Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1039 results about "Methylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methylamine is an organic compound with a formula of CH₃NH₂. This colorless gas is a derivative of ammonia, but with one hydrogen atom being replaced by a methyl group. It is the simplest primary amine. It is sold as a solution in methanol, ethanol, tetrahydrofuran, or water, or as the anhydrous gas in pressurized metal containers. Industrially, methylamine is transported in its anhydrous form in pressurized railcars and tank trailers. It has a strong odor similar to fish. Methylamine is used as a building block for the synthesis of many other commercially available compounds.

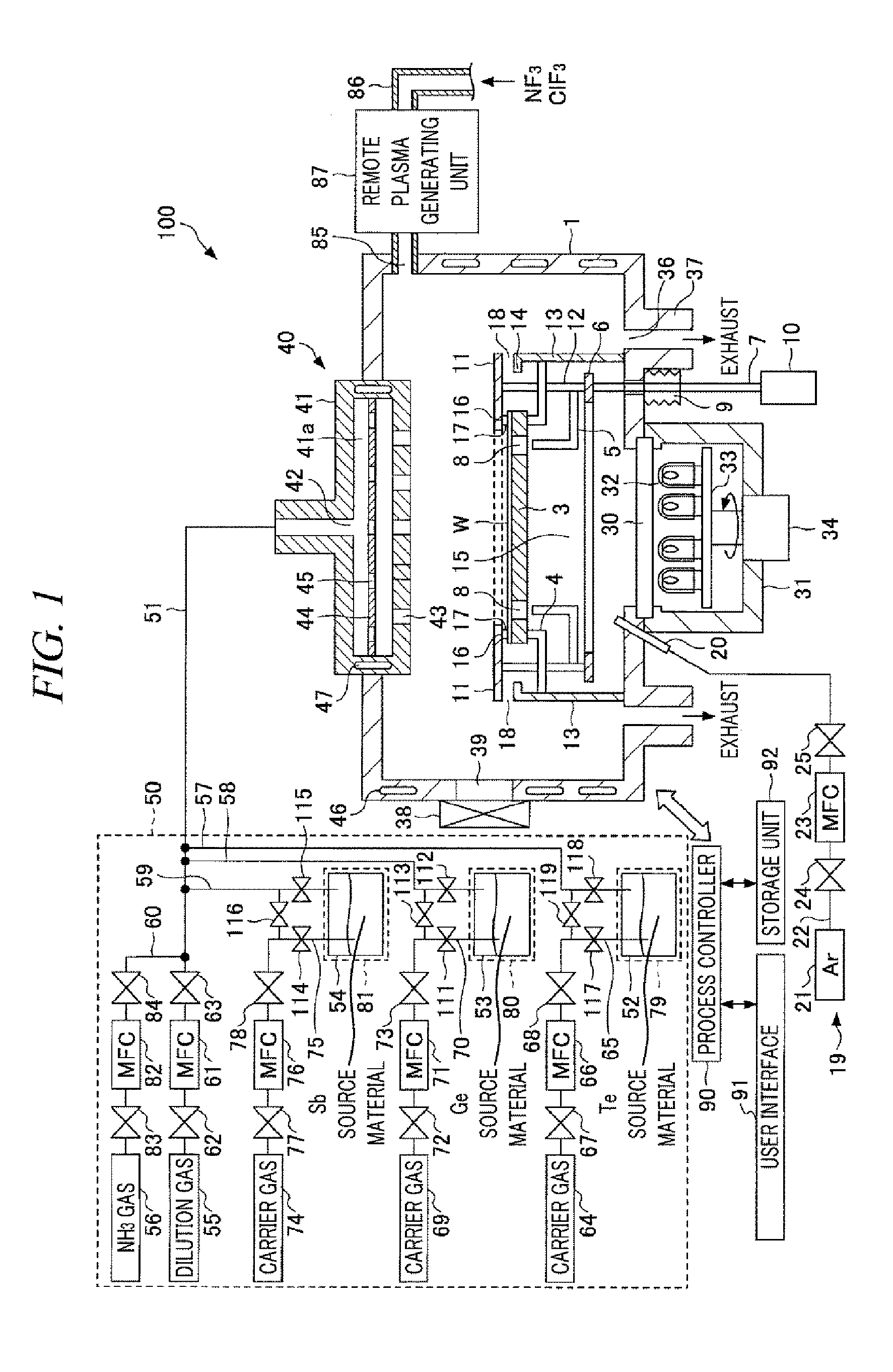

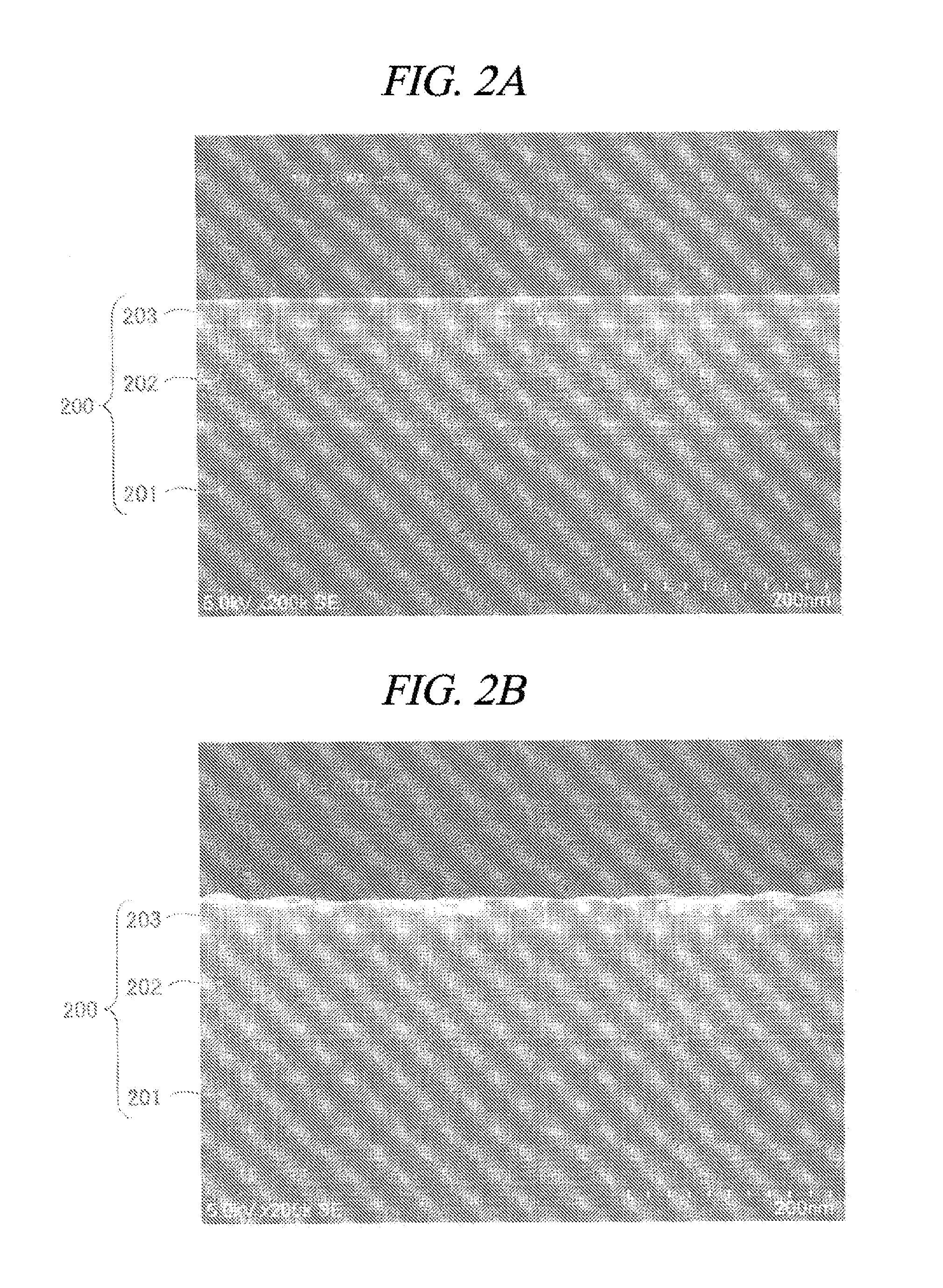

Ge-Sb-Te FILM FORMING METHOD, Ge-Te FILM FORMING METHOD, AND Sb-Te FILM FORMING METHOD

ActiveUS20140162401A1Improve surface smoothnessImprove featuresSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDimethylhydrazineMetallurgy

A Ge—Sb—Te film forming method includes a Sb source material introducing process, a first purging process, a Te source material introducing process, a second purging process, a Ge source material introducing process, a third purging process. An additive gas containing at least one of ammonia, methylamine, dimethylamine, hydrazine, monomethylhydrazine, dimethylhydrazine and pyridine is introduced in at least one of the Sb, Te and Ge source material introducing processes and the first to third purging processes.

Owner:TOKYO ELECTRON LTD

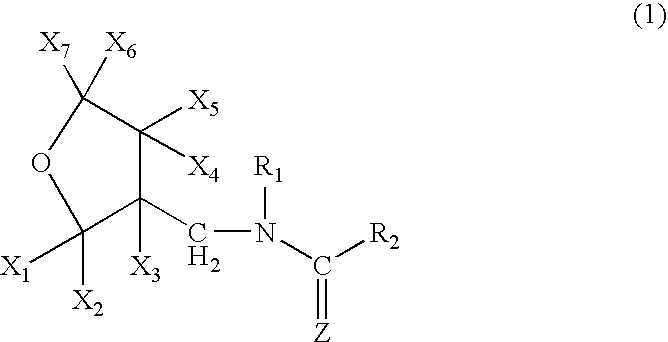

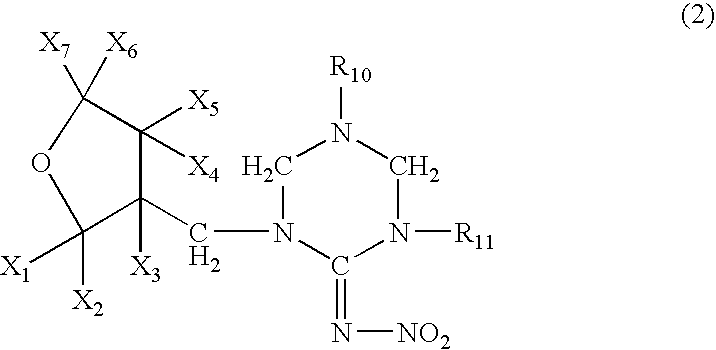

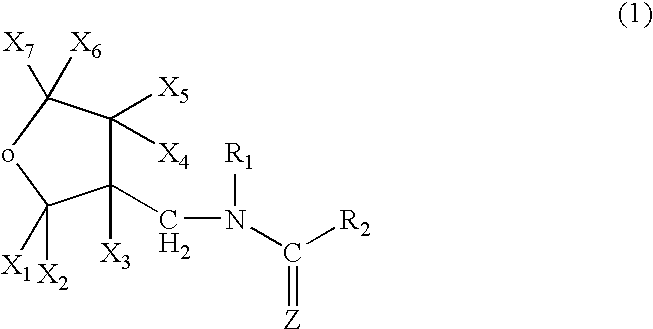

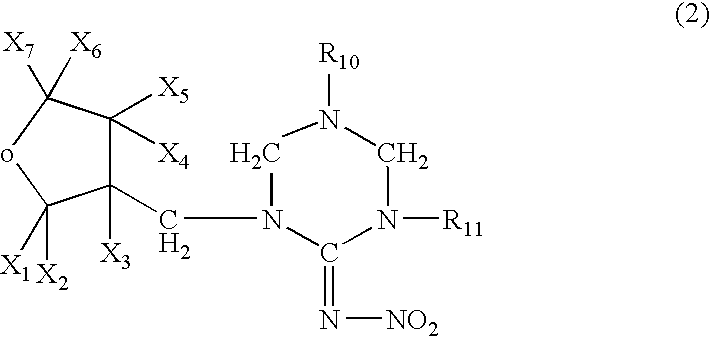

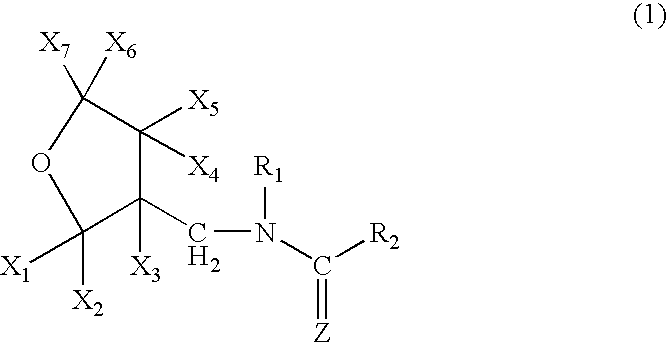

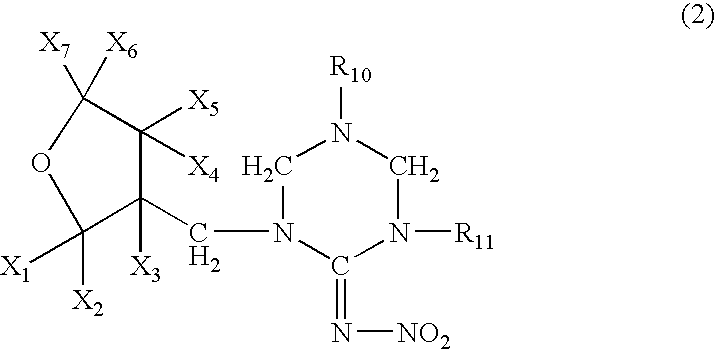

High concentration topical insecticide containing insect growth regulator

InactiveUS20050009880A1Easy to useOvercomes drawbackBiocideDead animal preservationHigh concentrationSide effect

A topical insecticide is provided which can be safe to use and avoids many common deleterious side effects of conventional topical insecticides. The insecticide contains an insecticide and an insect growth regulator effective for killing fleas, flea larvae and flea eggs. The insecticide is formulated by dissolving an insecticidal (tetrahydro-3-furanyl) methylamine derivative or a chloronicotinyl insecticide and an insect growth regulator (IGR) in a solvent containing a quaternary ammonium salt to increase the solvency of the IGR component, thereby providing an insecticide having high insecticidal activity.

Owner:CEVA ANIMAL HEALTH

High concentration topical insecticide containing insect growth regulator

ActiveUS20050096386A1Easy to useOvercomes drawbackBiocideDead animal preservationHigh concentrationSide effect

A topical insecticide is provided which can be safe to use and avoids many common deleterious side effects of conventional topical insecticides. The insecticide contains an insecticide and an insect growth regulator effective for killing fleas, flea larvae and flea eggs. The insecticide is formulated by dissolving an insecticidal (tetrahydro-3-furanyl) methylamine derivative and an insect growth regulator (IGR) in a solvent containing a quaternary ammonium salt to increase the solvency of the IGR component, thereby providing an insecticide having high insecticidal activity.

Owner:CEVA ANIMAL HEALTH

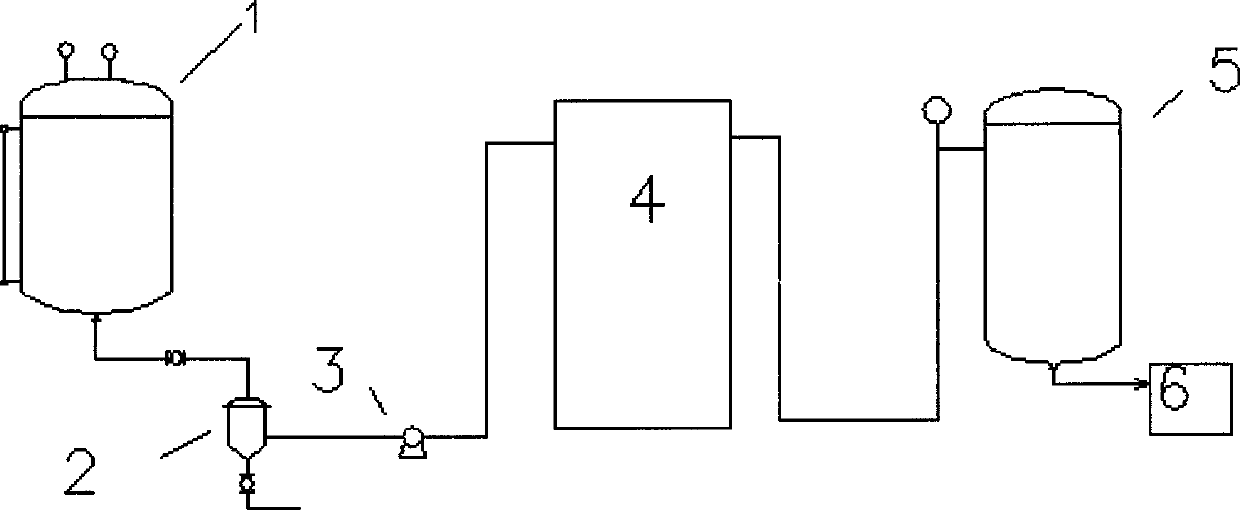

Absorption-biological treatment method for malodorous gas

The invention relates to an absorption and biological treatment method of malodorous waste gas. The malodorous waste gas enters a spray absorption tower to have an absorbing, humidifying and cooling function, and then enters into a biological dripping and filtrating device and contacts with a biological film attached to the surface of the filler in the process of rising to be degraded into odorless compounds, and then the purified gas is discharged. The residence time of a vacant bed is 11 to 45 seconds. Part of the waste water produced when spraying and absorbing can be used as biological circulating water, which can be reused again as spraying water after the biochemical treatment. The absorption and biological treatment method of the invention can effectively remove the odor polluting matters such as organic amine, ammonia gas, hydrogen sulfide, mercaptan type, dimethyl sulfide (DMS), dimethyl disulfide (DMDS), styrene, volatile organic compounds (VOC), dimethyl trisulfide, benzylamine, carbon disulfide, carbonyl sulfide, etc. and all kinds of malodorous smells, most of which are poisonous and a plurality of which are carcinogens. The deodorization effect can reach 99 percent, which can discharge by reaching the standard and can be applied to a deodorization and purification treatment of the large-capacity matters polluted by different malodorous gas with low concentration.

