Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6027 results about "Intermediate product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An intermediate product is a product that might require further processing before it is saleable to the ultimate consumer. This further processing might be done by the producer or by another processor. Thus, an intermediate product might be a final product for one company and an input for another company that will process it further.

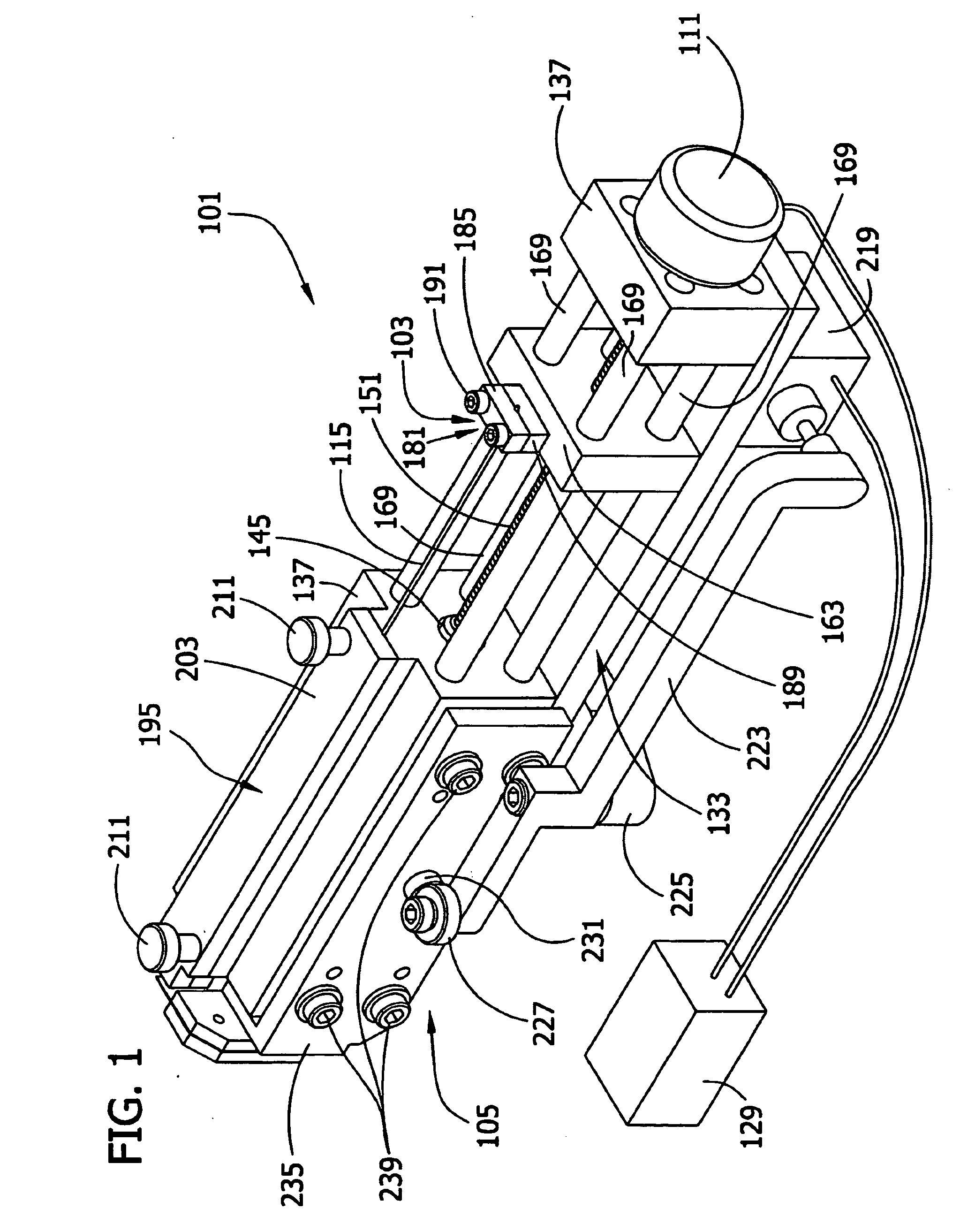

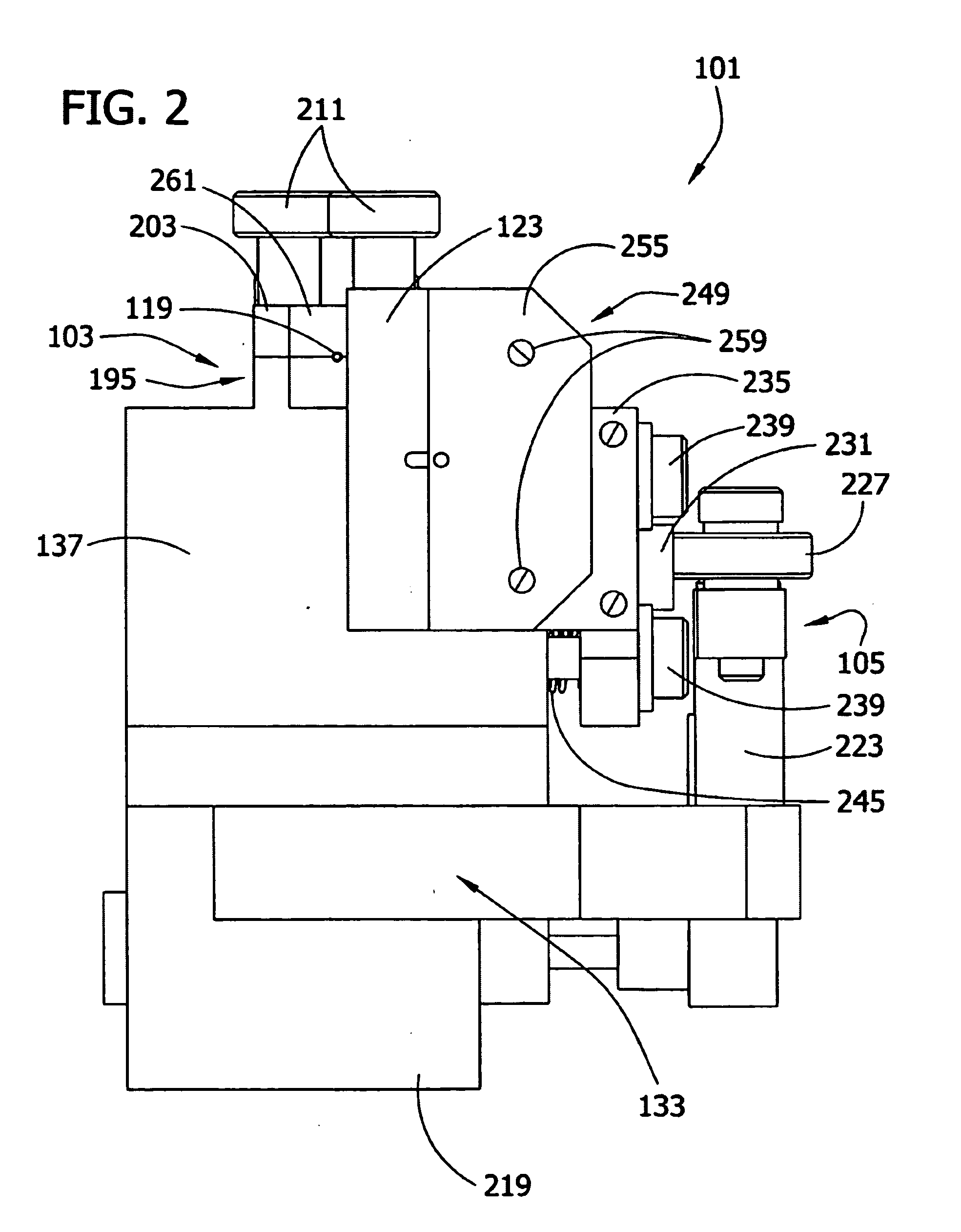

Method for providing a grinding surface on glass implements used in personal care

ActiveUS8790749B2Increase variabilityEasy to manufacturePretreated surfacesManicure/pedicurePersonal careFlat glass

Manufacturing method of grinding surface on glass cosmetics, in particular the nail and skin file, from flat glass of FLOAT type, is carried out by marking at least one abrasive surface on one or two sides of a glass pane or intermediate product. This surface is then coated with fusing glue, powdered with clean quartz sand with grain size between 1 and 500 μm using a sieve, and the surplus sand is knocked-down. The intermediate product with fixed sand is inserted into the fusing furnace where it is baked at the temperature of up to 900° C. The abrasive surface may be roughened by sand blasting before the fusing glue application; the intermediate product coated with fusing glue can be decorated with glass fritte.

Owner:HACEK OVER SKUTCHANOVA ZUZANA

System comprising the gasification of fossil fuels to process unconventional oil sources

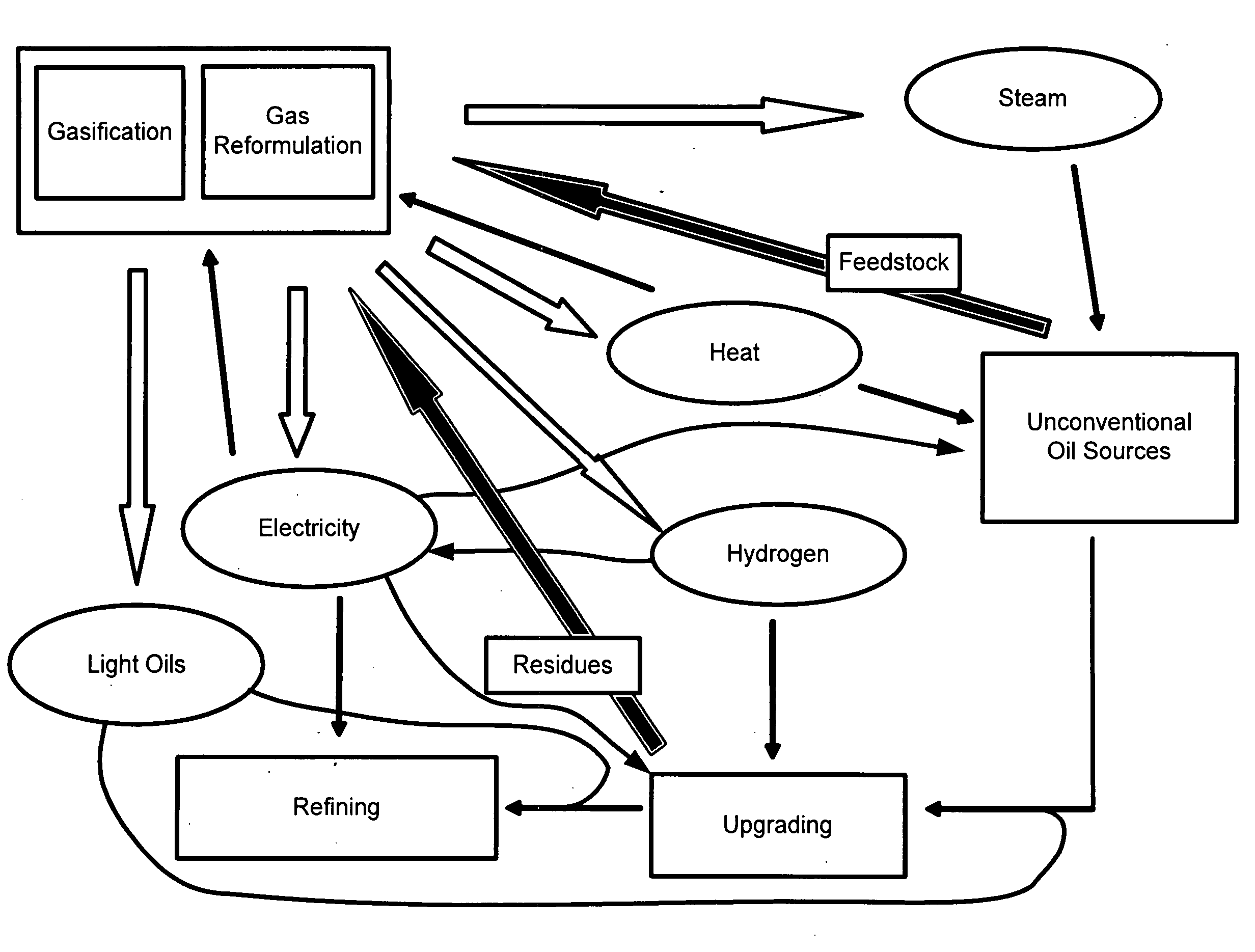

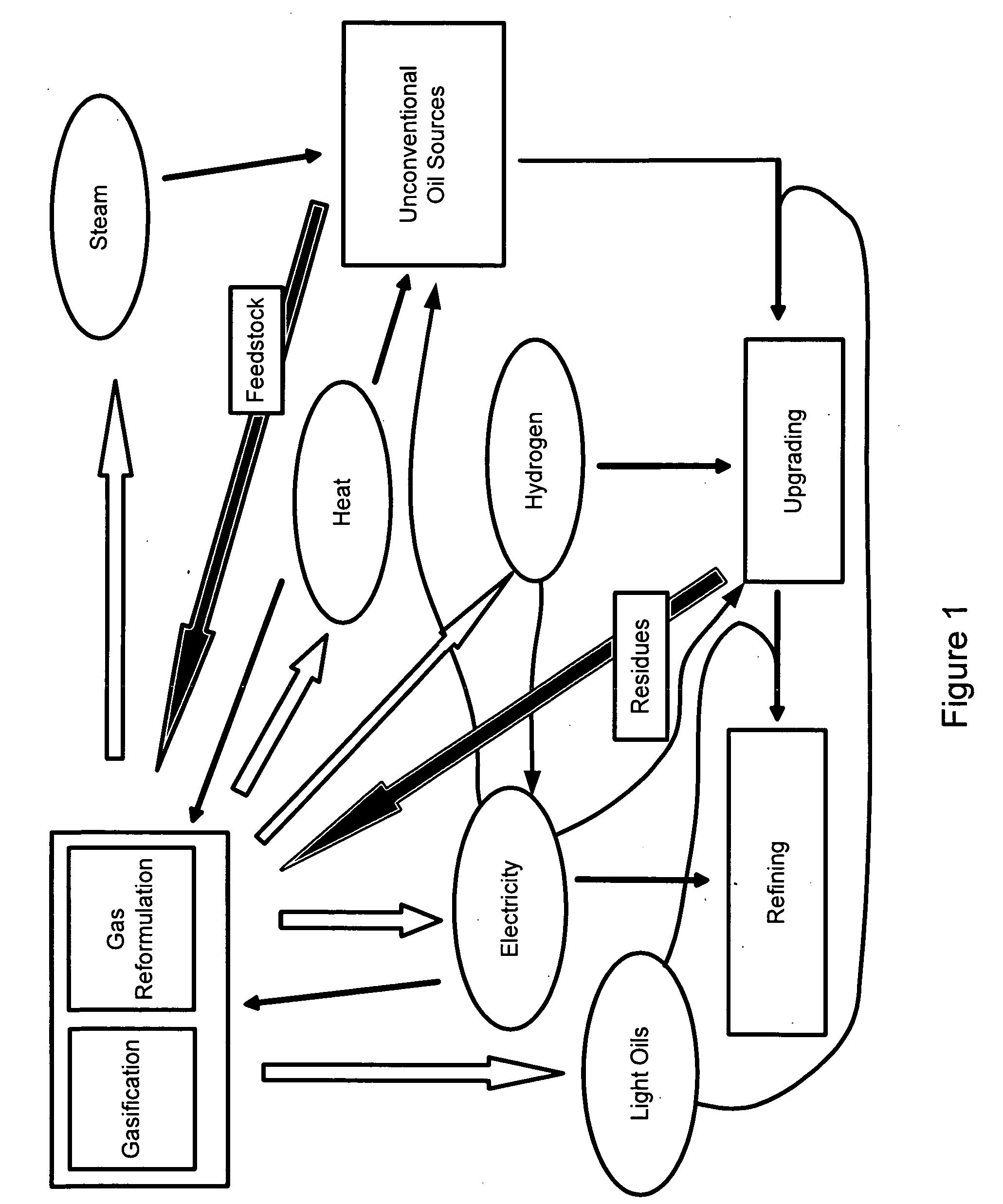

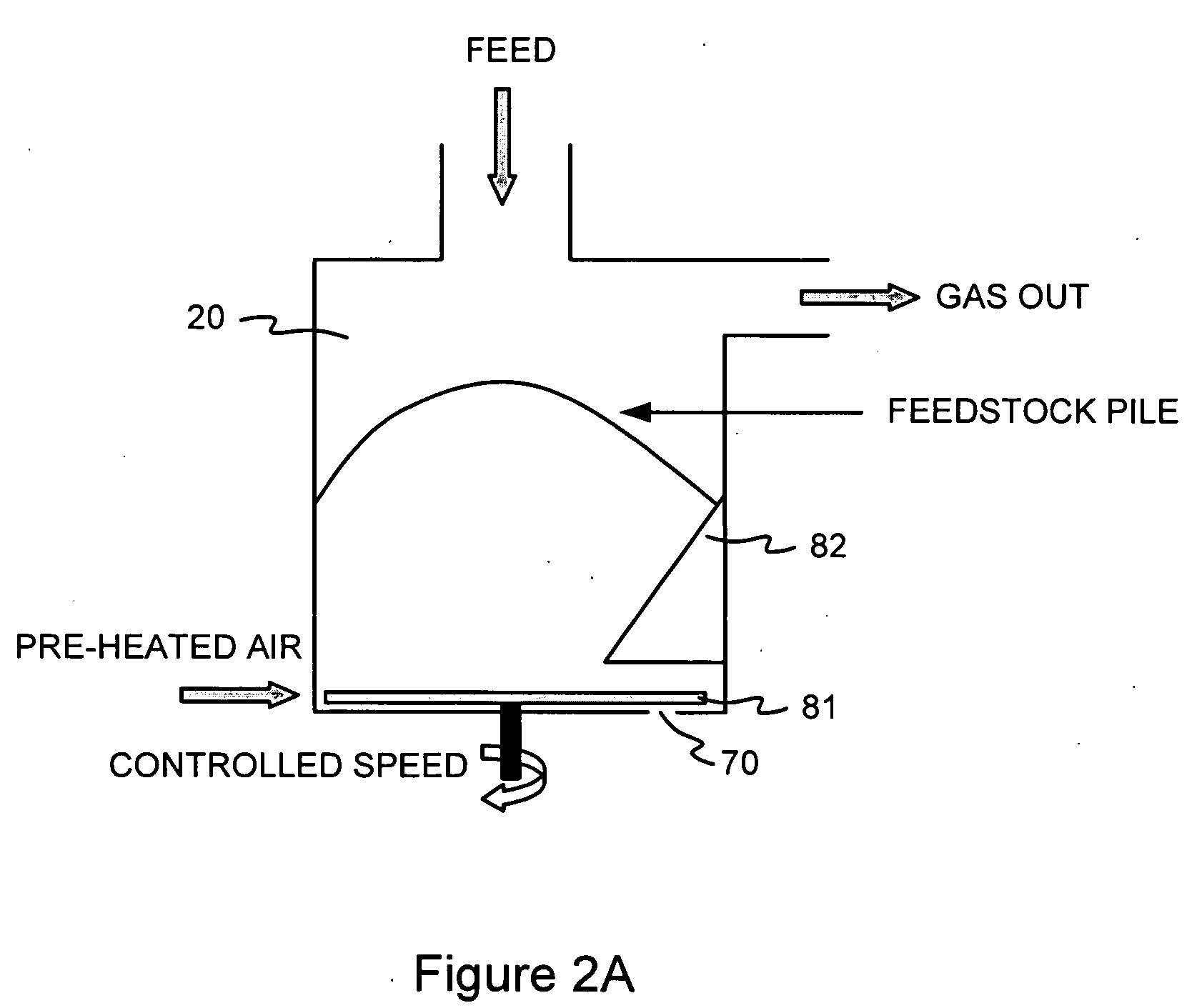

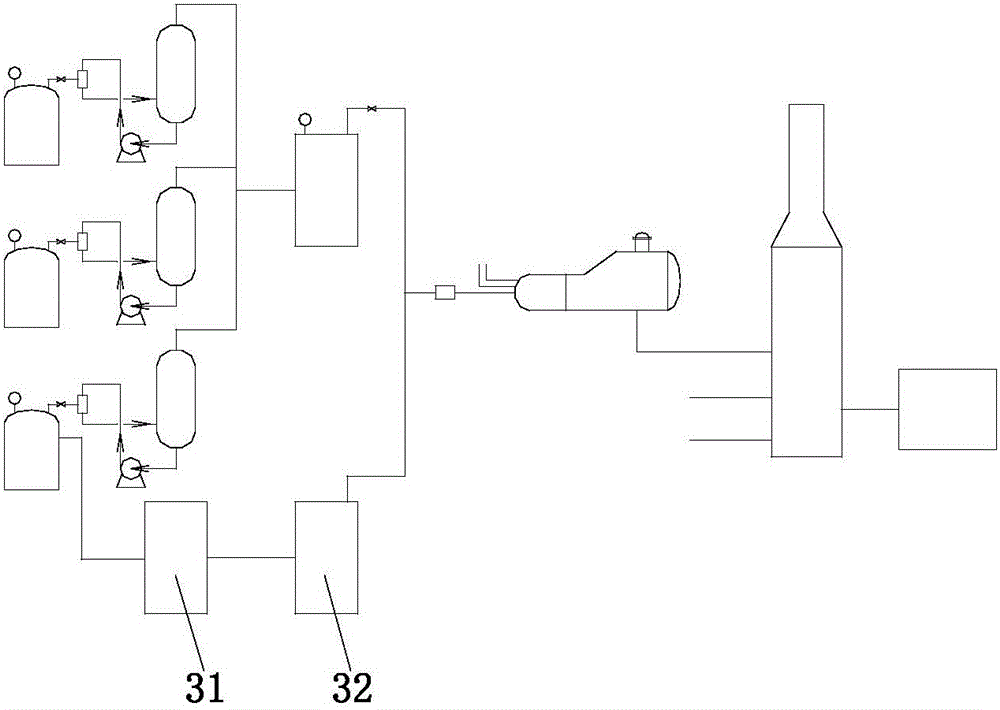

A facility comprising integrated systems for the extraction, and optionally upgrading and / or refinement, of unconventional oil sources, using fossil fuels as a primary source of energy. In particular, this facility provides a means to gasify one or more fossil fuels in an efficient manner, converting it into intermediate products such as heat, steam and electricity, which are then used by the system to obtain useful fuel products from unconventional oil sources such as tar sands and oil shale. The design of the components of this facility is optimized such that the overall costs are competitive with an equivalent unconventional oil source processing facility that uses natural gas as a source of processing energy. The facility can be used on its own, may use supplemental natural gas energy sources, or may be used in conjunction with an existing facility that uses natural gas as an energy source in order to improve the overall cost effectiveness of the processing and / or reduce the requirement for other energy sources, such as natural gas.

