Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16833results about How to "Achieve separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

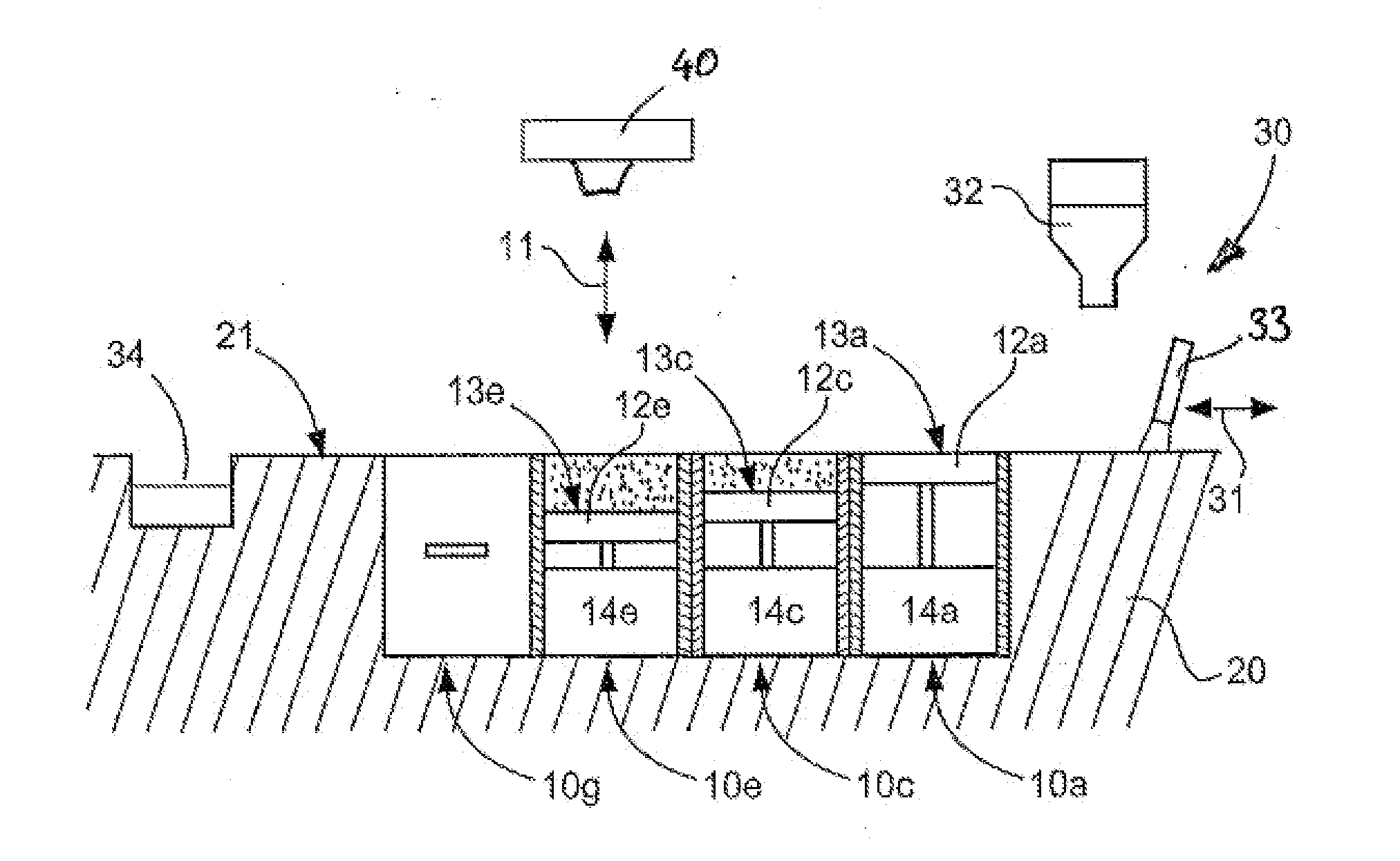

High precision orientation alignment and gap control stages for imprint lithography processes

InactiveUS6873087B1Achieve separationPiezoelectric/electrostriction/magnetostriction machinesNanoinformaticsLithography processEngineering

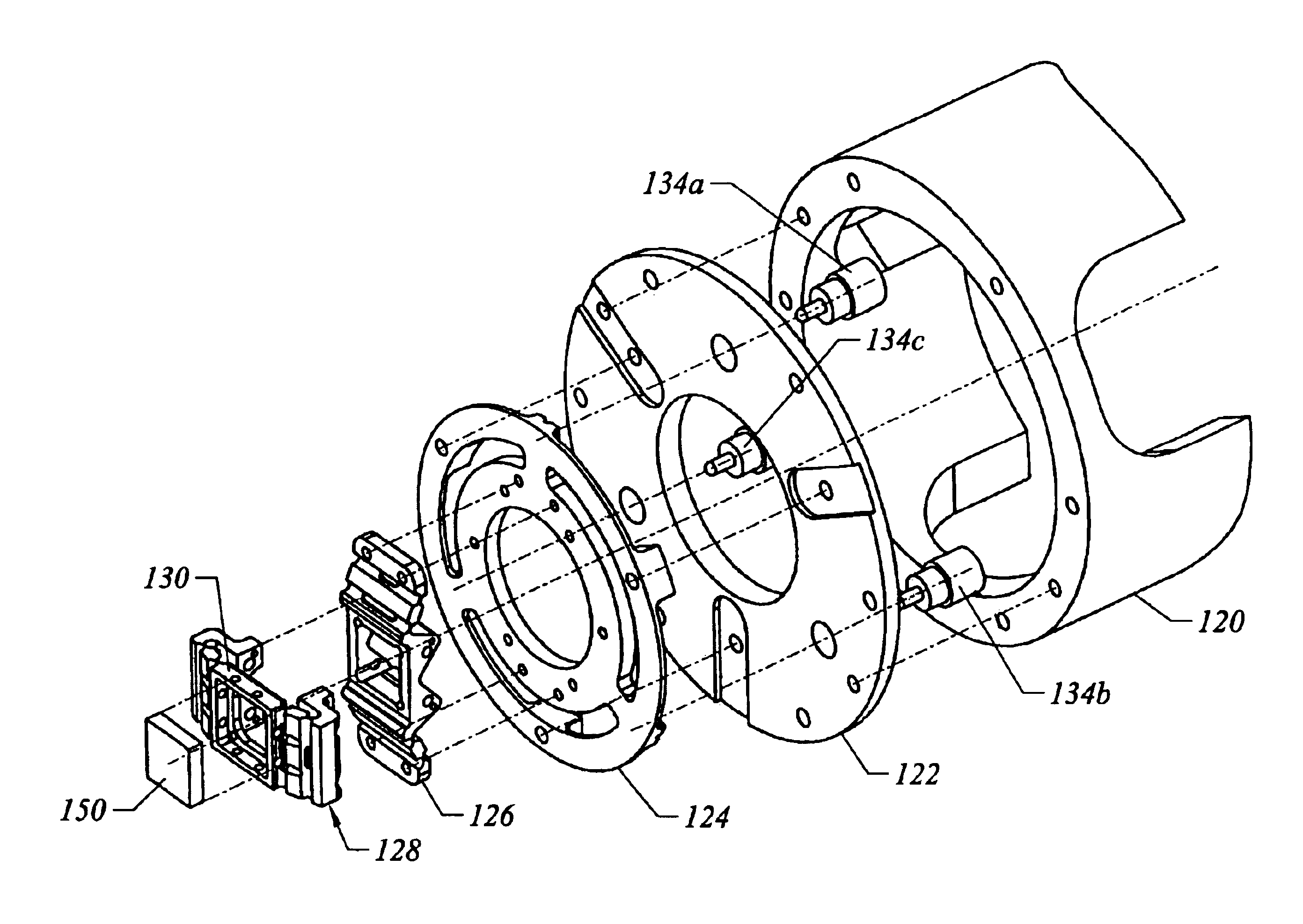

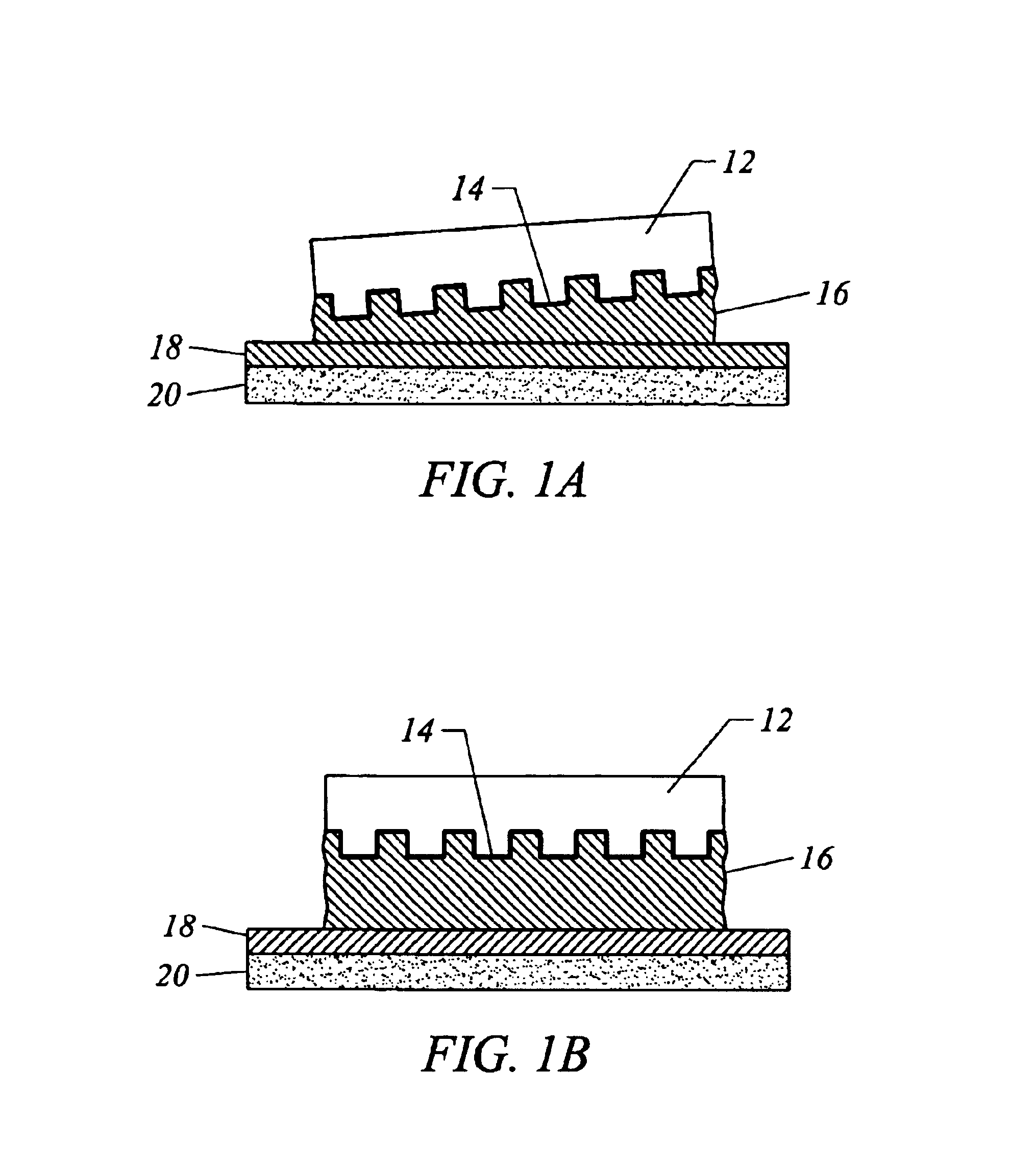

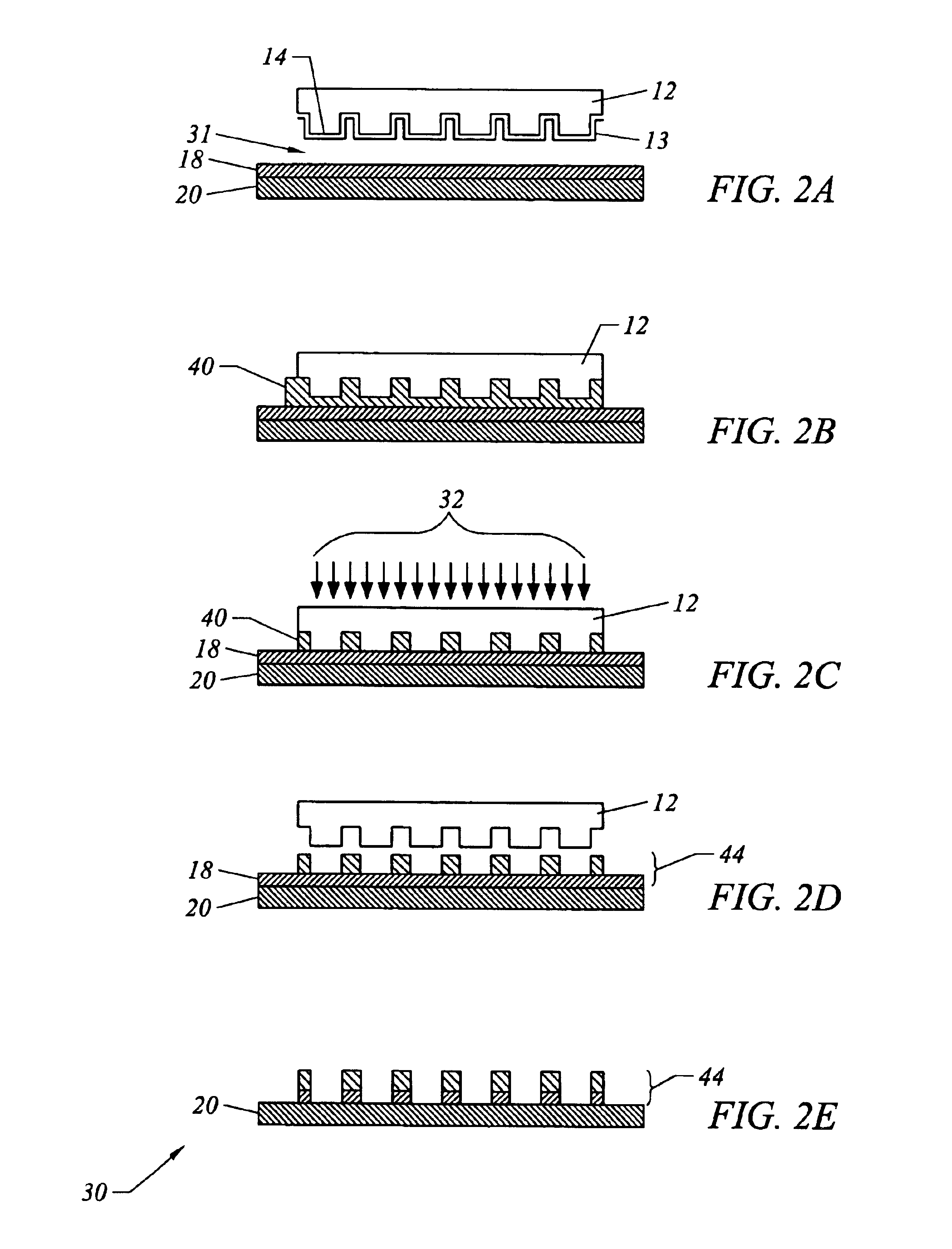

Processes and associated devices for high precision positioning of a template an substrate during imprint lithography includes a calibration system with a course calibration stage and a fine orientation stage capable of maintaining a uniform gap between the template and substrate. The fine orientation stage includes a pair of flexure members having flexure joints for motion about a pivot point intersected by first and second orientation axes. Actuators lengthen or shorten to expand or contract the flexure members. Separation of the template is achieved using a peel-and-pull method that avoids destruction of imprinted features from the substrate.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

Apparatus and method for flexible pick of orange picking robot

InactiveCN101273688AGuaranteed positioning accuracyAchieve separationProgramme-controlled manipulatorGripping headsThree dimensional modelVisual system

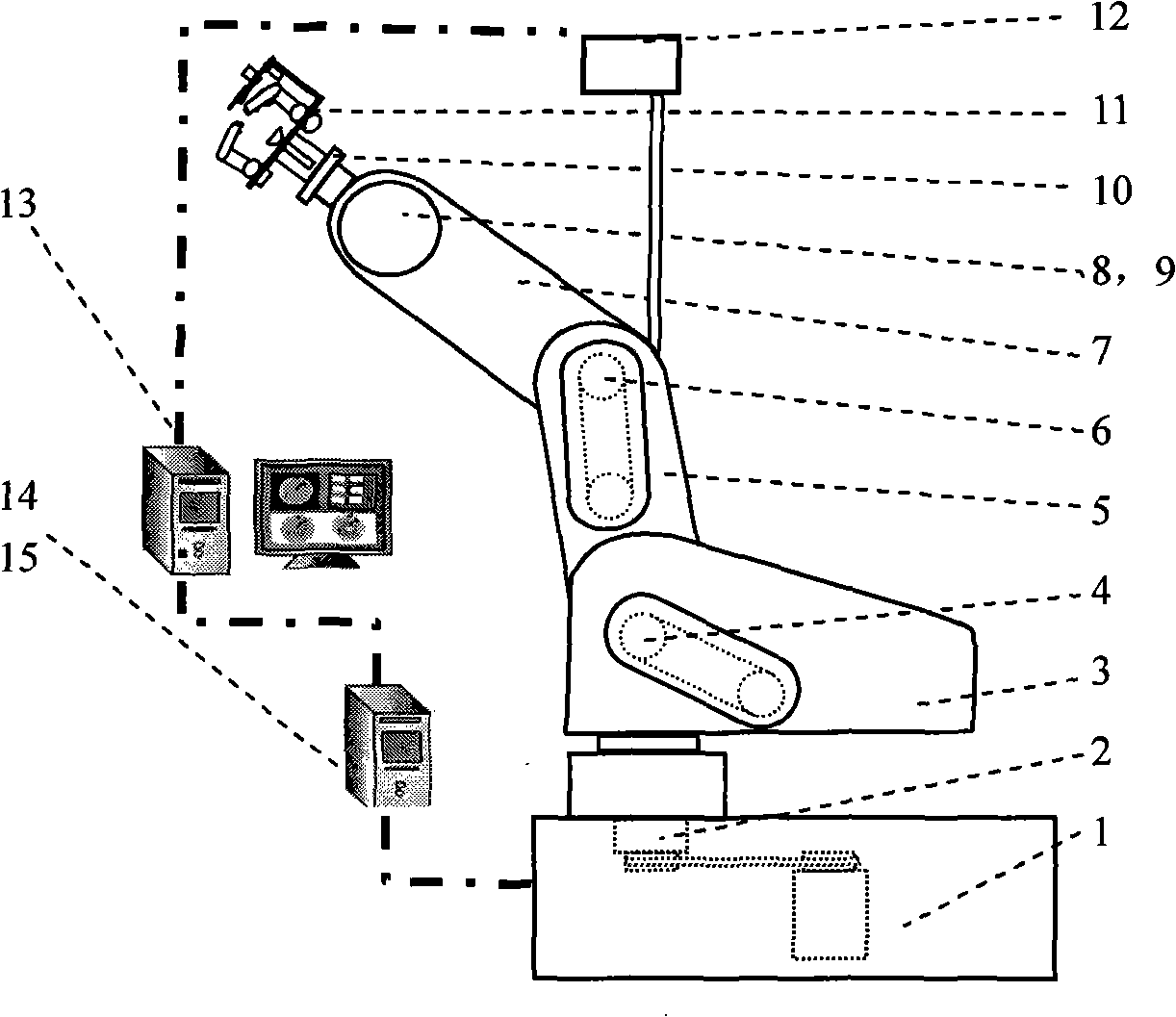

The invention relates to a picking method and a device for spherical citrus fruits, combining various sensor information of force sense, temperature sense, sight and distance, etc., and sending information back promptly to realize that an executive component picks up fruits flexibly. A flexible picking device consists of a fruit picking hardware device and a software control system, and the fruit picking hardware device consists of a computer visual system, an industrial control system, a mechanical arm and an end executor; the picking device utilizes a solid visual system to detect and identify mature fruit that can be picked, calculates the specific position of the fruit under world coordinate, and carries out feature extraction for the information of the obtained fruit position and barrier position, after the picking device establishes a three-dimensional model and obtains the movement path of a robot in virtual environment, an industrial personal computer system controls the mechanical arm and paws to reach a designated position; at last, the end executor is controlled to extend out of a sucker for sucking and drawing the fruit, then the fruit is fixed by the paw, finally a cutting device is rotated to the designated position for cutting off the stems.

Owner:JIANGSU UNIV

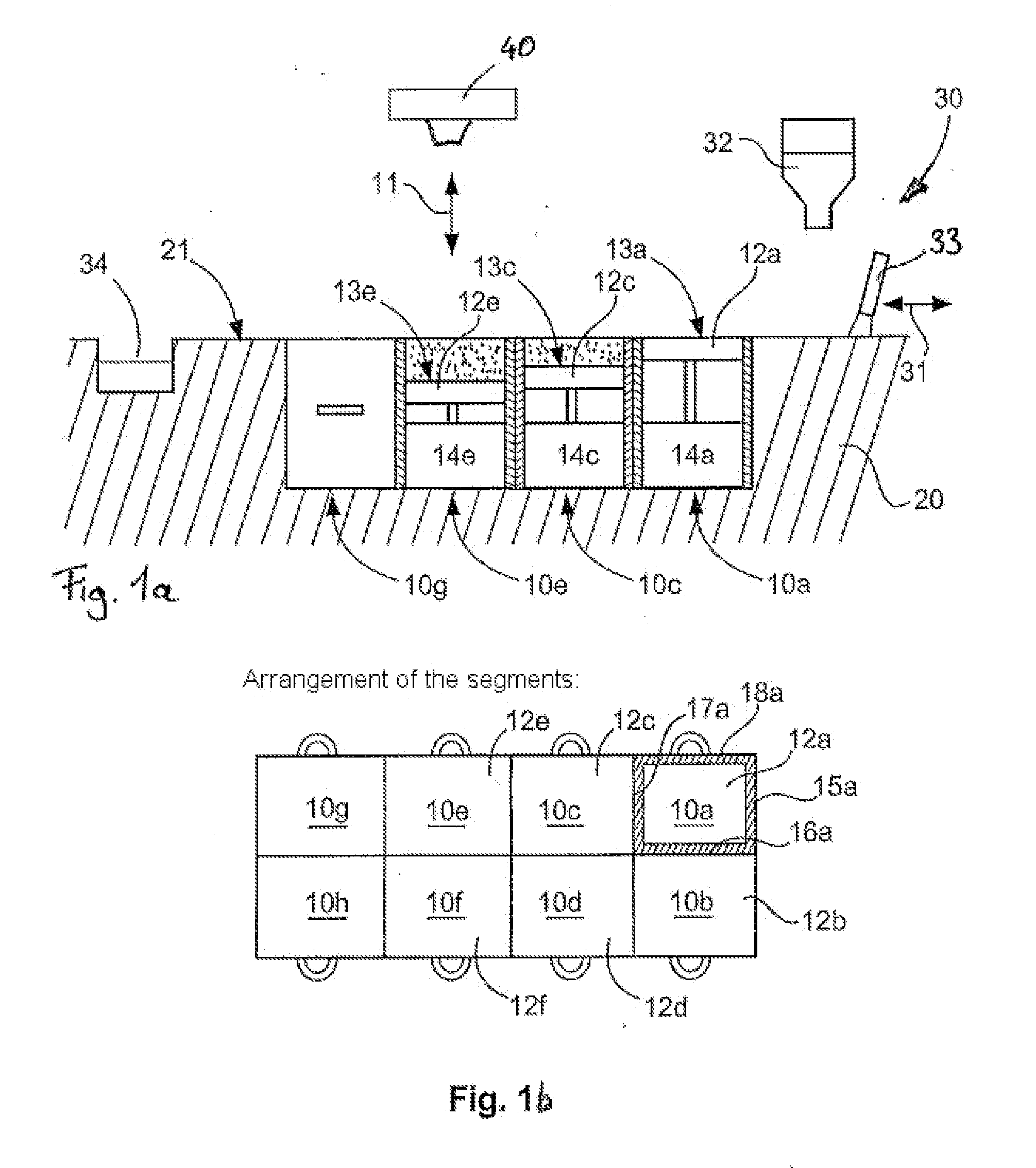

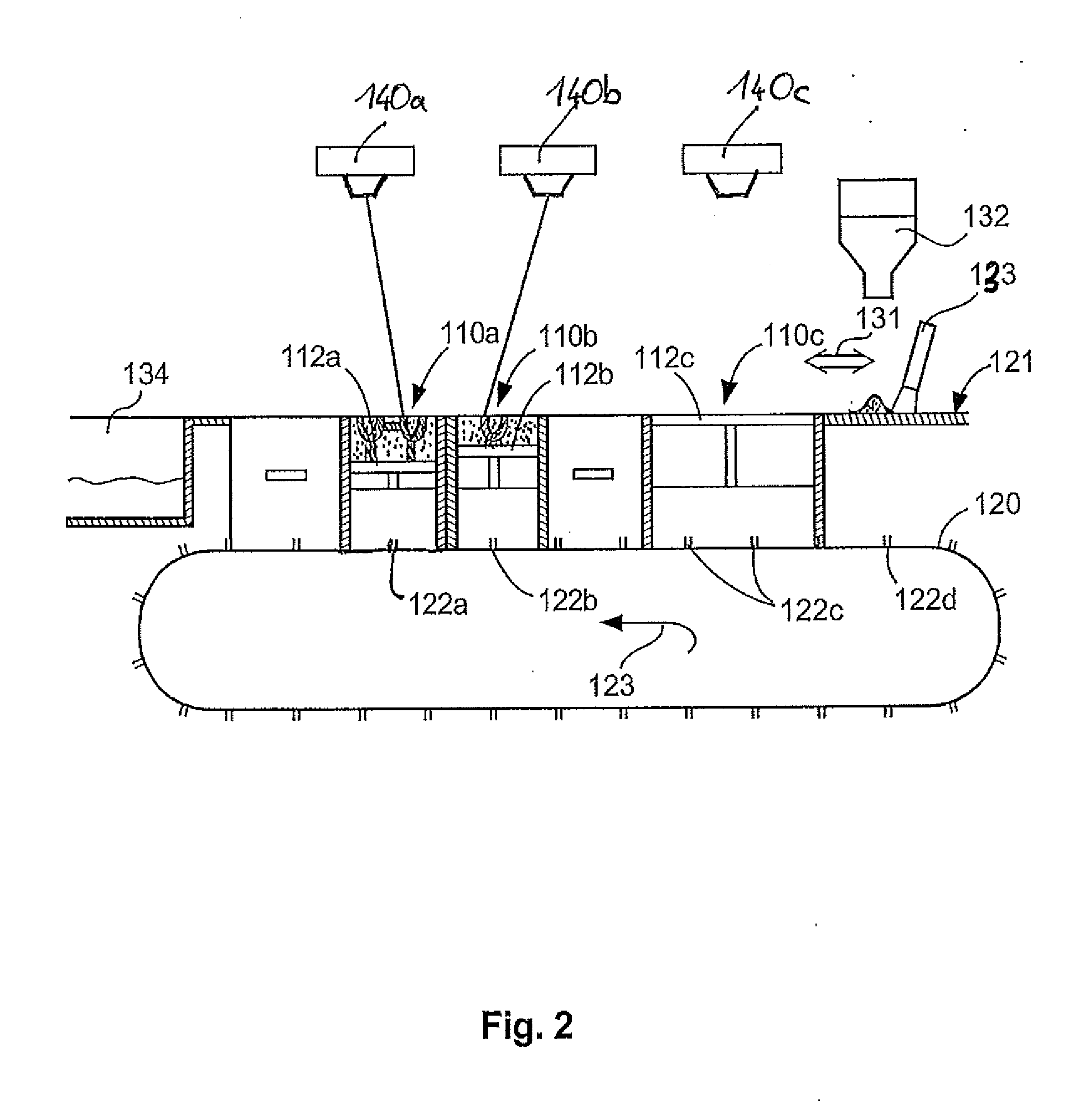

Device for the generative manufacturing of three-dimensional components

ActiveUS20130108726A1Efficient and cost-effective operationEfficiently formedManufacturing platforms/substratesConfectioneryEngineeringMonochrome

The invention relates to a device for producing products having individual geometries, comprising a substrate carrier device, a material application device for applying material, preferably above the substrate carrier device, which material application device can be moved relative to the substrate carrier device, and a control device which is coupled to the material application device for signaling. According to the invention, the material application device is coupled to an input interface for signaling and for selection of a first or a second application mode, the control device and the application device being designed such as to produce, in the first application mode, a three-dimensional product on the surface of a substrate plate by way of an additive production method, said substrate plate being connected to the substrate carrier device. According to the additive production method, a curable material is applied in consecutive layers, one or more predetermined regions are selectively cured after or during each application of a layer, the predetermined regions being bonded to one or more regions of the underlying layer. The predetermined region(s) is / are predetermined by a cross-section geometry of the product in the respective layer and is / are stored in the control device, and the curable material is applied in a plurality of consecutive layers to produce the three-dimensional product. The control device and the application device are further designed such that in the second mode of application one or more colors are applied to predetermined regions of a print substrate material connected to the substrate carrier device to produce a monochrome or polychrome print.

