Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7563results about How to "Achieve reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

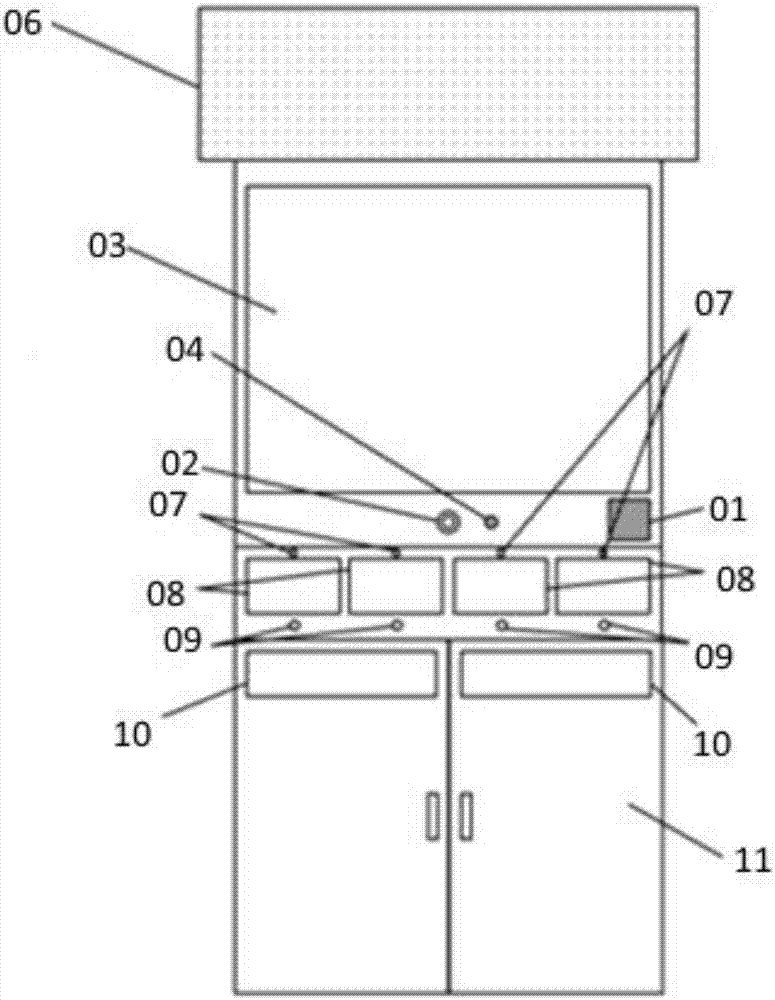

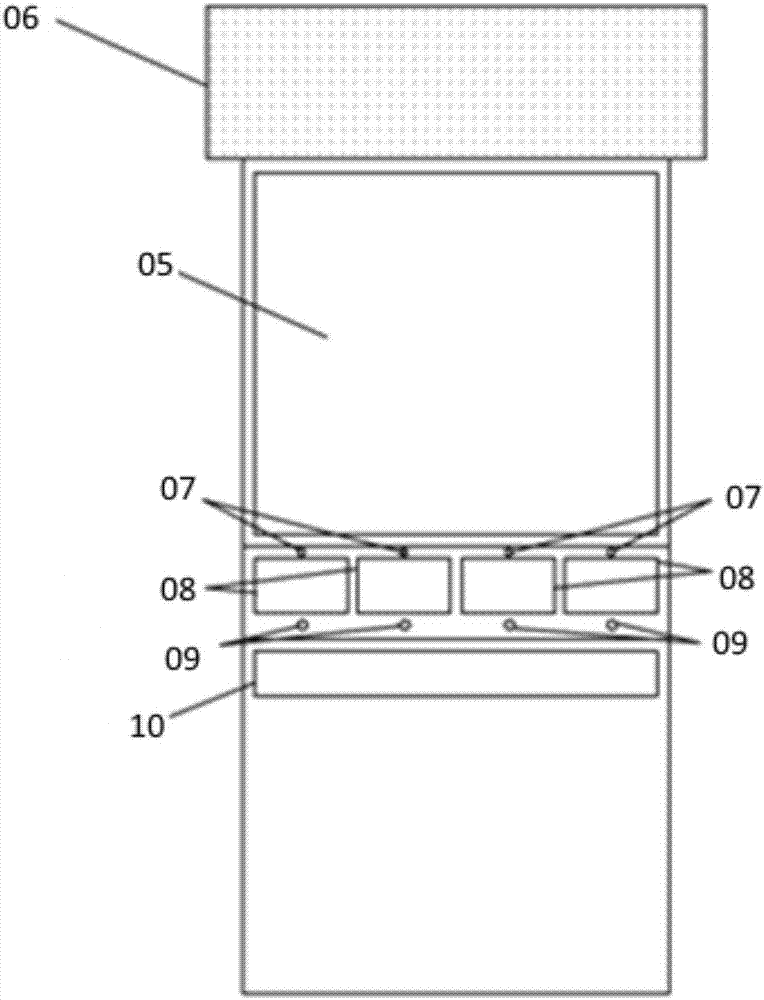

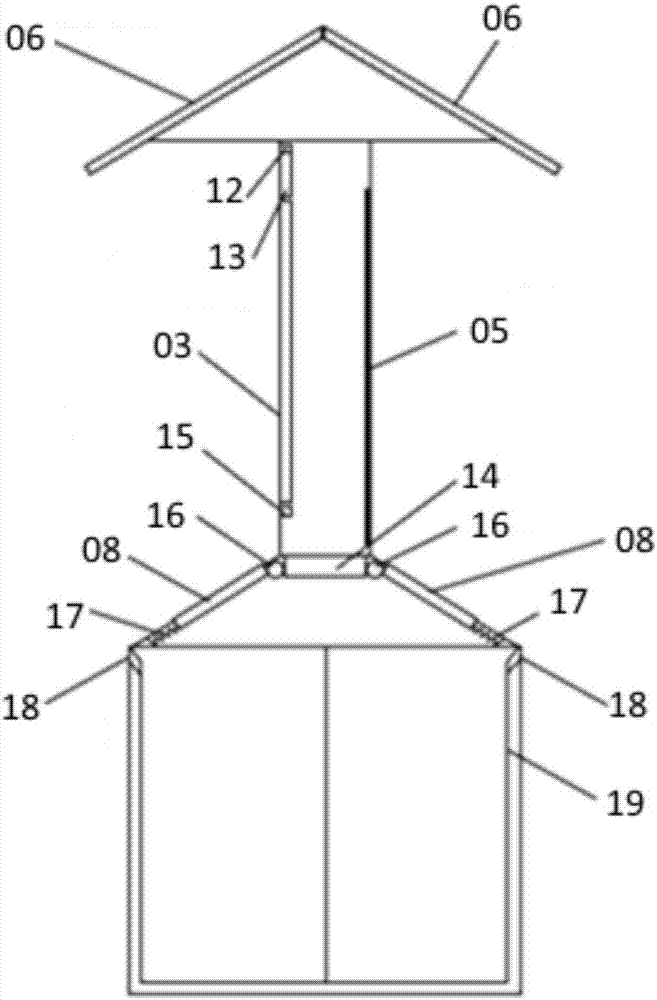

Garbage classification prompt garbage can and system based on image recognition

InactiveCN107054936AReduce workloadAchieve reuseWaste collection and transferRefuse receptaclesClassification resultImage based

The invention discloses a garbage classification prompt garbage can and system based on image recognition. The garbage classification prompt garbage can comprises a camera, an information processor, a garbage can shell, multiple internal garbage cans, an indicator lamp controller, multiple indicator lamps and a power supply module. The multiple internal garbage cans are located in the garbage can shell. The garbage can shell is provided with a distance sensing switch and multiple classification input ports. The camera is used for sending taken garbage pictures to the information processor. The information processor is used for classifying garbage according the garbage pictures and prestored standard templates in a standard template library, generating classification result information and sending lamp turning-on signals to the indicator lamp controller according to the classification result information so as enable the indicator lamp controller to control the corresponding indicator lamp to be turned on according to the turning-on signals. The garbage classification prompt garbage can has the advantages of rapidly recognizing garbage through the image recognition technology, helping people to rapidly classify garbage in daily life and reducing the workload of secondary garbage sorting.

Owner:GUANGDONG MATVIEW INTELLIGENT SCI & TECH CO LTD

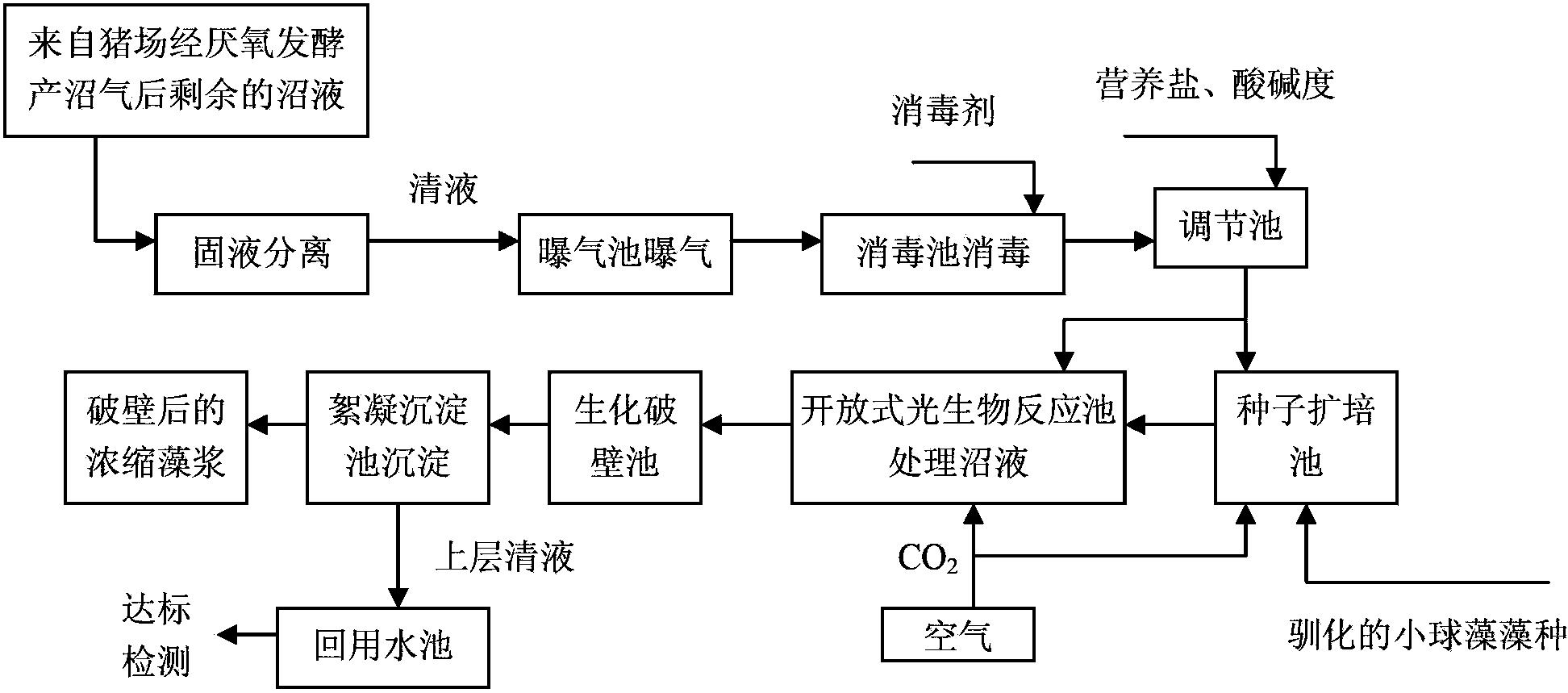

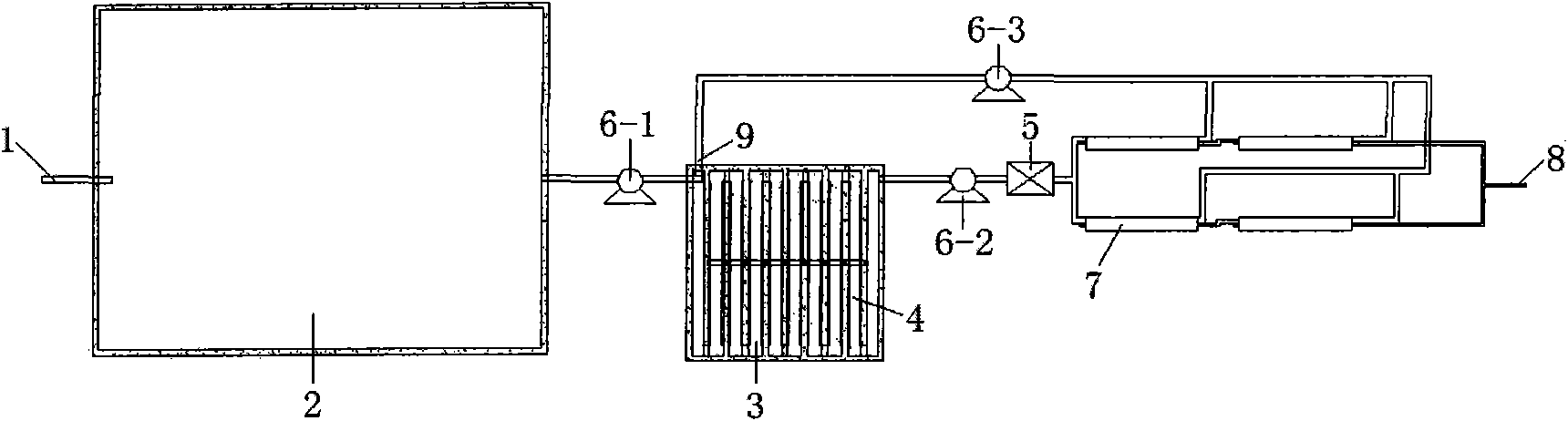

Biogas slurry ecological purification method based on microalgae cultivation

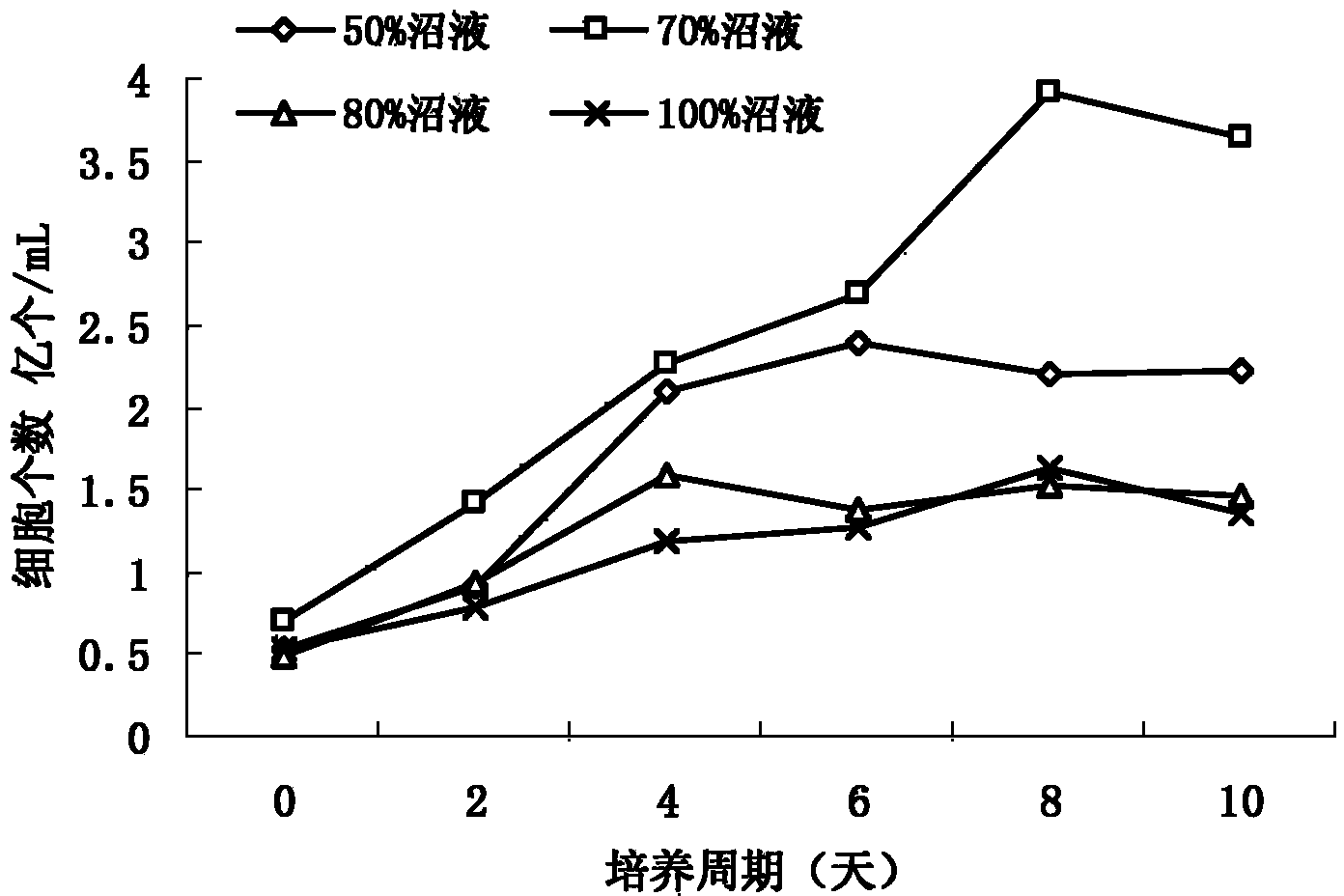

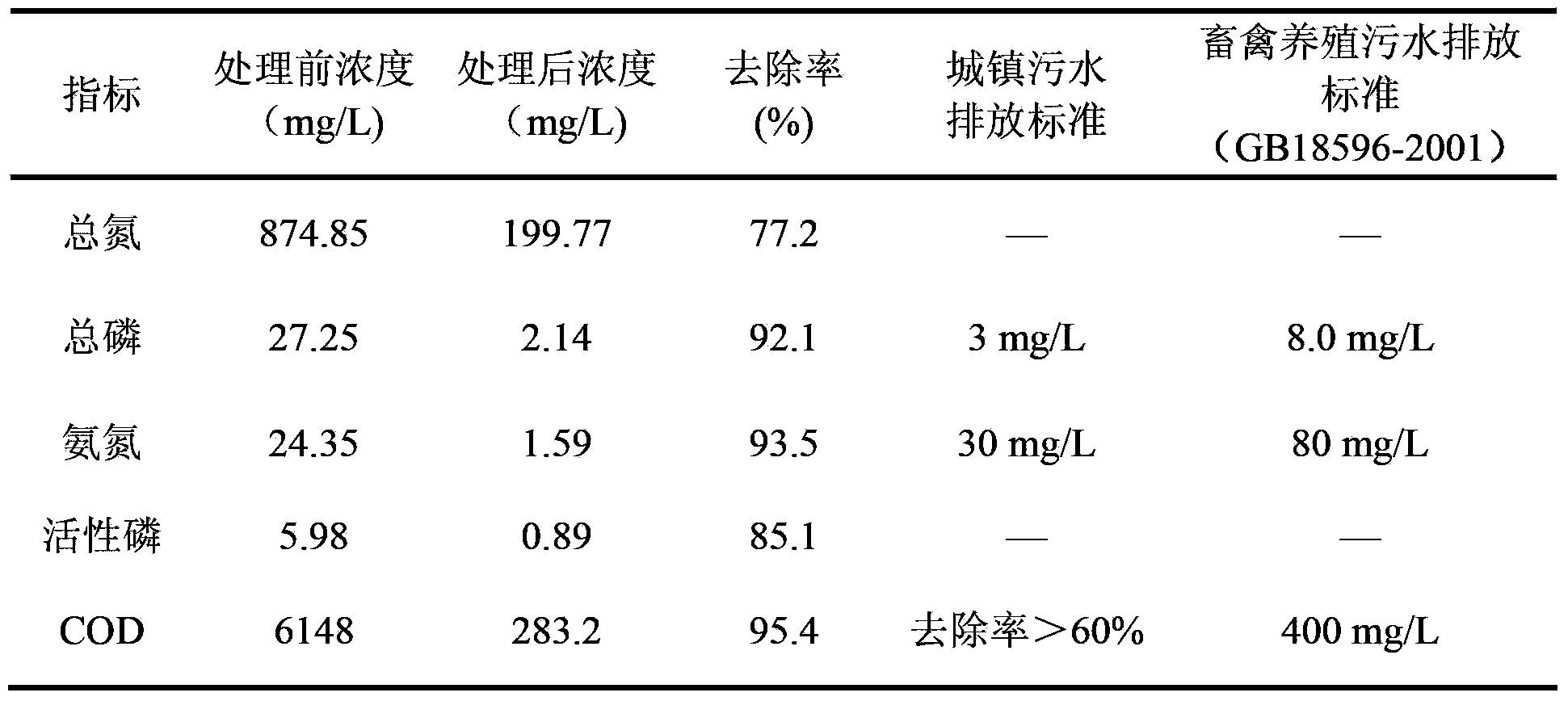

ActiveCN103396950AImprove photosynthetic efficiencyFast growthUnicellular algaeMicroorganism based processesSocial benefitsPurification methods

The invention discloses a biogas slurry ecological purification method based on microalgae cultivation. The method comprises the following steps: (1) biogas slurry pretreatment; (2) habituated culture of autotrophic microalgae, namely, obtaining algae strains capable of rapidly growing in 70%-100% biogas slurry; (3) preparation of a seed solution; (4) a biogas slurry purification method during growing of microalgae, namely, after expanded cultivation, inoculating the habituated algae species into an open photobioreactor for cultivation, obtaining chlorella biomass growing by high density through a semi-continuous culture method and optimized methods such as fed-batch cultivation, and purifying the biogas slurry; (5) biochemical breaking of microalgae cell walls, namely, introducing the microalgae cells into a biochemical wall breaking pool, putting freshwater fish into the pool, and obtaining algae slurry subjected to wall breaking; and (6) collection of the microalgae cells and recycling of the biogas slurry. According to the method, not only is a method provided for purifying the biogas slurry, but also the obtained algae cells and the biogas slurry can be recycled, so that ecologicalization treatment of the biogas slurry is realized, the environment is improved, and furthermore, the economic and social benefits are produced.

Owner:湖南瑞藻生物科技有限公司

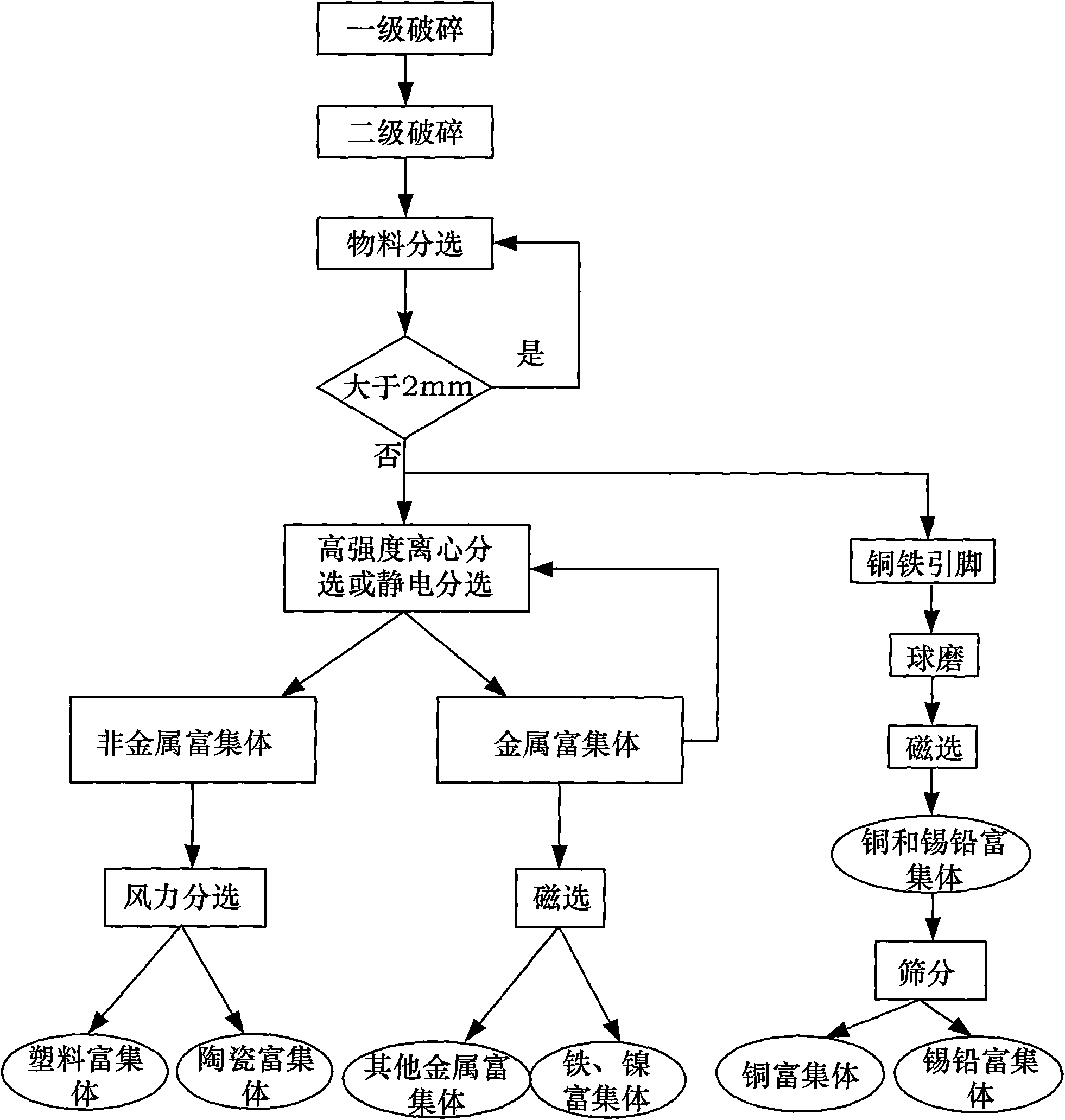

Recycling method of discarded circuit board

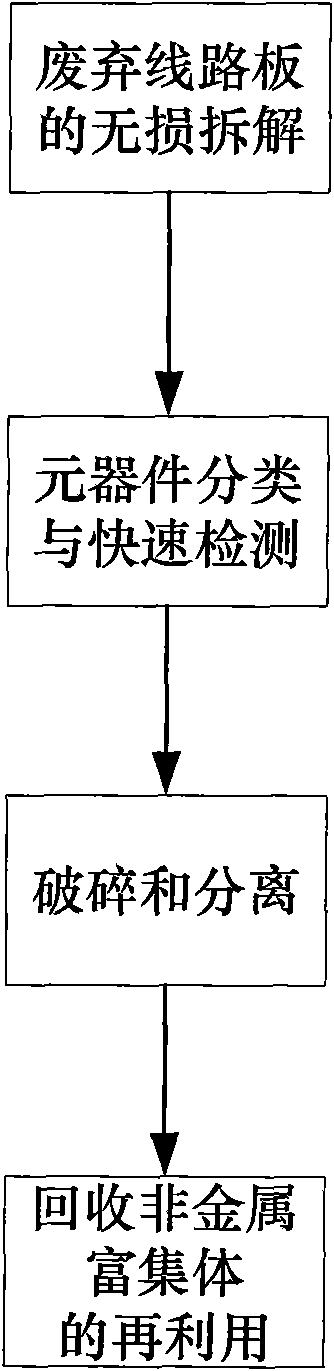

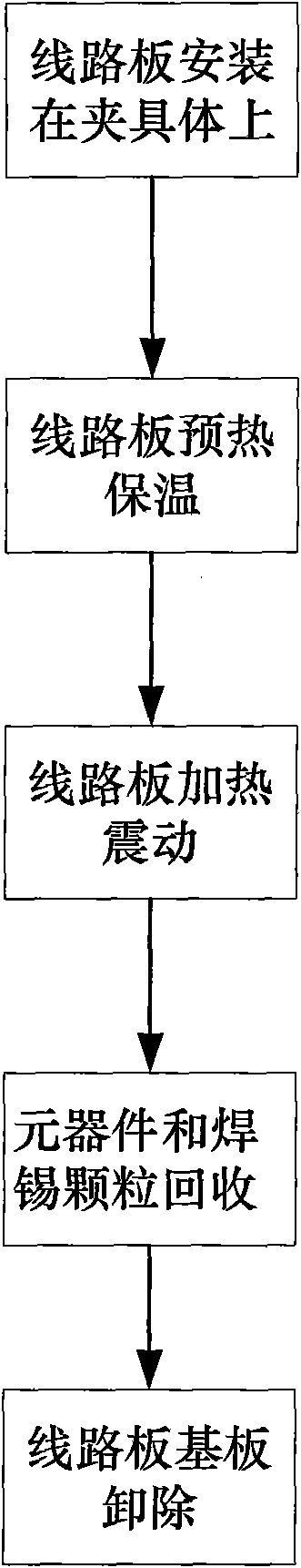

InactiveCN101642765ARealize separation and recoverySimplified brokenSolid waste disposalSoldering apparatusEngineeringMetal powder

The invention discloses a recycling method of discarded circuit boards, comprising the following steps: disassembling a discarded circuit board into three parts: a base plate, components and solder, then carrying out sorting and rapid detection on disassembled components; respectively crushing and separating the base plates and various loss-of-function components, and recycling the crushed and separated various powders, wherein the metal powder can be directly reused, and the recycled non-metal powder is used for being prepared into compound material. The method provided by the invention can realize sorting recycling of all resources of the discarded circuit boards; the recycled material can be reused, and therefore, the secondary pollution can not be generated.

