Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10712 results about "Dopant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

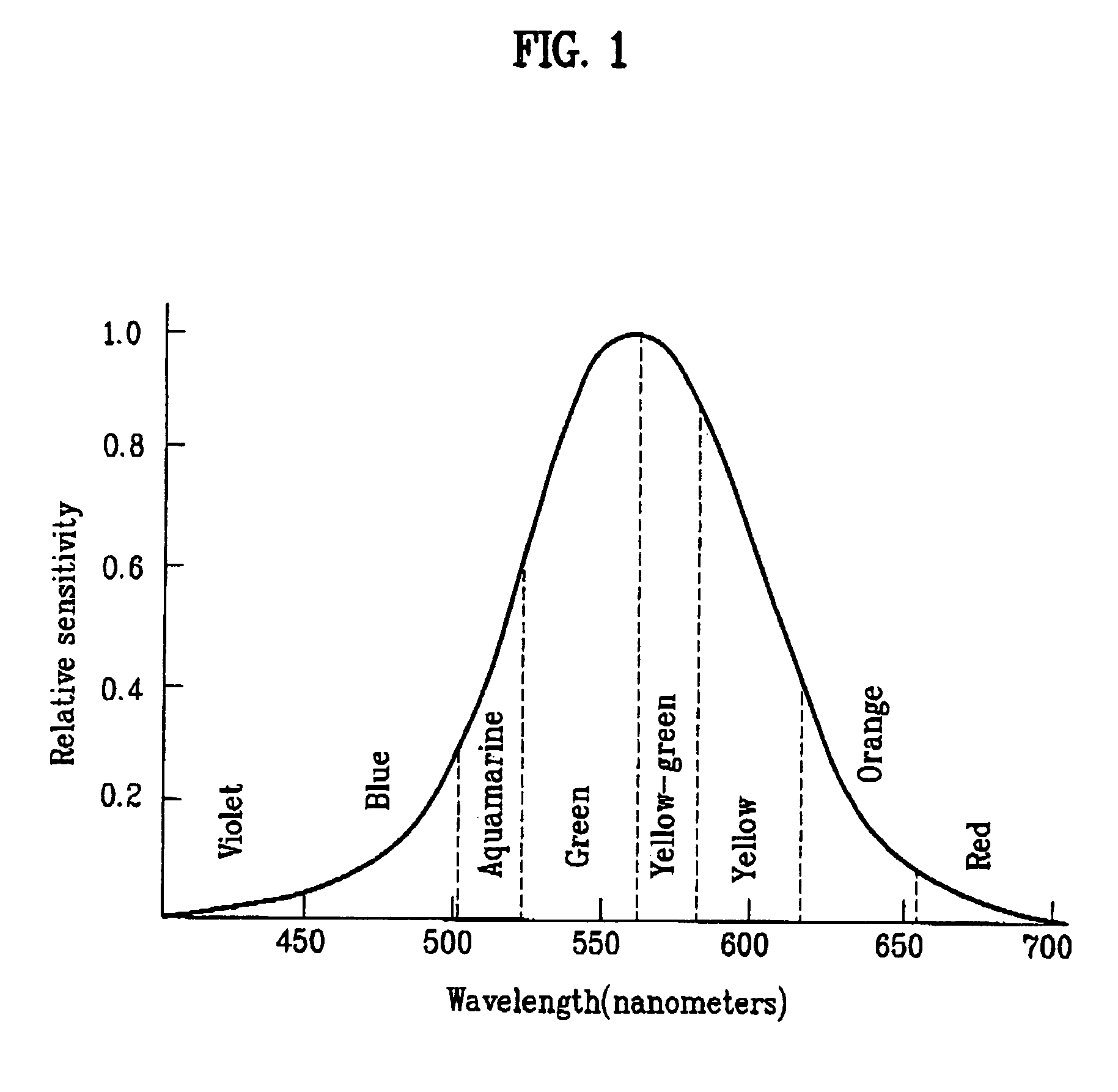

A dopant, also called a doping agent, is a trace of impurity element that is introduced into a chemical material to alter its original electrical or optical properties. The amount of dopant necessary to cause changes is typically very low. When doped into crystalline substances, the dopant's atoms get incorporated into its crystal lattice. The crystalline materials are frequently either crystals of a semiconductor such as silicon and germanium for use in solid-state electronics, or transparent crystals for use in the production of various laser types; however, in some cases of the latter, noncrystalline substances such as glass can also be doped with impurities.

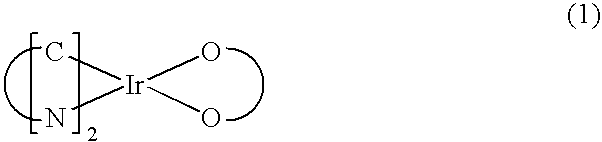

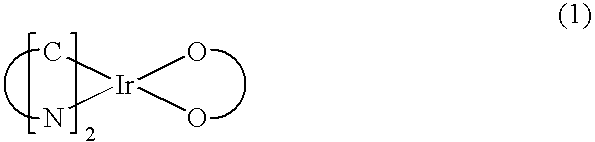

Cyclometallated iridium carbene complexes for use as hosts

ActiveUS7154114B2Electrolysis componentsElectroluminescent light sourcesDopantOrganic light emitting device

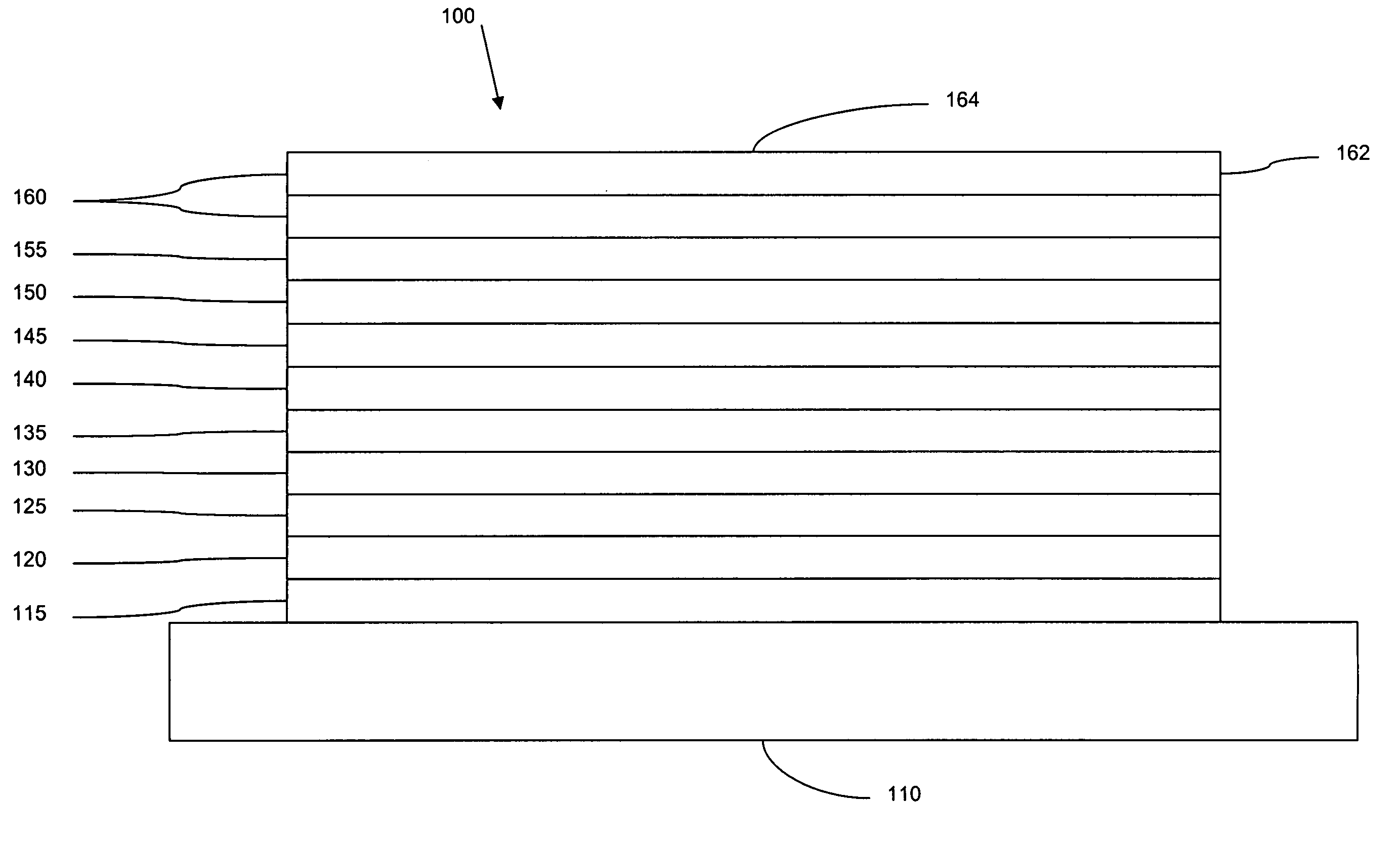

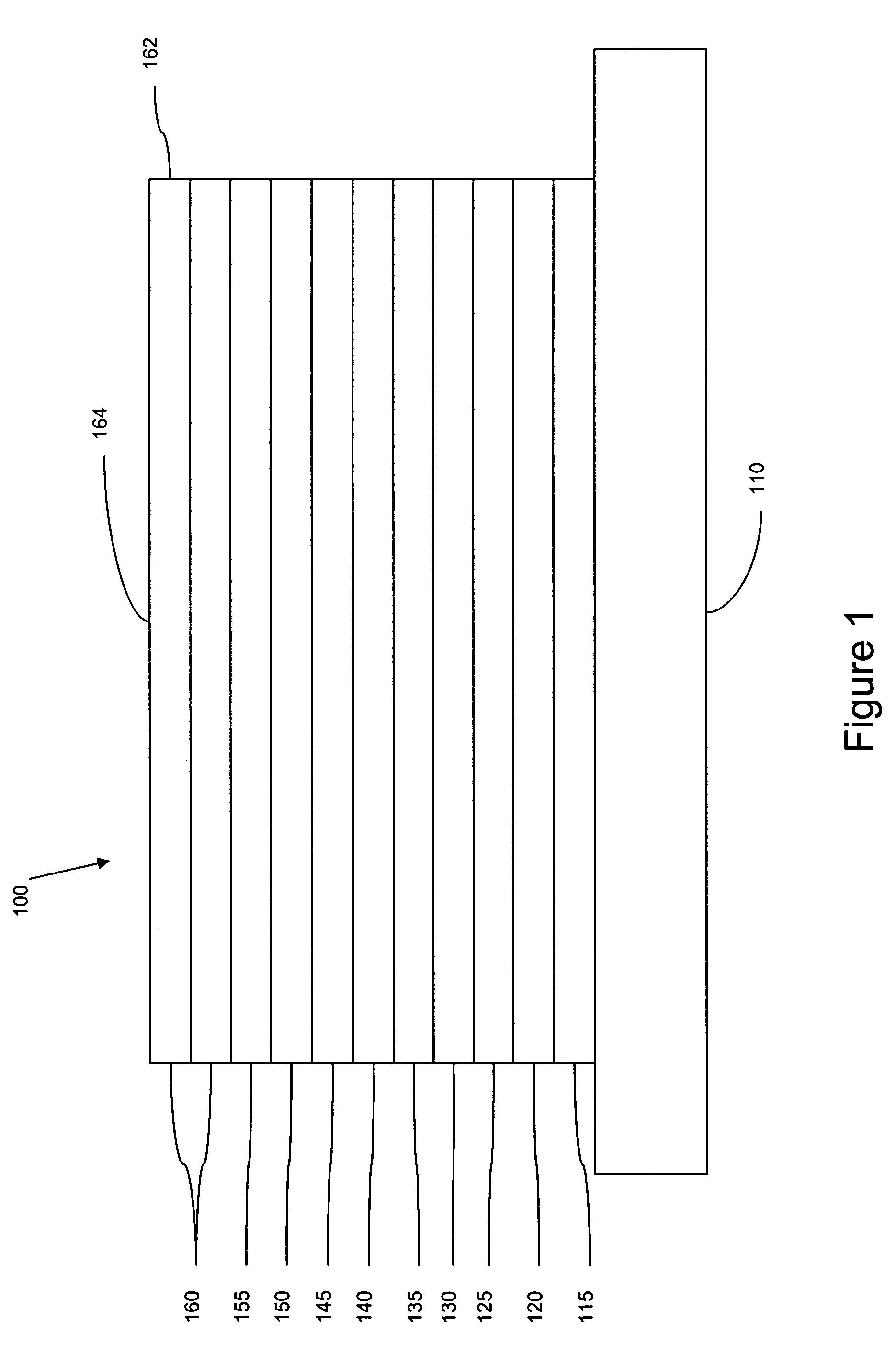

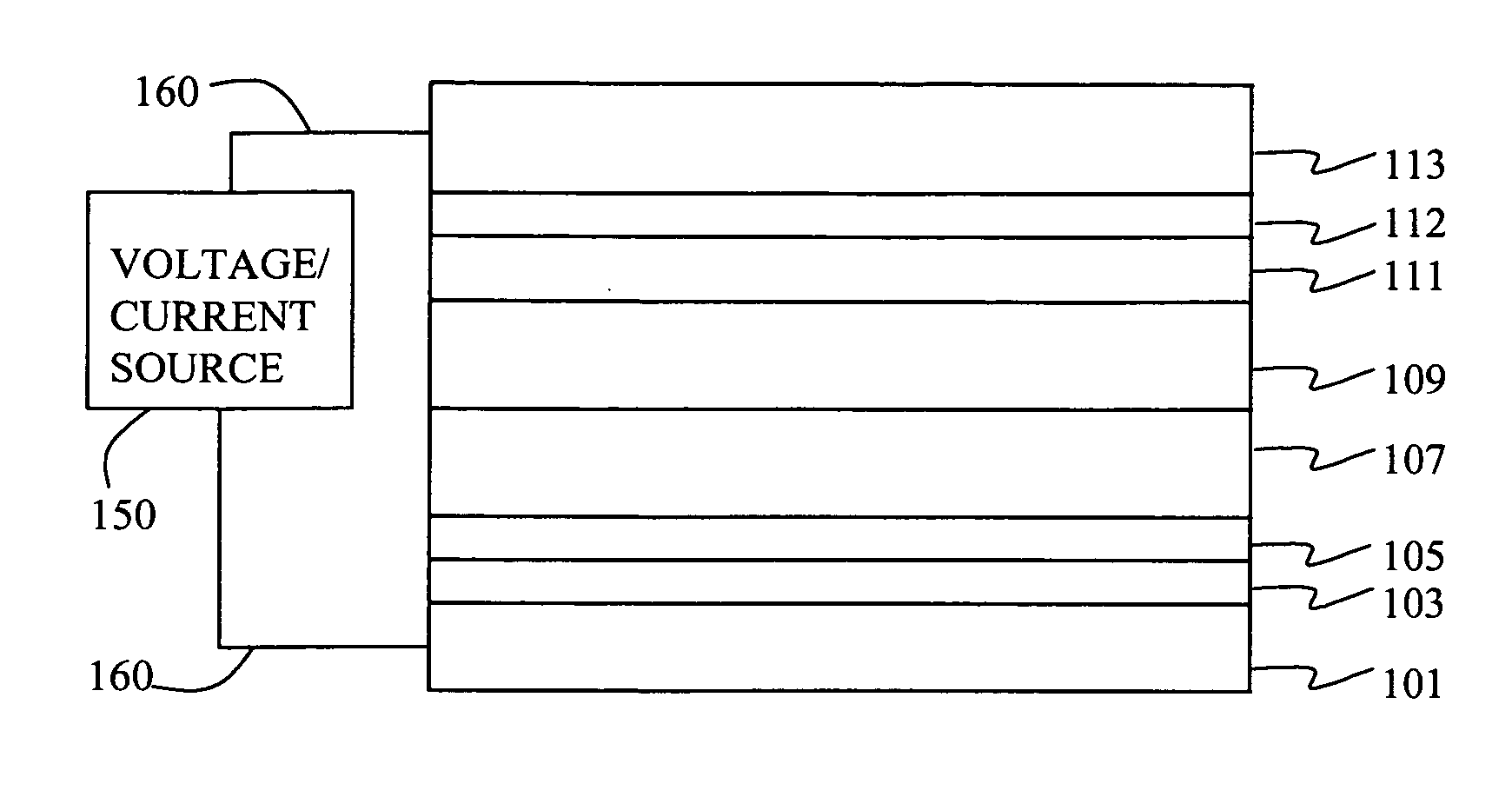

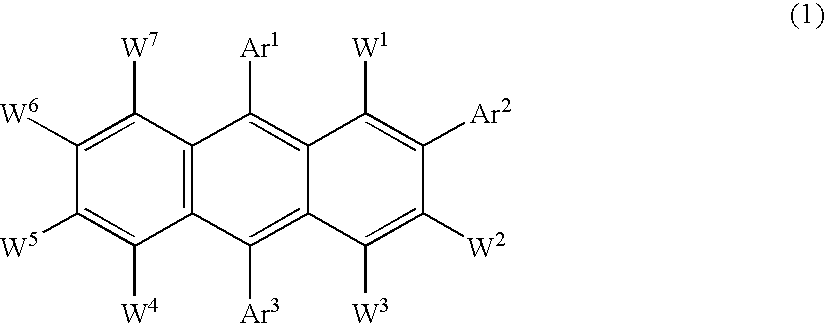

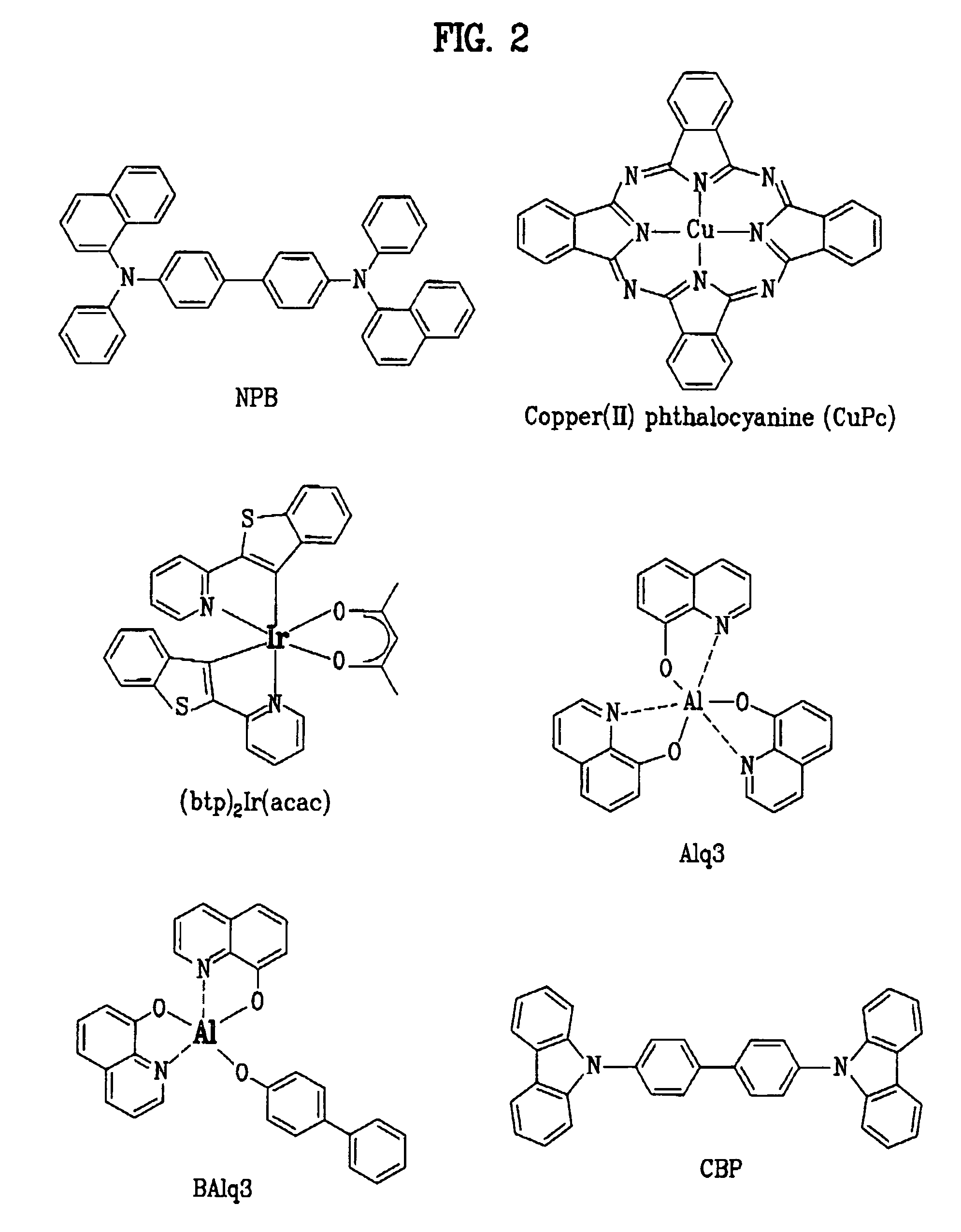

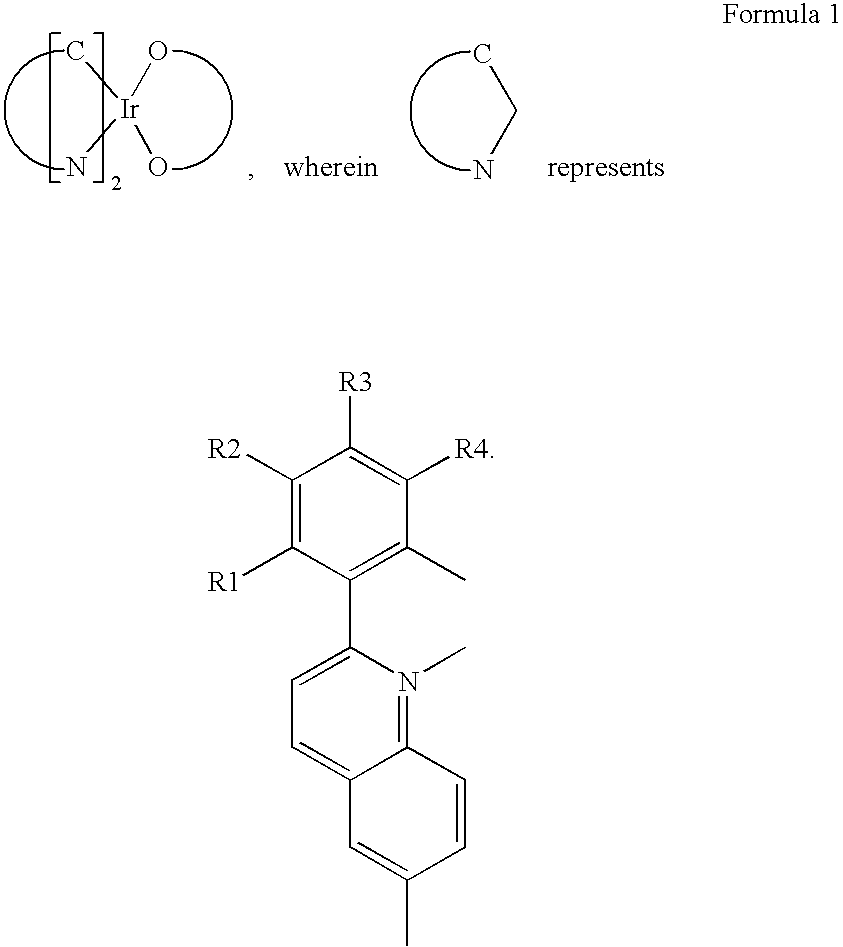

An organic light emitting device is provided. The device has an anode, a cathode and an organic layer disposed between the anode and the cathode. The organic layer comprises a host and a dopant, and the host comprises a compound having at least one carbene atom coordinated to iridium, and the compound has the structure:

Owner:UNIVERSAL DISPLAY +1

Electroluminescent device including an anthracene derivative

InactiveUS20070252517A1Reduce the driving voltageImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesDopantAnthracene

An OLED device comprises a cathode, an anode, and has therebetween a light emitting layer containing a host material and an emitting dopant material wherein the host includes a monoanthracene compound bearing aromatic groups in the 2-, 9-, and 10-positions and being further substituted or not with electron donating groups sufficient so as to provide an anthracene derivative that exhibits a measured oxidation potential of less than 1.28 V.

Owner:GLOBAL OLED TECH

High stress nitride film and method for formation thereof

ActiveUS20060199357A1Increase the tensile stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantNitrogen

A silicon nitride film is formed on a substrate in a reaction chamber by introducing trisilane and a reactive nitrogen species into the chamber in separate pulses. A carbon precursor gas is also flowed into the chamber during introduction of the trisilane and / or during introduction of the reactive nitrogen species, or in pulses separate from the trisilane and reactive nitrogen species pulses. The carbon is used as a dopant in the silicon nitride film and advantageously allows a high stress silicon nitride film to be formed.

Owner:ASM INTERNATIONAL

Method of doping organic semiconductors with quinone derivatives and 1, 3, 2 - dioxaborine derivatives

The invention relates to the use of an organic mesomeric compound as organic dopant for doping an organic semiconducting matrix material for varying the electrical properties thereof. In order to be able to handle organic semiconductors more easily in the production process and to be able to produce electronic components with doped organic semiconductors more reproducibly, a quinone or quinone derivative or a 1,3,2-dioxaborine or a 1,3,2-dioxaborine derivative may be used as a mesomeric compound, which under like evaporation conditions has a lower volatility than tetrafluorotetracyanoquinonedimethane (F4TCNQ).

Owner:KUEHL OLAF +4

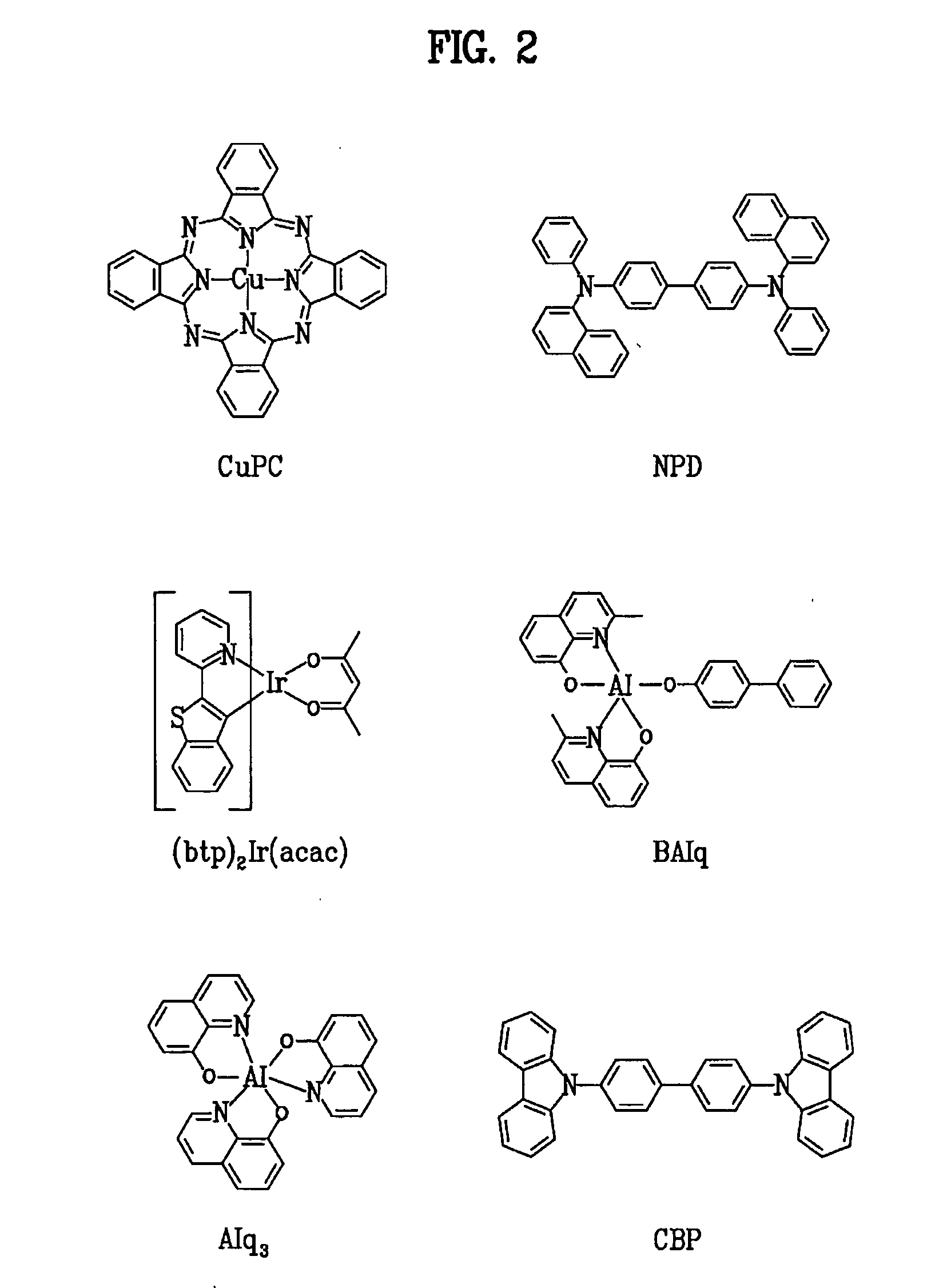

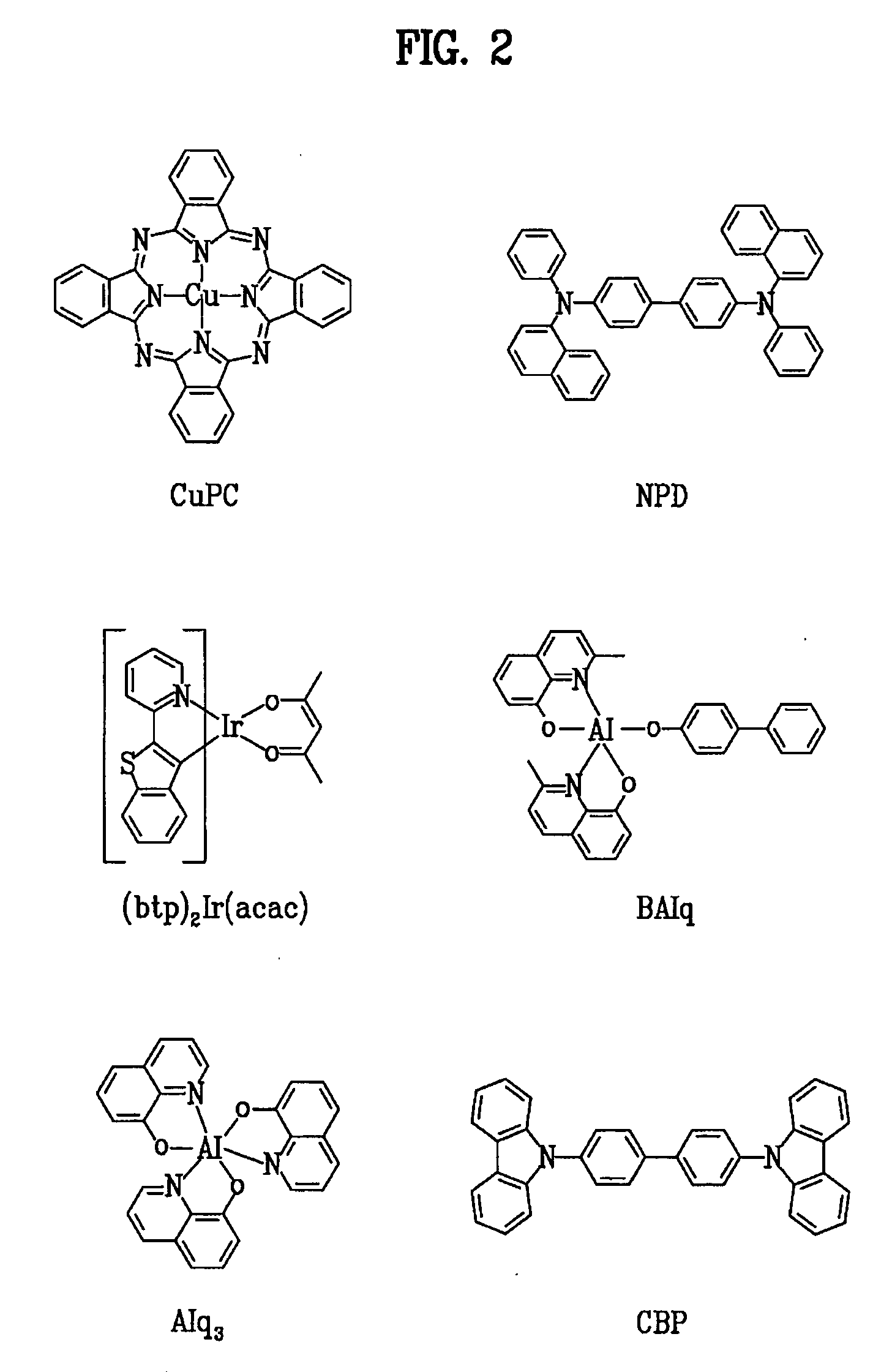

Red phosphorescent compounds and organic electroluminescent devices using the same

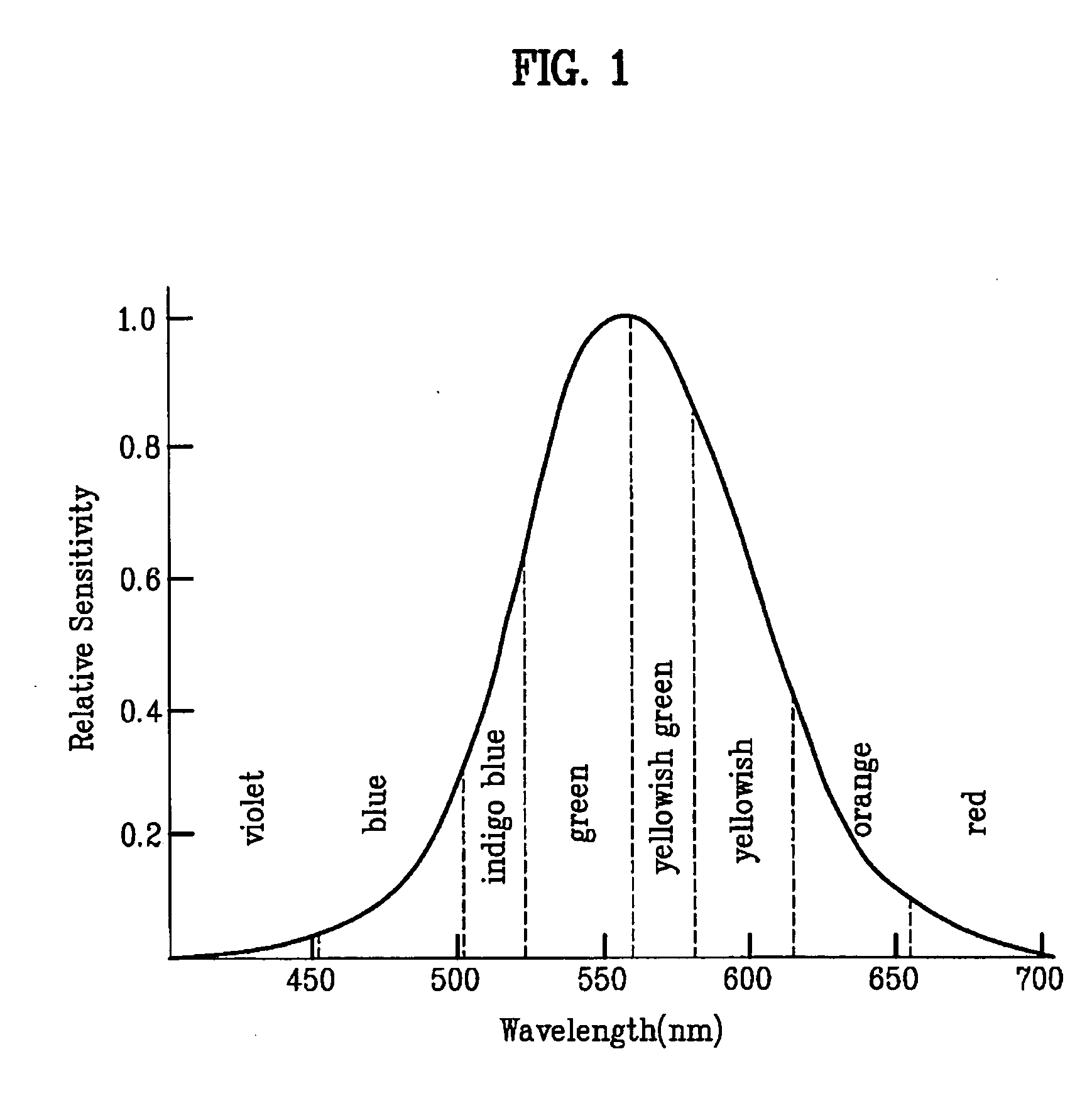

ActiveUS20070104980A1High color purityLong life-timeIndium organic compoundsDischarge tube luminescnet screensDopantHydrogen

Disclosed herein are red phosphorescent compounds of the following Formulas 1 to 4: wherein is R1, R2 and R3 are independently a C1-C4 alkyl group, R4, R5, R6 and R7 are independently selected from hydrogen, C1-C4 alkyl groups and C1-C4 alkoxy groups, and is selected from 2,4-pentanedione, 2,2,6,6,-tetramethylheptane-3,5-dione, 1,3-propanedione, 1,3-butanedione, 3,5-heptanedione, 1,1,1-trifluoro-2,4-pentanedione, 1,1,1,5,5,5-hexafluoro-2,4-pentanedione, and 2,2-dimethyl-3,5-hexanedione; wherein is R1 and R2 are independently selected from C1-C4 alkyl groups and C1-C4 alkoxy groups, R3, R4, R5 and R6 are independently selected from hydrogen, C1-C4 alkyl groups and C1-C4 alkoxy groups, and is selected from 2,4-pentanedione, 2,2,6,6,-tetramethylheptane-3,5-dione, 1,3-propanedione, 1,3-butanedione, 3,5-heptanedione, 1,1,1-trifluoro-2,4-pentanedione, 1,1,1,5,5,5-hexafluoro-2,4-pentanedione and 2,2-dimethyl-3,5-hexanedione; wherein is R1 and R2 are independently selected from C1-C4 alkyl groups and C1-C4 alkoxy groups, R3, R4, R5 and R6 are independently selected from hydrogen, C1-C4 alkyl groups and C1-C4 alkoxy groups, and is selected from 2,4-pentanedione, 2,2,6,6,-tetramethylheptane-3,5-dione, 1,3-propanedione, 1,3-butanedione, 3,5-heptanedione, 1,1,1-trifluoro-2,4-pentanedione, 1,1,1,5,5,5-hexafluoro-2,4-pentanedione and 2,2-dimethyl-3,5-hexanedione; and wherein is R1 and R2 are independently selected from C1-C4 alkyl groups and C1-C4 alkoxy groups, R3, R4, R5 and R6 are independently selected from hydrogen, C1-C4 alkyl groups and C1-C4 alkoxy groups, and is selected from 2,4-pentanedione, 2,2,6,6,-tetramethylheptane-3,5-dione, 1,3-propanedione, 1,3-butanedione, 3,5-heptanedione, 1,1,1-trifluoro-2,4-pentanedione, 1,1,1,5,5,5-hexafluoro-2,4-pentanedione and 2,2-dimethyl-3,5-hexanedione. Further disclosed herein is an organic electroluminescent (EL) device comprising an anode, a hole injecting layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron injecting layer, and a cathode laminated in this order wherein one of the red phosphorescent compounds is used as a dopant of the light-emitting layer.