Owner:BEGO MEDICAL

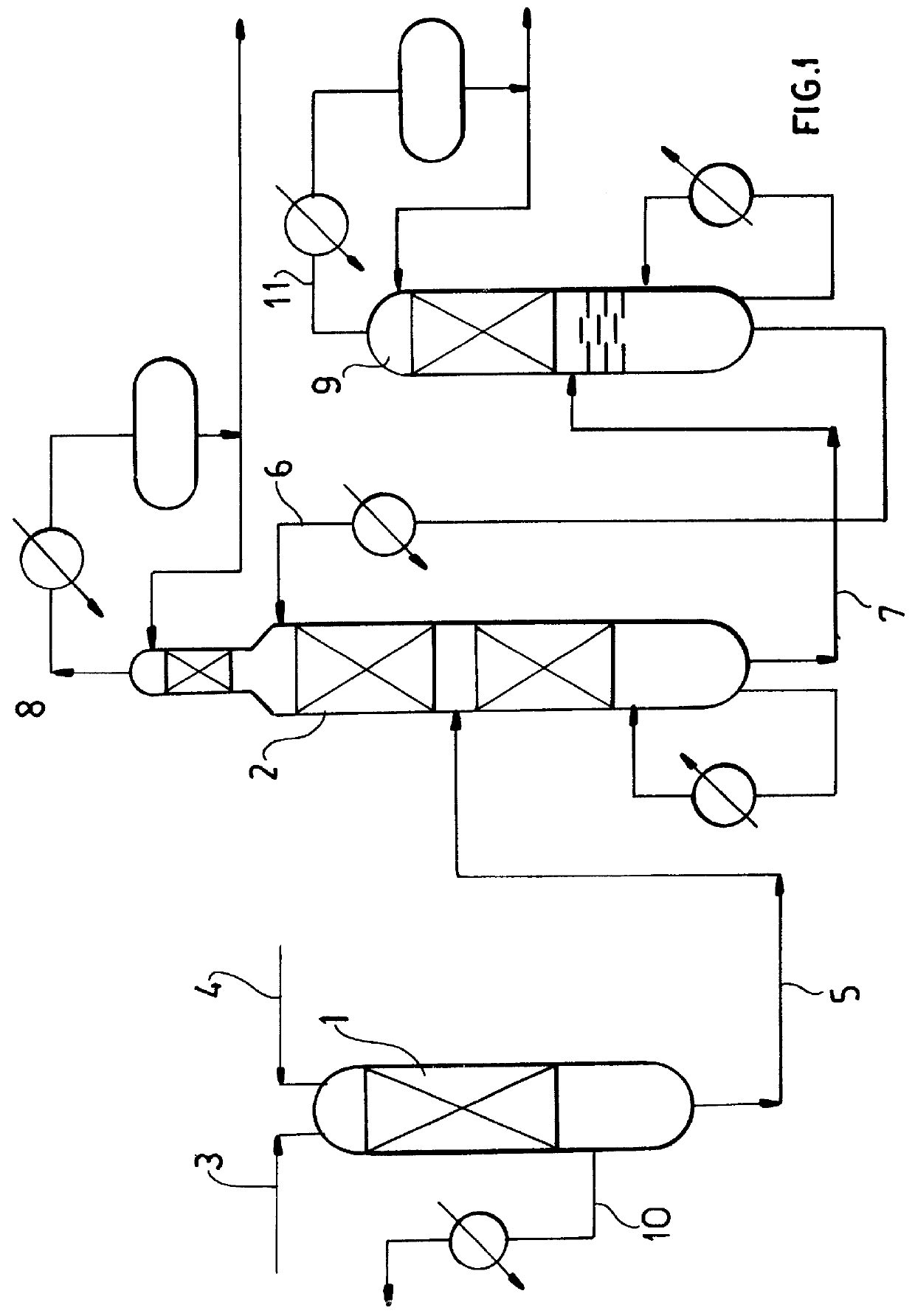

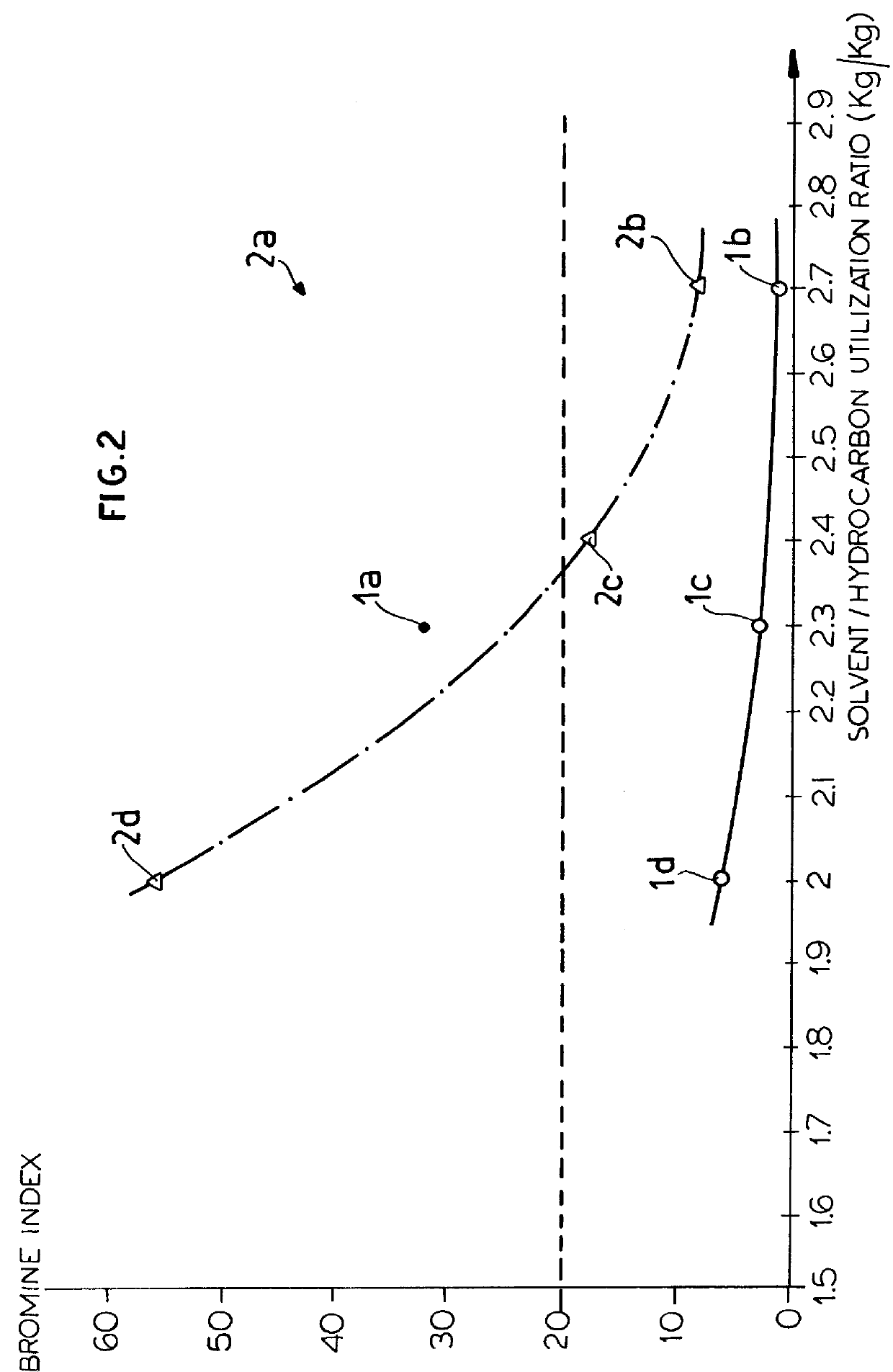

Process for generating pure benzene from reformed gasoline

InactiveUS6124514AReduce benzene contentAchieve separationThermal non-catalytic crackingCatalytic crackingBenzeneExtractive distillation

A process is disclosed for generating pure aromatic compounds from a reformed gasoline which contains aromatic compounds, olefins, diolefin, and triolefins, which comprises the steps of: (a) selectively hydrogenating the olefins, diolefins and triolefins in the reformed gasoline to obtain a mixture of hydrogenated, non-aromatic compounds and aromatic compounds; and (b) separating the aromatic compounds from the hydrogenated, non-aromatic compounds in the mixture formed during step (a) by either extractive distillation, liquid-liquid extraction or both to obtain the pure aromatic compounds.

Owner:BASF AG

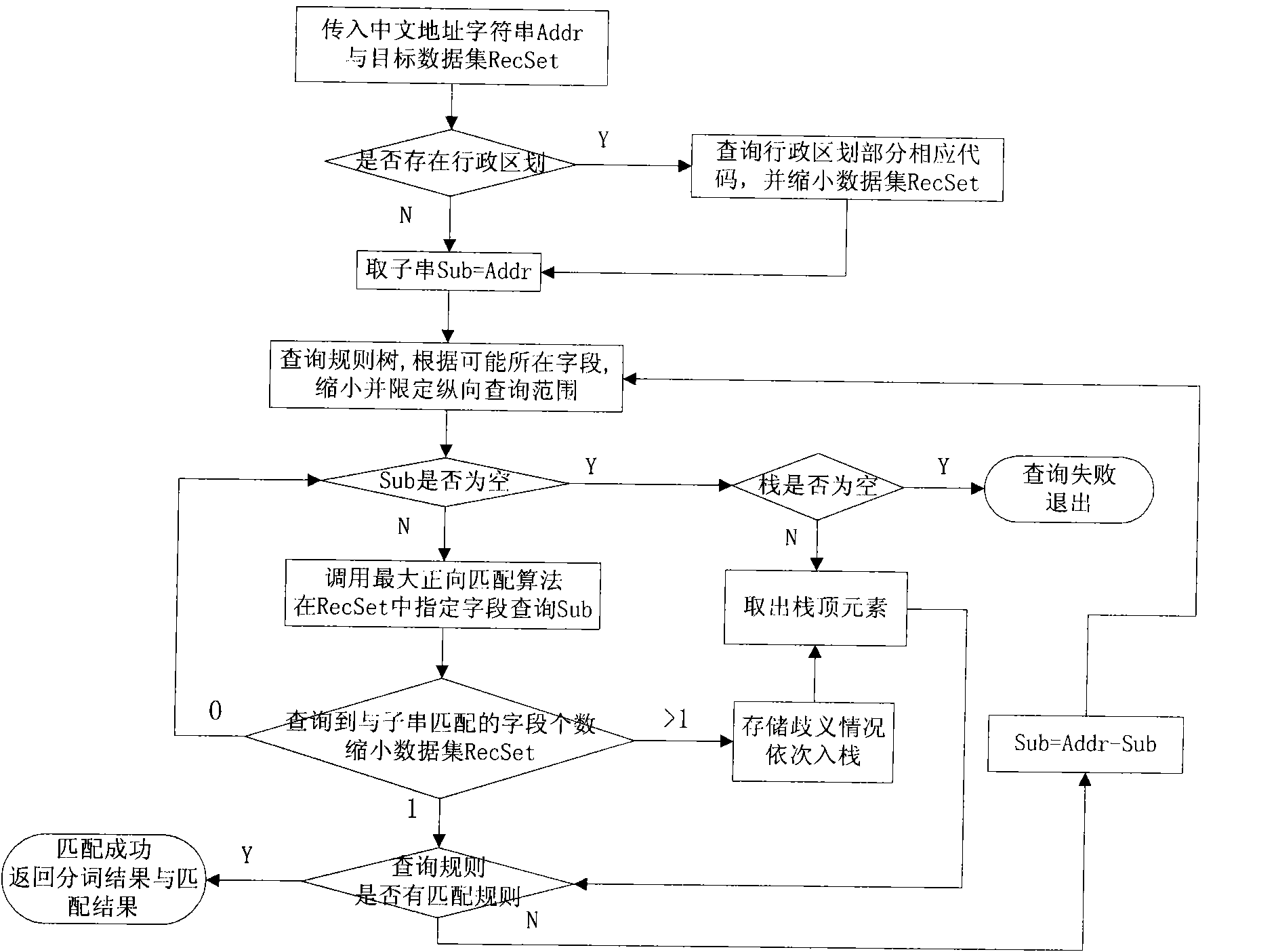

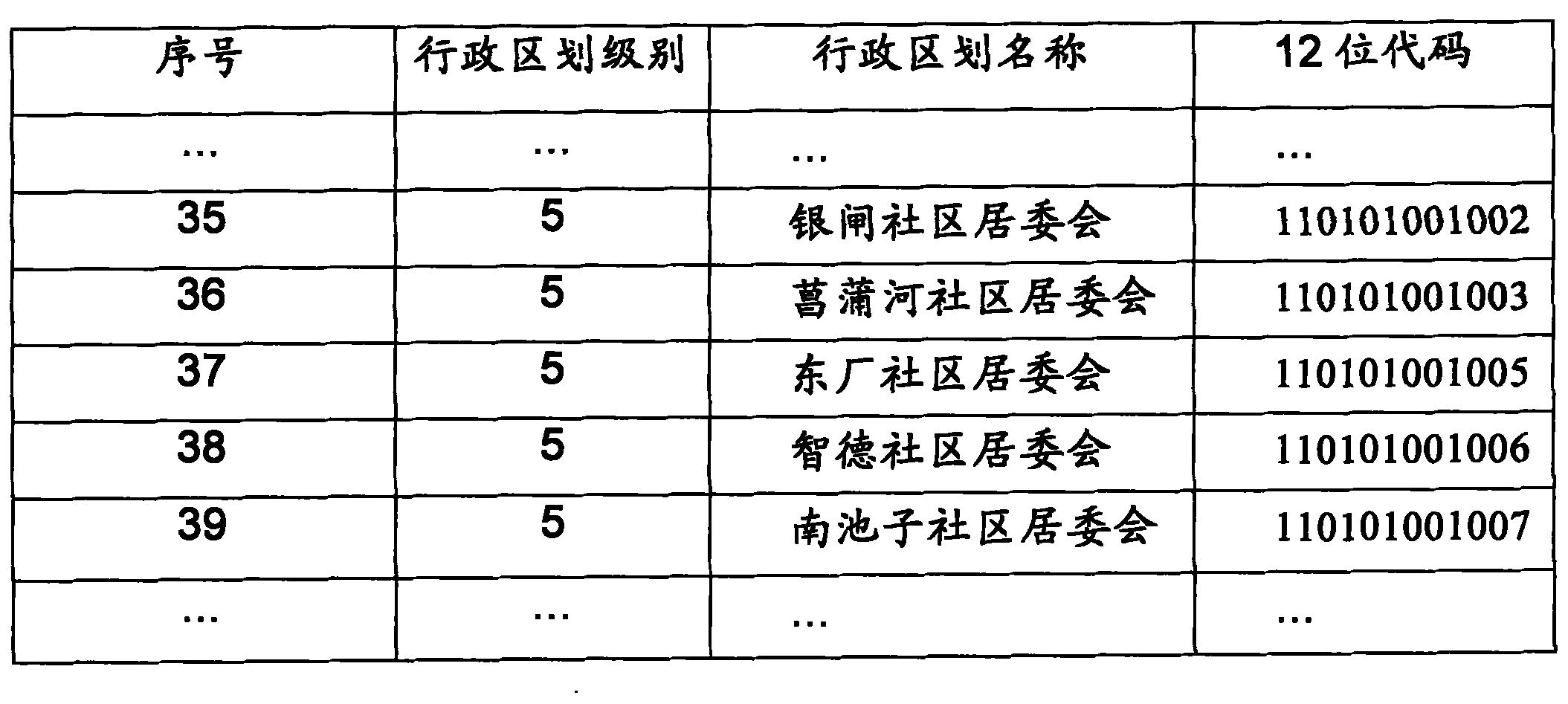

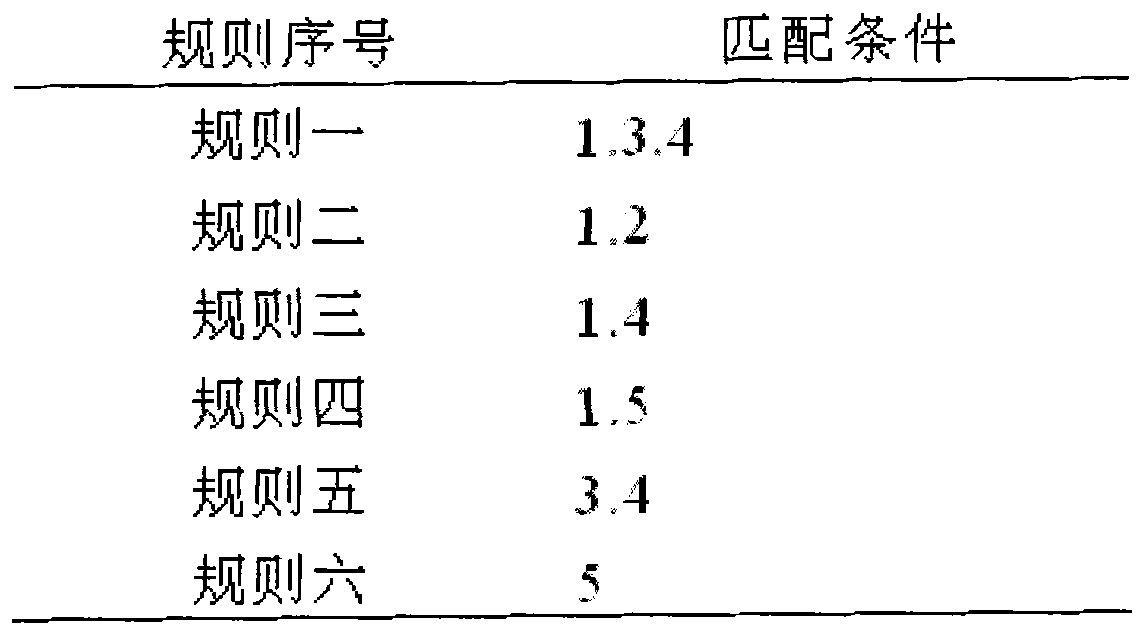

Fuzzy Chinese address geographic evaluation method based on matching rule

InactiveCN101882163AReduce the number of query visitsImprove matching speedSpecial data processing applicationsData setAmbiguity

The invention relates to a fuzzy Chinese address geographic evaluation method based on a matching rule, which belongs to the field of the address evaluation of a geographic information system. The method comprises the following steps: firstly, reading in an address character string and a standard address base; inquiring and dividing administrative division parts in the address character string and filtering reduced target data sets; then realizing the segmentation and the matching of an address by means of a matching rule tree and a rule base in allusion to the fuzzy problems of address element incompletion, address ambiguity and the like frequently appearing in the address character string, and returning a matching record meeting requirements. The invention integrates two important links of address segmentation and database matching in geographic evaluation, realizes that the database matching of the address is completed while in segmentation, effectively solves the address matching problem of the fuzzy Chinese address and improves the accuracy and correctness of address matching.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