Owner:BEIHANG UNIV

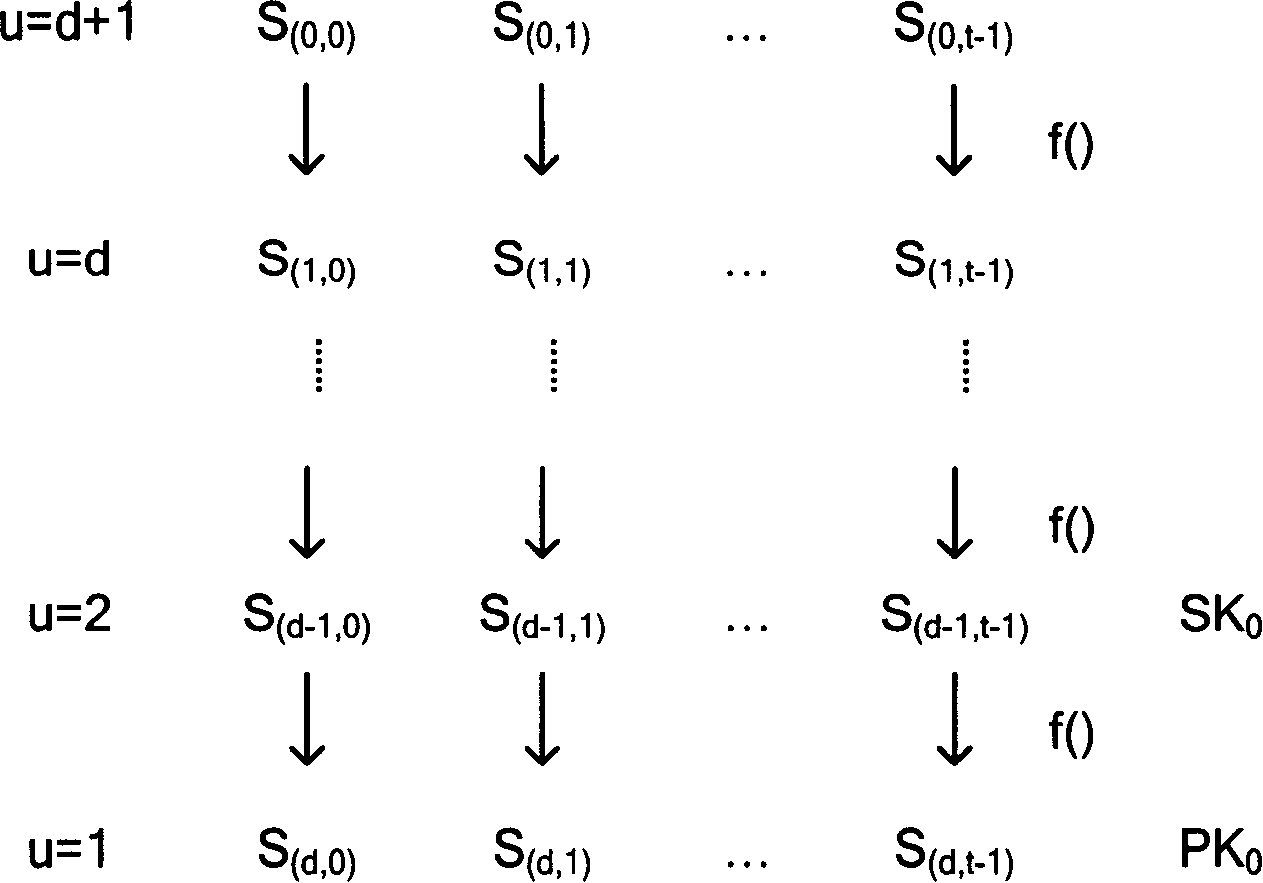

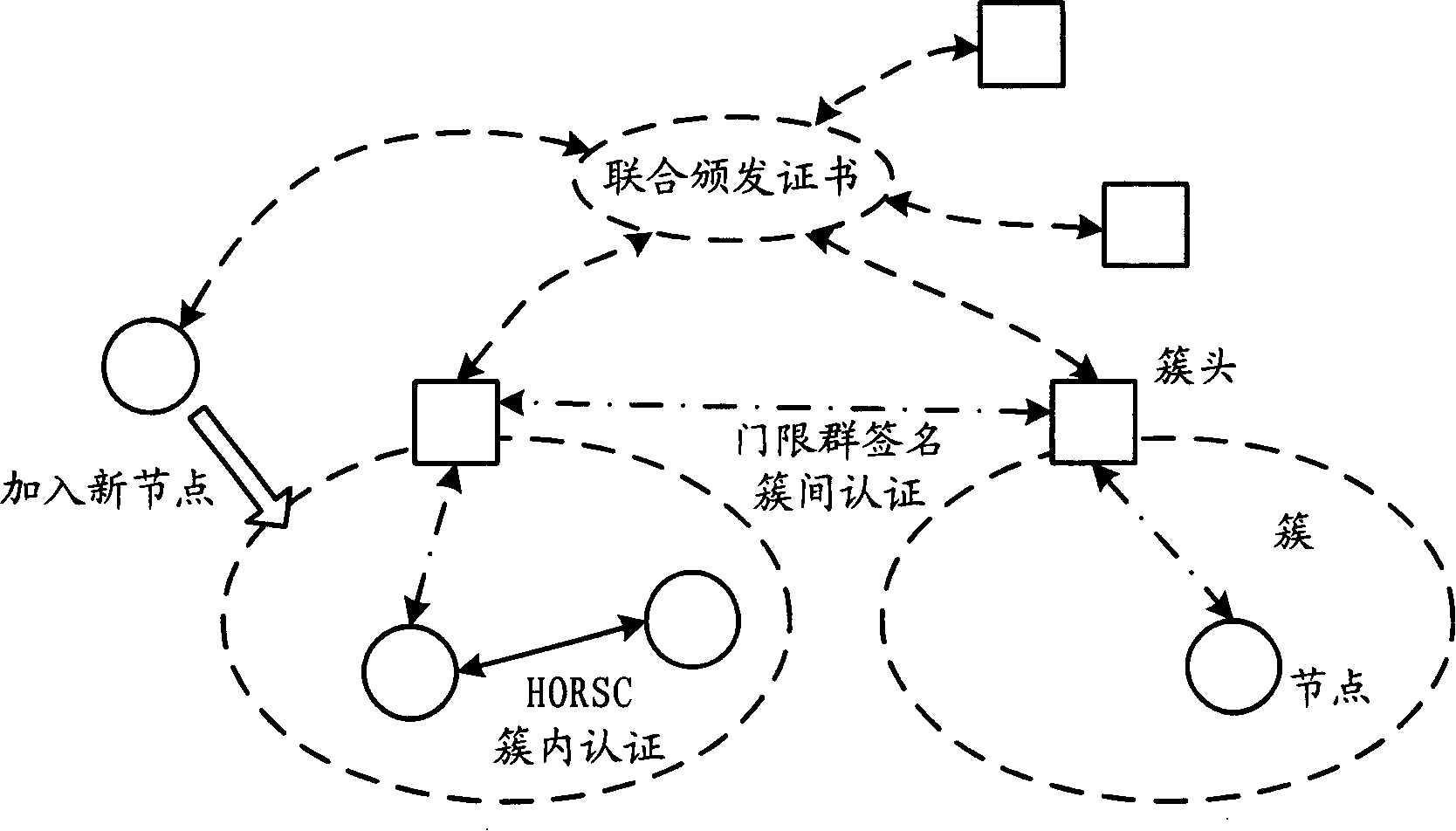

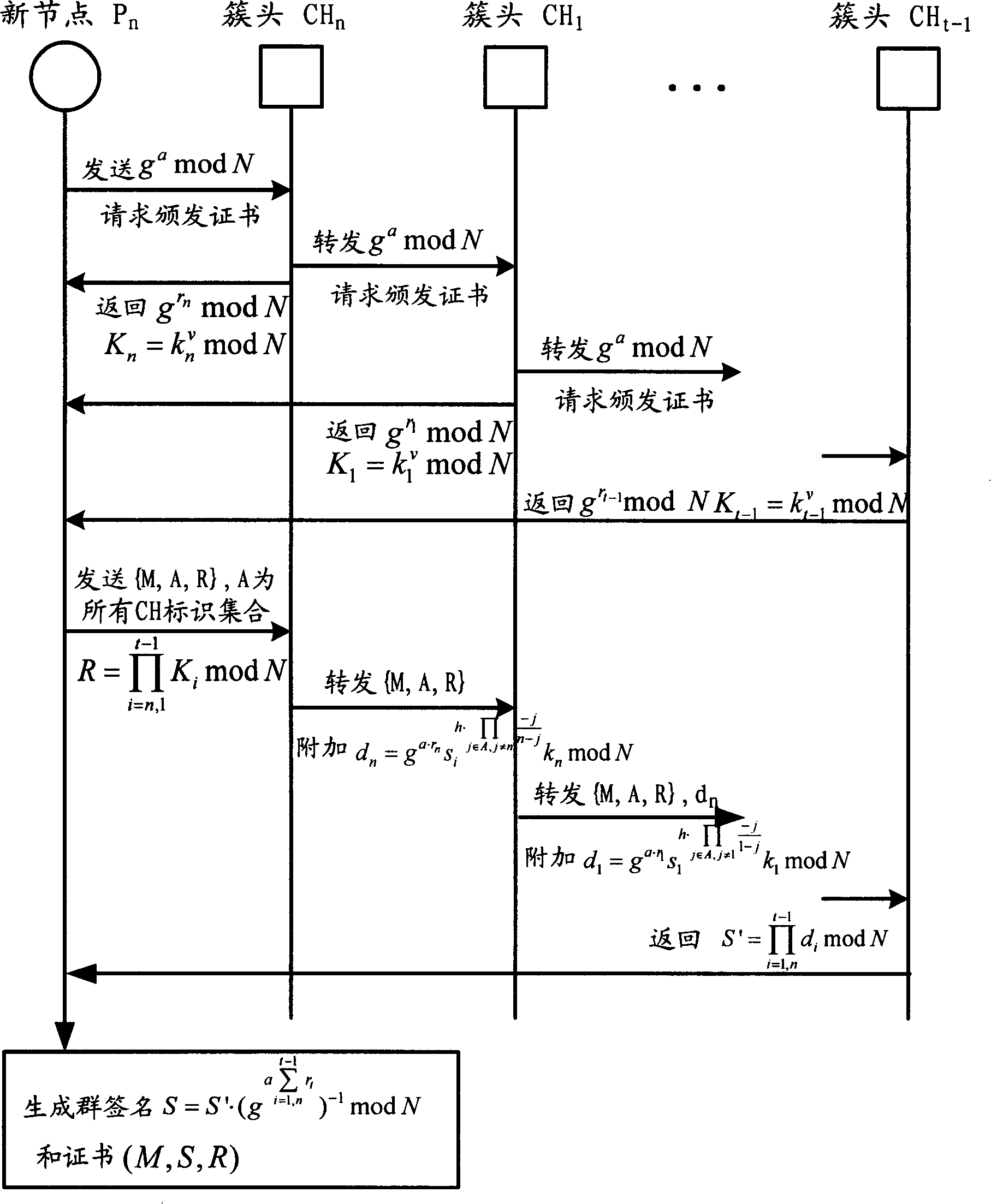

Mobile ad hoc authentication method, network and system

InactiveCN101192928AImprove efficiencyMake the most of processing resourcesEnergy efficient ICTUser identity/authority verificationNetwork structureMobile ad hoc network

The invention relates to the communication field and discloses an authentication method, a network and a system of mobile ad hoc network, which ensures the realization of layer distribution type authentication scheme of cluster mobile ad hoc network; and the requirement on computer processed resources is rational, which can be realized in practical application environment. The invention adopts a group network structure of cluster mobile ad hoc network and advocates layer distribution identity authentication scheme; and the inter-cluster communication used an improved new threshold group signature protocol which improves the original threshold group signature method based on GQ and decreases power index calculation times, improves calculation parallelism and reduces the requirement on processed resources; at the time of initialization, a certificate and a sub key are issued by the system uniformly; cluster heads which have enough numbers of sub keys can jointly recover system keys, thereby carrying out the group signature to issue certificates to new added nodes and using multi-leap serial communication for realizing united group signature.

Owner:HUAWEI TECH CO LTD +1

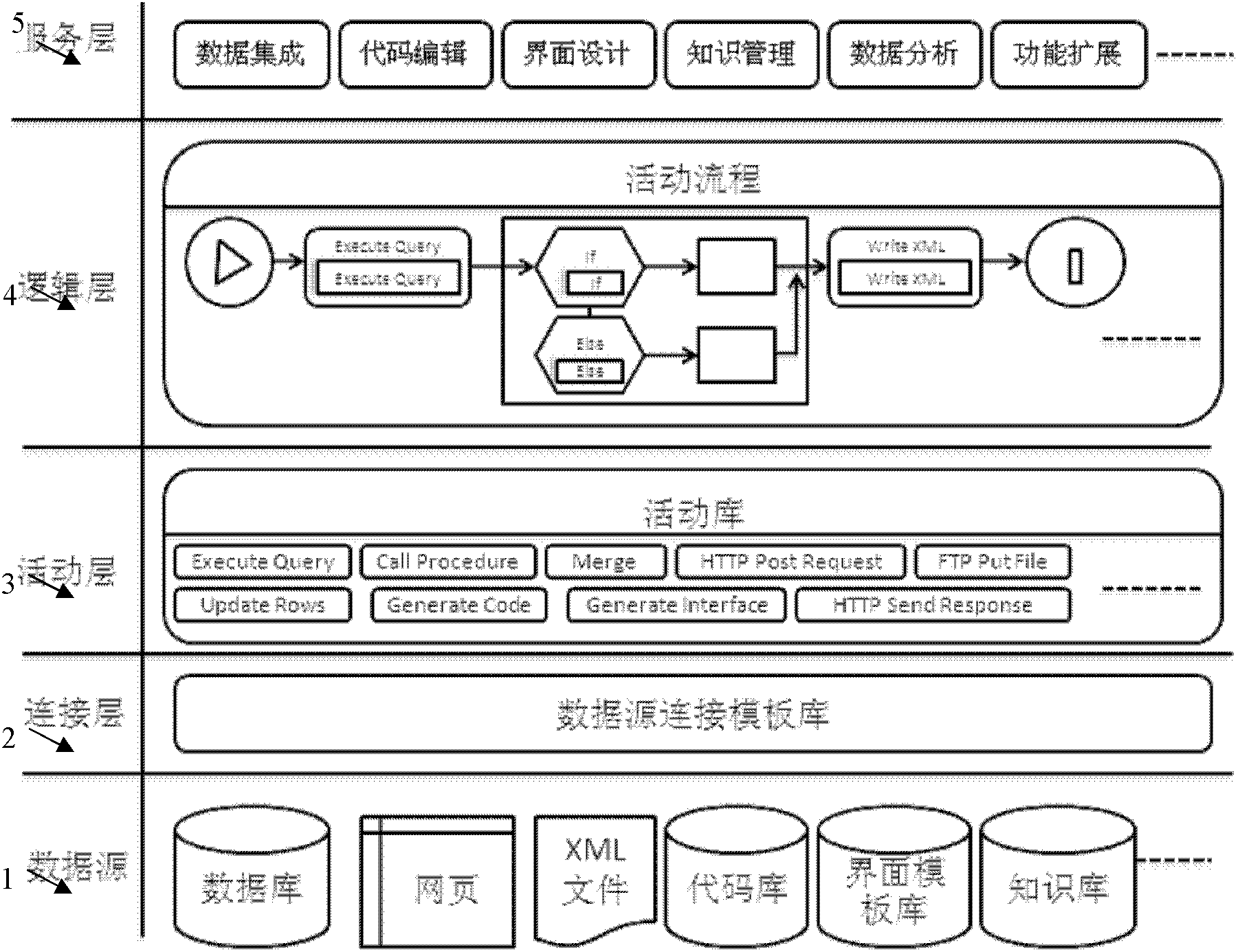

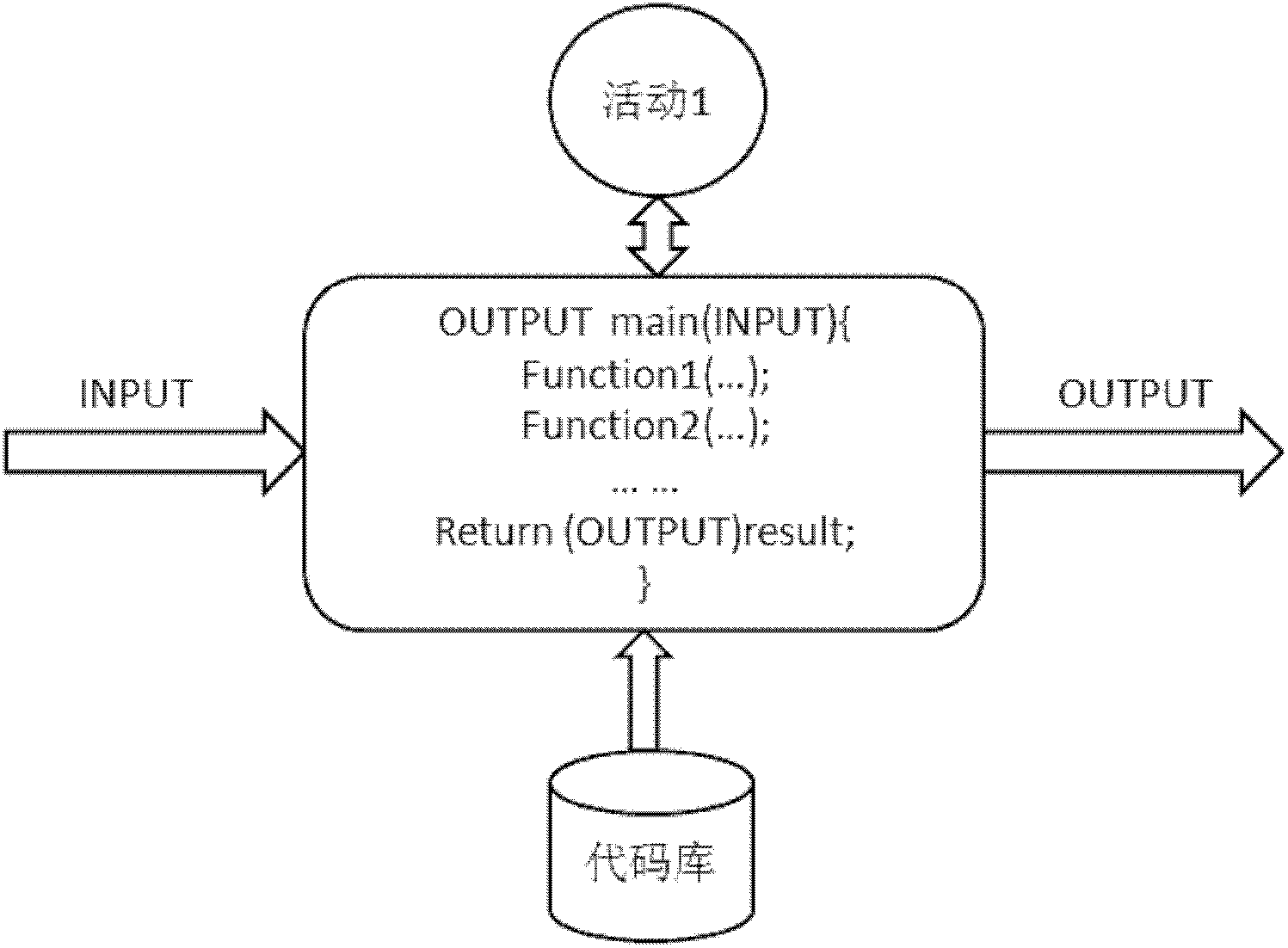

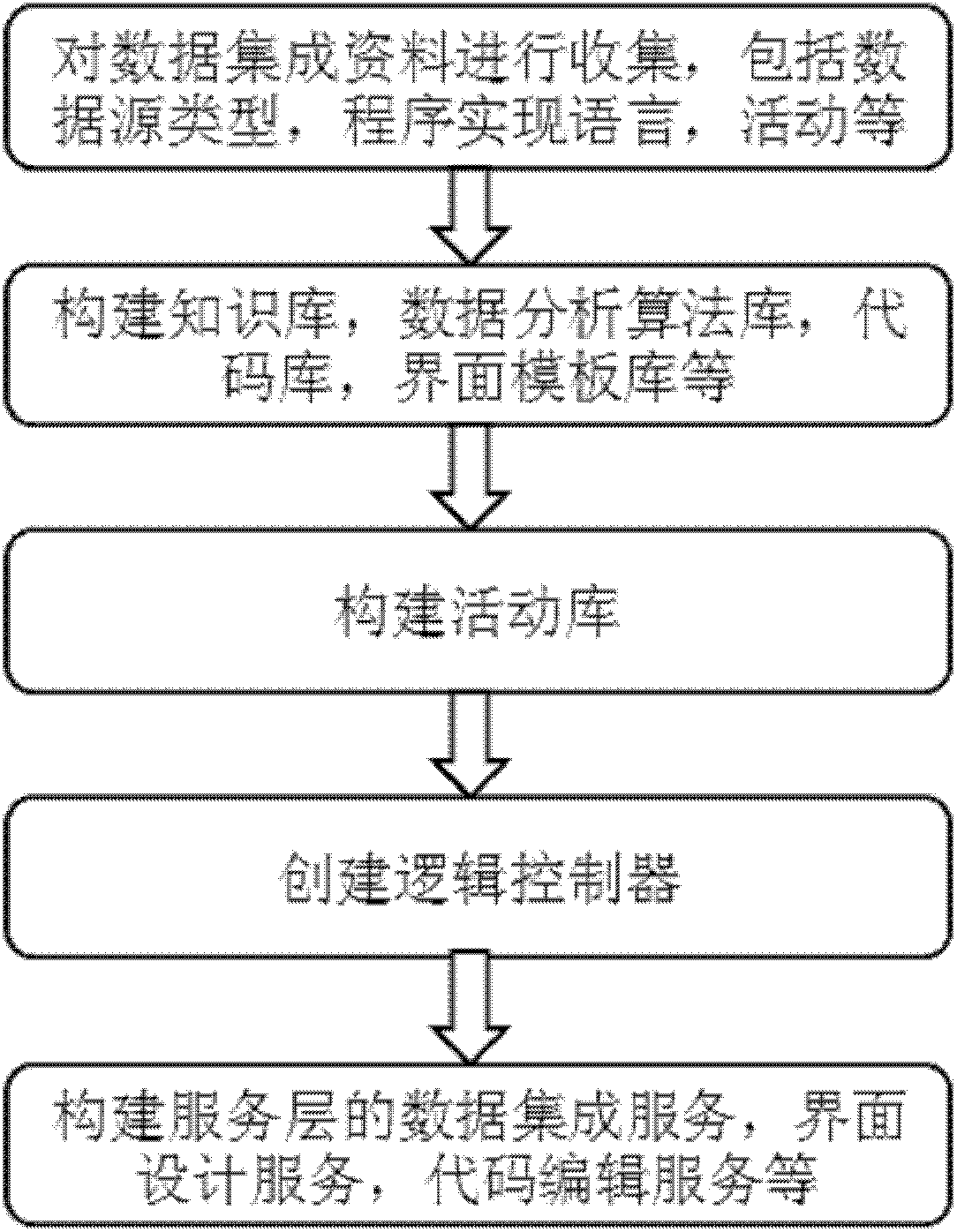

Multi-source data integrating platform and establishing method thereof

ActiveCN102508706AAchieve reuseRealize personalized customizationMultiprogramming arrangementsSpecial data processing applicationsData sourceData management

A multi-source data integrating platform consists of five parts, including data sources, a connecting layer, an active layer, a logic layer and a service layer, wherein the data sources provide an underlying data support for the platform; the connecting layer is used for connecting the data sources and the active layer, so that the active layer can operate the data sources; the logic layer organizes the activities of the active layer; the service layer comprises services supplied to a user; the data sources are data sources of the whole platform; the connecting layer is a connecting channel between an application in the upper layer and the data in the lower layer; the active layer is a set of system activities; the logic layer controls the activity process; and the service layer comprisesthe services supplied by the integrating platform to the user. An establishing method for the multi-source data integrating platform comprises six steps. The multi-source data integrating platform isscientific in concept and convenient to use, and has a relatively high practical value and a wide application prospect in the technical fields of data management, computer and integrating design environment.