Owner:SUN YAT SEN UNIV

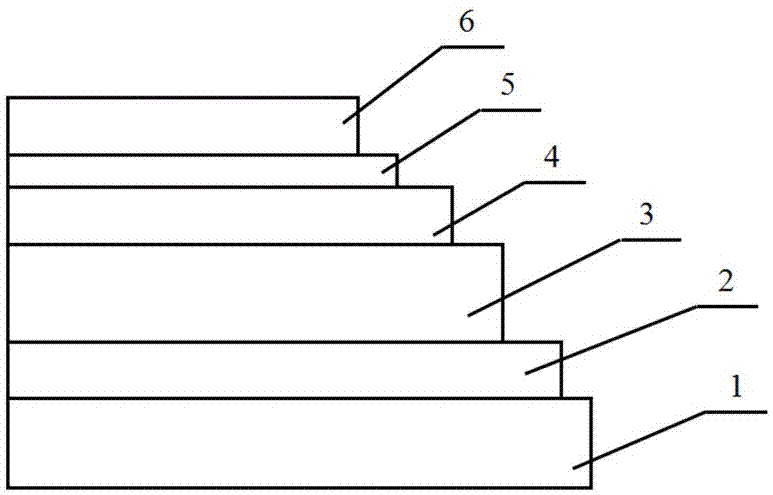

Perovskite solar cell and manufacturing method of perovskite solar cell

ActiveCN104576930AInsulationImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSilanesEvaporation

The invention discloses a perovskite solar cell. The perovskite solar cell is characterized by sequentially comprising a conductive glass layer, a compact titanium dioxide film, a porous titanium dioxide film, a methylamine lead iodine polycrystalline film, a hole-transport material layer and an evaporation silver electrode layer. Interface modification is carried out on the methylamine lead iodine polycrystalline film through long-chain alkyl silane coupling agents, and the number of carbon atoms of the long-chain alkyl silane coupling agents is larger than six and smaller than sixteen. The invention further discloses a manufacturing method of the perovskite solar cell. Compared with the prior art, the perovskite solar cell and the manufacturing method have the advantages that as interface modification is carried out through the long-chain alkyl silane coupling agents, the recombination of electrons in the cell can be suppressed, and the stability of the cell in the wet environment can be improved.

Owner:NINGBO UNIV

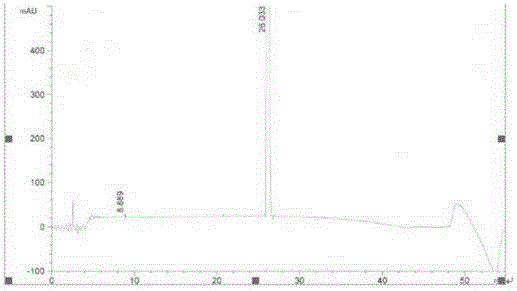

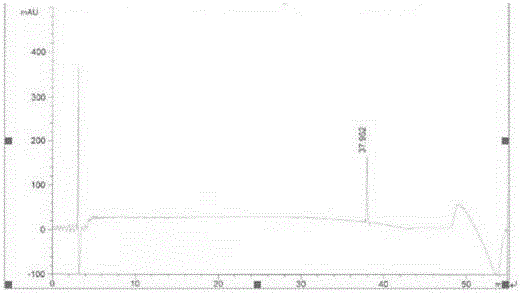

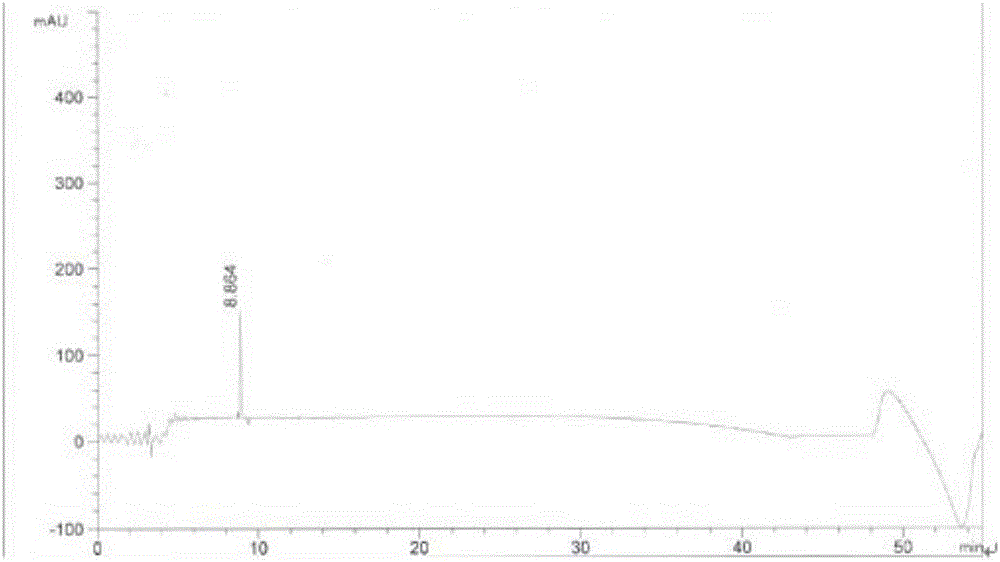

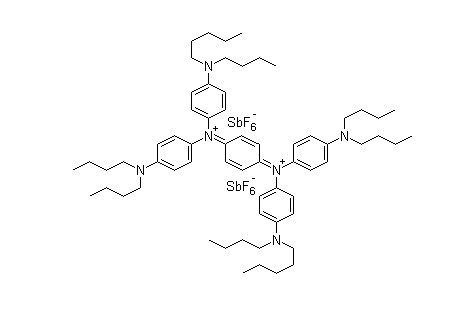

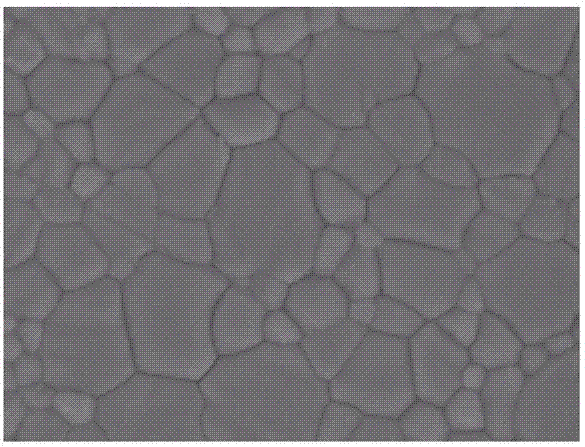

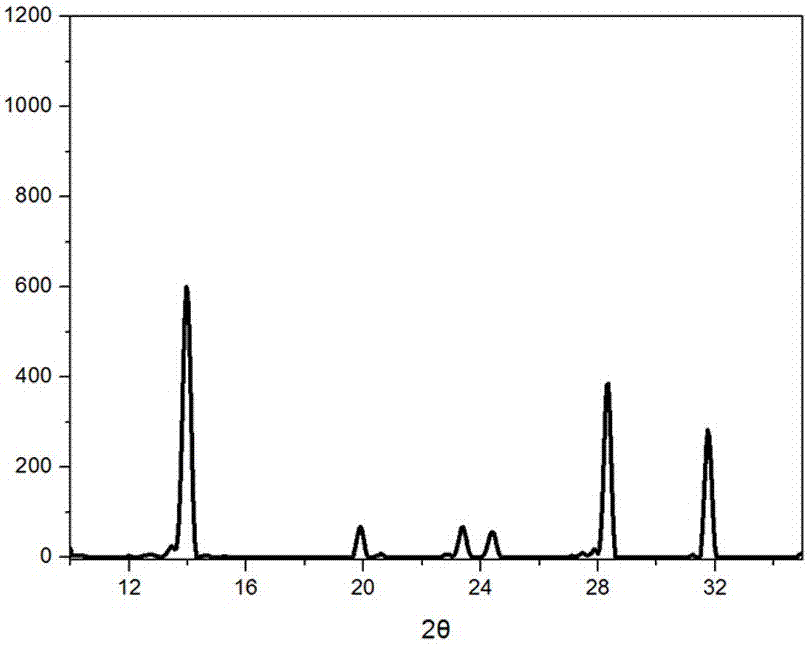

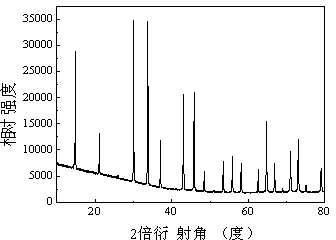

Crystal forms of (S)-(8(2,6-dichlorophenyl)-6-fluoro-2,3-dihydro benzo[b][1,4]dioxin-2-yl)methanamine hydrochloride salt

The present invention is directed to crystal forms of the 5-HT2C agonist (S)-(8-(2,6-dichlorophenyl)-6-fluoro-2,3-dihydrobenzo[b][1,4]dioxin-2-yl)methanamine hydrochloride, as well as compositions, processes of preparation, and uses thereof.

Owner:WYETH LLC

Mixed insecticide composition containing fipronil

The re-compounded pesticide composition includes fipronil in the weight ratio to other component of 0.02-50, and at least one of the following pesticides: lambda-cyhalothrin, fenpropathrin, cycloprothrin, esfenvalerate, etofenprox, etc. It may have functional assistant, diluent or carrier added to compound into oil emulsion, soluble liquid, super low capacity sprayed agent, water emulsion, microemulsion or other preparation forms. It has wide pesticidal spectrum, high activity, low cost, less resistance and other features, and may be applied in preventing and controlling pests of rice, vegetable, cotton, corn, fruit tree, tobacco and other crops.

Owner:安徽华信国际控股股份有限公司

Preparation method of pimavanserin

The invention discloses a preparation method of pimavanserin. The method comprises the following two steps: firstly, 4-isobutoxy benzene methylamine and carbonyl diimidazole are subjected to acylation reaction to obtain N-(4-isobutoxy phenyl)-1H-imidazole-1-formamide, and the N-(4-isobutoxy phenyl)-1H-imidazole-1-formamide and N-(4-fluorophenyl)-1-methylpiperidine-4-amine are subjected to urea reaction, so as to obtain the pimavanserin. The prepared pimavanserin is good in quality and high in yield, the reagent toxicity is relatively low, the operation is simple and easy to control, and the pimavanserin is suitable for industrial production.

Owner:NKD PHARMA CO LTD

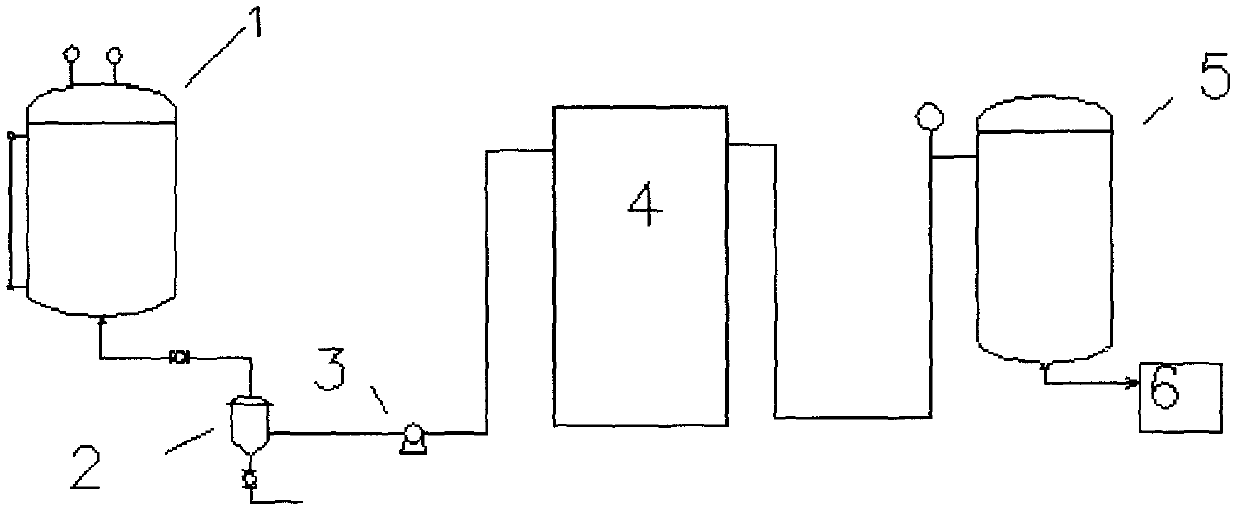

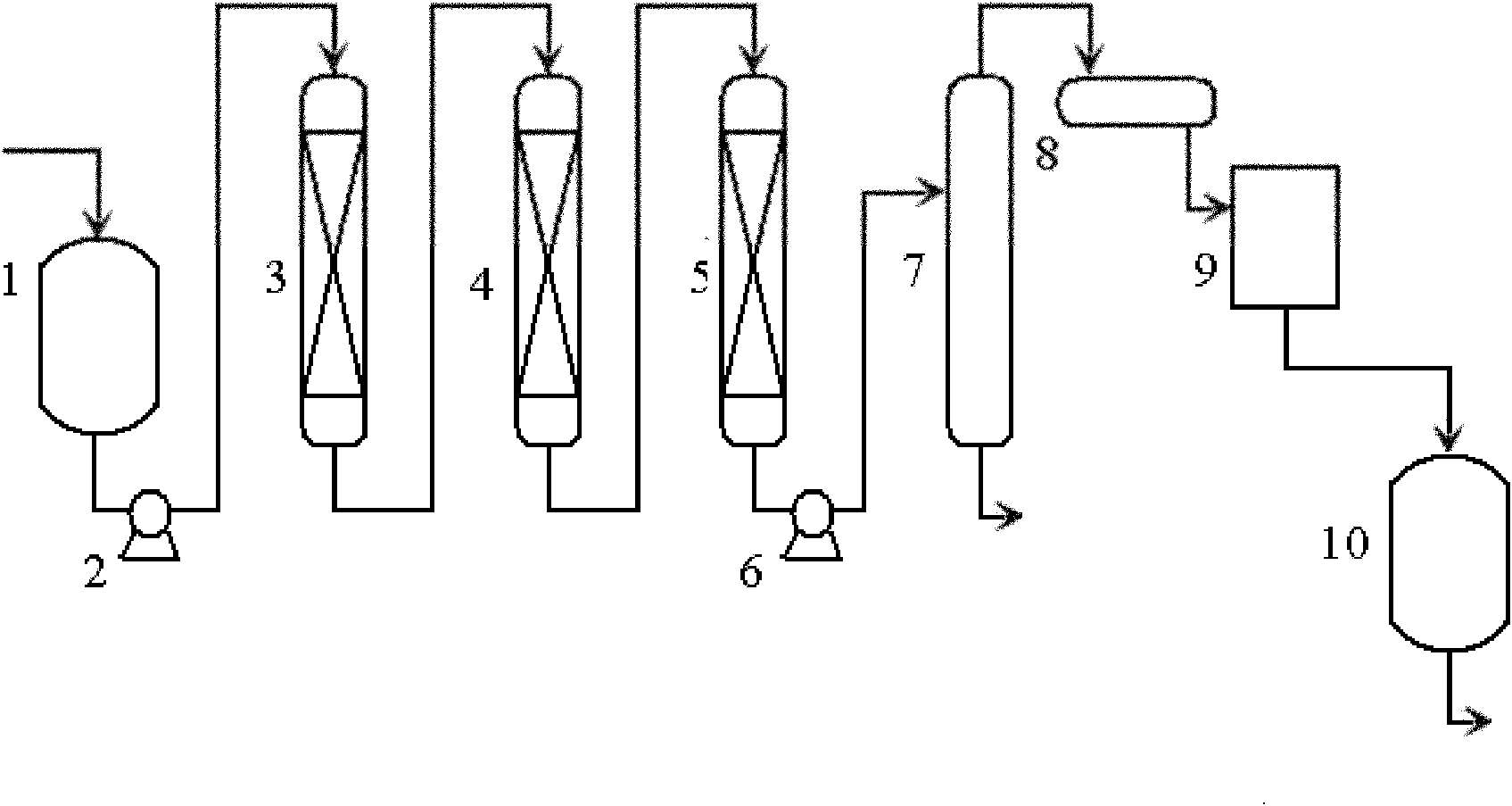

Device and method for continuously producing sodium methyl taurate in pipeline mode

InactiveCN102675160ALess energy consumptionStable concentrationSulfonic acids salts preparationHeat conductingDistillation

The invention relates to a device and a method for producing sodium methyl taurate, in particular to a device and a method for continuously producing sodium methyl taurate in a pipeline mode. The method comprises the following steps of: adding sodium hydroxyethyl sulfonate, water, methylamine and catalyst into a storage tank, pumping the materials into a continuous pipeline reactor through a boosting pipeline pump under the high pressure of 10 to 25MPa, heating to the temperature of between 150 and 300 DEG C through heat conducting oil, and reacting for 10 to 60 minutes in the pipeline reactor; and feeding the materials into an evaporator after reaction, performing multistage distillation, decolorizing, moisturizing, refining, and thus obtaining the qualified sodium methyl taurate. The device is simple and high in process safety, the reaction conditions are easy to control, continuous production is realized, the yield reaches over 90 percent, the sodium methyl taurate is stable in quality, and large-scale production can be realized with low investment in the industry.

