Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3121 results about "Femtosecond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A femtosecond is the SI unit of time equal to 10⁻¹⁵ or ¹/1,000,000,000,000,000 of a second; that is, one quadrillionth, or one millionth of one billionth, of a second. For context, a femtosecond is to a second as a second is to about 31.71 million years; a ray of light travels approximately 0.3 μm (micrometers) in 1 femtosecond, a distance comparable to the diameter of a virus. The word femtosecond is formed by the SI prefix femto and the SI unit second.

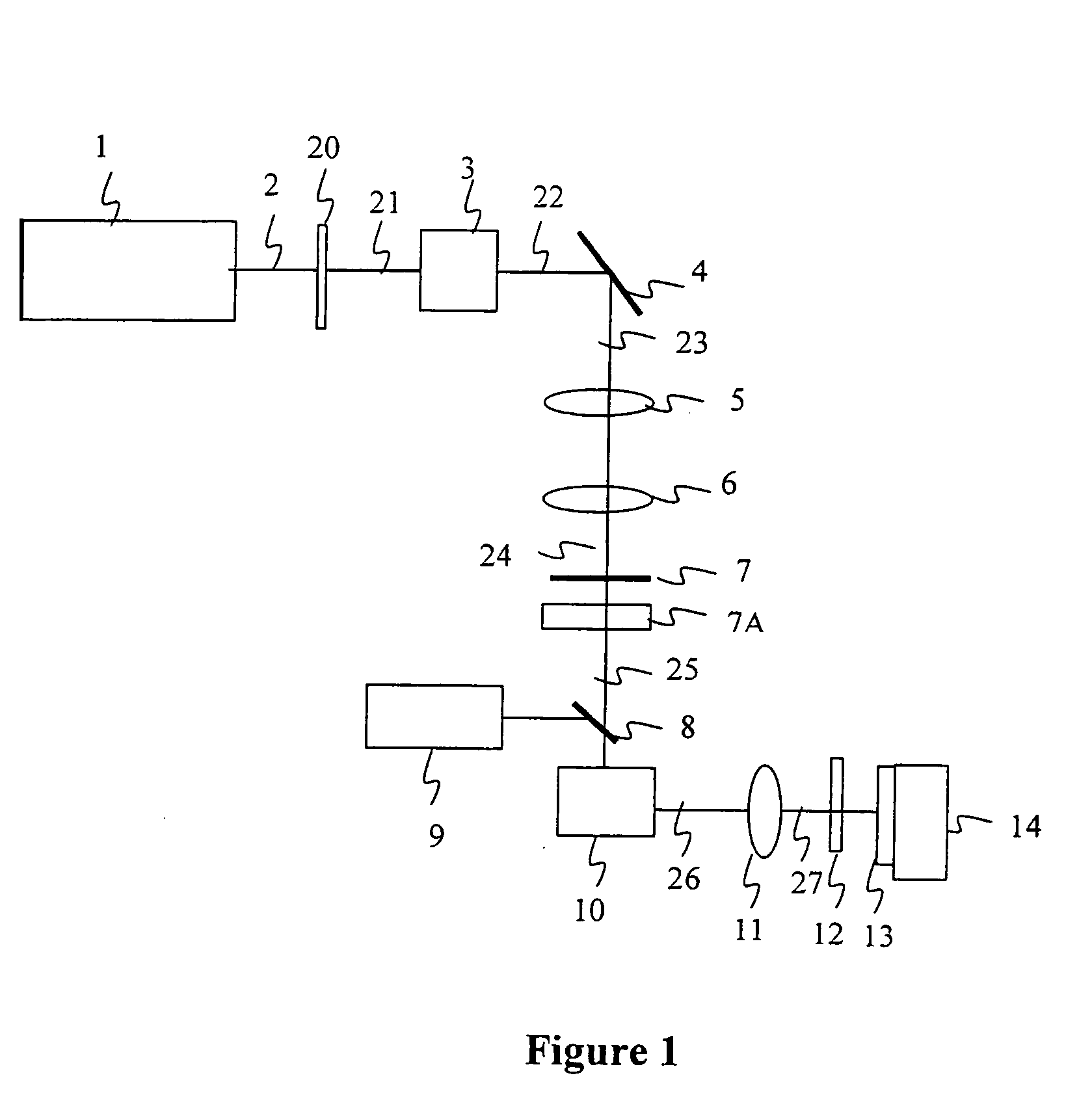

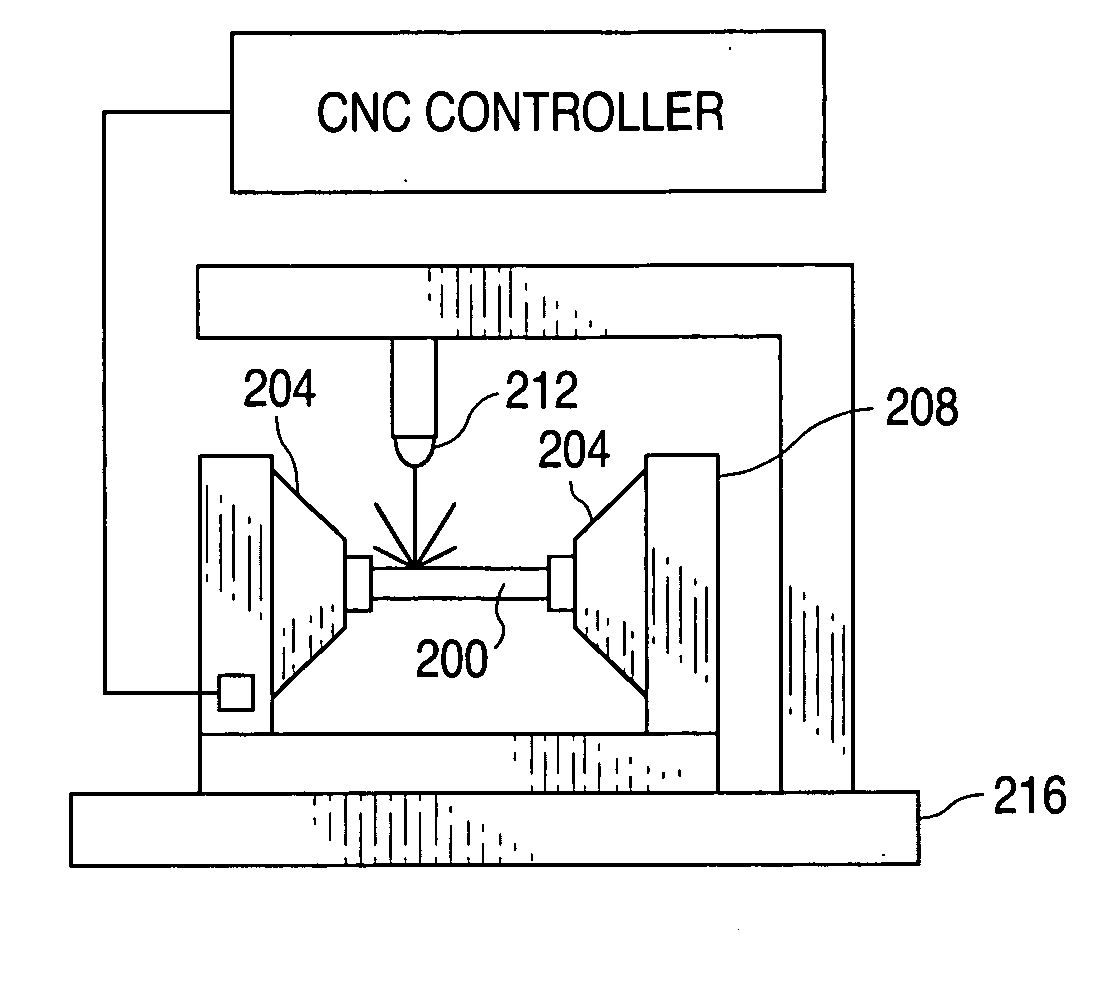

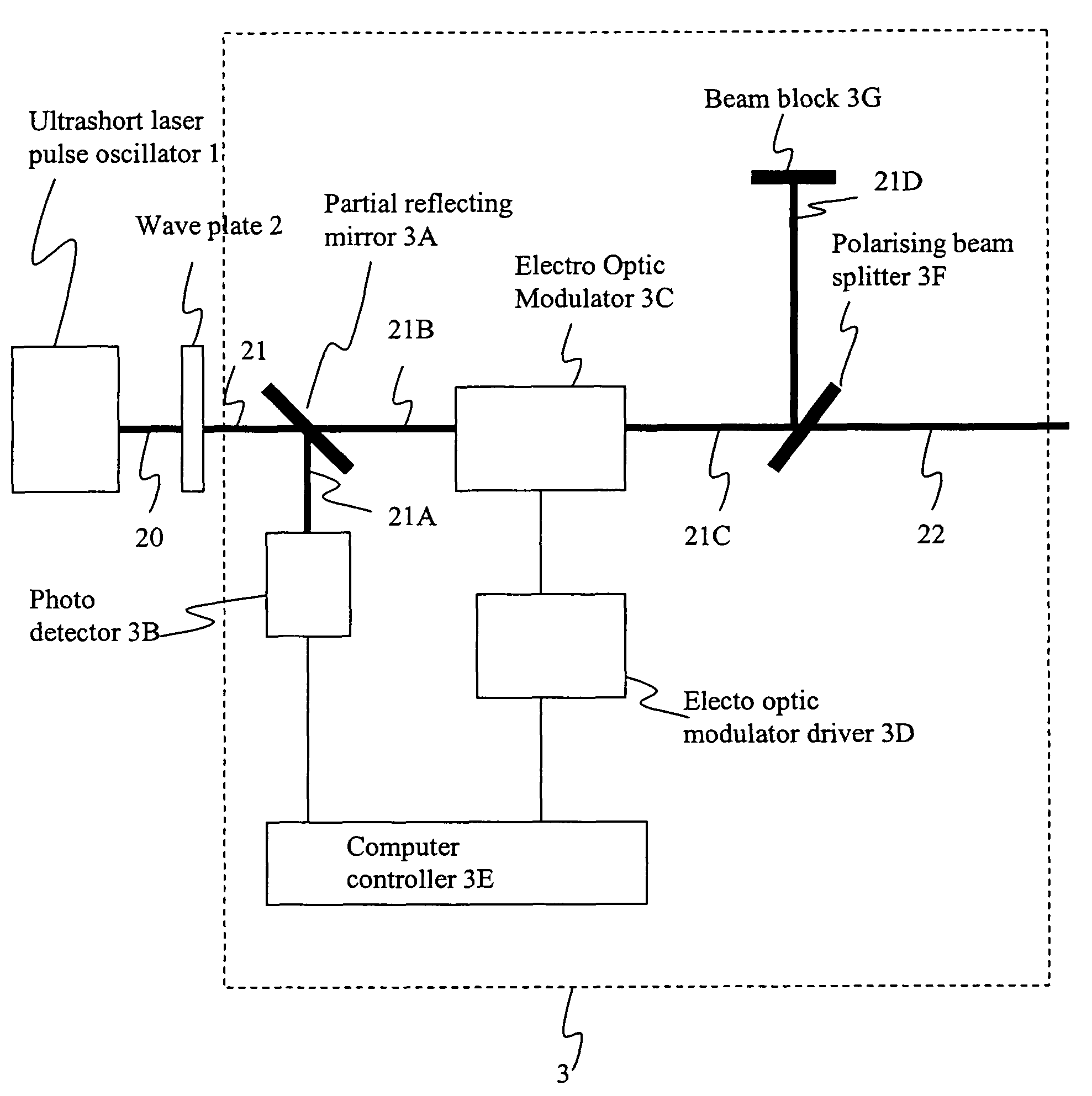

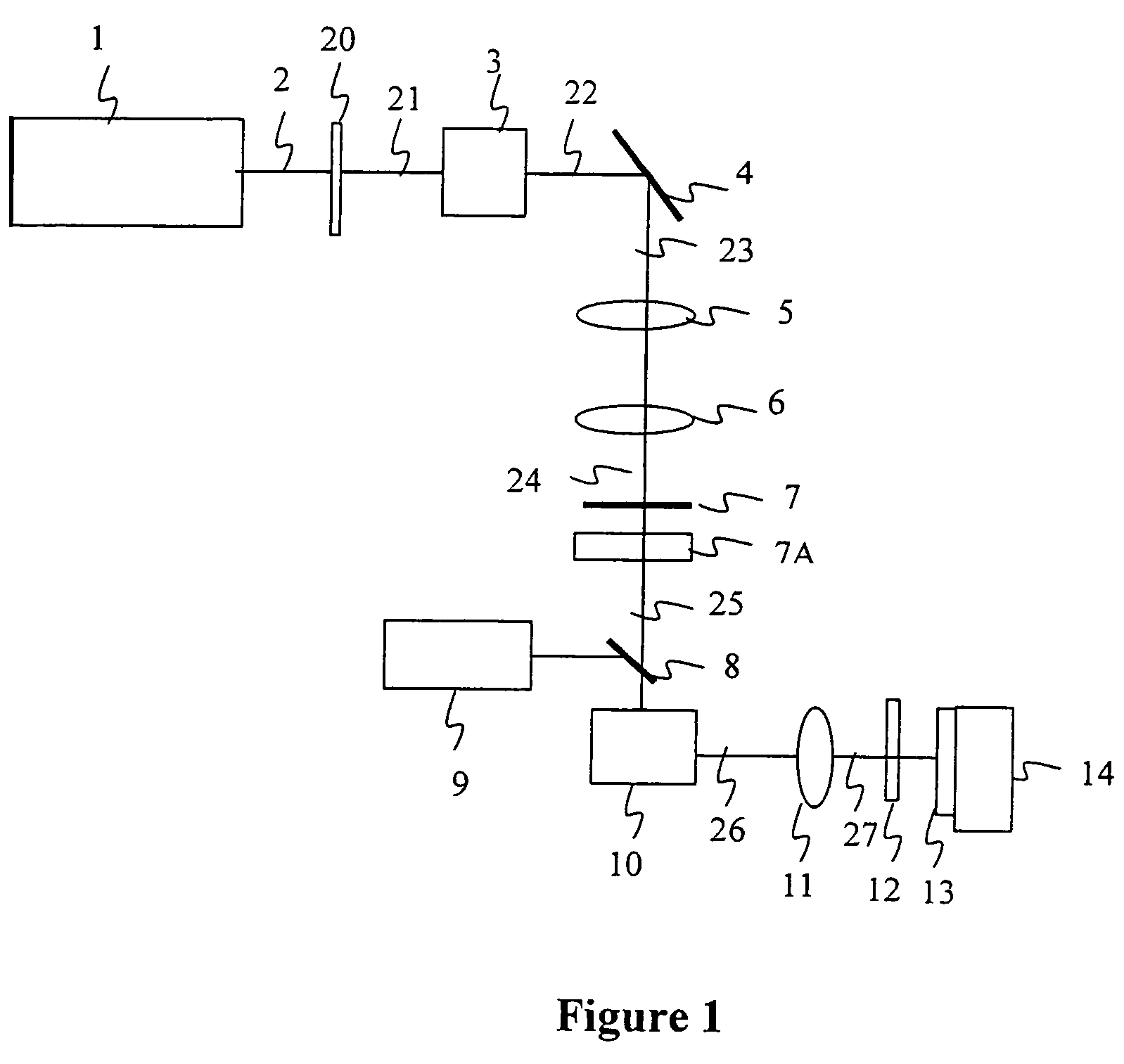

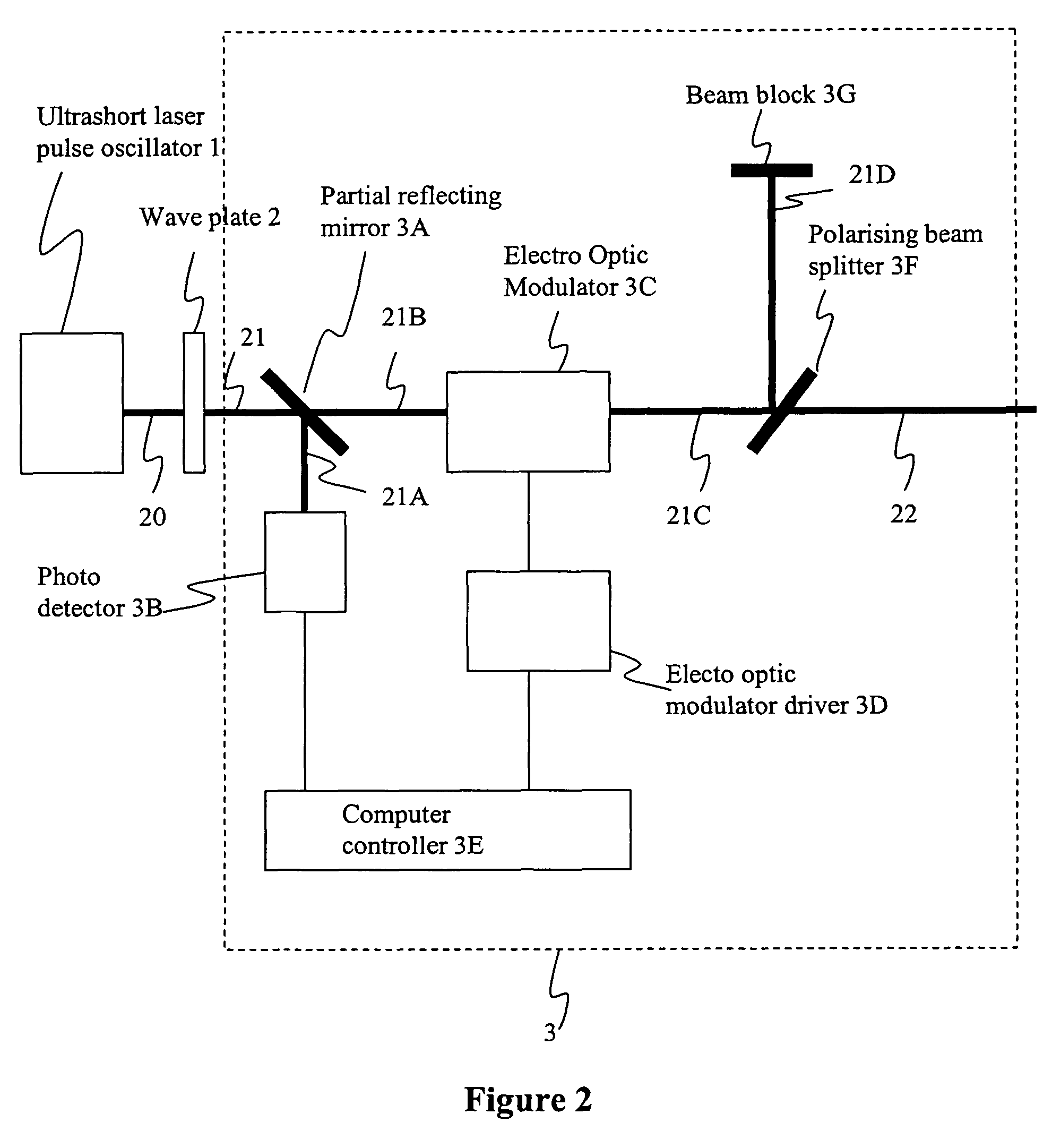

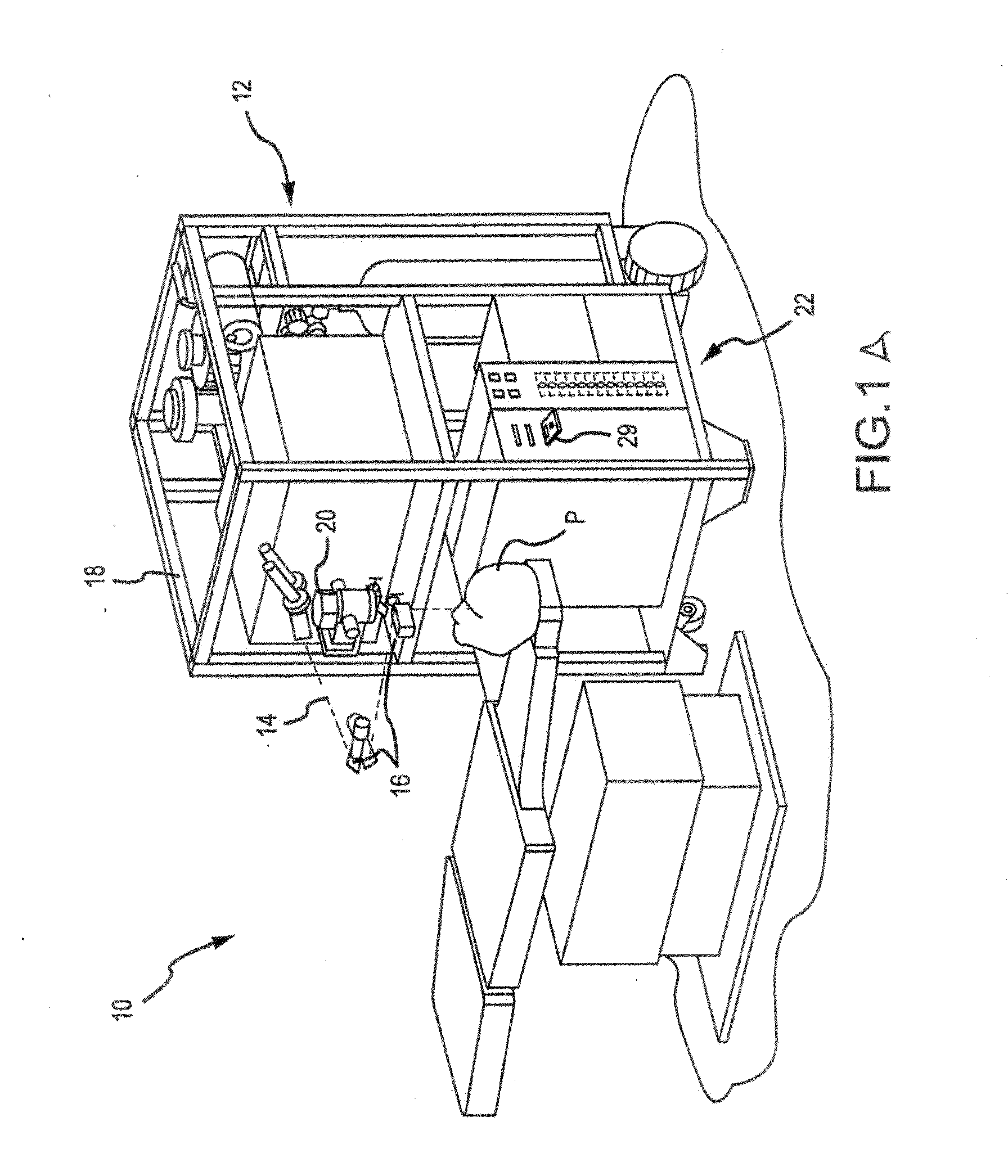

Method and apparatus for dicing of thin and ultra thin semiconductor wafer using ultrafast pulse laser

InactiveUS20050274702A1Improve inner wall qualityImprove surface qualityWelding/soldering/cutting articlesMetal working apparatusPicosecond laserFacula

The present invention relates to the apparatus, system and method for dicing of semiconductor wafers using an ultrafast laser pulse of femtosecond and picosecond pulse widths directly from the ultrafast laser oscillator without an amplifier. Thin and ultrathin simiconductor wafers below 250 micrometer thickness, are diced using diode pumped, solid state mode locked ultrafast laser pulses from oscillator without amplification. The invention disclosed has means to avoid / reduce the cumulative heating effect and to avoid machine quality degrading in multi shot ablation. Also the disclosed invention provides means to change the polarization state of the laser beam to reduce the focused spot size, and improve the machining efficiency and quality. The disclosed invention provides a cost effective and stable system for high volume manufacturing applications. An ultrafast laser oscillator can be a called as femtosecond laser oscillator or a picosecond laser oscillator depending on the pulse width of the laser beam generated.

Owner:LASERFACTURING

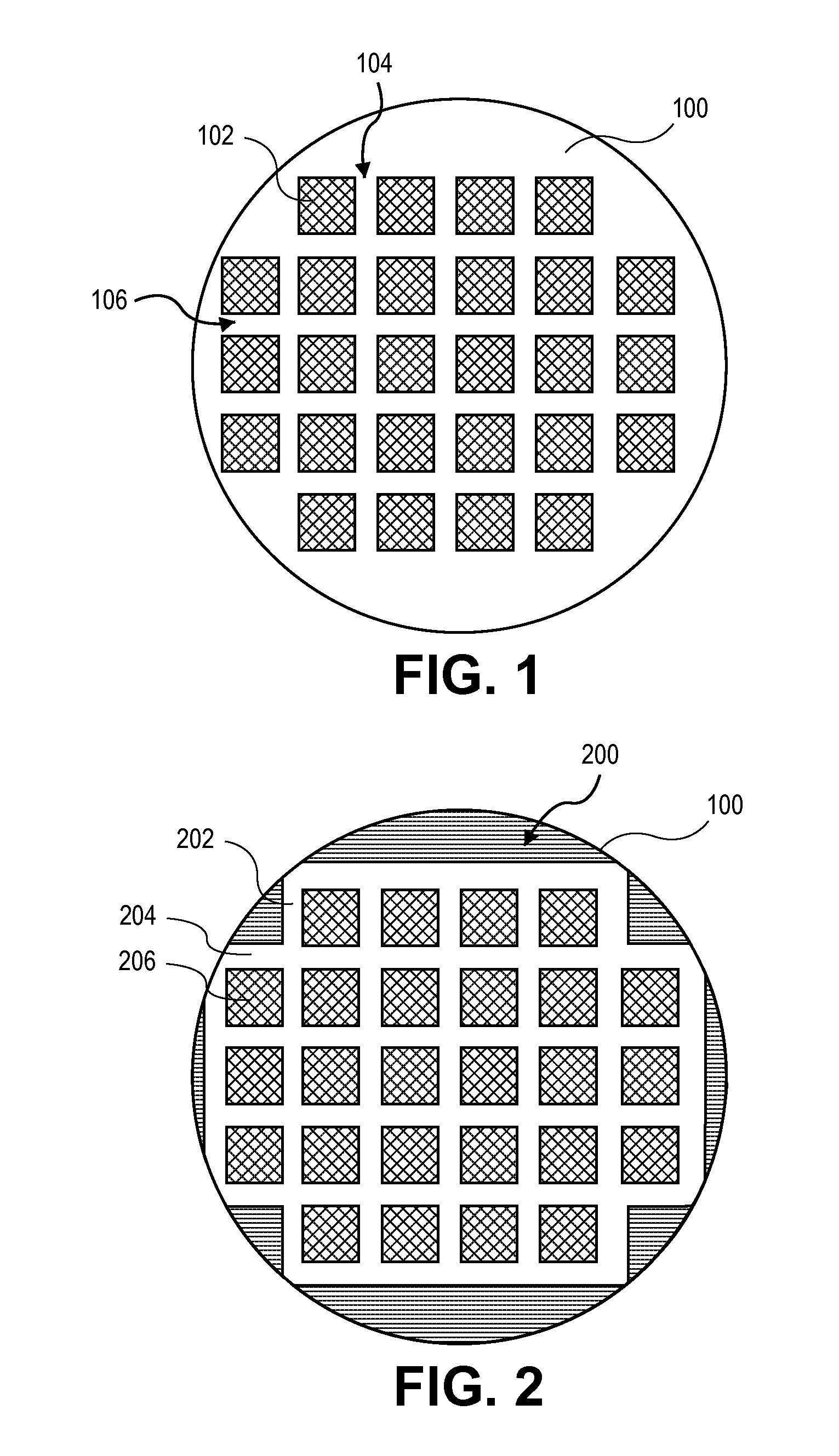

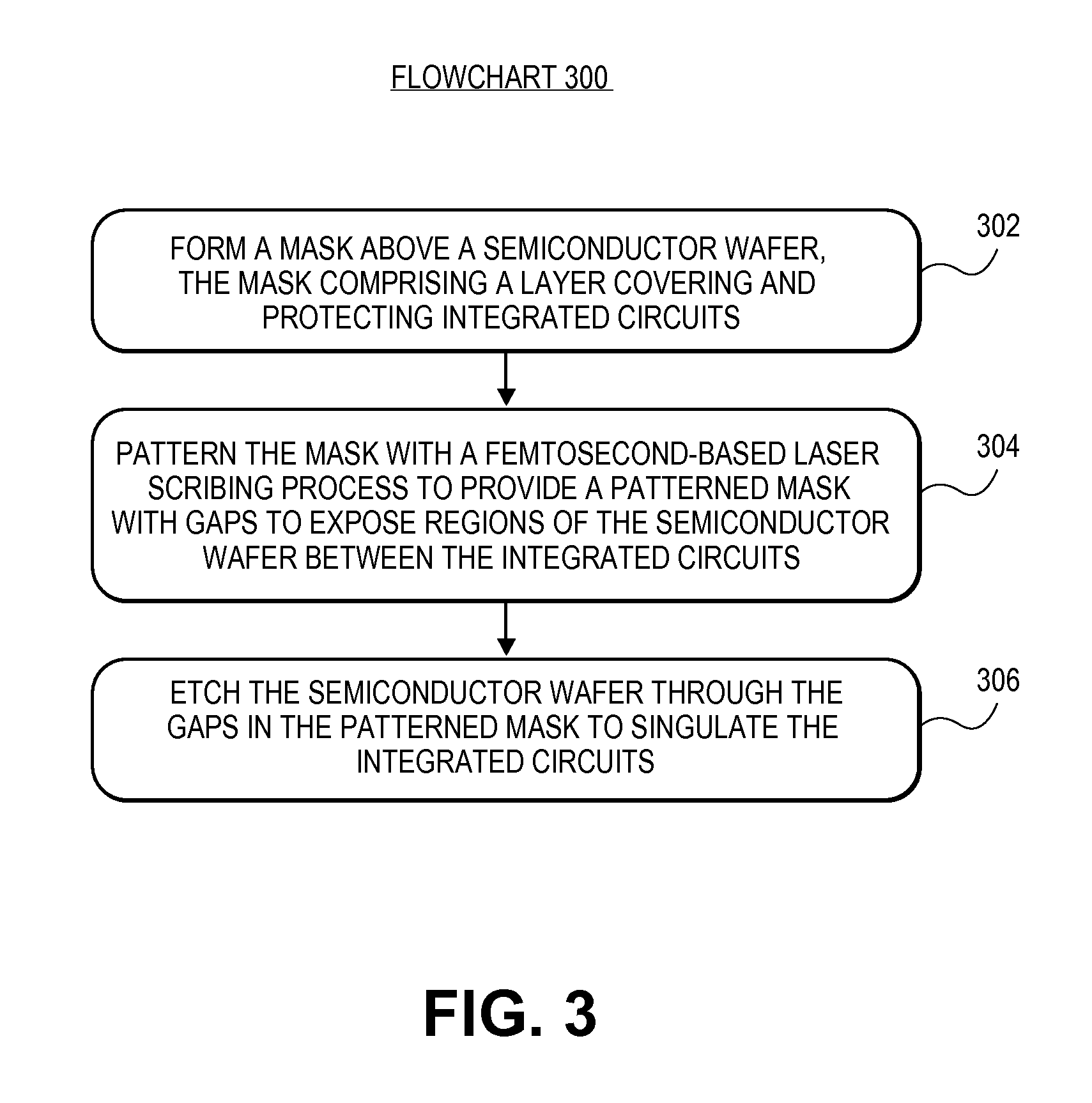

Wafer dicing using femtosecond-based laser and plasma etch

ActiveUS20110312157A1Electric discharge tubesSemiconductor/solid-state device detailsWafer dicingEngineering

Methods of dicing semiconductor wafers, each wafer having a plurality of integrated circuits, are described. A method includes forming a mask above the semiconductor wafer. The mask is composed of a layer covering and protecting the integrated circuits. The mask is patterned with a femtosecond-based laser scribing process to provide a patterned mask with gaps. The patterning exposes regions of the semiconductor wafer between the integrated circuits. The semiconductor wafer is then etched through the gaps in the patterned mask to singulate the integrated circuits.

Owner:APPLIED MATERIALS INC

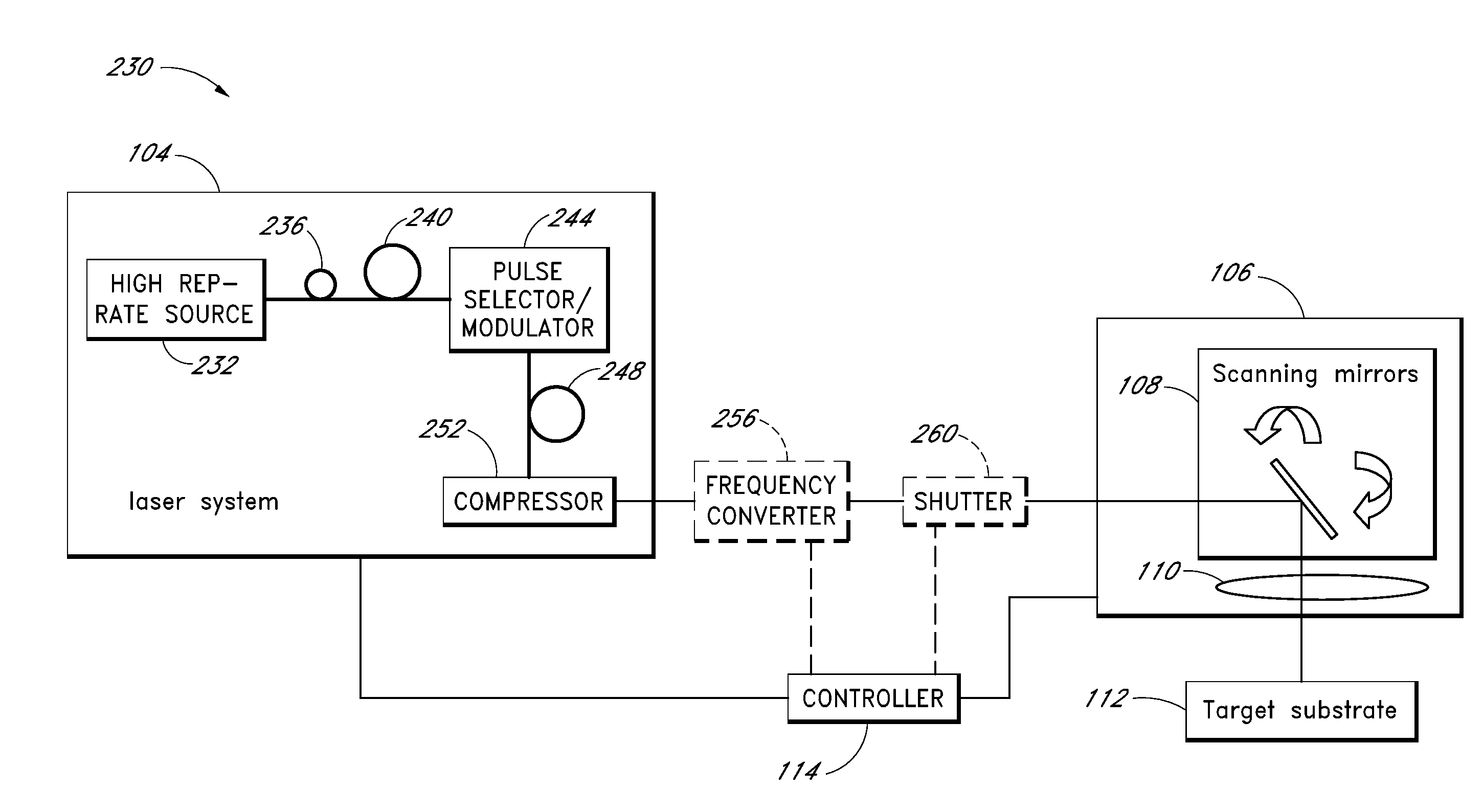

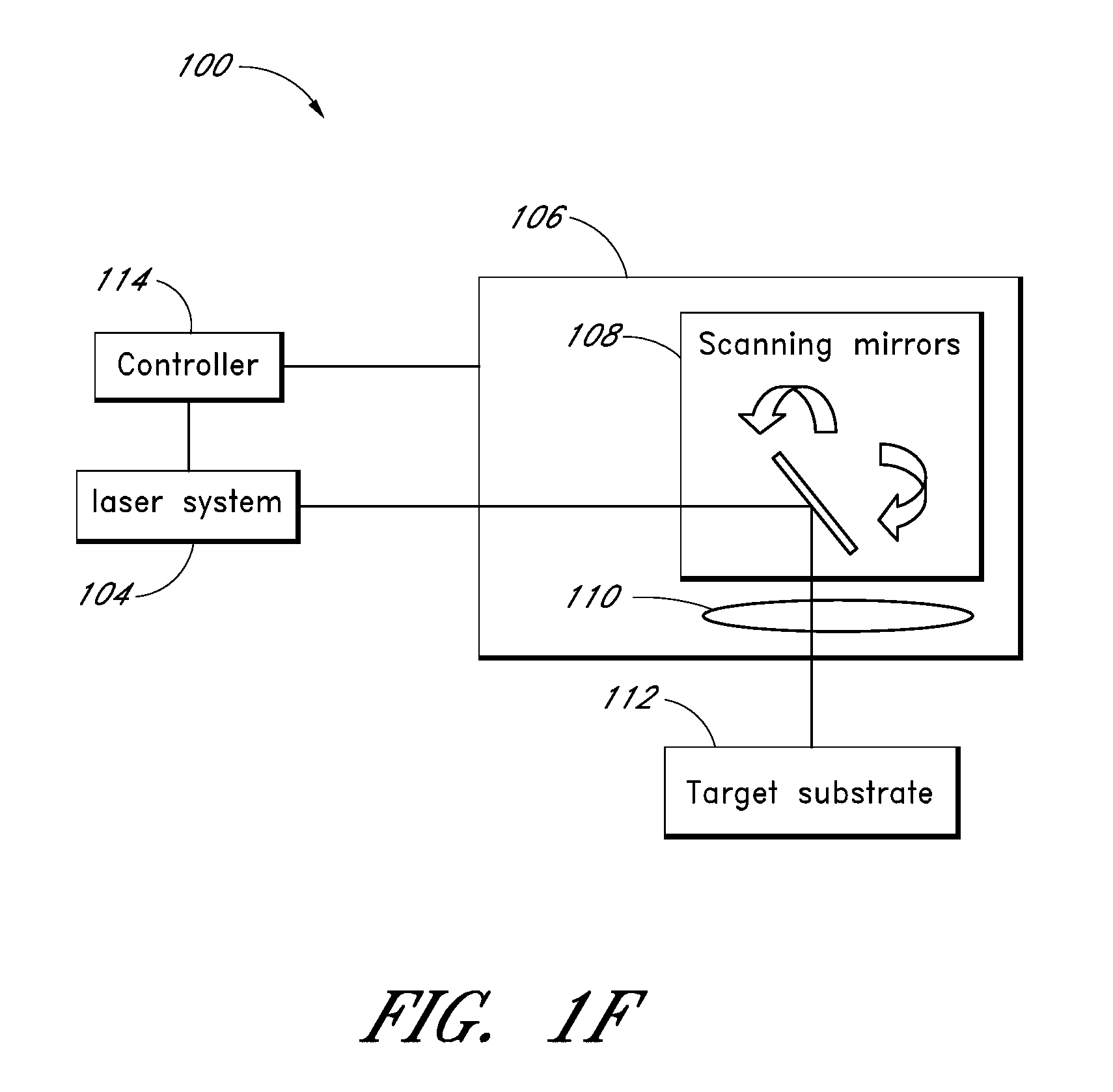

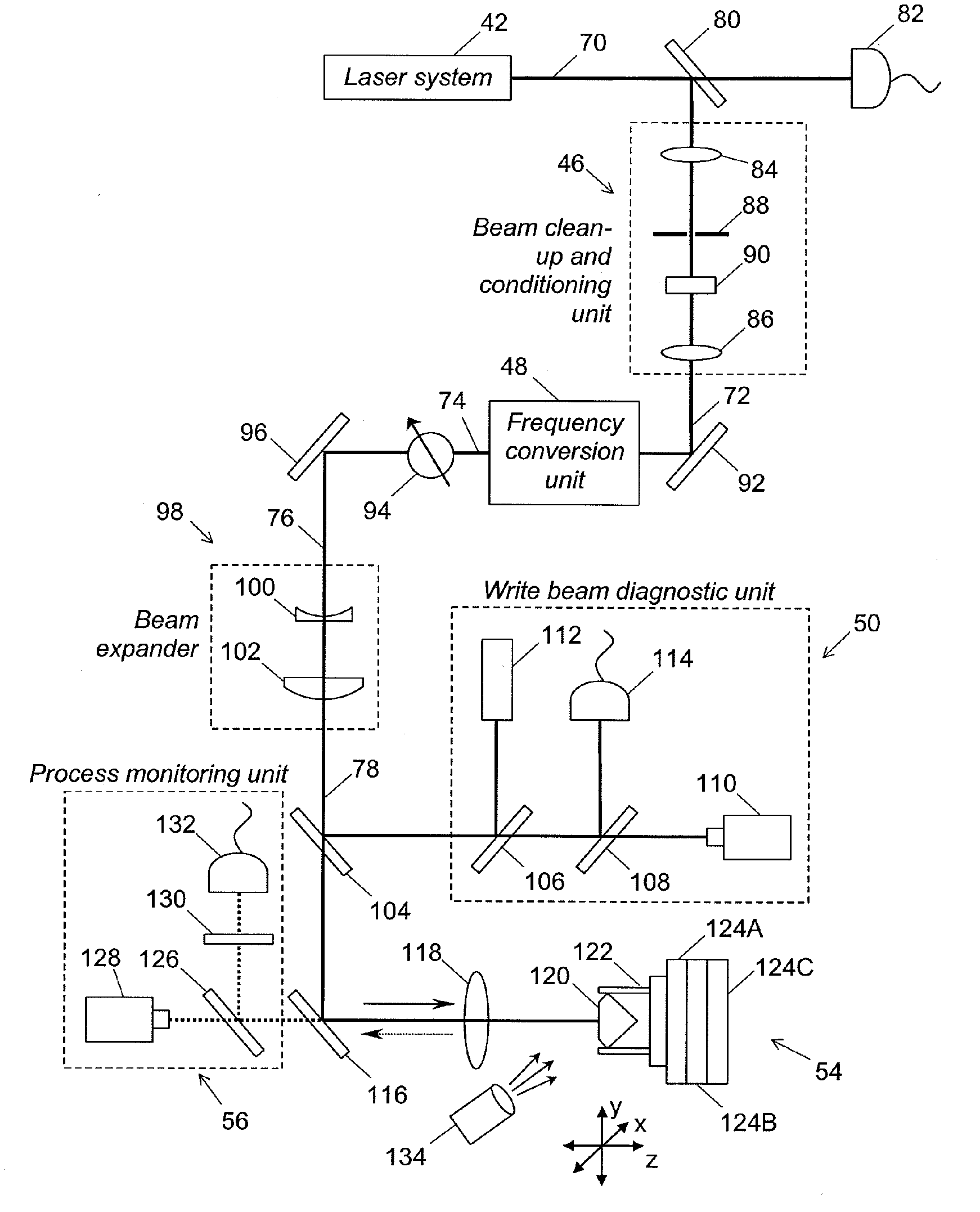

Laser-based material processing methods and systems

ActiveUS20100197116A1Efficient removalAvoid accumulationSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDielectricMaterials processing

Various embodiments may be used for laser-based modification of target material of a workpiece while advantageously achieving improvements in processing throughput and / or quality. Embodiments of a method of processing may include focusing and directing laser pulses to a region of the workpiece at a pulse repetition rate sufficiently high so that material is efficiently removed from the region and a quantity of unwanted material within the region, proximate to the region, or both is reduced relative to a quantity obtainable at a lower repetition rate. In at least one embodiment, an ultrashort pulse laser system may include at least one of a fiber amplifier or fiber laser. Various embodiments are suitable for at least one of dicing, cutting, scribing, and forming features on or within a semiconductor substrate. Workpiece materials may also include metals, inorganic or organic dielectrics, or any material to be micromachined with femtosecond and / or picosecond pulses, and in some embodiments with pulse widths up to a few nanoseconds.

