Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1855 results about "Toothed belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

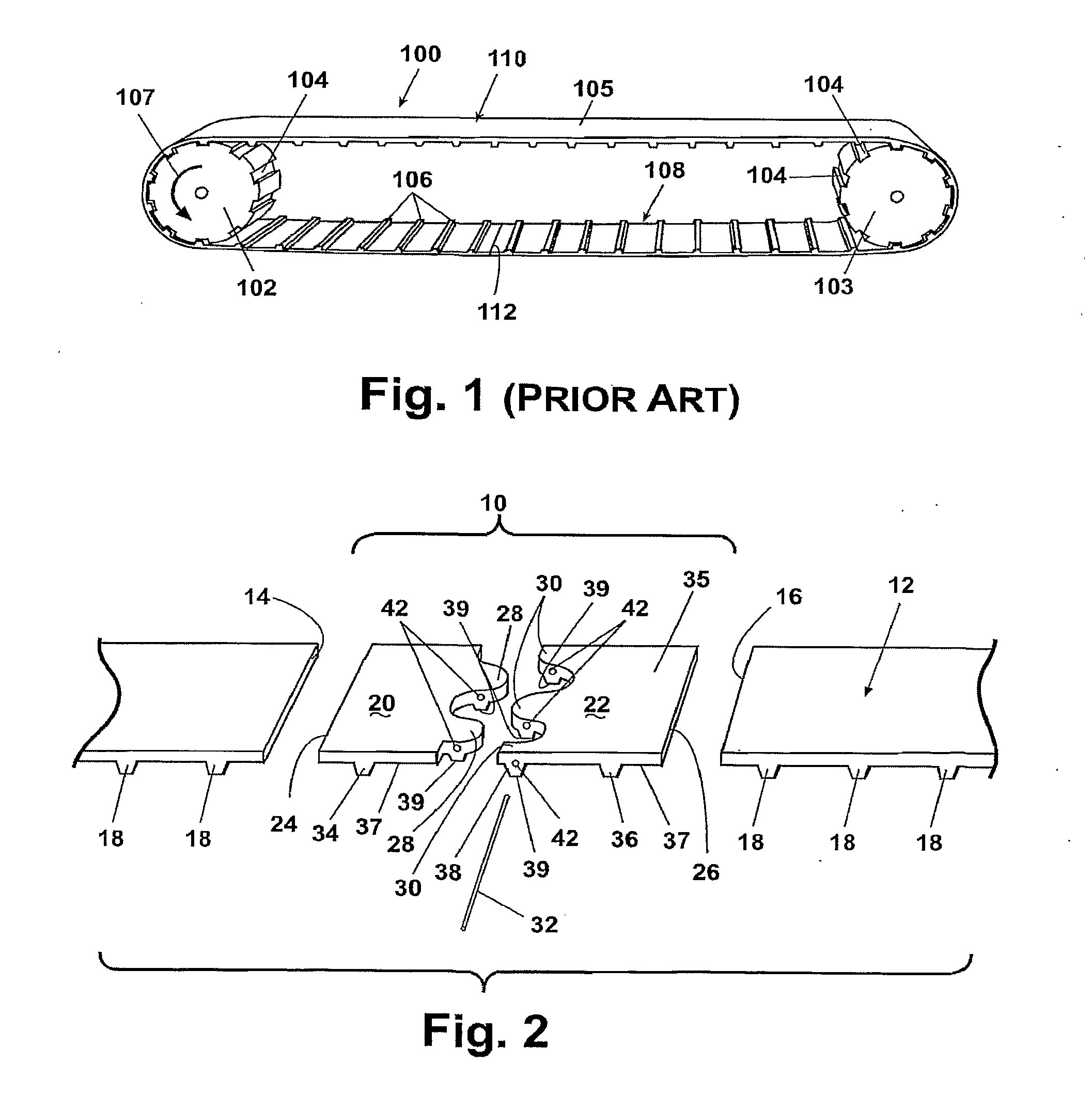

Inventor

A toothed belt; timing belt; cogged belt; cog belt; or synchronous belt is a flexible belt with teeth moulded onto its inner surface. It is designed to run over matching toothed pulleys or sprockets. Toothed belts are used in a wide array of in mechanical devices, where high-power transmission is desired.

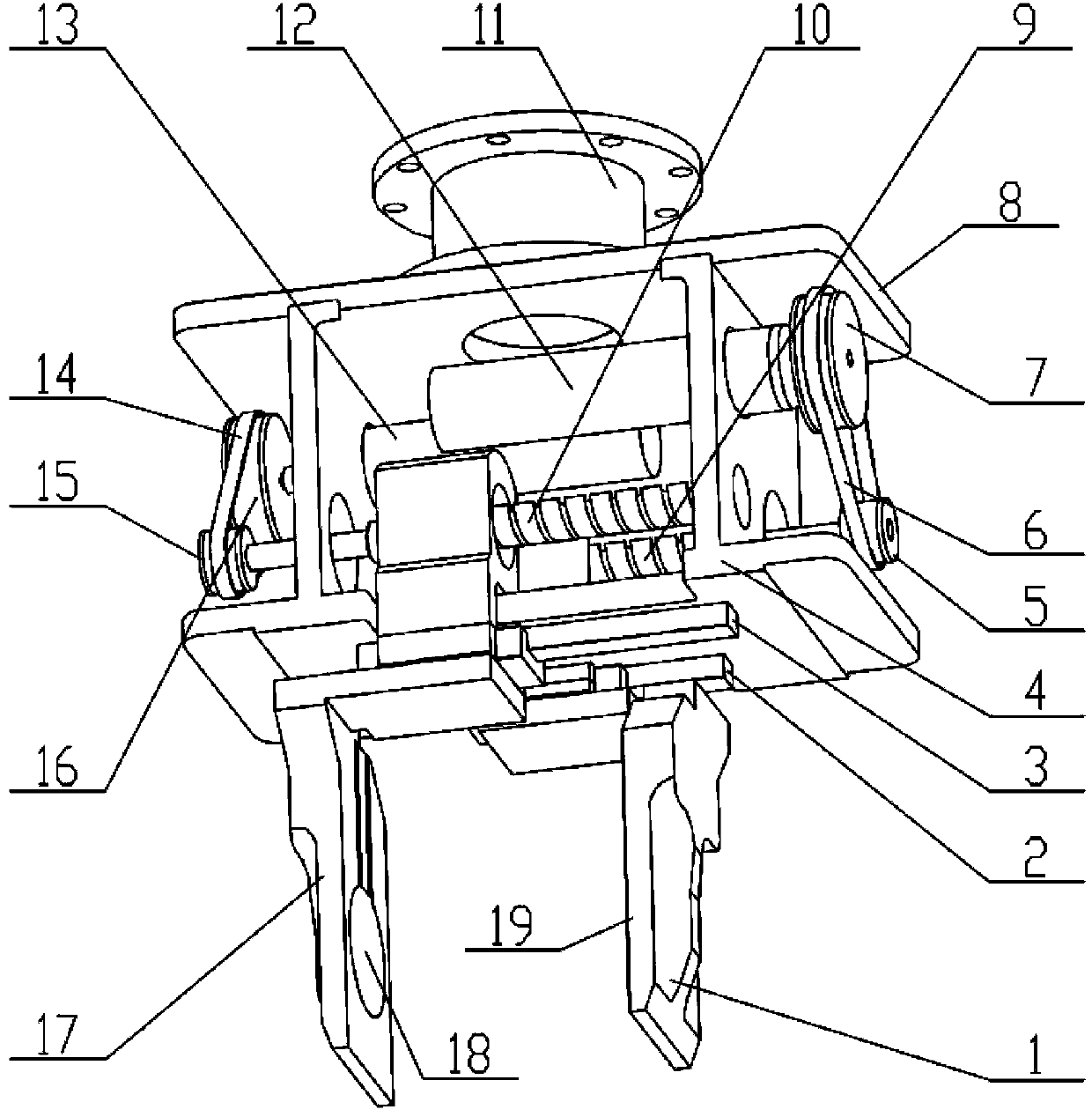

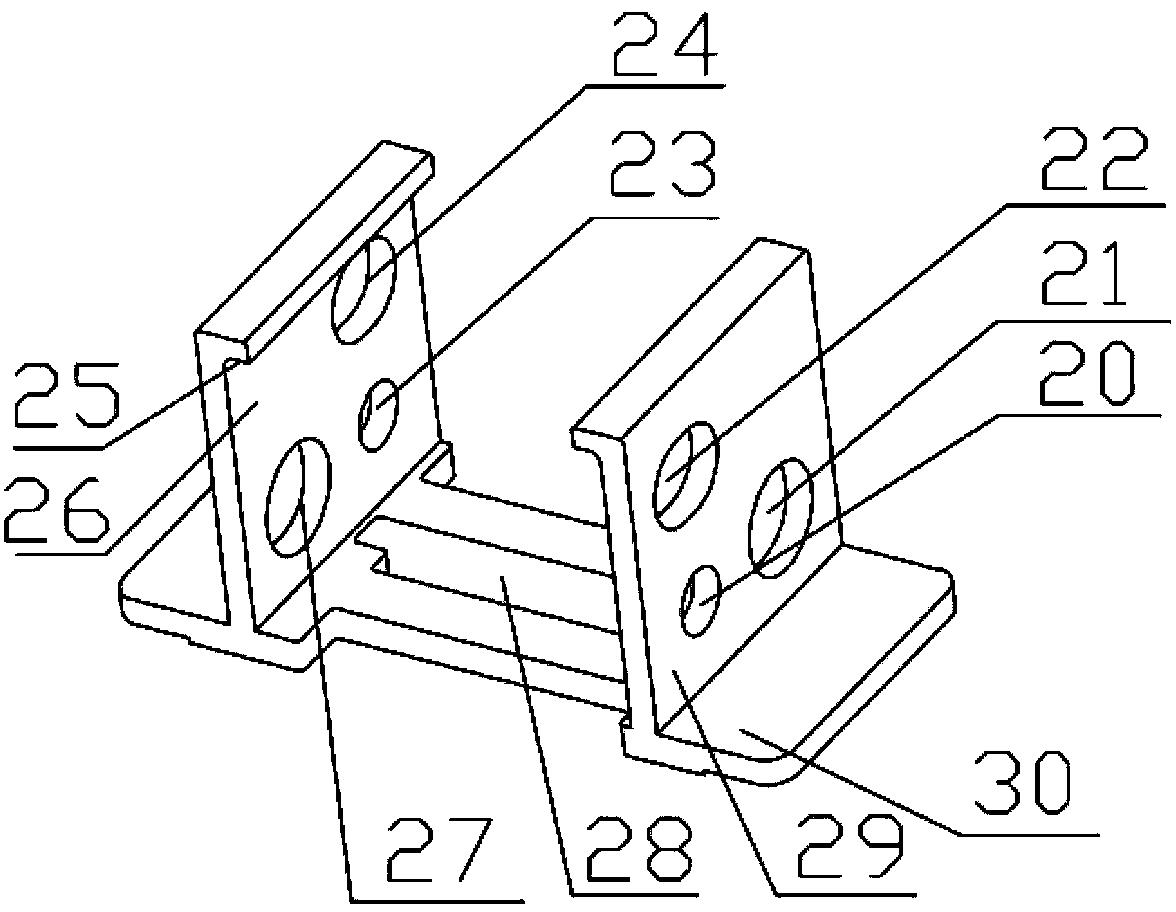

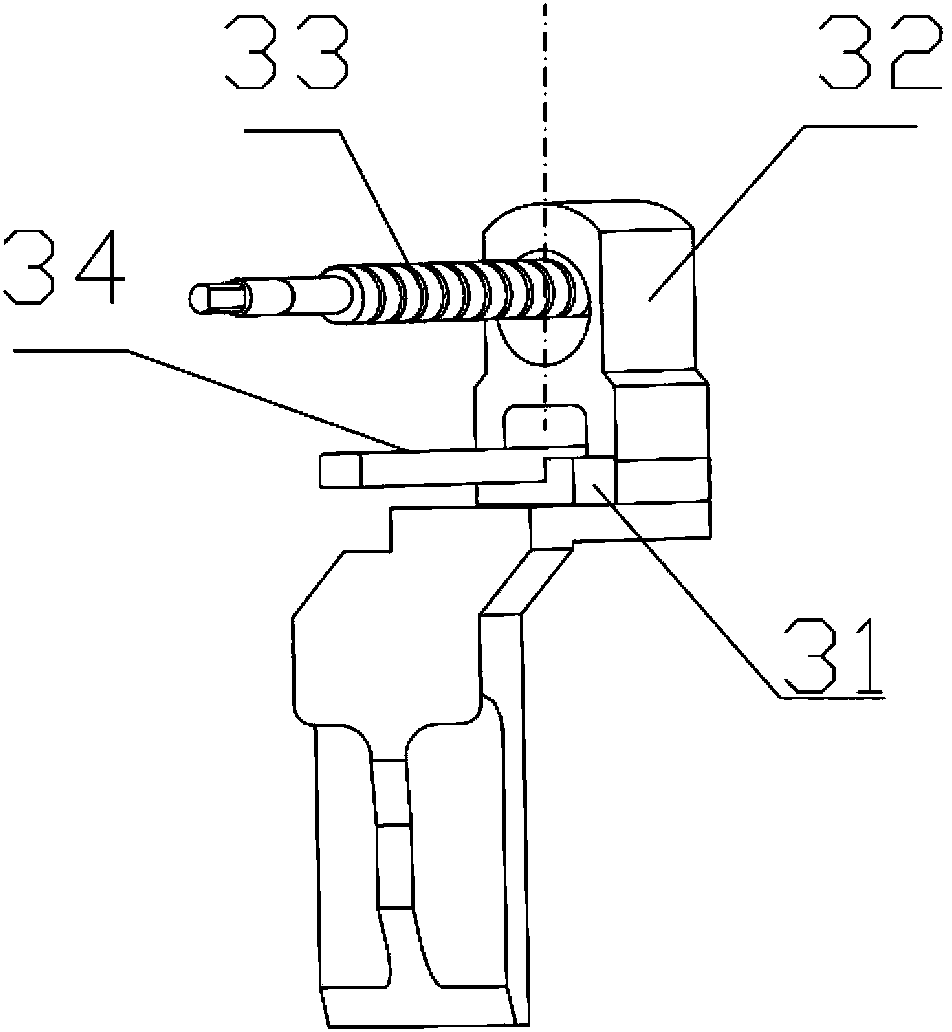

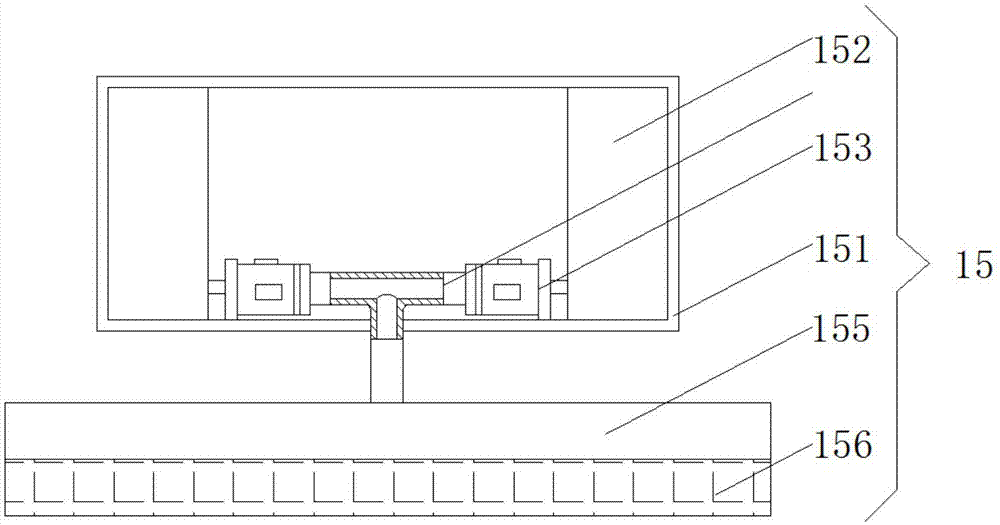

Double-finger double-driving translation clamping type flexible grip and control method

The invention discloses a double-finger double-driving translation clamping type flexible grip and a control method. The double-finger double-driving translation clamping type flexible grip comprises double servo motor systems, double motor end synchronous pulleys, double positioning sliding guide rail systems, double ball screw systems, double screw synchronous pulleys, double finger paws, a U-shaped main rack of the grip and a main rack cover plate, wherein the coordinating fetching action of two paws is realized by the control on two servo motors. A fetching method is characterized in that the double motors are used as power, double fingers are respectively fixedly arranged on two screw guide rail synchronous switching modules, through the rotation of two synchronous toothed belts between the double motor end synchronous pulleys and the ends of the double screw end synchronous pulleys, the rotation of the motor is converted into linear motion by a screw, so that the double fingers are translated respectively along two positioning sliding guide rails, and the translation switching on and off of the double paws along double guide rail surfaces can be realized. Due to the fact that the device is used for independently driving the corresponding paws to move by the double motors, so that the double fingers can more flexibly move, and different fetching speeds can be set for the double fingers, and the position precision is high.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

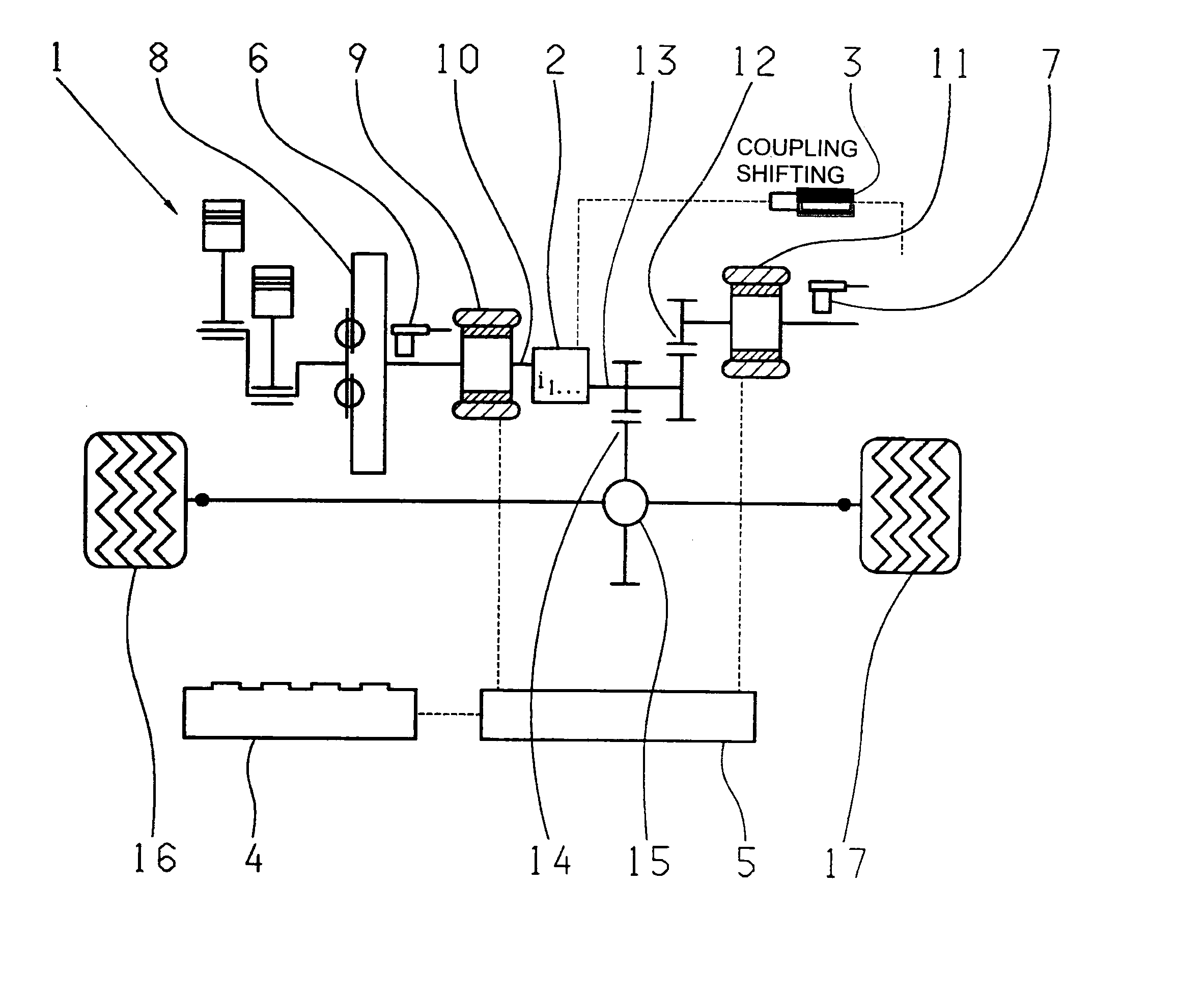

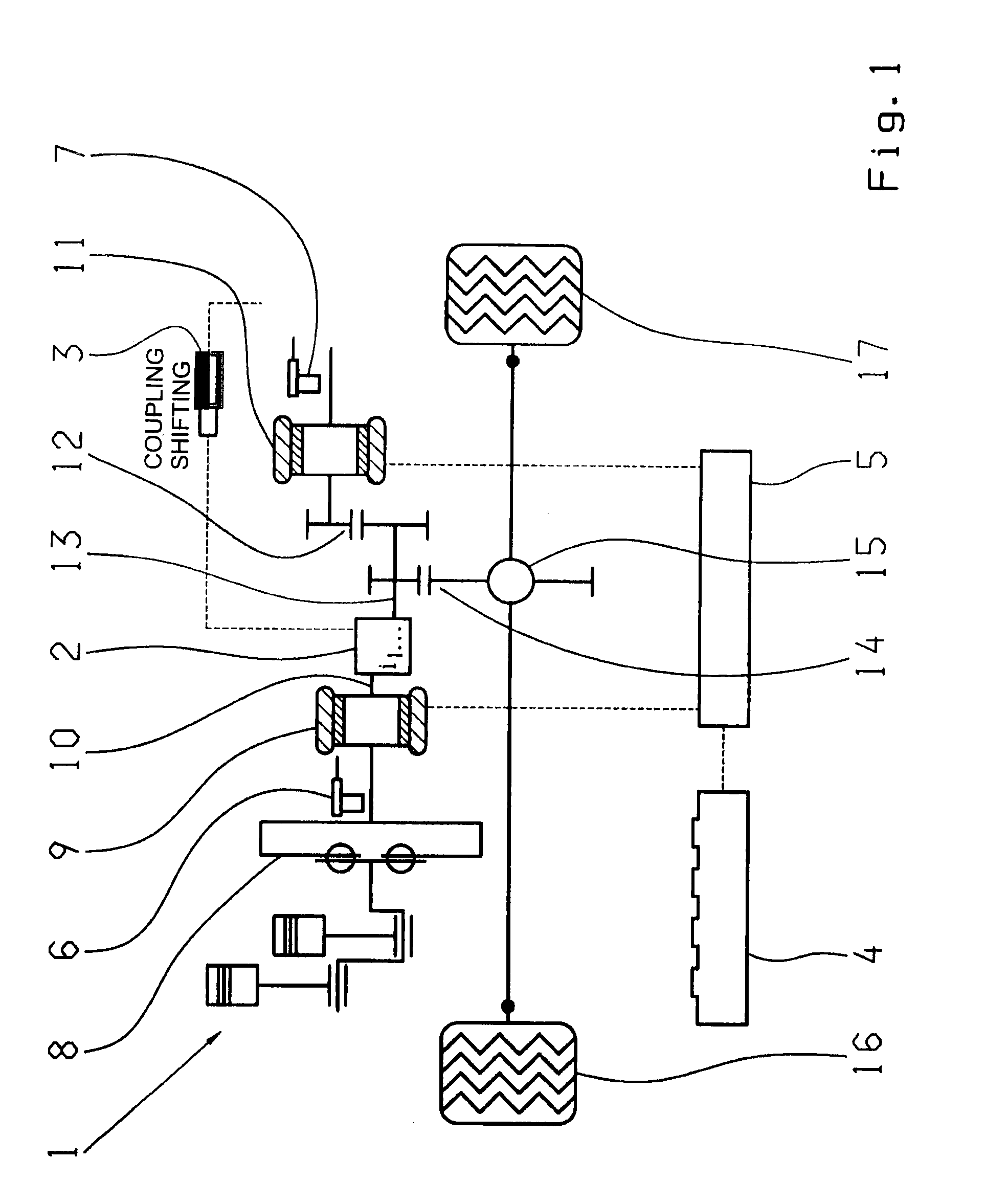

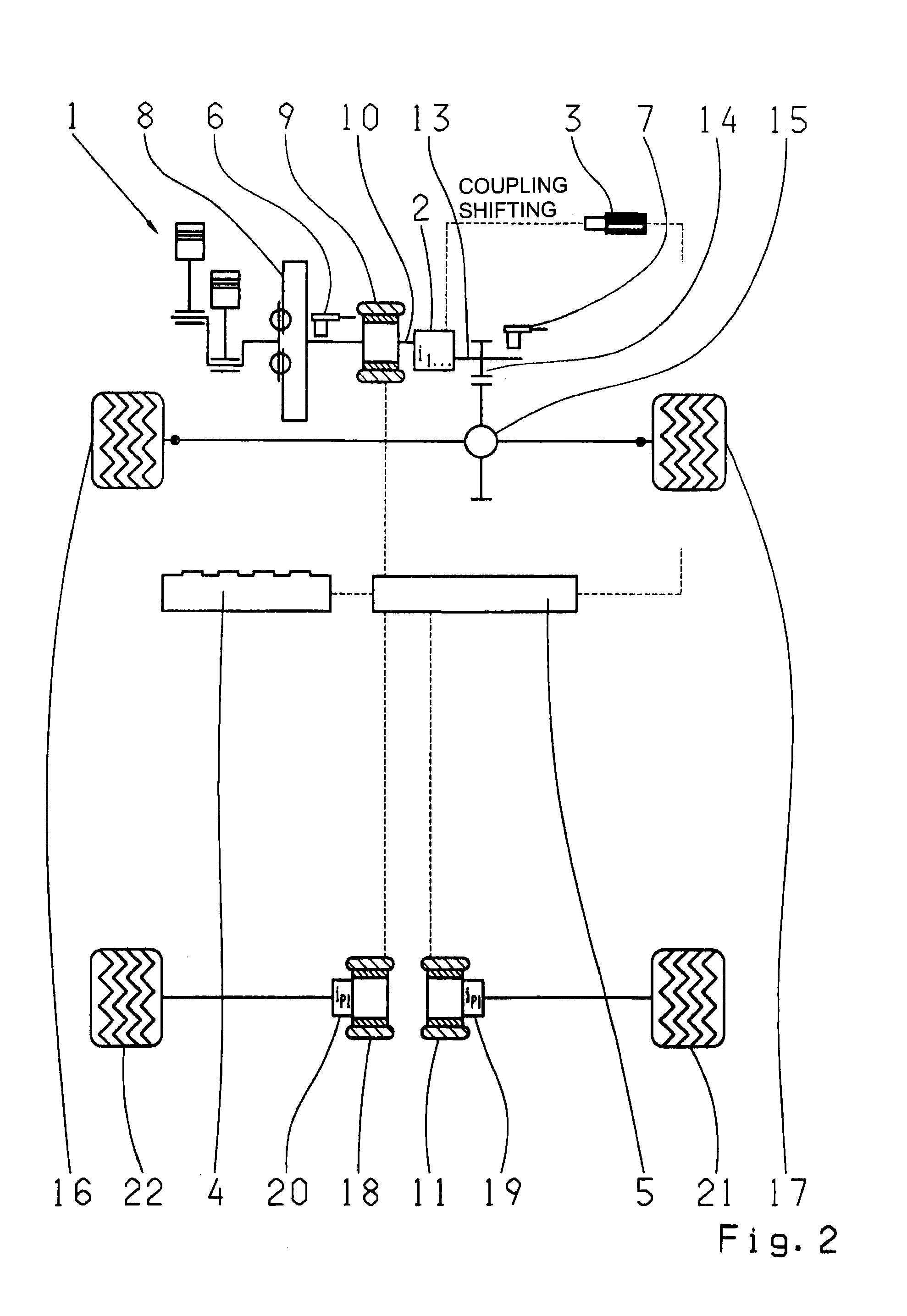

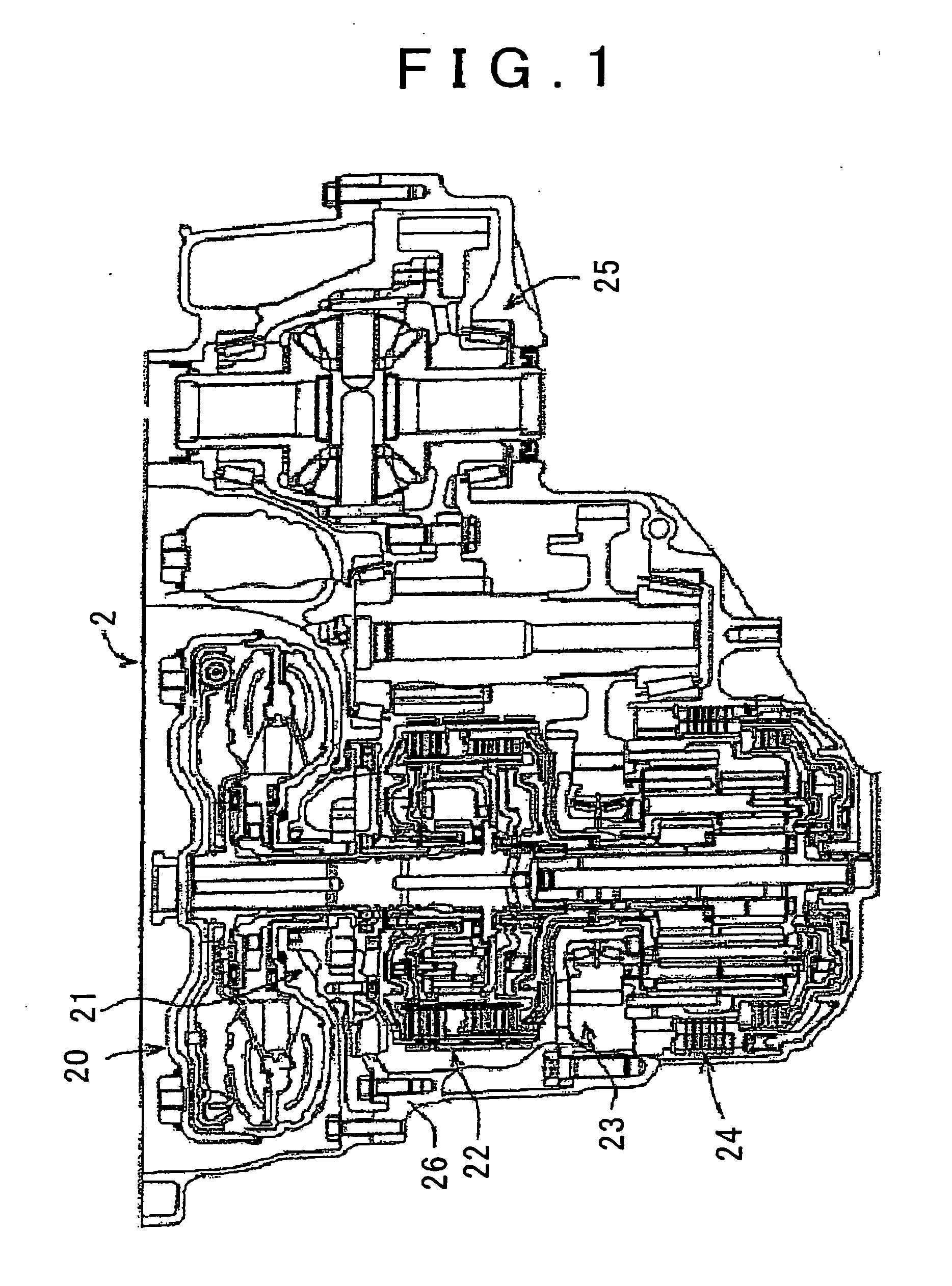

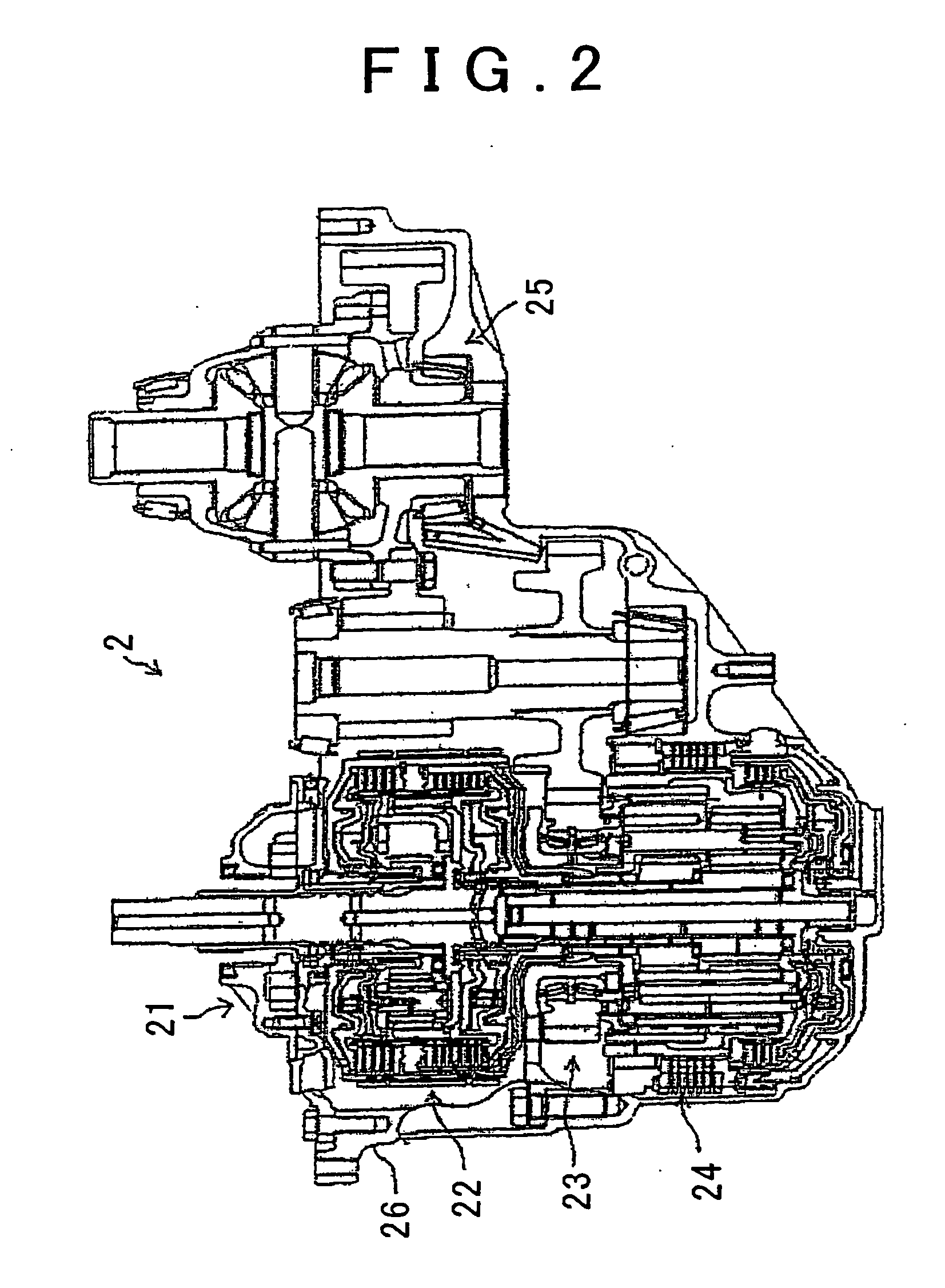

Hybrid drive train for a motor vehicle and method for operating the hybrid drive train

InactiveUS20110098151A1Simple engagementLessElectric propulsion mountingToothed gearingsMobile vehicleElectric machine

A hybrid drive train for a motor vehicle which comprises an combustion engine, at least two electric machines, a multi-gear transmission with transmission input and output shafts, a shift actuator, at least one energy storage device and a control unit arranged such that the combustion engine and the rotor of the first electric machine are connected to the transmission input shaft, and the transmission output shaft is connected either permanently or via a gearwheel arrangement or a chain or toothed-belt drive mechanism to at least one wheel or to a differential of a first vehicle axle. The rotor of the second electric machine is connected either permanently or via a chain or toothed-belt drive mechanism, either to at least one wheel or to a differential of the first vehicle axle, or to at least one wheel or to a differential of a second vehicle axle.

