Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1900 results about "Methanation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

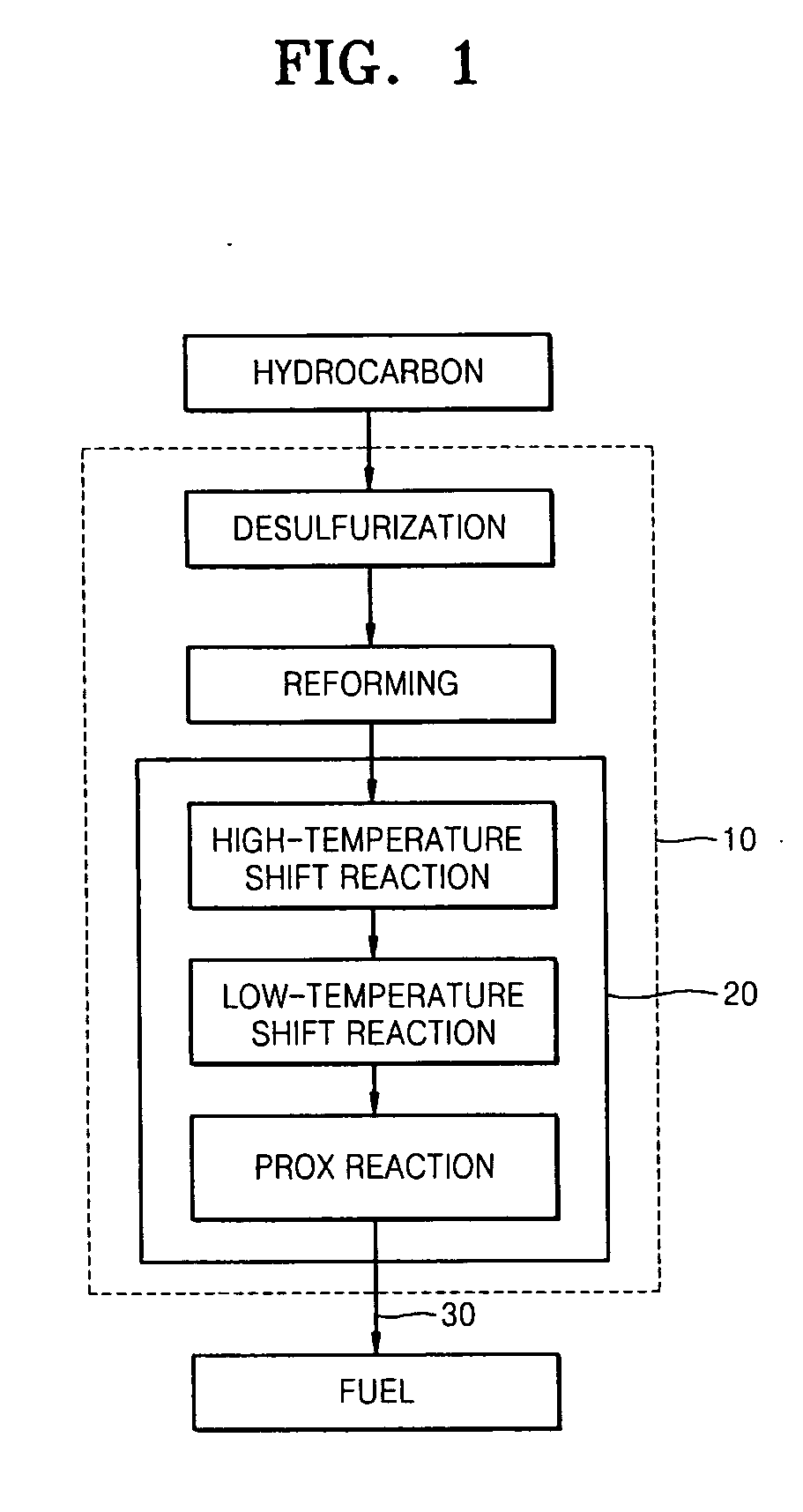

Methanation is the conversion of COₓ to methane CH₄ through hydrogenation. The methanation reactions of COx were first discovered by Sabatier and Senderens in 1902. COₓ methanation has many practical applications. It is a means of carbon oxide removal from process gases and is also being discussed as an alternative to PROX in fuel processors for mobile fuel cell applications.

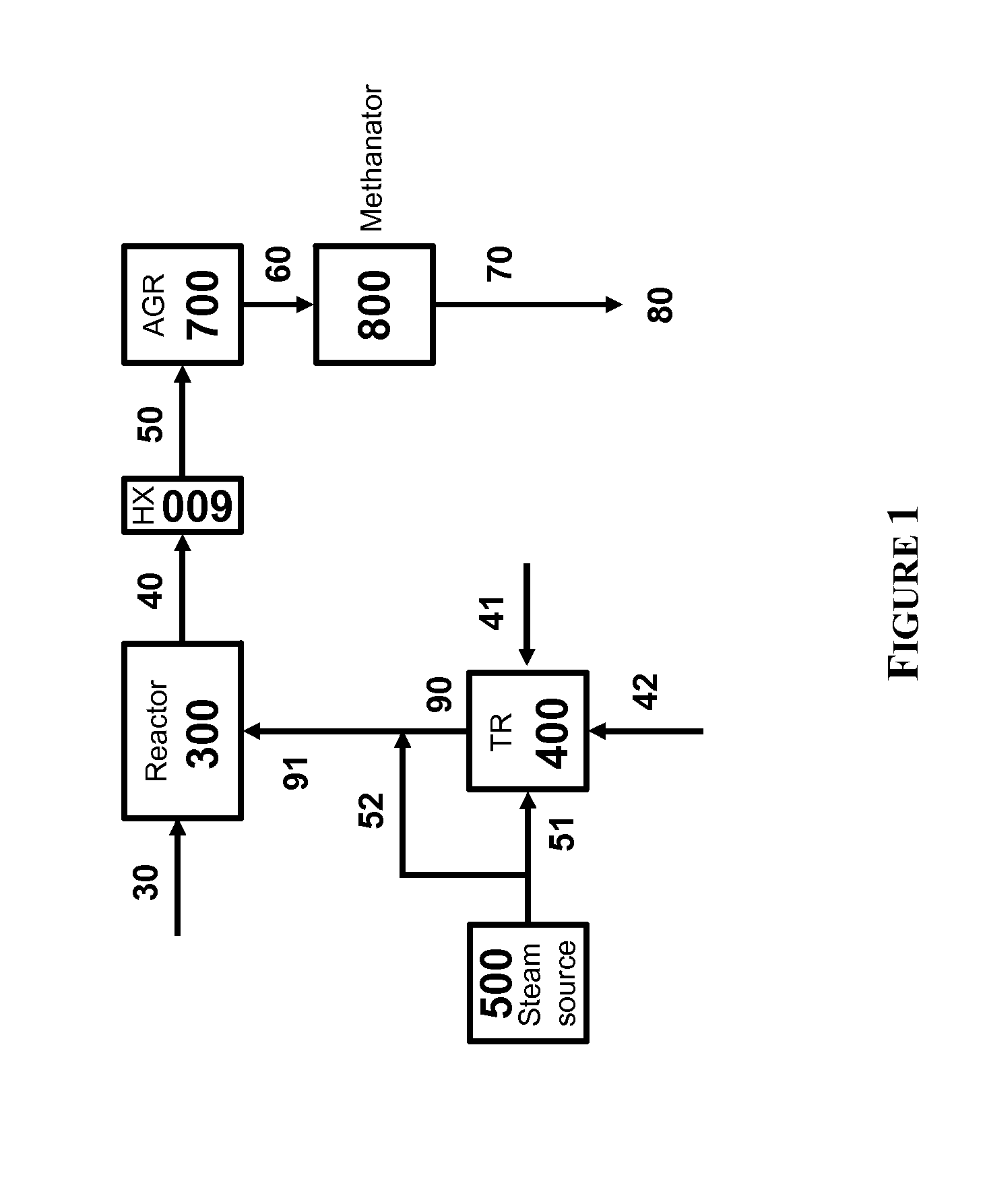

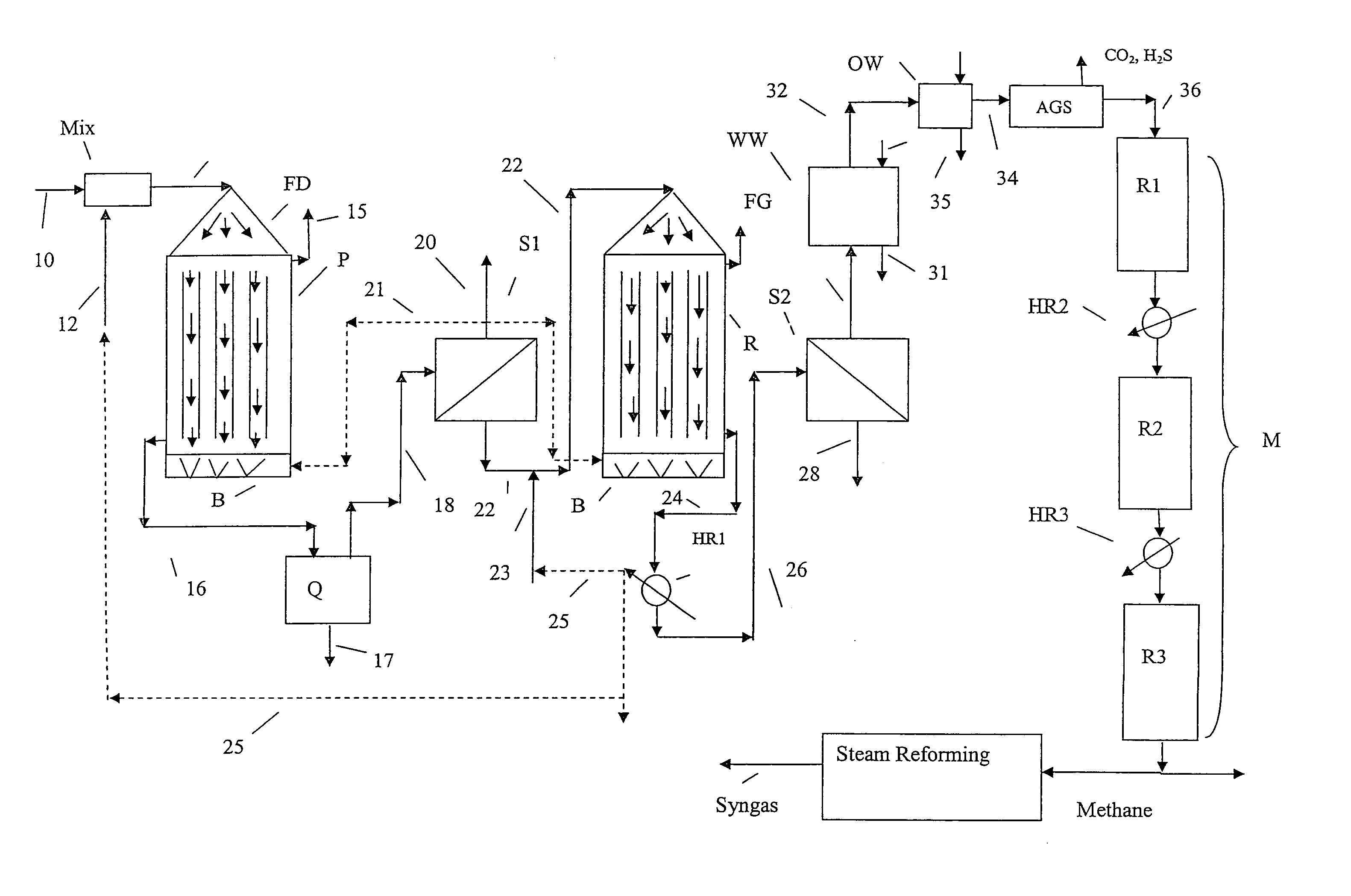

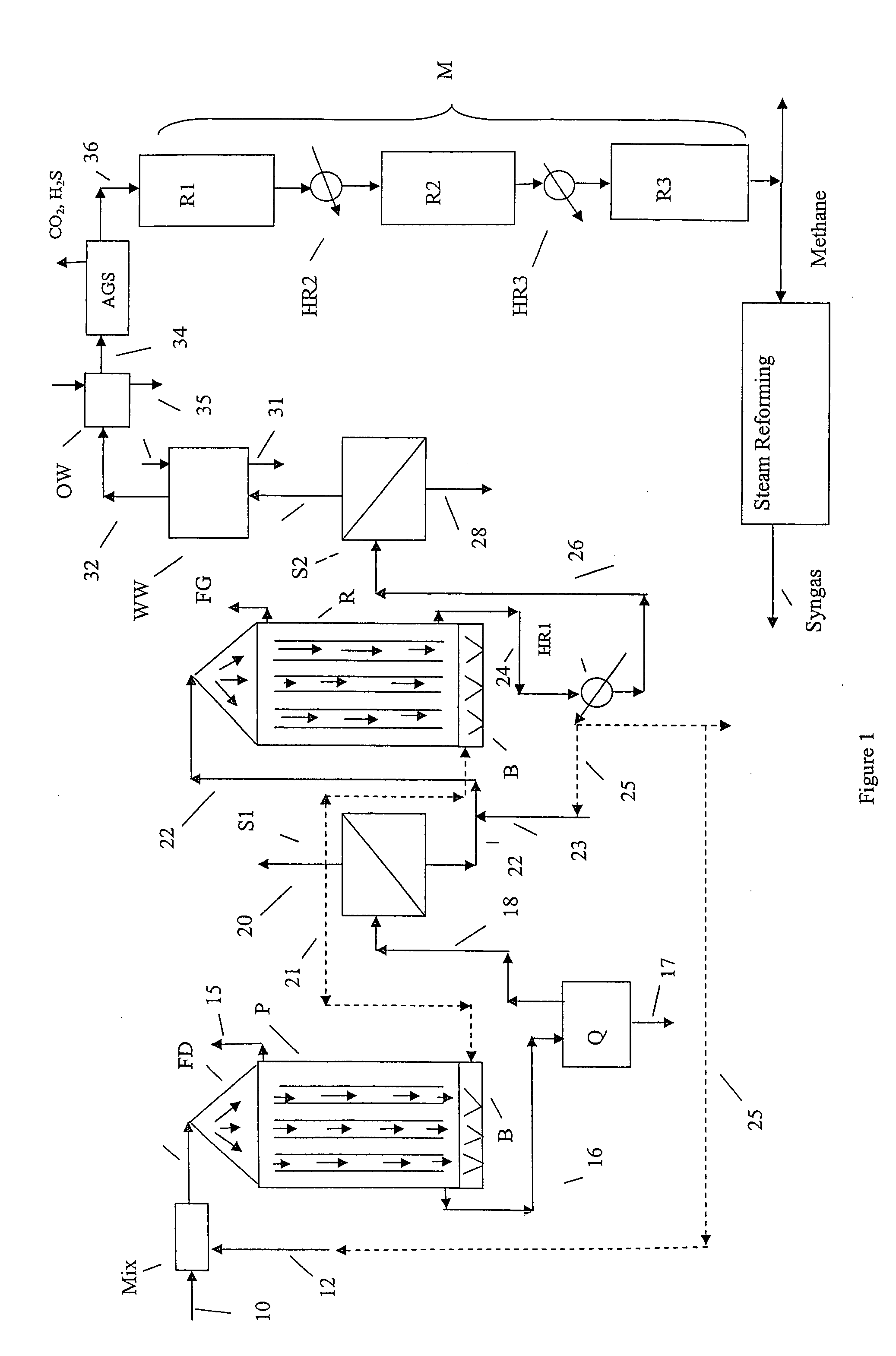

Processes for Gasification of a Carbonaceous Feedstock

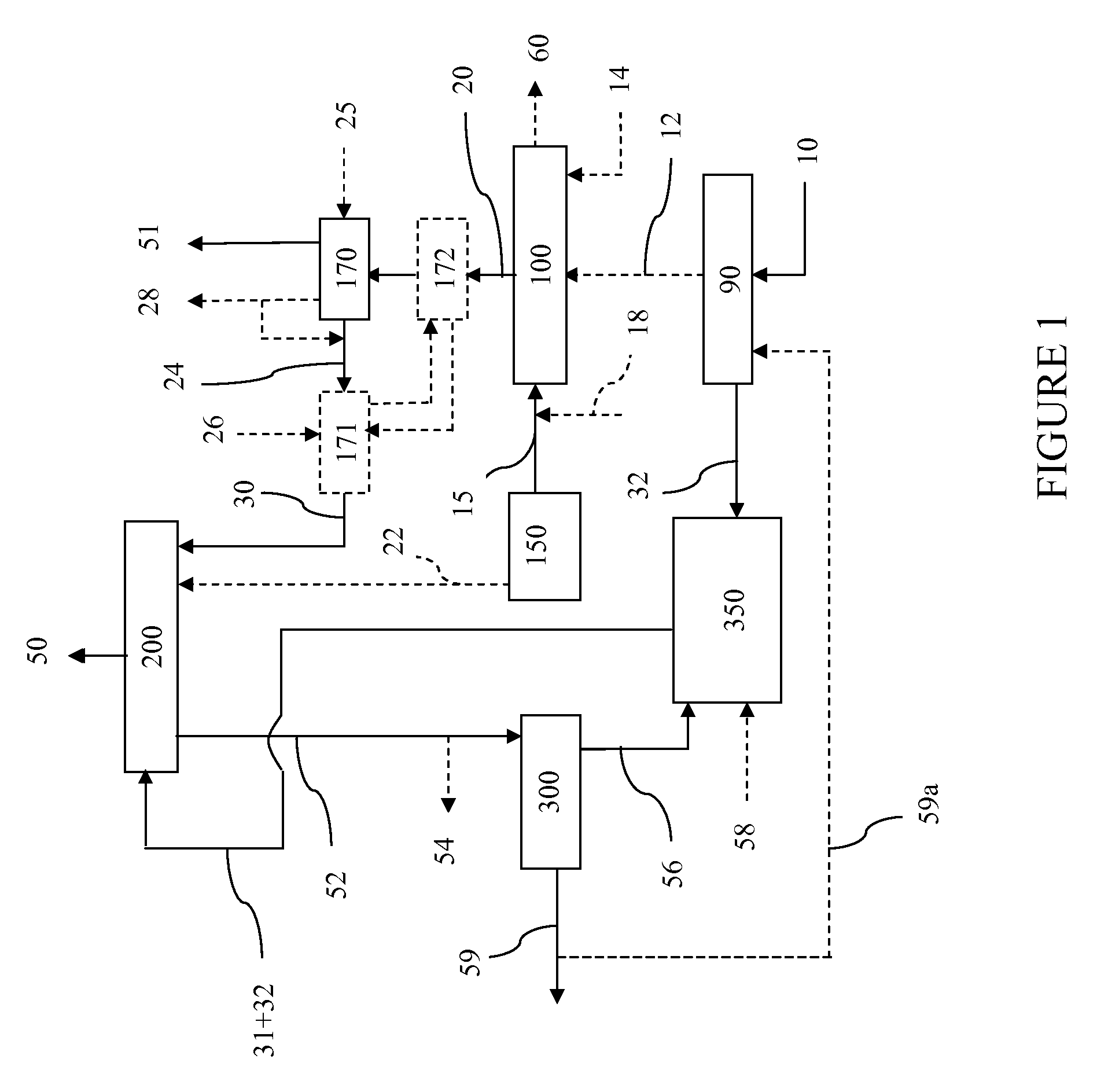

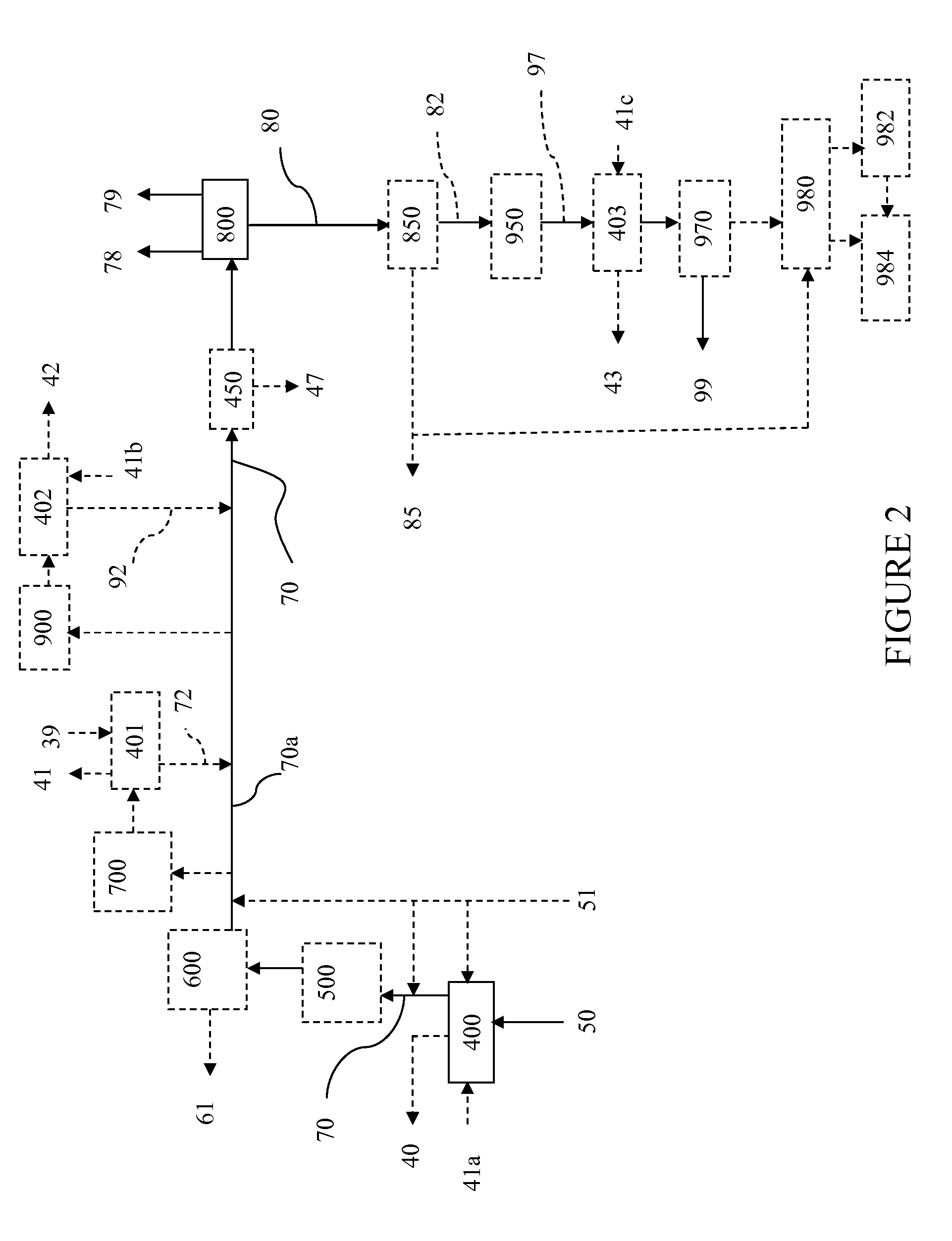

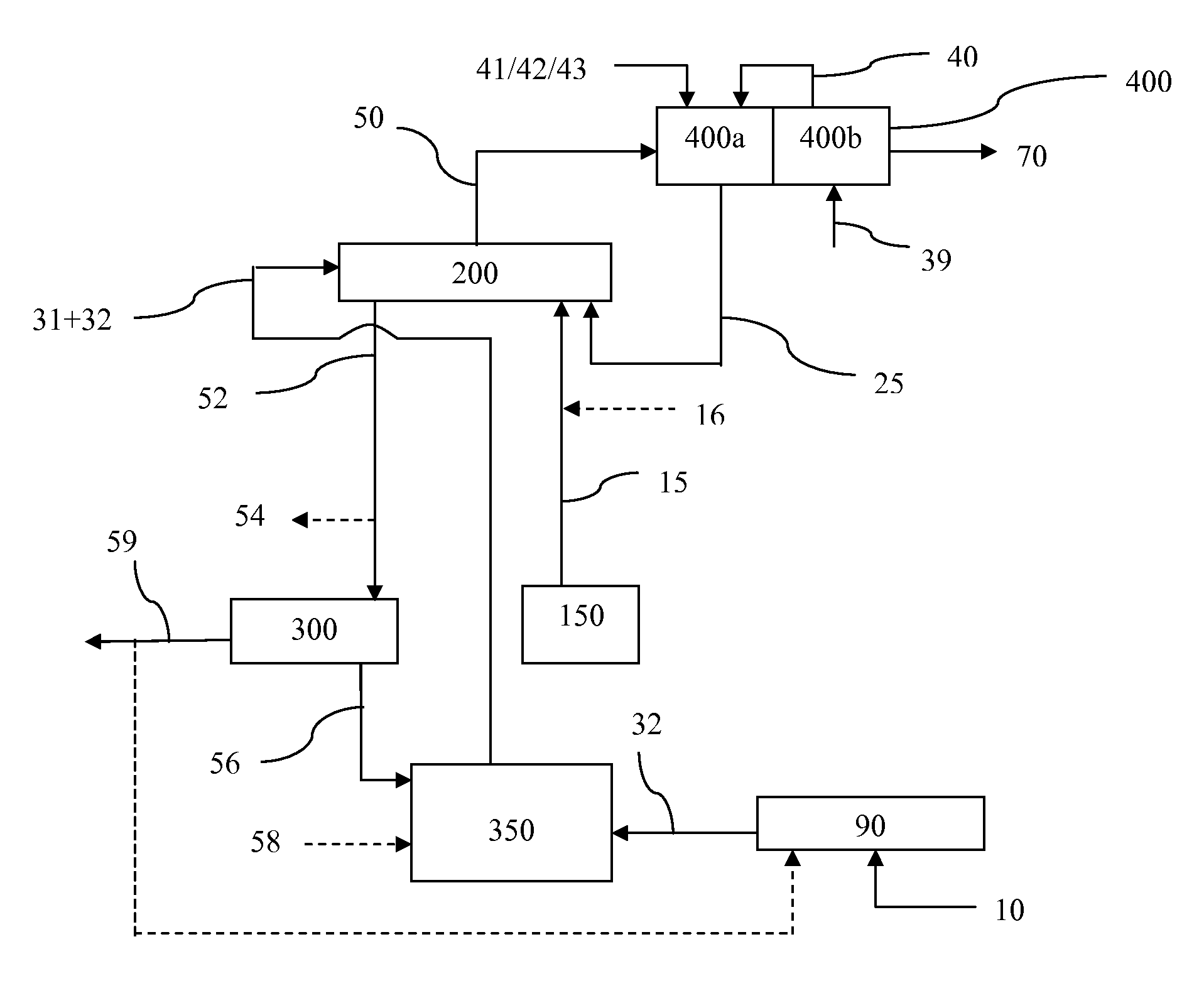

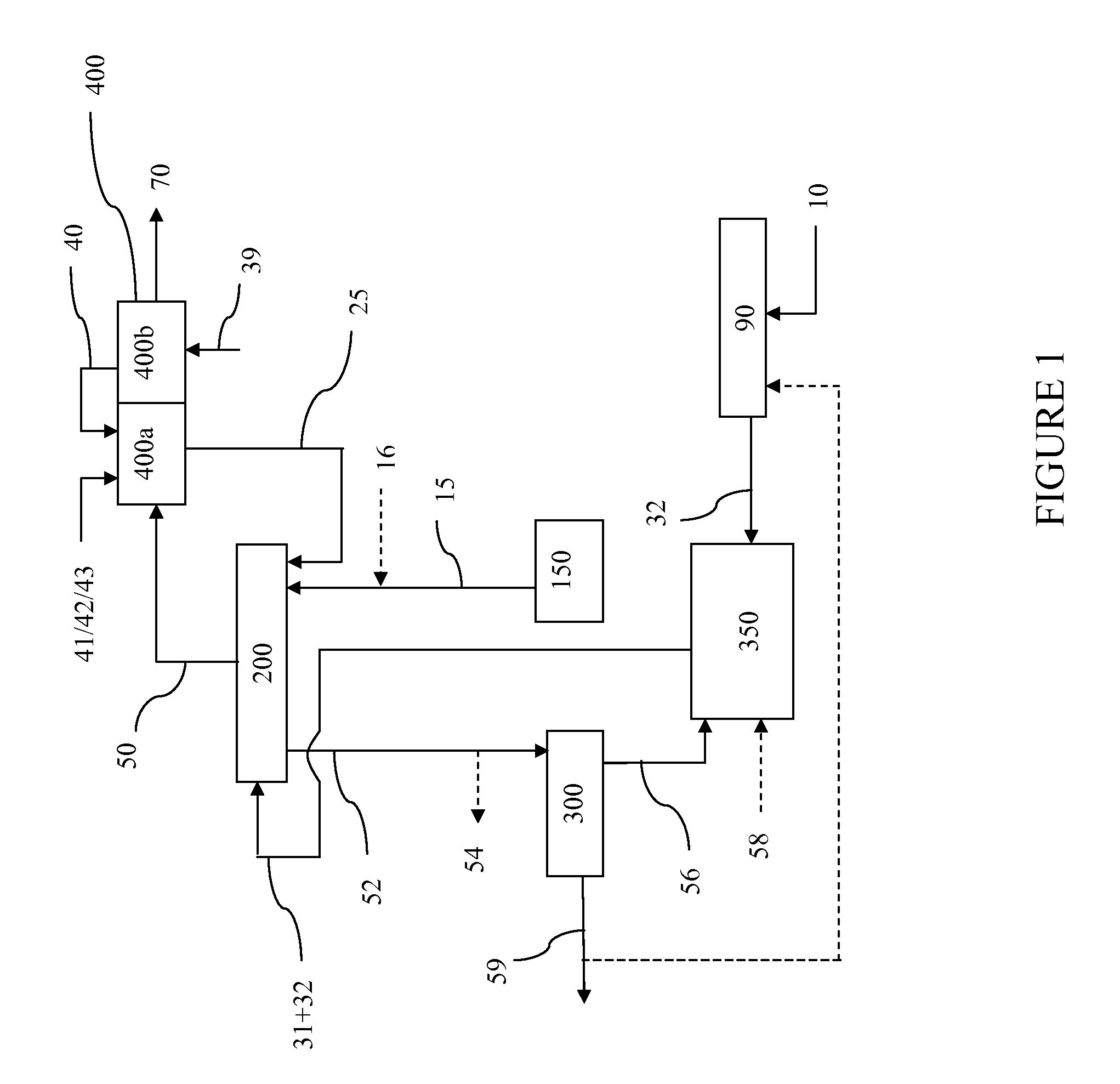

The present invention relates to processes for preparing gaseous products, and in particular, methane via the catalytic gasification of carbonaceous feedstocks in the presence of steam. The processes comprise using at least one methanation step to convert carbon monoxide and hydrogen in the gaseous products to methane and do not recycle carbon monoxide or hydrogen to the catalytic gasifier.

