Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Reactive nitrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive nitrogen ("Nr") is a term used for a variety of nitrogen compounds that support growth directly or indirectly. Representative species include the gases nitrogen oxides (NOₓ), ammonia (NH₃), nitrous oxide (N₂O), as well as the anion nitrate (NO₃⁻). Most of these species are the result of intensive farming, especially the (mis)use of fertilizers. Although required for life, nitrogen is stored in the biosphere in an unreactive ("unfixed") form N₂, which supports only a few life forms. Reactive nitrogen is however "fixed" and is readily converted into protein, which supports life, leading to depletion of oxygen in fresh waters by eutrophication. Nr is removed from the biosphere via Denitrification.

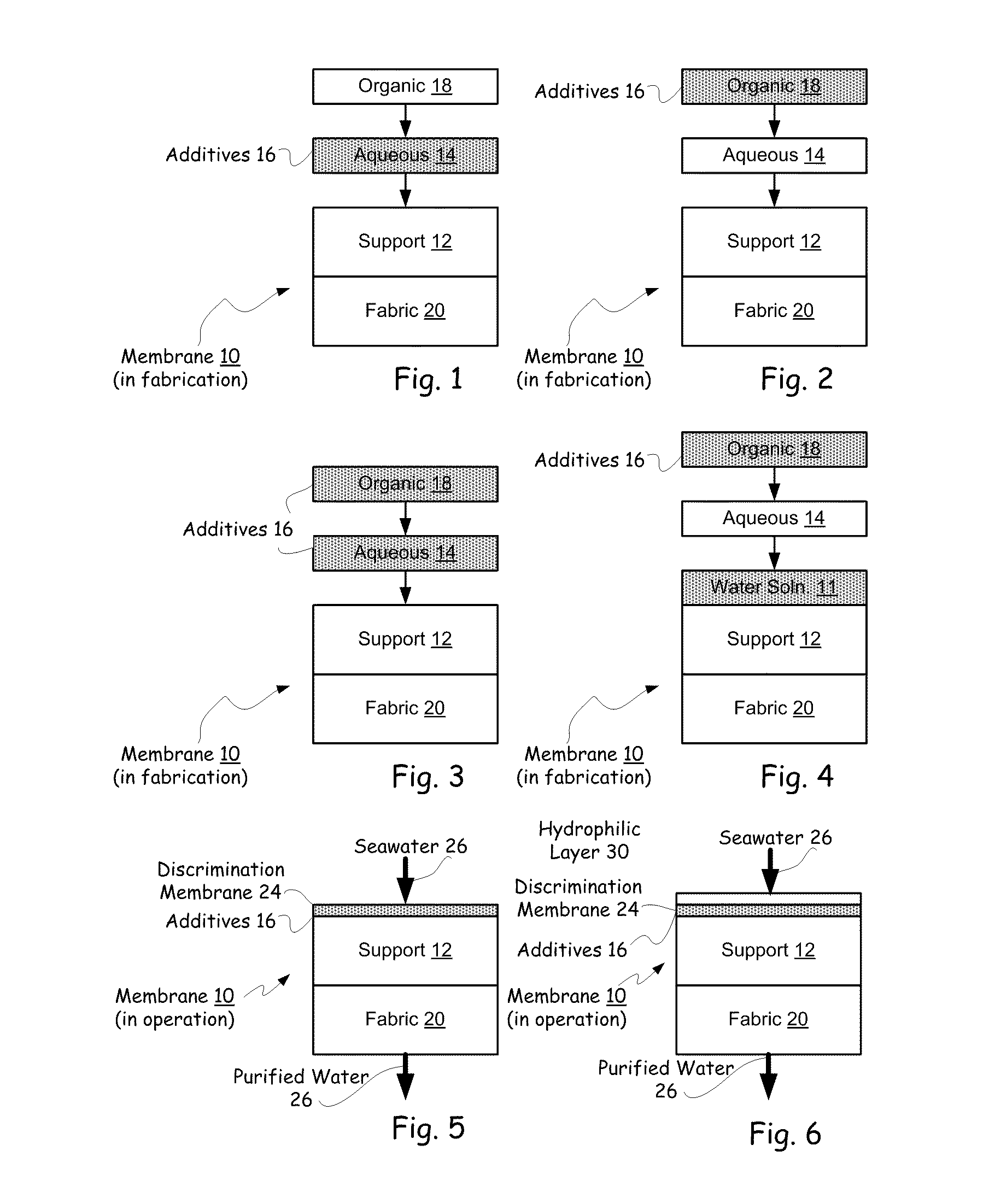

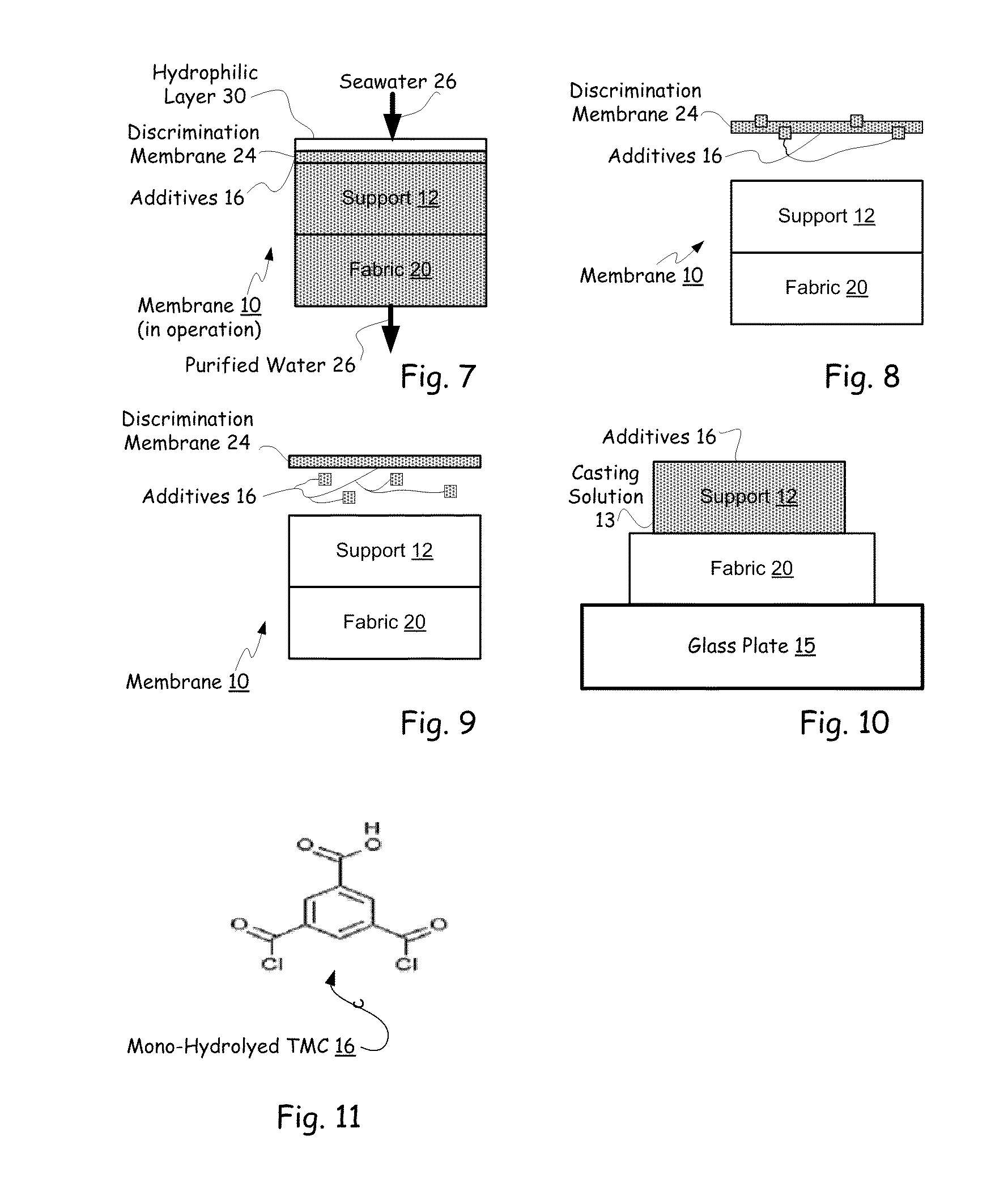

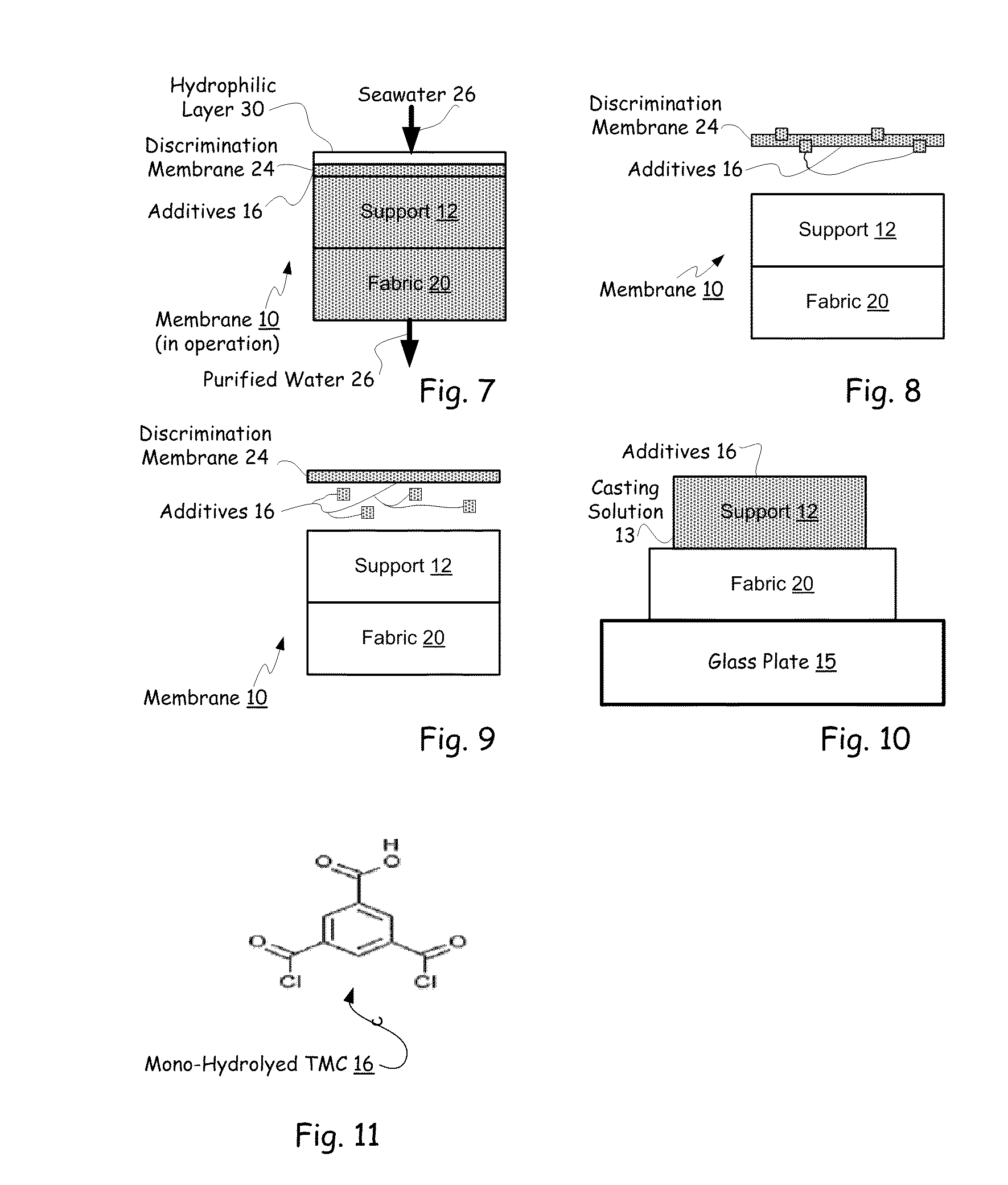

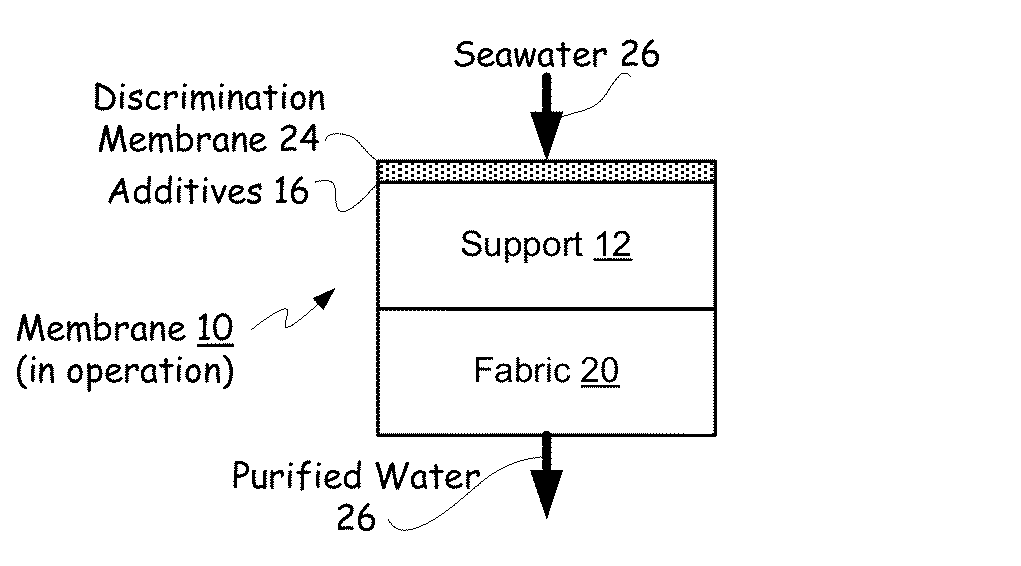

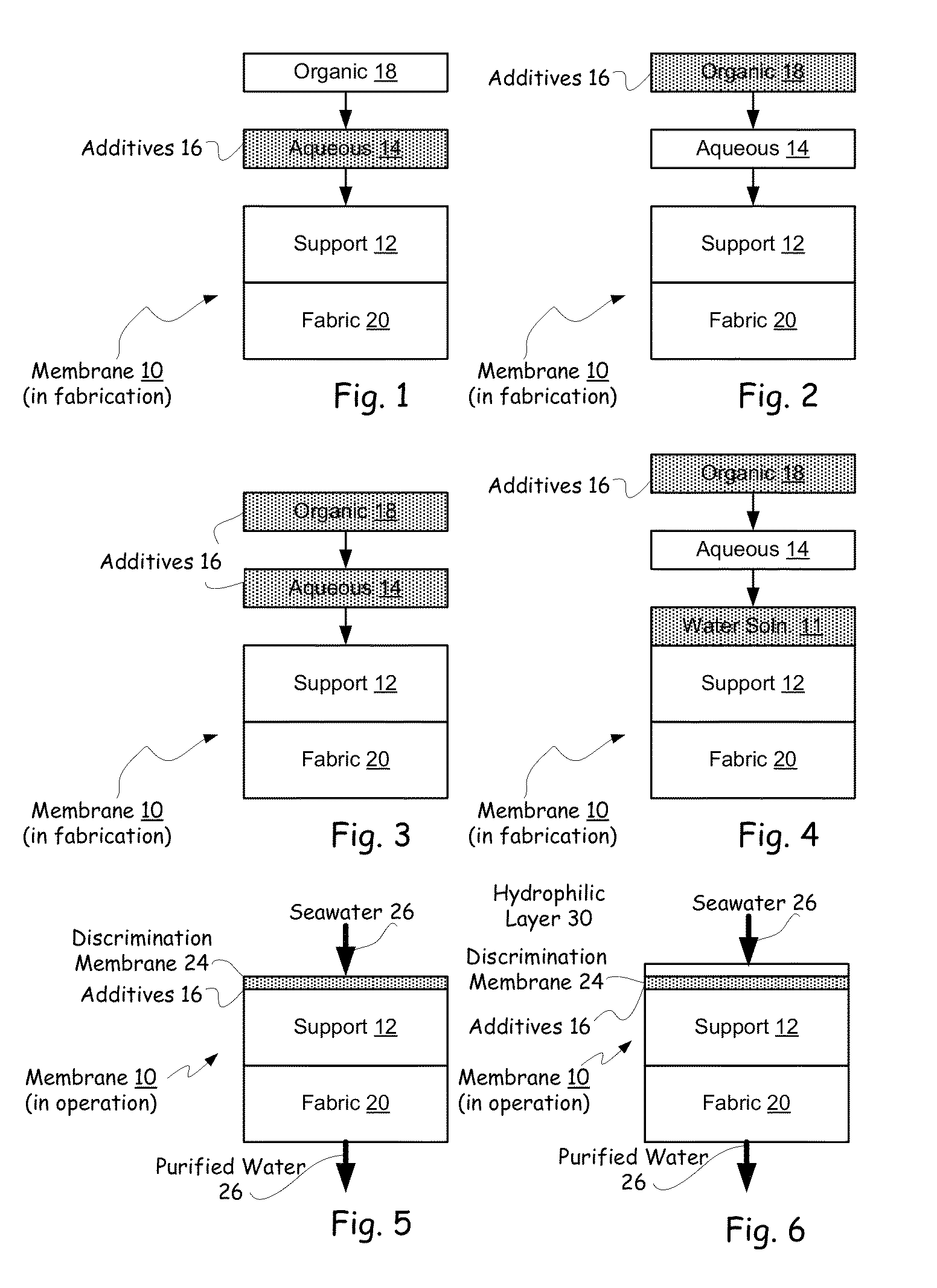

Hybrid tfc ro membranes with nitrogen additives

ActiveUS20110005997A1Increase fluxIncreased rejectionMembranesPretreated surfacesChloramine BAlkaline earth metal

Owner:NANOH2O

Hybrid TFC RO membranes with nitrogen additives

ActiveUS8567612B2Inhibits biofilm formationMembranesWater/sewage treatment bu osmosis/dialysisChloramine BAlkaline earth metal

RO membranes using chlorinated water as a feed stream maybe protected from damage by the chlorine with a protective layer including reactive nitrogen which forms chloromines on the surface of the membrane that reduce chlorine penetration. This protective layer also provides substantial anti-fouling capabilities, whether used with a chlorinated or unchlorinated feed stream because the chloramines are anti-bacterial. Although chlorine is lost in use, the anti-fouling layer or coating can be recharged with additional chlorine without damaging the discrimination layer. The anti-fouling layer or coating may be advantageously used with Thin film composite, TFC, membranes for use in forward and reverse osmosis may include nanoparticles, monohydrolyzed and / or di-hydrolyzed TMC, and / or alkaline earth alkaline metal complexes or other additives.