Owner:LG DISPLAY CO LTD

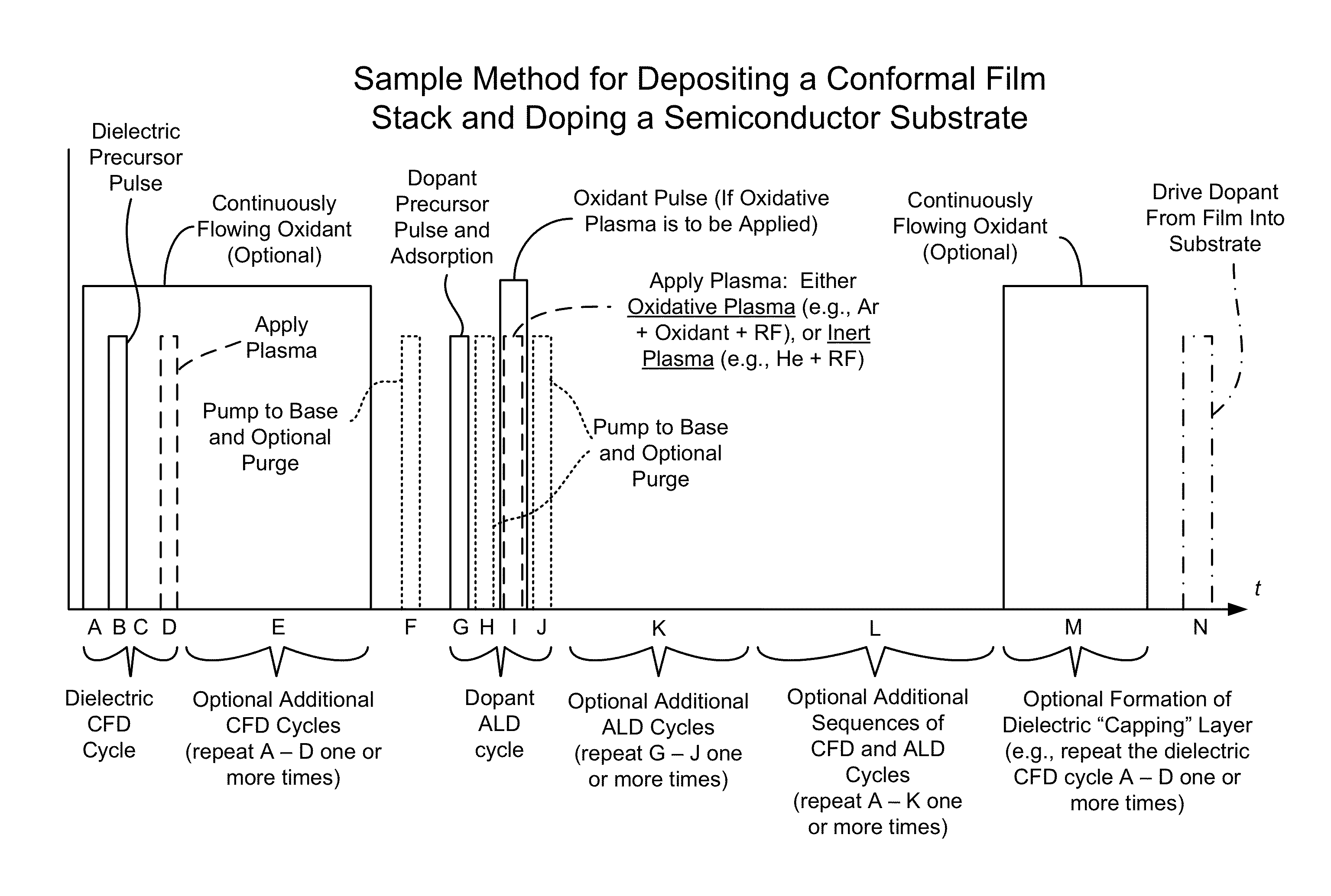

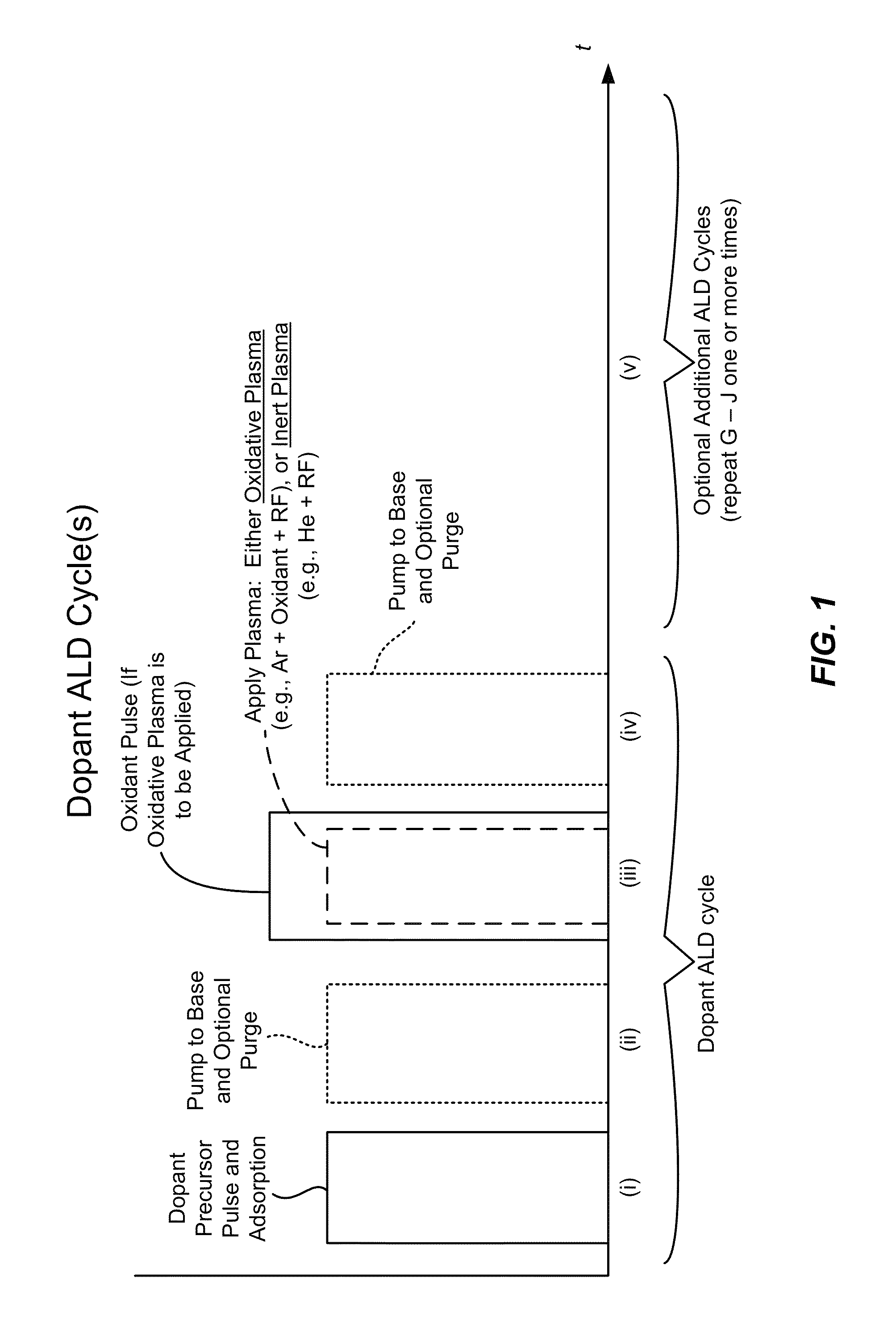

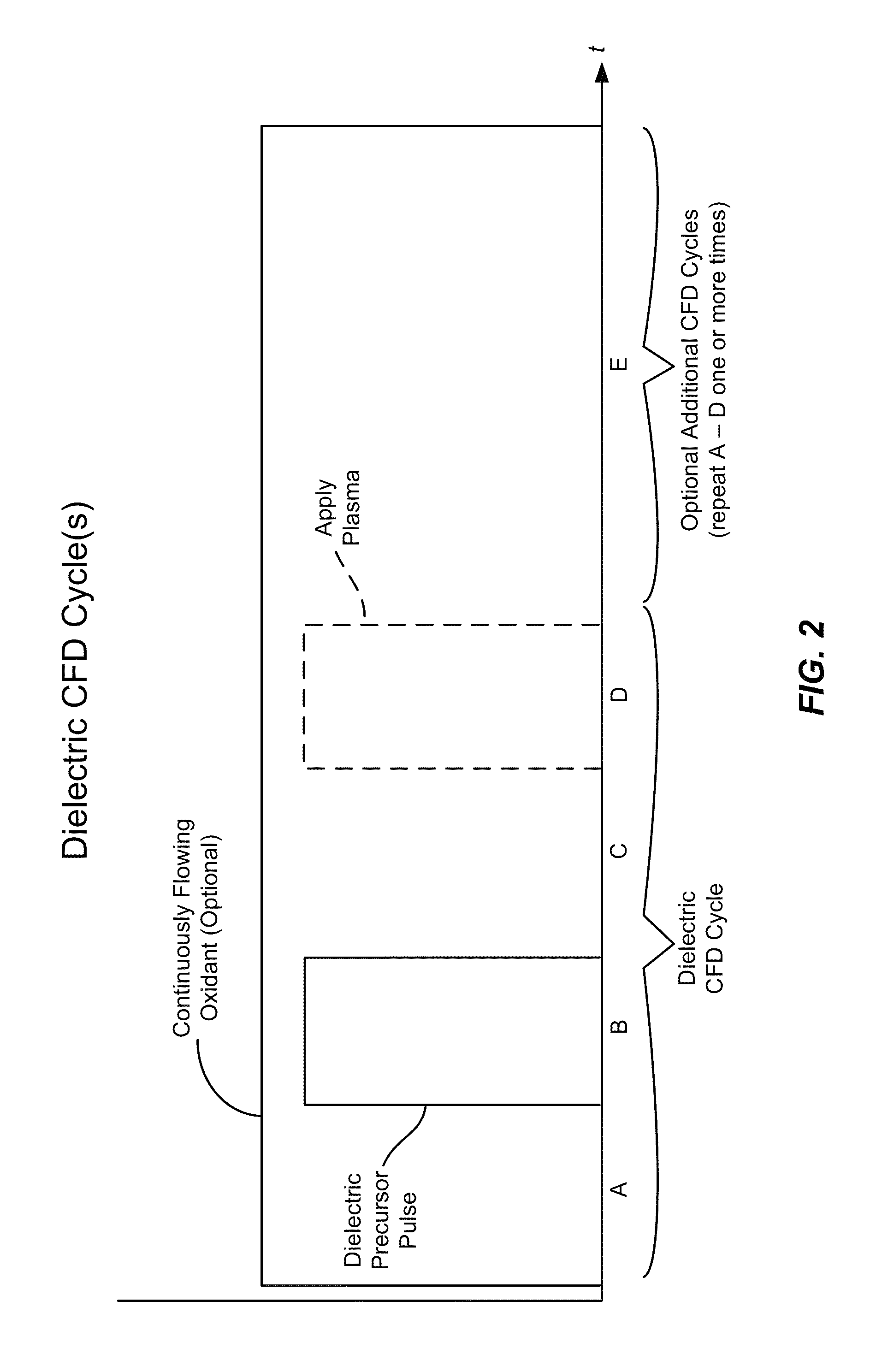

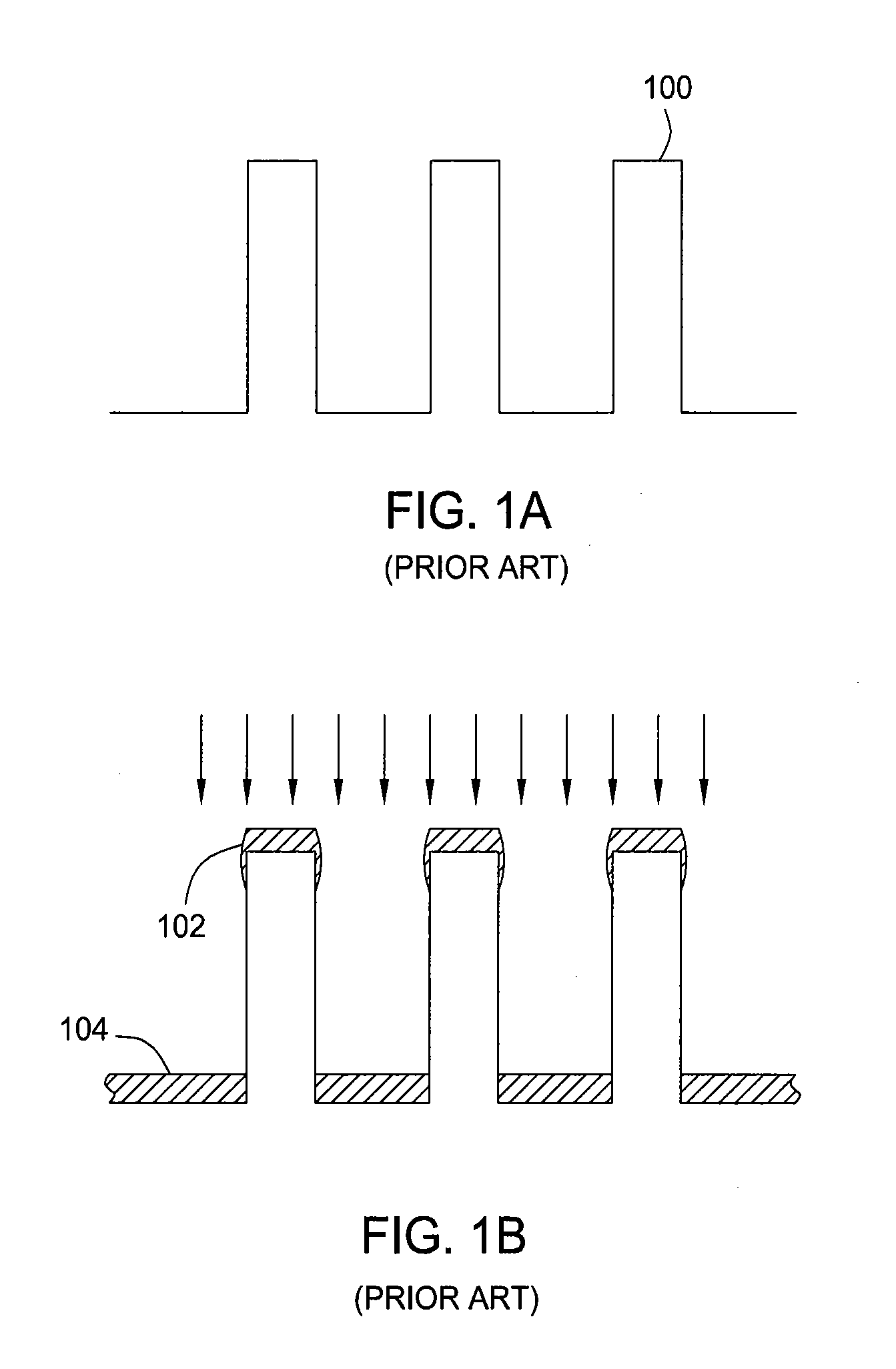

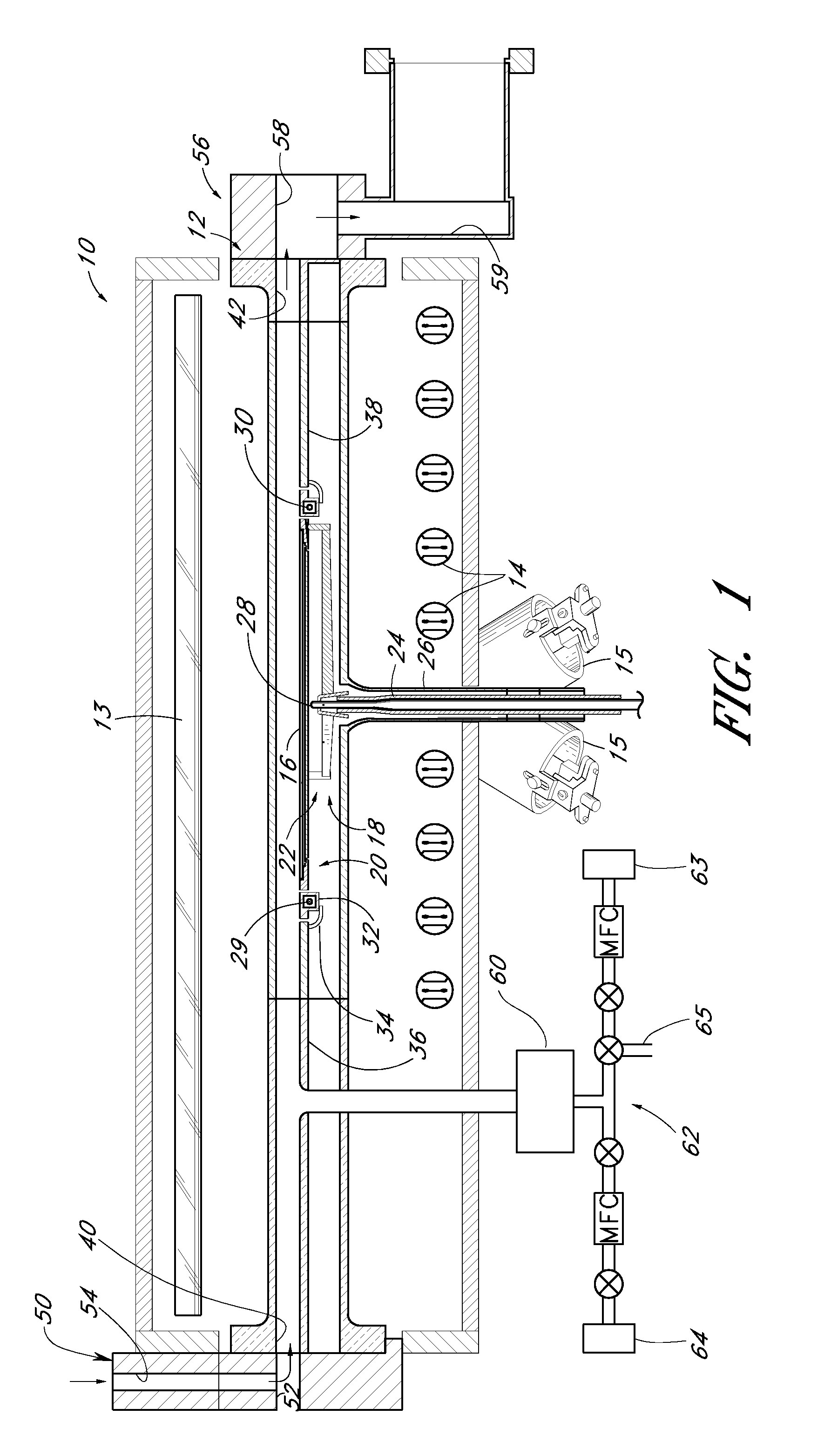

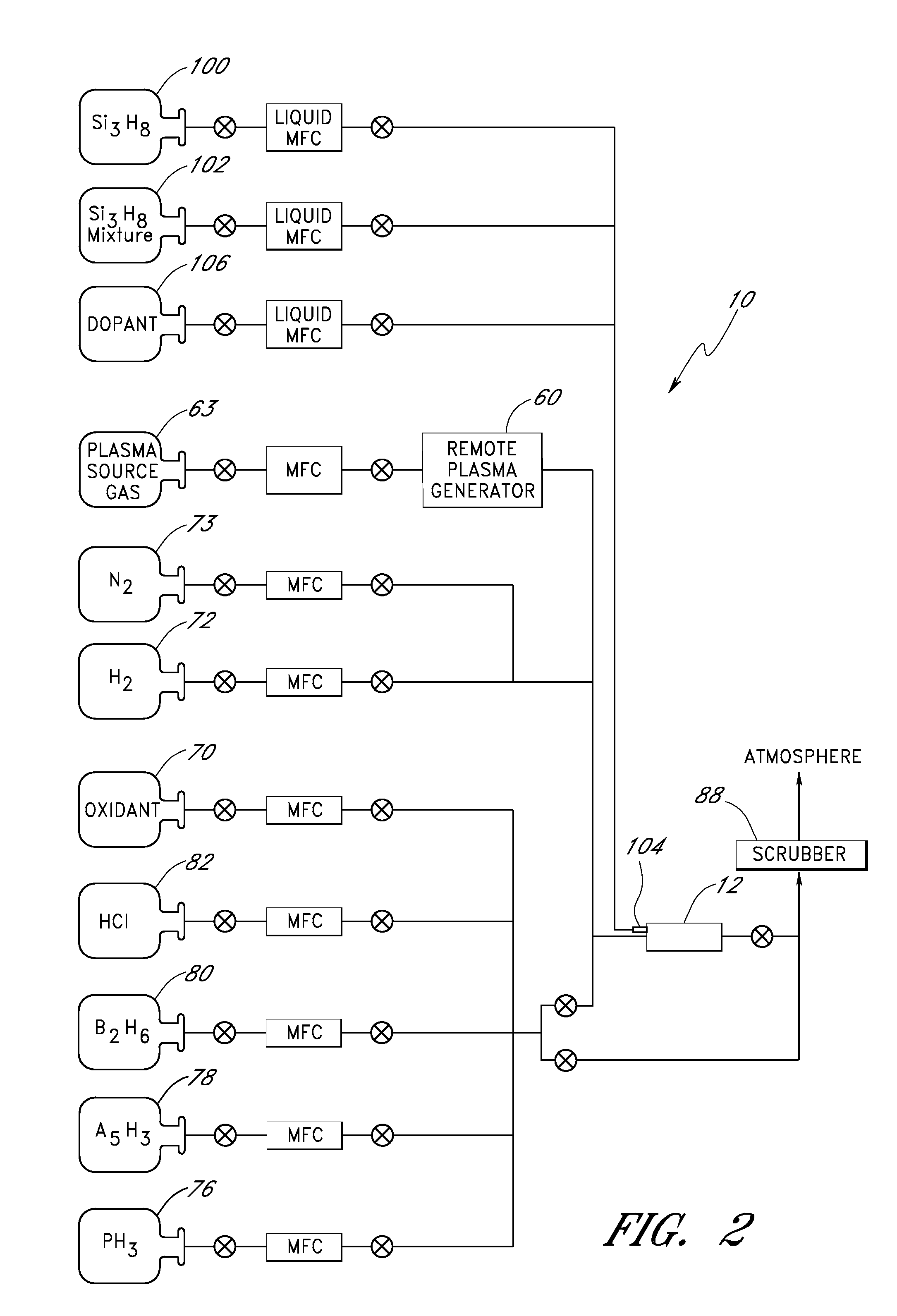

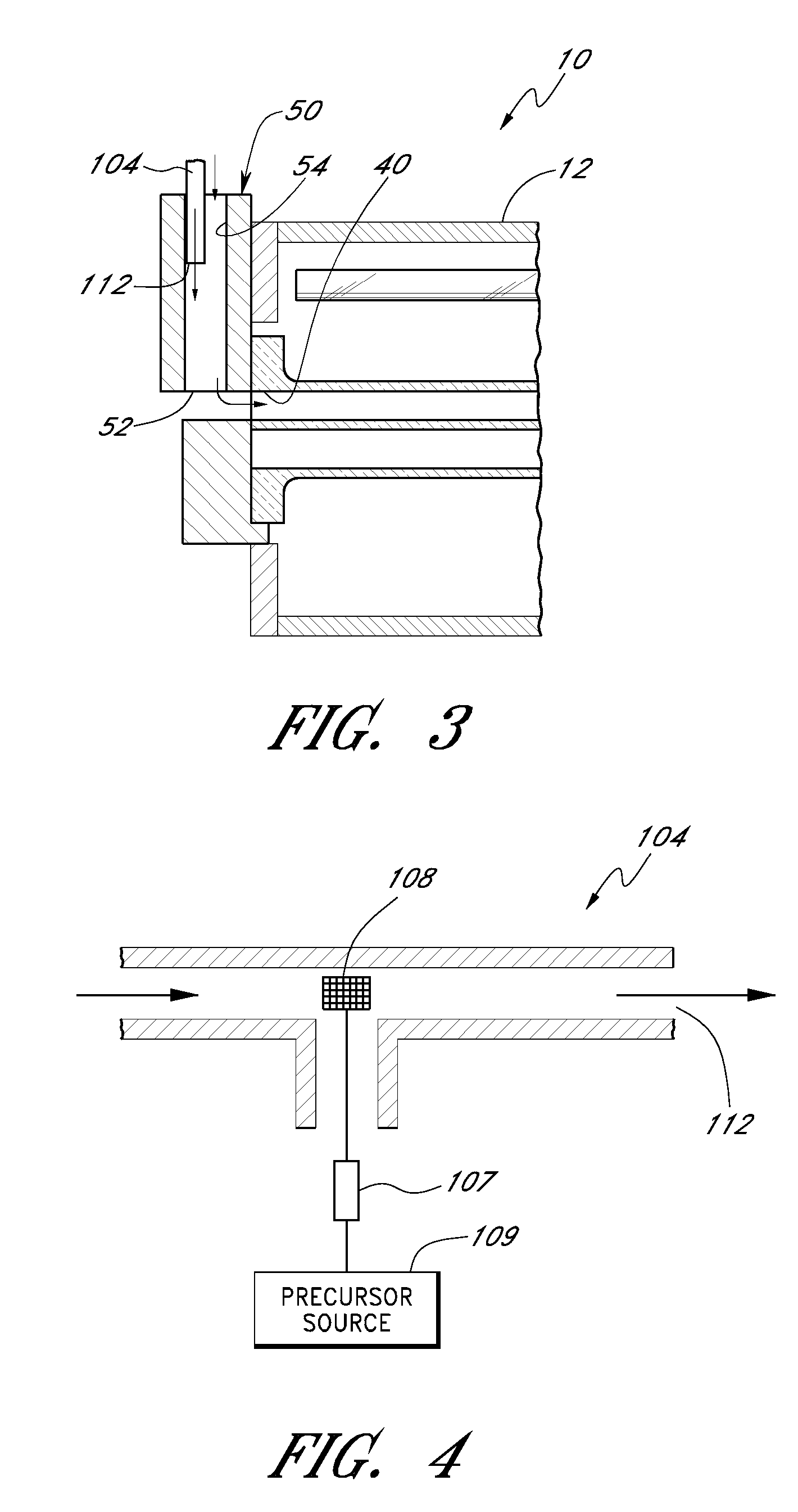

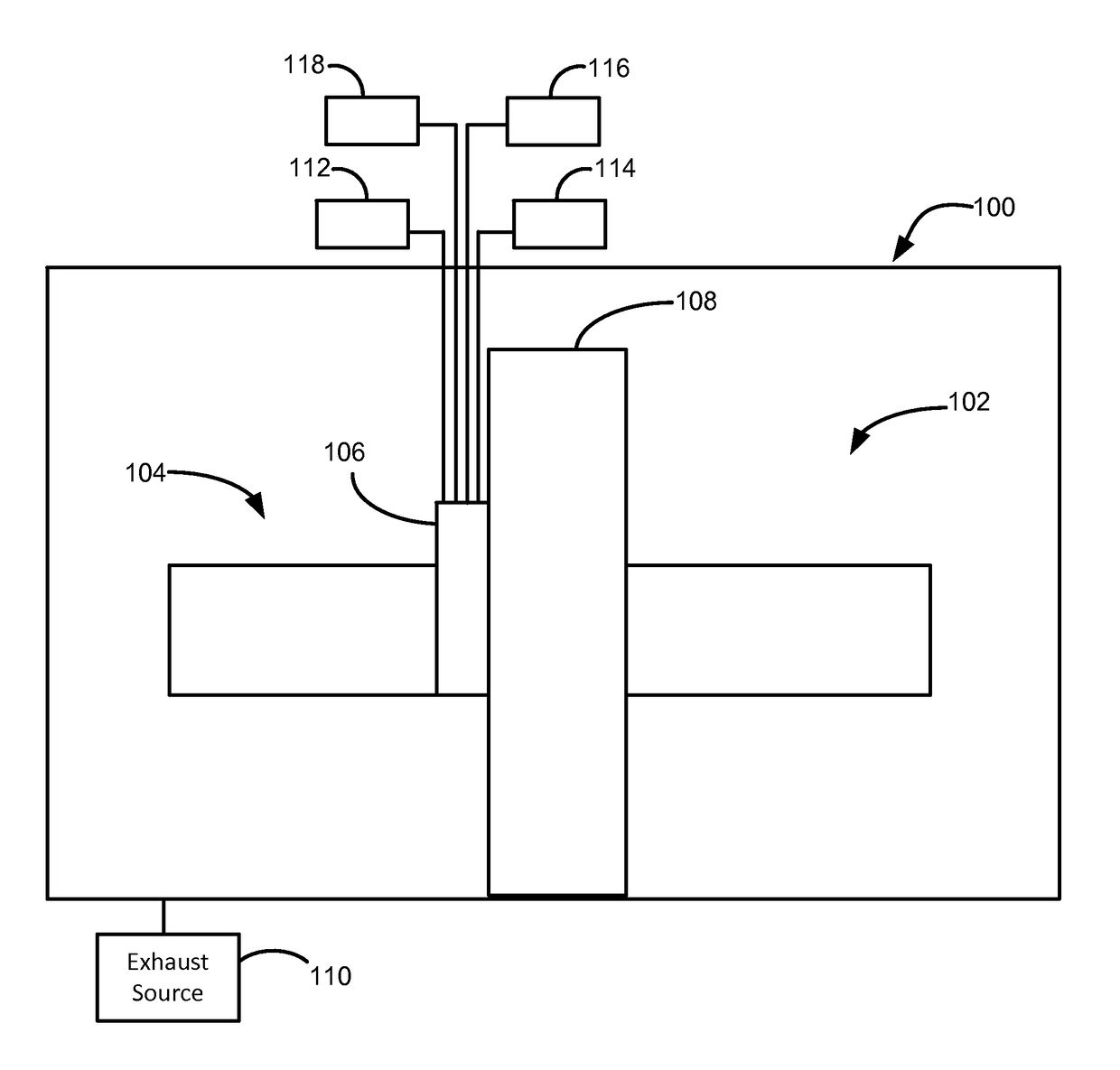

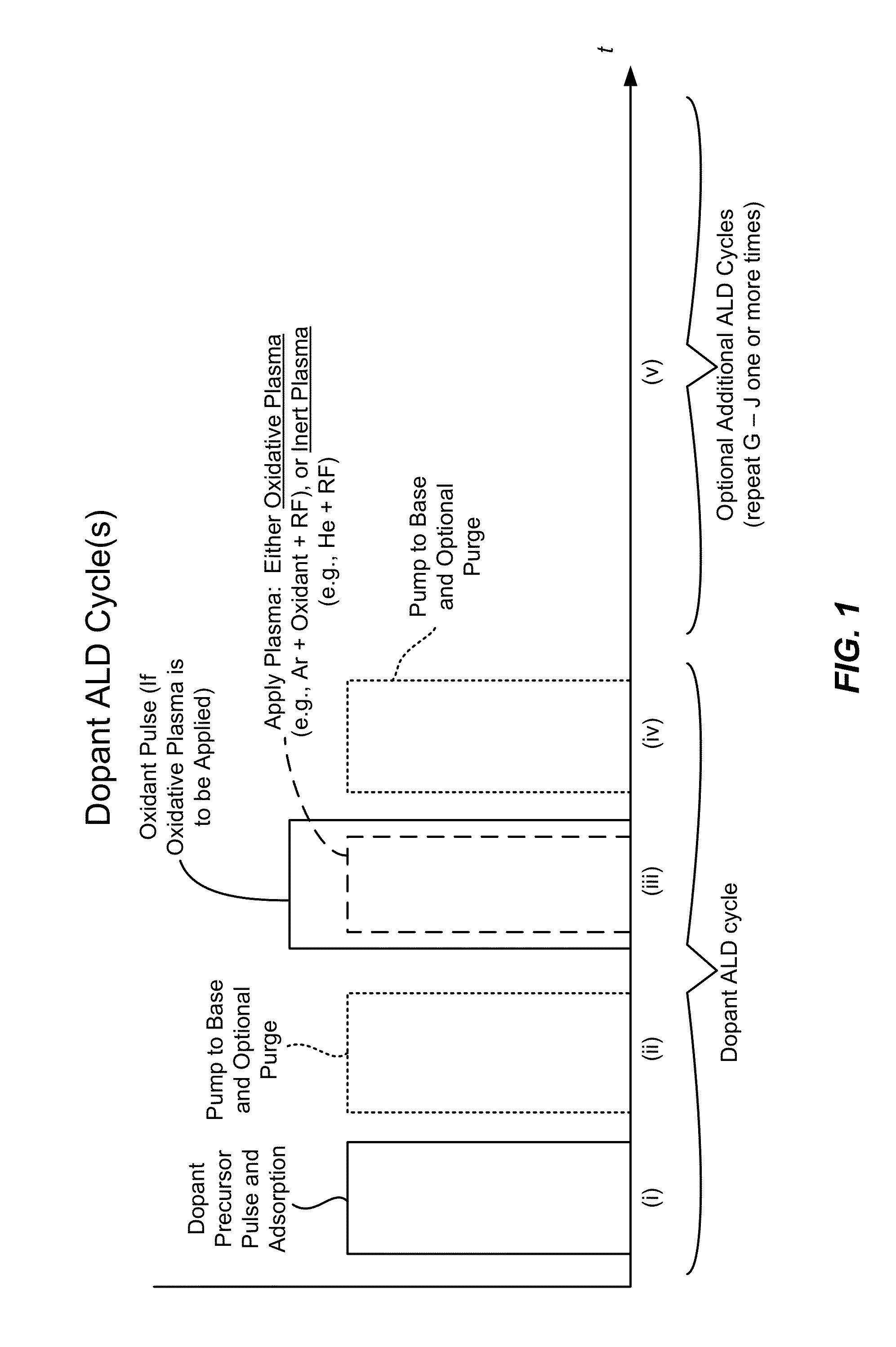

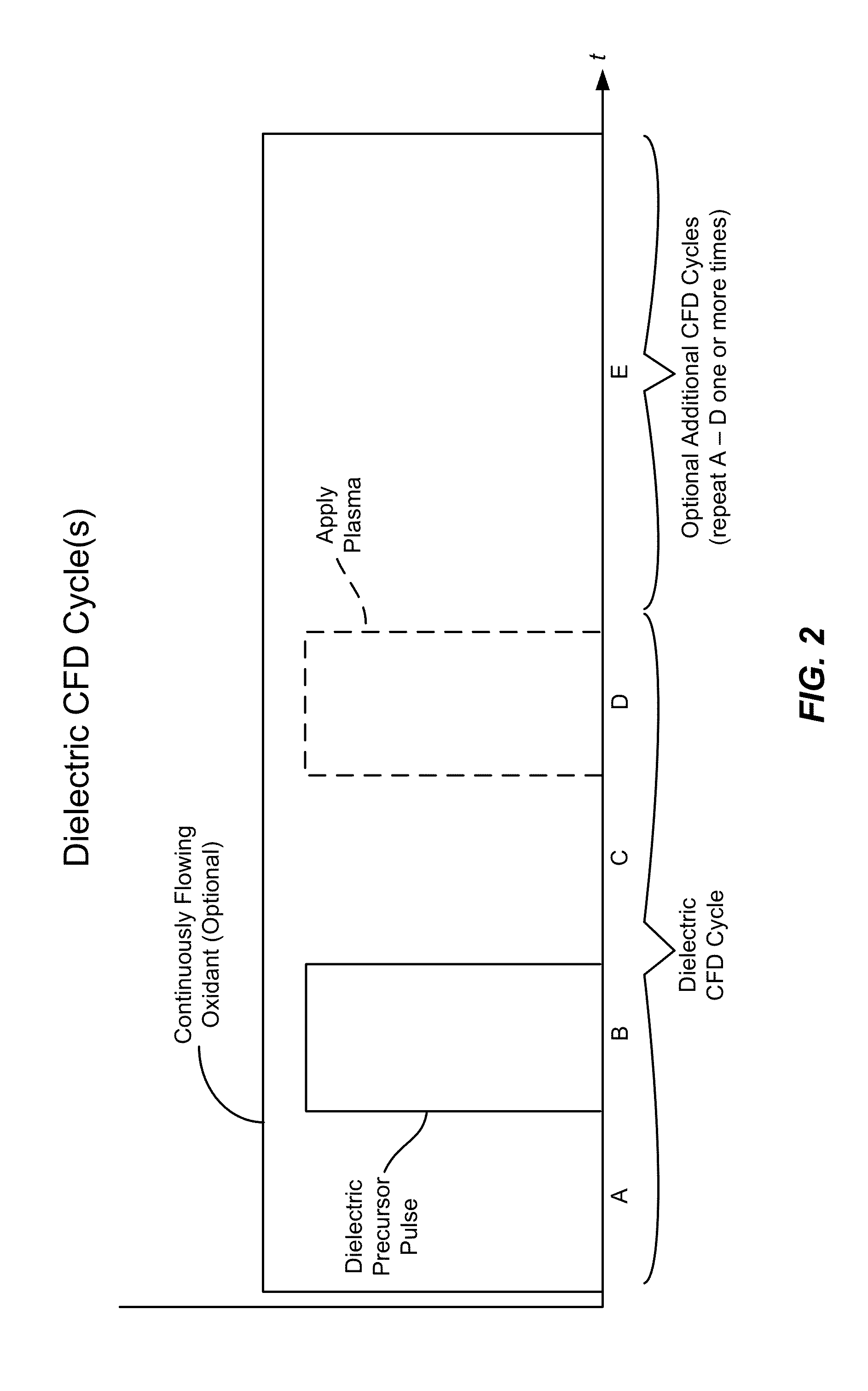

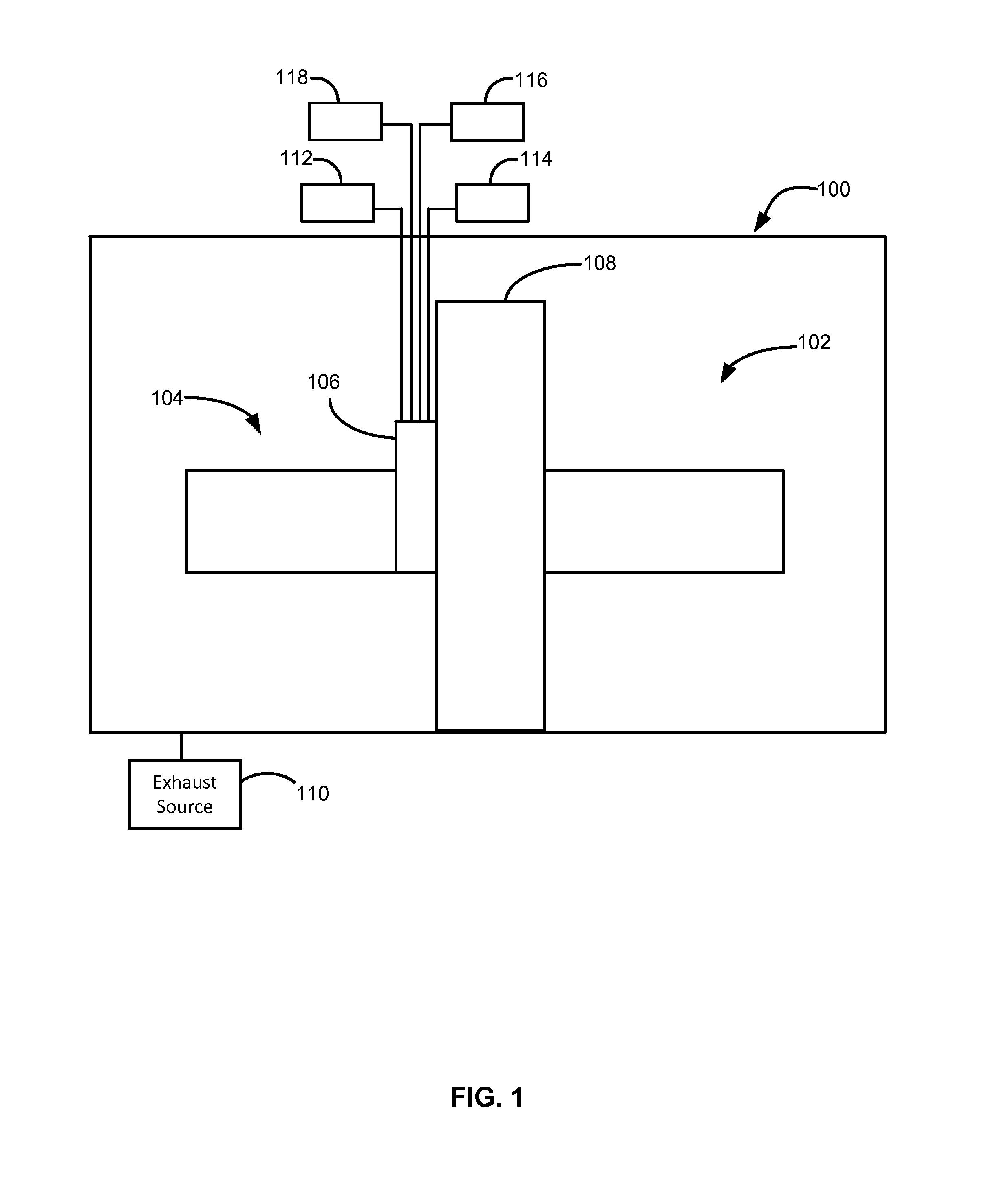

Conformal doping via plasma activated atomic layer deposition and conformal film deposition