Owner:IMRA AMERICA

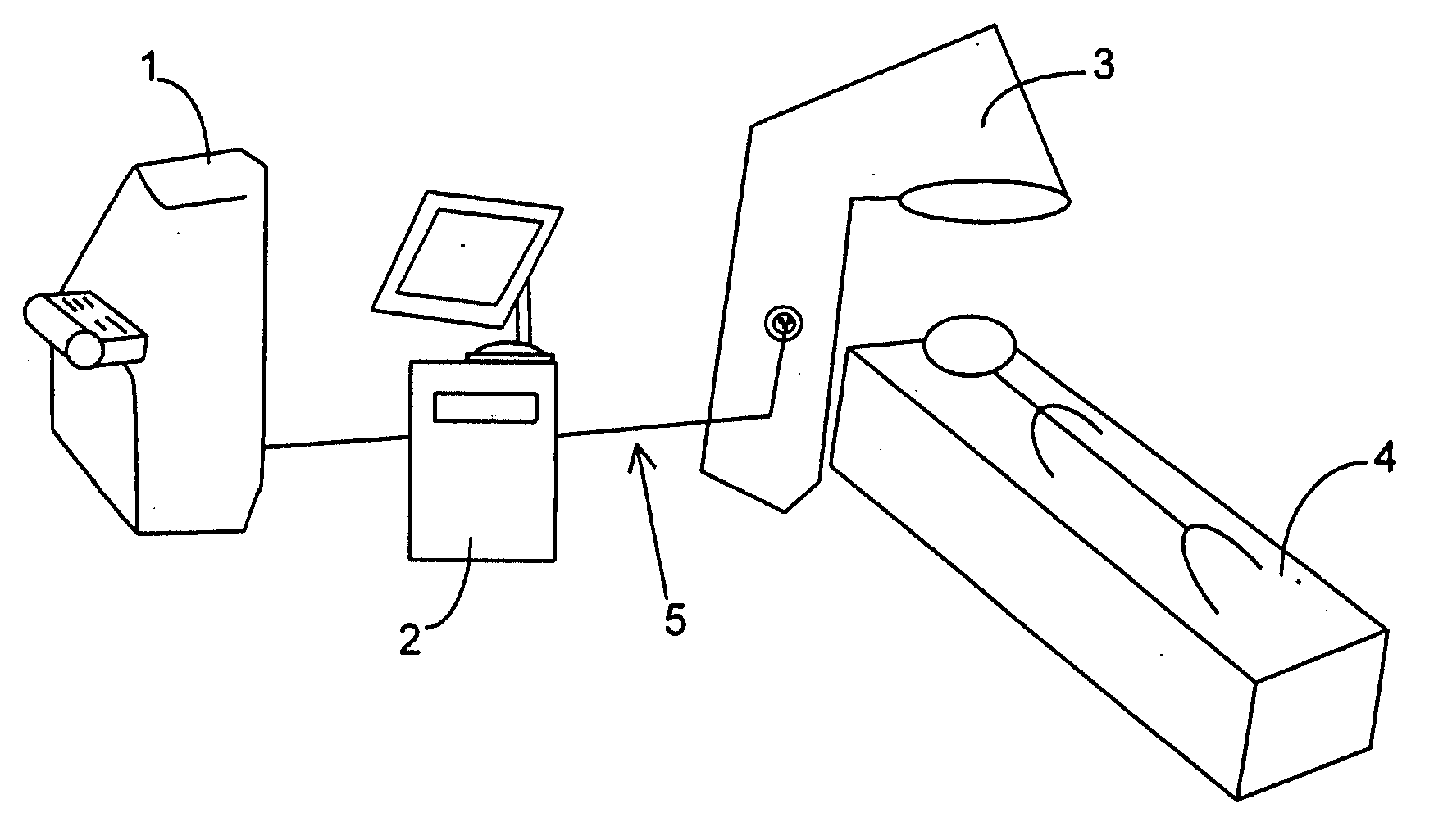

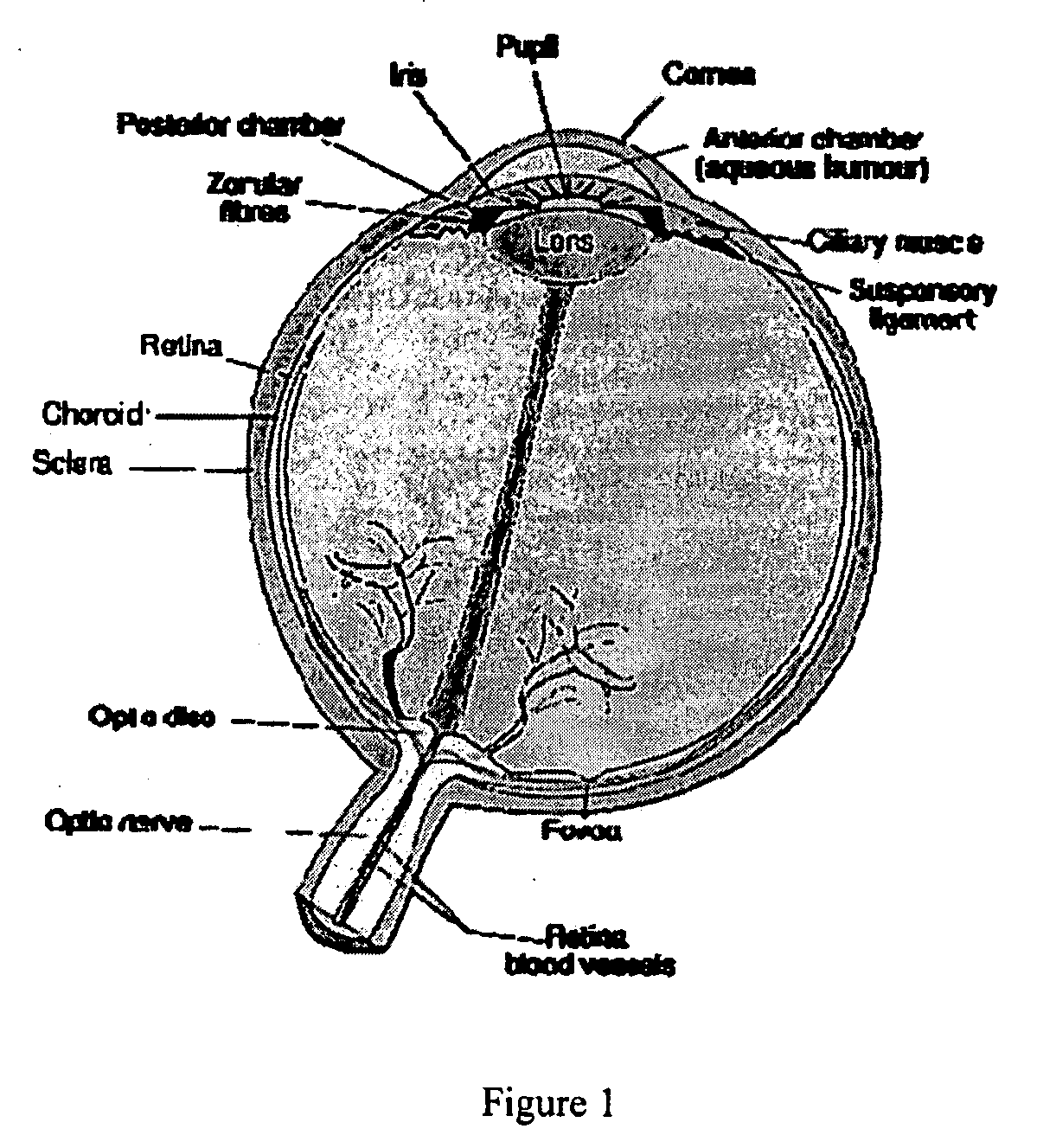

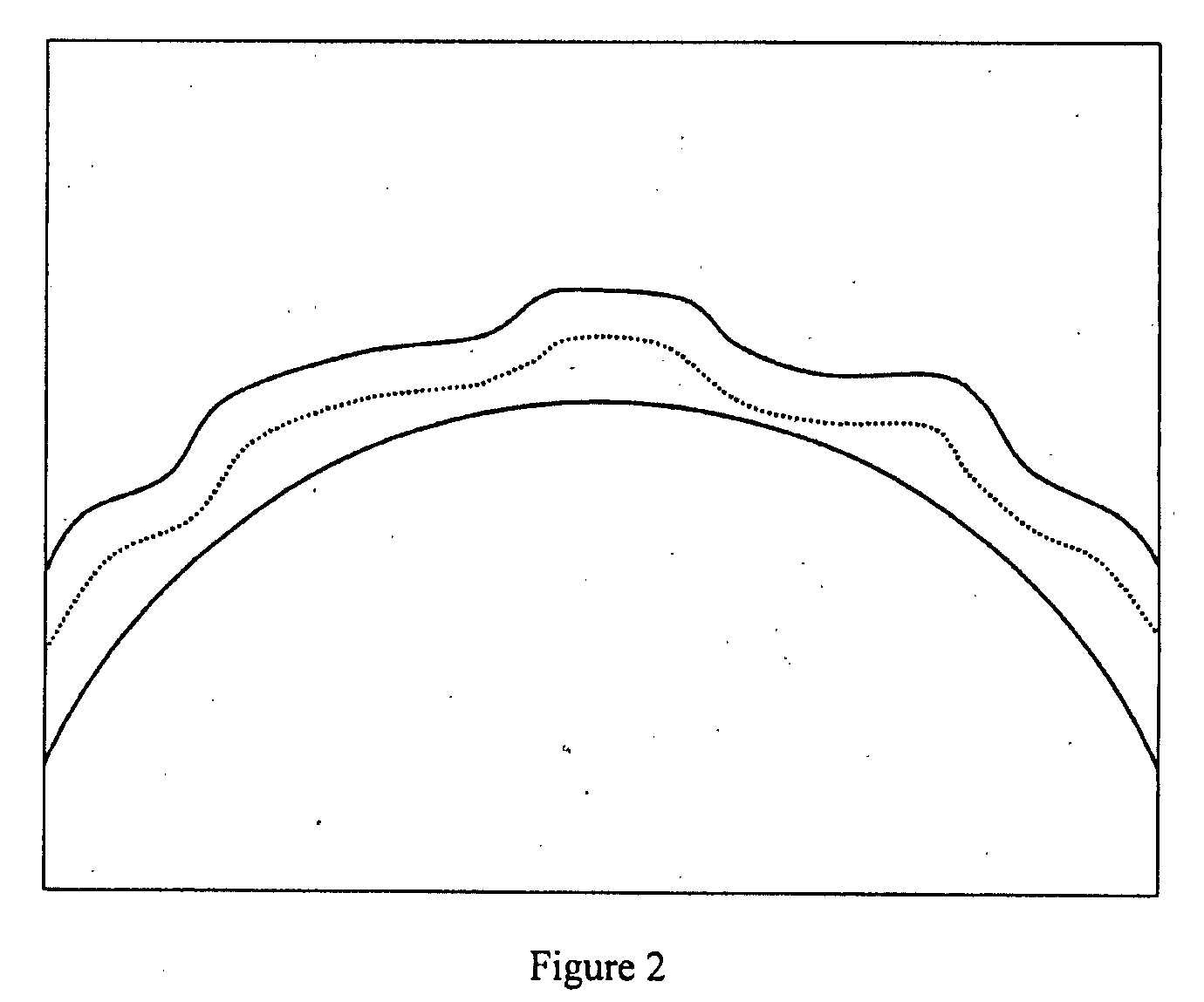

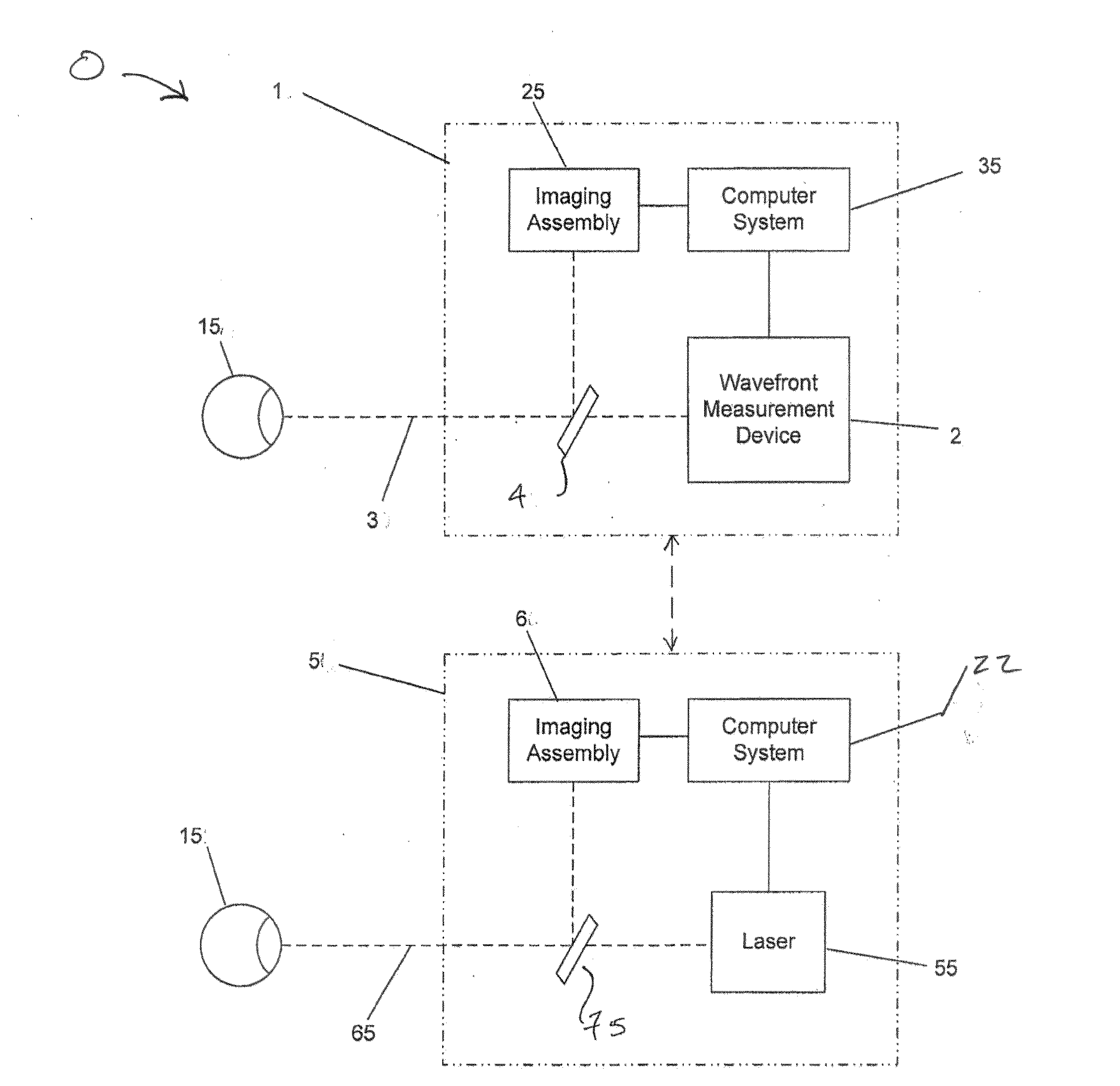

Method and apparatus to guide laser corneal surgery with optical measurement

InactiveUS20070282313A1Faster visual recoveryLess invasiveLaser surgerySurgical instrument detailsRefractive errorPhototherapeutic keratectomy

Optical coherence tomography (OCT) is used to map the surface elevation and thickness of the cornea. The OCT maps are used to plan laser procedures for the treatment of an irregular, opacified or weakened cornea, and in the treatment of refractive errors. In the excimer laser phototherapeutic keratectomy (PTK) procedure, the OCT data is used to plan a map of ablation depth needed to restore a smooth optical surface. In the excimer laser photorefractive keratectomy procedure, OCT mapping of epithelial thickness is used to achieve clean laser epithelial removal. In femtosecond laser anterior keratoplasty procedure, OCT data is used to plan the depth of femtosecond laser dissection to remove an anterior layer of the cornea, leaving a smooth recipient bed of uniform thickness to receive a disk of donated corneal tissue. The linkage of an OCT system to a precise laser surgical system enables the performance of new procedures that are safer, less invasive and produce faster visual recovery than conventional surgical procedures.

Owner:UNIV OF SOUTHERN CALIFORNIA

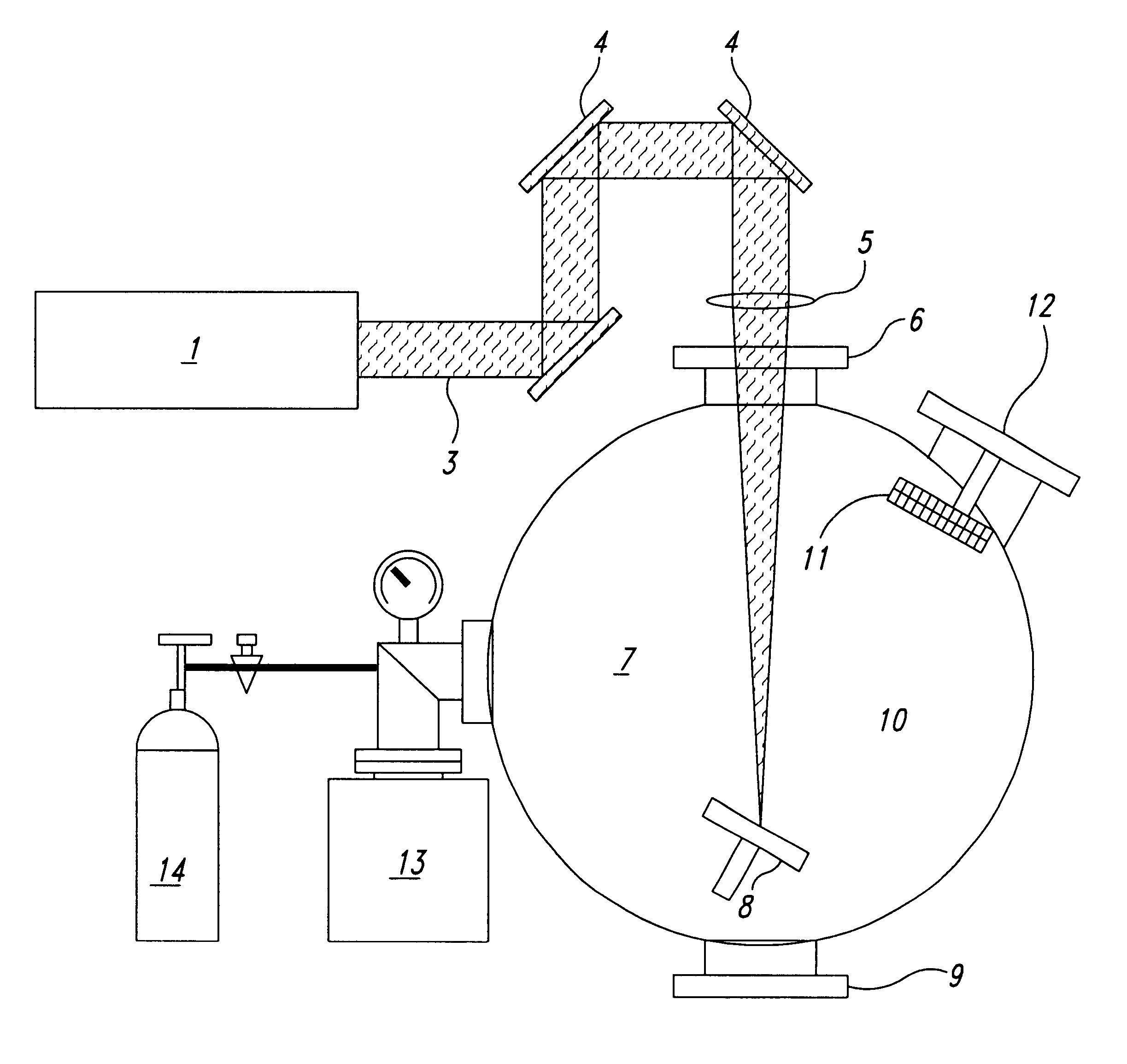

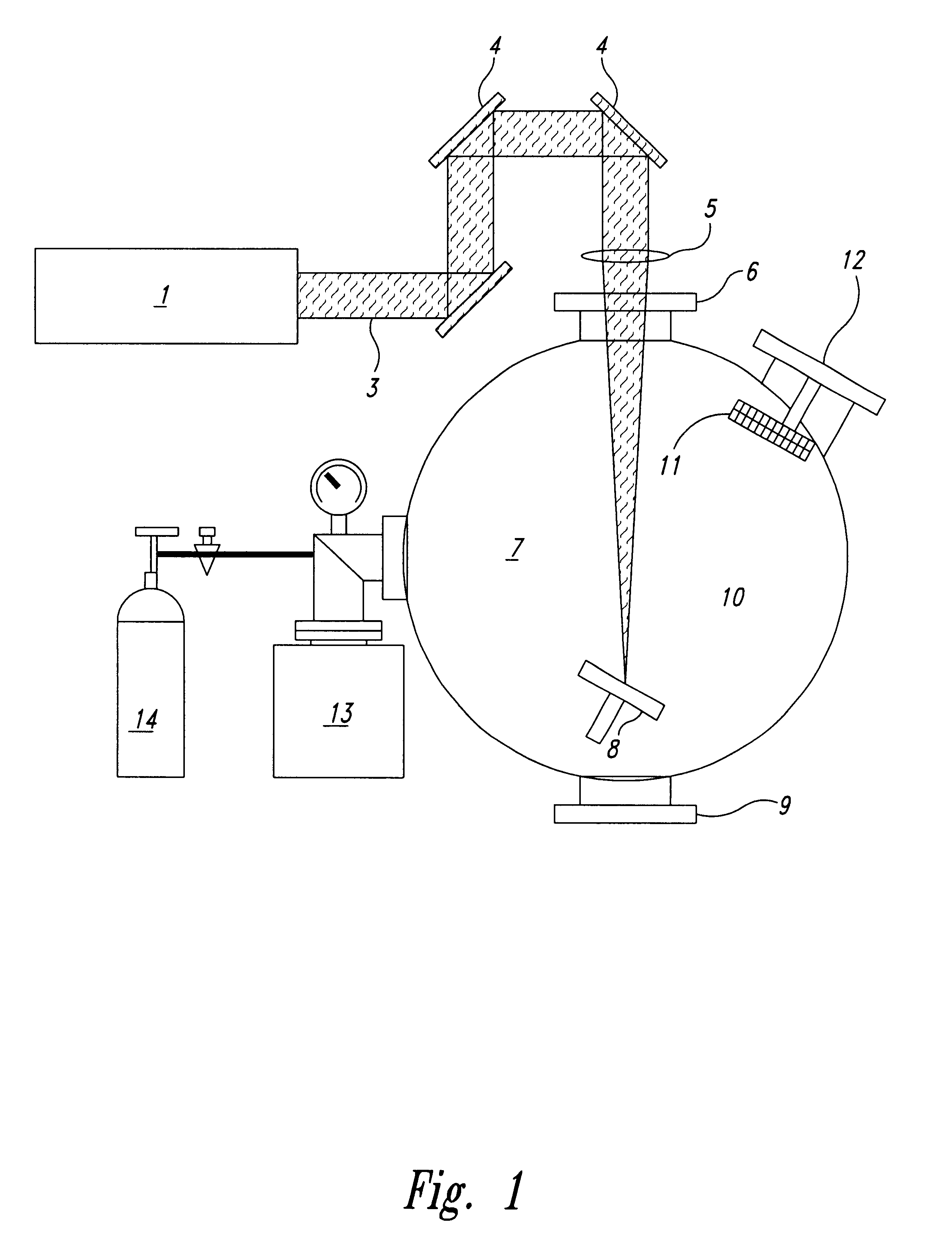

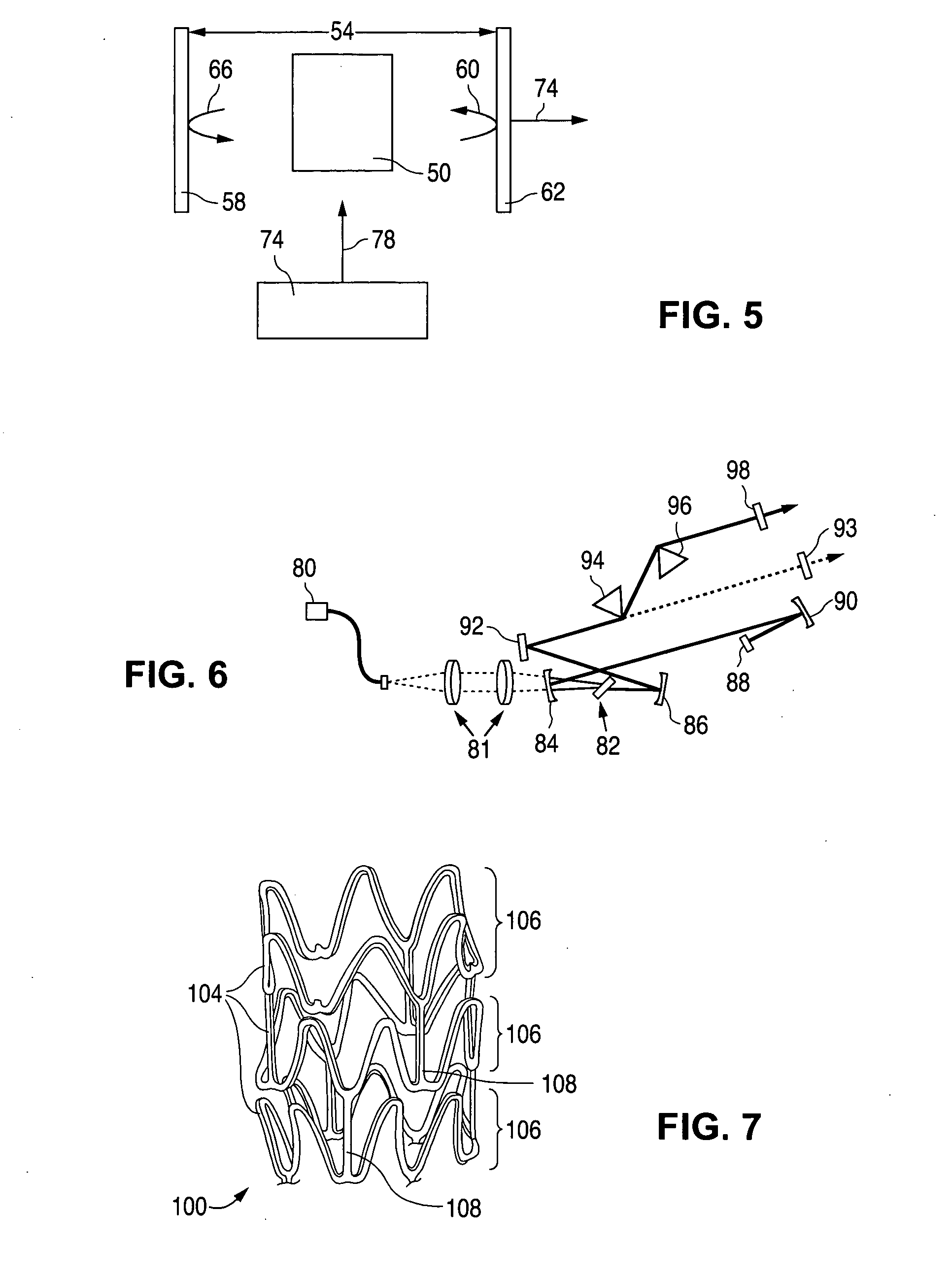

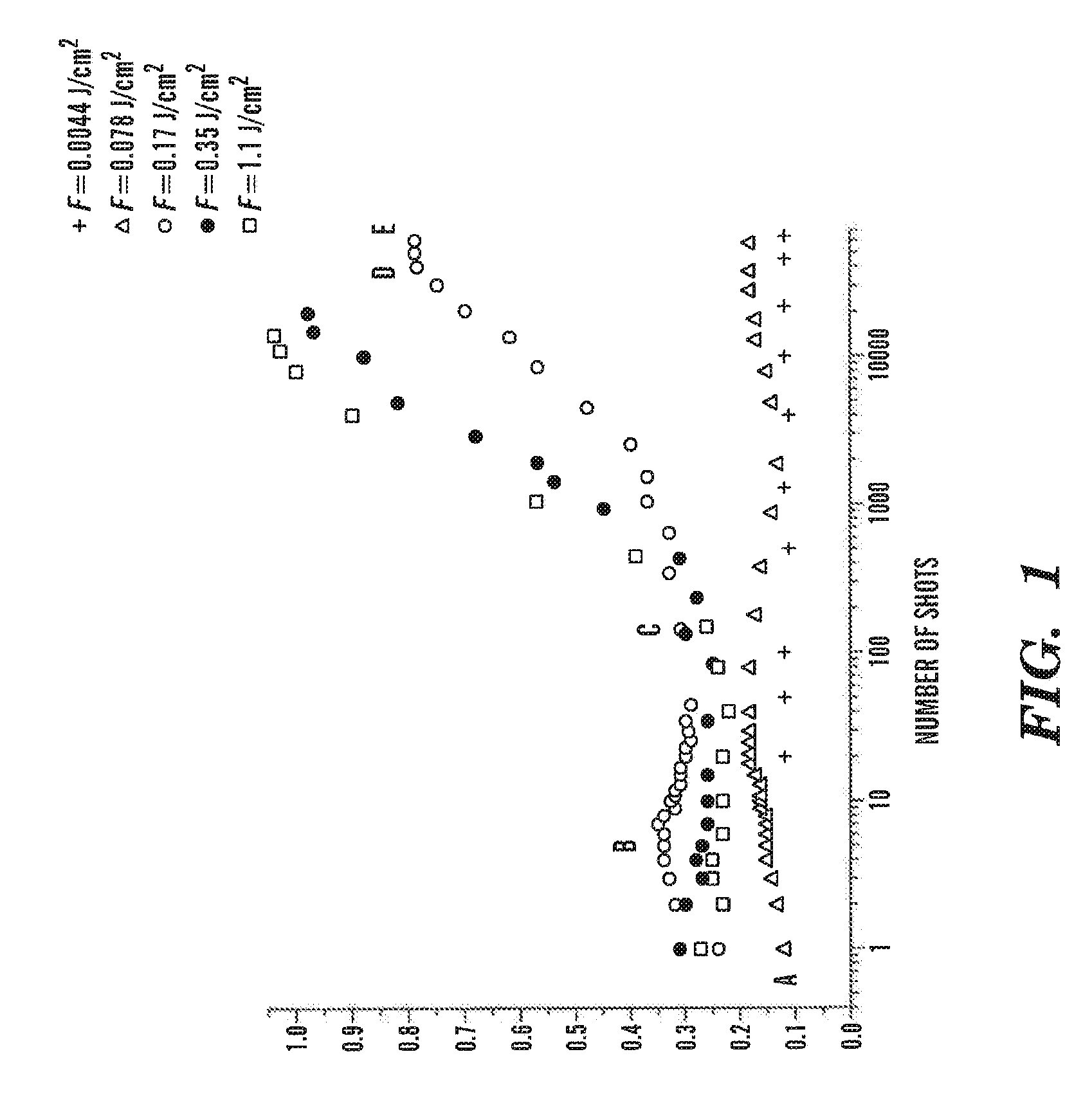

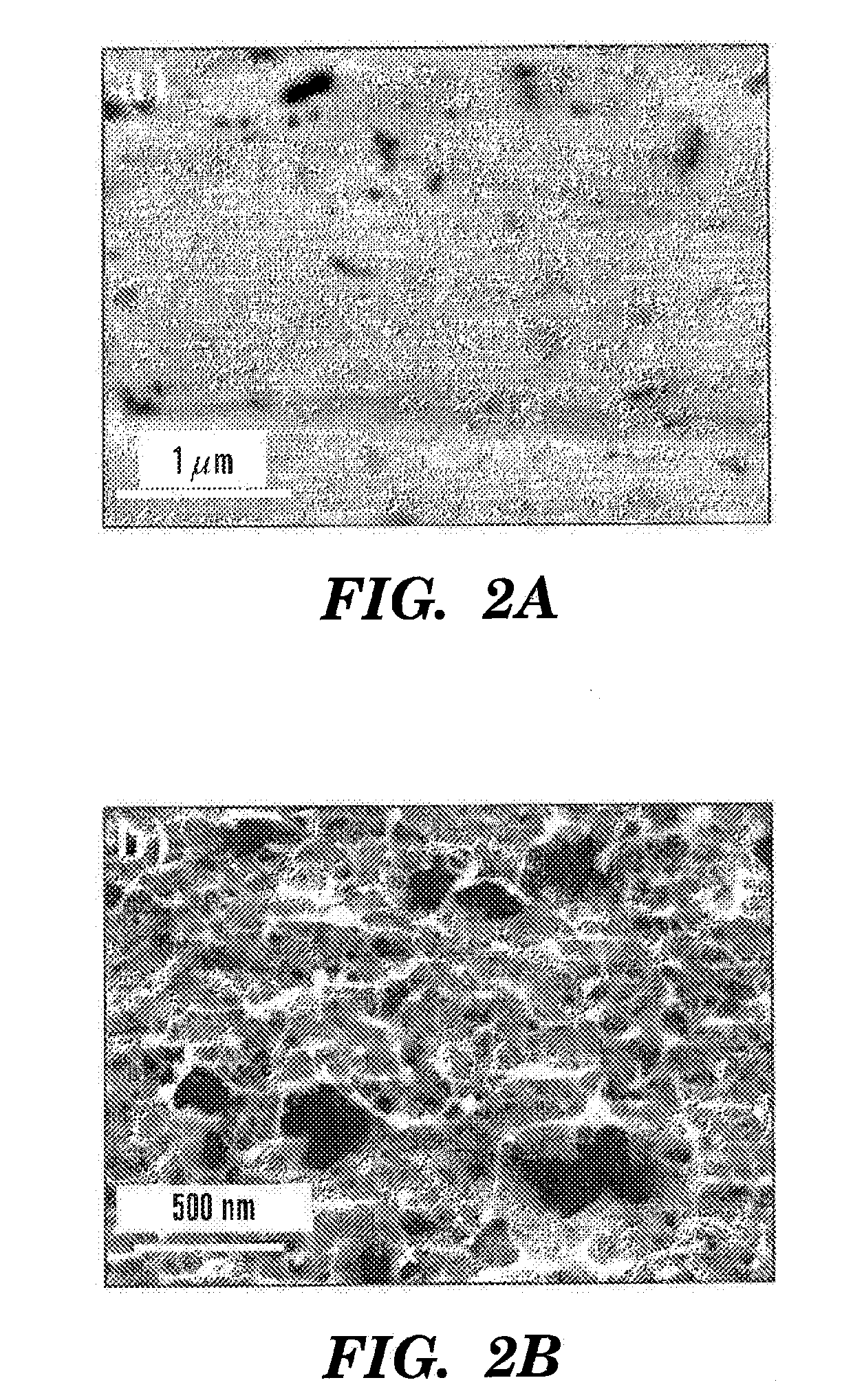

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

Fabricating medical devices with an ytterbium tungstate laser

Methods for fabricating a stent using a femtosecond laser with an Ytterbium Tungstate active medium are disclosed. In some embodiments, a method includes forming a pattern in the substrate with the laser, the pattern including a plurality of structural elements.