Owner:NANOH2O

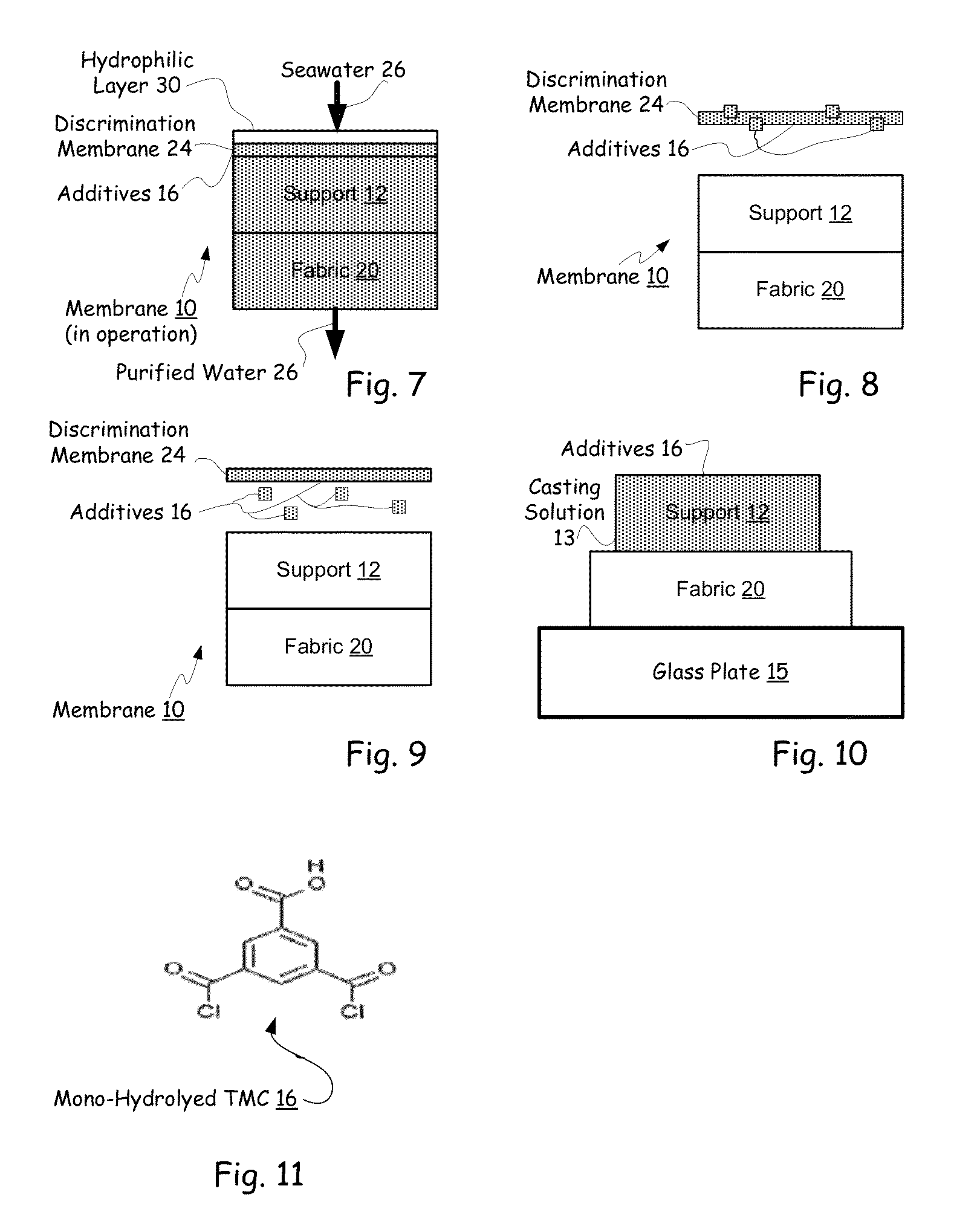

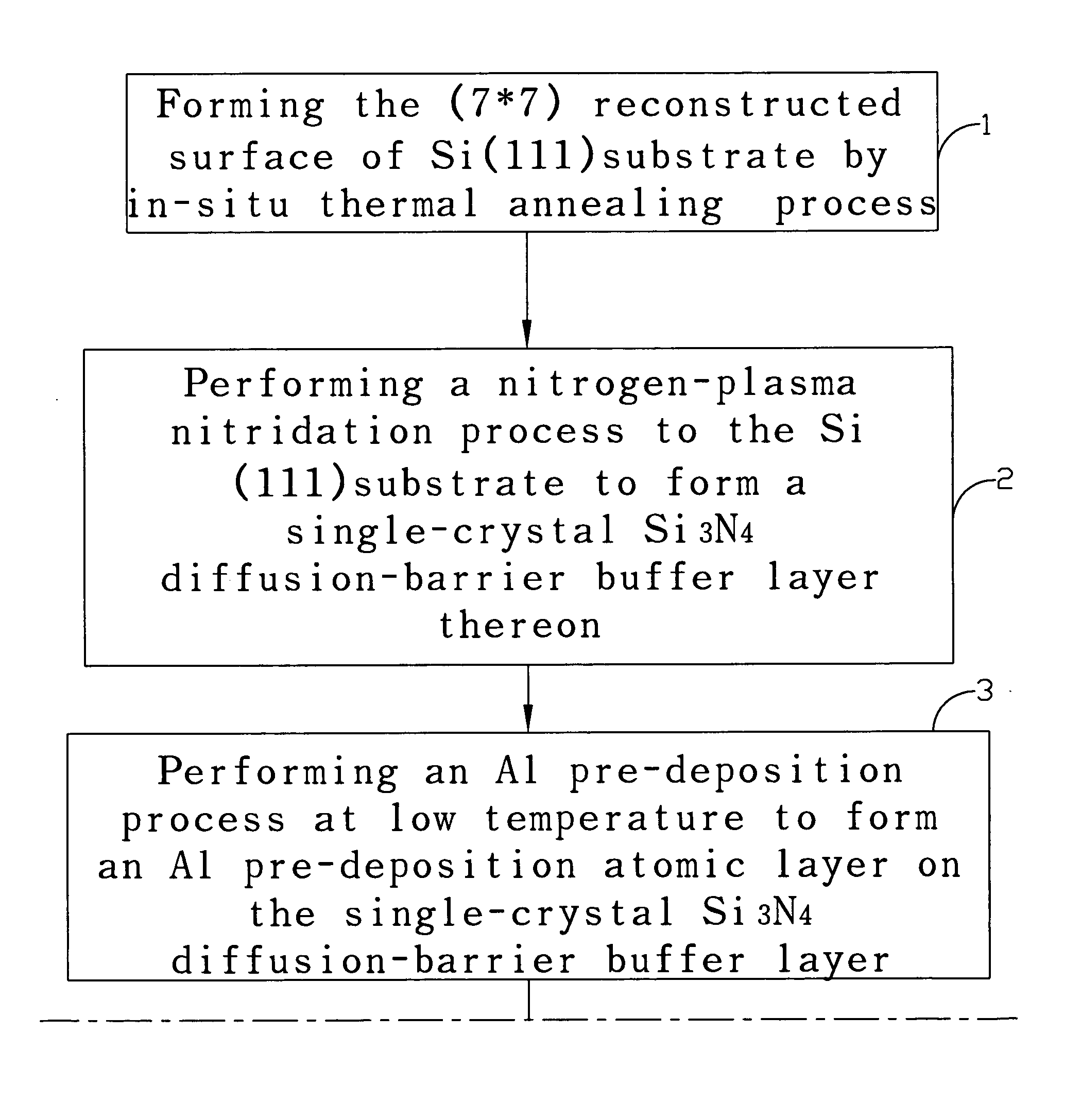

Method for growing group-III nitride semiconductor heterostructure on silicon substrate

InactiveUS20050106849A1Inhibition formationImprove scalabilitySemiconductor/solid-state device manufacturingSemiconductor devicesControl mannerSingle crystal

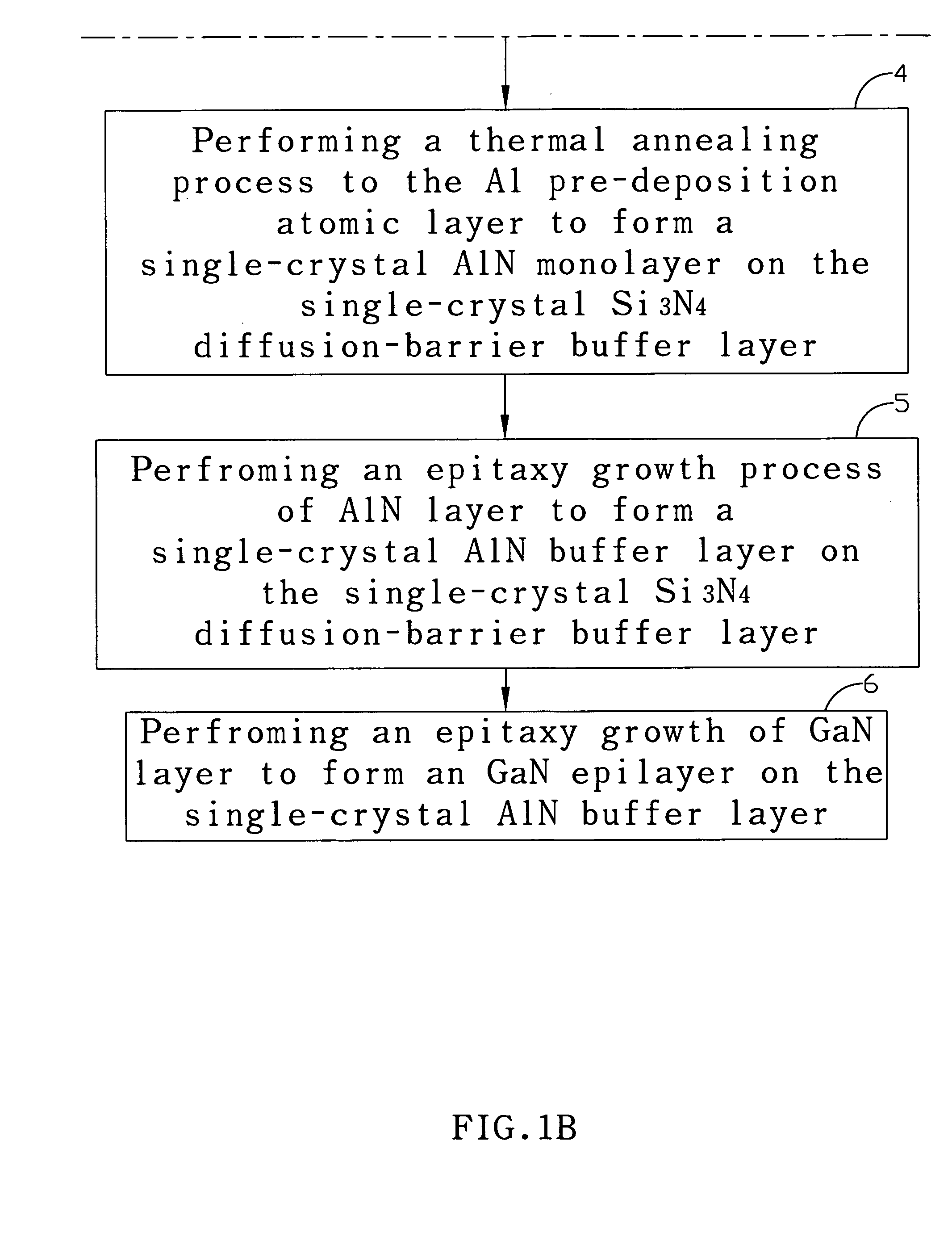

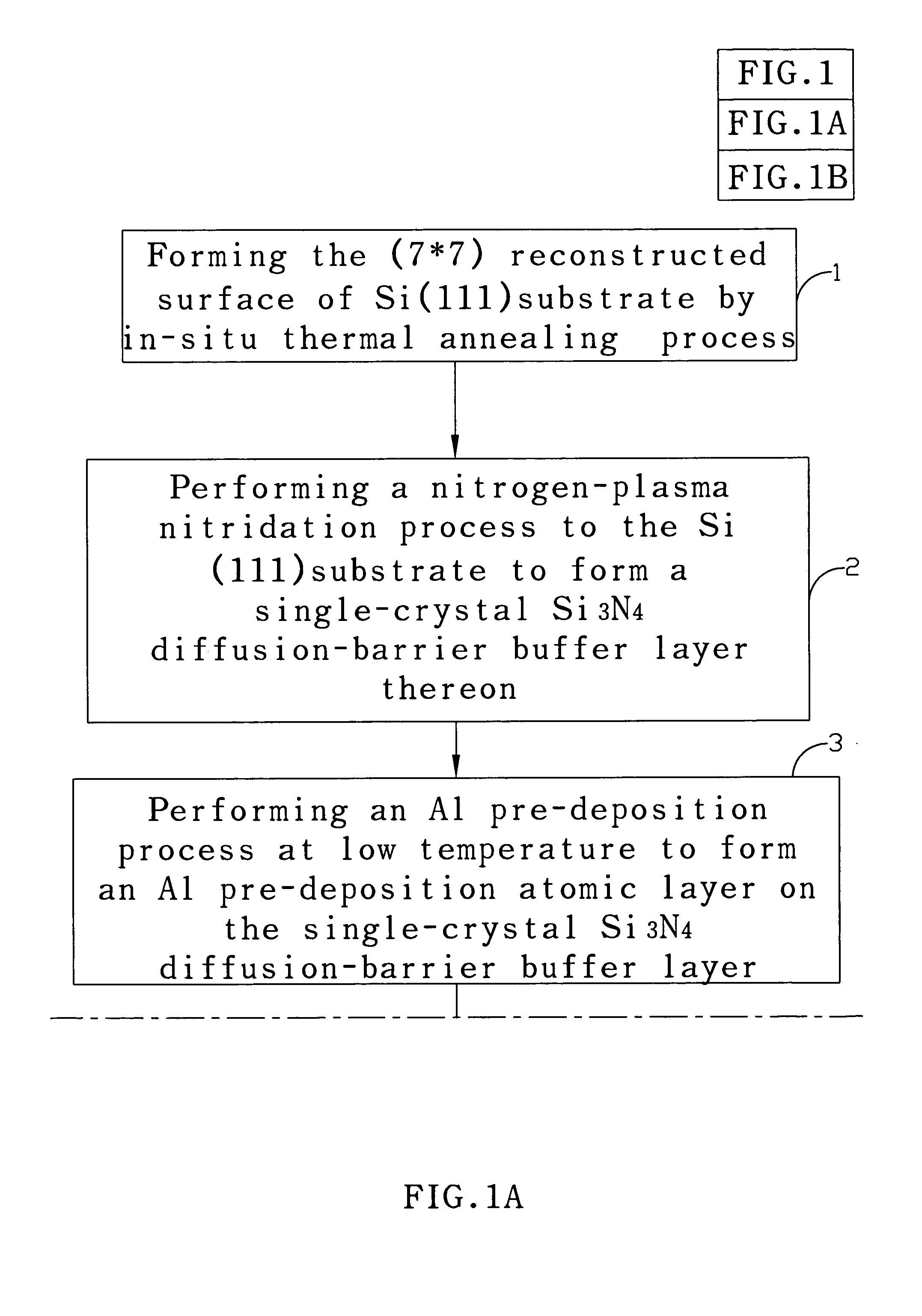

The present invention provides a method for growing group-III nitride semiconductor heteroepitaxial structures on a silicon (111) substrate by using a coincidently matched multiple-layer buffer that can be grown on the Si(111) substrate. The coincidently matched multiple-layer buffer comprises a single-crystal silicon nitride (Si3N4) layer that is formed in a controlled manner by introducing reactive nitrogen plasma or ammonia to the Si(111) substrate at a suitably high temperature. Then, an AlN buffer layer or other group-III nitride buffer layer is grown epitaxially on the single-crystal silicon nitride layer. Thereafter, the GaN epitaxial layer or group-III semiconductor heteroepitaxial structure can be grown on the coincidently matched multiple-layer buffer.