ActiveUS8956983B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingDopantPatterned substrate

Disclosed herein are methods of doping a patterned substrate in a reaction chamber. The methods may include forming a first conformal film layer which has a dopant source including a dopant, and driving some of the dopant into the substrate to form a conformal doping profile. In some embodiments, forming the first film layer may include introducing a dopant precursor into the reaction chamber, adsorbing the dopant precursor under conditions whereby it forms an adsorption-limited layer, and reacting the adsorbed dopant precursor to form the dopant source. Also disclosed herein are apparatuses for doping a substrate which may include a reaction chamber, a gas inlet, and a controller having machine readable code including instructions for operating the gas inlet to introduce dopant precursor into the reaction chamber so that it is adsorbed, and instructions for reacting the adsorbed dopant precursor to form a film layer containing a dopant source.

Owner:NOVELLUS SYSTEMS

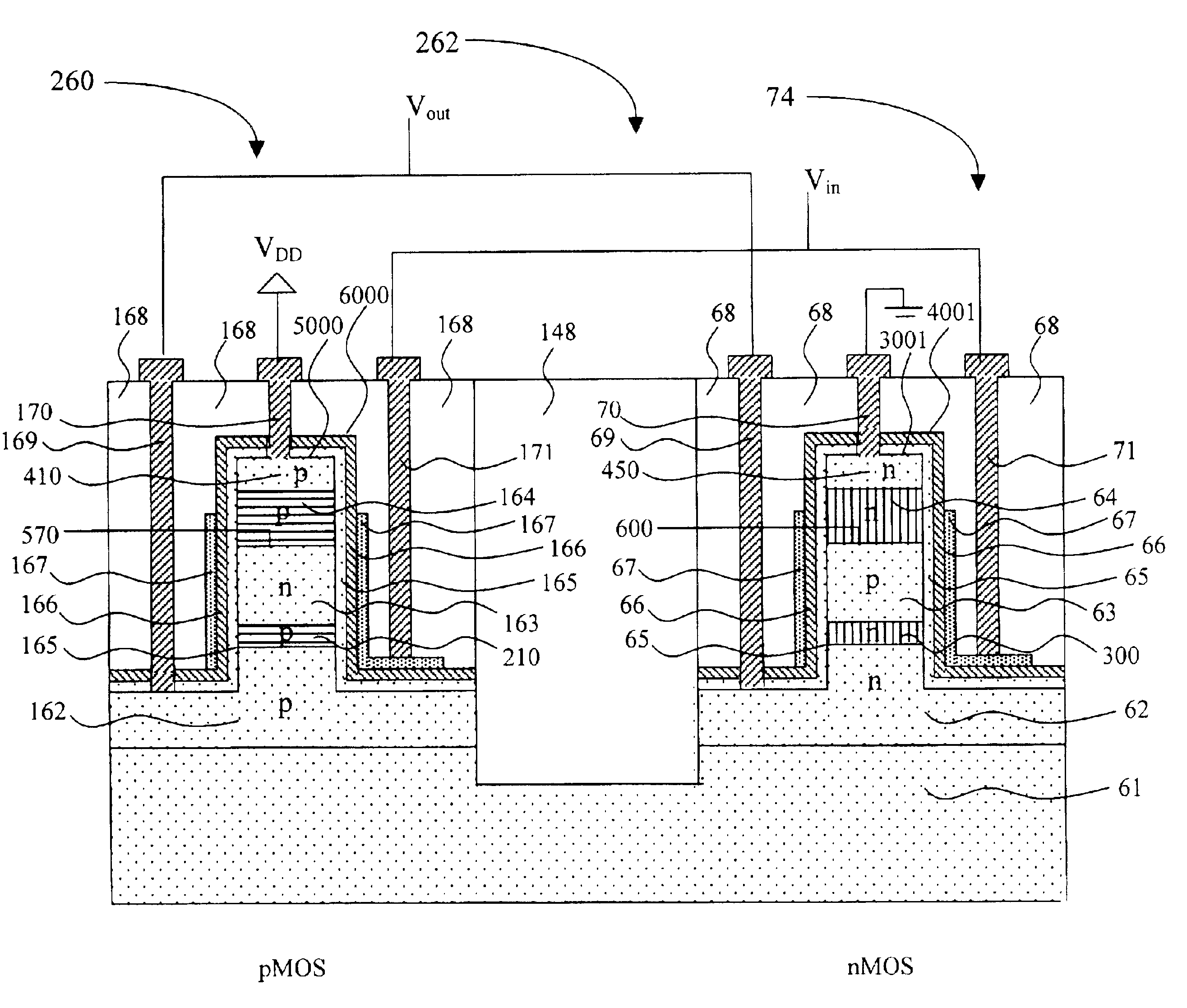

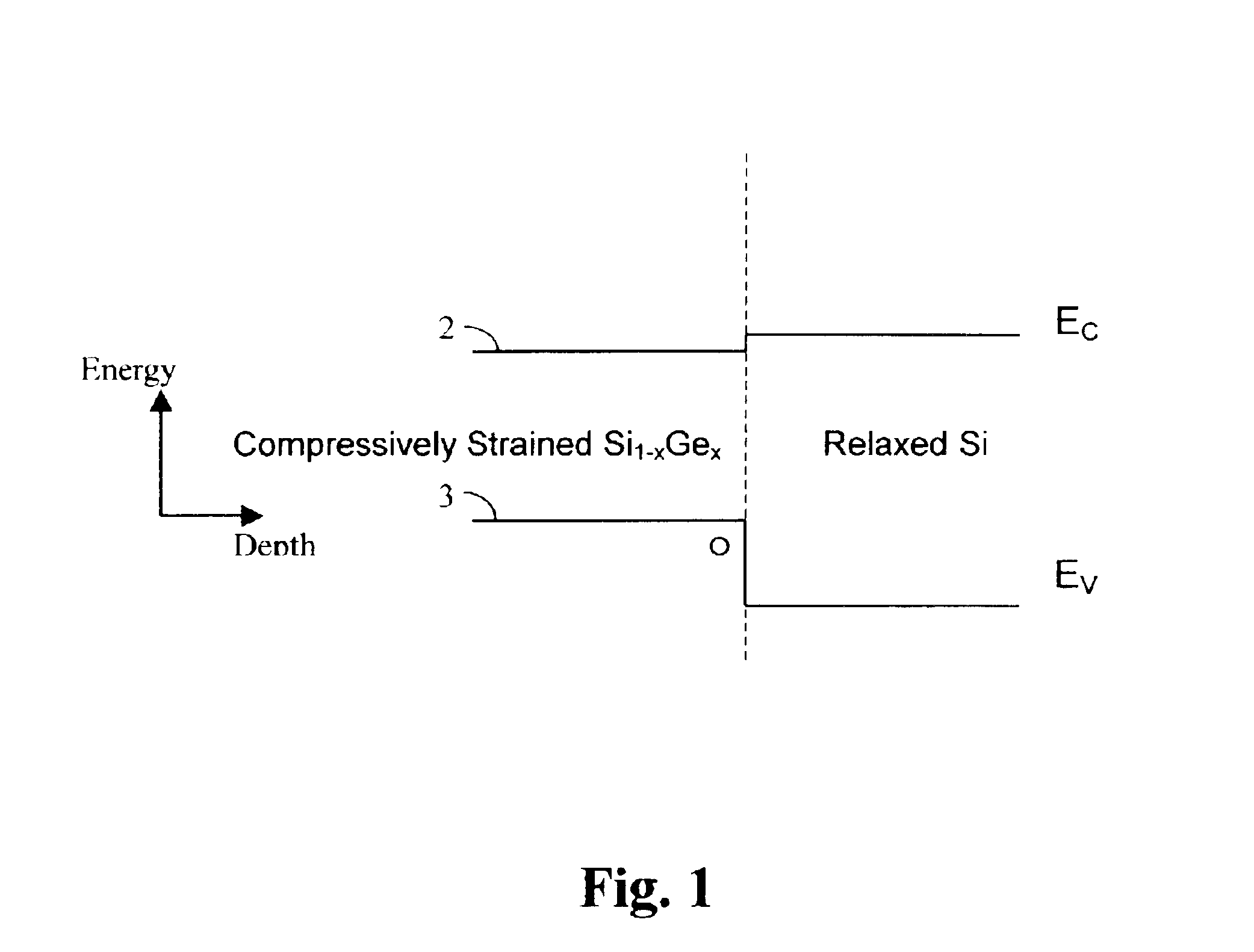

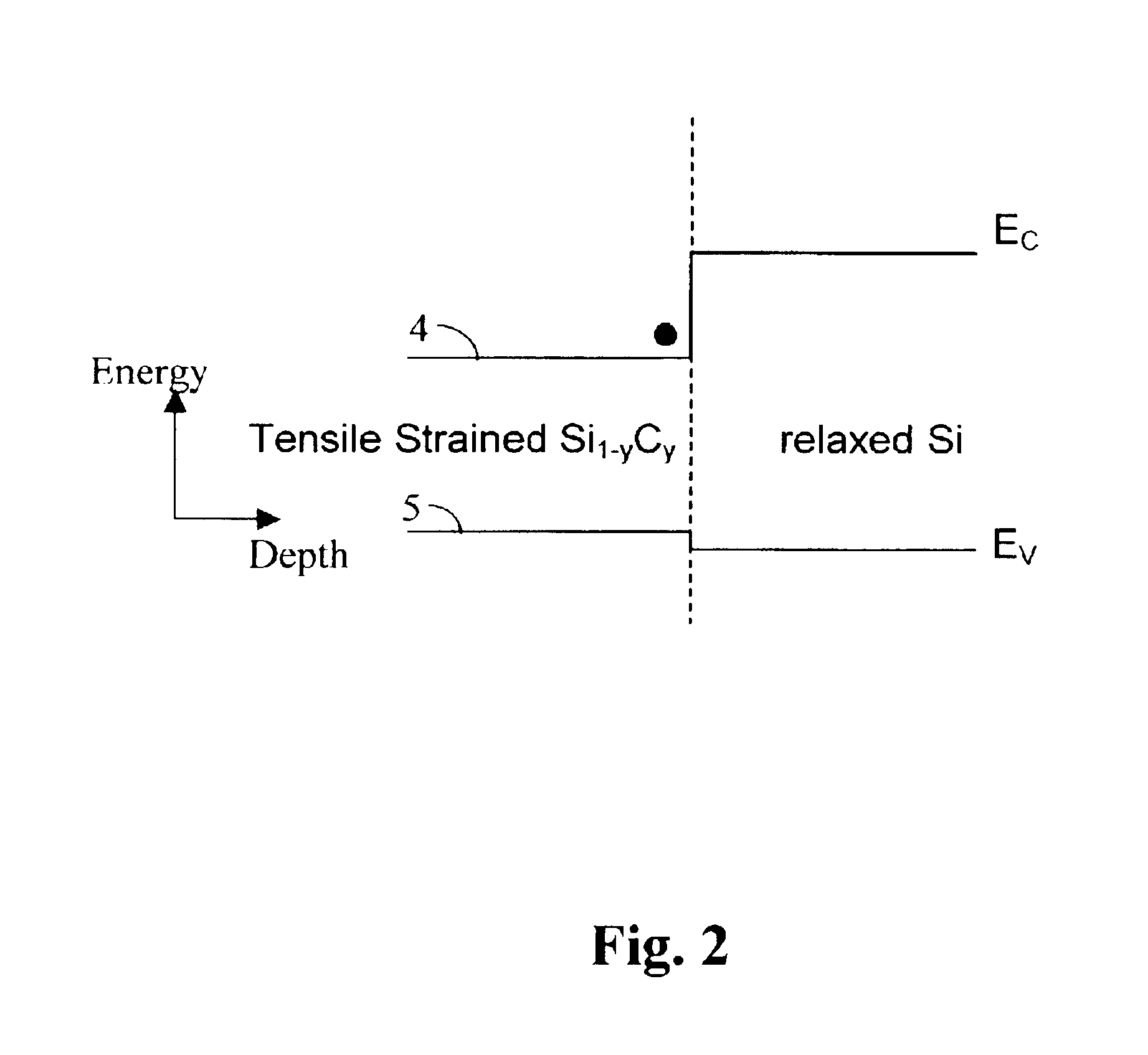

Low leakage heterojunction vertical transistors and high performance devices thereof

InactiveUS6943407B2Superb performanceSuperb scalabilityTransistorSolid-state devicesReverse short-channel effectHeterojunction

A method for forming and the structure of a vertical channel of a field effect transistor, a field effect transistor and CMOS circuitry are described incorporating a drain, body and source region on a sidewall of a vertical single crystal semiconductor structure wherein a hetero-junction is formed between the source and body of the transistor, wherein the source region and channel are independently lattice strained with respect the body region and wherein the drain region contains a carbon doped region to prevent the diffusion of dopants (i.e., B and P) into the body. The invention reduces the problem of short channel effects such as drain induced barrier lowering and the leakage current from the source to drain regions via the hetero-junction and while independently permitting lattice strain in the channel region for increased mobility via choice of the semiconductor materials. The problem of scalability of the gate length below 100 nm is overcome by the heterojunction between the source and body regions.

Owner:GLOBALFOUNDRIES INC

Red phosphorescent compound and organic electroluminescent device using the same

ActiveUS20070104979A1High color purityLong life-timeIndium organic compoundsDischarge tube luminescnet screensDopantHydrogen

Disclosed herein is a red phosphorescent compound of the following Formula 1: wherein is R1 is a C1-C4 alkoxy group, R2, R3, R4 and R5 are independently selected from hydrogen, C1-C4 alkyl groups and C1-C4 alkoxy groups, and is selected from 2,4-pentanedione, 2,2,6,6,-tetramethylheptane-3,5-dione, 1,3-propanedione, 1,3-butanedione, 3,5-heptanedione, 1,1,1-trifluoro-2,4-pentanedione, 1,1,1,5,5,5-hexafluoro-2,4-pentanedione, and 2,2-dimethyl-3,5-hexanedione. Further disclosed herein is an organic electroluminescent (EL) device comprising an anode, a hole injecting layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron injecting layer, and a cathode laminated in this order wherein one of the red phosphorescent compounds is used as a dopant of the light-emitting layer.

Owner:LG DISPLAY CO LTD

Red phosphorescence compounds and organic electroluminescence device using the same

ActiveUS7740957B2High color purityLong durabilityIndium organic compoundsDischarge tube luminescnet screensDopantOrganic electroluminescence

Red phosphorescence compounds and organic electro-luminescence device using the same are disclosed. In an organic electroluminescence device including an anode, a hole injecting layer, a hole transport layer, a light emitting layer, an electron transport layer, an electron injecting layer, and a cathode serially deposited on one another, the organic electroluminescence device may use a compound as a dopant of the light emitting layer.

Owner:LG ELECTRONICS INC

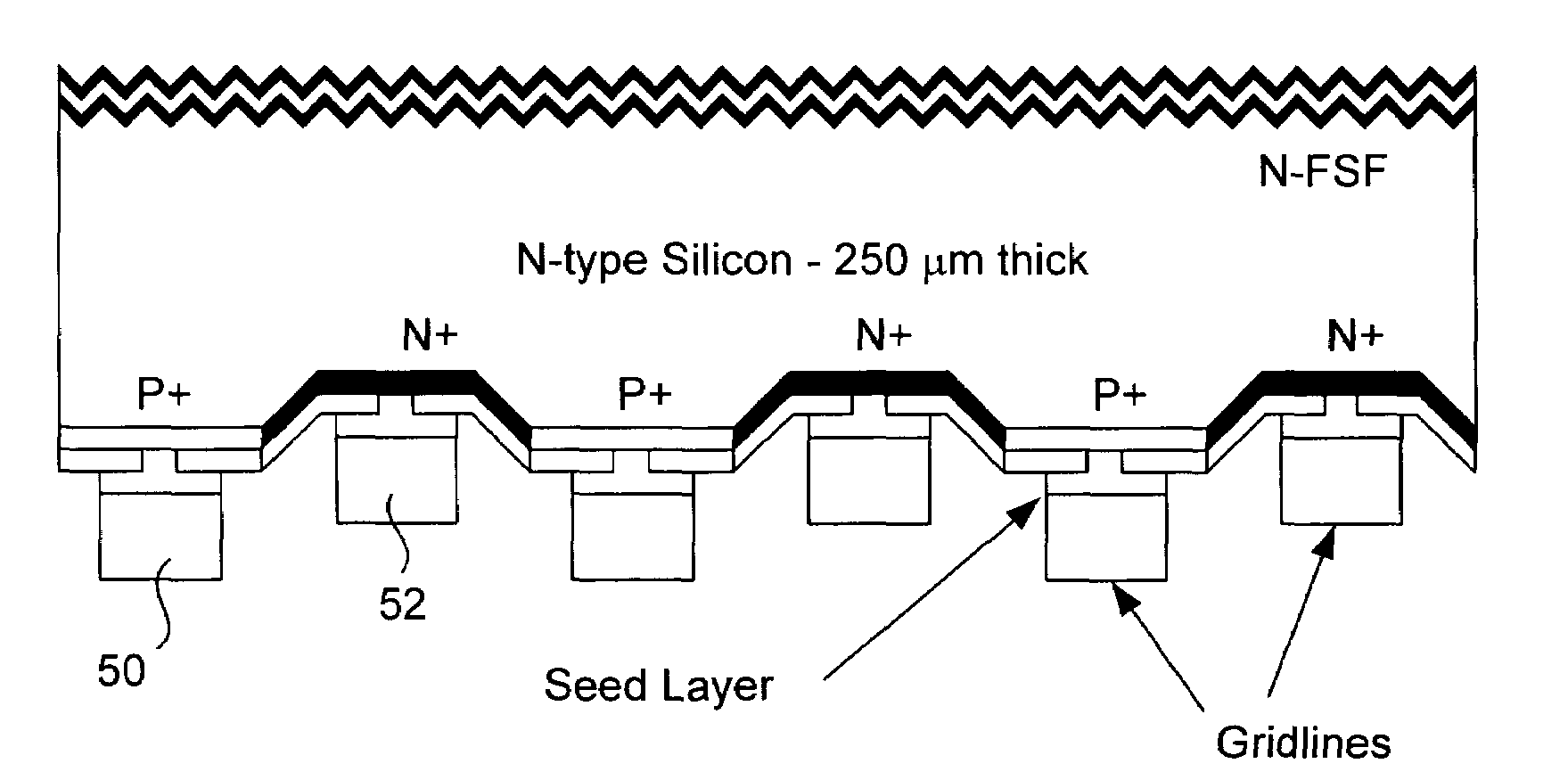

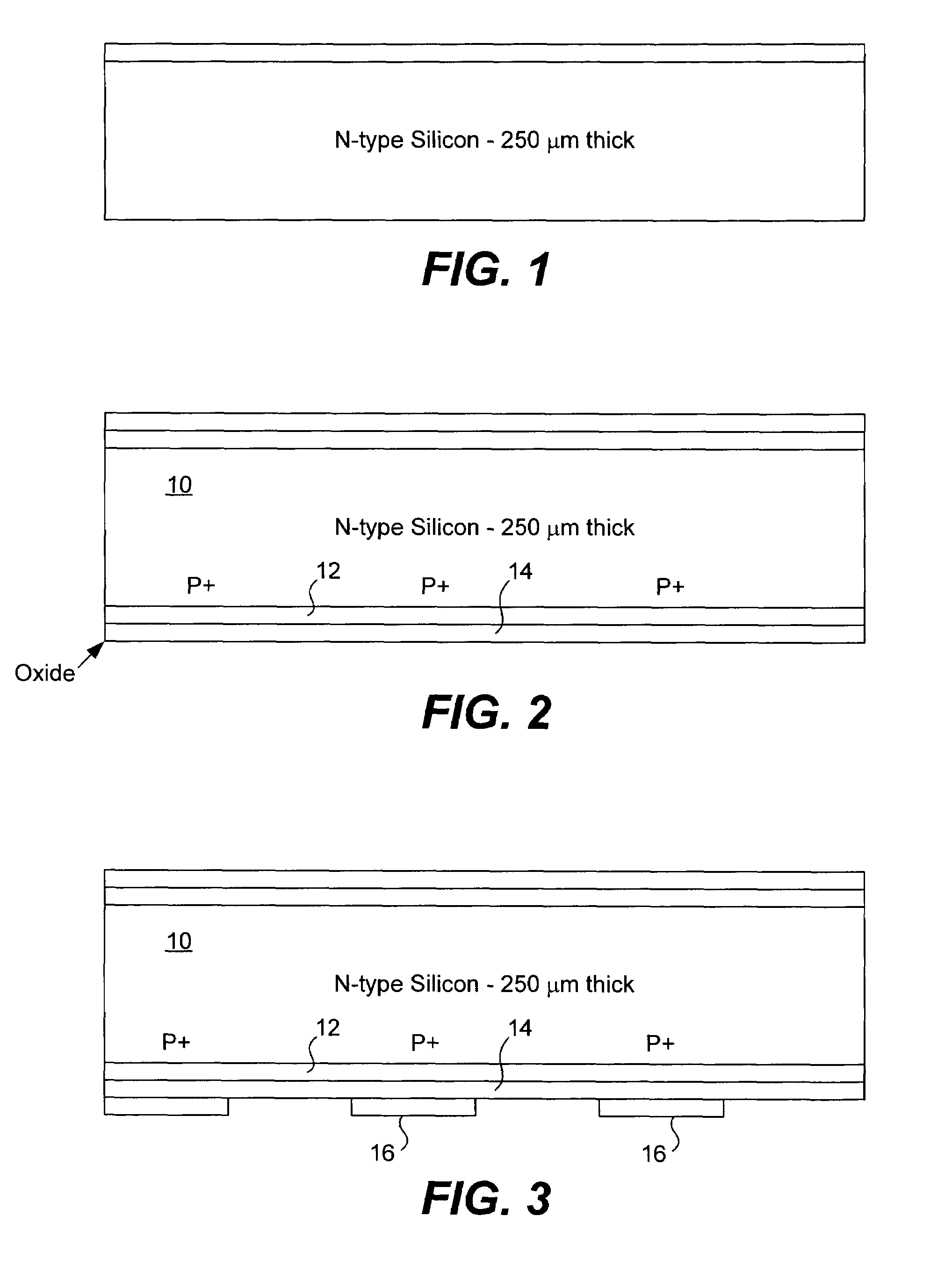

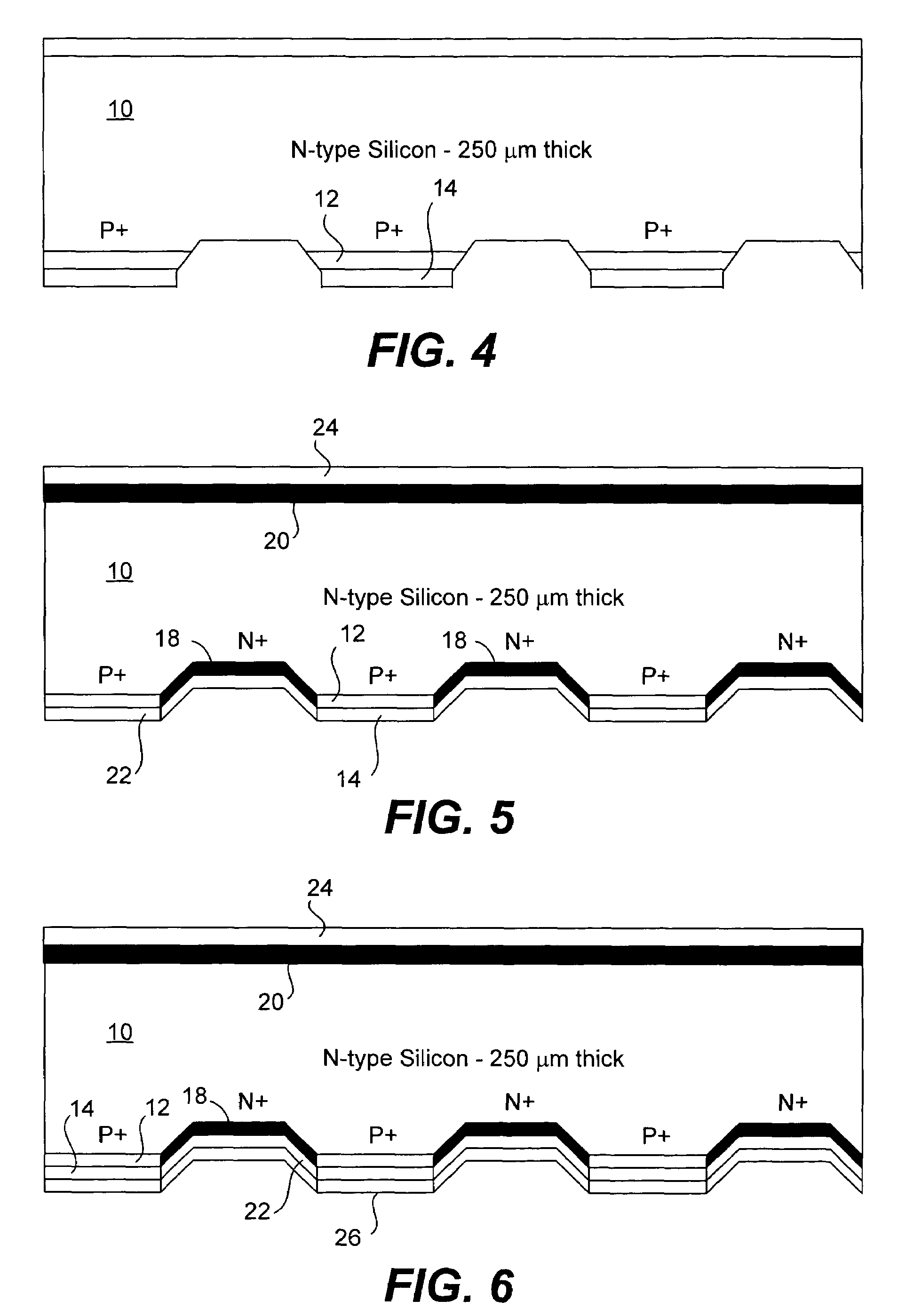

Solar cell and method of manufacture

ActiveUS7339110B1Easy to manufactureLess expensiveFinal product manufacturePhotovoltaic energy generationEngineeringSilicon oxide

A solar cell that is readily manufactured using processing techniques which are less expensive than microelectronic circuit processing. In preferred embodiments, printing techniques are utilized in selectively forming masks for use in etching of silicon oxide and diffusing dopants and in forming metal contacts to diffused regions. In a preferred embodiment, p-doped regions and n-doped regions are alternately formed in a surface of the wafer in offset levels through use of masking and etching techniques. Metal contacts are made to the p-regions and n-regions by first forming a seed layer stack that comprises a first layer such as aluminum that contacts silicon and functions as an infrared reflector, second layer such titanium tungsten that acts as diffusion barrier, and a third layer functions as a plating base. A thick conductive layer such as copper is then plated over the seed layer, and the seed layer between plated lines is removed. A front surface of the wafer is preferably textured by etching or mechanical abrasion with an antireflection layer provided over the textured surface. A field layer can be provided in the textured surface with the combined effect being a very low surface recombination velocity.