Owner:BEIHANG UNIV

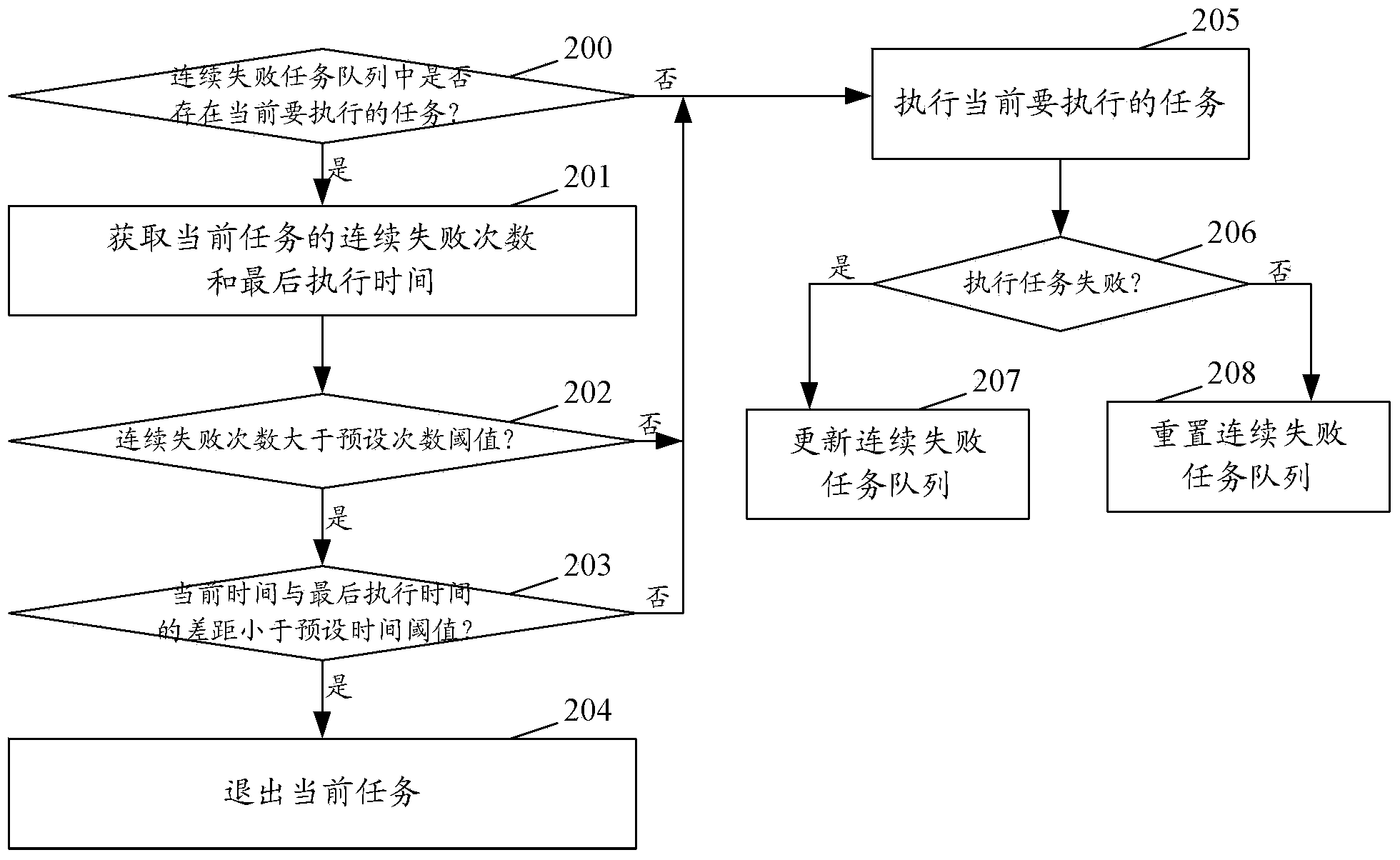

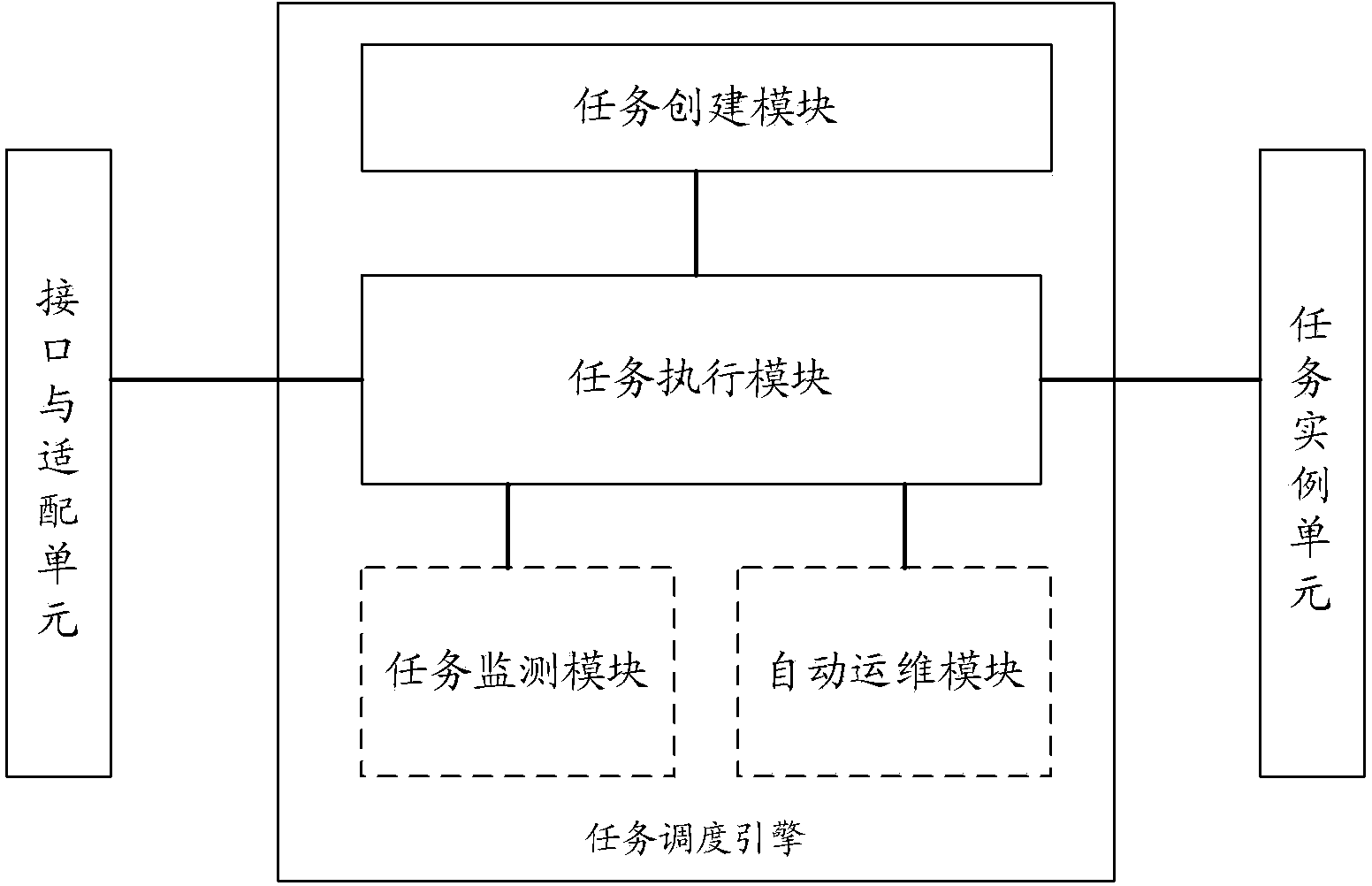

Task scheduling method and system

The invention discloses a task scheduling method and system. The method comprises the steps that a task template achieved by the adoption of plug-ins is utilized for creating a task, and the task is scheduled according to the real-time status of the task. Due to the fact that the task template achieved by the adoption of the plug-ins is utilized for creating the task, task expandability is improved, and the method can create the general task. In addition, due to the facts that the plug-ins exist in the task template, and mutual independence and expandability exist and permutation and combination can be achieved among template configurations and / or a parameter list and / or strategies and / or result responses, reuse of all the components is greatly achieved, task expandability is greatly improved, the universality of the task scheduling method is ensured, the expandability of a trigger event is greatly improved, working efficiency is improved, and the working cost is reduced.

Owner:ALIBABA GRP HLDG LTD

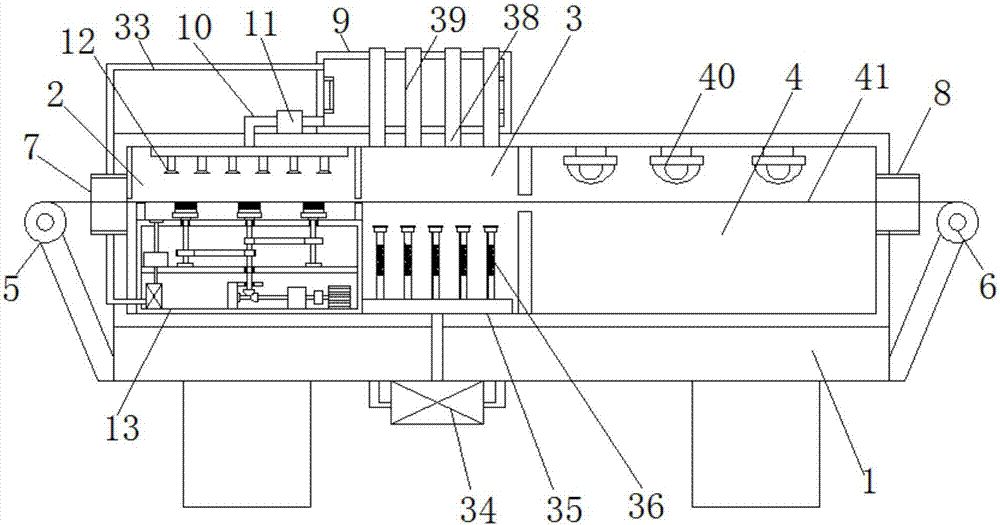

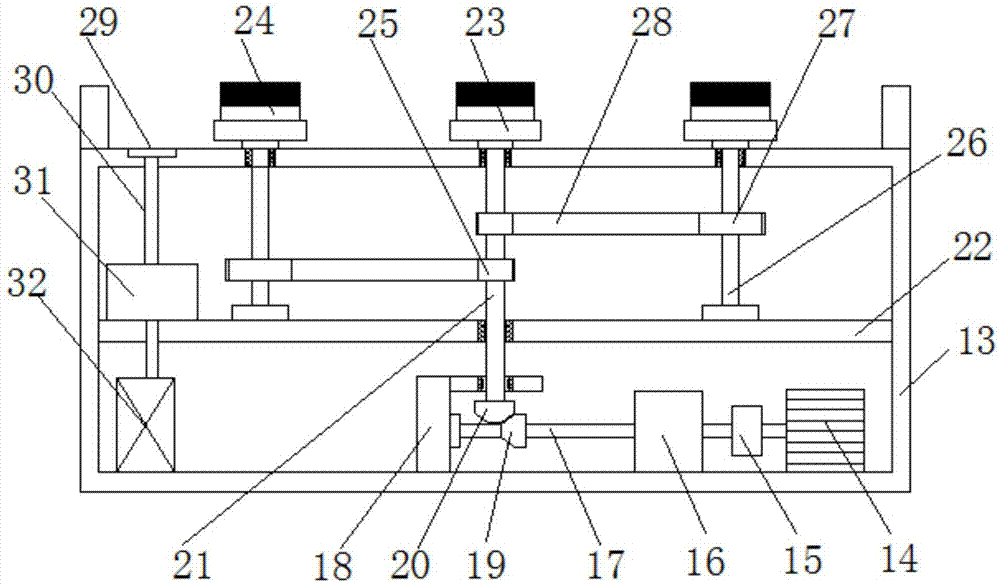

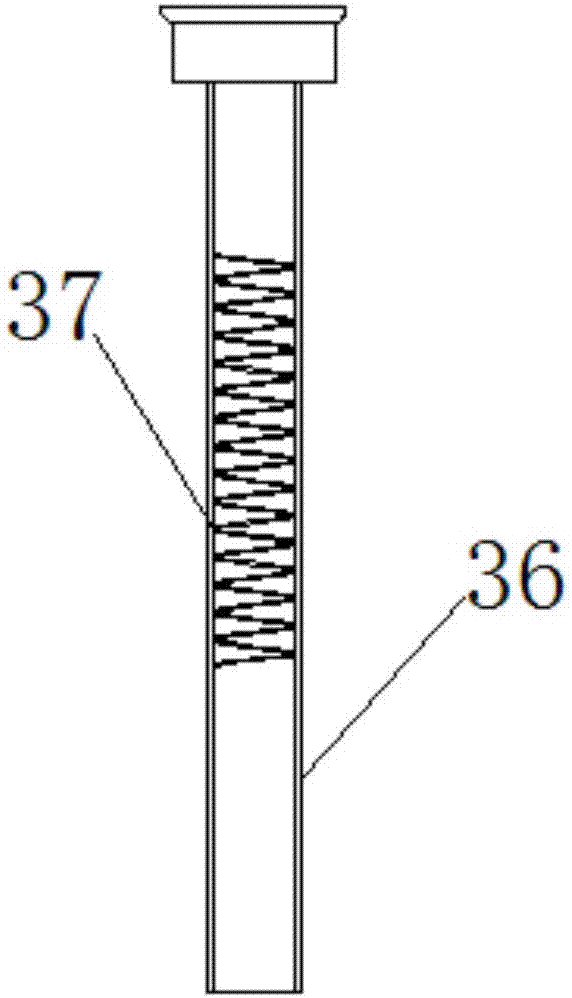

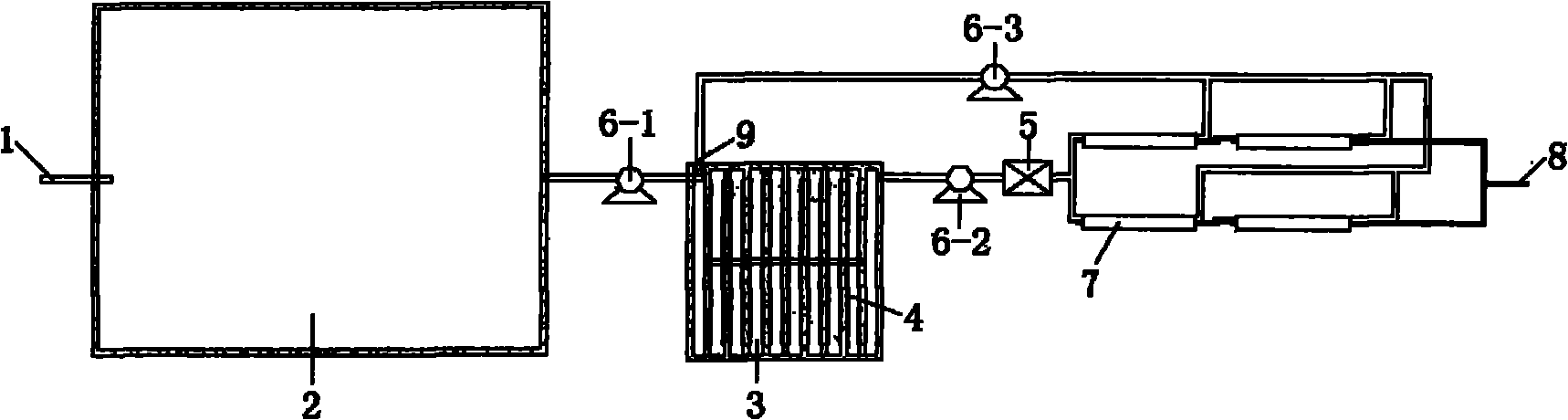

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

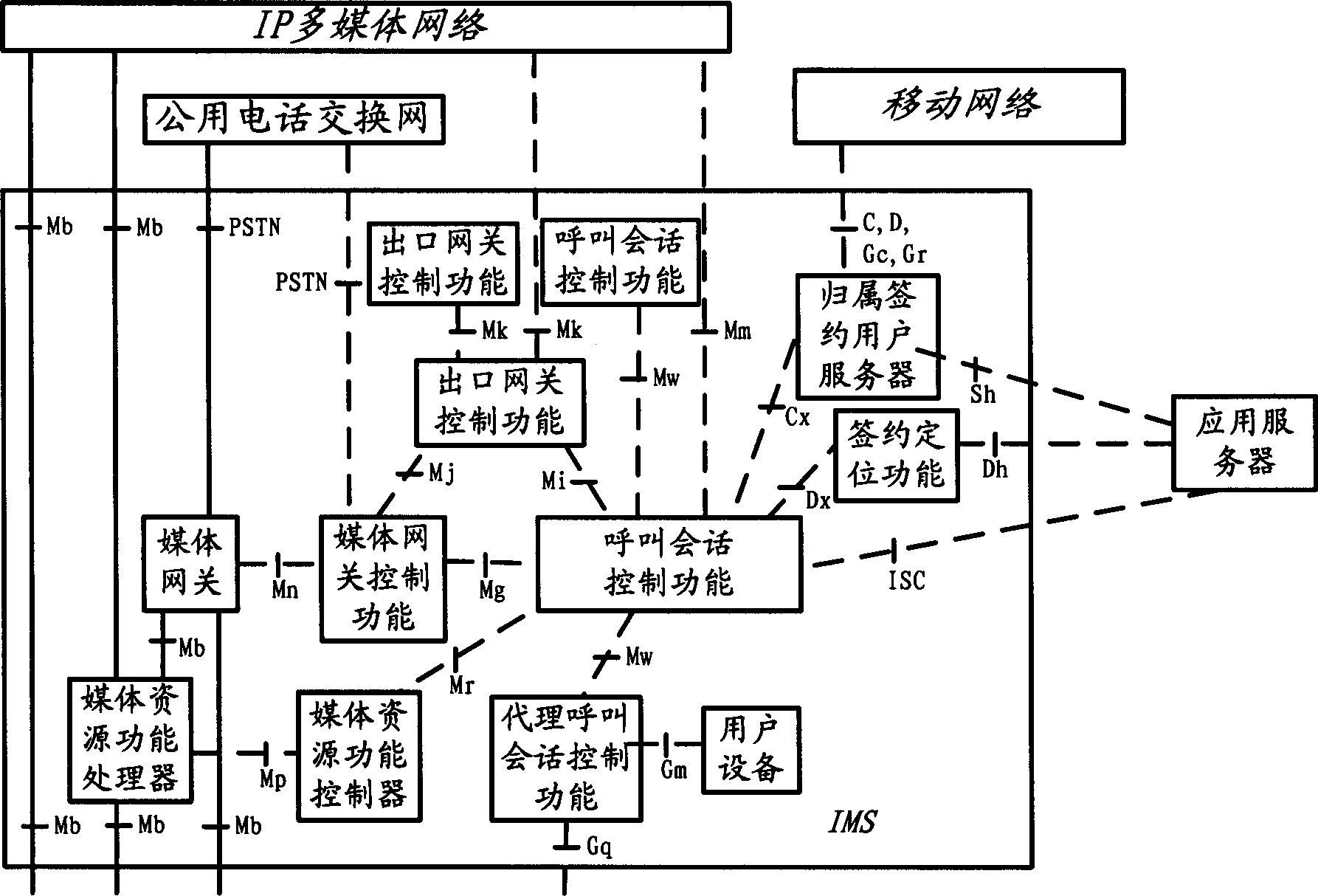

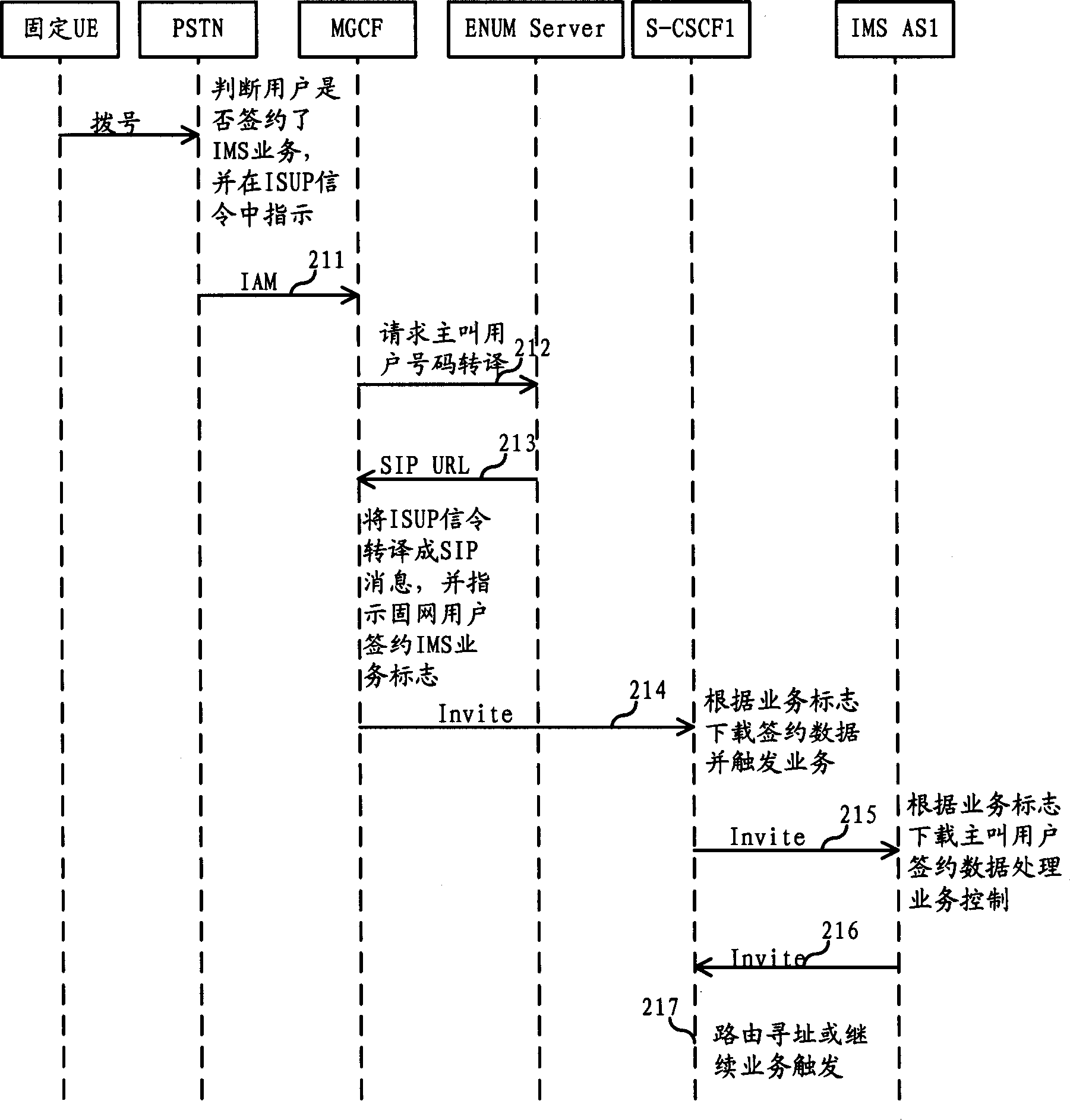

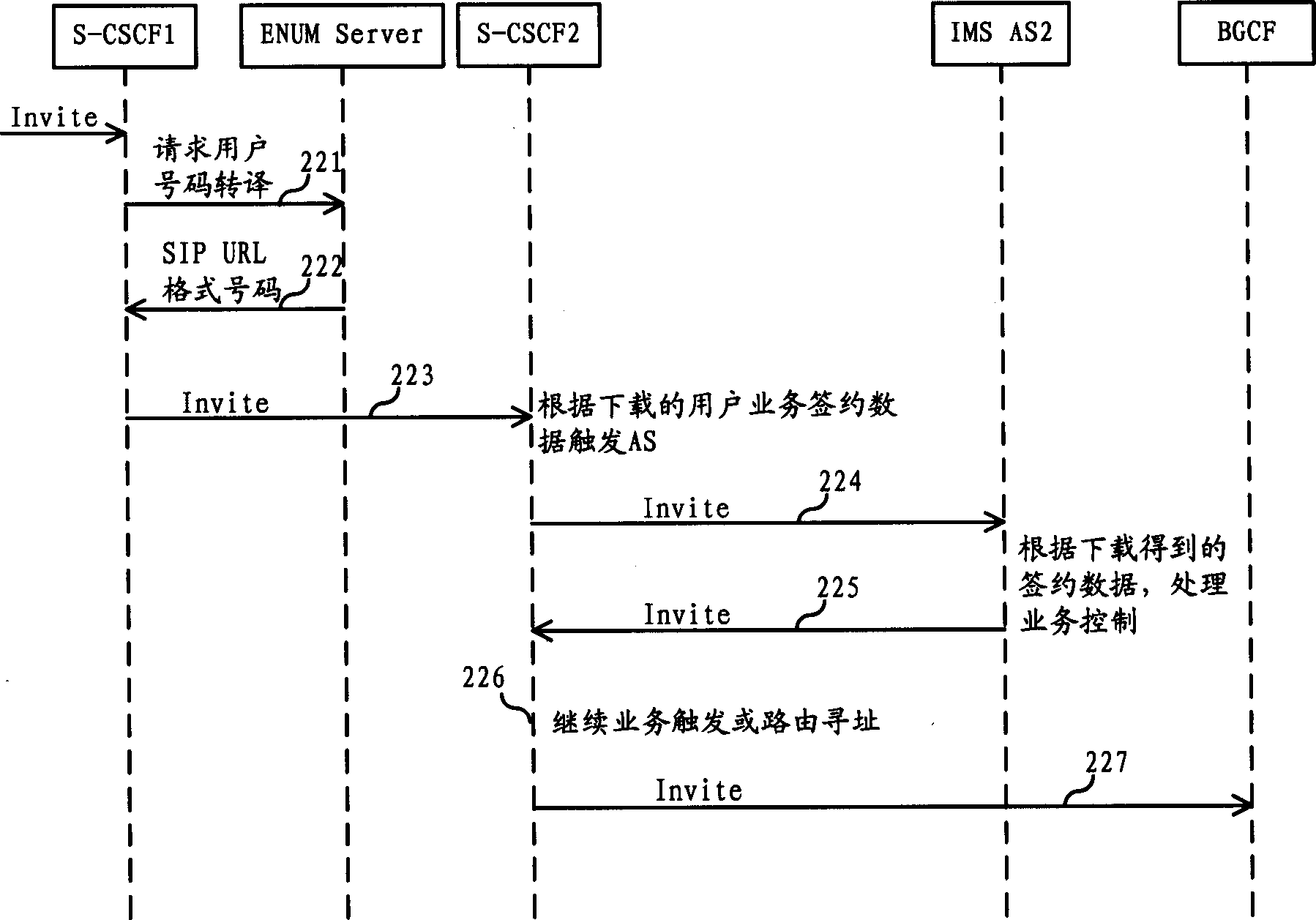

Method for providing service to circuit field user via group field

ActiveCN1773967AFunction increaseSimple interfaceHybrid switching systemsSelection arrangementsNetwork ConvergenceComputer science

A method of utilizing packet domain to provide service of circuit domain user includes expanding network node function of MGCF, S ¿C CSCF and AS to make IMS not only support interworking call of firm network circuit domain but also provide service for firm network domain user, furthermore expanding HSS function to store and manage IMS contracted service data related to firm network circuit domain user.