Owner:PLASCO ENERGY GROUP INC

Self-Assembling Cell Aggregates and Methods of Making Engineered Tissue Using the Same

Owner:MUSC FOUND FOR RES DEV +1

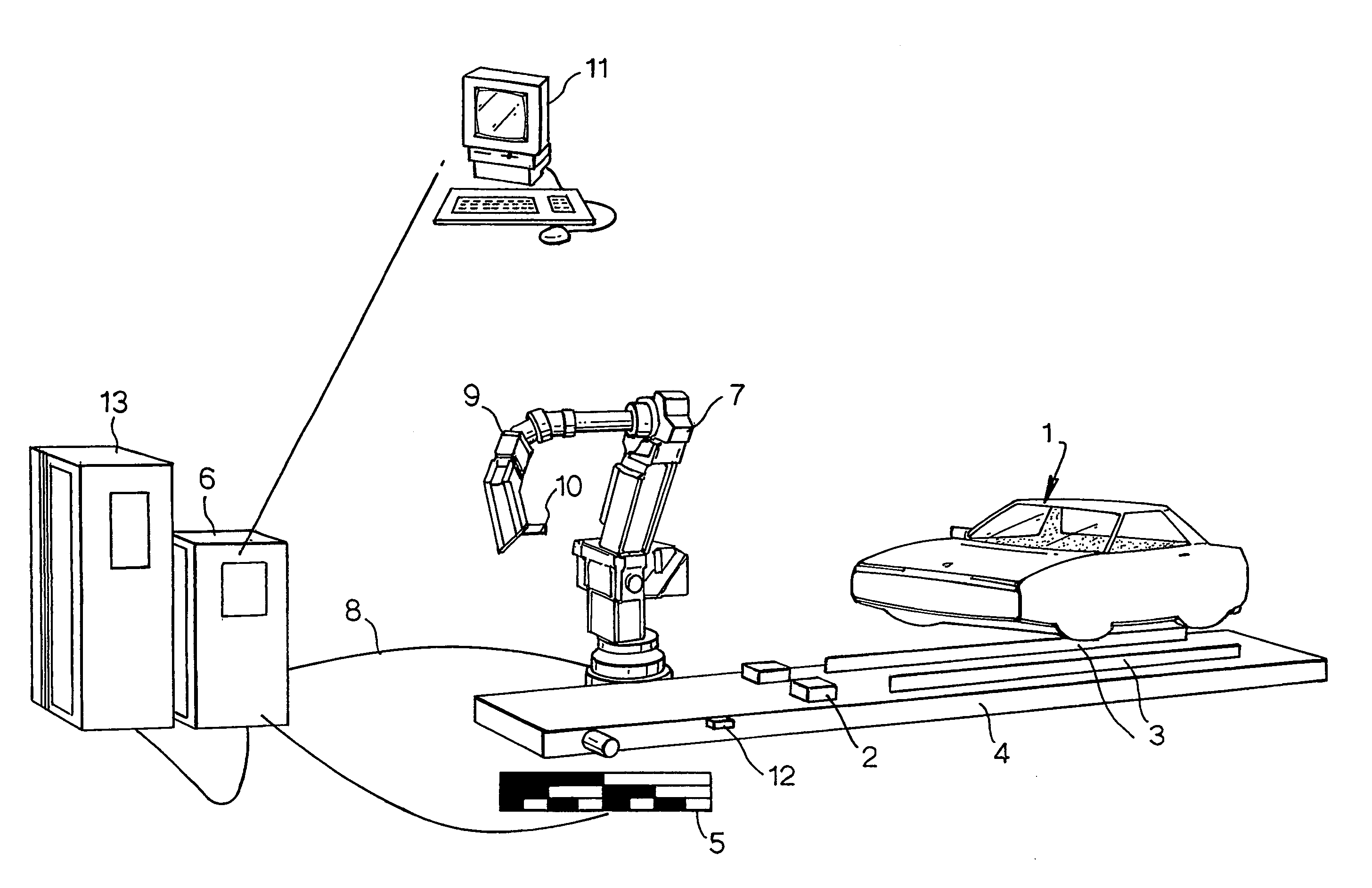

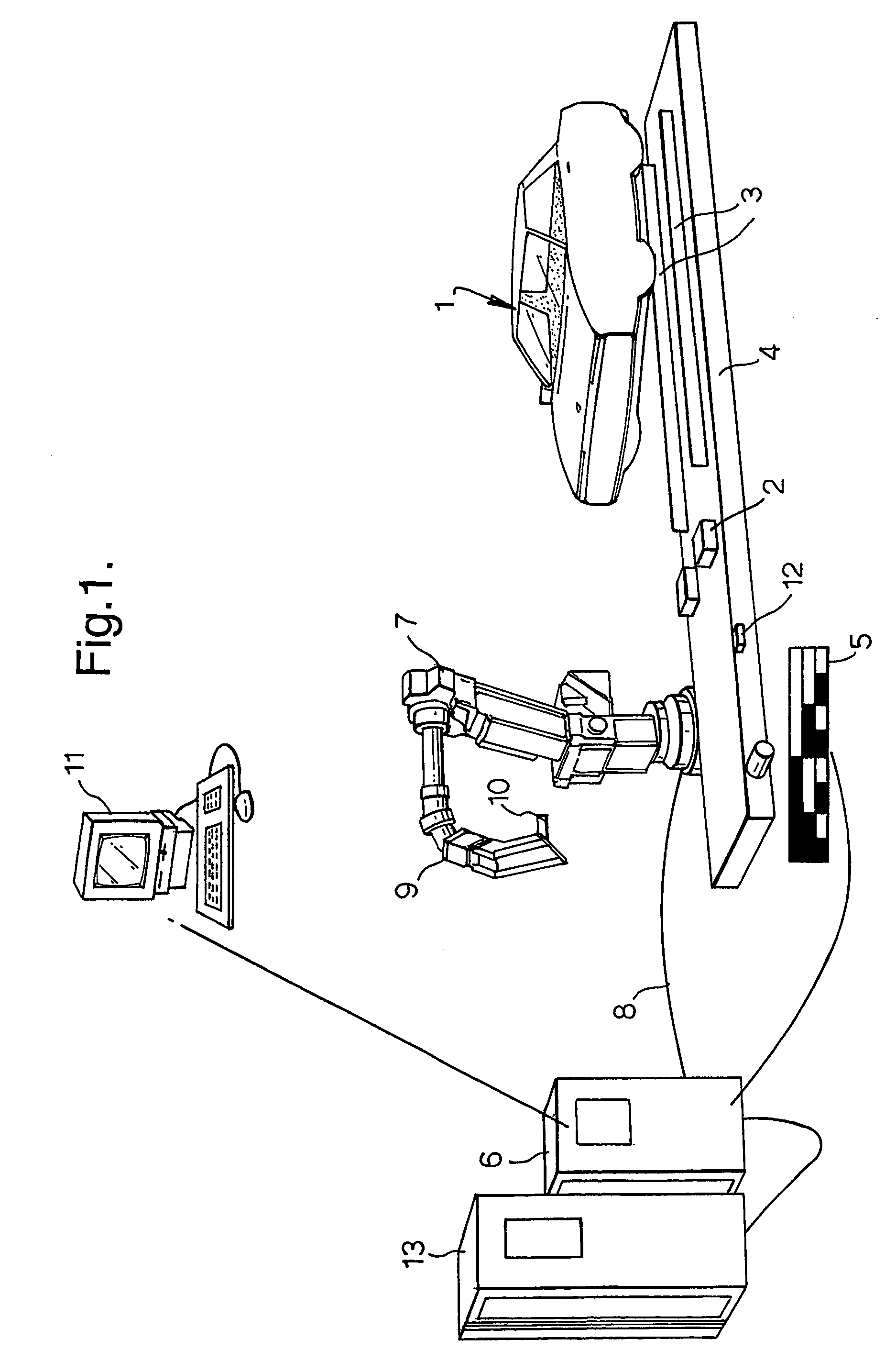

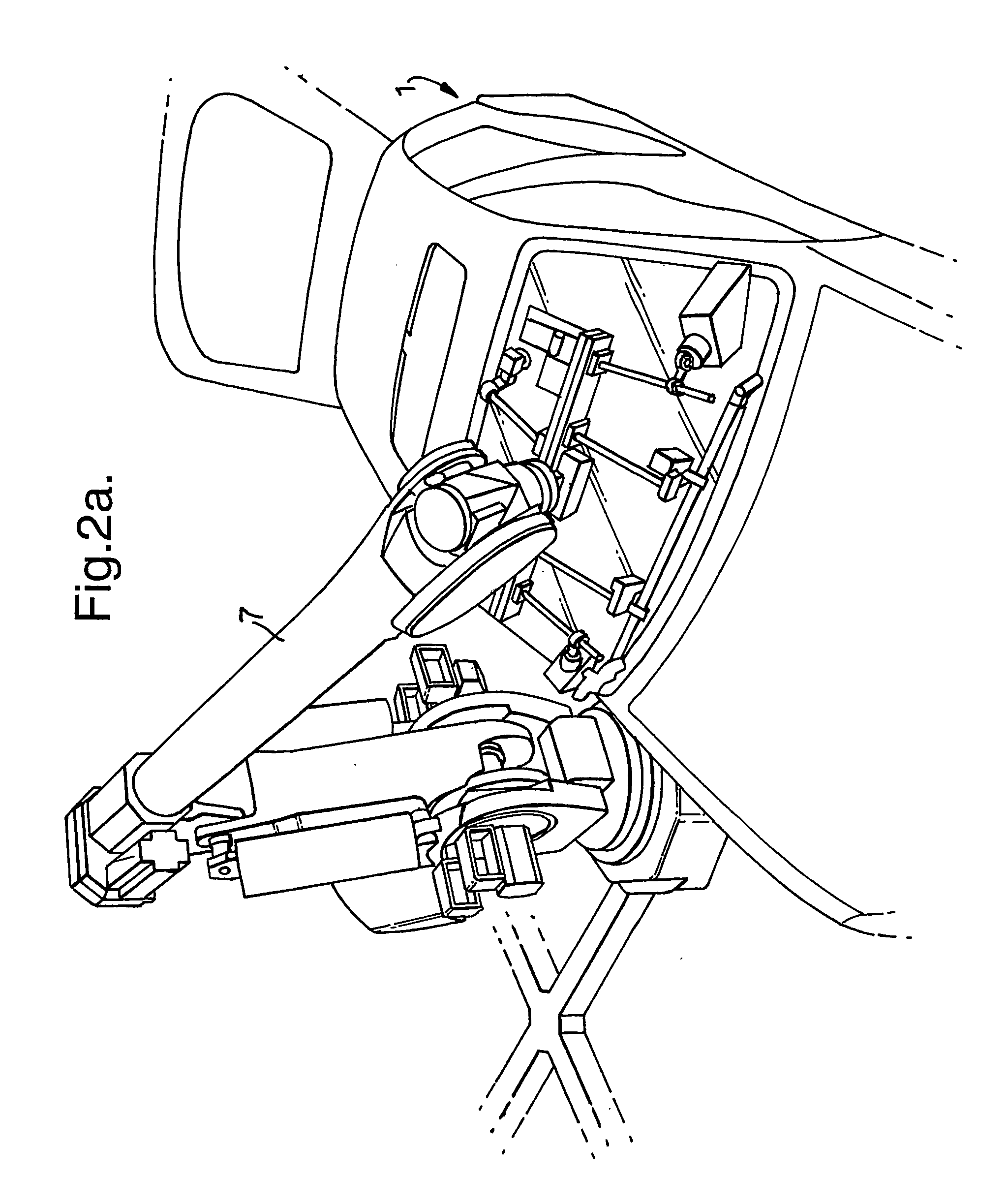

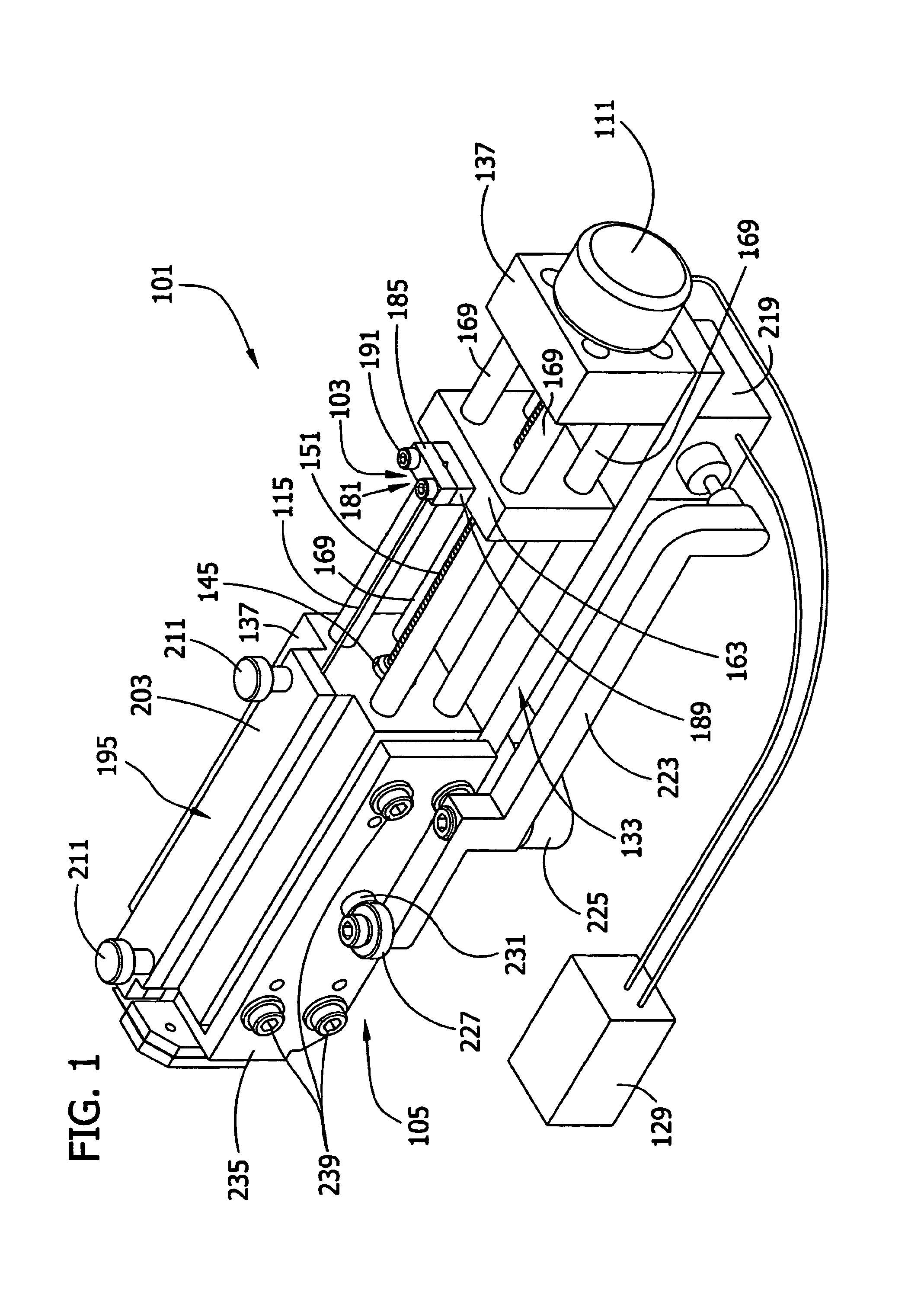

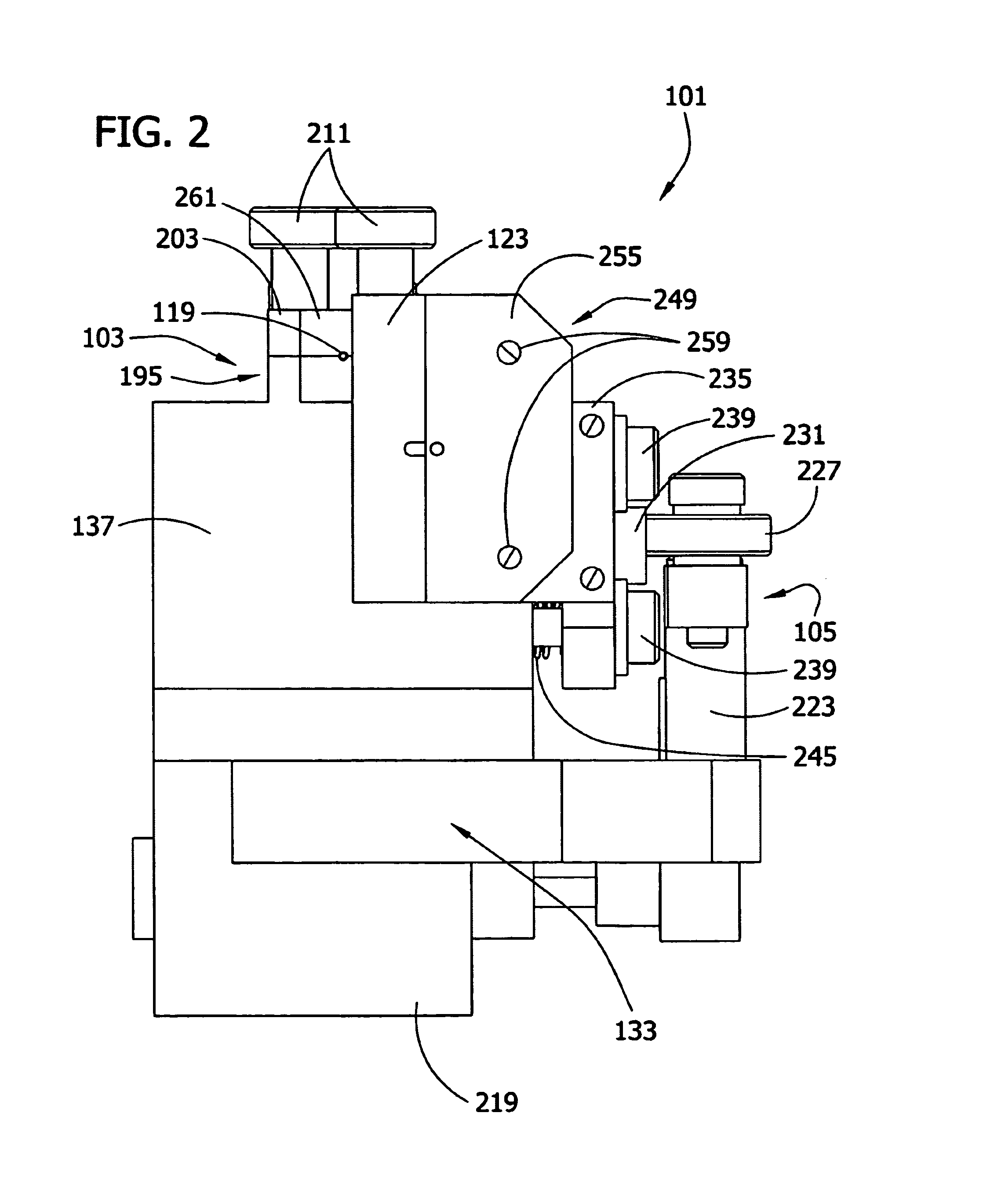

Auto Motion: Robot Guidance for Manufacturing

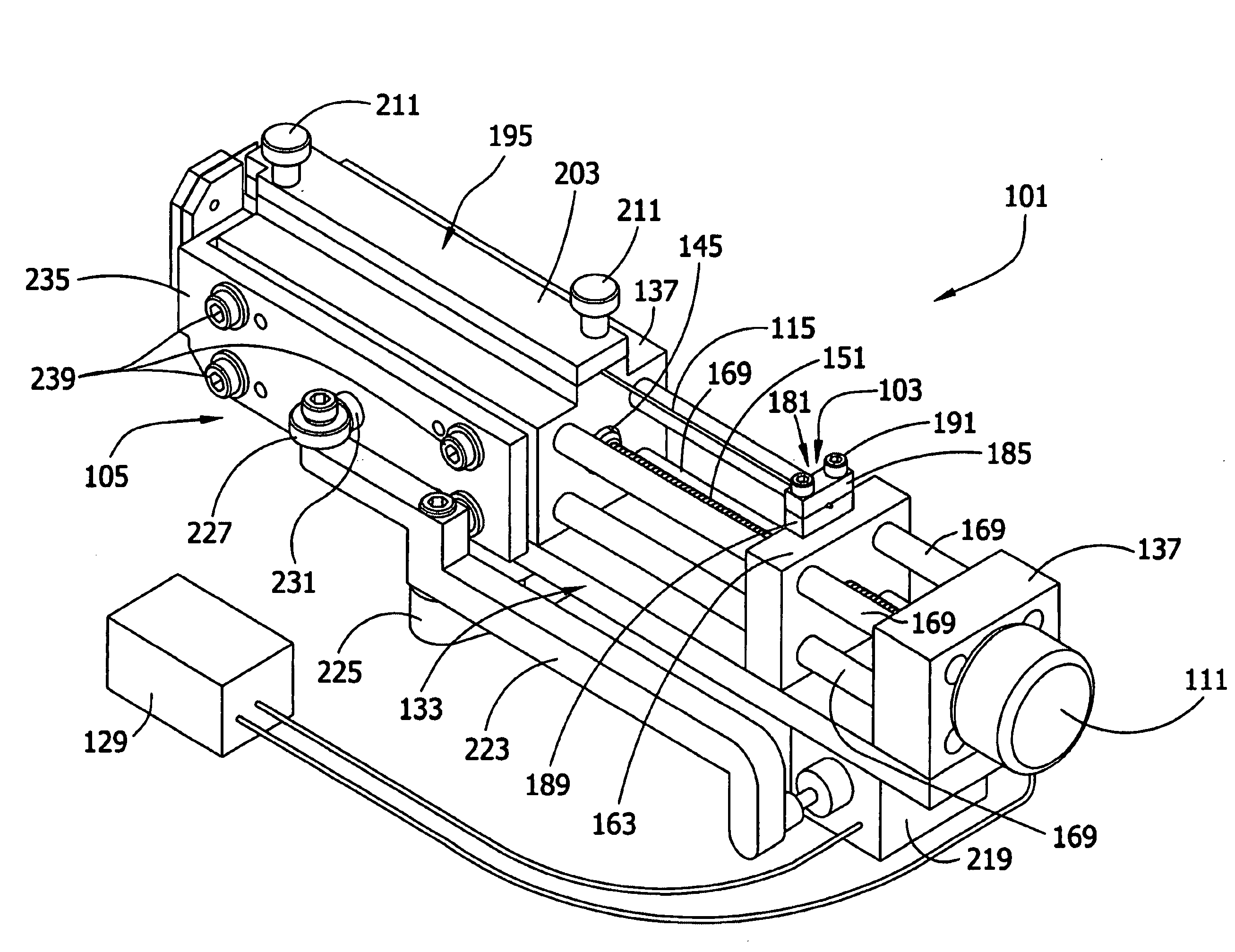

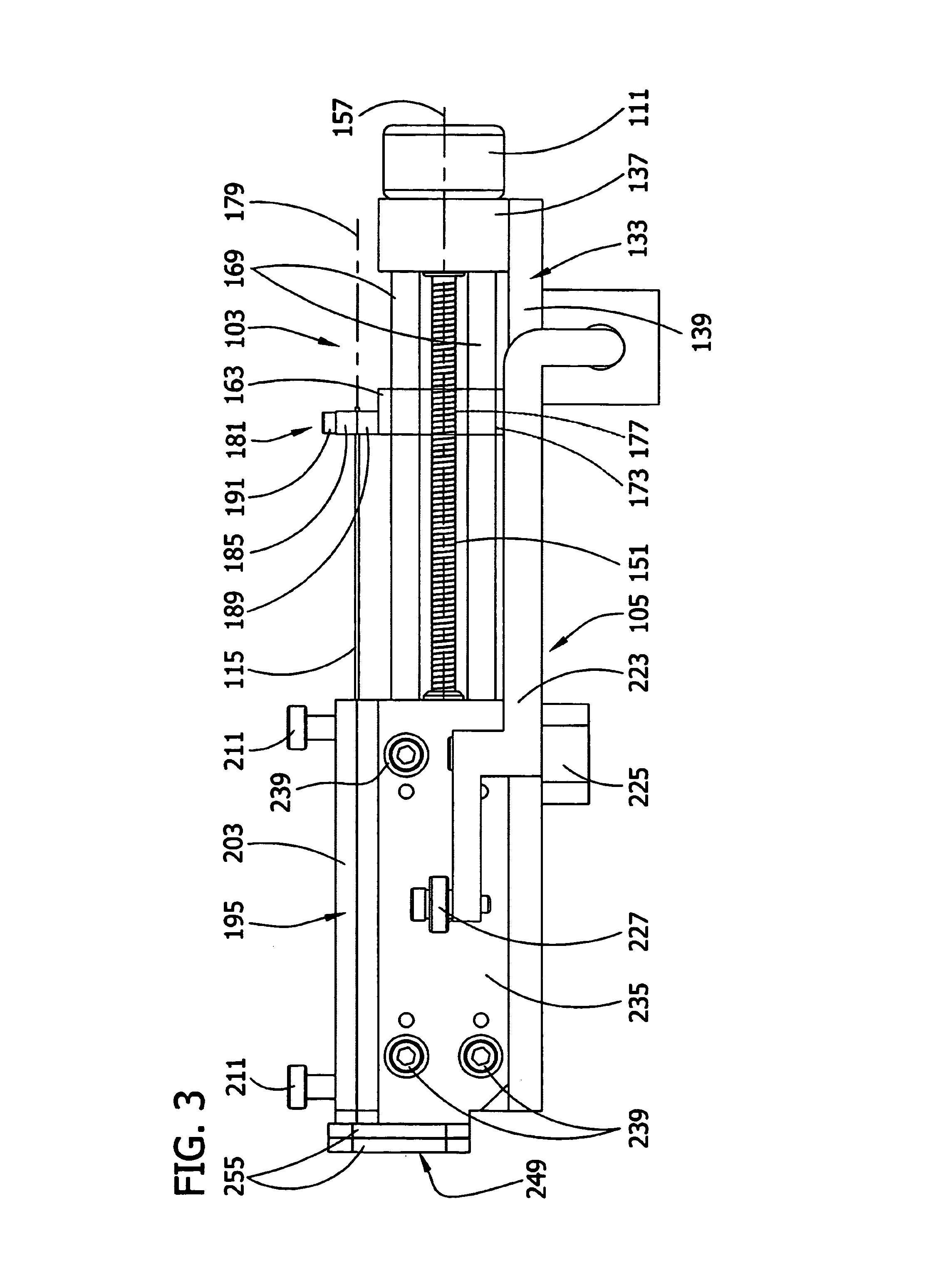

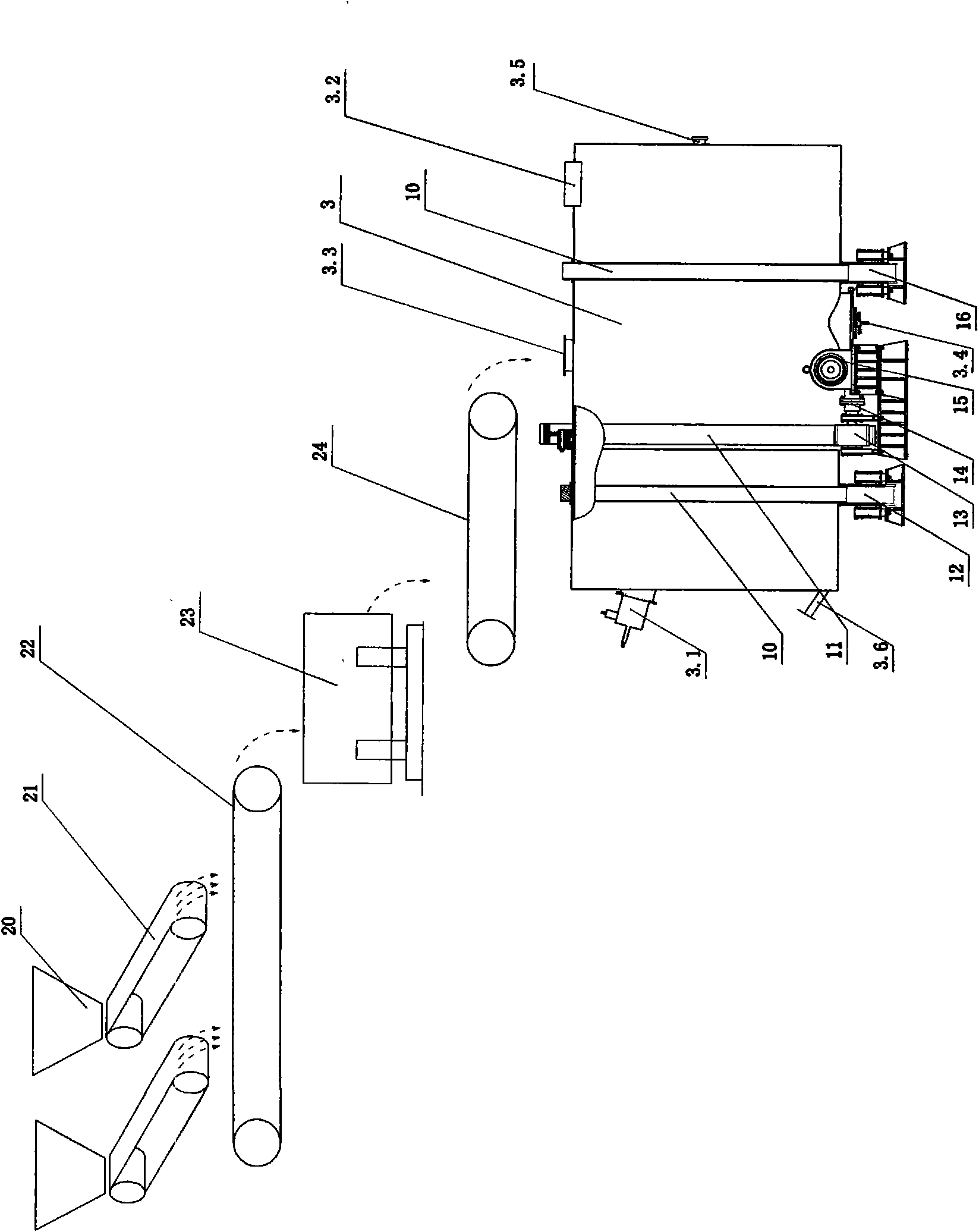

A robot manufacturing facility, for example for use in automobile manufacture, includes at least one robot for acting on a workpiece or intermediate product of a pre-calculated shape and dimensions at a pre-calculated position and orientation relative to a reference frame. The robot includes a body or base structure, at least one end effector movable with respect to the body or base structure for acting on workpieces, means for moving the end effector and sensing means for sensing the position of the each effector. The sensing means preferably includes a laser light source carried by the robot and means for detecting laser light, from said source, reflected from the workpiece. The movement of the end effector is controlled according to a predetermined program, modified in accordance with signals from the sending means, so that the robot is able to compensate for departures from pre-calculated values of the position and orientation and / or shape and / or dimensions of the workpiece.

