Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12342results about "Vegetal fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulosic fibers with odor control characteristics

ActiveUS20070077428A1Avoid odorMaintain activityEngine sealsInorganic pigment treatmentBiotechnologyAmmonia production

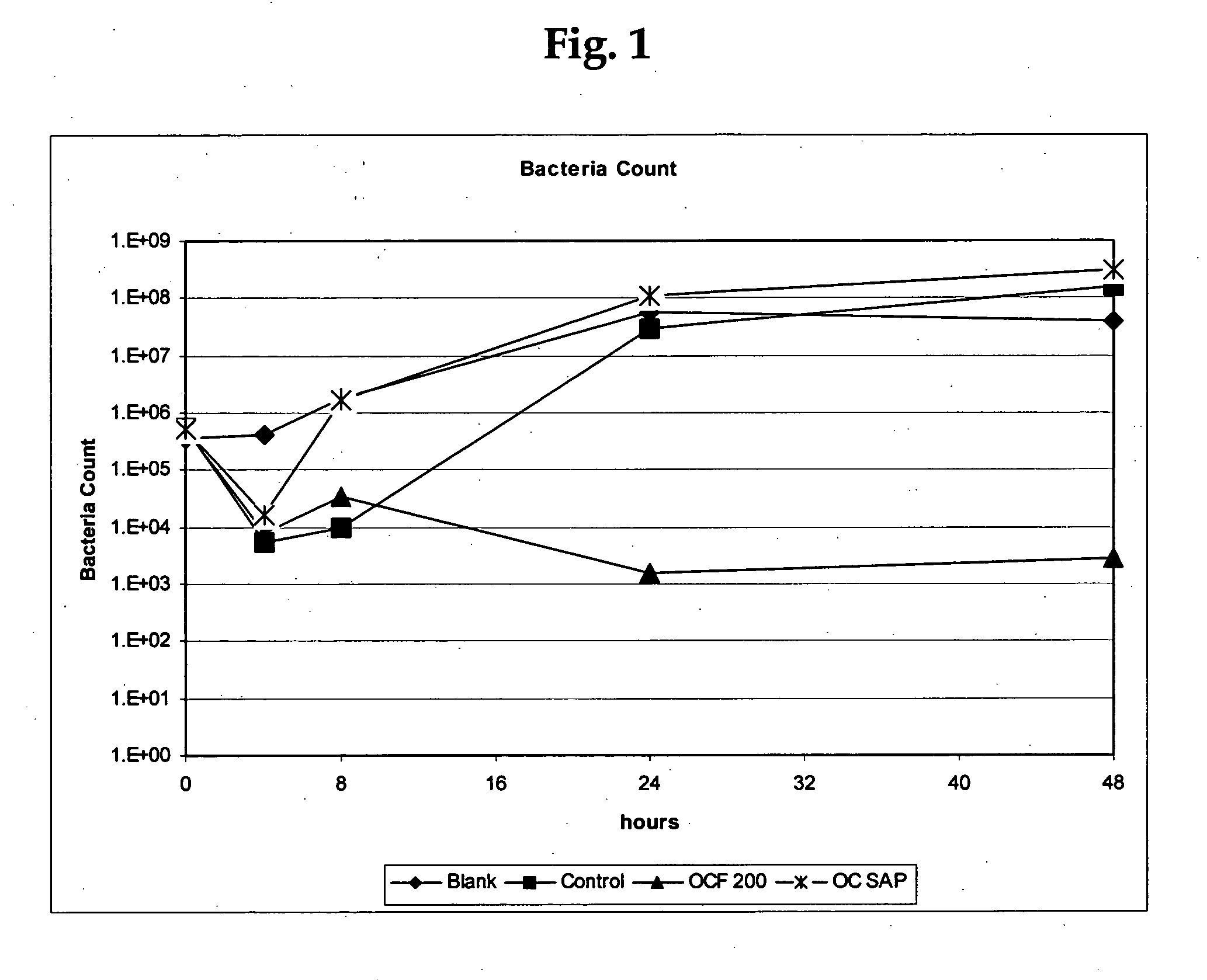

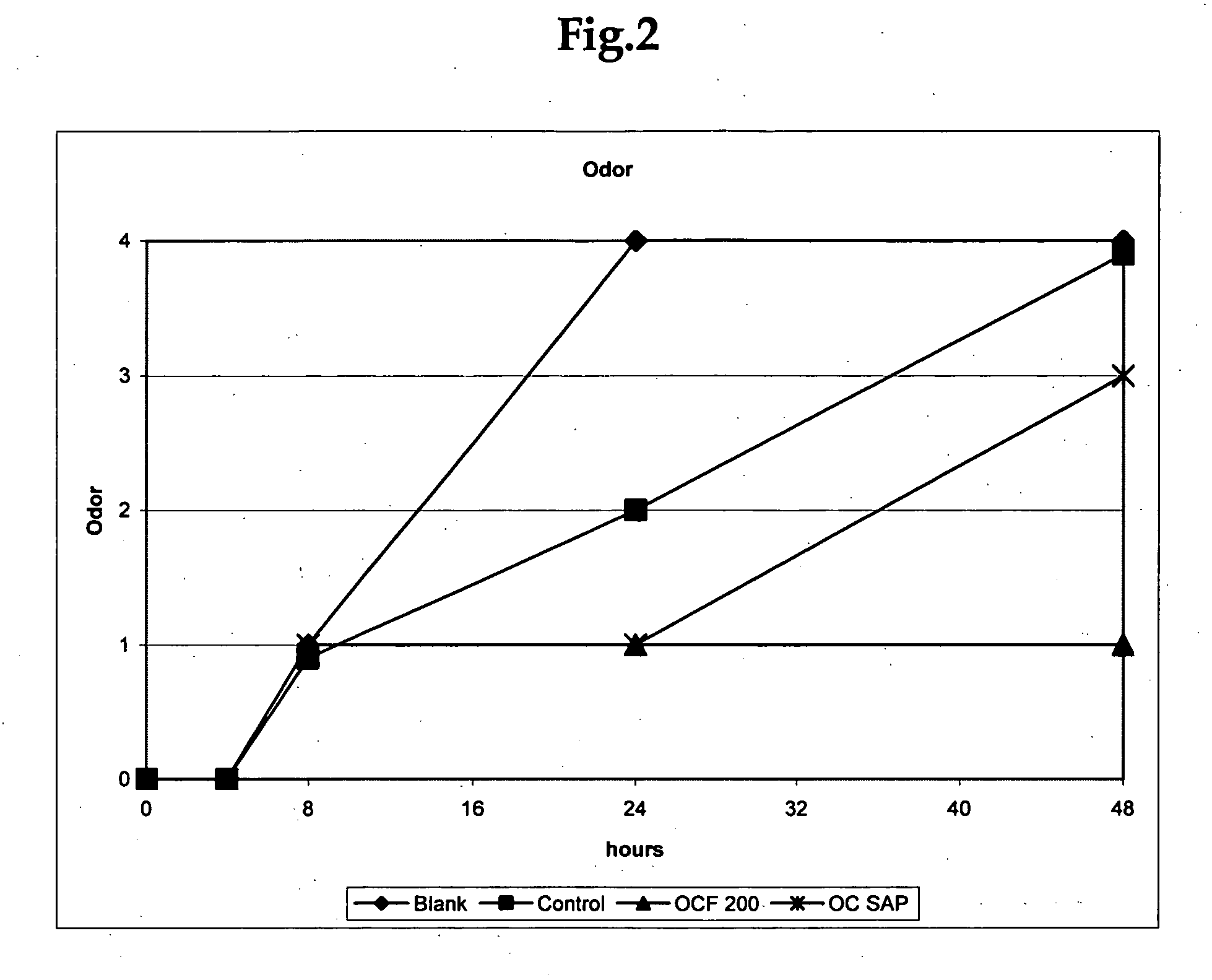

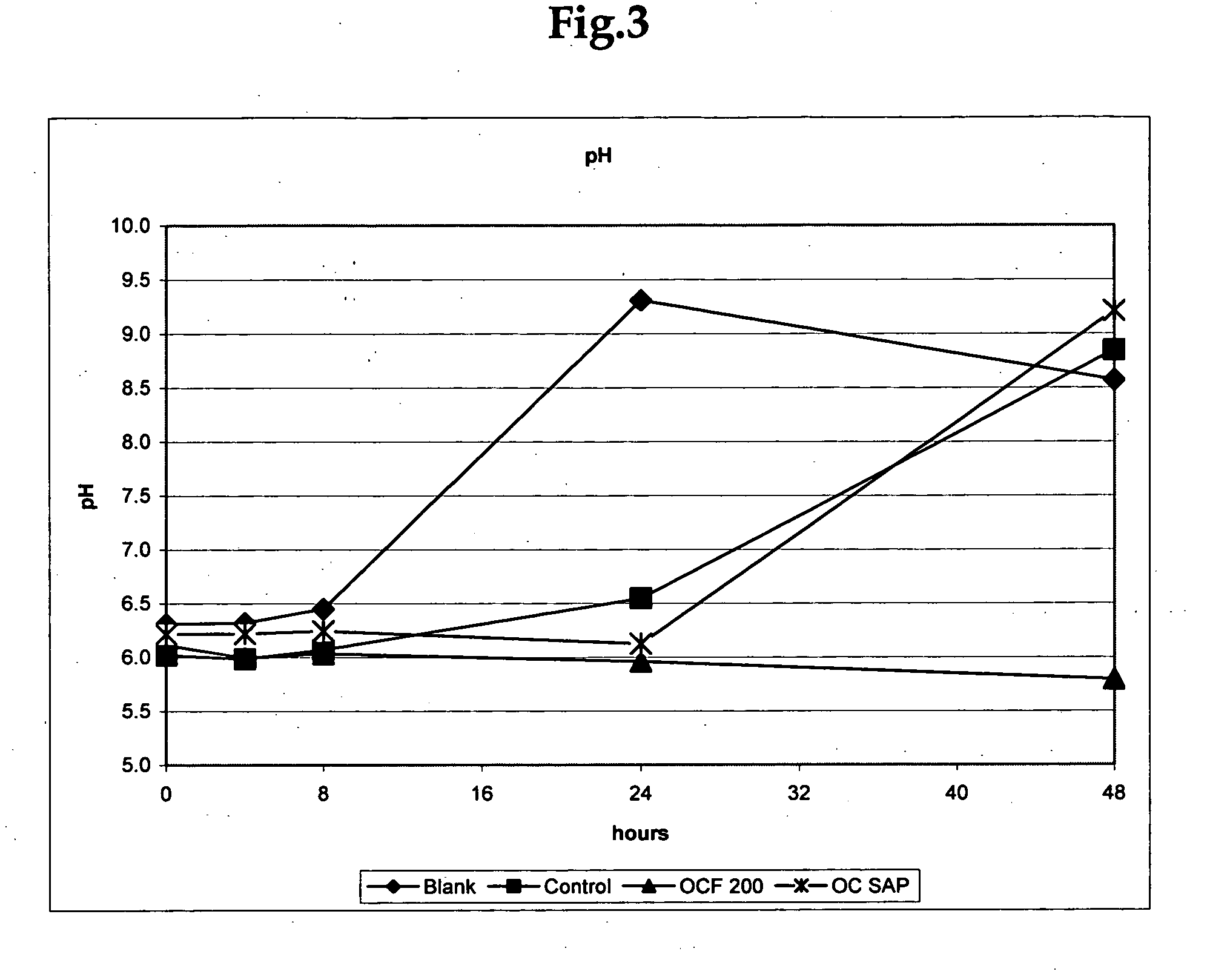

An odor-inhibiting fiber having a cellulosic fiber and an odor-inhibiting formulation. The odor-inhibiting formulation may contain an odor-inhibiting agent, such as a biocide, an enzyme, a urease inhibitor. The odor-inhibiting formulation also may contain a liquid carrier such as a hydrophobic or hydrophilic organic liquid, or a mixture of a hydrophobic and hydrophilic organic liquid. The cellulosic fiber is impregnated with the odor-inhibiting formulation to produce fiber having odor-inhibiting characteristics. The resultant odor-inhibiting fiber is useful in making absorbent articles with odor-inhibiting characteristics. The fiber of the embodiments prevents odor by inhibiting bacteria growth and ammonia production, especially when used in an absorbent article such as a diaper or adult incontinence device.