Owner:NATIONAL TSING HUA UNIVERSITY

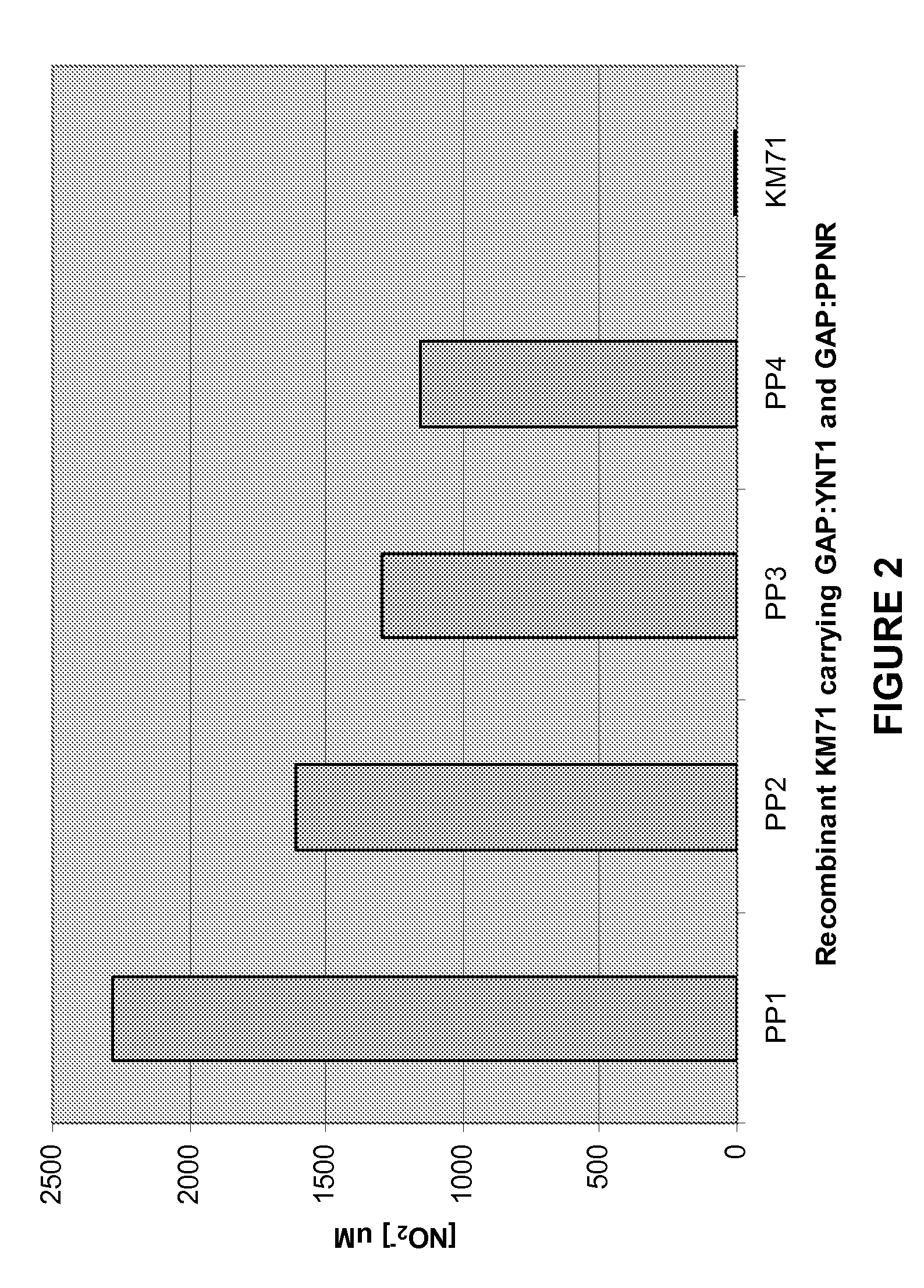

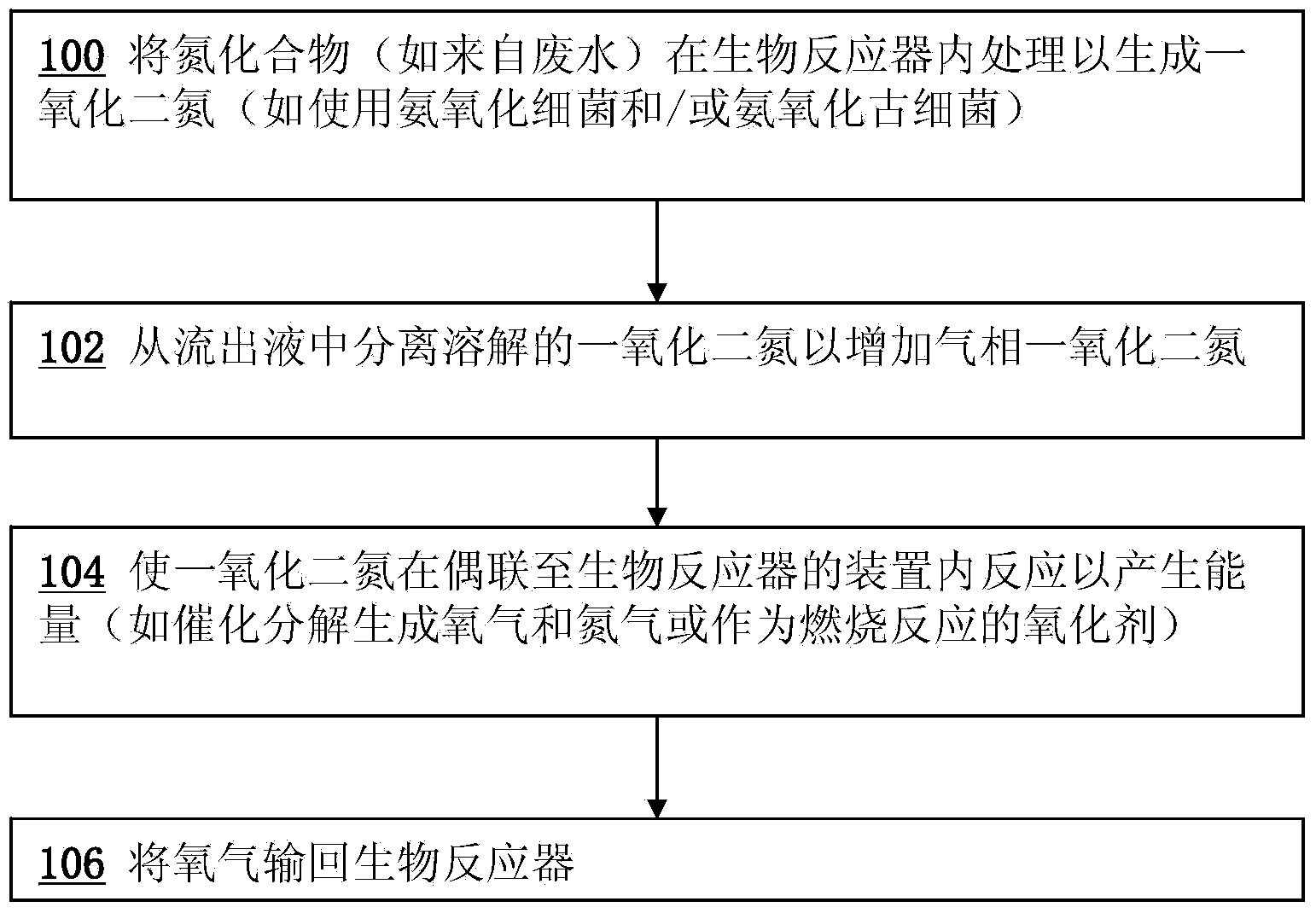

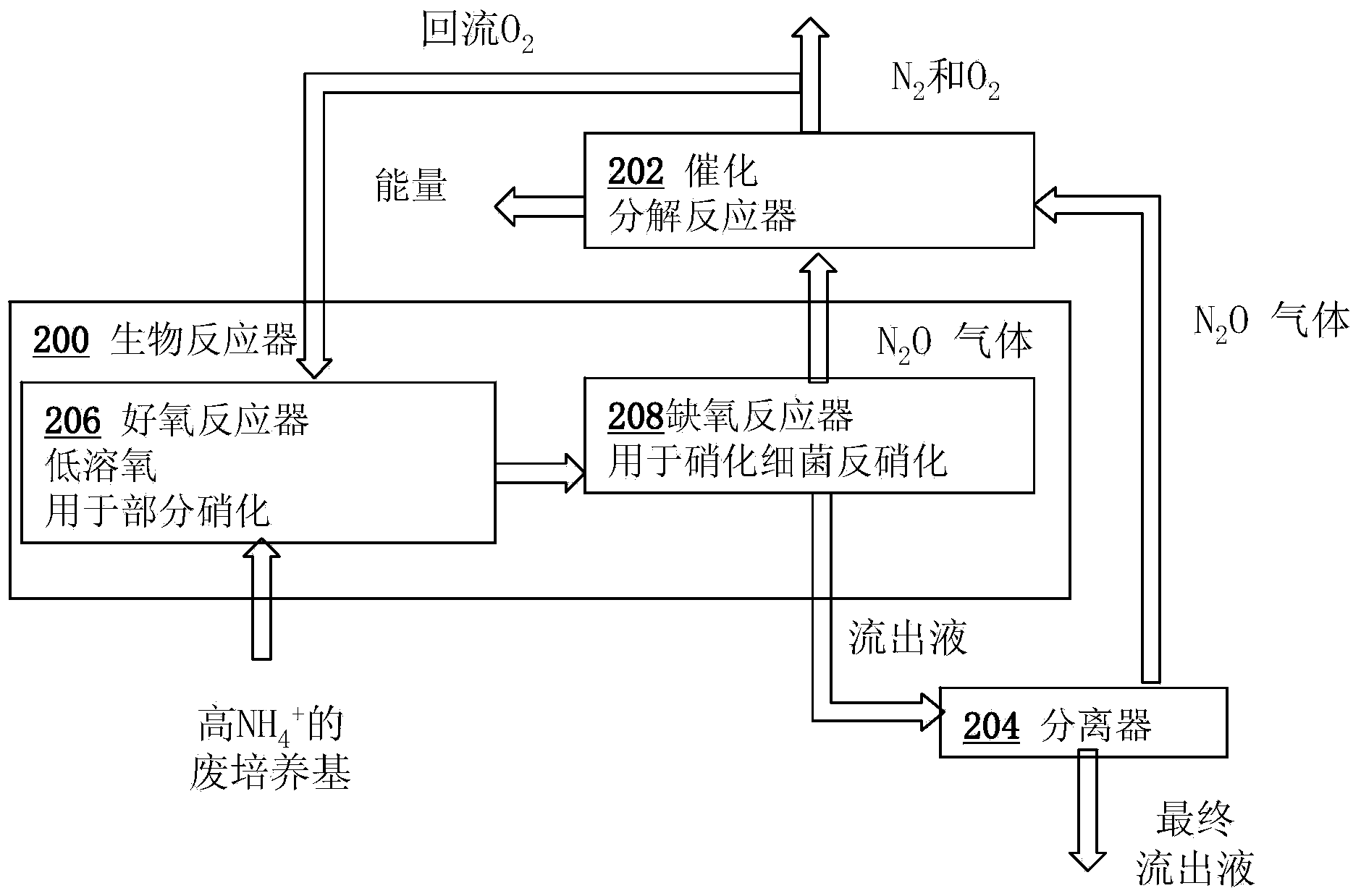

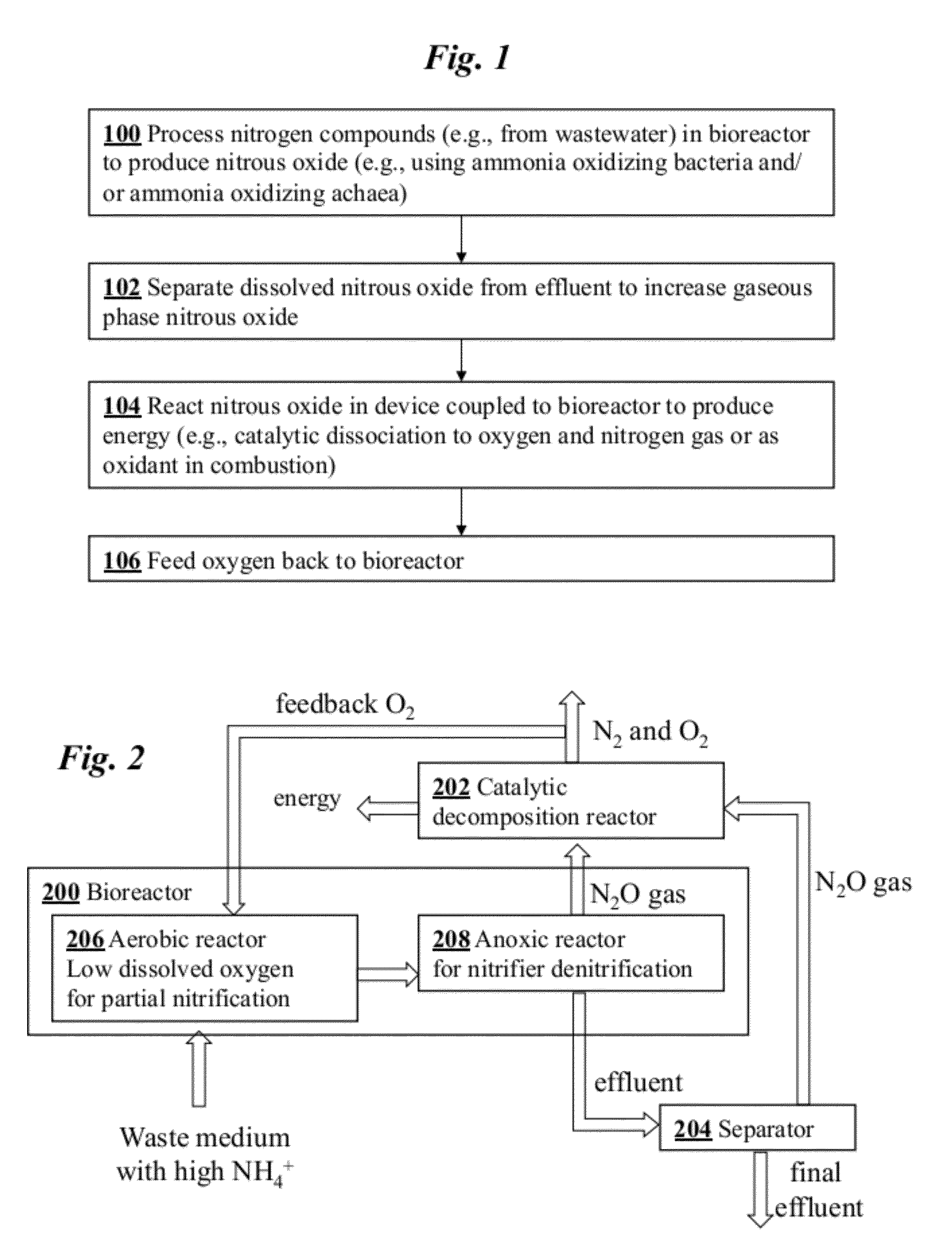

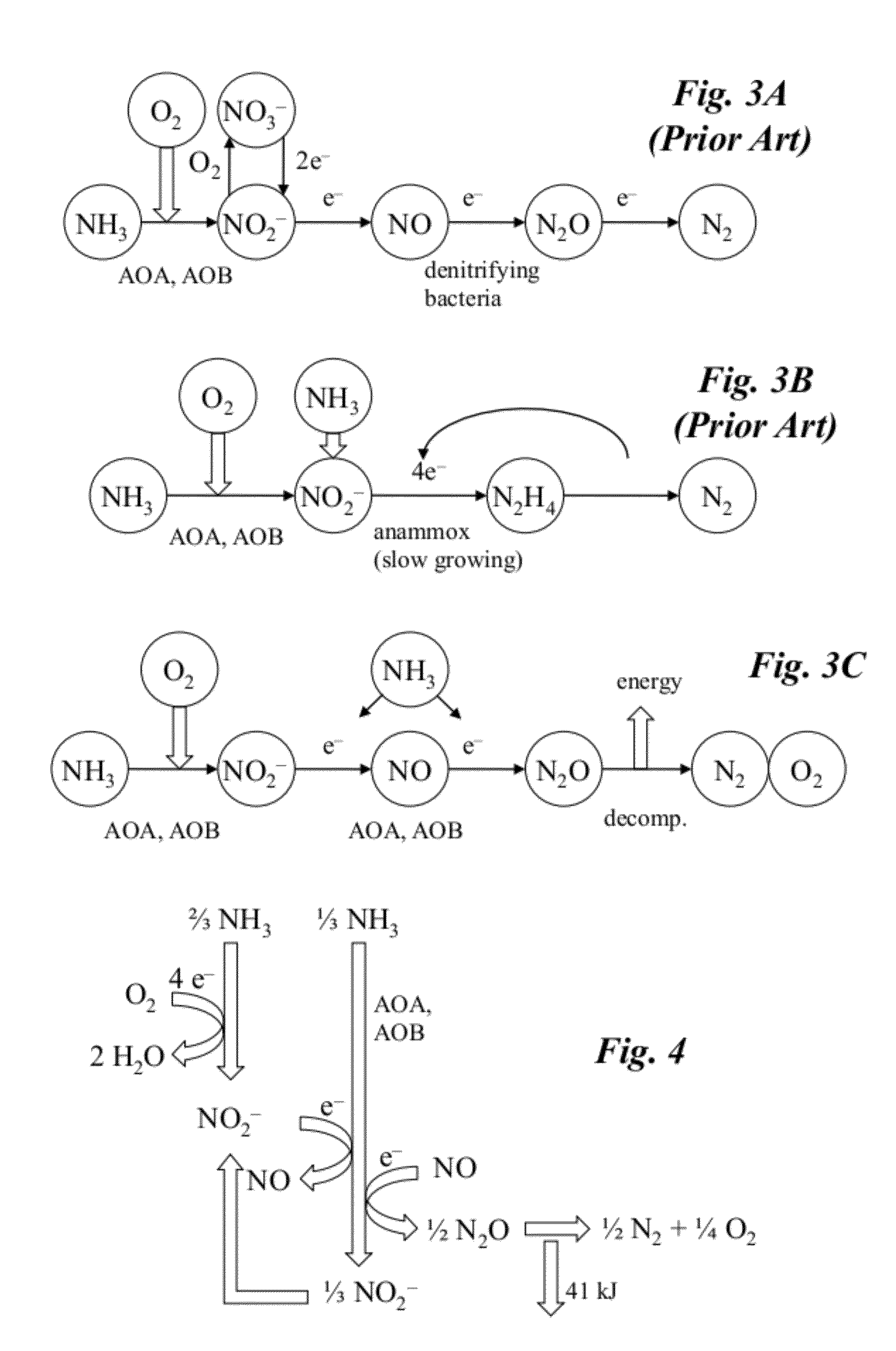

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide including phosphorus recovery and nitrite reduction to nitrous oxide

InactiveUS20120309071A1Minimize N2O productionProducer of clean energyWater treatment parameter controlOxygen/ozone/oxide/hydroxideChemical reactionGas phase