Owner:HUANGGANG YONG AN PHARMA

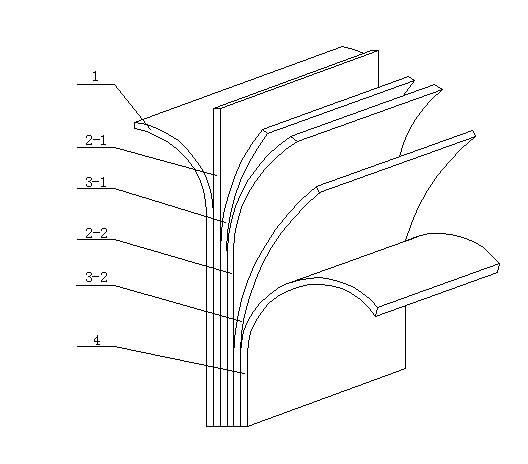

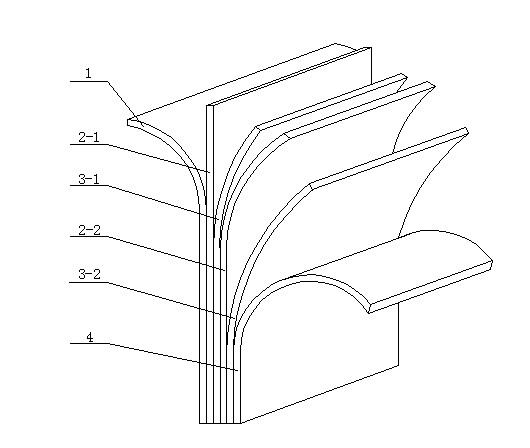

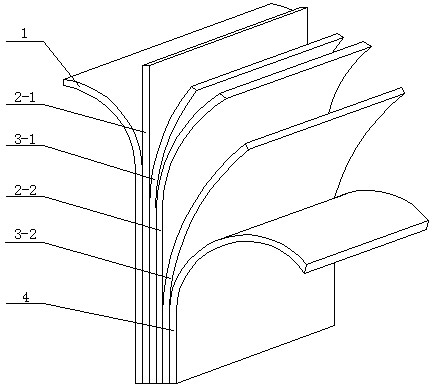

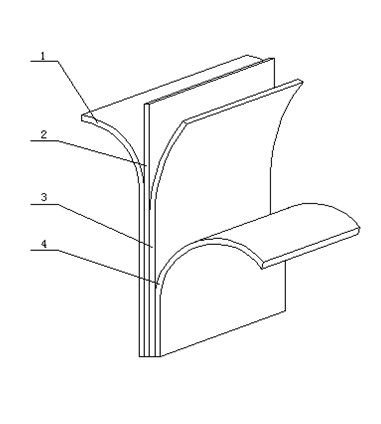

Anti-fogging agent composition and anti-fogging insulation window film formed thereby

InactiveCN102604460AGood anti-fog durabilityEasy to prepareFilm/foil adhesivesSynthetic resin layered productsPolyesterMonomethyl ether

The invention relates to an anti-fogging agent composition and an anti-fogging insulation window film formed thereby, wherein the anti-fogging agent composition comprises 9 to 14 wt% of hydrophilic resin, 55 to 76 wt% of propylene glycol monomethyl ether, 3 to 10 wt% of dimethyl methylamine, 1 to 5 wt% of triethylene diamine, 1 to 5 wt% of leveling agent, 5 to 26wt% of isopropanol and 5 to 24wt% of ethanol; the anti-fogging insulation window film comprises a first transparent polyester film or transparent polyethylene film substrate (2-1), a heat insulation acrylic adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic adhesive layer (3-2) and a release film (4), which are composited as a whole, wherein the anti-fogging coating (1) is formed by the anti-fogging agent composition; and the heat insulation acrylic adhesive layer (3-1) contains a specific insulation material. According to the invention, the anti-fogging insulation window film is anti-fogging, insulating and safe.

Owner:西安航天三沃化学有限公司

High concentration topical insecticide containing insect growth regulator

ActiveUS6984662B2Easy to useAvoids many common deleterious side effectsBiocideDead animal preservationHigh concentrationSide effect

A topical insecticide is provided which can be safe to use and avoids many common deleterious side effects of conventional topical insecticides. The insecticide contains an insecticide and an insect growth regulator effective for killing fleas, flea larvae and flea eggs. The insecticide is formulated by dissolving an insecticidal (tetrahydro-3-furanyl) methylamine derivative and an insect growth regulator (IGR) in a solvent containing a quaternary ammonium salt to increase the solvency of the IGR component, thereby providing an insecticide having high insecticidal activity.

Owner:CEVA ANIMAL HEALTH

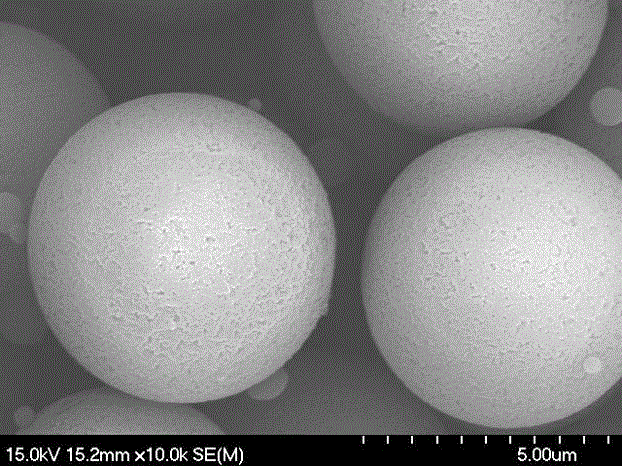

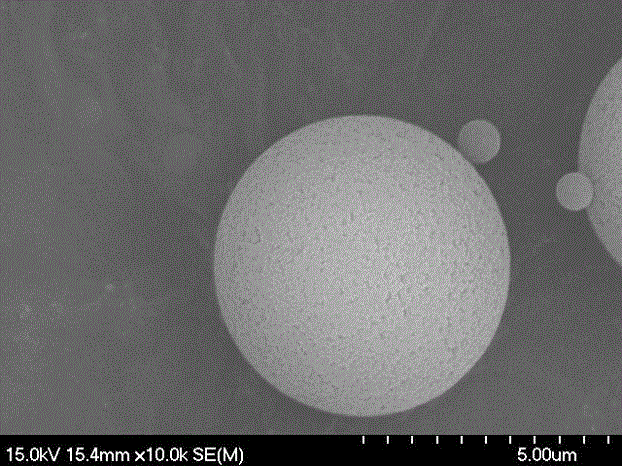

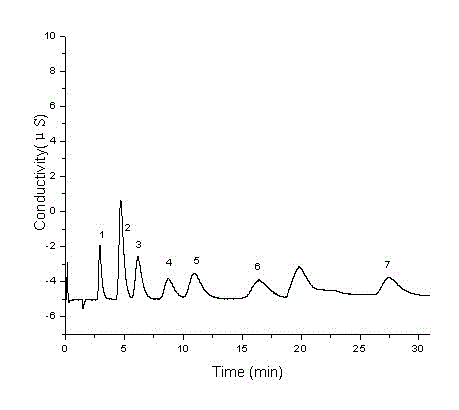

Preparation method of surface-grafting anion chromatography stationary phase

InactiveCN102941074ALow costNarrow particle size distributionOther chemical processesGlycidyl methacrylateMicrosphere

The invention relates to an anion chromatographic column a preparation method thereof, particularly relates to a preparation method of a surface-grafting anion chromatography stationary phase. The method disclosed herein is characterized by: preparing monodispersed linear polystyrene microspheres seeds by dispersion polymerization, activating the seeds, then synthesizing polystyrene-divinyl benzene-glycidyl methacrylate microballoons by one-step seed swelling method, and extracting to remove the pore forming agent; adopting multi-step grafting synthetic method, taking methylamine and 1,4-butanediol diglycidyl ether as raw materials, and introducing a large amount of positively charged quaternary ammonium groups as the anion exchange functional group to the surface of the prepared polystyrene-divinyl benzene-glycidyl methacrylate microballoons; and packing by homogenate method. According to the invention, the method disclosed herein has the advantages of low cost and simple process, the prepared filling material has uniform granularity and has no need to be screened, and the particle size distribution is narrow.