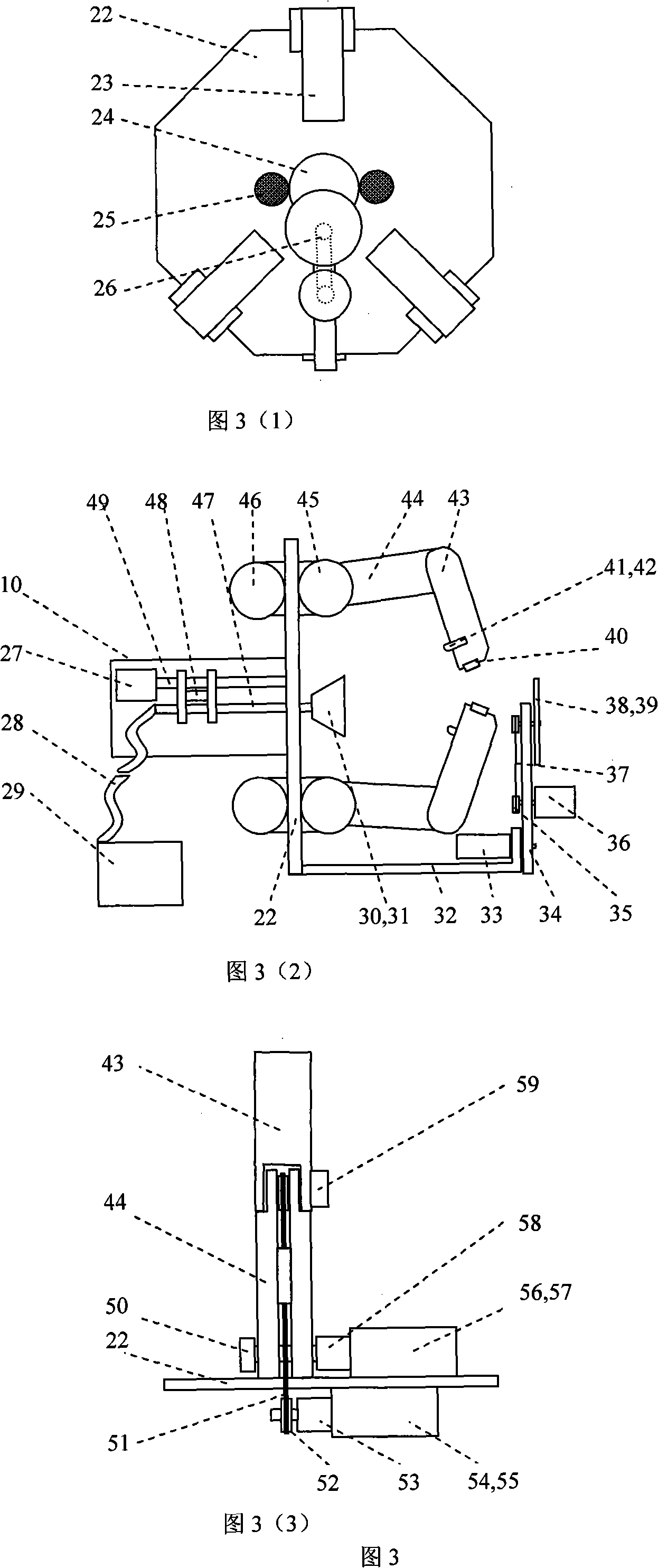

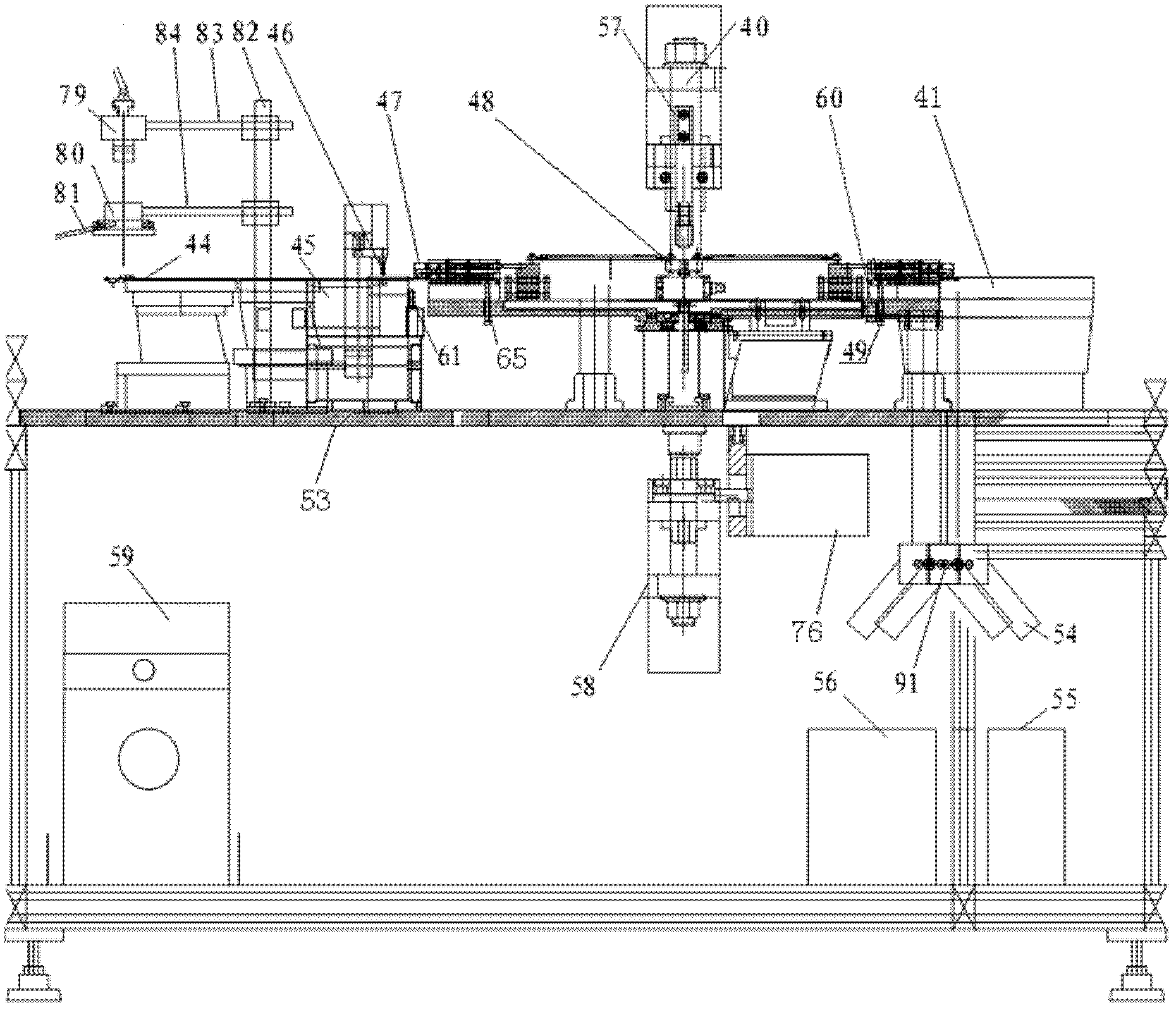

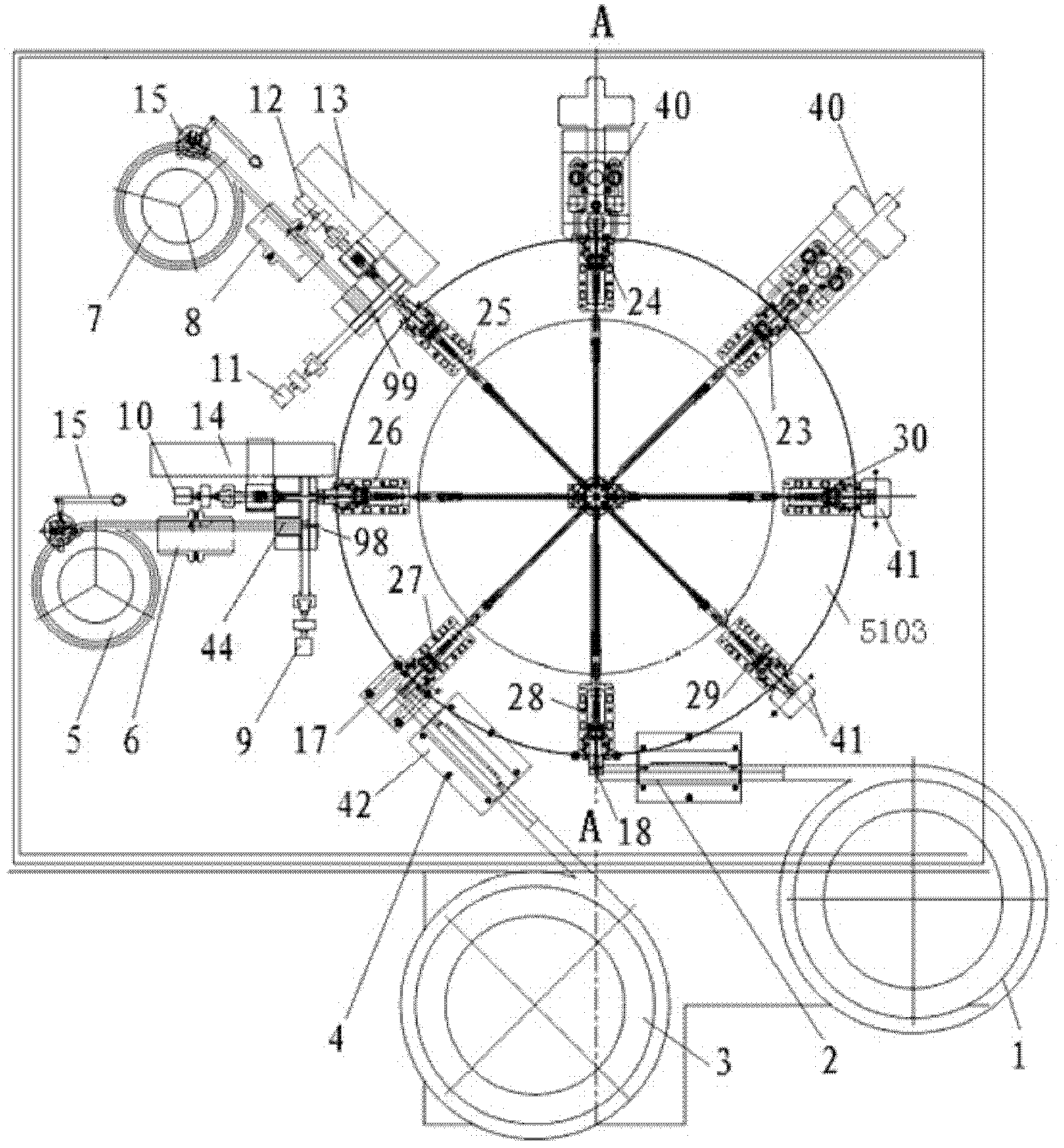

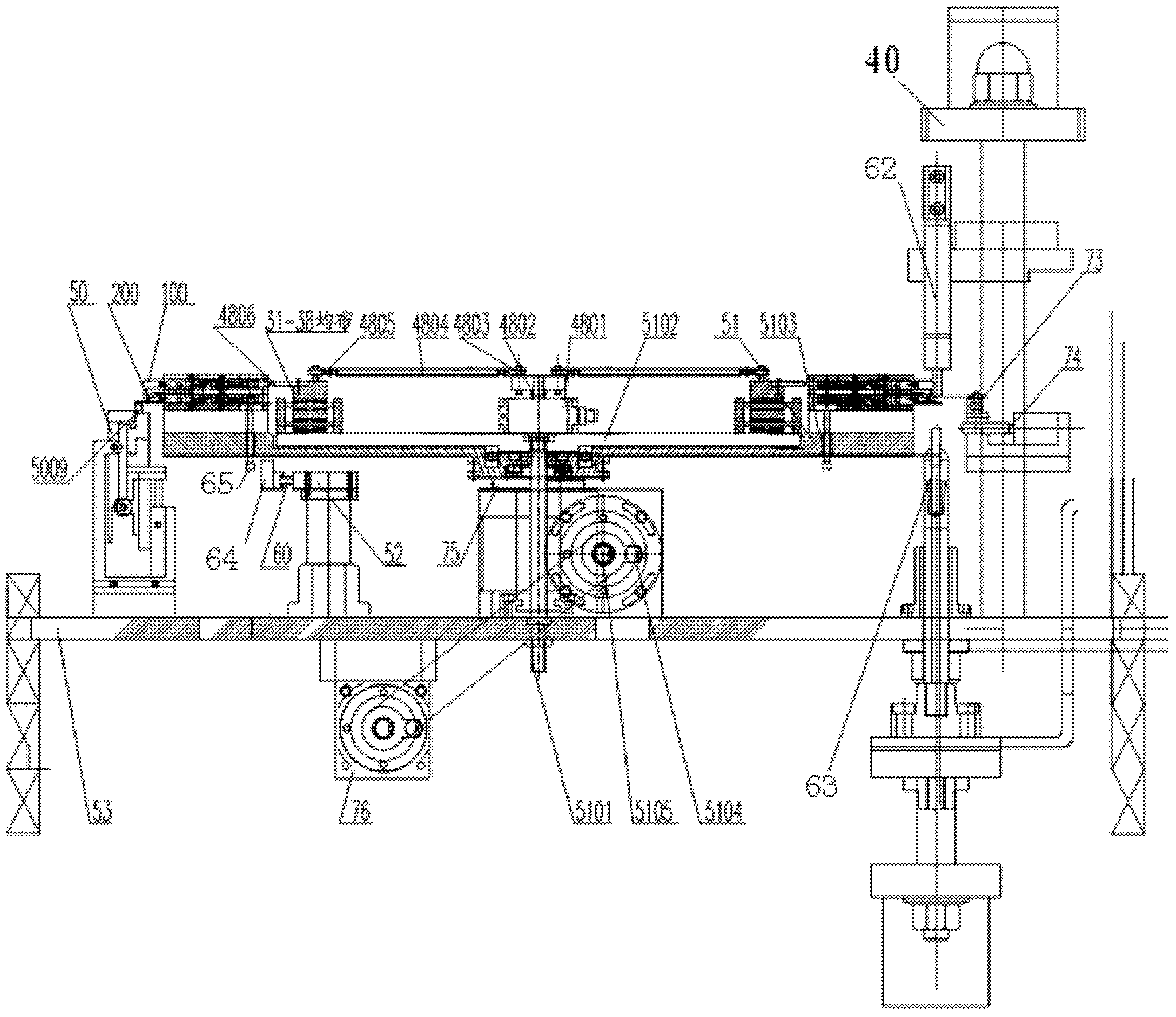

Full-automatic multi-station welding system

ActiveCN102528353AAchieve separationAchieve storageWelding/cutting auxillary devicesAuxillary welding devicesManipulatorContactor

The invention discloses a full-automatic multi-station welding system which mainly comprises a rotary table and driving device, contact bridge storage and feeding devices, contactor feeding and conveying devices, welding machine heads and a discharge component, wherein the rotary table and driving device is internally and externally divided in the shape of a ring in the such way of equal and concentric eight parts and four stations, and the positions are set to be an even number according to the welding positions of welded pieces; eight mechanical arm assemblies are uniformly distributed in the circumferential direction on the upper surface of an outer rotary table; two contact bridge storage and feeding devices, two contactor feeding and conveying devices, two welding machine heads and two discharge devices are correspondingly arranged in sequence on the outer side of eight positions; each contact bridge storage and feeding device is engaged with a lower mechanical arm in the present position; each contactor feeding and conveying device comprises a device for identifying front / back faces and sorting during contactor feeding, a solder dropping device and a contactor cross-pushing device. The full-automatic multi-position welding system achieves synchronization of fully automatically welding, assembling and forming multiple sets of equipment in multiple positions at the same time.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

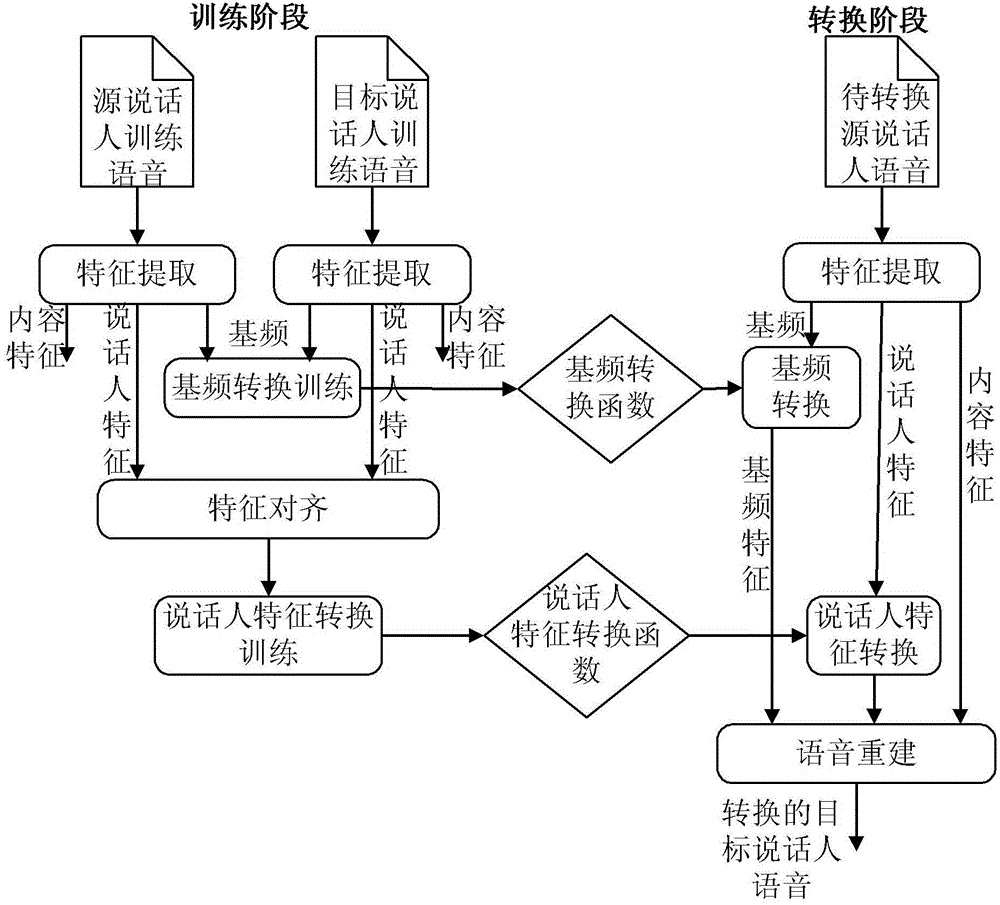

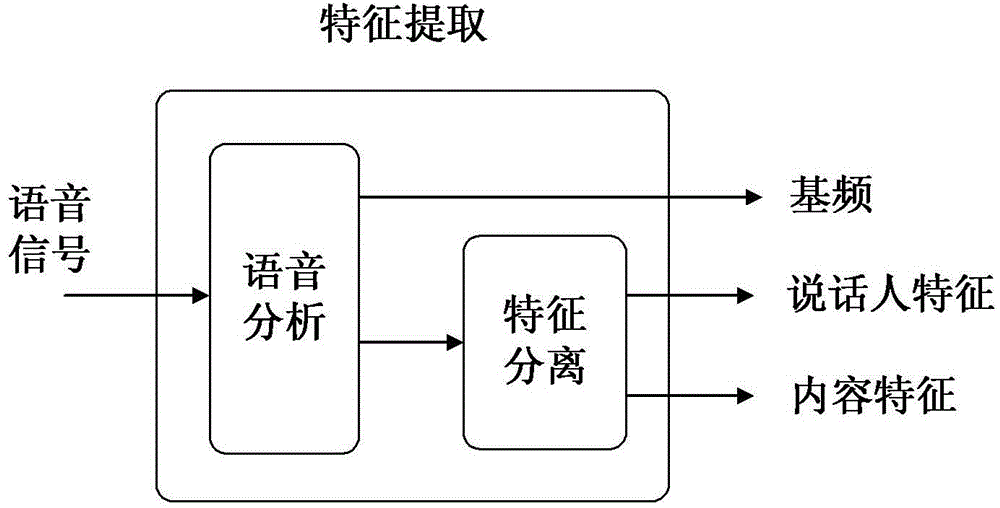

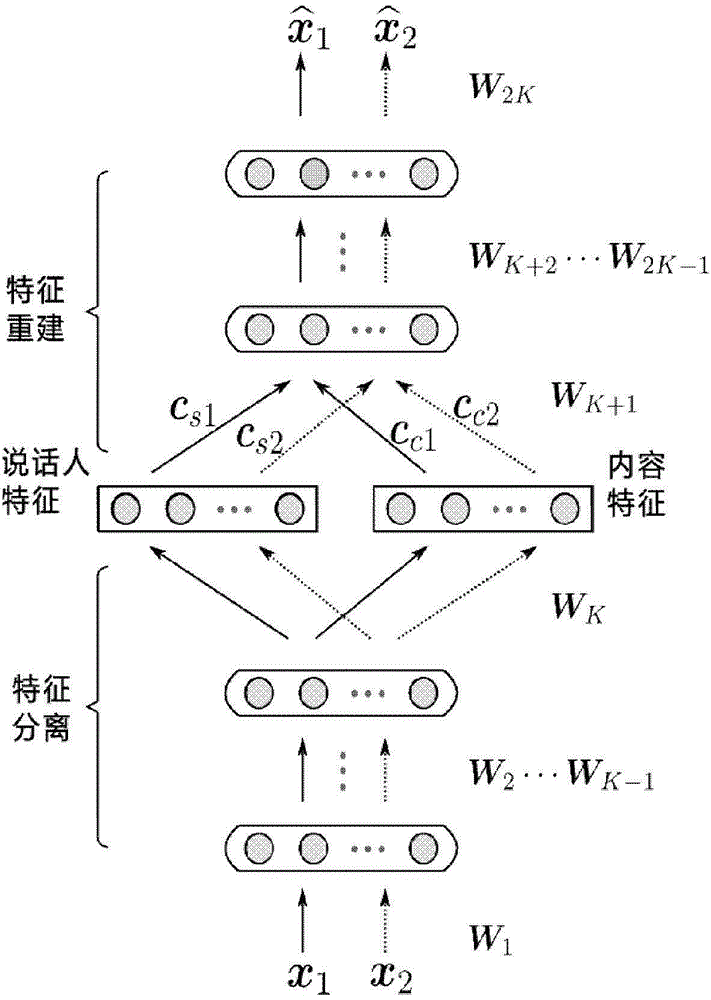

Conversion method for sound of speaker

ActiveCN102982809AAchieve separationMeet the needs of processing tasksSpeech analysisFrequency spectrumSound quality

The invention discloses a conversion method for sound of a speaker. The method comprises a training stage and a conversion stage, wherein the training stage comprises the steps of respectively extracting a fundamental frequency characteristic, a speaker characteristic and a content characteristic from training voice signals of a source speaker and a target speaker, constructing a fundamental frequency conversion function according to the fundamental frequency characteristic, and constructing a speaker conversion function according to the speaker characteristic. The conversion stage comprises the steps of extracting a fundamental frequency characteristic and a spectrum characteristic from a voice signal to be converted of the source speaker, using the fundamental frequency conversion function and the speaker conversion function obtained in the training stage to convert the fundamental frequency characteristic and the speaker characteristic extracted from the voice signal to be converted, obtaining the converted fundamental frequency characteristic and the speaker characteristic, and synthesizing voices of the target speaker according to the obtained converted fundamental frequency characteristic, the speaker characteristic and the content characteristic in the voice signal to be converted. The method is easy to realize, and the converted sound quality and similarity are higher.

Owner:UNIV OF SCI & TECH OF CHINA

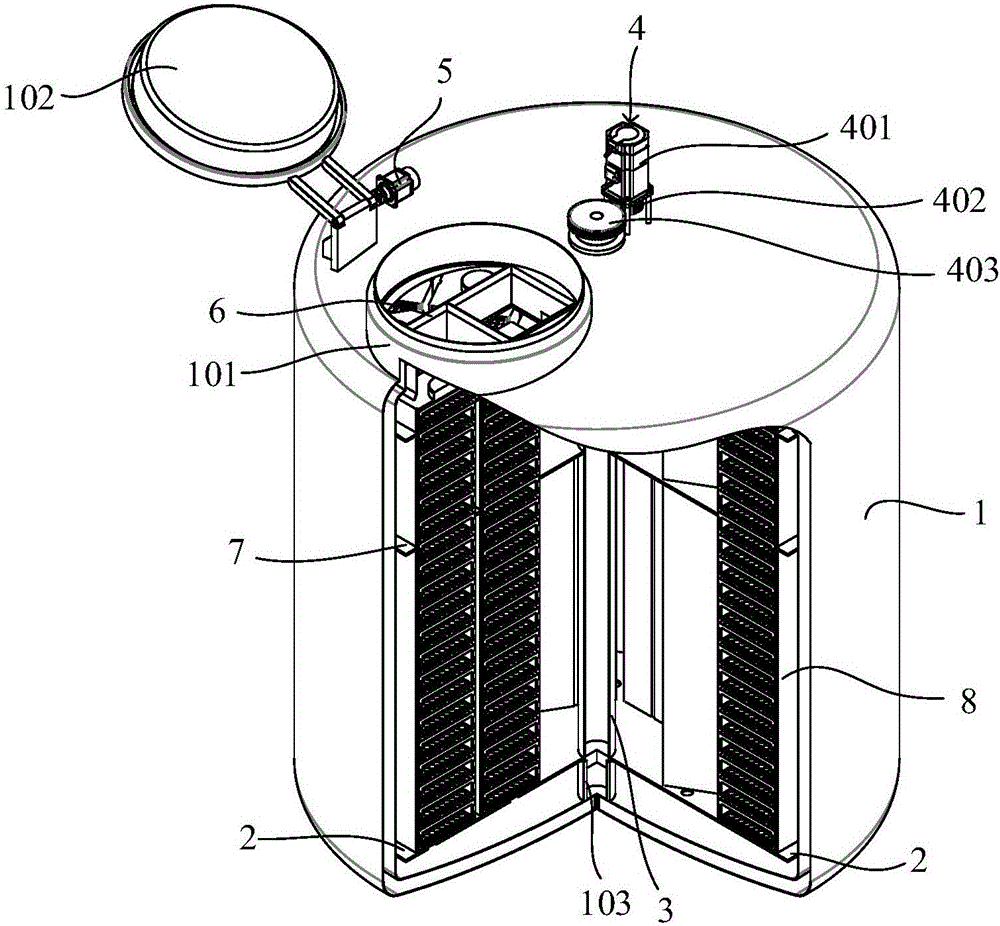

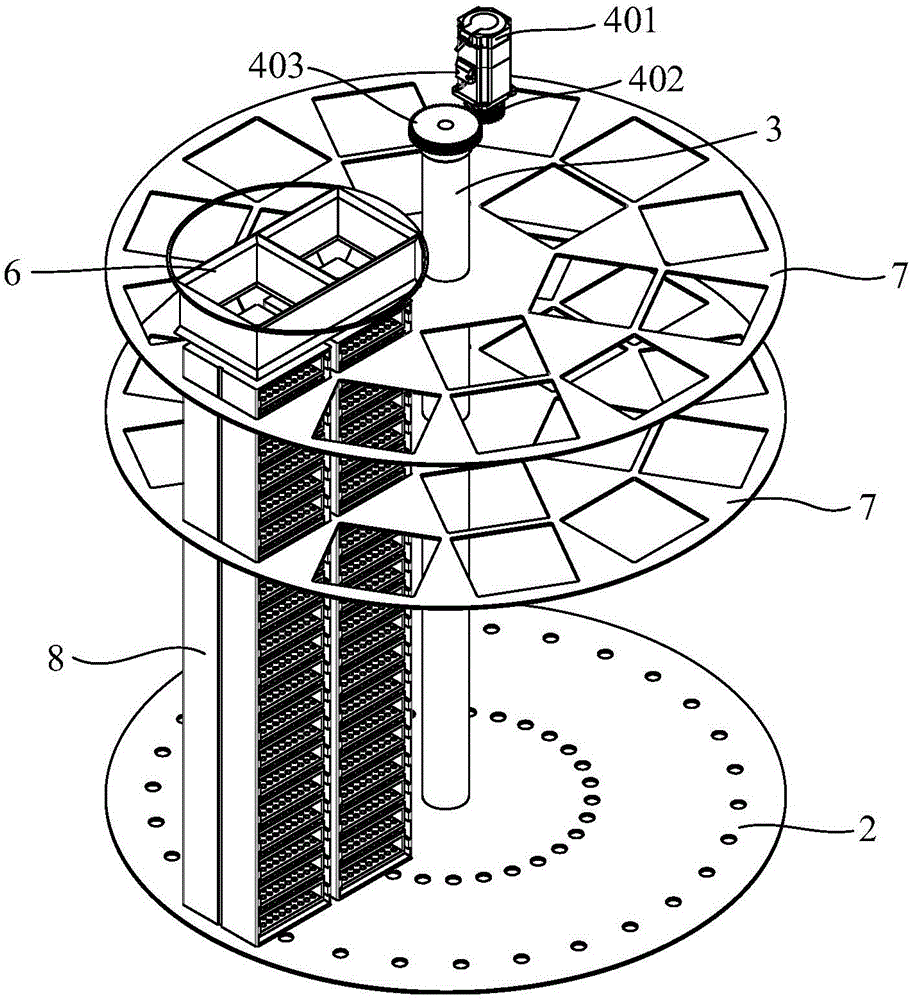

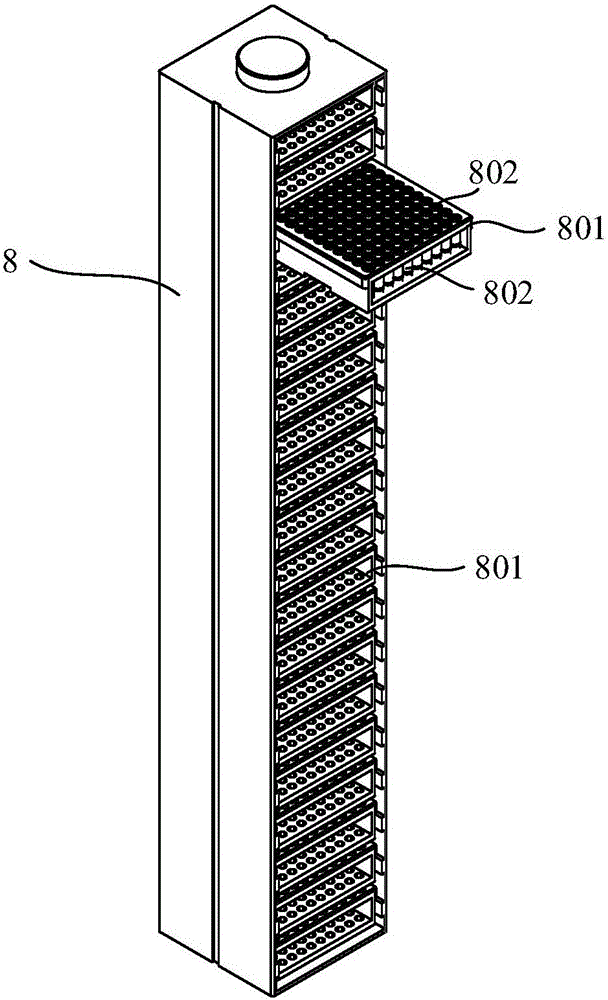

Liquid nitrogen cylinder, cryogenic vial storing and fetching device and liquid nitrogen cylinder storing and fetching system

ActiveCN105857937AReduce error rateAvoid safety hazardsLarge containersControl devices for conveyorsEngineeringLiquid nitrogen

The invention discloses a liquid nitrogen cylinder, a cryogenic vial storing and fetching device and a liquid nitrogen cylinder storing and fetching system. The liquid nitrogen cylinder comprises a cylinder body, wherein the cylinder body is provided with a sealed opening; the liquid nitrogen cylinder further comprises a bracket tray; the bracket tray is arranged in the cylinder body; the bracket tray is used for bearing cryogenic baskets; a central shaft is vertical to the bracket tray and is fixedly connected with the bracket tray; a driving component is electrically connected with the central shaft; the driving component is used for driving the central shaft to rotate; and the central shaft is used for driving the cryogenic baskets to rotate through the bracket tray and conveying the cryogenic baskets to the opening. By adopting the liquid nitrogen cylinder, the error rate of manual cryogenic vial selecting is reduced; and meanwhile, safety hazards for operation personnel during a manual bracket tray rotation process are avoided. By adopting the cryogenic vial storing and fetching device, the process for selecting a single target cryogenic vial for biological samples is realized; and during the whole selecting process, the cryogenic vials are all in a liquid nitrogen environment, so that non-target cryogenic vials are prevented from being exposed at environment temperature. The liquid nitrogen cylinder storing and fetching system is applicable to vial picking work for large biological sample banks.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

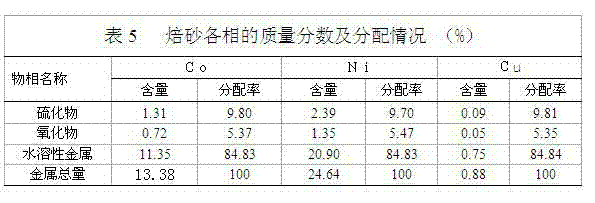

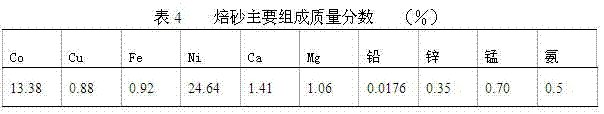

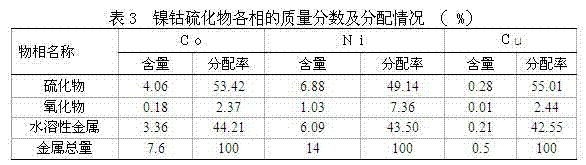

Treatment method of nickel-cobalt material

The invention provides a treatment method of a cobalt-containing material, belonging to the technical field of non-ferrous metal smelting. In the treatment method, through six steps such as peroxidation roasting, sulfuric acid leaching, N902 extraction of copper, chemical iron calcium magnesium removal, P204 extraction and impurity removal, P507 extraction and separation of nickel-cobalt, nickel,cobalt and copper in the nickel-cobalt material are extracted in high recovery, and impurities such as iron, zinc, manganese, calcium, magnesium and the like in the nickel-cobalt material are removed, thereby achieving nickel-cobalt-copper separation and resource comprehensive utilization. According to the treatment method provided by the invention, the process is simple and production cost is relatively low; the adaptability of the method on raw materials is strong and can be used for treating the nickel-cobalt material with complicated components and high copper-zinc-magnesium contents.