Owner:MAXEON SOLAR PTE LTD +1

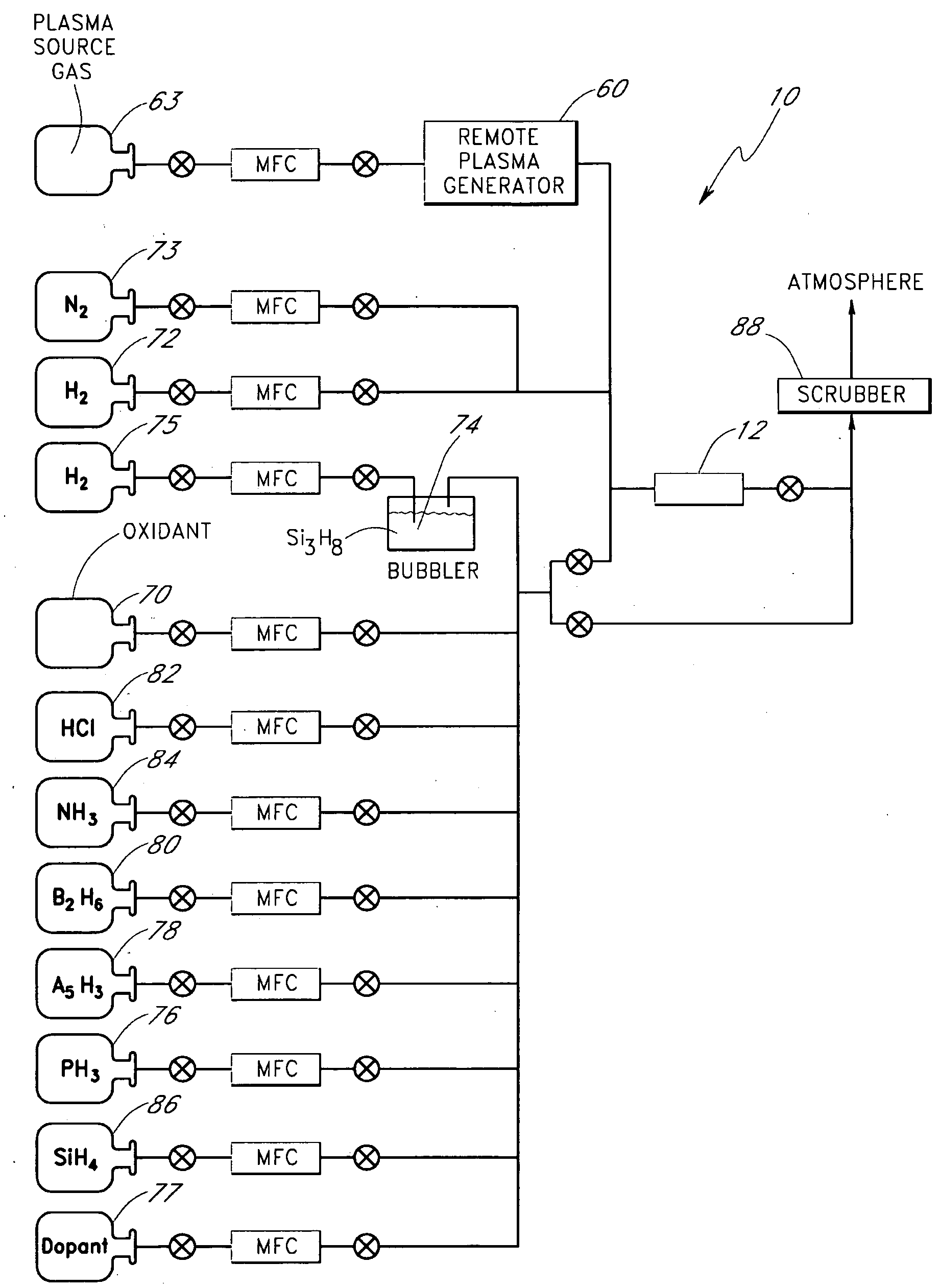

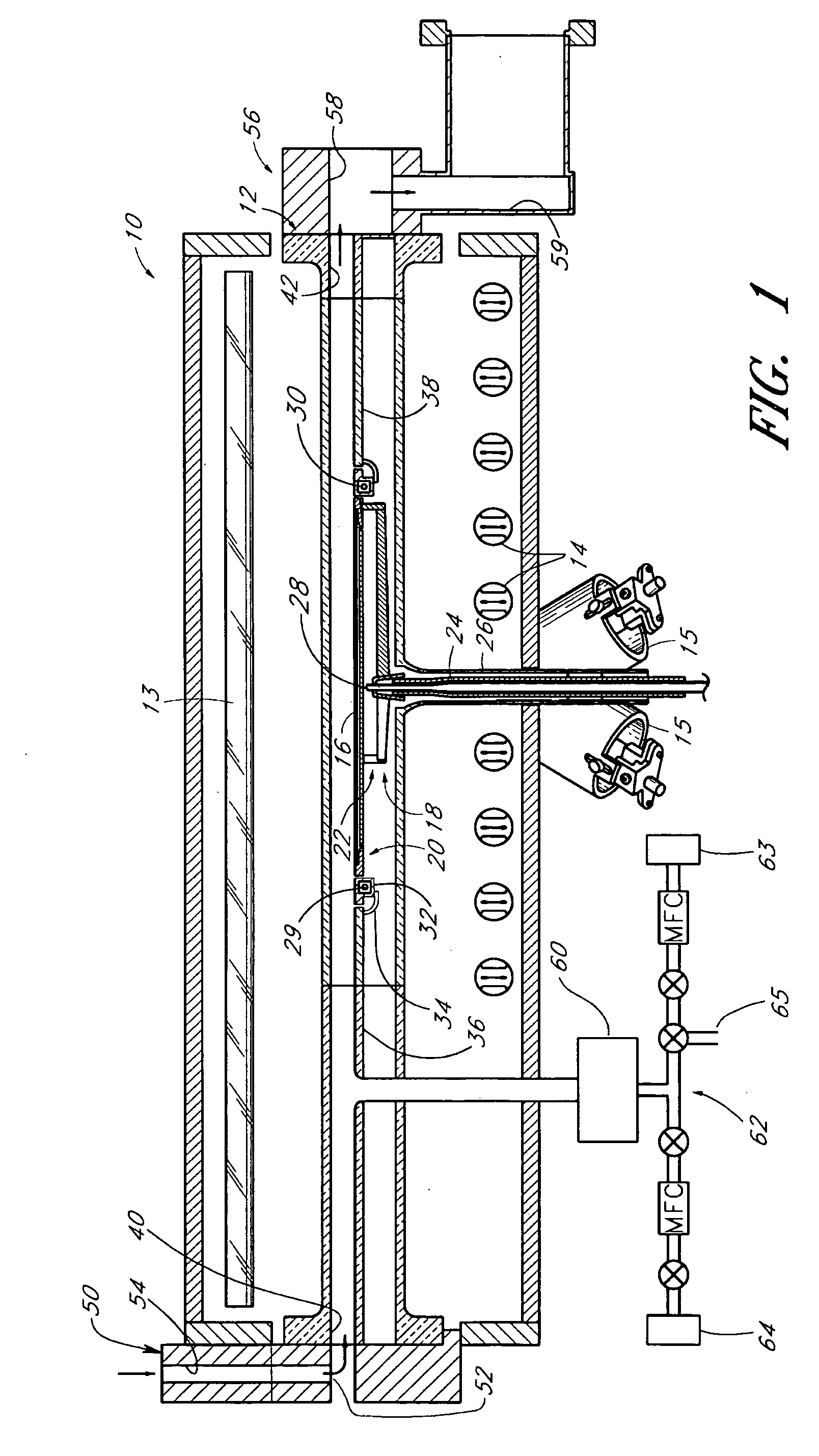

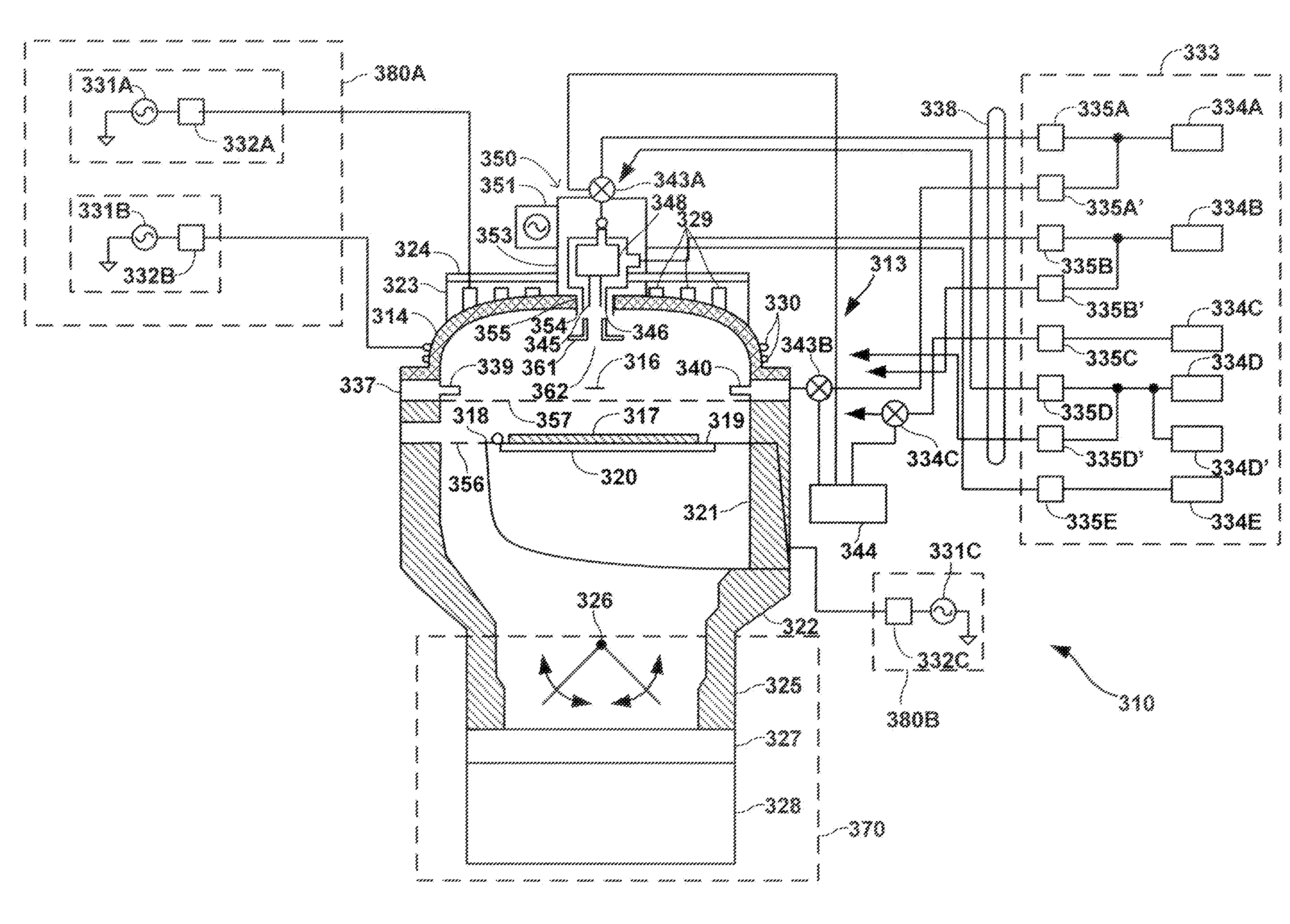

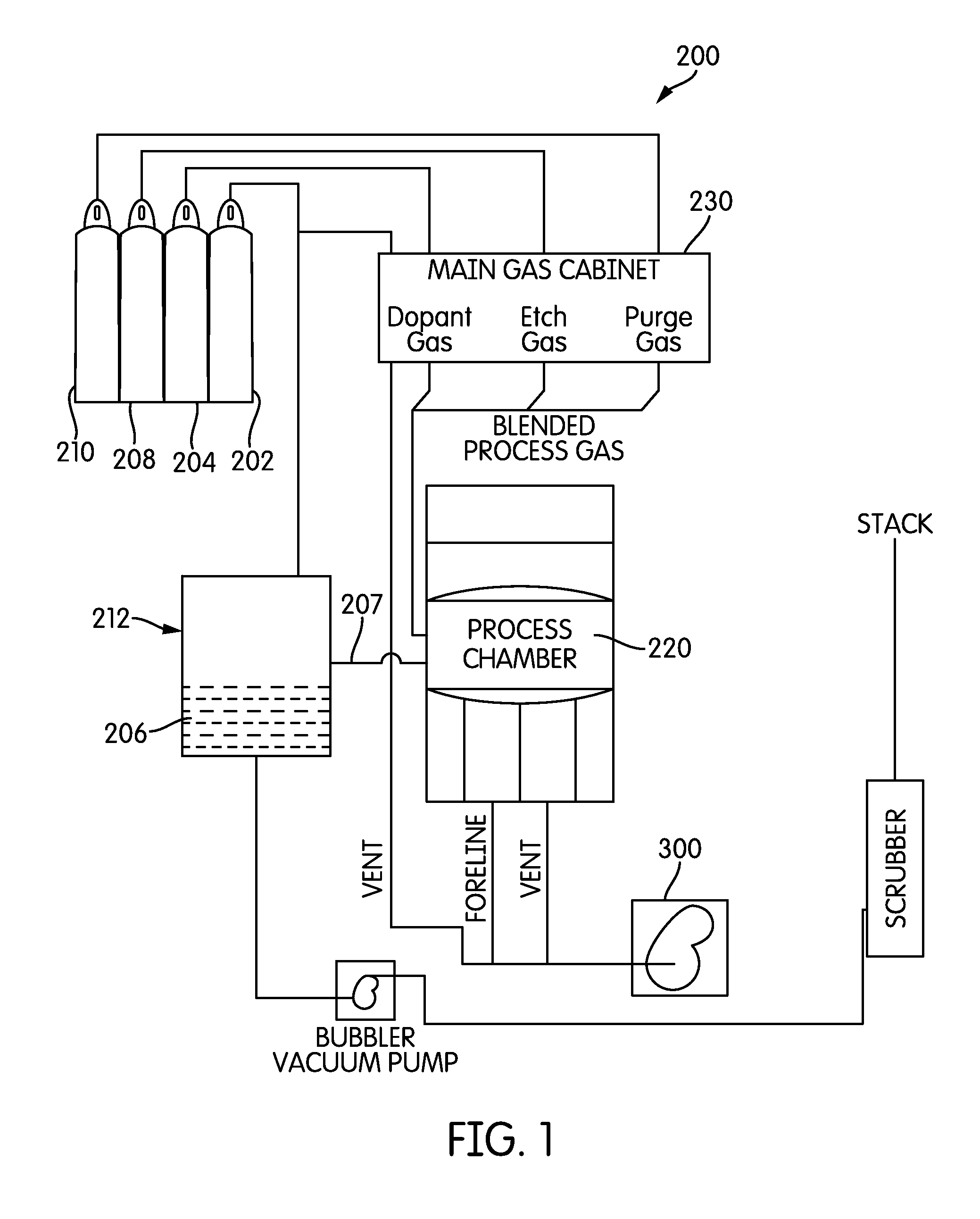

Novel method for conformal plasma immersed ion implantation assisted by atomic layer deposition

ActiveUS20110159673A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantSource material

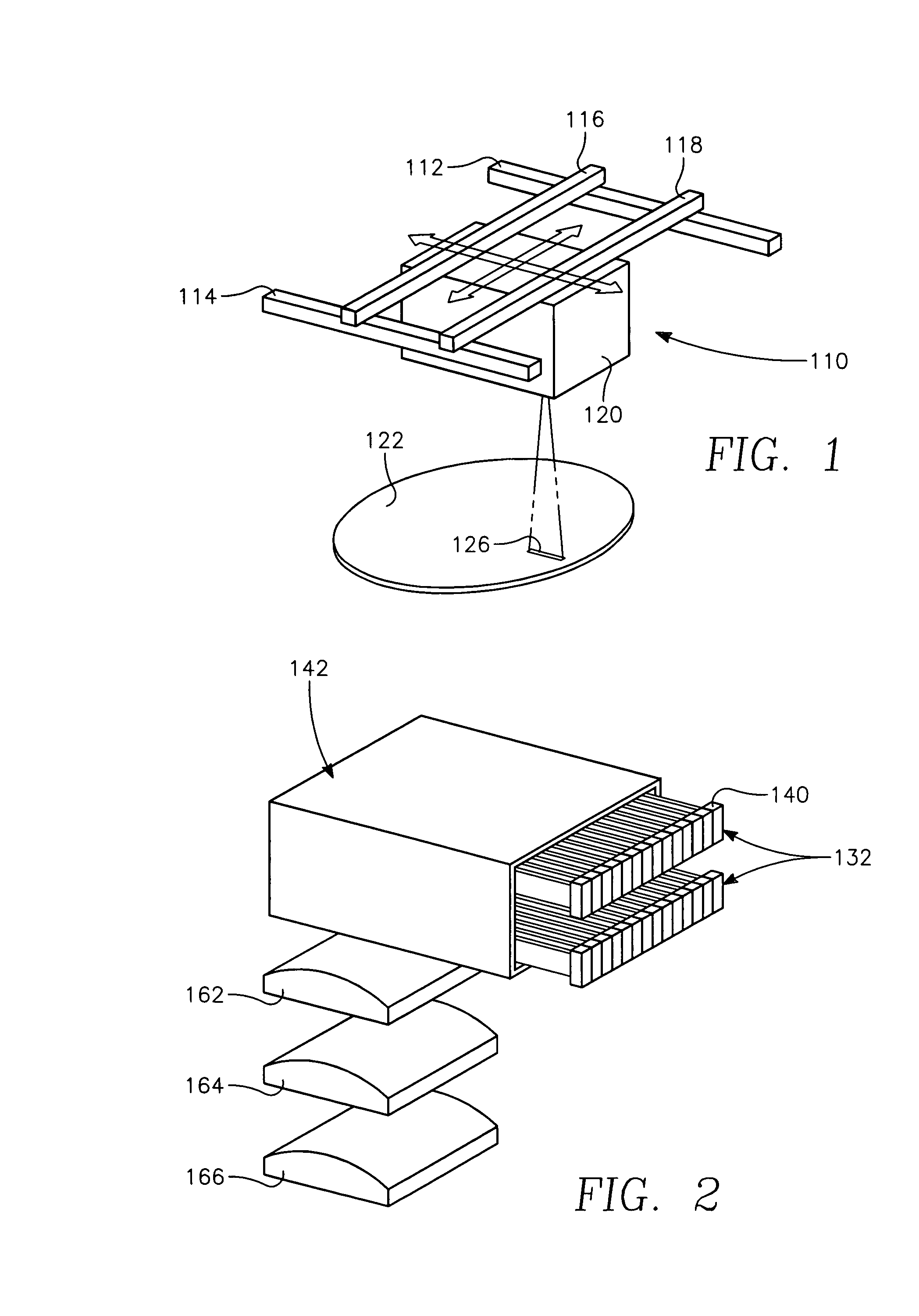

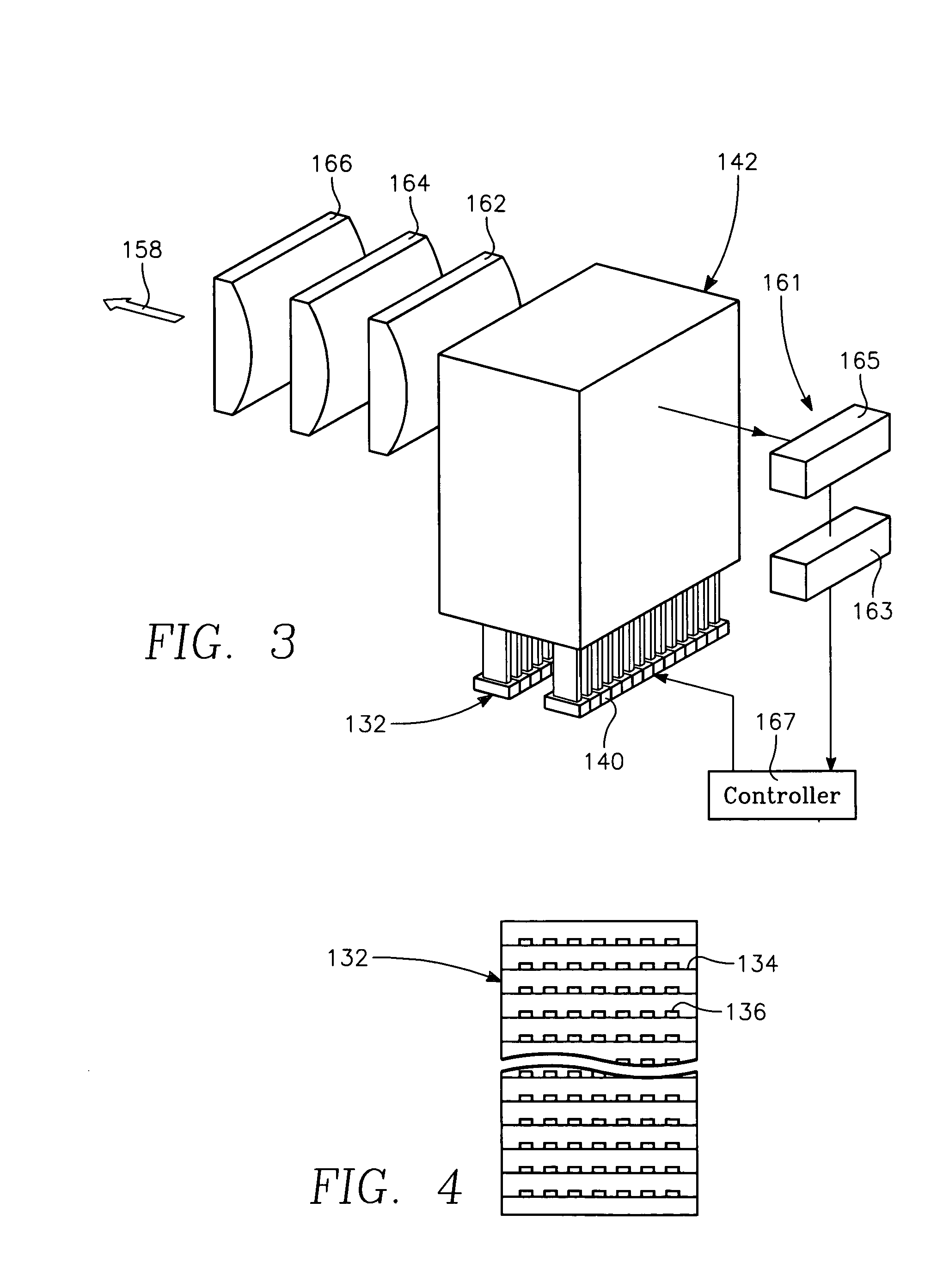

Embodiments of the invention provide a novel apparatus and methods for forming a conformal doped layer on the surface of a substrate. A substrate is provided to a process chamber, and a layer of dopant source material is deposited by plasma deposition, atomic layer deposition, or plasma-assisted atomic layer deposition. The substrate is then subjected to thermal processing to activate and diffuse dopants into the substrate surface.

Owner:APPLIED MATERIALS INC

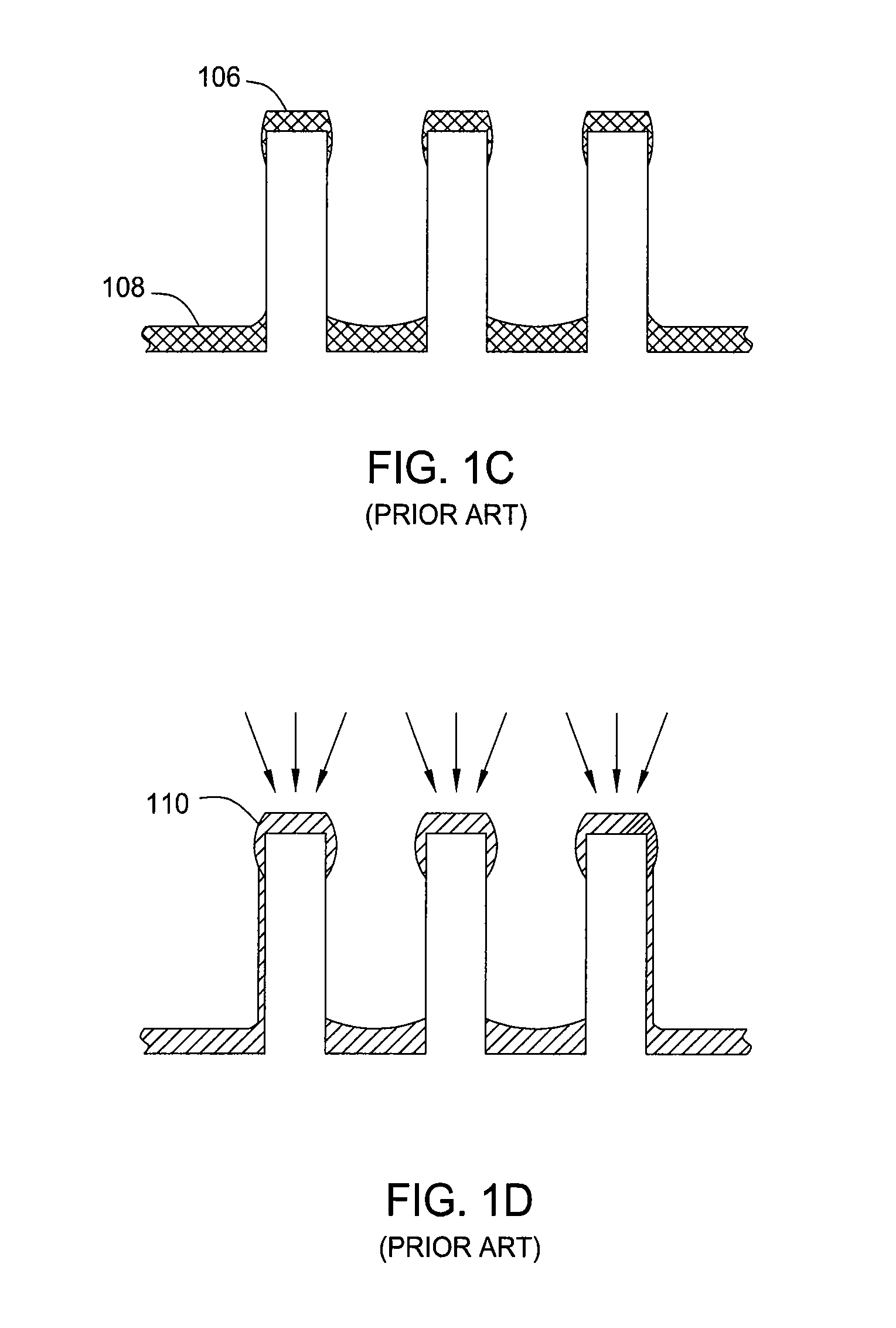

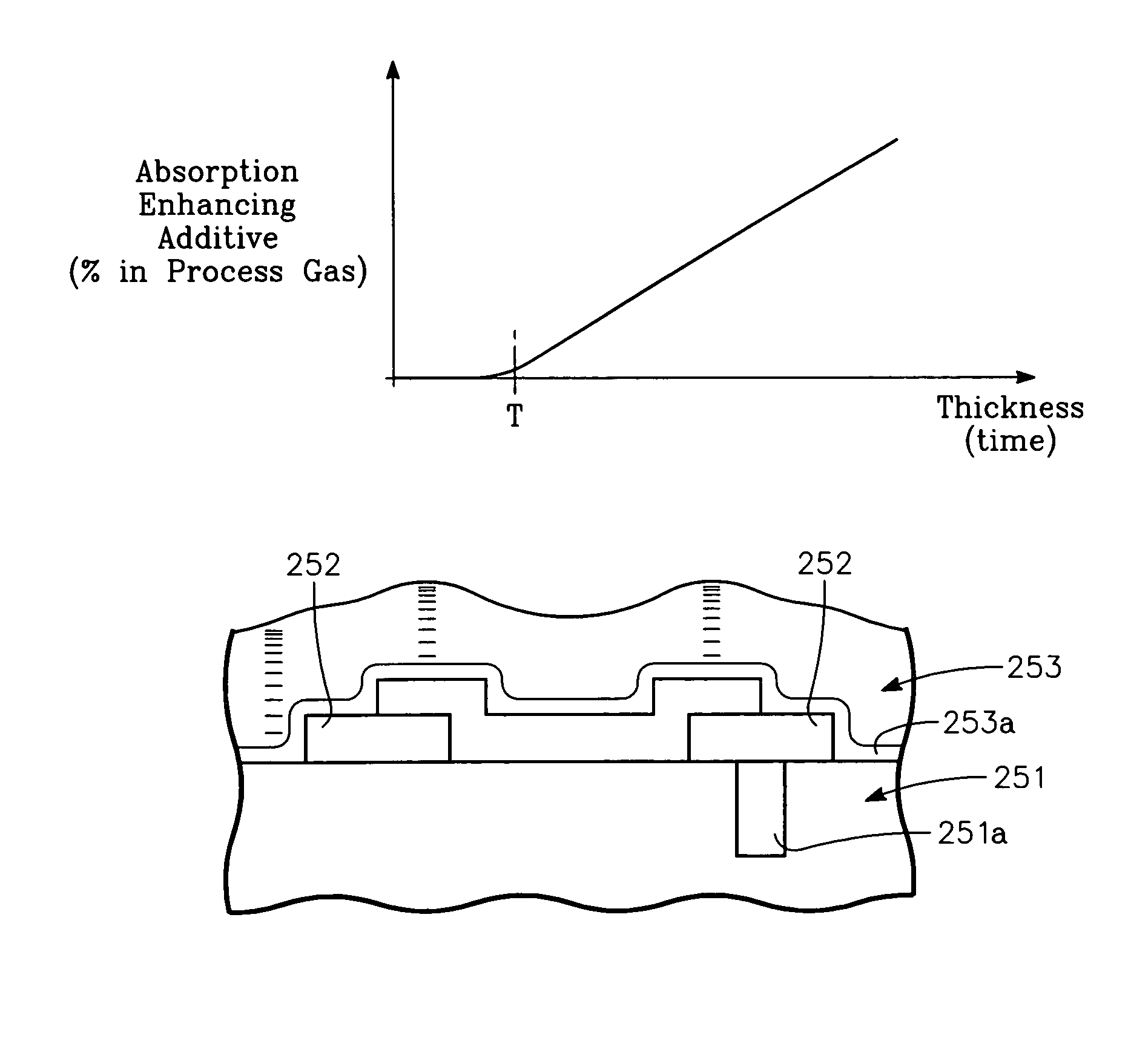

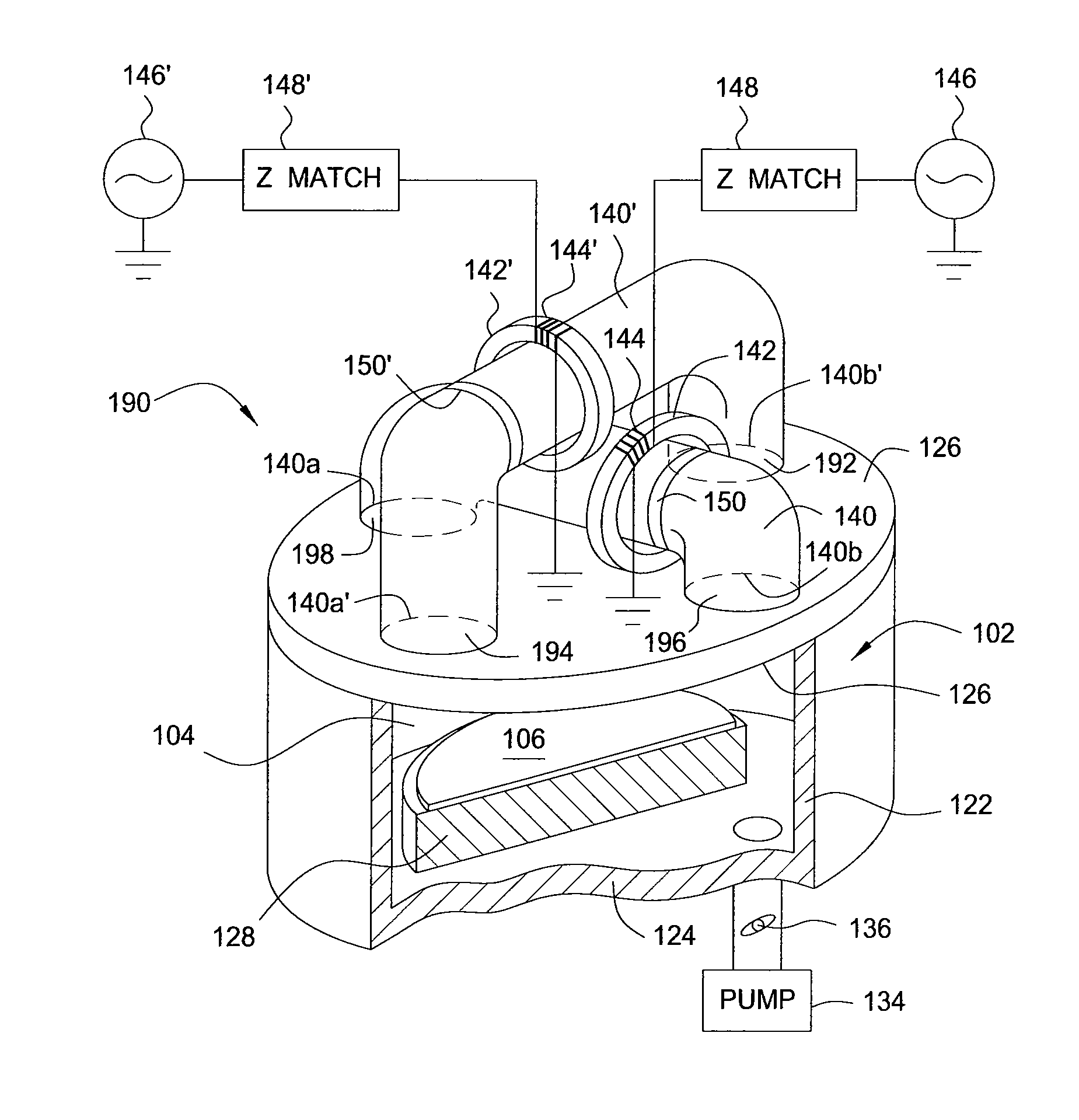

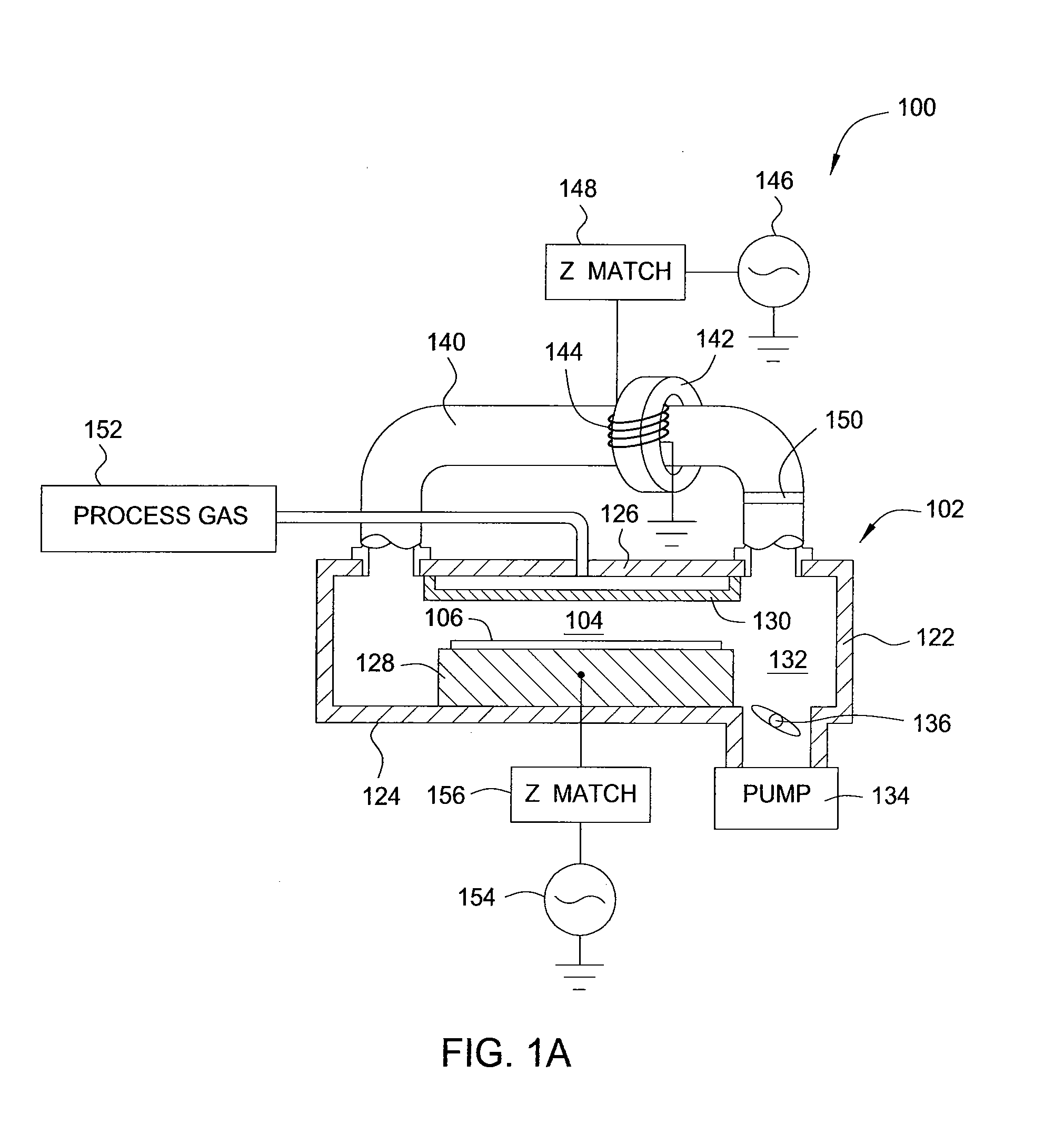

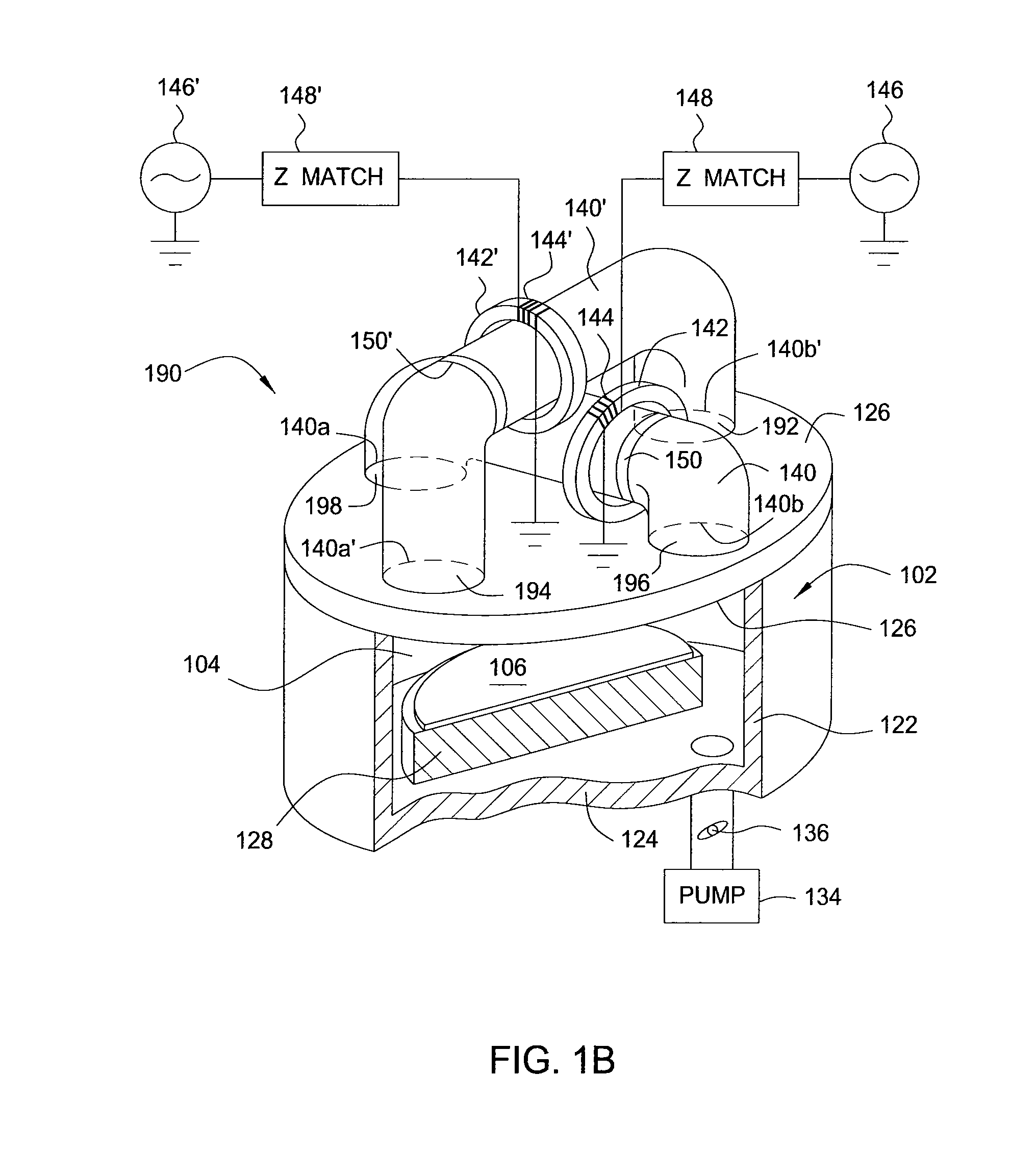

Semiconductor junction formation process including low temperature plasma deposition of an optical absorption layer and high speed optical annealing

A method of forming semiconductor junctions in a semiconductor material of a workpiece includes ion implanting dopant impurities in selected regions of the semiconductor material, introducing an optical absorber material precursor gas into a chamber containing the workpiece, generating an RF oscillating toroidal plasma current in a reentrant path that includes a process zone overlying the workpiece by applying RF source power, so as to deposit a layer of an optical absorber material on the workpiece, and optically annealing the workpiece so as to activate dopant impurities in the semiconductor material.