Owner:RAYONIER PERFORMANCE FIBERS

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

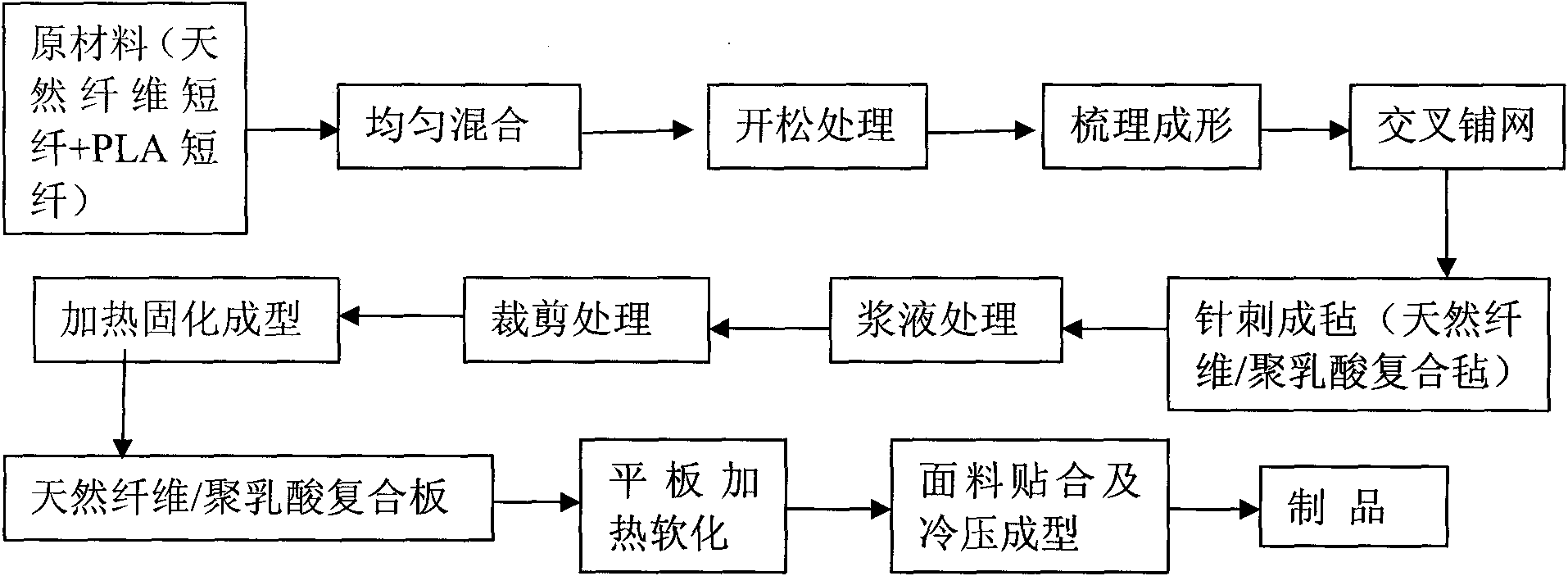

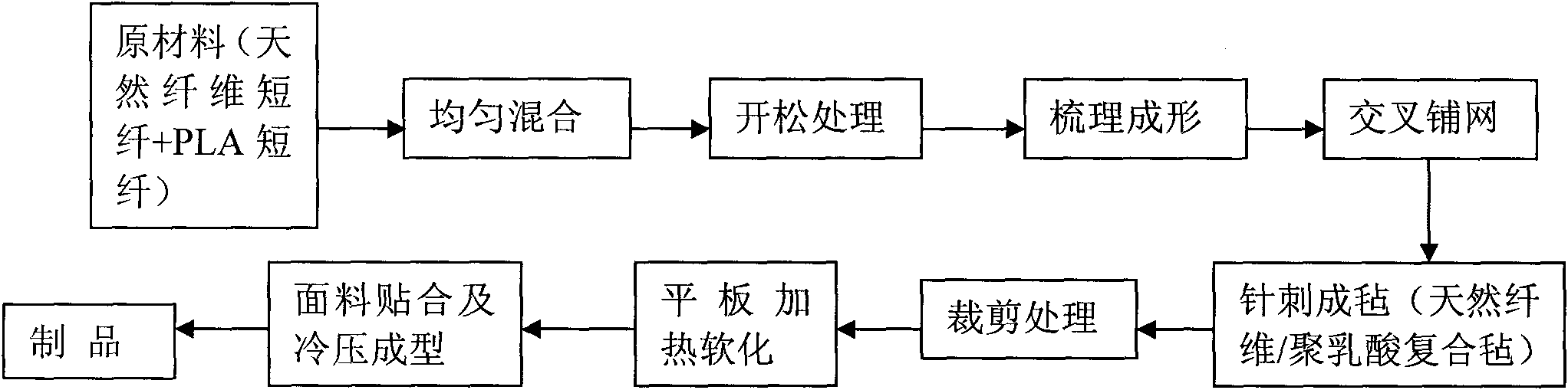

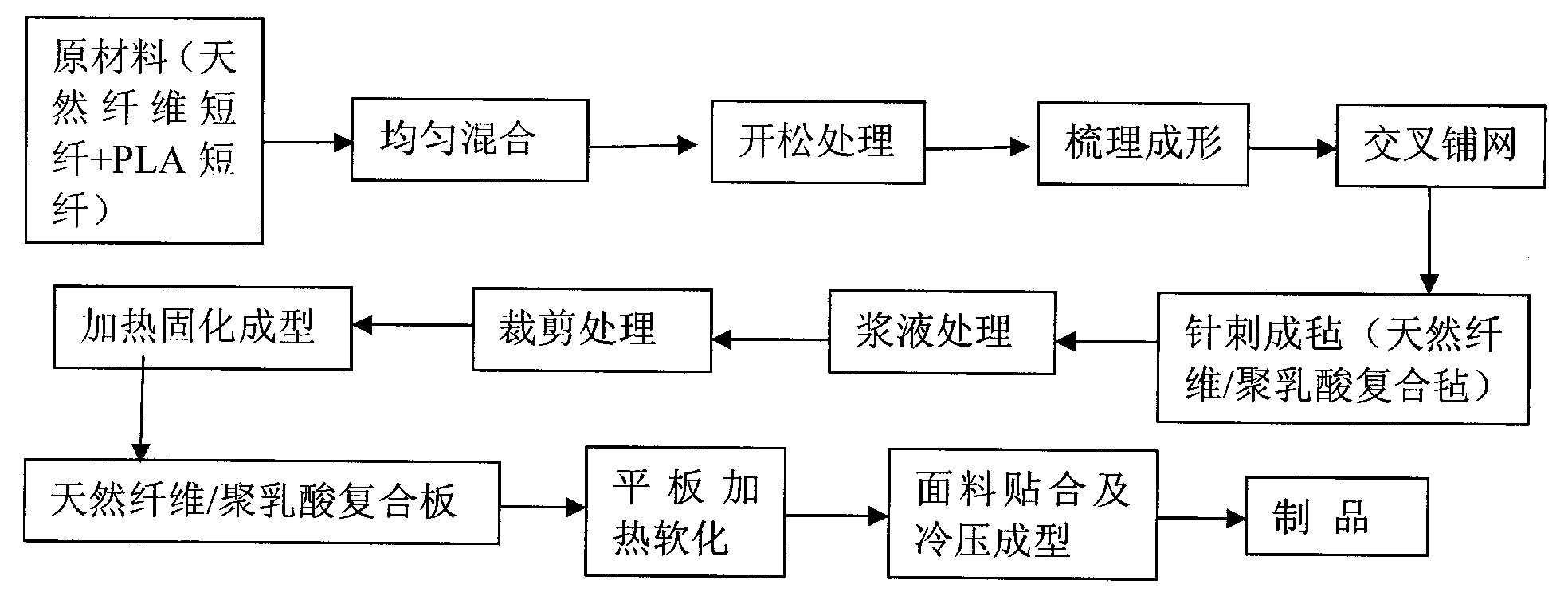

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

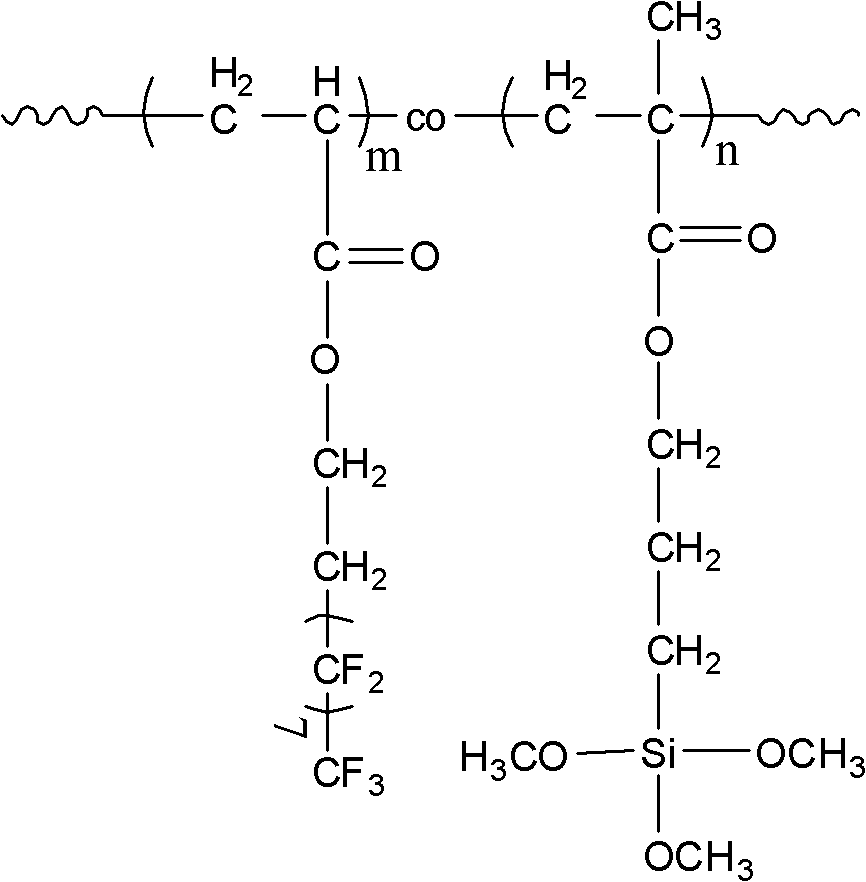

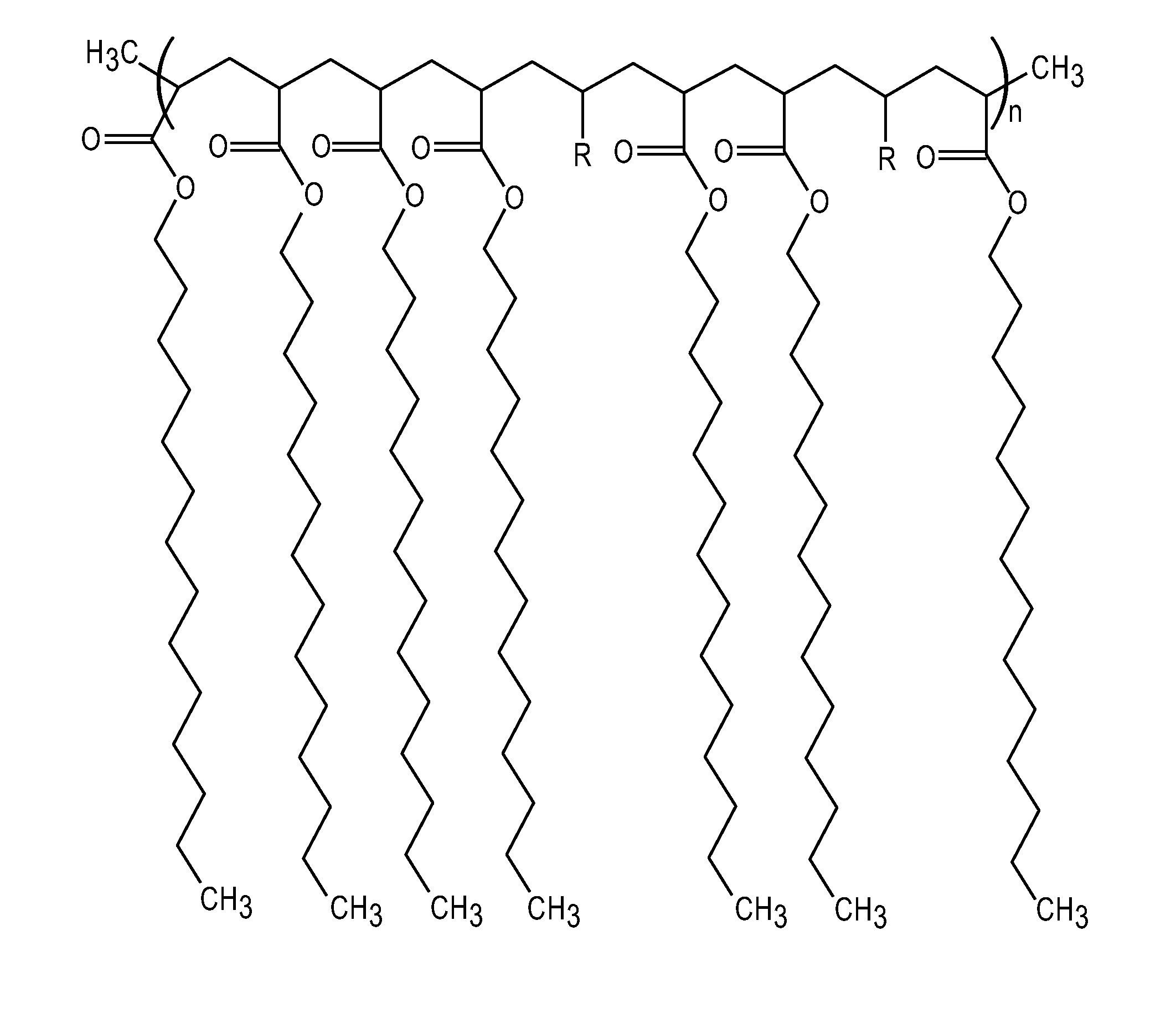

Super-amphiphobic polymer and super-amphiphobic surface prepared from super-amphiphobic polymer

InactiveCN102432742AGood scrub resistanceAccelerated corrosionWater-repelling agents additionPaper/cardboardPolymer scienceMicrosphere