Owner:READ DALE

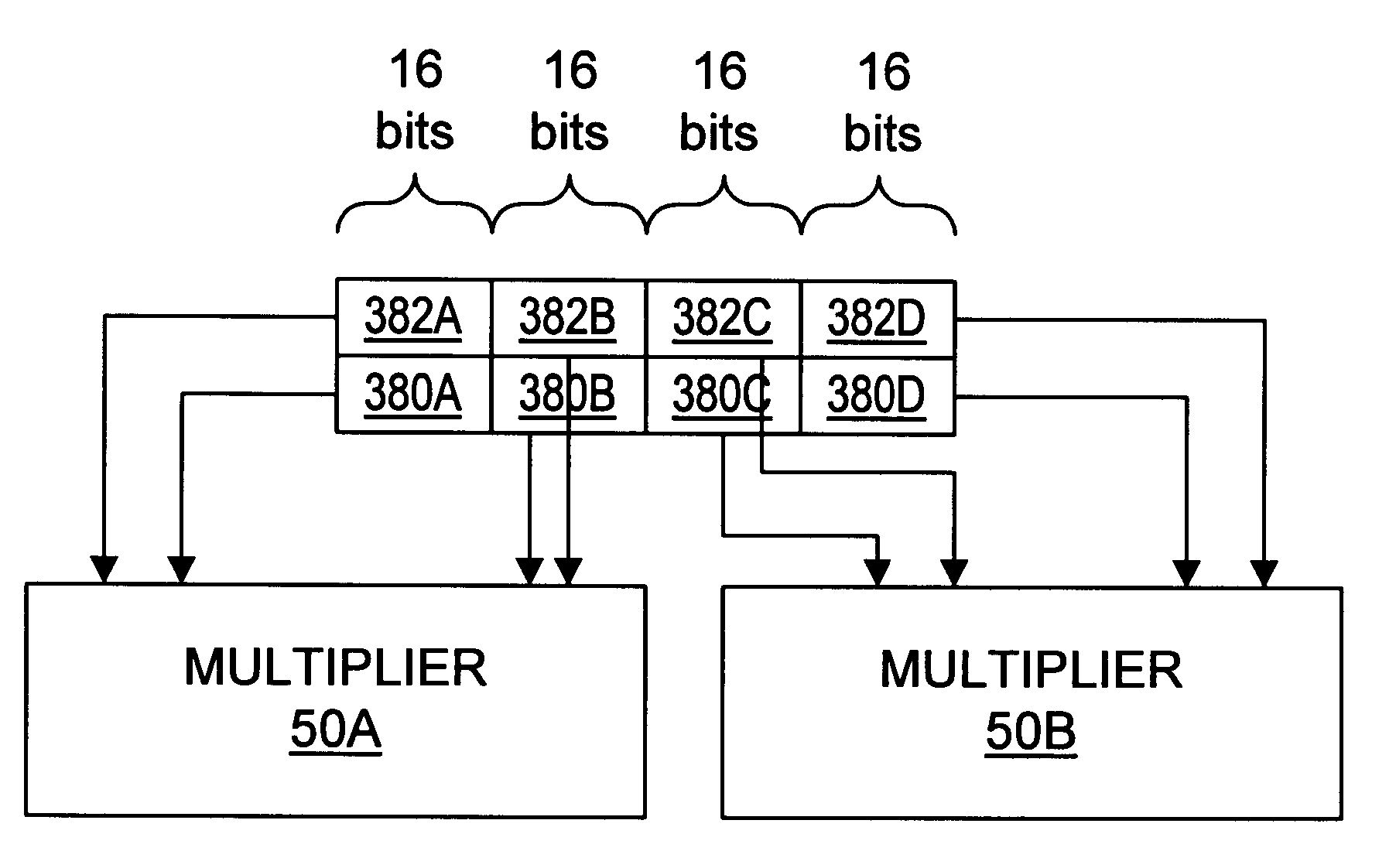

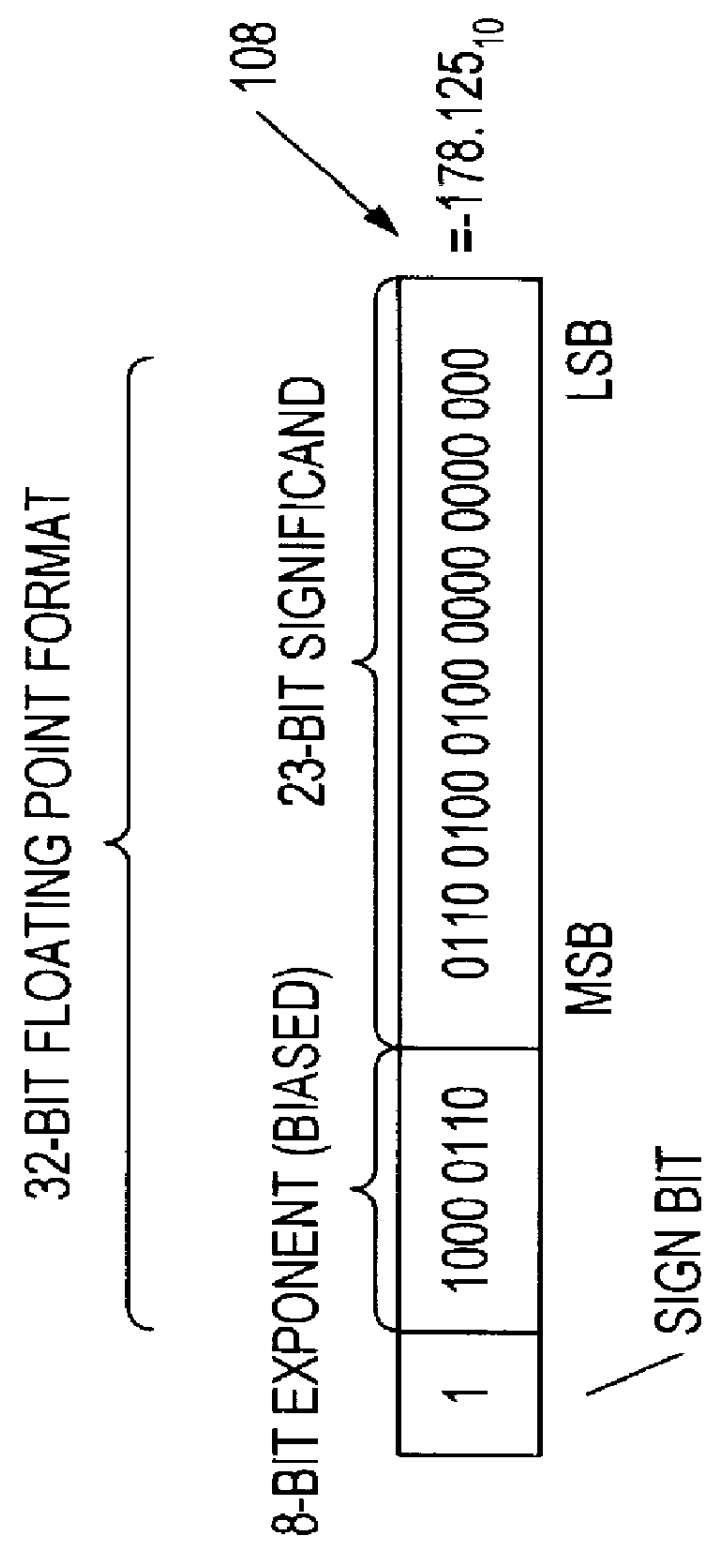

Method and apparatus for multi-function arithmetic

InactiveUS6223198B1Runtime instruction translationComputation using non-contact making devicesConstant powerRounding

A multiplier capable of performing signed and unsigned scalar and vector multiplication is disclosed. The multiplier is configured to receive signed or unsigned multiplier and multiplicand operands in scalar or packed vector form. An effective sign for the multiplier and multiplicand operands may be calculated and used to create and select a number of partial products according to Booth's algorithm. Once the partial products have been created and selected, they may be summed and the results may be output. The results may be signed or unsigned, and may represent vector or scalar quantities. When a vector multiplication is performed, the multiplier may be configured to generate and select partial products so as to effectively isolate the multiplication process for each pair of vector components. The multiplier may also be configured to sum the products of the vector components to form the vector dot product. The final product may be output in segments so as to require fewer bus lines. The segments may be rounded by adding a rounding constant. Rounding and normalization may be performed in two paths, one assuming an overflow will occur, the other assuming no overflow will occur. The multiplier may also be configured to perform iterative calculations to evaluate constant powers of an operand. Intermediate products that are formed may be rounded and normalized in two paths and then compressed and stored for use in the next iteration. An adjustment constant may also be added to increase the frequency of exactly rounded results.

Owner:ADVANCED SILICON TECH

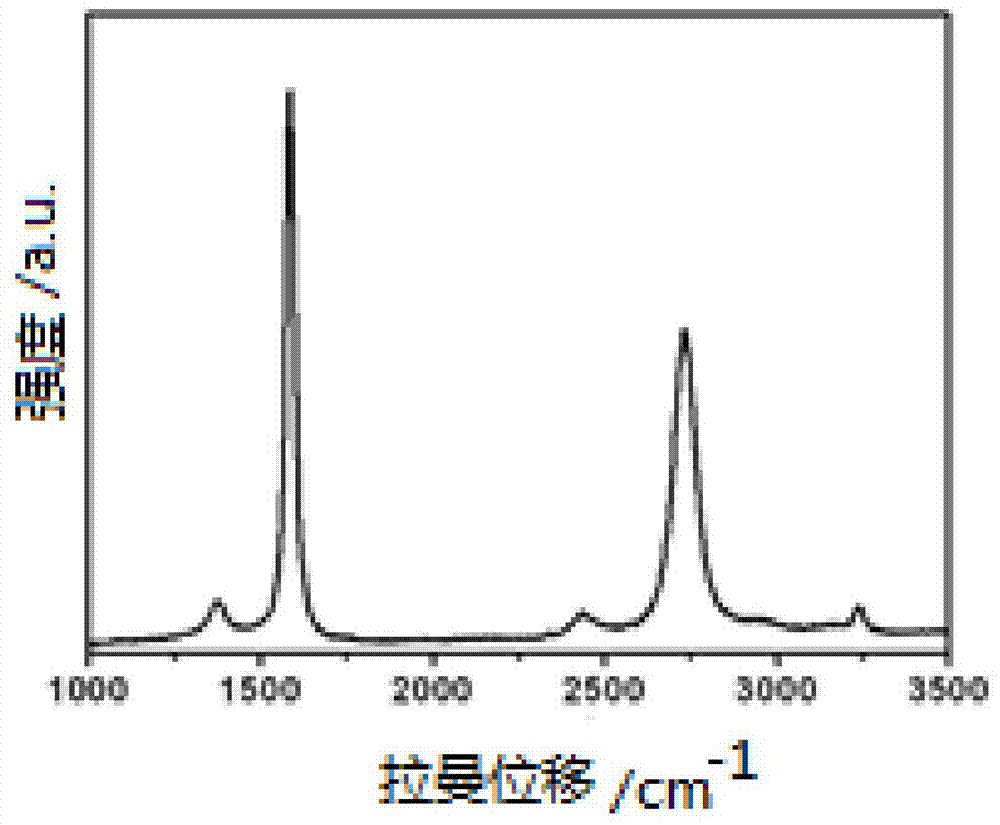

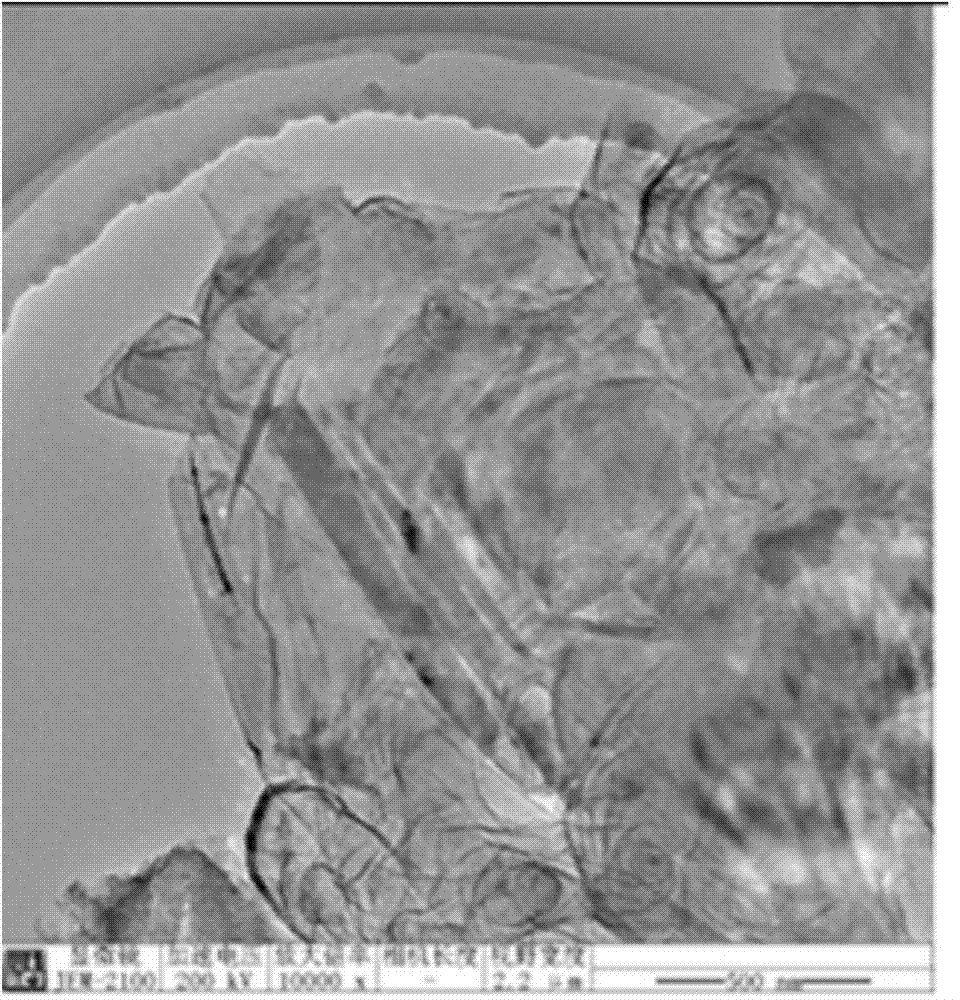

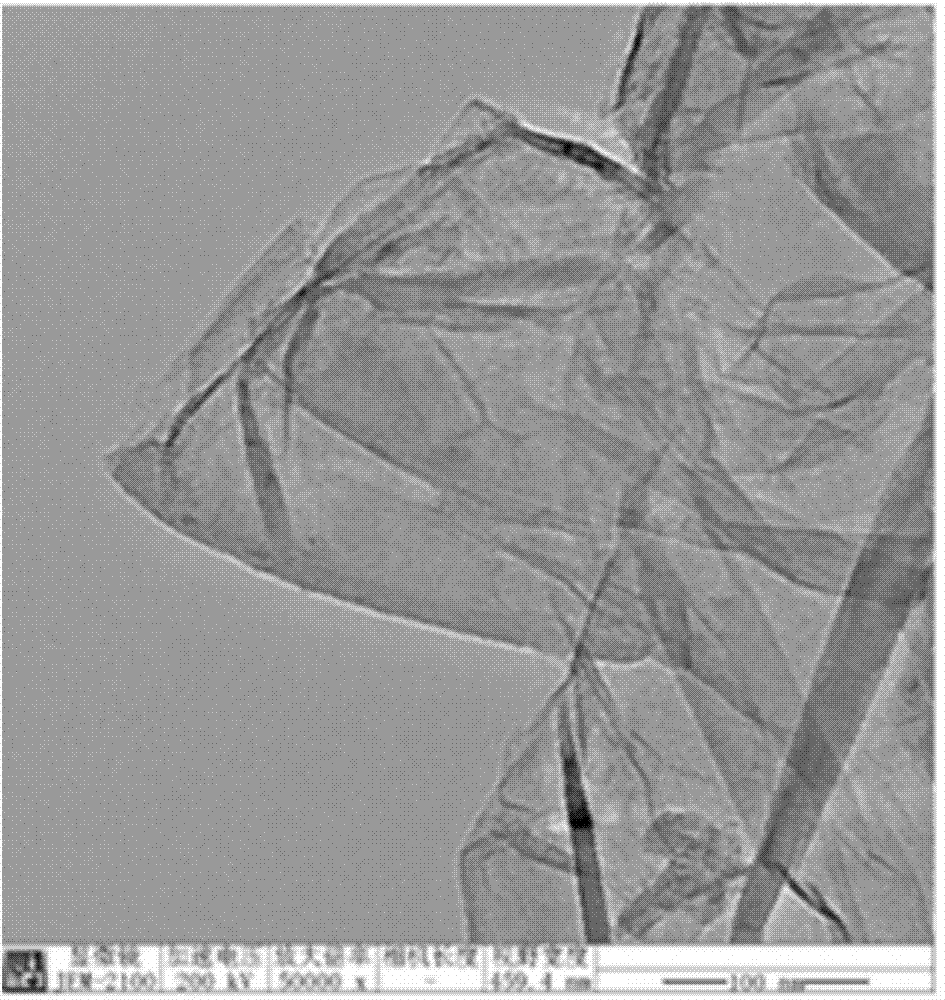

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Novel carbon-sulfur compound for lithium-sulfur battery

InactiveCN101587951AIncrease profitIncrease specific energyCell electrodesSulfur compoundsElectric capacityInternal resistance

The invention relates to a novel carbon-sulfur compound for an anode material of a lithium-sulfur battery and a preparation method thereof. Sulfur is filled into a nano and micron hole of a matrix in an elementary substance way by taking a macroporous carbon material with high pore volume, electrical conductivity and specific surface area as the matrix, and the sulfur and carbon can also carry out combination reaction so as to prepare the novel carbon-sulfur compound of which the sulfur exists in one or more chemical states in a carbon material. The novel carbon-sulfur compound used as the anode material of the lithium-sulfur battery has the advantages that the high pore volume has large contained sulfur contents and can ensure high electric capacity; the small granularity of the sulfur can reduce a conductive distance between ions and electrons and increase the utilization ratio of the sulfur; and the adsorption characteristics of the high specific surface of the carbon material can inhibit a discharging intermediate product from dissolving and moving towards a cathode, reduce the self discharge, prevent a nonconductive discharging product, namely lithium sulfide from largely accumulating outside carbon particles and reduce internal resistance, therefore, the material can improve the specific energy, the specific power and the cycle performance of the lithium-sulfur battery.

Owner:NO 63971 TROOPS PLA

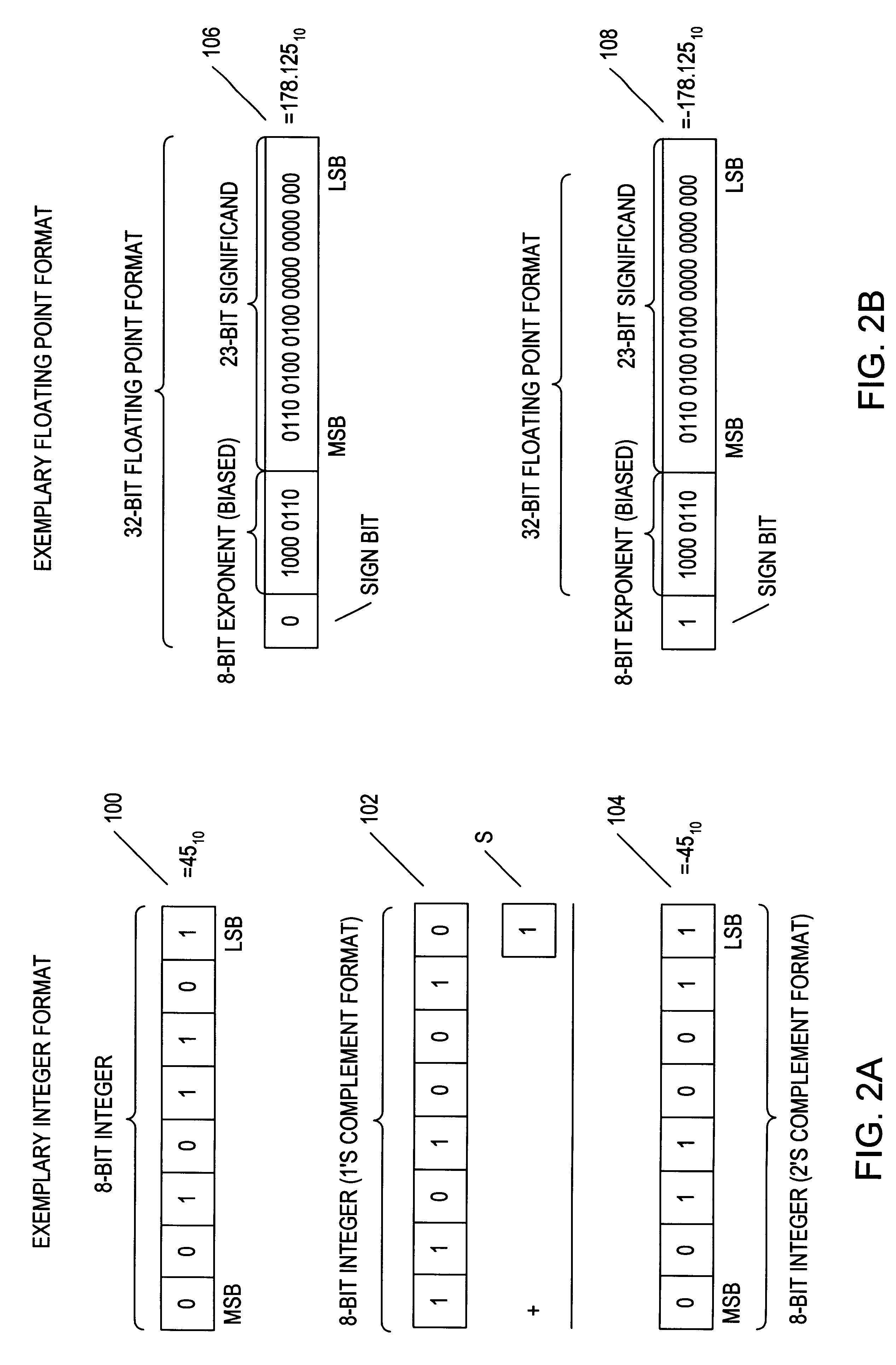

Method and apparatus for achieving higher frequencies of exactly rounded results

InactiveUS6134574ARuntime instruction translationComputation using non-contact making devicesBinary multiplierOperand

Owner:GLOBALFOUNDRIES INC

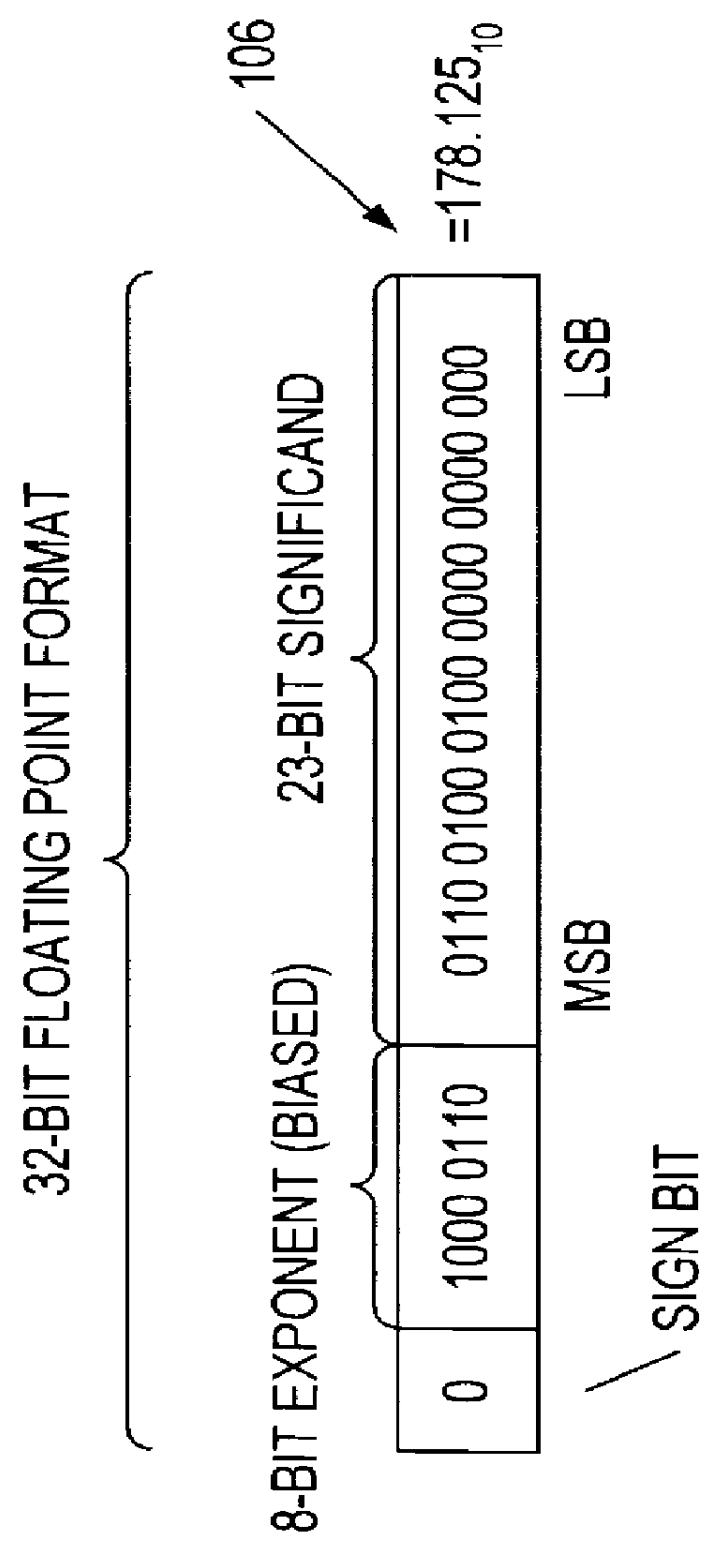

In-situ biological repairing method for biomass intensified petroleum contaminative soil