Owner:APPLIED MATERIALS INC

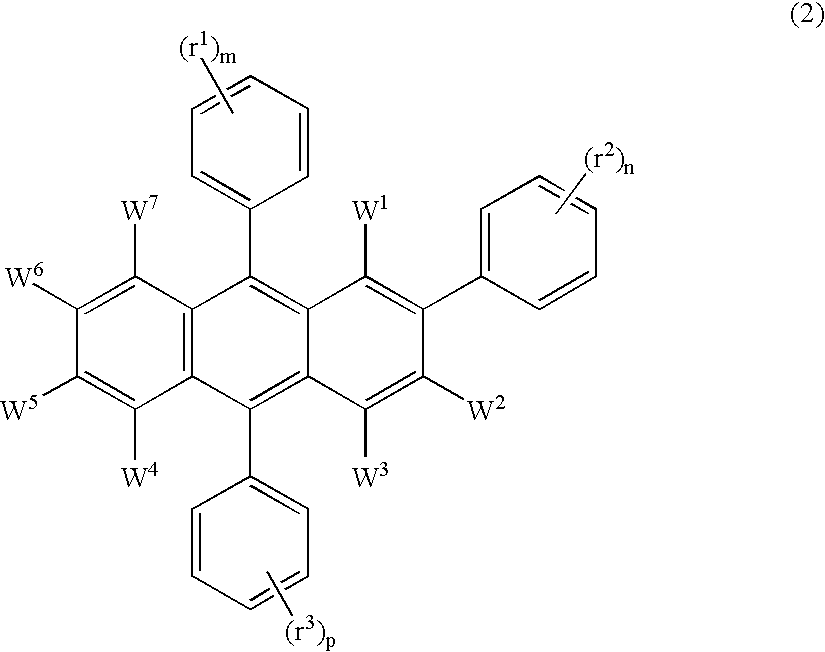

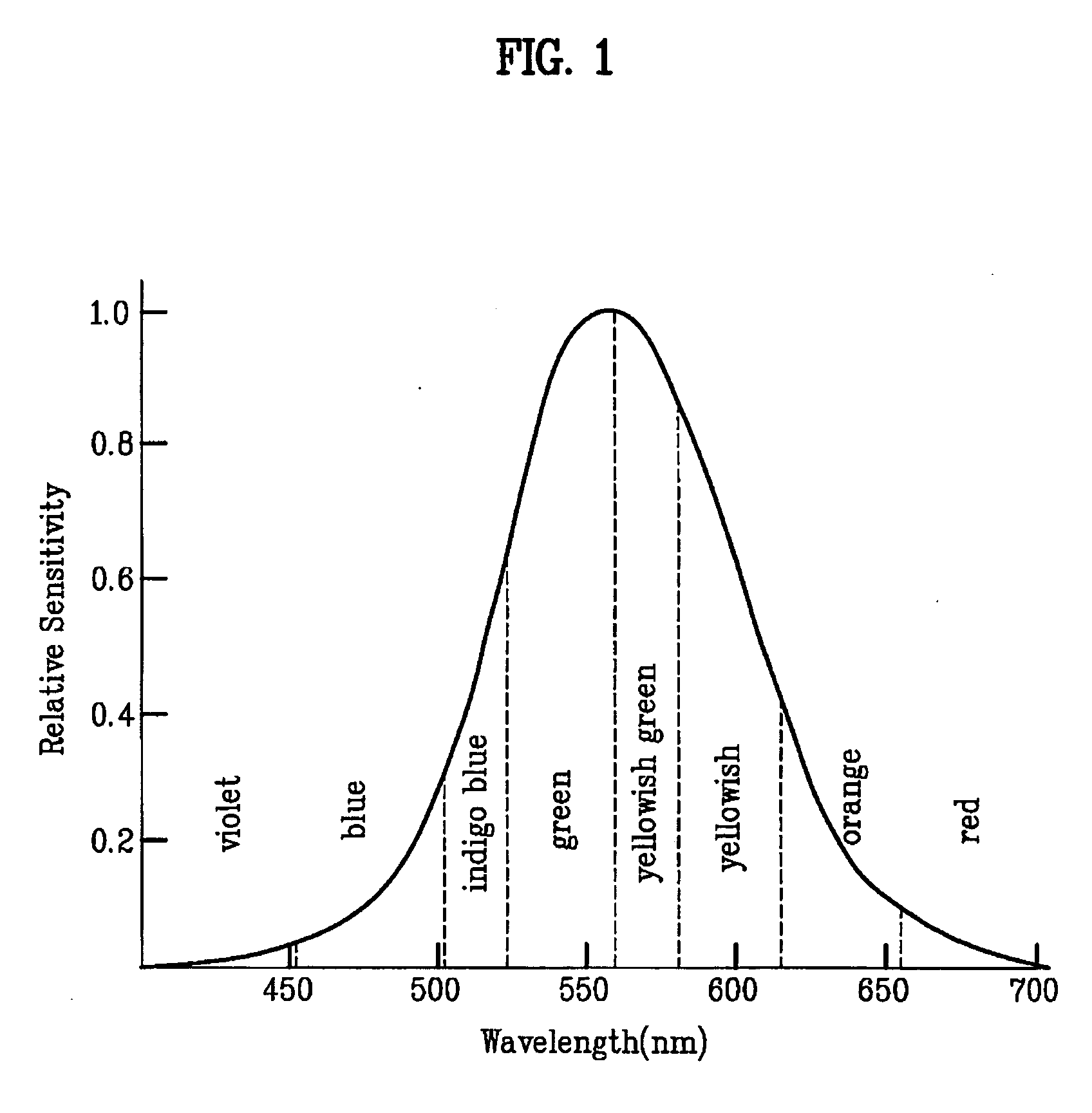

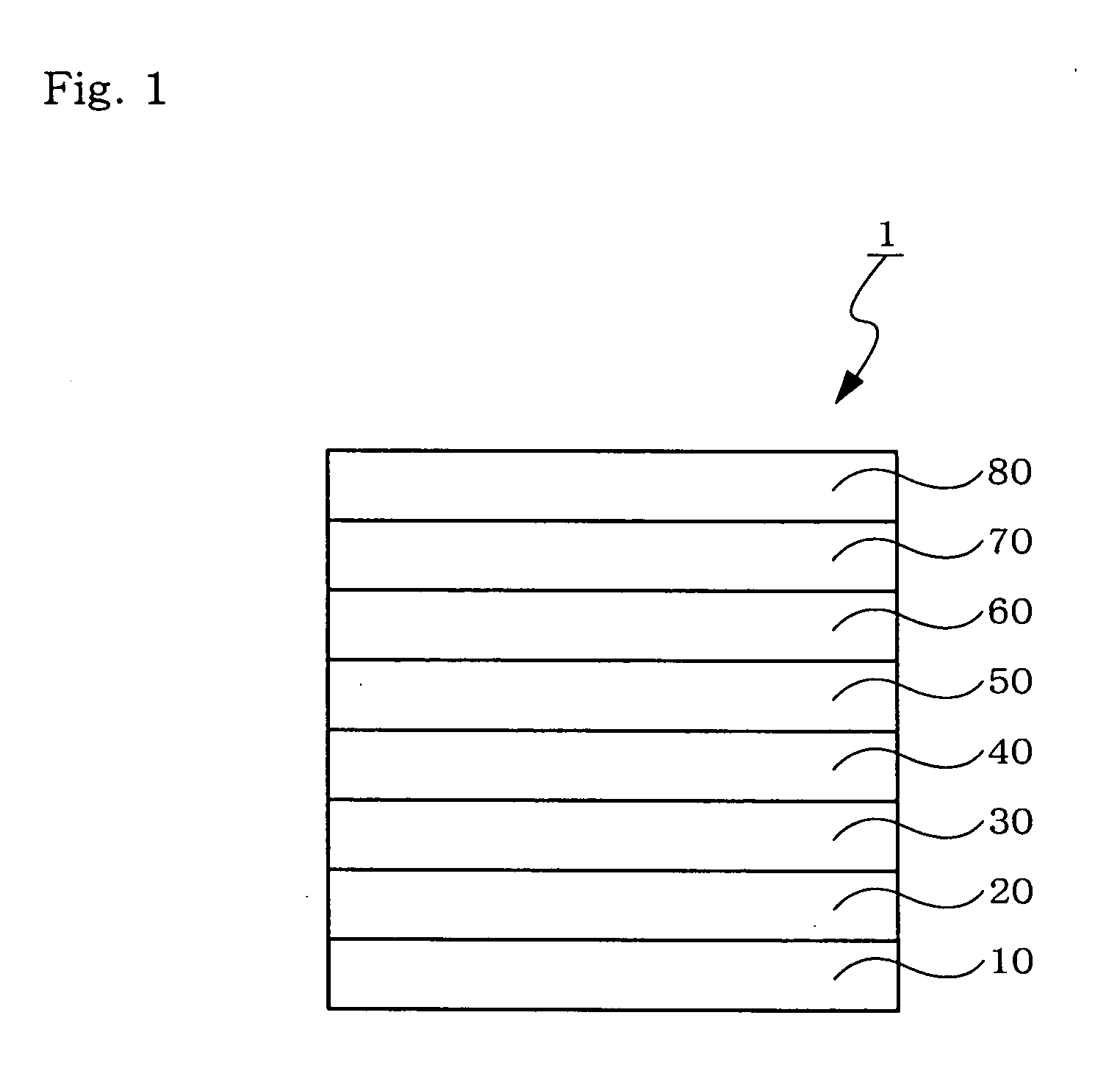

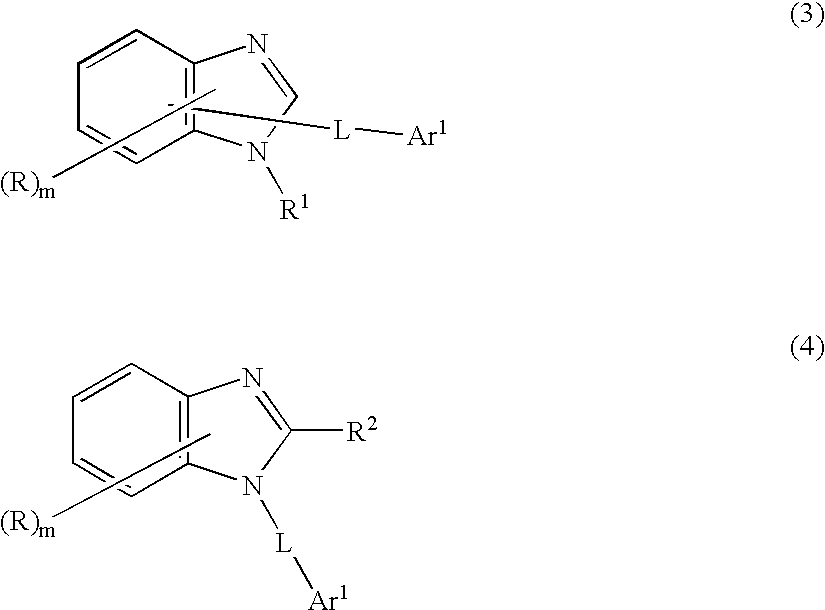

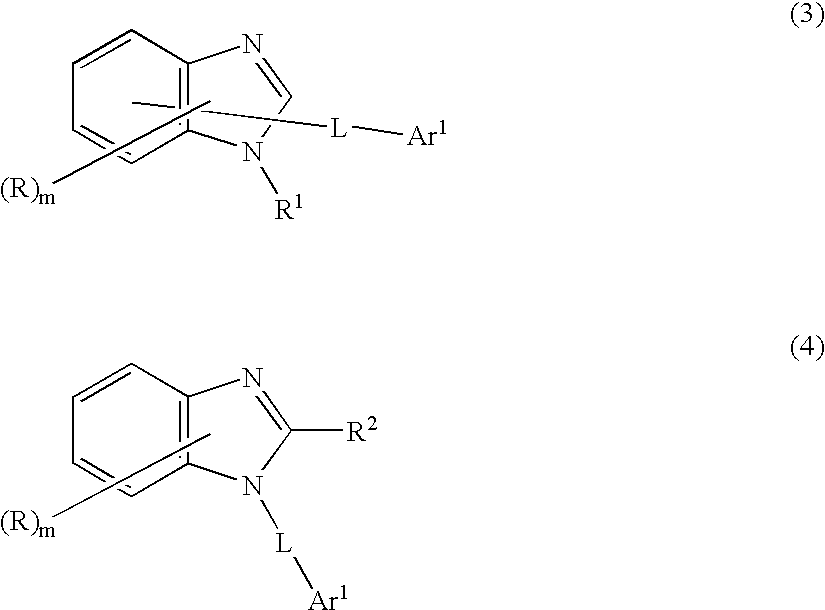

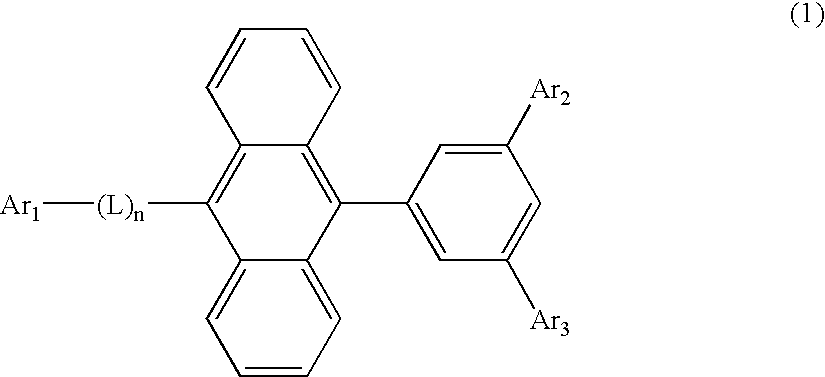

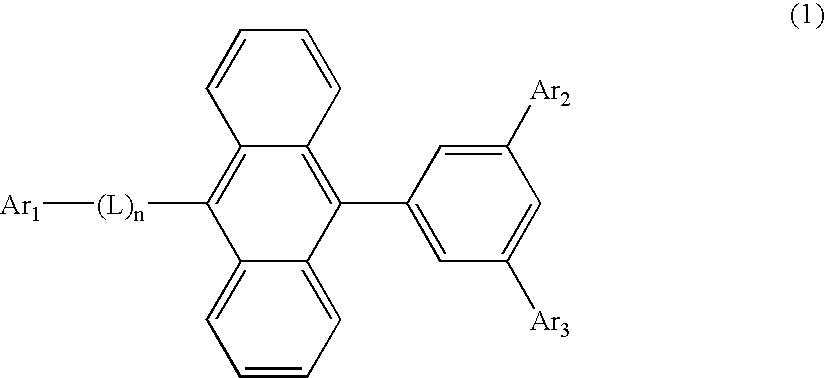

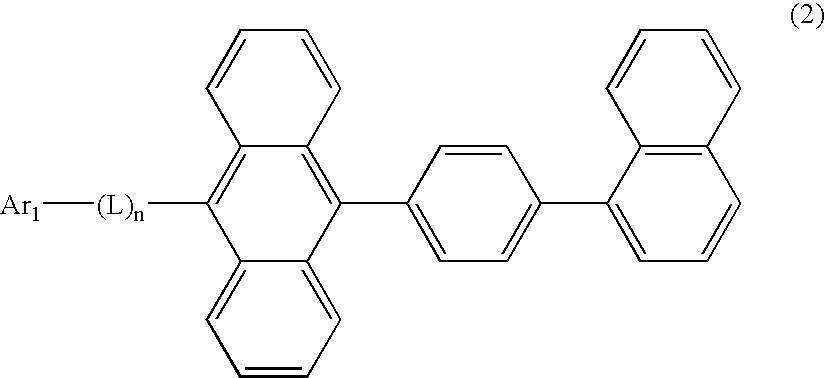

Organic electroluminescent device

InactiveUS20070104977A1Improve efficiencyHigh color purityDischarge tube luminescnet screensLamp detailsDopantAryl

An organic electroluminescent device 1 comprising, an emitting layer (50) and an electron-transporting layer (60) between a cathode (80) and an anode (20), the electron-transporting layer (60) comprising a compound represented by formula (1), the emitting layer (50) comprising a host material which is a compound with an energy gap of 2.8 eV or less represented by formula (2) and a dopant which is an indenoperylene derivative, A-B (1) wherein A is an aromatic hydrocarbon group with three or more carbocycles and B is a substituted or unsubstituted heterocyclic group, X—(Y)n (2) wherein X is a condensed aromatic ring group with three or more carbocycles, Y is a group selected from substituted or unsubstituted aryl, substituted or unsubstituted diarylamino, substituted or unsubstituted arylalkyl and substituted or unsubstituted alkyl groups, and n is an integer of 1 to 6, provided that Ys may be the same or different when n is 2 or more.

Owner:IDEMITSU KOSAN CO LTD

Organic-electroluminescence-material-containing solution, method for forming thin film of organic electroluminescence material, thin film of organic electroluminescence material and organic electroluminescence device

An organic EL material-containing solution contains an organic EL material, a solvent and a viscosity control agent. The organic EL material contains a host and a dopant.The host is a compound shown by Formula (1) below and has a solubility of 2 wt % or higher in the solvent. The solvent is an aromatic solvent, while the viscosity control agent is an alcohol type solution or an alkyl-substituted aromatic solution having 4 or more carbon atoms.

Owner:IDEMITSU KOSAN CO LTD

Deposition from liquid sources

ActiveUS20070166966A1Light-sensitive devicesSemiconductor/solid-state device manufacturingDopantSilicon

Owner:ASM IP HLDG BV +1

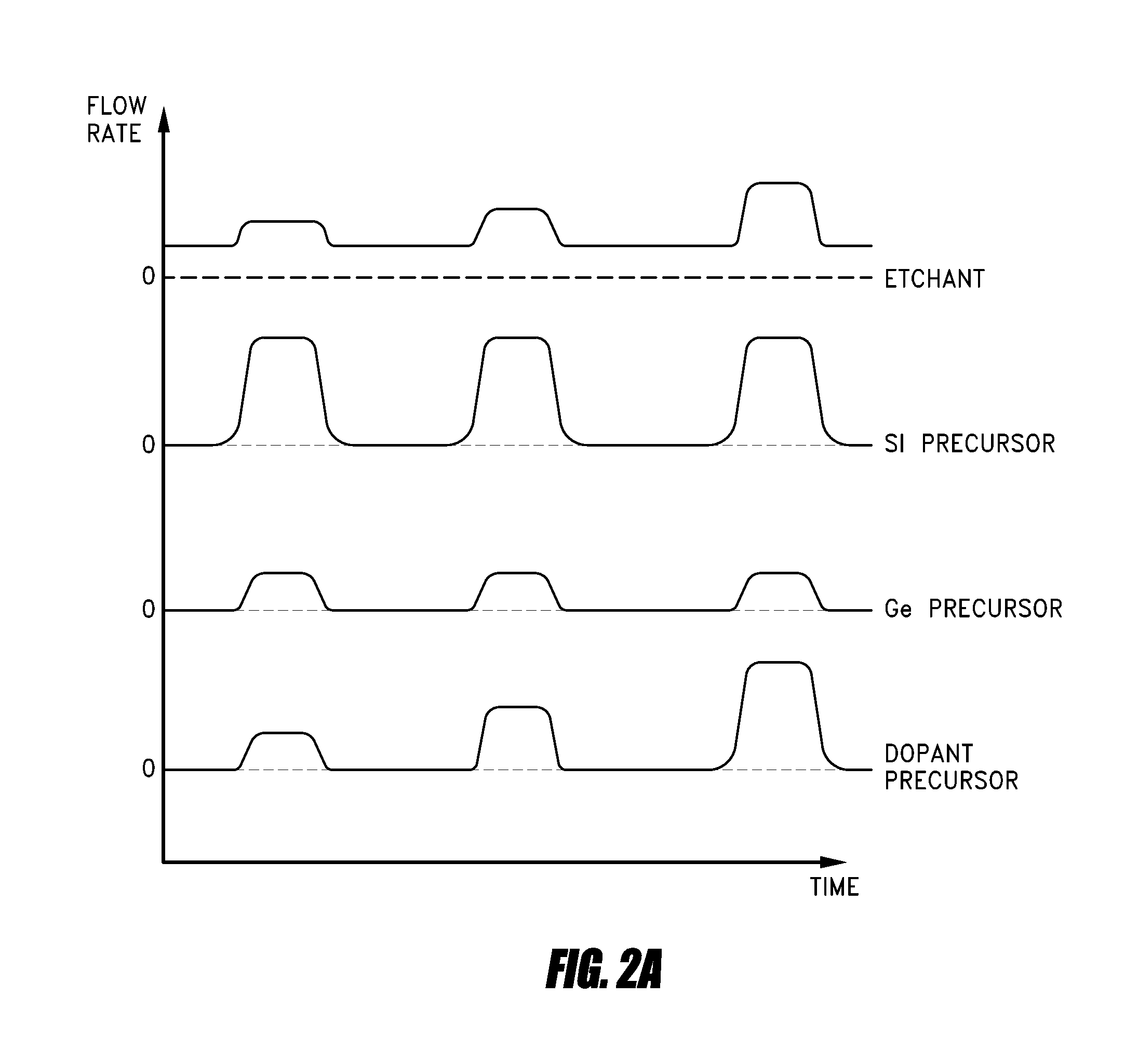

Phosphorus Containing Si Epitaxial Layers in N-Type Source/Drain Junctions

ActiveUS20080182075A1Keep the pressureLayered productsSemiconductor/solid-state device manufacturingMOSFETHigh concentration

Methods for formation of epitaxial layers containing n-doped silicon are disclosed. Specific embodiments pertain to the formation and treatment of epitaxial layers in semiconductor devices, for example, Metal Oxide Semiconductor Field Effect Transistor (MOSFET) devices. In specific embodiments, the formation of the n-doped epitaxial layer involves exposing a substrate in a process chamber to deposition gases including a silicon source, a carbon source and an n-dopant source. An epitaxial layer may have considerable tensile stress which may be created in a significant amount by a high concentration of n-dopant. A layer having n-dopant may also have substitutional carbon. Phosphorus as an n-dopant with a high concentration is provided. A substrate having an epitaxial layer with a high level of n-dopant is also disclosed.

Owner:APPLIED MATERIALS INC

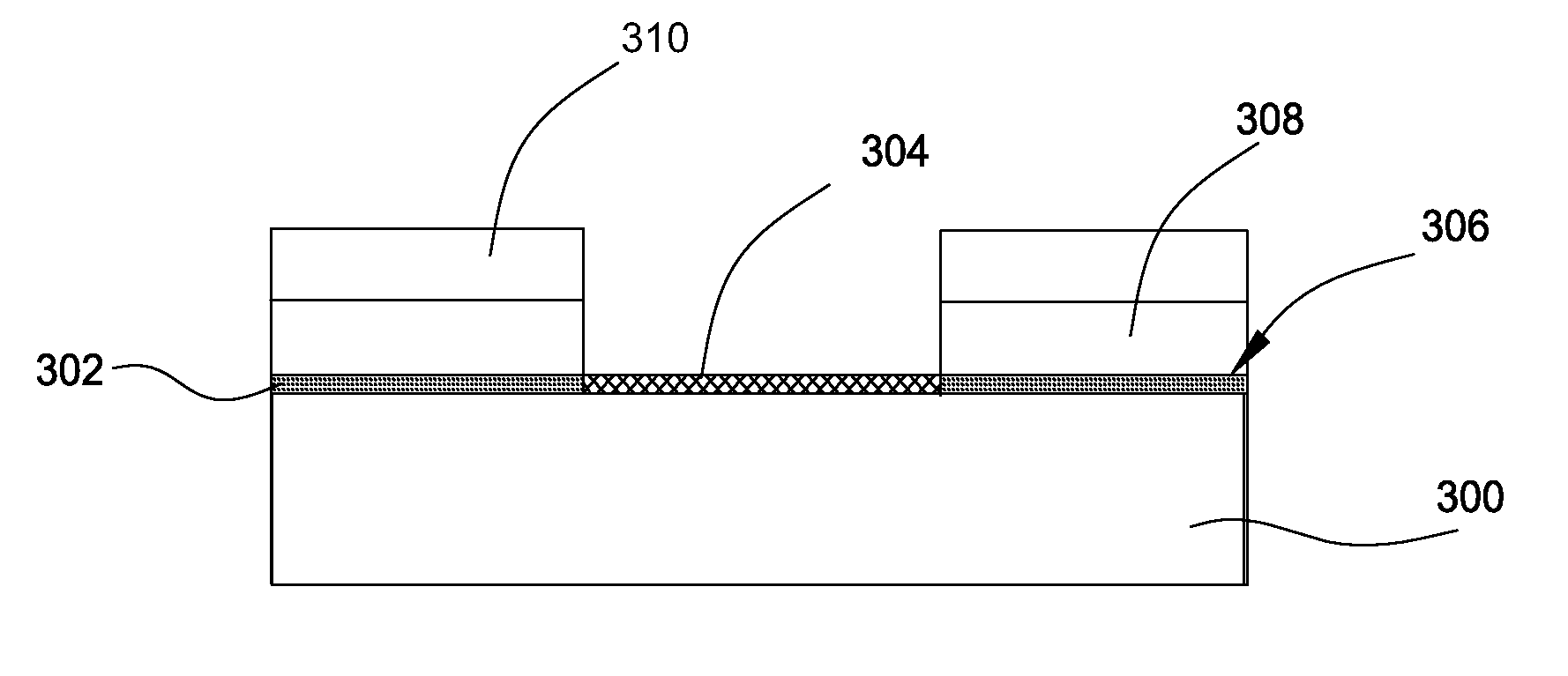

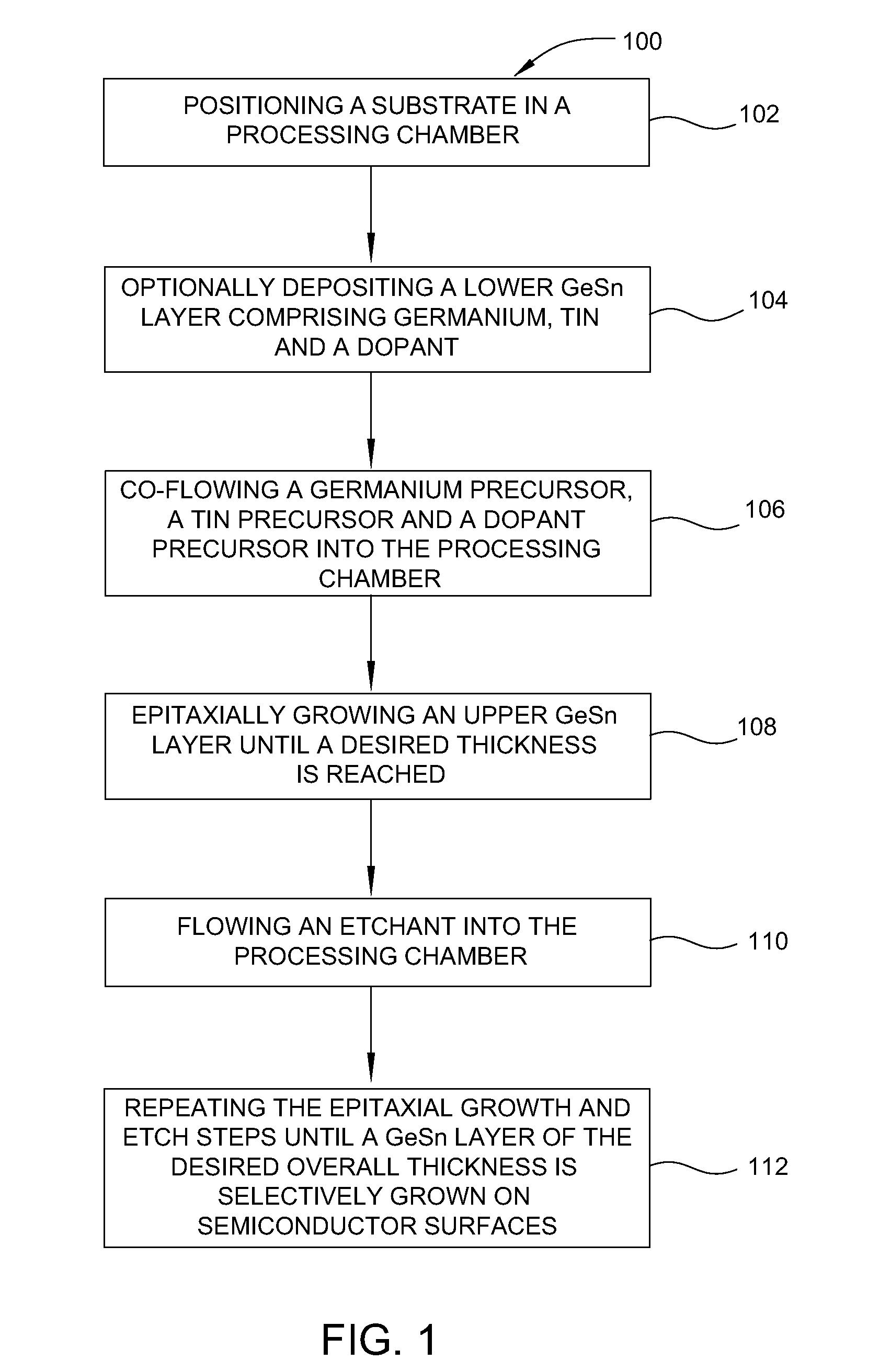

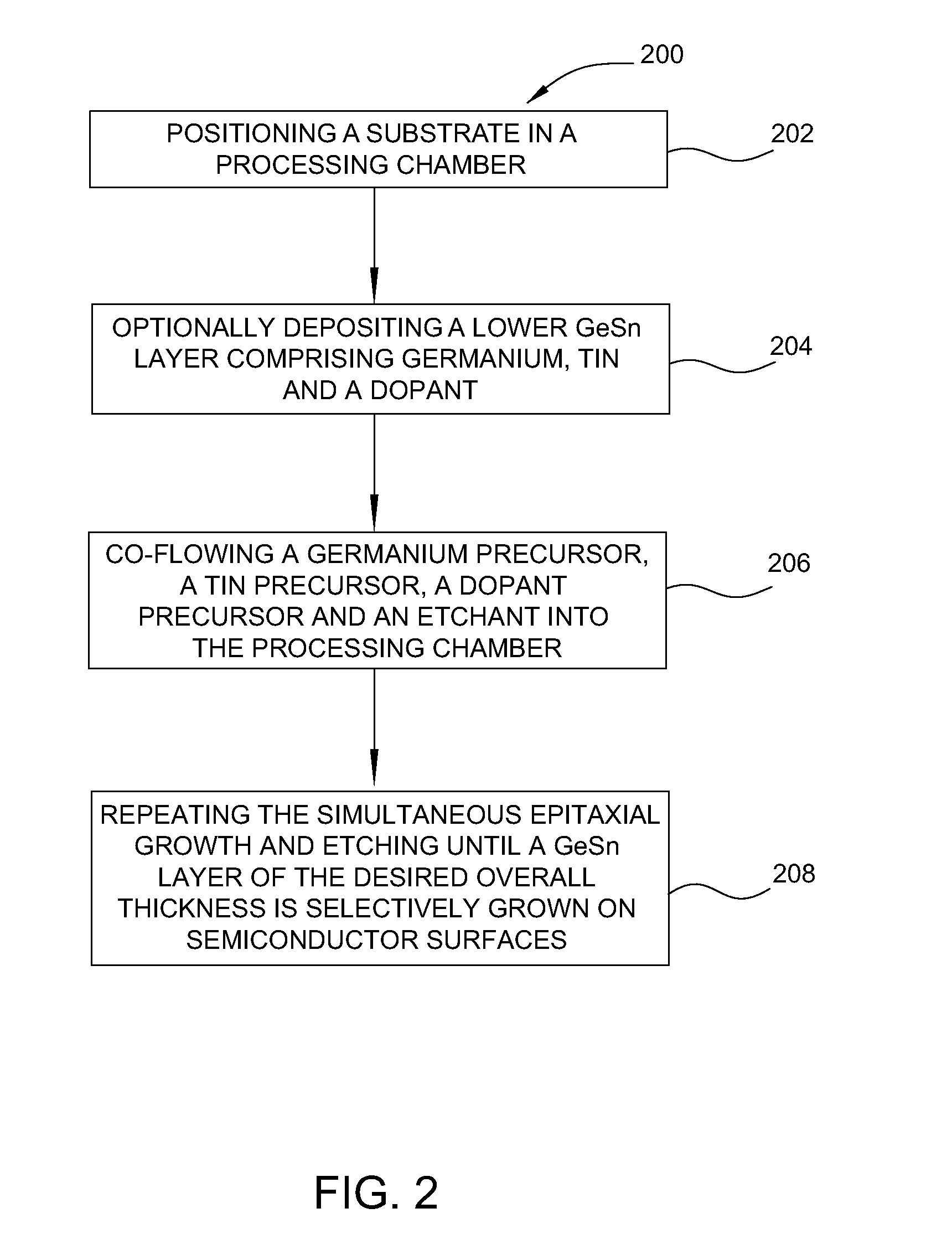

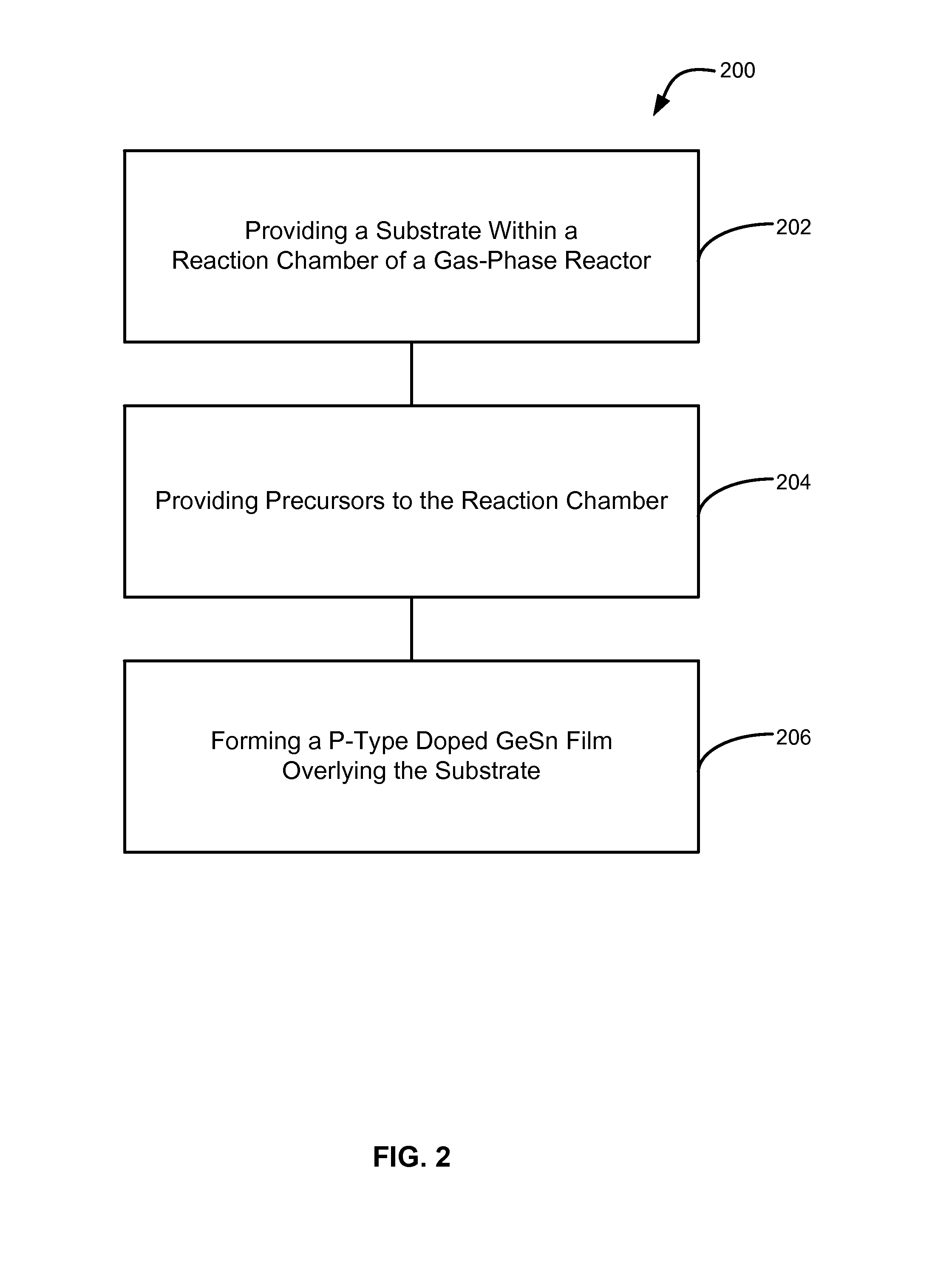

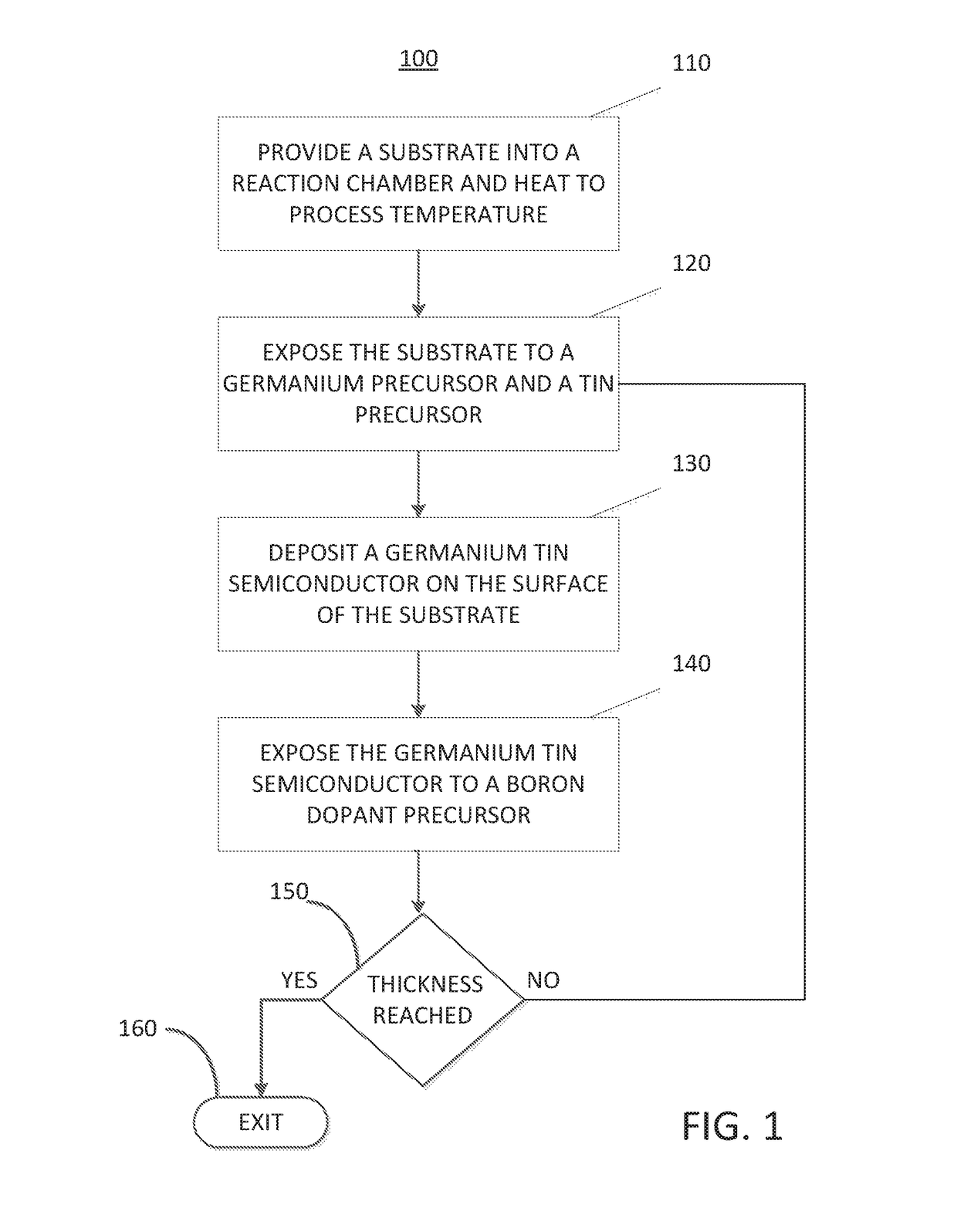

Method of epitaxial doped germanium tin alloy formation

ActiveUS20130256838A1Reduce lossesSemiconductor/solid-state device manufacturingSemiconductor devicesDopantAlloy

A method for forming germanium tin layers and the resulting embodiments are described. A germanium precursor and a tin precursor are provided to a chamber, and an epitaxial layer of germanium tin is formed on the substrate. The germanium tin layer is selectively deposited on the semiconductor regions of the substrate and can include thickness regions of varying tin and dopant concentrations. The germanium tin layer can be selectively deposited by either alternating or concurrent flow of a halide gas to etch the surface of the substrate.

