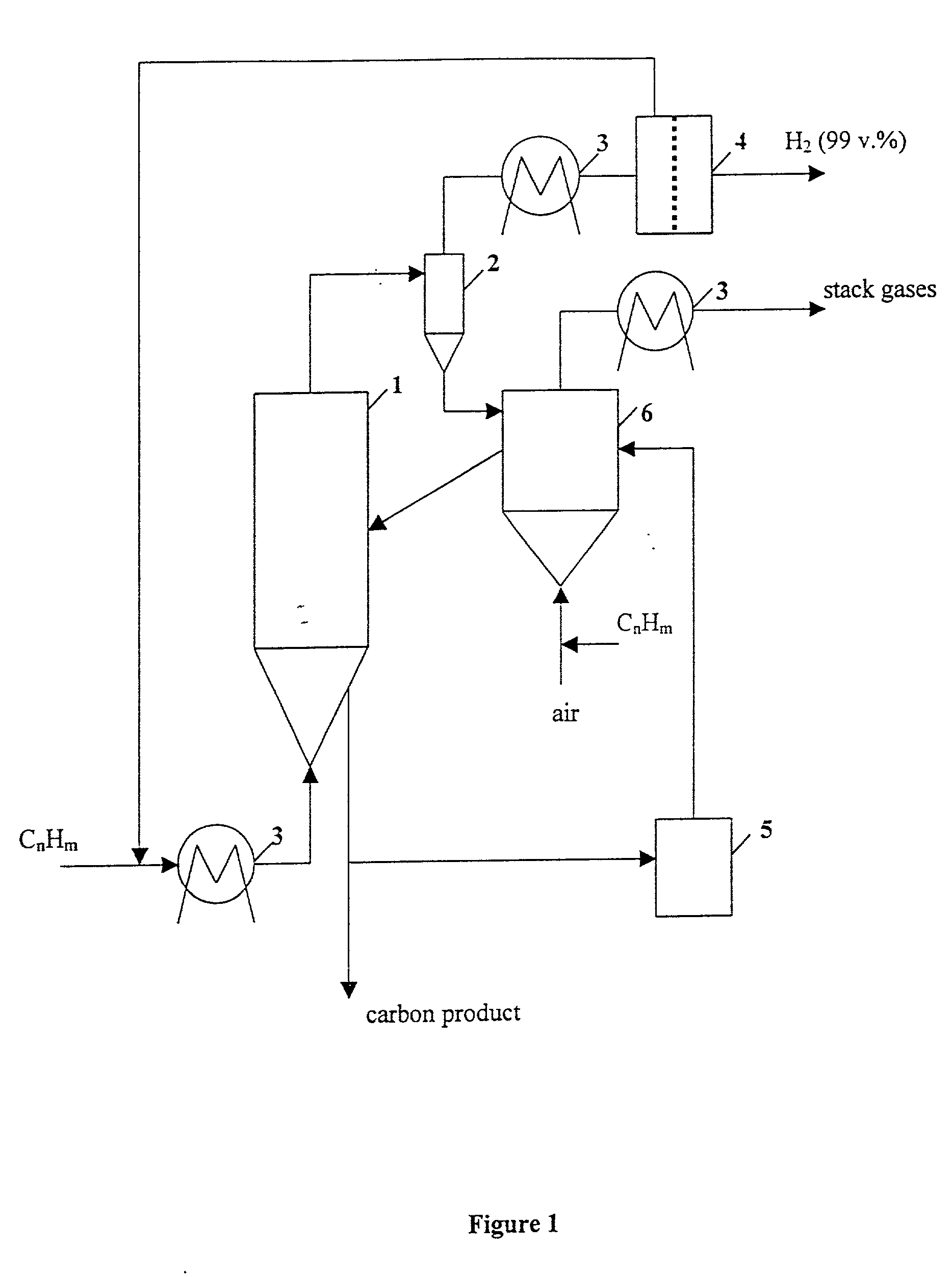

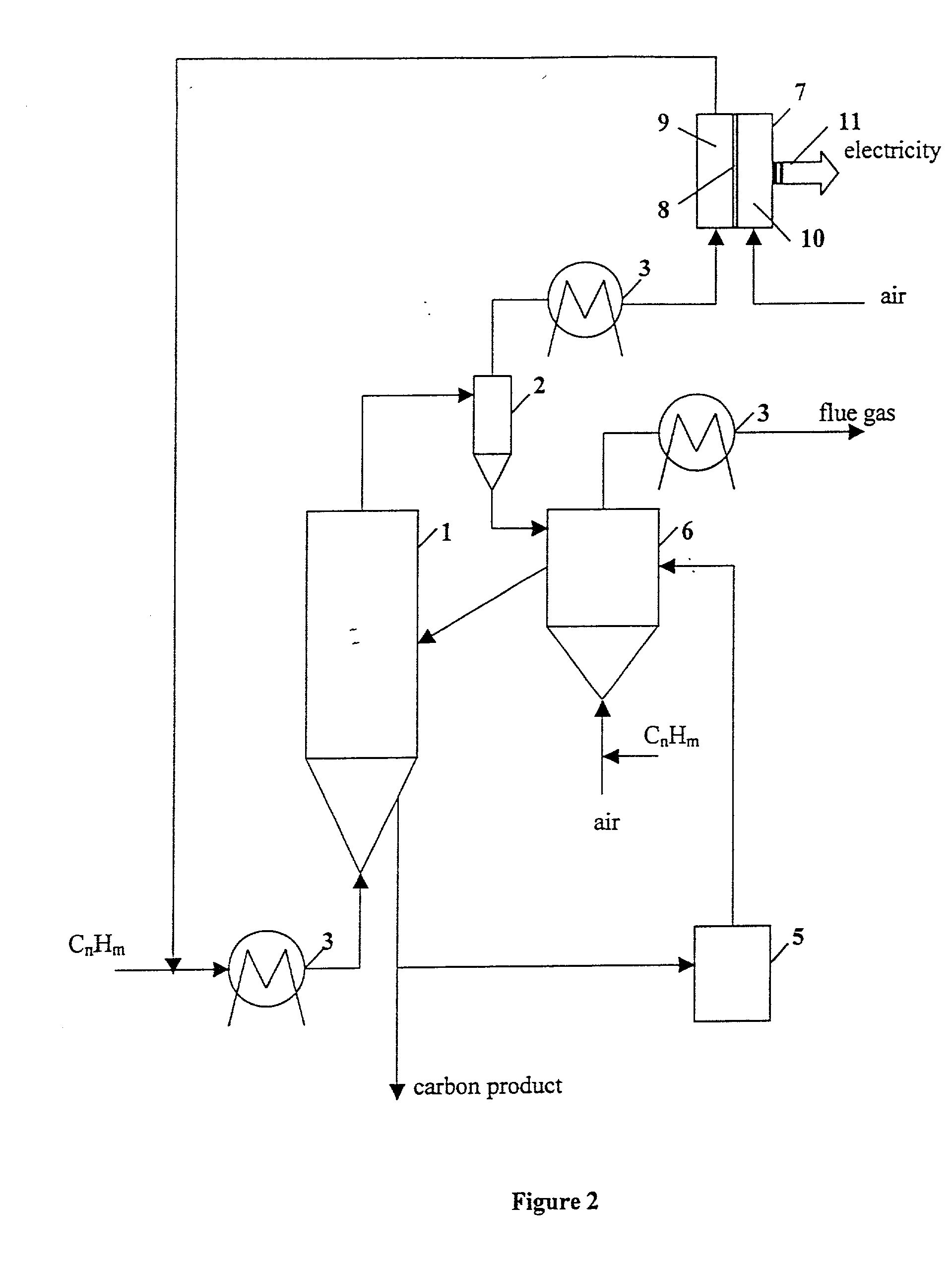

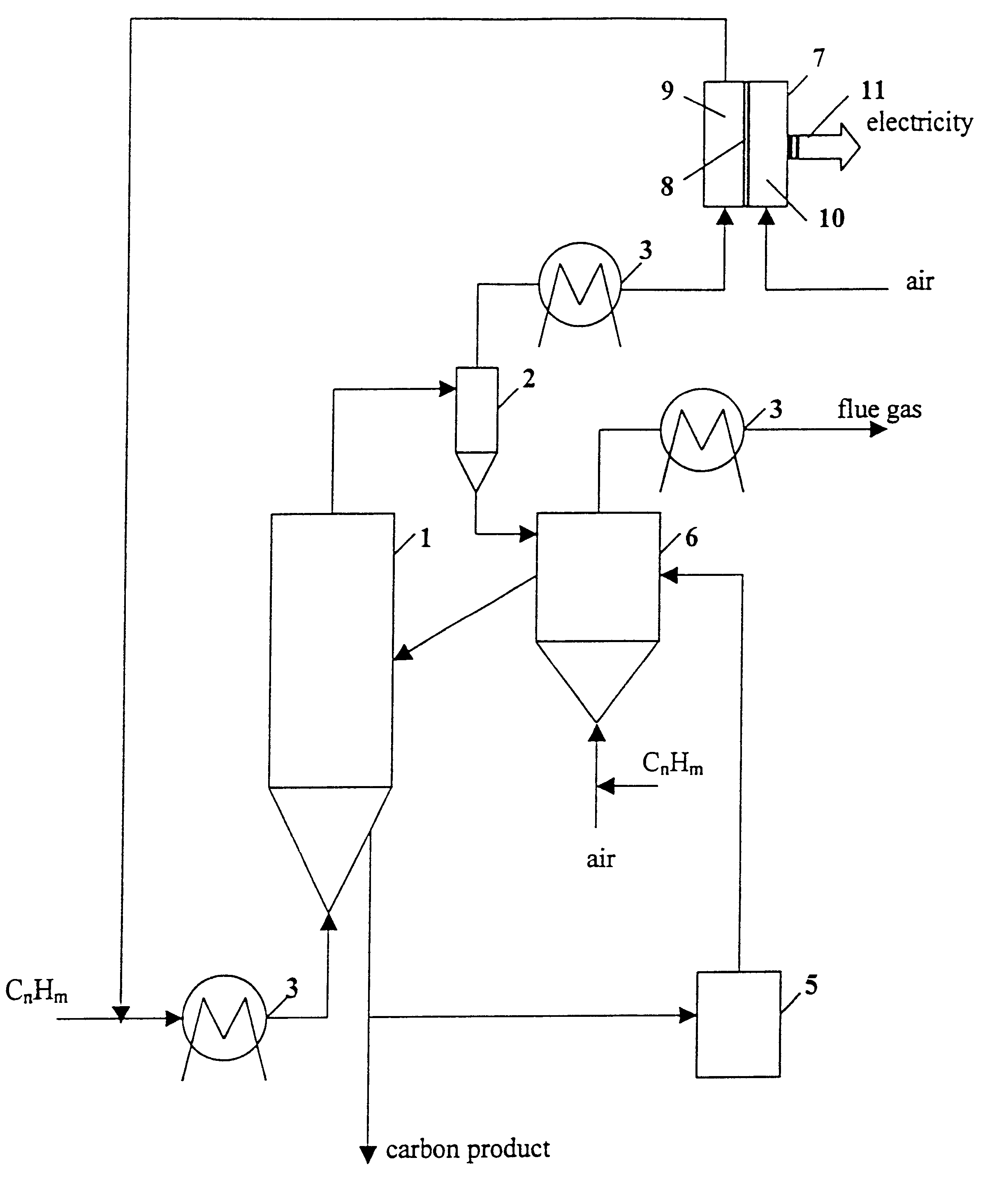

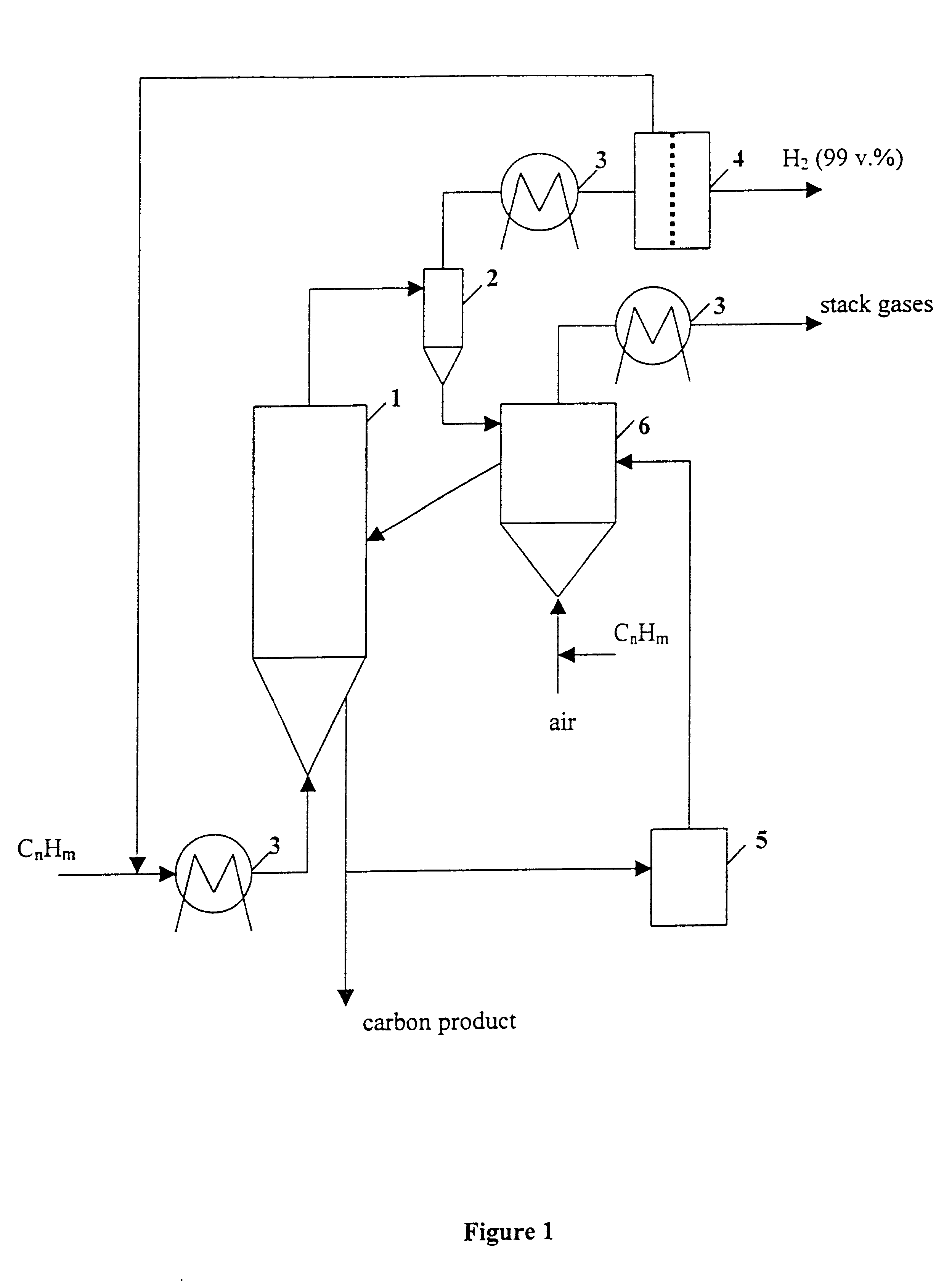

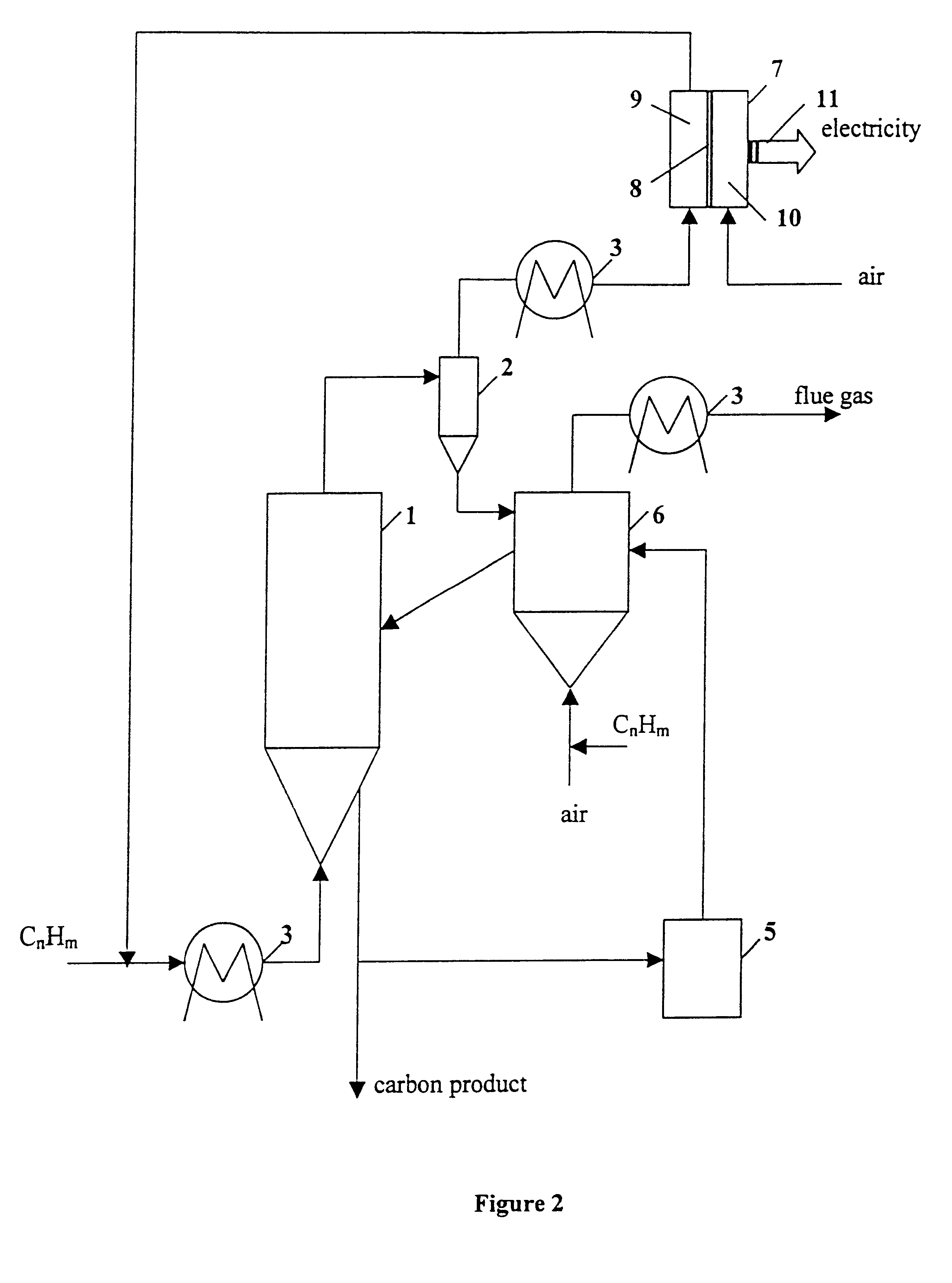

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

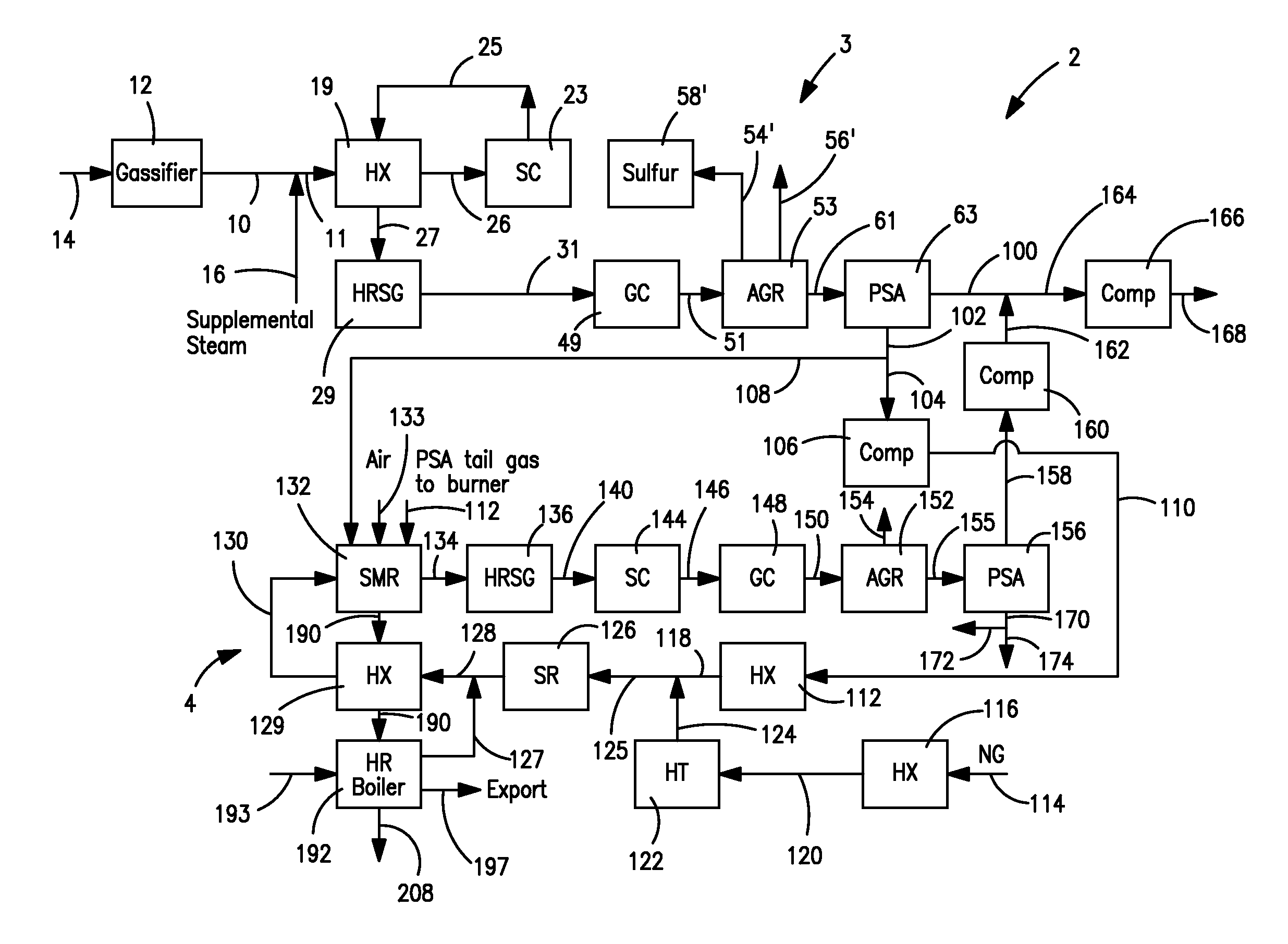

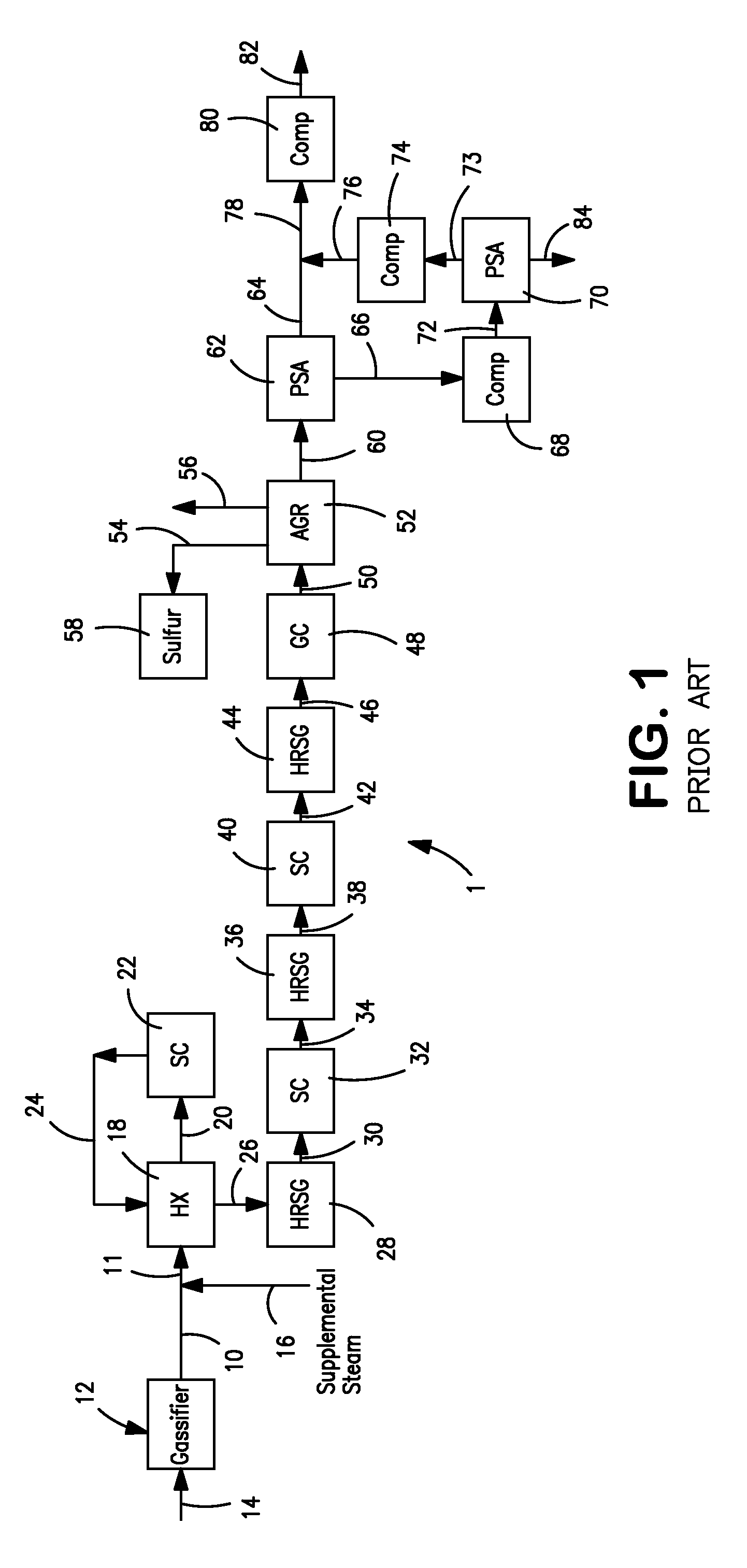

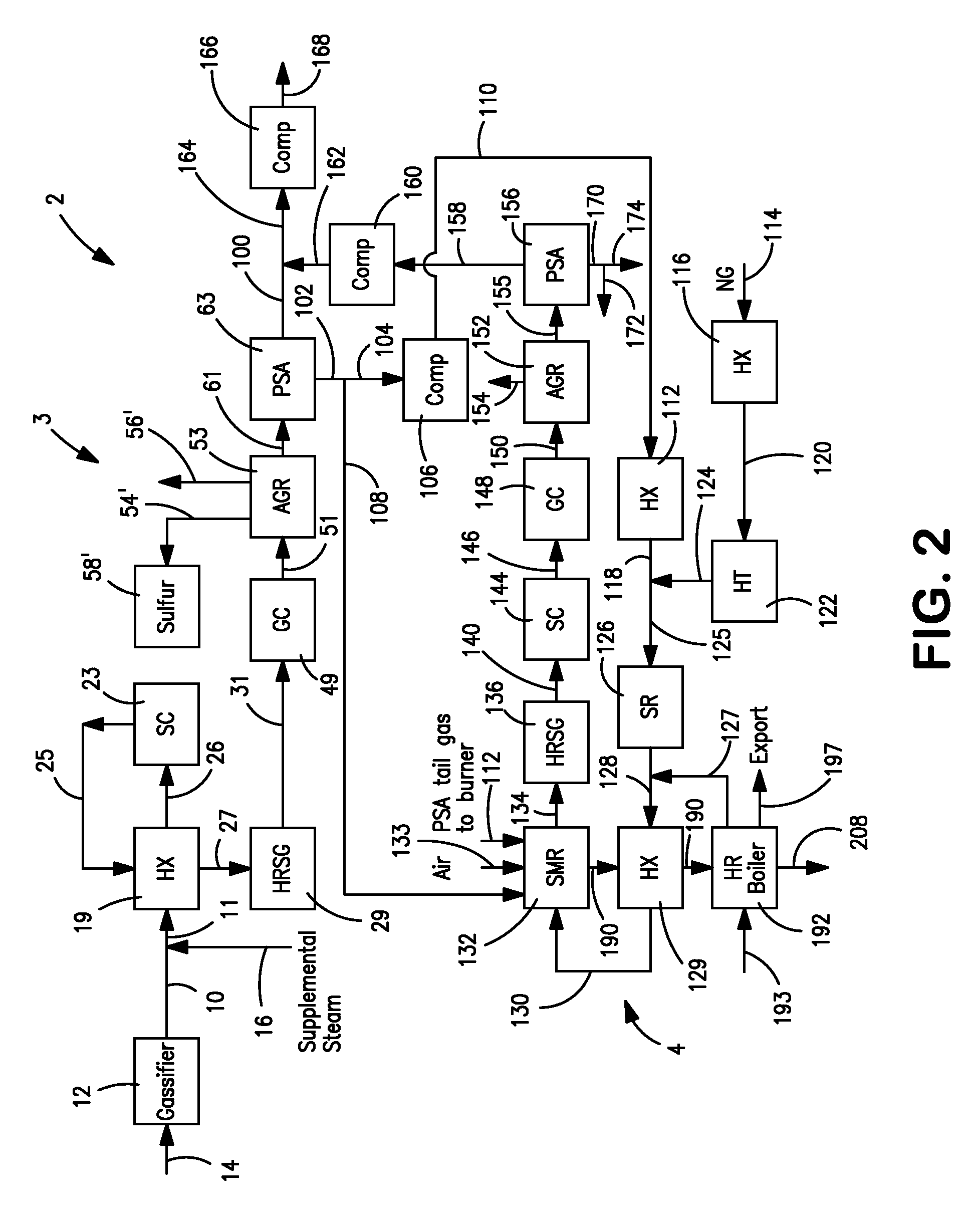

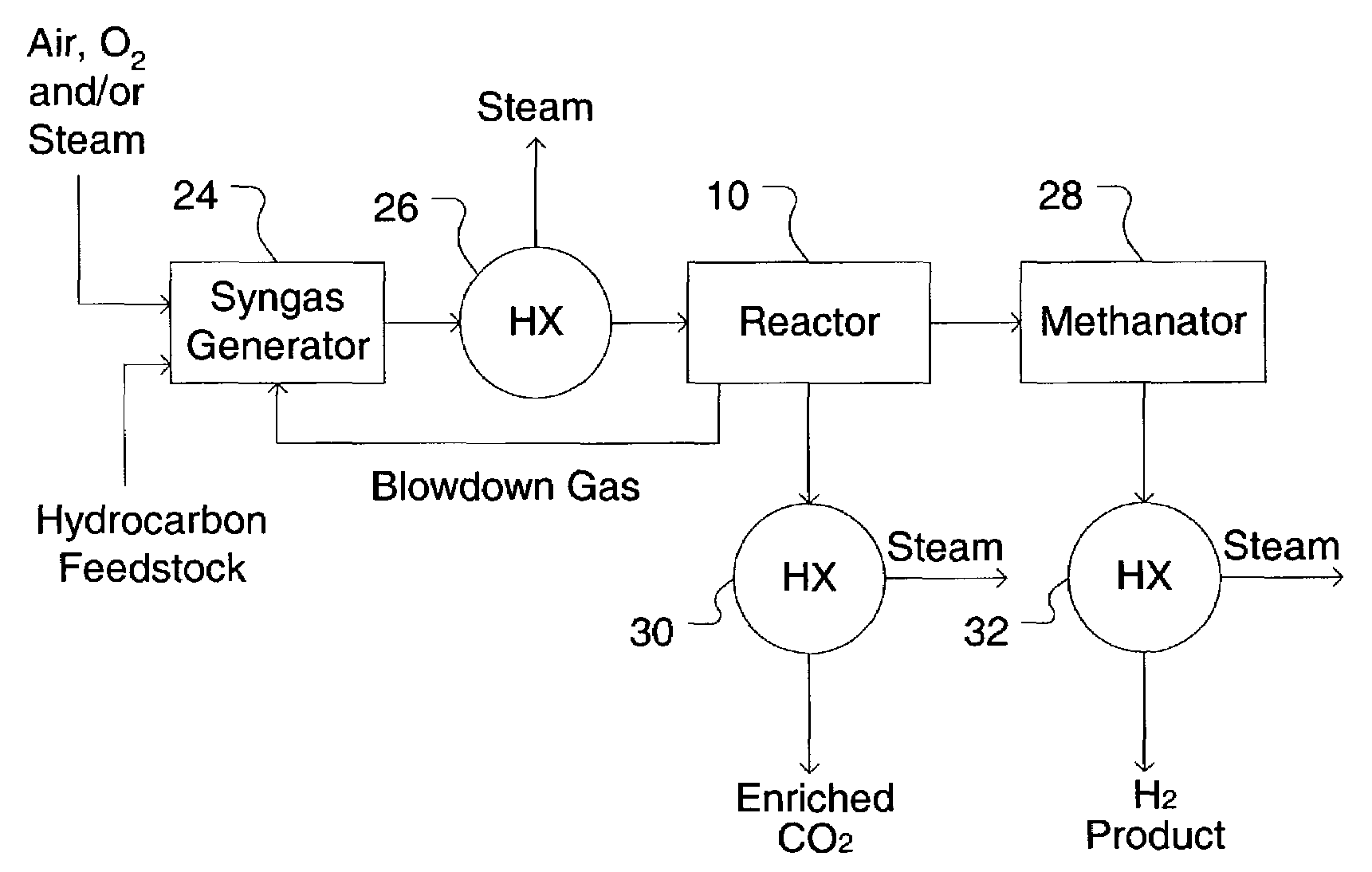

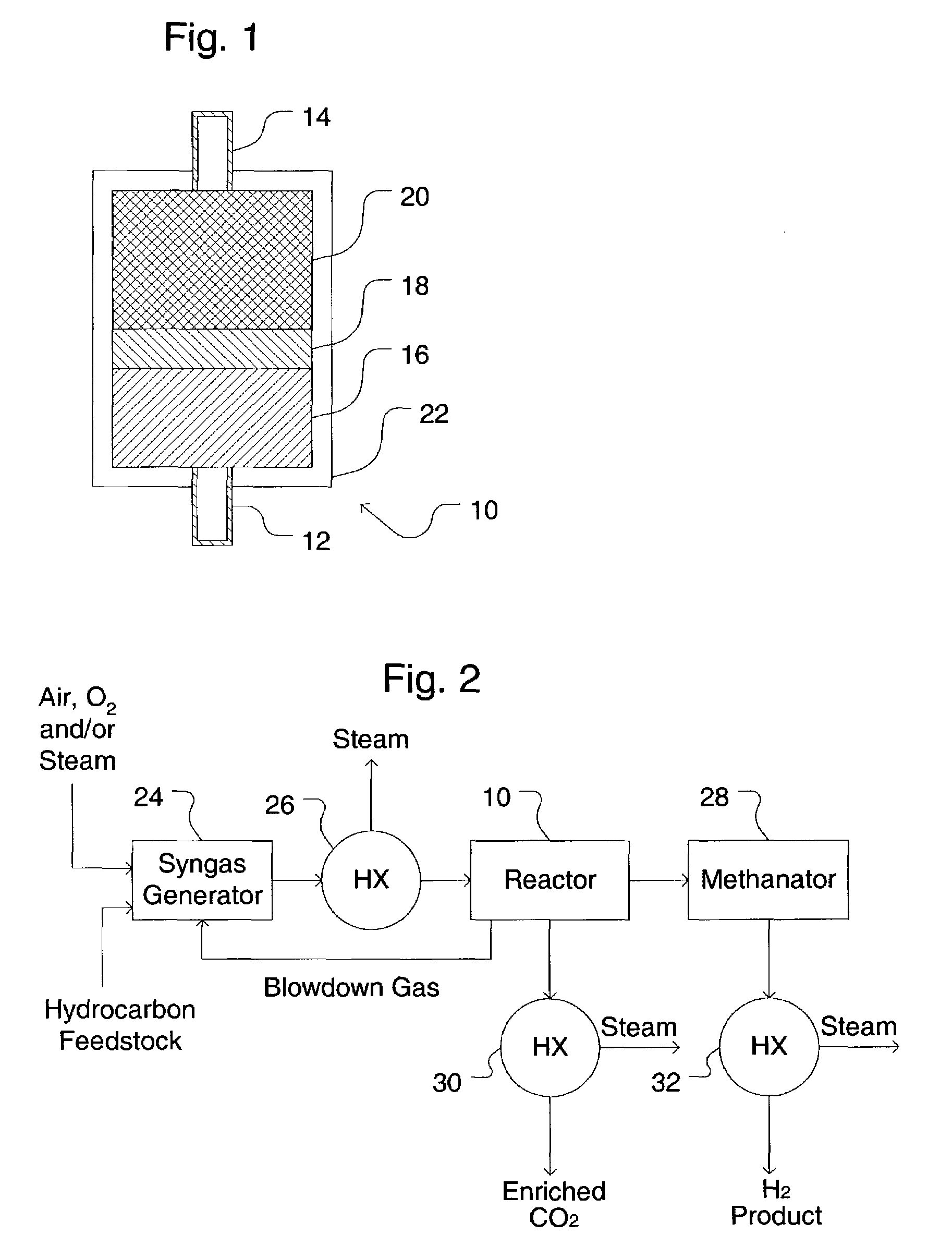

Hydrogen production method and facility

ActiveUS7985399B2High trafficHydrogen separation using solid contactHydrogen separation using liquid contactSyngasHydrocarbon