Owner:ZHEJIANG UNIV

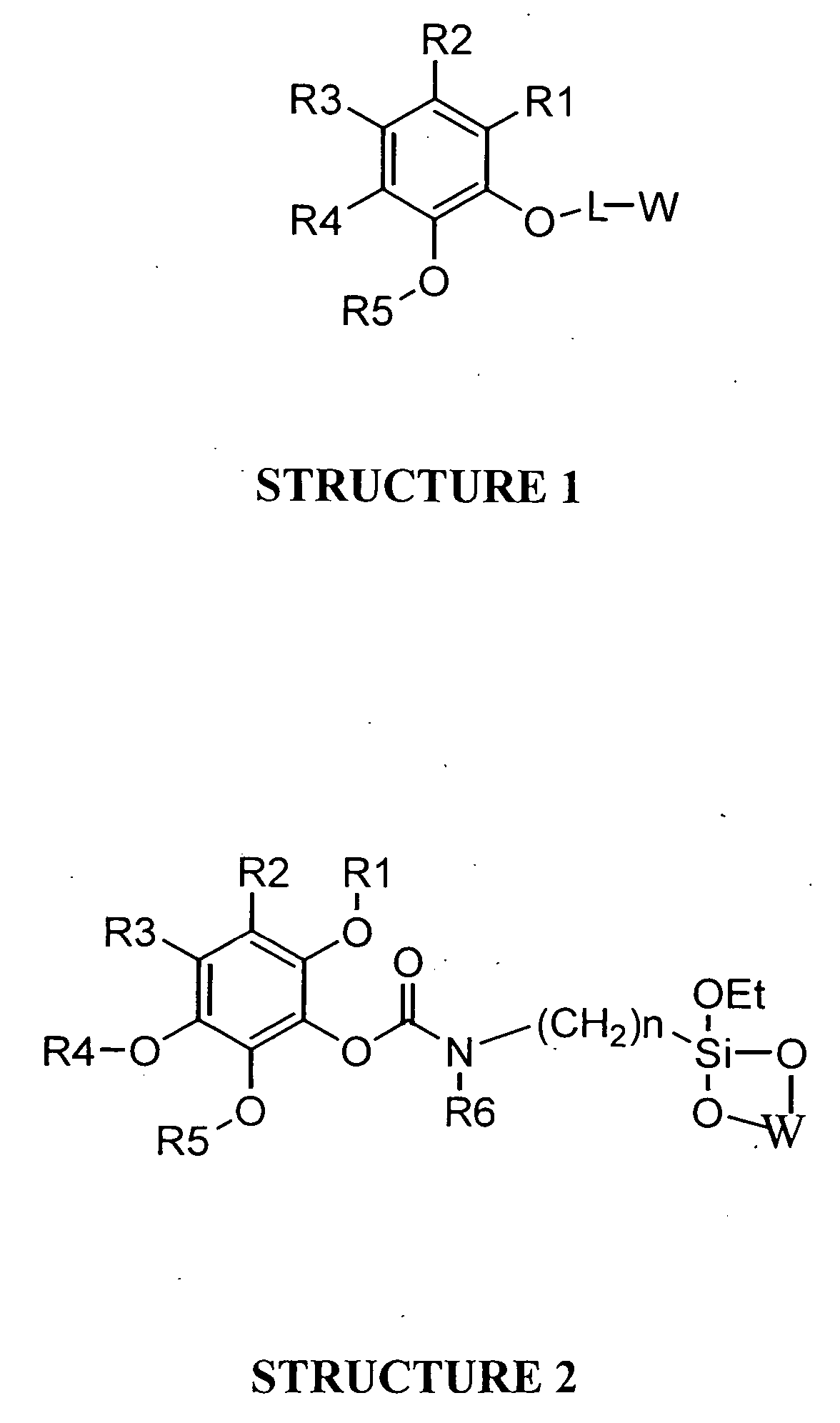

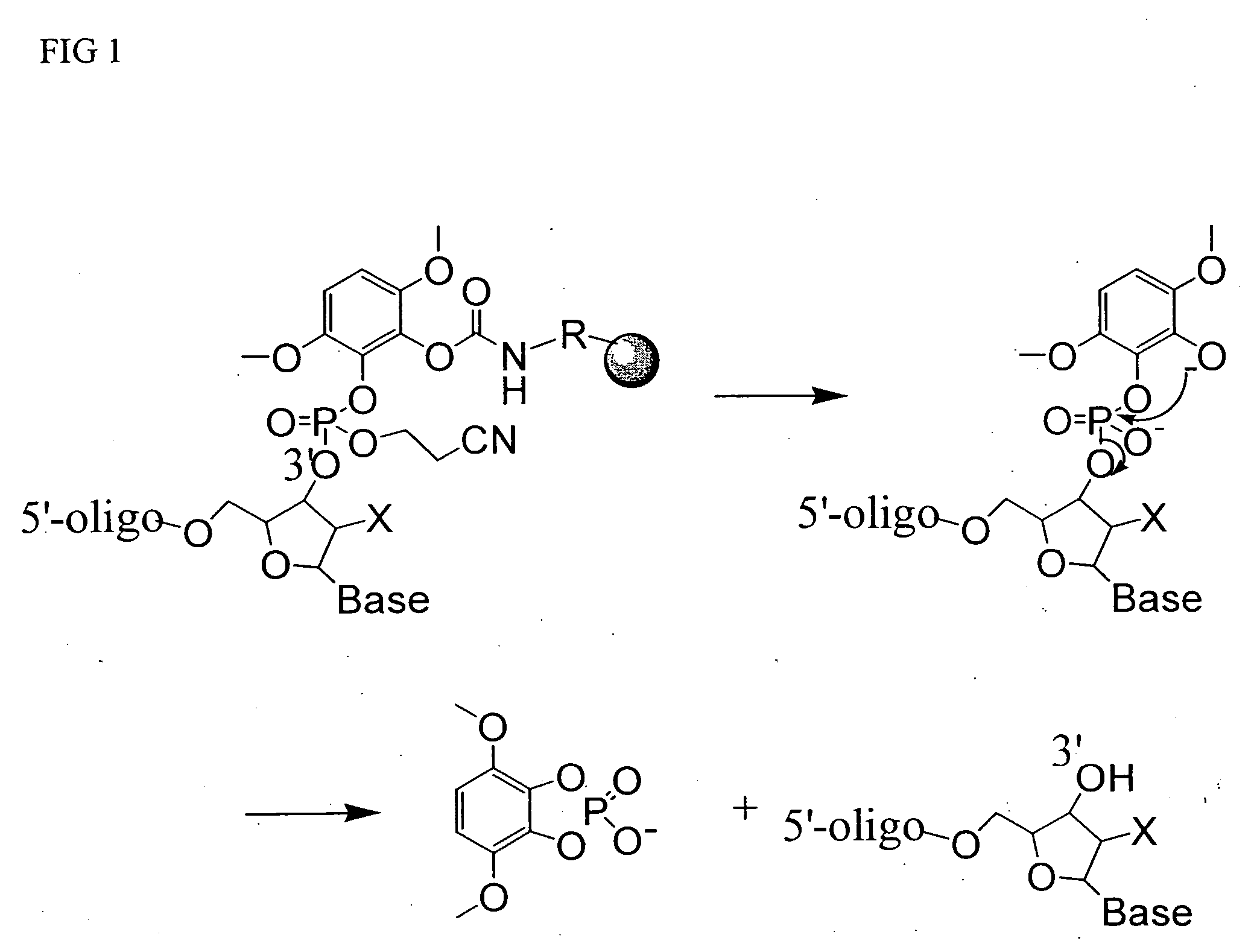

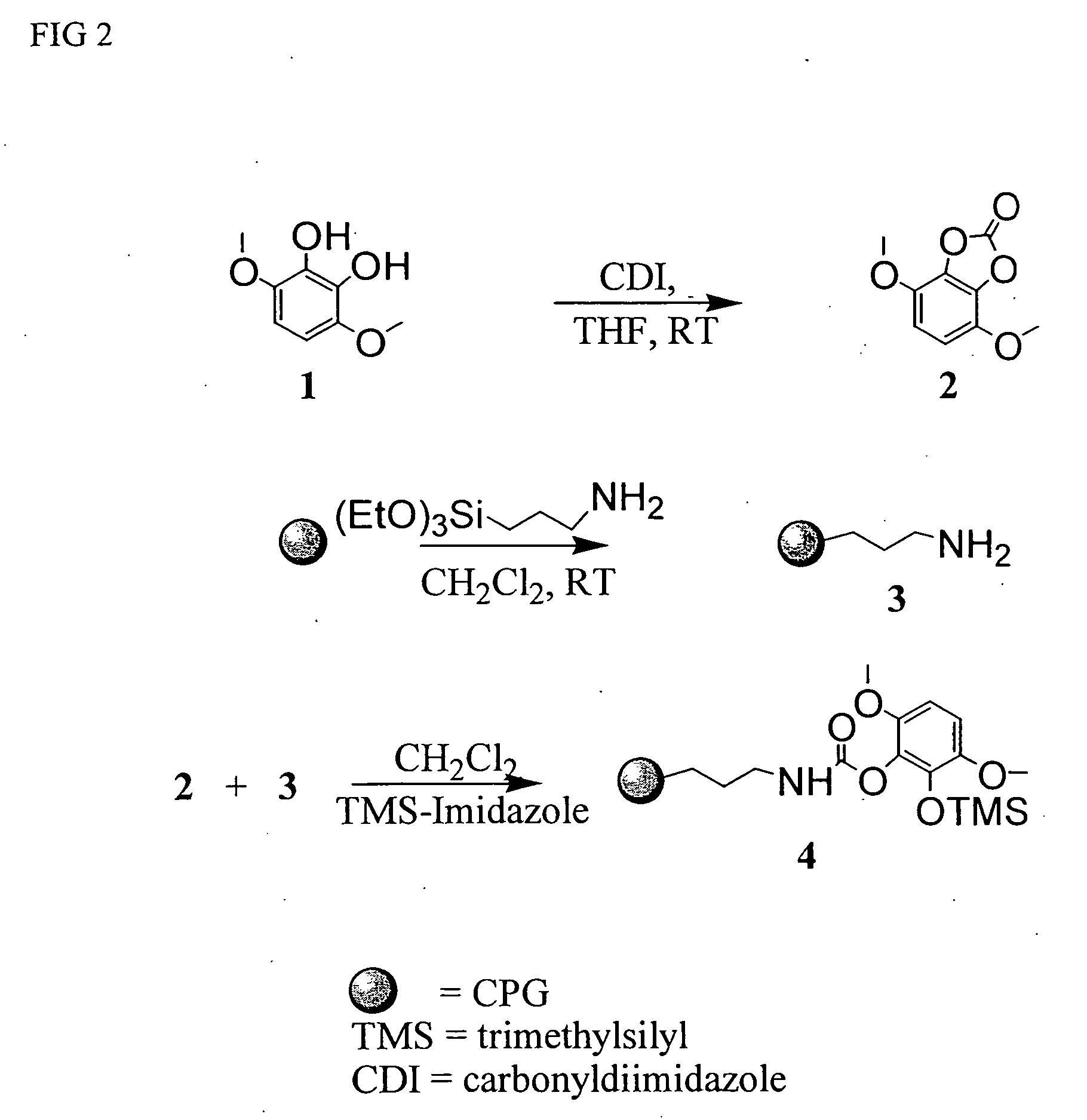

Universal support for nucleic acid synthesis

Polysubstituted catechol-based universal solid supports suitable for synthesizing oligonucleotides have been prepared. Following synthesis, cleavage of the oligonucleotide from the solid support and catechol-assisted elimination of the 3′-phosphate group is accomplished by treatment with standard basic media such as ammonium hydroxyde or1 methylamine.

Owner:CTGEN

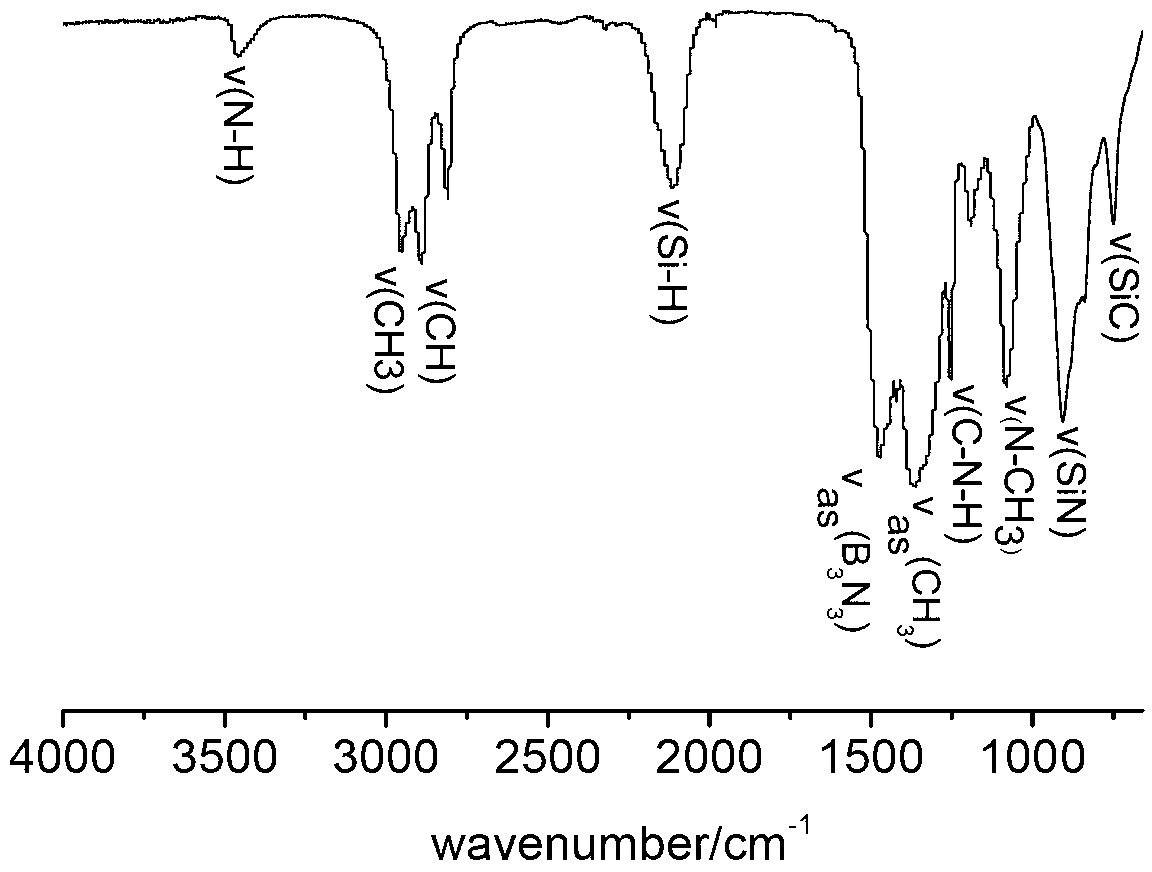

Preparation method for SiBN(C) ceramic fiber precursor

The invention relates to a preparation method for a SiBN(C) ceramic fiber precursor. The preparation method comprises the steps of synthesizing SiBN(C) ceramic fiber precursor molecules by using methyl dichlorosilane (MeHSiCl2), hexamethyl disilazane (HMDZ), boron trichloride (BCl3) and methylamine (CH3NH2) at a temperature ranging from-40 DEG C to-80 DEG C; removing toluene from an anhydrous toluene solution of the SiBN(C) ceramic fiber precursor molecules; heating to a temperature of 130-300 DEG C to obtain a prepolymer; then adding active group-terminated polydimethylsiloxane or active group-terminated long carbon chain molecules; keeping for 10-100 h at the temperature of 130-300 DEG C; defoaming and melt-spinning. Aiming at the problems of large friability, low strength and the like of the SiBN(C) ceramic fiber precursor, the SiBN(C) ceramic fiber precursor with excellent flexibility is prepared by employing a copolymerization method, thereby providing a foundation for continuous and integrated preparation of SiBN(C) ceramic fibers.

Owner:DONGHUA UNIV

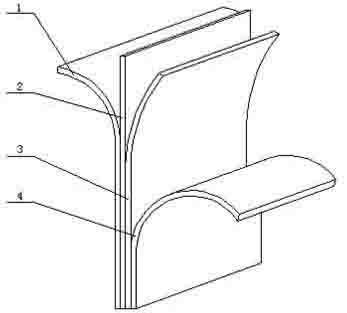

Antifogging agent composition and antifogging colored window film formed by same

ActiveCN102618102AEasy to prepareReduce manufacturing costOther chemical processesSynthetic resin layered productsPolyesterDiamine

The invention relates to an antifogging agent composition and an antifogging colored window film formed by the same. The antifogging agent composition comprises 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylene-diamine, 1-5wt% of leveling agent, 5-26wt% of isopropanol and 5-24wt% of ethanol. The antifogging colored window film comprises an antifogging agent coating layer (1), a first transparent polyester film or transparent polyethylene film substrate (2-1), a dyed acrylic acid adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic acid adhesive layer (3-2) and a releasing film (4) which are integrally composited, wherein the antifogging agent coating layer (1) is formed by the antifogging agent composition. The antifogging colored window film is antifogging, attractive, transparent and safe.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

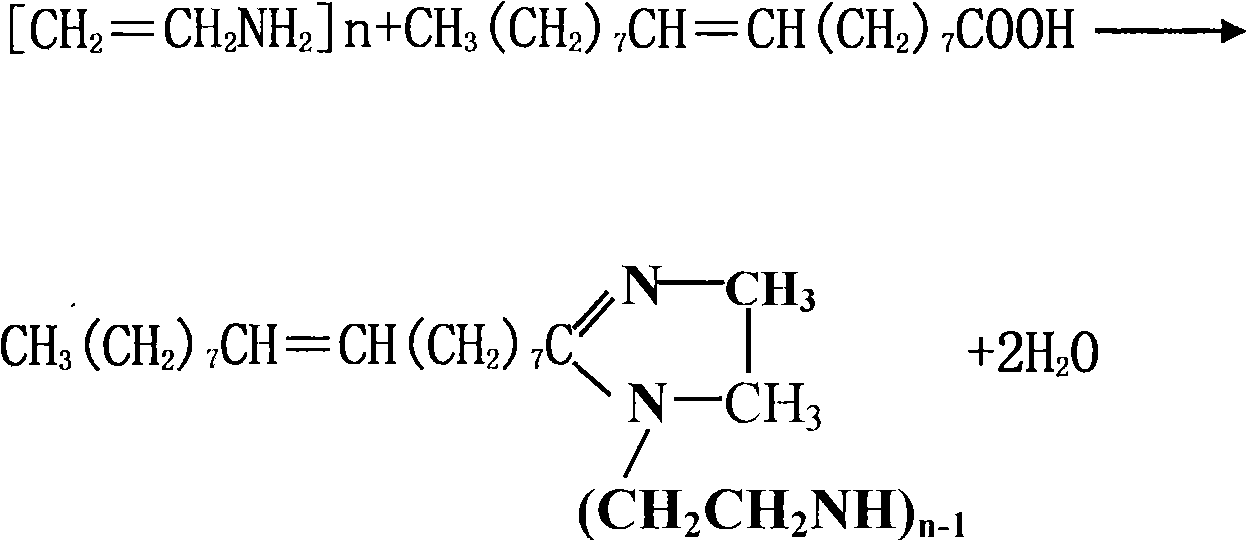

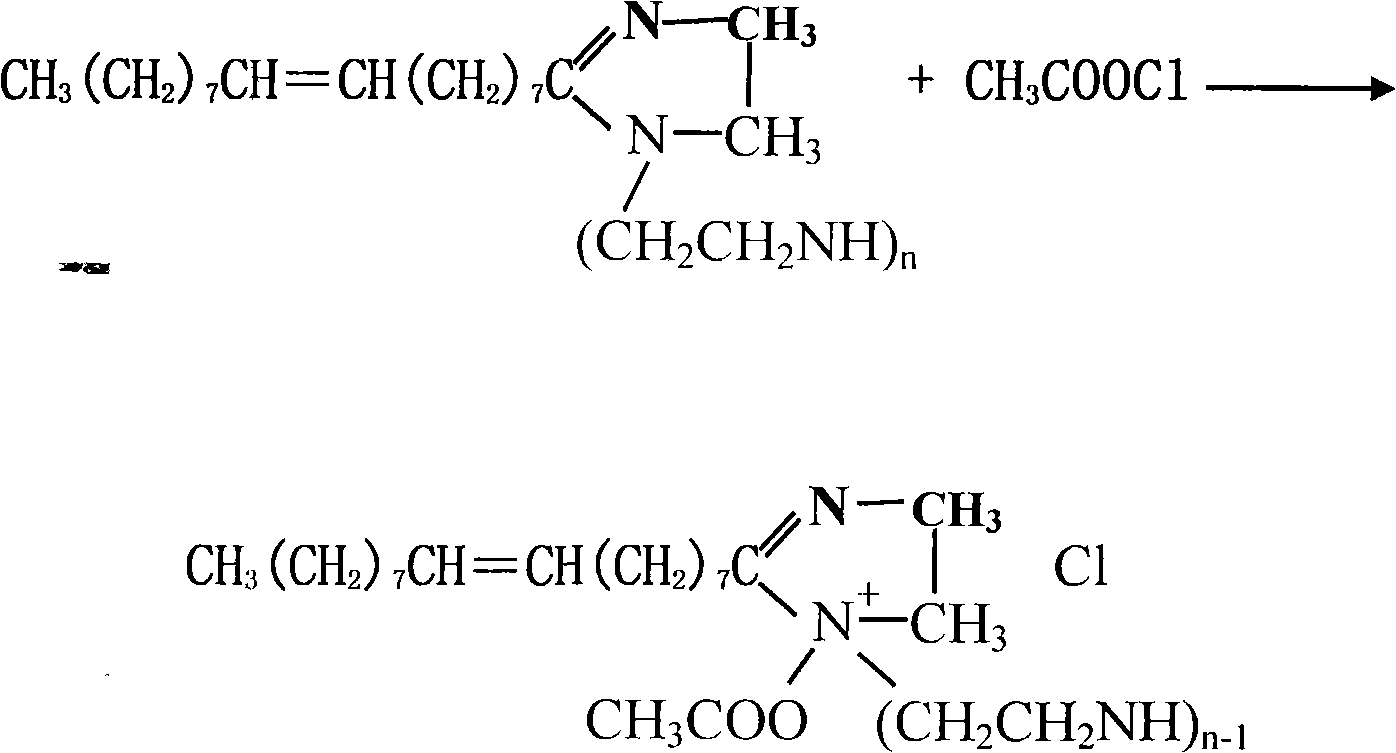

Corrosion inhibitor suitable for complex wastewater of oilfield and preparation method thereof

The invention relates to a corrosion inhibitor suitable for complex wastewater of oilfield and a preparation method thereof. The corrosion inhibitor is prepared by compounding imidazoline chloracetatecorrosion inhibitor and oxygen acetylene methyl amine quaternary ammonium salt corrosion inhibitor. The preparation method comprises the following steps: 1, synthesis of imidazoline chloracetate corrosion inhibitor, wherein a finished product of the imidazoline chloracetate corrosion inhibitor is generated after the synthesis of imidazoline matrix and quaternary amination of imidazoline; 2, synthesis of oxygen acetylene methyl amine quaternary ammonium salt corrosion inhibitor, wherein a finished product of the oxygen acetylene methyl amine quaternary ammonium salt corrosion inhibitor is generated after the synthesis of oxygen acetylene methyl alkyl amine salt and quaternary amination of dodecyl dimethyl amine; and 3, compounding of imidazoline chloracetate corrosion inhibitor and oxygenacetylene methyl amine quaternary ammonium salt corrosion inhibitor in a mass ratio of 0.5 to 2 so as to form the corrosion inhibitor.