Owner:ABBOTT CARDIOVASCULAR

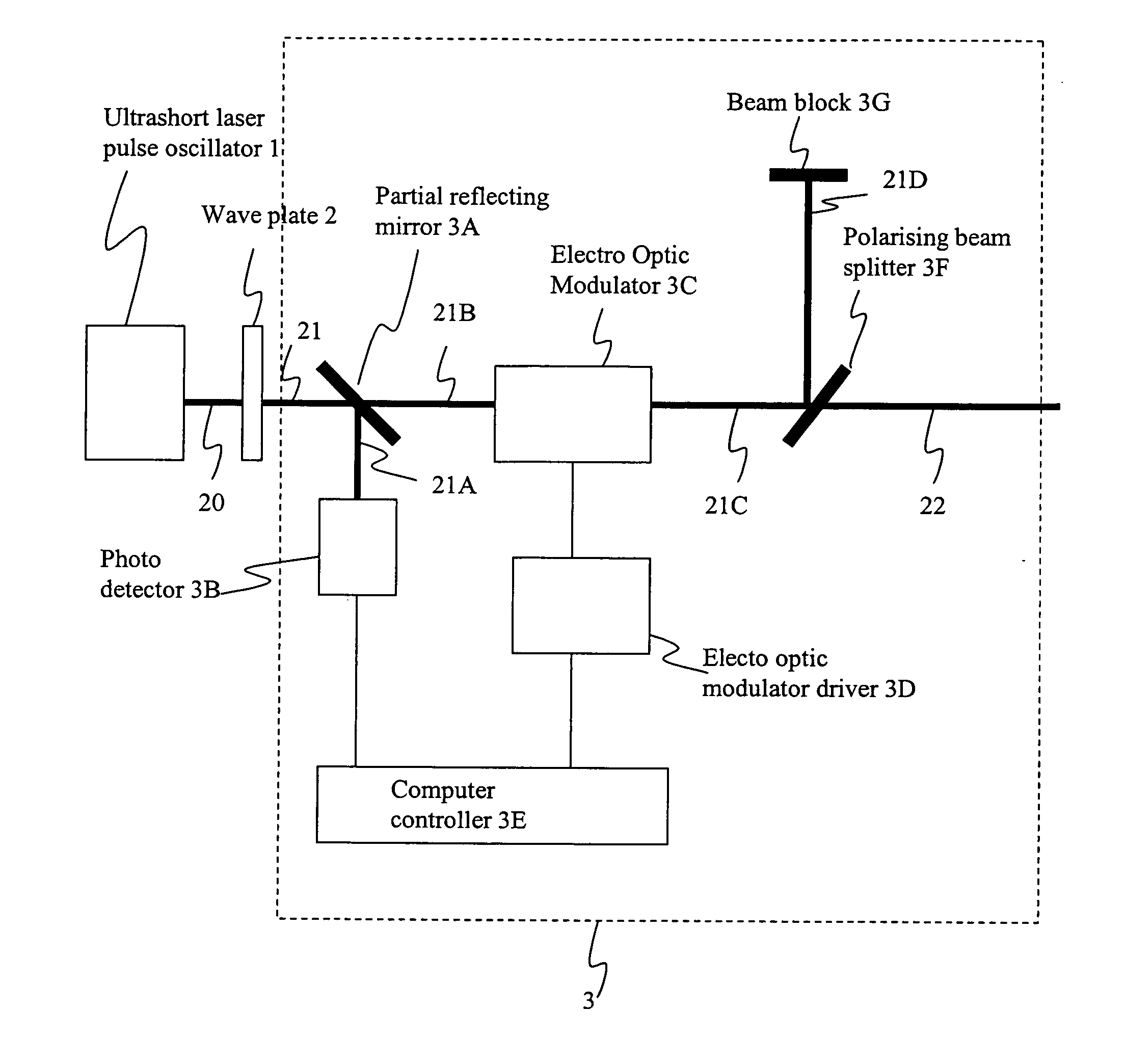

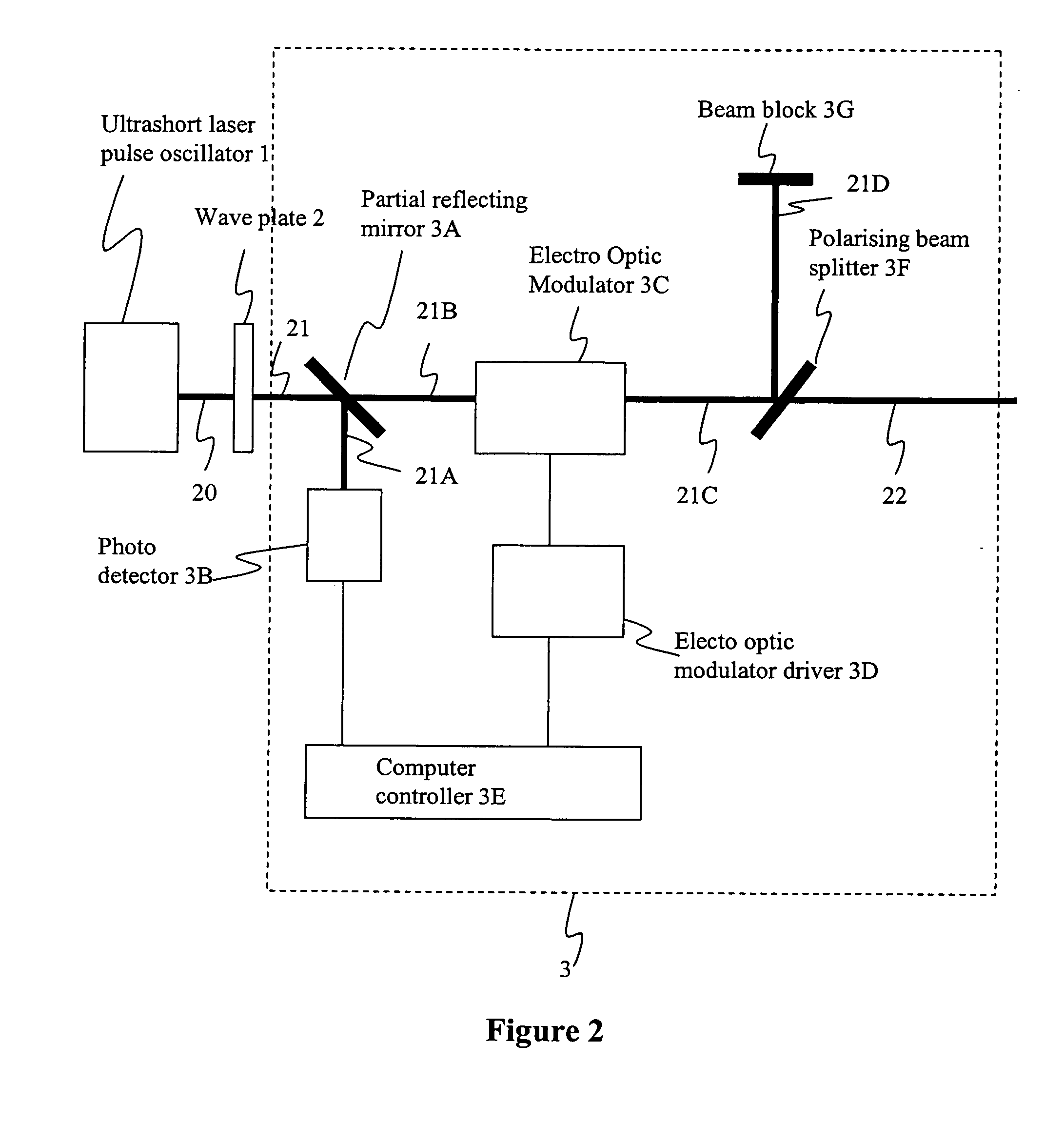

Method and apparatus for dicing of thin and ultra thin semiconductor wafer using ultrafast pulse laser

InactiveUS7804043B2Minimize heating effectImprove machine qualityWelding/soldering/cutting articlesMetal working apparatusPicosecond laserBeam polarization

The present invention relates to the apparatus, system and method for dicing of semiconductor wafers using an ultrafast laser pulse of femtosecond and picosecond pulse widths directly from the ultrafast laser oscillator without an amplifier. Thin and ultrathin semiconductor wafers below 250 micrometer thickness, are diced using diode pumped, solid state mode locked ultrafast laser pulses from oscillator without amplification. The invention disclosed has means to avoid / reduce the cumulative heating effect and to avoid machine quality degrading in multi shot ablation. Also the disclosed invention provides means to change the polarization state of the laser beam to reduce the focused spot size, and improve the machining efficiency and quality. The disclosed invention provides a cost effective and stable system for high volume manufacturing applications. An ultrafast laser oscillator can be a called as femtosecond laser oscillator or a picosecond laser oscillator depending on the pulse width of the laser beam generated.