Owner:HUAWEI TECH CO LTD

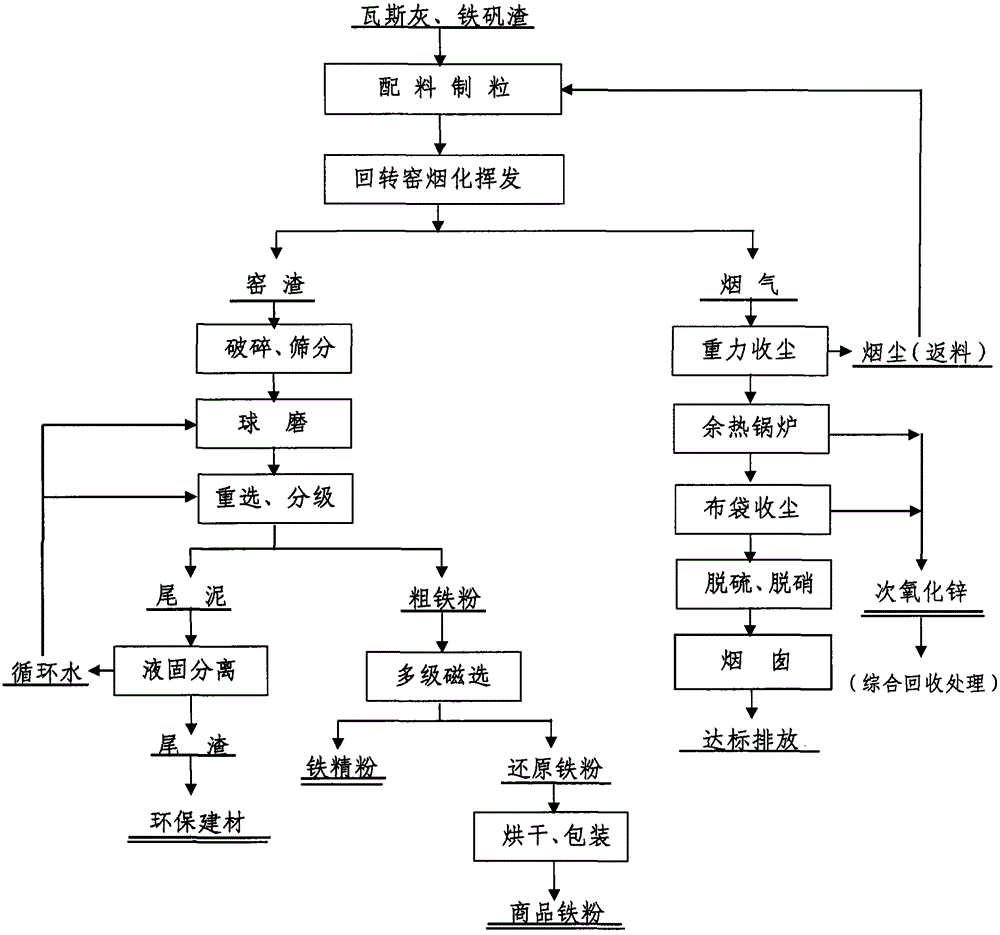

Comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag

ActiveCN104911356AImprove the level of comprehensive utilizationAchieve reductionProcess efficiency improvementSlagHigh energy

The invention provides a comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag. By combining advantages of low iron content and rich carbon of gas ash and characteristics of high iron content and rich precious metals of ferrovanadium slag, and by the adoption of a rotary-kiln fire method fuming enrichment technology, the material undergoes comprehensive recovery. Advanced equipment such as a waste heat boiler, a negative-pressure bag collector, a pneumatic emulsification desulfurization tower and the like are configured to carry out efficient recovery and harmless environmental-protection processing of flue gas so as to achieve the purpose of clean production. By a beneficiation combined method, iron-containing kiln slag undergoes high added-value exploitation. Thus, the environmental protection problem of resource disposition is solved, and the effect of comprehensive utilization with low energy consumption, high yield and high added-value is achieved. Problems of short kiln age, high energy consumption and low concentration of SO2 during the treating process of ferrovanadium slag can be solved by the technology provided by the invention, and problems of poor iron separation effect and overhigh content of fluorine and chlorine in zinc hypoxide also can be solved. The technology has good economic benefit and high popularization and practical value.

Owner:北京事竟成有色金属研究所

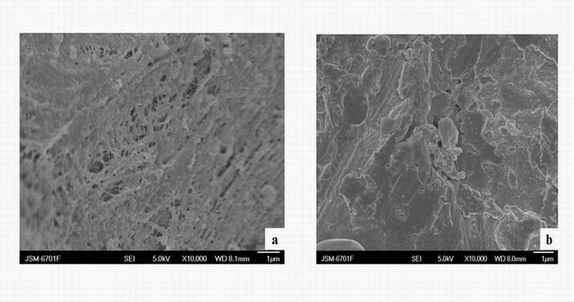

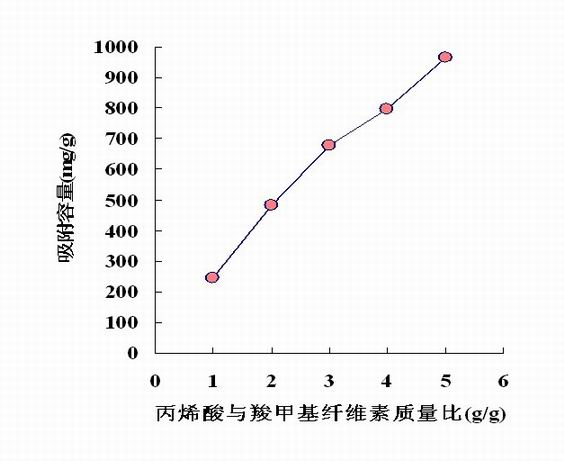

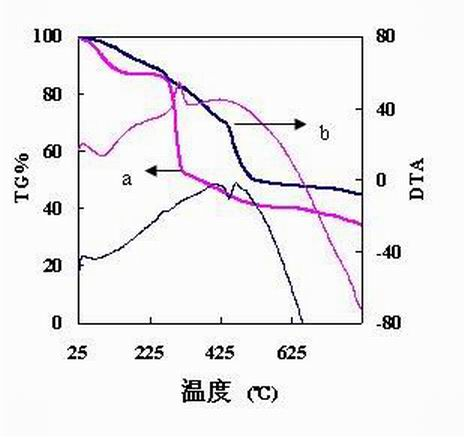

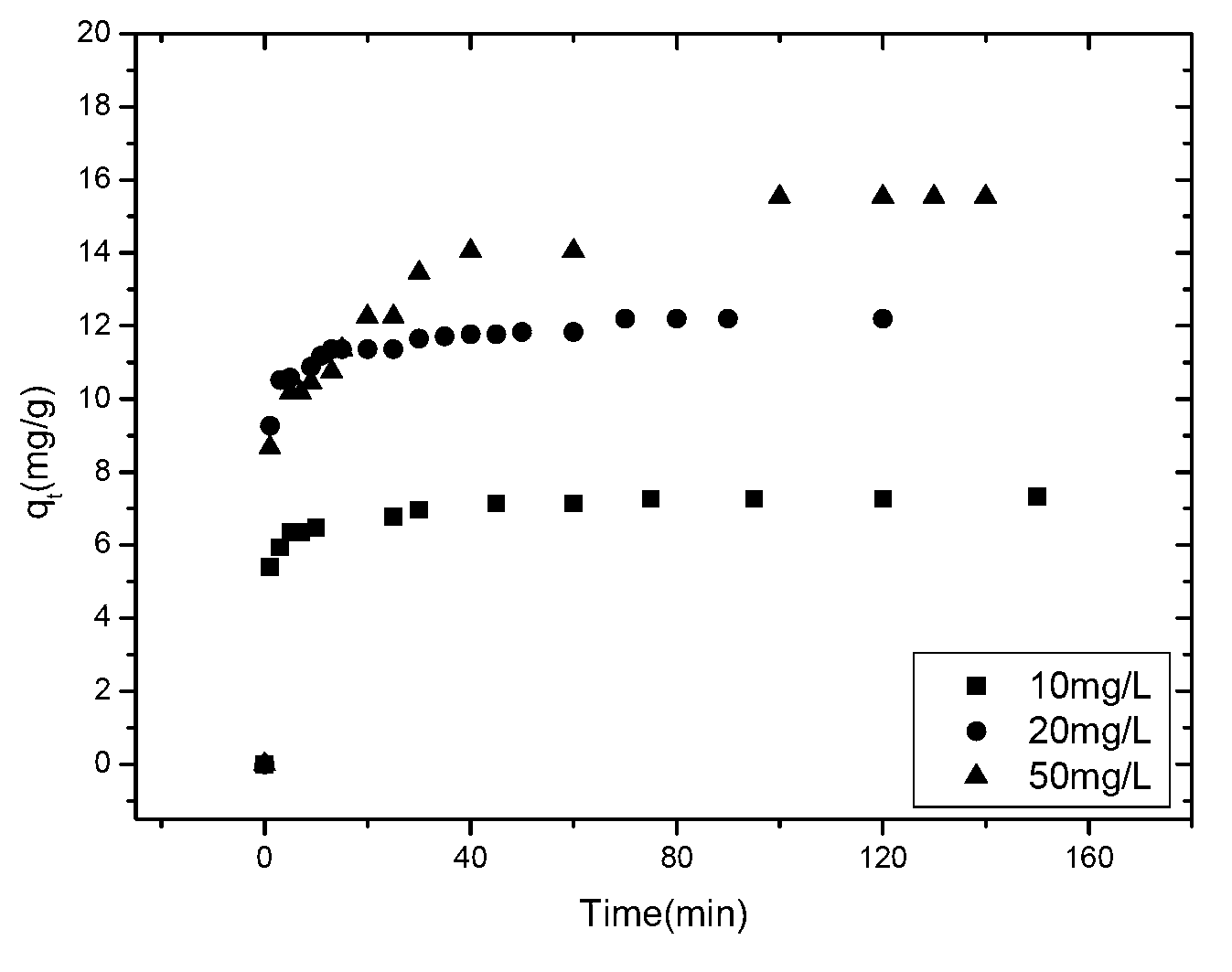

Preparation and application of carboxymethyl cellulose of wheat straw

InactiveCN101985479AReduce dosageImprove stabilityOther chemical processesWater contaminantsChloroacetic acidsChloroacetic acid

The invention discloses carboxymethyl cellulose of wheat straw. The wheat straw is crushed and subjected to pretreatment with dilute alkali, bleaching and alkalization, and then reacts with chloroacetic acid before being etherified so as to obtain the carboxymethyl cellulose of the wheat straw; and the carboxymethyl cellulose of the wheat straw is subjected to graft copolymerization together with acrylic acid to obtain a carboxymethyl cellulose-based polymer adsorbent. The adsorbent is applied to the treatment of wastewater containing heavy metal ions, has high adsorbability and large adsorption capacity and ensures high metal ion removal rate. After treatment, the adsorbent has high stability and can completely meet the requirements of heavy-metal wastewater treatment; and the treated wastewater is clear and transparent without odor and can meet the national emission standard. The invention has the advantage that the resources of raw materials are wide, the cost is low, the use of waste is realized, and secondary pollution caused by burning of the wheat straw is avoided, thus being conducive to environmental protection.

Owner:GANSU TIPTOP PLANT TECH CORP

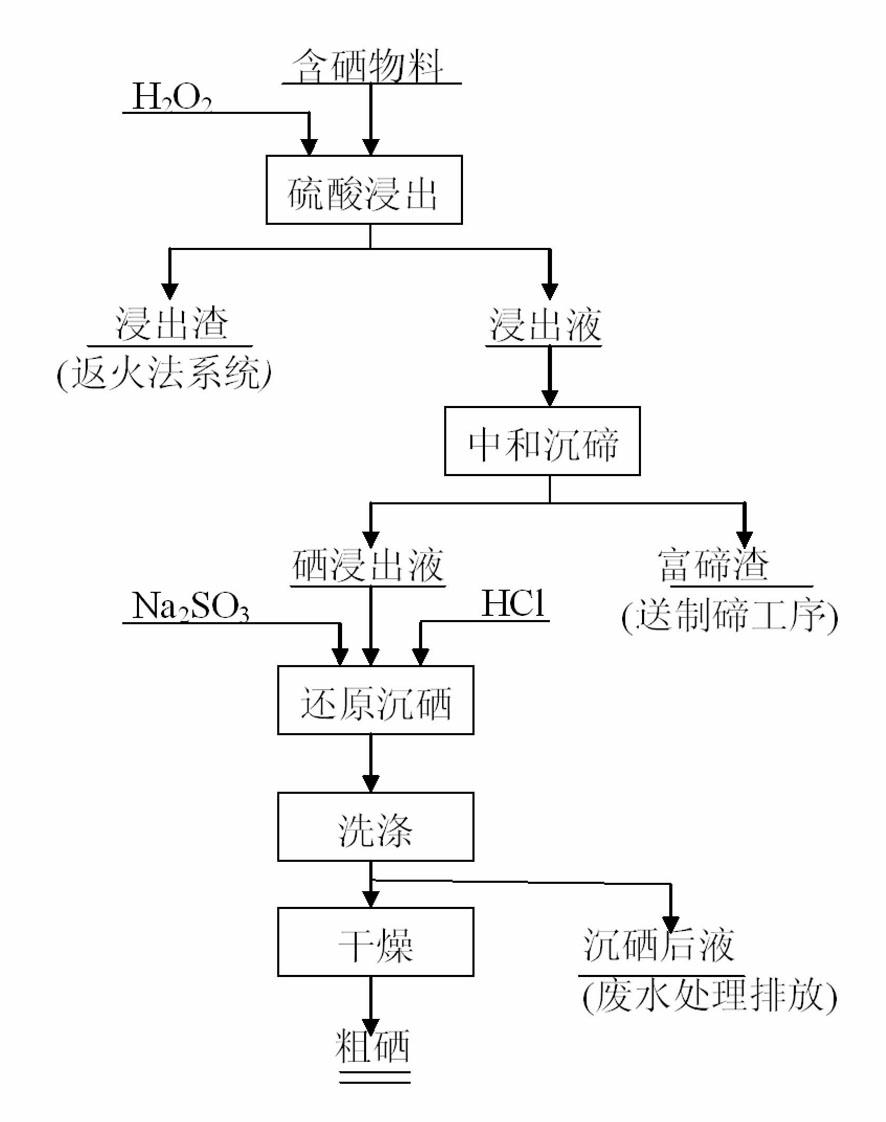

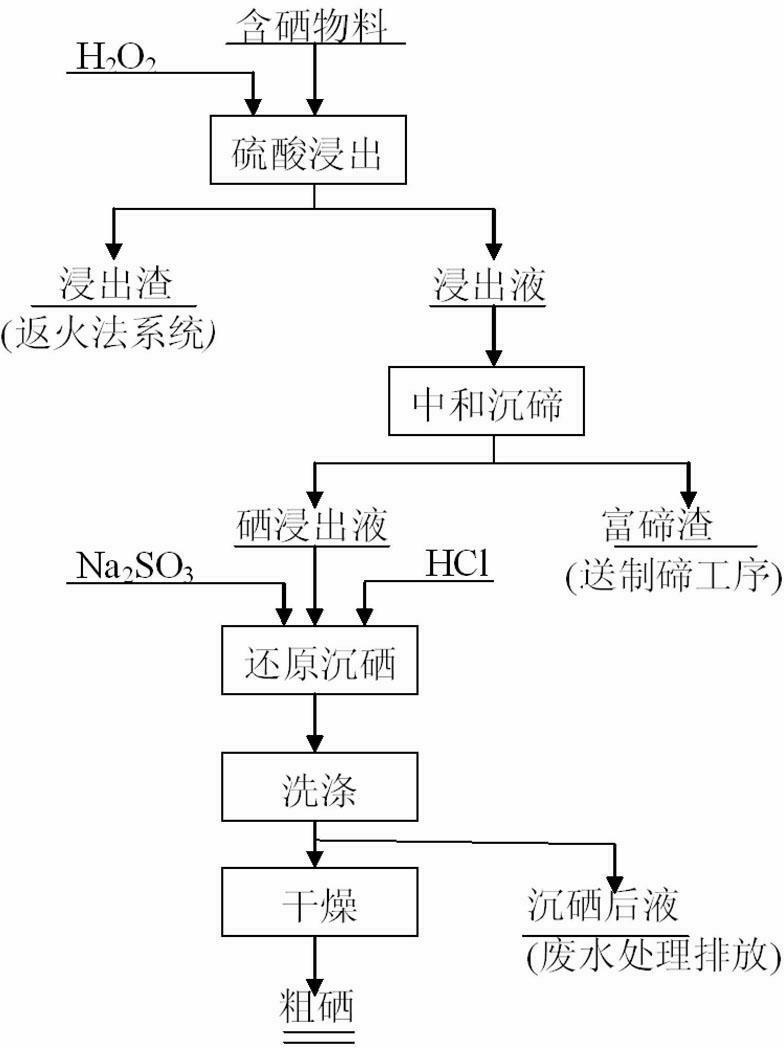

Process for separating and recovering selenium from selenium-containing material

The invention relates to a process for separating and recovering selenium from a selenium-containing material. The process comprises the following steps: dissolving the selenium-containing material into a sulfuric acid solution, adding 10% H2O2 into the mixture, filtering and separating to get leachate and residue containing silver, lead, copper and other valuable metals; separating the selenium from tellurium in the oxidation leachate by using sodium hydroxide; and acidifying the selenium leachate with hydrochloric acid, adding sodium sulfite to reduce the settled selenium, washing and drying to get crude selenium with the grade of not lower than 90%. The crude selenium which is separated by the process is higher in purity and can be directly refined, so that the process flow of recovering selenium is shortened, the recovery rate of selenium is improved, the production cost is reduced and the energy is saved; and the sodium sulfite is used for substituting sulfur dioxide to perform reduction, the control is easy and the environmental pollution is further reduced. The process has very important significance in both aspects of recovering resources and protecting an environment.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for transferring and washing graphene film

ActiveCN102583356AAvoid breakingIntegrity guaranteedElectrolysis componentsGraphenePolymer scienceElectrochemistry

The invention relates to a method for transferring and washing a graphene film, which belongs to the field of graphene film materials. An electrochemical method is used for peeling the graphene film, and a wetting agent is added in the used electrolyte after the graphene film is obtained by peeling. The method can achieve reutilization of a metal growth substrate, the obtained graphene film has good integrity and electrical conductivity, simultaneously the method for transferring and washing the graphene film has the advantages of being strong in applicability, low in cost and short in period and having wide application prospect.

Owner:WUXI GRAPHENE FILM +1

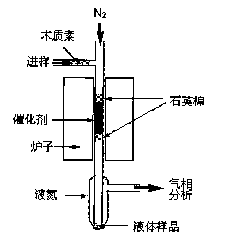

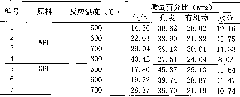

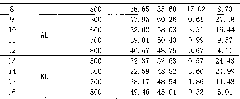

Catalytic thermal cracking method for lignin

InactiveCN101824330AAchieve reuseImprove catalytic performanceBiofuelsLiquid hydrocarbon mixture productionLiquid productMolecular sieve

The invention discloses a catalytic thermal cracking method for lignin. The method comprises the following steps: preheating a molecular sieve catalyst to 200-300 DEG C, gradually adding lignin into the molecular sieve catalyst to carry out catalytic cracking reaction under the temperature of 500-800 DEG C and in the protective atmosphere of inert gas, separating the catalytic thermal cracking product of lignin after the reaction to obtain liquid, gas and solid products. By GC / MS analysis, the main components of the liquid product comprise benzene, toluene, ethylbenzene, naphthalene and other aromatic compounds, which account for 70%-80% of the total mass of the liquid products. The gas product is measured by GC, in which the volume of methane and carbon monoxide accounts for over 90% of that of the total gas. The main component of the solid product is carbon the mass fraction of which is between 75% and 85%. The products can be used for preparing fuel or aromatic chemicals.

Owner:UNIV OF SCI & TECH OF CHINA

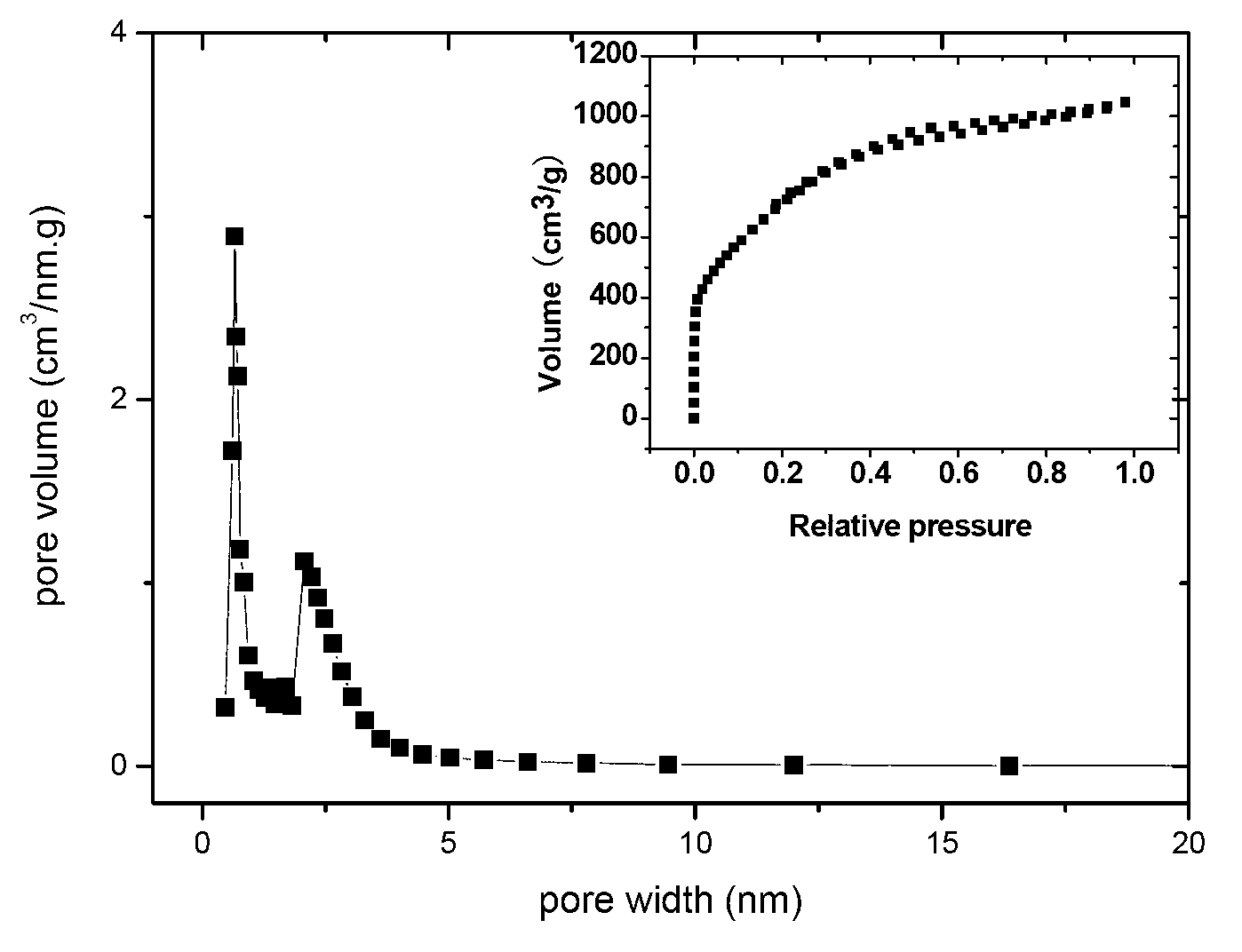

Method for preparing activated carbon powder with lignin from alkaline papermaking black liquor

The invention provides a method for preparing activated carbon powder with lignin from an alkaline papermaking black liquor. The method comprises the steps as follows: the lignin is extracted from the alkaline papermaking black liquor through acidification and is prepared after being purified; KOH (potassium hydroxide) is added after the lignin is carbonized; the mixture is placed in an ultrasonic water bath to be subjected to ultrasonic treatment for 30 to 35 min; and after being dried, the mixture of the lignin and the potassium hydroxide is heated and activated for 0.5 to 2.0 hours at 650 to 850 DEG C, so as to prepare the activated carbon powder. The method has the advantages that the process is simple; waste utilization is realized; and the prepared activated carbon powder has the effects of large specific surface area, high porosity, strong adsorption effect and excellent properties and can effectively remove heavy metals and organic pollutants.