Owner:天津中油科远石油工程有限责任公司

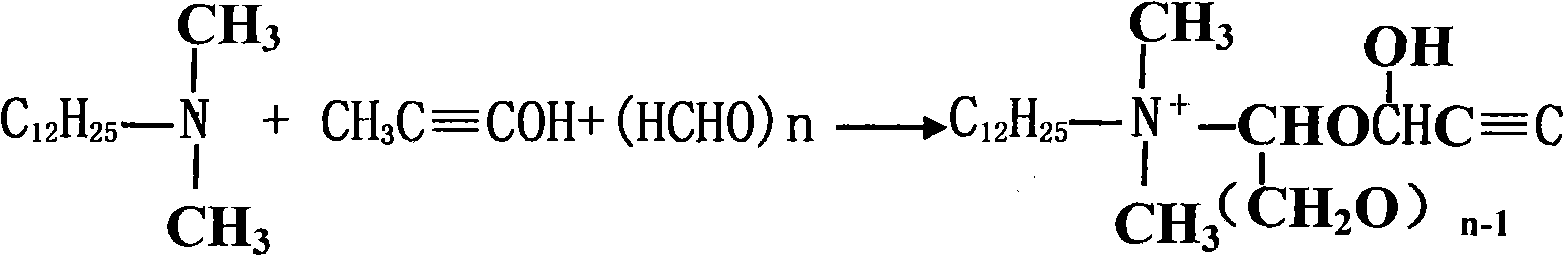

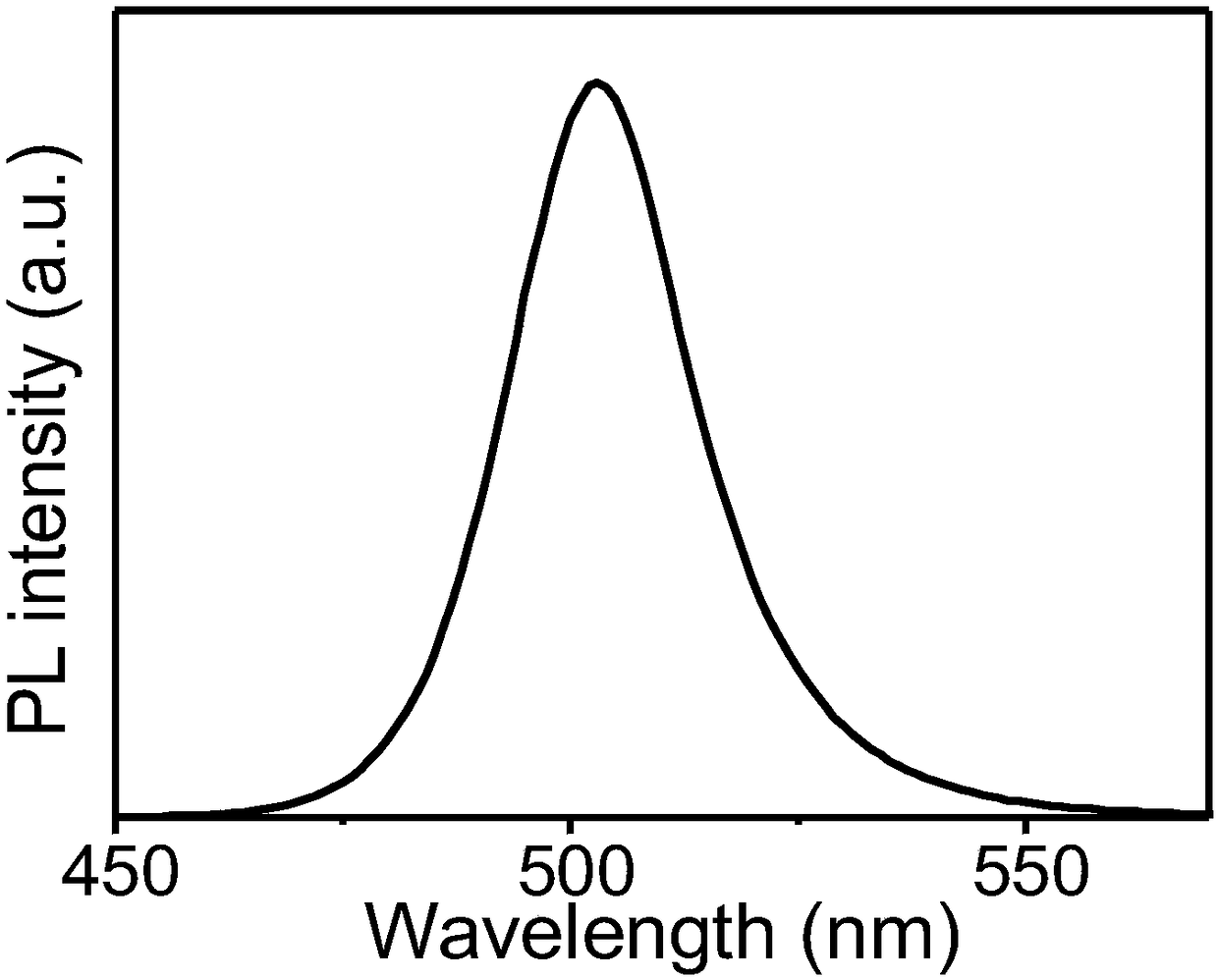

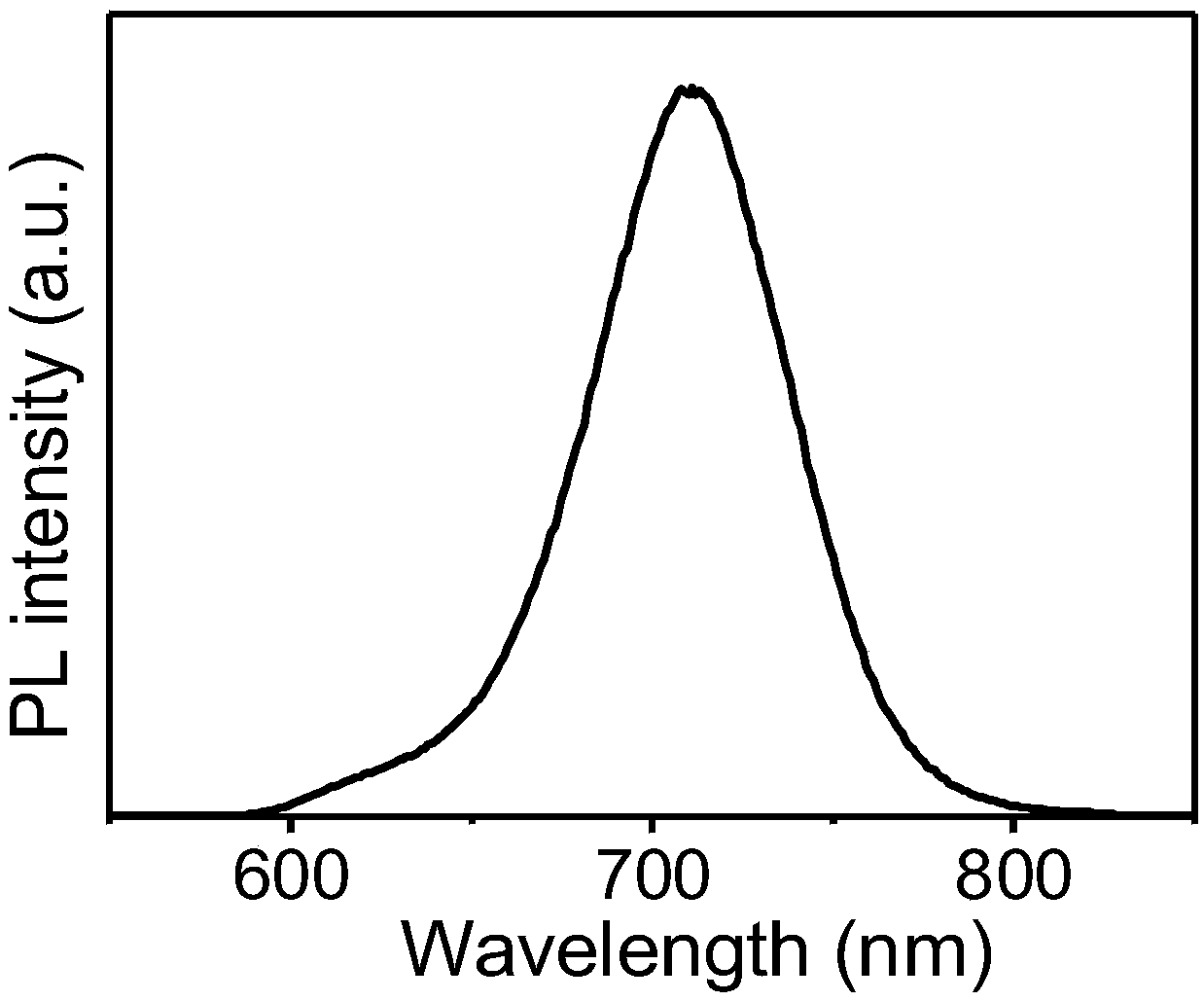

Method for preparing perovskite quantum dot at room temperature

InactiveCN108219786ASimple particle sizeUniform particle sizeLead halidesNanoopticsFluorescenceShielding gas

The invention discloses a method for preparing a perovskite quantum dot at a room temperature. The luminescent quantum dot is MPbX3; in the formula, M is methyl amine (MA) or Cs, and X is any one of Cl, Br and I. According to the method disclosed by the invention, MX and PbX2 are dissolved in an organic solvent, and a certain amount of surfactant is added to form a precursor solution; an appropriate amount of the precursor solution is added into a poor solvent to form the perovskite quantum dot. By changing the quantity of the surfactant, the luminescence wavelength of the quantum dot can be adjusted, so that luminescence of fully-visible wave bands is realized. The method disclosed by the invention can be carried out at the normal temperature, protective gas is not needed, equipment is simple, and scale production is realized. According to the perovskite quantum dot prepared by the method, the fluorescent full width at half maximum is 20 to 43nm; the fluorescent quantum efficiency isnearly 90 percent, and the perovskite quantum dot can be applied to the fields of solar batteries, laser, photo-detectors, light-emitting diodes and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Novel dehydrogenase and a gene encodign the same

InactiveUS20060205045A1High yieldProduced industrially and inexpensivelyFungiSugar derivativesPhenylpyruvic acidSubstrate specificity

Owner:MITSUBISHI CHEM CORP

Pipeline cleaning agent

InactiveCN103740489AEfficient removalKeep clean for a long timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBetaineActive agent

The invention relates to a pipeline cleaning agent which comprises the following components by weight: 15-28 parts of organic acid, 20-35 parts of an asurface active agent, 18-30 parts of a penetrating agent and 0.5-3 parts of an acorrosion inhibitor, wherein the surface active agent comprises one or more ofpolyether, butyl cellosolve, coconut oil fatty acid diethanol amide and fatty alcohol-polyoxyethylene ether sulfate sodium; the penetrating agent comprises one or more of alcohol, sodium dodecyl sulfate, sodium dioctyl sulfosuccinate,dodecyl dimethyl betaine, sodium oleoyl methylamine ethanesulfonate and calcium chloride; the corrosion inhibitor comprises one or more of imidazolinequaternary ammonium salts or imidazoline amides. The pipeline cleaning agent can effectively remove grease and dirt in a pipeline to keep the pipeline unblocked, is safe and non-toxic, cannot corrode equipment, is harmless tohuman skin and conforms to emission standards.

Owner:BEIJING DAISI SCI & TECH

Manufacturing method of methylamine lead iodine perovskite solar cell

ActiveCN107359246AImprove securityWon't breakSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellAnti solvent

The invention relates to the field of solar cells, and provides a manufacturing method of a methylamine lead iodine perovskite solar cell. A photosensitive layer is a methylamine lead iodine perovskite film. The methylamine lead iodine perovskite film is manufactured by the spin coating technology and the anti-solvent dropping and cleaning technology with combination of the solvent annealing technology. The spin coating technology refers to the process that a methylamine lead iodine perovskite CH3NH3PbI3 precursor solution is spin-coated on a PEDOT:PSS film. The anti-solvent cleaning technology refers to the process that the anti-solvent amyl alcohol is dropped in the process of spin-coating the CH3NH3PbI3 methylamine lead iodine perovskite precursor solution so that the perovskite is enabled to be quickly crystalized and precipitated, wherein the anti-solvent amyl alcohol is sec-amyl alcohol or tertiary amyl alcohol. The adopted preparation technology is simple so that the methylamine lead iodine perovskite solar cell of high efficiency and great repeatability without the hysteresis phenomenon can be prepared.

Owner:TAIYUAN UNIV OF TECH

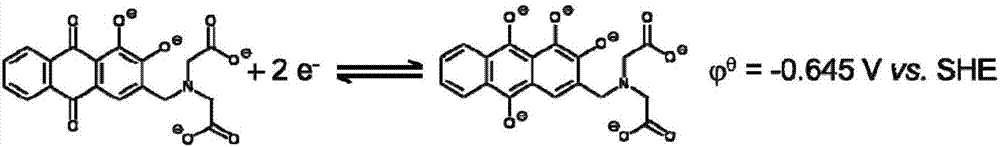

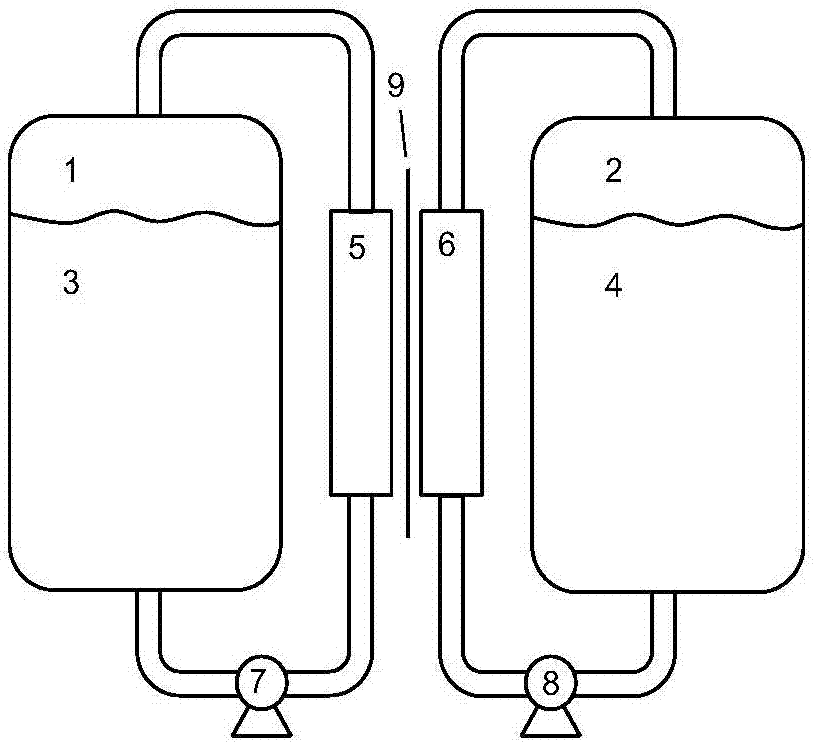

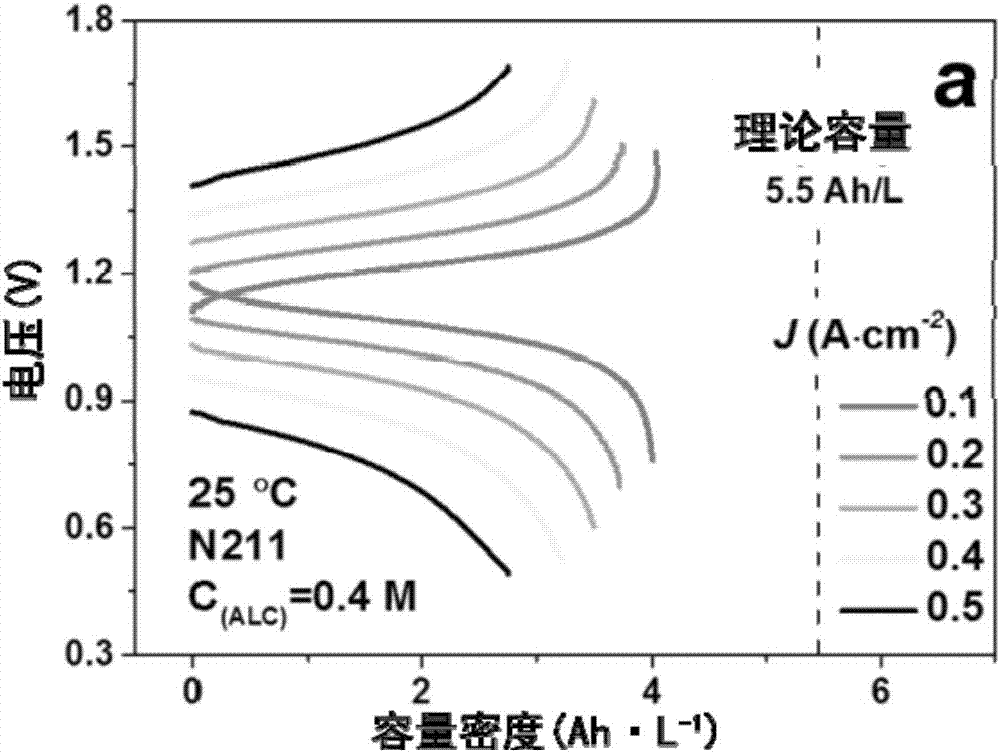

Alizarin flow battery negative electrode electrolyte, and alizarin flow battery adopting electrolyte