Owner:JINCHUAN GROUP LIMITED

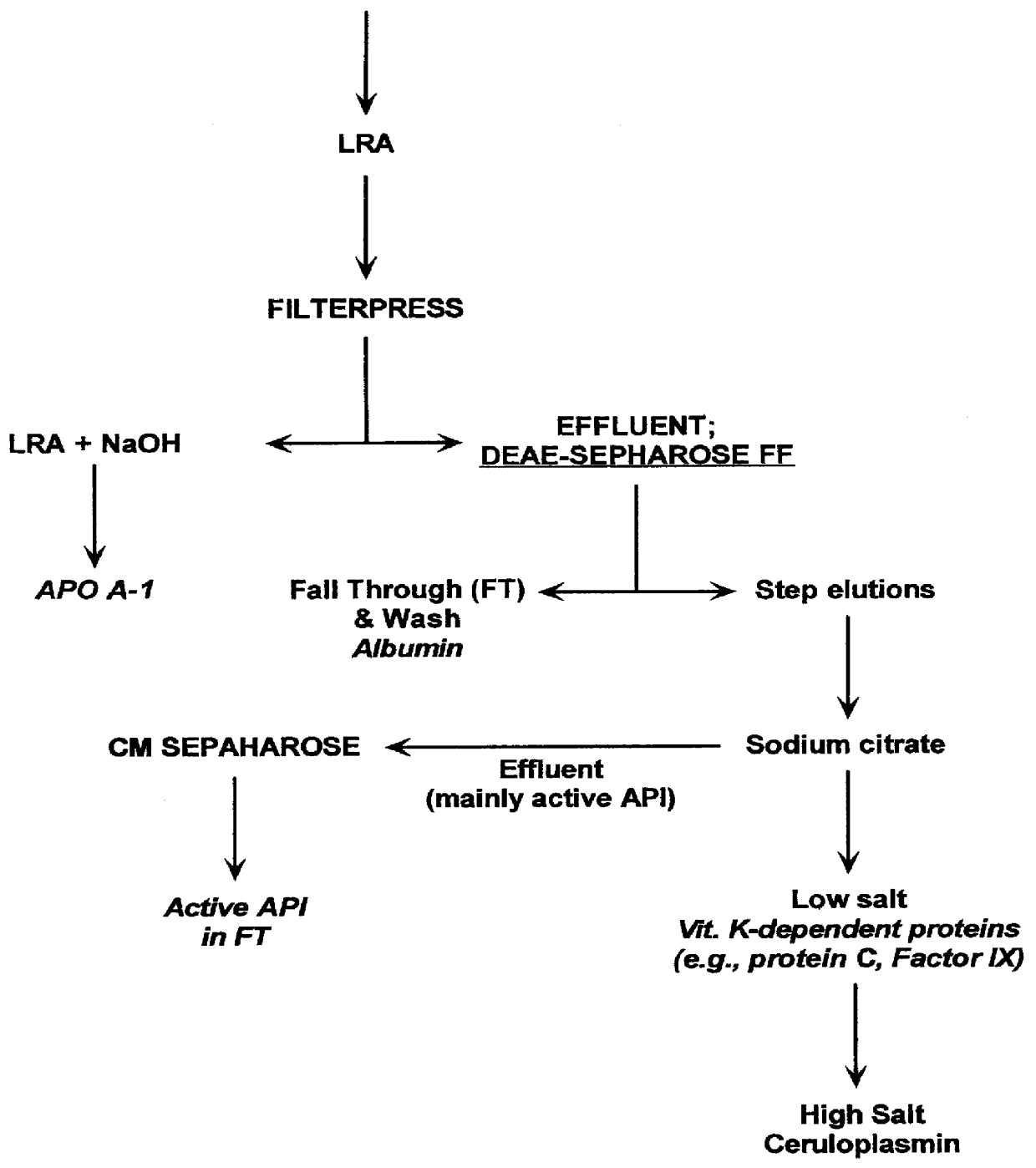

Method for purification of alpha-1 proteinase inhibitor

InactiveUS6093804AHigh yield isolationAchieve separationPeptide/protein ingredientsMammal material medical ingredientsPurification methodsEnzyme inhibitor

The methods of the present invention provide a simple means for separating active and inactive Alpha Proteinase Inhibitor (API). The methods further provide means for purifying API at high yield (>70%), and at levels of purity (>90%) and activity (>90%) not heretofore available. Moreover, the methods of the present invention are simple (i.e., two chromatographic steps) and efficient; and are thus especially suitable to large scale purification processes. These methods will contribute substantially to alleviating the unmet demand for API for therapeutic purposes.

Owner:KAMADA

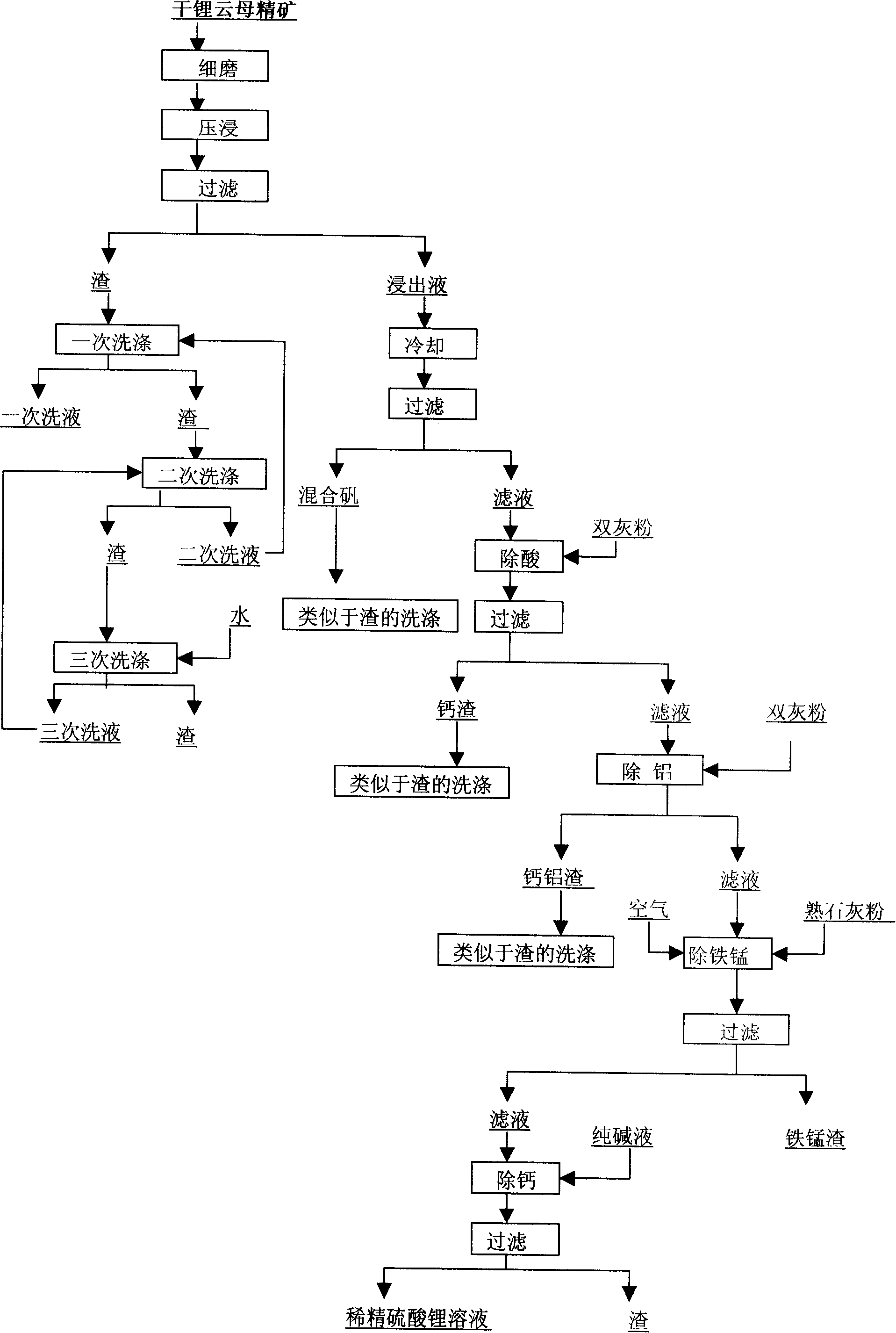

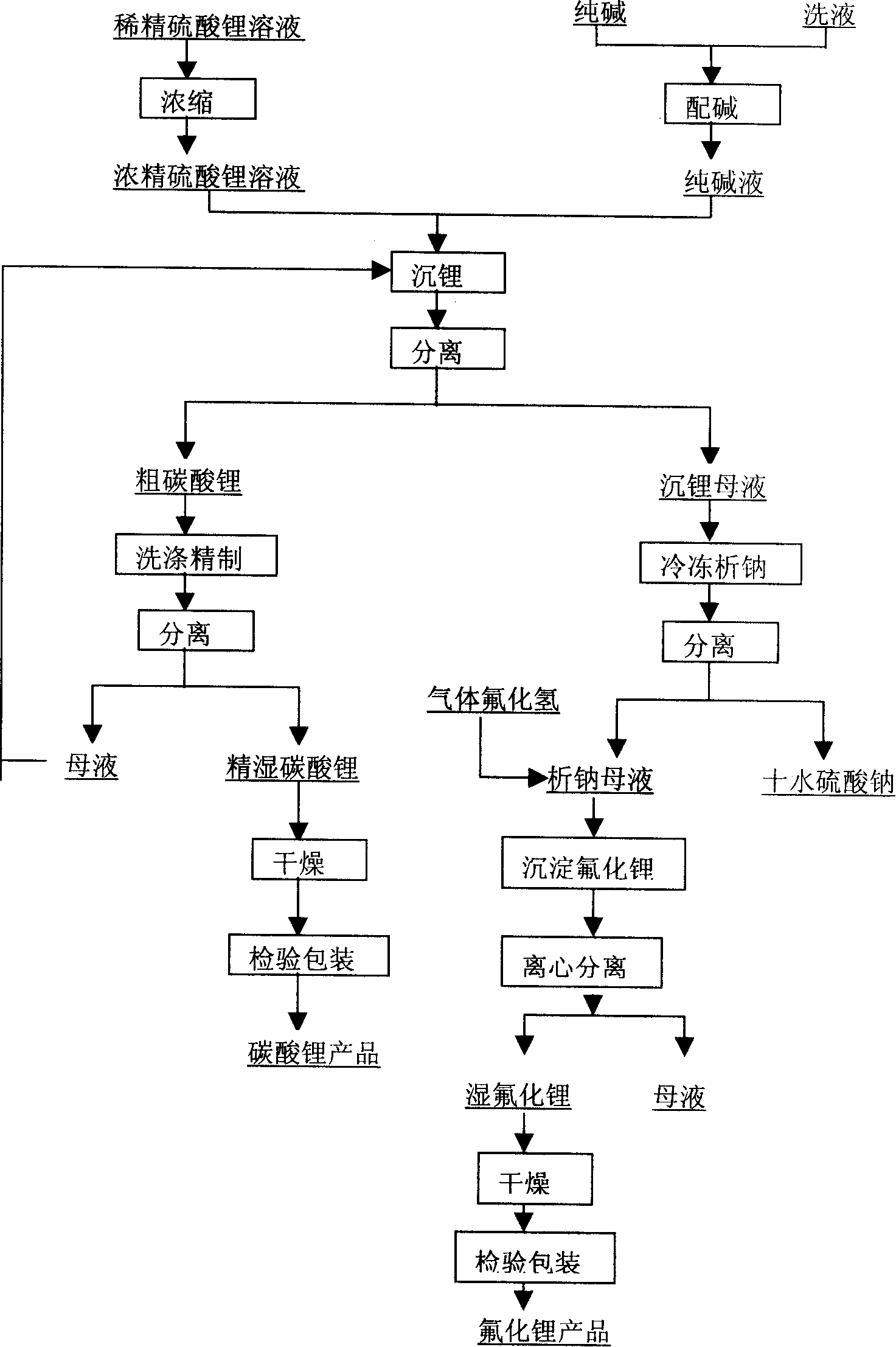

Method for producing refined lithium sulfate solution used in lepidolite lithium-extracting technique by sulfuric acid process

Provided is a process for producing refined lithium sulfate solution of lepidolite lithium extracting technology with sulfuric acid process, which takes lepidolite clean ore as raw material and sequentially includes the following steps, including leaching, alum cooling and decanting, acid removing, aluminum removing, decontaminating and deliming, thereby achieving refined lithium sulfate solution. The alum cooling and decanting process of the invention can precipitate kalium, rubidium and caesium in alum form, thereby the separation of lithium and kalium, rubidium and caesium is easily achieved, and the achieved alum dregs of kalium, rubidium and caesium are blend alum with high purity, which creates perfect condition for comprehensive utilization and simultaneously reduces the burdens of the separation of lithium and aluminum. The aluminum removing process can easily achieve the separation of lithium and aluminum. The process of the invention has the advantages that the energy consumption is relatively low, and the lithium yield is relatively high, most of the residues can be used and the process is favorable for comprehensive utilization. The invention further provides a process for producing lithium carbonate and lithium fluoride with the achieved refined lithium sulfate solution.

Owner:GANFENG LITHIUM CO LTD

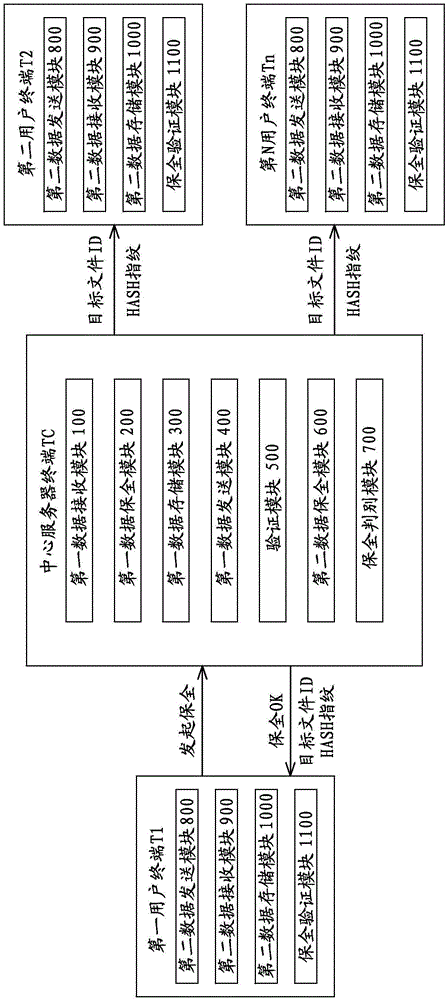

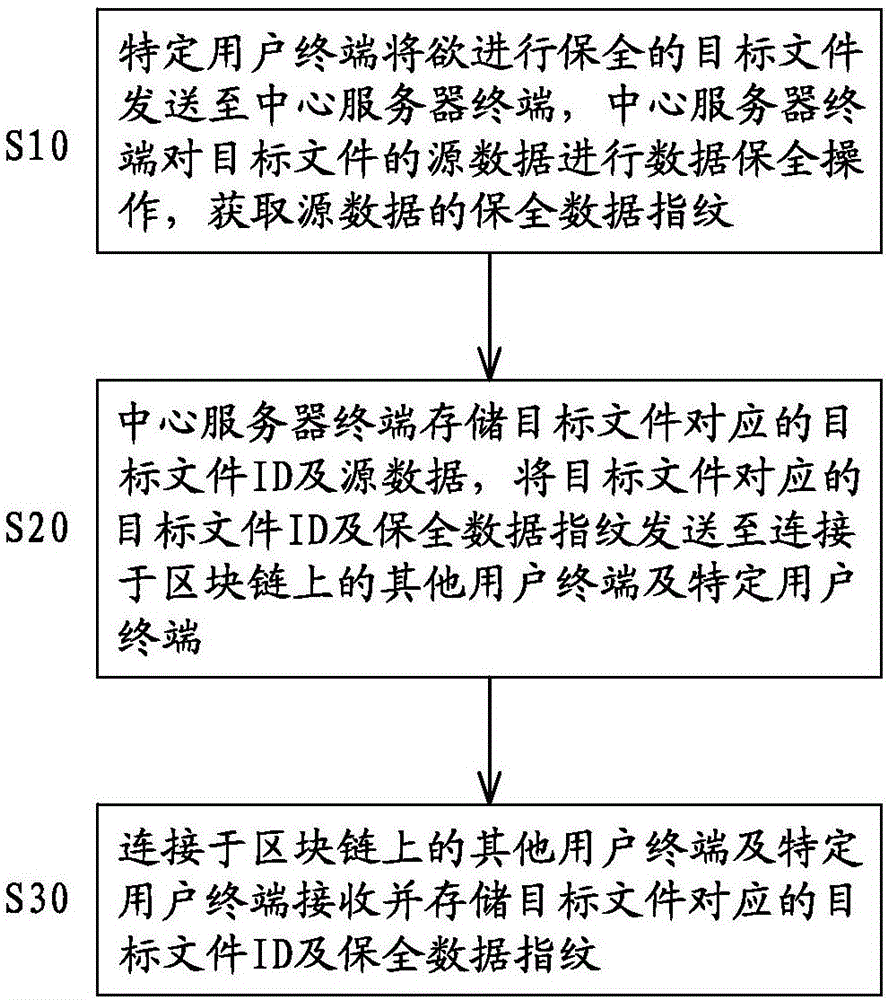

Data preservation method and system based on block chain

ActiveCN106230851AAchieve separationEnsure safetyDigital data protectionBuying/selling/leasing transactionsBlockchainFingerprint

The invention discloses a data preservation method and system based on a block chain. The method comprises the following steps: a specific user terminal sending a to-be-preserved target file to a center server terminal, the center server terminal performing a data preservation operation on source data of a target file to acquire a preserved data fingerprint of the source data; the center server terminal storing a target file ID corresponding to the target file and the source data, sending the target file ID corresponding to the target file and the preserved data fingerprint to other user terminal and the specific user terminal connected with the block chain; the other user terminal and the specific user terminal connected with the block chain receiving and storing the target file ID corresponding to the target file and the preserved data fingerprint. Each user terminal connected with the block chain only saves the fingerprint information and does not save the source data, and the center server terminal only saves the source data and does not save the fingerprint information; therefore, the source data and the fingerprint are separated, and security of the preserved data is guaranteed.

Owner:CENTRIN DATA SYST

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

The invention relates to a method for recycling copper, nickel, chromium, zinc and iron from plating sludge, belonging to the technical field of chemical engineering and metallurgy. The method comprises the following steps: acid leaching, vulcanizing for separation and enrichment, hot-pressure leaching, extracting for separation, hot-press oxidizing chromium, purifying chromium solution, extracting ferric chloride and the like. The method has obvious advantages of strong adaptability to different kinds of plating sludge, high utilization of metal resources, high value-added content of product,less process waste residue, thorough deintoxication and the like.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