Owner:ZF FRIEDRICHSHAFEN AG

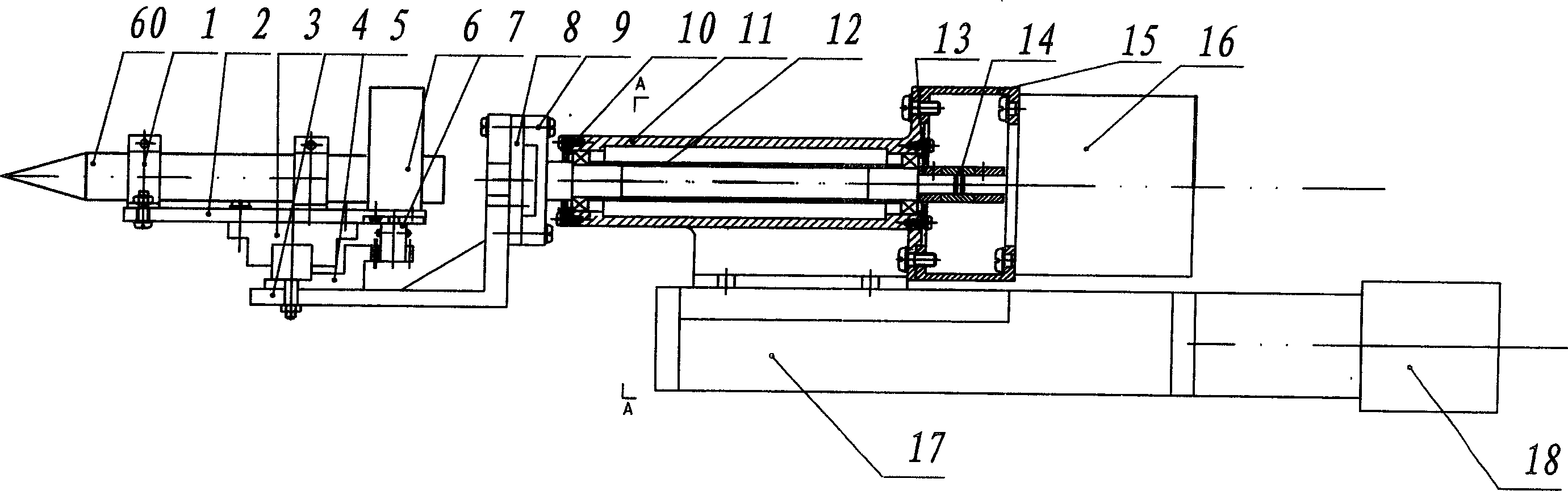

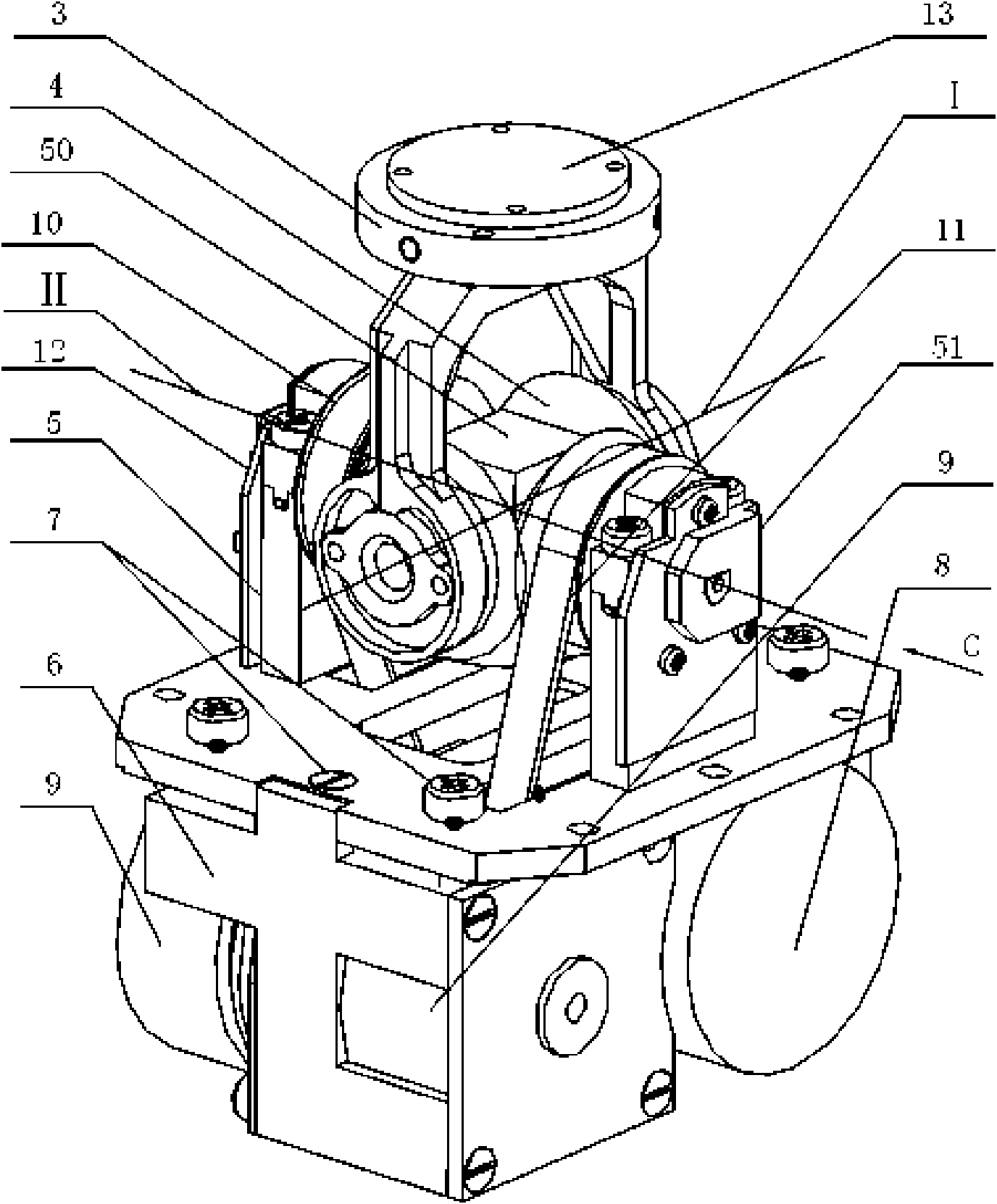

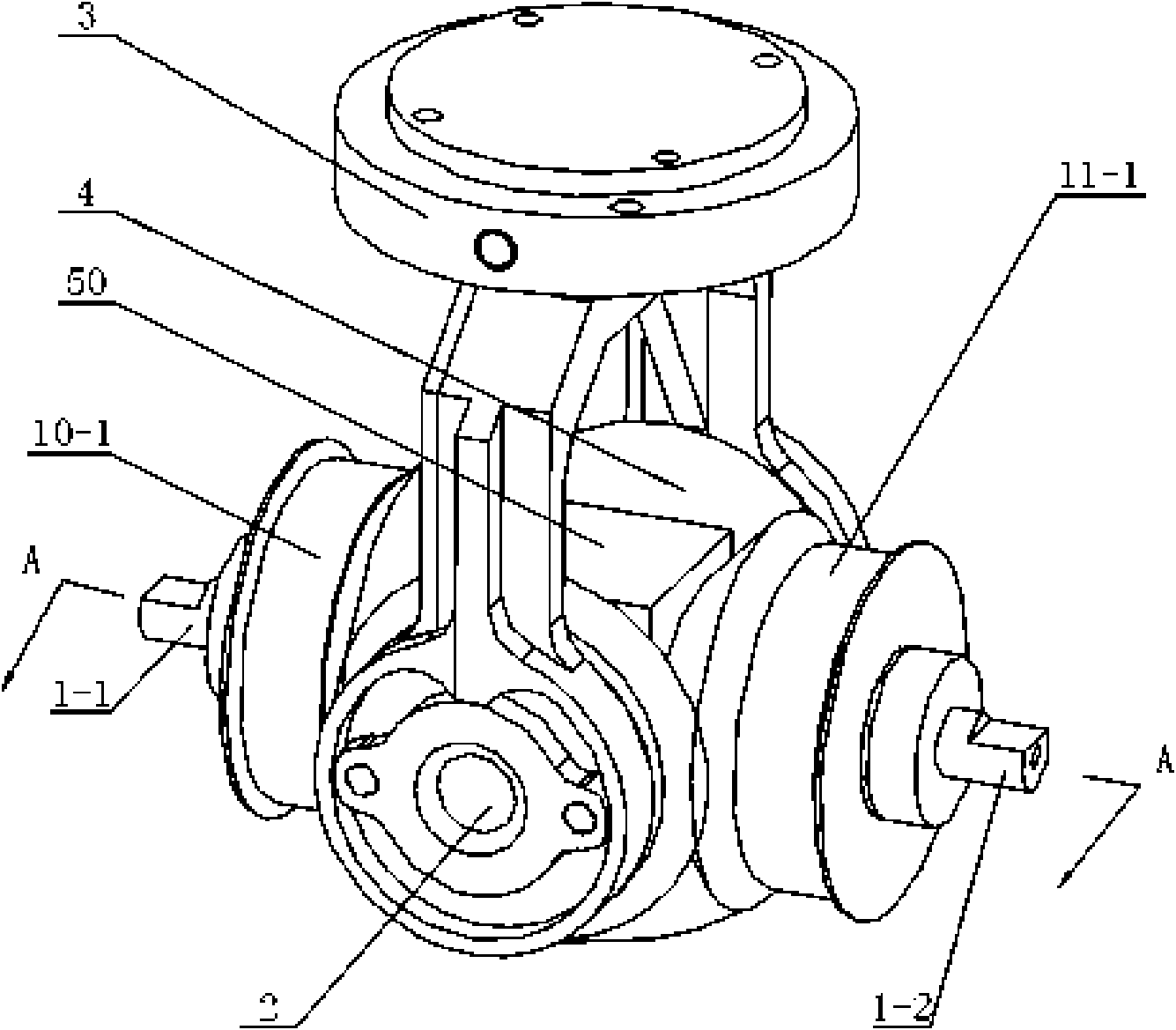

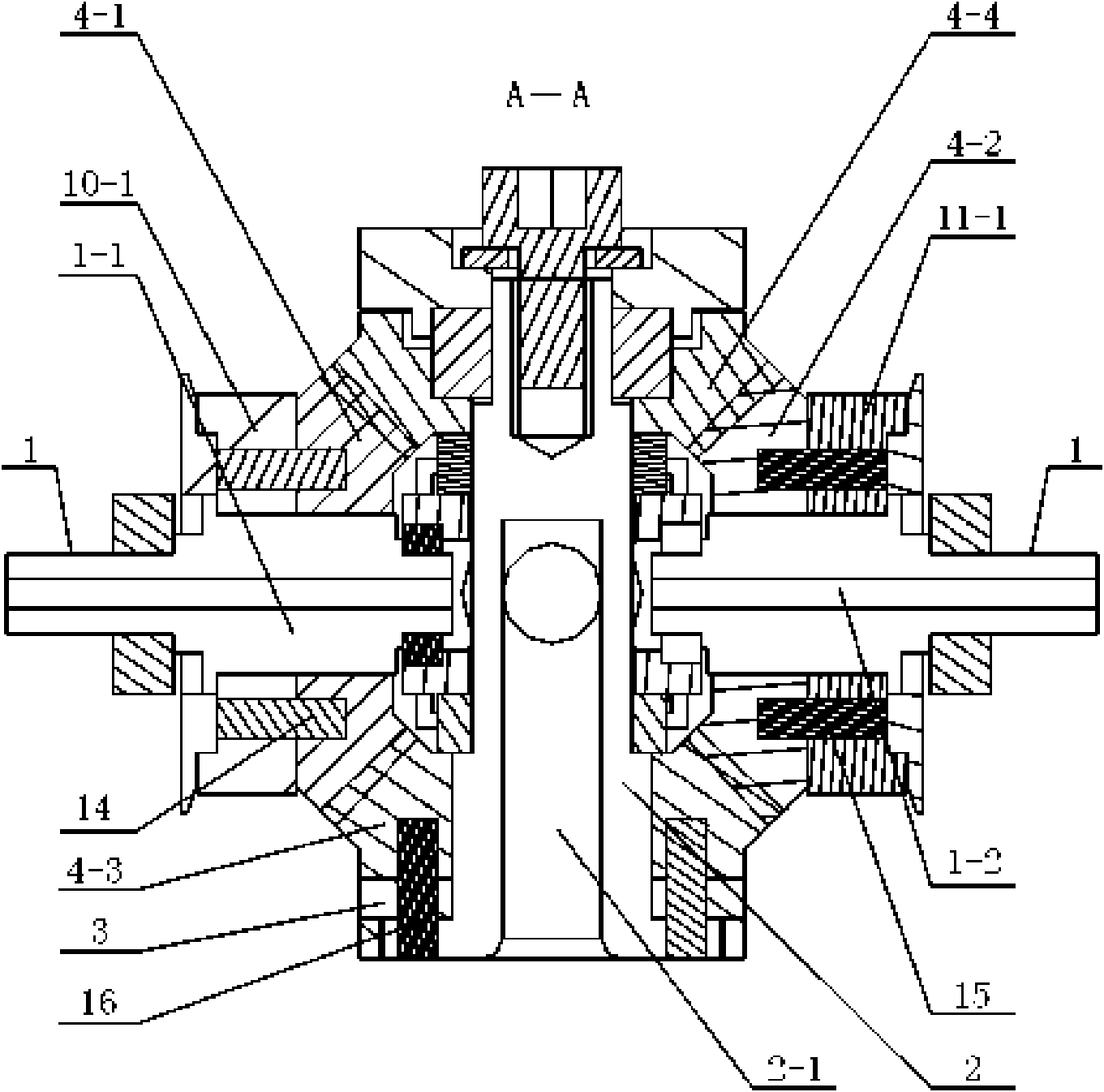

Secondary manipulator of surgery operation robot

ActiveCN1654174AEasy and flexible operationRealize mechanical structure uncouplingJointsDiagnosticsBlood vesselRobot manipulator

The servo actuated robot manipulator for surgical operation has fingers in the most front end as well as finger circularly moving joint mechanism, arc guide rotating joint mechanism, inclined guide straight motion joint mechanism, the first small arm rotating joint mechanism, the second small arm rotating joint mechanism, large arm rotating joint mechanism, vertical position regulating mechanism and sync toothed belt wheel mechanism. The present invention is used mainly in micro wound surgical operation, eye operation, orthopaedics operation, etc., especially in blood vessel stitching and other microscopic surgical operations.

Owner:TIANJIN UNIV

Two-degree-of-freedom robot wrist

InactiveCN101927498AHighly integratedSimple structureProgramme-controlled manipulatorJointsGear wheelDrive shaft

The invention discloses a two-degree-of-freedom robot wrist, which relates to a robot wrist and aims to solve the problems of complex structure, heavy weight, high control difficulty and low integration level existing in the conventional robot wrist. One of two input bases of a torque sensor is connected with a first driven bevel gear of a differential mechanism while the other is sleeved on a driven shaft of the differential mechanism; a support block is arranged on a bracket bottom plate of a support bracket; the differential mechanism is supported by the support block and two support arms of the support bracket; a driving frame is connected with the support bracket through a pre-tightening mechanism; first and second drivers are fixed on the driving frame and have opposite transmission directions; the first and second drivers are in transmission connection with first and second driving half shafts of the differential mechanism through first and second toothed belt transmission mechanisms; first and second position sensors are arranged on the first driving half shaft of the differential mechanism; and a tail end circuit board is fixedly arranged on an output base of the torque sensor. The robot wrist has the advantages of simple structure, light overall weight, easy control, high integration level and wrist pitching and deflection degrees of freedom.

Owner:HARBIN INST OF TECH

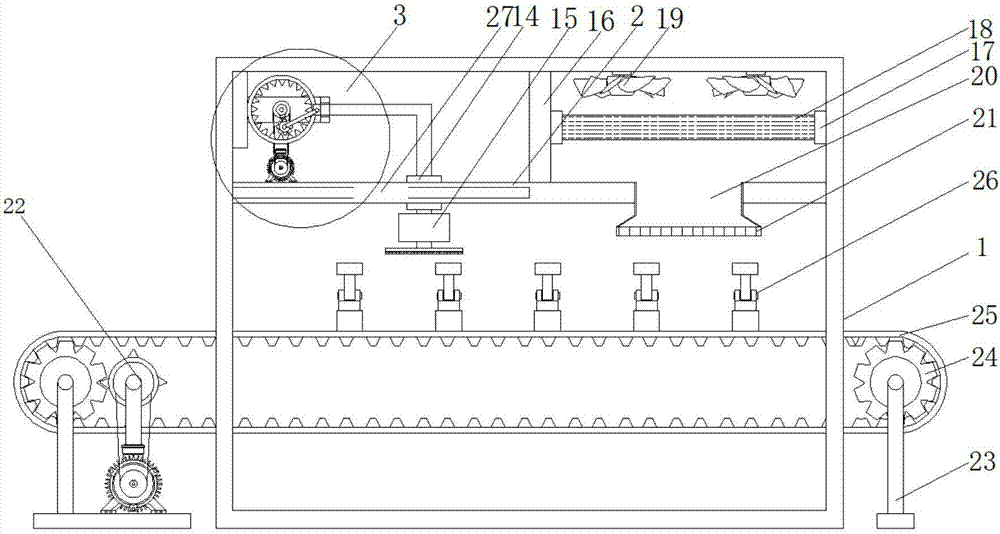

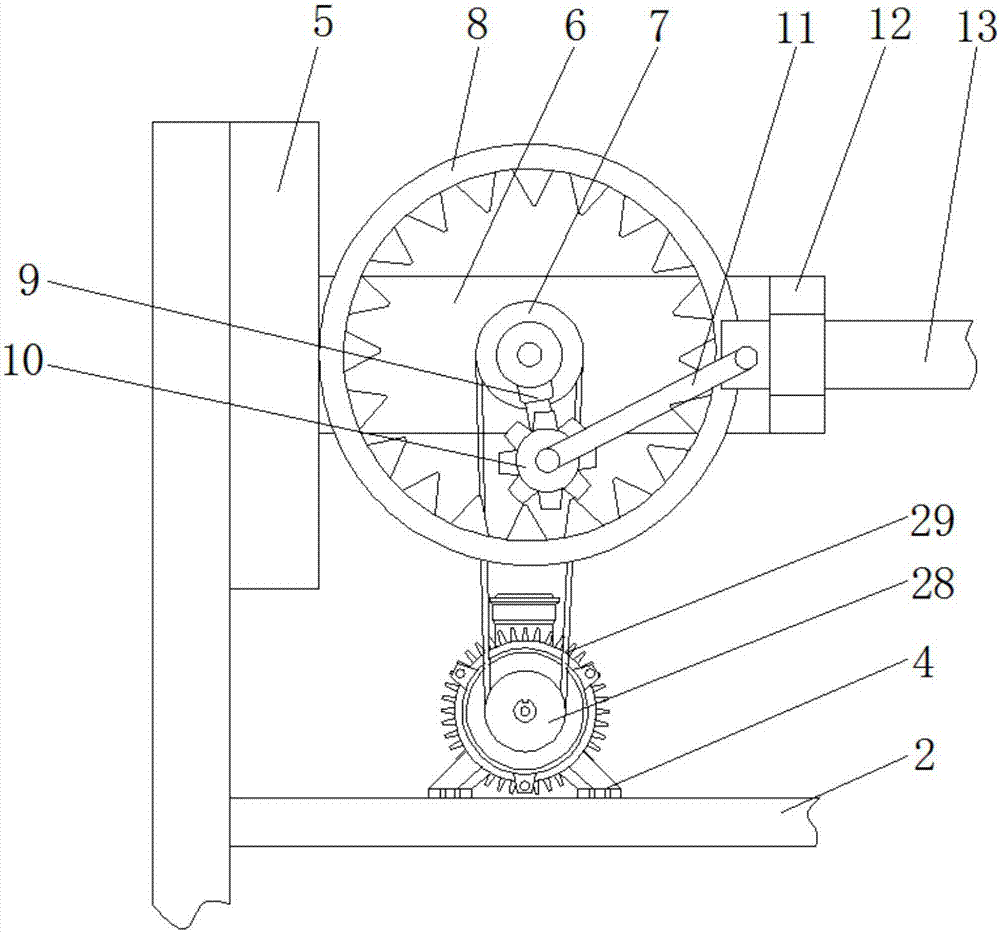

Bamboo wood toy paint spraying and drying device

InactiveCN107309119ATo achieve the purpose of reciprocating movementAchieve the purpose of turningSpraying apparatusPretreated surfacesDrive wheelGear wheel

The invention discloses a paint spraying and drying device for bamboo and wood toys, which comprises an outer frame, a moving device is fixedly connected to the top of the support plate, an internal gear is fixedly connected to the right side of the vertical plate, and the concentric gear of the second driven wheel The pinion is rotatably connected to the shaft through the rotating shaft connecting rod, and the pinion is meshed and connected to the internal gear. The pinion is rotatably connected to a transmission link, and the transmission link is rotatably connected to a push rod. The bottom end is fixedly connected with a spraying device, and the left side outside the outer frame is provided with an output end of a transmission device, and the surface of the straight-toothed conveyor belt is fixedly connected with a bamboo and wood toy clamping device. The present invention relates to the technical field of bamboo and wood toy processing machinery . The paint spraying and drying device for bamboo and wood toys solves the problems that the existing bamboo and wood toy spray paint causes harm to the workers' bodies, and the spraying and drying are not comprehensive and the efficiency is low. s damage.

Owner:安吉县怡成竹木工艺品厂

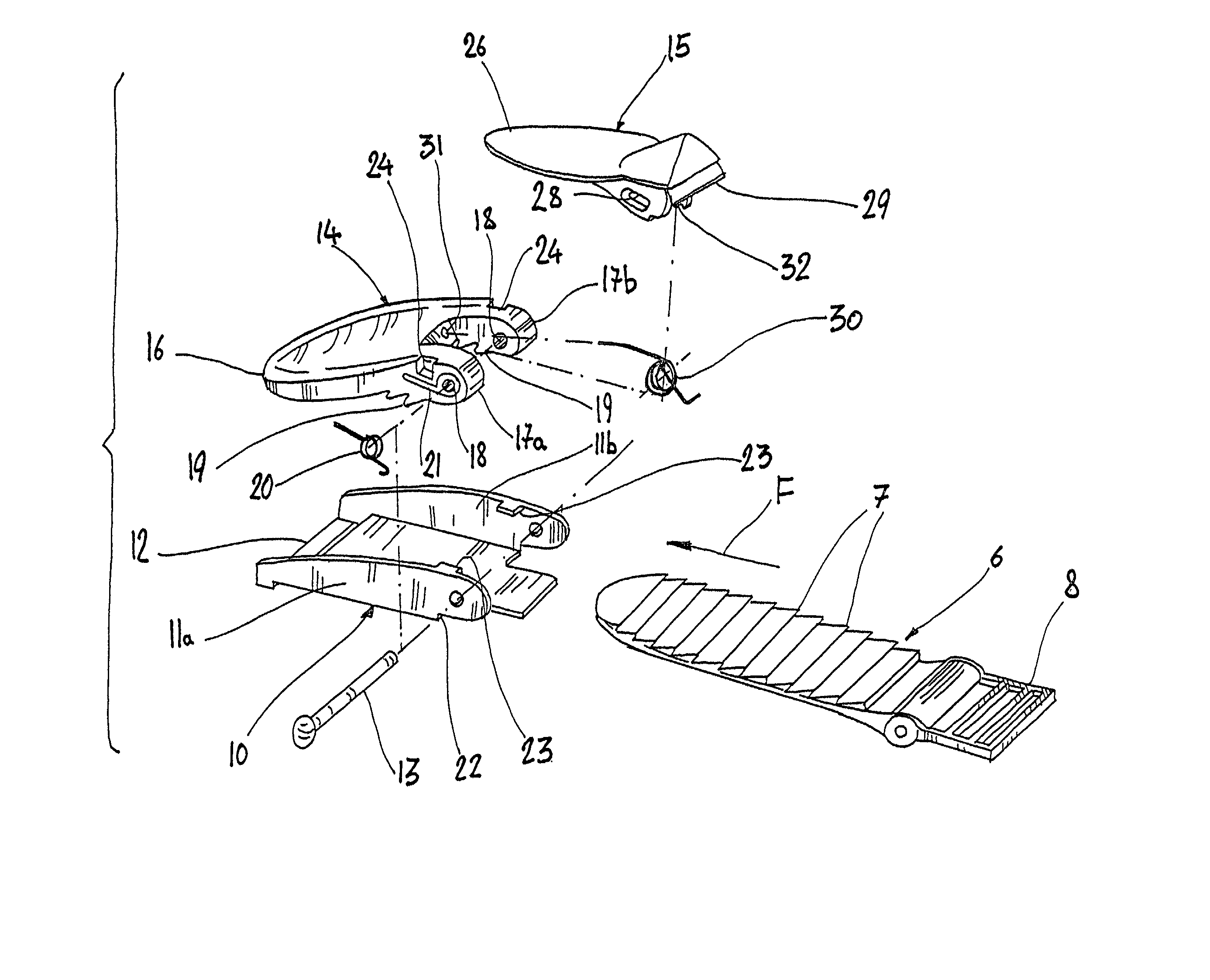

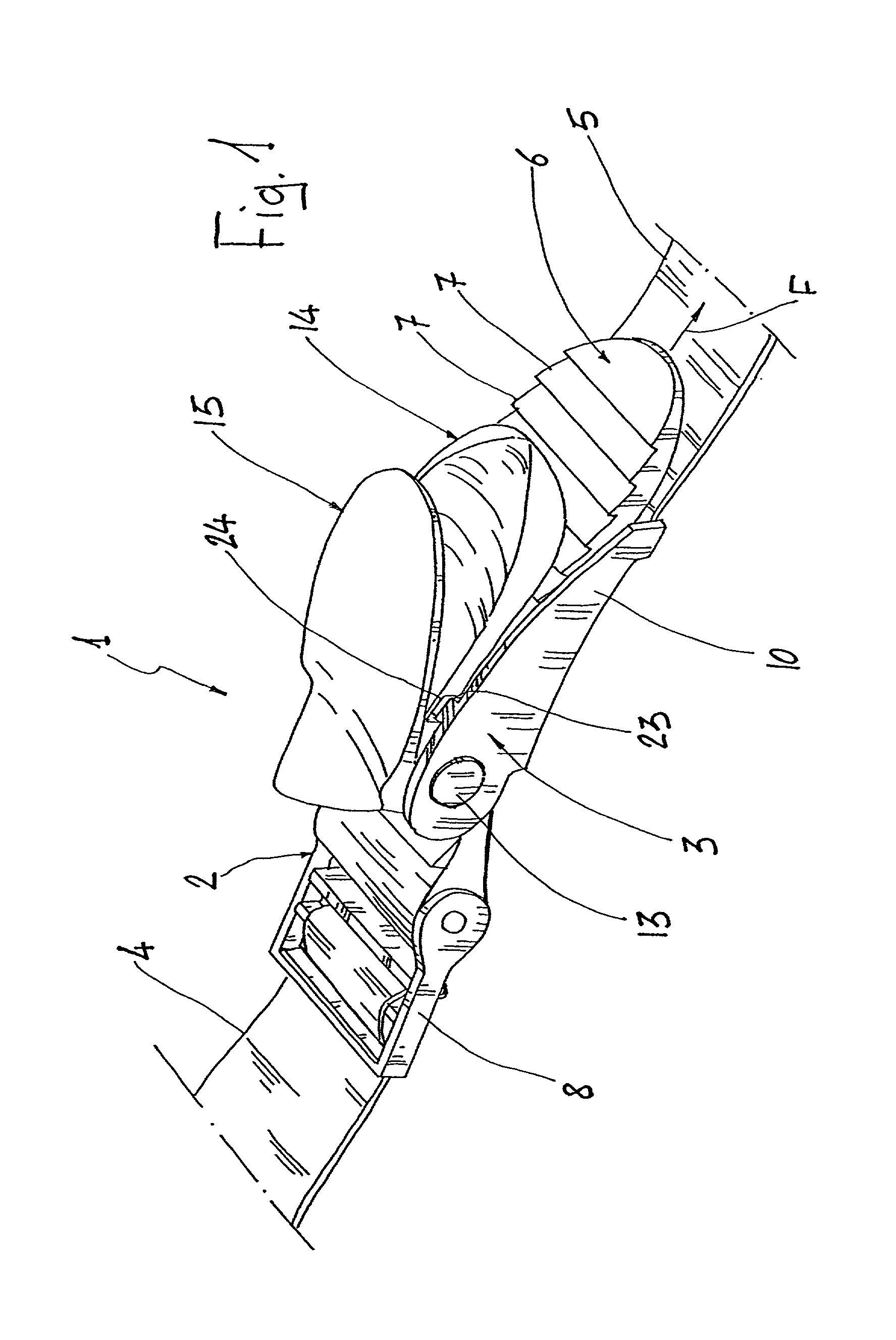

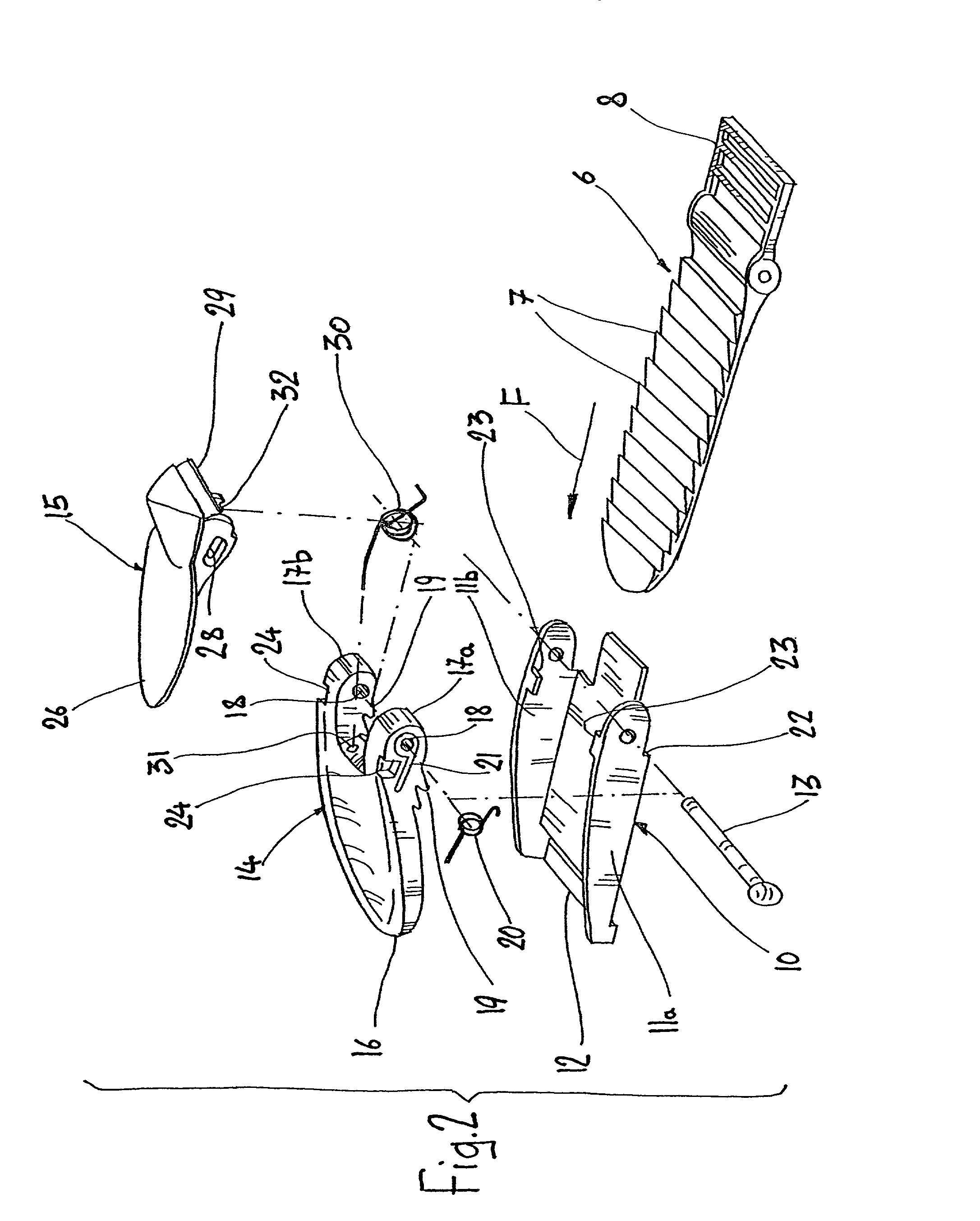

Toothed-belt fastening, in particular for chin-straps of helmets, protective headgear and the like

A toothed-belt fastening, in particular for chin-straps of helmets, protective headgear and the like, comprises a base on which the toothed belt can be slidably engaged, a first and a second pawl which are mounted in an oscillating manner on the base and can in turn be engaged with a toothing of the belt. The first pawl forms a member for unidirectionally locking the toothed belt with respect to the base and is disengageable from the toothing so as to slacken the fastening, while the second pawl is engageable with the toothing so as to tension the fastening and is hinged on the base coaxially with the first pawl.

