Method and device for catalyzing methanation of synthesis gas

A synthesis gas and methanation technology, applied in organic chemistry, hydrocarbon production from carbon oxides, etc., can solve the problems of uneconomical and universality, high price of aromatic hydrocarbons, and achieve enlarged production efficiency and high reaction space velocity. , enhance the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

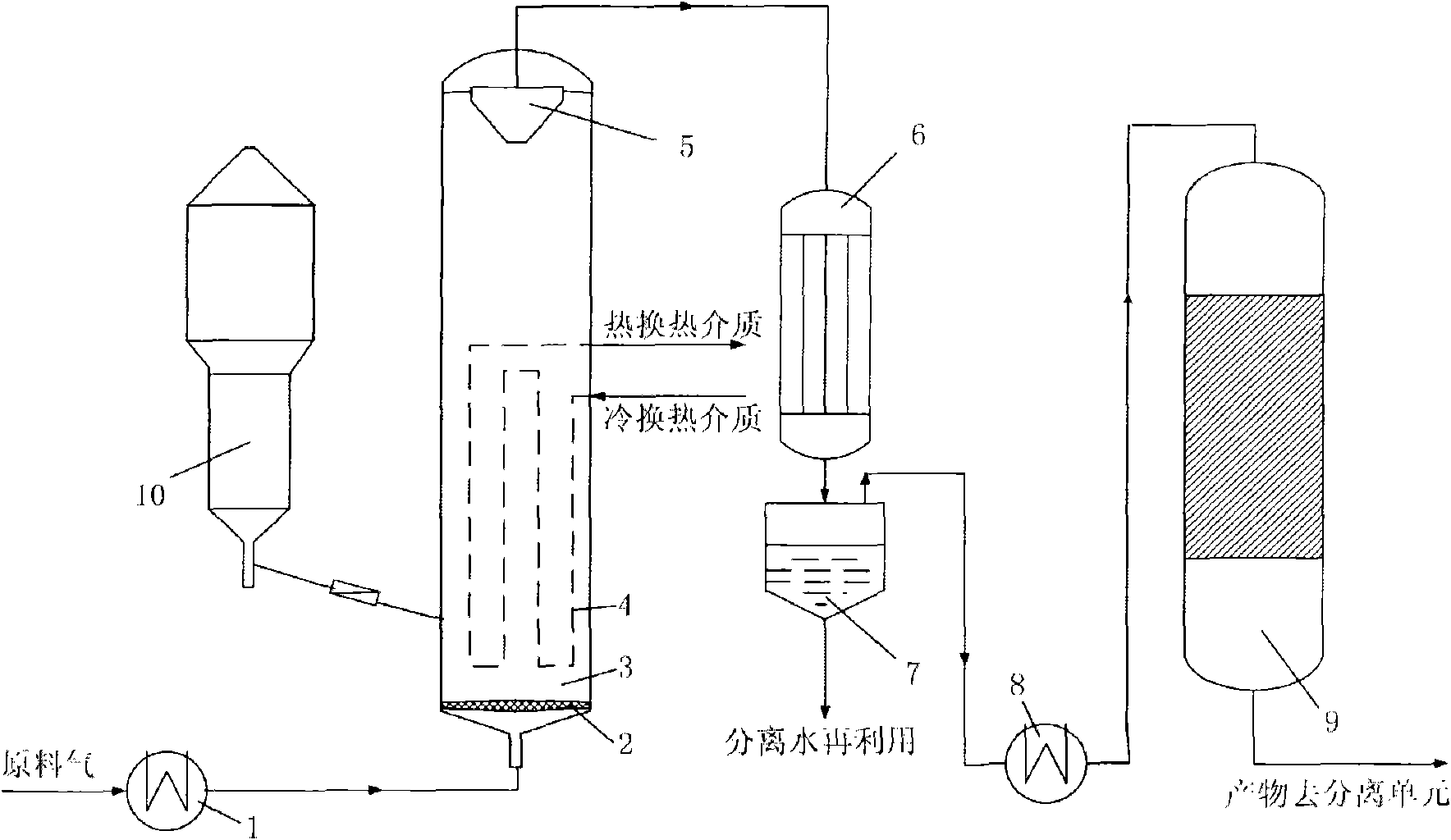

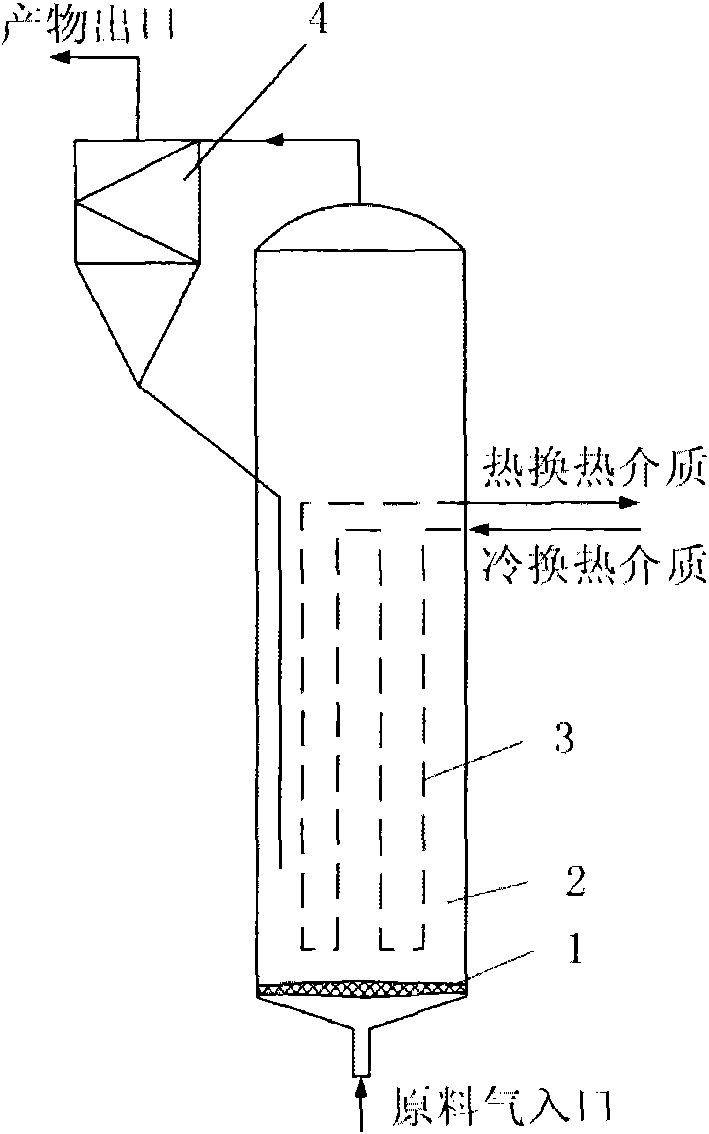

[0041] This embodiment is the method for catalytic methanation of syngas provided by the present invention, the fluidized bed reactor used adopts built-in gas-solid separator, and the specific device is as figure 1 shown.

[0042] The catalysts that are applied to the fixed bed and fluidized bed evaluation of the device of the present invention are all N182 methanation catalysts (purchased from Japan Nikki Catalyst Chemical Co., Ltd.), and Ni and Mg are active components in this catalyst, and alumina is a carrier. The fluidized bed catalyst adopts a spherical particle catalyst with a particle diameter of 40-100 μm, and the fixed bed catalyst adopts a columnar catalyst with a diameter and a height of 3 cm.

[0043] The composition and content of the reaction products were analyzed by Agilent Micro3000 gas chromatograph. The reaction conversion rate is calculated according to the following formula:

[0044] Conversion rate (%) = the amount of converted CO / the raw material amou...