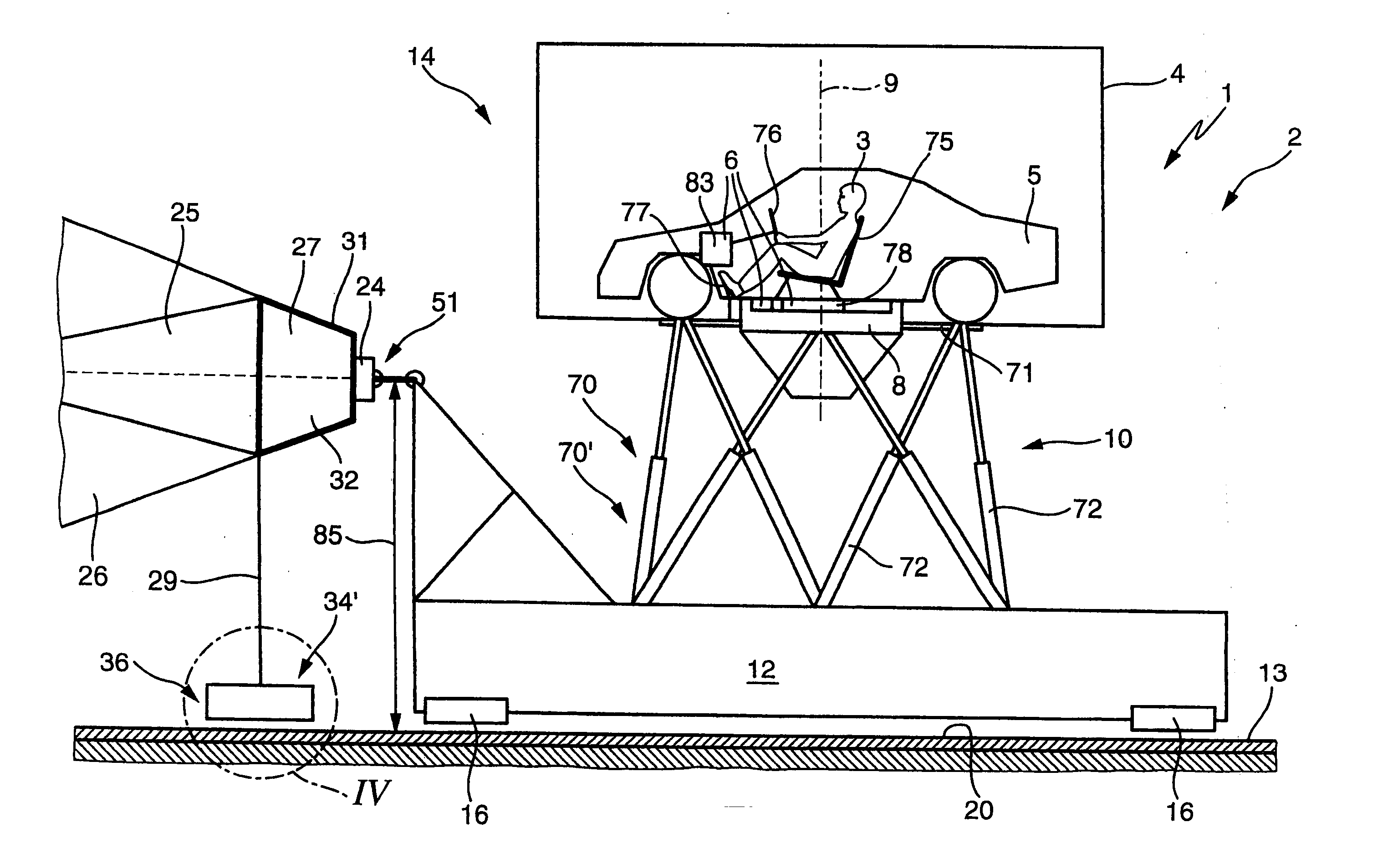

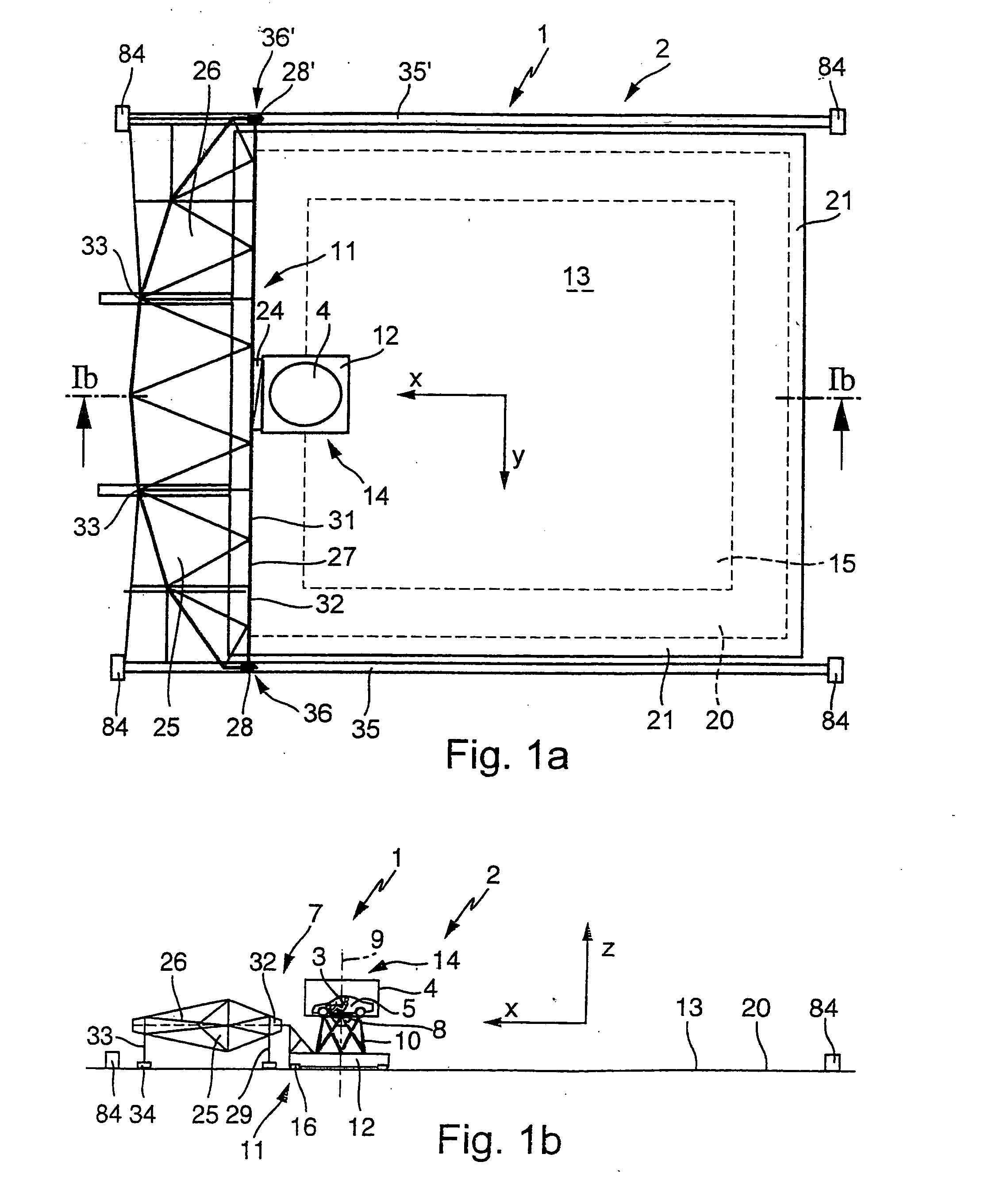

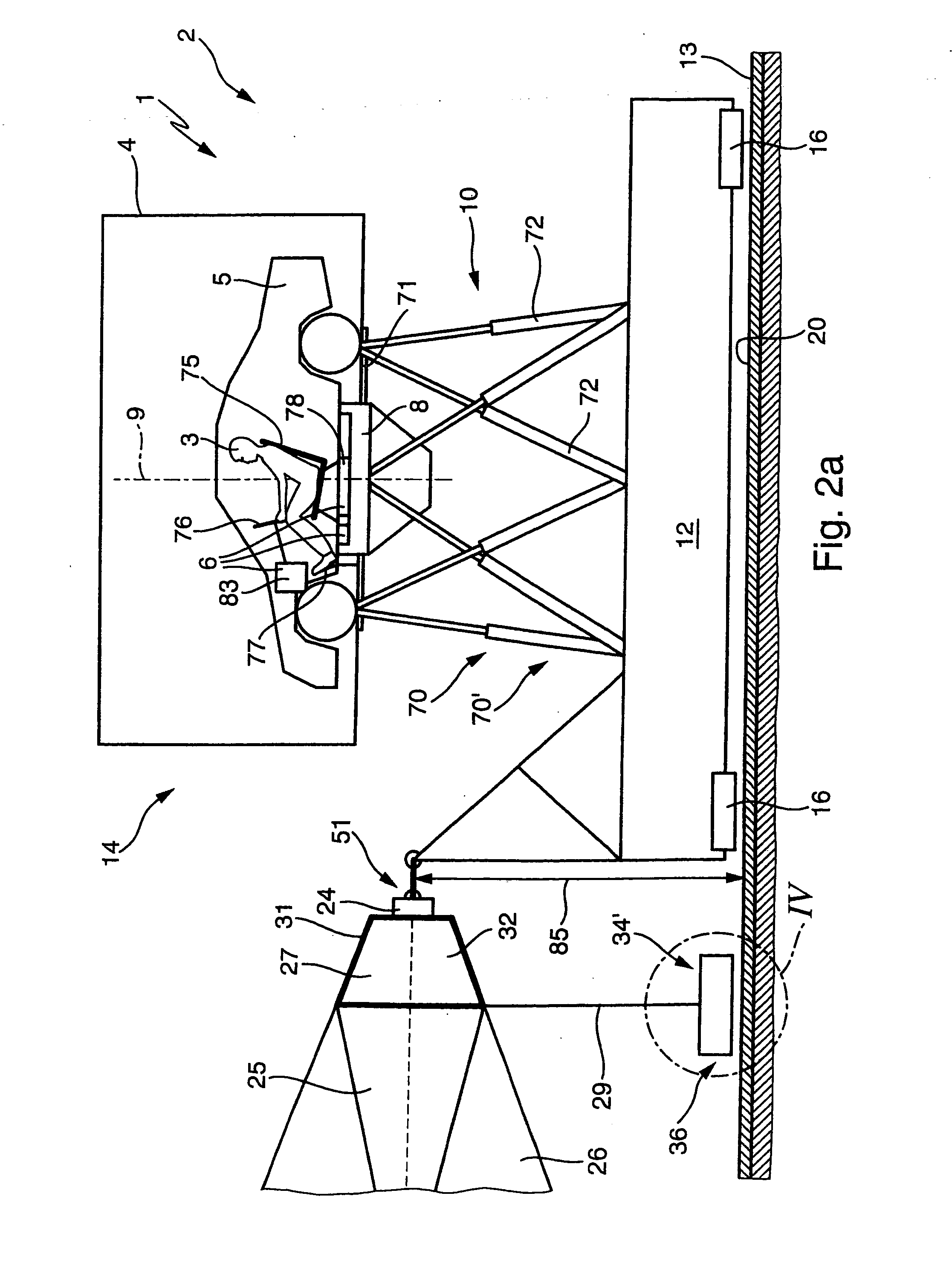

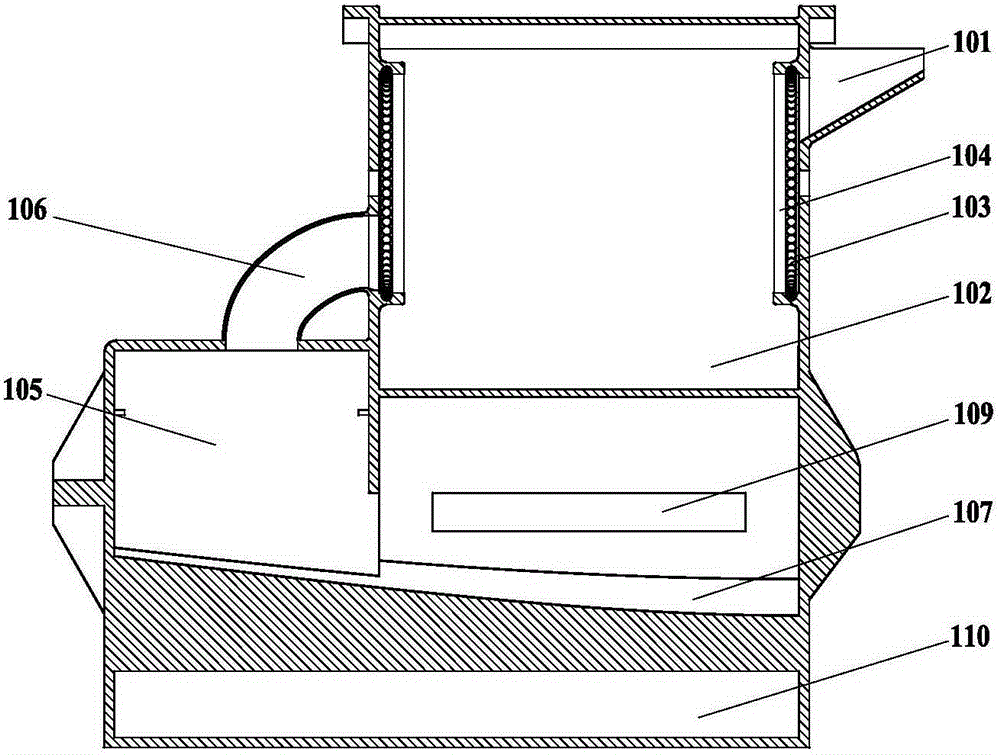

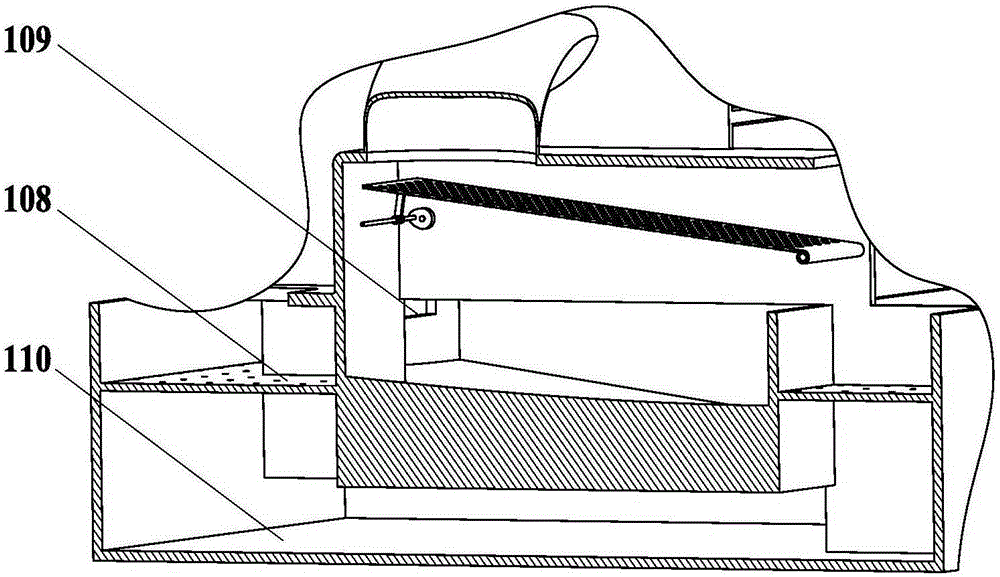

Driving simulator

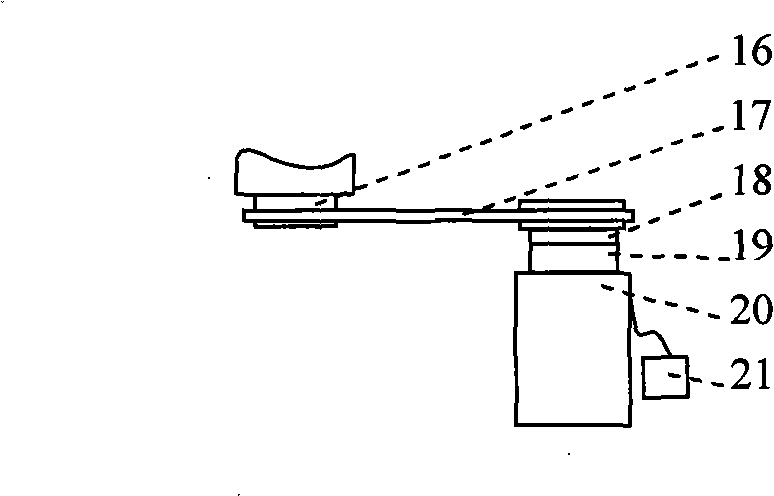

InactiveUS20050042578A1Prevent riskLow frictionVehicle testingCosmonautic condition simulationsManipulatorDriving simulator

Owner:DAIMLER AG

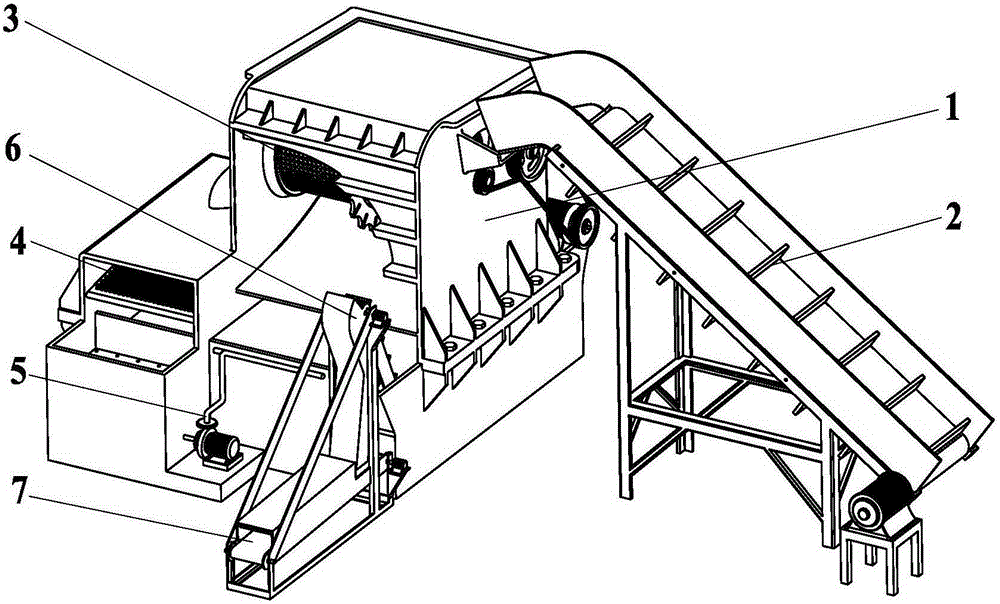

Three-time separating seed extractor for seed melons

The invention relates to the field of agricultural product processing, particularly a three-time separating seed extractor for seed melons. The seed extractor comprises a machine body, a whole seed melon transfer device, a roller separating device, a vibrating separation device, a washing device, a fishing device and a transferring and drying device, wherein the whole seed melon transfer device is positioned on the right side of the machine body for transferring the whole melon to the machine body; the roller separating device is mounted on the right side in the machine body for primarily separating the seed melon; the vibrating separating device is mounted on the left side of the roller separating device for secondarily separating the seed melon; the washing device is mounted at the front end of the machine body for separating the seed melon for the third time; the fishing device is positioned on the right side of the washing device for fishing out separated seeds; and the transferring and drying device is positioned below the front end of the fishing device for drying and transferring the seeds. The seed extractor provided by the invention can be used for separating seeds from melon pulp and melon peel for seed melons, soaking the seeds by melon juice and drying the seeds.

Owner:威海高新园区运营管理有限公司

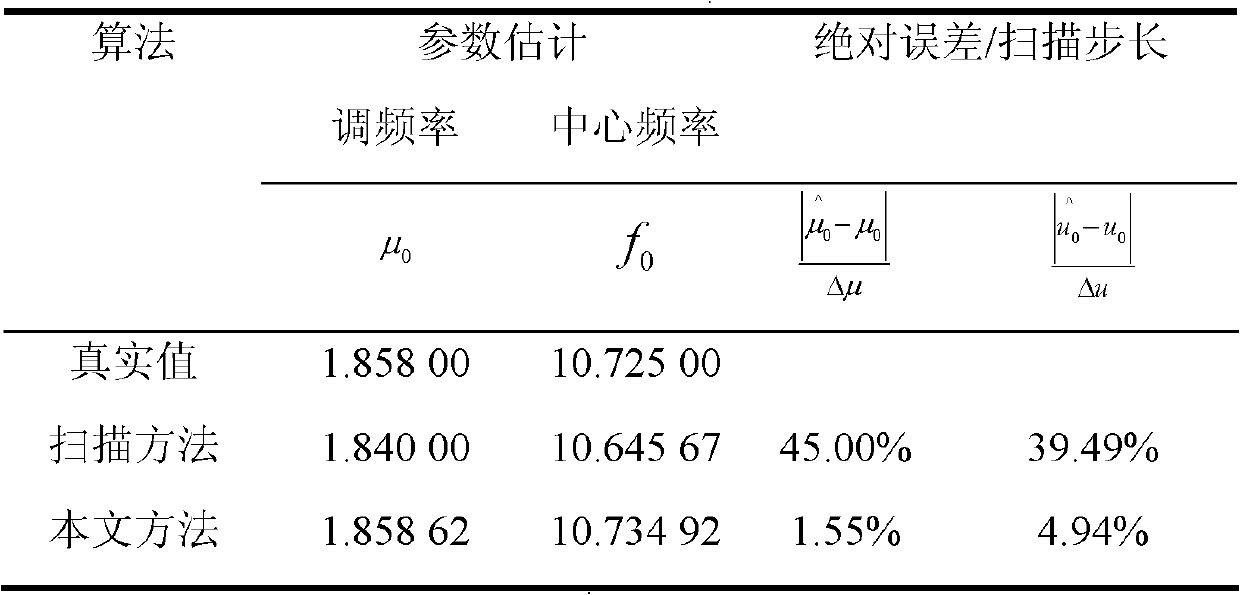

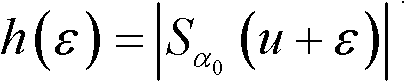

Linear frequency-modulated parameter estimating method and implementing device thereof

ActiveCN101833035AImprove estimation accuracyImprove estimation efficiencySpectral/fourier analysisFrequency measurement arrangementPeak valueDigital signal processing

The invention belongs to the technical field of digital signal processing and provides a linear frequency-modulated parameter estimating method with high precision, low complexity, high speed and high efficiency and an implementing device thereof. The invention adopts a technical scheme that: by means of an energy barycentre interpolation estimation and Radon ambiguity transformation (RAT) based modulating frequency estimating method, the method mainly comprises the following steps of: for a given input signal s(n), calculating an ambiguity function AFs(tau, xi) of the input signal s(n); exchanging scanning straight lines xi=k tau continuously; figuring out the projection of AFs(tau, xi) on the scanning straight lines by means of Radon transformation; recording all projection values; constructing a panorama discrete spectrum; searching out the peak position of the panorama discrete spectrum; estimating the projection value of the actual peak value; obtaining the estimated value of thesignal modulating frequency; searching out the peak value spectrum of a fractional order Fourier spectrum; and figuring out the energy barycentre position of the spectrum so as to estimate the signalbarycentre frequency. The method is mainly applied to the linear modulating frequency signal parameter estimation in the digital signal processing.

Owner:LIANYUNGANG RES INST NANJING UNIV OF SCI & TECH

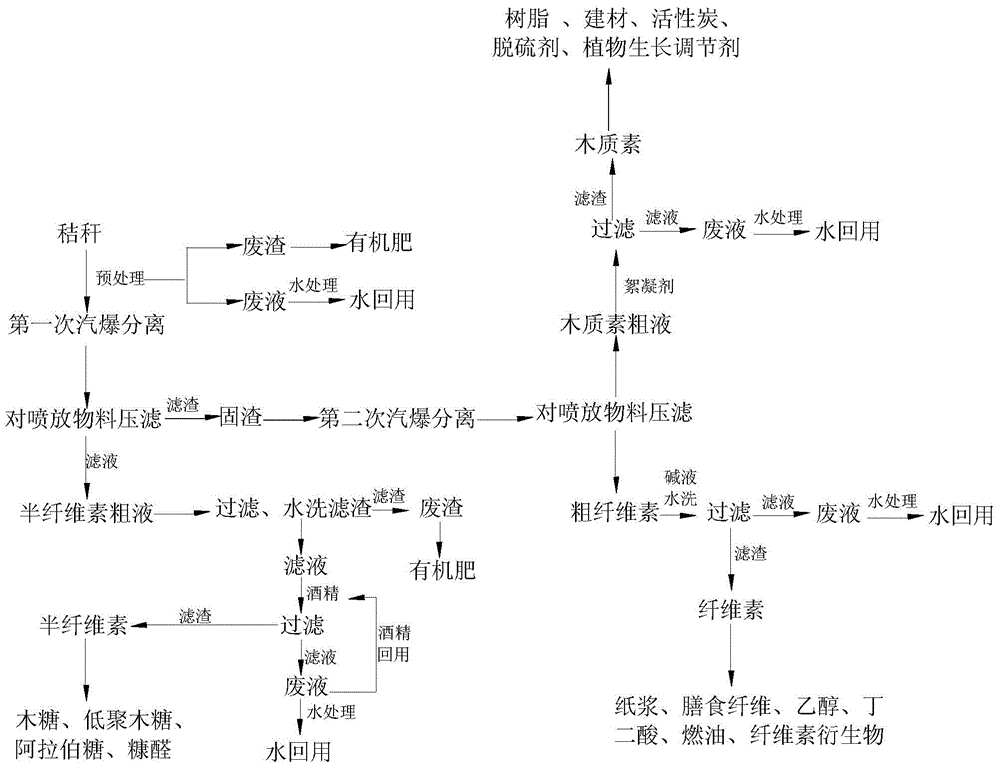

Straw component separation and straw component full utilization method

ActiveCN104404803AAchieve separationEasy to separateRaw material divisionSeparation technologyWastewater

The invention discloses a straw component separation and straw component full utilization method, and relates to the technical field of straw comprehensive utilization. According to the method, straws are subjected to a steam explosion treatment, such that hemicellulose is first separated; and the rest of the material after hemicellulose extraction is subjected to steam explosion treatment again, such that the separation of cellulose and lignin is realized. The method has the advantages of simple process, environment-friendliness, low cost, and thorough separation of hemicellulose, cellulose and lignin. With the method provided by the invention, an environment-friendly separation technology of cellulose and lignin is realized for the first time internationally, and a basis is provided for full-element, high-added-value and comprehensive utilization of straws. On the basis, products with higher added values can be derived or generated. With the production process provided by the invention, all wastewater is treated and is completely recycled, and all waste residue is used for producing organic fertilizers, such that straws are thoroughly utilized, and straw component full utilization is realized. Also, zero emission and zero pollution are realized, such that the difficulty of straw comprehensive utilization is solved.

Owner:JINAN MIDUOTAN NEW ENERGY TECH

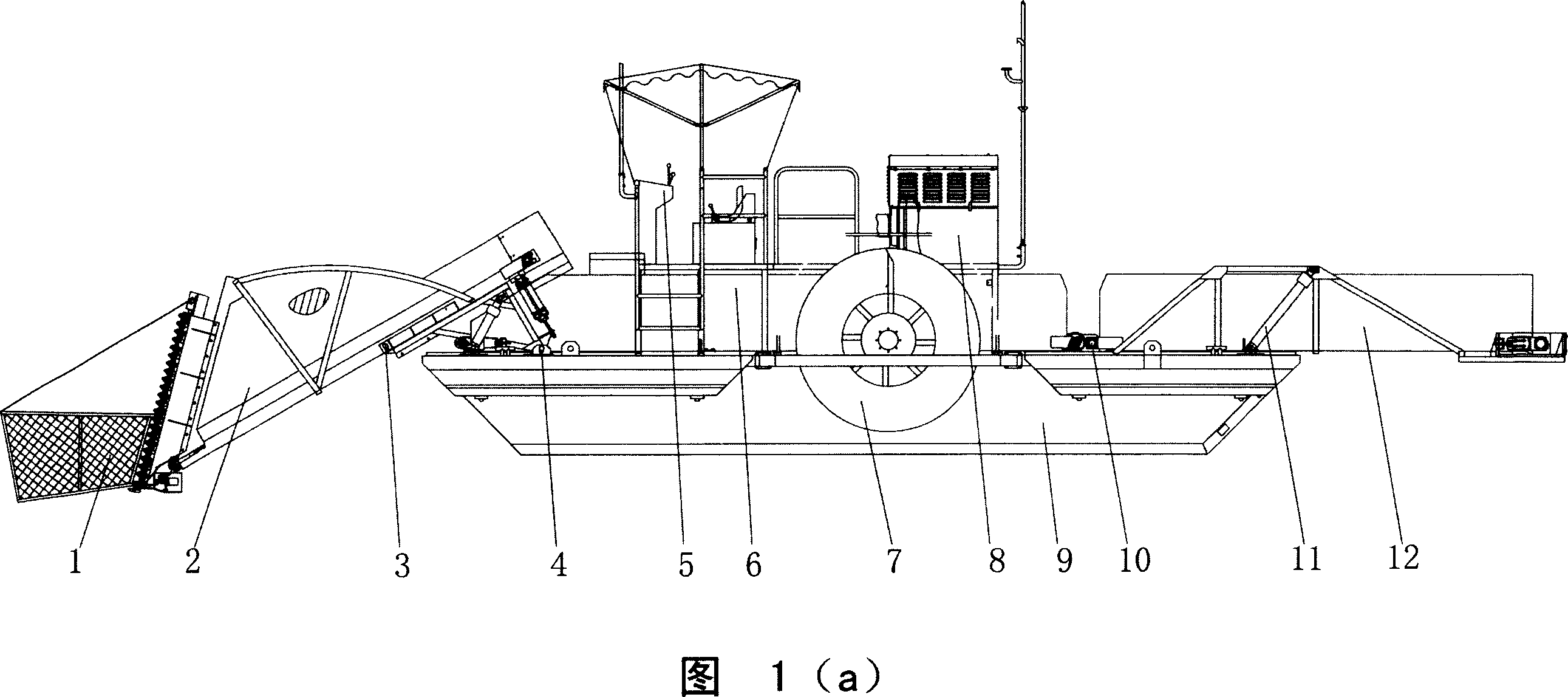

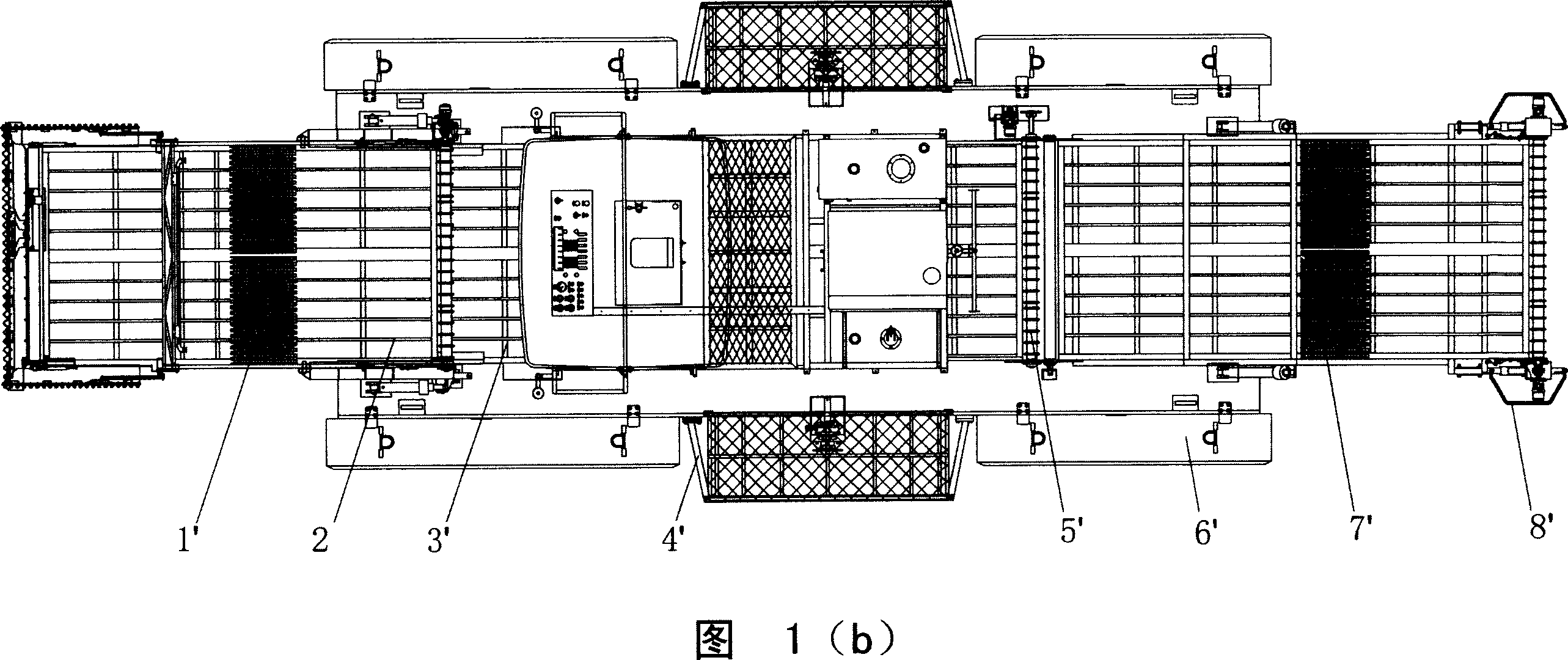

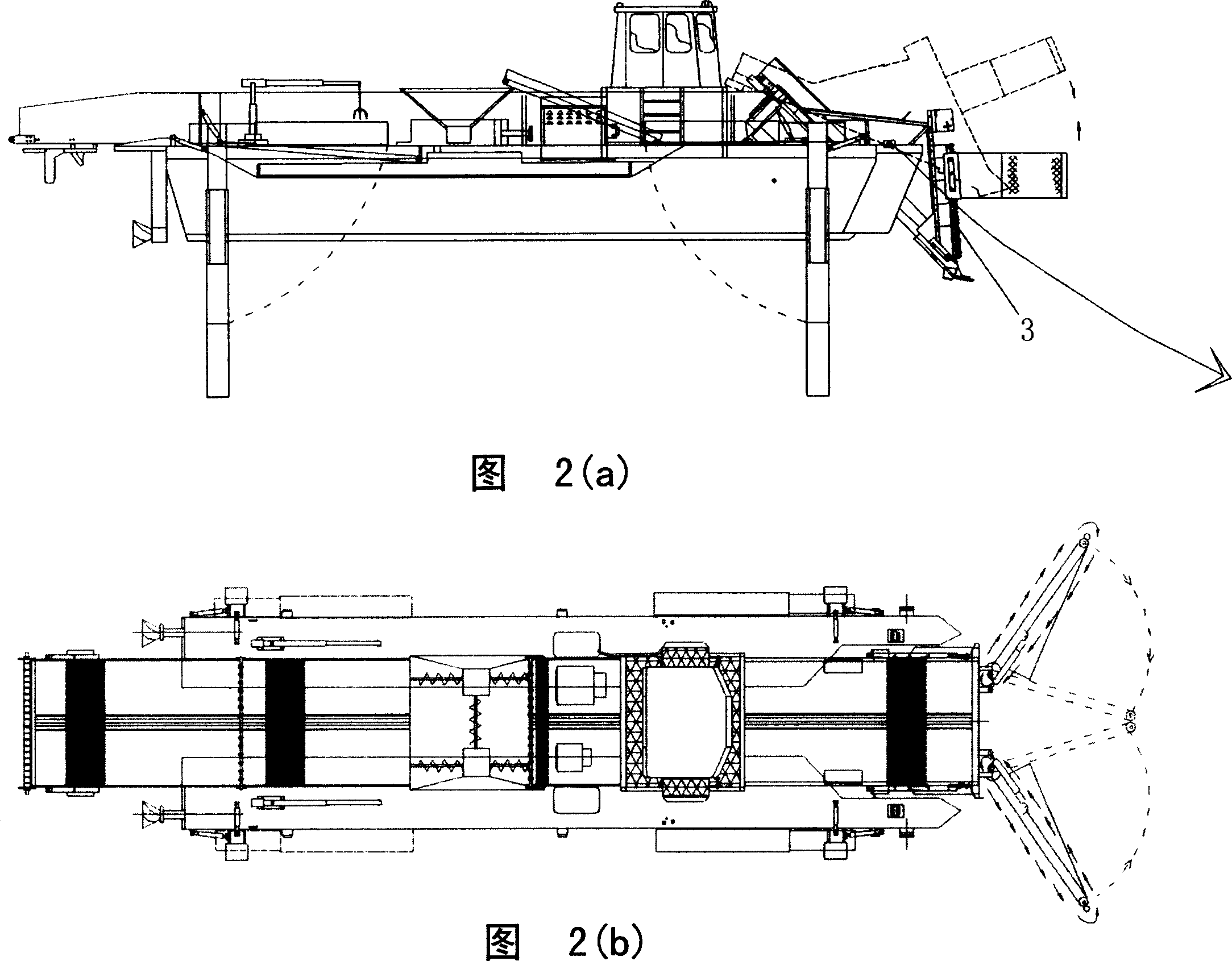

Chain-net type mechanical device for mowing and cleaning operation

InactiveCN101088856AImprove continuityAchieve separationWater cleaningWaterborne vesselsControl systemEnvironmental engineering

The chain-net type solid-liquid separating mechanical apparatus for cutting aquatic weed and cleaning river includes one aquatic weed cutting mechanism, one aquatic weed and waste fishing mechanism, one compressing and conveying mechanism, one flow forming mechanism, one anchor locating mechanism, one intercepting and driving mechanism and one control system. It is used to cut, collect, solid-liquid separate, pile, etc for maintaining clean river.