InactiveCN107171012ASolve the problem of electrolyte penetrationImprove cycle lifeRegenerative fuel cellsAlkaline electrolytesRare-earth elementPotassium hydroxide

The invention provides an flow battery negative electrode electrolyte based on alizarin or derivatives thereof, and a flow battery adopting the electrolyte as a negative electrode. The electrolyte is an alkaline aqueous solution containing the alizarin or the derivatives thereof. The alizarin and the derivatives contain at least one of alizarin (1,2-dihydroxyanthraquinone), alizarin red (1,2-dihydroxyanthraquinone-3-sulfonic acid) or alizarin fluorin blue (3-alizarin methylamine-N,N-diacetic acid and mixtures thereof. An alkali used in the invention comprises at least one of sodium hydroxide, potassium hydroxide and a sodium hydroxide and potassium hydroxide mixture. The working temperature of the electrolyte is 10-50 DEG C; and the flow battery based on the electrolyte is a traditional structure, and comprises a positive electrode liquid storage tank 1, a positive electrode electrolyte 3, a negative electrode liquid storage tank, the negative electrode electrolyte 4, pumps 7 and 8, and a cation exchange membrane 9 for conducting cations. The active substance of the alizarin flow battery negative electrode electrolyte is bulk anions, and difficultly penetrates through a proton exchange membrane; and the electrolyte disclosed in the invention has the characteristics of no toxicity, no pollution, no rare earth elements, and obvious price advantage.

Owner:BEIHANG UNIV

Crystalline silicoaluminophosphate salt molecular sieve having octaoxygen-membered ring pore, process for producing the same and process for producing methylamine with the molecular sieve as catalyst

InactiveUS20050249661A1High activity selectivityStable in dimethylamine selectivityAluminium compoundsPhosphatesPresent methodOxygen

Problems on catalyst production and catalyst performance with respect to conventional 8-oxygen-membered ring micropore-containing crystalline silicoaluminophosphate molecular sieves as non-equilibrium methylamine synthesis catalysts, are resolved. A chabazite type crystalline silicoaluminophosphate molecular sieve having high purity and high crystallinity and having, on a crystal grain surface, an amorphous oxide layer whose Si / Al atomic ratio is greater than that of the whole crystal grain can be stably produced with high yield with the use of a small amount of structure directing agents by the present method characterized in that hydrothermal treatment conducted in the production of 8-oxygen-membered ring micropore-containing crystalline silicoaluminophosphate sieves is controlled under specified treating conditions. The thickness and composition of the amorphous oxide layer, which exert marked influence on the yield of dimethylamine synthesis, can be easily controlled and reproduced under the conditions of catalyst synthesis according to the invention. Thus, the catalyst of high performance can be stably supplied by the present invention at a low cost with reduced output of waste.

Owner:MITSUBISHI GAS CHEM CO INC

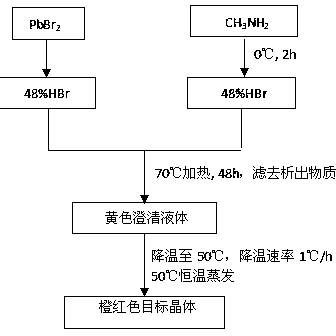

Preparing method for methylamine bromide lead crystals of large-size perovskite structure

ActiveCN104141166AThe synthesis process is simpleLess side effectsPolycrystalline material growthFrom normal temperature solutionsWater bathsSolvent

The invention discloses a preparing method for methylamine bromide lead crystals of a large-size perovskite structure. According to the preparing method, PbBr2 is dissolved with a HBr solution to obtain a Pb <2+>-HBr solution; the HBr solution and a CH3NH2 solution are mixed according to the mole ratio of 1:1, and react for two hours at the temperature of 0 DEG C to obtain a CH3NH2Br solution; then the obtained Pb <2+>-HBr solution and the CH3NH2Br solution are mixed and preheated for 48 hours at the temperature of 70 DEG C to obtain a CH3NH3PbBr3 super-saturated solution which is filtered to obtain clear yellow liquid, the clear yellow liquid is preheated for 12 hours in water bath with the temperature of 70 DEG C, the temperature falls to 50 DEG C, and the clear yellow liquid is evaporated at the constant temperature to obtain the CH3NH3PbBr3 crystals. According to the preparing method, in the process, the HBr solution participates in raw material synthesis and is the solvent for growth of the crystals, and the method has the advantages that the synthetic process is simple, and the side reaction is less; the growth device is simple, and the high-quality and large-size crystals can grow.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

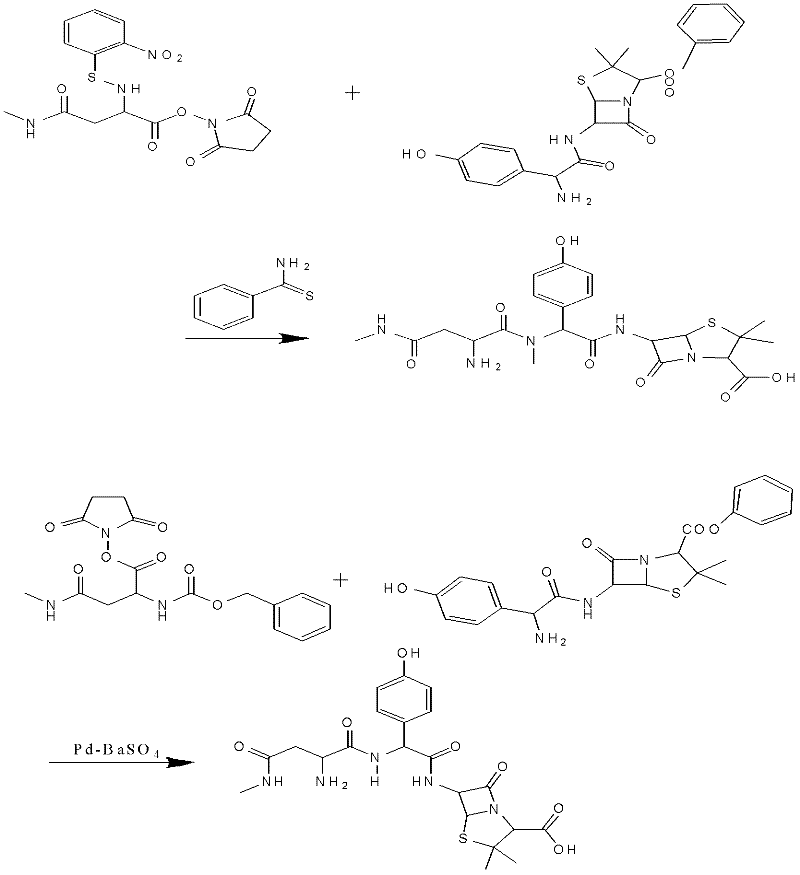

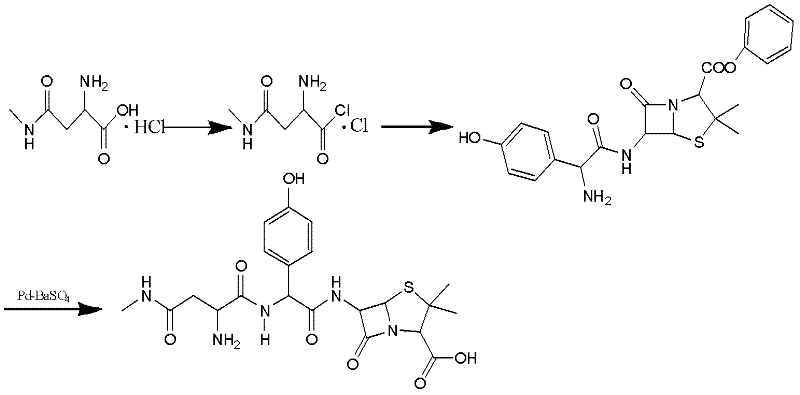

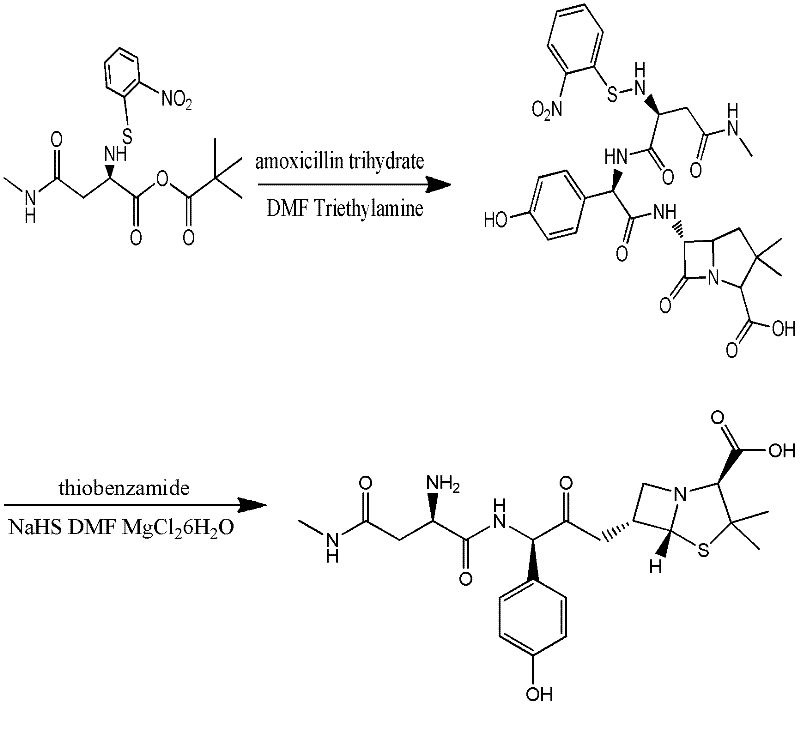

Preparation method for Aspoxicillin

The invention discloses a preparation method for Aspoxicillin. D-aspartic acid is added into a mixture liquid of sulfuryl chloride and carbinol under a low temperature of zero to prepare D-aspartic acid methyl ester hydrochloride; the obtained D-aspartic acid methyl ester hydrochloride and triethylamine are reacted in ethanol to obtain D-aspartic acid methyl ester educt; the D-aspartic acid methyl ester educt and methylamine aqueous liquid with a concentration of 40 percent are reacted in a room temperature to prepare aspartic formamide; the aspartic formamide, ethyl acetoacetate and potassium hydroxide are reacted in isopropanol to prepare diene salt (D-2-amino-3N-methylamino oxo-propionic acid diene formamide); the diene salt and pivaloyl chloride are reacted in acetone under the catalysis of pyridine to obtain active anhydride; then the active anhydride is condensed and further protected by deacidification to obtain a target product-crude product of Aspoxicillin. The preparation method for Aspoxicillin has the advantages of cheap and easily-obtained reagent, lower toxicity and lower environment pressure, stable and simple technological operation and high yield.

Owner:SOUTHWEST JIAOTONG UNIV

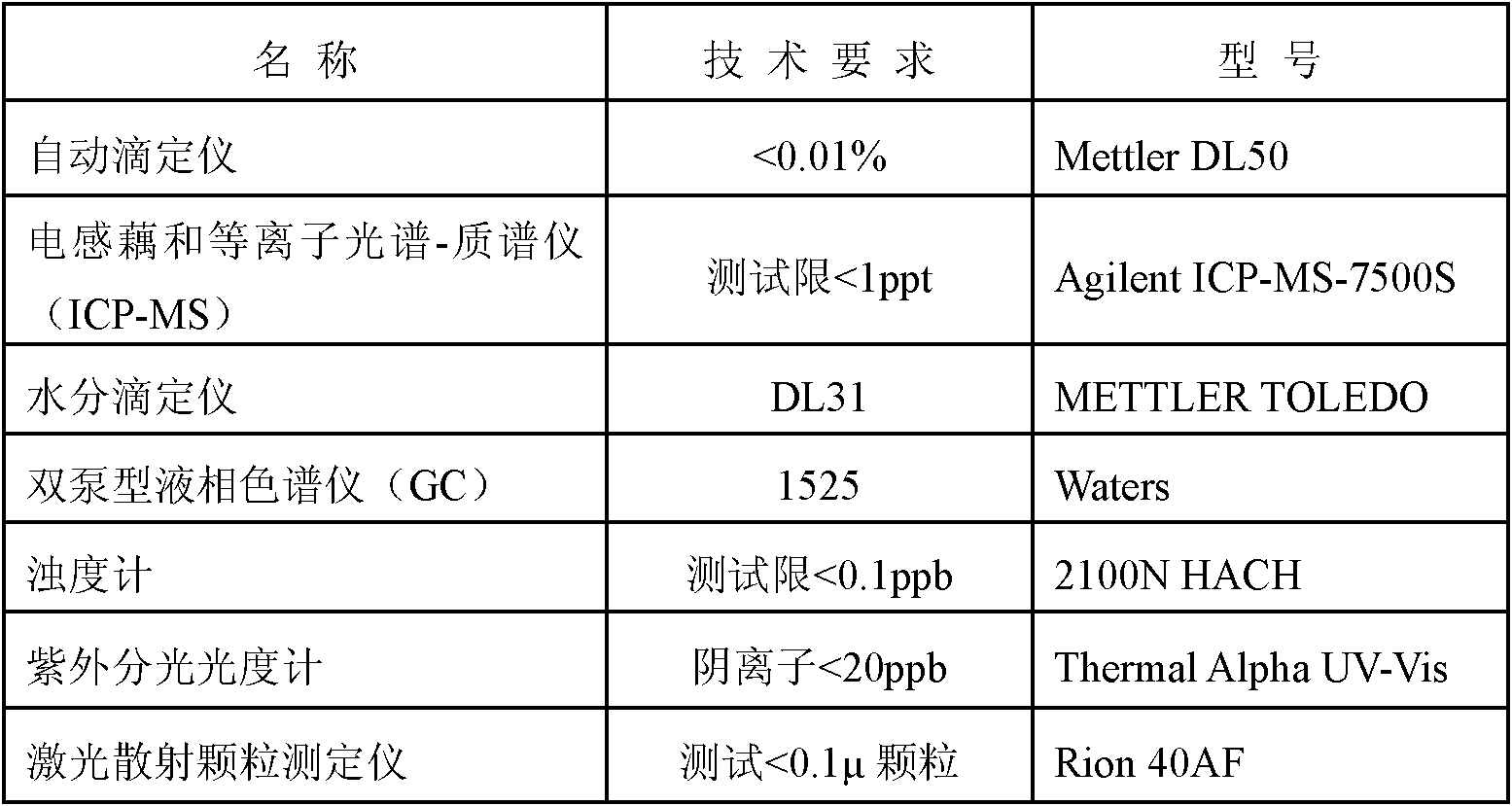

Method for improving quality of industrial N-methylpyrrolidone

The invention discloses a method for improving the quality of industrial N-methylpyrrolidone, comprising the following steps of: taking industrial N-methylpyrrolidone as a raw material, orderly removing amine, cation and anion impurities in the industrial N-methylpyrrolidone with a macroporous absorbent resin column, a strong-acid cation exchange resin column and a strong-base anion exchange resin column which are connected in series to form an ion exchange device, and then rectifying and filtering with a membrane to obtain N-methylpyrrolidone with improved quality. Analysis and detection show that the free amine content (based on methylamine) of the product is smaller than 5ppm, and both the anion impurity content and the cation impurity content meet the requirements on SEMI-C8 standards of chemical material part, established by the Semiconduct or Equipment and Materials International. The ion exchange resin used in the method can be regenerated and reclaimed, has the advantage of low carbon and is environment-friendly. The operation process is simple, and product quality is stable. The method is suitable for industrial production.