A hydrogen production method and facility in which a synthesis gas stream produced by the gasification of a carbonaceous substance is processed within a synthesis gas processing unit in which the carbon monoxide content is reacted with steam to produce additional hydrogen that is removed by a pressure swing adsorption unit. The tail gas from the pressure swing adsorption unit is further reformed with the addition of a hydrocarbon containing stream in a steam methane reforming system, further shifted to produce further additional hydrogen. The further hydrogen is then separated in another pressure swing adsorption unit.

Owner:PRAXAIR TECH INC

Methods and apparatus for hydrogen gas production

InactiveUS20070072949A1Gas turbine plantsHydrogen/synthetic gas productionHydrogenMembrane configuration

An apparatus for producing hydrogen gas, wherein the apparatus includes a reactor. The reactor includes a catalyst, a membrane in flow communication with the catalyst, and a heat exchanger integrated with the reactor.

Owner:GENERAL ELECTRIC CO

Systems and processes for providing hydrogen to fuel cells

InactiveUS7041272B2Minimized in sizeMaximize energy efficiencyFuel cell auxillariesHydrogen/synthetic gas productionFuel cellsInternal combustion engine

Owner:AIR PROD & CHEM INC

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

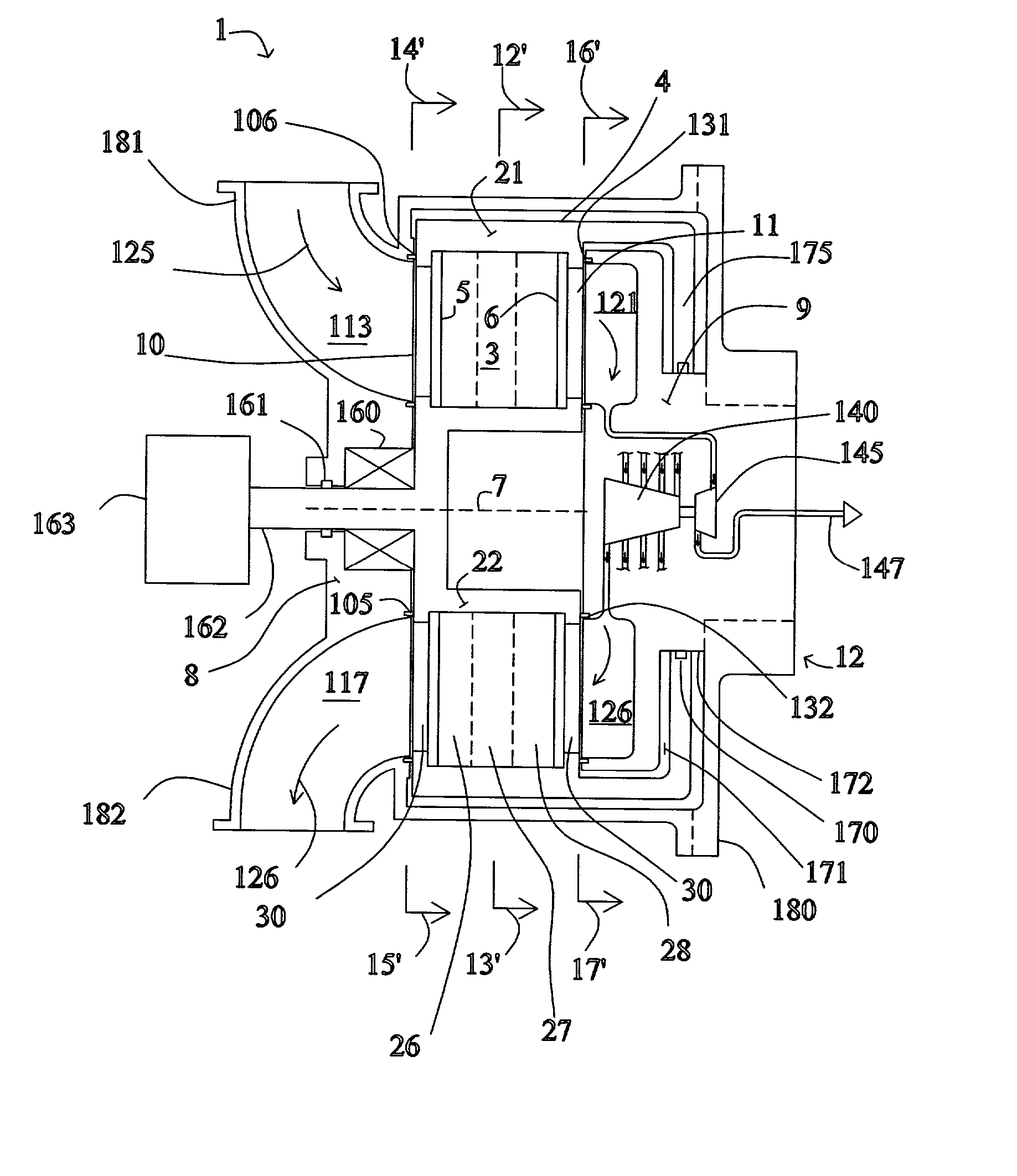

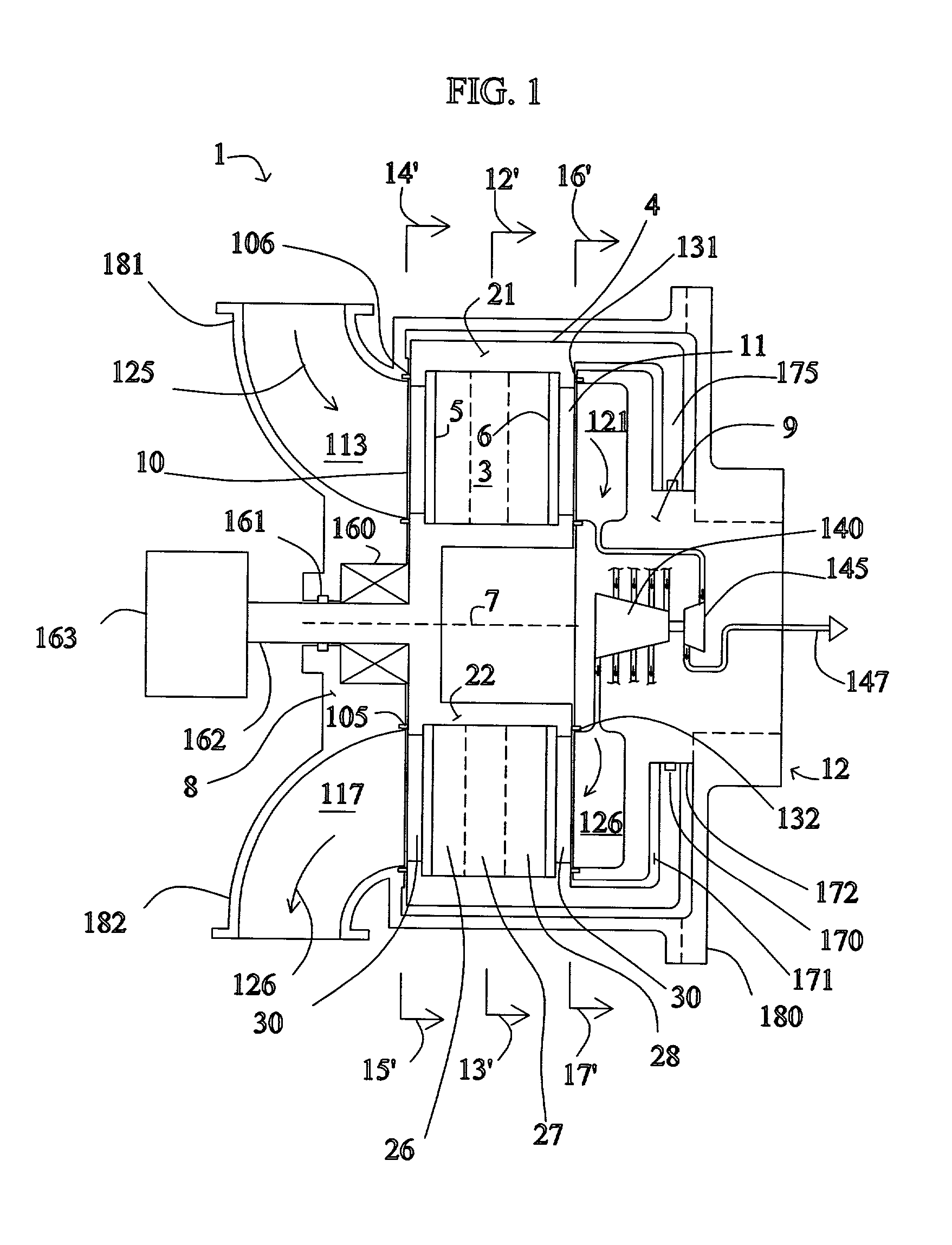

Energy efficient gas separation for fuel cells

InactiveUS7087331B2Intuitive effectFully purifiedFuel cell heat exchangeFused electrolyte fuel cellsDelivery systemSolid oxide fuel cell