Owner:LASERFACTURING

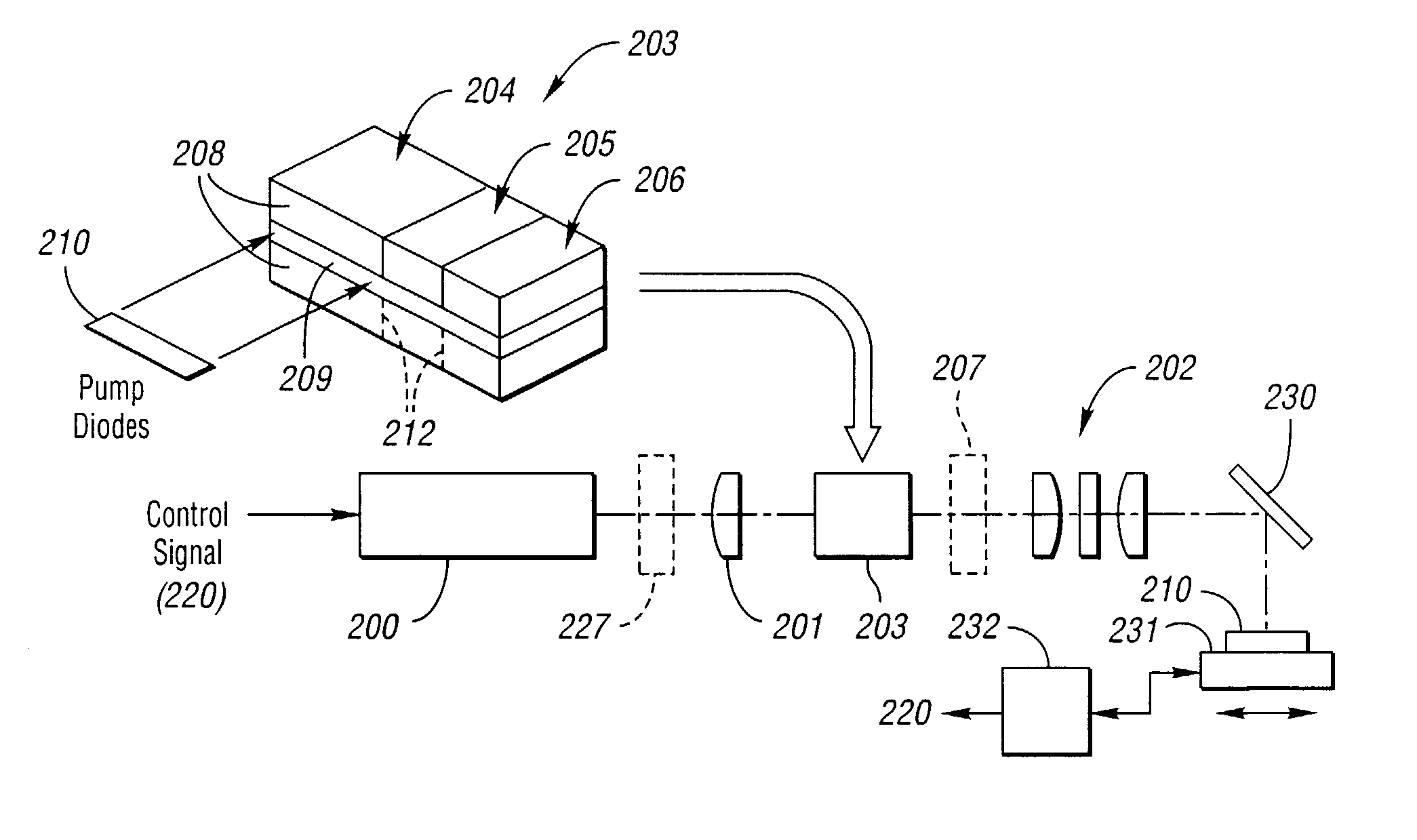

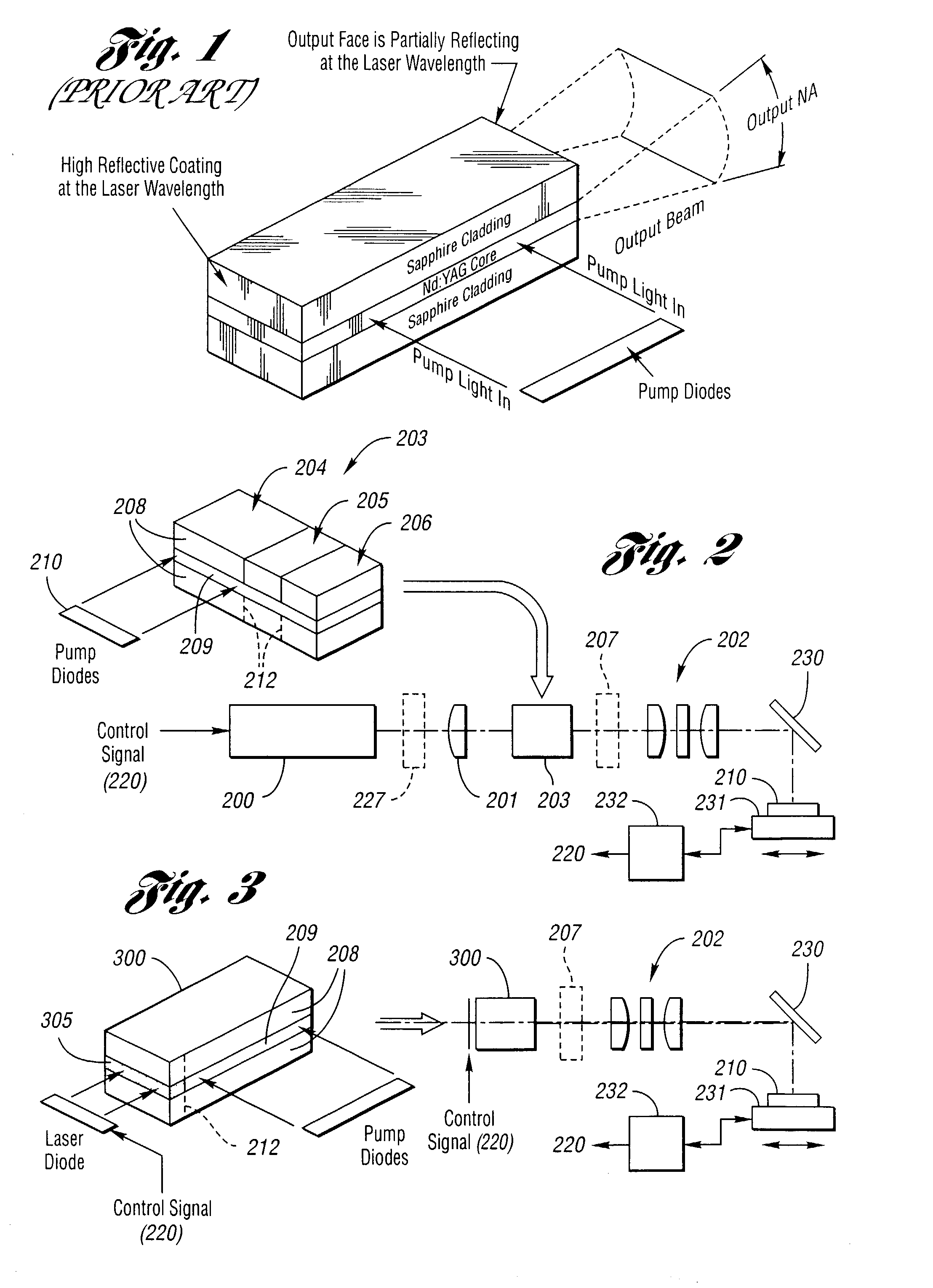

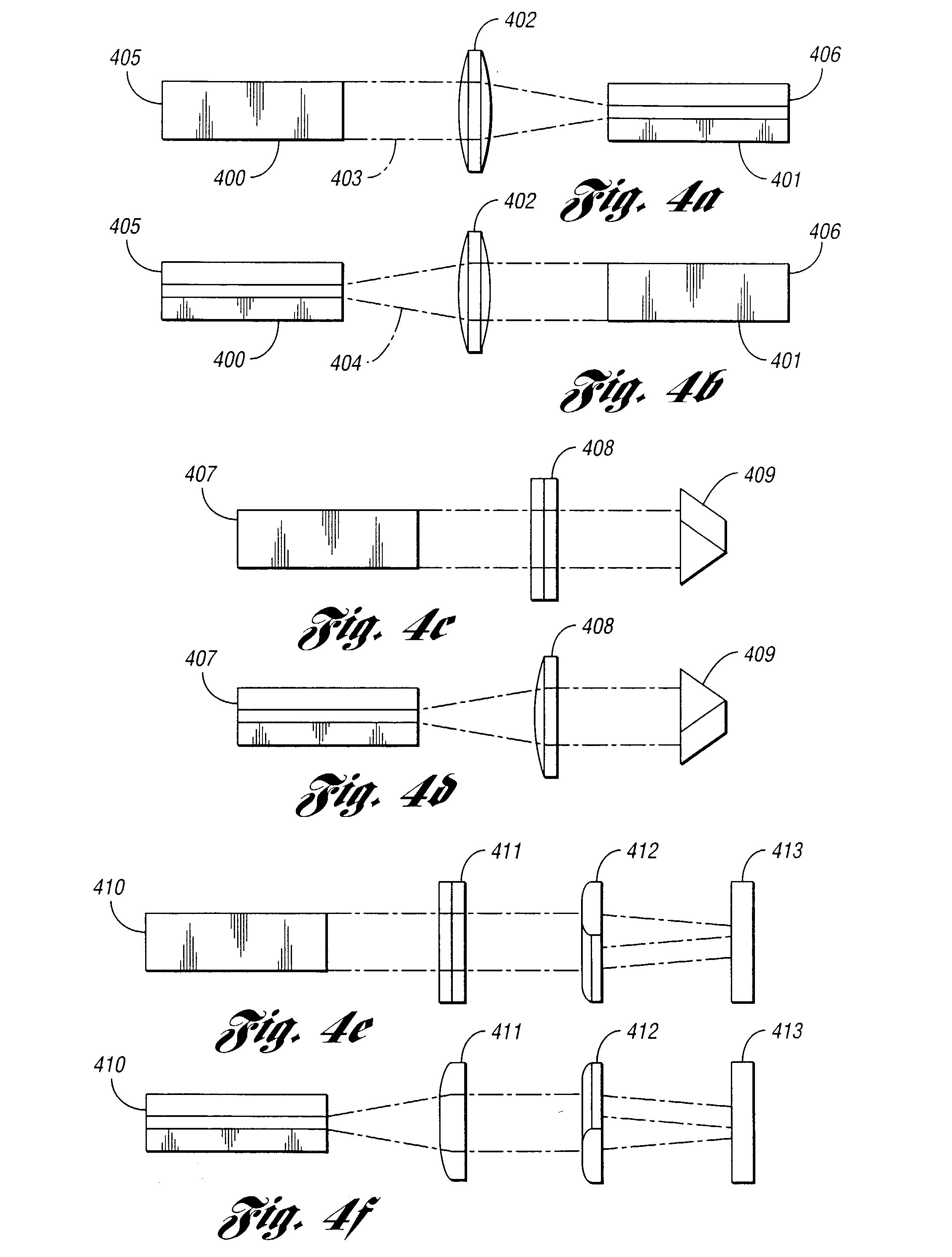

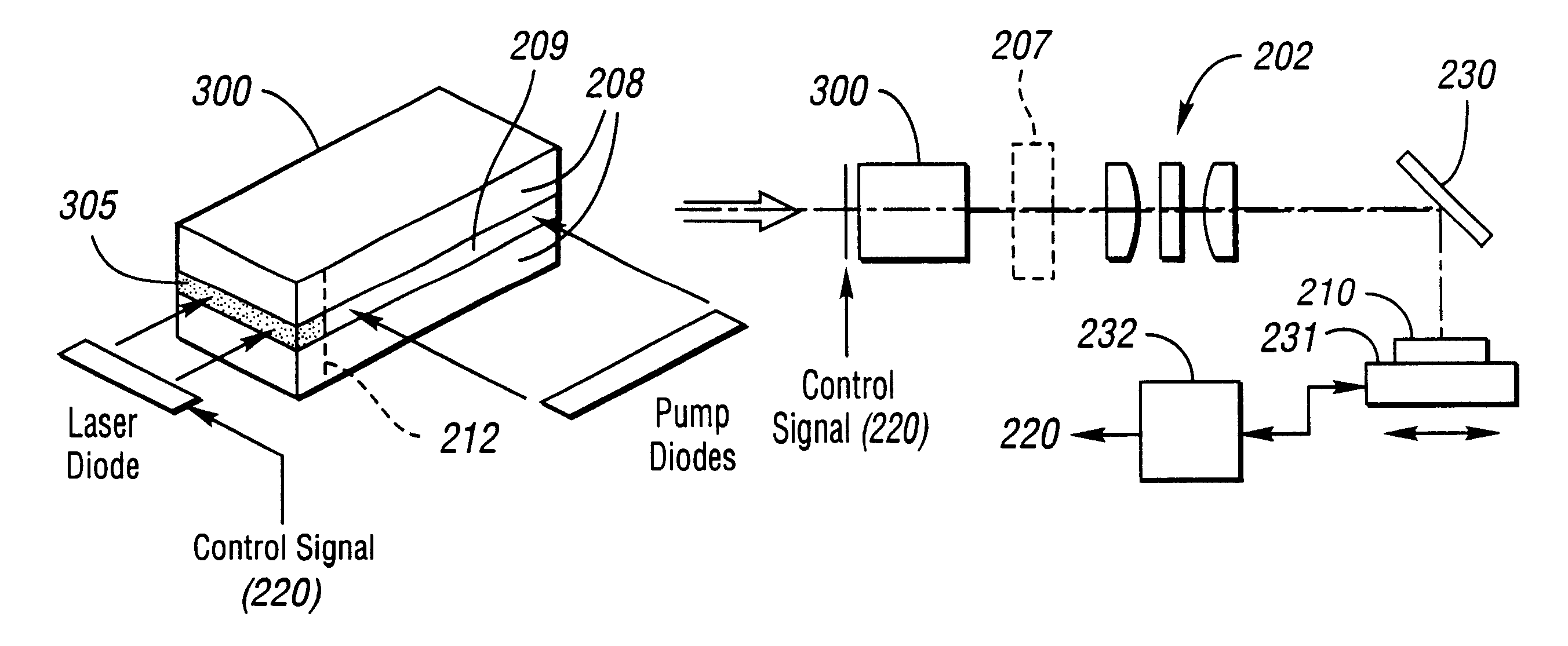

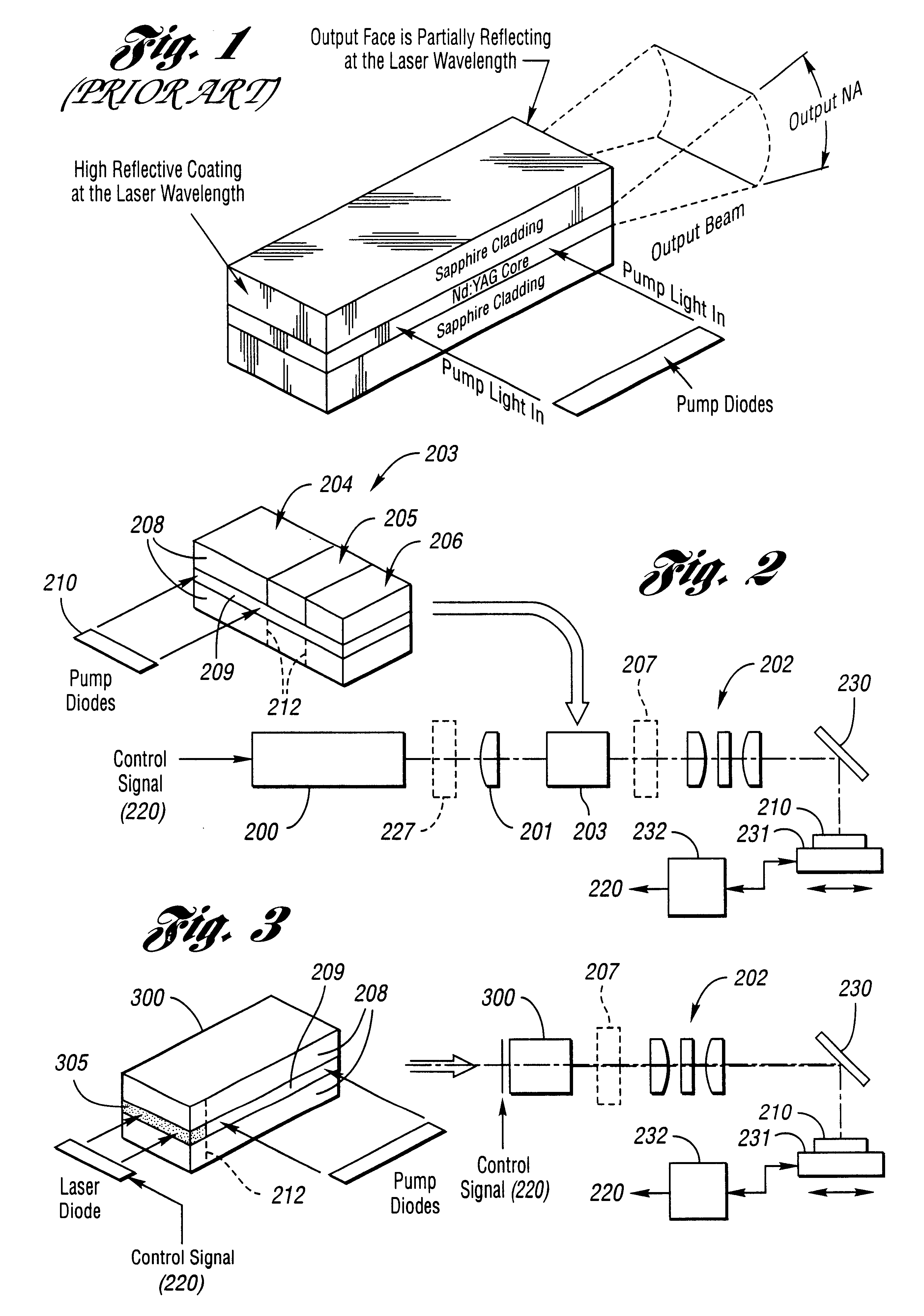

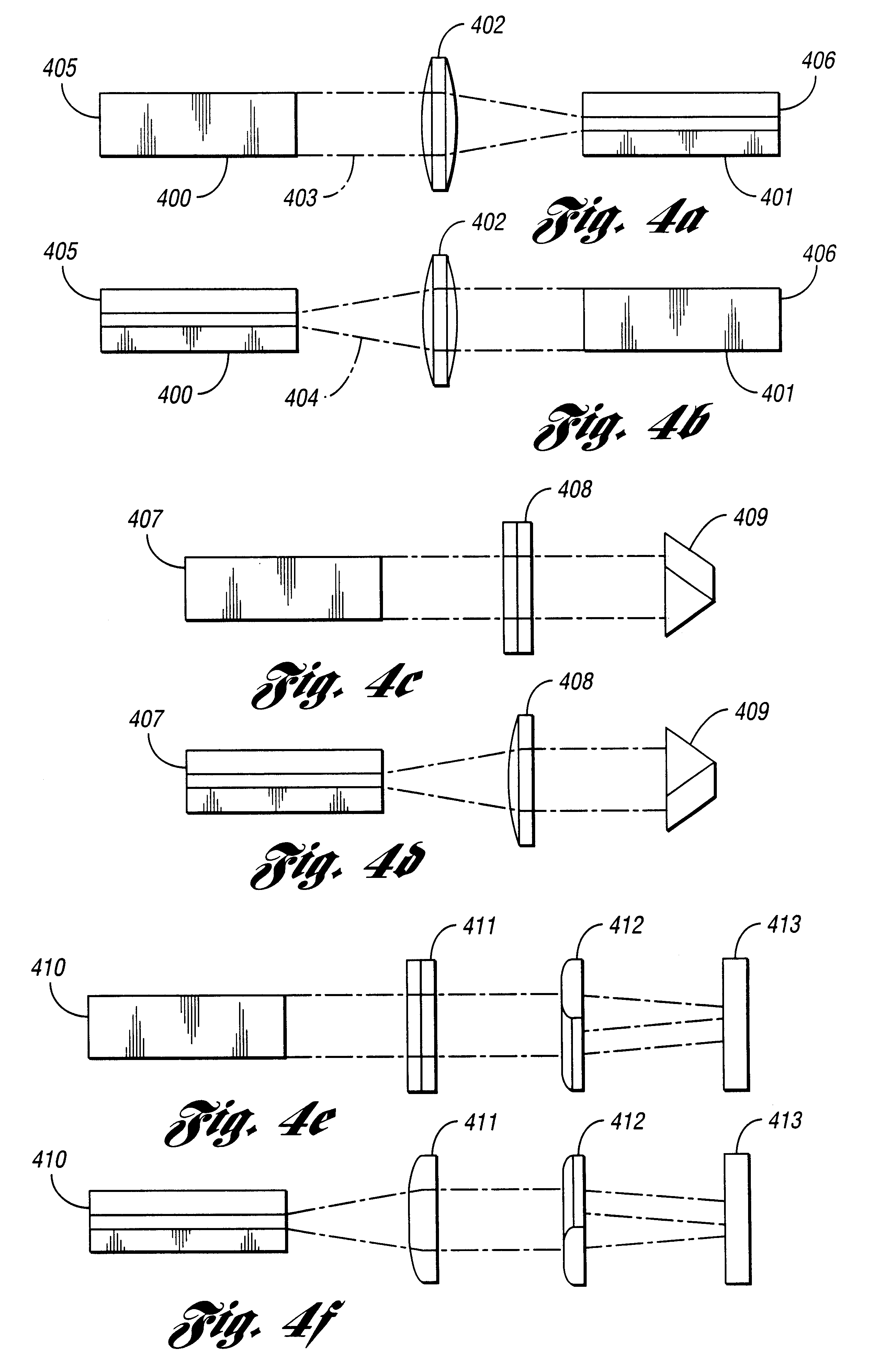

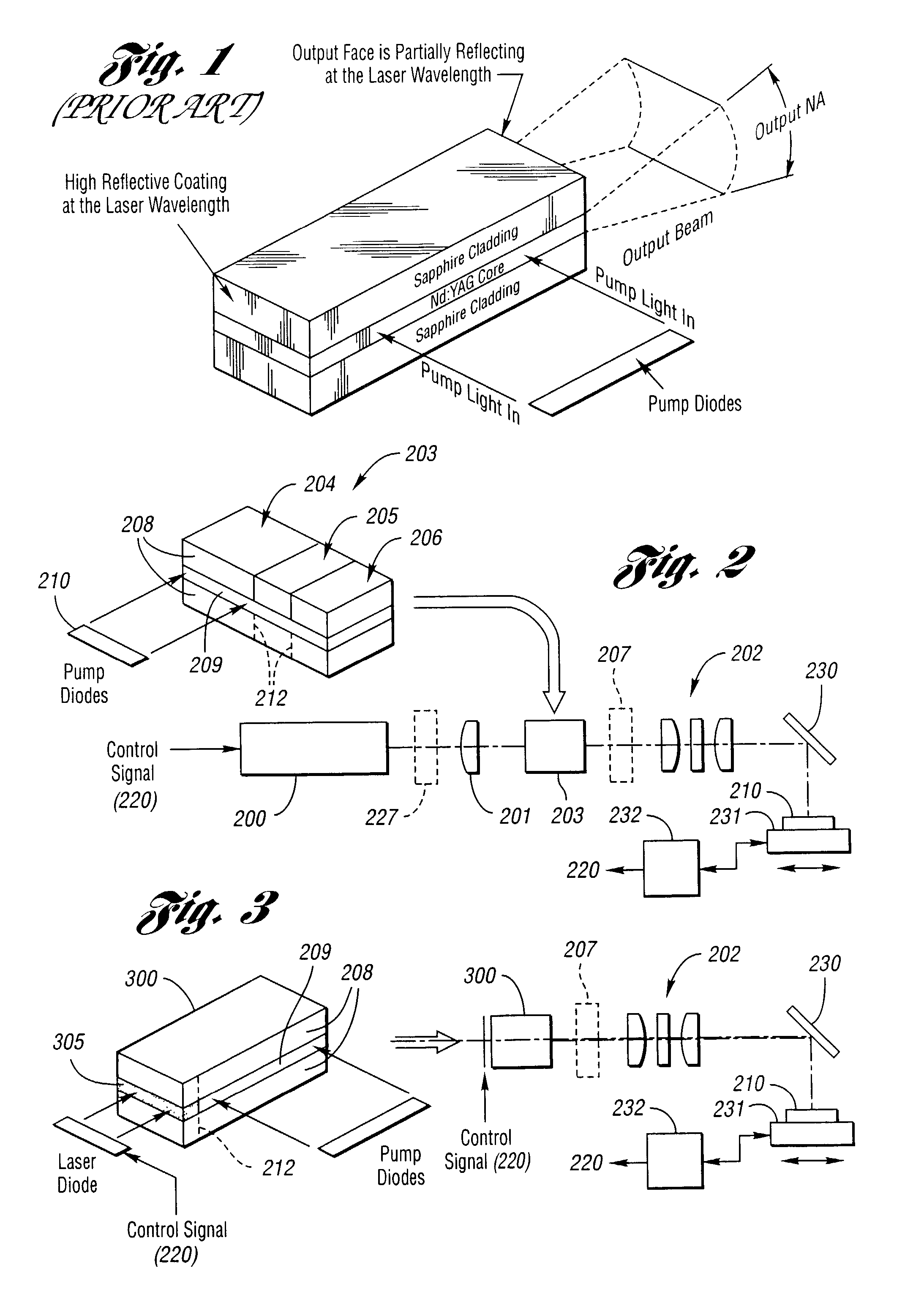

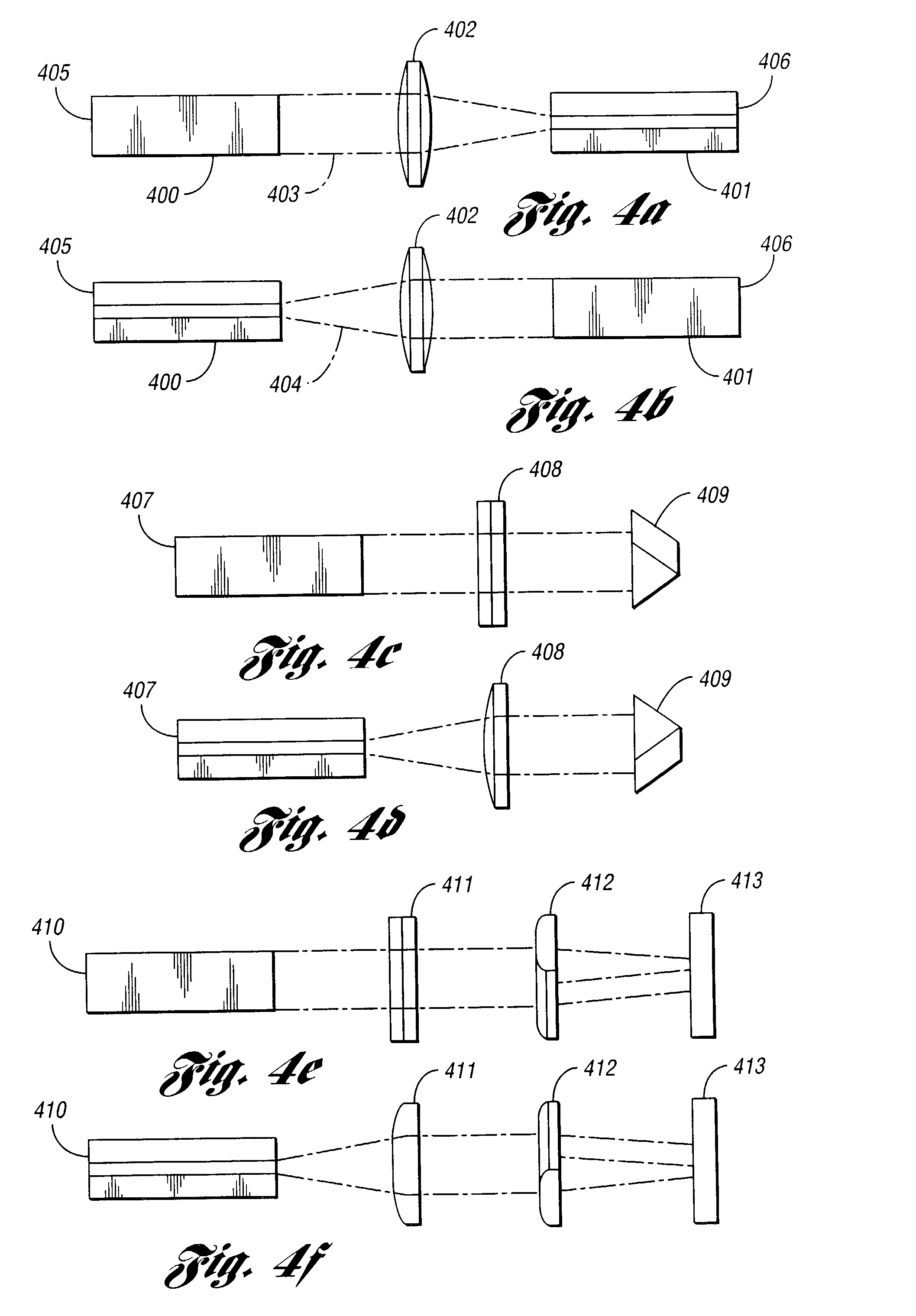

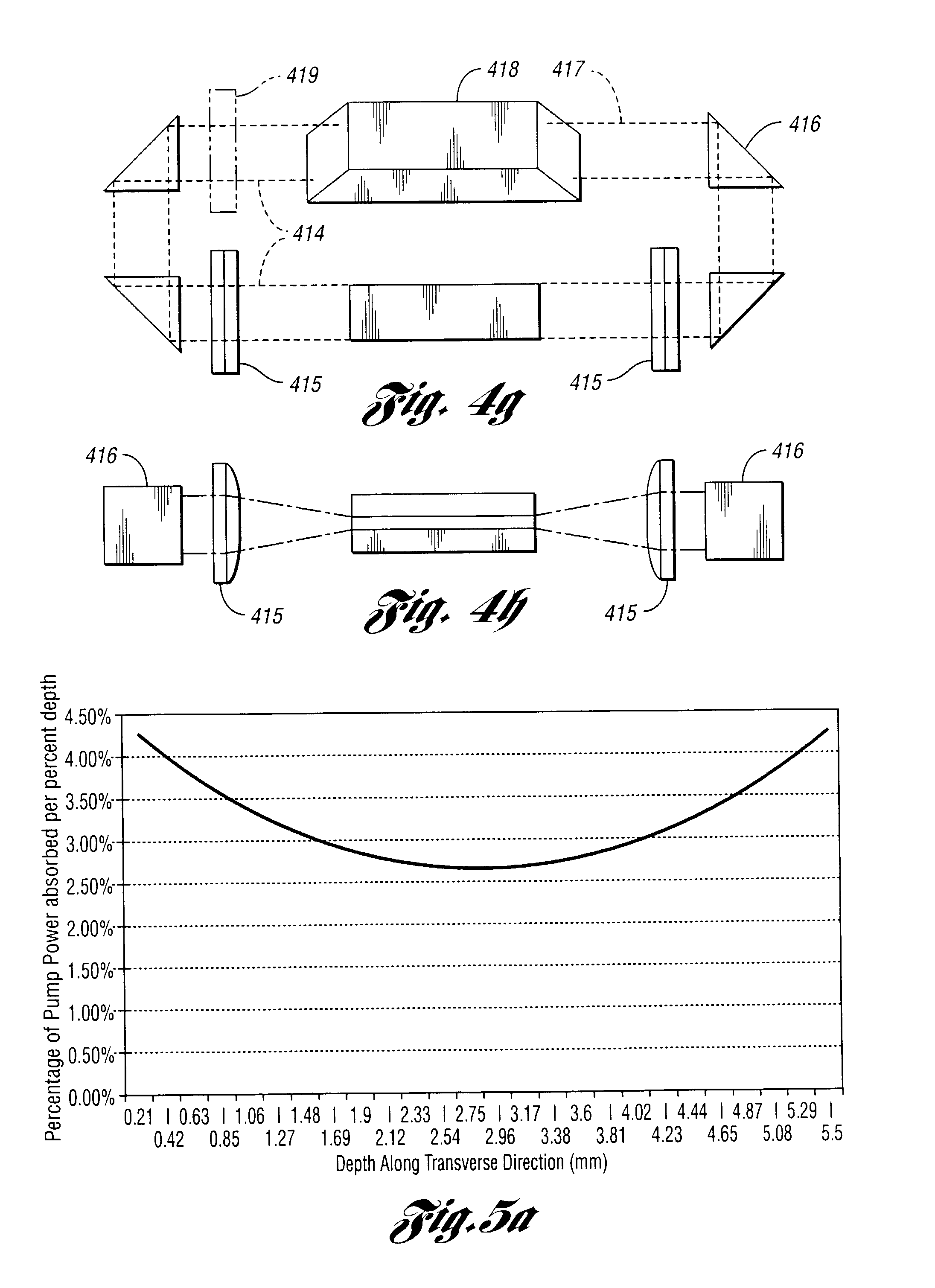

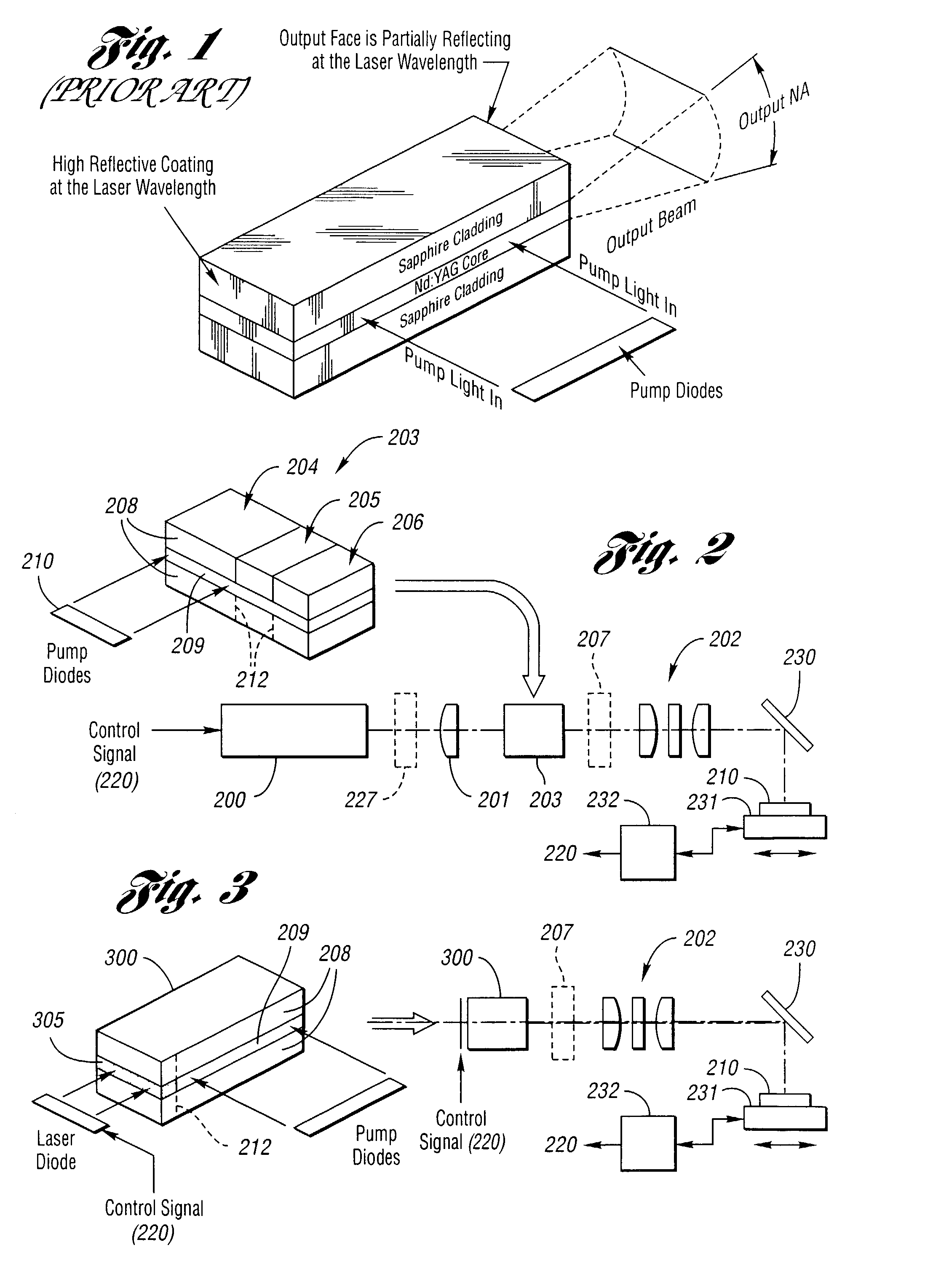

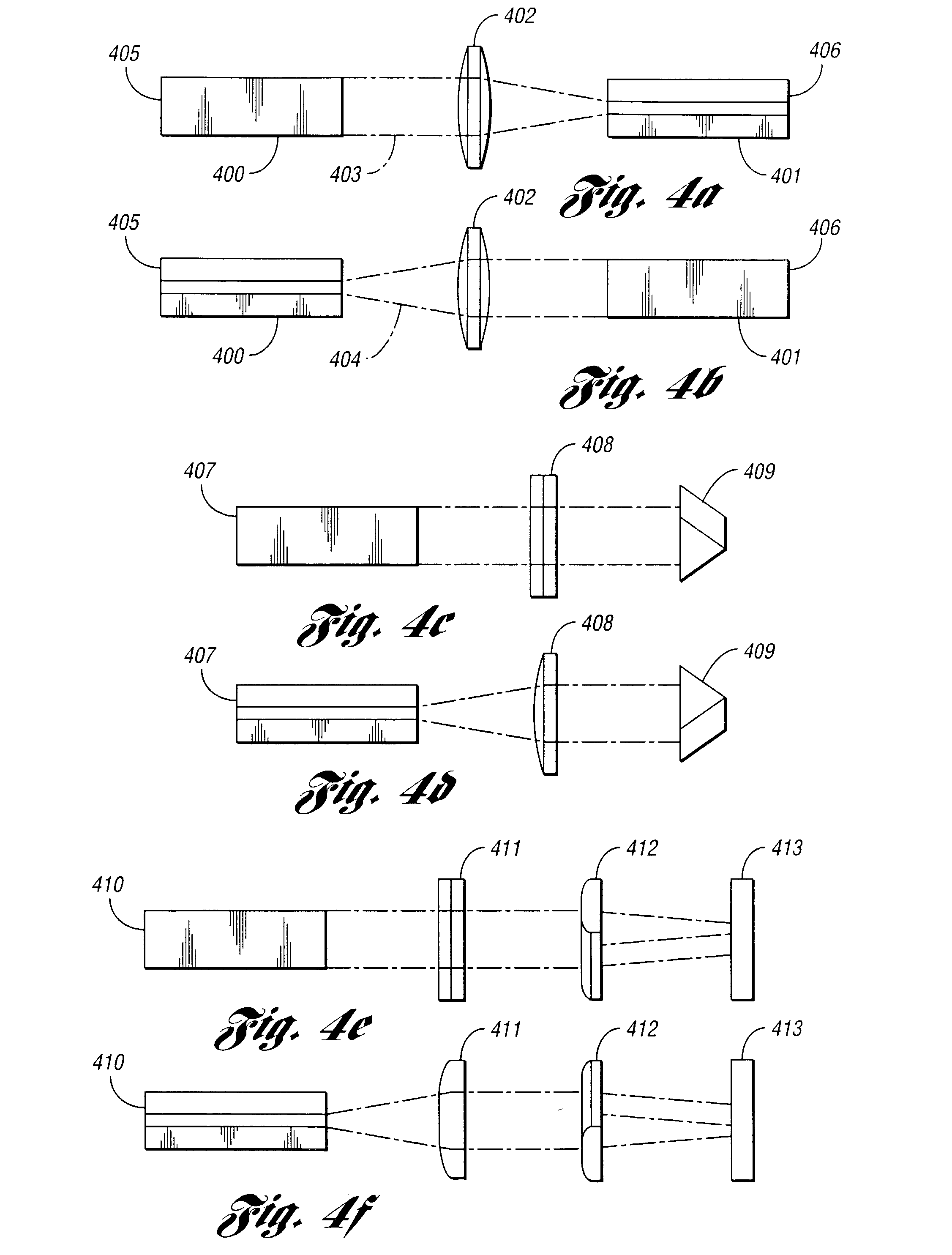

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

InactiveUS20030161375A1Optical resonator shape and constructionActive medium shape and constructionEngineeringWaveguide

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

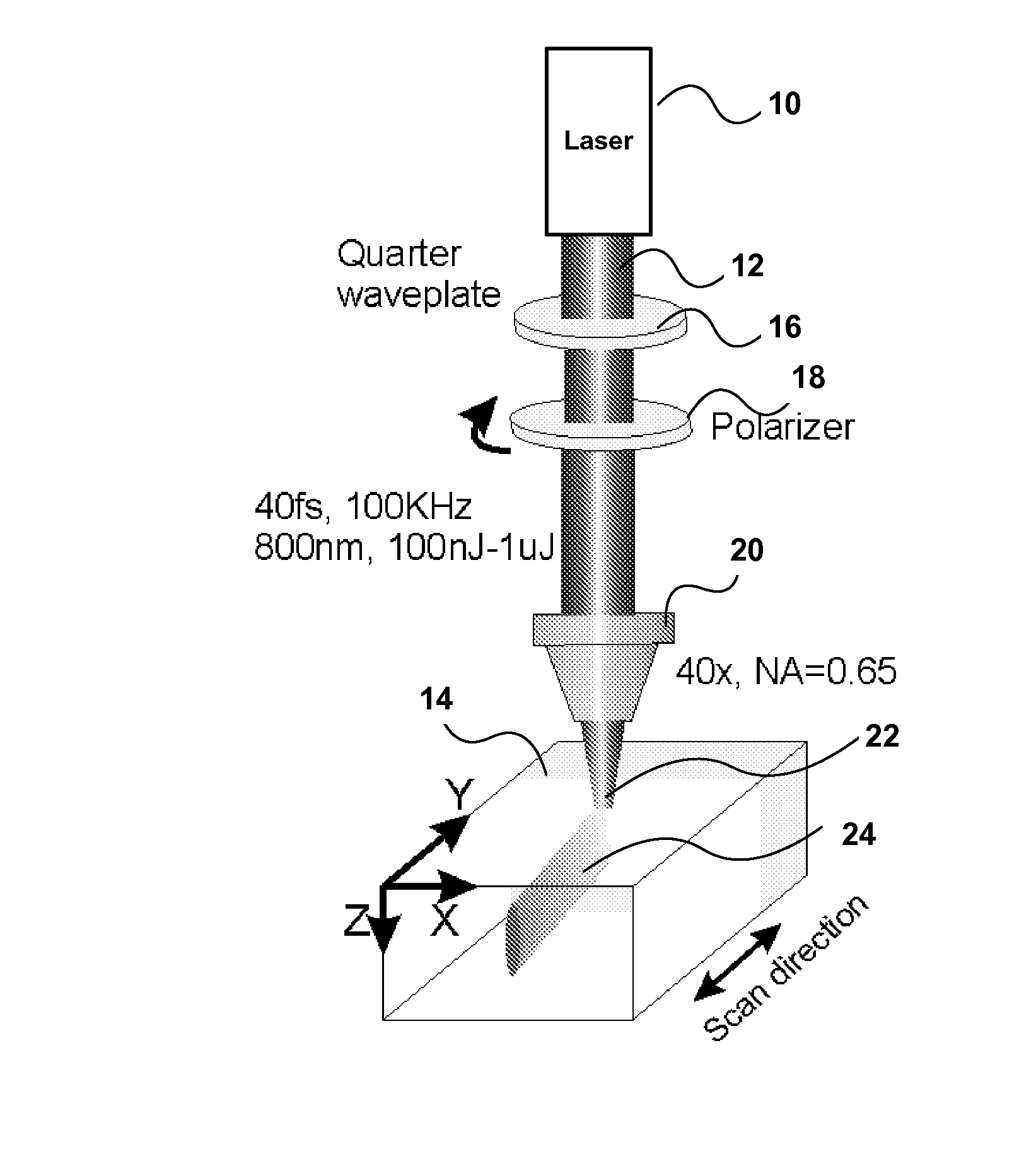

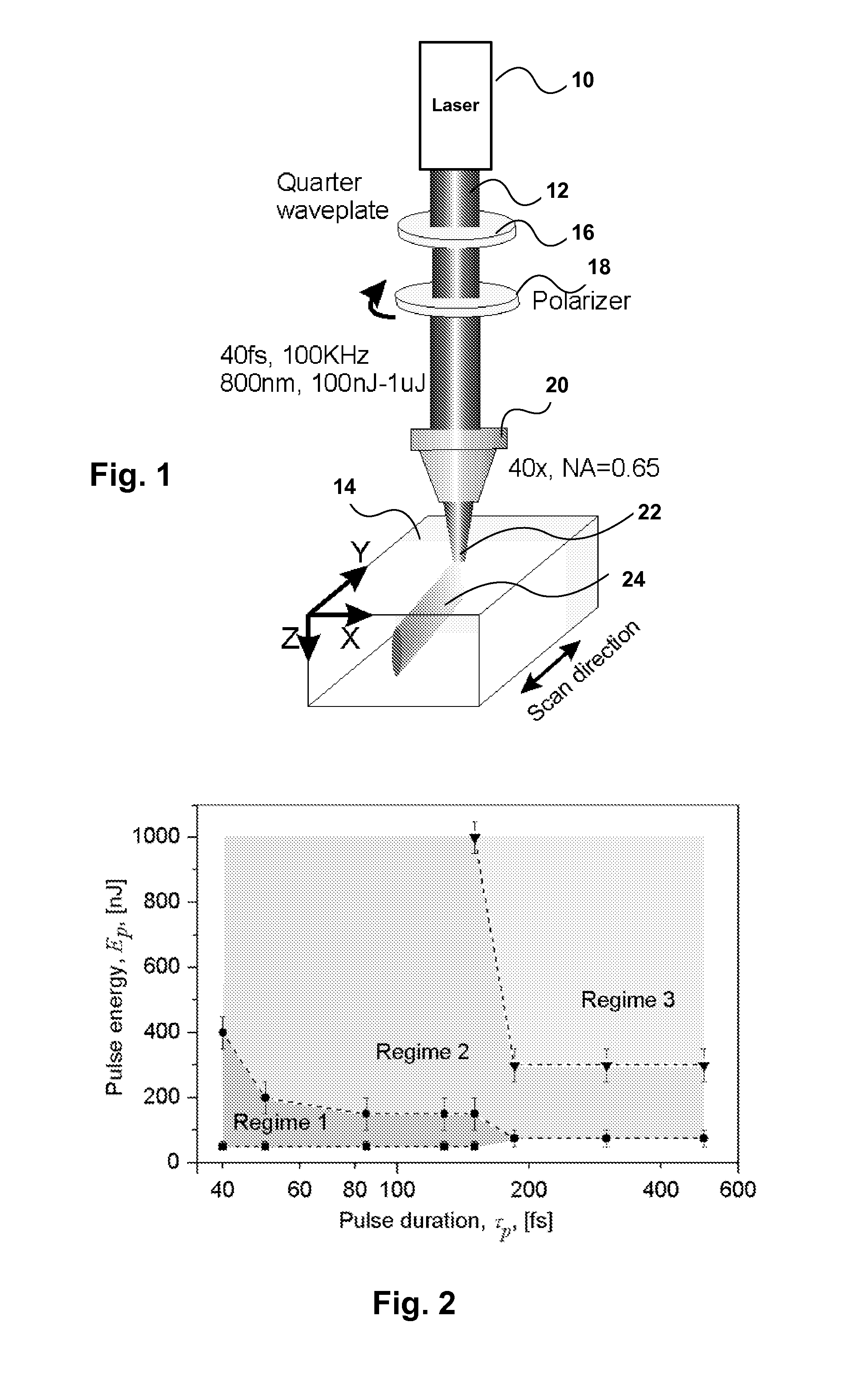

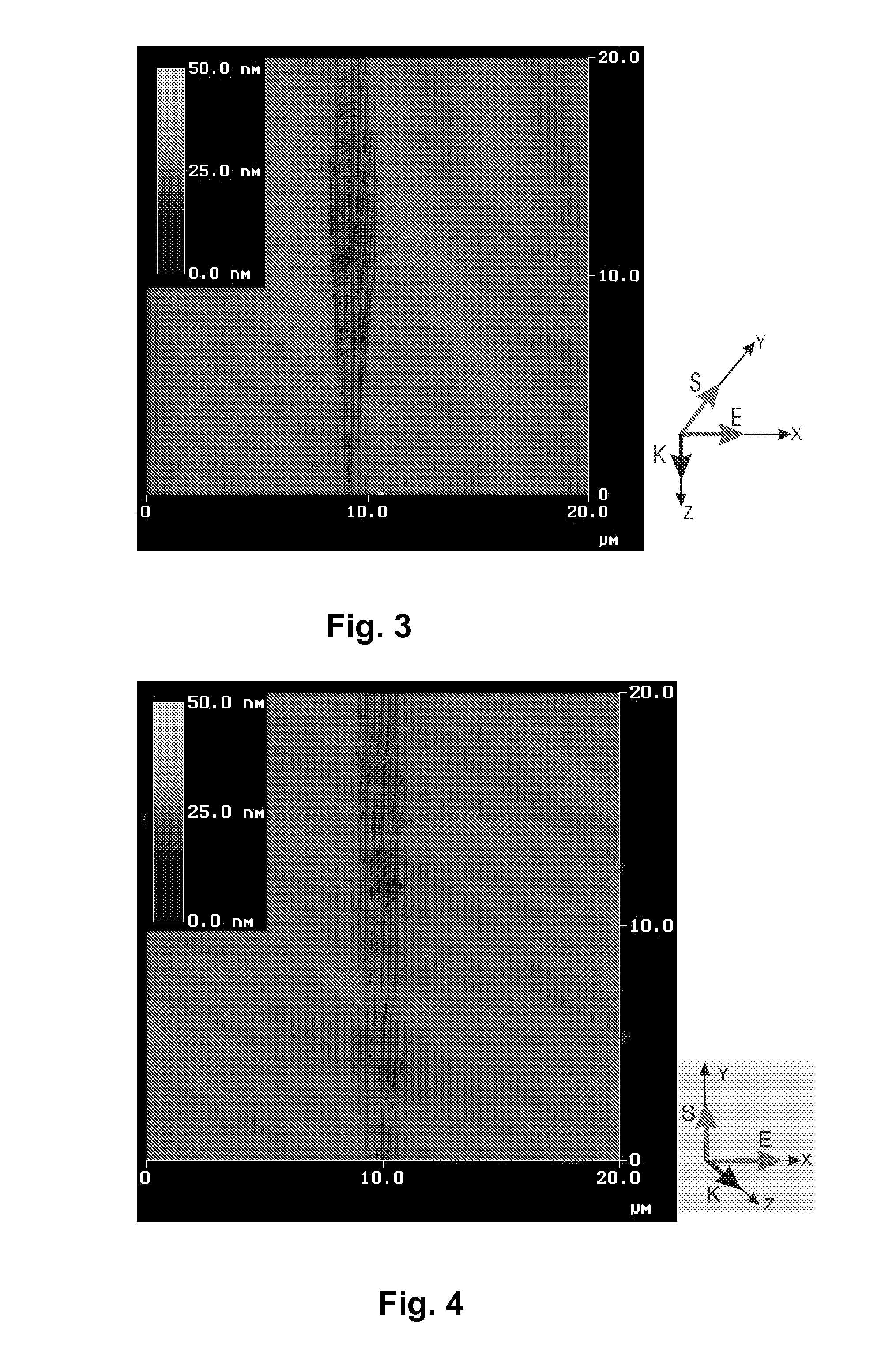

Fabrication of long range periodic nanostructures in transparent or semitransparent dielectrics

ActiveUS20060219676A1Eliminate periodicityExtended cycleRadiation applicationsDecorative surface effectsDielectricPeriodic nanostructures

To make high quality long-range periodic nanostructures in a transparent or semi-transparent substrate, the transparent or semi-transparent substrate is scanned with a linearly polarized laser beam generated by a femtosecond laser and exceeding a predetermined energy / pulse threshold along a scanning path. Sub-diffraction limit structures are formed as periodic planes of modified material in the transparent or semi-transparent substrate extending along the scanning path. The modified material can then be chemically etched to form cavities.

Owner:NAT RES COUNCIL OF CANADA

Treatment planning method and system for controlling laser refractive surgery

ActiveUS20120172854A1Improve accuracyImproved refractive correctionsLaser surgerySurgical instrument detailsPlan treatmentRefractive surgery

Improved devices, systems, and methods for diagnosing, planning treatments of, and / or treating the refractive structures of an eye of a patient incorporate results of prior refractive corrections into a planned refractive treatment of a particular patient by driving an effective treatment vector function based on data from the prior eye treatments. The exemplary effective treatment vector employs an influence matrix which may allow improved refractive corrections to be generated so as to increase the overall accuracy of laser eye surgery (including LASIK, PRK, and the like), customized intraocular lenses (IOLs), refractive femtosecond treatments, and the like.

Owner:AMO DEVMENT

Laser based material processing methods and scalable architecture for material processing

InactiveUS6738396B2Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

Femtosecond Laser Pulse Surface Structuring Methods and Materials Resulting Therefrom

InactiveUS20080299408A1Material nanotechnologyEngine sealsBiocompatibility TestingMaterials processing

Embodiments of the present invention are generally directed to materials processing methods using femtosecond duration laser pulses, and to the altered materials obtained by such methods. The resulting nanostructured (with or without macro- and micro-structuring) materials have a variety of applications, including, for example, aesthetic applications for jewelry or ornamentation; biomedical applications related to biocompatibility; catalysis applications; and modification of, for example, the optical and hydrophilic properties of materials including selective coloring.

Owner:UNIVERSITY OF ROCHESTER

Laser based material processing methods and scalable architecture for material processing

InactiveUS20030160034A1Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

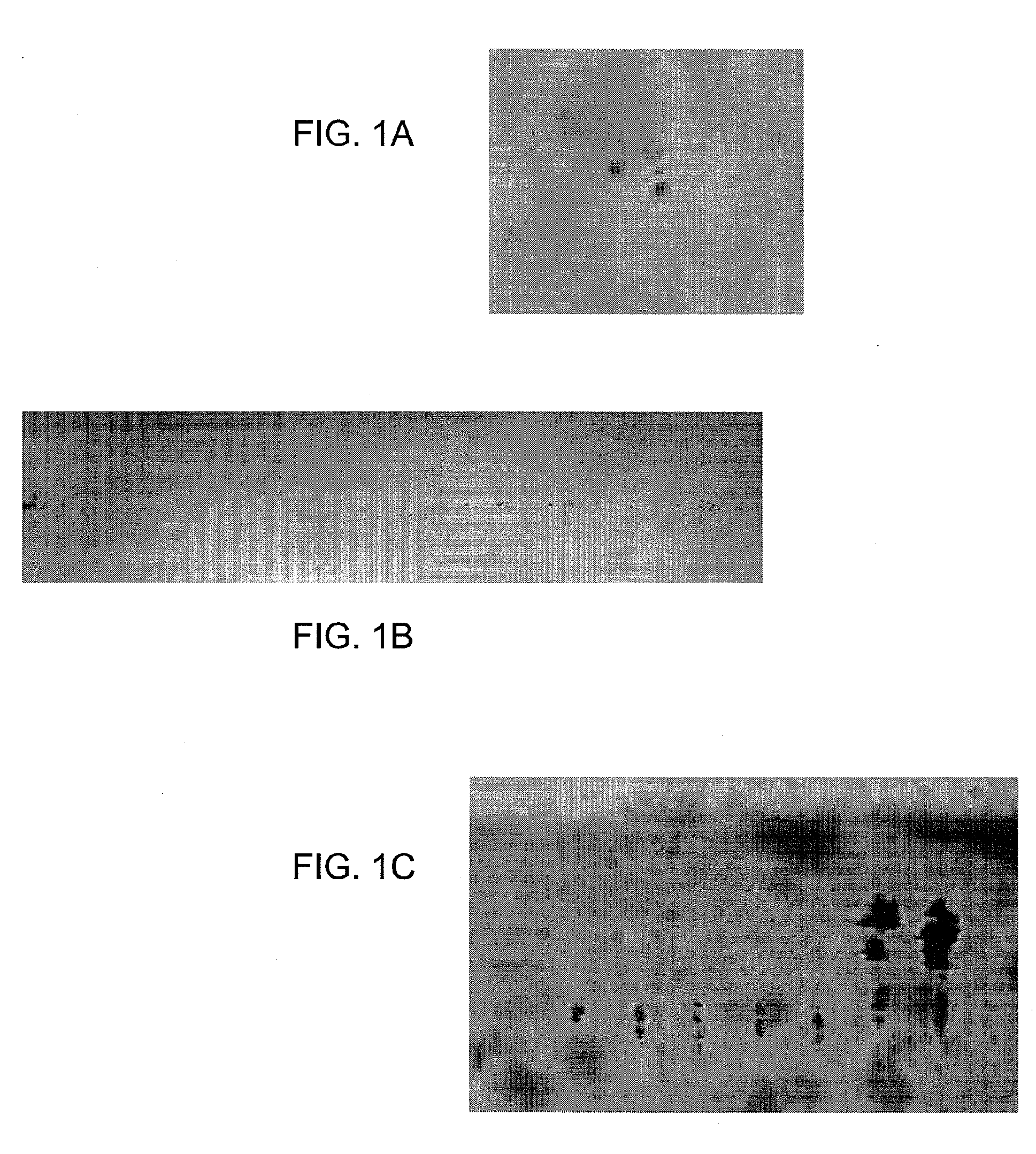

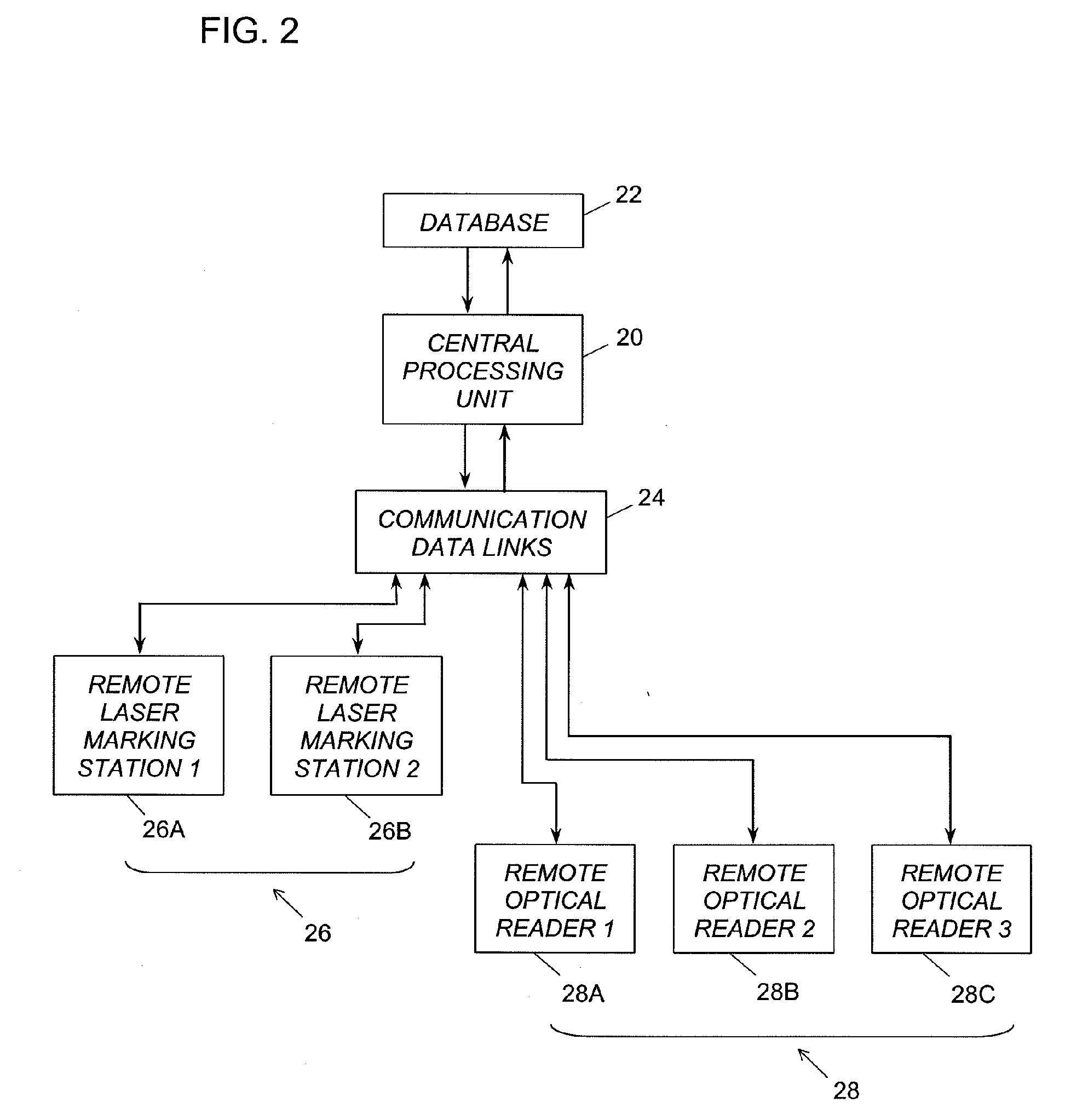

Method and system for laser marking in the volume of gemstones such as diamonds

ActiveUS20060196858A1Suitable contrastImprove image contrastLight effect designsInvestigating jewelsMagnifying glassGemstone

A method and an apparatus for laser marking indicia in the volume of gemstones such as diamonds, the indicia being made up of a plurality of microscopic dot-shaped marks whose build-up can be initiated by exposing naturally-occurring internal defects or impurities in the volume of a gemstone to a tightly focused train of laser pulses. Authentication data is encoded in the gemstone from the relative spatial arrangement of the dot-shaped marks that form the indicium. Taking advantage of the presence of otherwise invisible defects in the gemstone allows for inscribing indicia with laser pulses carrying energies substantially lower than the threshold energy required for inscribing in the volume of a perfect gemstone material. The marking process is then much less susceptible to inflict damages to the surface of the gemstone, and the marking can be performed using a broad variety of femtosecond laser systems. The dot-shaped marks engraved at a depth below the surface of a gemstone can be made undetectable with the unaided eye or with a loupe by limiting their individual size to a few micrometres, while devising indicia made up of only a few marks. As a result, the marking does not detract from the appearance and value of the gemstone. The procedure for laser marking accounts for the random spatial distribution of the defects present in natural gemstones as well as for their strongly localized character. The presence of an indicium can be detected by using a dedicated optical reader that can be afforded by every jewellery store.