Owner:SHANDONG UNIV

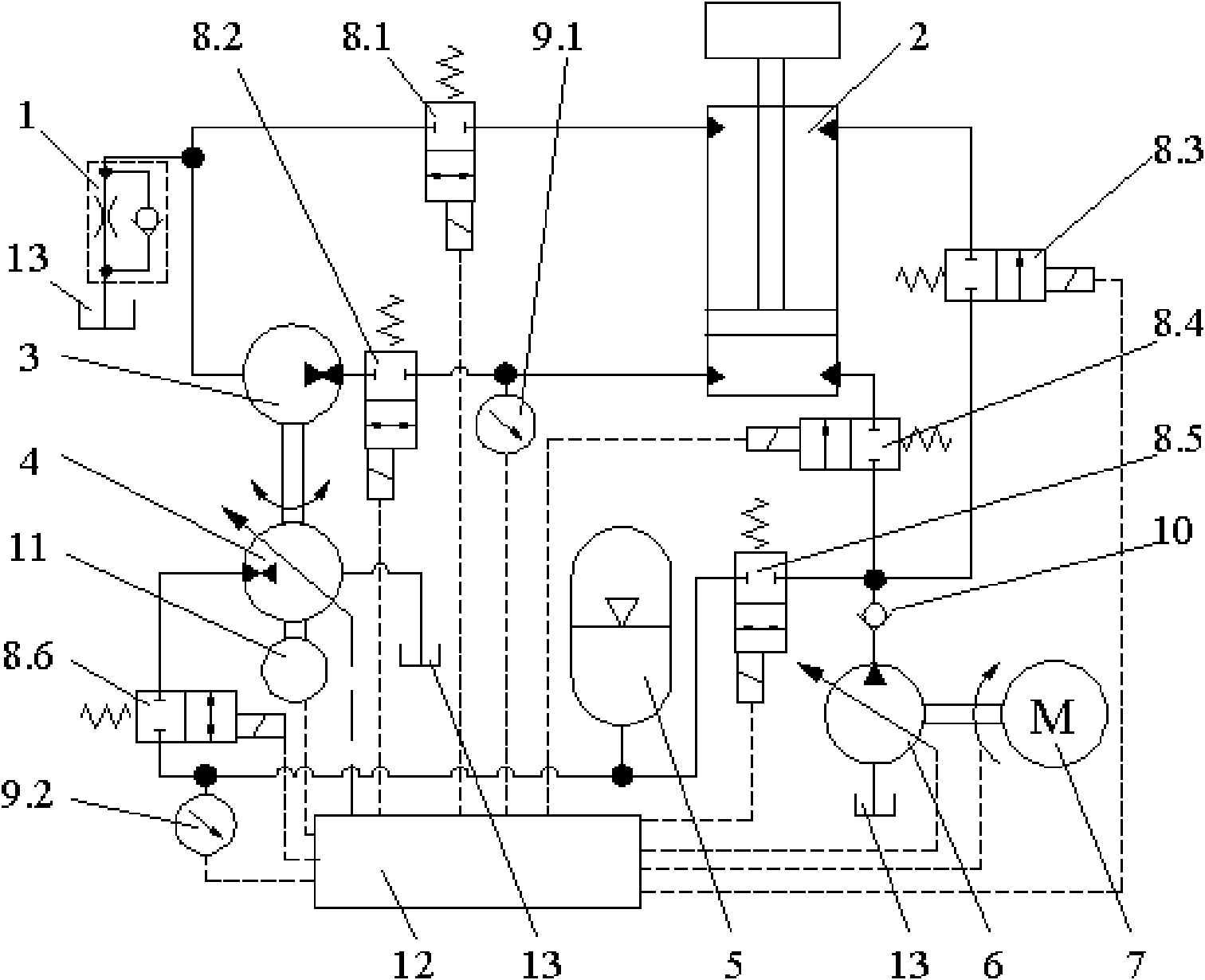

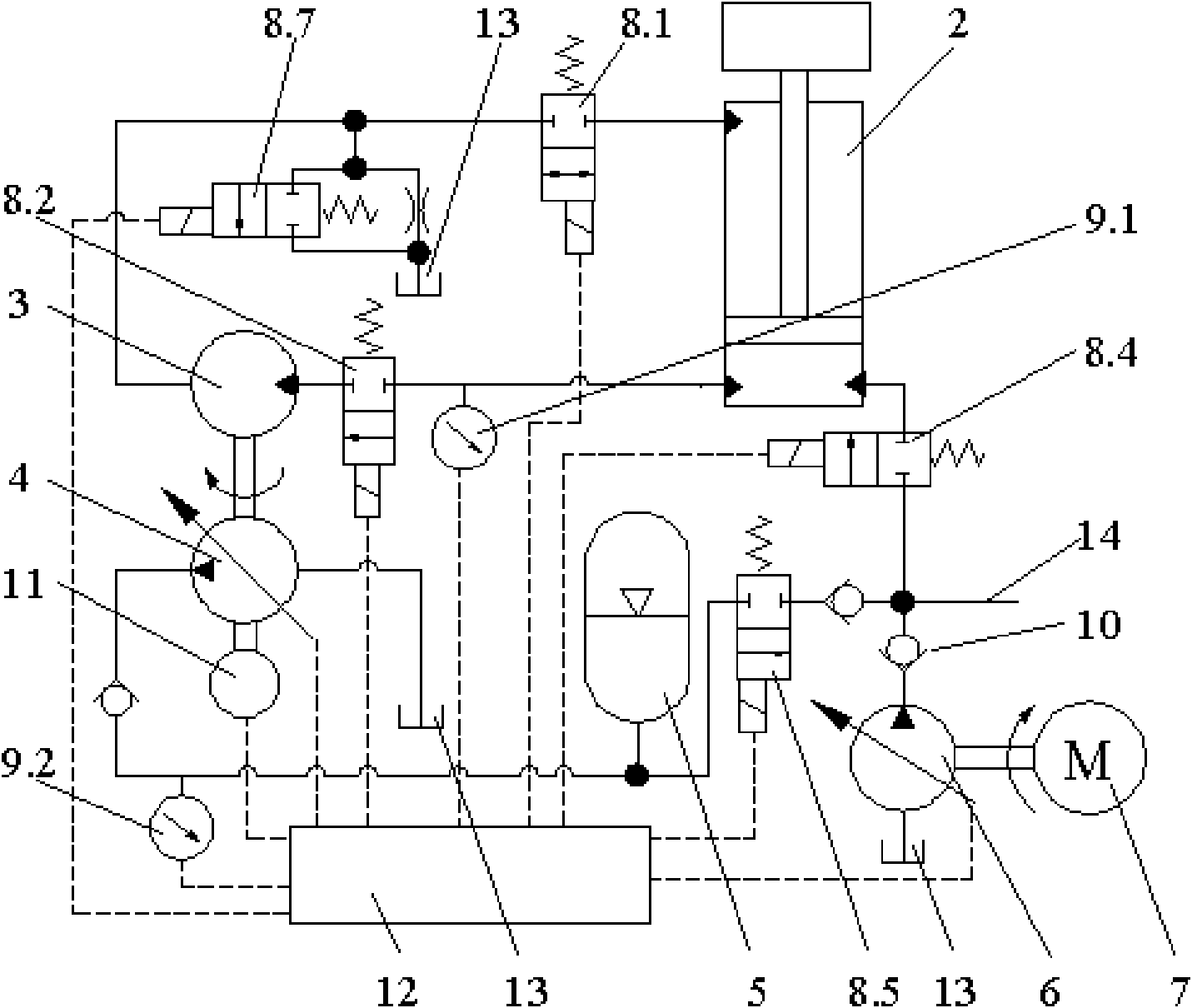

Excavator energy-recuperation system

InactiveCN101654915ARealize the regeneration functionImprove energy utilizationMechanical machines/dredgersHydraulic cylinderFuel tank

An excavator energy-recuperation system relates to an excavator moving arm energy saving system, comprising a hydraulic cylinder, a fuel tank, a quantitative pump, a valve and an engine. The key technology is that a first variable pump and a speed determining photoelectric encoder are coaxial equipped with the quantitative pump. One end of the quantitative pump is connected with a hydraulic cylinder through a reversing valve and the other end of the quantitative pump is respectively connected with the fuel tank and the hydraulic cylinder on two branches. One end of the first variable pump is connected with the fuel tank and the other end is connected with an accumulator through the reversing valve. A second variable pump is coaxial arranged with the engine, one end of the second variable pump is connected with the fuel tank and and the other end is connected with a check valve; a fuel outlet of the check valve has three branches, wherein the first one is connected with the accumulatorthrough the reversing valve; the second one is connected with a hydraulic cylinder through the reversing valve; and the third one is connected with a hydraulic cylinder through the reversing valve. The invention combines the flow regeneration and potential energy recuperation, thus simultaneously realizing the flow regeneration and the energy-recuperation recycling, improving the utilization rateof the excavator energy and prolonging the service life of the excavator.

Owner:四川升腾元创机电技术研究有限公司

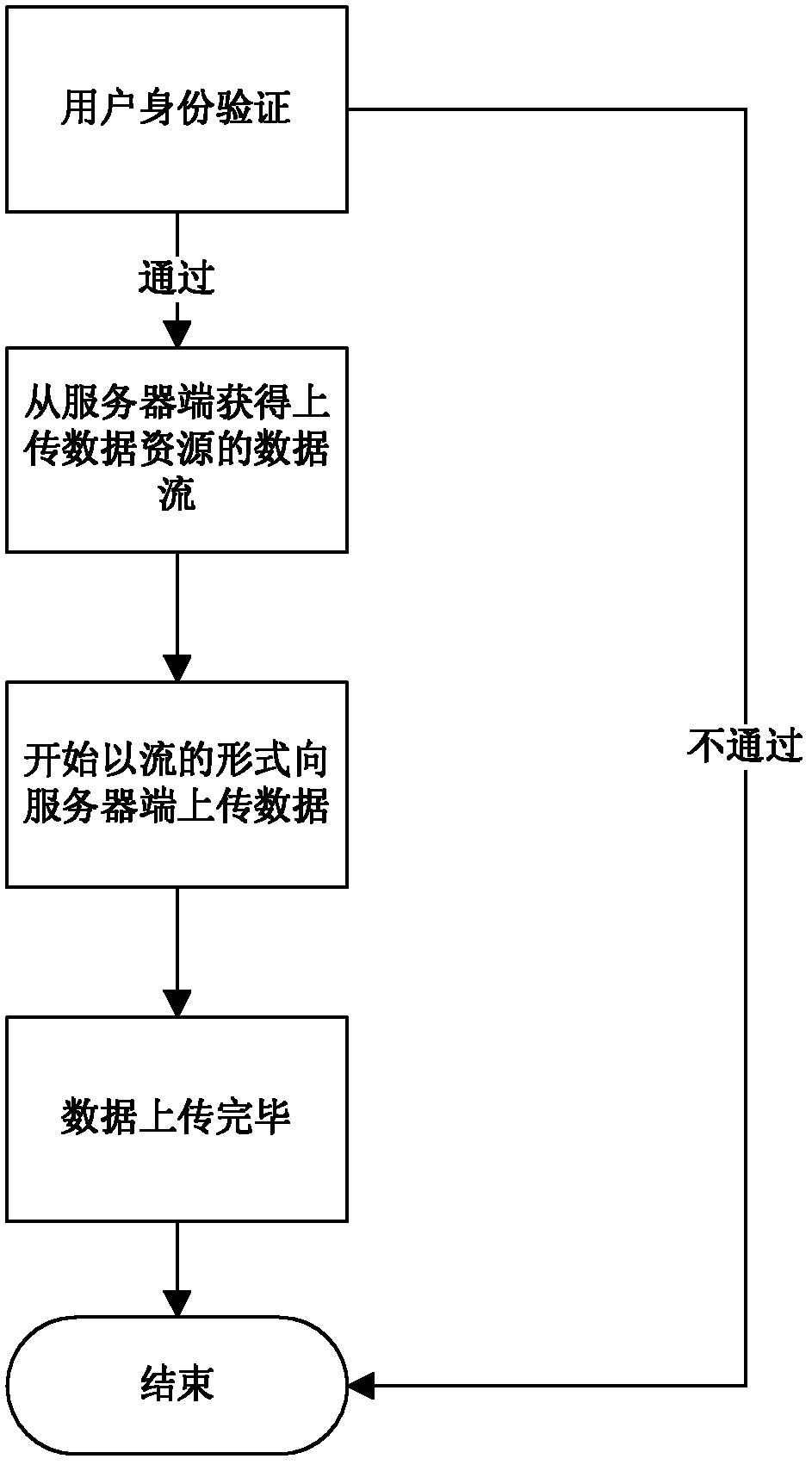

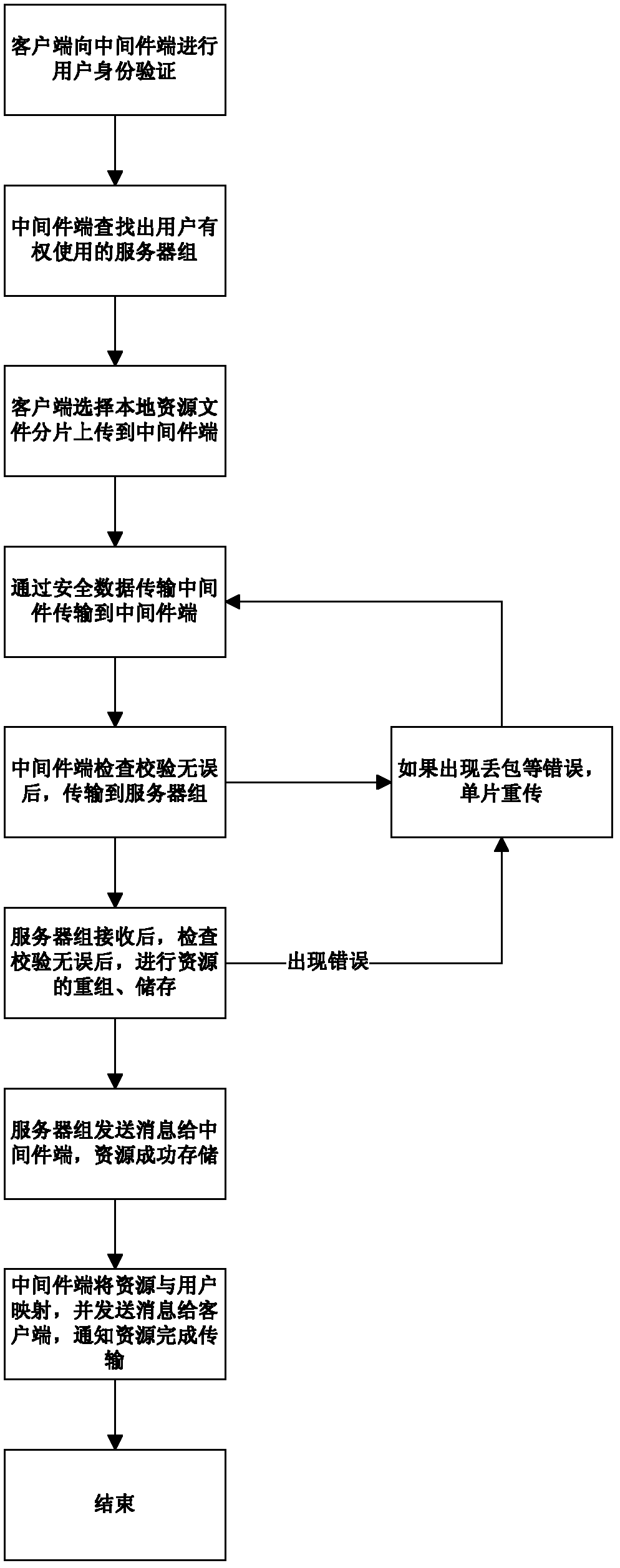

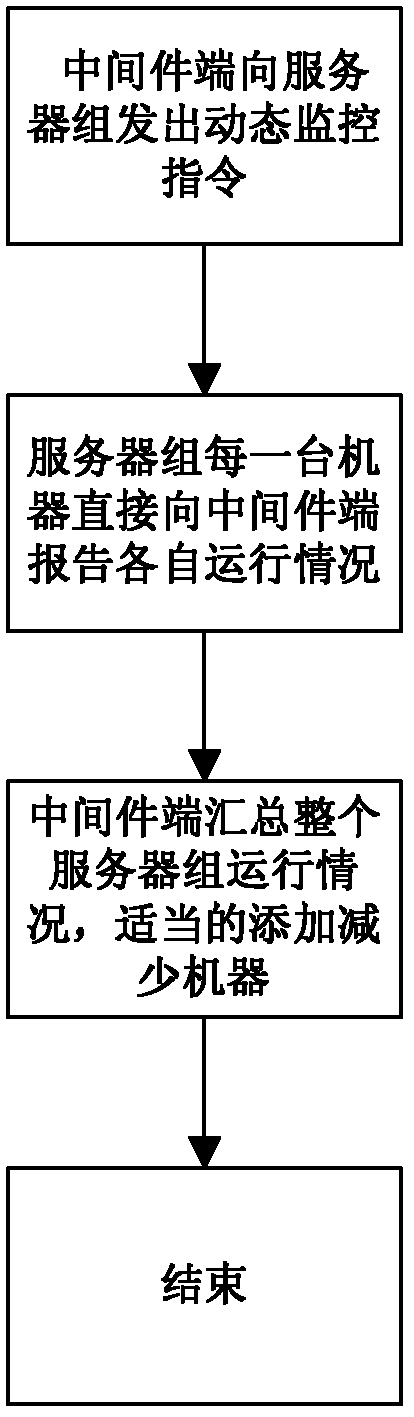

Cloud storage method for cloud computing server

InactiveCN102255974AFix security issuesGuaranteed correctnessTransmissionComputer network technologyClient-side

The invention discloses a cloud storage method for a cloud computing server, belonging to the technical field of computer networks. The method comprises the following steps: (1) a cloud computing server group server and a client registers on a middleware server respectively; (2) the middleware server searches a local database and looks up an operable file and a usable cloud computing server group for a current user; (3) the user selects an upload file, fragments the file and transmits the file fragments to the middleware server; (4) the middleware server verifies the upload file, requires the user to retransmit if the upload file is wrong, and transmits data to the cloud computing server group usable for the user if the upload file is correct; (5) the cloud computer server group rearranges and stores the received data and sends a success message to the middleware server; and (6) the middleware server establishes mapping between the name of the upload file and the user. According to the invention, the correctness and integrity of a data transmitting process and the privacy of data are ensured, and high reliability of normal work of the server group is ensured.

Owner:无锡中科方德软件有限公司

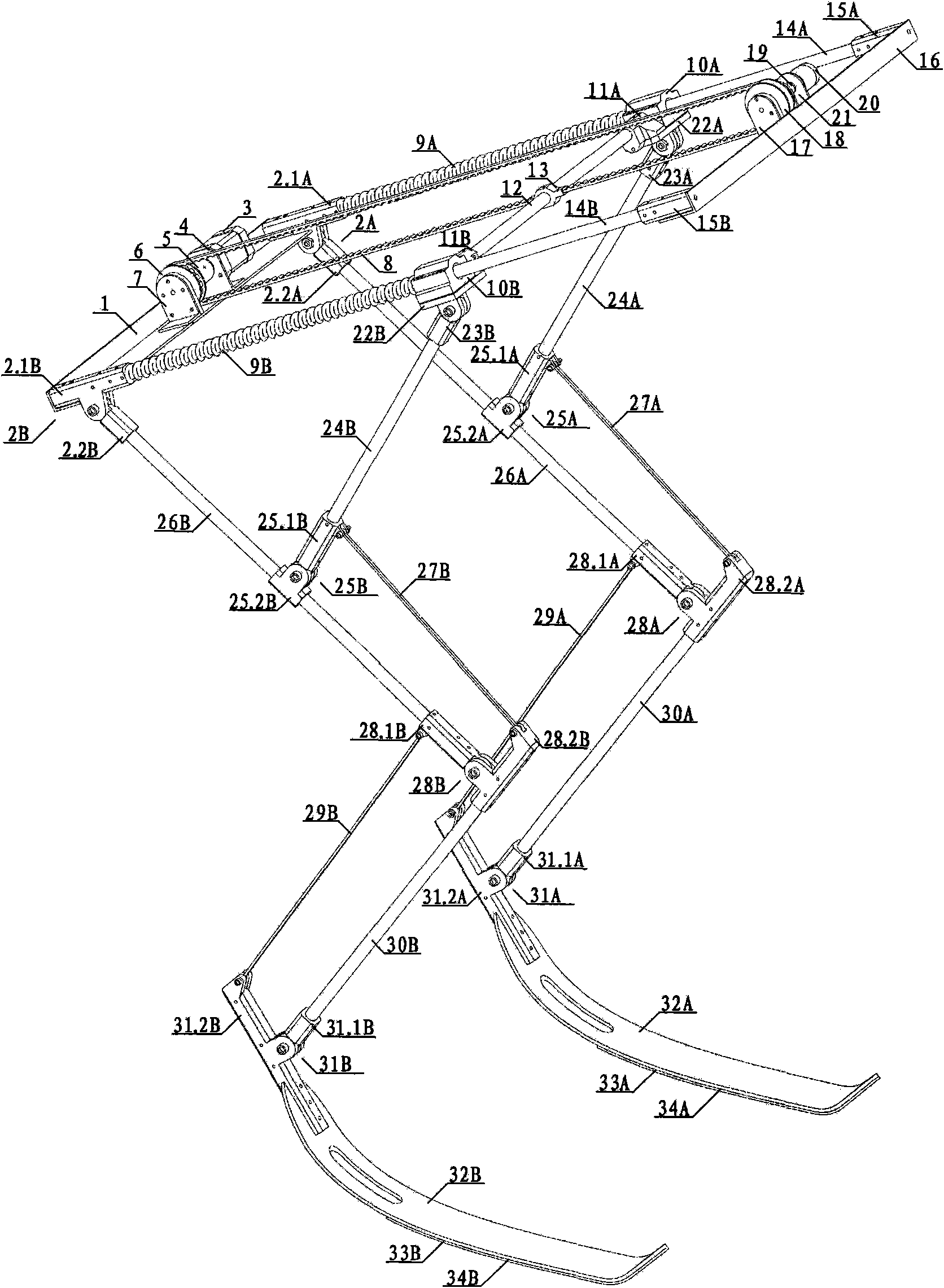

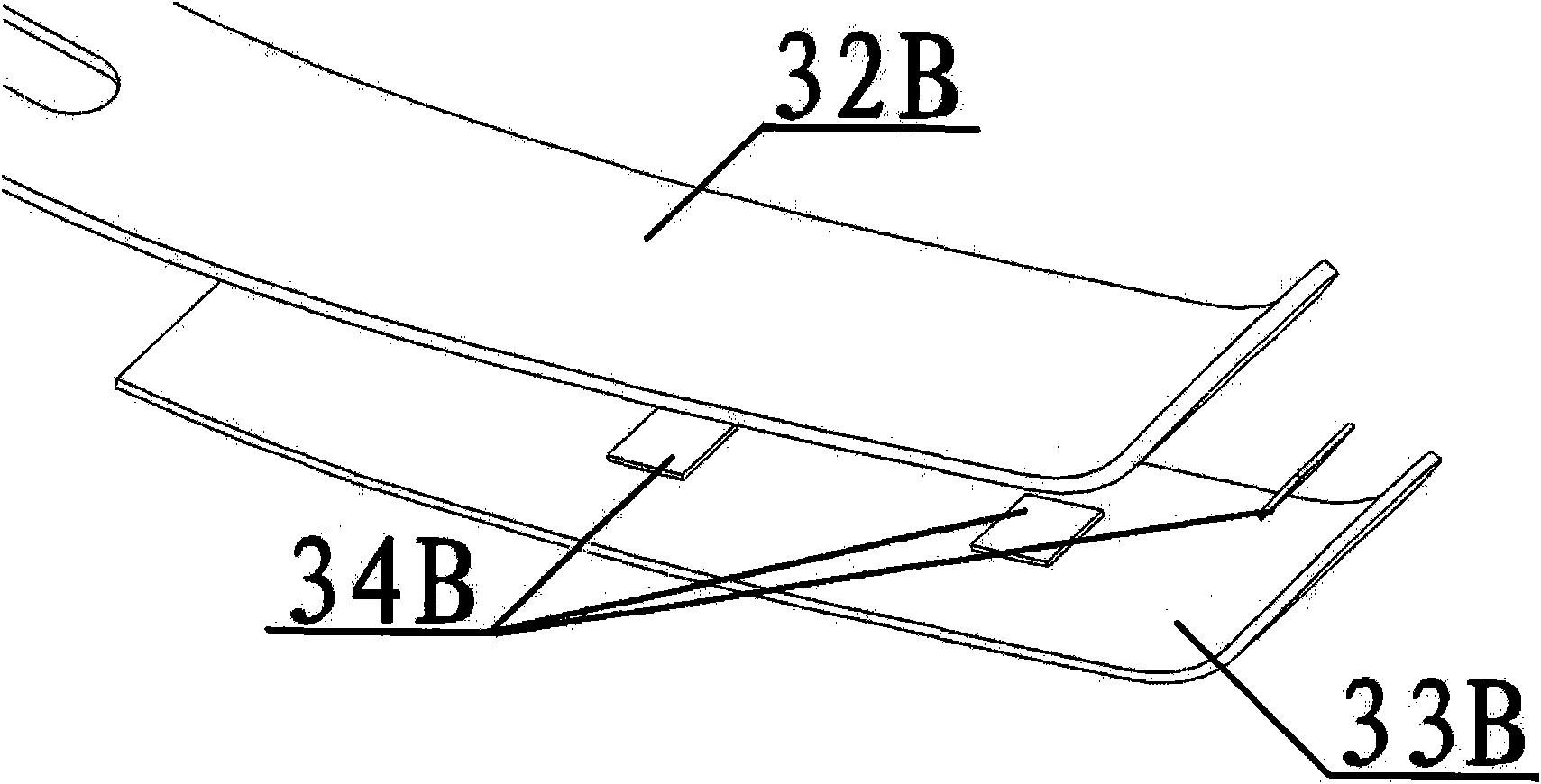

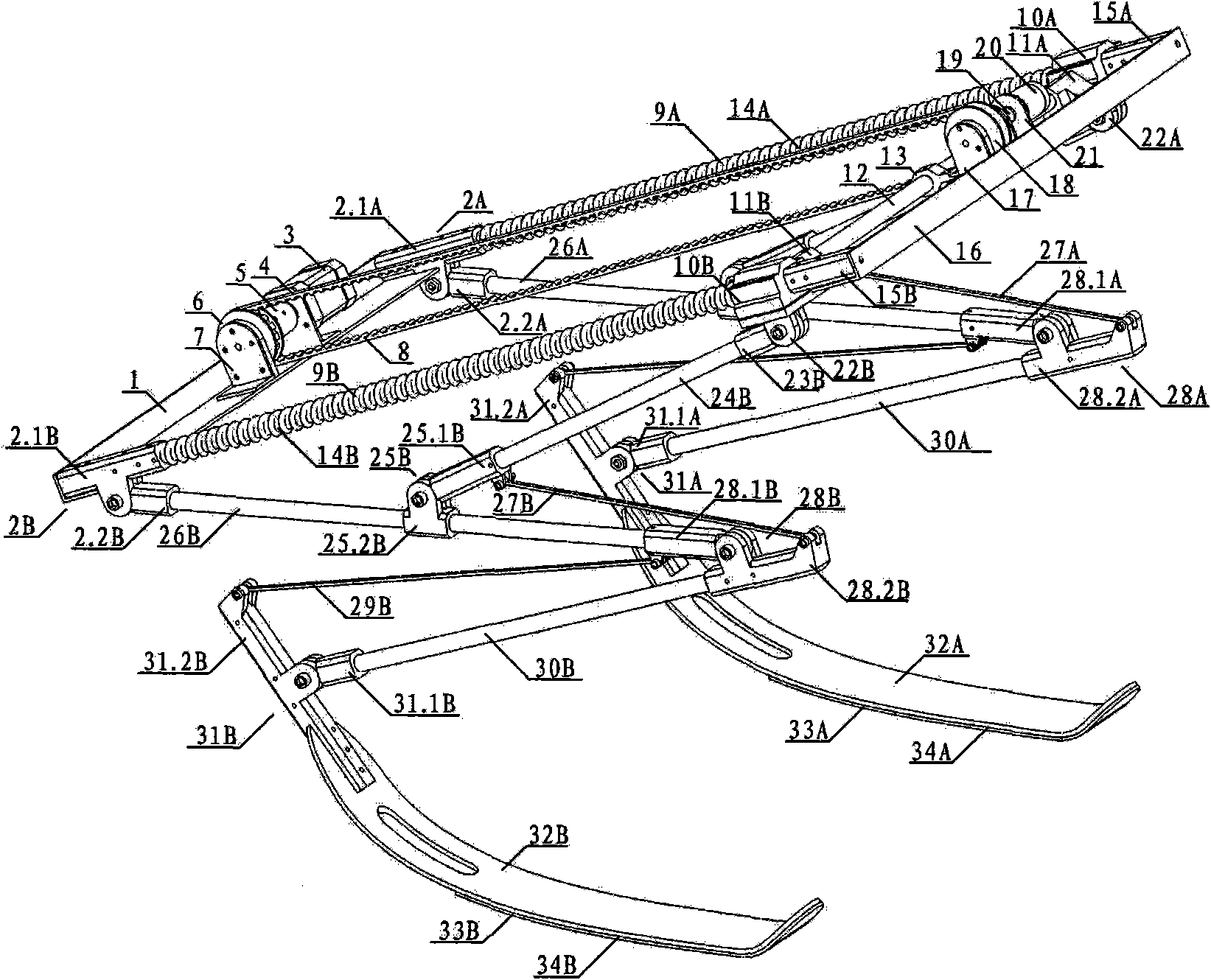

Frog jump robot

The invention discloses a frog jump robot. A motor is used as a power element; devices such as an overrunning clutch, a gear toothed belt and the like are used as transmission mechanisms; a slide block can move on a guide rail under the drive of the motor through the transmission devices; and double legs of the robot stretch or retract under the drive of the slide block so as to finish jump motion. After the robot jumps, the double legs immediately retract to perform air posture adjustment, and the double legs are fully retracted by using self gravity potential and kinetic energy at the monument of landing to perform posture adjustment again. The energy utilization rate of the power element is improved, reclamation and reutilization of energy during jumping are realized, the flexibility of the robot is increased, and the jumping capability of the robot is promoted.