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

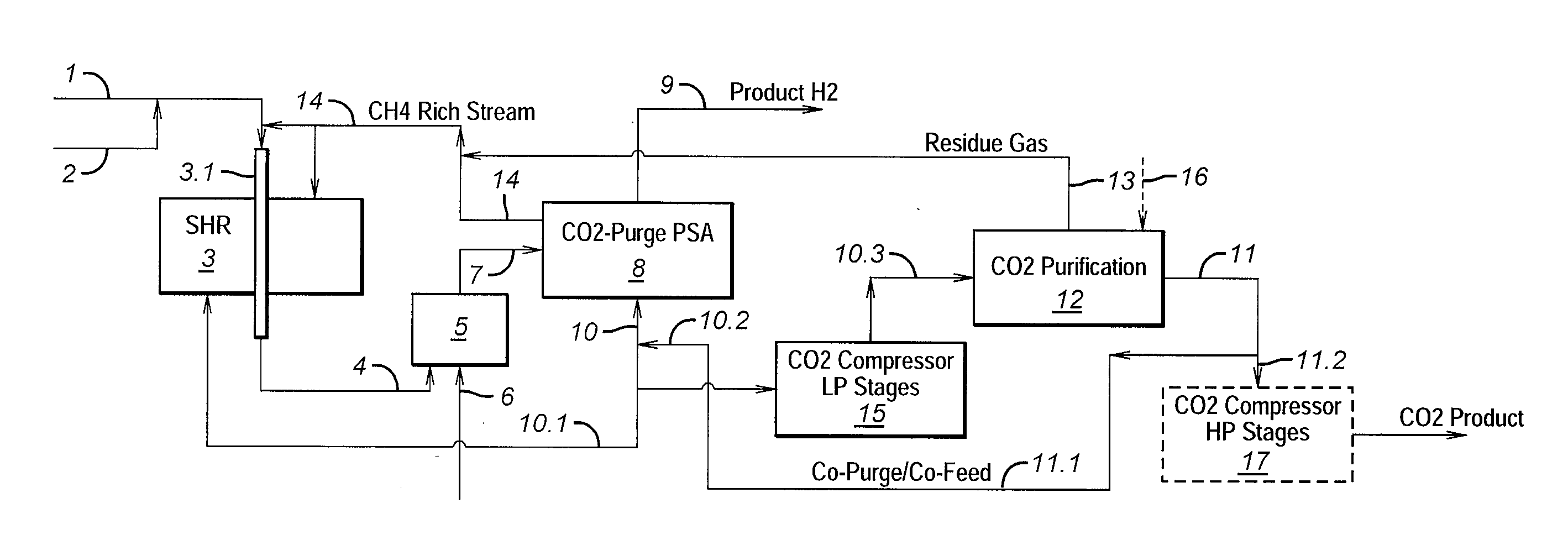

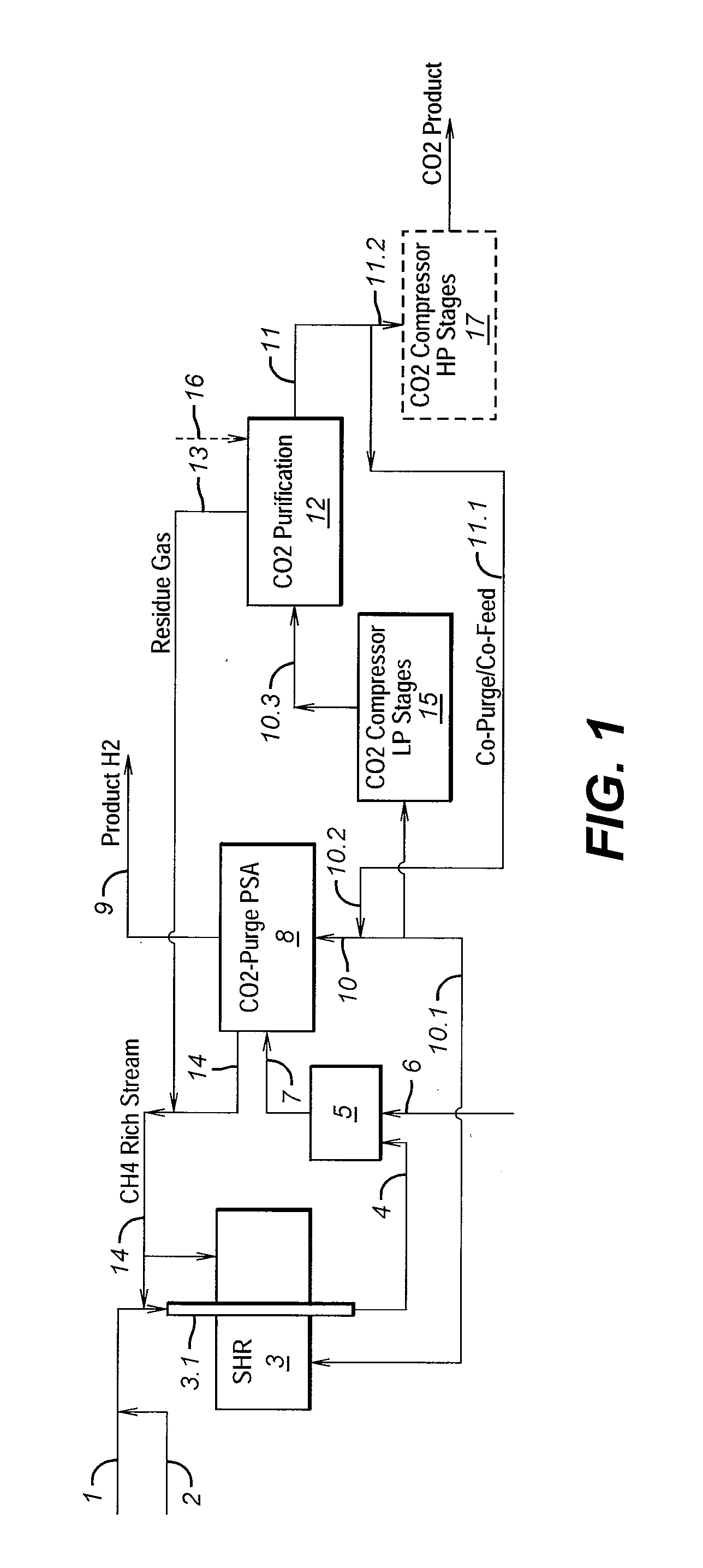

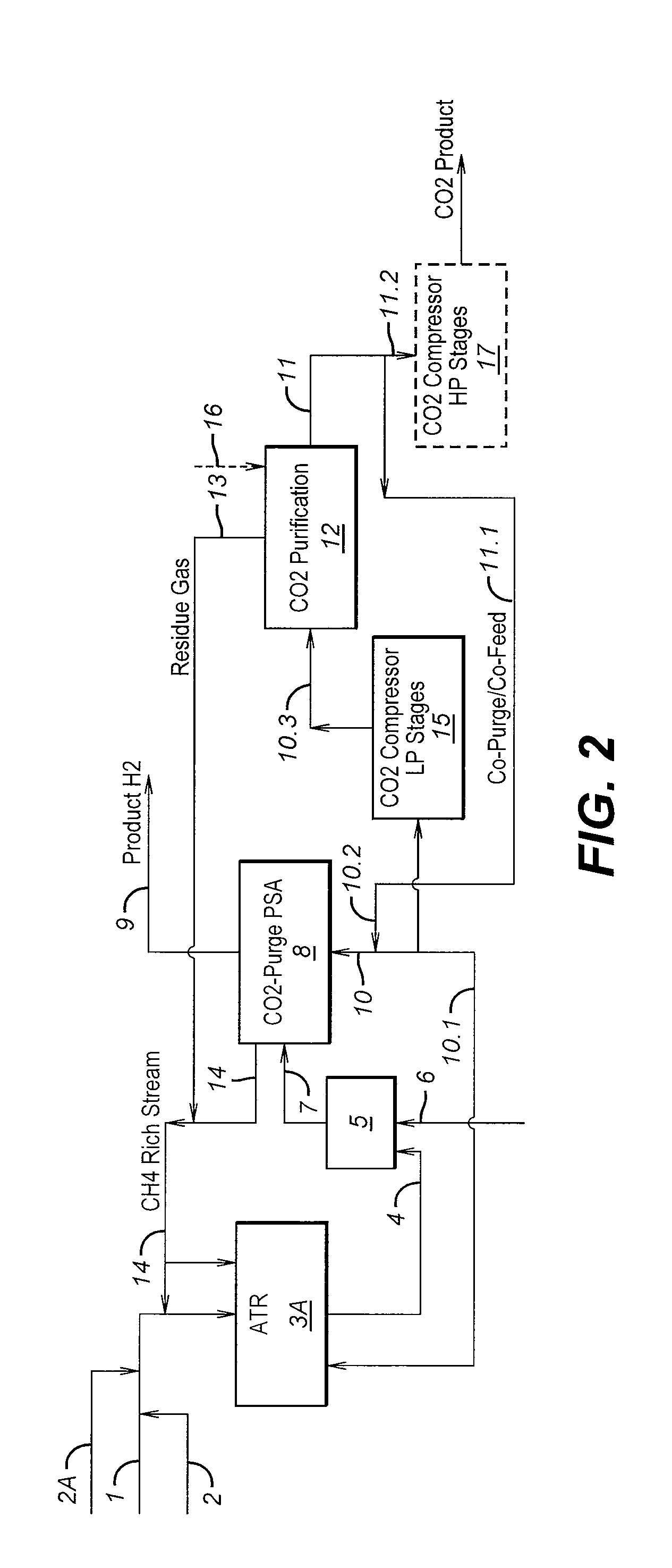

Process For The Production Of Carbon Dioxide Utilizing A Co-Purge Pressure Swing Adsorption Unit

The present invention provides a process for recovering gaseous hydrogen and gaseous carbon dioxide from a mixture of hydrocarbons by utilizing a system that includes a reformer unit, an optional water gas shift reactor, and a pressure swing adsorption unit in conjunction with a carbon dioxide purification unit such as a cryogenic purification unit or a catalytic oxidizer. In this process, purified CO2 from the CO2 purification unit is used as a co-feed / co-purge in the pressure swing adsorption unit in order to produce a CO2 tail gas that includes a higher concentration of CO2.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