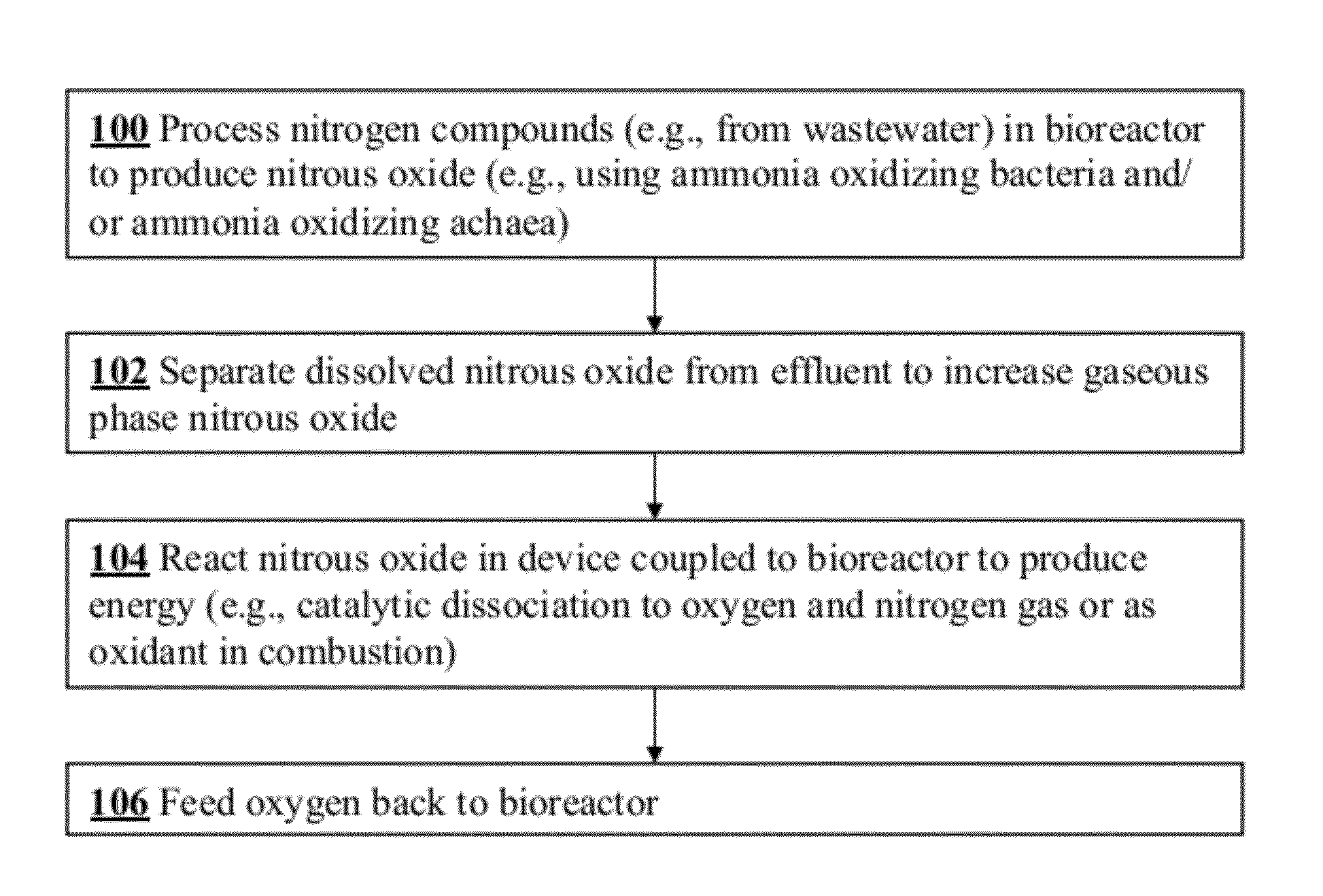

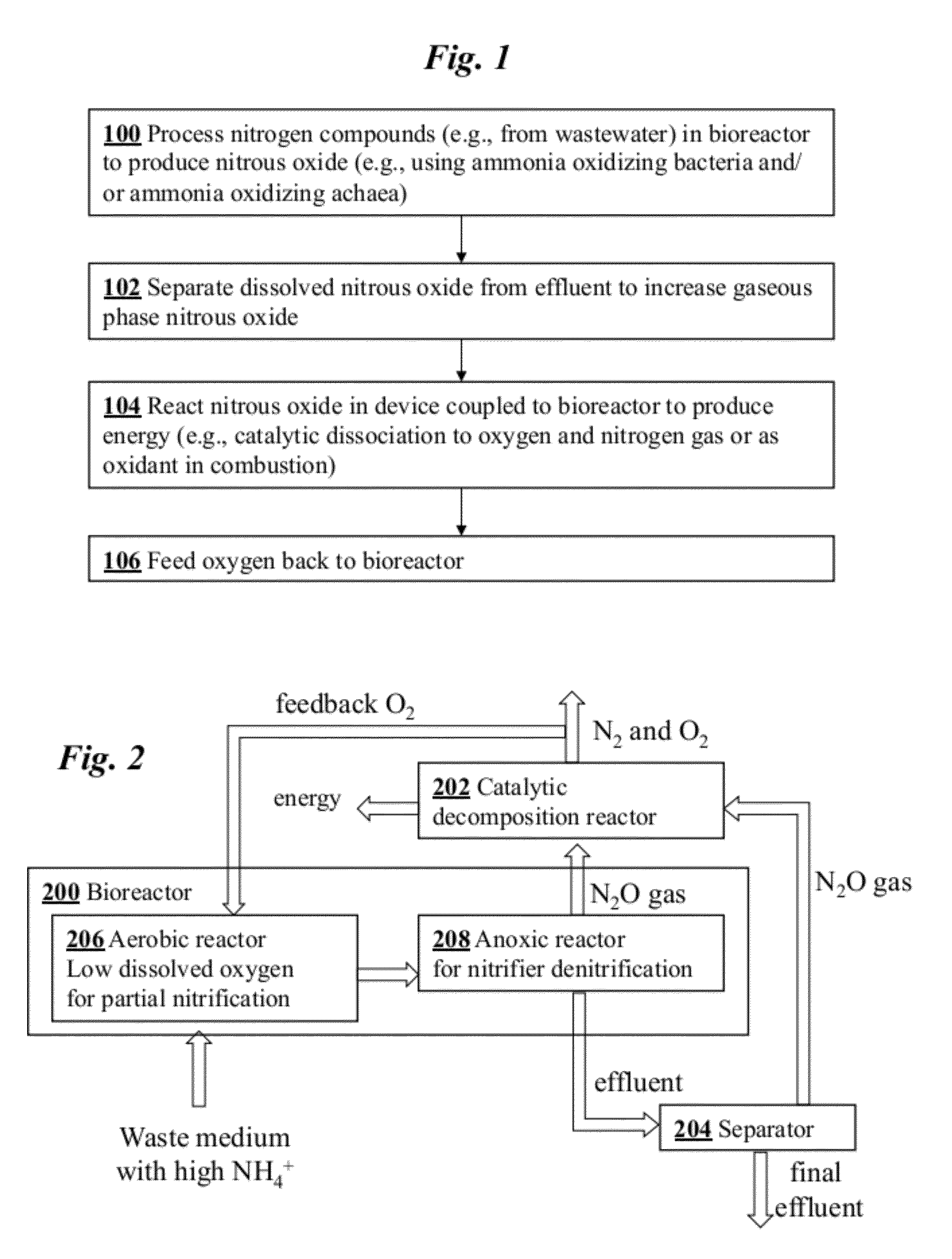

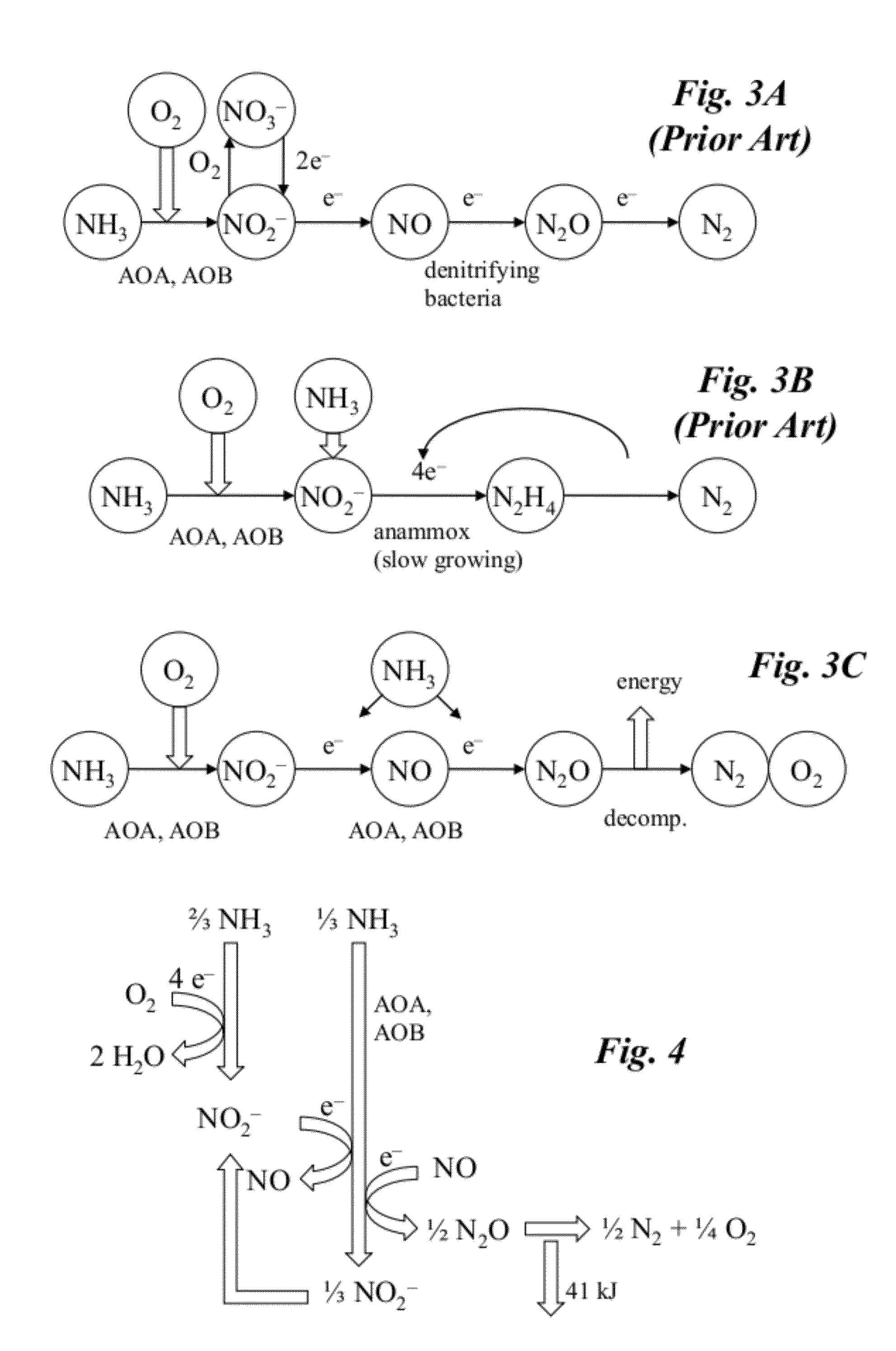

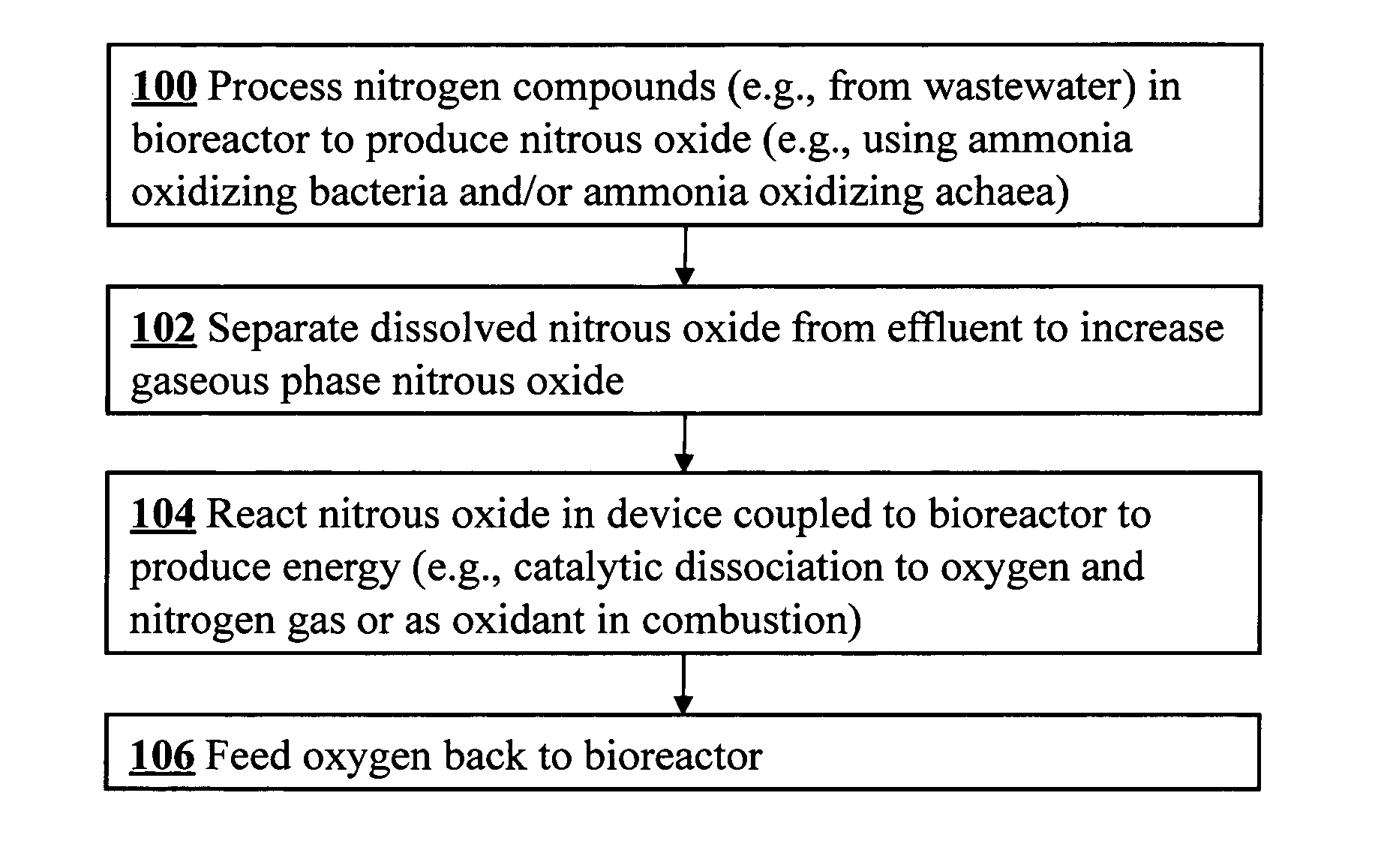

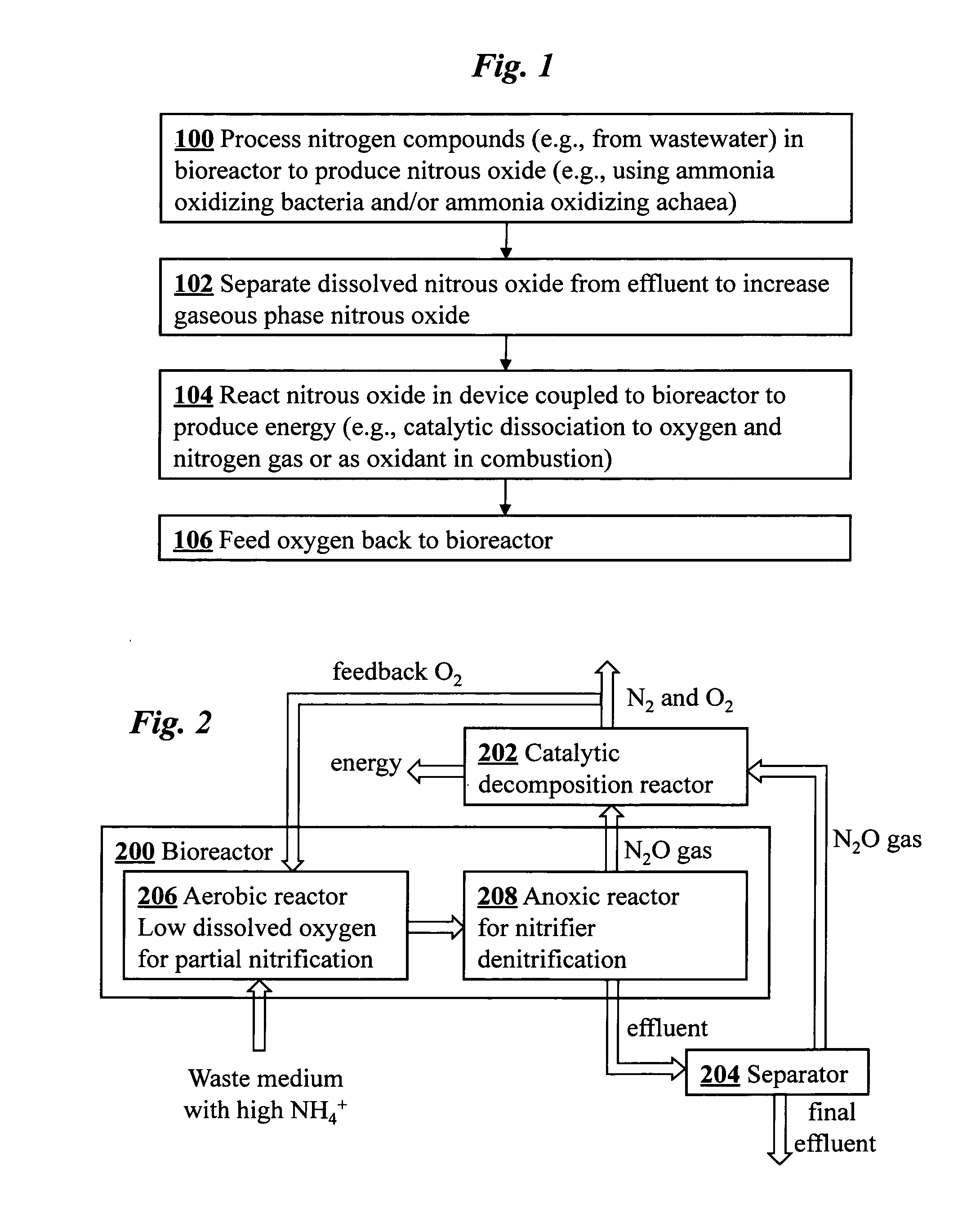

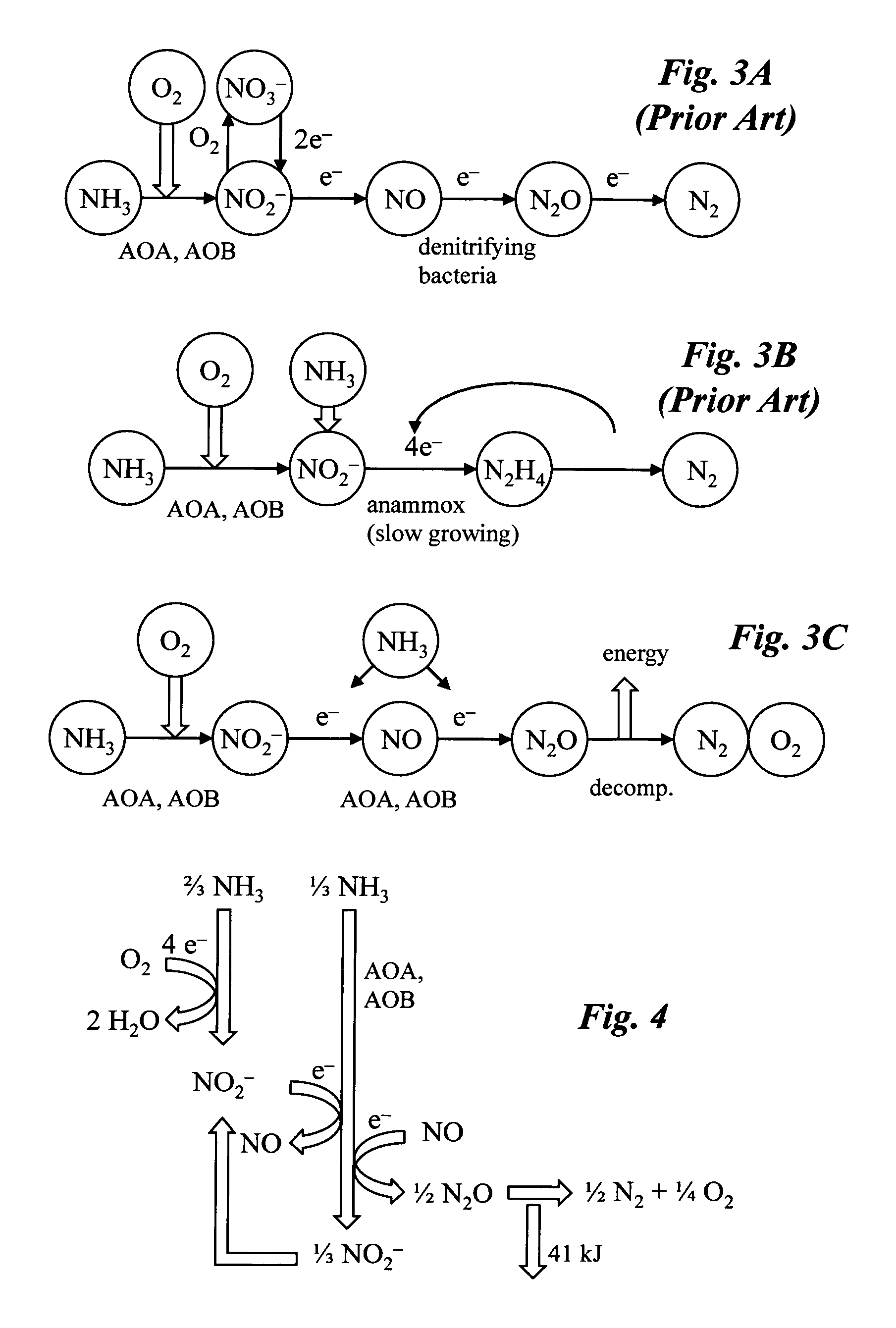

A method to produce N2O from organic nitrogen and / or reactive nitrogen in waste uses a bioreactor coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas. Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Waterborne crosslinkable coating compositions

Disclosed are aqueous, storage-stable, crosslinkable polymer compositions comprising: (a) an aqueous dispersion of a an acrylic polymer component containing certain carbonyl-containing functional-groups; (b) a nitrogen-containing compound having at least two carbonyl-reactive nitrogen groups; and (c) optionally, co-solvents, pigments, fillers, dispersants, wetting agents, anti-foam agents, UV absorbers, antioxidants, biocides, and stabilizers. Such compositions are useful as coatings or binders in coating compositions, or as adhesives.

Owner:ROHM & HAAS CO

Method for growing group-III nitride semiconductor heterostructure on silicon substrate

InactiveUS7012016B2Improve scalabilityLarge lattice mismatchSemiconductor/solid-state device manufacturingSemiconductor devicesControl mannerSingle crystal

The present invention provides a method for growing group-III nitride semiconductor heteroepitaxial structures on a silicon (111) substrate by using a coincidently matched multiple-layer buffer that can be grown on the Si(111) substrate. The coincidently matched multiple-layer buffer comprises a single-crystal silicon nitride (Si3N4) layer that is formed in a controlled manner by introducing reactive nitrogen plasma or ammonia to the Si(111) substrate at a suitably high temperature. Then, an AlN buffer layer or other group-III nitride buffer layer is grown epitaxially on the single-crystal silicon nitride layer. Thereafter, the GaN epitaxial layer or group-III semiconductor heteroepitaxial structure can be grown on the coincidently matched multiple-layer buffer.

Owner:NATIONAL TSING HUA UNIVERSITY

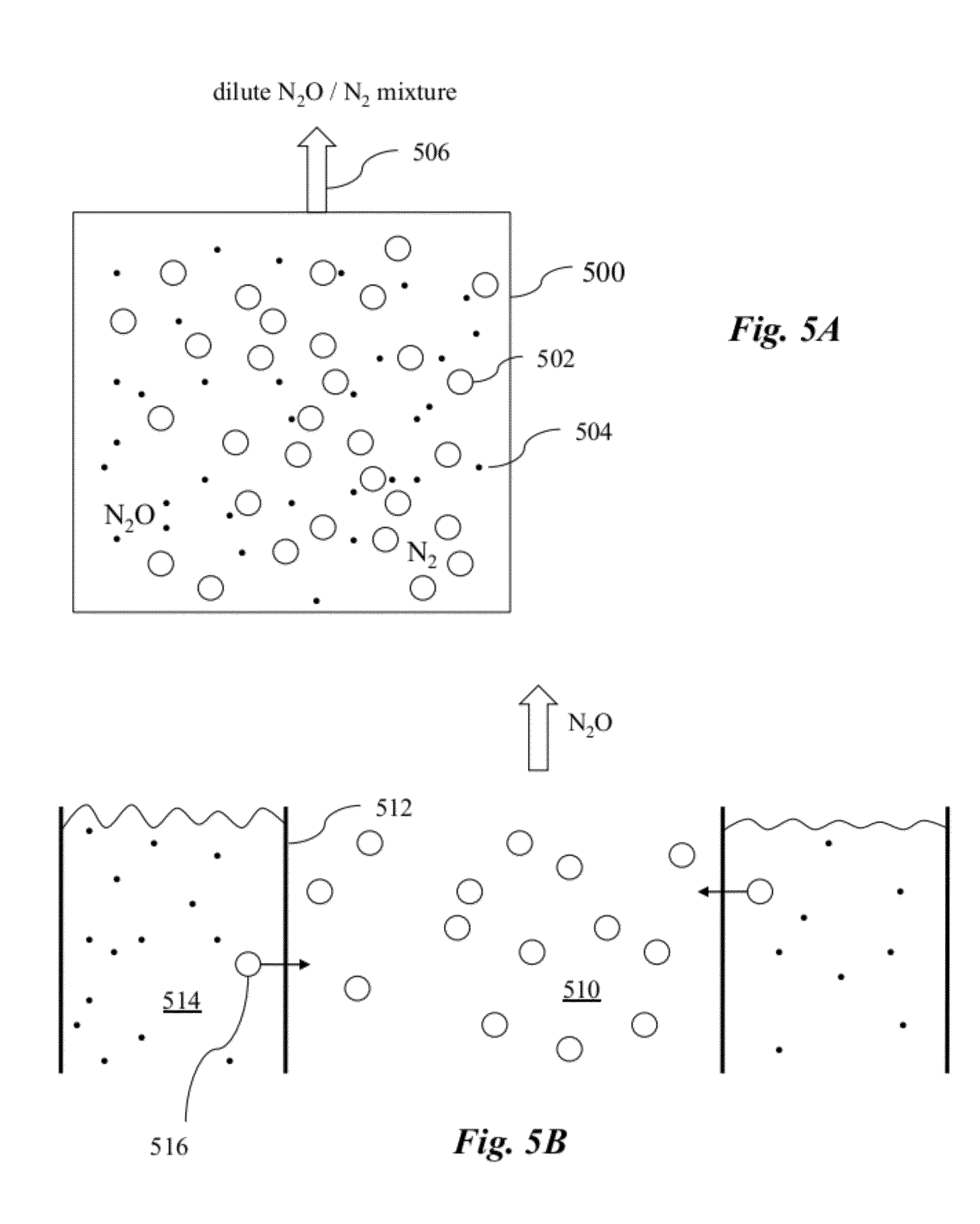

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide

InactiveUS20110207061A1Treatment with aerobic and anaerobic processesSustainable biological treatmentSequencing batch reactorFiber

A bioreactor designed to produce N2O from organic nitrogen and / or reactive nitrogen in waste is coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas.Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane. The bioreactor may have various designs including a two-stage bioreactor, a hollow-fiber membrane bioreactor, or a sequencing batch reactor. The bioreactor may involve Fe(II)-mediated reduction of nitrite to nitrous oxide.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide

InactiveUS20100272626A1Minimize N2O productionProducer of clean energyWater treatment parameter controlOxygen/ozone/oxide/hydroxideChemical reactionAmmonia-oxidizing bacteria

A bioreactor designed to produce N2O from organic nitrogen and / or reactive nitrogen in waste is coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas. Heat from the exothermic reaction may be used to generate power. The bioreactor may use communities of autotrophic microorganisms such as those capable of nitrifier denitrification, ammonia oxidizing bacteria, and / or ammonia oxidizing archaea. A portion of the N2O dissolved in aqueous effluent from the bioreactor may be separated to increase the amount of gas phase N2O product. The amount of the gas phase N2O in a gas stream may also be concentrated prior to undergoing the chemical reaction. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

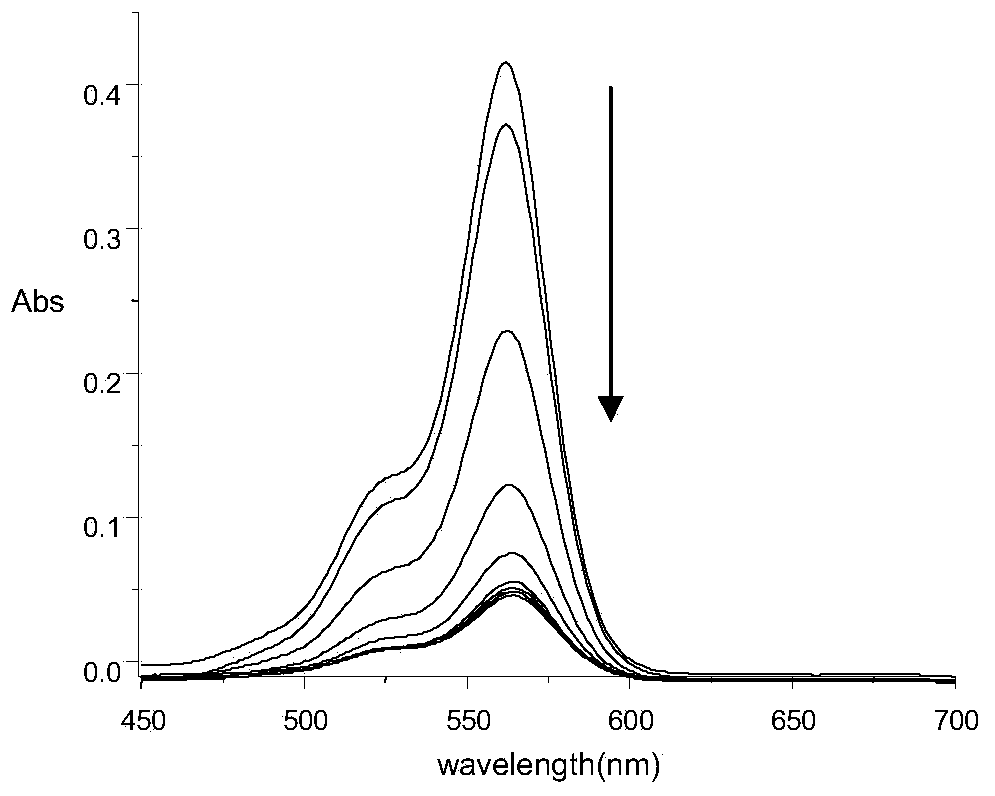

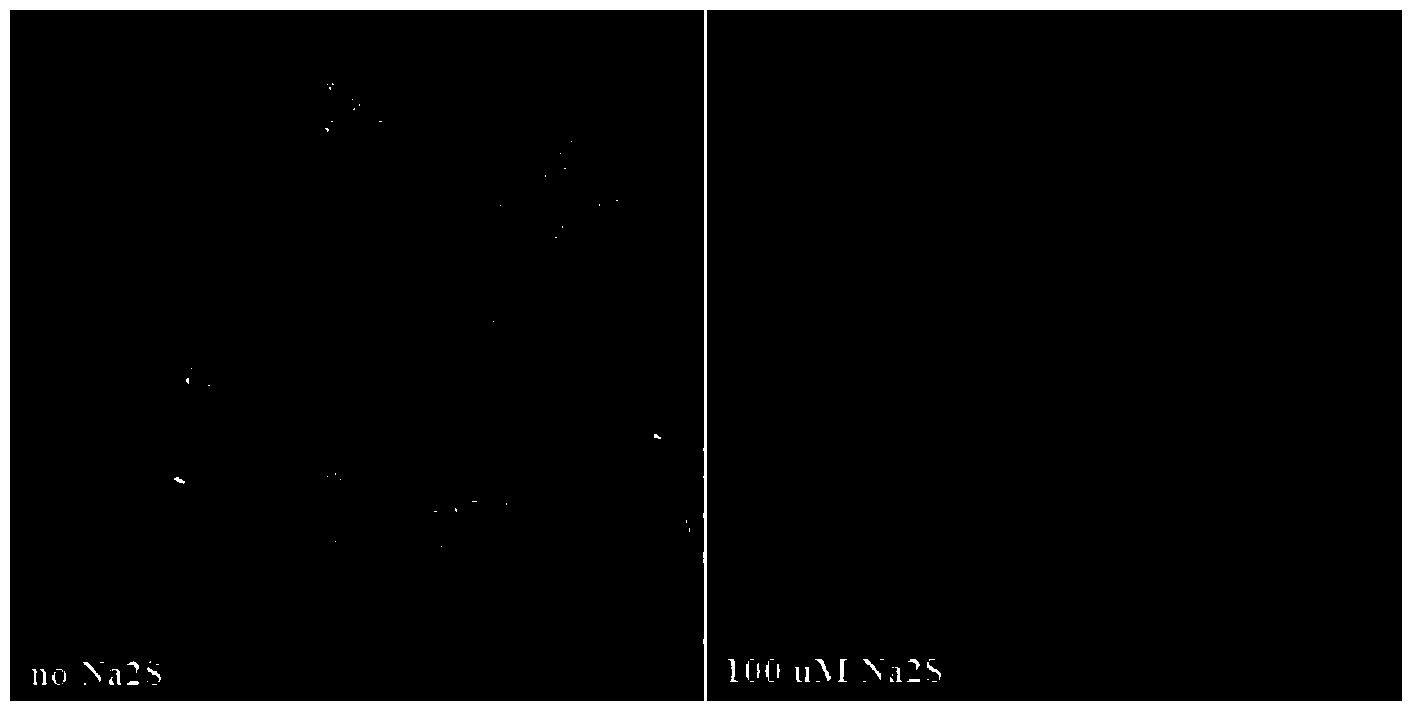

Fluorescent probe for detecting sulfur ions in mitochondria and application thereof

ActiveCN103937490ARapid positioningGood chemical stabilityOrganic chemistryFluorescence/phosphorescenceSolubilitySide effect

The invention relates to a fluorescent probe for detecting sulfur ions in mitochondria. The fluorescent probe is an RhS fluorescent probe, and the structural general formula of the RhS fluorescent probe is shown in the formula (I). The fluorescent probe can be rapidly positioned in the mitochondria and used for performing online real-time detection on the sulfur ions and hydrogen sulfide ions in the mitochondria. In addition, the probe also has relatively good chemical and optical stability, relatively good solubility and bio-compatibility and relatively high sulfur ion selectivity without interferences caused by other species such as reactive oxygen, reactive nitrogen and the like. Laser confocal imaging experiments show that the probe has relatively good cell permeability without causing toxic or side effects to cells and organisms.