Owner:SURE CHAMPION INVESTMENT LTD

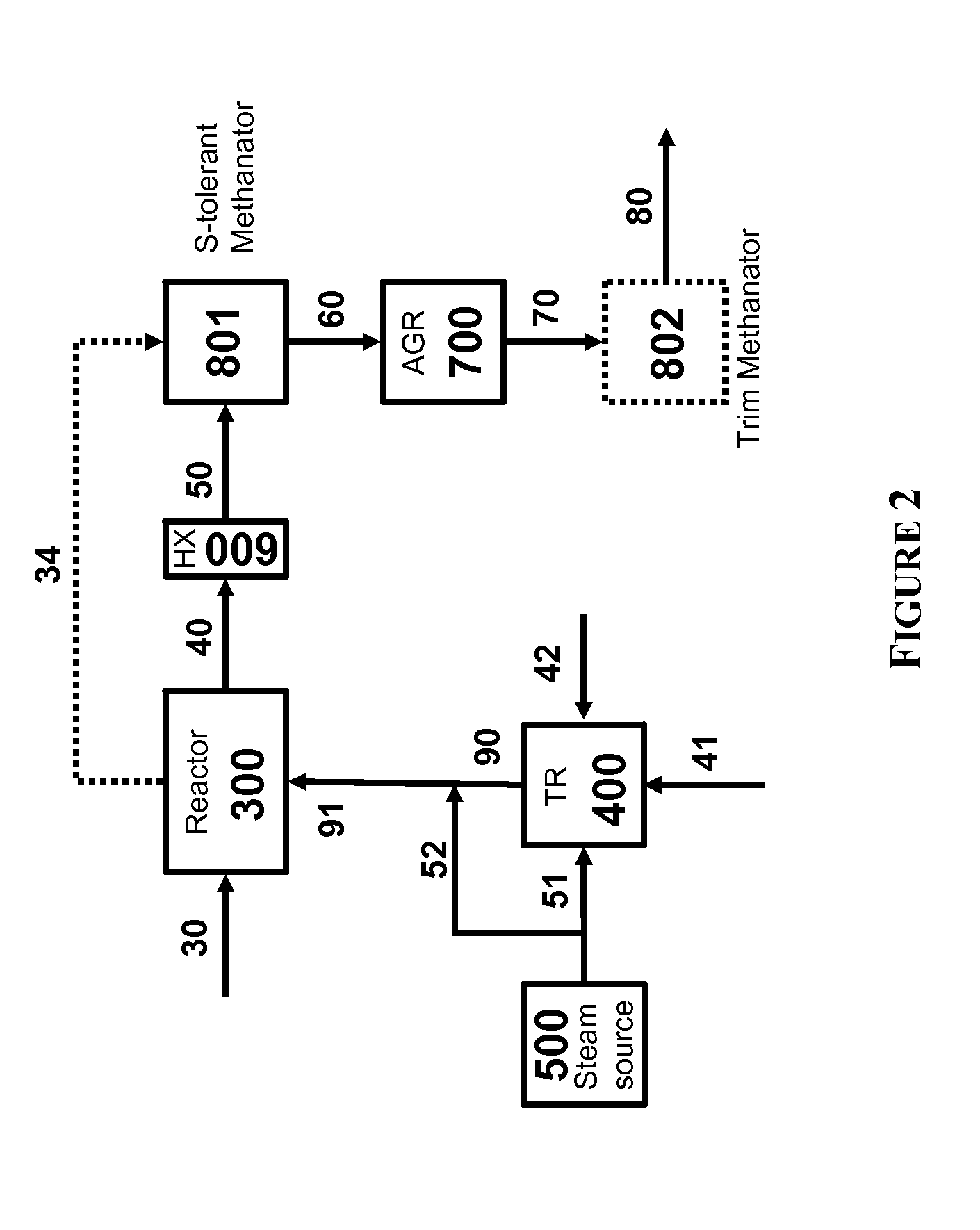

Processes for hydromethanation of a carbonaceous feedstock

InactiveUS20110062012A1Combustible gas chemical modificationCoke ovensMethanationCatalytic hydrogenation

The present invention relates to processes for preparing gaseous products, and in particular methane and / other value added gases such as hydrogen, via the catalytic hydromethanation of a carbonaceous feedstock in the presence of steam and syngas, wherein a hydromethanation reactor is combined with a syngas generator in a particular combination.

Owner:SURE CHAMPION INVESTMENT LTD

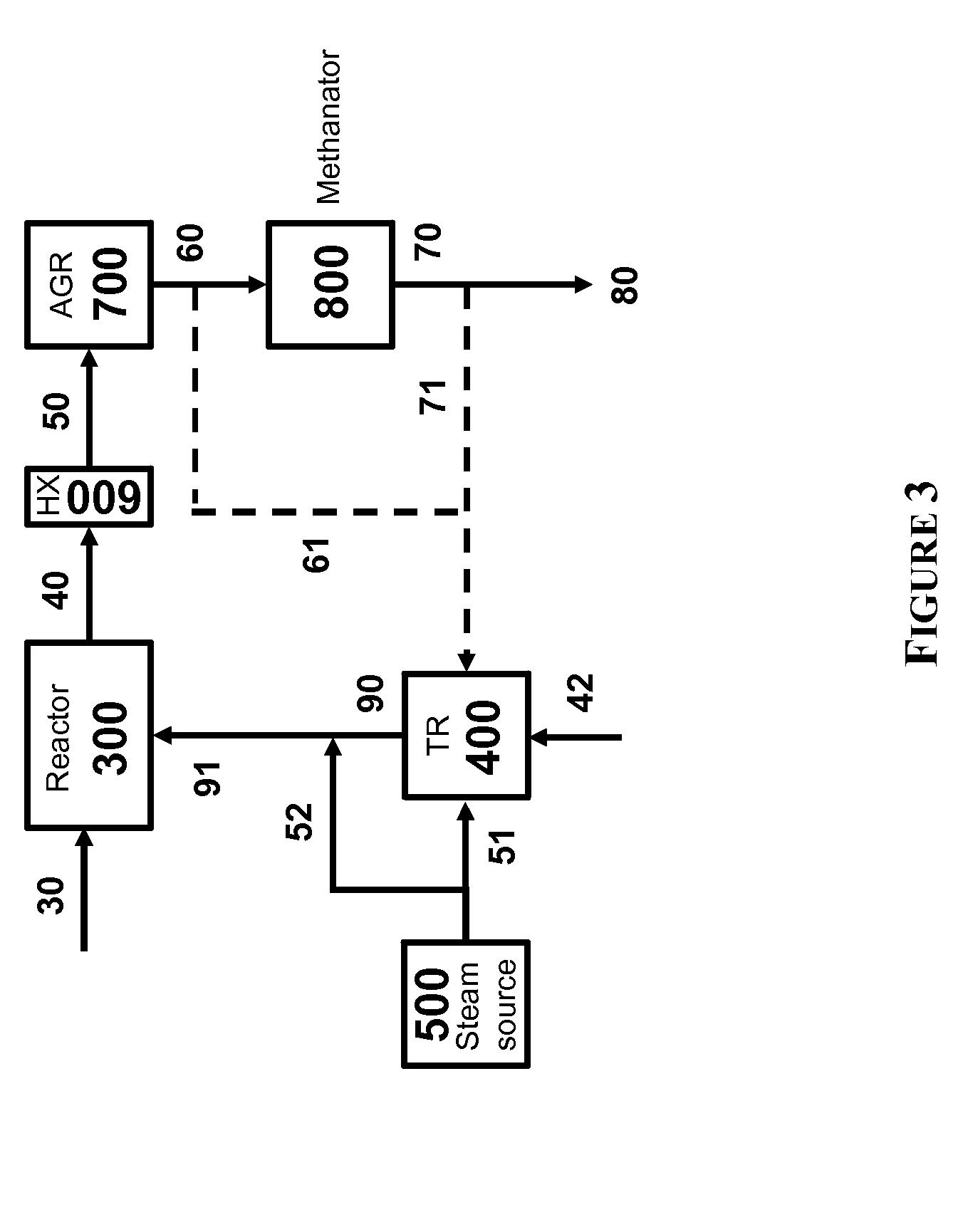

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287835A1Increase the amount of carbonIncrease volumeHydrocarbon by isomerisationHydrogen separationMethanationOrganic chemistry

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of a carbonaceous feedstock in the presence of steam, syngas, a hydromethanation catalyst and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287836A1Hydrogen separation at low temperatureCarbon compoundsMethanationHydromethanation

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen and a hydromethanation catalyst.

Owner:SURE CHAMPION INVESTMENT LTD

Conversion of carbonaceous materials to synthetic natural gas by pyrolysis, reforming, and methanation

InactiveUS20080016769A1Reduce the temperatureCombustible gas chemical modificationProductsSyngasSteam reforming

The production of synthetic natural gas from a carbonaceous material, preferably a biomass material, such as wood. The carbonaceous material is first pyrolyzed, then subjected to steam reforming to produce a syngas, which is then passed to several clean-up steps then to a methanation zone to produce synthetic natural gas.

Owner:CLEAN ENERGY LLC

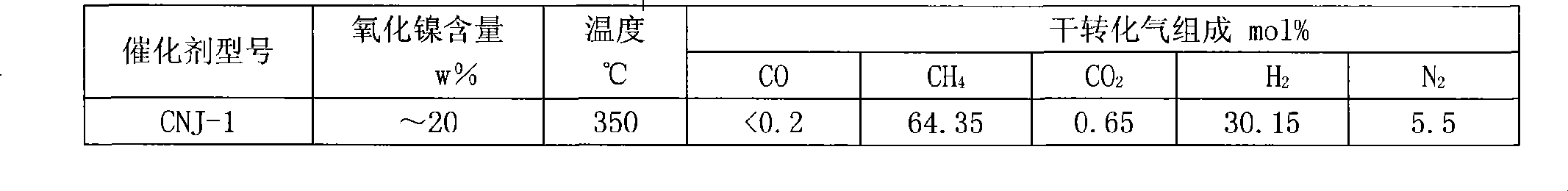

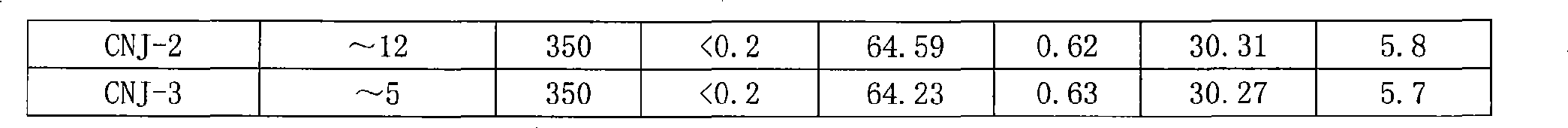

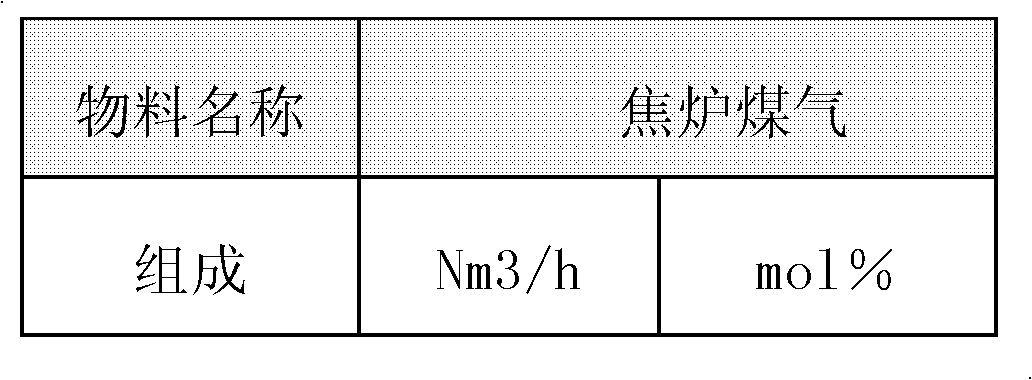

Coke-oven gas methanation catalyst and preparation method thereof

ActiveCN101391218AHigh activityImprove carbon resistanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationActive component

The invention discloses a coke oven gas methanation catalyst, which takes Al2O3 as a carrier, nickel as a main active component, and MgO as an auxiliary agent; wherein: the active component nickel exists in the catalyst in the form of NiO, and the carrier Al2O3 and the auxiliary agent MgO form a carrier structure of magnesia-alumina spinel; the main components respectively include, by weight percentage: 5 percent to 20 percent of NiO, 30 percent to 80 percent of Al2O3, and 1 percent to 50 percent of MgO. The catalyst has the advantages of high strength, good activity, good thermal stability, excellent anti-coking performance and good low temperature activity, and also has the properties of transforming high hydrocarbon and good anti-oxidation. The invention also discloses a preparation method of the coke oven gas methanation catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

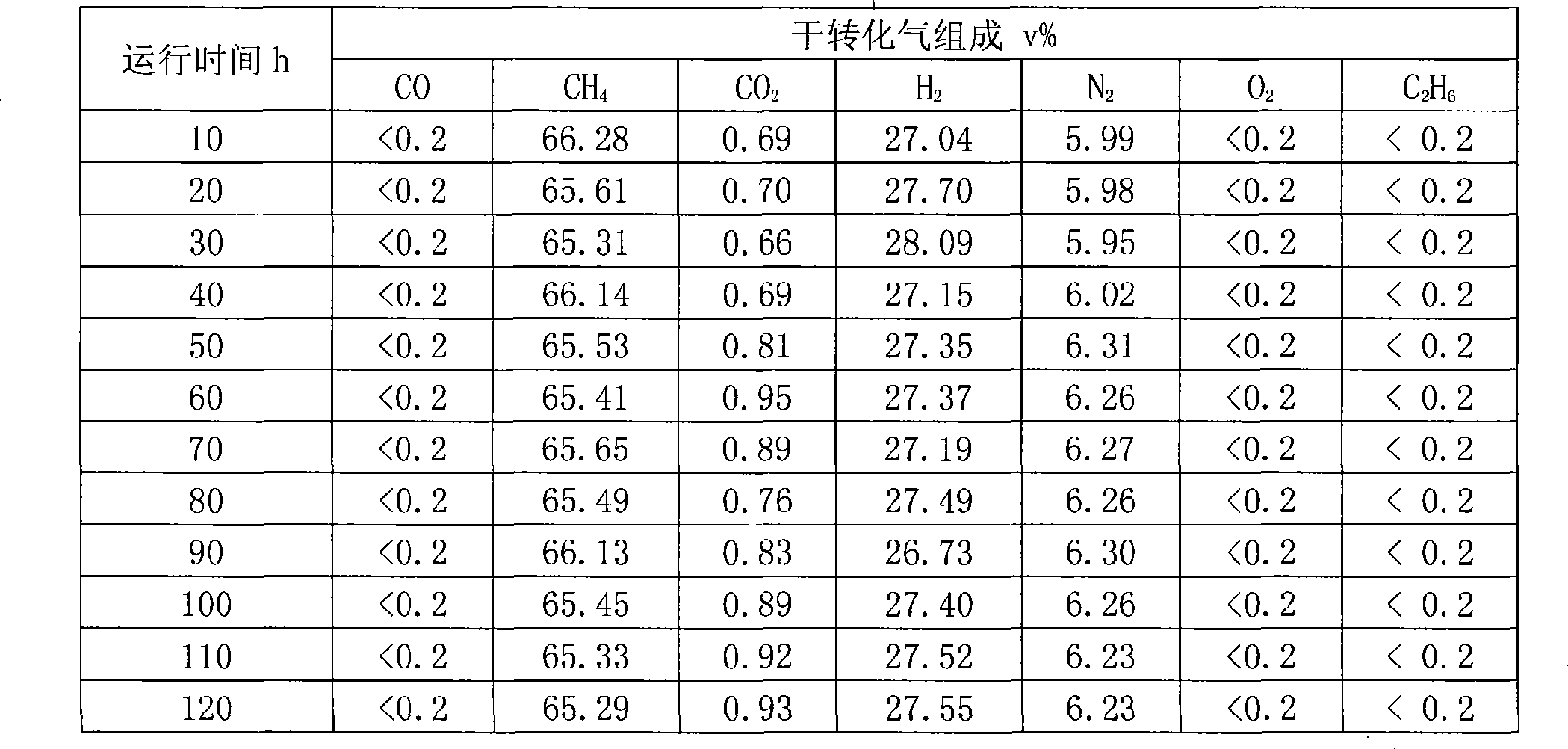

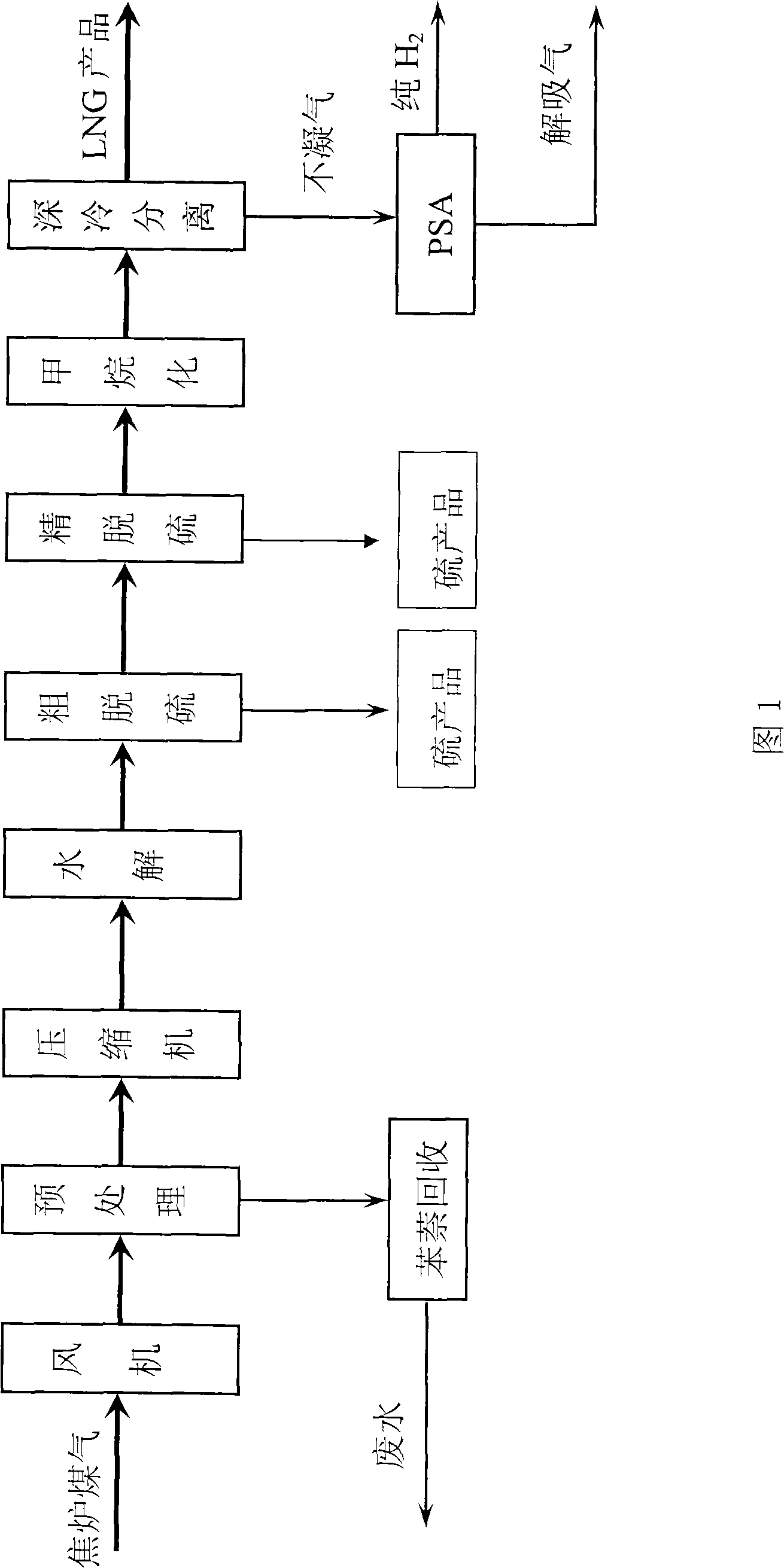

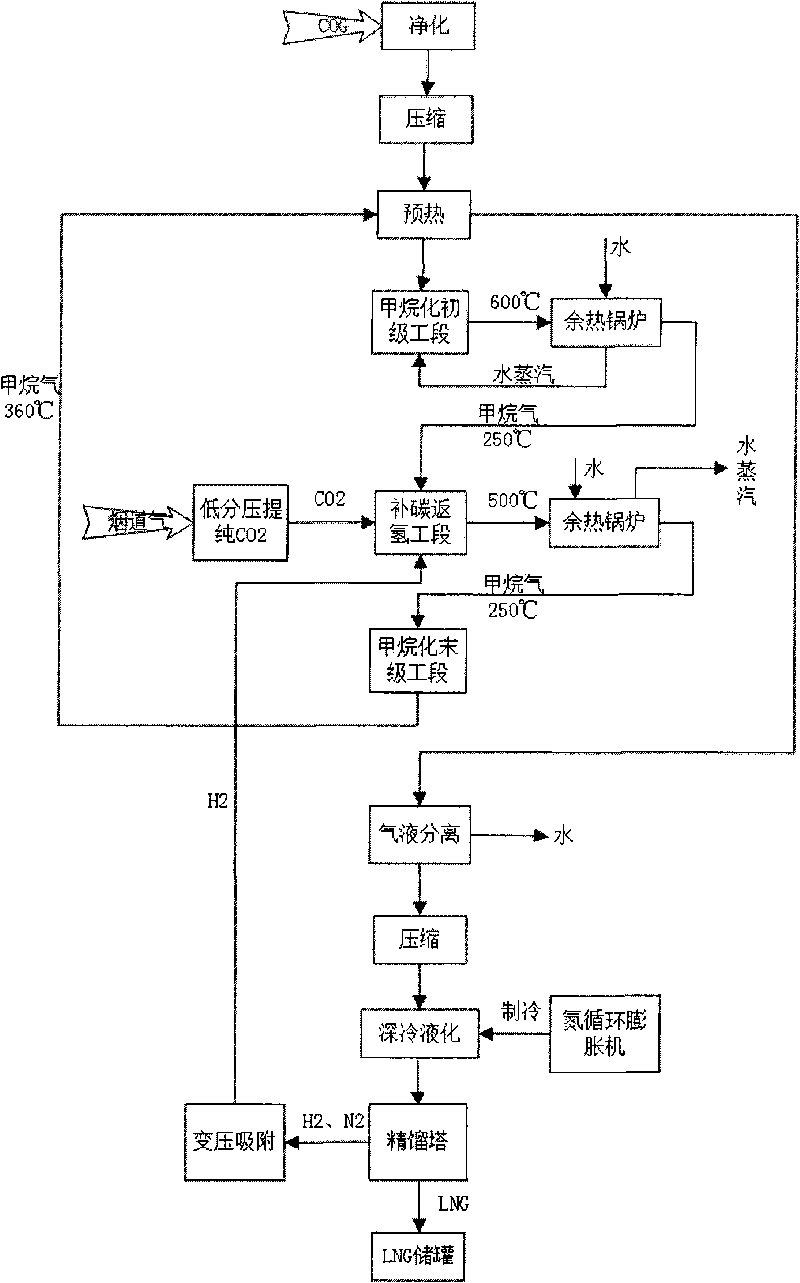

Method for preparing liquefied natural gas from coke oven gas

InactiveCN101280235ATo achieve coordinated developmentReasonable process combinationCombustible gas chemical modificationChemical industryMethanationImpurity

Disclosed is a method which uses coke-oven gas as the raw material to produce liquefied natural gas; the method includes that the coke-oven gas is pretreated firstly to enable the tar, naphthalene and benzene impurities contained in the coke-oven gas to be purified deeply; and the purified coke-oven gas is processed with methanation reaction after compression and desulfurization; the liquefied natural gas product which contains CH4 with the content of more than 85% through the cryogenic separation process; the residual non-condensable gas is prepared to obtain the hydrogen with the purity of 99% through the PSA separation technique; the residual desorbed gas can be used as manufactured gas. The method which uses the coke-oven gas as the raw material to produce liquefied natural gas has the advantages of making full use of the compositions, saving energy, water and the investment, simple process and realizing the trinity coordinated development of economy, environment and energy sources.