Owner:BEIJING UNIV OF TECH

High density aquatic plant ditch sewage treatment system

InactiveCN1533990ASimple processAchieve reuseSustainable biological treatmentBiological water/sewage treatmentNatural ecosystemHazardous substance

A system and method for treating sewage features that a high-density hydrophyte ditch is used to simulate a natural ecological system, which can absorb the nutrients from sewage, adsorb heavy metals and toxic and hamful substance, and remove nitrogen from sewage. Its advantages are high effect and low cost.

Owner:邱江平

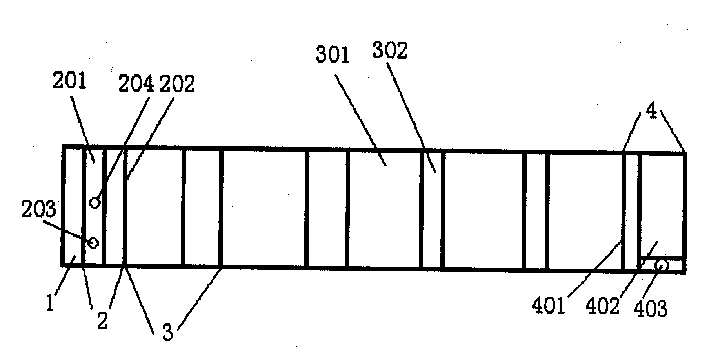

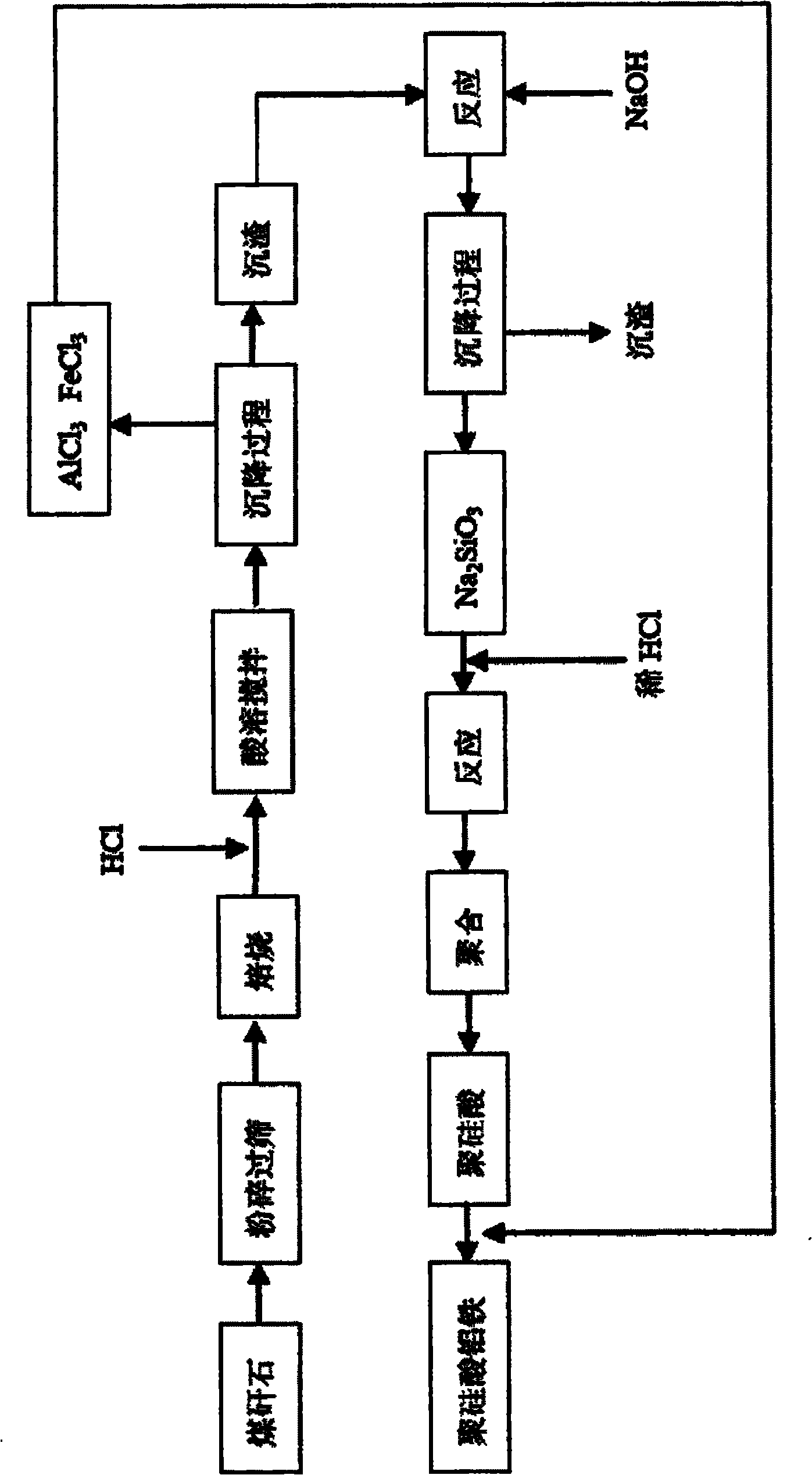

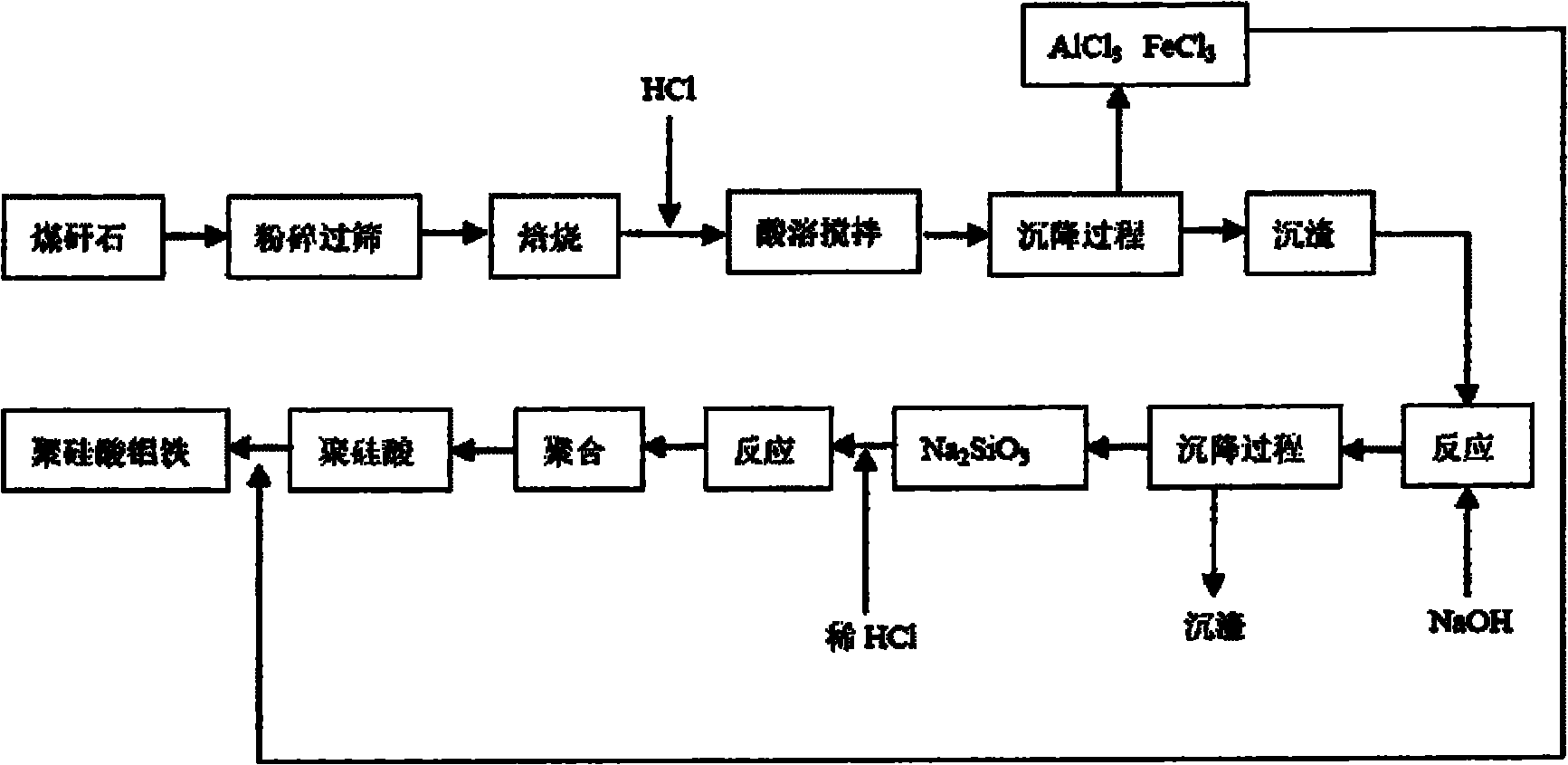

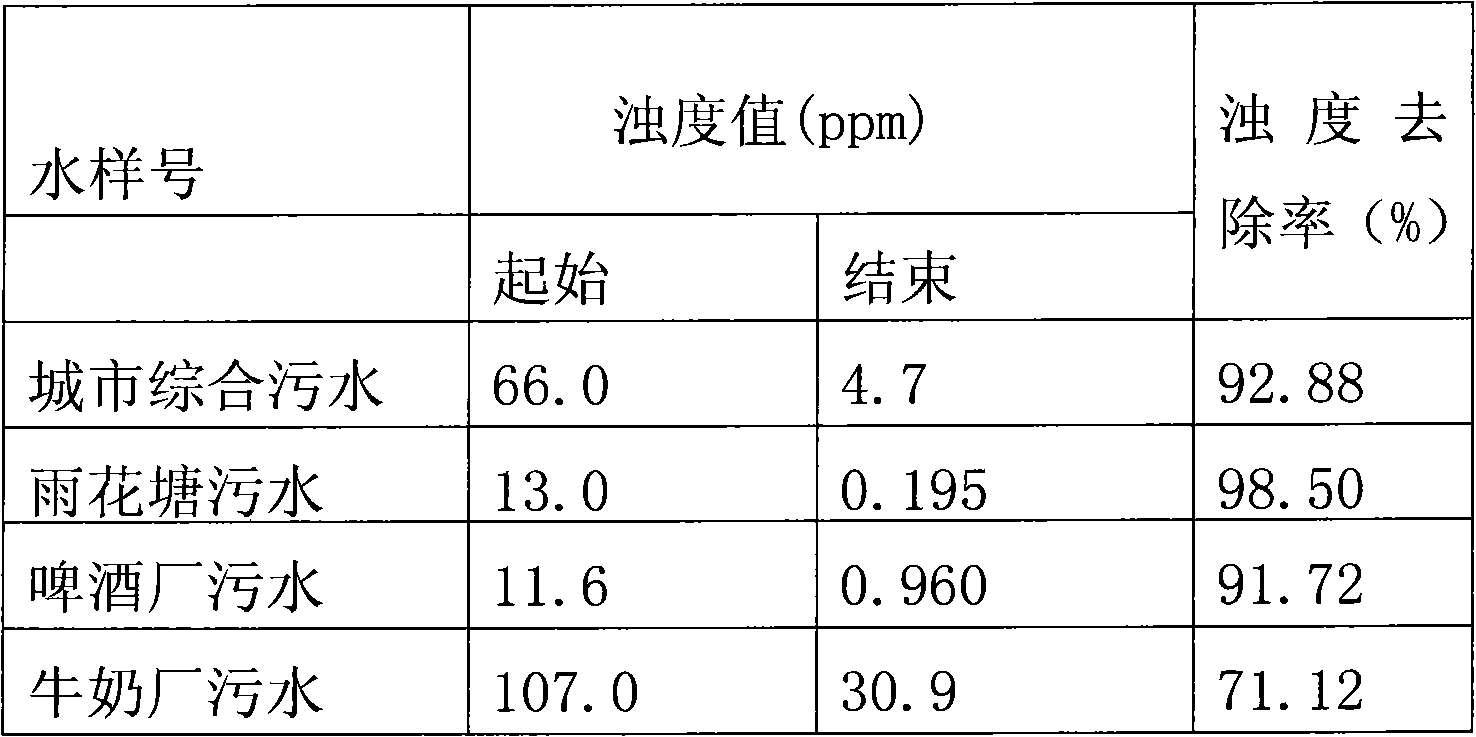

Method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue

InactiveCN101823721ASolve the problem of stockpiling and polluting the environmentScientific and streamlined processAluminium silicatesSolid waste disposalSilicic acidMass ratio

The invention relates to the inorganic macromolecule flocculating agent technical field, in particular to a method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue. The method includes the following steps: firstly coal gangue is smashed, roasted and mixed with hydrochloric acid by solid-liquid volume ratio of 1:4-6, reaction is carried out, then the obtained reaction liquid is filtered, the obtained residue is for spare use, and the pH value of the obtained filtrate is regulated to be 3-3.5, thus obtaining the poly aluminium ferric solution; then the obtained residue and sodium hydroxide are mixed for reaction by mass ratio of 2-4:1, and the filtrate obtained by filtration of reaction liquid is sodium silicate solution namely; the prepared sodium silicate solution is added with acid for carrying out activation treatment; then the prepared poly aluminium ferric solution and the activated sodium silicate solution are mixed for reaction by mass ratio of 1:1, thus obtaining the poly silicate aluminium ferric flocculating agent. The invention adopts coal gangue as raw material, cost is low, and meanwhile the poly silicate aluminium ferric flocculating agent prepared by the invention has better stability and flocculation effect.

Owner:HEFEI UNIV

Resource recycling method of waste ammonium alkali liquid for well injection and brine extraction of sodium sulfate type salt mine

ActiveCN101629484AAchieve reuseImprove protectionFluid removalAlkali metal chloridesChemical industrySulfate

The invention discloses a resource recycling method of waste ammonium alkali liquid for well injection and brine extraction of a sodium sulfate type salt mine, which comprises the following steps: injecting waste ammonium alkali liquid under the salt mine instead of fresh water directly or after being added with fresh water, dissolving rock salt to from mine brine, and extracting the mine brine after natural sedimentation. In the invention, the waste ammonium alkali liquid is used for the sodium sulfate type salt mine, the waste ammonium alkali liquid is injected under the salt mine for brine extraction directly or after being added with water to obtain high-quality brine with low sodium sulfate content, thereby not only the sodium sulfate content in the brine is reduced, but also NaCl in the waste ammonium alkali liquid is recycled, the resource recycling of the waste ammonium alkali is achieved, and the emission of wastes is reduced. The prepared brine can be used in vacuum salt manufacturing, brine alkali manufacturing, mine brine air-cured salt manufacturing and other chemical industries.

Owner:江苏省制盐工业研究所有限公司 +1

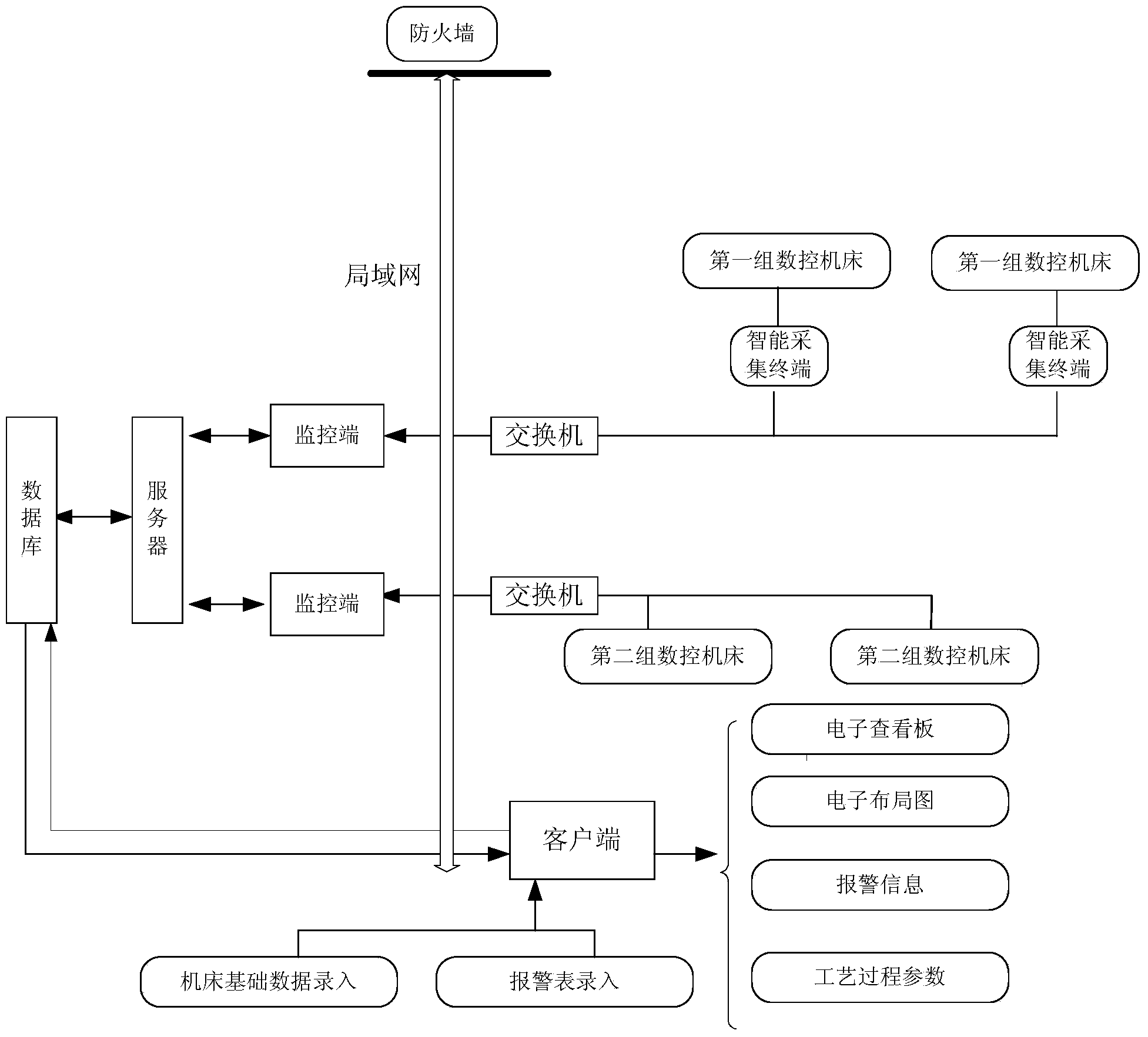

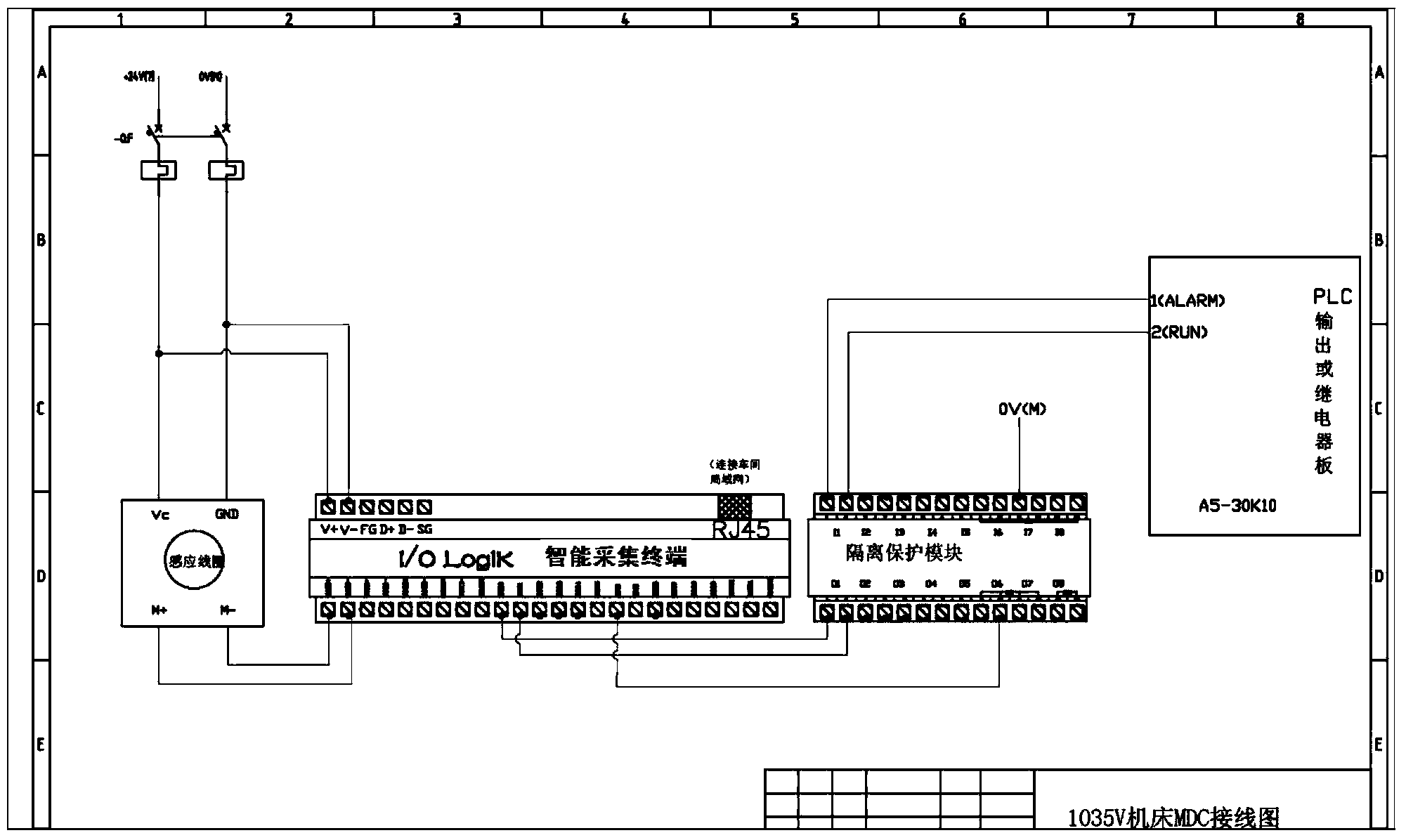

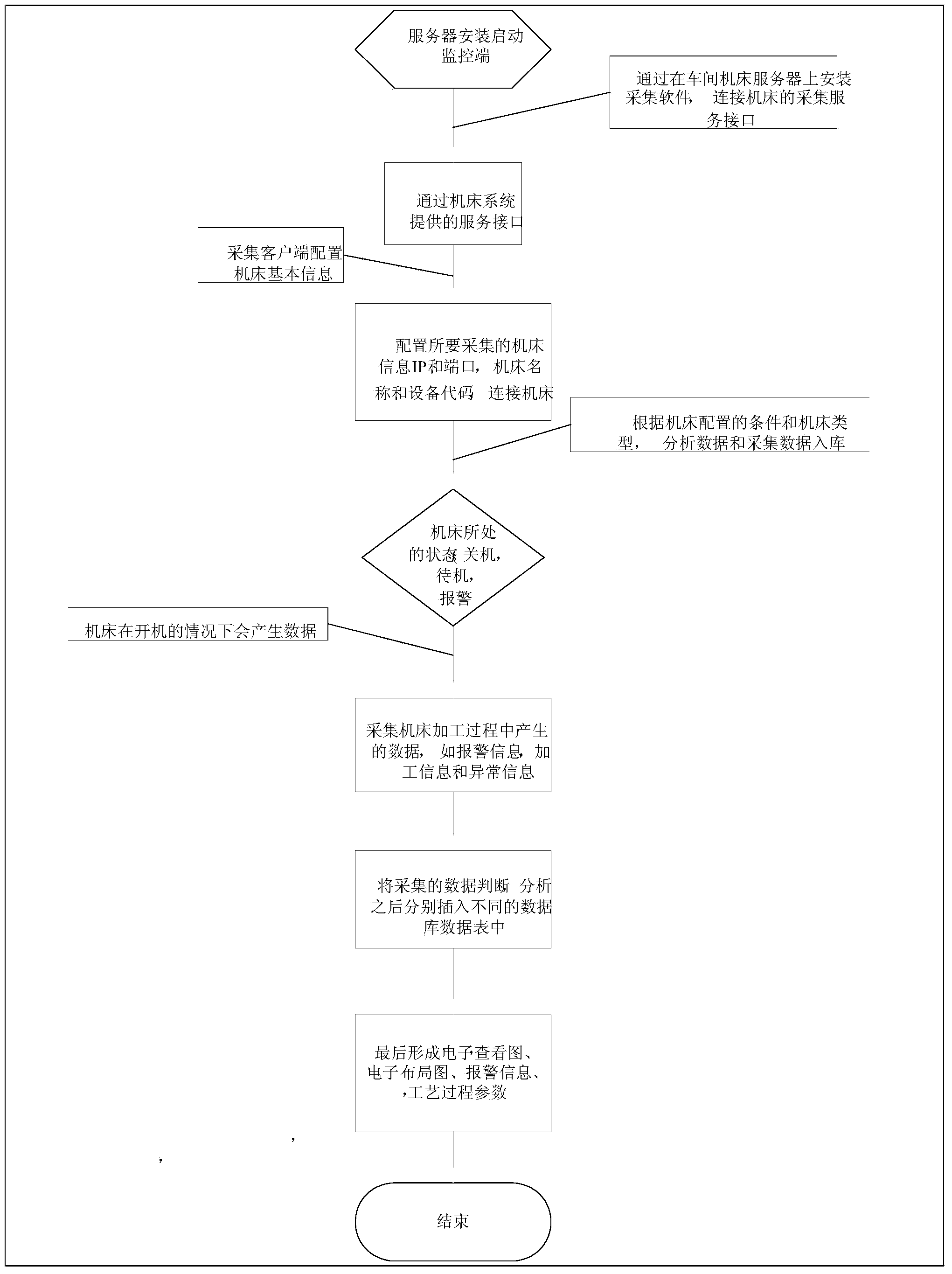

Networked real-time monitoring-oriented numerically-controlled machine tool machining process parameter acquiring method

ActiveCN104298173AAutomate the processImplement automatic deliveryProgramme controlComputer controlNumerical controlCommunication interface

The invention relates to a networked real-time monitoring-oriented numerically-controlled machine tool machining process parameter acquiring method. According to the method, networked real-time monitoring of the machining states of multiple numerically-controlled machine tools with different control system types and different communication interface modes is achieved based on one server, real-time acquisition and recording of technological process parameters of FANUC, SIEMENS, HEIDENHAIN system machine tools can be achieved based on program names of NC programs and rules with a specific postprocessing format, and automatic transmission, storage and reusing of technological process parameters are achieved. The method is characterized in real-time performance, visibility, integrity, accuracy and the like. Real-time monitoring of the states of the numerically-controlled machine tools, full display of alarm number-based automatch alarm information and automatic transmission, storage and reusing of technological process parameters are achieved based on the spacecraft product numerically-controlled processing flow and the normalized numerically-controlled program format, and integrated application of a digital workshop information system is achieved on the basis.