Owner:BAUER ITALA

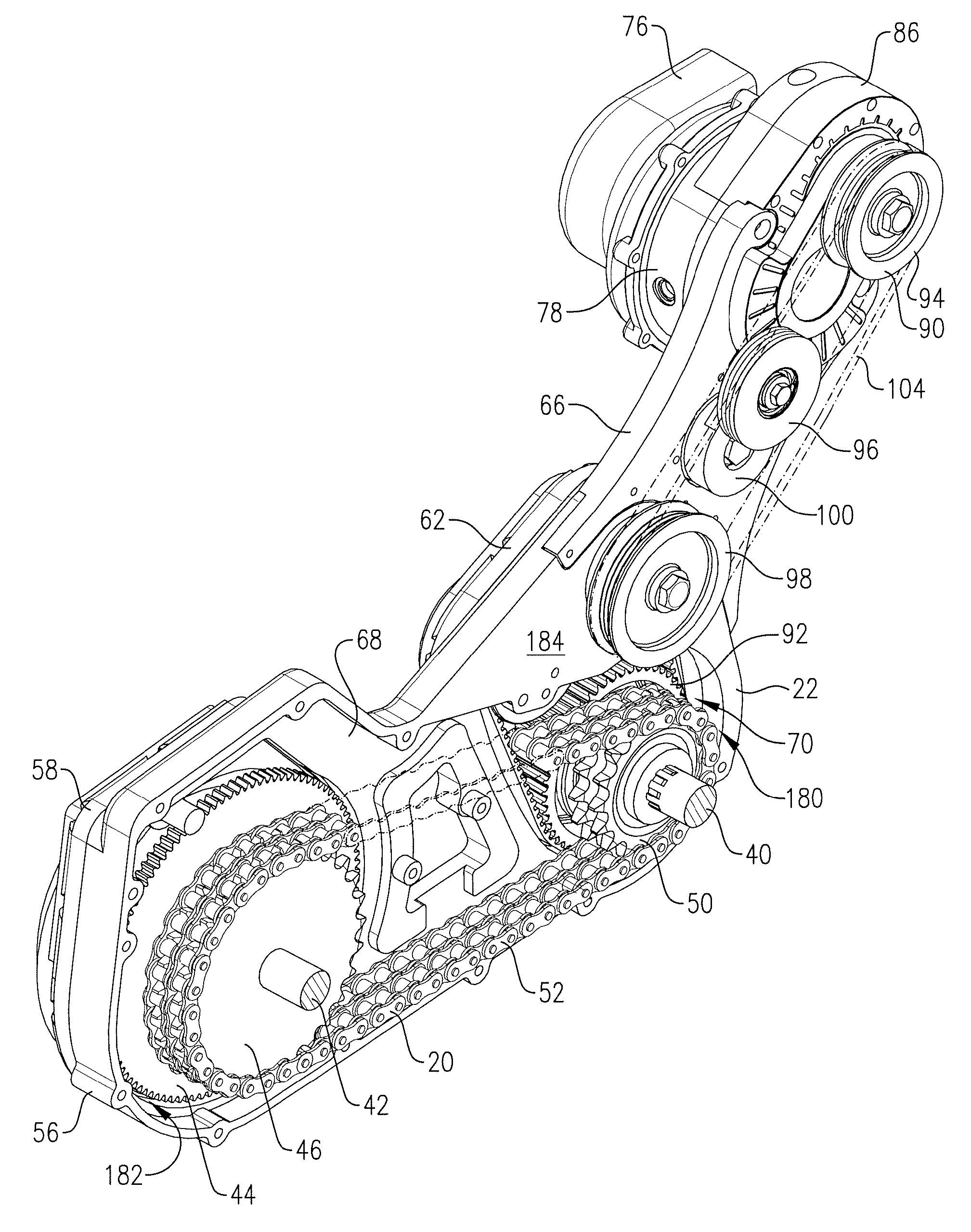

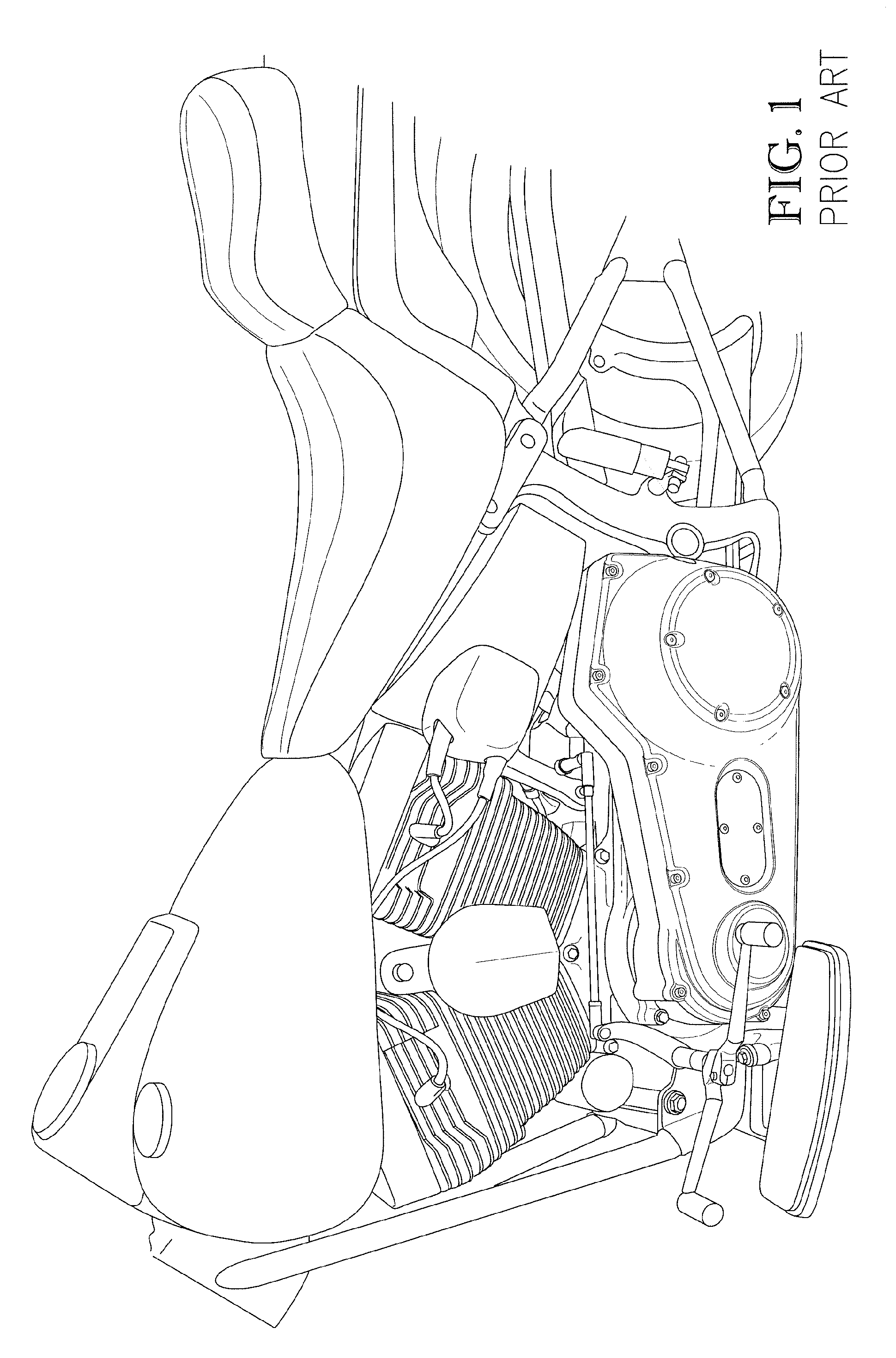

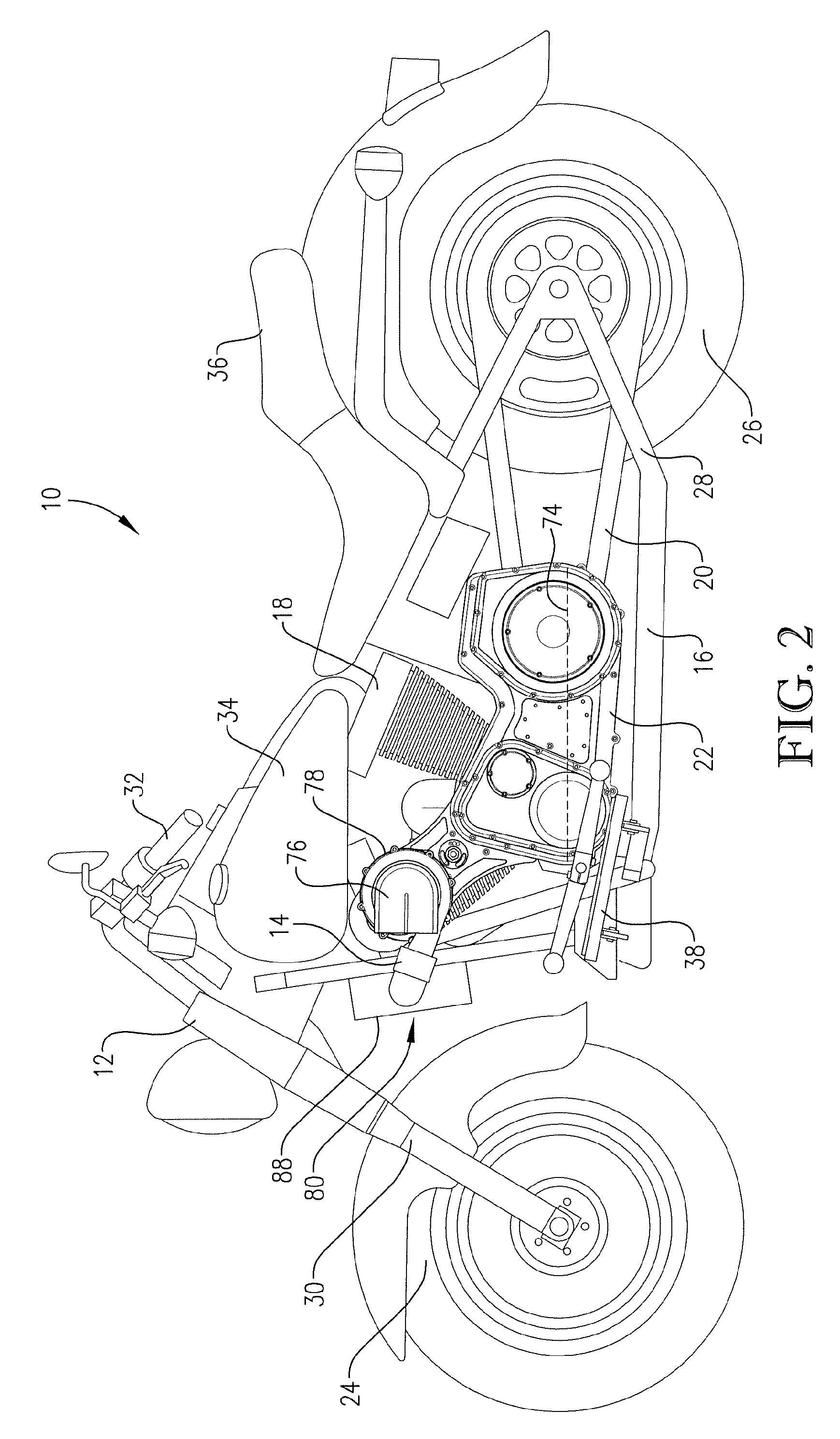

Wet belt supercharger drive for a motorcycle

A supercharged motorcycle is disclosed and broadly includes a motorcycle and an air induction system. The supercharged motorcycle includes a case that partly houses a drive train of the motorcycle within a first case compartment and a wet belt drive of the air induction system within a second case compartment. The wet belt drive incorporates a toothed belt that enables a slip mechanism of the wet belt drive for protecting the motorcycle engine. The two adjacent compartments of the case fluidly communicate and are configured such that the wet belt drive can be compactly assembled onto the motorcycle.

Owner:ACCESSIBLE TECHONOLOGIES

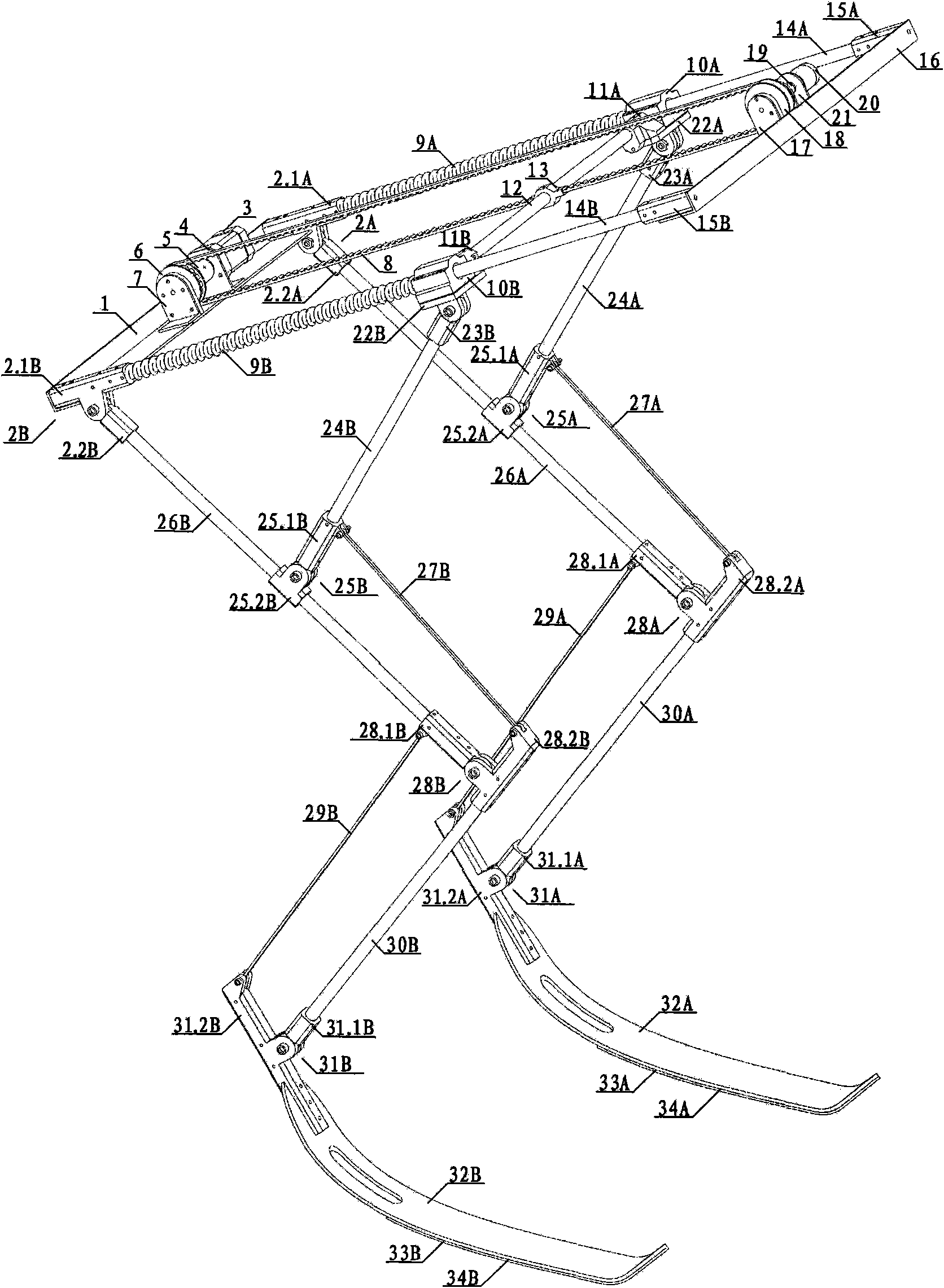

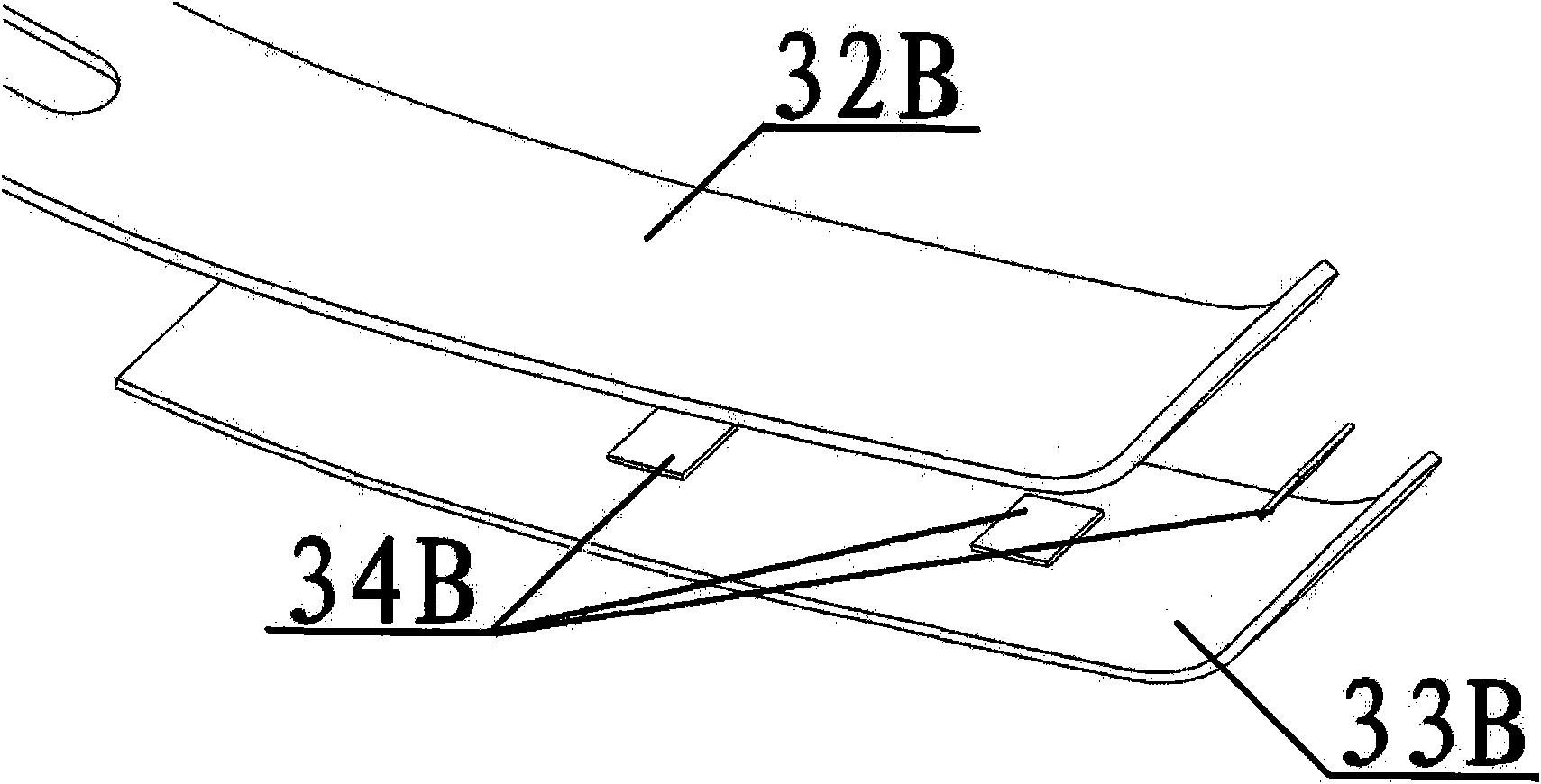

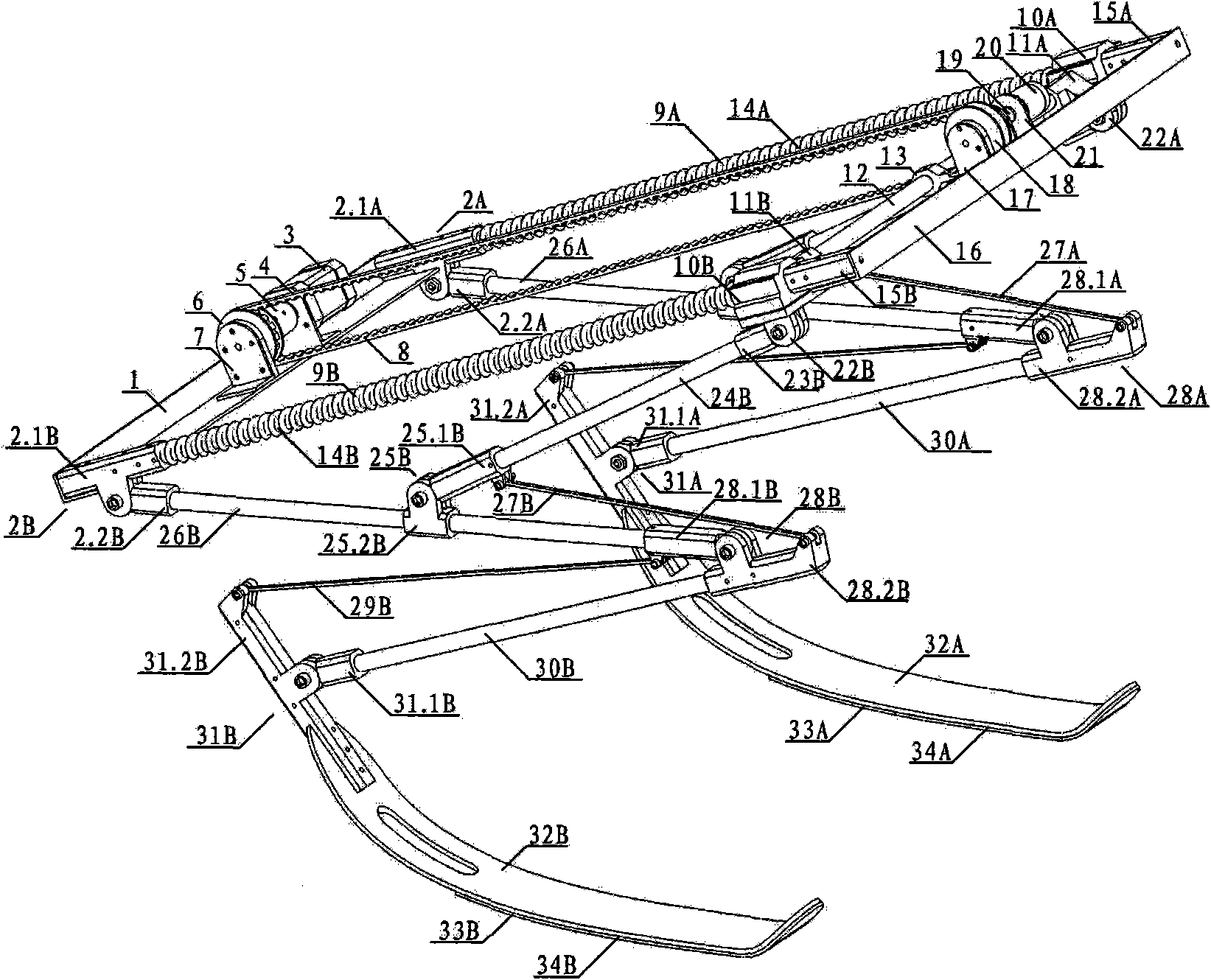

Frog jump robot

The invention discloses a frog jump robot. A motor is used as a power element; devices such as an overrunning clutch, a gear toothed belt and the like are used as transmission mechanisms; a slide block can move on a guide rail under the drive of the motor through the transmission devices; and double legs of the robot stretch or retract under the drive of the slide block so as to finish jump motion. After the robot jumps, the double legs immediately retract to perform air posture adjustment, and the double legs are fully retracted by using self gravity potential and kinetic energy at the monument of landing to perform posture adjustment again. The energy utilization rate of the power element is improved, reclamation and reutilization of energy during jumping are realized, the flexibility of the robot is increased, and the jumping capability of the robot is promoted.

Owner:BEIJING UNIV OF TECH

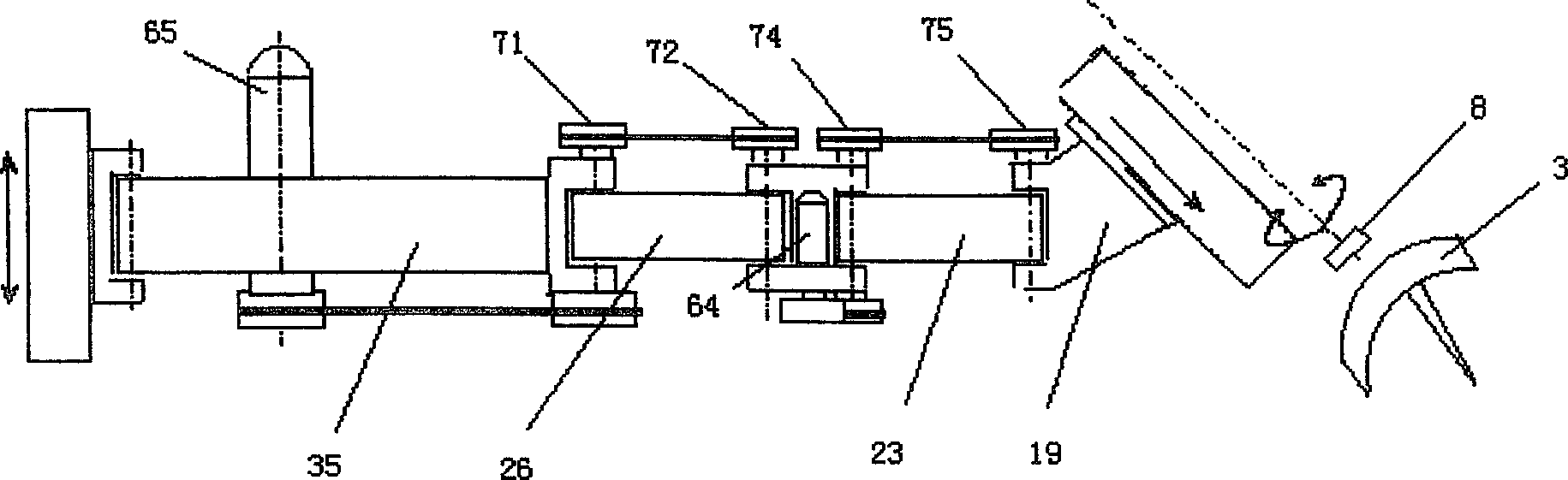

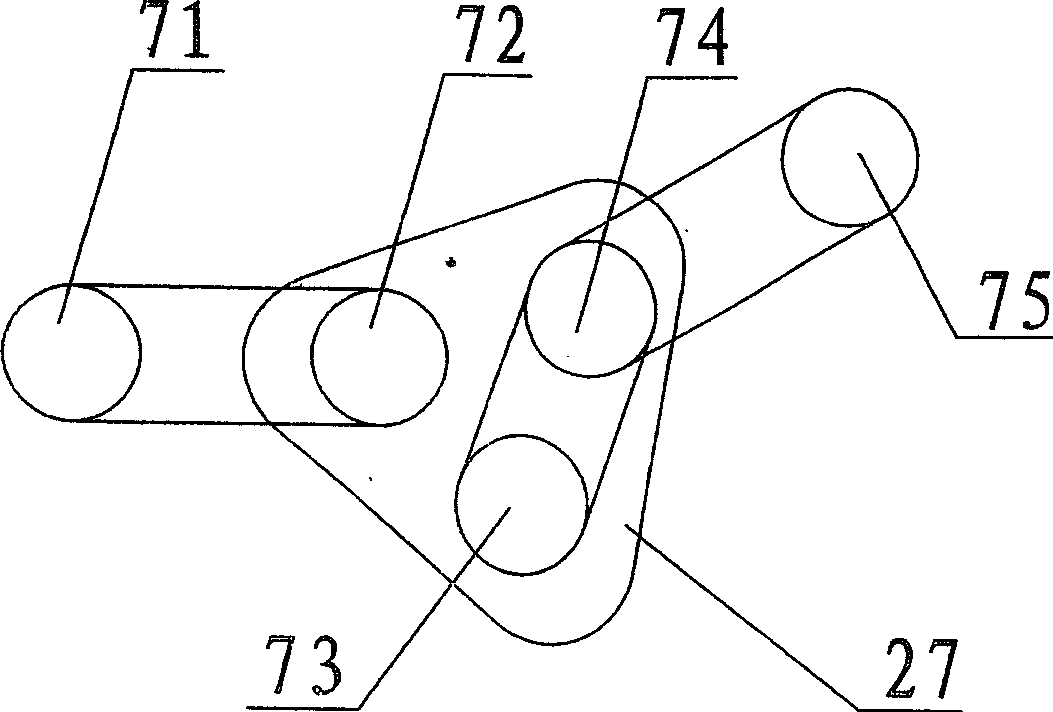

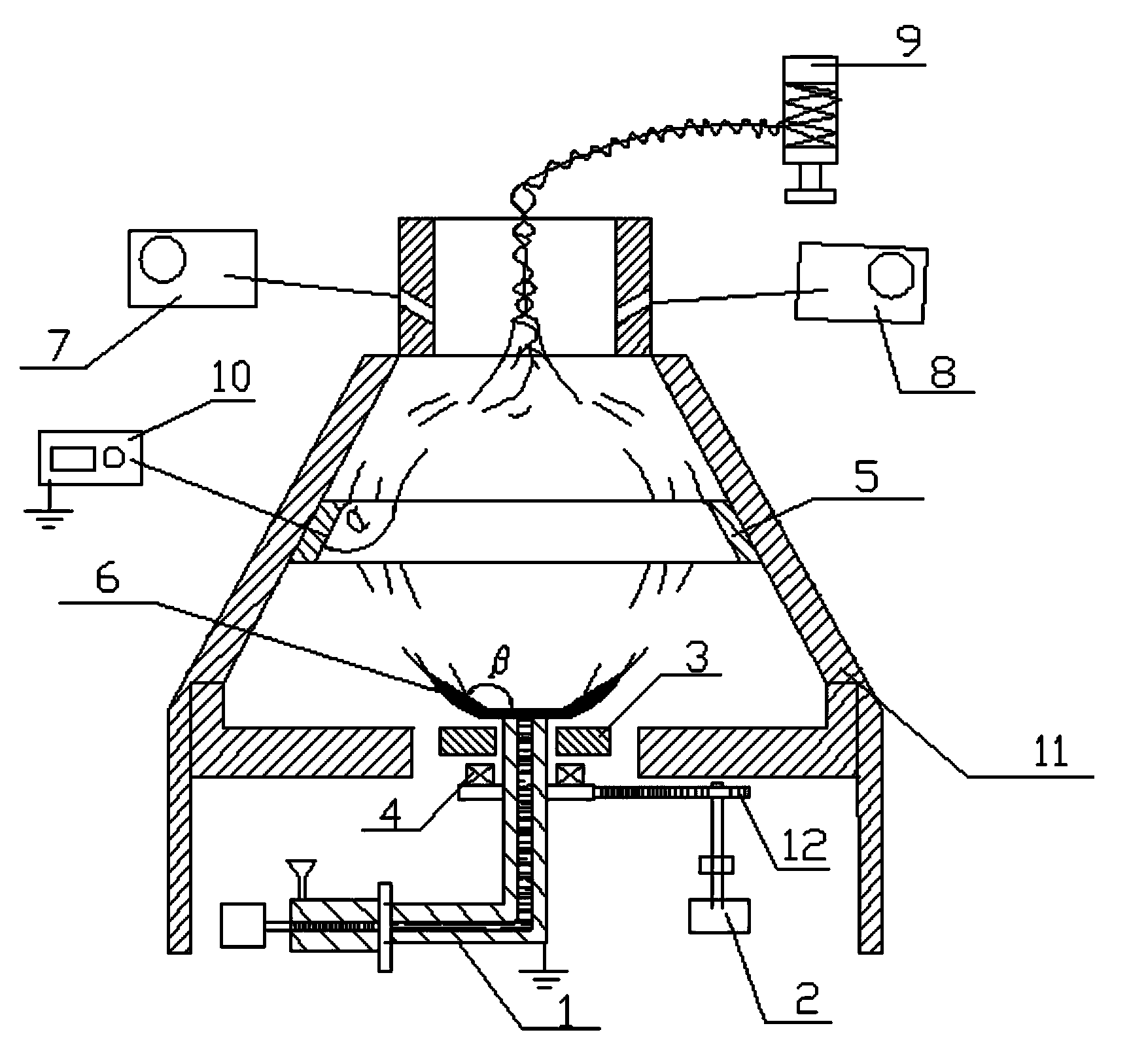

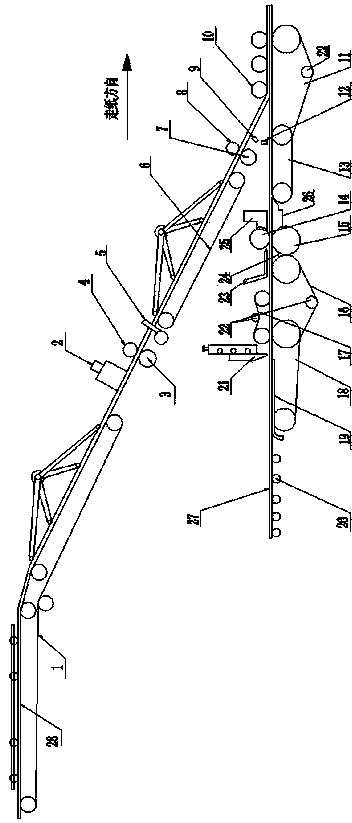

High-speed preparation device and process of centrifugal electrostatic spinning nanometer twisted yarns

ActiveCN103409861AAchieving Orientation ControllabilityIncrease elasticityFilament/thread formingContinuous wound-up machinesFiberYarn

The invention discloses a high-speed preparation device of centrifugal electrostatic spinning nanometer twisted yarns. The high-speed preparation device mainly comprises a feed extrusion device, a motor, an electromagnetic heating coil, a bearing, a conical ring perforated electrode, a centrifugal rotating umbrella-type spray head, an air compressor, a cyclone vacuum generator, a roller receiving device, a high-voltage electrostatic generator, a synchronous toothed belt and a rack, wherein the motor drives the centrifugal rotating umbrella-type spray head to rotate at high speed; the electromagnetic heating coil is in non-contact connection with the centrifugal rotating umbrella-type spray head and is heated through radiation; the feed extrusion device is used for supplying feed to the centrifugal rotating umbrella-type spray head through a hole in the center of the centrifugal rotating umbrella-type spray head; the conical ring perforated electrode is fixed at the middle position of the center of the rack. The high-speed preparation device is combined with an electrostatic spinning technology and a centrifugal spinning technology; a rotating airflow is formed in a chamber by the combined use of the air compressor and the cyclone vacuum generator to guide fiber to form twisted yarns, so that the orientation controllability of nanofiber is achieved; conditions are created for industrial application of the nanofiber in the specific industries, such as water treatment.