ActiveCN101104177APromote accumulationIncrease intakeFungiBacteriaBiomass degradationIn situ bioremediation

Owner:CHINA PETROLEUM & CHEM CORP +1

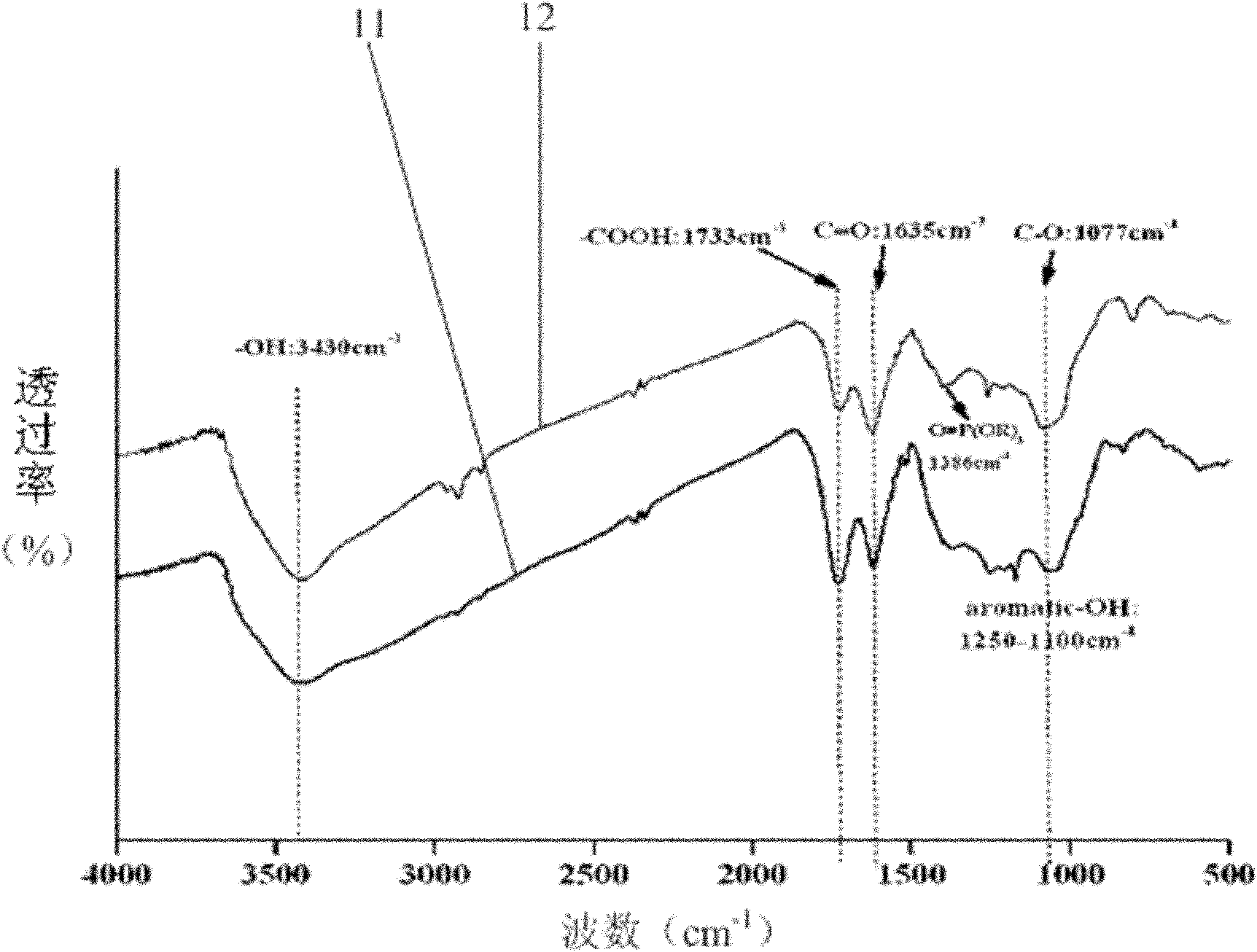

Preparation method of modified graphene oxide and preparation method of composite material containing modified graphene oxide

ActiveCN102127324AImprove flame retardant performanceEvenly dispersedPigment treatment with non-polymer organic compoundsEpoxyPolyamide

The invention provides a preparation method of a modified graphene oxide, comprising the following steps of: (a) reacting a phosphorus oxychloride compound, cyanuric chloride or diisocyanate with glycidol to obtain an intermediate product; and (b) dispersing graphite oxide in an organic solvent, dropwise adding to the intermediate product obtained through reaction, and reacting to obtain the modified graphene oxide. The invention also provides a preparation method of a composite material containing the modified graphene oxide, comprising the following steps of: dispersing the modified graphene oxide obtained through the preparation method in the technical scheme in an organic solvent, mixing the modified graphene oxide containing epoxide groups with epoxy resin oligomers and a polyamide curing agent, and curing to obtain the composite material containing the modified graphene oxide. In the composite material provided by the invention, the modified graphene oxide reacts with a resin substrate, is more uniform to disperse in the obtained composite material, and has better flame-retarding performance.

Owner:UNIV OF SCI & TECH OF CHINA

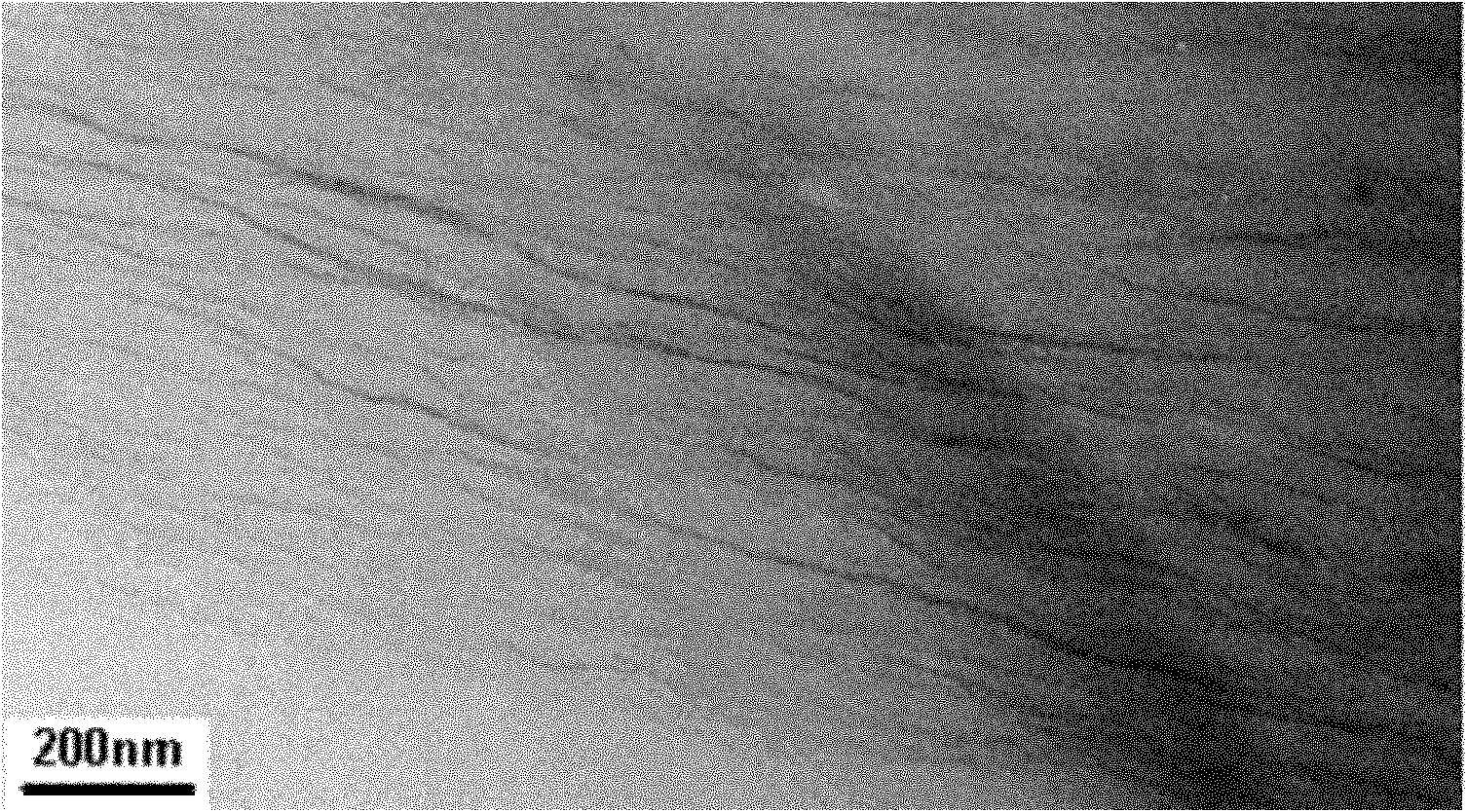

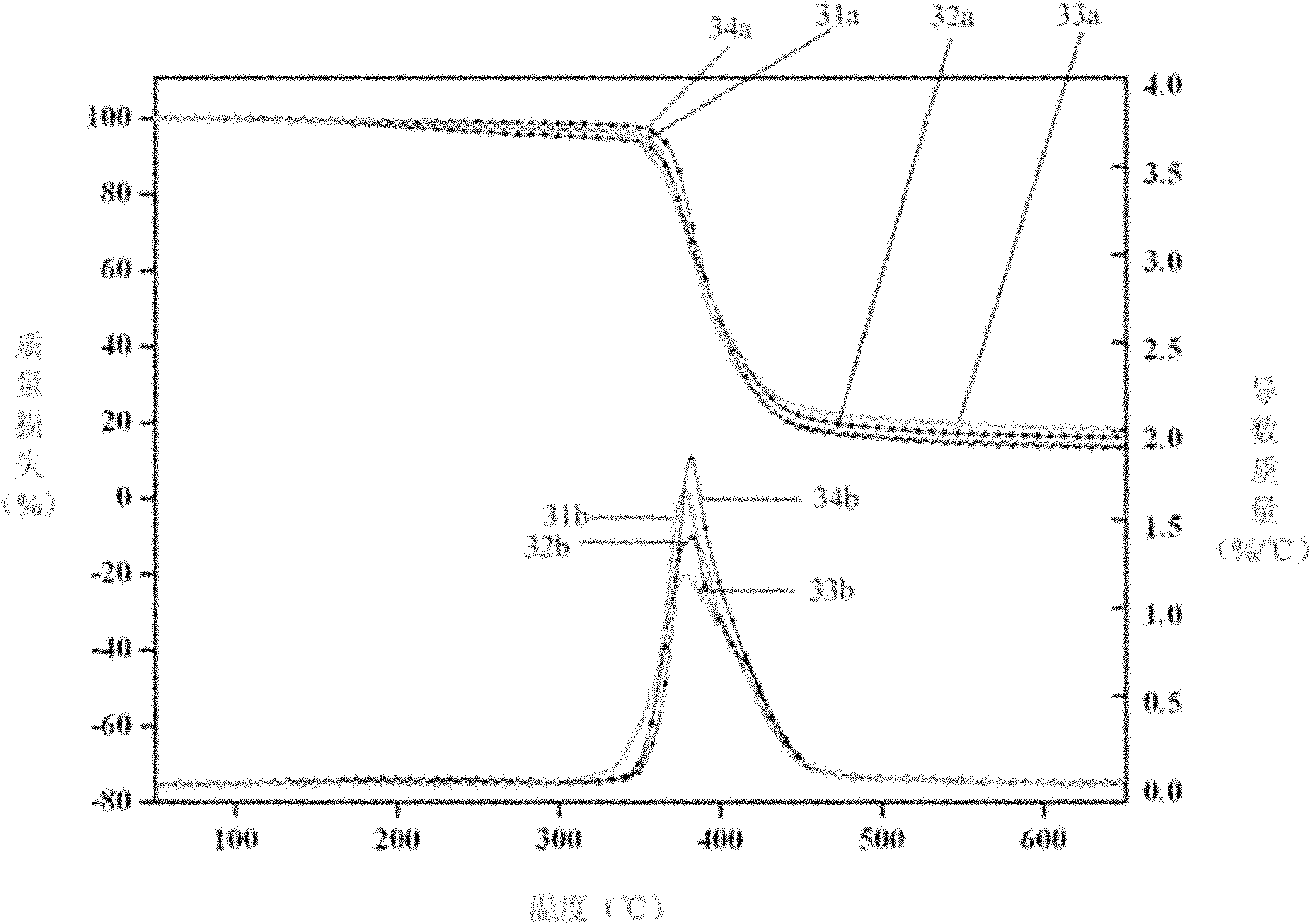

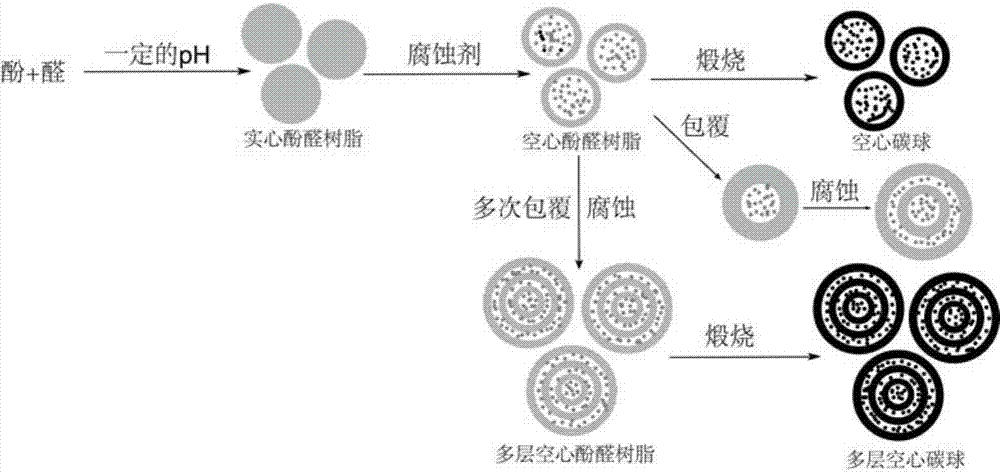

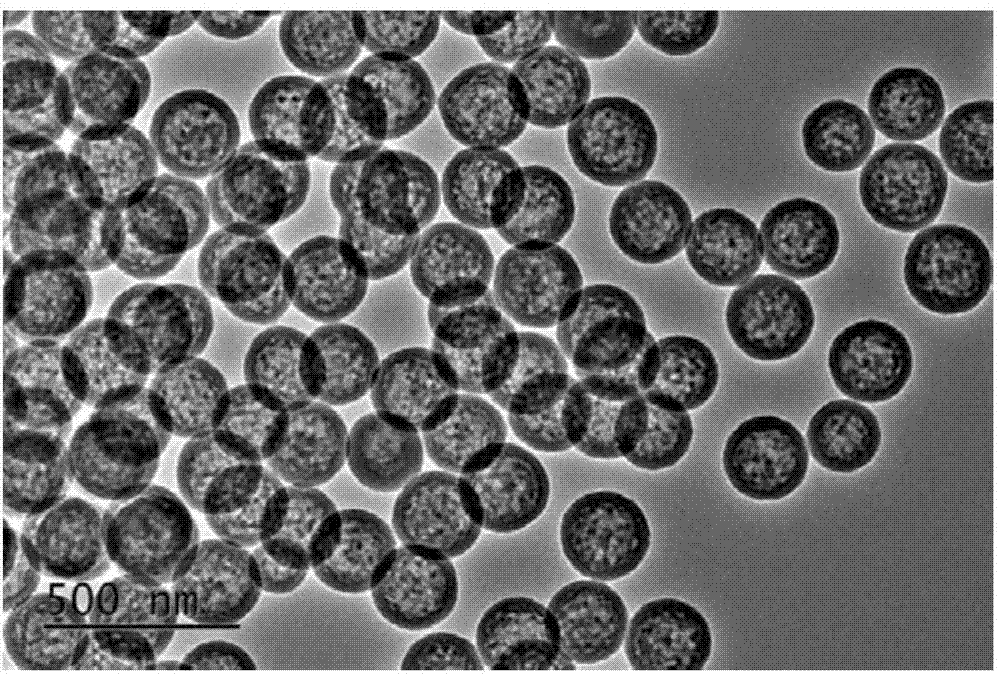

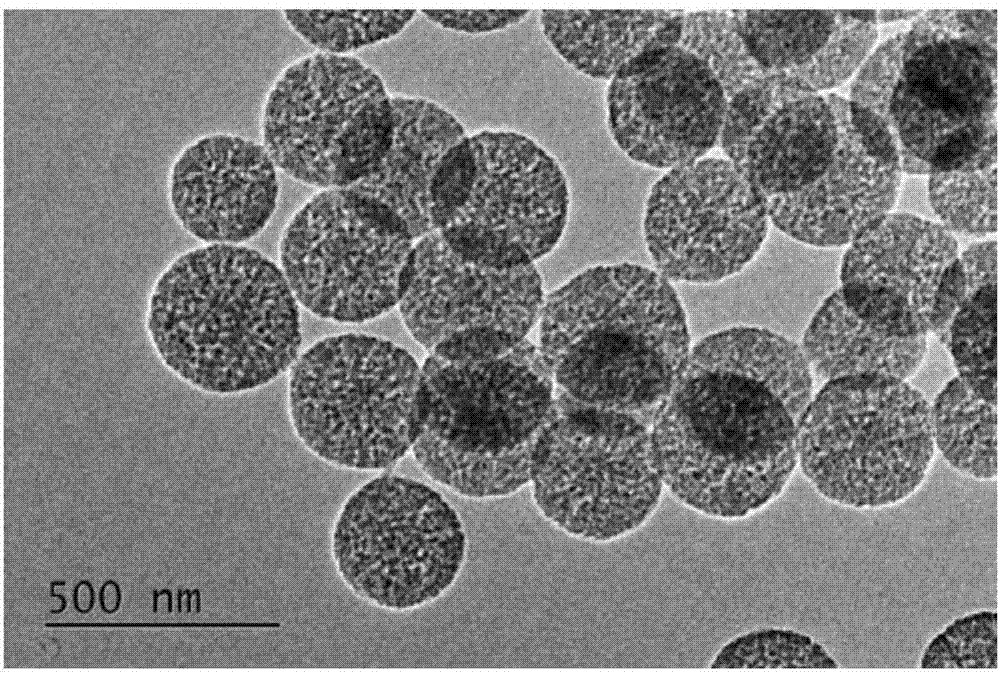

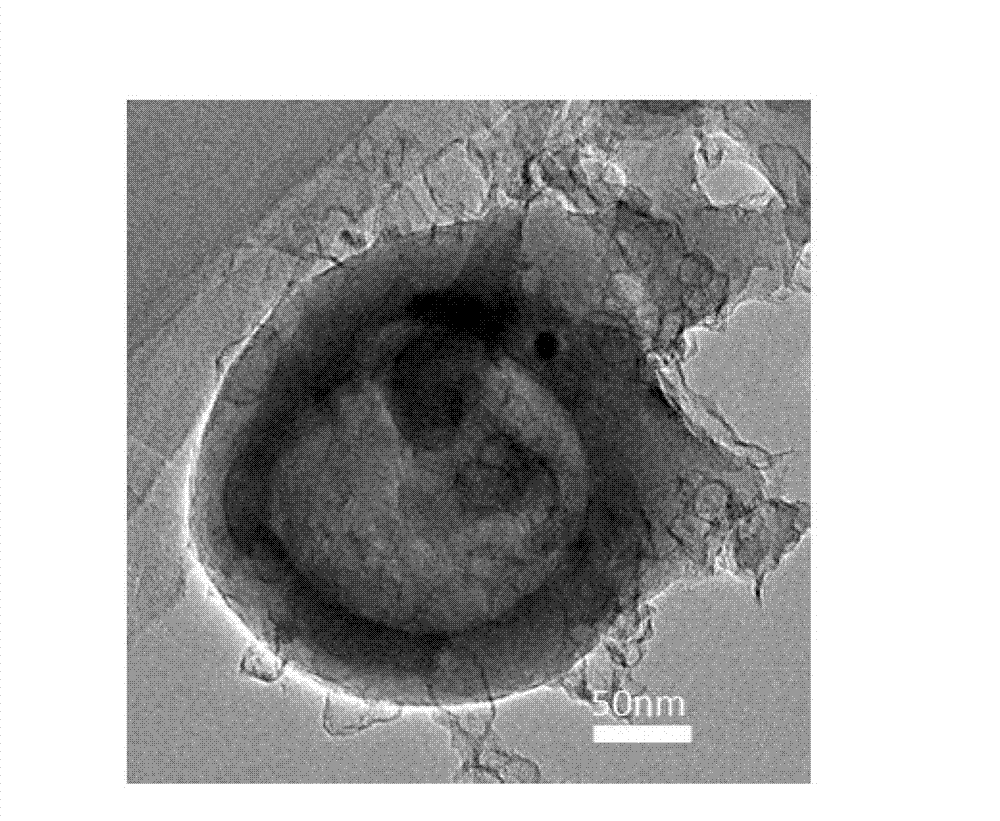

Single-layer and multi-layer hollow carbon nanosphere and preparation method and application thereof

ActiveCN104843665AEasy to operateMild reaction conditionsMaterial nanotechnologySolubilityIn situ polymerization

The invention discovers and proposes a characteristic that interior species of phenolic resin are nonuniform in distribution in a polymerization process, and discloses a method for preparing a hollow carbon sphere by utilizing the characteristic of phenolic resin. The method comprises: (1) putting phenol into water or a solvent, adjusting the pH, then adding aldehyde and stirring at a certain temperature for a period of time; (2) adding a corrosive agent in a reaction system, stirring at a certain temperature, and selectively removing a part with a relatively low polymerization degree inside a polymer by utilizing a solubility difference of interior species for different solvents, to obtain an intermediate product, that is, a hollow sphere of phenolic resin polymer; and (3) calcining the intermediate product that is obtained in step (2) in an inertia or reducing atmosphere, naturally cooling to room temperature, and thus completing preparation of the hollow carbon sphere. The method is simple and practicable, and the prepared hollow carbon sphere is uniform in shape and controllable in dimension. Moreover, by utilizing a characteristic that the phenolic resin can be in-situ polymerized on surfaces of different nanometer particles, on one hand, a multi-layer hollow structure can be prepared in a multi-cladding and layer-by-layer corrosion manner, and on the other hand, the different nanometer particles can also be packaged in a cavity in an in-situ mode, so as to prepare a nuclear shell or egg yolk-nuclear structure. The prepared hollow carbon sphere has a potential application value in aspects of silicon-carbon negative electrode material, Li-S battery, supercapacitor, heavy metal ion adsorption, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