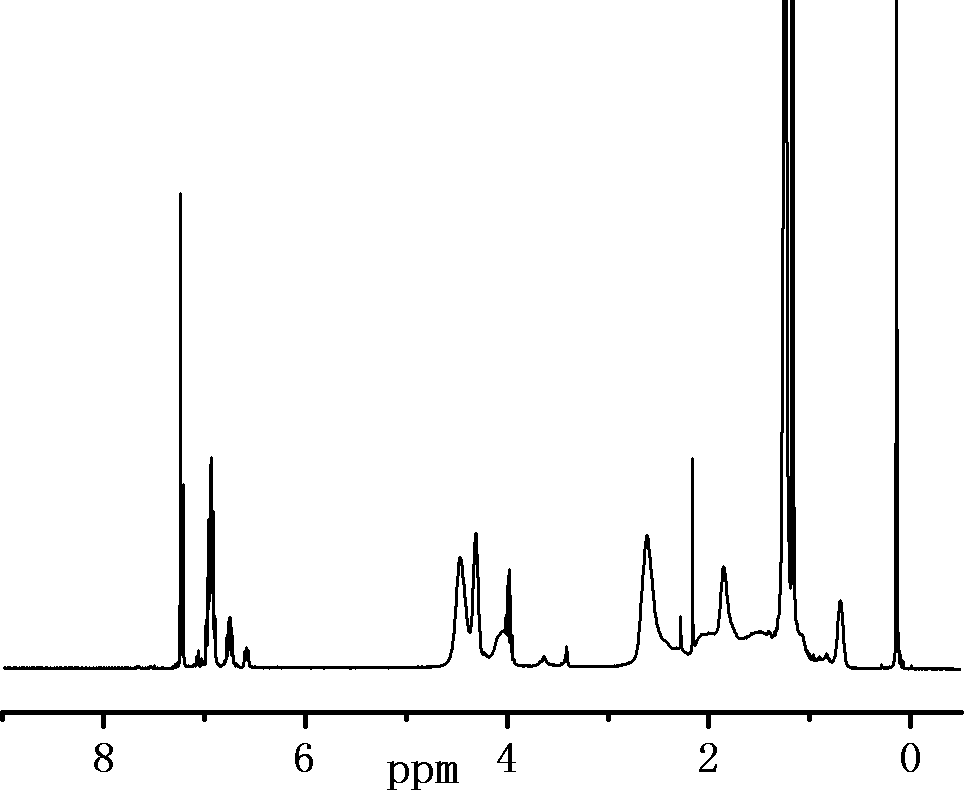

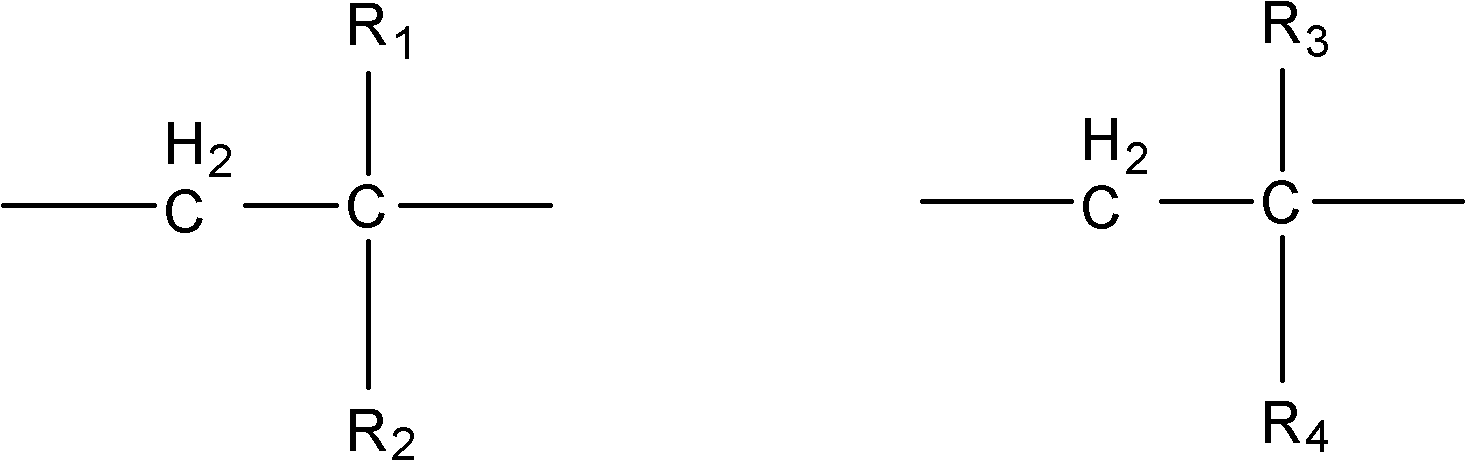

The invention belongs to the field of macromolecule super-amphiphobic materials and discloses a super-amphiphobic polymer and a super-amphiphobic surface. The super-amphiphobic polymer is a random copolymer composed of structural units shown as a formula I and a formula II. The super-amphiphobic surface is obtained by comprising the following steps of: pre-processing a substrate material; placinga micro-balloon in a fluorine-containing solvent, and ultrasonically dissolving to obtain a micro-balloon supernatant solution; adding the super-amphiphobic polymer, a hydrochloric acid tetrahydrofuran solution and water into the micro-balloon solution while stirring, placing the substrate material, and reacting for 5-24 h; and taking out the substrate material, washing by using the fluorine-containing solvent, methanol and water in turn, drying in vacuum, and obtaining the super-amphiphobic surface. The super-amphiphobic polymer disclosed by the invention can give good surface hydrophobic ability and oleophobic ability to the substrate. Because the polymer has the characteristics of the fluorine-containing polymer so that the polymer can be chemically bonded with the surface of the substrate, the obtained super-amphiphobic surface has good scrubbing resistant property and corrosion resistant property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

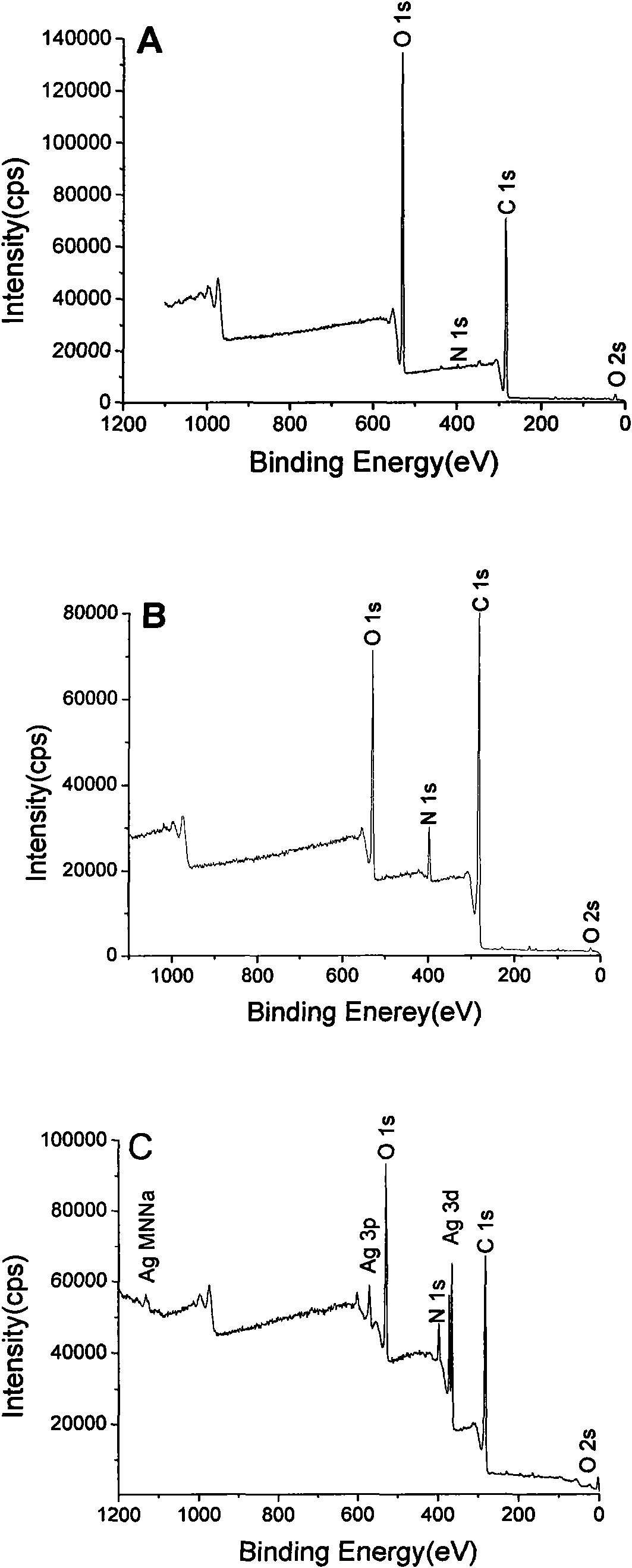

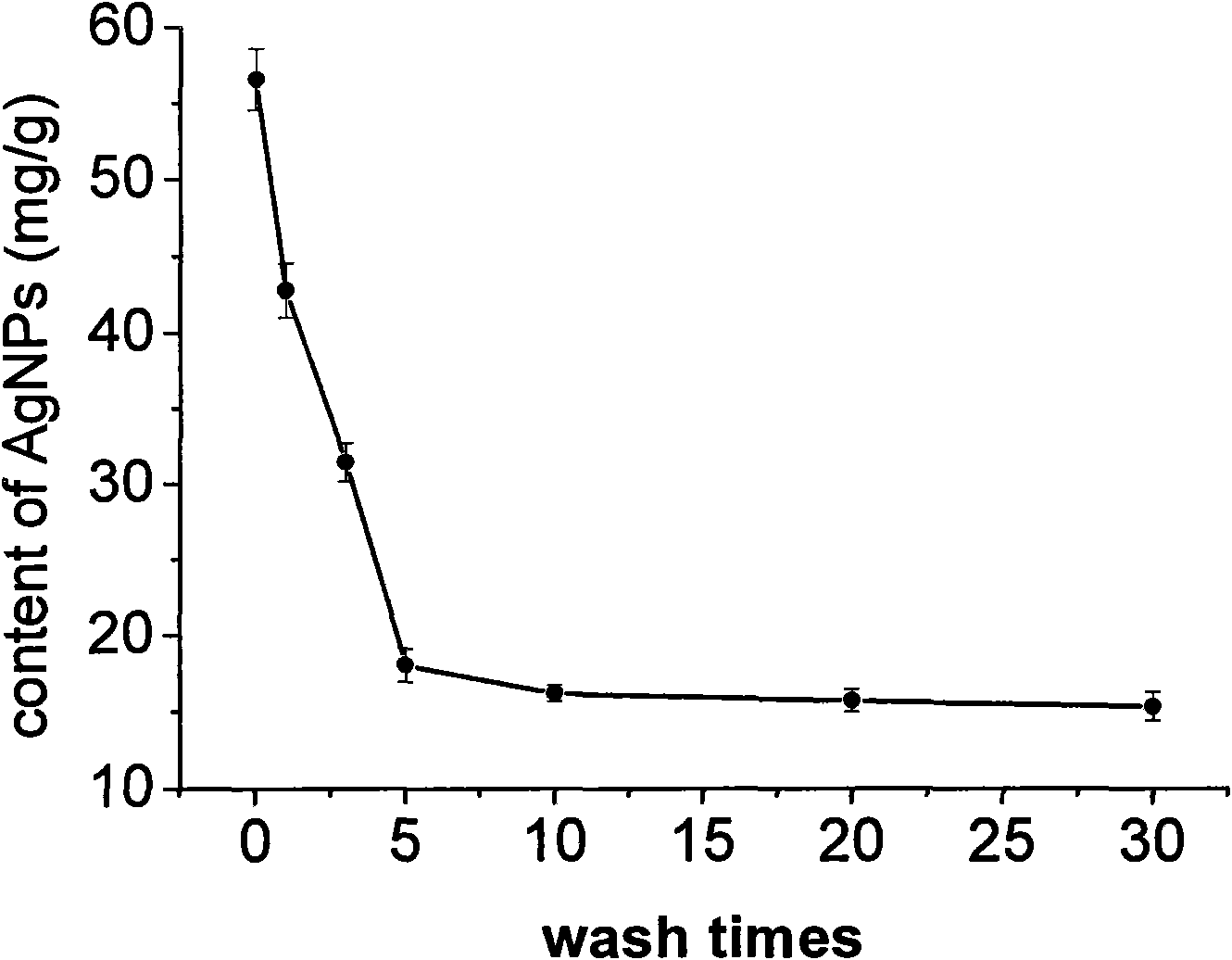

Method for preparing nano silver-containing anti-bacterial fabric by immersion process

ActiveCN101864670AGood soaping fastnessEfficient and durable antibacterialVegetal fibresAnimal fibresChemistryAnti bacterial

The invention relates to a method for preparing a nano silver-containing anti-bacterial fabric by an immersion process. The method comprises the following steps: dissolving dopamine hydrochloride in Tris buffer solution; adjusting the pH value of solution to be between 7 and 10 by using hydrochloric acid; immerging a fabric into prepared dopamine solution in a bath ratio of 1:30; after stirring for reacting at the temperature of between 20 and 40 DEG C for 20 to 30 hours, taking the fabric out and washing to obtain a poly dopamine film-coated fabric; putting the fabric into silver nitrate aqueous solution; and after immerging for 8 to 10 hours, washing and drying the fabric to obtain the nano silver-containing fabric. The nano silver-containing fabric prepared by the method has the characteristics of high soaping fastness resistance and lasting antibiotic property; a sterilizing rate is still up to 100 percent after the fabric is washed with water for 30 times; and the preparation method has the characteristics of simple process, no pollution to the environment, low cost and large-scale production.

Owner:DONGHUA UNIV

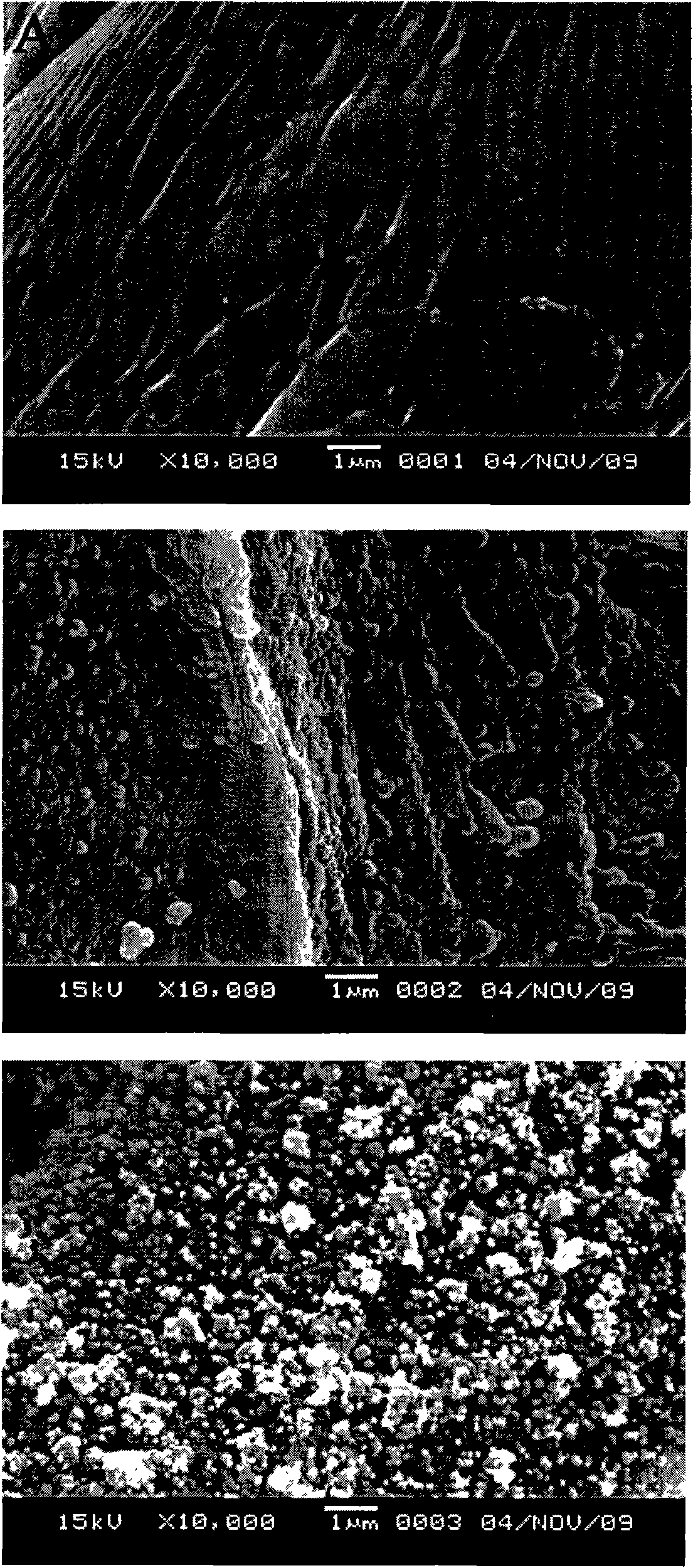

Nano silver bacterial fibre and preparation method thereof

ActiveCN101942759AEvenly distributedImprove antibacterial propertiesVegetal fibresNatural fiberAntibacterial property

The invention discloses a nano silver bacterial fibre preparation method comprising: adding fibre into AgNO3 solution, and adsorbing the mixture; and carrying out reduction reaction on the adsorbed fibre to obtain the nano silver bacterial fibre. The invention has simple production step, and the obtained product has the advantages of even silver nanoparticle distribution and long-lasting fibre antibacterial property and can be washed several times. The invention is suitable for natural fibre and synthetic fibre and can be used for health-care underwear, medicinal gauze, clothes, decorative textiles and the like.