Owner:SHANGHAI CHEM REAGENT RES INST

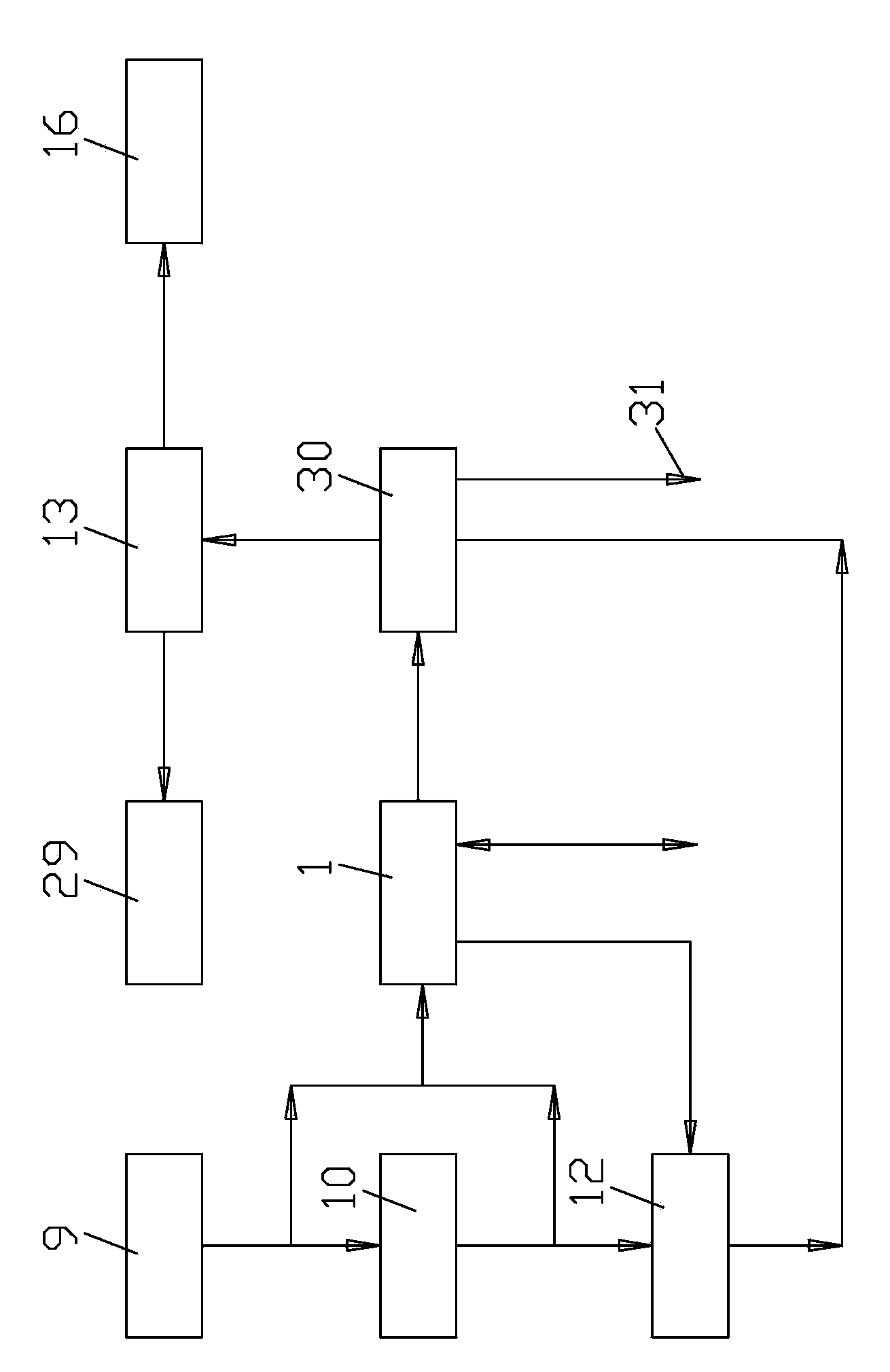

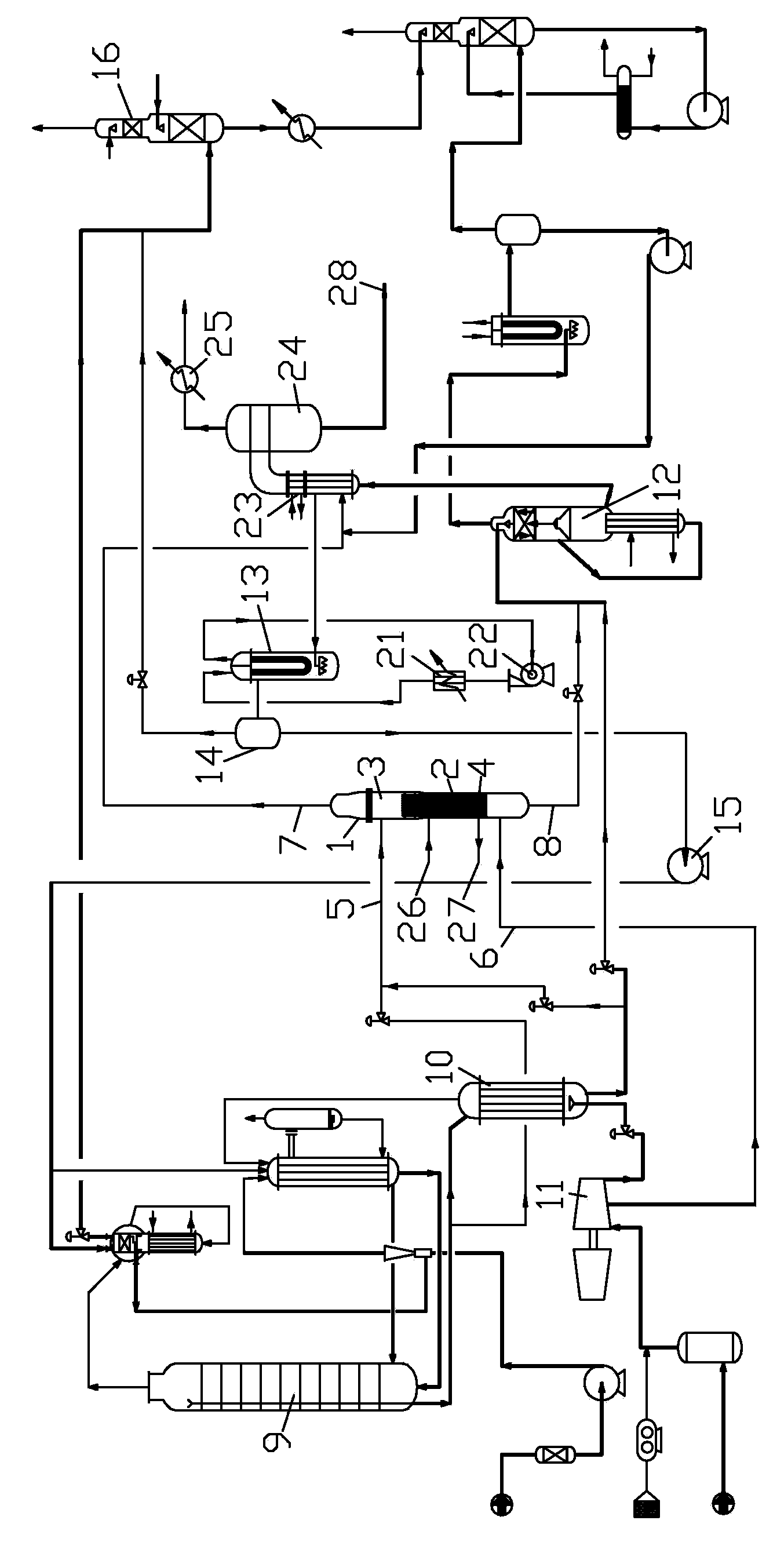

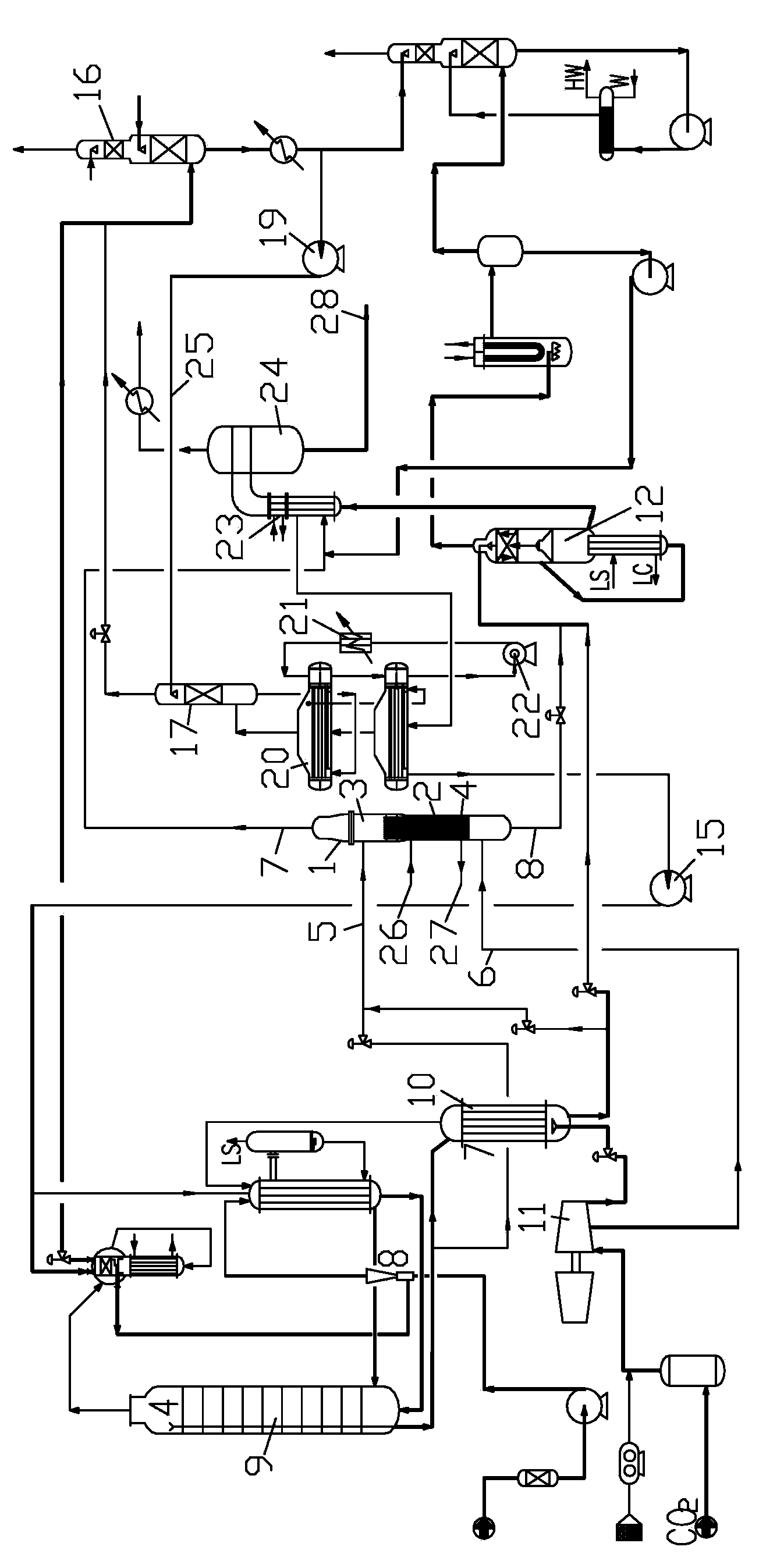

Yield-increasing and energy-saving technology of carbon dioxide stripping urea and equipment of carbon dioxide stripping urea

ActiveCN103435517AIncrease production capacitySolve the contradiction of insufficient production capacityUrea derivatives preparationProductsDecompositionEvaporation