Owner:LIAONING UNIVERSITY

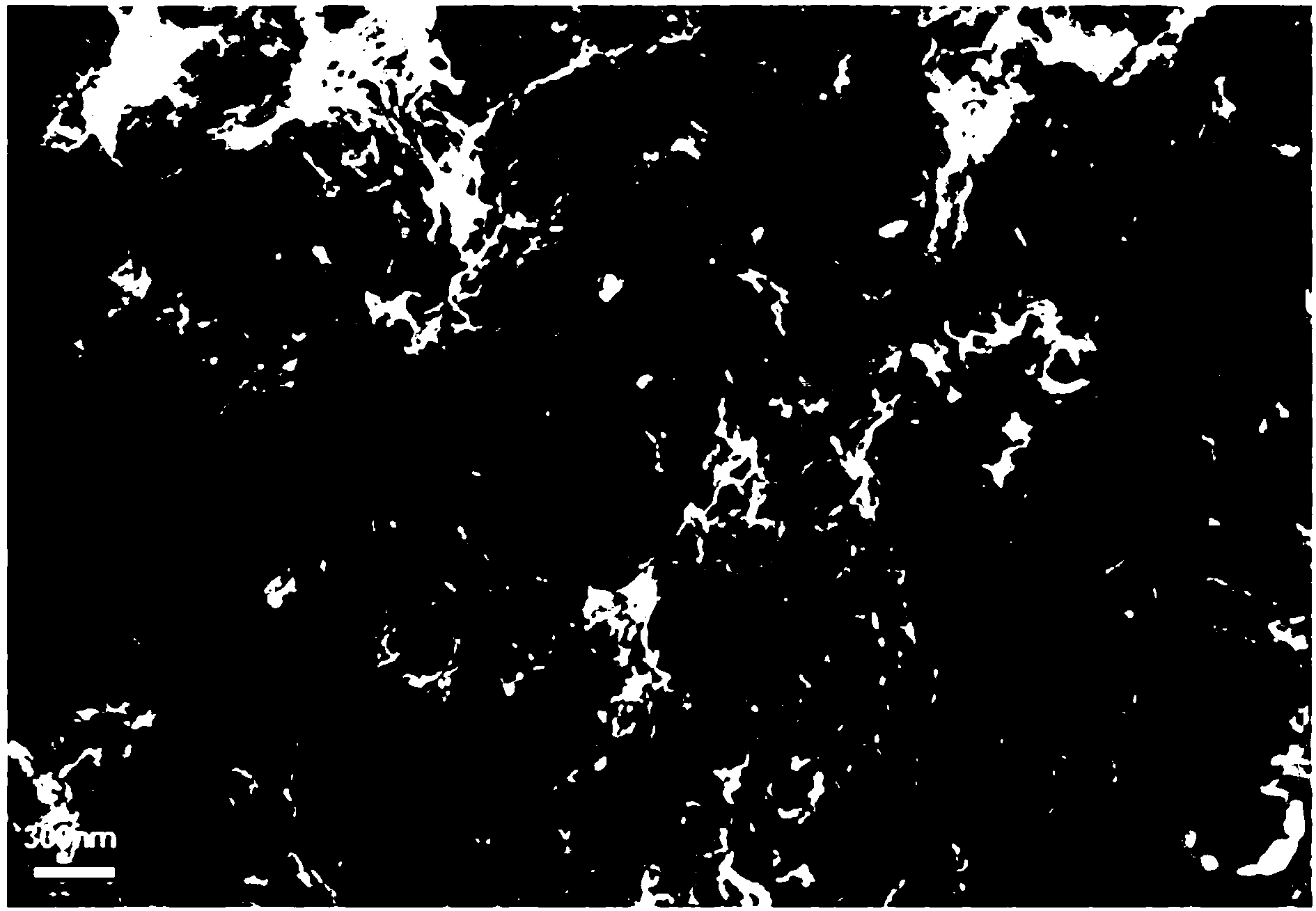

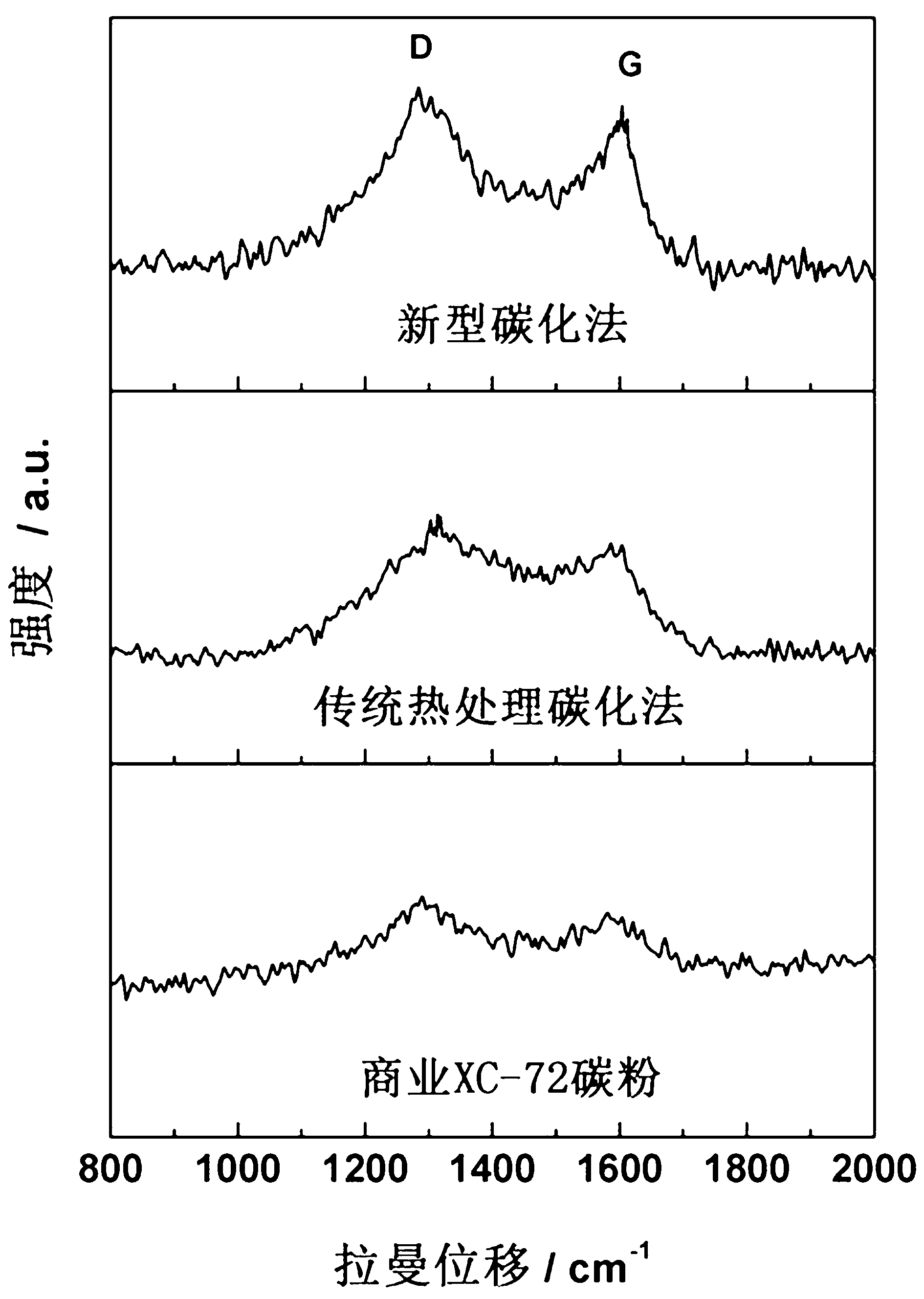

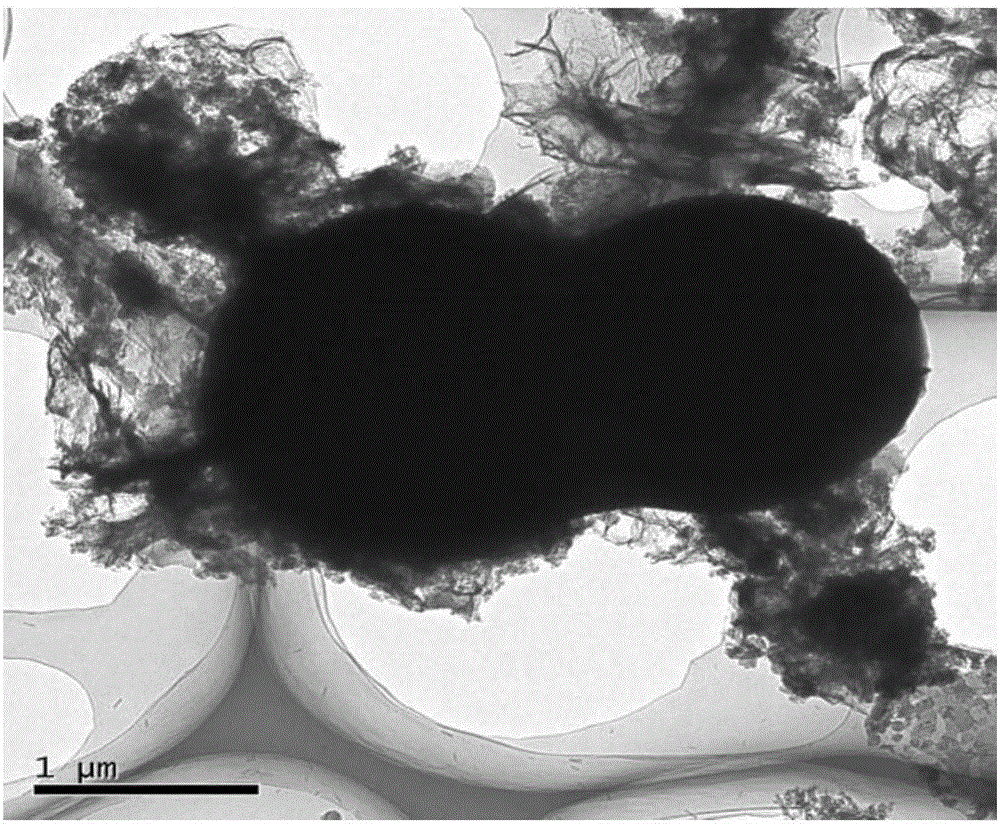

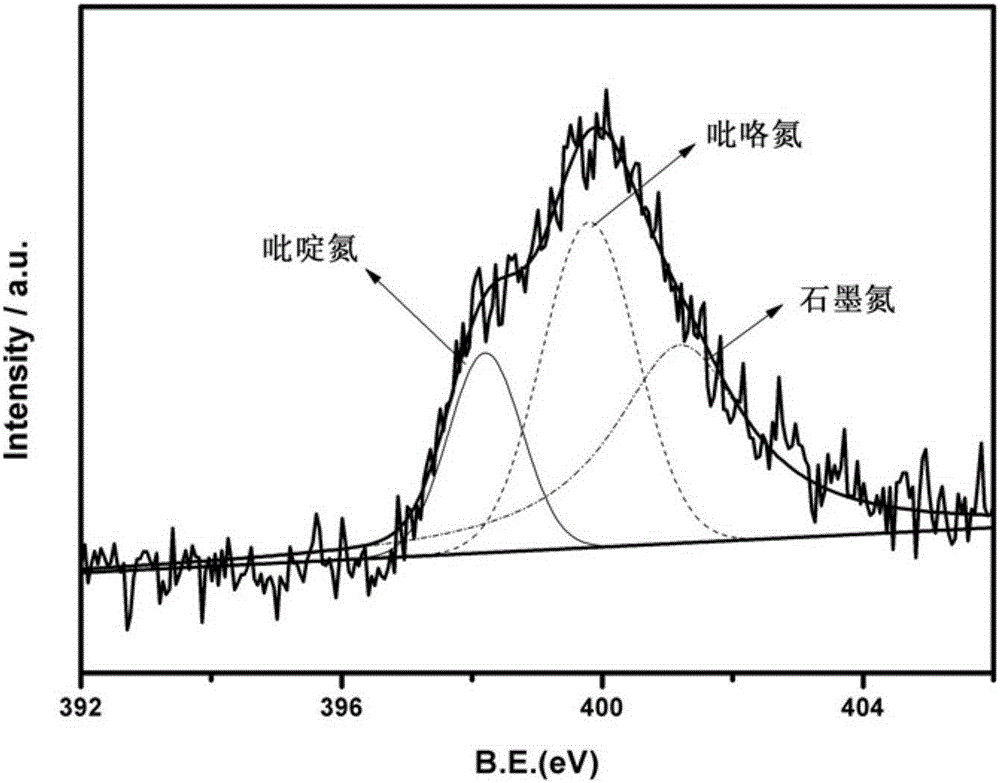

Method for synthesizing nitrogen-carbon nonmetal reducing catalyst by utilizing concentrated sulfuric acid carbonization

InactiveCN103212430AEffectively fixedHigh catalytic activity for oxygen reductionPhysical/chemical process catalystsCell electrodesCarbon compositesPtru catalyst

The invention provides a method for synthesizing a nitrogen-carbon compound nonmetal reducing catalyst by utilizing concentrated sulfuric acid carbonization. The method utilizing an organic compound containing carbon, hydrogen and oxygen as a carbon source and utilizing melamine as a nitrogen source comprises the following steps of: preliminarily carbonizing the hydrogen and the oxygen in the organic compound containing the carbon, the hydrogen and the oxygen by utilizing dehydration characteristic of the concentrated sulfuric acid, so that the melamine enters a duct of the preliminary carbonizing product, and the nitrogen source is effectively fixed; carrying out high-temperature deep carbonization under the protection of the nitrogen gas to obtain a compound material which is effectively combined with the nitrogen and the carbon, so that the active nitrogen with the effect of promoting oxygen reduction catalysis has a good effect, and therefore, a nitrogen loss problem generated by the conventional high-temperature treatment method is avoided, and the oxygen reduction catalysis activity of the nitrogen-carbon composite material is effectively improved.

Owner:NORTHWEST NORMAL UNIVERSITY

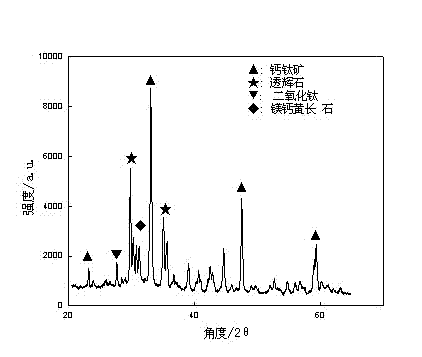

Nitrogen organic modified titanium-containing blast furnace slag catalyst with visible light catalytic activity and preparation method thereof

InactiveCN102861562AStrong absorption capacityStrong photoresponsePhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystSlag

The invention belongs to the field of a catalyst and particularly relates to a nitrogen organic modified titanium-containing blast furnace slag catalyst with visible light catalytic activity and a preparation method thereof. The preparation method comprises the steps of after crushing titanium-containing blast furnace slag, mixing the crushed titanium-containing blast furnace slag with industrial urea and milling; adding absolute ethyl alcohol into mixed powder to carry out ultrasonic dispersion; then agitating and drying and conducting ball milling; pressing the mixture into a sheet and roasting under an oxidization atmosphere; roasting and cooling; and milling the product to be the diameter of 0.5-50 microns to obtain the nitrogen organic modified titanium-containing blast furnace slag catalyst with the visible light catalytic activity. The nitrogen organic modified titanium-containing blast furnace slag catalyst has strong light absorption and light responses under the stimulation of visible light with the wavelength range of 400-700nm, so as to realize the full-amount absorption of the visible light, and the visible light catalytic activity of the nitrogen organic modified titanium-containing blast furnace slag catalyst is obviously improved.

Owner:东北大学秦皇岛分校

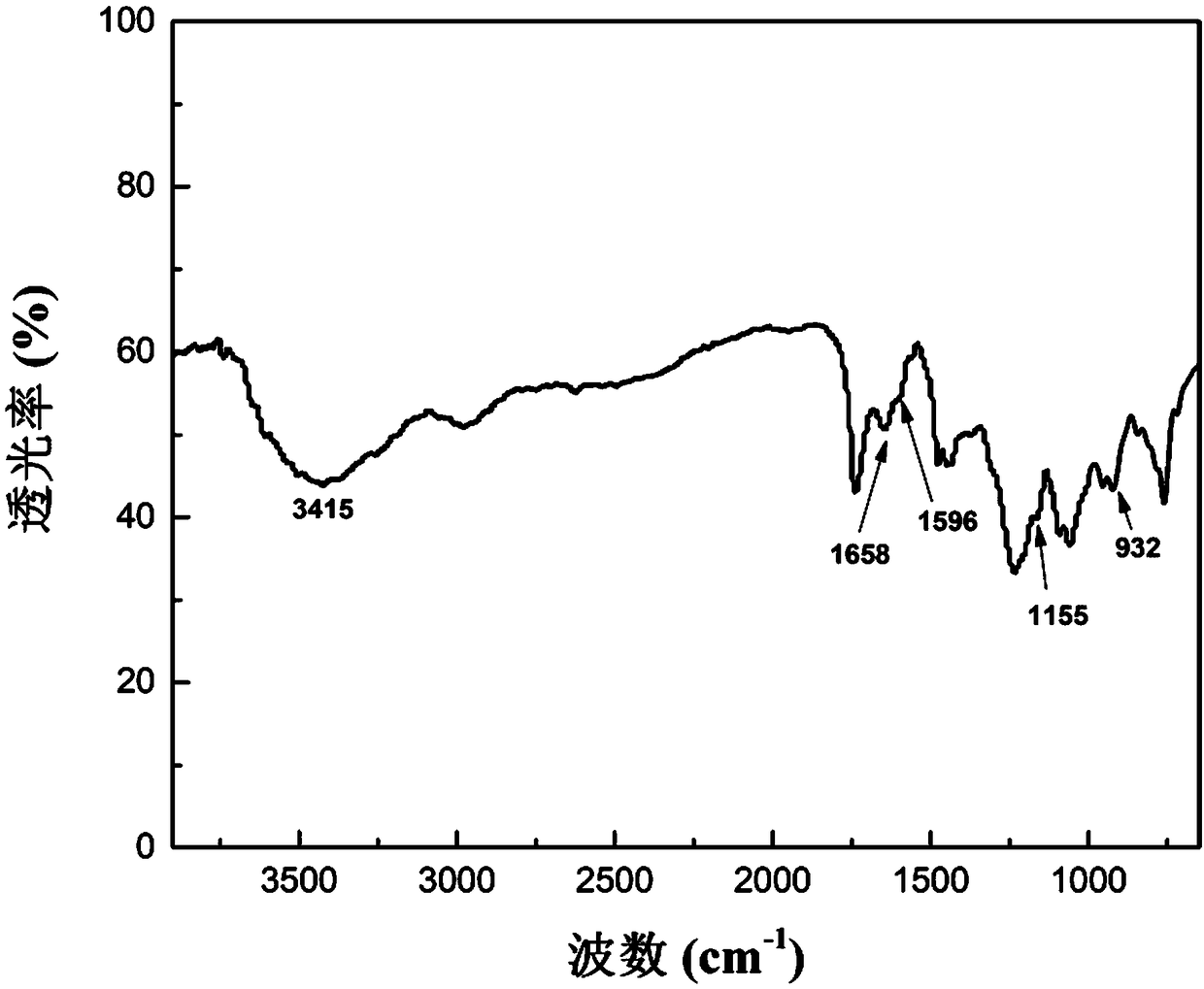

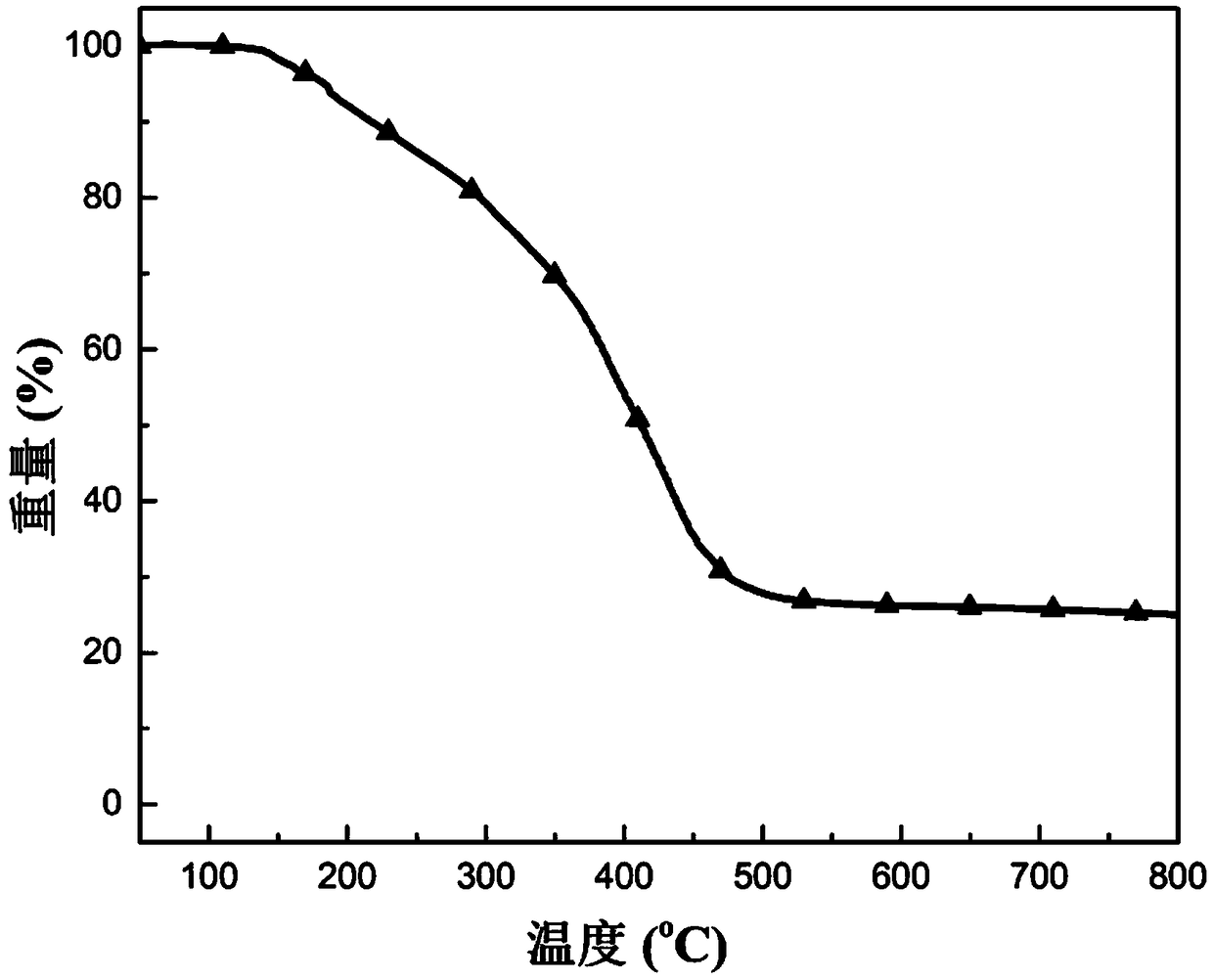

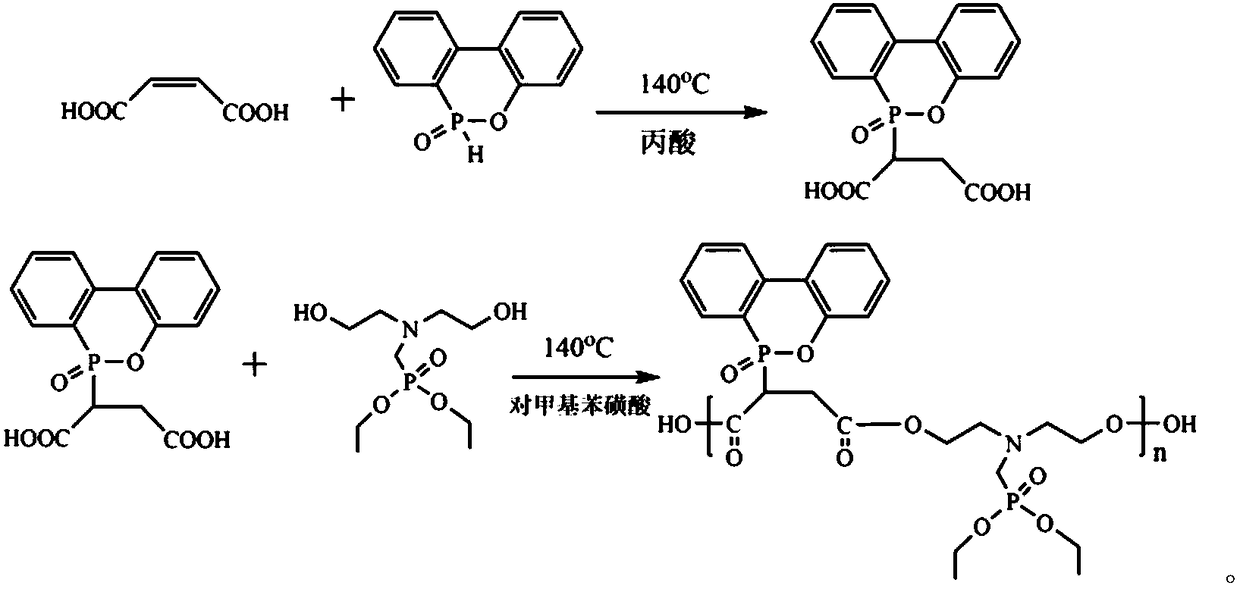

Preparation method of reactive nitrogen-phosphorus flame retardant for aqueous polyurethane