Owner:金湖县农副产品营销协会

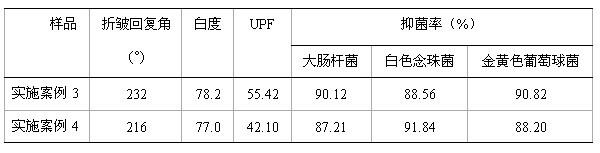

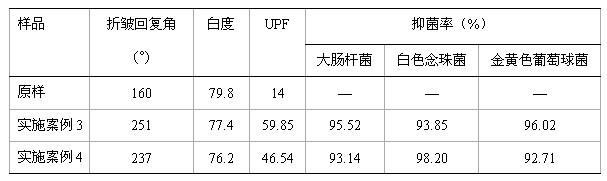

Ionic cross-linking of ionic cotton with small molecular weight anionic or cationic molecules

InactiveUS7201778B2Improved wrinkle recovery anglePromote recoveryWrinkle resistant fibresDetergent compounding agentsCelluloseFiber

A process for producing an ionic crosslinked fibrous material, such as a cellulosic fabric, paper, or other substrate, wherein the ionic crosslinked fiber exhibits an increased wrinkle resistance angle. A process for producing a cationized chitosan, wherein the cationized chitosan exhibits cationization at the C6 and ring hydroxyl sites and the reactivity of the ring NH2 sites is preserved. A process for applying a polycation to an anionic fibrous material to form an ionic crosslinked fibrous material. A process for producing a cationized fibrous material, wherein the process is performed as a pad-batch process, an exhaust fixation process, a pad-steam process, or a pad-dry-cure process.

Owner:NORTH CAROLINA STATE UNIV

Fluorescent pseudomonad DA4 strain as well as acquisition method and application thereof

InactiveCN102002468AHigh enzyme productionEnzyme richBacteriaBiochemical fibre treatmentFlax fiberUltimate tensile strength

The invention relates to a fluorescent pseudomonad DA4 strain as well as an acquisition method and application thereof. The fluorescent pseudomonad DA4 strain has pectase and hemicellulase producing capacity and flax degumming activity. The fluorescent pseudomonad strain screened by the invention has fast propagation, high antipollution capacity and good heat and alkali resistance; since a composite degumming enzyme solution is used for flax degumming, the degumming period is shortened greatly, and the system and the culturing process is safe for operation without toxicity or environmental pollution; the invention can shorten the flax degumming period, enhance the flax yield and the strength of flax fibers, improve the quality of the flax fibers by adopting the composite degumming enzyme solution for flax microbial degumming, thereby being beneficial to popularization; in addition, the invention can not only be used for flax raw stem degumming, roving scouring and the biological pretreatment of flax fabrics, but also can be used for the degumming and the biological pretreatment of hemp bast fibers, i.e. ramie, jute, hemps, and the like.

Owner:DONGHUA UNIV

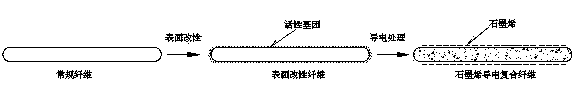

Preparation method of graphene electroconductive composite fiber

The invention provides a preparation method of a graphene electroconductive composite fiber. The method is characterized by comprising the following procedures: in a textile fiber surface modification procedure, a textile fiber is soaked into a silane coupling agent KH560 solution with the concentration of 1-30 percent for 2-3 hours and then is put into an oven of 50-65 DEG C to be dried to prepare the surfactant modified textile fiber; in a graphene dispersion system preparation procedure, graphene is prepared from an oxidized graphene aqueous solution prepared by means of a Hummer's method in a chemical reduction method, and a uniform and stable graphene dispersion system with the concentration of 0.1-5 percent is prepared under the function of a dispersing agent; in a graphene composite fiber preparation procedure, the modified textile fiber is soaked in the graphene dispersion system for 2-3 hours and then put into the oven of 50-65 DEG C to be dried to obtain the graphene electroconductive composite fiber. The preparation method is simple and reasonable in process, easy to operate, high in yield, high in reduction degree and high in conductivity and anti-radiation performance; the using amount of graphene is less and the dispersion system is uniform and stable.

Owner:QINGDAO UNIV

Method for preparing floride-free super-hydrophobic cotton fabric

InactiveCN101397754AMeet the requirementsWide variety of sourcesVegetal fibresSilicon dioxideMechanical property

The invention provides a preparation method of fluoride-free super-hydrophobic cotton fabrics, pertaining to the technical field of water repellent finishing of cotton fabrics. The preparation method is characterized in that the concrete steps comprise: 3ml to 6ml of ammonia water with a mass concentration of 25wt percent to 28wt percent is added into 50ml to 100ml of ethanol and stirred. 5ml to 6ml of N-tetraethyl silicate is added in a dropwise manner and aged for 30min to 80min to obtain silica sol; the cotton fabric is immersed in the silica sol, dipped and rolled, and then dried at 60 DEG C to 100 DEG C for 1min to 5min; and the cotton fabric is immersed in alkane siloxane hydrolyzate, dried at room temperature and roasted for 30min to 120min in an oven which is preheated to 120 DEG C to 160 DEG C. The preparation method is environmentally-friendly, convenient and effective and meets the requirements of ecotypic textiles; the preparation method has wide sources of raw materials and the contact angle of the prepared cotton fabrics and water dripping exceeds 150 degrees and the prepared cotton fabrics have super-hydrophobic performance and does not influence the physical and mechanical properties of the cotton fabrics.

Owner:DONGHUA UNIV

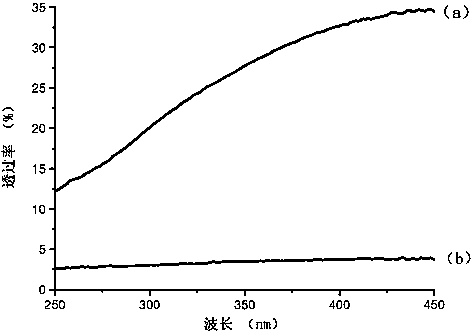

Preparation method of ultraviolet-proof antistatic graphene coating textile fabric

ActiveCN103469555ASimple production processEasy to operateVegetal fibresGraphene coatingFixation time

The invention provides a preparation method of ultraviolet-proof antistatic graphene coating textile fabric. The method is characterized by comprising the following steps: adding a graphene solution to a water-soluble polyurethane solution after shaking and dispersing so as to obtain a mixed solution; fully stirring the mixed solution; putting a graphene screening agent solution into a padder immersion tank; processing textile base fabric under room temperature through implementing a two-dipping and two-rolling procedure; padding the graphene screening agent on a textile, putting kinds of textiles on which the graphene screening agent is padded into a high-temperature oven for drying, wherein the temperature of the high-temperature oven is 75-95 DEG C; the high-temperature fixation time lasts for 5-30 minutes, so as to prepare the ultraviolet-proof antistatic graphene coating textile fabric. The method is simple in process, and easy to operate, and the yield is high; the produced textile fabric has the excellent function of preventing ultraviolet rays and static electricity.

Owner:QINGDAO UNIV

Preparation method of super-hydrophobic cellulose material with micro-nano structure

The invention relates to a preparation method of a super-hydrophobic cellulose material with a micro-nano structure. The method comprises the following steps: (1) adding ethyl orthosilicate and functionalized siloxane into an ethanol system containing deionized water to obtain a dispersion liquid of functionalized silica particles A in the presence of ammonium hydroxide serving as a catalyst; with the dispersion liquid of functionalized silica particles A as seeds, sequentially adding the ethyl orthosilicate, the functionalized siloxane, the deionized water, the ammonium hydroxide and the ethanol so as to obtain a dispersion liquid of functionalized silica particles B; (2) performing ultrasonic dispersion on the two types of functionalized silica particles in dimethylformamide, then adding a hydrophobic polymer and a low surface energy additive into the system and evenly stirring so as to form white dispersion liquid; and (3) coating the white dispersion liquid obtained in the step (2) on a natural cellulose material in a direct spraying manner or a spin coating manner so as to obtain the super-hydrophobic cellulose material with the micro-nano structure. The coating material has strong scouring resistance and acid-alkali resistance besides the excellent hydrophobic property.

Owner:山东天洋新材料有限公司

Storage mildew-proof and moth-proof packaging hemp cloth and preparation method thereof

InactiveCN102310966APrevent intrusionPrevent mildewBio-packagingBiochemical fibre treatmentProcess dynamicsMildew

The invention provides storage mildew-proof and moth-proof packaging hemp cloth and a preparation method thereof. The hemp cloth comprises green harmless storage protective agent and is prepared by taking common packaging hemp cloth as a material and adding 0.01-10wt% of storage protective agent. The preparation method comprises the following steps of: dissolving the storage protective agent in a solvent to prepare a solution, then impregnating the hemp cloth in the protective agent solution, removing the solution after the hemp cloth sufficiently absorbs the solution, and drying; or dissolving the storage protective agent in the solvent, then uniformly spraying the protective agent solution on the hemp cloth and drying the hemp cloth after the hemp cloth sufficiently absorbs the protective agent solution to prepare the storage mildew-proof and moth-proof packaging hemp cloth. The storage hemp cloth is used for packaging tobaccos or crops, can realize the whole process dynamic and real-time protection of the tobaccos, the crops and the like in purchase, transport and storage processes, protect products from mildew and moths, effectively prevent the mildew and the moths from spreading between bags and prevent the tobaccos, the crops and the like which are soaked by rain water from mildewing. Besides, the invention has an important function for reducing environment pollution and hidden safety danger which are caused by common technologies.