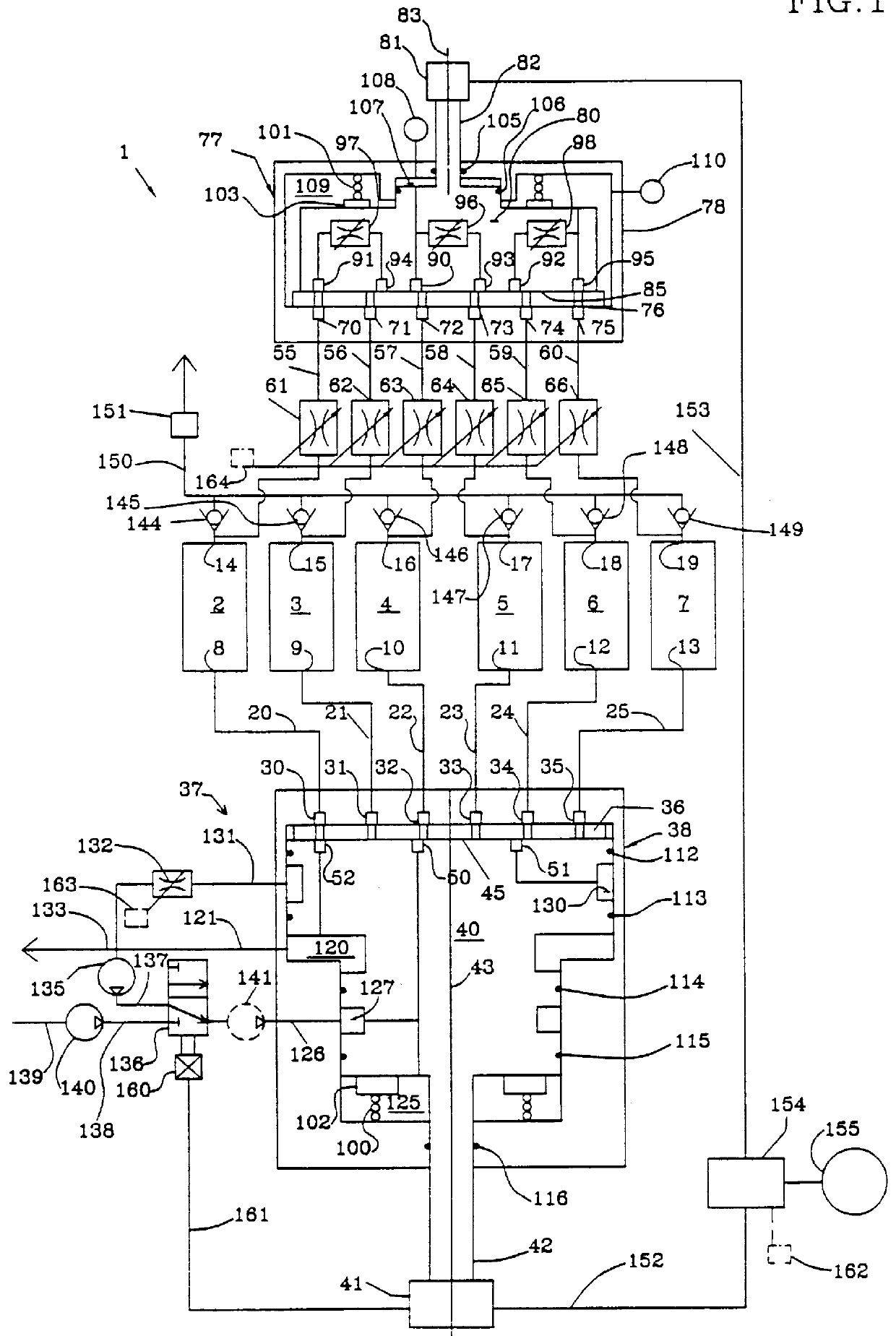

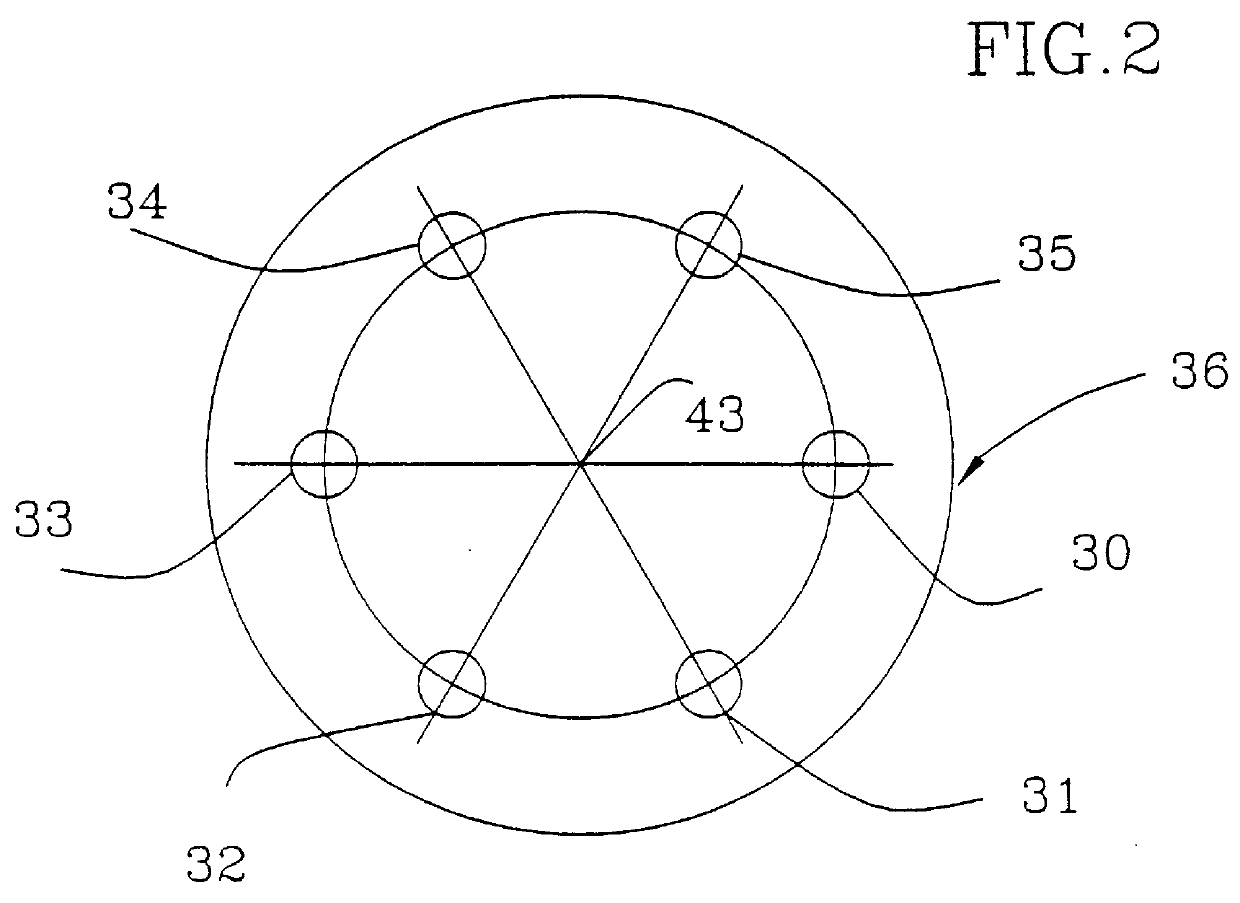

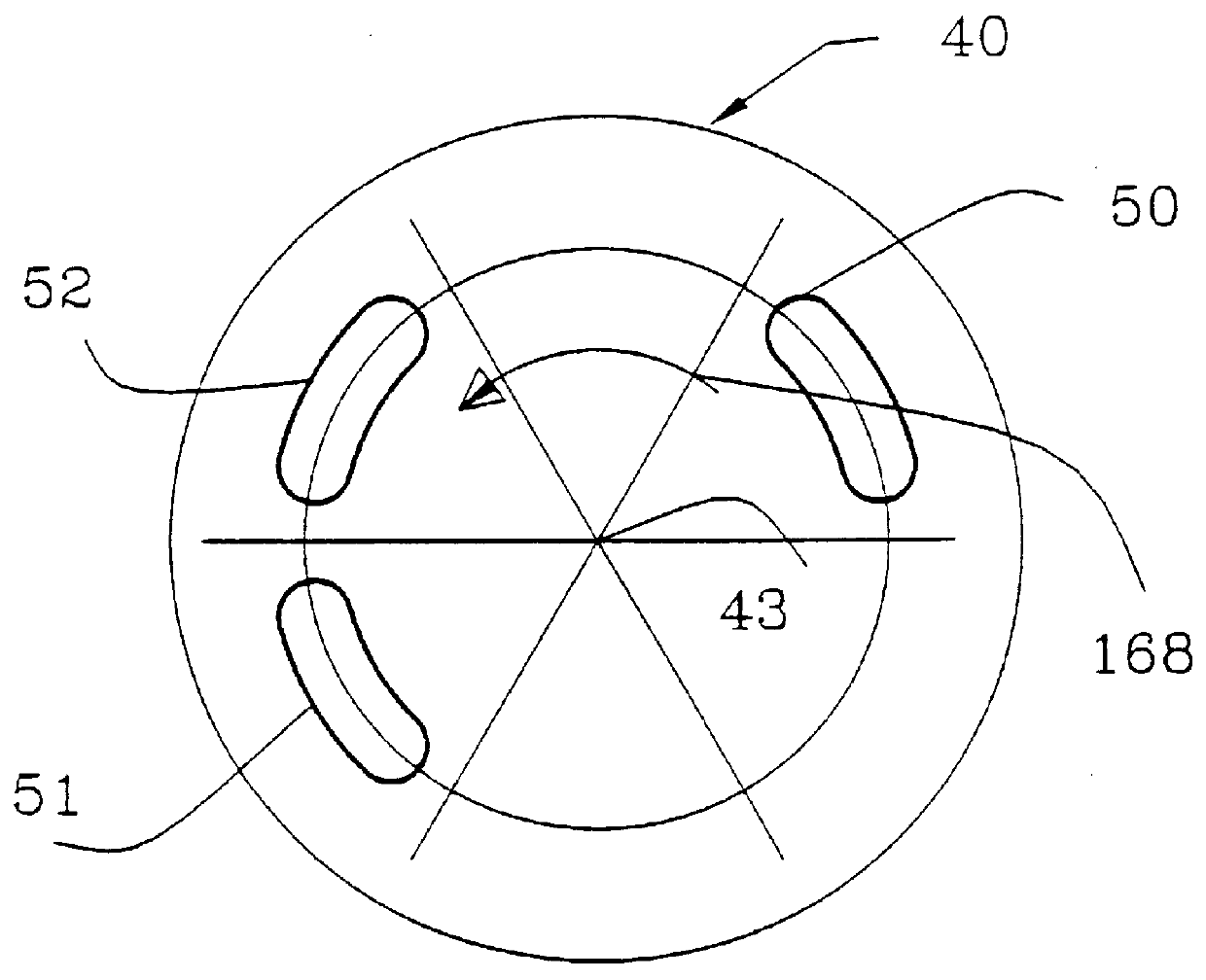

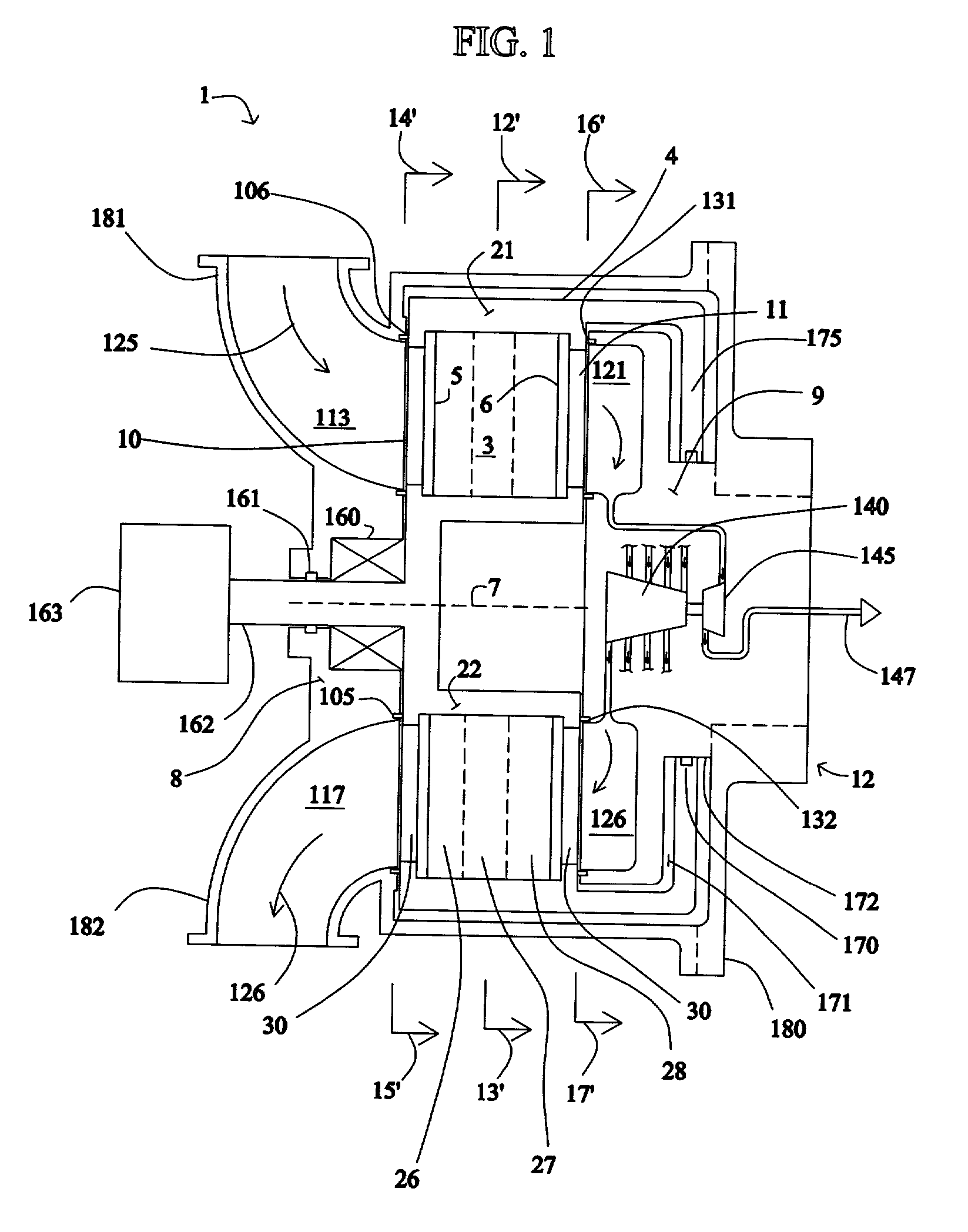

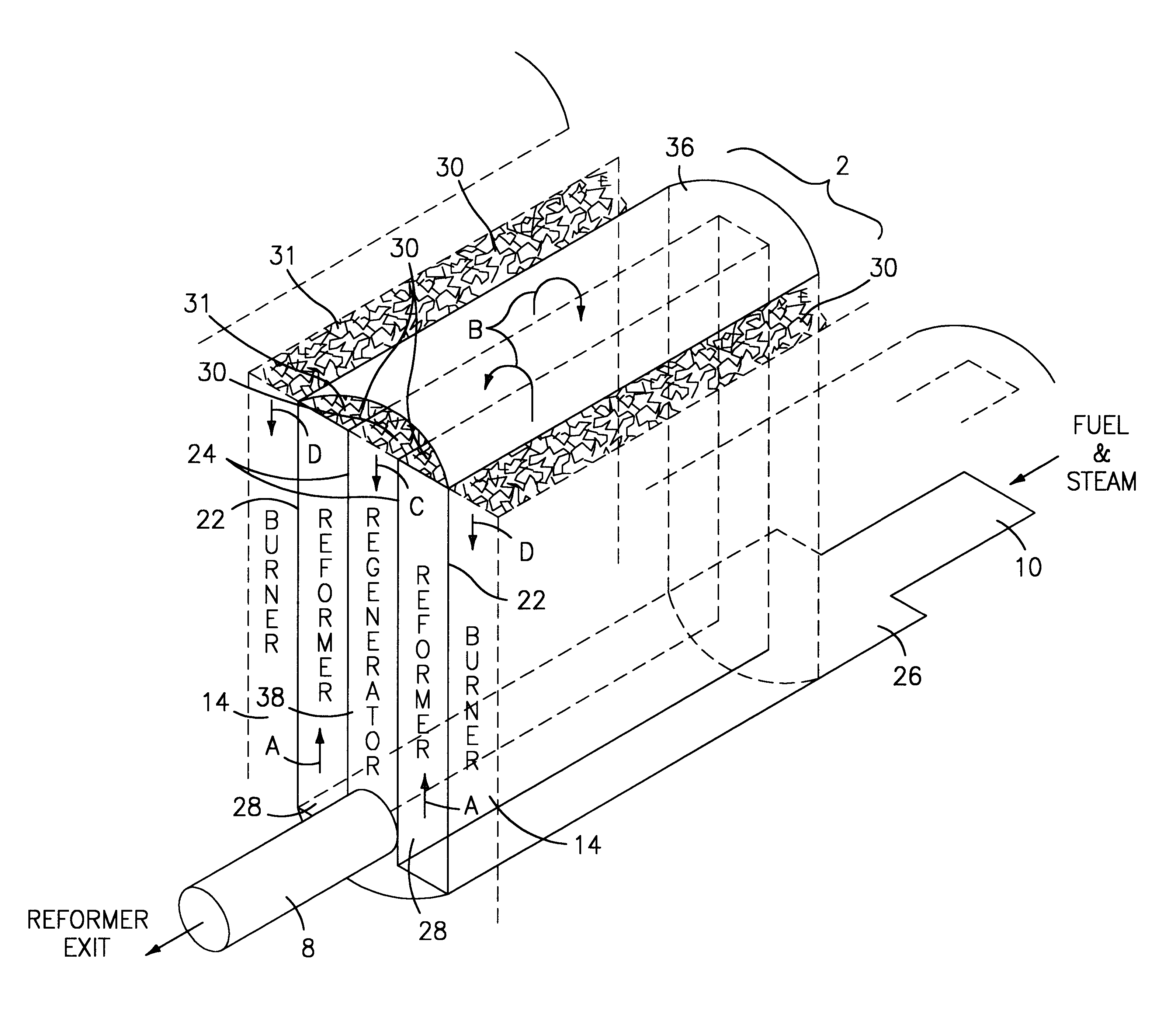

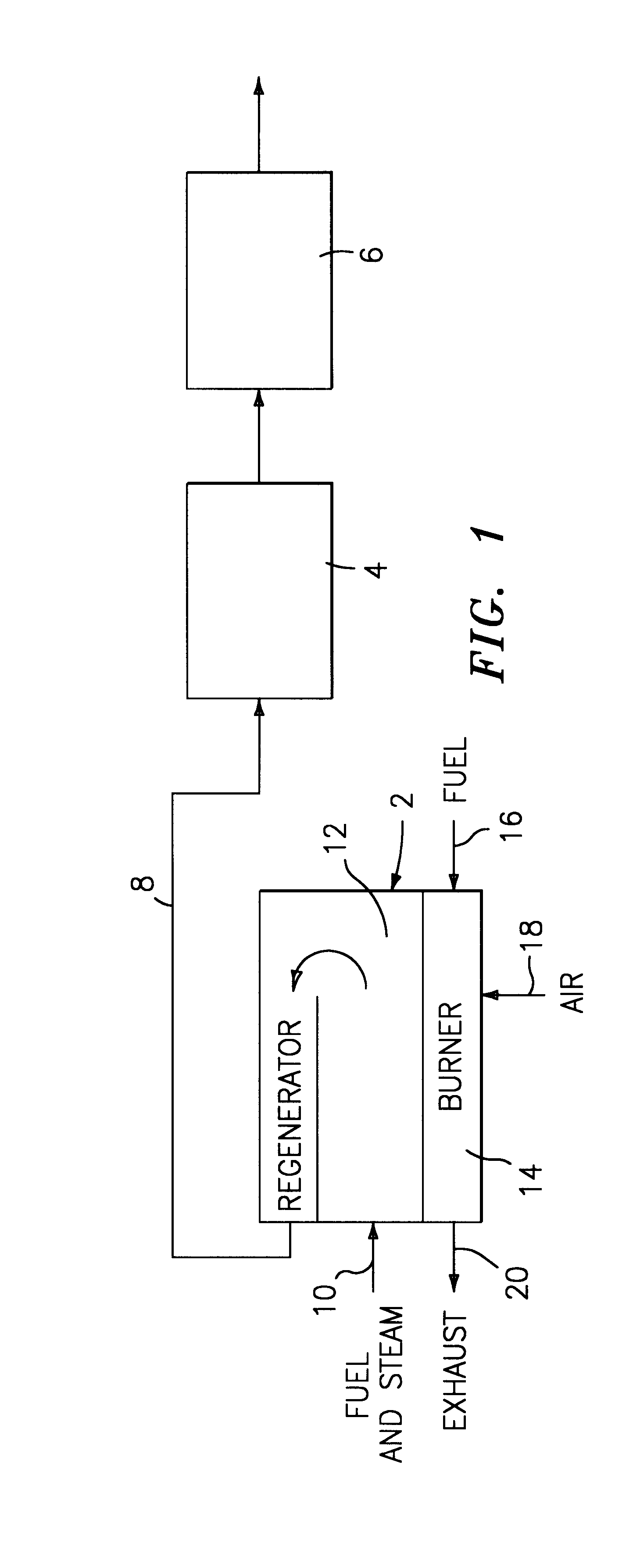

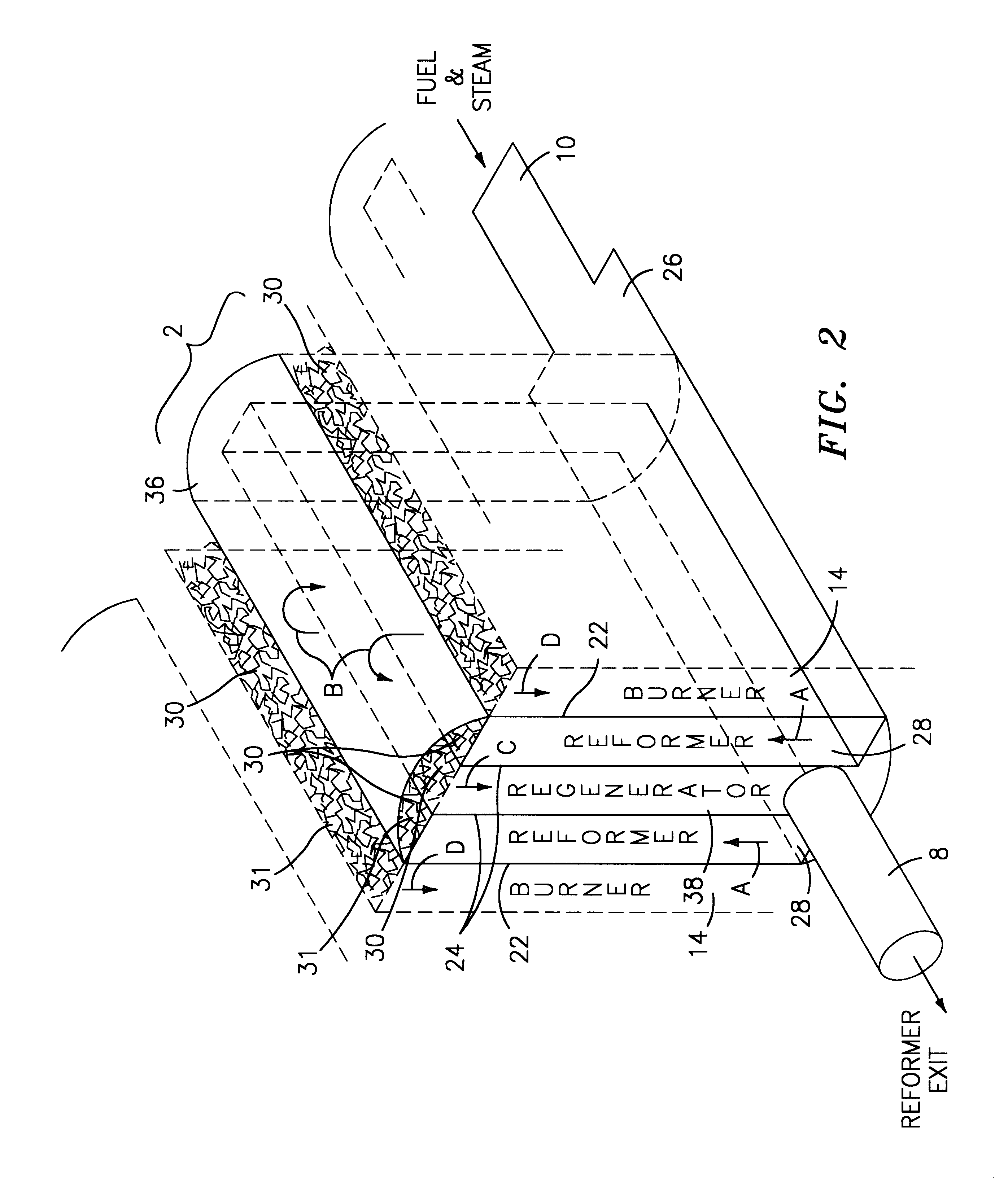

Compact fuel gas reformer assemblage

InactiveUS6203587B1Improve heat transfer performanceReduce the temperatureSemi-permeable membranesHydrogen separation using solid contactFuel cellsForming gas

A fuel gas reformer assemblage for use in a fuel cell power plant is formed from a composite plate assembly which includes spaced-apart divider plates with interposed monolithic open cell sponge-like members which form gas passages. The monolithic members have a lattice of internal open cells which are both laterally and longitudinally interconnected so as to provide for a diffuse gas flow. The entire surface area of the monolithic components is wash coated with a porous alumina layer, and selected areas of the wash coat are also catalyzed. The reformer assemblage is constructed from a series of repeating sub-assemblies, each of which includes a core of separate regenerator / heat exchanger gas passages. The core in each sub-assembly is sandwiched between a pair of reformer gas passage skins, which complete the subassembly. Adjacent reformer gas / regenerator / reformer gas passage sub-assemblies in the composite plate assembly are separated from each other by burner gas passages. The regenerator / heat exchanger gas passages and the reformer gas passages in each sub-assembly are connected by gas flow return manifolds which form a part of each sub-assembly. The fuel gases flow in one end of the assemblage, through the reformer gas passages, and then reverse their direction of flow in the return manifolds so as to exit the reformer assemblage through the regenerator gas flow passages. The burner gases flow in one end of the reformer assemblage and out the other end.