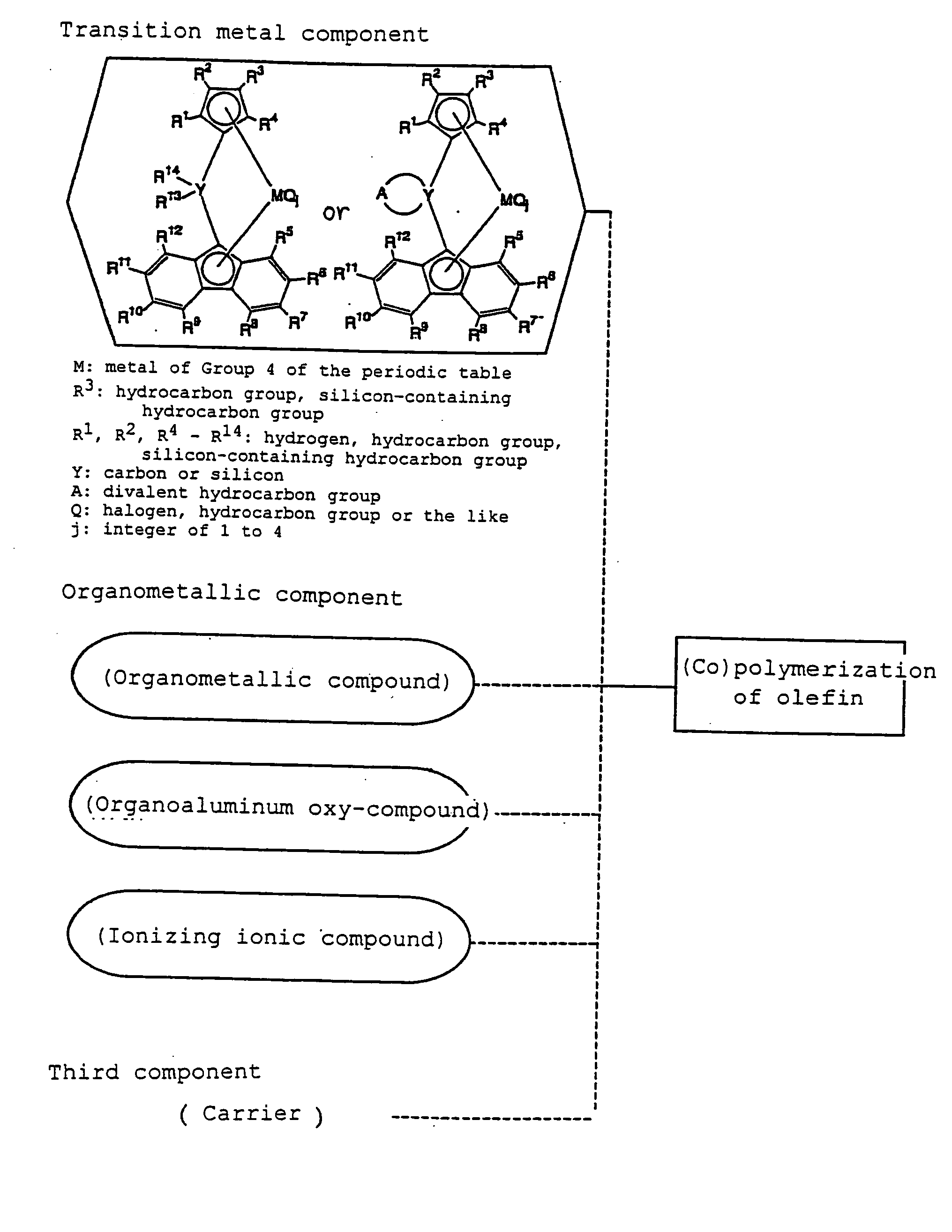

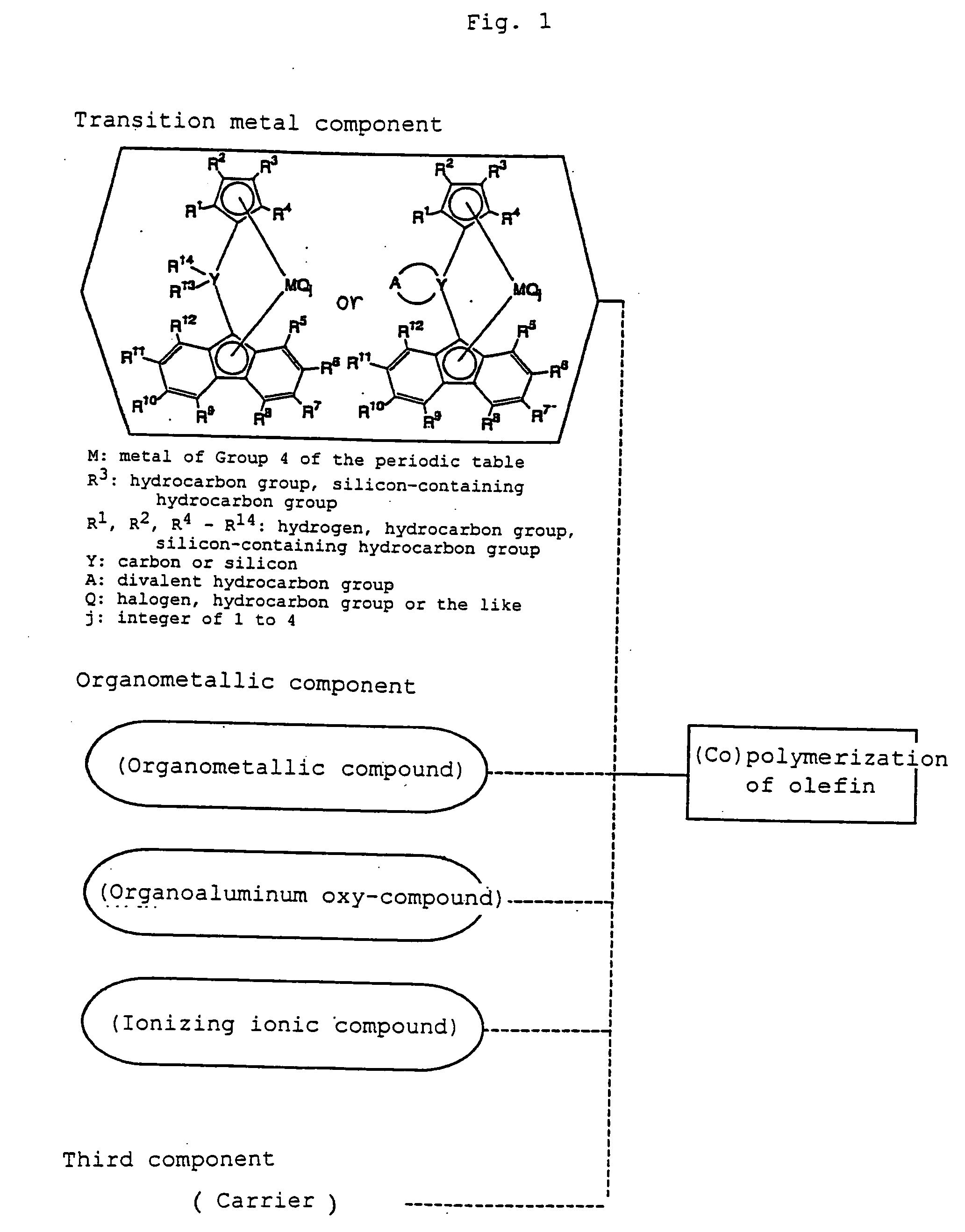

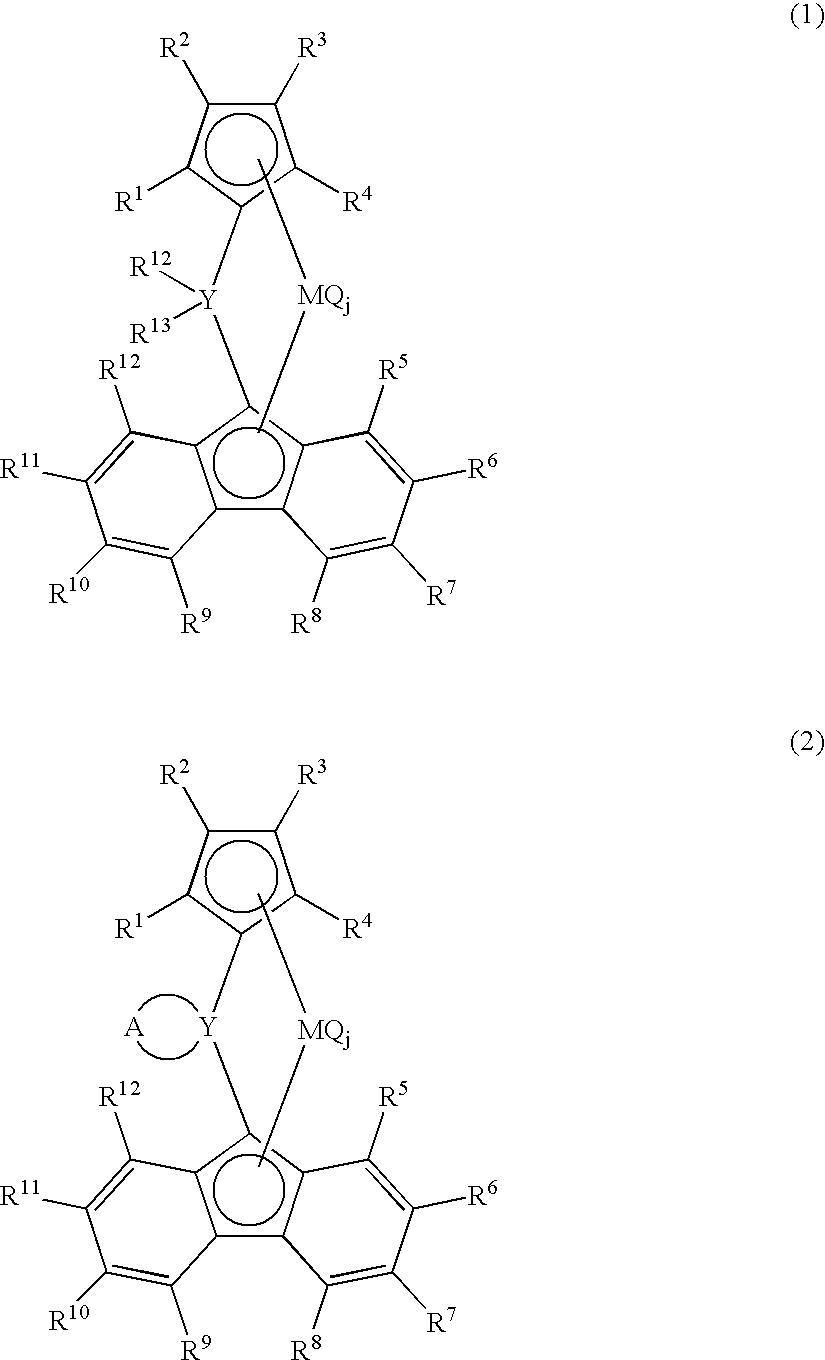

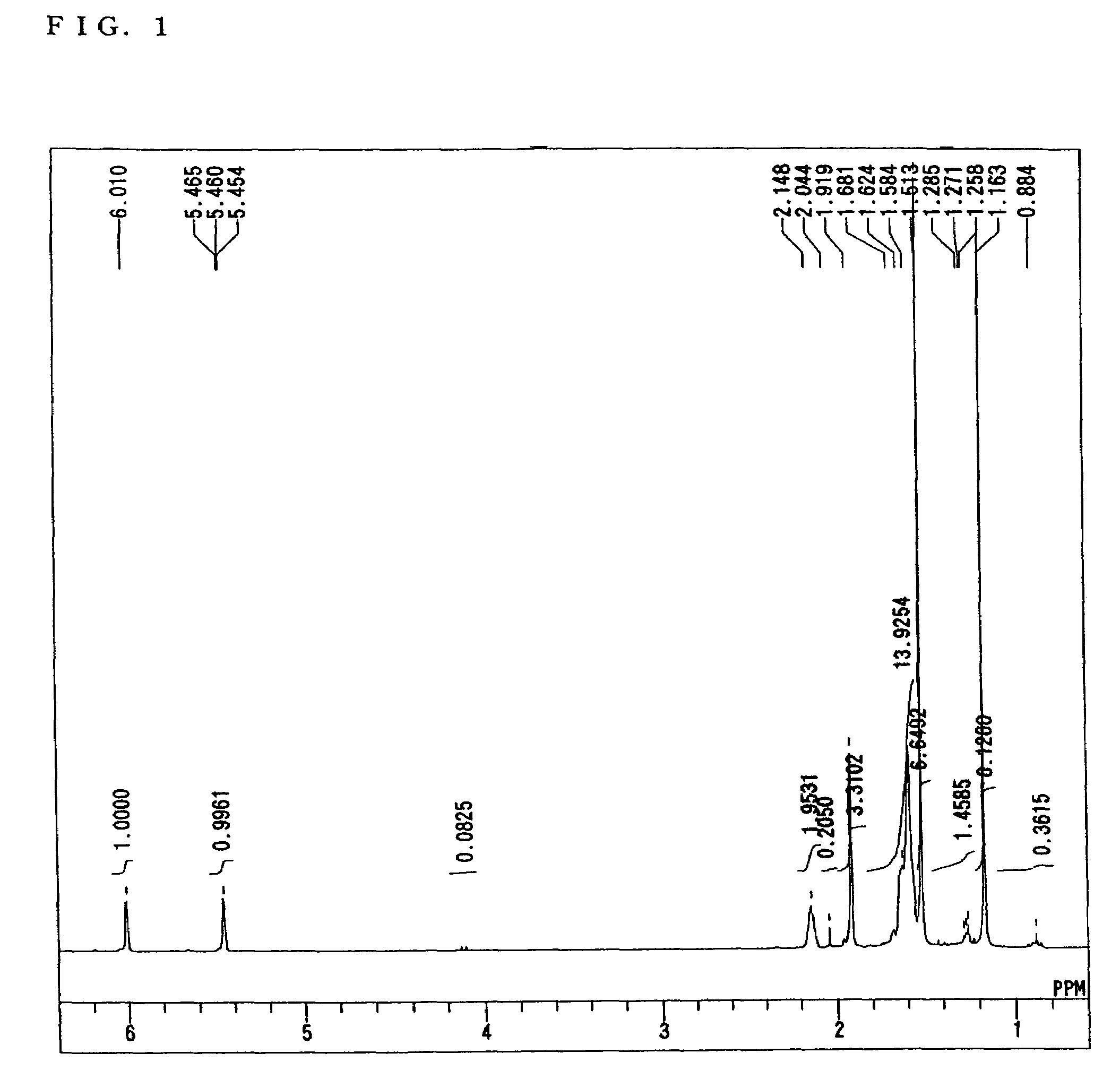

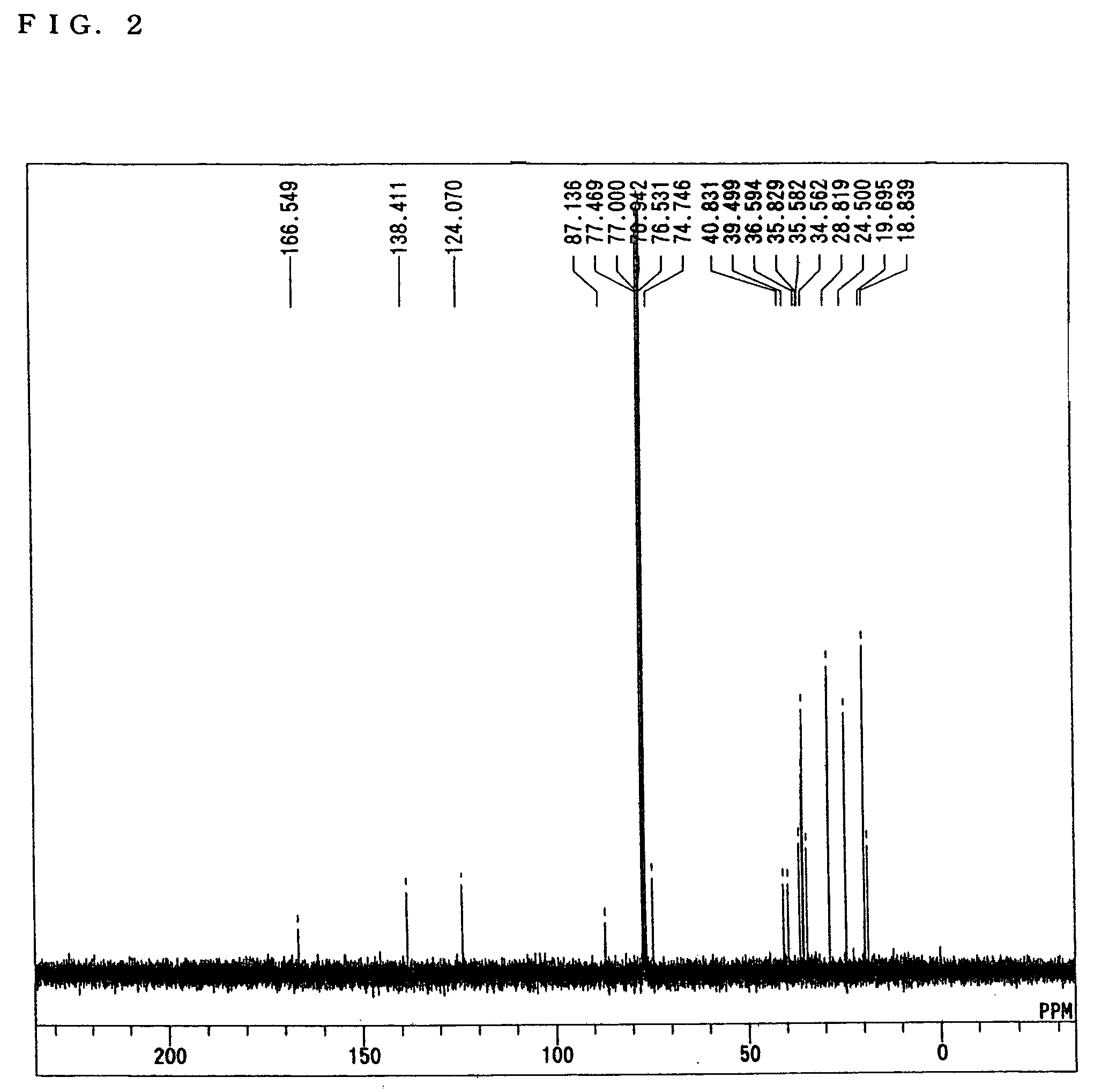

Metallocene compound, process for preparing metallocene compund, olefin polymerization catalyst, process for preparing polyolefin, and polyolefin

InactiveUS20050228155A1High activityModulus improvementSilicon organic compoundsMetallocenesPolymer sciencePolyolefin

The metallocene compound according to the invention and the olefin polymerization catalyst containing the compound are intended to produce a catalyst capable of preparing an isotactic polymer with a high polymerization activity. The metallocene compound contains a substituted cyclopentadienyl group and a (substituted) fluorenyl group and has a structure wherein these groups are bridged by a hydrocarbon group or the like. The process for preparing a metallocene compound according to the invention is intended to selectively prepare a specific metallocene compound so as not to produce an isomer, and in this process an intermediate product is synthesized by a specific method. The process for preparing a polyolefin according to the invention is intended to prepare a polyolefin having excellent impact resistance and transparency, and this process comprises homopolymerizing an α-olefin of 3 to 8 carbon-atoms or copolymerizing an olefin of 3 to 8 carbon atoms and another α-olefin in the presence of an olefin polymerization catalyst containing the above-mentioned metallocene compound.

Owner:MITSUI CHEM INC

Method for preparing active porous graphene

The invention provides a method for preparing active porous graphene. The method comprises the following steps: 1) bleaching cellulose by use of hydrogen peroxide to obtain a first intermediate product; 2) activating the first intermediate product by use of an activating agent to obtain a second intermediate product; 3) performing carbonization treatment on the second intermediate product at 600-1100 DEG C to obtain the active porous graphene. The invention aims to provide a method for preparing active porous graphene, and the active porous graphene prepared from the method provided by the invention has better conductivity and has better dispersity.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

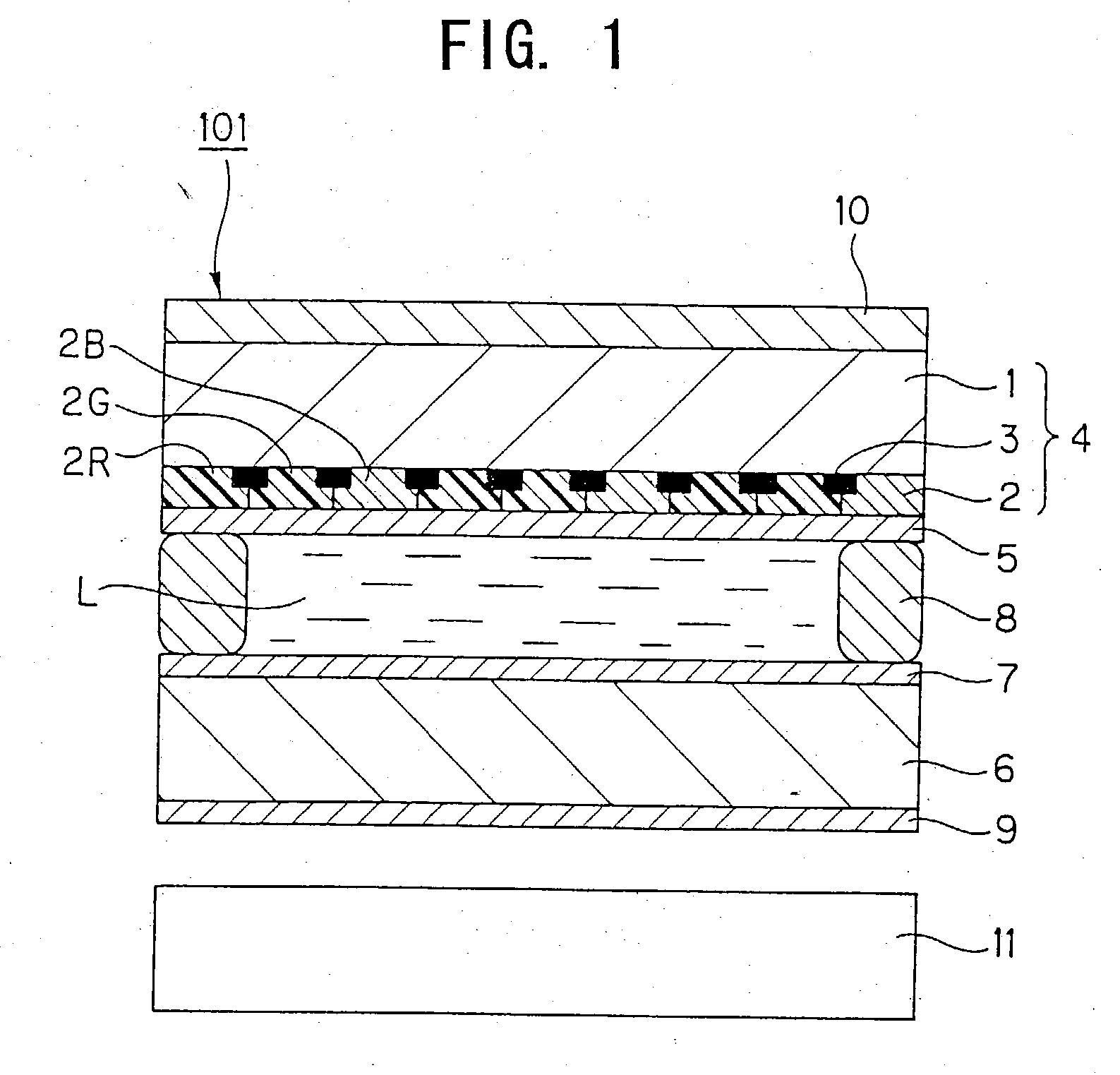

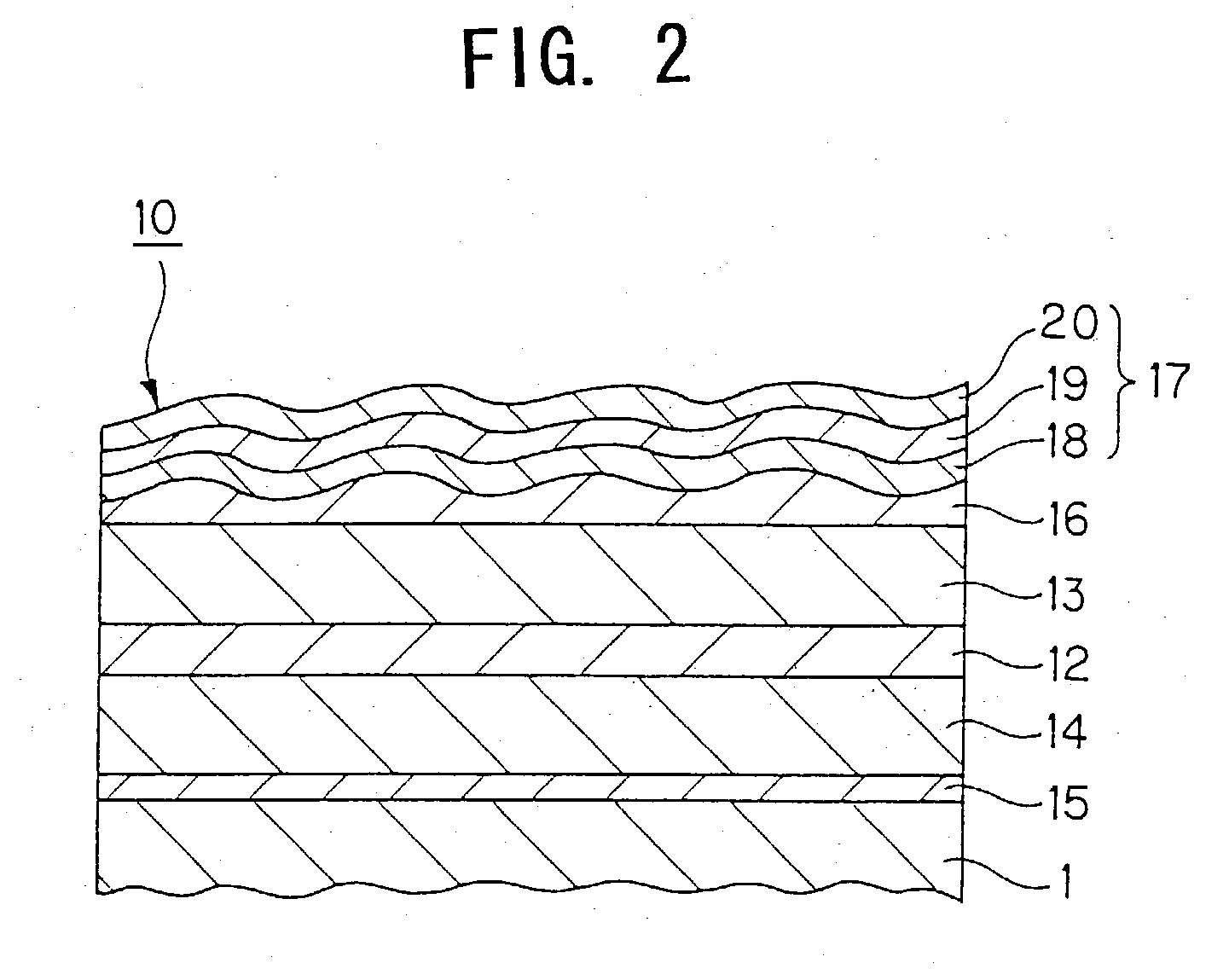

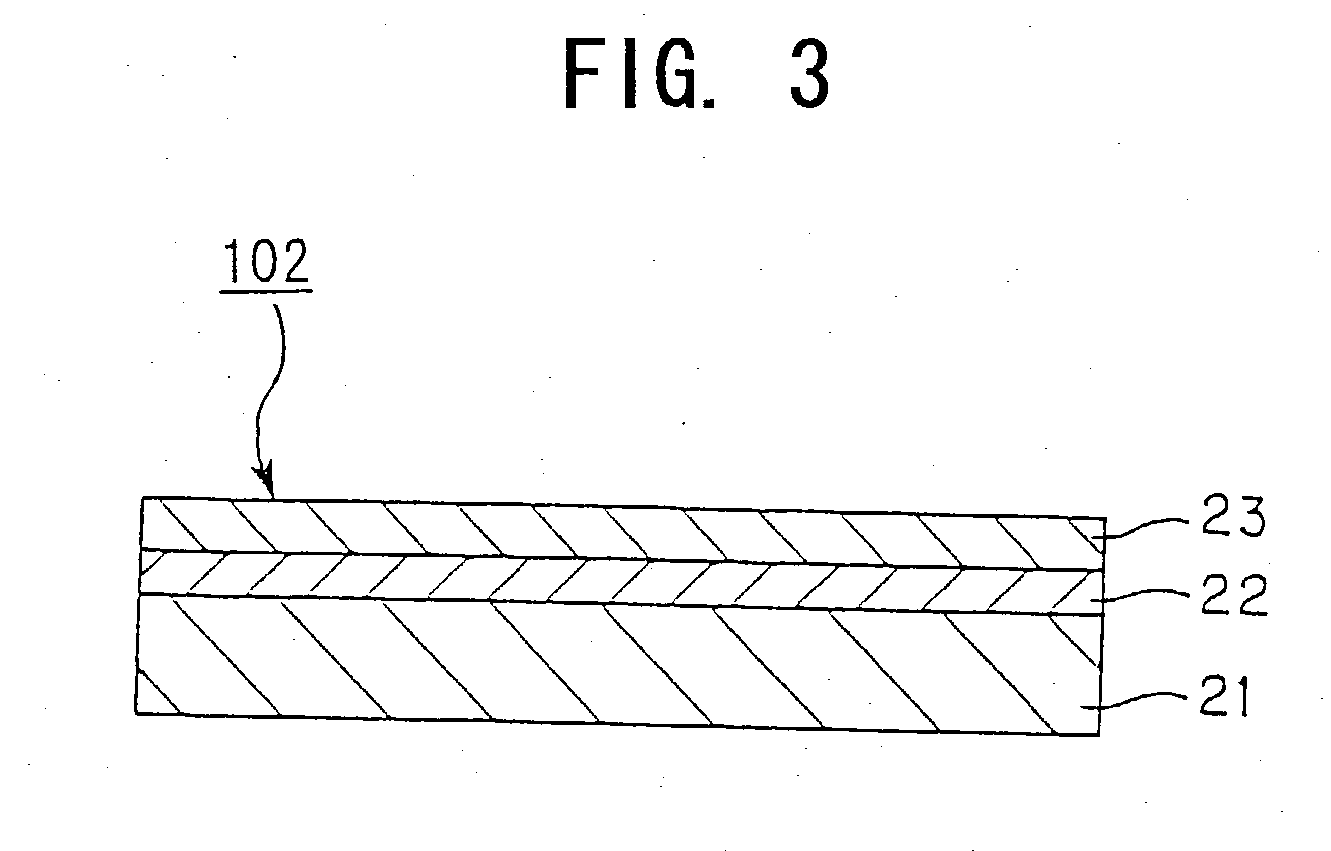

Coating composition, coating film thereof, antireflection coating, antireflection film, image display, and intermediate product