Owner:GEMOLOGICAL INST OF AMERICA INC

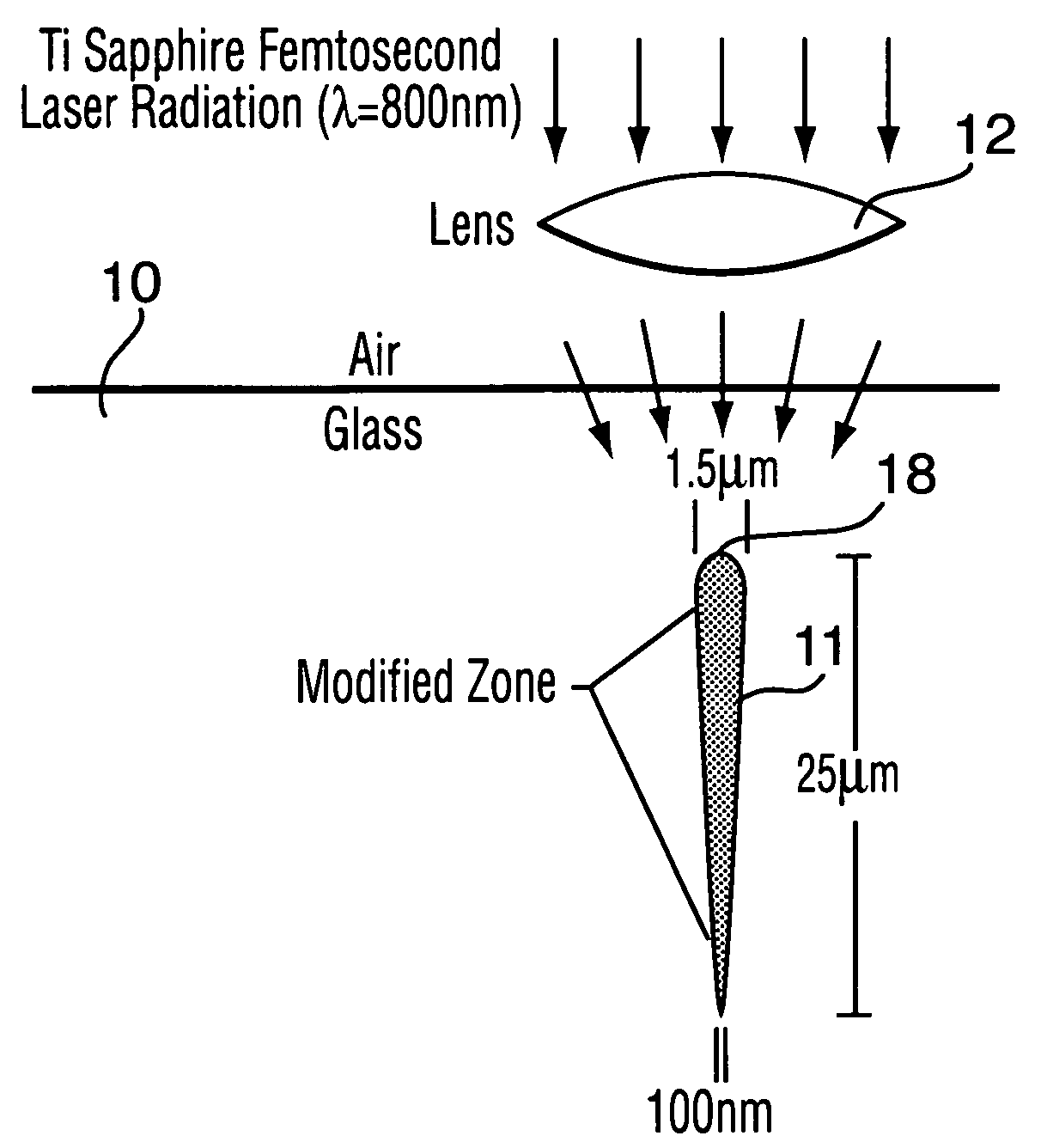

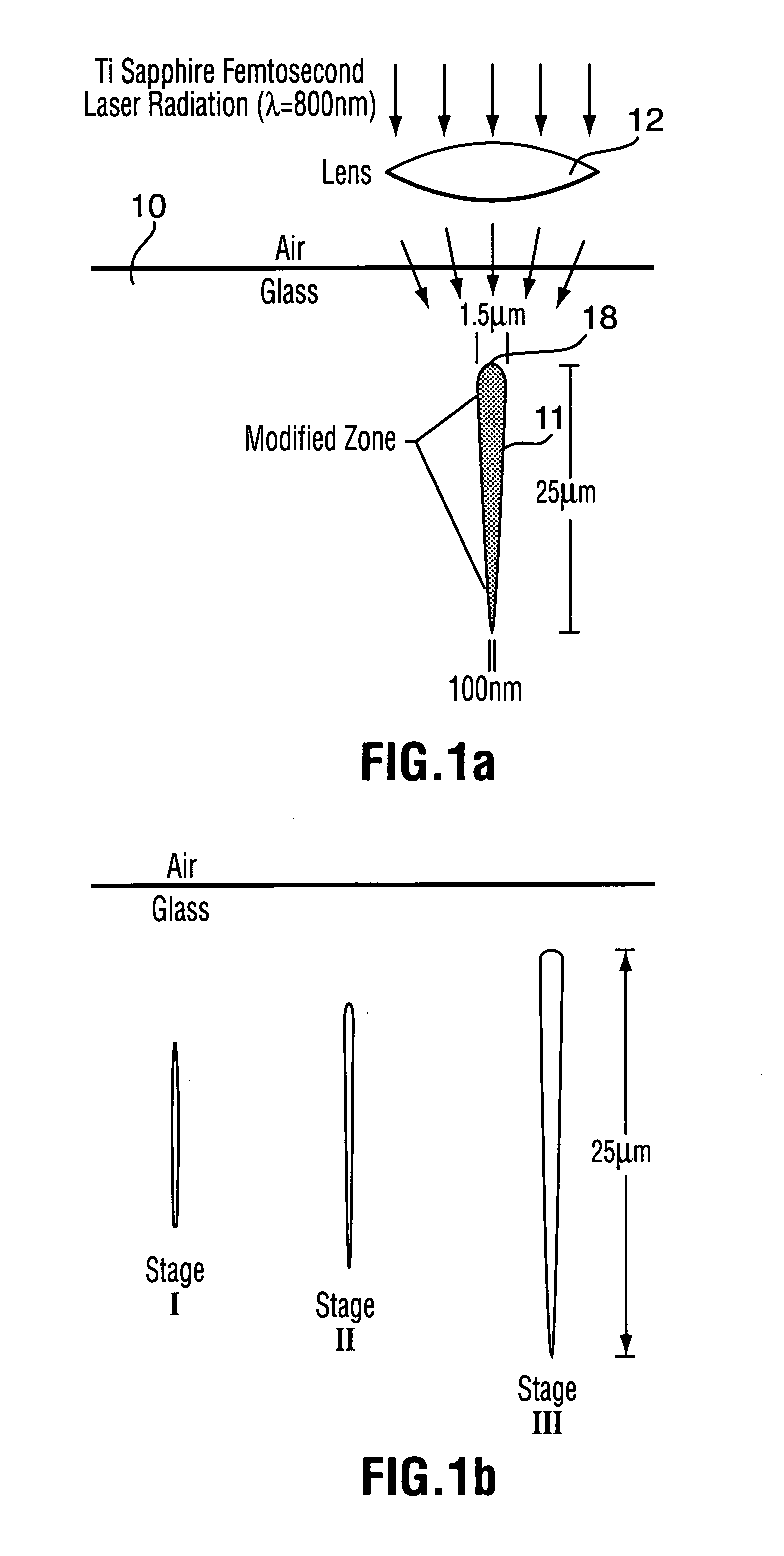

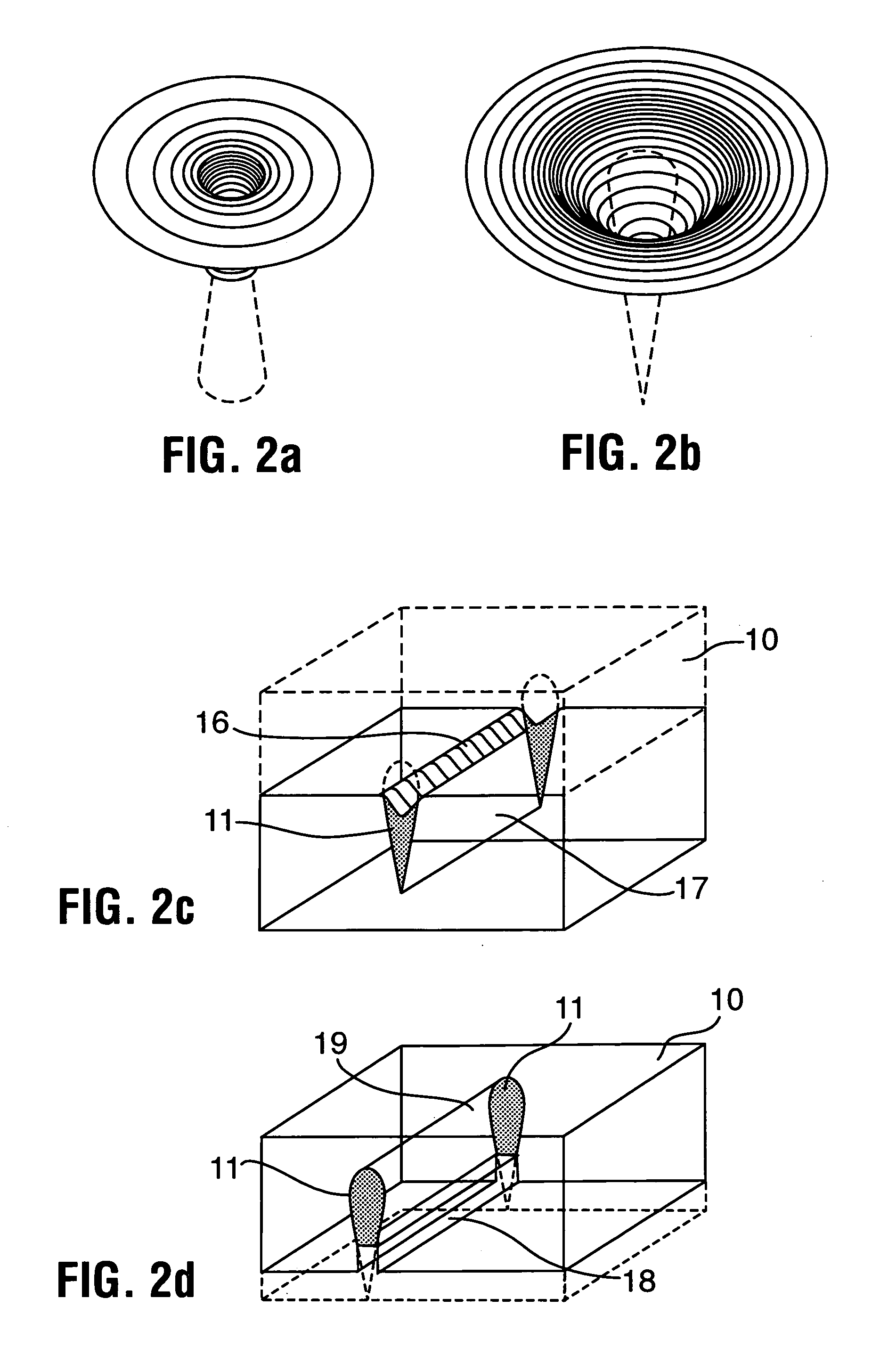

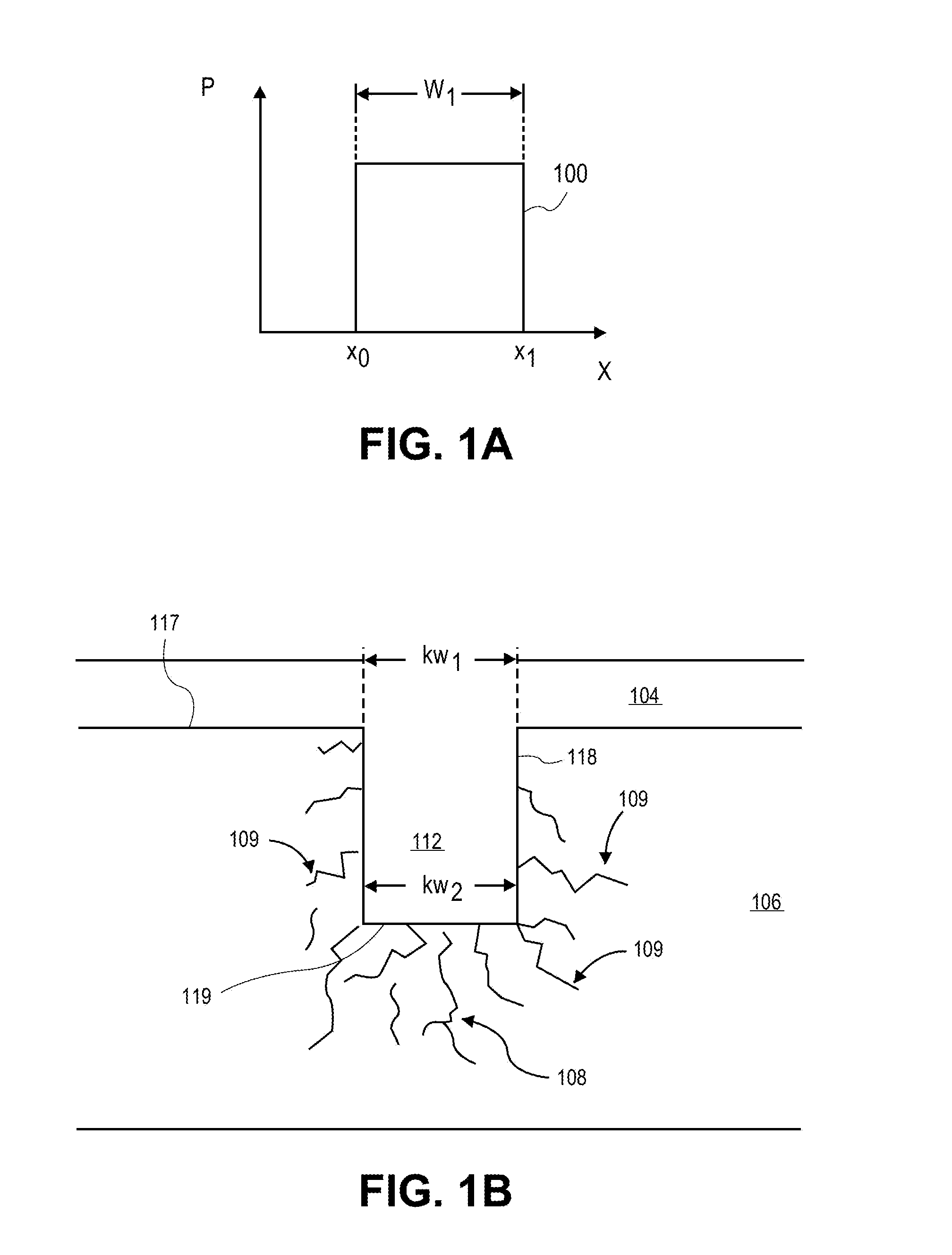

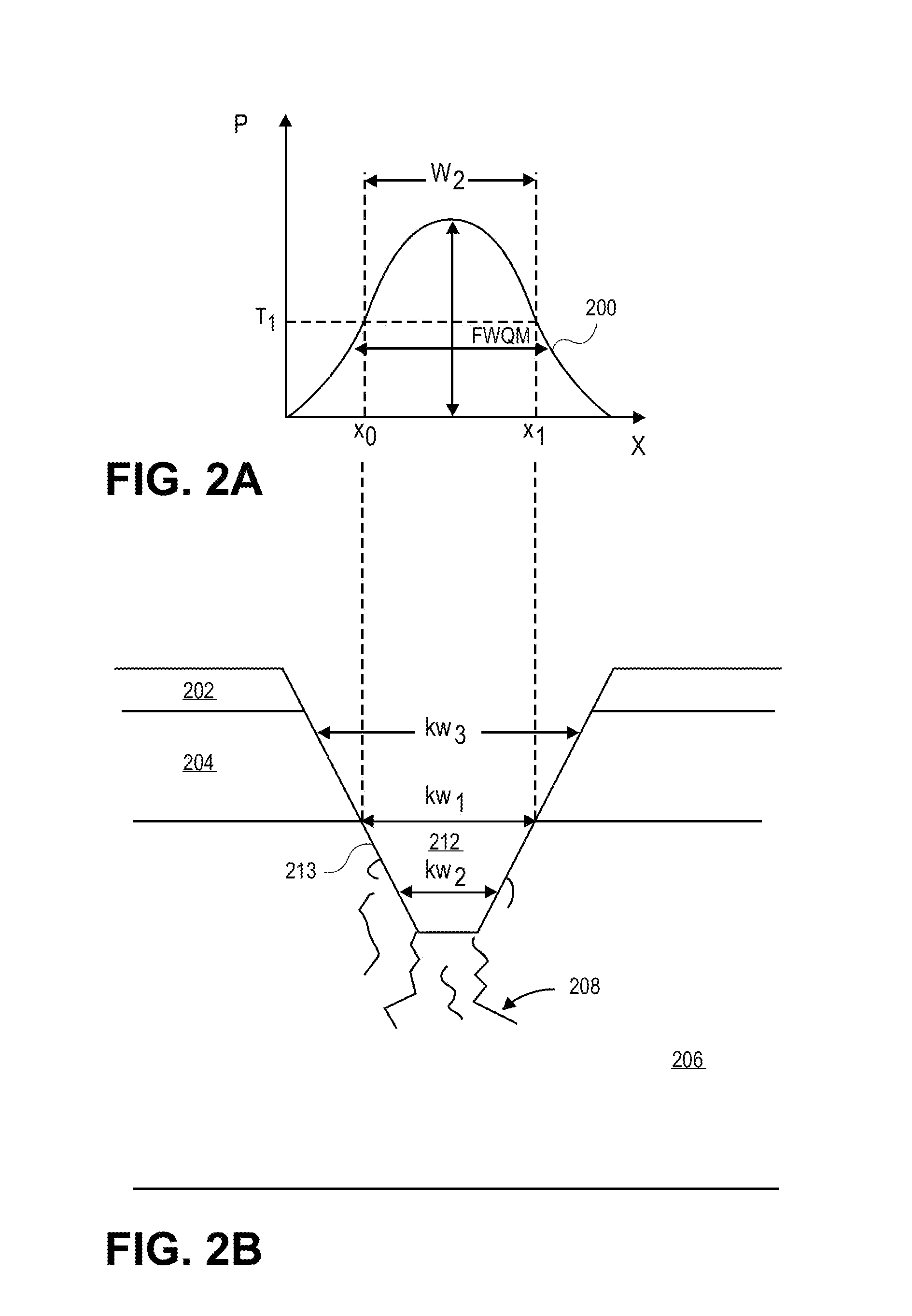

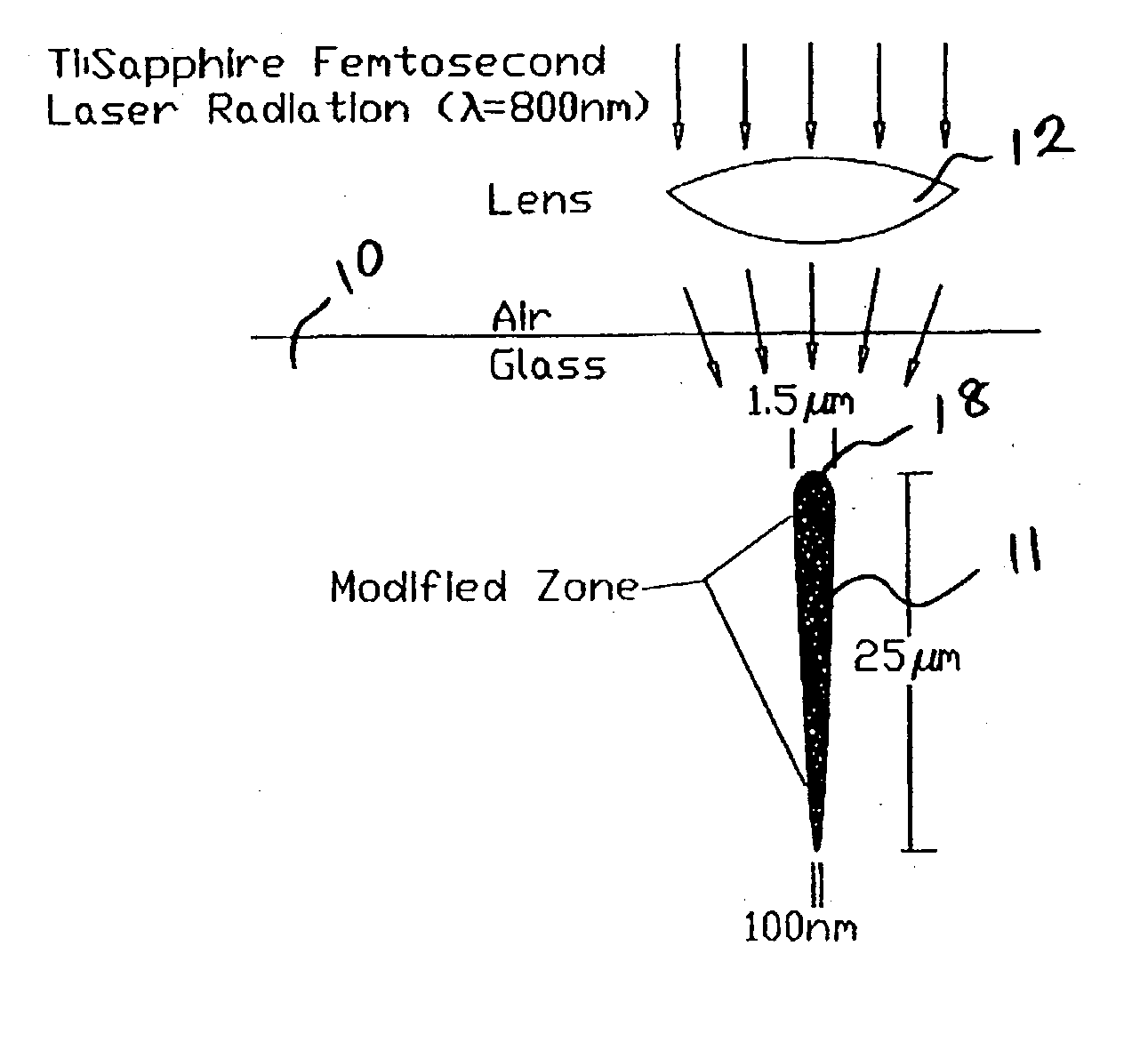

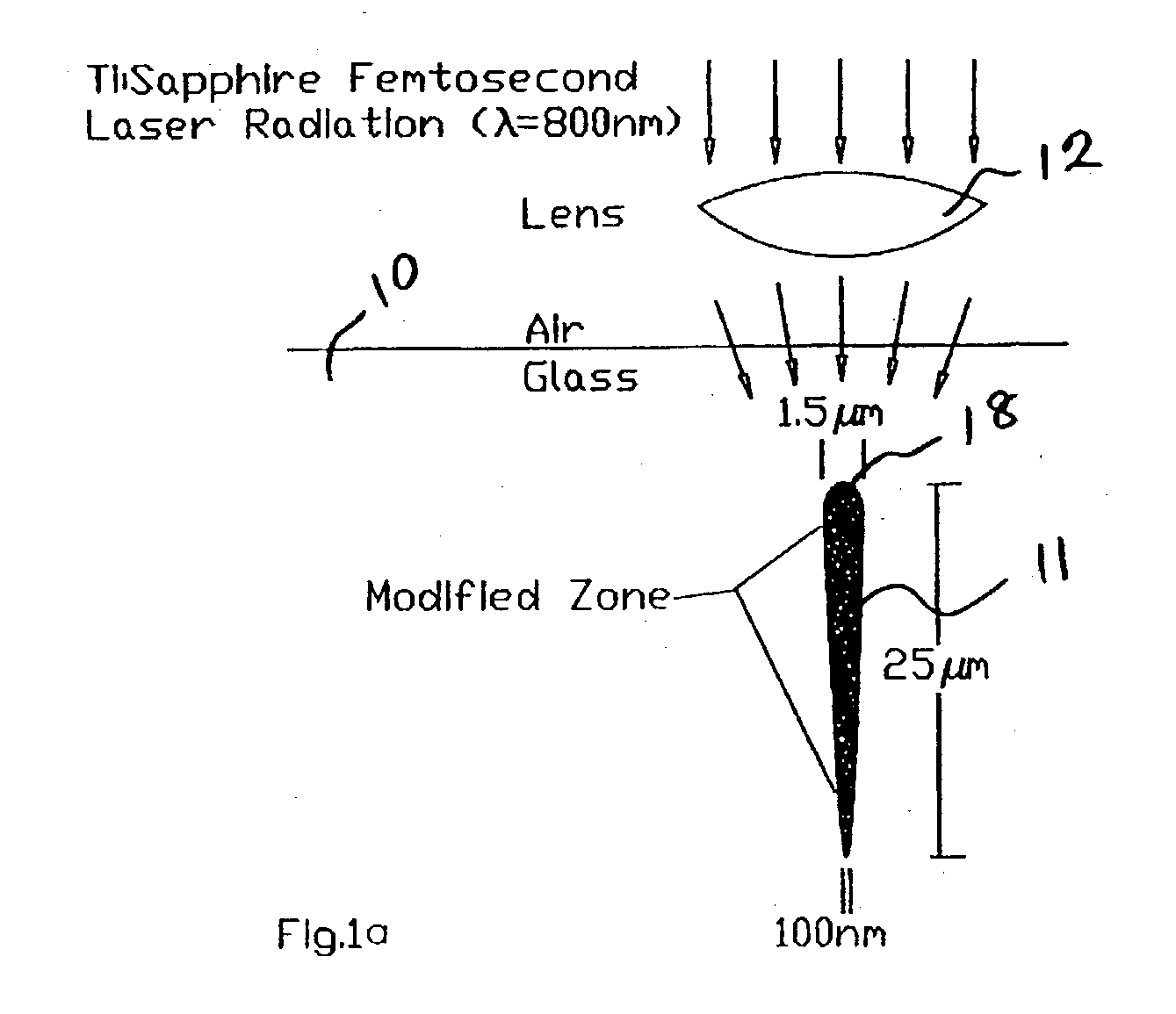

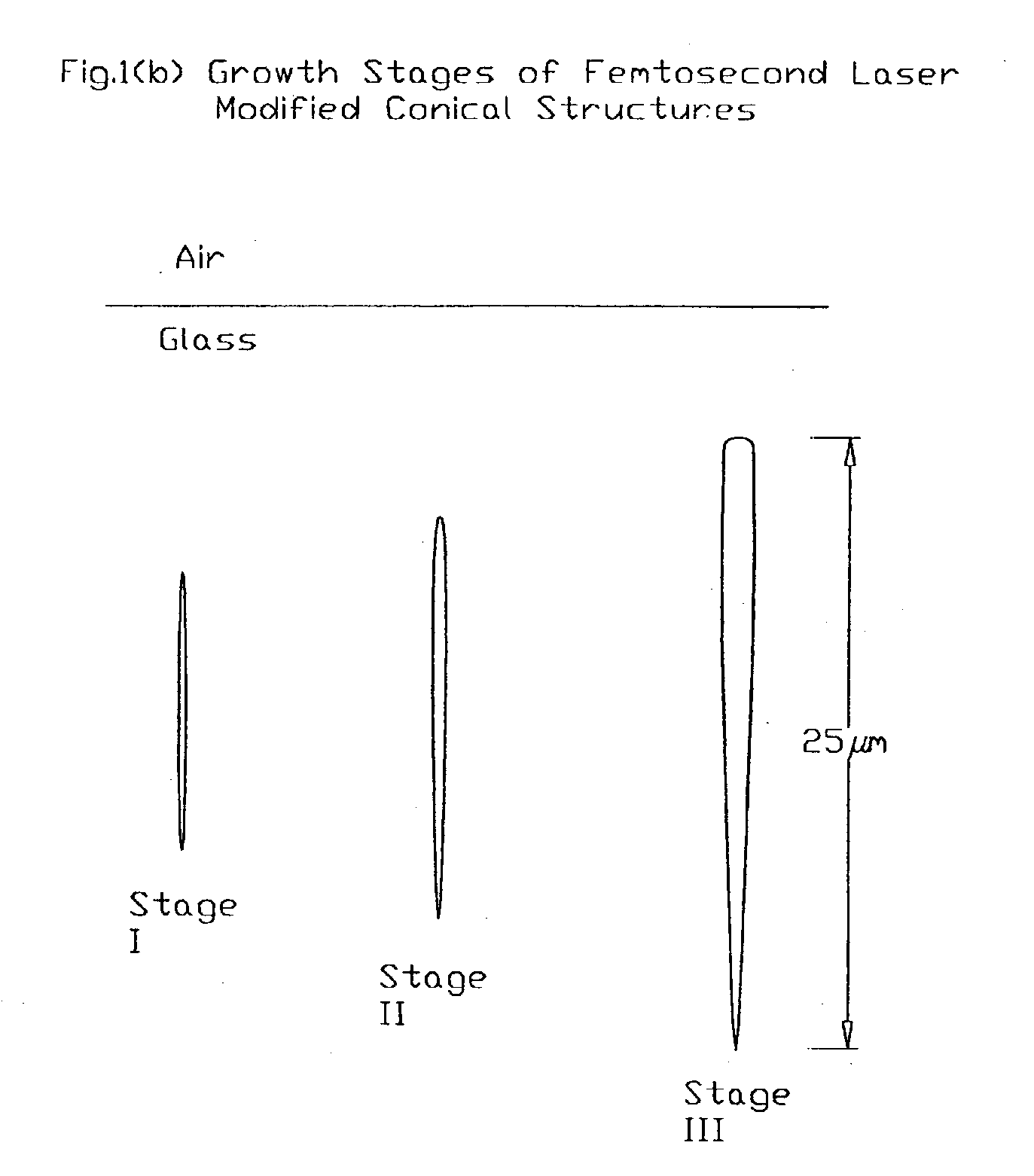

Method of fabricating sub-micron structures in transparent dielectric materials

A sub-micron structure is fabricated in a transparent dielectric material by focusing femtosecond laser pulses into the dielectric to create a highly tapered modified zone with modified etch properties. The dielectric material is then selectively etched into the modified zone from the direction of the narrow end of the tapered zone so that as the selective etching proceeds longitudinally into the modified zone, the progressively increasing width of the modified zone compensates for lateral etching occurring closer to the narrow end so as to produce steep-walled holes. The unetched portion of the modified zone produced by translating the laser beam close to and parallel to the bottom surface of the dielectric can serve as an optical waveguide to collect light from or deliver light to the etched channel which can contain various biological, optical, or chemical materials for sensing applications.

Owner:NAT RES COUNCIL OF CANADA

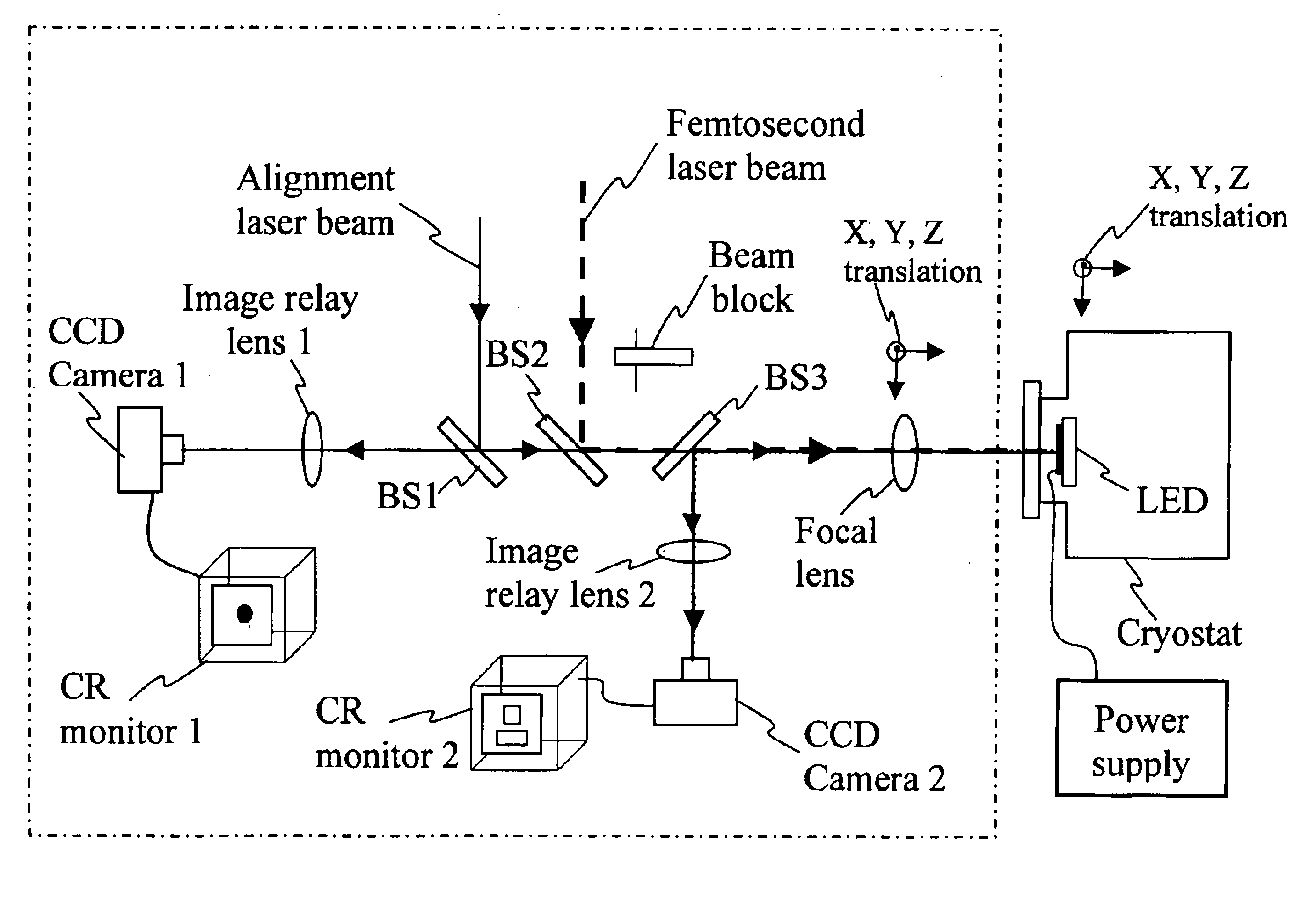

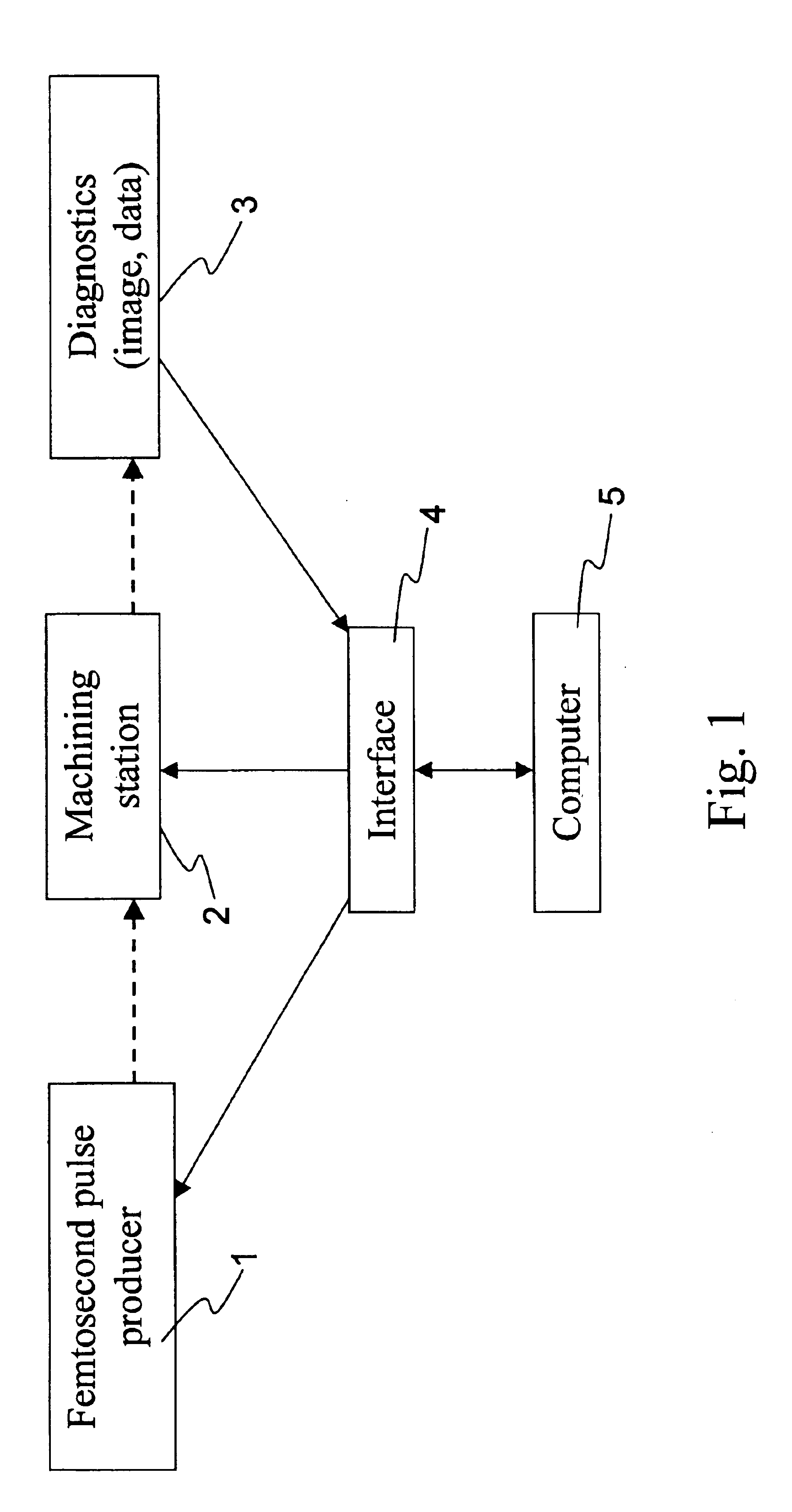

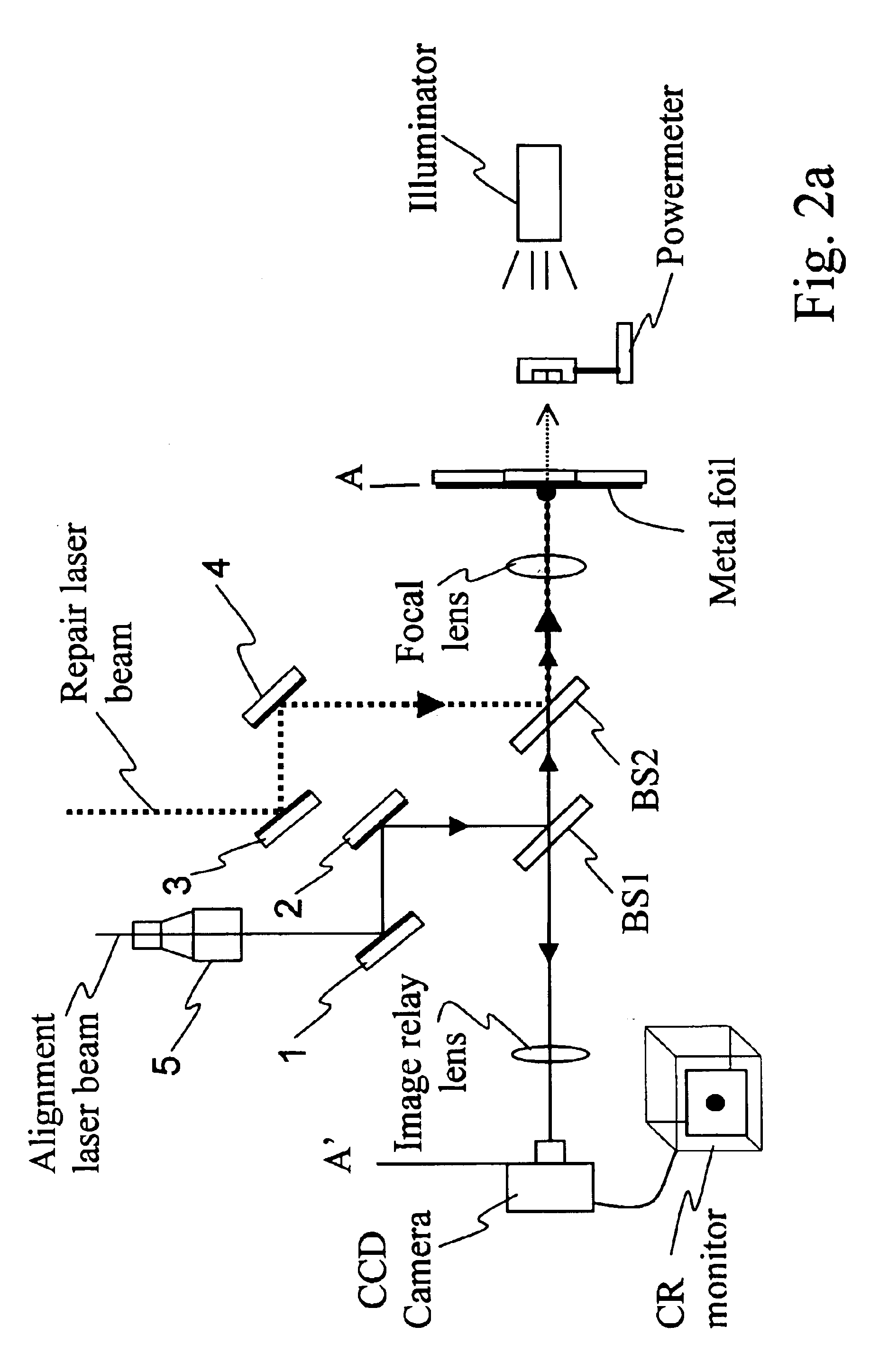

Method and apparatus for repair of defects in materials with short laser pulses

InactiveUS6878900B2Minimize damageSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentRepair materialEngineering

A method of accurately and precisely providing desired functionality to an electronic or opto-electronic component is disclosed in which a Femtosecond laser pulse is used to ablate material from a surface of or from within a component. The component is in active operation during the ablation process in order to facilitate the ablation process. The process also involves detection and feedback to indicate when a repair is sufficiently complete. The detection is also performed while the component is powered allowing in-situ detection and ablation. Of course, forms of facilitation other than feedback such as monitoring are also applicable to the invention.

Owner:NAT RES COUNCIL OF CANADA

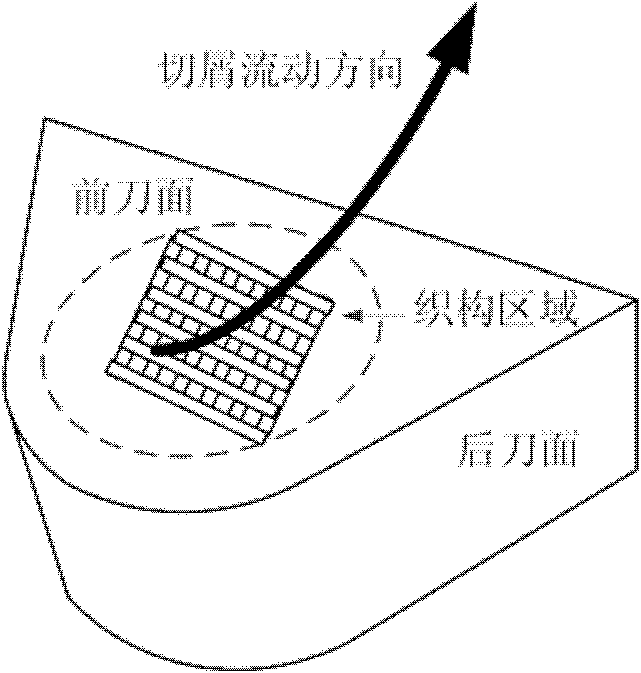

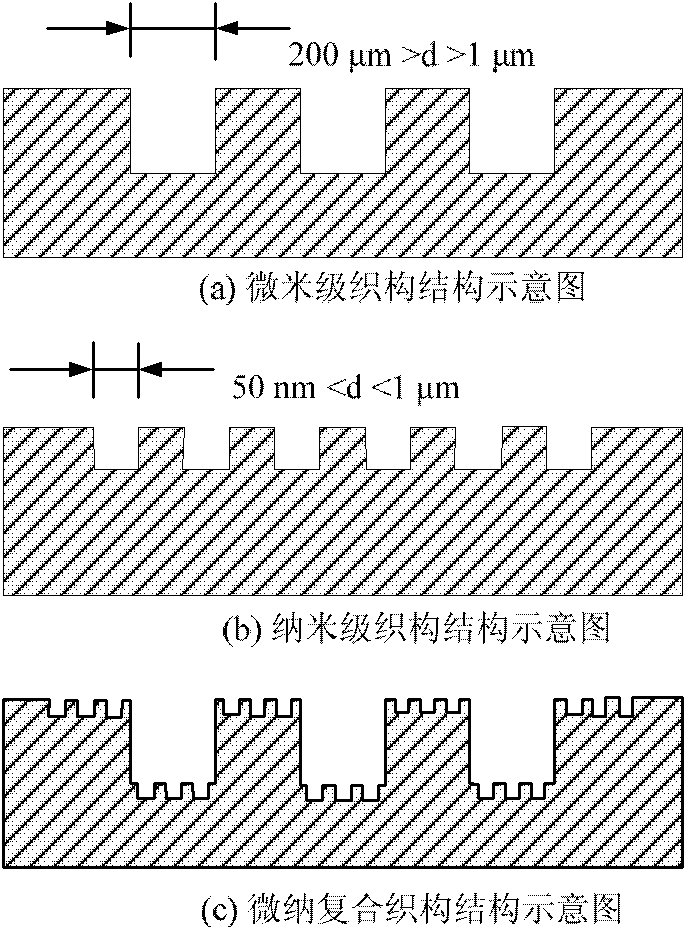

Method for preparing micro-nano composite texturing cutting tool by using femtosecond laser

The invention relates to the technical field of micro-structural surface preparation and laser micro-processing, and in particular provides a method for preparing a micro-nano composite texturing cutting tool by using femtosecond laser. In the method, micro-nano texturing and micro / nano composite texturing preparation is performed on the cutting tool surface by utilizing the unique interaction property between femtosecond laser and materials, the operation is simple, and the accuracy can be controlled. The preparation of micro / nano composite texture can be performed on a coated cutting tool by adopting a coated surface direct texturing method or a two-step composite texturing method. The method overcomes the defect of singleness of texturing only in micron scale in the conventional cutting tool texturing technology, and can further improve the abrasion resistance of the cutting tool, and prolong the service life of the cutting tool.