Embodiment 2

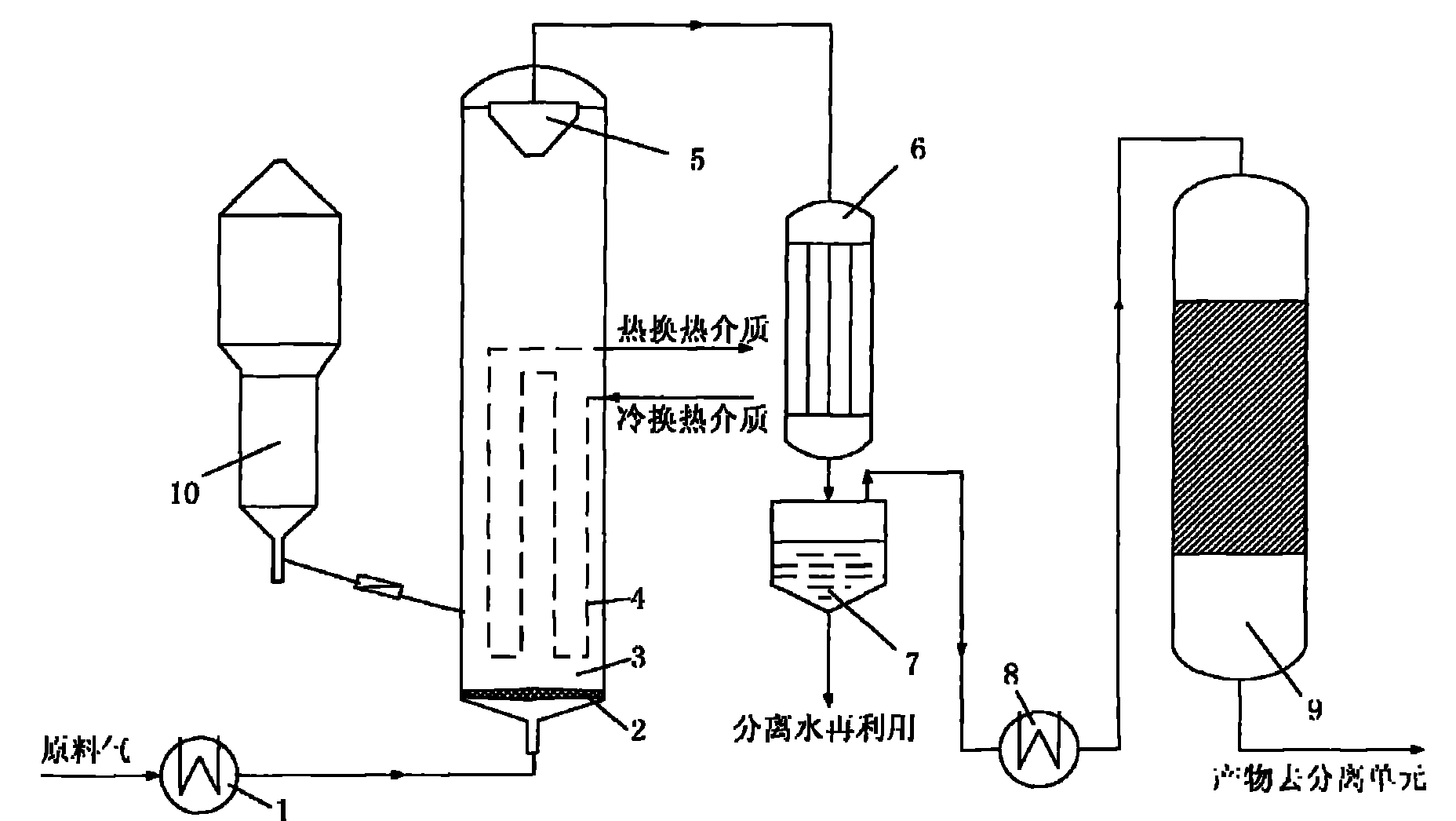

[0047] This example is the method for catalytic methanation of synthesis gas provided by the present invention, the fluidized bed reactor used adopts an external gas-solid separator, and the specific device is as figure 2 shown.

[0048] The reaction operating conditions and experimental results are the same as in Example 1, the only difference being that the gas-solid separator is external, that is, the prepared synthesis gas enters the fluidized bed reactor 3 after being uniformly distributed by the gas distributor. The intermediate product of the reaction in the fluidized bed reactor 3 is quickly separated from the catalyst through the external gas-solid separator 5, and the separated gas intermediate product is condensed through the heat exchanger 6 and the gas-liquid separator 7 and the water in it is separated , the mixed gas enters the fixed-bed reactor unit, and the separated solid catalyst flows into the fluidized-bed reactor for recycling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com