InactiveUS20030096102A1Good dispersibilityGood dispersionSynthetic resin layered productsCellulosic plastic layered productsMetallurgyRefractive index

A coating material capable of forming a high-quality thin film having a regulated refractive index; a coating film formed from the coating material; an antireflection coating comprising the coating film; an antireflection film to which the antireflection coating is applied; and an image display. The coating composition comprises (1) rutile-form titanium oxide having primary particle diameter of 0.01 to 0.1 mum and coated with an inorganic compound for reducing or eliminating the photocatalytic activity and with an organic compound having an anionic polar group and / or an organometallic compound, (2) a binder ingredient curable with an ionizing radiation, (3) a dispersant having an anionic polar group, and (4) an organic solvent. The coating film formed from the coating composition is suitable for forming a light-transmitting layer constituting or contained in a single- or multi-layer antireflection coating (17), in particular, a medium-refractive-index layer (18), high-refractive-index layer (19), or hard coat layer (16) having a high refractive index.

Owner:DAI NIPPON PRINTING CO LTD

PROCESS FOR THE PREPARATION OF 2,3,3,3-TETRAFLUOROPROPENE (HFO-1234yf)

A process for the preparation of 2,3,3,3-tetrafluoropropene (HFO-1234yf). HFO-1234yf is a refrigerant with low global warming potential. A process comprises a) reacting chlorotrifluoroethylene with a methyl halide to form an intermediate product stream; and b) reacting the intermediate product stream with hydrogen fluoride to thereby produce a result comprising 2,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

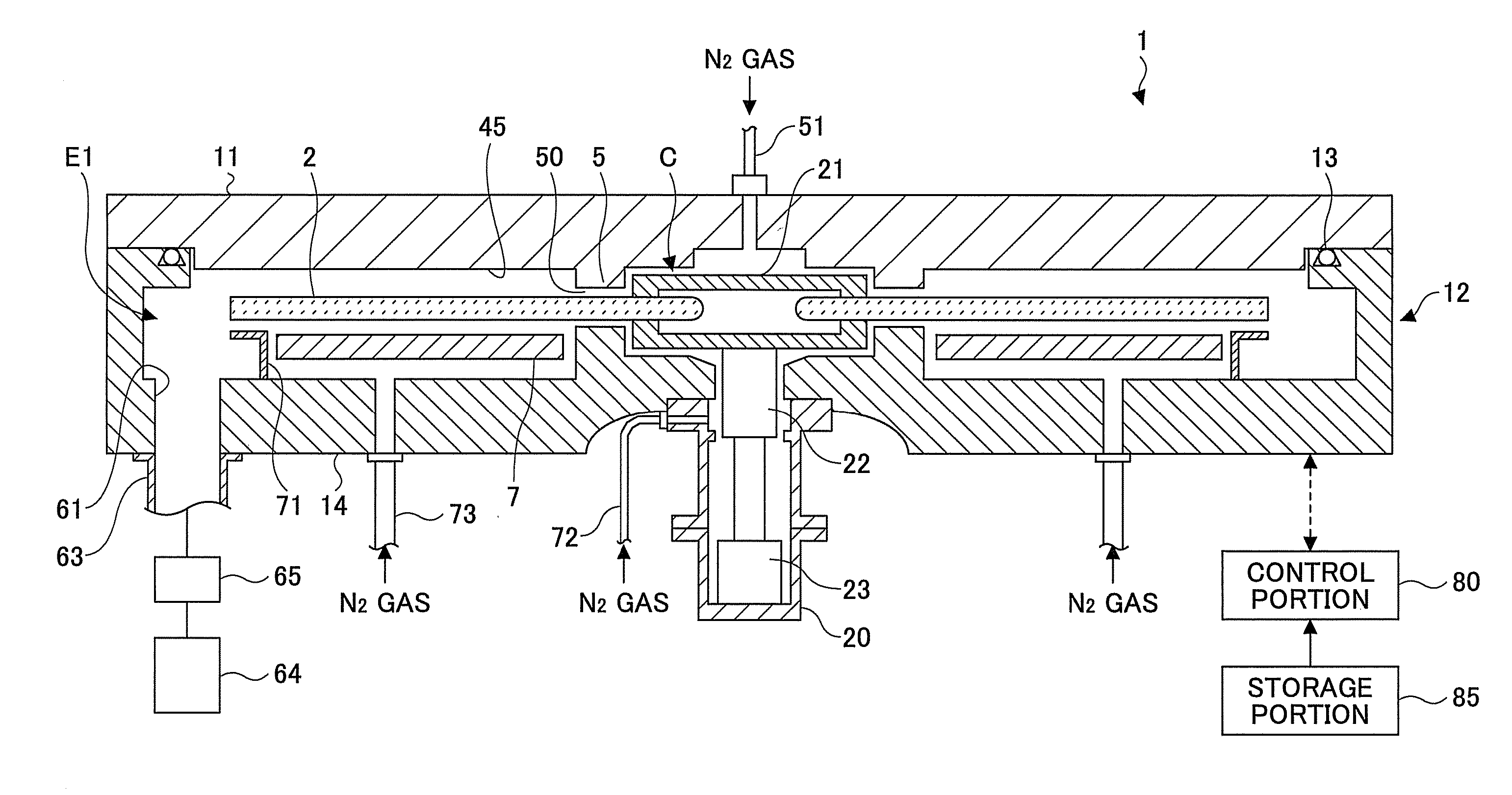

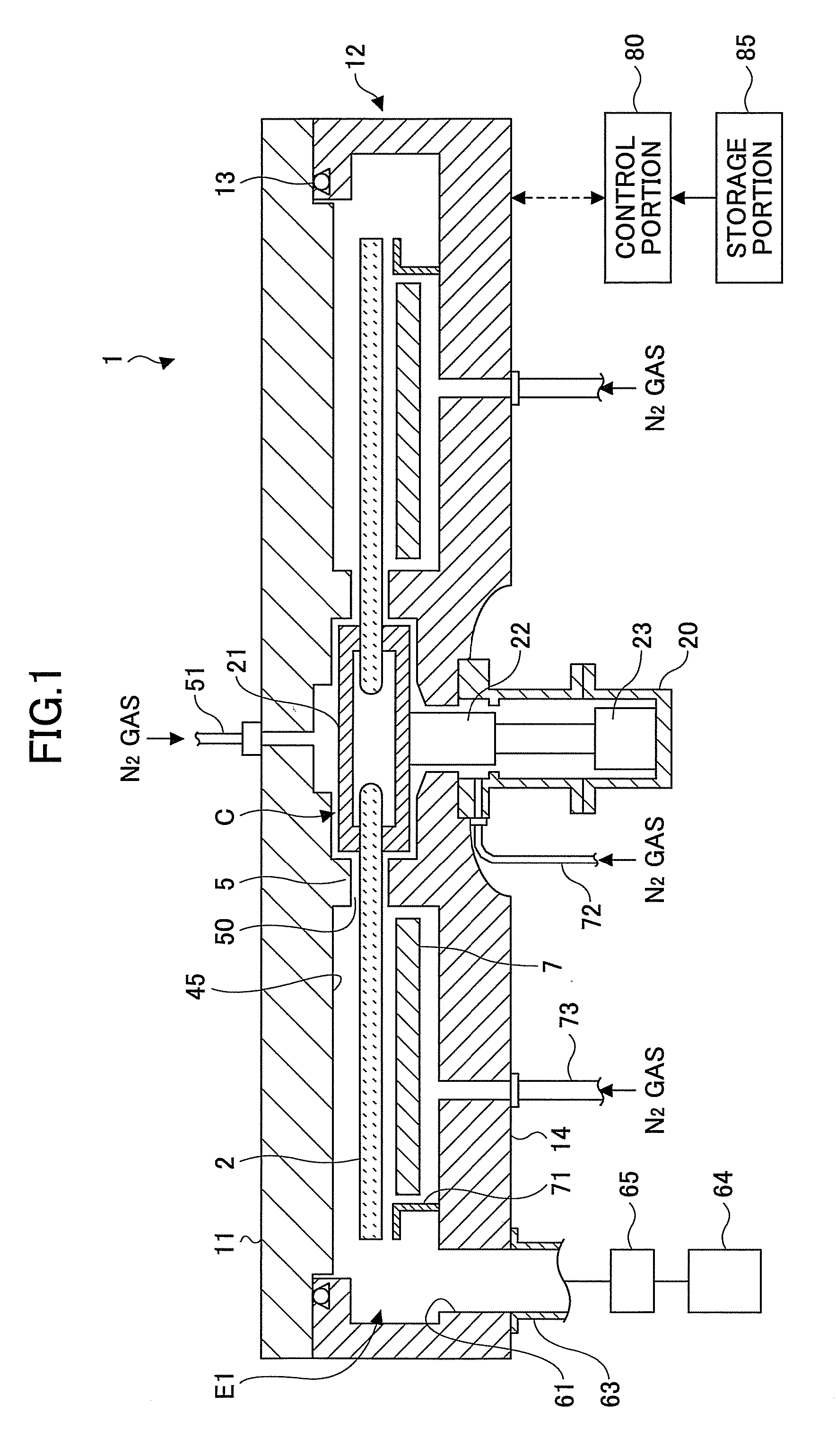

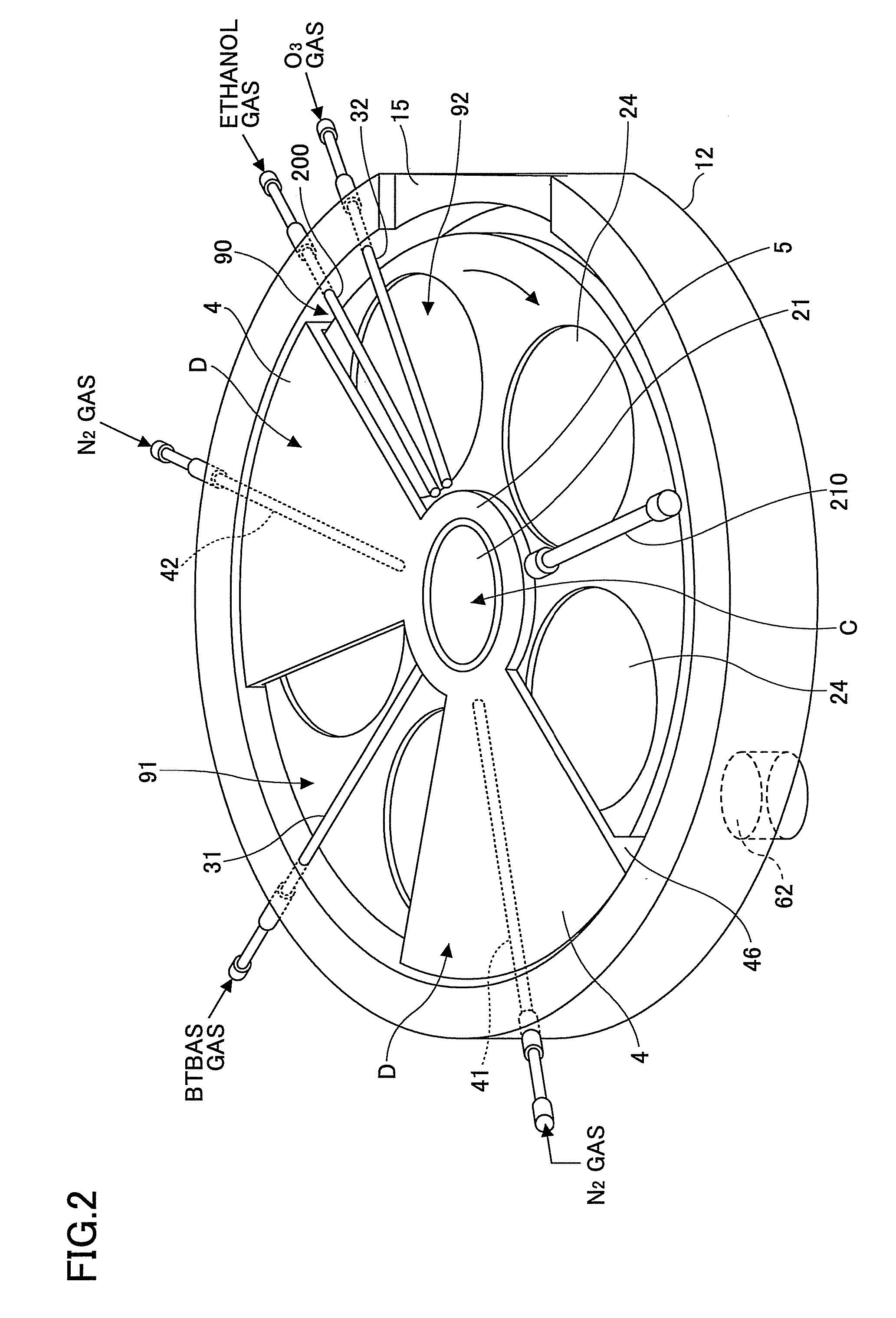

Film deposition apparatus, film deposition method, and computer readable storage medium

ActiveUS20100260935A1High purityExcellent gap fillingLiquid surface applicatorsSemiconductor/solid-state device manufacturingVertical axisPhotochemistry

A rotation table on which a wafer is placed is rotated around a vertical axis in order to supply to an upper surface of the wafer a first reaction gas for allowing the first reaction gas to be adsorbed on the upper surface, an auxiliary gas that reacts with the first reaction gas to produce an intermediate product having reflowability, and a second reaction gas that is reacted with the intermediate product to produce a reaction product in this order; and the reaction product is heated by a heating lamp in order to densify the reaction product.

Owner:TOKYO ELECTRON LTD

Integrated granule product

InactiveUS7125601B1PliabilityPliable and durableRoof covering using tiles/slatesRoof covering using flexible materialsEngineeringGranule Product

An integrated granule product that includes a film having a plurality of ceramic coated granules bonded to the film by a cured adhesive. The integrated granule product is generally considered an intermediate product because it is suitable for application onto various substrates for end use applications such as roofing products and flooring products.

Owner:3M INNOVATIVE PROPERTIES CO

Self-assembling cell aggregates and methods of making engineered tissue using the same

A composition comprising a plurality of cell aggregates for use in the production of engineered organotypic tissue by organ printing. A method of making a plurality of cell aggregates comprises centrifuging a cell suspension to form a pellet, extruding the pellet through an orifice, and cutting the extruded pellet into pieces. Apparatus for making cell aggregates comprises an extrusion system and a cutting system. In a method of organ printing, a plurality of cell aggregates are embedded in a polymeric or gel matrix and allowed to fuse to form a desired three-dimensional tissue structure. An intermediate product comprises at least one layer of matrix and a plurality of cell aggregates embedded therein in a predetermined pattern. Modeling methods predict the structural evolution of fusing cell aggregates for combinations of cell type, matrix, and embedding patterns to enable selection of organ printing processes parameters for use in producing an engineered tissue having a desired three-dimensional structure.

Owner:MUSC FOUND FOR RES DEV +1

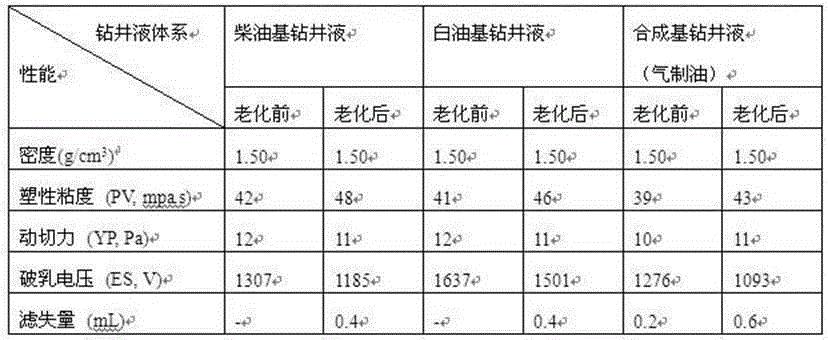

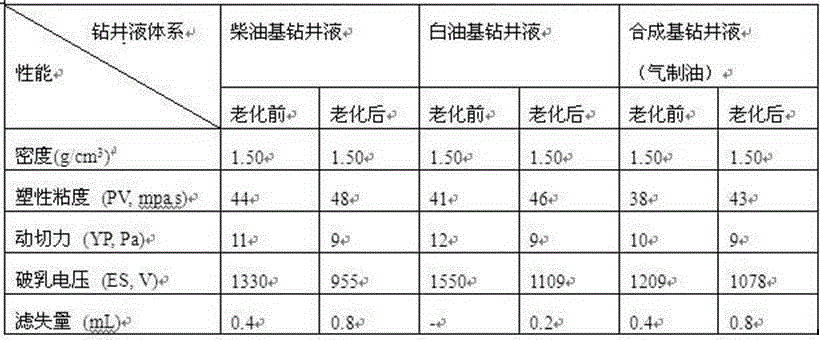

Solid emulsifier used for oil base drilling fluid, preparation method thereof and application of oil base drilling fluid

ActiveCN103980869AStrong emulsifying abilityEasy to storeOrganic compound preparationCarboxylic acid amides preparationRoom temperatureReaction temperature

The invention relates to a solid emulsifier used for oil base drilling fluid, a preparation method and an application of the oil base drilling fluid. The preparation method comprises the following steps: adding diethylenetriamine in organic acidity, adding a catalyst, heating to the temperature of 175-185 DEG C, and reacting for 1-3 hours to obtain an intermediate product which has a code name AMI-1. cooling the reaction temperature to 90-120 DEG C, adding acid anhydrides, continuously reacting for 2-4 hours, cooling to the room temperature, wherein the products is the dark brown solid, using a pulverizer for crushing to obtain the brown-red solid powder which is the emulsifier with code name EmuL-S. The emulsifier has good emulsification effect on the diesel oil, the white oil and a synthesis group, and has strong anti-temperature capability, and is cooperated with organic soil, a filtrate reducer, a wetting agent and a weighting material for constructing a high performance oil base drilling fluid system; because that the emulsifier is the powdery solid, so that the influence due to environment is little, and the storage and transport are convenient.

Owner:中石化石油工程技术服务有限公司 +2

Method for producing wood fibre composite products

A process for producing a thermoformable fibre-plastics composite product comprising lignolcellulosic or natural fibres, particularly but not exclusively useful as an intermediate product in subsequent manufacture, comprises conveying the fibres in a dry or wet air stream and applying to the fibres a thermoplastic binding agent, and forming the fibres into a solid or semi-solid product such as a panel, which is thermoformable. In at least a preferred embodiment the process may be carried out in known plant for manufacture of medium density fibre board.

Owner:NEW ZEALAND FOREST RES INST

Adamantane derivatives and resin compositions using the same as raw material

ActiveUS7078562B2Good optical performanceImprove adhesionOrganic chemistryOrganic compound preparationPhotoresistPhotochemistry