Owner:XI AN JIAOTONG UNIV

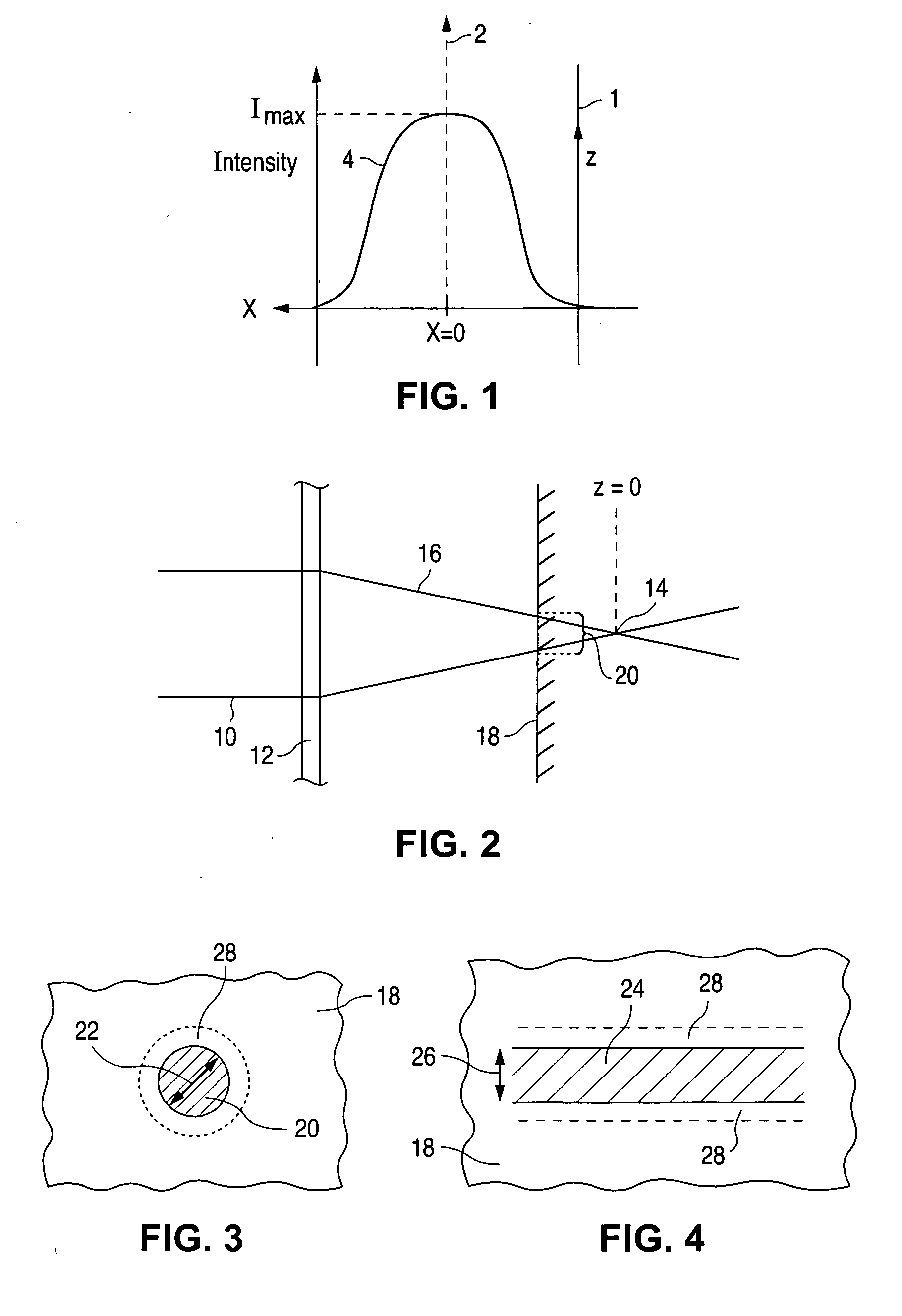

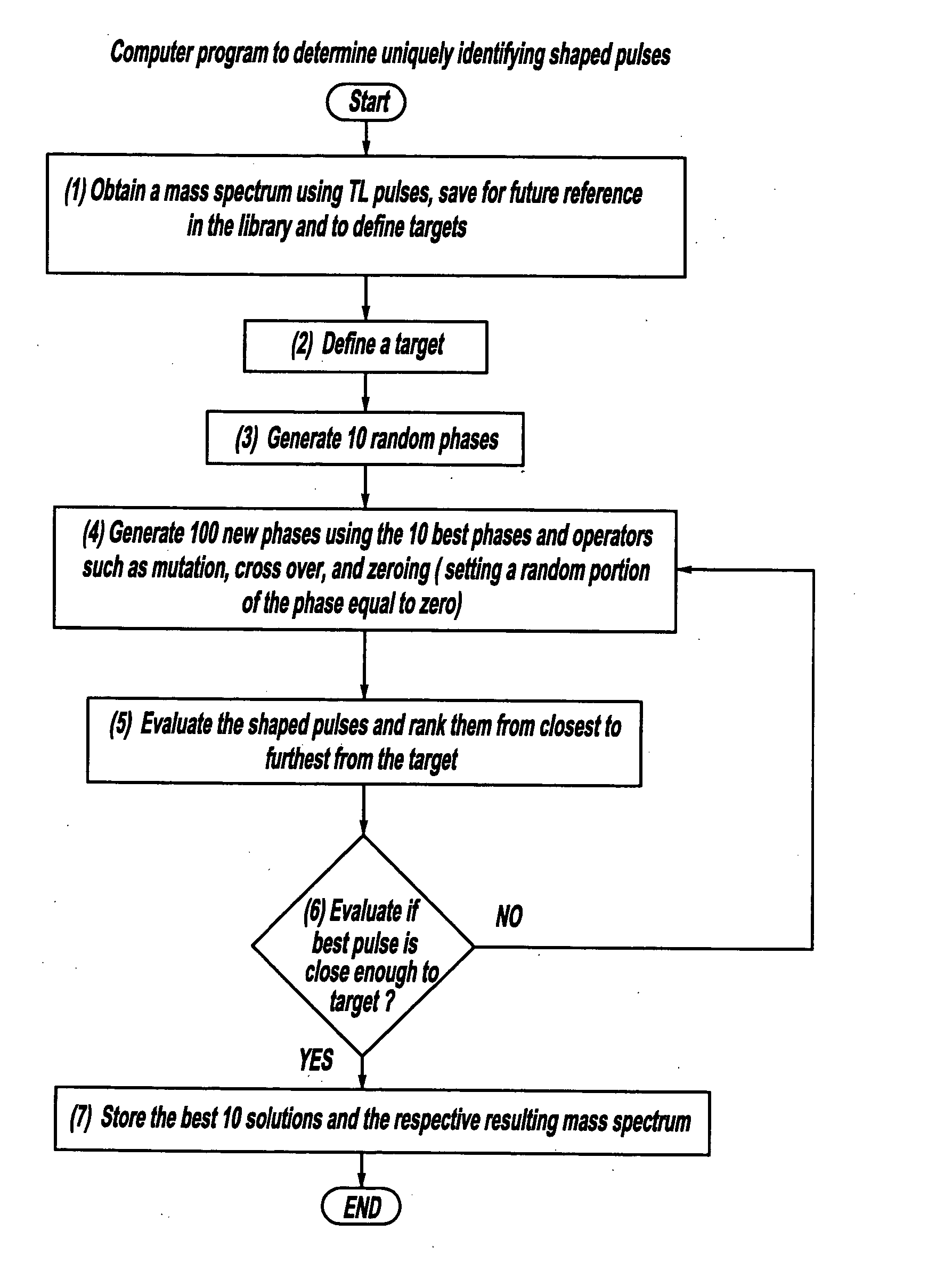

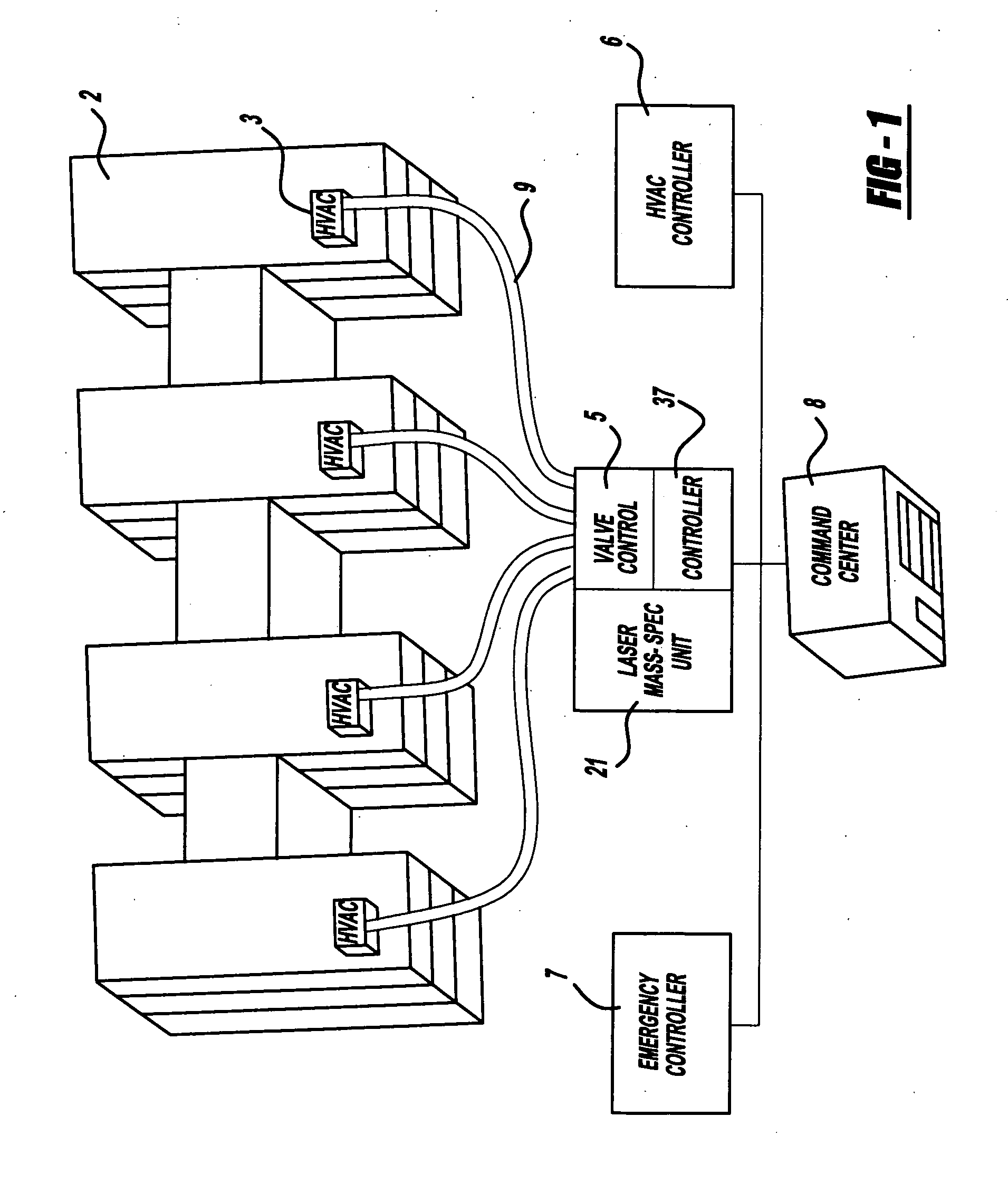

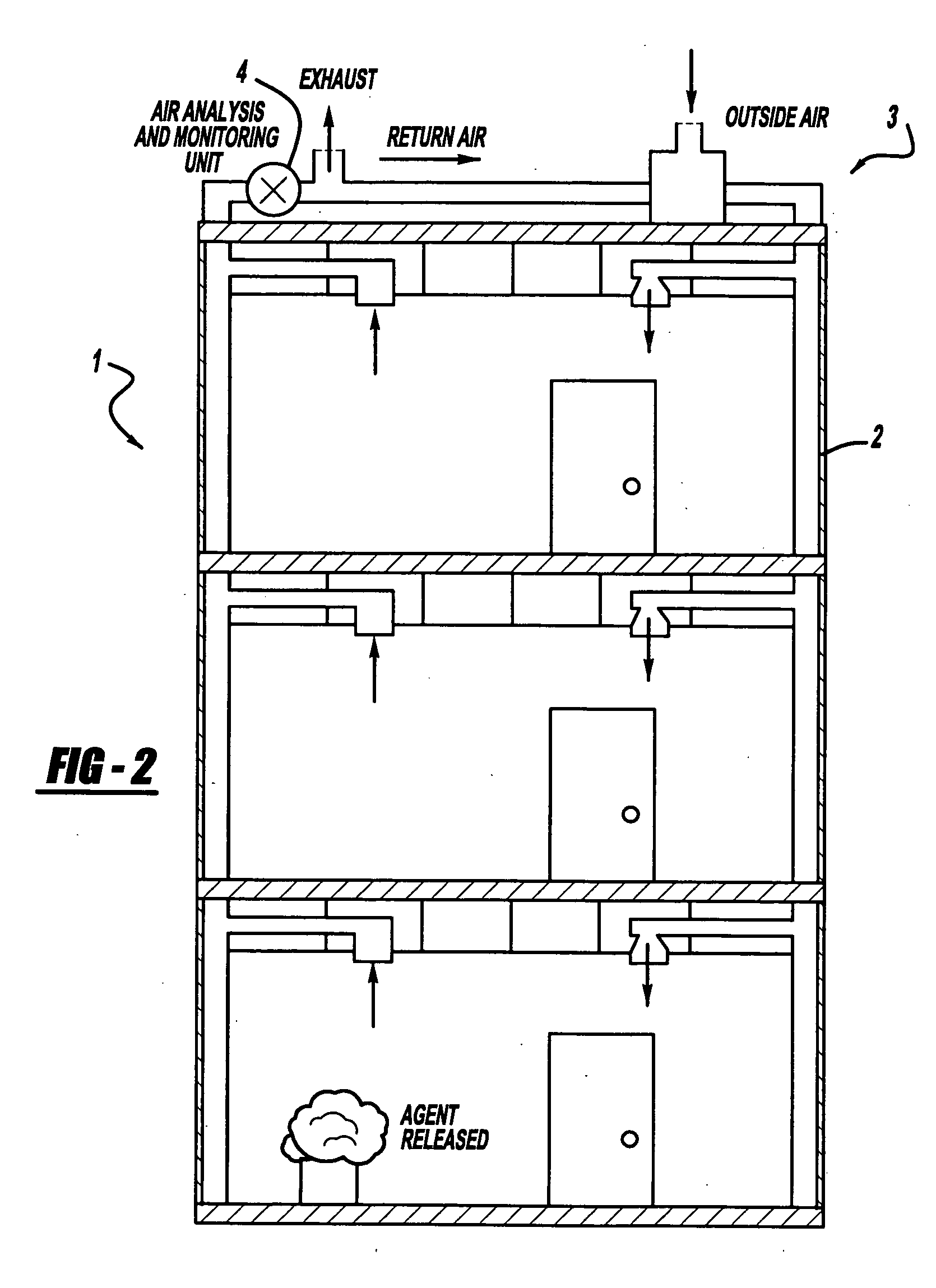

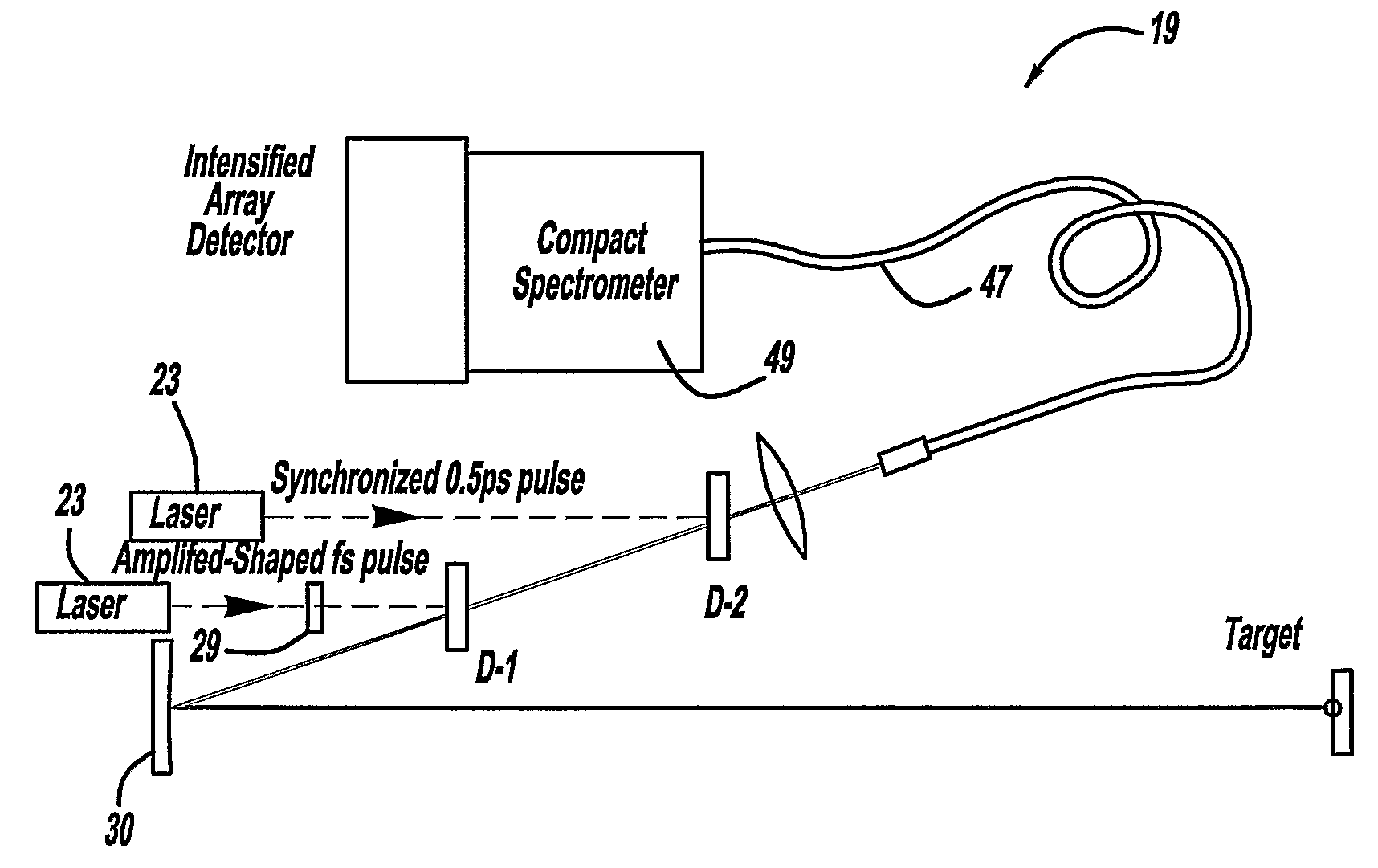

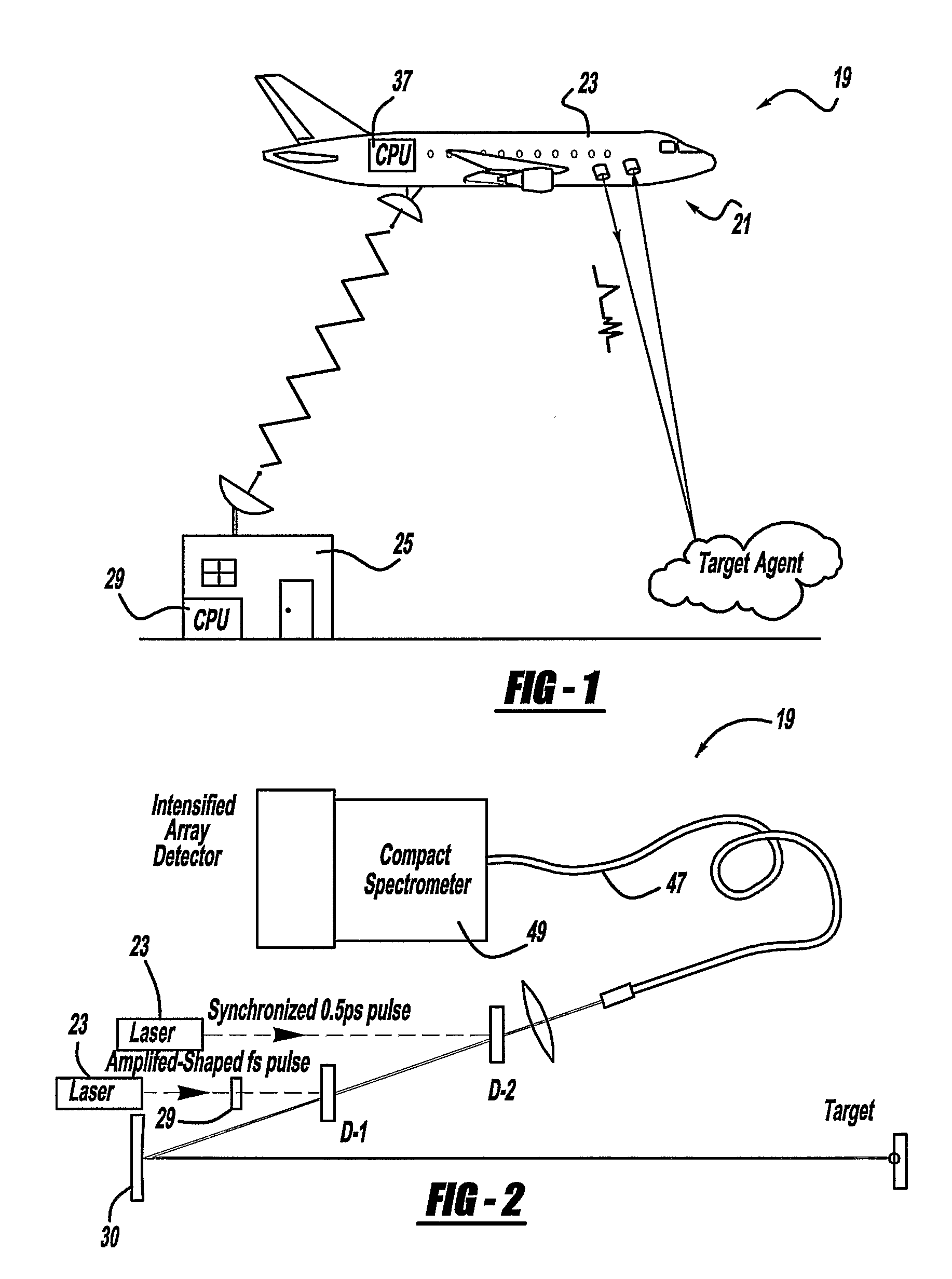

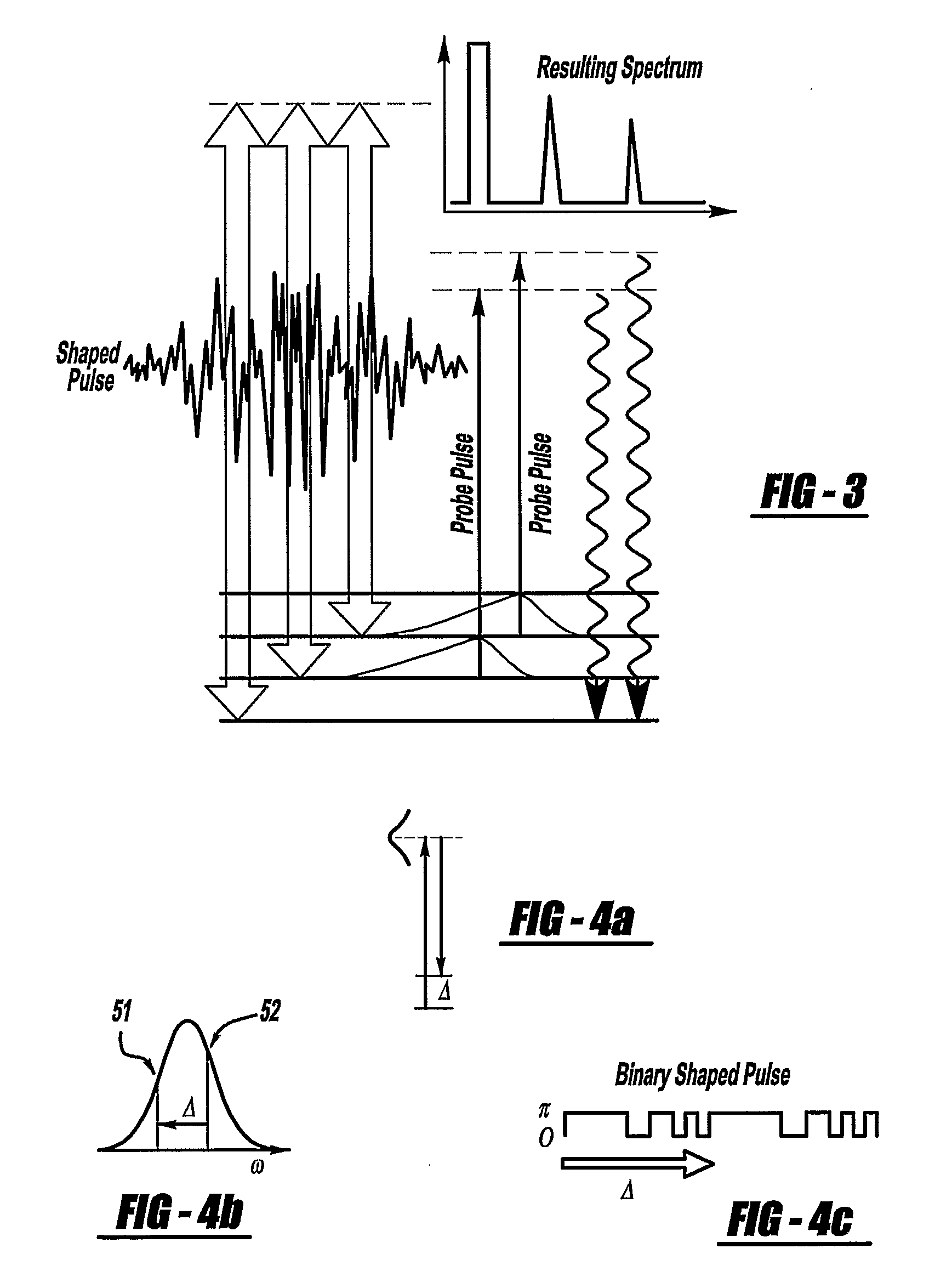

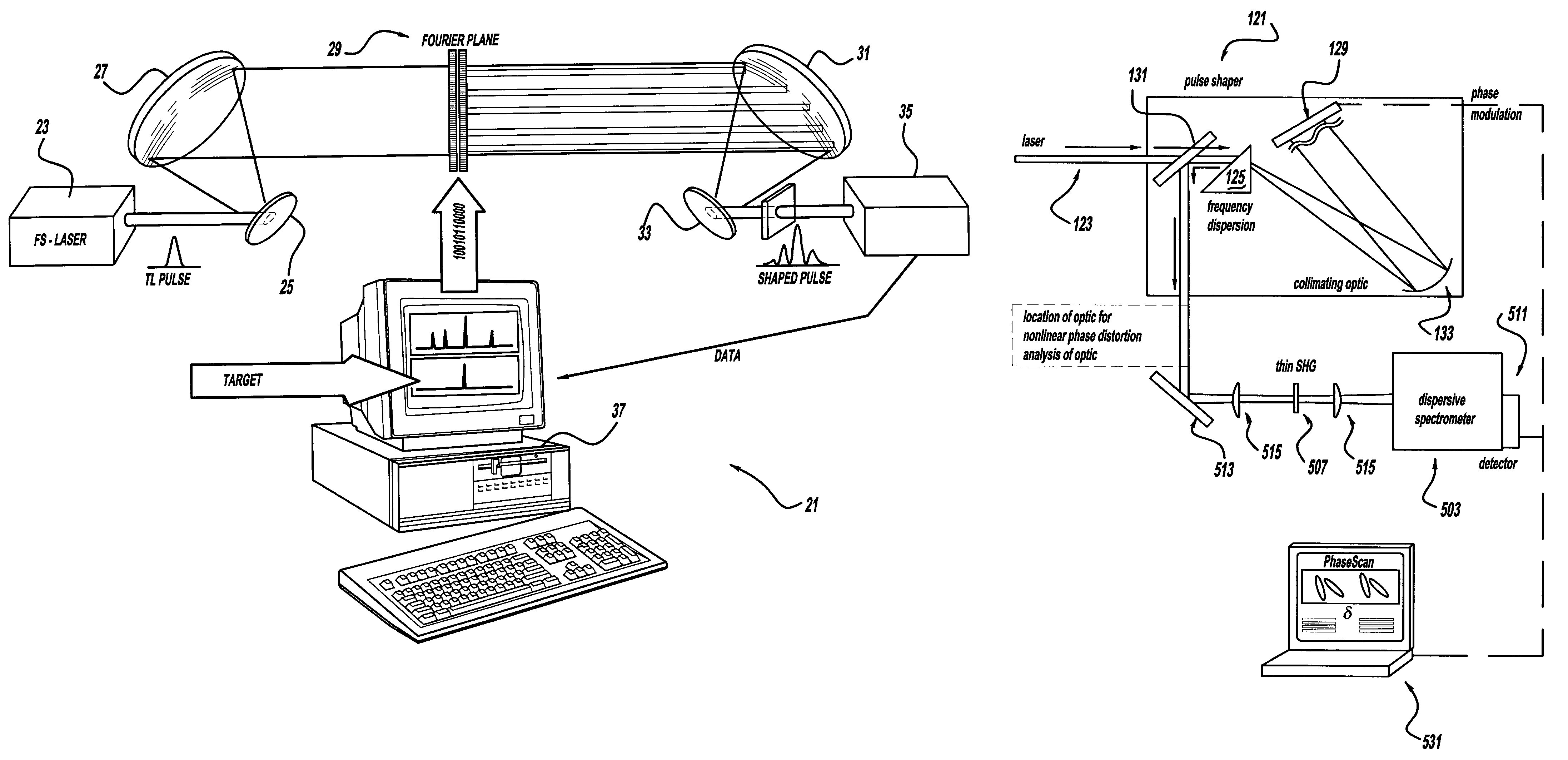

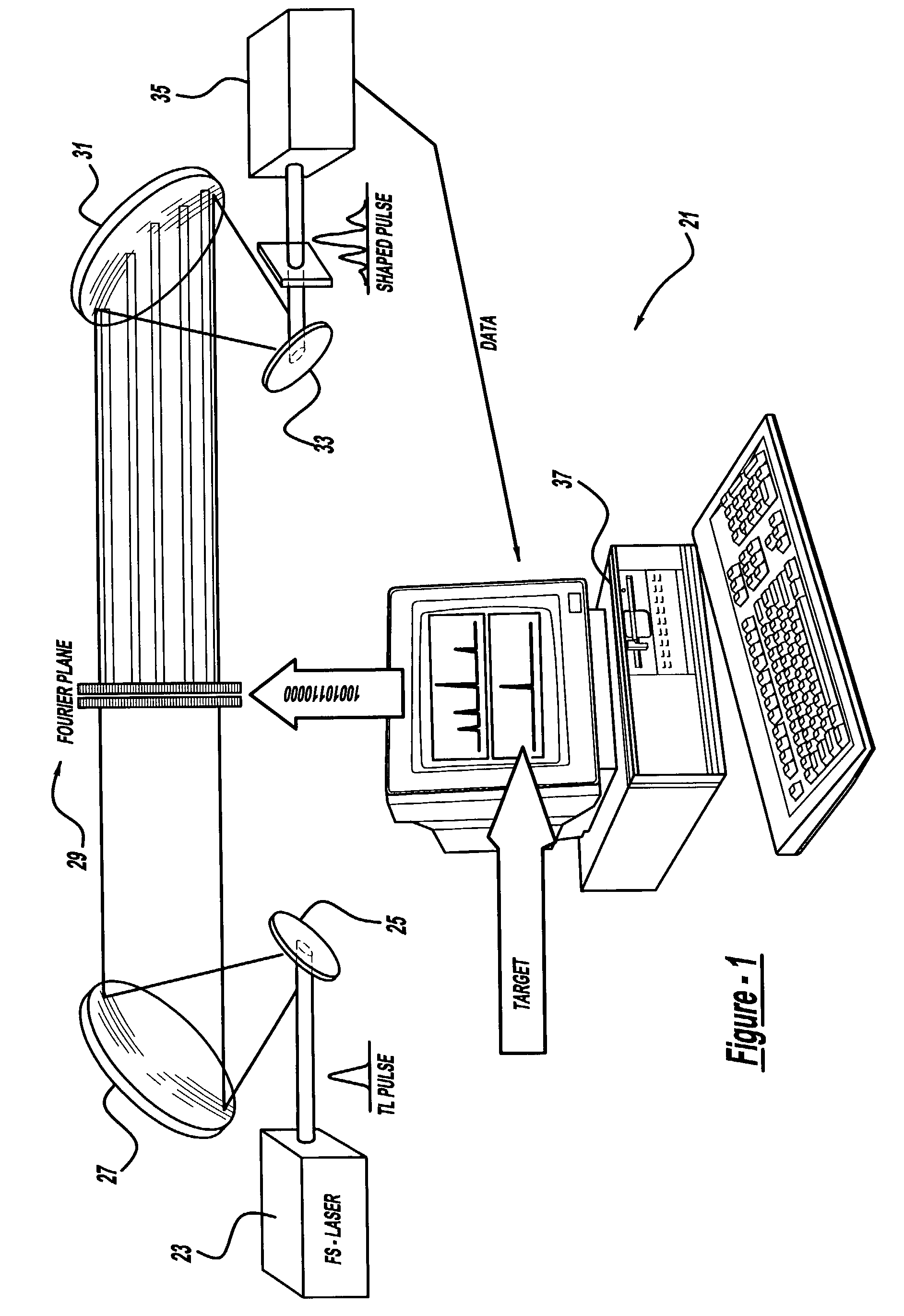

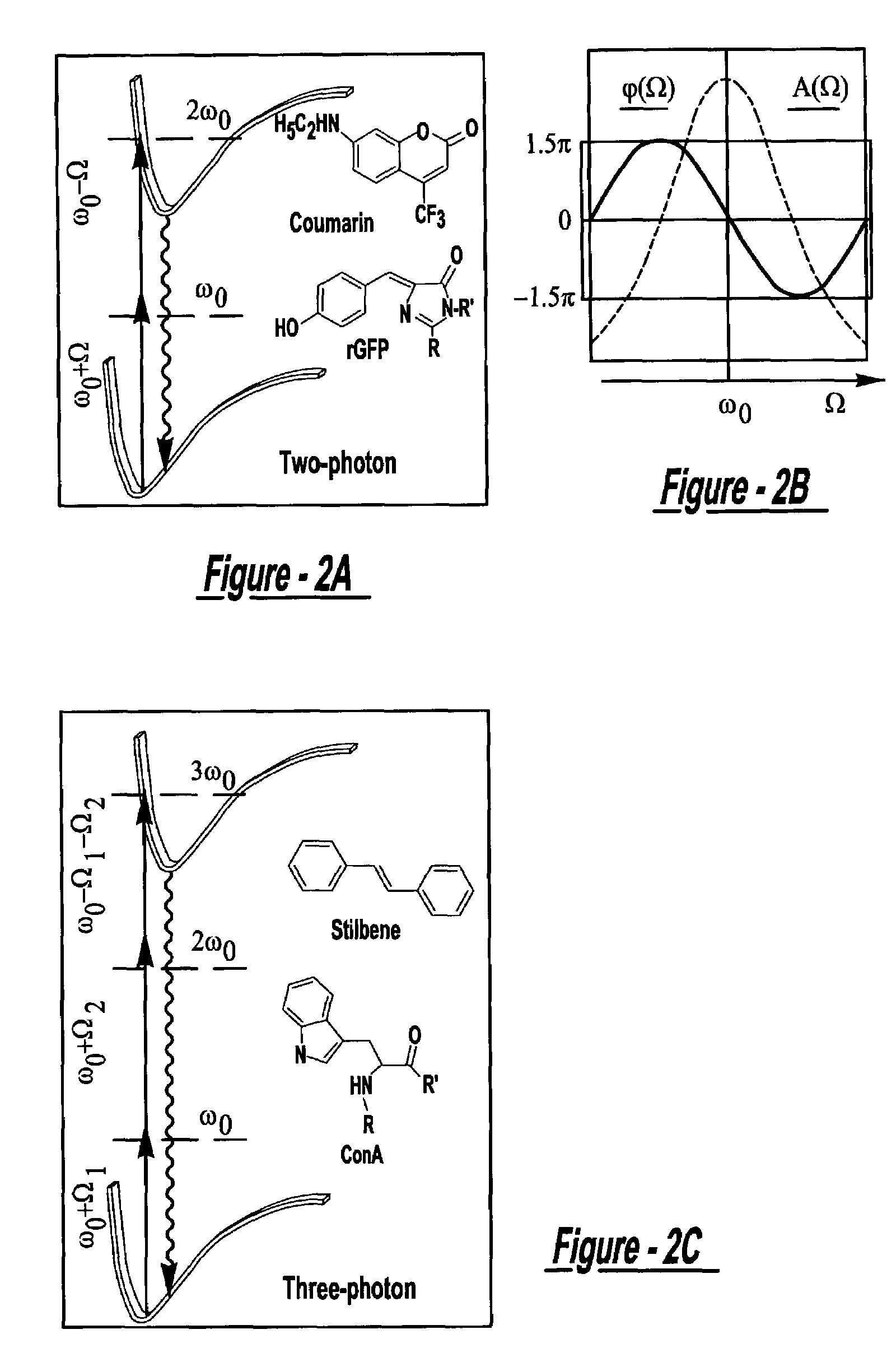

Laser and environmental monitoring system

A laser and monitoring system is provided. In another aspect of the present invention, the system includes a laser, pulse shaper and detection device. A further aspect of the present invention employs a femtosecond laser and binary pulse shaping (BPS). Still another aspect of the present invention uses a laser beam pulse, a pulse shaper and a SHG crystal. In yet another aspect of the present invention, a multiphoton intrapulse interference phase scan (hereinafter “MIIPS”) method is used to characterize the spectral phase of femtosecond laser pulses and to correct them. A further aspect of the system of the present invention is employed to monitor environmental chemicals and biological agents, including toxins, explosives, and diseases.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