Owner:SHENGHE RESOURCES HLDG CO LTD

Method and device for synthesizing natural gas by using coke oven gas

A method for synthesizing and producing natural gas by hydrogen of coal gas and its synthesizer are disclosed. The process is carried out by purifying tar, crude removing sulfur, ammonia, benzene and naphthalene, compressing to 0.5-5.0 MPa, removing sulfur impurities, supplementing carbon 5-20 wt%, and methanation reacting to obtain final product. It saves energy resources and has no environmental pollution.

Owner:张文慧 +1

Catalyst for methanation of carbon dioxide-containing synthesis gas, preparation method and application

ActiveCN101733104AEase of hydroconversionAchieving HydroconversionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationActive component

The invention discloses a catalyst for methanation of carbon dioxide-containing synthesis gas, which is characterized by comprising the following components in percentage by weight: 5 to 65 percent of active component, 0 to 45 percent of metal assistant and 25 to 90 percent of carrier; and the calculation of the catalyst is based on the weights of an active component element, a metal assistant element and the carrier. The catalyst has the advantages of catalyzing the carbon dioxide-containing synthesis gas to perform methanation and running efficiently and stably.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method and device for producing synthetic natural gas, and natural gas product thereof

InactiveCN101812339AImprove utilization efficiencyControl reaction temperatureGaseous fuelsNatural productMethanation

The invention provides a method for producing synthetic natural gas and a device thereof. The continuous technological process of the invention is realized in a way that gasified product gas is used as the raw material for producing high methane gas containing more than 94 mol% of methane. The method can well adjust the methanation reaction temperature and avoid the problems of catalyst temperature-runaway sintering and the like due to improper material composition, excessive fluctuation or unexpected accident, thereby reducing the recycle gas amount and enhancing the energy comprehensive utilization efficiency.

Owner:DATANG INT CHEM TECH RESINST

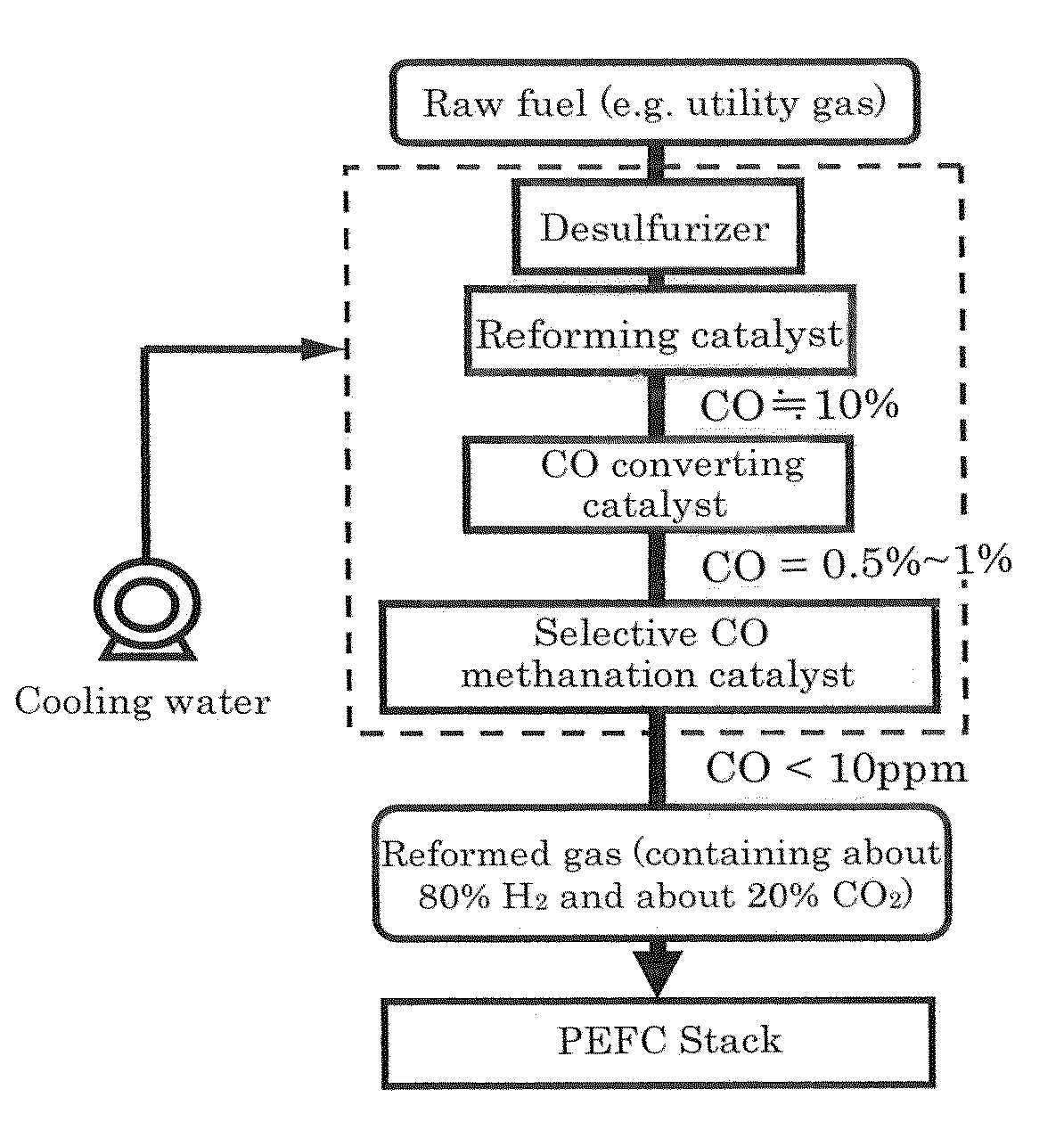

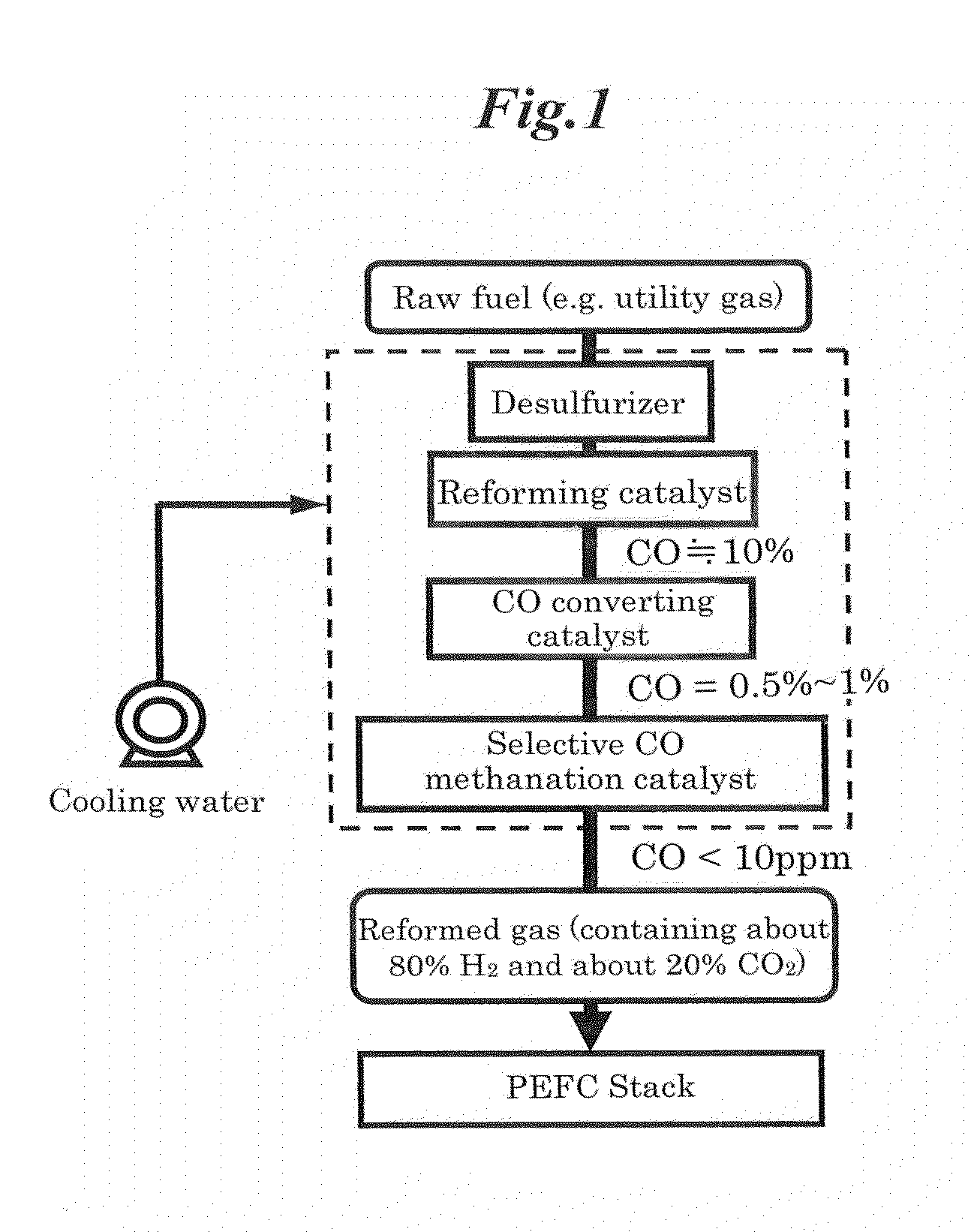

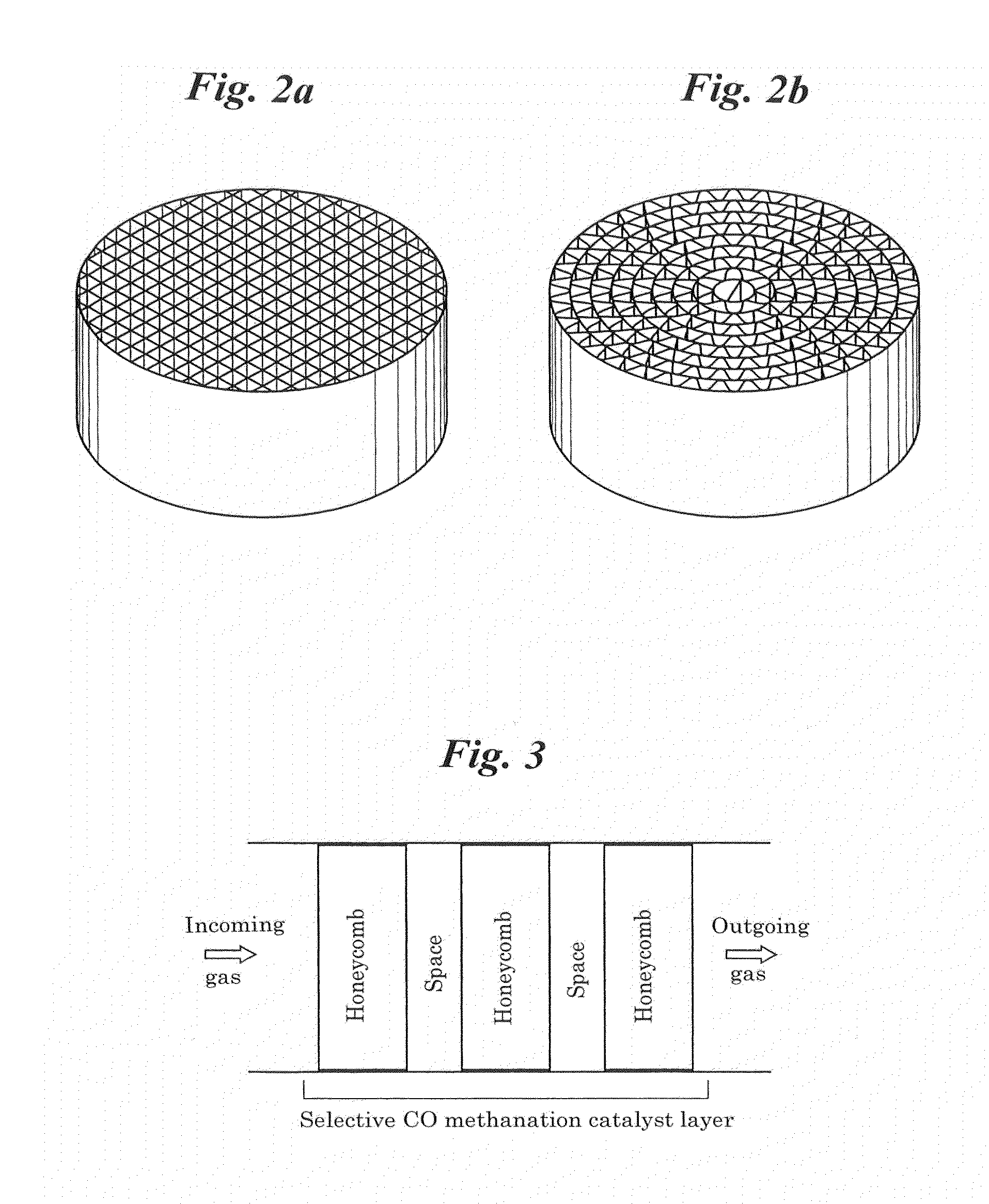

Selective co methanation catalyst, method of producing the same, and apparatus using the same

ActiveUS20120063963A1High low temperature activityReduce supportHydrogenFinal product manufactureReduction treatmentMethanation

Provided is a new catalyst capable of removing carbon monoxide economically without adding particular reaction gas externally. Also provided are a process for producing and an apparatus using such a catalyst. Impregnation of a Ni—Al composite oxide precursor of a nonstoichiometric composition prepared by the solution-spray plasma technique with a ruthenium salt to be supported and performing reduction treatment allows CO methanation reaction to selectively proceed even in the high-temperature range in which CO2 methanation reaction and reverse water-gas-shift reaction proceed preferentially with conventional catalysts. Selective CO methanation reaction occurs reproducibly with another Ni—Al composite oxide precursor or an additive metallic species. Also, the low-temperature activity of CO methanation reaction can be improved through steps different from conventional catalyst production processes in producing such a catalyst material, whereby the temperature window the resulting catalyst material has can be utilized most effectively.

Owner:UNIVERSITY OF YAMANASHI

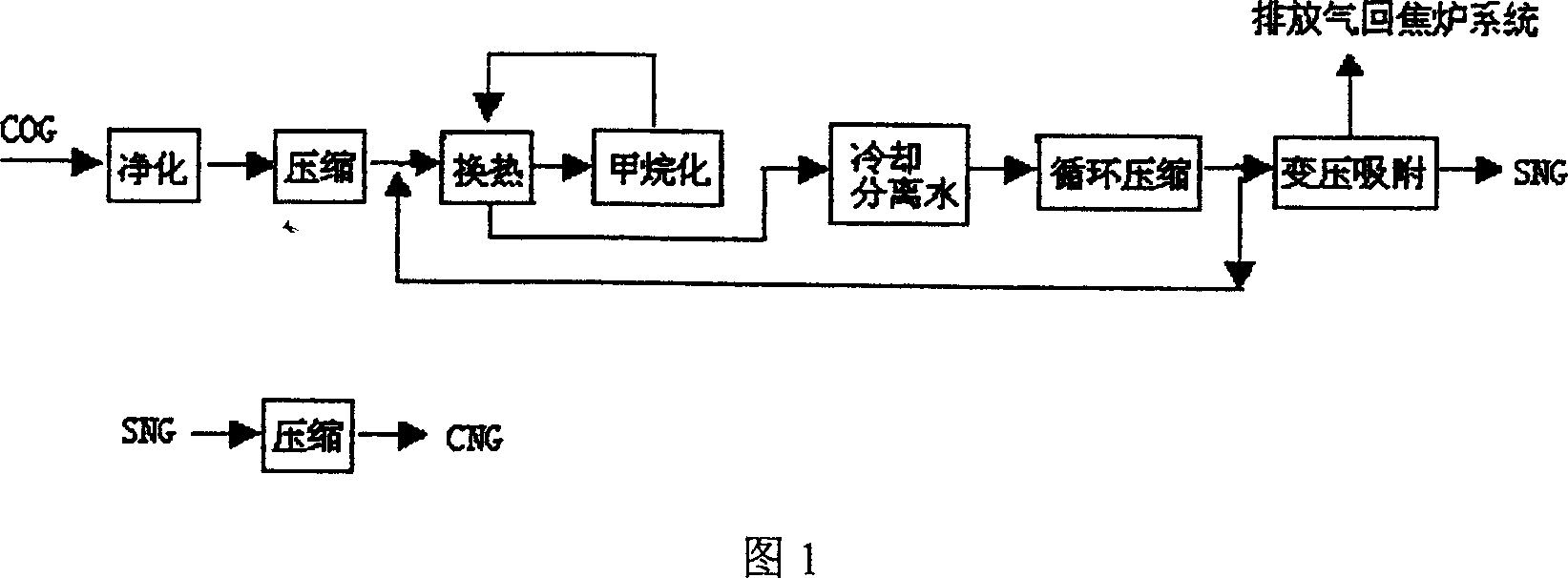

Method of preparing synthetic natural gas by coke oven gas

ActiveCN1919985AHigh calorific valueLow impurity contentGaseous fuelsCompressed natural gasMethanation

The invention discloses the method for producing natural gas with coking gas, comprising the following steps: purifying coking gas and removing benzene, naphthalene, hydrocarbon and sulphide, compressing, heat transferring, carrying out methanation reaction with catalyst, hydrogen in COG reacting with carbonic oxide and carbon dioxide to get methane; putting the mixture gas into pressure swing adsorbing device, and getting natural gas whose concentration is 90%. The natural gas has high caloric value, low impurity content.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

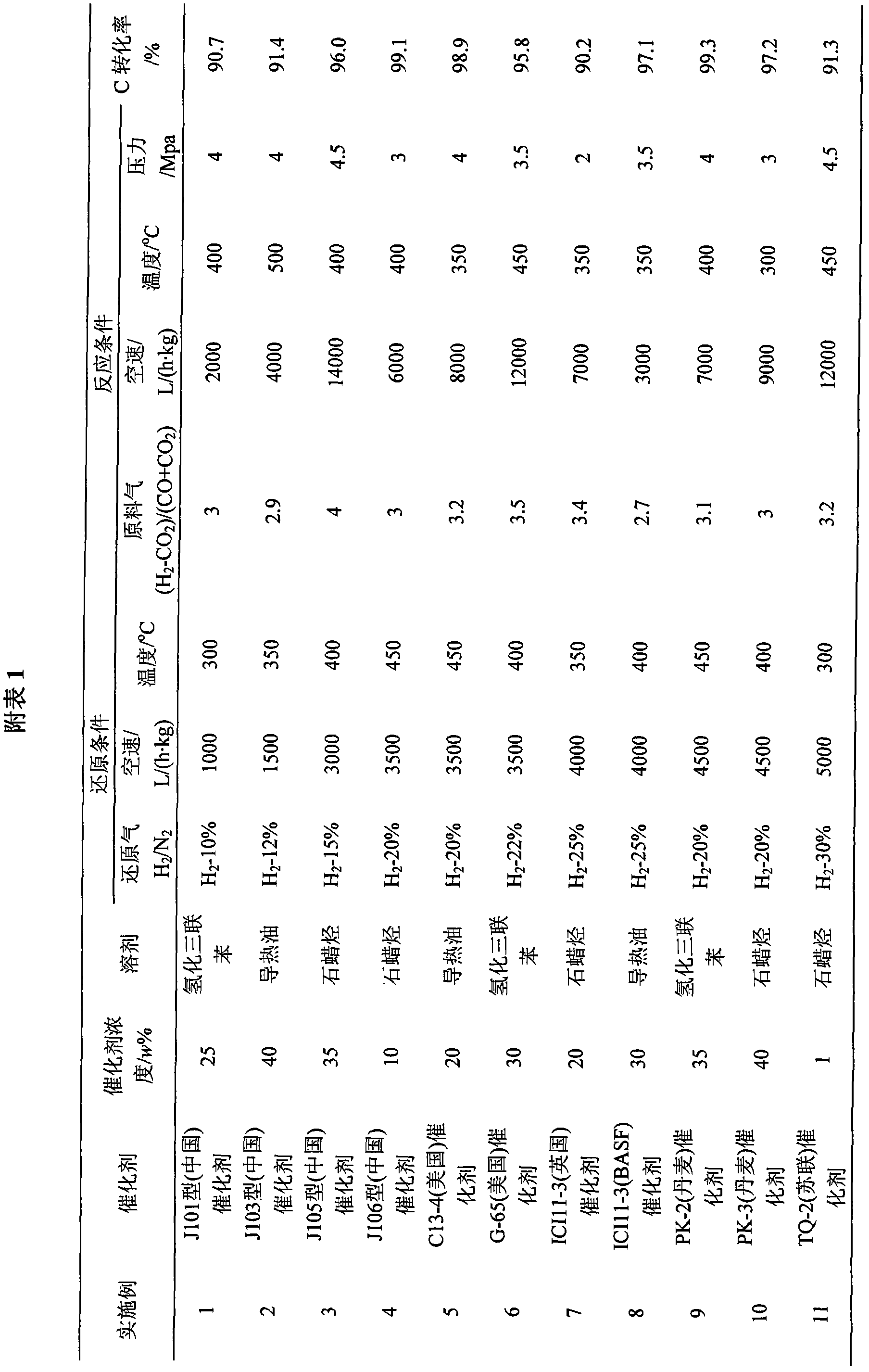

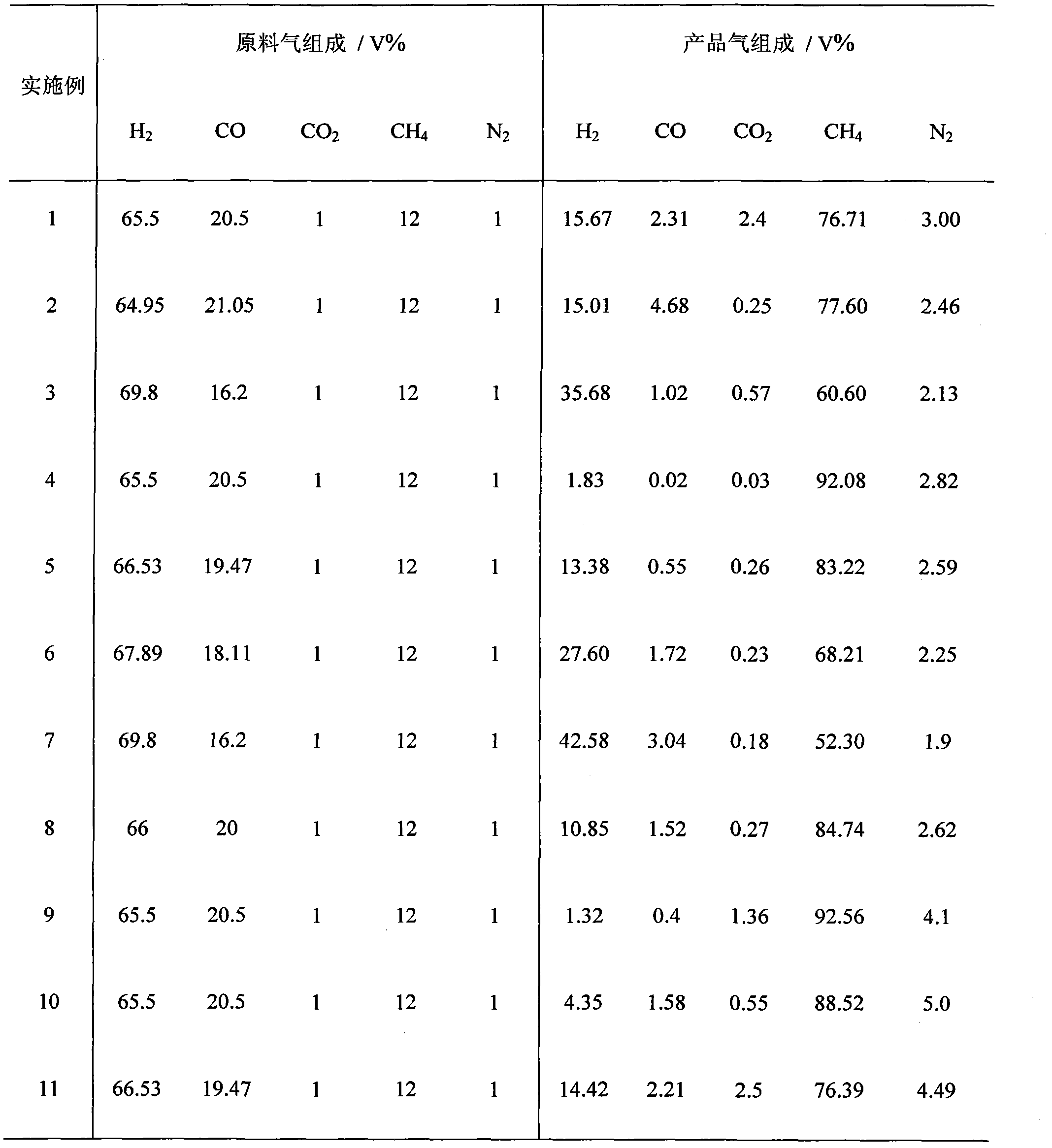

Process for synthesizing natural gas by methanation of coal synthesis gas

The invention discloses a process for synthesizing natural gas by methanation of coal synthesis gas, which comprises the following steps of: dispersing a fresh methanation catalyst into an inert liquid medium, delivering the medium into a slurry bed methanation reactor to perform reduction, performing methanation reaction on the transformed methanation raw gas after the reduction is finished, delivering the tail gas to a gas-liquid separator I, discharging the slurry liquid component and the catalyst in the tail gas from the bottom of the gas-liquid separator I, discharging the gas phase in the tail gas from the top of the gas-liquid separator I, delivering partial slurry liquid component containing the catalyst into a gas-liquid separator II, discharging the gas phase from the top of thegas-liquid separator II, merging the gas phases discharged from the tops of the gas-liquid separators I and II, cooling and purifying the gas phases to obtain synthesized natural gas, discharging theslurry liquid component containing the catalyst from the bottom of the gas-liquid separator II, merging the slurry liquid component discharged from the bottom of the gas-liquid separator II and the slurry liquid component and the catalyst discharged from the bottom of the gas-liquid separator I, discharging 1 to 5 percent of the weight sum of the slurry liquid component and the catalyst separatedfrom the two gas-liquid separators, and performing methanation reaction on the cooled rest slurry liquid component and catalyst and the fresh methanation catalyst dispersed into the insert liquid medium together. The process has the advantages of low power consumption and low equipment investment, and is easy to operate.