Owner:INT FUEL CELLS

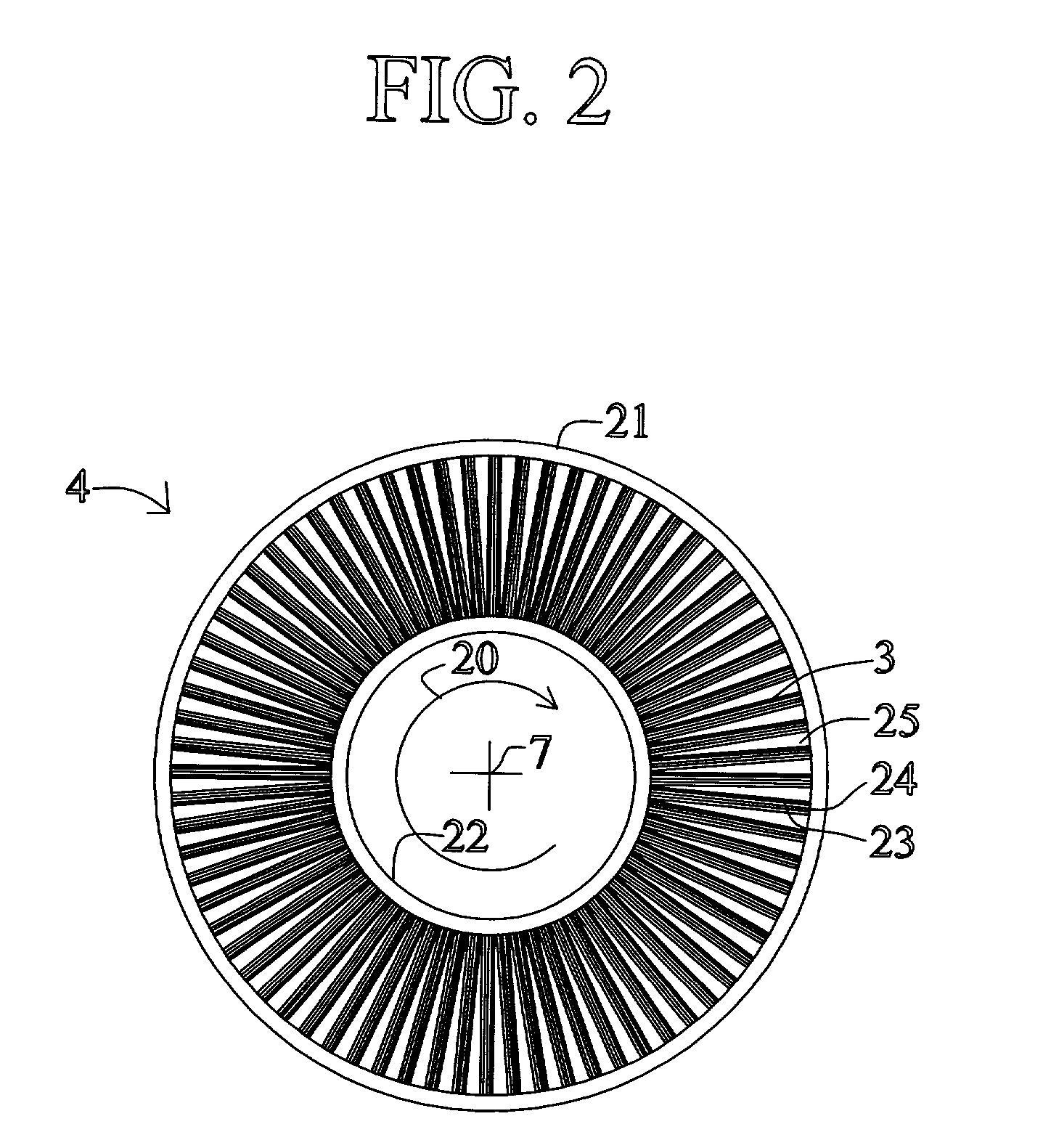

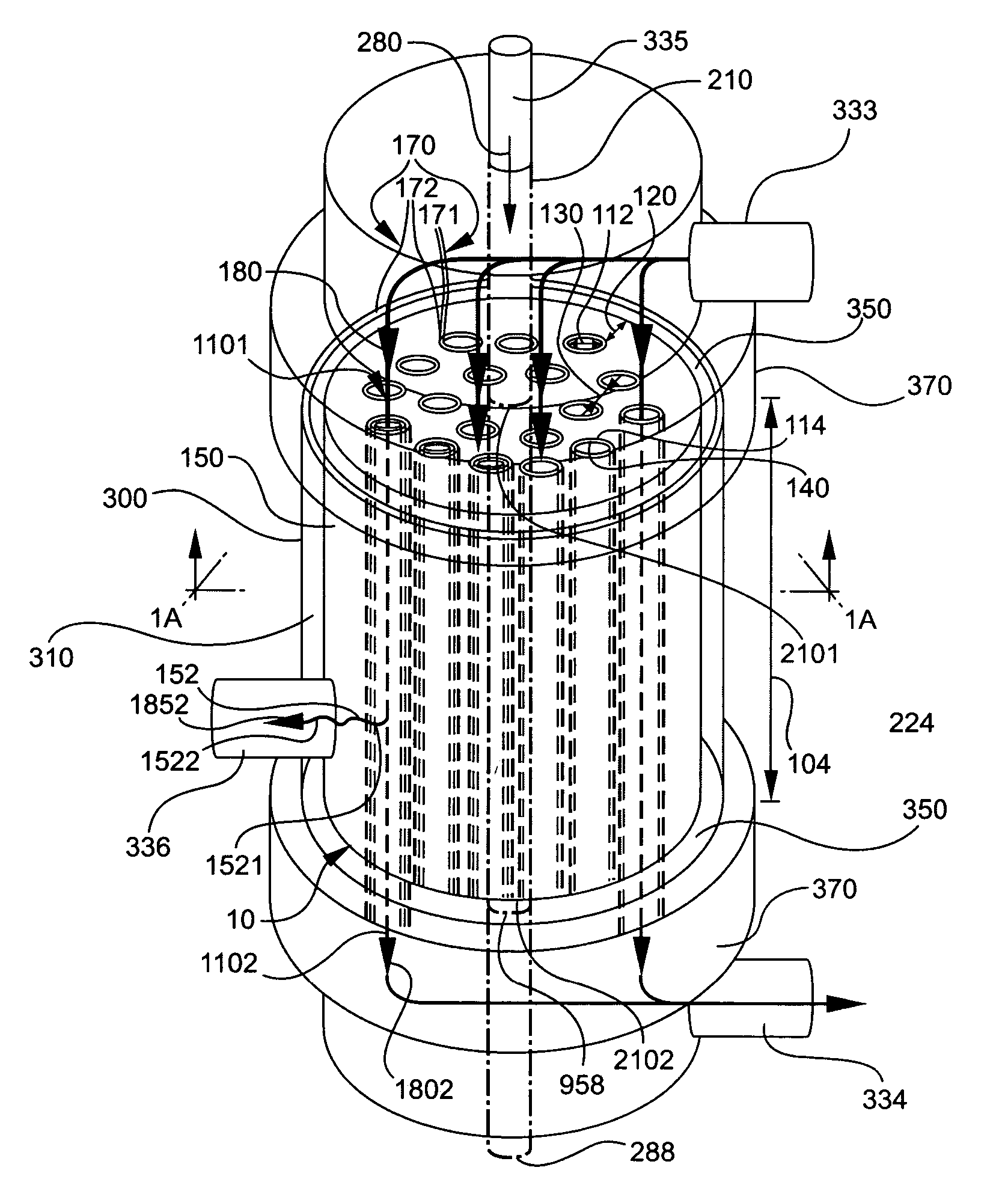

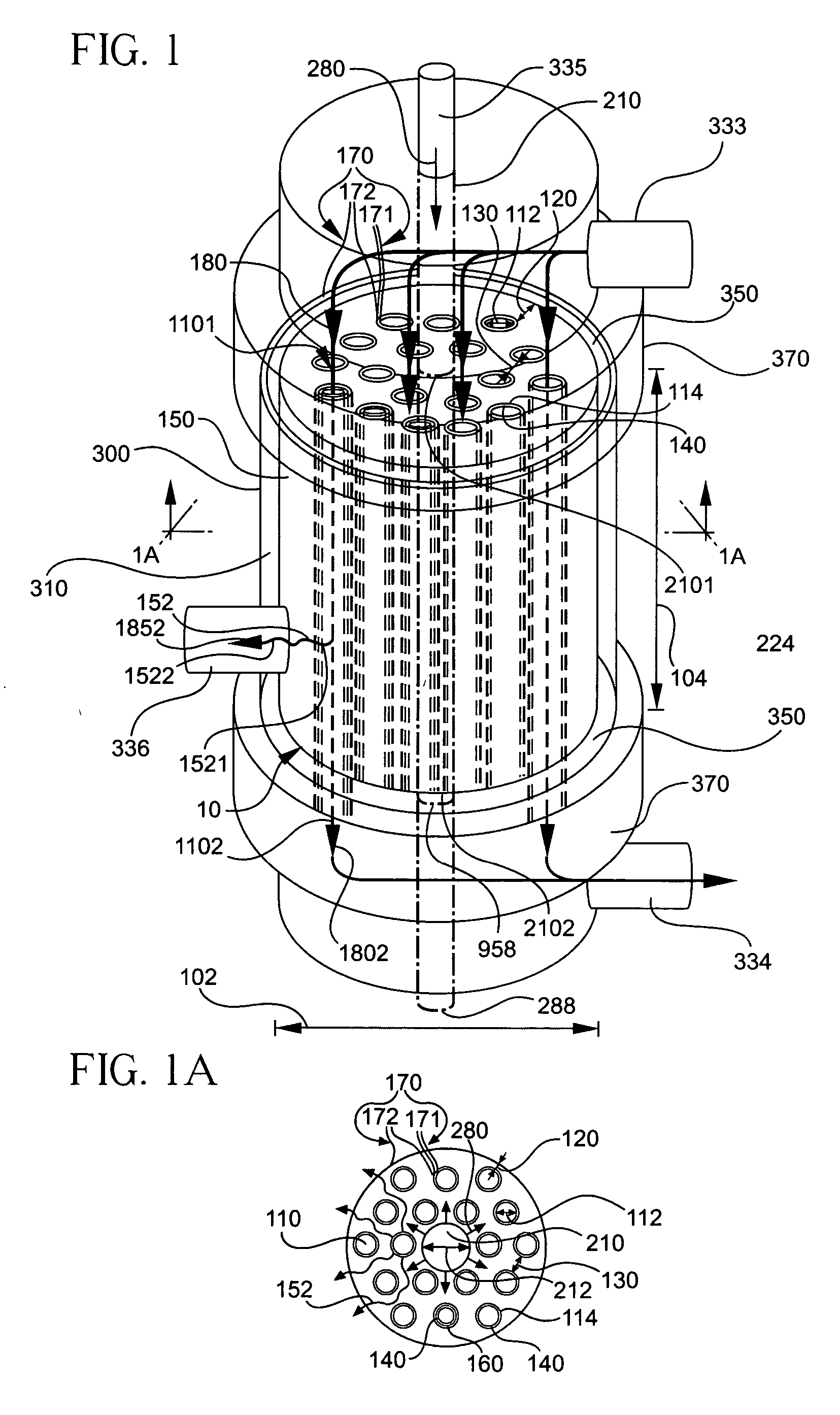

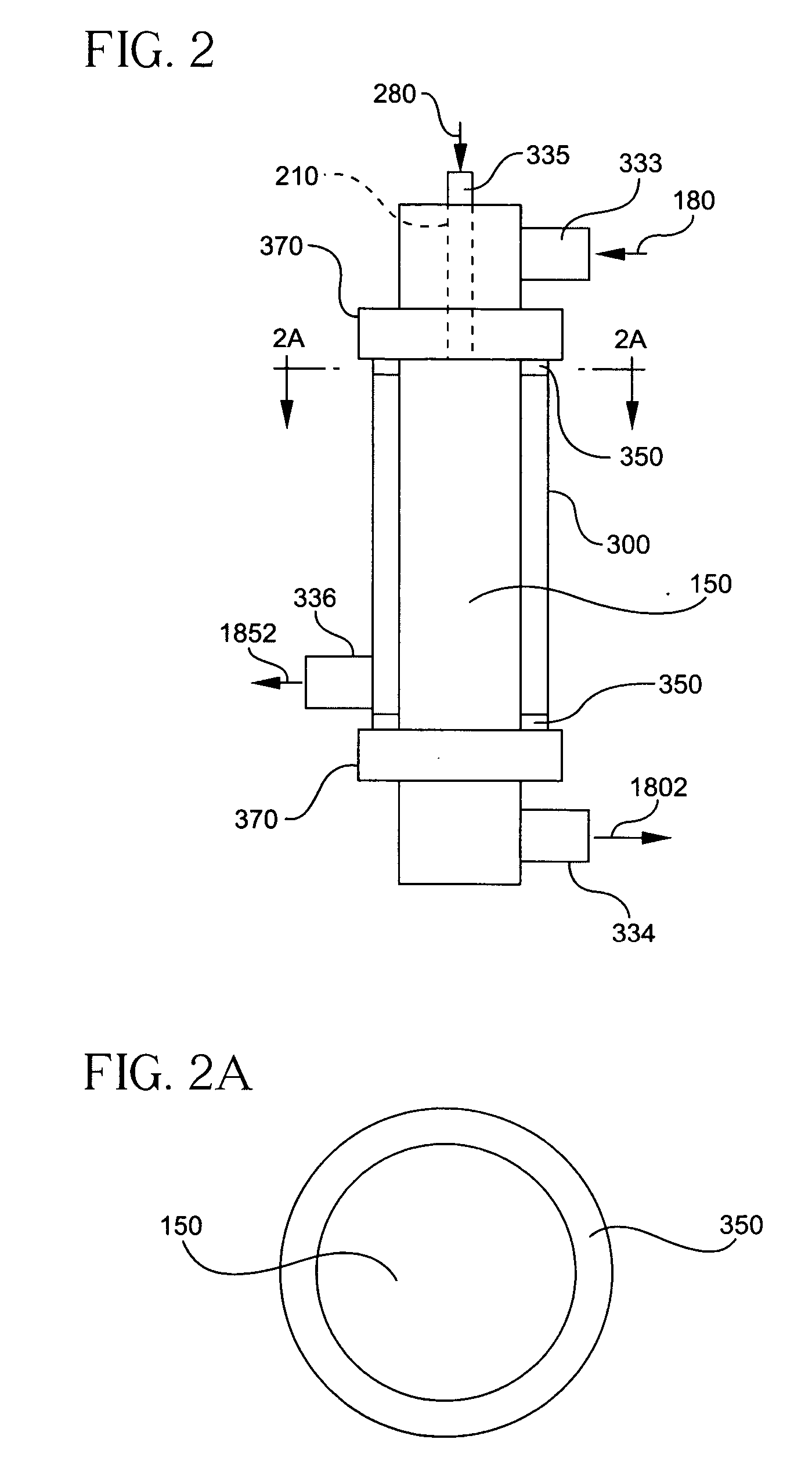

Multi-channel cross-flow porous device

InactiveUS20060090651A1Dispersed particle filtrationTransportation and packagingStream flowEngineering

A multi-channel modular device (10) processes between two fluid streams of different compositions. The device (10) includes a porous body (150) having a first plurality of feed-flow pathways (110) disposed in the body (150) for transporting a first stream (180). A pathway wall (114) surrounds each of the first plurality of feed-flow pathways (110) for processing the first stream (180) into a first composition (1852) and a second composition (1802). At least one feed-flow inlet (1101) is disposed in the body (150) for introducing the first stream (180) into the first plurality of feed-flow pathways (110). At least one feed-flow outlet (1102) is disposed in the body (150) for discharging the remaining first stream containing the second composition (1802). At least one second pathway (210) is disposed in the body (150) for transporting a second stream (280) having a second inlet (2101) and a second outlet (2102). A networked plurality of fluid conduits (152) formed in the porous body (150) provides the flow-conduit for the second stream (280) to sweep the first composition (1852) from each of the first plurality of the feed-flow pathways (110) to the second outlet (2102). A vessel (300) ports the inlets (1101 and 2101) and outlets (1102 and 2102) to provide a second stream flow access and for spacing the body within and away from the inner surfaces of the vessel (300) to provide a gap (310) for access. A partition (350) is disposed in the gap between the body and the vessel for diverting the flow within the gap (310).