Owner:SHANGHAI LIXIN HYDRAULIC +1

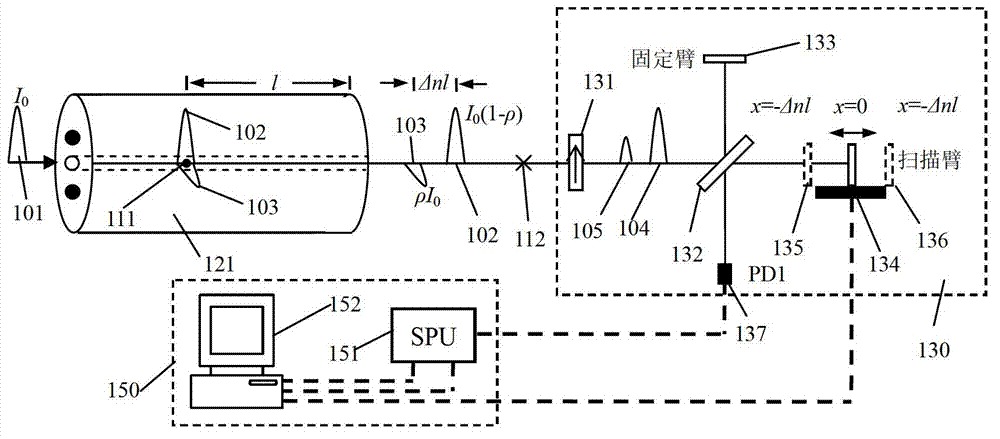

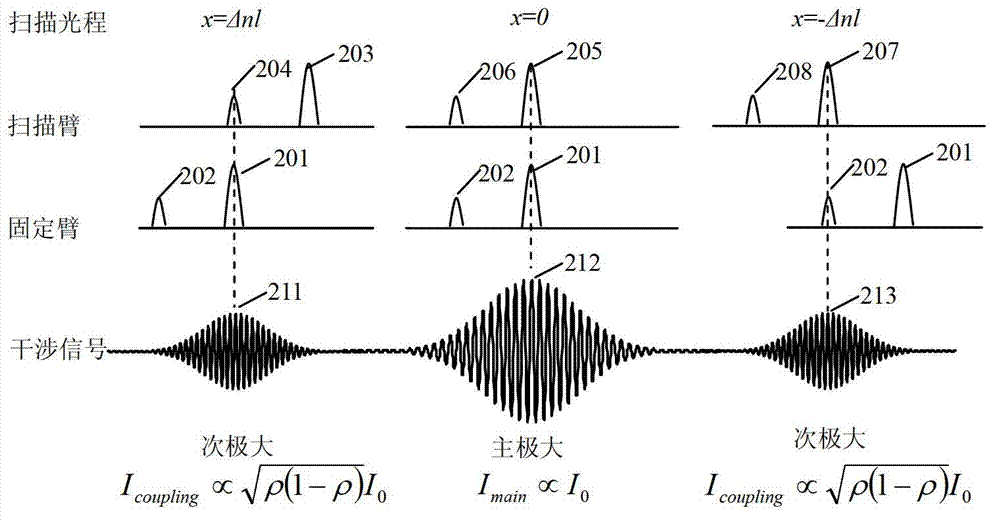

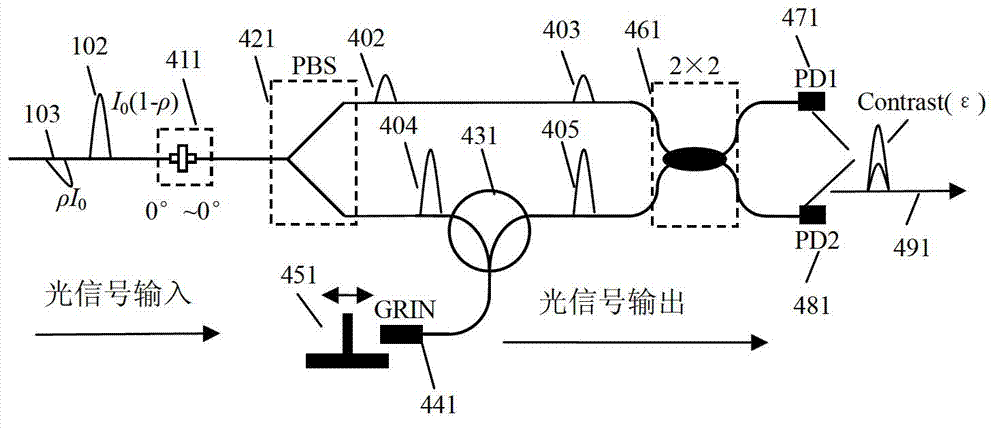

Device and method for improving polarization crosstalk measurement performance of optical device

ActiveCN102928199AFunction increaseIncrease signal amplitudeTesting optical propertiesCrosstalk measurementPolarizer

The invention provides a device and a method for improving polarization crosstalk measurement performance of an optical device. The device comprises a wide spectrum light source (301), a polarizer (311), a polarization device to be tested (632), an optical path correlator (640) and a polarization crosstalk detection and signal recording device (150), wherein the wide spectrum light source (301) is connected with the optical device to be tested (632) by the polarizer (311) and a first rotation connector (631) and then is connected with the optical path correlator (640) by a second rotation connector (633). By the device and the method, noise amplitude can be greatly suppressed, the sensitivity of polarization crosstalk measurement is improved, the dynamic range of polarization crosstalk measurement is expanded, and the device and the method are widely used for high-precision measurement and analysis on polarization performance of the optical device.

Owner:HARBIN ENG UNIV

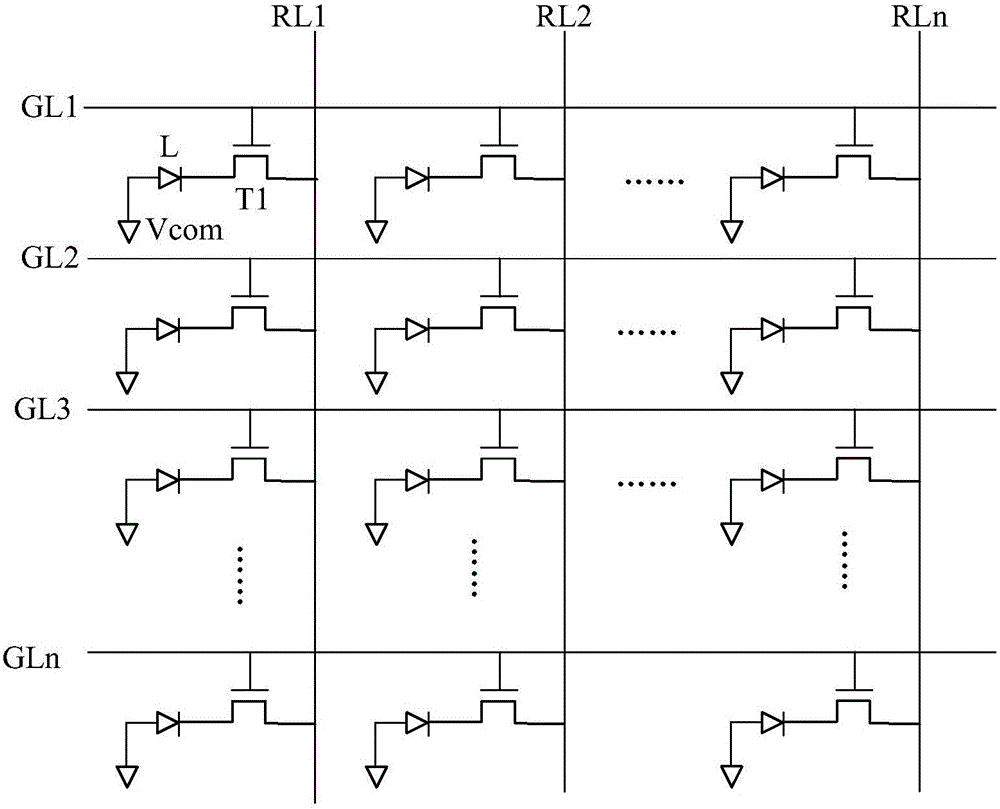

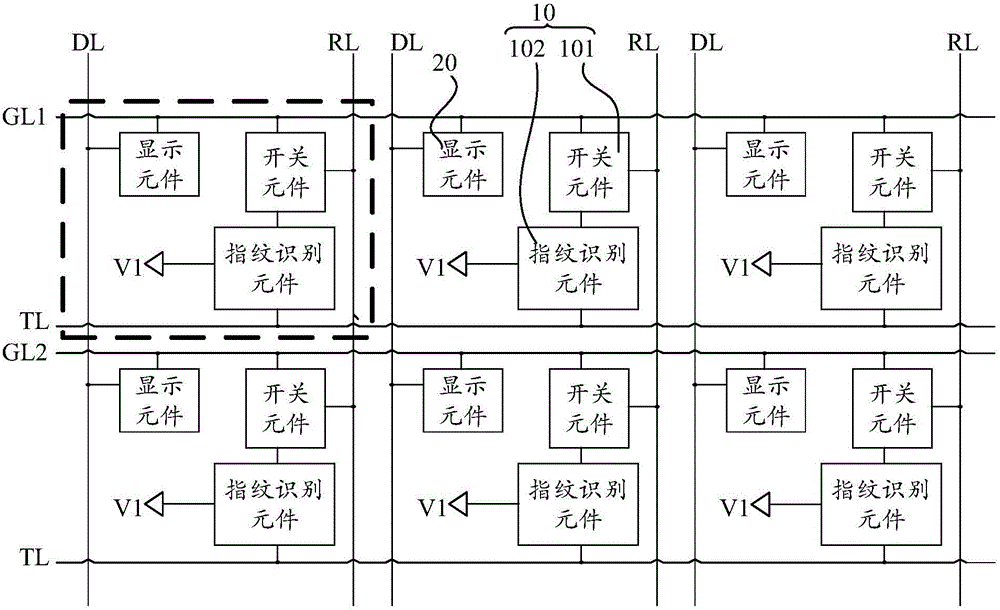

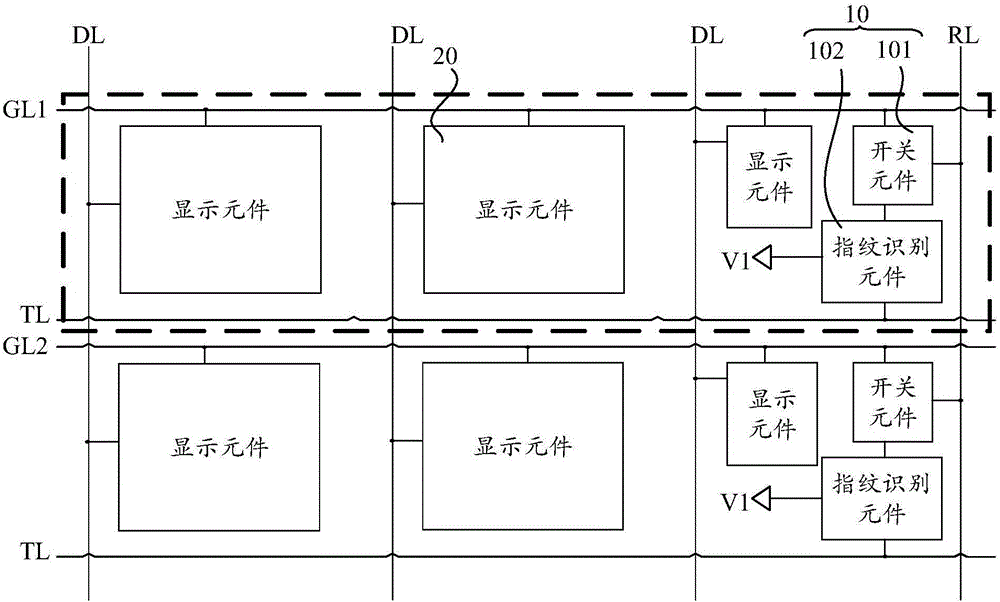

Array substrate, display device, and driving method for display device

ActiveCN105930827AAffect accuracyGuaranteed image display functionPrint image acquisitionDisplay deviceData signal

The embodiment of the invention provides an array substrate, a display device and a driving method for the display device, relates to the technical field of display, and can improve the fingerprint detection precision. The array substrate comprises a plurality of subpixels, and each subpixel comprises a display element. At least one subpixel forms one repetition unit, and one subpixel in the repetition unit also comprises a fingerprint recognition assembly, wherein the fingerprint recognition assembly comprises a fingerprint recognition element and a switching element. The switching element is controlled by a grid line to be started, so as to enable the fingerprint recognition unit to be connected with a reading signal line. The fingerprint recognition element is controlled by a first voltage end to collect fingerprint information, and is controlled by a transfer signal line to store the fingerprint information, so as to enable the fingerprint information to be transmitted to the reading signal line when the fingerprint recognition element is connected with the reading signal line. The display element is controlled by a grid line to be turned on or off, and a data signal is inputted to the display element through a data line when the display element is turned on. The array substrate is used for the display device with a function of fingerprint recognition.

Owner:BOE TECH GRP CO LTD +1

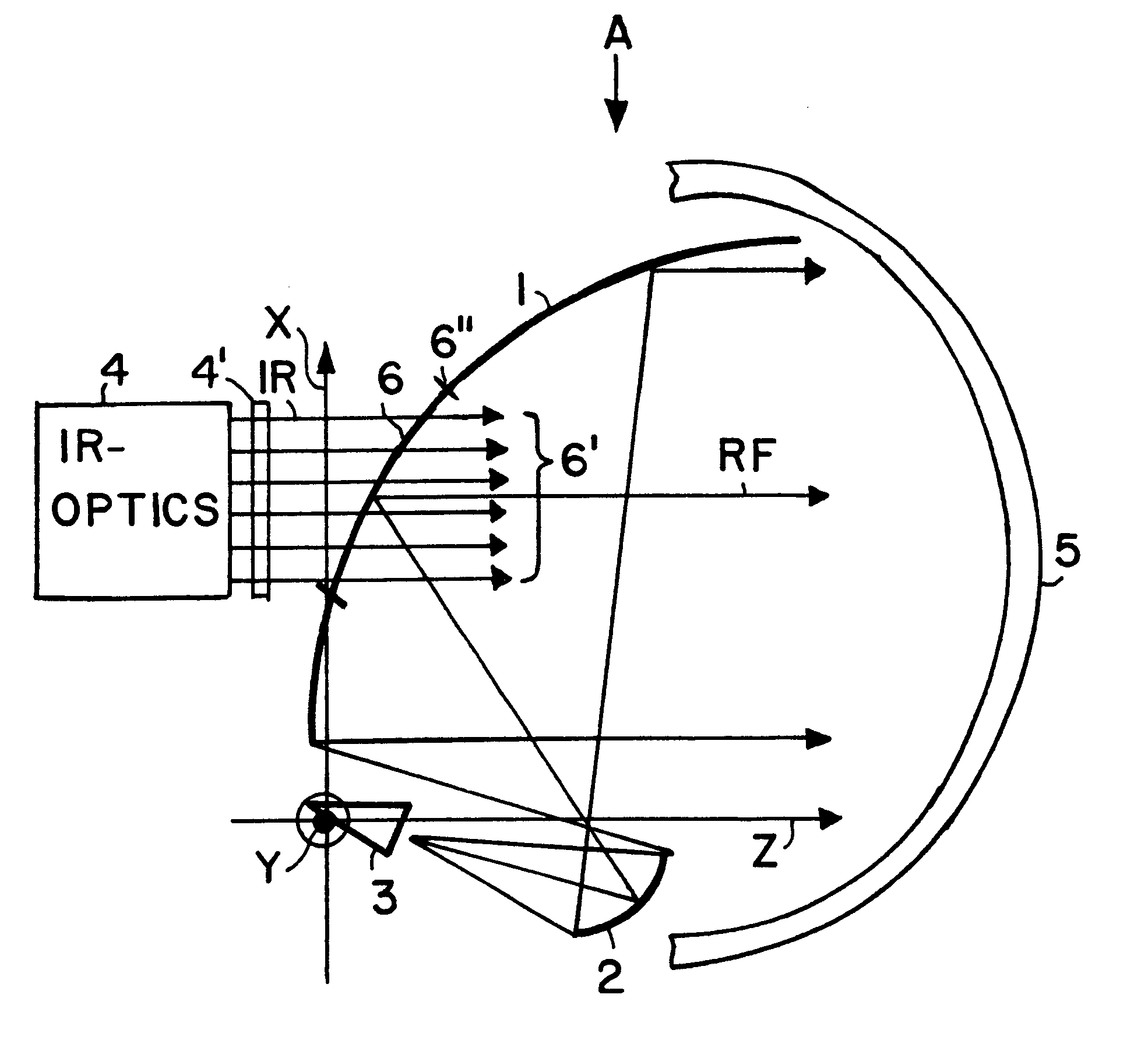

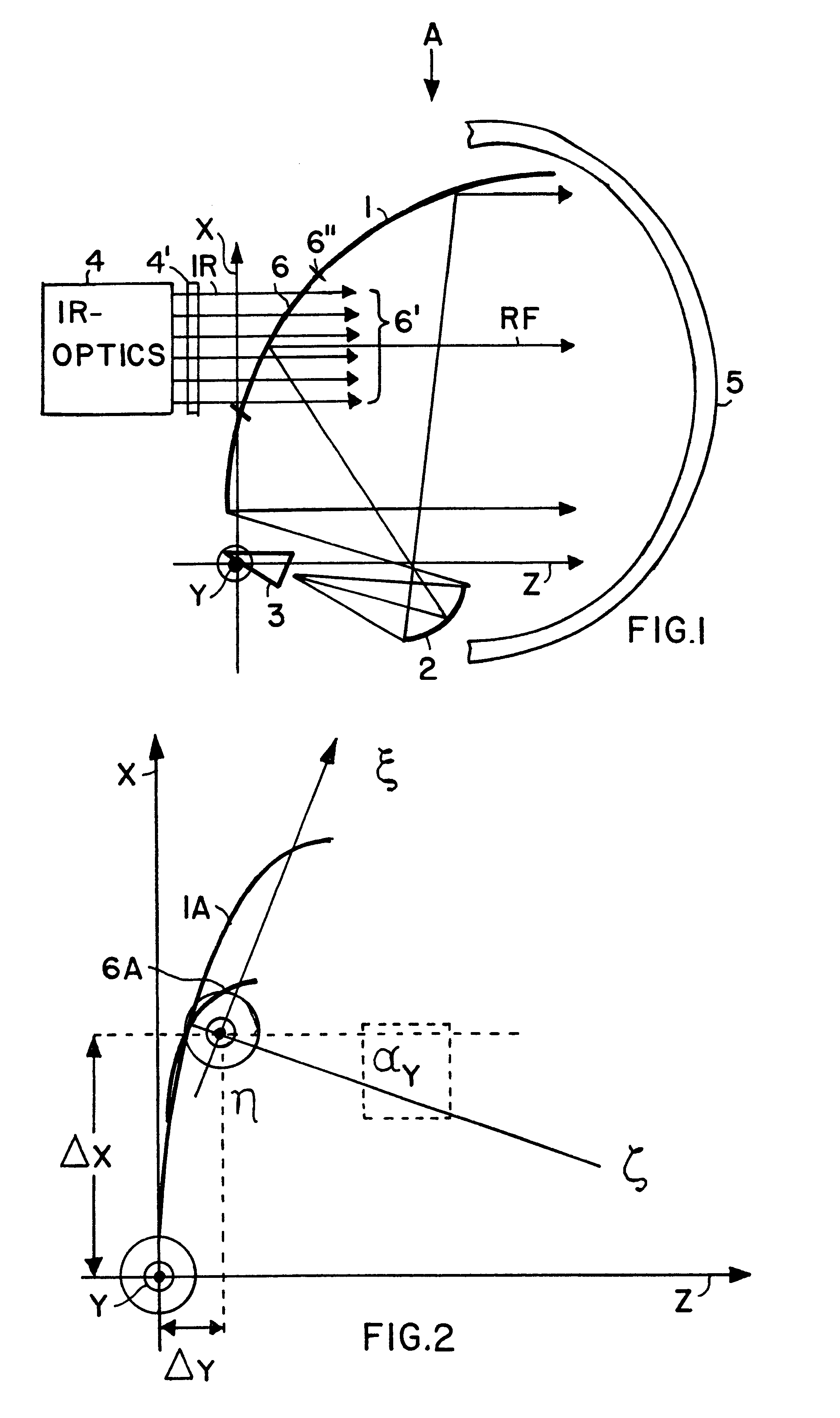

RF and IR bispectral window and reflector antenna arrangement including the same

InactiveUS6307521B1Undesirable side effect can be preventedCompact and space-saving arrangementSimultaneous aerial operationsRadio wave reradiation/reflectionLight beamSignal beam

A reflector antenna arrangement can transmit and receive both infrared (IR) and millimeter wave (RF) radiation. The arrangement includes a main reflector (1), a subreflector (2), an IR feed system (4), an RF feed system (3), a radome (5), and a bispectral window (6) arranged in an opening provided in a central area of the main reflector (1). The RF feed system is oriented so that the RF radiation path includes a double reflection from the subreflector and from the main reflector, while the IR feed system is arranged directly behind the bispectral window so that the IR beam path extends directly through the bispectral window without reflecting from the main reflector or the subreflector. The bispectral window has a high reflectance for the RF radiation and a high transmittance of the IR radiation. The bispectral window is made of a dielectric material and has rotationally symmetrical front and back surfaces, whereby the front surface contour is optimally matched to the front surface of the main reflector and the back surface contour achieves an optimal reflectivity of the RF radiation and an optimal transmissivity of the IR radiation. Undesired influences between the IR radiation and the RF radiation are avoided by the separation of the signal beam paths.

Owner:MBDA DEUTSCHLAND GMBH

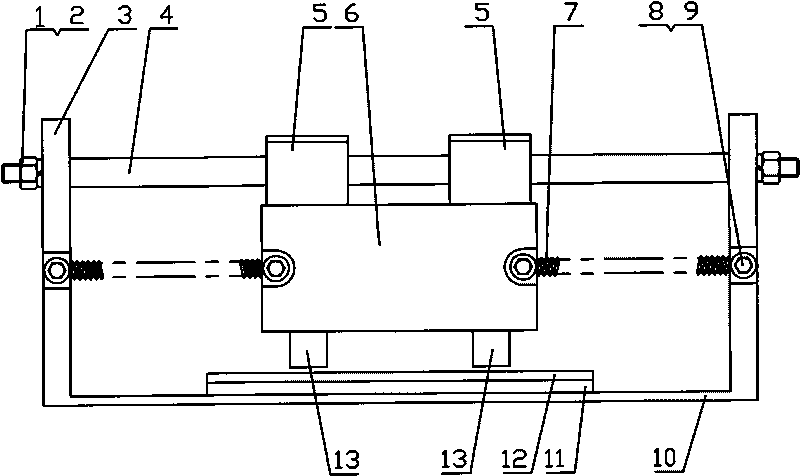

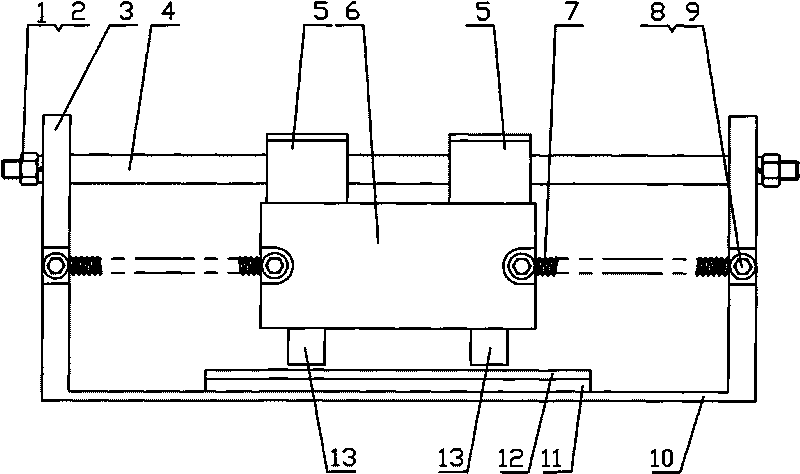

Permanent-magnet type eddy current tuned mass damper

ActiveCN101761146APrecise linear motionStructural damping dropBridge structural detailsTowersStress concentrationElectricity

The invention relates to a permanent-magnet type eddy current tuned mass damper which comprises a steel magnetic-conducting baseplate (10), wherein end plates (3) are respectively arranged at two ends of the baseplate (10). The permanent-magnet type eddy current tuned mass damper is characterized by also comprising a circular shaft (4) and a linear bearing seat (5), wherein two ends of the circular shaft (4) are respectively arranged on the corresponding end plates (3), and the linear bearing seat (5) is sleeved on the circular shaft (4) and can slide on the circular shaft (4); the lower part of the bearing seat (5) is connected with a mass block (6), and two ends of the mass block (6) are respectively connected with the corresponding end plates (3) through spiral springs (7); the lower part of the mass block (6) is connected with a permanent magnet (13), and a copper plate (12) is arranged below the permanent magnet (13) and connected with the baseplate (12) through a cushion block (11). By adopting an eddy current damping model with special design, the permanent-magnet type eddy current tuned mass damper realizes the damping adjustability of the damper in a larger range, realizes the complete separation between the system rigidity and the damper, and cancels the mechanical friction energy consumption and stress concentration elements, thereby avoiding the common TMD damage failure.