Owner:SEDIN ENG +1

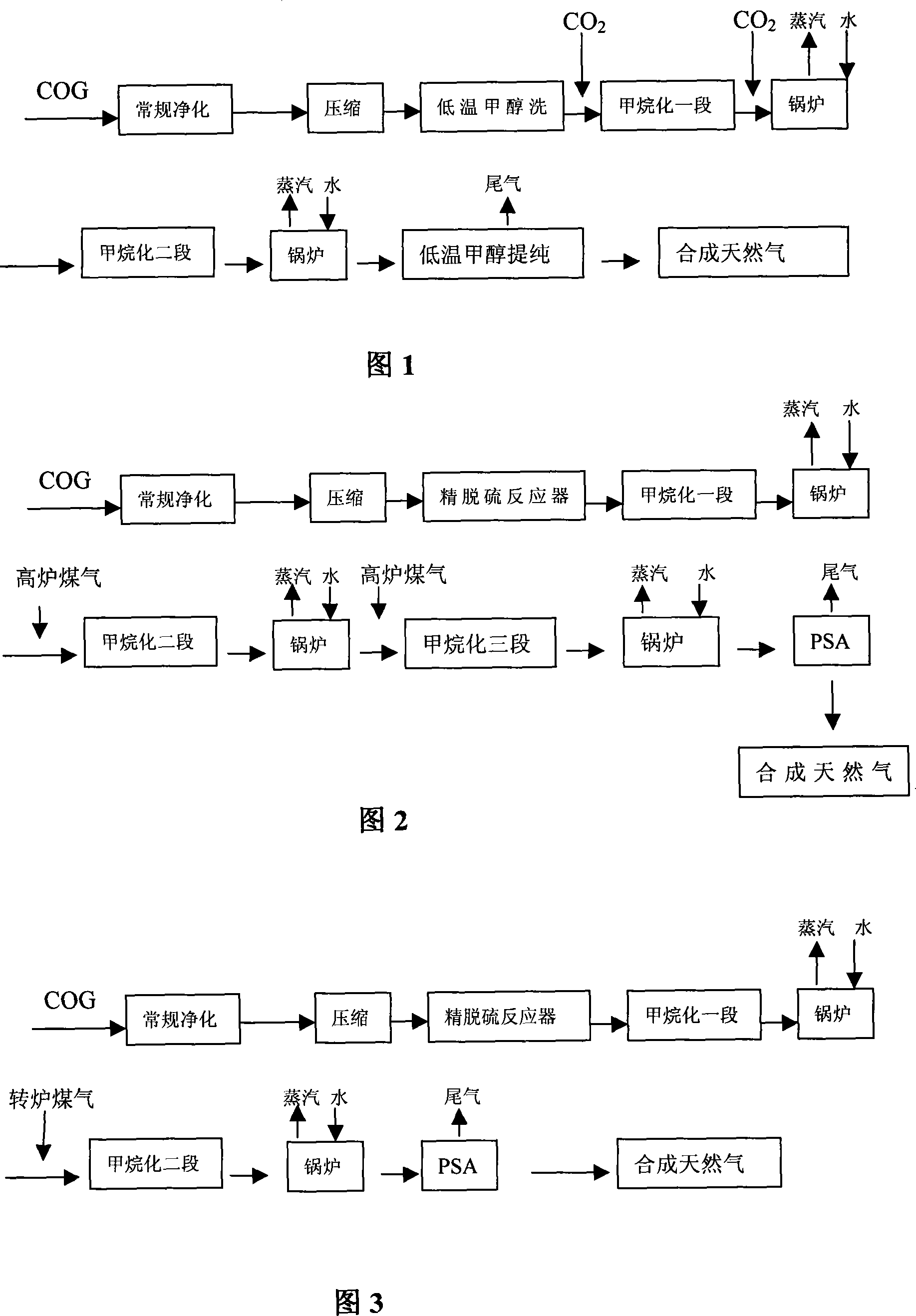

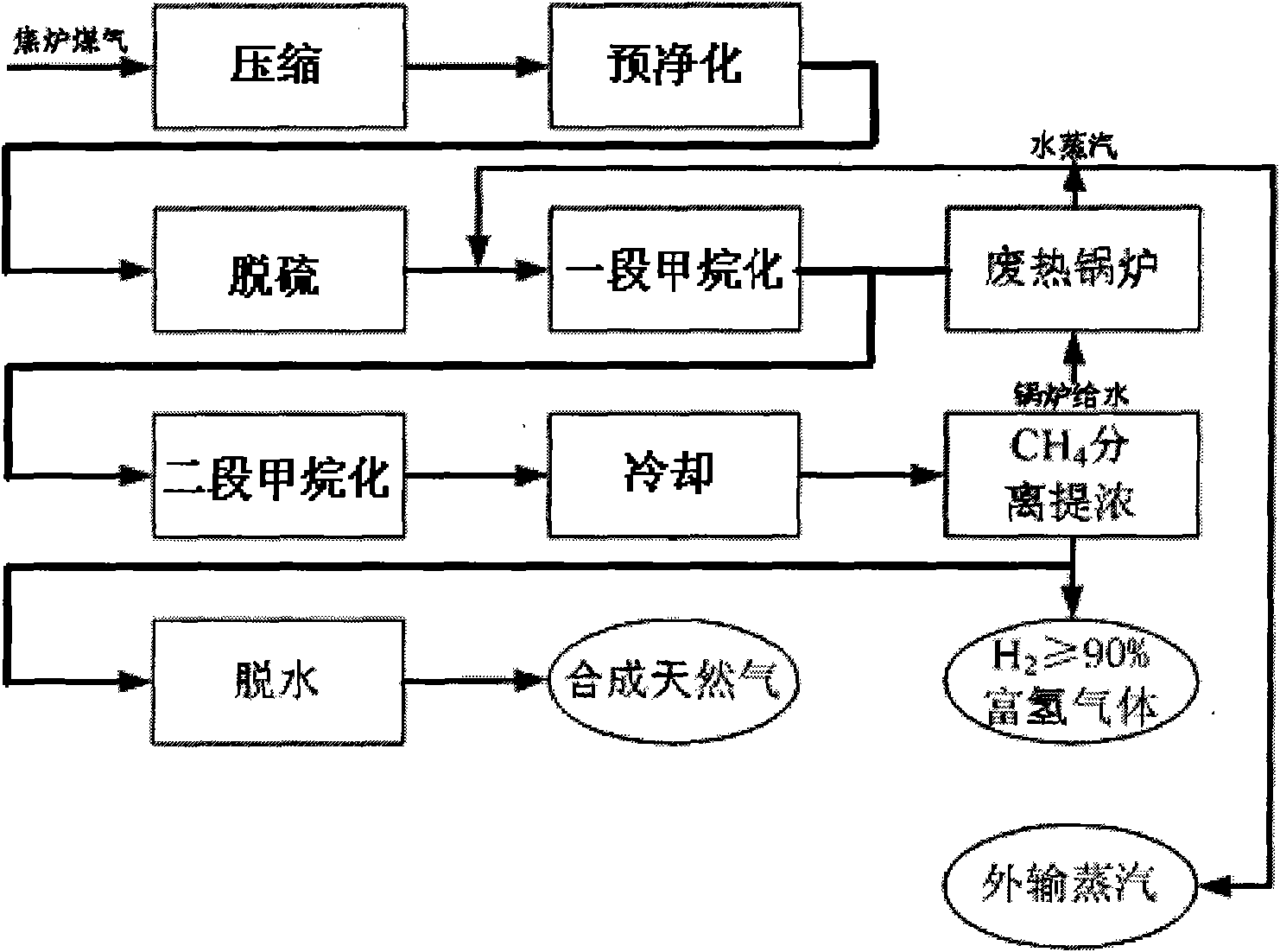

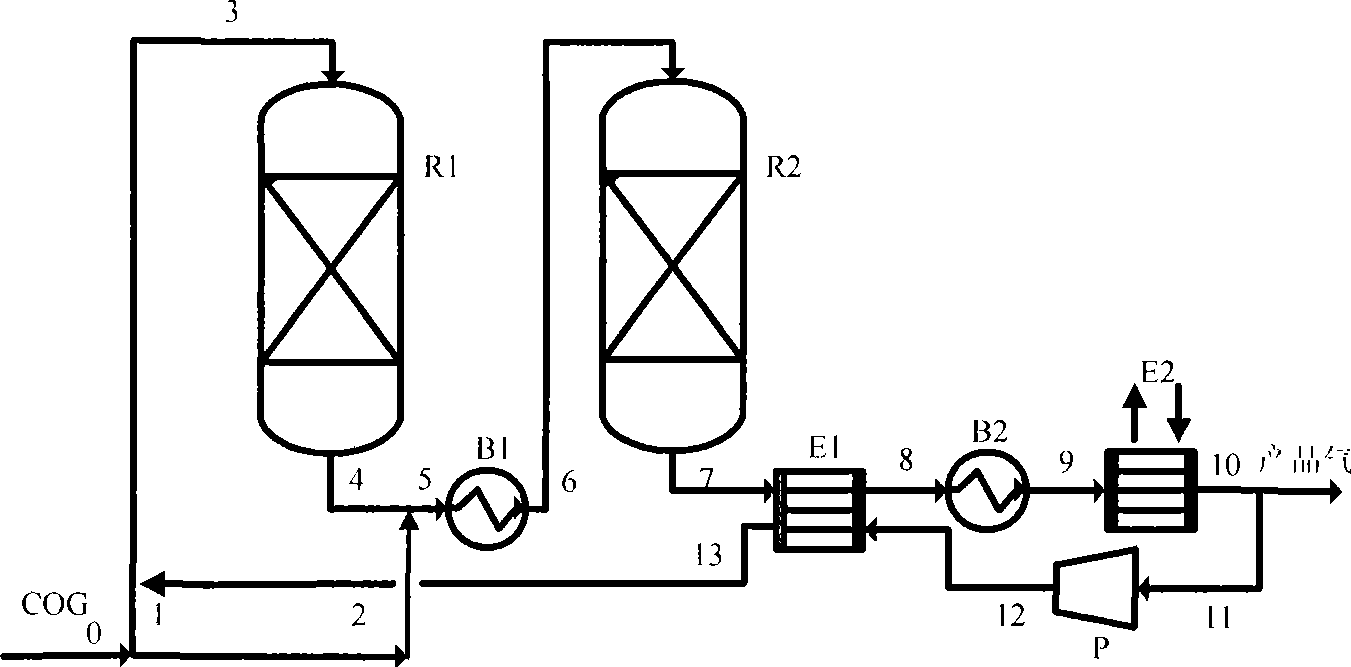

Synthesis process of natural gas employing methanation of coke oven gas

The invention relates to a comprehensive utilization synthesis process of natural gas employing methanation of coke oven gas, belonging to the technical field of new energy utilization. The process comprises the following steps: compressing coke oven gas, preliminary cleaning, removing sulfur, performing first section methanation, performing second section methanation and separating natural gas toprepare natural gas which reaches the grade A technological requirements of natural gas national standard (GB17820-1999). The synthesis process of natural gas employing methanation of coke oven gas reaches the aim of high effective comprehensive utilization of natural gas and provides a new way of preparing and synthesizing natural gas.

Owner:SHANDONG TIEXIONG METALLURGICAL TECH CO LTD +2

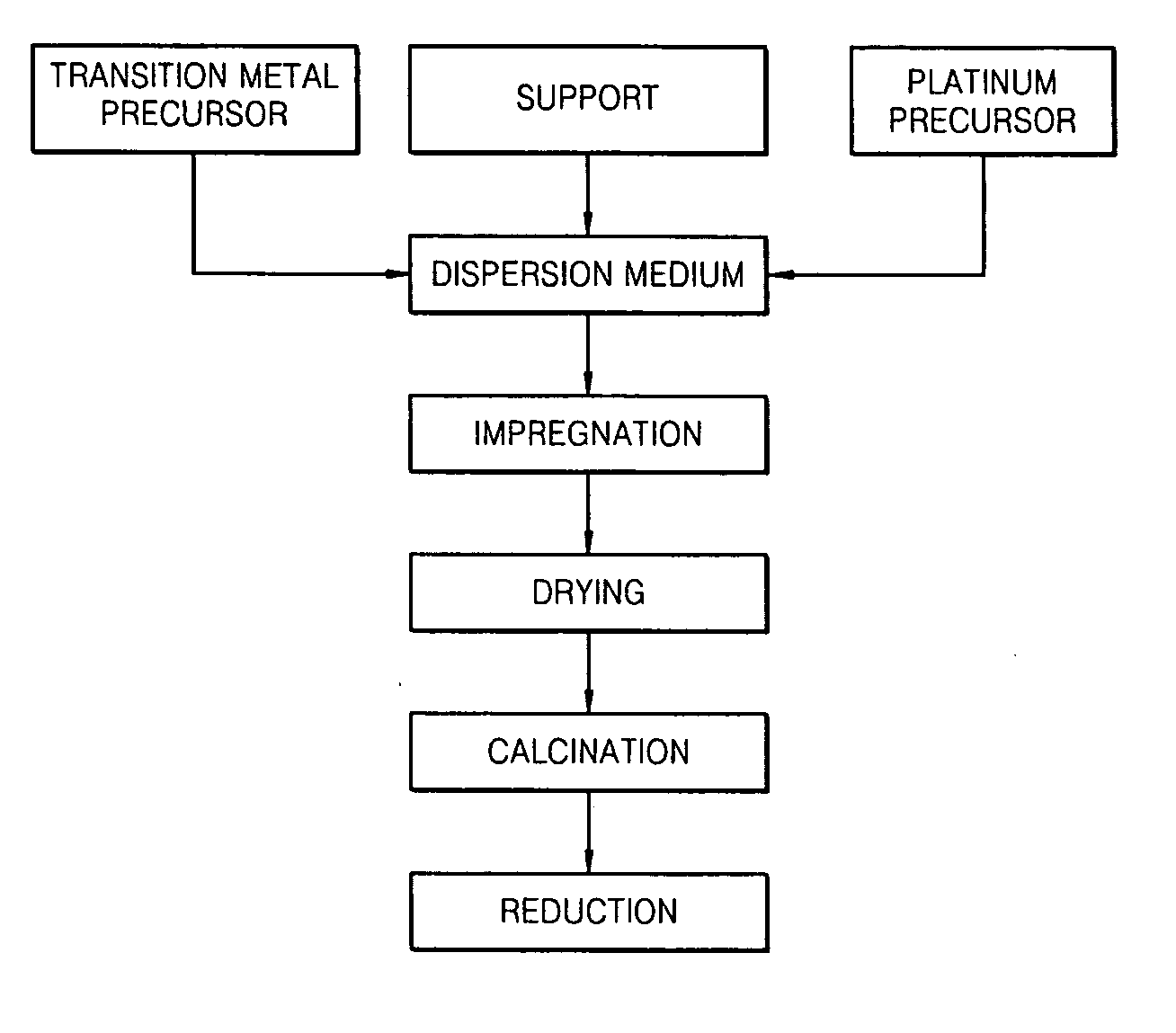

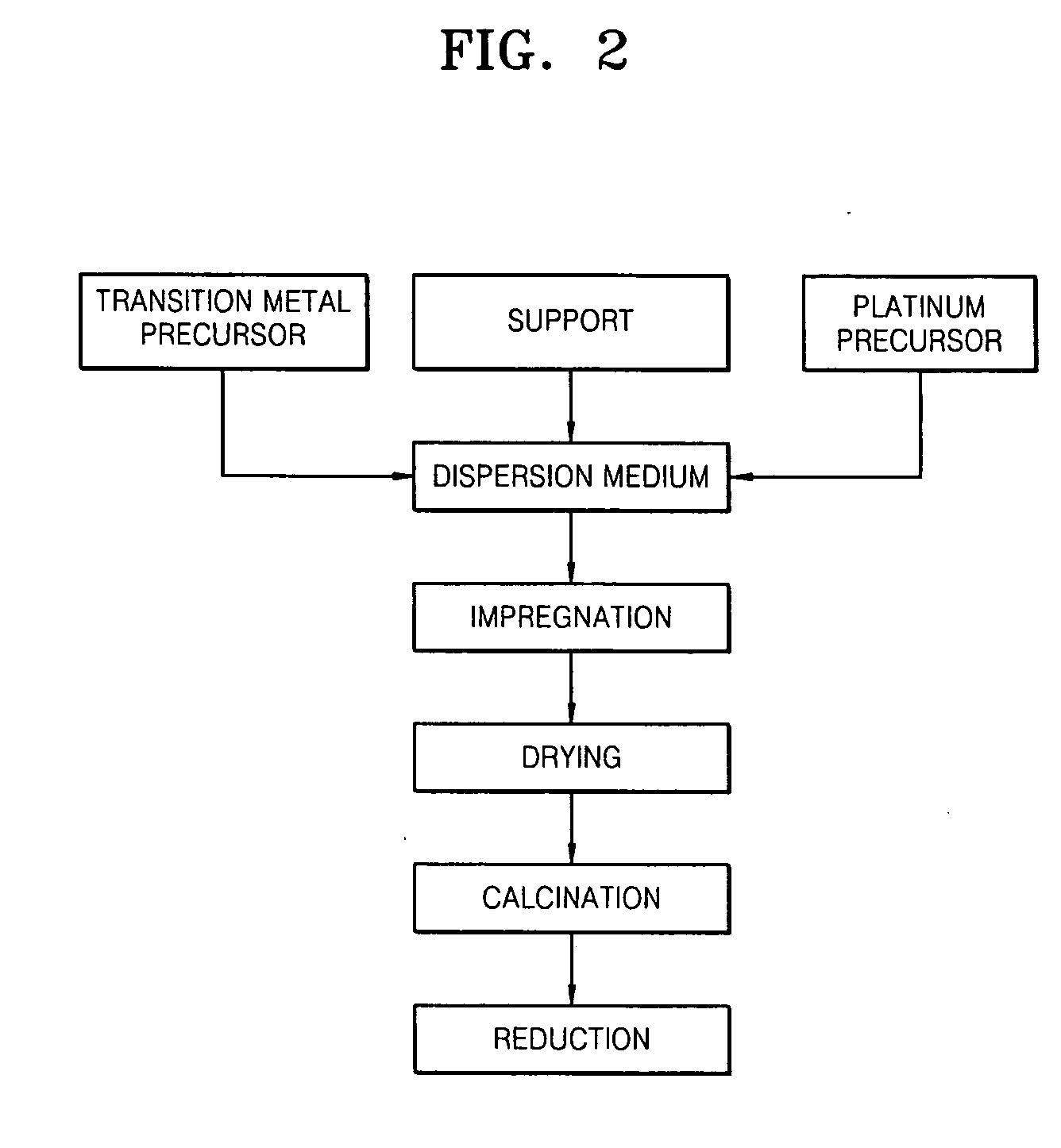

Catalyst for oxidizing carbon monoxide and method of manufacturing the same

InactiveUS20070092768A1Good reaction selectivityWide temperature rangeHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumMethanation

A catalyst that oxidizes carbon monoxide includes a bimetal consisting of platinum and a transition metal in a bimetallic phase that is loaded on γ-alumina support. The catalyst is manufactured by uniformly mixing a platinum precursor, a transition metal precursor, and γ-alumina (γ-Al2O3) in a dispersion medium to provide a mixture; drying the mixture; calcining the dried mixture; and reducing the calcined dried mixture. Since the catalyst that oxidizes carbon monoxide has high reaction activity even at low temperature and excellent reaction selectivity, and a methanation reaction and reoxidization do not occur, and the catalyst can effectively eliminate carbon monoxide in the fuel.

Owner:SAMSUNG SDI CO LTD

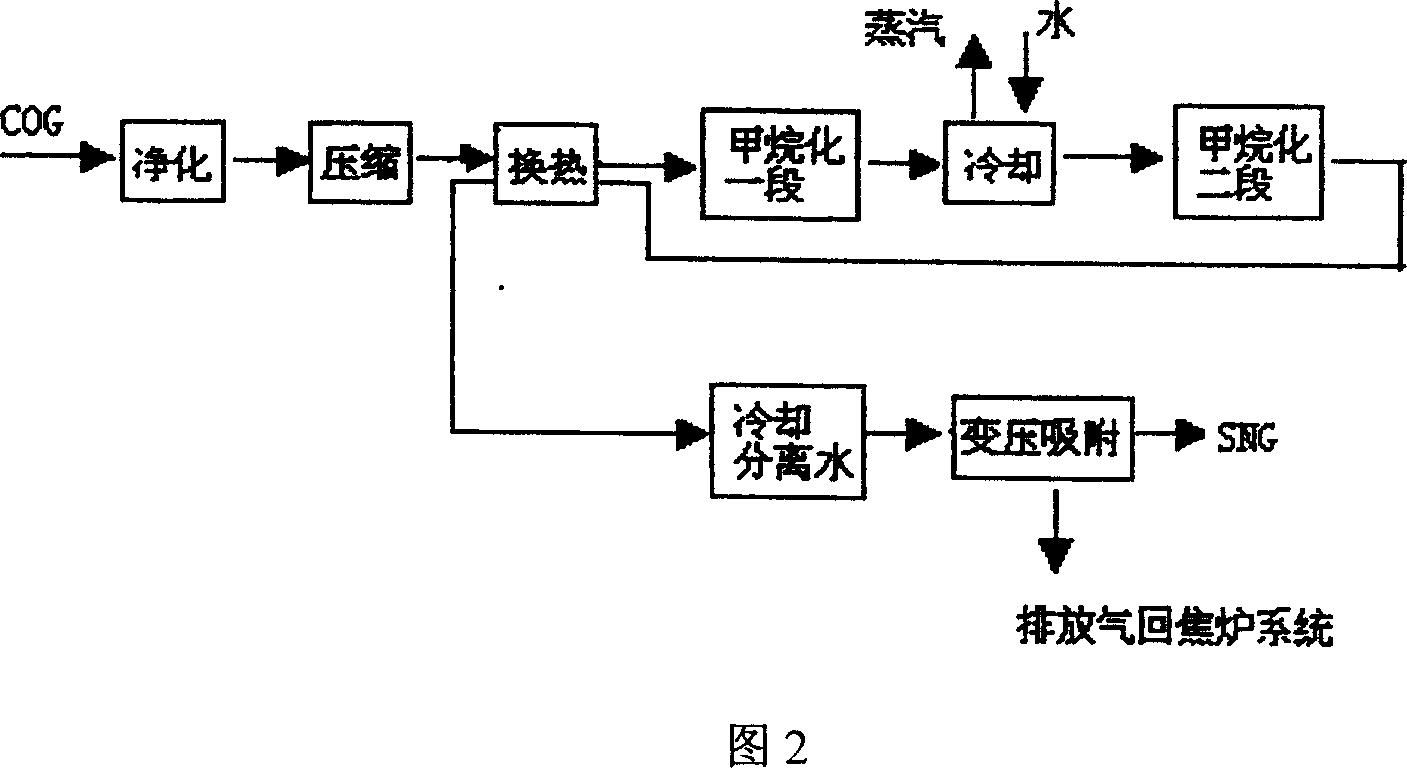

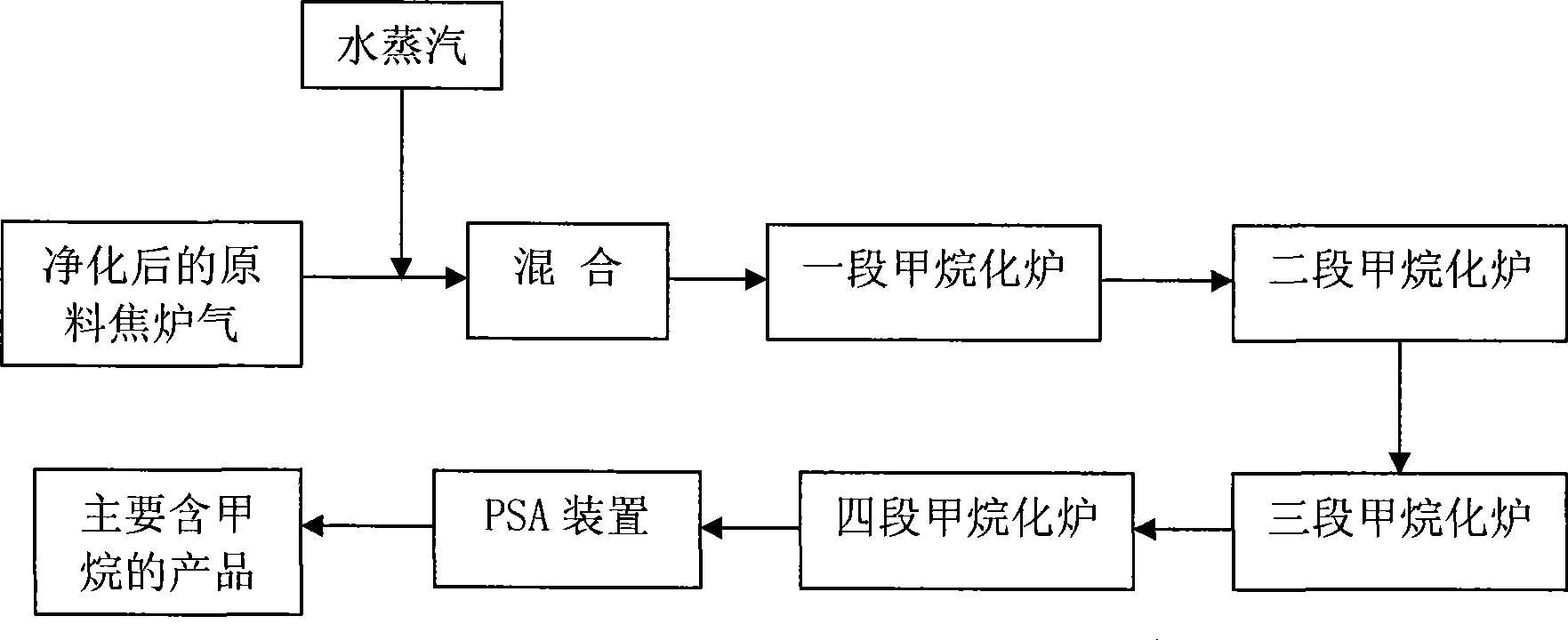

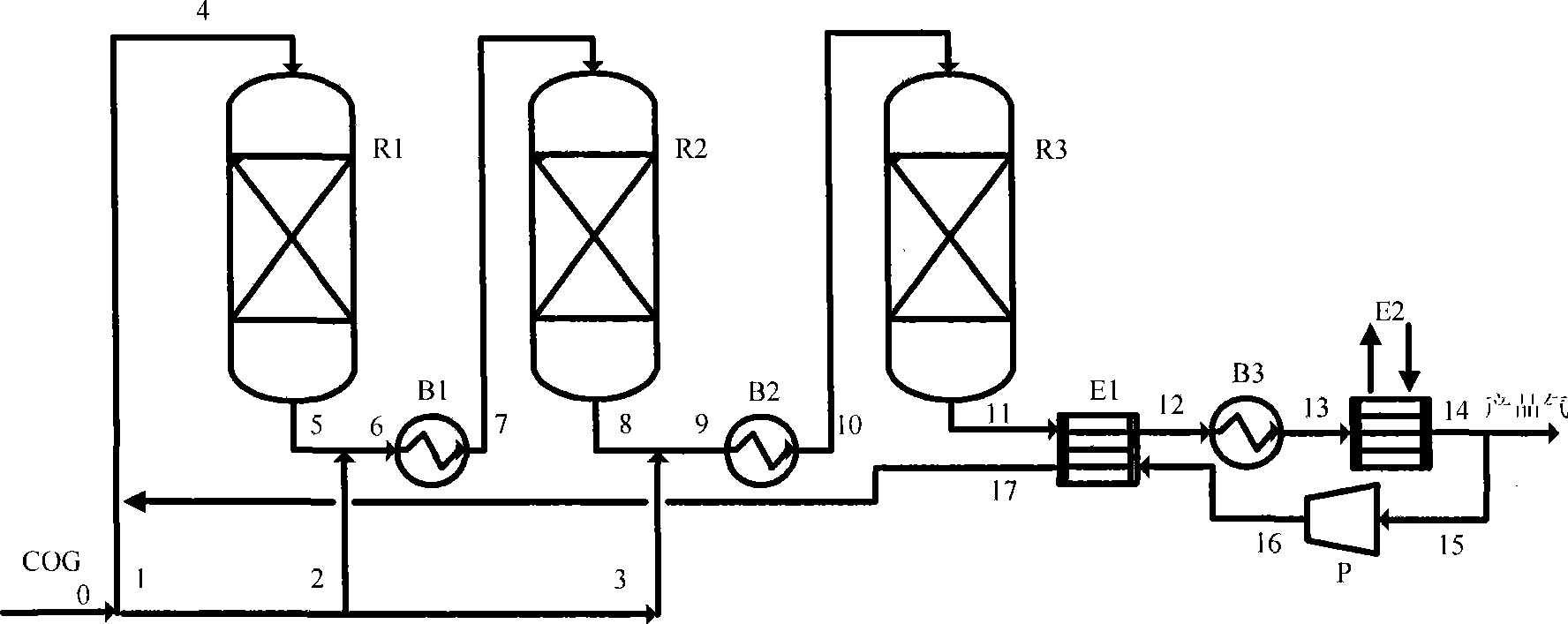

Method for synthesizing methane by using coke-oven gas

ActiveCN101391935AHigh methane contentHigh calorific valueHydrocarbon from carbon oxidesChemical industryWater vaporMethanation