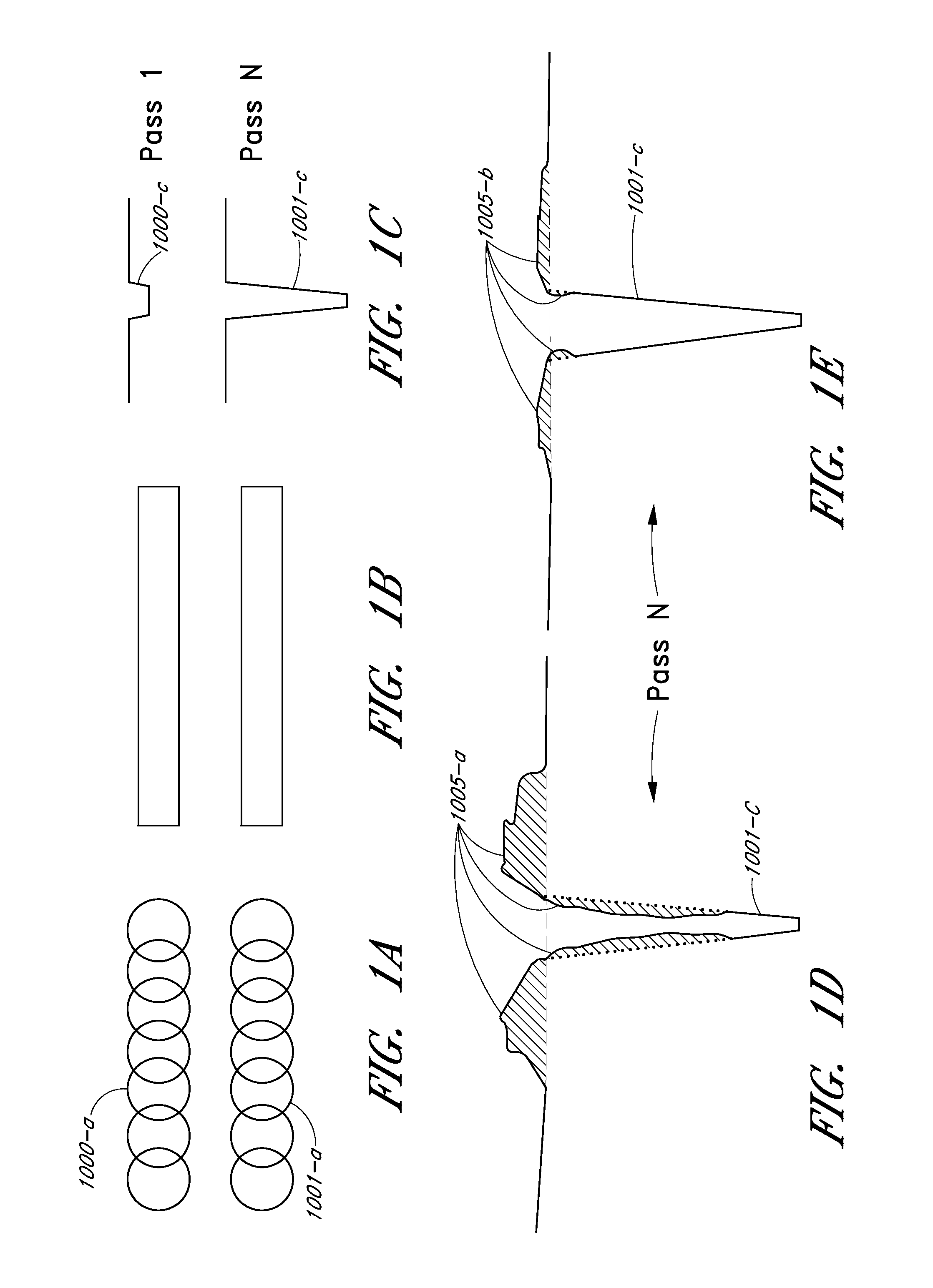

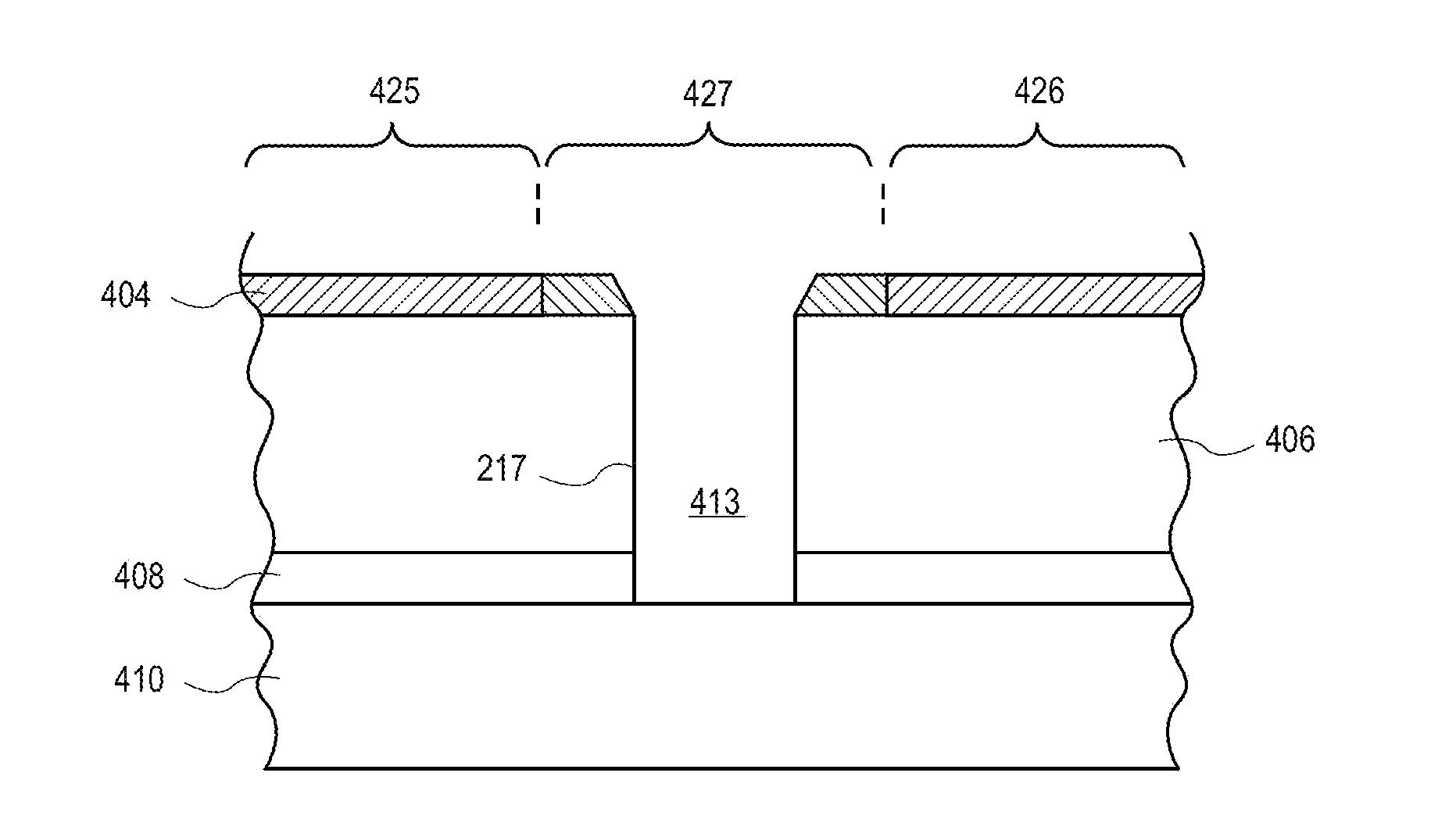

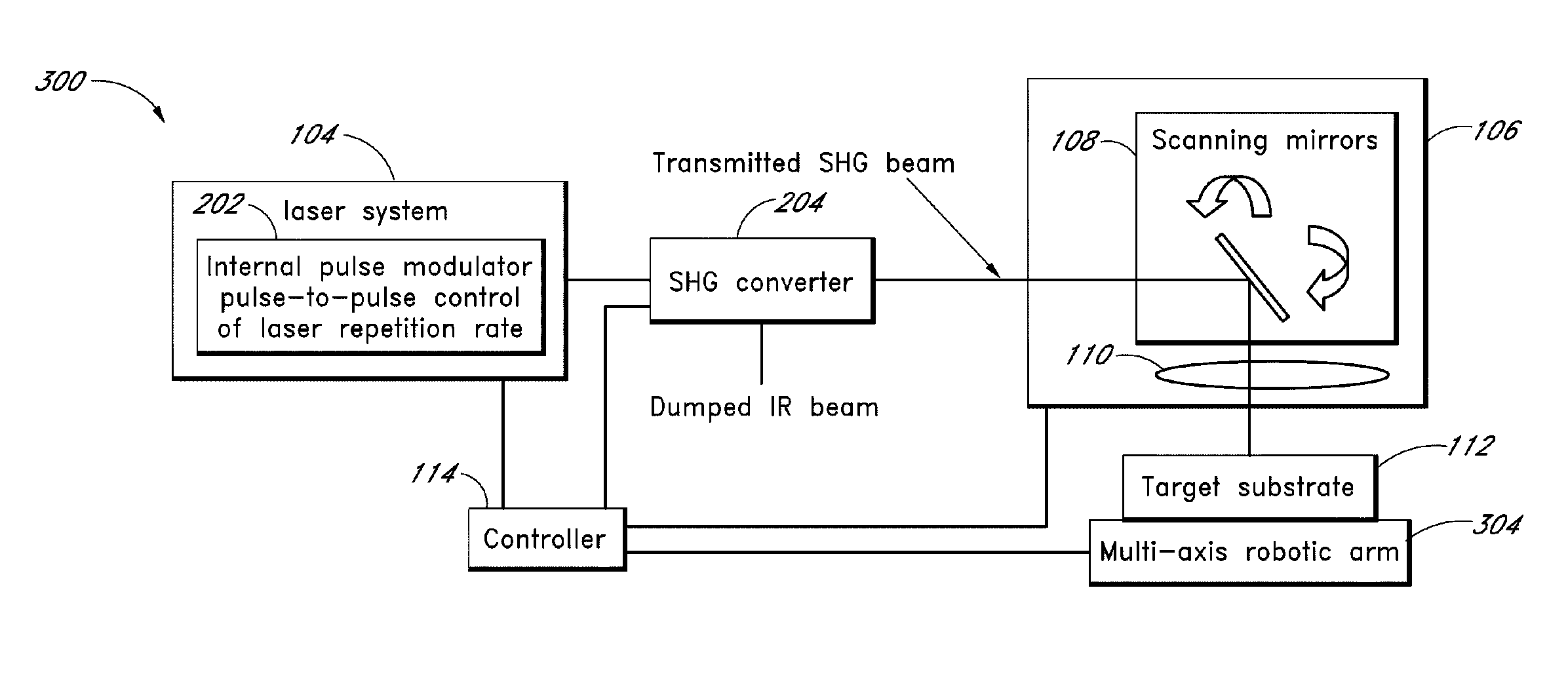

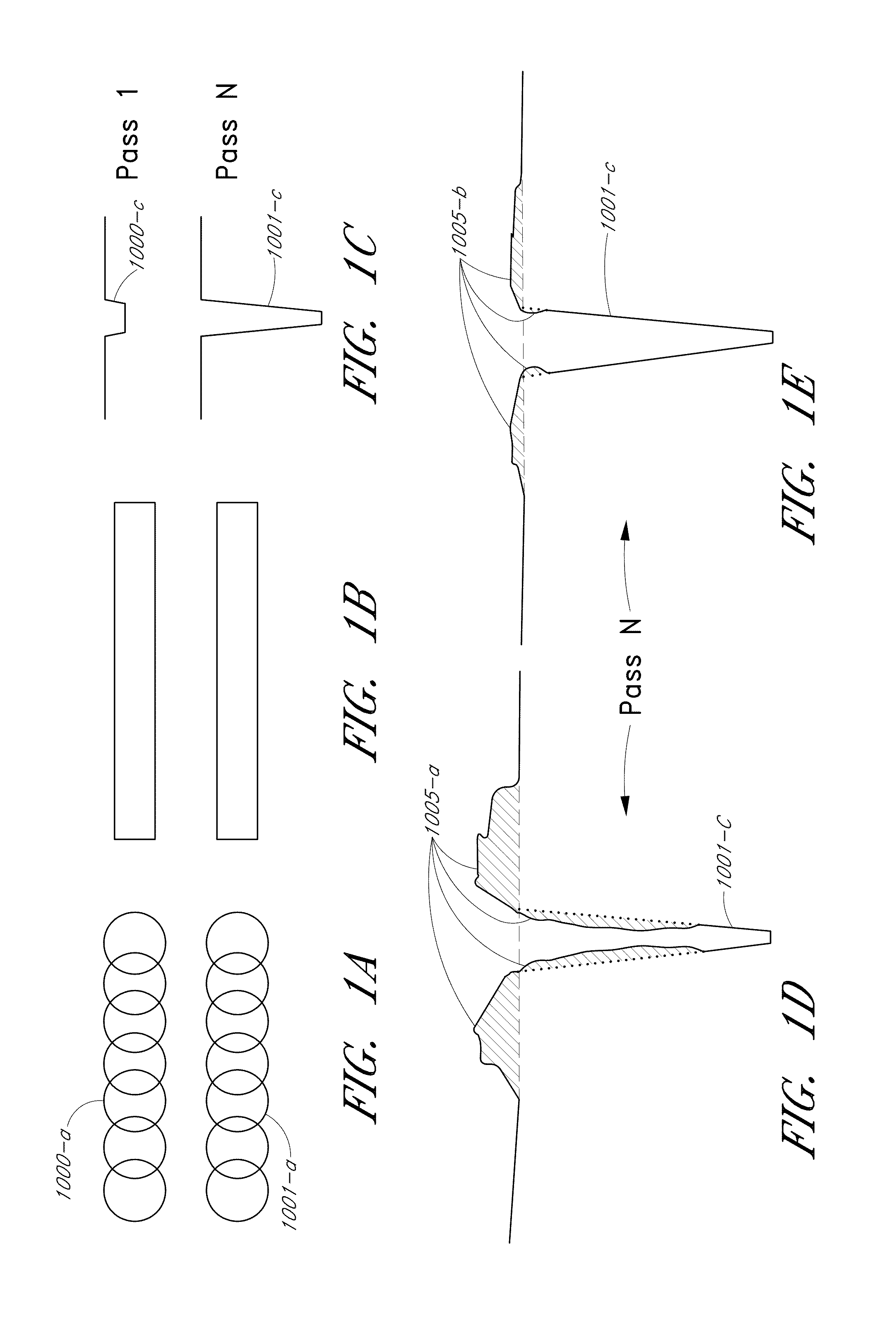

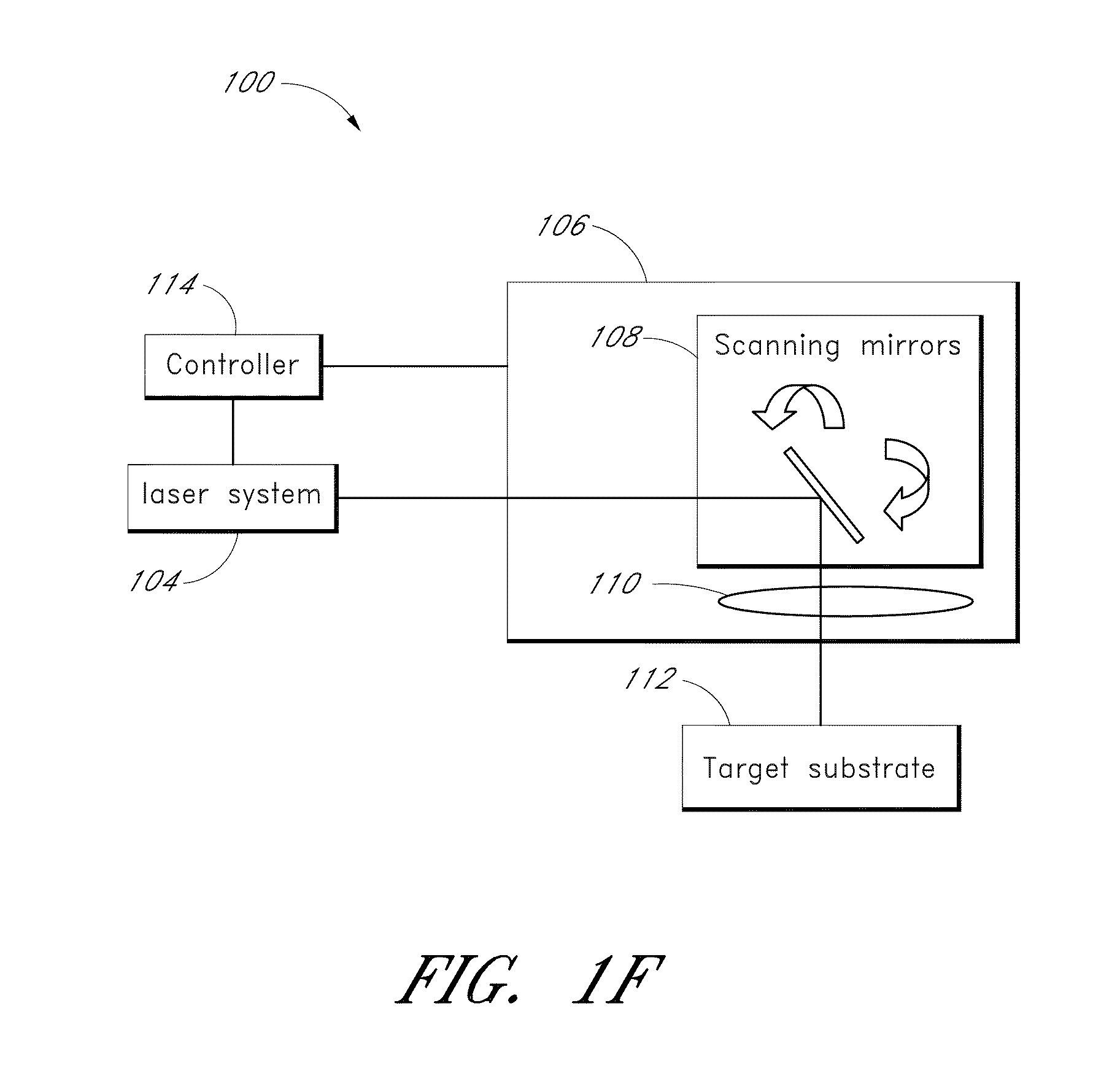

Damage isolation by shaped beam delivery in laser scribing process

ActiveUS20120322240A1Electric discharge tubesSemiconductor/solid-state device manufacturingShaped beamOptoelectronics

Owner:APPLIED MATERIALS INC

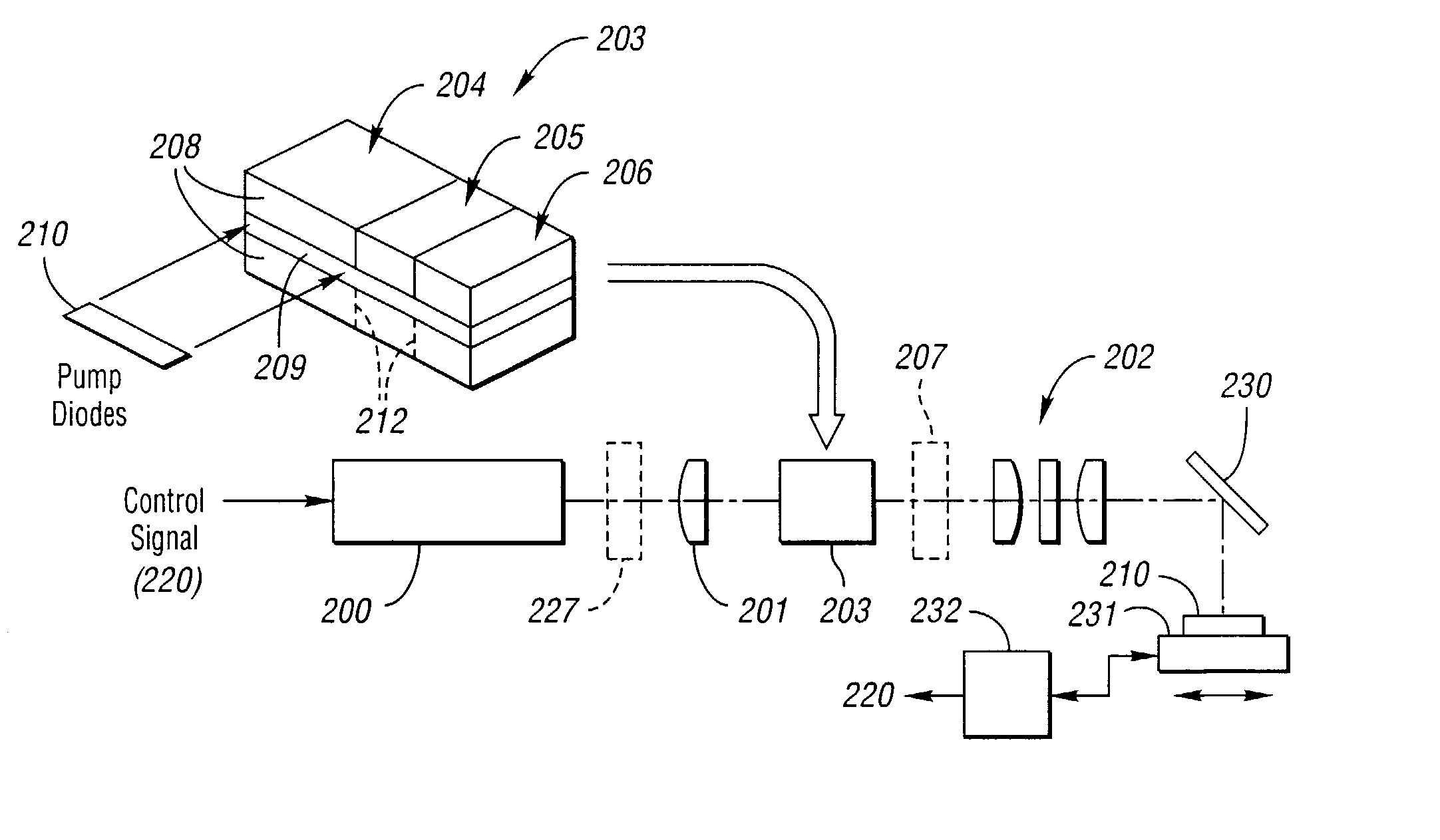

Ultra-Fast Laser System

ActiveUS20080170218A1Accurate and redundant identificationCost effectiveRadiation pyrometryLaser using scattering effectsPulse shaperUltra fast

A laser system is provided which selectively excites Raman active vibrations in molecules. In another aspect of the present invention, the system includes a laser, pulse shaper and detection device. A further aspect of the present invention employs a femtosecond laser and binary pulse shaping (BPS). Still another aspect of the present invention uses a laser beam pulse, a pulse shaper and remote sensing.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Laser system using ultrashort laser pulses

ActiveUS7450618B2Easy to set upEasy to useLaser detailsMaterial analysis by optical meansFemto second laserCharacterization test

A laser system using ultrashort laser pulses is provided. In another aspect of the present invention, the system includes a laser, pulse shaper and detection device. A further aspect of the present invention employs a femtosecond laser and a spectrometer. Still another aspect of the present invention uses a laser beam pulse, a pulse shaper and a SHG crystal. In yet another aspect of the present invention, a multiphoton intrapulse interference phase scan system and method characterize the spectral phase of femtosecond laser pulses. Fiber optic communication systems, photodynamic therapy and pulse characterization tests use the laser system with additional aspects of the present invention.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Method of fabricating sub-micron structures in transparent dielectric materials

A sub-micron structure is fabricated in a transparent dielectric material by focusing femtosecond laser pulses into the dielectric to create a highly tapered modified zone with modified etch properties. The dielectric material is then selectively etched into the modified zone from the direction of the narrow end of the tapered zone so that as the selective etching proceeds longitudinally into the modified zone, the progressively increasing width of the modified zone compensates for lateral etching occurring closer to the narrow end so as to produce steep-walled holes. The unetched portion of the modified zone produced by translating the laser beam close to and parallel to the bottom surface of the dielectric can serve as an optical waveguide to collect light from or deliver light to the etched channel which can contain various biological, optical, or chemical materials for sensing applications.

Owner:NAT RES COUNCIL OF CANADA

Laser-based material processing methods and systems

ActiveUS8158493B2Avoid insufficient heatingAvoid layeringSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDielectricPicosecond

Various embodiments may be used for laser-based modification of target material of a workpiece while advantageously achieving improvements in processing throughput and / or quality. Embodiments of a method of processing may include focusing and directing laser pulses to a region of the workpiece at a pulse repetition rate sufficiently high so that material is efficiently removed from the region and a quantity of unwanted material within the region, proximate to the region, or both is reduced relative to a quantity obtainable at a lower repetition rate. Embodiments of an ultrashort pulse laser system may include at least one of a fiber amplifier or fiber laser. Various embodiments are suitable for at least one of dicing, cutting, scribing, and forming features on or within a semiconductor substrate. Workpiece materials may also include metals, inorganic or organic dielectrics, or any material to be micromachined with femtosecond, picosecond, and / or nanosecond pulses.

Owner:IMRA AMERICA

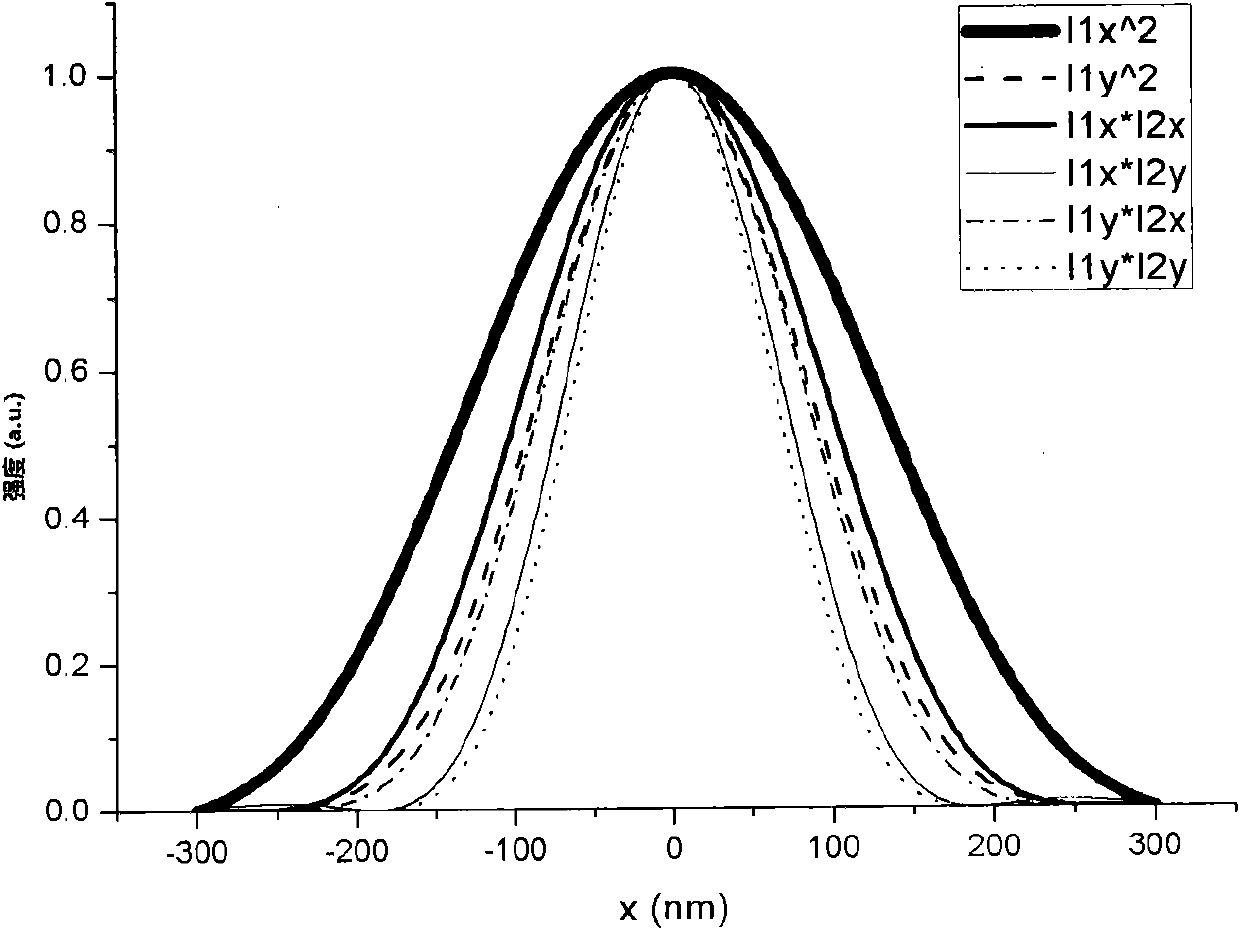

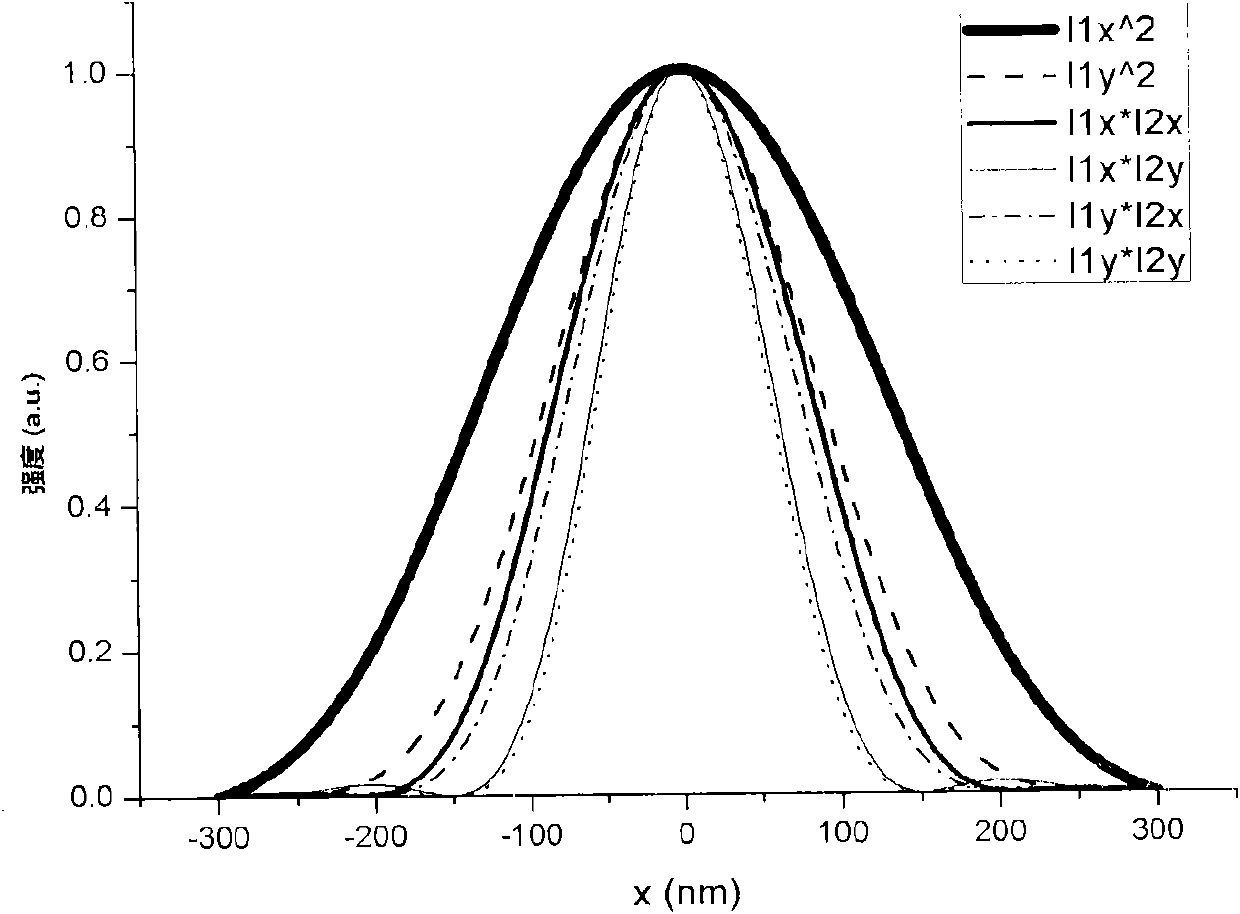

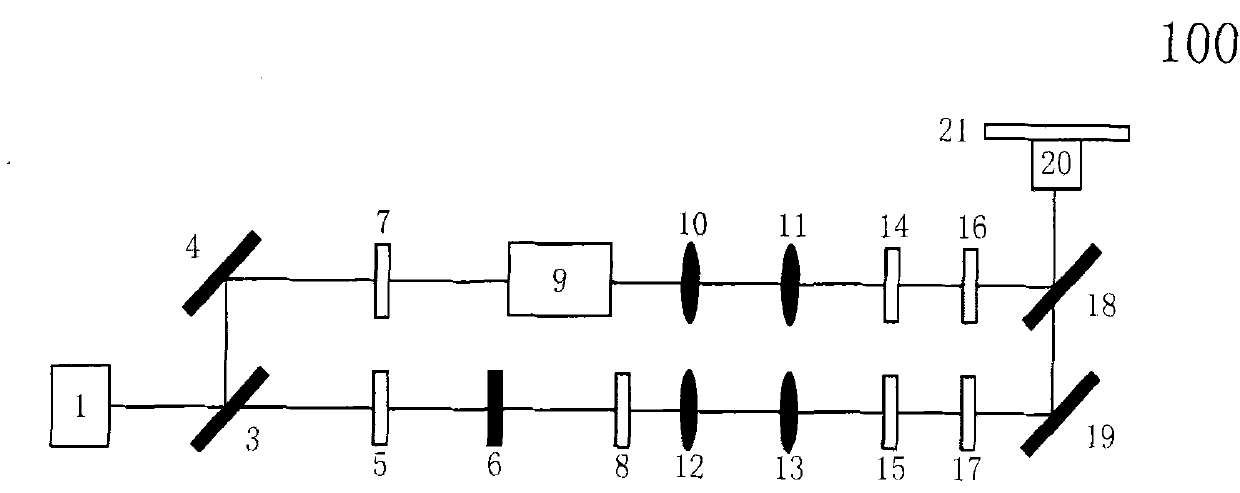

Laser micro/nano processing system and method

ActiveCN102000912AHigh processing resolutionPrecise Control of ResolutionNanostructure manufactureDecorative surface effectsLaser lightMobile station

The invention provides a laser micro / nano processing system and a laser micro / nano processing method. The system of the invention comprises a laser light source, an optical retardation component, an optical focusing component and a computer-controlled micro mobile station, wherein the laser light source is used for providing a first laser beam having a first wavelength and a second laser beam having a second wavelength, the pulse widths of the first laser beam and the second laser beam range from femtosecond to nanosecond and the first wavelength is different from the second wavelength; the optical retardation component is used for regulating the optical path of the first laser beam or the second laser beam so that the difference between the arrival times of the first laser beam and the second laser beam at a focus is not greater than the level life time for a photochromic material to be processed to be excited to an excited state; the optical focusing component is used for focusing the first laser beam and the second laser beam onto the same focus; and the computer-controlled micro mobile station is used for regulating a photochromic material on the computer-controlled micro mobile station to the focus.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

InactiveUS7065121B2Optical resonator shape and constructionActive medium shape and constructionWaveguideBeam control

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100 W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

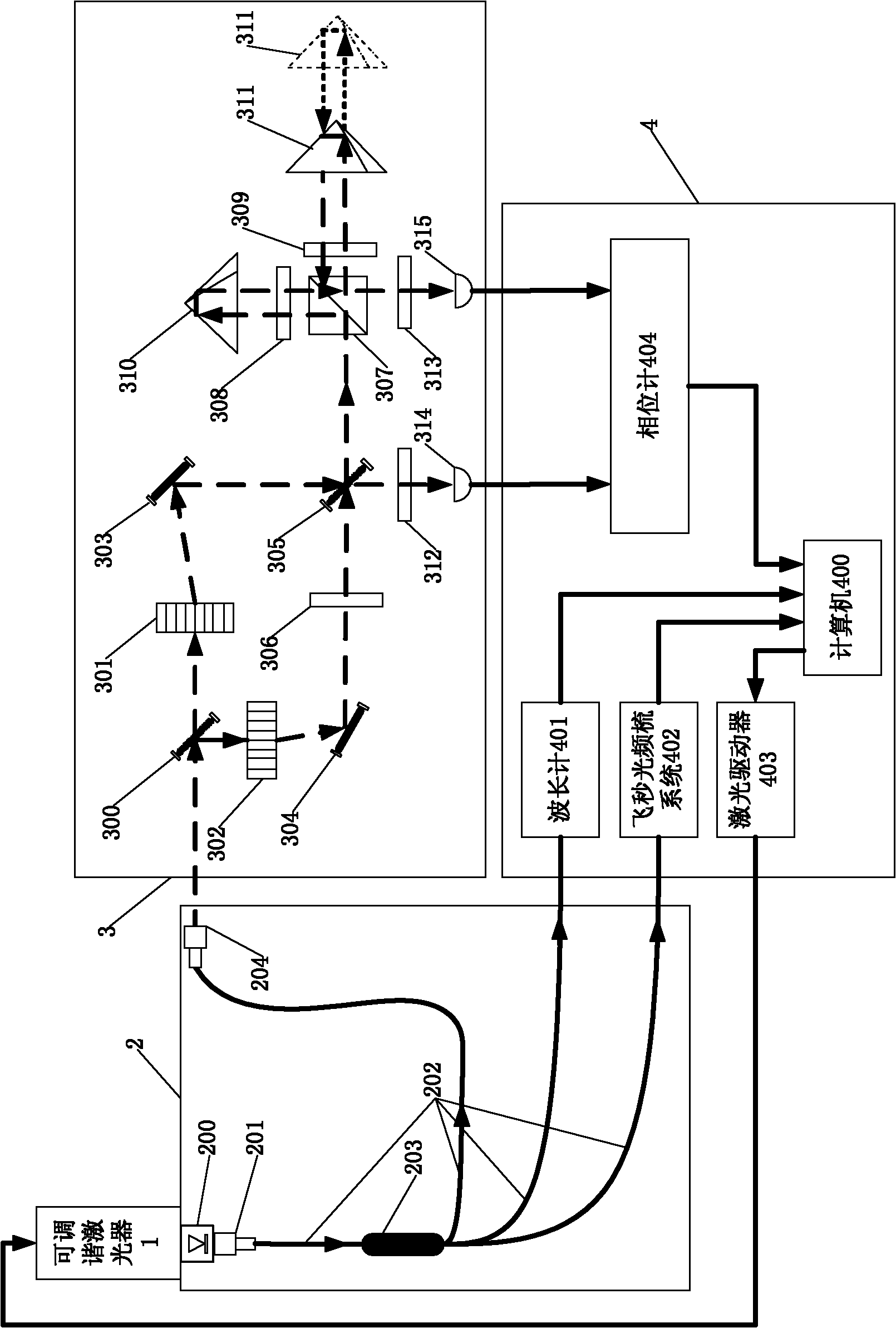

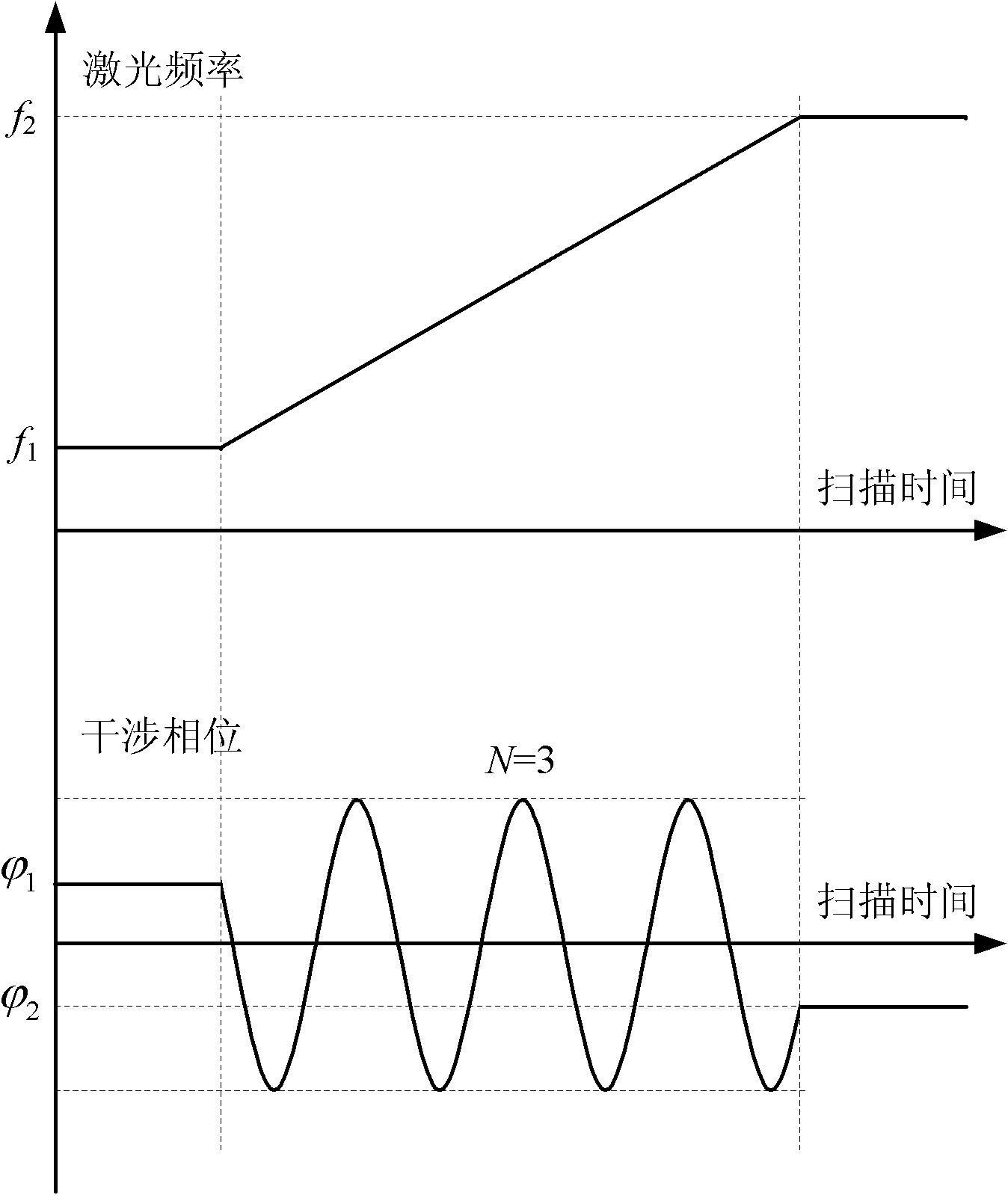

Method and device for measuring frequency scanning absolute distance based on femtosecond optical frequency comb

InactiveCN102183234AHigh precisionGood repeatabilityOptical measurementsOptical rangefindersFiberHeterodyne interferometer

The invention relates to a device for measuring a frequency scanning absolute distance based on a femtosecond optical frequency comb and a method for measuring the absolute distance based on the device. The device comprises: a tunable laser (1), a polarization maintaining fiber system (2), a double-frequency heterodyne interferometer (3) and a system for measuring a laser frequency and an interferometric phase (4); the tunable laser (1) is used for generating single-frequency, single-line polarization laser, and an output laser frequency can be controlled by the working voltage and current ofthe tunable laser; the polarization maintaining fiber system (2) is used for coupling space laser with a polarization maintaining fiber in an unreflected way, and dividing the space laser into three paths of optical signals with equal optical intensity, and keeping an output laser polarization direction the same as an input laser polarization direction; the double-frequency heterodyne interferometer (3) is used for converting single-frequency laser into double-frequency orthogonal polarization laser, and converting distance information to be measured into phase information of a laser beat signal; and the system for measuring the laser frequency and the interferometric phase (4) is used for precisely measuring and locking and inputting the frequency of the laser, and measuring a phase different between the two paths of alternating current signals.