Owner:BEIJING UNIV OF CHEM TECH

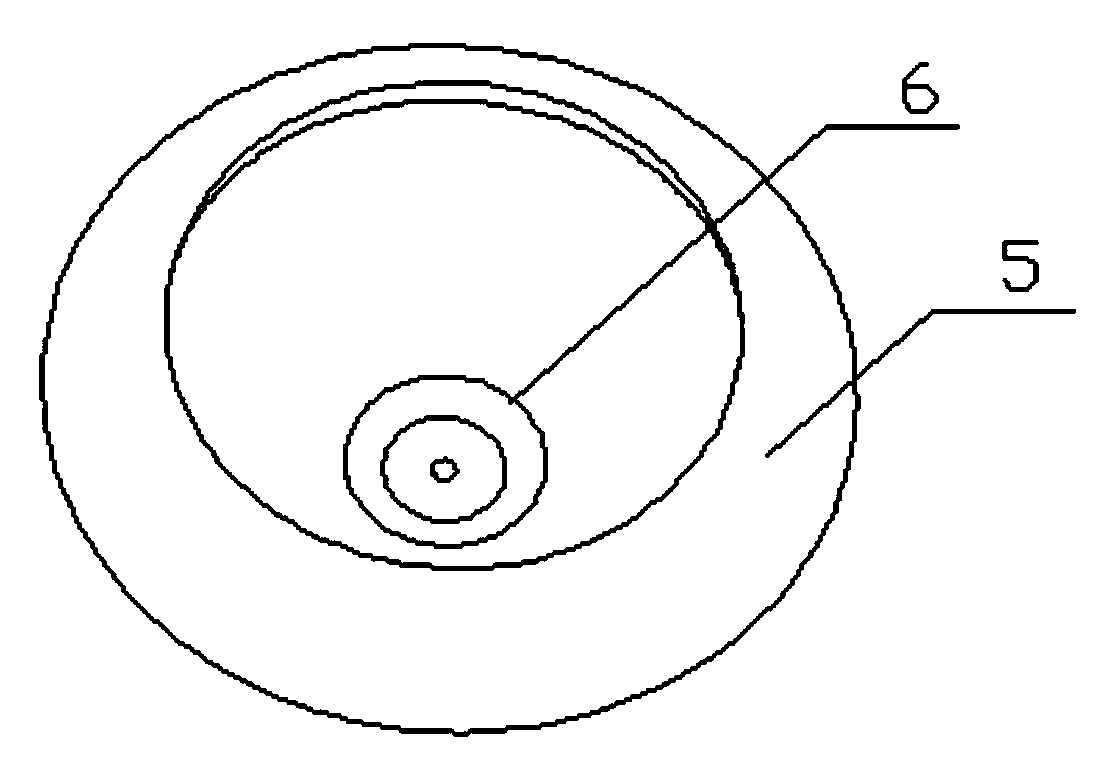

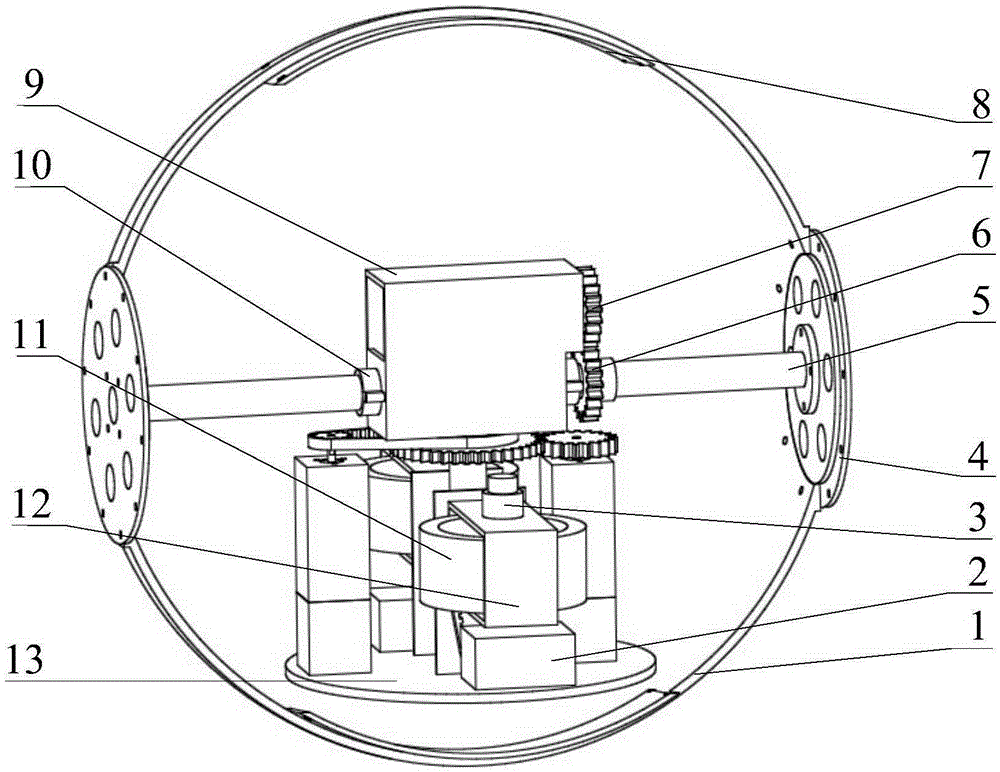

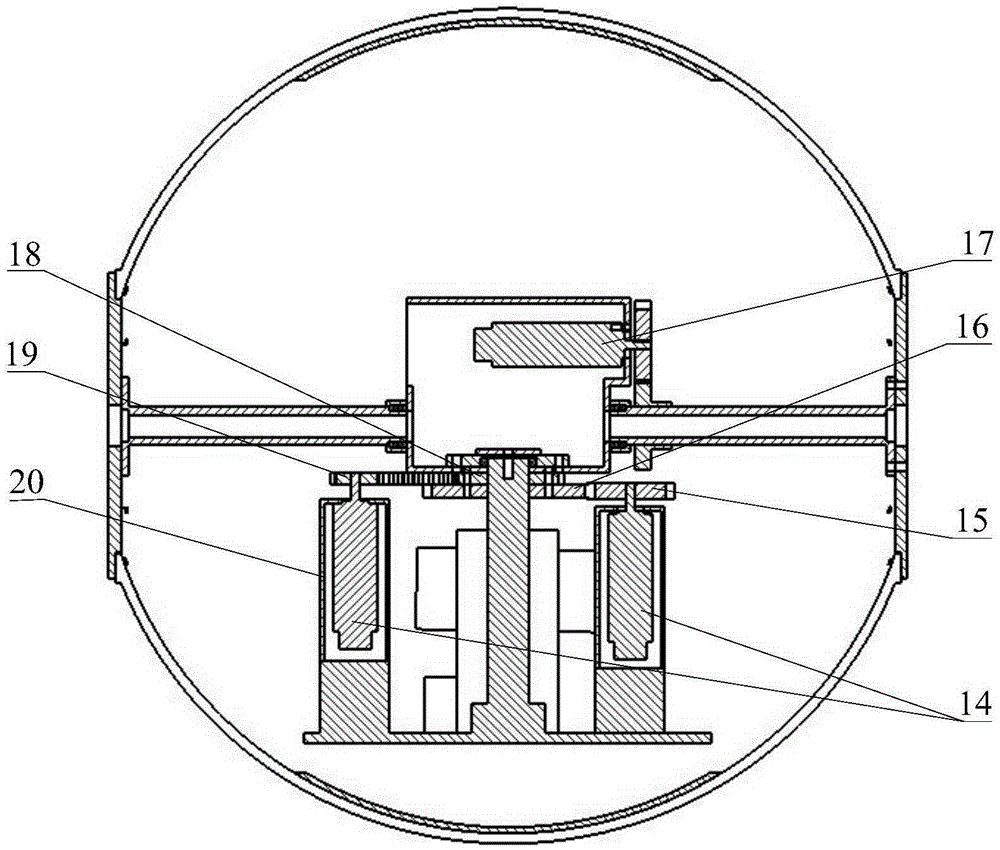

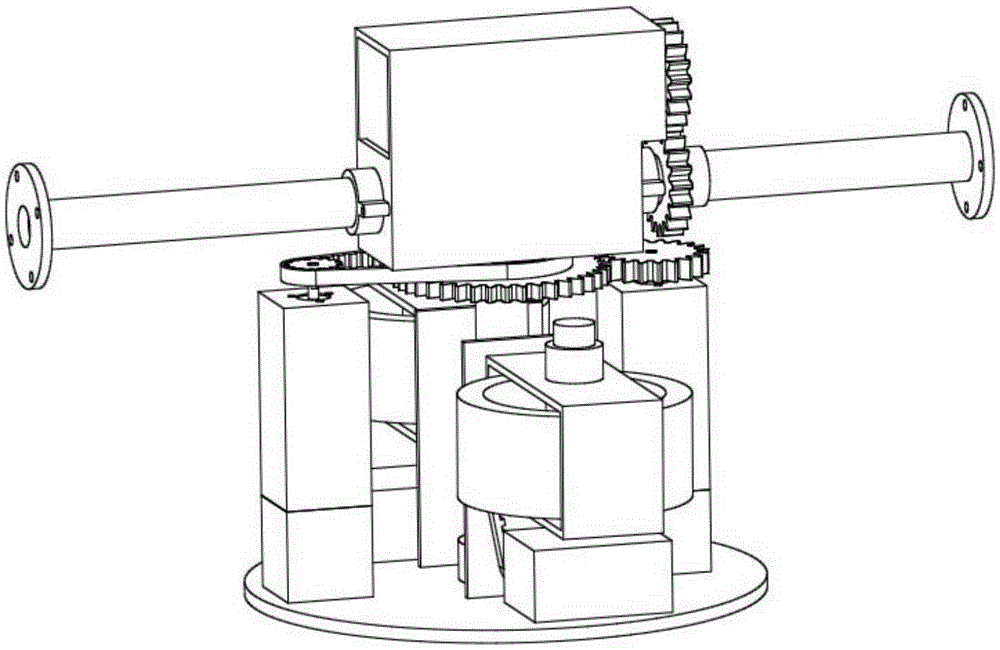

Spherical robot with in-situ rotation function carried with control moment gyro

The invention discloses a spherical robot with an in-situ rotation function carried with a control moment gyro. The robot is mainly composed of a homogeneous spherical shell, an advance driving mechanism, a steering mechanism, a control moment gyro mechanism, a heavy pendulum and the like. The steering mechanism is composed of two steering motors, a steering gear mechanism, a toothed belt wheel mechanism and the like. In-situ steering of the sphere is achieved through the cooperation of output torques of the two motors. Meanwhile, the robot is carried with the control moment gyro mechanism, and the control moment gyro mechanism is mainly composed of a flywheel, a flywheel rotation motor, a flywheel fixing frame, a frame rotation steering engine, the toothed belt wheel mechanism and the like; extra precession moment is provided through the precession effect of a gyro rotor which rotates at a high speed, so that the operation speed of the robot is higher, and the climbing and obstacle crossing capacity is improved. The spherical robot can steer in-situ and is high in operation speed, the movement rapidity and flexibility of the spherical robot are greatly improved, and the spherical robot has great application prospects.

Owner:BEIJING UNIV OF POSTS & TELECOMM

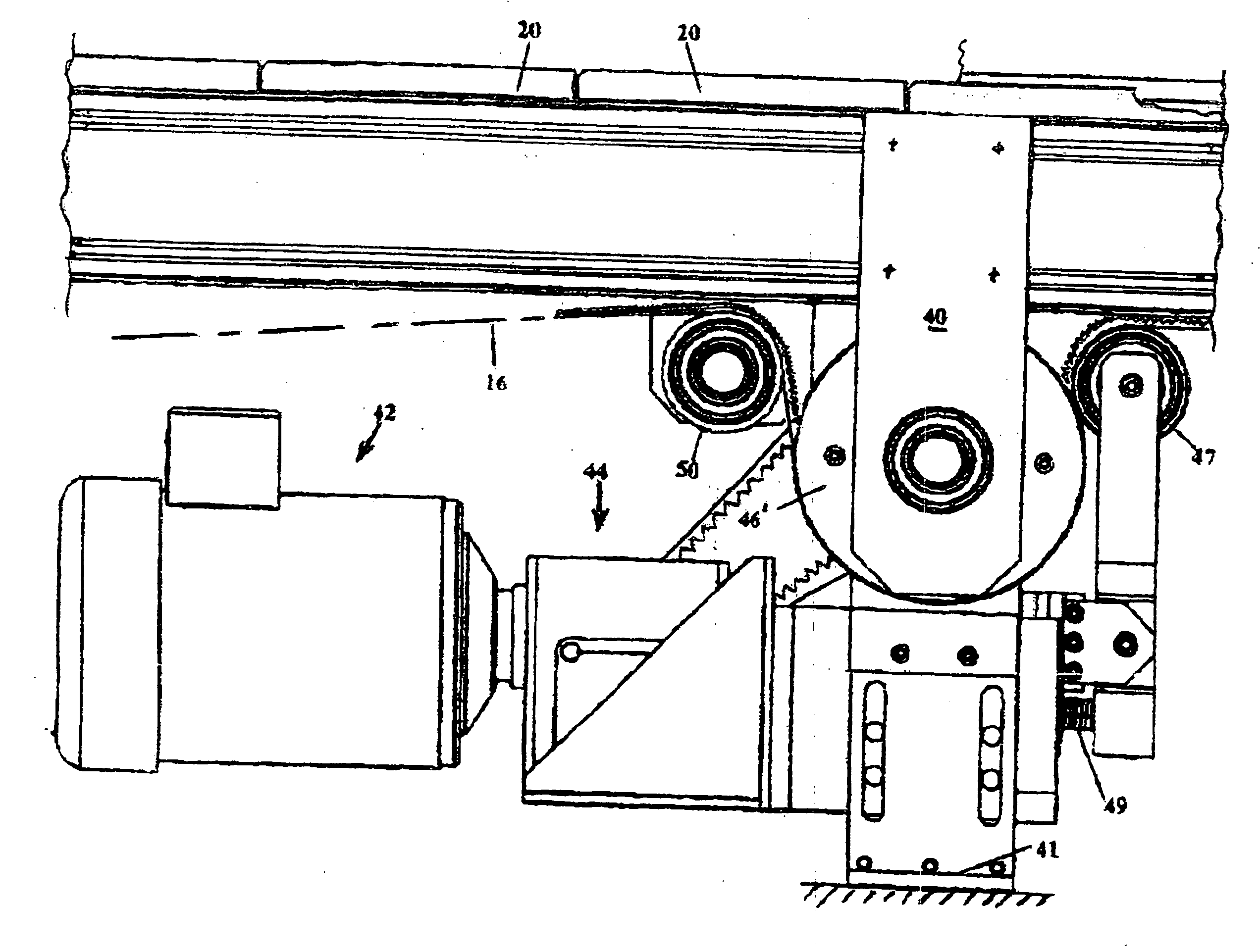

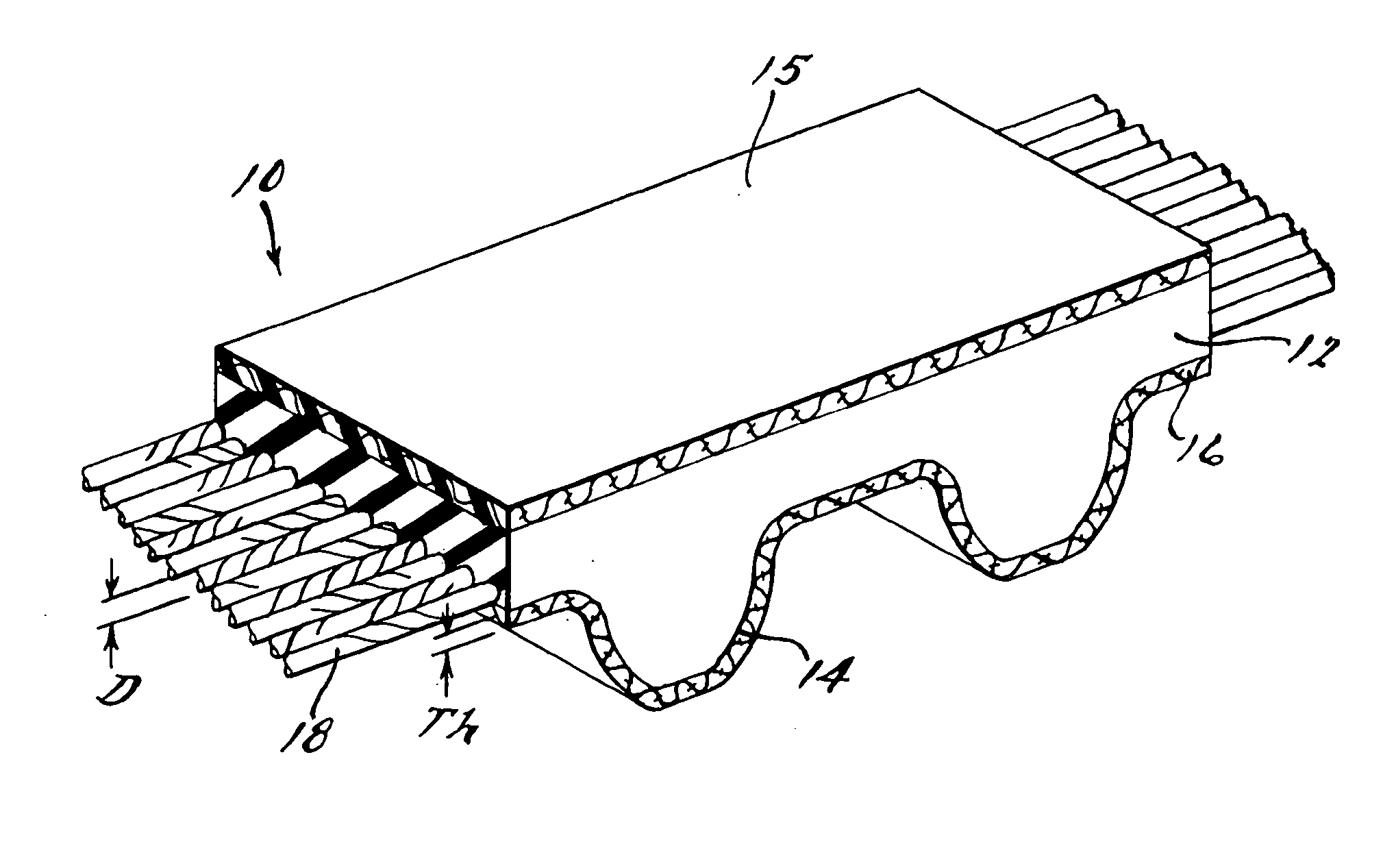

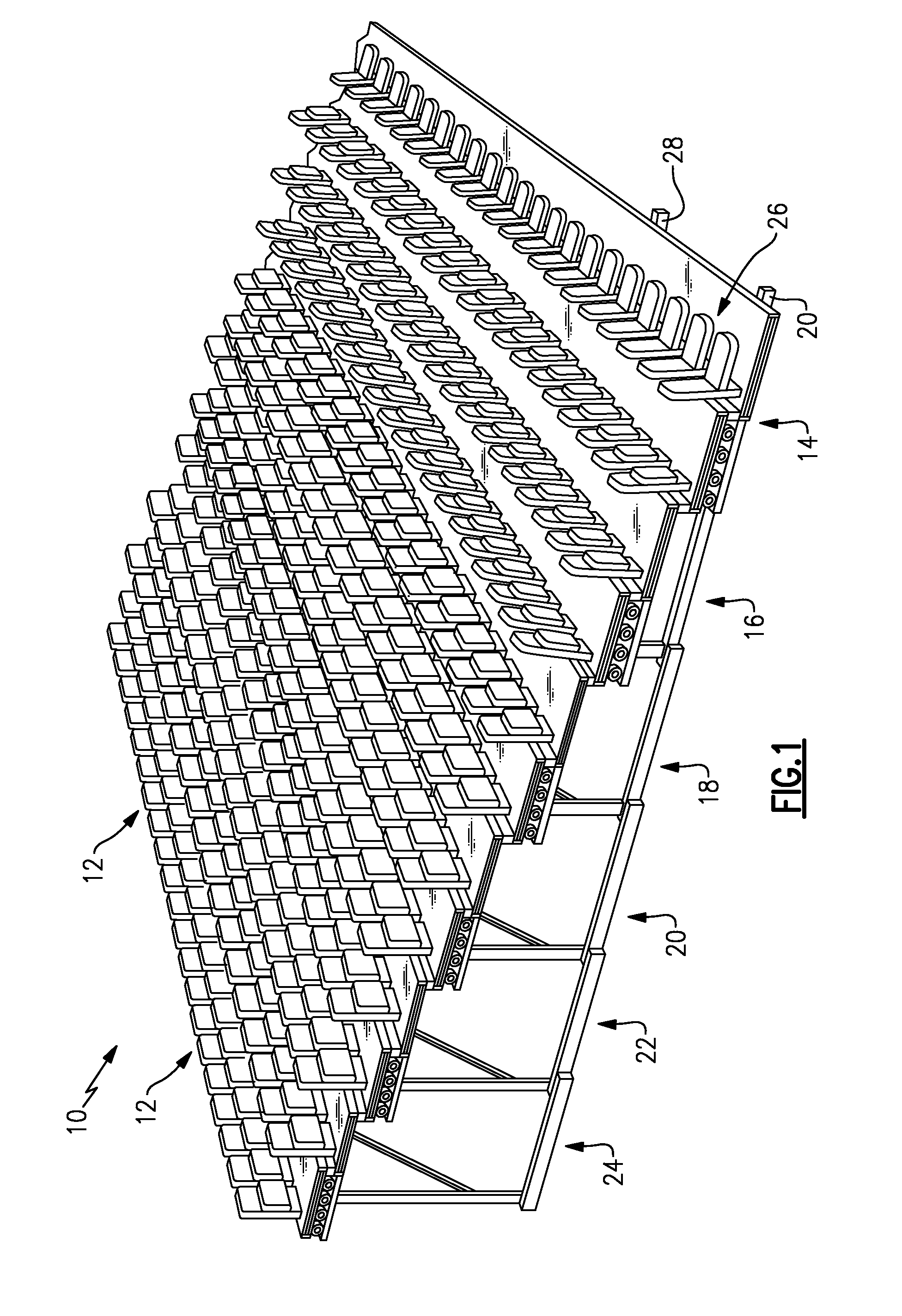

Vacuum belt conveyor system

ActiveUS20060021858A1Minimize air consumptionEfficient use ofConveyor partsRotary conveyorsSynchronous motorMotor drive

A vacuum conveyor has a toothed belt with opposed sets of teeth along the sides of the belt inner surface; the belt is driven by a synchronous motor giving very precise delivery, the motor driving a toothed roll located in the conveyor centre section within the loop of the belt. The oncoming and offgoing belt guidance rolls have replaceable bearing inserts; two rolls control the wrap and load transfer between the belt and the driving roll; the top reach of the perforated belt slides on plastic vacuum blocks, having through air passages in corresponding patterned relation at the surfaces of the blocks, bounded by air-sealing shoulder portions of the blocks.

Owner:SHERWOOD BERNARD J

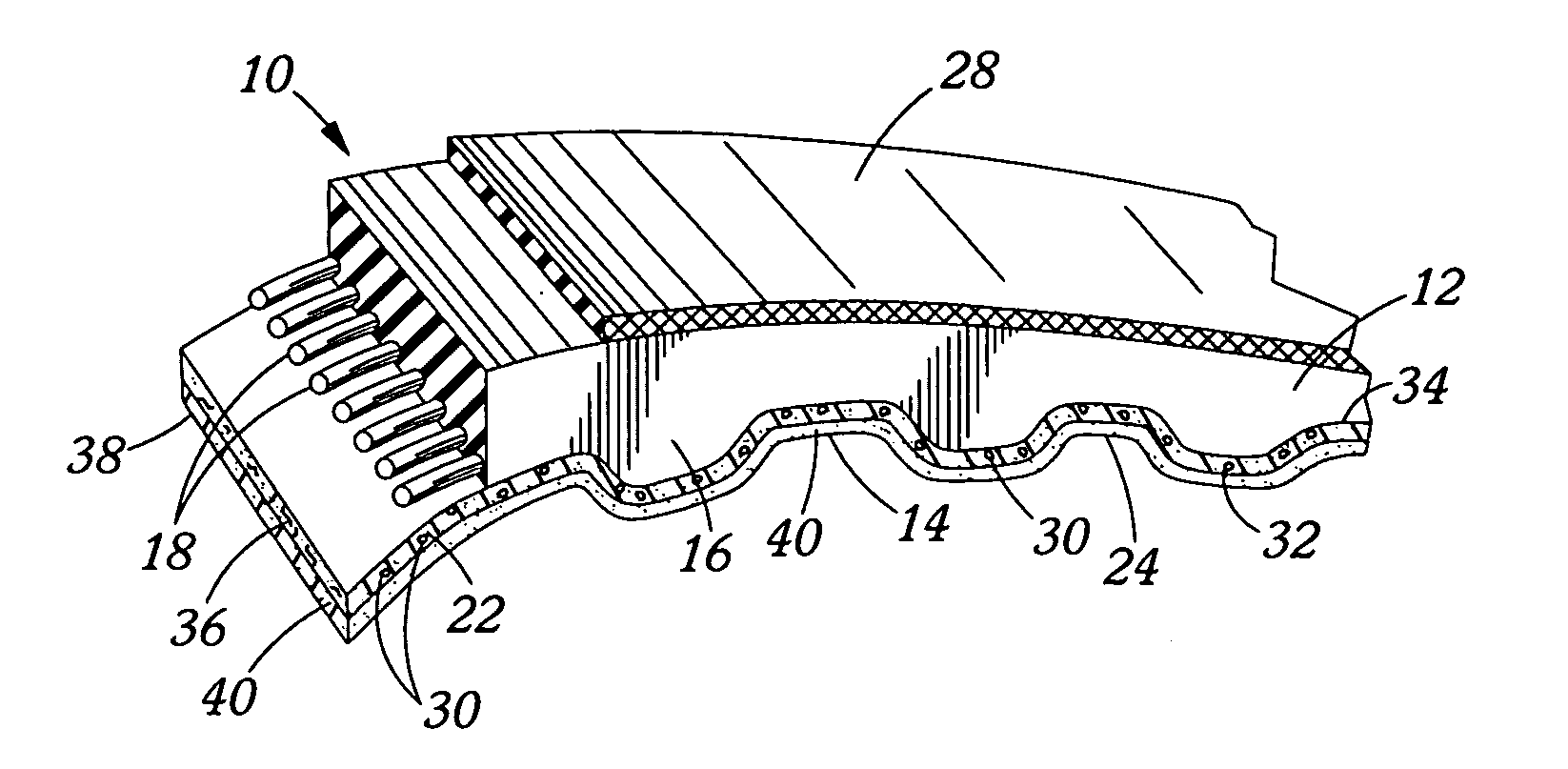

Power transmission belt, toothed belt and high duty power transmission V belt

InactiveUS20050113200A1Excellent abrasion resistanceImprove adhesionV-beltsRopes and cables for vehicles/pulleyElastomerEngineering

In a power transmission belt having a belt body made of a rubber composition, a belt cloth is provided at a friction force acting part of the belt body. The belt cloth is subjected to dipping treatment in a treatment solution obtained by dissolving into a solution a rubber composition in which uncrosslinked ethylene-α-olefin elastomer is mixed with a metal salt of unsaturated carboxylic acid and an organic peroxide as a crosslinking agent.

Owner:BANDO CHEM IND LTD

Synchronous body paper and face paper feeding device and control method

ActiveCN104340703ARealize synchronous high-speed paper feedingRealize functionArticle feedersWebs handlingMotor driveLow speed

The invention provides a synchronous body paper and face paper feeding device and a control method. The device is characterized in that a face paper front lay gauge, a face paper pressing wheel, a face paper side lay gauge, a body paper front lay gauge and a body paper lifting plate assembly are configured with cam mechanisms respectively and are driven by the respective cam mechanisms; a face paper motor drives a low-speed face paper feeding belt assembly, a body paper induced draft air distribution valve, a face paper side pull gauge and cam mechanisms thereof through a synchronous toothed belt or a roller chain; a paper injection driving roller, an upper pressing driving roller, a paper feeding driving roller, a high-speed face paper injection wheel and a high-speed face paper conveying belt assembly are driven by a body paper motor at the same speed. The distance between the face paper front lay gauge and a laminating roller is equal to the distance between the body paper front lay gauge and the laminating roller, so that body paper and face paper reach a converging point at the same time, and surface lamination is completed. The functions of synchronously feeding the body paper and the face paper at a high speed and automatically aligning the body paper with the face paper can be realized, the use of the motors is reduced, and the phenomenon that the motors are frequently started is avoided. The working efficiency is improved, and the manufacturing cost is reduced.

Owner:QINGDAO MEIDA INTELLIGENT TECH CO LTD

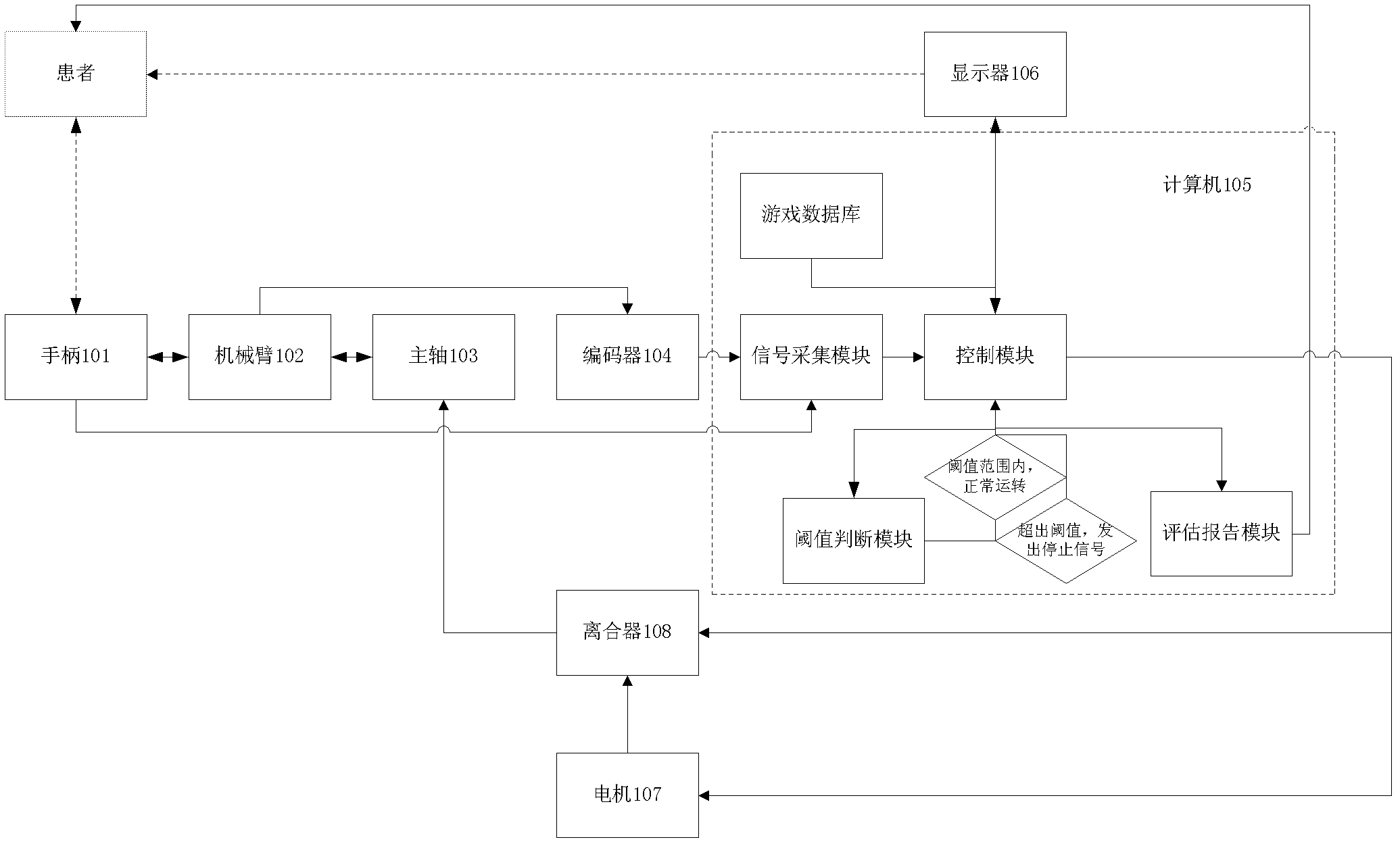

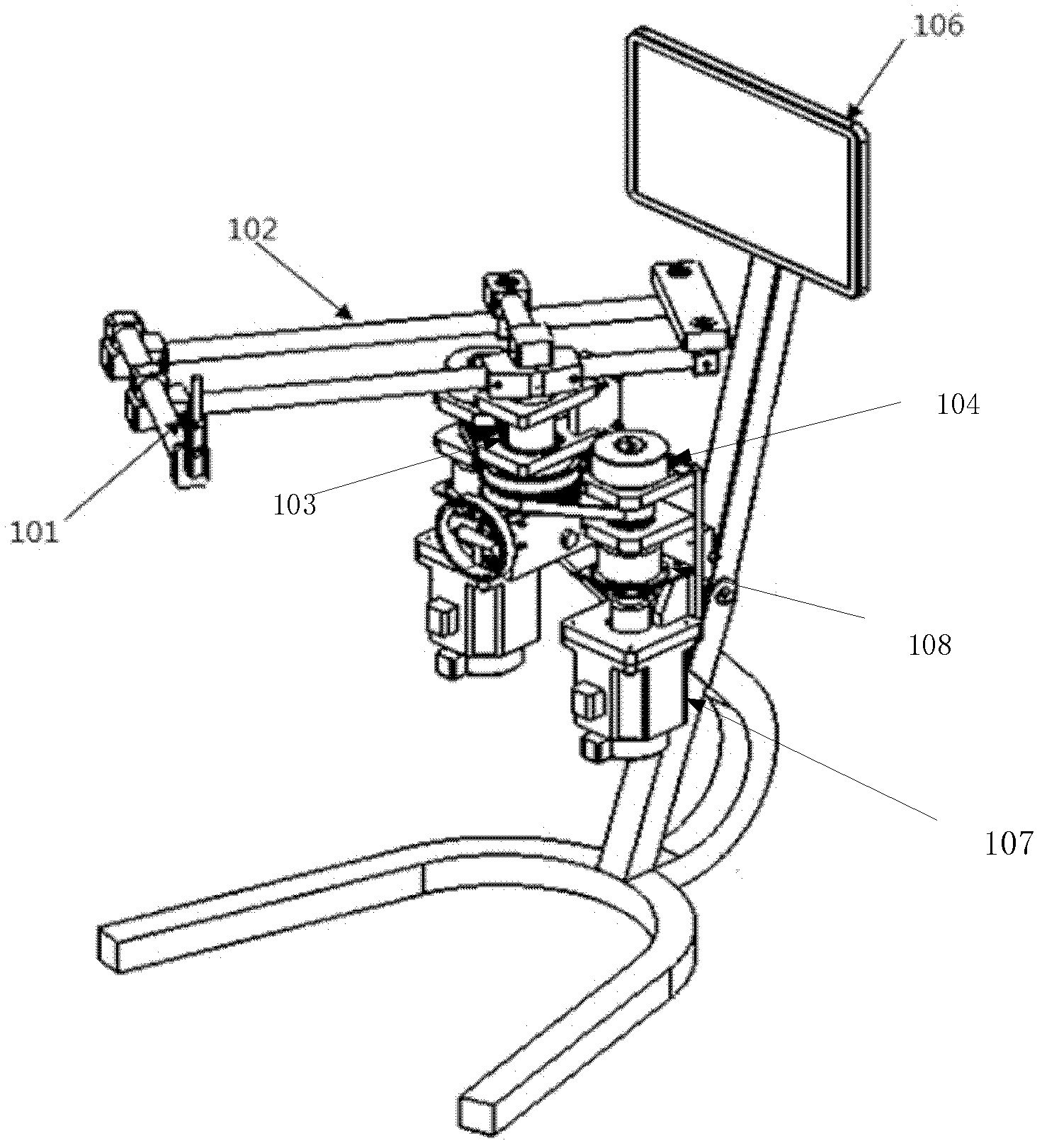

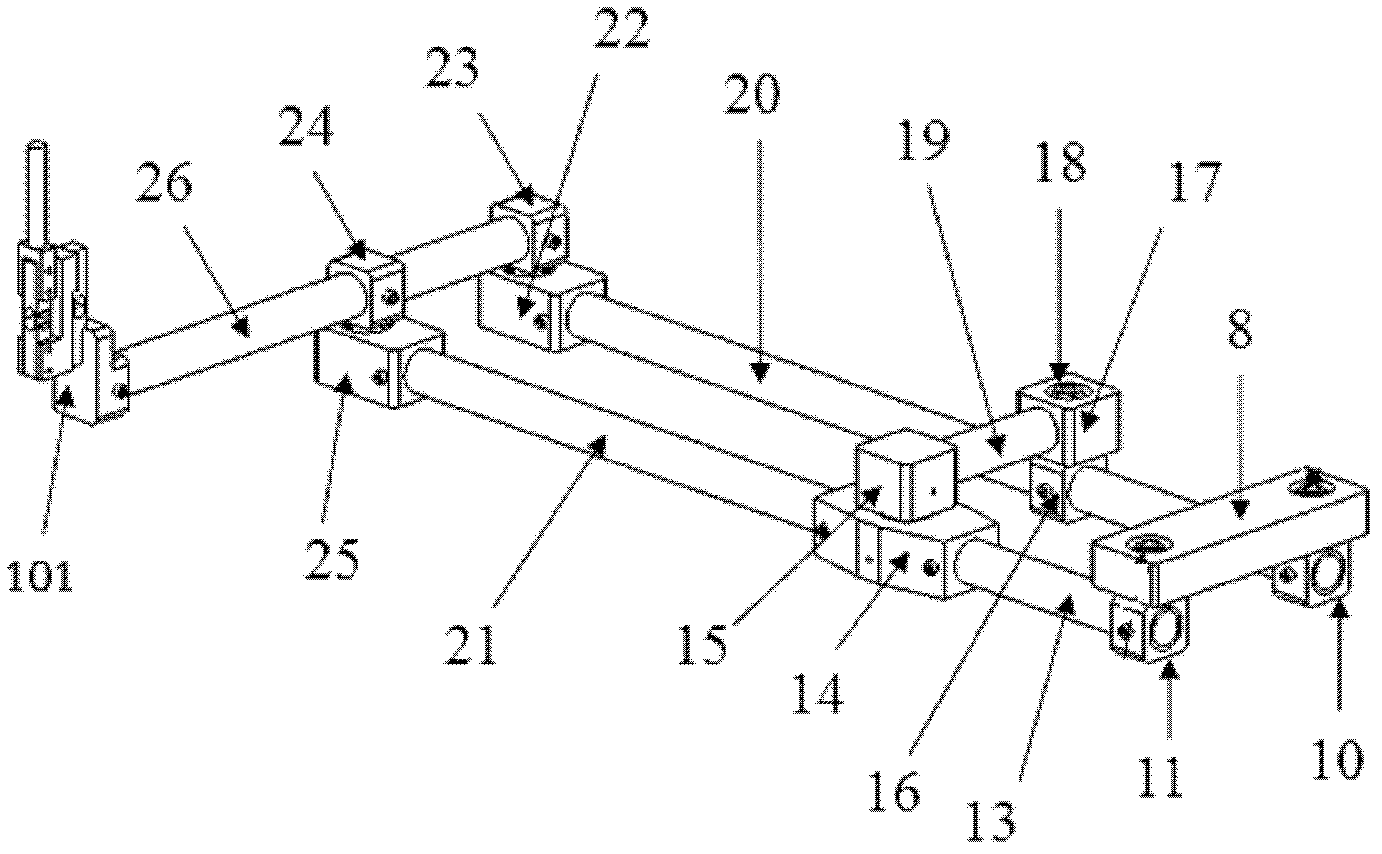

Upper limb rehabilitation training system with active-passive modes

InactiveCN102499853AWith security protectionFacilitate rehabilitation trainingGymnastic exercisingChiropractic devicesPatient needUpper limb rehabilitation

The invention belongs to the technical field of medical instruments, and relates to a rehabilitation training system, in particular to an upper limb rehabilitation training system with active-passive modes. The technical scheme includes that the upper limb rehabilitation training system with the active-passive modes comprises a handle, a mechanical arm, a spindle, an encoder, a computer, a display, a motor, a clutch, a coupler, a belt pulley, a belt pulley shaft, a synchronous toothed belt and a rehabilitation device base. Compared with equipment in the past, the upper limb rehabilitation training system has the advantages that active acting force is provided for a patient needing rehabilitation, the mechanical arm can drive an arm of the patient to perform rehabilitation training in the active mode so as to achieve better rehabilitation training effects, and a threshold safety module is arranged inside the computer so that safety of the patient in rehabilitation training can be enhanced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