Owner:MITSUBISHI GAS CHEM CO INC

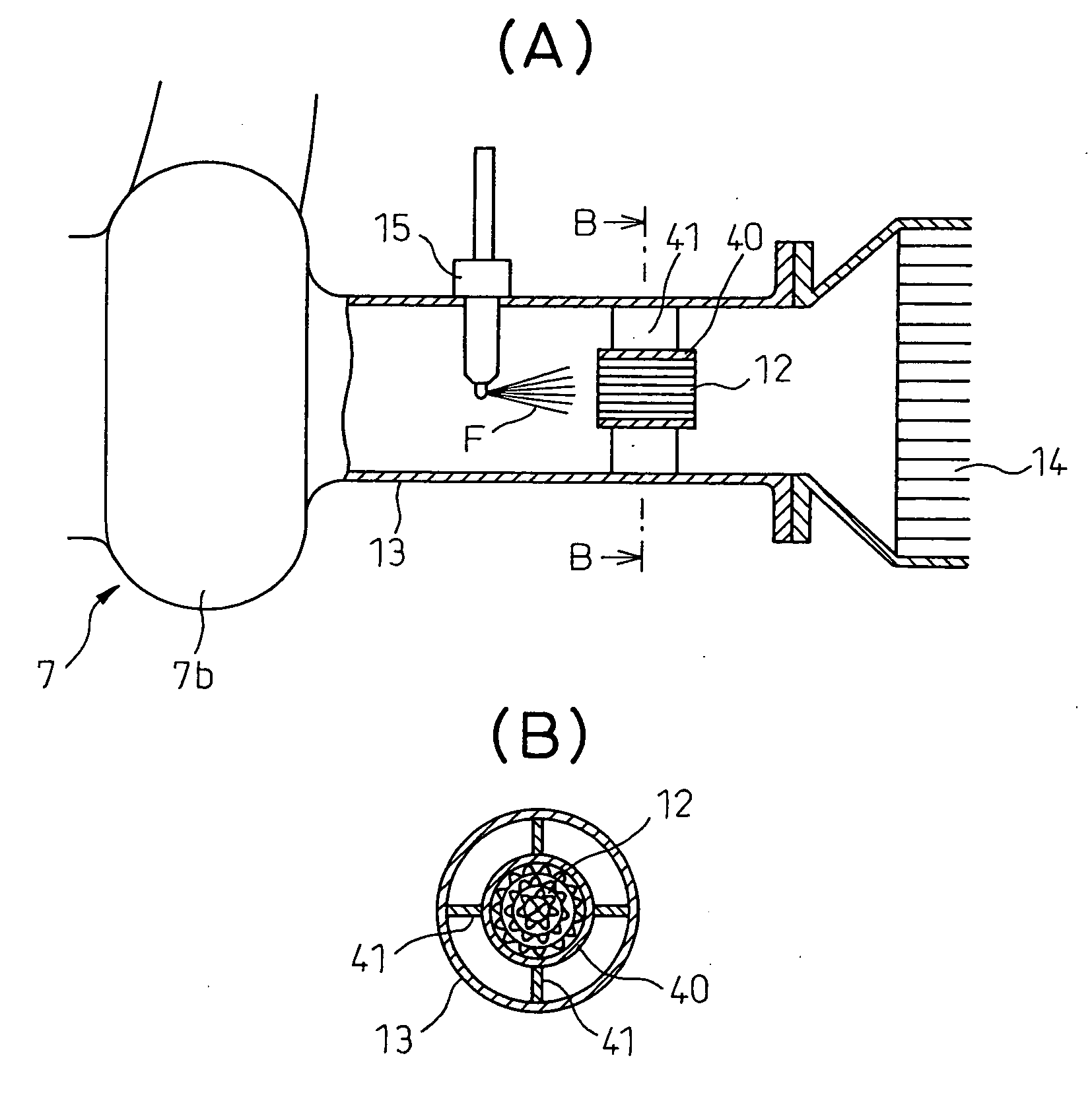

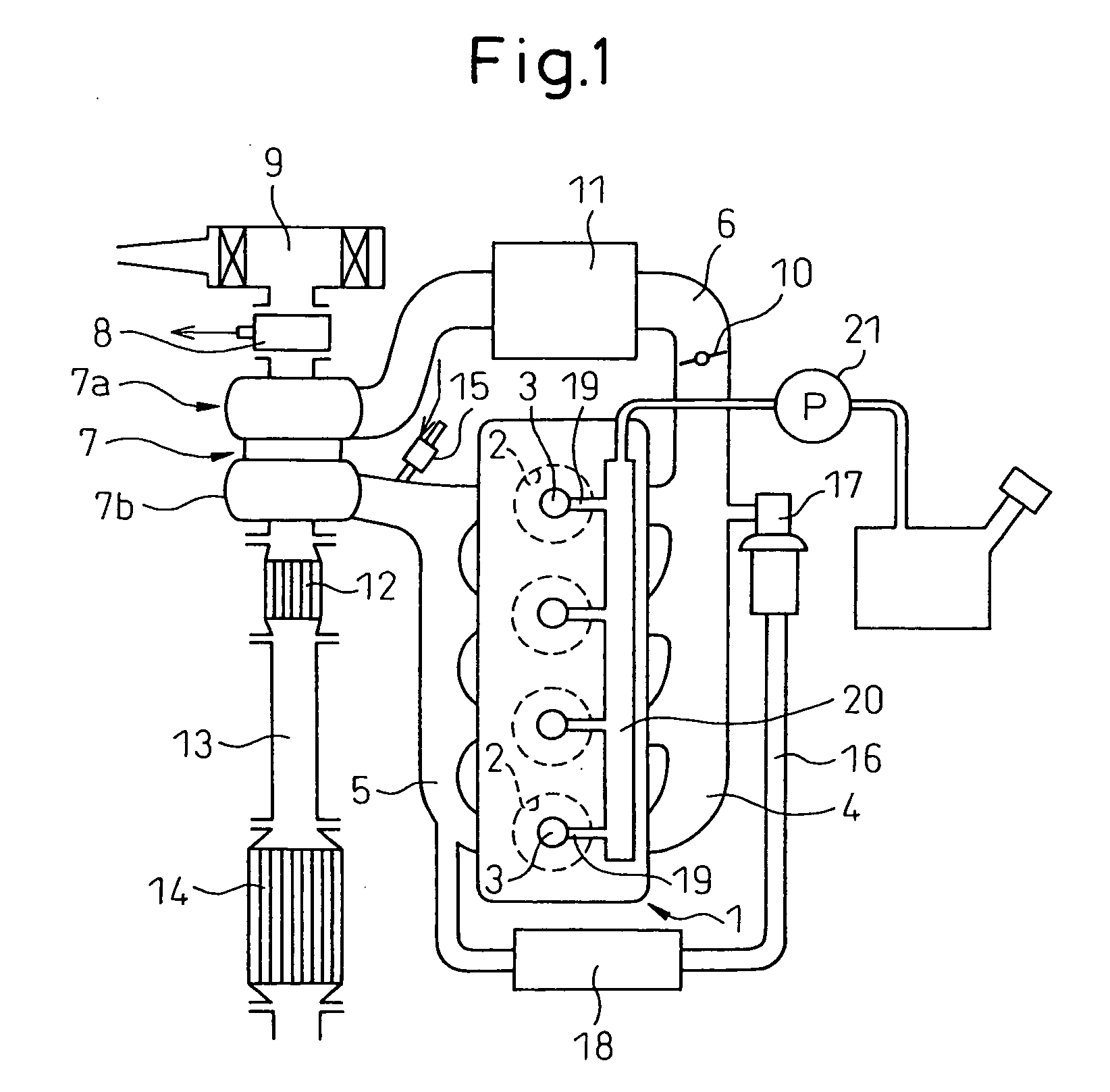

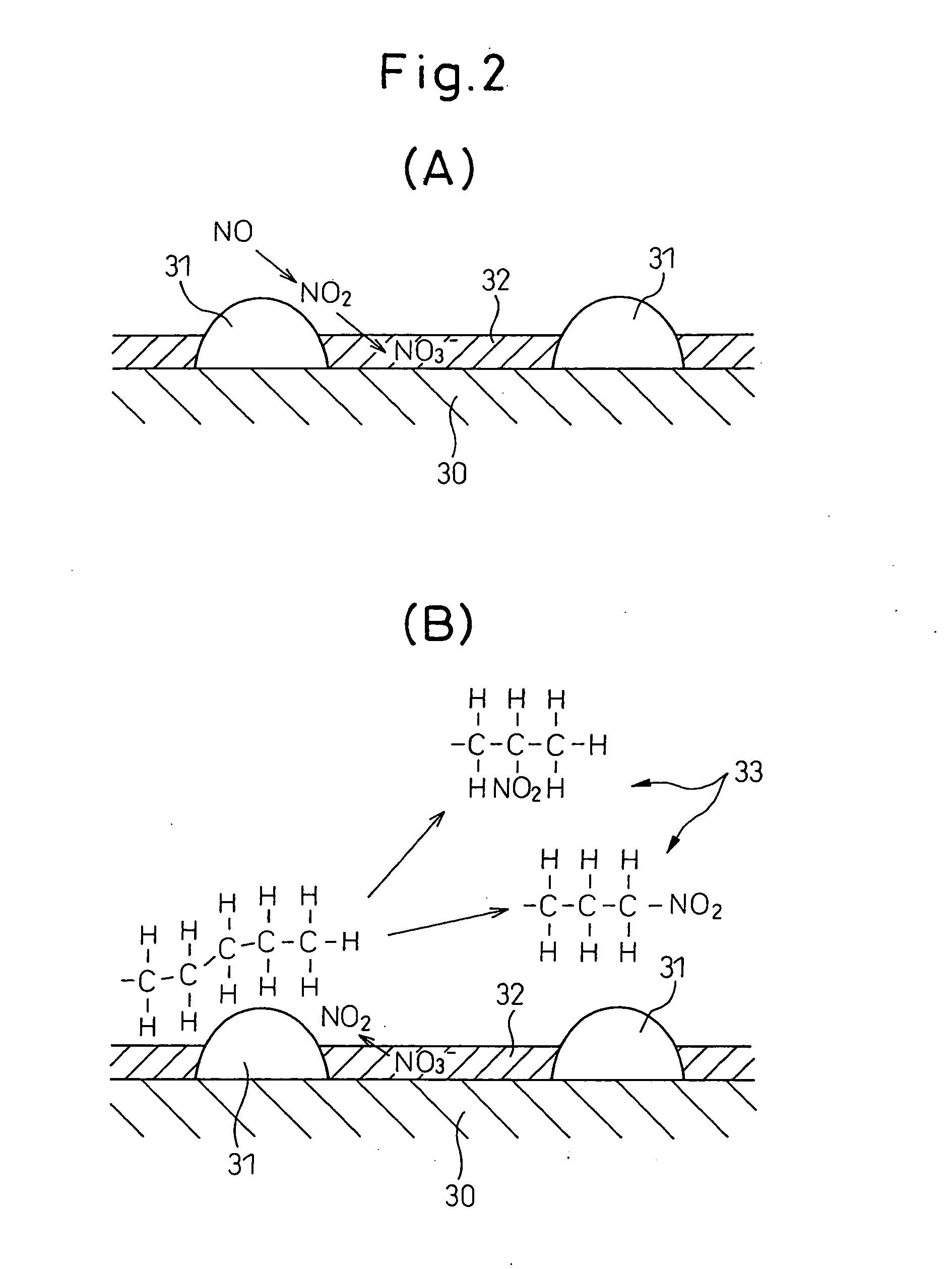

Exhaust Purification Device of an Internal Combustion Engine

ActiveUS20090084091A1Improve purification effectGas treatmentInternal combustion piston enginesEngineeringInternal combustion engine

In an internal combustion engine, an NOX purification catalyst (14) is arranged in the engine exhaust passage and an intermediate product producing catalyst (12) able to store NOX contained in the exhaust gas is arranged at the upstream of the NOX purification catalyst (14). The intermediate product producing catalyst (12) is fed with mist fuel, and intermediate products (33) comprising bonded molecules comprised of an NOX and hydrocarbon molecules more than an equivalent ratio with respect to an NOX molecule are produced from the NOX trapped in the intermediate product producing catalyst (12) or the NOX contained in the exhaust gas and the fed fuel.

Owner:TOYOTA JIDOSHA KK

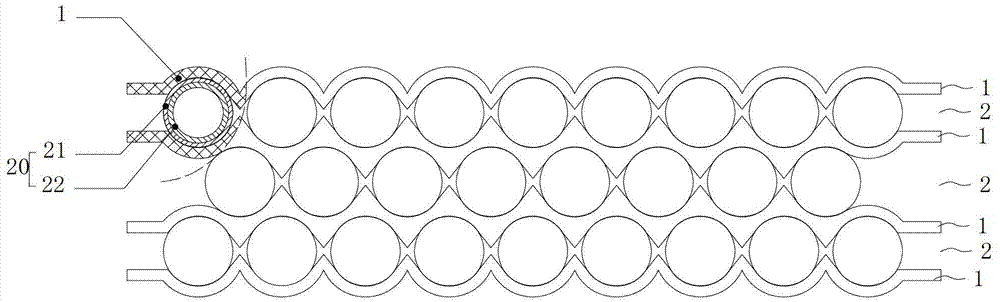

Lithium ion battery cathode material compounded with graphene and preparation method thereof

ActiveCN103050661AIncrease energy densityImprove cycle performanceMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSurface-active agentsSilicon dioxide

The invention discloses a lithium ion battery cathode material compounded with graphene and a preparation method thereof. The cathode material comprises multiple layers of graphene sheets, a hollow nano cathode granular layer is arranged between adjacent grapheme sheets so as to be respectively separated through half surrounding, and a clearance is reserved between adjacent graphene sheets; and the hollow nano cathode granule consists of a carbon outer layer and a hollow metal cathode material inner layer. The preparation method comprises the following steps of: mixing the organic presoma of silica, cationic surface active agent, tin salt solution, and organic carbon source for reaction, adding oxidized graphene or dispersion liquid of the graphene for reacting and drying so as to obtain intermediate products, obtaining head products through treatment of the treating liquid, and obtaining the product through heat treatment of the head products. The cathode material has good conductivity, and is large in electrochemical lithium storage volume, high in energy density, and good in circulation. The preparation method is easy for realization of industrialization and is low in cost.

Owner:深圳石墨烯创新中心有限公司

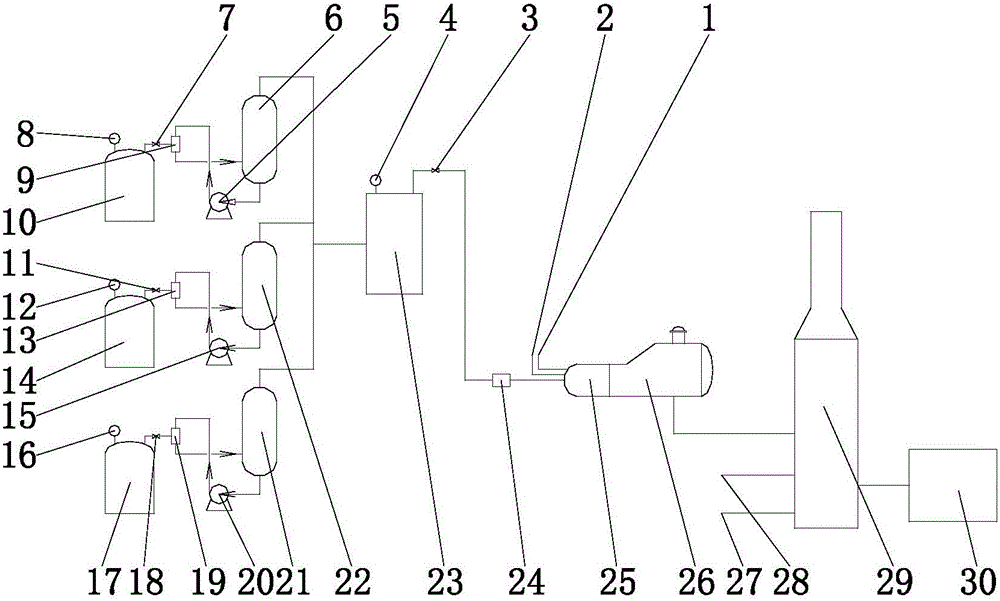

Integrated treatment method for malodorous VOCs gas of refining devices

InactiveCN105841168AReduce dosageSimple processDispersed particle separationIncinerator apparatusLiquid jetBurn units

The invention discloses an integrated treatment method for unorganized emission of malodorous VOCs gas from refining and chemical equipment, which collects VOCs gas emitted from refining and chemical storage tanks including residual oil tanks, intermediate product tanks, and acid water tanks. The VOCs gas outlet of the tank is connected to the injection fluid inlet of the liquid jet vacuum pump; the working fluid inlet of the liquid jet vacuum pump is connected to the outlet of the circulation pump, and the mixed fluid outlet is connected to the gas-liquid separation tank; the inlet of the circulation pump is connected to the The liquid outlet of the gas-liquid separation device is connected; the gas outlet of the gas-liquid separation device is connected with the buffer tank; the inlet of the incineration unit is also fed with combustion-supporting gas and air in addition to the VOCs gas in the gas storage buffer tank. , VOCs gas and malodorous gas are incinerated in the incineration unit, and the incineration temperature is 800-1000°C.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

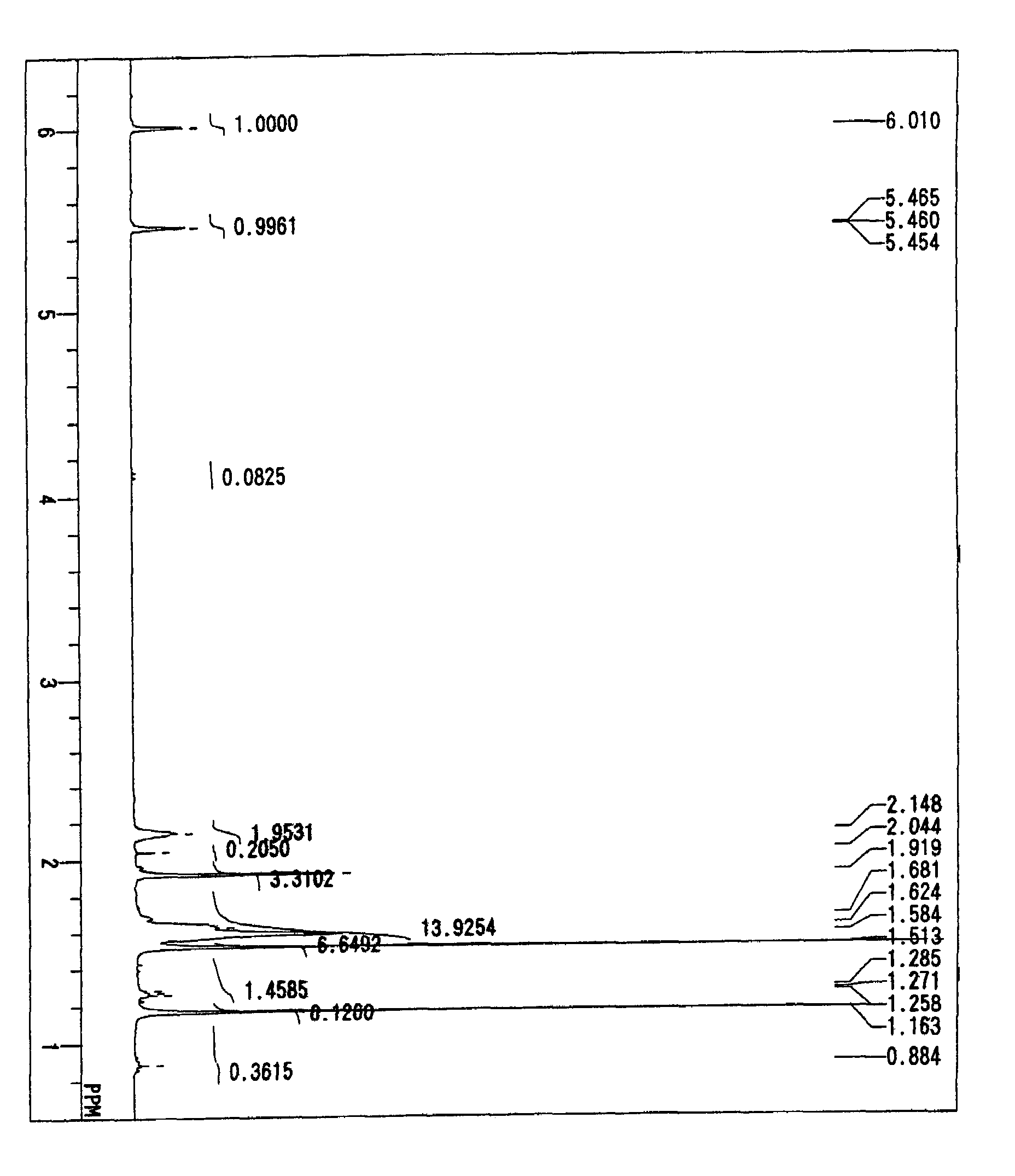

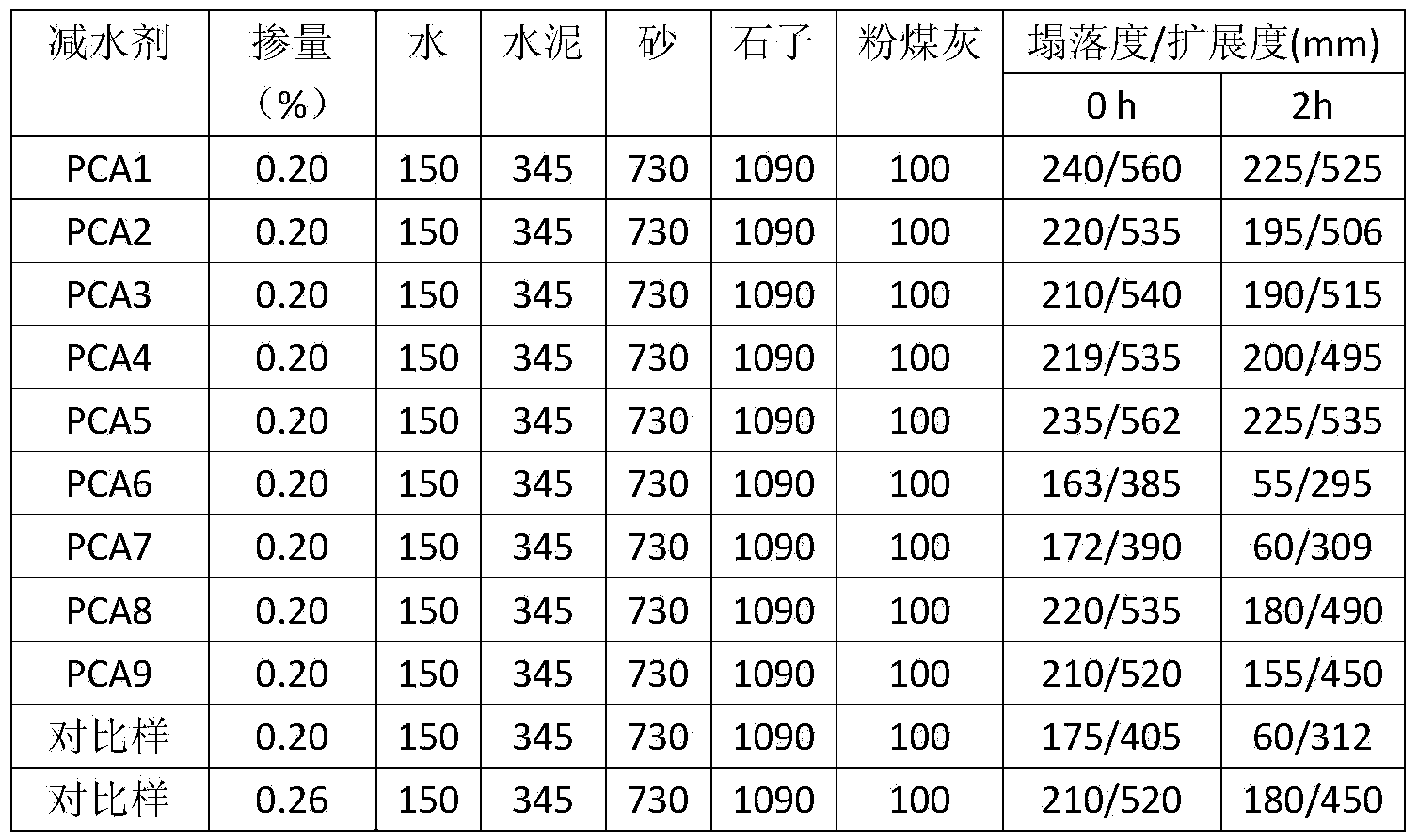

Preparation method and application of unsaturated polyether

The invention relates to a preparation method and application of unsaturated polyether. The preparation method comprises the following steps: (1) adding unsaturated alcohol and a catalyst into a first reactor, replacing with nitrogen, continuously adding epoxide with short branches and reacting to obtain an intermediate product A, wherein the unsaturated alcohol is one or a mixture of more than two of methyl allyl alcohol and isoamyl alcohol at any proportion and the mass ratio of the unsaturated alcohol to epoxide is 1.0:(0.1-5.0); and (2) putting the intermediate product A obtained in the step (1) and the catalyst into a second reactor, replacing with nitrogen, continuously introducing ethylene oxide and reacting to obtain polyether B, and neutralizing the pH value of the polyether B product to be 5-7 with a neutralizing reagent, wherein the mass ratio of the intermediate product A to ethylene oxide is 1.0:(15.0-51.0). The invention also provides the unsaturated polyether prepared by the preparation method, which is disclosed by the invention and application of unsaturated polyether in synthesis of polycarboxylic water reducer and the water reducer prepared from the unsaturated polyether synthesized by the method has the advantages of low doping amount, high water reduction rate, good slump-retaining agent and like.

Owner:HONGBAOLI GRP CO LTD

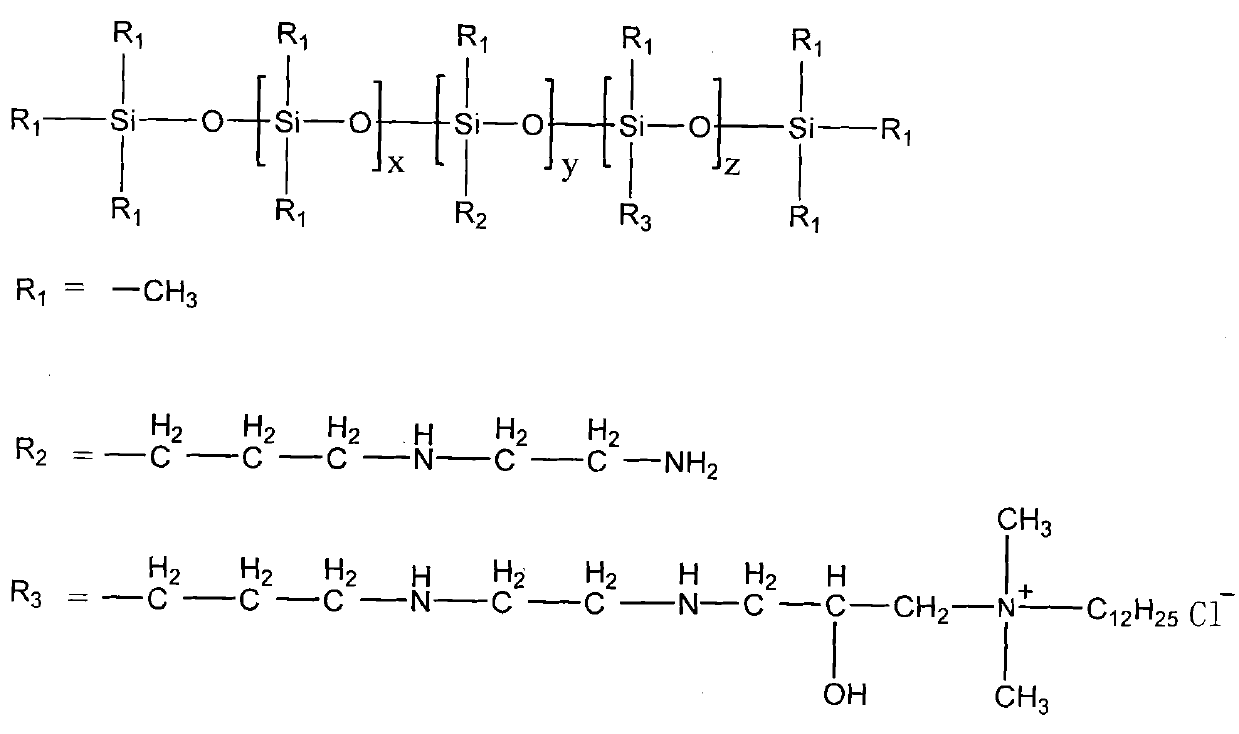

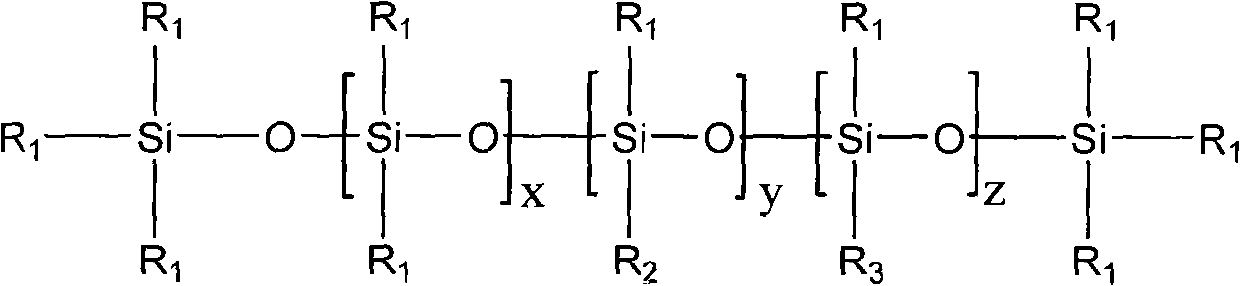

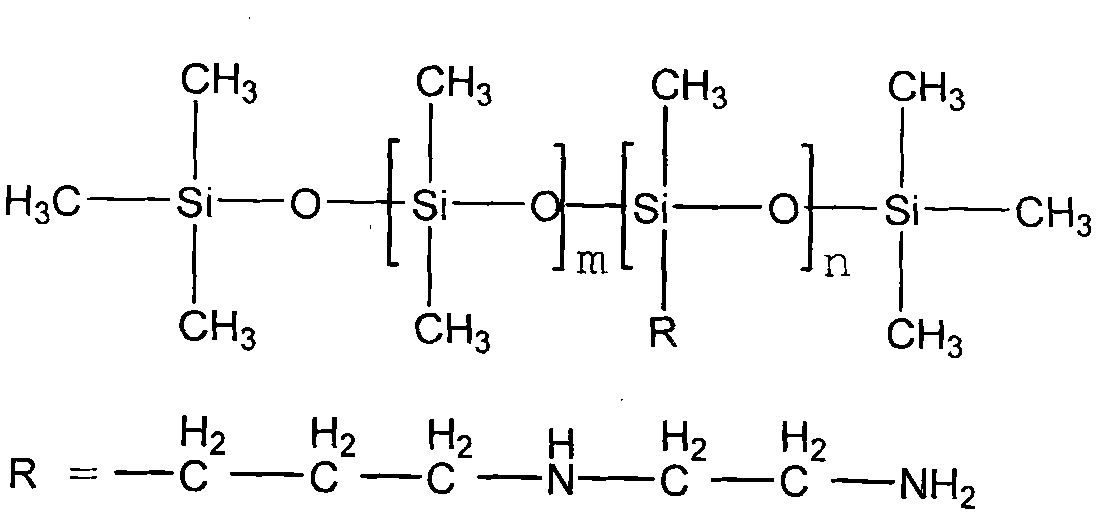

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

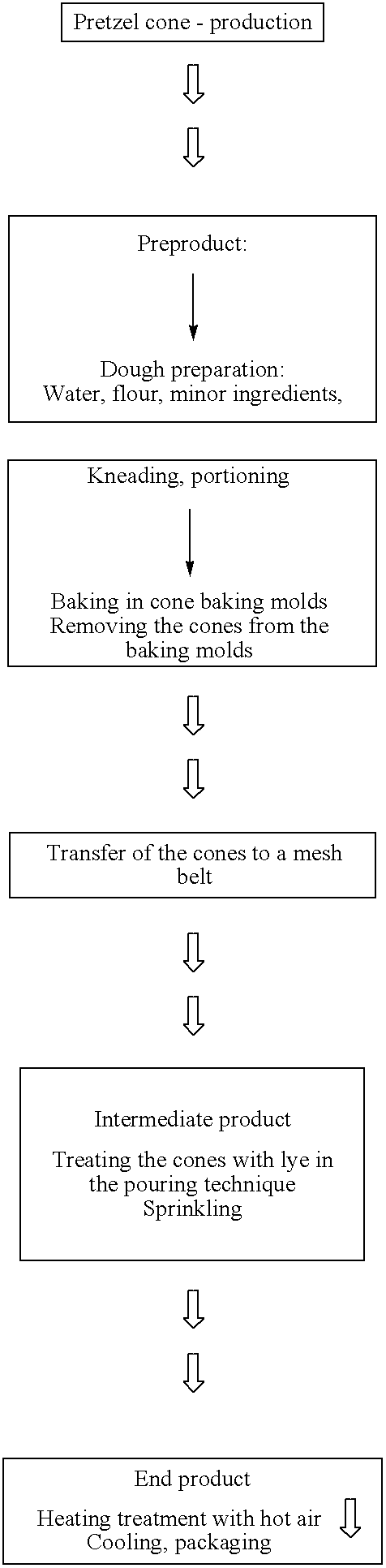

Method for producing baked objects, at least parts of which are a glossy brown

InactiveUS20060057269A1Adverse flavoring effectAdverse nutritional effectBaking mixturesPreservation by heat treatmentThermal treatmentMoisture