Owner:ZHENGZHOU UNIV

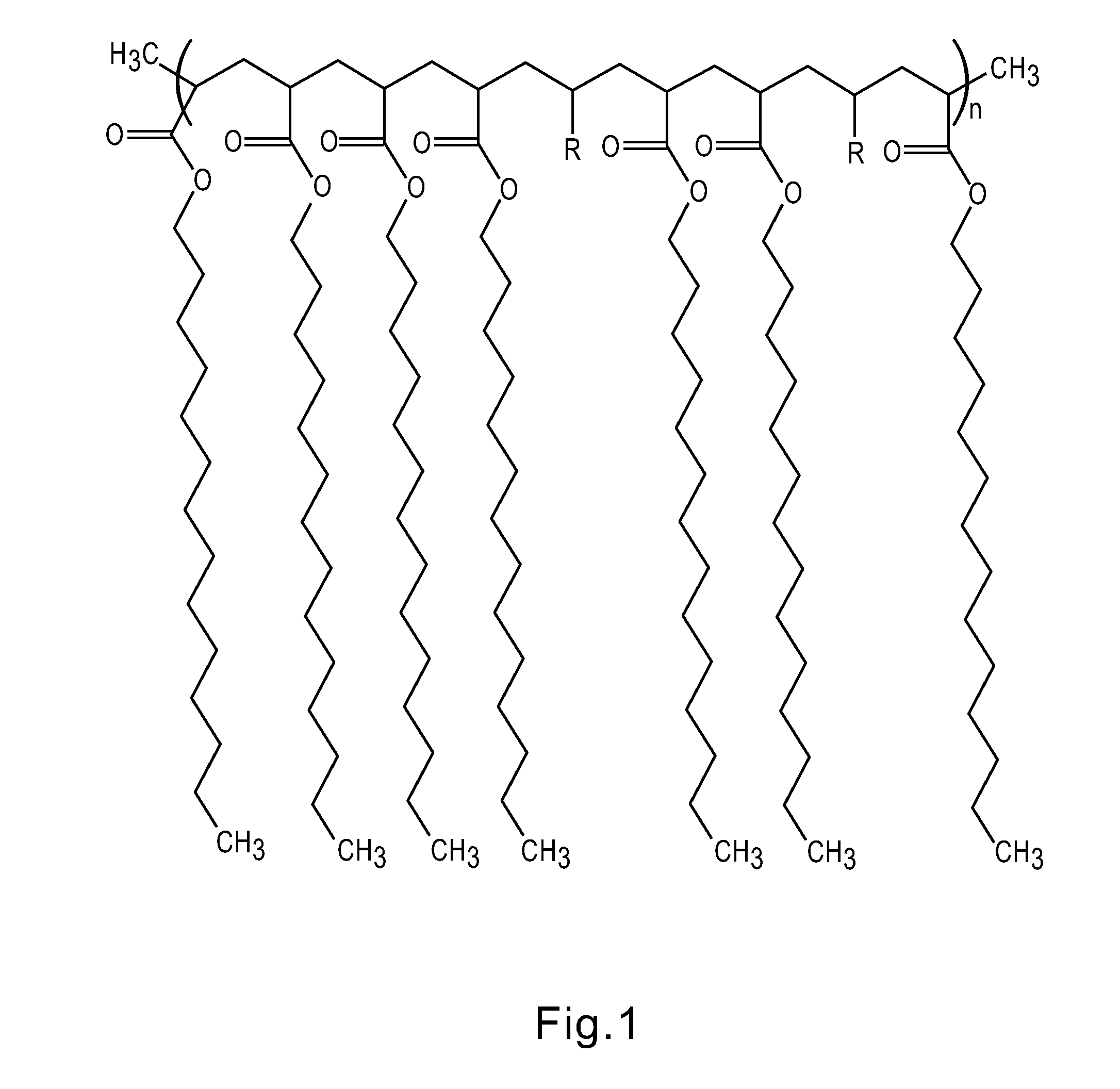

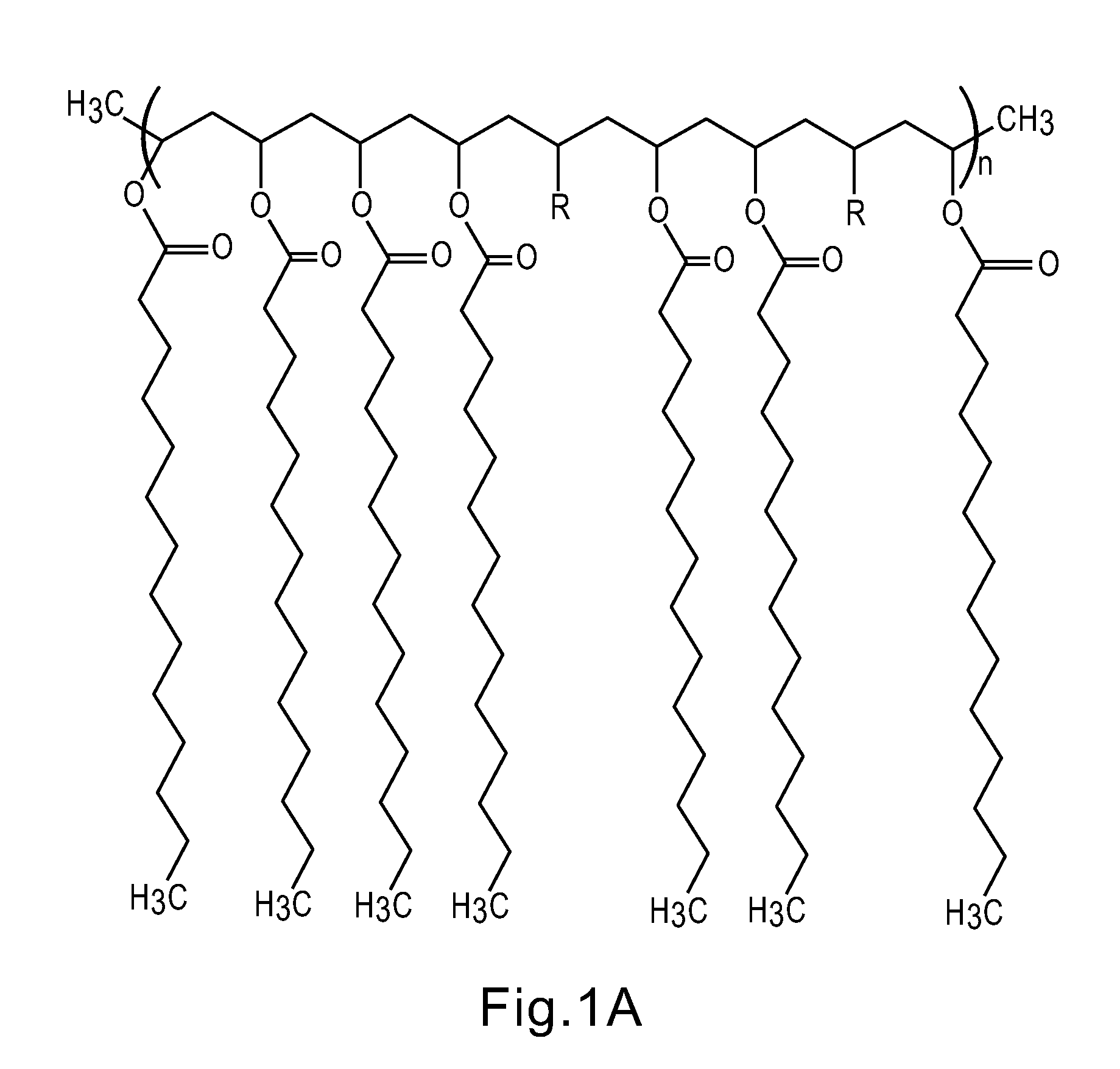

Thermal regulating building materials and other construction components containing polymeric phase change materials

In accordance with one aspect, a thermally regulating construction material comprises a base material and a polymeric phase change material bound to the base material, wherein the base material provides reversible temperature regulation properties to the building construction material. In accordance with another aspect, an insulation material for use in building construction comprises a base material and a polymeric phase change material bound to the base material, wherein the base material provides reversible temperature regulation properties to the insulation material. The base material may be selected from the group consisting of foam insulation, loose fill insulation, and batted insulation.

Owner:LATENT HEAT SOLUTIONS LLC

Wallpaper with air purifying function and preparation method

InactiveCN103866651APlay a decorative roleTo achieve the function of purifying the airCovering/liningsSpecial paperDeodorantMildew

The invention discloses wallpaper with an air purifying function and a preparation method. The wallpaper comprises a wallpaper base layer, wherein the wallpaper base layer is printed with a coating and the coating comprises film-forming resin, an inorganic porous powder, a photocatalyst, an antibacterial agent, an organic aldehyde removing agent and an organic deodorant. In the wallpaper with the air purifying function, the inorganic porous powder is capable of quickly adsorbing harmful gases in air, the organic aldehyde removing agent and the organic deodorant are capable of removing formaldehyde and deodorizing quickly and efficiently, the antibacterial agent is capable of preventing mildew and sterilizing efficiently, and the photocatalyst is capable of decomposing indoor volatile organic contaminants everlastingly, and therefore, the capability of purifying the air of the wallpaper for a long time is improved. The wallpaper has the functions of removing the formaldehyde, deodorizing and sterilizing quickly and efficiently at the beginning of home decoration, and purifying the air everlastingly in daily life.

Owner:宋旭 +1

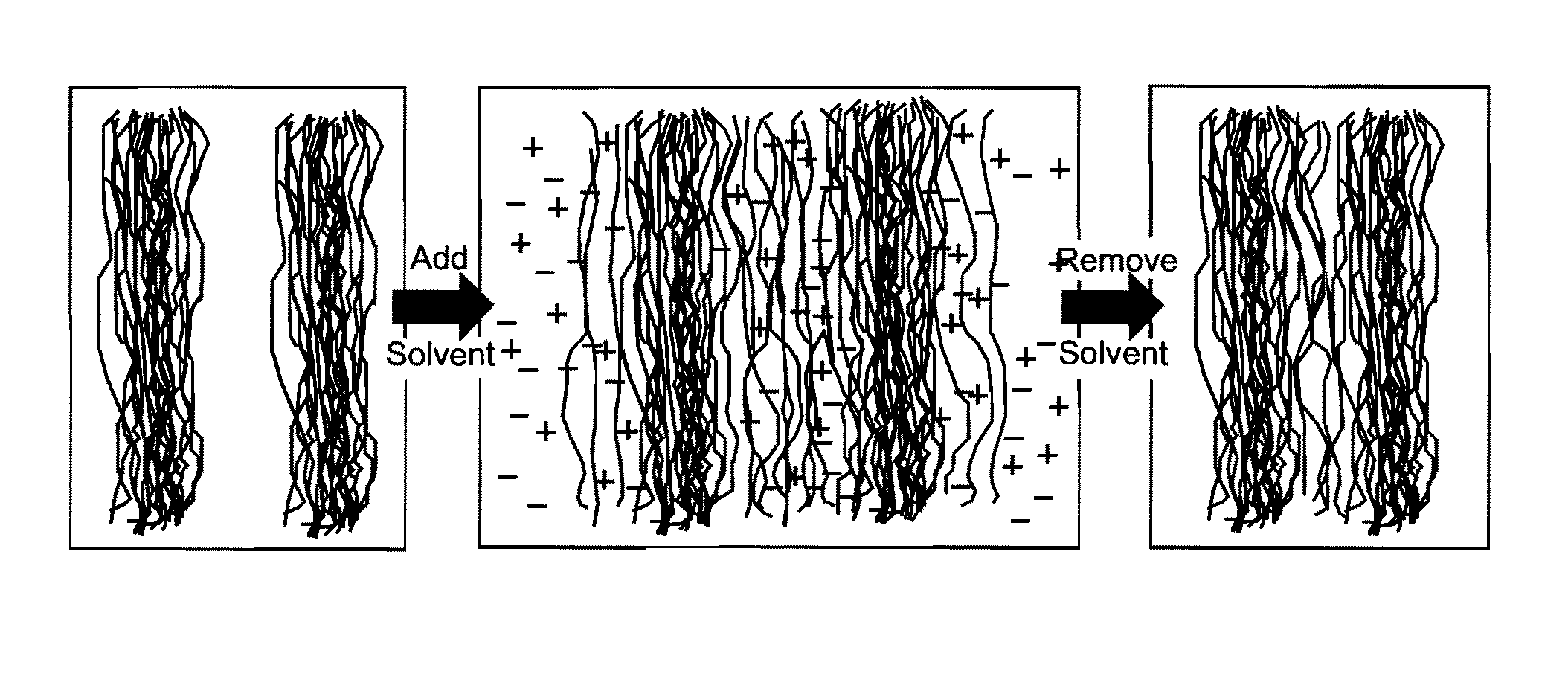

Natural fiber welding

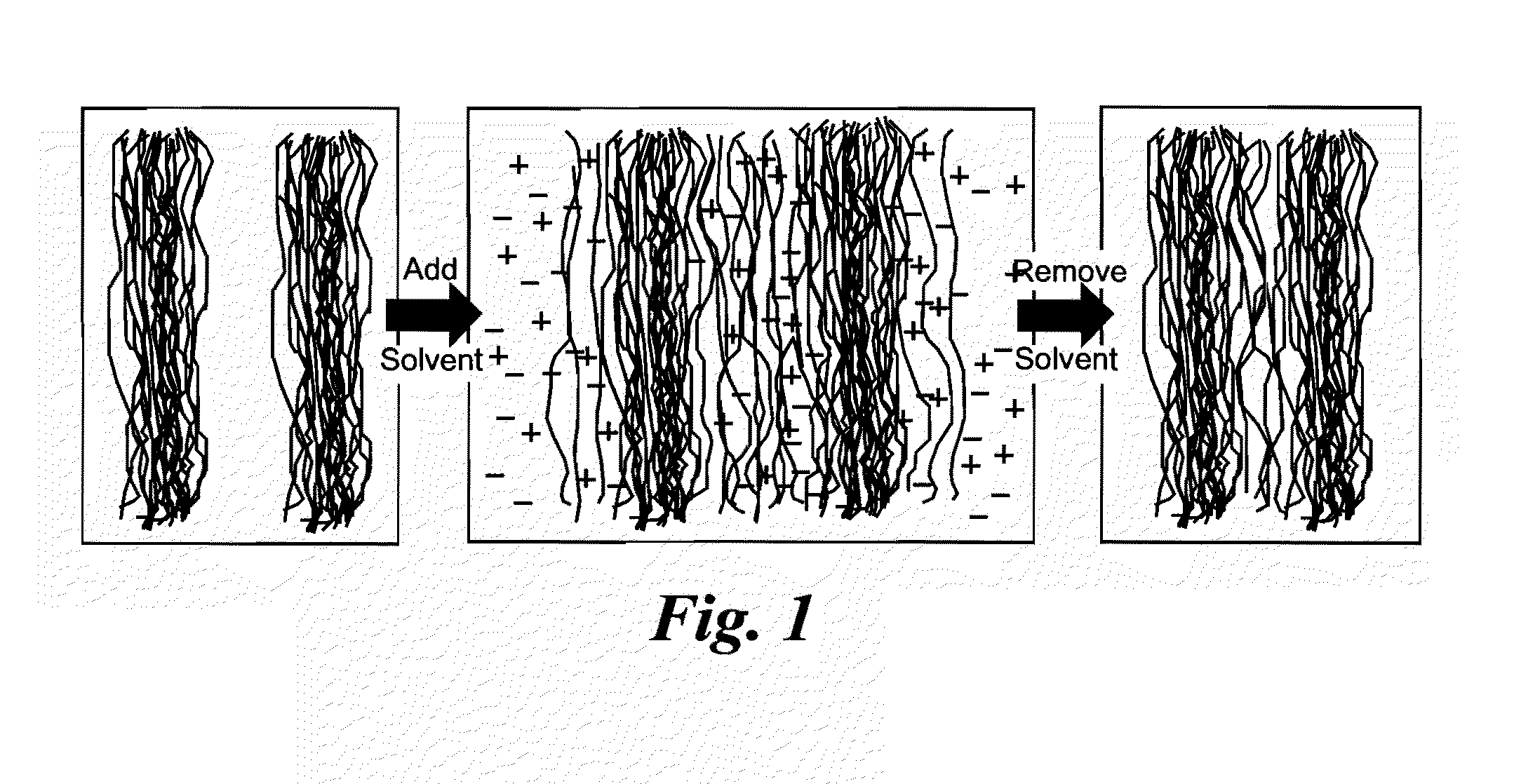

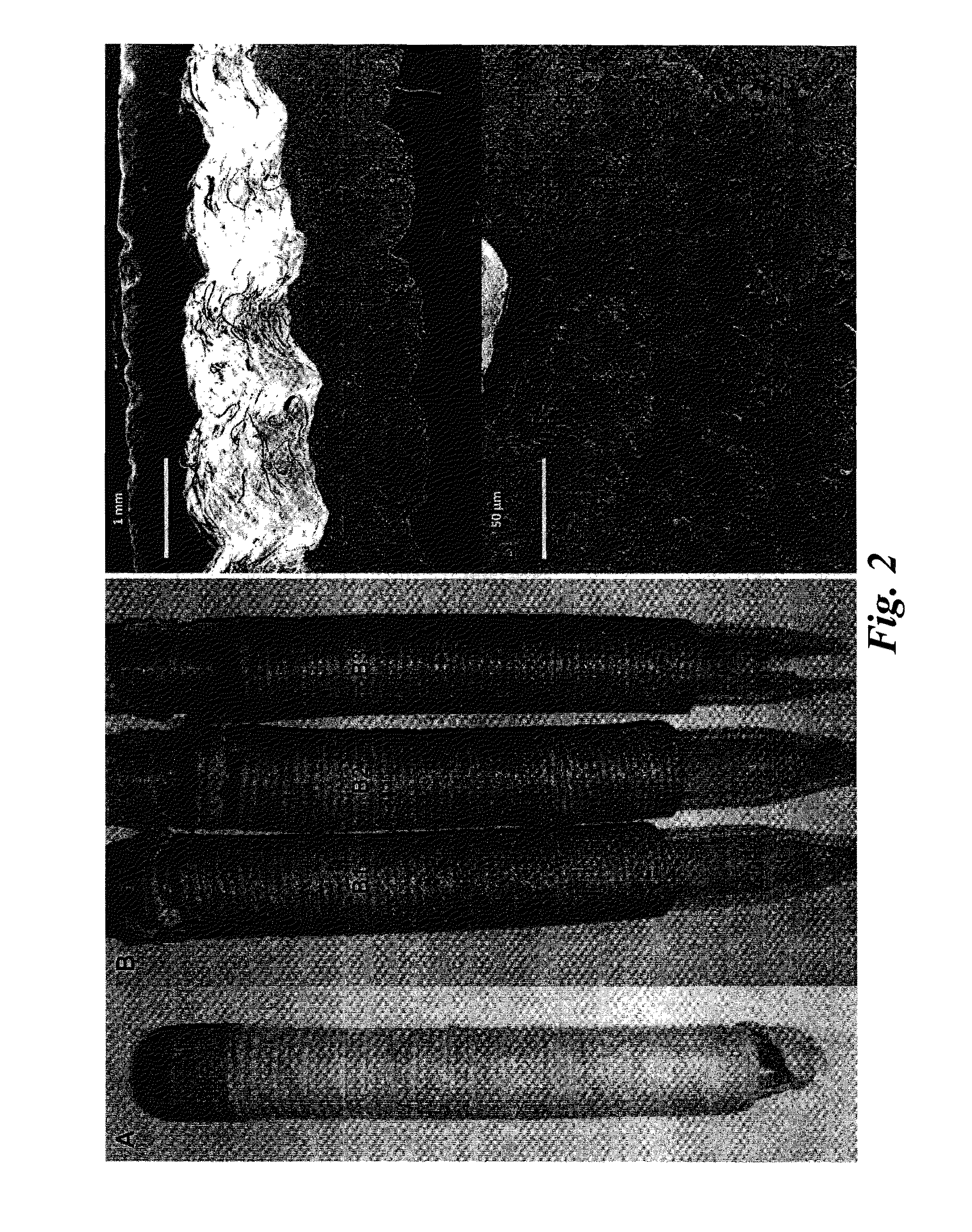

ActiveUS8202379B1Increase material densitySmall surface areaAdhesive processesLaminationPolymer scienceMixed materials

Natural fiber welding is a process by which individual fibers are swollen by an appropriate ionic liquid-based solvent system to form a congealed network. Manipulated fibrous materials may be either composed of natural polymers such as cellulose, hemicellulose, silk, et cetera, or synthetic polymers, or mixed materials. The process is principally controlled by the composition of the solvent system which includes an ionic liquid solvent plus additives such as water, methanol, et cetera. Other conditions such as the amount and placement of solvent, as well as time, temperature, and pressure control the extent to which neighboring fibers are fused. Only the material at the outer surface of fibers need be sufficiently mobile to merge with that of neighboring fibers. Material in the fiber core may be left in the native state by controlling process variables. Fibers form a congealed network upon removal of the ionic liquid-based solvent.