ActiveCN109180924AStable structureImprove flame retardant performanceDiethyl methylphosphonateCarboxylic acid

The invention relates to a preparation method of a reactive nitrogen-phosphorus flame retardant for aqueous polyurethane. The preparation method comprises: (1) adding 9,10-dihydro-9-oxa-10-phospha-phenanthrene-10-oxide, a dicarboxylic acid with a double bond or an anhydride with a double bond, and a solvent A to a reaction container, uniformly mixing, carrying out an addition reaction for 12-24 hat a temperature of 140-180 DEG C under stirring, and carrying out vacuum drying on the mixture obtained by the reaction after achieving the reaction time to obtain a phosphorus-containing derivative;and (2) adding the phosphorus-containing derivative obtained in the step (1), diethyl bis(2-hydroxyethyl)aminomethylphosphonate, a water-carrying agent B and a catalyst C to a reaction container, mixing uniformly, carrying out an esterification reaction for 12-24 h at a temperature of 140-160 DEG C under stirring, and carrying out vacuum drying on the mixture obtained by the reaction after achieving the reaction time to obtain the reactive nitrogen-phosphorus flame retardant. According to the present invention, the reactive nitrogen-phosphorus flame retardant for aqueous polyurethane is prepared by the above method.

Owner:SICHUAN UNIV

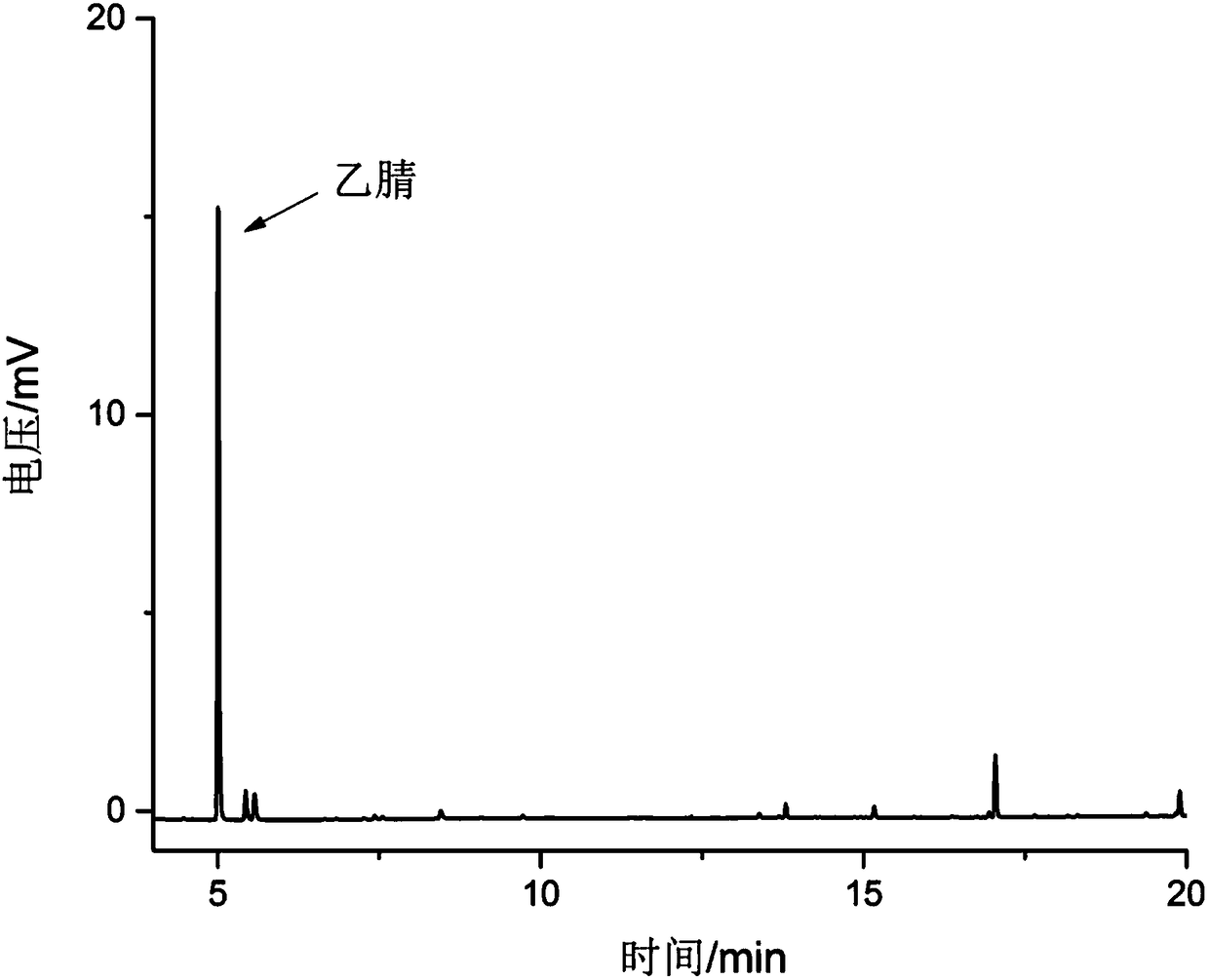

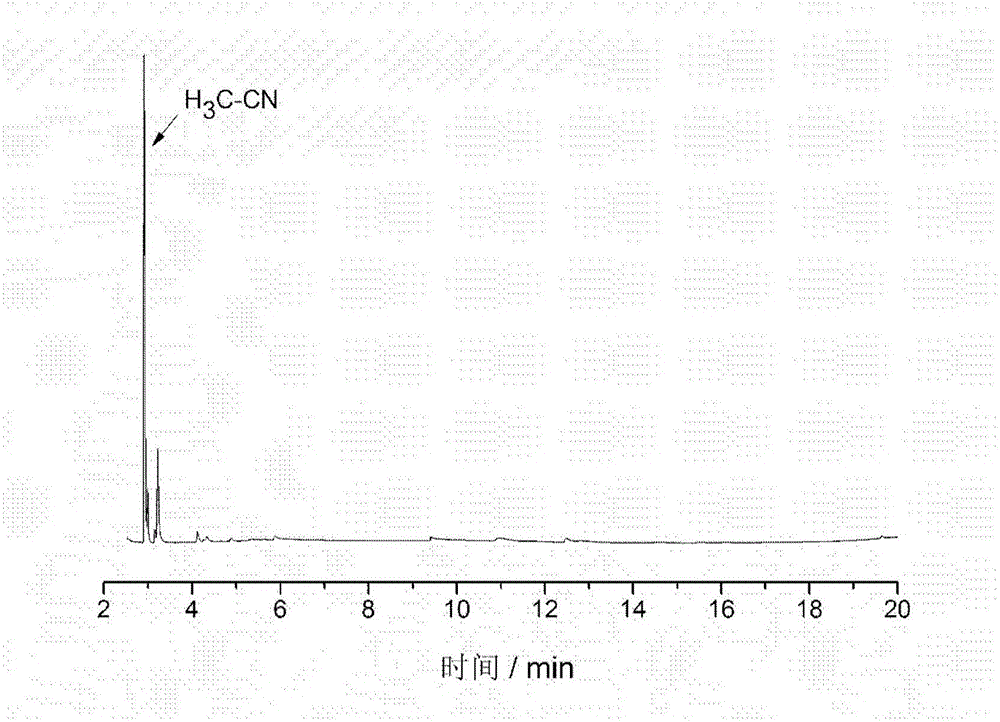

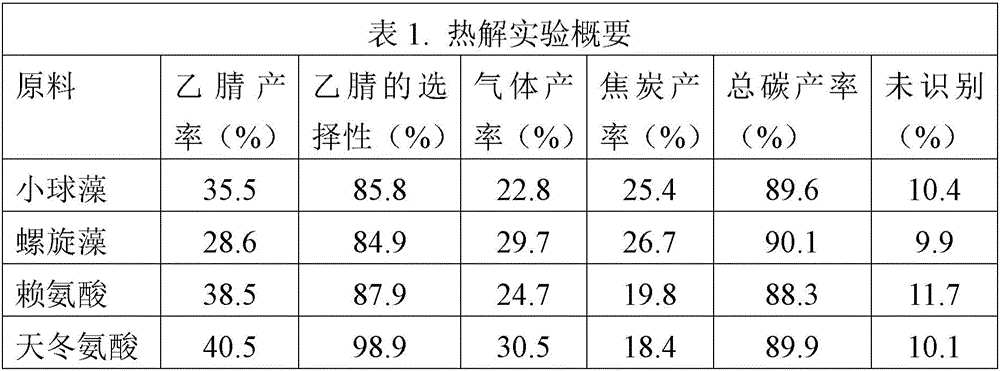

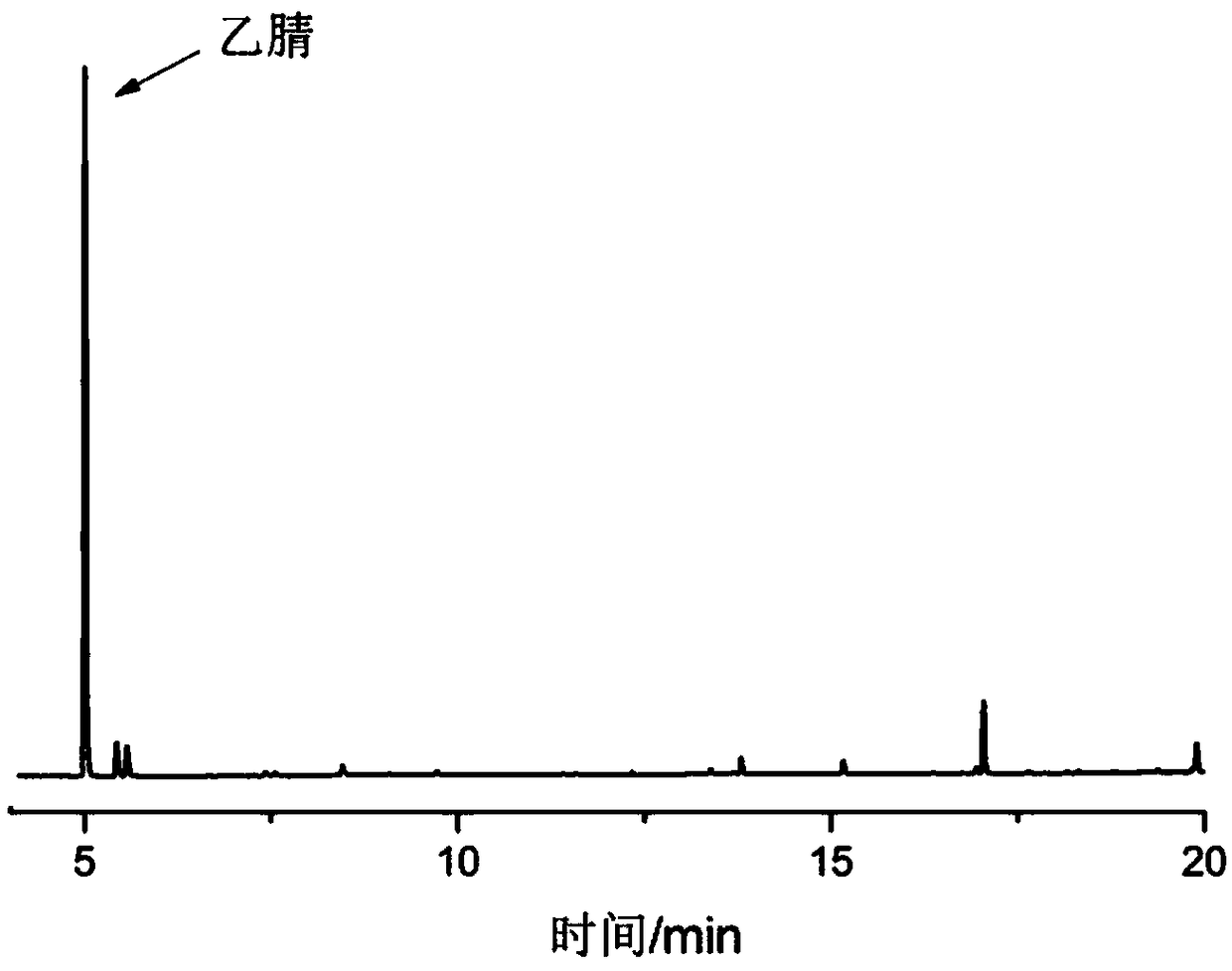

Method for preparing acetonitrile from lignocellulosic biomass material

ActiveCN108084053AHigh yieldHigh selectivityCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrileLignocellulosic biomass

The invention relates to a method for preparing acetonitrile from a lignocellulosic biomass material. The method comprises feeding a lignocellulosic biomass material into a reactor, heating the material for a reaction in the presence of a reactive nitrogen compound and an acidic catalyst, and carrying out condensation and separation to obtain a product acetonitrile. Through the method, acetonitrile is high selectively prepared from the lignocellulosic biomass material. The method is simple and easy, utilizes cheap and easily available raw materials in a wide resource and provides a reproducible and eco-friendly synthesis route from raw material acquisition to product production. The product acetonitrile can be widely used in the fields of medicines, pesticides, spices, fabric dyeing and photosensitive materials.

Owner:UNIV OF SCI & TECH OF CHINA

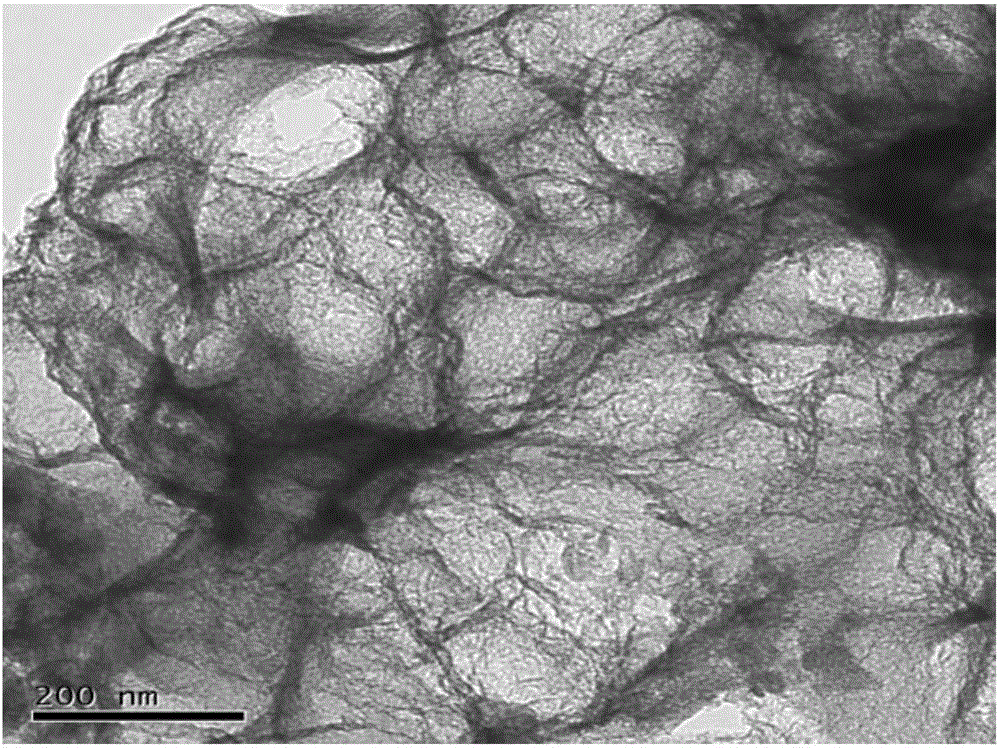

Nitrogen-sulfur co-doping carbon material with electro-catalysis oxygen reduction activity on acid and alkali conditions and preparation method

The invention discloses a nitrogen-sulfur co-doping carbon material with electro-catalysis oxygen reduction activity on acid and alkali conditions and a preparation method, and belongs to the technical field of novel material application. The method comprises the technological processes that clean animal hair is put into a reaction kettle liner, analytic pure ammonia water is added, a hydrothermal degradation reaction is performed, hydrothermal degradation is performed on the obtained solution, drying is performed and then grinding is performed to obtain biological organic solid powder; the solid powder is dissolved into methyl alcohol, then zinc nitrate is added, and the obtained suspension is magnetically stirred evenly and then poured into the reaction kettle liner; after the solvothermal process is finished, centrifugal separation is performed to obtain a metal organic coordination polymer which is used as a precursor, and heat treatment is performed on the precursor at the inert atmosphere; an obtained sample is cleaned with diluted hydrochloric acid, and suction filtration and drying are performed to obtain the nitrogen-sulfur co-doping carbon material. The material has the large specific surface area and the abundant hole structure. The nitrogen-sulfur co-doping carbon material obtained through the method has the excellent performance on fuel cell cathode oxygen reduction catalysis on the acid and alkali conditions.

Owner:SOUTH CHINA UNIV OF TECH

Process for producing an antimicrobial coating

A process for covalently attaching an antimicrobial coating to a polymeric surface. The process comprises contacting the surface of the polymer with a plasma having reactive nitrogen compounds to provide a plasma-treated surface with —NHR groups, wherein R is hydrogen, hydroxyl or C1-2alkyl, reacting the —NHR groups with a surface linking agent, and attaching an amine-containing polymer to the linking agent to form the antimicrobial coating. The surface linking agent is selected from the group consisting of dihaloalkyl, a dihaloalkenyl, and a dihalomethylaryl. The invention is also directed to a contact lens case or a contact lens with an antimicrobial coating.

Owner:BAUSCH & LOMB INC

High-selectivity acetonitrile preparation method

ActiveCN106117082AHigh yieldHigh selectivityCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrileRenewable resource

The invention relates to a high-selectivity acetonitrile preparation method. The method comprises the steps that in a reactor, under the condition that gas containing a reactive nitrogen compound is used as carrier gas, organic materials are reacted under catalysis of a catalyst in a heated mode; liquid is condensed and collected, and acetonitrile is obtained through separation. According to the method, renewable resources are utilized, and acetonitrile is prepared in a high-selectivity mode through an appropriate reaction method. The whole process from raw materials to the production process is renewable, green and environmentally friendly.