Owner:TSINGHUA UNIV

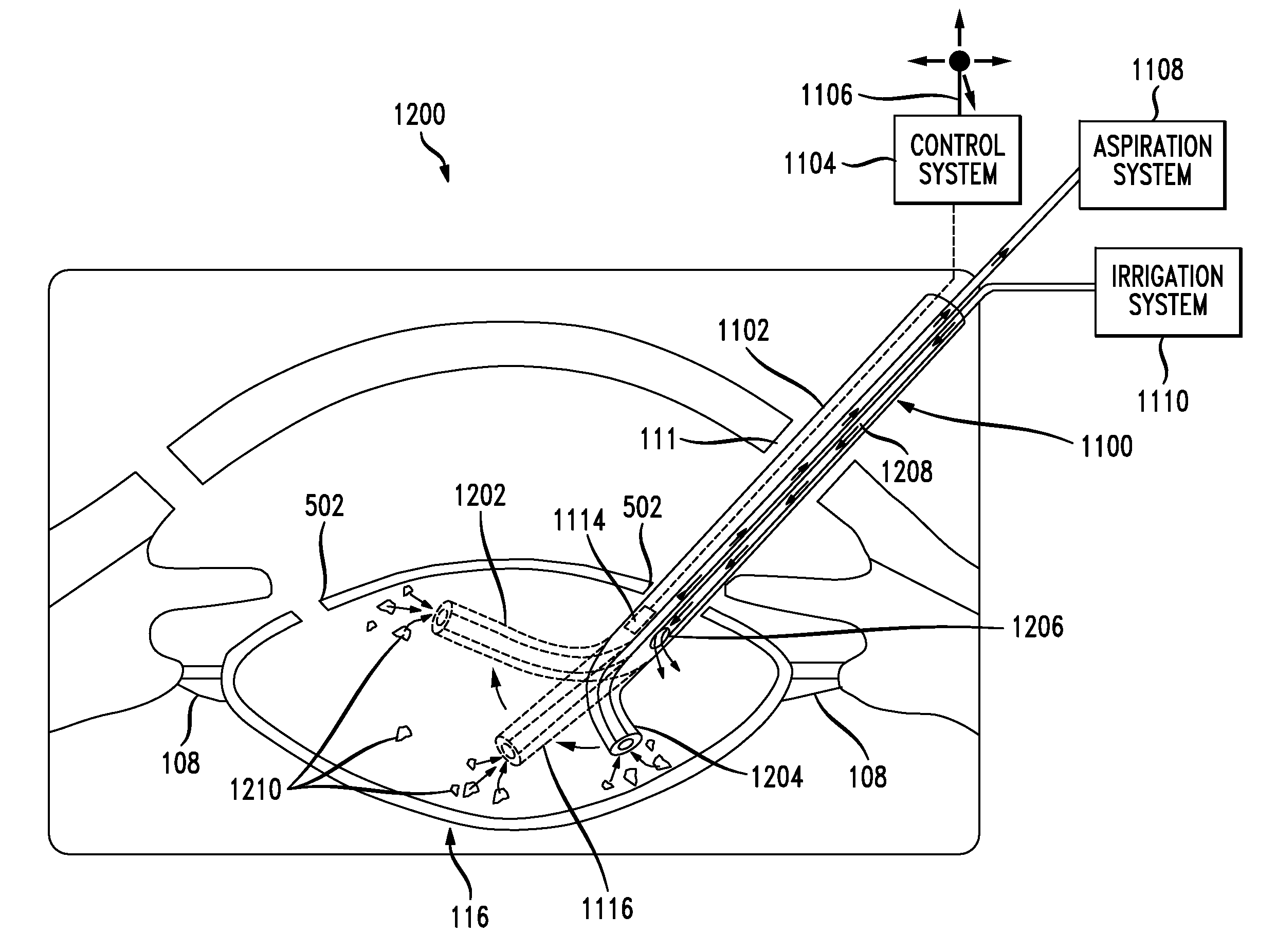

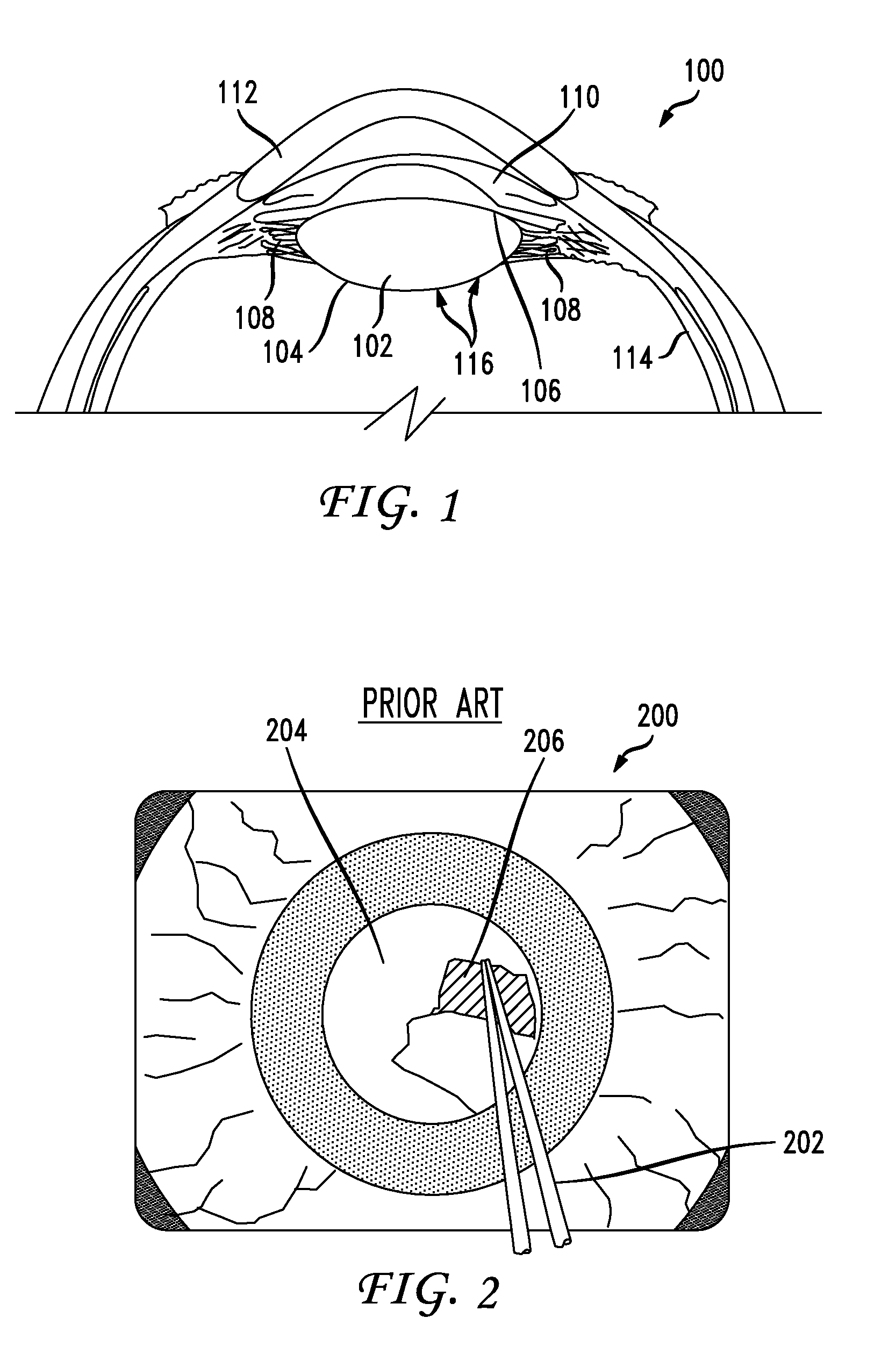

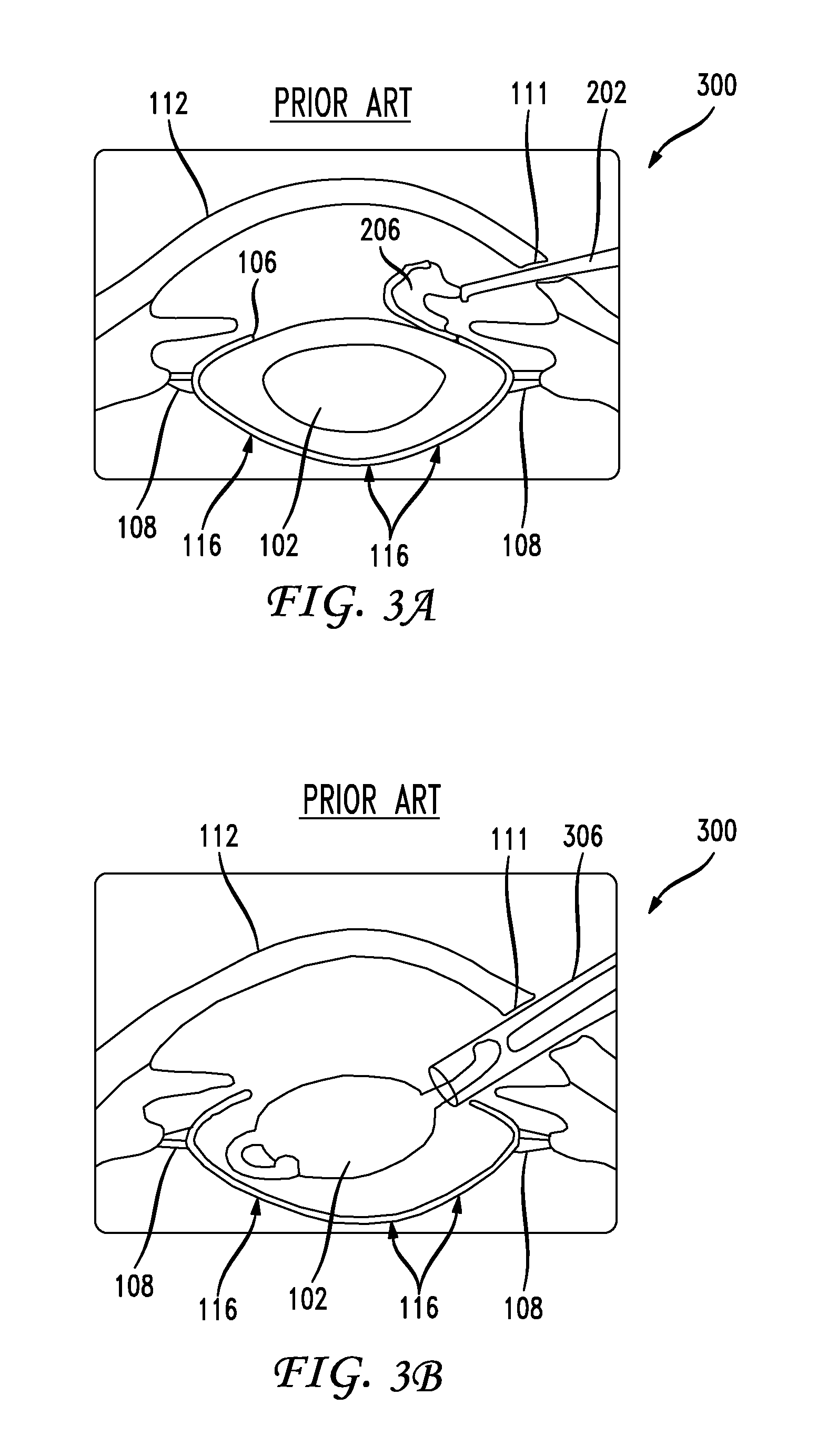

System and method of performing femtosecond laser accomodative capsulotomy

Disclosed is a system and method for making a first incision in an anterior capsule of a capsular bag, the first incision being less than or equal to approximately 3.5 mm in diameter and making a second incision in the anterior capsule, the second incision being less than or equal to approximately 3.0 mm in diameter. The first incision and the second incision are positioned off-center from a center portion of the anterior capsule. The method includes performing lens fragmentation of a lens in the capsular bag to yield lens material, inserting a first instrument into the first incision, inserting a second first instrument into the second incision and removing the lens material via one of the first instrument and the second instrument and through one of the first incision and the second incision. The tensile structure of the anterior portion of the capsular bag is maintained such that accommodation exists within the eye after insertion of the intraocular lens.

Owner:IANCHULEV PRAVOSLAVA

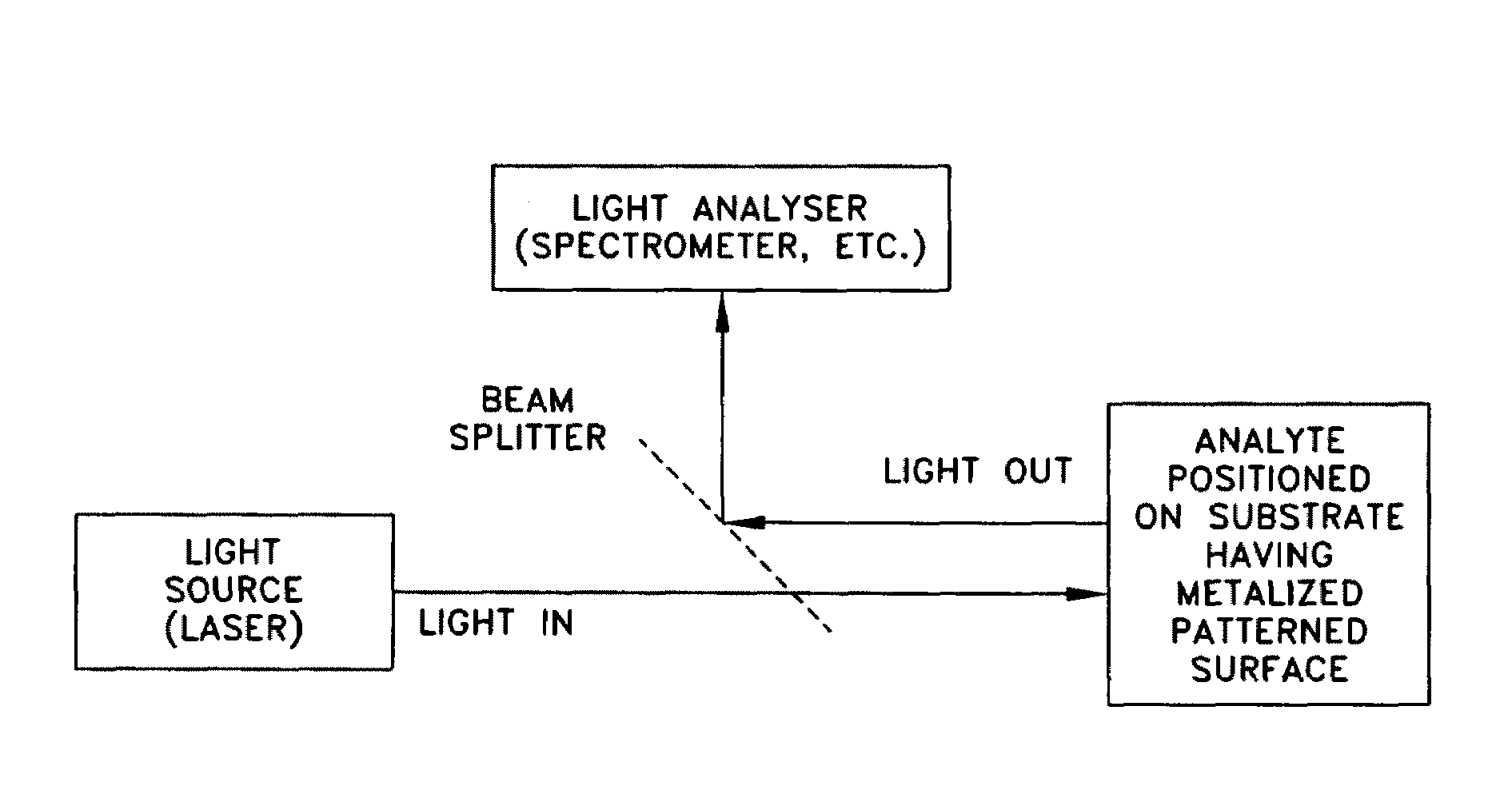

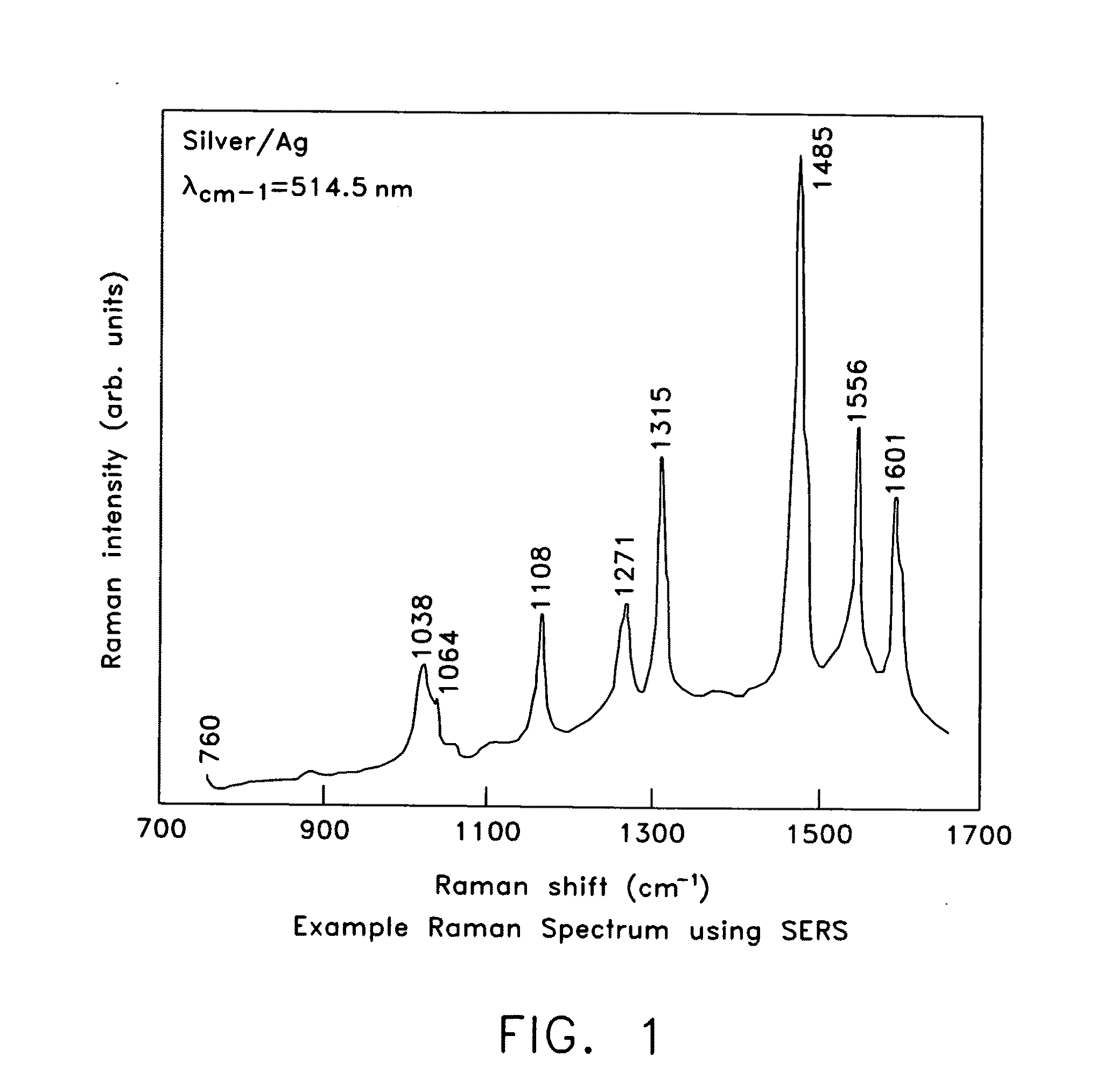

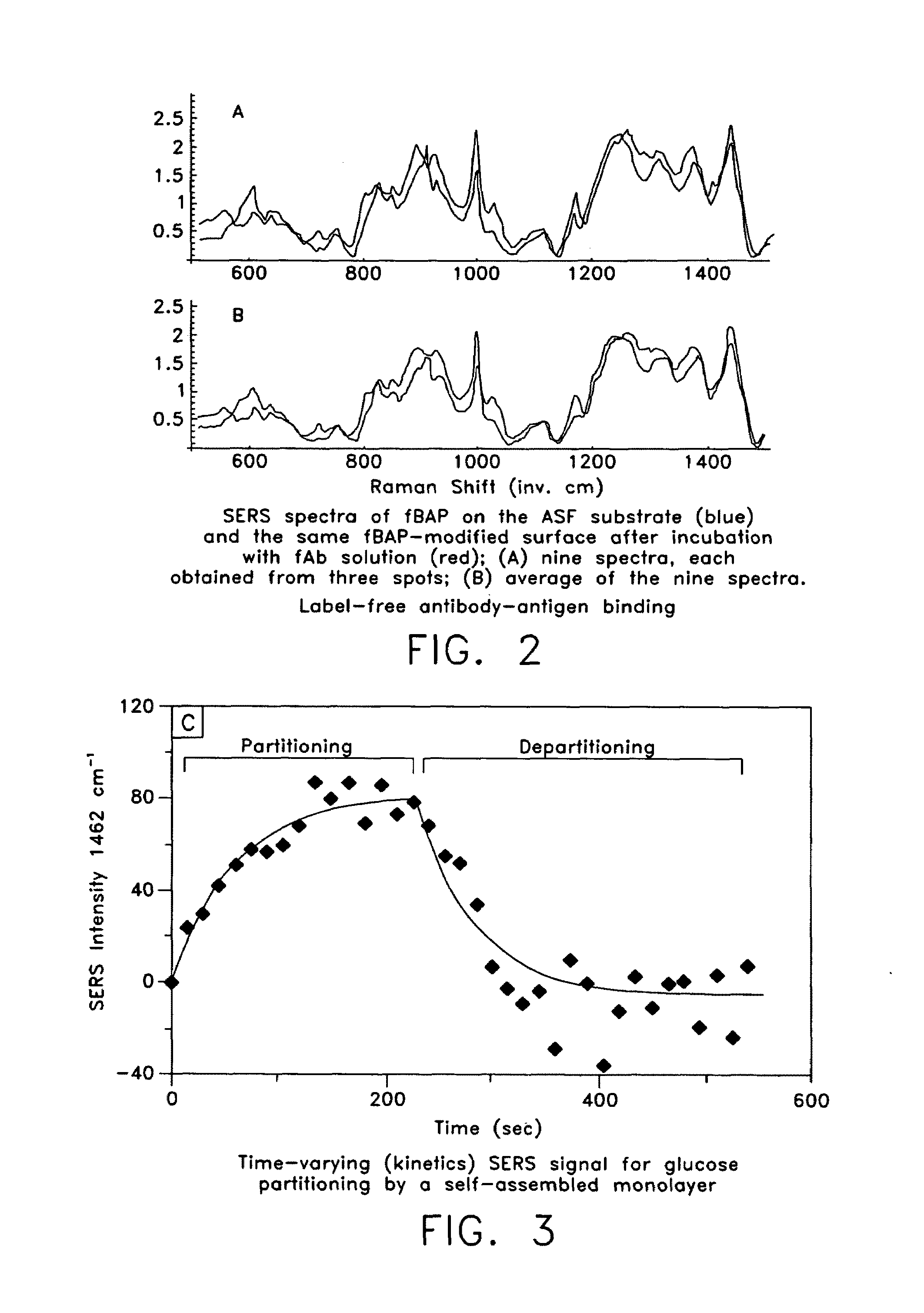

Applications of laser-processed substrate for molecular diagnostics

Owner:EBSTEIN STEVEN M

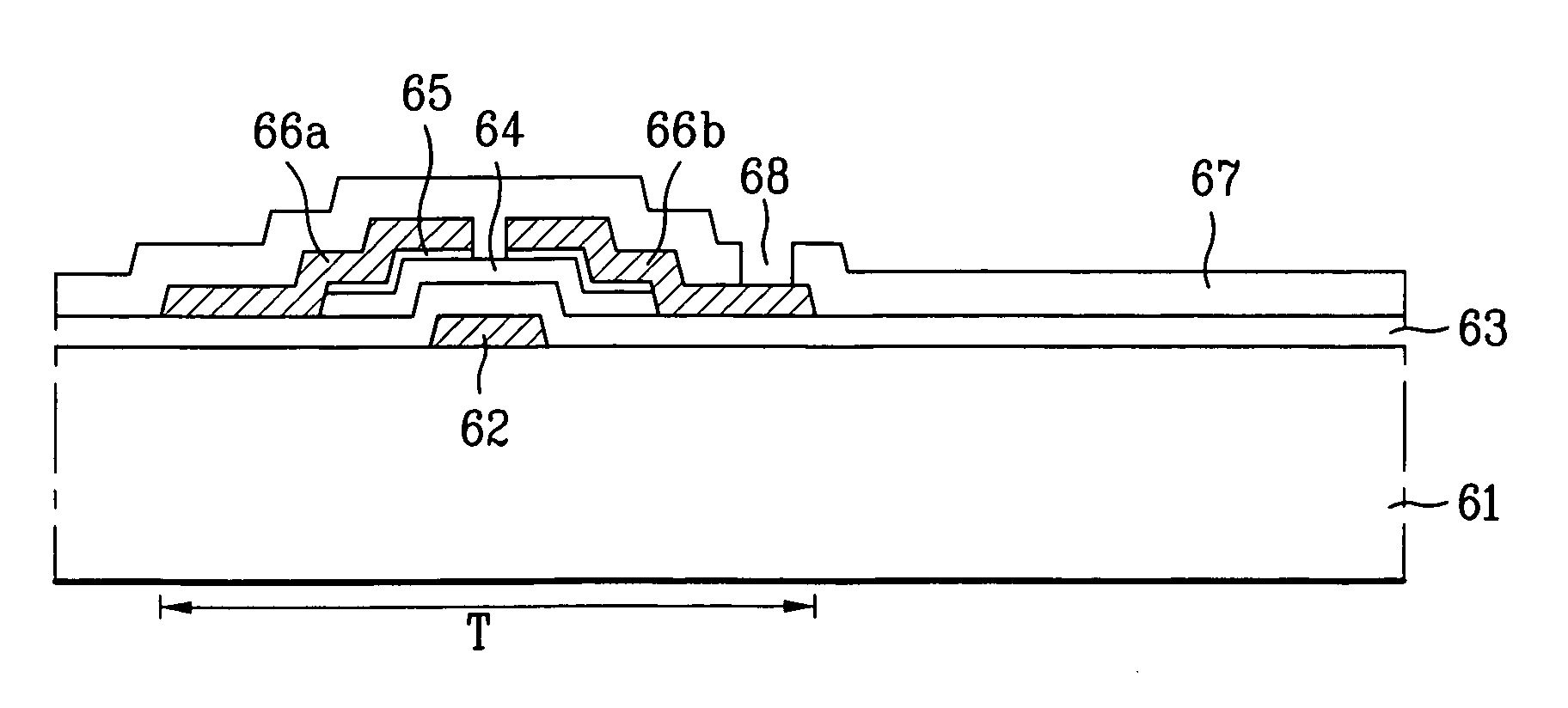

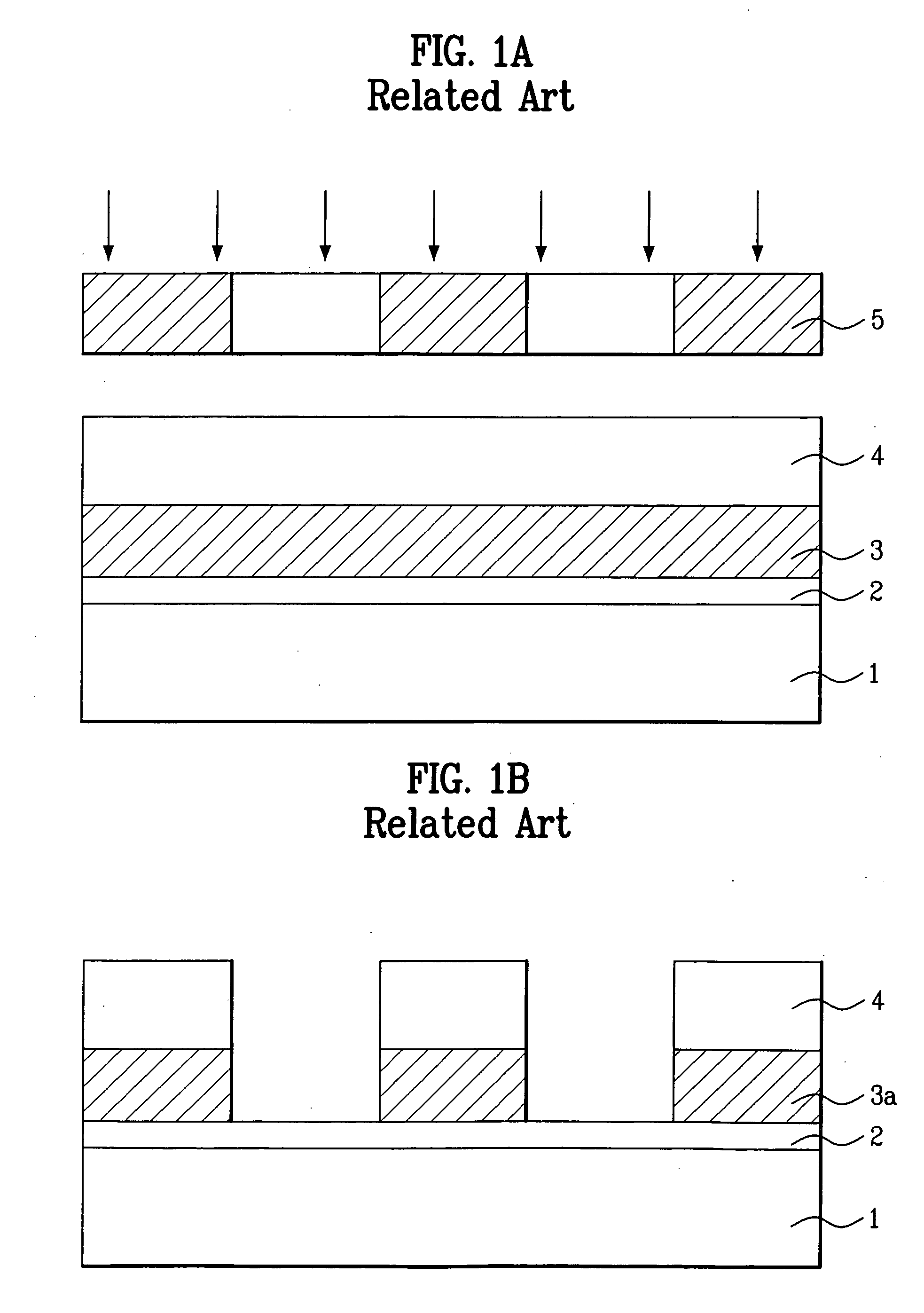

Thin film etching method and method of fabricating liquid crystal display device using the same

ActiveUS20060099747A1Simple processImprove machining productivitySolid-state devicesSemiconductor/solid-state device manufacturingEtchingLiquid-crystal display

A thin film etching method includes forming a layer on a substrate, aligning a mask having a pattern defined thereon above the layer, and removing a portion of the layer by irradiating the substrate with a femtosecond laser through the mask.

Owner:LG DISPLAY CO LTD

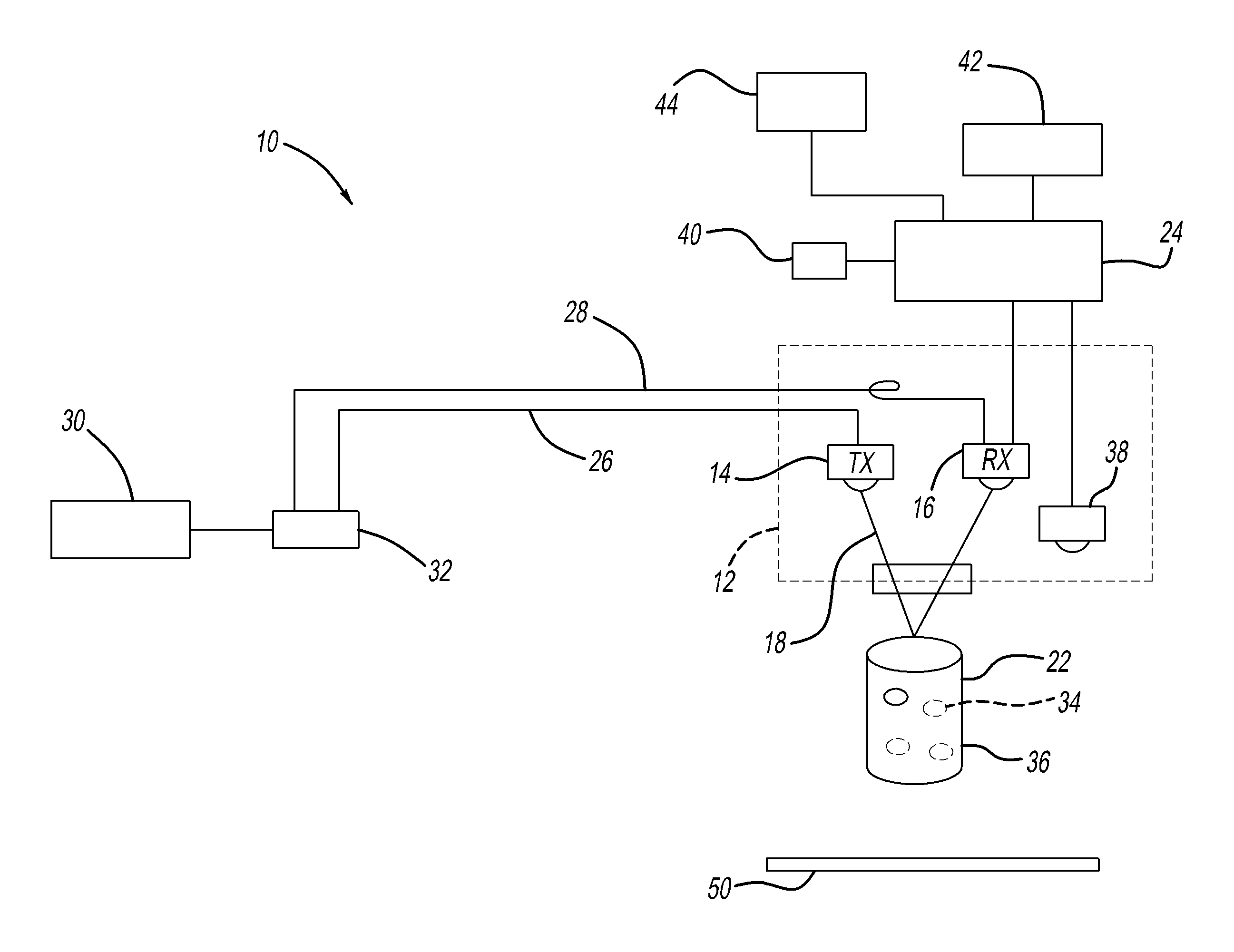

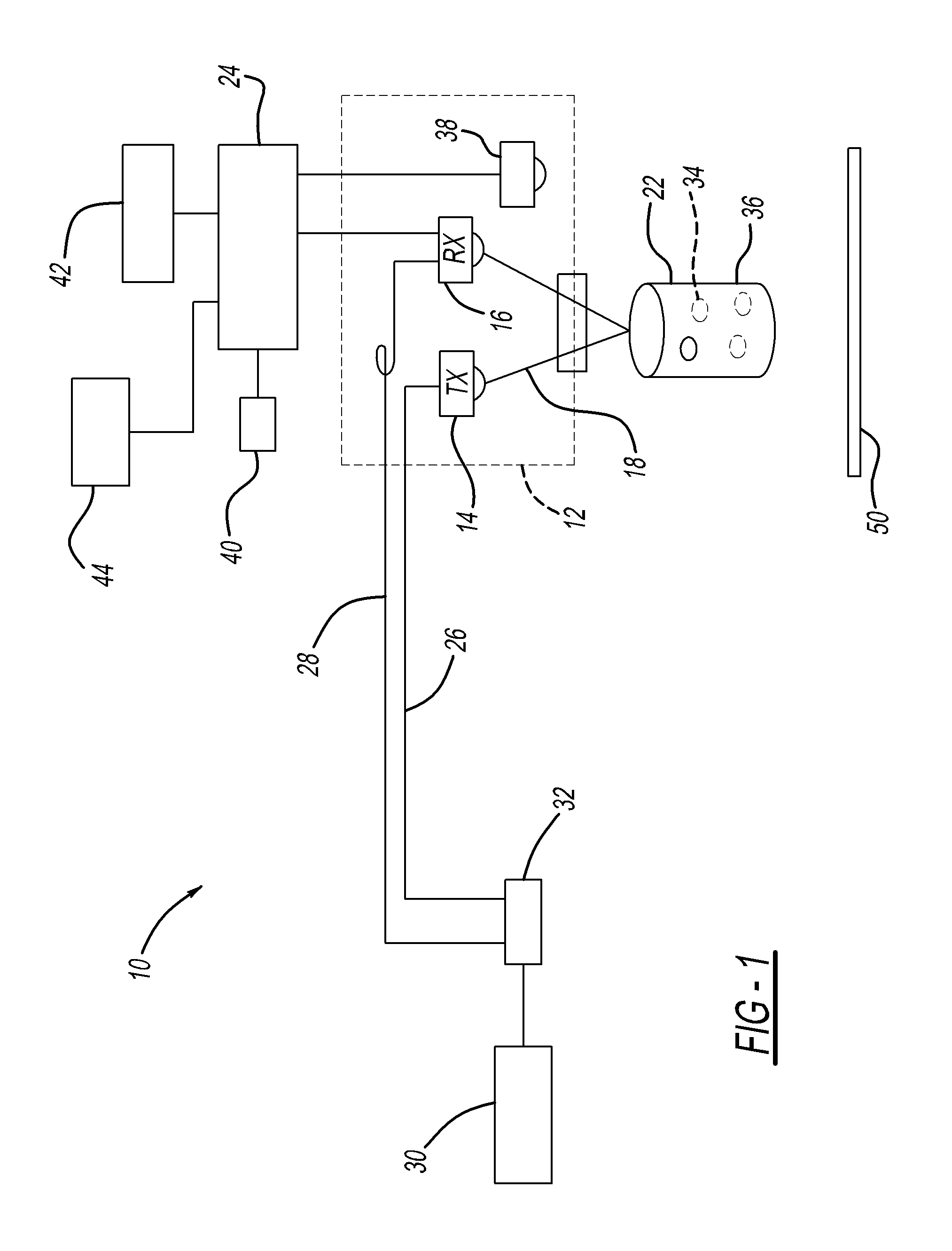

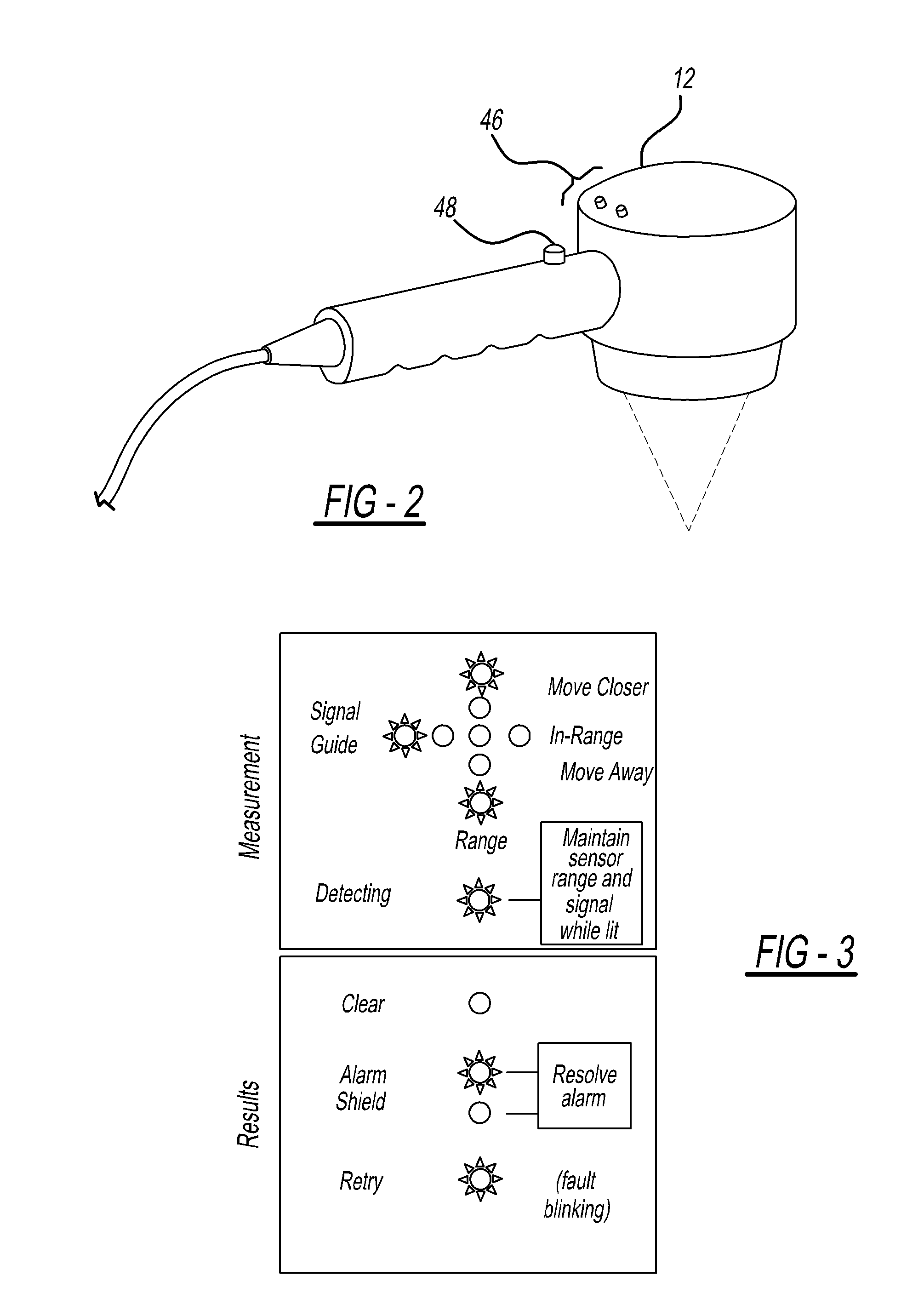

System and method to detect anomalies

ActiveUS20150060673A1Minimal equipment footprintMinimal ease-of-useRadiation pyrometryMaterial analysis by optical meansElectromagnetic launchElectromagnetic pulse

A system and method for detecting anomalies concealed upon a person may include a detection probe having an electromagnetic transmitter and an electromagnetic receiver. The electromagnetic transmitter is configured to emit electromagnetic pulses, while the electromagnetic receiver is configured to sample electromagnetic pulses from the electromagnetic receiver at specified times within a waveform window. The electromagnetic pulses may span the terahertz spectral region of 0.04 to 4 THz. The system may also have optical fibers connected to the electromagnetic transmitter and electromagnetic receiver, wherein femtosecond laser pulses are directed from a source to the electromagnetic transmitter and the electromagnetic receiver by the optical fibers.

Owner:LUNA INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com