Owner:APPLIED MATERIALS INC

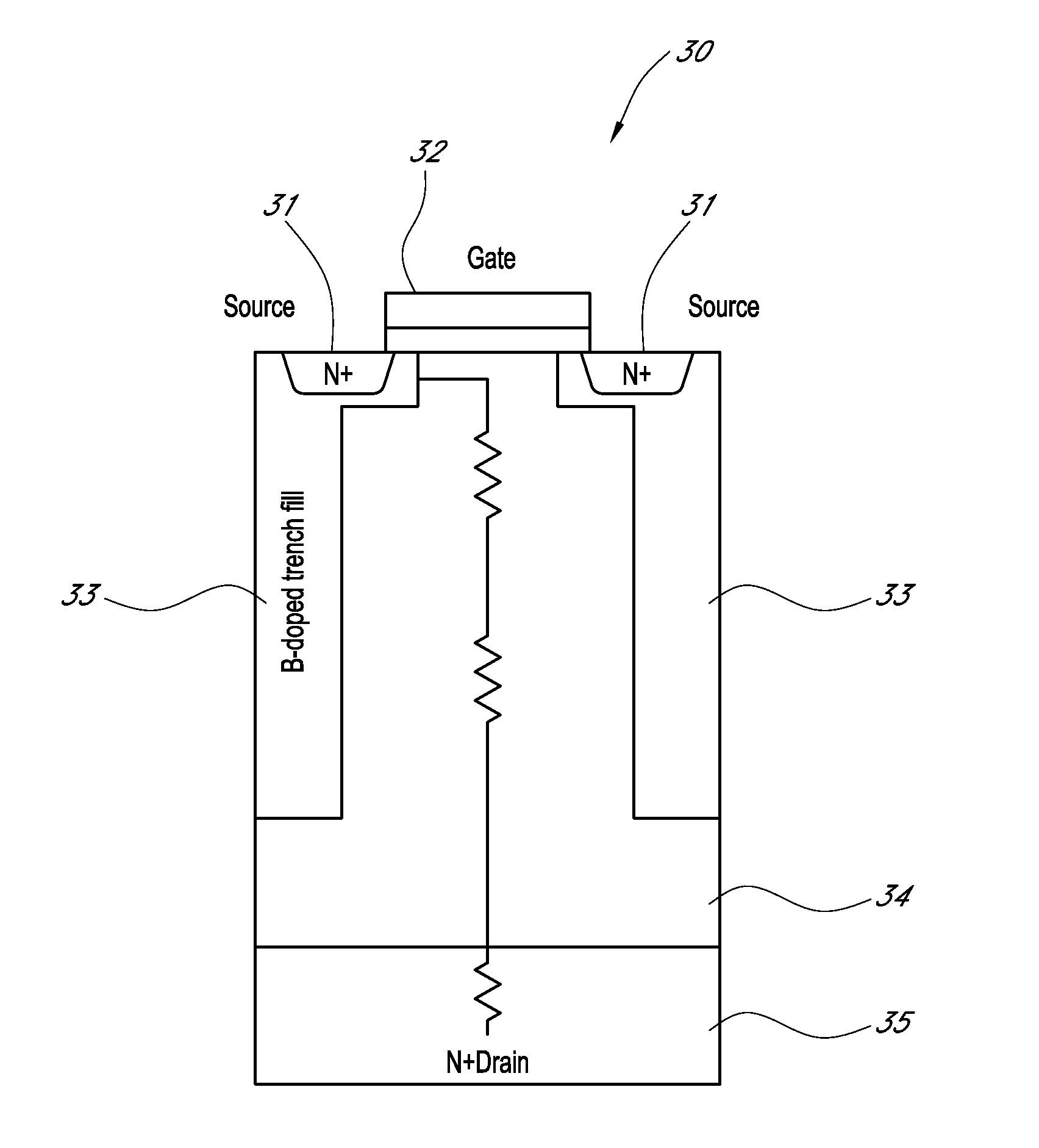

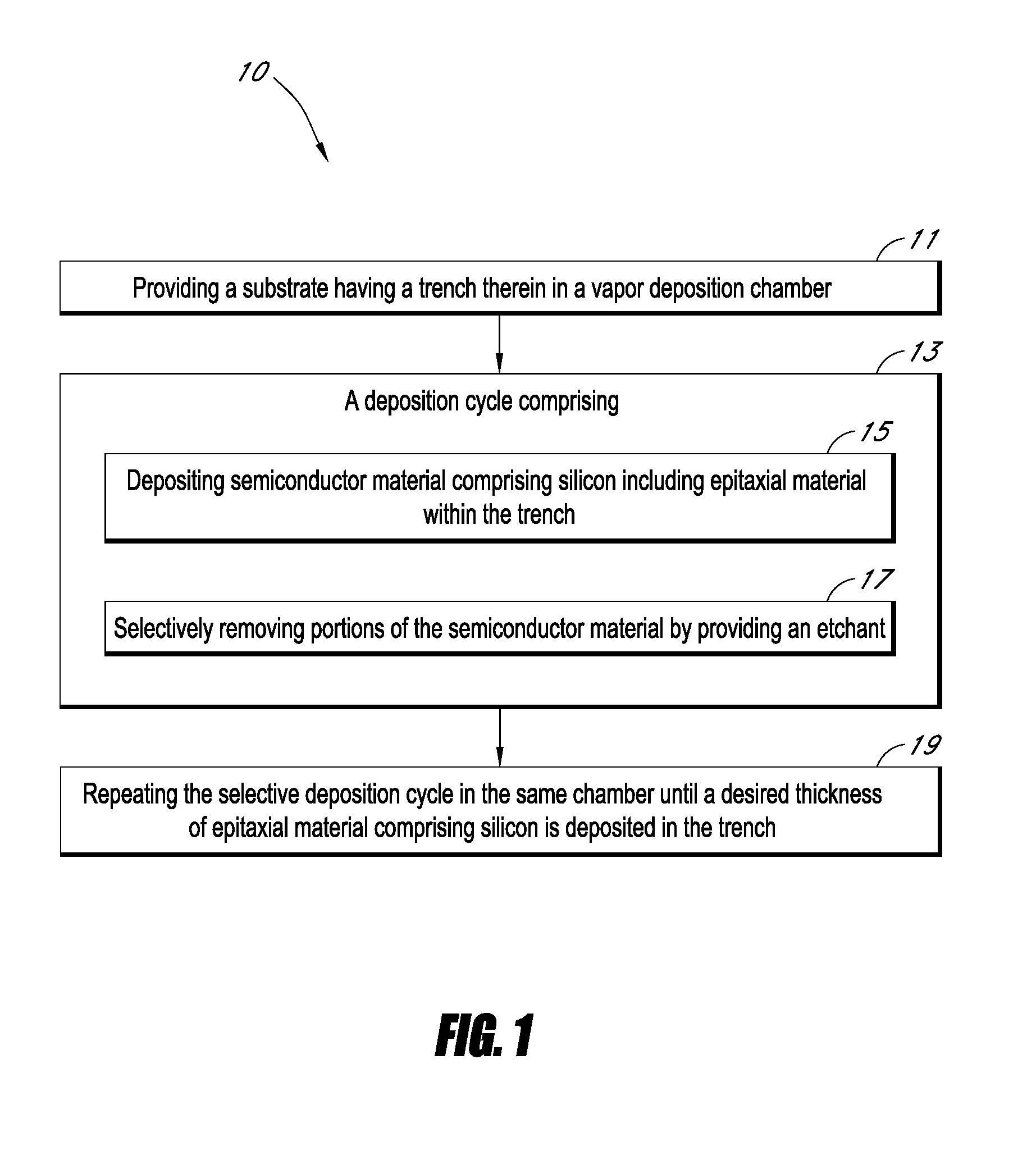

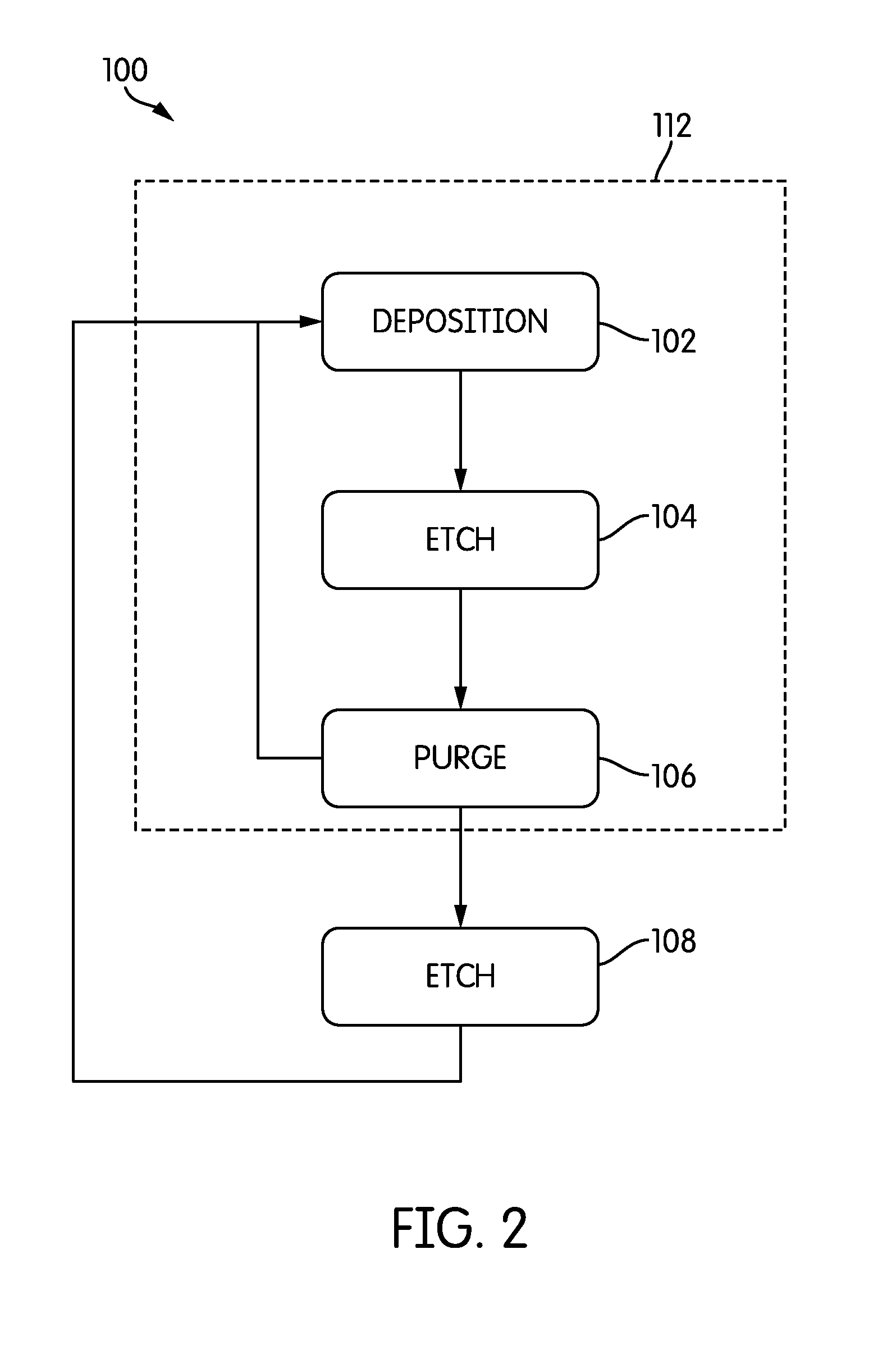

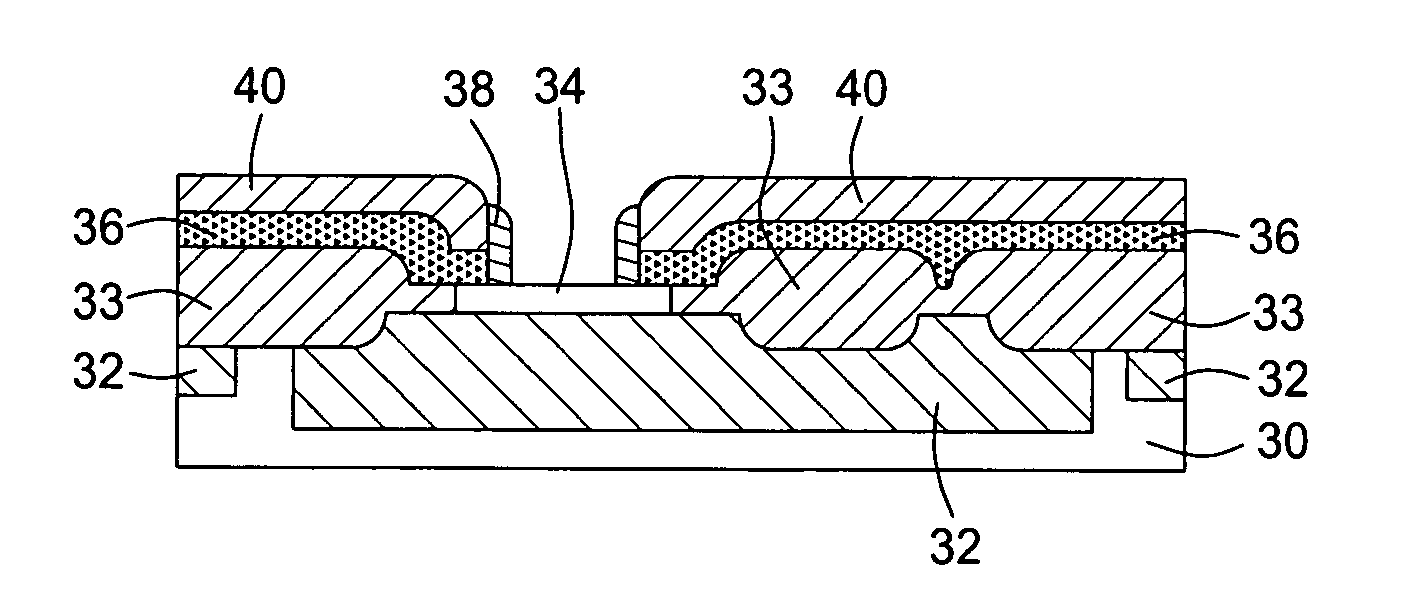

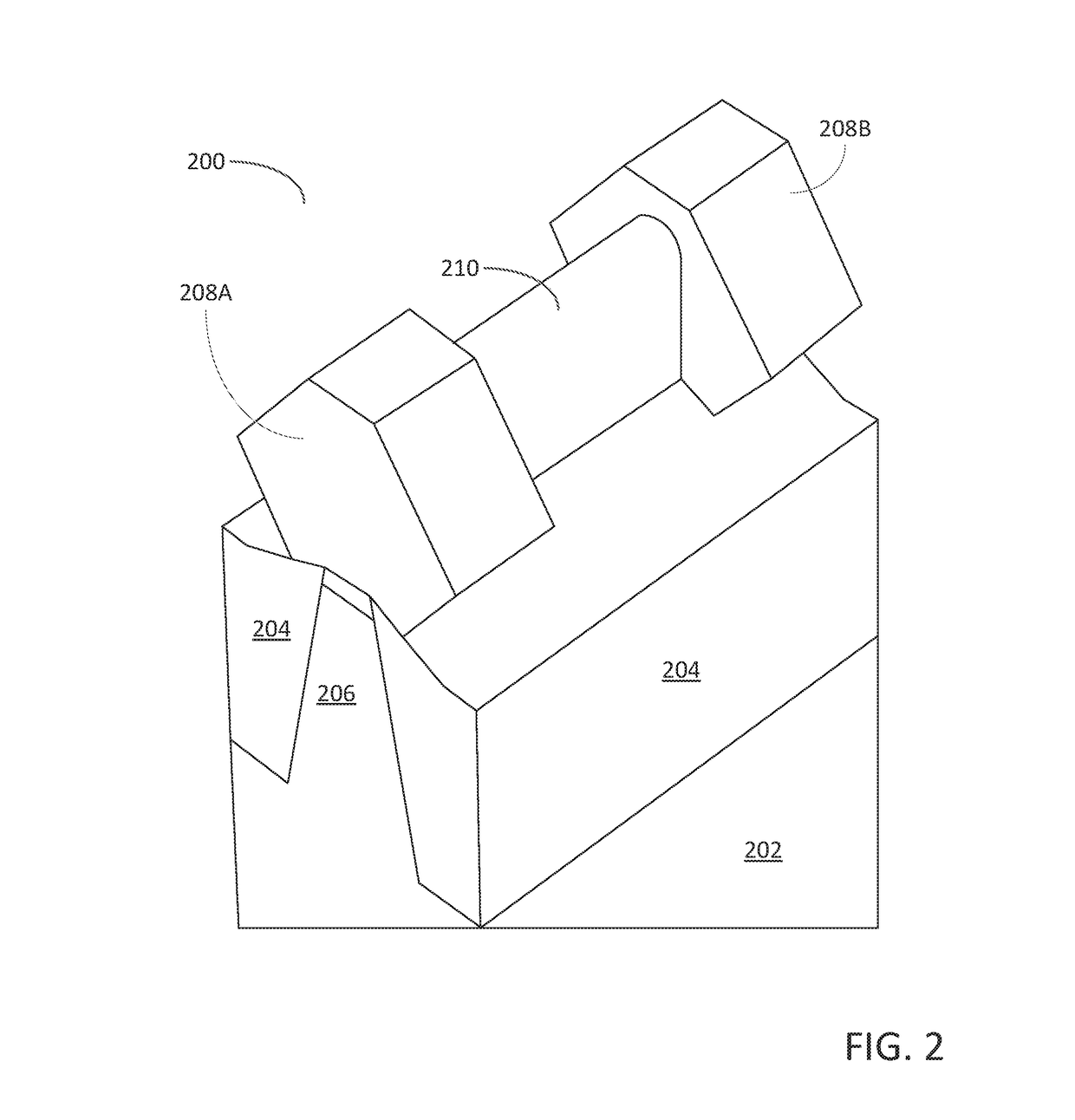

Processes and structures for dopant profile control in epitaxial trench fill

InactiveUS20130320429A1Semiconductor/solid-state device manufacturingSemiconductor devicesDopantEpitaxial material

Methods of depositing epitaxial material using a repeated deposition and etch process. The deposition and etch processes can be repeated until a desired thickness of silicon-containing material is achieved. During the deposition process, a doped silicon film can be deposited. The doped silicon film can be selectively deposited in a trench on a substrate. The trench can have a liner comprising silicon and carbon prior to depositing the doped silicon film. The doped silicon film may also contain germanium. Germanium can promote uniform dopant distribution within the doped silicon film.

Owner:ASM IP HLDG BV

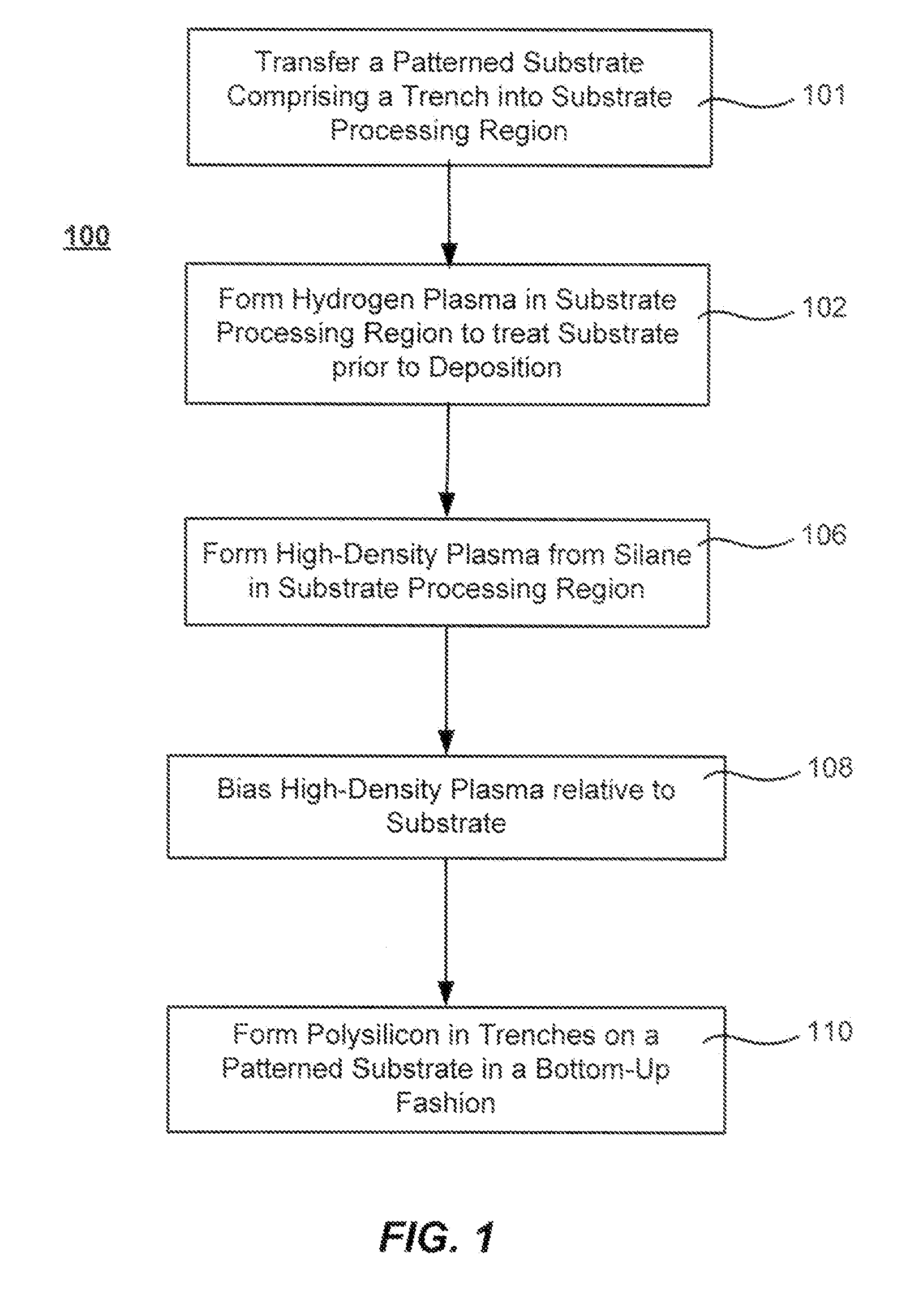

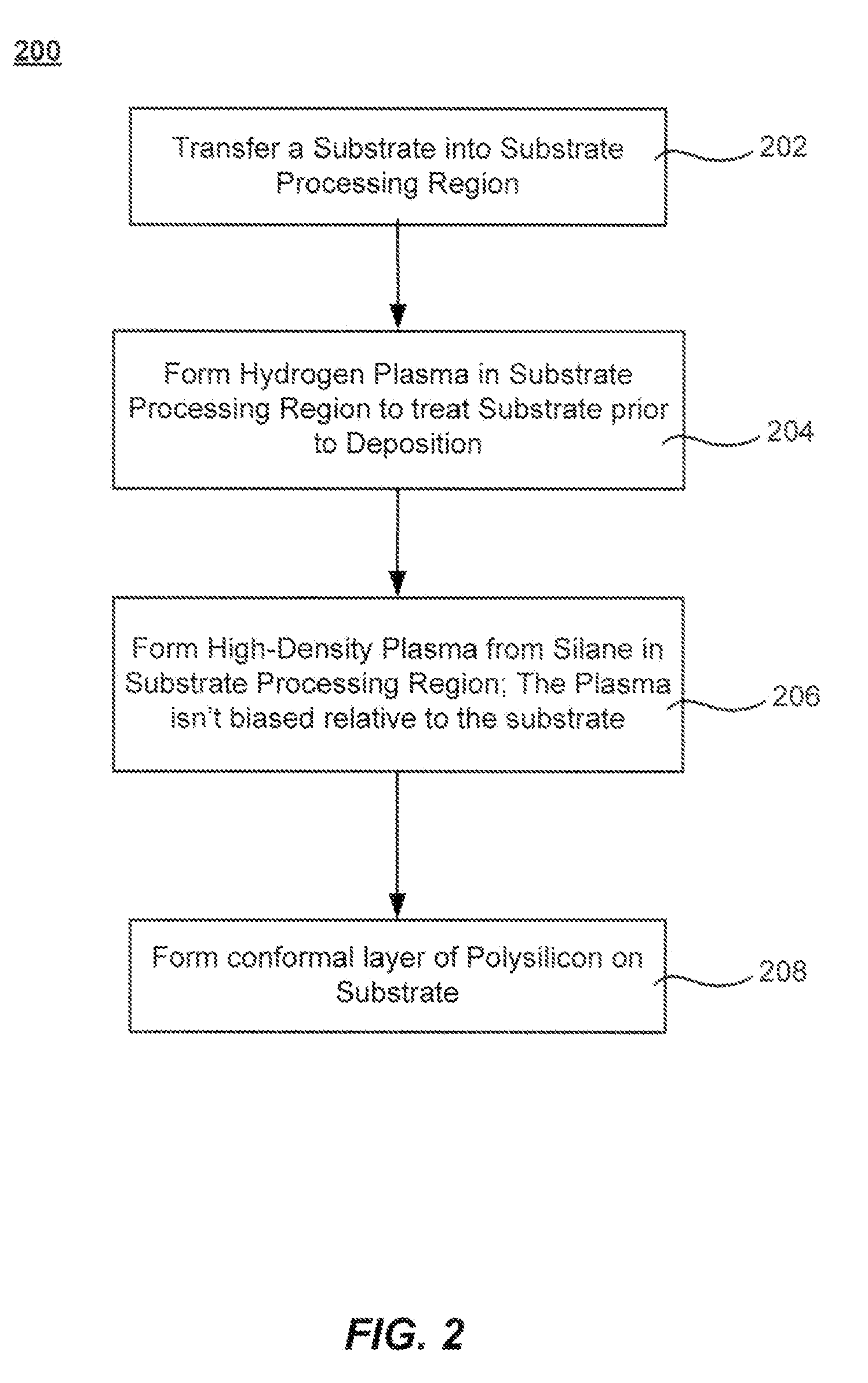

Polysilicon films by HDP-CVD

InactiveUS8450191B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantHigh density

Methods of forming polysilicon layers are described. The methods include forming a high-density plasma from a silicon precursor in a substrate processing region containing the deposition substrate. The described methods produce polycrystalline films at reduced substrate temperature (e.g. <500° C.) relative to prior art techniques. The availability of a bias plasma power adjustment further enables adjustment of conformality of the formed polysilicon layer. When dopants are included in the high density plasma, they may be incorporated into the polysilicon layer in such a way that they do not require a separate activation step.

Owner:APPLIED MATERIALS INC

Semiconductor fin isolation by a well trapping fin portion

ActiveUS20140252479A1Solid-state devicesSemiconductor/solid-state device manufacturingDopantSemiconductor materials

A bulk semiconductor substrate including a first semiconductor material is provided. A well trapping layer including a second semiconductor material and a dopant is formed on a top surface of the bulk semiconductor substrate. The combination of the second semiconductor material and the dopant within the well trapping layer is selected such that diffusion of the dopant is limited within the well trapping layer. A device semiconductor material layer including a third semiconductor material can be epitaxially grown on the top surface of the well trapping layer. The device semiconductor material layer, the well trapping layer, and an upper portion of the bulk semiconductor substrate are patterned to form at least one semiconductor fin. Semiconductor devices formed in each semiconductor fin can be electrically isolated from the bulk semiconductor substrate by the remaining portions of the well trapping layer.