The invention discloses a method for synthesizing methane by utilizing oven gas. Product gas with methane concentration of more than 90 percent is obtained through the main steps of purifying to remove impurities, compressing to exchange heat, adding water vapor, first stage of methanation reaction, second stage of methanation reaction, third stage of methanation reaction, PSA methane separation and the like. By adopting the method and utilizing the oven gas as raw materials, synthetic natural gas with high content of methane, low content of impurities and high heating value can be obtained, which is favorable to protecting the environment, saving energy and developing new energy; in addition, in the method, the addition of appropriate water vapor in the raw materials of oven gas before the fist sage of reaction properly inhibits the depth of the methanation reaction, reduces the heat amount released in the whole reaction process, conduces the cooling of the gas after the reaction and prevents the occurrence of carbon deposition reaction to devitalize the activity of a catalyst, thus being beneficial to the continuous normal operation of the whole synthesizing process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

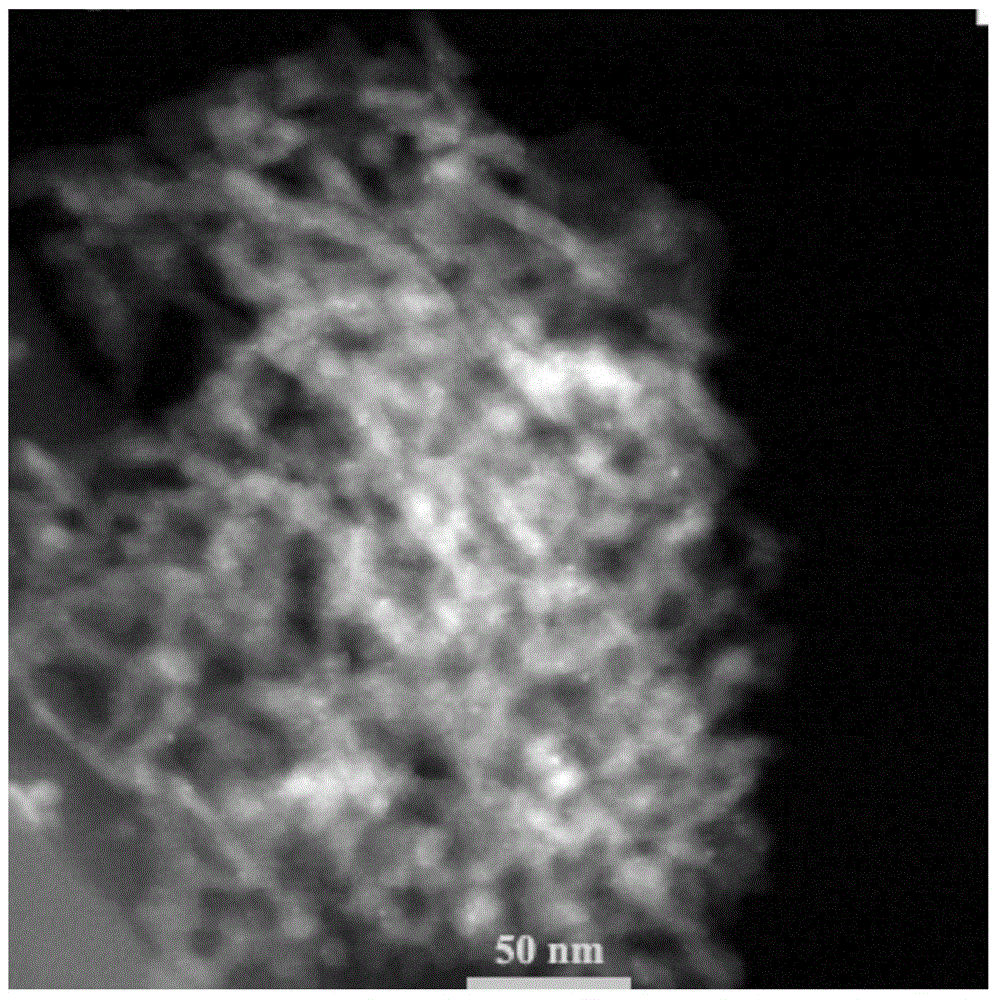

Supported noble metal catalyst and preparation and application thereof

ActiveCN104923225AGood dispersionEnhanced strong interactionHydrocarbon from carbon oxidesDispersed particle separationMethanationHigh activity

The invention relates to a preparation method and a catalytic application of a supported noble metal catalyst. Active components are noble metals Ru, Rh and Pd, and a carrier is MxOy or perovskite MAlO3 or spinel MAl2O4. The composite oxide carrier is prepared by an impregnation method or a coprecipitation method and is roasted under a medium-high temperature condition of 650-1200 DEG C ultimately, so that while the formed MxOy, MAlO3 or MAl2O4 or even a mixture thereof has a closer effect with an Al2O3 carrier, the number of defects and holes on the surface of Al2O3 is greatly increased, and thus prepared noble metal nanoparticles have high dispersion degree and strong stability. The catalyst preparation method has the advantages of simple operation, convenience for production and application, good product repeatability, high activity in a carbon dioxide methanation reaction and a carbon monoxide oxidation reaction, strong stability in a storage state and reaction, and quite good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

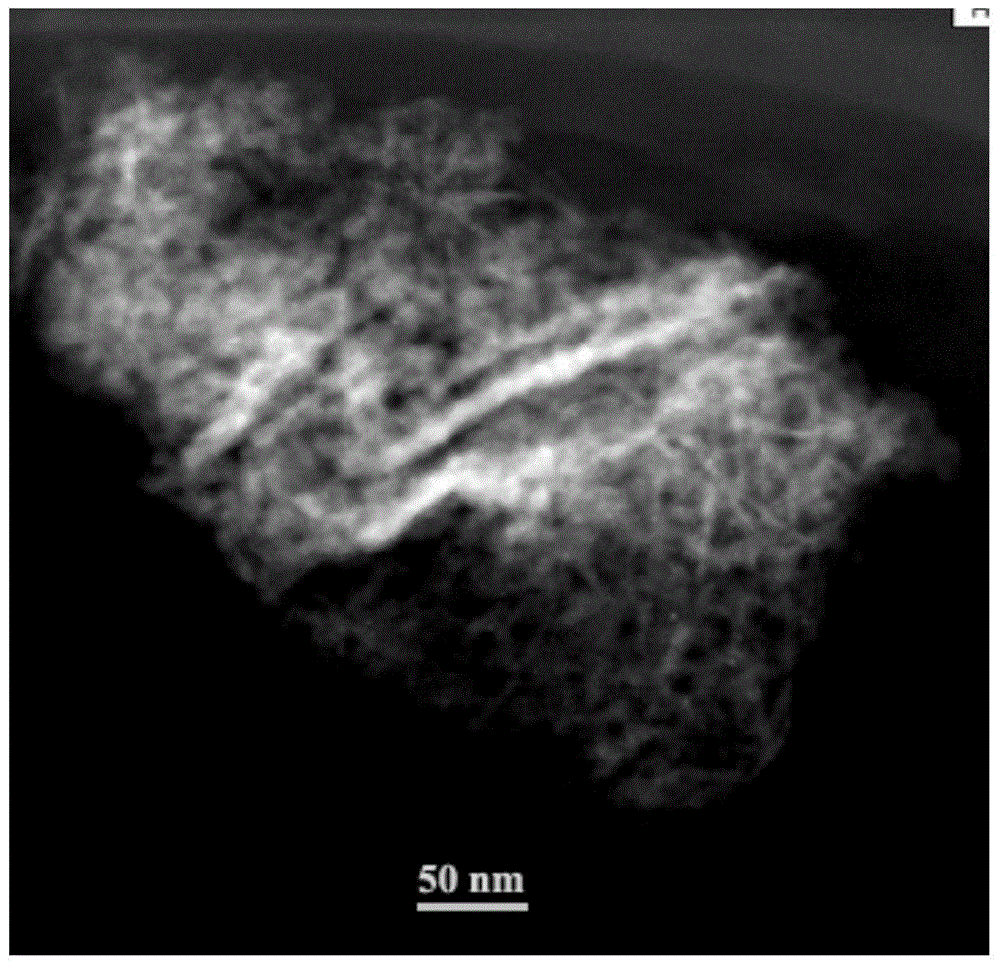

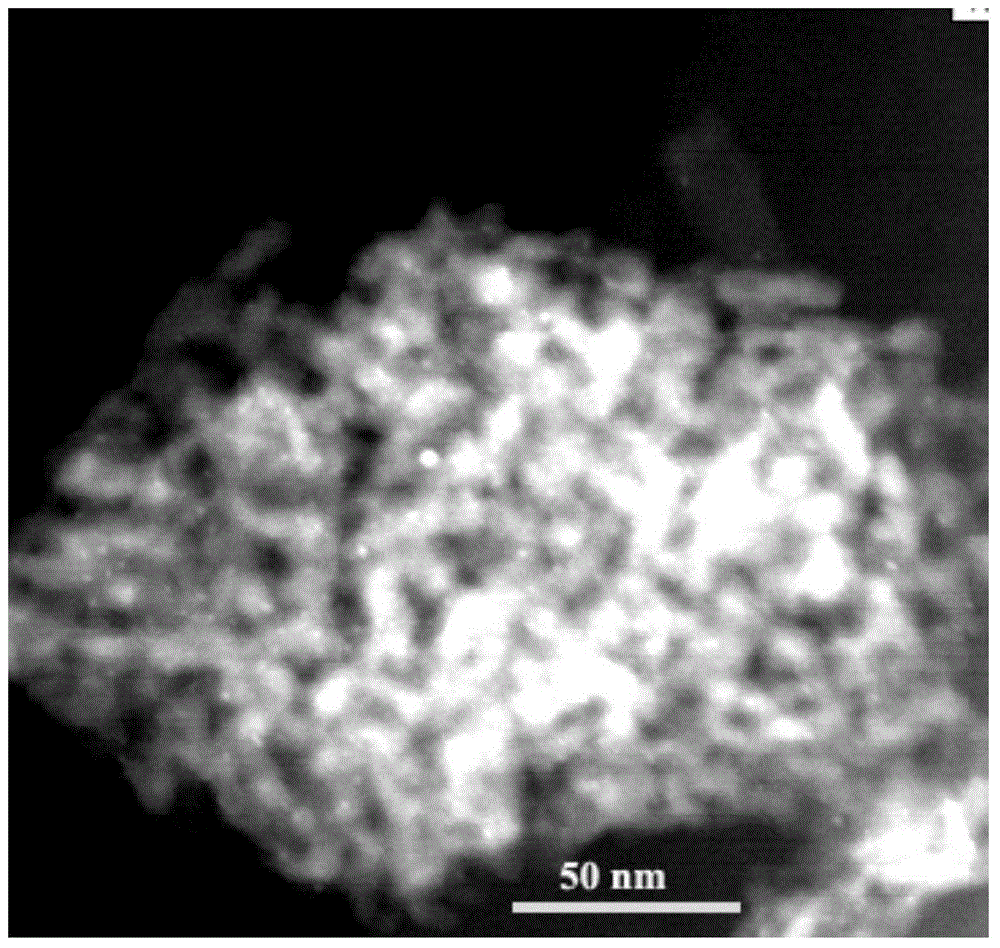

Load type sulfur-tolerant methanation catalyst and preparation method and application thereof

ActiveCN101745401ASmall particle sizeIncrease profitHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsActive componentSulfur

The invention discloses a load type sulfur-tolerant methanation catalyst, which is characterized by taking a main metal M as an active component, a second metal M1 as an auxiliary agent and S as a carrier, and consisting of the metal M, the metal M1 and the carrier S, wherein the mass ratio of the M1 to the M to the S is 0.01-39:1-30:0.01-90; the main metal M is one or more of Mo, W and V; the second metal M1 is one or more of Fe, Co, Ni, Cr, Mn, La, Y or Ce; and the carrier S is SiO2, ZrO2, Al2O3, MgO or TiO2. The load type sulfur-tolerant methanation catalyst is prepared by a sol-gel method. The metallic carbide catalyst prepared by the method has the advantages of low cost, high specific area, small particles, high methane selectivity and better sulfur tolerance when used for CO hydrogenation methanation reaction, and the like.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