Owner:BEIJING SATELLITE MFG FACTORY

Electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater

InactiveCN101921032AEfficient use ofLess investmentWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectricityElectrolysis

The invention discloses an electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater, comprising a liquid inlet pipe, an adjusting tank, an electrolytic deposition device, a three-dimensional fixed bed device, a safety filter, three circulating pumps, a membrane assembly, a clear water outlet and a condensed liquid reflex hole, wherein the connection of various components is detailed in the description. The invention has the advantages that: by combining the electrolytic deposition technology with the membrane separation technology, the device has the advantages of less investment, high handle capacity, low energy consumption, high benefit, easy industrialization and easy implementation of the comprehensive utilization of resources; the effluent discharge after reaching standards and the recycling are realized, the heavy metal resources in the wastewater are effectively recycled; and automation degree is high and manual operation is simple and convenient, the complete recovery and zero discharge of heavy metals can be basically realized and water resources are completely recycled and the wastewater is deeply purified.

Owner:PEKING UNIV

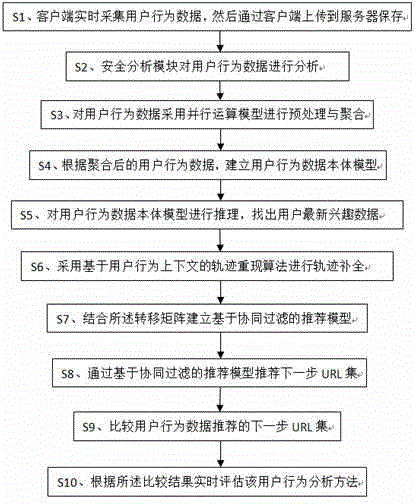

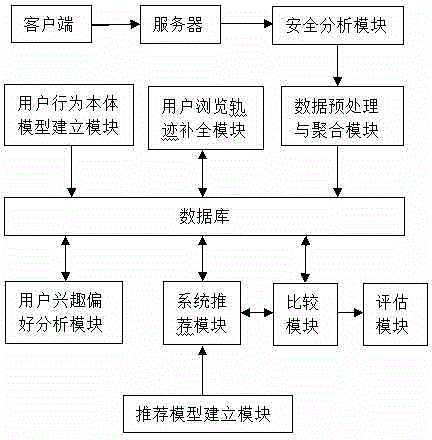

User behavior analysis method and system based on big data

InactiveCN104462213AGain interest in timeEffective and accurate pushWebsite content managementSpecial data processing applicationsEngineeringContext data

The invention discloses a user behavior analysis method and system based on big data. According to the method, user behavior data are collected through a client side in real time, user behaviors and contextual information of a page URL are combined, the real scene that a user browses Web pages is reproduced to the greatest extent, comprehensive user behavior tracks are extracted, and effective data assurance is provided for analyzing the user behaviors; security assurance is provided for the user behavior data through a safety analysis module, and a user behavior data body model is used for modeling the user behaviors, so that behavior information semantic levels are shared and reused, and the interoperability and the reliability of the model are improved; the user behavior and context data are collected in real time for analysis, so that a result is more reliable; body and behavior information is stored through a column storage database, and therefore the foundation of massive data management is laid; the powerful processing capacity and the large-scale data storage capacity of the cloud computing technology, the body and a reasoning and knowledge discovery method of the body are combined, the massive user behavior data are analyzed in real time to obtain user interest in time, and then effective and accurate user push is achieved.

Owner:成都逸动无限网络科技有限公司

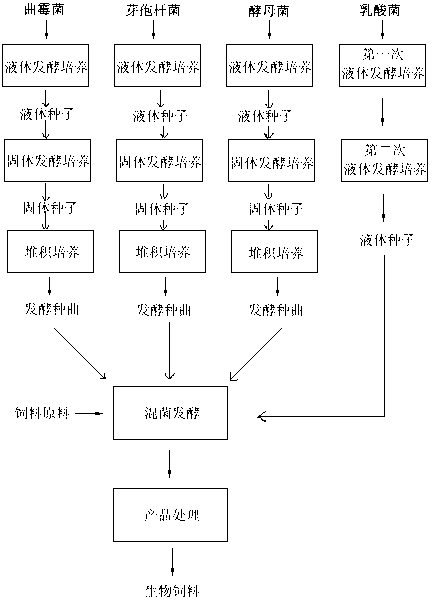

Method for preparing biological feed by taking manioc residues as raw materials

The invention provides a method for preparing a biological feed by taking manioc residues as raw materials. The method comprises the following steps of: preparing fermentation strains and fermentation mother cultures from aspergillus, bacillaceae, lievito and lactobacillus, and performing mixed fermentation by taking the manioc residues as the raw materials to obtain a biological feed crude product; and mixing uniformly, crushing, sieving, drying and packaging to obtain a biological feed finished product. According to the method, the manioc residues are used as the raw materials, so the biological feed is low in cost and wide in source, industrial waste residues are recycled, and the problem of the pollution of the manioc residues is solved. Simultaneously, the strains which are high in cellulose degradation effect and high in yield of mycoprotein are selected, so that cellulose in the manioc residues is degraded fully, the protein content of the feed is improved, a large number of enzymes, beneficial viable bacteria and organic acids are added.

Owner:广西九通王环保生物工程有限公司

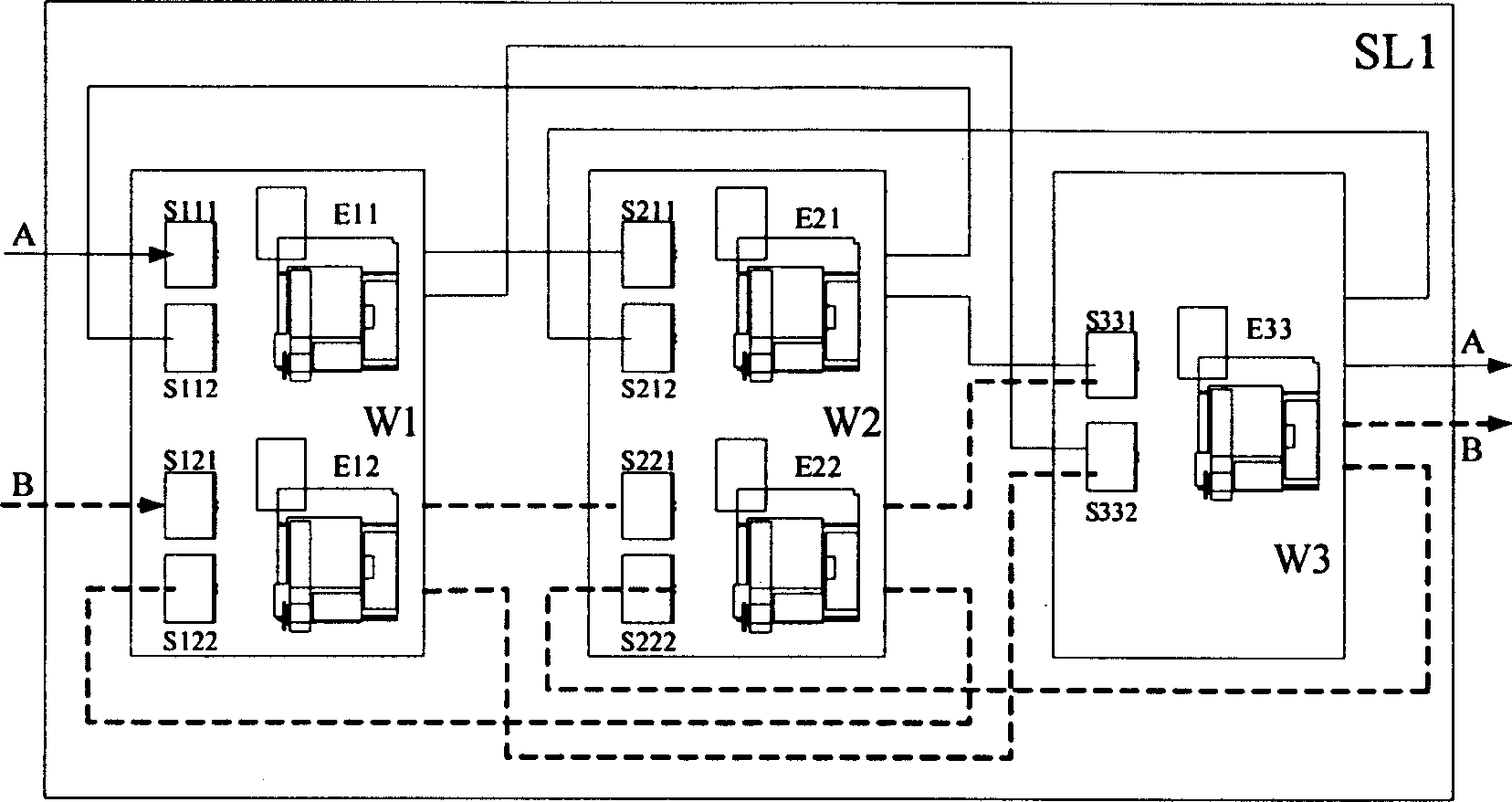

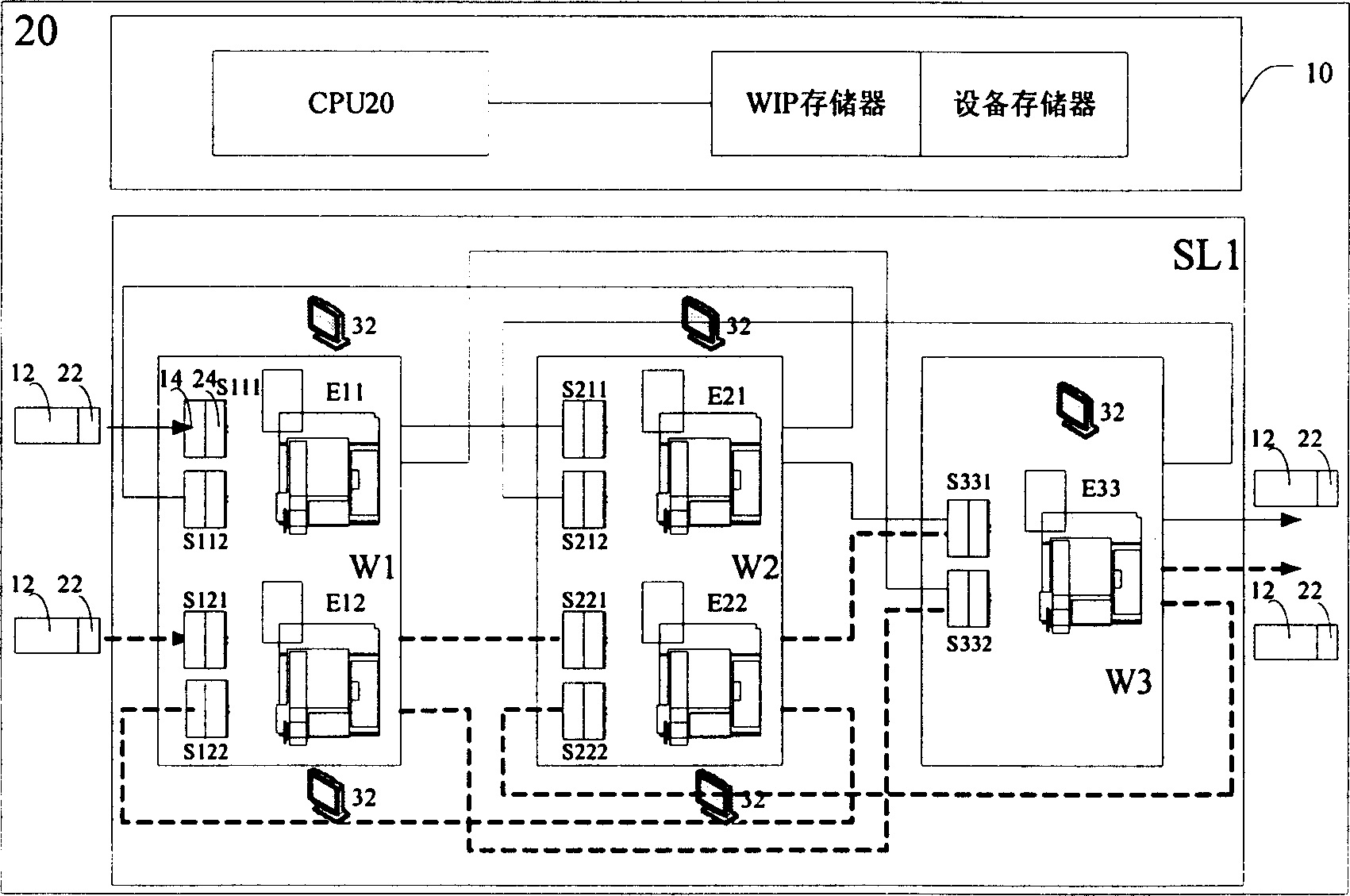

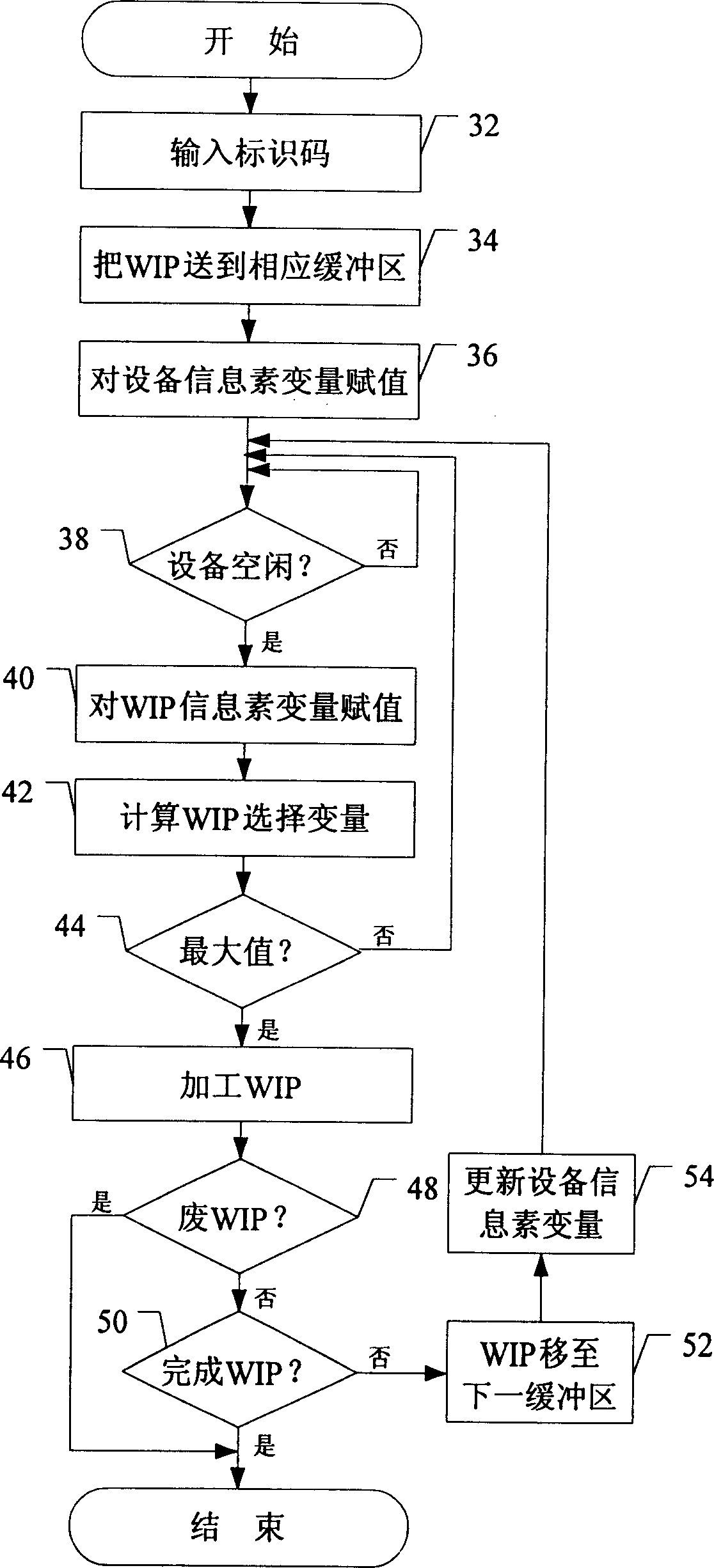

Dynamic scheduling method based on pheromone for semiconductor production line

InactiveCN1734382AScheduling method is stableRobust and stableData processing applicationsTotal factory controlShort termsComputer science

The invention discloses a dynamic dispatching method on the base of pheromone in semi-conductive product line, which comprises the following steps: first, storing pheromone variation of each WIP which relates to the WIP delivery date, holding time of waiting processing equipment, pure processing time and production periodic multiplication factor; second, storing pheromone variation which relates to equipment load; then, integrating the WIP pheromone variation and relating equipment pheromone variation, generating a selective variation of each WIP; finally, elaborating them on the equipment according to the method which consists of short-term and long-term function index to improve multi-function index production or making system.

Owner:TONGJI UNIV

Matrix material and restoration method for ecological restoration of gangue dump of mining area

InactiveCN105993259AEnsure balanceReduce the cost of ecological reconstructionGrowth substratesCulture mediaFiberRestoration method

The invention provides a matrix material and restoration method for ecological restoration of a gangue dump of a mining area. The matrix material consists of two parts, i.e., a seed germination layer and a root inducing layer and is mainly prepared from loam, acidified coal gangue, inorganic nonmetallic minerals, plant fibers, a water retention agent, an agglomerating agent, a disinfectant, a compound fertilizer, a seed mixture and the like. The matrix material has the characteristics of water retention, fertilizer retention, good stability, erosion resistance, easiness in plant establishment and the like; and by using wastes such as the coal gangue as main matrix materials, the consumption of imported soil can be effectively lowered, the soil environment of abandoned mines is improved, the environmental pollution is reduced, and the ecological restoration cost is reduced.

Owner:SHANXI UNIV

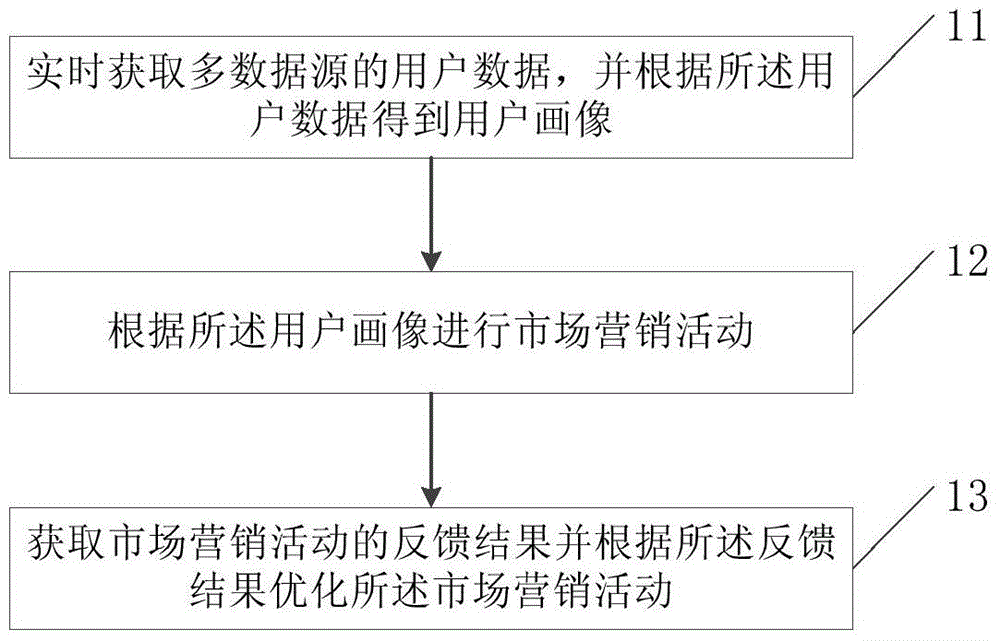

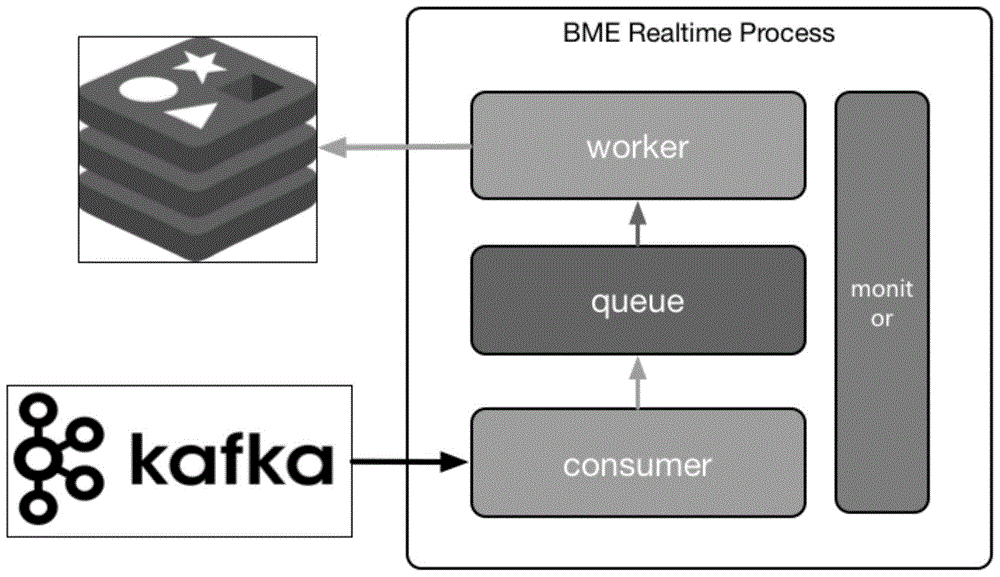

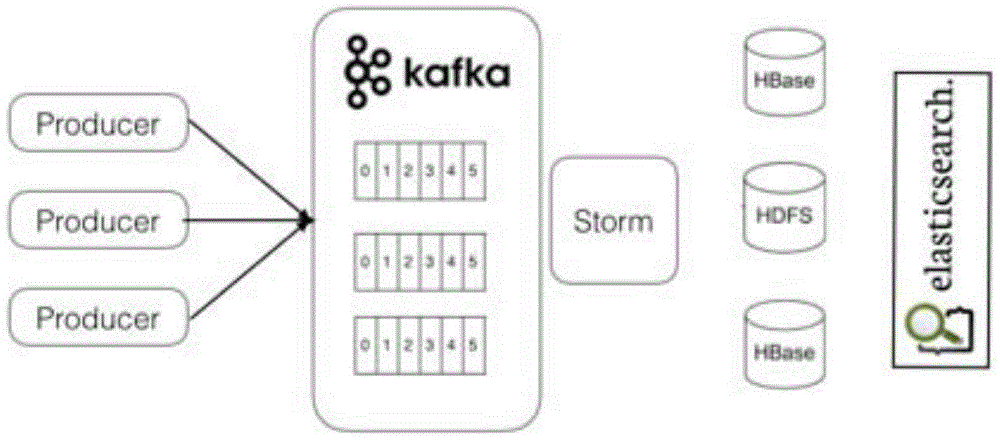

Method and apparatus for applying cross-data-source marketing crowds to marketing

Embodiments of the invention provide a method and an apparatus for applying cross-data-source marketing crowds to marketing. The method comprises the steps of obtaining user data of multiple data sources in real time and obtaining user portraits according to the user data; performing marketing activities according to the user portraits; and obtaining feedback results of the marketing activities and optimizing the marketing activities according to the feedback results. Therefore, an objective data basis is provided for each marketing link, and high-quality data and marketing experience are accumulated.