Owner:IBM CORP

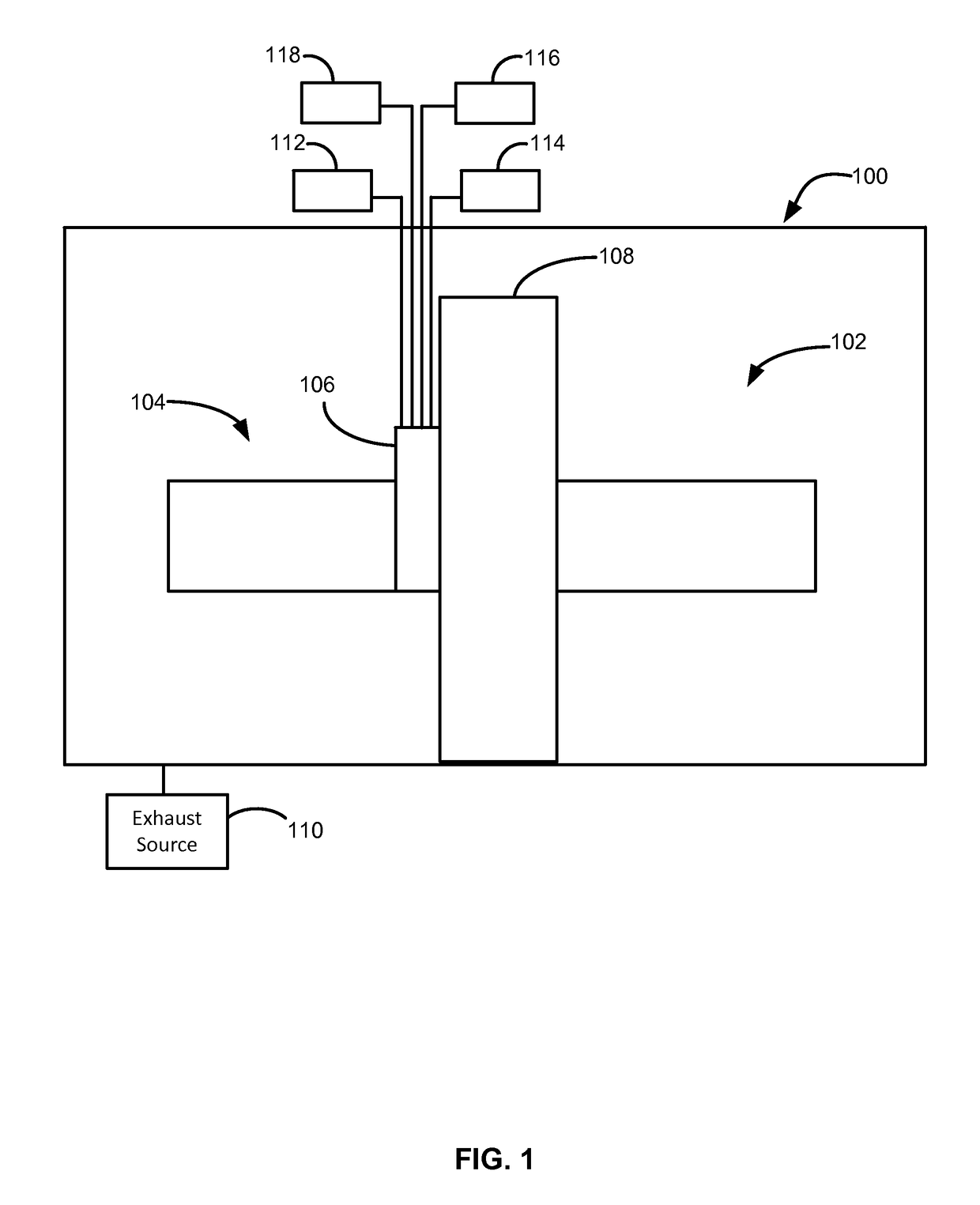

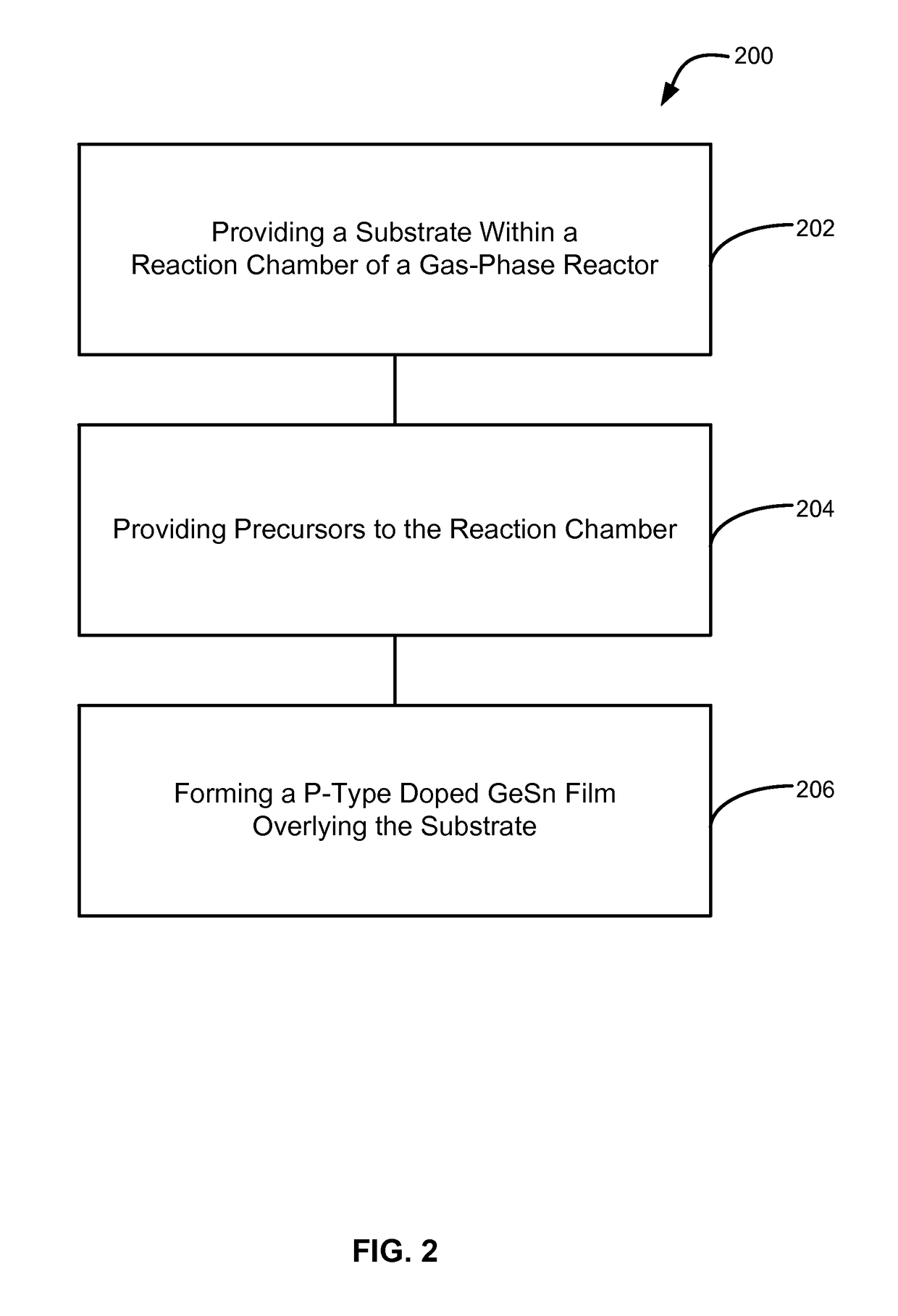

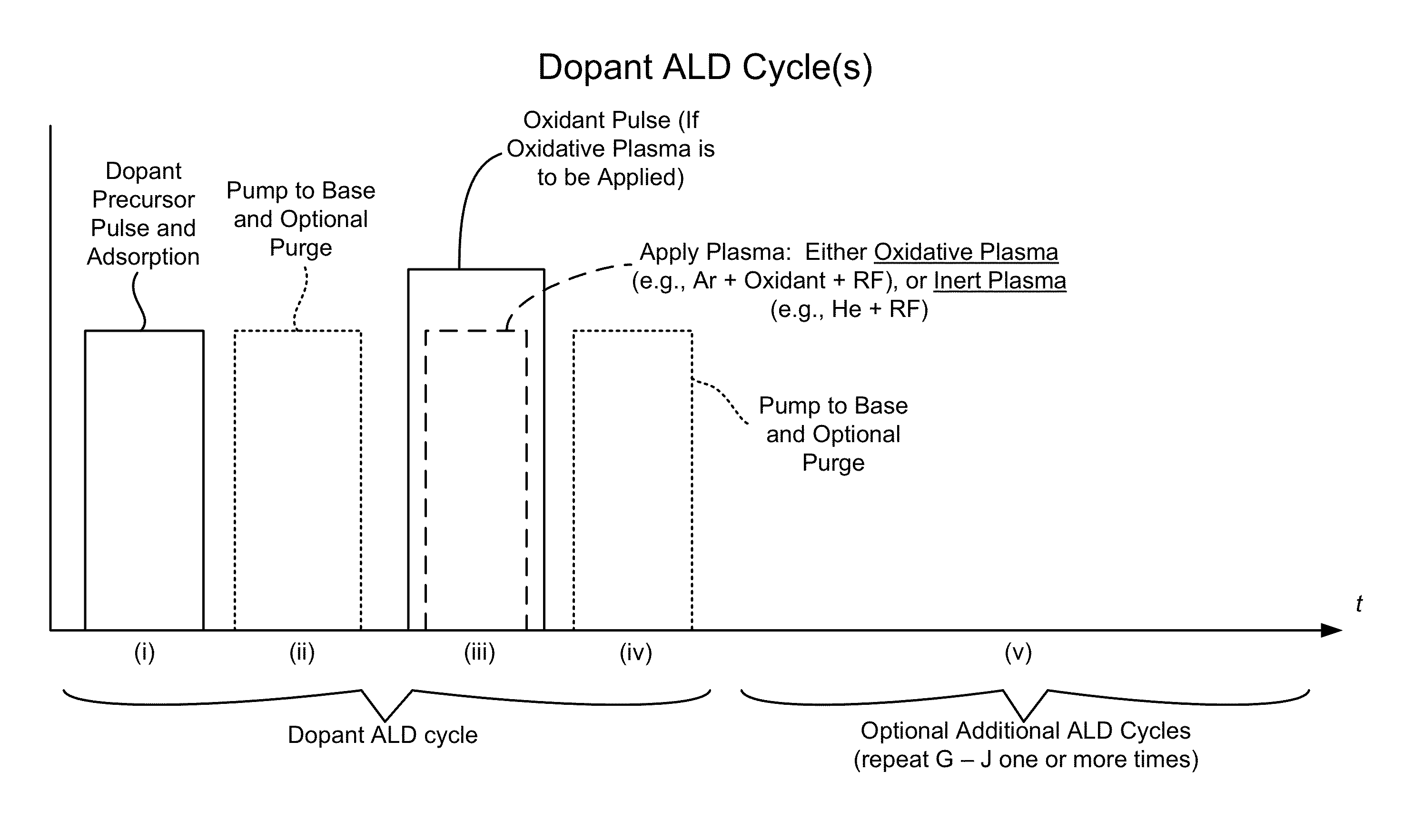

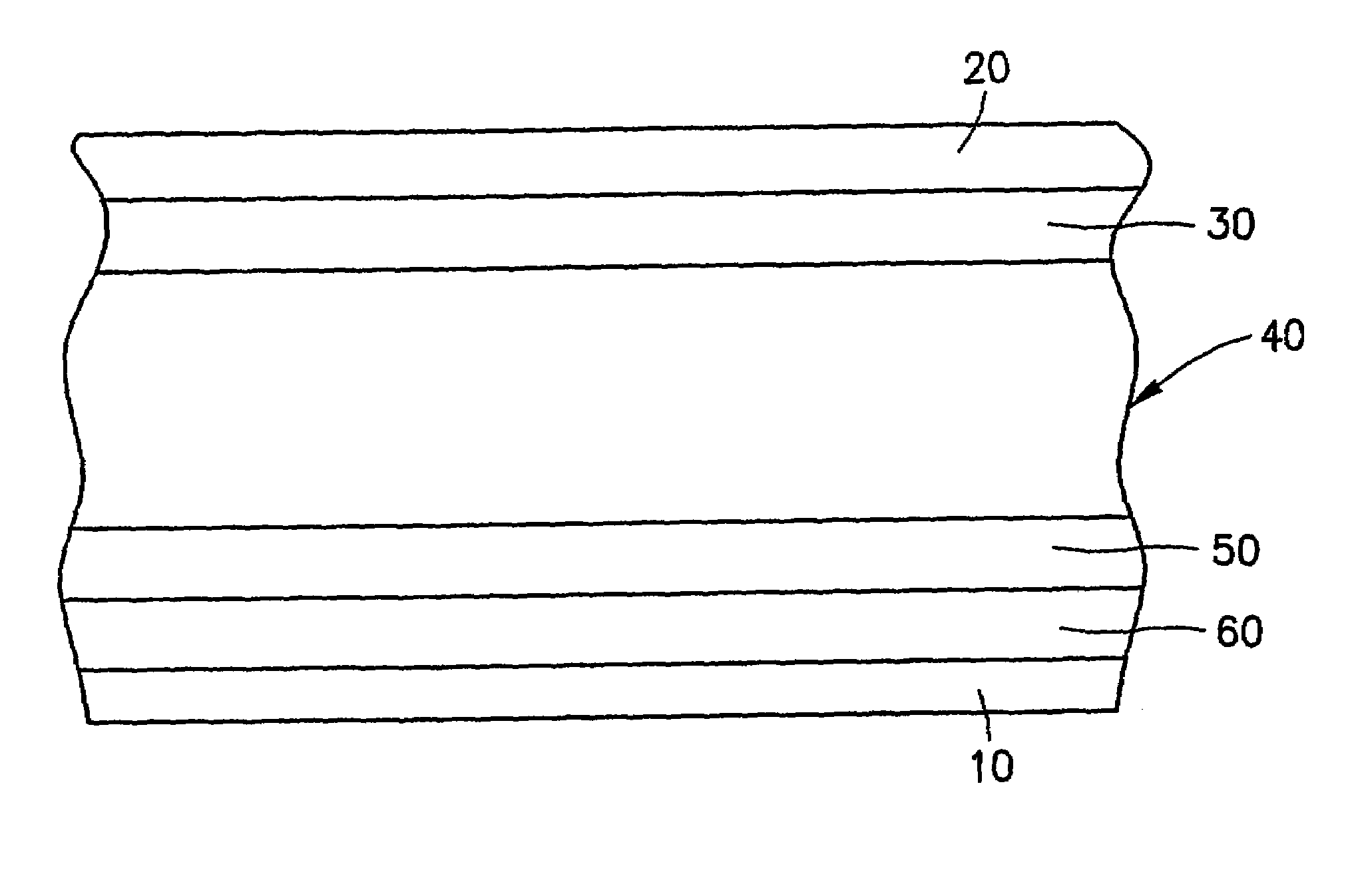

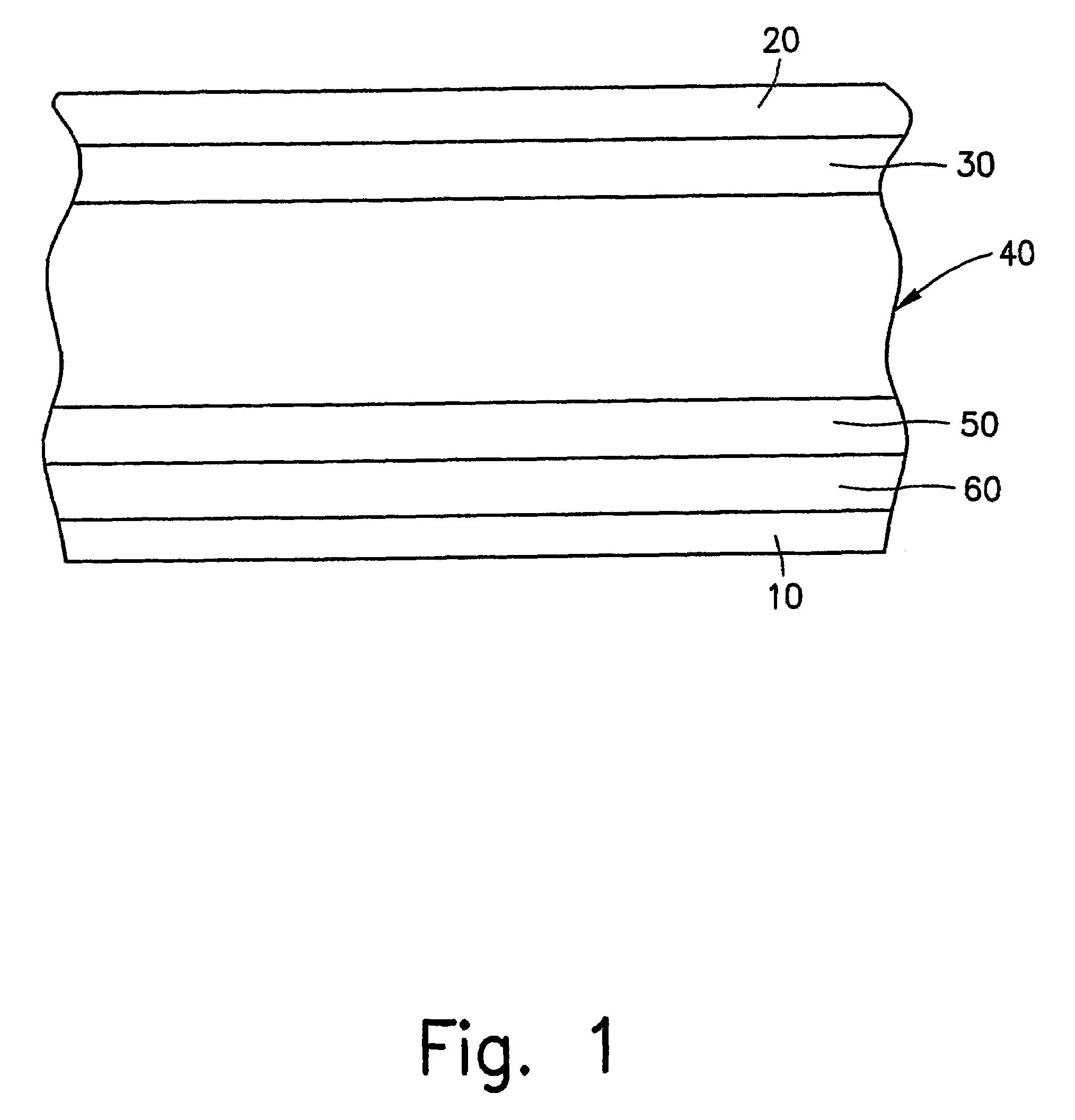

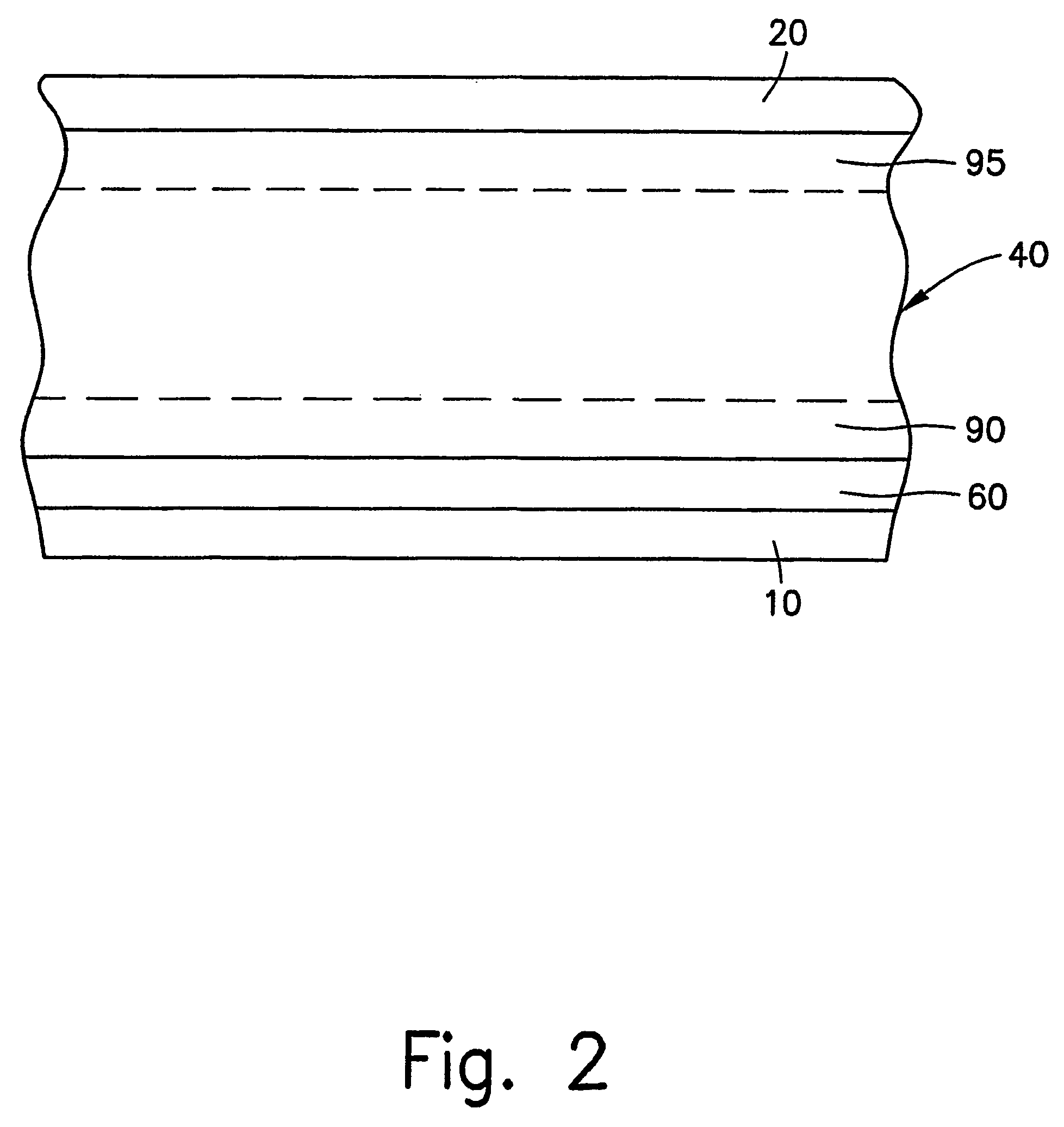

Methods of forming highly p-type doped germanium tin films and structures and devices including the films

ActiveUS9647114B2Polycrystalline material growthSemiconductor/solid-state device manufacturingDopantP type doping

Methods of forming p-type doped germanium-tin layers, systems for forming the p-type doped germanium-tin layers, and structures including the p-type doped germanium-tin layers are disclosed. The p-type doped germanium-tin layers include an n-type dopant, which allows relatively high levels of tin and / or p-type dopant to be included into the p-type doped germanium-tin layers.

Owner:ASM IP HLDG BV

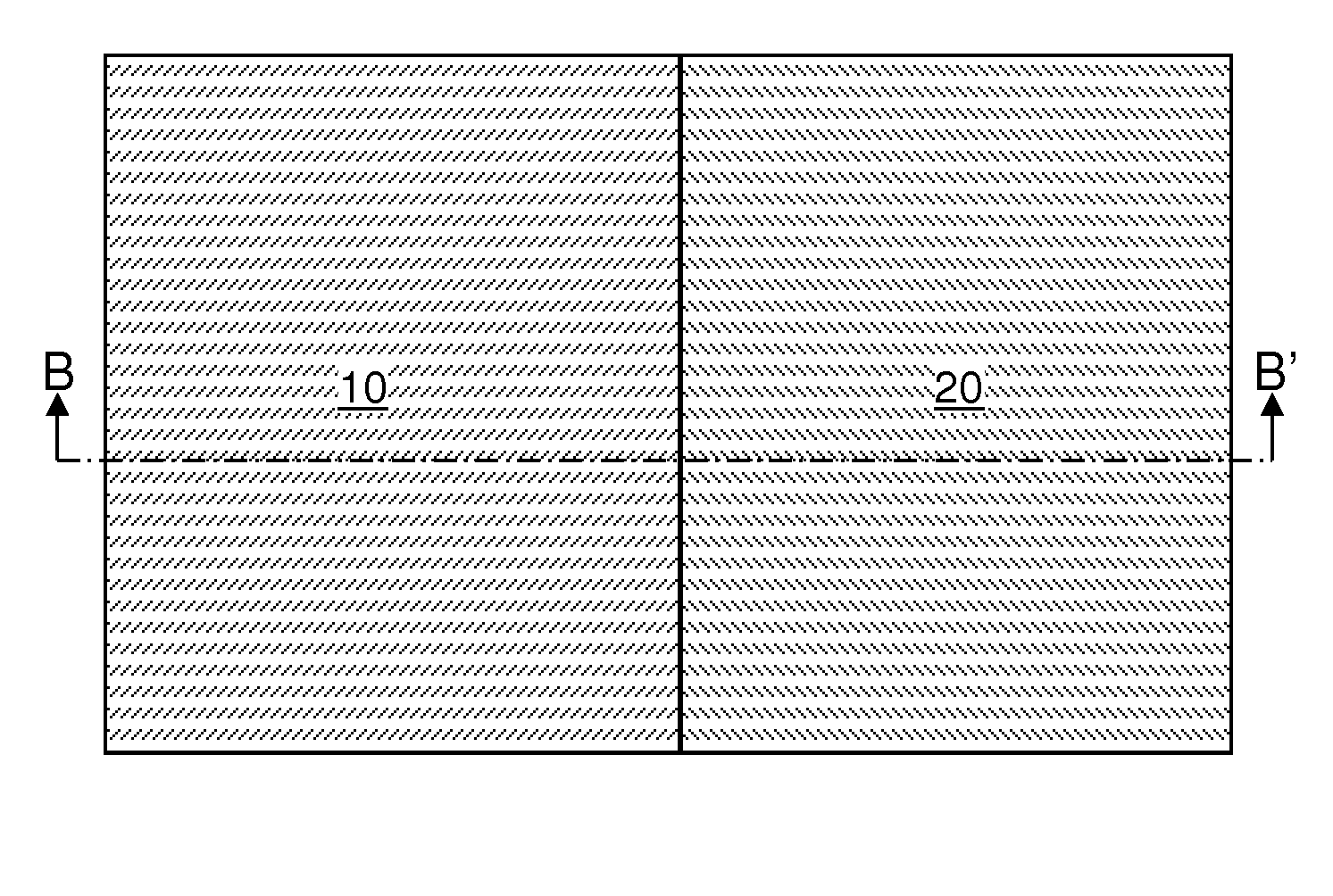

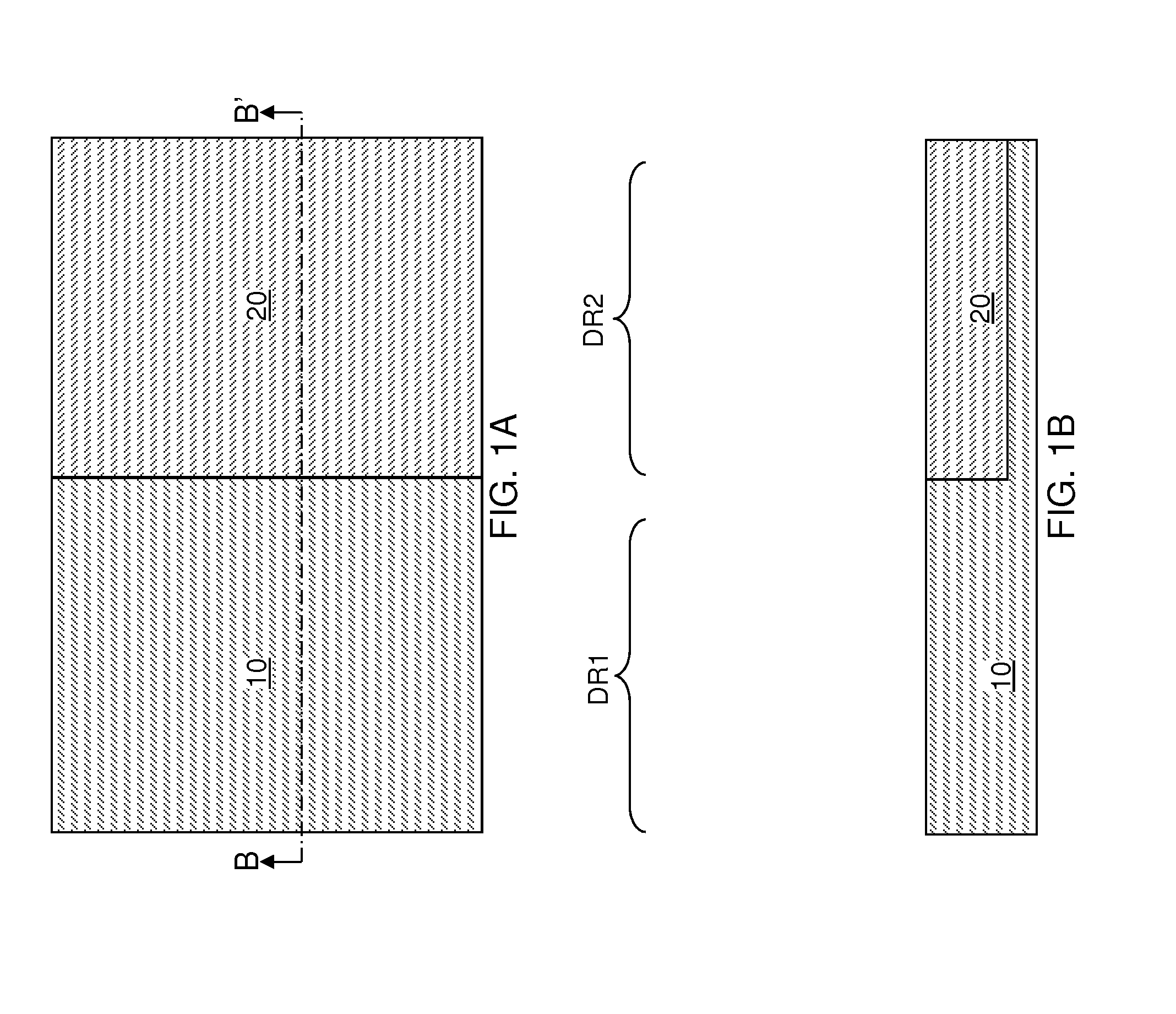

Conformal doping via plasma activated atomic layer deposition and conformal film deposition

ActiveUS20130040447A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingDopantPatterned substrate

Disclosed herein are methods of doping a patterned substrate in a reaction chamber. The methods may include forming a first conformal film layer which has a dopant source including a dopant, and driving some of the dopant into the substrate to form a conformal doping profile. In some embodiments, forming the first film layer may include introducing a dopant precursor into the reaction chamber, adsorbing the dopant precursor under conditions whereby it forms an adsorption-limited layer, and reacting the adsorbed dopant precursor to form the dopant source. Also disclosed herein are apparatuses for doping a substrate which may include a reaction chamber, a gas inlet, and a controller having machine readable code including instructions for operating the gas inlet to introduce dopant precursor into the reaction chamber so that it is adsorbed, and instructions for reacting the adsorbed dopant precursor to form a film layer containing a dopant source.

Owner:NOVELLUS SYSTEMS

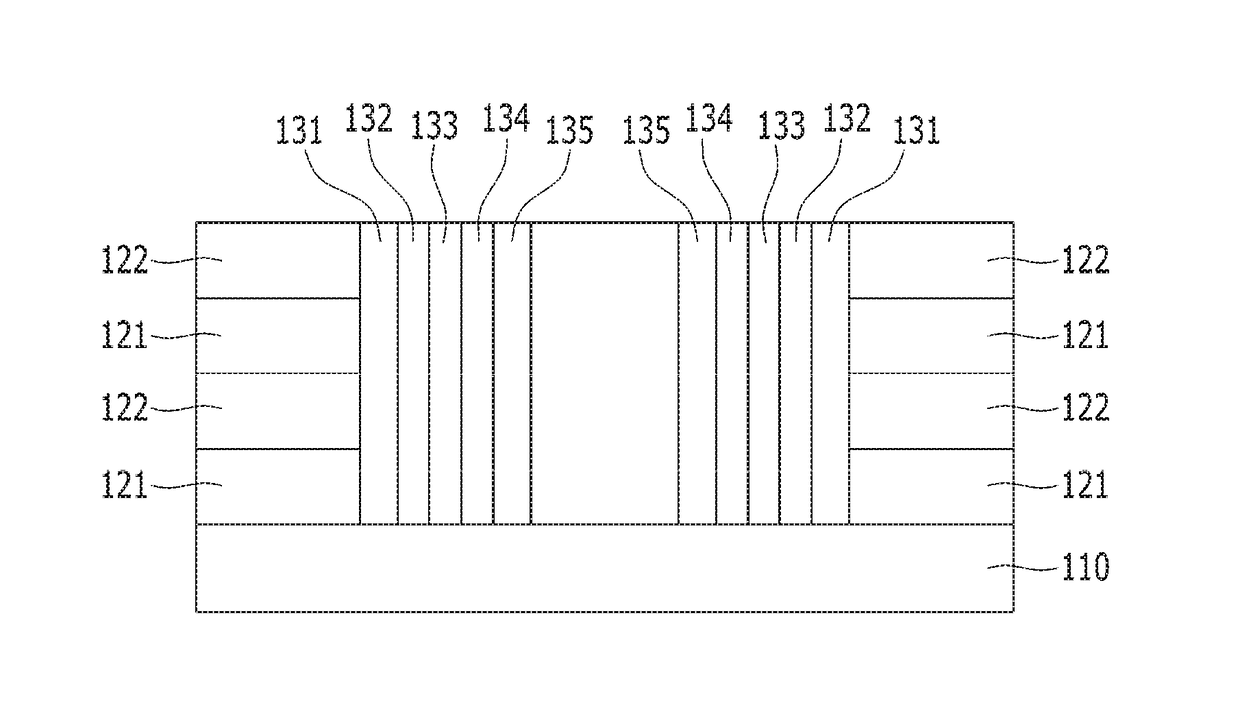

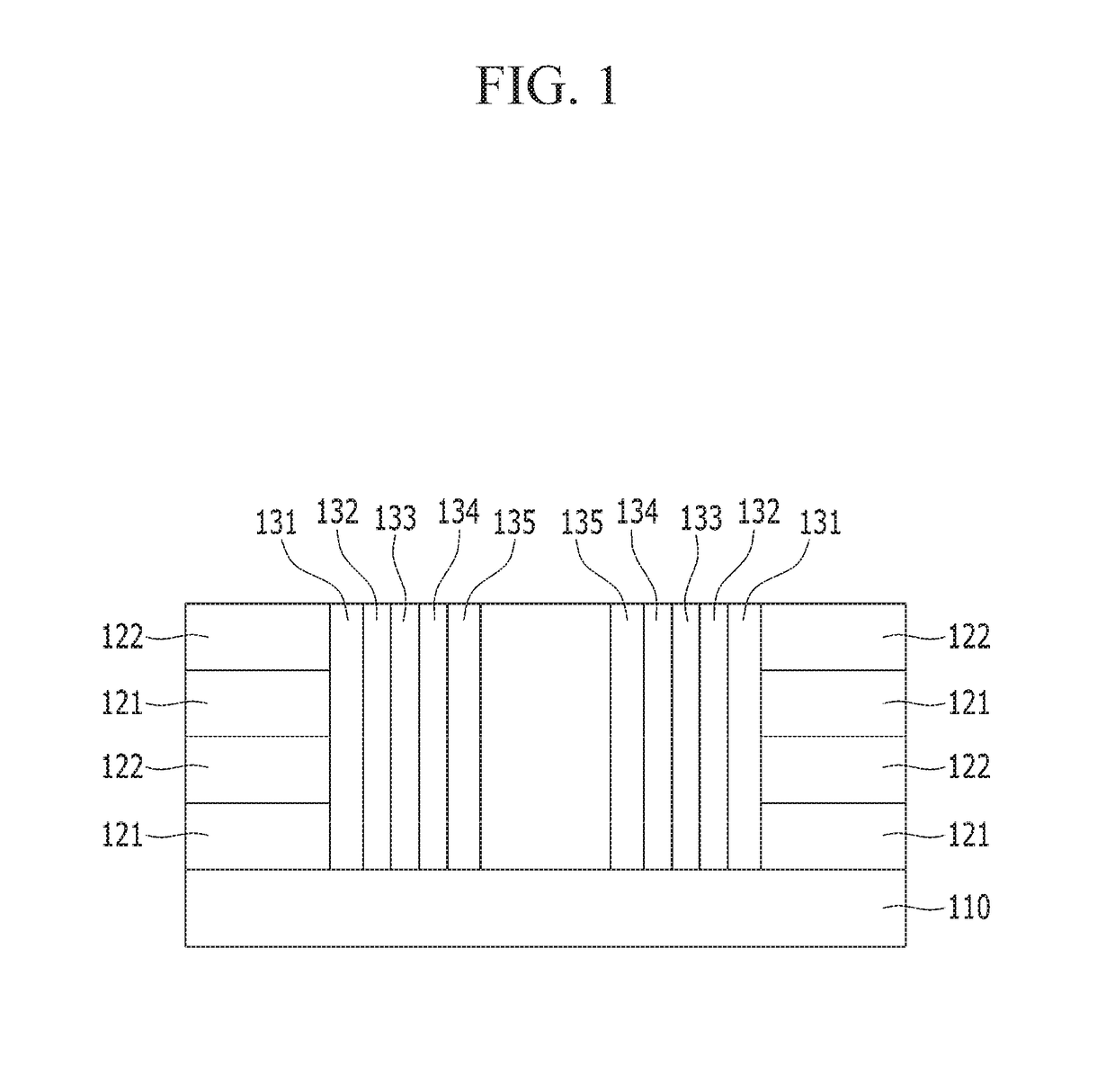

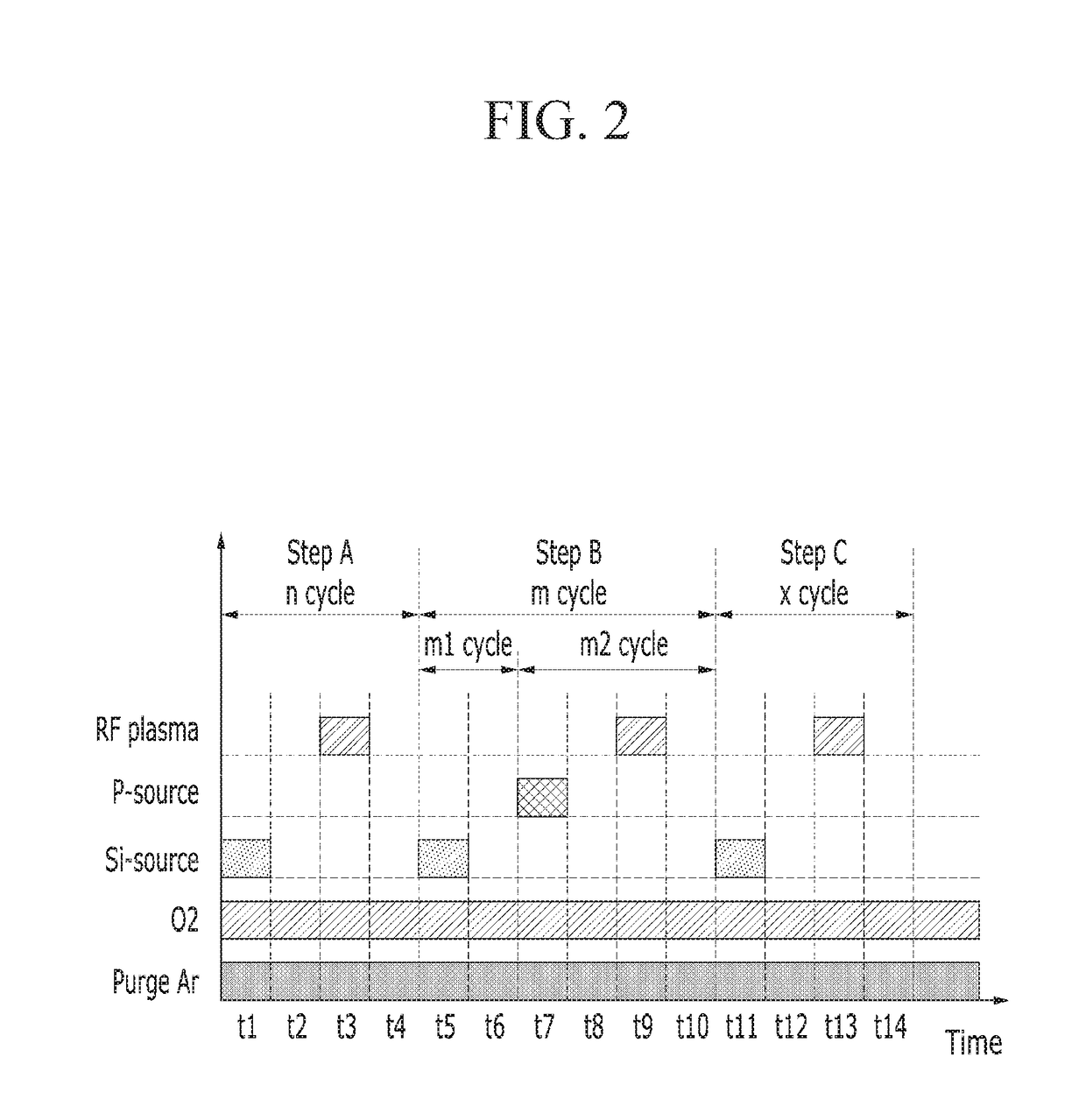

Semiconductor device and manufacturing method thereof

ActiveUS20180047749A1Reduce chargeAvoid chargingSolid-state devicesSemiconductor/solid-state device manufacturingDopantCharge carrier

Disclosed are a semiconductor device and a manufacturing method thereof. According to the semiconductor device and the manufacturing method thereof according to exemplary embodiments of the present invention, after the dopant source layer is uniformly deposited on a channel layer of the device with the 3-demensional vertical structure by the plasma-enhanced atomic layer deposition (PEALD) method, the deposited dopant source layer is heat-treated so that the dopants are diffused into the channel layer to function as charge carriers, thereby preventing the charges in the channel layer from being reduced. According to the exemplary embodiments of the present invention, the diffusion speed and concentration of the dopant may be controlled by forming the barrier layer between the channel layer and the dopant source layer.