Owner:UNIV OF SCI & TECH OF CHINA

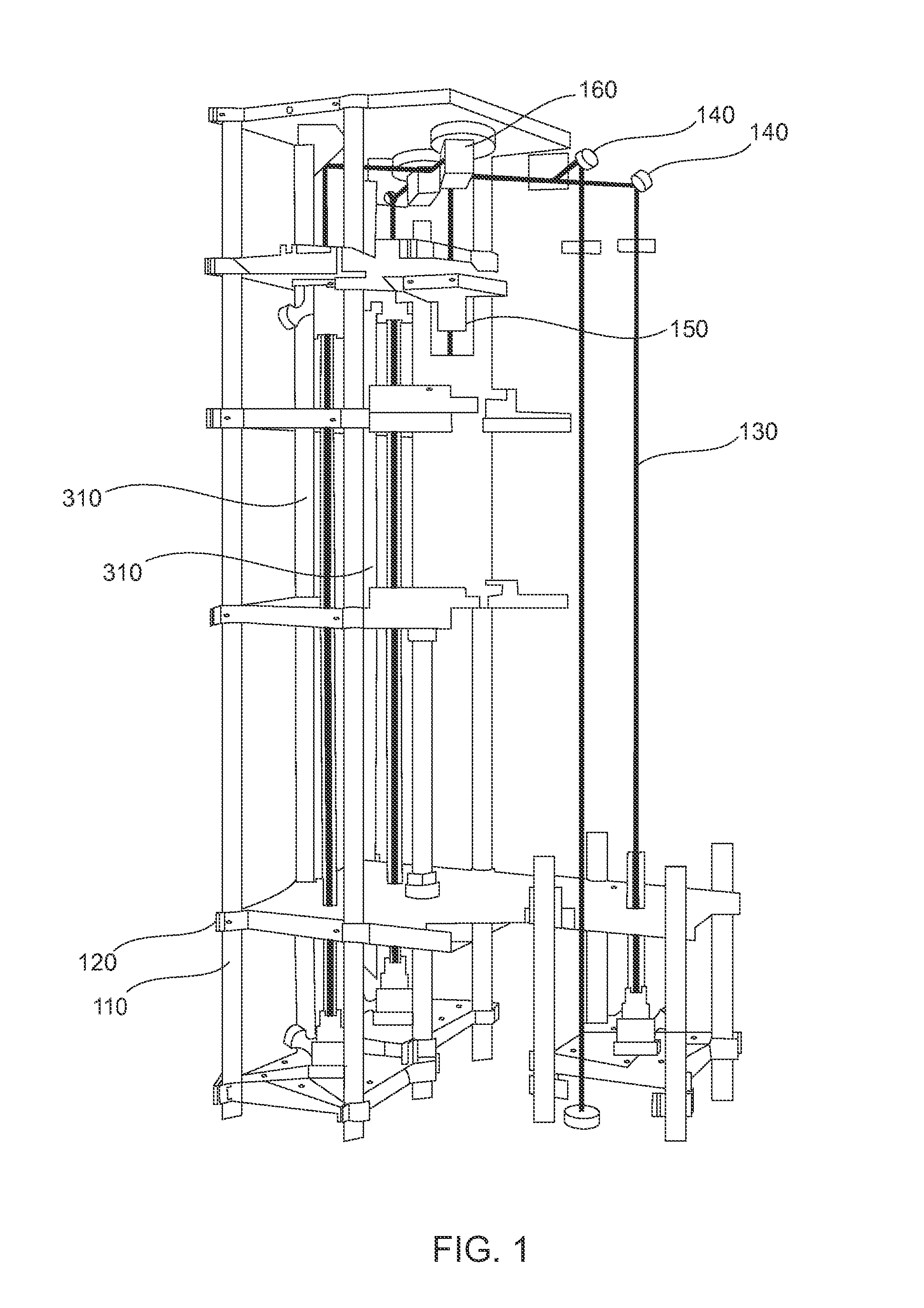

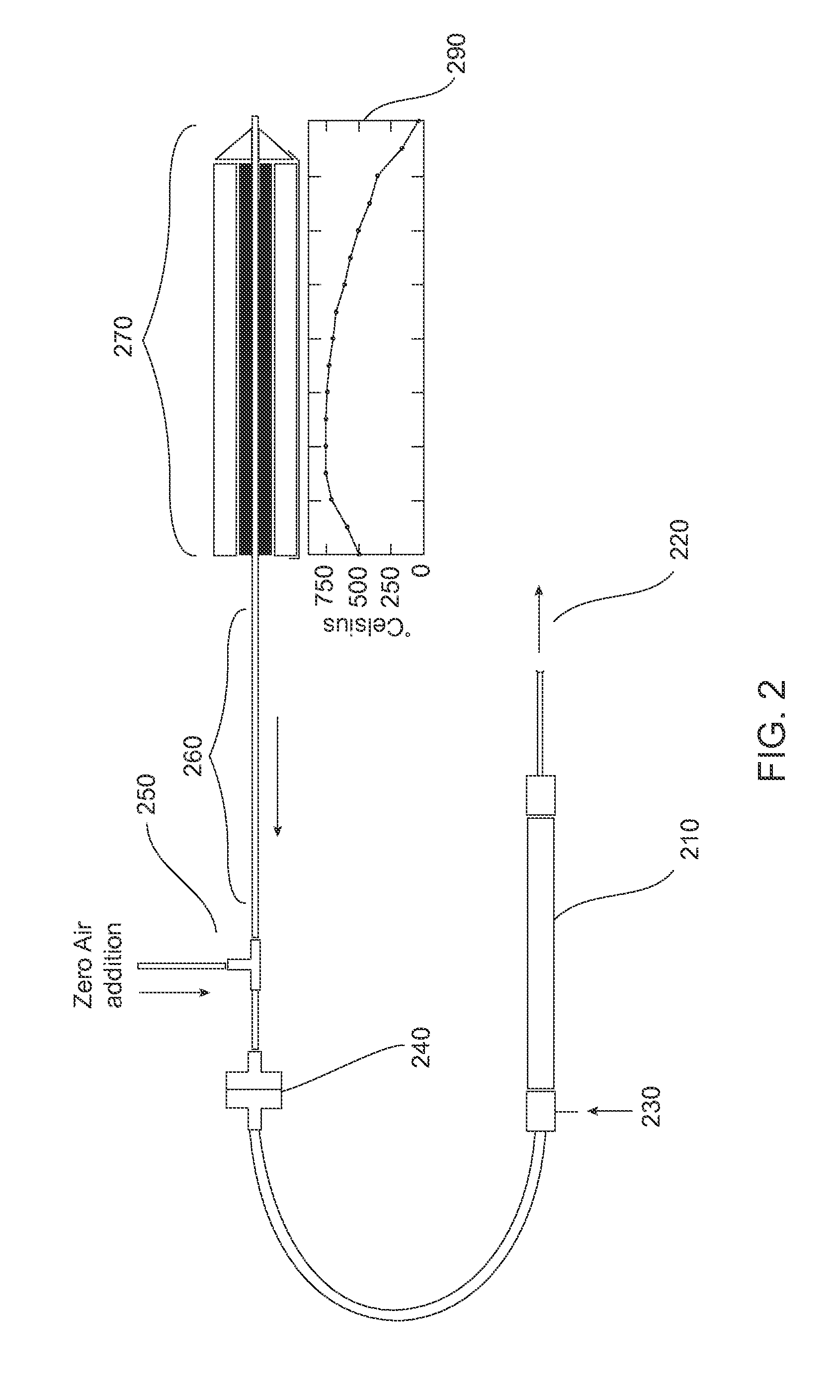

Measurement of Total Reactive Nitrogen, NOy, together with NO2, NO, and O3 via Cavity Ring-down Spectroscopy

ActiveUS20150377850A1Accuracy sufficientSolve the lack of precisionMaterial analysis by electric/magnetic meansMaterial analysis by optical meansThermal dissociationCavity ring-down spectroscopy

A sensitive, compact detector measures total reactive nitrogen (NOy), as well as NO2, NO, and O3. In all channels, NO2 is directly detected by laser diode based cavity ring-down spectroscopy (CRDS) at 405 nm. Ambient O3 is converted to NO2 in excess NO for the O3 measurement channel. Likewise, ambient NO is converted to NO2 in excess O3. Ambient NOy is thermally dissociated at 700C to form NO2 or NO in a heated quartz inlet. Any NO present in ambient air or formed from thermal dissociation of other reactive nitrogen compounds is converted to NO2 in excess O3 after the thermal converter. The precision and accuracy of this instrument make it a versatile alternative to standard chemiluminescence-based NOy instruments.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE COMMERCE

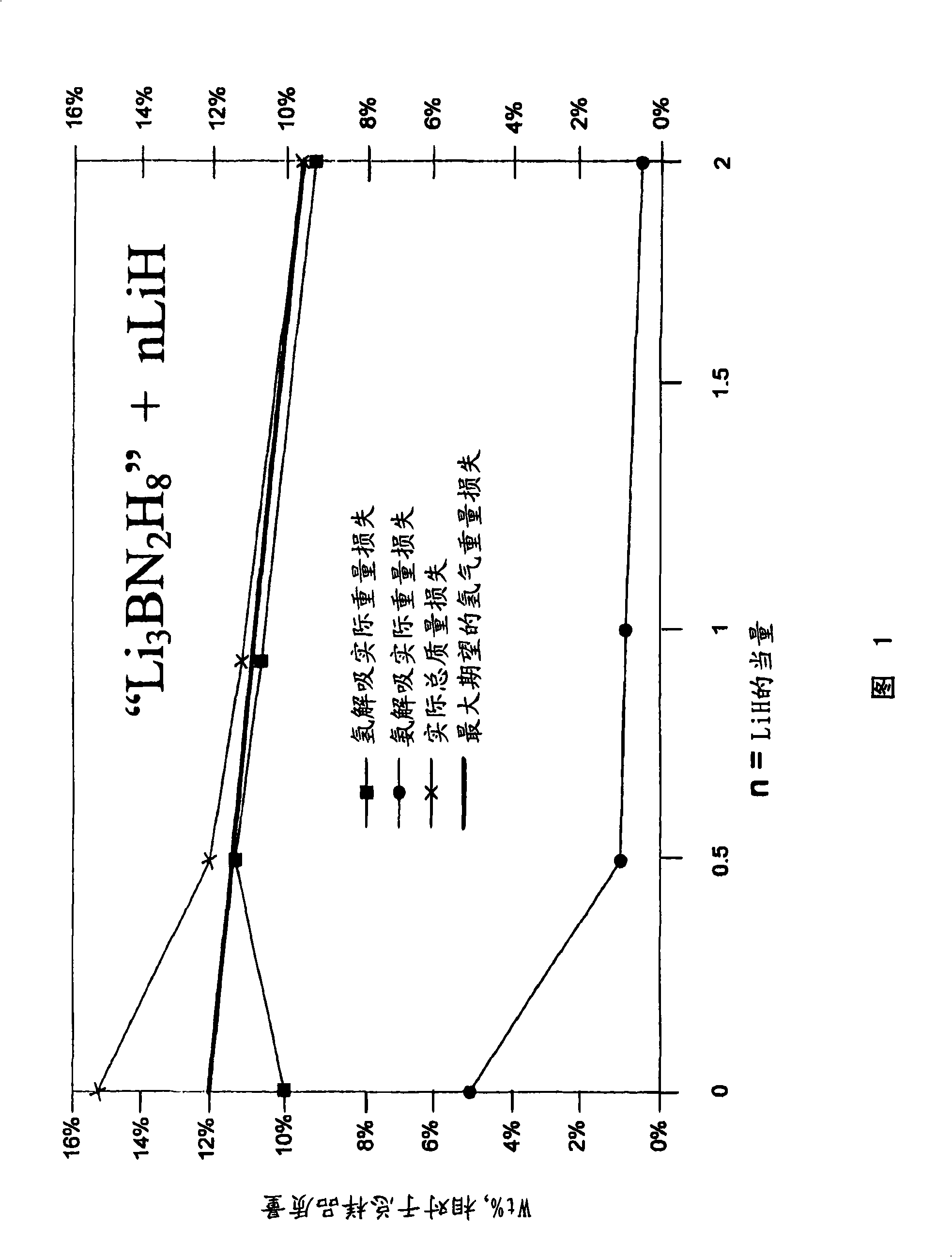

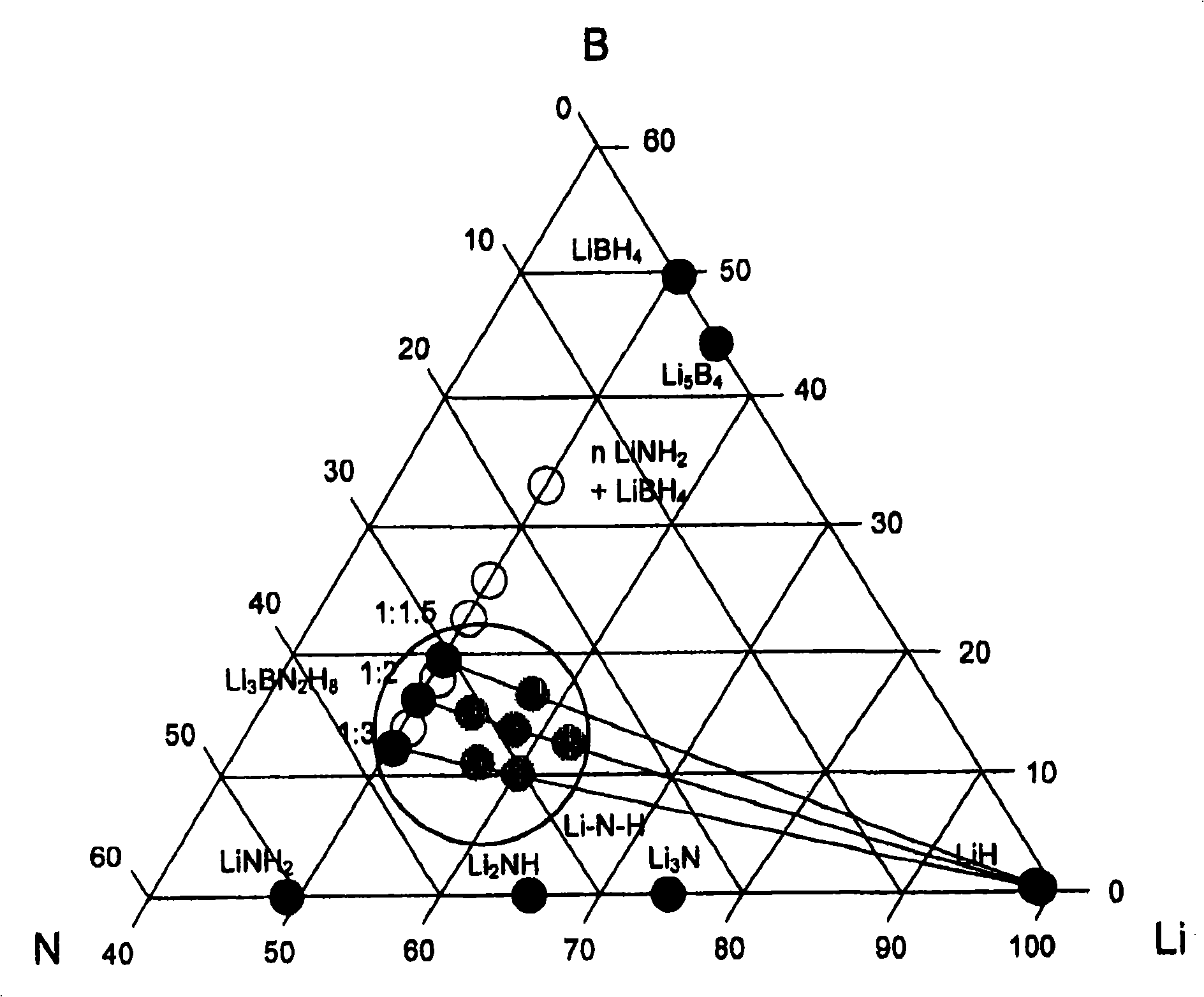

Methods of generating hydrogen with nitrogen-containing hydrogen storage materials

InactiveCN101298316AAlkali/alkaline-earth/beryllium/magnesium hydridesMonoborane/diborane hydridesAlkaline earth metalAmmonia

Methods of generating hydrogen-containing streams having a minimal concentration of gaseous reactive nitrogen-containing compounds, e.g., ammonia, are provided. Hydrogen storage material systems are also provided that generate such hydrogen-containing streams. A first composition comprising a nitride, a second composition comprising a hydride, and a third composition having a cation selected from the group consisting of: alkali metals, alkaline earth metals, and mixtures thereof are combined together. The hydrogen-containing stream thus generated has a minimal concentration of gaseous reactive nitrogen-containing compounds.

Owner:GM GLOBAL TECH OPERATIONS LLC

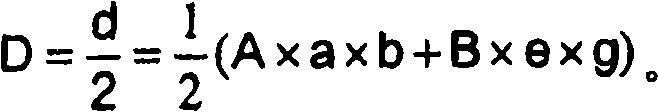

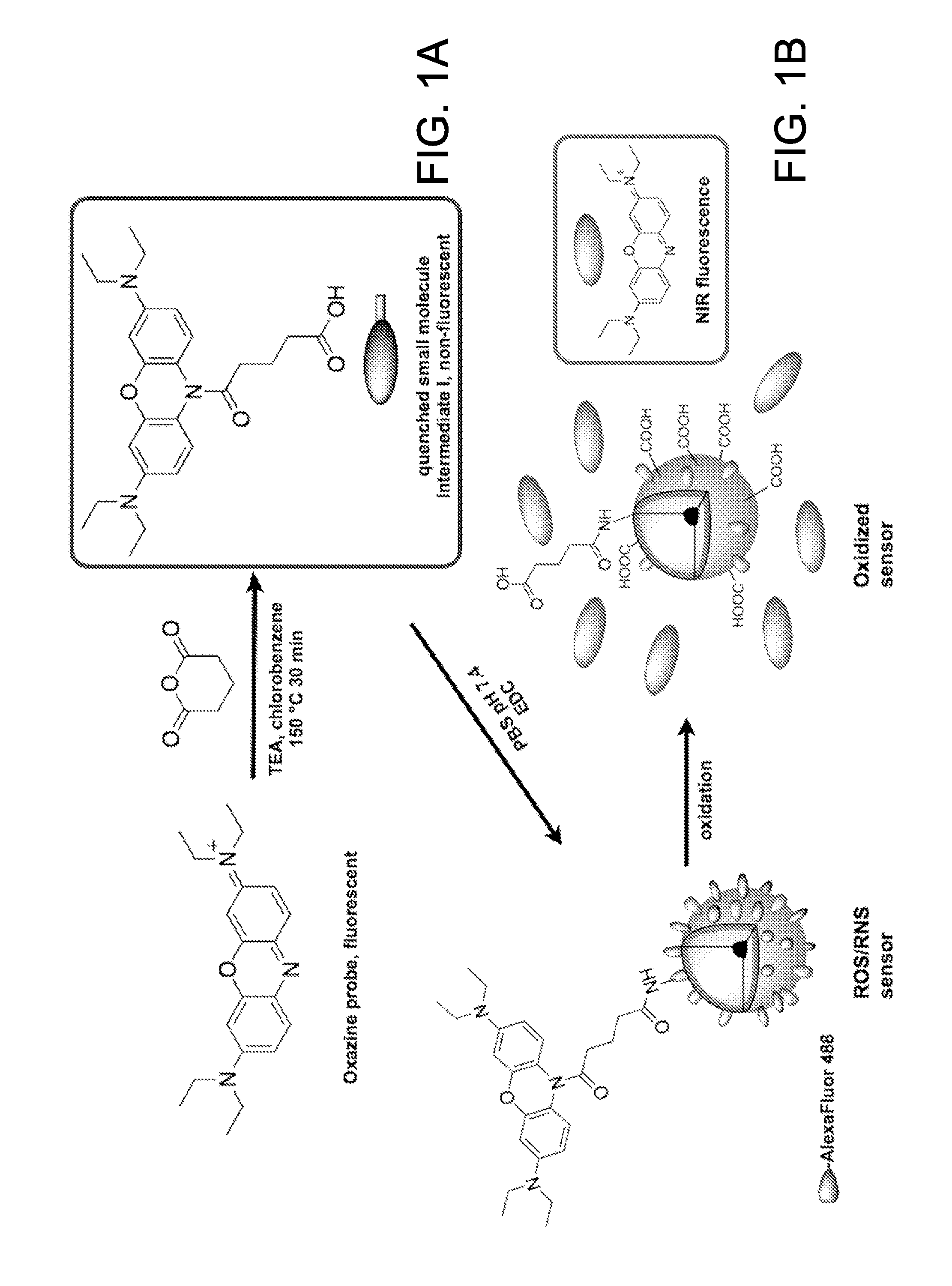

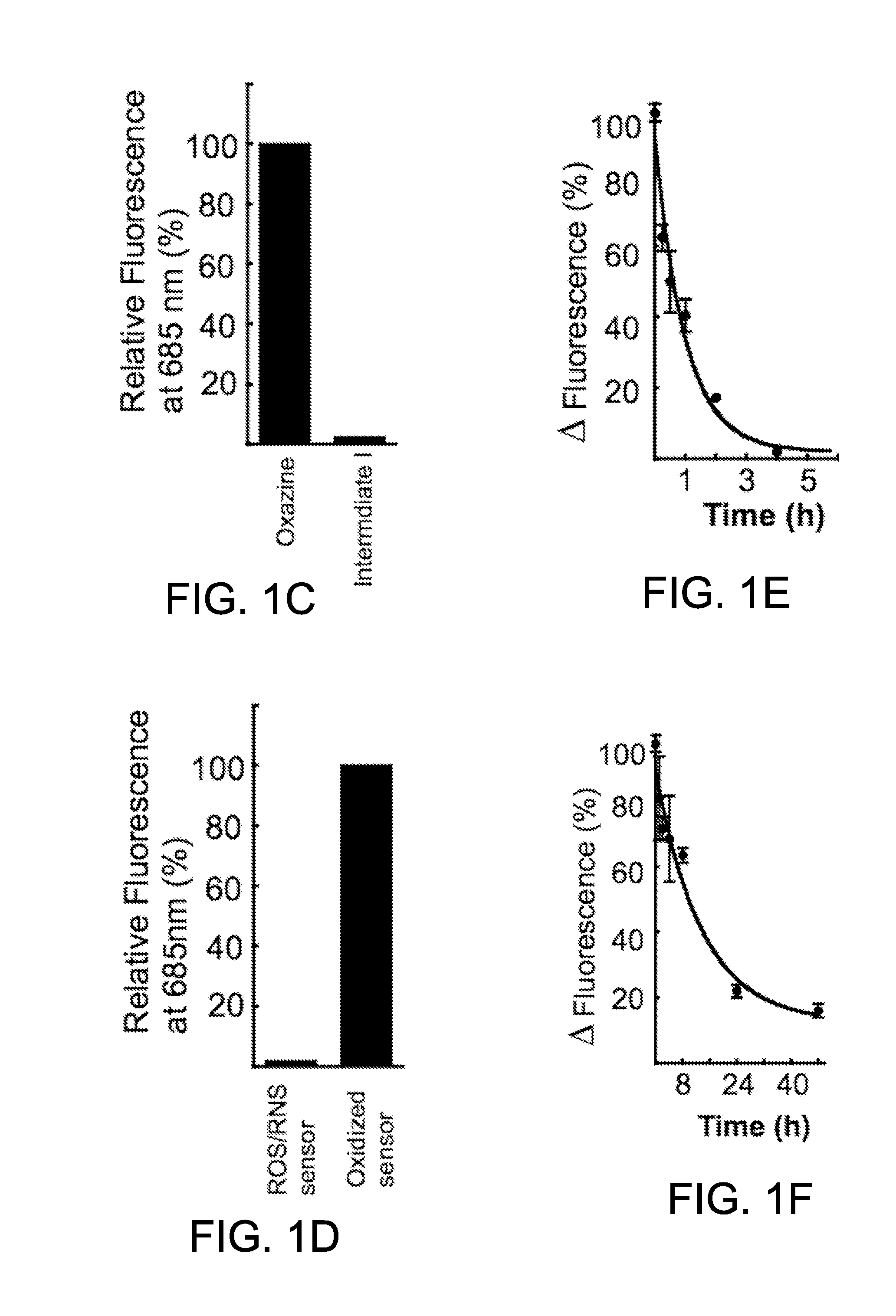

Optical sensor conjugates for detecting reactive oxygen and/or reactive nitrogen species in vivo

InactiveUS20130149251A1High substrate target concentrationImprove pharmacokineticsUltrasonic/sonic/infrasonic diagnosticsPowder deliveryOxygenIn vivo

The present invention provides methods and compositions based on optical sensor conjugates that are useful for detecting reactive oxygen, reactive nitrogen, or both species that are a direct result of inflammation caused by tissue damage.