Owner:US SEC THE AIR FORCE THE

Super hydrophobic cotton fabric and preparation method thereof

The invention belongs to the fabric water-repellent finishing and processing field, in particular relates a super hydrophobic cotton fabric and a preparation method thereof. The preparation method of the super hydrophobic cotton fabric is characterized in that the epoxy-functionalized modification is performed to the cotton fiber of fabric, then aminated nano-SiO2 and epoxy-functionalized nano-SiO2 are used to impregnate the cotton fabric in turn so as to increase the surface roughness of the fabric, finally a low-surface-energy material is adopted to perform hydrophobization treatment to the fabric; the contact angle between the prepared cotton fabric and water drops is more than 150 degrees; the method utilizes the covalent reaction of epoxy groups of cotton fabric, amino groups of nano-SiO2 and epoxy groups of nano-SiO2 to ensure the built rough surface to have good fastness; and the built surface has a large number of Si-OHs and epoxy groups so as to facilitate the chemical combination of the low-surface-energy material and the surface, thus the superhydrophobic property of the prepared fabric has excellent stability.

Owner:SHAANXI UNIV OF SCI & TECH

Multifunctional textile finishing agent, preparation method thereof and cotton textile finishing method

InactiveCN102002854AEasy to processNo pollution in the processVegetal fibresAcetic acidPolymer science

The invention discloses a multifunctional textile finishing agent. The multifunctional textile finishing agent comprises the following components in percentage by weight: 1.00 to 5.00 percent of fibroin, 0.01 to 0.10 percent of chitosan, 0.01 to 0.50 percent of titanium dioxide, 0.01 to 1.50 percent of cross-linking agent, 0.50 to 5.00 percent of acetic acid, 0.10 to 0.80 percent of metal salt catalyst and the balance of water. The ecological multifunctional textile finishing agent involved by the invention is made of environment-friendly raw materials, is convenient to process, is not toxic or harmful to a human body and have no pollution; a finishing method is simple and is suitable for industrial production by a padding method; and the appearance of a finished textile is not influenced, namely the color does not turn yellow and the finished textile has a good anti-wrinkle effect and comfortable handfeel.

Owner:ZHONGYUAN ENGINEERING COLLEGE

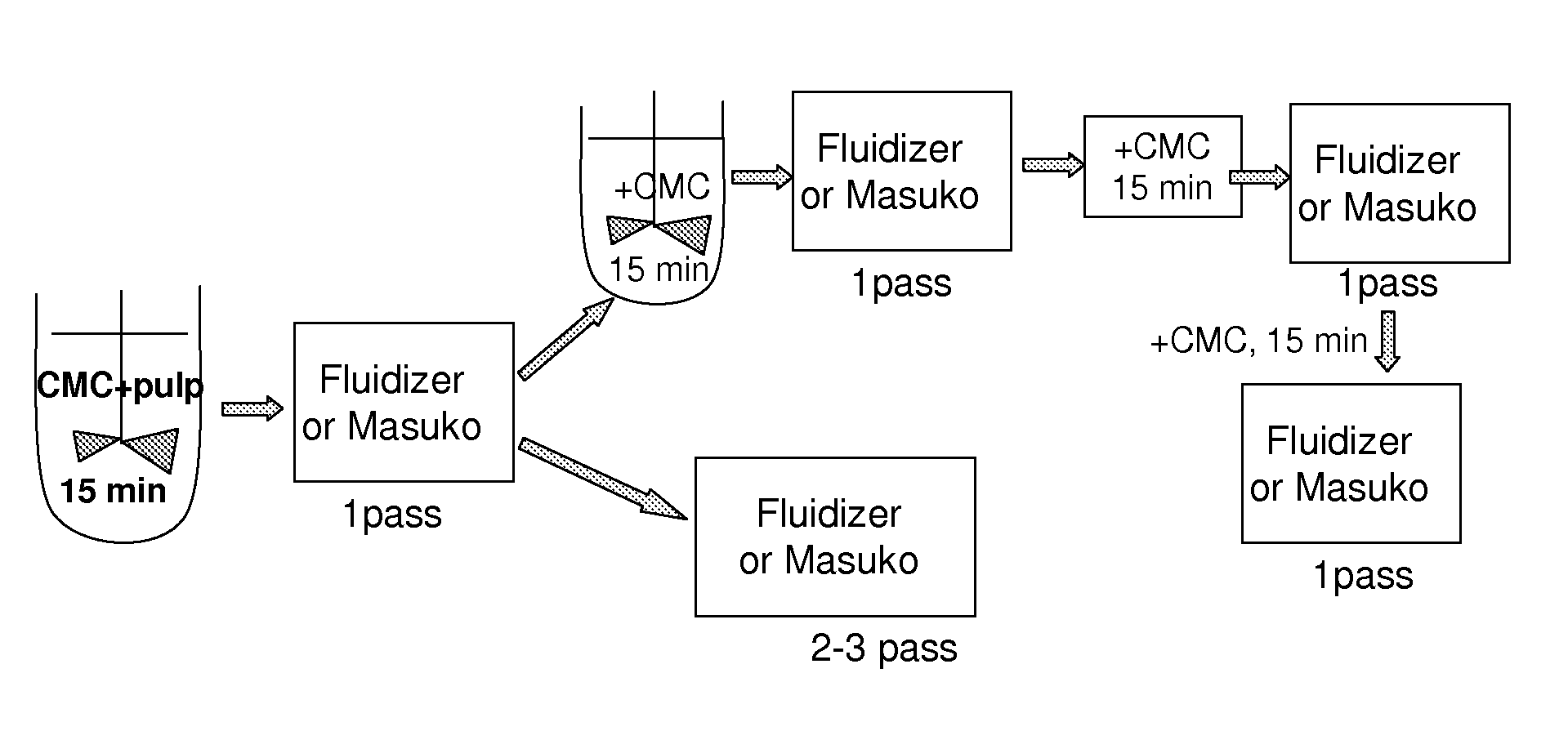

Method for producing modified cellulose

InactiveUS20120043039A1Improve propertiesEfficient productionSpecial paperPaper after-treatmentFiberFiber suspension

The present invention provides a method for producing modified nanofibrillated cellulose characterized by bringing cellulosic material into a fiber suspension, adsorbing a cellulose derivative or polysaccharide or polysaccharide derivative onto fibers in said fiber suspension under special conditions and subjecting the obtained fiber suspension derivative to mechanical disintegration. A modified nanofibrillated cellulose obtainable by a method of the present invention is provided. Furthermore, the invention relates to the use of said modified nanotibrillated cellulose.

Owner:UPM-KYMMENE OYJ

Wiper containing a controlled-release anti-microbial agent

InactiveUS6916480B2Controlled release rateGood flexibilityHeavy metal active ingredientsBiocideControlled releaseSimple Organic Compounds

A wiper having a controlled release anti-microbial agent therein for providing anti-microbial cleansing of surfaces is provided. The wiper is formed from an absorbent base web to which an anti-microbial formulation is adhered. The formulation includes an anti-microbial agent that is capable of being controllably released from the wiper. In some embodiments, a polymer mixture may be employed to control the rate of release of the anti-microbial agent. Various anti-microbial agents, such as metal ions and organic compounds may be employed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Composite fiber as well as preparation method and application thereof

ActiveCN105603718ARetains the property of large specific surface areaAchieve reuseOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiberSpecific adsorption

The invention relates to a composite fiber. The composite fiber comprises a fiber carrier, and a graphene aerogel layer covering the outer side of the fiber carrier. According to the composite fiber provided by the invention, the relatively thin graphene aerogel layer covers the surface of the composite fiber, and a self surface shielding effect of existing graphene aerogel is overcome; the adsorption speed and adsorption efficiency of the graphene aerogel of the unit volume are improved; the fiber carrier of the composite fiber provided by the invention provides a bracket for the graphene aerogel and the mechanical strength is enhanced; when the composite fiber is used as an adsorption material, the composite fiber can be in seamless butt joint with an existing cigarette production process directly, and replaces an existing adsorption fiber so that the specific adsorption on benzopyrene polycyclic aromatic hydrocarbon type harmful substances can be realized; and meanwhile, other aromatic substances in smoke are kept so that the flavor and aroma of cigarettes are not influenced.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

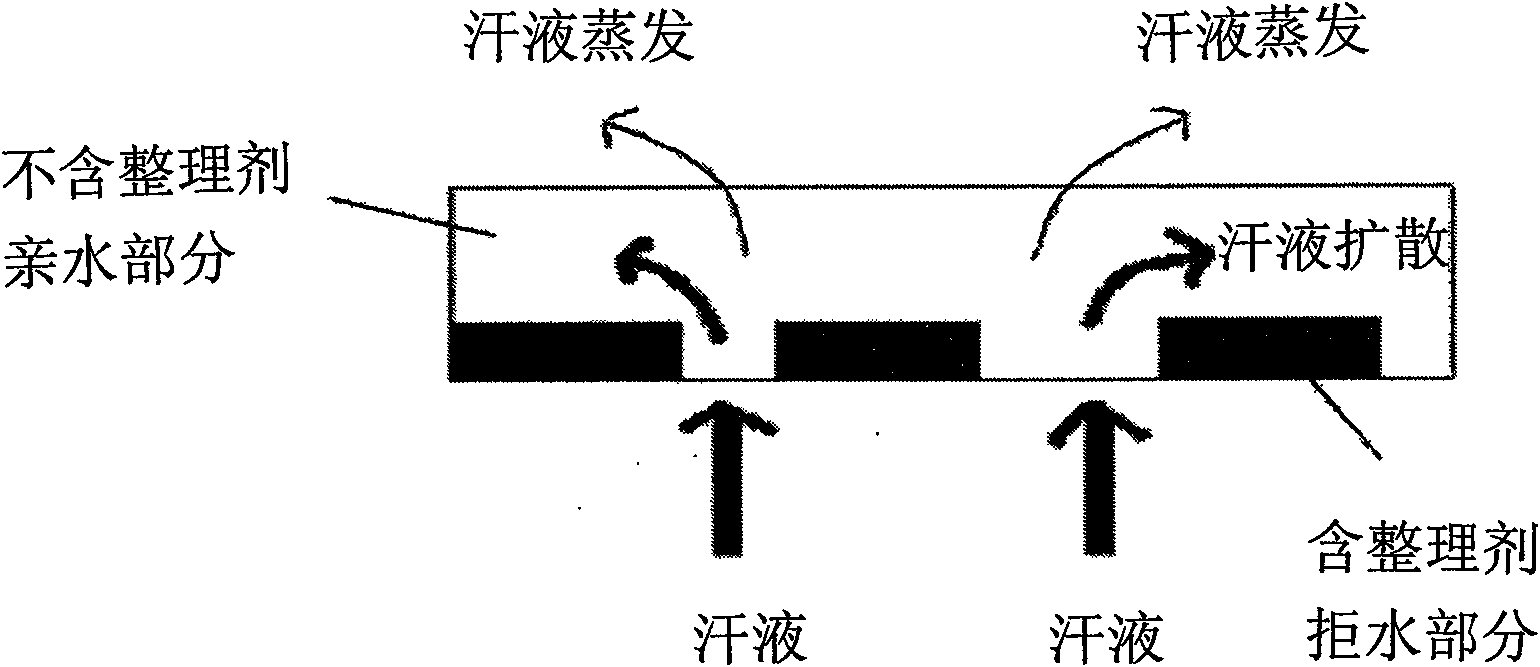

One-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and processing method thereof

InactiveCN101649558ASolve moisture absorptionSolve the contradiction of dehumidificationVegetal fibresAnimal fibresEngineeringMoisture absorption

The invention relates to a one-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and a processing method thereof. A double-lateral surface structure with differenthydrophilic and hydrophobic properties is constructed at the front and reverse sides of the woven fabric product in a single-face liquid feeding way, wherein the front sides of the products are all hydrophilic sides with favorable hygroscopic property, hydrophobic areas with a hydrophobic structure are discontinuously distributed at the reverse side of the product, and the hydrophobic area occupies 20-80 percent of the total area of the lateral side. The processing method comprises the steps of preprocessing fabric, mixing printing paste and finishing agent, printing or feeding liquid at single side, drying, washing and shrinking, processing flexibly, drying again and finally ironing. The invention has the advantages of reasonably solving the contradiction between moisture absorption and moisture discharge as well as the contradiction between hydrophilic and hydrophobic of the fabric, ensuring favorable one-way moisture-conducting effect, achieving the aim of conducting sweat from oneside clinging to the skin to outside and maintaining relatively dry and comfortable efficiency at one side of the skin.

Owner:INNER MONGOLIA ERDUOSI CASHMERE PRODS

Aqueous foaming flame-retardant coating glue for textile and preparation thereof

ActiveCN101498105AMeet the new demands of finishingMeet the technical requirements of foam finishingVegetal fibresPolymer scienceEmulsion

The invention discloses an aqueous foaming flame-retardant coating gum for textiles and a preparation method thereof. The existing flame-retardant coating gum can not meet requirements of a foaming finishing process. The aqueous foaming flame-retardant coating gum is prepared from the following components: aqueous substrate emulsion comprising aqueous polyurethane emulsion and aqueous acrylic ester emulsion, brominated flame retardant additive, phosphate based flame retardant additive, a flame retardant synergistic agent, a thickening agent, a foaming agent, a foaming stabilizer, an anti-settling agent and a feeling agent. The coating gum can meet the requirements of a foaming finishing technique, finishes coatings of fabrics after directly being physically foamed by a mechanical foaming machine and meets new requirements of textiles for coating finishing.