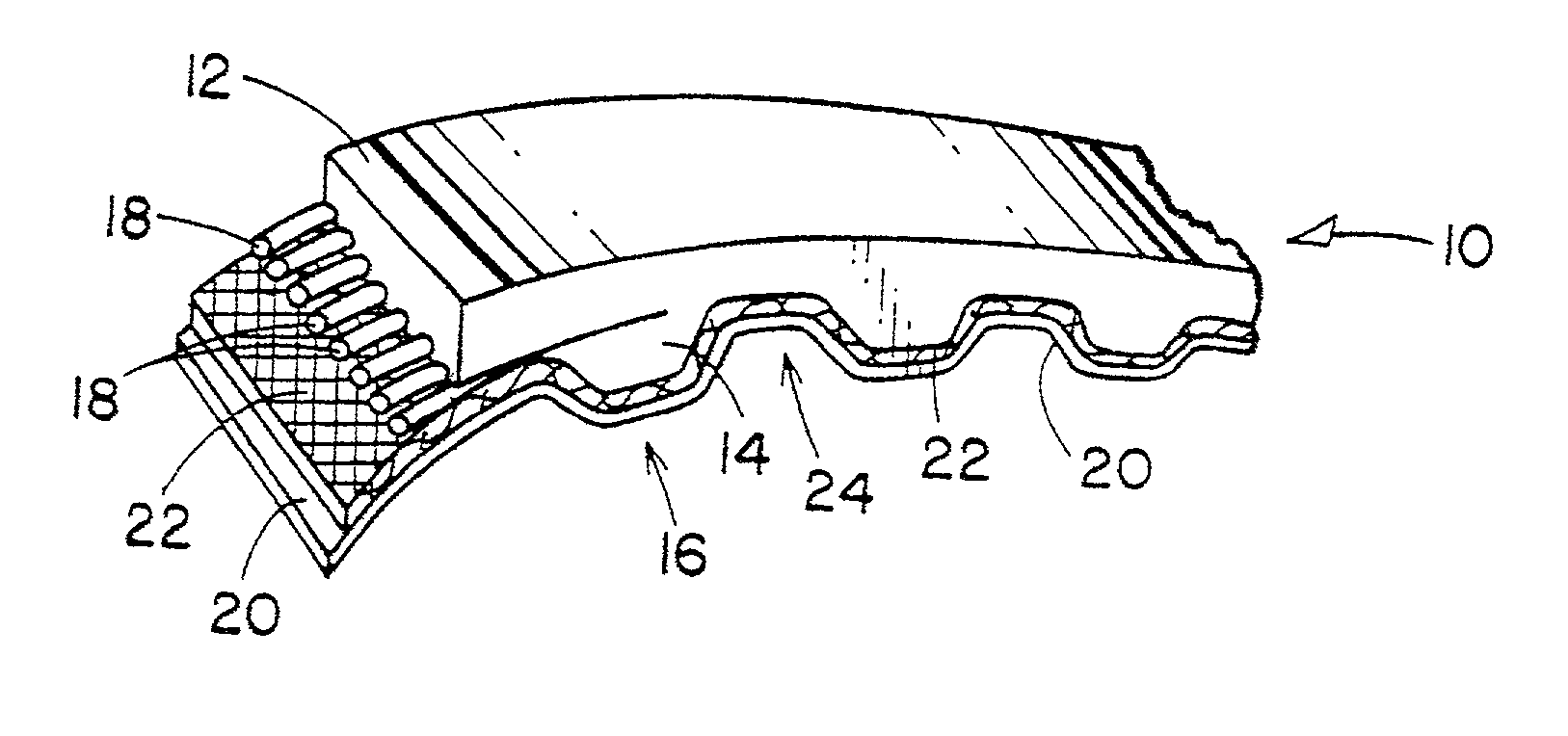

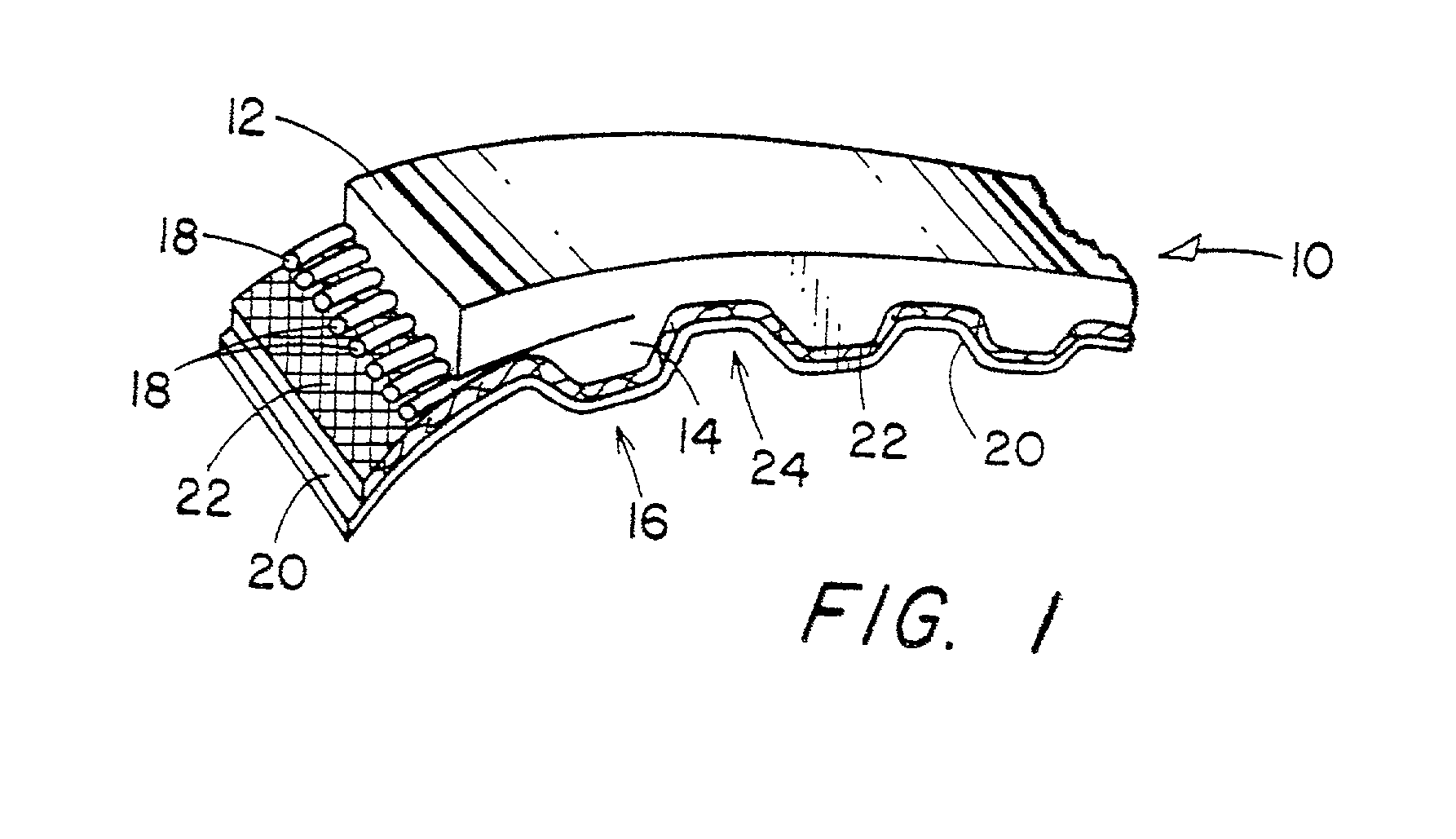

Power transmission belt and a process for its manufacture

ActiveUS20080004145A1Increase concentrationReduce concentrationV-beltsDriving beltsWear resistantTotal thickness

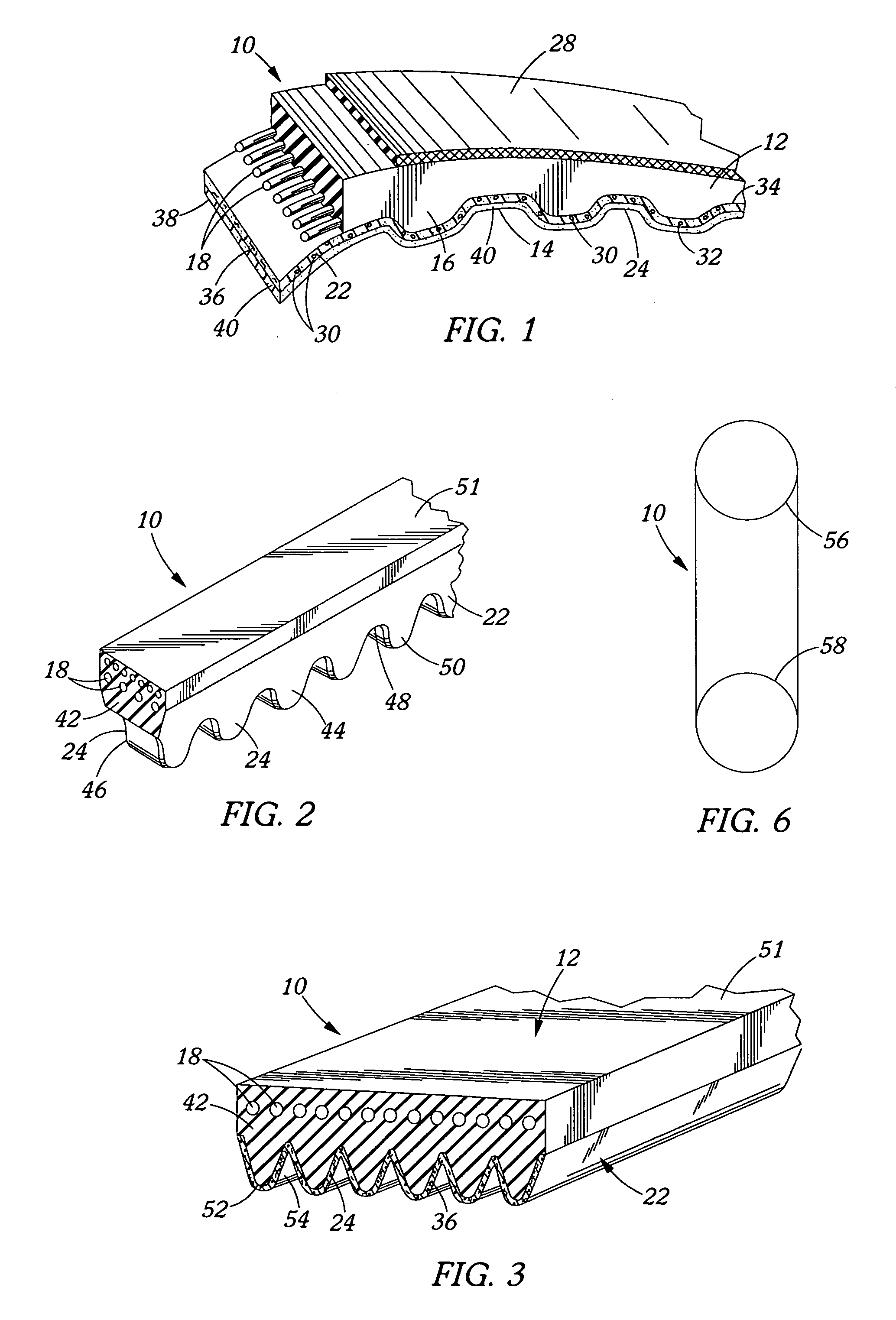

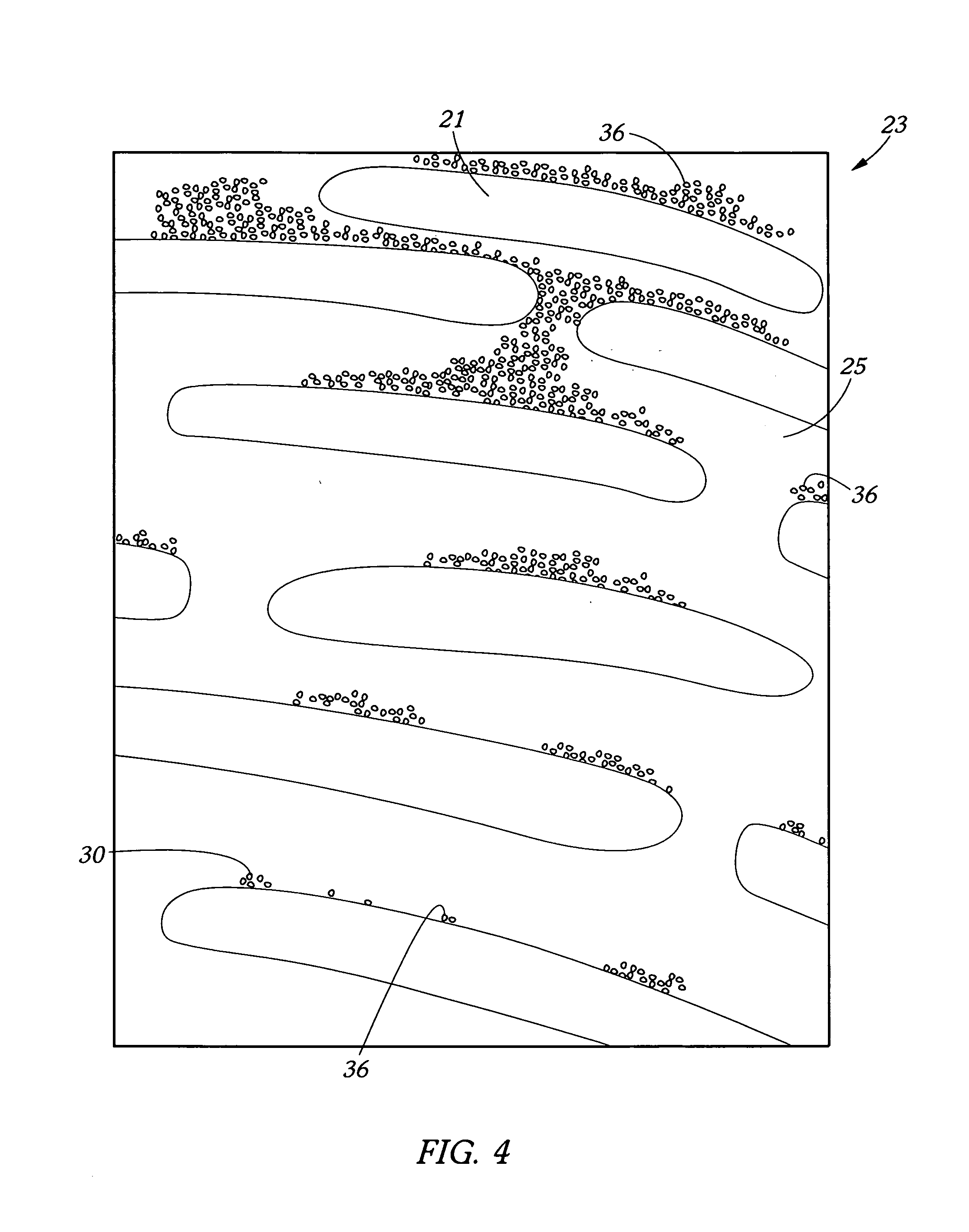

An endless power transmission belt having a internal lubricating agent-containing fabric element extending along at least the pulley-engaging, power-transmitting surface of the belt, as well as processes for manufacturing same. More particularly, an endless toothed belt having a wear-resistant fabric cover element that comprises at least one internal lubricating agent in the form of one or more clusters within at least a portion of the total thickness of the fabric element.

Owner:THE GATES CORP

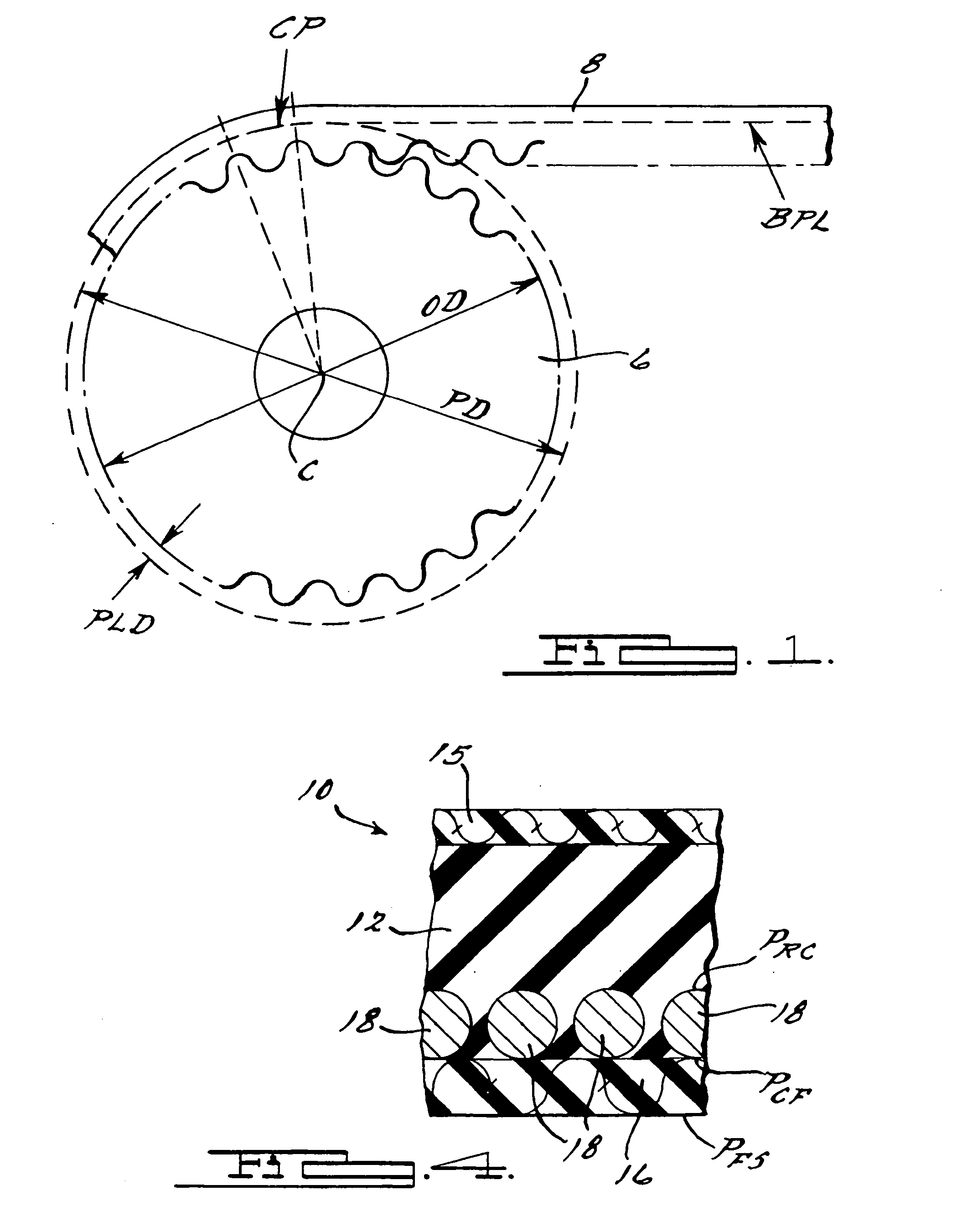

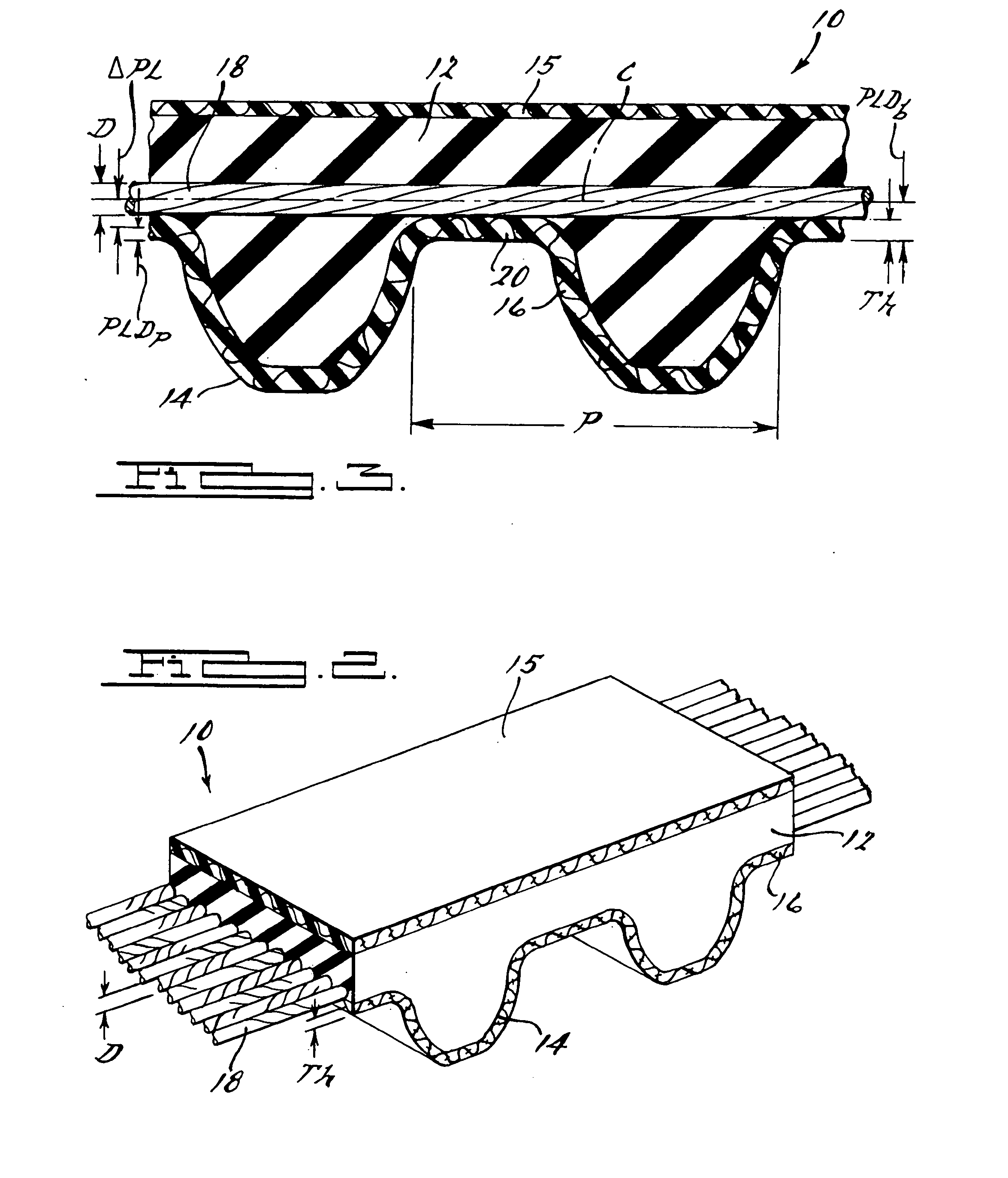

Toothed power transmission belt

ActiveUS20070232429A1Increase flexibilityImprove carrying capacityV-beltsRopes and cables for vehicles/pulleyEngineeringPower transmission

A toothed belt includes a body, at least one tooth formed of the body, a jacket disposed along a peripheral surface of the at least one tooth and having a compressed thickness in the range from 0.5 mm to about 0.8 mm, and at least one cord embedded in the body and having a diameter. The at least one cord and said jacket have a ratio of said cord diameter to said jacket thickness of less than 1.8, and said cord diameter and said jacket thickness describe an optical belt PLD of about 1.2 mm or less.

Owner:THE GATES CORP

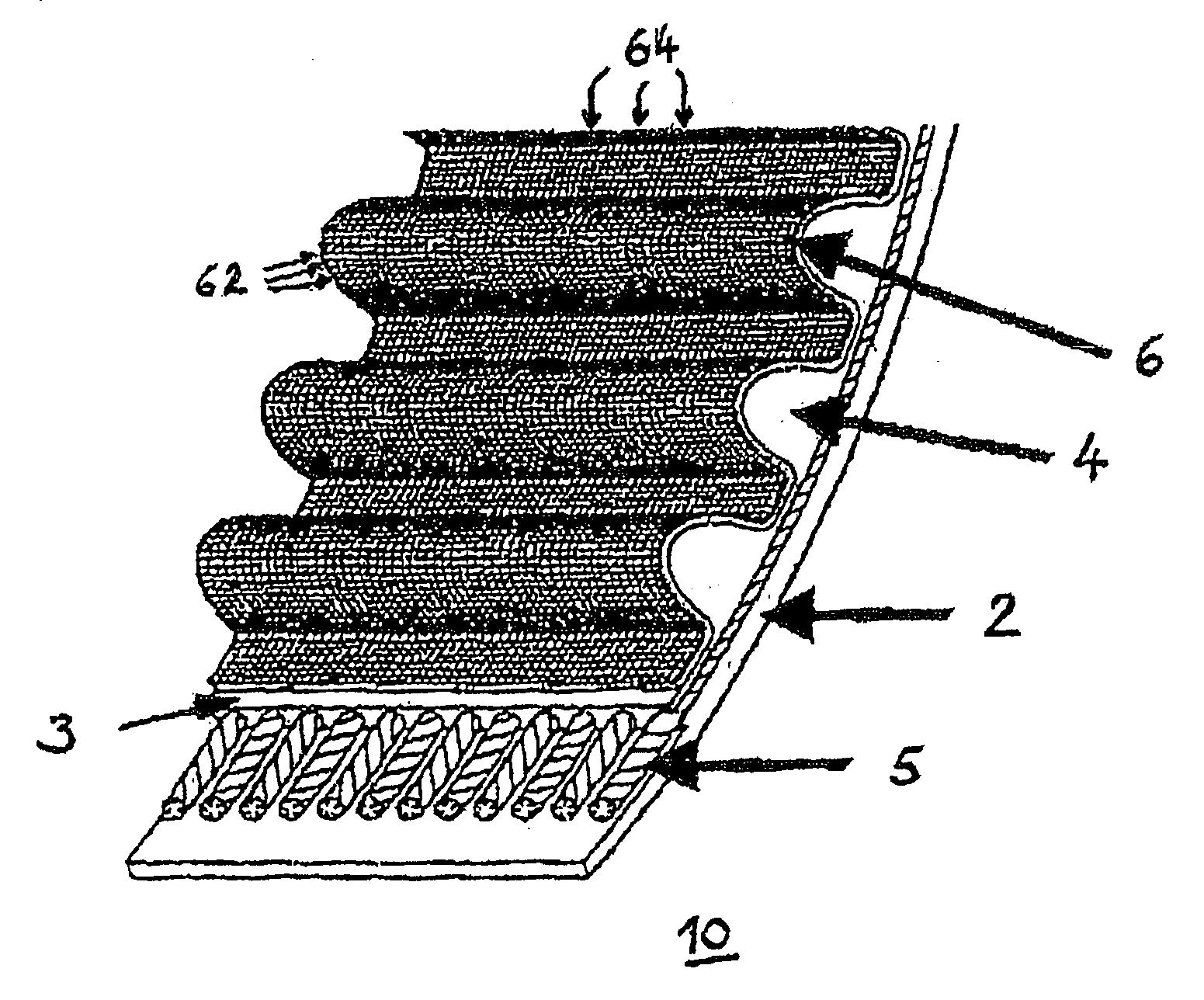

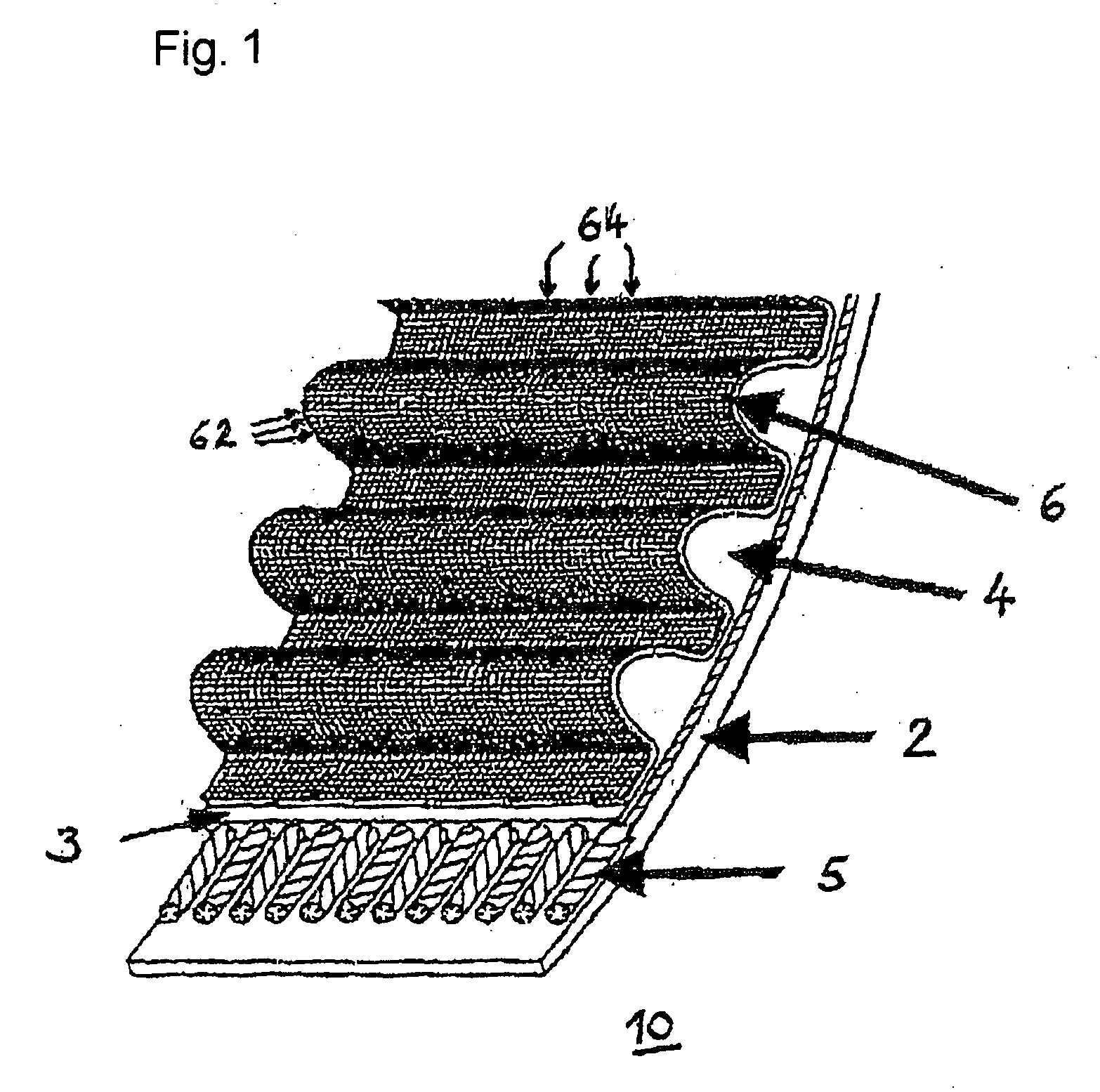

Toothed belt having a tooth covering made of fabric

An HNBR-based toothed rubber belt (10) with a glass, carbon and / or aramid cord reinforcement (5) has a modified tooth covering (6) made of polyamide 6.6 fabric having weft threads (64) entirely or partly replaced in the peripheral / longitudinal direction of the belt by yarns made of polyether ether ketone (PEEK), polyimide (PI) and / or meta-aramid (M-A) or modified with PEEK, PI and / or M-A.

Owner:CONTITECH ANTRIEBSSYST

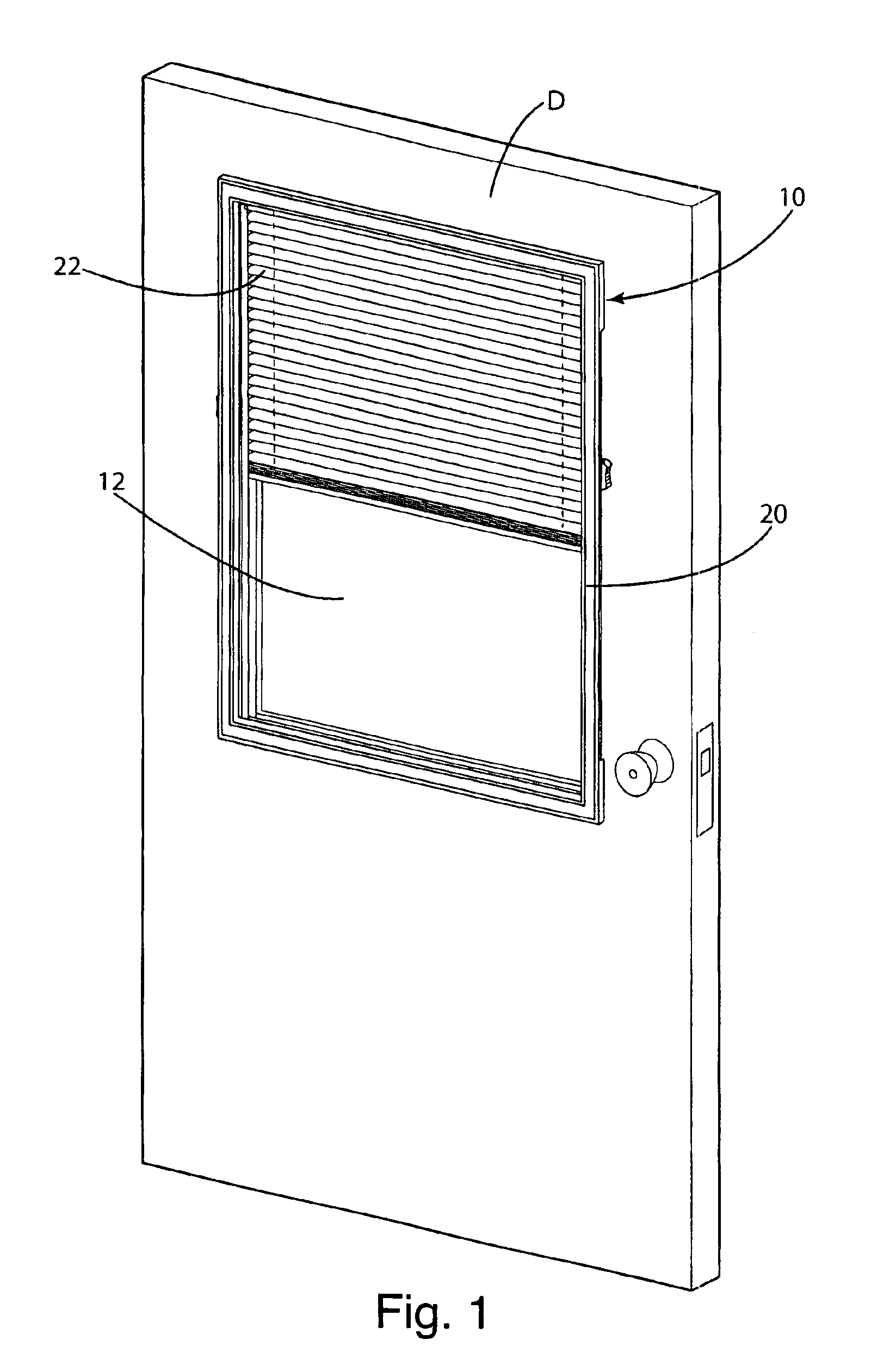

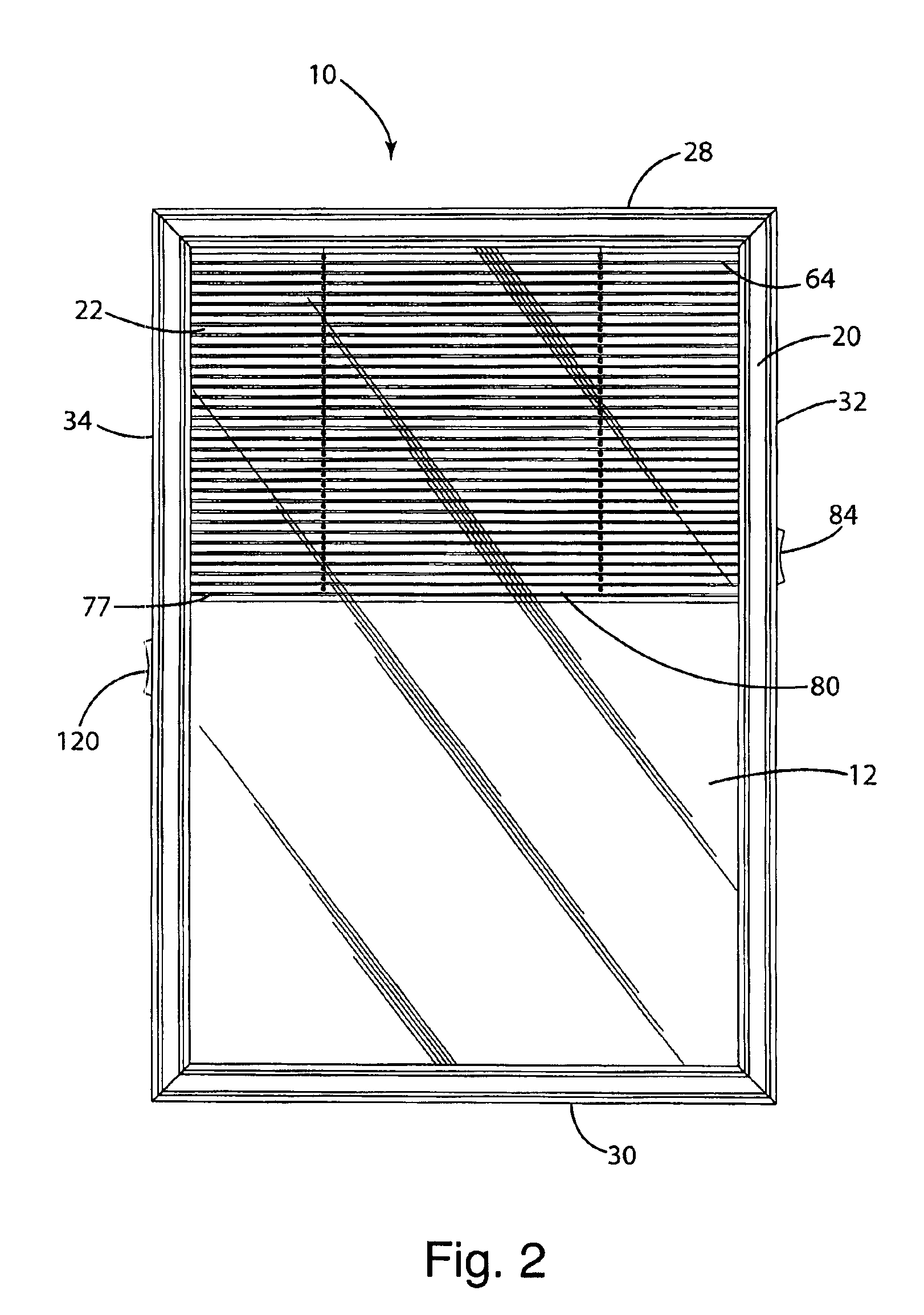

Retrofit doorlight blind assembly

InactiveUS7082982B2Good adhesionEasy detachmentVentilation arrangementCurtain suspension devicesEngineeringActuator

A retrofit blind assembly for a doorlight. The assembly includes a frame, a transparent panel, and a blind snap-fitted to the frame. The blind actuator includes gears and a toothed belt for positive, non-slip actuation. A pair of blind guides are mounted on the opposite sides of the frame to receive and guide the opposite ends of the blind. The mounting system includes a pair of brackets that can be secured between the doorlight and the door and upon which the assembly can be hung. The mounting system also includes a pair of movable catches on the lower portion of the frame snap that can be locked behind the doorlight to secure the lower end of the assembly.