Owner:湖南省潇振工程科技有限公司 +1

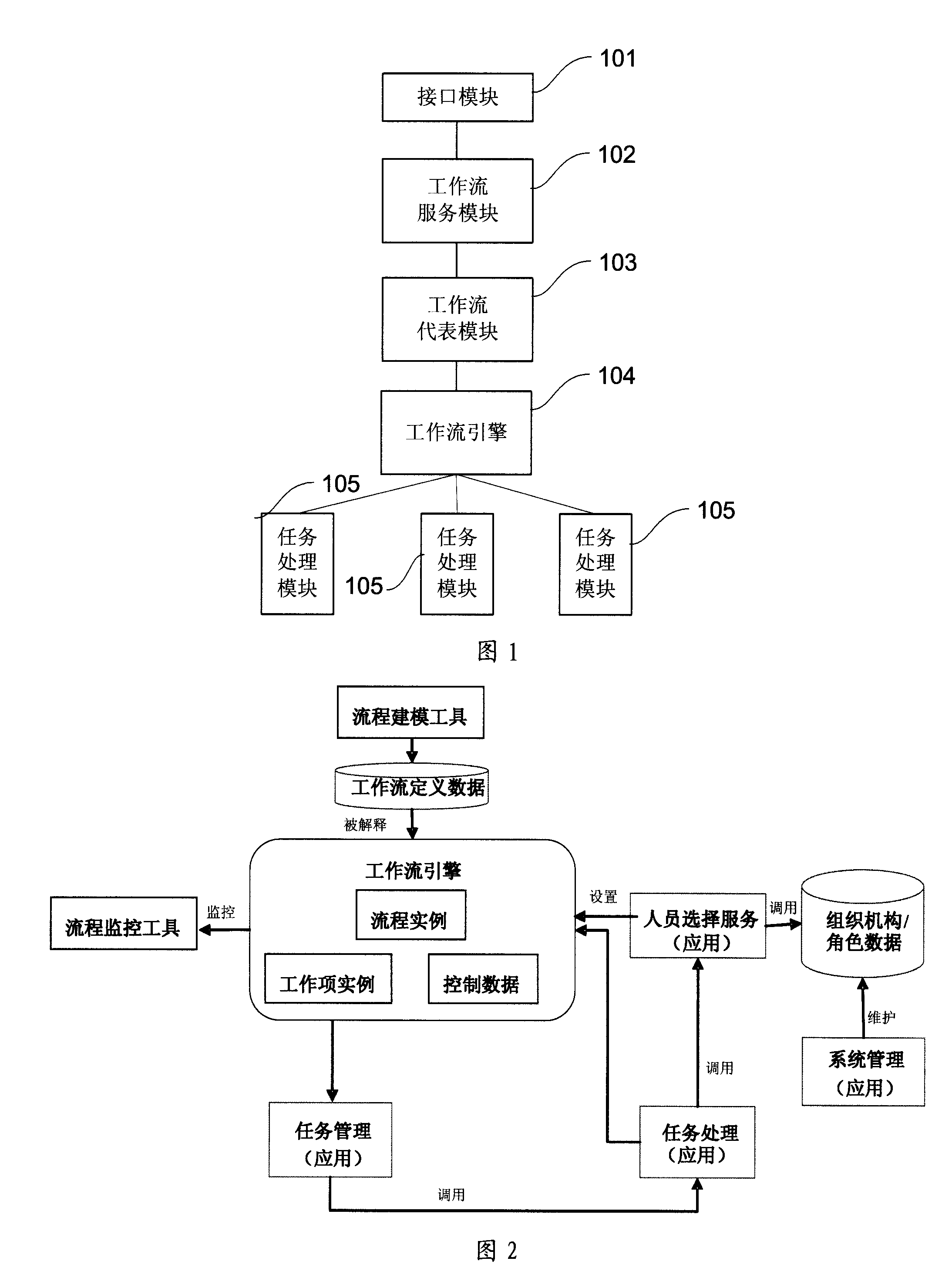

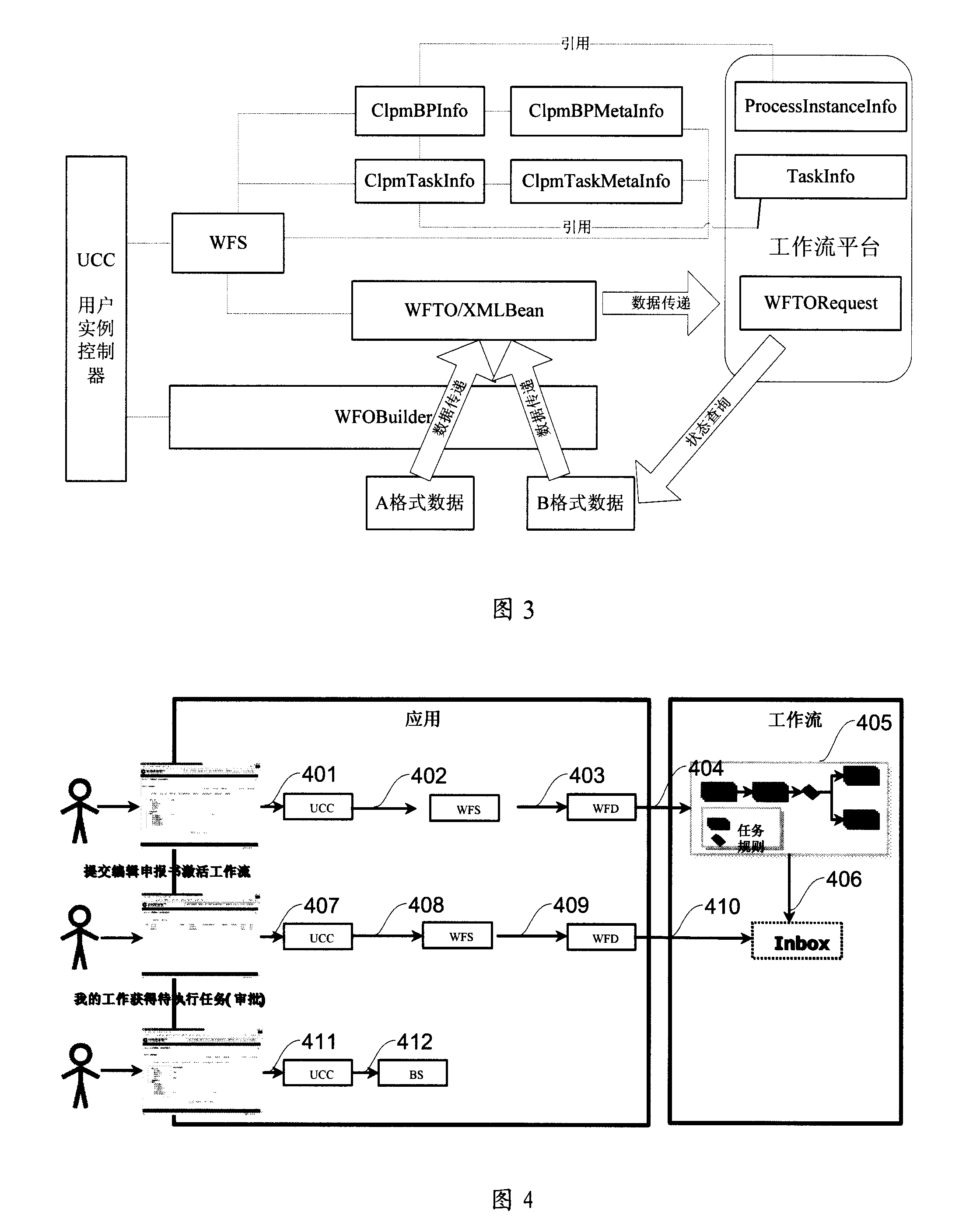

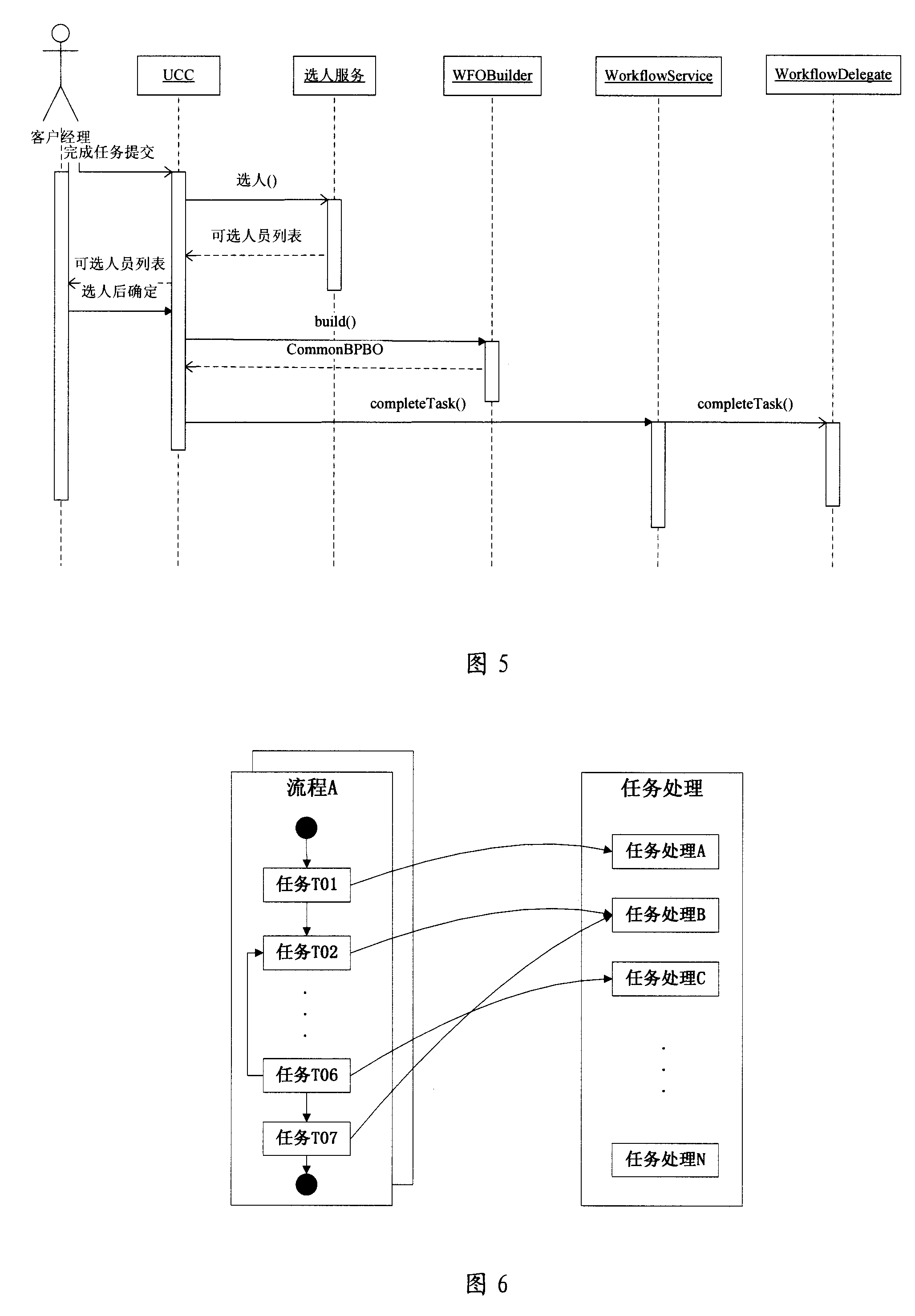

Data processing management system facing to process flow

InactiveCN101226612AReduce couplingAchieve separationResourcesSoftware engineeringBiological activation

The invention provides a management system of data processing for flow, which comprises an interface module, a service module of working flow, a representative module of working flow, an engine of working flow, a working flow module and at least a task processing module, wherein the interface module is used to change the request of the user interface to business event and notice the service module of working flow, the service module of working flow is used to provide uniform working flow service for the various users and call the representative module of working flow when receiving the notice from the interface module, the representative module of working flow is used for the engine of working flow which provides various specific working flows and complete the data conversion between the service module of working flow and the engine of working flow, the engine of working flow is used to deliver task case to the working list of the task executor according to the model of working flow, the model of working flow is used to record the relative information of the business flow, the task processing module, which is linked with the working list, is used to receive activation and complete relative processing procedure of task data. The invention can support large-scale and complex working flow management which is cross organization and quickly adapt for the need of changed business.

Owner:CHINA CONSTRUCTION BANK

Spatially-separated pump-probe transient absorption spectrograph and realization method

ActiveCN103868595AMotivating realizationImprove spatial resolutionMaterial analysis by optical meansAbsorption/flicker/reflection spectroscopyBeam splitterVertical plane

The invention discloses a spatially-separated pump-probe transient absorption spectrograph and a realization method. The realization method is characterized by generating a light source through a femtosecond light source system; realizing the beam splitting of pump light and probe light through a beam splitter; realizing the different time delay of the probe light through a time delay line; realizing the two-dimensional rotation and the calibration of the probe light within a horizontal plane and a vertical plane through a sweep reflector group; calibrating which means guaranteeing the incidence of the rotated probe light into a aperture within the front section of an objective lens; finally, obtaining a two-dimensional image formed on a sample under the combined action of the probe light and the pump light by a data collection system. According to the spatially-separated pump-probe transient absorption spectrograph and the realization method, the extremely high spatial discrimination can be realized, and moreover, the visual probe of carriers, excitors or plasmons can be realized.

Owner:HUNAN UNIV

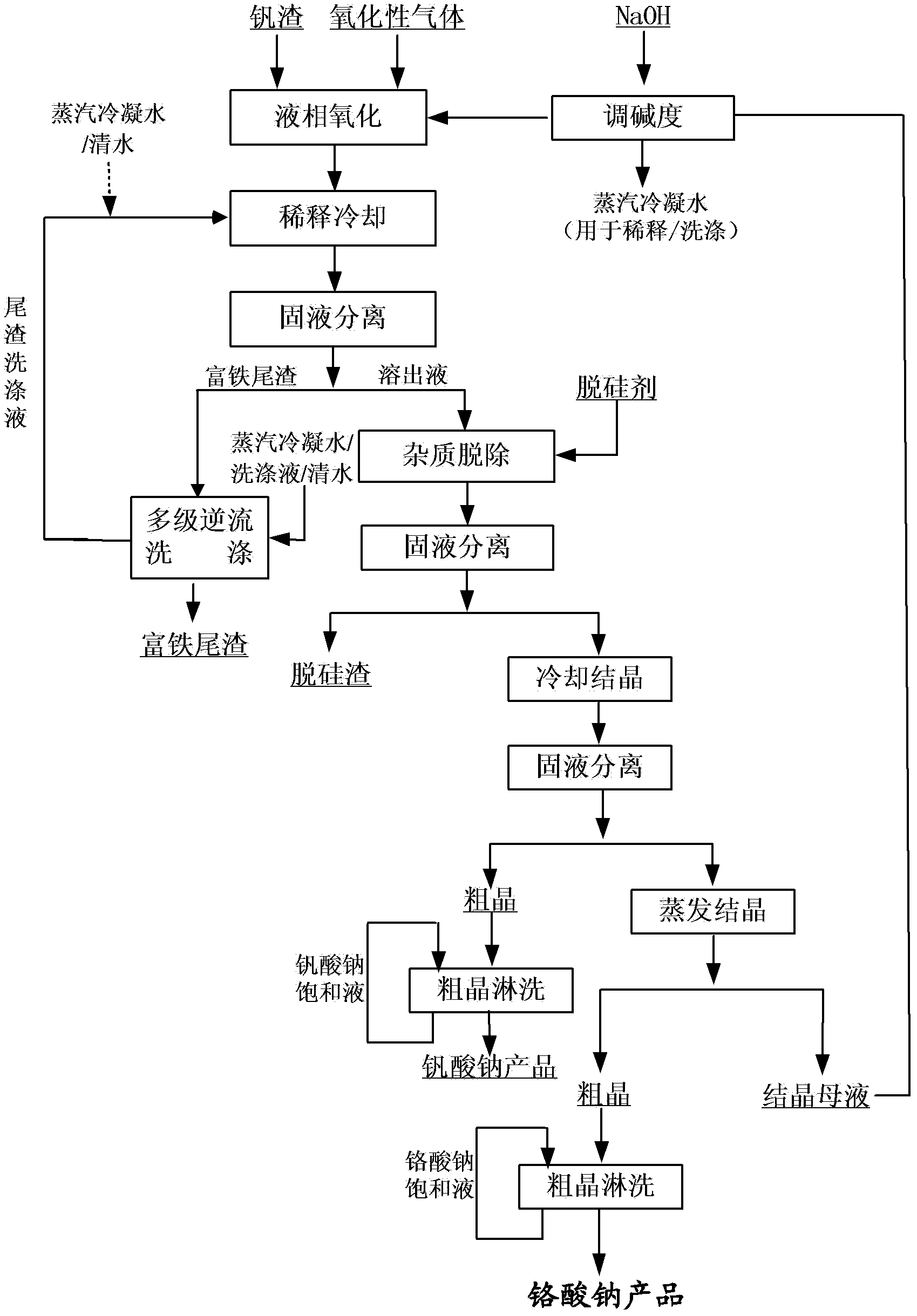

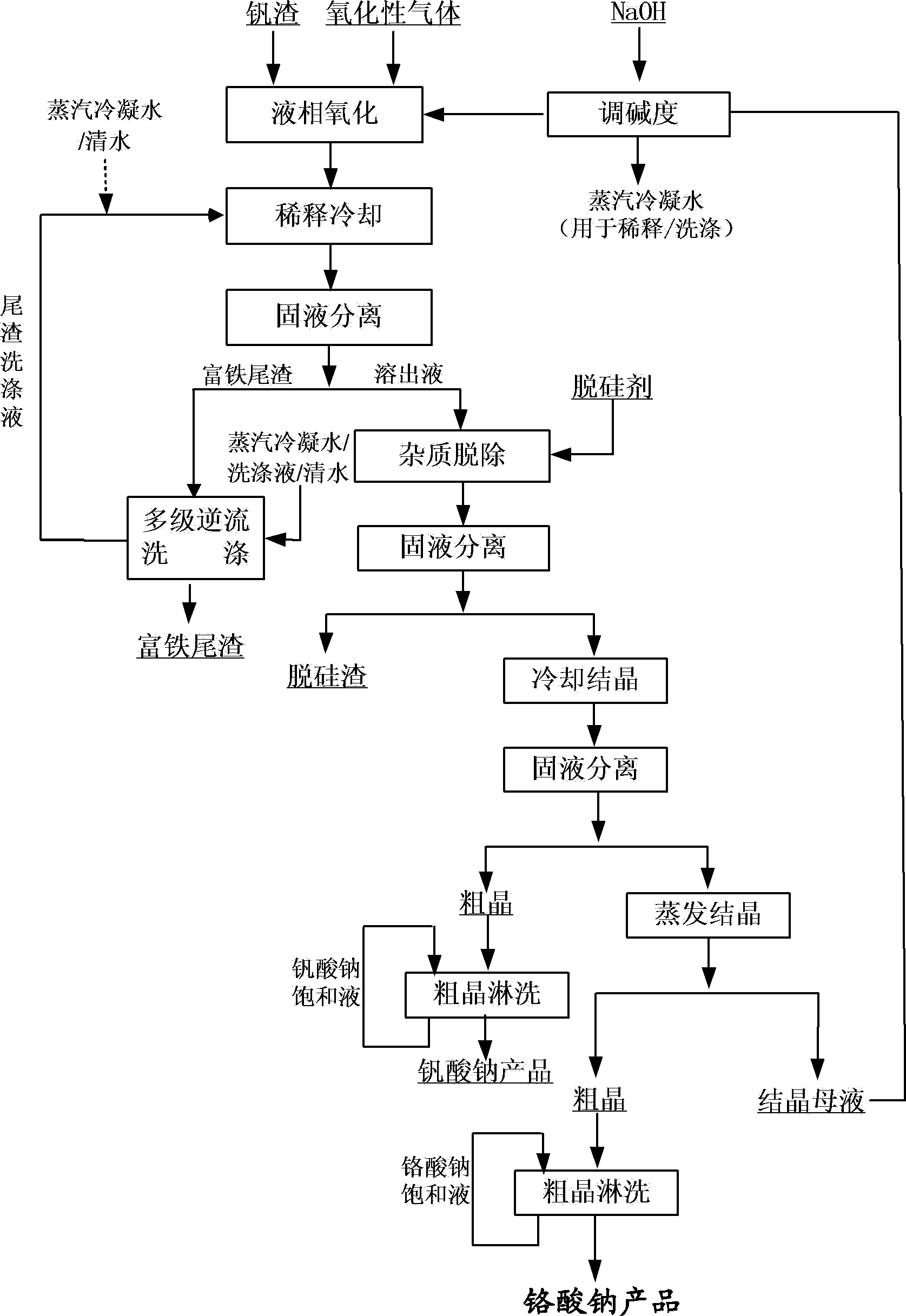

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056ASimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

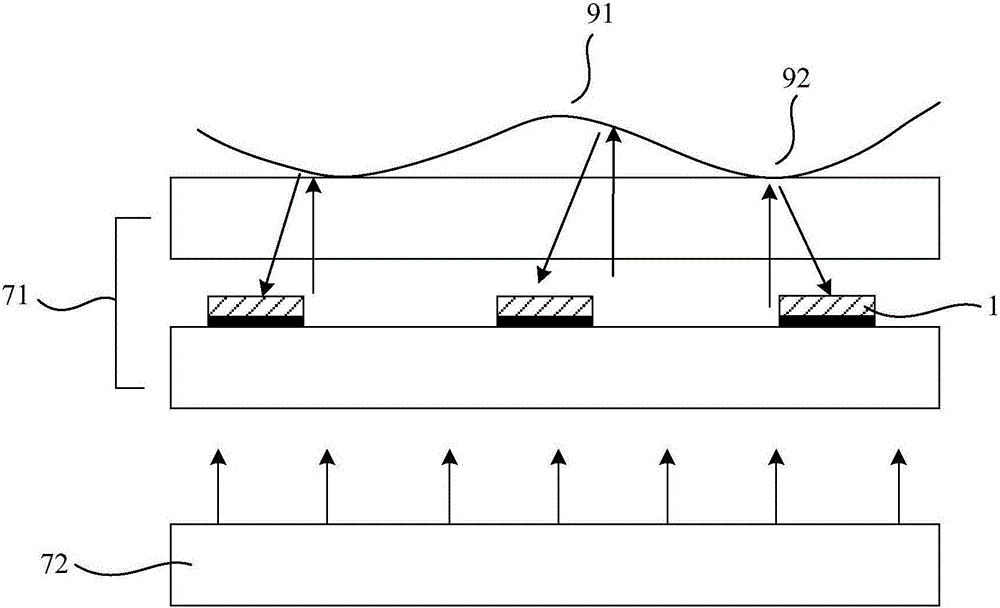

Fingerprint identification structure and method and display device

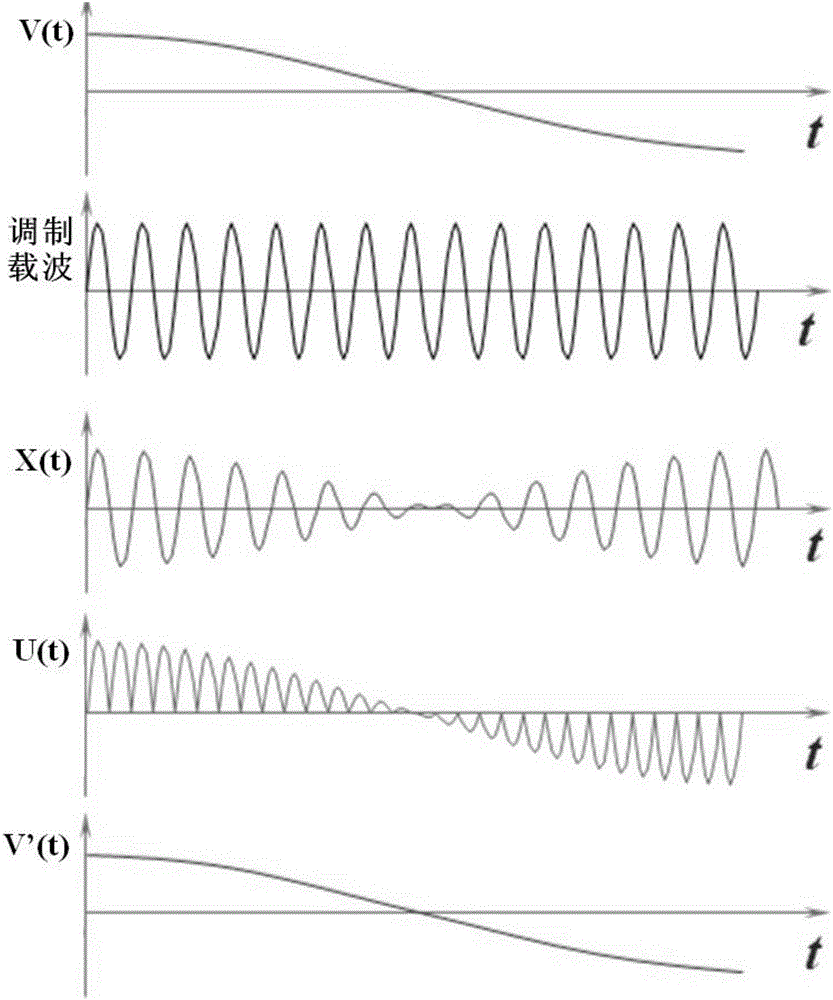

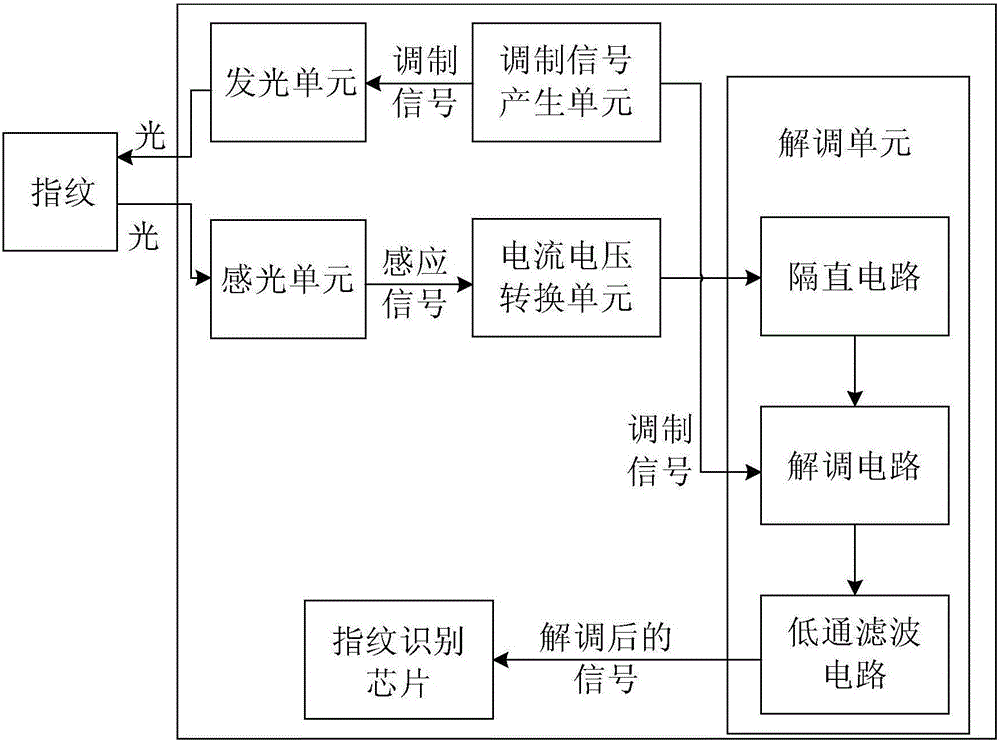

PendingCN105893992AImprove signal-to-noise ratioFingerprint recognition is accurateStatic indicating devicesPrint image acquisitionSignal-to-noise ratio (imaging)Generating unit

The invention provides a fingerprint identification structure, a fingerprint identification method and a display device, belongs to the technical field of fingerprint identification, and can solve the problems of the exiting fingerprint identification method of low signal-to-noise ratio of an induction signal and poor fingerprint recognition accuracy. The fingerprint identification structure disclosed by the invention comprises a light emitting unit for emitting light to a finger, a light sensing unit arranged at the positions that light reflected by the finger and emitted by the light emitting unit can be received and used for generating the induction signal according to the intensity of the received light, a modulating signal generating unit for generating a modulating signal with modulation frequency and controlling the light emitting unit by the modulating signal to flicker by the modulation frequency, and a demodulation unit which is connected with the light sensing unit and used for demodulating the induction signal.

Owner:BOE TECH GRP CO LTD

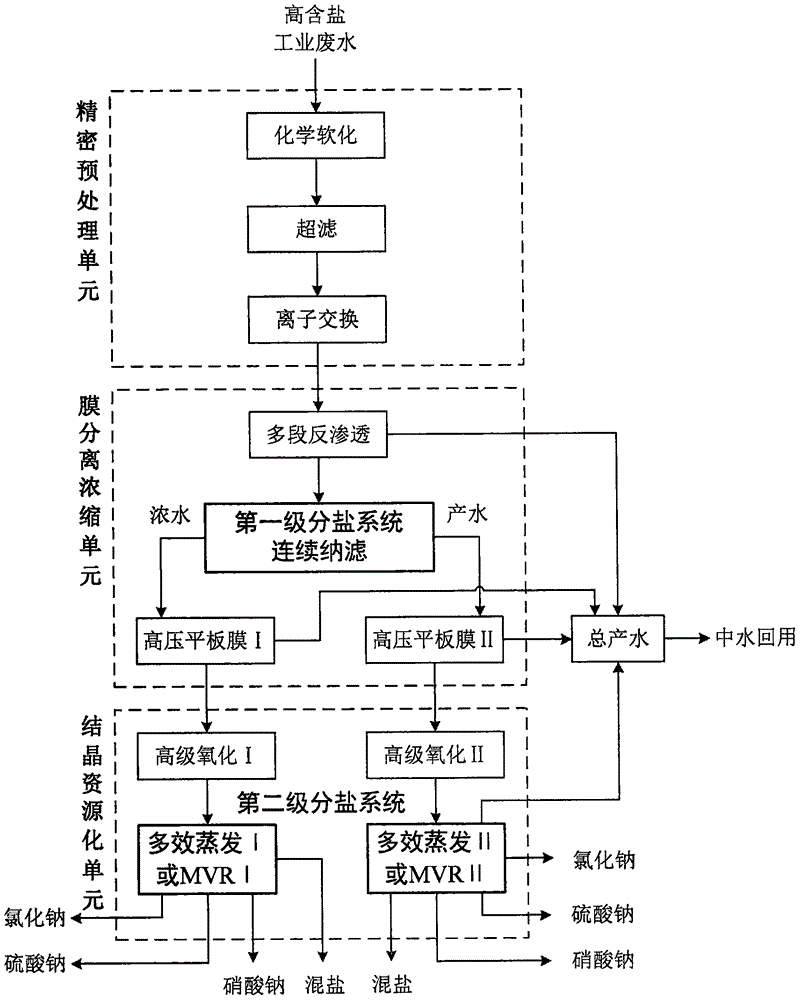

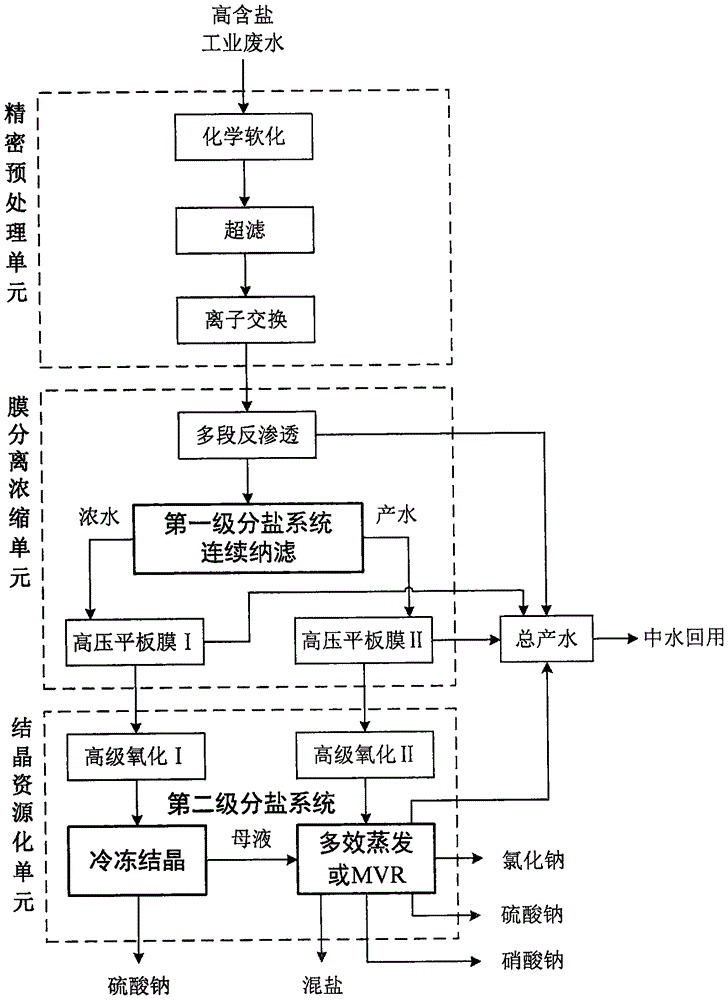

Salt-separation zero-discharge system for high-salt industrial wastewater

ActiveCN105668893AReduce outputImproved resistance to shock loadsTreatment involving filtrationWater/sewage treatment by ion-exchangeLoad resistanceChemistry