Owner:CORNING INC

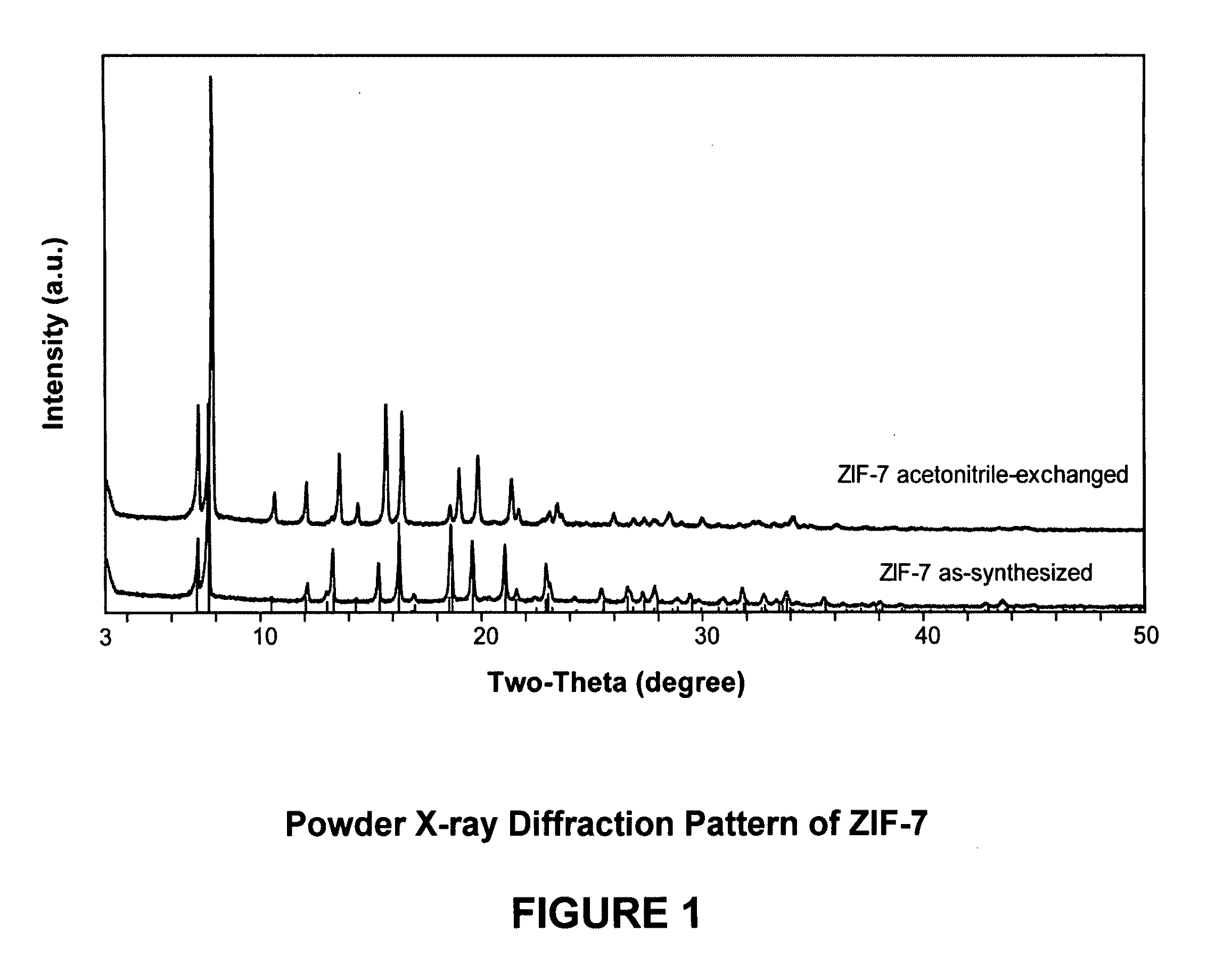

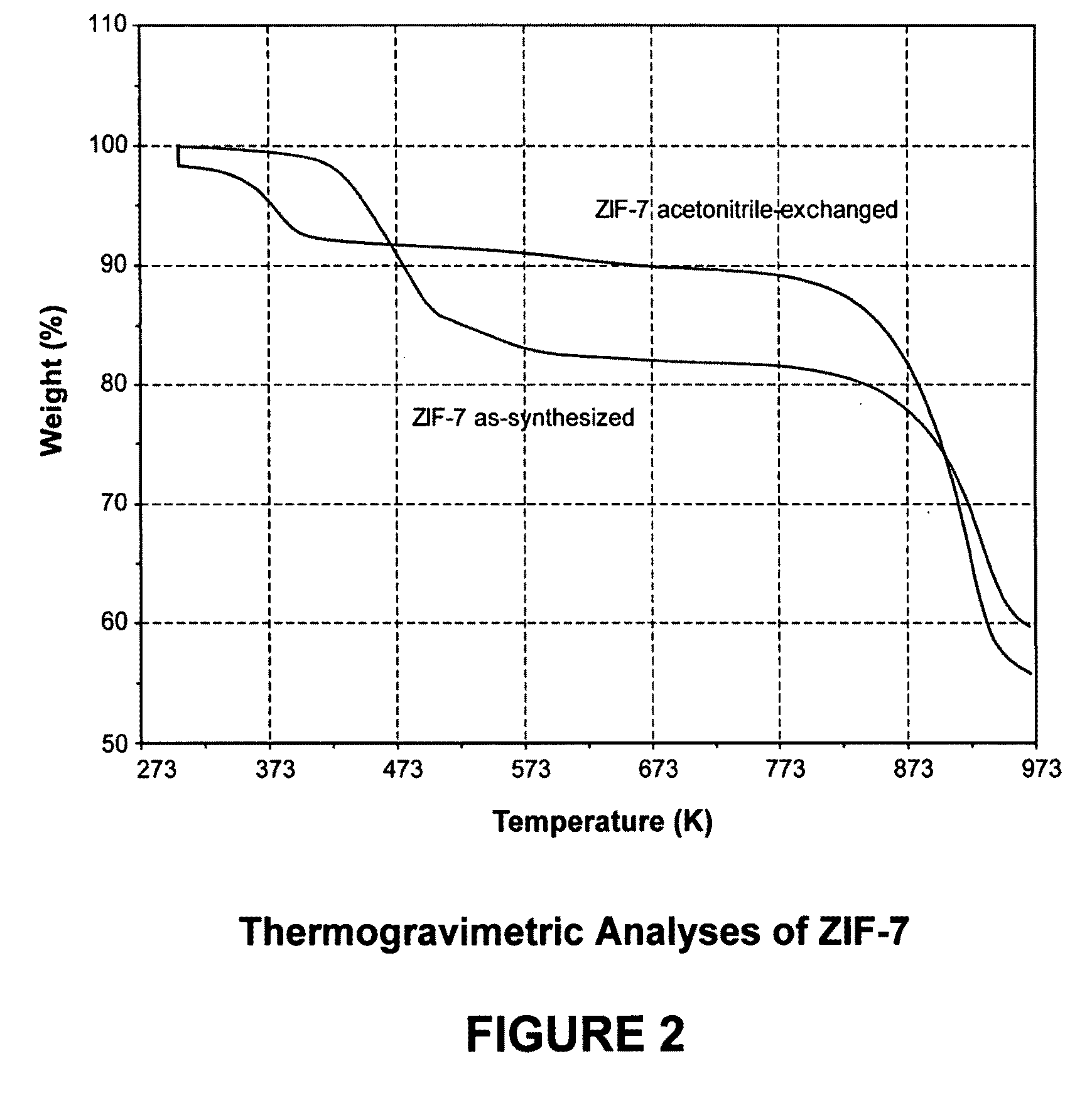

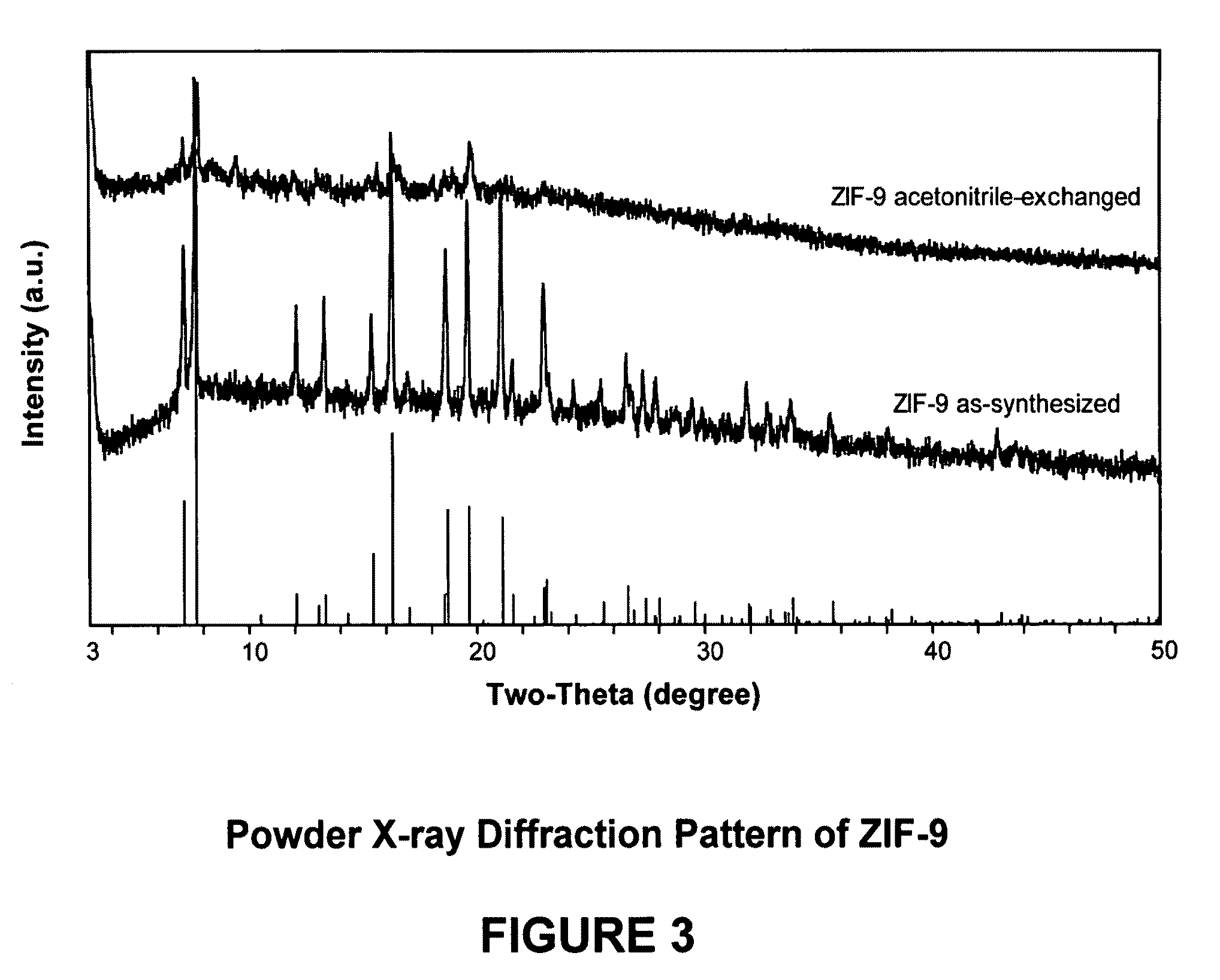

Separation of carbon dioxide from methane utilizing zeolitic imidazolate framework materials

The present invention relates to the selective separation of carbon dioxide (“CO2”) from methane (“CH4”) in streams containing both carbon dioxide and methane utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in a process to separate carbon dioxide from natural gas streams preferably for sequestration of at least a portion of the carbon dioxide present in the natural gas.

Owner:EXXON RES & ENG CO

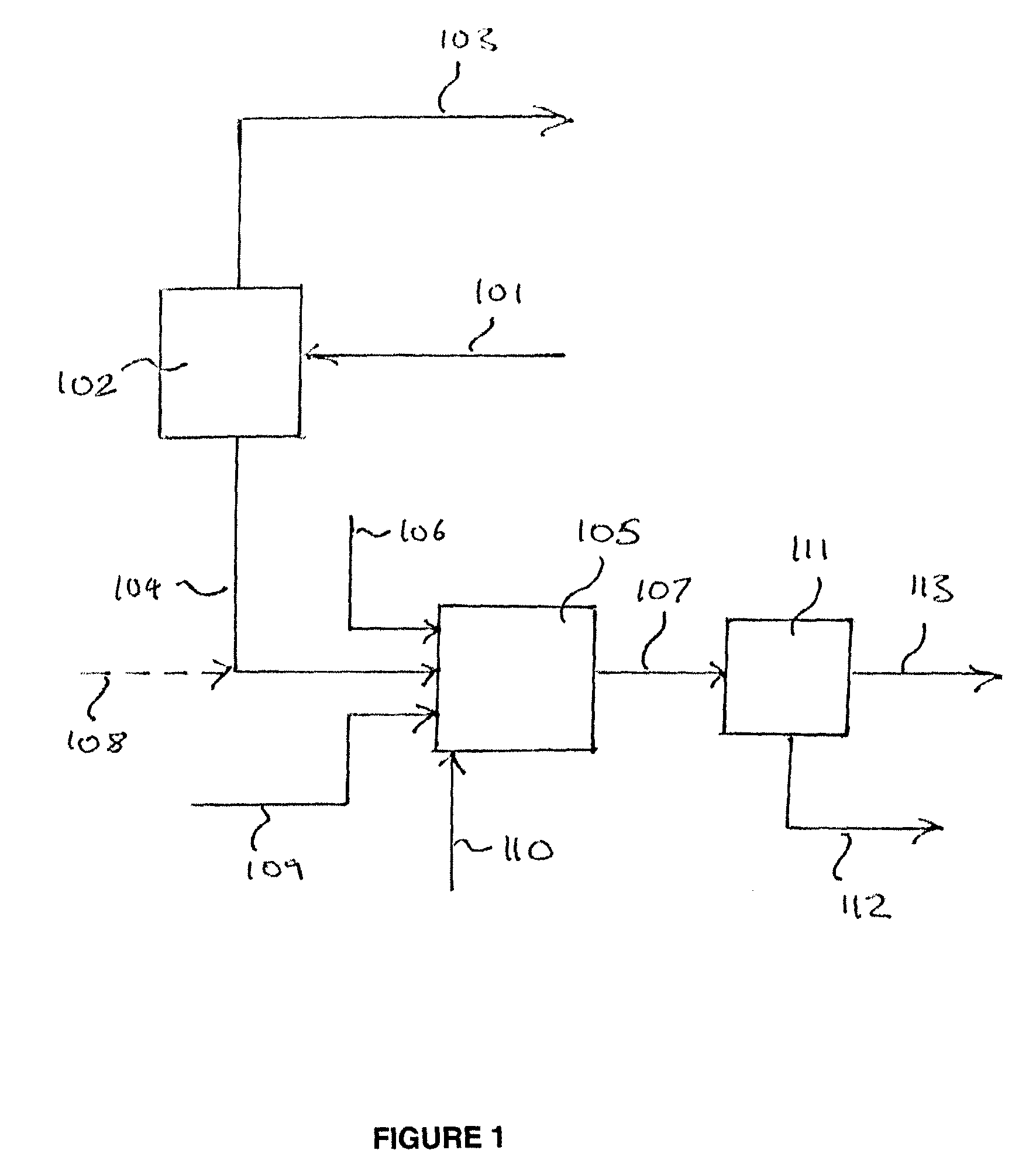

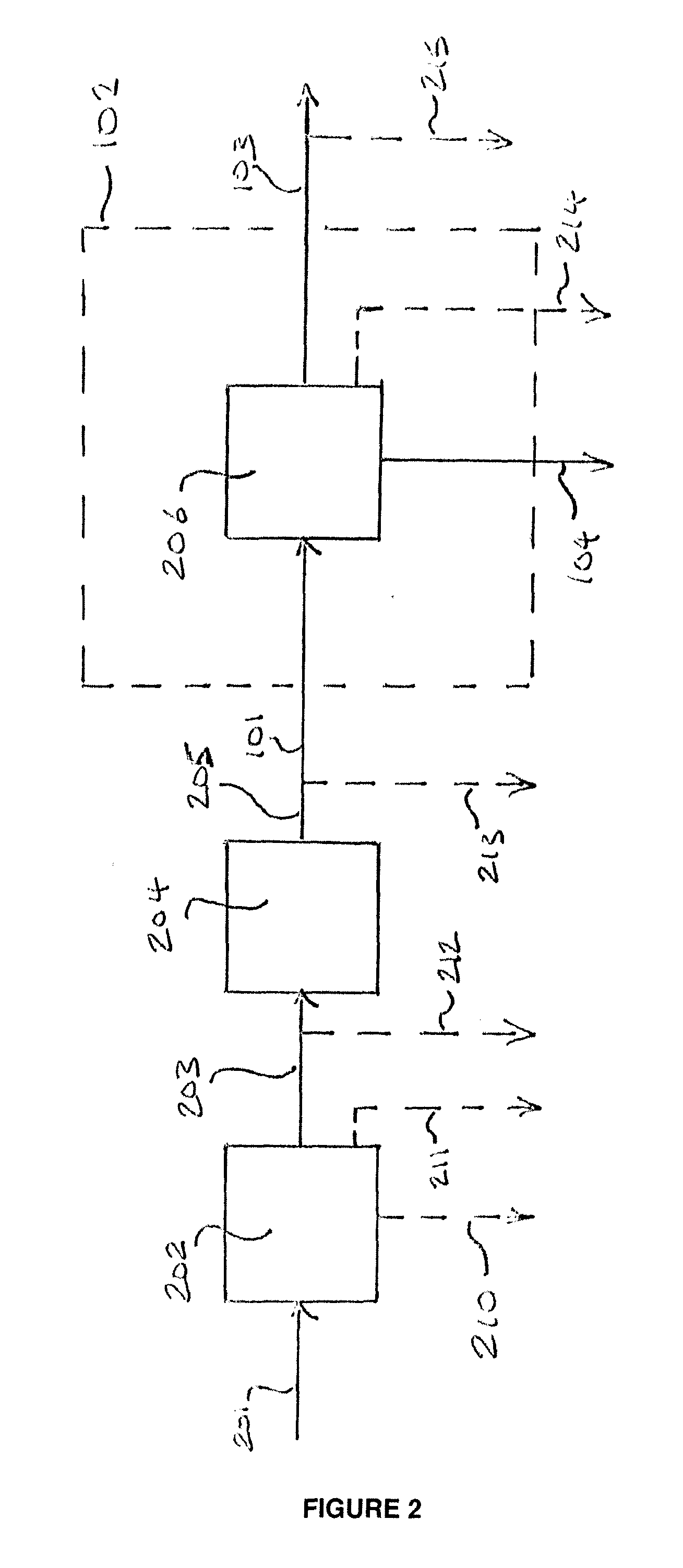

Simultaneous shift-reactive and adsorptive process to produce hydrogen

A process for producing a high temperature COx-lean product gas from a high temperature COx-containing feed gas, includes: providing a sorption enhanced reactor containing a first adsorbent, a shift catalyst and a second adsorbent; feeding into the reactor a feed gas containing H2, H2O, CO and CO2; contacting the feed gas with the first adsorbent to provide a CO2 depleted feed gas; contacting the CO2 depleted feed gas with the shift catalyst to form a product mixture comprising CO2 and H2; and contacting the product mixture with a mixture of second adsorbent and shift catalyst to produce the product gas, which contains at least 50 vol. % H2, and less than 5 combined vol. % of CO2 and CO. The adsorbent is a high temperature adsorbent for a Sorption Enhanced Reaction process, such as K2CO3 promoted hydrotalcites, modified double-layered hydroxides, spinels, modified spinels, and magnesium oxides.

Owner:AIR PROD & CHEM INC

Method of treating a gaseous mixture comprising hydrogen, carbon dioxide and hydrogen sulphide

A gaseous mixture, comprising CO2, H2, H2S and optionally CO, is separated into an H2 or H2 and CO product stream (H2 / CO product stream), and a CO2 enriched stream containing at least one combustible component selected from H2S, H2, CO and any additional combustible components present in the gaseous mixture. A support fuel stream, comprising one or more combustible components, is combusted to form a stable flame, and the CO2 enriched stream and flame are contacted in the presence of sufficient O2 to combust all or substantially all of the combustible component(s) present in said CO2 enriched stream. A CO2 product stream is formed from said combustion effluent. The support fuel stream may be generated from the process of generating or separating the gaseous mixture or from the H2 / CO product stream. Where the CO2 enriched stream contains H2S, the support fuel stream may also be a stream obtained off-site that comprises H2S.