Owner:传化智联股份有限公司 +2

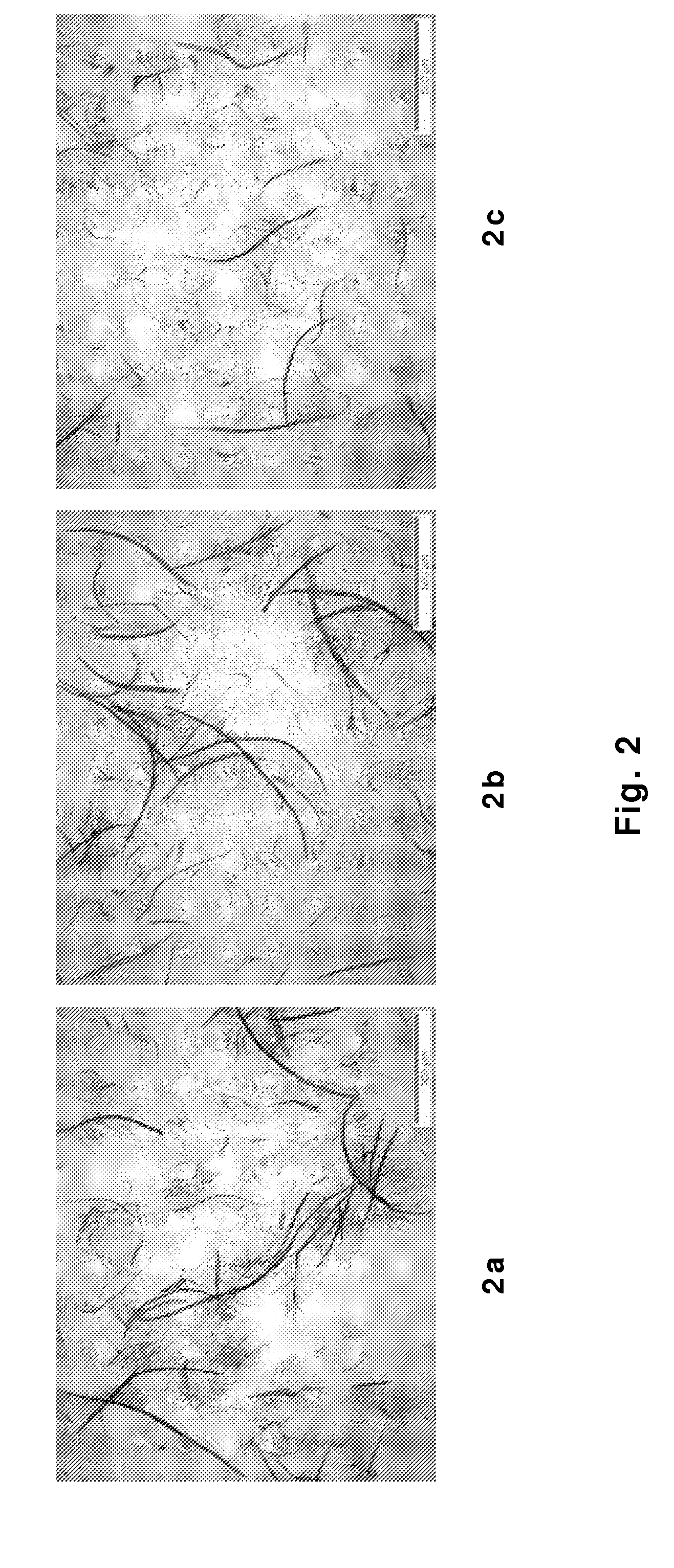

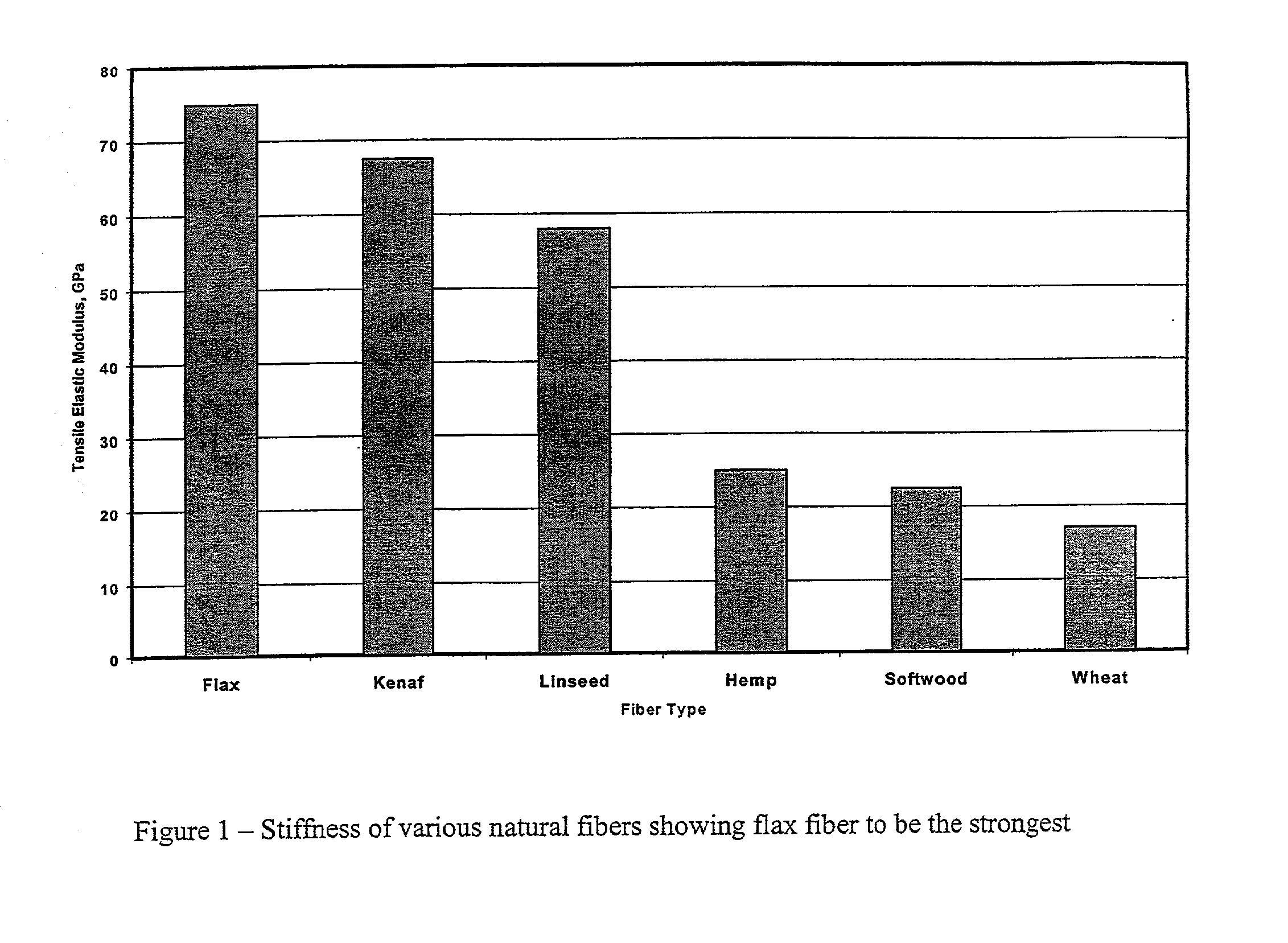

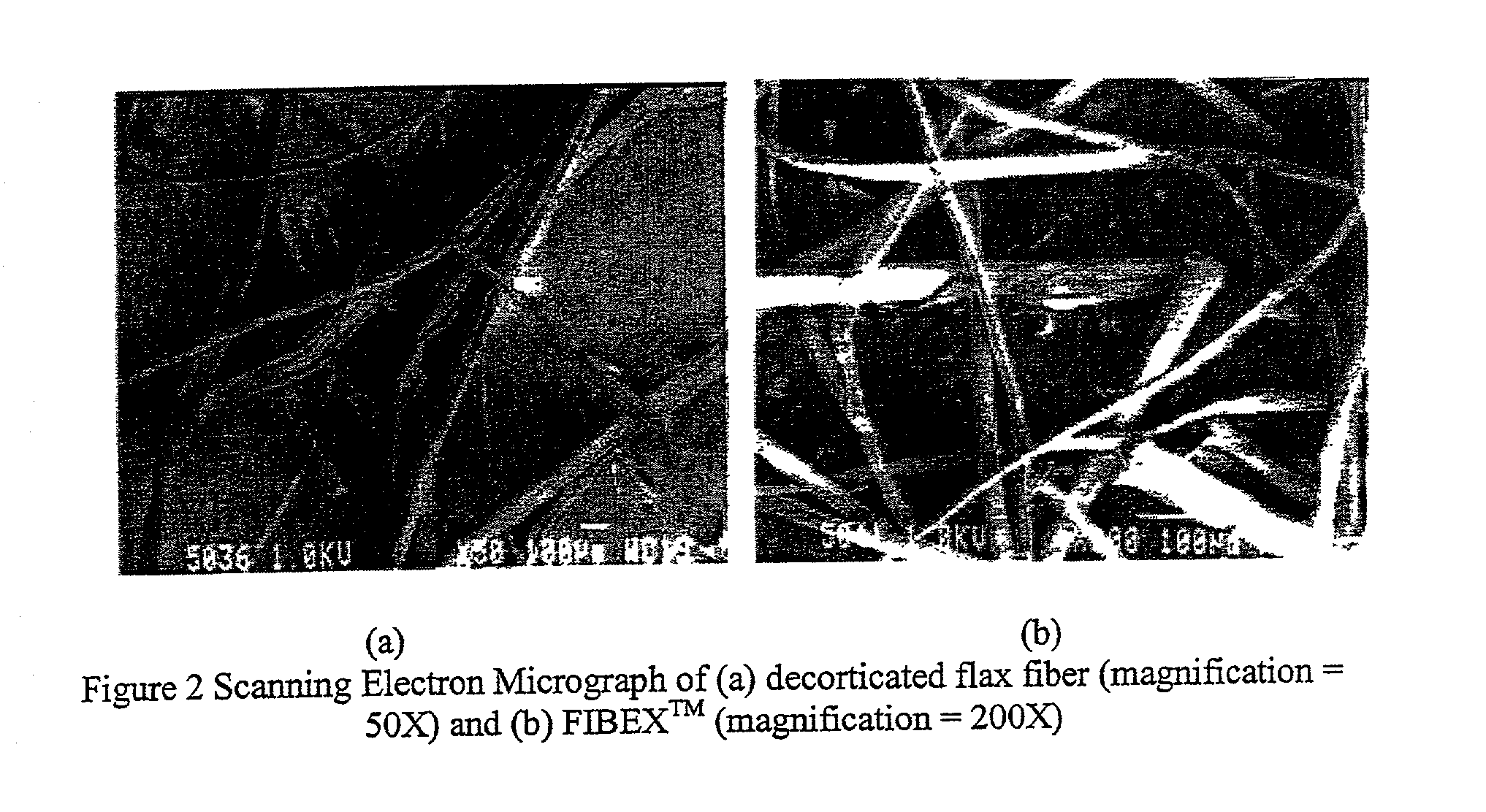

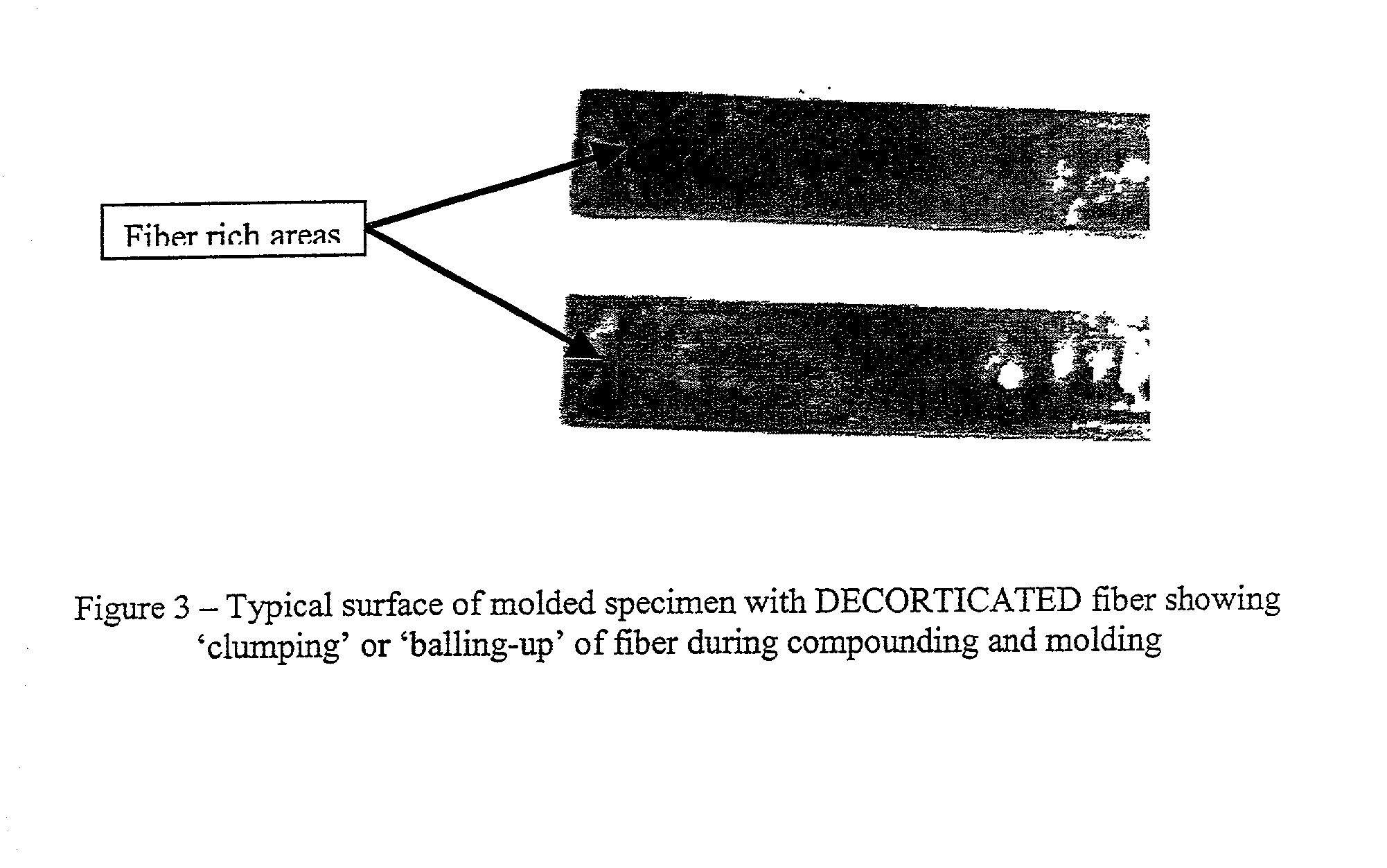

Fibrillated bast fibers as reinforcement for polymeric composites

A decorticated bast fiber such as from flax that is particularly suitable as a reinforcement for polymeric resins, thermoplastic, and thermoset composites. The invention specifically overcomes past difficulties involving compounding and injection molding of composite specimens with bast fiber reinforcements. In one form, ultrasonic energy is applied to decorticated bast fibers to cause fibrillation.