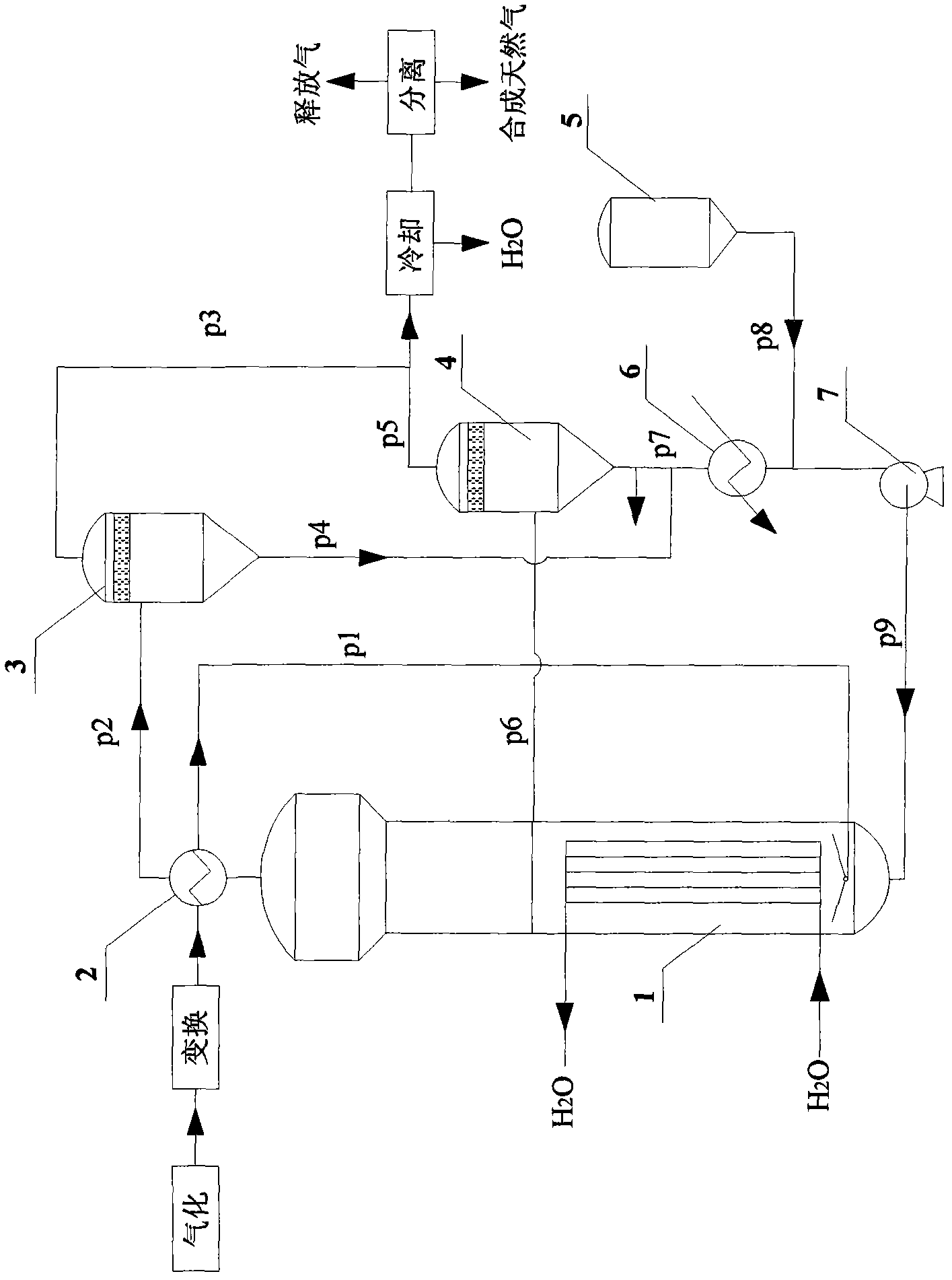

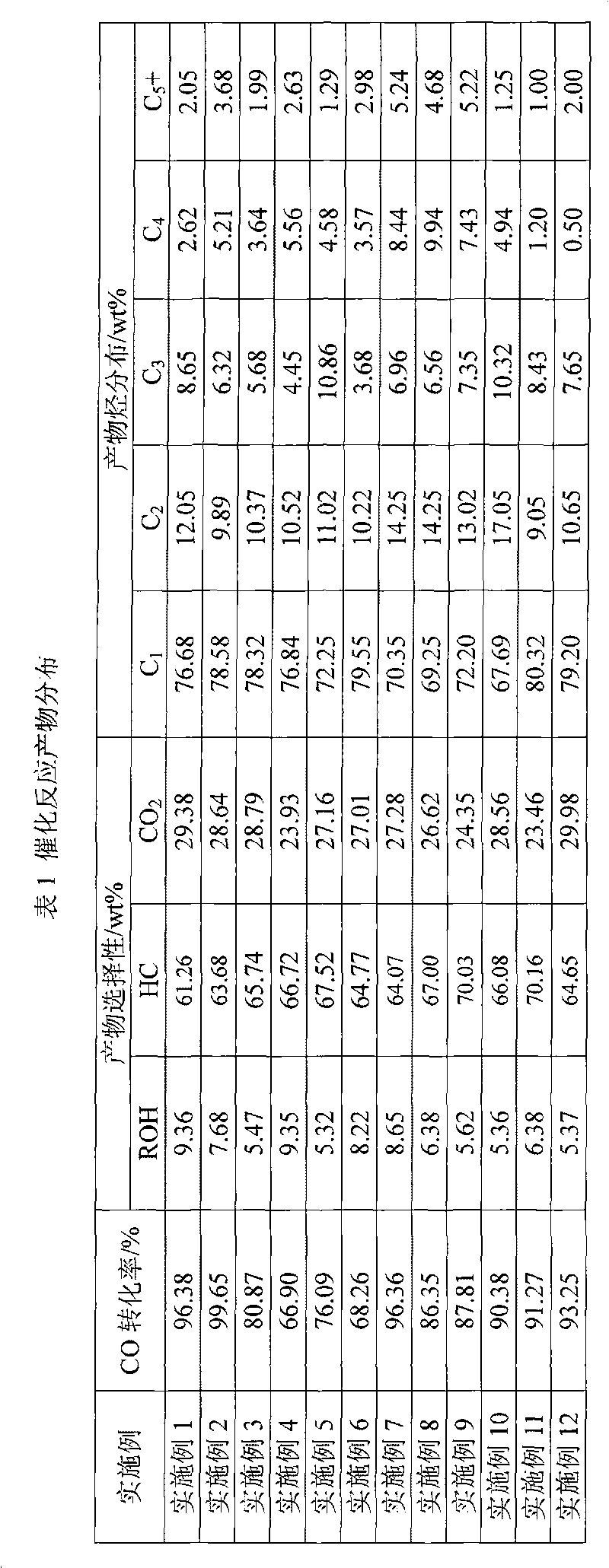

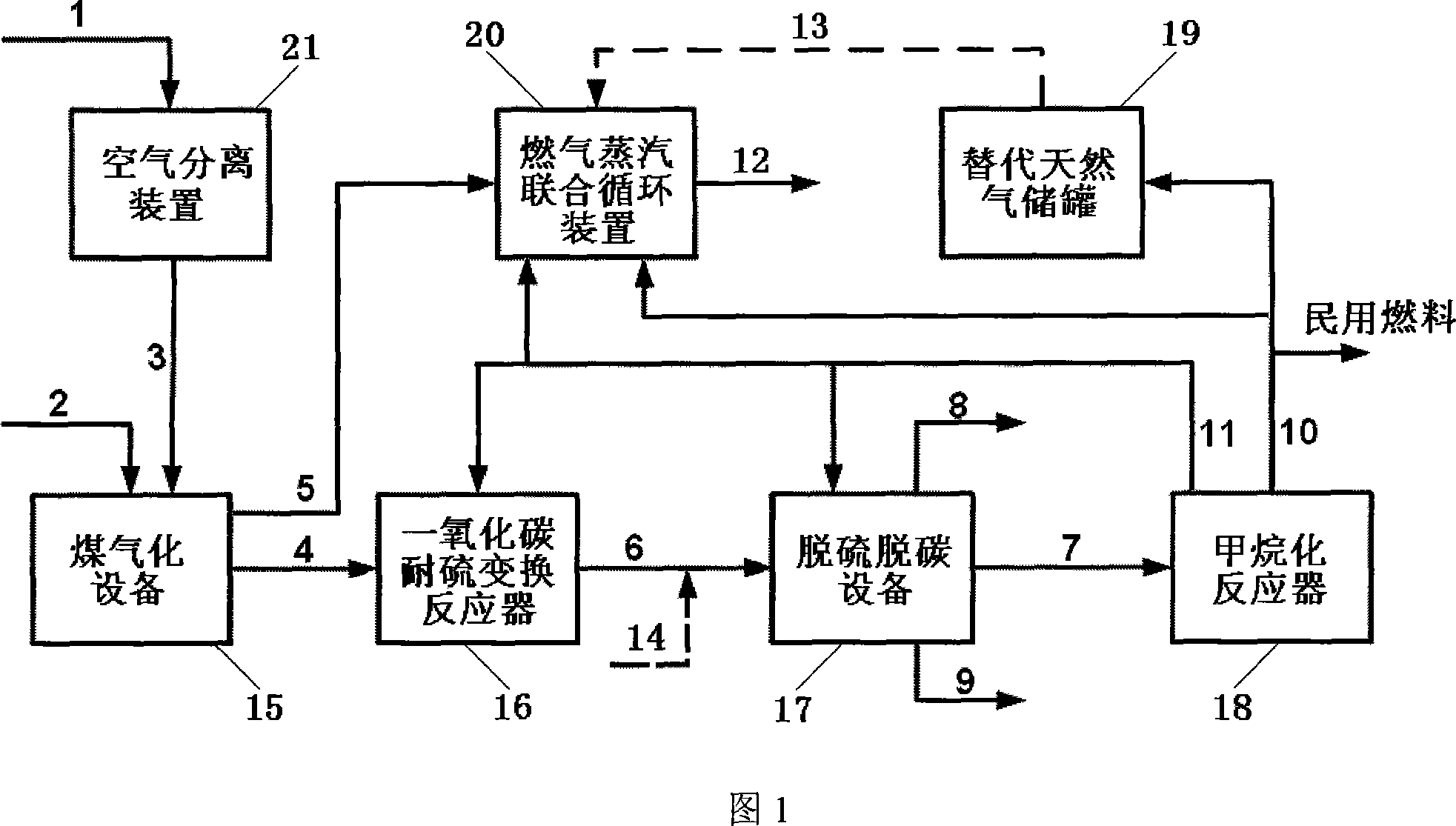

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

ActiveCN101074397AEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

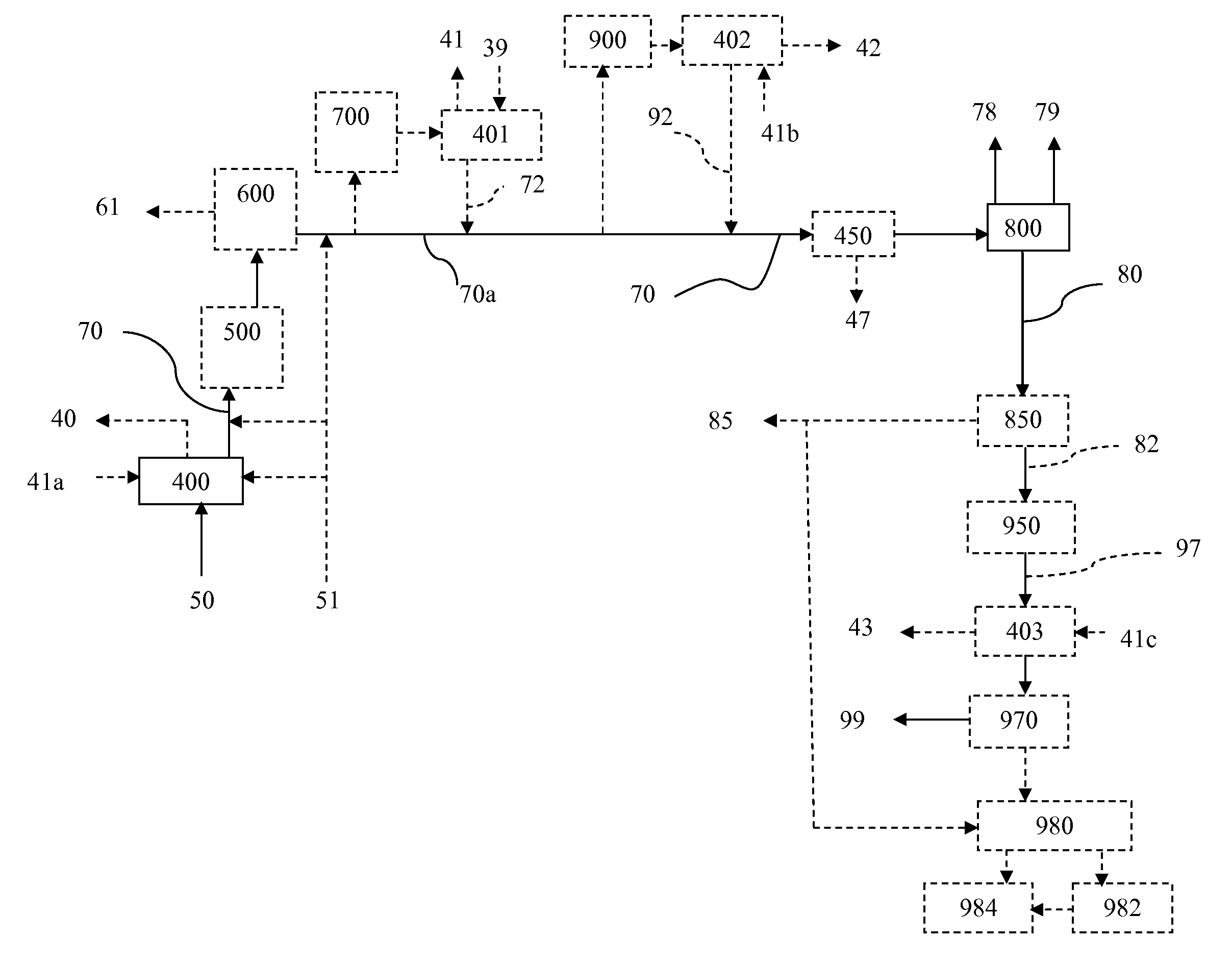

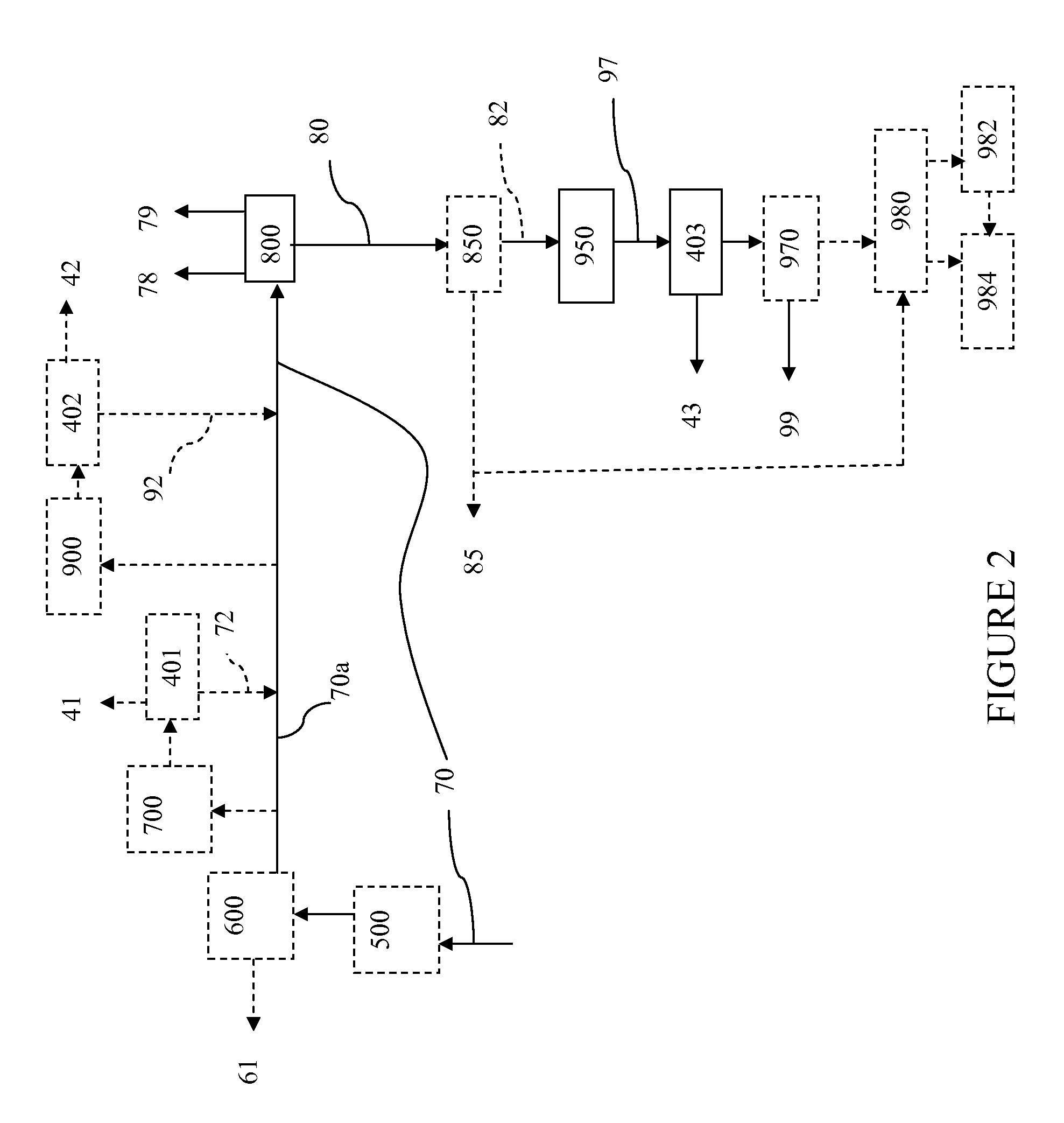

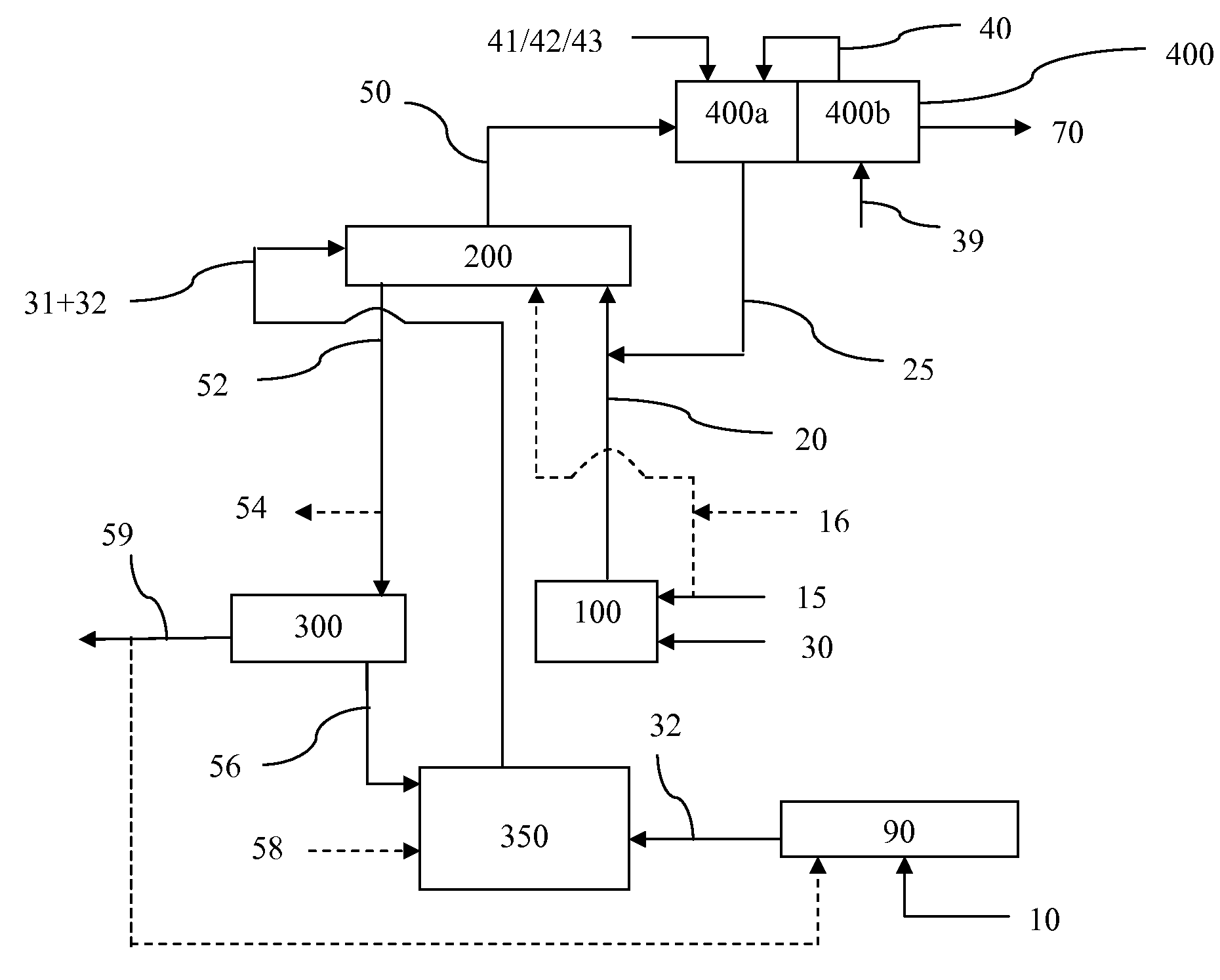

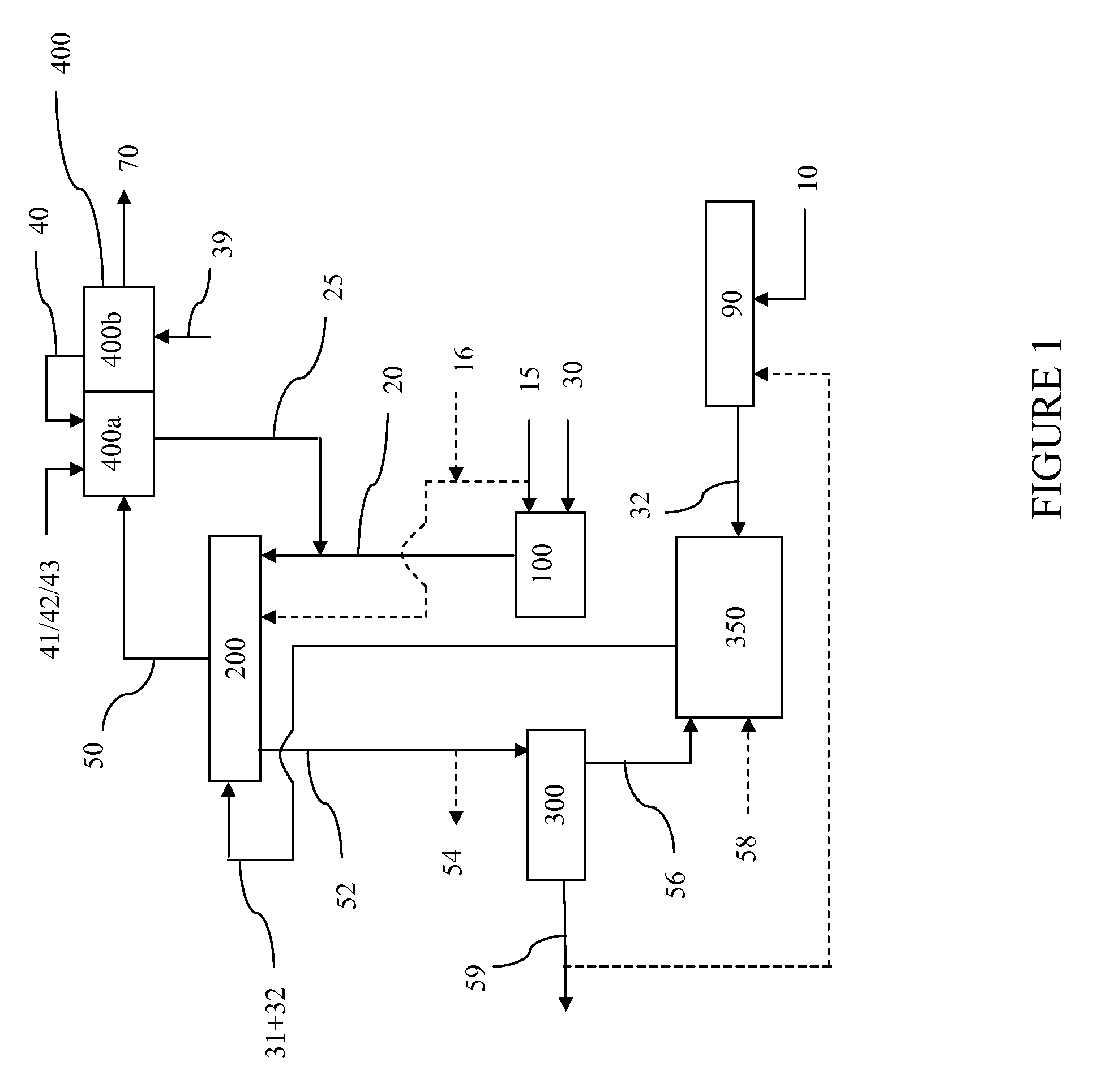

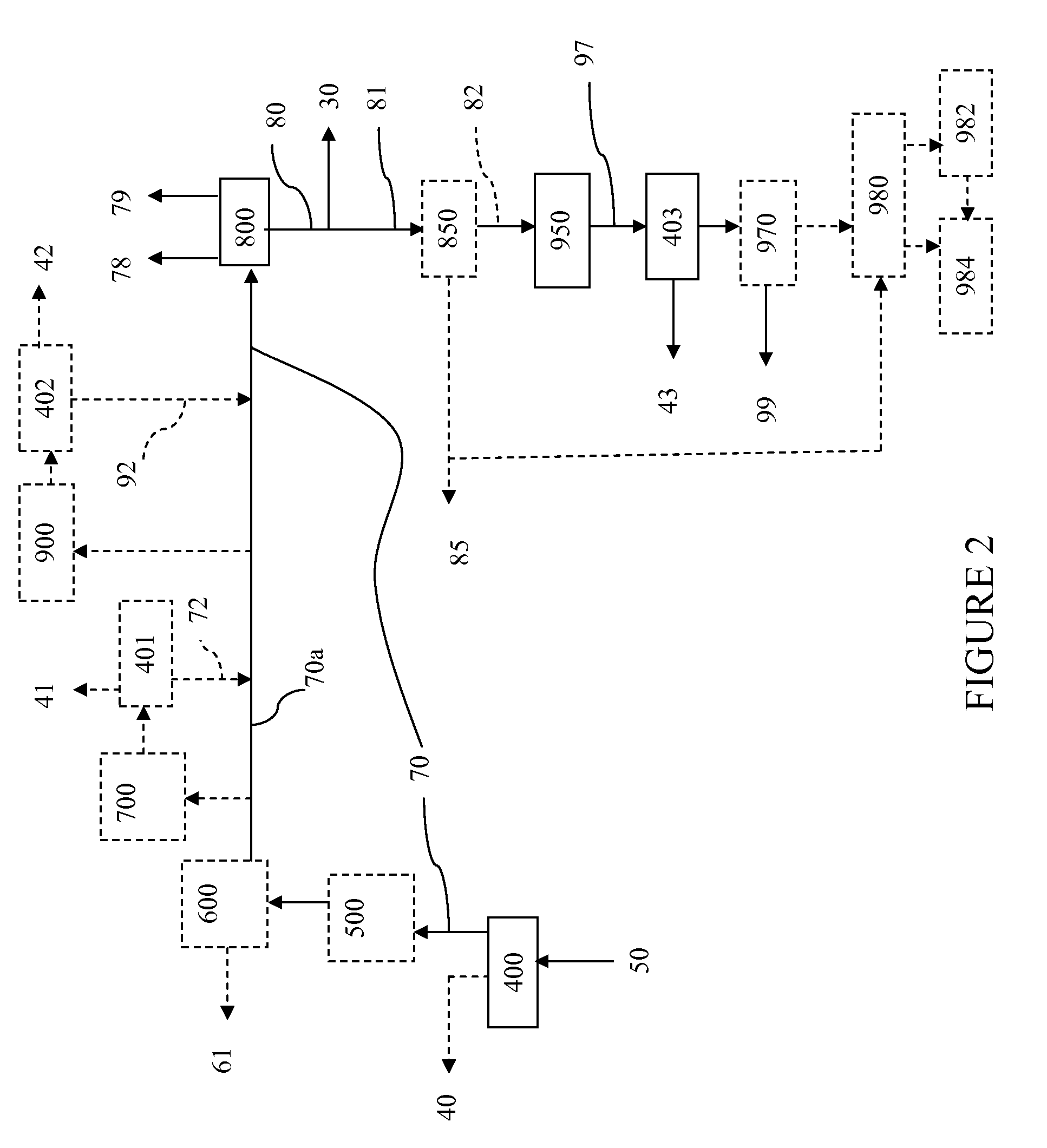

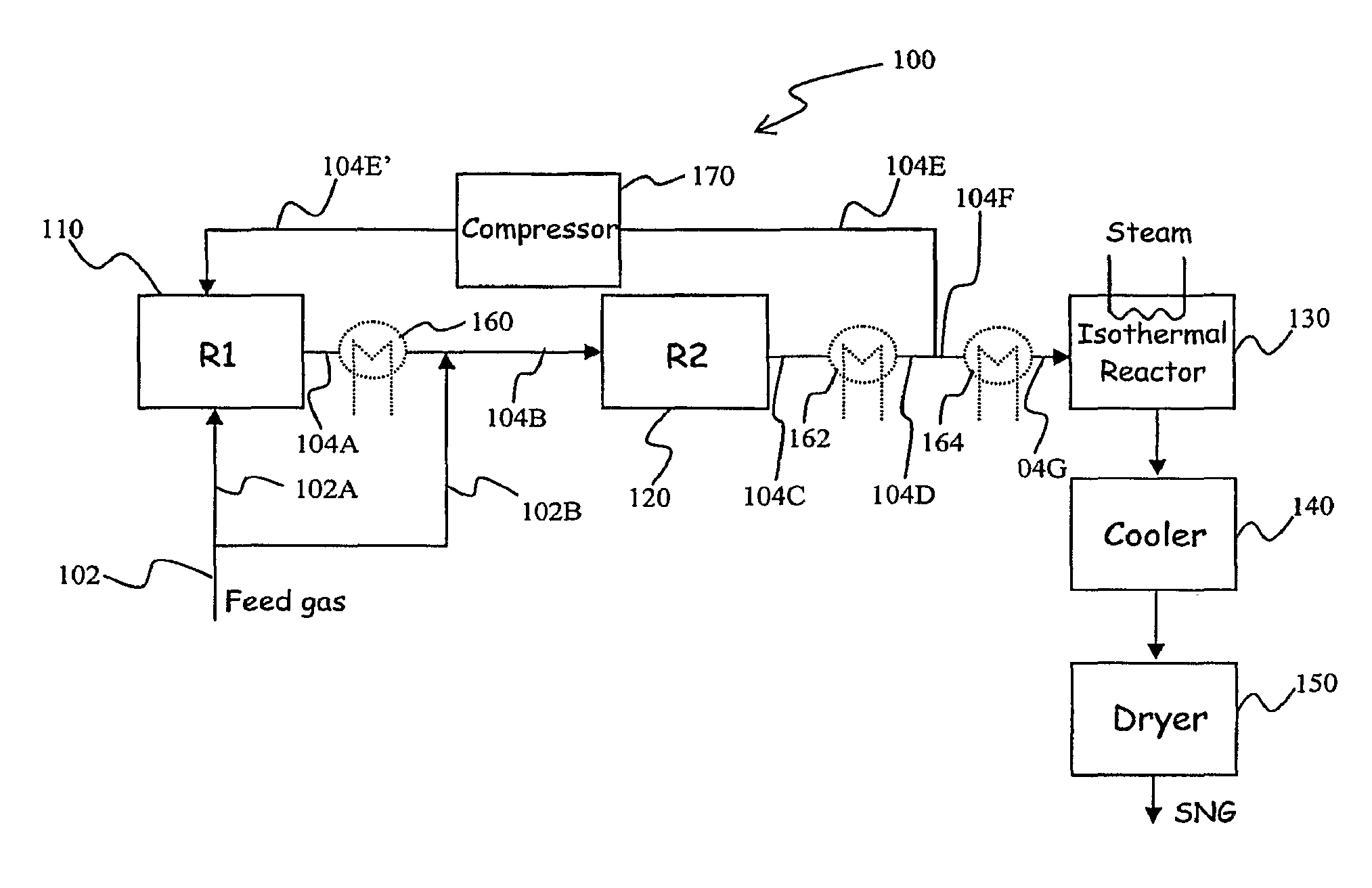

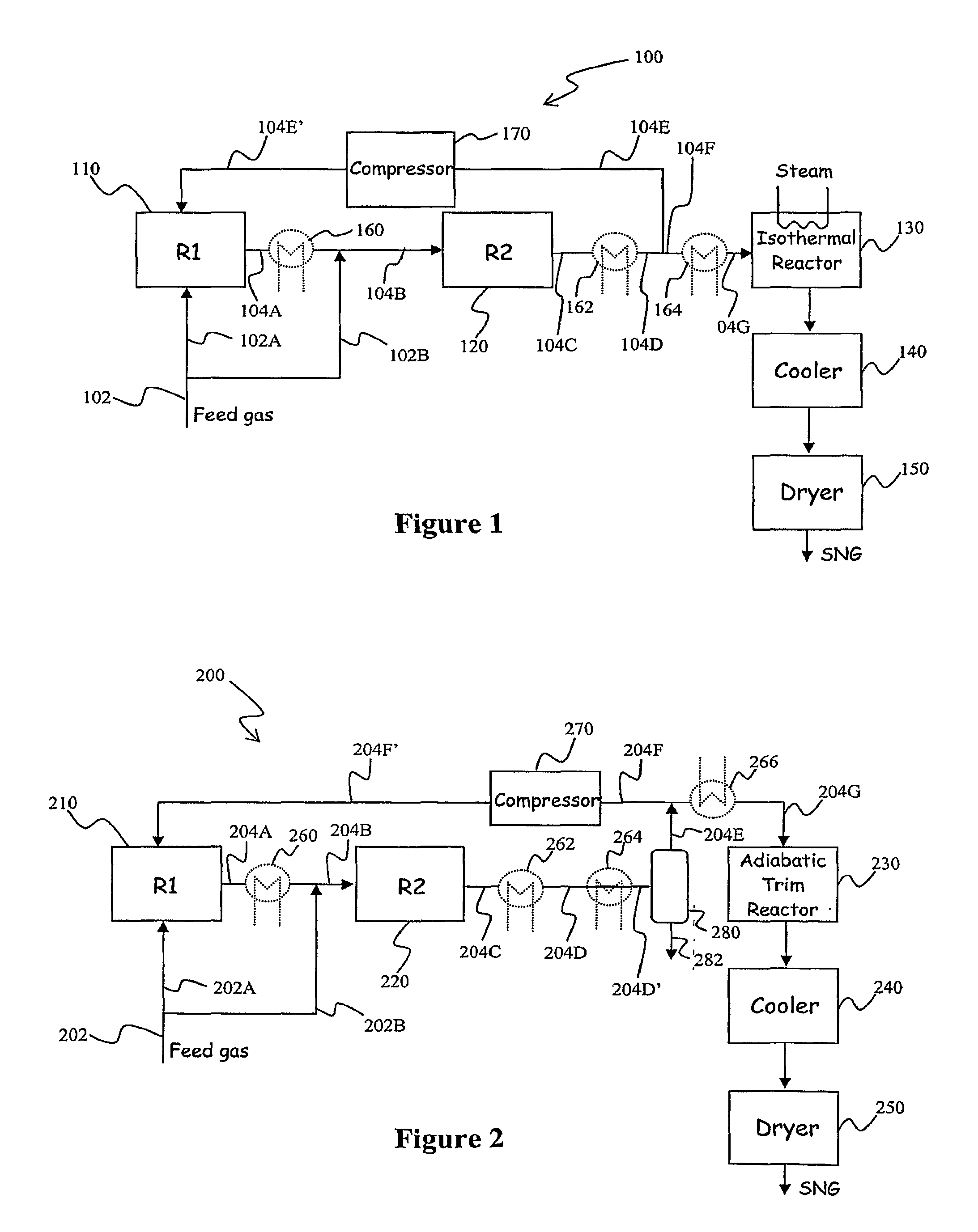

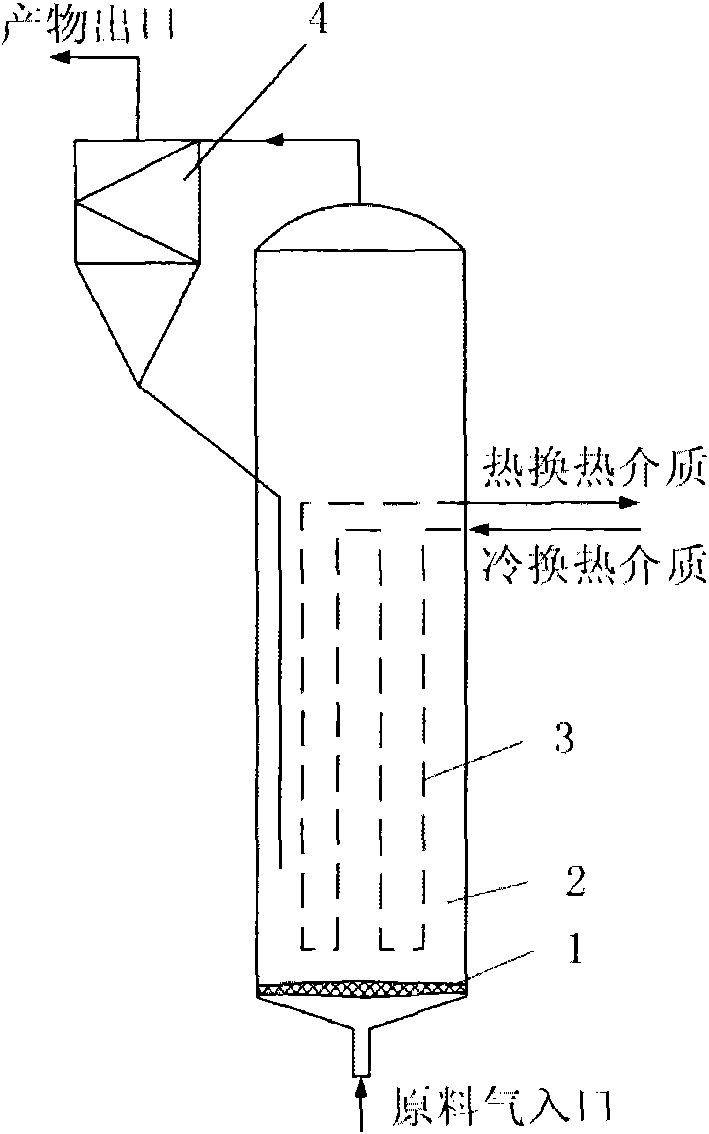

Configurations And Methods of SNG Production

InactiveUS20090247653A1Lower cost of capitalIncreased trim reactor inlet temperatureOrganic compound preparationOxygen compounds preparation by reductionMethanationSubject matter

SNG plants according to the inventive subject matter include one or more methanation reactors that produce a primary methanation product that is cooled to a temperature sufficient to condense water, which is removed in a separator. So produced dried methanation product is then split to provide a reflux stream to the methanation reactors and a feed stream to an adiabatic trim reactor. Most preferably, the plant comprises at least two methanation reactors that are operated in series, wherein the first reactor receives the recycle stream and wherein the second reactor receives a portion of the first methanation reactor effluent and a portion of the first methanation reactor feed.