Owner:BEIJING UNITY ENG

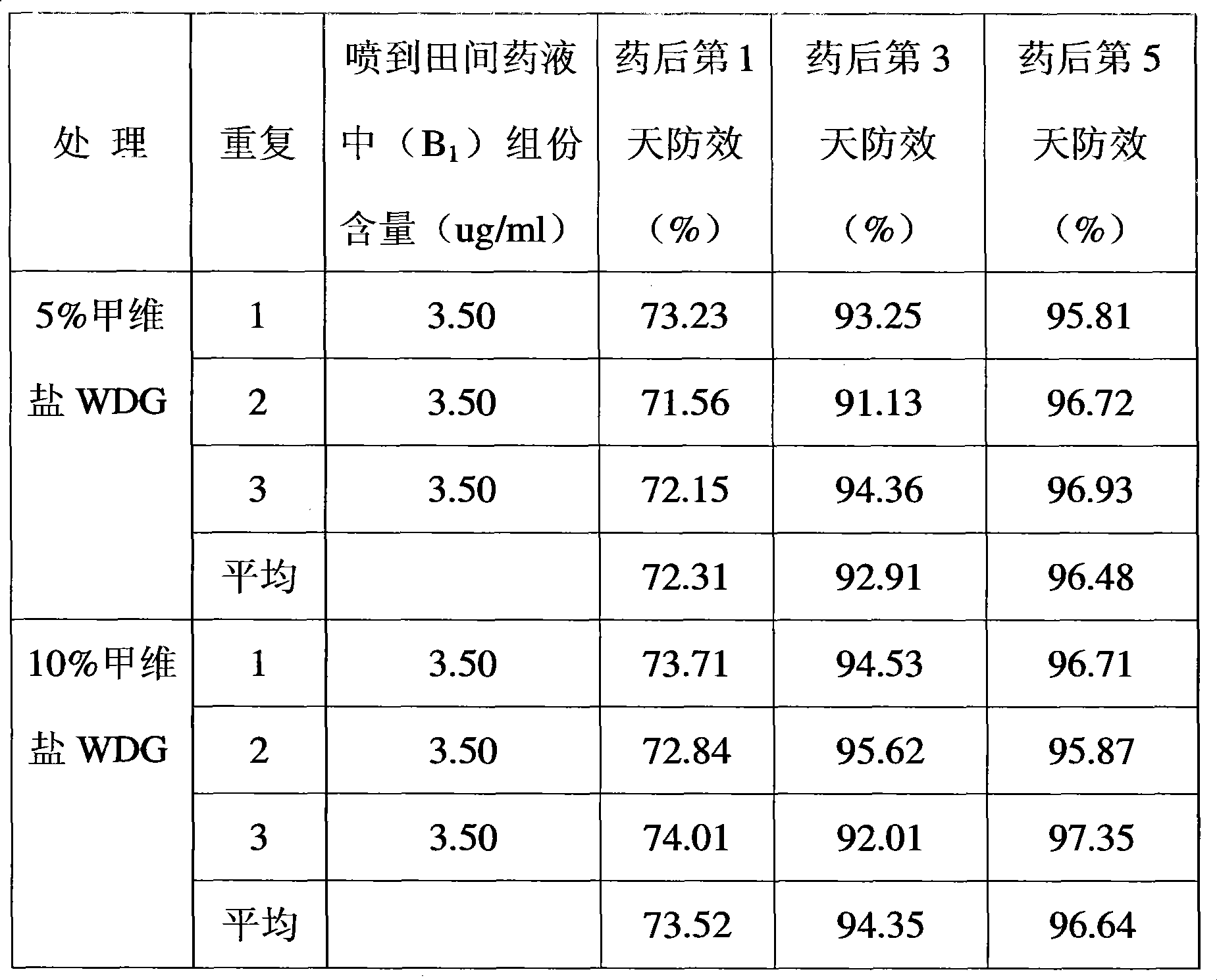

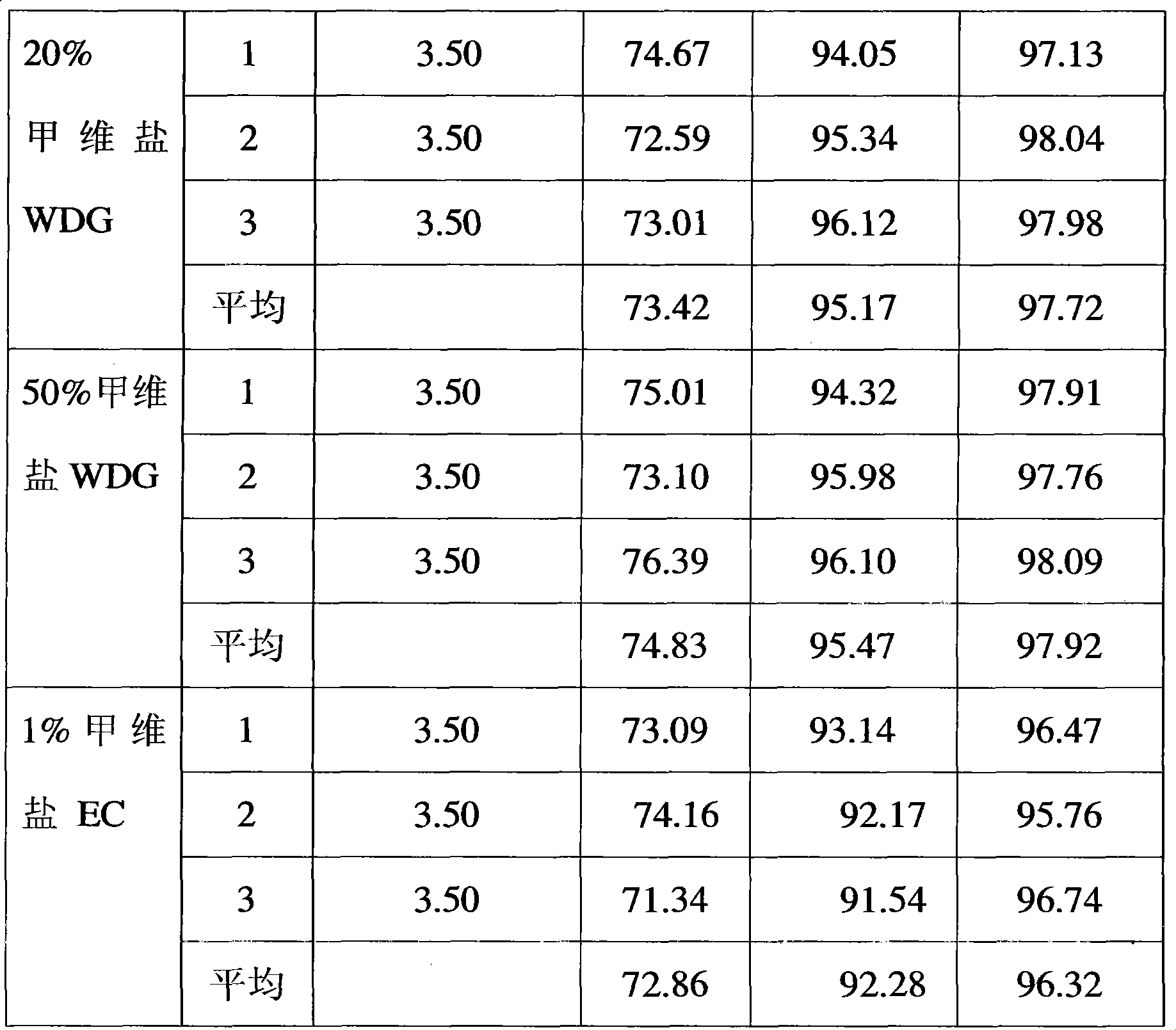

Water dispersion granule of methylamino avermectin benzoate and preparation method thereof

InactiveCN101361479ALow costReduce shipping costsBiocideArthropodicidesWater dispersibleOrganic solvent

The invention discloses a water dispersible granule of methylamine-avermectins benzoate and a preparation method thereof, wherein, the water dispersible granule is composed of the following components by weight percentage: 1 to 50 percent of methylamine-avermectins benzoate, 10 to 20 percent of wetting-dispersing agent, 1 to 5 percent of disintegrant, 0.1 to 2 percent of caking agent, and 38.9 to 72 percent of carrier. The invention adopts the special formula to overcome the exsiting technical problems of preparing the water dispersible granule by the methylamine-avermectins benzoate, and processes the methylamine-avermectins benzoate into the water dispersible granule for the first time, the invention not only can reduce the solvent cost, the packing cost and the transport cost, but also has safe storage and transport, and more importantly, and more importantly reduces the pollution of the organic solvent to the environment.

Owner:广州市顾地丰农药有限公司 +1

Antifogging agent composition and transparent antifogging window membrane formed therefrom

ActiveCN102627880AGood anti-fog durabilityEasy to prepareOther chemical processesFilm/foil adhesivesPolyesterPolymer science

The invention relates to an antifogging agent composition and a transparent antifogging window membrane formed from the composition. The antifogging agent composition consists of 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylenediamine, 1-5wt% of a levelling agent, 5-26wt% of isopropanol, and 5-24wt% of ethanol. The antifogging window membrane is composed of an antifogging agent coating (1), a transparent polyester membrane or transparent polyethylene membrane base material (2), an acrylic adhesive layer (3) and a release membrane (4), and all layers are integrated. The antifogging agent coating (1) is formed by the antifogging agent composition, while the acrylic adhesive layer (3) is formed by a mixture of an acrylic adhesive, a curing agent, toluene and butanone. The transparent antifogging window membrane has effective antifogging function and high light transmittance, as well as a protection effect.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

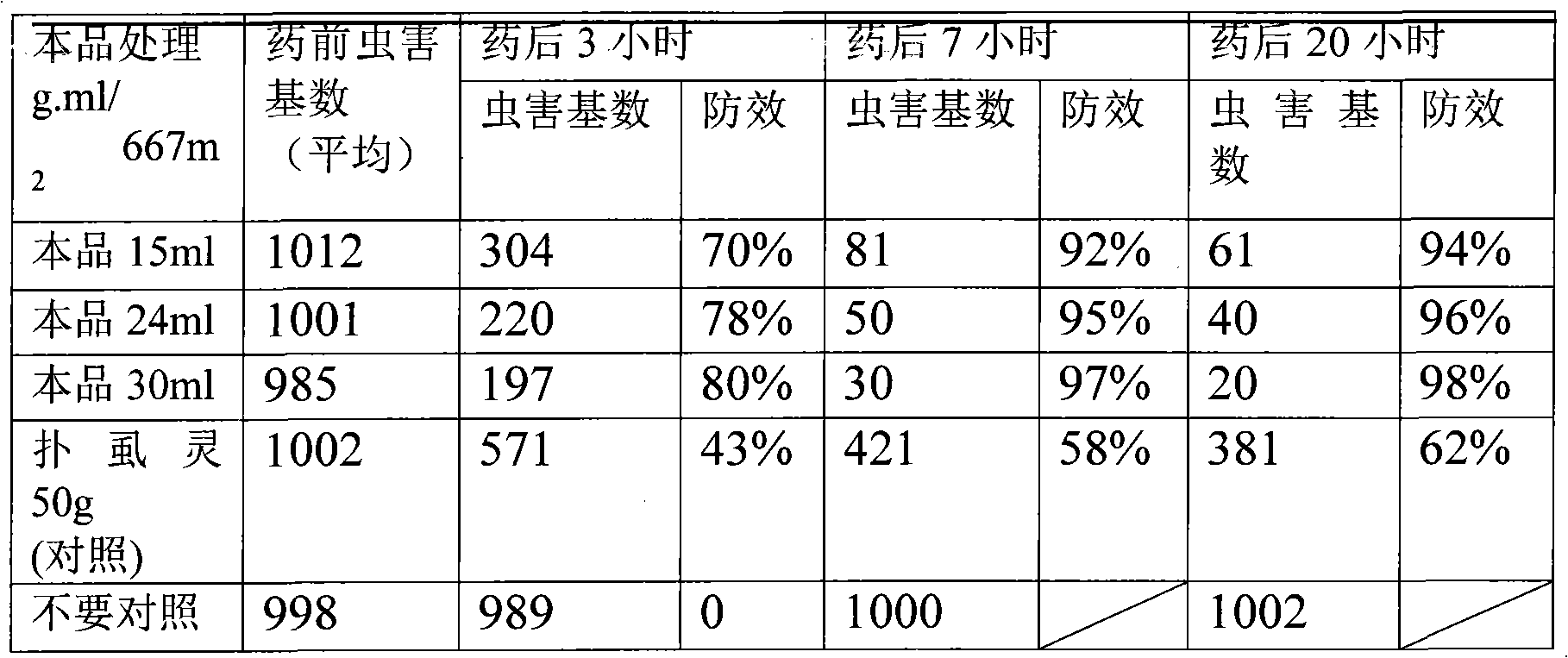

Insecticidal composition containing propylene glycol alginate

InactiveCN101926367AHigh surface tensionHigh viscosityBiocideArthropodicidesAvermectinActive component

The invention relates to an agricultural insecticidal composition, in particular to an insecticidal composition consisting of propylene glycol alginate and nitenpyram or avermectin or methylamine avermectins benzote. The insecticidal composition containing the propylene glycol alginate comprises an A active component and a B active component, wherein the A component comprises 0.1-30 percent of the propylene glycol alginate; the B component comprises the components in percentage by weight: 0.5-40 percent of the nitenpyram or the avermectin or the methylamine avermectins benzote, 10-50 percent of additive and 5-50 percent of excipient. The insecticidal composition containing the propylene glycol alginate has the advantages of low use cost, friendliness to a human body and the environment, long persistent period and different resistance generation and also enhances the utilization ratio of drug effective components.

Owner:ZHEJIANG SEGA SCI & TECH

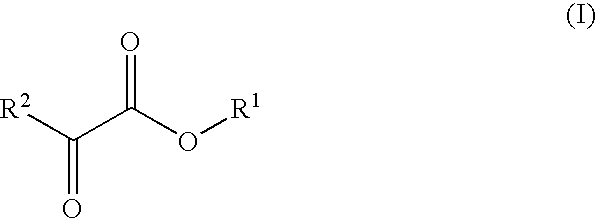

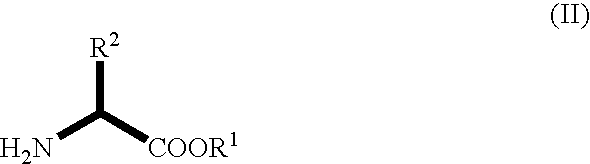

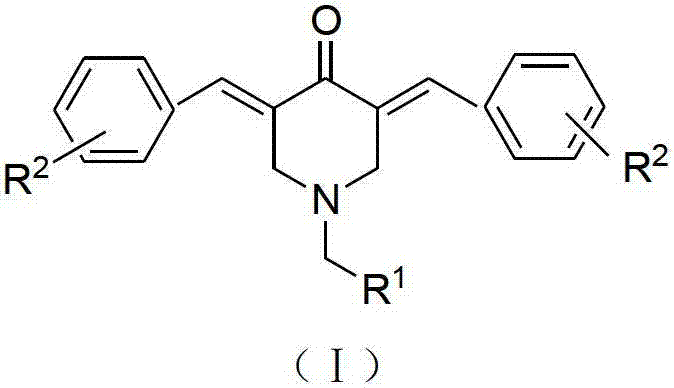

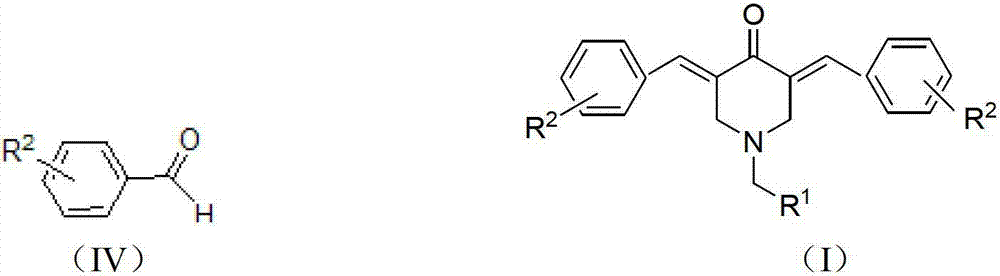

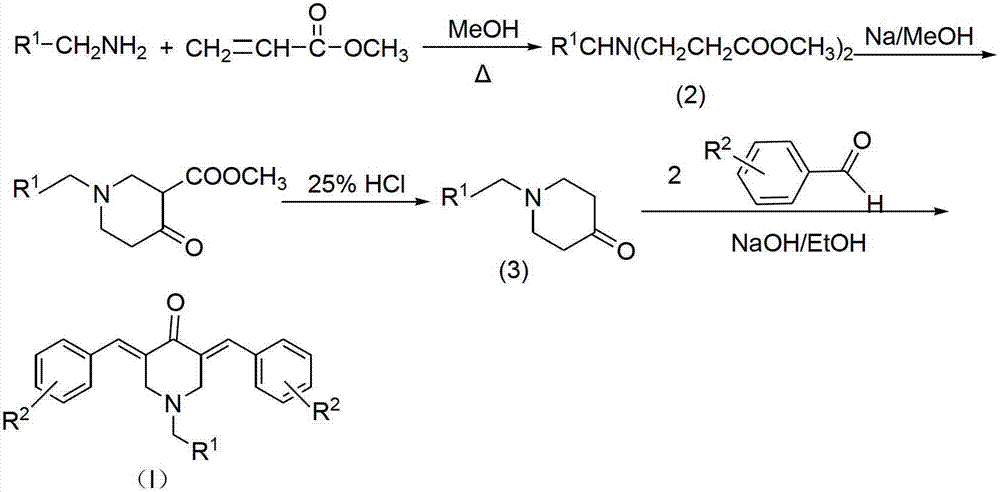

N-substituted methyl-3,5-disubstituted benzylidene base-4-piperidone and preparation method and application thereof

InactiveCN102863376AInhibit biological activitySmall side effectsOrganic chemistryAntineoplastic agentsCarcinoma cell lineCancer cell

The invention relates to the field of organic synthesis and medicine, and discloses a preparation method for N-substituted methyl-3,5-disubstituted benzylidene base-4-piperidone and biological activity for efficiently inhibiting cell line proliferation such as leukemia, ovarian cancer, breast cancer, liver cancer and esophagus cancer. The method includes: starting from various substituted methylamine and methyl acrylate, sequentially going through Michael addition, Dieckmann condensation, acidolysis and decarboxylation to obtain N-substituted methyl-4-piperidone, and subjecting the N-substituted methyl-4-piperidone to aldol reaction with substituted benzaldehyde to obtain a target compound N-substituted methyl-3,5-disubstituted benzylidene base-4-piperidone. The target compound can selectively and efficiently inhibit cell line proliferation such as leukemia, ovarian cancer, breast cancer, liver cancer and esophagus cancer, and activity of inhibiting carcinoma cell line proliferation is obviously higher than conventional chemotherapeutic 5-fluorouracil.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Crystal forms of (S)-(8(2,6-dichlorophenyl)-6-fluoro-2,3-dihydro benzo[b][1,4]dioxin-2-yl)methanamine hydrochloride salt Crystal forms of (S)-(8(2,6-dichlorophenyl)-6-fluoro-2,3-dihydro benzo[b][1,4]dioxin-2-yl)methanamine hydrochloride salt](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7283b8dc-b41e-4576-b2fc-94f10515bd79/US20070249709A1-20071025-D00000.png)

![Crystal forms of (S)-(8(2,6-dichlorophenyl)-6-fluoro-2,3-dihydro benzo[b][1,4]dioxin-2-yl)methanamine hydrochloride salt Crystal forms of (S)-(8(2,6-dichlorophenyl)-6-fluoro-2,3-dihydro benzo[b][1,4]dioxin-2-yl)methanamine hydrochloride salt](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7283b8dc-b41e-4576-b2fc-94f10515bd79/US20070249709A1-20071025-D00001.png)

![Crystal forms of (S)-(8(2,6-dichlorophenyl)-6-fluoro-2,3-dihydro benzo[b][1,4]dioxin-2-yl)methanamine hydrochloride salt Crystal forms of (S)-(8(2,6-dichlorophenyl)-6-fluoro-2,3-dihydro benzo[b][1,4]dioxin-2-yl)methanamine hydrochloride salt](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7283b8dc-b41e-4576-b2fc-94f10515bd79/US20070249709A1-20071025-D00002.png)