The invention relates to a method for producing objects, at least parts of which are a glossy brown. In a first step, an at least par-baked, dimensionally stable shaped body is produced, said body is treated as a dimensionally stable pre-product in a second step at least partially with lye. The intermediate product thus obtained can be sprinkled with a granular topping in an additional step. In the final step, the intermediate product is subjected to renewed thermal treatment, in order to brown the areas treated with lye and optionally reduce the moisture in its interior.

Owner:FRANZ HAAS WAFFELMASCHEN IND MBH

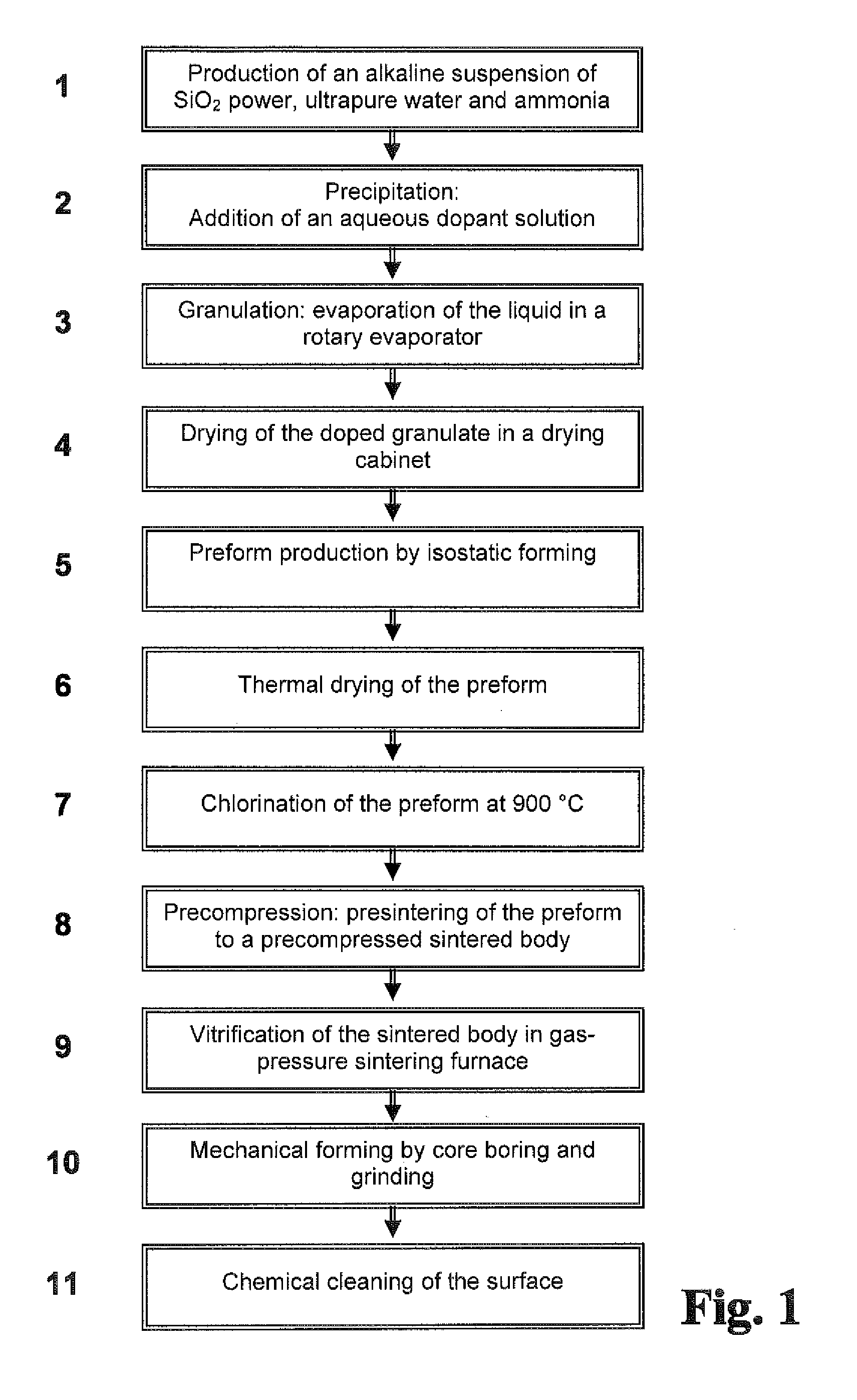

Method for producing doped quartz glass

ActiveUS20100251771A1Improve homogeneityGlass shaping apparatusCeramic shaping apparatusMaterial distributionQuartz

The invention relates to a method allowing cost-effective production of doped quartz glass, particularly laser-active quartz glass, that is improved with regard to the homogeneity of the doping material distribution, in that a suspension is provided comprising SiO2 particles and an initial compound for at least one doping material in an aqueous fluid, the fluid being removed under formation of a doped intermediate product comprising particles of the doping material or particles of the precursor substance or the doping material, and the doped quartz glass is formed by sintering the doped intermediate product, wherein at least part of the particles of the doping material or the particles of the precursor substance of the same is generated in the suspension as a precipitate of a pH-value-controlled precipitation reaction of the initial compound.

Owner:HERAEUS QUARZGLAS +1

Method and device for smelting jamesonite by bottom-blowing pool

The invention relates to a method and a device for smelting jamesonite by a bottom-blowing pool. The method comprises the following steps of: performing pool smelting, oxidation and desulfurization on the jamesonite by using a bottom-blowing oxidation furnace to produce antimony-containing high-lead slag, a lead-antimony alloy and flue gases suitable for acid preparation; reducing the antimony-containing high-lead slag and blowing the lead-antimony alloy by using a bottom-blowing smelting furnace to produce antimony oxides and lead bullion capable of being used for electrolysis; and reducing the antimony oxides by using a bottom-blowing reduction furnace to produce needle antimony. In the smelting method of the invention, the three bottom-blowing furnaces and an electrically-heated settler are adopted to treat the jamesonite to produce the lead bullion, the needle antimony and the slag; therefore, compared with the prior art, the method has the advantages of short flow, good lead-antimony separation effect, fewer intermediate products, less revert, high resource utilization rate and production continuity; and the bottom-blowing oxidation furnace can realize spontaneous heating balance by sulfide combustion with low energy consumption and high recovery rate and can greatly reduce the cost.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

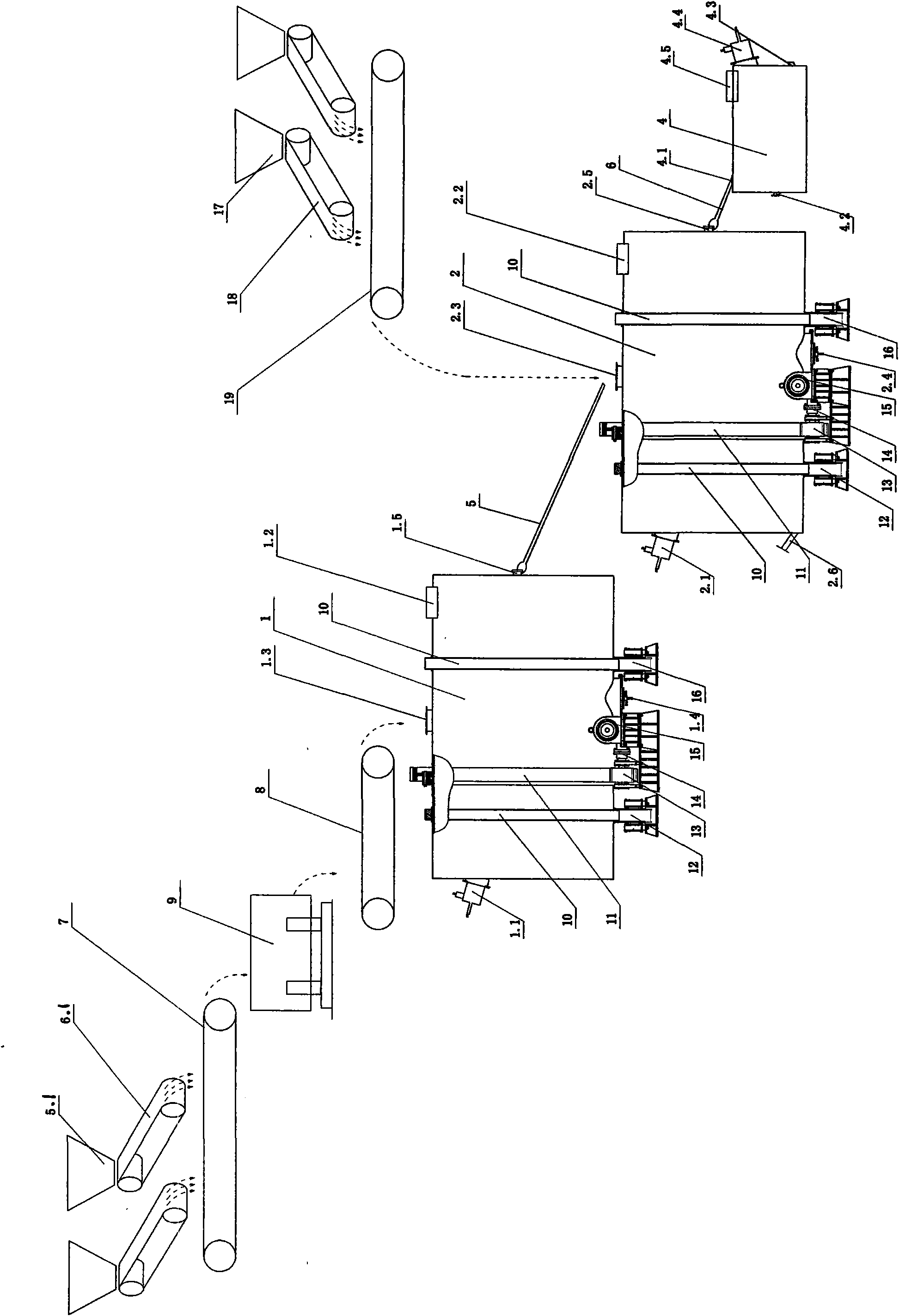

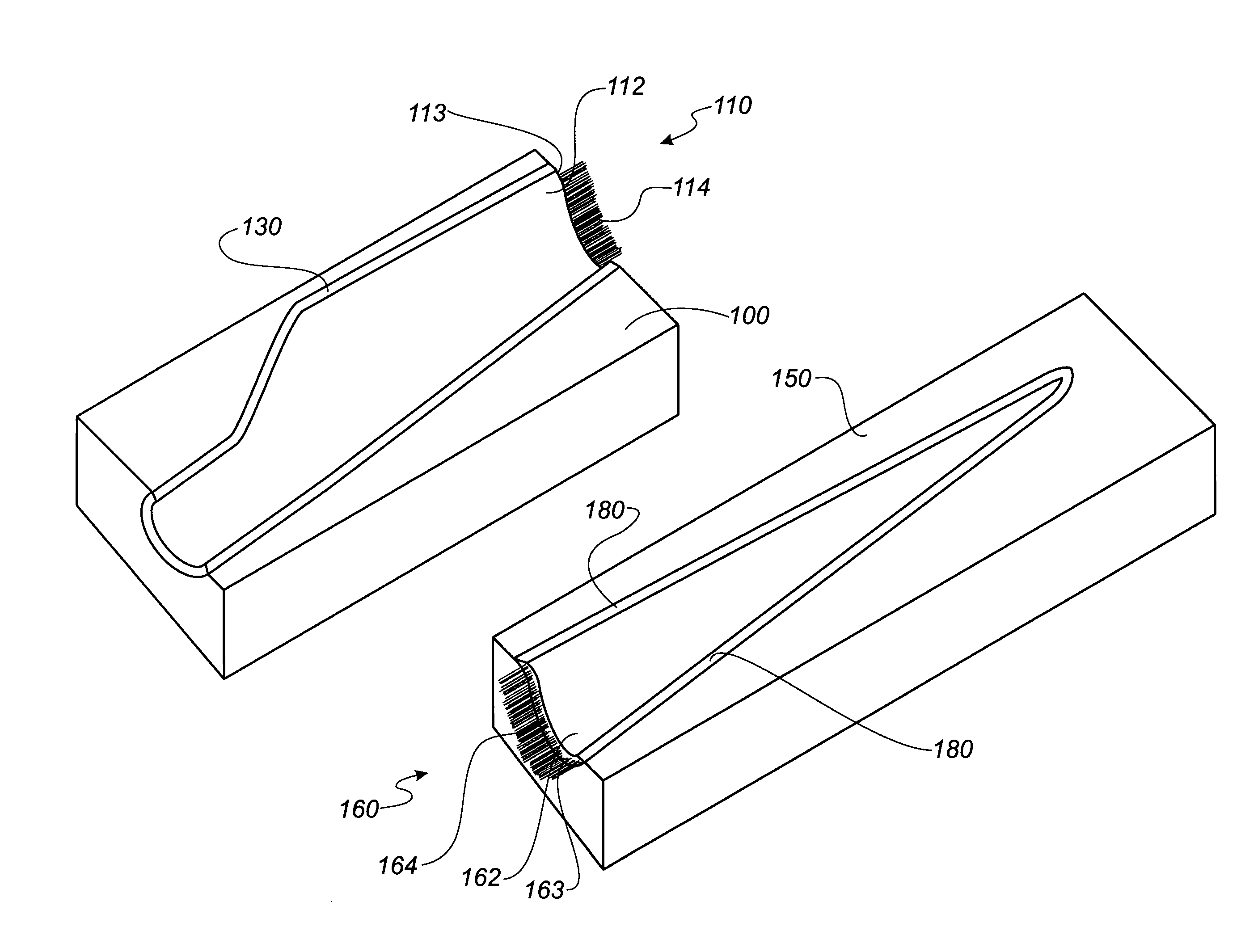

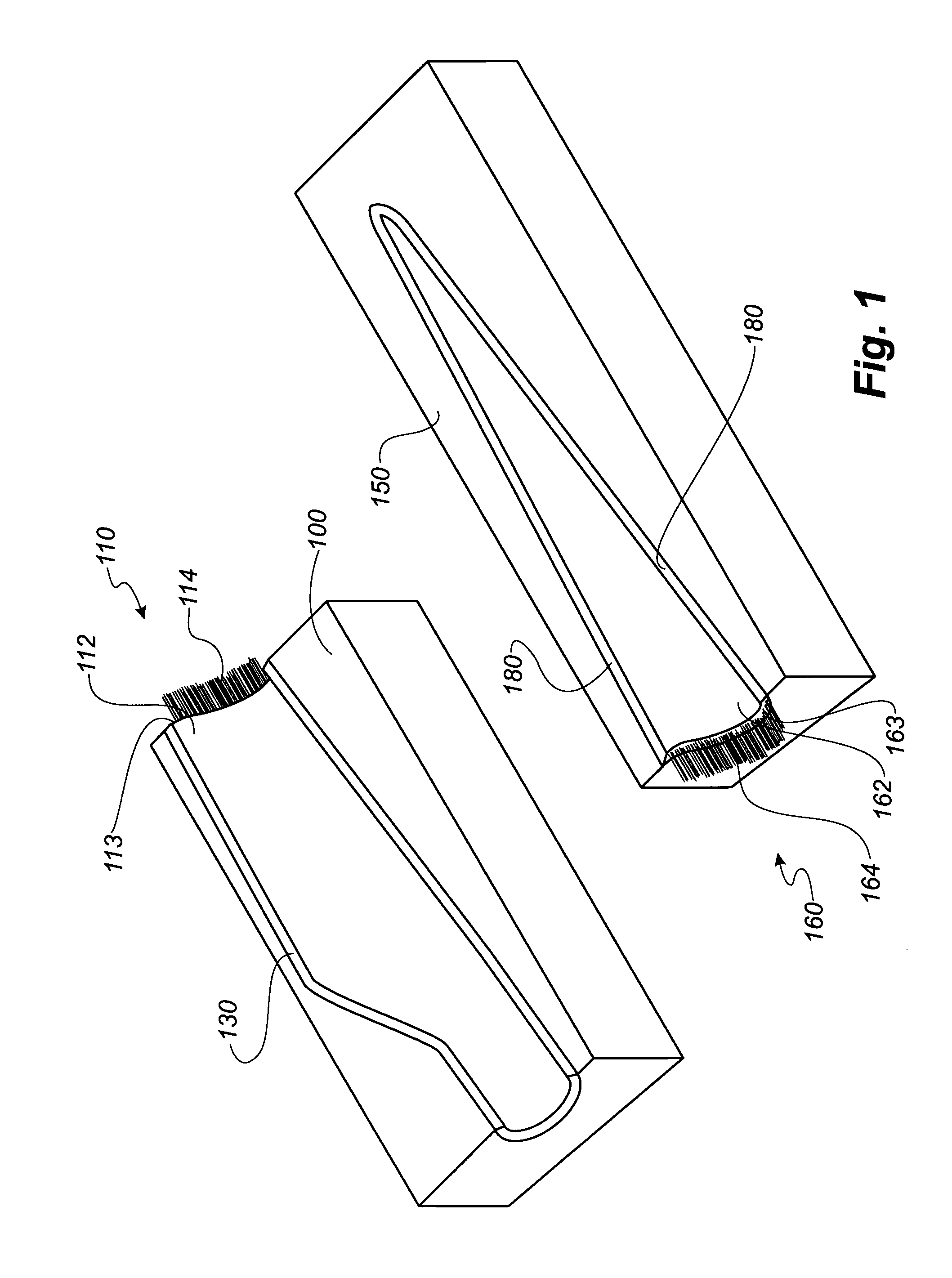

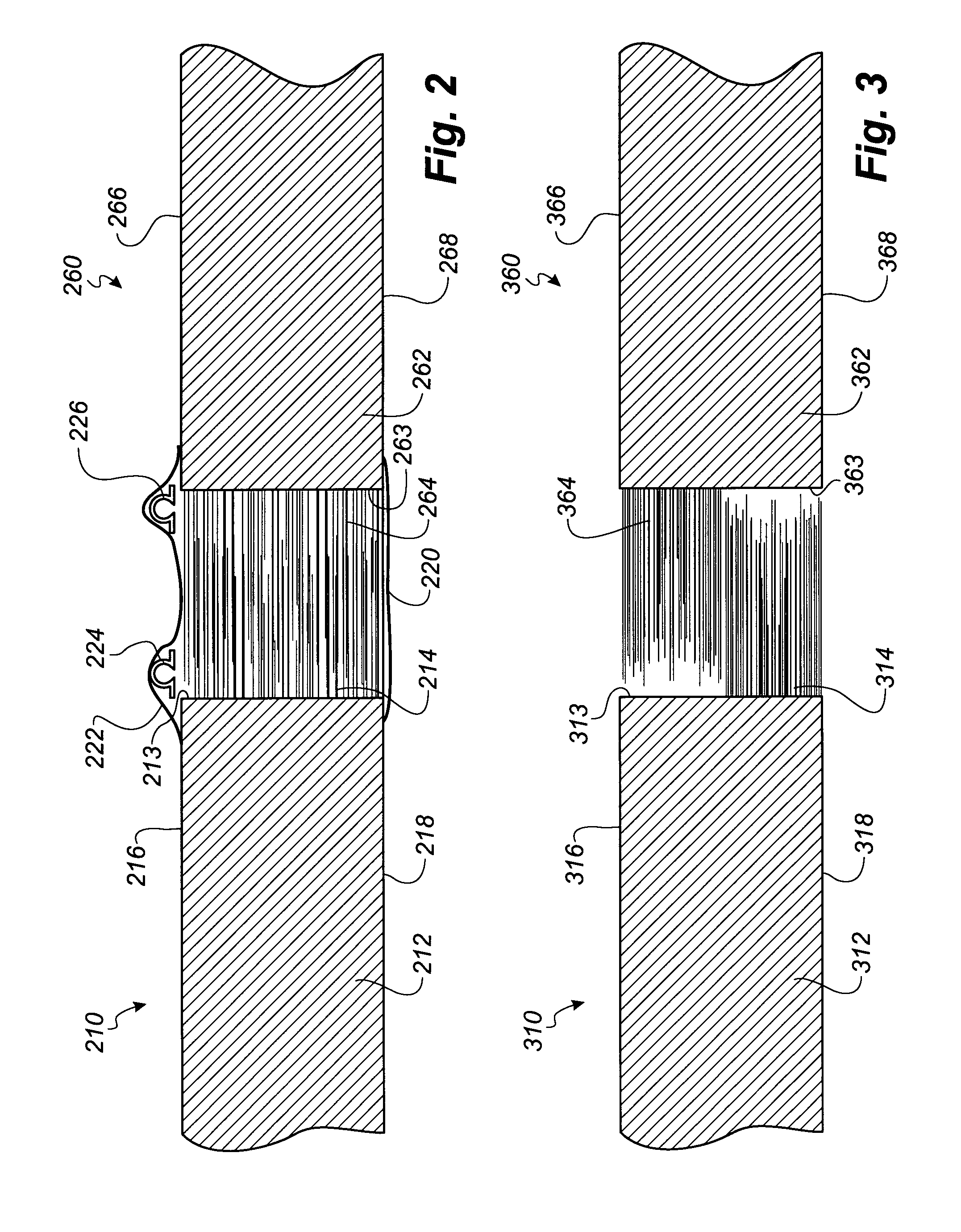

Method of producing a composite structure via intermediate products, the related apparatus and a composite structure obtainable by the method

ActiveUS20100304170A1High fiber densityFirmly connectedLaminationLamination apparatusFiberLiquid resin

A method of producing a composite structure comprising fibre reinforced material and having a longitudinal direction is described. The method comprises the following steps: a) manufacturing a first structure comprising a first cured composite part having a first thickness and a longitudinal direction with a first end, and a number of first fibre layers extending from the first end, b) manufacturing a second structure comprising a second cured composite part having a second thickness and a longitudinal direction with a second end, and a number of second fibre layers extending from the second end, and c) arranging the first structure and the second structure so that the first end faces towards the second end, and arranging the first fibre layers and the second fibre layers so that at least a part of the first fibre layers overlap at least a part of the second fibre layers in the longitudinal direction, d) supplying liquid resin in order to impregnate the first fibre layers and the second fibre layers, and e) curing the liquid resin in order to form the composite structure comprising the first cured composite part, the second cured composite part, and an intermediate composite part including the first fibre layers and the second fibre layers.

Owner:LM GLASSFIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com