Owner:ODL

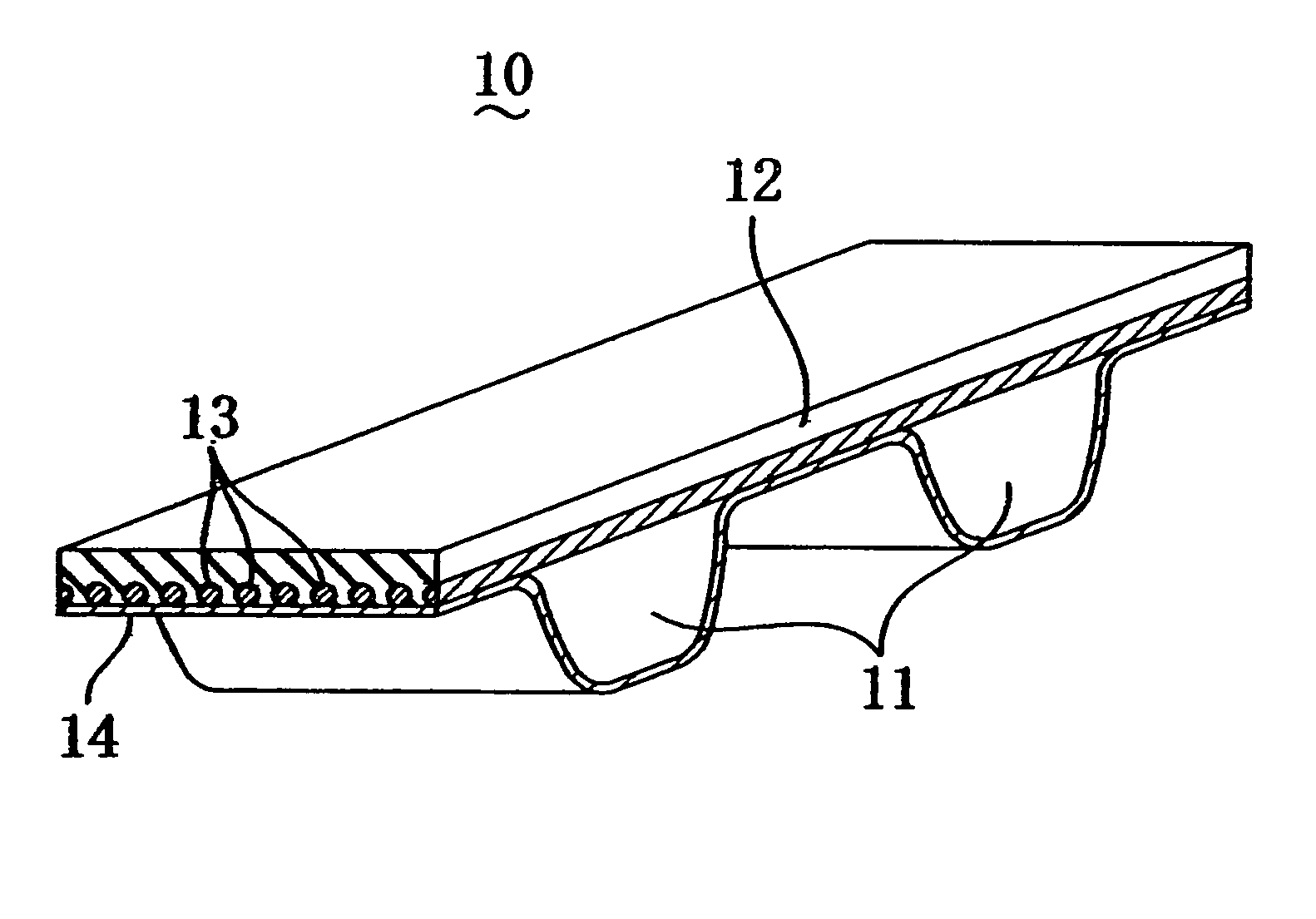

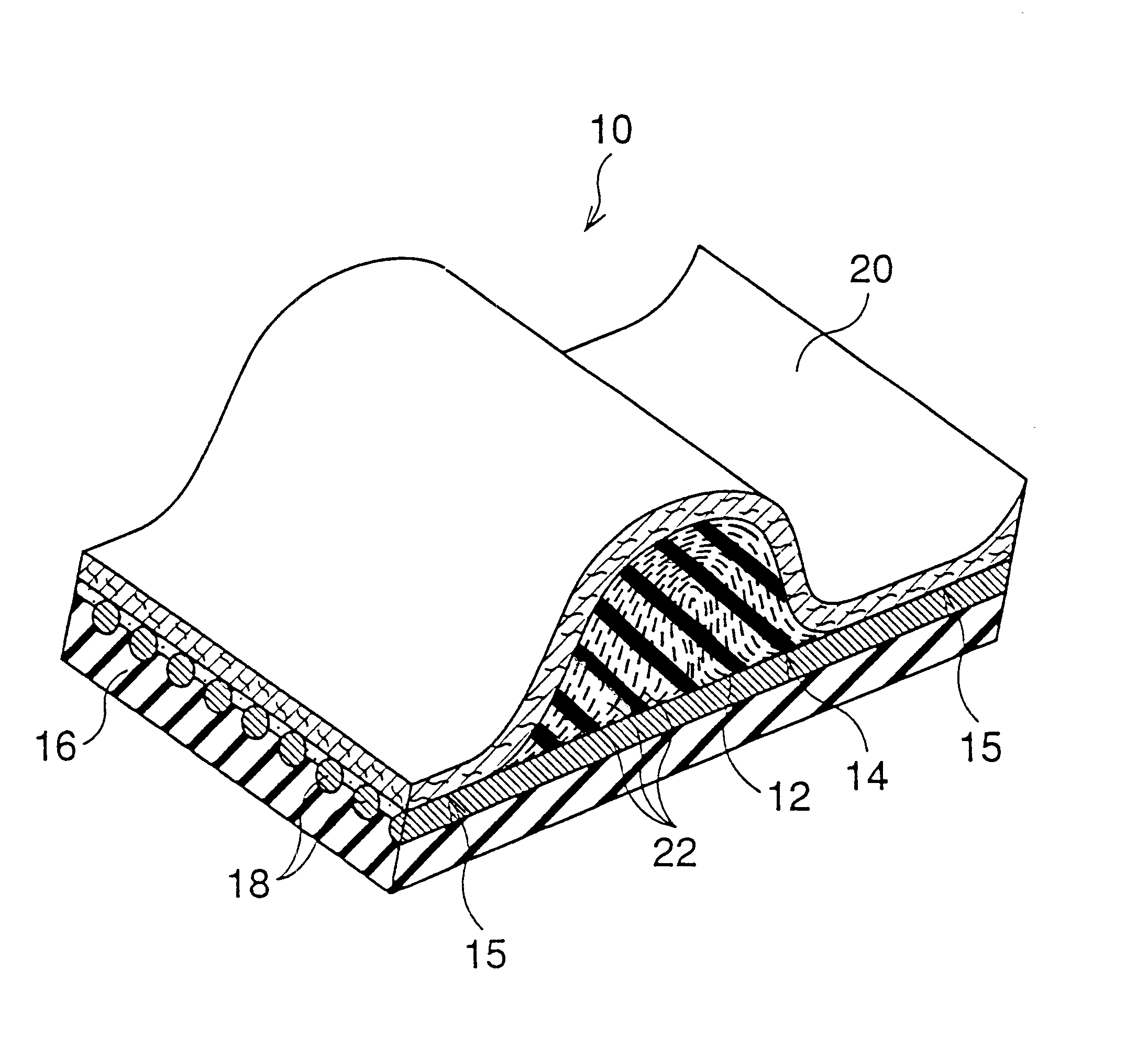

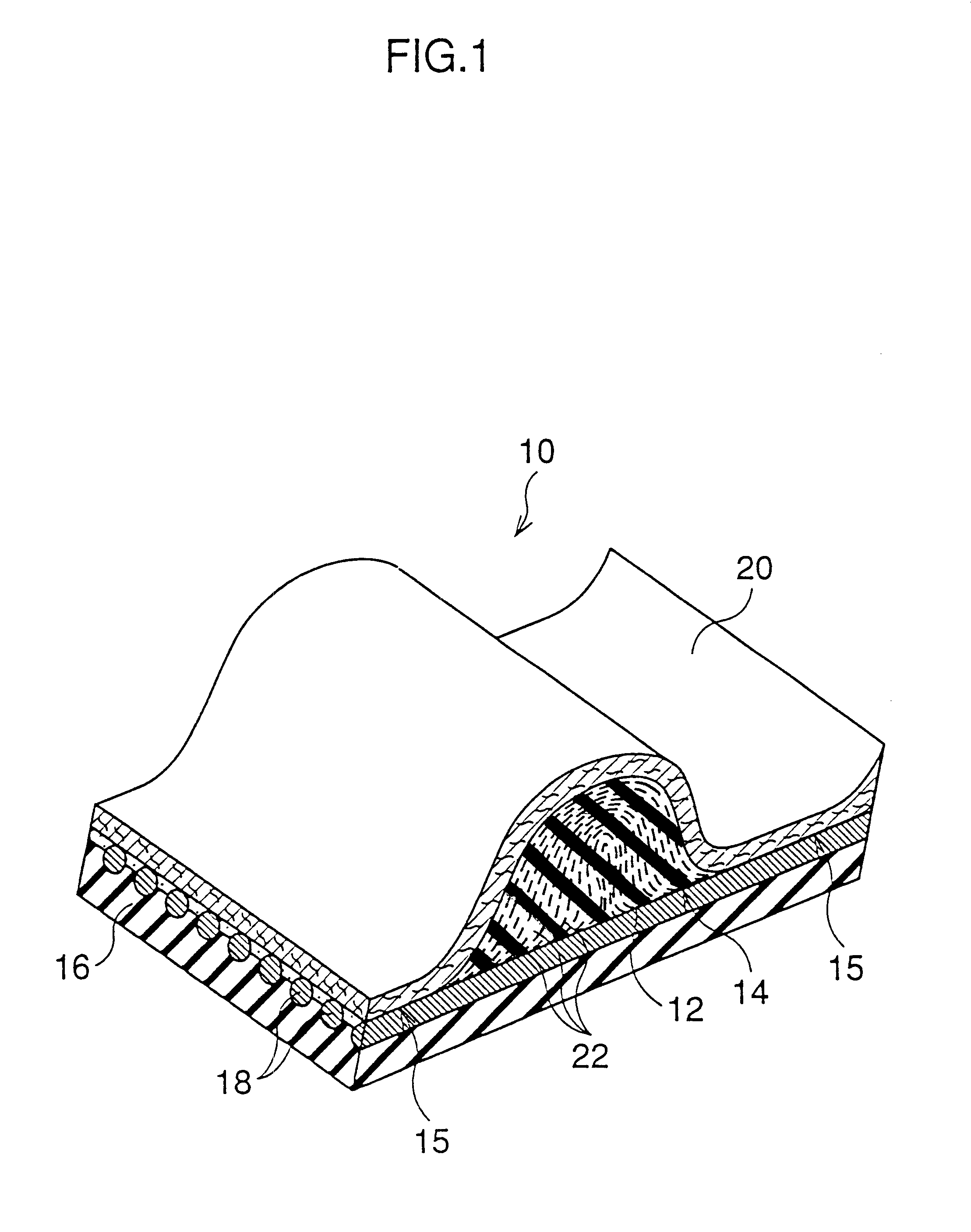

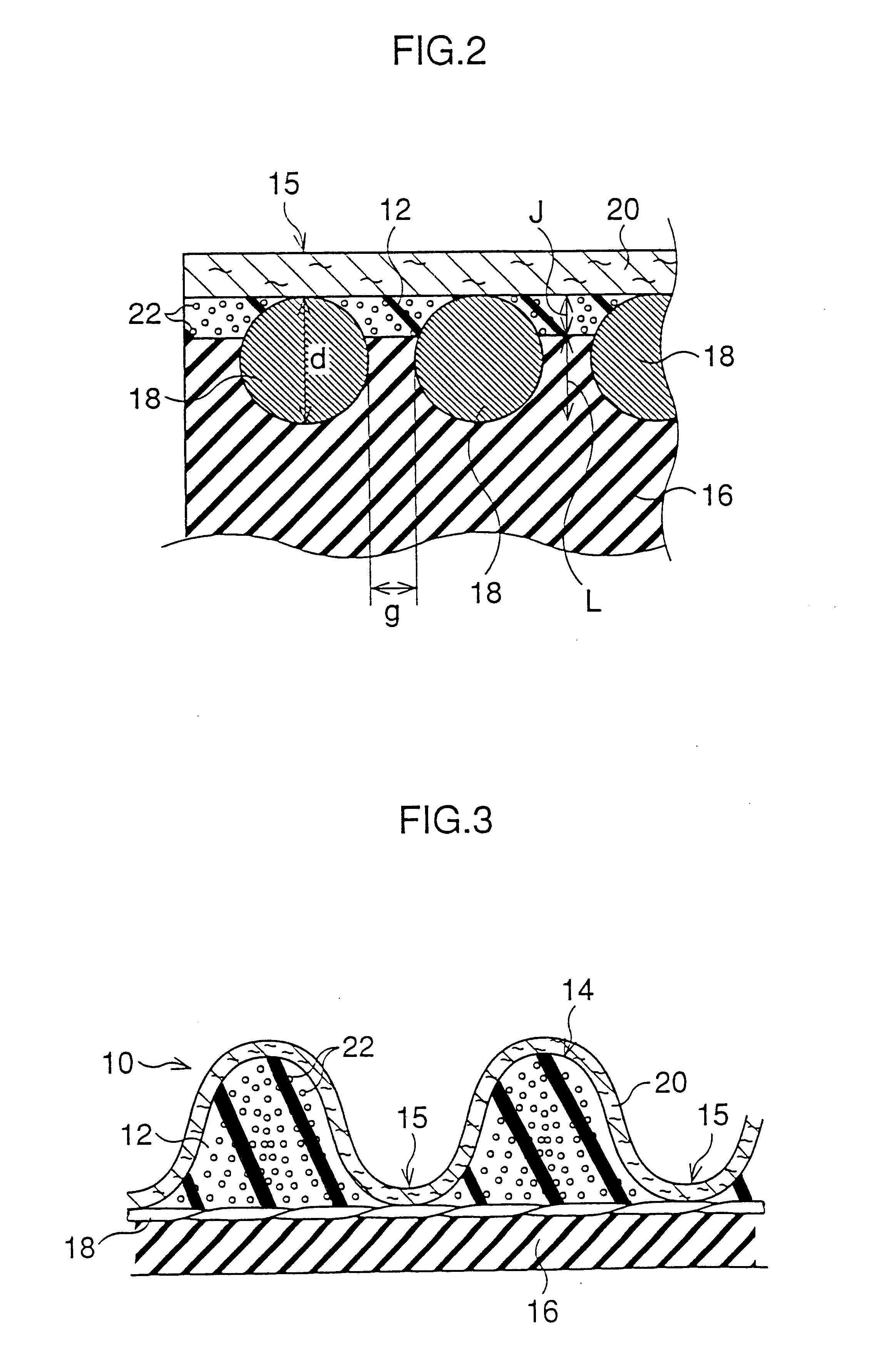

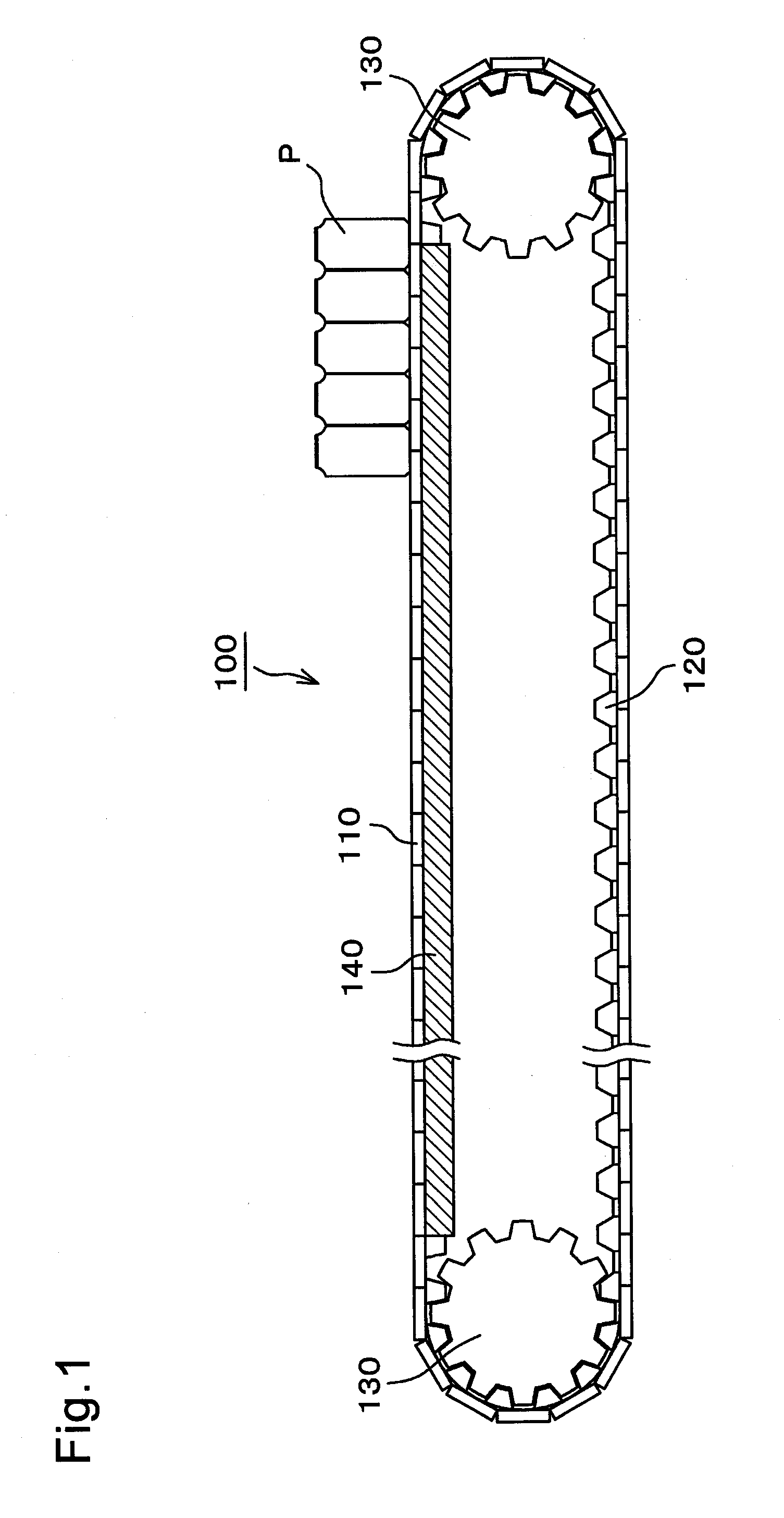

Toothed belt including short fibers distributed therein

A toothed belt includes a toothed rubber layer having teeth formed on a surface thereof and containing a plurality of short fibers entirely distributed therein. The surface of the toothed rubber layer, on which the teeth are formed, is covered with a cover fabric. A back rubber layer is integrally applied to the other surface of the toothed rubber layer. A plurality of cord elements is disposed across a width of the belt and is intervened between the toothed rubber layer and the back layer in such a manner that a portion of each cord element is embedded in the toothed rubber layer, and the remaining portion thereof is embedded in the back rubber layer. The short fibers are entirely distributed in the toothed rubber layer and are regularly oriented.

Owner:UNITTA

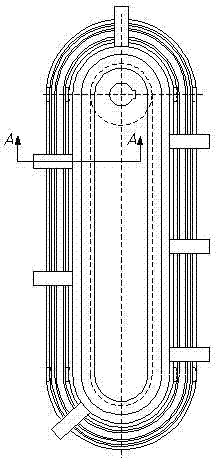

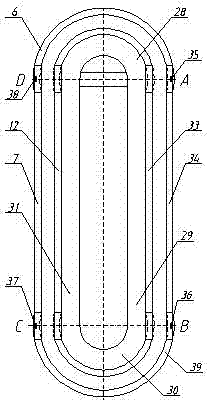

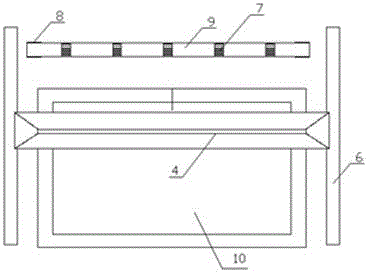

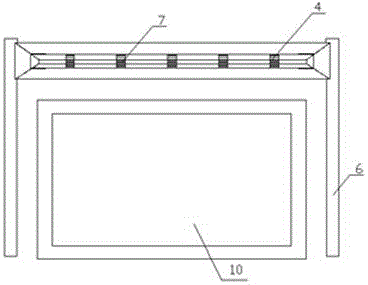

Magnetic suspension tentering sizing transmitting unit

ActiveCN103046280AAchieve separationReasonable structureStretchingMechanical engineeringMagnetic levitation

The invention discloses a magnetic suspension tentering sizing transmitting unit which comprises a bracket, wherein a support base is arranged on the bracket, a support guide rail and a guide rail are arranged on the support base, a working platform is sleeved on the support base, a toothed belt is arranged on the working platform, a needle felt is arranged on the toothed belt, a rotary motor is arranged on one arc end of the support end, a gear disk is arranged on the rotary motor, and the gear disk is meshed with the toothed belt corresponding to the gear disk in position. The magnetic suspension tentering sizing transmitting unit is reasonable and simple in structure and reliable in operation.

Owner:泰州市海通资产管理有限公司

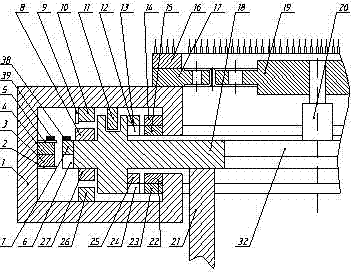

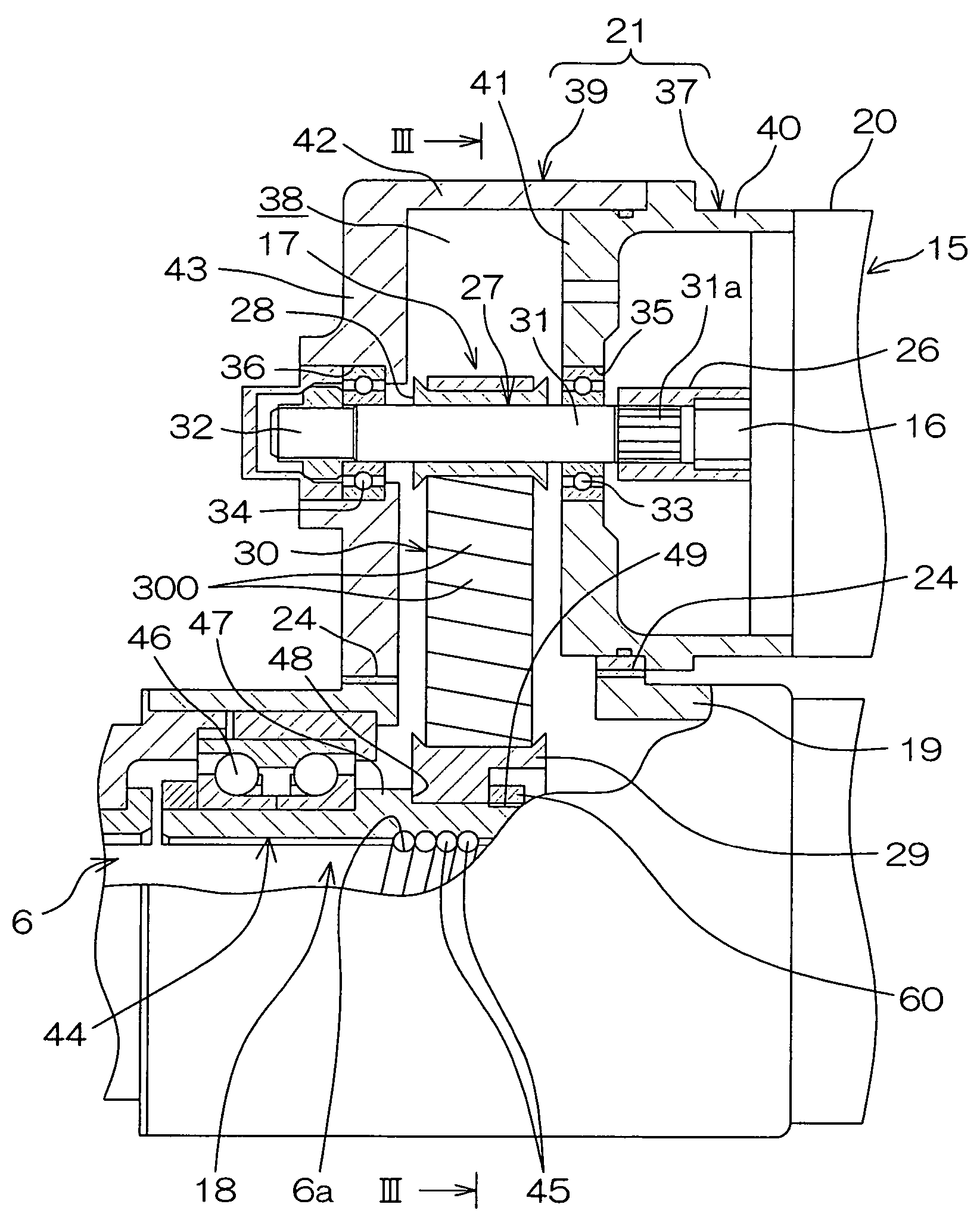

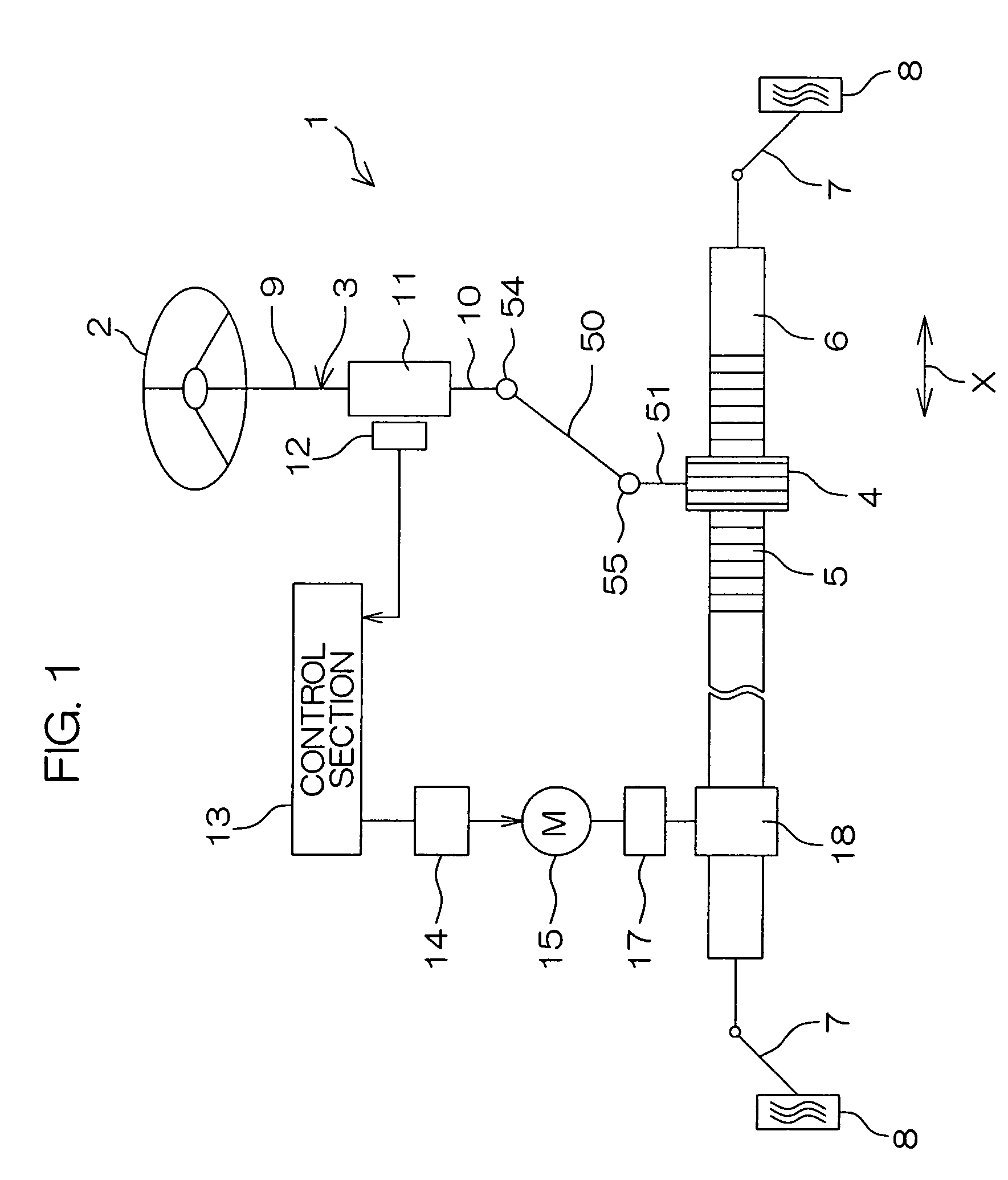

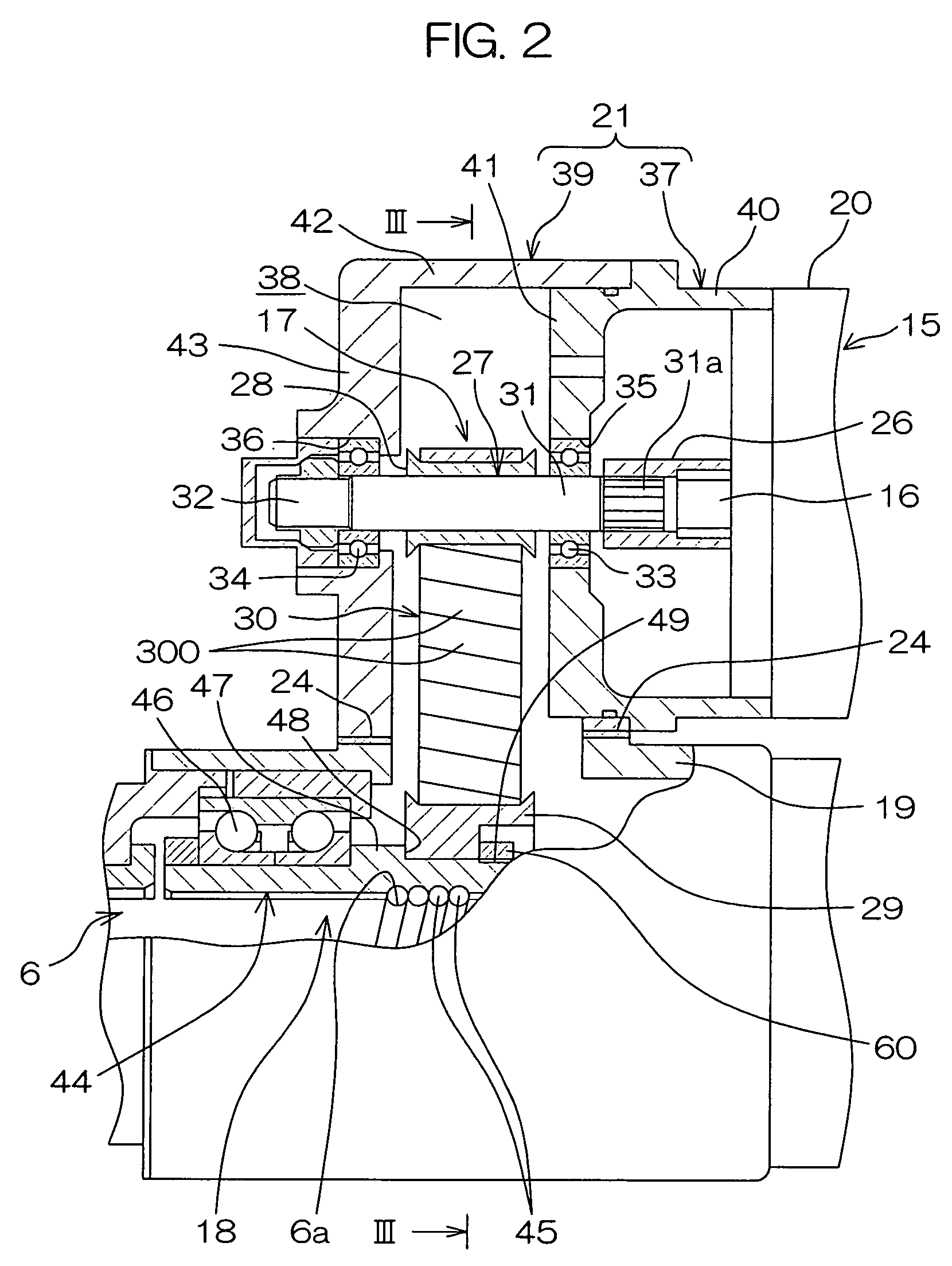

Electric power steering apparatus

ActiveUS7278334B2Reduce vibrationReduce noiseGearingElectrical steeringElectric power steeringEngineering

An electric power steering apparatus comprises an electric motor for producing a steering assist force, and a speed reduction mechanism for decelerating the rotation of an output shaft in the electric motor. The speed reduction mechanism comprises an input pulley driven by the electric motor, an output pulley connected to a steering shaft, and a belt for connecting the input pulley and the output pulley to each other. The belt comprises a helical toothed belt. The input pulley and the output pulley respectively include helical toothed pulleys meshed with the helical toothed belt.