Owner:THE GENERAL HOSPITAL CORP

Composition gradient cermets and reactive heat treatment process for preparing same

Cermets, particularly composition gradient cermets can be prepared starting with suitable bulk metal alloys by a reactive heat treatment process involving a reactive environment selected from the group consisting of reactive carbon, reactive nitrogen, reactive boron, reactive oxygen and mixtures thereof.

Owner:EXXON RES & ENG CO

Nitrate reductases from red algae, compositions and methods of use thereof

InactiveUS20080313775A1Lower Level RequirementsSmall statureBacteriaImmunoglobulinsNucleotideLow nitrogen

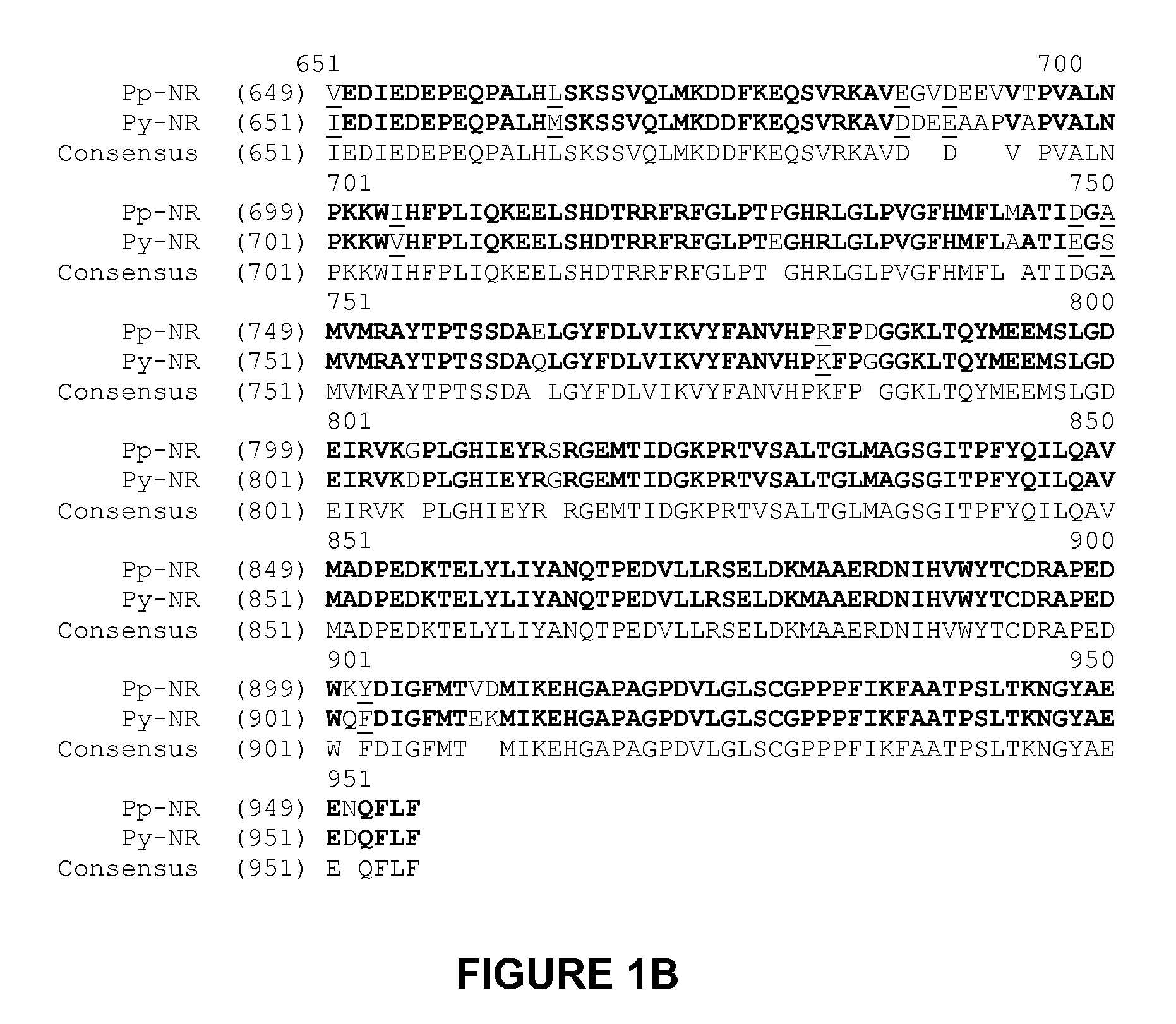

The NR enzymes described herein were discovered in the red algae of Porphyra perforata (PpNR) and Porphyra yezoensis (PyNR). The present invention provides methods and compositions relating to altering NR activity, nitrogen utilization and / or uptake in plants. The invention relates to a method for the production of plants with maintained or increased yield under low nitrogen fertility. The invention provides isolated nitrate reductase (NR) nucleic acids and their encoded proteins. The invention further provides recombinant expression cassettes, host cells, and transgenic plants. Plants transformed with nucleotide sequences encoding the NR enzyme show improved properties, for example, increased yield and growth.

Owner:PIONEER HI BRED INT INC

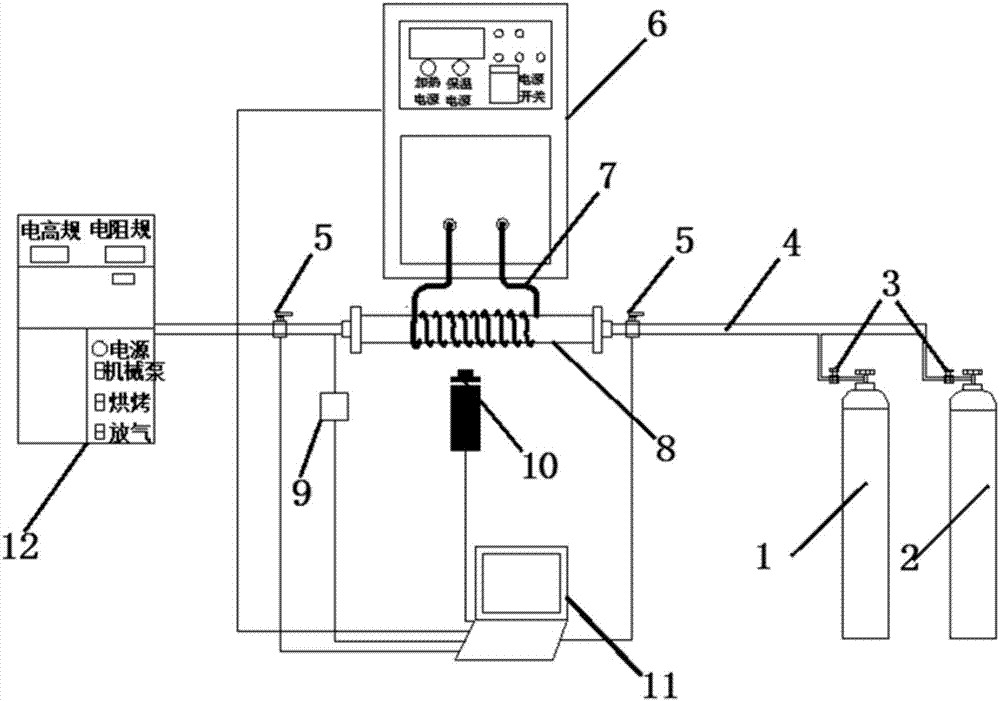

Vacuum high pressure pulse discharge catalyzed chemical heat treatment apparatus and method

InactiveCN1740374AHigh surface hardnessImprove surface qualitySolid state diffusion coatingHigh pressure pulsePulse voltage

The present invention is vacuum high pressure pulse discharge catalyzed chemical heat treatment apparatus and method. The apparatus consists of furnace seat, catalytic discharge electrode on the furnace, catalytic discharge electrode, pulse power supply, furnace gas circulating system, heat isolating layer structure, inside AC heater, etc. The method includes setting the workpiece inside furnace, heating with the inside AC heater to nitriding temperature, applying pulse voltage of 0-8000 V between the catalytic discharge electrode on the furnace and the catalytic discharge electrode, ionizing the nitrogen containing gas inside the furnace and of pressure 100-50000 Pa to discharge intensively to generate active nitrogen atoms permeating into the workpiece at high speed, and circulating nitriding gas for passing by the workpiece homogeneously. The present invention has the advantages of fast nitriding, high heat efficiency, no oxidation of the workpiece, etc.

Owner:DALIAN MARITIME UNIVERSITY

Pyrotechnic composition generating clean gases with low levels of nitrogen oxides, and pellets of such a composition

InactiveUS6024811ARaise the ratioReduce the ratioAmmonium perchlorate explosive compositionsPressure gas generationEpoxyAmmonium nitrate

The present invention relates to gas-generating pyrotechnic compositions. The compositions according to the invention contain a small amount of epoxy binder, stabilized ammonium nitrate, optionally potassium perchlorate or an organic oxidant containing nitrogen and, characteristically, a reactive organic nitrogen compound selected from nitroguanidine, guanidinium nitrate and oxamide. This reactive nitrogen compound may advantageously be combined with cupric oxide. The compositions according to the invention produce nitrogen-rich gases with very low levels of nitrogen oxides, and find their preferred application in the form of pellets as pyrotechnic charges in gas generators for pyrotechnic extinguishers, for devices designed to inflate external structures or for devices designed to protect the occupants of a motor vehicle.

Owner:SNPE MATERIAUX ENERGETIQUES

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide including phosphorus recovery and nitrite reduction to nitrous oxide

InactiveCN103827285AImplementation AdvantagesBioreactor/fermenter combinationsBiological substance pretreatmentsChemical reactionGas phase

A method to produce N2O from organic nitrogen and / or reactive nitrogen in waste uses a bioreactor coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas. Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Dual-pulse quick nitriding method and device based on induction heating

PendingCN106868445AHigh vibration frequencyIncrease vibration amplitudeSolid state diffusion coatingControl systemDual pulse

The invention discloses a dual-pulse quick nitriding method and device based on induction heating. A workpiece in a vacuum tube is subjected to quick heating and nitriding through a high-frequency power supply; the surface temperature of the workpiece and the pressure of nitriding gas in the vacuum tube are monitored through an infrared temperature detector and a pressure sensor; and a control system is used for controlling the workpiece to make pulse cycle within the set temperature range or be stabilized at the set temperature through a temperature signal, and controlling the pressure in the tube to present rectangular pulse change through a pressure signal. The dual-pulse quick nitriding method and device based on induction heating have the advantages that temperature pulses improve the vibration frequency and amplitude of surface atoms, pressure pulses improve the quantity of active nitrogen atoms in media, nitriding of nitrogen atoms is accelerated finally on the condition of dual pulses, and quick nitriding of metal is achieved.

Owner:GUIZHOU NORMAL UNIVERSITY

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide including phosphorus recovery and nitrite reduction to nitrous oxide

InactiveUS8932849B2Producer of clean energyTreatment with aerobic and anaerobic processesSustainable biological treatmentChemical reactionGas phase

A method to produce N2O from organic nitrogen and / or reactive nitrogen in waste uses a bioreactor coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas. Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

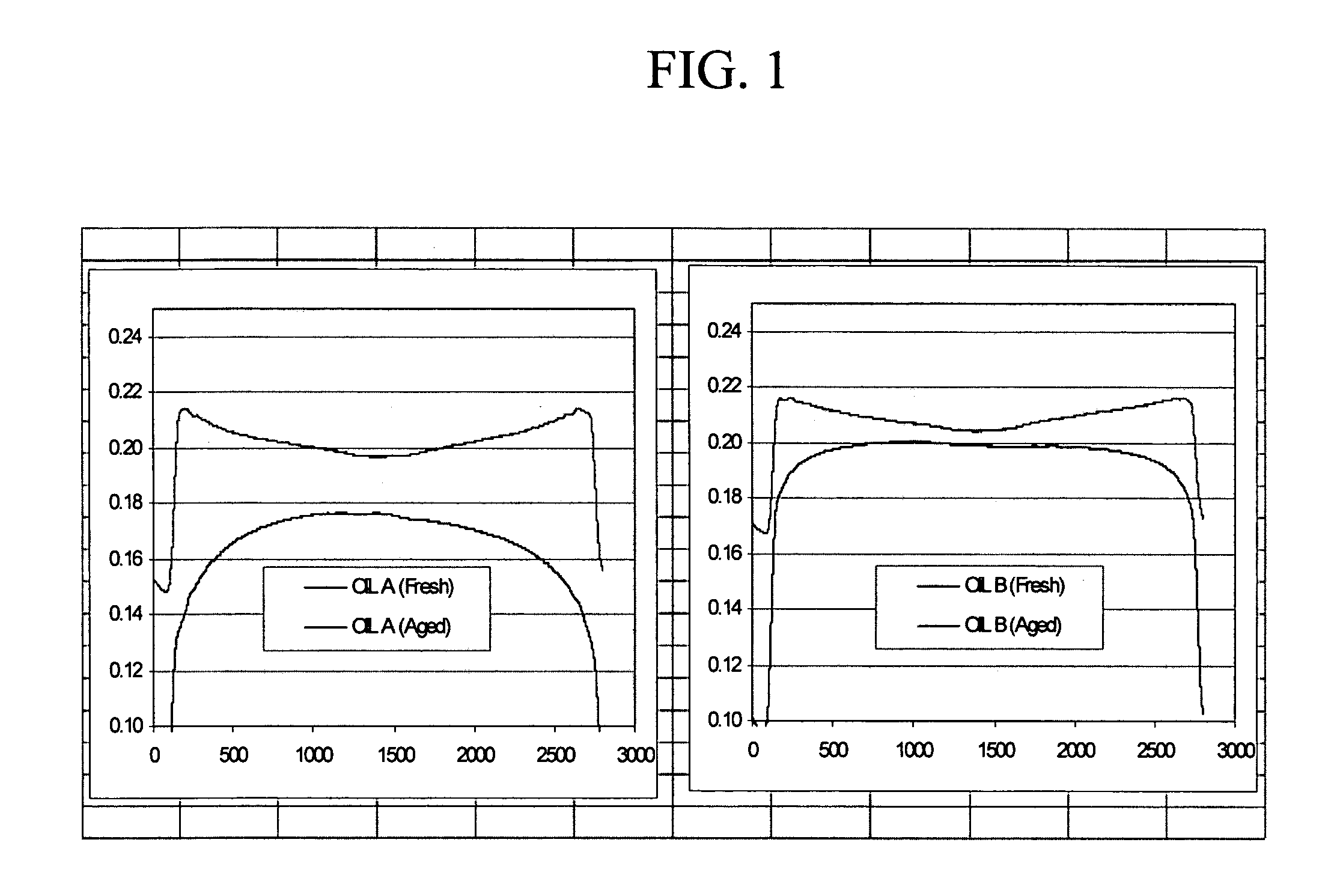

Power transmission fluids with enhanced antishudder durability and handling characteristics

InactiveUS20060079412A1Improving stability against oxidation degradationHigh capacitanceOrganic chemistryGear lubrication/coolingFiberCarbon fibers

A finished power transmitting fluid having enhanced friction durability and improved μ / v characteristics on paper, steel and advanced friction materials such as carbon fiber, and which may provide a lubricant composition that carries minimal concern for skin sensitization and related health, safety, and environmental issues, can contain lubricating base oil, a friction modifier produced by reacting a polyamine with an aliphatic mono acid such as oleic or isostearic acid under conditions to form a mixture of 1,2-disubstituted imidazoline containing components, wherein further acylation of residual active nitrogens with mono or diacids or anhydrides affords friction modifier compositions having enhanced frictional and handling characteristics.

Owner:AFTON CHEMICAL

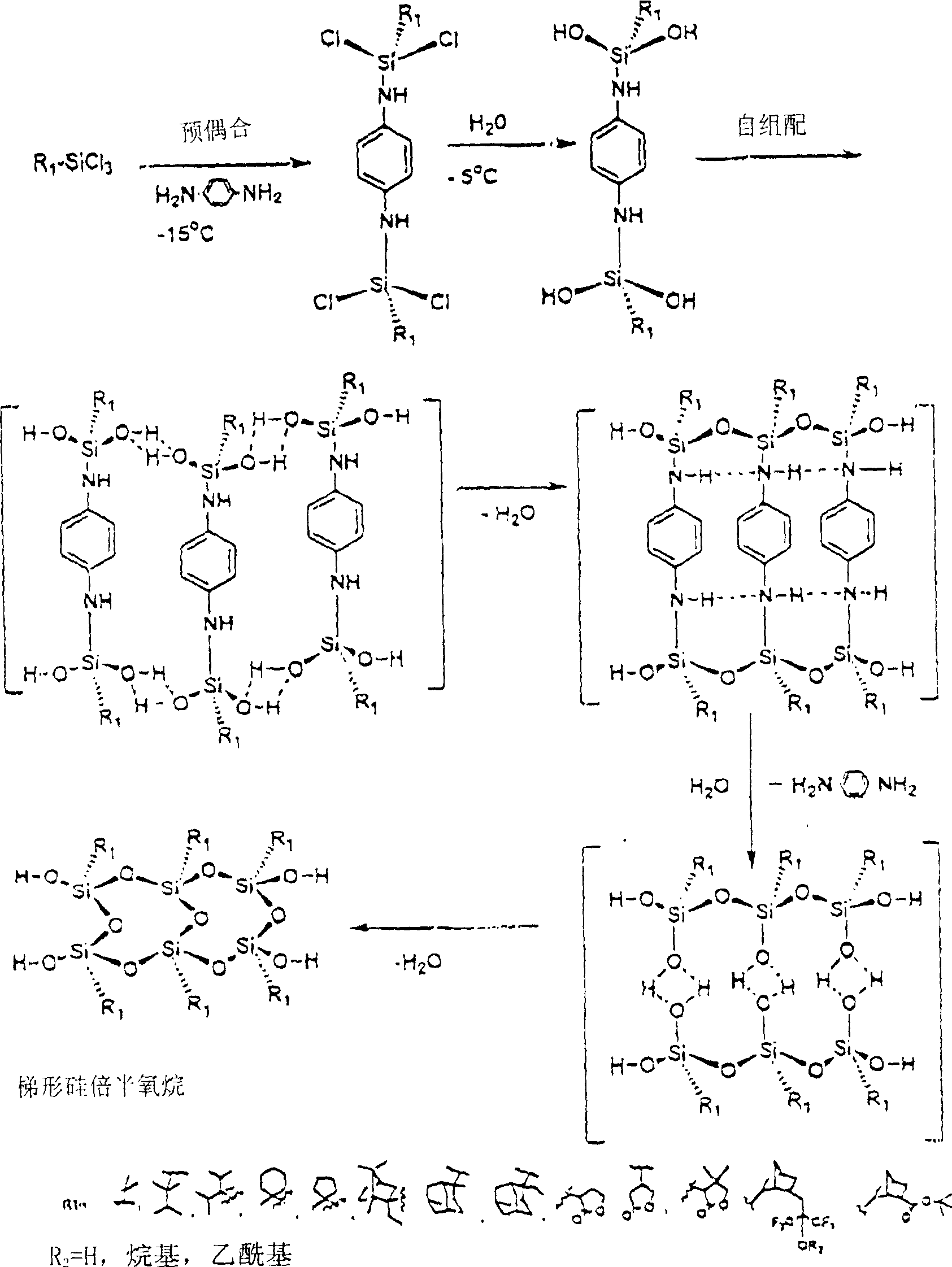

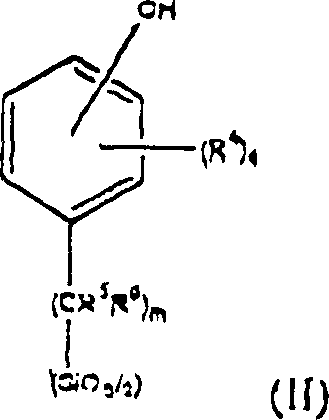

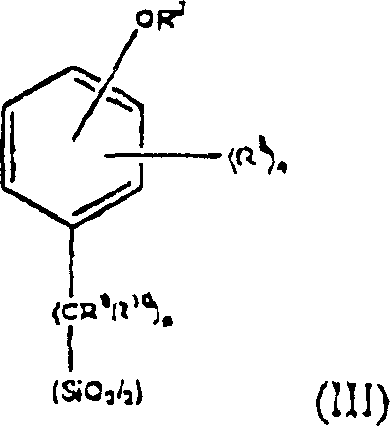

Polyorganosiloxane and preparing method for photoresist composition containing the said polyorganosiloxane

The present invention relates to polysiloxane and the synthesis of photoresist containing the said polysiloxane. The synthesis process of the present invention includes using polymerizing template reagent with several reactive nitrogen-containing radicals, especially diamine reagent.

Owner:SHIPLEY CO INC

Method for preparing acetonitrile

ActiveCN109369451AHigh selectivityWell sourcedCarboxylic acid nitrile preparationOrganic compound preparationLiquid productPollution

The invention discloses a method for preparing acetonitrile. The method comprises the following steps: heating waste organic plastic in a reactor in the presence of a catalyst and carrier gas and reacting; then cooling and separating to obtain a liquid product containing the acetonitrile, wherein the catalyst is composed of a carrier and active metal oxide, the carrier gas is composed of reactivenitrogen-containing compound gas and random inert gas and the reactive nitrogen-containing compound gas is selected from ammonia gas, methylamine gas, dimethylamine gas, ammonium salt pyrolysis gas, urea pyrolysis gas or a combination thereof. According to the method disclosed by the invention, the waste organic plastic is used as a raw material and an acetonitrile product is highly selectively prepared through a simple preparation process, the environment pollution can be reduced and waste utilization is realized. Furthermore, the method is a renewable, green and environment-friendly route ina whole process from the raw material to a production technology and has a great industrial prospect.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com