Owner:FLUOR TECH CORP

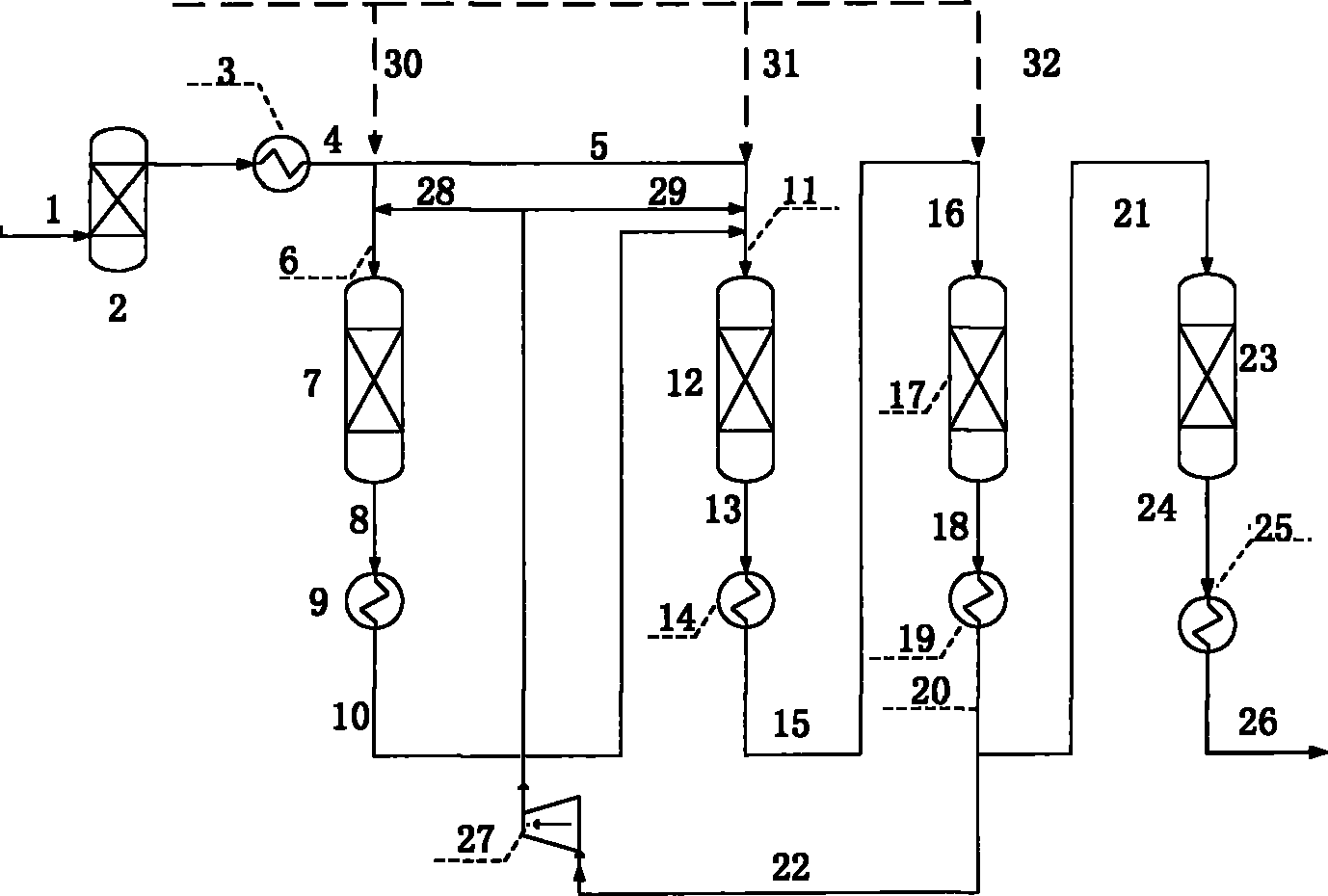

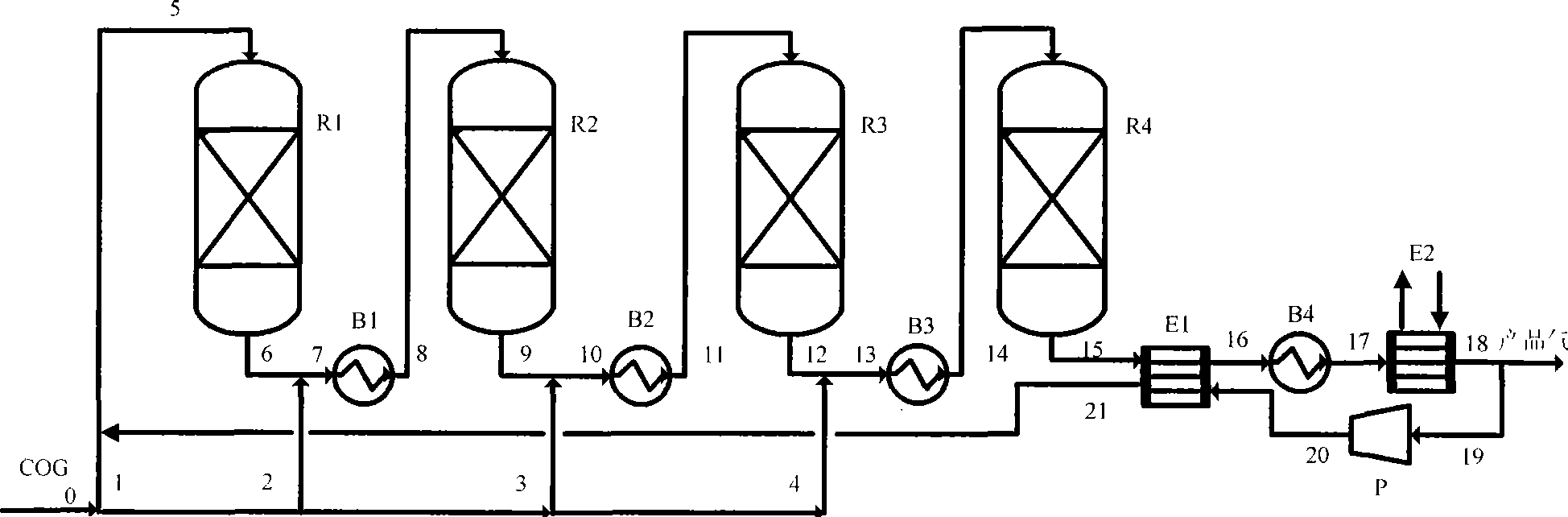

Methanation reaction process using oven gas to prepare substitute natural gas

The invention discloses a methanation reaction technique using oven gas for preparing synthetic natural gas. A multilevel methanation reactor is adopted to control the temperature of gas at the inlet of every level of methanation reactor and the total content of CO+CO2 in the gas at the inlet to be less than or equal to 3.5%, so as to ensure the temperature of gas at the outlet of every level of methanation reactor to be less than or equal to 450 DEG C after methanation. By adopting the technique, the quantity of the gas used for diluting CO+CO2 in the oven gas of the raw materials can be greatly reduced, and the energy consumption is remarkably lowered; meanwhile, the gas temperature at the outlet of the methanation reactor can be effectively controlled, thus being beneficial to methanation reaction and the selection of the materials of the reactor.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

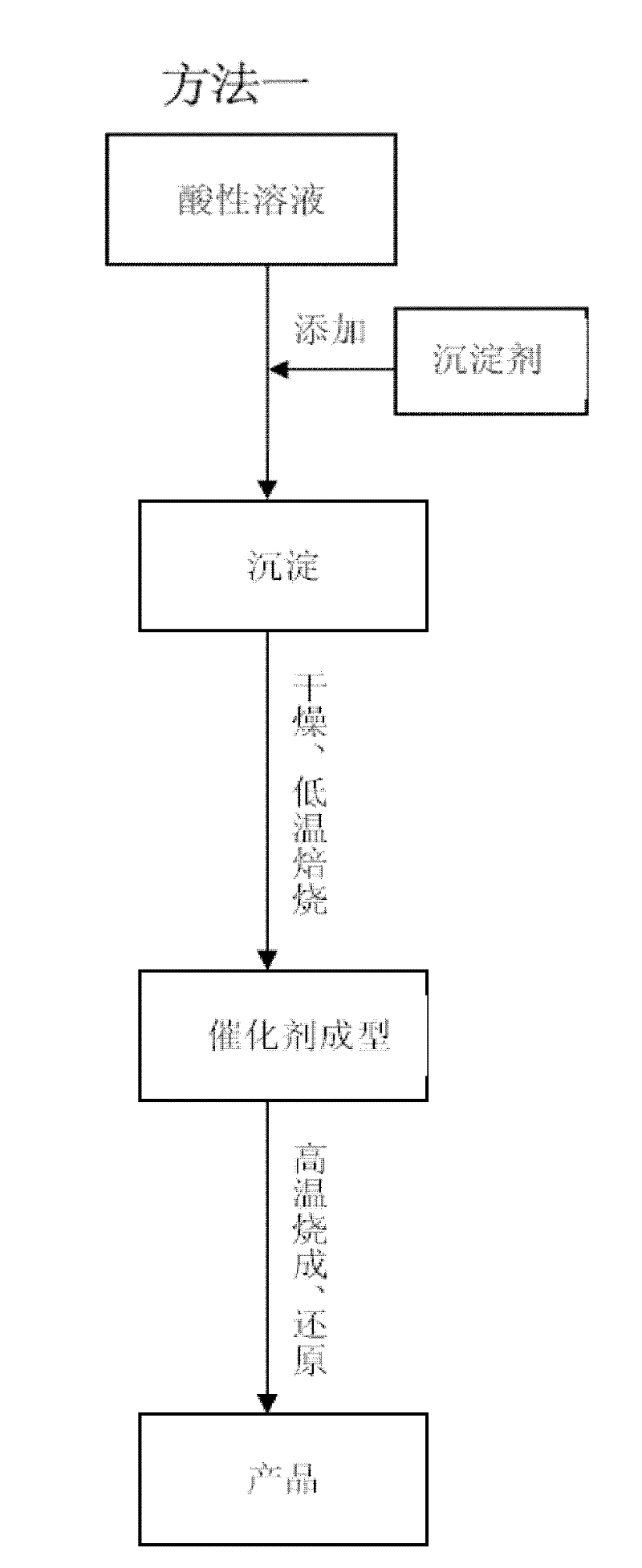

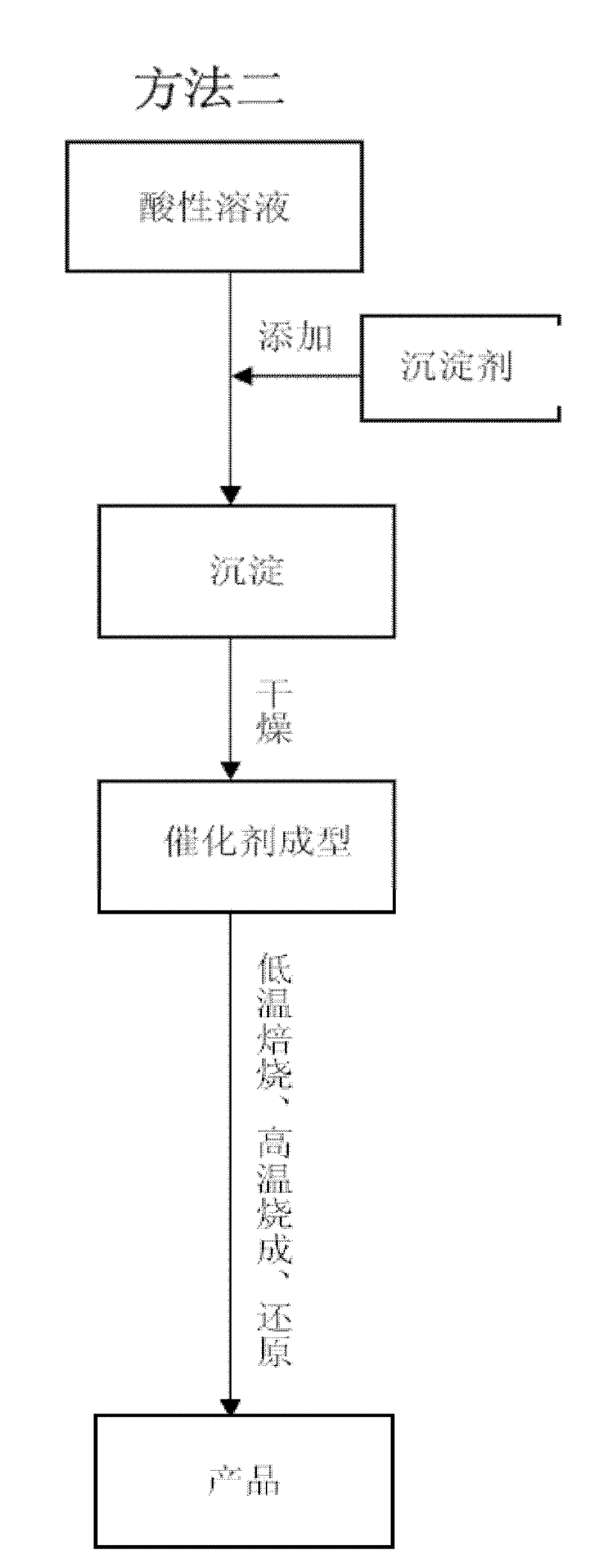

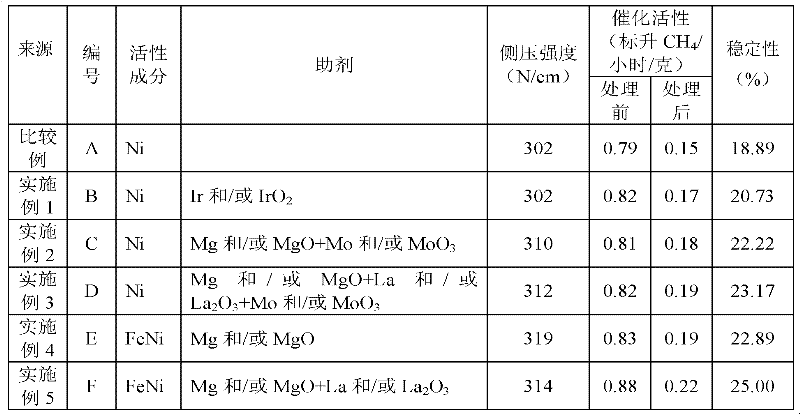

Coal gas high-temperature methanation catalyst and preparation method thereof

InactiveCN102247861AHigh Methanation Catalytic ActivityReduce dosageHydrocarbon from carbon oxidesGaseous fuelsActive componentMethanation

The invention discloses a coal gas high-temperature methanation catalyst and a preparation method thereof. The coal gas high-temperature methanation catalyst is prepared from a Ni or FeNi alloy as an active component, Al2O3 and ZrO2 as carriers, and one or more of metals of Mo, V, W, Ir, Cr, Mg, Ca, Y, Ce and La and / or oxides thereof, wherein the one or more of the metals and / or the oxides are utilized as auxiliary agent. The coal gas high-temperature methanation catalyst comprises: by weight, 1 to 50% of Ni or 1 to 55% of FeNi as an active component, 0.01 to 25% of one or more metals and / or oxides thereof as an auxiliary agent, and the balance Al2O3 and ZrO2 as carriers, wherein a weight ratio of Al2O3 to ZrO2 is in a range of 50 to 0.1. The coal gas high-temperature methanation catalyst has good high-temperature hydrothermal stability and high activity, and can reduce production cost and satisfy requirements of application of an adiabatic fixed bed high-temperature methanation process and other high-temperature methanation processes.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

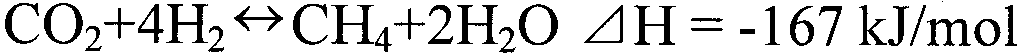

Catalyst for full methanation of carbon dioxide and preparation method thereof

ActiveCN101884927AImprove fluidization qualityHigh strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationThermal stability

The invention discloses a catalyst for full methanation of carbon dioxide, which belongs to the technical field of methanation of carbon dioxide. In the catalyst, spherical gamma-Al2O3 is used as a carrier, Ni and Fe are used as active ingredients, and MgO, La2O3 or CeO2 is used as an auxiliary agent. The catalyst is prepared by adopting an ordered soaking method through drying, roasting and reduction. The catalyst comprises the following components in percentage by mass: 60 to 80 percent of gamma-Al2O3, 10 to 20 percent of NiO, 5 to 15 percent of Fe2O3, 1 to 10 percent of MgO, and 1 to 10 percent of La2O3 or CeO2. Under the reaction conditions that the pressure is between 3.0 and 5.0MPa, the volume airspeed of the raw material gas is 5,000 to 10,000 per hour and the ratio of H2 to CO2 is 4.1, both the CO2 conversion rate and the CH4 selectivity can be close to 100 percent. The catalyst has the characteristics of high strength, good thermal stability, carbon deposition resistance, easy fluidization and the like.

Owner:TSINGHUA UNIV

Catalyst used for methanation of carbon dioxide, preparation method therefor and applications thereof

ActiveCN104148065ASmall particle sizeNarrow distributionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsElectrolysisMethanation

The invention provides a catalyst used for methanation of carbon dioxide, a preparation method therefor and applications thereof. The catalyst employs precious metal Ru or Rh as a main catalytic activity component, employs one or more selected from elements of the I and II main groups and the II, III and VII subgroups as auxiliary agents, and employs one or more selected from SiO2, TiO2, Al2O3, CeO2 and ZrO2 as carriers. The above catalyst is used in graininess or the carriers, the auxiliary agents and the activity component are subjected to coating (wall loading) on a whole structural catalyst and metal honeycombs. The catalyst has characteristics of high activity and selectivity and wide temperature and pressure operation windows. The catalyst can be used for hydrogenation methanation removal of CO2 in a space station, then generated H2O is subjected to electrolysis, and circulation supply of oxygen is achieved. The catalyst also can be used for processes of other CO2 conversion utilization of coal-made natural gases and process gases and the like and new energy development and energy saving and emission reduction are achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Bimetal methanation catalyst and preparation method thereof

InactiveCN101703933ARestoredGood dispersionHydrogen separation using solid contactCatalyst activation/preparationLow loadMethanation

The invention discloses a bimetal methanation catalyst for the removal of micro carbon monoxide from a hydrogen-rich gas and a preparation method thereof. The bimetal methanation catalyst contains active components, namely nickel oxide and ferric oxide, loaded on an oxide carrier and an assistant, wherein the assistant is at least one element selected from the main group I, the main group II, the subgroup I, the subgroup III, the subgroup VI and the subgroup VIII of the periodic table, and the oxide carrier is alumina, titanium dioxide, zirconium dioxide and silicon dioxide or a mixture thereof. The catalyst of the invention can allow the micro carbon monoxide to be removed from the hydrogen-rich gas at a relatively low temperature and has the advantages of low load, high activity, relatively low cost and wide application prospect.

Owner:SHANXI UNIV

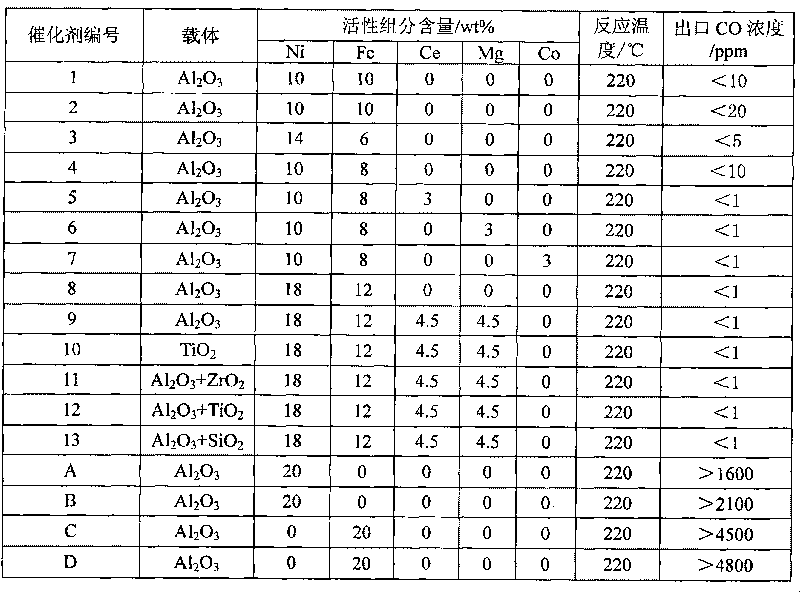

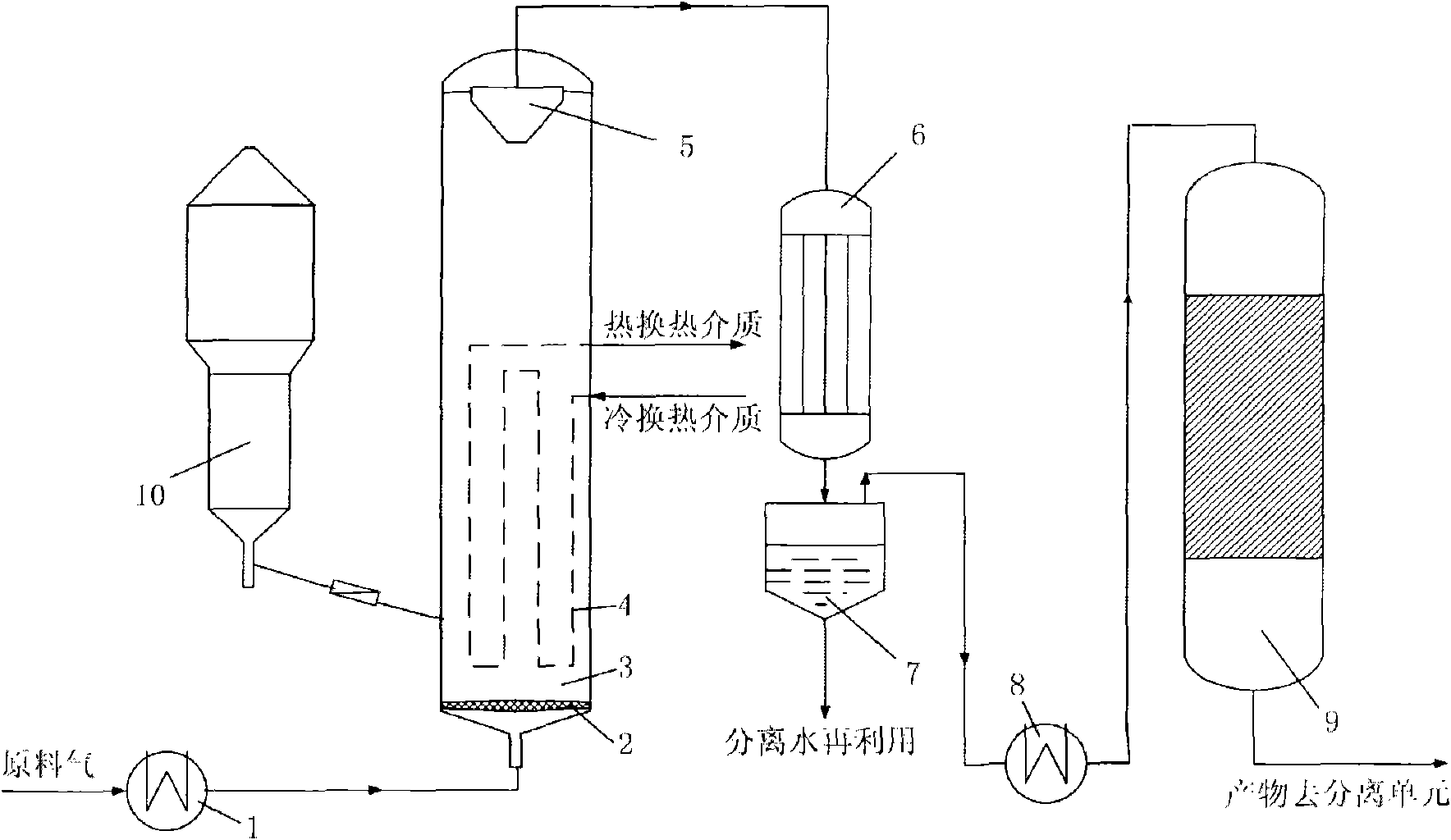

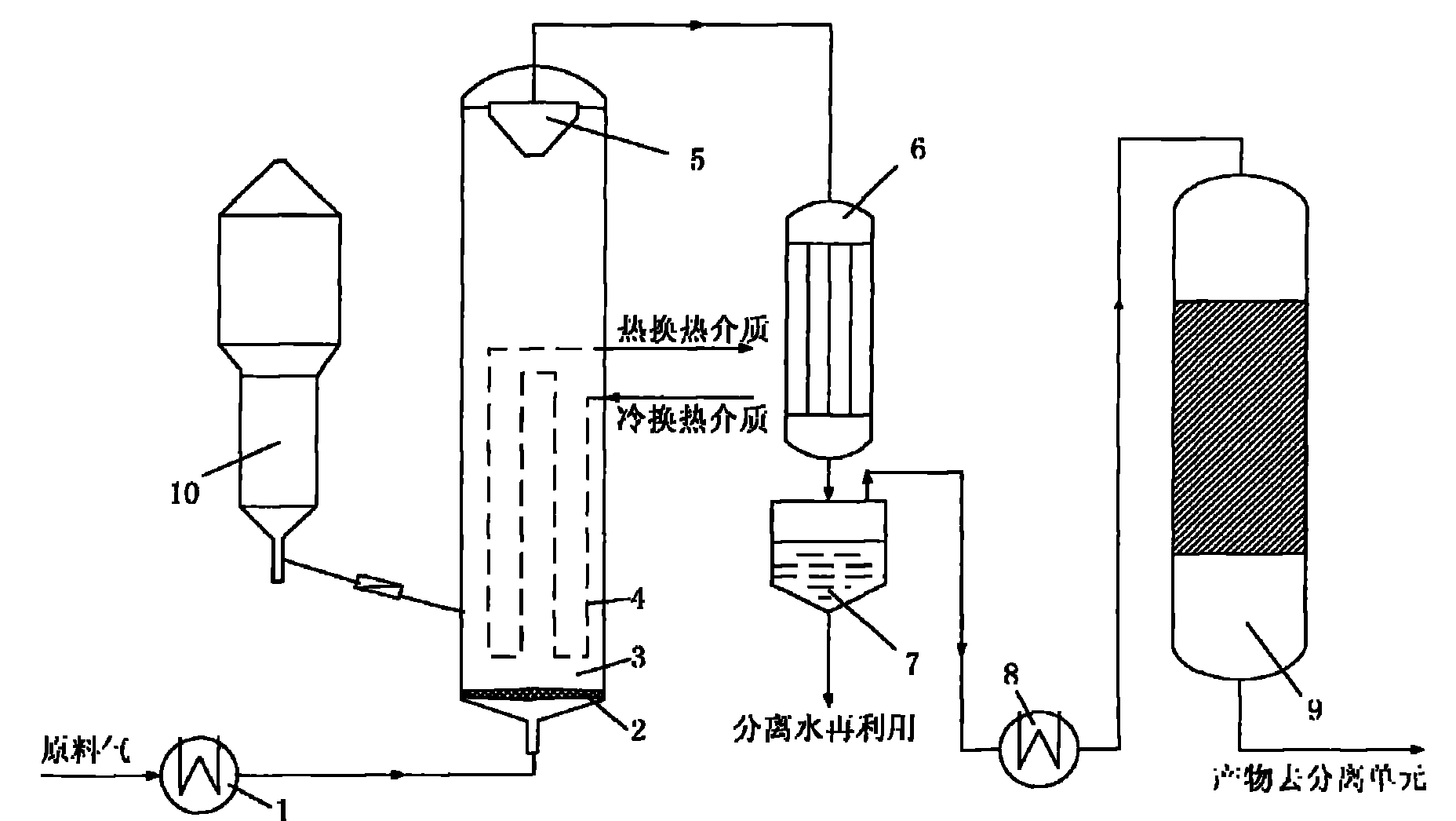

Method and device for catalyzing methanation of synthesis gas

ActiveCN101817716AIncrease productivityEasy to removeHydrocarbon from carbon oxidesSyngasMethanation