Owner:ENG MECHANICS CORP OF COLUMBUS

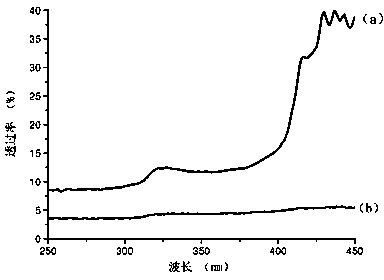

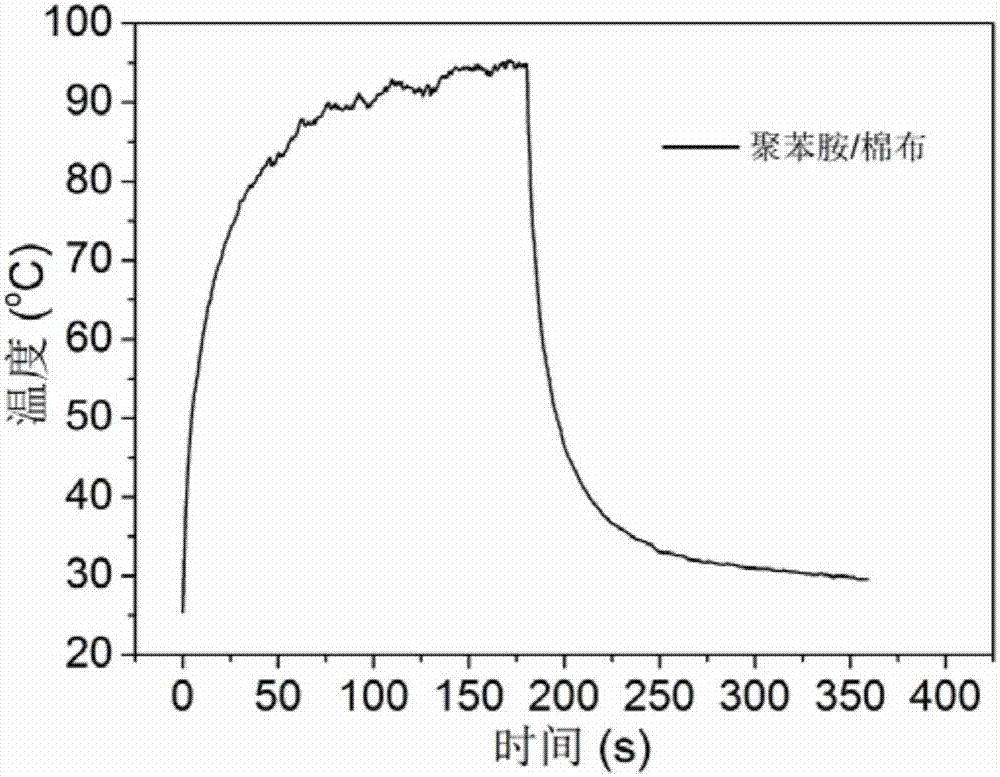

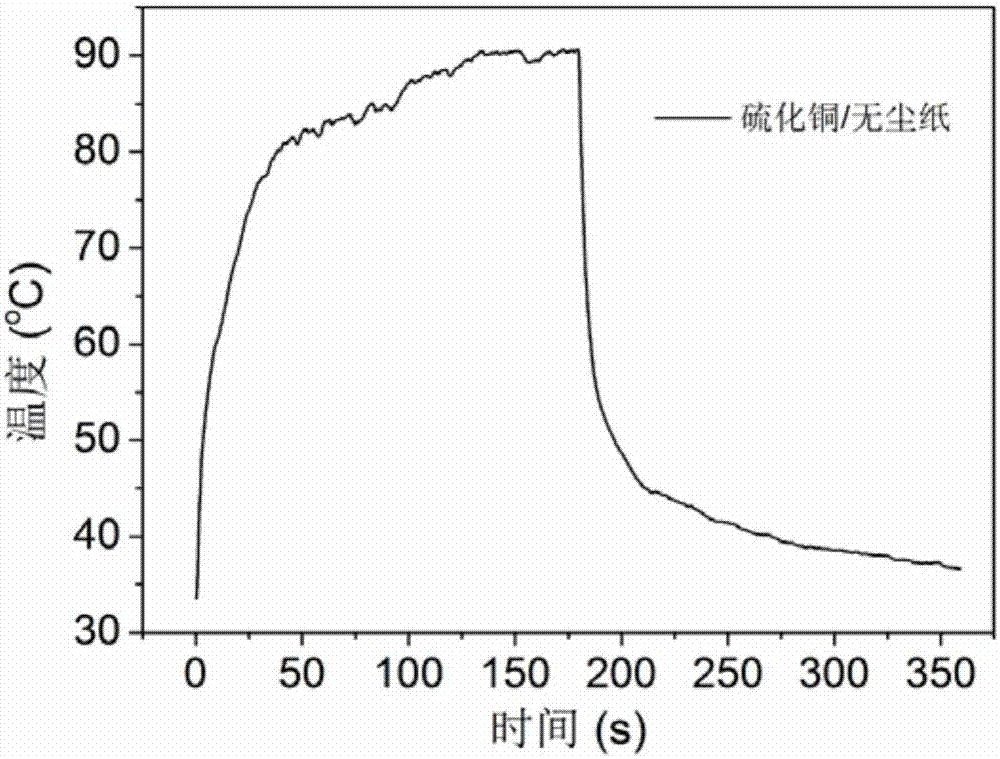

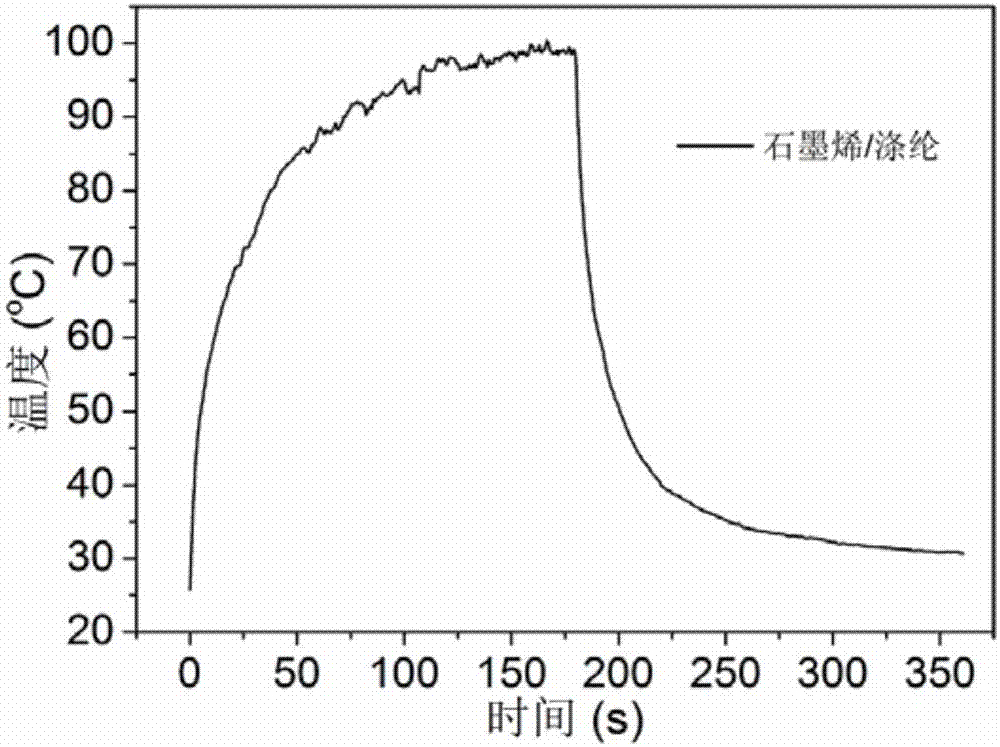

Method for preparing photothermal conversion textile

InactiveCN106958141AImprove photothermal efficiencyImprove mechanical propertiesVegetal fibresAnimal fibresPhotothermal conversionEngineering

The invention relates to a method for preparing a light-to-heat conversion fabric. The light-to-heat conversion fabric uses the fabric as a matrix to attach photothermal nanomaterials to the surface of the fabric matrix. The method includes the following steps: dispersing the photothermal nanomaterials into a solvent to obtain light thermal nanometer material dispersion liquid; uniformly distributing the photothermal nanometer material dispersion liquid on the fabric substrate; drying to obtain light heat conversion fabric. The invention expands the photothermal nano-material from the solution to the surface of the fabric, has the characteristics of rapid temperature rise and high temperature rise, greatly improves the application range, simple operation, mild conditions, low cost, and the obtained photothermal conversion fabric has high photothermal efficiency , with good mechanical properties, it is expected to have great application value in the fields of winter heating, a new generation of solar thermal insulation clothing, new solar heating equipment and new solar desalination.

Owner:DONGHUA UNIV

Method for preparing product with one-way moisture-conducting function

ActiveCN101962885AExcellent unidirectional moisture transfer performanceFeel coolTextile treatment by spraying/projectingVegetal fibresHydrophilizationEngineering

The invention relates to a method for preparing a product with a one-way moisture-conducting function. The method comprises the following steps of: 1) performing hydrophilization pretreatment on a textile; and 2) spraying water repellent finishing agent-containing working solution on one face of the treated textile, so that liquid drops with diameter of 0.1 to 2mm and spacing of 0.1 to 2mm are formed on the face of the textile and the product with the one-way moisture-conducting function is obtained. Fabrics prepared by the method has the advantages of greatly reducing the using amount of a plurality of resources such as water, energy and the like and solving the environmental problems of pollution discharge and the like, along with the one-way moisture-conducting property.

Owner:CHINA TEXTILE ENG SOC +3

Stable and transparent super-hydrophobic or super-amphiphobic coating as well as preparation method and application thereof

ActiveCN103436138AGood adhesionBroaden applicationCoatings with pigmentsVegetal fibresEpoxyNanoparticle

The invention belongs to the field of super-amphiphobic materials, and discloses a stable and transparent super-hydrophobic or super-amphiphobic coating as well as a preparation method and the application thereof. The preparation method for the coating comprises the steps as follows: blending nanoparticles, epoxy resin with a solvent to obtain the epoxy resin hybridization solution; dissolving fluorine-containing substances and a catalyst into a solvent to obtain the fluorine-containing solution; spraying the epoxy resin hybridization solution on the surface of a substrate, drying the substrate for 0.5-5 h at the temperature of 80-130 DEG C, spraying the fluorine-containing solution on the surface of the substrate, drying the substrate for 0.5-5 h at the temperature of 80-130 DEG C after the solvent is volatilized, and finally washing the surface of the substrate by using the solvent, so as to obtain the stable and transparent super-hydrophobic or super-amphiphobic coating. The super-hydrophobic or super-amphiphobic coating can be applied to hydrophobic and oleophobic modification of surfaces of the vast majority of substrates.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

Method of treatment of a textile or non-woven substrate to render same water and oil repellent

The present invention relates to a method of treating a non-woven substrate or textile, comprising the step of applying to said non-woven substrate or textile a fluorochemical composition comprising a fluoropolymer that comprises:(a) between 10 and 97 mole % of units that can be derived from fluorinated monomer selected from the group consisting of monomers according to the general formula: Rf-X—OC(O)—C(R)═CH2 wherein Rf represents a perfluorinated aliphatic group having 3 or 4 carbon atoms, X is an organic divalent linking group and R represent hydrogen or a lower alkyl group having 1 to 4 carbon atoms; (b) between 3 and 75 mole % of units derived from a chlorine containing comonomer selected from the group consisting of vinylidene chloride, vinyl chloride and mixtures thereof; and (c) optionally further units derived from monomers other than a fluorinated monomer and said chlorine containing comonomers; wherein the amount of units (a), (b) and (c) adding up to 100%, whereby said fluorochemical composition is applied in such amount that the weight of fluoropolymer on said non-woven substrate or textile is not more than 3% by weight based on the weight of said non-woven substrate or textile.

Owner:3M INNOVATIVE PROPERTIES CO

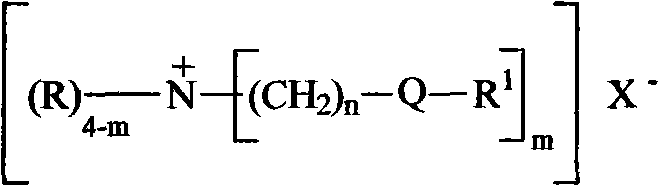

Fabric maintenance softener

ActiveCN101736580AReduce wearImprove the lubrication effectOrganic detergent compounding agentsVegetal fibresWrinkleFabric softener

The invention provides a fabric maintenance softener, which consists of active ingredients and auxiliary material. The fabric maintenance softener is characterized in that the active ingredients comprise a cationic polymer and a quaternary ammonium salt fabric softener. The fabric maintenance softener not only can provide more effective functions of softening, removing static electricity and deodorizing, but also can play a role in maintaining, fixing color, keeping new and removing wrinkles for the fabrics.

Owner:杭州千岛湖佳蔚日用品有限公司

Manufacturing technique of wash-resistant and flame-retardant blended fabric

ActiveCN102392356AImprove flame retardant performanceImprove wash resistanceHeating/cooling textile fabricsYarnGlass fiberPolyester

The invention provides a manufacturing technique of a wash-resistant and flame-retardant blended fabric. The technique comprises the following steps of: 1) preparing a cotton fiber flame-retardant coating adhesive; 2) coating the coating adhesive obtained in the step 1) on the cotton fiber and carrying out heat setting to the cotton fiber so as to obtain a flame-retardant cotton fiber; 3) preparing a glass fiber flame-retardant coating adhesive; 4) directly coating the coating adhesive obtained in the step 3) on the glass fiber and carrying heat setting on the coating adhesive so as to obtaina flame-retardant glass fiber; and 5) blending one of the flame-retardant cotton fiber obtained in the step 2) and a carbon fiber or the flame-retardant glass fiber obtained in the step 4) and one ofa flame-retardant polyester fiber or a flame-retardant nylon fiber so as to obtain the product of the invention. The manufacturing technique of the wash-resistant and flame-retardant blended fabric, provided by the invention, has the advantages of simple process, low cost, good product permeability, softness as well as good wash resistance and flame retardation. The manufacturing technique of thewash-resistant and flame-retardant blended fabric, provided by the invention, is mainly used for manufacturing products like smoke screens, fire-proof insulated curtains, bedspreads, flame-retardant furniture and the like.

Owner:应急管理部四川消防研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com