Owner:北京百分点科技集团股份有限公司

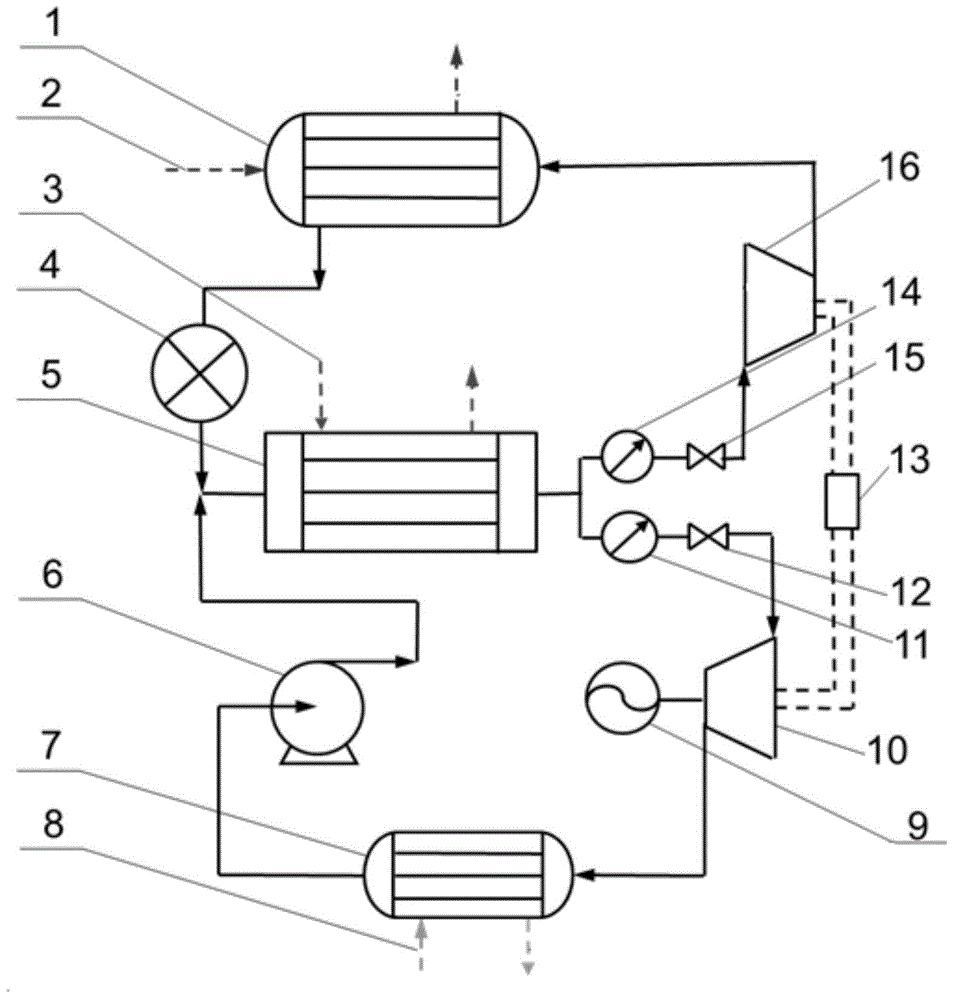

Organic Rankin cycle and heat pump cycle coupling system

InactiveCN104879177AMeet power needsMeet the needs of different heat-to-electricity ratiosClimate change adaptationEnergy industryOrganic Rankine cycleHeat energy

The invention relates to an organic Rankin cycle and heat pump cycle coupling system. The organic Rankin cycle and heat pump cycle coupling system comprises an organic Rankin cycle unit and a heat pump cycle unit, which are coupled. The organic Rankin cycle unit and the heat pump cycle unit share the same evaporator and are coupled by the same. During operation, cycle working medium and recovered low-temperature waste heat exchanges heat in the evaporator and are divided into two parts of gaseous working medium, one part enters an expansion machine to be involved in organic Rankin cycle, and the other part enters a compressor to be involved in heat pump cycle. The power of the expansion machine superiorly drives the compressor coaxially connected with the expansion machine, output of high-temperature heat energy of the heat pump cycle is realized, the rest power drives a generator to generate power and heat and power are supplied at the same time. Compared with the prior art, the organic Rankin cycle and heat pump cycle coupling system is energy saving and environment friendly, low-grade waste heat can be effectively recycled and utilized at high temperature, consumption of electric energy or fossil energy is reduced, heat and power can be supplied together, and greenhouse effect and air pollution are reduced.

Owner:TONGJI UNIV

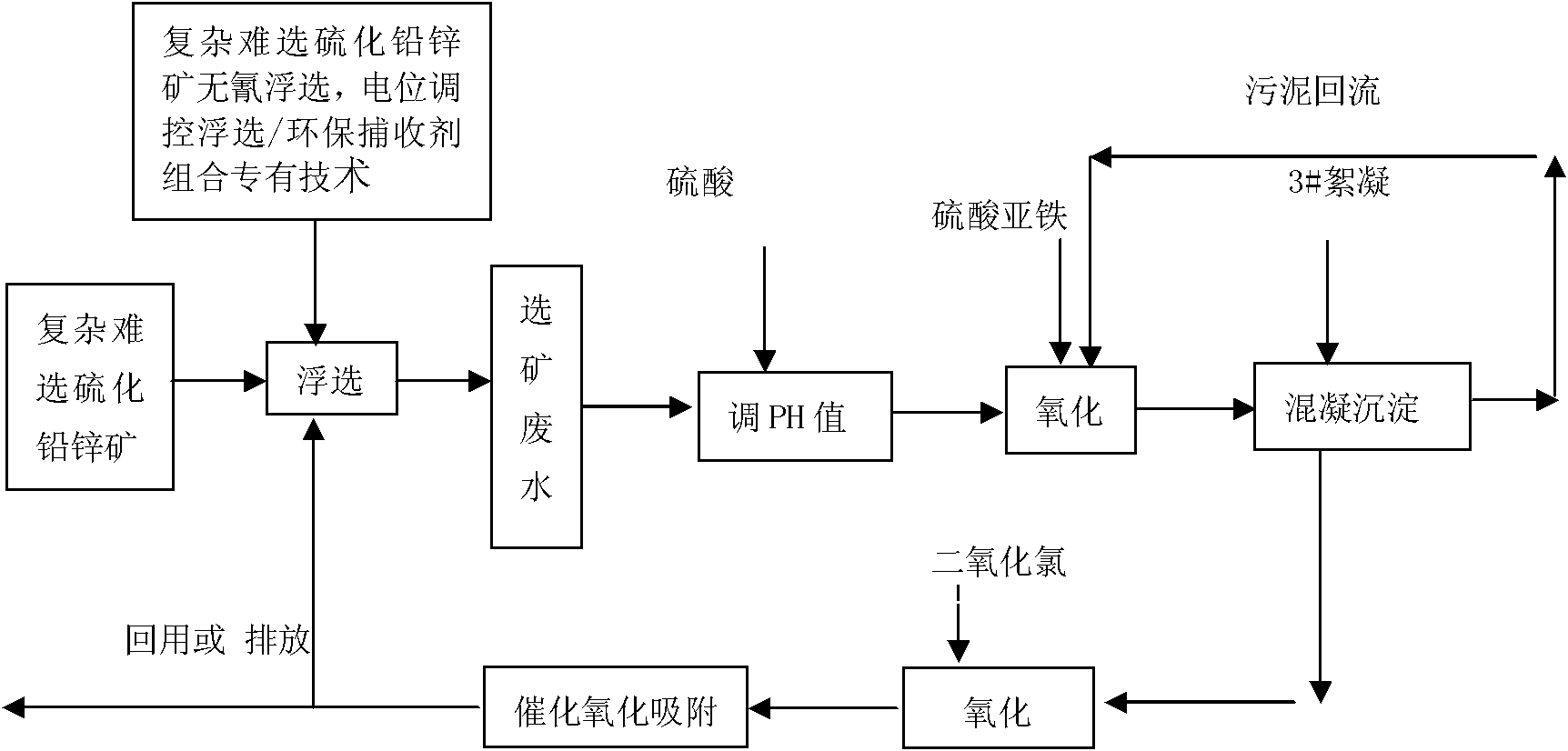

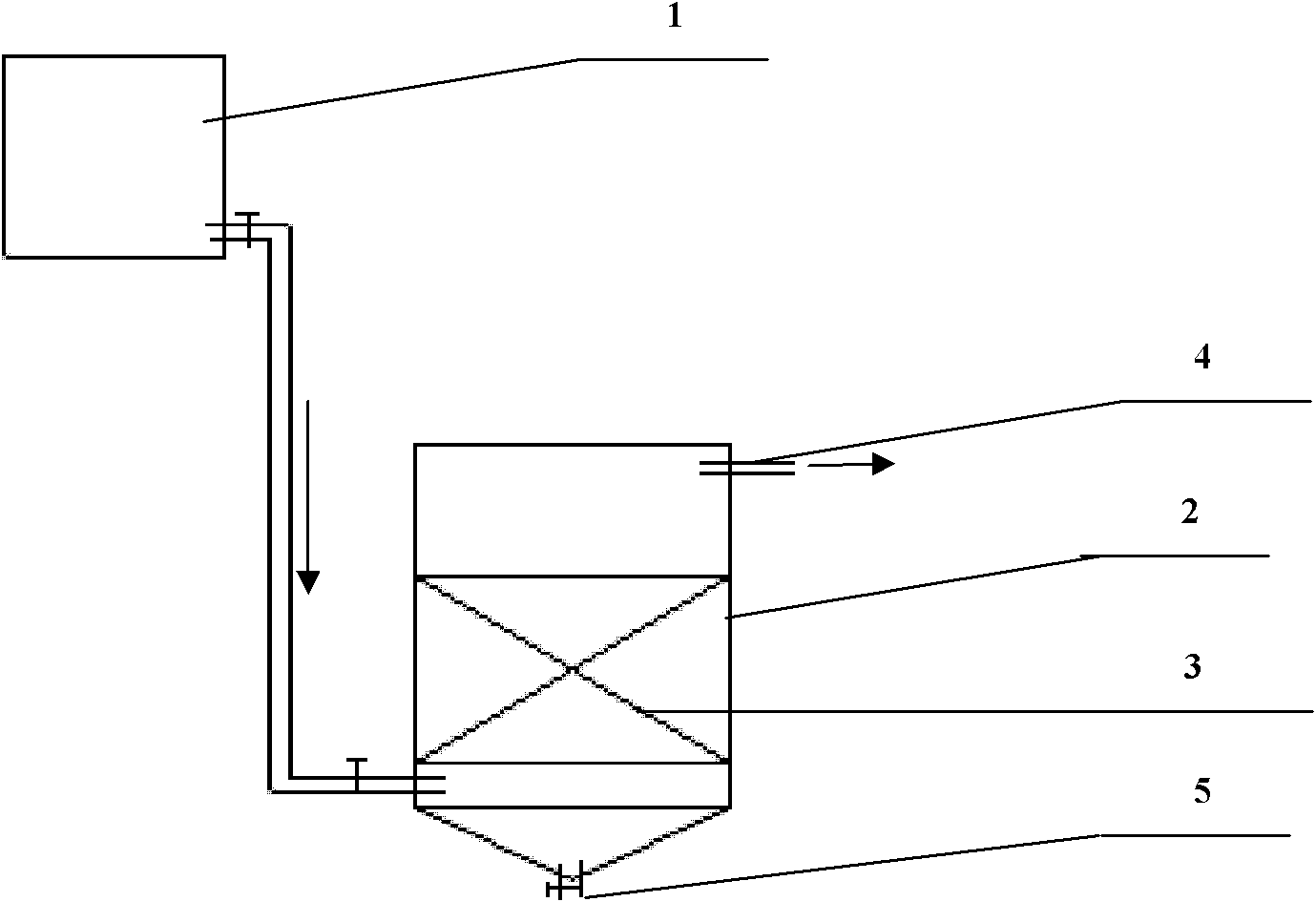

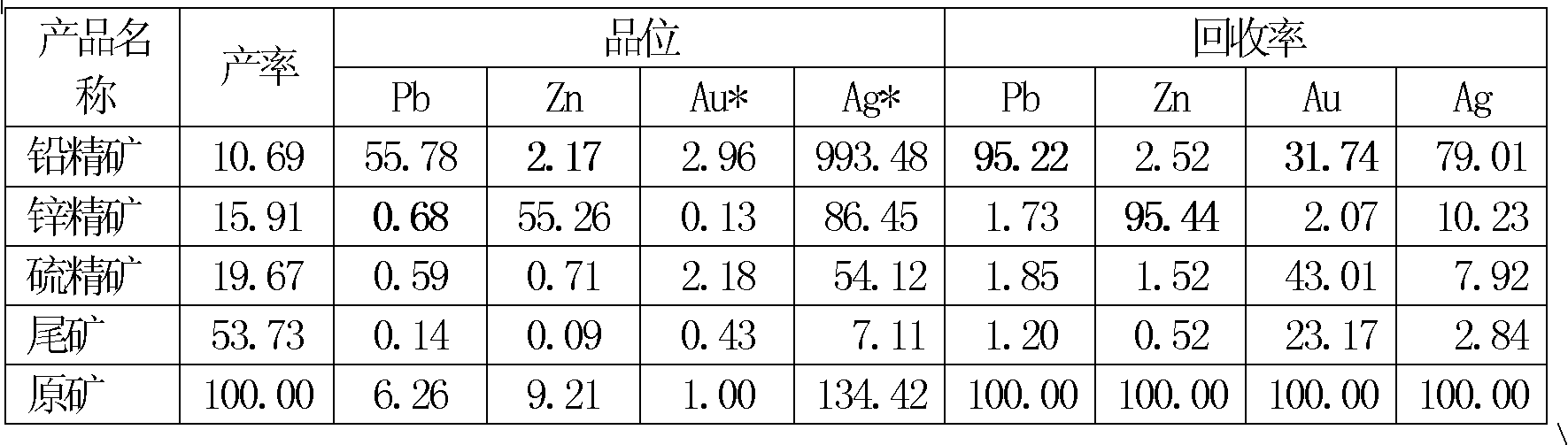

Method for treating and recycling lead-zinc sulfide ore dressing wastewater

ActiveCN101913720AEliminate the effects ofExtended service lifeWaste water treatment from quariesMultistage water/sewage treatmentActive carbonNovel technique

The invention provides a technique for treating and recycling lead-zinc ore dressing wastewater and aims to solve the problems of influence on the ore dressing index due to the recycling of the ore dressing wastewater for production and environmental pollution caused by drainage. The novel technique for treating and recycling the lead-zinc sulfide ore dressing wastewater comprises the steps of: adjusting the pH value of the total wastewater of an ore dressing plant; adding ferrous sulfate and flocculant into the wastewater to perform oxidation-coagulation treatment; and oxidizing the treated water by using chlorine dioxide, and performing catalytic oxidation and adsorption by using an active carbon bed, so that the treated water reaches the relevant discharge standard of China; and totally recycling the treated water by adopting the combined application of potential-controlled flotation and an environmental-protection collector. Compared with the field process technique, the method saves the cyanide flotation process and improves the recovery rates of lead, zinc and gold. The method provides whole technical integration of the combined application technique of the potential-controlled flotation and the environmental-protection collector and the wastewater treatment technique for the treatment and recycling of the lead-zinc ore dressing wastewater, and realizes recycling of the ore dressing wastewater.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

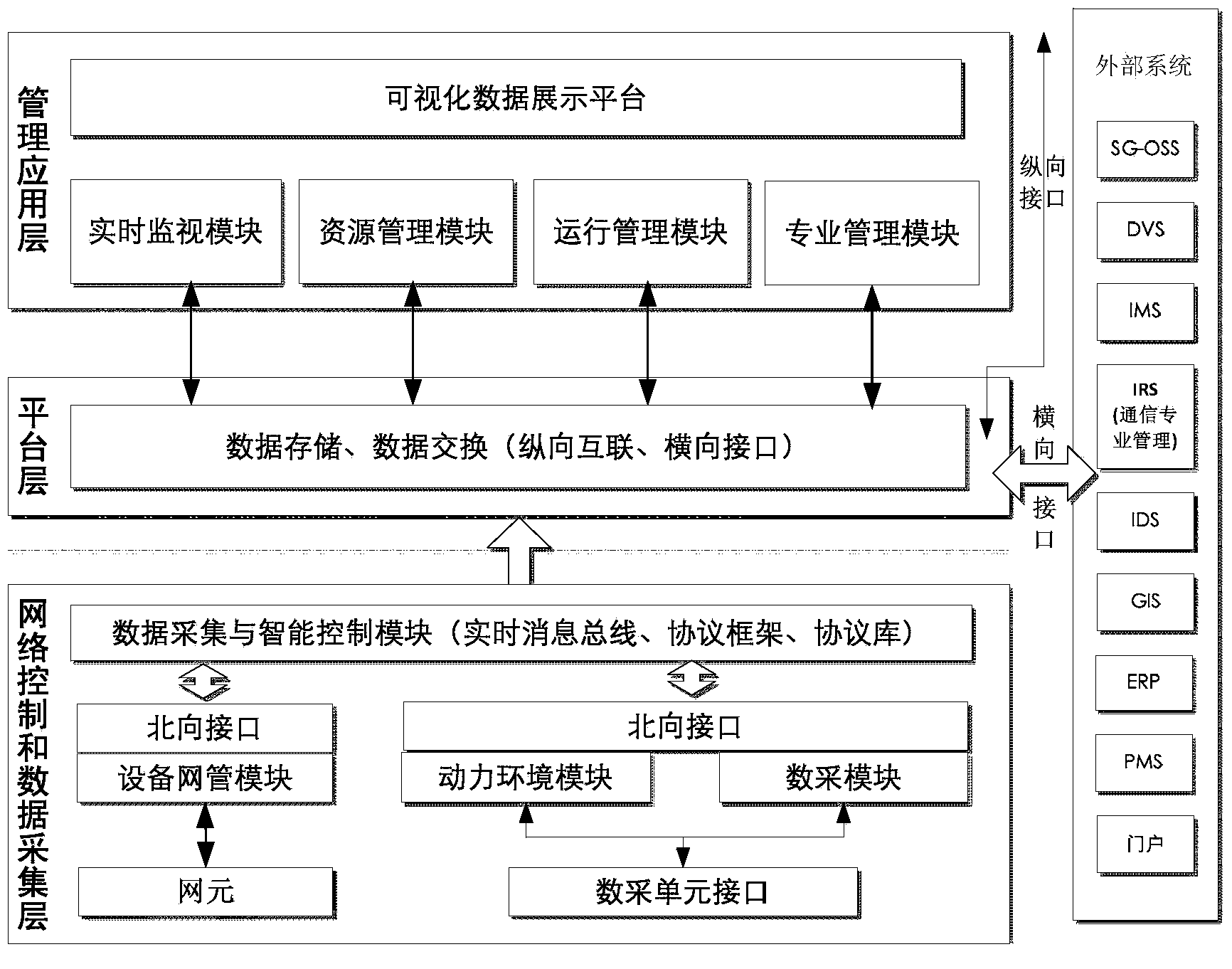

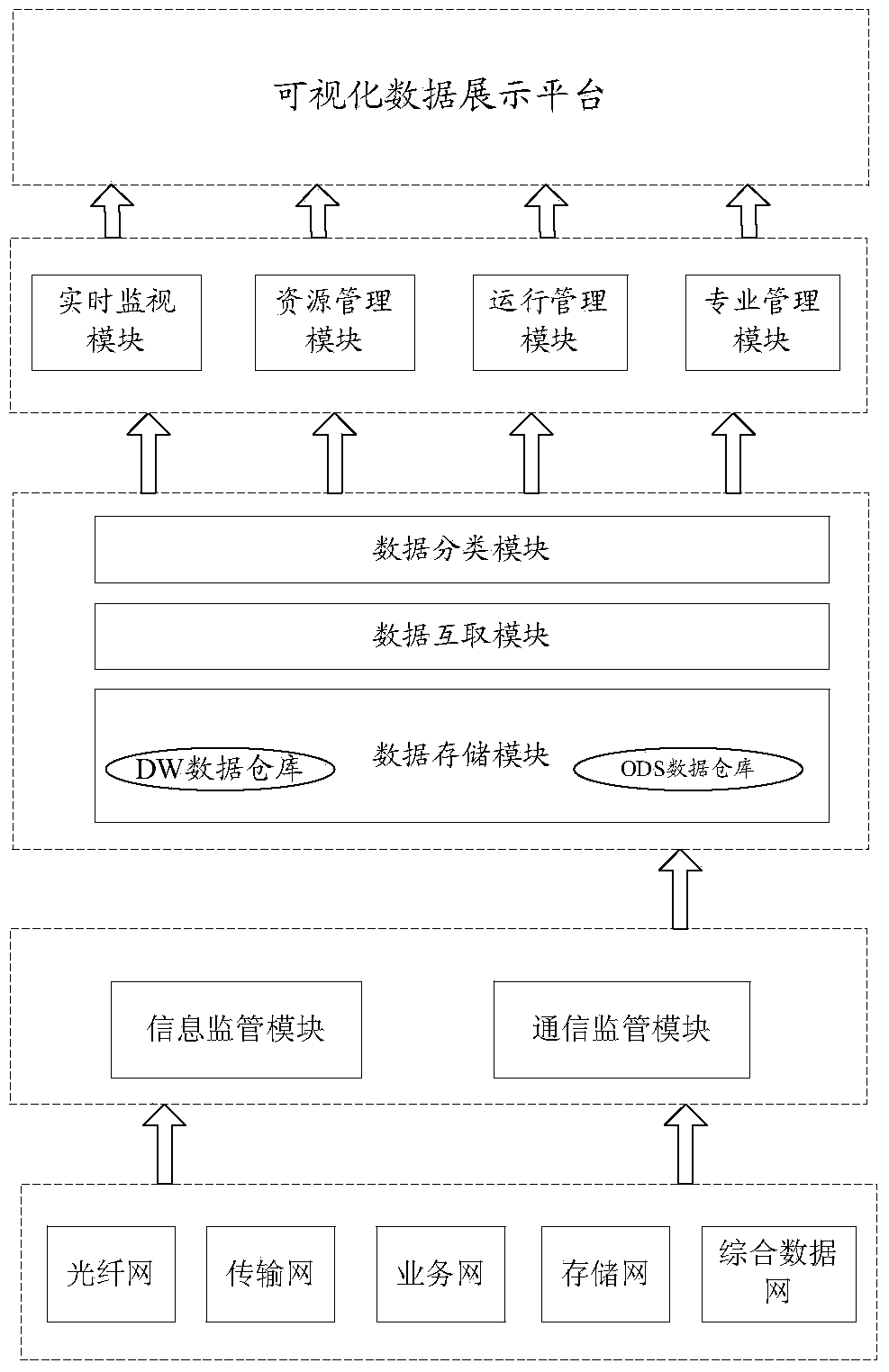

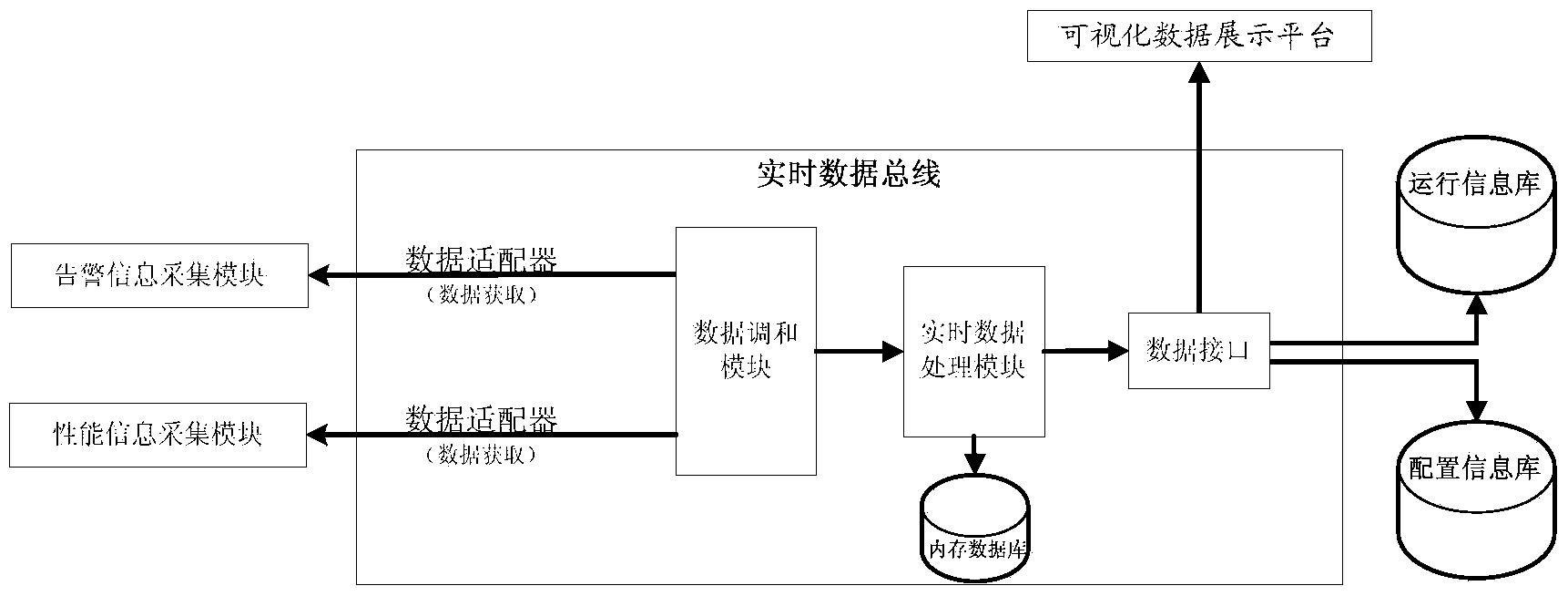

Information-communication integrated supporting platform of intelligent power grid

InactiveCN103532744AIntegrity guaranteedNo repetitionData switching networksTime informationData display

The invention relates to an information-communication integrated supporting platform of an intelligent power grid. The information-communication integrated supporting platform comprises a network control and data acquisition layer, a platform layer and a management application layer which are arranged from the lower layer to the upper layer in sequence. All lower layers provide information services to the corresponding upper layers, receive instructions of the upper layers and carry out corresponding actions, and all the upper layers and all the lower layers are connected by real-time data buses in a communication manner; the network control and data acquisition layer acquires data and transfers the data to the platform layer; the platform layer provides a universal management tool, calls the data by adopting a classified manner in use and transfers the data to corresponding modules of the management application layer; the management application layer is connected with the platform layer by a data bus, analyzes and processes the data called from a data storage module, and carries out visualized display by a visualized data display platform. The information-communication integrated supporting platform comprises two main special information and service fusions in information communication, forms a unified system structure, and has the advantages that the repeated utilization of a multifunctional module is realized by one-time information acquisition, and resource waste caused by multi-time data acquisition is avoided.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com