Owner:JTEKT CORP +1

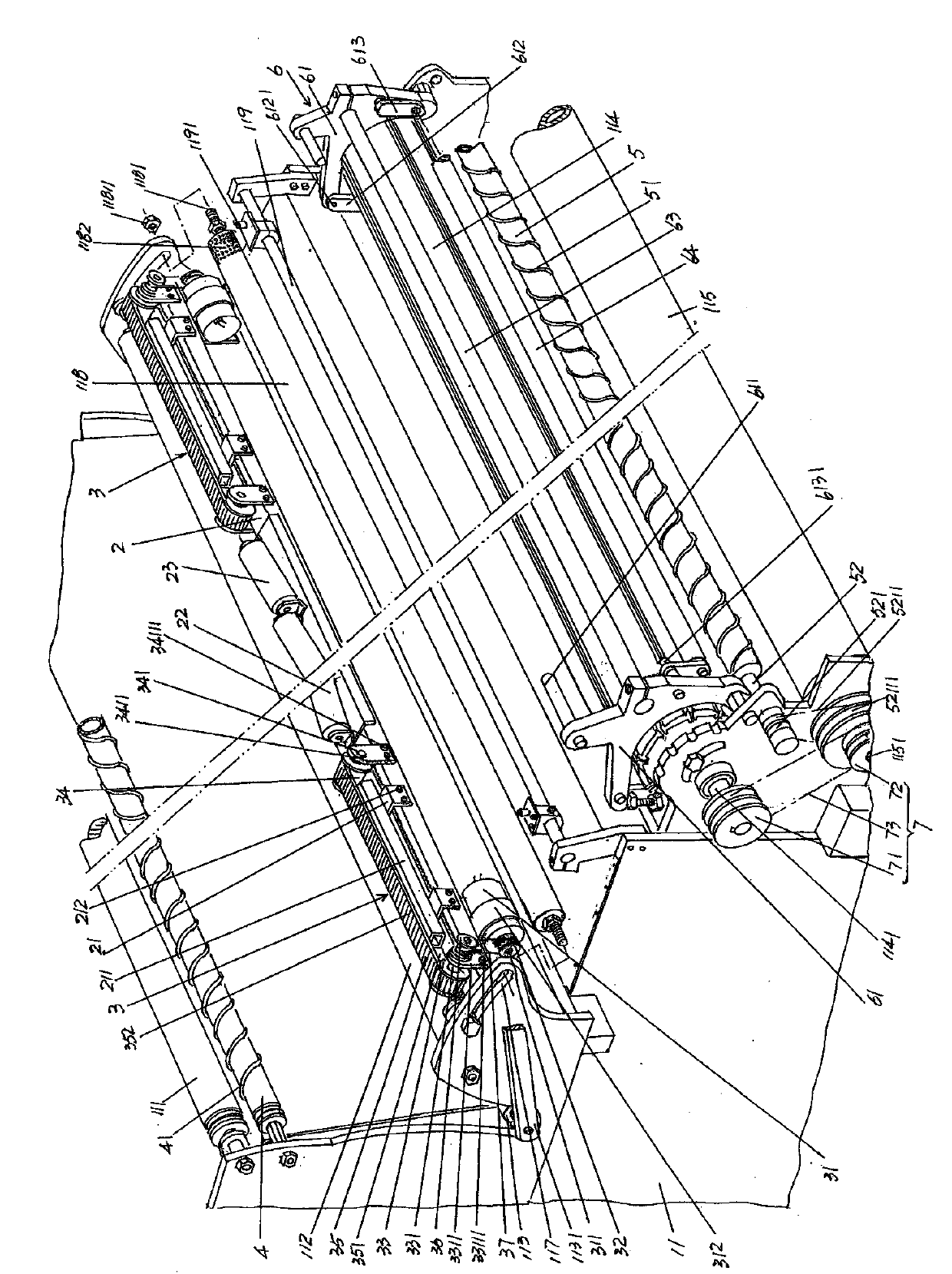

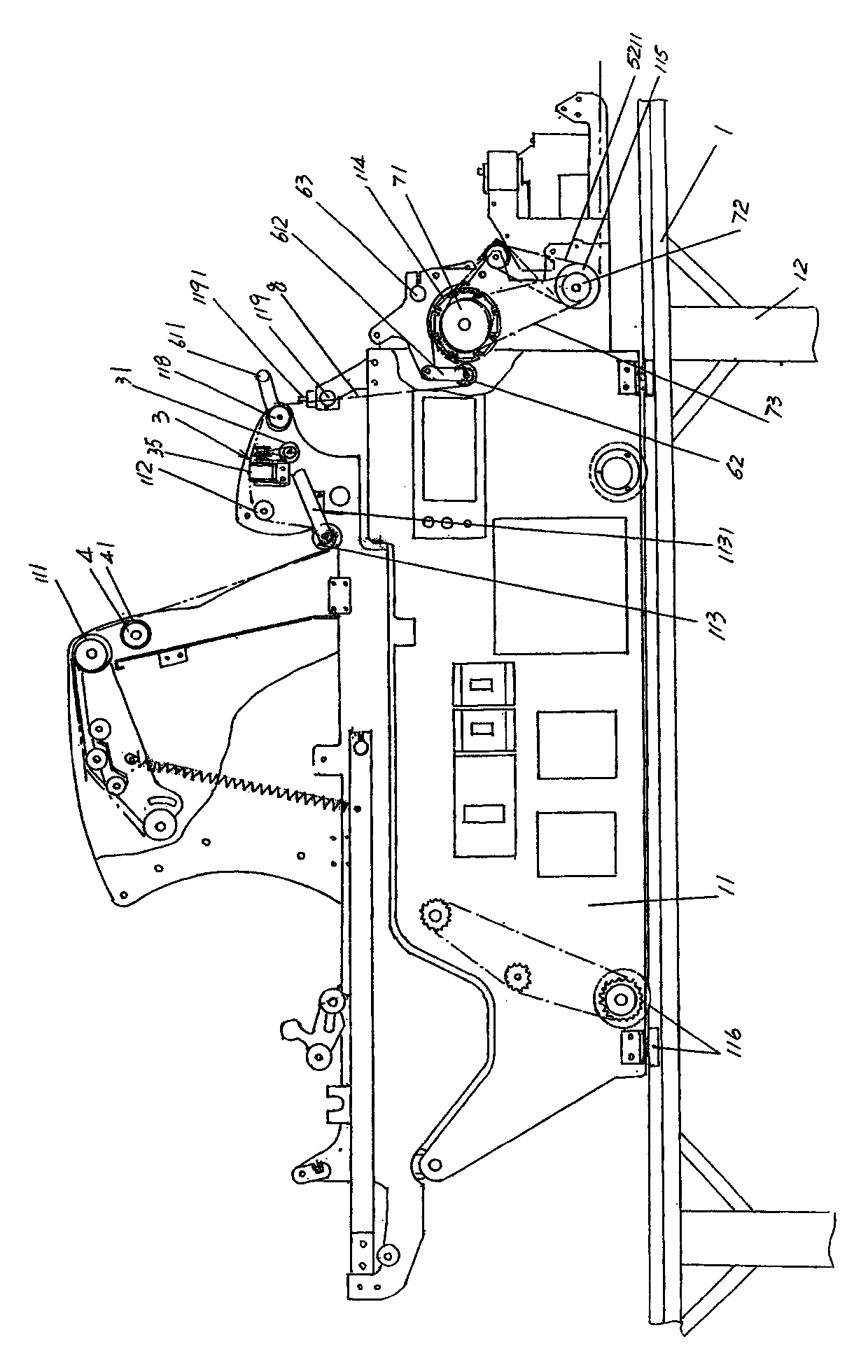

Cloth pressing device of spreading machine

ActiveCN103991750AMake sure to rabEnsure the effect of spreadingUnfolding thin materialsWebs handlingEngineeringMechanical engineering

The invention provides a cloth pressing device of a spreading machine and belongs to the technical field of garment processing machinery. The spreading machine comprises a spreading table, a cross beam, a pair of toothed belt edge stripping mechanisms and front and rear cloth spreading rollers, wherein a rack is arranged on the spreading table, upper and lower cloth guiding roller, a cloth guiding roller, a large cloth spreading roller and a lower cloth spreading roller are arranged on the rack. The cloth pressing device is characterized by comprising a large cloth spreading roller cloth pressing mechanism, wherein the large cloth spreading roller cloth pressing mechanism comprises a pair of cloth pressing roller carriers, a large cloth spreading roller front cloth pressing roller, a large cloth spreading roller upper cloth pressing roller and a large cloth spreading roller rear cloth pressing roller, the right end of one pair of cloth pressing roller carriers is pivoted on the rack, a handle is fixed in the middle of one pair of cloth pressing roller carriers, one opposite side of one end of one pair of cloth pressing roller carriers is connected with the upper end of a front pressing roller arm, one opposite side of the right end of one pair of cloth pressing roller carriers is connected with the upper end of a rear pressing roller arm, a large cloth spreading roller front cloth pressing roller is arranged at the lower end of the front pressing roller arm, the large cloth spreading roller upper cloth pressing roller is arranged between one pair of cloth pressing roller carriers, and the large cloth spreading roller rear cloth pressing roller is fixed at the lower end of the rear pressing roller arm. The cloth pressing device creates edge stripping conditions for a toothed belt edge stripping mechanism and ensures the cloth pulling and spreading effects.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

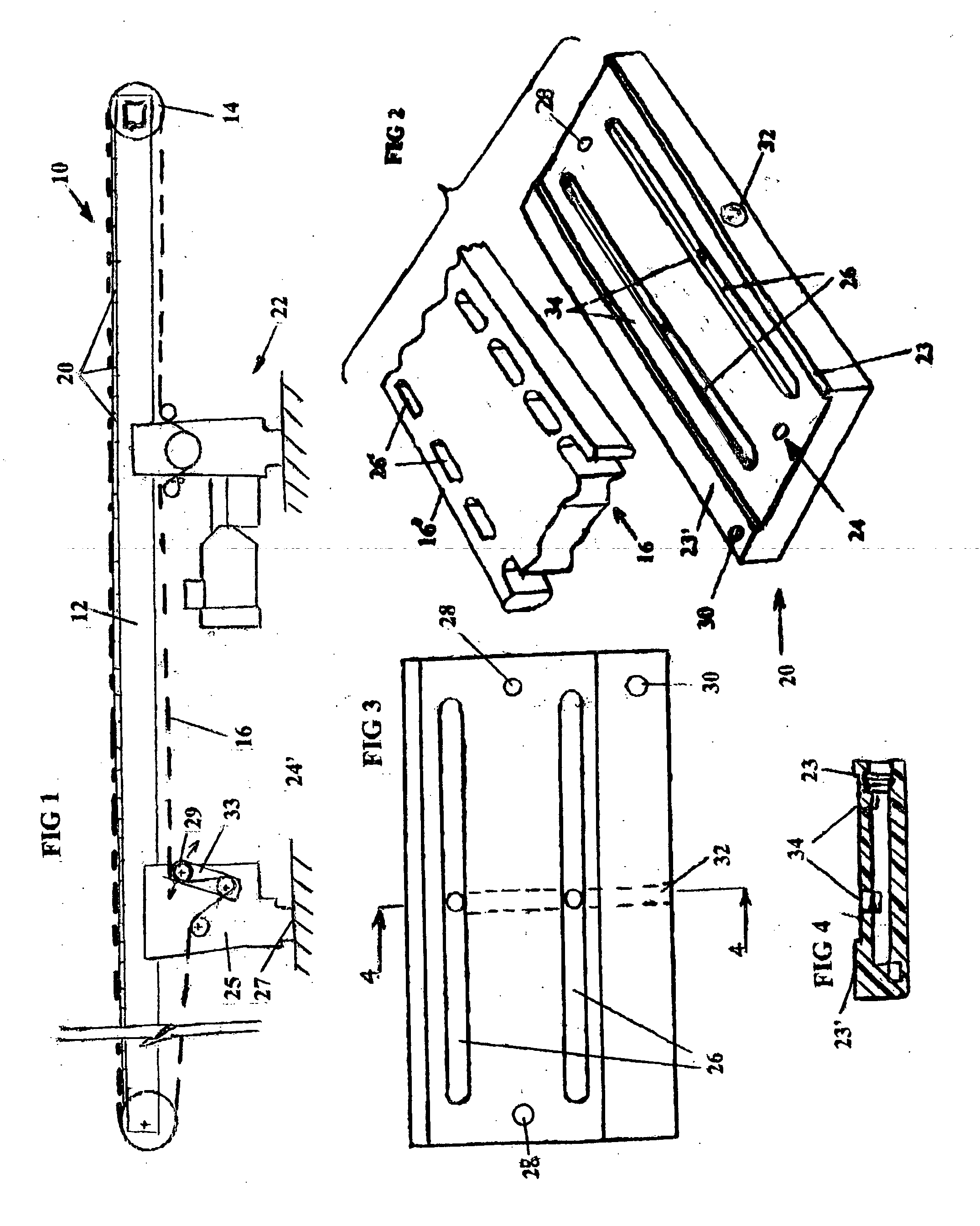

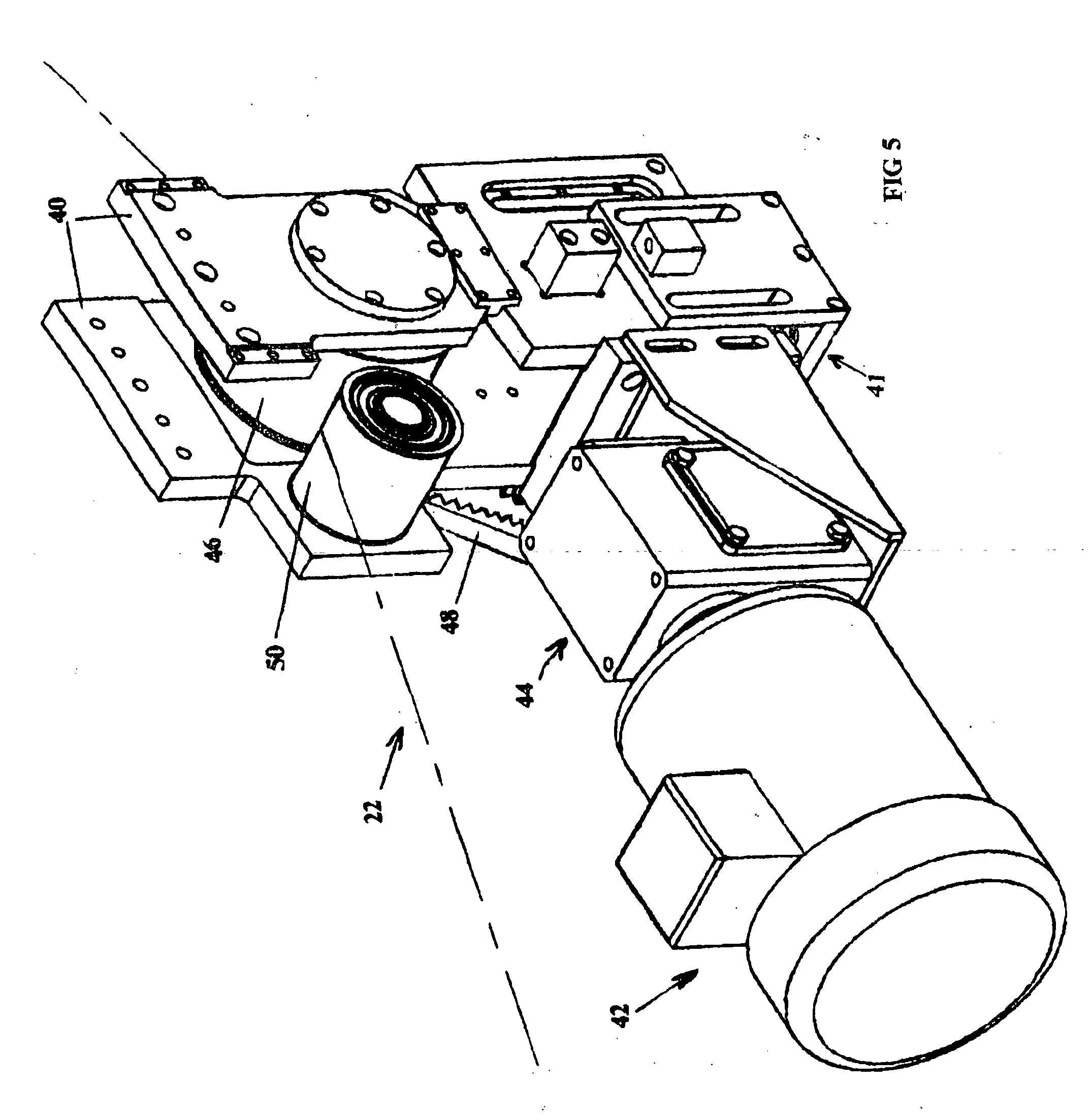

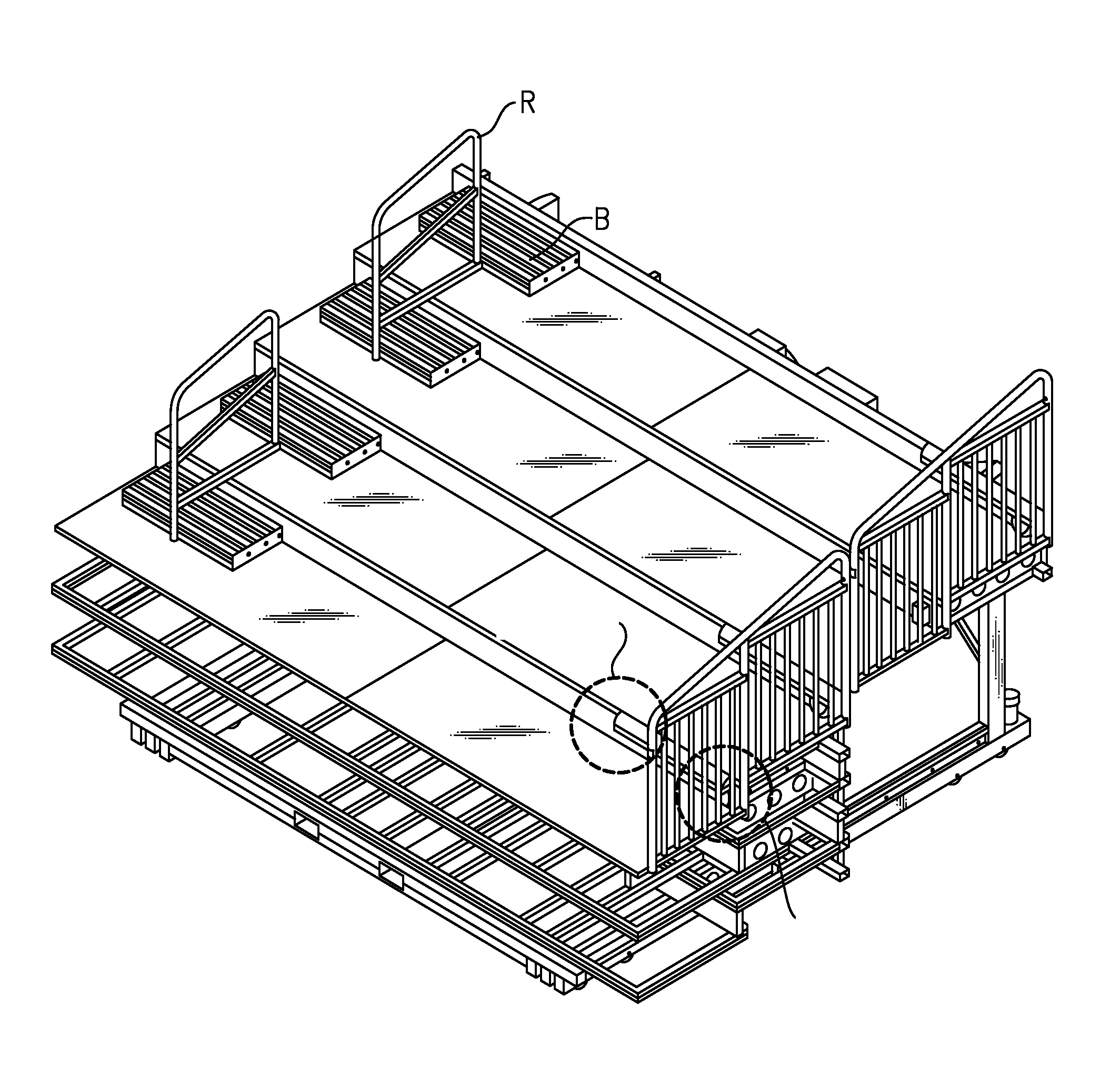

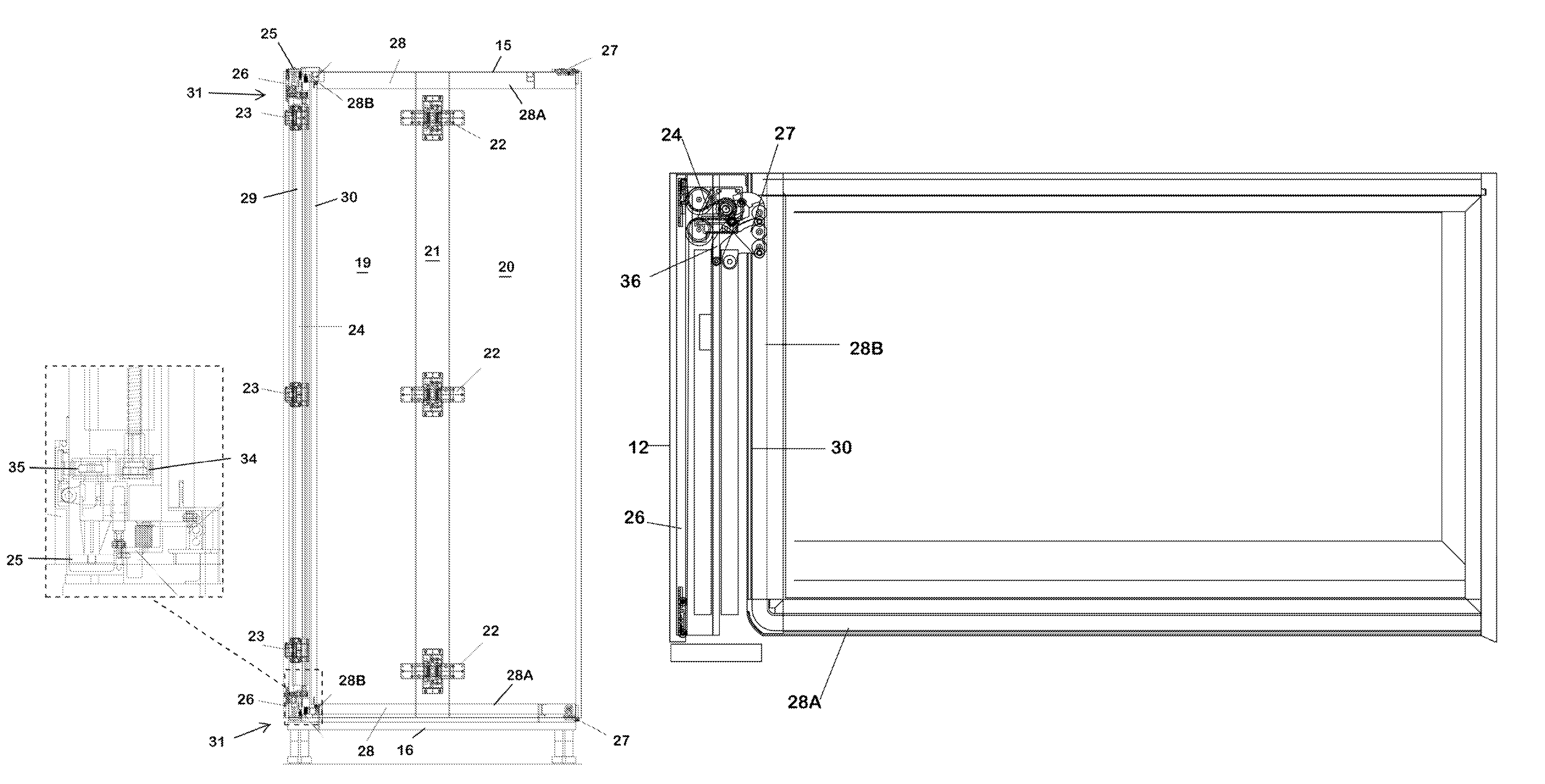

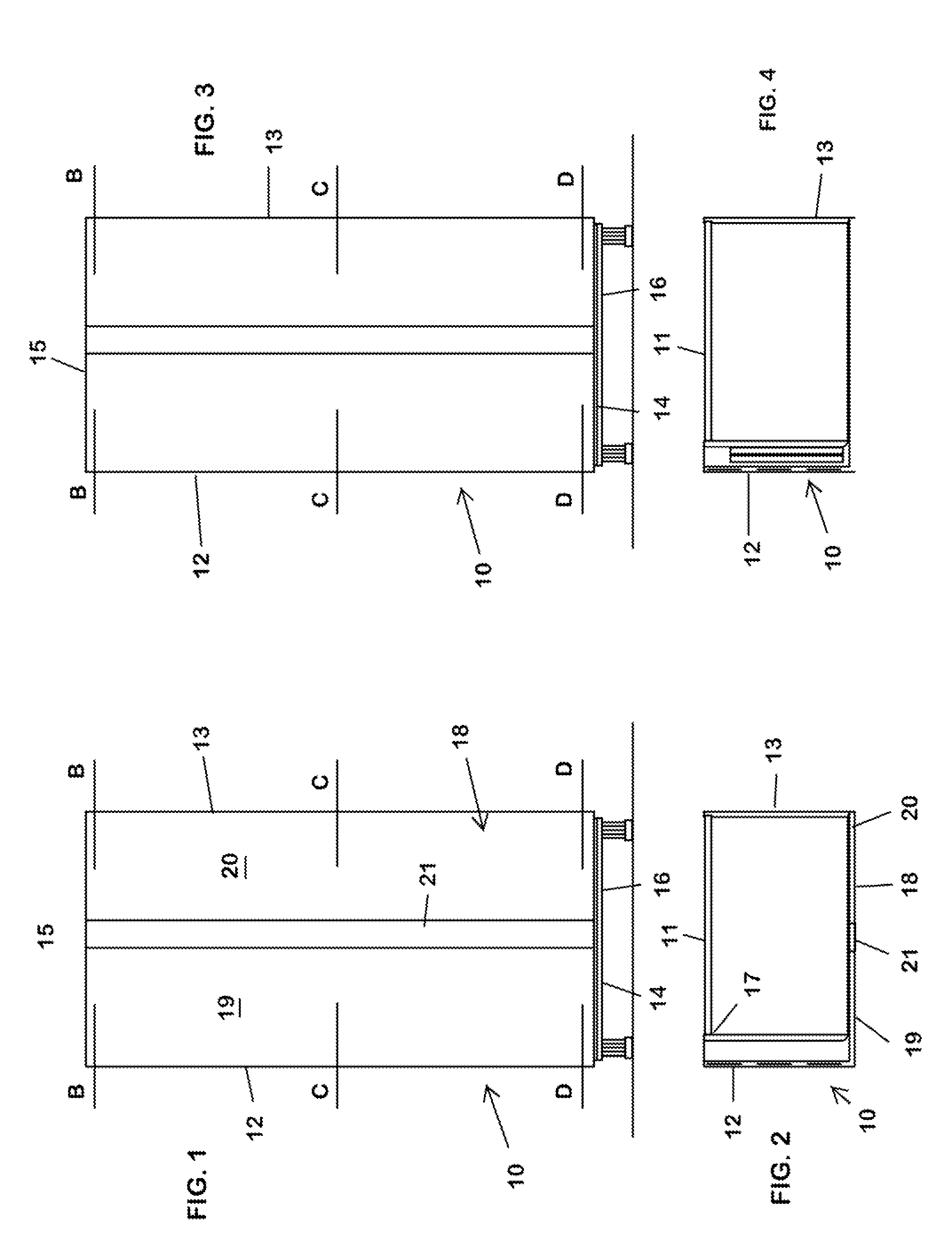

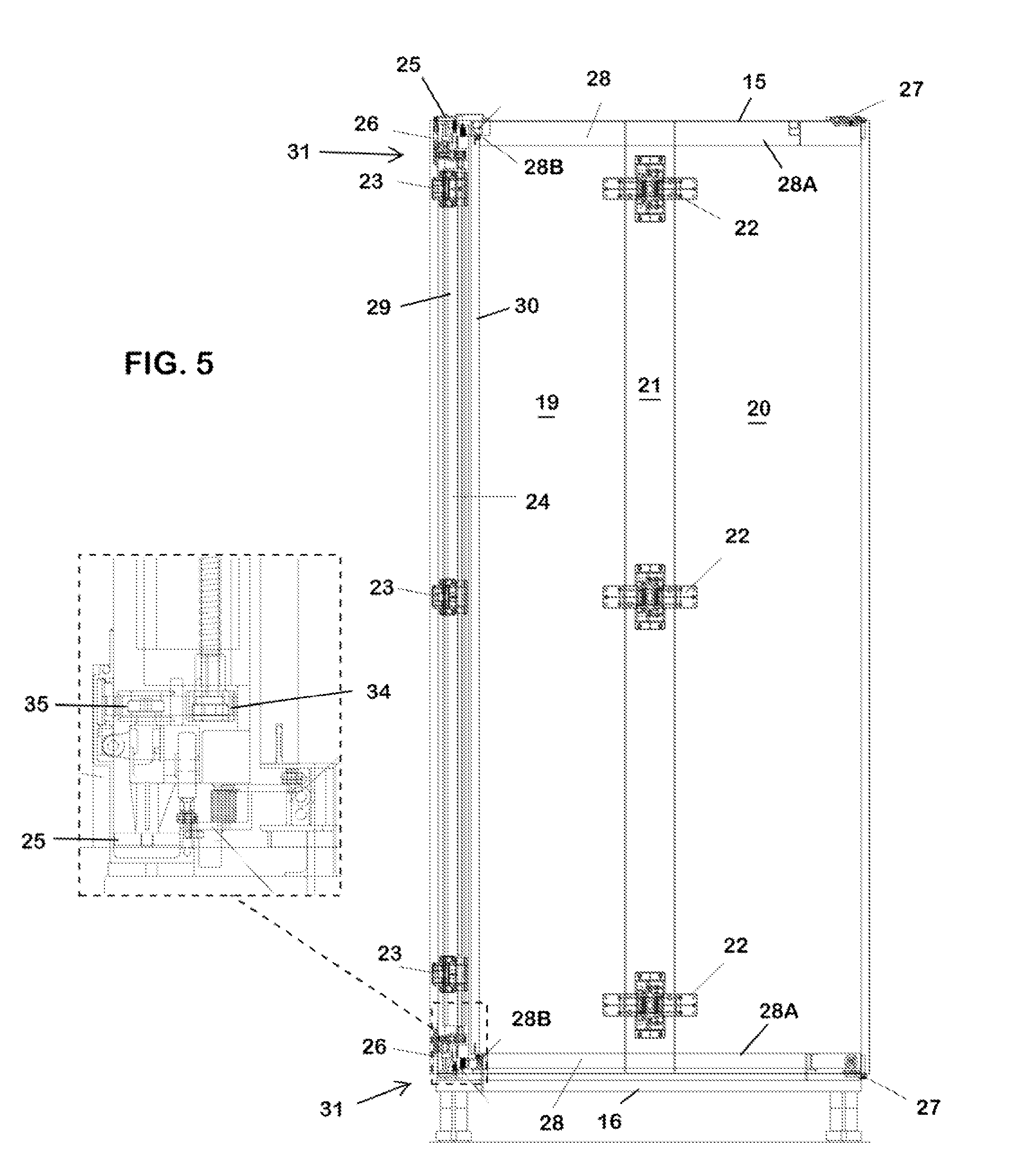

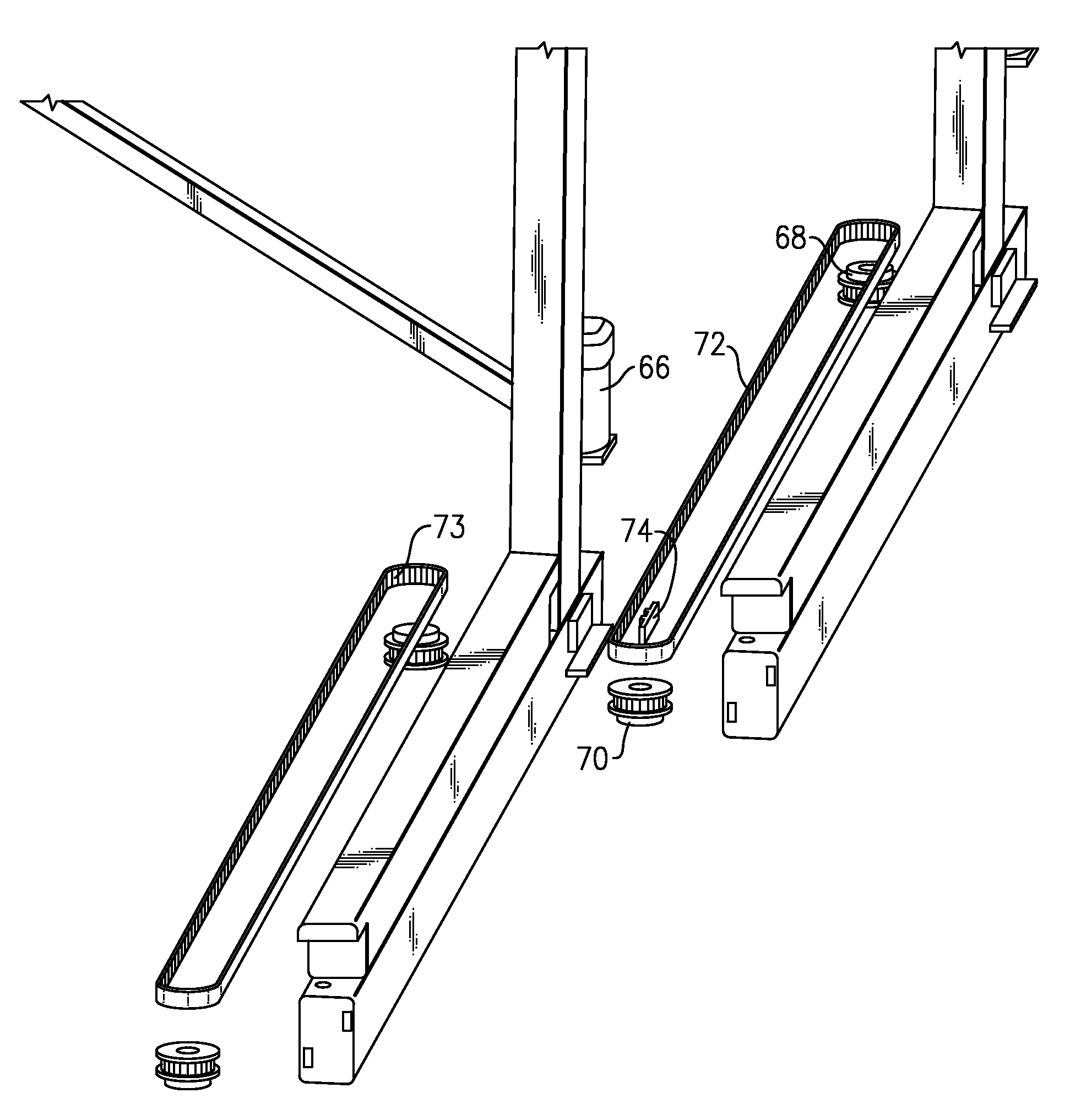

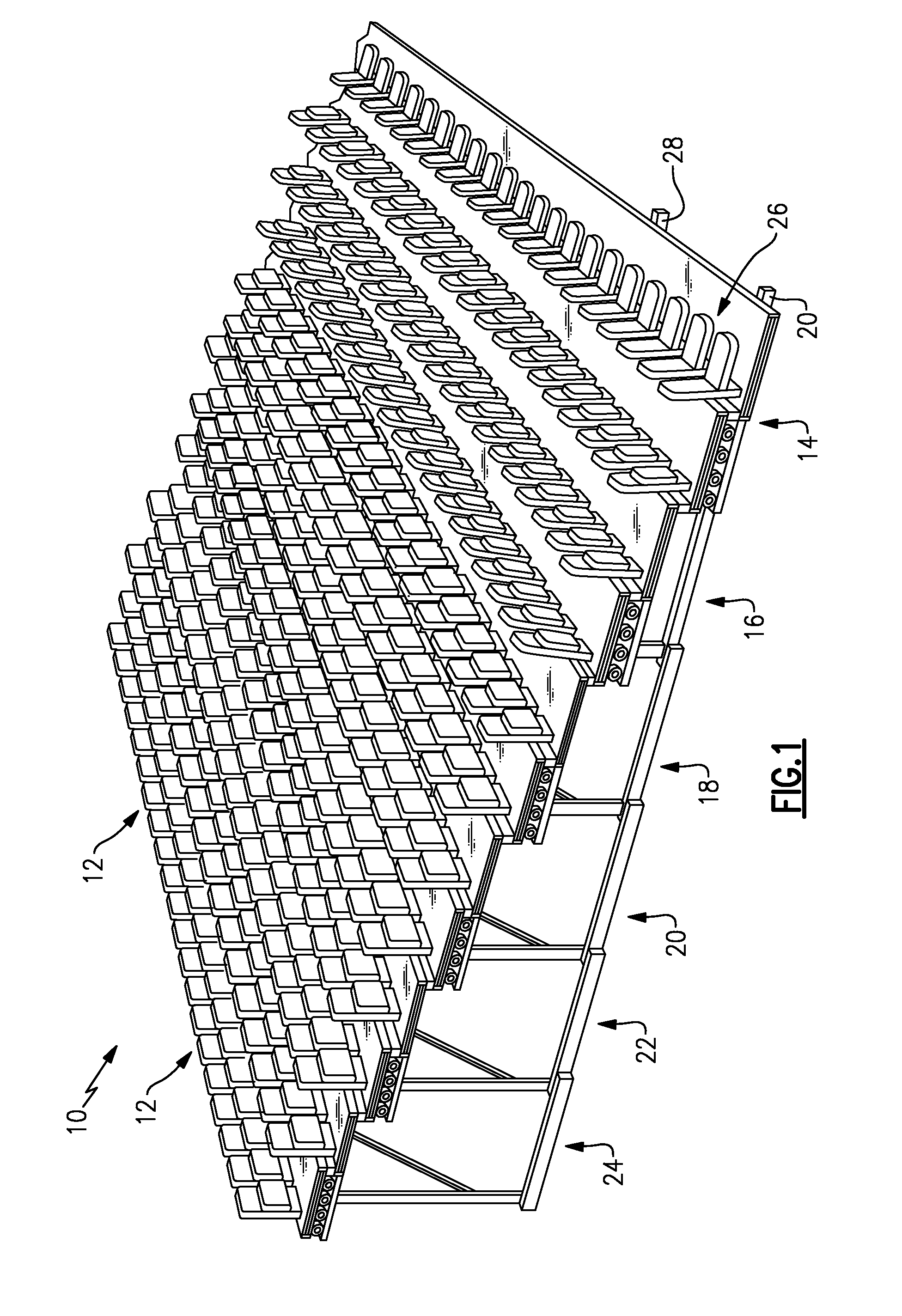

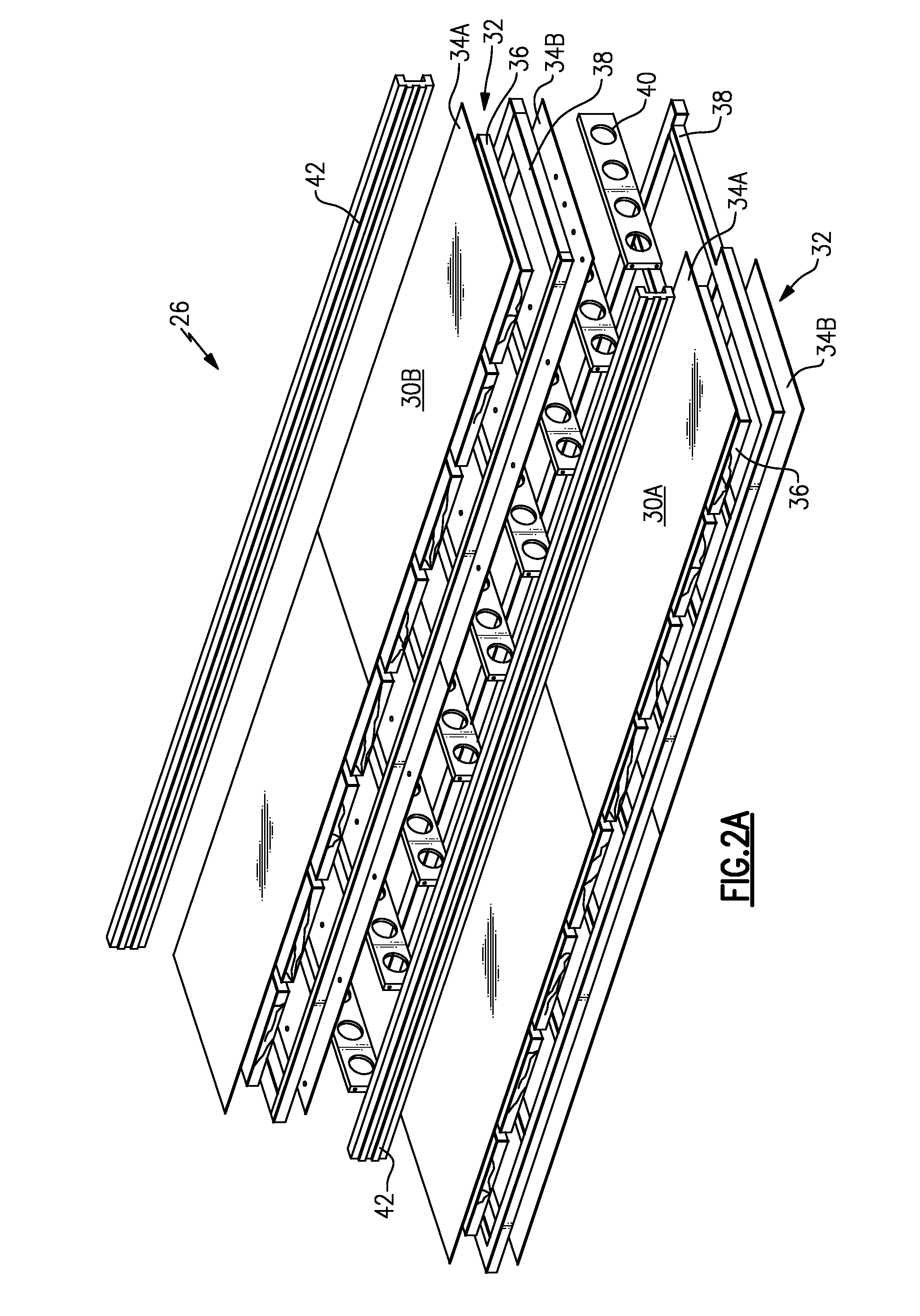

Powered dual level telescopic seating riser assembly

ActiveUS20080083170A1Easy to deployThe implementation process is simpleGrandstandsBuilding constructionsSeating capacityEngineering