Owner:ASM IP HLDG BV

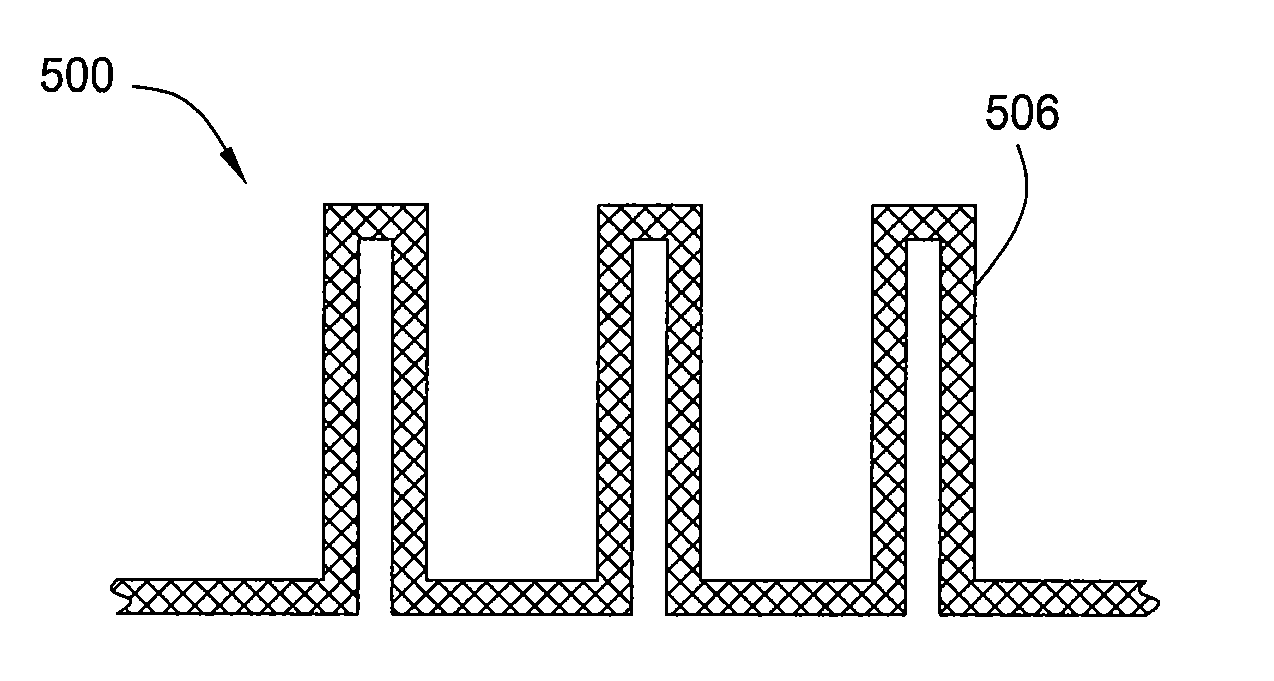

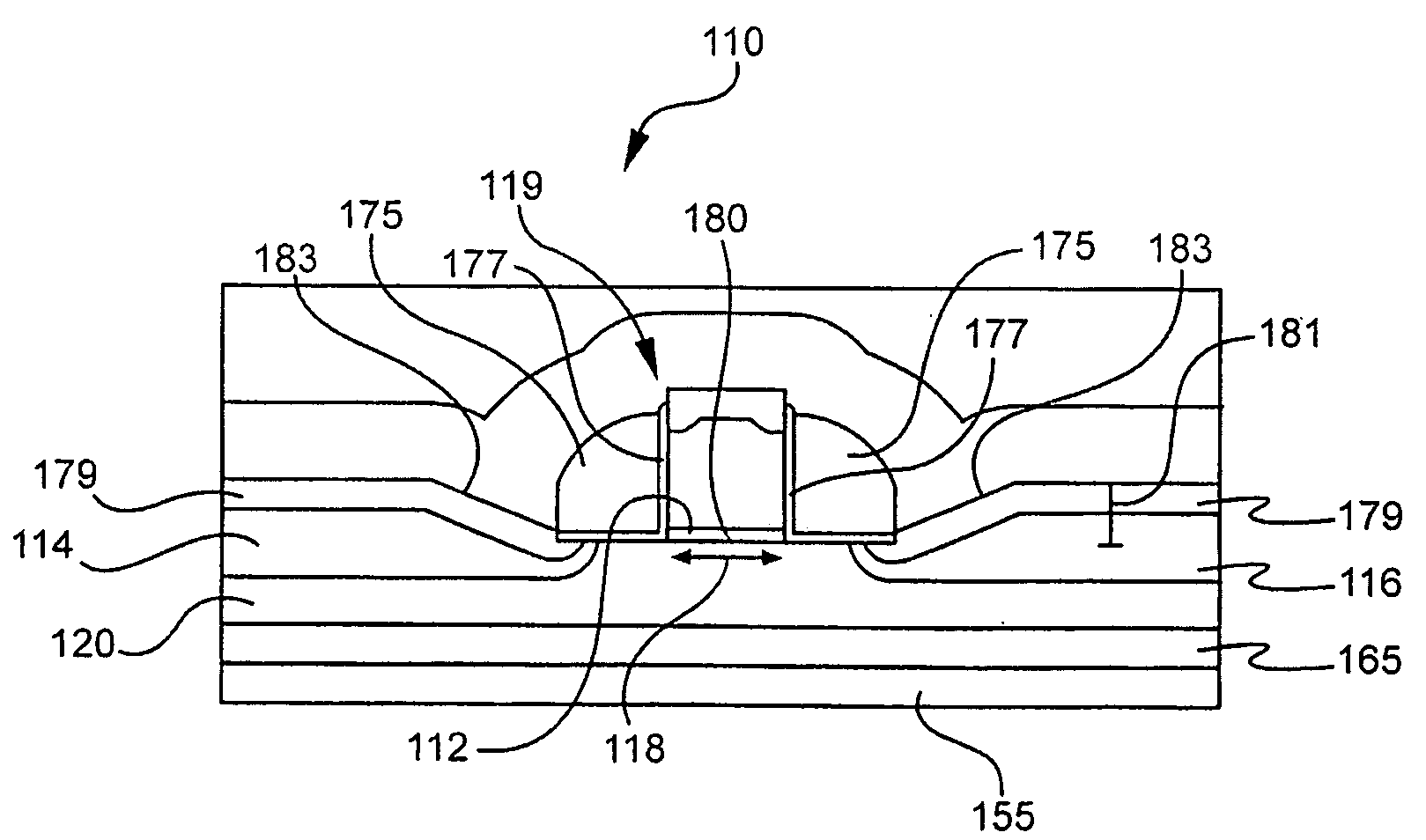

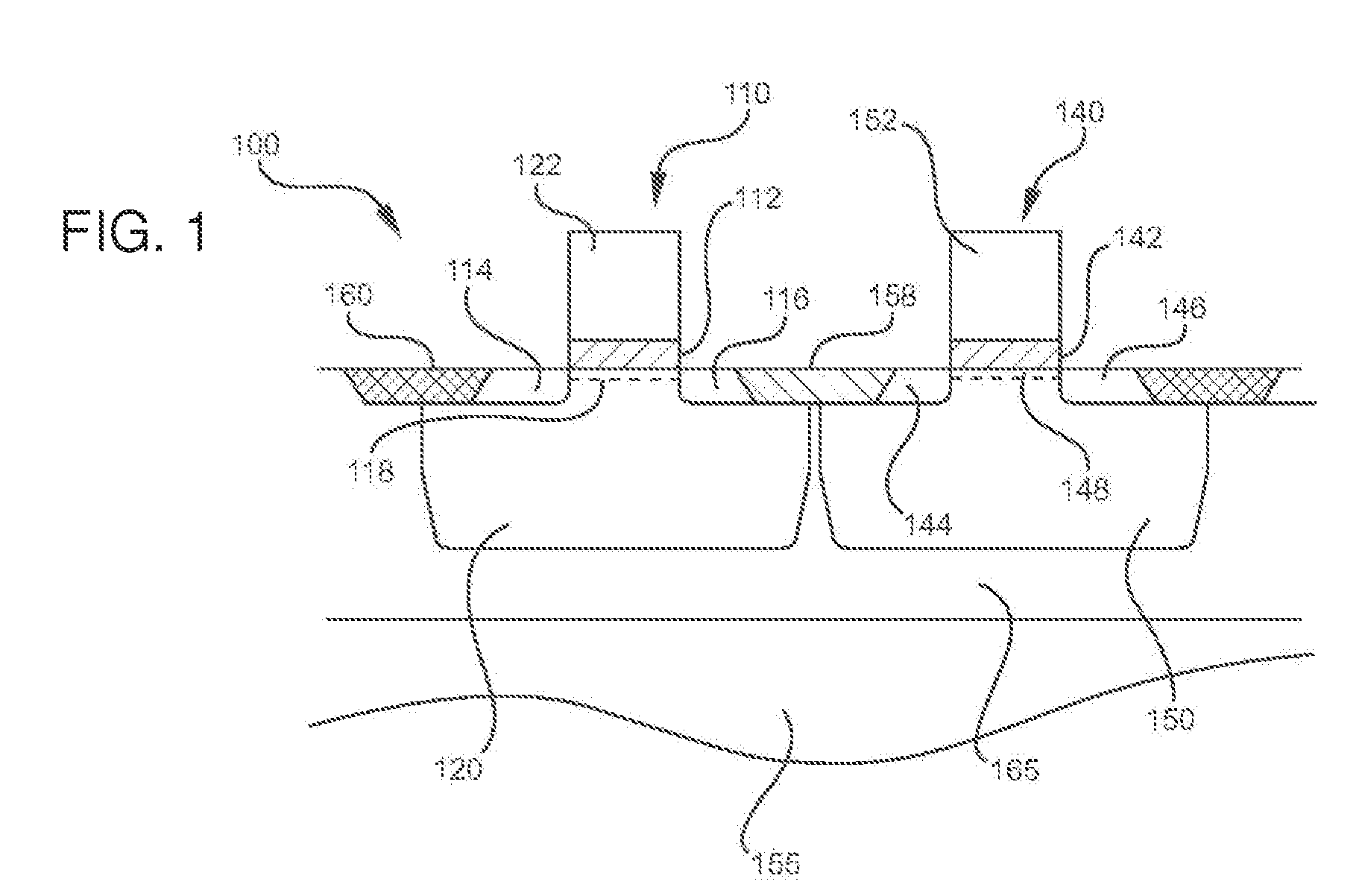

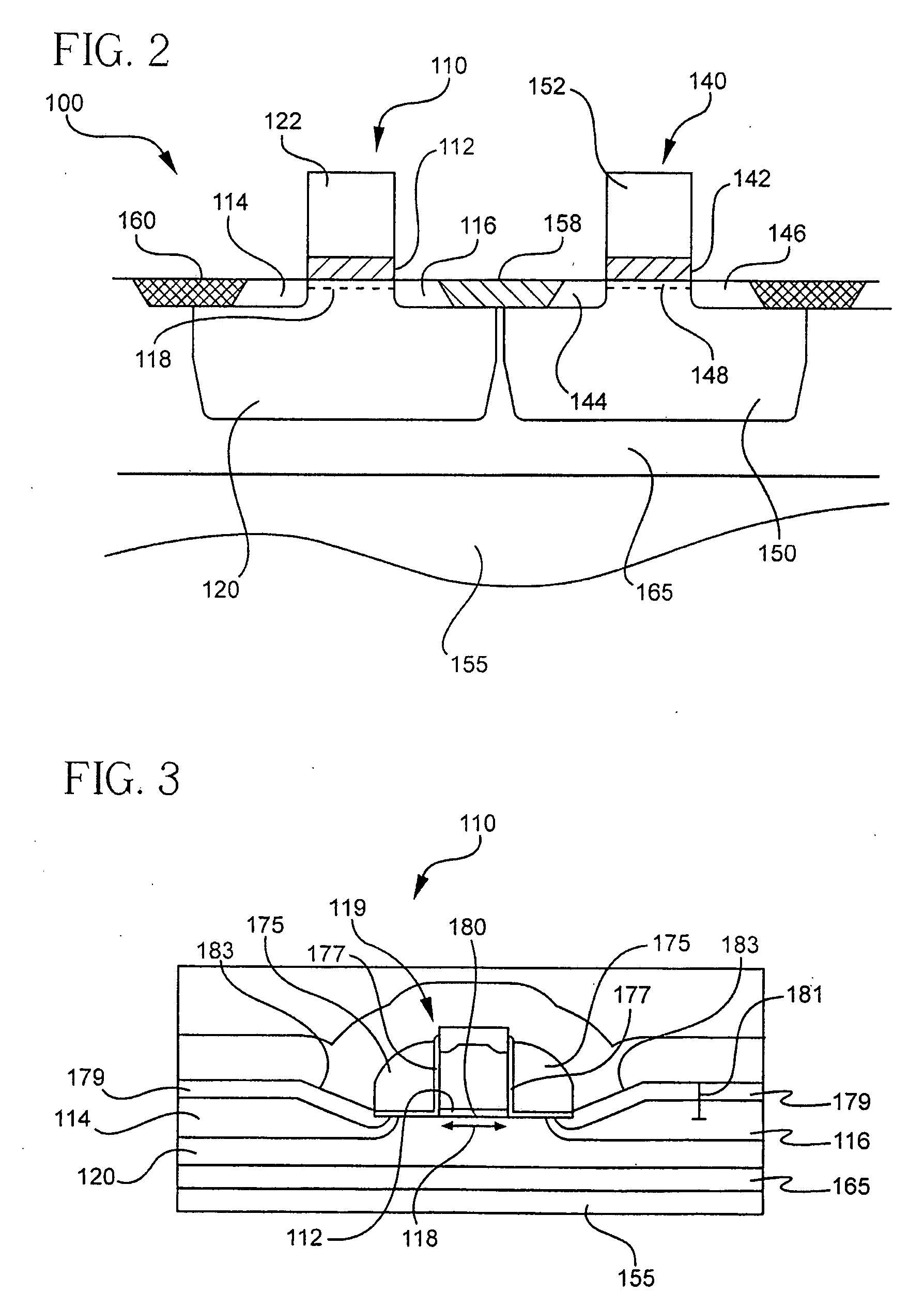

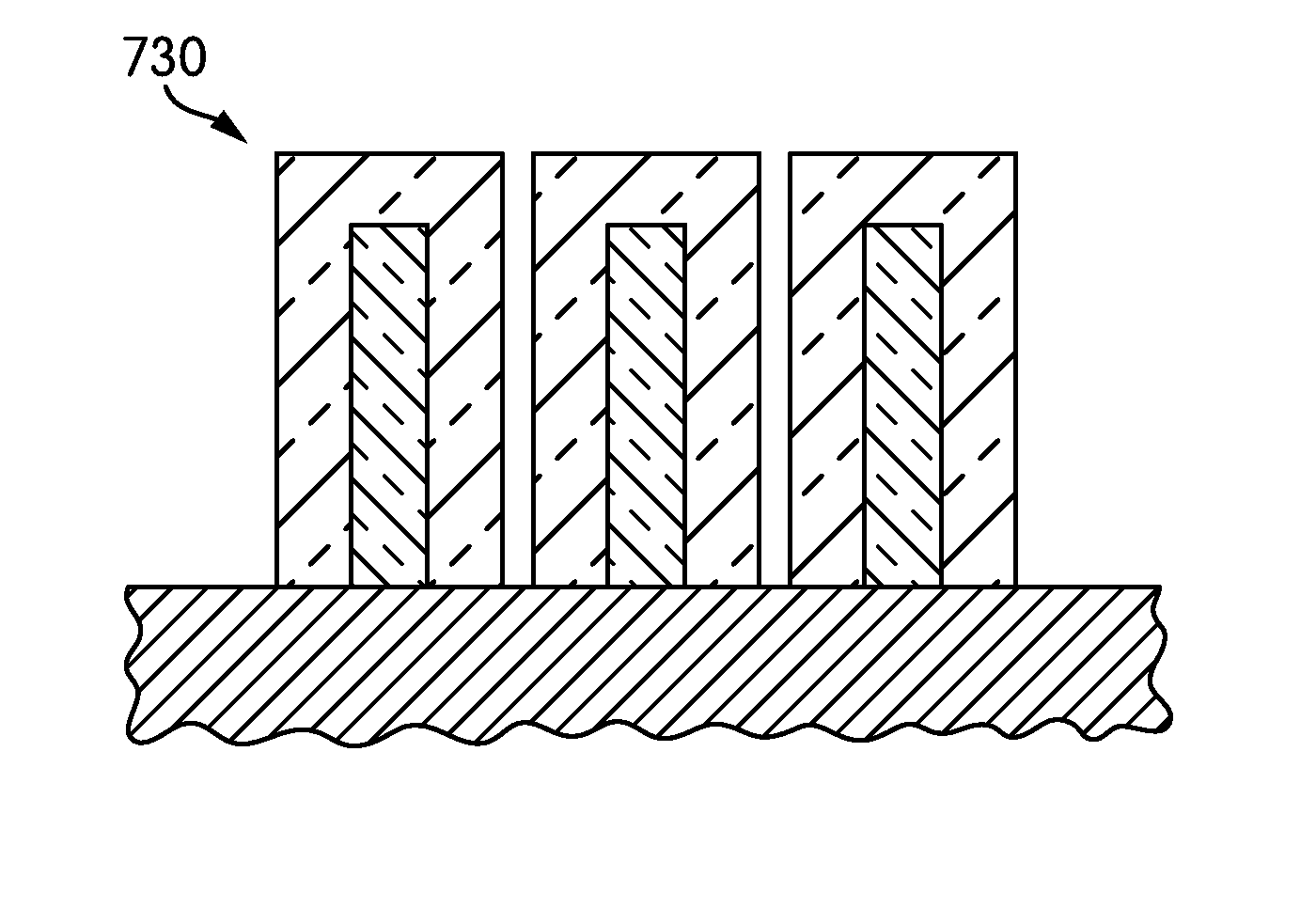

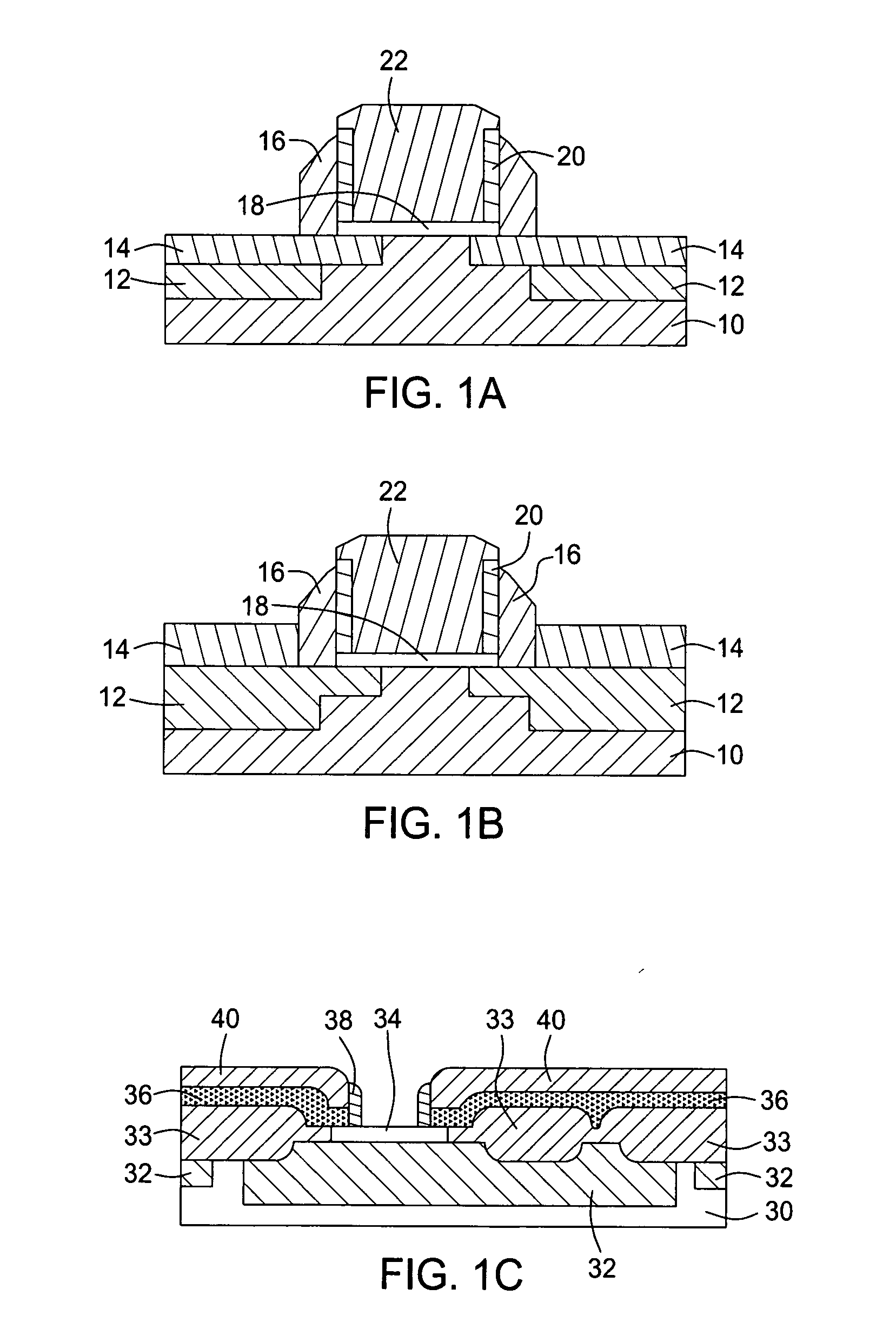

Methods for Selective and Conformal Epitaxy of Highly Doped Si-containing Materials for Three Dimensional Structures

InactiveUS20140120678A1Improve crystal qualityIncreased junctionSemiconductor/solid-state device manufacturingSemiconductor devicesDopantPhosphate

The present invention addresses the key challenges in FinFET fabrication, that is, the fabrications of thin, uniform fins and also reducing the source / drain series resistance. More particularly, this application relates to FinFET fabrication techniques utilizing tetrasilane to enable conformal deposition with high doping using phosphate, arsenic and boron as dopants thereby creating thin fins having uniform thickness (uniformity across devices) as well as smooth, vertical sidewalls, while simultaneously reducing the parasitic series resistance.

Owner:MATHESON TRI GAS INC

Removal of surface dopants from a substrate

InactiveUS20090162996A1Semiconductor/solid-state device detailsSolid-state devicesDopantHigh concentration

A method and apparatus for removing excess dopant from a doped substrate is provided. In one embodiment, a substrate is doped by surfaced deposition of dopant followed by formation of a capping layer and thermal diffusion drive-in. A reactive etchant mixture is provided to the process chamber, with optional plasma, to etch away the capping layer and form volatile compounds by reacting with excess dopant. In another embodiment, a substrate is doped by energetic implantation of dopant. A reactive gas mixture is provided to the process chamber, with optional plasma, to remove excess dopant adsorbed on the surface and high-concentration dopant near the surface by reacting with the dopant to form volatile compounds. The reactive gas mixture may be provided during thermal treatment, or it may be provided before or after at temperatures different from the thermal treatment temperature. The volatile compounds are removed. Substrates so treated do not form toxic compounds when stored or transported outside process equipment.

Owner:APPLIED MATERIALS INC

Methods of forming highly p-type doped germanium tin films and structures and devices including the films

ActiveUS20170047446A1High tin contentSuitable for applicationPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantP type doping

Methods of forming p-type doped germanium-tin layers, systems for forming the p-type doped germanium-tin layers, and structures including the p-type doped germanium-tin layers are disclosed. The p-type doped germanium-tin layers include an n-type dopant, which allows relatively high levels of tin and / or p-type dopant to be included into the p-type doped germanium-tin layers.

Owner:ASM IP HLDG BV

Methods of selective deposition of heavily doped epitaxial SiGe

ActiveUS20050079691A1Semiconductor/solid-state device manufacturingSemiconductor devicesDopantSelective deposition

The invention generally teaches a method for depositing a silicon film or silicon germanium film on a substrate comprising placing the substrate within a process chamber and heating the substrate surface to a temperature in the range from about 600° C. to about 900° C. while maintaining a pressure in the range from about 0.1 Torr to about 200 Torr. A deposition gas is provided to the process chamber and includes SiH4, an optional germanium source gas, an etchant, a carrier gas and optionally at least one dopant gas. The silicon film or the silicon germanium film is selectively and epitaxially grown on the substrate. One embodiment teaches a method for depositing a silicon-containing film with an inert gas as the carrier gas. Methods may include the fabrication of electronic devices utilizing selective silicon germanium epitaxial films.

Owner:APPLIED MATERIALS INC

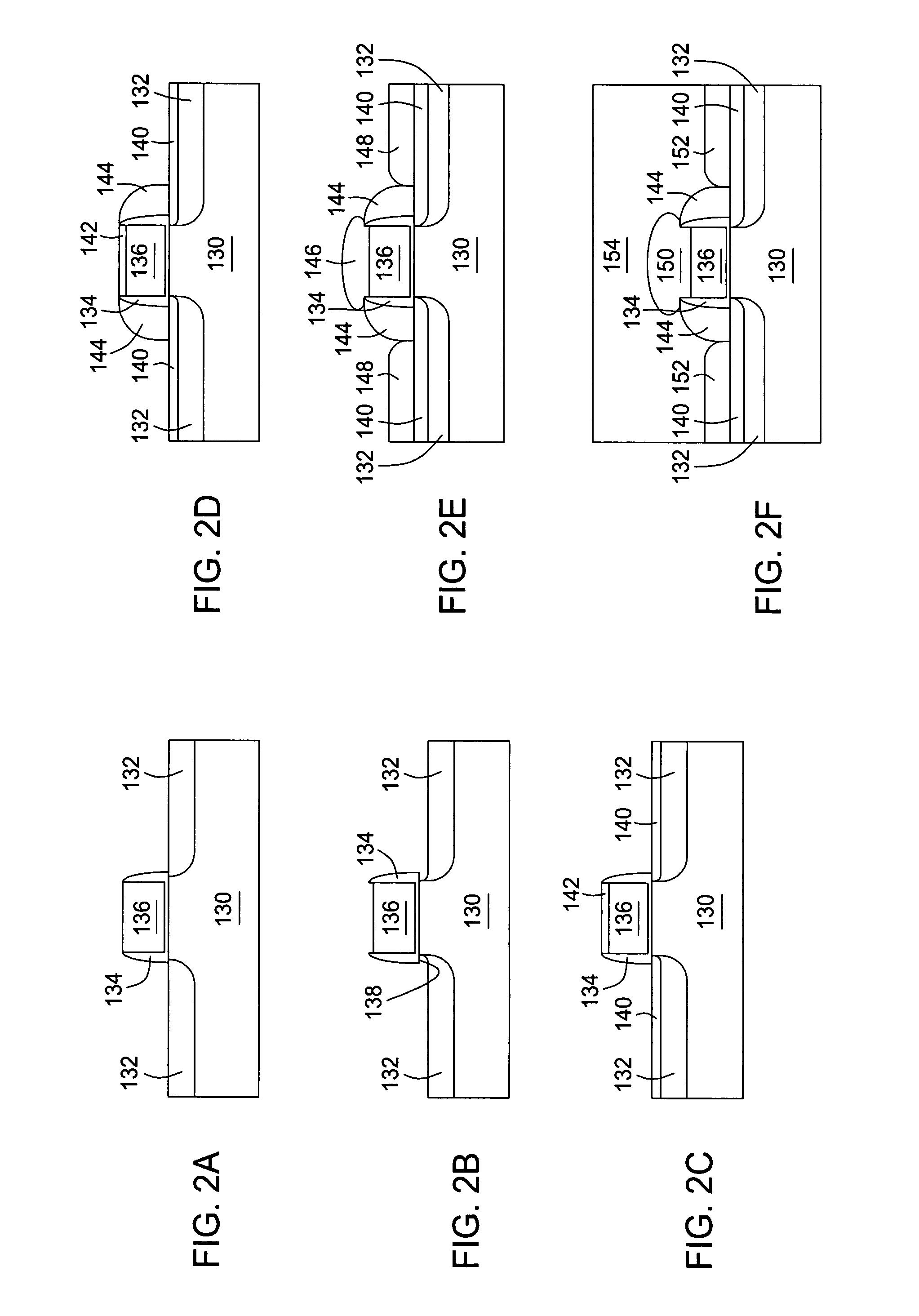

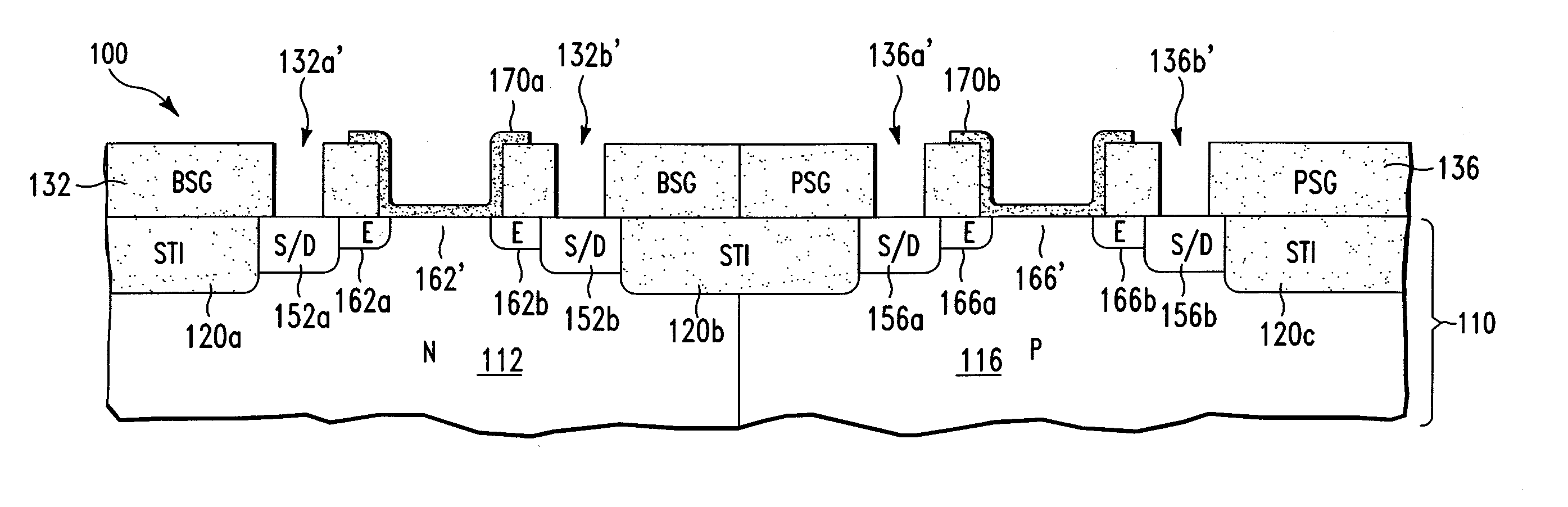

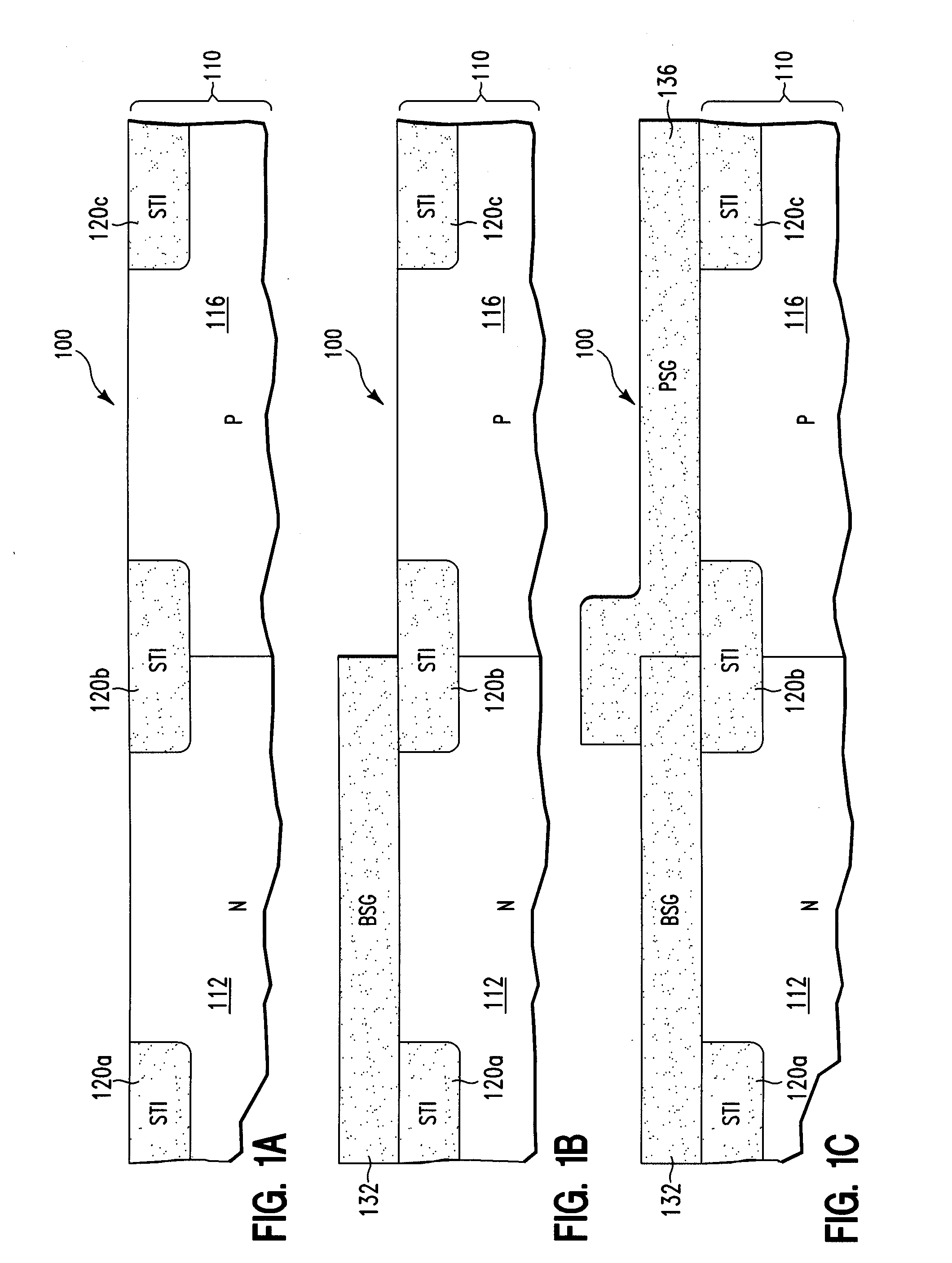

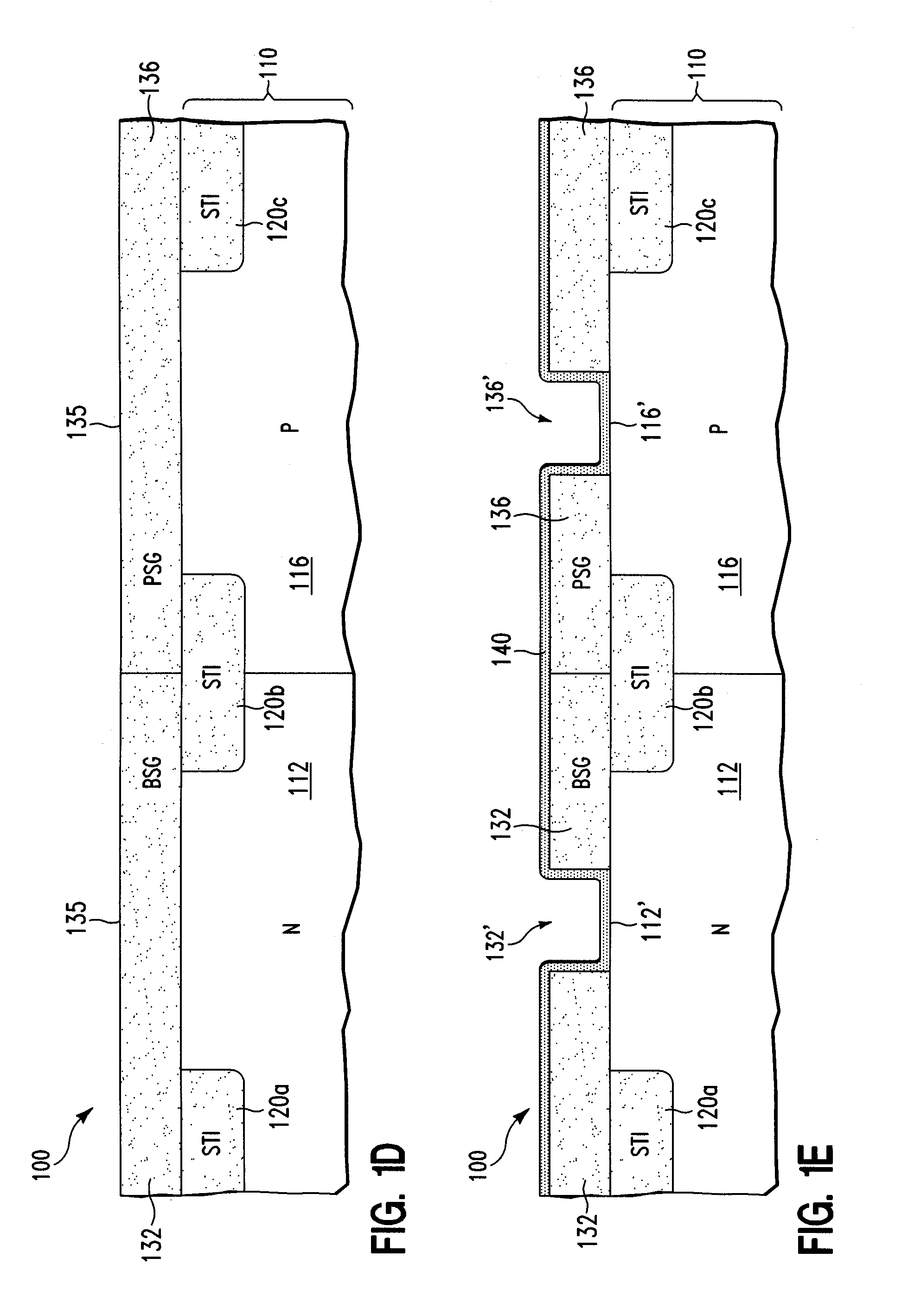

IMPROVED CMOS (Complementary Metal Oxide Semiconductor) TECHNOLOGY

InactiveUS20070020830A1Leakage problemSemiconductor/solid-state device manufacturingSemiconductor devicesDopantCMOS

A method for forming semiconductor transistor. The method comprises providing a structure including (a) a semiconductor region, and (b) first and second dopant source regions on and in direct physical contact with the semiconductor region, wherein each region of the first and second dopant source regions comprises a dielectric material which contains dopants; causing the dopants to diffuse from the first and second dopant source regions into the semiconductor region so as to form first and second source / drain extension regions, respectively, wherein the first and second source / drain extension regions define a channel region disposed between; forming a gate dielectric region on a channel region; and forming a gate region on the gate dielectric region, wherein the gate dielectric region electrically insulates the gate region from the channel region.

Owner:IBM CORP

Materials and devices for blue phosphorescence based organic light emitting diodes

InactiveUS7294849B2Effective lightingElectroluminescent light sourcesSolid-state devicesHigh energyTriplet state

An OLED includes a wide gap inert host material doped with two dopants. One of the dopants is an emissive phosphorescent material that can transport either electrons or holes. The other dopant is a charge carrying material that can transport whichever of the electrons and holes that is not transported by the phosphorescent dopant. The materials are selected so that the lowest triplet energy level of the host material and the lowest triplet energy level of the charge carrying dopant material are each at a higher energy level than the lowest triplet state energy level of the phosphorescent dopant material. The device is capable, in particular, of efficiently emitting light in the blue region of the visible spectrum.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

Methods for depositing a doped germanium tin semiconductor and related semiconductor device structures

ActiveUS10236177B1Polycrystalline material growthAfter-treatment detailsDopantDeposition temperature

A method for depositing a germanium tin (Ge1-xSnx) semiconductor is disclosed. The method may include; providing a substrate within a reaction chamber, heating the substrate to a deposition temperature and exposing the substrate to a germanium precursor and a tin precursor. The method may further include; depositing a germanium tin (Ge1-xSnx) semiconductor on the surface of the substrate, and exposing the germanium tin (Ge1-xSnx) semiconductor to a boron dopant precursor. Semiconductor device structures including a germanium tin (Ge1-xSnx) semiconductor formed by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com