The invention relates to a method and a device for catalyzing methanation of synthesis gas. The method has the process characteristics that synthesis gas as a raw material firstly realizes the conversion rate of 60 to 95% in a built-in heat exchanger type fluid bed reactor, the reaction temperature is from 200 to 700 DEG C, the pressure is from 0.1 to 6.0 MPa, and the reaction airspeed is from 1000 to 50000 h<-1>; gas-solid separation is carried out on reaction products and a catalyst, and water therein is separated and enters a fixed bed reactor after temperature raise; and the rest raw material synthesis gas is converted to methane, the operation temperature is from 180 to 700 DEG C, the pressure is from 0 to 6.0 MPa, the reaction airspeed is from 500 to 600h<-1>, and the final raw material synthesis gas conversion rate reaches more than 98%. Compared with the fixed bed reactor adiabatic reaction process generally adopted currently, the process of the method has simpler process flow. The space time yield of the methane can be obviously improved, and the invention has better industrialized application value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

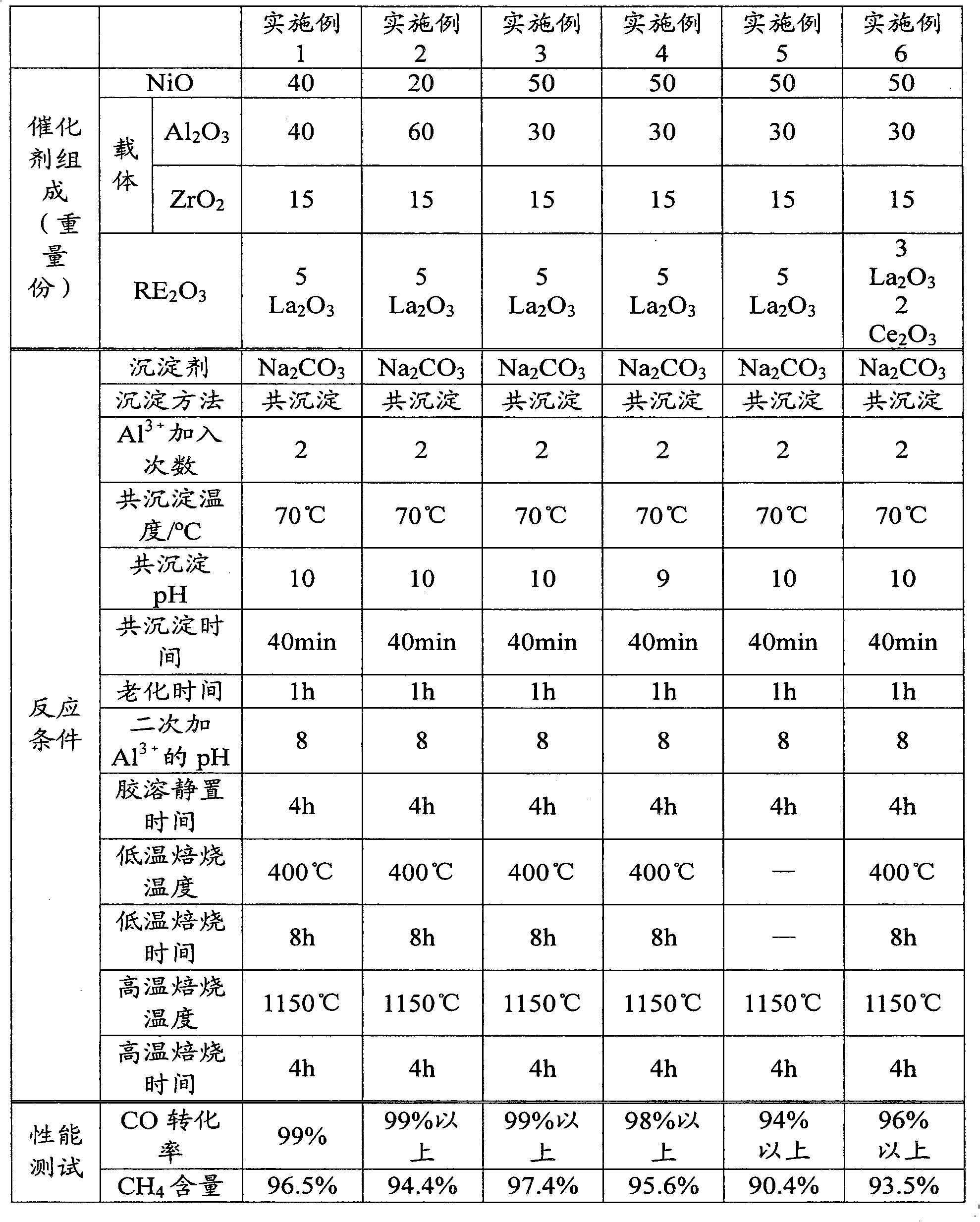

High-temperature methanation catalyst, preparation method and application thereof

ActiveCN101890353AHigh activityHigh selectivityHydrocarbon from carbon oxidesGaseous fuelsMethanationRare earth

The invention relates to a high-temperature methanation catalyst, a preparation method and application thereof. The high temperature methanation catalyst comprises the following components: a) NiO serving as an active ingredient; b) a metallic oxide carrier comprising Al2O3 and ZrO2; and c) a metallic oxide auxiliary agent which is at least one of rare-earth metallic oxide RE2O3, and metallic oxide of magnesium Mg, copper Cu and chromium Cr. The method comprises the following steps of: A) preparing an aqueous solution of water soluble salt, wherein the water soluble salt comprises Ni, the metallic oxide carrier and optional metallic cation corresponding to the metallic oxide auxiliary agent, performing precipitation reaction with a precipitator to ensure that the metallic cation in the water soluble salt is precipitated; B) separating solid from liquid to obtain a precipitated solid; and C) performing dry granulating and calcining to ensure that the metallic cation is converted into the corresponding metallic oxide, wherein the calcining comprises high-temperature calcining. The catalyst still has higher activity and selectivity at higher temperature.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Waste water biological treatment method for realizing anaerobic ammoxidation and methanation denitrification coupling

InactiveCN101058463ASave energySave organic carbon sourcesTreatment with aerobic and anaerobic processesIndustrial effluentMethanation

The invention discloses a biological disposing method of waste water through coupling the anaerobic ammonoxidation and methanation denitrification, which is characterized by the following: inoculating the particle sludge with methanation, denitrification and anaerobic ammonoxidation activity in the expansion grain sludge bed (EGSB); inoculating aerobic ammonoxidation bacteria in the biological aerating filter (BAF) or SHARON technique or SBR reactor; connecting the EGSB reactor and BAF or SHARON technique or SBR reactor; realizing the biological disposal of waste water through controlling pH value, temperature, dissolved oxygen, external reflow rate, load velocity, oxidizing reducing potential and organic COD density, ammonia nitrogen density.

Owner:CHONGQING UNIV

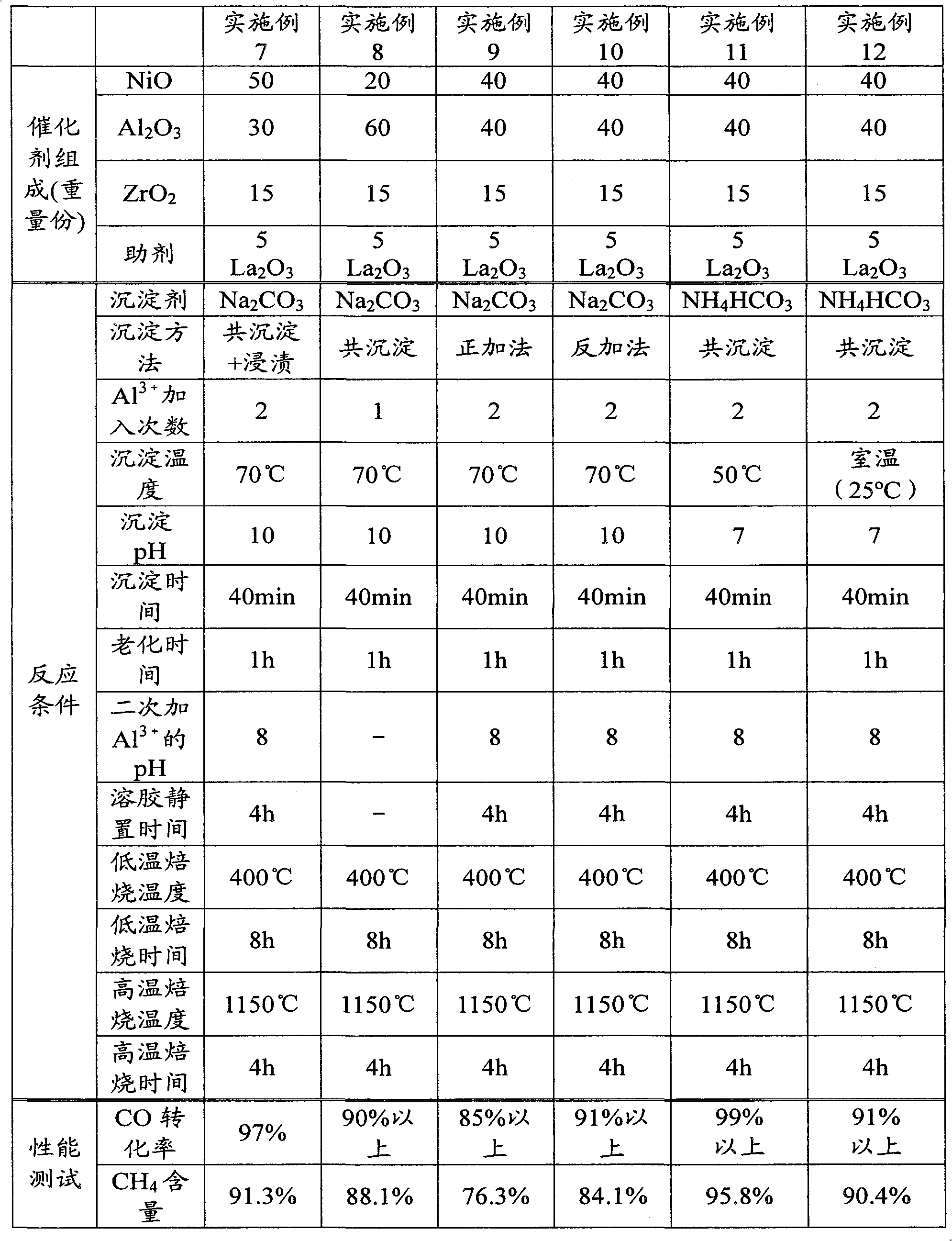

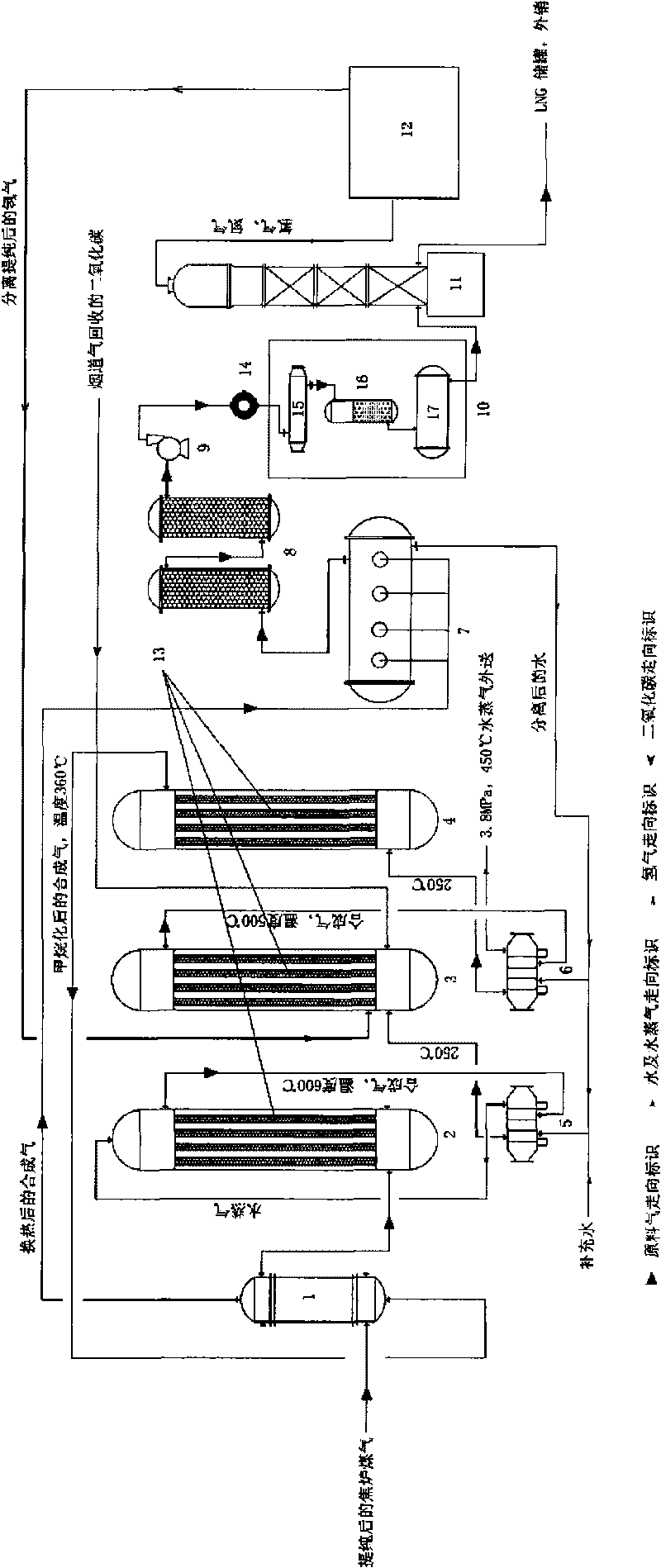

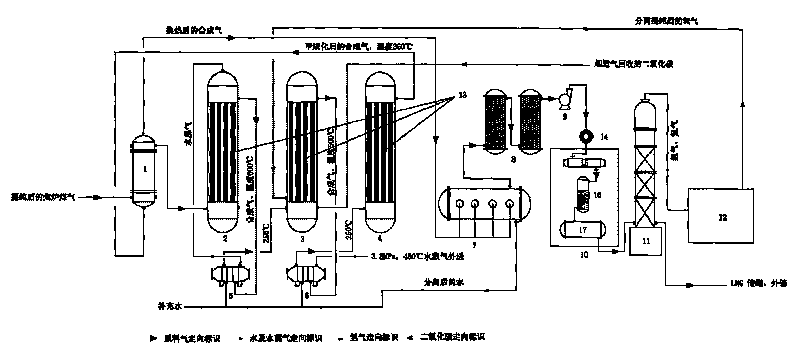

Method for realizing methanation of coke oven gas through carbon-replenishing hydrogen-returning process for synthetic natural gas

InactiveCN101712897AReduce unit energy consumptionIncrease productionGaseous fuelsMethanationSynthesis methods

The invention relates to the field of coal coking production, in particular to a method for realizing methanation of coke oven gas through carbon-replenishing hydrogen-returning process for synthetic natural gas. The method comprises: pressurizing purified coke oven gas to 1 MPa; raising temperature to 250 DEG C for heat exchange; under the action of catalysts, performing three-stage methanation reaction of CO2 recycled by a low-partial-pressure system added with flue gas and H2 obtained through the separation of a membrane separation device after methanation to obtain synthetic gas of which the concentration of methane is over 94 percent. The method adopts a low-pressure non-cyclic methanation process, and the reaction temperature of the method is as follows: a primary stage is at 600 DEG C; a carbon-replenishing hydrogen-returning stage is at about 500 DEG C; a final stage is at 360 DEG C; and the temperature before every stage of methanation reaction is controlled at 250 DEG C through balancing control. Through a heat-insulating reactor and a waste-heat boiler heat exchange system, the method not only controls reaction temperature, but also produces steam serving as a byproduct at 3.8 MPa and 450 DEG C. Compared with other synthesis methods, waste heat energy produced during the methanation reaction is utilized more fully, so that the aims of saving energy, reducing emission and causing no environmental pollution are achieved while capacity is expanded.

Owner:SHANGHAI EUROFO ENTERPRISE GROUP

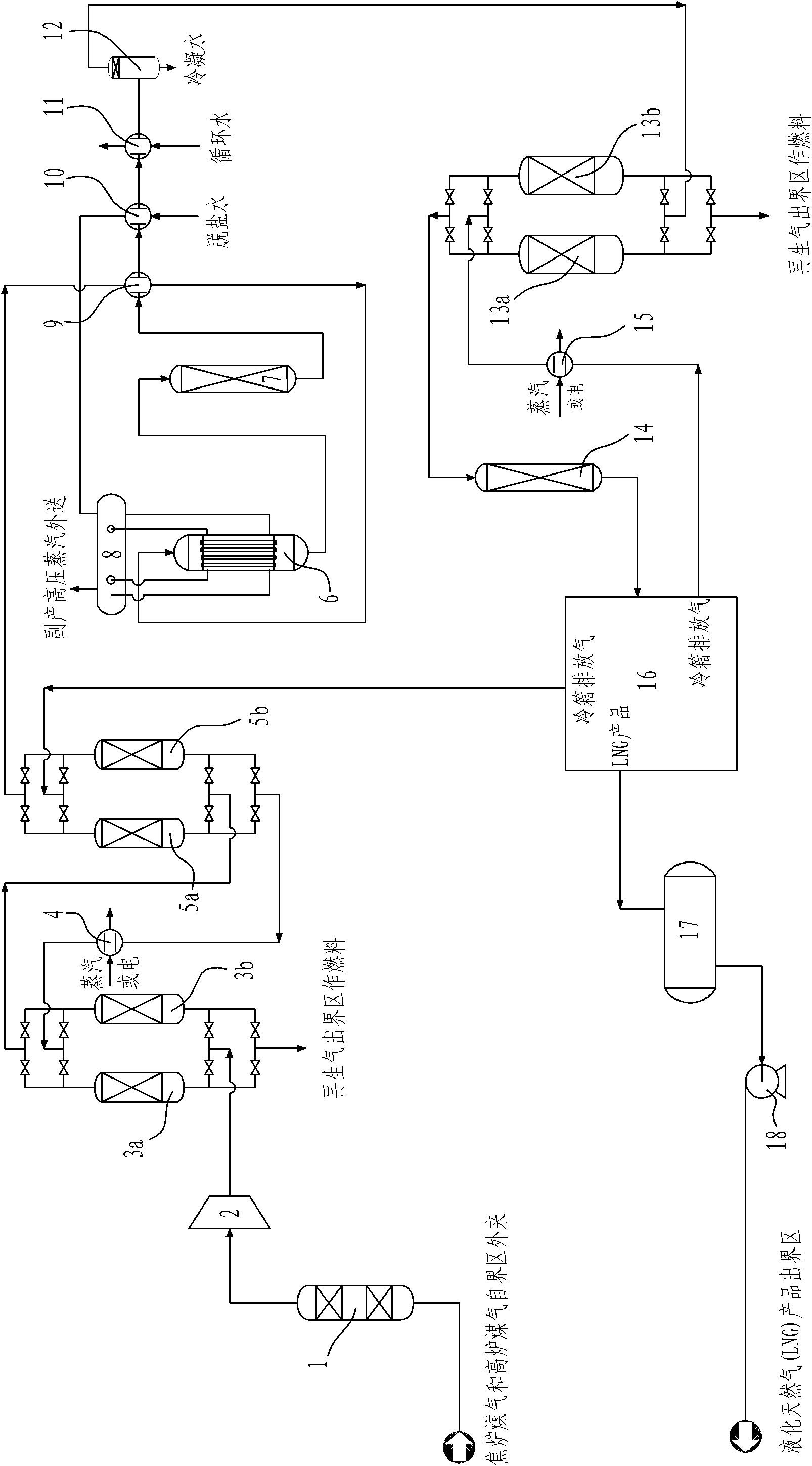

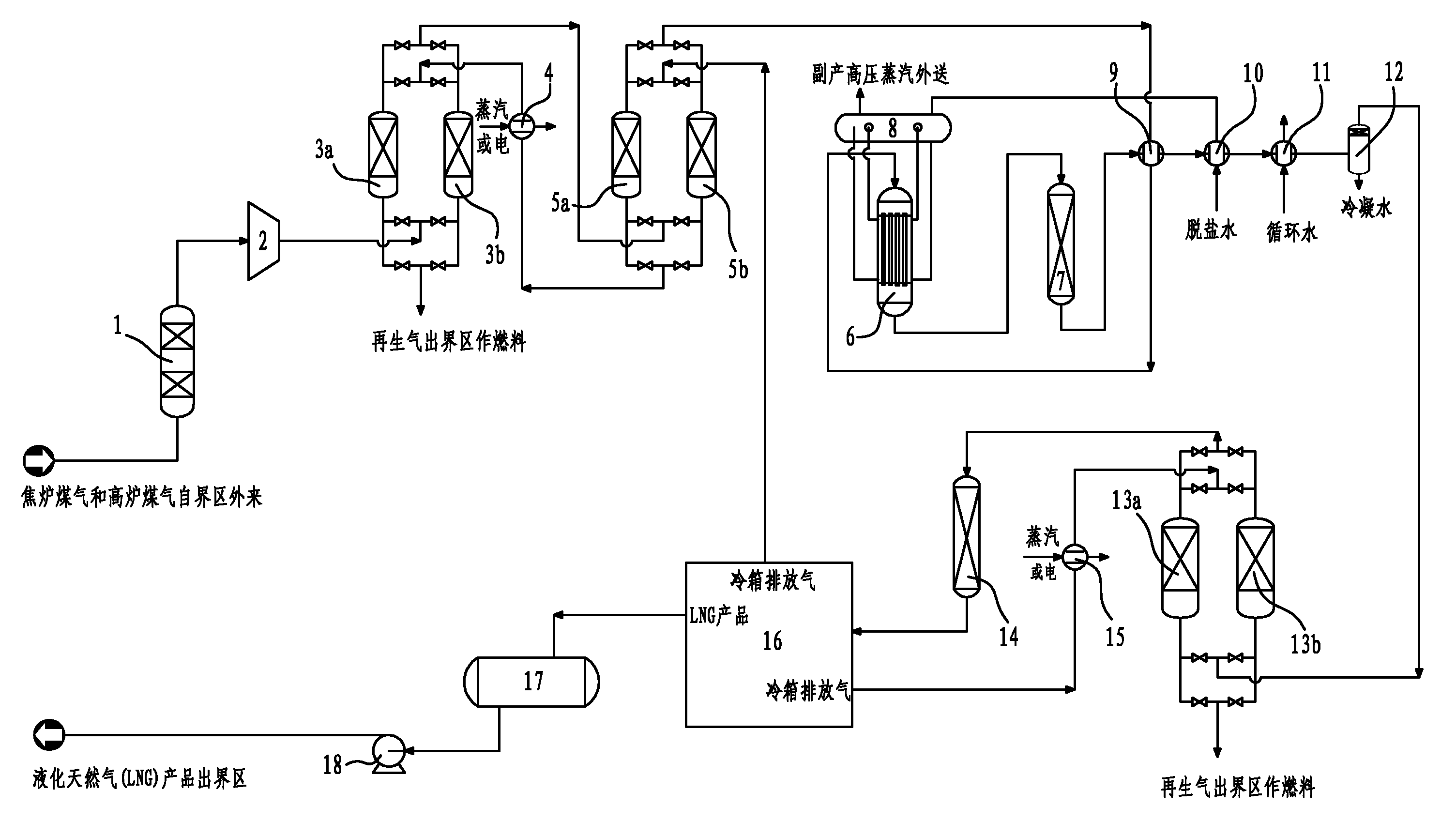

Method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas

InactiveCN102250658AEasy to operateSimple processGaseous fuelsGas purification with selectively adsorptive solidsMethanationImpurity

The invention discloses a method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas. In the technology, the coke oven gas and the blast furnace gas are taken as the raw materials, the raw materials are subjected to normal-temperature normal-pressure dry desulfurization, gas compression, gas adsorption purification, gas isothermal-adiabatic serial methanation, gas adsorption drying and demetalization, freezing liquefication separation and other technical processes, and high-quality liquefied natural gas with the purity of over 99 percent is produced. By the technology, harmful impurities such as sulfur, naphthalene, tar, benzene, mercury and the like in the gas can be efficiently and easily removed fully at low cost, and components with low value, such as H2, CO, CO2 and the like are completely converted into required CH4 component with high value, so the method has the characteristics of low requirement on quality of feed gas, high yield of liquefied natural gas product, high product purity, low production energy consumption, no environmental pollution, reliable flow, low investment, simple operation and good economic benefit.

Owner:SHANGHAI HANXING ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com