A telescopic seating system generally includes an innermost lower riser assembly and successive outer elevated riser assemblies. Each elevated riser assembly includes a dual deck surface and a telescopic leg assembly. Each elevated riser assembly supports a toothed belt drive system which provides the interface between each adjacent elevated riser assembly and the motive force to extend and retract the riser system. In operation, electric motors of the toothed belt drive system on each elevated riser assembly are driven by a controller to extend and retract the telescopic seating system between a fully extended position, a half-deployed position and a storage position. The half-deployed position utilizes the dual deck surface to provide half the seating capacity of each riser at twice the rise between each seating row to thereby accommodate particular venues.

Owner:STAGERIGHT CORP

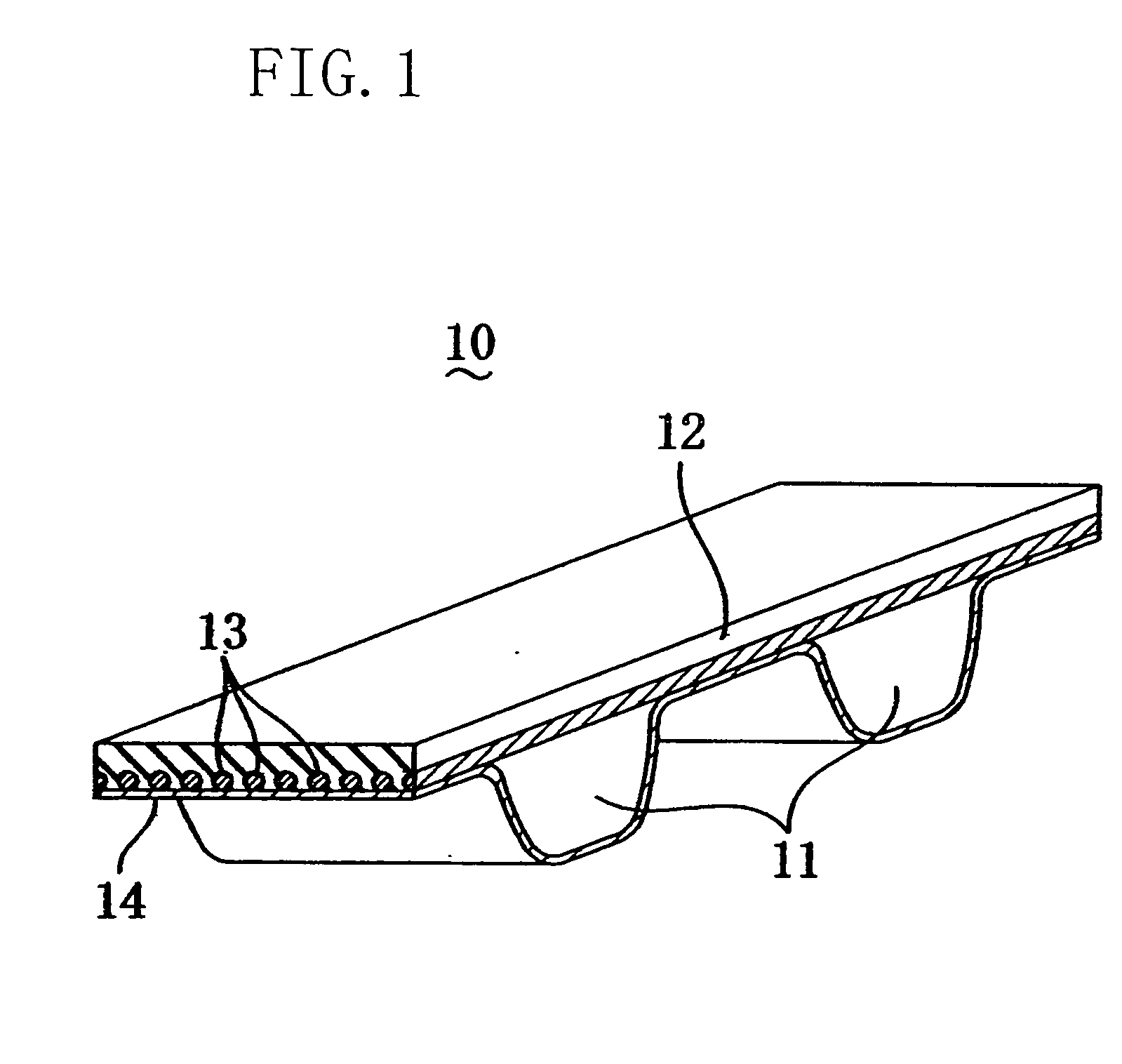

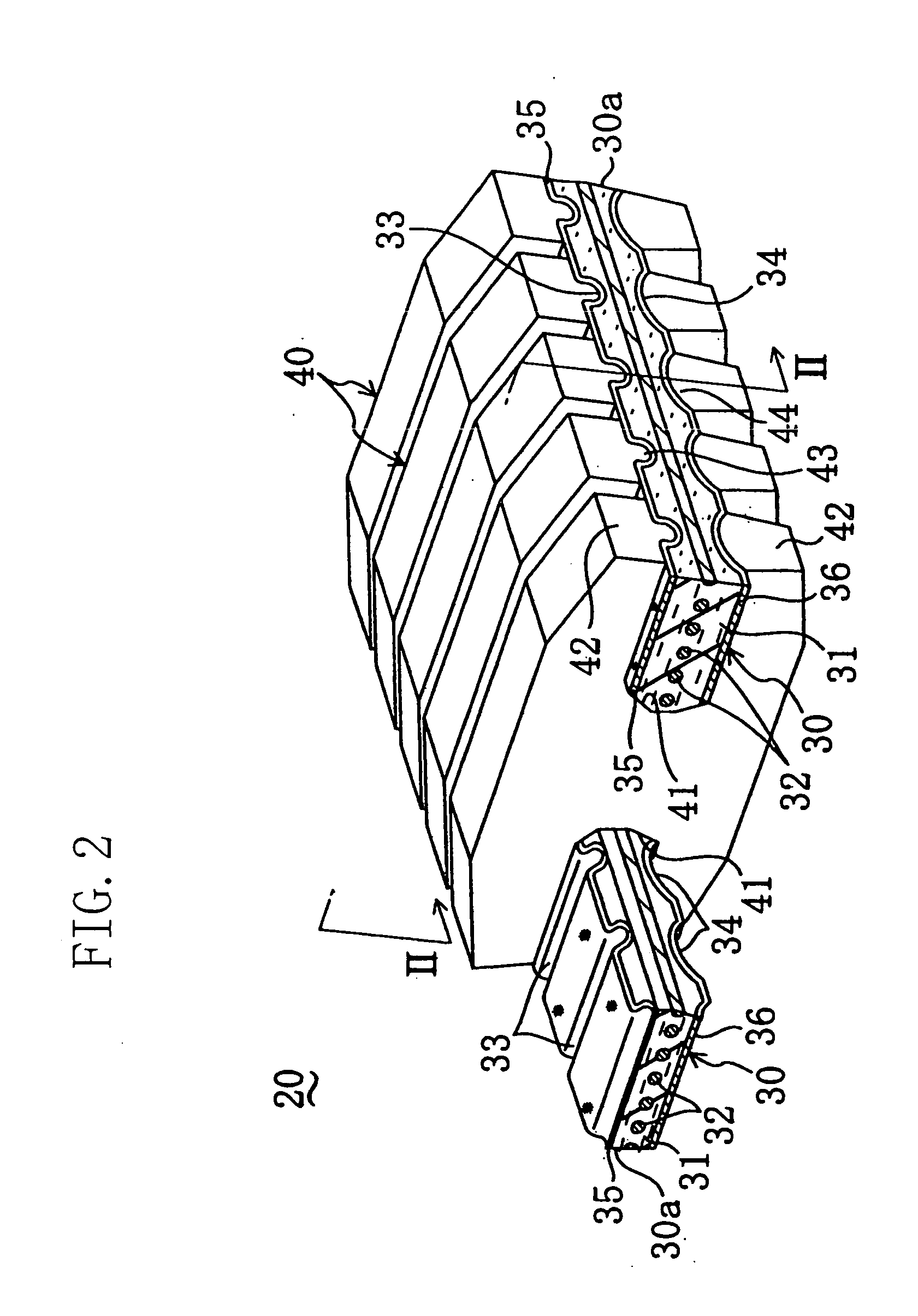

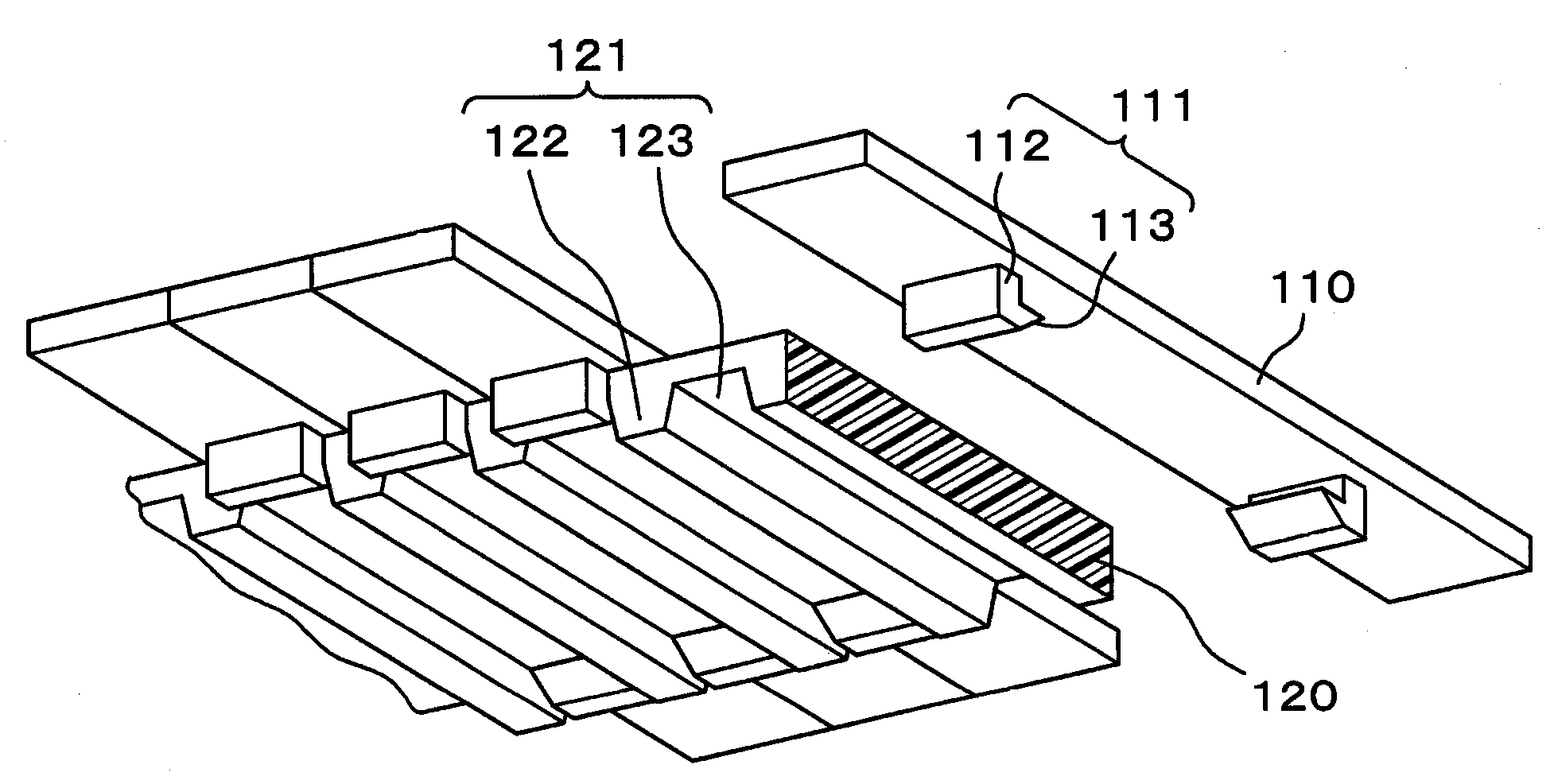

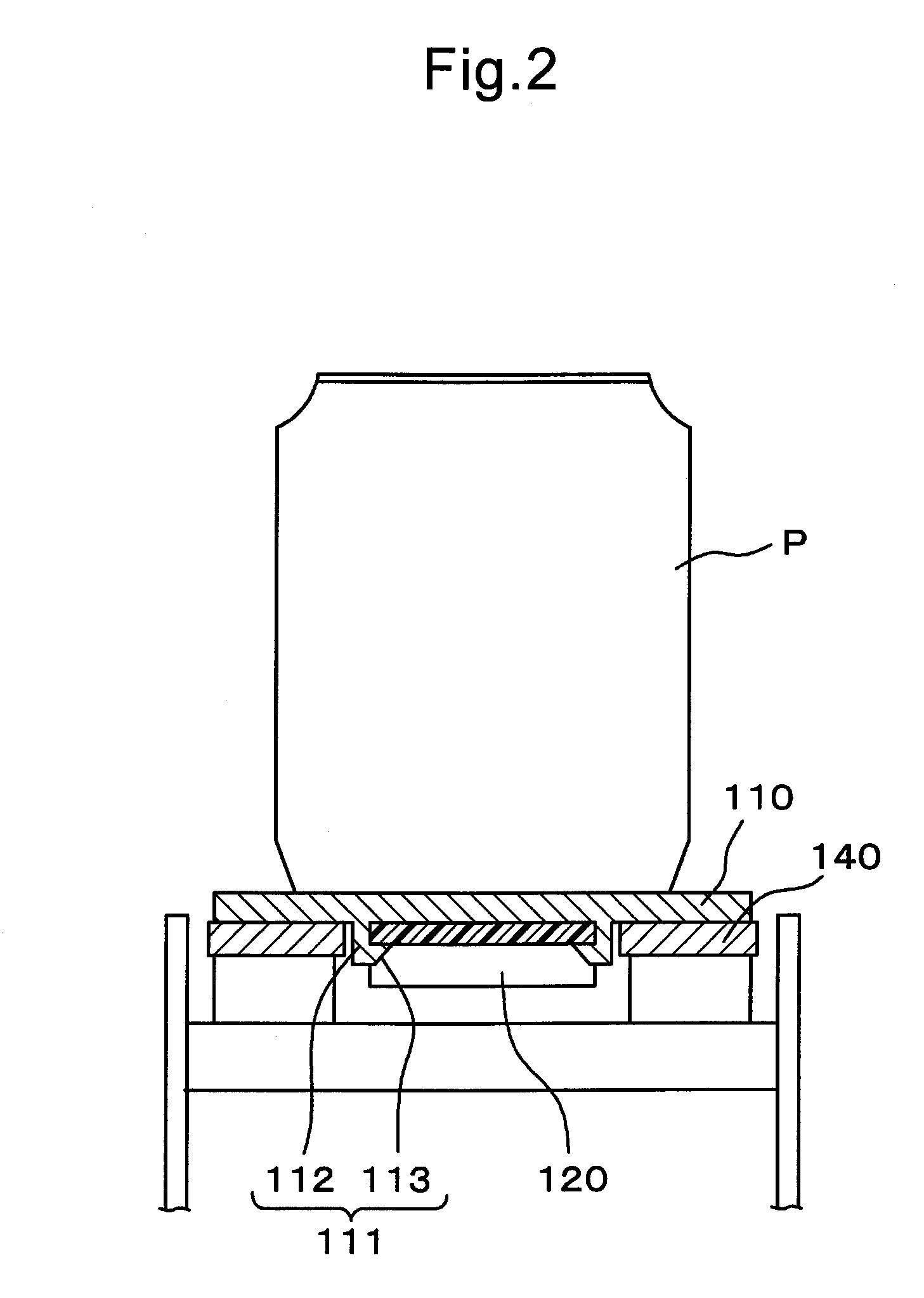

Top plate conveyor device

InactiveUS20090133993A1Reduce noiseReduce vibrationRollersRotary conveyorsMechanical engineeringToothed belt

A top plate conveyor device, in which vibrations and noises are reduced, and the structure is simple and the production assembly and handling are easy. Top plates 110 are removably provided on a rubber toothed belt 120 by engagement members 111 provided on the back surfaces of the top plates 110, and engagement members 111 include sandwiching portions 112 which sandwich the toothed belt 120 from both outer sides in the width direction and terminate in pawl portions 113, which snap-connect the top plates to the toothed belt 120.

Owner:TSUBAKIMOTO CHAIN CO

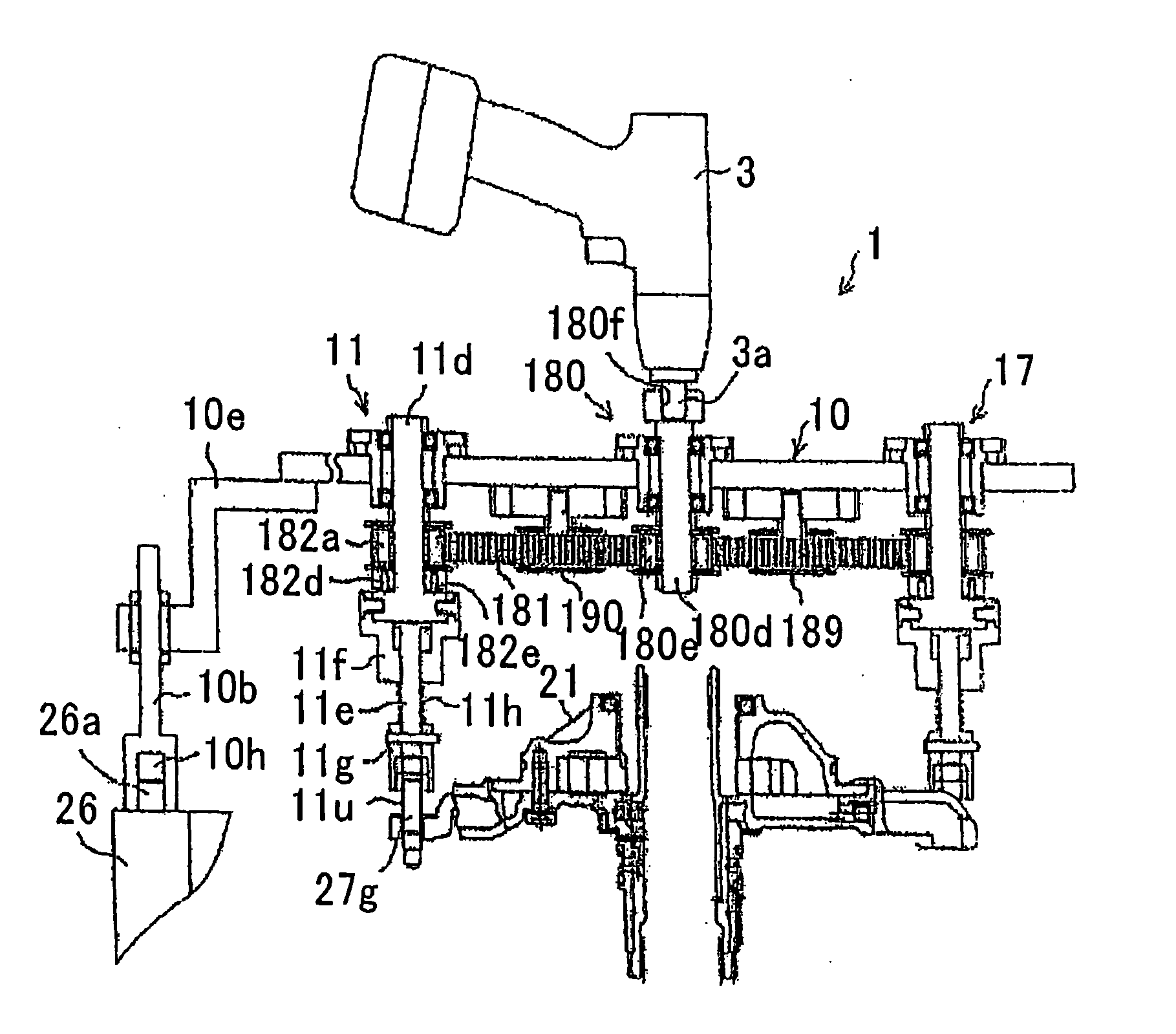

Fastener tightening device

A bolt tightening device includes bolt tightening mechanisms, a torque input unit, a toothed belt and torque transmission units. The torque transmission units are provided with toothed pulleys and are integrated with the bolt tightening mechanisms. A toothed pulley is fixed to the torque input unit, and drivably connected to all the toothed pulleys of the plural torque input units by the single toothed belt. Torque input to the torque input unit is transmitted to the bolt tightening mechanisms by the toothed belt, and used to simultaneously tighten, for example, seven bolts. Because, torque can be simultaneously transmitted to plural bolt tightening mechanisms using a single belt, the number of components is reduced and the size, weight and cost are reduced and ease of use is improved.

Owner:AISIN AW CO LTD

Cabinet or similar article of furniture with a sliding foldaway door

A cabinet door collapses and slides into a concealed position inside a door compartment of a cabinet. The door has a first wing which is pivotally connected to a second wing and to a vertical door-supporting bar which travel insides the door compartment. The second wing is guided by carriages running in upper and lower continuous guideways that extend inside the door compartment. A device for moving the door-supporting bar includes a stationary toothed belt inside the door compartment, a toothed wheel and guide pulleys carried by the door-supporting bar. The toothed wheel is operatively connected to a torsion spring inside the door-supporting bar. A locking device locks the toothed wheel, when the door wings are in a coplanar closed position, and releases the toothed wheel, when they are in a parallel open position.

Owner:DADA SRL

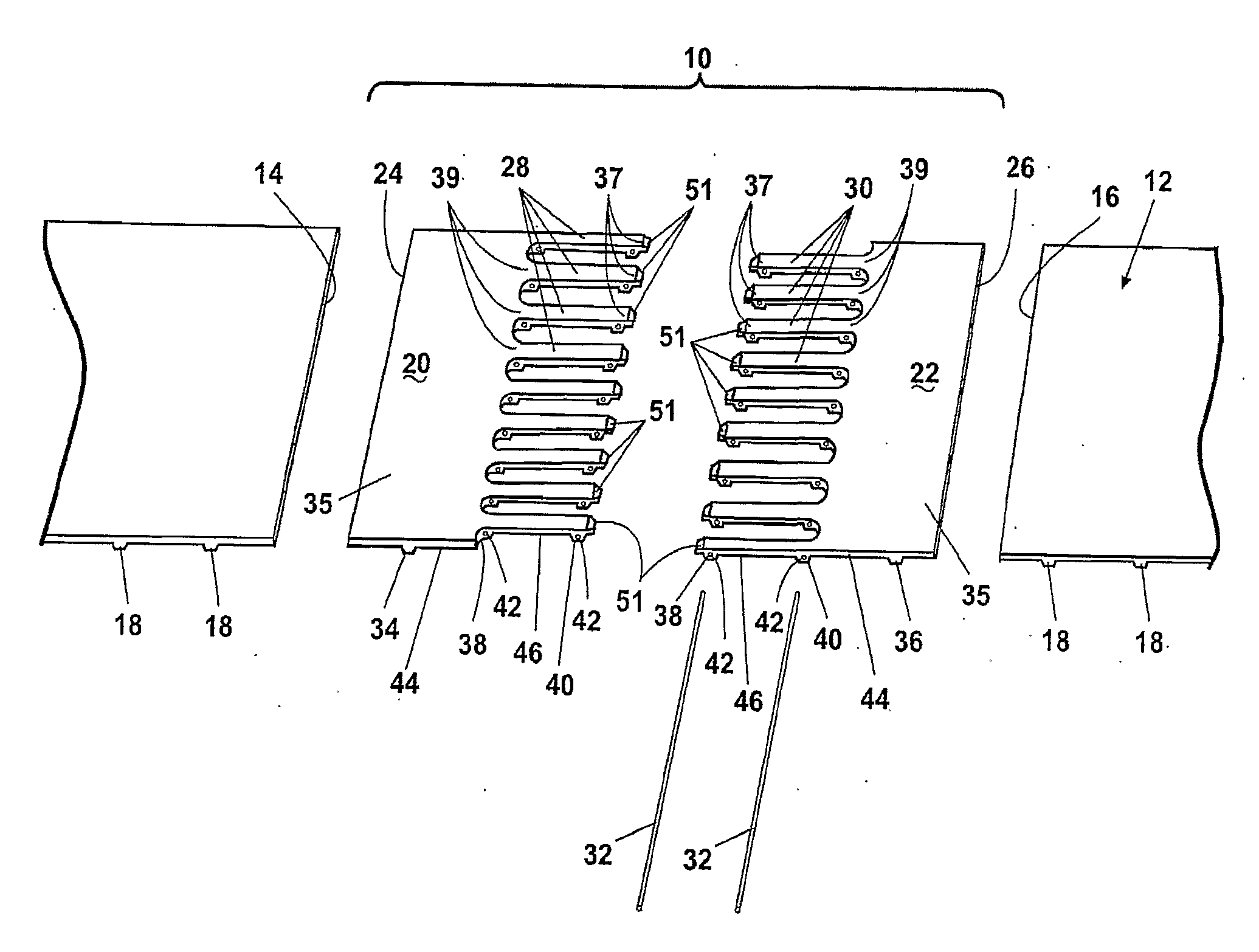

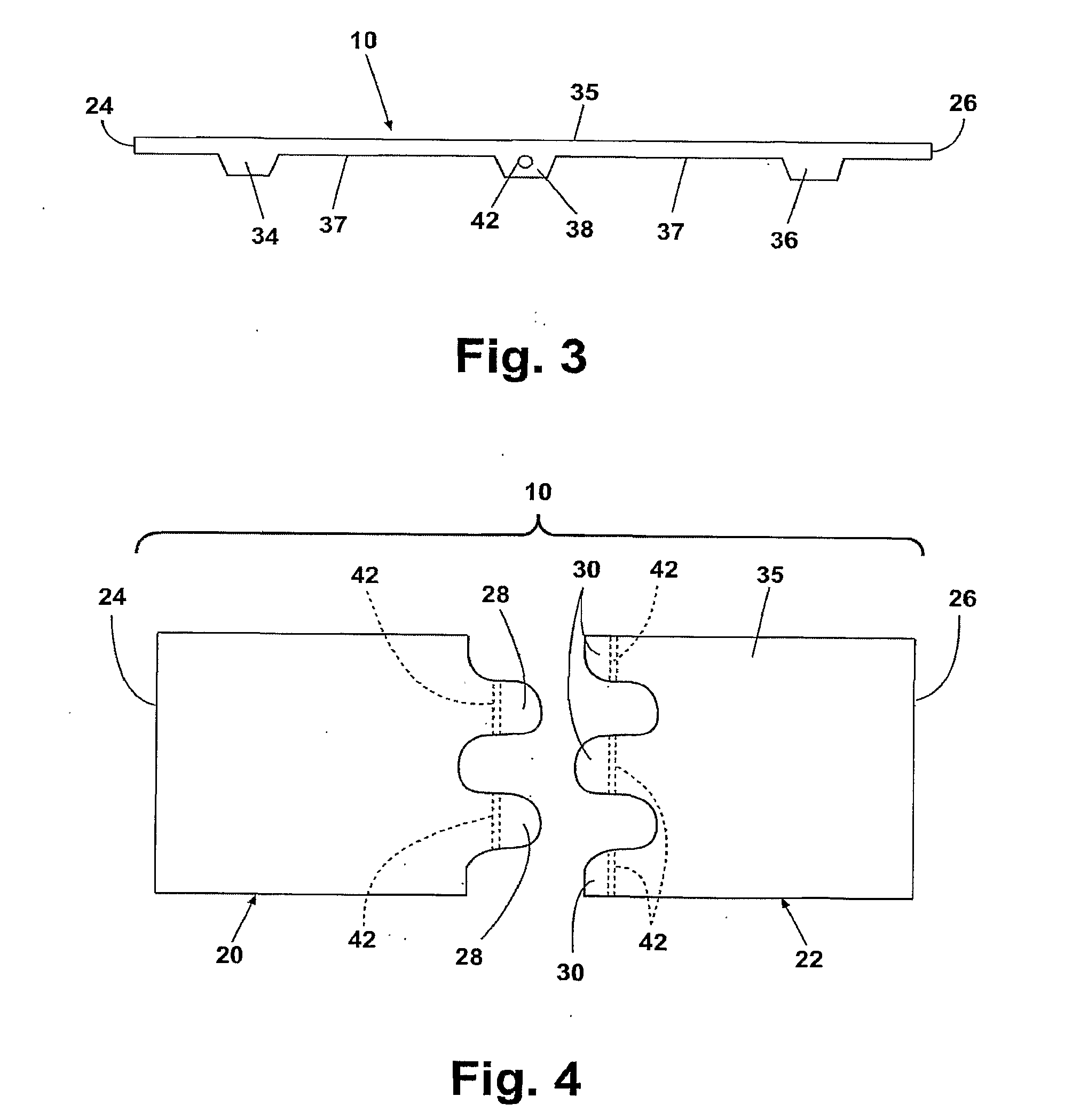

Thermoplastic belt connector with fingers

A toothed belt connector for making an endless belt has two leaves, adapted to be connected to each other by knuckles along one or more teeth. Each knuckle has at least one hole extending through tooth portions so that when the holes are in registry, a pin can be extended through the holes to connect the leaves at the teeth. The leaves can be adjoined to the ends of a belt to make the belt endless. The tip end of each knuckle can be beveled or it can have a stepped finger that fits into a cutout on the opposite leaf to keep the end of the knuckle from protruding as the belt wraps around a sprocket.

Owner:LAITRAM LLC

Wear resistant belts, and a process for their manufacture

Endless power transmission belts and processes for their manufacture, having power transmitting surfaces comprising a wear resistant composite, which belts exhibit improved abrasion- or wear resistance, reduced noise, reduced frictional heat generation, and improved dimensional stability compared to known belt constructions, as well as processes for manufacturing same. More particularly, an endless toothed belt having an abrasion- and noise resistant cover element, which comprises at least one friction-modifying constituent and at least one binder constituent.

Owner:THE GATES CORP

Powered dual level telescopic seating riser assembly

ActiveUS7900402B2Easy to deployThe implementation process is simpleGrandstandsBuilding constructionsSeating capacityEngineering

Owner:STAGERIGHT CORP

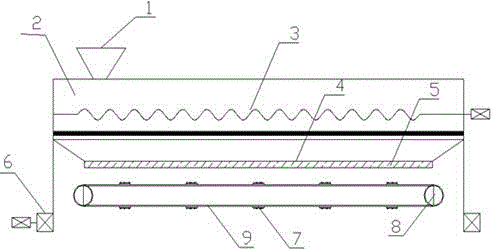

3D printing equipment spreading device capable of automatically sweeping

ActiveCN105666883AImprove efficiencyExtended service lifeAdditive manufacturing apparatusEngineeringElectrical and Electronics engineering

The invention relates to the field of 3D printing spreading and particularly relates to 3D printing equipment spreading device capable of automatically sweeping. The device comprises a feeding hole, a stock bin, a spiral conveyer, a blanking hole, a scraping plate, linear guide rails, sweeping hairbrushes, gears, a toothed belt and a working box. In a printing process, the blanking hole and the scraping plate of a spreader are swept when reaching a certain number of layers or time, so that the condition that the blanking hole at the bottom of the spreader is greatly reduced, the uniformity of each blanking quantity is guaranteed, and therefore, 3D printing equipment can stably work for a long time and is relatively high in efficiency and relatively long in service life; the 3D printing equipment spreading device has important significance in the application of a 3D printing technique and the popularization of 3D equipment.

Owner:NINGXIA KOCEL MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com