The invention discloses a salt-separation zero-discharge system for high-salt industrial wastewater and belongs to the field of water treatment. The high-salt industrial wastewater enters a first-stage salt separation system after subjected to chemical softening through a precise pretreatment unit and concentration desalination through a membrane separation concentration unit, nanofiltration produced water and nanofiltration concentrated water which are produced after first-stage salt separation are concentrated by a high-pressure flat membrane system and conveyed to an advanced oxidation system of a crystallization recycling unit for oxidation treatment respectively, and obtained products are supplied to a second-stage salt separation system; the second-stage salt separation system adopts two multiple-effect evaporation or MVR systems or adopts a multiple-effect evaporation or MVR system and a freezing crystallization system. The salt-separation zero-discharge system has the beneficial effects as follows: the two stages of salt separation systems supplement each other, various inorganic salts are separated completely, and production of mixed abraum salts is reduced to the greatest extent; first-stage salt separation serves as guarantee of second-stage salt separation, the salt separation efficiency of the whole system can be guaranteed under the condition of larger fluctuation of quality of inflow water, and the impact load resistance of the system is enhanced.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

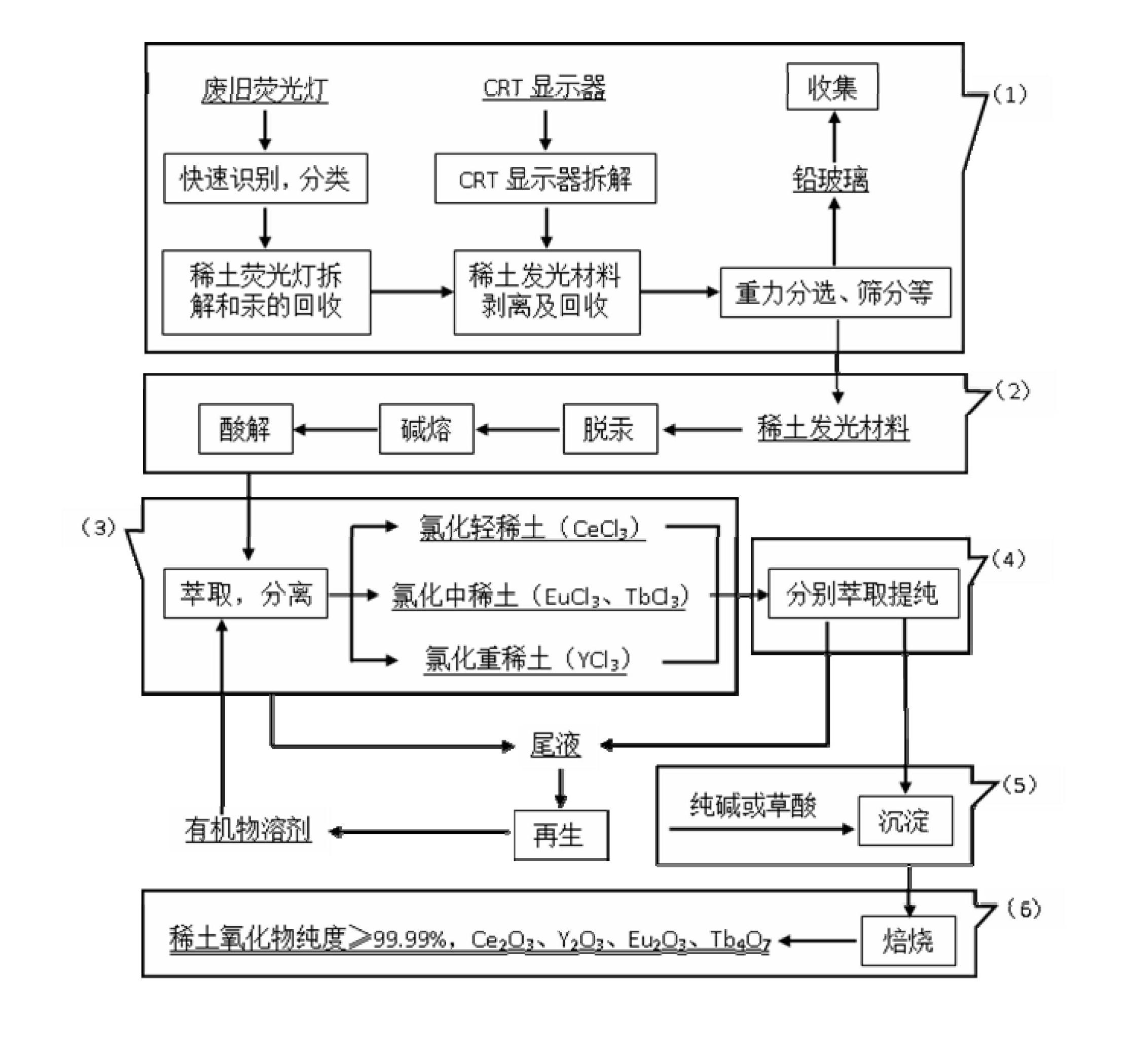

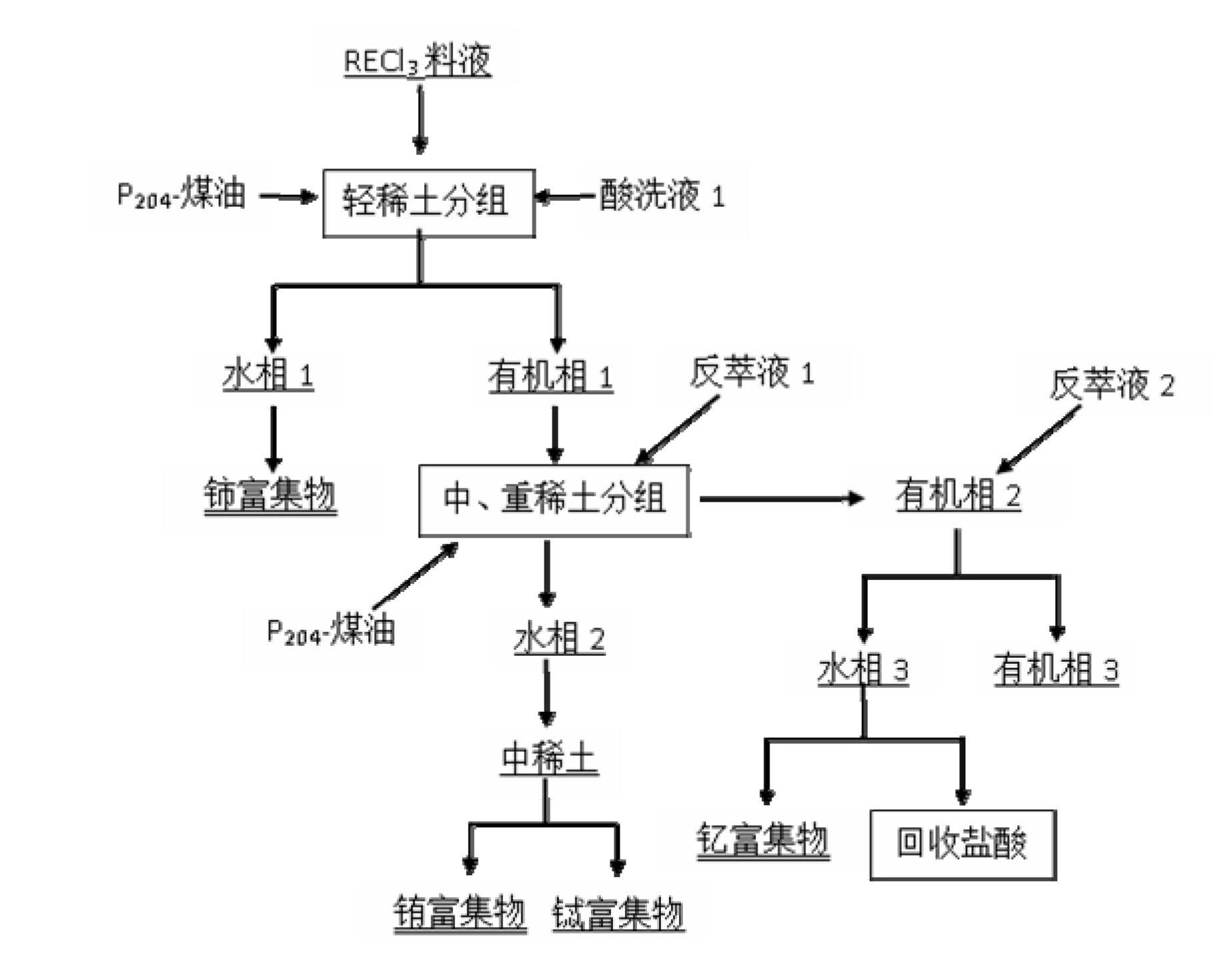

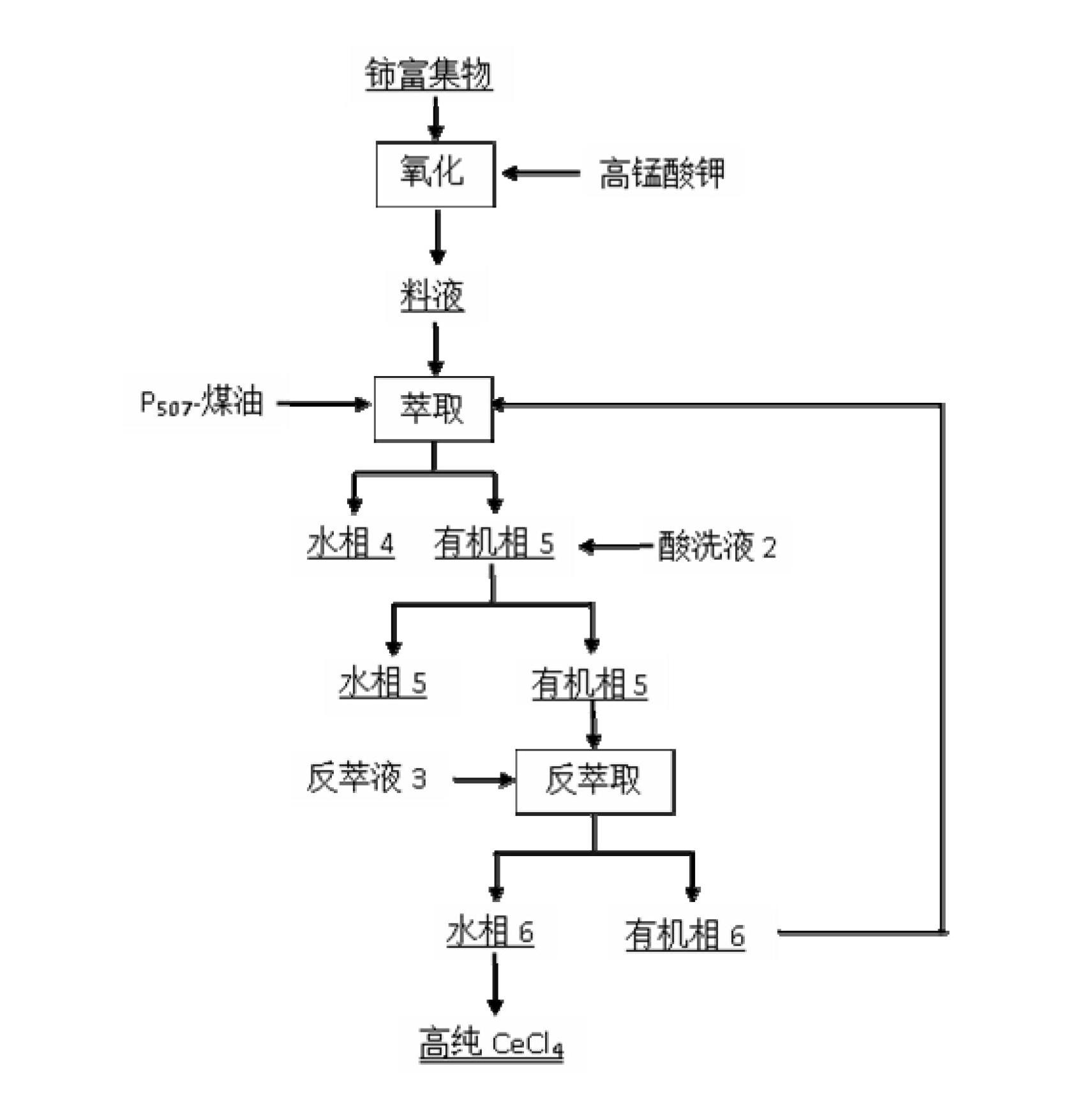

Method for recovering rare earth from waste rare earth luminescent material

InactiveCN102660688AHigh recovery rateProtect environmentGlass recyclingCerium oxides/hydroxidesRare-earth elementGlass matrix

The invention relates to a method for recovering rare earth from waste rare earth luminescent material, comprising the following steps: collection of waste rare earth luminescent material, including quick identification on rare earth fluorescent lamp and dismantling and breaking of the rare earth fluorescent lamp, breaking of a CRT display, and peeling and collection of the waste rare earth luminescent material and a glass matrix; pretreatment on the waste rare earth luminescent material, including demercuration oxidation precipitation, alkali fusion and acidolysis; extraction separation of rare earth elements to obtain rare earth chloride enrichment; extraction purification of the rare earth elements to obtain high-purity rare earth chloride; precipitation separation of the rare earth elements to obtain oxalate rare earth or carbonic acid rare earth precipitates; and sintering of the oxalate rare earth or carbonic acid rare earth precipitates to obtain high-purity-level rare earth oxide. The method realizes separation of rare earth elements including Ce, Eu, Tb and Y from impurity elements including Mg, Ba, Ca and the like and complete separation and recovery of light, mediate and heavy rare earth elements, and purification is carried out to obtain the high-purity rare earth oxide, so that the resources are comprehensively recycled, the process flow is reasonable, economic and practical, the rare earth recovery rate is high and the added value of the product is high.

Owner:UNIV OF SCI & TECH BEIJING

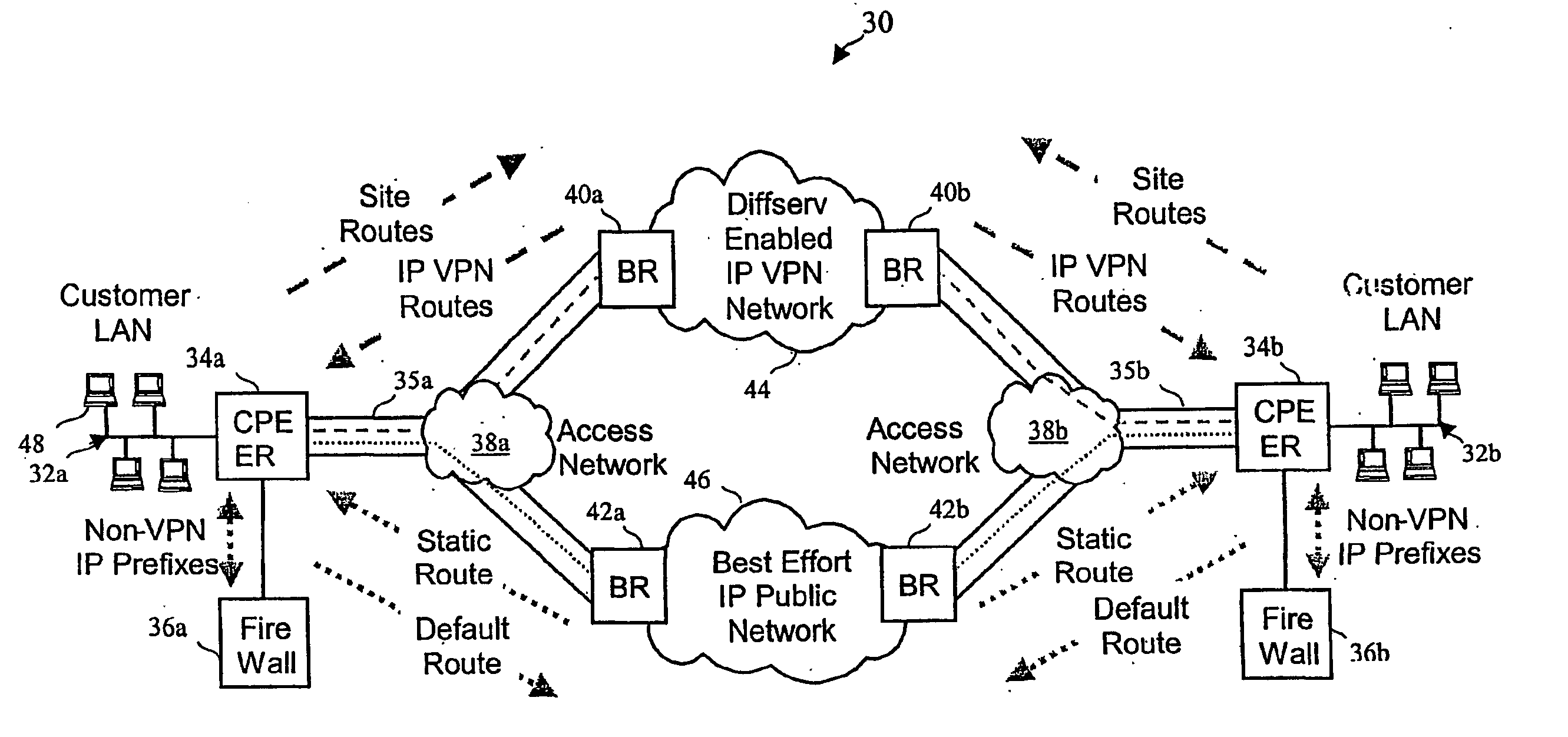

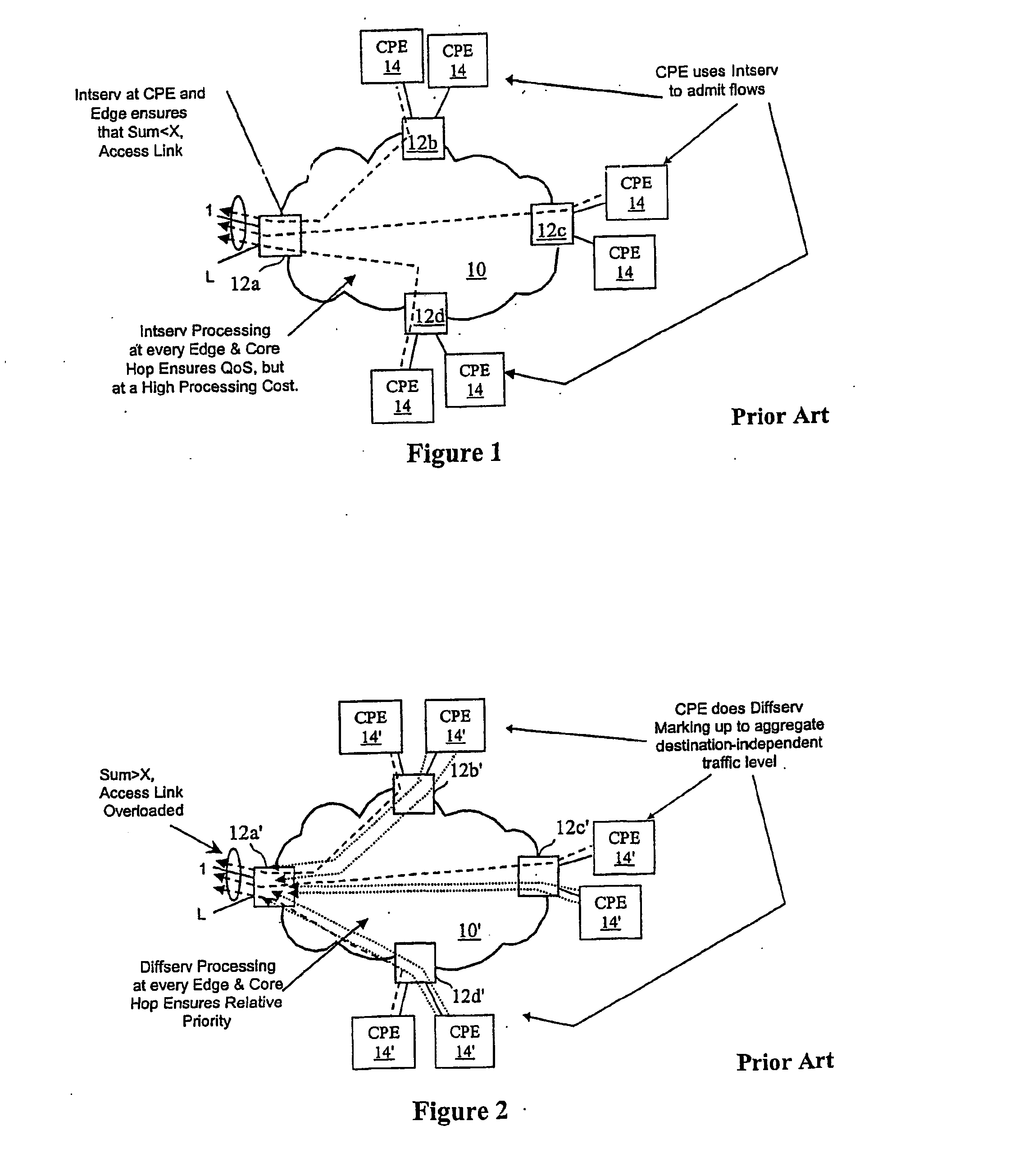

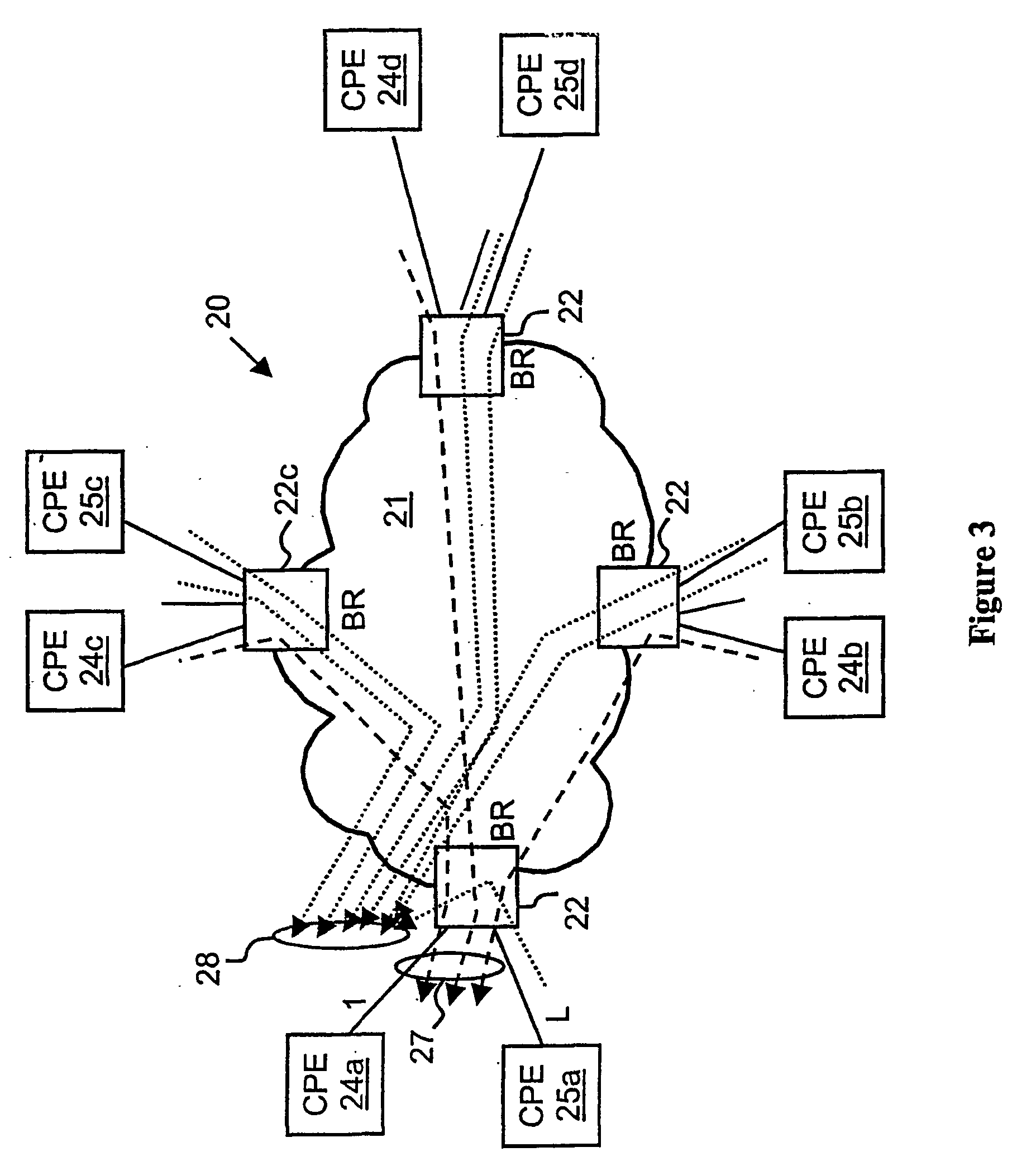

System, method and apparatus that isolate virtual private network (VPN) and best effort traffic to resist denial of service attacks

InactiveUS20050066053A1Improve scalabilityAvoid trafficMetering/charging/biilling arrangementsMultiple digital computer combinationsDenial-of-service attackNetwork element

A network architecture in accordance with the present invention includes a communication network that supports one or more network-based Virtual Private Networks (VPNs). The communication network includes a plurality of boundary routers that are connected by access links to CPE edge routers belonging to the one or more VPNs. To prevent traffic from outside a customer's VPN (e.g., traffic from other VPNs or the Internet at large) from degrading the QoS provided to traffic from within the customer's VPN, the present invention gives precedence to intra-VPN traffic over extra-VPN traffic on each customer's access link through access link prioritization or access link capacity allocation, such that extra-VPN traffic cannot interfere with inter-VPN traffic. Granting precedence to intra-VPN traffic over extra-VPN traffic in this manner entails special configuration of network elements and protocols, including partitioning between intra-VPN and extra-VPN traffic on the physical access link using layer 2 multiplexing and the configuration of routing protocols to achieve logical traffic separation between intra-VPN traffic and extra-VPN traffic at the VPN boundary routers and CPE edge routers. By configuring the access networks, the VPN boundary routers and CPE edge routers, and the routing protocols of the edge and boundary routers in this manner, the high-level service of DoS attack prevention is achieved.

Owner:VERIZON PATENT & LICENSING INC

Device and method for nitrogen and phosphorus removal for low CN ratio urban sewage through nitrosation and anaerobic ammonia oxidation coupling denitrifying phosphorus removal intensification

ActiveCN103663862AUnified denitrificationUnified phosphorus removal processMultistage water/sewage treatmentMunicipal sewageAmmonia

The invention discloses a device and a method for nitrogen and phosphorus removal for low CN ratio urban sewage through nitrosation and anaerobic ammonia oxidation coupling denitrifying phosphorus removal intensification, and belongs to the field of biological sewage treatment. The device comprises an urban sewage raw water tank, a denitrifying phosphorus removal reactor, an adjusting water tank, a sedimentation tank, and an integrated partial nitrification and anaerobic ammonia oxidation reactor; when the urban sewage enters the denitrifying phosphorus removal reactor, phosphorus-accumulating bacteria utilizes organic carbon source in the urban sewage for anaerobic phosphorus release, sedimentation and water drainage are performed, the amount of output water is adjusted by the adjusting water tank, then the output water enters the integrated partial nitrification and anaerobic ammonia oxidation reactor, contained NH4<+>-N is converted into N2 to be effectively removed through partial nitrification and anaerobic ammonia oxidation, contained PO4 <3-> and a small amount of NO3<->-N produced in the anaerobic ammonia oxidation flow back with the output water to the denitrifying phosphorus removal reactor for denitrifying phosphorus removal, and then micro-aeration is carried out for a period of time. The method reduces oxygen consumption and energy consumption, improves the nitrogen and phosphorus removal rate, and avoids the problem of insufficient carbon source.

Owner:贵州筑信水务环境产业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com