Owner:AIR PROD & CHEM INC

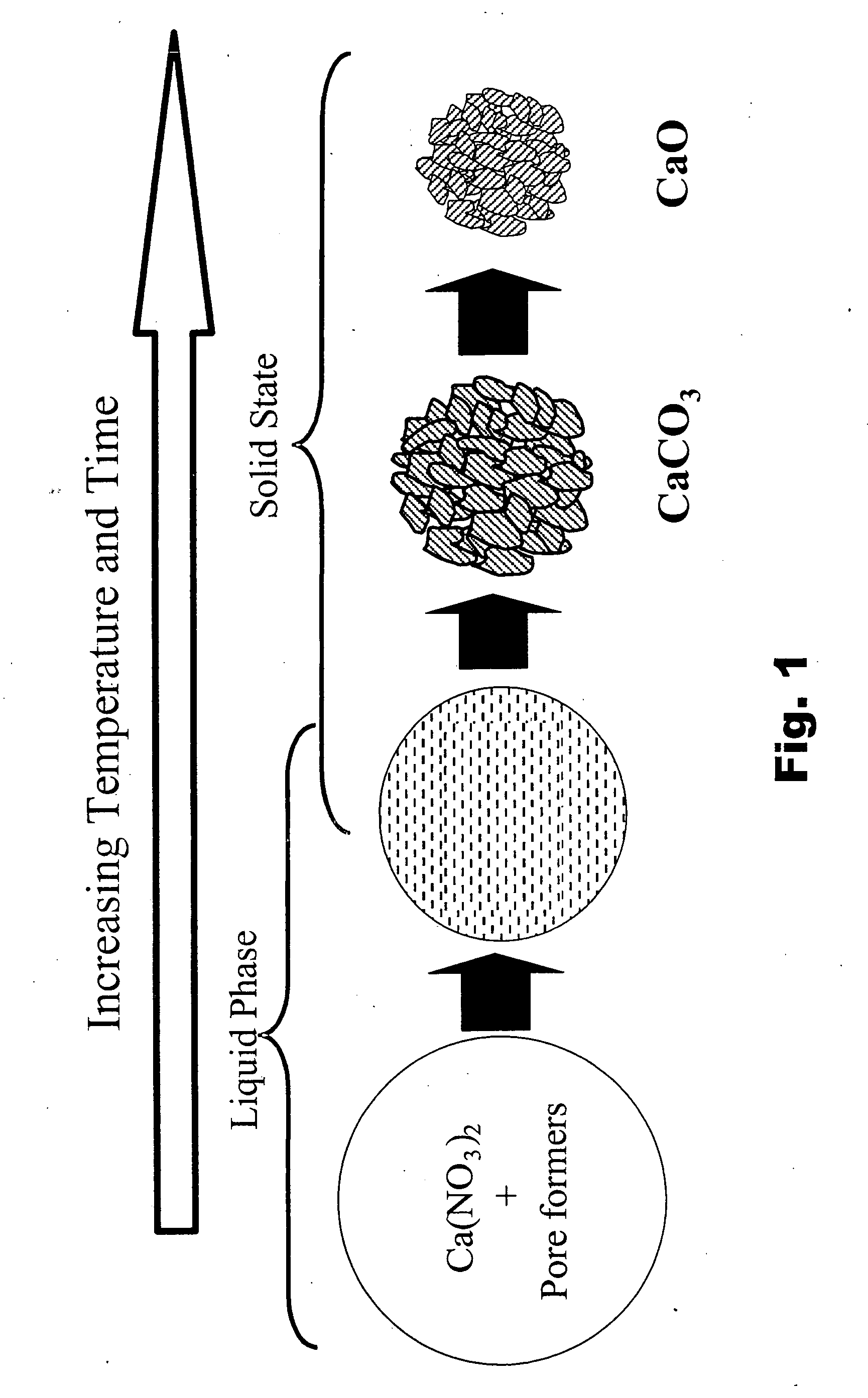

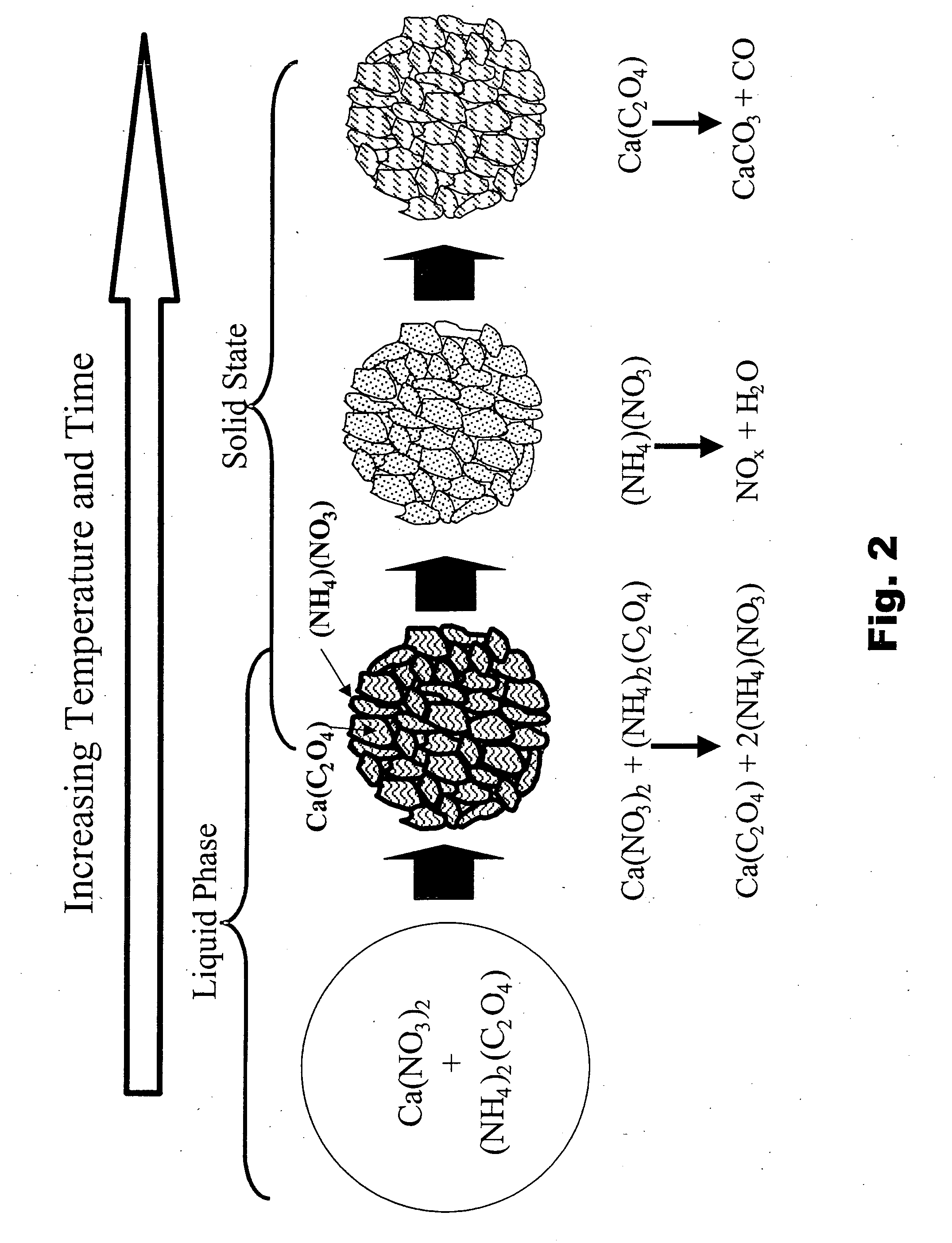

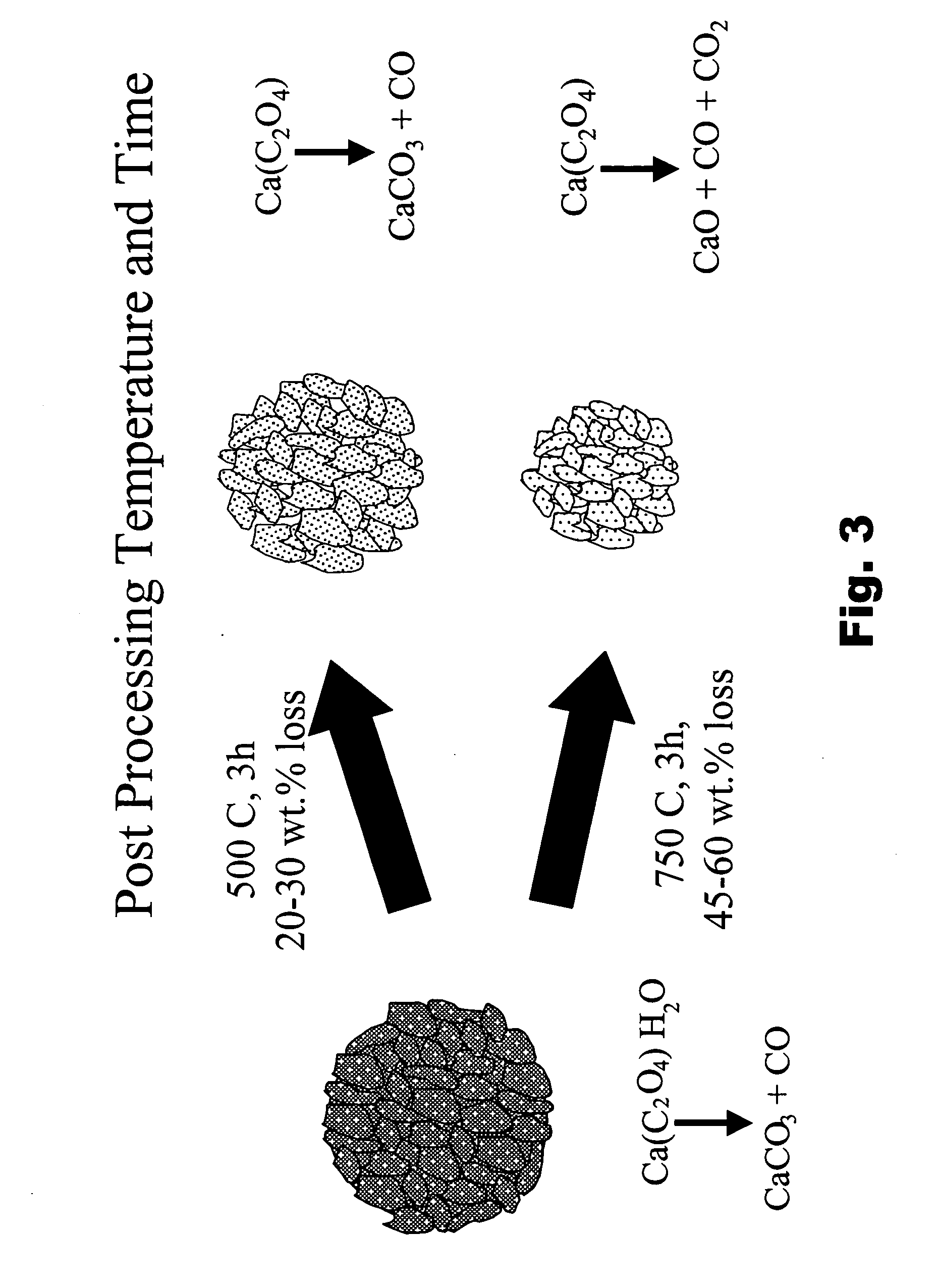

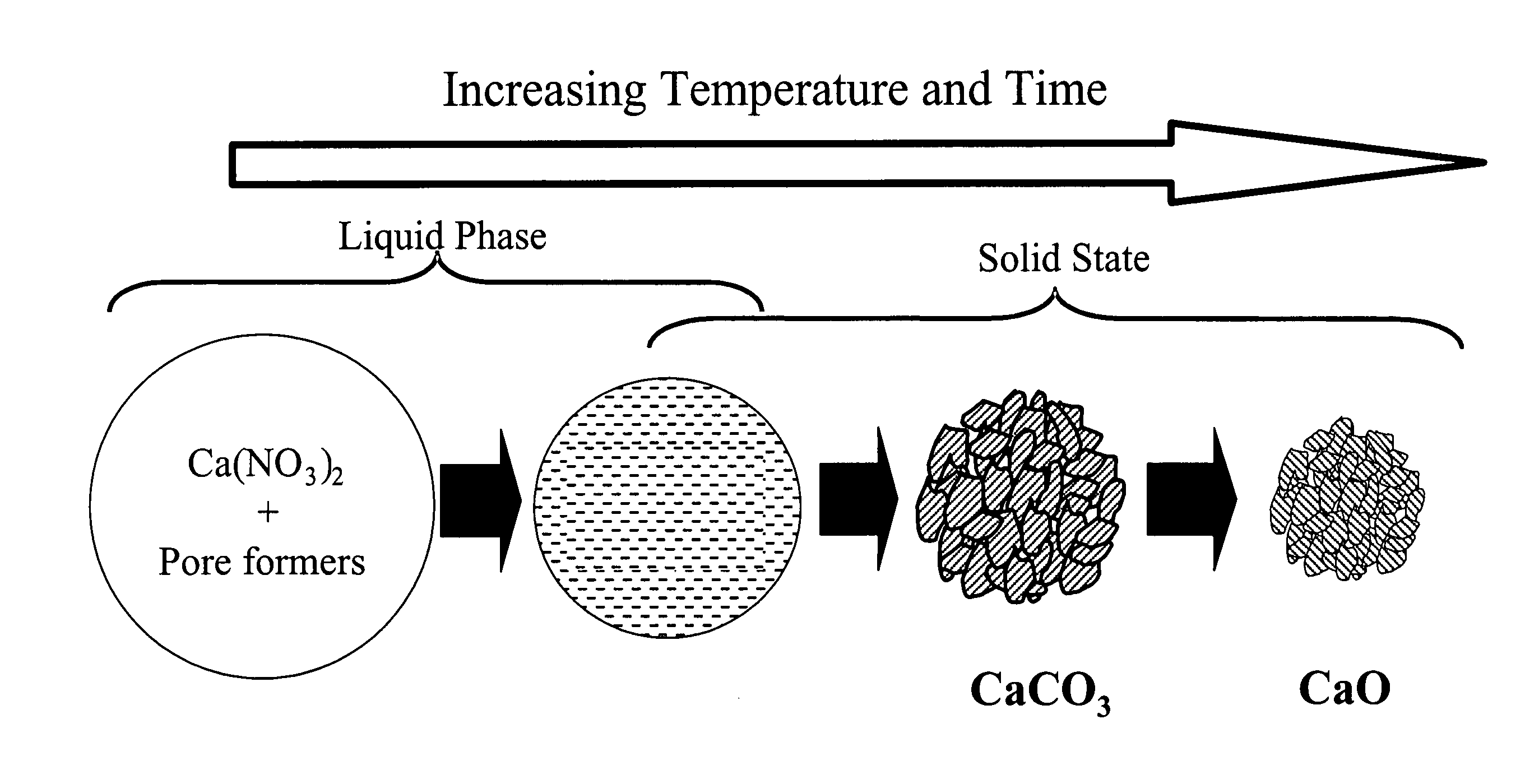

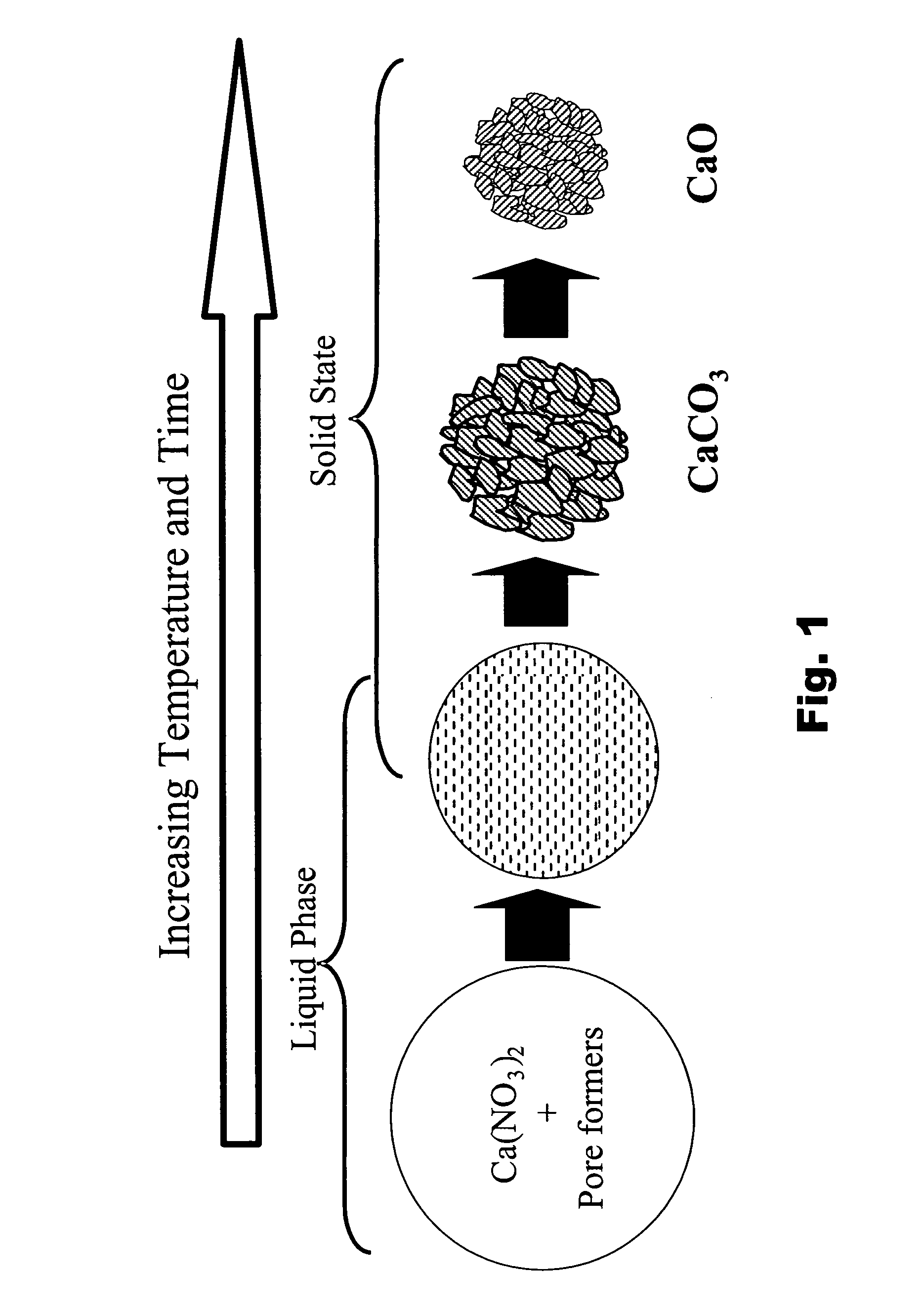

Fuel reformer catalyst and absorbent materials

InactiveUS20050112056A1Enhanced reformingOther chemical processesHydrogen separation using solid contactAbsorbent materialProduct gas

Materials that are useful for absorption enhanced reforming (AER) of a fuel, including absorbent materials and catalyst materials. The materials can be fabricated by spray processing. The use of the materials in AER can produce a H2 product gas having a high H2 content and a low level of carbon oxides.

Owner:CABOT CORP

Particulate absorbent materials and methods for making same

InactiveUS20050230659A1Improve heat transfer characteristicsHigh airspeedOther chemical processesHydrogen separation using solid contactChemical compositionHigh absorption

Solid absorbent materials that are useful for absorption of chemical species from a fluid, such as a gas stream or a liquid stream. The absorbent materials are formed by spray processing and posses a well-defined chemical composition and microstructure. The absorbent materials can have a high absorption capacity for a chemical species such as H2S, CO2, NO, and H2 and have a high recylability, such that the chemical species can be absorbed and desorbed over a large number of cycles.

Owner:CABOT CORP

Popular searches

Solid electrolyte fuel cells Motive system fuel cells Hydrogen separation by diffusion Evaporation apparatus Iron oxides/hydroxides Chemical industry Chemical/physical/physico-chemical stationary reactors Liquid-gas reaction processes Transportation fuel cell technology Transportation hydrogen technology

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com